Patents

Literature

15550results about How to "Improve flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor device including active layer made of zinc oxide with controlled orientations and manufacturing method thereof

InactiveUS20070187678A1Improve heat resistanceImprove propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesZincActive layer

A semiconductor device includes an oxide semiconductor thin film layer primarily including zinc oxide having at least one orientation other than (002) orientation. The zinc oxide may have a mixed orientation including (002) orientation and (101) orientation. Alternatively, the zinc oxide may have a mixed orientation including (100) orientation and (101) orientation.

Owner:KOICHI IND PROMOTION CENT +1

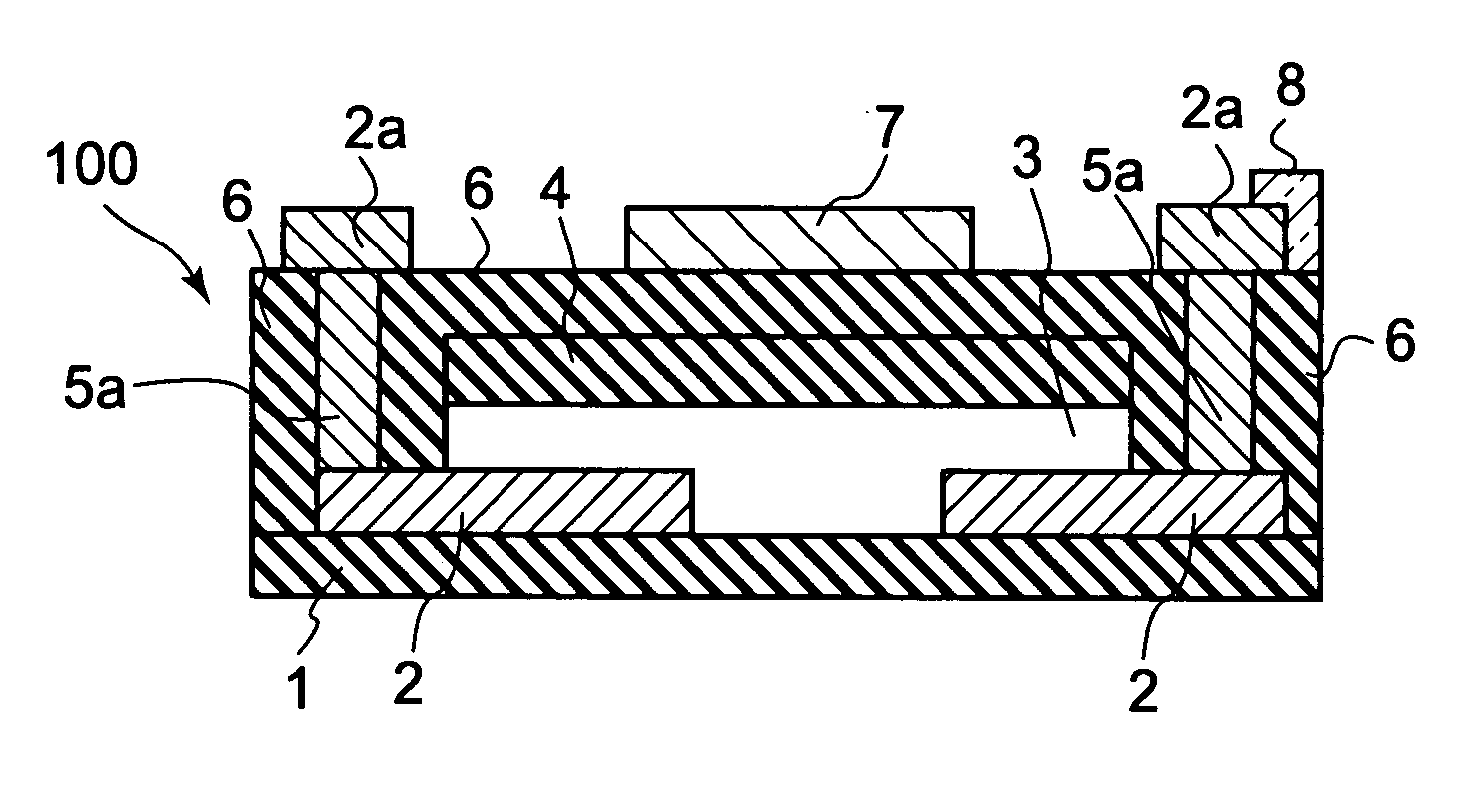

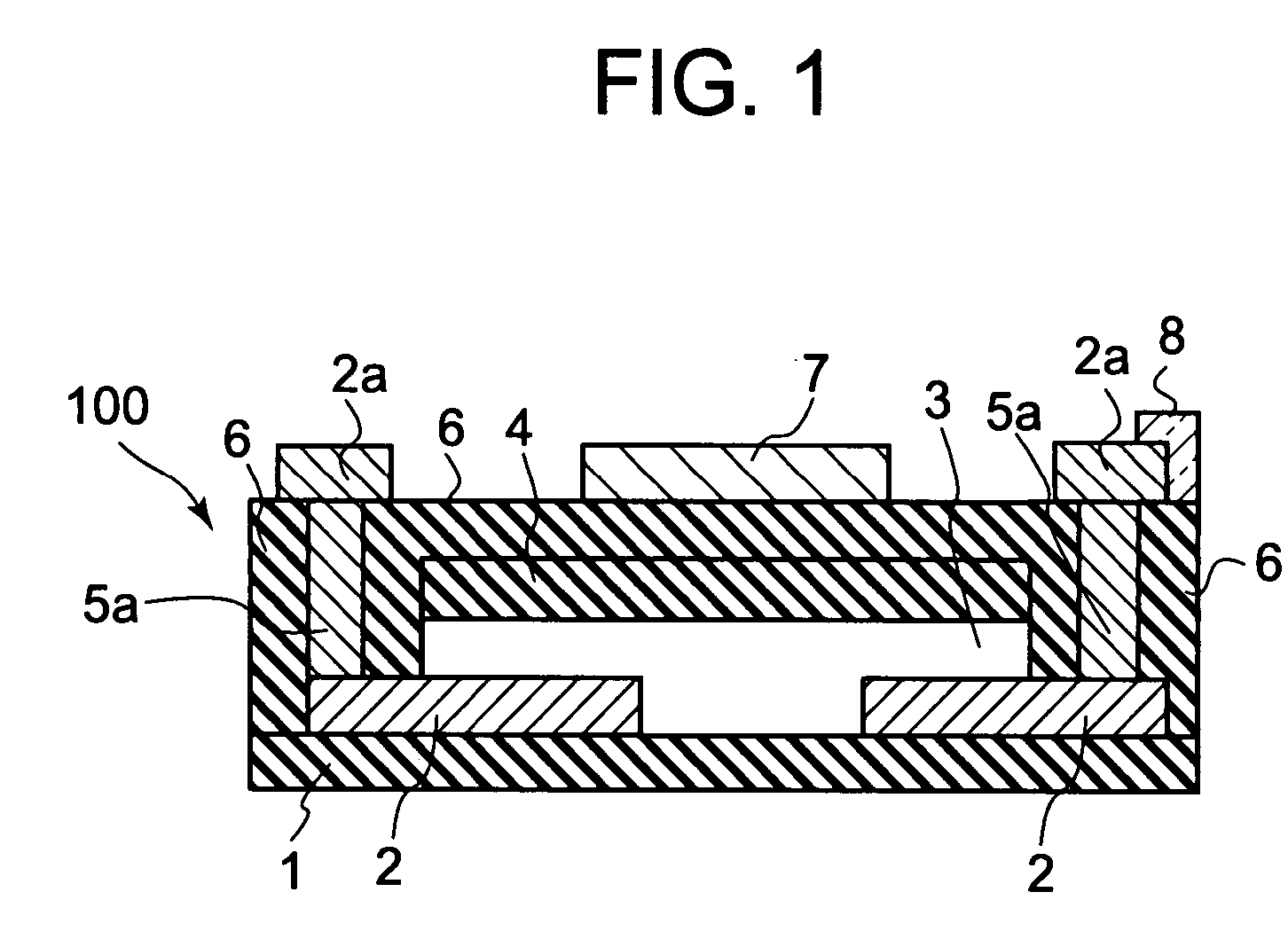

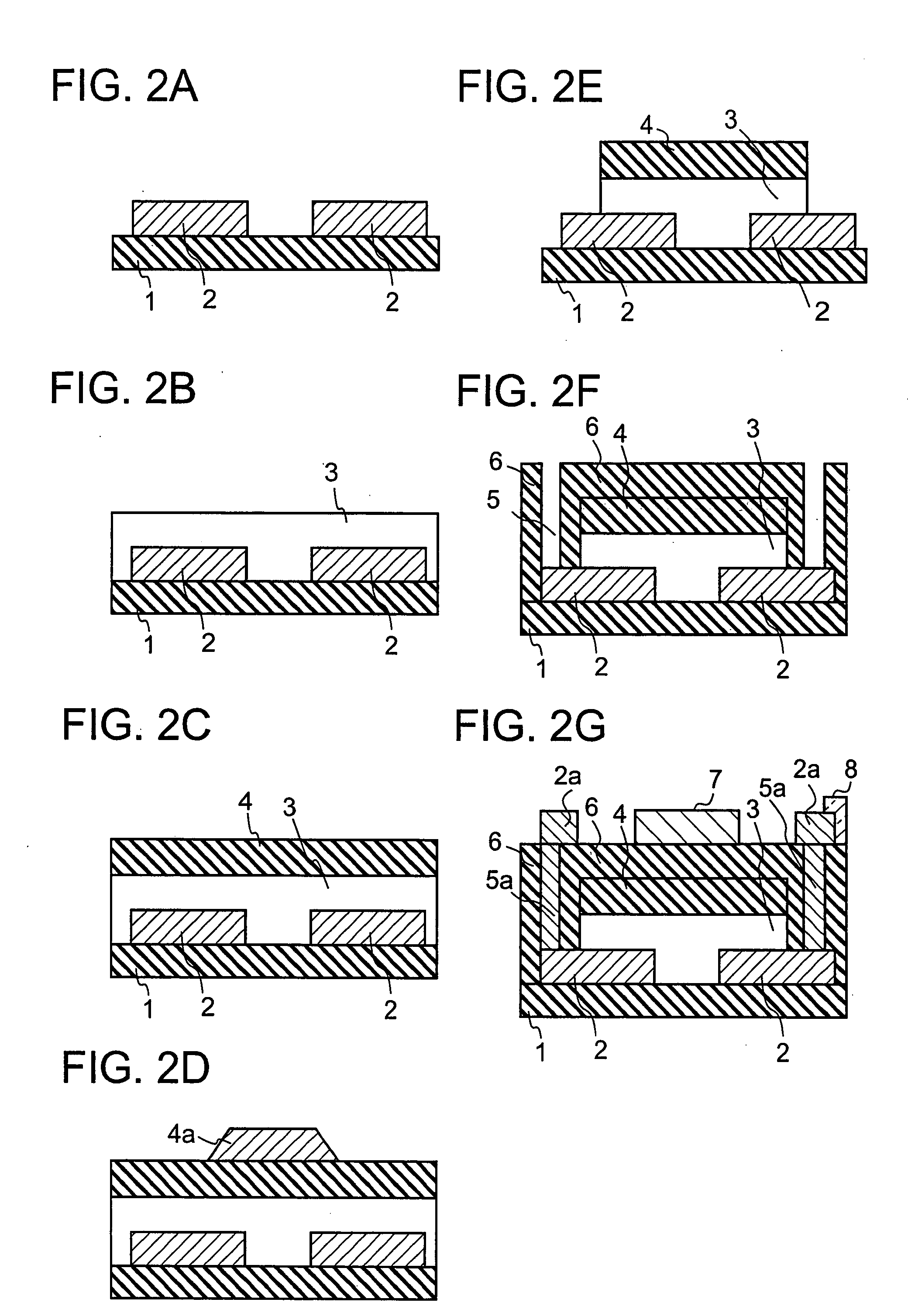

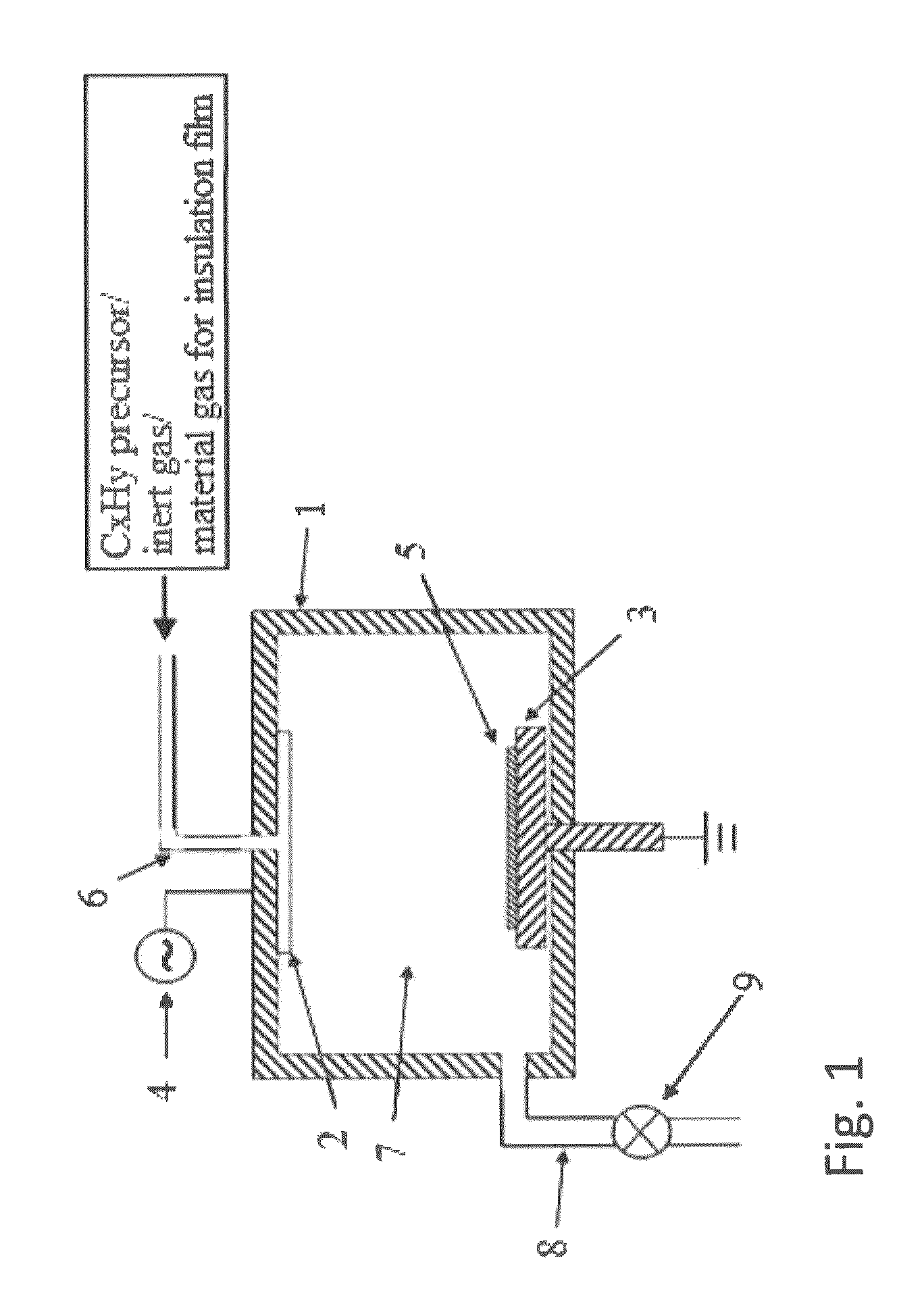

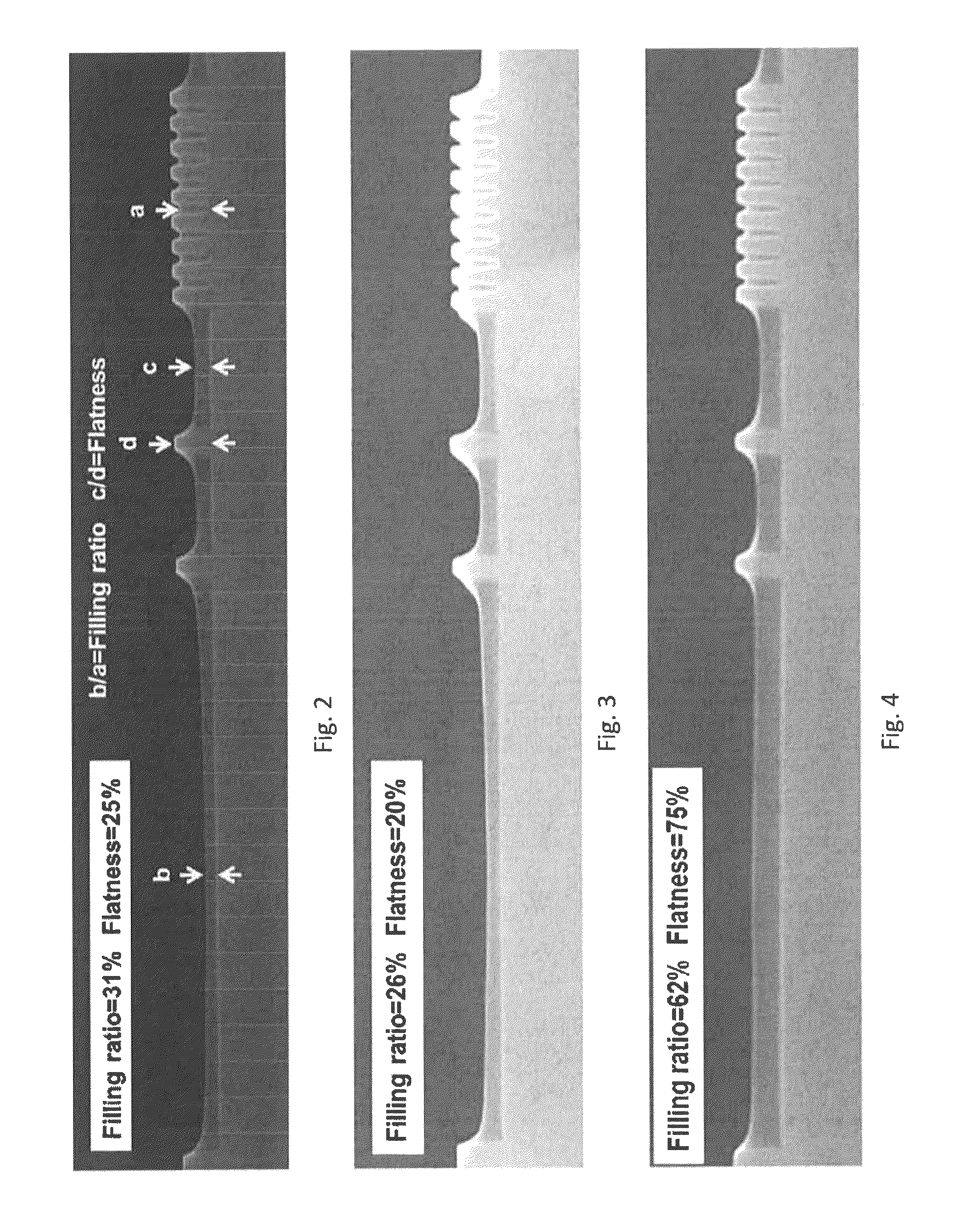

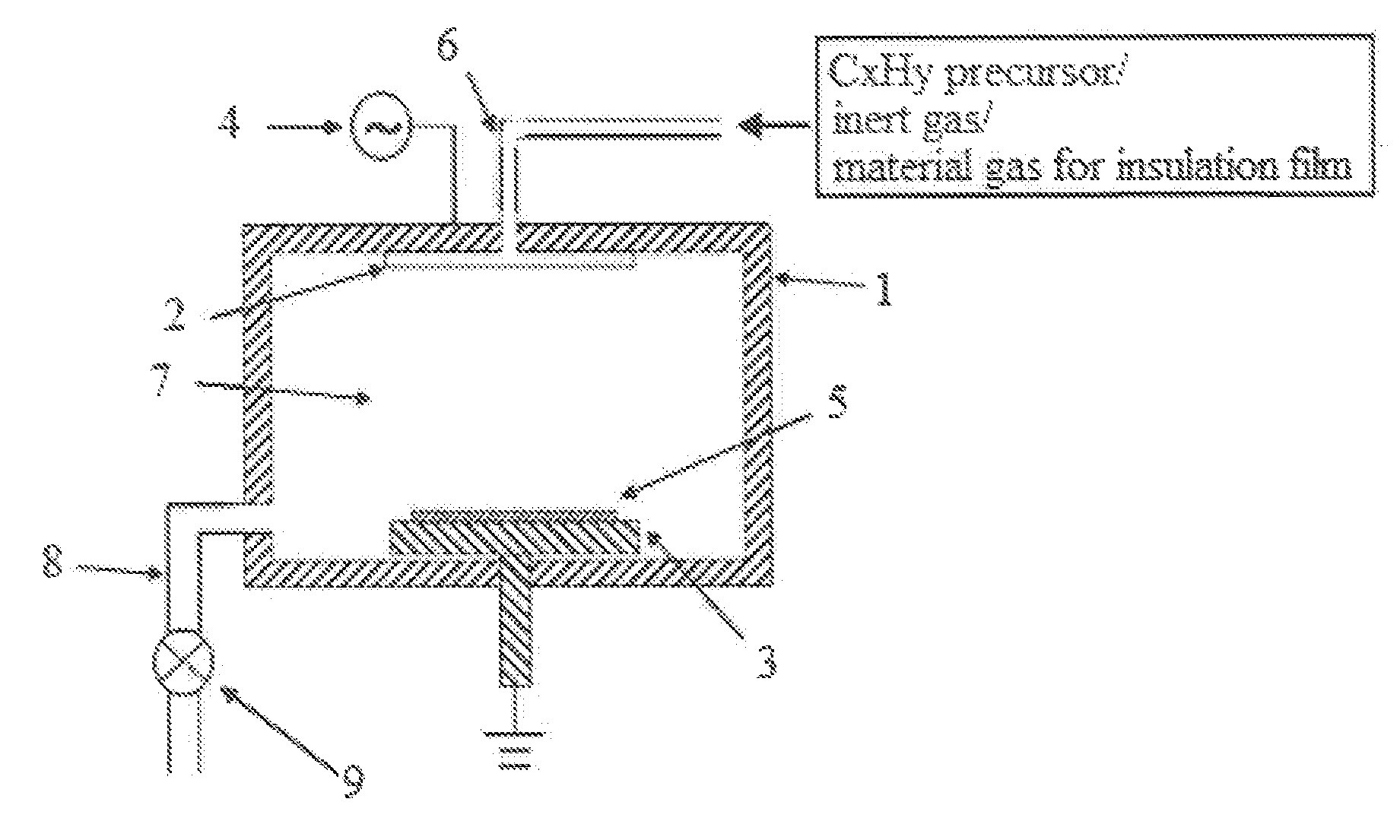

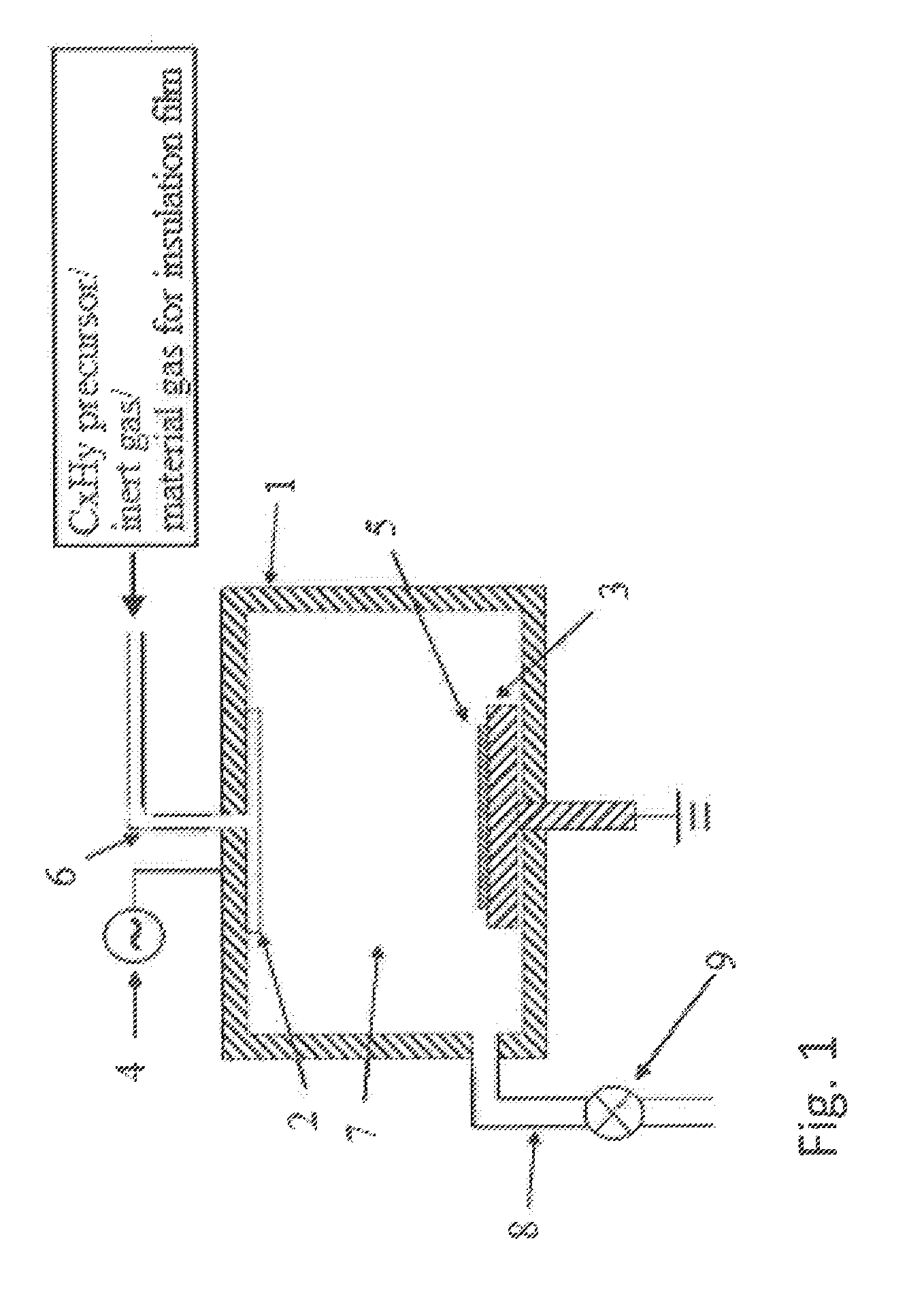

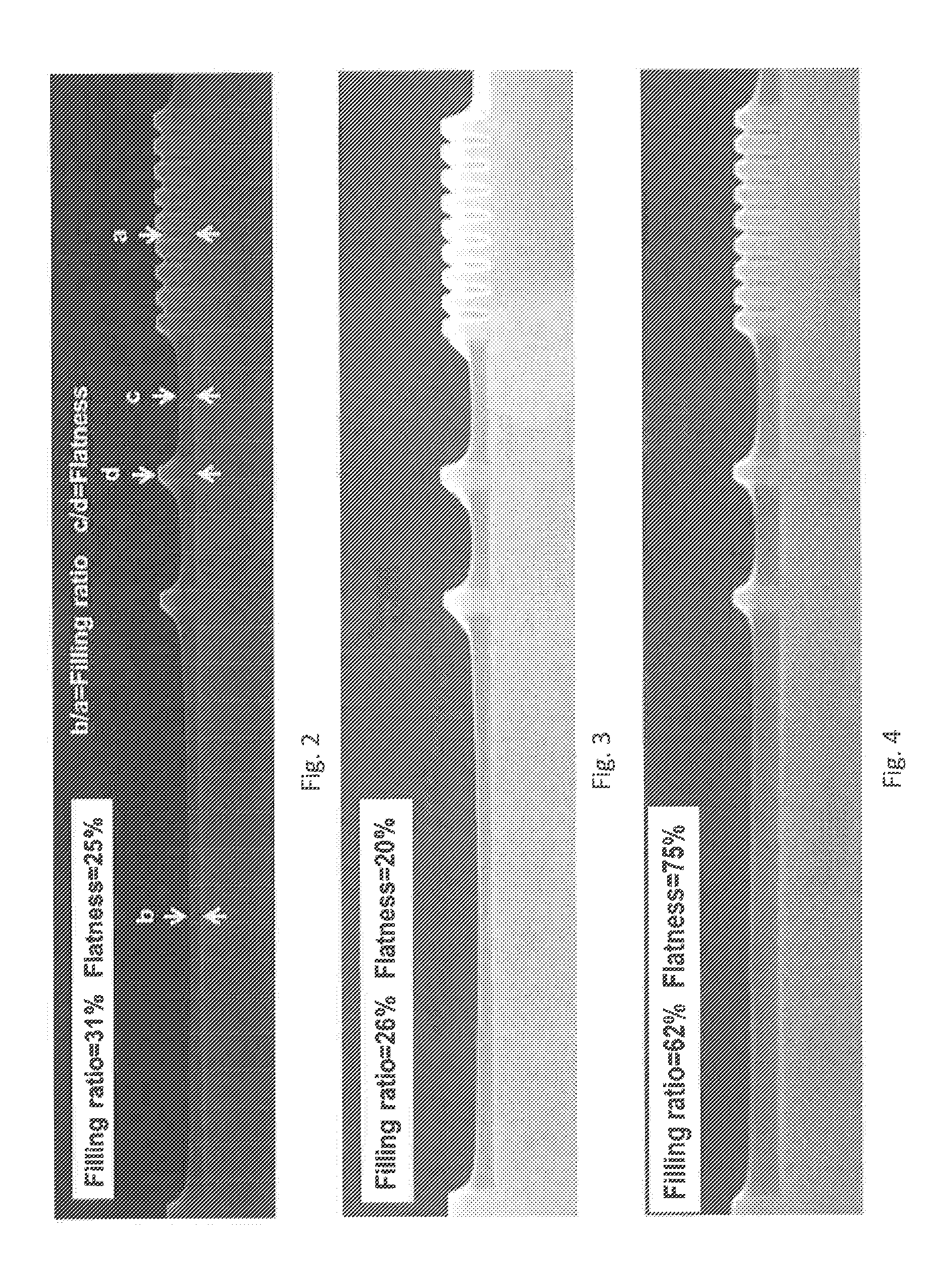

Method for filling recesses using pre-treatment with hydrocarbon-containing gas

ActiveUS9117657B2Improve flatnessHighly effectiveSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentPre deposition

A method for filling recesses of a substrate with an insulation film includes: (i) exposing surfaces of the recesses of the substrate to a pre-deposition gas in a reactive state in a reaction space to treat the surfaces with reactive hydrocarbons generated from the pre-deposition gas without filling the recesses; and (ii) depositing a flowable insulation film using a process gas other than the pre-deposition gas on a surface of the substrate to fill the recesses treated in step (i) therewith by plasma reaction. The pre-deposition gas has at least one hydrocarbon unit in its molecule.

Owner:ASM IP HLDG BV

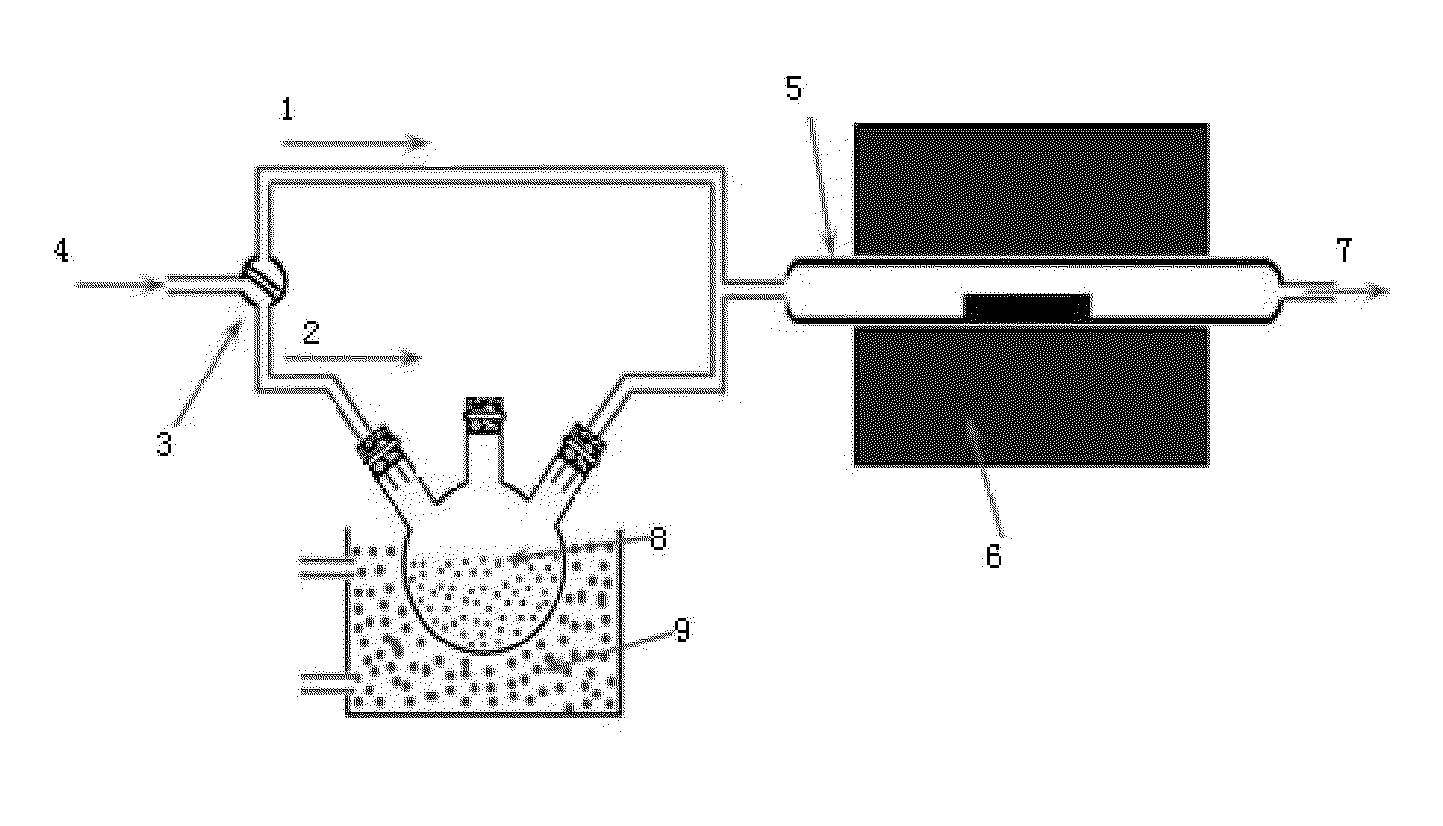

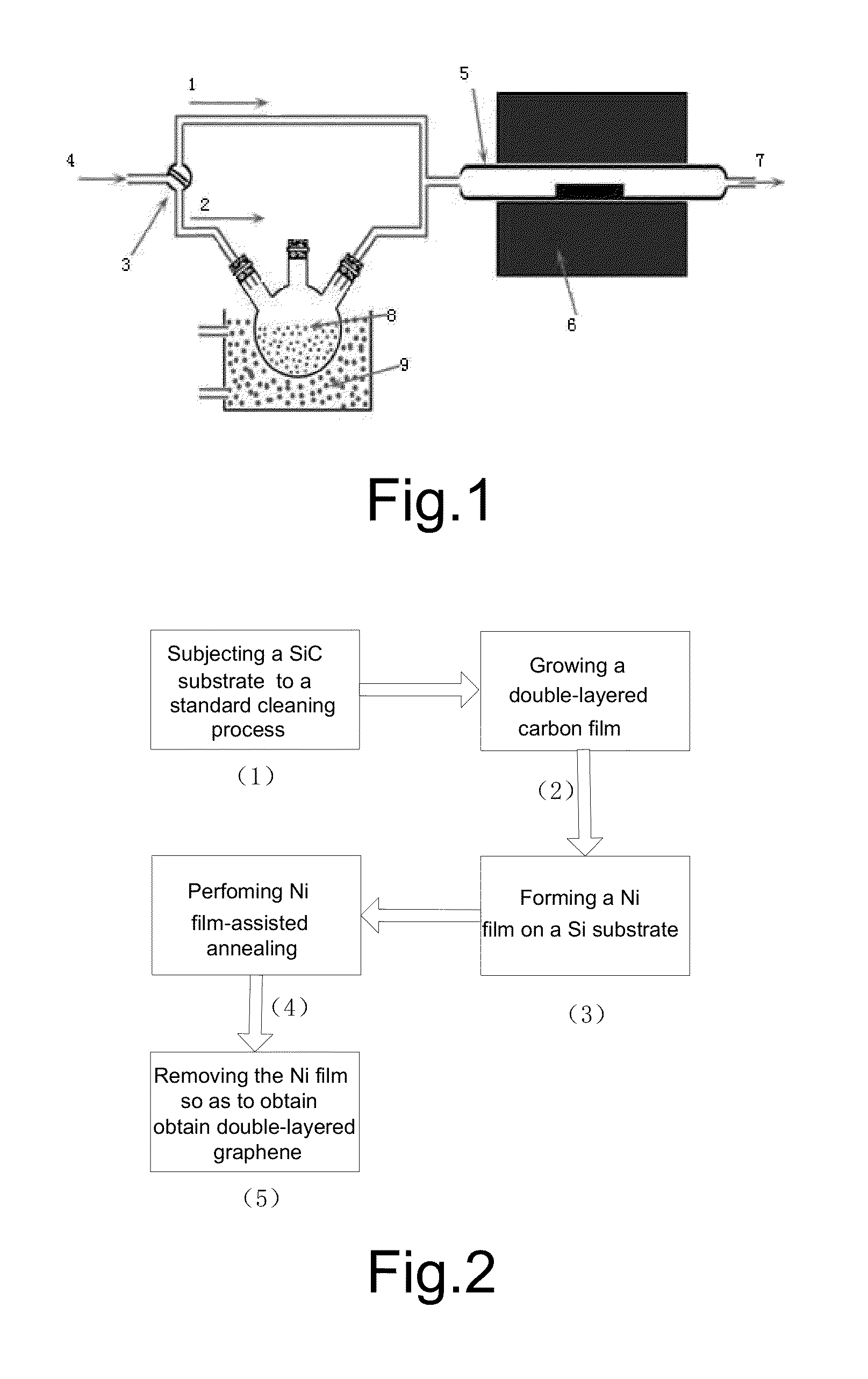

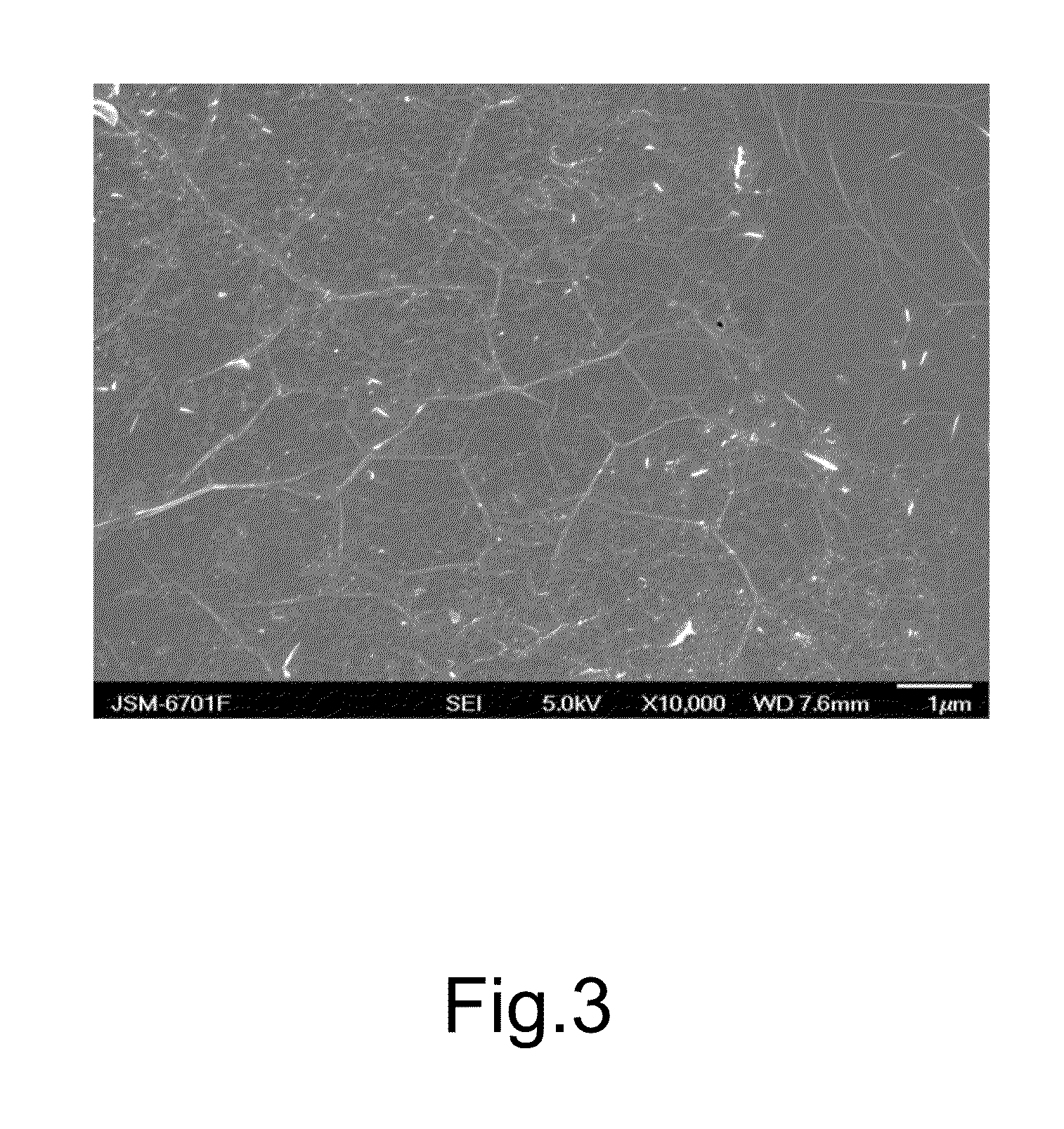

Process for Preparing Graphene on a SiC Substrate Based on Metal Film-Assisted Annealing

ActiveUS20140367642A1Simply and energy-efficientFlat surfaceMaterial nanotechnologyVacuum evaporation coatingCarbon filmElectron beam deposition

Provided is a process for preparing graphene on a SiC substrate, based on metal film-assisted annealing, comprising the following steps: subjecting a SiC substrate to a standard cleaning process; placing the cleaned SiC substrate into a quartz tube and heating the quartz tube up to a temperature of 750 to 1150° C.; introducing CCl4vapor into the quartz tube to react with SiC for a period of 20 to 100 minutes so as to generate a double-layered carbon film, wherein the CCl4 vapor is carried by Ar gas; forming a metal film with a thickness of 350 to 600 nm on a Si substrate by electron beam deposition; placing the obtained double-layered carbon film sample onto the metal film; subsequently annealing them in an Ar atmosphere at a temperature of 900 to 1100° C. for 10-30 minutes so as to reconstitute the double-layered carbon film into double-layered graphene; and removing the metal film from the double-layered graphene, thereby obtaining double-layered graphene. Also provided is double-layered graphene prepared by said process.

