Manufacturing method of lamp-cover-supporting LED tubular lamp with self-clamping heat transmission substrate

A technology of LED tube lamps and heat transfer substrates, which is applied to the cooling/heating devices of lighting devices, lighting and heating equipment, and components of lighting devices, etc., which can solve the problems of long time consumption, low work efficiency, and inability to meet mass and rapid production and other issues, to achieve the effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

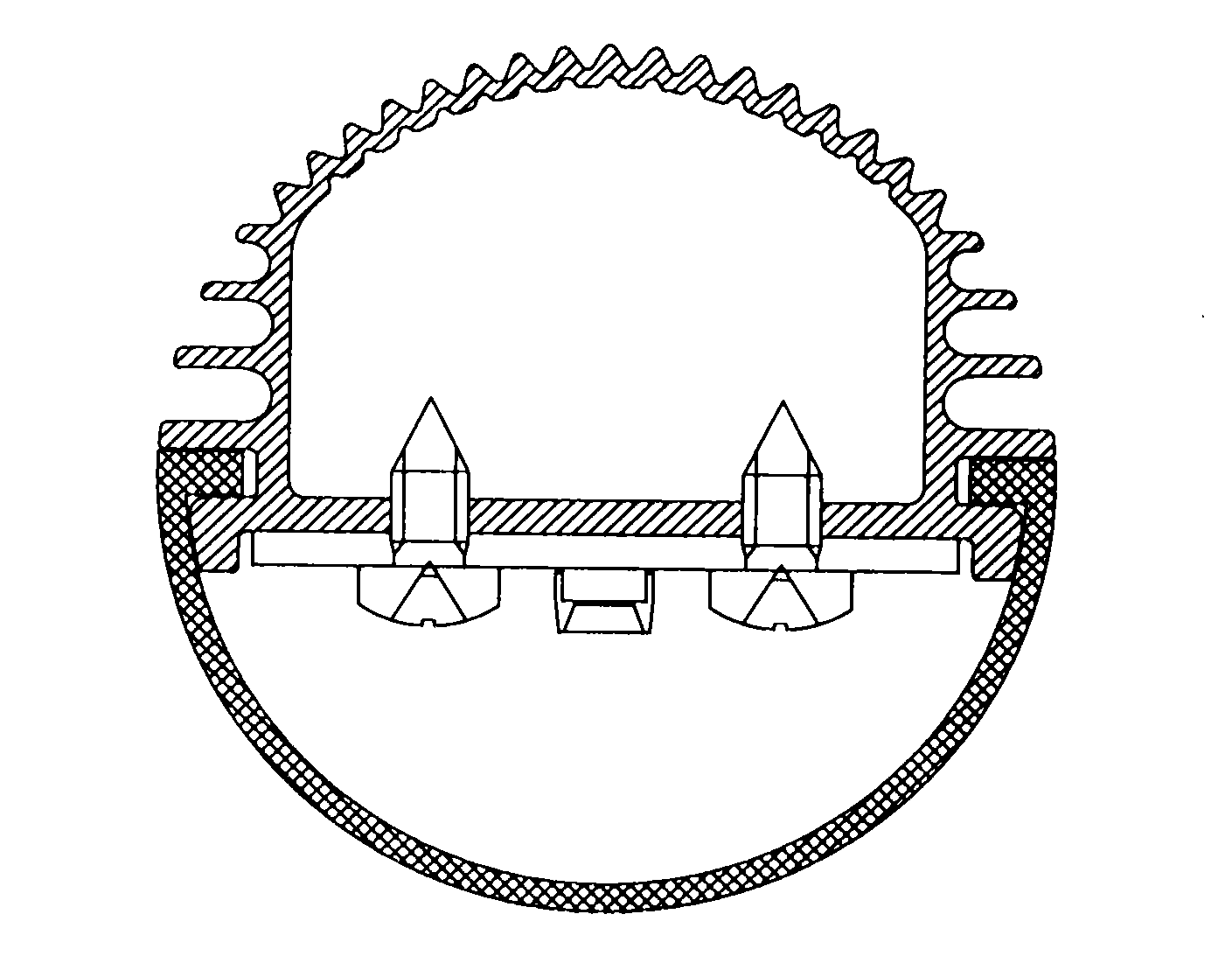

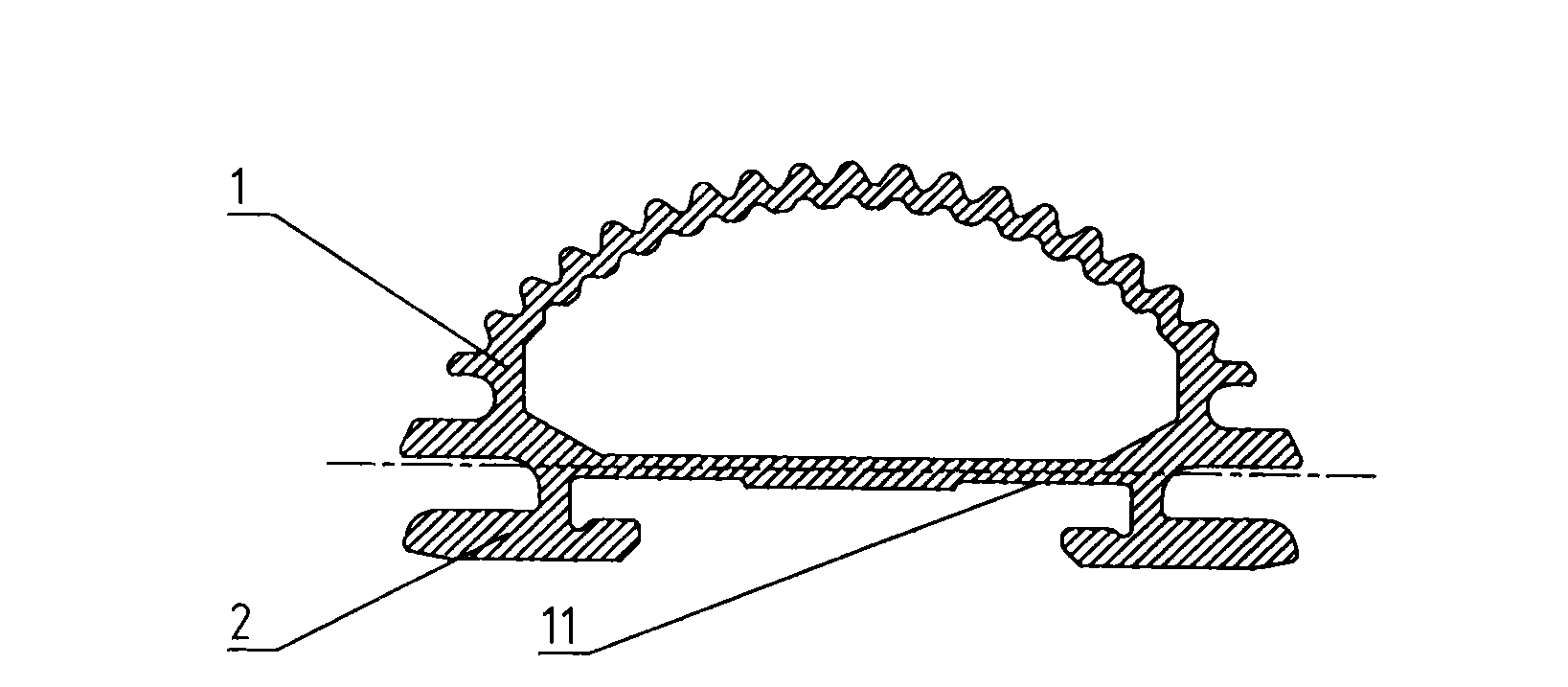

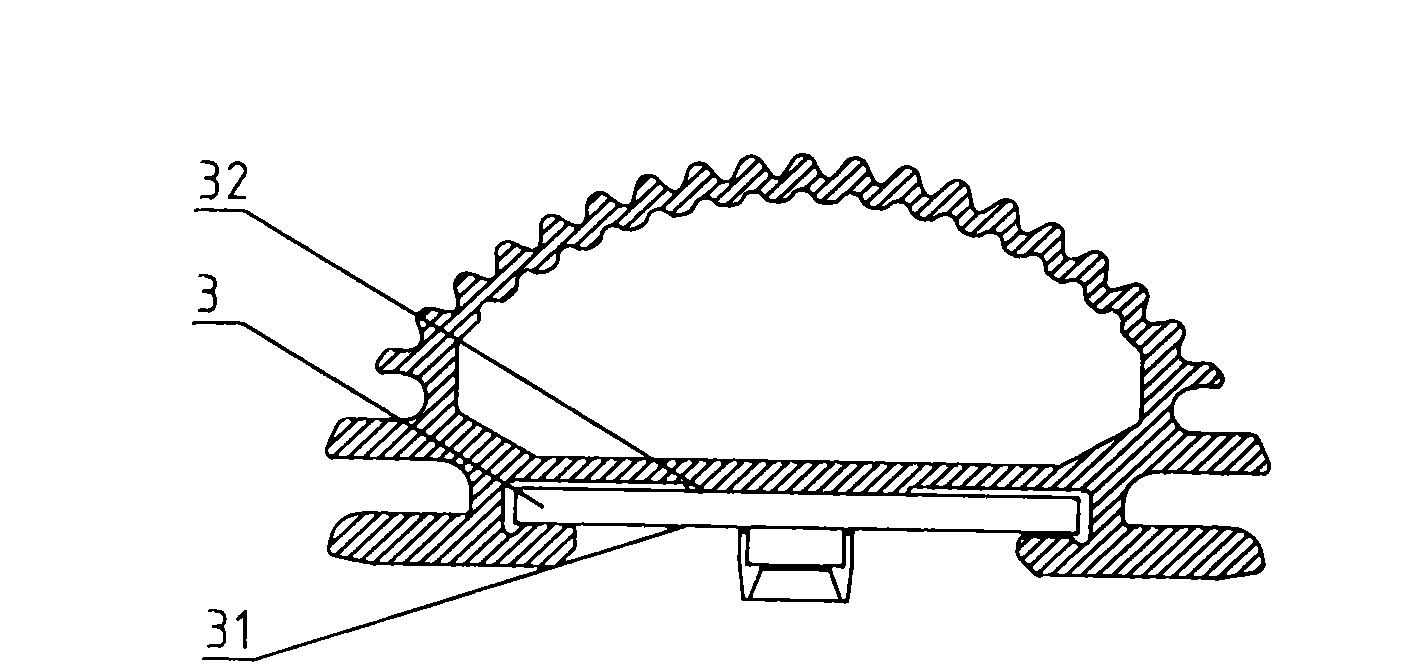

[0068] figure 2 It is the first radiator front view of the heat transfer substrate self-clamping LED tube lamp of the present invention Figure 1 ; image 3 It is a structural schematic diagram of the heat transfer substrate installed on the