Patents

Literature

3320results about How to "Easy to peel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Films having a desiccant material incorporated therein and methods of use and manufacture

InactiveUS20070160789A1Improve efficacyExtended shelf lifeSurgical furnitureDiagnosticsDesiccantInsertion stent

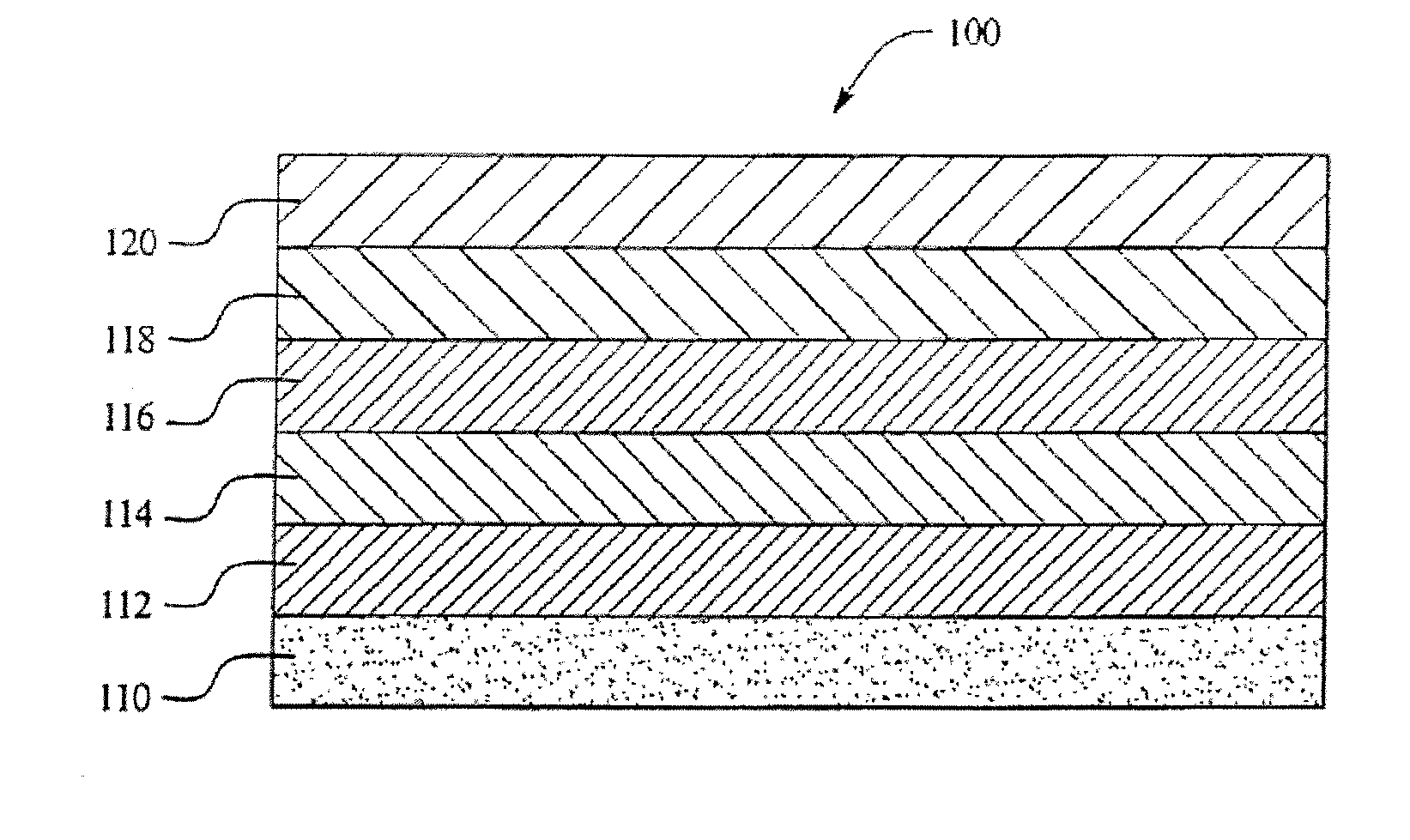

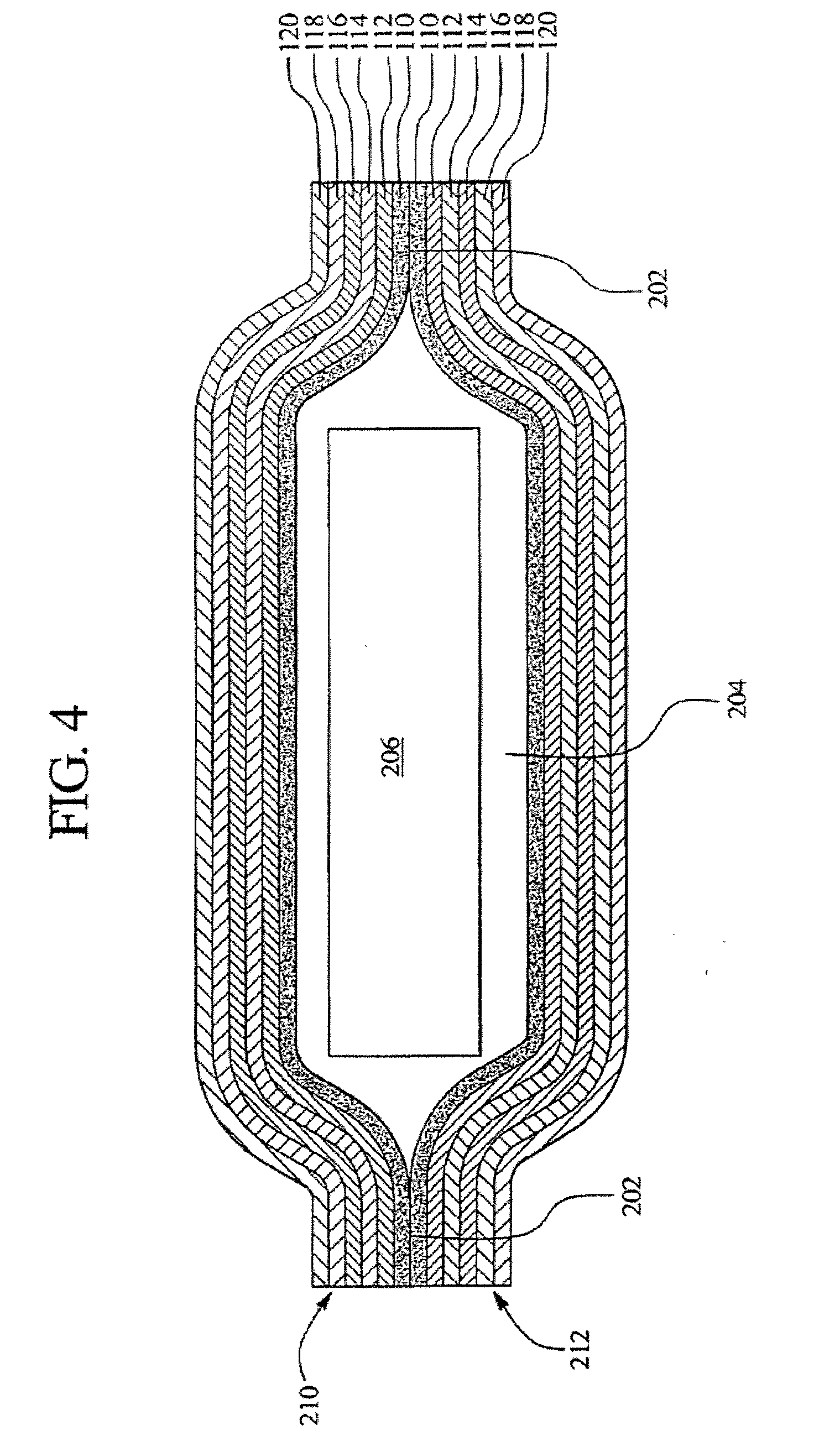

Film structures, packages, films and methods of making the same are provided wherein the film structures have a desiccant material incorporated into at least one layer of the film structures and further wherein the film structures can comprise a material for making a peelable seal when the film structures are heat sealed to other film structures. The film structures are utilized for a package to hold a product that may be sensitive to the presence of moisture. The product may preferably be pharmaceutical products, nutraceutical products, or devices such as absorbable sutures or medical stents, although any moisture-sensitive product is contemplated by the present invention.

Owner:ALCAN PACKAGING FLEXIBLE FRANCE

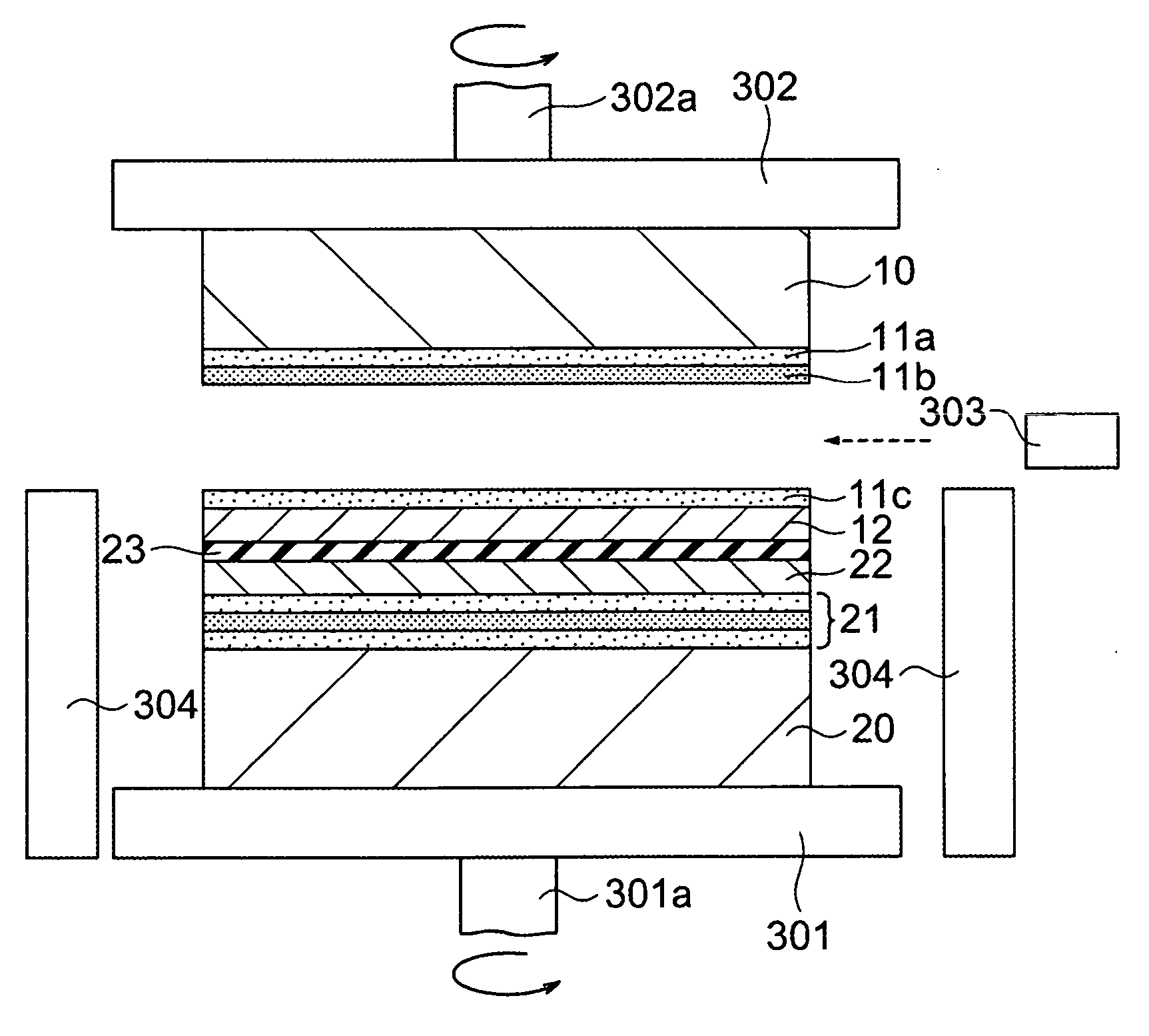

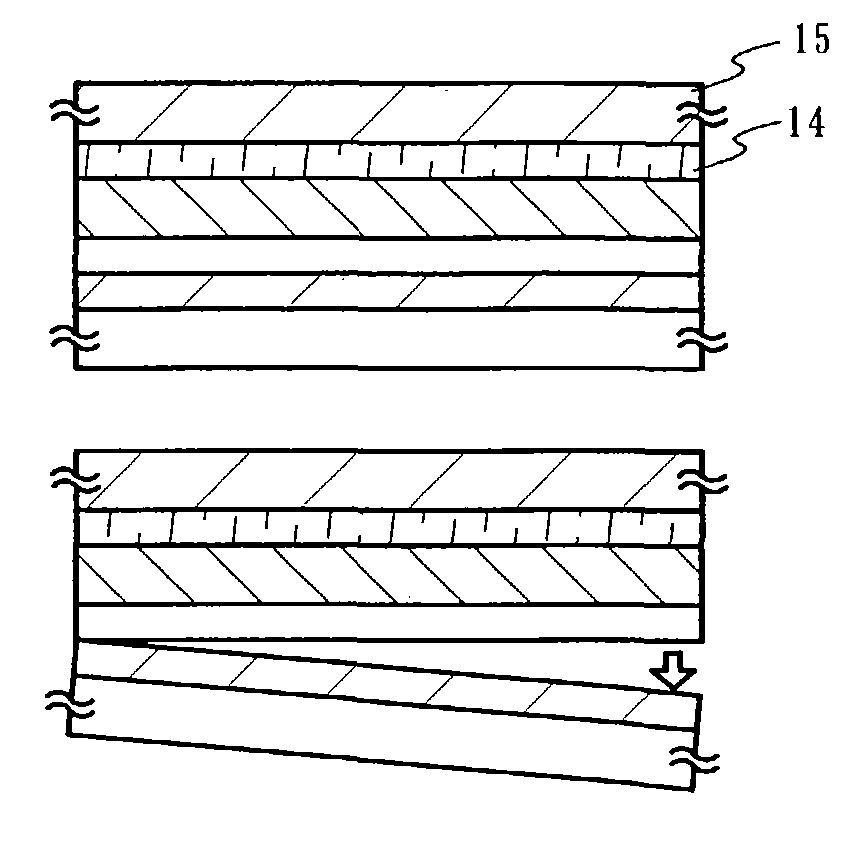

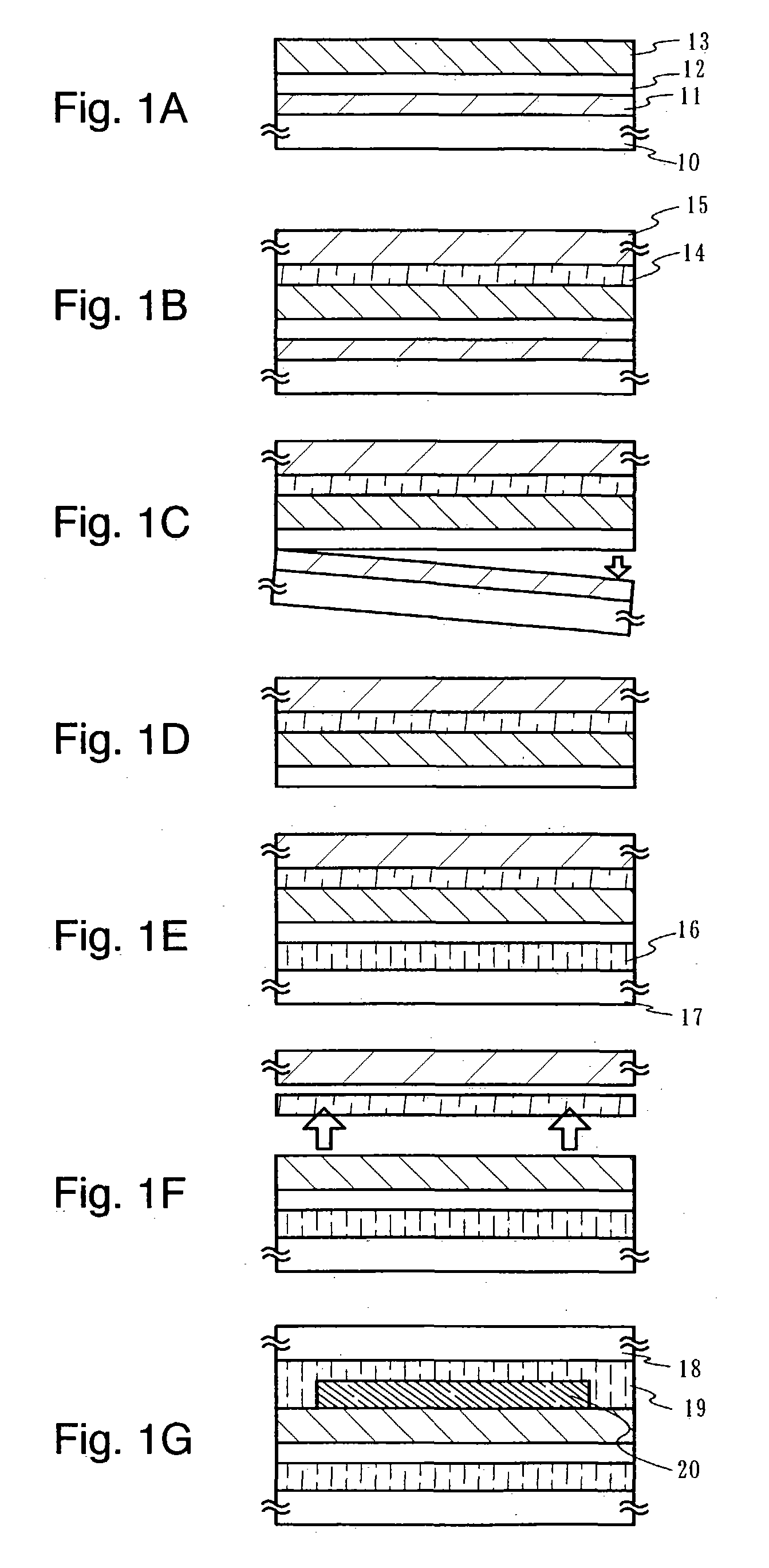

Method and apparatus for producing ultra-thin semiconductor chip and method and apparatus for producing ultra-thin back-illuminated solid-state image pickup device

InactiveUS20050074954A1Easy to separateIncrease productivitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

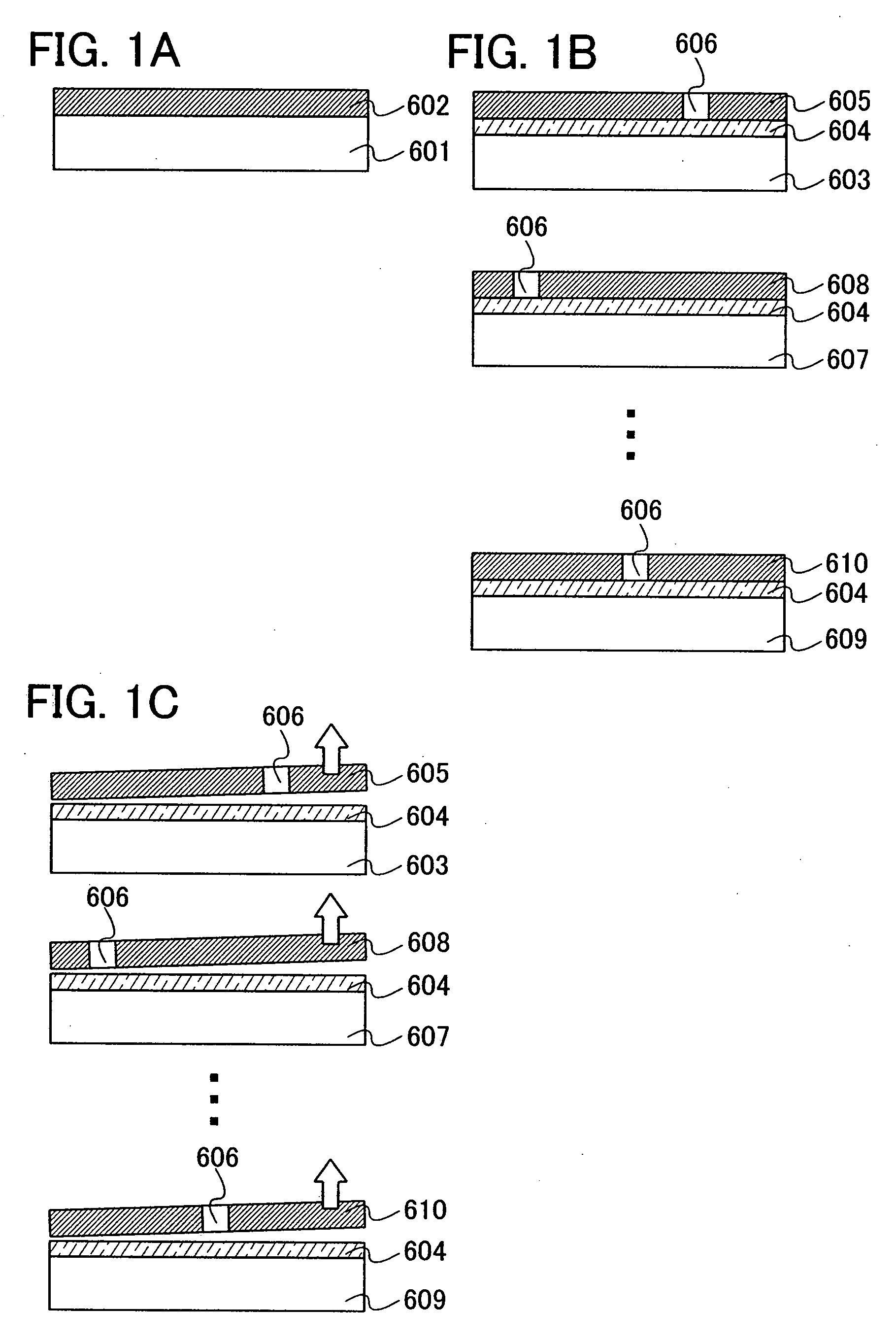

A method for producing an ultra-thin semiconductor chip and an ultra-thin back-illuminated solid-state image pickup device utilizing a semiconductor layer formed on a support substrate via an insulating layer to improve separation performance of a semiconductor layer from a support substrate and thereby improve the productivity and quality. The method uses two porous peeling layers on opposite sides of a substrate to produce an ultra-thin substrate.

Owner:SONY CORP

Peeling method

InactiveUS7122445B2Slow performanceImprove suppression propertiesTransistorSolid-state devicesHydrogenEngineering

Owner:SEMICON ENERGY LAB CO LTD

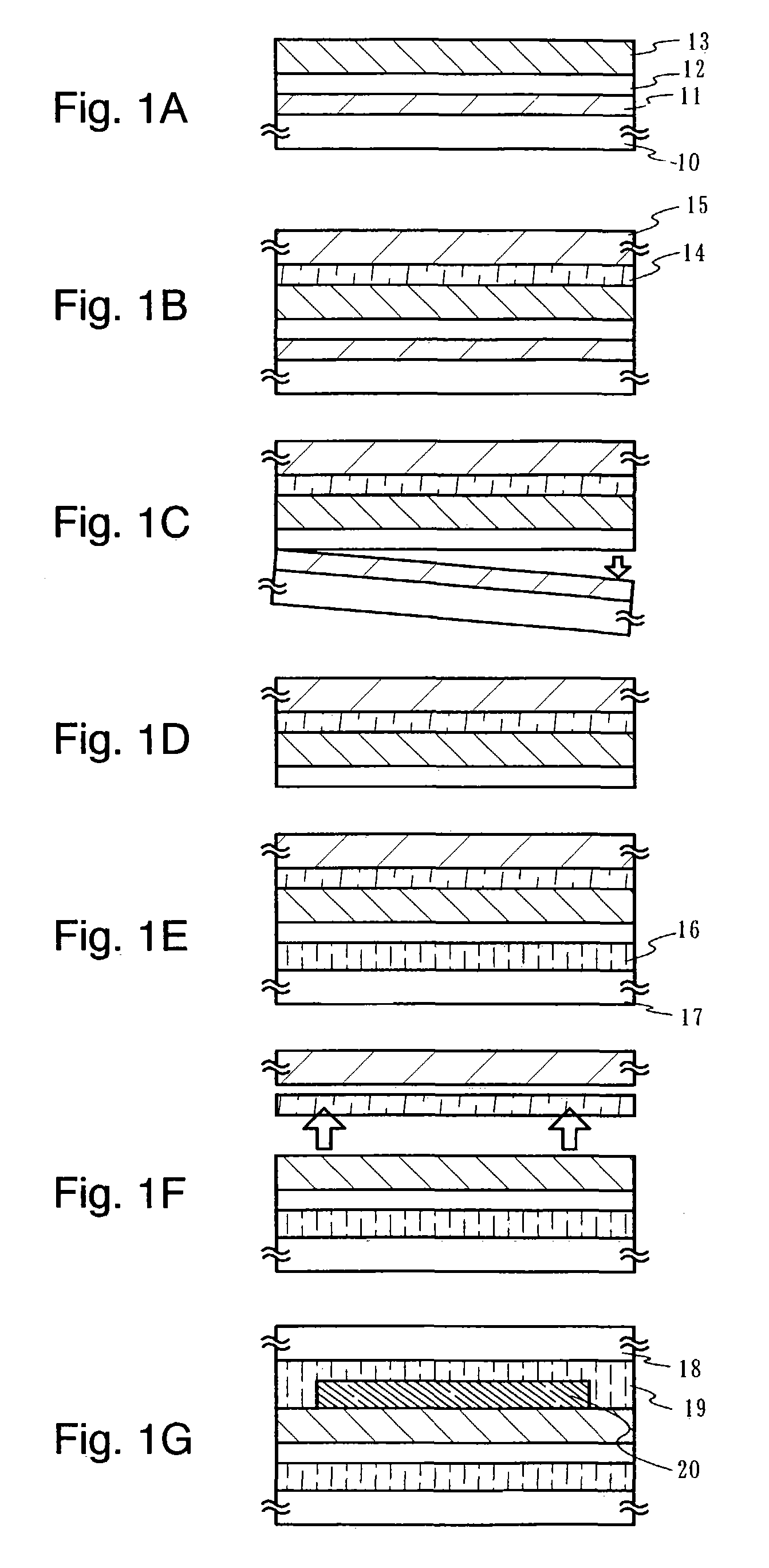

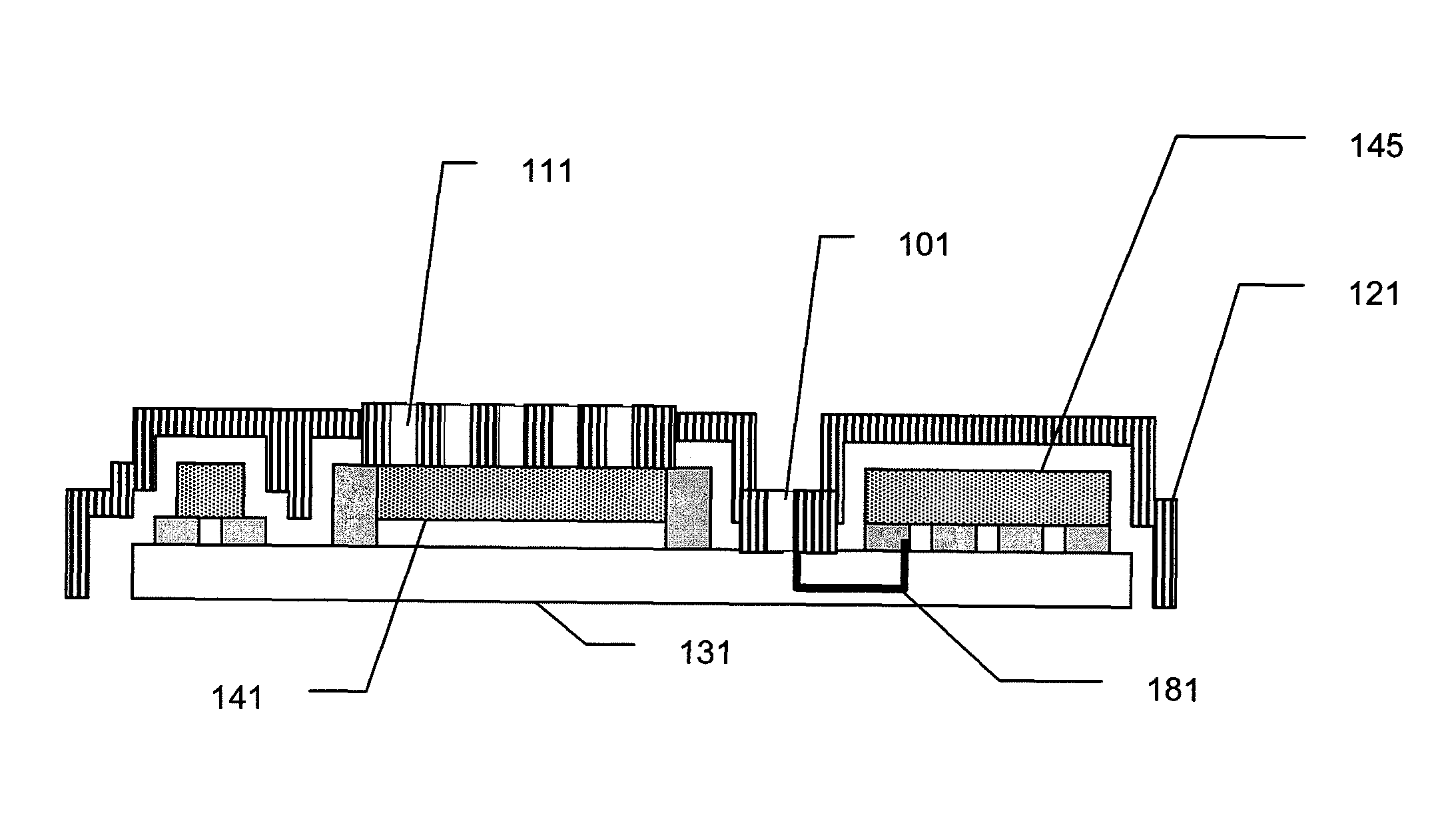

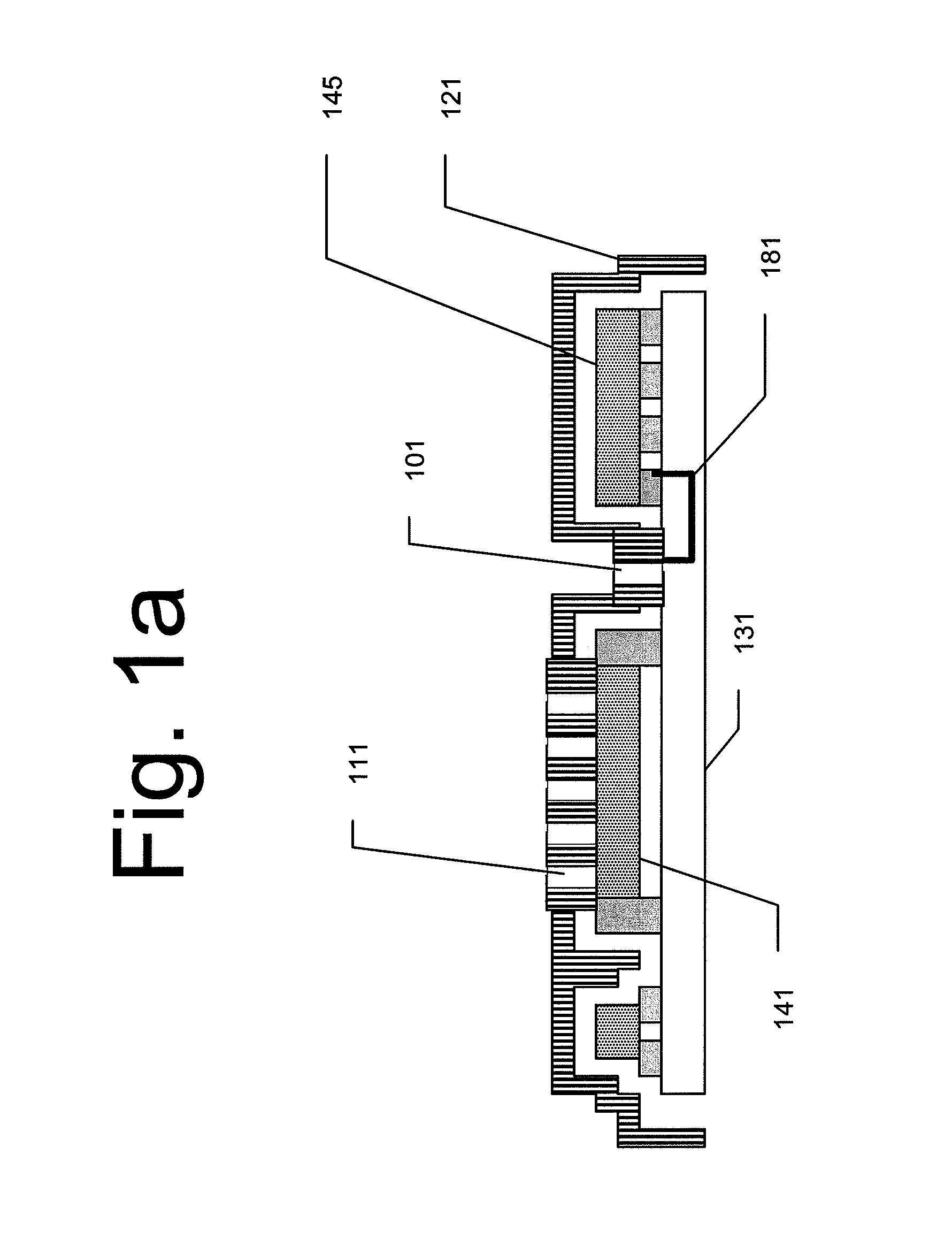

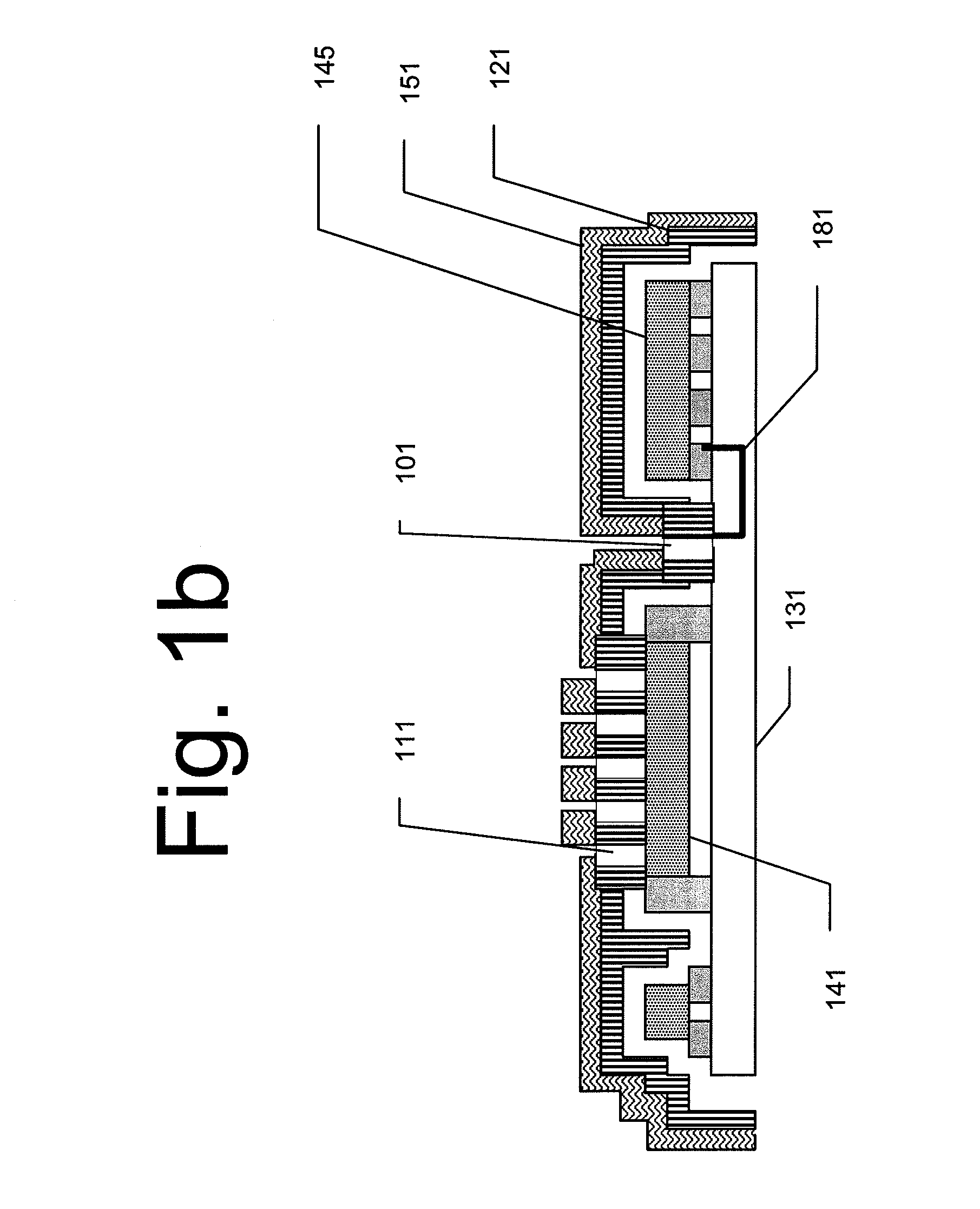

Semiconductor device and manufacturing method thereof

InactiveUS7189631B2High yieldSmall areaTransistorSemiconductor/solid-state device detailsOxideLaser beams

