Patents

Literature

37results about How to "Large distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

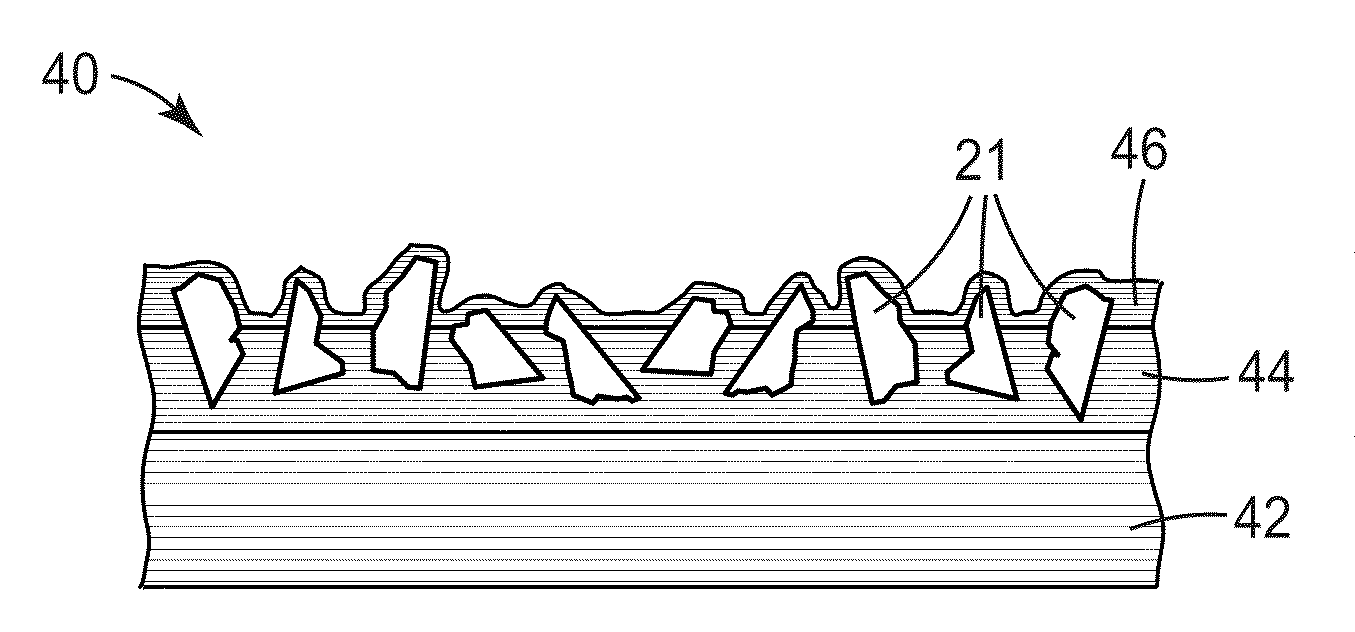

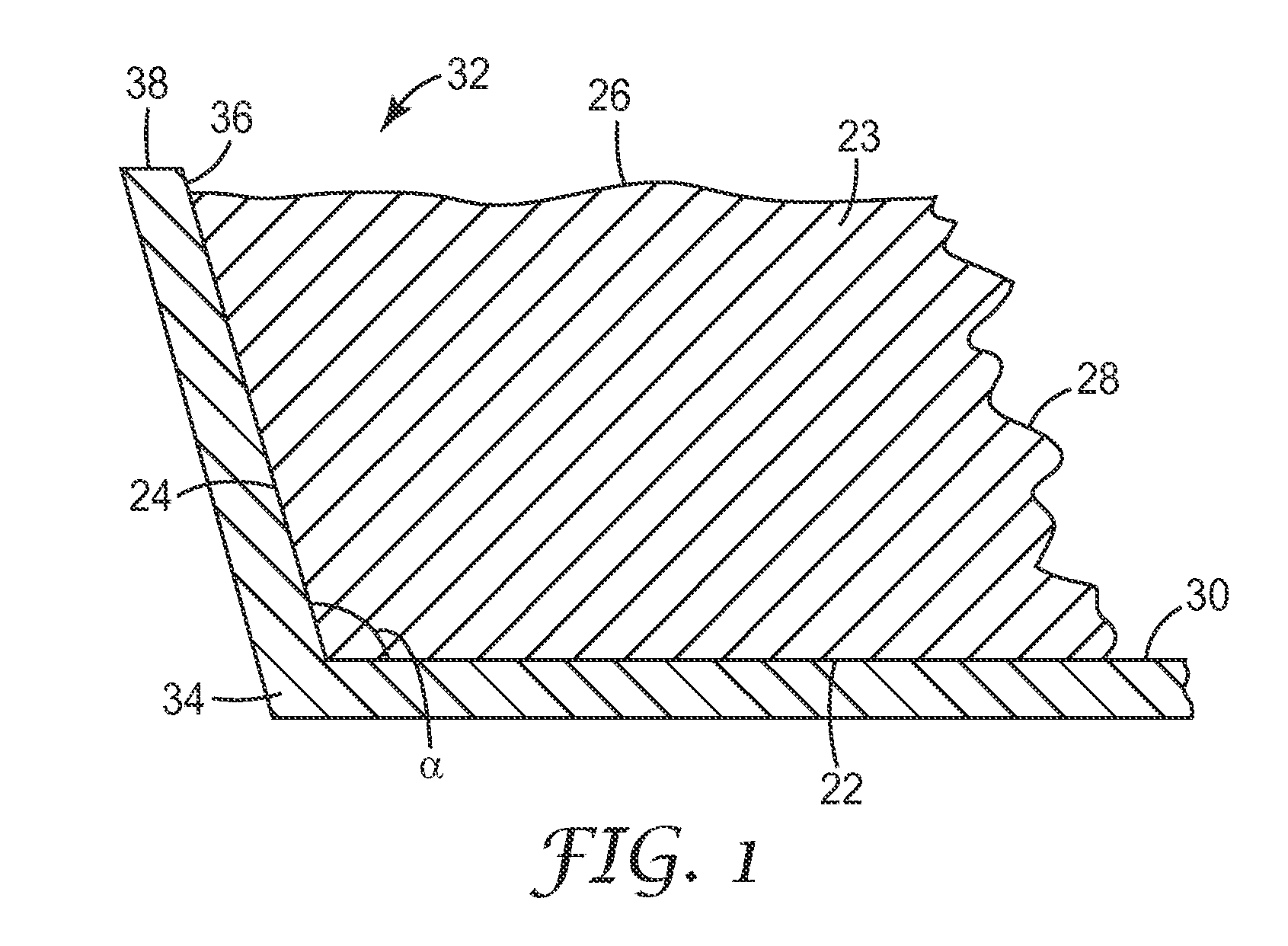

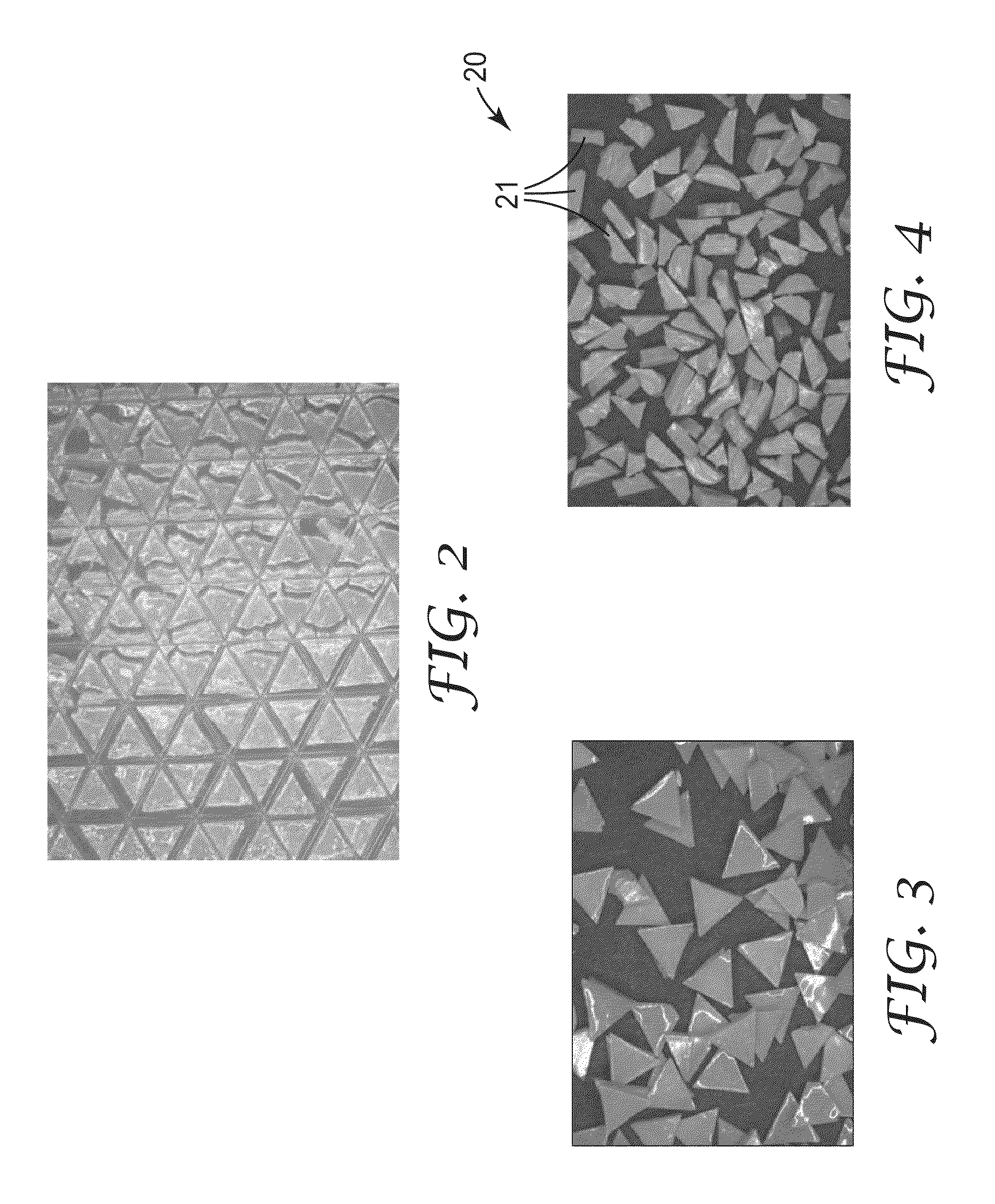

Shaped, fractured abrasive particle, abrasive article using same and method of making

ActiveUS20090169816A1Improve performanceLarge distributionPigmenting treatmentSpecial ornamental structuresPolymer chemistryAbrasive

Precursor alpha alumina abrasive particles in a mold are subjected to a drying process that cracks or fractures at least a majority of the precursor abrasive particles into at least two pieces thereby producing abrasive shards having a smaller size than the mold cavity from which they were made. The smaller abrasive shards, once formed, could be reassembled like jigsaw puzzle pieces to reproduce the original cavity shape of the mold from which they were made. The cracking or fracturing of the precursor abrasive particles is believed to occur by ensuring that the surface tension of the abrasive dispersion to the walls of the mold is greater than the internal attractive forces of the abrasive dispersion as the abrasive dispersion is dried within the mold cavity.

