Composite structural material and method of making same

a technology of composite materials and structural materials, applied in the field of composite structural materials and methods of making same, can solve the problems of increasing static strength and stiffness requirements, /or requiring greater shock and impact resistance, and general consideration of unsuitable synthetic lumber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

process example 1

ILLUSTRATED PROCESS EXAMPLE 1

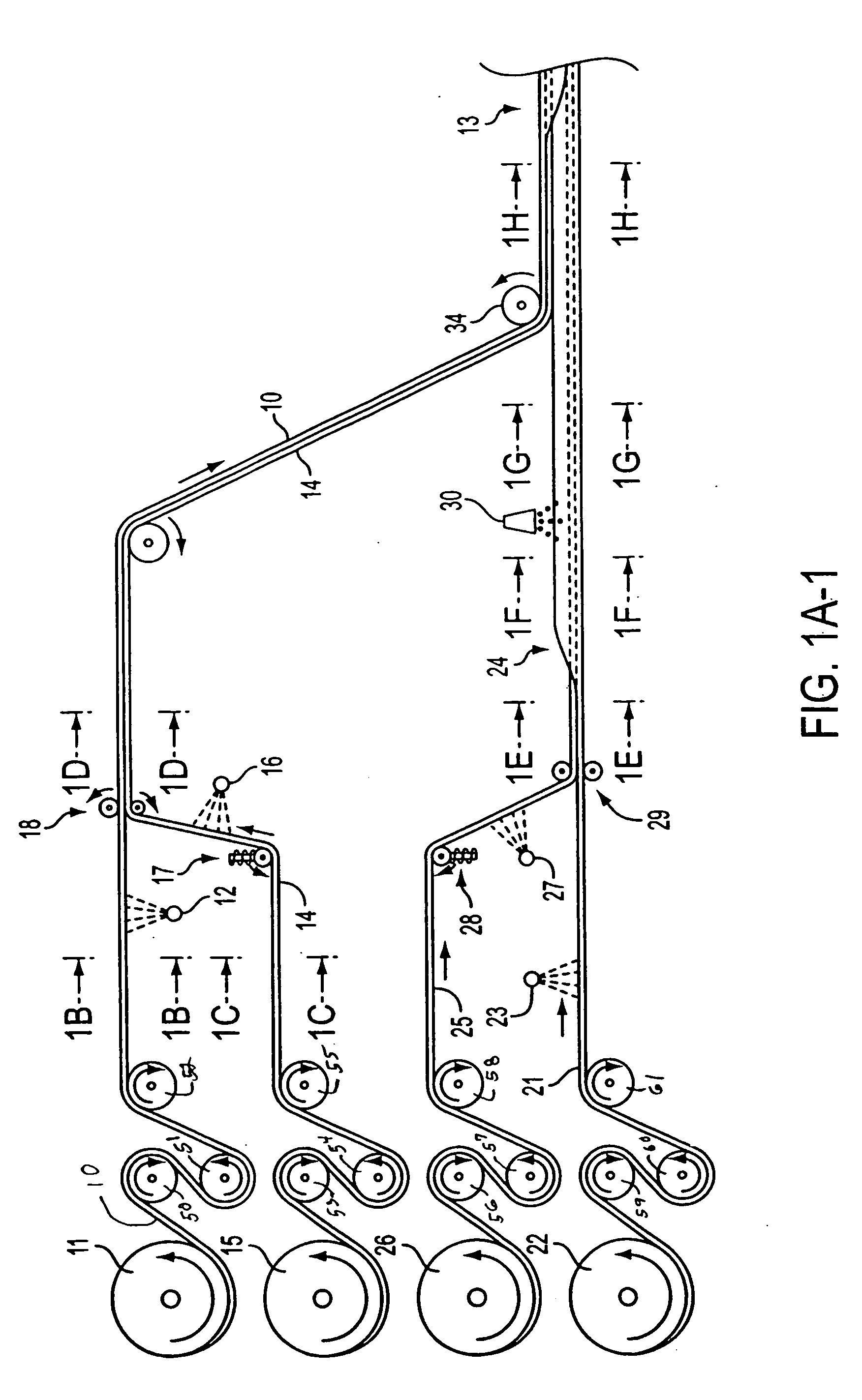

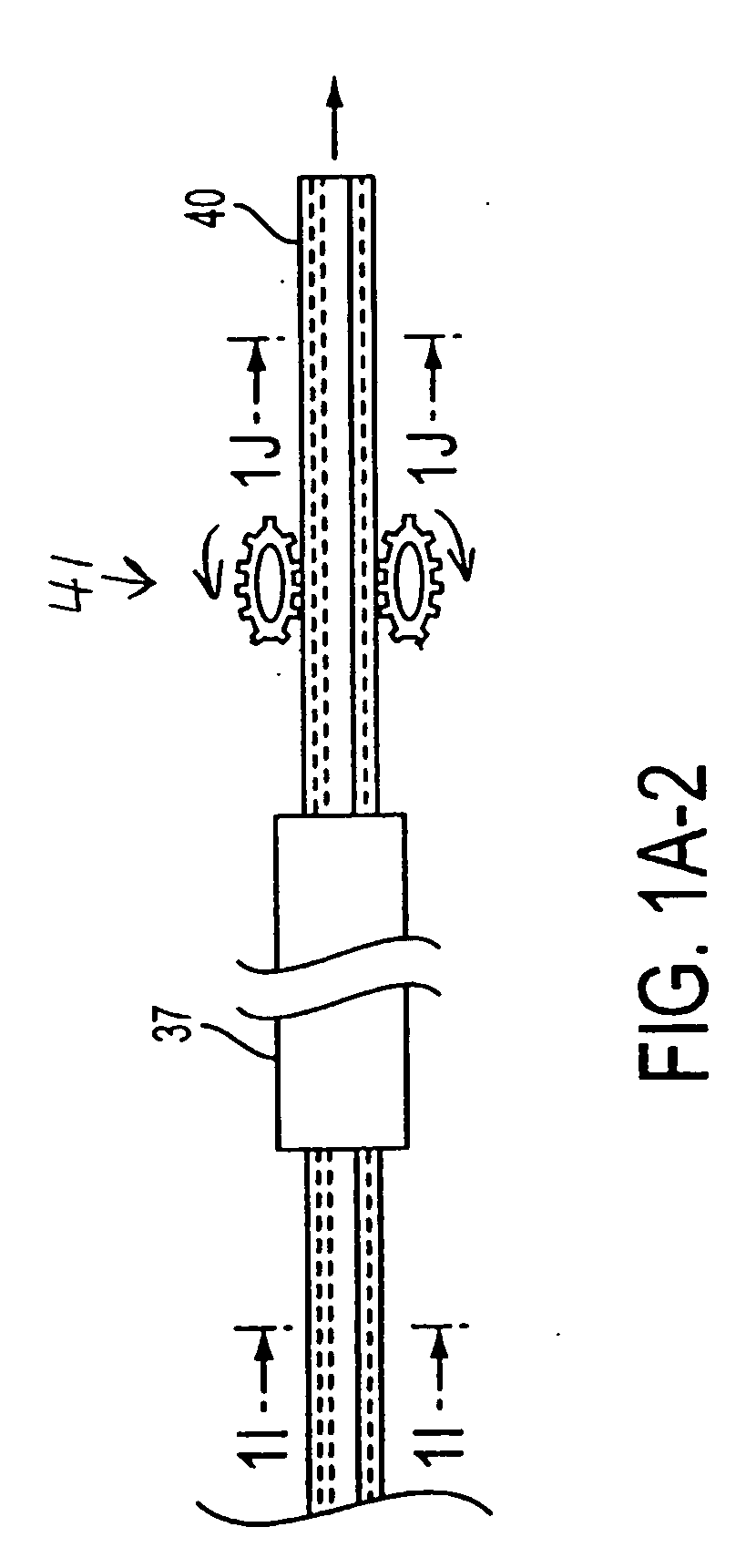

[0158] The invention perhaps will be better understood by considering the following description of one way of manufacturing the new composite structural material.