Owner:XIDIAN UNIV

Method For Filling Recesses Using Pre-Treatment With Hydrocarbon-Containing Gas

ActiveUS20140363983A1Improve flatnessHighly effectiveSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPre treatmentPlasma reaction

A method for filling recesses of a substrate with an insulation film includes: (i) exposing surfaces of the recesses of the substrate to a pre-deposition gas in a reactive state in a reaction space to treat the surfaces with reactive hydrocarbons generated from the pre-deposition gas without filling the recesses; and (ii) depositing a flowable insulation film using a process gas other than the pre-deposition gas on a surface of the substrate to fill the recesses treated in step (i) therewith by plasma reaction. The pre-deposition gas has at least one hydrocarbon unit in its molecule.

Owner:ASM IP HLDG BV

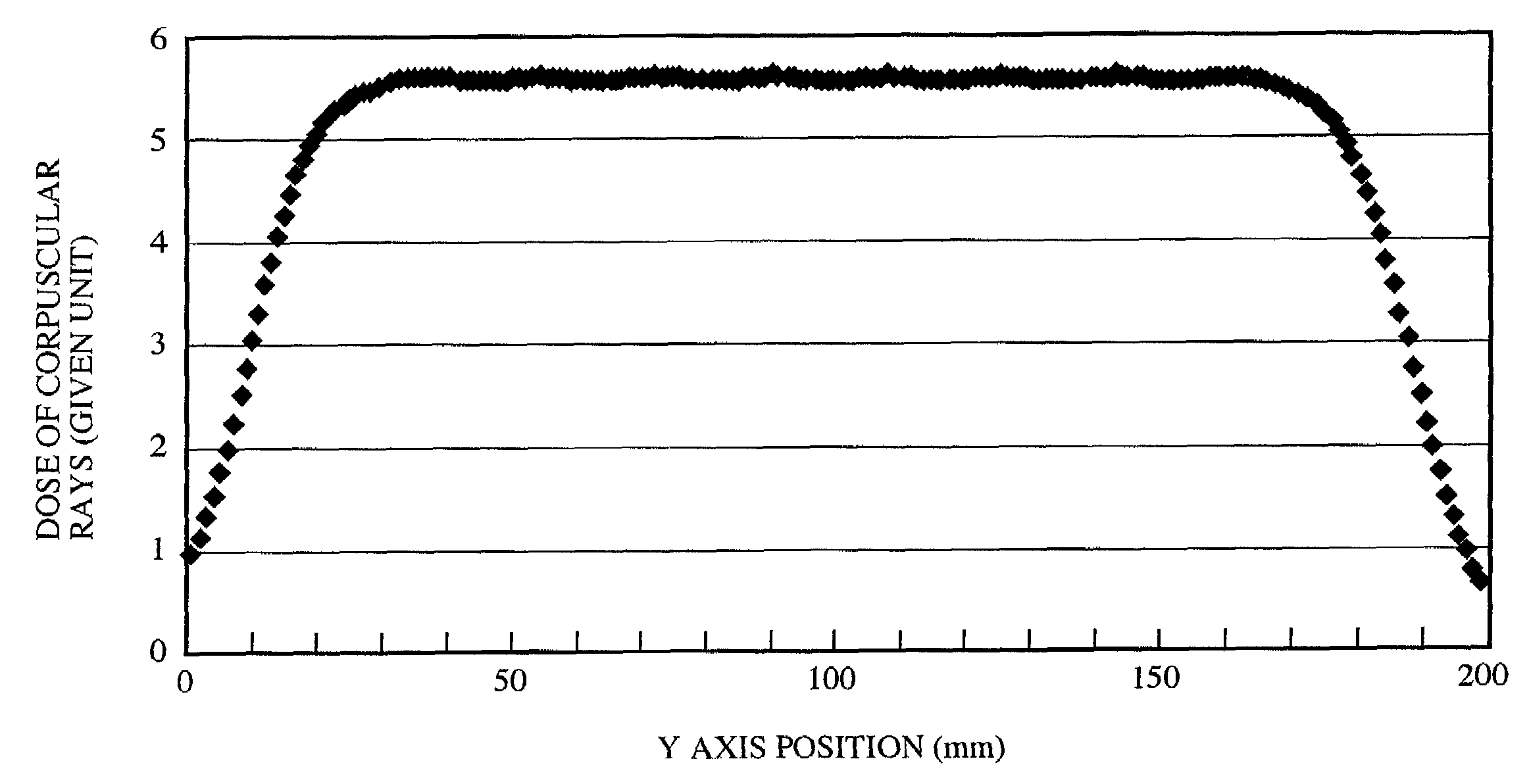

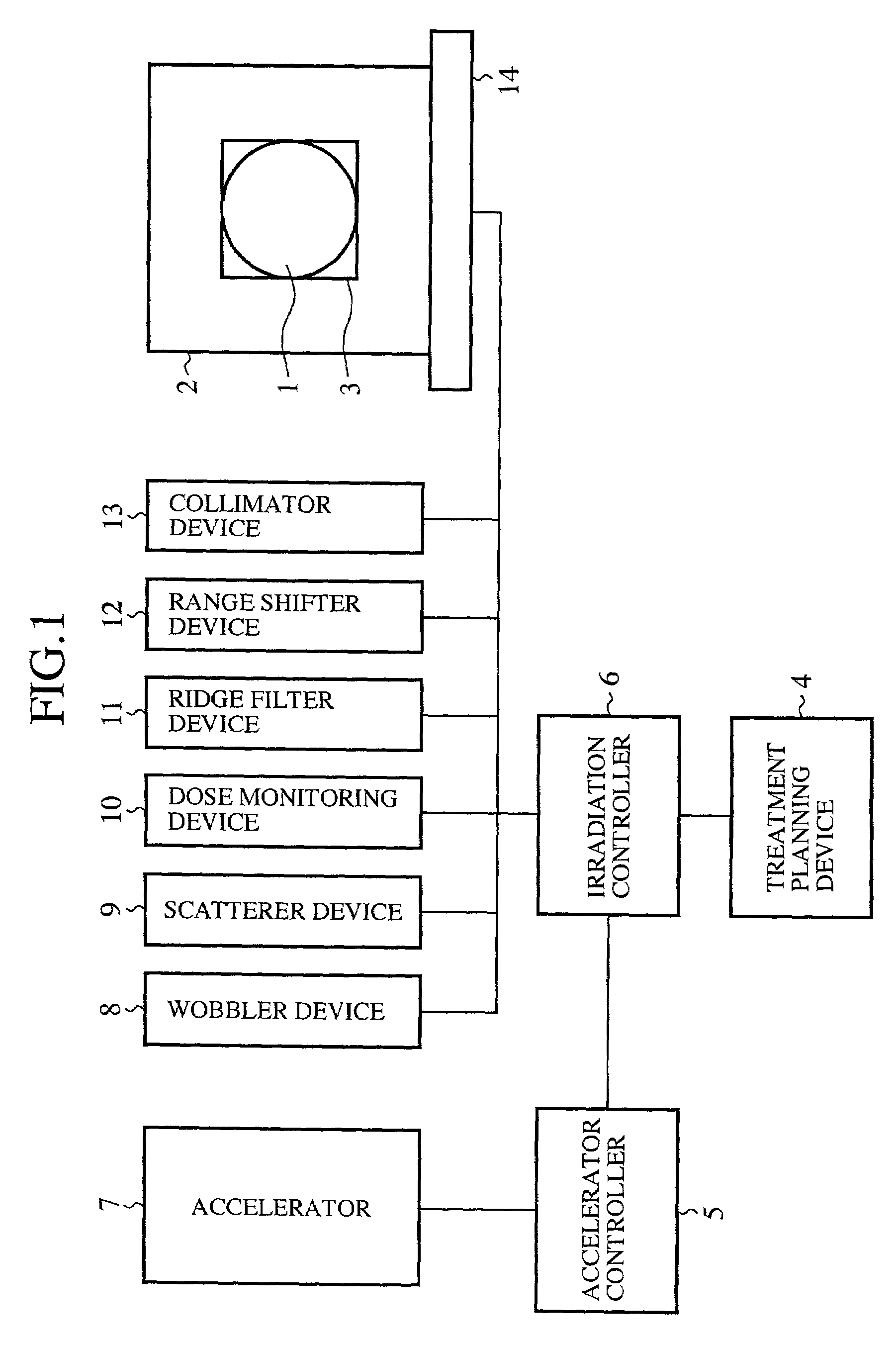

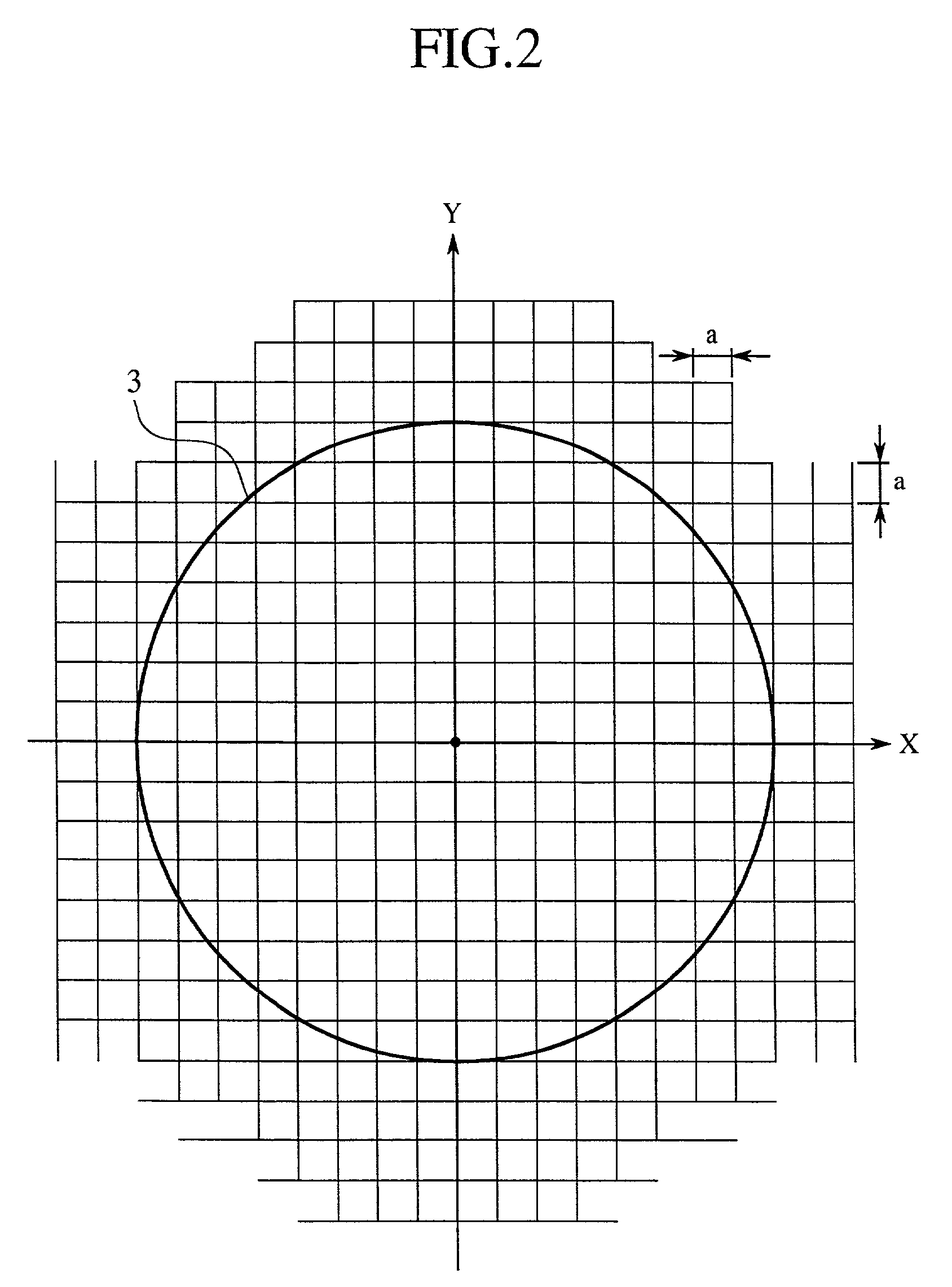

Radiation treatment plan making system and method

InactiveUS7054801B2Improve efficiencyImprove flatnessAnalogue computers for electric apparatusAnalogue computers for chemical processesParticle beamRadiation exposure

A radiation exposure region to be irradiated with particle beams and a peripheral region thereof are respectively divided into pluralities of exposure regions, radiation treatment simulation for applying particle beams according to the shape of each divided exposure region is performed, and a radiation treatment condition is obtained for causing the flatness of the radiation exposure region to be in a desired range, and a dose of particle beams applied to the unit exposure region of the peripheral region to be minimum. Thus, the problem of low efficiency of radiation is solved.

Owner:MITSUBISHI ELECTRIC CORP

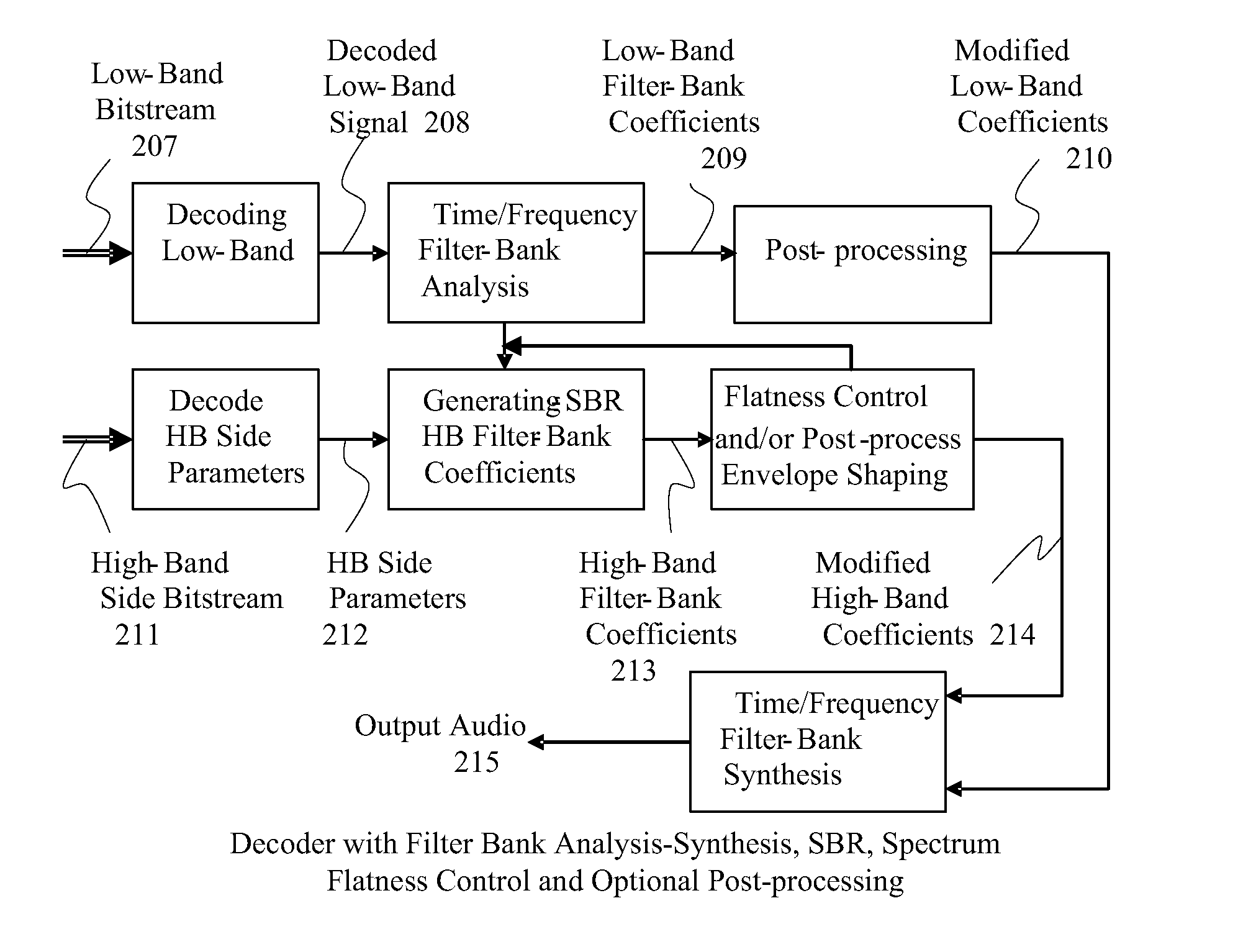

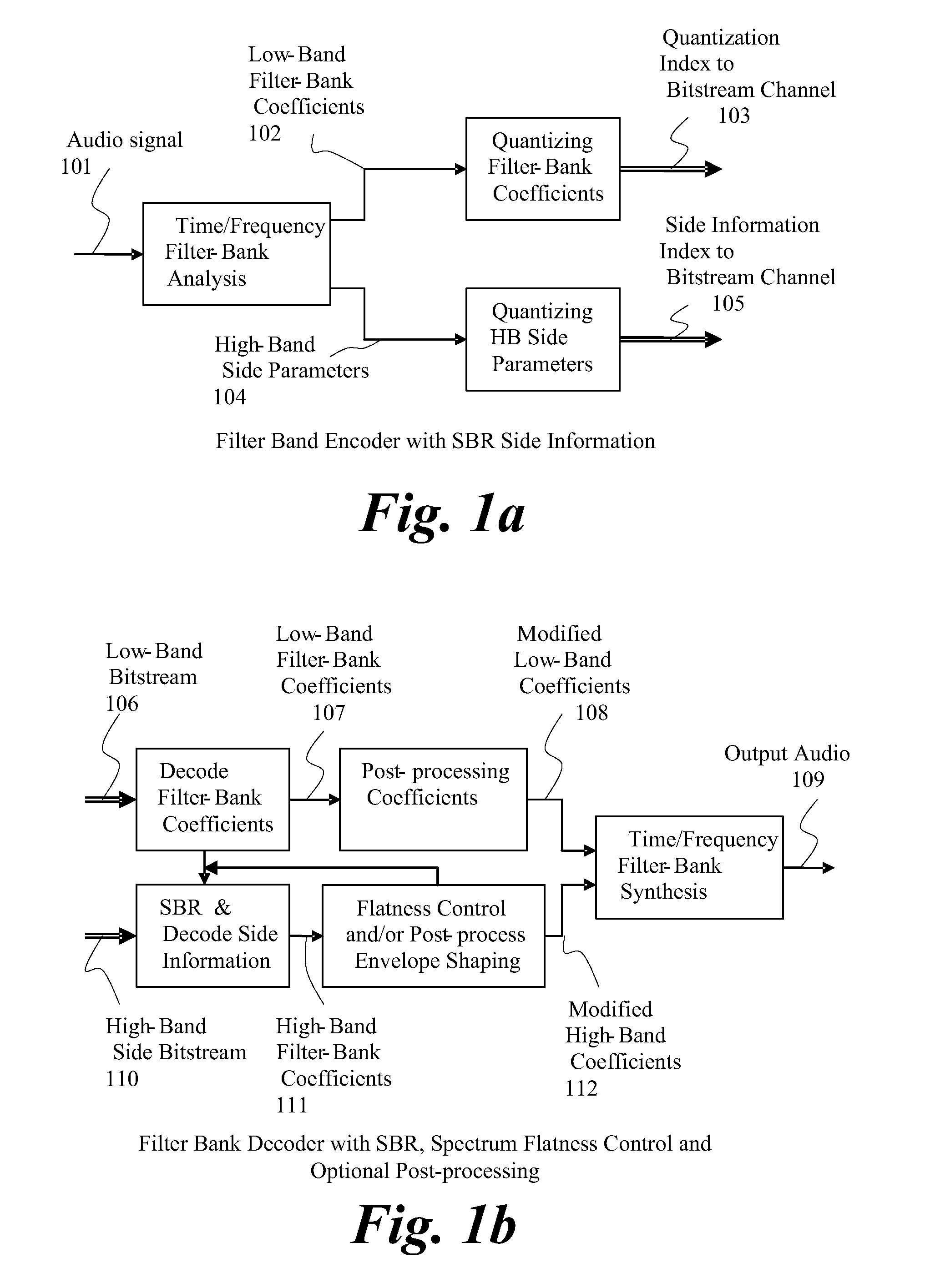

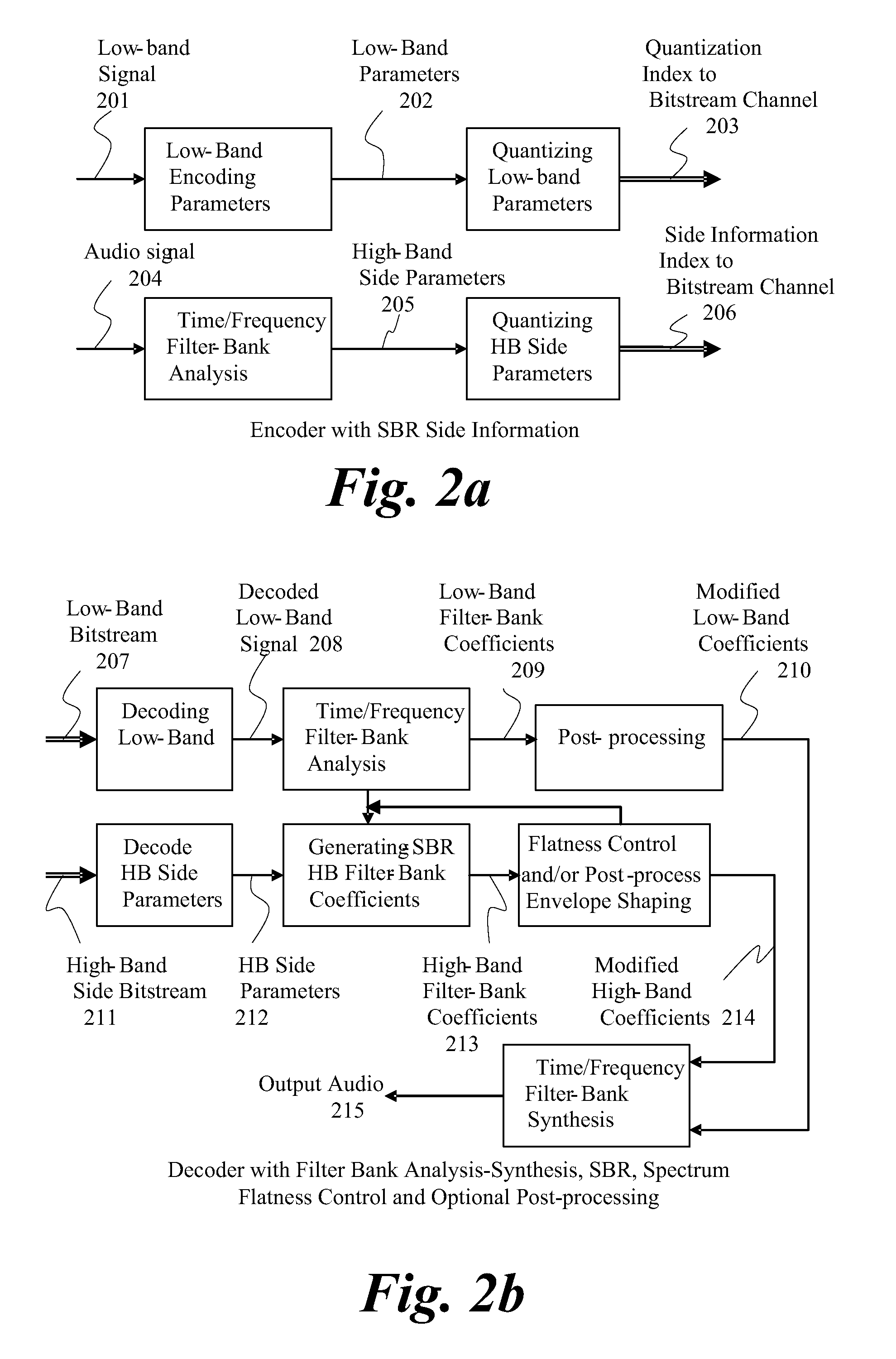

Spectrum Flatness Control for Bandwidth Extension

ActiveUS20120016667A1Improvement factorImproving spectrum flatness of high-frequencySpeech analysisFrequency spectrumBand width

In accordance with an embodiment, a method of decoding an encoded audio bitstream at a decoder includes receiving the audio bitstream, decoding a low band bitstream of the audio bitstream to get low band coefficients in a frequency domain, and copying a plurality of the low band coefficients to a high frequency band location to generate high band coefficients. The method further includes processing the high band coefficients to form processed high band coefficients. Processing includes modifying an energy envelope of the high band coefficients by multiplying modification gains to flatten or smooth the high band coefficients, and applying a received spectral envelope decoded from the received audio bitstream to the high band coefficients. The low band coefficients and the processed high band coefficients are then inverse-transformed to the time domain to obtain a time domain output signal.

