Patents

Literature

529 results about "Composite construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite construction is a generic term to describe any building construction involving multiple dissimilar materials. Composite construction is often used in building aircraft, watercraft, and building construction. There are several reasons to use composite materials including increased strength, aesthetics, and environmental sustainability.

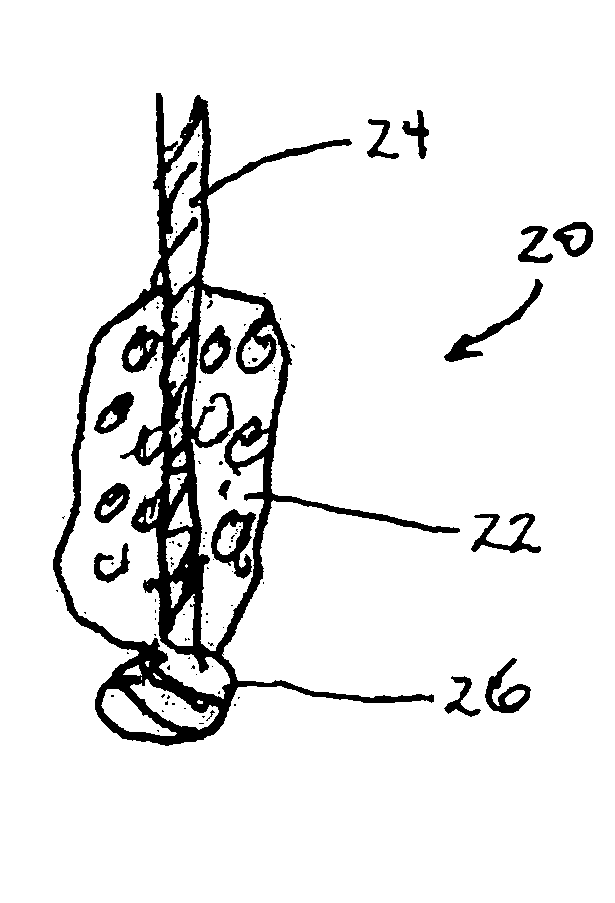

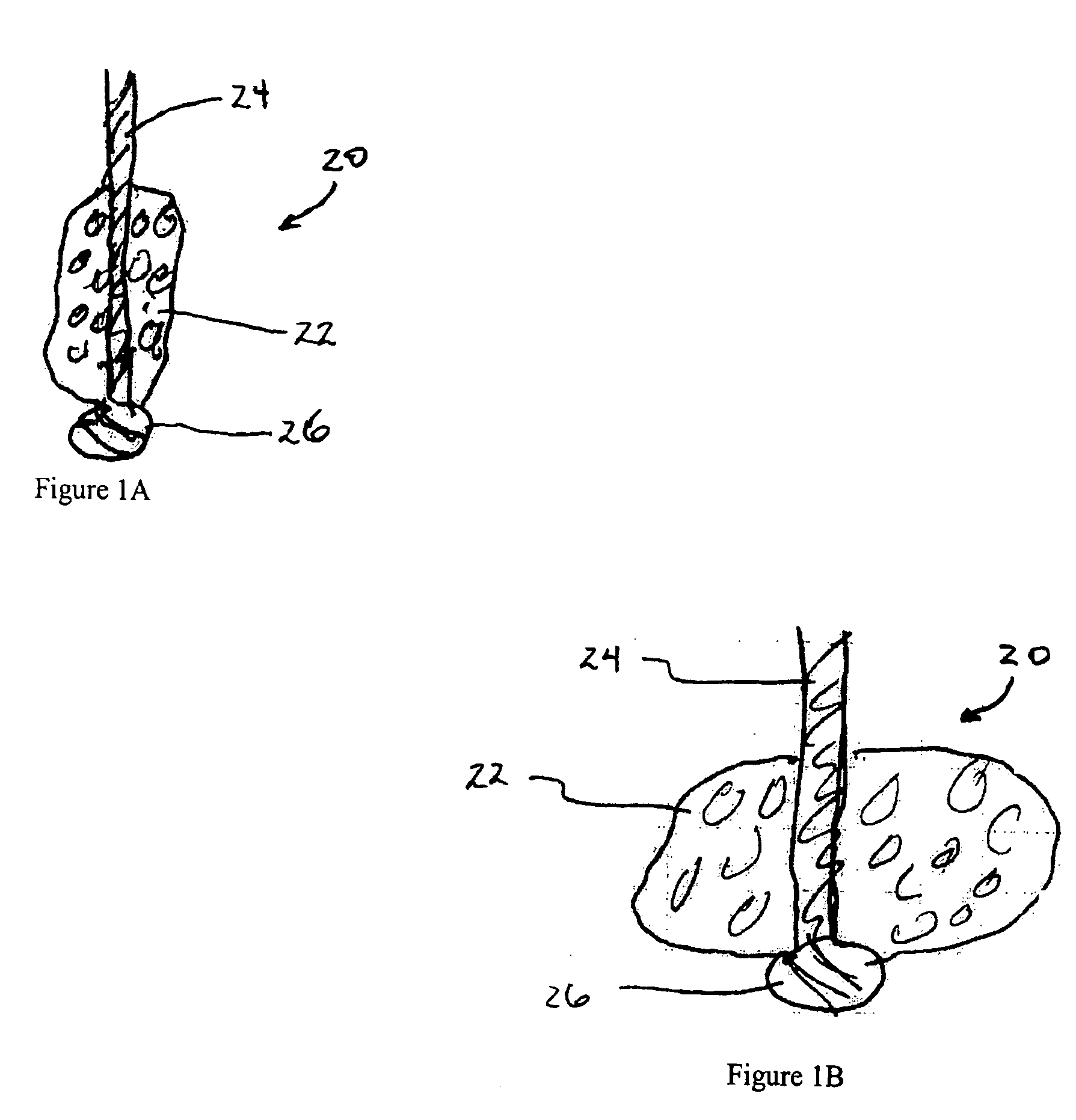

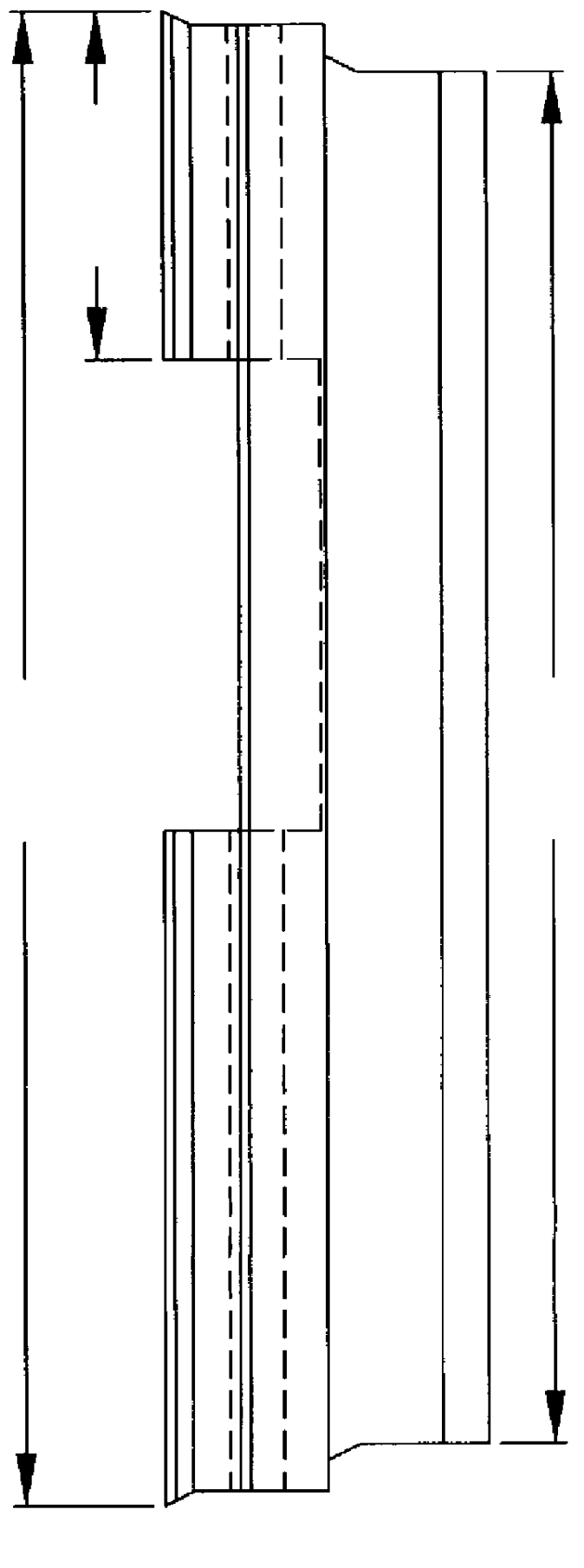

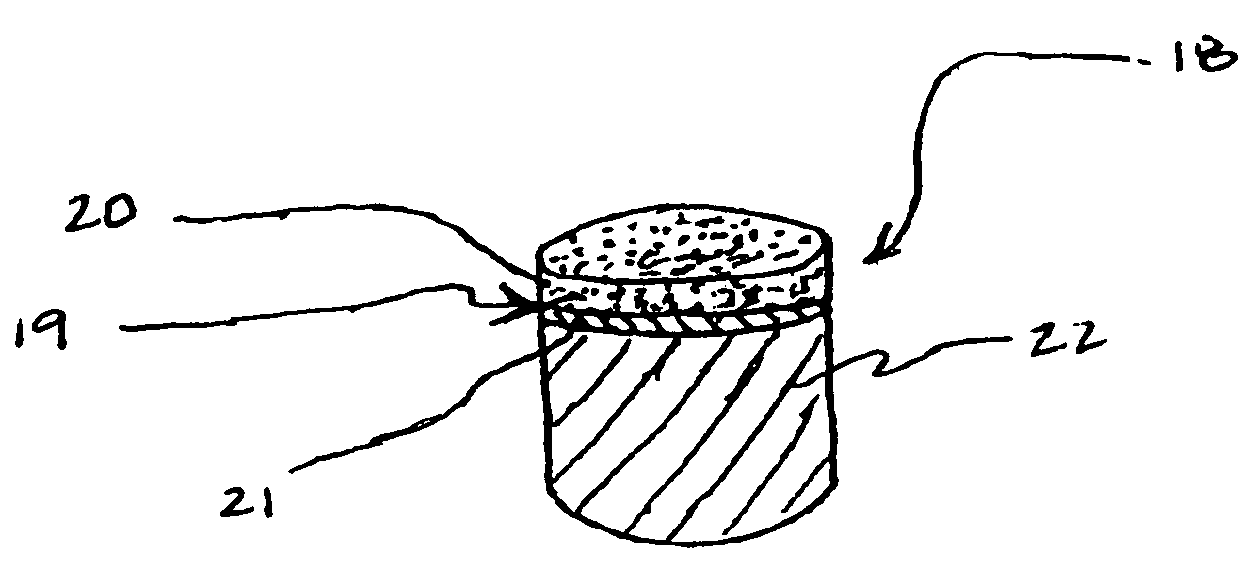

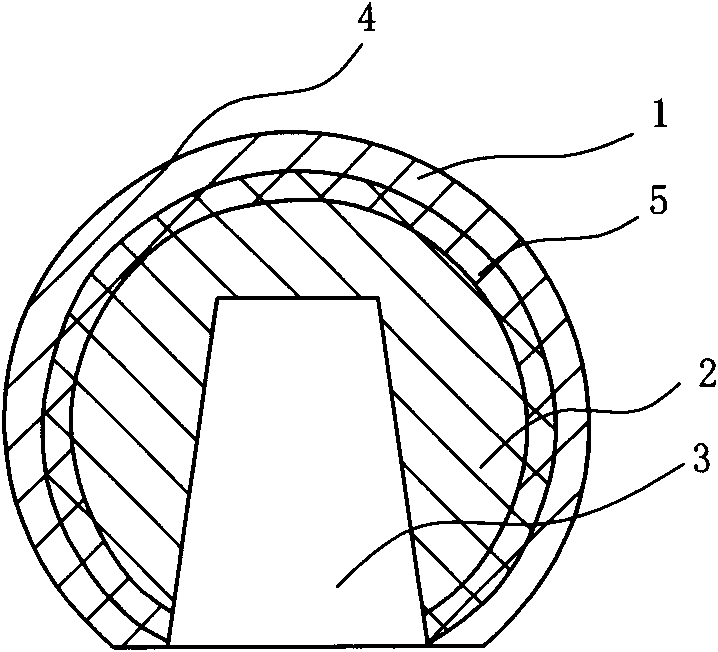

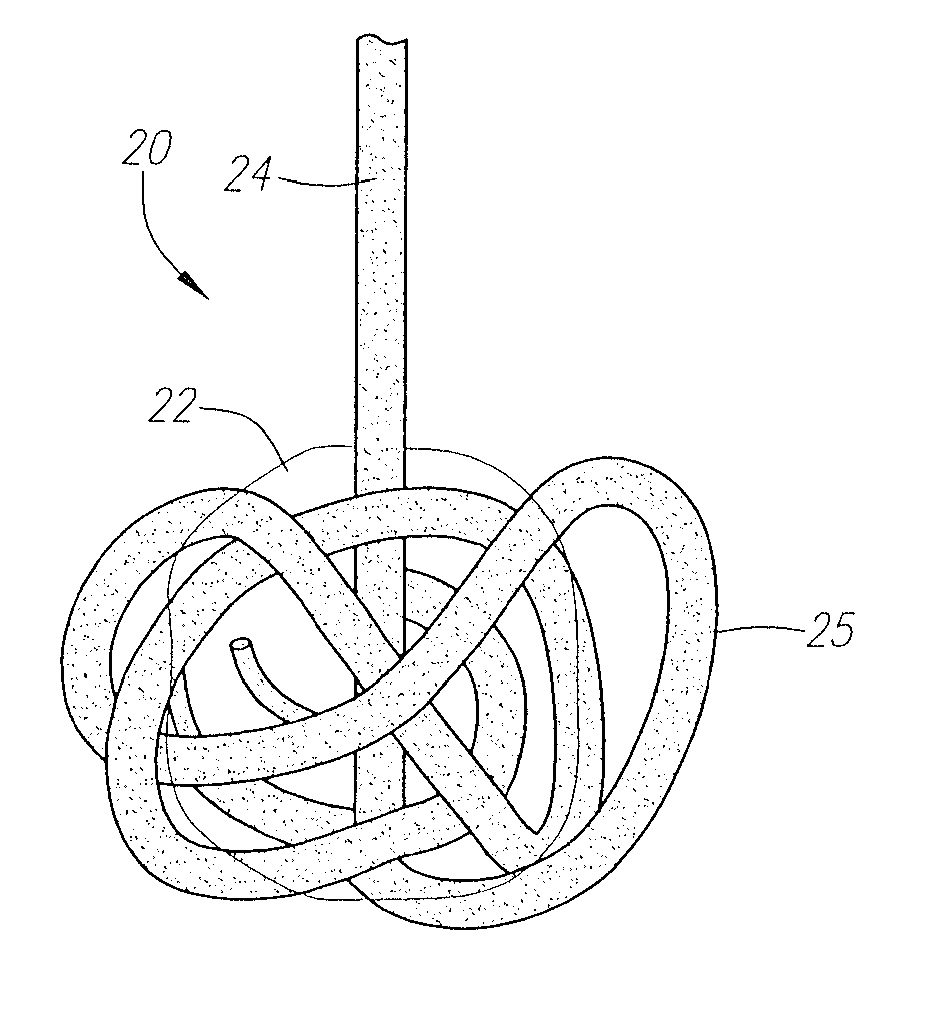

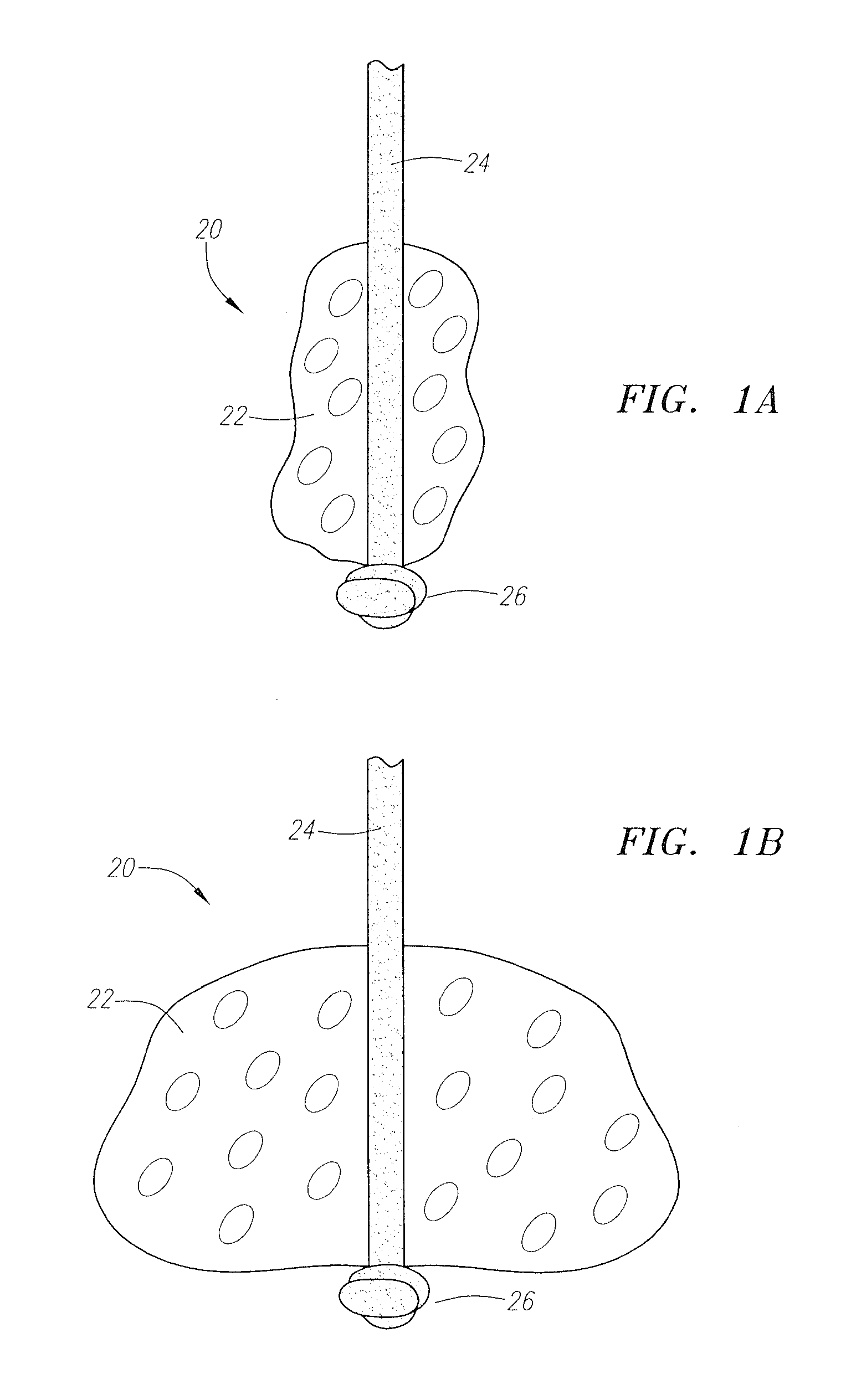

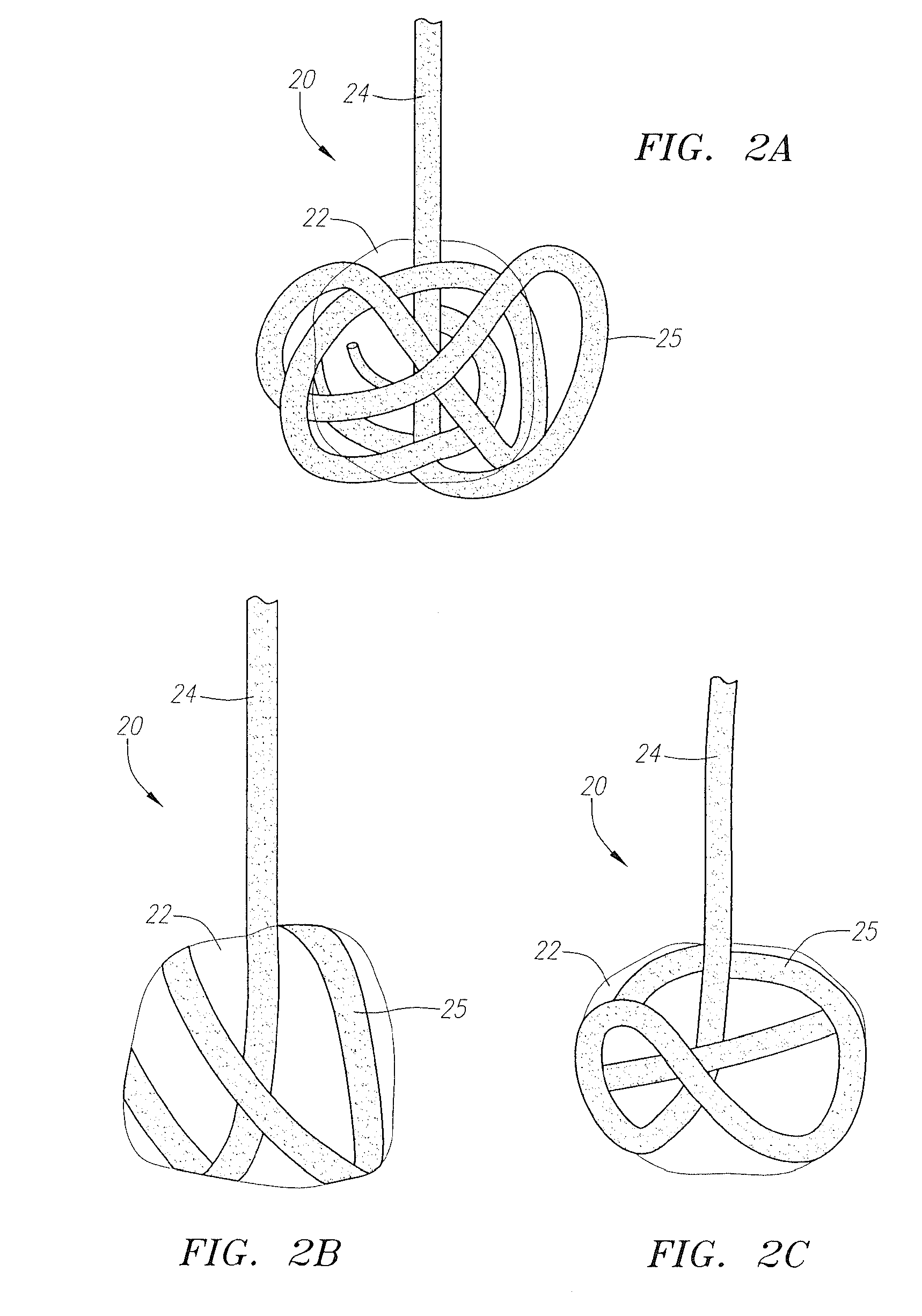

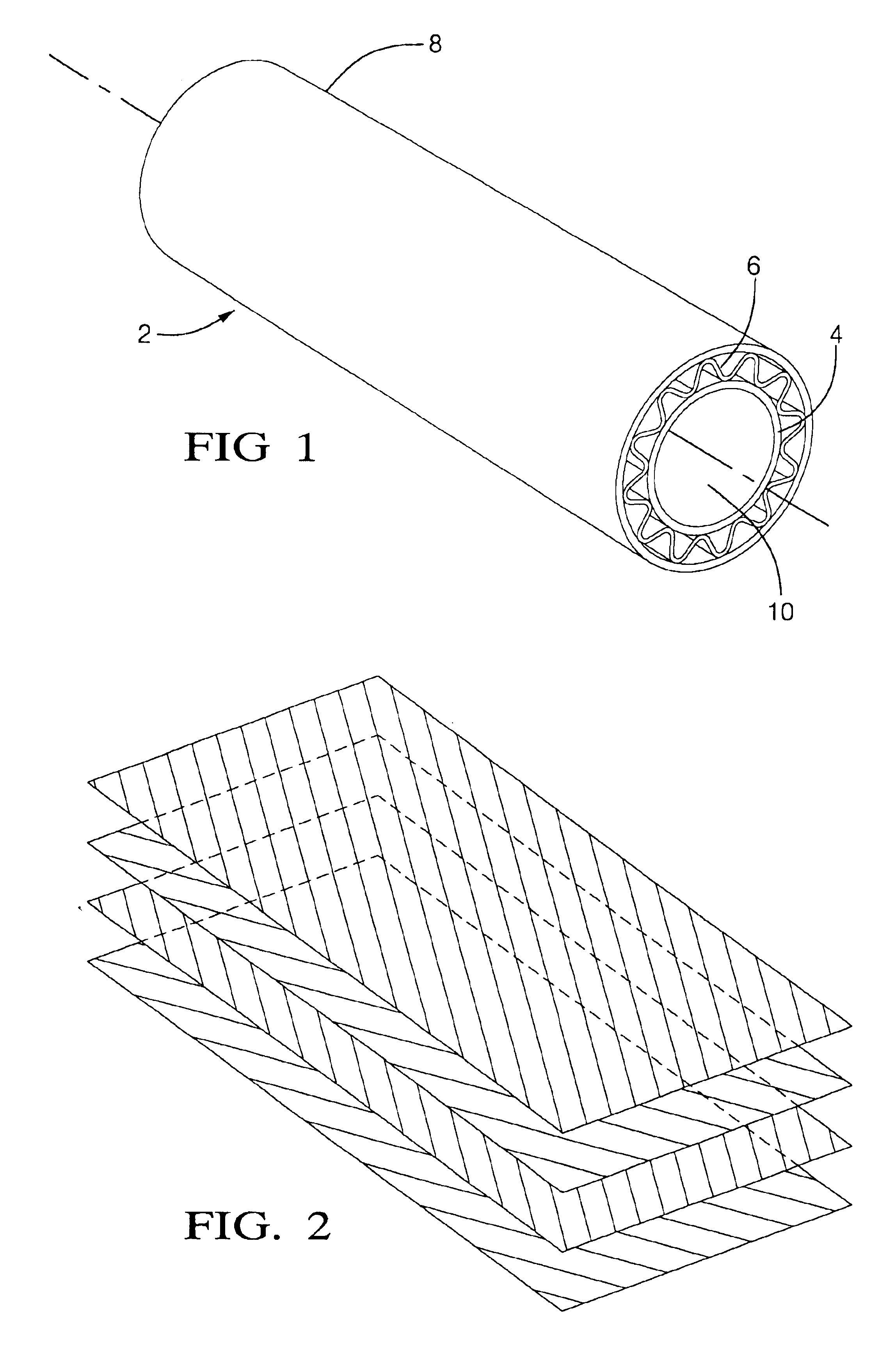

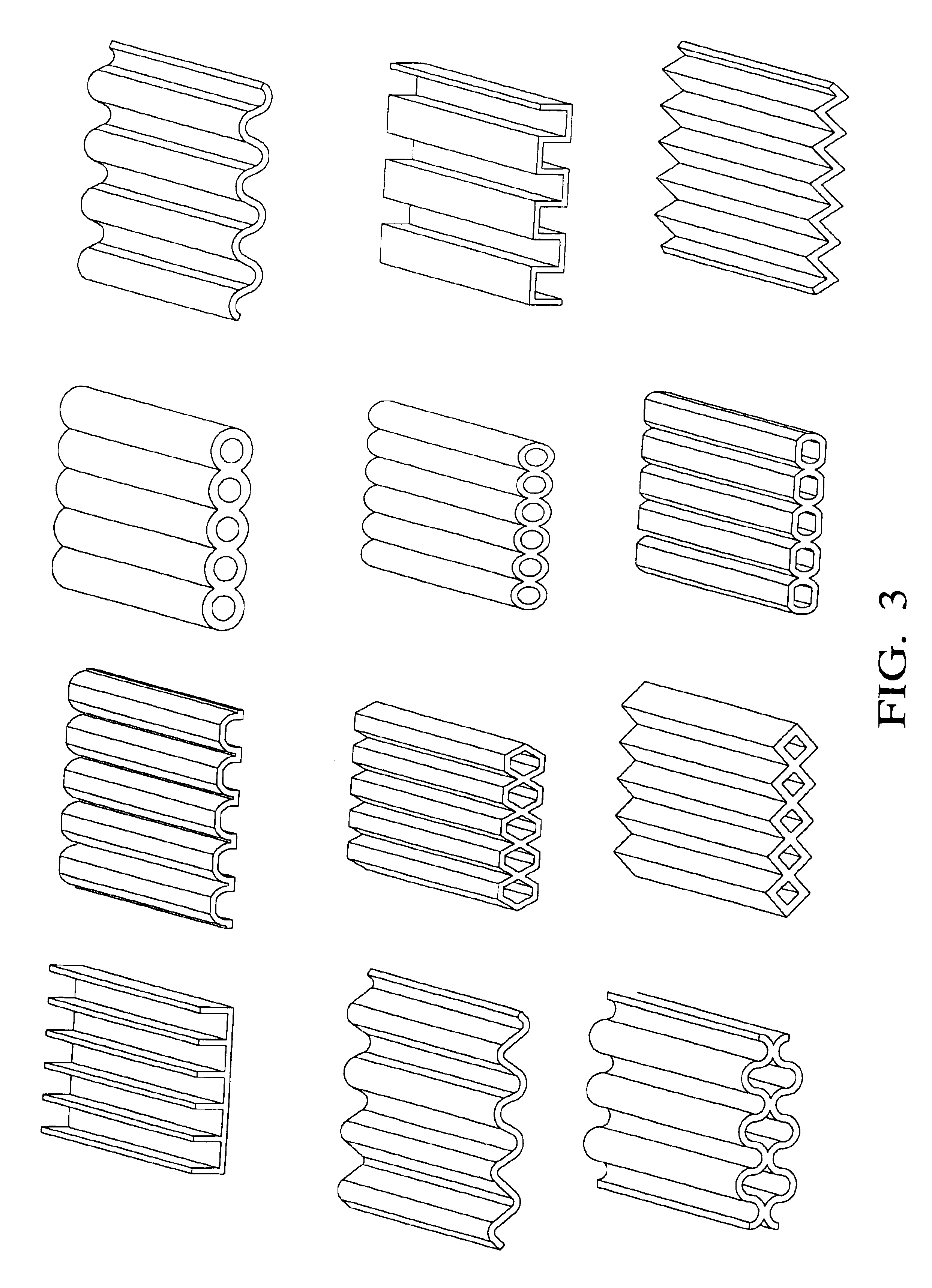

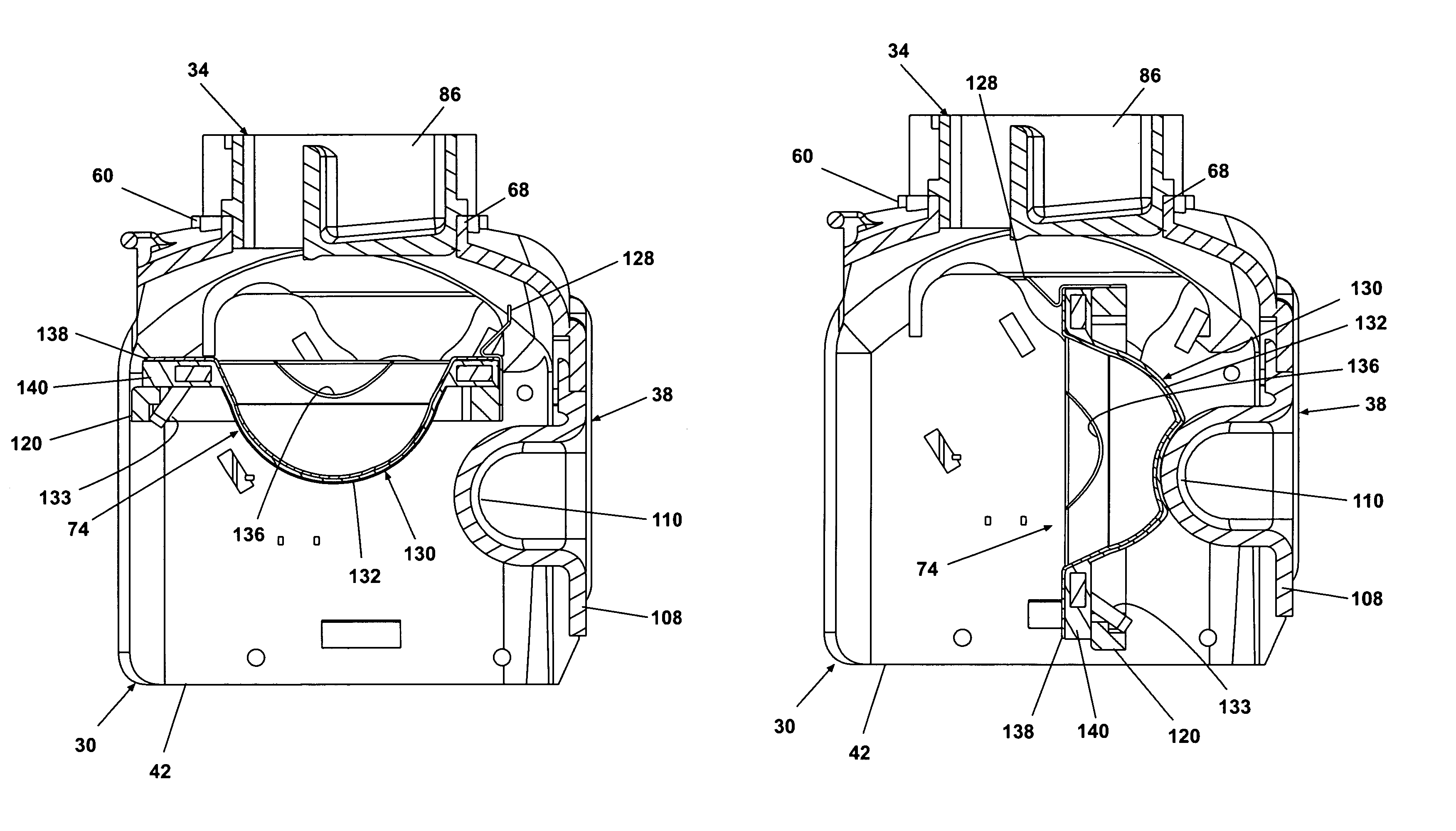

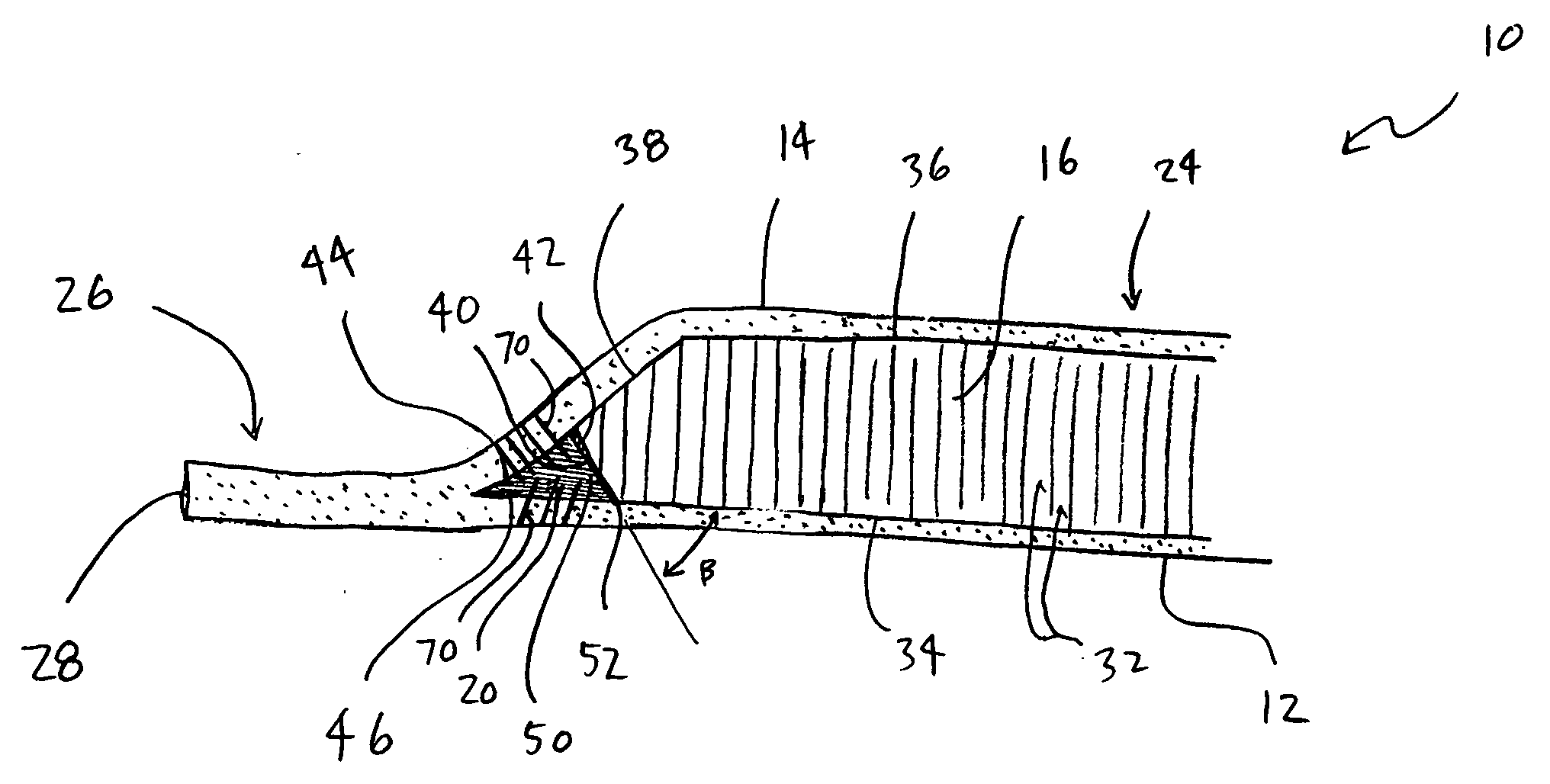

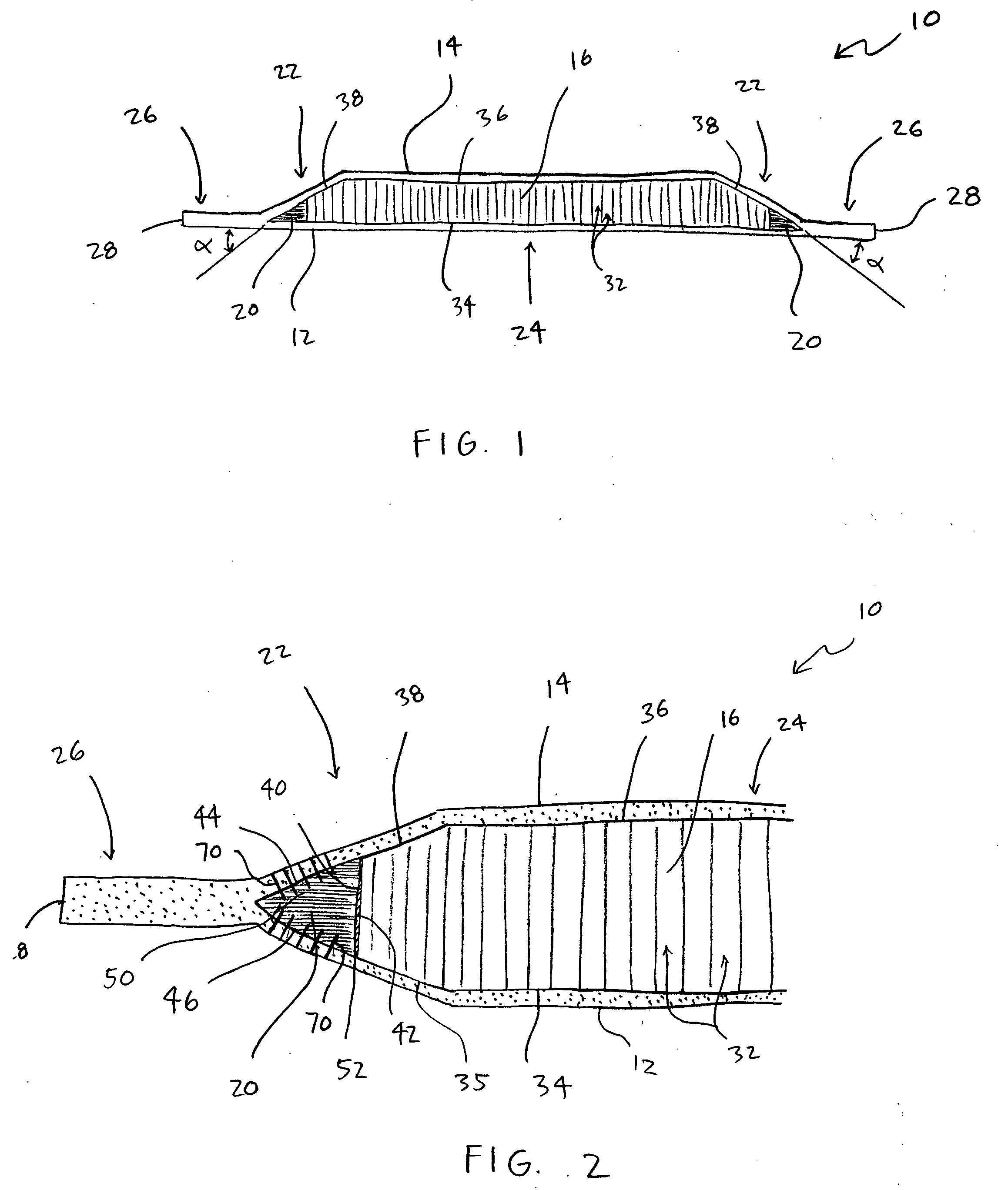

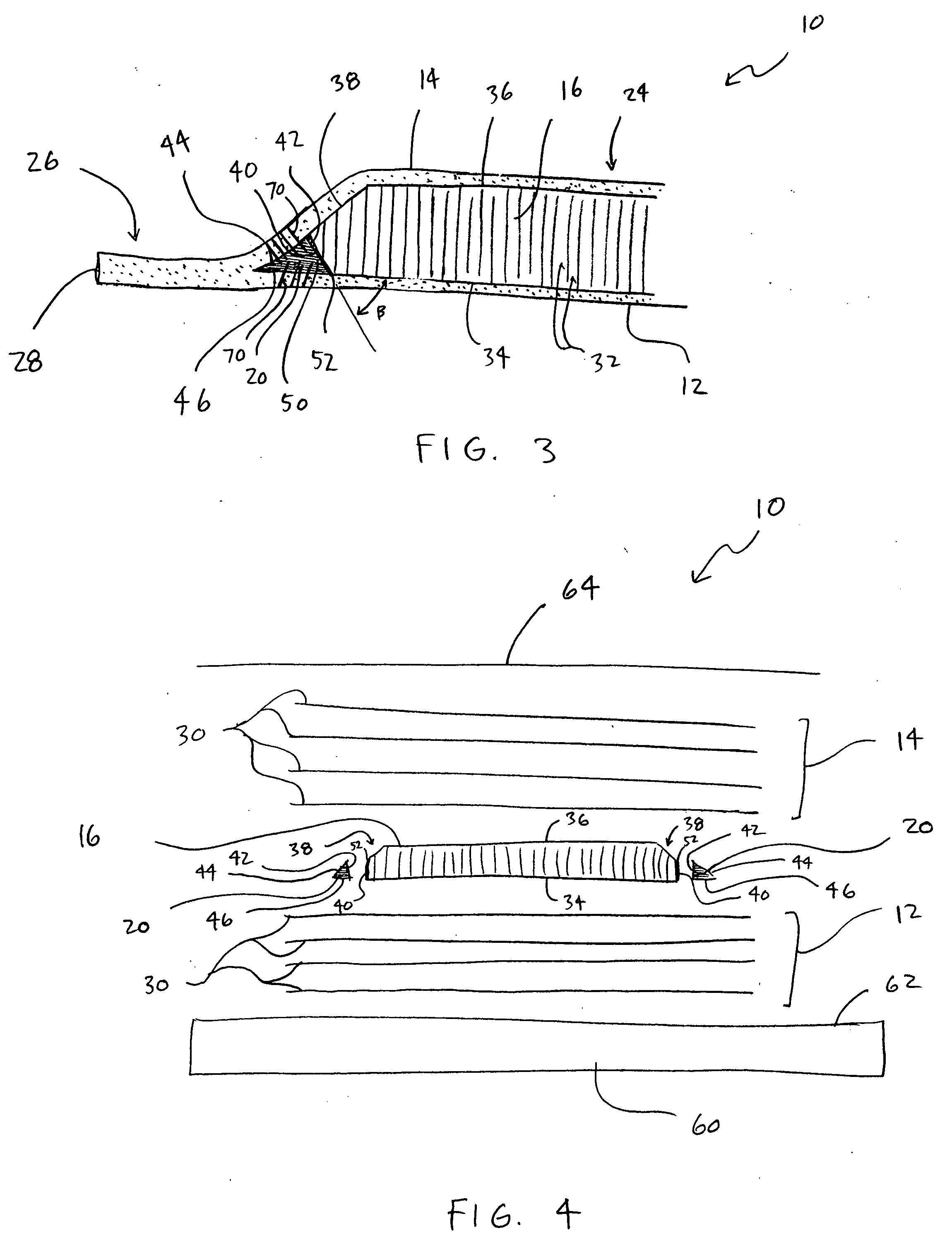

Vascular plug having composite construction

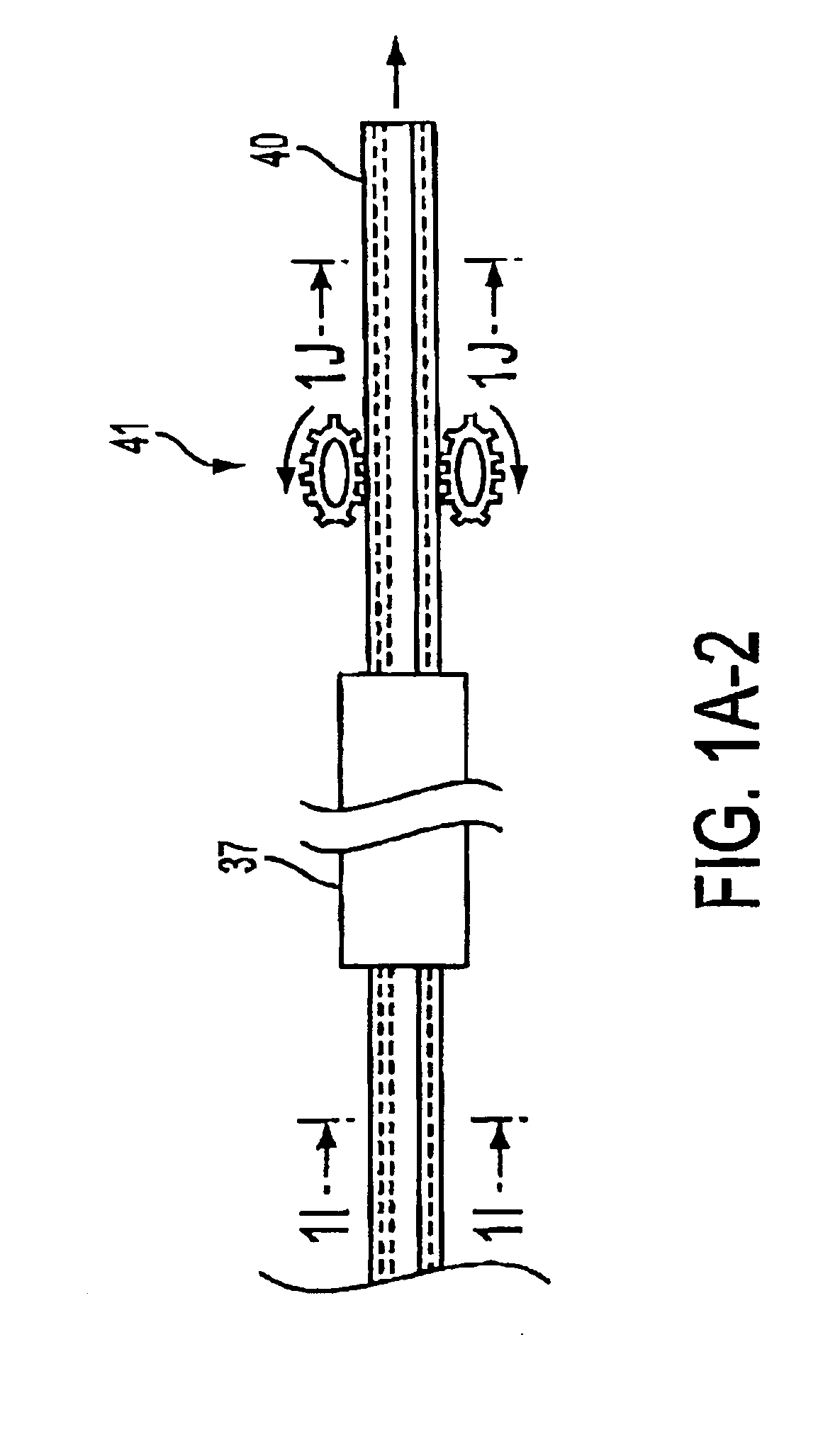

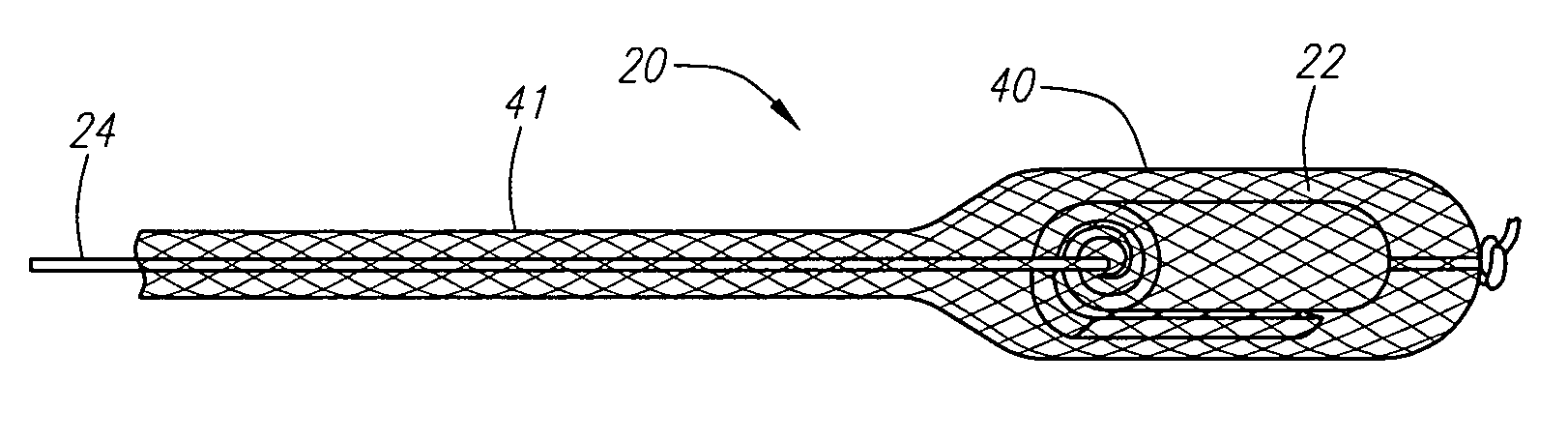

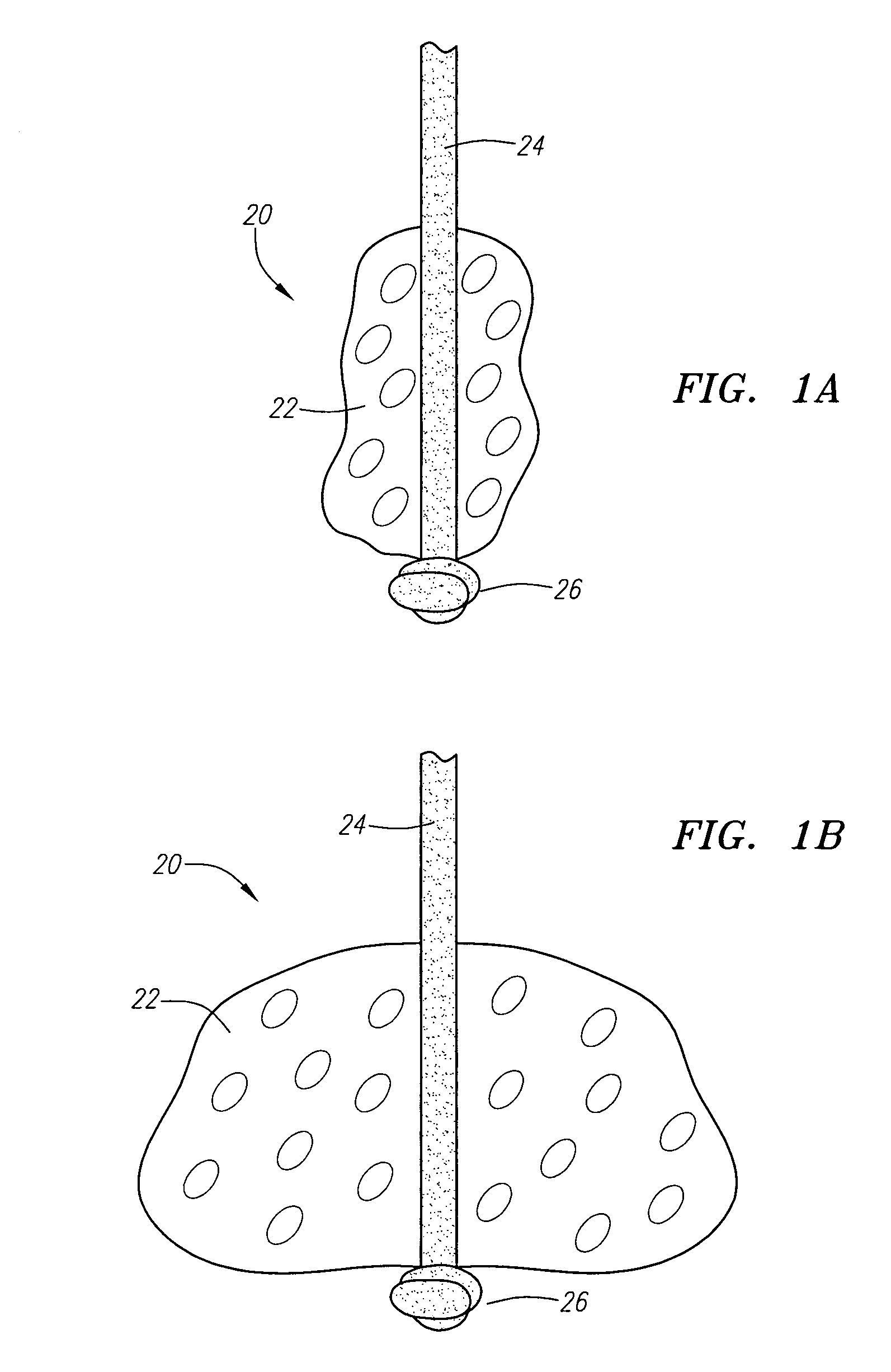

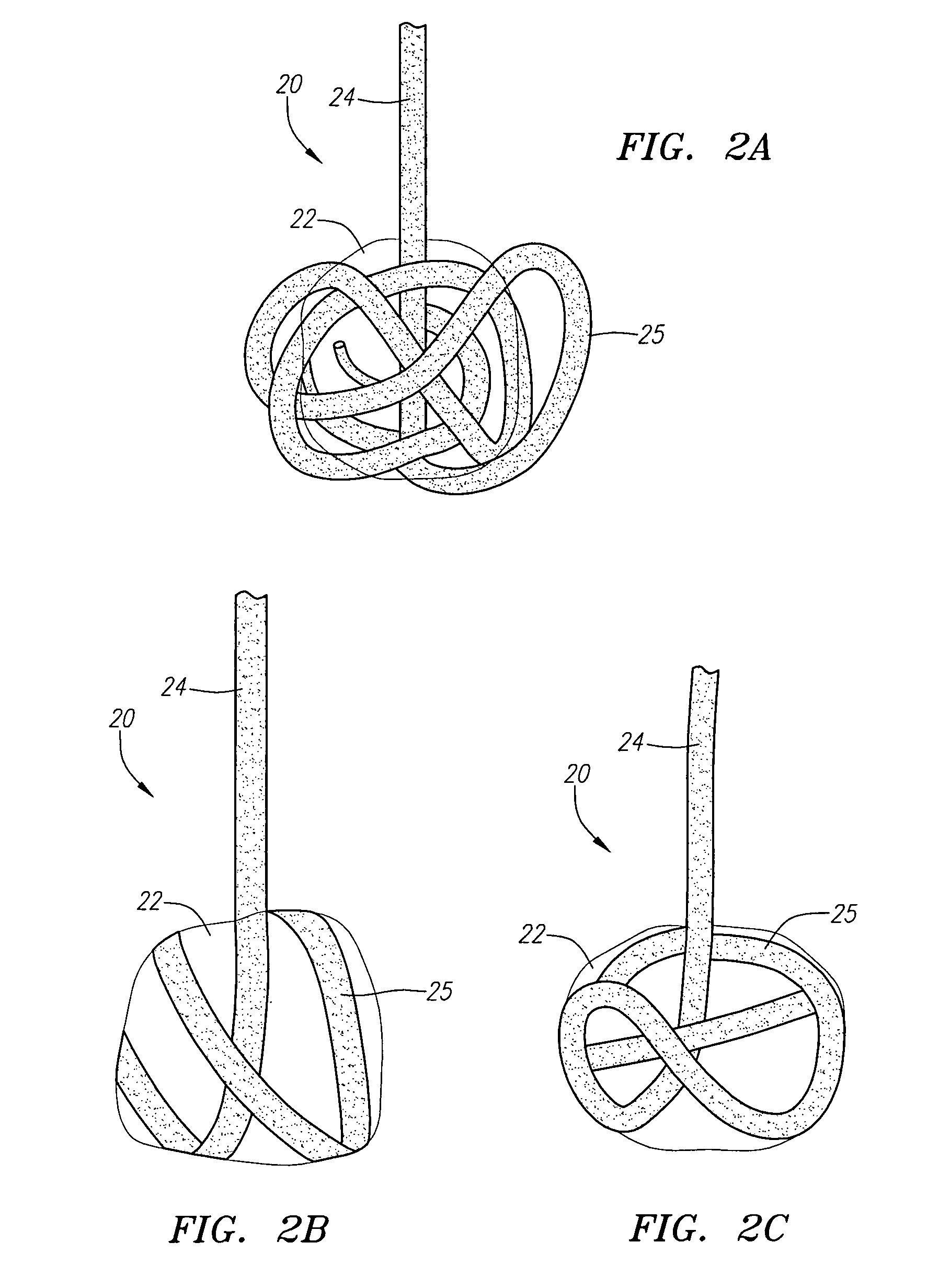

InactiveUS20050267528A1Increasing effective radial dimensionReduce deliverySuture equipmentsOcculdersComposite constructionVascular plug

This invention relates to apparatus and methods for use in sealing a vascular puncture site, particularly sites of punctures that are the result of catheterization or other interventional procedures. In several of the preferred embodiments, the sealing device includes a sealing member and a tether. The sealing member generally performs the function of occupying a space in an incision, puncture, or other wound and sealing the space in the incision, puncture, or wound that it occupies, to prevent further blood flow. The tether is typically attached in some manner to the sealing member, and provides the user with