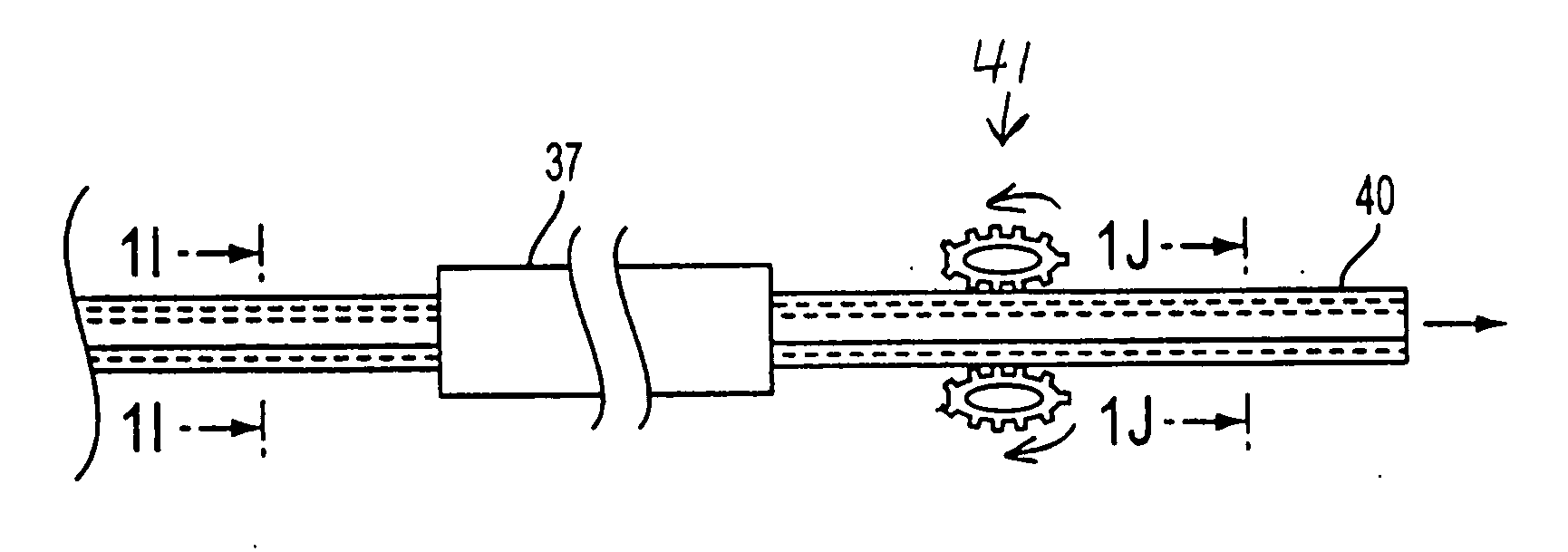

[0159] This example describes the construction of a composite board having the cross-sectional dimensions of a 1×4, i.e., ¾ inch by 3½ inches, using the C-channel method. The process is continuous and is illustrated schematically in FIG. 1. The proportions in FIG. 1 are not to actual scale. For example, for ease of illustration the thickness of papers 10 and 21 is exaggerated. So is the diameter of the warp cords 19 and the woof cords 20. And whereas the drawings depict approximately two dozen warp cords across the width of a 1×4, in actual practice there would preferably be at least 70. Also, FIGS. 1B through 1J are on a larger scale than FIG. 1A, for ease of illustrating certain details.

[0160] Referring to FIG. 1, a strip of recycled kraft paper 10 is pulled off supply roll 11, passed around...

process example 2

ILLUSTRATED PROCESS EXAMPLE 2

[0163] Another process for making a composite board of the present invention is schematically illustrated in FIGS. 3 and 4. In FIG. 3, two-ply paper 101, which has an internal barrier layer of poly(vinyl alcohol), is fed from roll 102 over guide roller 103 through an epoxy resin applicator 104, using known technology and equipment for manufacturing paper and plastic laminates. Polyester scrim 106 is taken off roll 107 and also is passed through epoxy resin applicator 104. At the same time, single-ply paper 108 is taken off roll 109 and also is passed through epoxy resin applicator 104. The liquid epoxy resin precursor composition 113 (hereinafter called “epoxy resin,” for short) is delivered through supply nozzle 110 to the space between papers 101 and 108.

[0164] As depicted coming off roll 102, the underside ply of paper 101 might advantageously be thinner than the upperside ply. This is because the underside ply only needs to be thick enough to receiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| volume percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com