Owner:HUAWEI TECH CO LTD

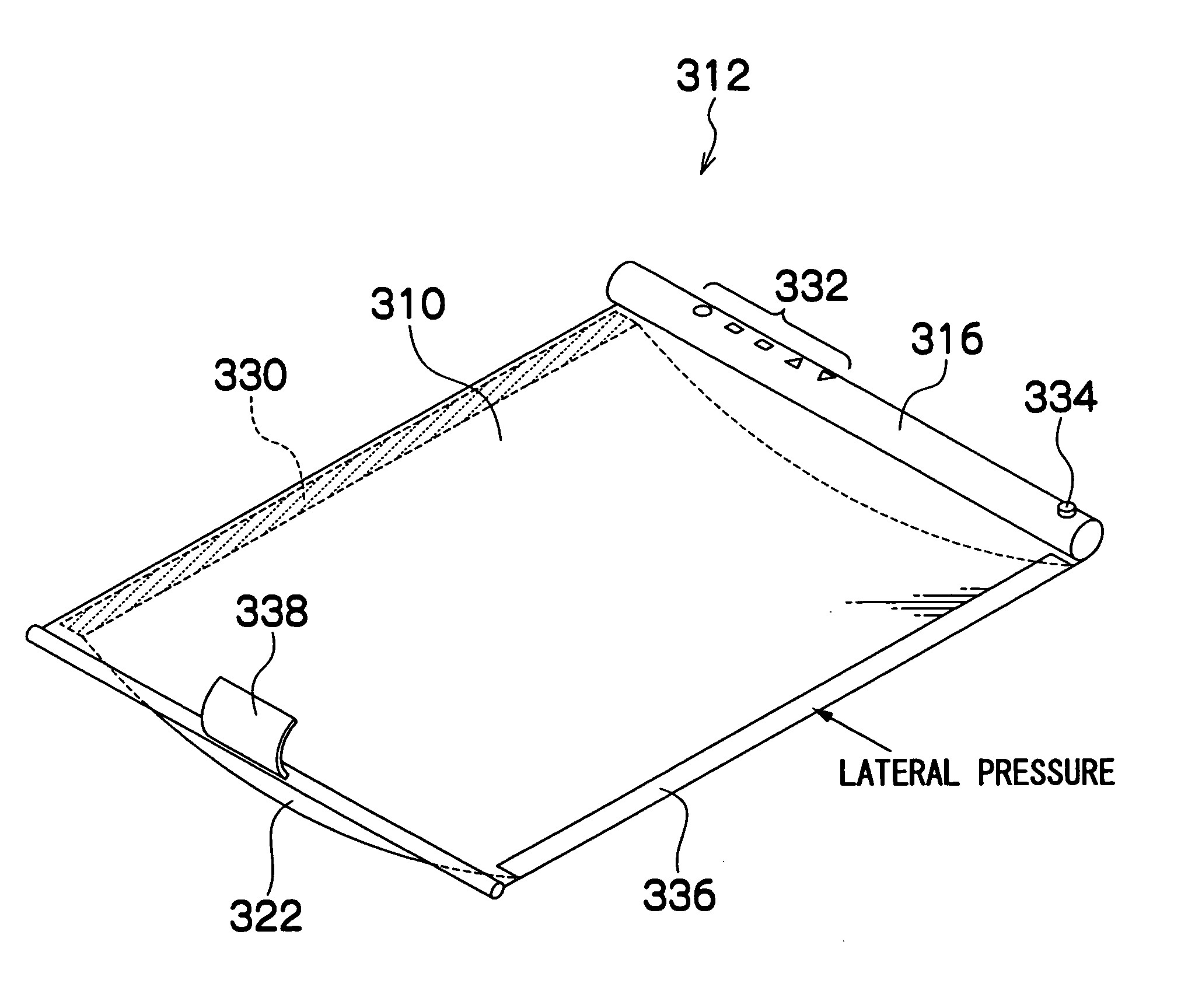

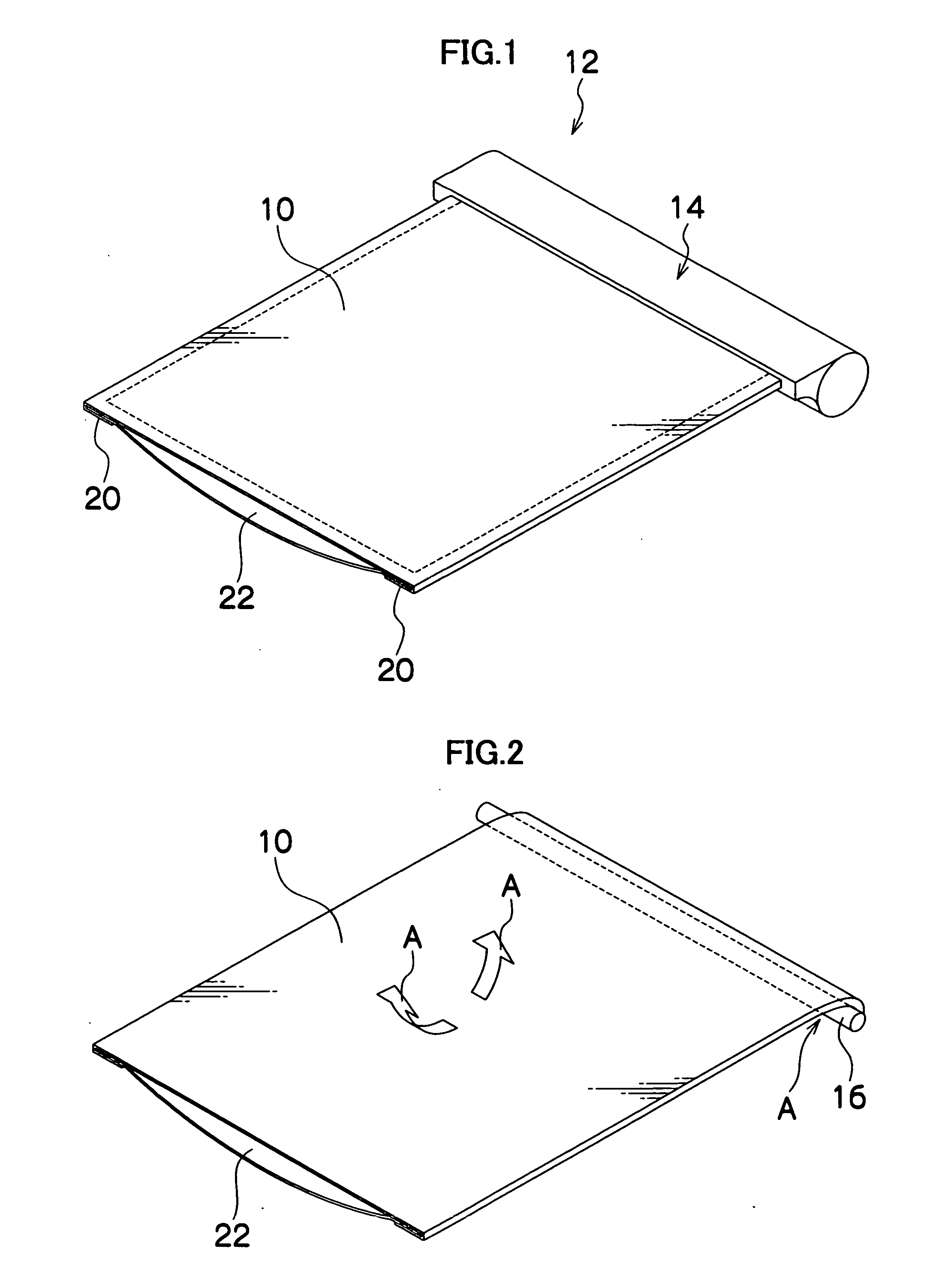

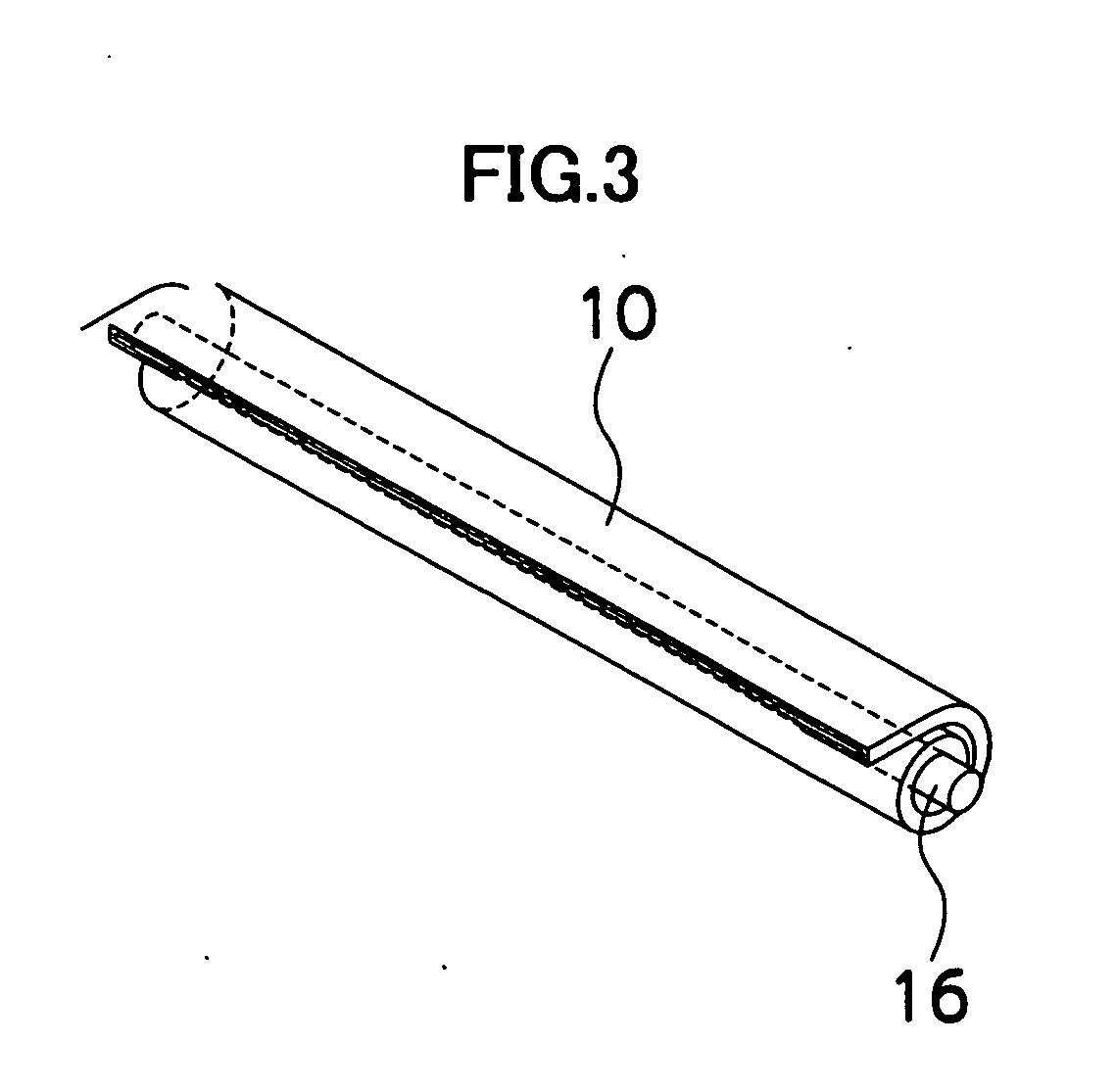

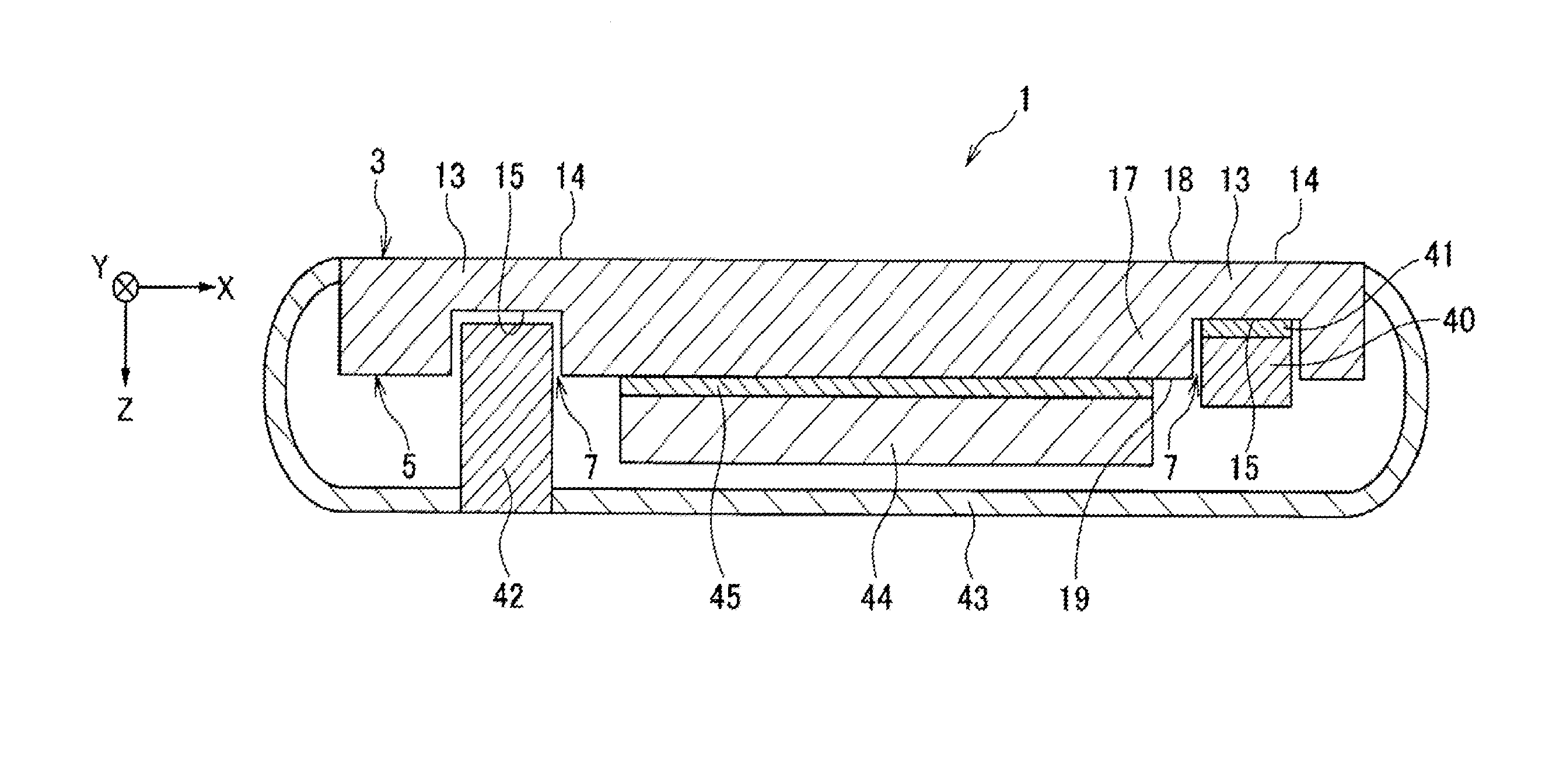

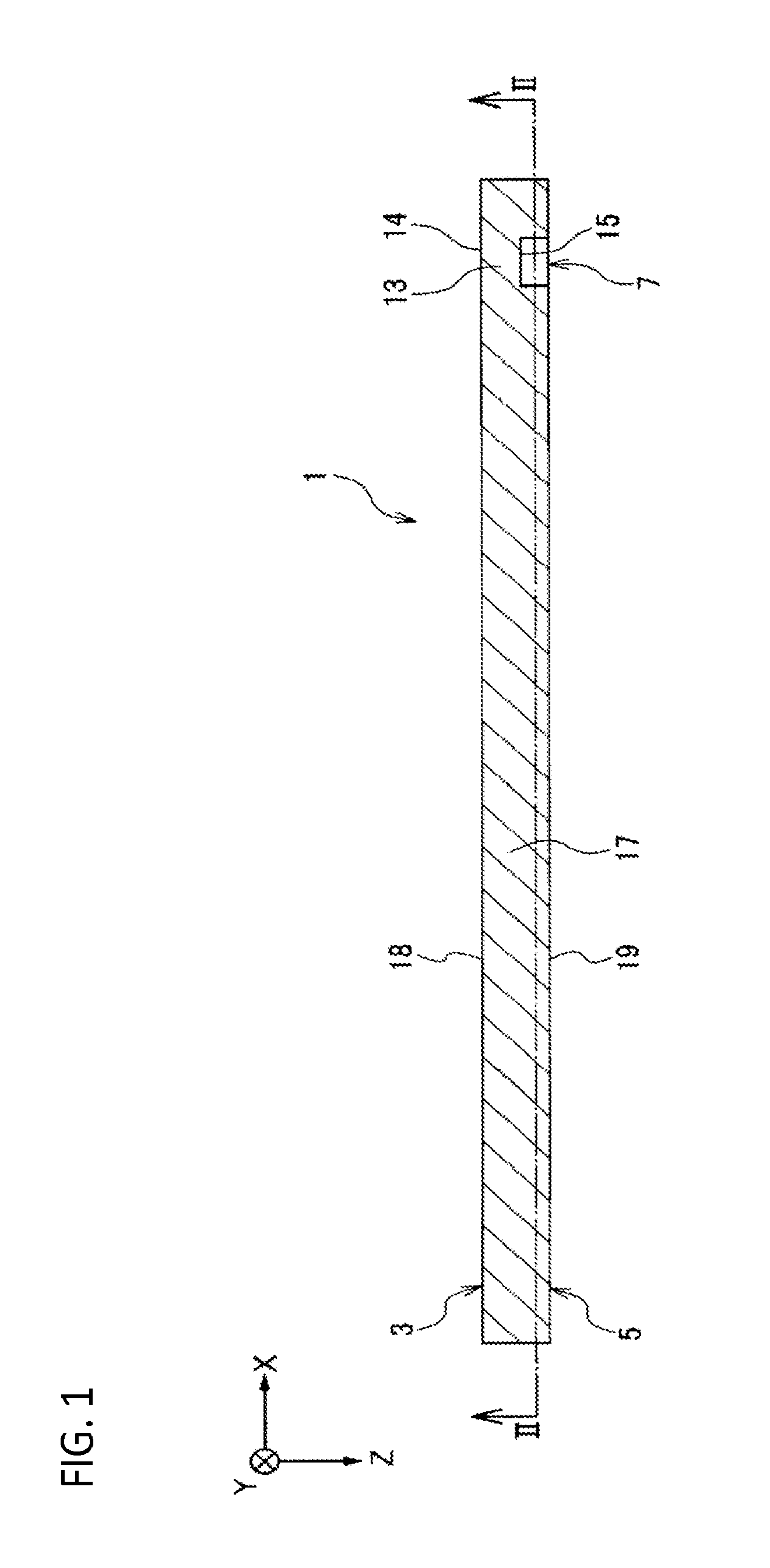

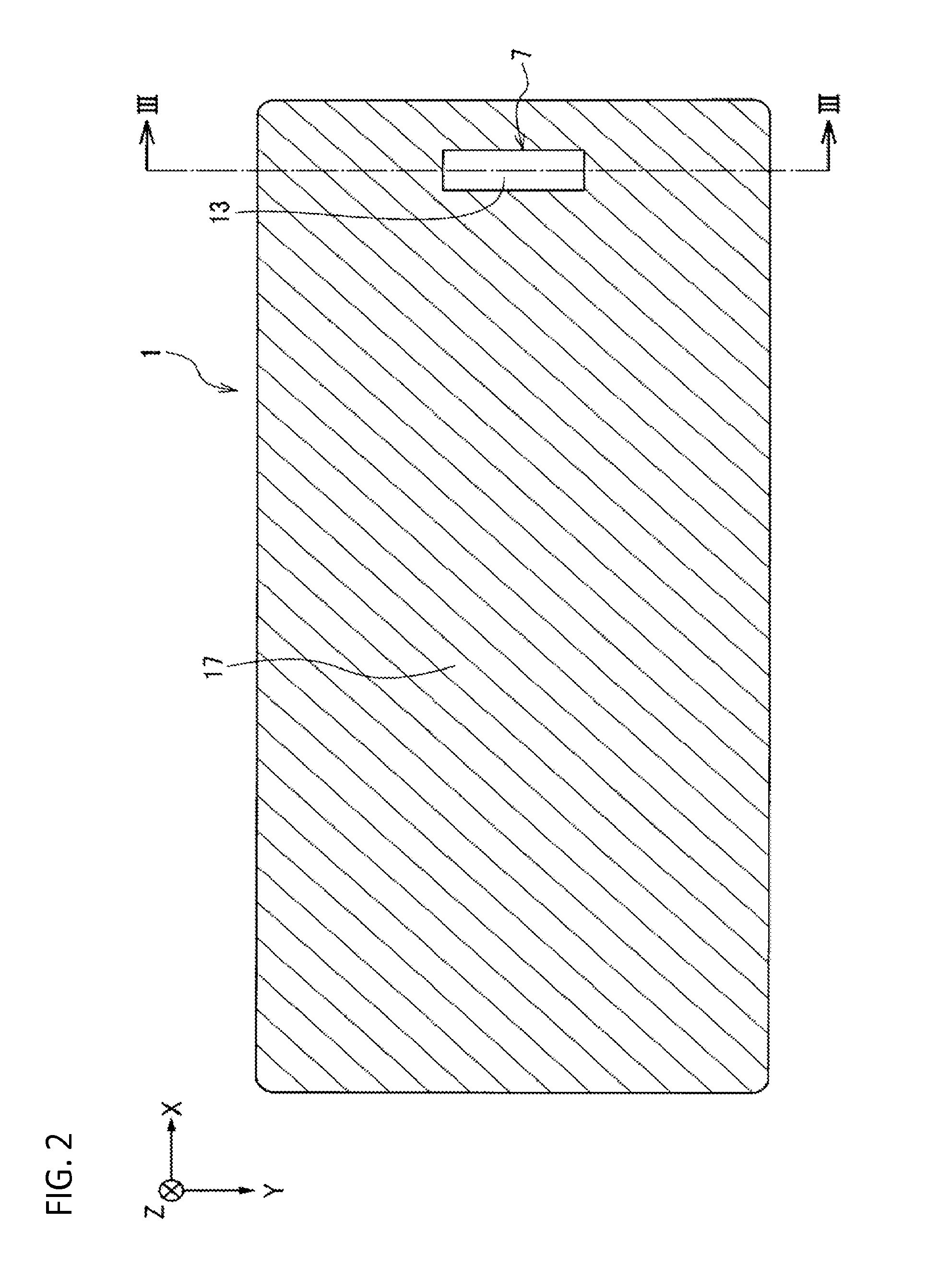

Display element, portable equipment and imaging device

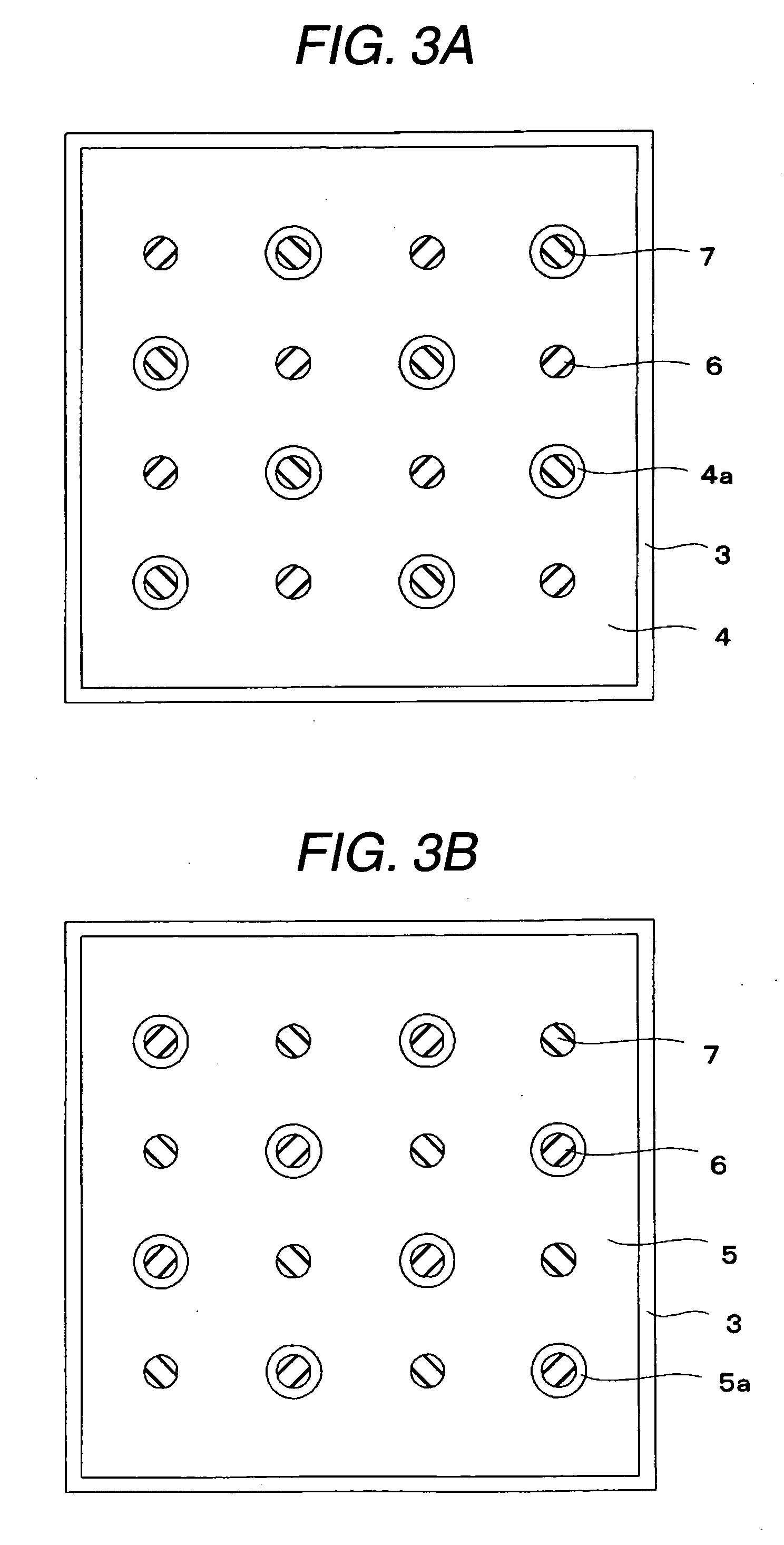

ActiveUS20080212271A1Improve portabilityGood for scrollingInput/output for user-computer interactionDigital data processing detailsEngineeringFlexible display

A flexible display element capable of being rolled up and unfurled, comprises a back plate covering a back side of the display element, wherein the back plate comes into contact with the back side of the display element when the display element is rolled up, and at least a central portion of the back plate is separated from the display element to support the display element in a flat shape when the display element is unfurled. Thus, the display element and the back plate can be rolled up and carried with a simple configuration of the display element and the back plate, and the display element can be supported in a flat shape when unfurled. Therefore, it is possible to provide a flexible display element having high portability, ease of rolling, and retention of flatness during periods of use.

Owner:FUJIFILM CORP

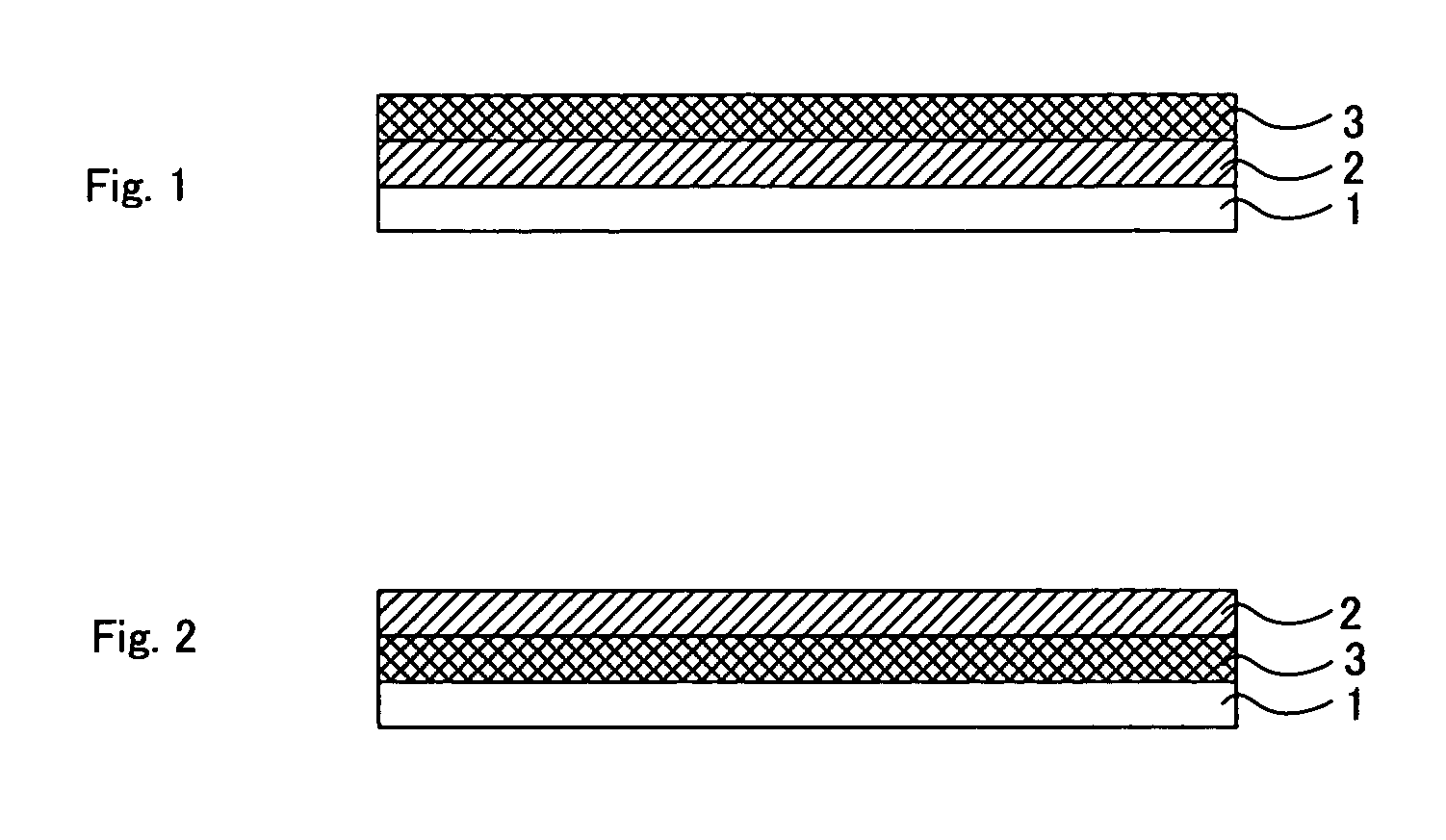

Gas barrier substrate

InactiveUS20050029513A1Quality improvementExcellent gas barrier performanceSolid-state devicesVacuum evaporation coatingMetallurgyGas formation

The main object of the present invention is to provide a gas barrier substrate having a high gas barrier property without a ruggedness, a pin hole or the like in the gas barrier layer. The present invention solves the problem by providing a gas barrier substrate having a base material, a planarization layer formed on the base material, and a gas barrier layer comprising a deposition film formed on the planarization layer.

Owner:DAI NIPPON PRINTING CO LTD

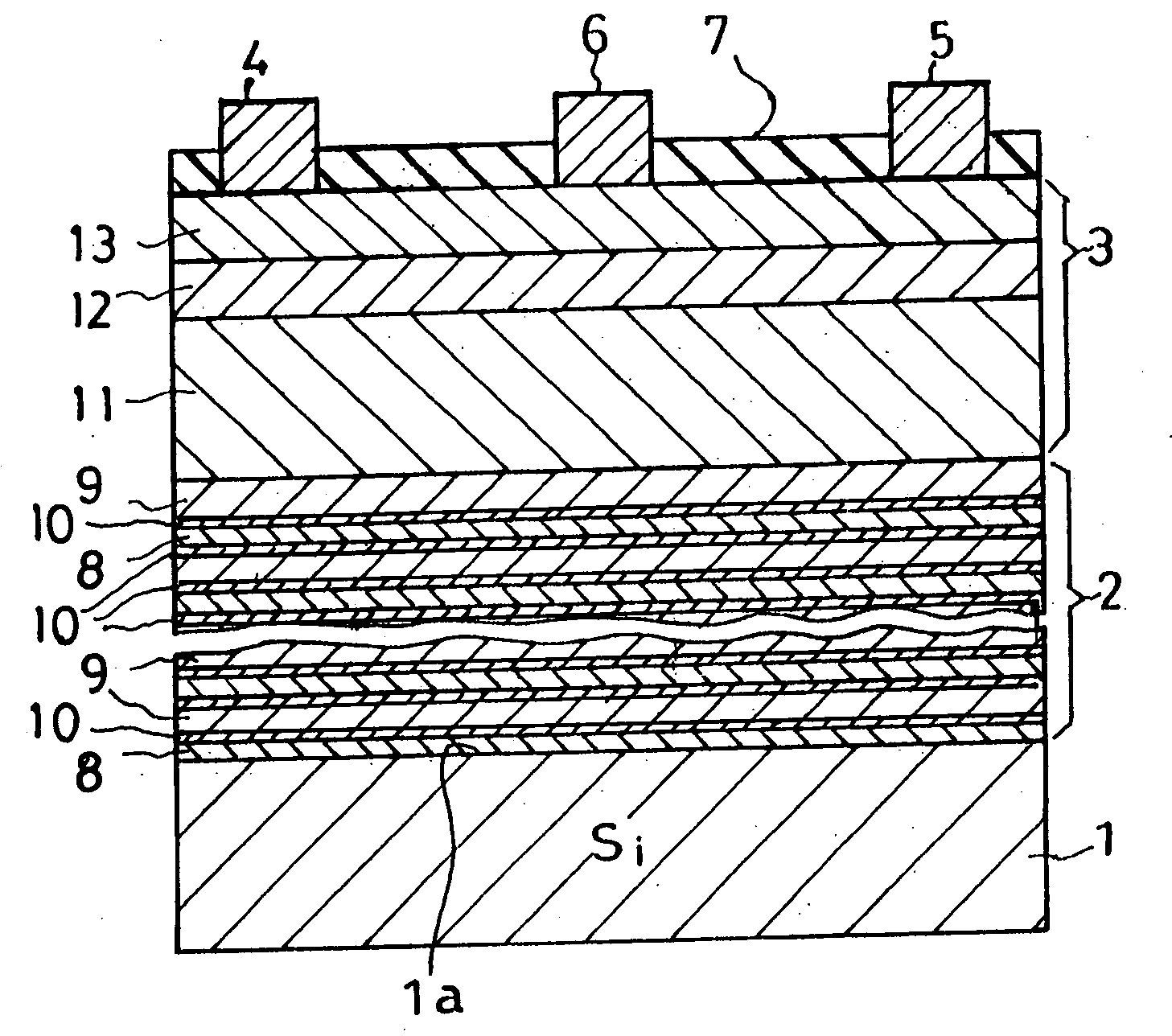

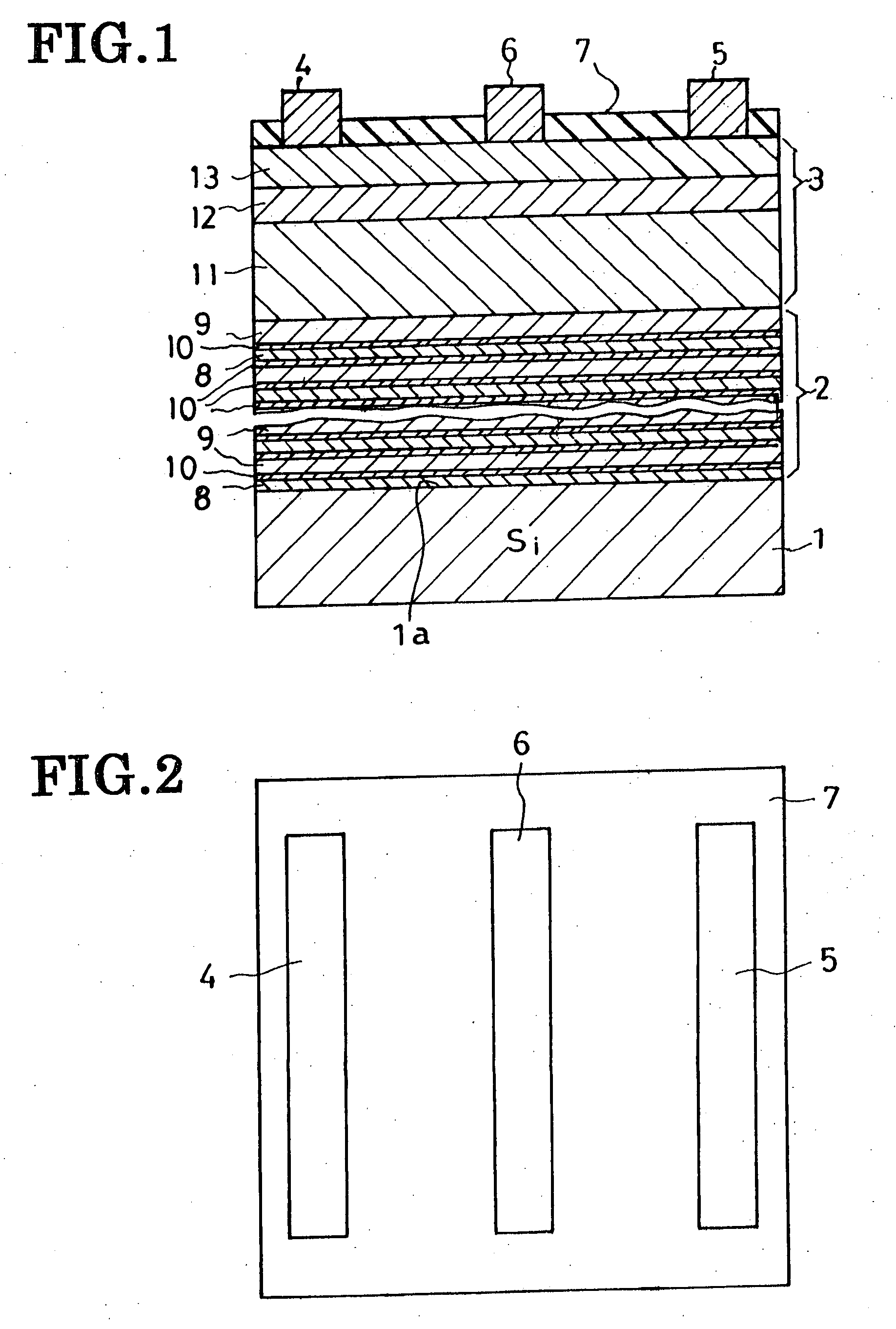

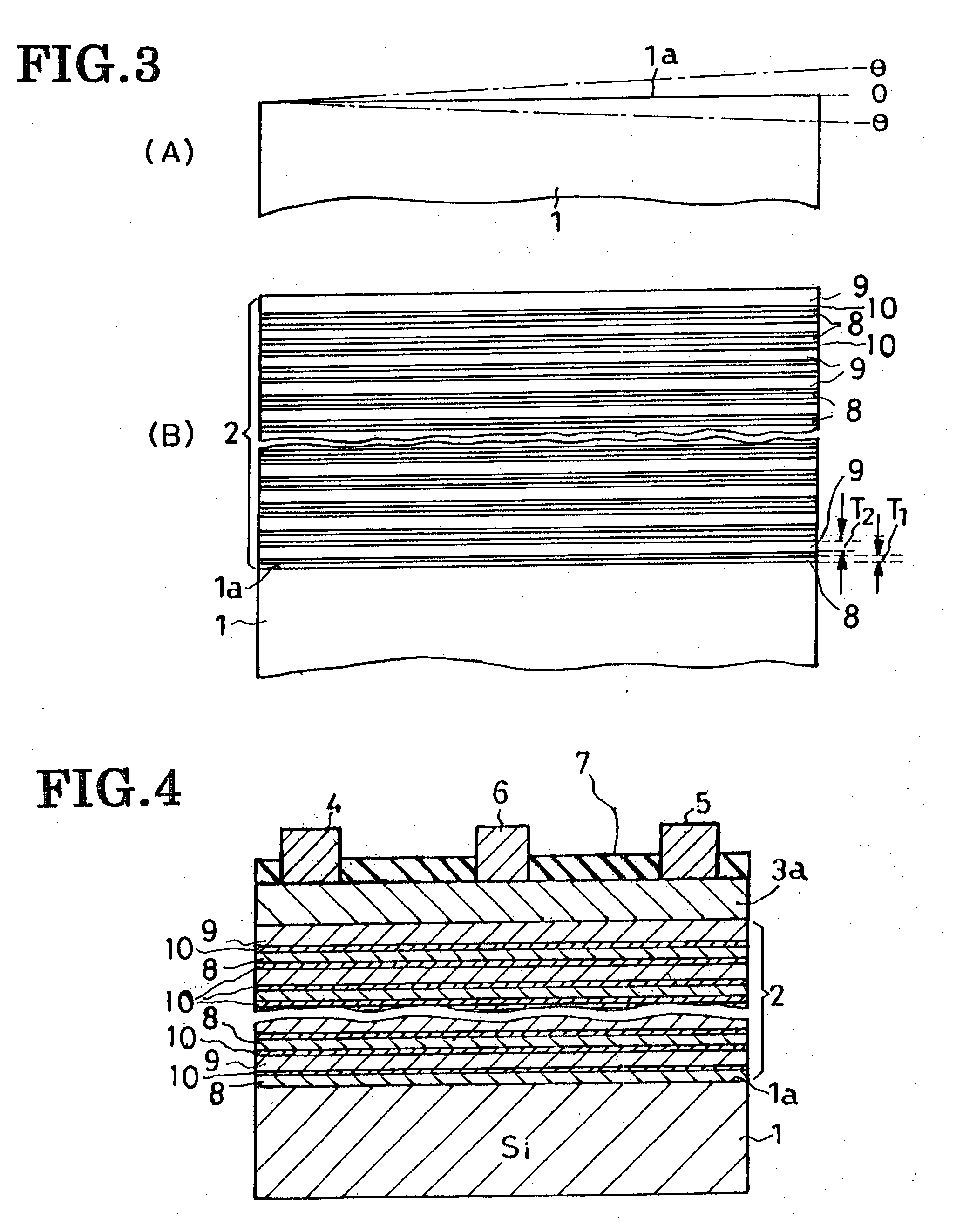

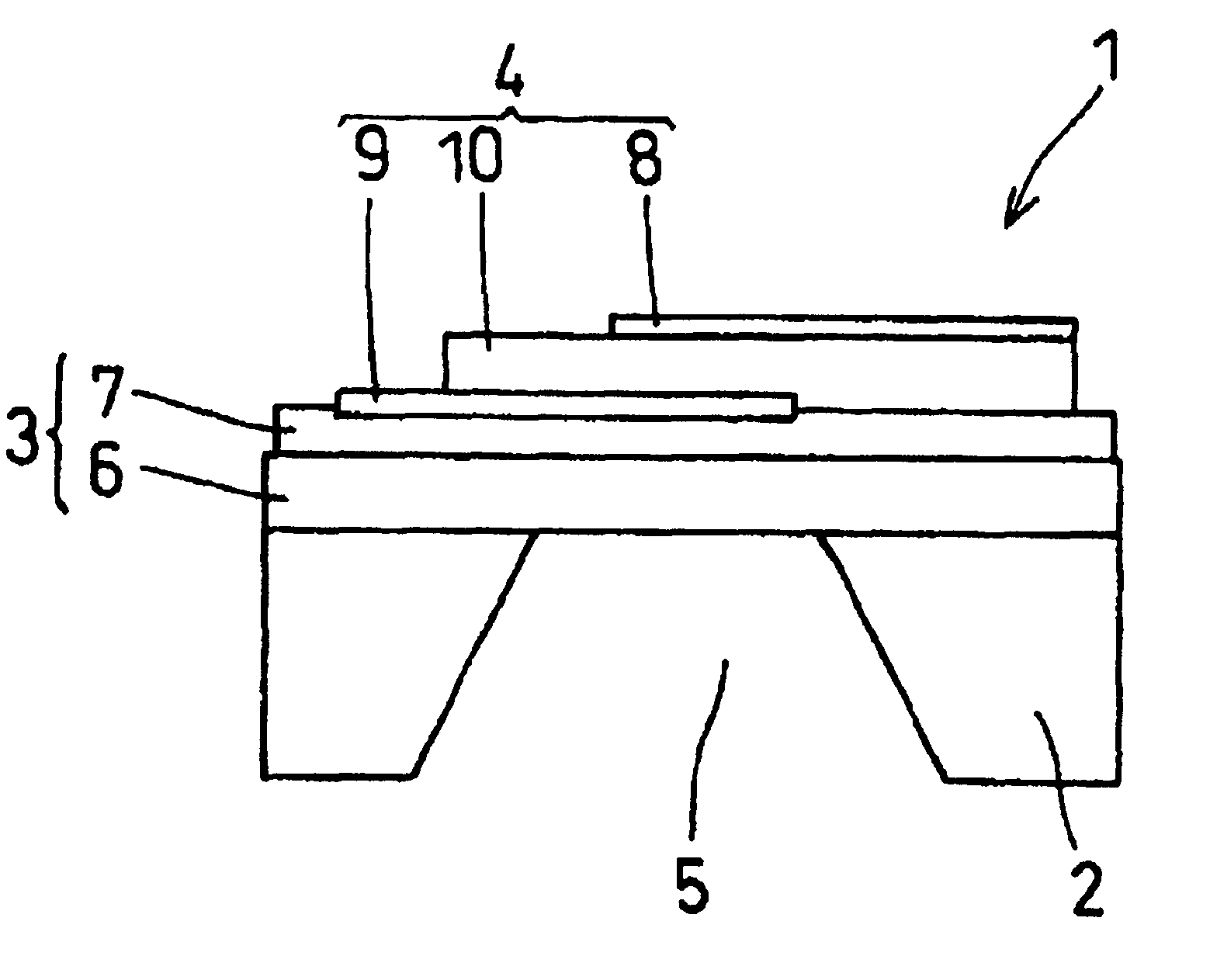

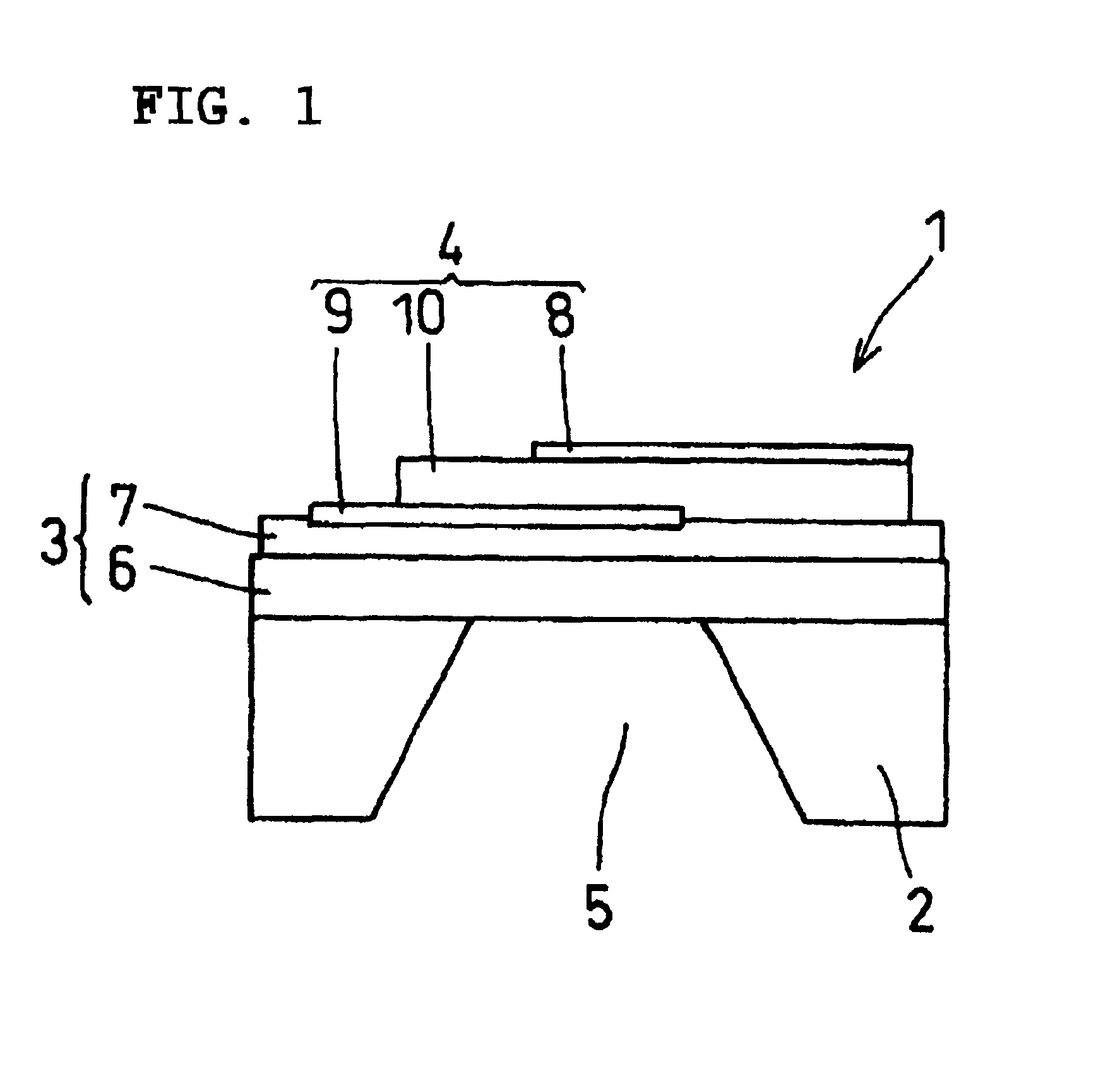

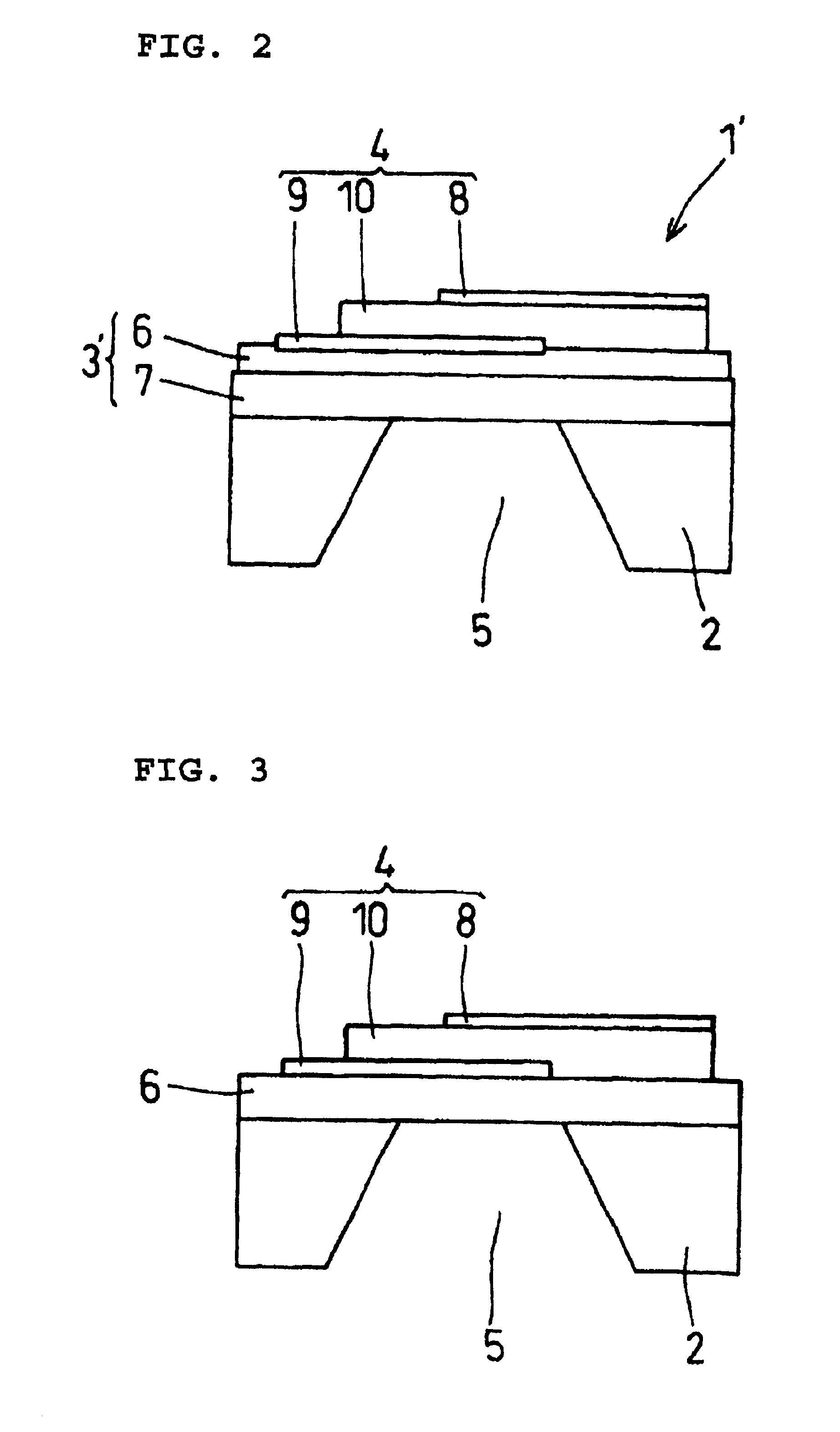

Semiconductor device and a method of making the same

InactiveUS20050263791A1Relieve pressureControl generationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialNanometre

A semiconductor device having nitride semiconductor layers has a buffer layer (2) in the form of alternations of a first sublayer (8) of AlN and a second layer (9) of GaN with interposition of a third layer (10) of p-type GaN therebetween. On this buffer layer there is grown a main semiconductor region (3) having nitride semiconductor layers for providing a high-electron-mobility transistor or the like. From 0.5 to 50.0 nanometers thick, the third sublayers (10) of the buffer layer restrict the generation of two-dimensional electron gas and so prevent the buffer layer from becoming unnecessarily low in resistance.

Owner:SANKEN ELECTRIC CO LTD

Semiconductor device including active layer made of zinc oxide with controlled orientations and manufacturing method thereof

InactiveUS7977169B2Improve propertiesIncrease resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesActive layerZinc

A semiconductor device includes an oxide semiconductor thin film layer primarily including zinc oxide having at least one orientation other than (002) orientation. The zinc oxide may have a mixed orientation including (002) orientation and (101) orientation. Alternatively, the zinc oxide may have a mixed orientation including (100) orientation and (101) orientation.

Owner:KOICHI IND PROMOTION CENT +1

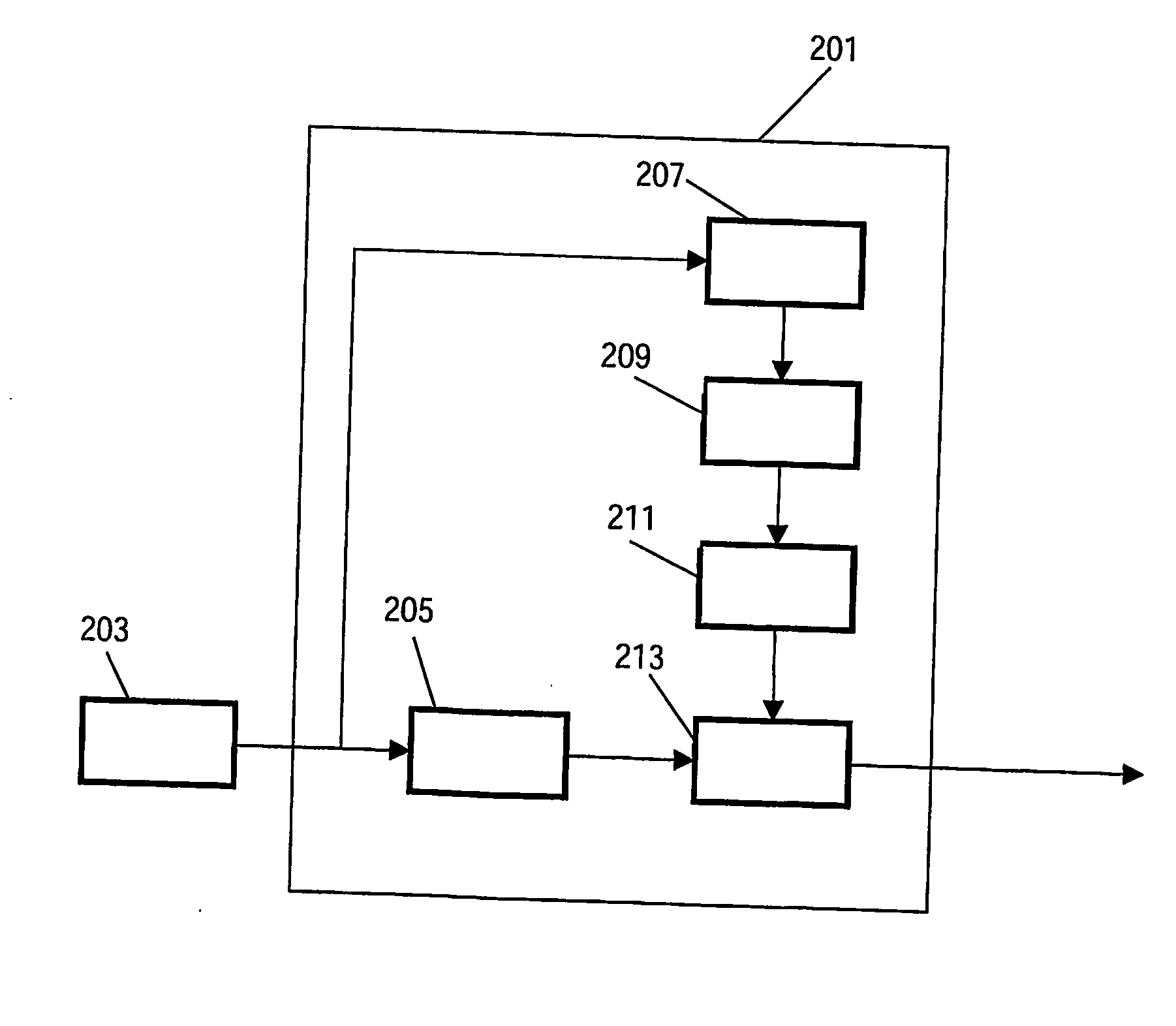

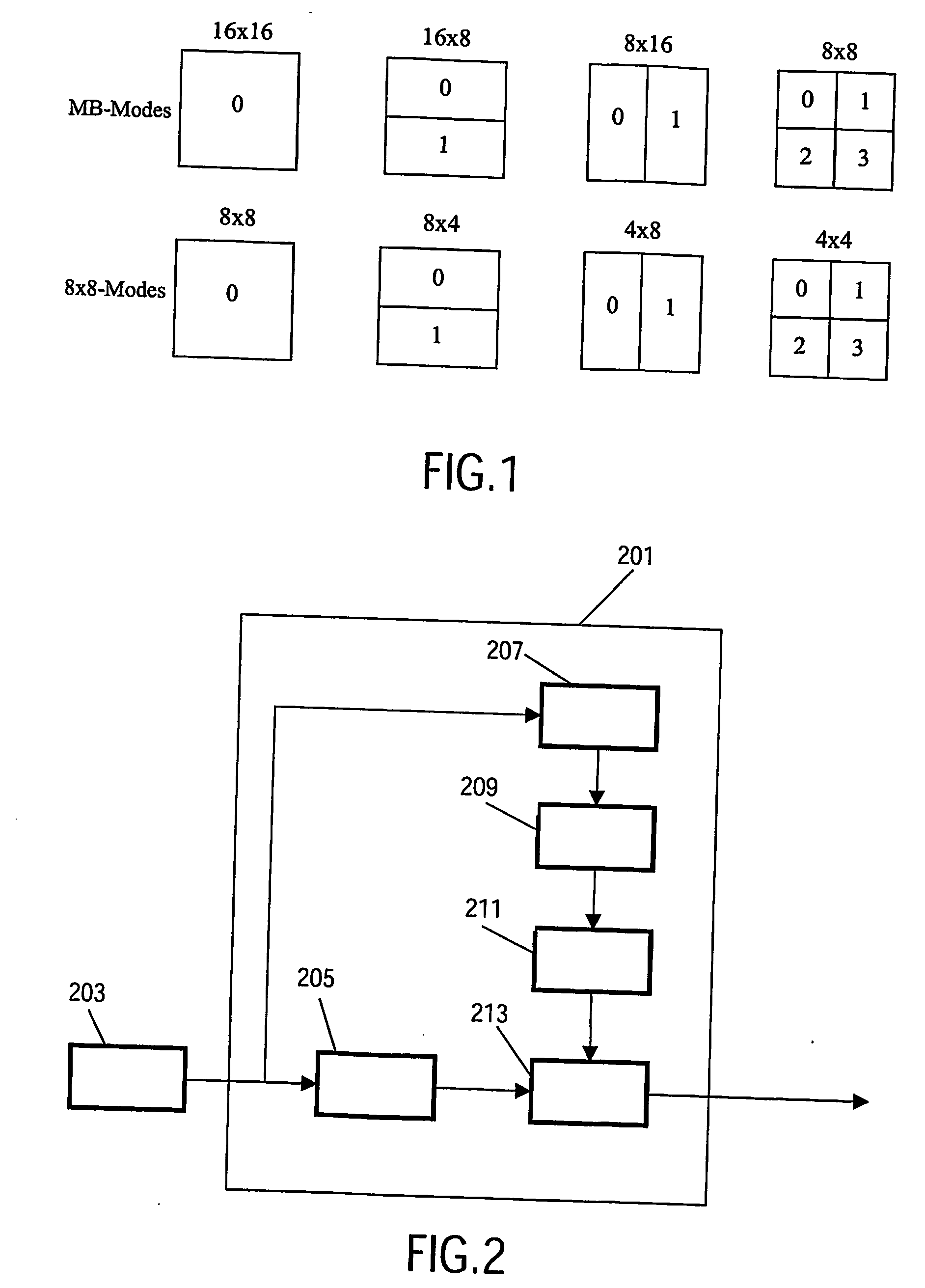

Video encoding

InactiveUS20060165163A1Improve performanceReduce lossesColor television with pulse code modulationColor television with bandwidth reductionPattern recognitionVideo encoding

The invention relates to a video encoder (201) for encoding a video signal. The video encoder comprises a segmentation processor (207) which divides the picture into picture regions. Preferably, picture regions having a high degree of flatness or uniformity are determined in this way. A characteristics processor (209) determine a spatial frequency characteristic for each picture region, and a coding controller (211) selects an encoding block size, such as a prediction block size for motion estimation, in response to the spatial frequency characteristic. An encode processor (213) encodes the picture using the selected encoding block size. Specifically, increasing block sizes are selected for increasing degrees of uniformity or flatness indicated by the spatial frequency characteristic. Thereby, an increasing proportion of high frequency components and a consistent choice of encoding block sizes are maintained, and thus the coding artefacts from many encoders having variable prediction block sizes is reduced. The invention is particularly suitable for H.264 and similar encoders.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

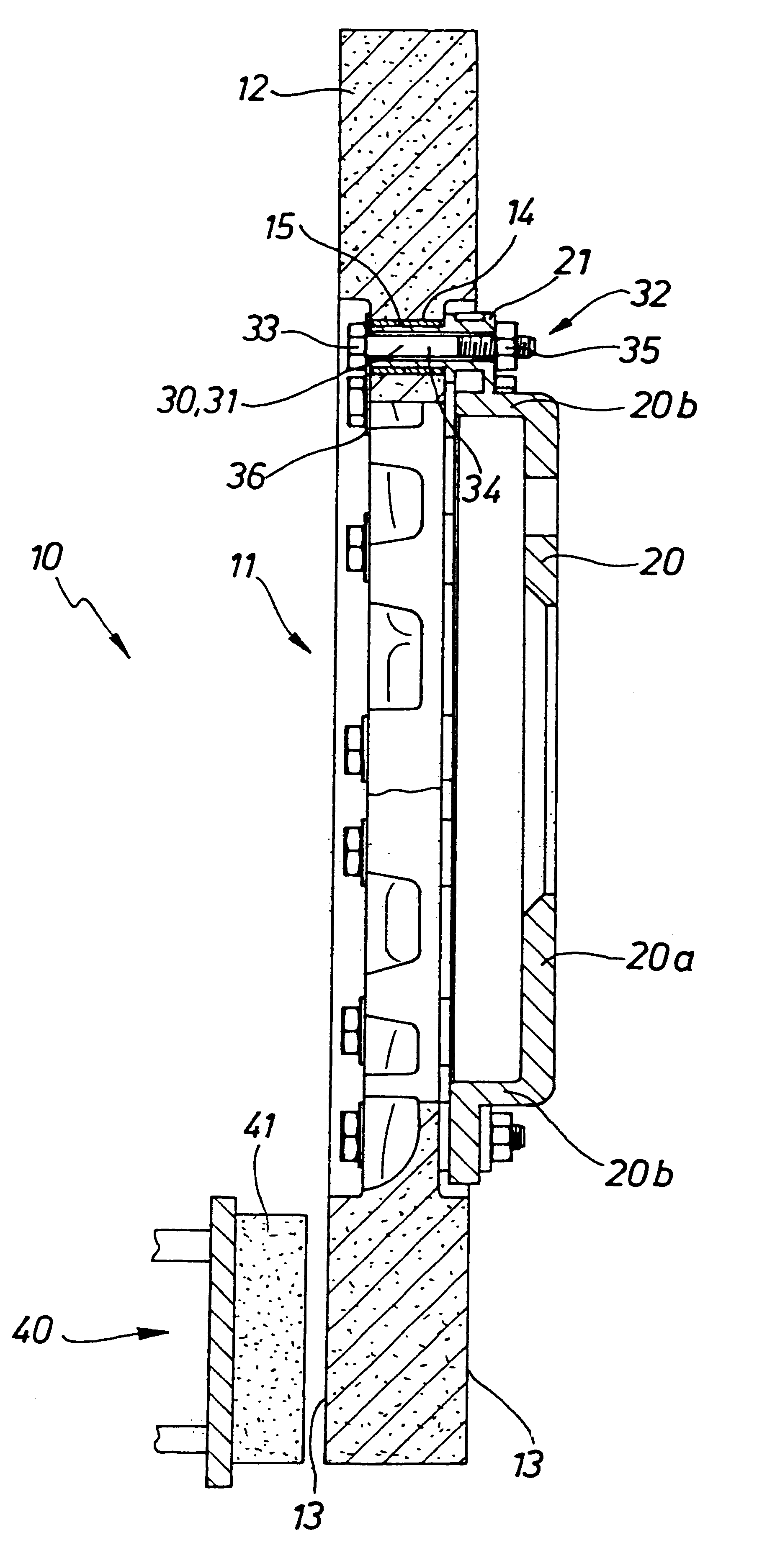

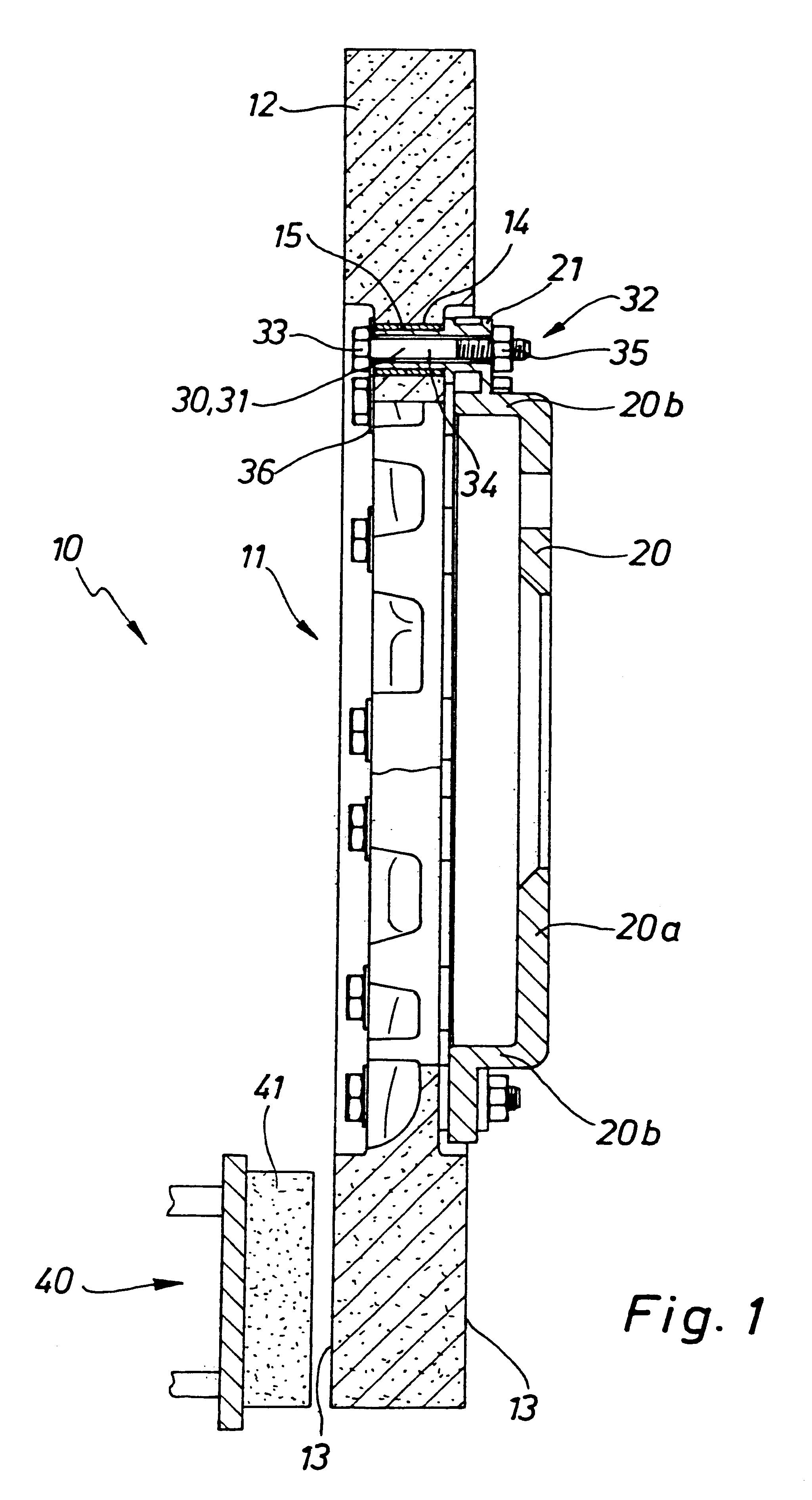

Brake unit

InactiveUS6302246B1Prolong lifeImprove flatnessBraking element arrangementsNoise/vibration controlEngineeringCeramic metal

A brake unit comprising at least one brake and at least one brake pad having at least one friction lining is described. The brake has a disk brake with a brake rotor made of a ceramic-metal composite (CMC) whose outer surface or surfaces at least partially form a friction surface for the at least one friction lining, and a disk brake cup that is mounted on the disk brake by way of one or more mounting elements. The friction surface of the disk brake has a hardness of approximately 1600 to 2500 HV, and the at least one friction lining has a coefficient of friction of approximately 0.3 to 0.5. The disk brake cup and / or the mounting elements form a corrosion-inhibiting attachment to the disk brake. The brake unit can be operated in corrosion-free fashion over a service life of at least approximately eight to 10 years or approximately 200,000 to 300,000 km.

Owner:FRENI BREMBO SPA

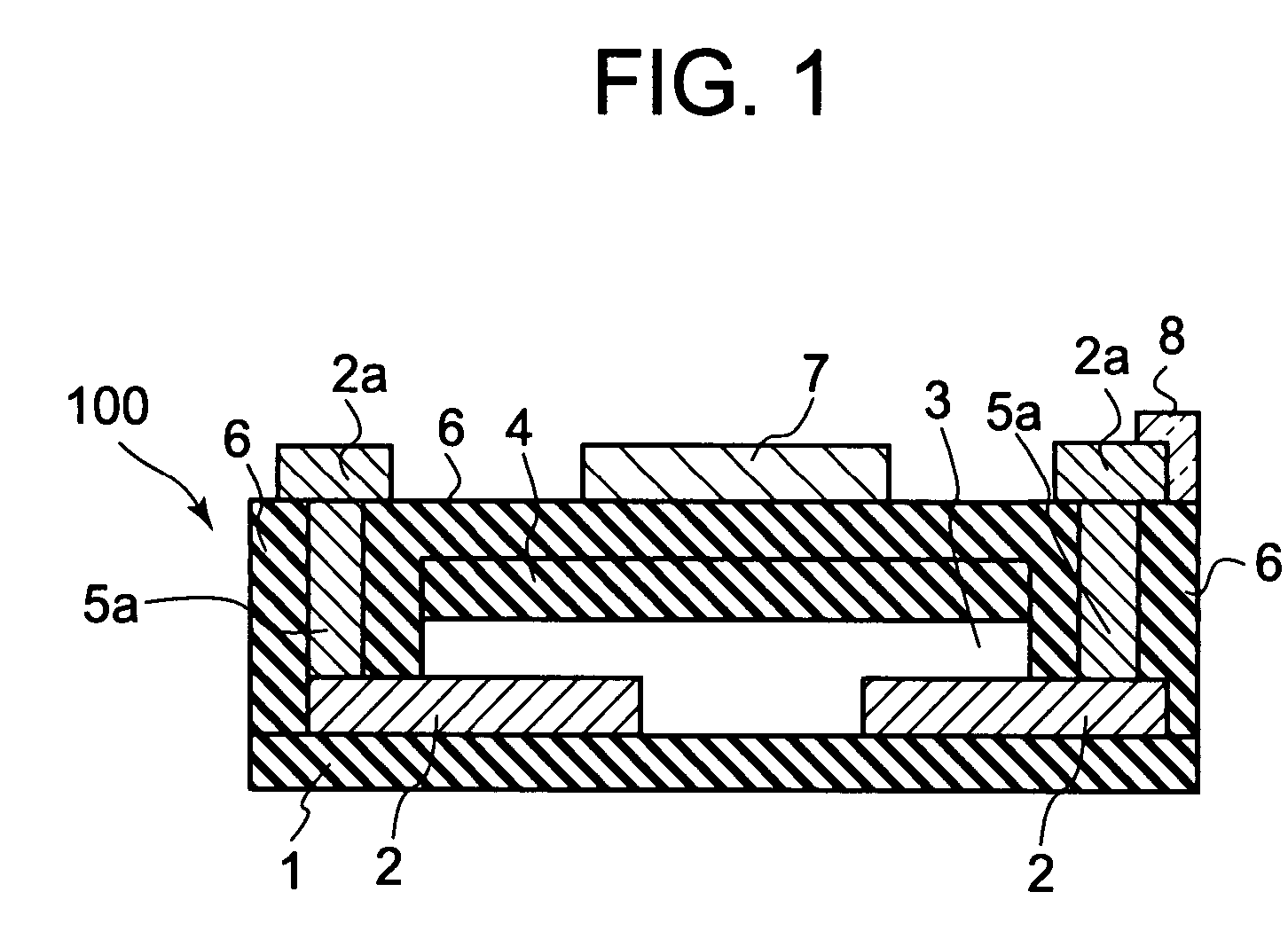

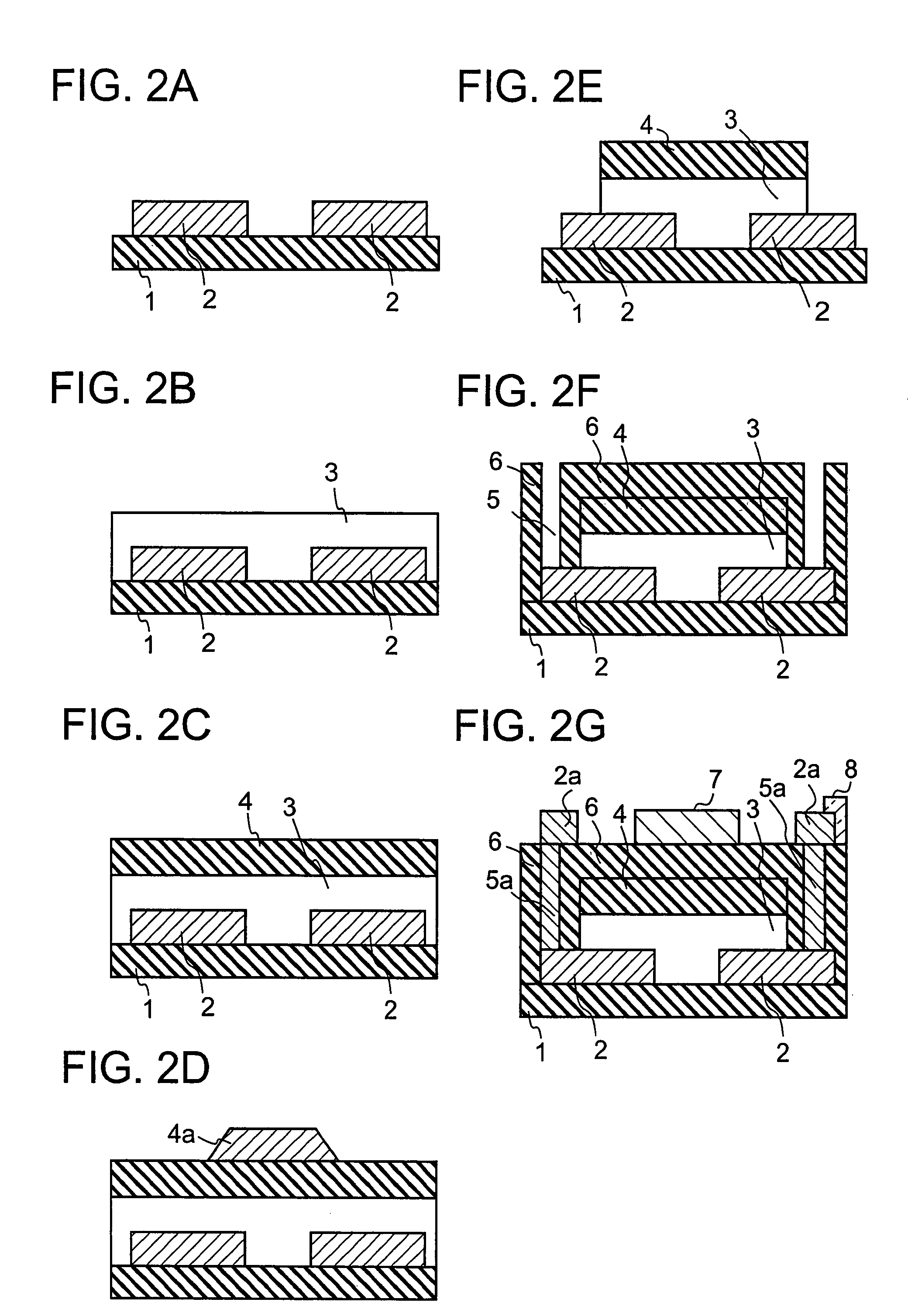

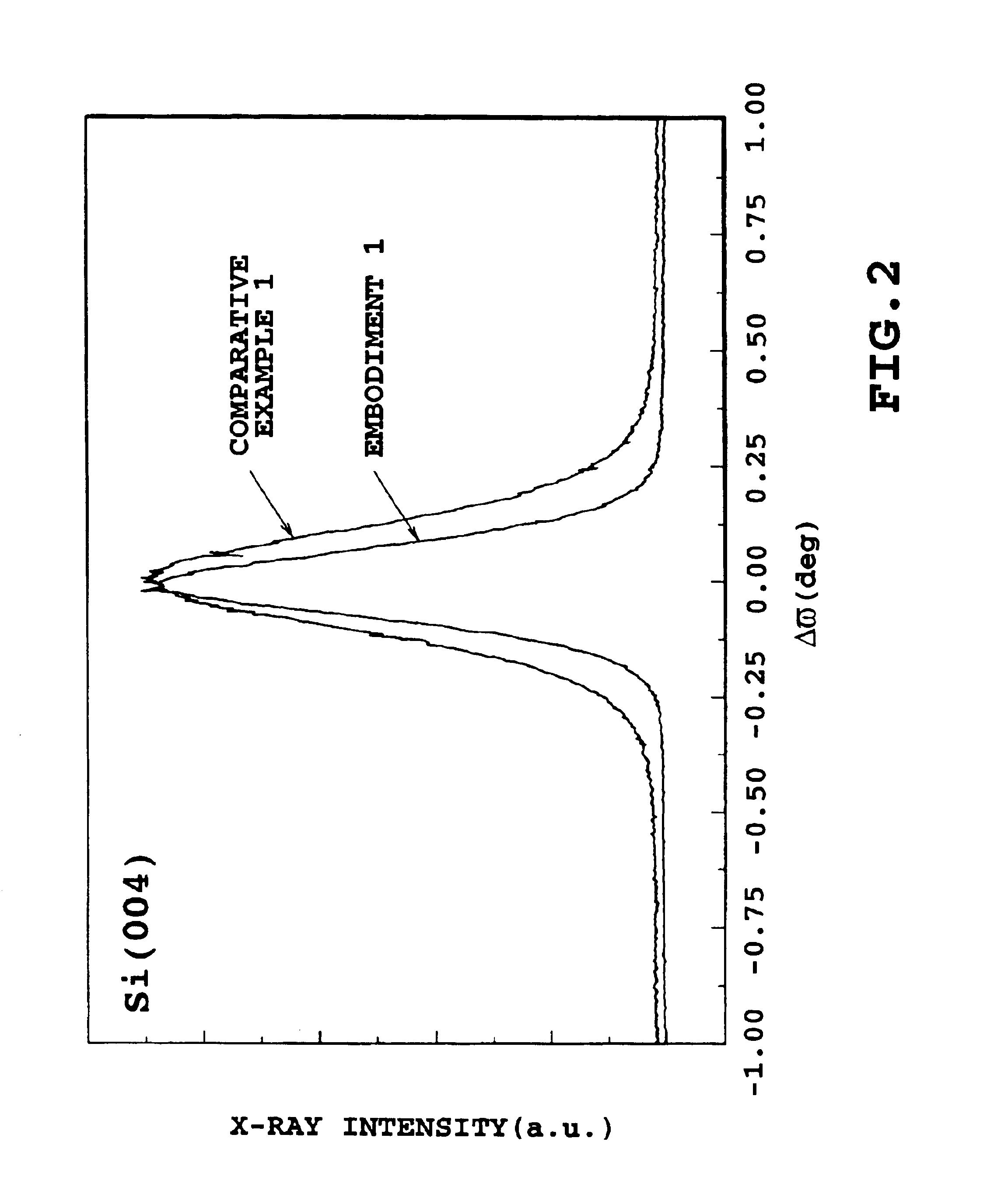

Piezoelectric resonator, piezoelectric filter, duplexer, communication apparatus, and method for manufacturing piezoelectric resonator

InactiveUS6906451B2Improve flatnessOutstanding crystallinityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksOxygenPiezoelectric thin films

A piezoelectric thin film resonator having a stabilized temperature characteristic of resonant frequency, a method for manufacturing the same, and a communication apparatus using the piezoelectric thin film resonator are provided. The piezoelectric thin film resonator is provided with a substrate having an opening, first and second insulation films which are provided on one surface of the substrate while covering the opening and which primarily include SiO2 and Al2O3, respectively, Al2O3 having oxygen defect and being in an amorphous state, and a piezoelectric thin film which is provided on the second insulation film and is sandwiched between electrodes and which primarily includes ZnO.