the ability to withdraw the sealing member if necessary. In a particularly preferred form, the sealing device further includes a restraining member associated with the sealing member. The restraining member provides the ability to more securely restrain the sealing member to prevent it from migrating from the deployment location within a tissue tract. The restraining member may also provide an additional capability of manipulating the sealing member after deployment.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

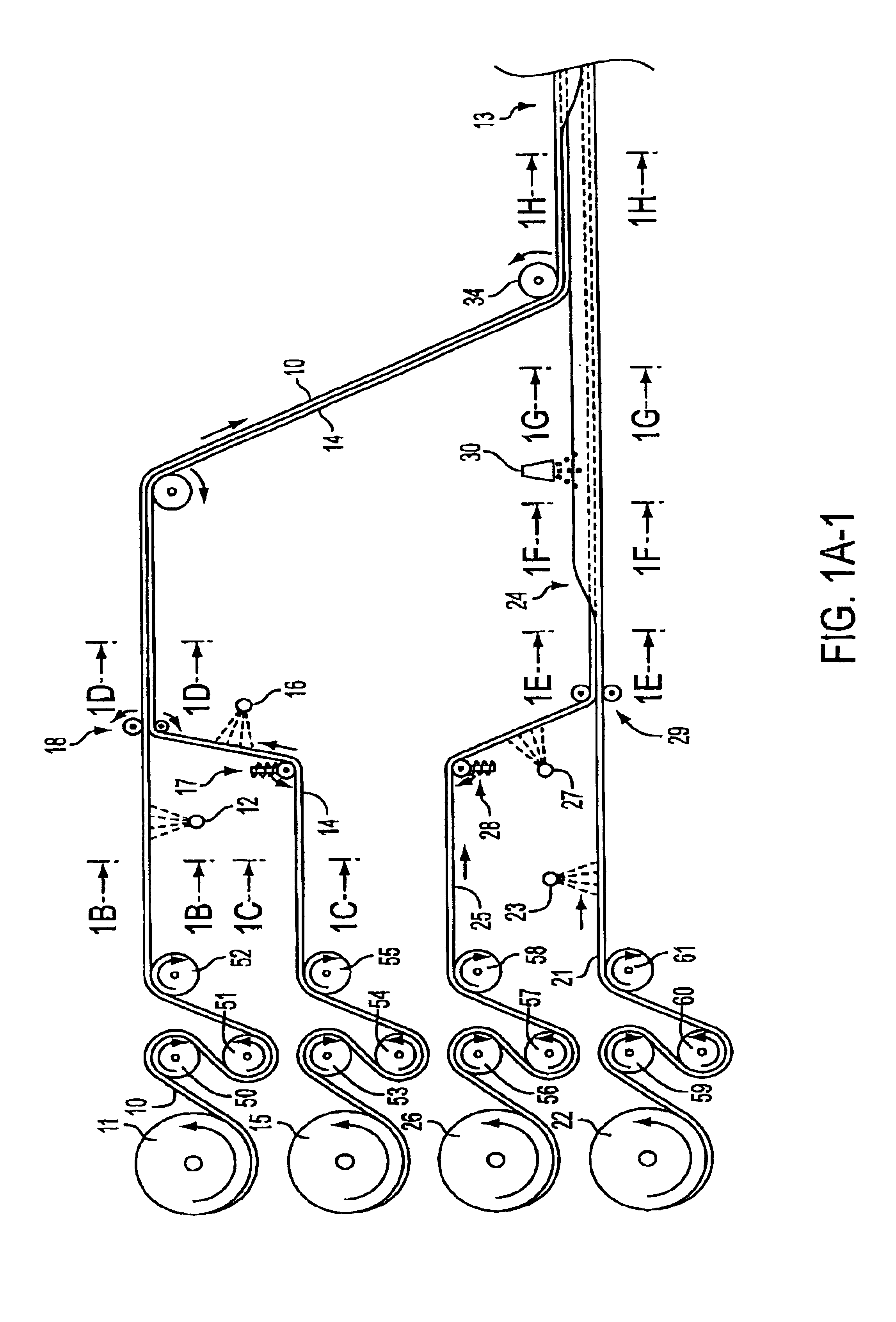

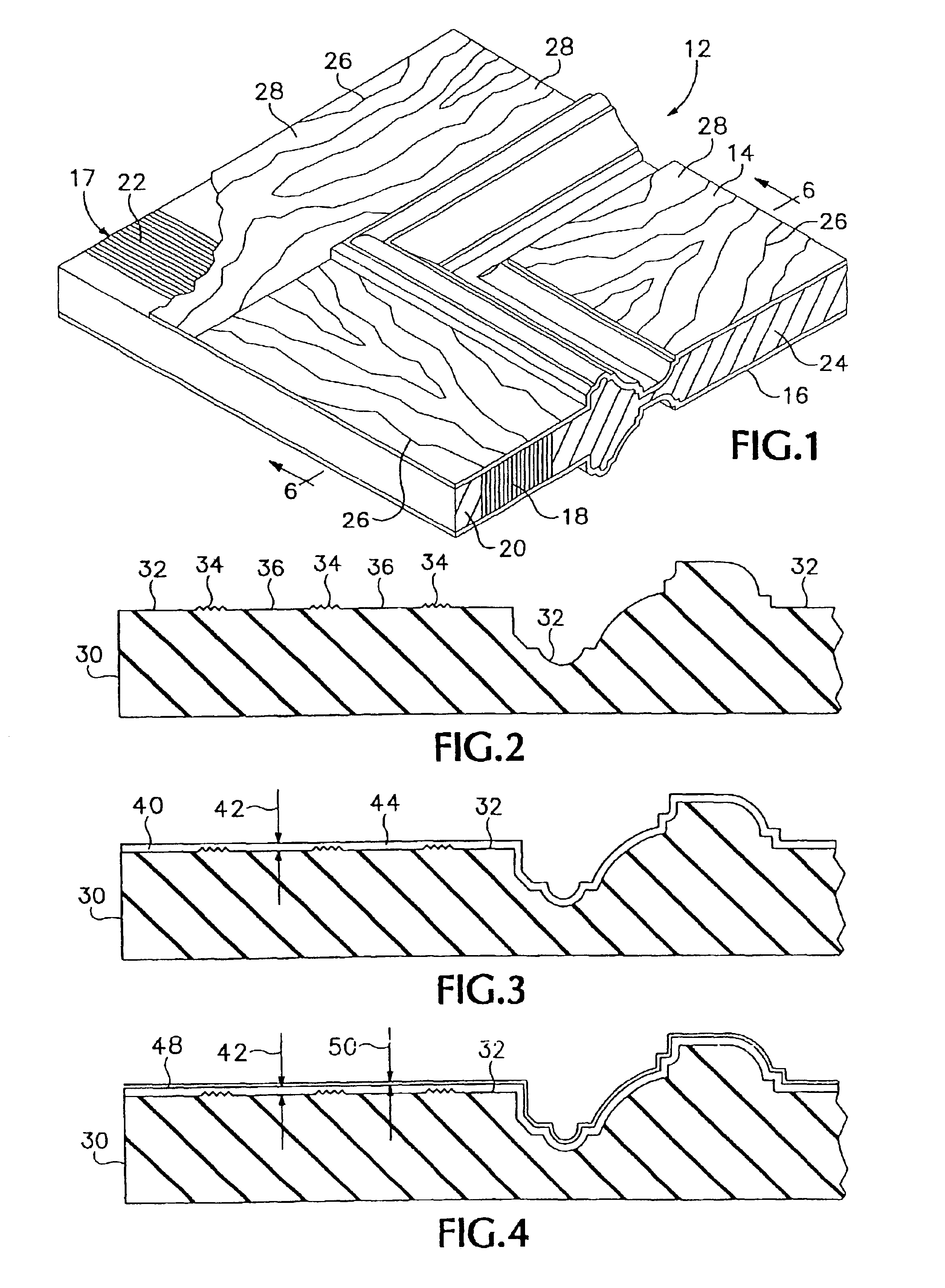

Foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6054207AHigh compressive strengthImproved fastener retentionConstruction materialLoad-supporting elementsComposite constructionThermoplastic

Advanced structural components comprising a foamed thermoplastic that can be used in virtually any application where wooden components have a use. Such structural components can comprise sized lumber, shaped trim, posts, beams or shaped structural members. An advanced profile composite structural component comprising an exterior capping layer with an interior comprising a foamed thermoplastic can be used in the assembly of fenestration units adapted to residential and commercial structures. Preferably the profile structural component can be used in a window or door assembly. The profile member is adapted for ease of construction of the fenestration units, can be easily installed in a rough opening to framing members, and can be trimmed and adjusted on site. The profile is structurally strong, thermally stable, shrink resistant and will accept and retain the insertion of fasteners such as staples, nails and screws permanently with substantial retention and little or no damage to the units. The profile structural components possess strength that permits the manufacture of a structurally sound fenestration unit from two or more foamed profile members or other conventional members.

