Patents

Literature

11731results about "Wood layered products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Support for high performance affinity chromatography and other uses

Multilayered particulate materials are formed by coating a particulate substrate with a metal and adsorbing an organic layer comprising a recognition moiety onto the metal film. The recognition moiety interacts with an analyte of interest allowing for its detection, purification, etc. Suitable recognition moieties can be selected from a range of species including, small molecules, polymers and biomolecules and the like. The novel particulate materials of the invention can be utilized in an array of methods including, ion-exchange, ion-selective ion-exchange, assays, affinity dialysis, size exclusion dialysis, as supports in solid phase synthesis, combinatorial synthesis and screening of compound libraries and the like.

Owner:RGT UNIV OF CALIFORNIA

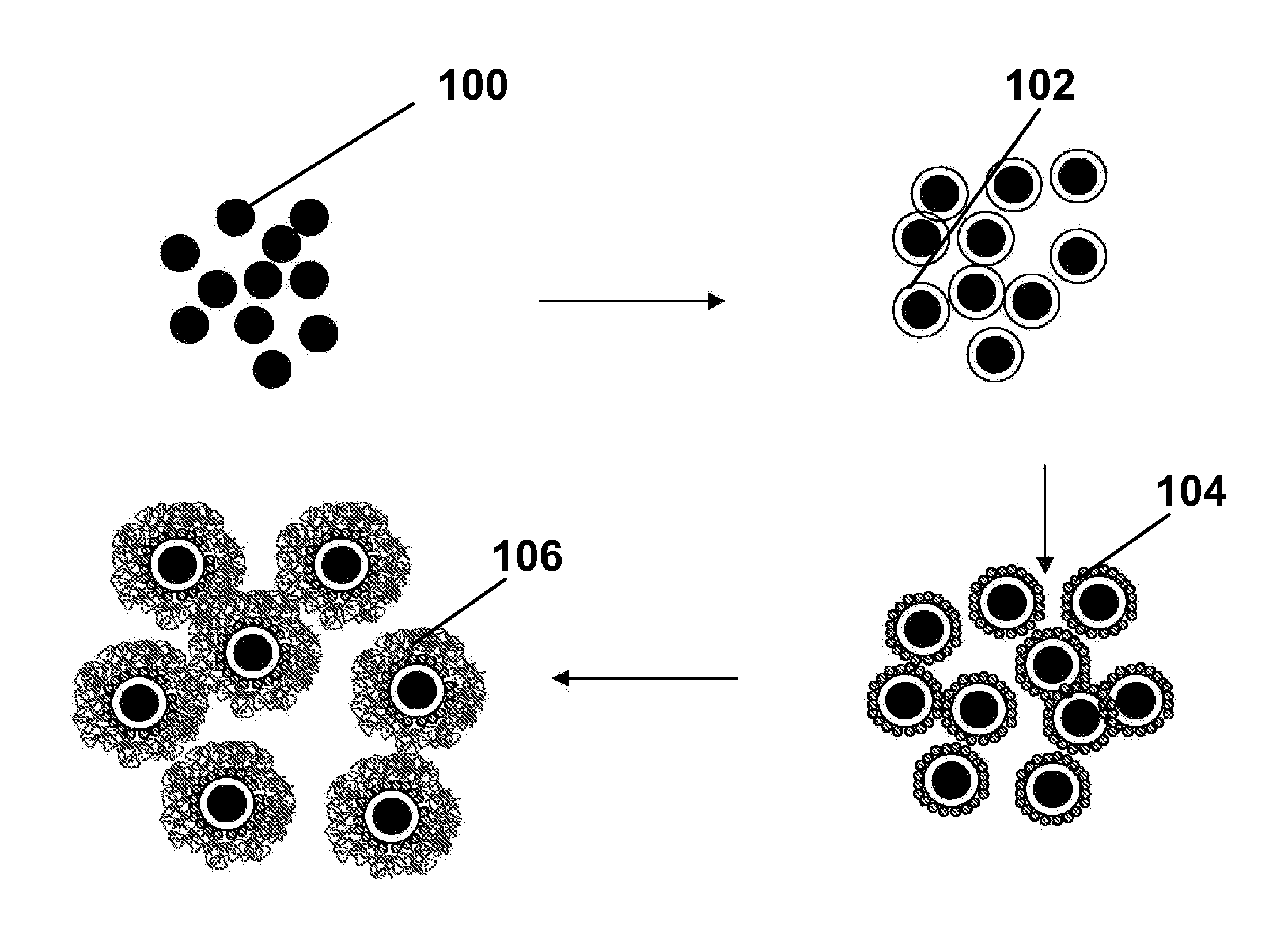

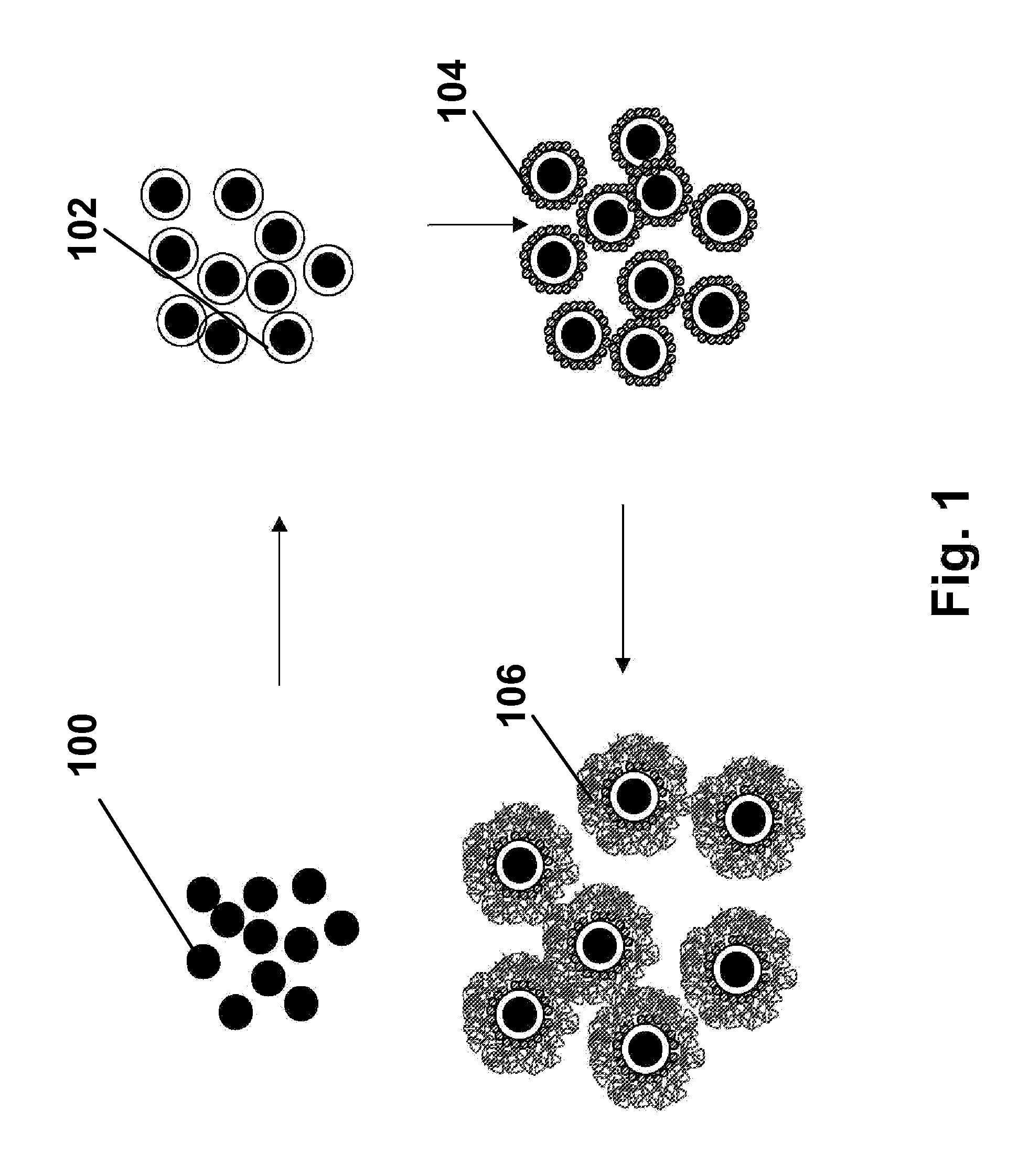

Organo luminescent semiconductor nanocrystal probes for biological applications and process for making and using such probes

A semiconductor nanocrystal compound is described capable of linking to an affinity molecule. The compound comprises (1) a semiconductor nanocrystal capable of emitting electromagnetic radiation and / or absorbing energy, and / or scattering or diffracting electromagnetic radiation-when excited by an electromagnetic radiation source or a particle beam; and (2) at least one linking agent, having a first portion linked to the semiconductor nanocrystal and a second portion capable of linking to an affity molecule. The compound is linked to an affinity molecule to form a semiconductor nanocrystal probe capable of bonding with a detectable substance. Subsequent exposure to excitation energy will excite the semiconductor nanocrystal in he probe, causing the emission of electromagnetic radiation. Further described are processes for respectively: making the semiconductor nanocrystal compound; making the semiconductor nanocrystal probe; and using the probe to determine the presence of a detectable substance in a material.

Owner:RGT UNIV OF CALIFORNIA

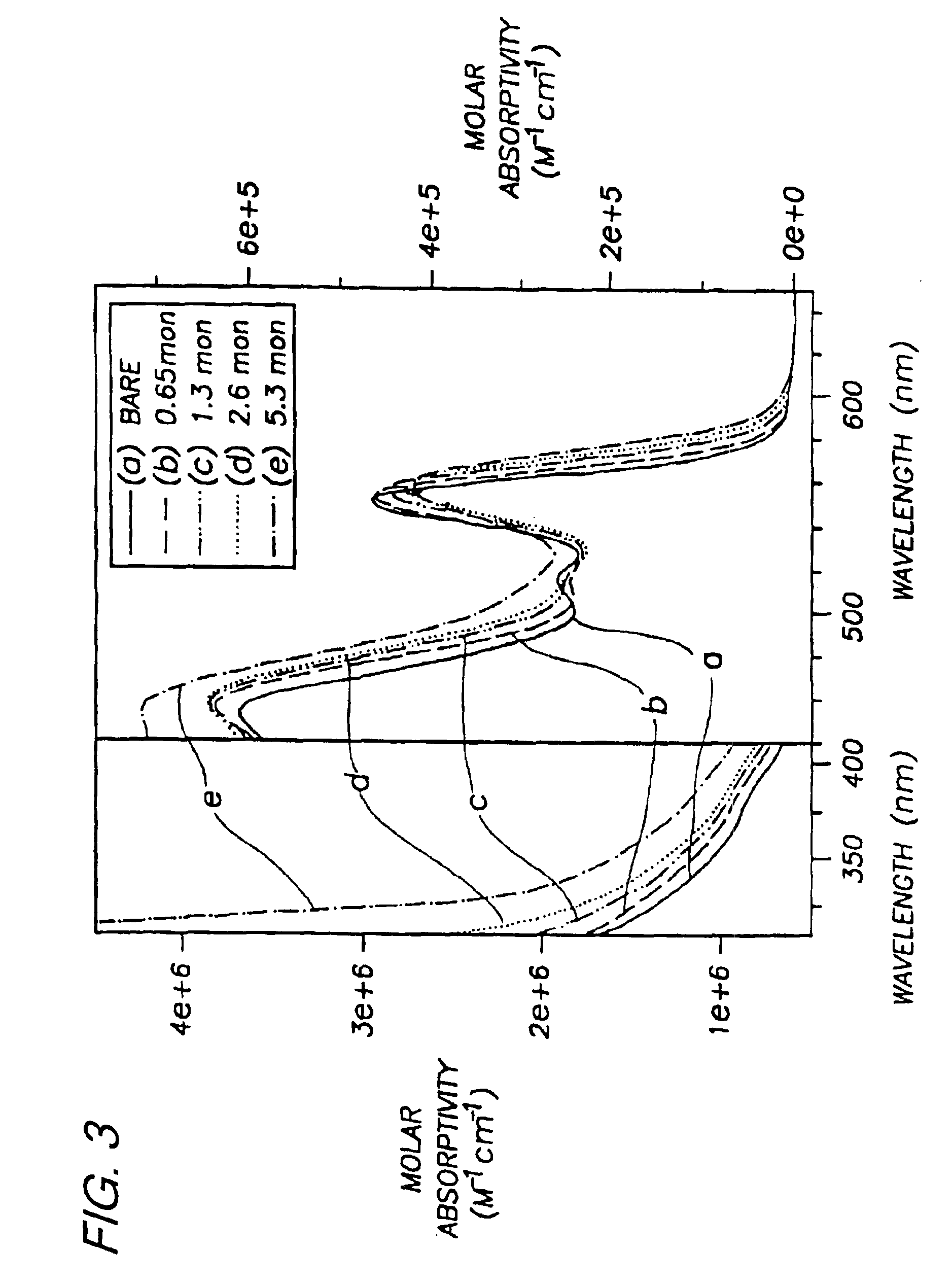

Water-soluble fluorescent nanocrystals

InactiveUS6444143B2High quantum yieldHigh spectral purityMaterial nanotechnologyNanosensorsQuantum yieldOrganic layer

A water soluble semiconductor nanocrystal capable of light emission is provided, including a quantum dot having a selected band gap energy, a layer overcoating the quantum dot, the overcoating layer comprised of a material having a band gap energy greater than that of the quantum dot, and an organic outer layer, the organic layer comprising a compound having a least one linking group for attachment of the compound to the overcoating layer and at least one hydrophilic group space apart from the linking group by a hydrophobic region sufficient to prevent electron charge transfer across the hydrophobic region. The particle size of the nanocrystal core is in the range of about 12.ANG. to about 150.ANG., with a deviation of less than 10% in the core. The coated nanocrystal exhibits photoluminescende having quantum yield of greater than 10% in water.

Owner:MASSACHUSETTS INST OF TECH

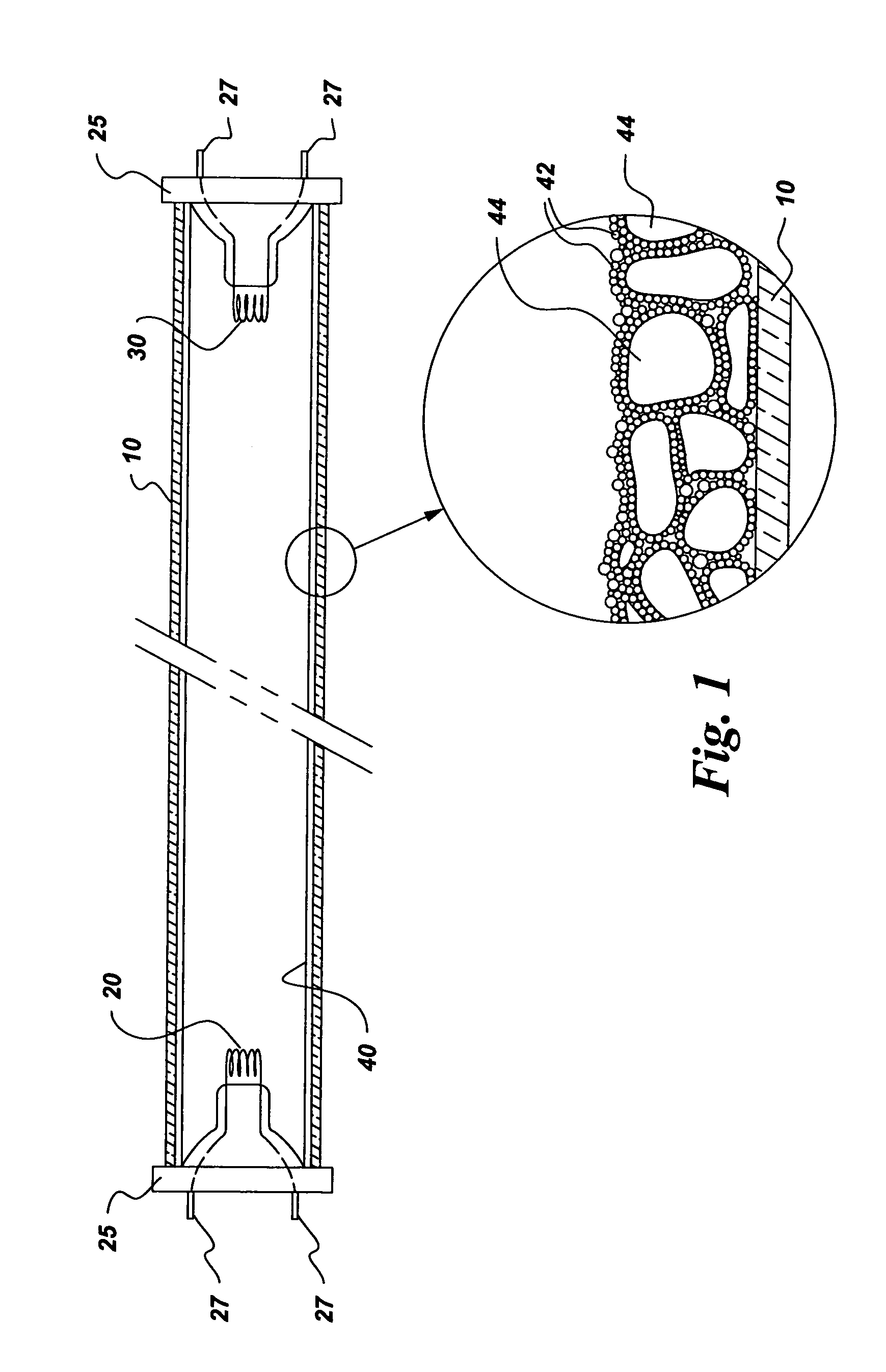

Composite proppant, composite filtration media and methods for making and using same

InactiveUS6632527B1Avoid condensationReduce molecular weightPretreated surfacesGlass/slag layered productsFiberFiltration

