Self-aligning thrust bearing for submerged pump

A thrust bearing and self-aligning technology, applied in the mechanical field, can solve the problems that the center of gravity and the axis cannot overlap, the service life of a pump is shortened, and the wear of the thrust bearing increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

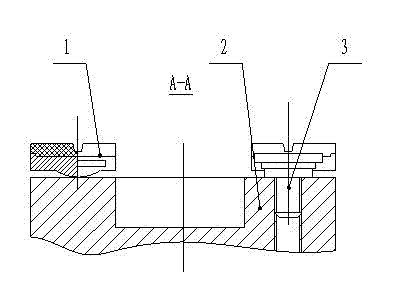

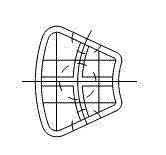

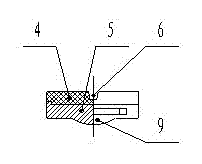

[0031] The present invention proposes a self-aligning type thrust bearing for a submersible pump, such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 As shown, it includes a disk-shaped base 2 and at least two thrust bearing blocks 1 evenly distributed on the circumference of the base. The thrust bearing block 1 is composed of a base 5 made of metal and a friction plate 4 made of polymer material. At least one concave water channel 6 is provided on the surface of the friction plate 4, a protrusion 6 is provided in the middle of the bottom 5 of the base, the protrusion 6 is arranged in contact with the base 2, and the thrust bearing block has a locking mechanism, So that the thrust bearing block 1 can be fixed on the base 2 .

[0032] The clamping mechanism is a boss 7-2 respectively arranged on both sides of the thrust bearing block, and the two ends of the boss 7-2 are provided with stoppers. When the thrust bearing block 1 is installed on the base 2 , the he...

Embodiment 2

[0034] like image 3 , Figure 4 , Figure 8 , Figure 9 As shown, as another form of the snap-in mechanism, the snap-in mechanism is a groove 7-1 respectively provided on both sides of the thrust bearing block 1, when the thrust bearing block 1 is installed on the base 2 , the heads of the fixing bolts 3 are accommodated in the grooves 7-1 of the two adjacent thrust bearing blocks 1, the circumference of the disc-shaped base is provided with mounting holes, and the fastening bolts are fastened on the mounting hole to secure the thrust bearing block.

Embodiment 3

[0036] like Figure 10 , Figure 11 As shown, as another form of the clamping mechanism, the clamping mechanism is the installation through hole 8 respectively provided on both sides of the protrusion 9. When the thrust bearing block is installed on the base, the fixing bolt Fastened in the installation through hole 8, the circumference of the disc-shaped base is provided with installation holes, and the fastening bolts are fastened in the installation holes, thereby fixing the thrust bearing block on the base.

[0037] like Figure 12 , Figure 13 As shown, the head of the fixing bolt is composed of two cylinders with different diameters superimposed, wherein the cylinder with a larger diameter is located at the top of the head, and the top of the head of the fixing bolt is provided with an inner hexagon. During installation, the end face of the smaller cylinder contacts with the base 2 to generate frictional force, which prevents the screw from rotating, and plays a guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com