Owner:ANDERSEN CORPORATION

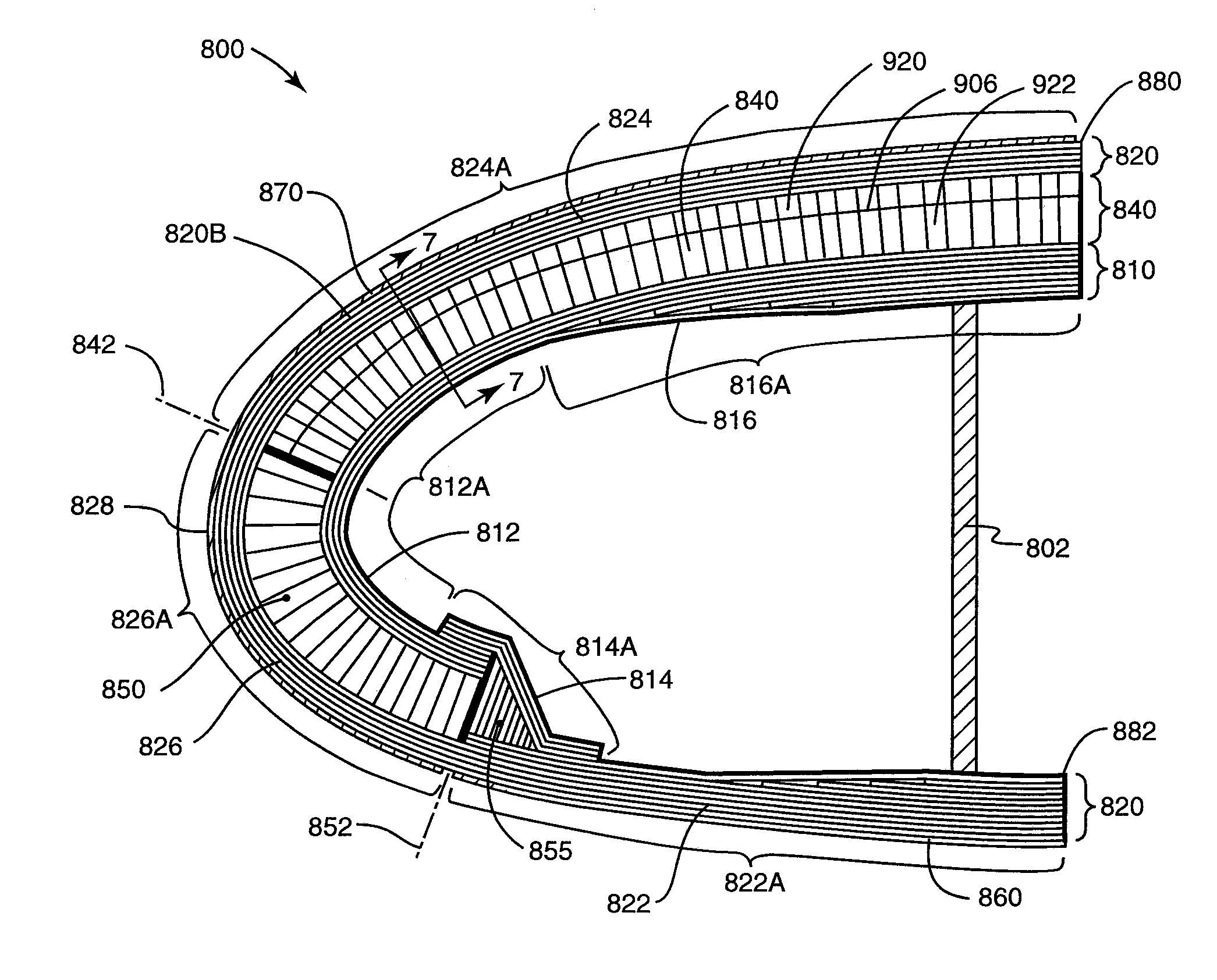

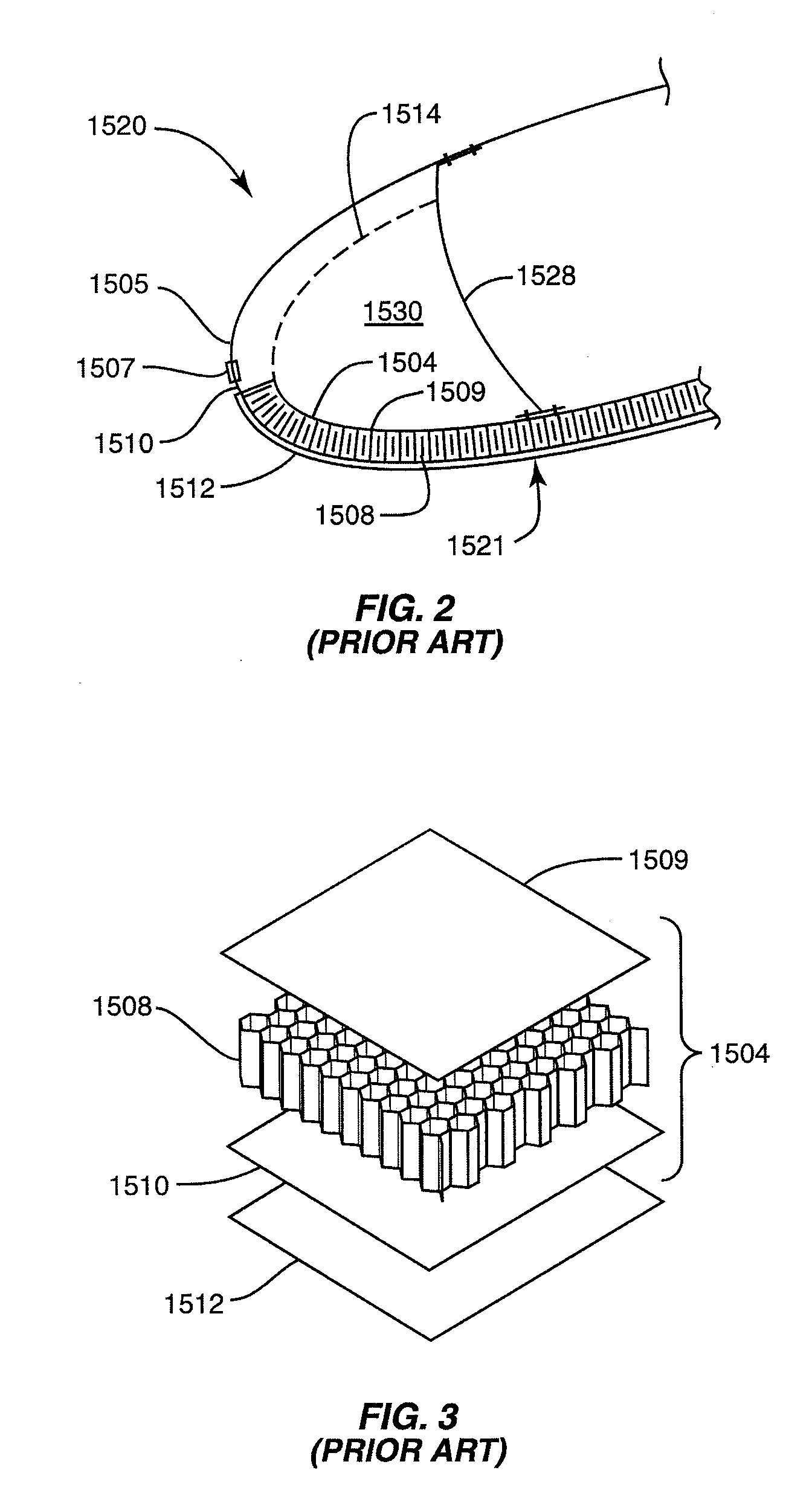

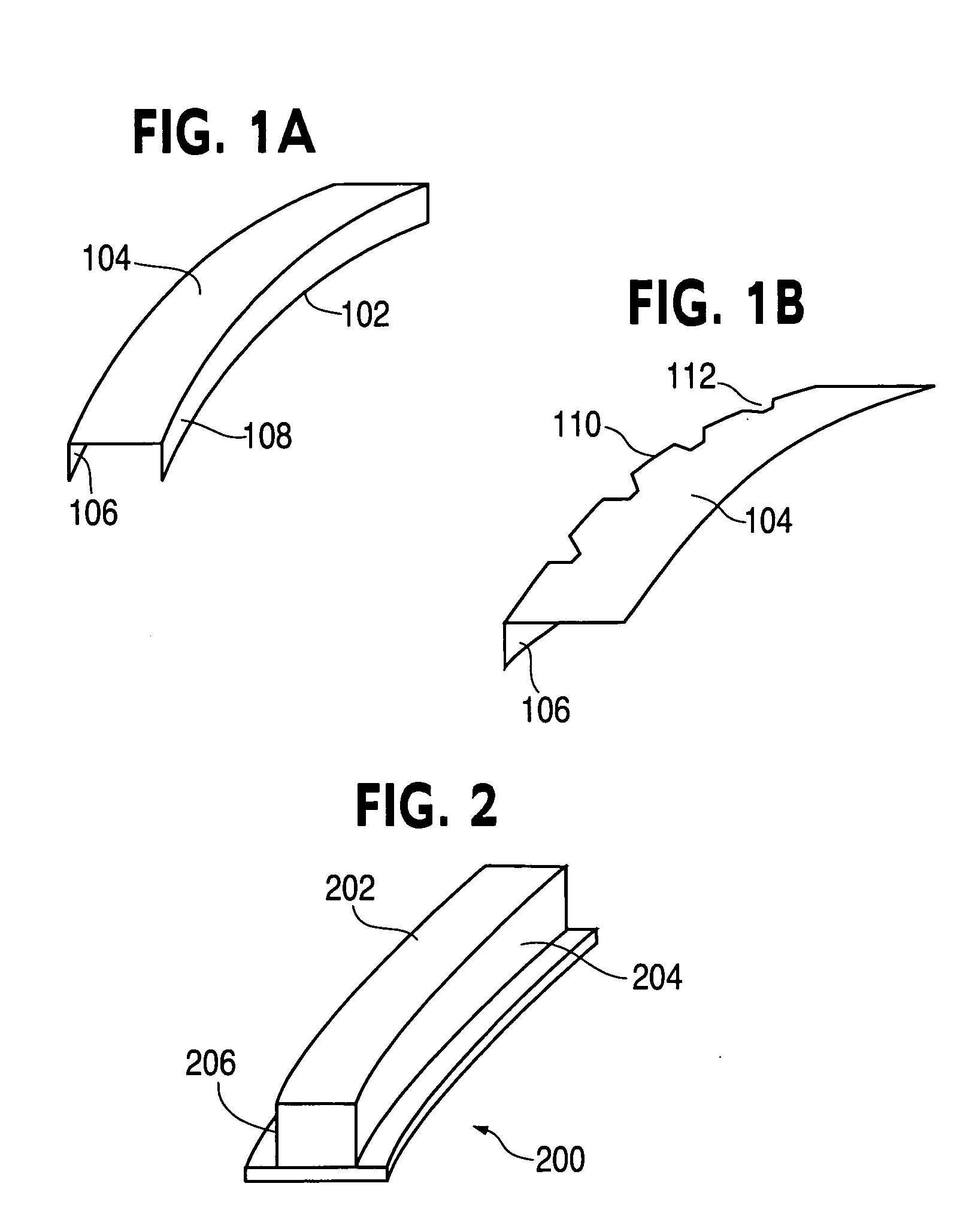

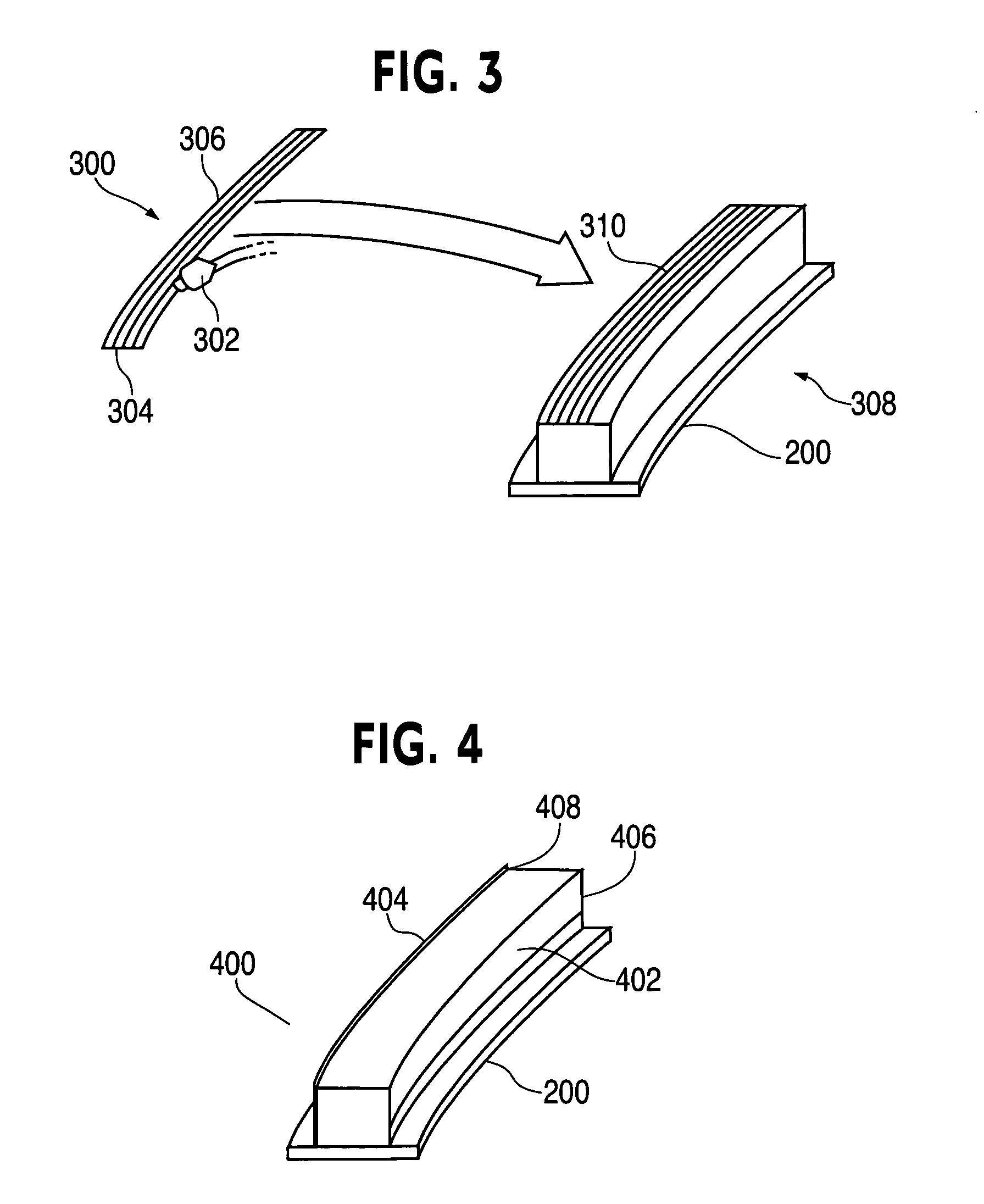

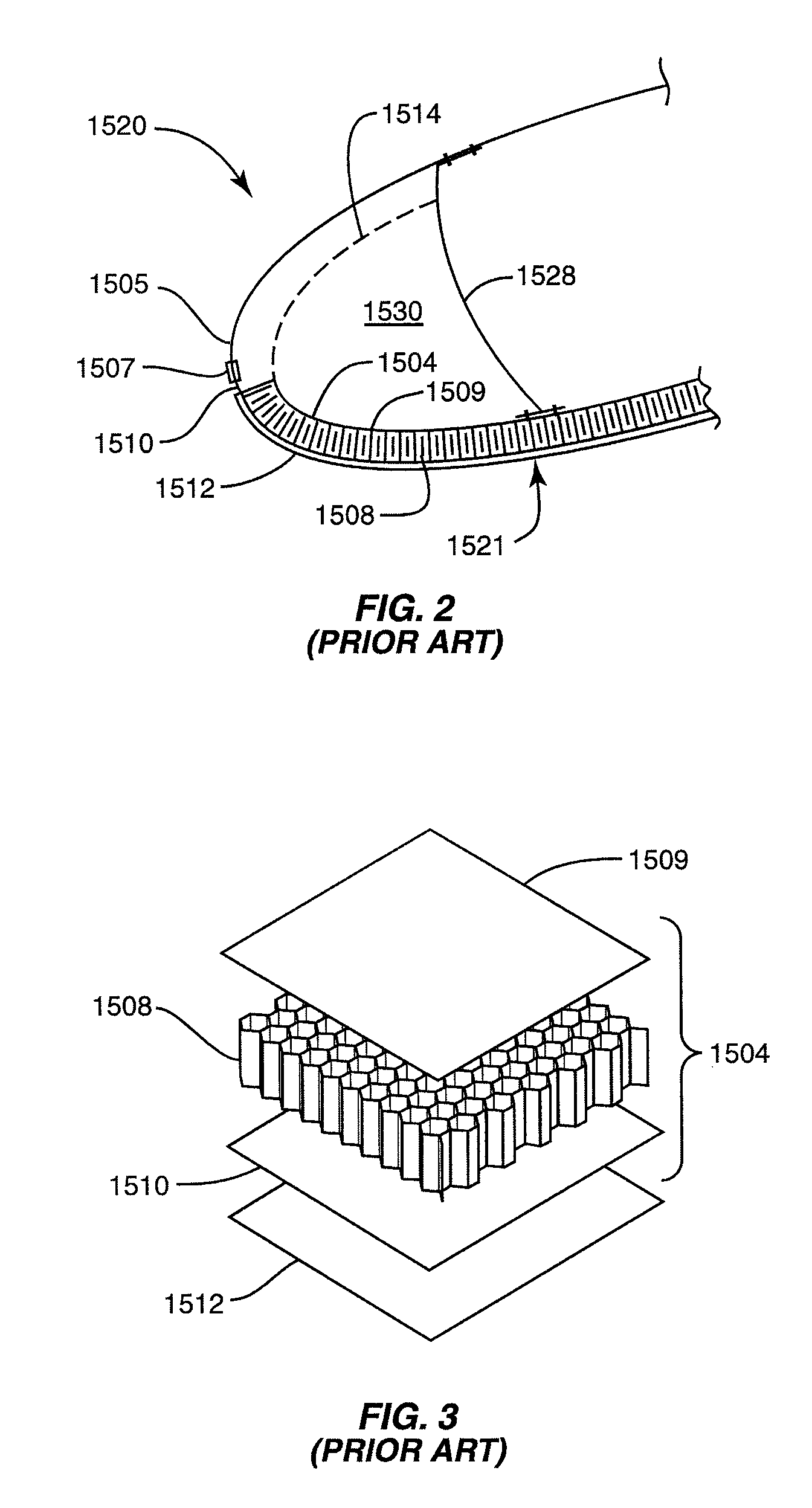

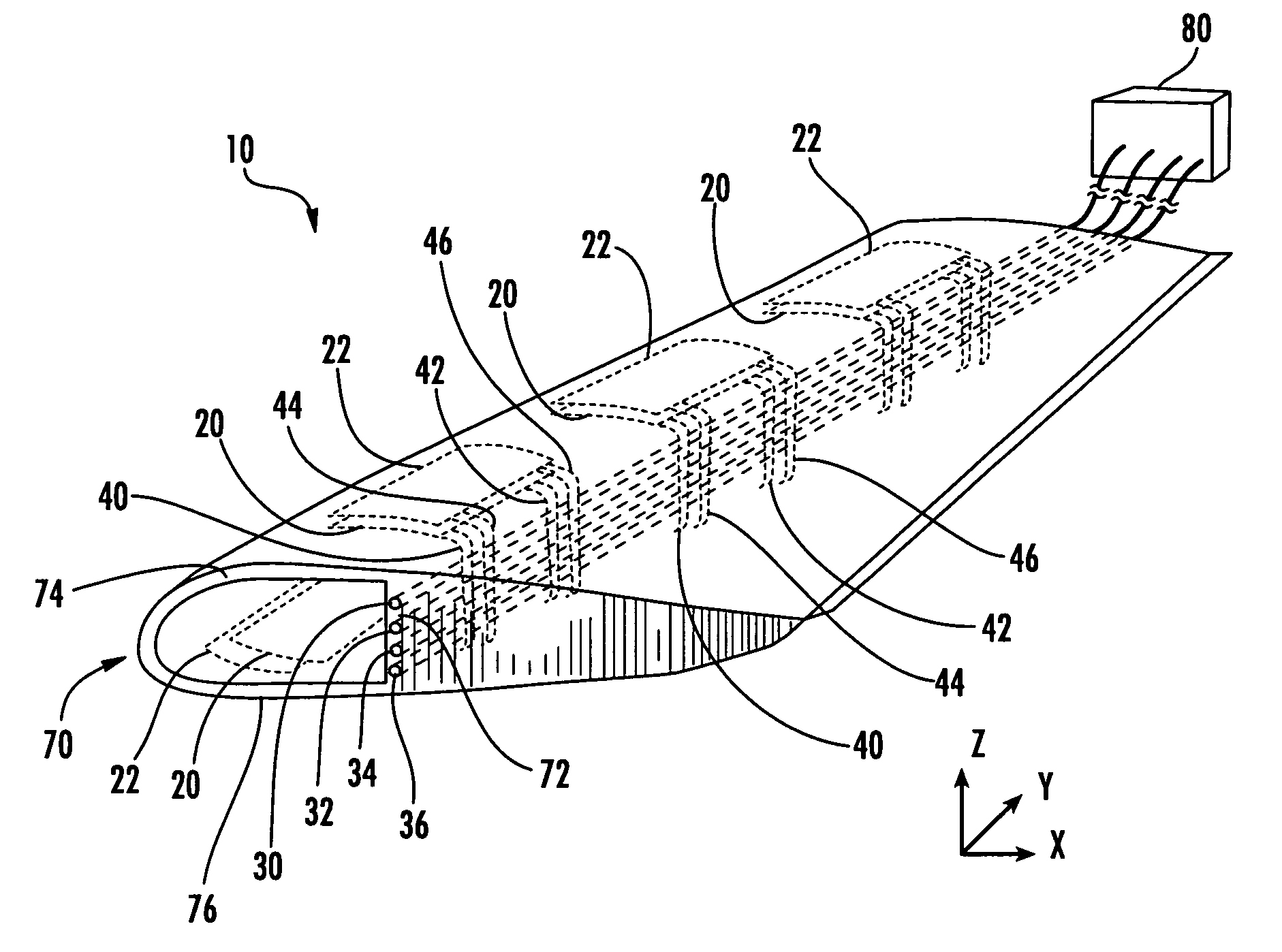

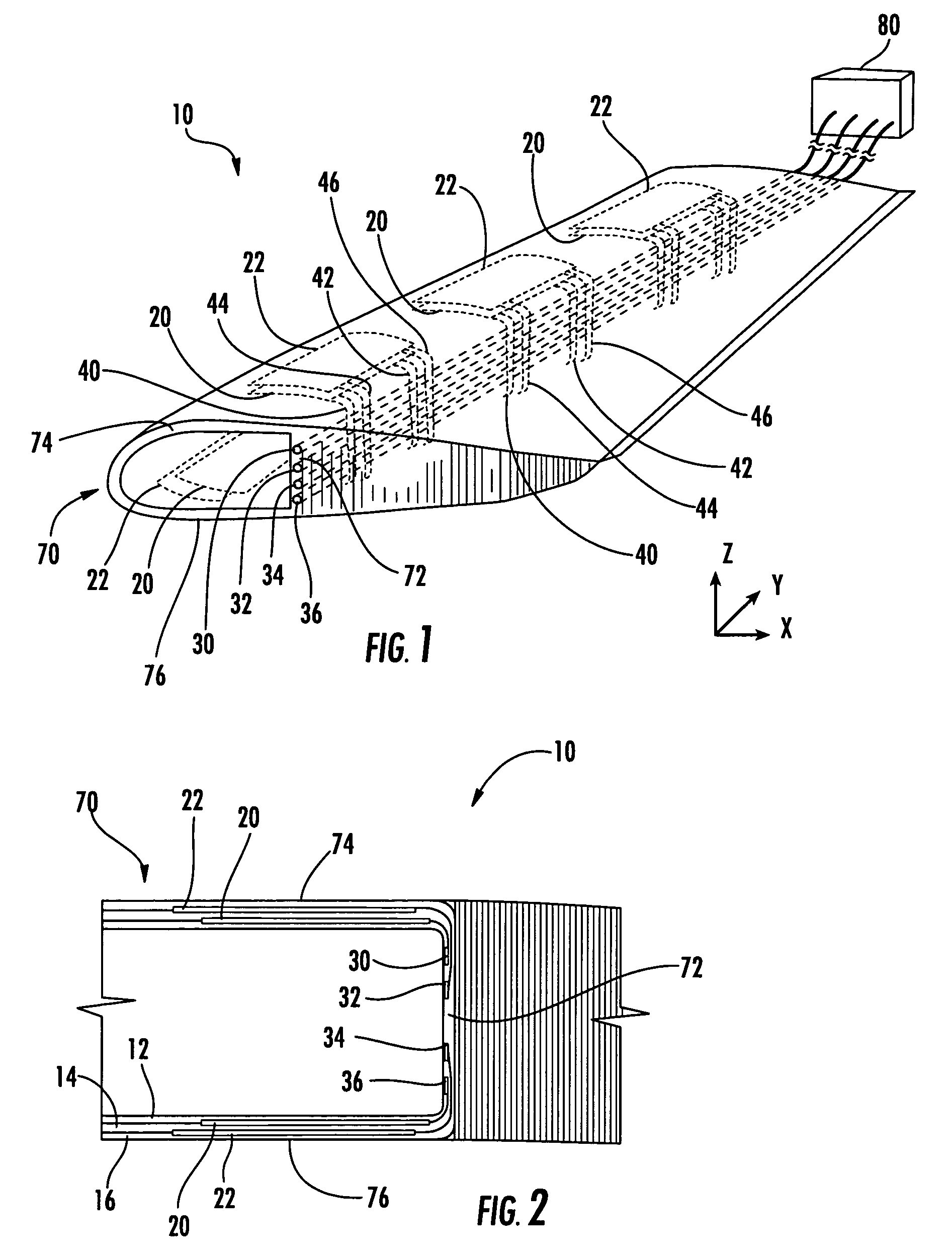

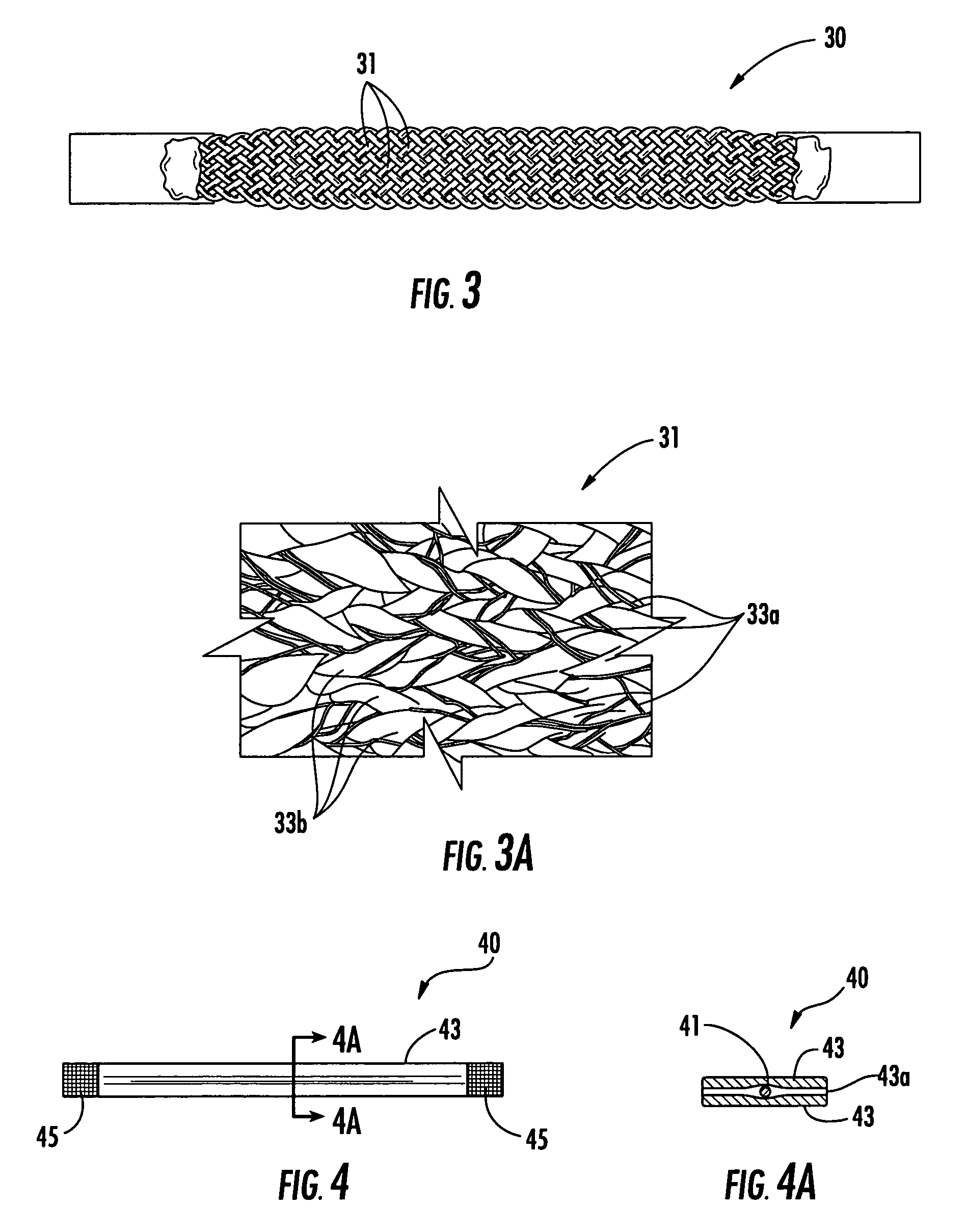

Acoustic nacelle inlet lip having composite construction and an integral electric ice protection heater disposed therein

An engine nacelle inlet lip includes both acoustic treatment and electric heating for ice protection. The inlet lip has a composite outer skin and a composite inner skin, with the composite outer skin having at least one integrated heater element embedded in the composite material. An acoustic cellular core positioned between the outer and inner skin acts to attenuate fan noise from the engine. Covering the outer skin and overlying the acoustic core is a perforated erosion shield having a first set of openings that pass entirely thorough its thickness. The composite outer skin includes a second set of openings such that sound waves can pass from an inner barrel portion of the inlet lip through the erosion shield, outer skin, and heater element to the underlying acoustic cellular core.

Owner:THE BF GOODRICH CO +1

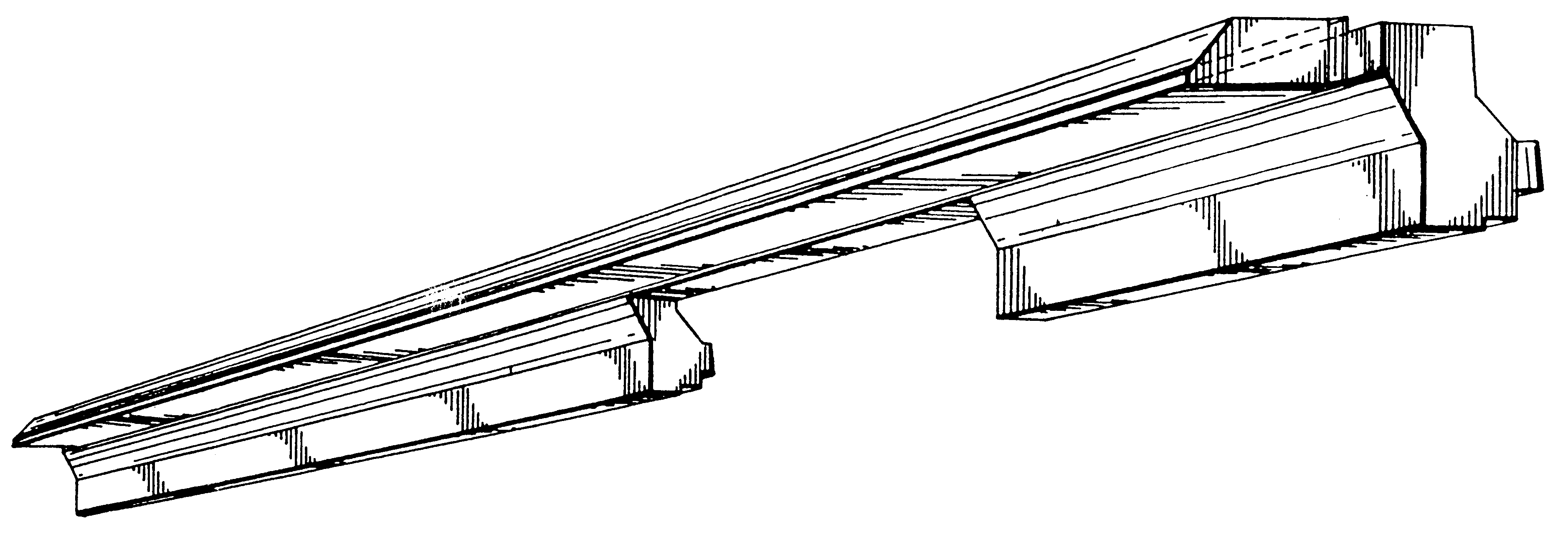

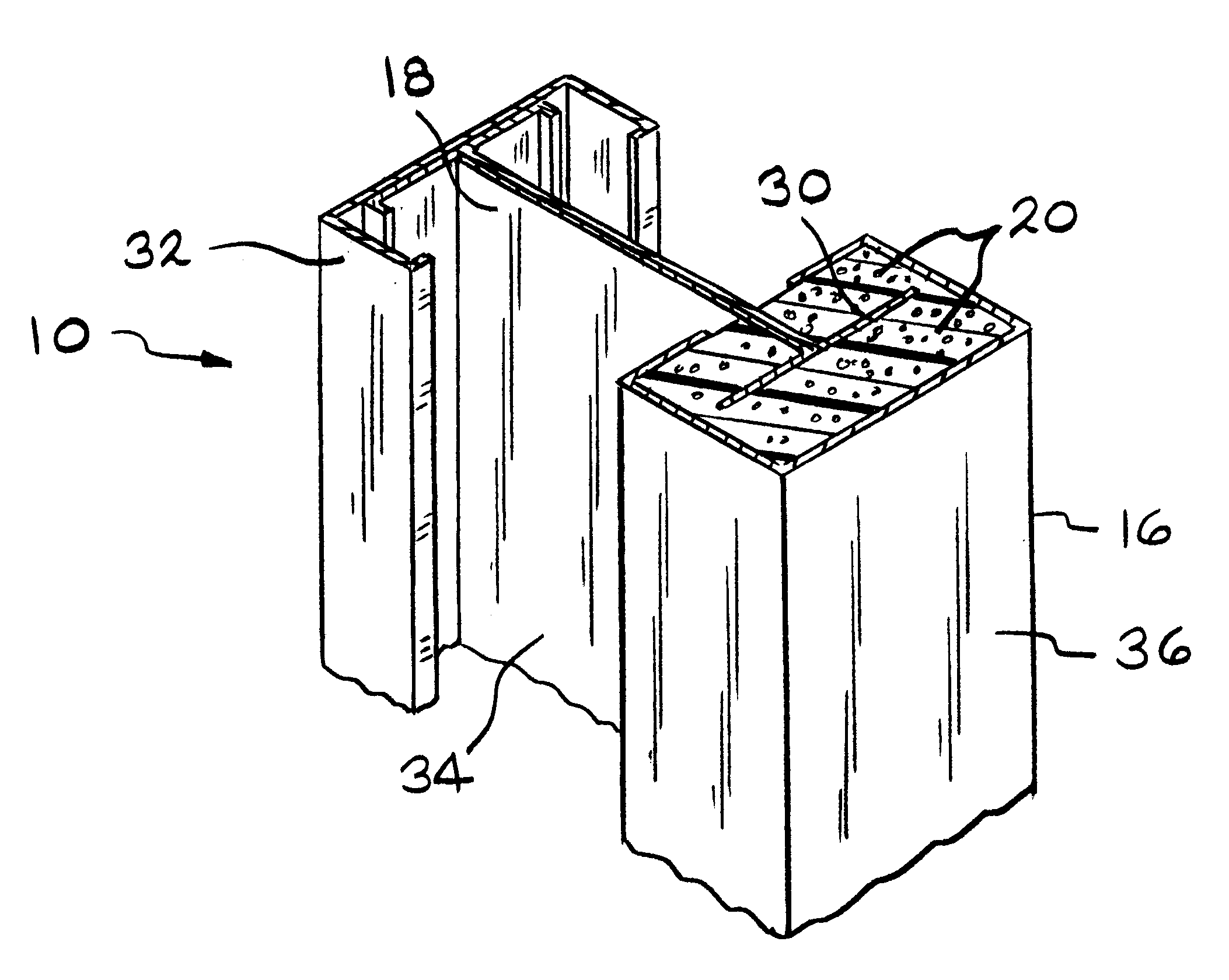

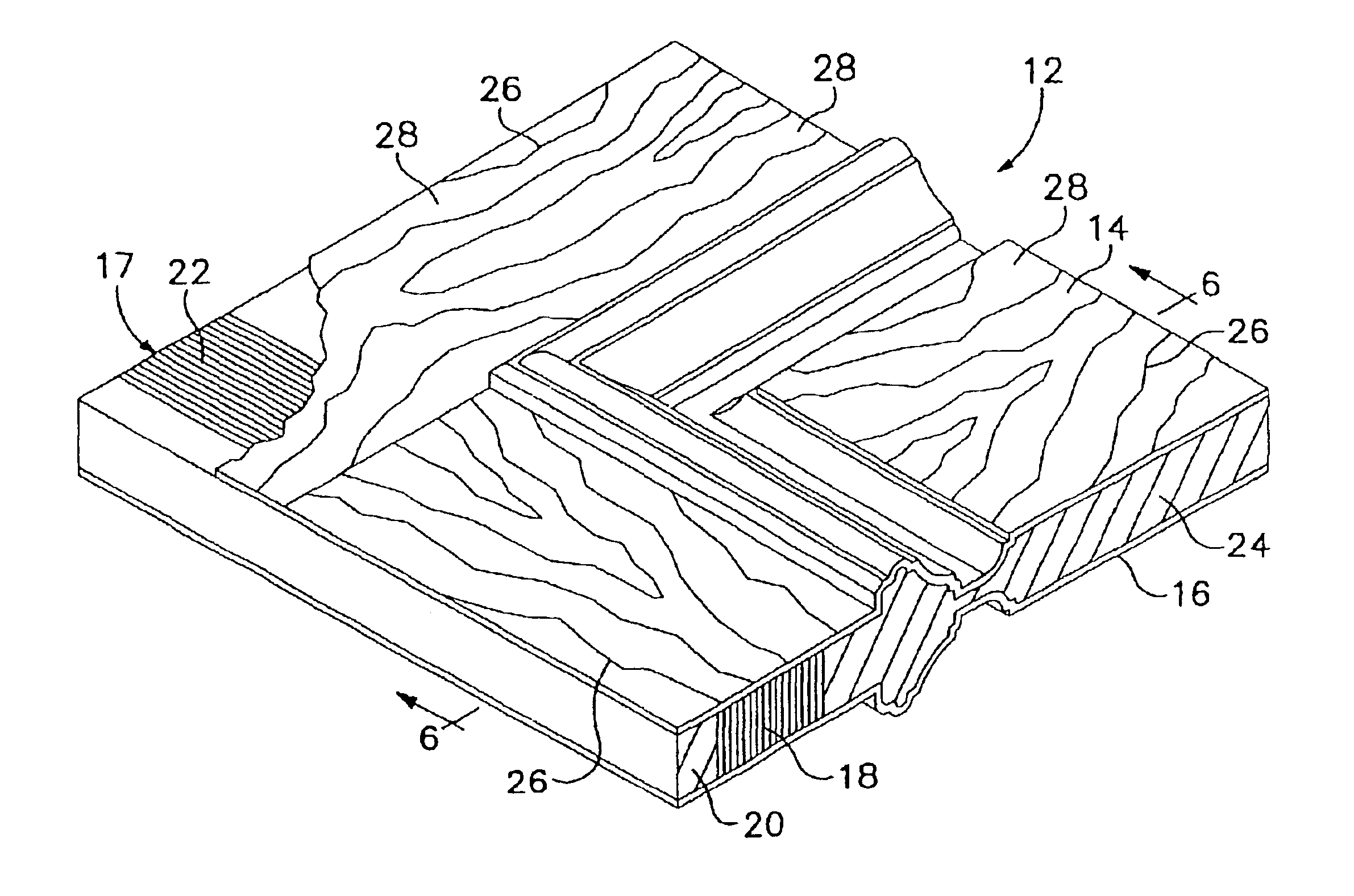

Polymer covered advanced polymer/wood composite structural member

InactiveUS6357197B1Corner/edge jointsMetal rolling stand detailsComposite constructionMoisture absorption

A composite structural member of the invention comprises a linear member having a first end and a second end attached to each end of the linear member as an end piece or end cap structure. Covering the composite member is a thermoplastic envelope preferably adherently bonded to the composite member. The end caps or end pieces are preferably thermoplastic materials typically thermoplastic composites comprising a thermoplastic resin and a fiber. Such a member is environmentally stable, resists moisture absorption, forms strong mitered joints and can be used in the assembly of fenestration products for commercial and residential real estate.