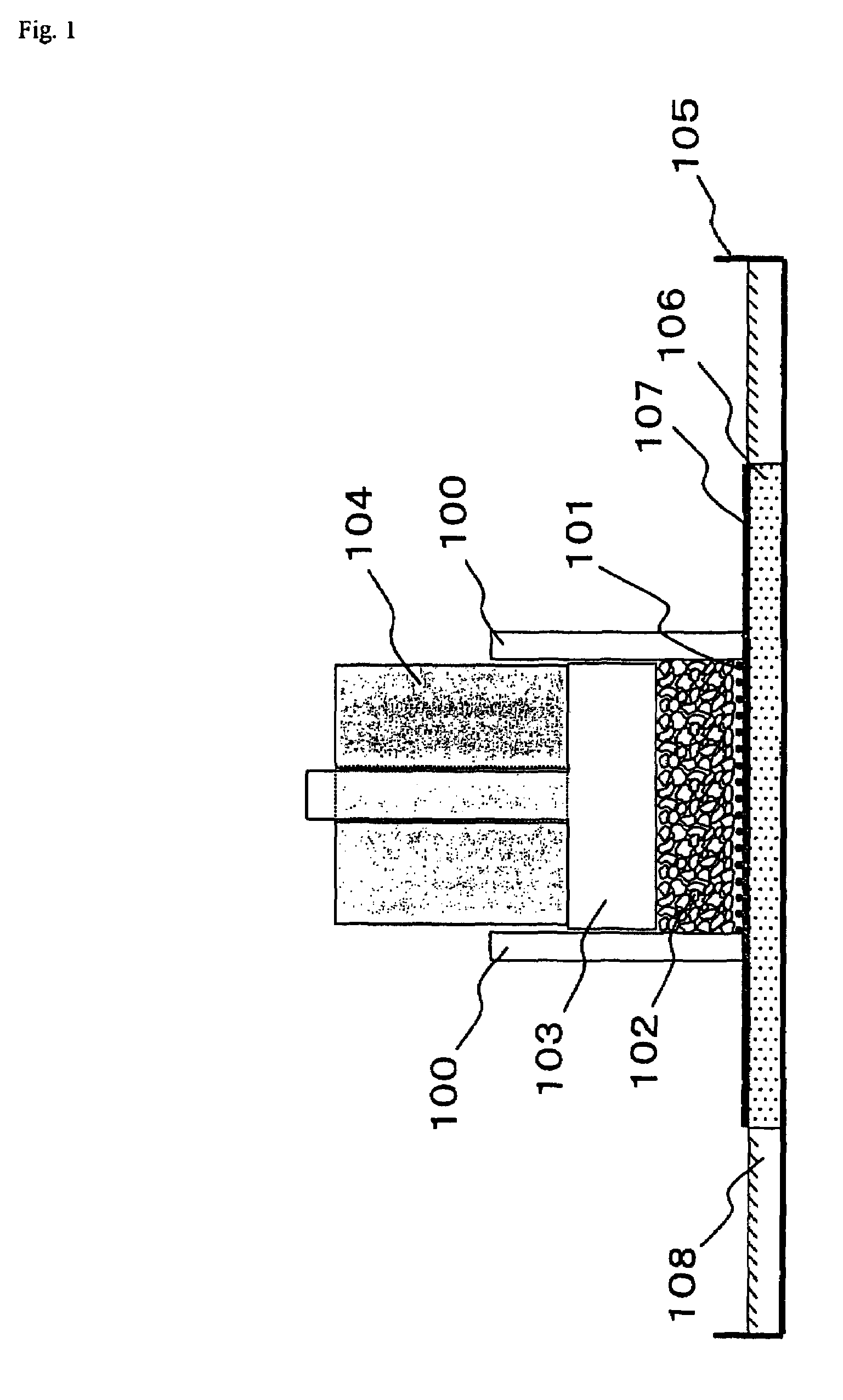

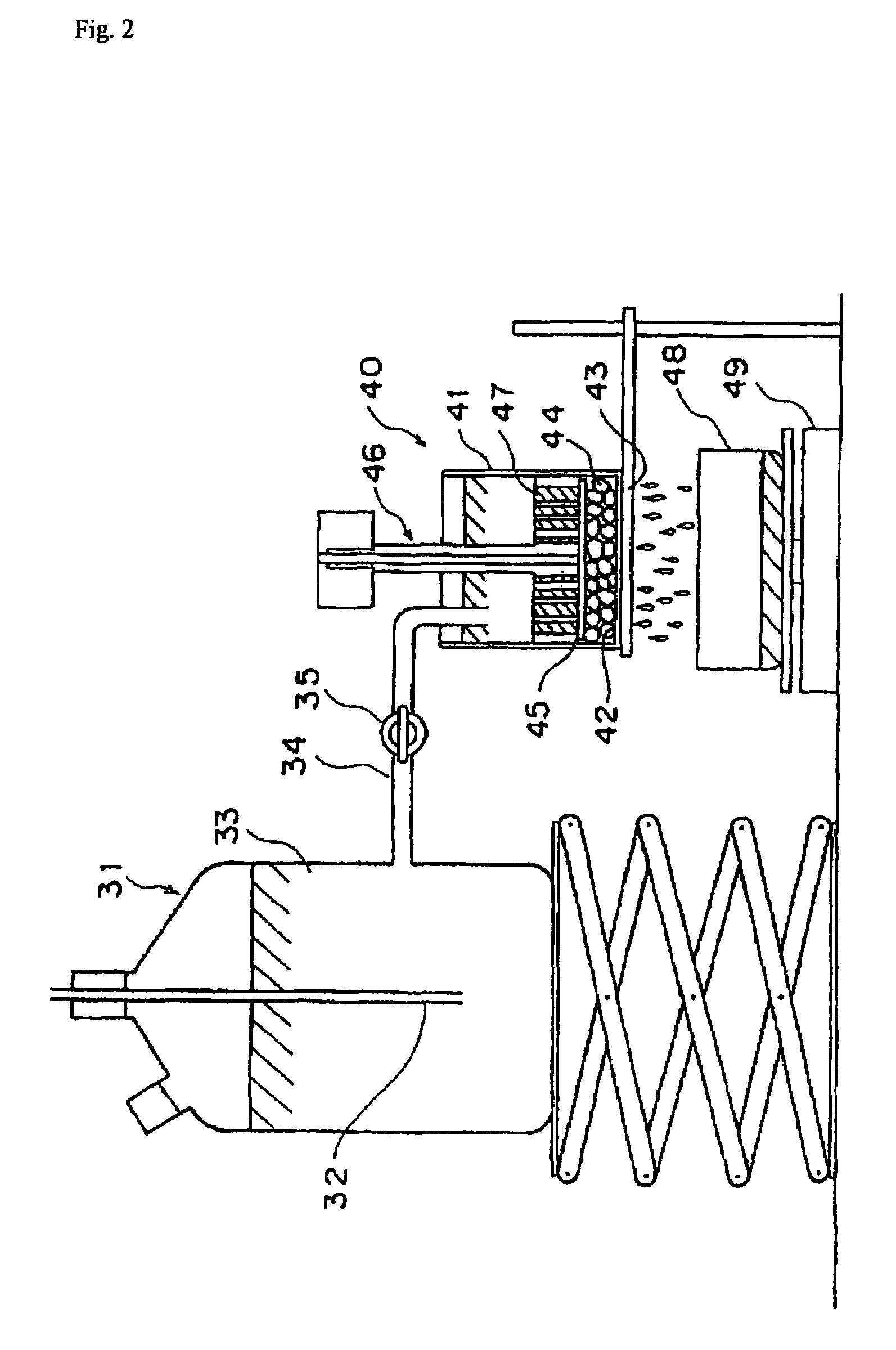

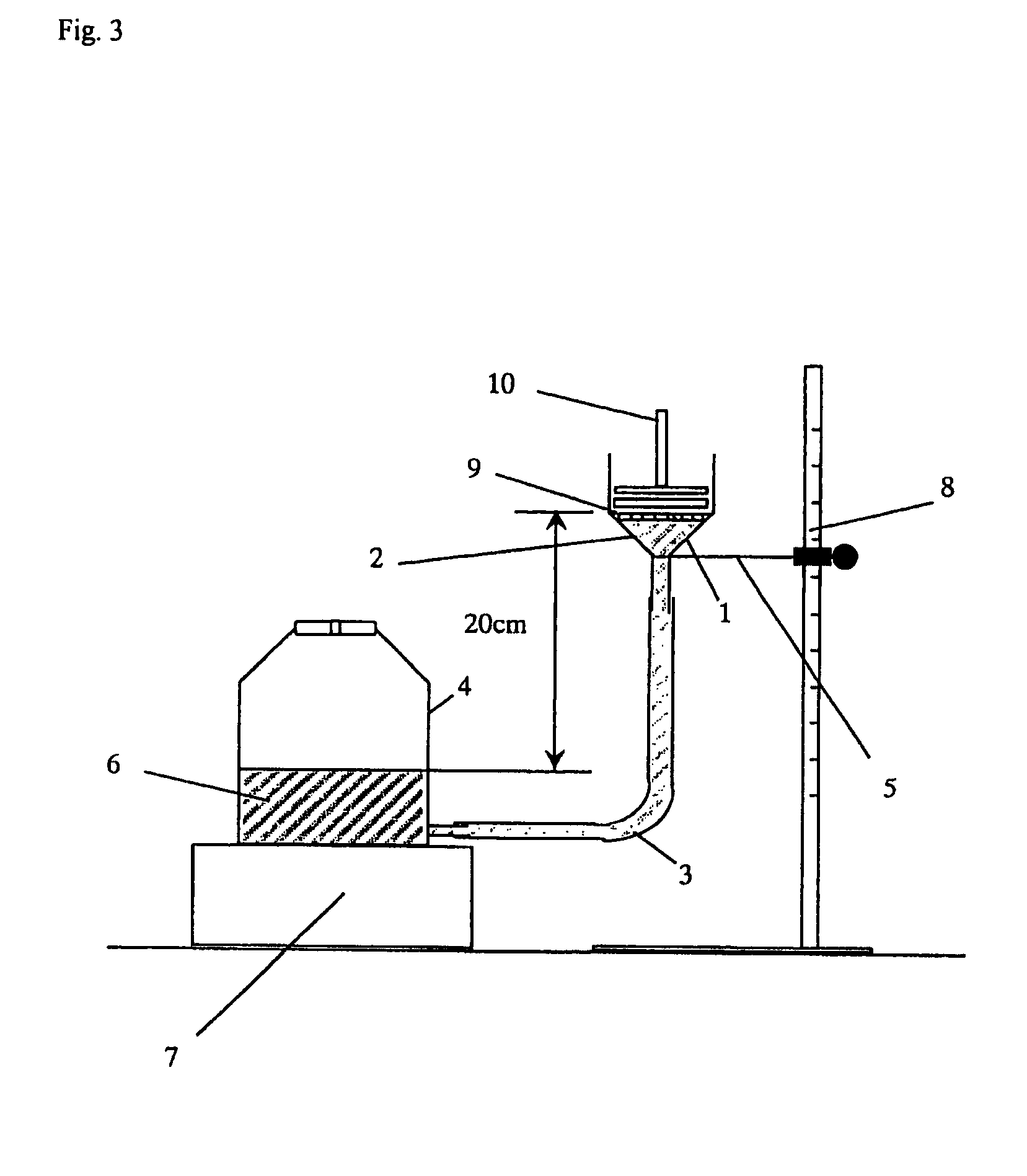

Composite particles made of a binder and filler material are provided for use in subterranean formations. The filler is finely divided mineral and optional fiber. The particles are proppants useful to prop open subterranean formation fractures. The particles are also useful for water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.< / PTEXT>

Owner:HEXION INC

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

InactiveUS6582819B2Low densityEasy to transportGranule coatingPretreated surfacesFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

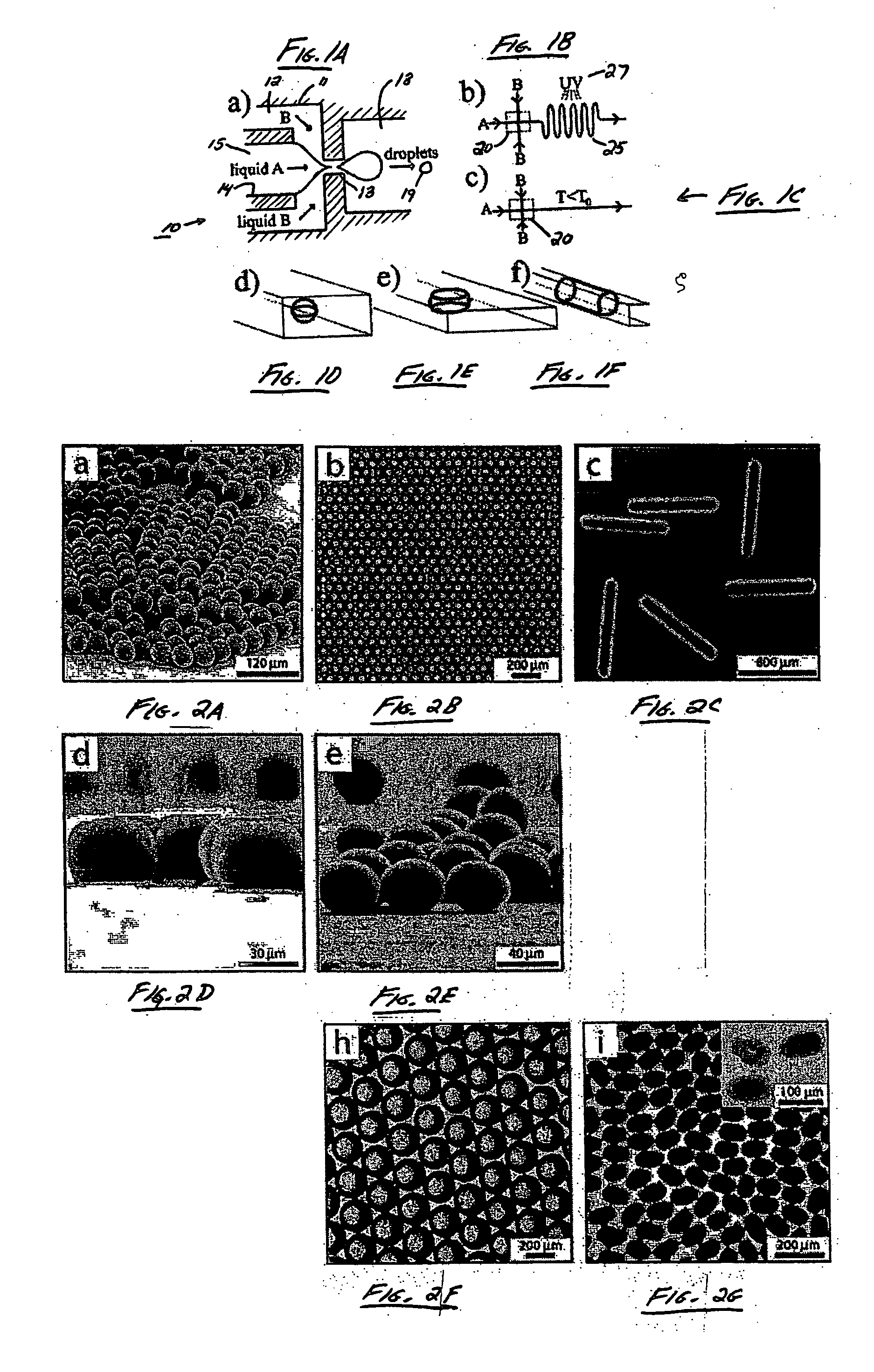

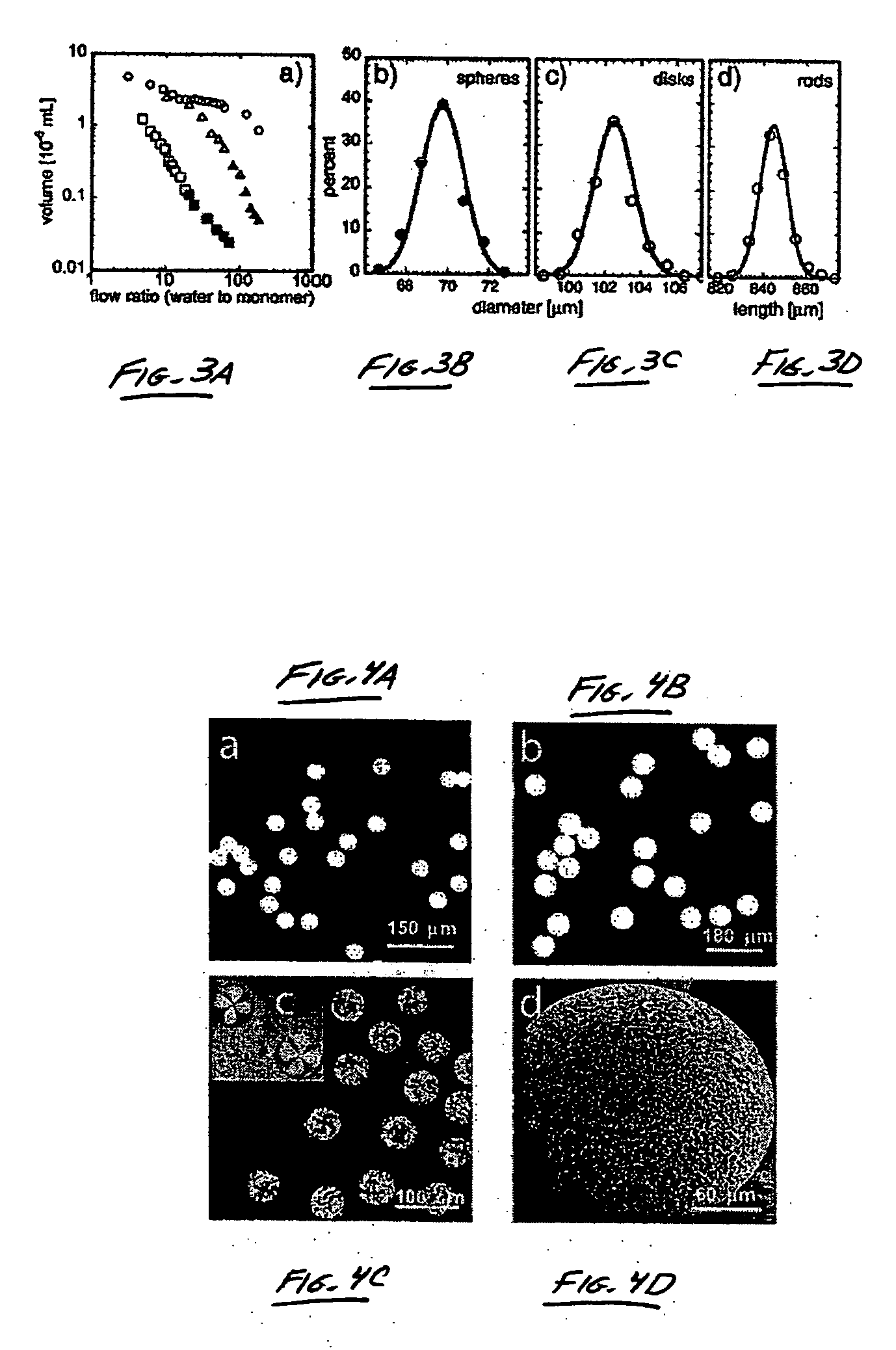

Systems and methods of forming particles

InactiveUS20070054119A1Synthetic resin layered productsChemical/physical/physico-chemical microreactorsChemical reactionMicrometer

The present invention generally relates to systems and methods of forming particles and, in certain aspects, to systems and methods of forming particles that are substantially monodisperse. Microfluidic systems and techniques for forming such particles are provided, for instance, particles may be formed using gellation, solidification, and / or chemical reactions such as cross-linking, polymerization, and / or interfacial polymerization reactions. In one aspect, the present invention is directed to a plurality of particles having an average dimension of less than about 500 micrometers and a distribution of dimensions such that no more than about 5% of the particles have a dimension greater than about 10% of the average dimension, which can be made via microfluidic systems. In one set of embodiments, at least some of the particles may comprise a metal, and in certain embodiments, at least some of the particles may comprise a magnetizable material. In another set of embodiments, at least some of the particles may be porous. In some embodiments, the invention includes non-spherical particles. Non-spherical particles may be formed, for example, by urging a fluidic droplet into a channel having a smallest dimension that is smaller than the diameter of a perfect mathematical sphere having a volume of the droplet, and solidifying the droplet, and / or by exposing at least a portion of a plurality of particles to an agent able to remove at least a portion of the particles.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

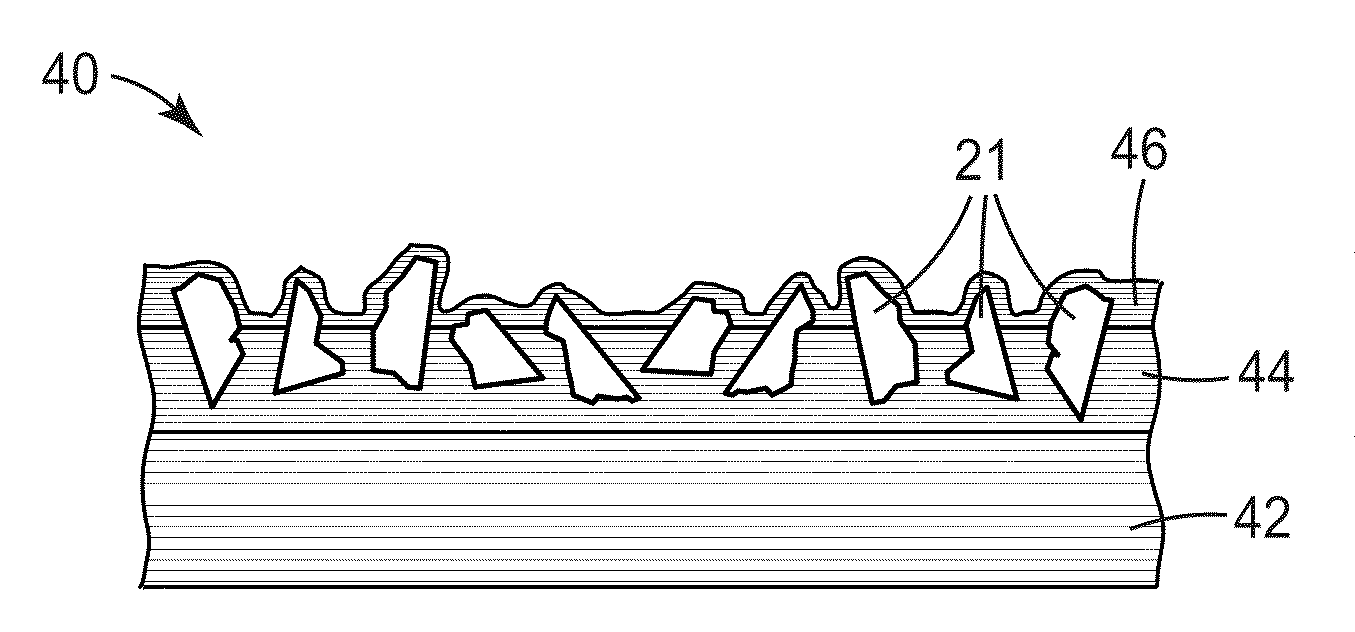

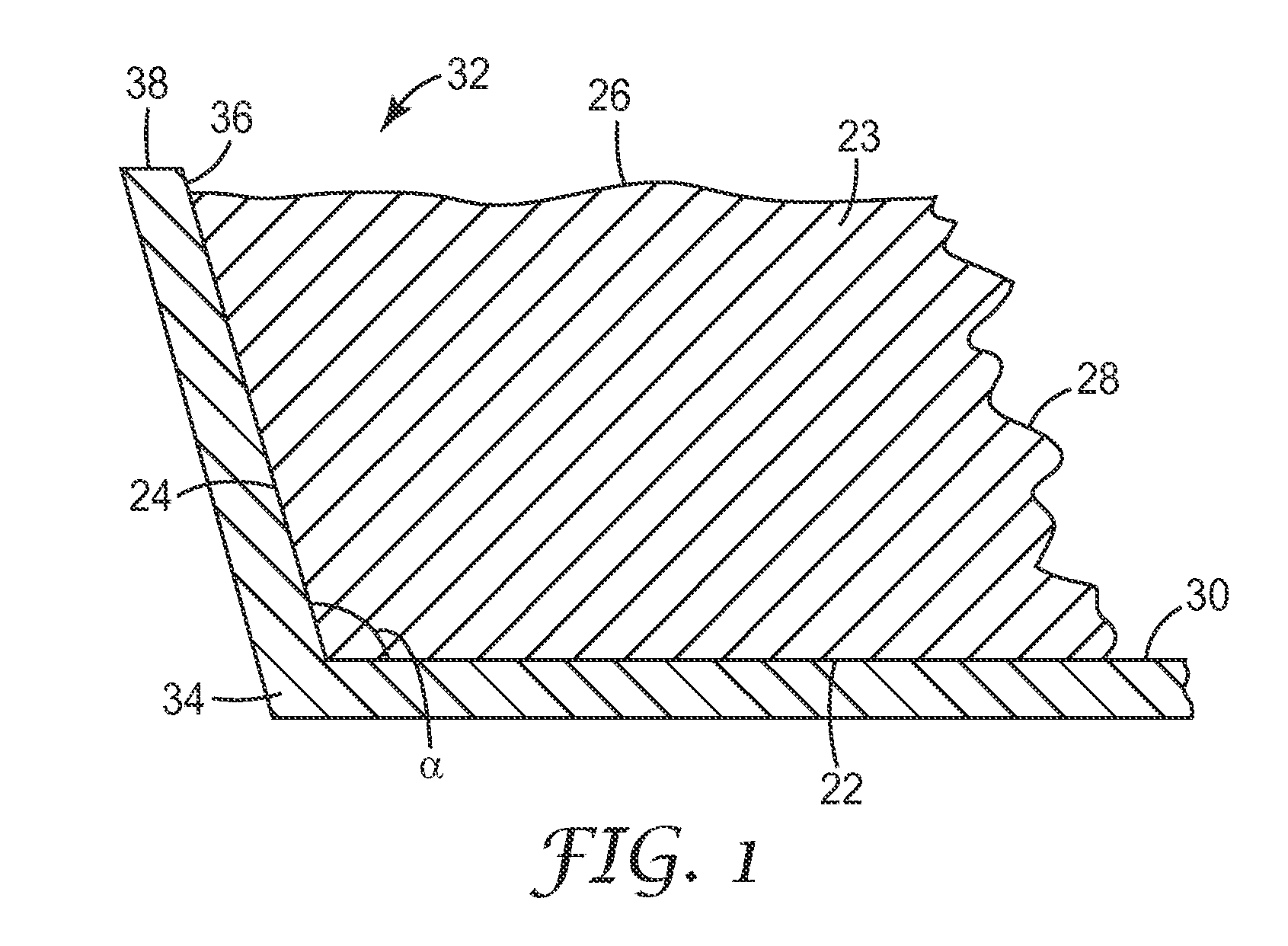

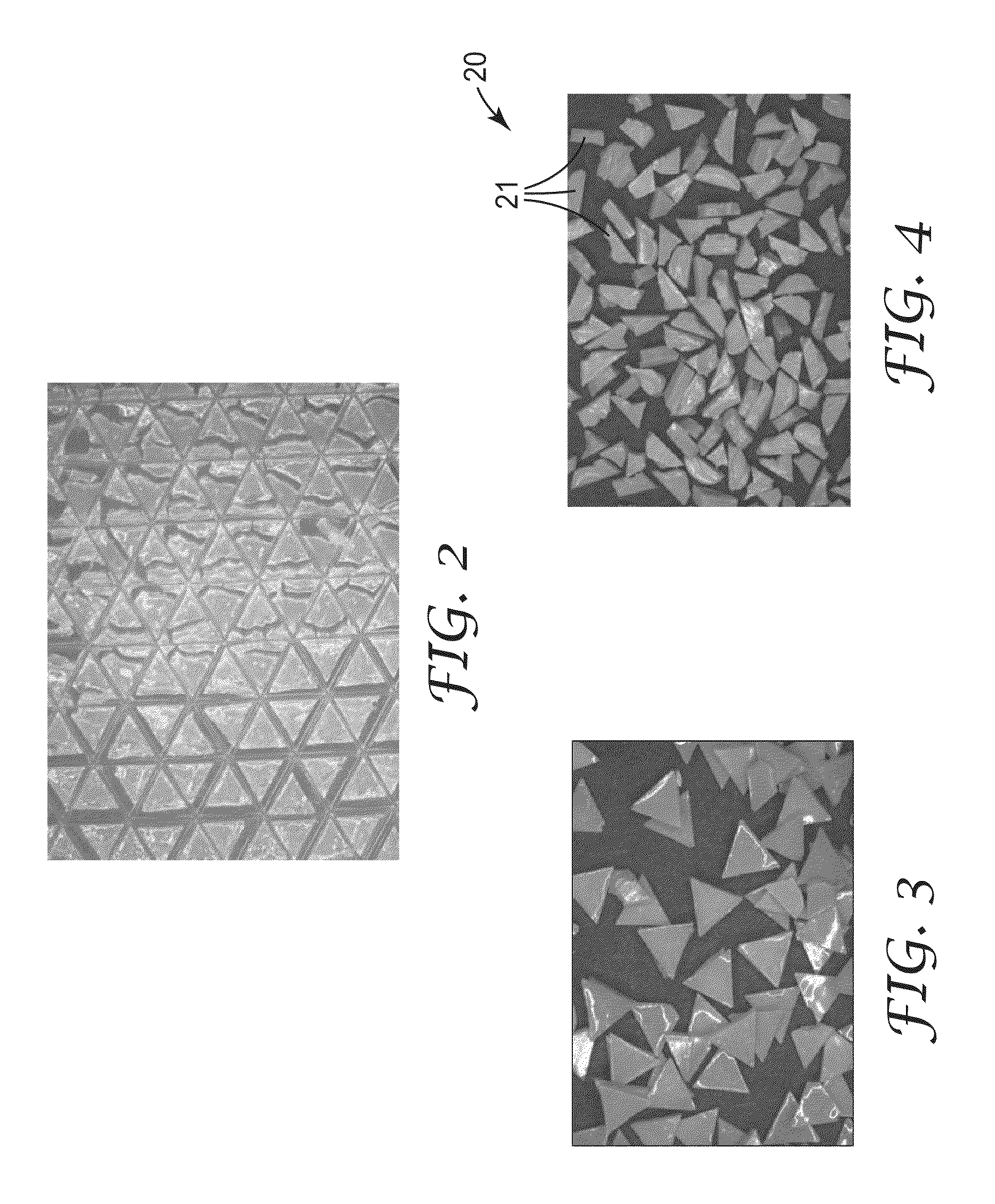

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

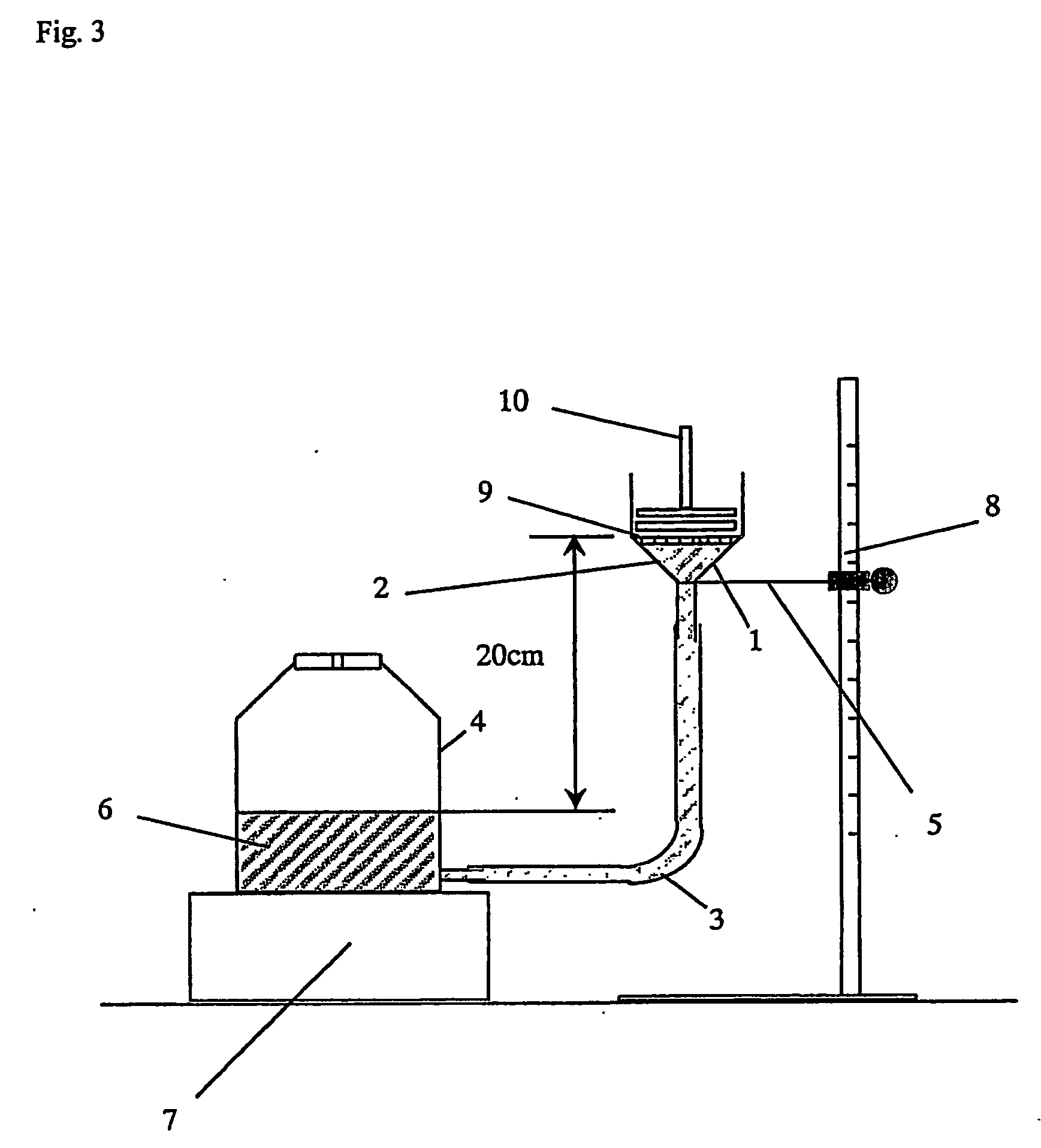

Compositions for nasal drug delivery, methods of making same, and methods of removing residual solvent from pharmaceutical preparations