first radiator of the clamping LED tube lamp of the present invention after the heat transfer substrate is installed; Figure 4 It is the first radiator front view of the heat transfer substrate self-clamping LED tube lamp of the present invention Figure II ; Figure 5 It is a three-dimensional view of the first heat sink of the self-clamping LED tube lamp of the heat transfer substrate of the present invention; Figure 7 It is a schematic diagram of the structure of the heat transfer substrate of the present invention after installing the heat transfer substrate and the lampshade on the first radiator of the clamping LED tube lamp, Figure 13 It is a schematic diagram of the lampshade structure of the heat transfer substrate self-cl...

Embodiment approach 2

[0099] Figure 8 The front view of the second heat sink of the heat transfer substrate self-clamping LED tube lamp of the present invention Figure 1 ; Figure 9 It is a structural schematic diagram of the heat transfer substrate installed on the second radiator of the clamping LED tube lamp of the present invention after the heat transfer substrate is installed; Figure 10 It is a schematic diagram of the structure of the heat transfer substrate of the present invention after installing the heat transfer substrate and the lampshade on the second radiator of the clamping LED tube lamp; Figure 11 The front view of the second heat sink of the heat transfer substrate self-clamping LED tube lamp of the present invention Figure II ; Figure 12 It is a perspective view of the second radiator of the heat transfer substrate self-clamping LED tube lamp of the present invention, Figure 13 It is a schematic diagram of the lampshade structure of the heat transfer substrate self-cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com