Owner:ANDERSEN CORPORATION

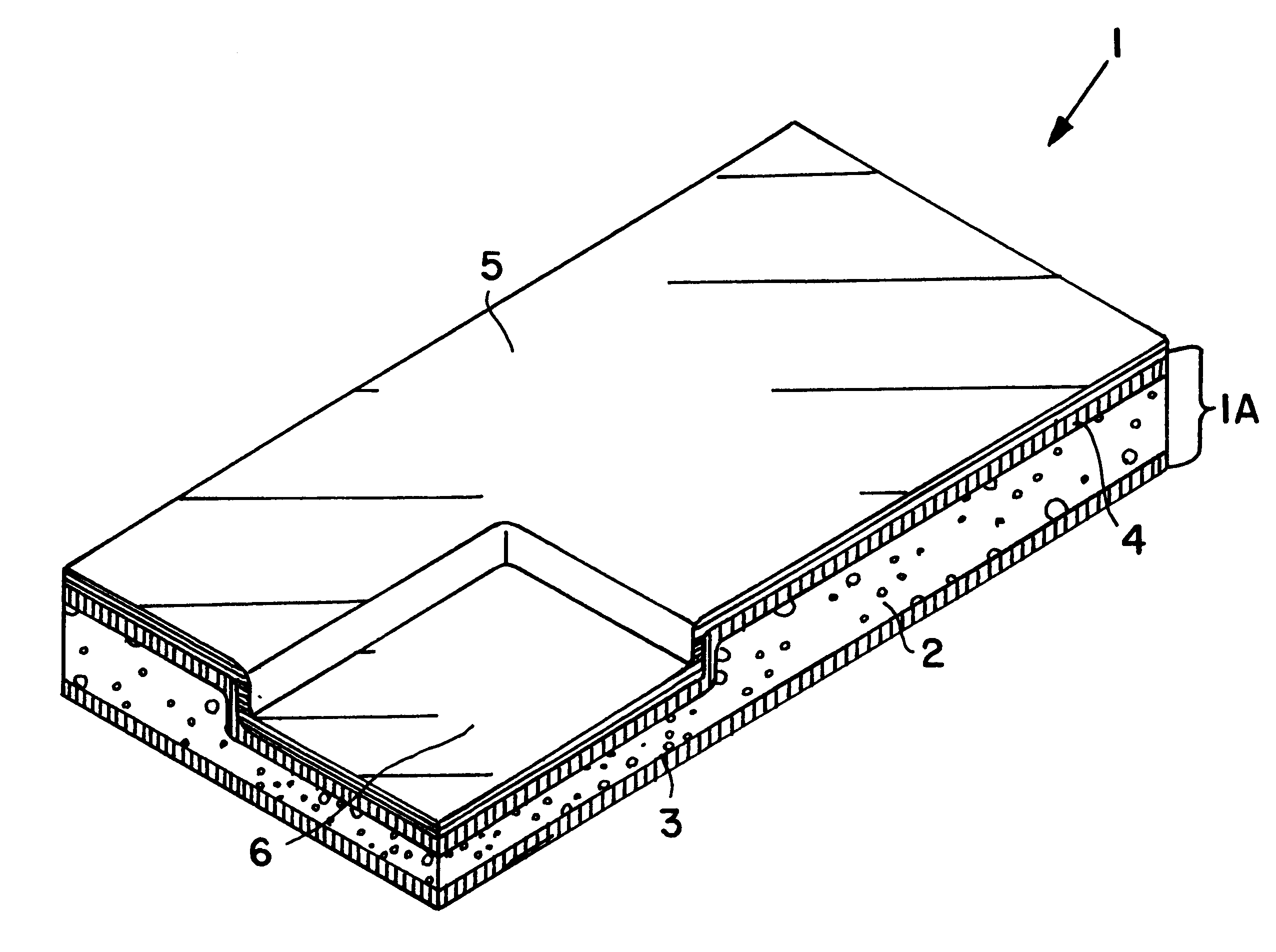

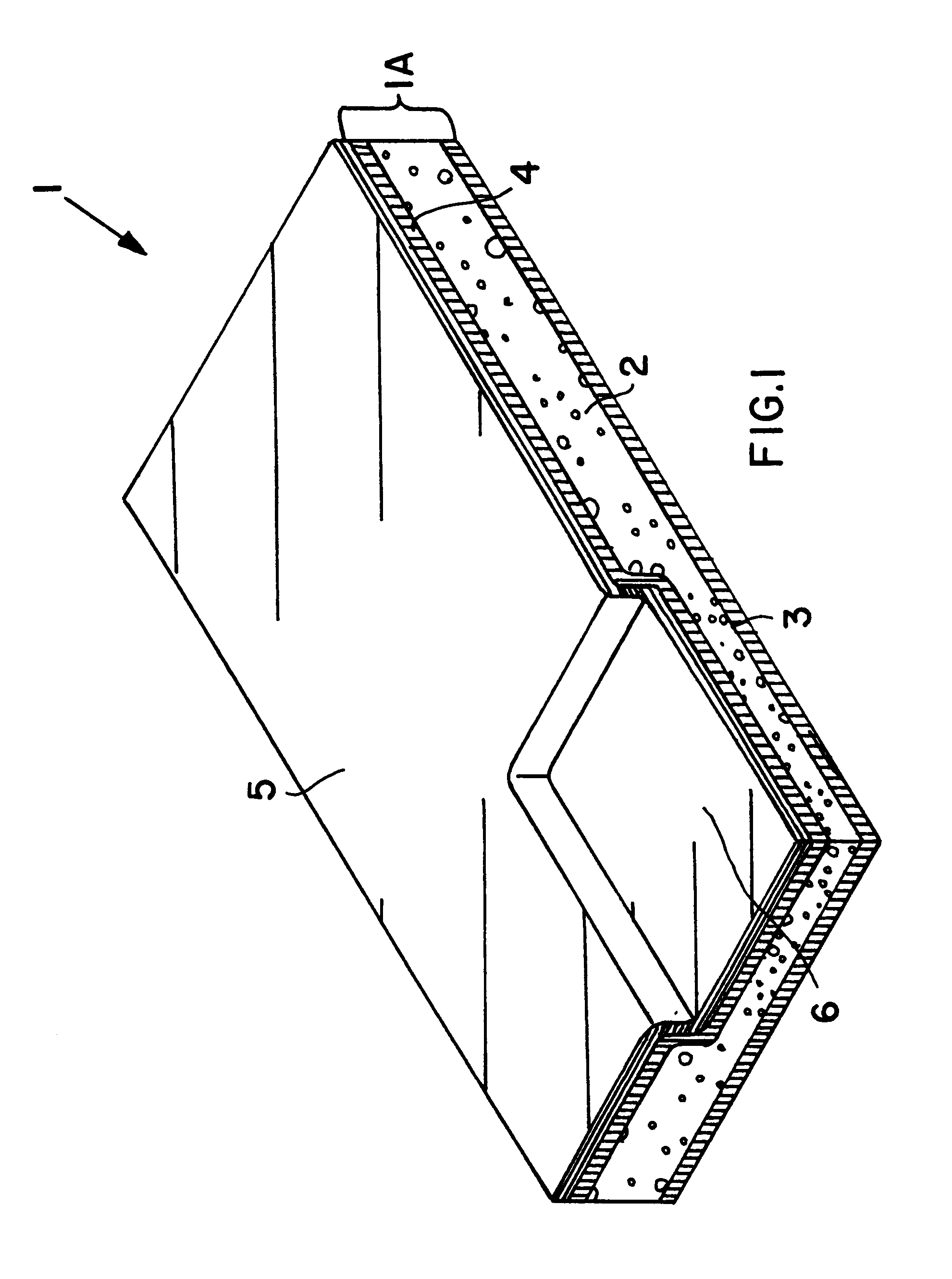

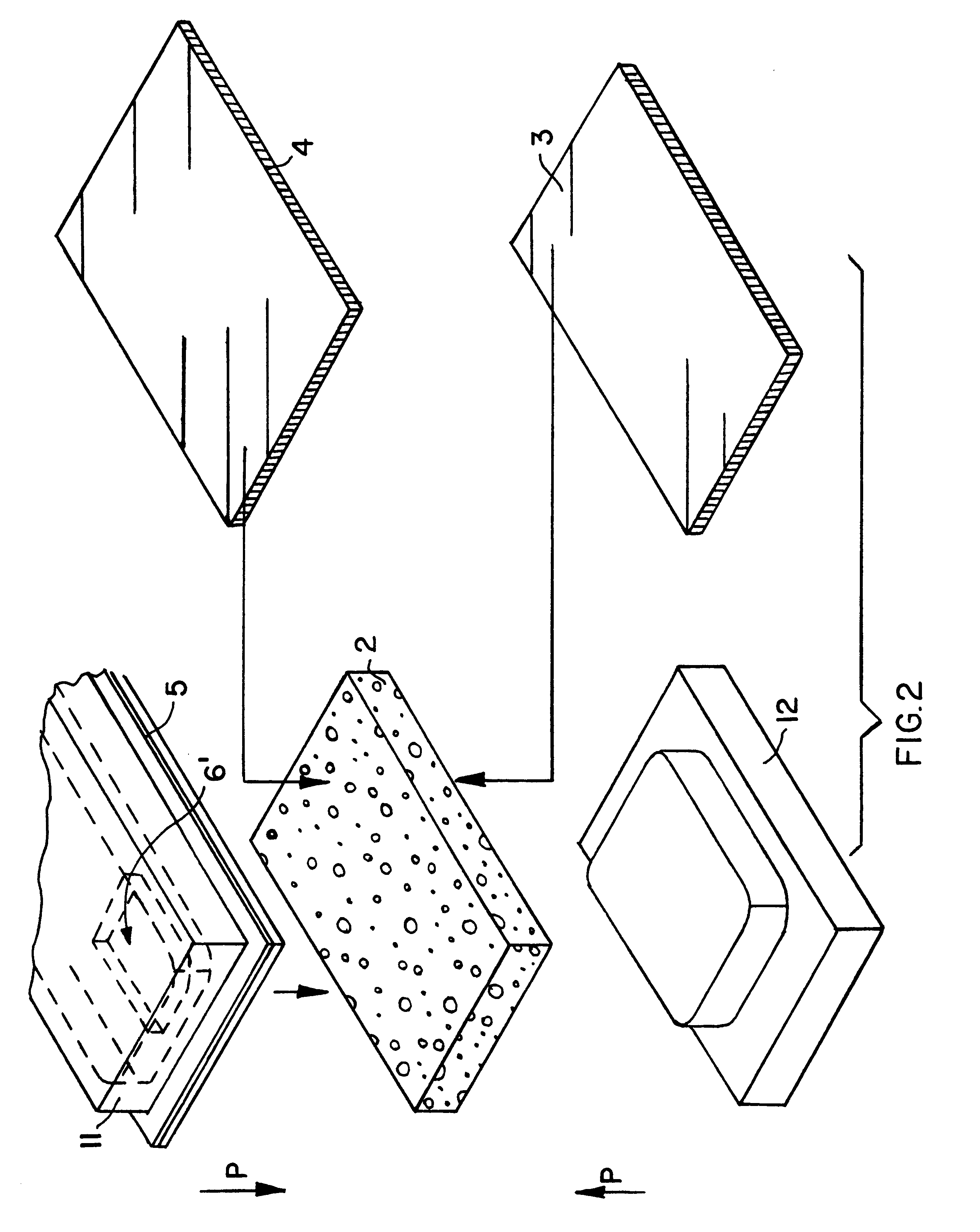

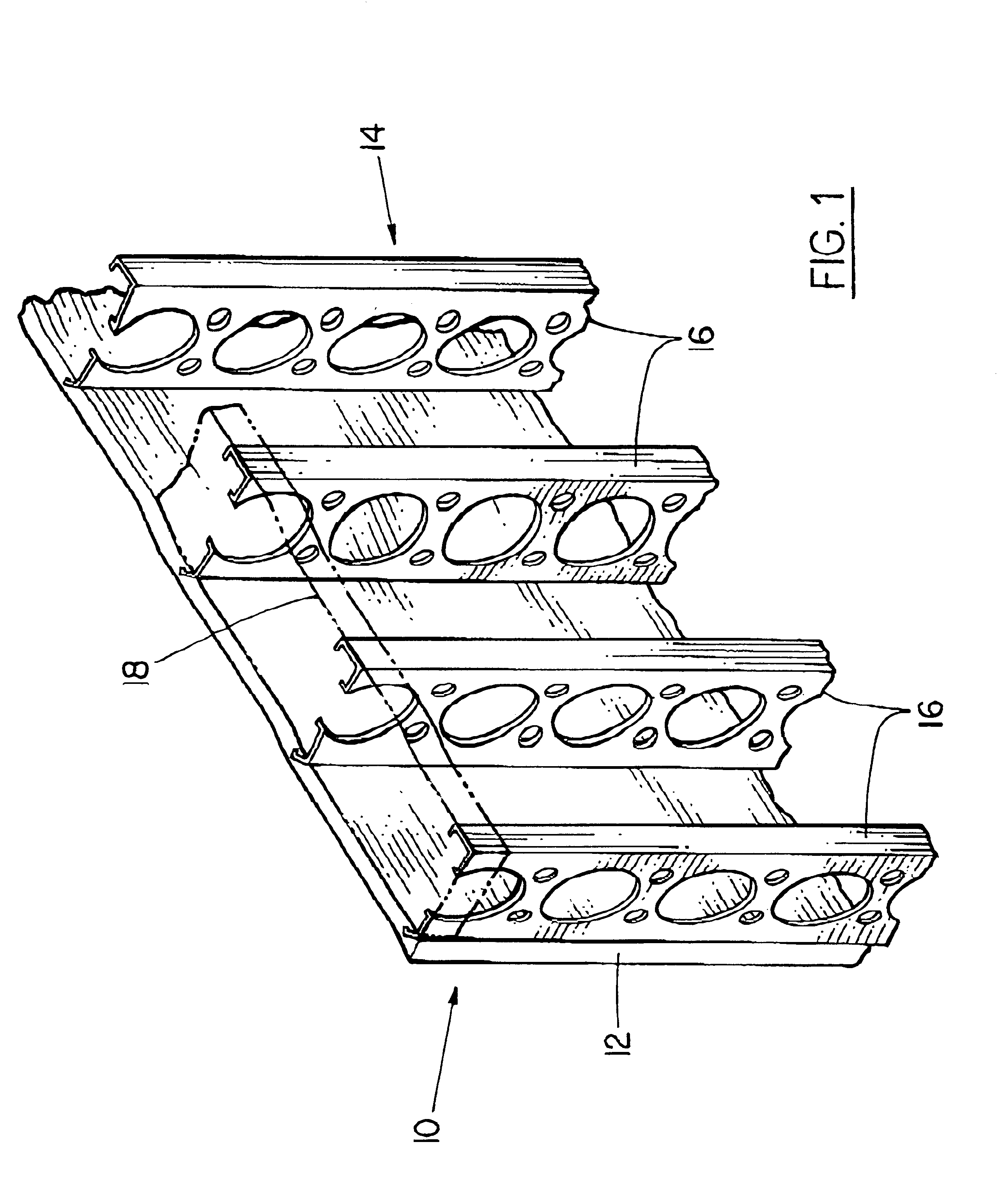

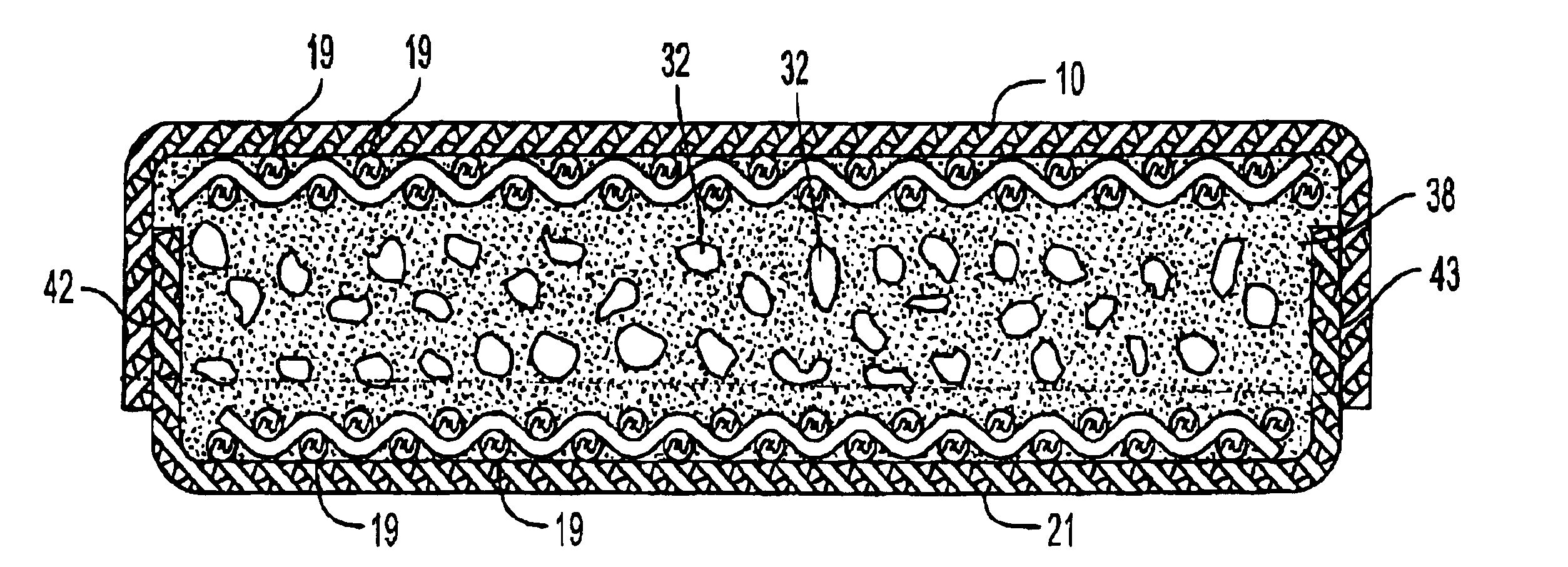

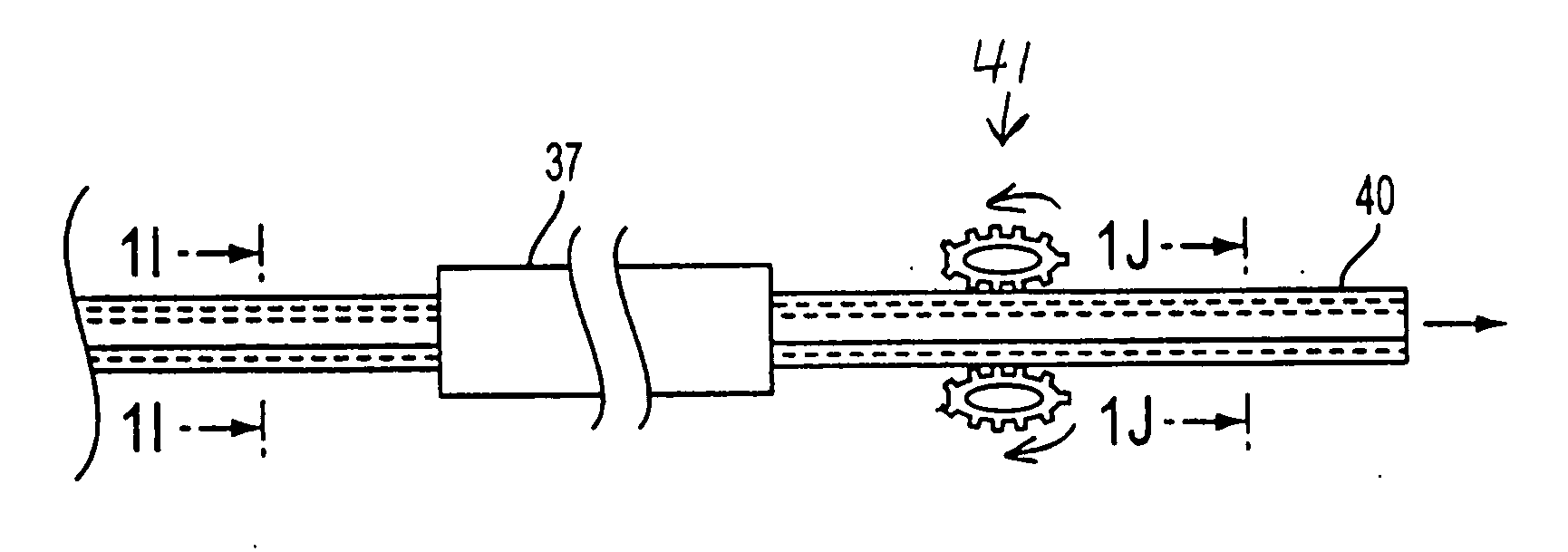

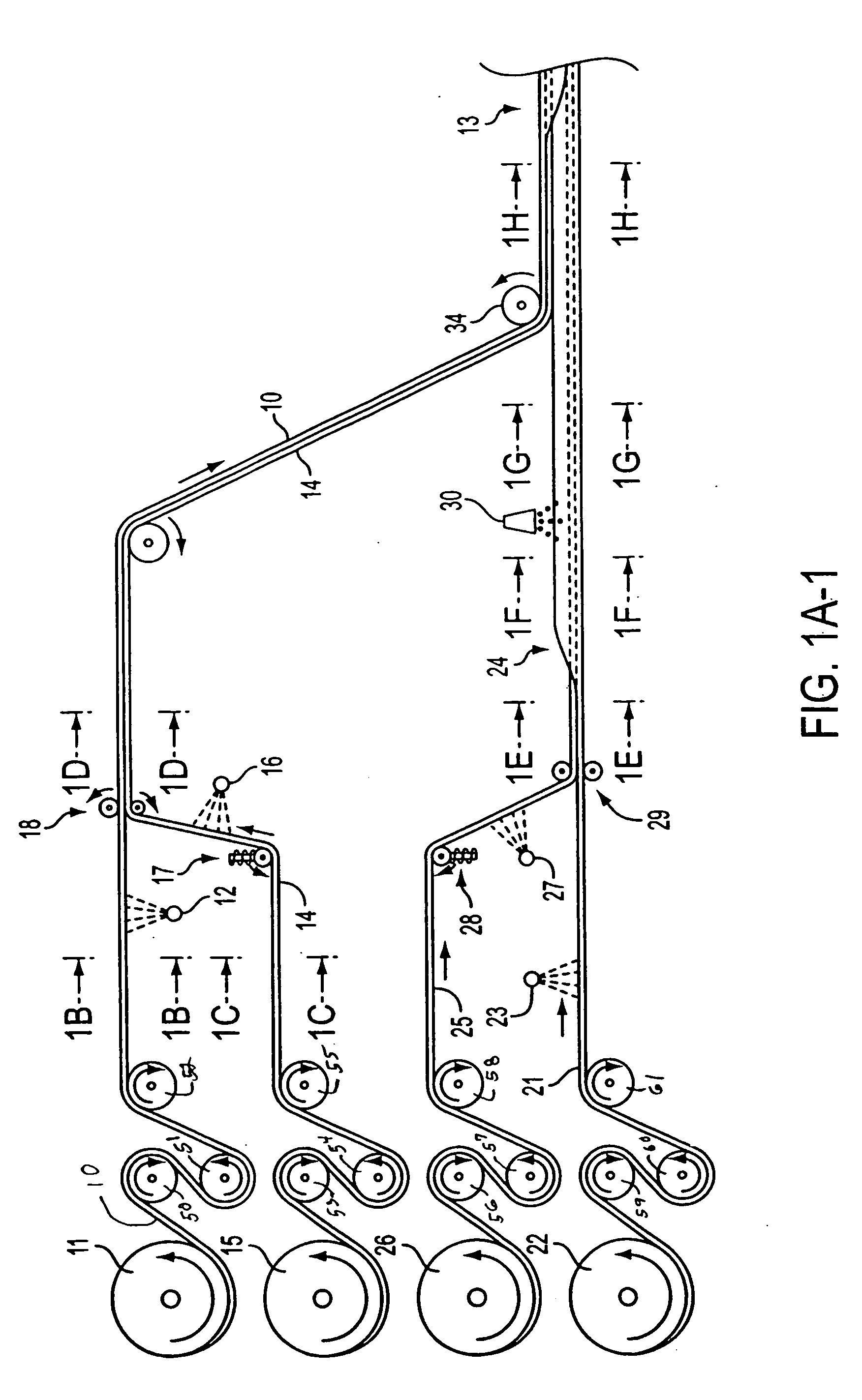

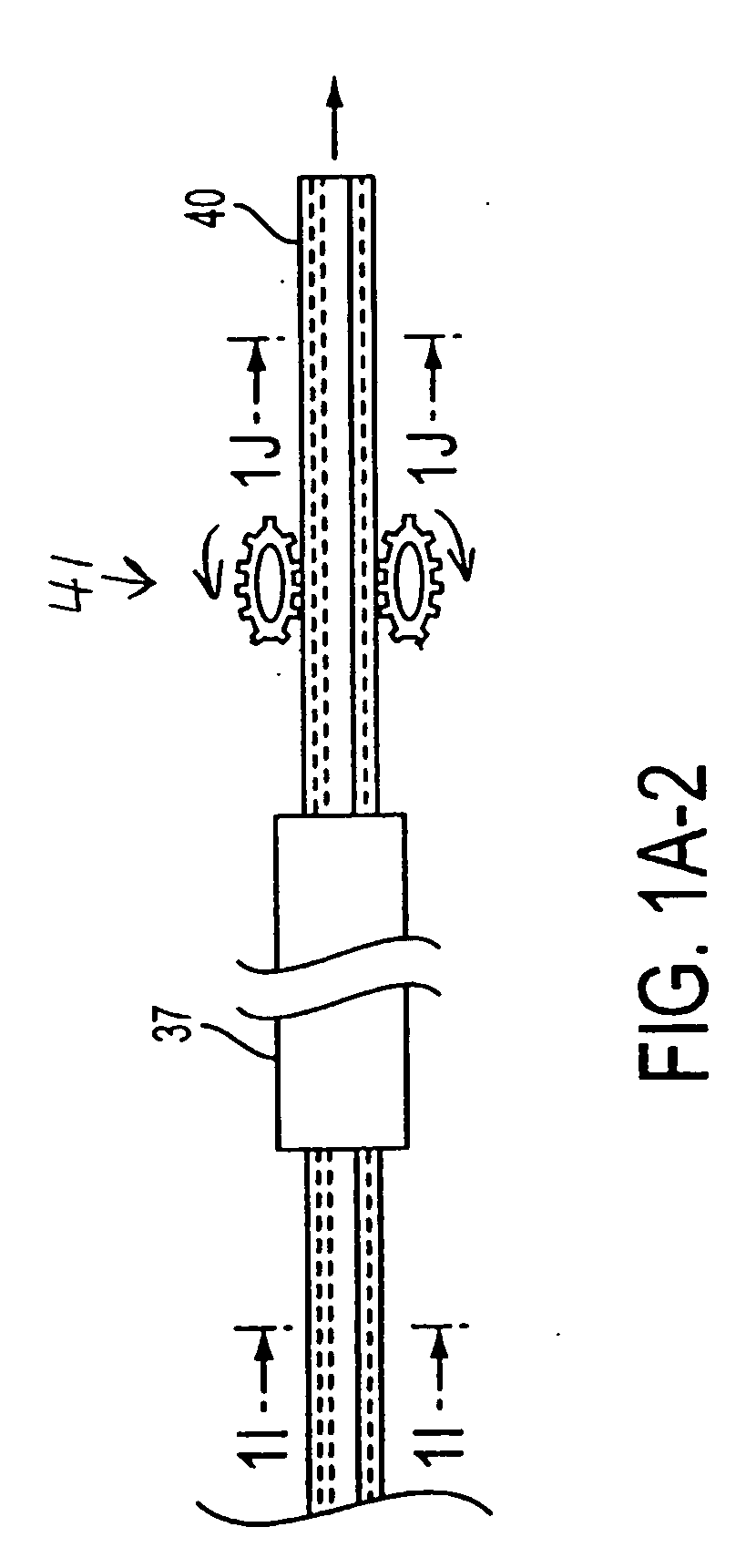

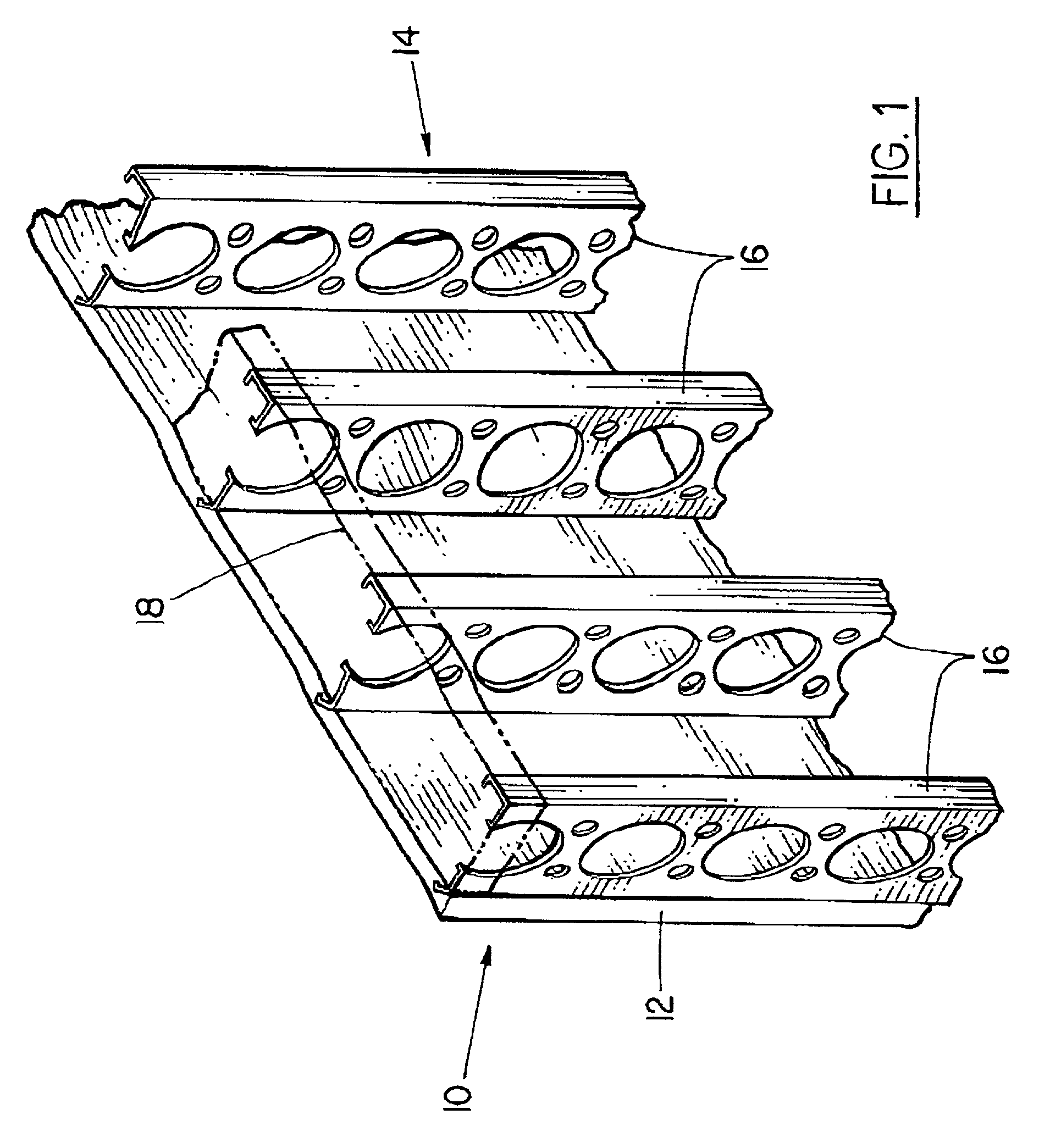

Composite structural panel with thermoplastic foam core and natural fibers, and method and apparatus for producing the same

InactiveUS6287678B1Easy to recycleEasily thermo-processedAdhesive processesLamination ancillary operationsComposite constructionShell molding

A composite structural panel includes a cover sheet laminated onto a three-layered substrate including a thermoplastic foam core sandwiched between two composite outer layers. Each composite outer layer includes natural fibers embedded in a thermoplastic matrix. The thermoplastic material of all layers is preferably polypropylene, and the core consists of an expanded cellular polypropylene rigid foam. In a method for forming the composite structural panel, a first preheated outer layer is laminated and molded onto the foam core in a first molding step, and then the second preheated outer layer and the cover sheet are laminated and molded onto the foam core in a second molding step, with a cooling-down time allowed between the two molding steps. In this manner, each preheated outer layer provides enough heat to thermally fuse the outer layer onto the foam core, without overheating the foam core to the point of softening or melting the foam core. The low density foam core provides a spacing distance between the strong composite outer layers, and therefore the finished composite structural panel has a high strength and rigidity, and a high strength-to-weight ratio. The structural panel can be molded into any desired three-dimensional contoured configuration during the molding process.

Owner:HERBERT OLBRICH

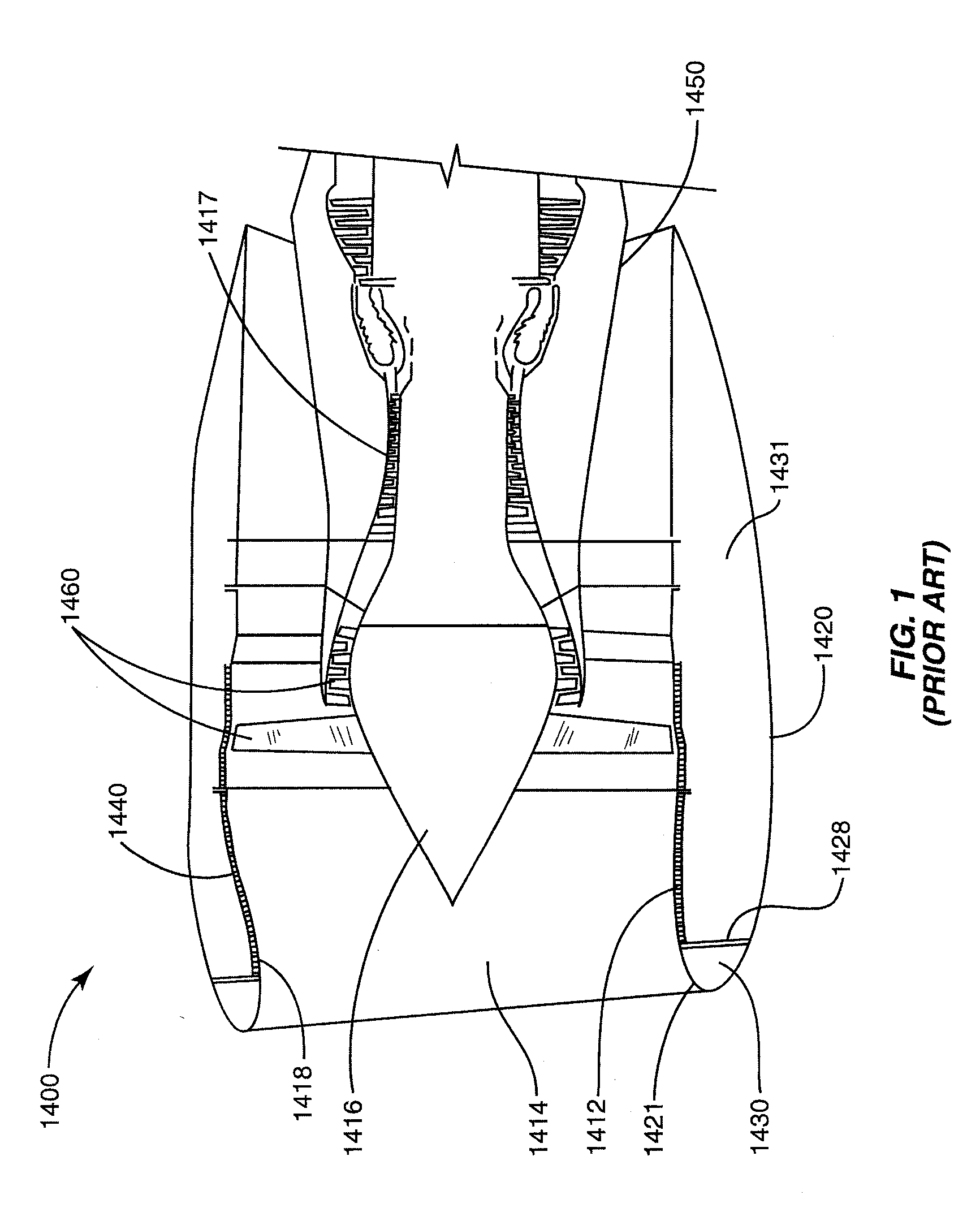

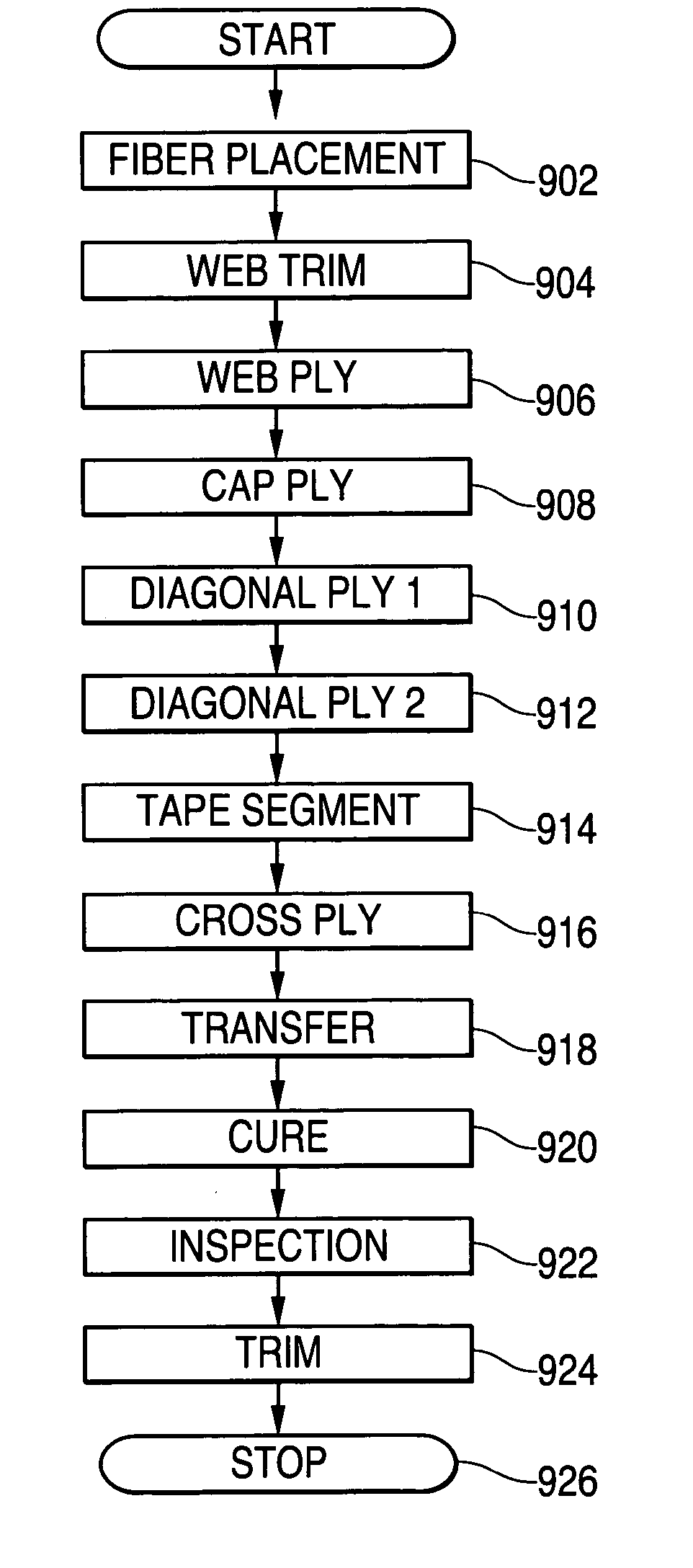

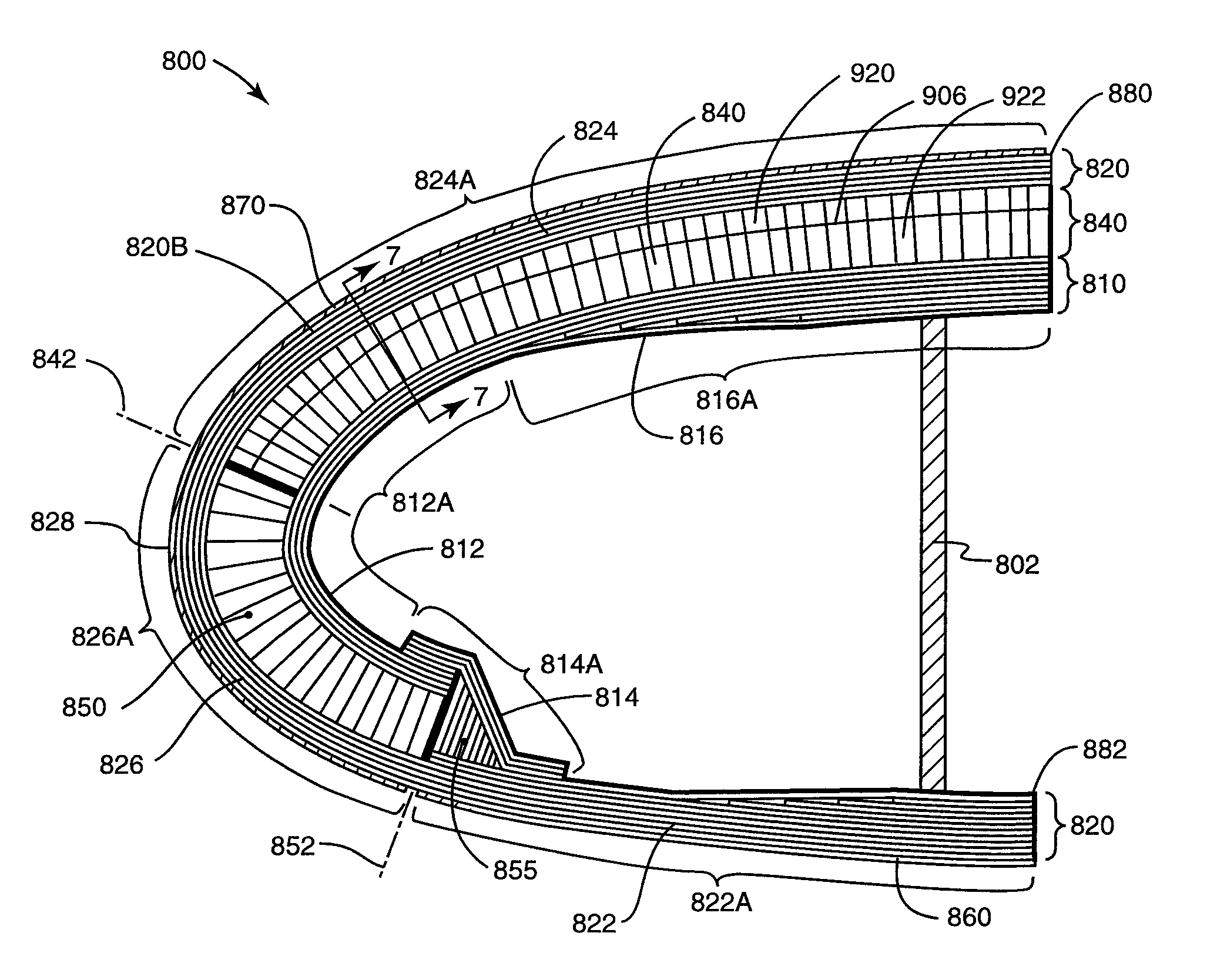

Method of manufacturing curved composite structural elements

A method of manufacturing curved composite structural elements can include fabricating a web ply in a flat curve over a removable substrate and laying up the ply on a curved web surface of a manufacturing tool. The method also can include laying up a diagonal ply with fibers oriented at + / −45° from the centerline of the web surface. The method further can include cutting a unidirectional composite tape into segments and laying up the tape segments to form a cross ply with a fiber orientation normal to the centerline of the web surface. One or both edges of the diagonal and cross plies may be folded over one or two sides of the manufacturing tool to form one or two flange surfaces. Additionally, a cap ply can be laid up on one or both flange surfaces using composite tape. The structural element layup can then be inspected and any excess composite material can be trimmed away.