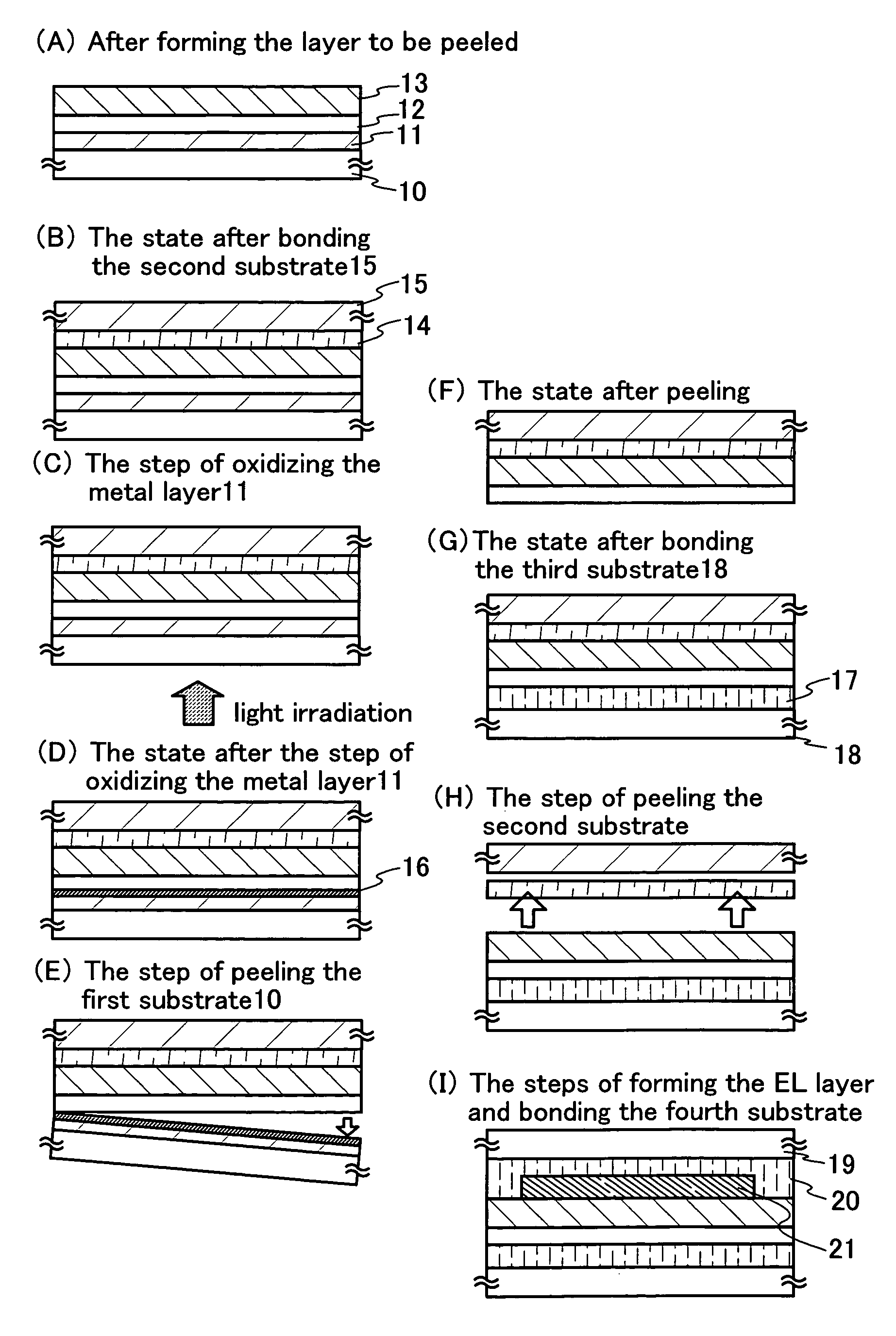

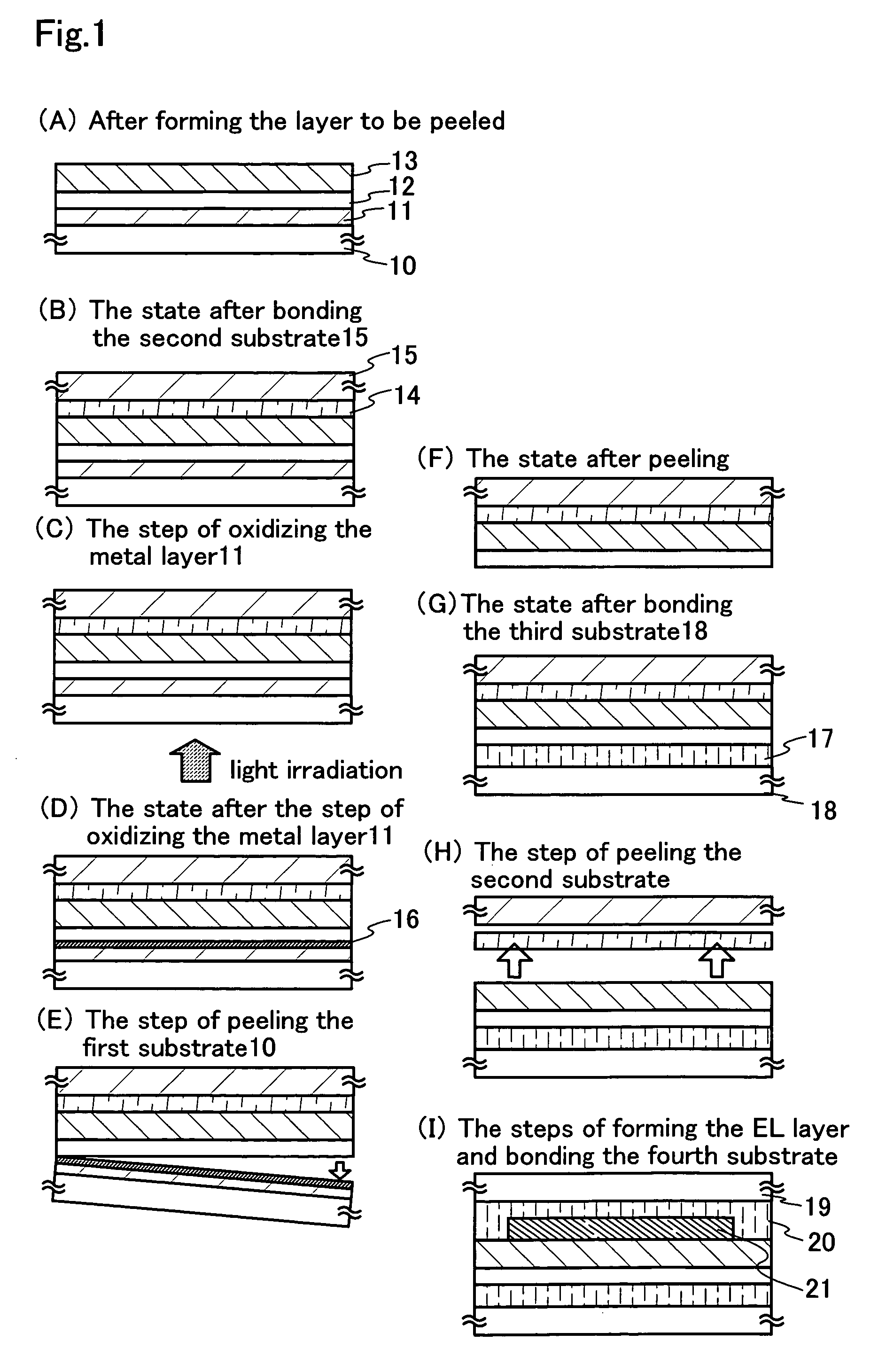

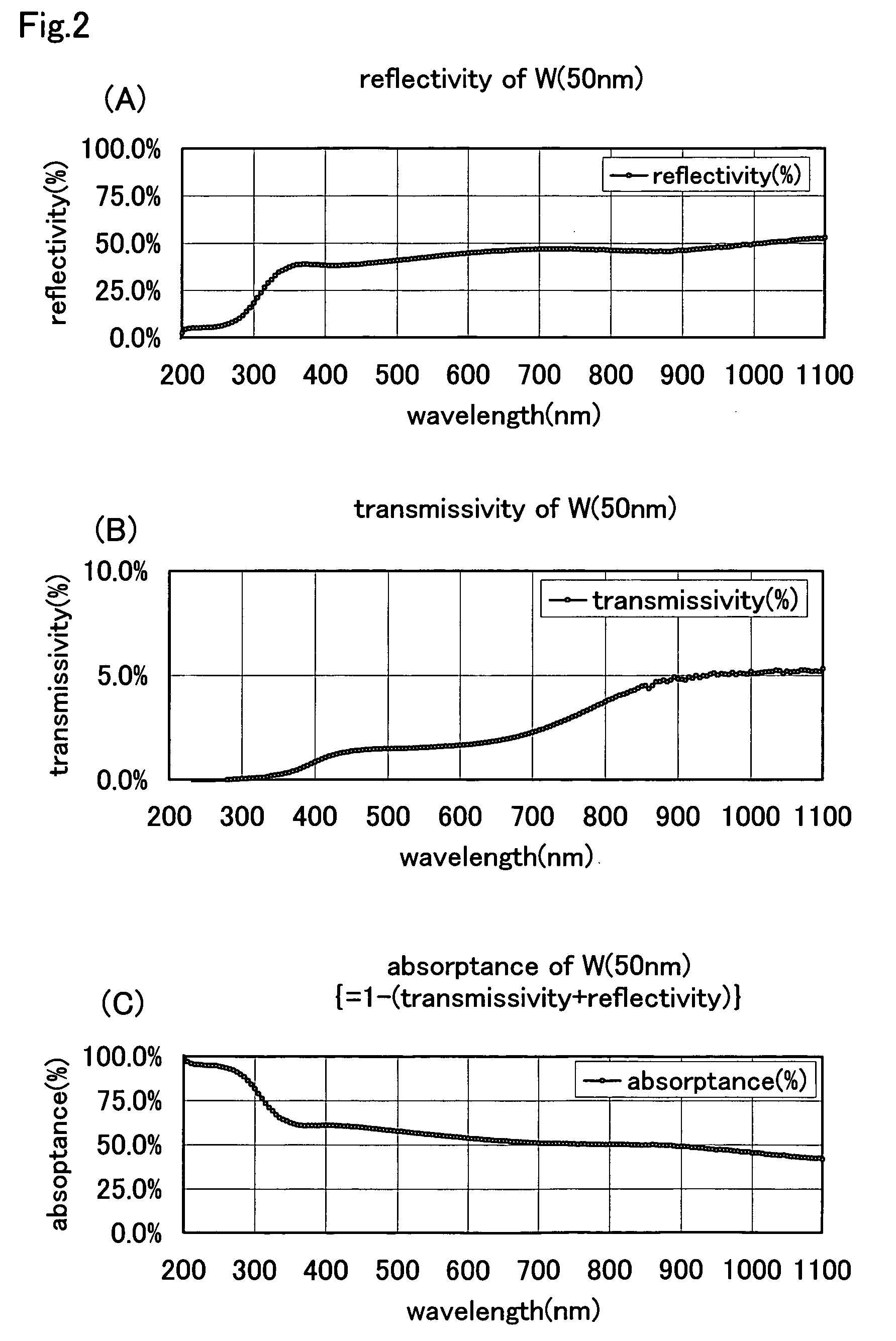

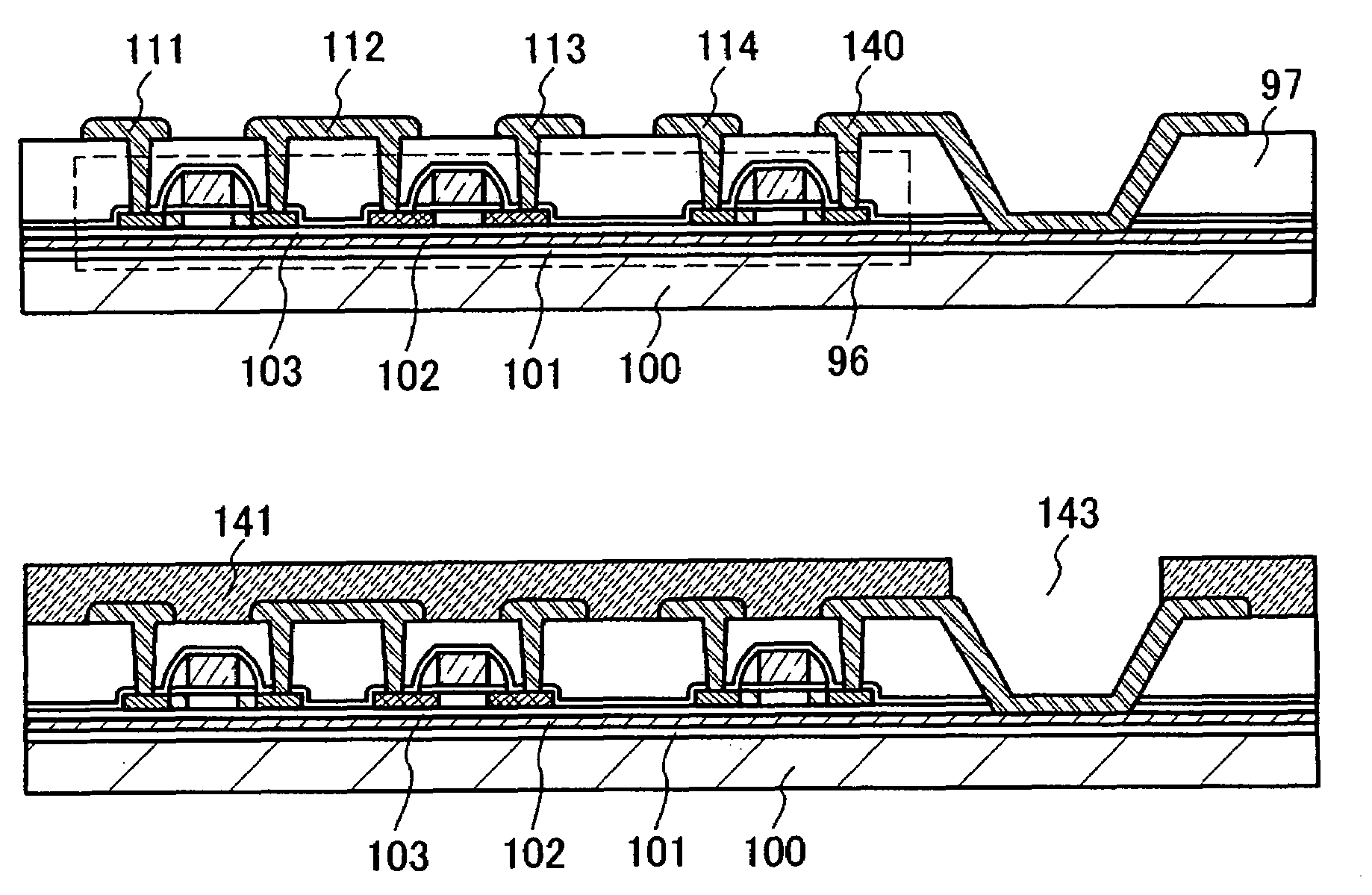

It is an object of the present invention to provide a peeling method that causes no damage to a layer to be peeled and to allow not only a layer to be peeled with a small surface area but also a layer to be peeled with a large surface area to be peeled entirely. Further, it is also an object of the present invention to bond a layer to be peeled to various base materials to provide a lighter semiconductor device and a manufacturing method thereof. Particularly, it is an object to bond various elements typified by a TFT, (a thin film diode, a photoelectric conversion element comprising a PIN junction of silicon, or a silicon resistance element) to a flexible film to provide a lighter semiconductor device and a manufacturing method thereof.When a metal layer 11 is provided over a substrate, an oxide layer 12 is provided in contact with the metal layer 11, a layer to be peeled 13 is formed, and the metal layer 11 is irradiated with a laser beam to perform oxidization and form a metal oxide layer 16, a clear separation is possible with a physical means within the metal oxide layer 12 or at an interface between the metal oxide layer 16 and the oxide layer 12.

Owner:SEMICON ENERGY LAB CO LTD

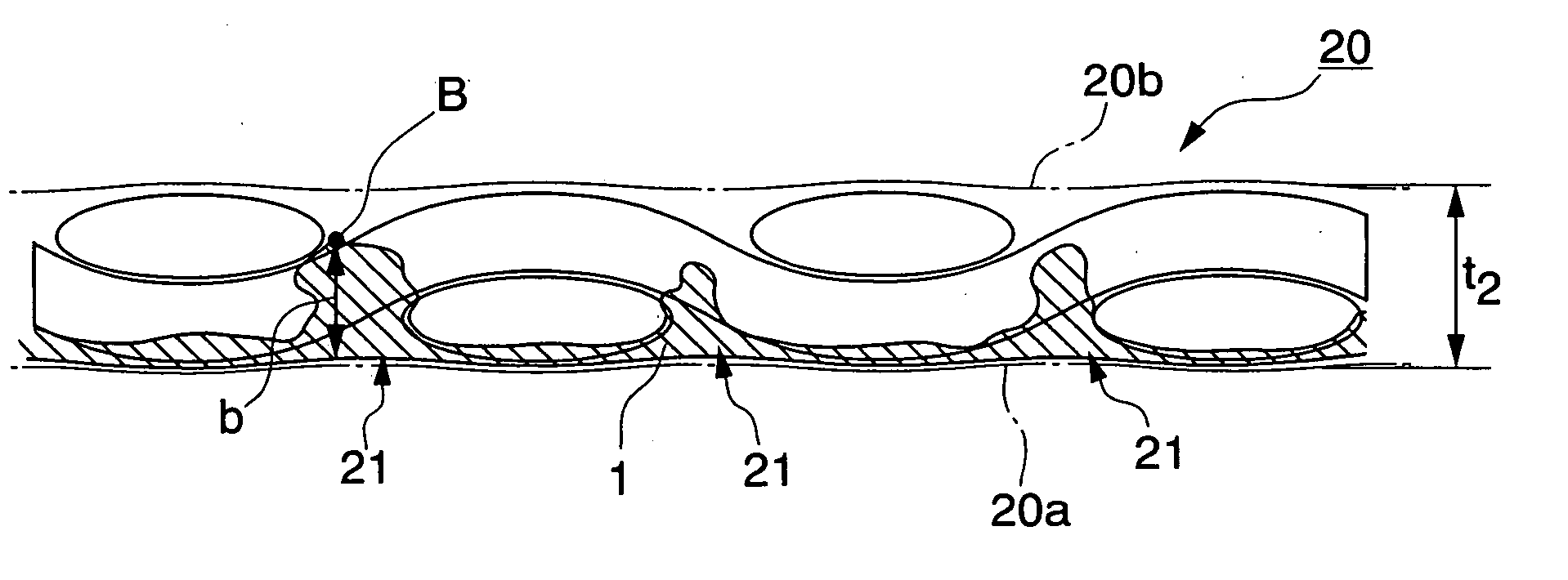

Composite structural panel with thermoplastic foam core and natural fibers, and method and apparatus for producing the same

InactiveUS6287678B1Easy to recycleEasily thermo-processedAdhesive processesLamination ancillary operationsComposite constructionShell molding

A composite structural panel includes a cover sheet laminated onto a three-layered substrate including a thermoplastic foam core sandwiched between two composite outer layers. Each composite outer layer includes natural fibers embedded in a thermoplastic matrix. The thermoplastic material of all layers is preferably polypropylene, and the core consists of an expanded cellular polypropylene rigid foam. In a method for forming the composite structural panel, a first preheated outer layer is laminated and molded onto the foam core in a first molding step, and then the second preheated outer layer and the cover sheet are laminated and molded onto the foam core in a second molding step, with a cooling-down time allowed between the two molding steps. In this manner, each preheated outer layer provides enough heat to thermally fuse the outer layer onto the foam core, without overheating the foam core to the point of softening or melting the foam core. The low density foam core provides a spacing distance between the strong composite outer layers, and therefore the finished composite structural panel has a high strength and rigidity, and a high strength-to-weight ratio. The structural panel can be molded into any desired three-dimensional contoured configuration during the molding process.