Owner:MURATA MFG CO LTD

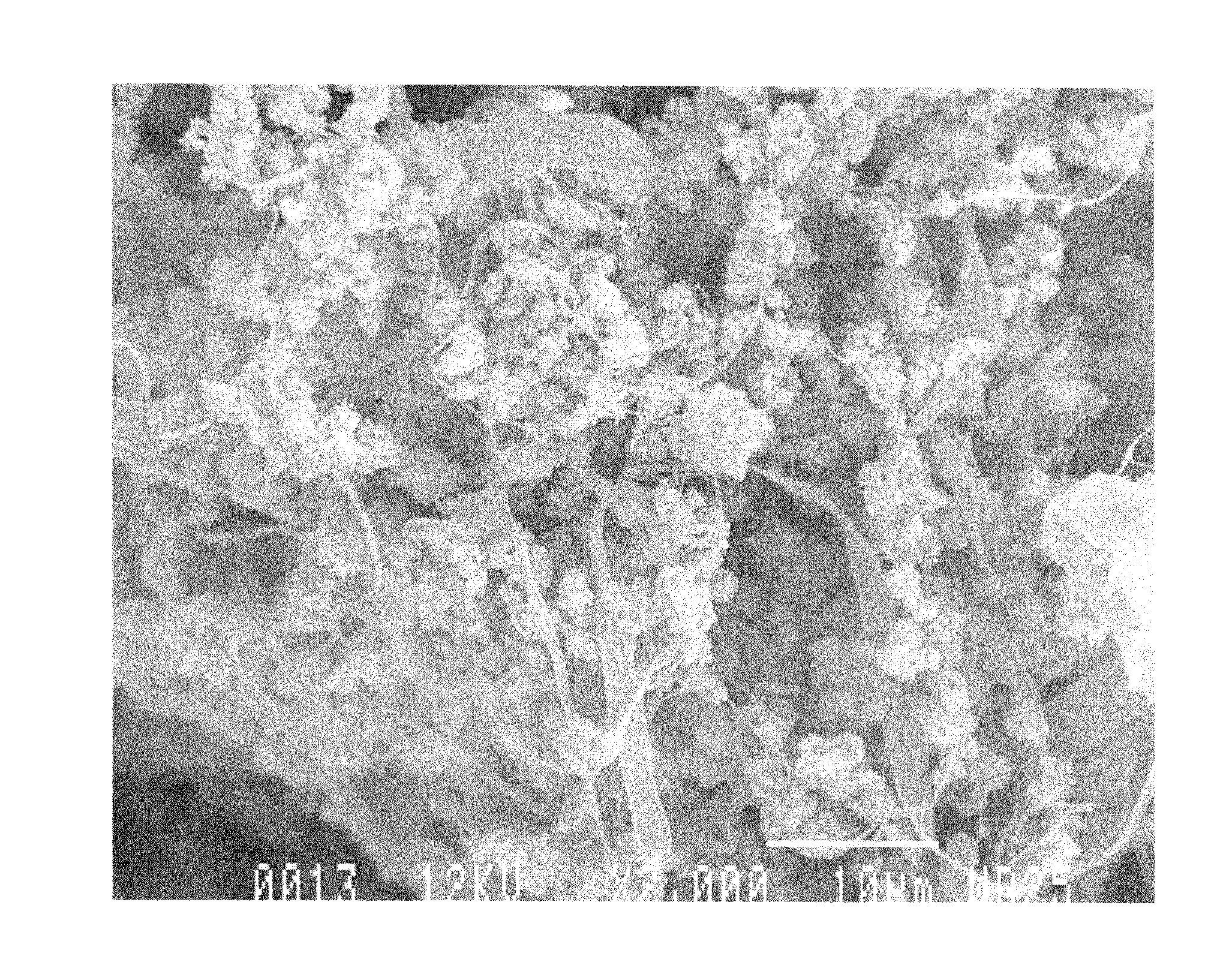

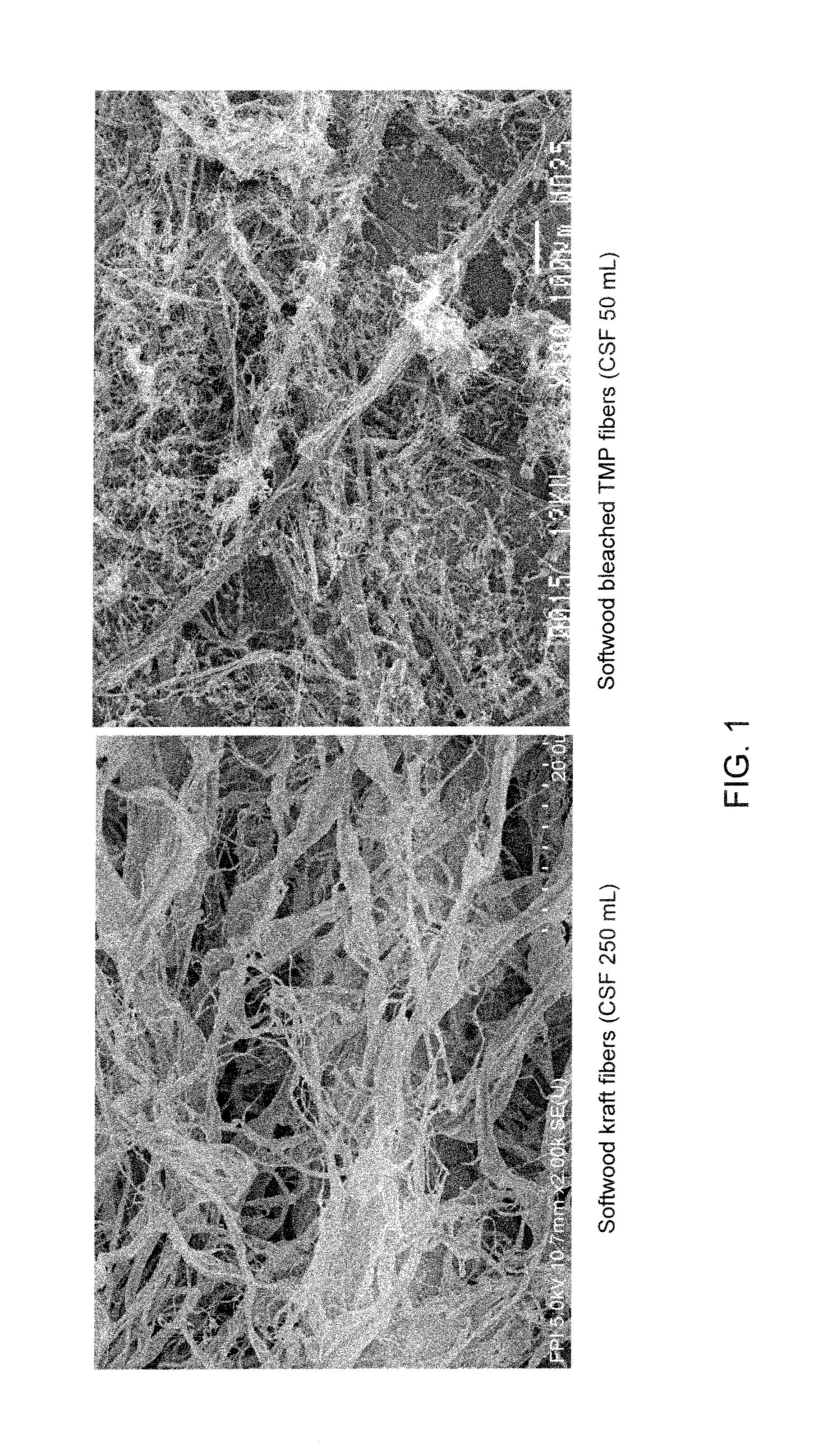

Cellulose-reinforced high mineral content products and methods of making the same

ActiveUS20120080156A1Great filler fixationStrengthen and consolidateSpecial paperPaper after-treatmentCelluloseFiber

A method to prepare aqueous furnishes useful as feedstock in the manufacture of very high-mineral content products, particularly paper sheets having mineral filler content up to 90% that display the required physical properties for the intended applications; the furnishes comprise fibrillated long fibres / mineral fillers mixed with anionic acrylic binders and co-additives, in presence or absence of cellulose fibrils; the fibrillated long fibres and cellulose fibrils provide high surface area for greater filler fixation and the reinforcement backbone network that ties all of the product components together; the anionic binders allow rapid and strong fixation of filler particles onto the surfaces of fibrils when mixing is conducted at temperatures higher than the glass transition temperature (Tg) of the binder. The aqueous furnish provides excellent filler retention and drainage during product fabrication.

Owner:FPINNOVATIONS INC

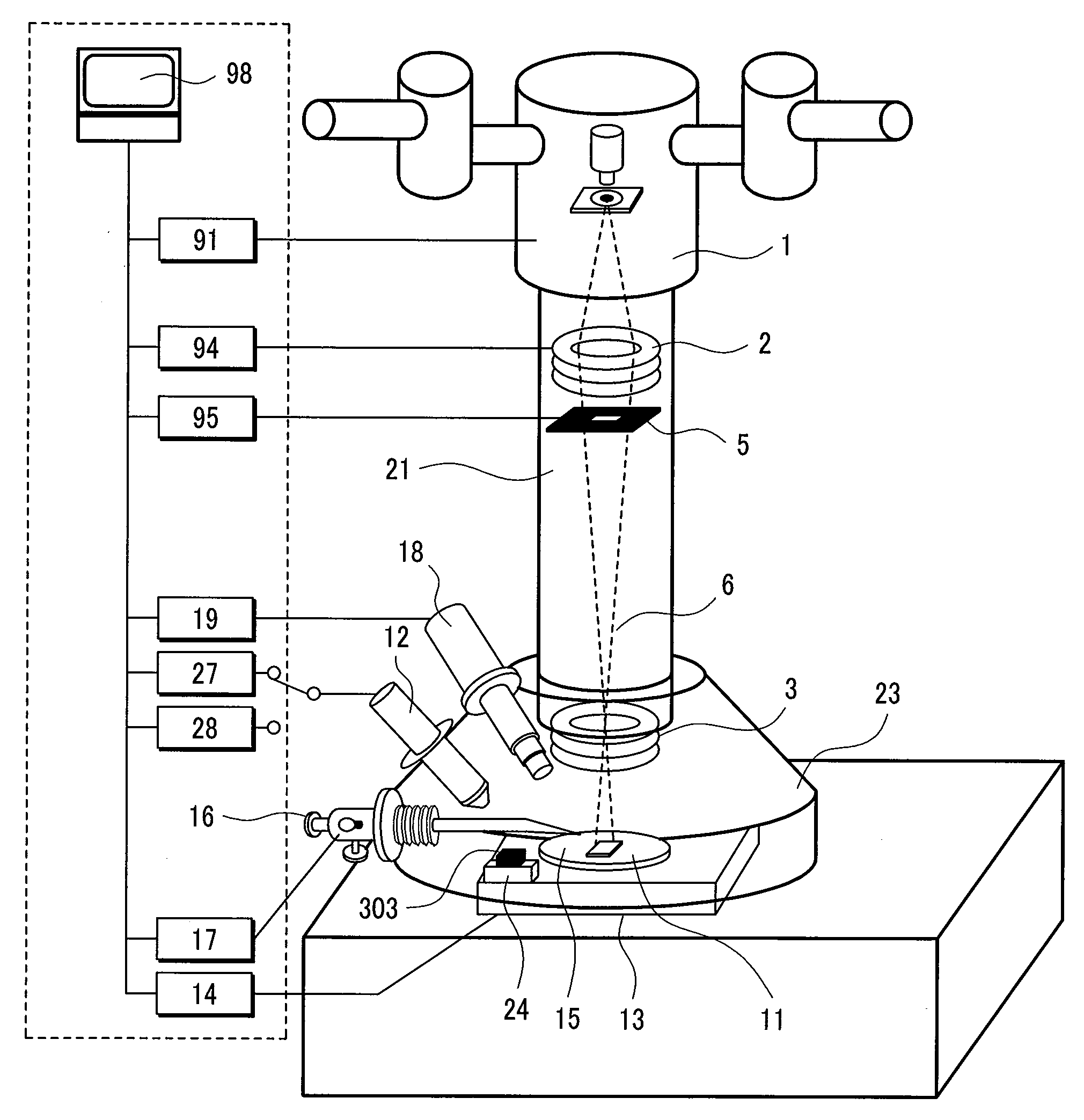

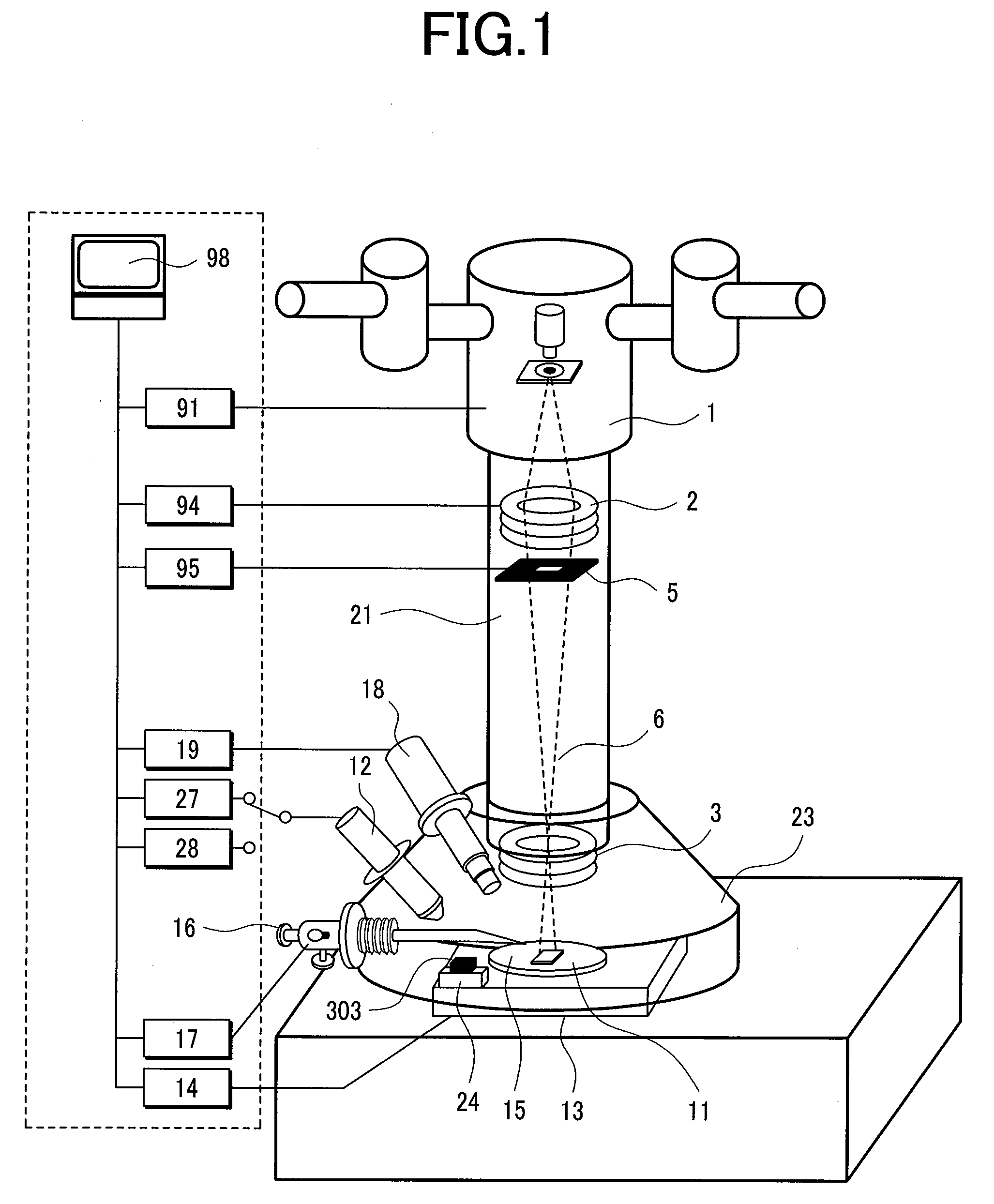

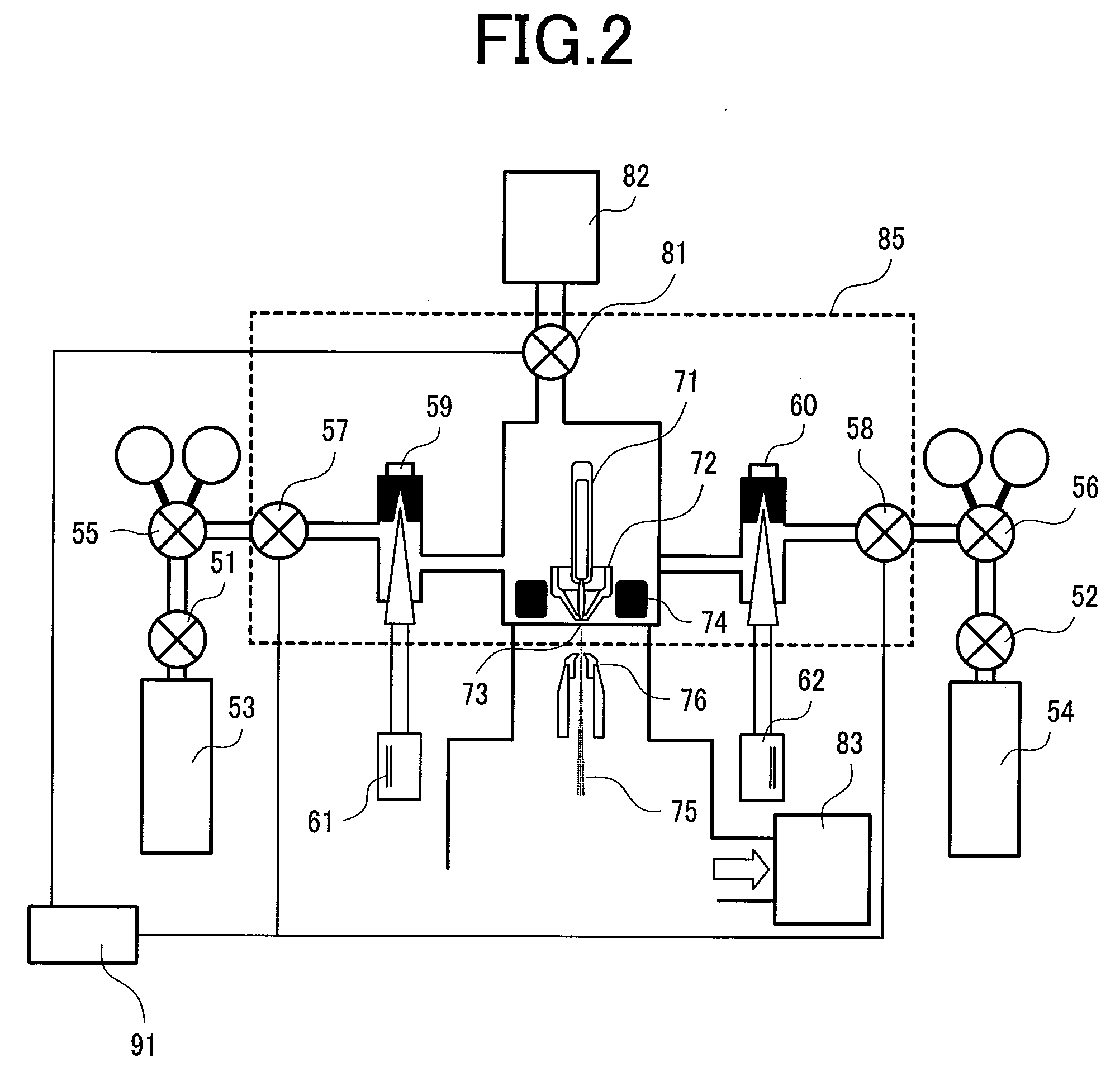

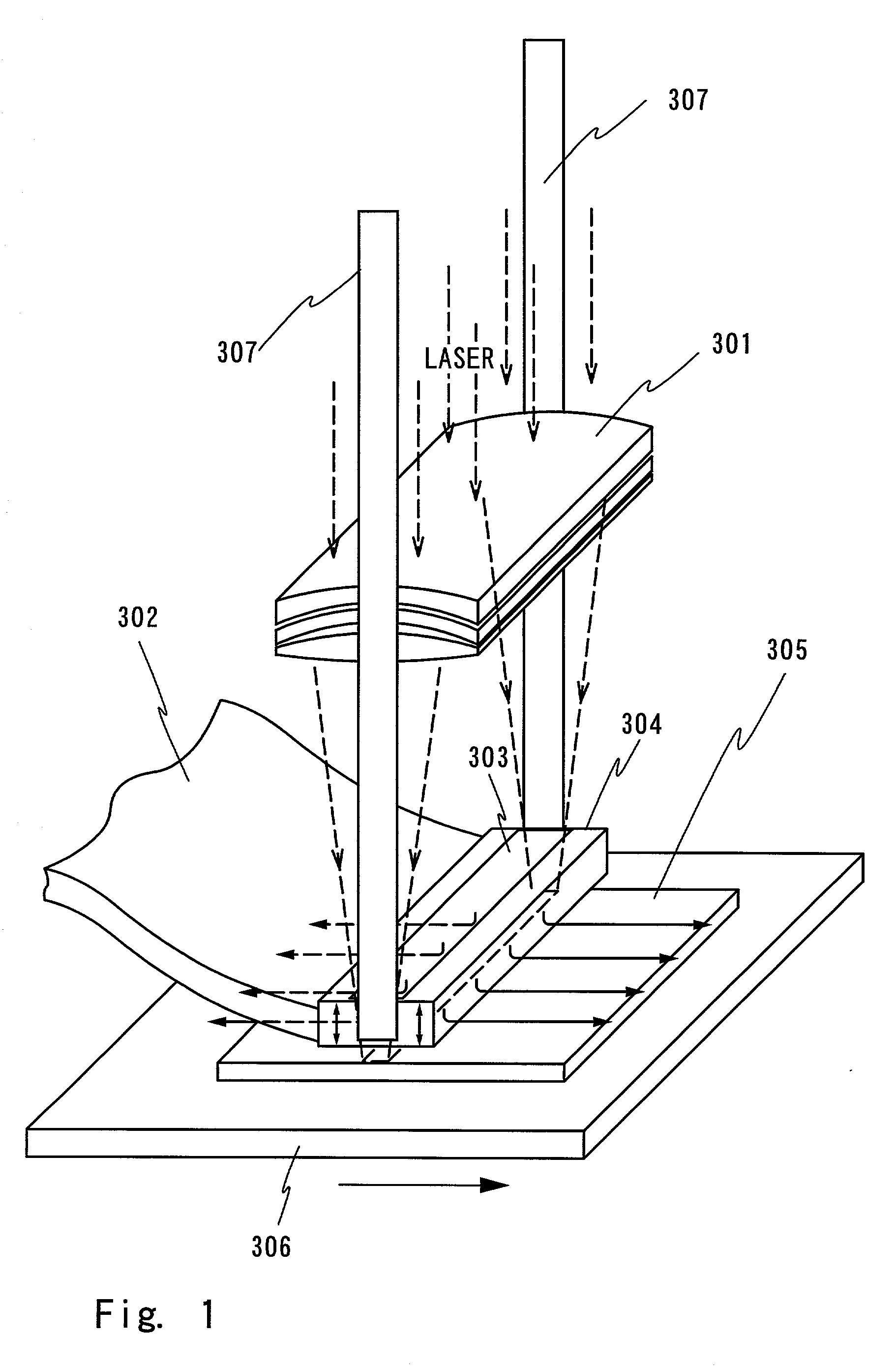

Ion source, ion beam processing/observation apparatus, charged particle beam apparatus, and method for observing cross section of sample

ActiveUS20090230299A1Shorten the timeImprove flatnessVacuum evaporation coatingSputtering coatingIon beam processingGas cylinder

An ion beam machining and observation method relevant to a technique of cross sectional observation of an electronic component, through which a sample is machined by using an ion beam and a charged particle beam processor capable of reducing the time it takes to fill up a processed hole with a high degree of flatness at the filled area. The observation device is capable of switching the kind of gas ion beam used for machining a sample with the kind of a gas ion beam used for observing the sample. To implement the switch between the kind of a gas ion beam used for sample machining and the kind of a gas ion beam used for sample observation, at least two gas introduction systems are used, each system having a gas cylinder a gas tube, a gas volume control valve, and a stop valve.

Owner:HITACHI HIGH-TECH CORP

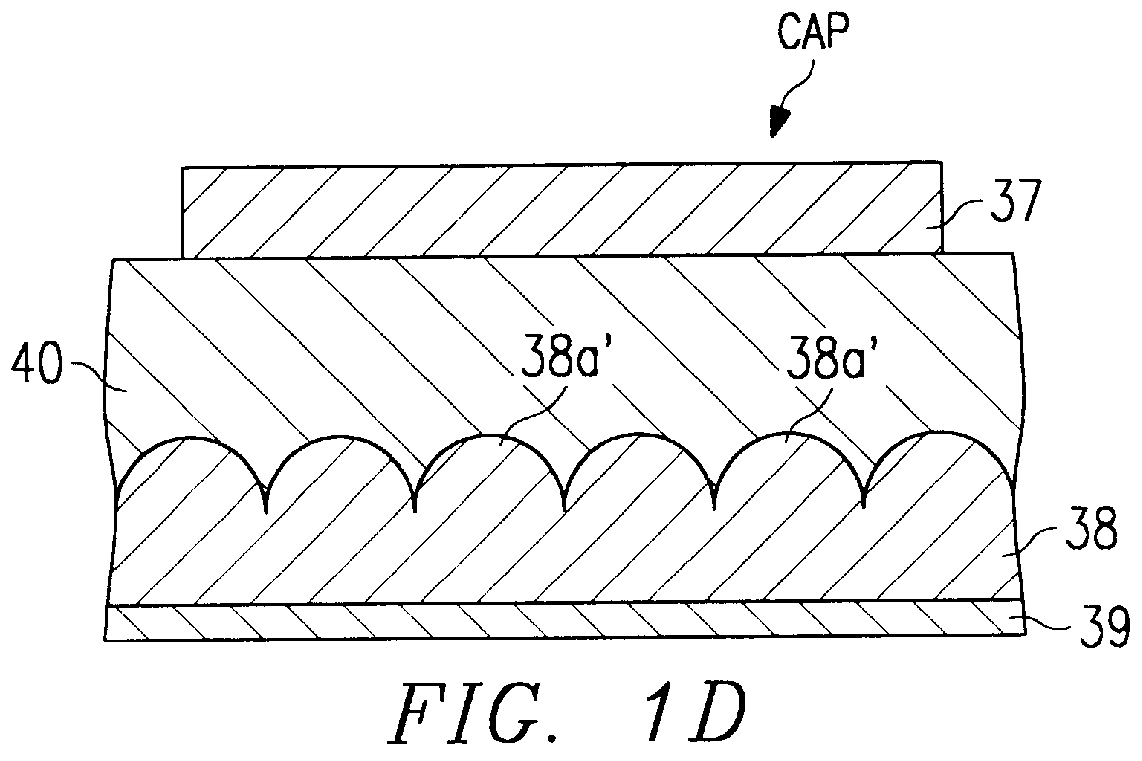

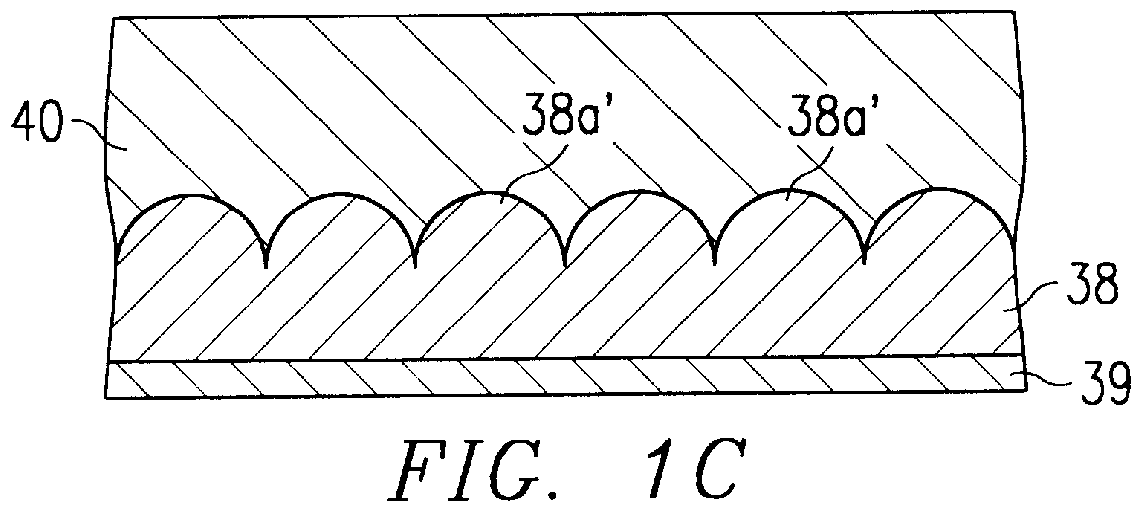

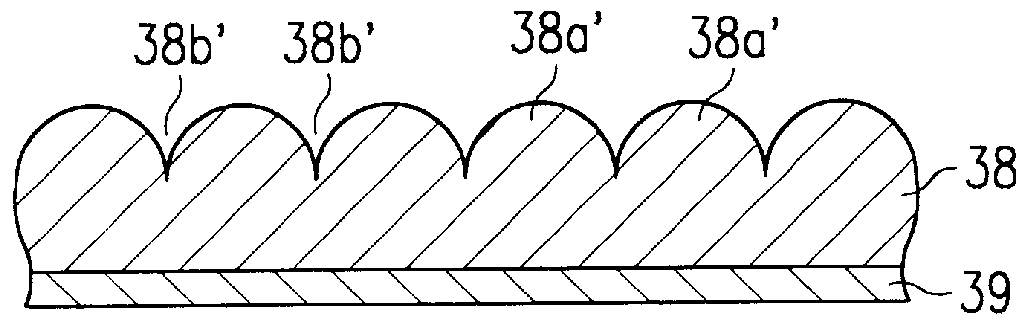

Method for manufacturing dielectric capacitor, dielectric memory device

InactiveUS6033953AReduce leakage currentImprove flatnessTransistorThin/thick film capacitorElectrolysisCapacitor

A dielectric capacitor is provided which has a reduced leakage current. The surface of a first electrode (38) of the capacitor is electropolished and a dielectric film (40) and a second electrode (37) are successively laminated on it. The convex parts pointed end (38a) existing on the surface of the first electrode is very finely polished uniformly by dissolving according to electropolishing, a spherical curved surface in which the radius of curvature has been enlarged is formed, and the surface of the first electrode is flattened. Therefore, concentration of electrolysis can be prevented during the operation at the interface of the first electrode and the dielectric film, and the leakage current can be reduced considerably.

Owner:TEXAS INSTR INC

Anti-aging skin care composition and uses thereof

The present invention is directed toward anti-aging skin care compositions comprising Vitamin B1, Vitamin B5, Vitamin C, N-acetyl-cysteine and, optionally, lipoic acid. The present invention is further directed toward methods for therapeutically or prophylactically treating the consequences of aging on the condition or appearance of the skin. The present invention further provides one or more kits that are useful for delaying, treating or preventing the consequences of aging on the condition or appearance of the skin.

Owner:KLYSZ BEATRICE M

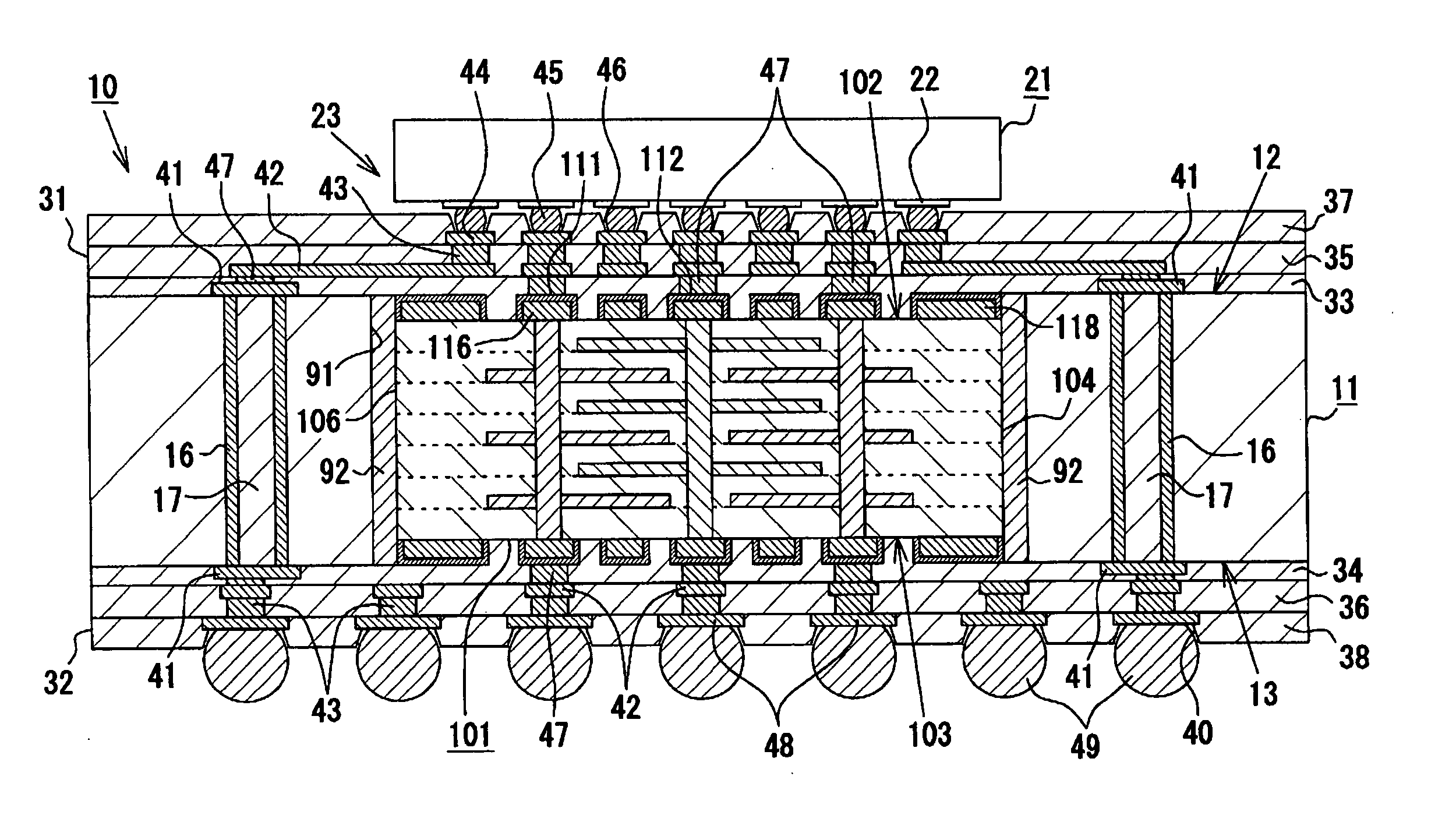

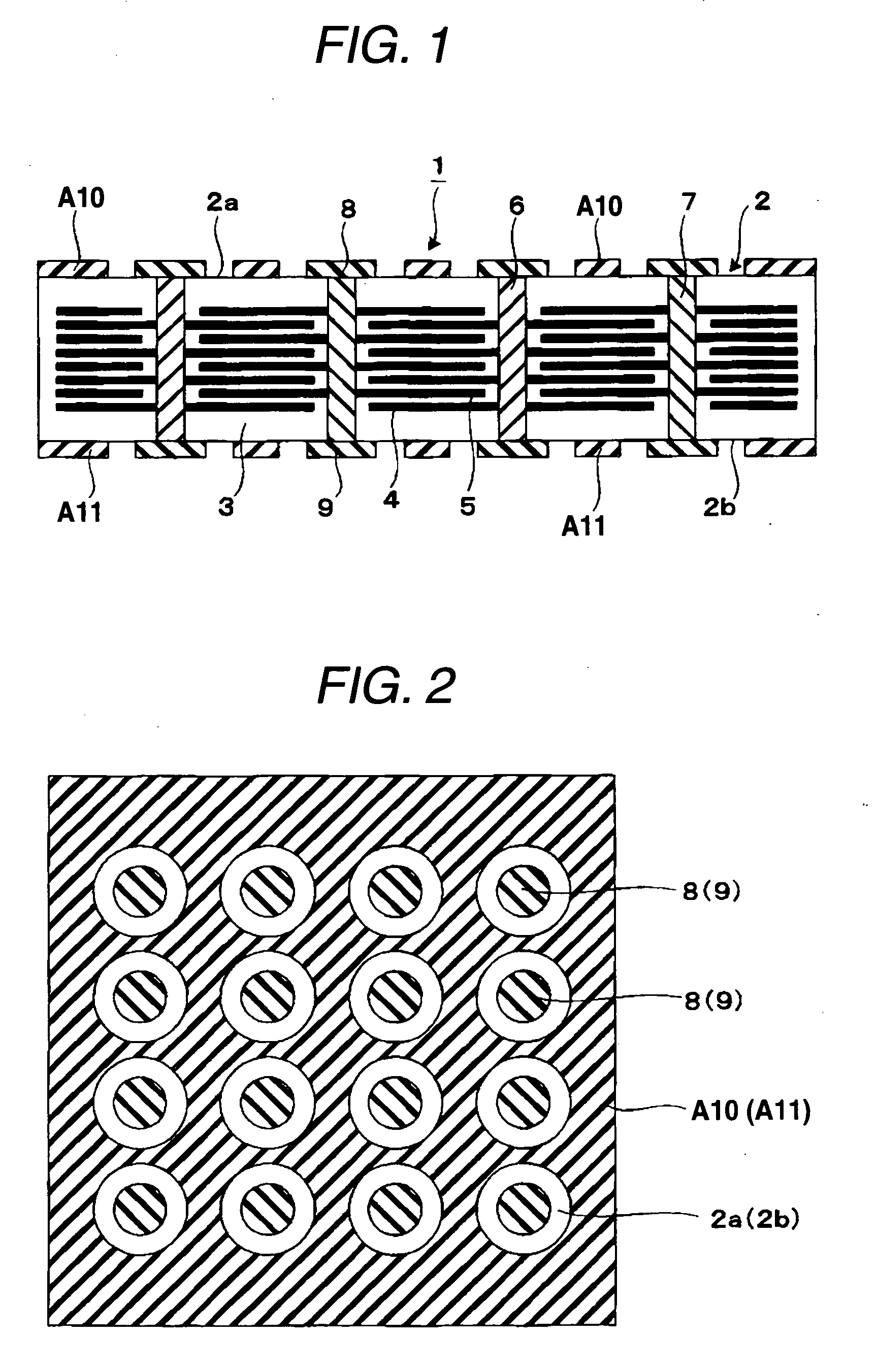

Capacitor for incorporation in wiring board, wiring board, method of manufacturing wiring board, and ceramic chip for embedment

InactiveUS20070030628A1High bonding strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDielectric layerCapacitor

A capacitor comprising: a capacitor body including a plurality of laminated dielectric layers, a plurality of inner electrode layers which are respectively disposed between mutually adjacent ones of the dielectric layers, a first main surface located in a laminated direction of the dielectric layers, and a second main surface opposite to the first main surface; a first outer electrode formed on the first main surface of the capacitor body and electrically connected to the inner electrode layers; a second outer electrode formed on the second main surface of the capacitor body and electrically connected to the inner electrode layers; a first dummy electrode formed on the first main surface of the capacitor body; and a second dummy electrode formed on the second main surface of the capacitor body.