Owner:THE BOEING CO

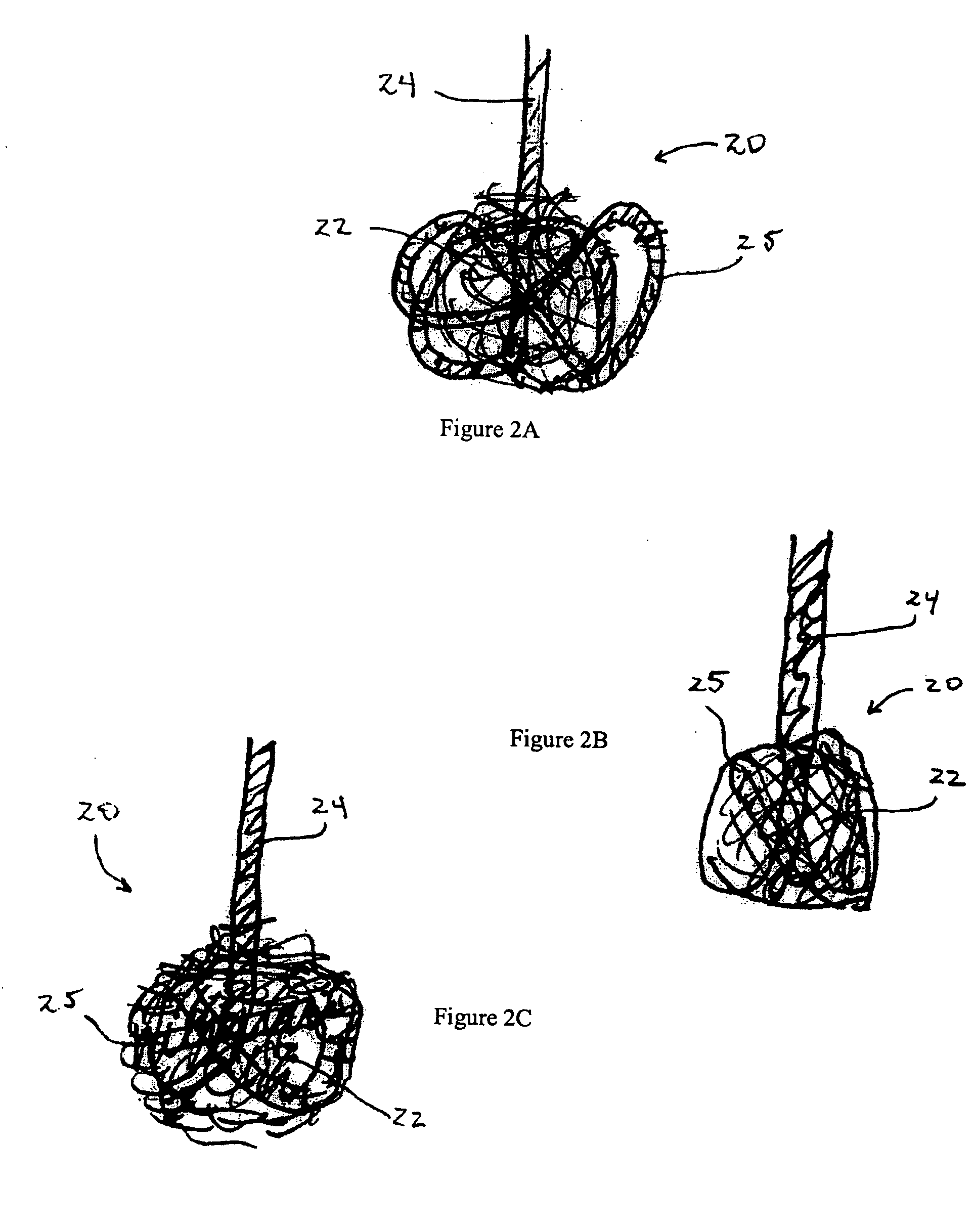

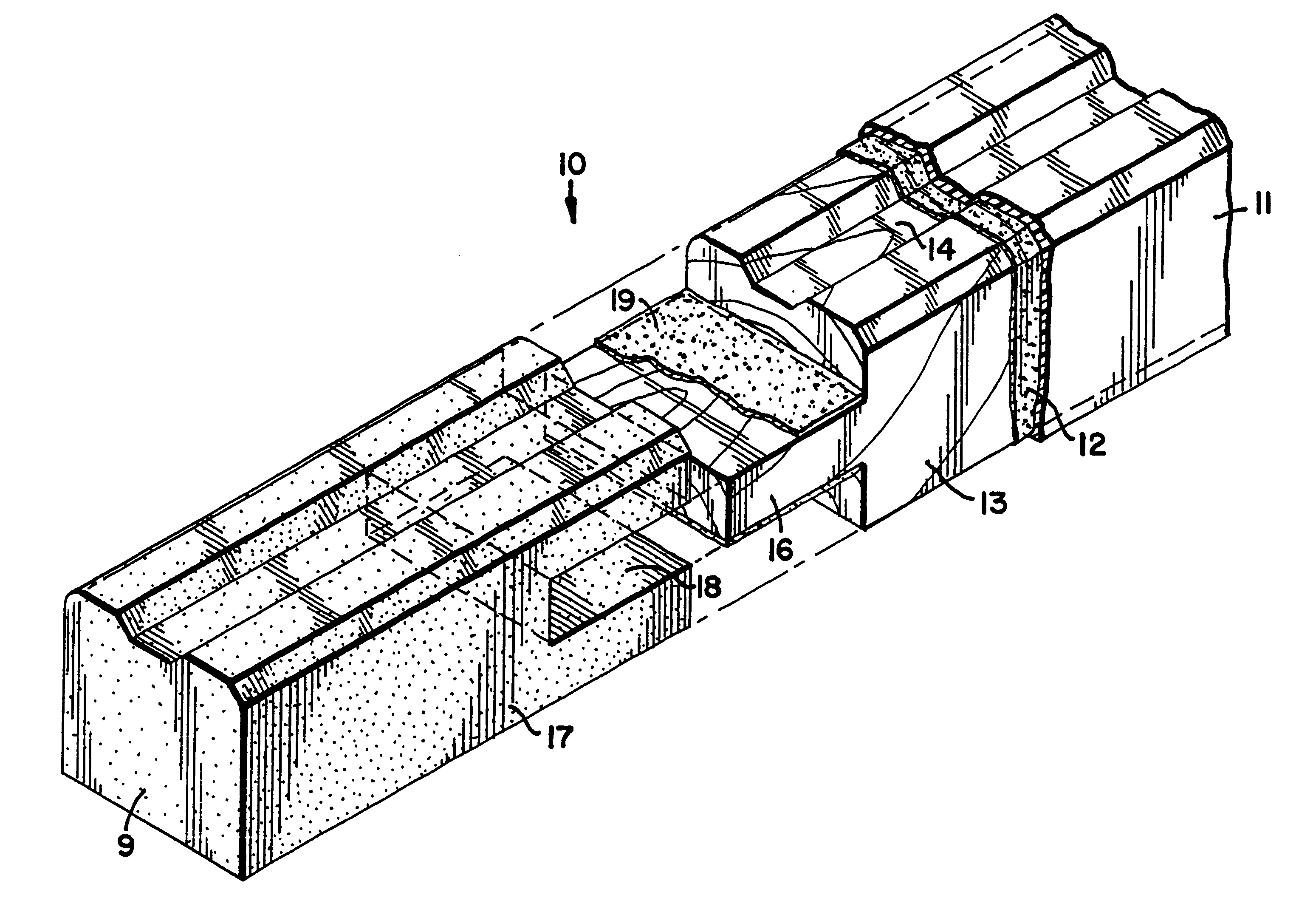

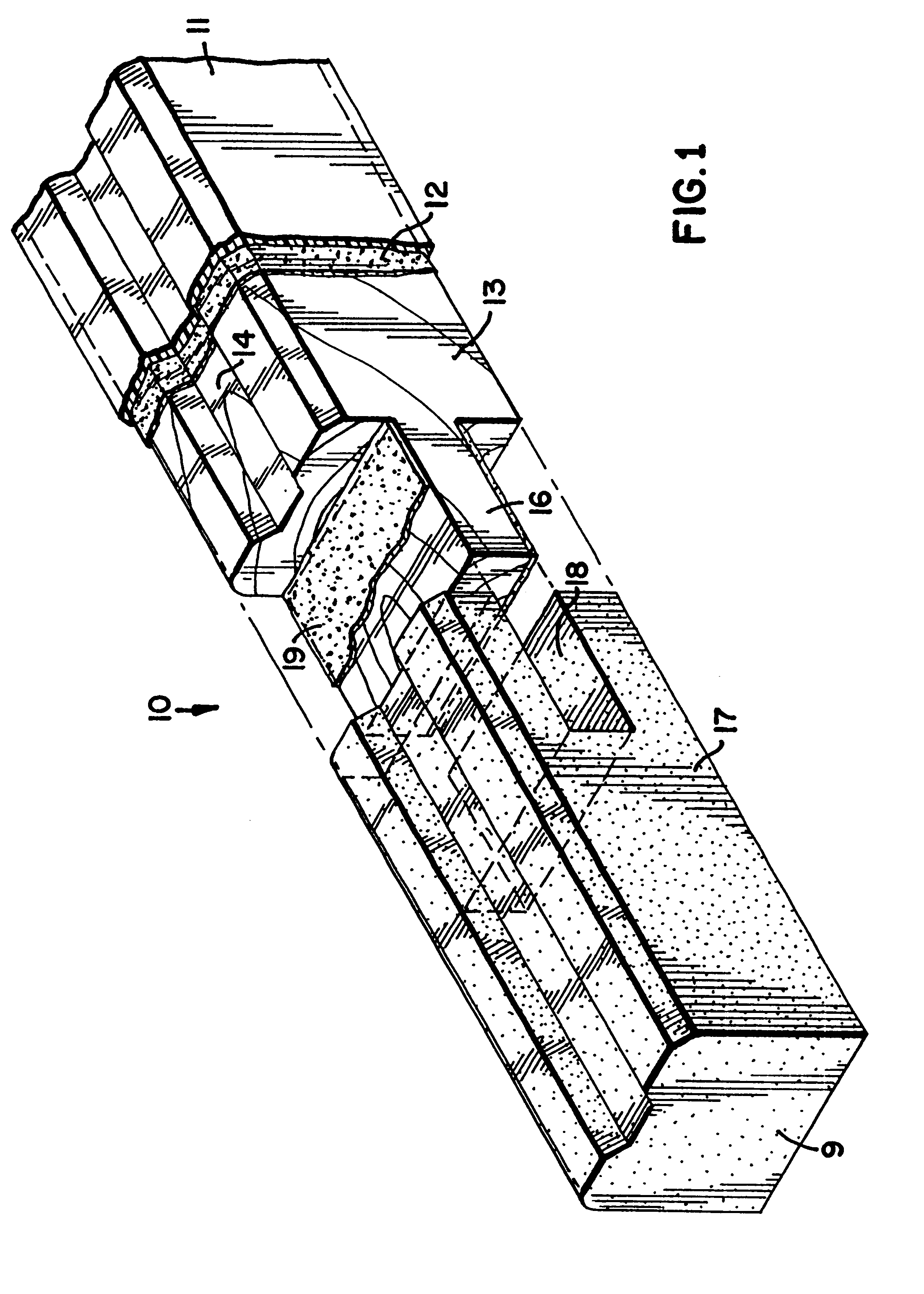

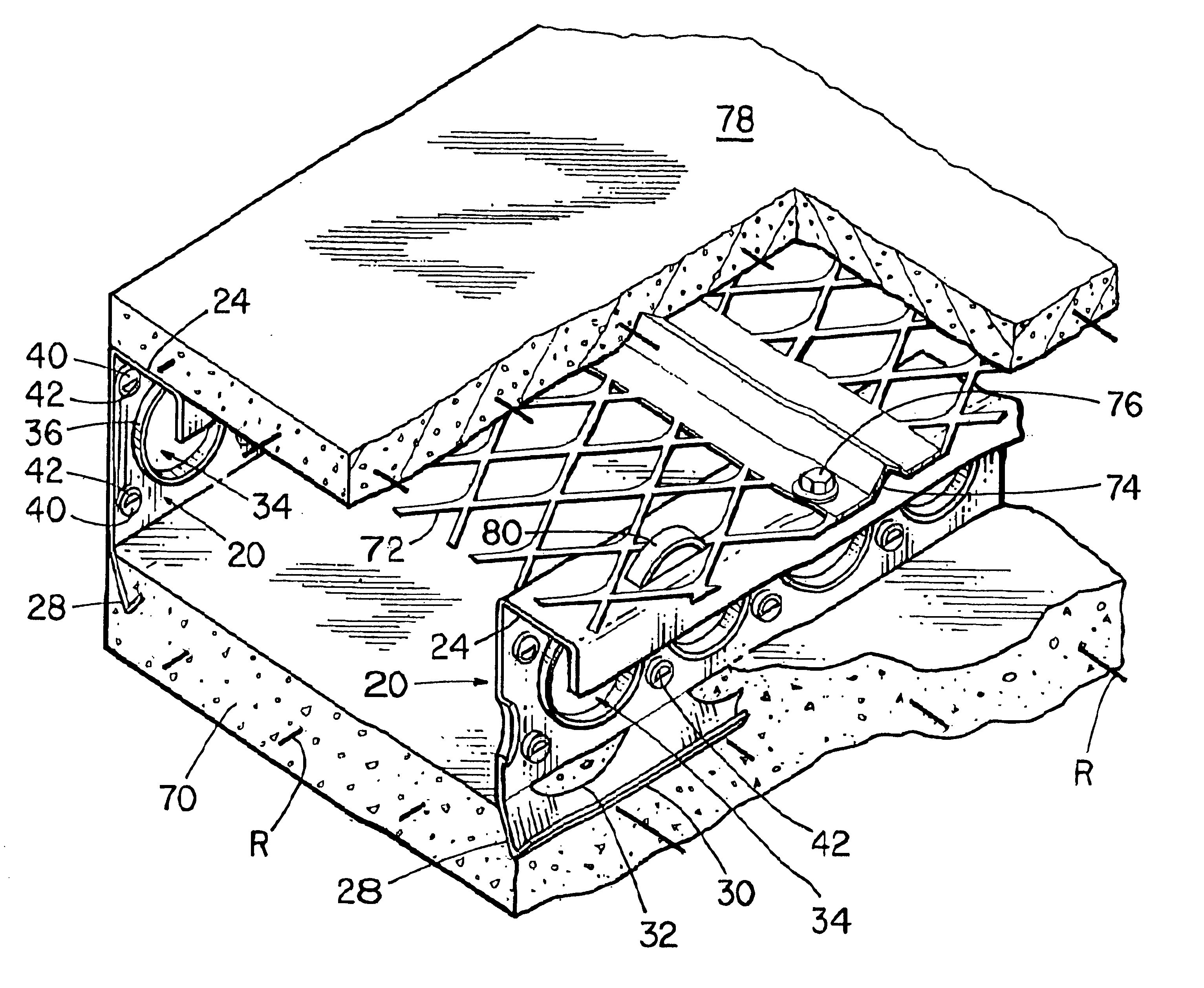

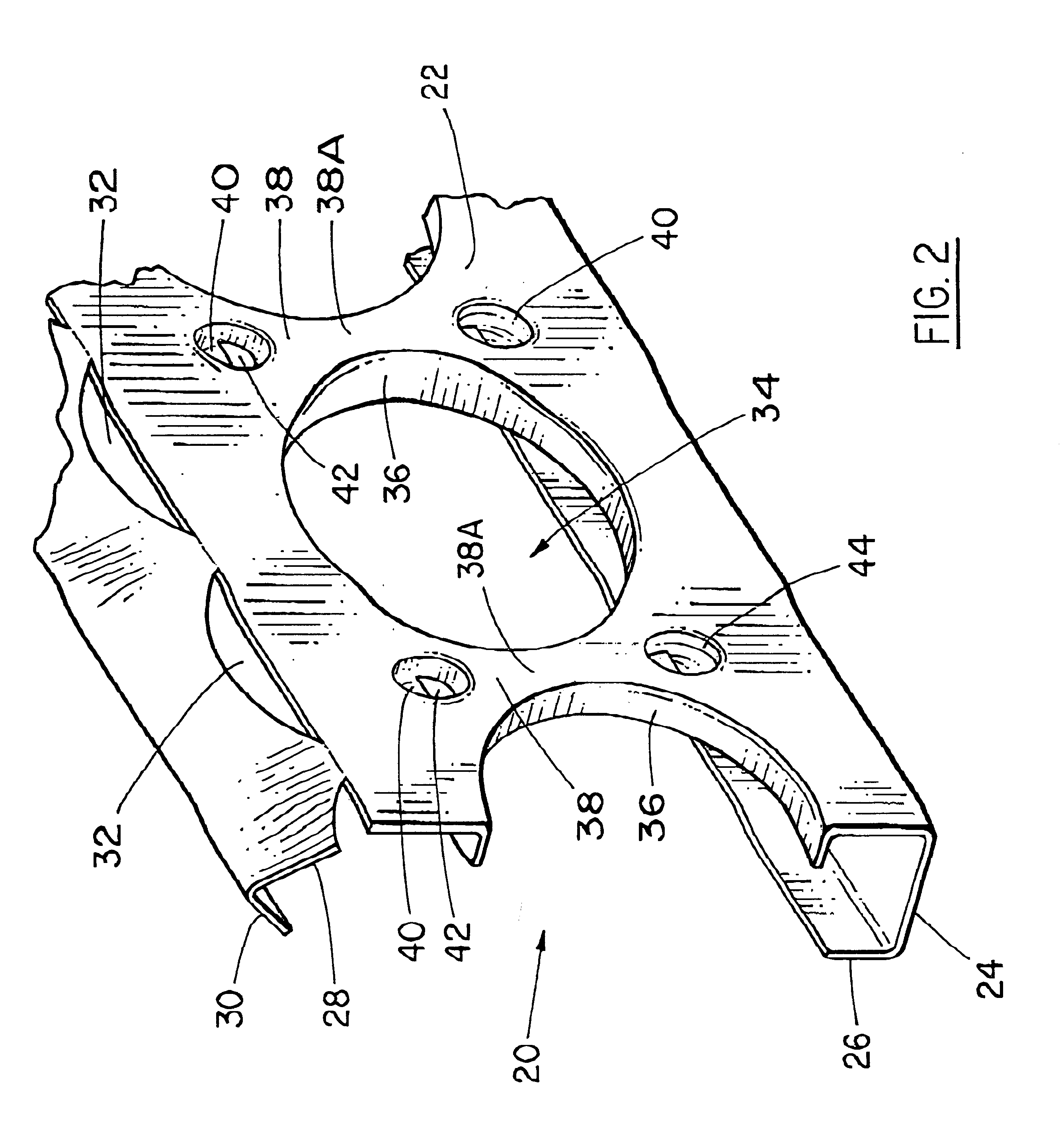

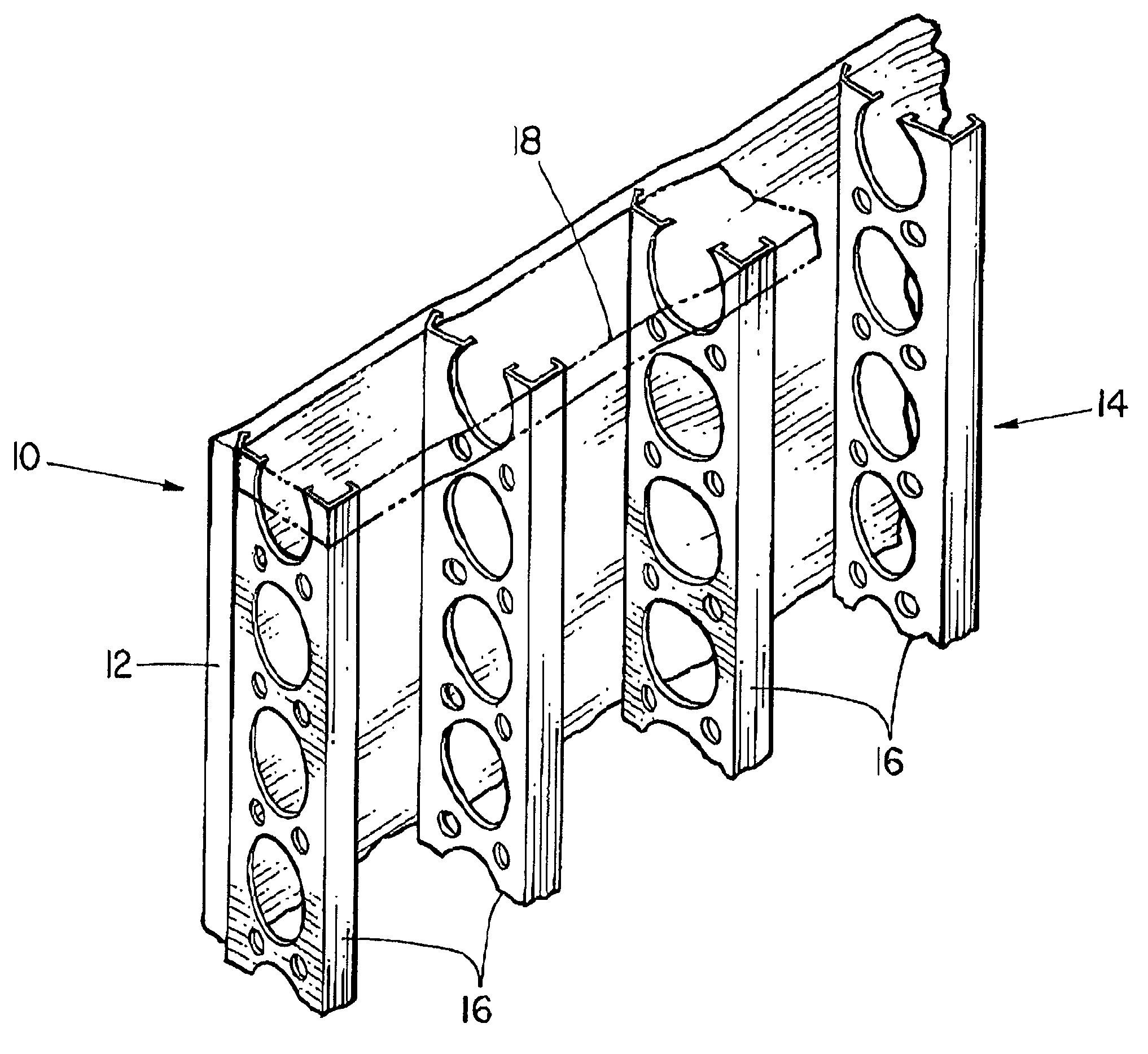

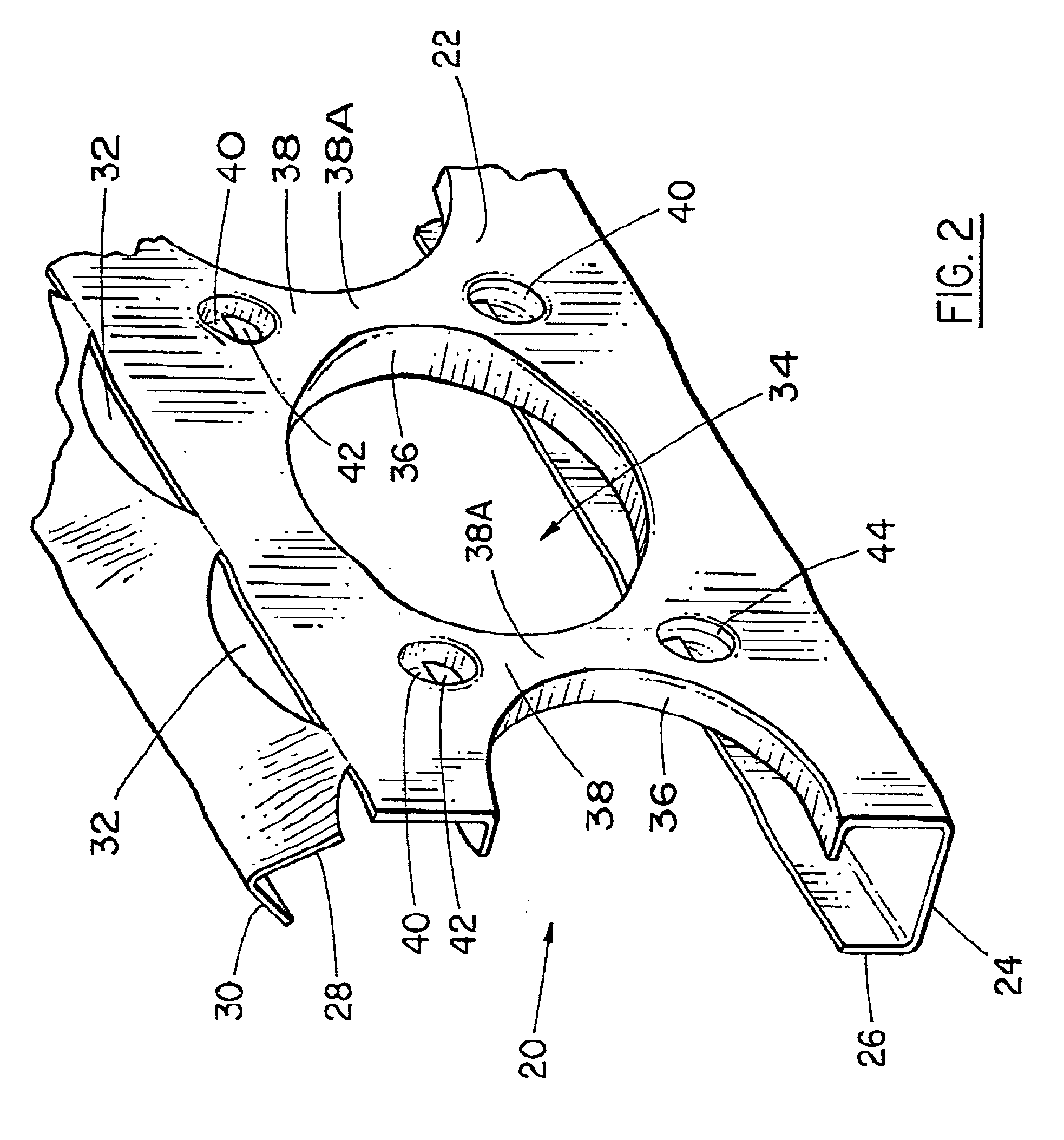

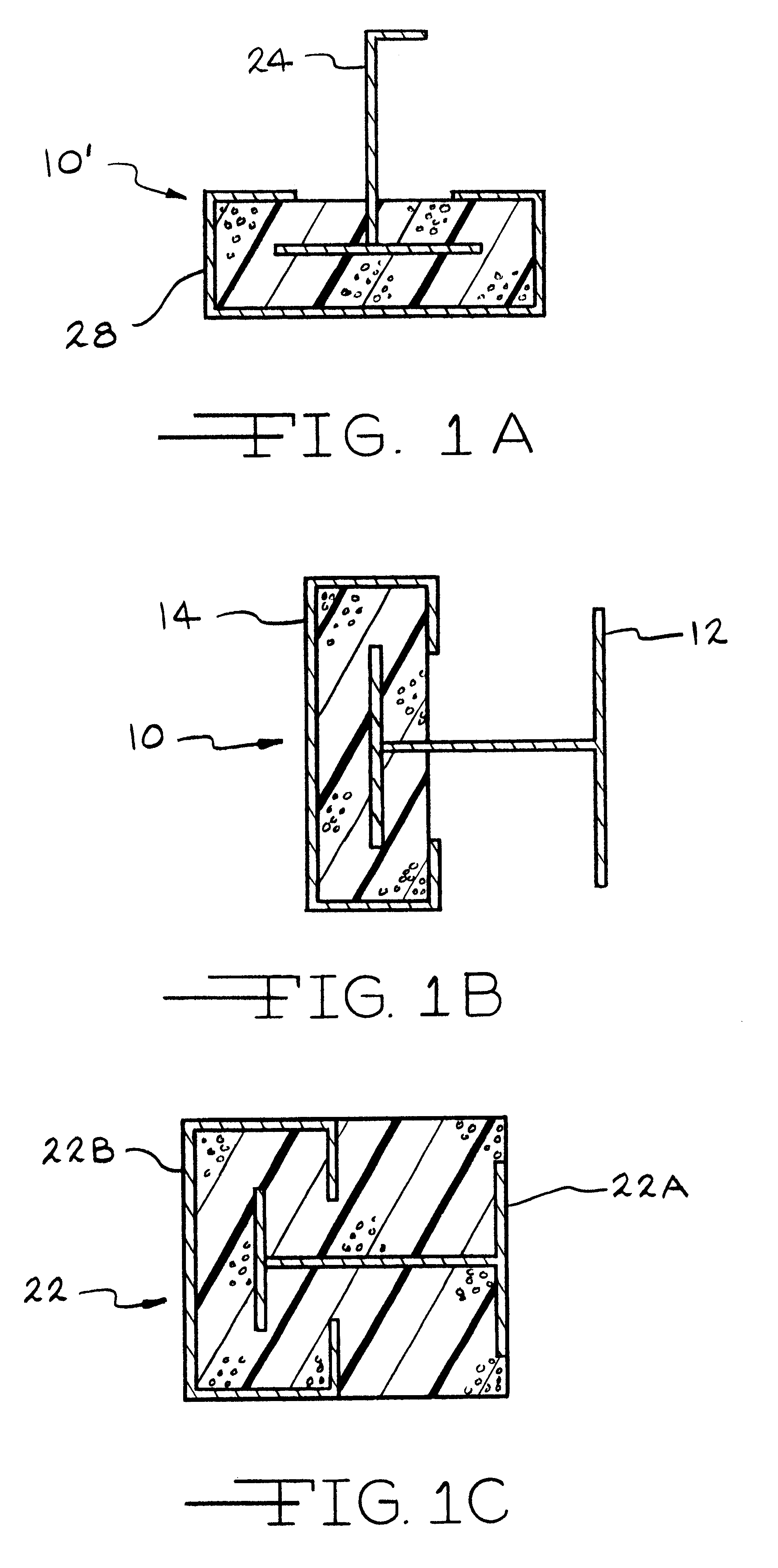

Sheet metal stud and composite construction panel and method

A composite construction panel having a thin panel of concrete material and a reinforcing grid of sheet metal studs with embedment portions which are actually embedded into the concrete panel, each of the studs having a web, main web openings through the web, a right angular flange formed on a free edge of the web, an embedment angled flange portion formed along the opposite edge of the web, an edge strip formed on the angled flange at an angle thereto; and, spaced apart angled flange openings formed in the angled flange for flow of concrete therethrough. An alternate form of stud has a triangular tube structure along one edge of the web. Another form of stud has a discontinuous webs defining spaces between them. In one embodiment two concrete panels may be secured to the studs in spaced relation to create a hollow structure.

Owner:GCG HLDG

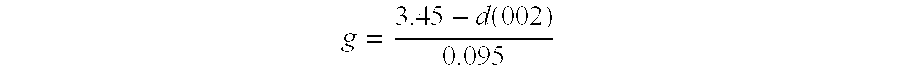

Polycrystalline diamond composite constructions comprising thermally stable diamond volume

ActiveUS7462003B2Improve thermal stabilityConstructionsRecord information storageComposite constructionDiamond crystal

PCD composite constructions comprise a diamond body bonded to a substrate. The diamond body comprises a thermally stable diamond bonded region that is made up of a single phase of diamond crystals bonded together. The diamond body includes a PCD region bonded to the thermally stable region and that comprises bonded together diamond crystals and interstitial regions interposed between the diamond crystals. The PCD composite is prepared by combining a first volume of PCD with a second volume of diamond crystal-containing material consisting essentially of a single phase of bonded together diamond crystals. A substrate is positioned adjacent to or joined to the first volume. The first and second volumes are subjected to high pressure / high temperature process conditions, during process the first and second volumes form a diamond bonded body that is attached to the substrate, and the second volume forms the thermally stable diamond bonded region.

Owner:SMITH INT INC

Method of forming a foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6342172B1Improved thermal and physical propertyImprove performanceSemi-permeable membranesLaminationComposite constructionThermoplastic

Owner:ANDERSEN CORPORATION

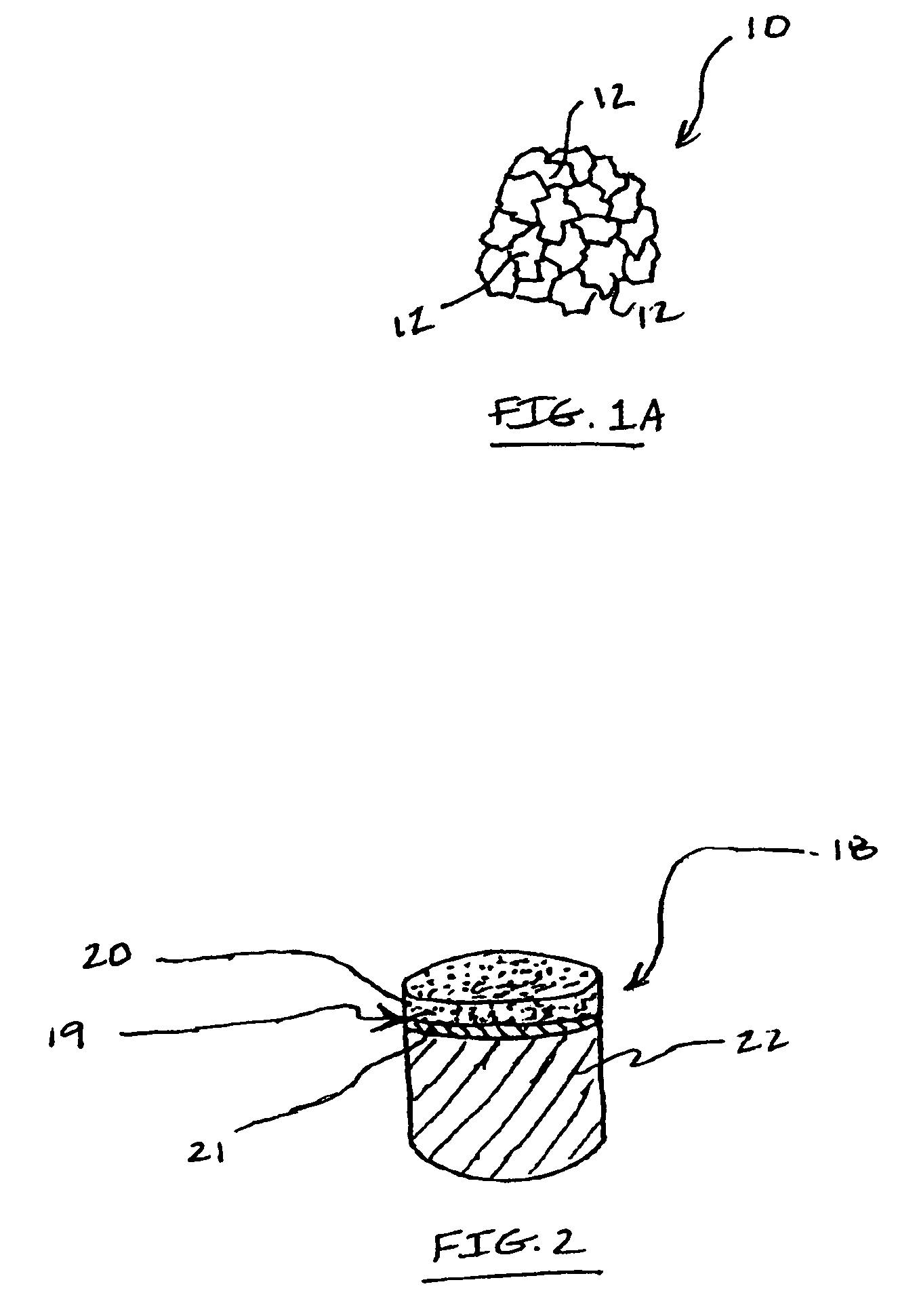

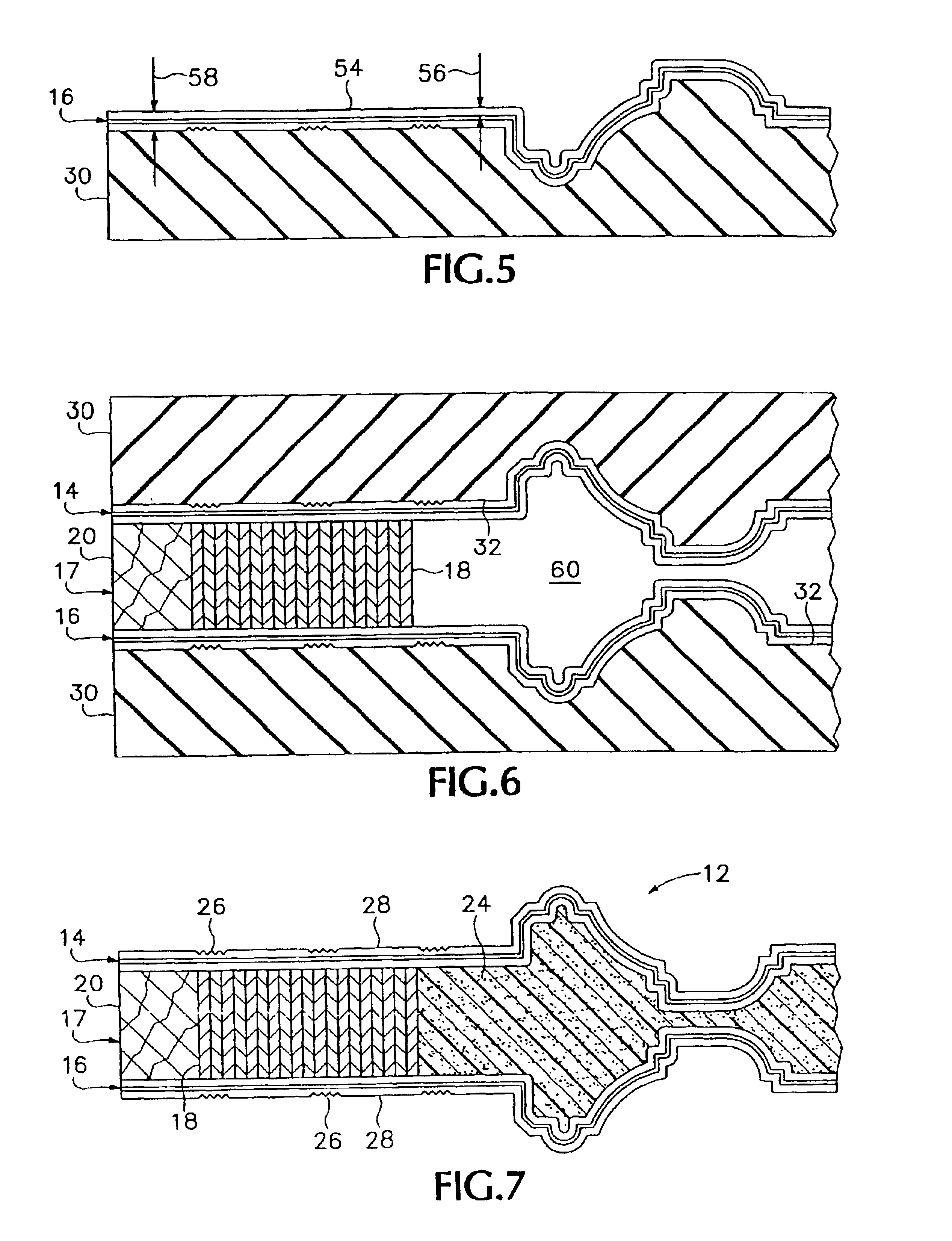

Composite structural material and method of making same

A composite structural material suitable, for example, as a replacement for wooden boards, is disclosed. It comprises a dimensionally stable core material ensheathed in a dimensionally stable, laminar covering that is adherent to the core material. The laminar covering is comprised of at least one layer of parallel cords bonded to at least one layer of a rigidified web material selected from the group consisting of paper and cloth. Suitable core materials include polyurethane foam, optionally filled with granulated rubber and / or expandable polymer beads. The parallel cords preferably are supplied in the form of a strip of polyester cloth, as the warp cords thereof. The web material preferably is kraft paper that is rigidified with an epoxy resin.