Owner:3M INNOVATIVE PROPERTIES CO

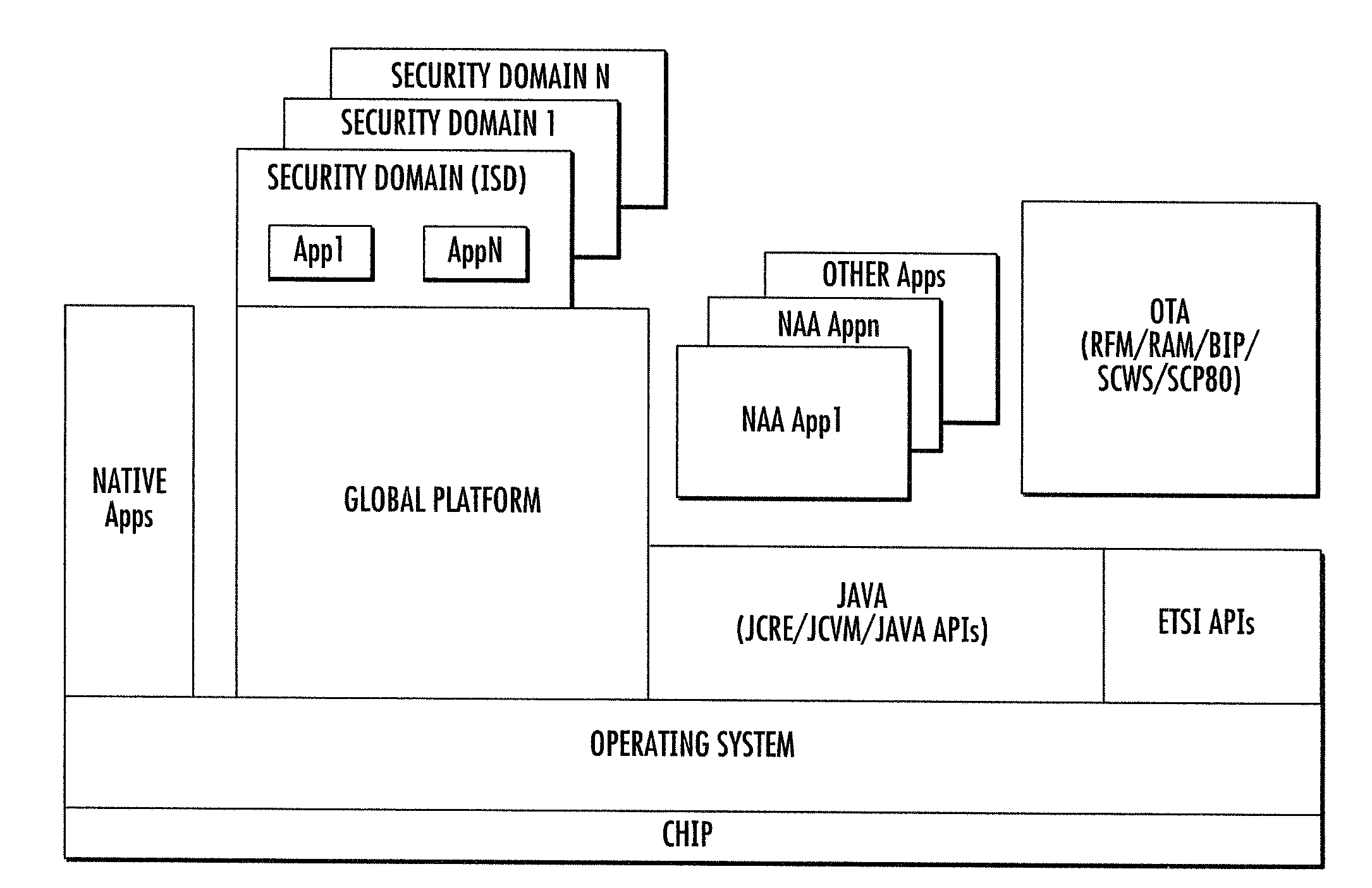

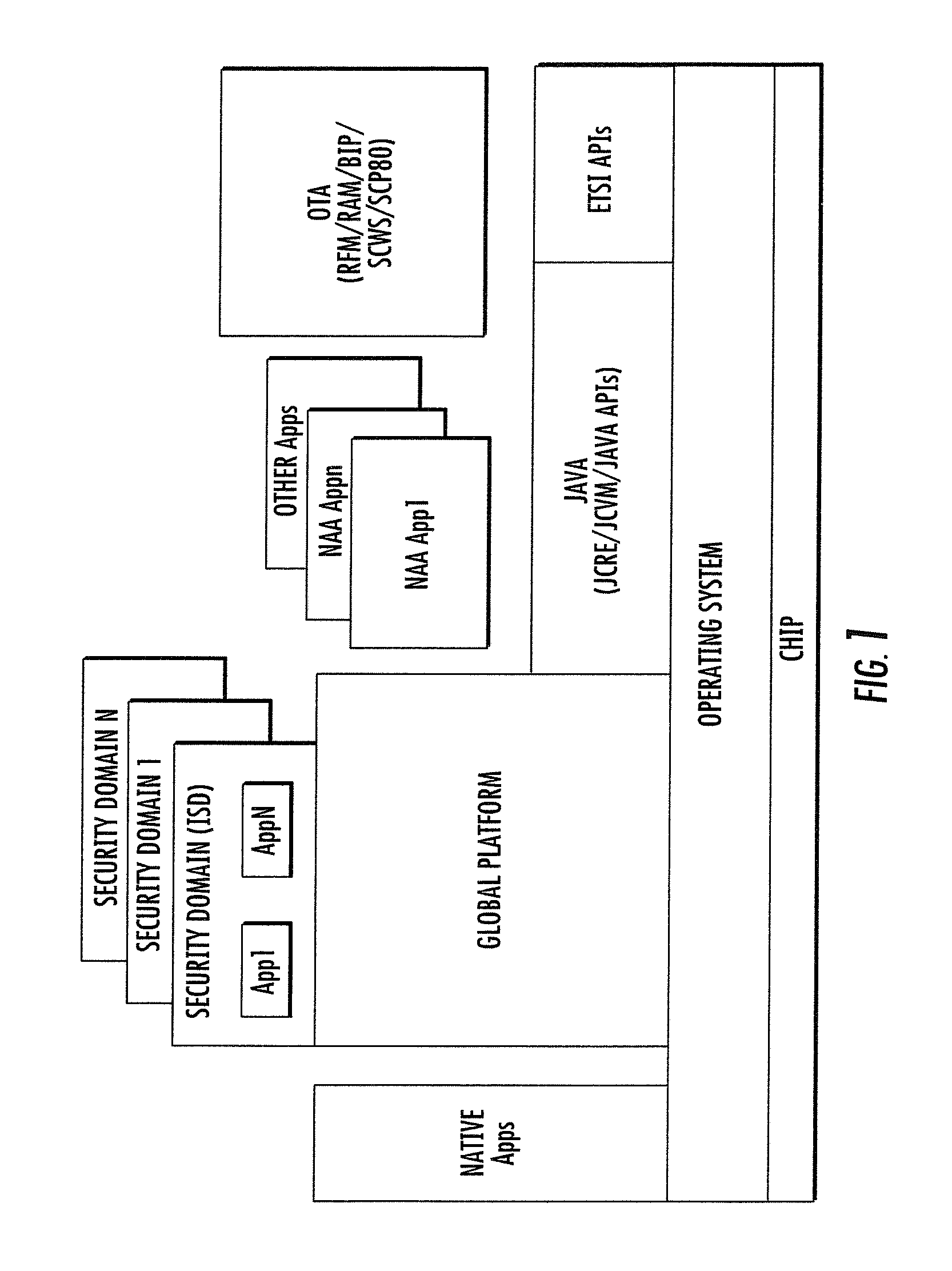

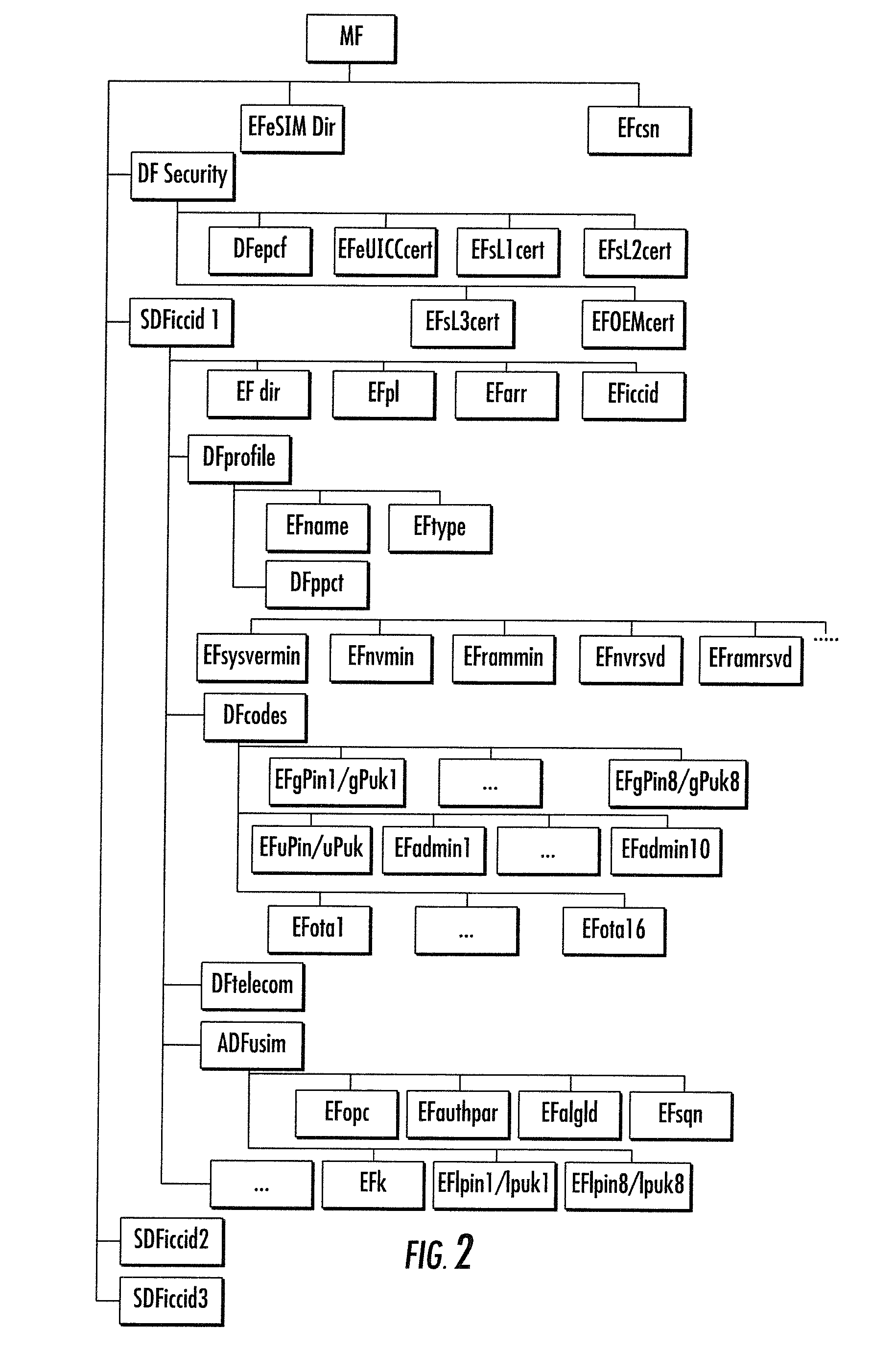