Owner:HERBERT OLBRICH

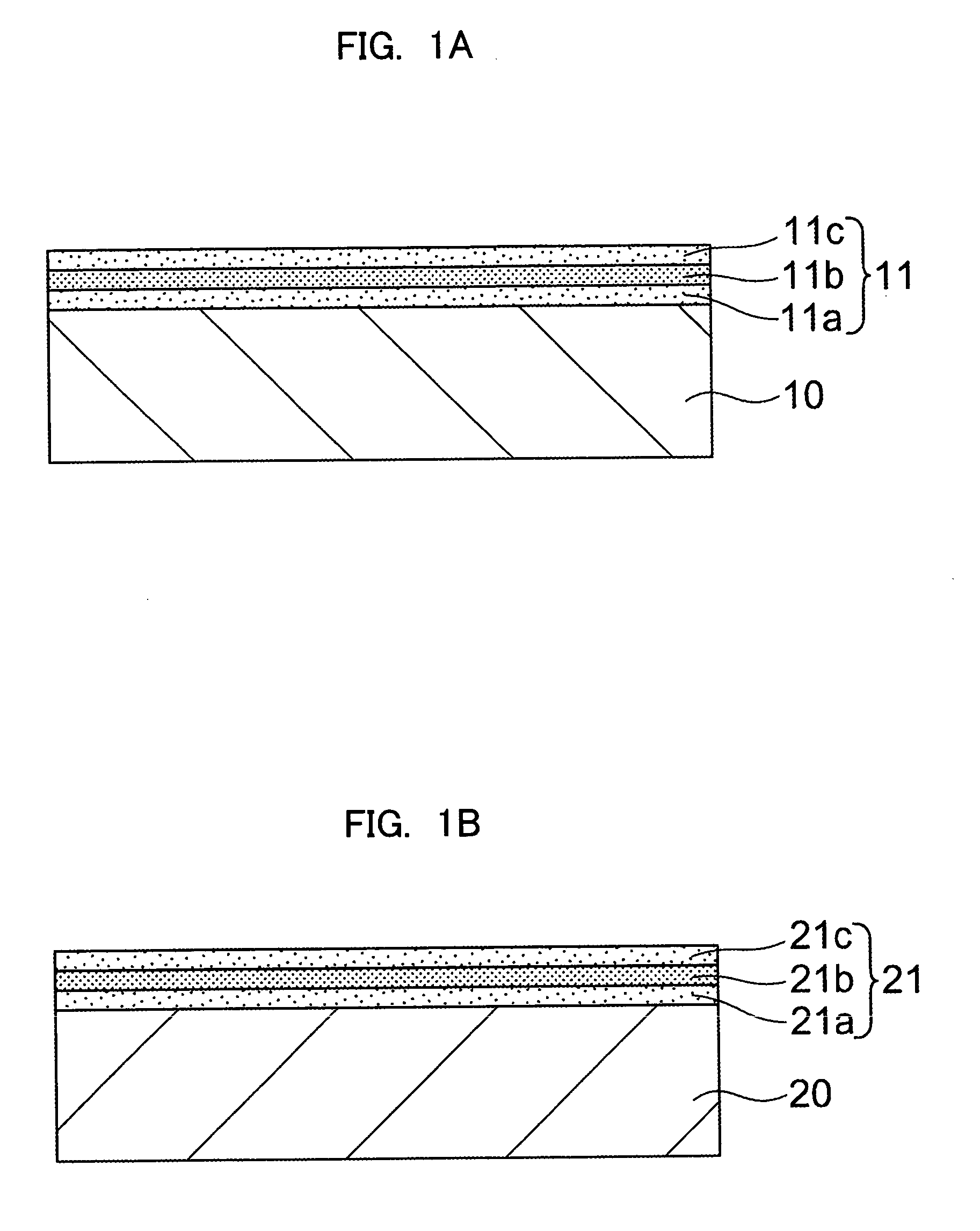

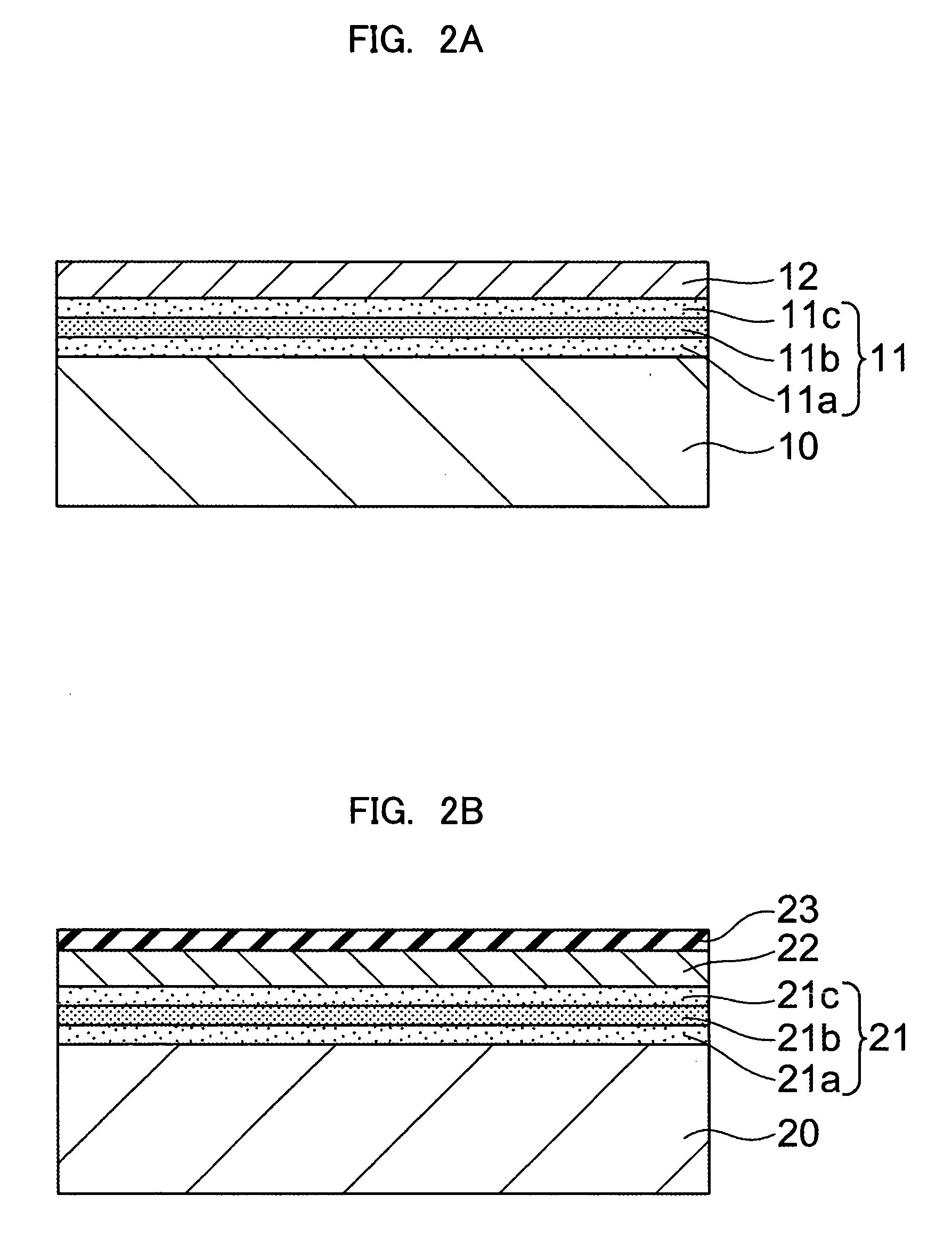

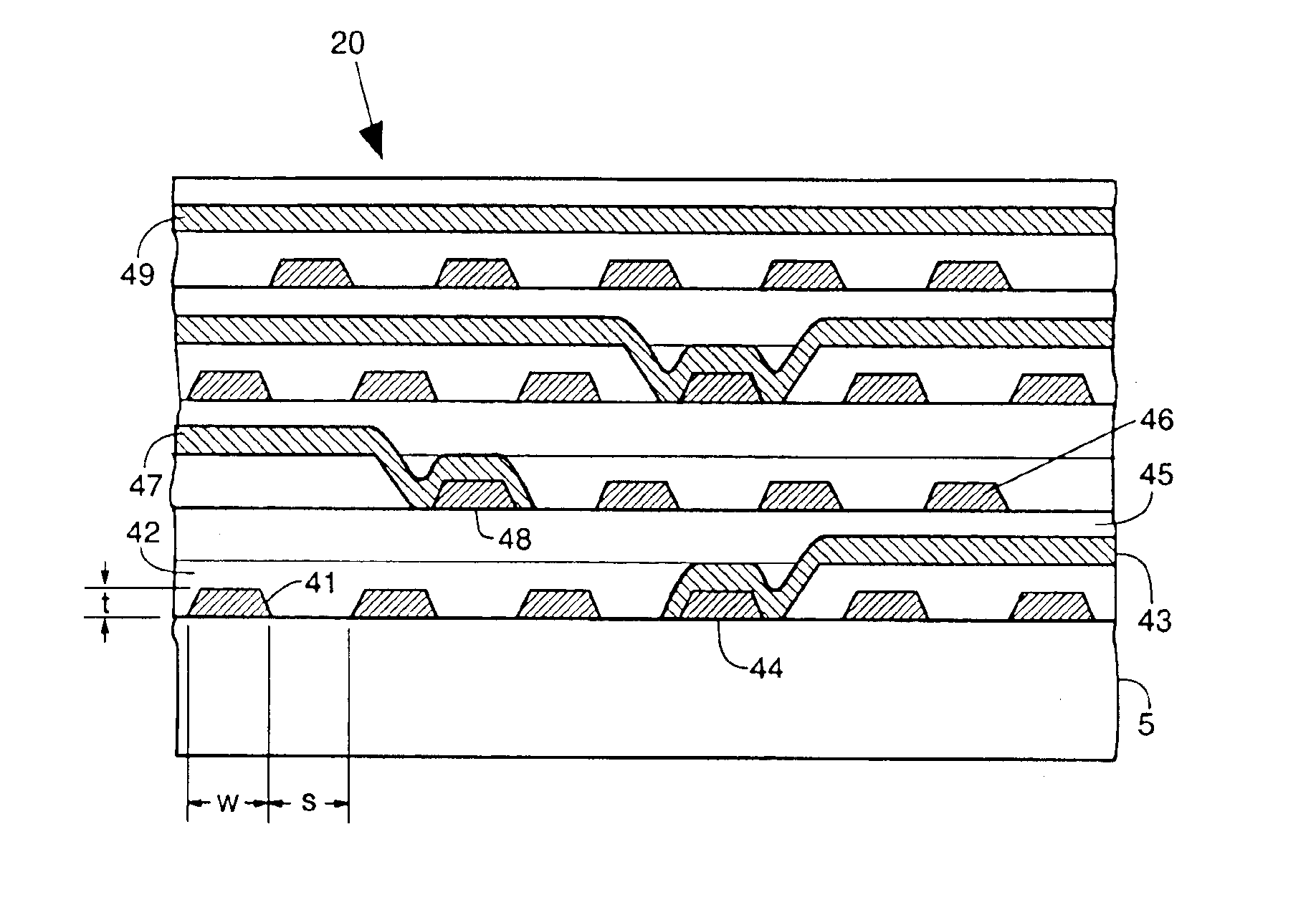

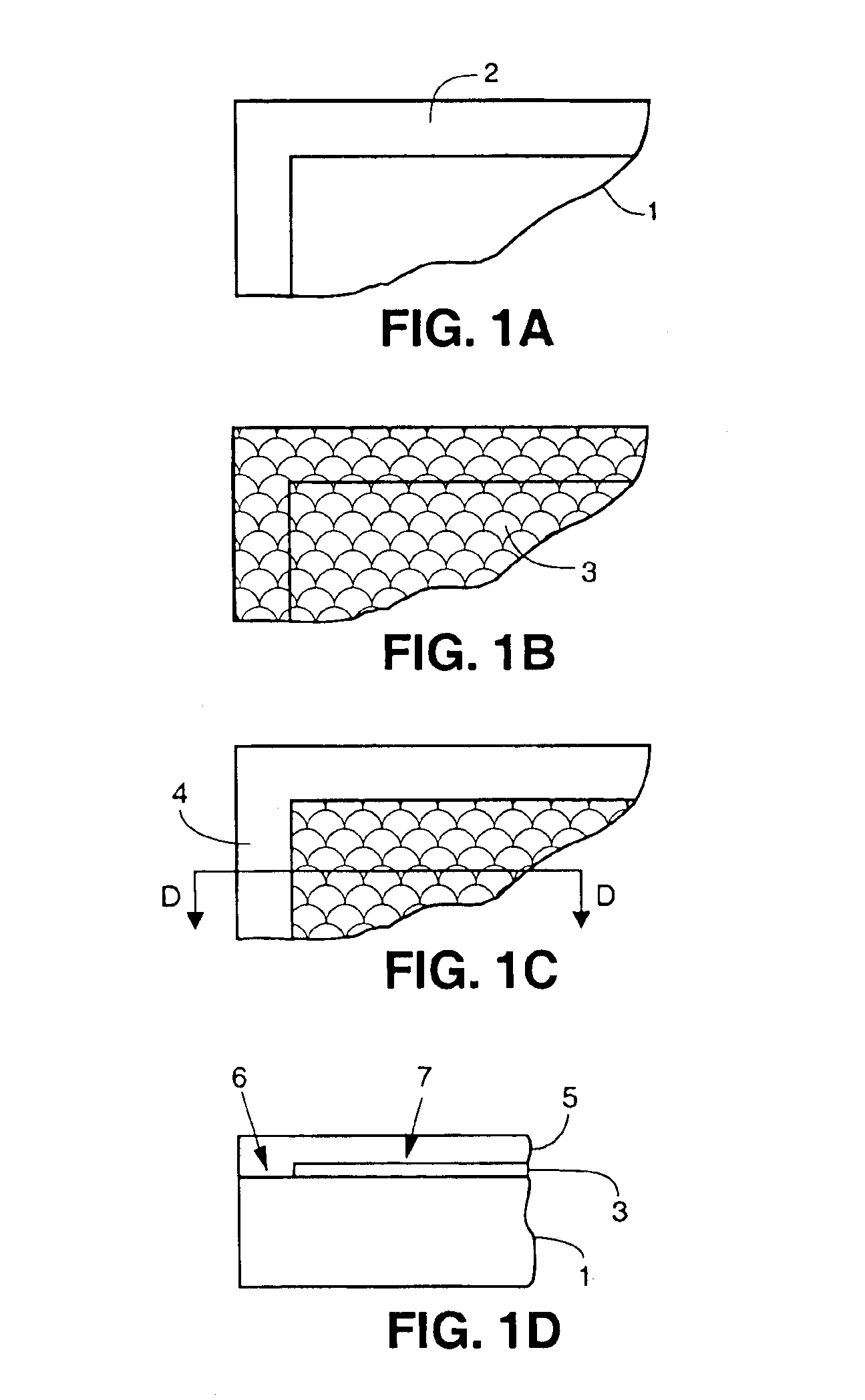

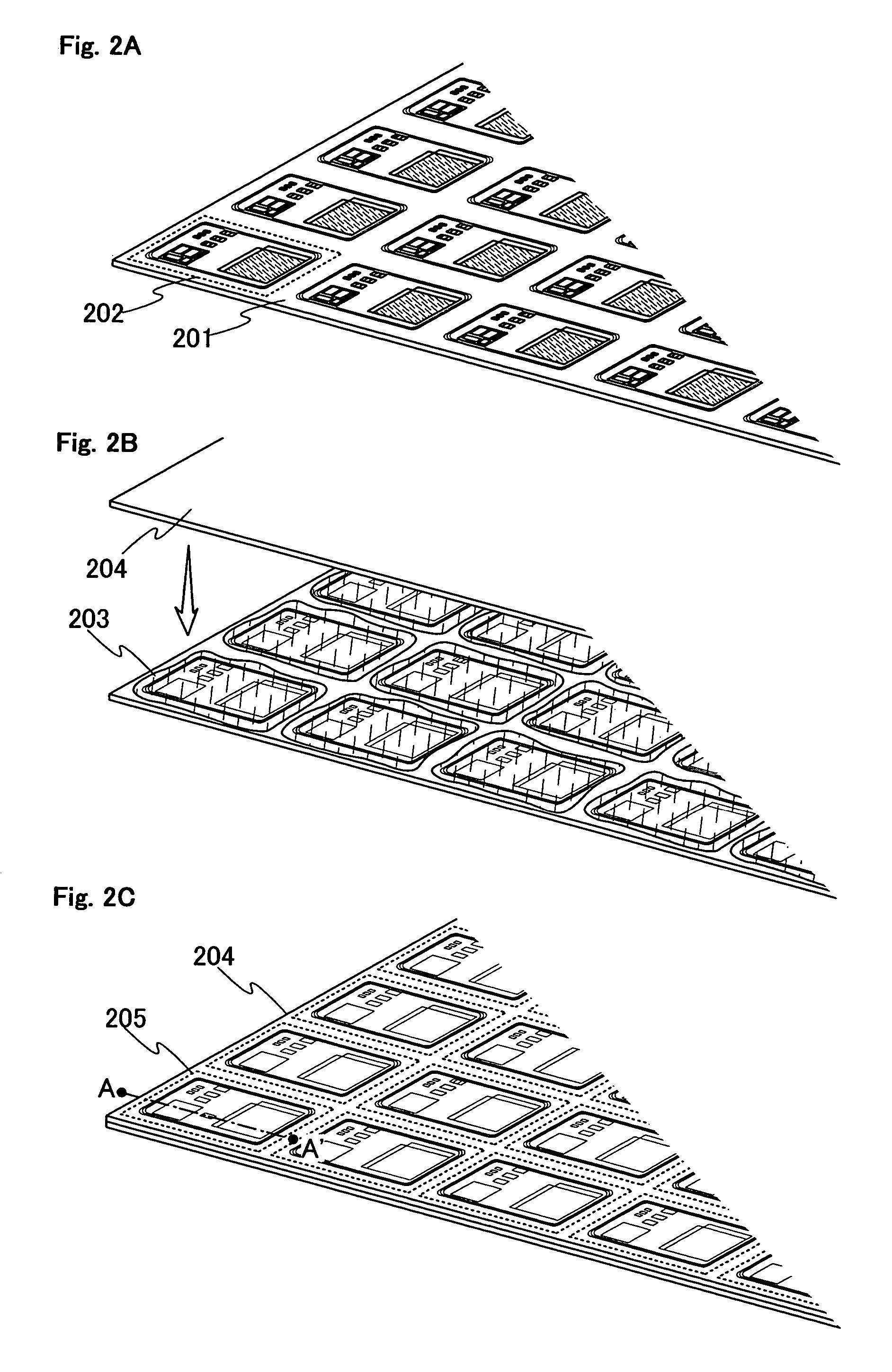

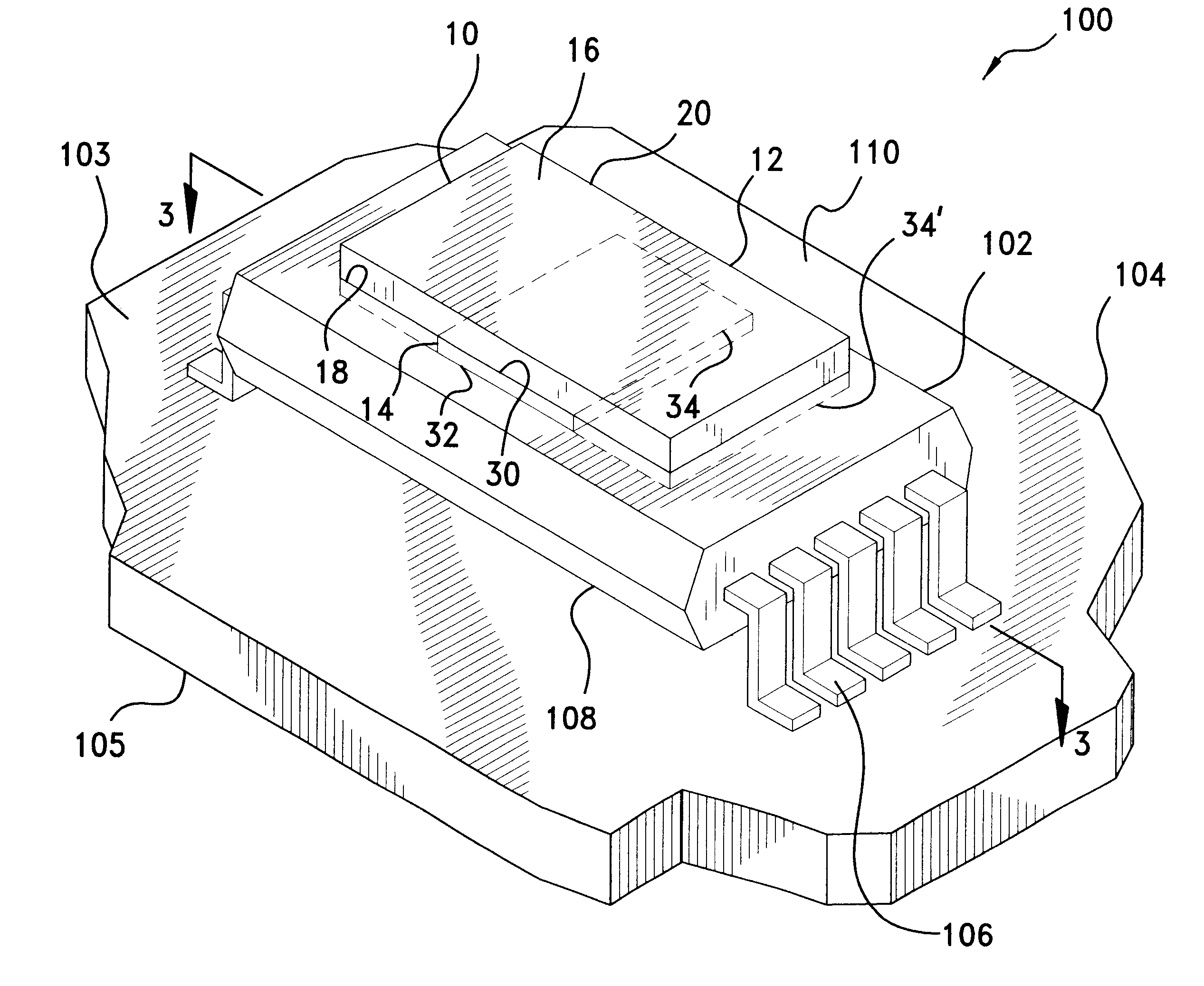

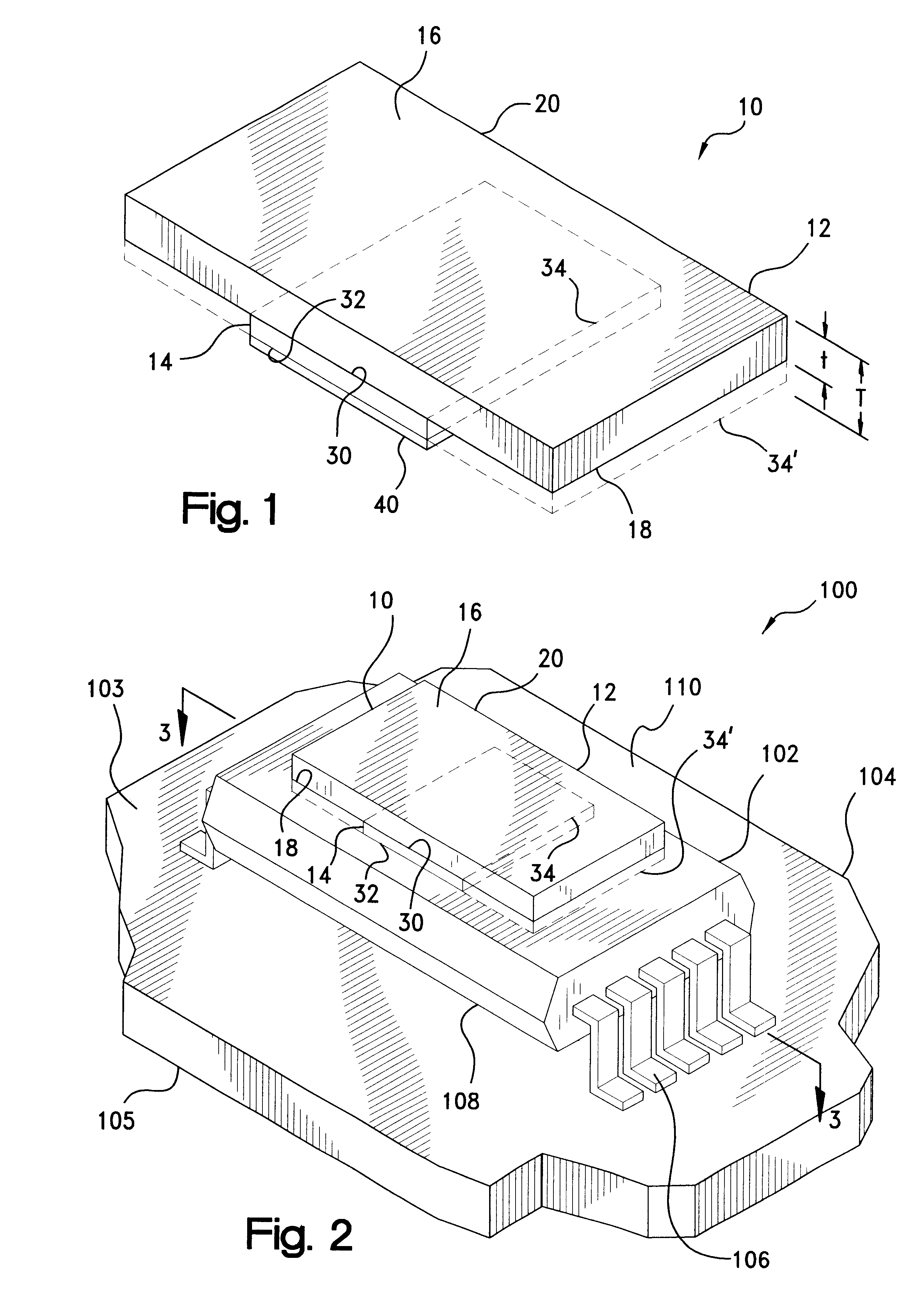

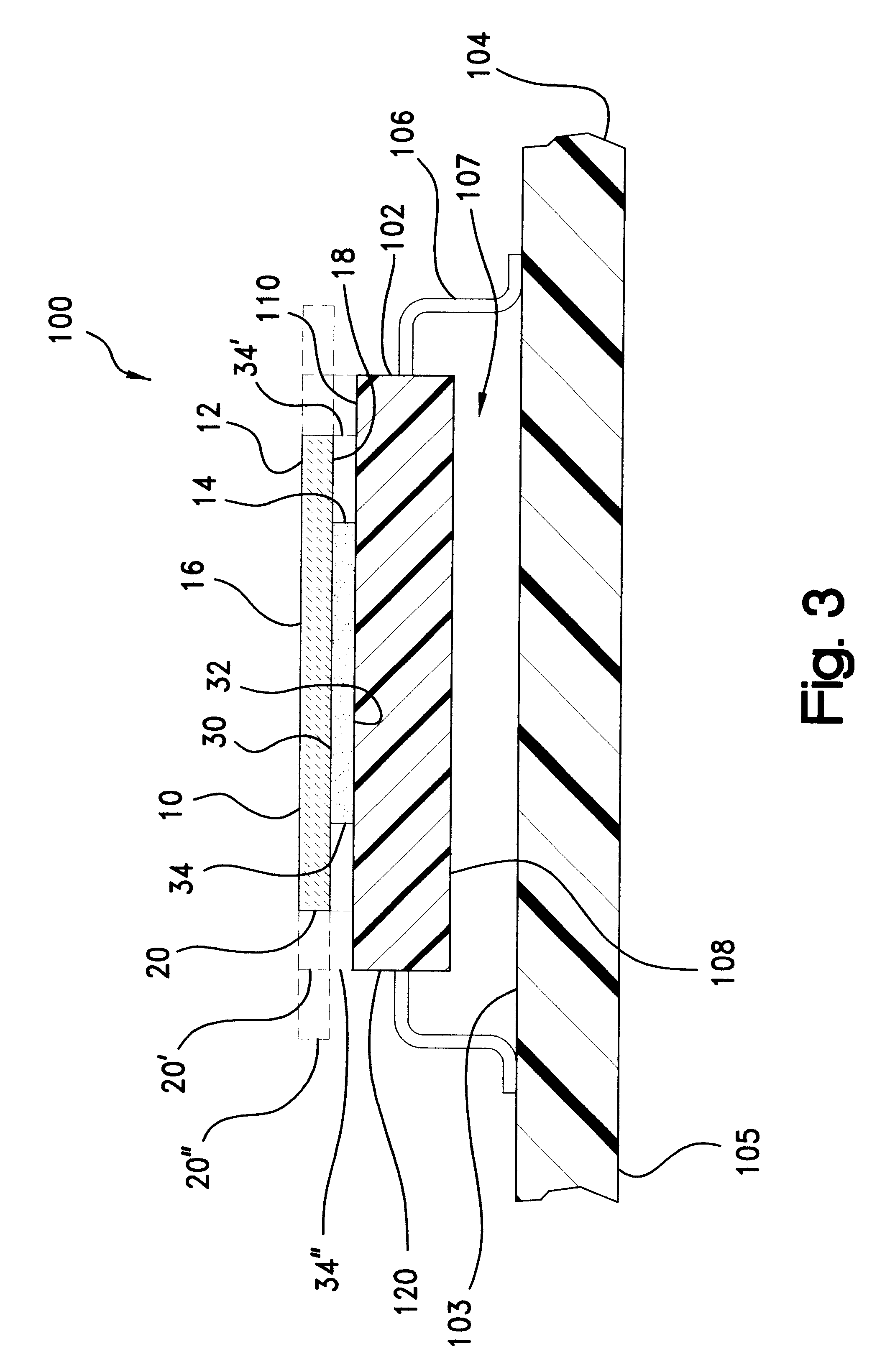

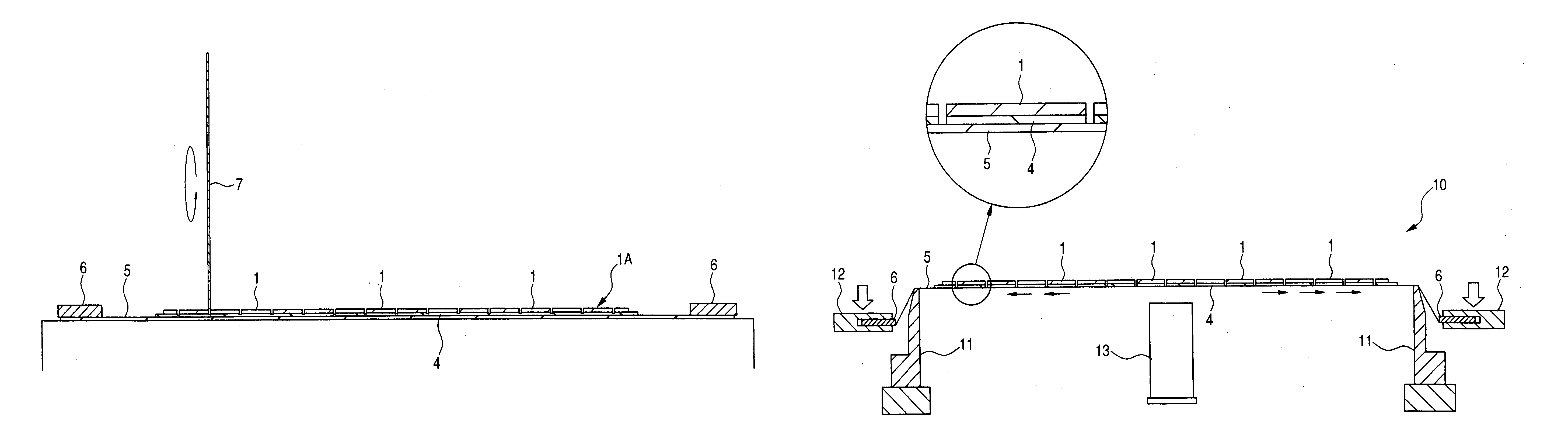

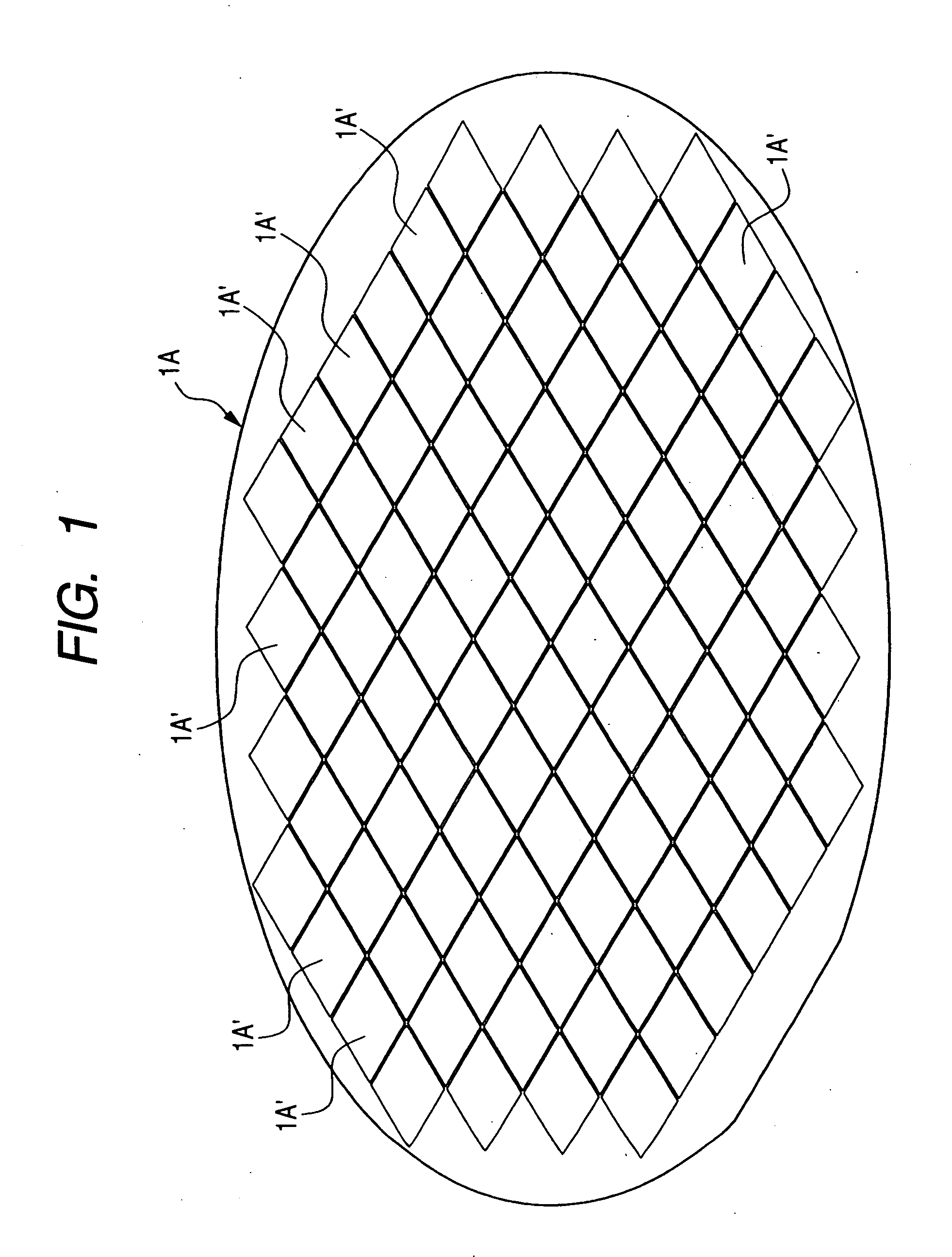

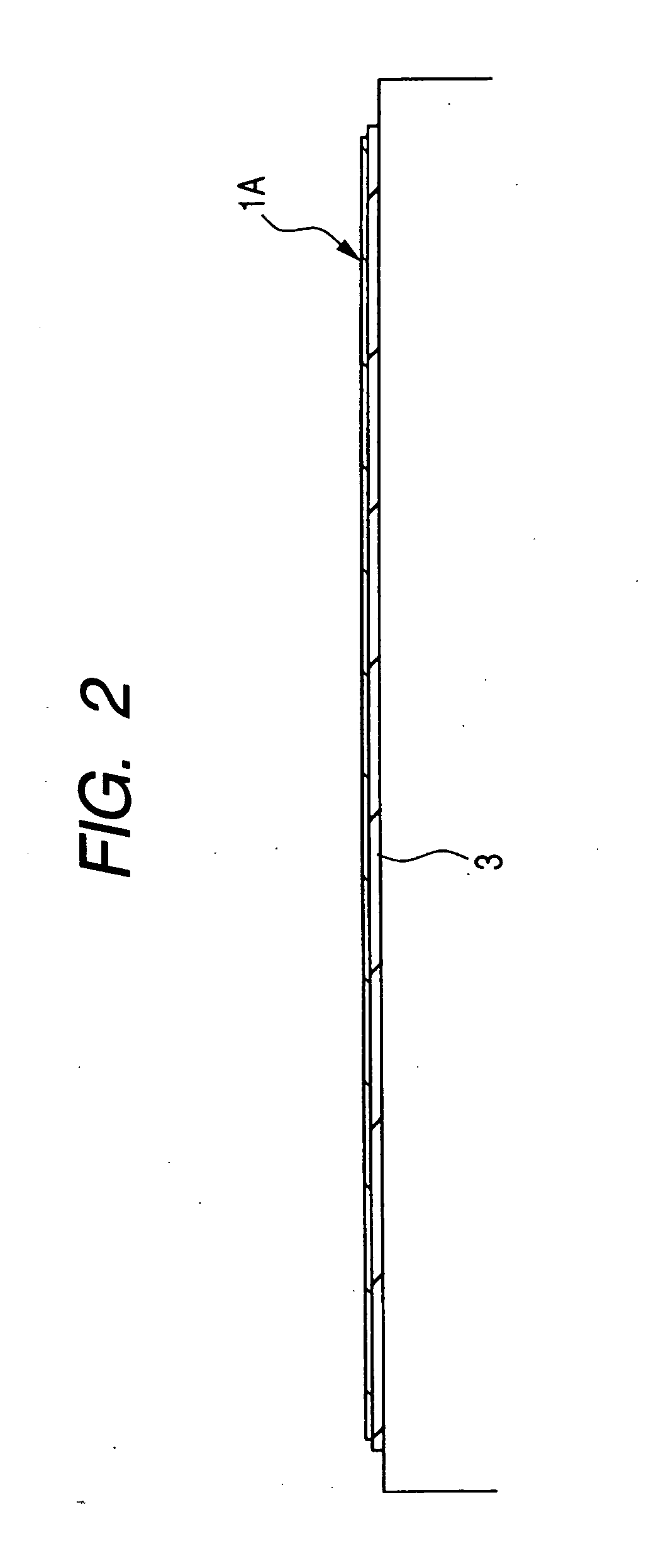

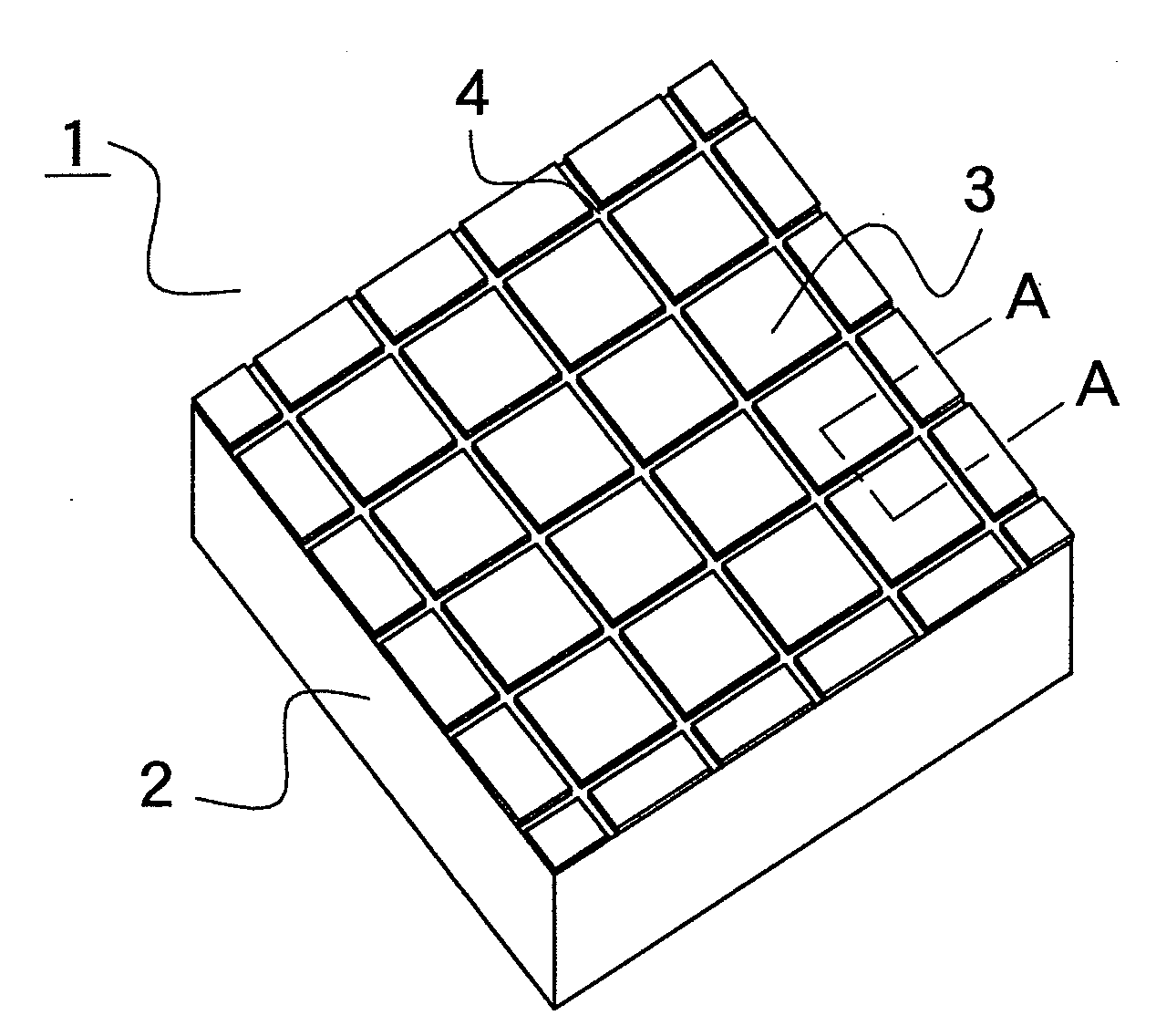

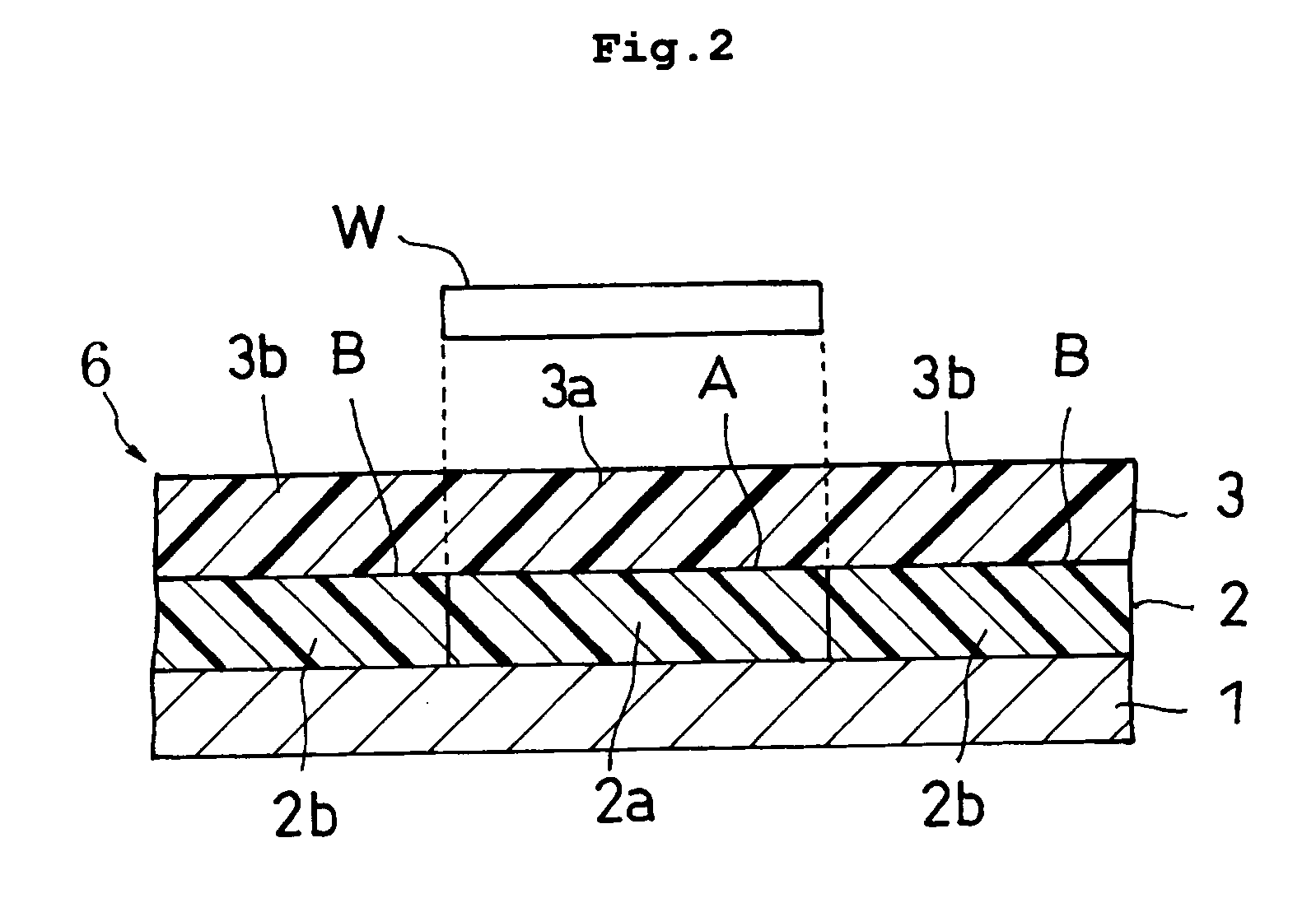

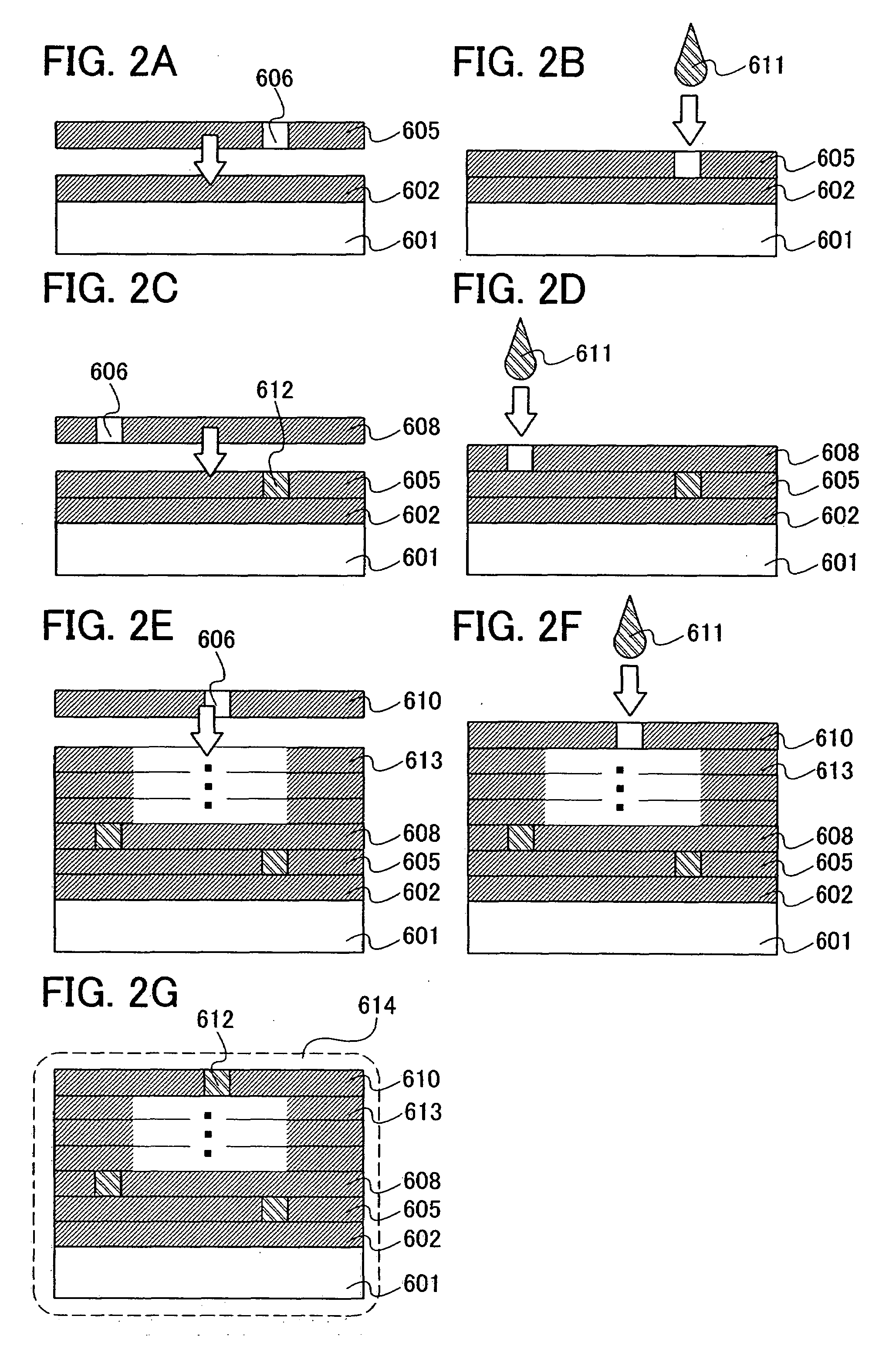

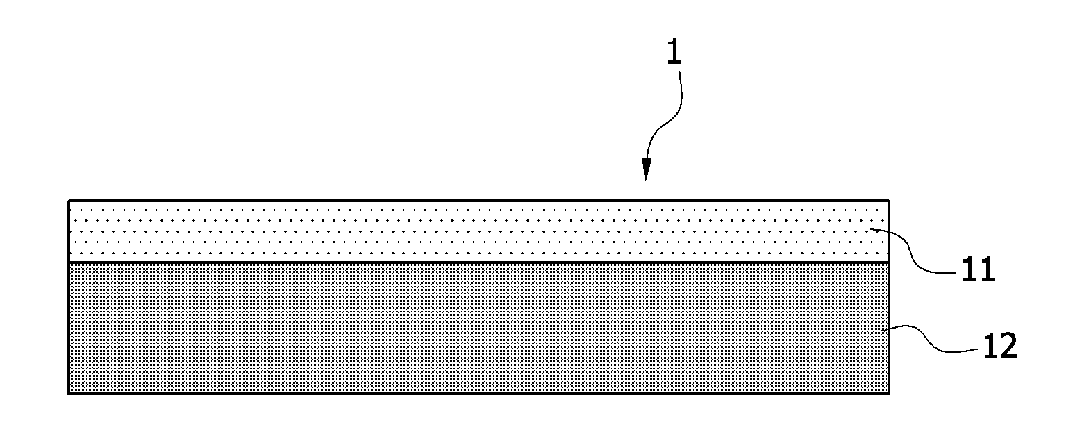

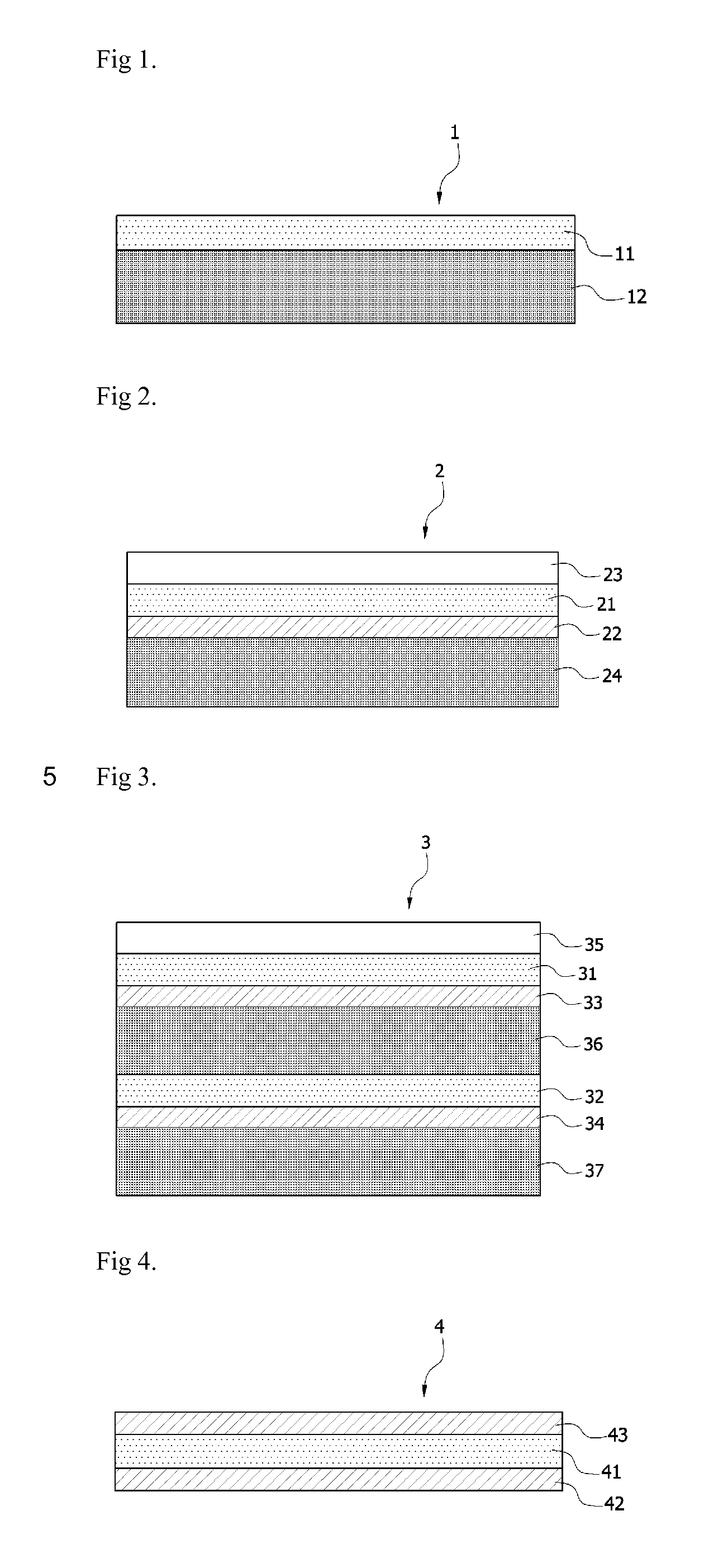

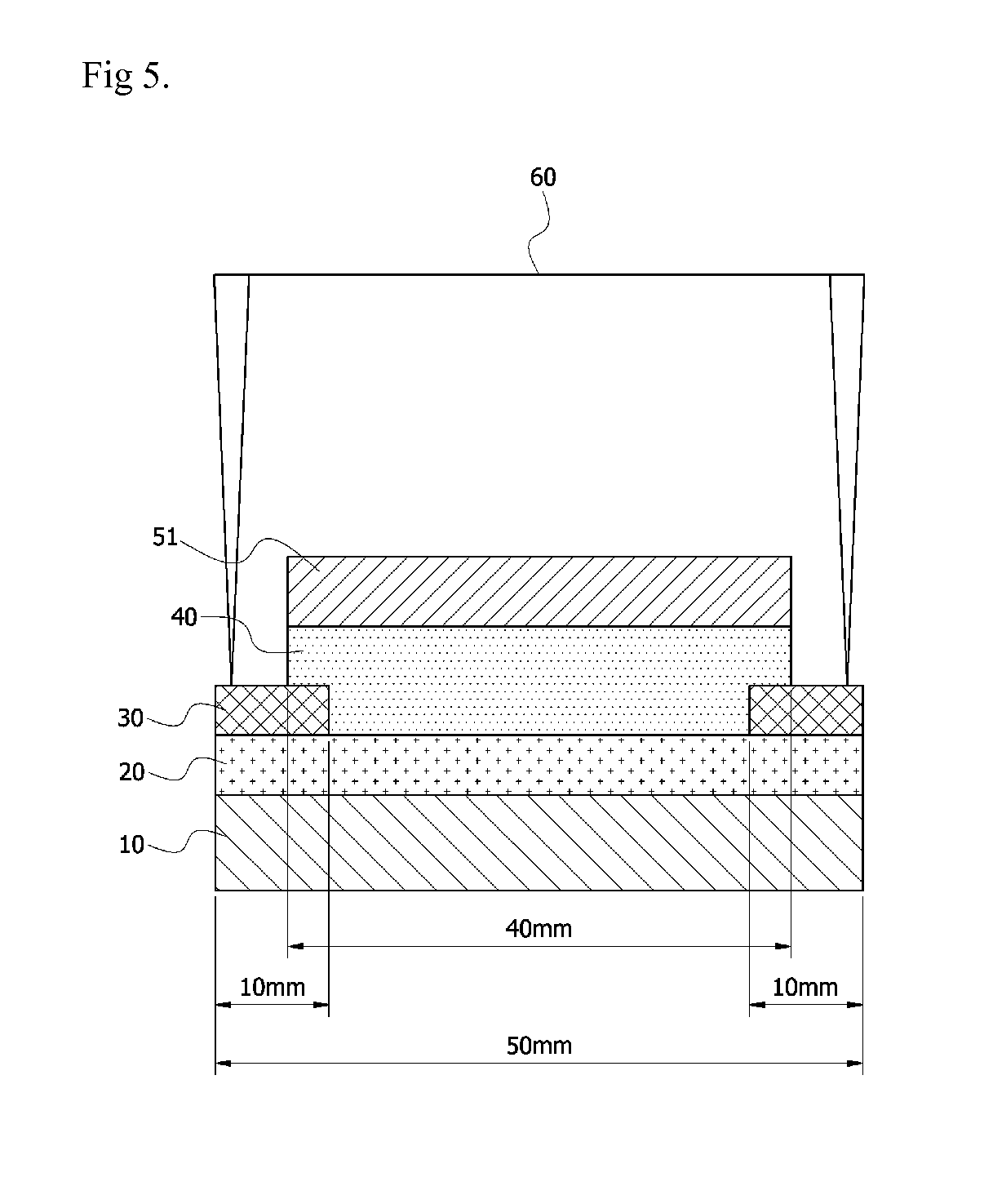