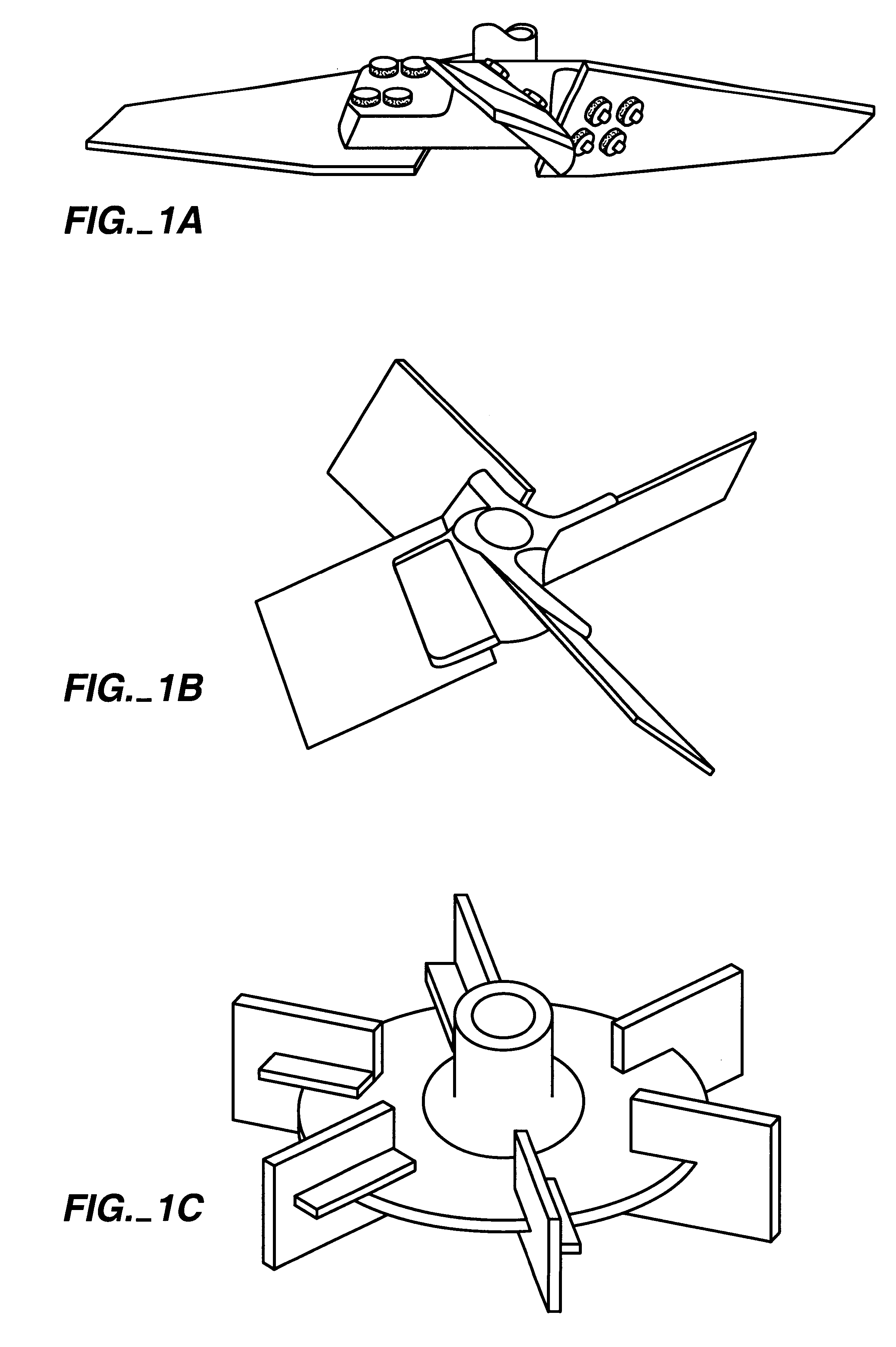

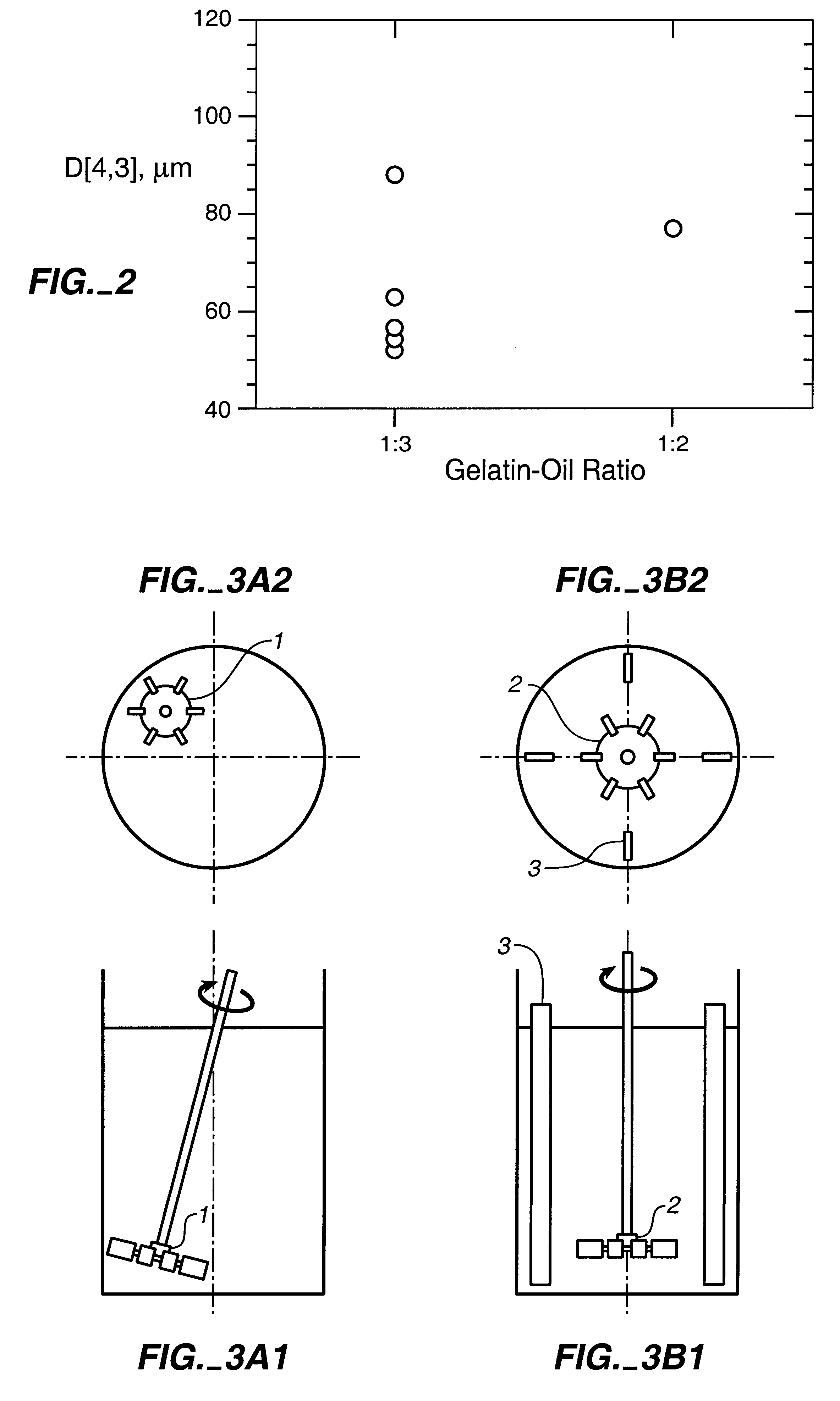

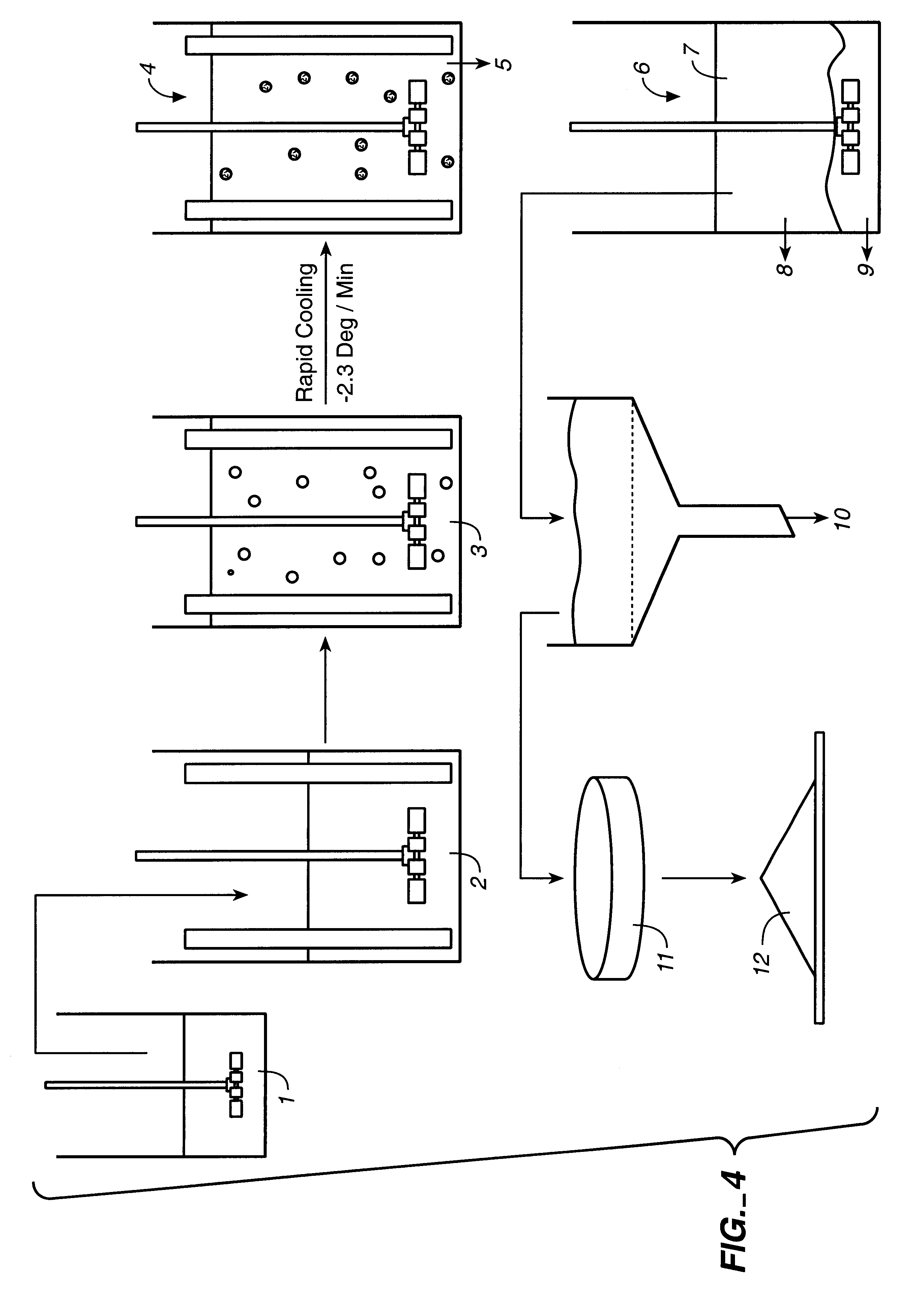

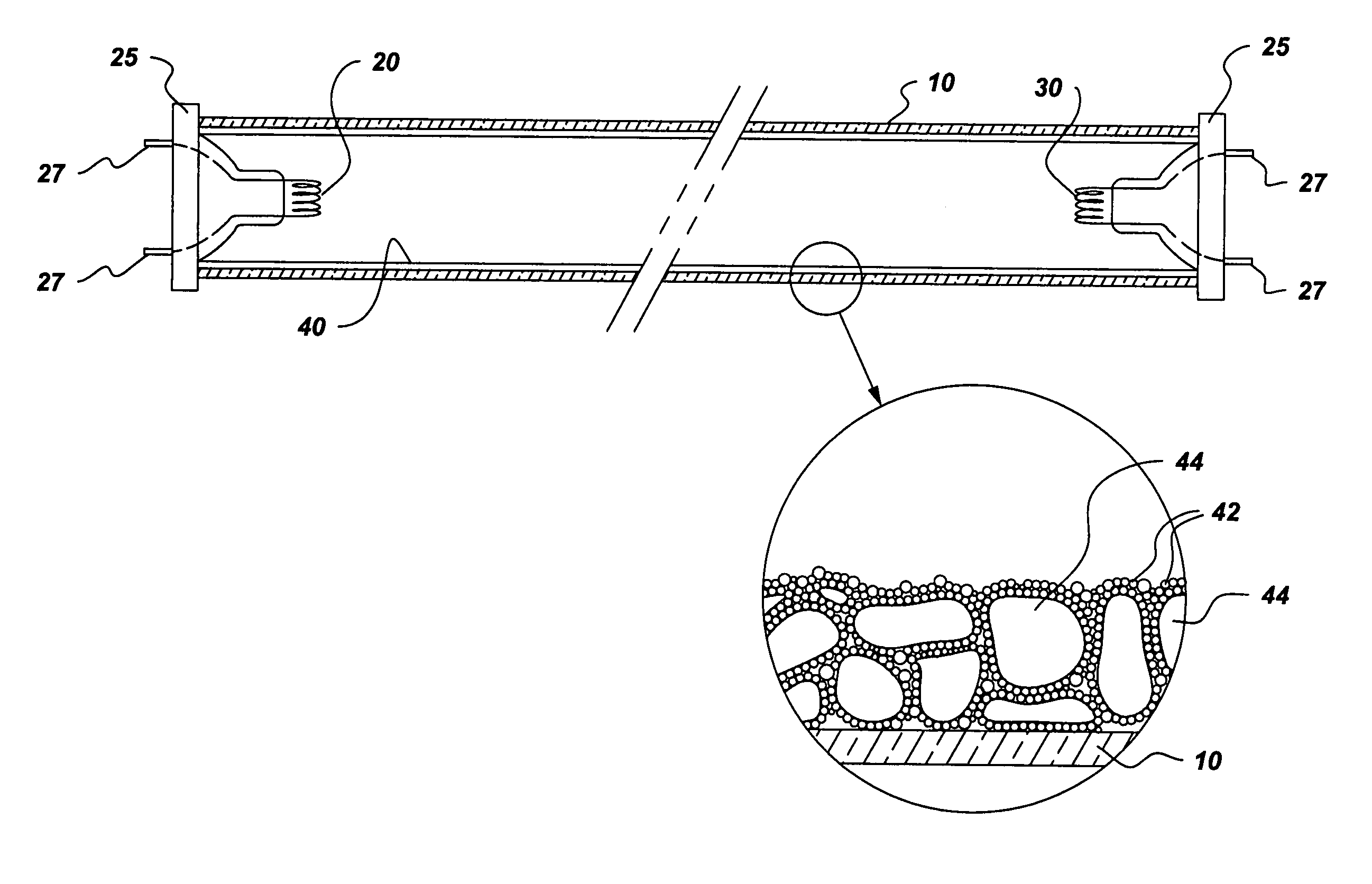

InactiveUS6391452B1Taller in heightSlow down the mixing speedLiquid surface applicatorsPeptide/protein ingredientsNasal cavityNose

The present invention relates to pharmaceutical compositions for delivery of drugs intended to reside in the nose, compositions for nasal administration of drugs, e.g., antiviral agents, and particularly antiviral agents comprising the human major rhinovirus receptor, also known as intercellular adhesion molecule-1 (ICAM-1); to methods of making said nasal drug compositions, and to an improved process for the removal of residual solvent from pharmaceutical matrices.

Owner:BAYER PHARMA CORP

Light sources with nanometer-sized VUV radiation-absorbing phosphors

A light source comprises: (a) a source of plasma discharge that emits electromagnetic radiation, a portion of which has wavelengths shorter than about 200 nm; and (b) a phosphor composition that comprises particles, each of the particles comprising at least a first phosphor and at least a second phosphor, the phosphor composition is disposed such that the first phosphor absorbs substantially the portion of EM radiation having wavelengths shorter than about 200 nm, and the first phosphor emits EM radiation having wavelengths longer than about 200 nm.