Owner:CODA CAPITAL MANAGEMENT GROUP

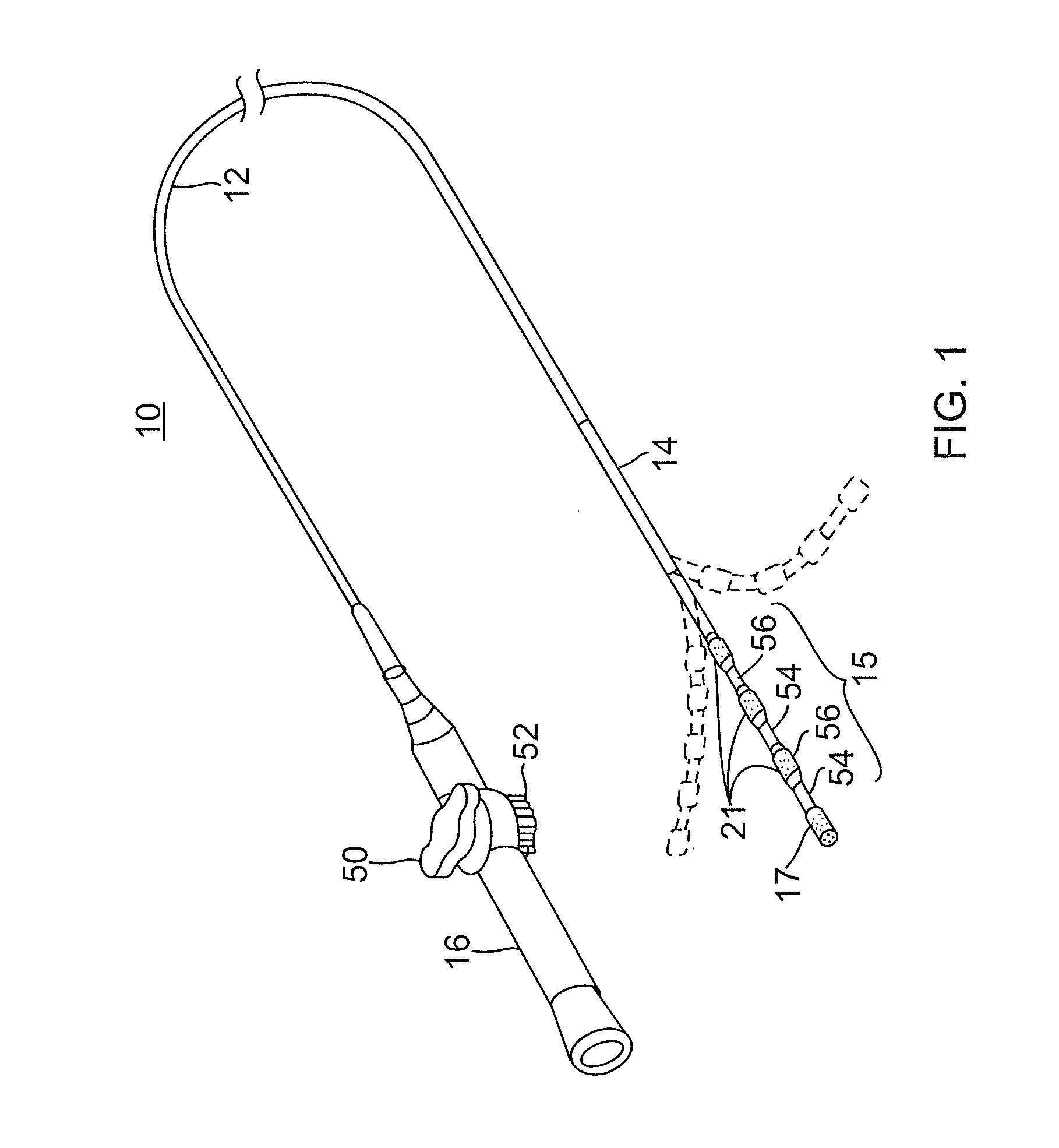

Vascular plug having composite construction

InactiveUS8083768B2Avoid flowInhibit migrationSuture equipmentsOcculdersComposite constructionVascular plug

This invention relates to apparatus and methods for use in sealing a vascular puncture site, particularly sites of punctures that are the result of catheterization or other interventional procedures. In several of the preferred embodiments, the sealing device includes a sealing member and a tether. The sealing member generally performs the function of occupying a space in an incision, puncture, or other wound and sealing the space in the incision, puncture, or wound that it occupies, to prevent further blood flow. The tether is typically attached in some manner to the sealing member, and provides the user with the ability to withdraw the sealing member if necessary. In a particularly preferred form, the sealing device further includes a restraining member associated with the sealing member. The restraining member provides the ability to more securely restrain the sealing member to prevent it from migrating from the deployment location within a tissue tract. The restraining member may also provide an additional capability of manipulating the sealing member after deployment.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

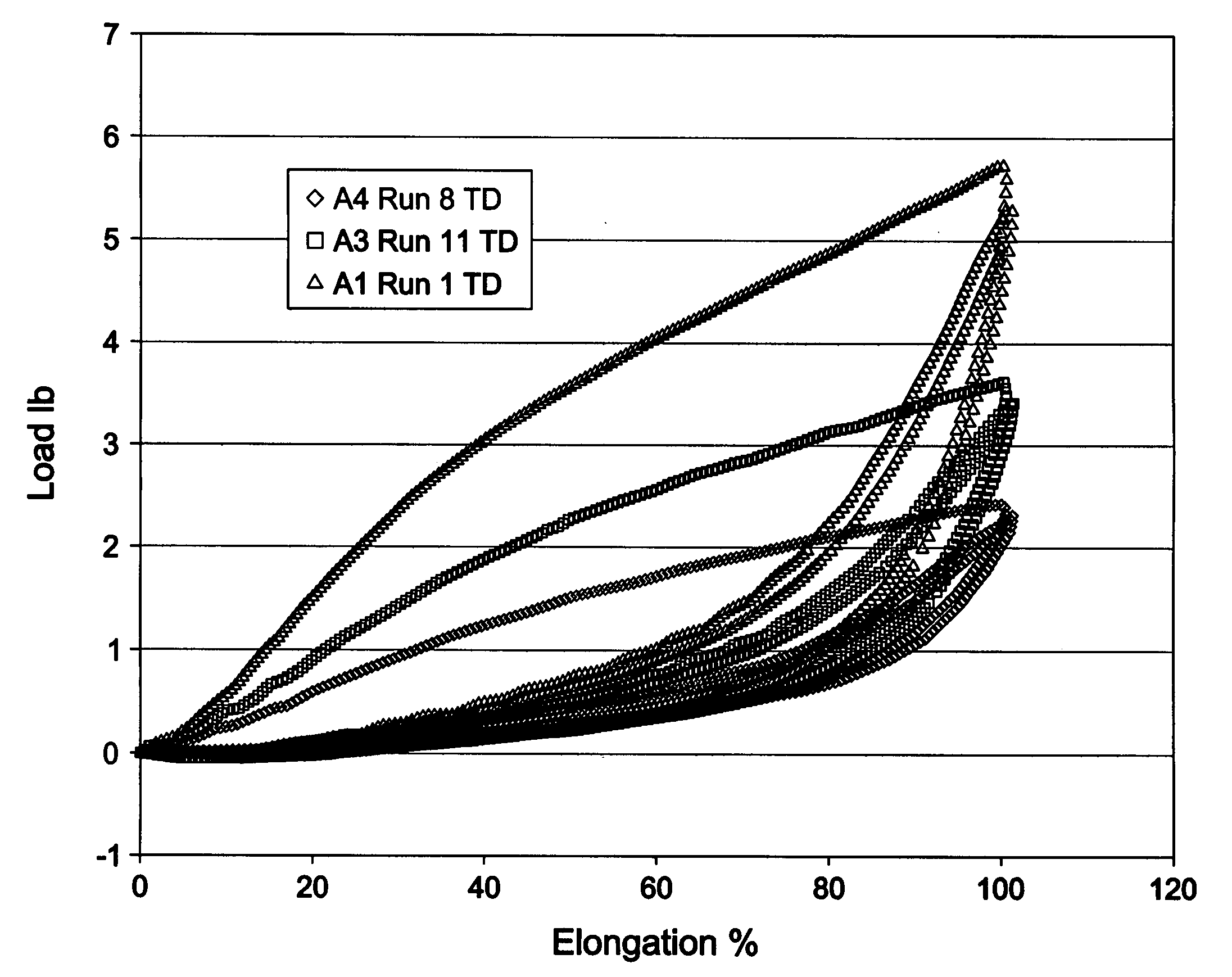

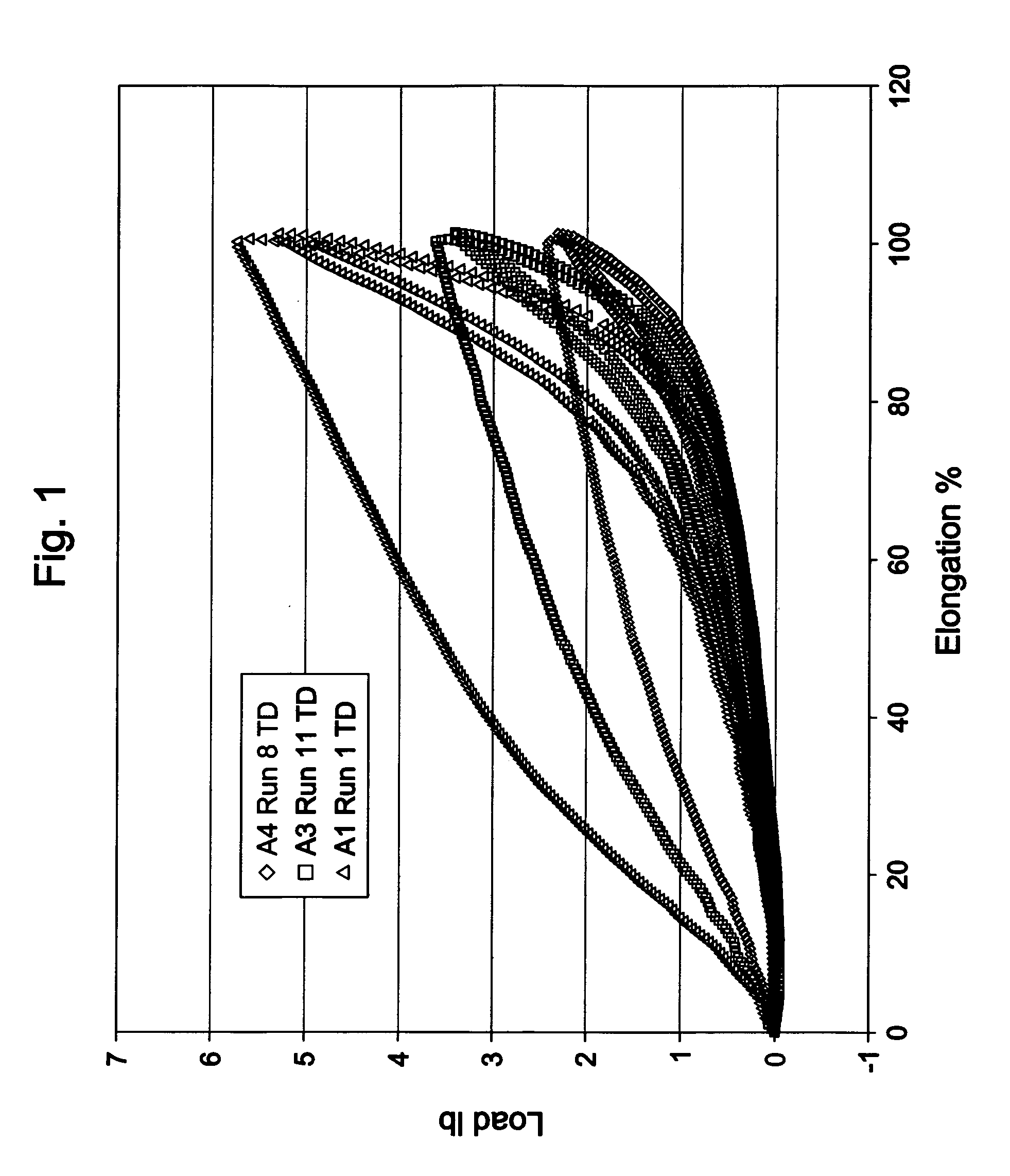

Spunbond fibers and fabrics from polyolefin blends

The invention described relates to a polyolefin blend composition suitable for spunbond fiber or filament compositions, and to fabric compositions and composite constructions therefrom, said blend comprising a) from 60-98 wt % of at least one random propylene copolymer having a comonomer content of from 8 to 25 wt % and a crystalline melting point (Tm) as determined by differential scanning calorimetry (DSC) of from about 40° C. to about 110° C.; and b) from 2-40 wt % of at least one substantially isotactic polypropylene homopolymer or copolymer comprising one or more C2 and / or C4-C8 comonomer, having a crystalline melting point (Tm) as determined by DSC greater than or equal to 120° C. The blends of the present invention typically have a melt flow rate (MFR) of from 100 g / 10min to about 500 g / 10min.

Owner:EXXONMOBIL CHEM PAT INC

Acoustic nacelle inlet lip having composite construction and an integral electric ice protection heater disposed therein

An engine nacelle inlet lip includes both acoustic treatment and electric heating for ice protection. The inlet lip has a composite outer skin and a composite inner skin, with the composite outer skin having at least one integrated heater element embedded in the composite material. An acoustic cellular core positioned between the outer and inner skin acts to attenuate fan noise from the engine. Covering the outer skin and overlying the acoustic core is a perforated erosion shield having a first set of openings that pass entirely thorough its thickness. The composite outer skin includes a second set of openings such that sound waves can pass from an inner barrel portion of the inlet lip through the erosion shield, outer skin, and heater element to the underlying acoustic cellular core.

Owner:THE BF GOODRICH CO +1

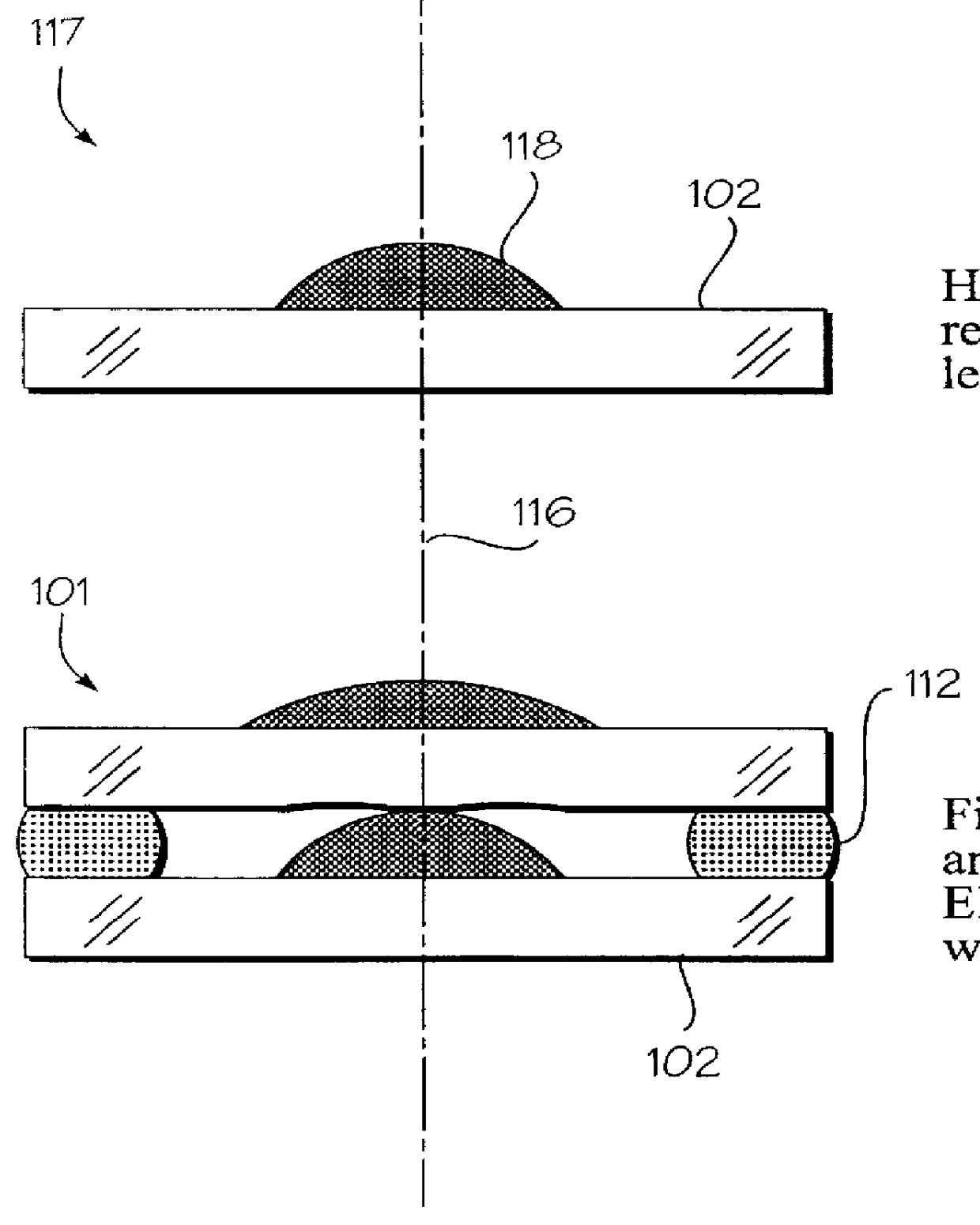

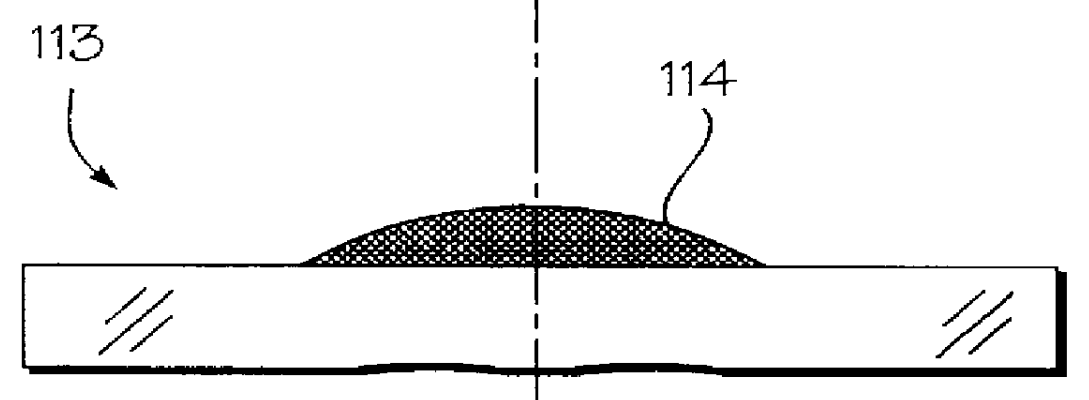

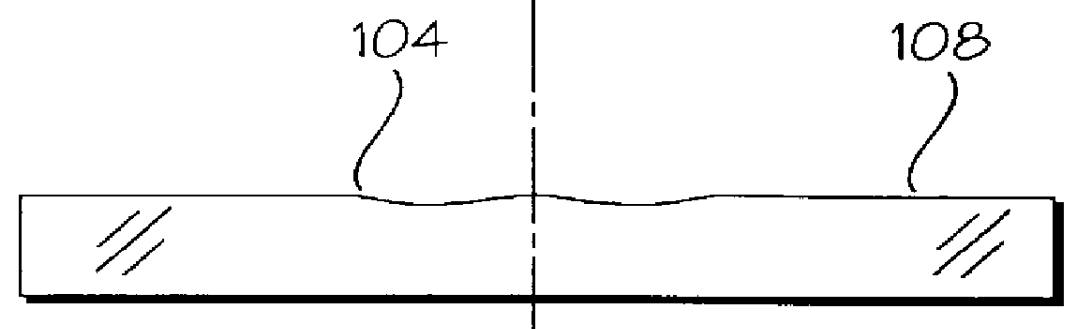

High numerical aperture objective lens manufacturable in wafer form

A composite micro-lens for use in an optical or magneto-optical information storage system, made up of one or more lens elements which, when coupled in assembly, provide a desired numerical aperture. The design may provide, if necessary, a photo resist lens, a shaped ball lens, or one or more contoured surfaces within the composite construction to correct for aberrations. The composite lens designed in this manner allowing for the use of wafer-level assembly processes to provide high volume production capabilities. It is further intended that this micro-lens design support integration in an optical or magneto-optical head design.

Owner:SEAGATE TECH LLC

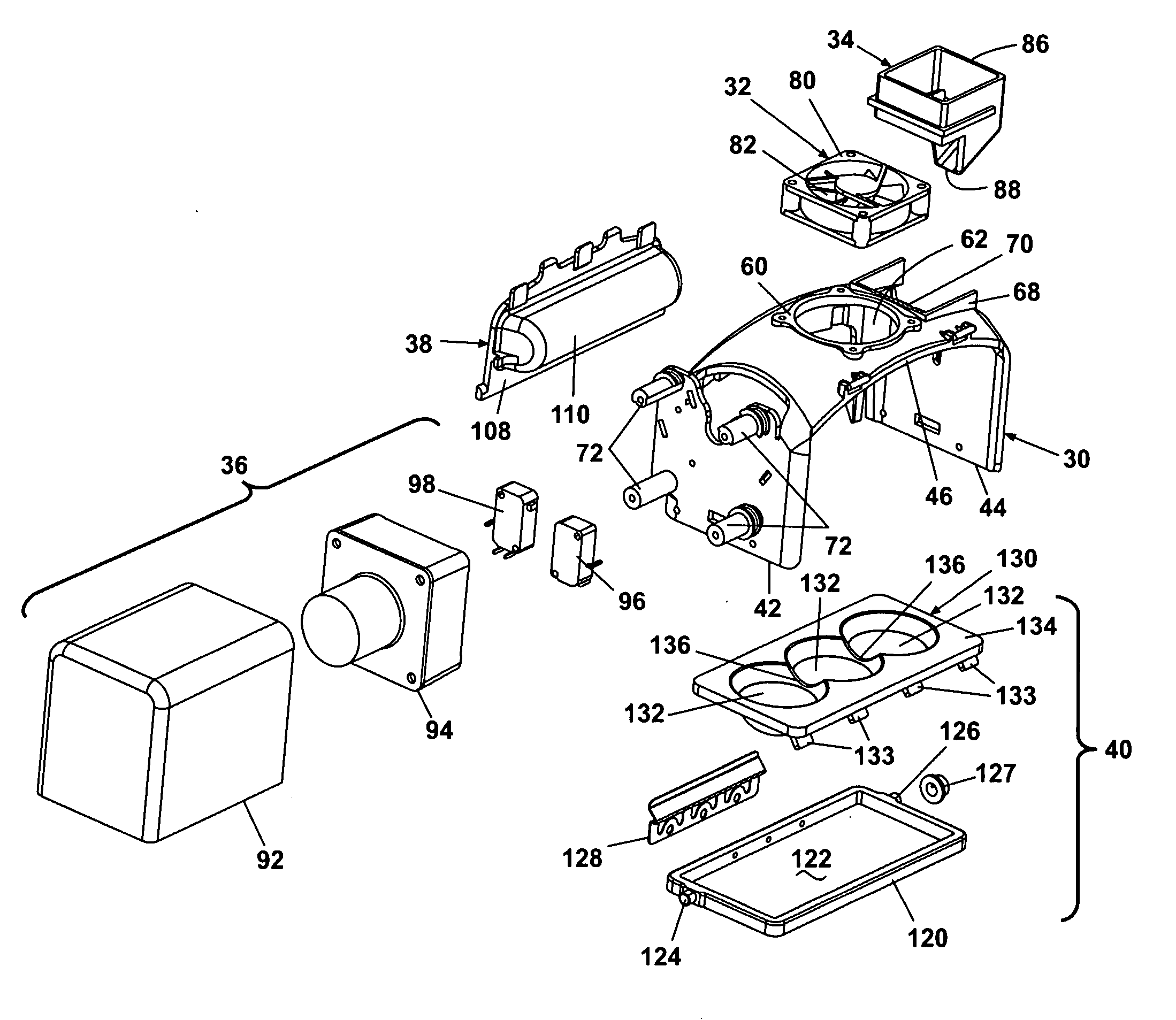

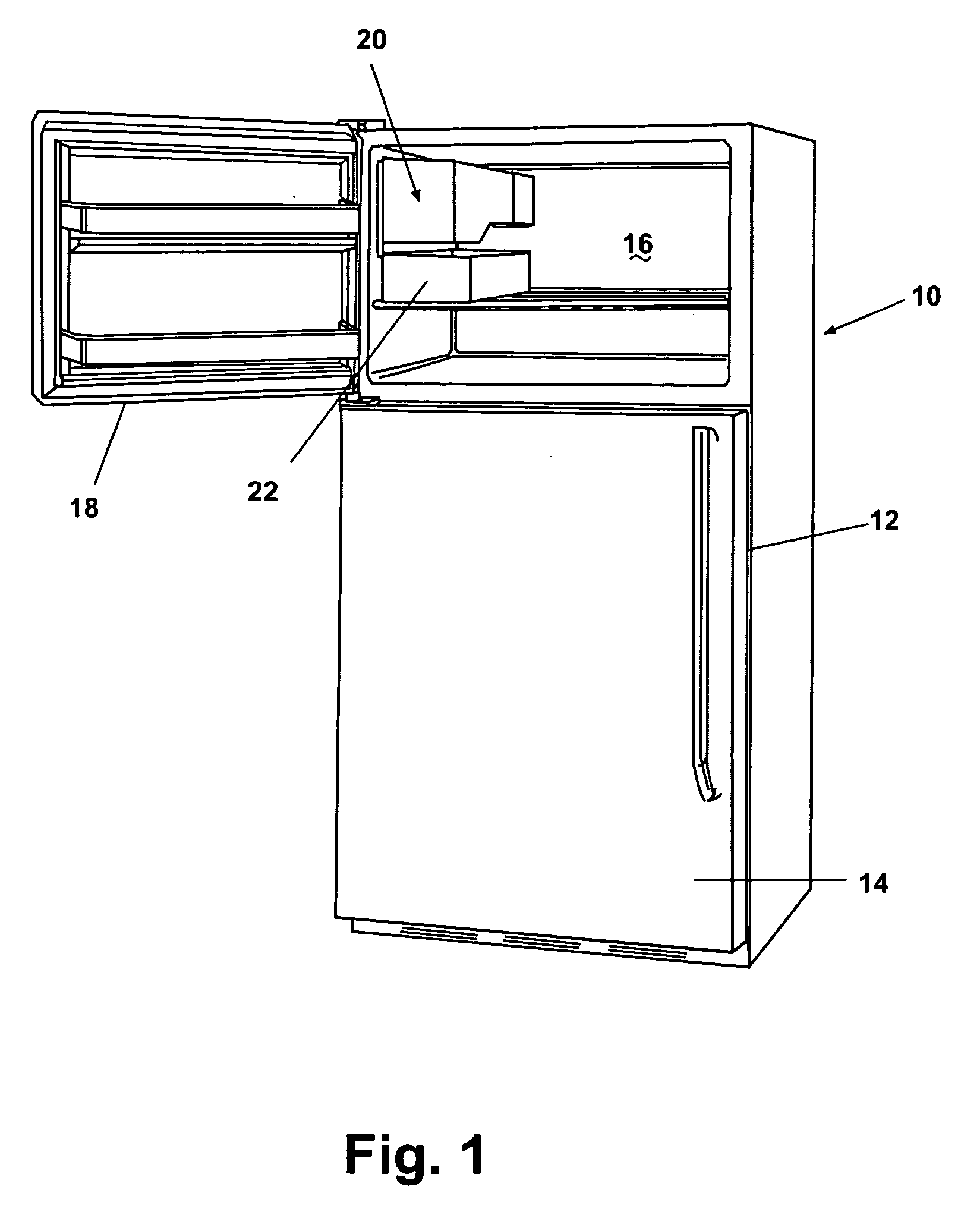

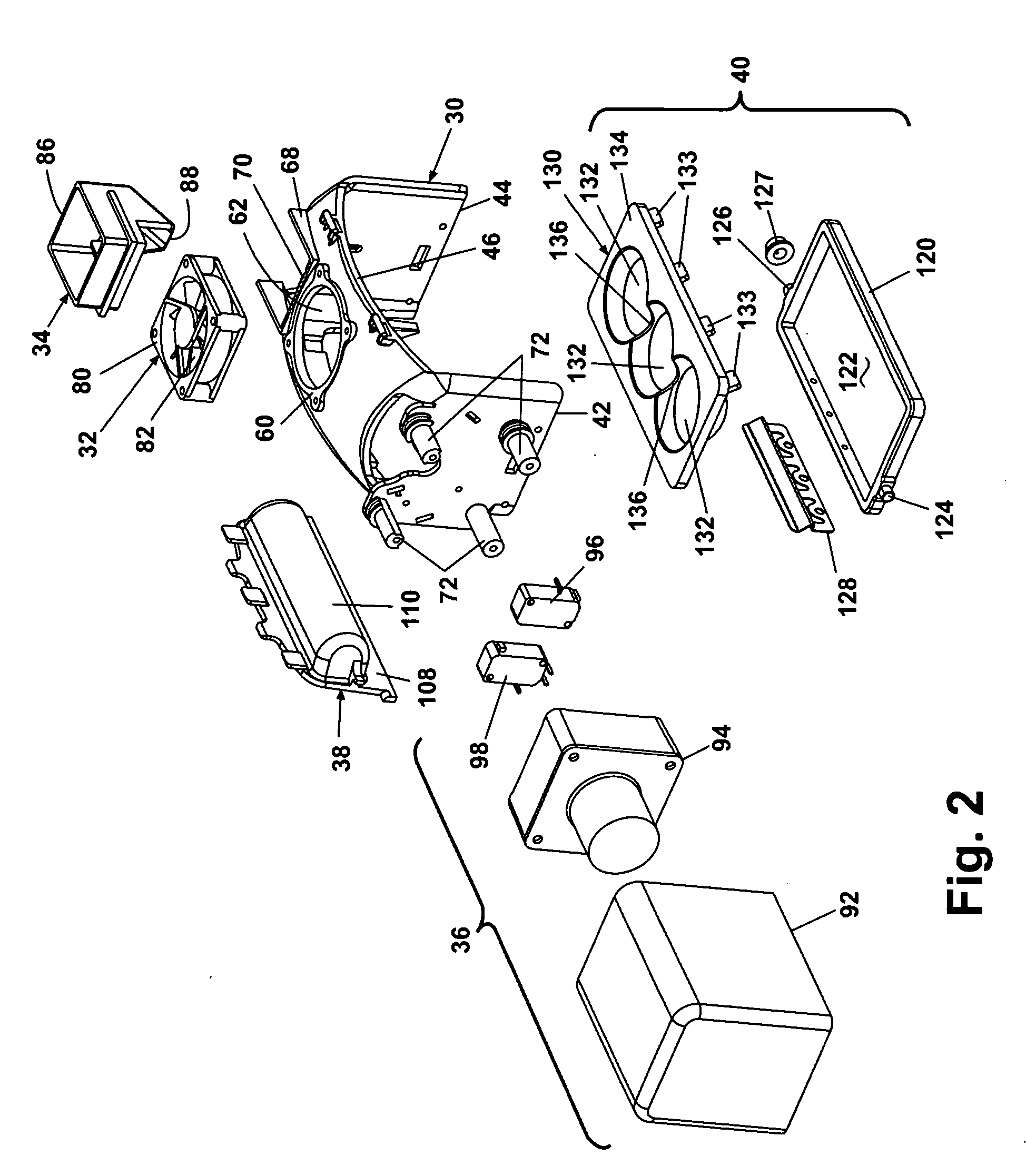

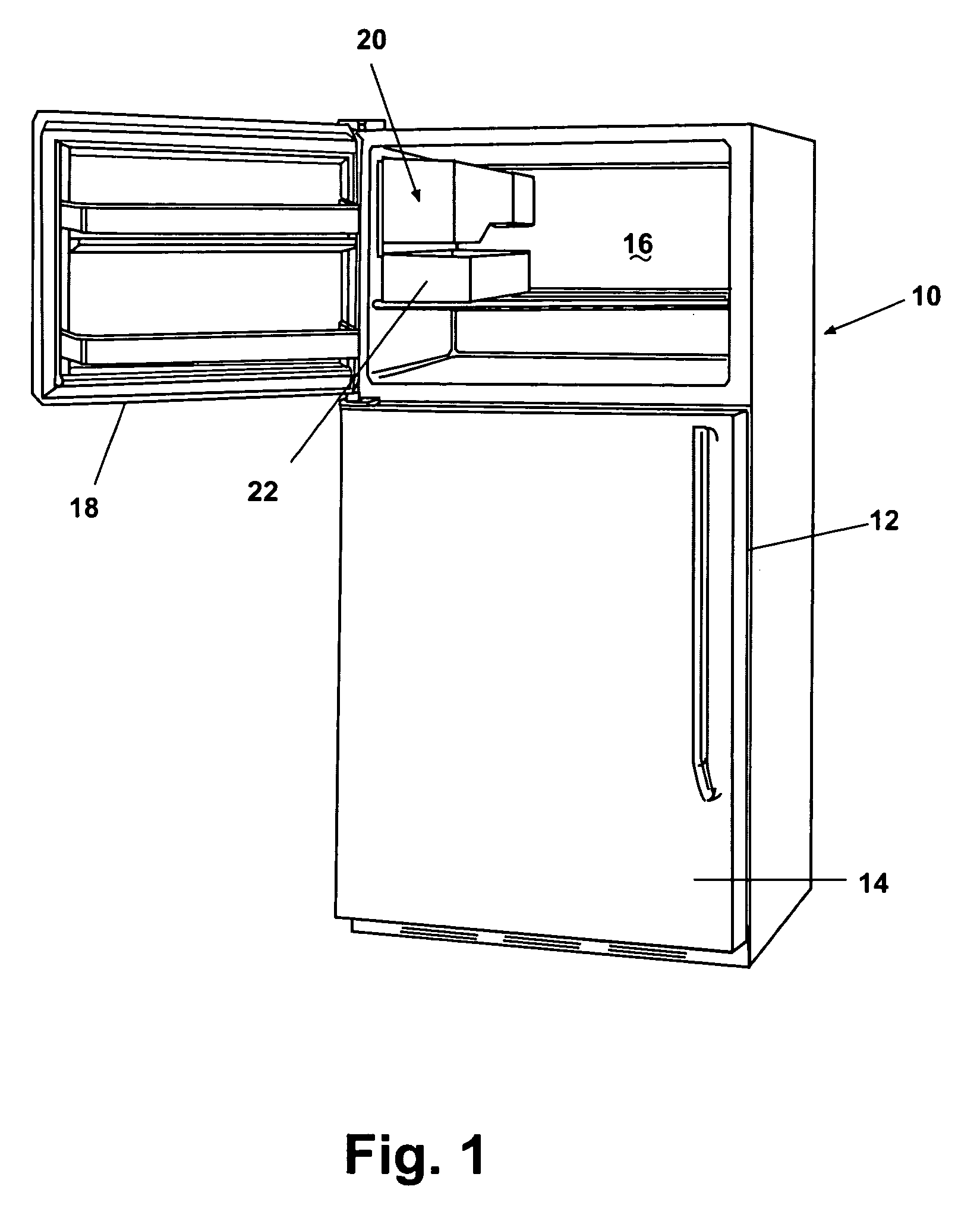

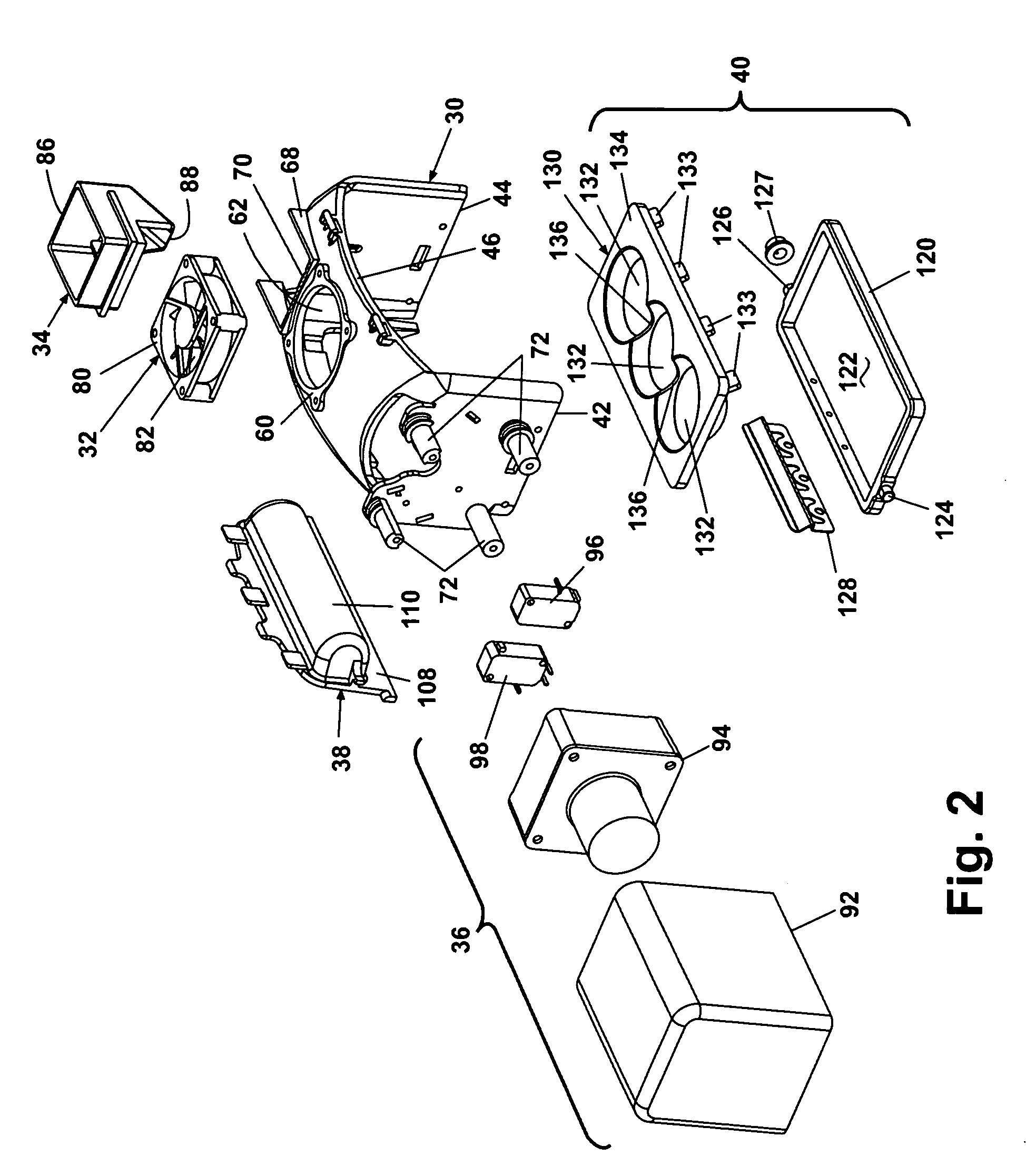

Refrigerator with compact icemaker

InactiveUS20060086134A1Aid removalEasy to disassembleLighting and heating apparatusIce productionComposite constructionMechanical engineering

A refrigerator / freezer with an ice maker having an ice cube tray in which are formed multiple ice cube recesses. The ice cube tray is movable between a fill position and a harvest position. The ice cube tray has a composite construction comprising a base layer and a top layer, with the base layer being made of a flexible material and the top layer being made of a low friction material. The ice cubes are harvested by deflecting or deforming the ice cube recesses to expel the ice cube therefrom when the tray is moved into the harvest position.