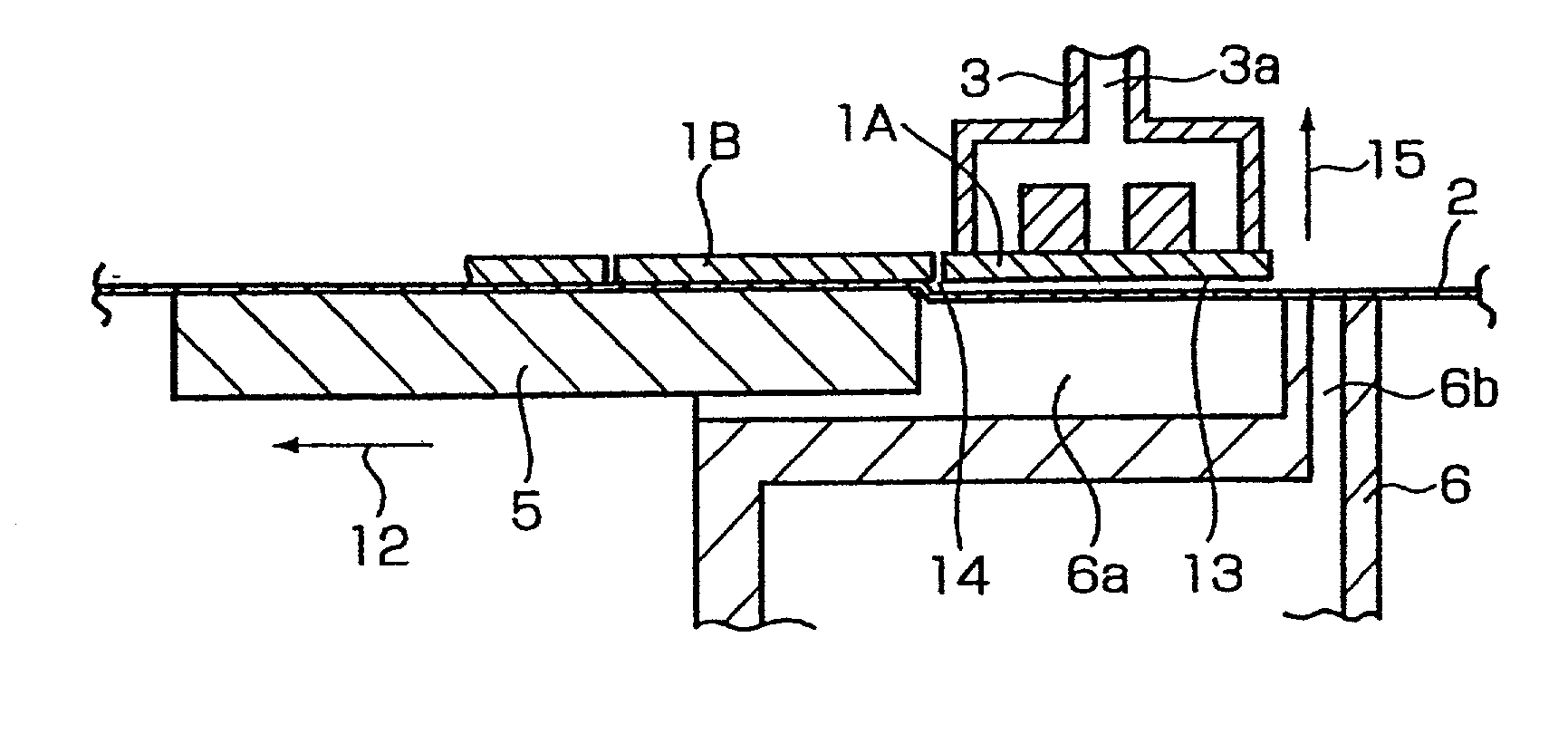

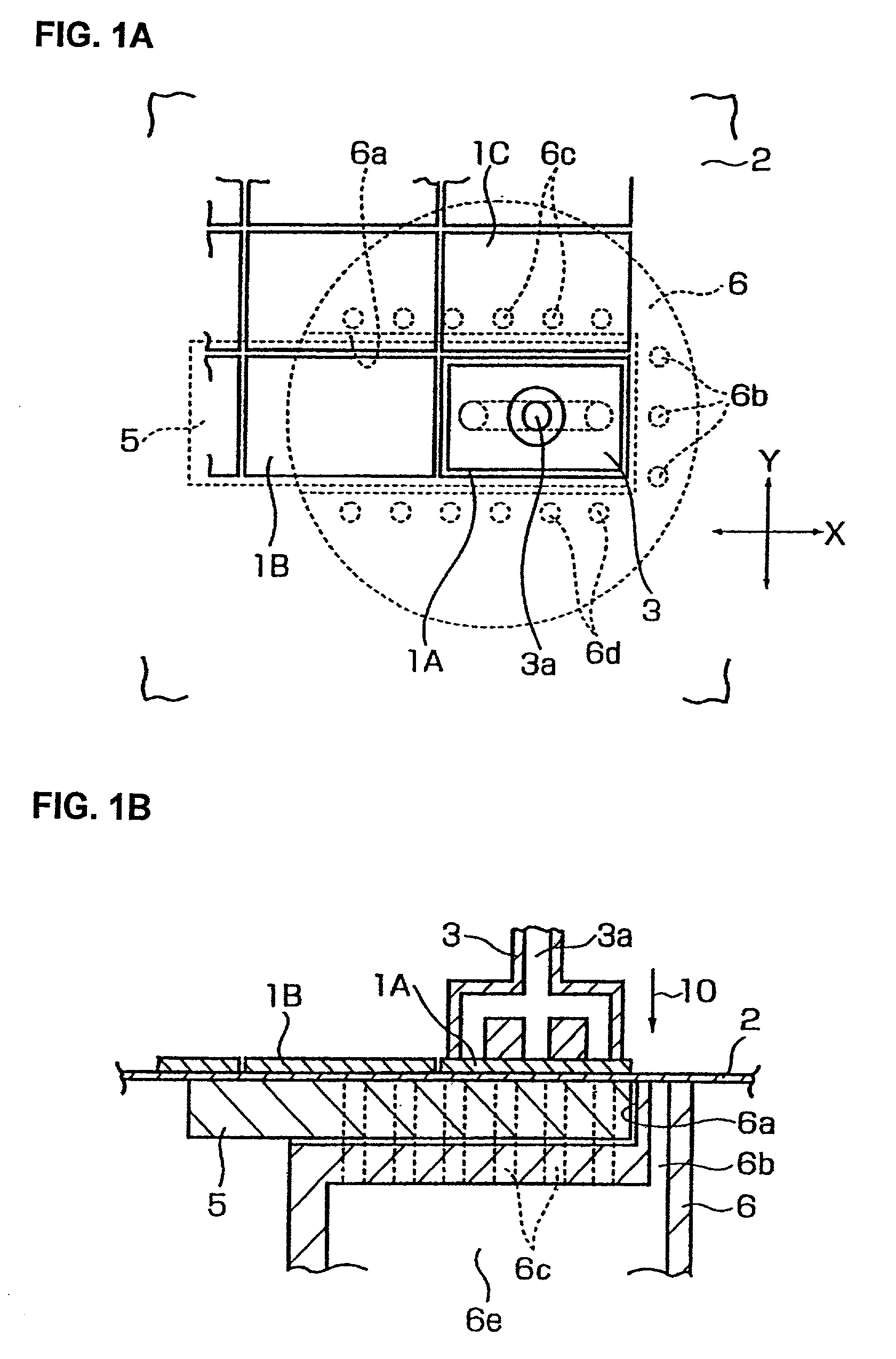

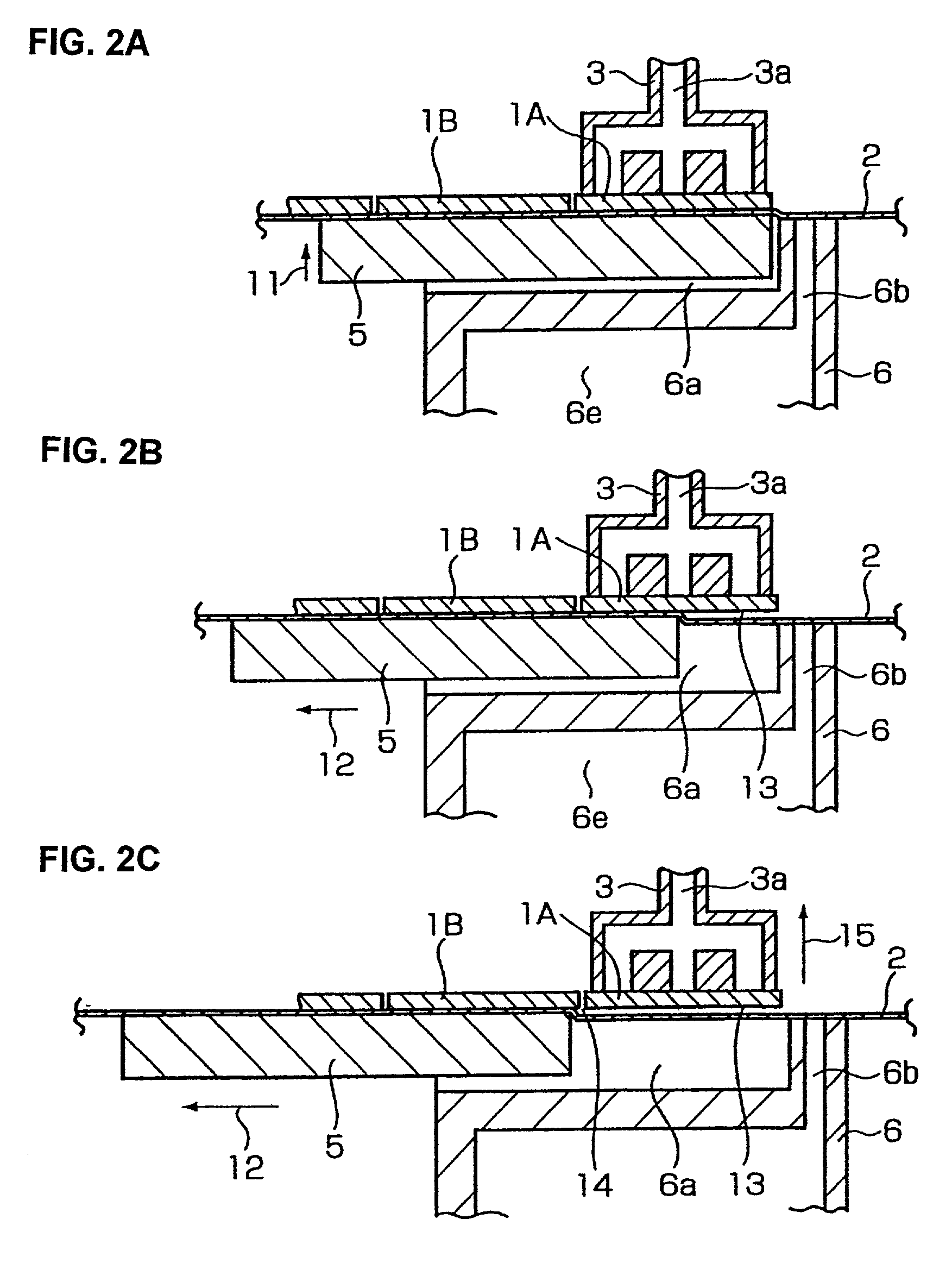

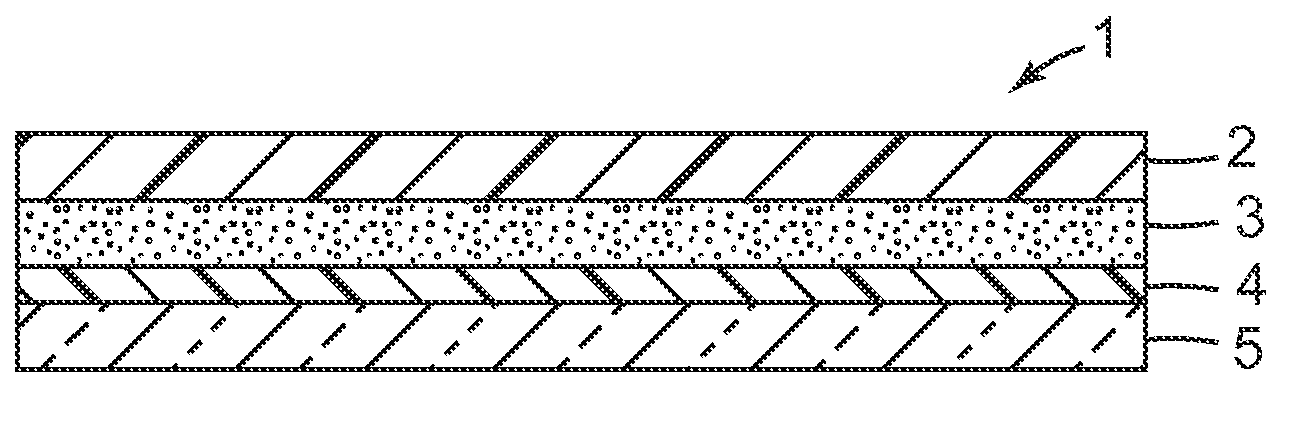

Laminate body, method, and apparatus for manufacturing ultrathin substrate using the laminate body

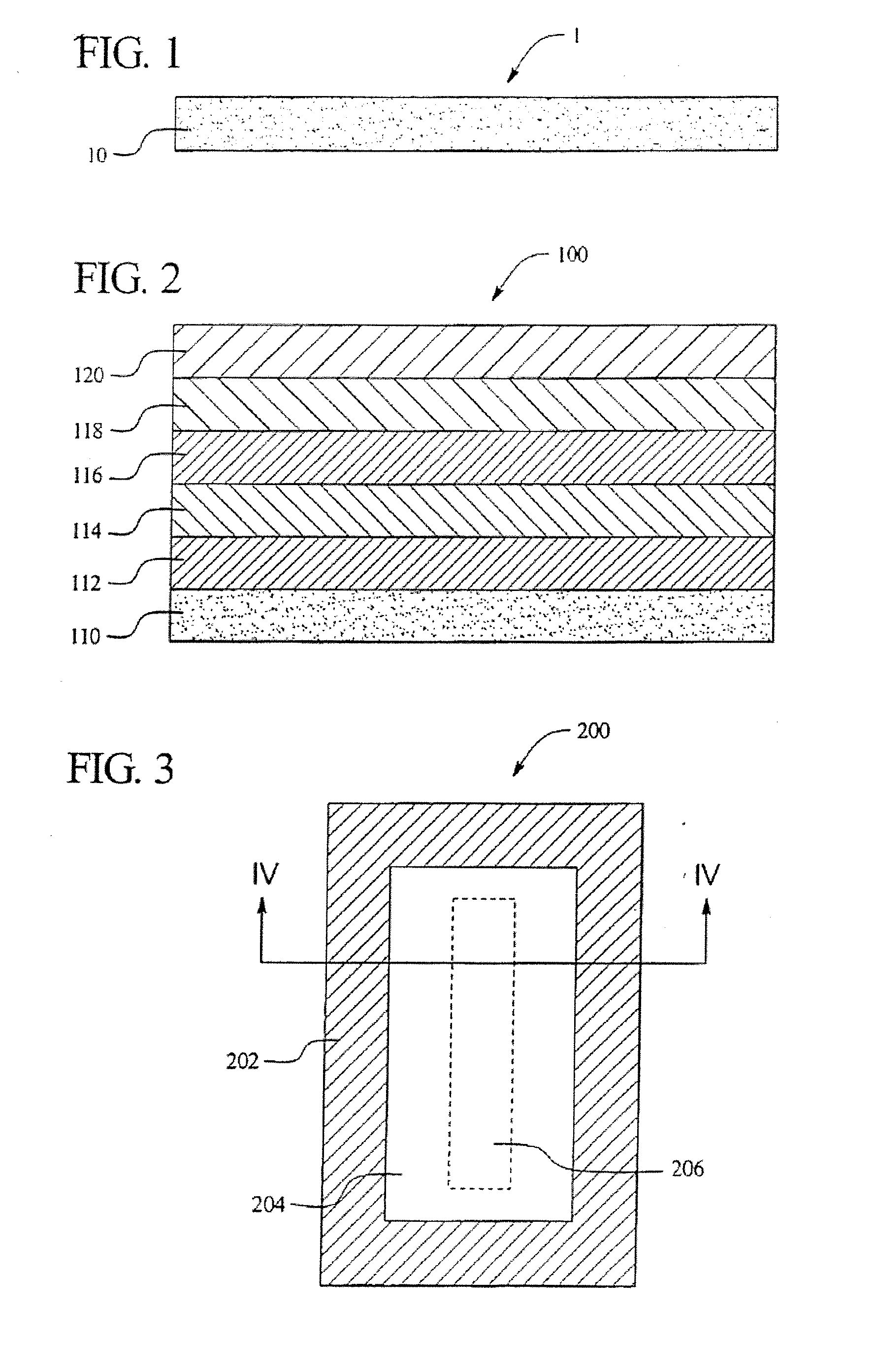

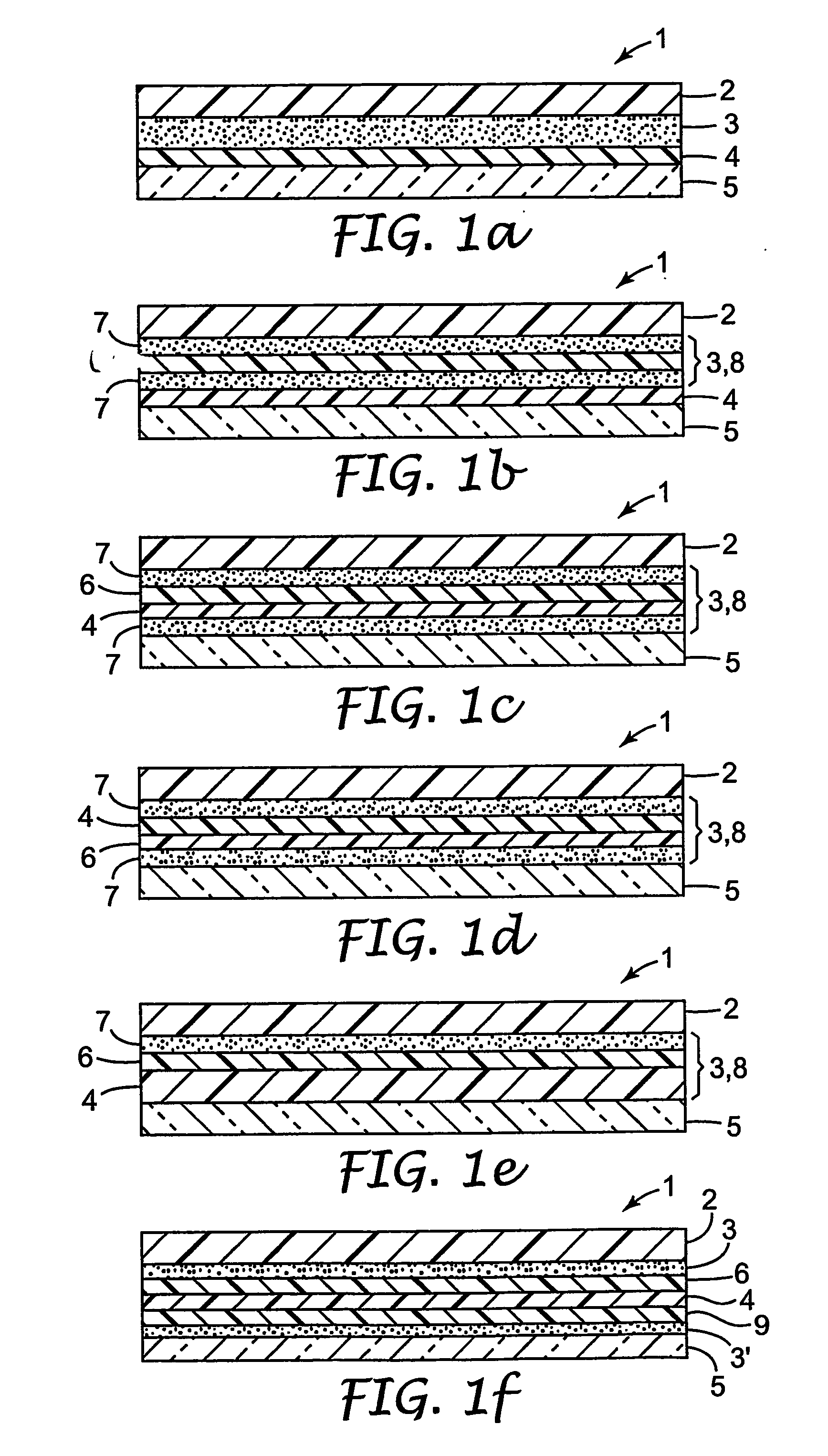

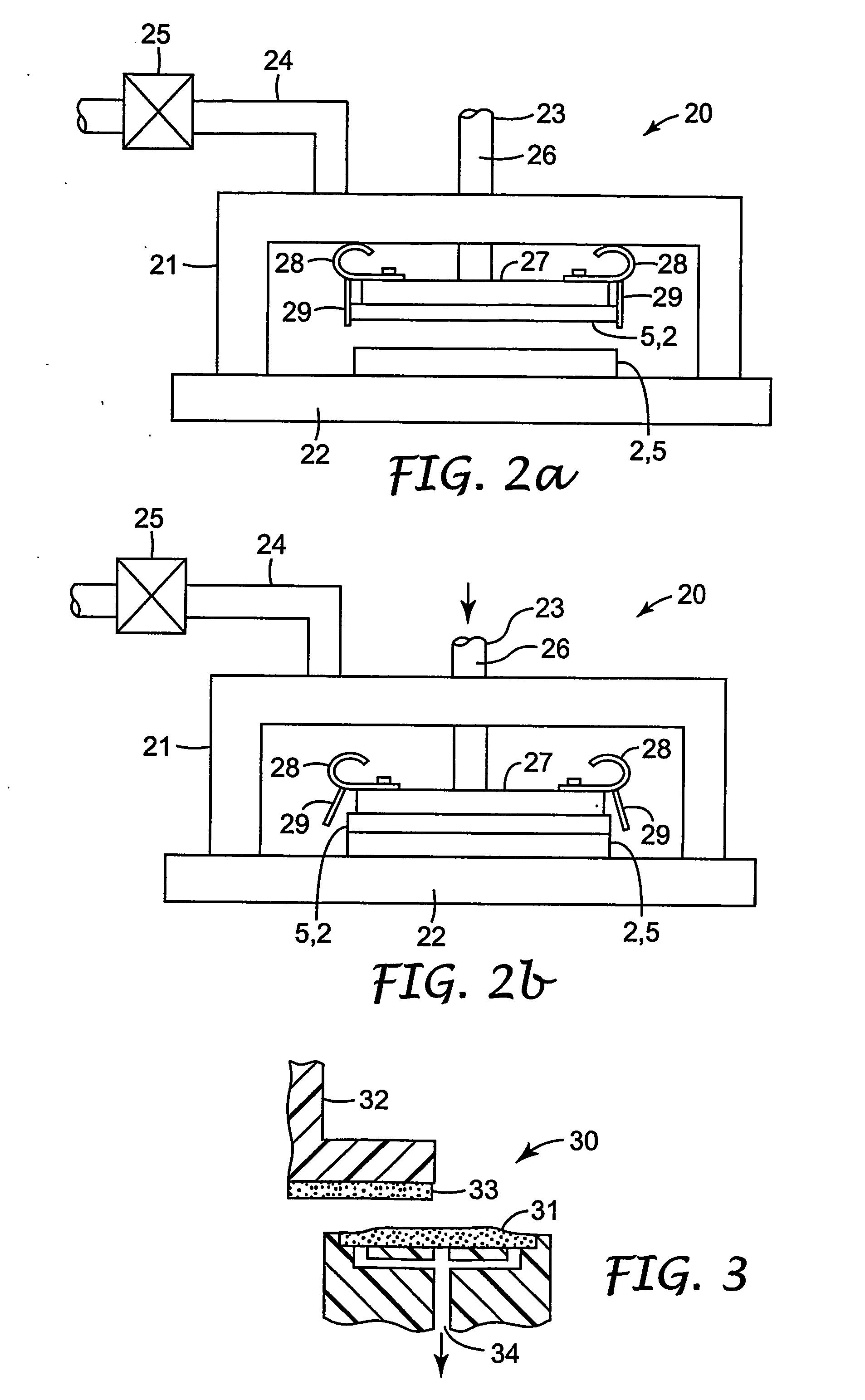

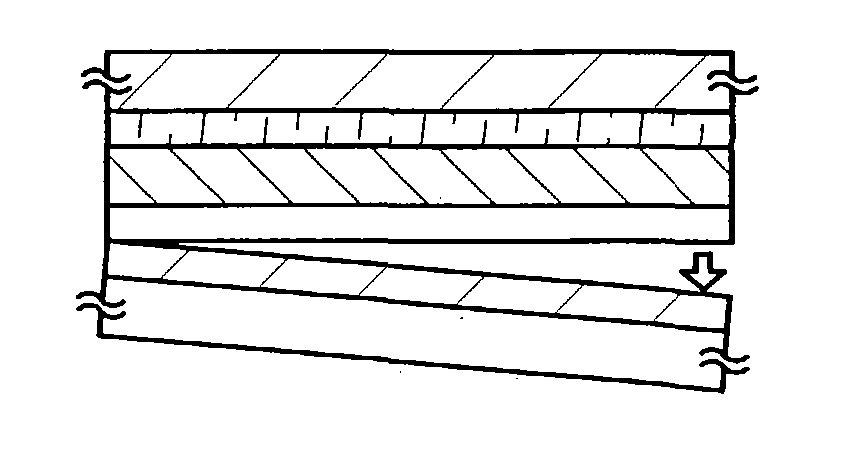

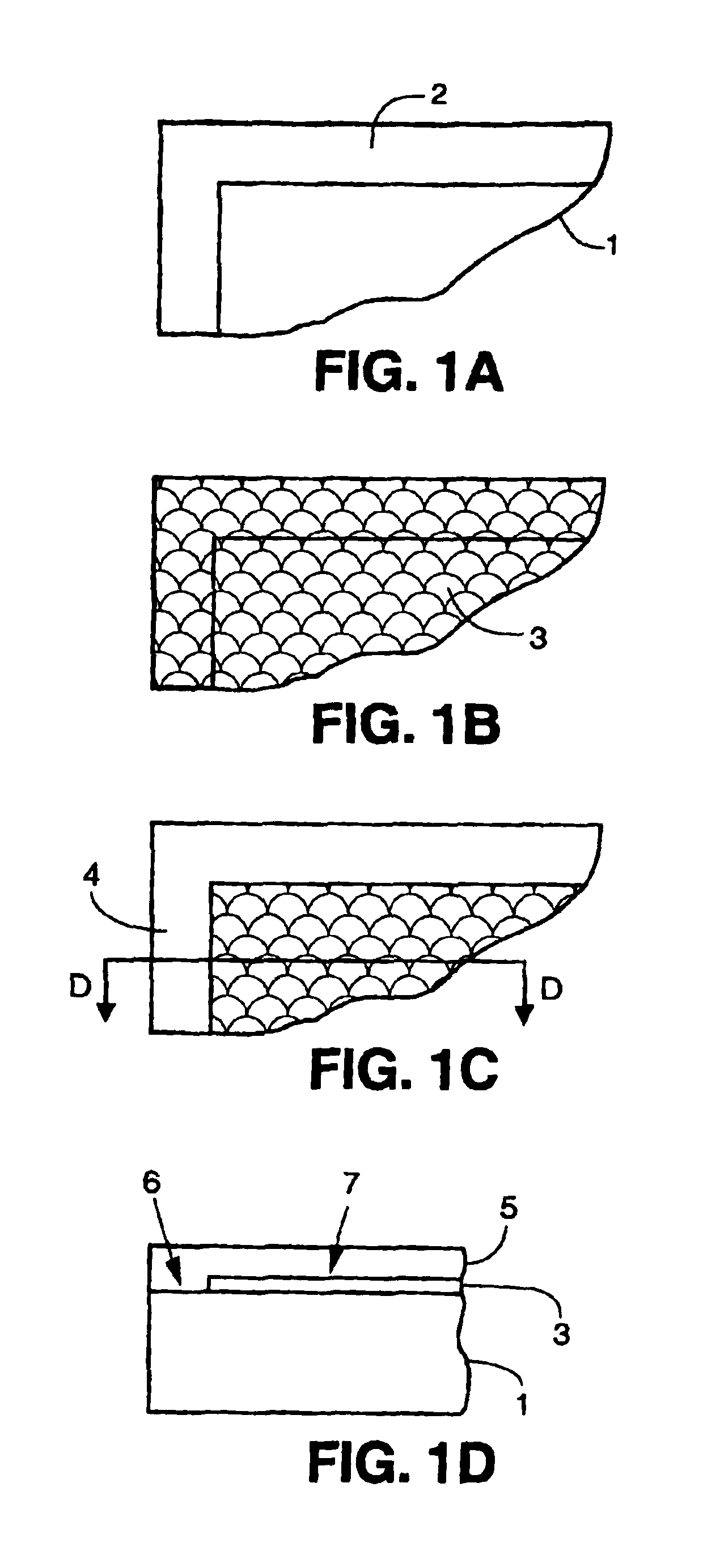

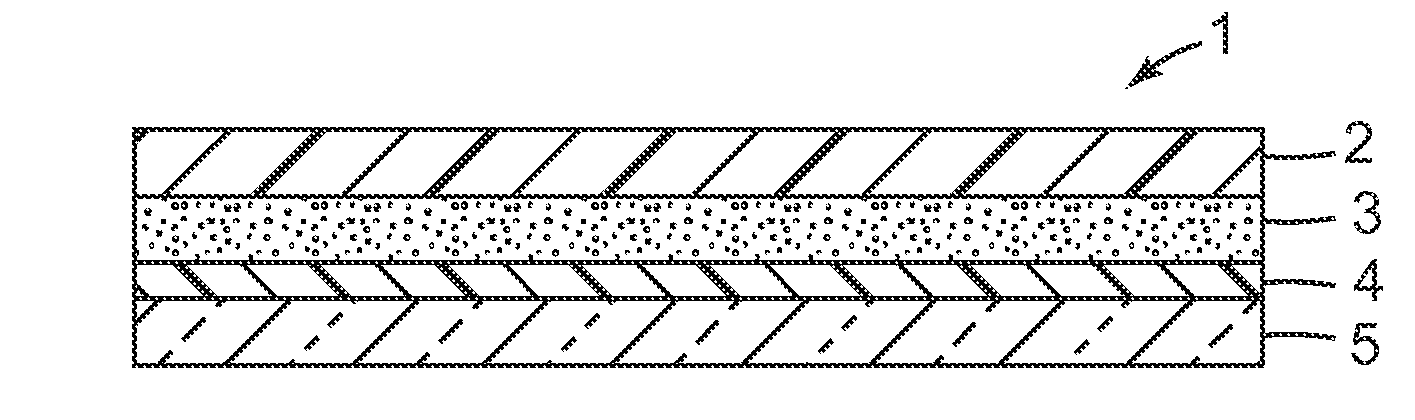

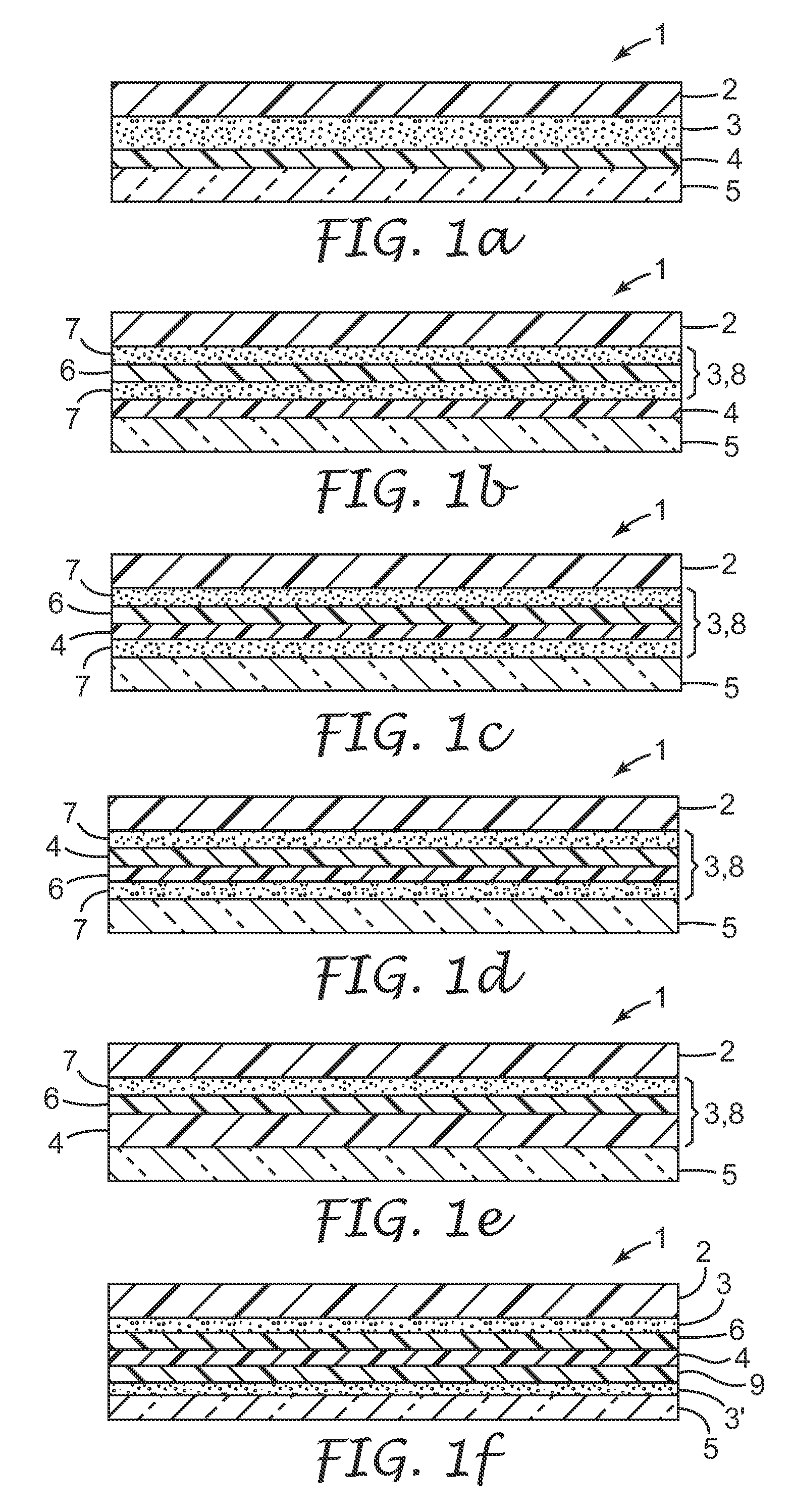

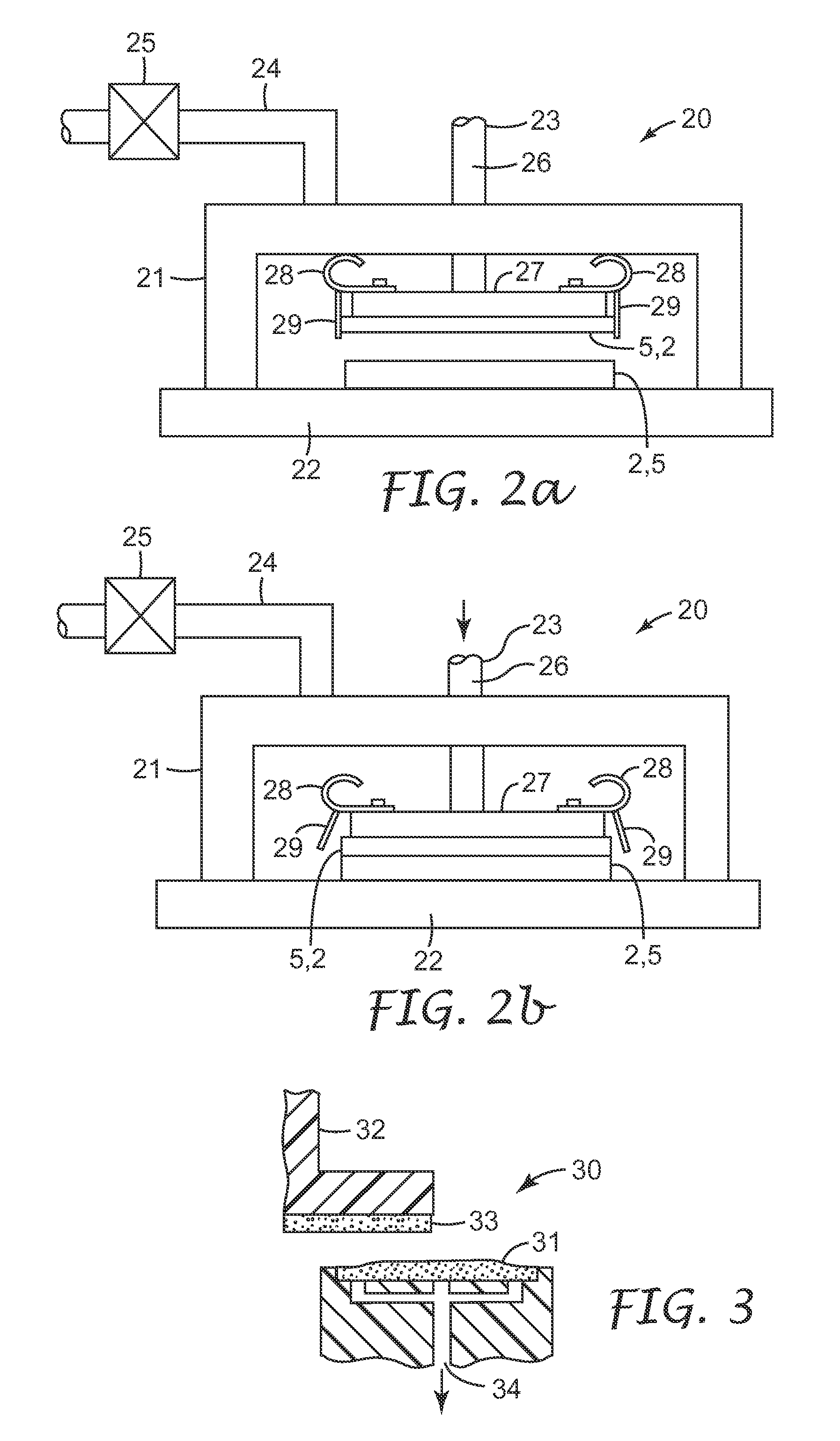

ActiveUS20050233547A1Easy to peelReduce pressureDiffusion transfer processesPhotosensitive materialsPolymer sciencePhotothermal conversion