Owner:GENERAL ELECTRIC CO

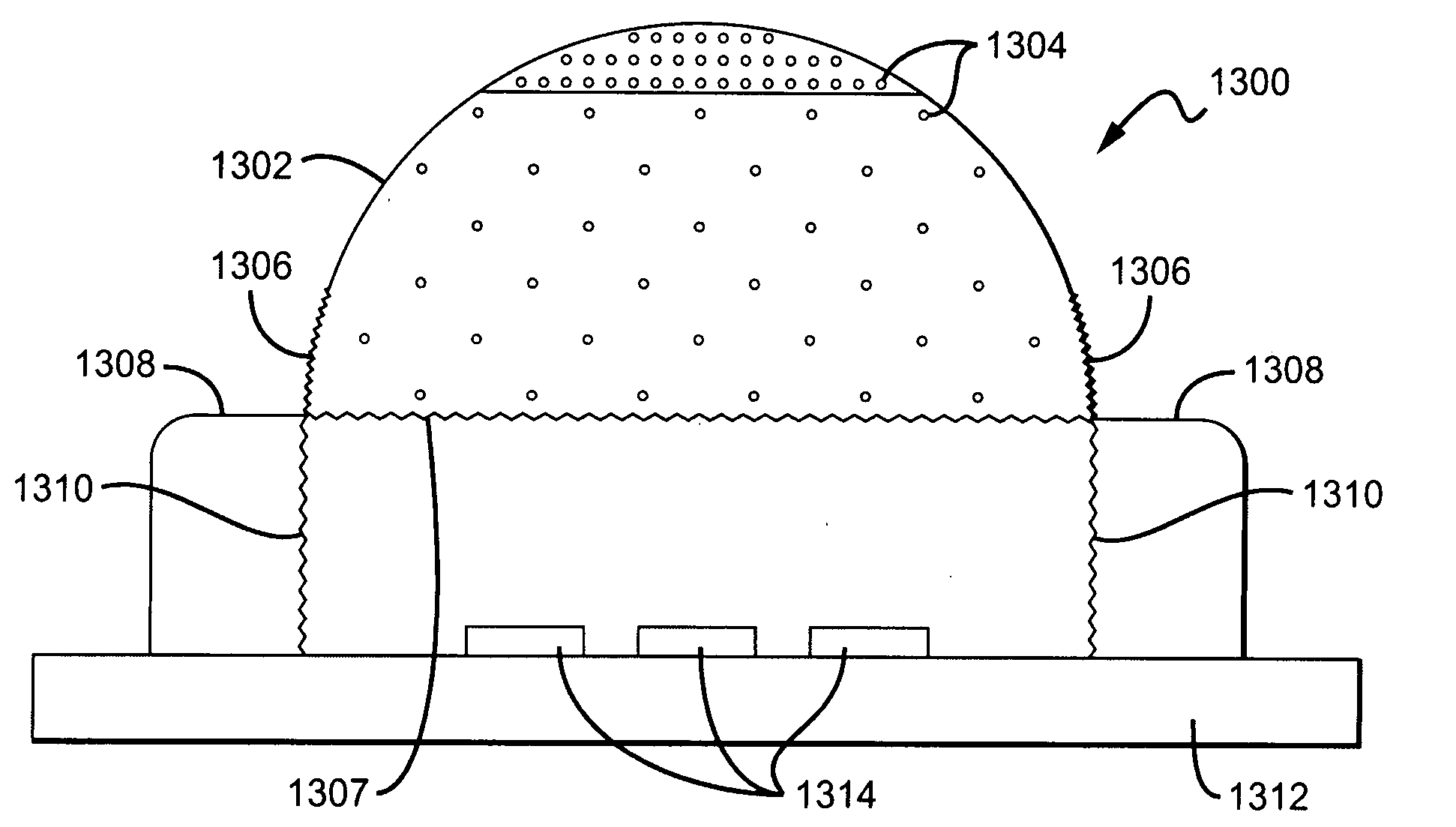

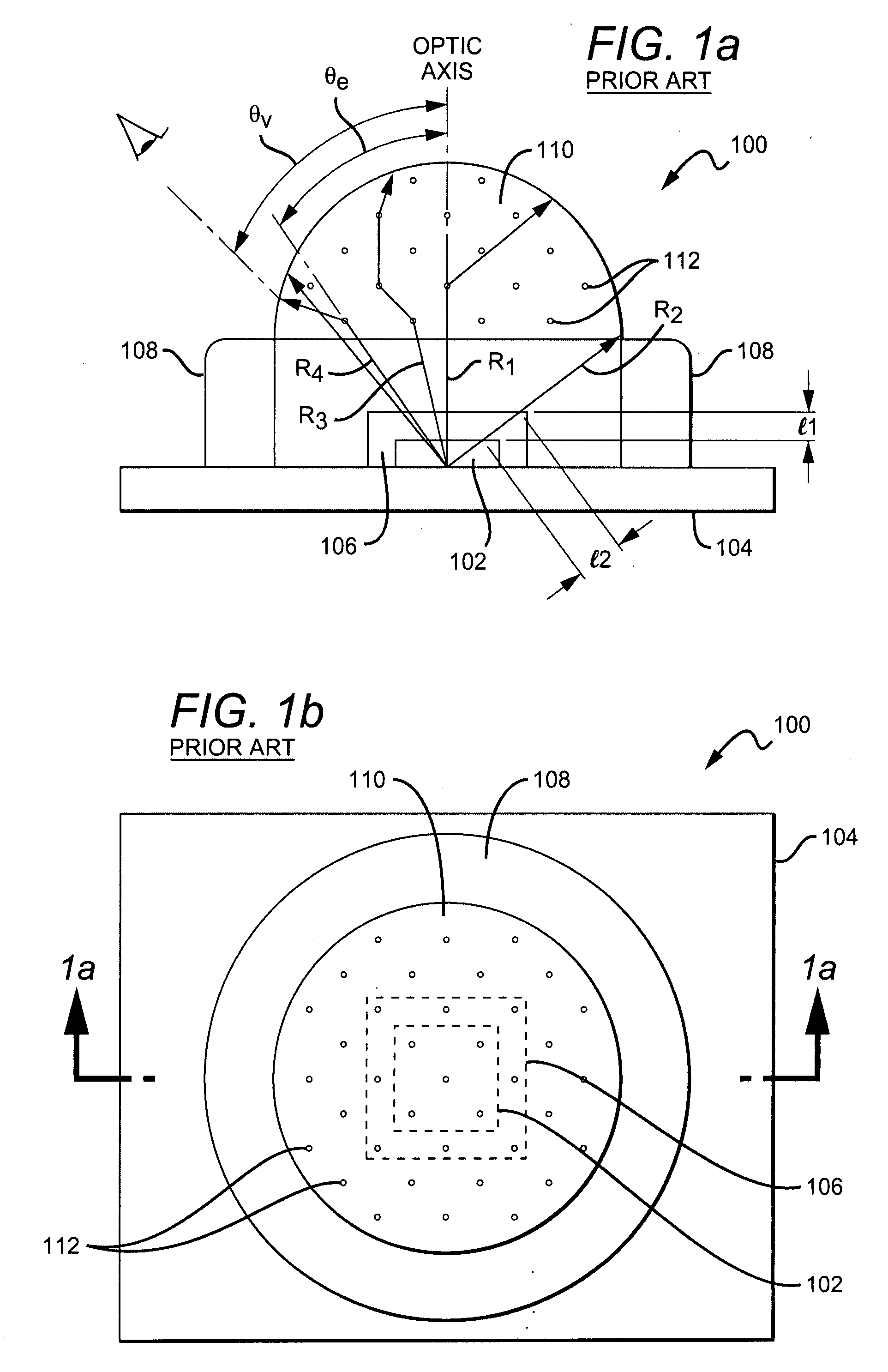

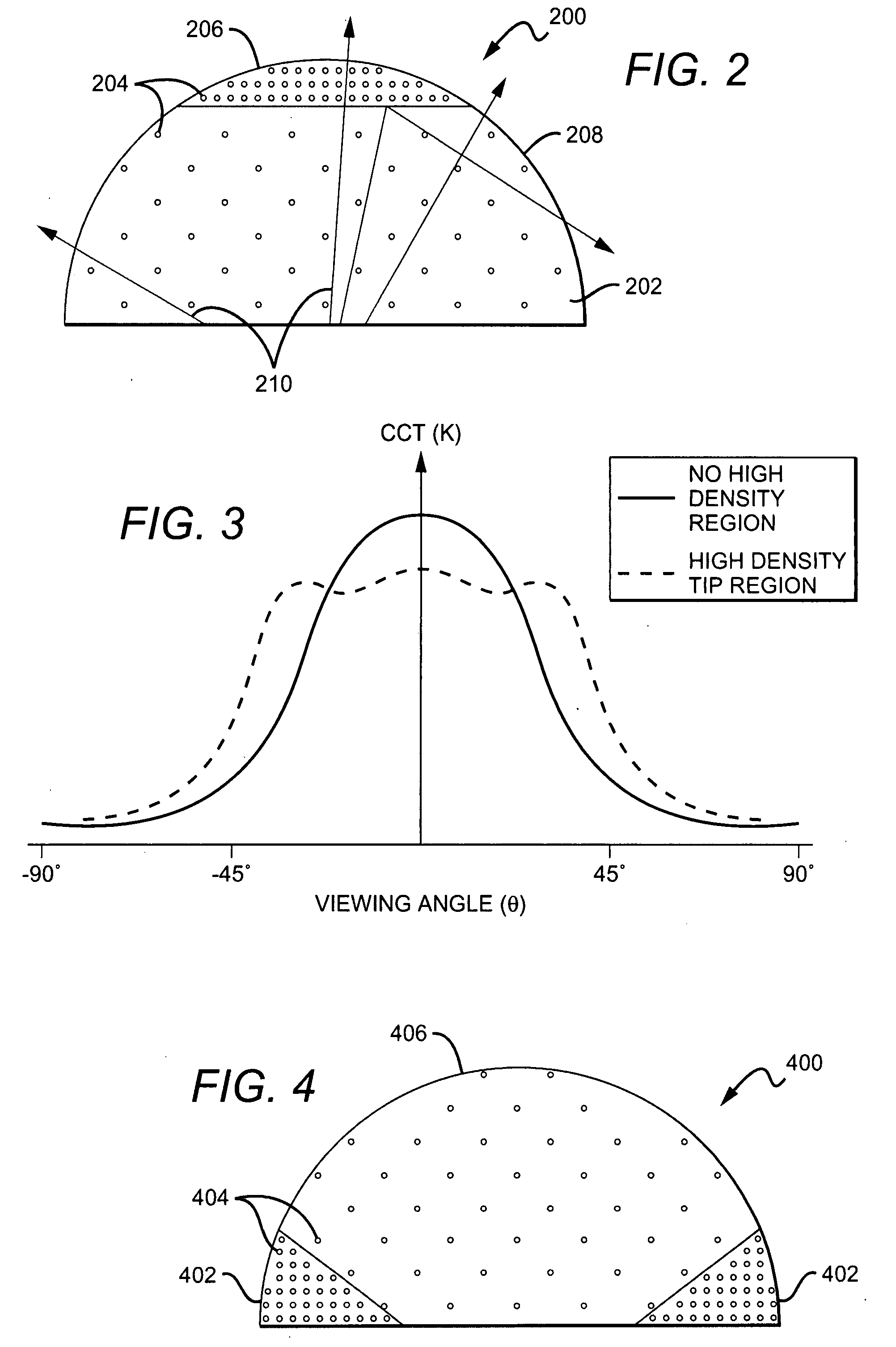

Encapsulant with scatterer to tailor spatial emission pattern and color uniformity in light emitting diodes

ActiveUS20080308825A1Solid-state devicesSemiconductor/solid-state device manufacturingHigh densityLight beam

A light emitting device having an encapsulant with scattering features to tailor the spatial emission pattern and color temperature uniformity of the output profile. The encapsulant is formed with materials having light scattering properties. The concentration of these light scatterers is varied spatially within the encapsulant and / or on the surface of the encapsulant. The regions having a high density of scatterers are arranged in the encapsulant to interact with light entering the encapsulant over a desired range of source emission angles. By increasing the probability that light from a particular range of emission angles will experience at least one scattering event, both the intensity and color temperature profiles of the output light beam can be tuned.

Owner:CREELED INC

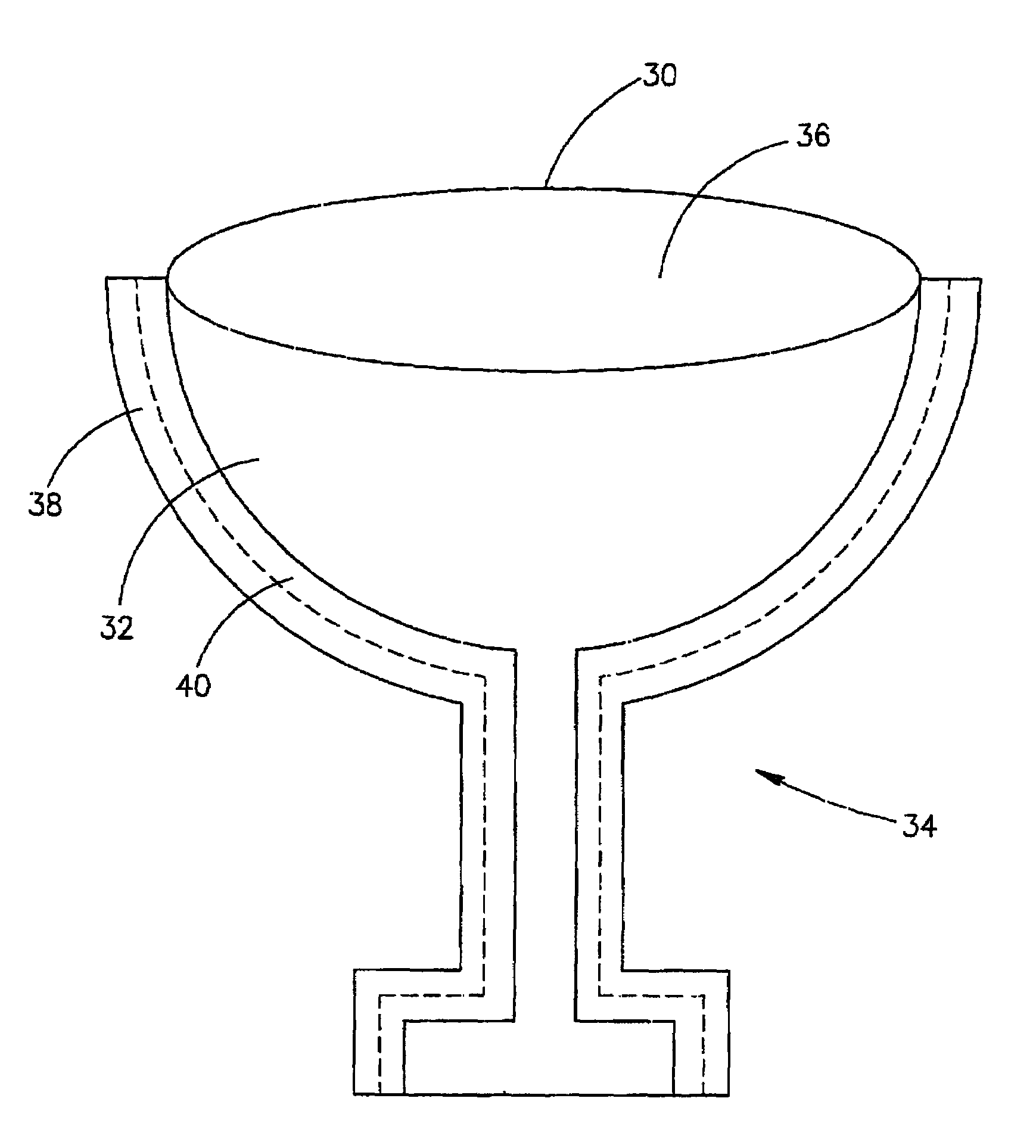

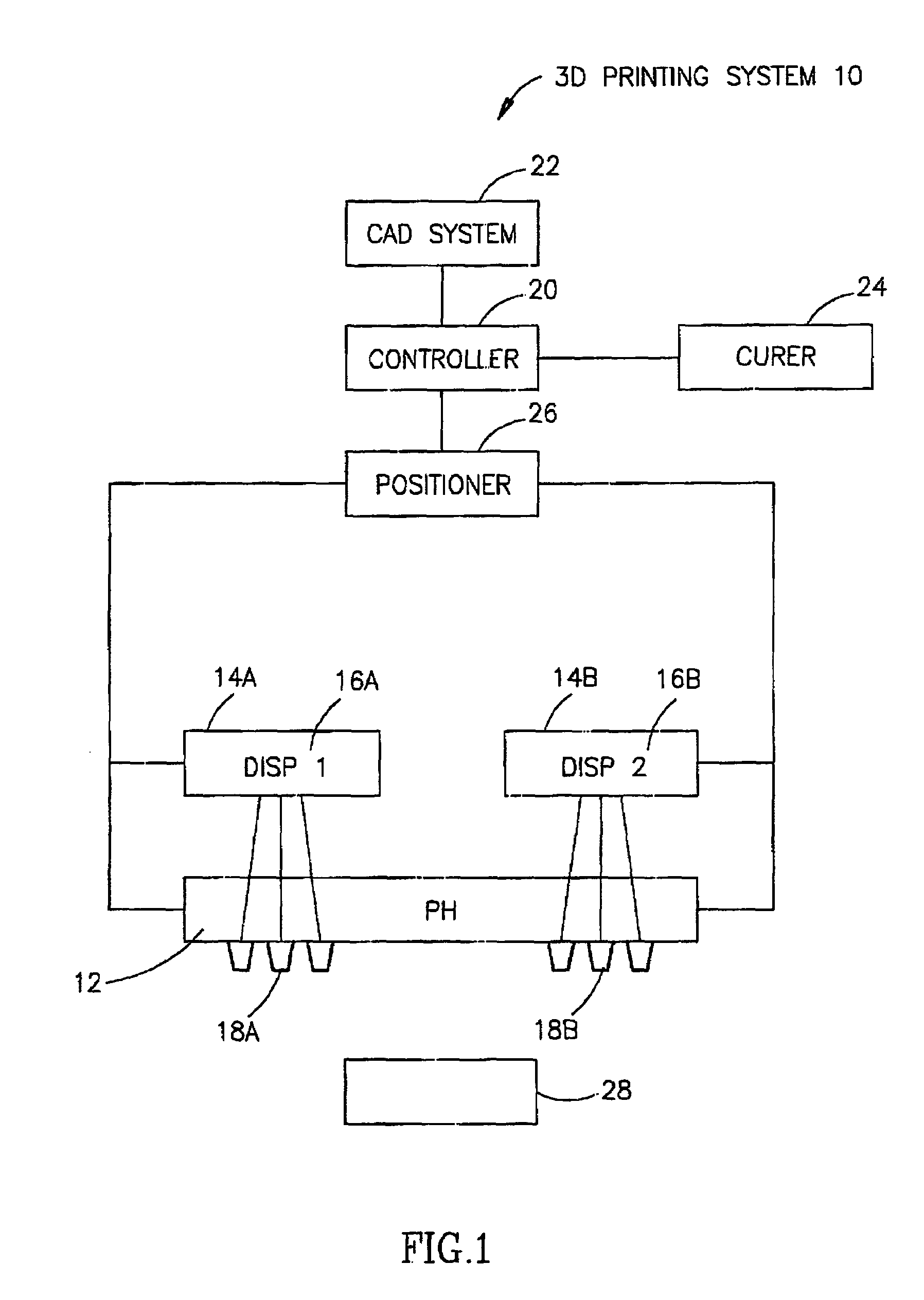

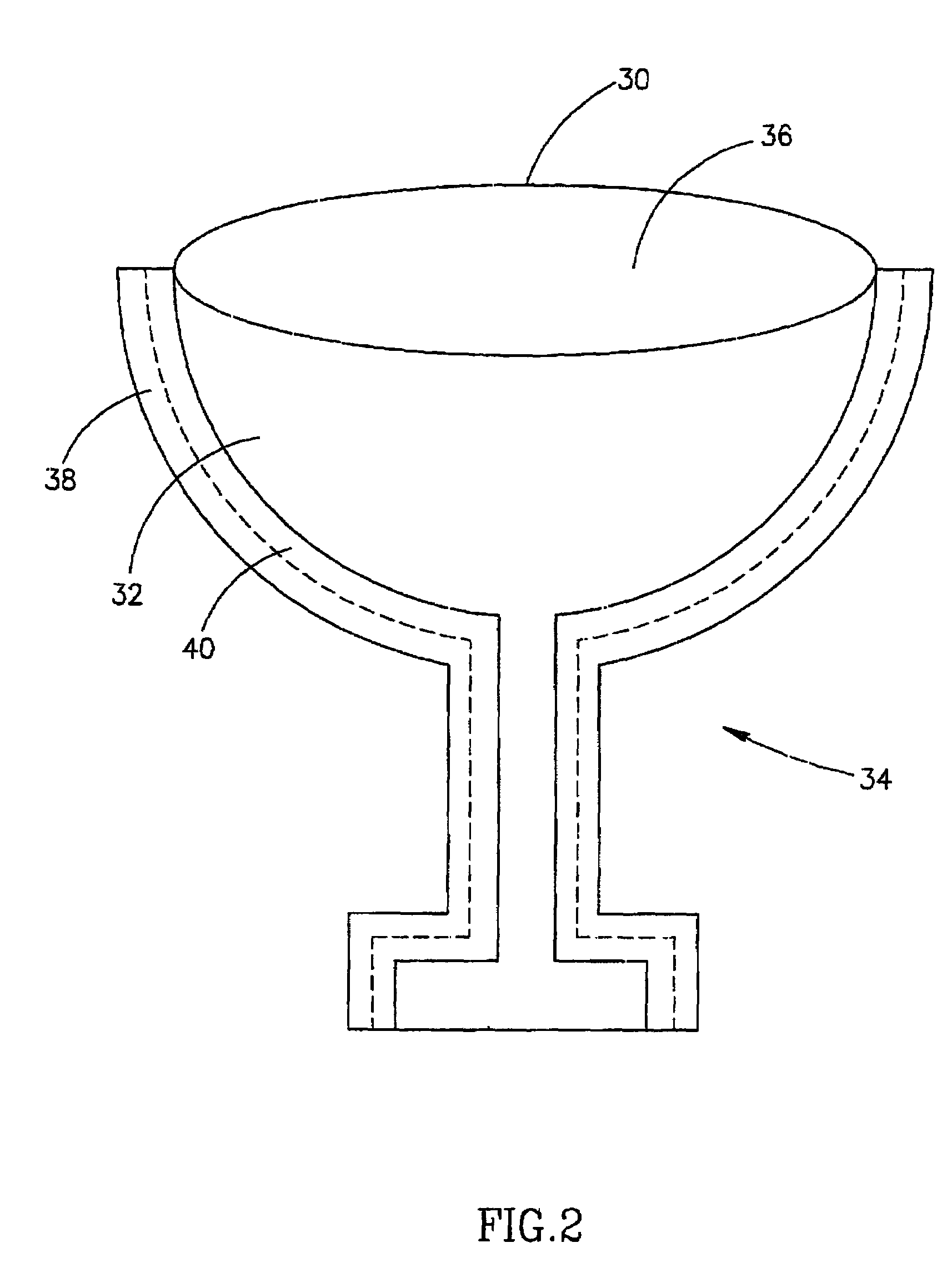

Compositions and methods for use in three dimensional model printing

Compositions for use in the manufacture of three-dimensional objects including compositions for use as a support and / or release material in the manufacture of the three-dimensional objects are provided. There is thus provided, in accordance with an embodiment of the present invention, a composition suitable for building a three-dimensional object. The compositions may include, inter alia, a curable component, having a functional group, wherein if the functional group is a polymerizable reactive functional group, then the functional group is a (meth)acrylic functional group, a photo-initiator, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 50–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after curing, the composition results in a solid form. There is thus provided, in accordance with another embodiment of the present invention, a composition suitable for support in building a three-dimensional object. The compositions may include, inter alia: a non-curable component, a curable component, wherein the non-curable component is not reactive with said curable component, a surface-active agent and a stabilizer; wherein said composition has a first viscosity of about 20–500 cps at a first temperature, wherein said first temperature is ambient temperature, and a second viscosity lower than 20 cps at a second temperature wherein said second temperature is higher than said first temperature, wherein, after irradiation, the composition results in a solid, a semi-solid or liquid material. A method for the preparation of a three-dimensional object by three-dimensional printing is provided in accordance with embodiments of the present invention. Embodiments of the present invention further provide a three-dimensional object prepared according to the methods of the invention.

Owner:STRATASYS LTD

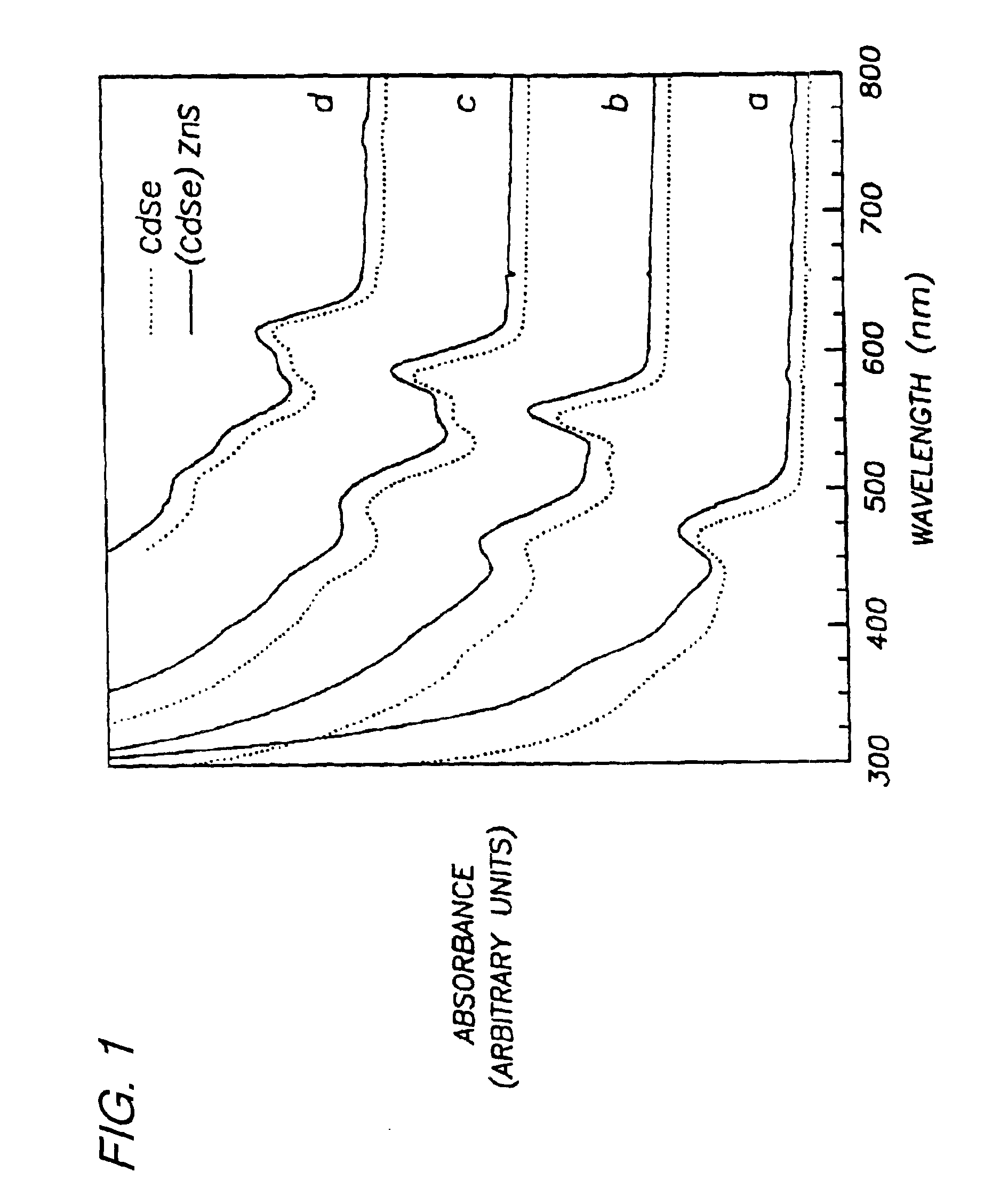

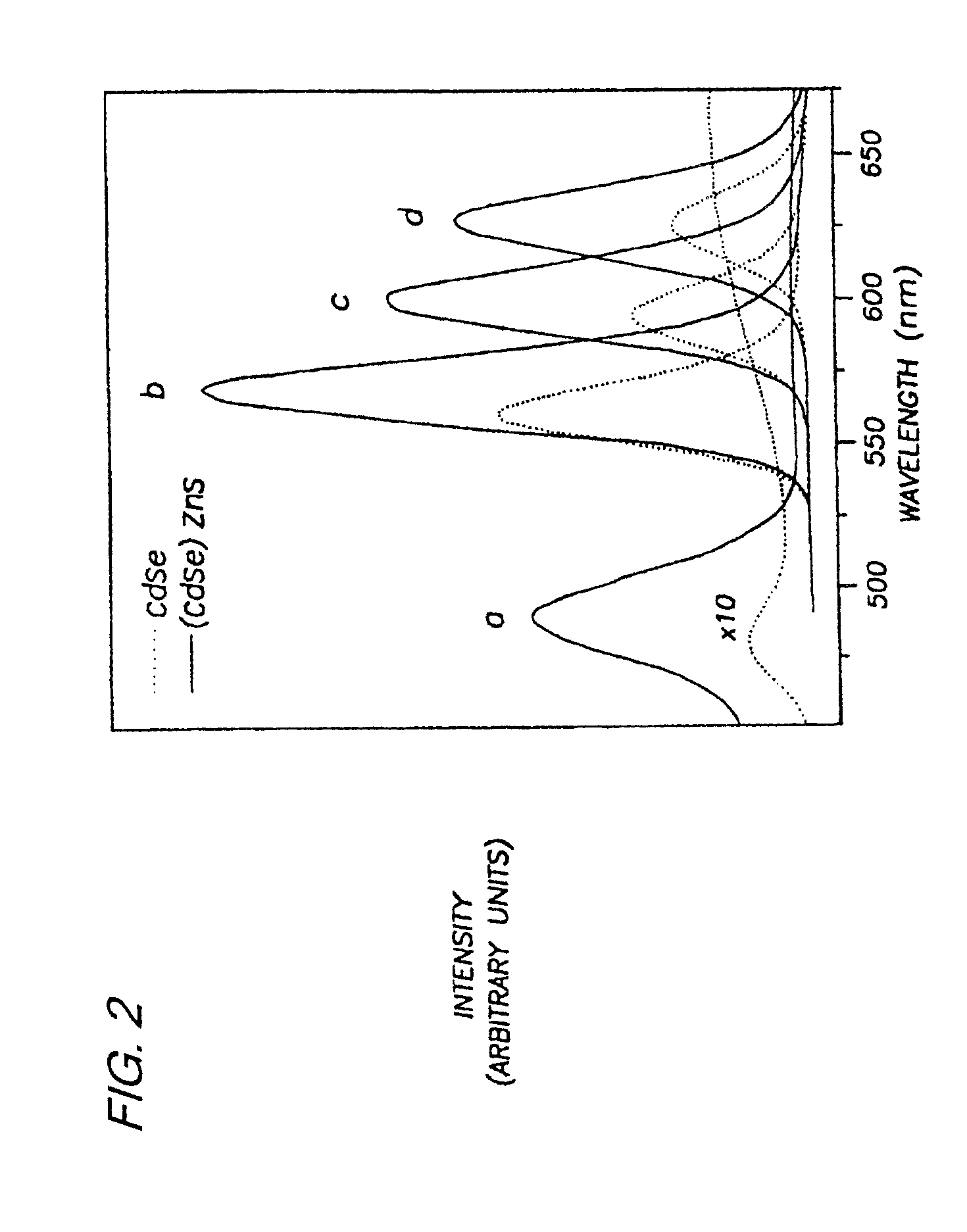

Highly luminescent color selective nanocrystalline materials

InactiveUS6861155B2Improve coordinationMaterial nanotechnologyFrom normal temperature solutionsQuantum yieldPhotoluminescence

A coated nanocrystal capable of light emission includes a substantially monodisperse nanoparticle selected from the group consisting of CdX, where x=S, Se, Te and an overcoating of ZnY, where Y=S, Se, uniformly deposited thereon, said coated nanoparticle characterized in that when irradiated the particles exhibit photoluminescence in a narrow spectral range of no greater than about 60 nm, and most preferably 40 nm, at full width half max (FWHM). The particle size of the nanocrystallite core is in the range of about 20 Å to about 125 Å, with a deviation of less than 10% in the core. The coated nanocrystal exhibits photoluminescence having quantum yields of greater than 30%.