Owner:NGK SPARK PLUG CO LTD

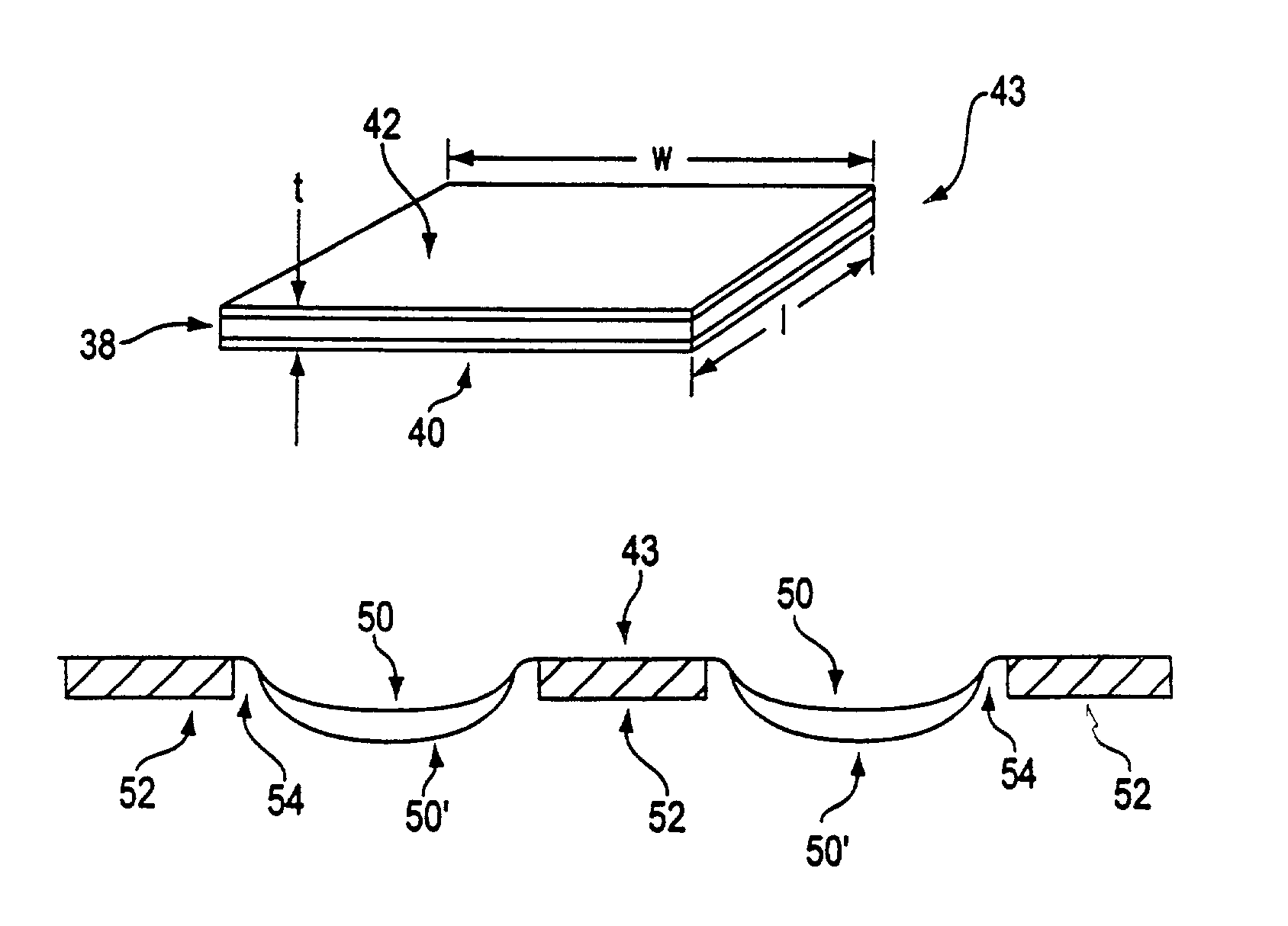

Elastomeric dielectric polymer film sonic actuator

InactiveUS7062055B2Optimize power outputLow working voltagePiezoelectric/electrostrictive gramophone pickupsStirling type enginesDielectricConductive polymer

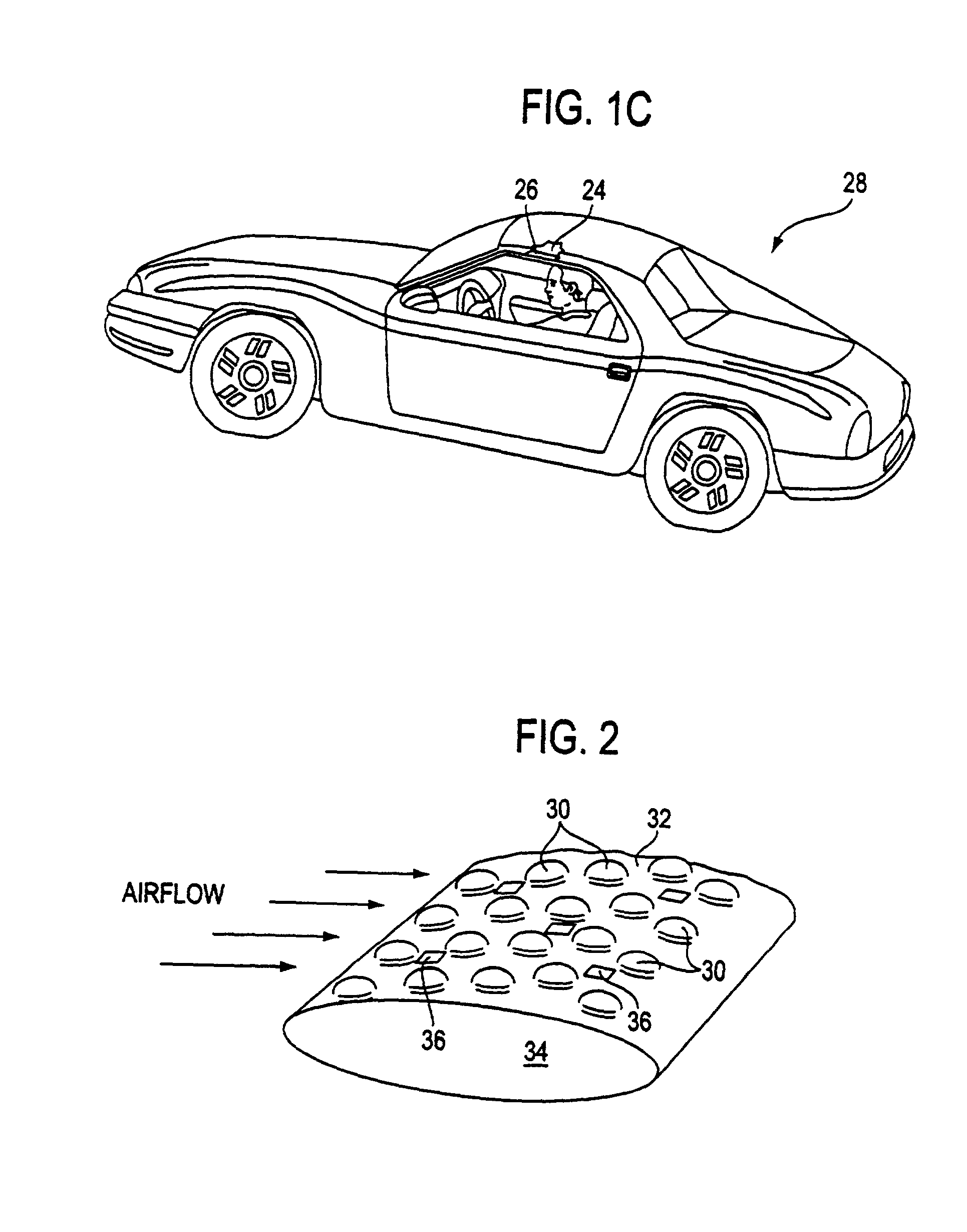

A sonic actuator including a multi-layer membrane having a non-metallic elastomeric dielectric polymer layer with a first surface and a second surface, a first compliant electrode layer contacting the first surface of the polymer layer, and a second compliant electrode layer contacting the second surface of the polymer layer. The actuator further includes a support structure in contact with the sonic actuator film. Preferably, the non-metallic dielectric polymer is selected from the group consisting essentially of silicone, fluorosilicone, fluoroelastomer, natural rubber, polybutadiene, nitrile rubber, isoprene, and ethylene propylene diene. Also preferably, the compliant electrode layer is made from the group consisting essentially of graphite, carbon, and conductive polymers. The support structure can take the form of grid having a number of circular apertures. When a voltage is applied to the electrodes, portions of the film held at the aperture of the support structure can bulge due to the electrostriction phenomenon. The resultant “bubbles” can be modulated to generate sonic vibrations, or can be used to create a variable surface for airflow control.

Owner:SRI INTERNATIONAL

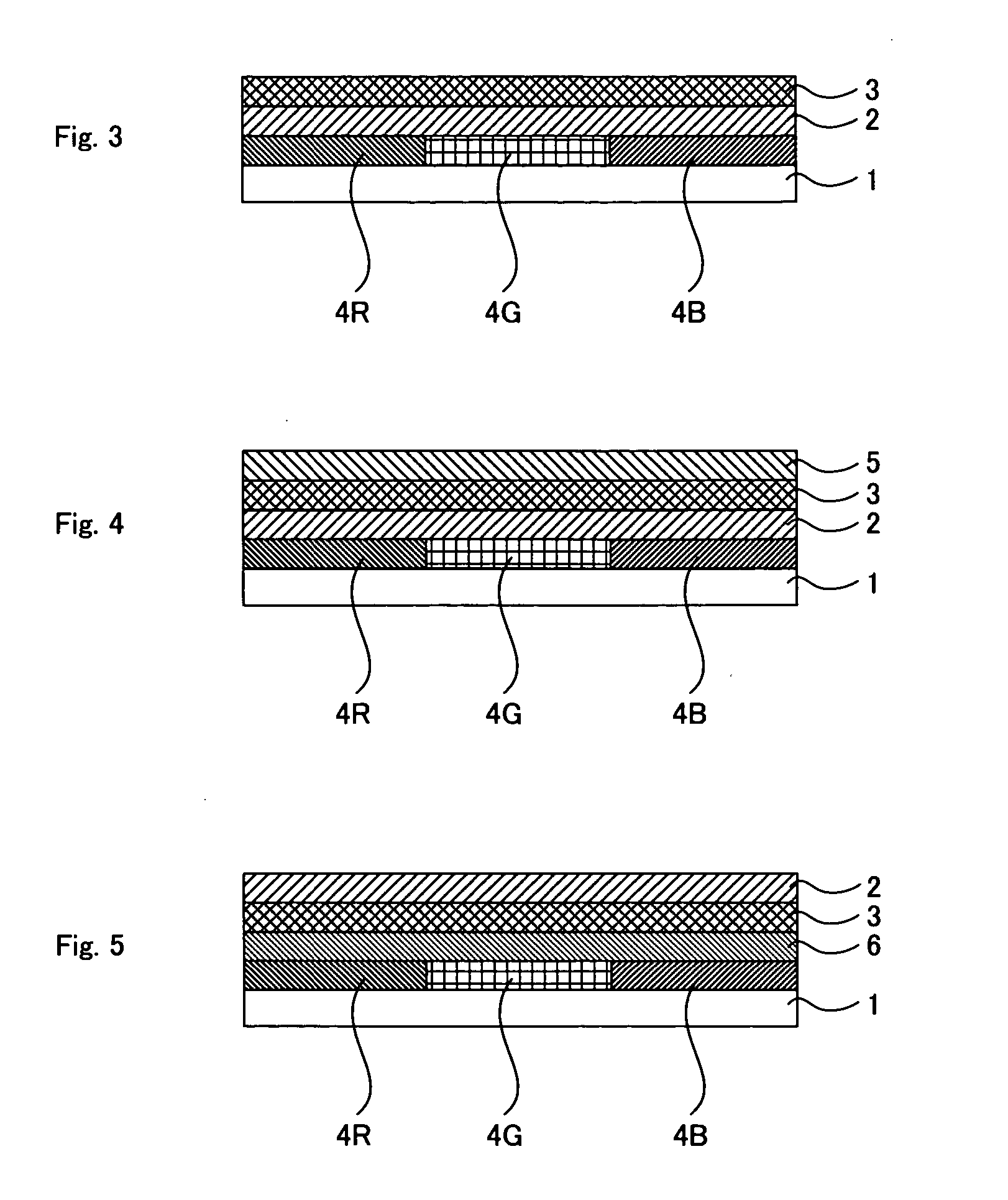

Display device and method for manufacturing the same

InactiveUS20060091397A1Improve reliabilityHigh definitionElectroluminescent light sourcesSolid-state devicesSimple Organic CompoundsDisplay device

It is an object of the invention to manufacture a highly reliable display device at a low cost with high yield. A display device of the invention includes: a first reflective electrode layer; and a second transparent electrode layer with an electroluminescent layer interposed therebetween, wherein the electroluminescent layer has a layer containing an organic compound and an inorganic compound, and the first electrode layer contains an aluminum alloy containing at least one or more selected from the group consisting of molybdenum, titanium, and carbon.

Owner:SEMICON ENERGY LAB CO LTD

Polishing pad and method for manufacturing semiconductor device

InactiveUS20060037699A1Detection accuracy meetsHigh measurement accuracySemiconductor/solid-state device manufacturingLapping machinesWaferingDevice material

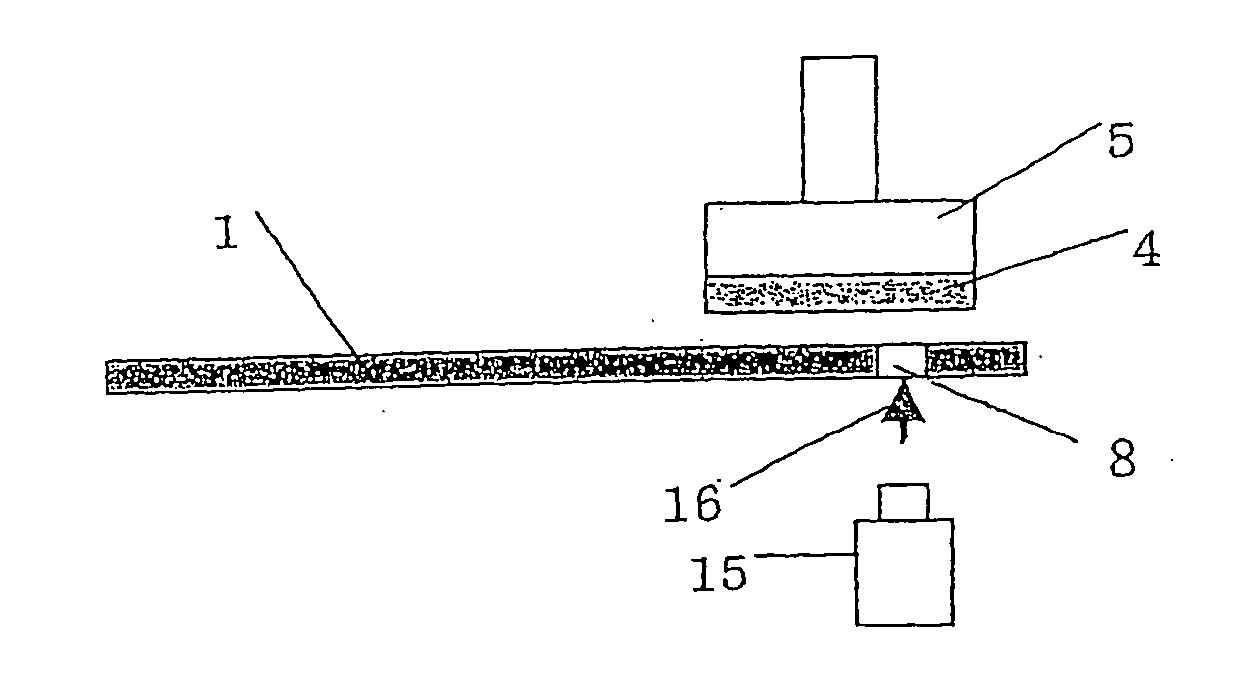

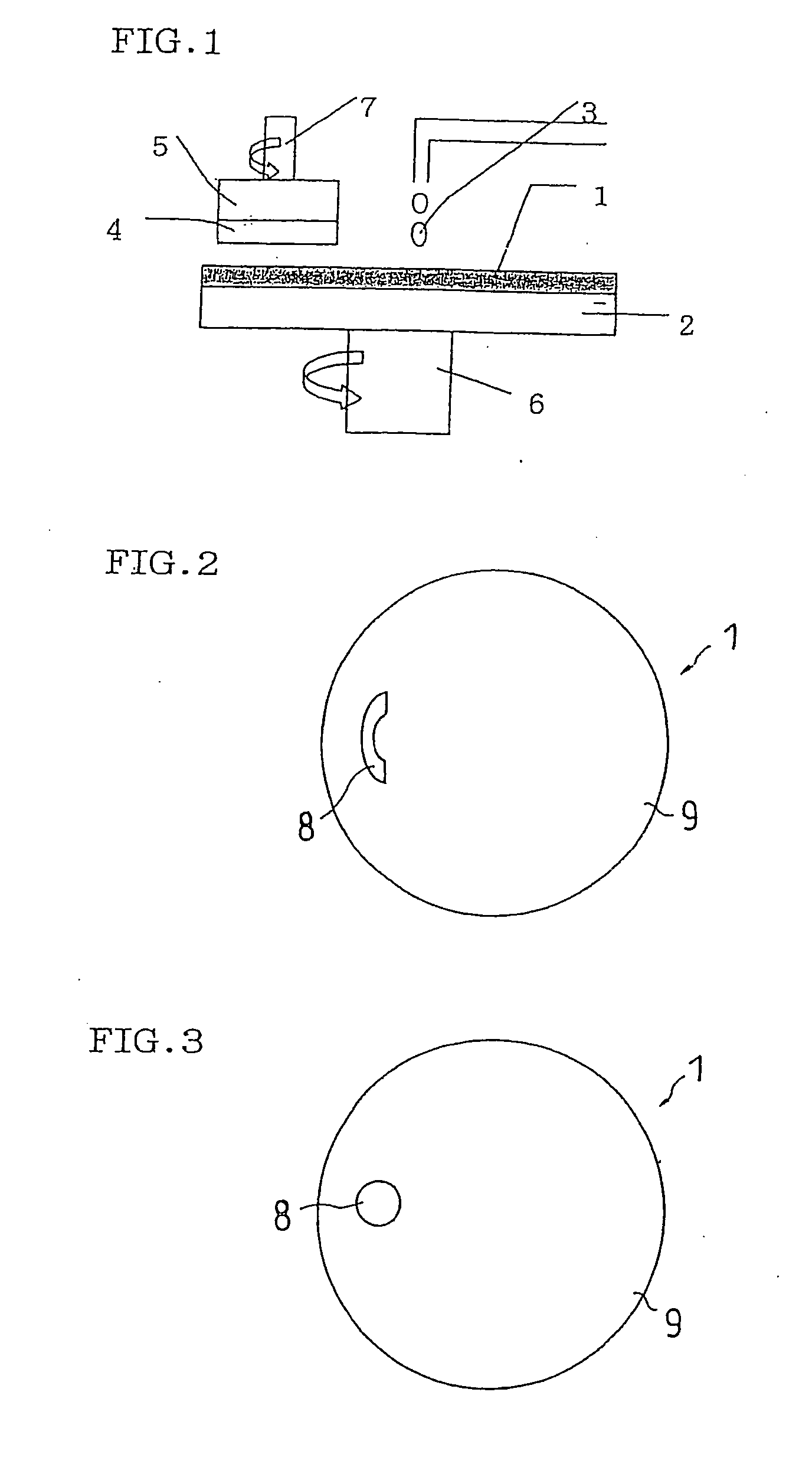

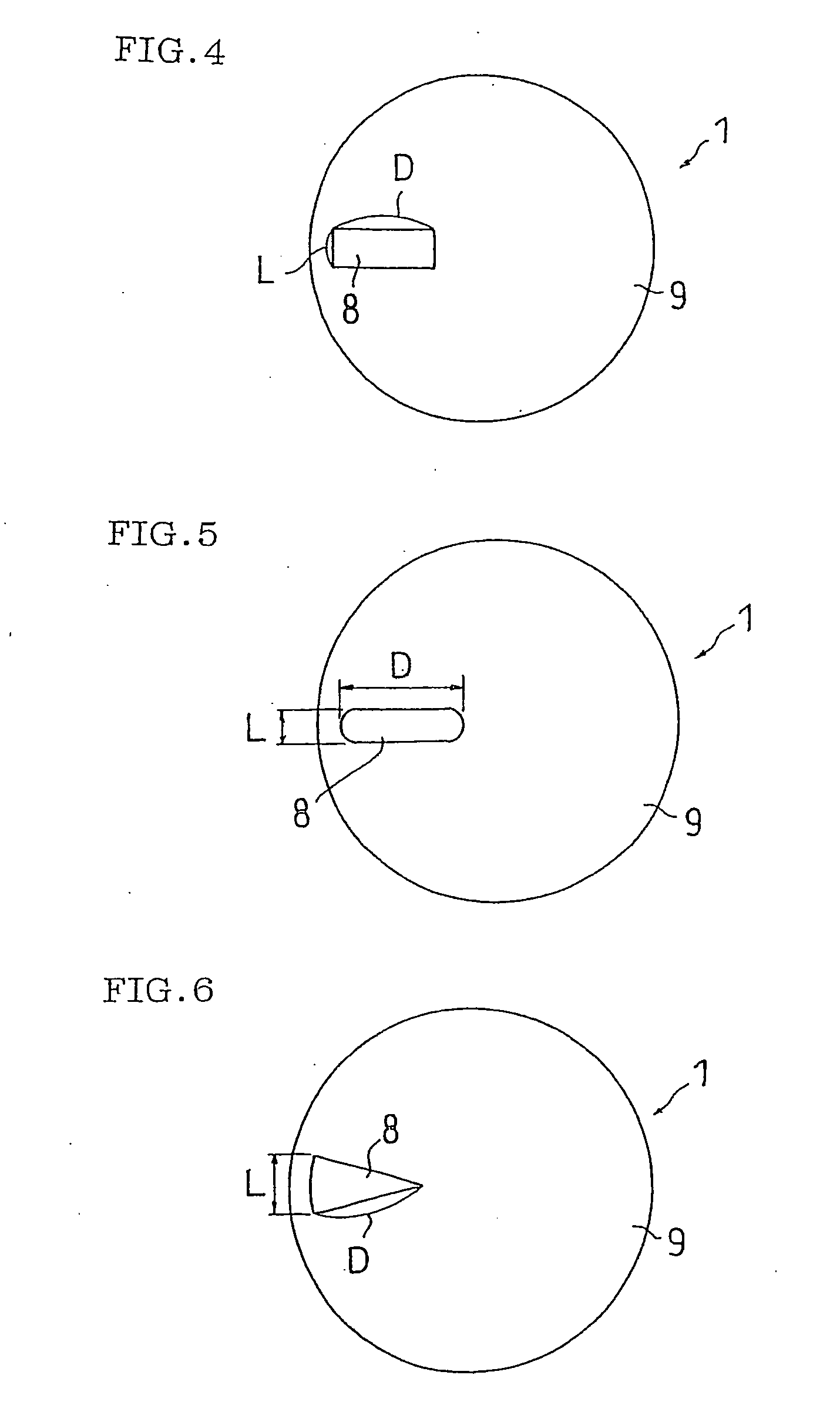

A polishing pad enabling a highly precise optical endpoint sensing during the polishing process and thus having excellent polishing characteristics (such as surface uniformity and in-plane uniformity) is disclosed. A polishing pad enabling to obtain the polishing profile of a large area of a wafer is also disclosed. A polishing pad of a first invention comprises a light-transmitting region having a transmittance of not less than 50% over the wavelength range of 400 to 700 nm. A polishing pad of a second invention comprises a light-transmitting region having a thickness of 0.5 to 4 mm and a transmittance of not less than 80% over the wavelength range of 600 to 700 nm. A polishing pad of a third invention comprises a light-transmitting region arranged between the central portion and the peripheral portion of the polishing pad and having a length (D) in the diametrical direction which is three times or more longer than the length (L) in the circumferential direction.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

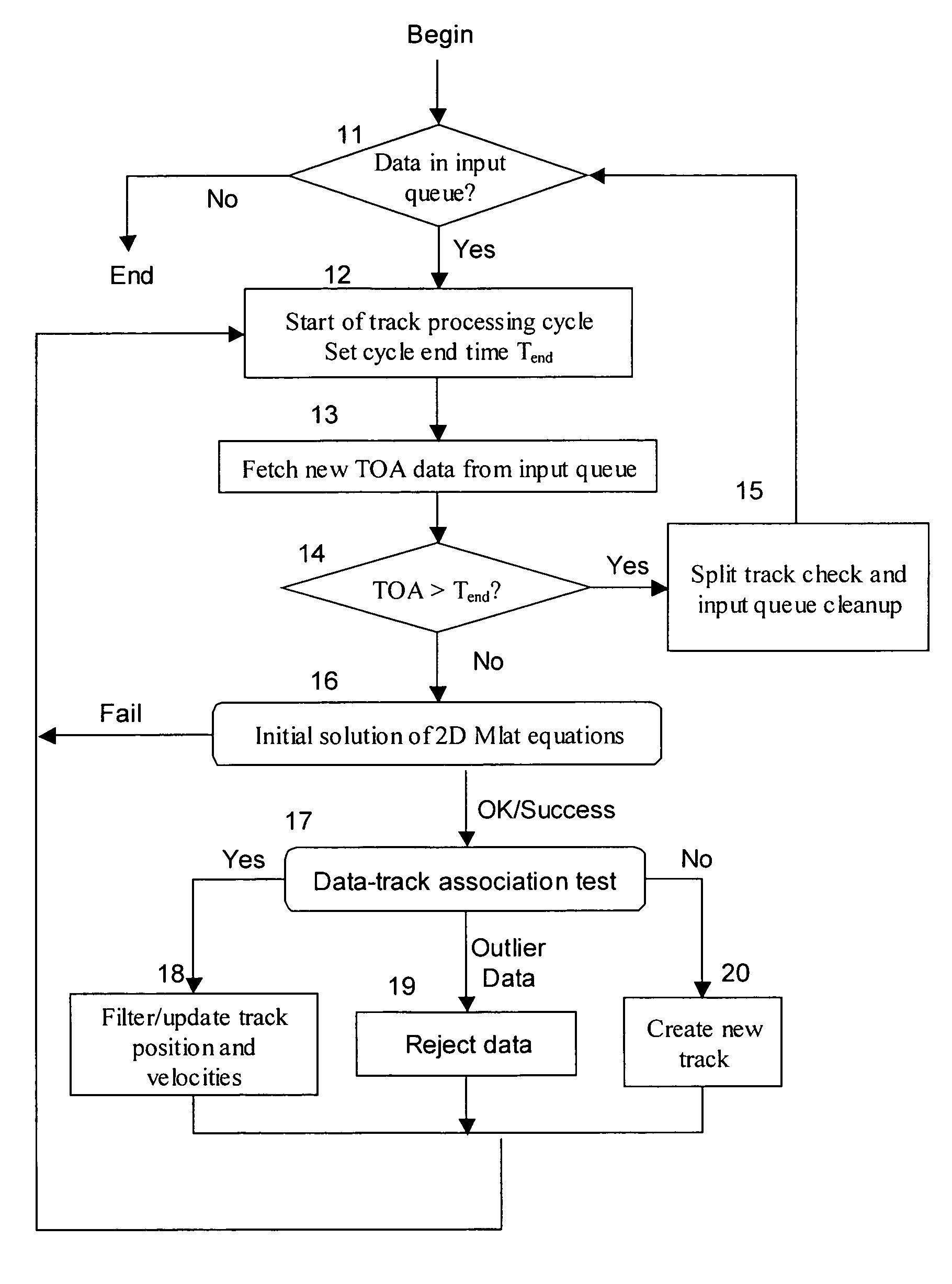

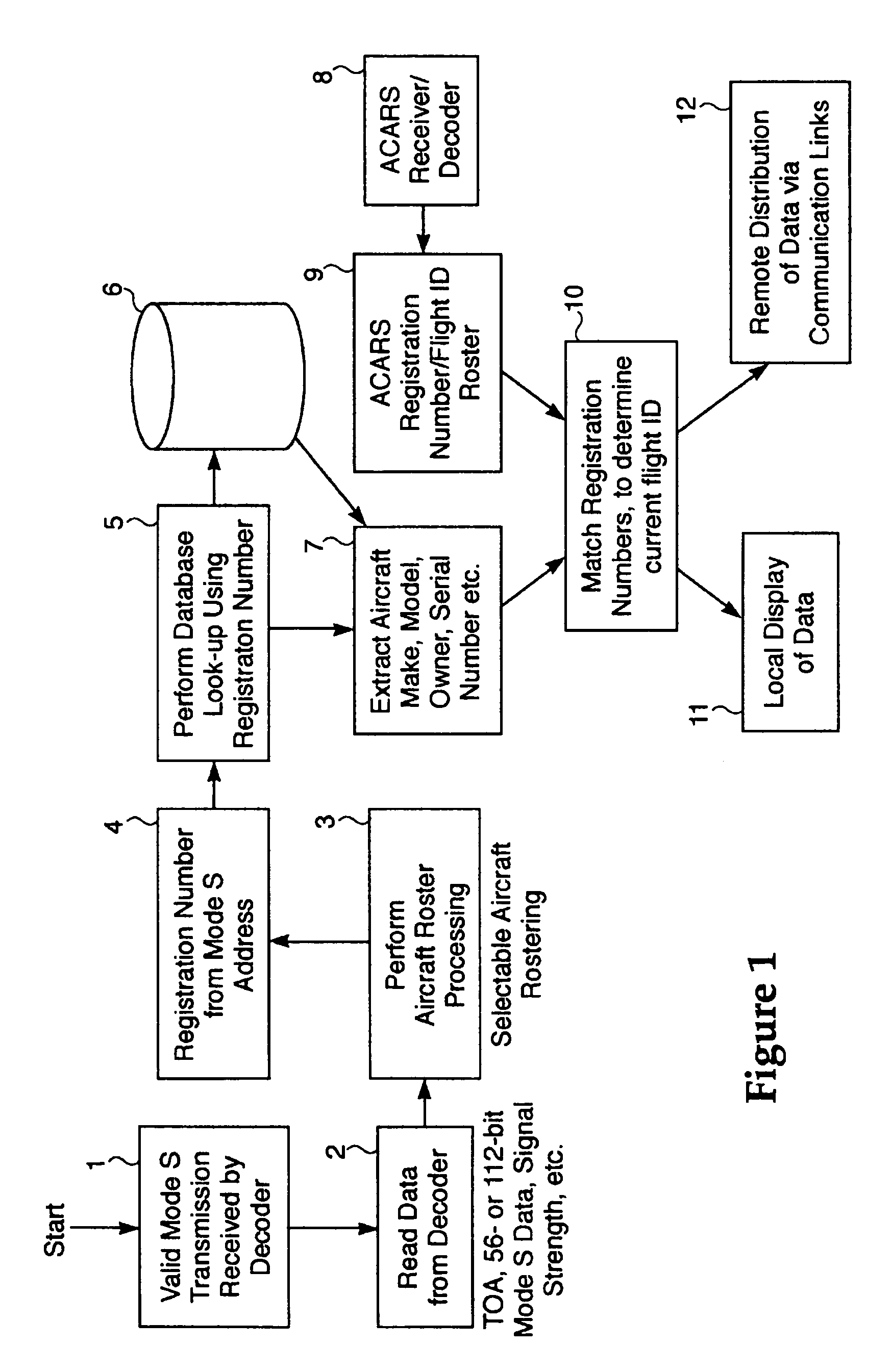

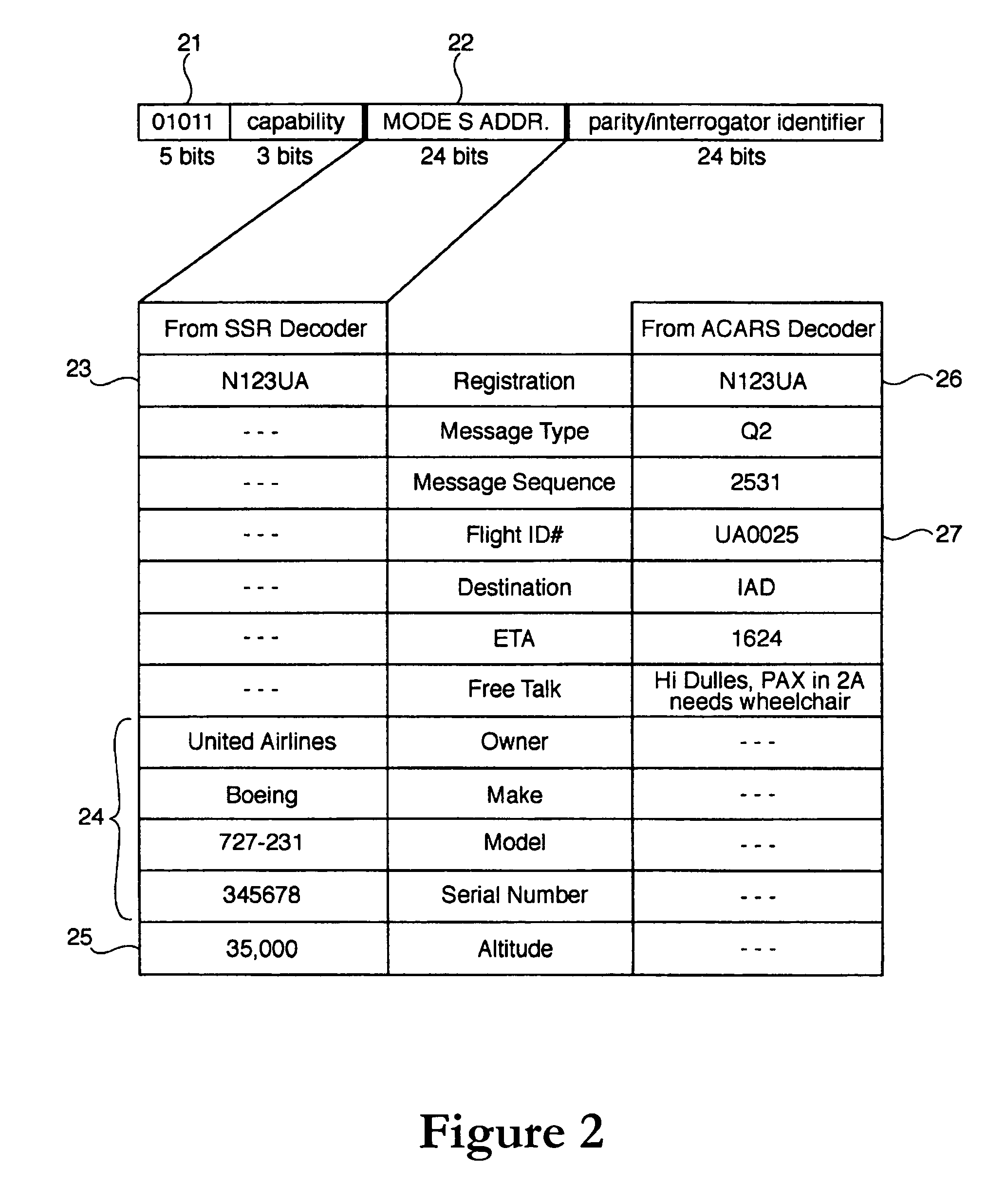

Method and apparatus for accurate aircraft and vehicle tracking

InactiveUS7132982B2Improve vertical accuracyGood HDOPDirection finders using radio wavesBeacon systemsFlight vehicleMultilateration

A direct multilateration target tracking system is provided with the TOA time stamp as an input. A technique of tracking targets with varying receiver combinations is provided. Methods of correlating and combining Mode A, Mode C, and Mode S messages to enhance target tracking in a passive surveillance system are provided. A direct multilateration target tracking system is provided by TOA tracking and smoothing. A technique for selecting best receiver combination and / or solution of multilateration equations from a multitude of combinations and / or solutions is provided. A technique for correcting pseudorange values with atmospheric conditions is provided. A technique for improving height determination for regions of poor VDOP in a 3D multilateration system is provided.