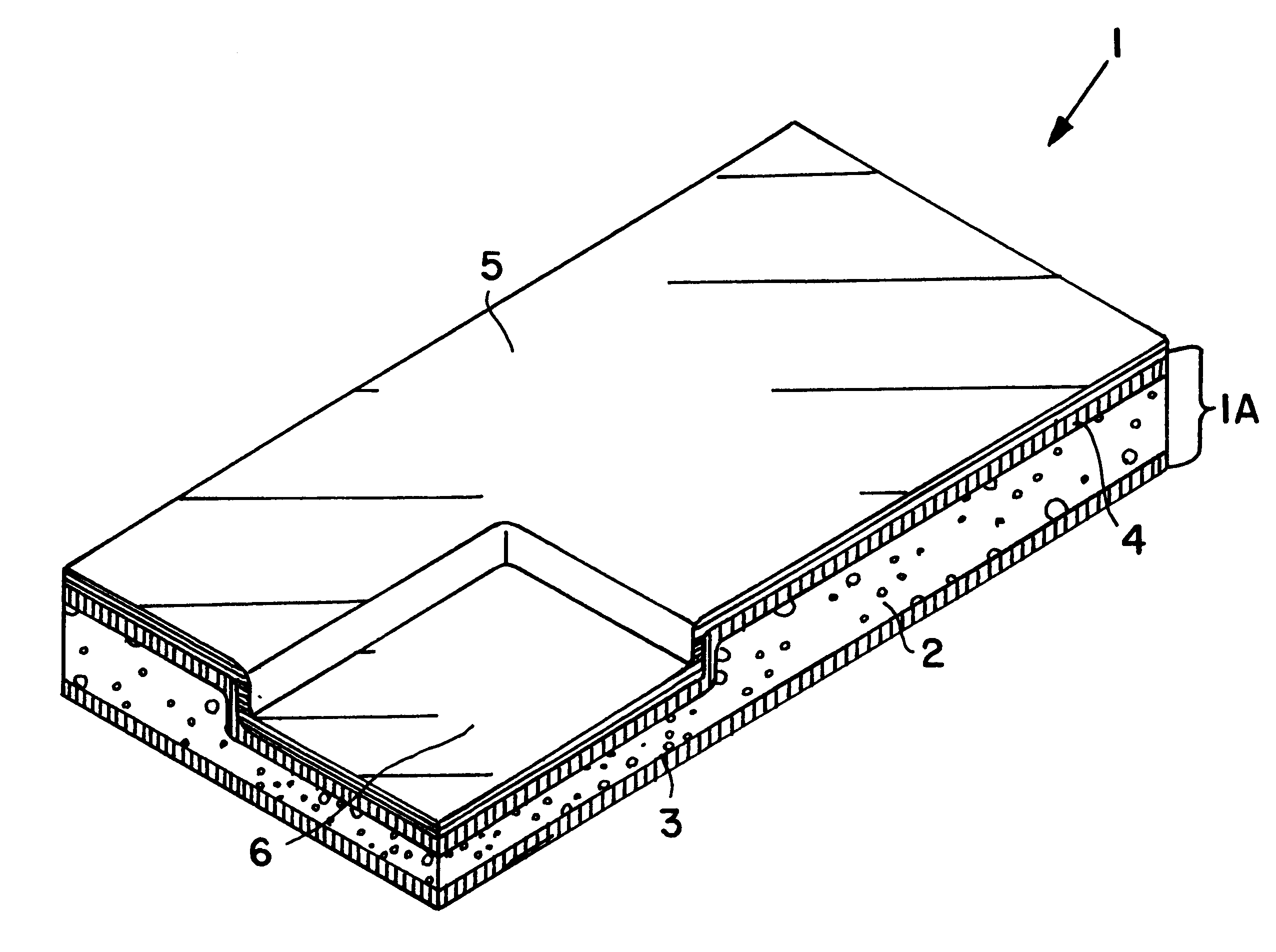

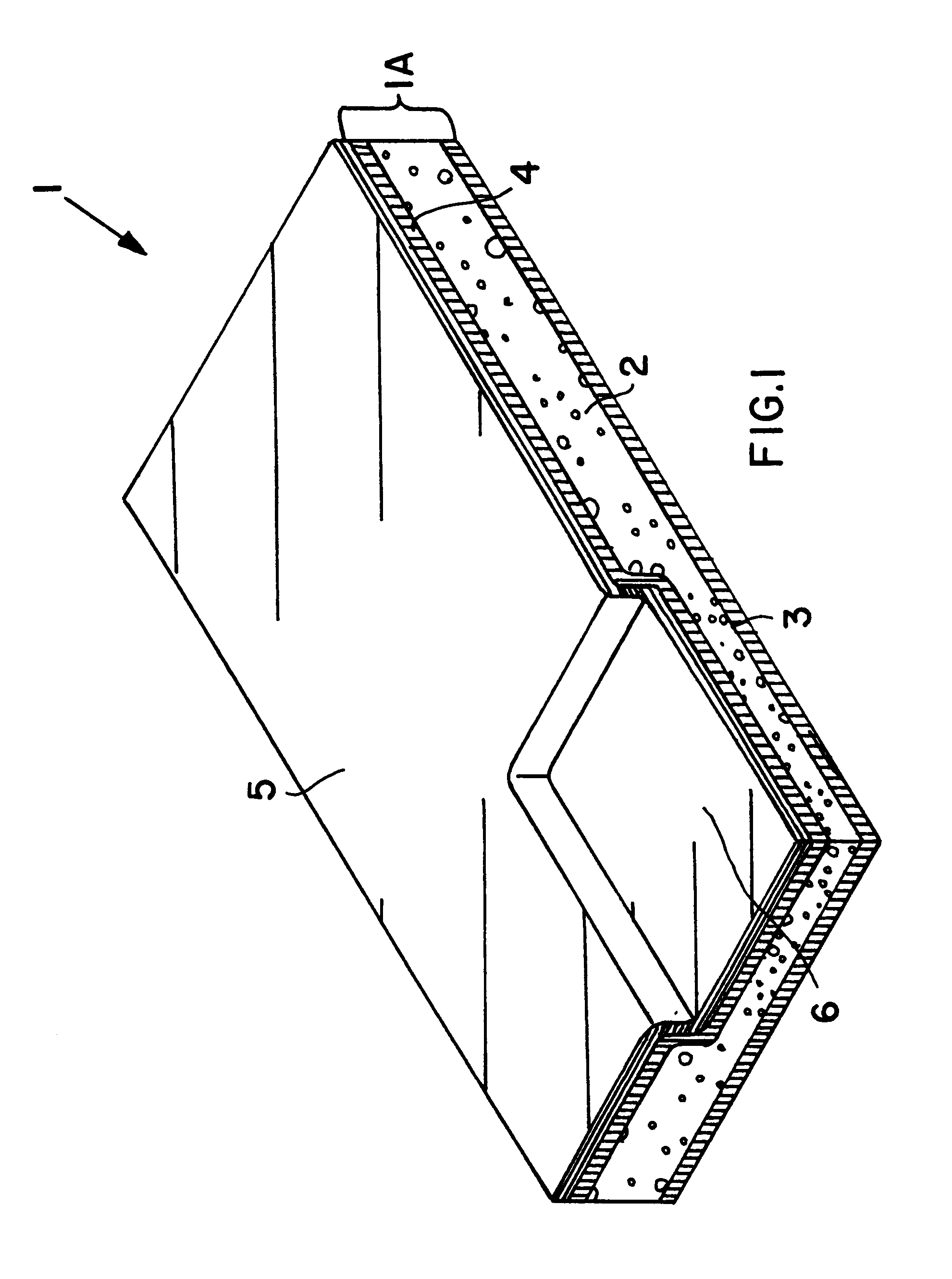

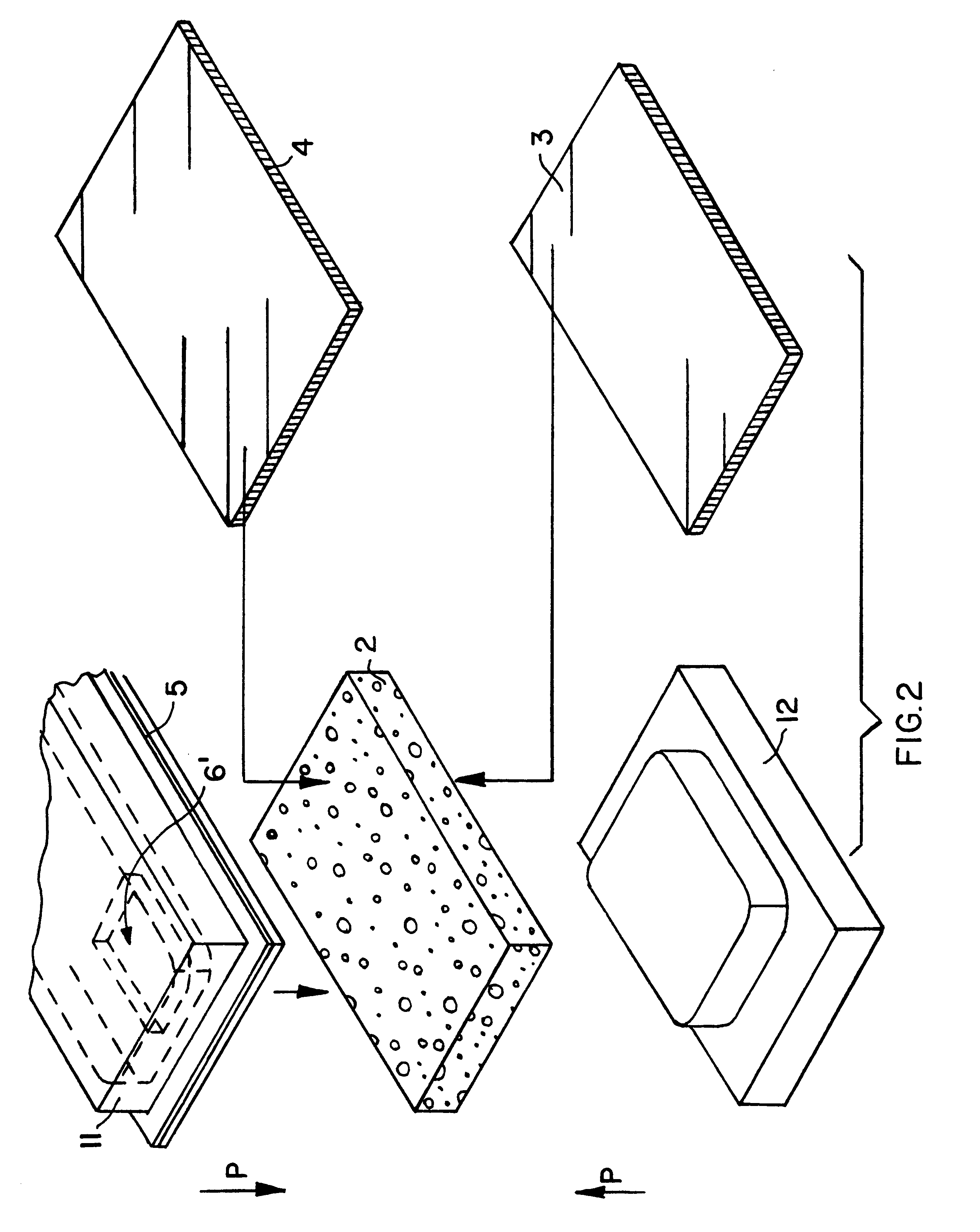

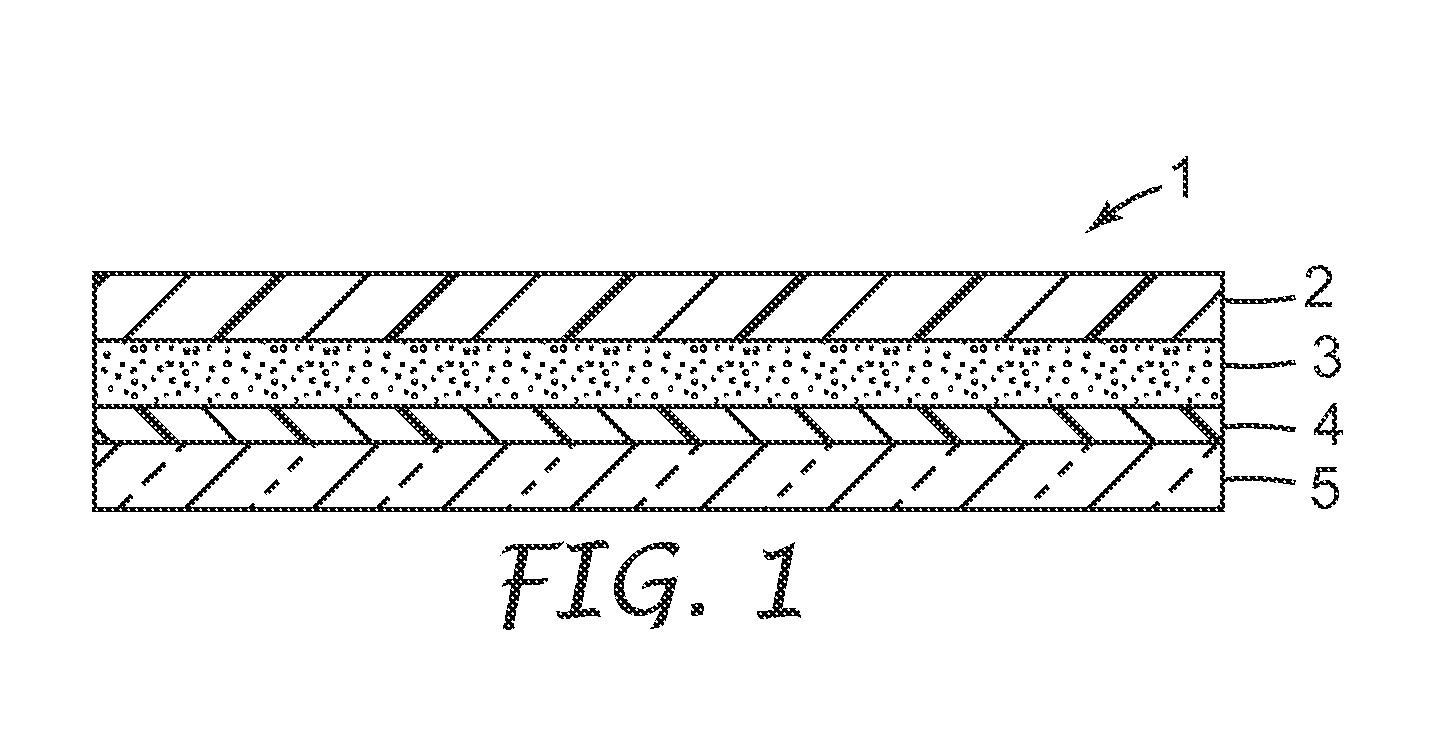

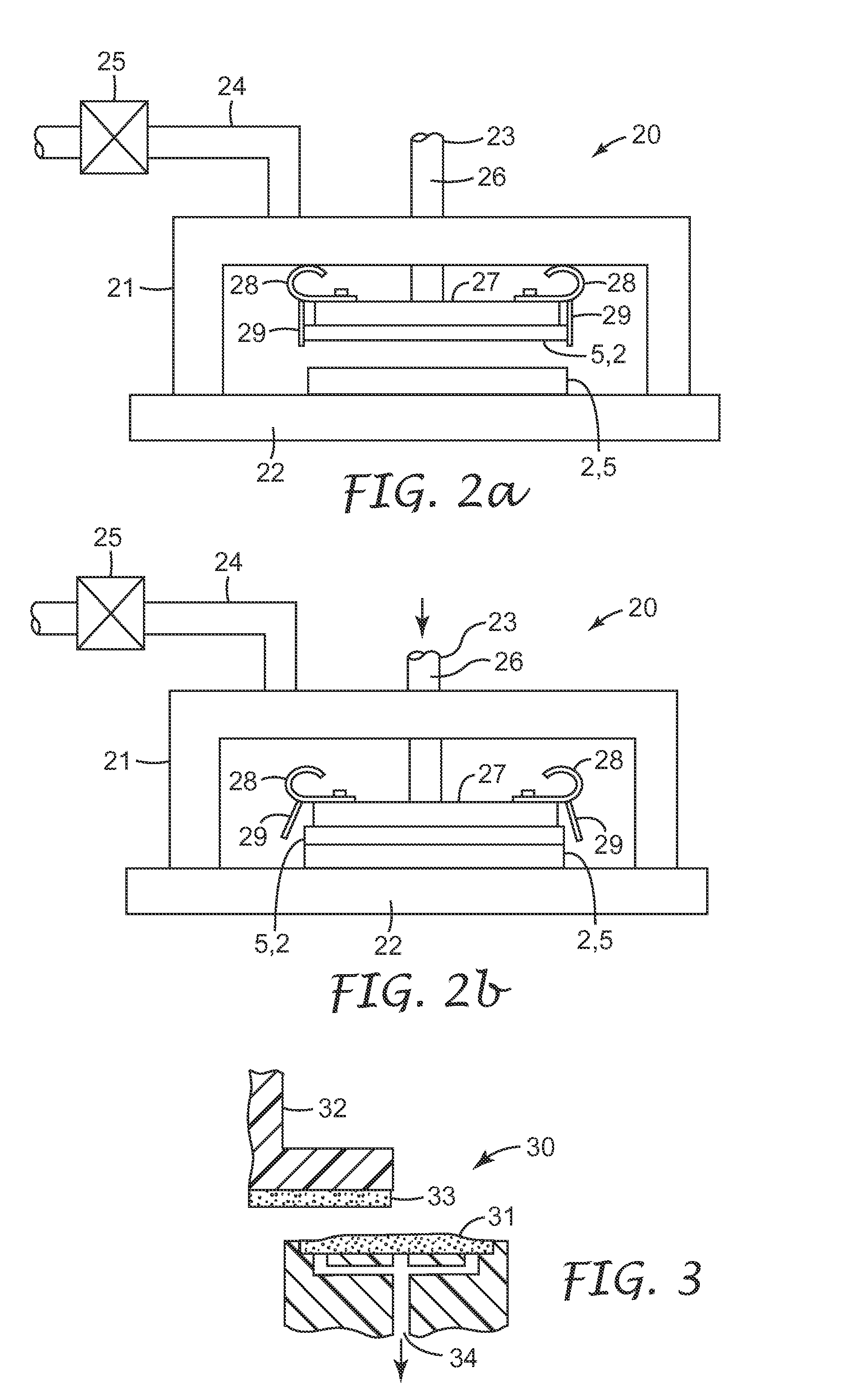

Provided is a laminated body (1) comprising a substrate (2) to be ground and a support (5), where the substrate (2) is ground to a very small thickness and can then be separated from the support (5) without damaging the substrate (2). One embodiment of the present invention is a laminated body (1) comprising a substrate (2) to be ground, a joining layer (3) in contact with the substrate (2) to be ground, a photothermal conversion layer (4) comprising a light absorbing agent and a heat decomposable resin, and a light transmitting support (5). After grinding the substrate surface which is opposite that in contact with the joining layer (3), the laminated body (1) is irradiated through the light transmitting support (5) and the photothermal conversion layer (4) decomposes to separate the substrate (2) and the light transmitting support (5).

Owner:3M INNOVATIVE PROPERTIES CO

Peeling method

InactiveUS20040087110A1Slow performanceAdhesive propertyTransistorSolid-state devicesHydrogenEngineering

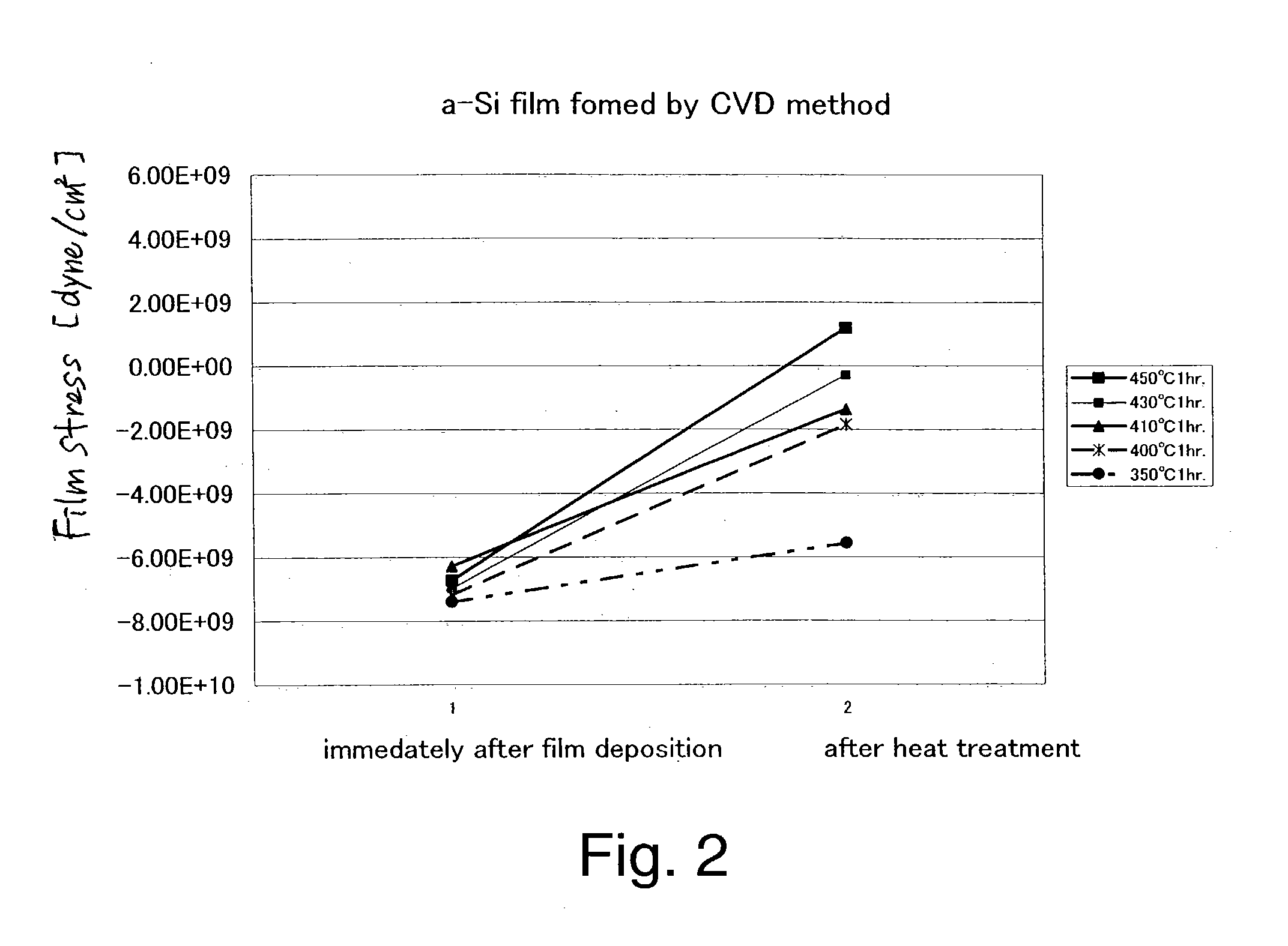

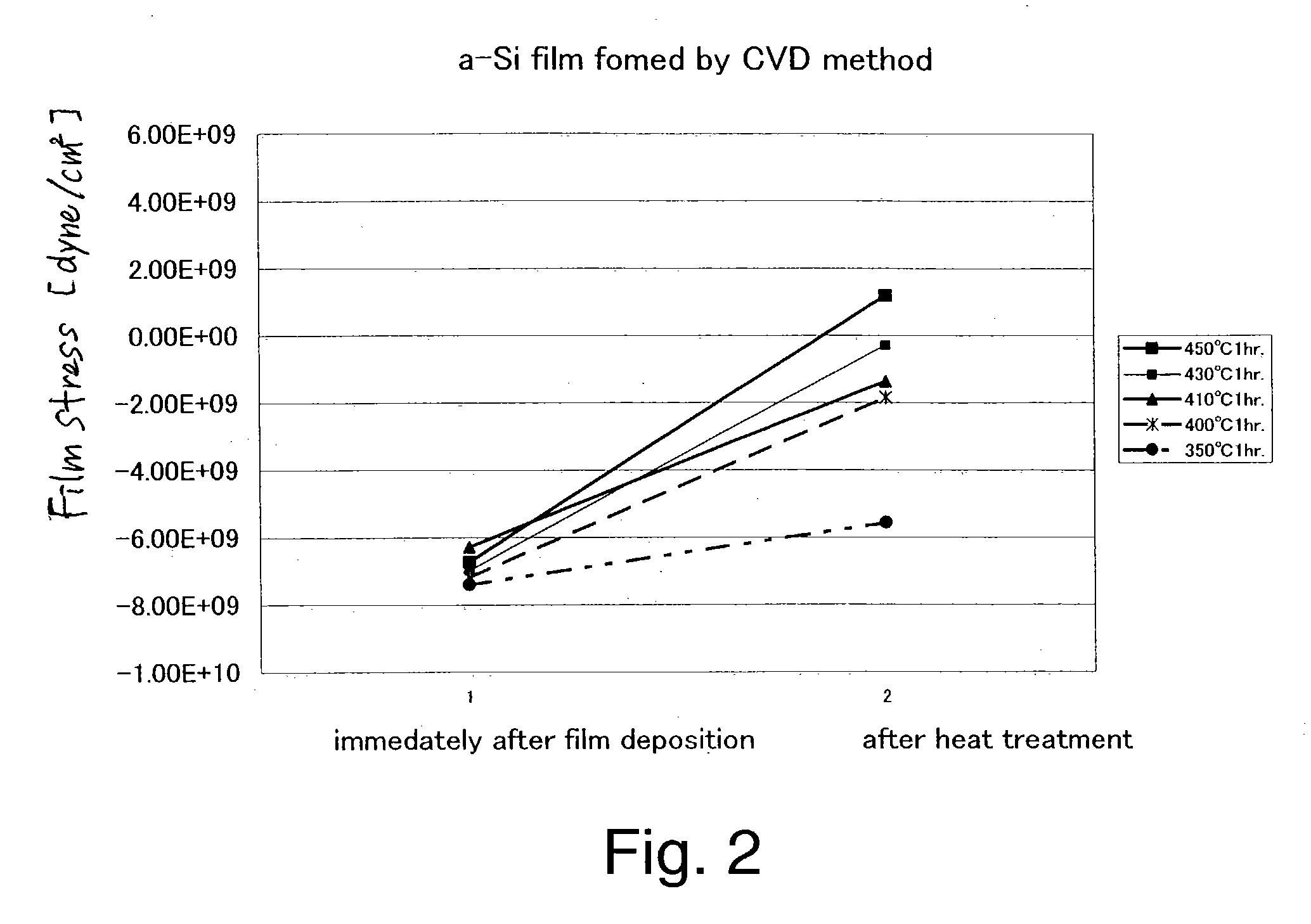

A peeling method is provided which does not cause damage to a layer to be peeled, and the method enables not only peeling of the layer to be peeled having a small area but also peeling of the entire layer to be peeled having a large area at a high yield. Further, there are provided a semiconductor device, which is reduced in weight through adhesion of the layer to be peeled to various base materials, and a manufacturing method thereof. In particular, there are provided a semiconductor device, which is reduced in weight through adhesion of various elements, typically a TFT, to a flexible film, and a manufacturing method thereof. A metal layer or nitride layer is provided on a substrate; an oxide layer is provided contacting with the metal layer or nitride layer; then, a base insulating film and a layer to be peeled containing hydrogen are formed; and heat treatment for diffusing hydrogen is performed thereto at 410° C. or more. As a result, complete peeling can be attained in the oxide layer or at an interface thereof by using physical means.

Owner:SEMICON ENERGY LAB CO LTD

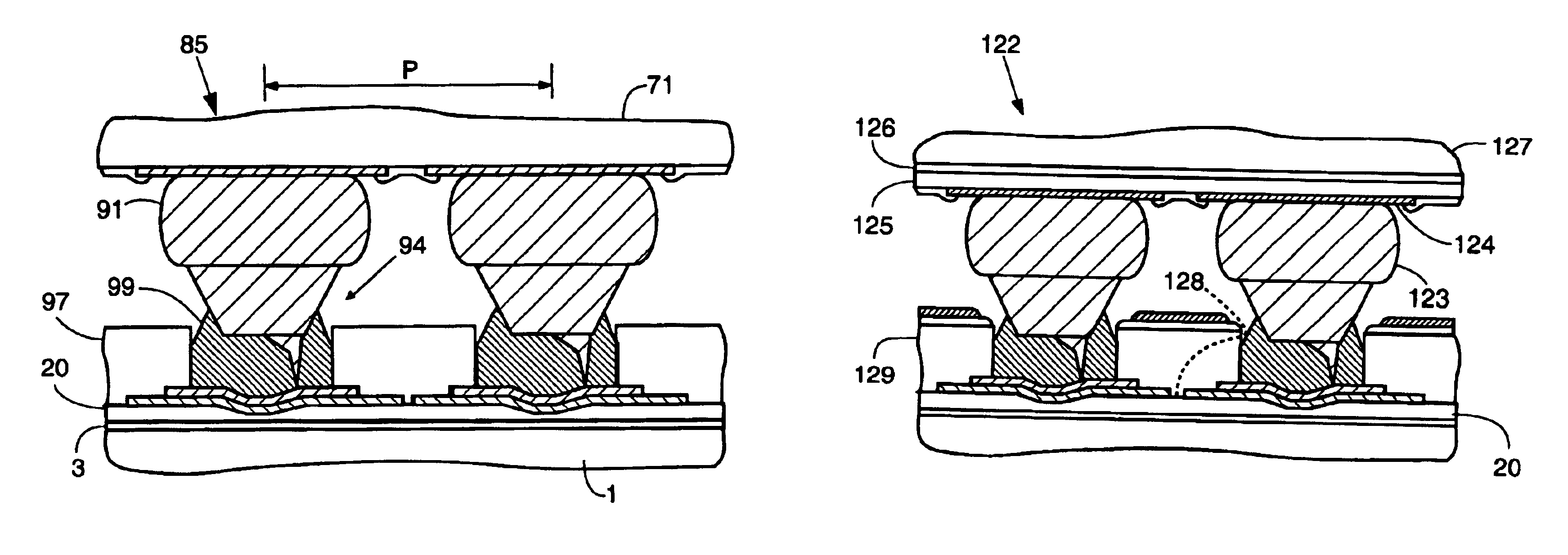

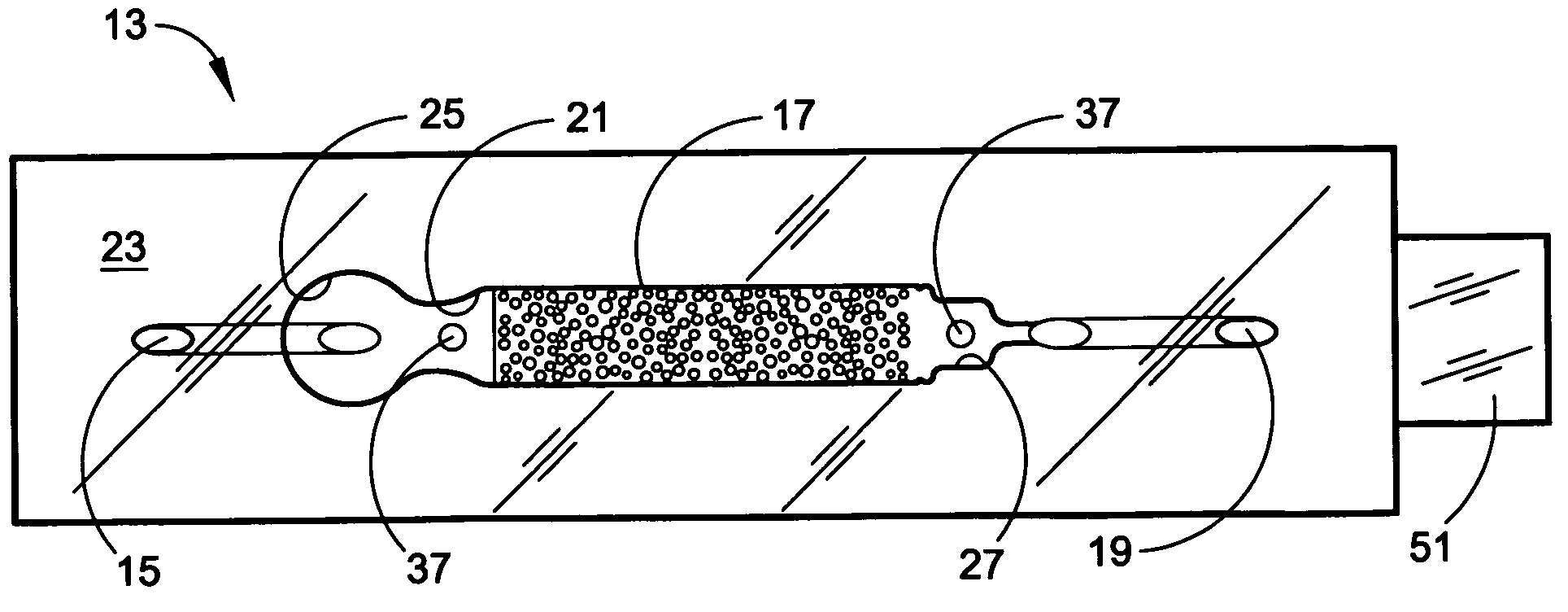

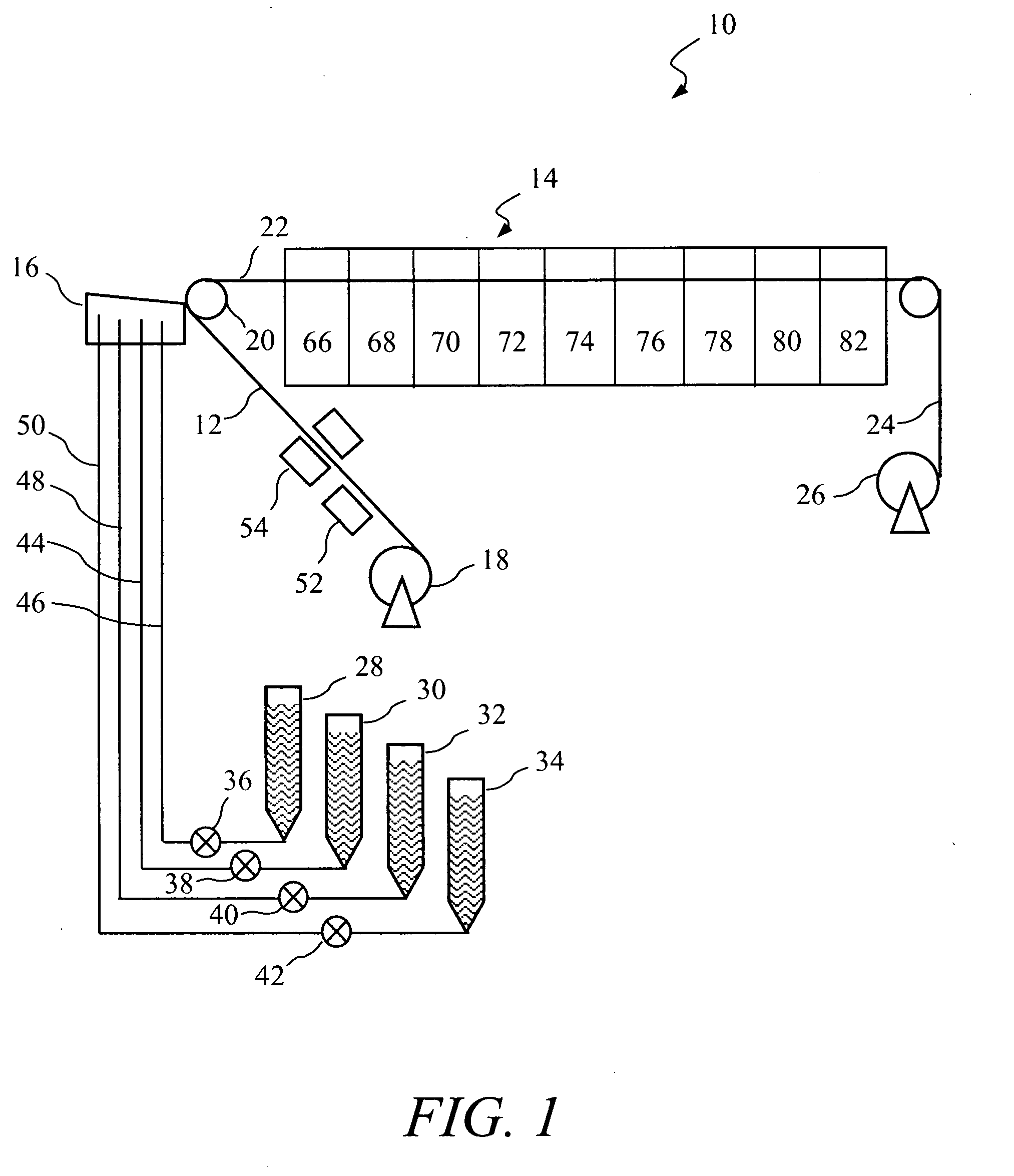

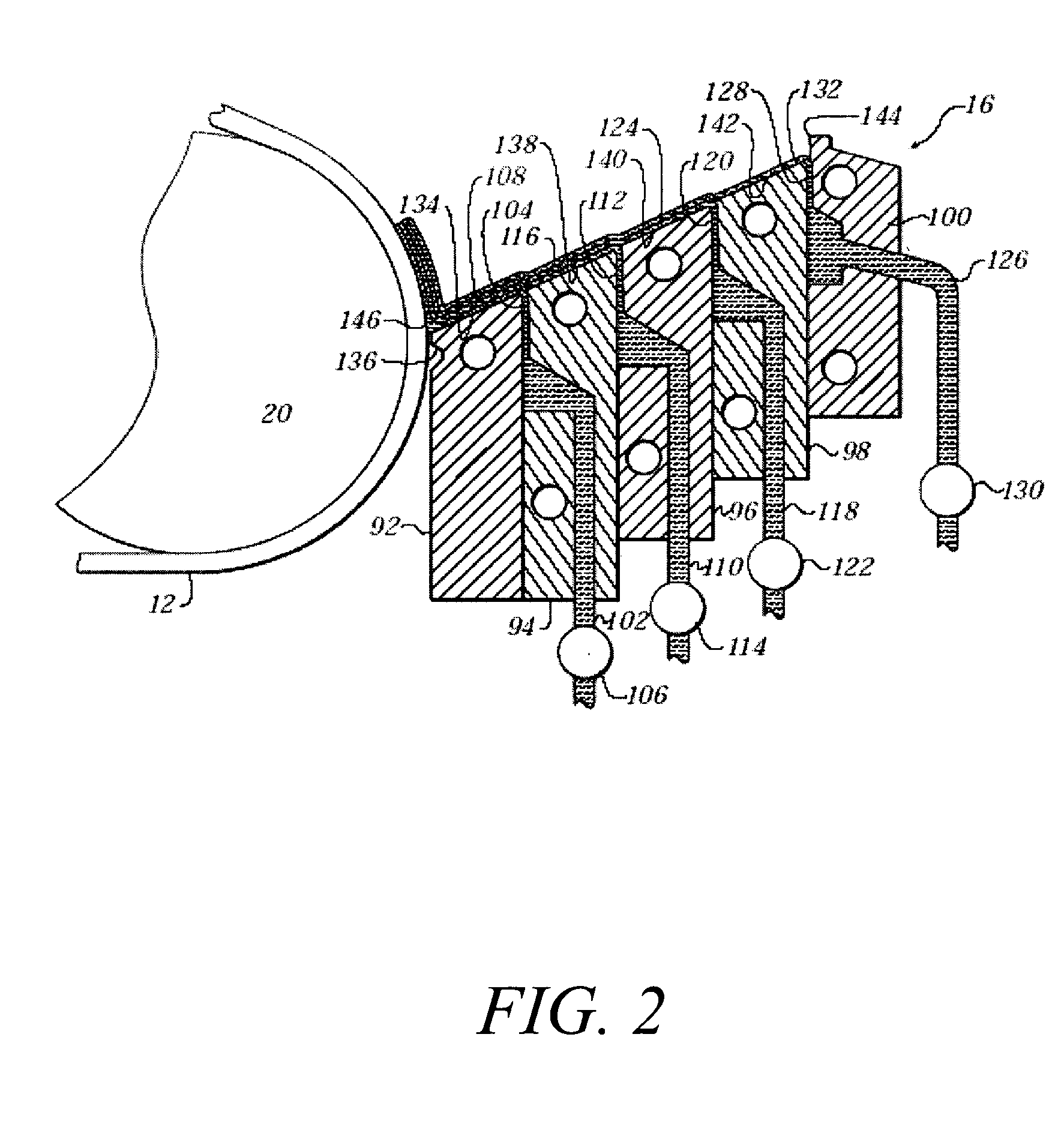

Component connections using bumps and wells

InactiveUS6881609B2Conveniently formedAccurate locationPrinted circuit assemblingFinal product manufactureHigh densityInterconnection

This specification describes techniques for fabricating connections between pairs of components. Each connection includes an array of bumps on a male component, and a matching array of wells filled with bonding material on a female component. The bump / well connections can be spaced with a pitch of less than 100 microns. One application of the invention is the attachment of electronic components to interconnection circuits or circuit assemblies to form electronic modules. The electronic components may be IC chips or high-density interconnect cables. Another application is alignment of optical components. The direct chip attachment techniques are described in the context of fabrication, assembly, test, rework, and cooling of electronic modules employing flip chip components. The preferred method is to fabricate the module on a glass carrier using a release layer so that the carrier can be removed after most of the processing is done.