Owner:MASSACHUSETTS INST OF TECH

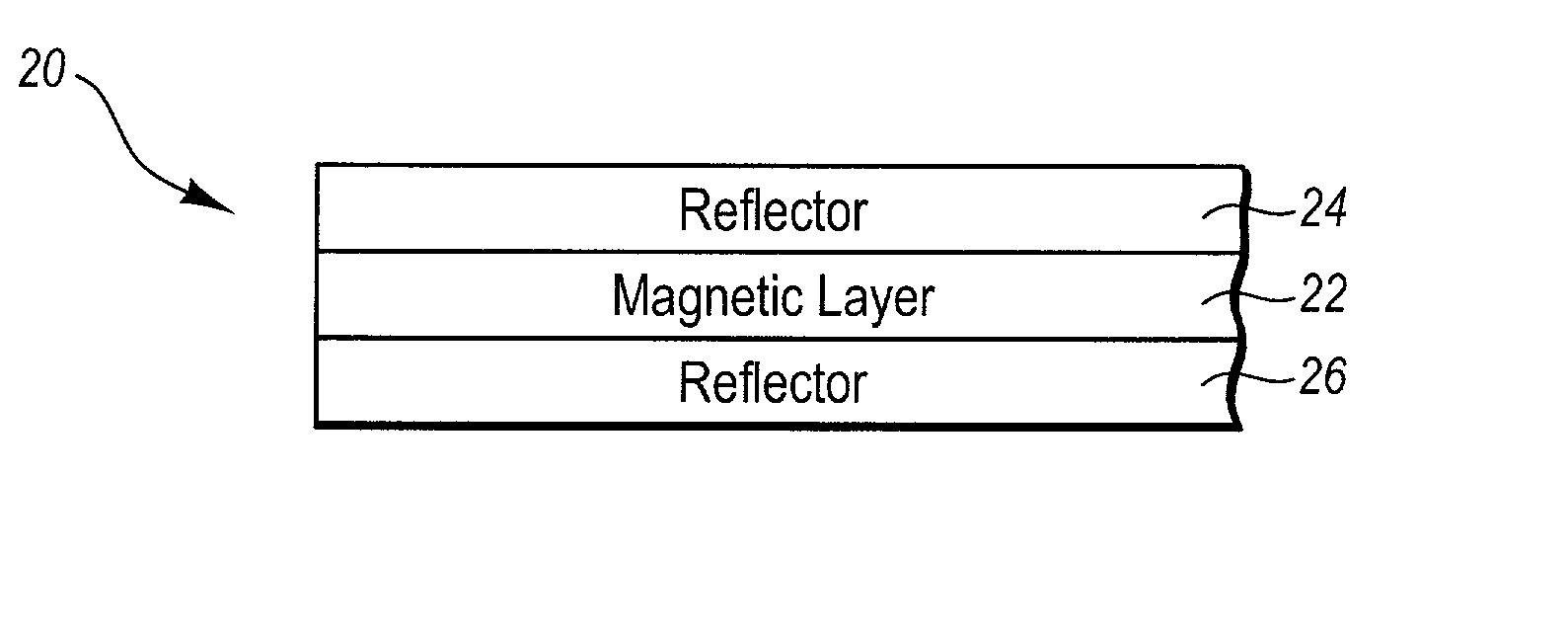

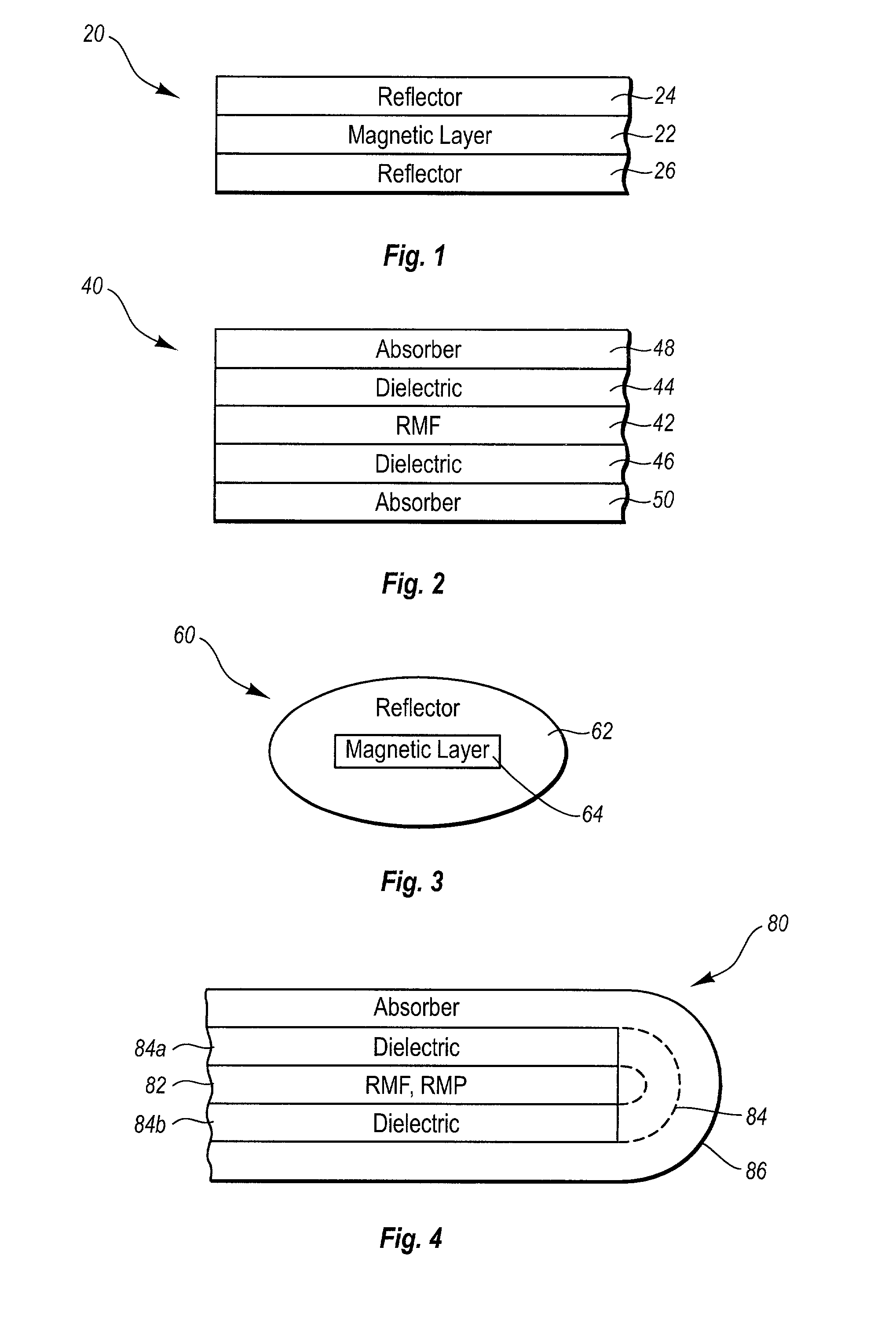

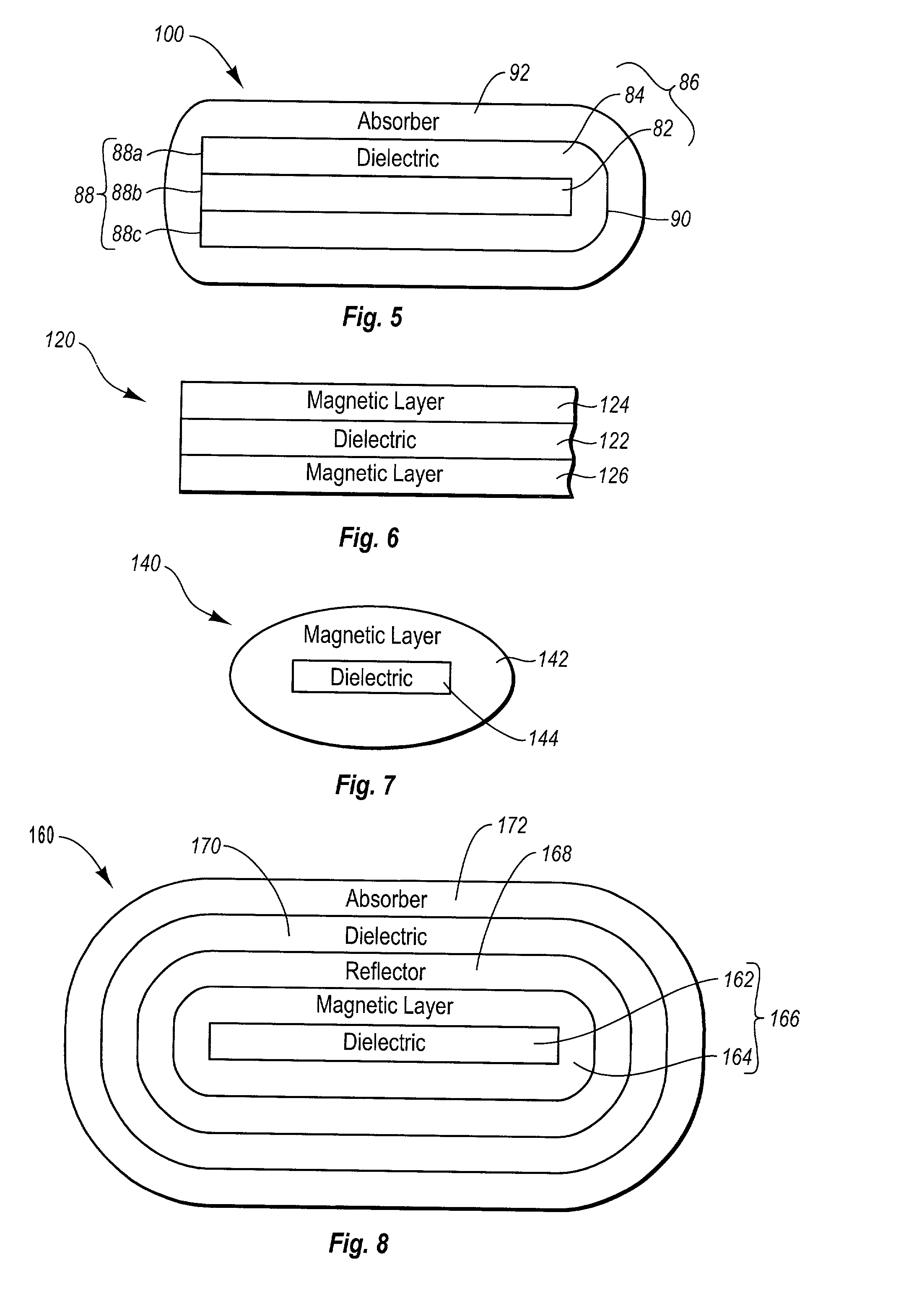

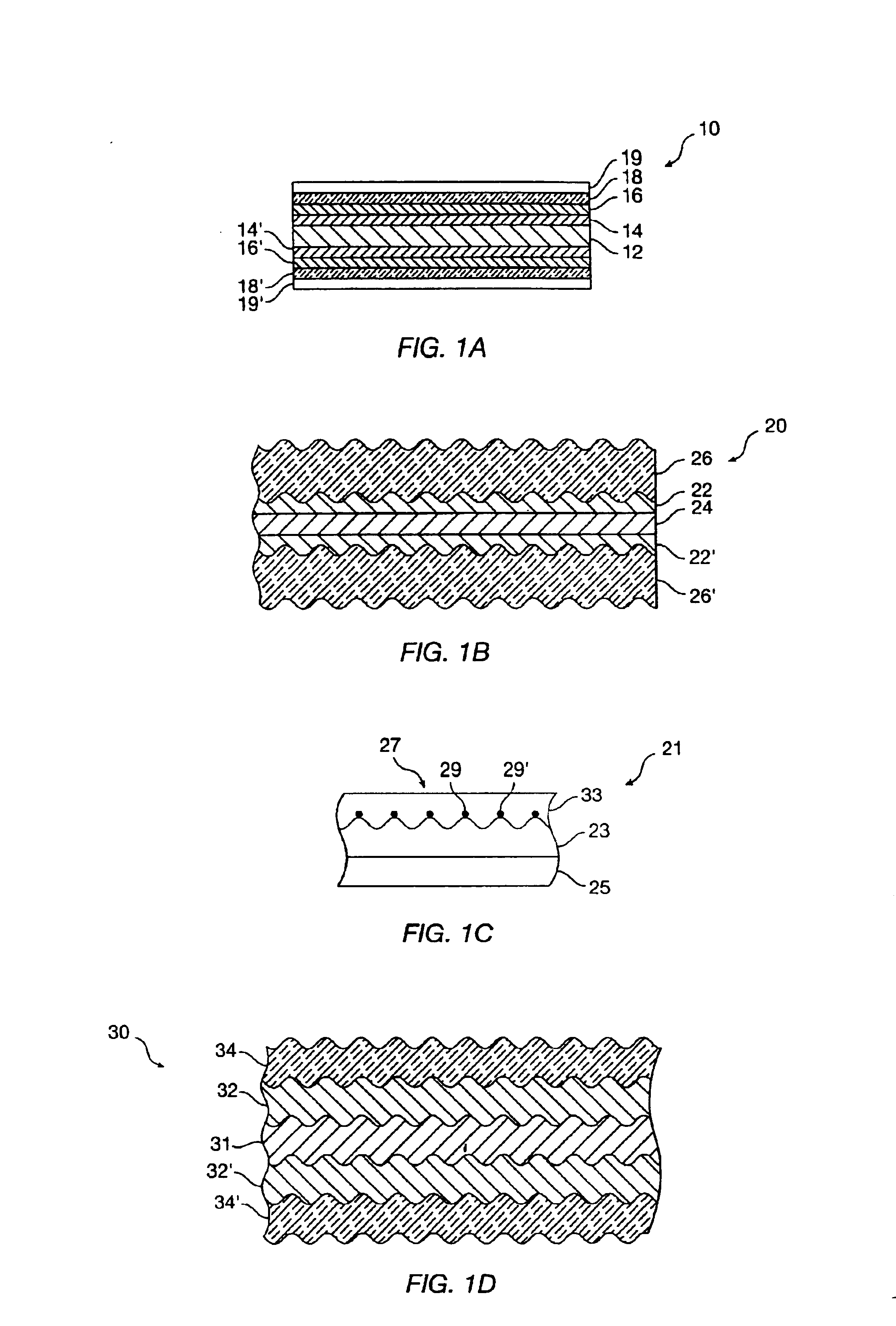

Multi-layered magnetic pigments and foils

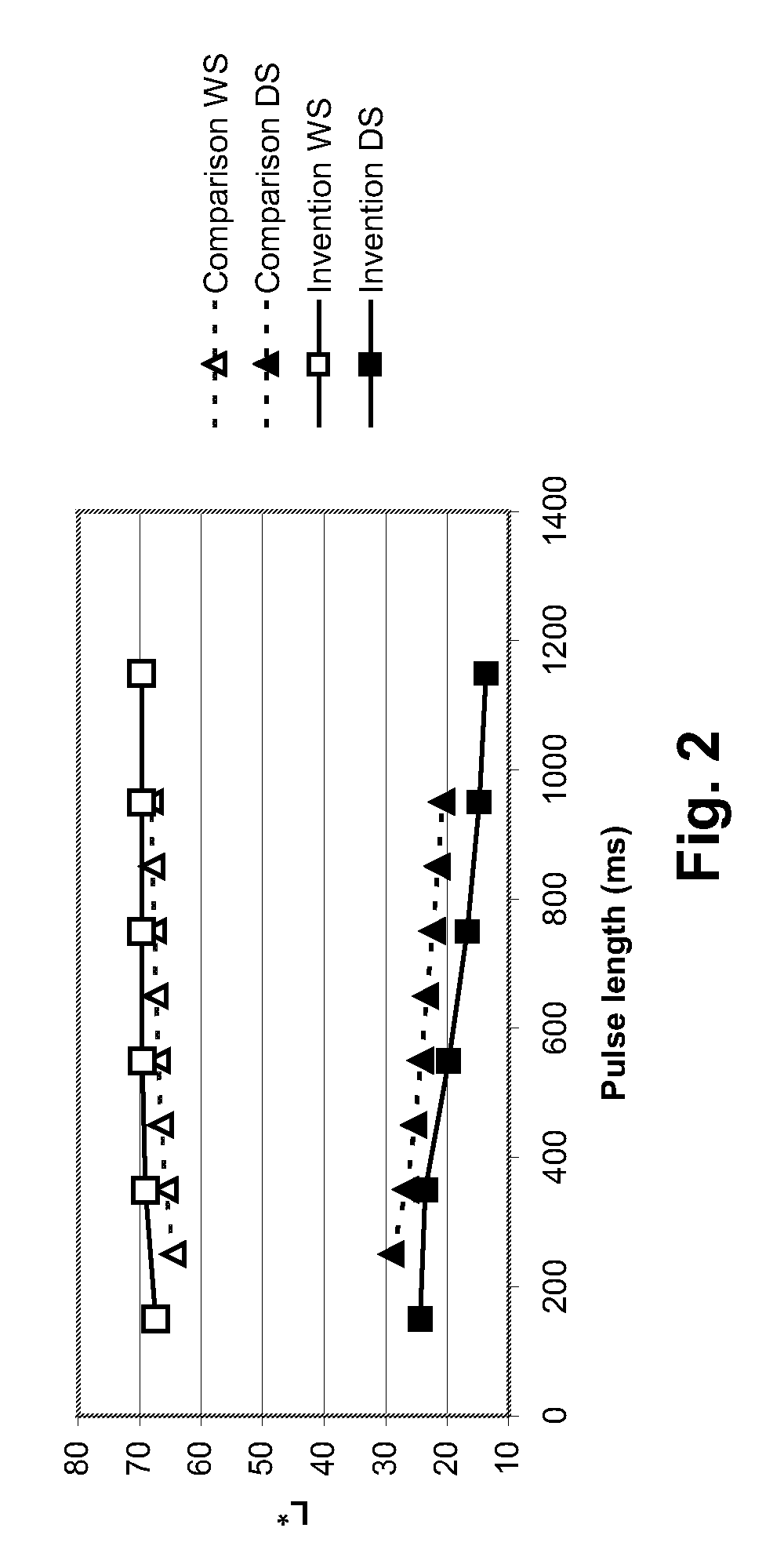

InactiveUS20020160194A1High chromaIncreased durabilityPigment preparation by PVD/CVD methodsPattern printingLiquid mediumColor shift

Multilayered magnetic pigment flakes and foils are provided. The pigment flakes can have a symmetrical coating structure on opposing sides of a magnetic core, or can be formed with encapsulating coatings around the magnetic core. The magnetic core can be a magnetic layer between reflector or dielectric layers, a dielectric layer between magnetic layers, or only a magnetic layer. Some embodiments of the pigment flakes and foils exhibit a discrete color shift so as to have distinct colors at differing angles of incident light or viewing. The pigment flakes can be interspersed into liquid media such as paints or inks to produce colorant compositions for subsequent application to objects or papers. The foils can be laminated to various objects or can be formed on a carrier substrate.

Owner:FLEX PRODUCTS INC

Light-emitting nanoparticles and method of making same

InactiveUS6846565B2Reduce aggregationResist formationMaterial nanotechnologyLiquid surface applicatorsParticle compositionHigh pressure

A method for the production of a robust, chemically stable, crystalline, passivated nanoparticle and composition containing the same, that emit light with high efficiencies and size-tunable and excitation energy tunable color. The methods include the thermal degradation of a precursor molecule in the presence of a capping agent at high temperature and elevated pressure. A particular composition prepared by the methods is a passivated silicon nanoparticle composition displaying discrete optical transitions.