Owner:WHIRLPOOL CORP

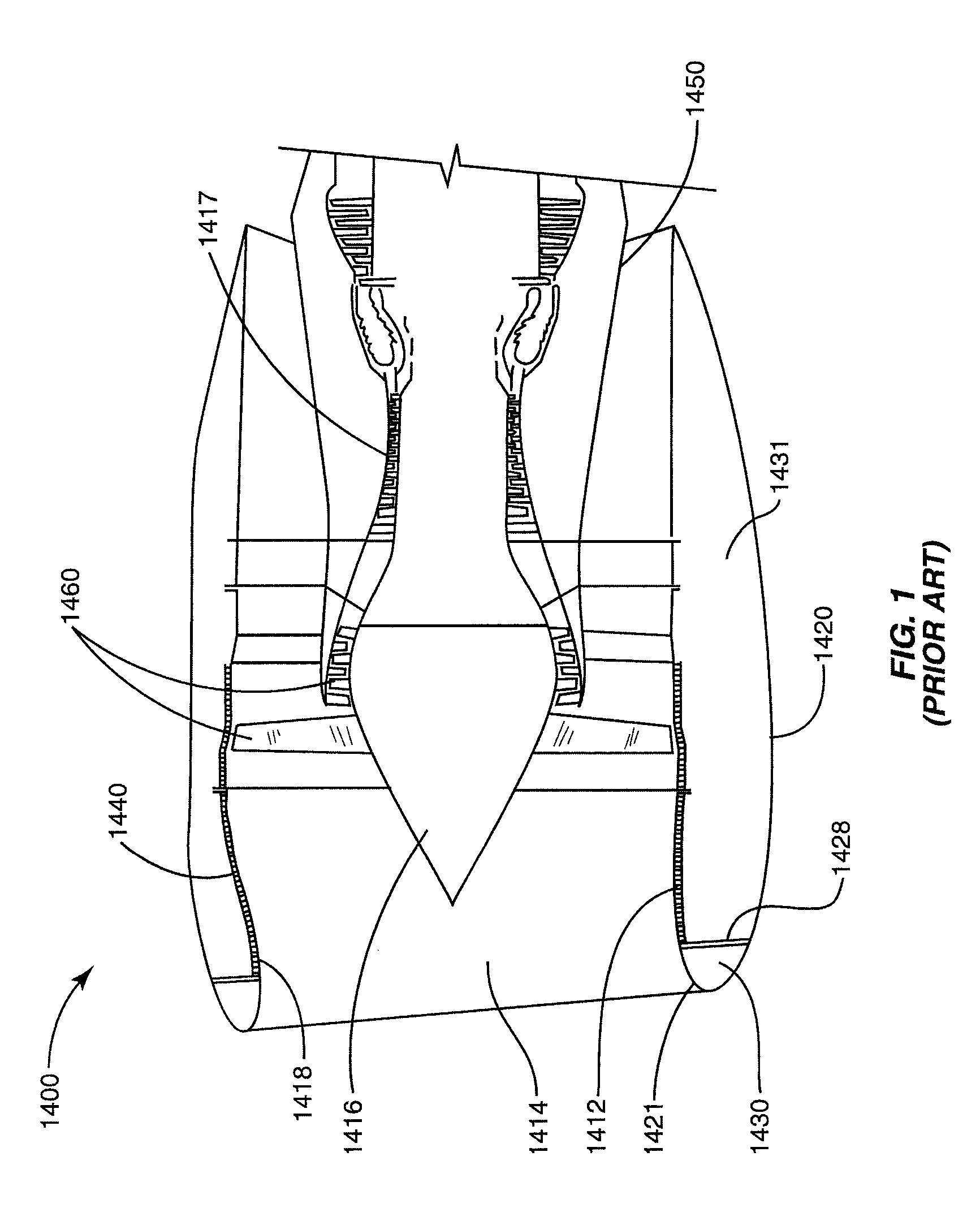

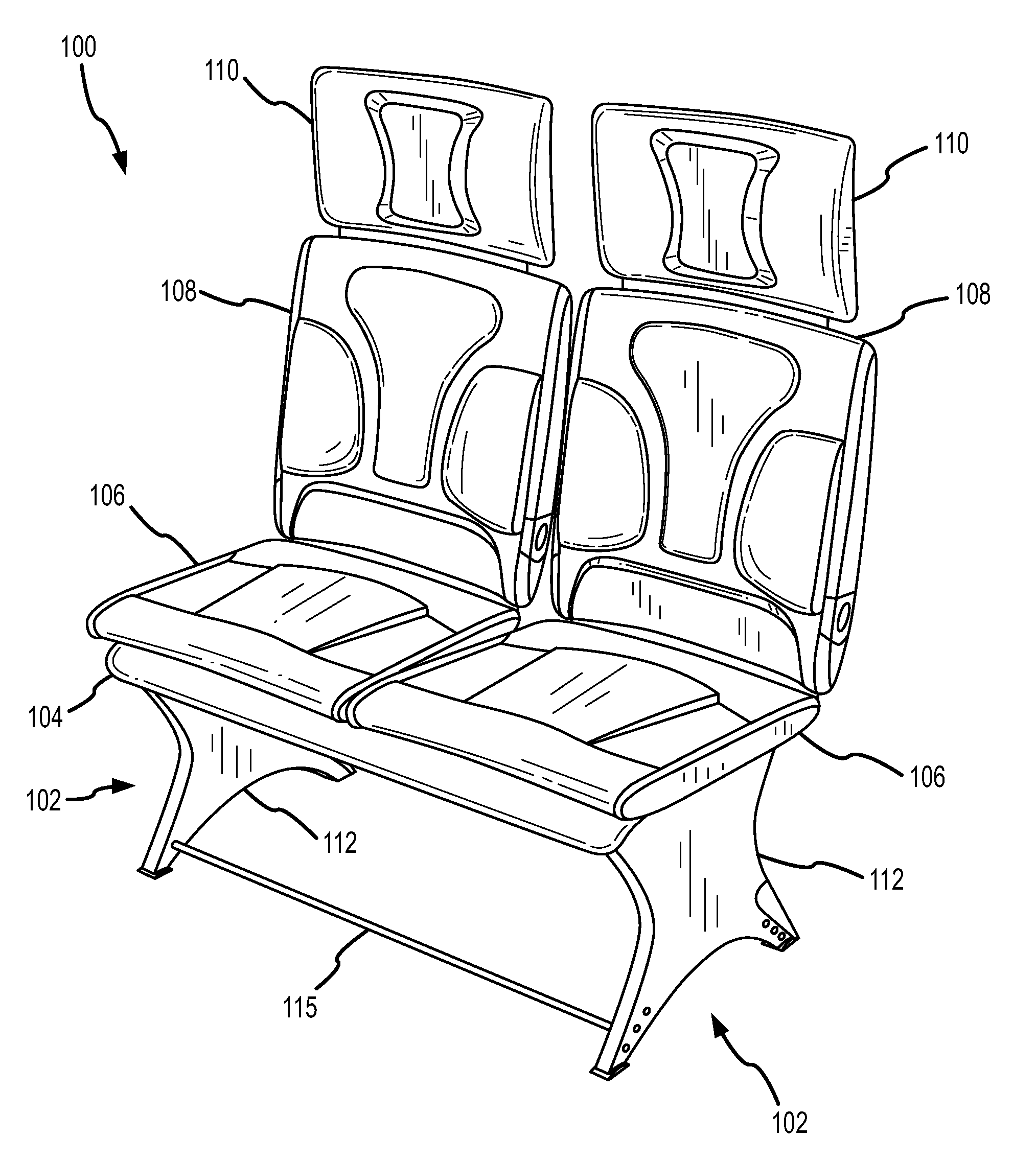

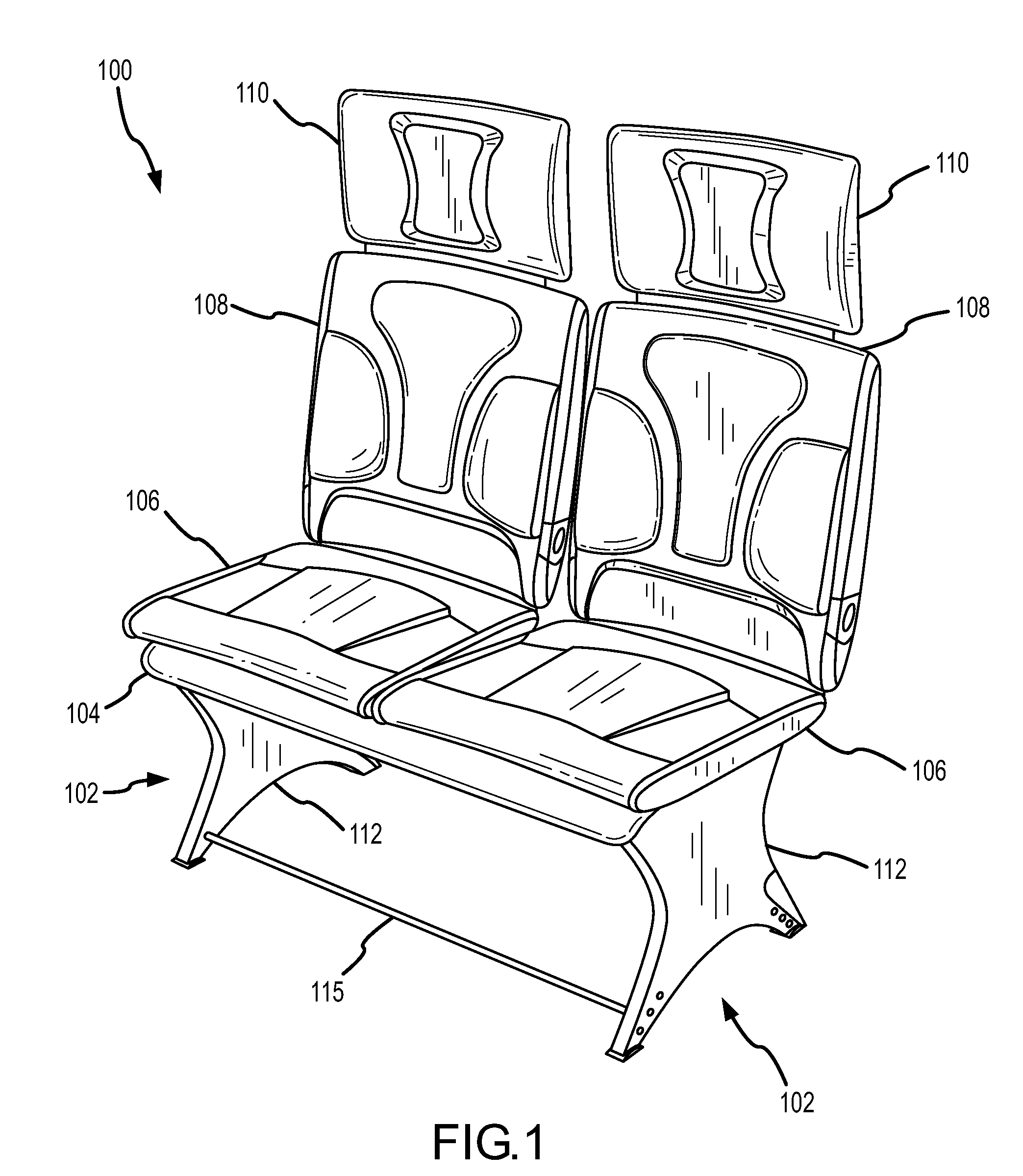

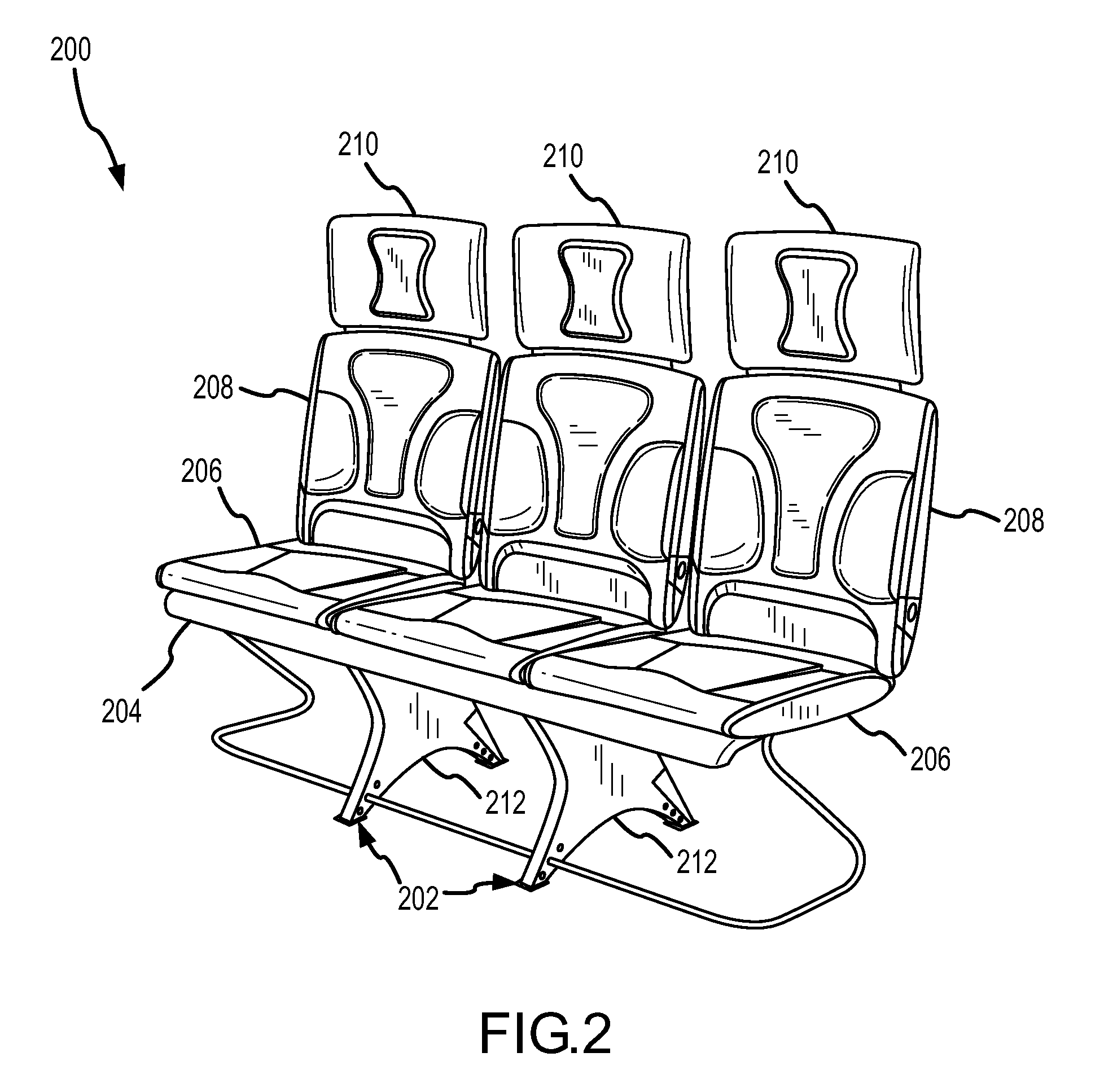

Lightweight aircraft passenger seat with composite construction

InactiveUS20070267543A1Reduce weightSmall sizeVehicle seatsSeating arrangementsComposite constructionManufacturing technology

An aircraft seat assembly configured in accordance with an example embodiment of the invention utilizes composite materials to achieve significant weight savings relative to conventional seat designs. The seat assembly includes a lightweight composite support structure, a lightweight composite seat base, and a seat back assembly that employs a lightweight inner frame. The seat cushion and the seat back cushion may utilize a sealed pneumatic element that self-inflates to provide increased air cushioning during flight. The seat assembly can leverage inexpensive manufacturing techniques such that the seat assembly can be economically produced for use as an economy class seat.

Owner:THE BOEING CO

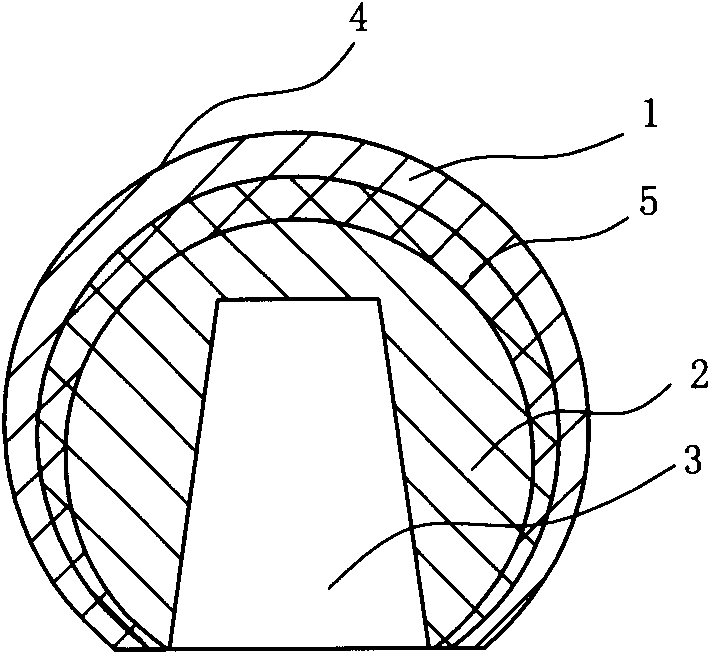

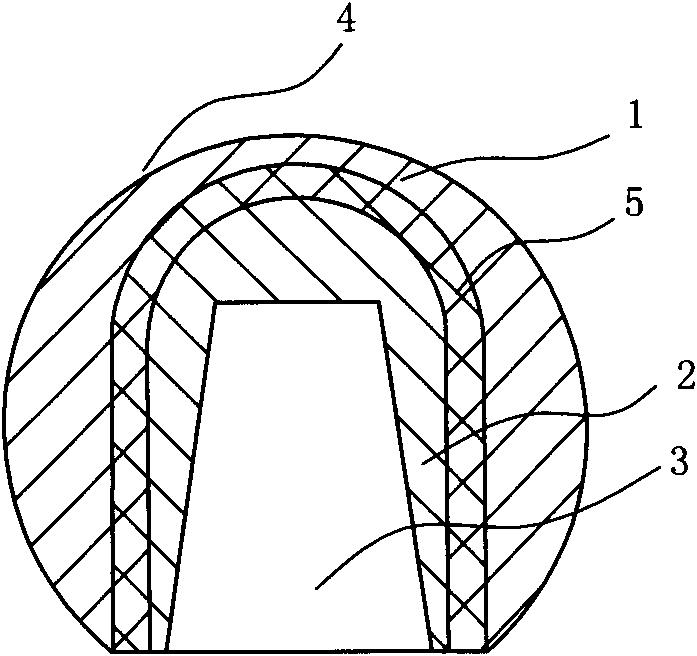

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

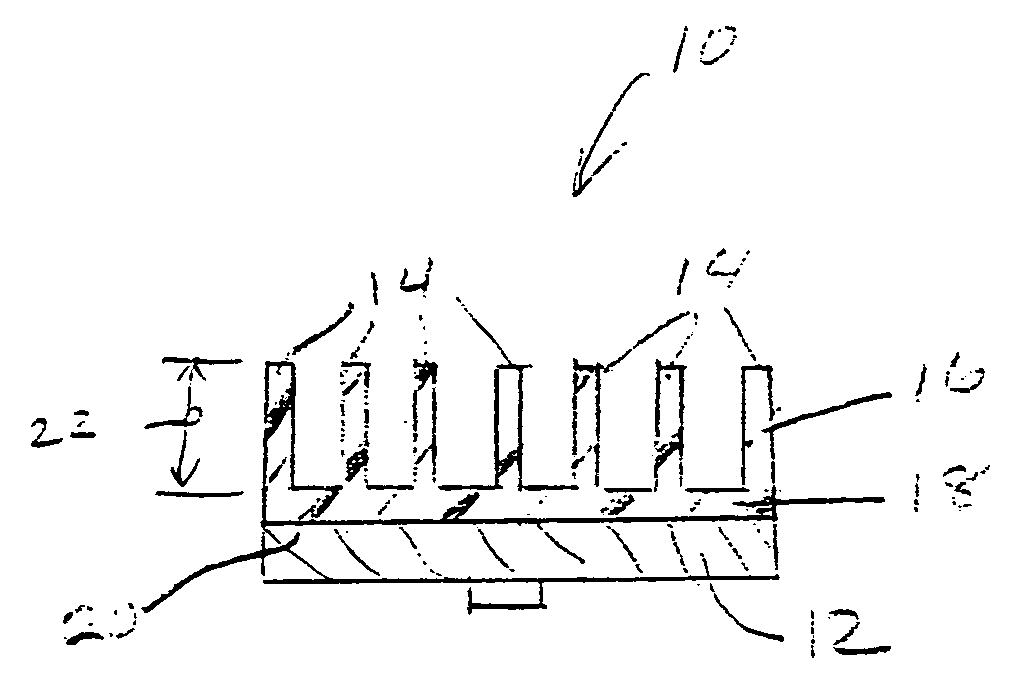

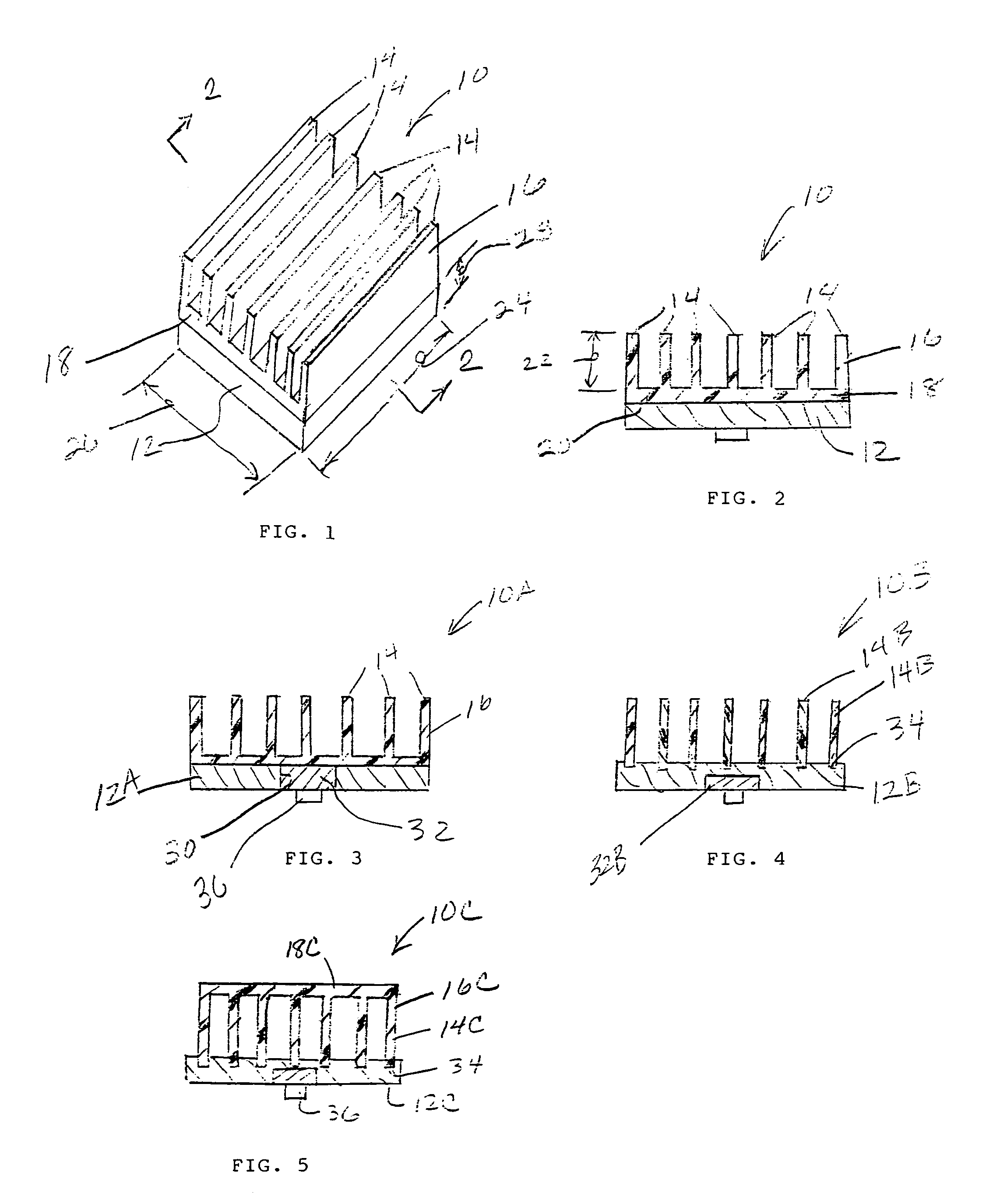

Optimized heat sink using high thermal conducting base and low thermal conducting fins

InactiveUS7108055B2Cheap constructionSemiconductor/solid-state device detailsSolid-state devicesComposite constructionPlastic materials

An optimized design for a composite heat sink is provided utilizing a high thermal conducting base and low thermal conducting fins. The base preferably is constructed from anisotropic graphite material, and the fins are preferably constructed from a thermally conductive plastic material. In the case of a low profile heat sink having a fin height of no greater than about 3 times that of the base, the composite construction provides superior cooling yet lighter weight as compared to a conventional all-aluminum heat sink of the same dimensions.

Owner:NEOGRAF SOLUTIONS LLC

Vascular plug having composite construction

InactiveUS20120101520A1Avoid flowInhibit migrationOcculdersSurgical veterinaryComposite constructionVascular plug

This invention relates to apparatus and methods used to seal a vascular puncture site, particularly sites of punctures that are the result of catheterization or other interventional procedures. The sealing device includes a sealing member and a tether. The sealing member occupies a space in an incision, puncture, or other wound and sealing the space that it occupies, to prevent further blood flow. The tether is attached to the sealing member, and provides the user with the ability to withdraw the sealing member if necessary. The sealing device further includes a restraining member associated with the sealing member. The restraining member provides the ability to more securely restrain the sealing member to prevent it from migrating from the deployment location within a tissue tract. The restraining member also provides an additional capability of manipulating the sealing member after deployment.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Contoured crushable composite structural members and methods for making the same

Owner:DELPHI TECH INC

Refrigerator with compact icemaker

InactiveUS7185508B2Aid removalEasy to disassembleLighting and heating apparatusIce productionComposite constructionMechanical engineering

A refrigerator / freezer with an ice maker having an ice cube tray in which are formed multiple ice cube recesses. The ice cube tray is movable between a fill position and a harvest position. The ice cube tray has a composite construction comprising a base layer and a top layer, with the base layer being made of a flexible material and the top layer being made of a low friction material. The ice cubes are harvested by deflecting or deforming the ice cube recesses to expel the ice cube therefrom when the tray is moved into the harvest position.

Owner:WHIRLPOOL CORP

Reinforced rampdown for composite structural member and method for same

InactiveUS20060188696A1Synthetic resin layered productsLaminationMaterials scienceComposite construction

Owner:THE BOEING CO

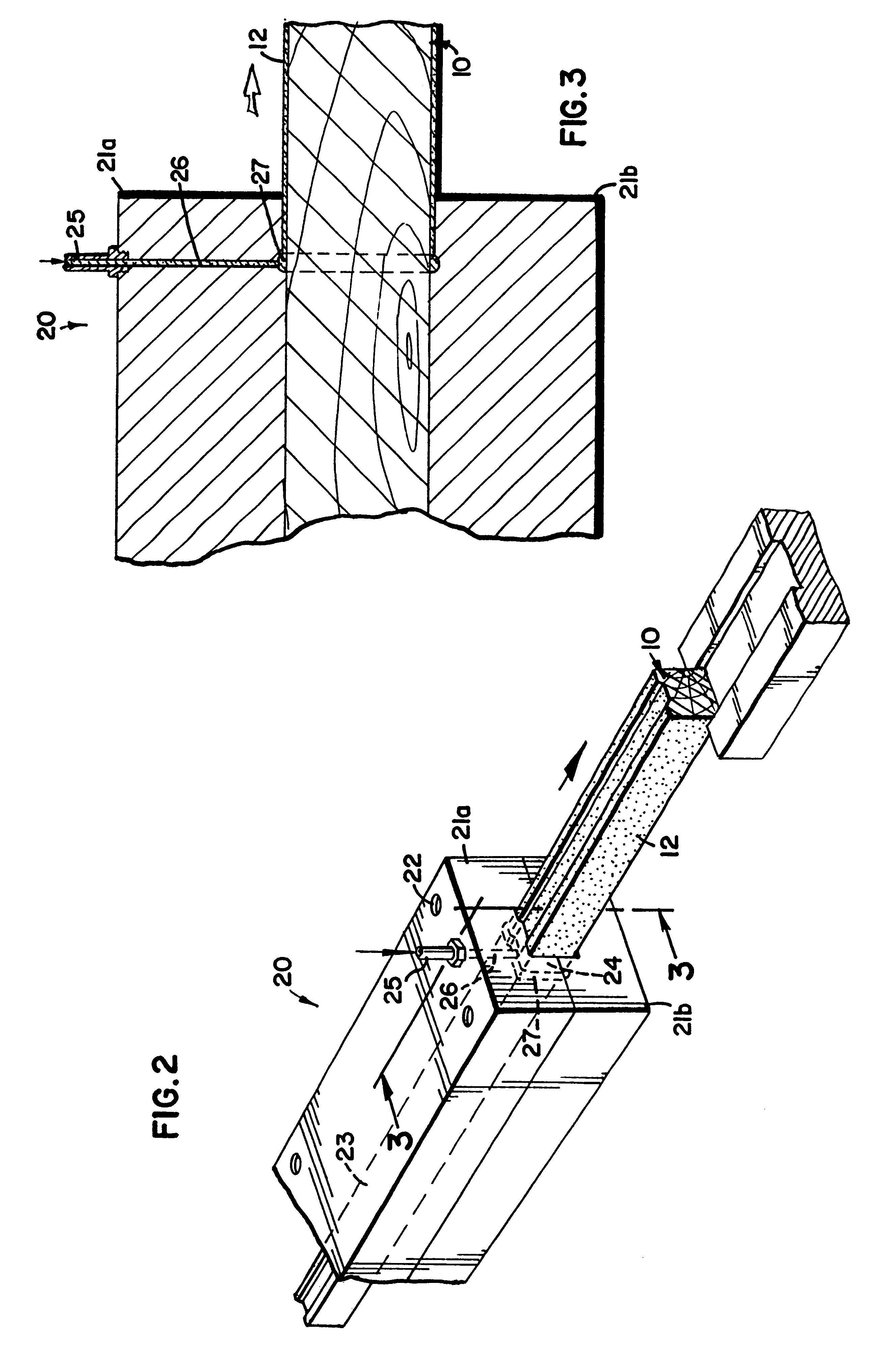

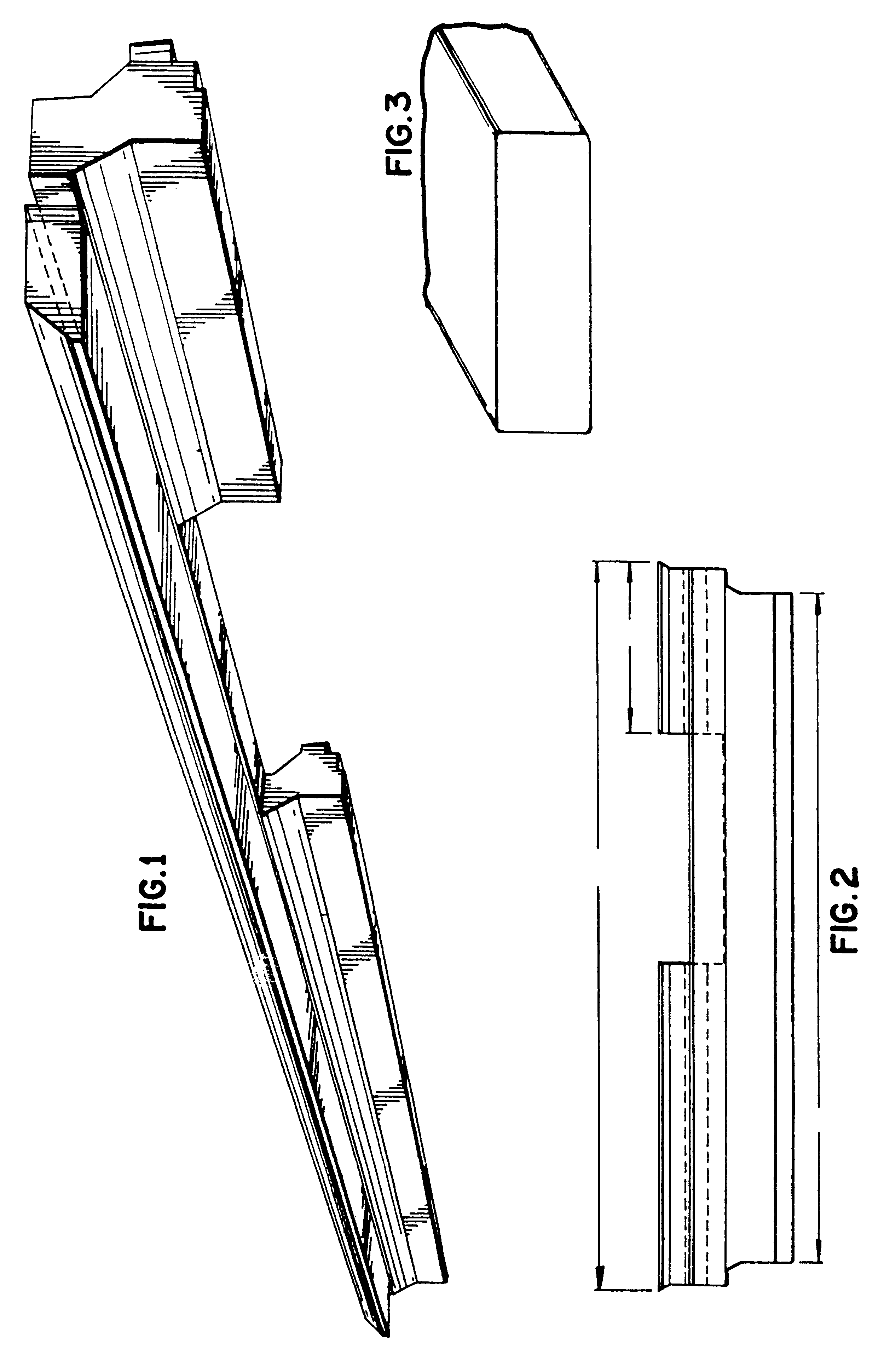

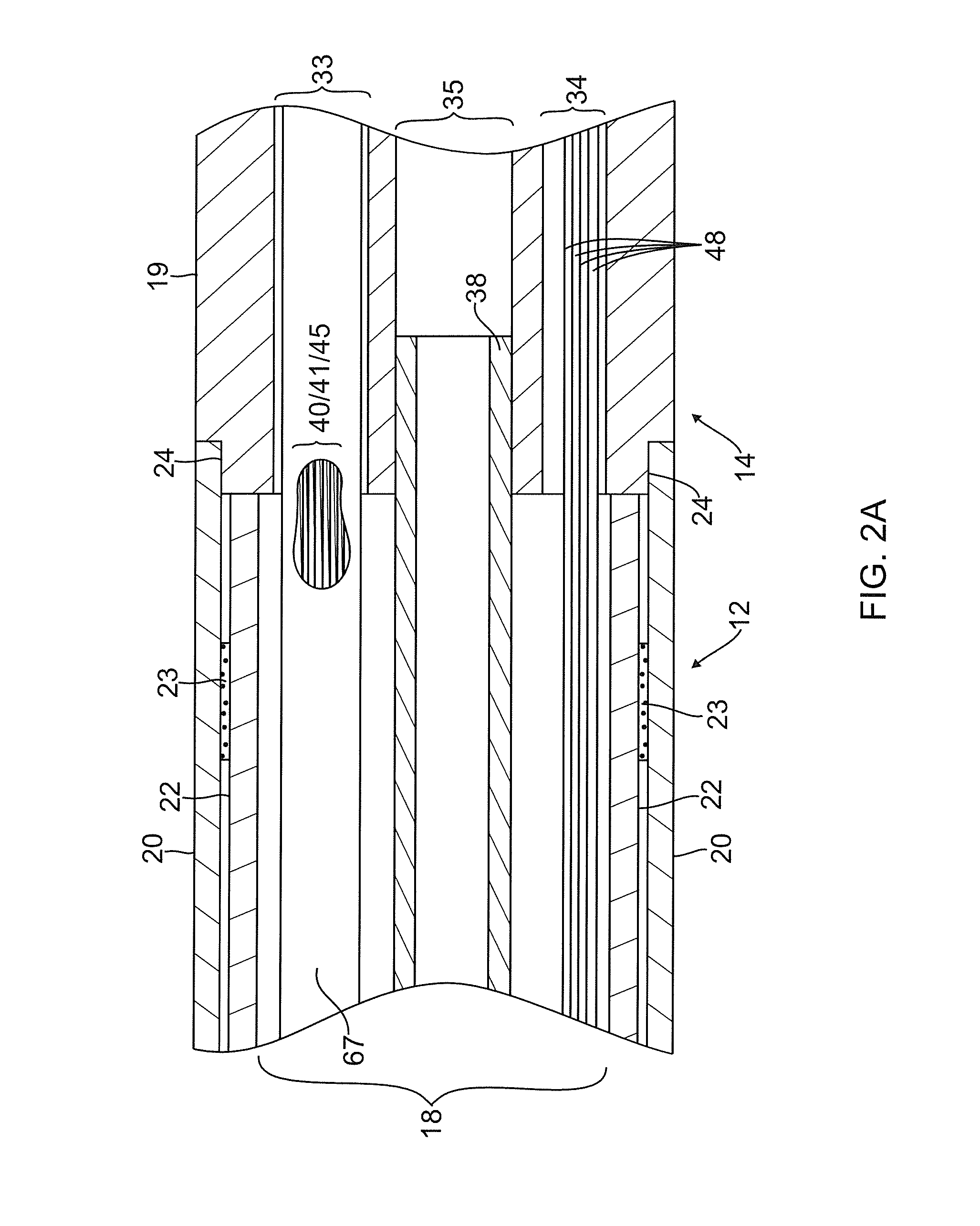

Composite structural material and method of making same

InactiveUS20070113759A1Conserve costIncrease the proportionSynthetic resin layered productsPaper/cardboard layered productsPolyesterEpoxy

A composite structural material suitable, for example, as a replacement for wooden boards, is disclosed. It comprises a dimensionally stable core material ensheathed in a dimensionally stable, laminar covering that is adherent to the core material. The laminar covering is comprised of at least one layer of parallel cords (19) bonded to at least one layer of a rigidified web material (10) selected from the group consisting of paper and cloth. Suitable core materials include polyurethane foam (38), optionally filled with particles (32) of granulated rubber, expanded perlite, expandable polymer beads, and / or glass microspheres. The parallel cords (19) preferably are supplied in the form of a strip of polyester cloth, as the warp cords thereof. The web material (10) preferably is kraft paper that is rigidified with an epoxy resin.