Owner:SRA INTERNATIONAL

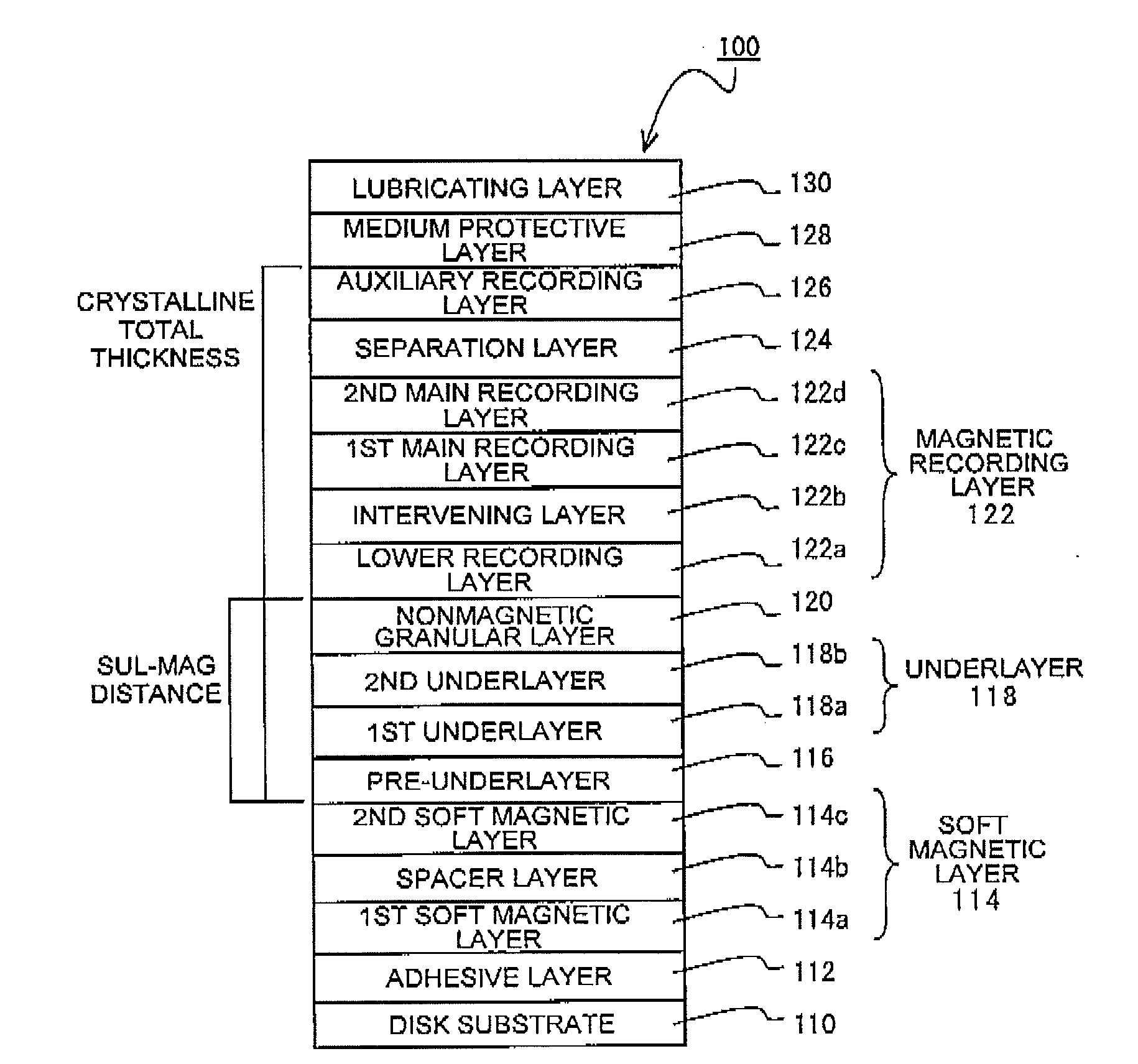

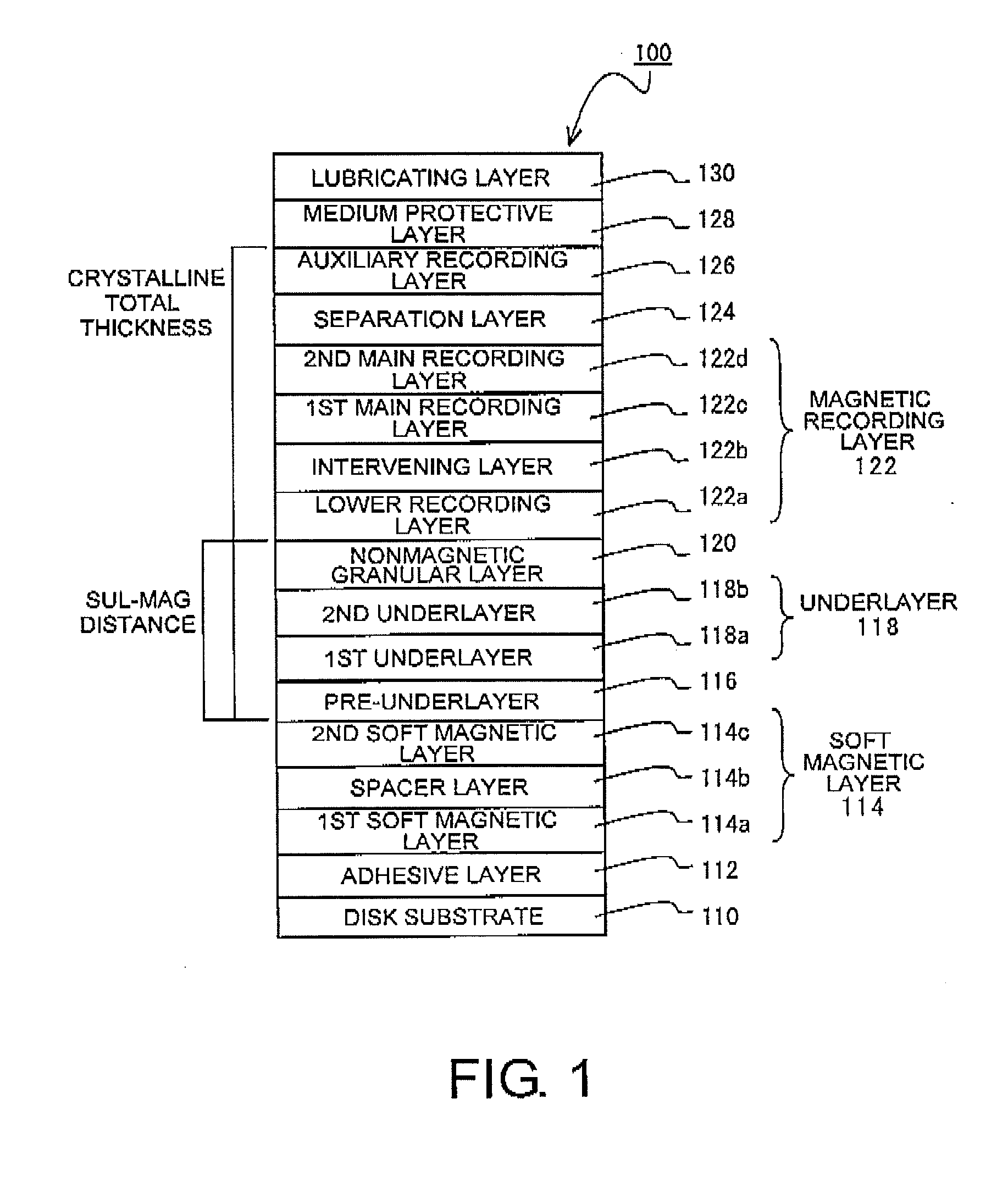

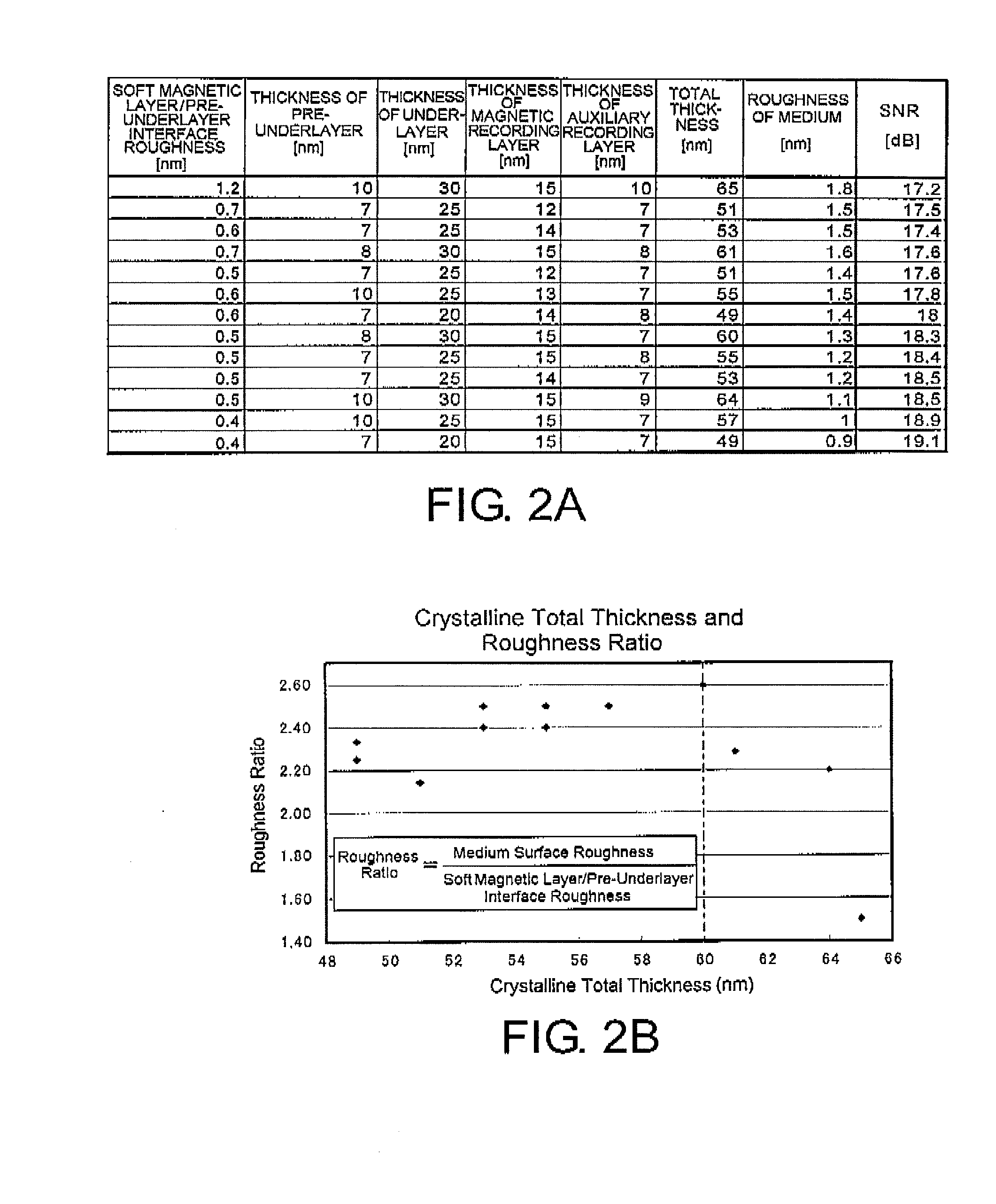

Perpendicular magnetic recording medium

ActiveUS20100247965A1Reduce surface roughnessImprove recording densityRecord information storageManufacture of flux-sensitive headsCrystalline materialsNon magnetic

In a perpendicular magnetic recording medium having, over a substrate, a magnetic recording layer, an underlayer made of Ru or a Ru compound and provided below the magnetic recording layer, a pre-underlayer made of a nonmagnetic crystalline material, and a soft magnetic layer provided below the pre-underlayer, when the difference between the highest point and the lowest point of unevenness of the interface between the soft magnetic layer and the pre-underlayer, derived by a cross-sectional TEM image, is given as an interface roughness (nm) and the distance between the soft magnetic layer and the magnetic recording layer, excluding the soft magnetic layer and the magnetic recording layer, is given as a SUL-MAG distance (nm), interface roughness (nm)≦0.4 (nm) and interface roughness×SUL-MAG distance (nm)≦12 (nm) are satisfied.

Owner:WESTERN DIGITAL TECH INC

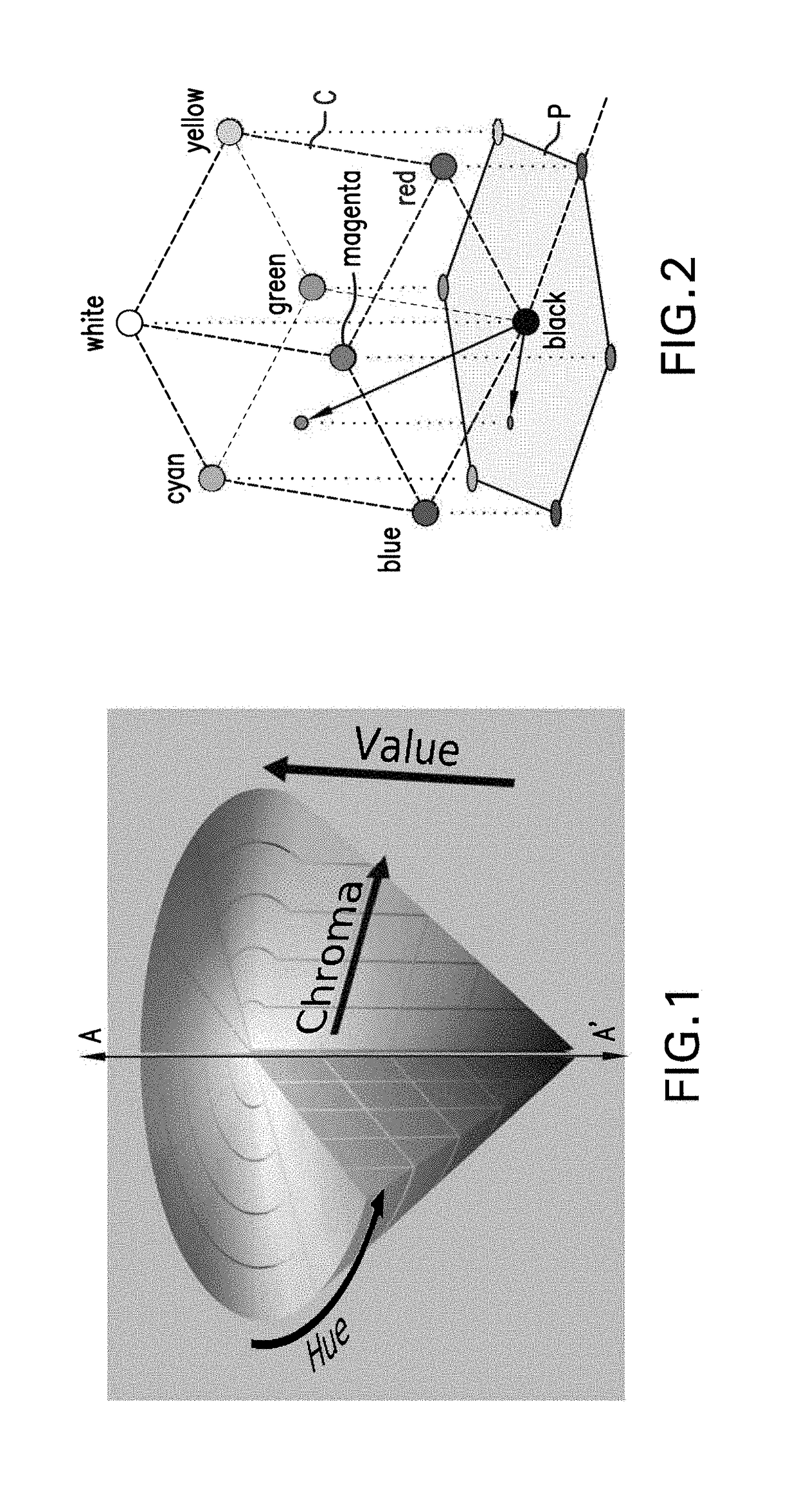

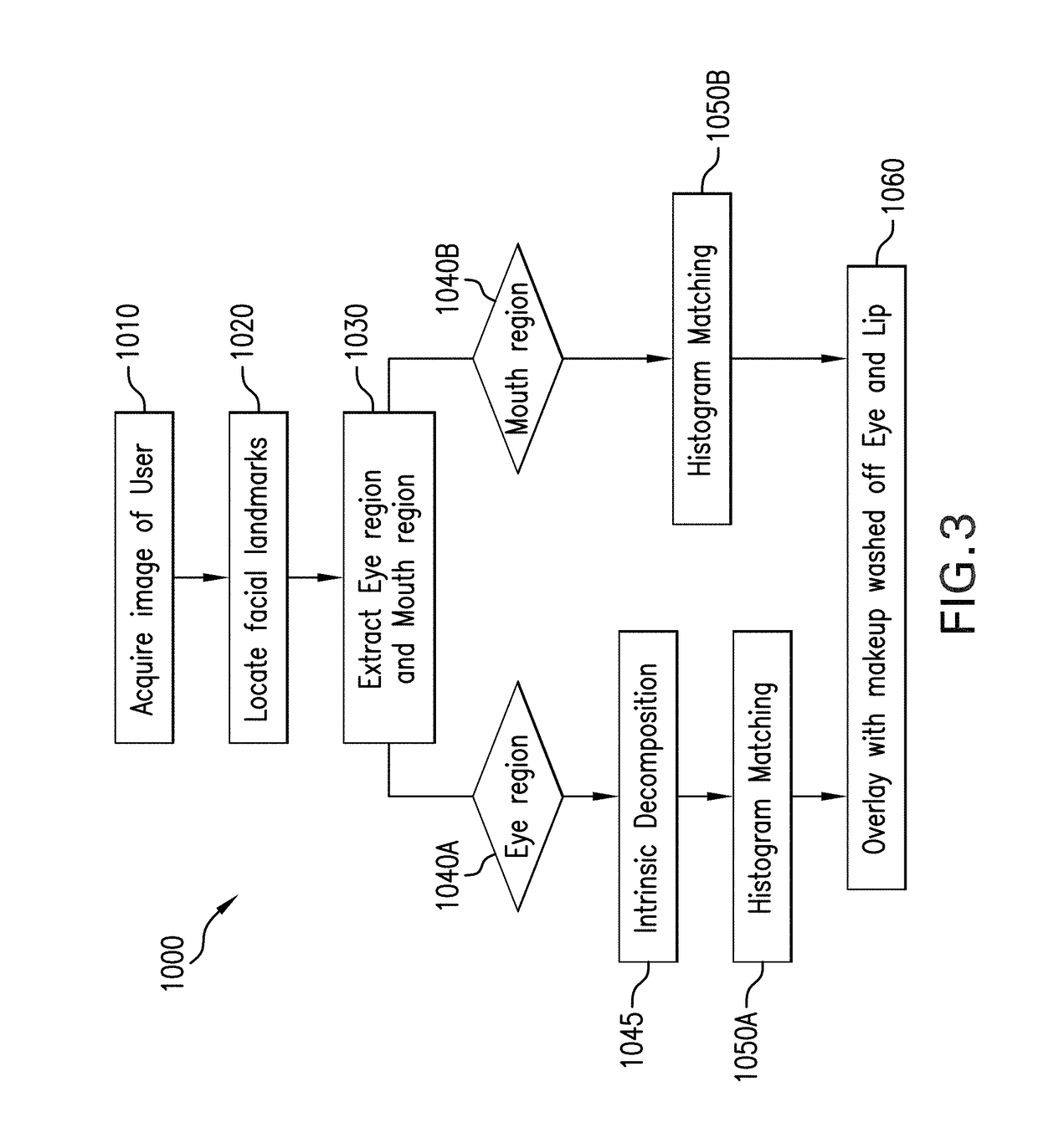

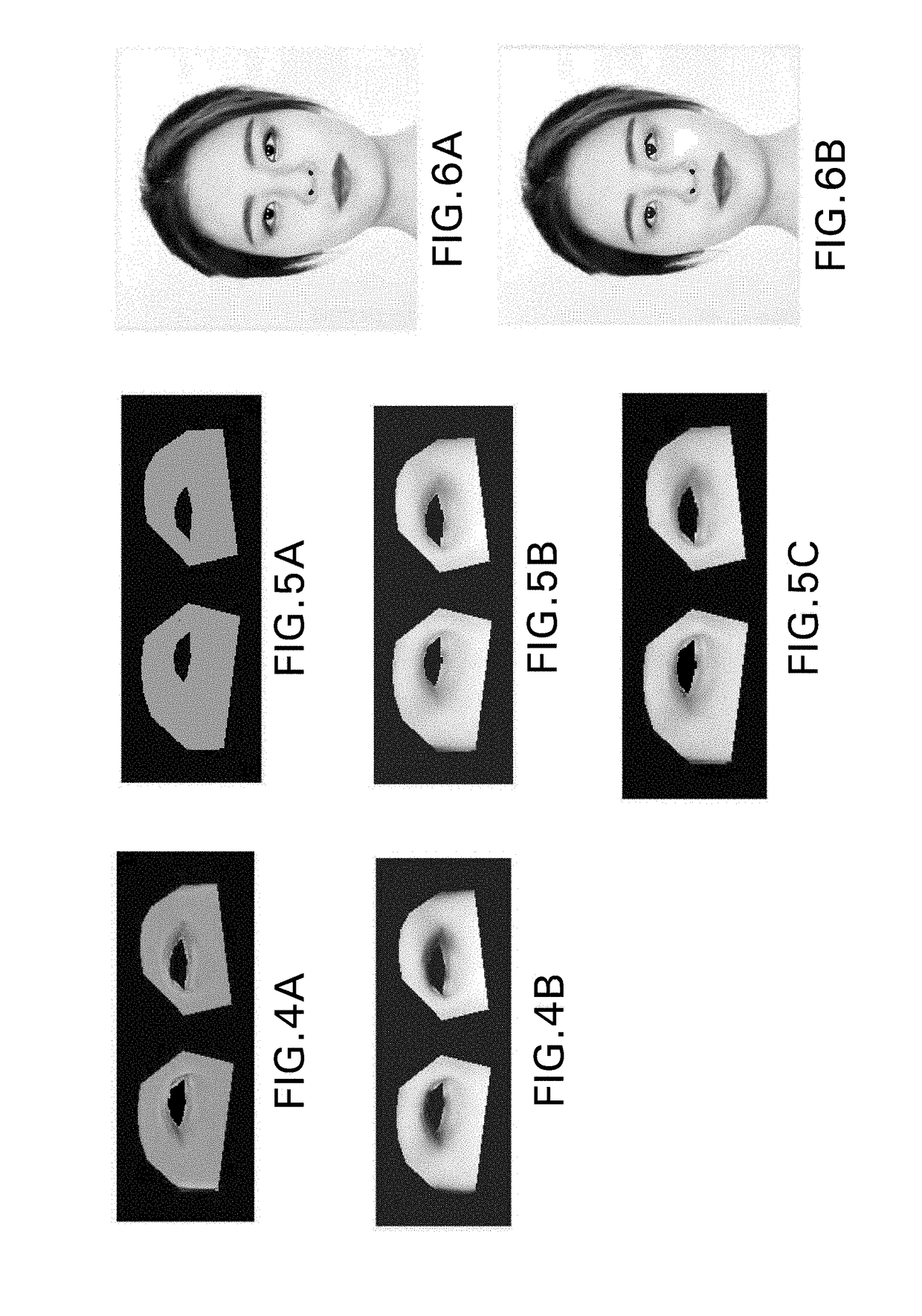

Systems and Methods for Virtual Facial Makeup Removal and Simulation, Fast Facial Detection and Landmark Tracking, Reduction in Input Video Lag and Shaking, and a Method for Recommending Makeup

ActiveUS20190014884A1High transparencyImprove flatnessImage enhancementImage analysisFacial regionNetwork model

The present disclosure provides systems and methods for virtual facial makeup simulation through virtual makeup removal and virtual makeup add-ons, virtual end effects and simulated textures. In one aspect, the present disclosure provides a method for virtually removing facial makeup, the method comprising providing a facial image of a user with makeups being applied thereto, locating facial landmarks from the facial image of the user in one or more regions, decomposing some regions into first channels which are fed to histogram matching to obtain a first image without makeup in that region and transferring other regions into color channels which are fed into histogram matching under different lighting conditions to obtain a second image without makeup in that region, and combining the images to form a resultant image with makeups removed in the facial regions. The disclosure also provides systems and methods for virtually generating output effects on an input image having a face, for creating dynamic texturing to a lip region of a facial image, for a virtual eye makeup add-on that may include multiple layers, a makeup recommendation system based on a trained neural network model, a method for providing a virtual makeup tutorial, a method for fast facial detection and landmark tracking which may also reduce lag associated with fast movement and to reduce shaking from lack of movement, a method of adjusting brightness and of calibrating a color and a method for advanced landmark location and feature detection using a Gaussian mixture model.

Owner:SHISEIDO CO LTD

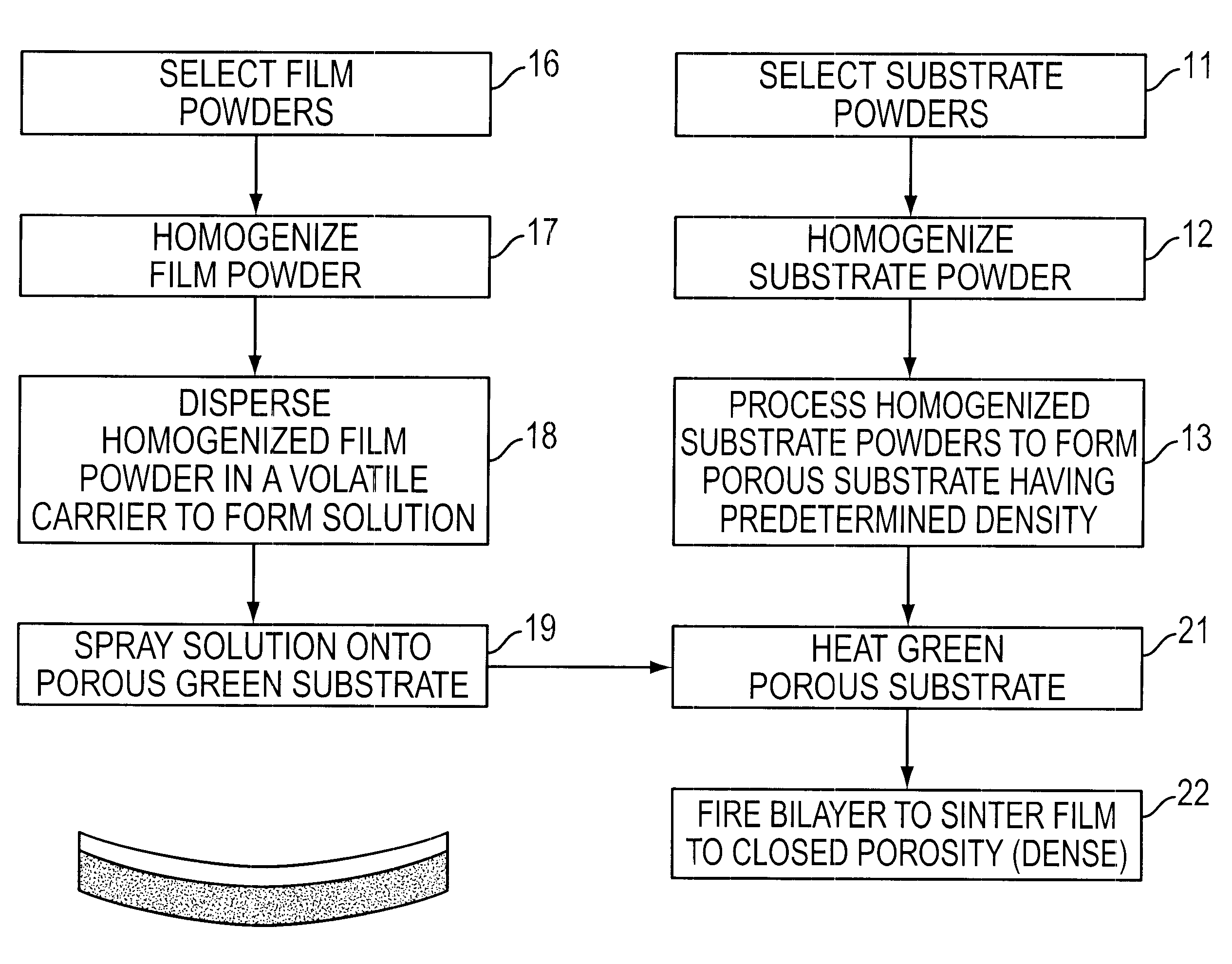

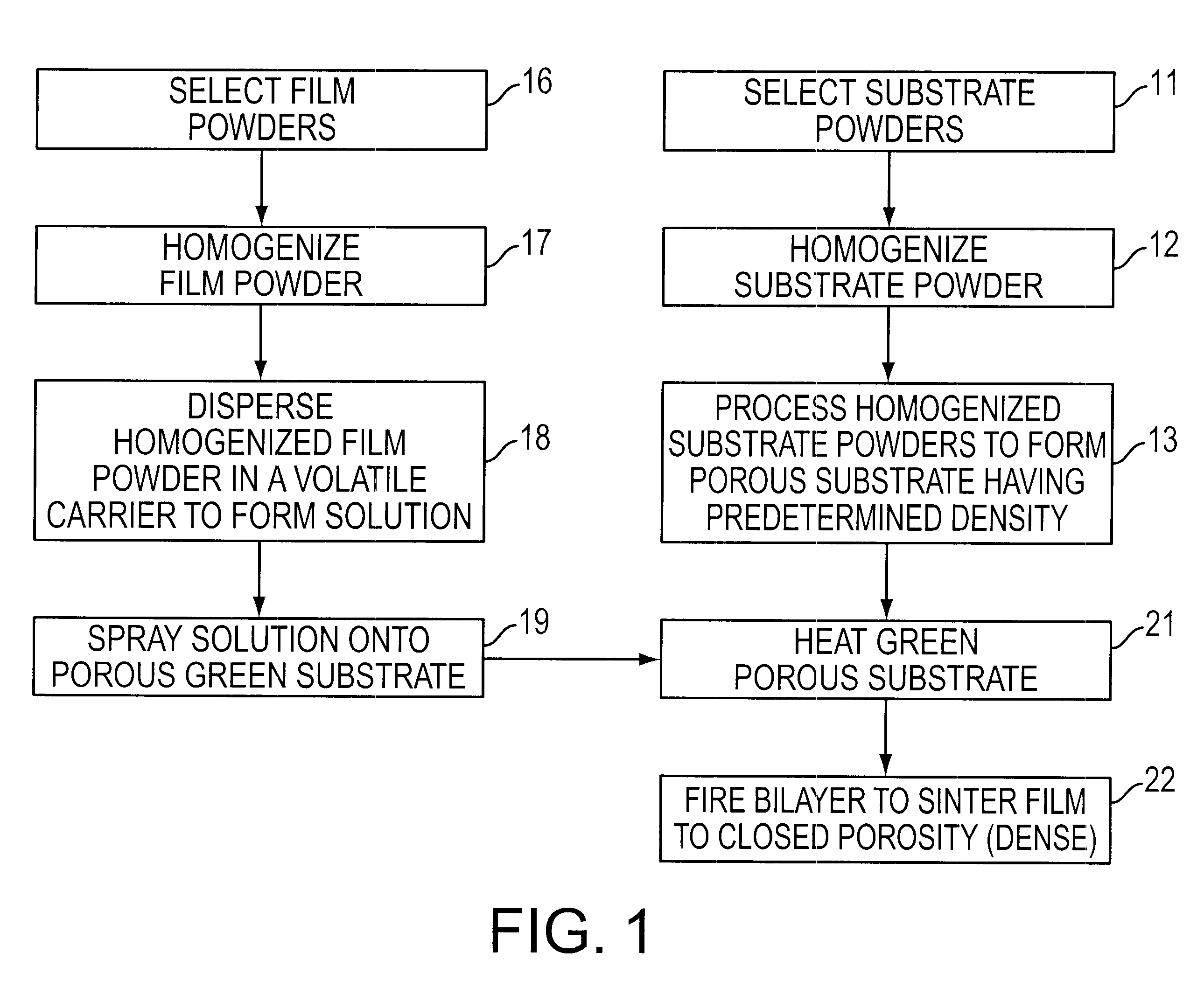

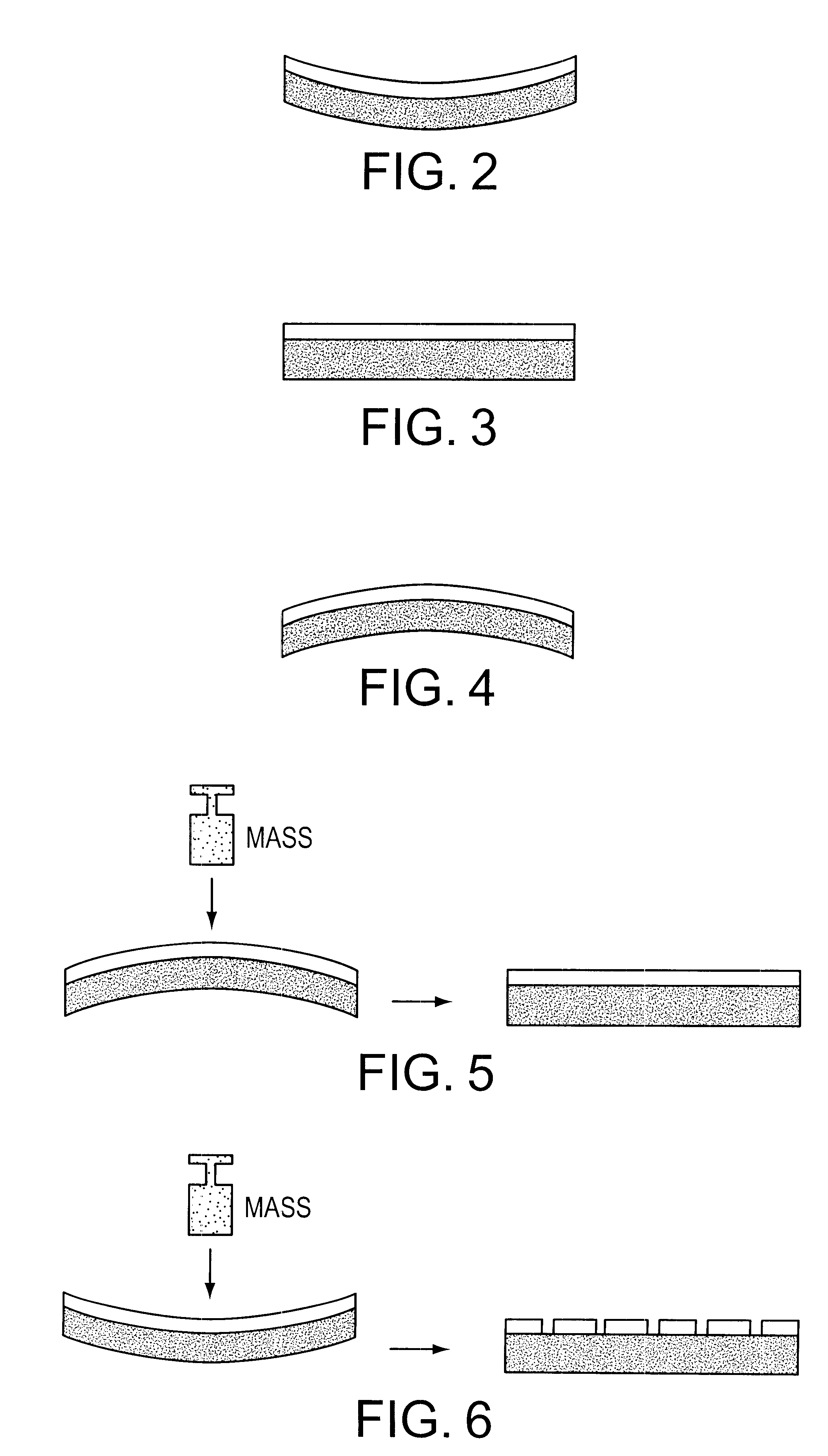

Method for making thin, flat, dense membranes on porous substrates

InactiveUS6458170B1Quality improvementImprove flatnessFuel cell auxillariesElectrode carriers/collectorsPorous substrateMaterials science

A method of fabricating a thin, flat dense membrane on a porous substrate in which the green substrate is selected to have a predetermined shrinkage on firing which matches or is greater than the shrinkage of a thin uniformly applied film on firing.

Owner:RGT UNIV OF CALIFORNIA

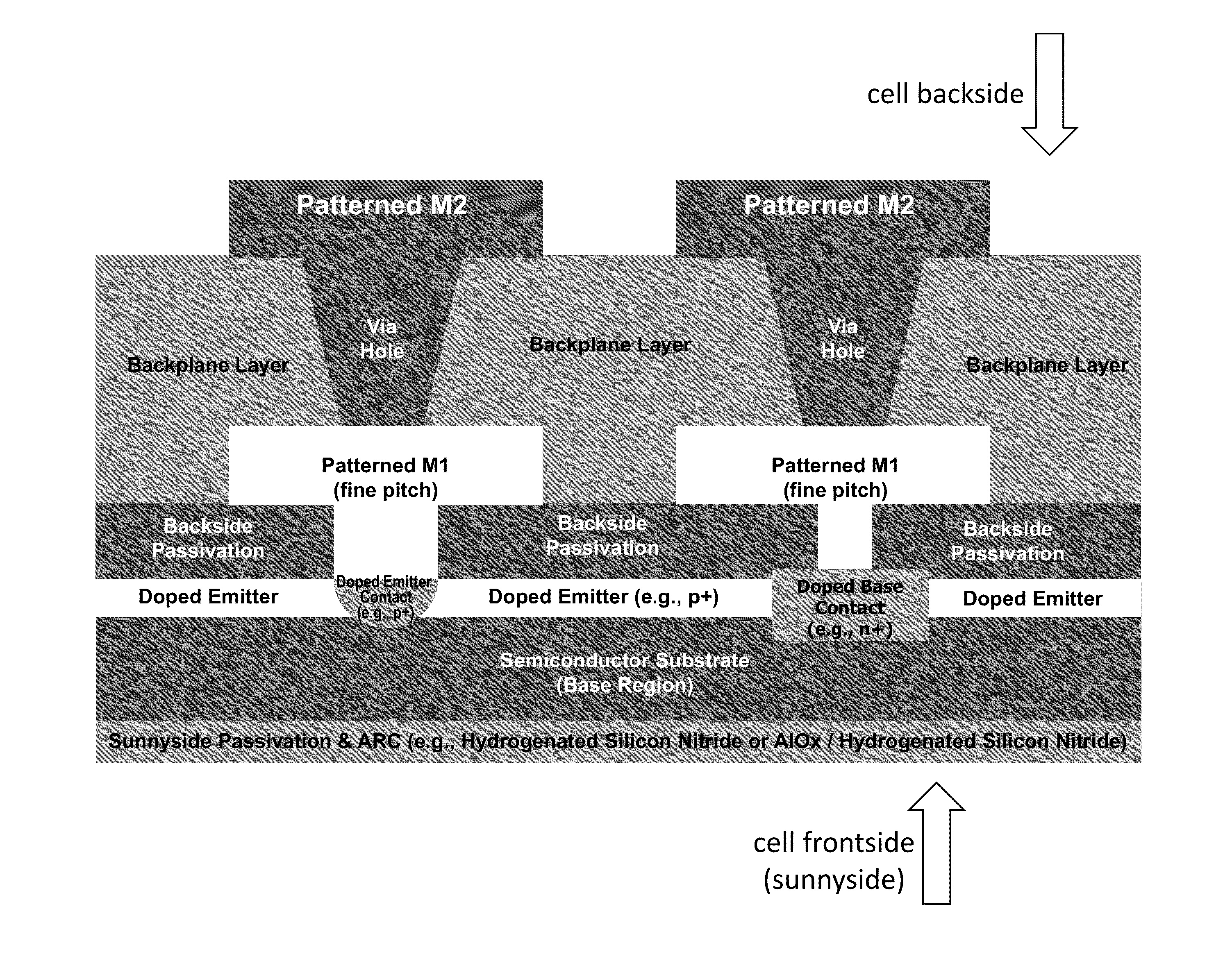

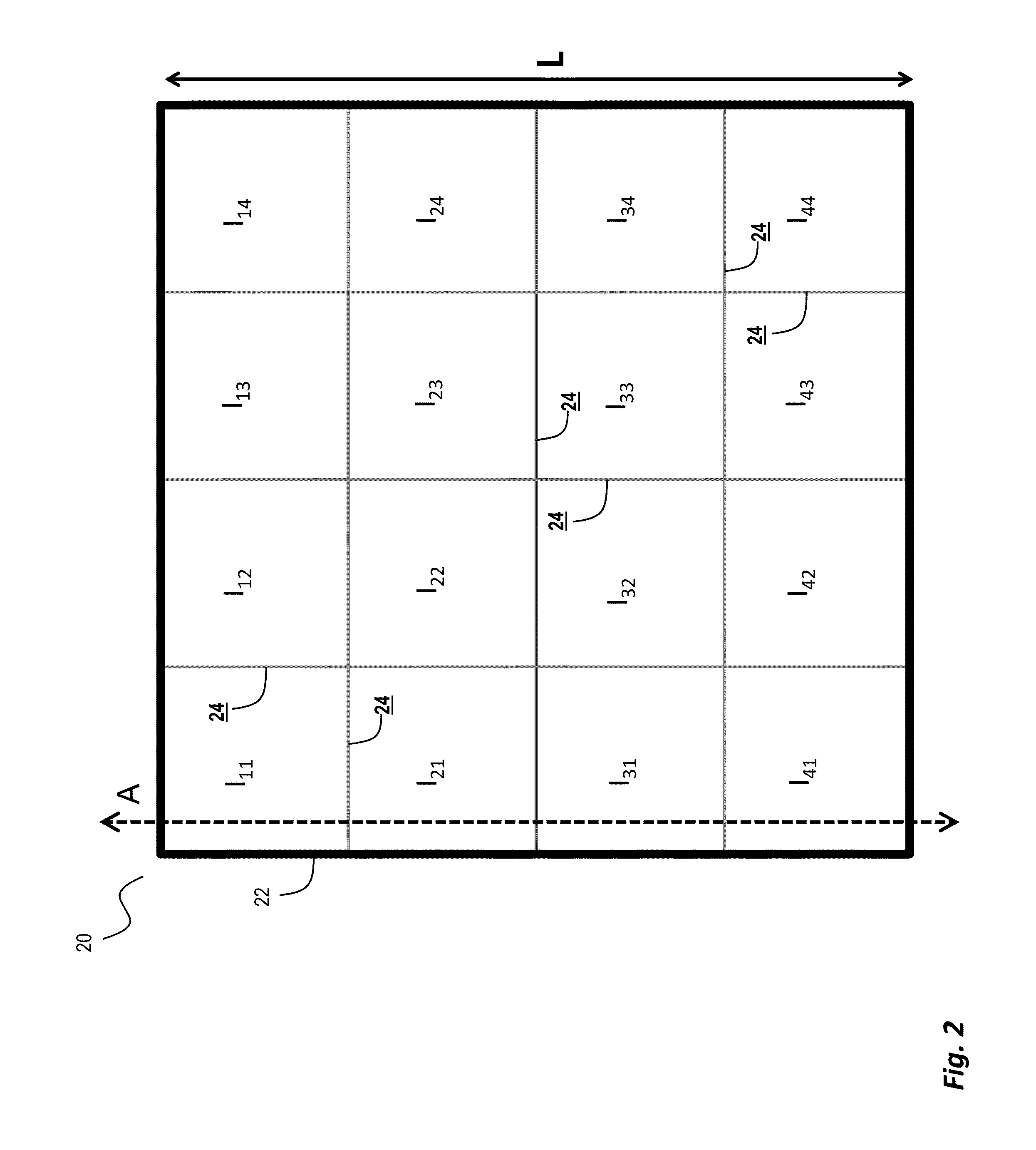

Systems and methods for monolithically isled solar photovoltaic cells and modules

InactiveUS20140326295A1Reduce and eliminate disadvantageReduce and eliminate and problemPhotovoltaic supportsPV power plantsEngineeringBattery cell

According to one aspect of the disclosed subject matter, a monolithically isled solar cell is provided. The solar cell comprises a semiconductor layer having a light receiving frontside and a backside opposite the frontside and attached to an electrically insulating backplane. A trench isolation pattern partitions the semiconductor layer into electrically isolated isles on the electrically insulating backplane. A first metal layer having base and emitter electrodes is positioned on the semiconductor layer backside. A patterned second metal layer providing cell interconnection and connected to the first metal layer by via plugs is positioned on the backplane.