Owner:MERCK PATENT GMBH +1

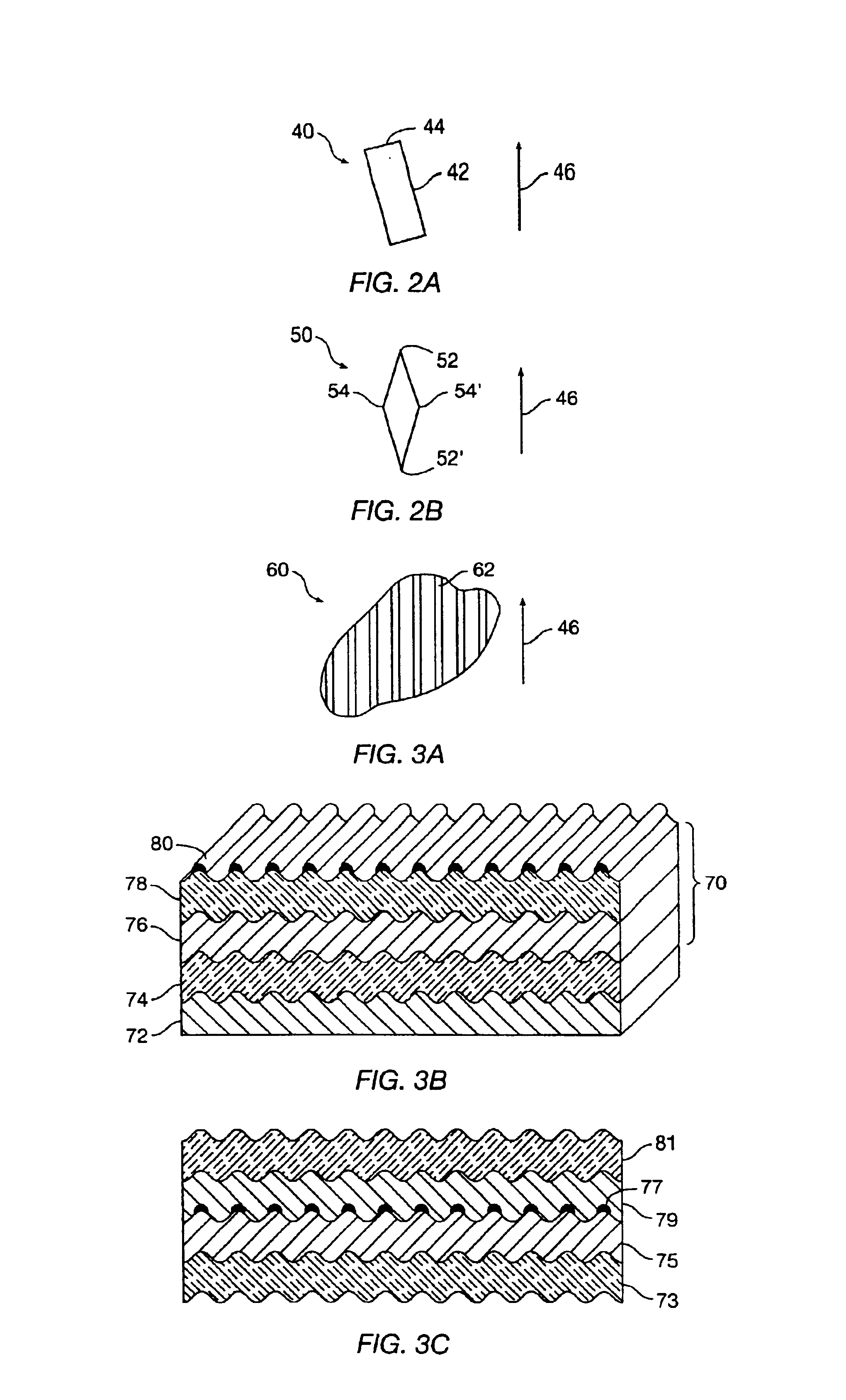

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

Reduced-density proppants and methods of using reduced-density proppants to enhance their transport in well bores and fractures

InactiveUS20050006095A1Easy to transportImprove conductivitySynthetic resin layered productsCellulosic plastic layered productsParticulatesMaterials science

The present invention provides reduced-density coated particulates and methods for enhancing the transport of such particulates into well bores and fractures, and for enhancing the conductivity and permeability of subterranean formations using such particulates, and for sand control treatments using such particulates. The reduced-density, coated particulates of the present invention generally comprise particulate having a surface and a coating wherein the surface comprises a porous or partially hollow geometry and coating is capable of trapping a fluid between the particulate's surface and the coating.

Owner:HALLIBURTON ENERGY SERVICES INC

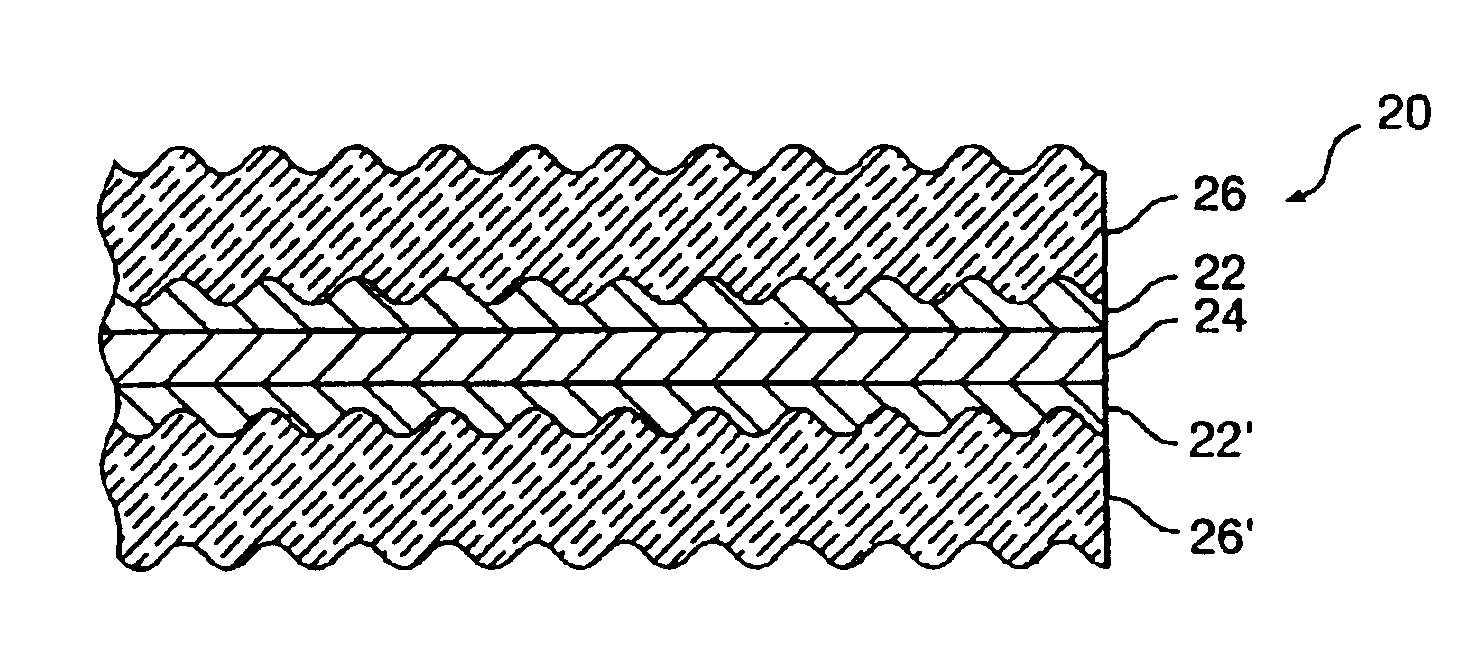

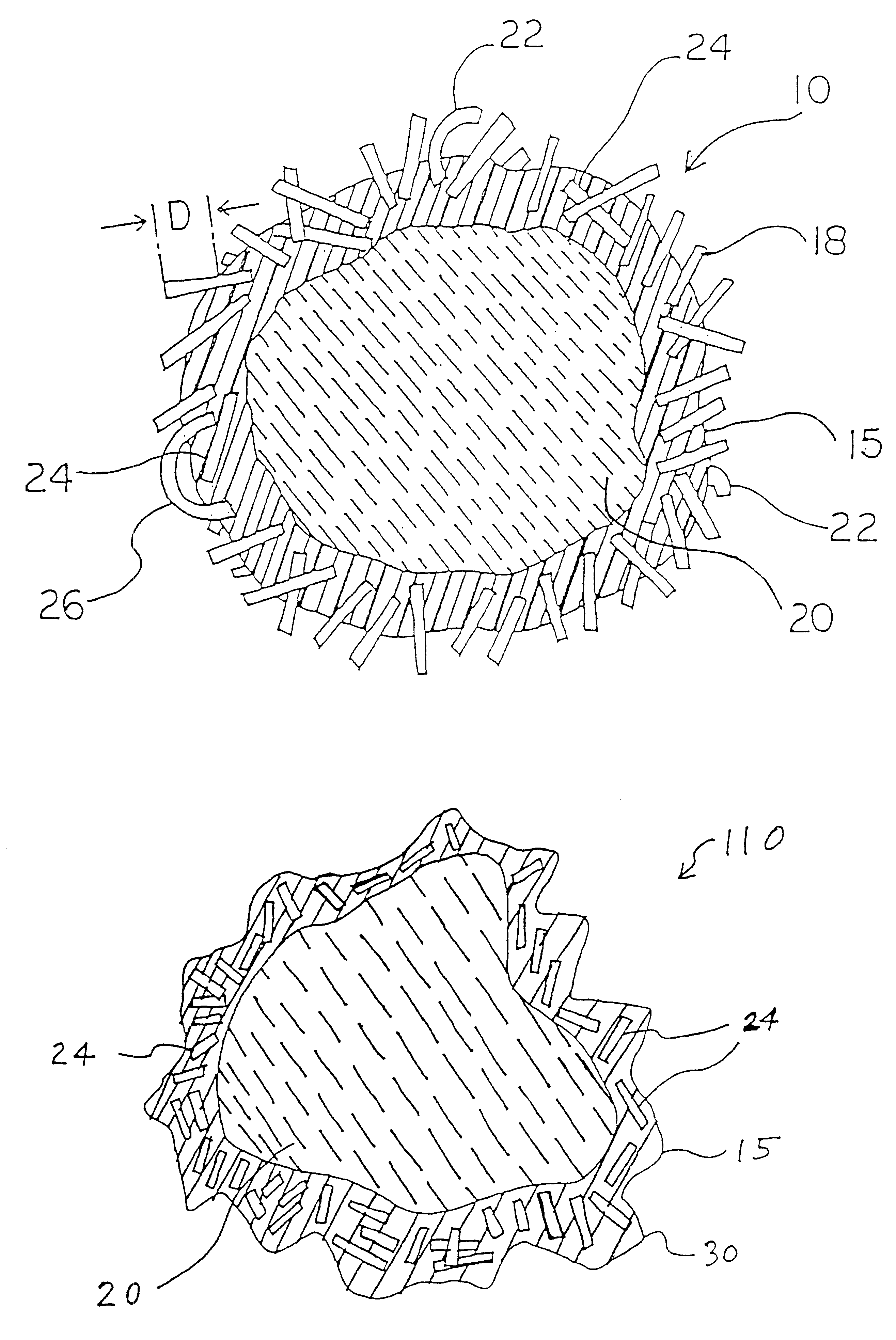

Proppants with fiber reinforced resin coatings

InactiveUS6528157B1High compressive strengthWithstanding stressCeramic layered productsDrilling compositionParticulatesResin coating

Coated particles made of particulate substrates having a coating of resin and fibrous material are provided for use in subterranean formations. The coated substrate particles are proppants useful to prop open subterranean formation fractures. The coated substrate particles are also useful for sand control, that is, acting as a filter or screen to prevent backwards flow of sand, other proppants or subterranean formation particles. Methods of making the coated particles are also disclosed.

Owner:HEXION INC

Walter-absorbing agent

There is disclosed a water-absorbing agent which combines both performances of the capillary suction force and the liquid permeability. This water-absorbing agent is a particulate water-absorbing agent comprising water-absorbent resin particles (α) and a liquid-permeability-enhancing agent (β), wherein the water-absorbent resin particles (α) are surface-crosslink-treated particles of a crosslinked polymer of a monomer including acrylic acid and / or its salt; with the water-absorbing agent being characterized in that the particulate water-absorbing agent has: a mass-average particle diameter (D50) in the range of 234 to 394 gm, a logarithmic standard deviation (σξY) of a particle diameter distribution in the range of 0.25 to 0.45, an absorption capacity without load (CRC) of not less than 15 g / g, and a water-extractable component content of not higher than 15 mass %; and further a liquid-permeability-enhancing agent (β) content in the range of 0.01 to 5 mass parts per 100 mass parts of the water-absorbent resin particles (α).

Owner:NIPPON SHOKUBAI CO LTD

Organically-functionalized monodisperse nanocrystals of metals

InactiveUS6103868AHigh selectivityAvoid problemsPolycrystalline material growthLiquid surface applicatorsNanocrystalReducing agent

PCT No. PCT / US96 / 20402 Sec. 371 Date Jun. 18, 1998 Sec. 102(e) Date Jun. 18, 1998 PCT Filed Dec. 27, 1996 PCT Pub. No. WO97 / 24224 PCT Pub. Date Jul. 10, 1997Organically functionalized metal nanoparticles are produced by mixing a metal precursor with an organic surface passivant and reacting the resulting mixture with a reducing agent to generate free metal while binding the passivant to the surface of the free metal to produce organically functionalized metal particles.

Owner:RGT UNIV OF CALIFORNIA

Aqueous dispersions of polymer-enclosed particles, related coating compositions and coated substrates

ActiveUS20060251896A1Nanostructure manufactureSynthetic resin layered productsNanoparticleMaterials science

Disclosed are aqueous dispersions of polymer-enclosed particles, such as nanoparticles. Also disclosed are methods for making an aqueous dispersion of polymer-enclosed particles, polymerizable polymers useful in such a method, powder coating compositions formed from such an aqueous dispersion, substrates at least partially coated with such a composition, and reflective surfaces comprising a non-hiding coating layer deposited from such a composition.

Owner:PPG IND OHIO INC

Flooring products and methods of making the same

InactiveUS20060032175A1Improve moisture resistanceStrutsSynthetic resin layered productsThick plateNatural fiber

A plank is described wherein the plank comprises a core, and optionally, a print layer, and optionally an overlay. The core includes from about 30 wt % to about 95 wt % at least one polymeric material, by weight of the core, and from about 5 wt % to about 70 wt % of least one natural fiber or flour, by weight of the core, wherein the core includes a top surface and a bottom surface, and opposing sides, wherein said plank is substantially moisture resistant, having a swelling property of from about 0.5% to about 5% by NALFA Thickness Test Section 3.2 LF 01-2003 standard, and wherein said plank includes a bow of from about 0.5% to about 4%. In addition, a method of making the plank is further described.

Owner:MANNINGTON MILLS

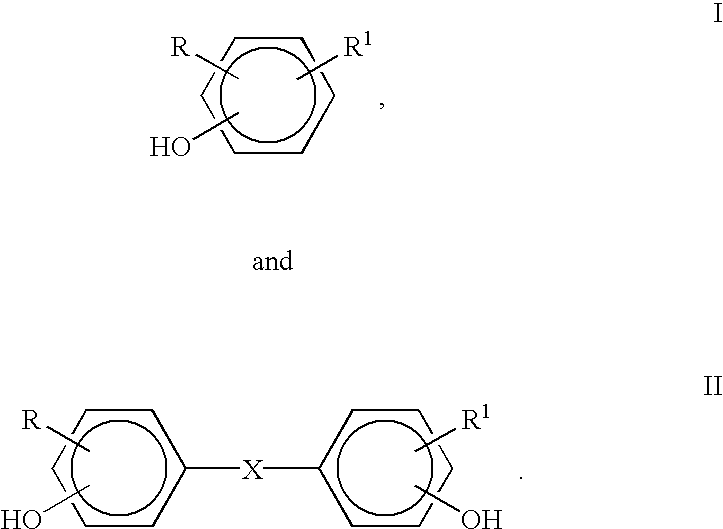

Low density composite proppant, filtration media, gravel packing media, and sports field media, and methods for making and using same

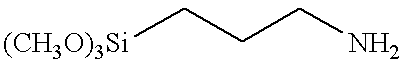

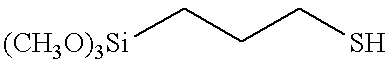

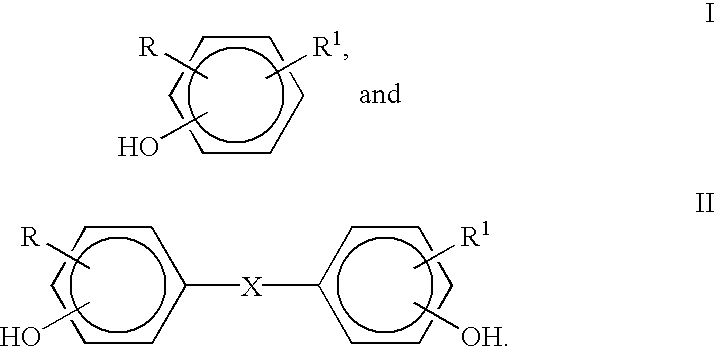

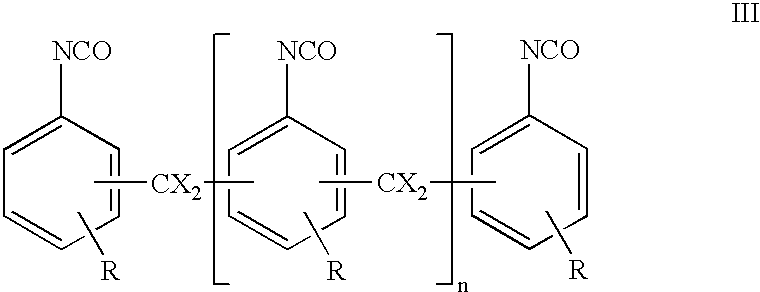

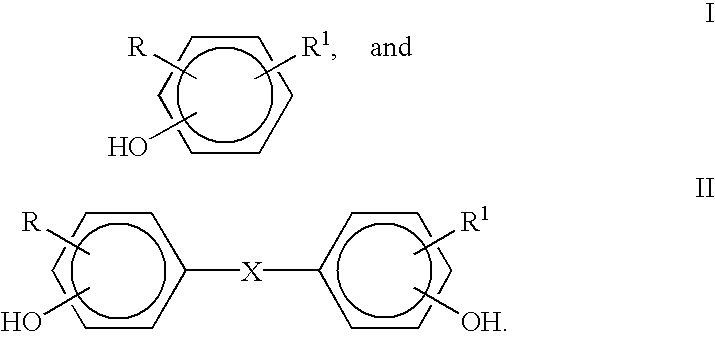

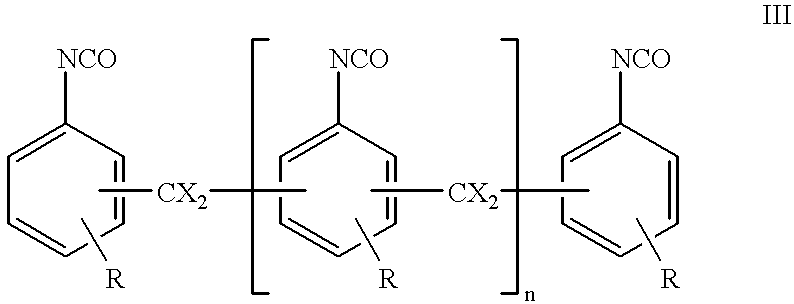

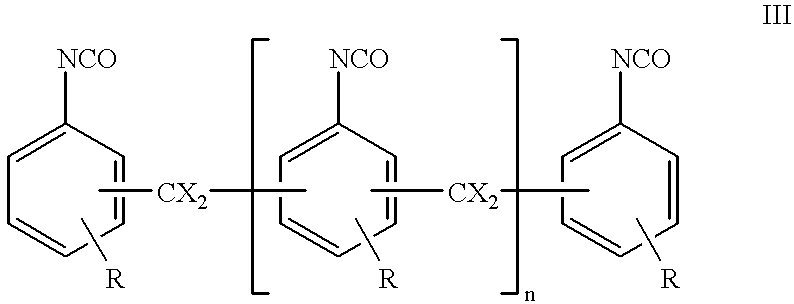

InactiveUS20020048676A1Point becomes highImprove interfacial organic-inorganic adhesionPigmenting treatmentDead plant preservationFiltrationArtificial turf

Low density composite particles made of a binder and filler material are provided for use in subterranean formations. The filler includes low density filler and optionally other filler. The binder includes a polymer and optionally cement. The particles may be employed as proppants useful to prop open subterranean formation fractures. The particles are also useful for gravel packing in subterranean formations, water filtration and artificial turf for sports fields. Methods of making the composite particles are also disclosed.