Owner:SK HYNIX INC

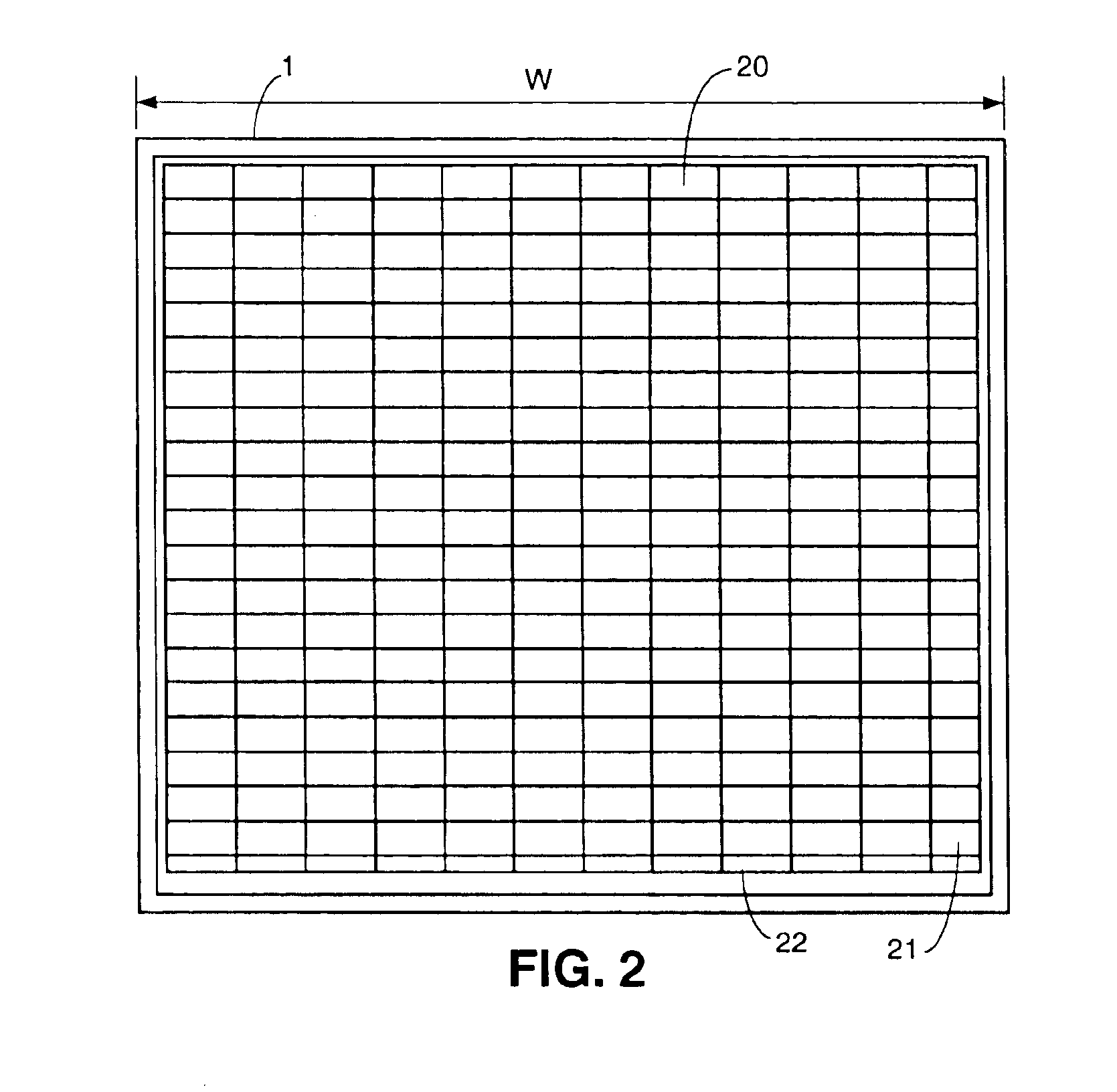

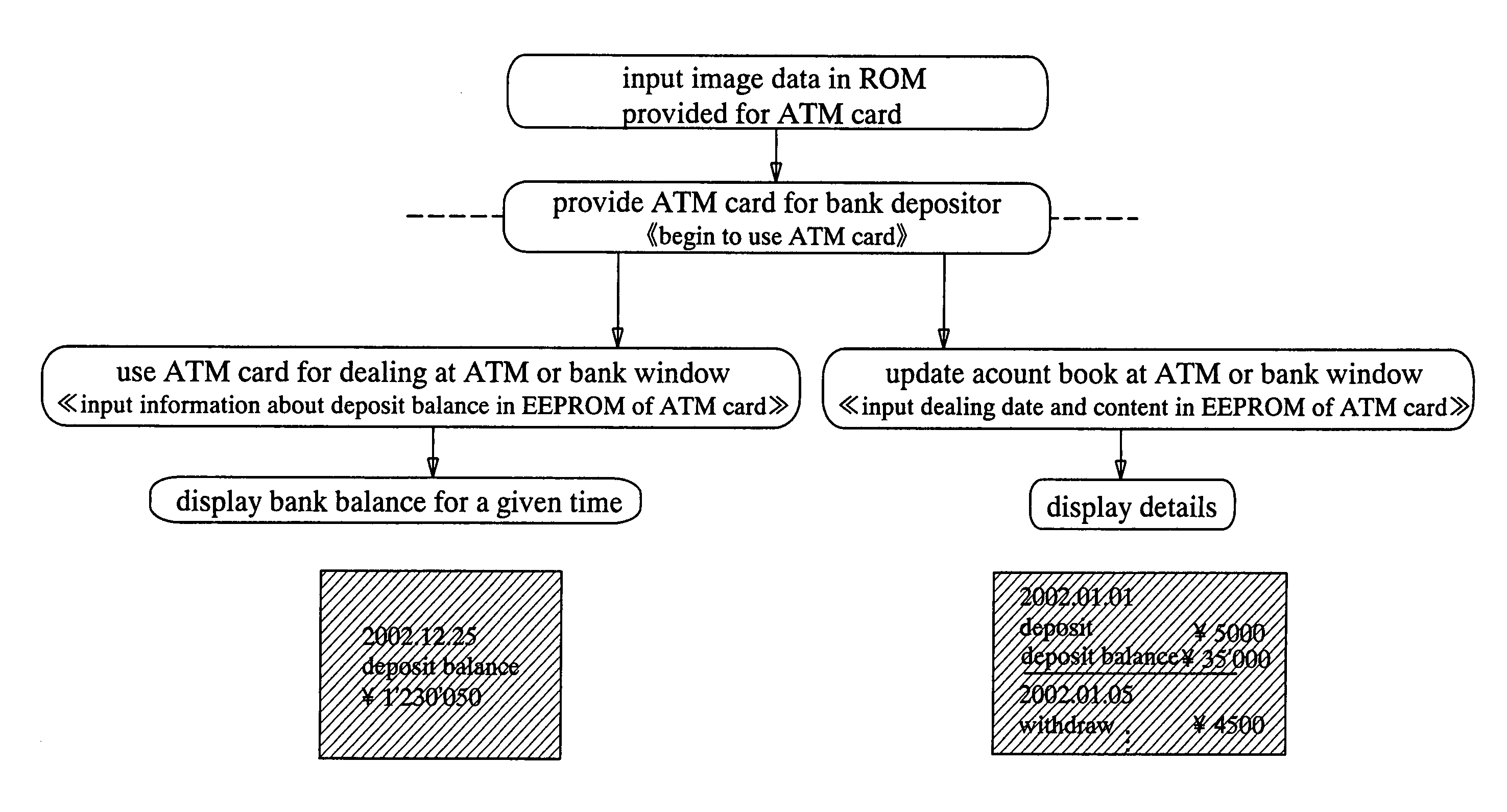

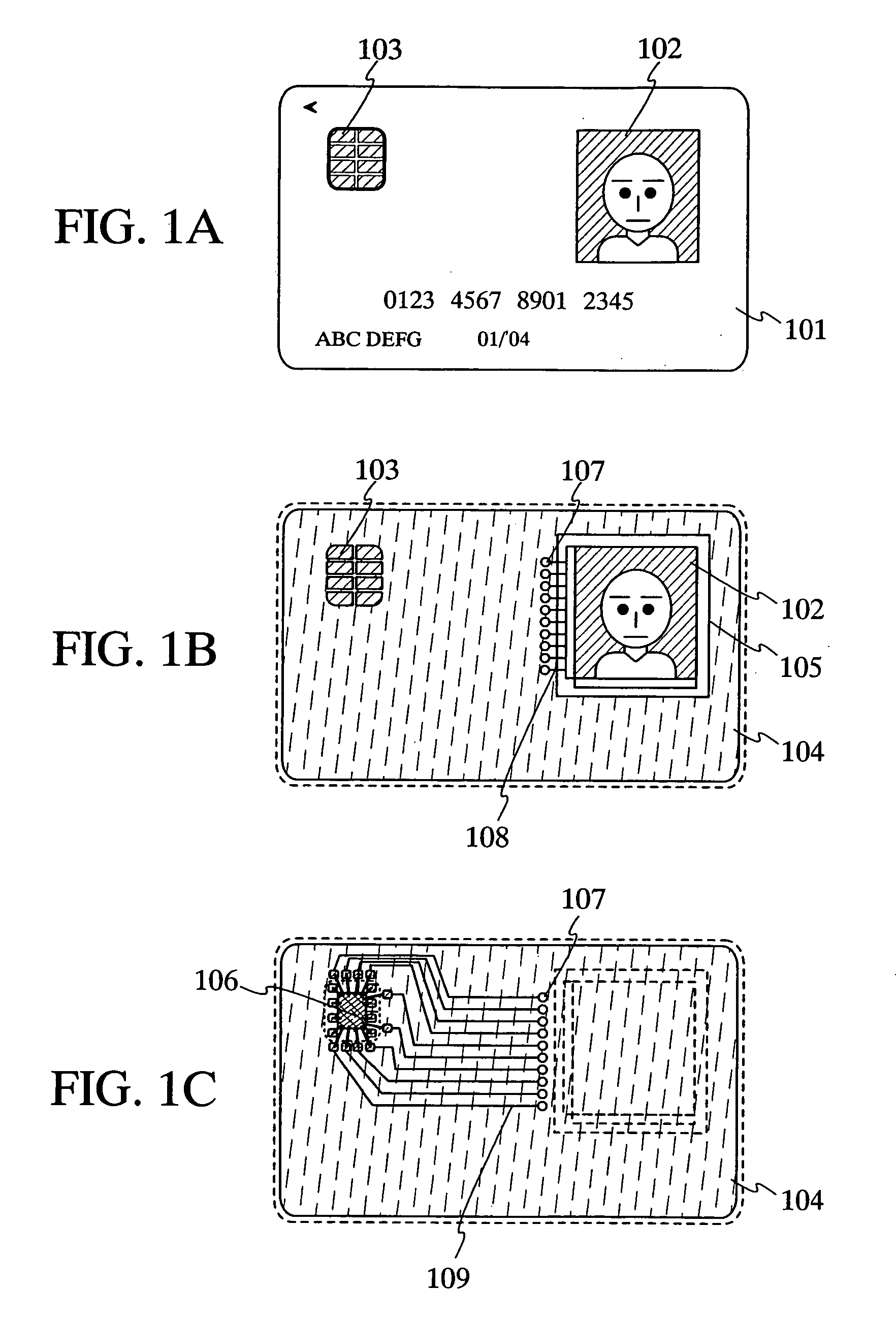

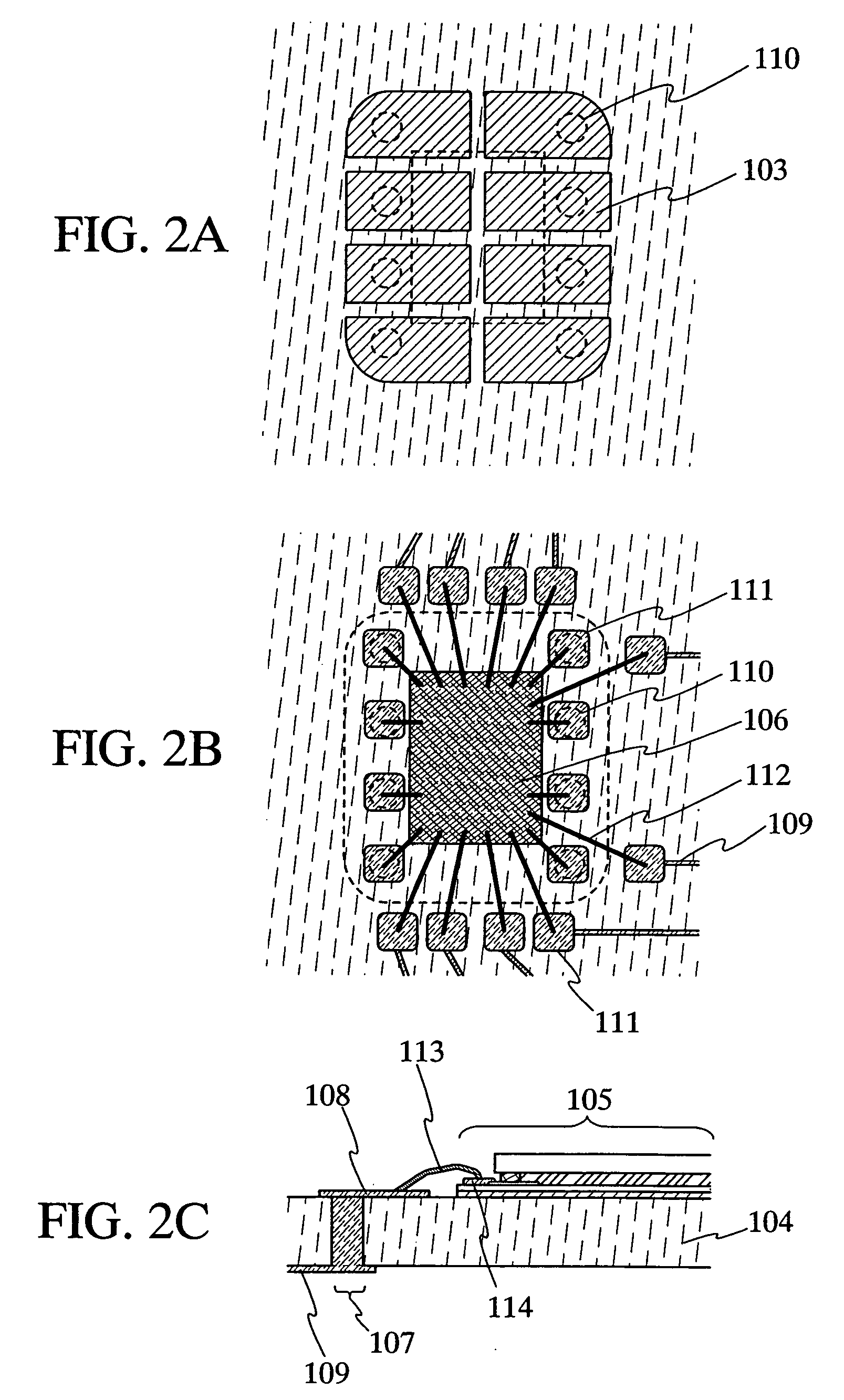

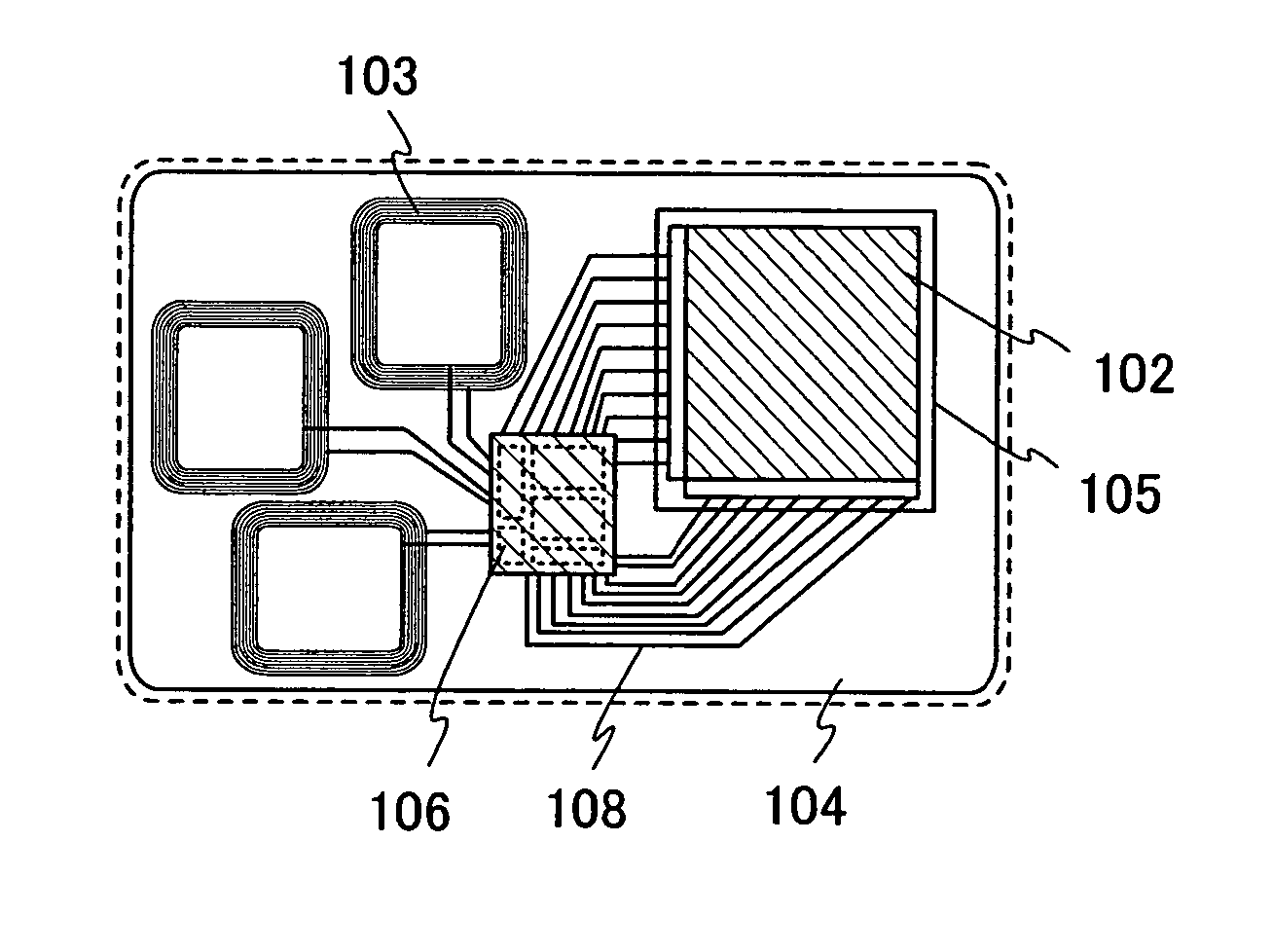

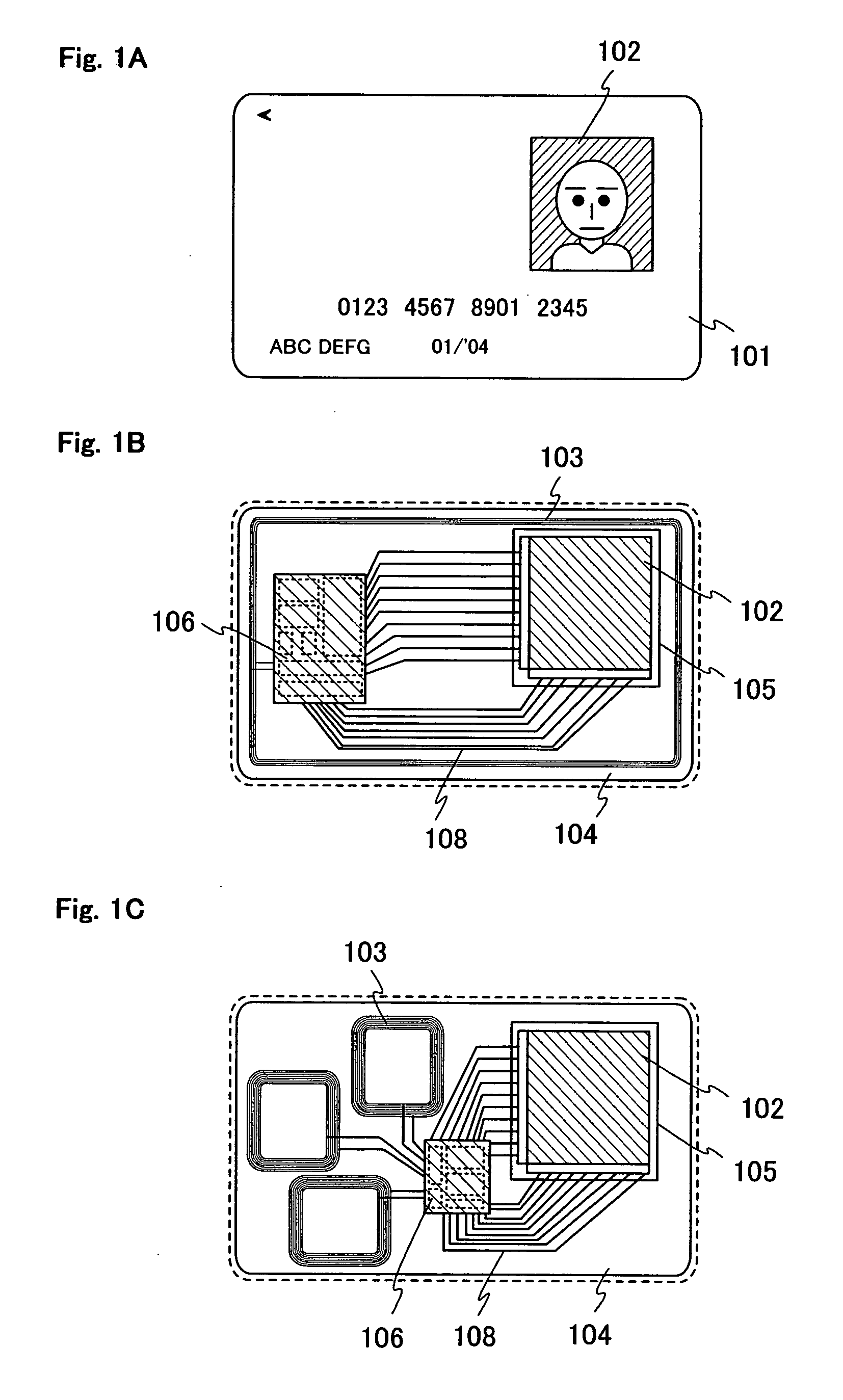

IC card and booking-account system using the IC card

InactiveUS20040128246A1Improve rigidityAvoid damageFinanceStatic indicating devicesDisplay deviceEngineering

It is an object of the present invention to provide a highly sophisticated functional IC card that can ensure security by preventing forgery such as changing a picture of a face, and display other images as well as the picture of a face. An IC card comprising a display device and a plurality of thin film integrated circuits; wherein driving of the display device is controlled by the plurality of thin film integrated circuits; a semiconductor element used for the plurality of thin film integrated circuits and the display device is formed by using a polycrystalline semiconductor film; the plurality of thin film integrated circuits are laminated; the display device and the plurality of thin film integrated circuits are equipped for the same printed wiring board; and the IC card has a thickness of from 0.05 mm to 1 mm.

Owner:SEMICON ENERGY LAB CO LTD

IC card and booking account system using the IC card

InactiveUS20040129450A1Poor heat resistanceImprove brittlenessSolid-state devicesPayment architectureDisplay deviceIntegrated circuit

It is an object of the present invention to provide a highly sophisticated functional card that can ensure security by preventing forgery such as changing a picture of a face, and display other images as well as the picture of a face. A card comprising a display device and a thin film integrated circuit; wherein driving of the display device is controlled by the thin film integrated circuit; a semiconductor element used for the thin film integrated circuit and the display device is formed by using a polycrystalline semiconductor film; the thin film integrated circuit and the display device are sealed with a resin between a first substrate and a second substrate of the card; and the first substrate and the second substrate are plastic substrates.

Owner:SEMICON ENERGY LAB CO LTD

Protective circuit board cover

ActiveUS8659908B2Mitigate and reduce material stressImprove adhesionMagnetic/electric field screeningCircuit security detailsGround planeBiological activation

A protective, anti-tamper coating and methods of coating creation and application are provided. The coating may include an elastomeric layer to allow for strippability / removal. The coating may also include a “smart layer” for tamper detection, imaging prevention, and tamper prevention or underlying device de-activation / alteration upon tamper detection. The coating may also include one or more ground planes around the smart layer and one or more frangible layers designed to interrupt or alter smart layer function in the event of a tamper attempt.

Owner:LOCKHEED MARTIN CORP

Non-electrically conductive thermal dissipator for electronic components

InactiveUS6705388B1Improve consistencyEasy to disassembleSemiconductor/solid-state device detailsSolid-state devicesElectronic componentPrinted circuit board

A thermal dissipator disposable in a heat transfer relationship with a heat-generating source, such as an electronic component, which is mounted on a substrate, such as a printed circuit board. The dissipator includes a thermal dissipation member having a top and bottom surface, and a pressure sensitive adhesive layer disposed on the thermal dissipation member to cover at-least a portion of the bottom surface thereof. The dissipation member is formed of a thermally-conductive, electrically-nonconductive ceramic material. The pressure sensitive adhesive layer has an inner surface adhered to the bottom surface of the thermal dissipation member, and an outer surface bondable to a heat transfer surface of the source for attaching the dissipator to the source in a heat transfer relationship therewith.

Owner:PARKER INTANGIBLES LLC

Electronic system modules and method of fabrication

InactiveUS6927471B2Good dimensional stabilityLow costPrinted circuit assemblingFinal product manufactureDielectricEngineering

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths of 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is used to fabricate the interconnection circuits. A polymer base layer is formed on a glass carrier with an intermediate release layer. Alternate layers of metal and dielectric are formed on the base layer, and patterned to create an array of multi-layer interconnection circuits on the glass panel. A thick layer of polymer is deposited on the interconnection circuit, and openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings to form wells filled with solder. After dicing the glass carrier to form separated interconnection circuits, IC chips are stud bumped and assembled using flip chip bonding, wherein the stud bumps on the components are inserted into corresponding wells on the interconnection circuits. The IC chips are tested and reworked to form tested circuit assemblies. Methods for connecting to testers and to other modules and electronic systems are described. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server embodiment is also described.

Owner:SK HYNIX INC

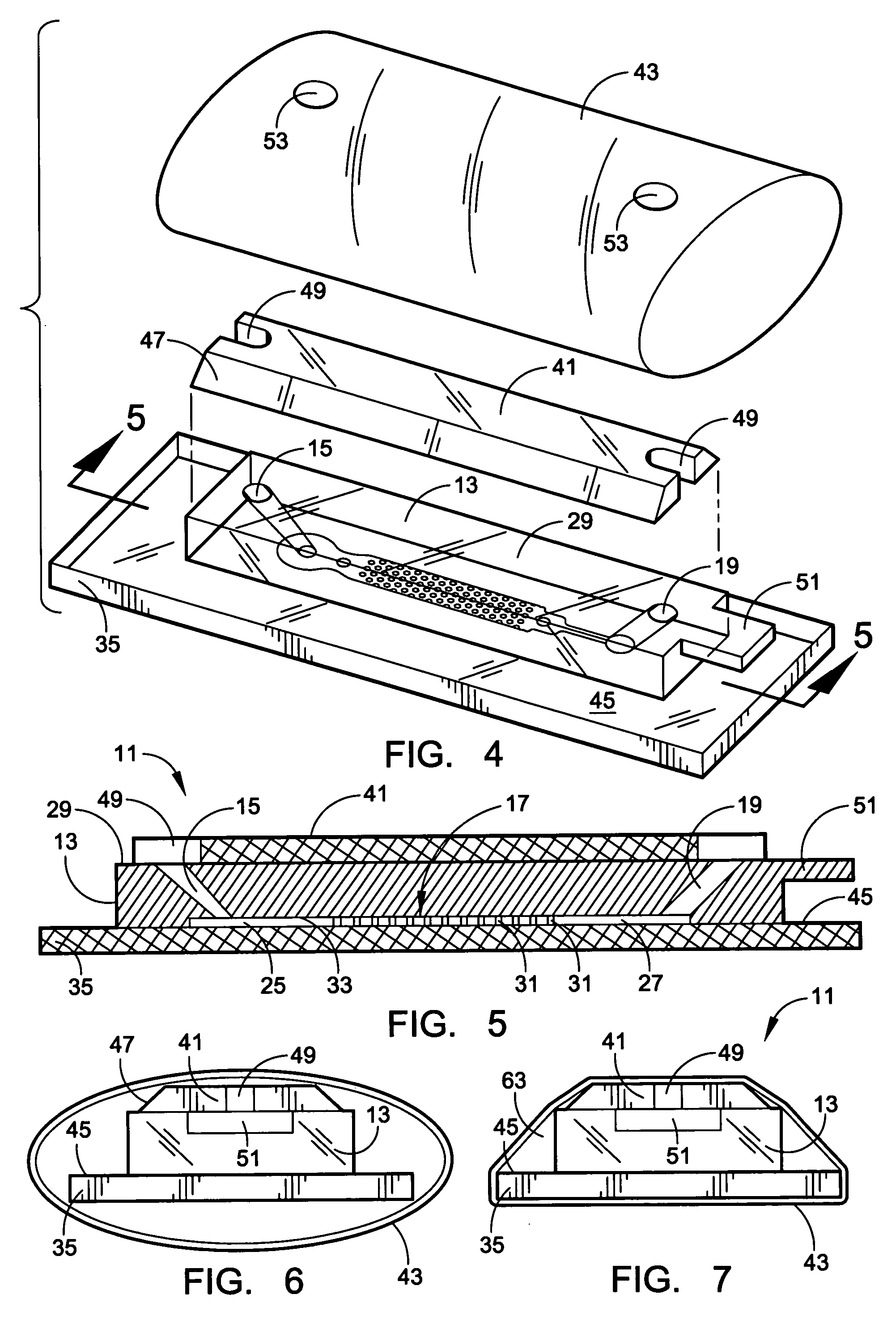

Device for cell separation and analysis and method of using

ActiveUS7695956B2Easy to separateEasy to peelBioreactor/fermenter combinationsBiological substance pretreatmentsMicroscopic examEngineering

A microflow device for separating or isolating cells from a bodily fluid or other liquid sample uses a flow path where straight-line flow is interrupted by a pattern of transverse posts which are arranged across the width of a collection region in an irregular or set random pattern so as to disrupt streamlined flow. Sequestering agents, such as Abs, are attached to all surfaces in the collection region via a hydrophilic permeable hydrogel coating. The collection region is formed as a cavity in a body molded from PDMS, which flexible body is sandwiched between a glass slide or comparable flat plate and a rigid top cap plate, both of which are pressed into abutting relation with the PDMS body by a heat-shrunk polymeric sleeve. Following cell separation and washing, cells can be released from the sequestering agents and the device centrifuged to force said cells to collect adjacent the hydrogel-coated slide or plate. Slitting the polymeric sleeve allows the body to then be peeled from the slide or plate, using an integral tab, to expose the separated cells on the top surface thereof for ready microscopic examination.

Owner:BIOCEPT INC

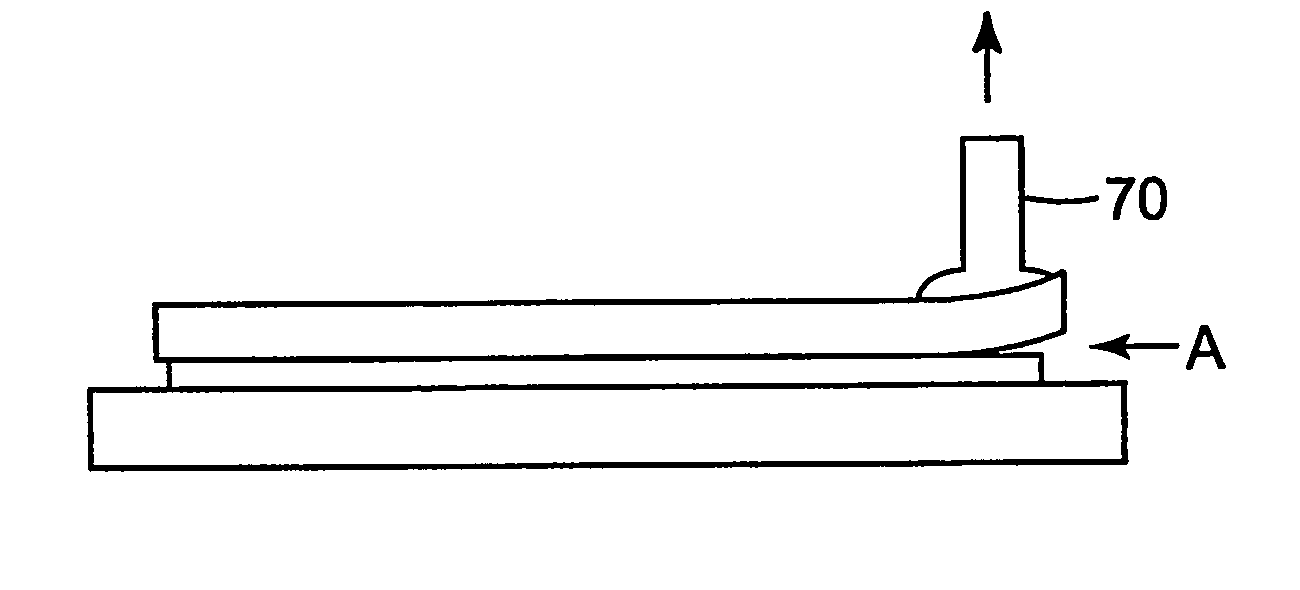

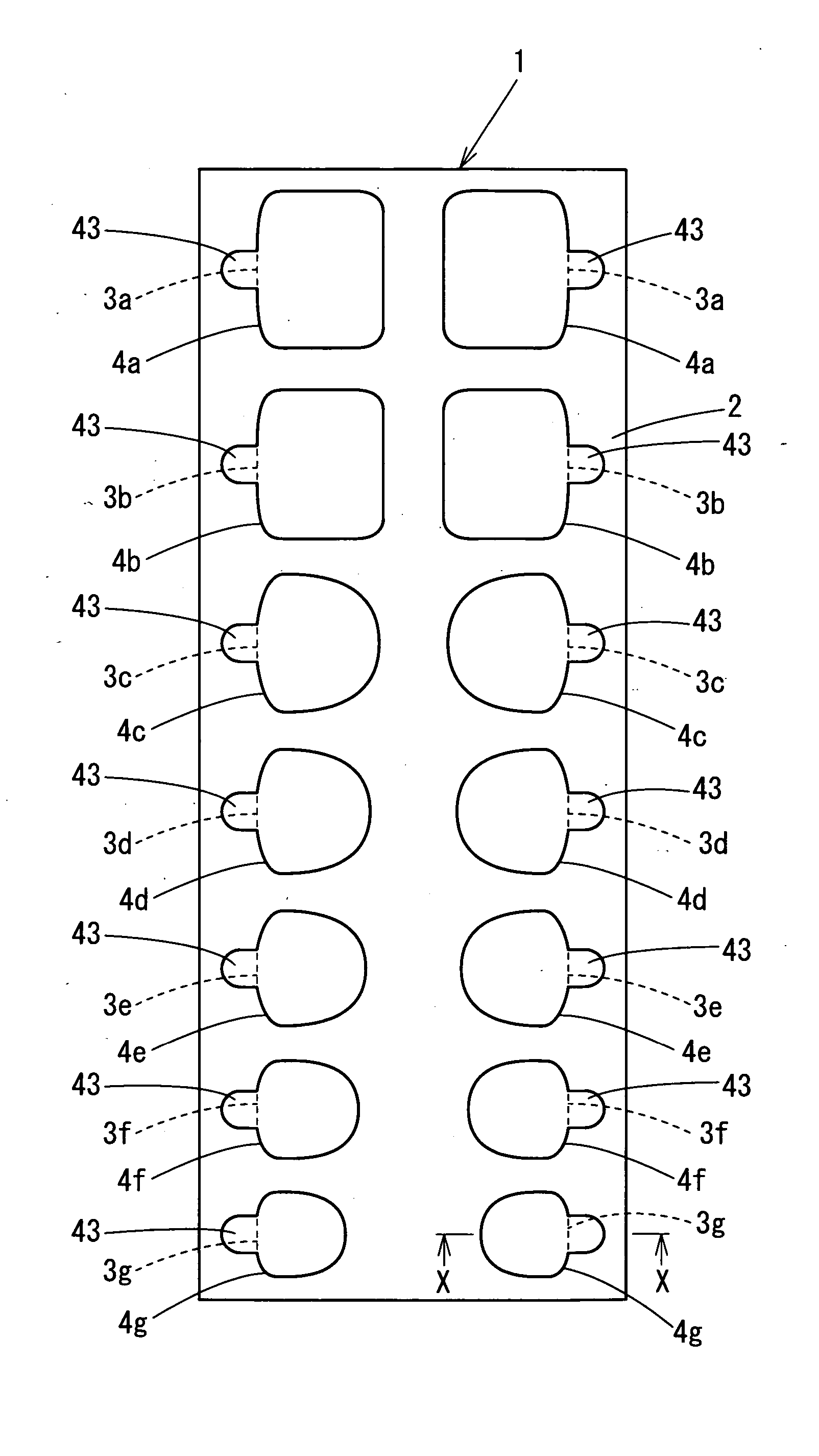

Adhesive sheet for artificial nail

An adhesive sheet for an artificial nail comprises a releasable protective film having, at a tip end side of a bare nail to which a double-sided adhesive sheet member is attached, a peeling tongue piece having a width smaller than the width of the double-sided adhesive sheet member and projecting outward from the double-sided adhesive sheet member, wherein the double-sided adhesive sheet member and the releasable protective film are chamfered in a convex R shape from a base end of the peeling tongue piece toward both sides in a width direction.

Owner:MURAKI

Semiconductor manufacturing method of die-pick-up from wafer

InactiveUS20060166466A1Low costEasy to peelSemiconductor/solid-state device manufacturingAdhesivesWaferingDevice material

A manufacturing method of a semiconductor device comprising the steps of: affixing a die attach film and a dicing film to a back surface of a semiconductor wafer: thereafter dicing the semiconductor wafer and the die attach film to divide the semiconductor wafer into a plurality of semiconductor chips: thereafter pulling the dicing film from the center toward the outer periphery of the dicing film with a first tensile force to cut the die attach film chip by chip; and thereafter picking up the semiconductor chips together with the die attach film while pulling the dicing film from the center toward the outer periphery of the dicing film with a second tensile force smaller than the first tensile force.