Owner:CODA CAPITAL MANAGEMENT GROUP

Sheet metal stud and composite construction panel and method

A composite construction panel having a thin panel of concrete material and a reinforcing grid of sheet metal studs with embedment portions which are actually embedded into the concrete panel, each of the studs having a web, right angular flange formed on a free edge of the web, an angled edge strip formed along the free edge of the right angular flange, an embedment angled flange portion formed along the opposite edge of the web, an edge strip formed on the angled flange at an angle thereto; and, spaced apart angled flange openings formed in the angled flange for flow of concrete therethrough. An alternate form of stud has a triangular tube structure along one edge of the web. Another form of stud has a discontinuous webs defining spaces between them. In one embodiment two concrete panels may be secured to the studs in spaced relation to create a hollow structure.

Owner:BODNAR ERNEST R

Acoustical composite steel member

InactiveUS6494012B2Excellent acoustical and sound dampening propertyImprove acoustic propertiesStrutsWallsComposite constructionUltimate tensile strength

This composite building stud combines two metal shapes, inner and outer, with an insulating material to form a composite structural member having excellent acoustical properties. The stud also has an insulating valve (R-value) greater than a similar metal member normally used as a stud in a residential structure. The composite also has a strength comparable to that of a similar steel member normally used as a stud in a residential structure. One shape encompasses the other shape. The composite structural member eliminates any direct metal connections and thus eliminates any thermal shorts that reduce the overall insulating value (R-value) of the composite member.

Owner:EAST OHIO MACHINERY

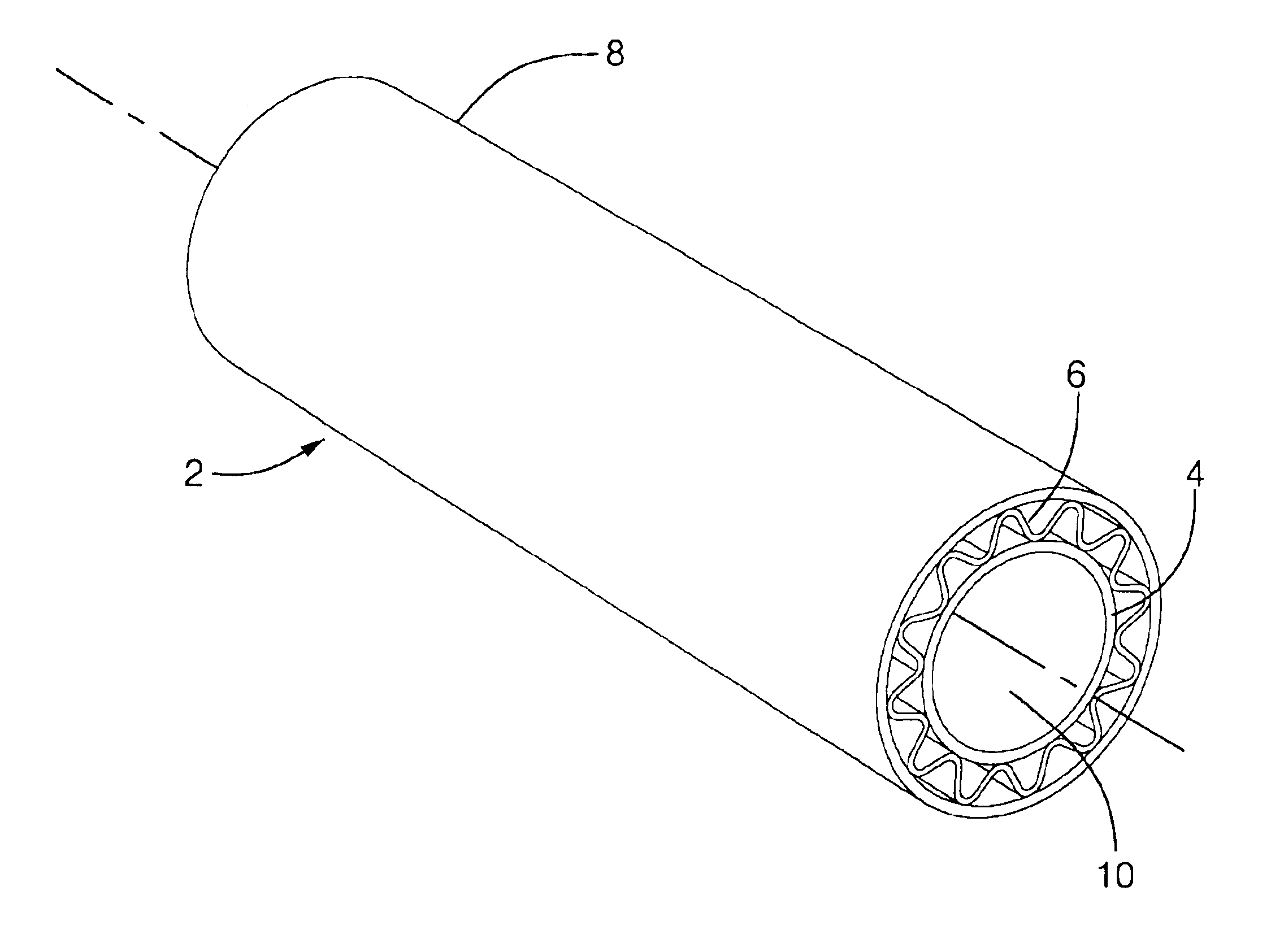

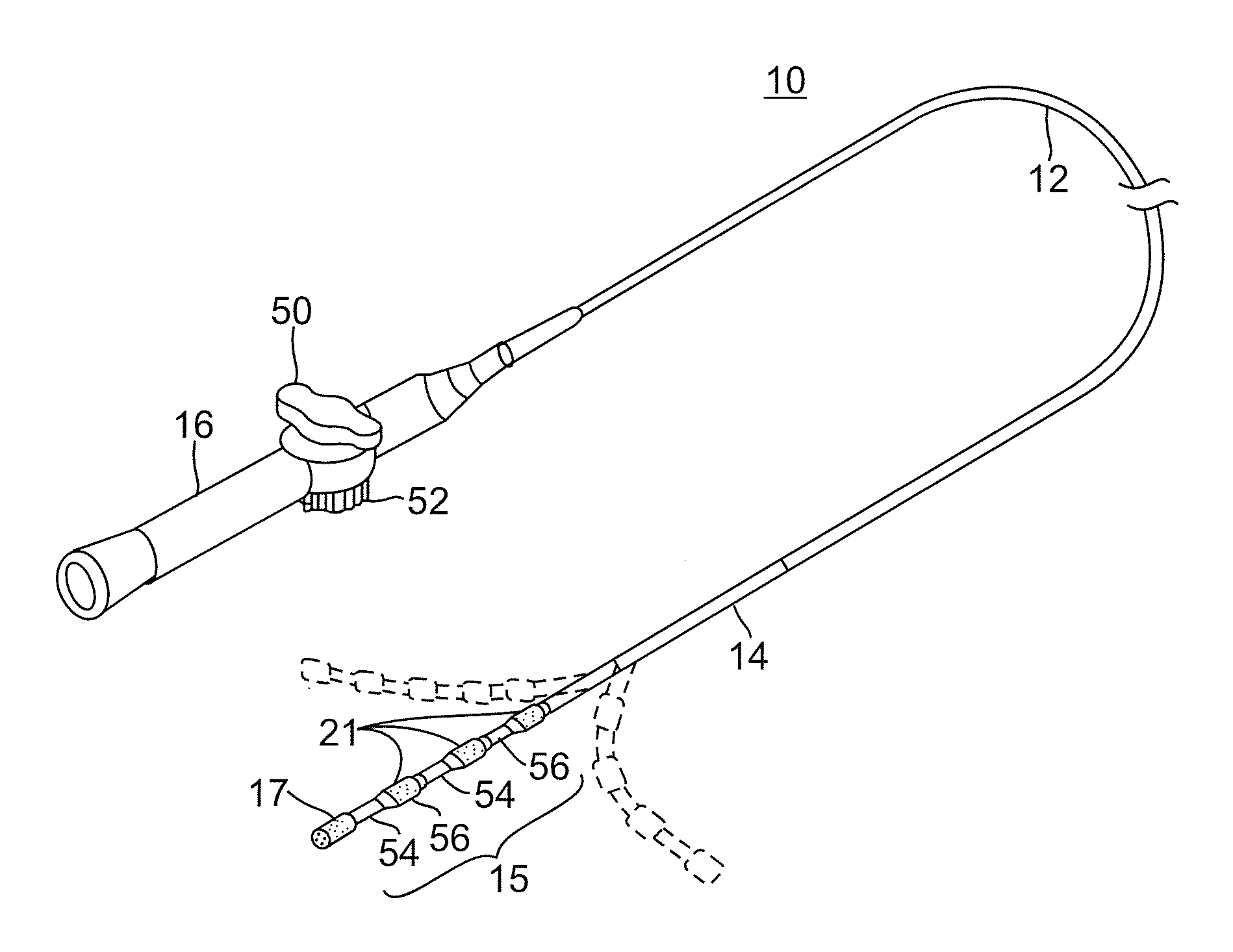

Catheter with composite construction

ActiveUS20130253505A1Increase catheter sizeLess spaceDiagnosticsSurgical navigation systemsComposite constructionEngineering

A catheter has a composite and segmented construction in a distal section that includes deflectable members and support member arranged in alternating sequence, with each support member carrying a ring electrode and the deflectable members being flexible to allow deflection of the distal section as a whole. Carried on an outer surface of the support member is a coil location sensor. The distal section is configured with a distal irrigation fluid path extending axially through the deflectable members and the support members to deliver irrigation fluid to the ring electrode and the tip electrode. A method of constructing a catheter includes building a section of the catheter from the inside out by mounting the support members on a tubing at predetermined locations and filling gaps in between with a more flexible material to form the deflectable members by extrusion segments or injection molding over assembled components internal to the catheter.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

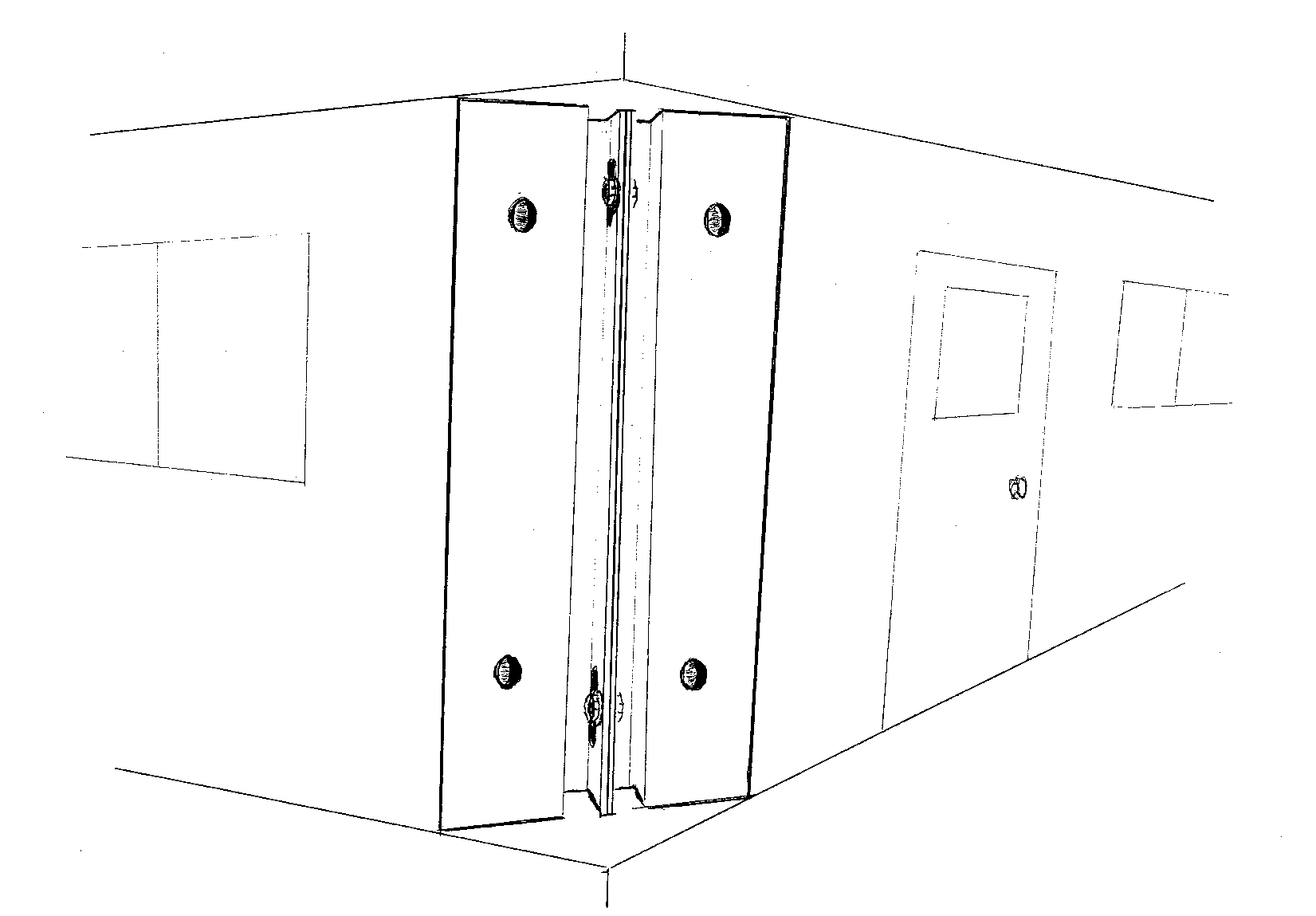

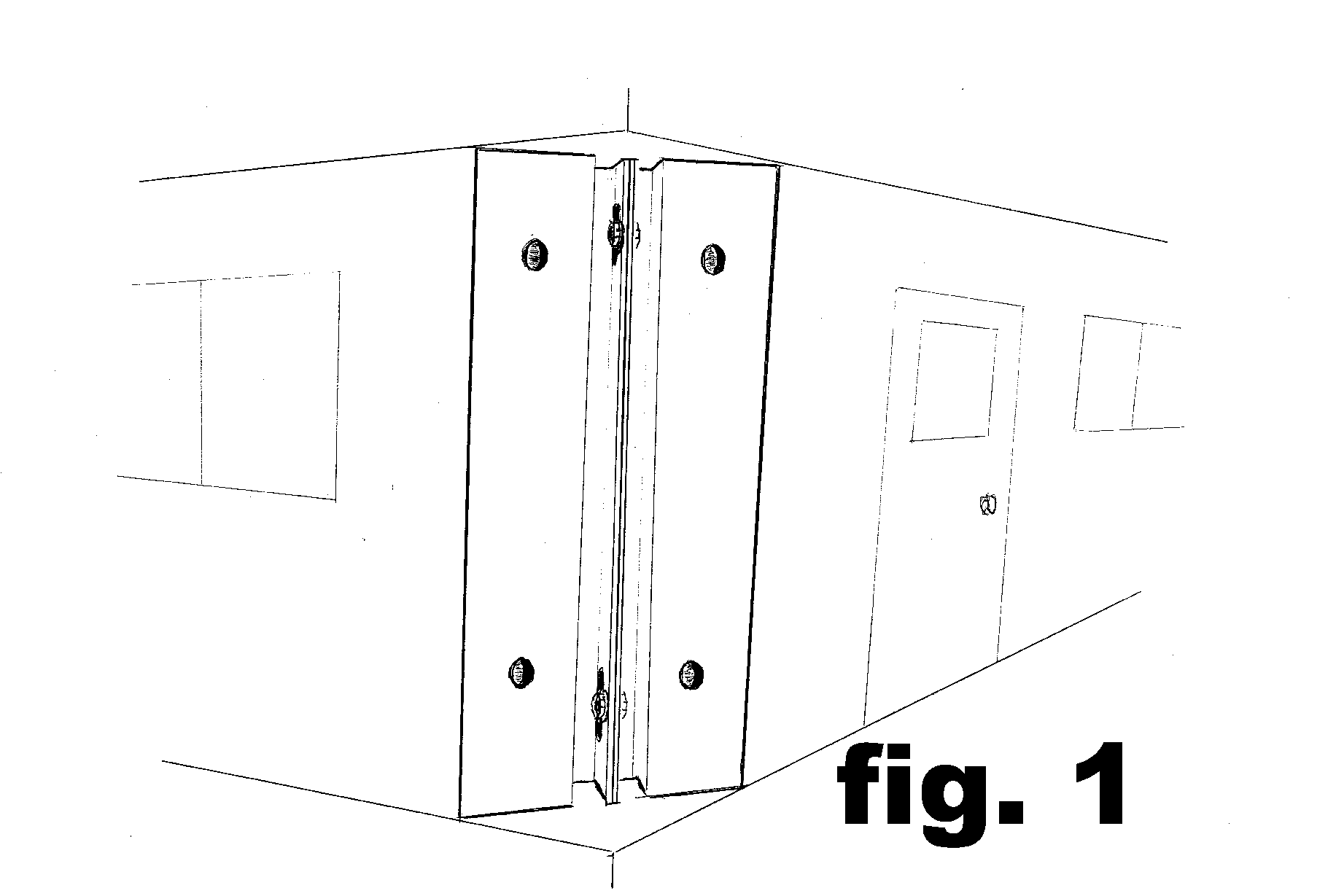

Articles of composite structure having appearance of wood

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

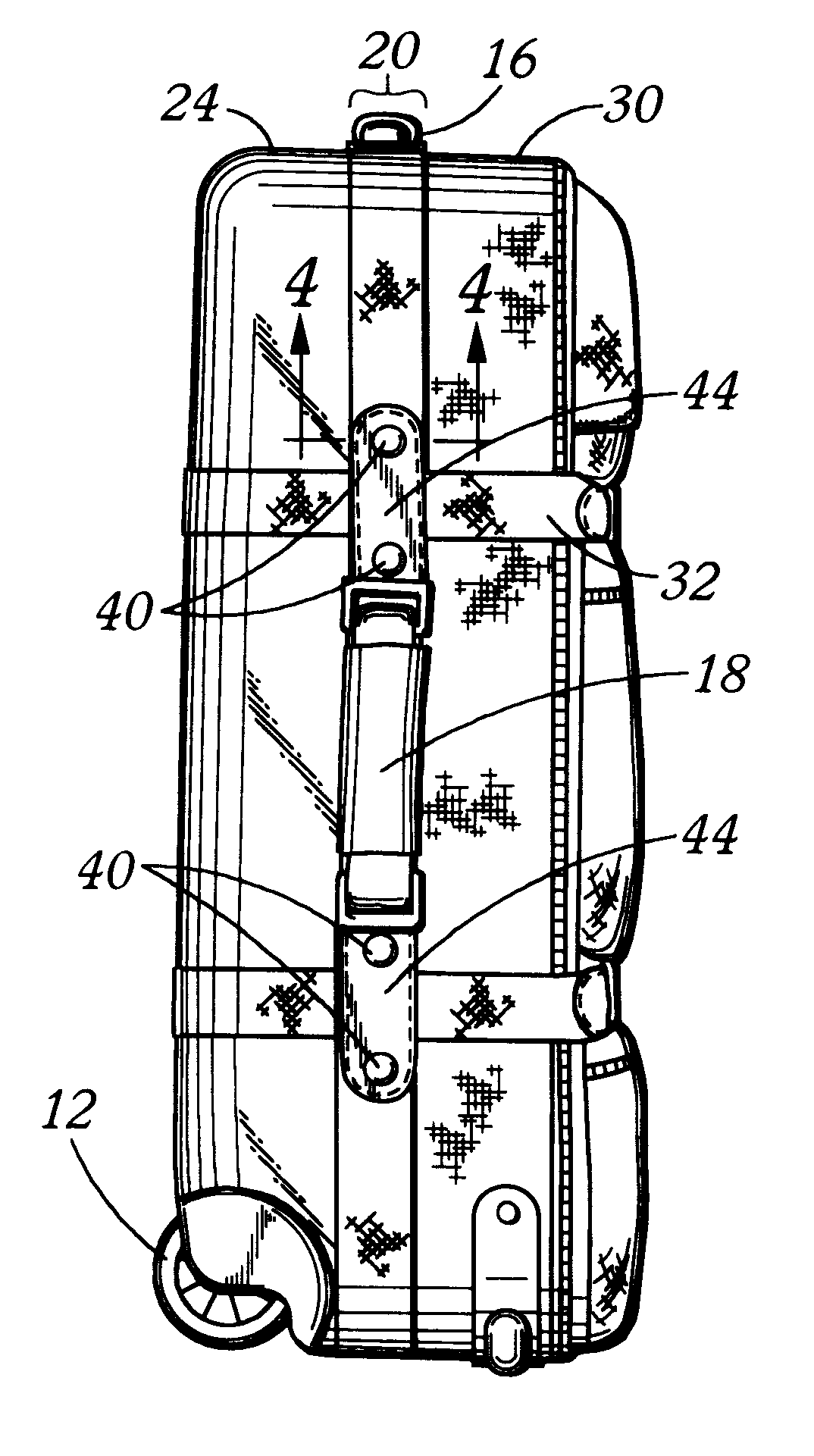

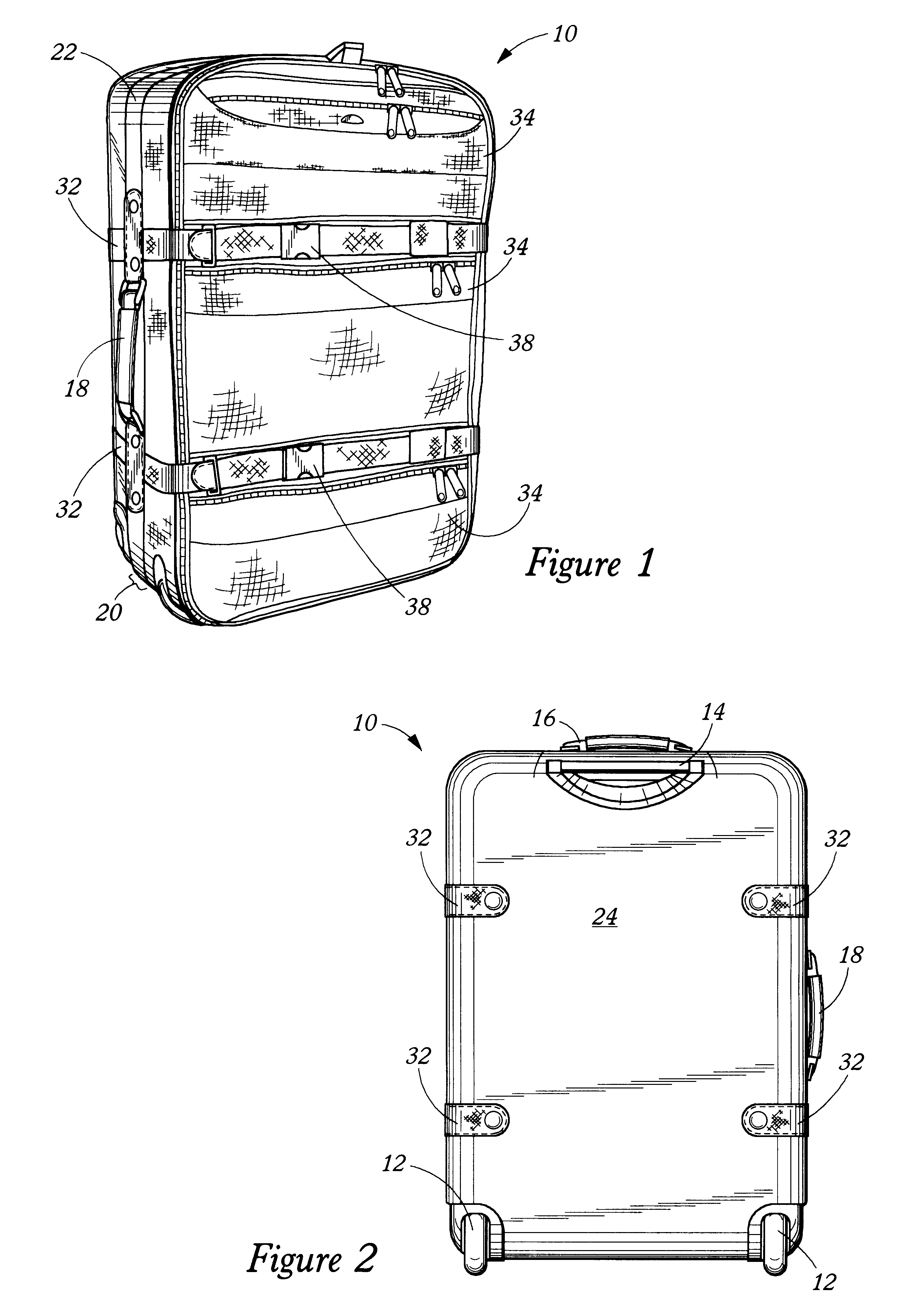

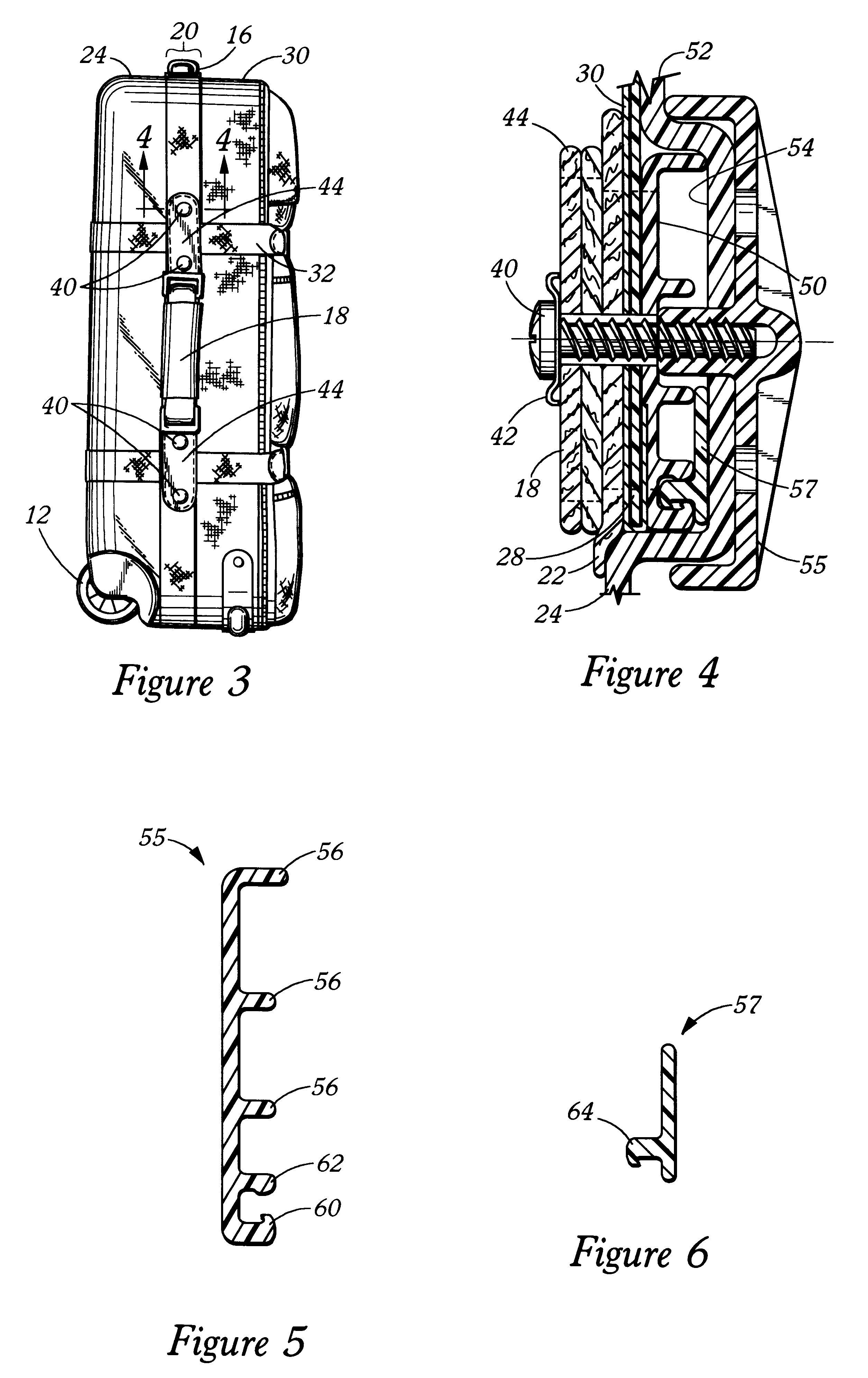

Hybrid construction luggage case

InactiveUS6325189B1Firmly connectedEasy to holdTravelling sacksHandbagsComposite constructionEngineering

A two-wheeled luggage cases 10 formed of substantially two parts, the base shell 24 of a generally one-piece molded plastic construction, the lid shell 30 of a composite construction primarily of textile fabric panels assembled to form a covering that provides an access to the interior of the case. Properly fitting a textile lid to the integrally molded sides of a base shell is difficult, especially if the case is large, and most especially where the lid shell is constructed at a location remote from where the lid and base shell are joined to integrate the two and form the overall luggage case. Accordingly, the luggage case has a body portion which comprises a generally one piece base shell defining an interior volume to contain the user's things, and a lid shell is affixed to the base shell, the lid shell being mostly formed of fabric materials, and having a peripheral edge portion and an access opening. An elongated extrusion 55 is sewn along a peripheral edge portion of the lid shell. An outwardly facing groove is molded into the base shell adjacent and parallel to its peripheral edge, and fasteners 40 are passed through the edge portion of the base shell and through the first elongated extrusion. Straps 32 attach to the base shell and extend perpendicular to the peripheral edge of the base shell to embrace the lid shell and help provide a strong connection between the lid and base shell.

Owner:SAMSONITE CORP

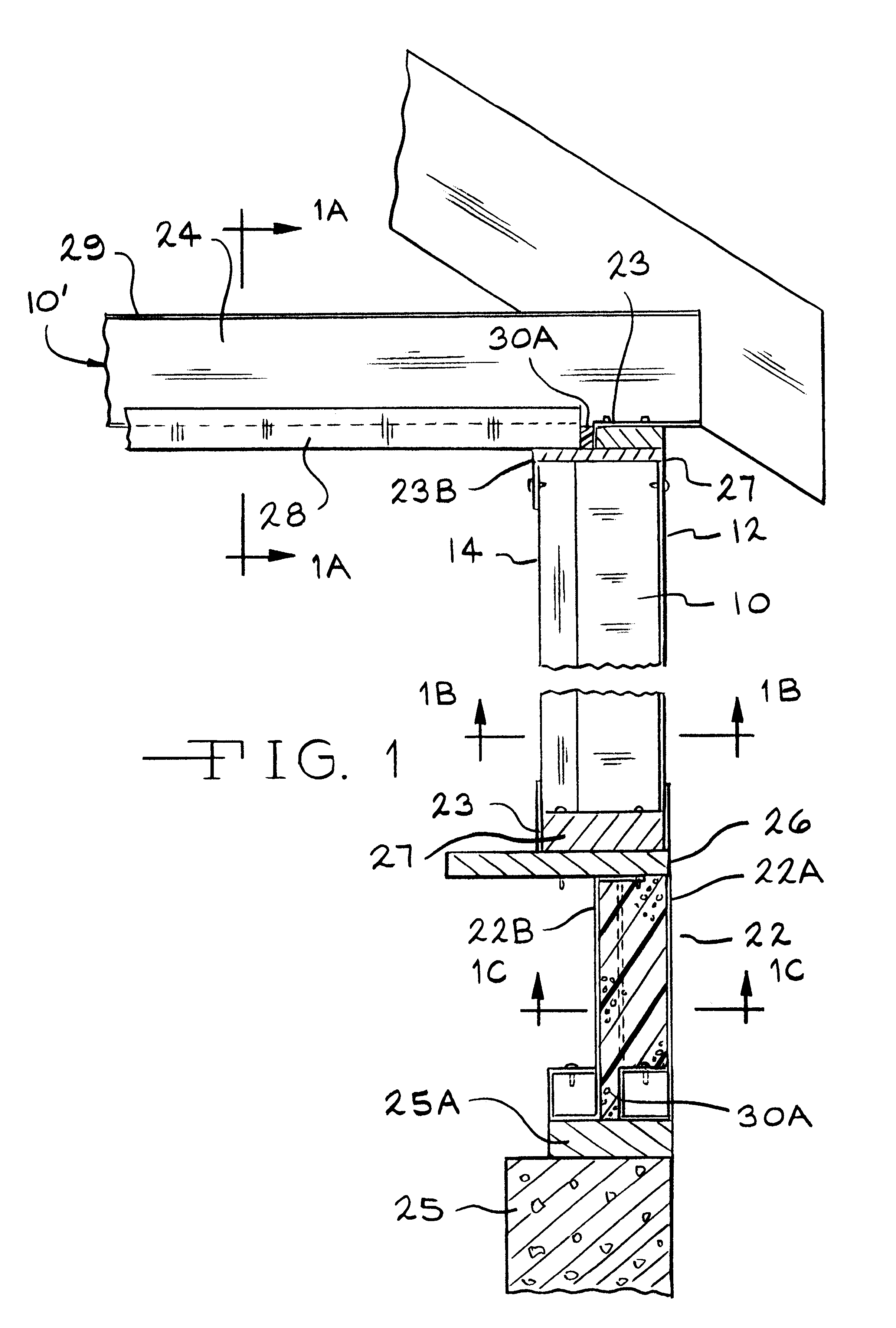

Connectors and Methods of Construction for a Precast Special Concrete Moment Resisting Shear Wall and Precast Special Concrete Moment Resisting Frame Building Panel System

InactiveUS20080098676A1Saving environment protectionThermally efficientMoulding surfacesBuilding roofsComposite constructionInternational Building Code

A precast concrete wall panel molding system for fabricating a wall shell and a plurality of ribs and beams. A precast concrete wall panel molding system with facilities for incorporating door and window frames. A ductile panel end connector for attaching panels one to another whether in parallel or angled as in inside or outside corners. A ductile panel end connector for attaching panels to columns. A wall anchor / shear plate with post-tensioning brace plate. A hybrid precast / cast-in-place special moment resisting shear wall / special moment resisting frame reinforced concrete building system for regions of potential seismic activity. A prescriptive method building system for composite structural building assemblies with conventional wood and light-gauge steel framing, structural steel, and other building code approved and tested building systems, building components, building panel systems, building roofing systems, modular and manufactured buildings, and building electrical, mechanical, and plumbing systems. A precast concrete wall panel system conforming to industry practices and standards as published by the Precast / Prestressed Concrete Institute, (PCI) in it's “PCI Design Handbook” (fifth edition, 1999), the American Concrete Institute “Building Code Requirements for Structural Concrete” (ACI 318-05), The “International Building Code 2006” and the “Uniform Building Code”.

Owner:HUTCHENS JOHN FRANCIS

Method of manufacturing a composite structural member having an integrated electrical circuit

ActiveUS7281318B2Laminating printed circuit boardsInsulated cablesComposite constructionElectrical devices

A method of manufacturing a composite structural member with an integrated electrical circuit is provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com