Owner:HEXION INC

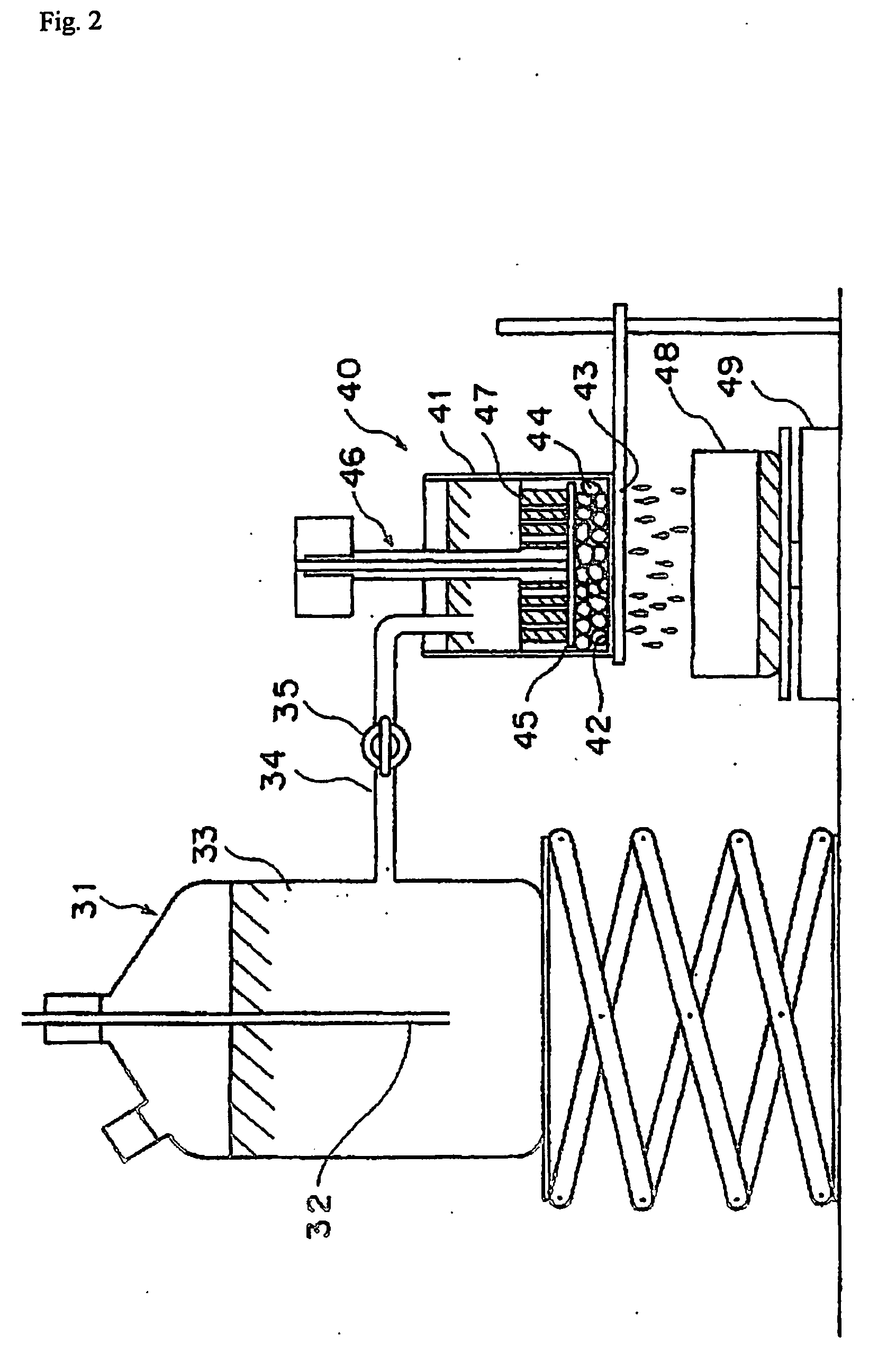

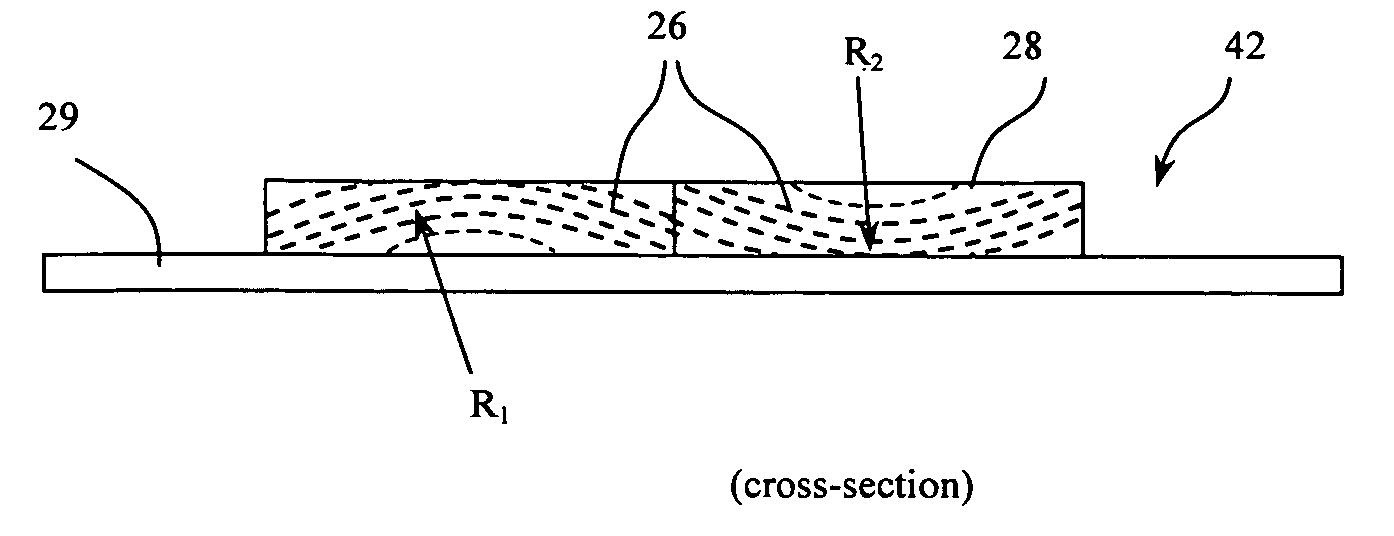

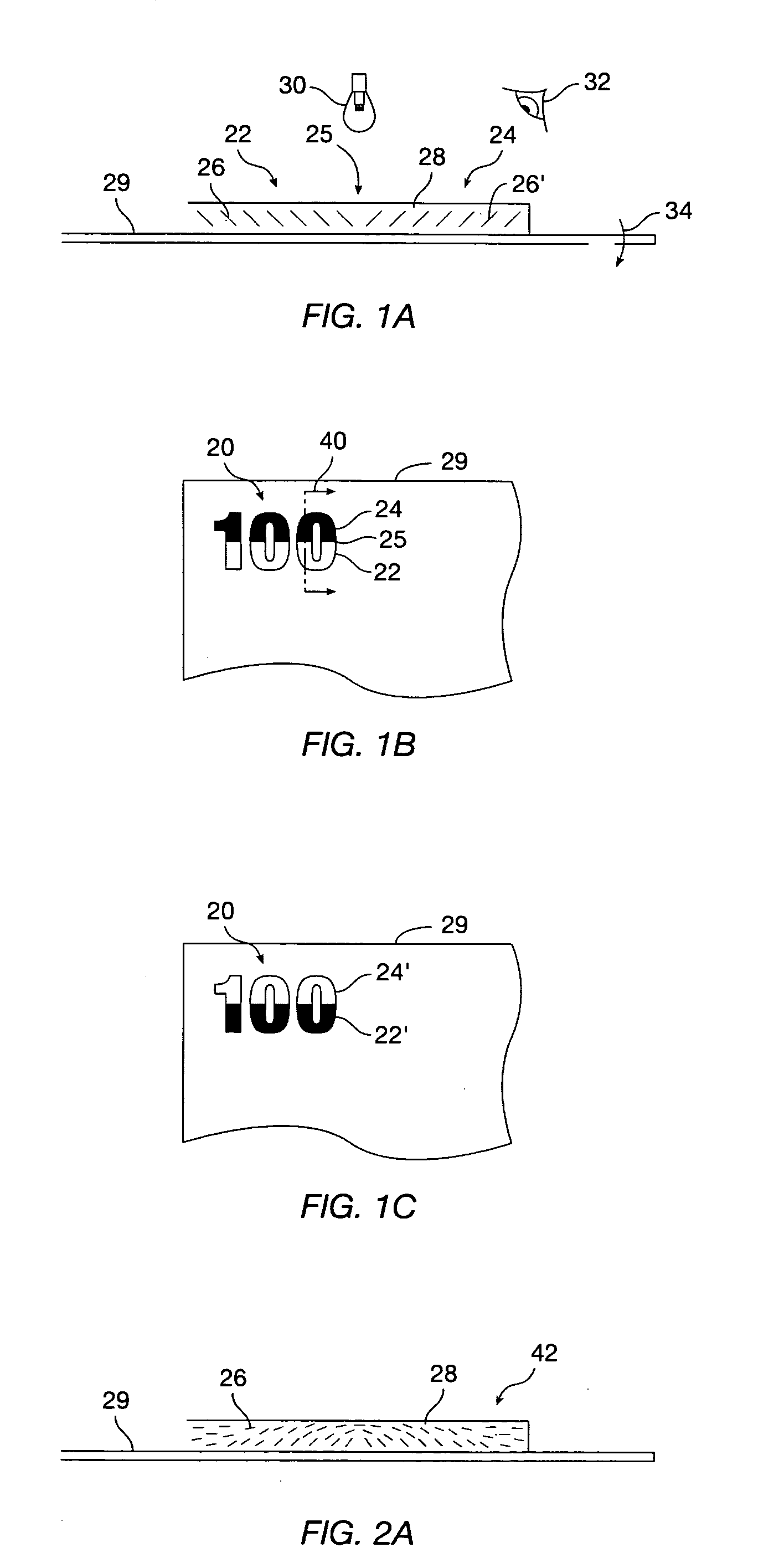

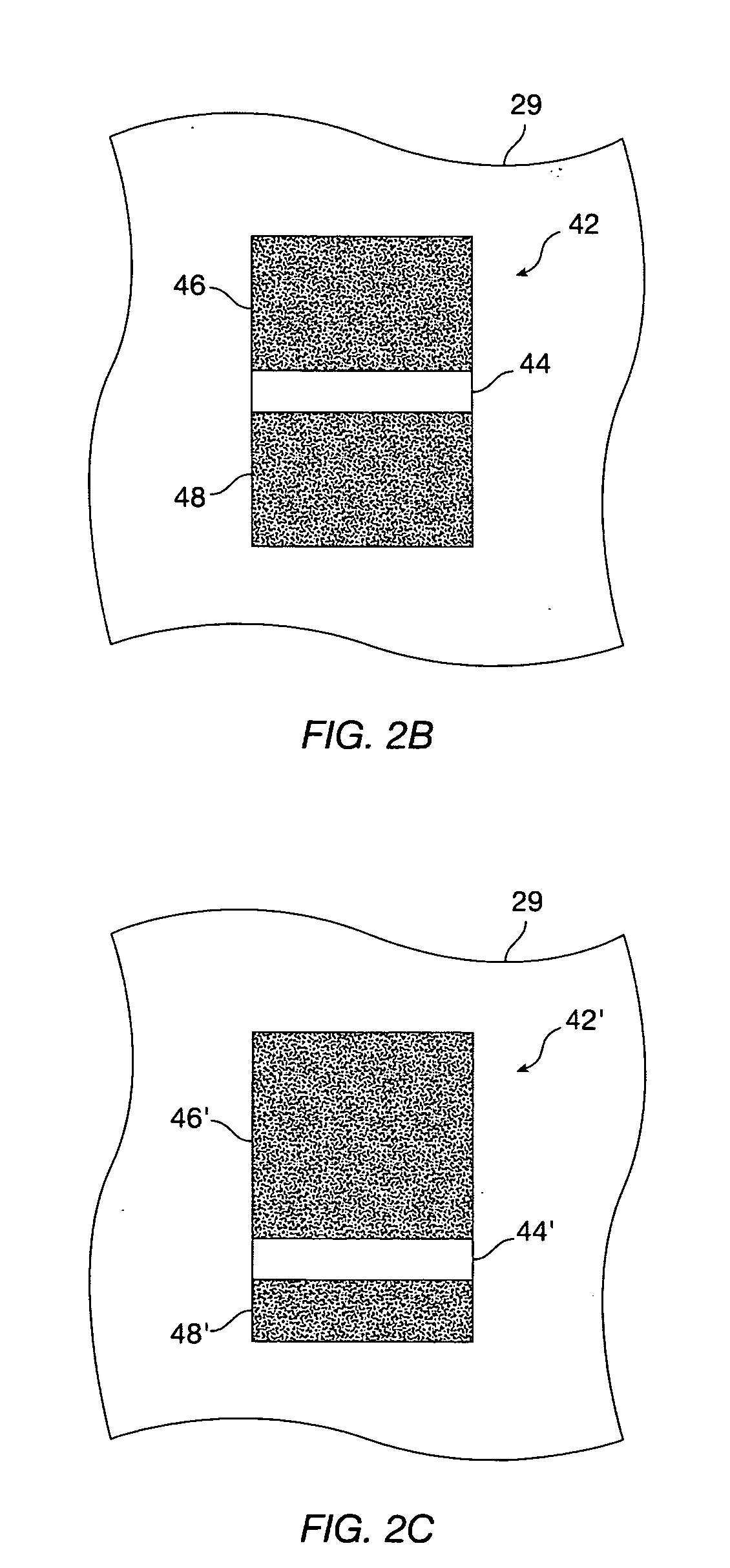

Method and apparatus for orienting magnetic flakes

InactiveUS20050106367A1Non-fibrous pulp additionDecorative surface effectsPaper documentDocument preparation

Apparatus and related methods align magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnets in a linear printing operation. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

Water-absorbing agent

There is disclosed a water-absorbing agent which combines both performances of the capillary suction force and the liquid permeability. This water-absorbing agent is a particulate water-absorbing agent comprising water-absorbent resin particles (α) and a liquid-permeability-enhancing agent (β), wherein the water-absorbent resin particles (α) are surface-crosslink-treated particles of a crosslinked polymer of a monomer including acrylic acid and / or its salt; with the water-absorbing agent being characterized in that the particulate water-absorbing agent has: a mass-average particle diameter (D50) in the range of 234 to 394 gm, a logarithmic standard deviation (σζ) of a particle diameter distribution in the range of 0.25 to 0.45, an absorption capacity without load (CRC) of not less than 15 g / g, and a water-extractable component content of not higher than 15 mass %; and further a liquid-permeability-enhancing agent (β) content in the range of 0.01 to 5 mass parts per 100 mass parts of the water-absorbent resin particles (α).