Owner:BEAMREACH SOLAR INC

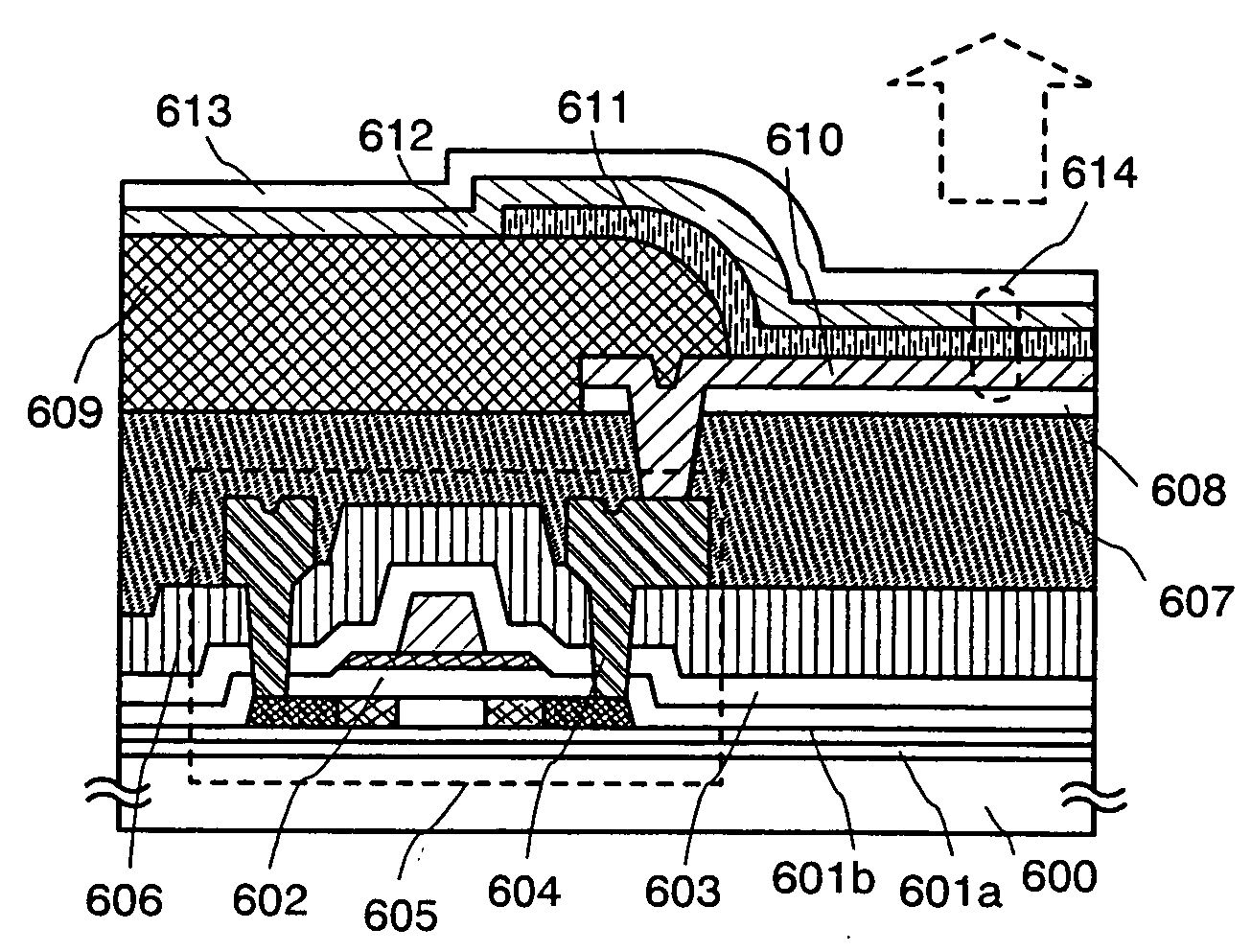

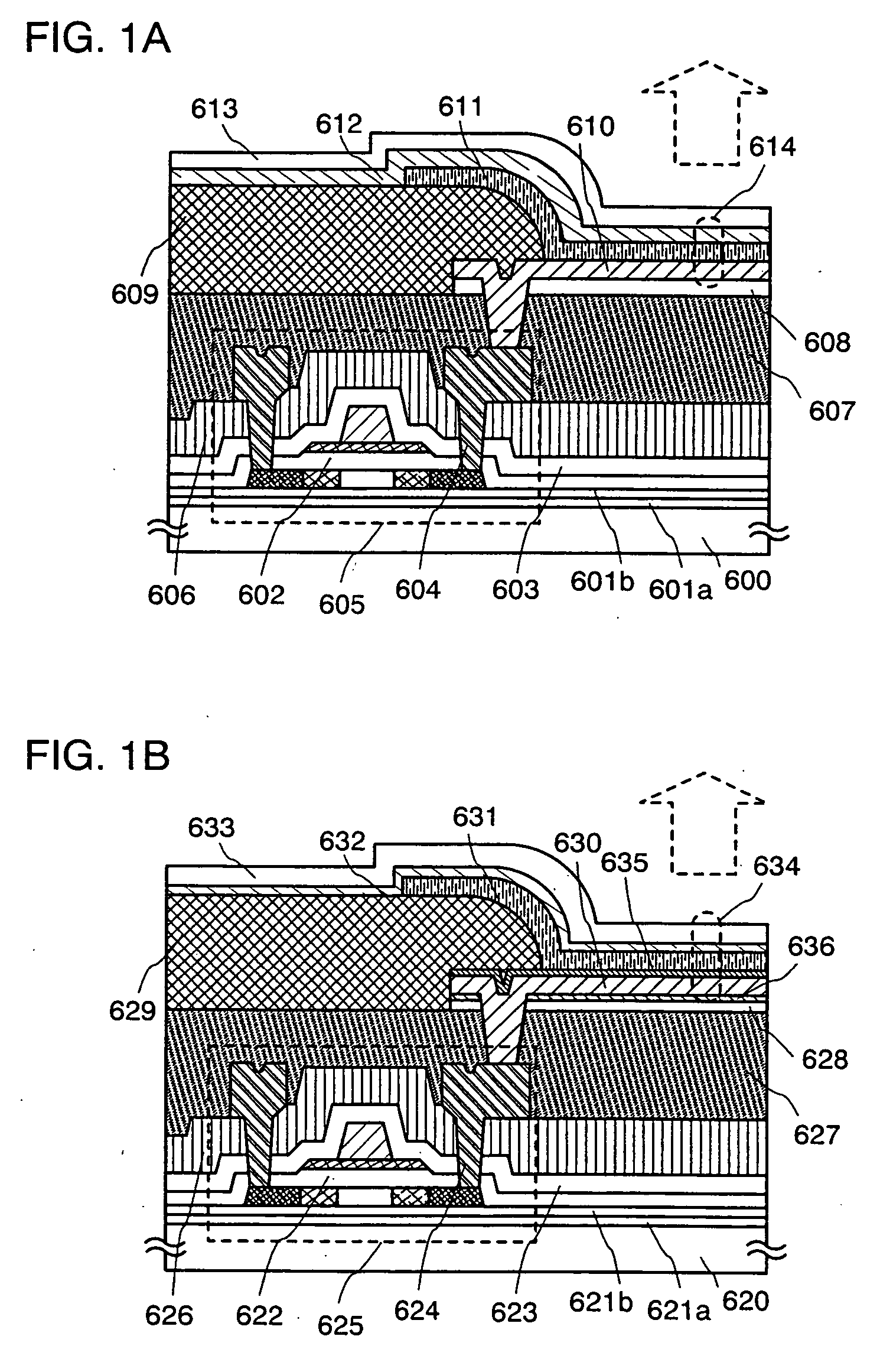

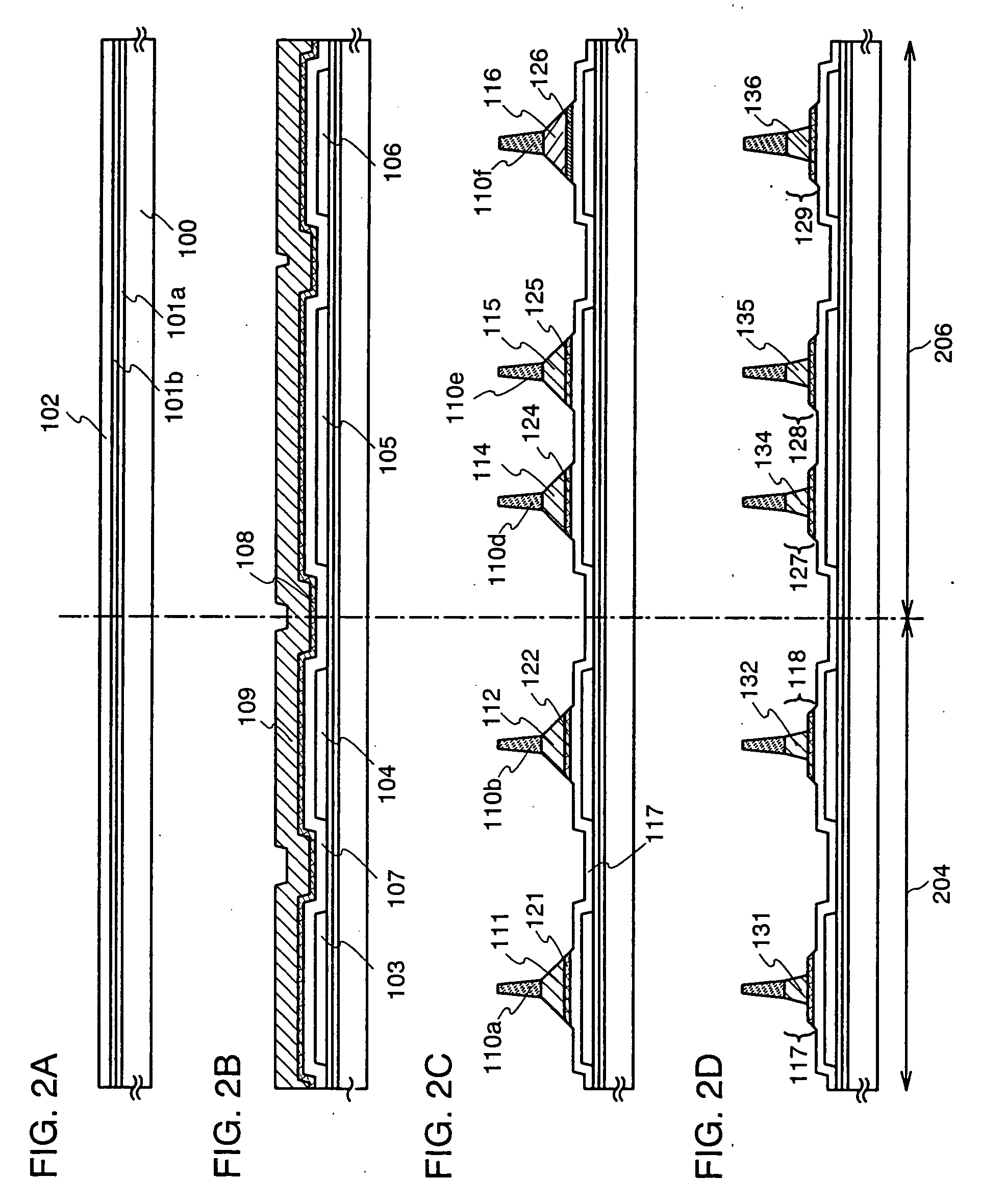

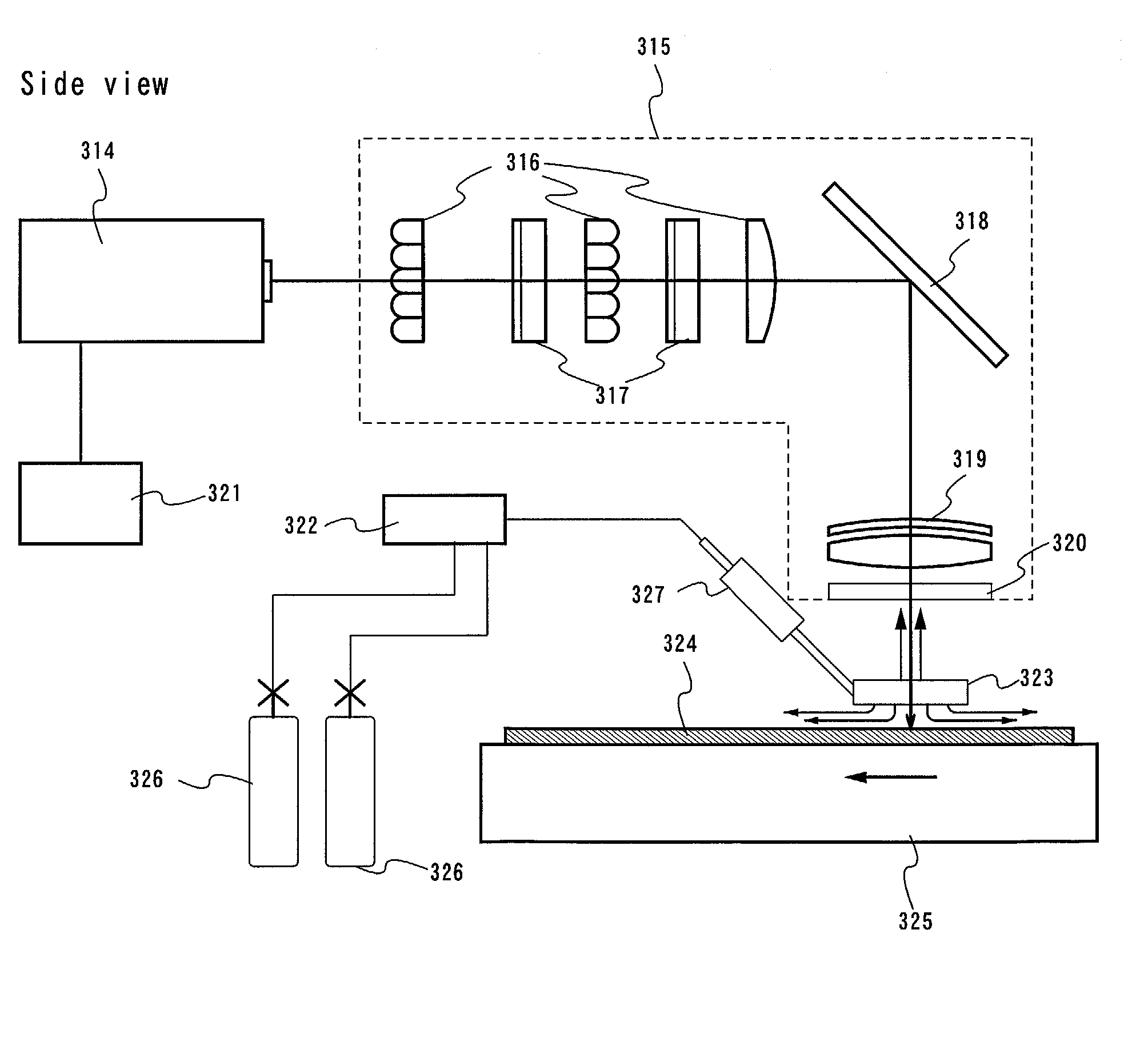

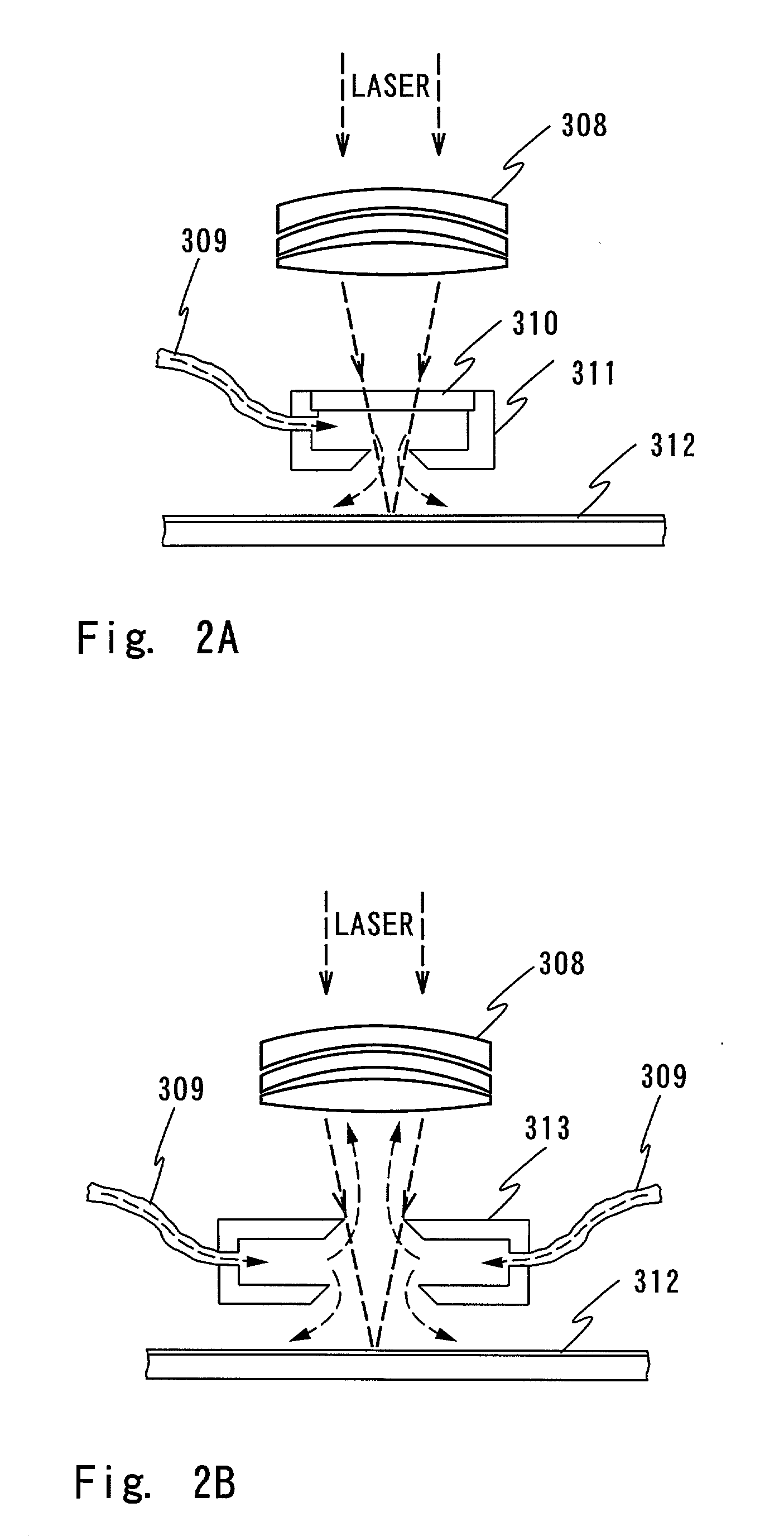

Laser irradiating apparatus and method of manufacturing semiconductor apparatus

InactiveUS20020153360A1Improve featuresGrowth inhibitionSemiconductor/solid-state device manufacturingLaser beam welding apparatusVolumetric Mass DensityLaser light

First laser light is irradiated (energy density of 400 to 500 mj / cm2) to a semiconductor film 102 in an atmosphere containing oxygen in order to obtain a semiconductor film 102b having large depressions and projections on the surface. Then, an oxidized film 105a formed by the irradiation of the first laser light is removed. After that, an inert gas with an oxygen density of 10 ppm or below is blown thereto, and, at the same time, second laser light is irradiated thereto (the energy density is higher than that of the irradiation of the first laser light). Thus, the surface of the semiconductor film 102b is flattened, and a semiconductor film 102c having fewer depressions and projections on the surface can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

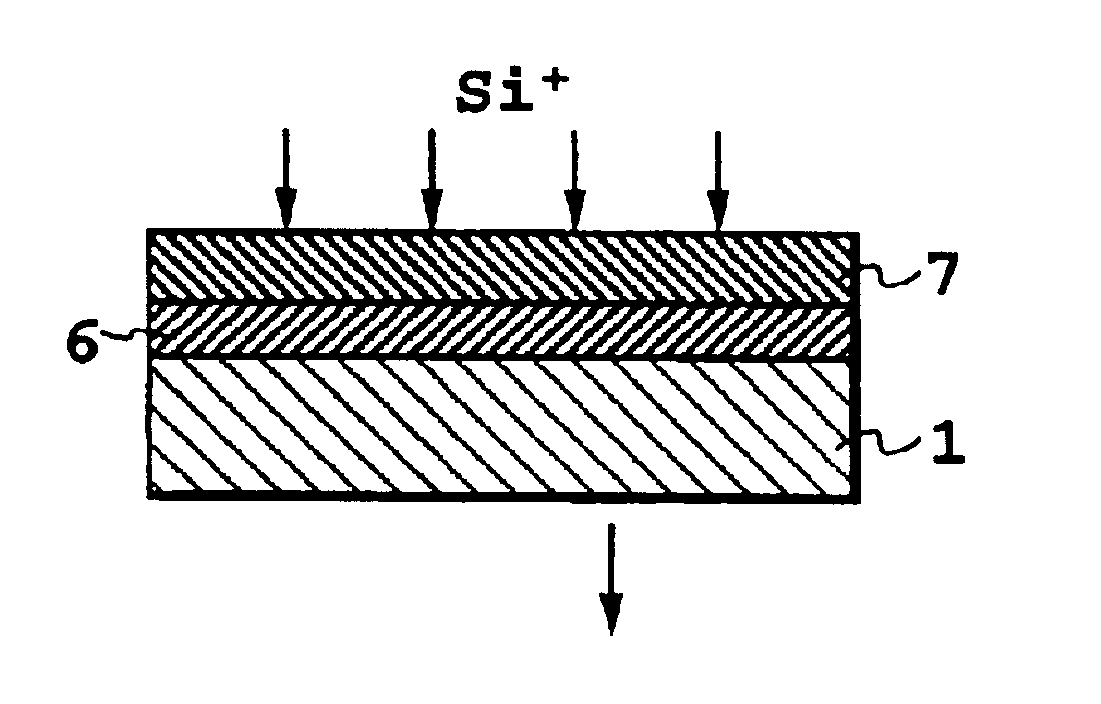

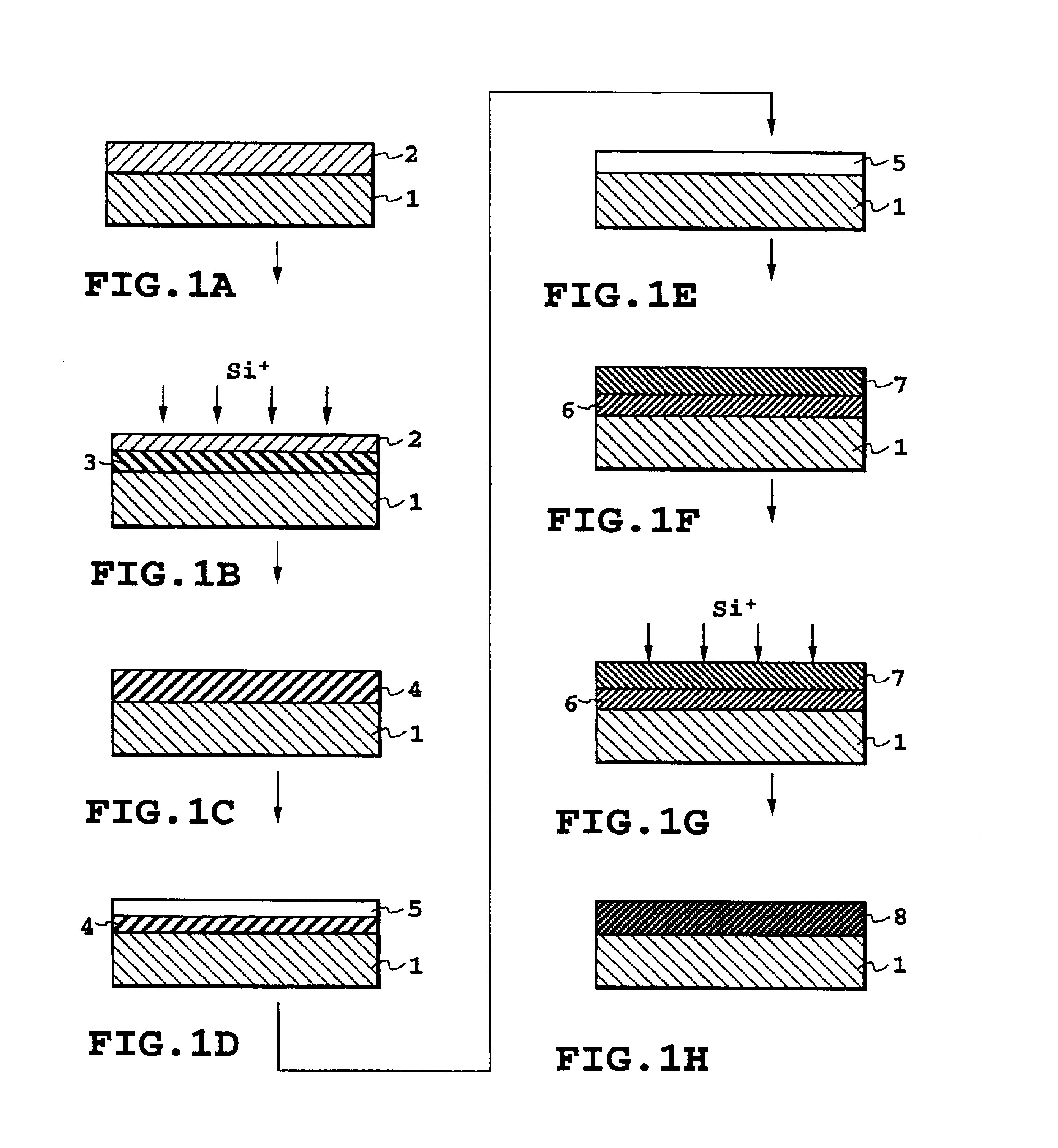

Semiconductor substrate and its production method, semiconductor device comprising the same and its production method

InactiveUS6768175B1High crystallinityFew defectSemiconductor/solid-state device testing/measurementSolid-state devicesSilicon oxideSoi substrate

When a SOI substrate is produced a first silicon layer epitaxially grown on the insulating underlay is ion implanted to make deep part of interface of the silicon layer amorphous, and then annealed to recrystallize. Next, the silicon layer is heat treated to oxidize part of the surface side, and after the silicon oxide is removed by etching, a silicon layer is epitaxially grown on the remaining first silicon layer to form a second silicon layer. Subsequently, the second silicon layer is again ion implanted to make deep part of interface amorphous, then annealing is performed to recrystallize. With this method, a SOI substrate, which is very small in crystal defect density of the silicon layer and good in surface flatness, can be produced. Therefore, on the semiconductor substrate an electronic device or optical device having high device performance and reliability can be realized.

Owner:ASAHI KASEI KK

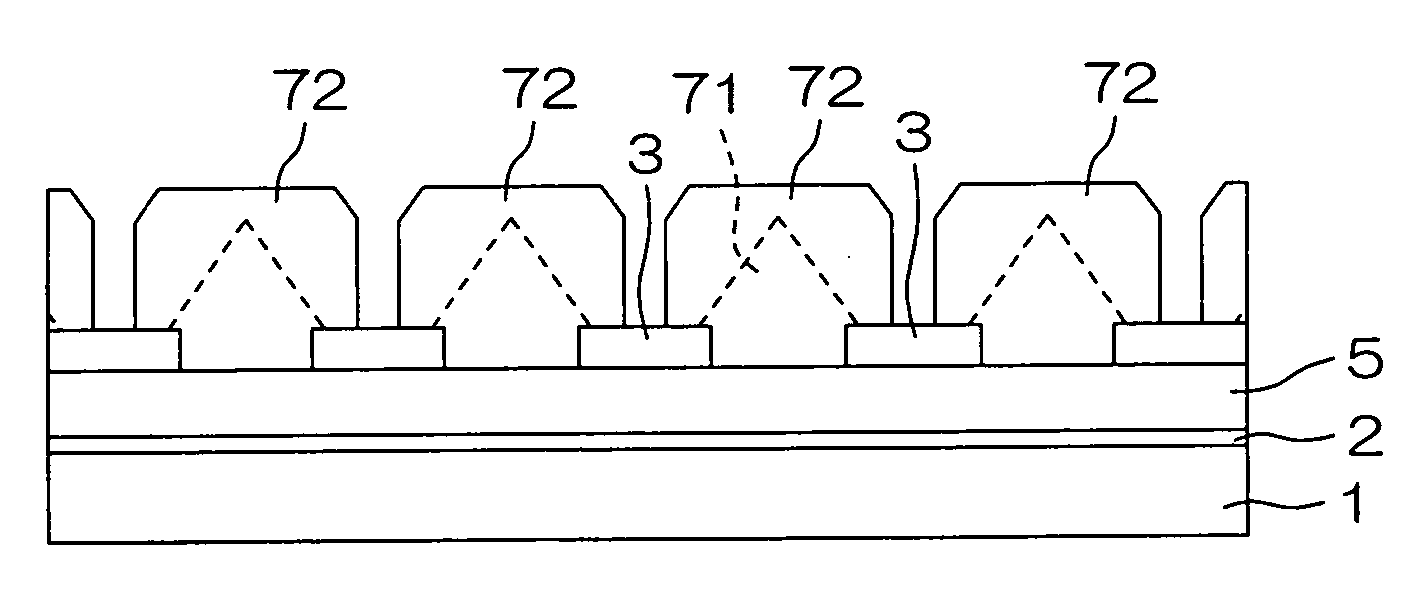

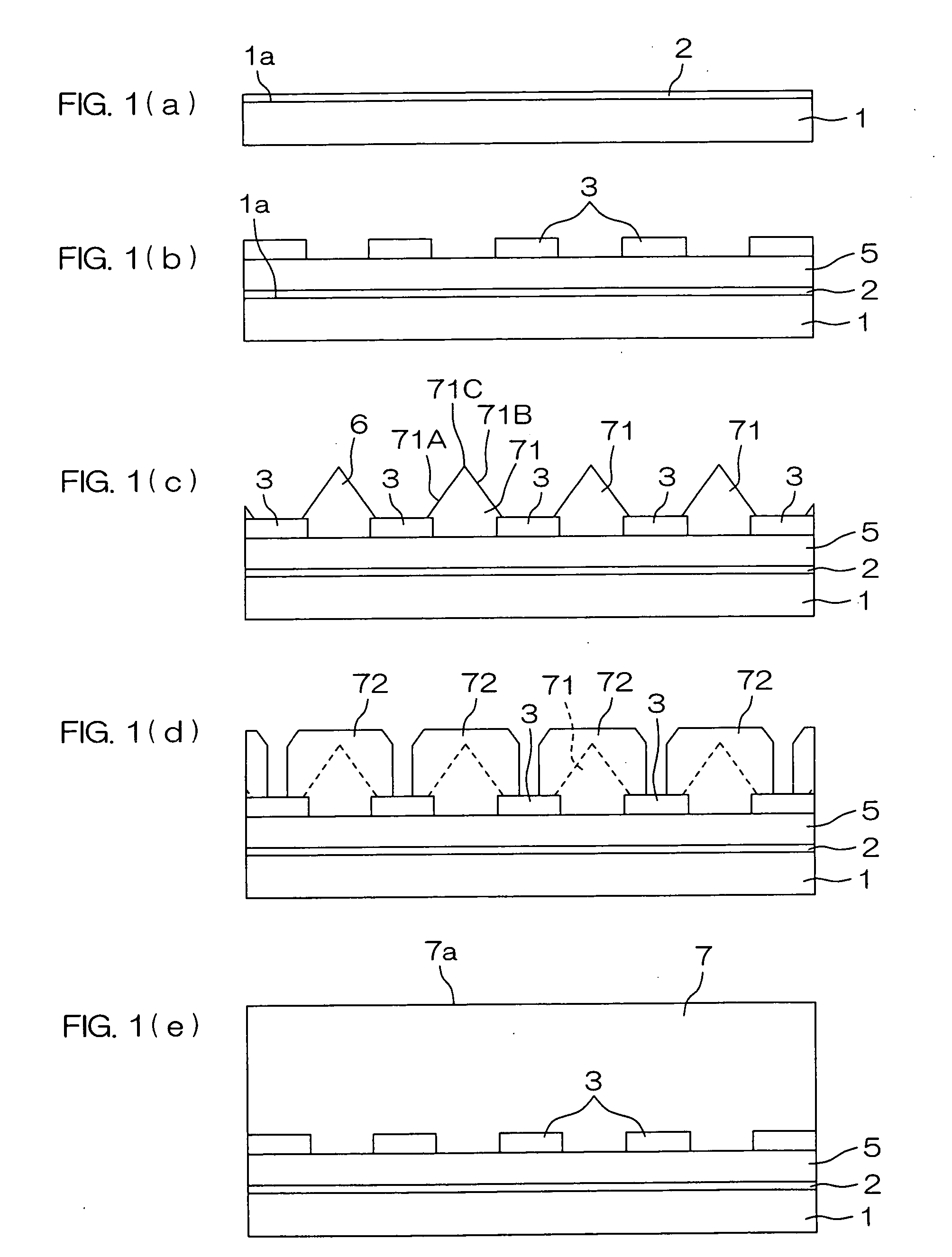

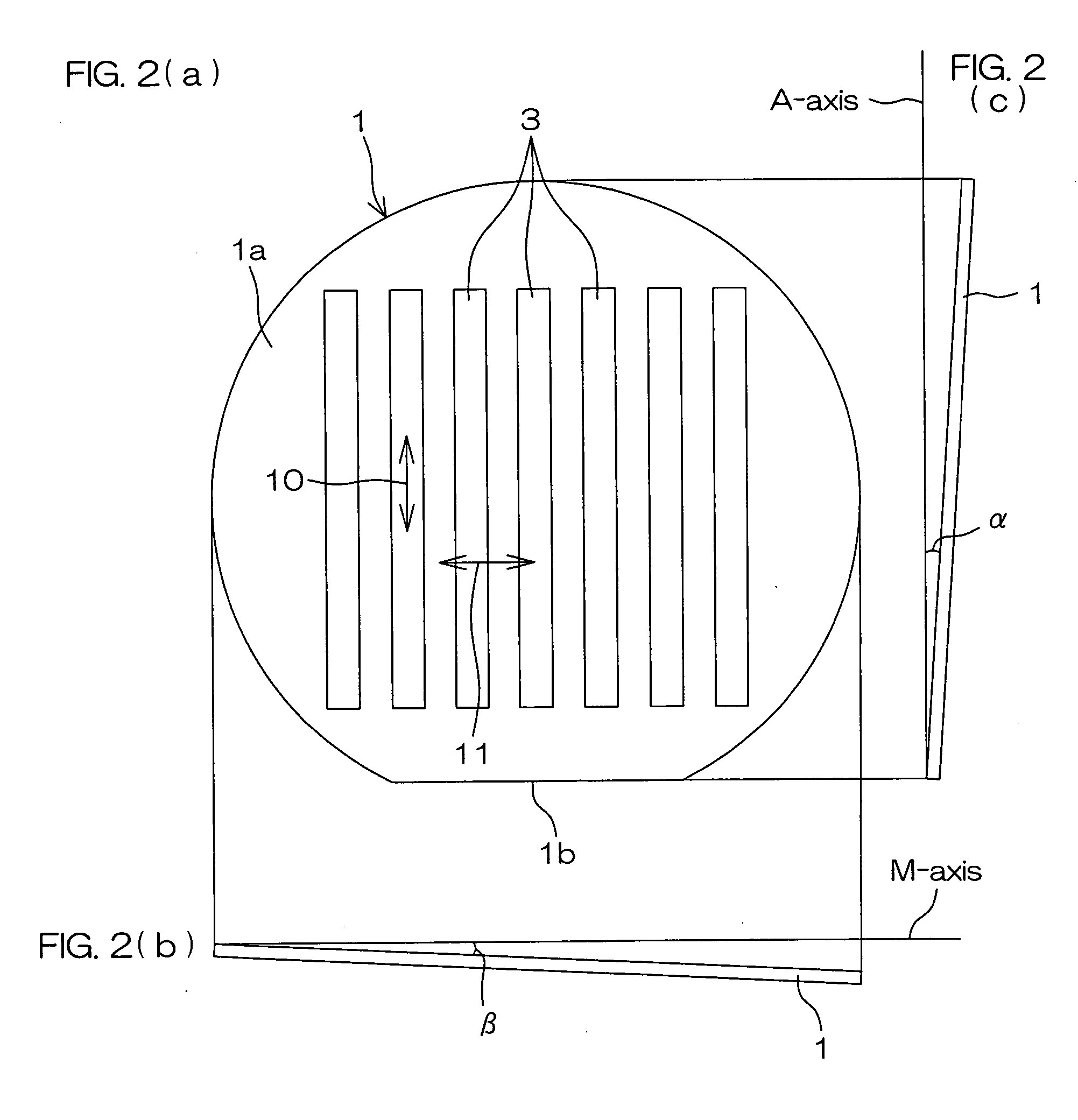

Semiconductor device, semiconductor device production method, and substrate for the semiconductor device

InactiveUS20060084245A1Good surface smoothnessHigh crystallinitySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal planeGallium nitride

A semiconductor device production method includes the steps of: forming a linear gallium nitride stripe pattern on a major surface of a substrate, the major surface of the substrate being offset from a predetermined crystal plane by offset angles of 0.1 degree to 0.5 degrees respectively defined with respect to a first crystal axis and a second crystal axis parallel to the predetermined crystal plane, the linear gallium nitride stripe pattern extending along the first crystal axis; and growing a gallium nitride compound semiconductor crystal along the predetermined crystal plane by selective lateral epitaxial growth to form a gallium nitride compound semiconductor layer on the major surface of the substrate formed with the gallium nitride stripe pattern. The first crystal axis and the second crystal axis may be perpendicular to each other. The substrate may be a sapphire substrate, a silicon carbide substrate, an aluminum nitride substrate or a gallium nitride substrate. In this case, the predetermined crystal plane is preferably a C-plane.

Owner:ROHM CO LTD

Glass substrate and method for manufacturing the same, cover glass and method for manufacturing the same, personal digital assistant, and display device

ActiveUS20160357294A1Flatness of thinExcellent surface appearanceDevices with sensorCharacter and pattern recognitionDisplay deviceEngineering

In a glass substrate for extracting therefrom a plurality of cover glasses to protect a protection object, plural concave portions are provided in a front surface or back surface of the glass substrate. The glass substrate includes plural thin portions formed by providing the plural concave portions and a thick portion connecting to the thin portion, and a haze value of the thin portion is 8% or less.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com