Owner:RENESAS ELECTRONICS CORP

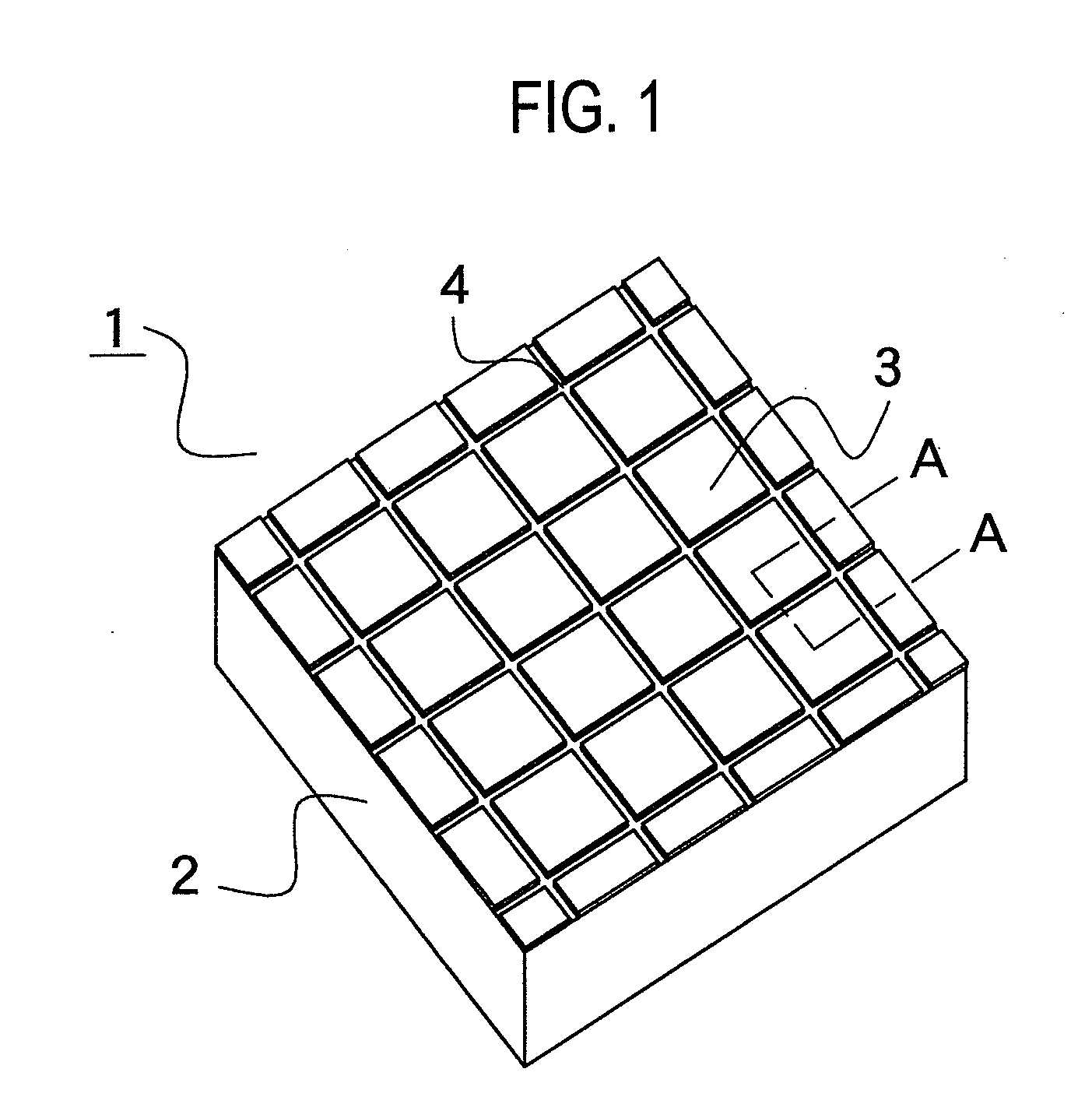

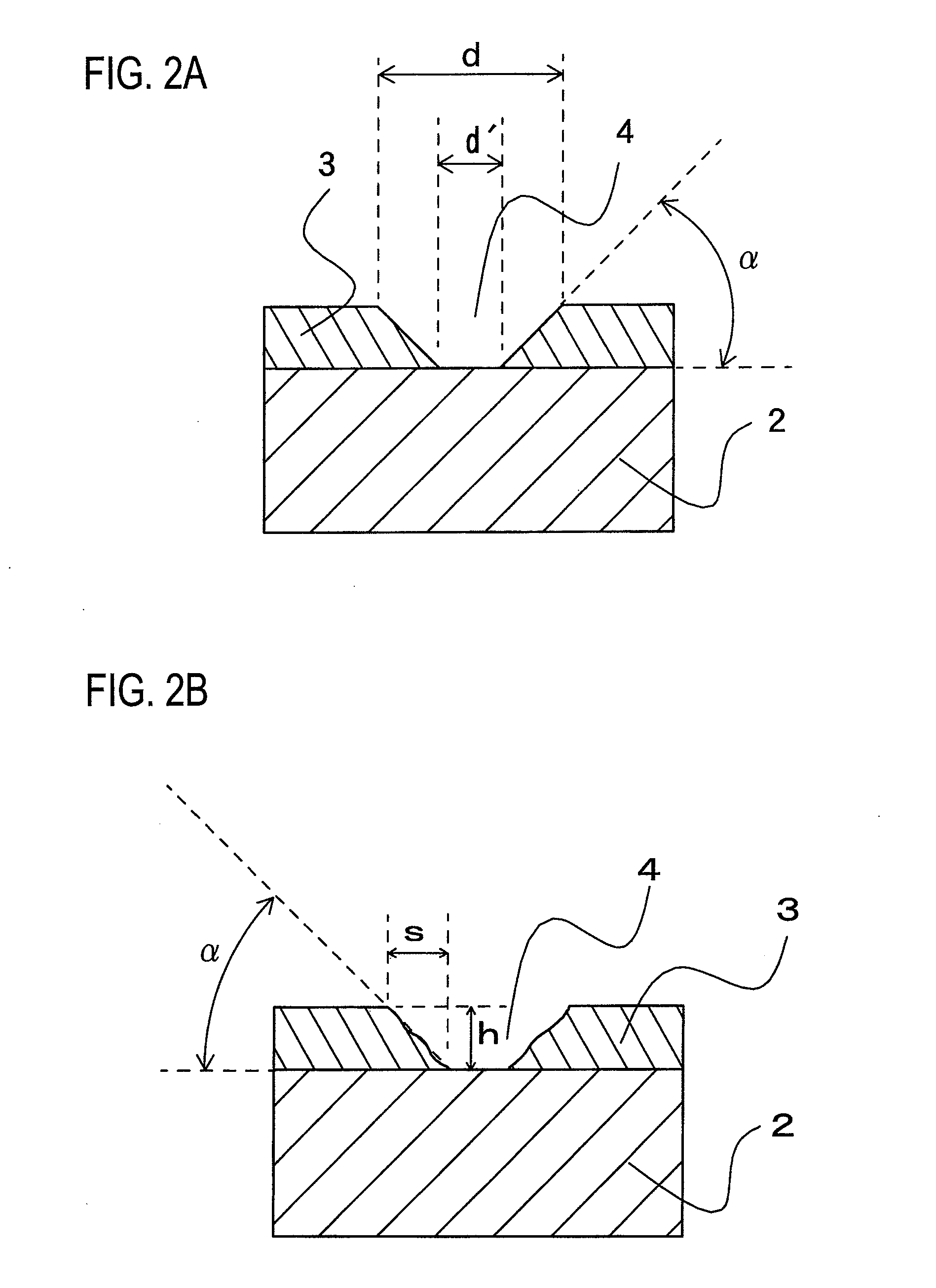

Engraved plate and substrate with conductor layer pattern using the same

InactiveUS20100021695A1High precision and miniaturization of patterningFlat surfaceMagnetic/electric field screeningLayered productsElectrical conductorEngineering

Owner:HITACHI CHEM CO LTD

Dicing die-bonding film

InactiveUS20050139973A1Easy to peelImprove balanceSemiconductor/solid-state device testing/measurementFilm/foil adhesivesAdhesive cementWafering

A dicing die-bonding film has a supporting substrate, an adhesive layer formed on the supporting substrate, and a die-bonding adhesive layer formed on the adhesive layer, and further has a mark for recognizing the position of the die-bonding adhesive layer. It is possible to provide a dicing die-bonding film in which in the case a semiconductor wafer and the dicing die-bonding film are stuck onto each other, the position of the die-bonding adhesive layer in the film can be recognized.

Owner:NITTO DENKO CORP

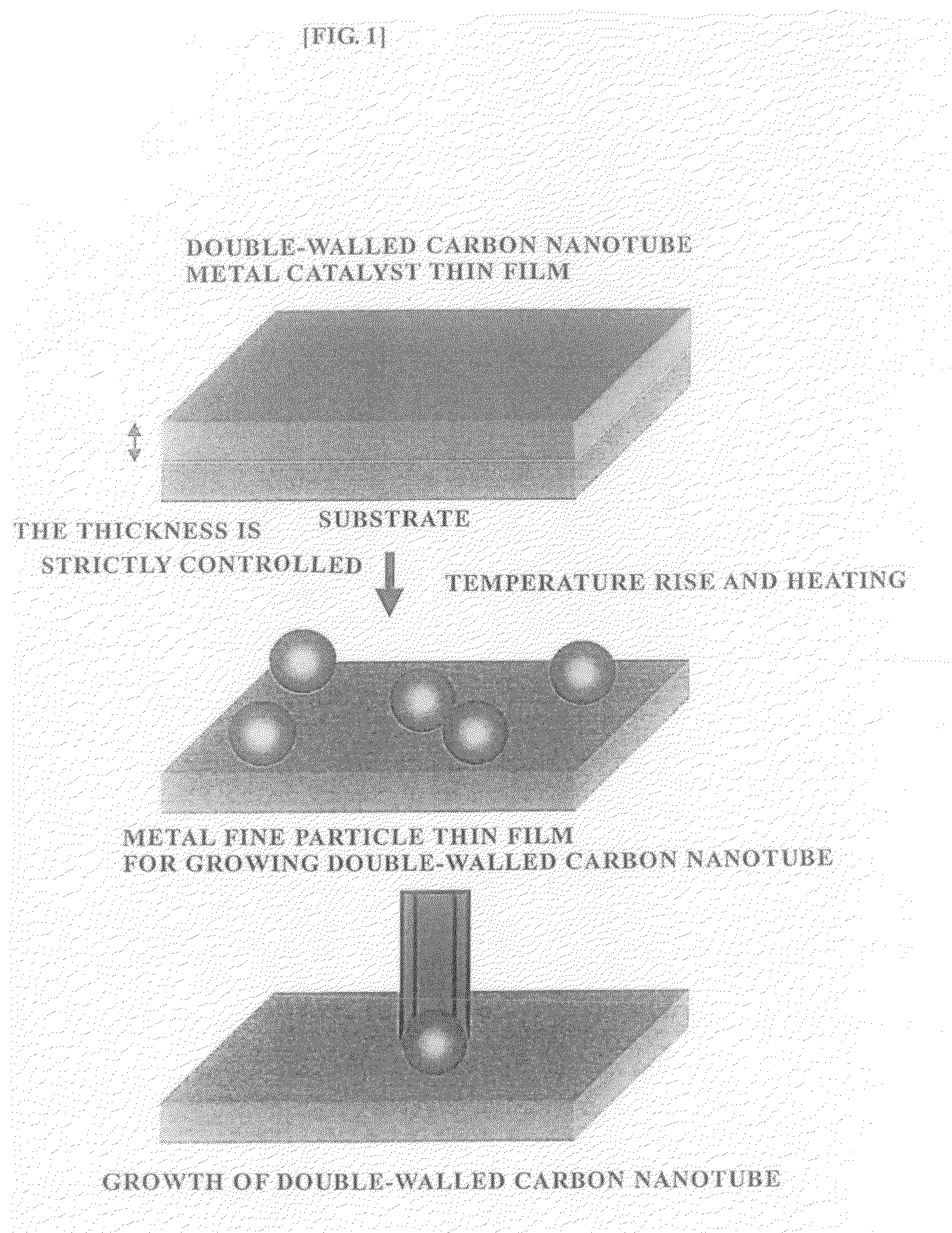

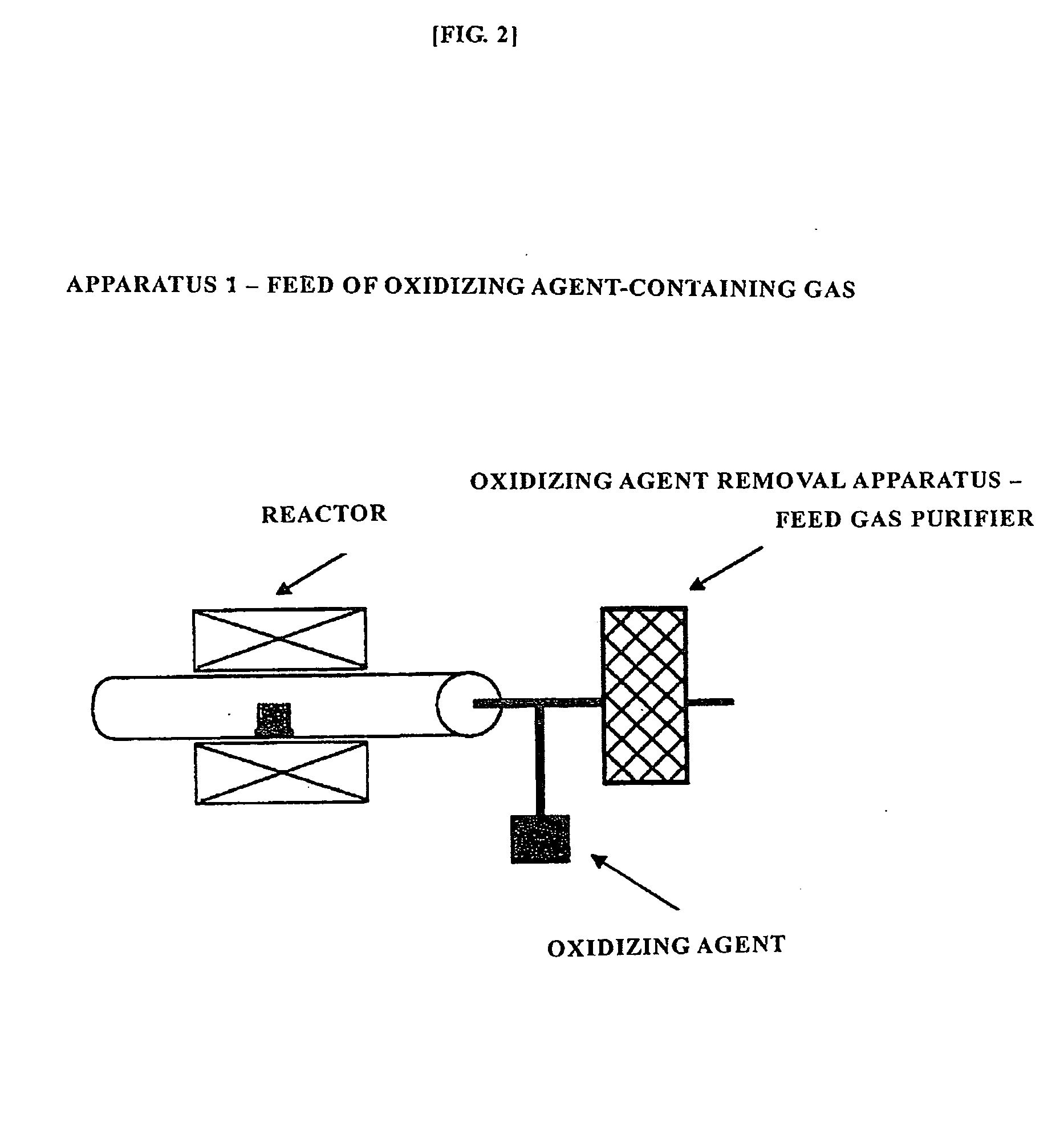

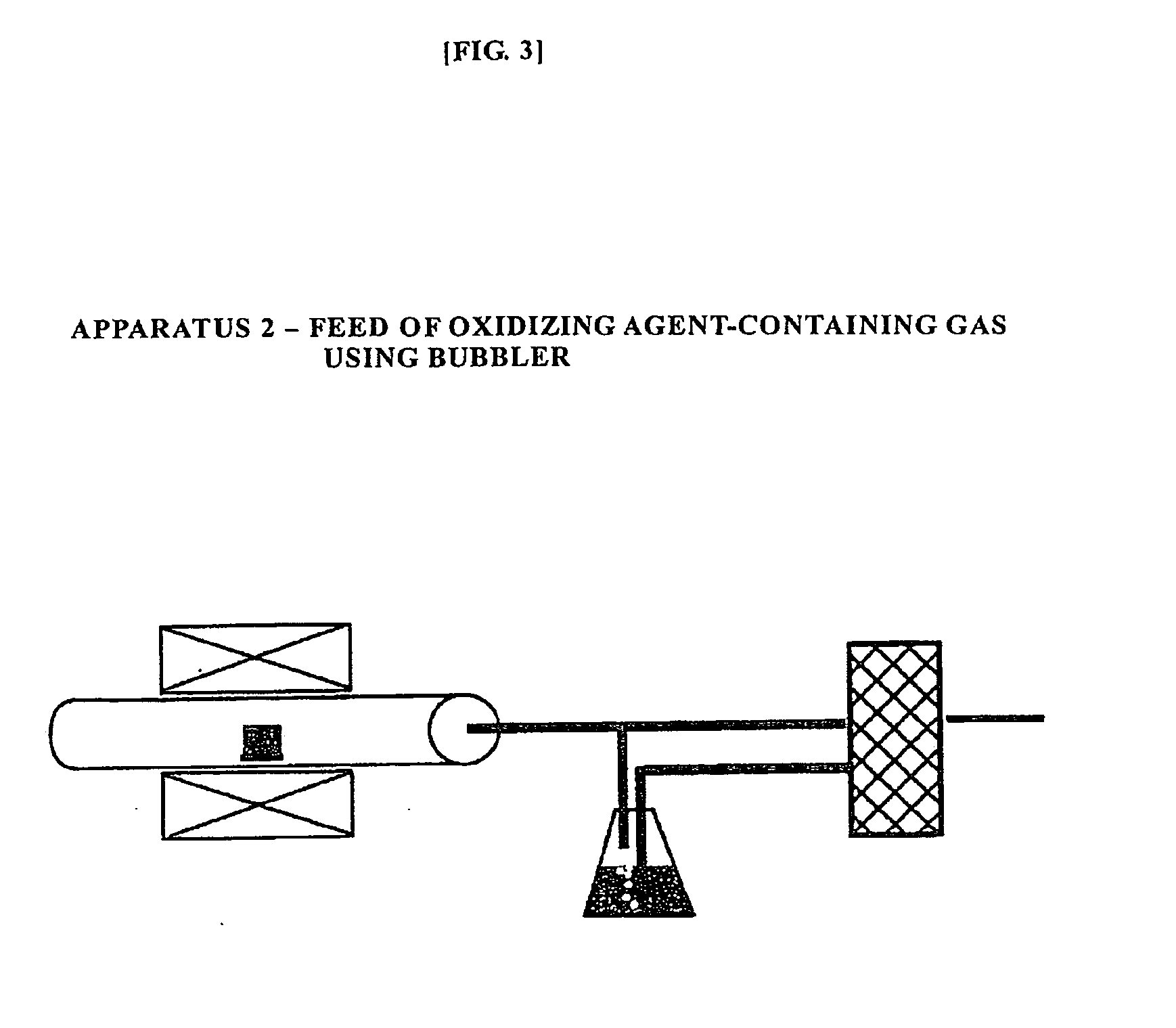

Double-Walled Carbon Nanotube, Aligned Double-Walled Carbon Nanotube Bulk Structure and Process for Producing the Same

InactiveUS20090297846A1High purityEasy to control alignmentMaterial nanotechnologyCarbon compoundsMetal catalystChemical vapor deposition

An aligned double-walled carbon nanotube bulk structure composed of plural aligned double-walled carbon nanotubes and having a height of 0.1 μm or more and a double-walled carbon nanotube are produced by chemically vapor depositing (CVD) a carbon nanotube in the presence of a metal catalyst with controlled particle size and thickness, preferably in the presence of moisture. According to this, it is possible to provide a double-walled nanotube which is free from inclusion of the catalyst, has high purity, is easy to control the alignment and growth, is able to achieve the fabrication through the formation of a bulk structure and has excellent electron emission characteristic (particularly, a double-walled carbon nanotube bulk structure) and also to provide a production technology thereof.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Semiconductor integrated circuit, manufacturing method thereof, and semiconductor device using semiconductor integrated circuit

InactiveUS20070254455A1Improve productivityMechanical flexibilitySemiconductor/solid-state device detailsSolid-state devicesProduction rateEngineering

A step of forming a through hole in a semiconductor substrate, or a step of polishing the semiconductor substrate from its back surface requires a very long time and causes decrease of productivity. In addition, when semiconductor substrates are stacked, a semiconductor integrated circuit which is formed of the stack is thick and has poor mechanical flexibility. A release layer is formed over each of a plurality of substrates, layers each having a semiconductor element and an opening for forming a through wiring are formed over each of the release layers. Then, layers each having the semiconductor element are peeled off from the substrates, and then overlapped and stacked, a conductive layer is formed in the opening, and the through wiring is formed; thus, a semiconductor integrated circuit is formed.

Owner:SEMICON ENERGY LAB CO LTD

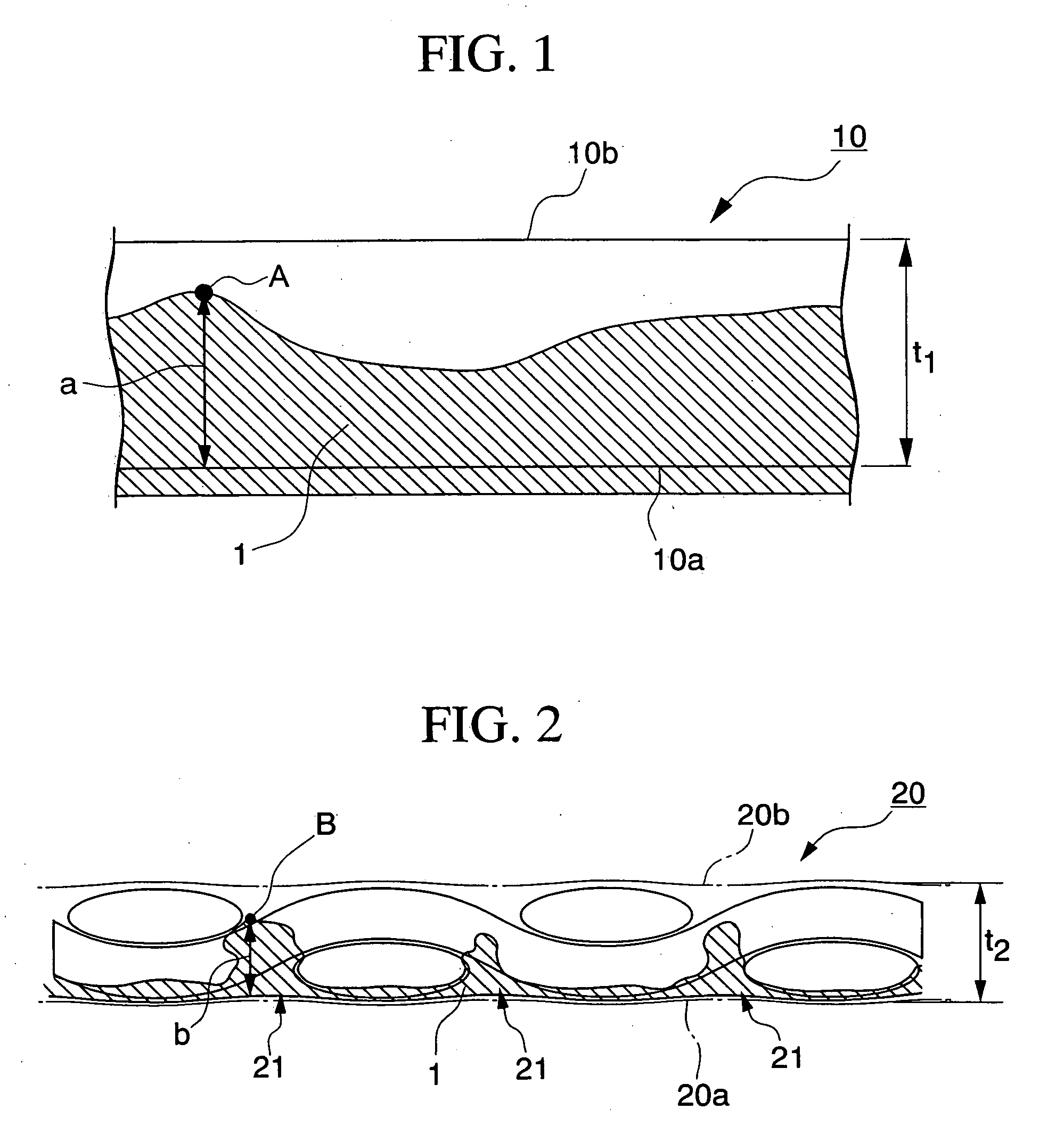

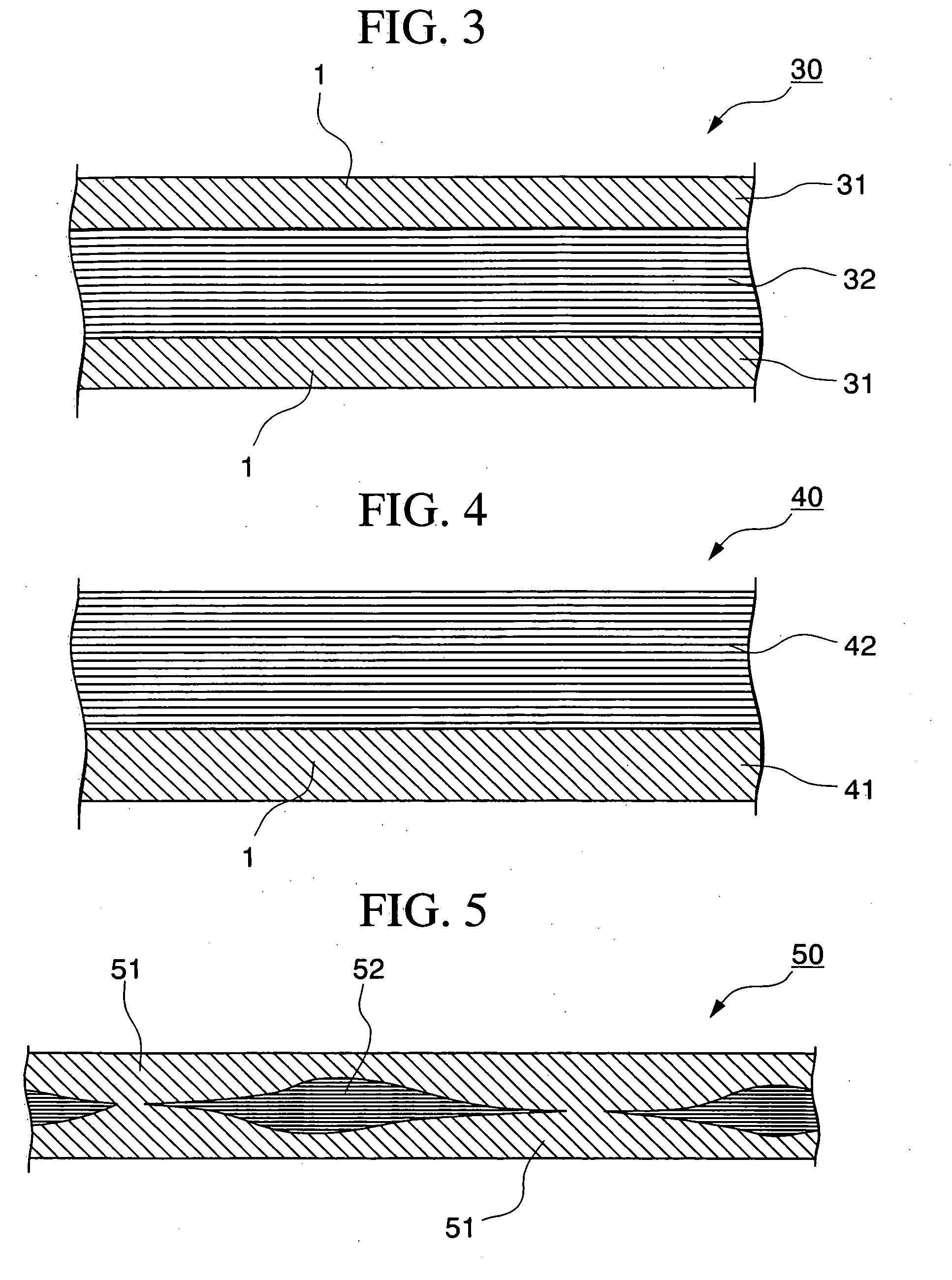

Prepreg, intermediate material for forming frp, and method for production thereof and method for production of fiber-reinforced composite material

InactiveUS20060035548A1Reduce resin viscosityLow viscosityFibre treatmentSynthetic resin layered productsVacuum pressureCoverage ratio

An FRP is produced using a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein the matrix resin is impregnated into the sheet-like reinforcing fiber substrate and also covers one surface of the sheet-like reinforcing fiber substrate, and the matrix resin impregnation ratio is within a range of 35% to 95%; a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein the matrix resin exists on both surfaces of the sheet-like reinforcing fiber substrate, and the portion inside the sheet-like reinforcing fiber substrate into which the matrix resin has not been impregnated is continuous; or a prepreg comprising reinforcing fiber, a sheet-like reinforcing fiber substrate containing reinforcing fiber, and a matrix resin, wherein at least one surface exhibits a sea-and-island-type pattern comprising resin-impregnated portions (island portions) where the matrix resin is present at the surface and fiber portions (sea portions) where the matrix resin is not present at the surface, the surface coverage ratio of the matrix resin on those surfaces with said a sea-and-island-type pattern is within a range of 3% to 80%, and the weave intersection coverage ratio for the island portions, represented by a formula (1) shown below, is at least 40%, displays excellent external appearance, with no internal voids or surface pinholes, even when molded is conducted using only vacuum pressure. Island portions weave intersection coverage ratio (%)=(T / Y)×100 (1) (wherein, T represents a number of island portions that cover weave intersections, and Y represents a number of weave intersections within said reinforcing fiber woven fabric on said surface with said sea-and-island-type pattern).

Owner:MITSUBISHI RAYON CO LTD

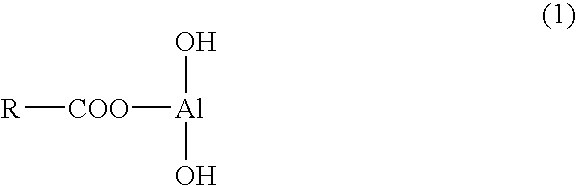

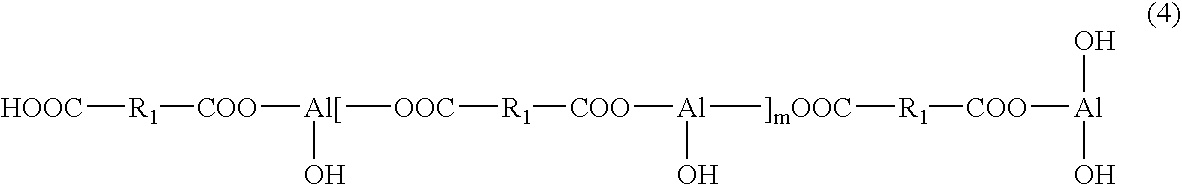

Latex composition comprising a cross-linking agent and molded product thereof

InactiveUS20080227913A1Easy to peelExcellent peelabilityGroup 3/13 element organic compoundsTitanium organic compoundsIonPolyamide

A carboxyl group-containing diene-based rubber latex composition comprising (a) a carboxyl group-containing diene-based rubber latex and one or more compounds selected from the following (b) to (e):(b) an organometallic crosslinking agent containing two or more hydroxyl groups each bonded to a metal atom;(c) a cationic property-deactivated, modified polyamine-based resin, a cationic property-deactivated polyamide-epichlorohydrin resin, a cationic property-deactivated polyamine-epichlorohydrin resin, a cationic property-deactivated amine group- or quaternary ammonium base-containing polyvinyl alcohol, a cationic property-deactivated amine group- or quaternary ammonium base-containing polyacrylamide, a cationic property-deactivated amine group- or quaternary ammonium base-containing carbohydrate, or a polyacrylamide, polyvinyl alcohol, or carbohydrate into which a crosslinkable functional group is introduced;(d) an anionic or nonionic polyvinyl alcohol, anionic or nonionic polyacrylamide, or anionic or nonionic carbohydrate to which a water resistant additive is added; and(e) a cationizing agent.

Owner:YUGENKAISHA FOUR ROAD RES

Touch panel

ActiveUS20140134433A1Enhancing performance of inhibiting changeImprove cohesive strengthFilm/foil adhesivesMacromolecular adhesive additivesElectrical conductorMeth-

Provided is a touch panel. The touch panel includes a base and a pressure-sensitive adhesive layer attached to the base and including an acryl-based polymer containing an acryl polymer containing 5 to 30 parts by weight of isobornyl (meth)acrylate, and 5 to 40 parts by weight of methyl (meth)acrylate in a polymerized form. Accordingly, it can effectively inhibit penetration of oxygen, moisture or other impurities at an interface between the base and the pressure-sensitive adhesive layer, or at an interface between a conductor thin film and the pressure-sensitive adhesive layer, and prevent degradation in optical properties such as visibility, etc. due to bubbles generated at the pressure-sensitive adhesive interface. In addition, when the pressure-sensitive adhesive layer is directly attached to the conductor thin film and even exposed to severe conditions such as high temperature or high temperature and high humidity, a change in the resistance of the conductor thin film may be effectively inhibited, and thus the touch panel can be stably driven for a long time.

Owner:LG CHEM LTD

Die pickup method and die pickup apparatus

InactiveUS20020129899A1Easy to peelLayered productsSolid-state devicesEngineeringMechanical engineering

A die pickup method and apparatus that uses a tape peeling stage which supports a portion of an adhesive tape that corresponds to a die to be picked up, and a suction holding stage in which suction holding holes that, with vacuum suction, holds areas of the adhesive tape that surround the die to be picked up, thus separating the die from the adhesive tape by forming an air layer between the die and the adhesive tape, and then picking up the die. The air layer is formed, with the die being held via vacuum suction by a suction nozzle provided above the suction holding stage, by raising the tape peeling stage and then by moving the tape peeling stage horizontally in a direction away from the die.

Owner:SHINKAWA CO LTD

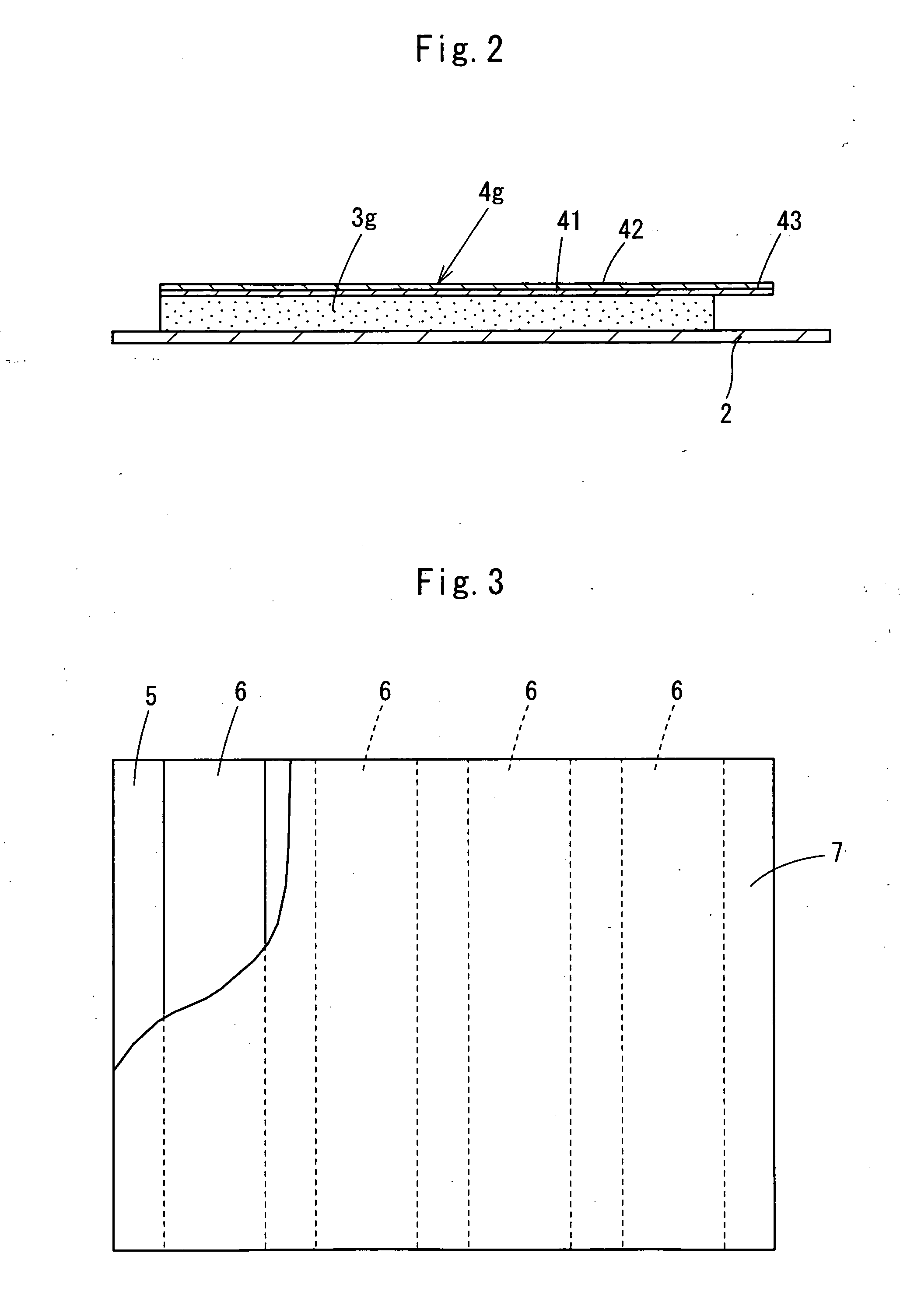

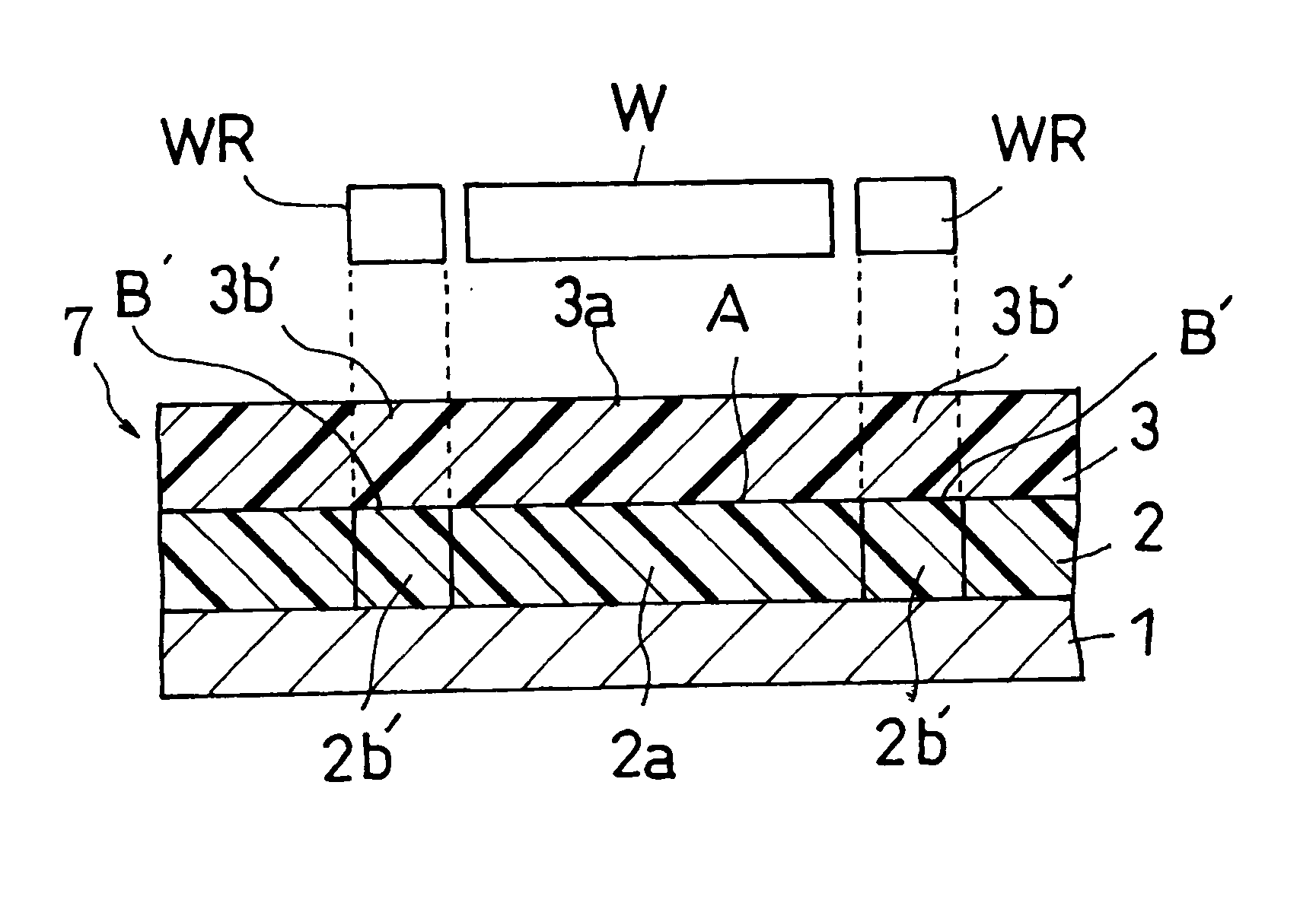

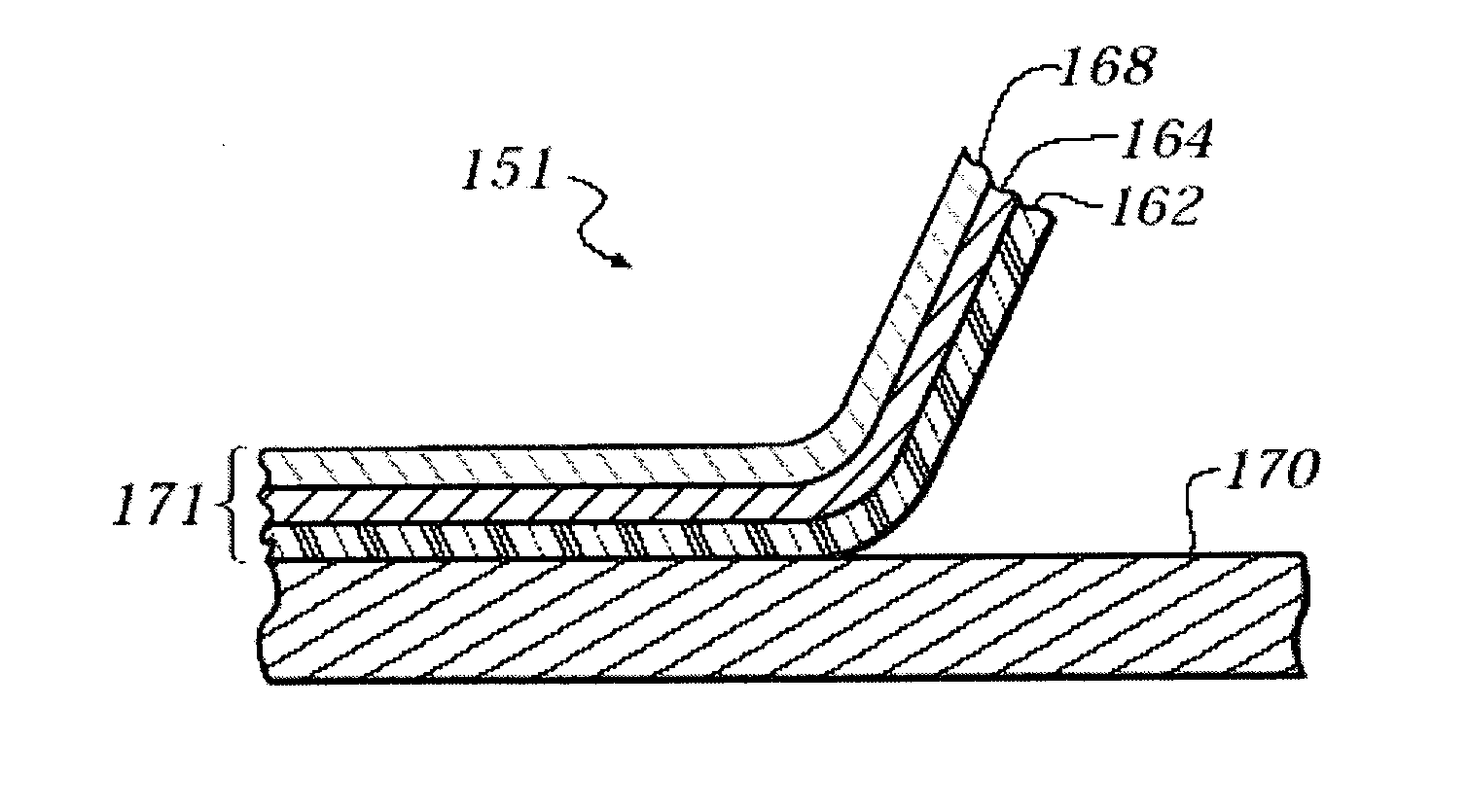

Layered body and method for manufacturing thin substrate using the layered body

InactiveUS20090017323A1Reduce pressureEasily peelLamination ancillary operationsLayered product treatmentPhotothermal conversionAdhesive

Provided is a layered body comprising a substrate to be ground and a support, where the substrate may be ground to a very small (thin) thickness and can then be separated from the support without damaging the substrate. One embodiment is a layered body comprising a substrate to be ground, a joining layer including a curable adhesive in contact with the substrate to be ground, a photothermal conversion layer comprising a light absorbing agent and a heat decomposable resin, and a light transmitting support. After grinding the substrate surface which is opposite that in contact with the joining layer, the layered body is irradiated through the light transmitting layer and the photothermal conversion layer decomposes to separate the substrate and the light transmitting support.