Owner:NIPPON SHOKUBAI CO LTD

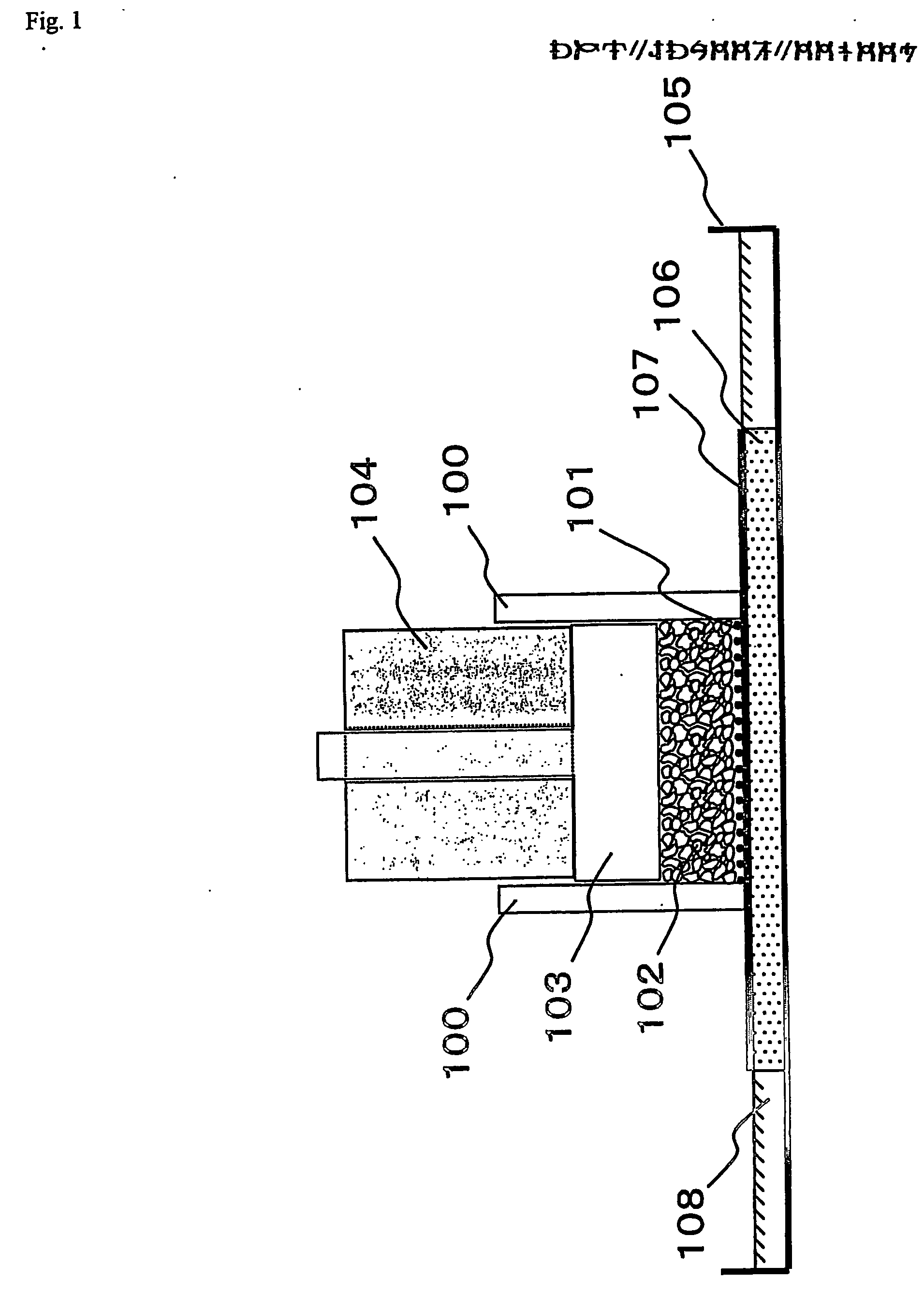

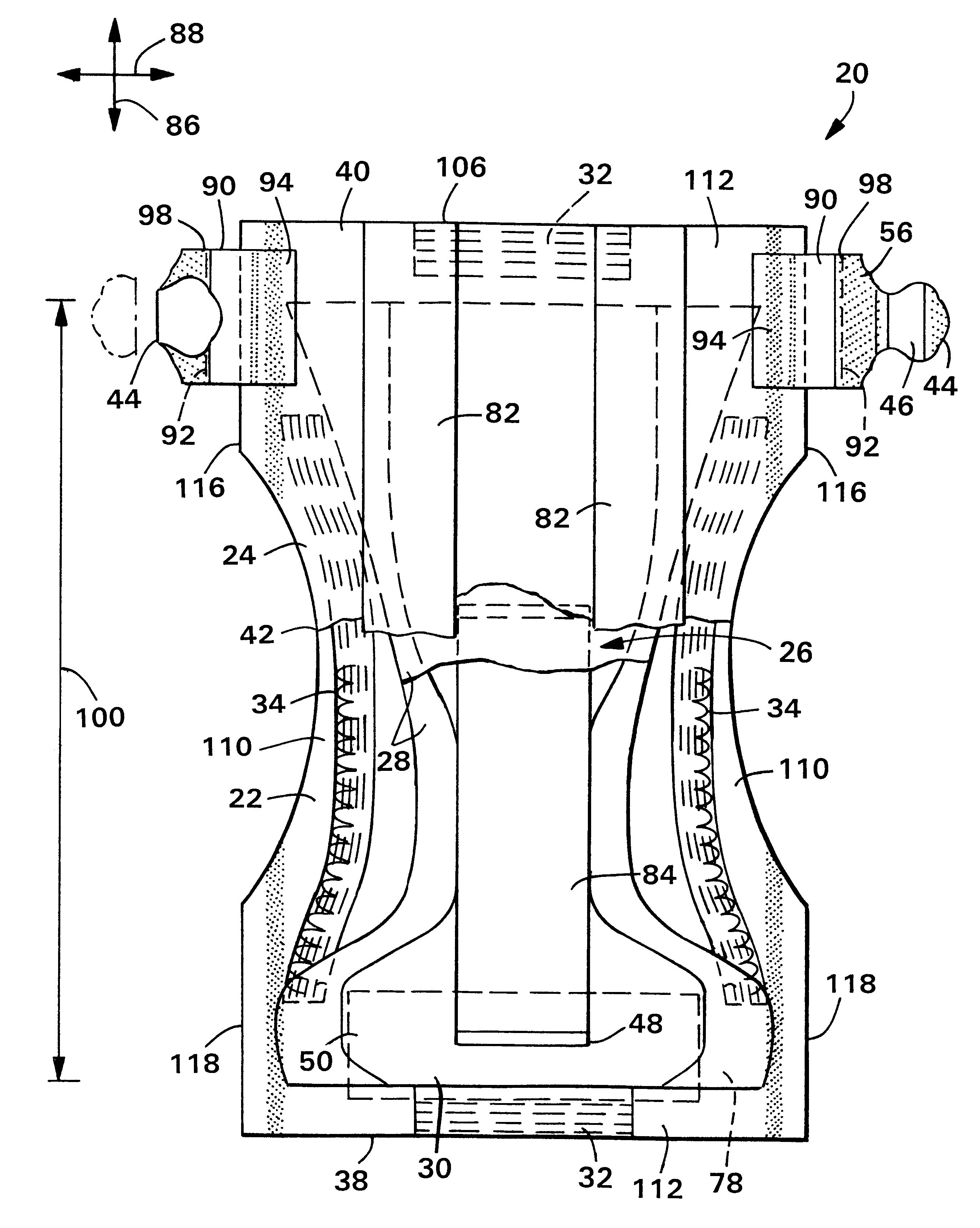

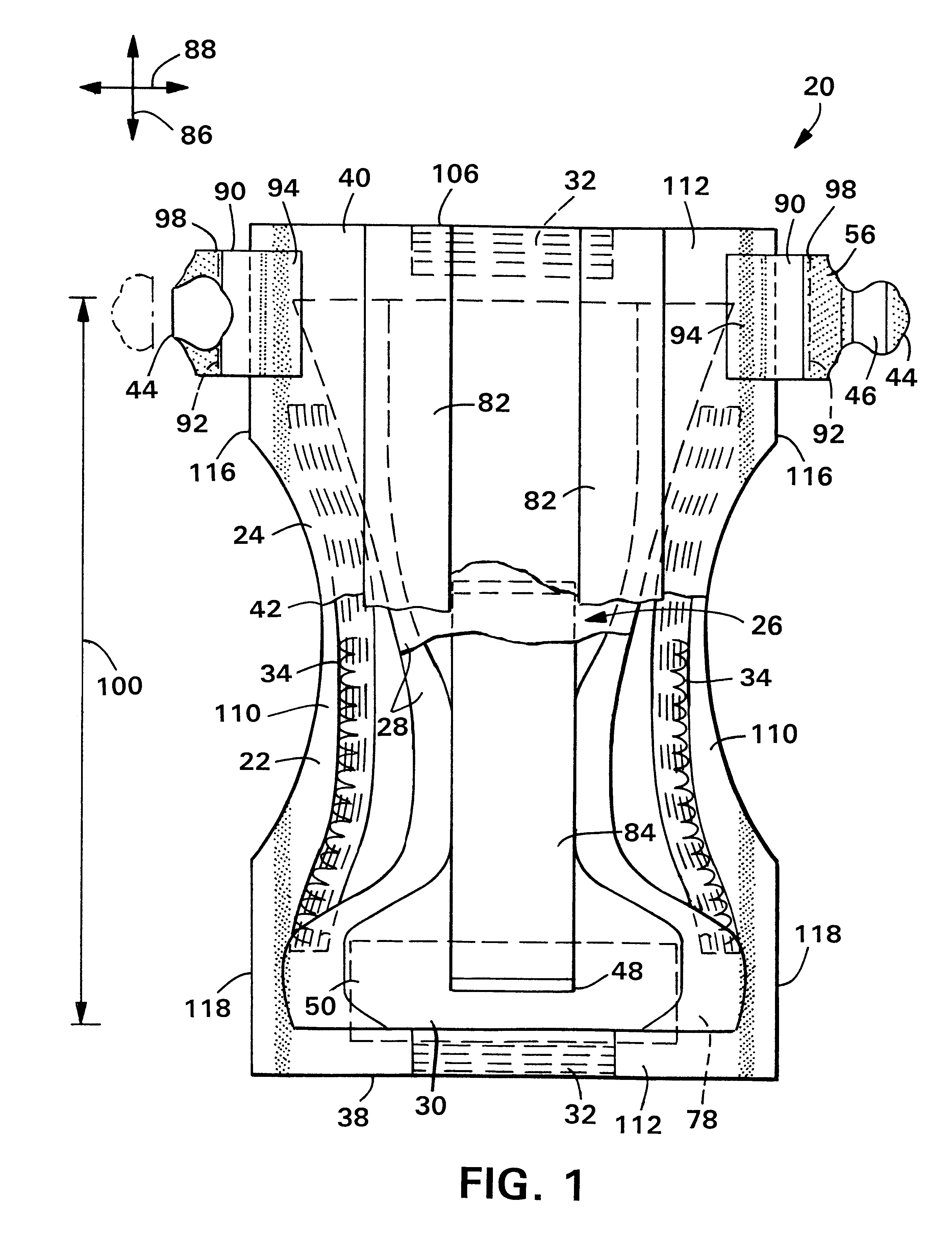

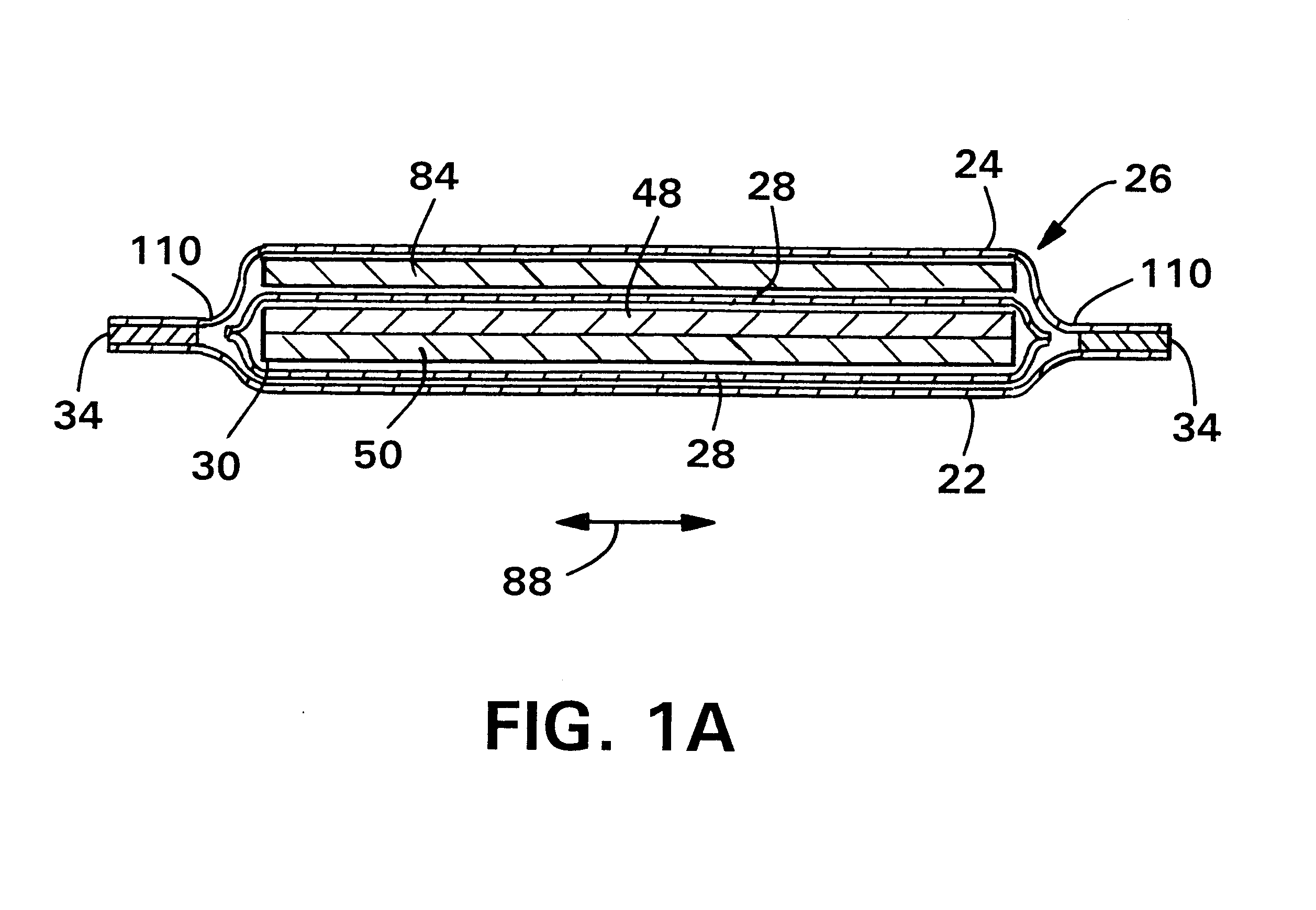

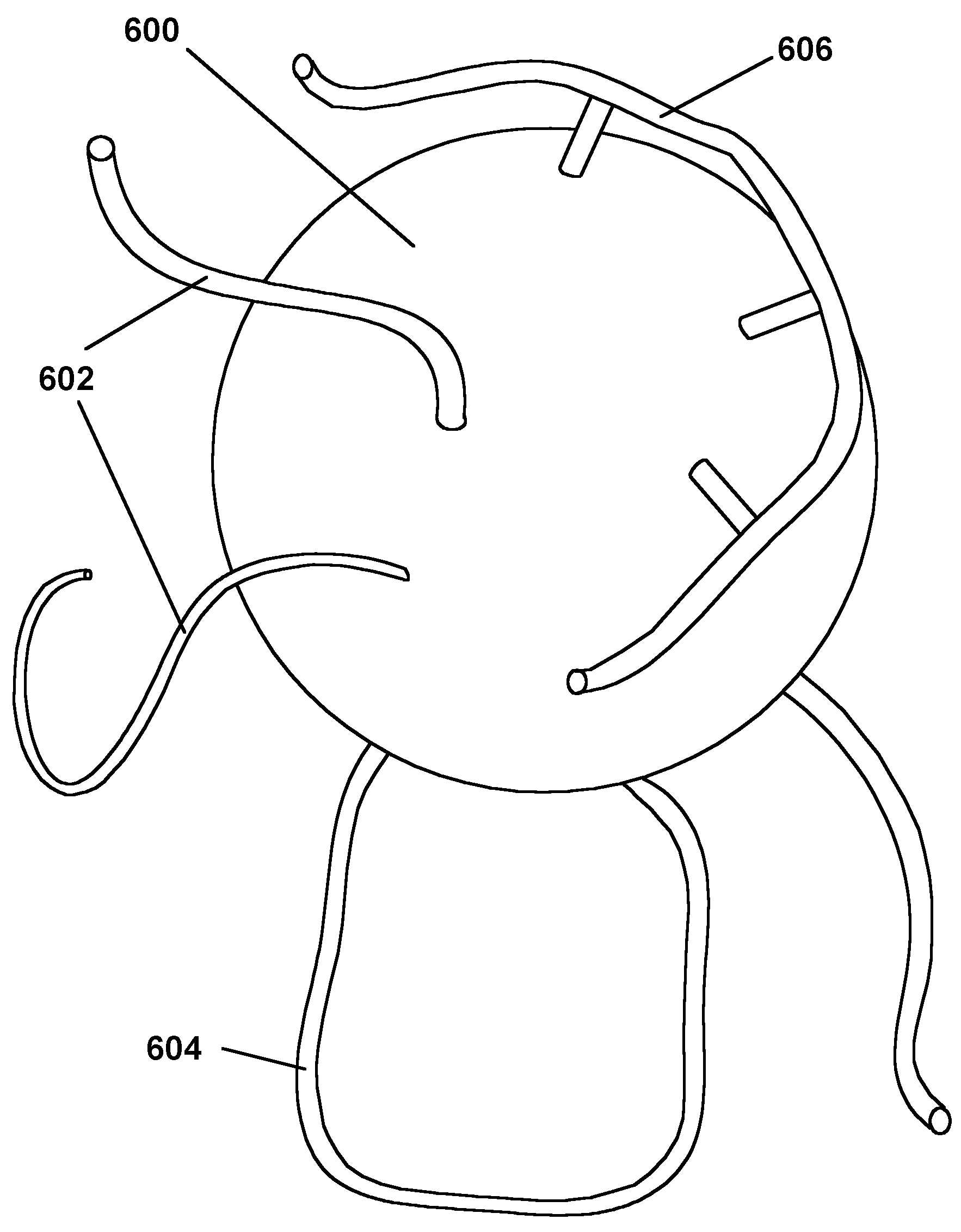

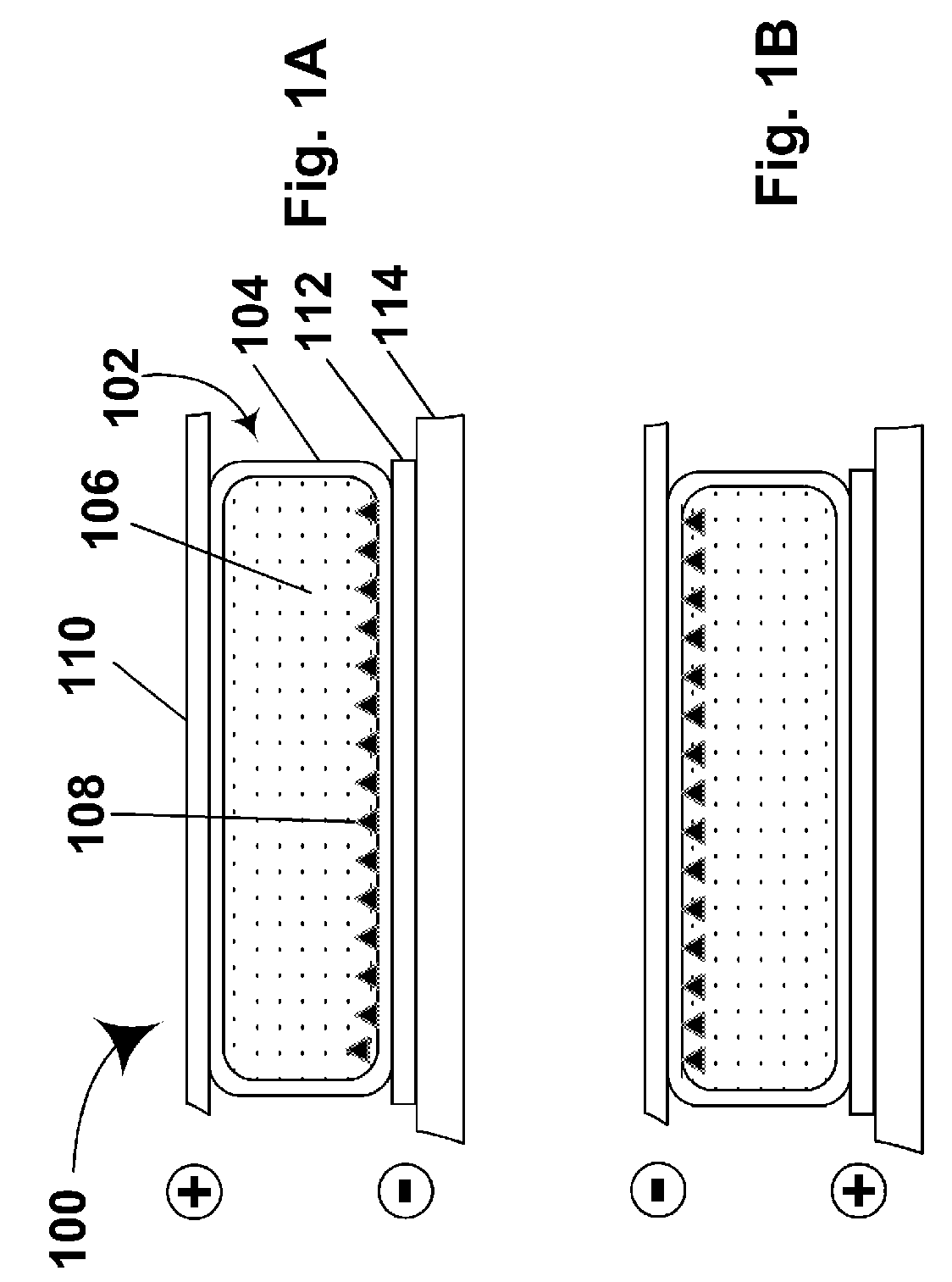

Layered absorbent structure

A distinctive absorbent article includes an absorbent core having multiple absorbent layers, wherein the absorbent layers interact in such a manner which preferentially locates absorbed liquid in an appointed, high saturation wicking layer. The localization of the liquid within this wicking layer increases the potential of this layer to move liquid through capillary action due to the higher saturation level and increased amount of liquid available. The intake capability of the absorbent system is maintained or improved over current systems by keeping a second layer of the absorbent system at low saturation levels through as many insults of the product as possible, while providing optimum intake performance through appropriate control of the composite properties. The low saturation in this layer provides void volume for the incoming insult as well, as a high permeability, thus increasing the intake rate of the absorbent system as a whole, but the structure of the low saturation layer is also balanced to provide an appropriately high level of capillary tension to provide enough control of the liquid to stop leakage from occurring. This low saturation layer is used in addition to a surge material and provides intake functionality in addition to that provided by the surge material. In particular aspects of the invention, the body side layer of the absorbent core does not extend over the entire surface of the overall absorbent core, therefore is not used as the high saturation, wicking layer, but as the intake layer. This arrangement also allows the intake layer to be in direct contact with the incoming liquid, therefore allowing for more immediate access and improved intake function.

Owner:KIMBERLY-CLARK WORLDWIDE INC

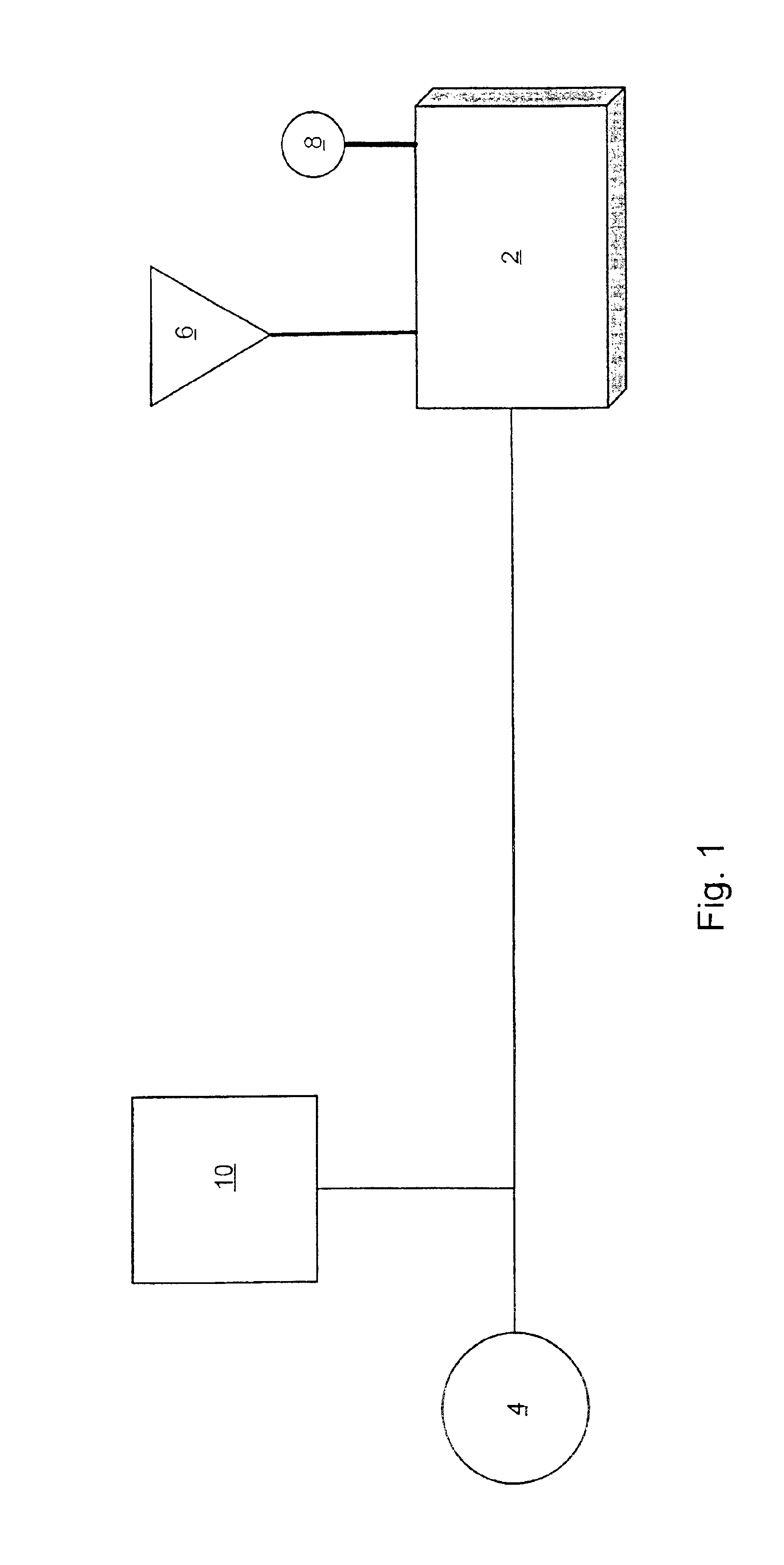

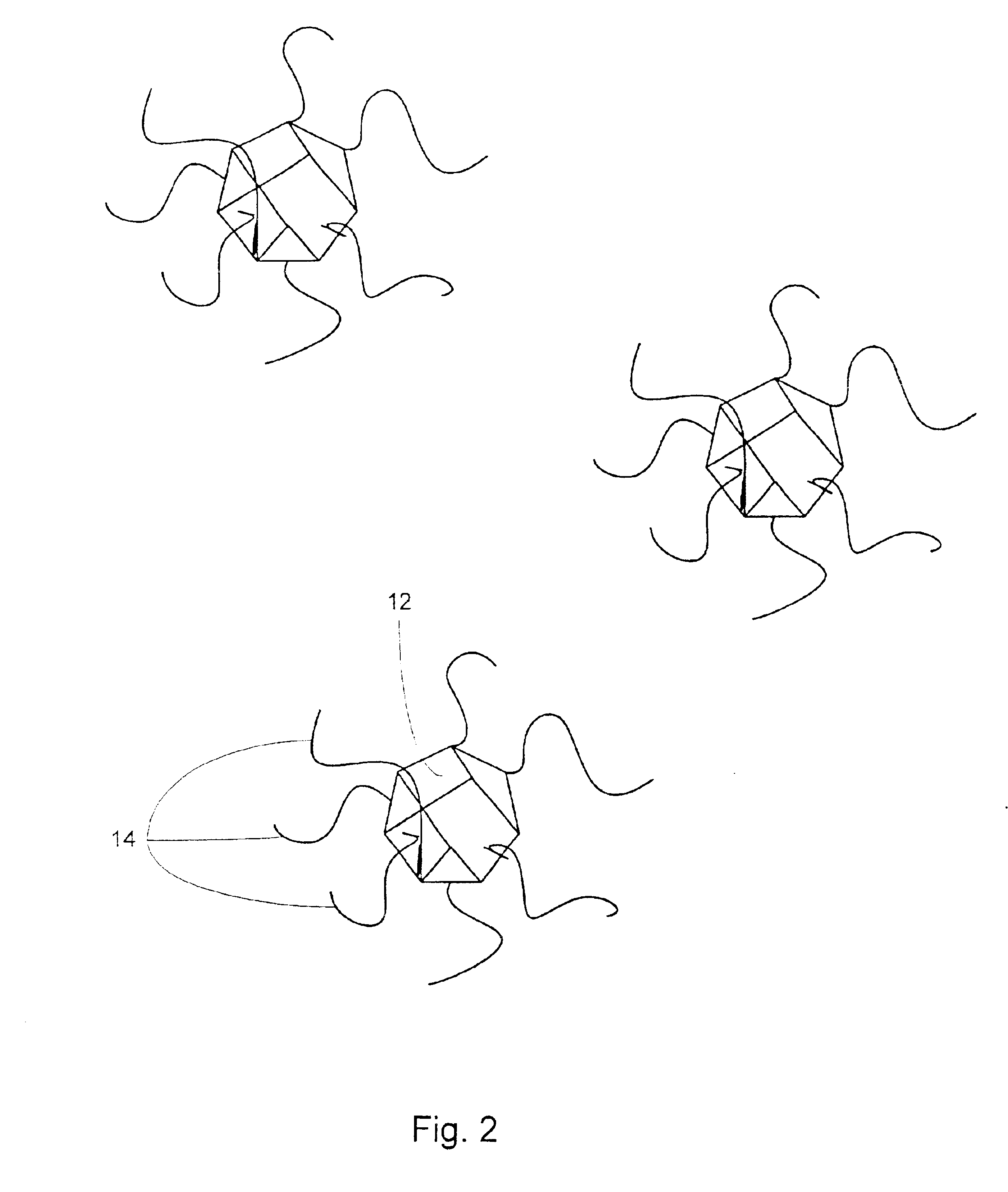

Method Of Manufacture And The Use Of A Functional Proppant For Determination Of Subterranean Fracture Geometries

ActiveUS20090288820A1Accurate imagingPromote recoveryMaterial nanotechnologyElectric/magnetic detection for well-loggingElectricityGeophone

Proppants having added functional properties are provided, as are methods that use the proppants to track and trace the characteristics of a fracture in a geologic formation. Information obtained by the methods can be used to design a fracturing job, to increase conductivity in the fracture, and to enhance oil and gas recovery from the geologic formation. The functionalized proppants can be detected by a variety of methods utilizing, for example, an airborne magnetometer survey, ground penetrating radar, a high resolution accelerometer, a geophone, nuclear magnetic resonance, ultra-sound, impedance measurements, piezoelectric activity, radioactivity, and the like. Methods of mapping a subterranean formation are also provided and use the functionalized proppants to detect characteristics of the formation.

Owner:HALLIBURTON ENERGY SERVICES INC

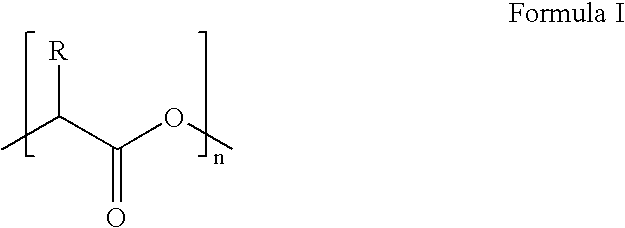

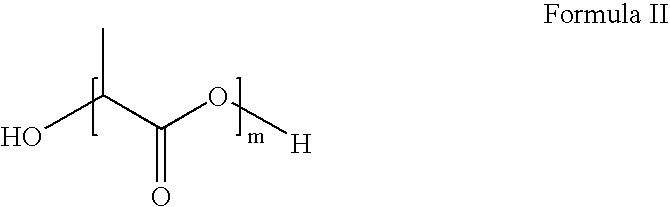

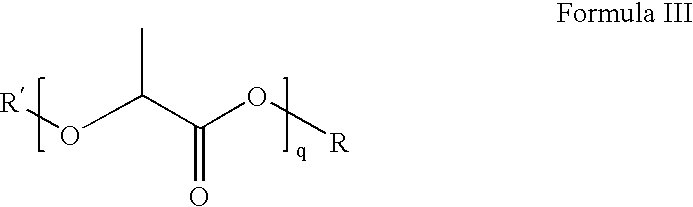

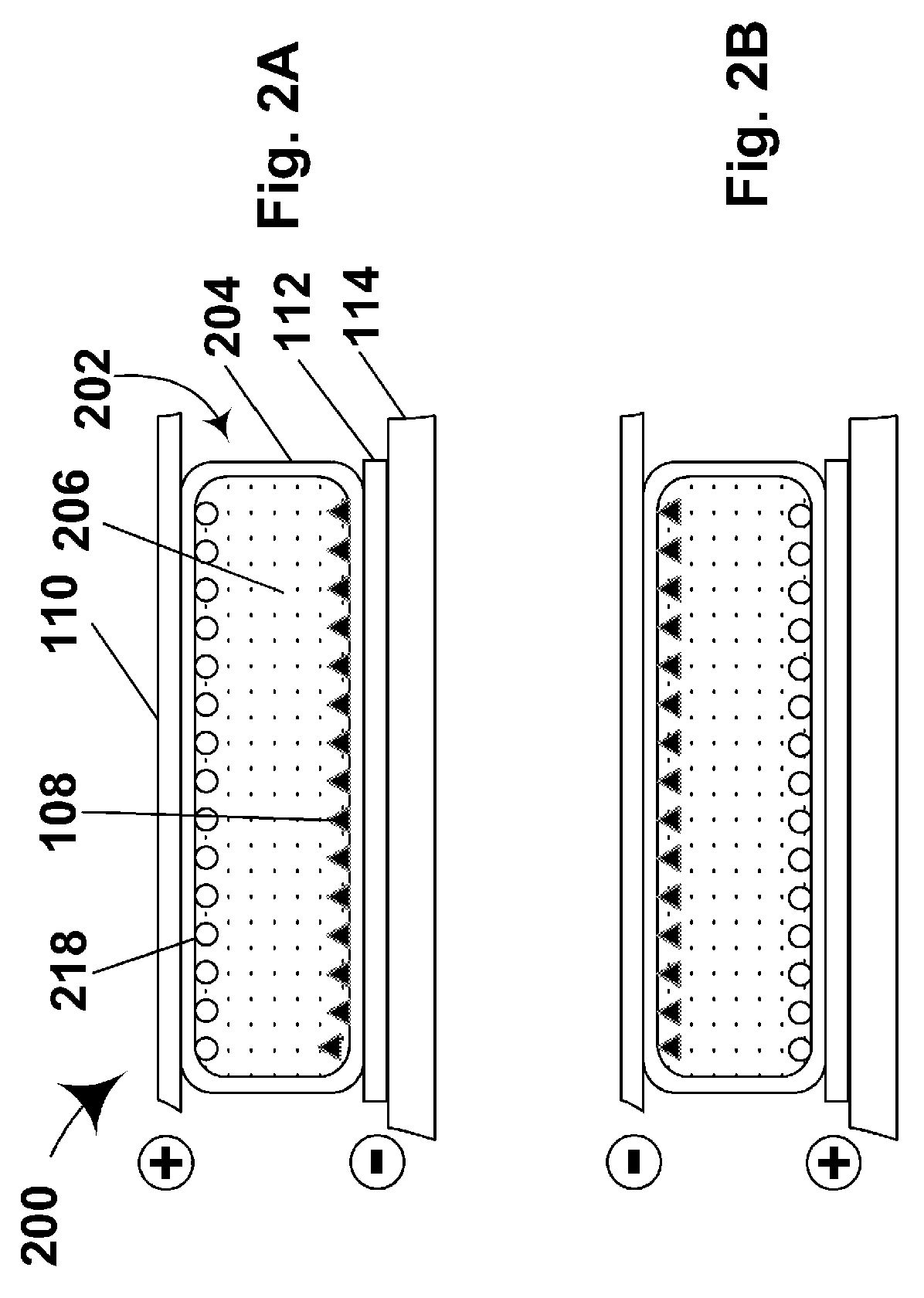

Electrophoretic media and processes for the production thereof

InactiveUS7230750B2Improve stabilityEasy to adaptMaterial nanotechnologyStatic indicating devicesElectrophoresisEthylene Homopolymers

A first electrophoretic medium comprises an electrically charged particle suspended in a suspending fluid, the particle having a polymeric shell having repeating units derived from at least one monomer the homopolymer of which is incompatible with the suspending fluid. A second, similar electrophoretic medium comprises a suspending fluid, and first and second types of electrically charged particle suspended in the suspending fluid, the two types of particle having differing optical characteristics but both having polymeric shells. The polymeric shells are arranged such that homoaggregation of the two types of particles is thermodynamically favored over heteroaggregation.

Owner:E INK CORPORATION

Fire retardant compositions and methods for preserving wood products

Wood preservative compositions are disclosed. Treatment of lumber, plywood, and other wood products with a novel composition comprising the boron source composition, a melamine binder resin, and a urea casein activator resin protects lumber, plywood, and other wood products from attack by termites, fungi, fire and flame. The preservative can be formed by combining a source of boron such as boric acid and the water-soluble salts thereof, a melamine binder resin, and a urea casein resin. A wood preservative is characterized by a weight ratio of the urea casing activator resin to the melamine binder resin ranging from about 1:20 to 1:4 and a weight ratio of the boron source composition to the melamine binder resin ranging from about 1.3:1 to 9.6:1.

Owner:LOPEZ RICHARD A

Compositions and methods for controlling the release of chemicals placed on particulates

InactiveUS20050028976A1Simple methodSynthetic resin layered productsCellulosic plastic layered productsParticulatesCompound (substance)

The present invention relates to methods and compositions for creating and using particulate materials having treating agents absorbed thereon and coated with a degradable coating material. One embodiment of a method of the present invention provides a method treating to a subterranean formation comprising placing a coated, treated particulate into a subterranean formation wherein the coated, treated particulate comprises a particulate material having a treating agent placed thereon and a substantially complete layer of a degradable coating material coated placed thereon over the treating agent.

Owner:HALLIBURTON ENERGY SERVICES INC

Popular searches

Biological substance pretreatments Biochemistry cleaning apparatus Solid sorbent liquid separation Biomass after-treatment Enzymology/microbiology apparatus Tissue/virus culture apparatus Wood layered products Natural mineral layered products Specific use bioreactors/fermenters Metal layered products

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com