Owner:3M INNOVATIVE PROPERTIES CO

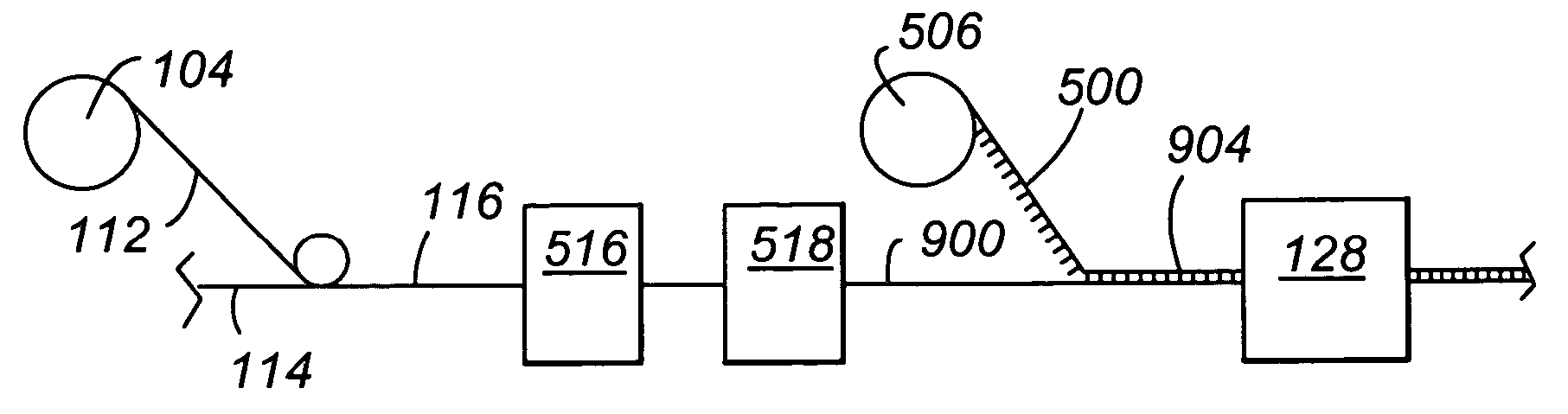

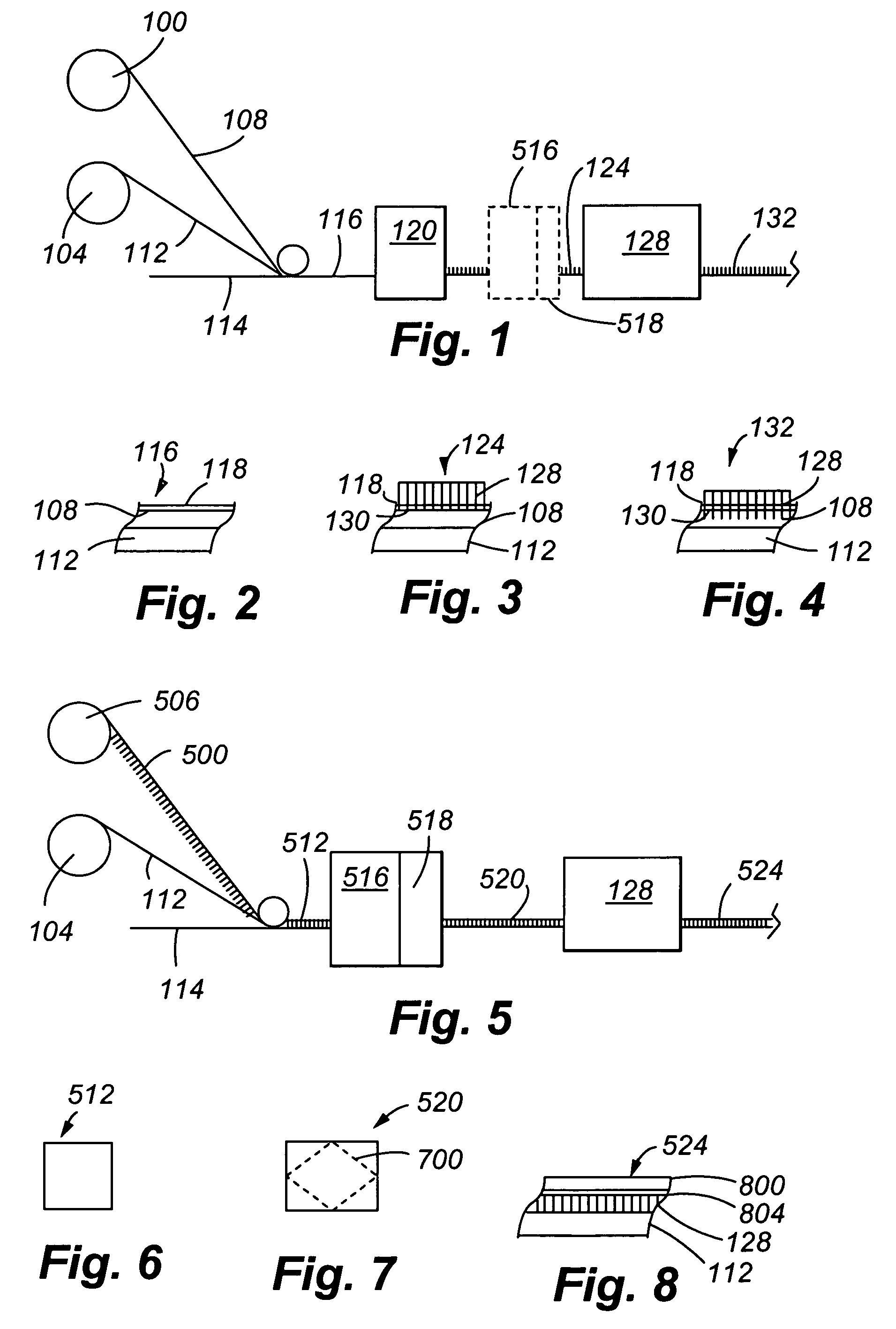

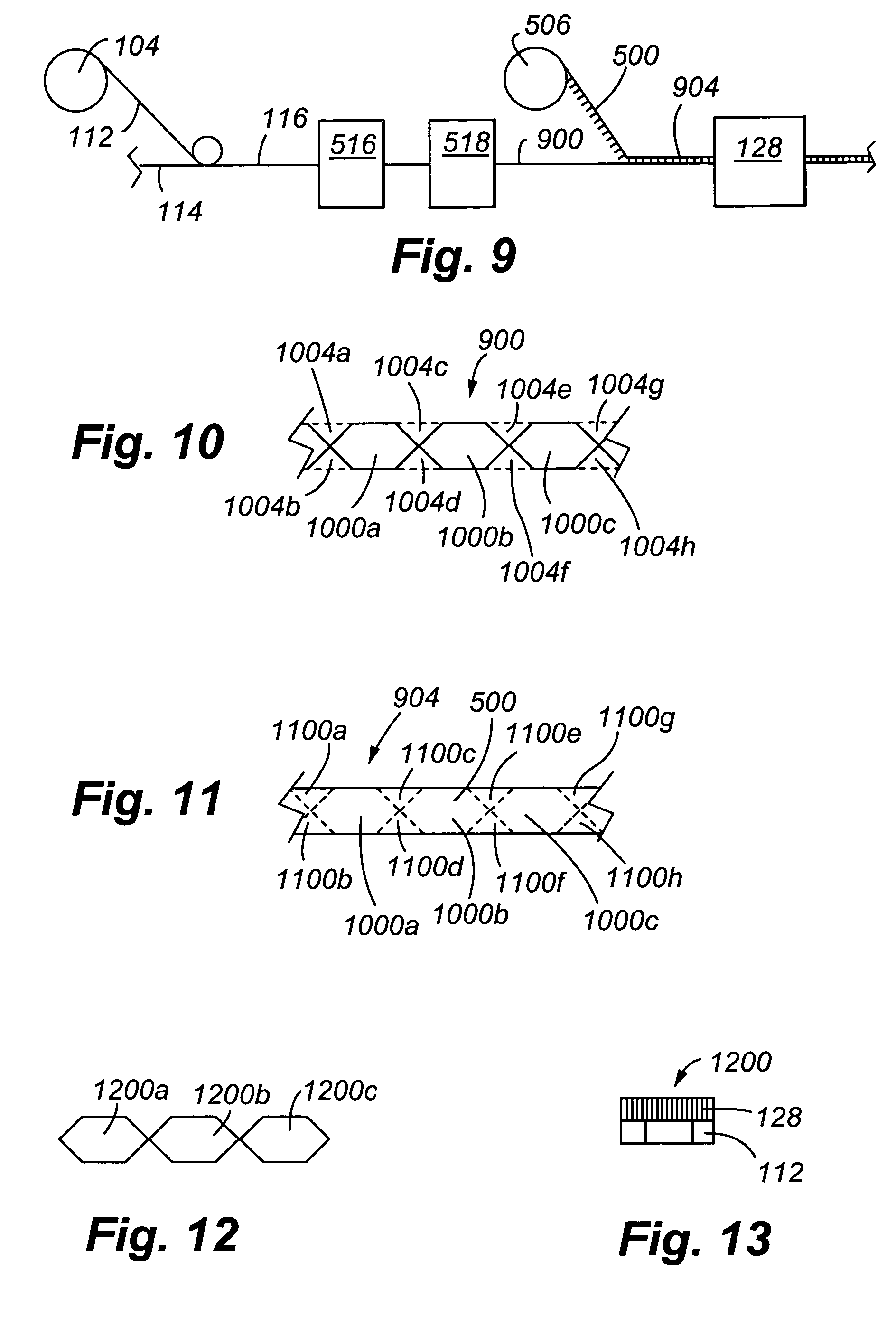

Processes for precutting laminated flocked articles

InactiveUS20050081985A1Reduce adjustmentMuch fastLiquid surface applicatorsLamination ancillary operationsEngineering

A process for forming a flocked article is provided that includes the steps of: (a) cutting a pre-formed adhesive film into a desired shape; (b) removing a first portion of the cut pre-formed adhesive film from a second portion of the cut pre-formed adhesive film; and (c) heating and applying pressure to the cut pre-formed adhesive film to adhere the film to flock to form a flocked article.

Owner:HIGH VOLTAGE GRAPHICS

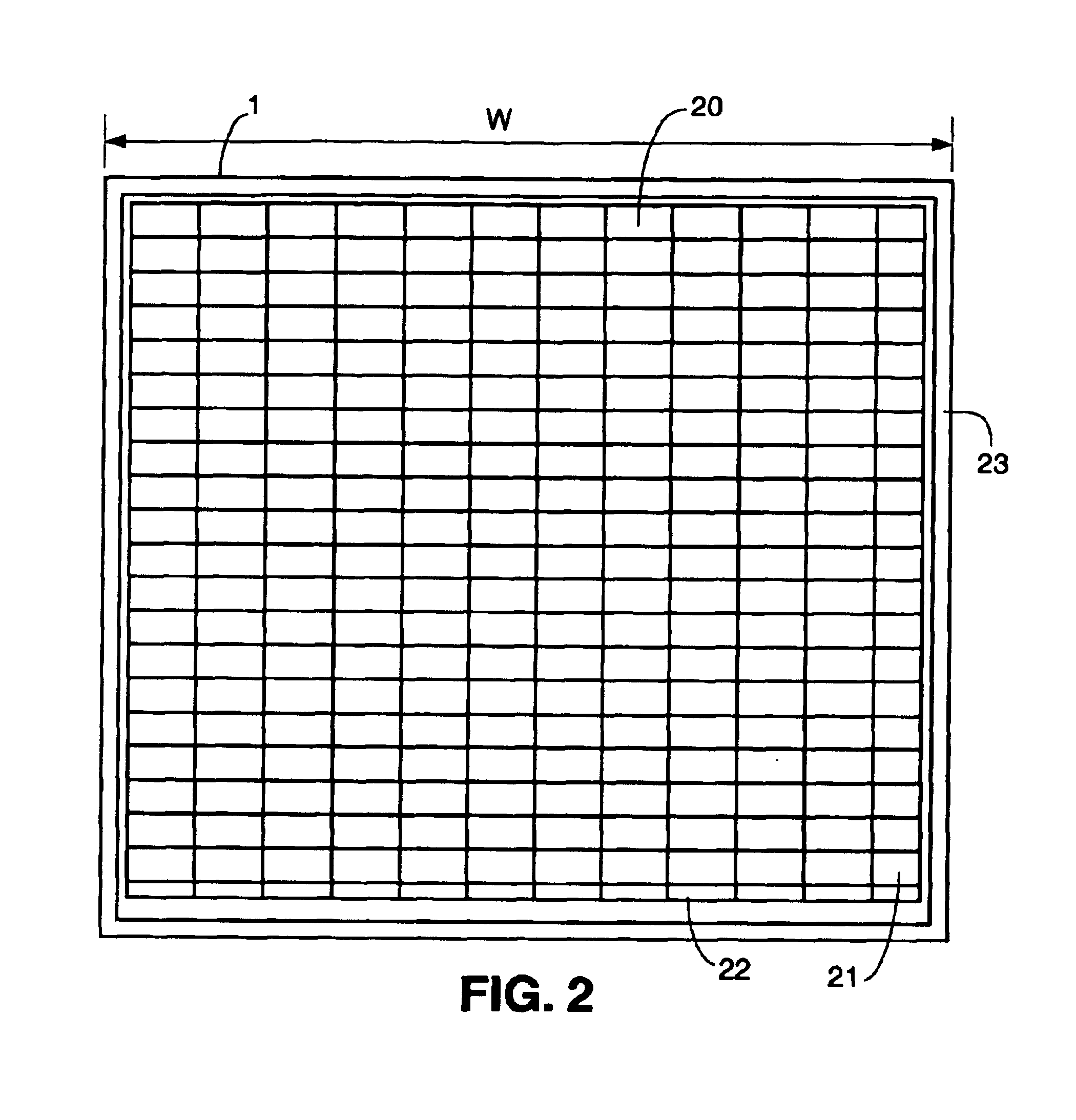

Optical film composite having spatially controlled adhesive strength

InactiveUS20070134459A1Improve handlingSimple processLamination ancillary operationsLayered product treatmentLiquid-crystal displayPolarizer

The present invention generally relates to optical films useful in the manufacture of polarizer plates, an improved method for producing polarizing plates, and a Liquid Crystal Display employing the same. More particularly, the invention relates to an optical film composite comprising a temporary carrier substrate having a center area and an edge area, said substrate having coated thereon an optical film wherein the adhesive strength between the optical film and the substrate is greater at the edge area than at the center area of the substrate.

Owner:EASTMAN KODAK CO

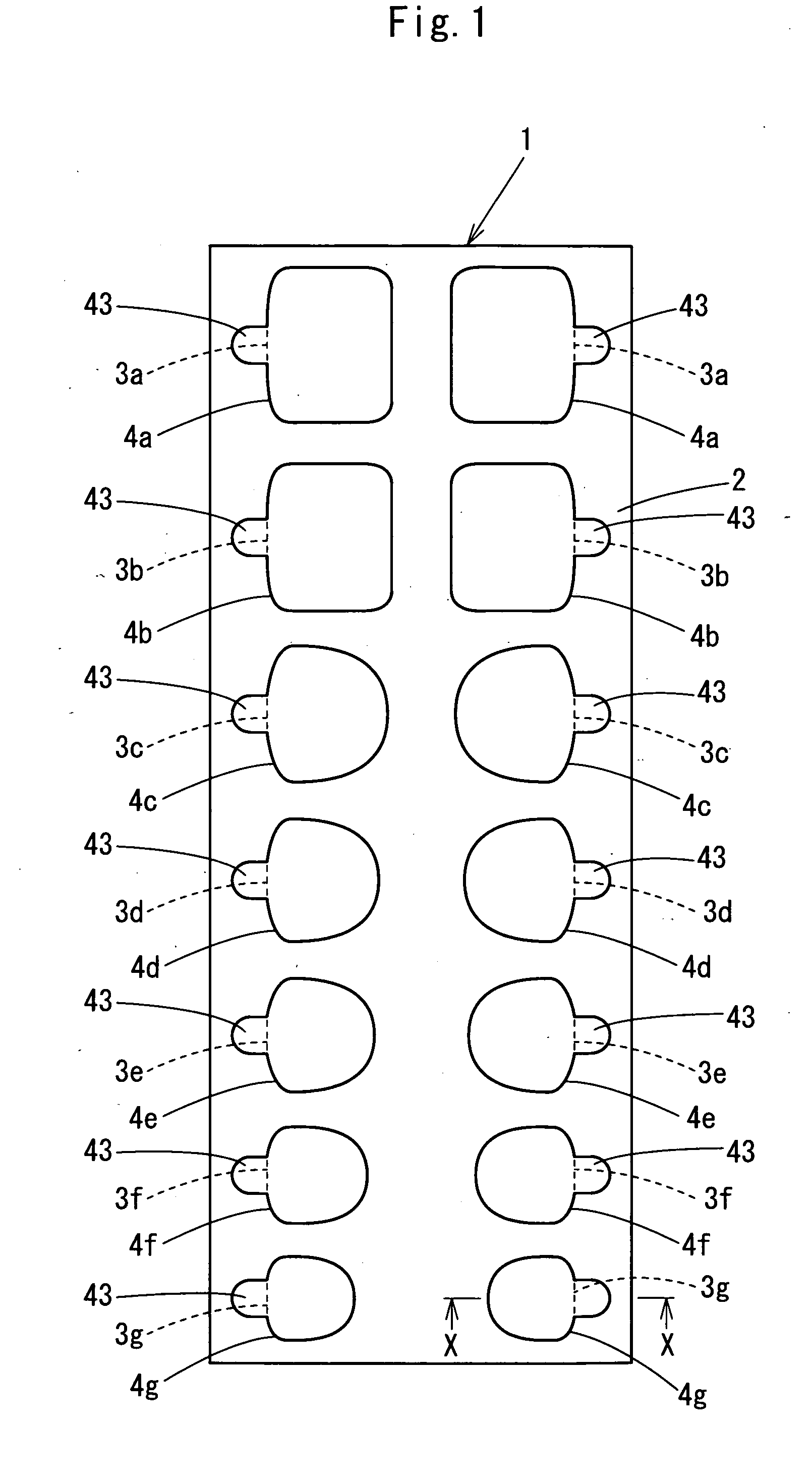

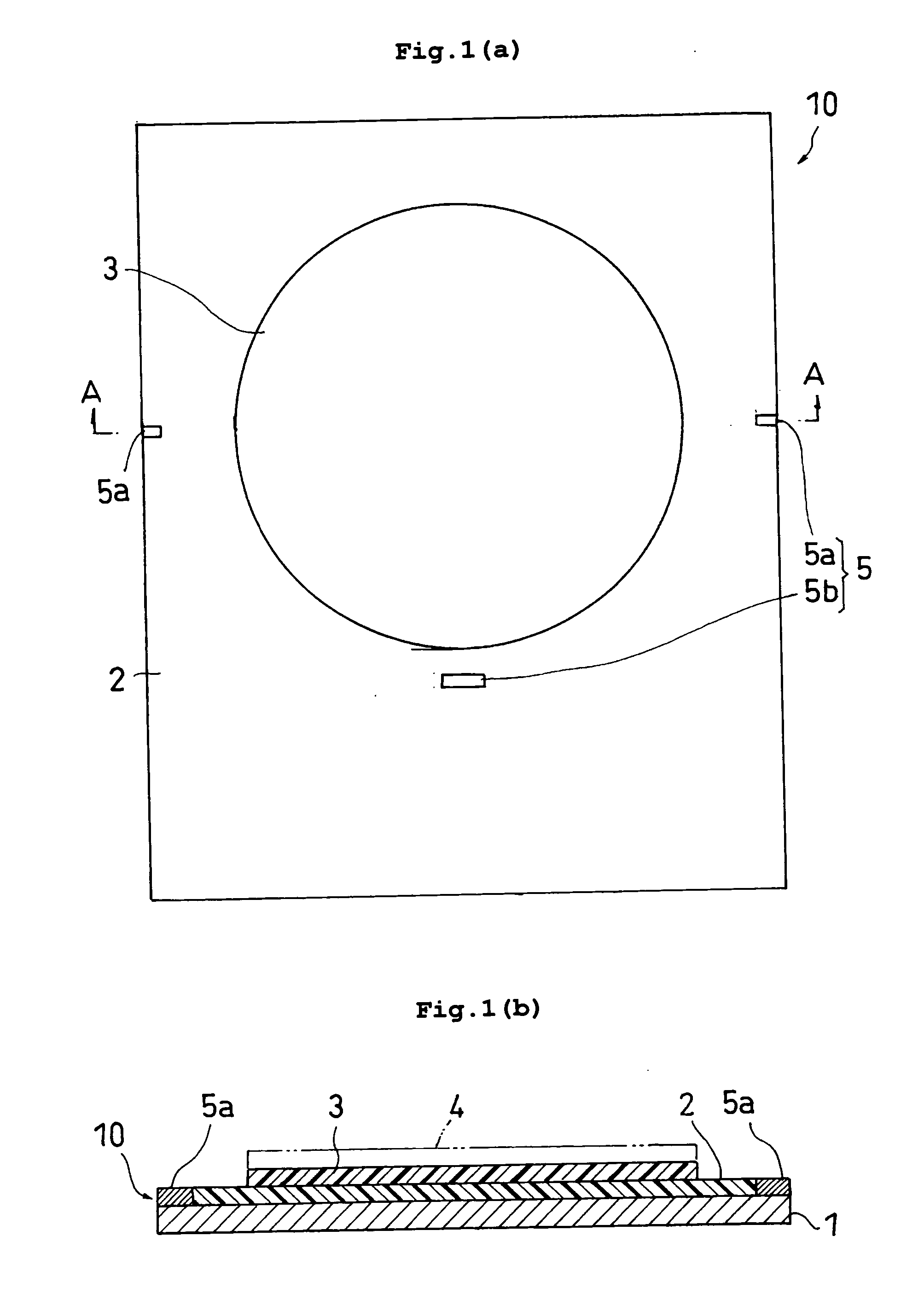

Laminate body, method, and apparatus for manufacturing ultrathin substrate using the laminate body

ActiveUS7534498B2Easy to peelNot to damageDiffusion transfer processesPhotosensitive materialsPhotothermal conversionEngineering

Provided is a laminated body (1) comprising a substrate (2) to be ground and a support (5), where the substrate (2) is ground to a very small thickness and can then be separated from the support (5) without damaging the substrate (2). One embodiment of the present invention is a laminated body (1) comprising a substrate (2) to be ground, a joining layer (3) in contact with the substrate (2) to be ground, a photothermal conversion layer (4) comprising a light absorbing agent and a heat decomposable resin, and a light transmitting support (5). After grinding the substrate surface which is opposite that in contact with the joining layer (3), the laminated body (1) is irradiated through the light transmitting support (5) and the photothermal conversion layer (4) decomposes to separate the substrate (2) and the light transmitting support (5).

Owner:3M INNOVATIVE PROPERTIES CO

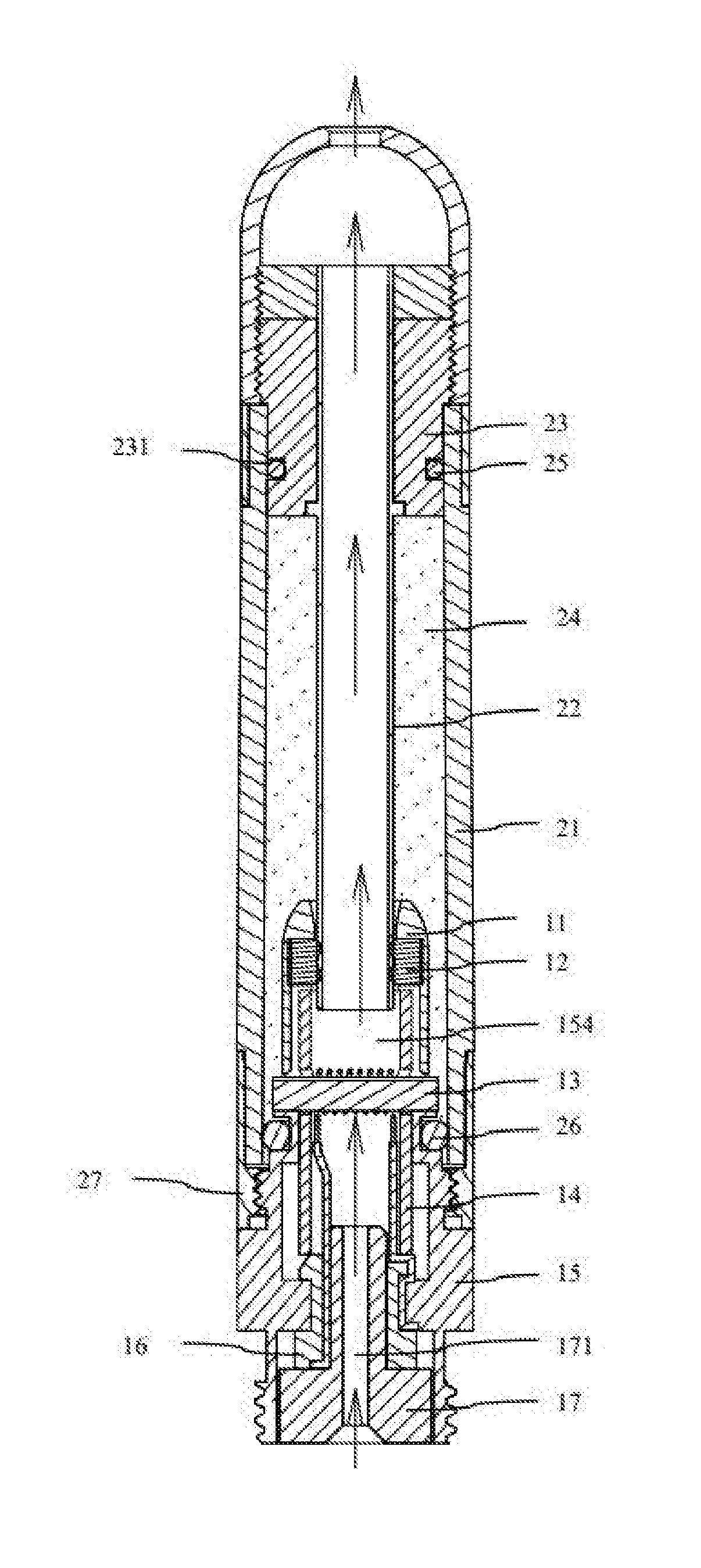

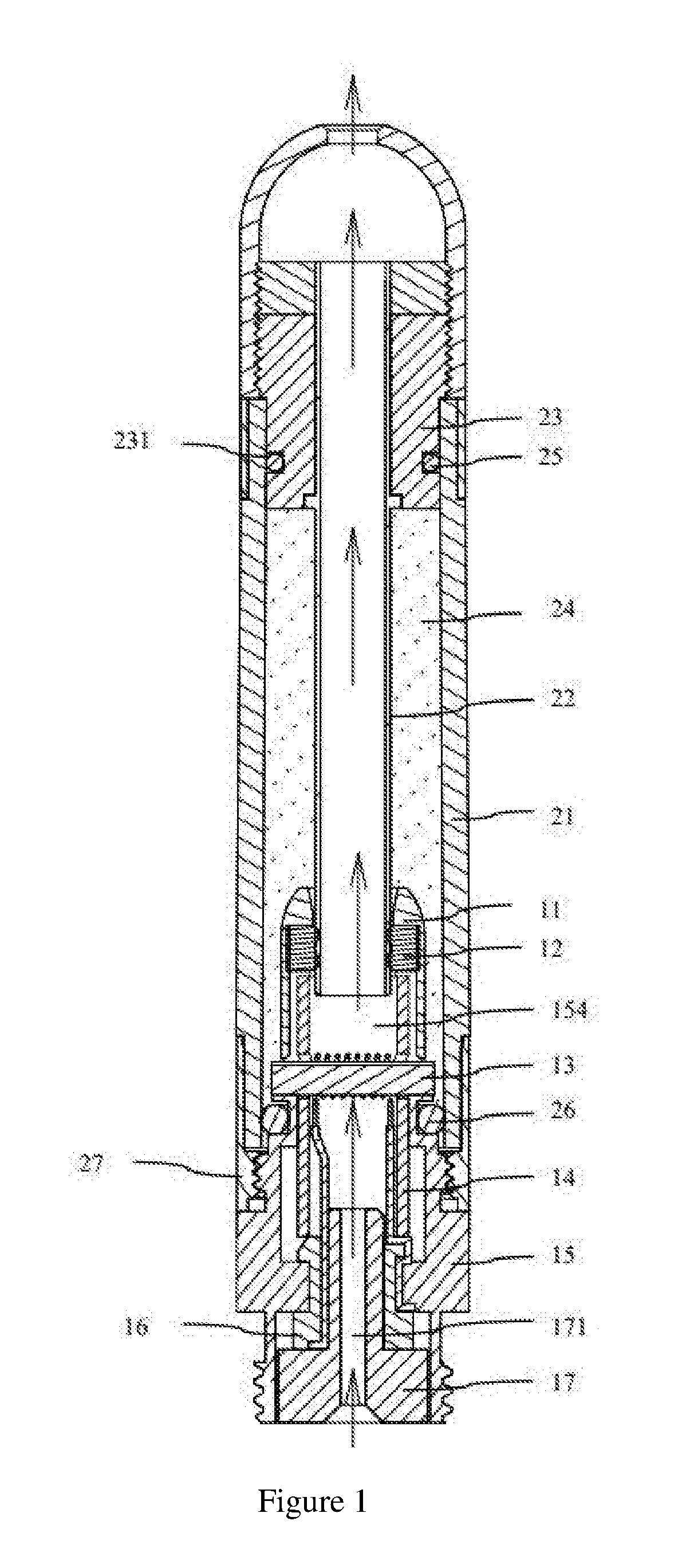

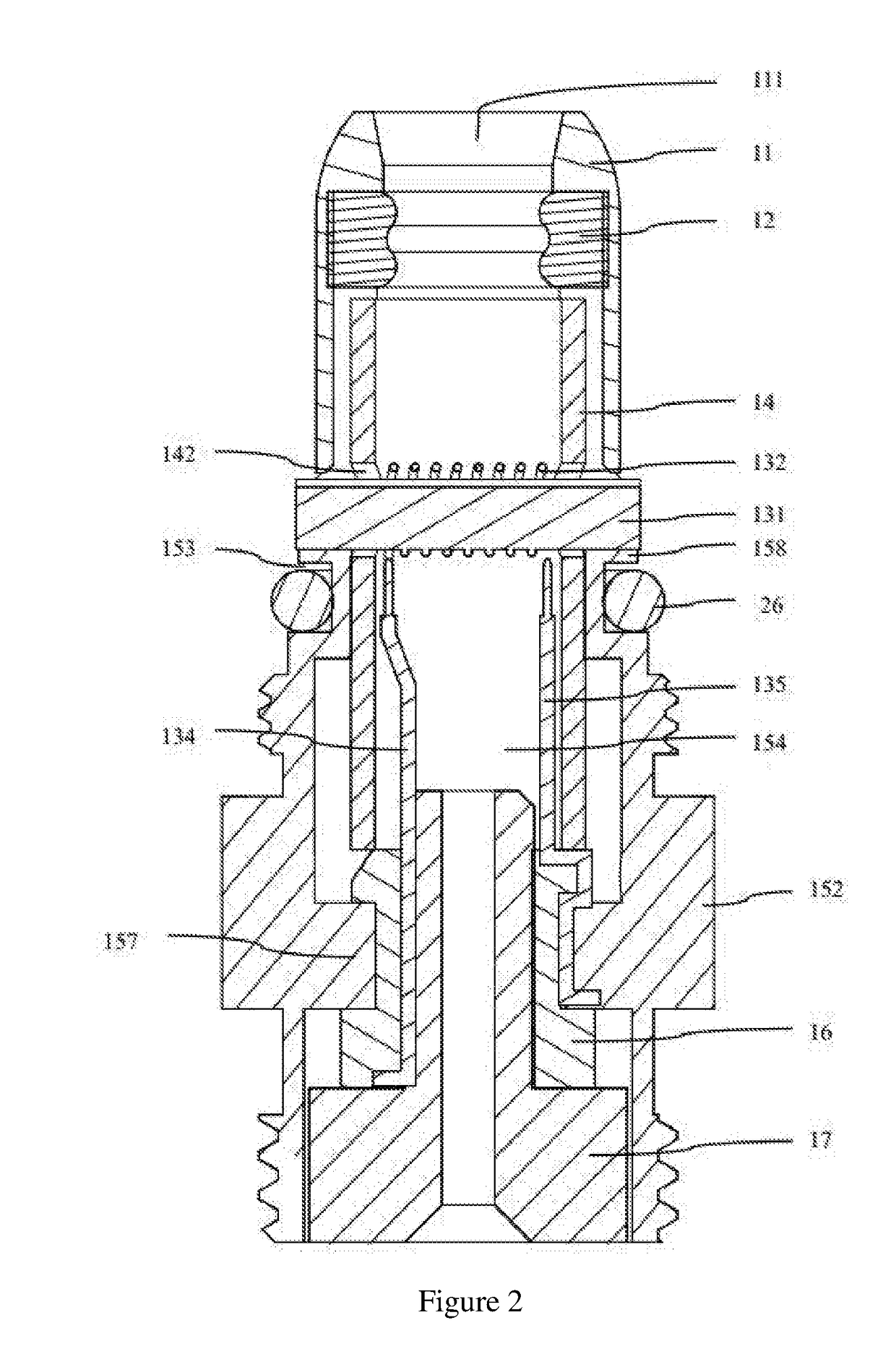

Vaporization assembly and electronic cigarette

InactiveUS20170295846A1Avoid heatingAvoid instabilitySteam generation heating methodsTobacco devicesEngineeringElectronic cigarette

The invention relates to a vaporization assembly and an electronic cigarette; the vaporization assembly comprises an e-liquid cup assembly and a vaporization core arranged in the e-liquid cup assembly; the e-liquid cup assembly has an e-liquid storage chamber used for accommodating e-liquid; the vaporization core comprises a vaporization base and an electric heating wire assembly; the vaporization base is internally provided with a smoke passageway used for providing passage to the smoke produced by vaporization; the electric heating wire assembly is arranged on the smoke passageway; the electric heating wire assembly comprises an electric heating wire used for heating and vaporizing the e-liquid; the vaporization core comprises an insulating tube used for isolating the vaporization base from the electric heating wire; the insulating tube is interposed in the vaporization base, and supports the electric heating wire along the length of the vaporization base.

Owner:HUIZHOU KIMREE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com