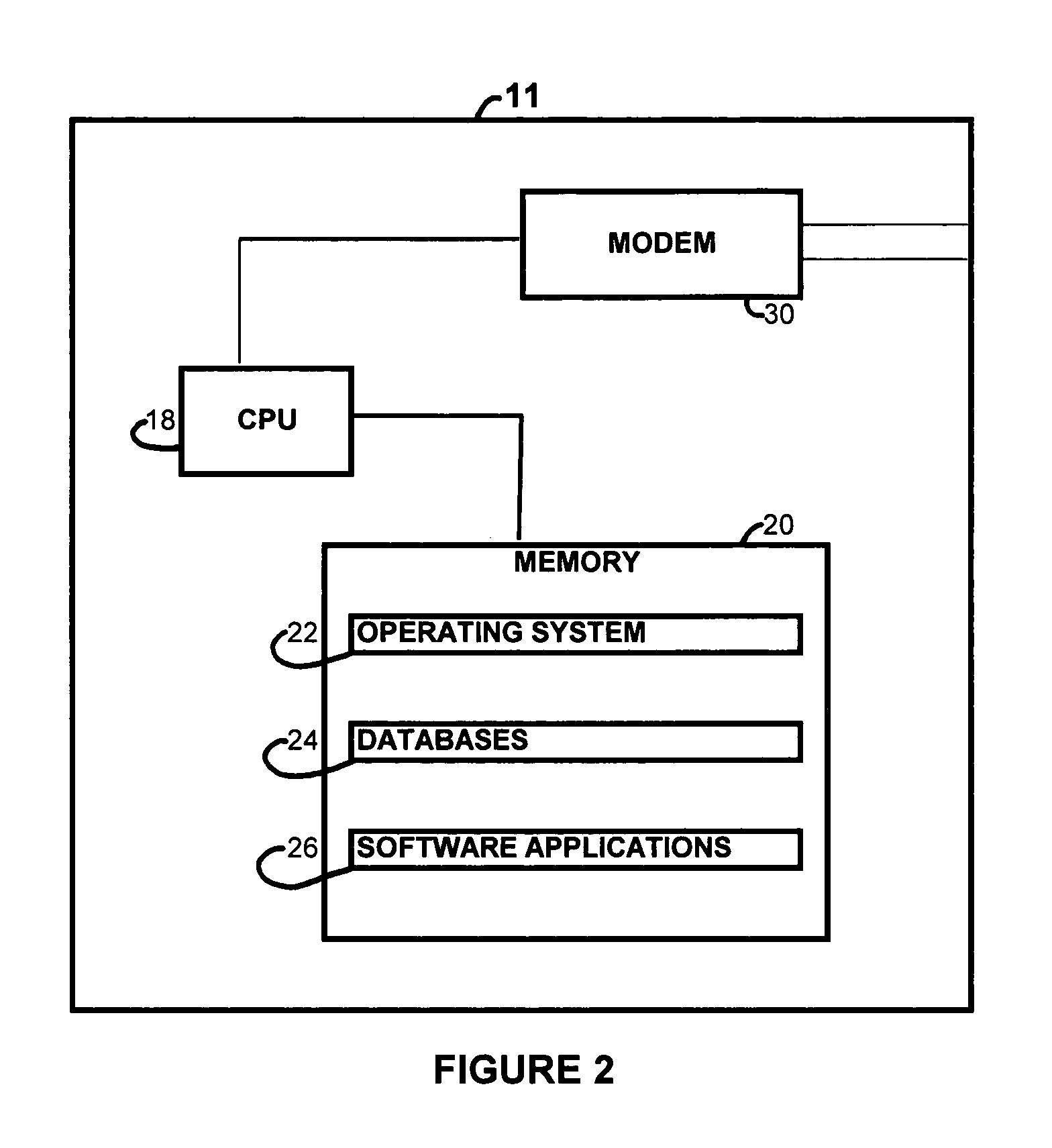

Methods and apparatus for large scale distribution of electronic access clients

ActiveUS20130227646A1Large distributionDigital data processing detailsMultiple digital computer combinationsElectronic accessSecurity software

Methods and apparatus for large scale distribution of electronic access control clients. In one aspect, a tiered security software protocol is disclosed. In one exemplary embodiment, a server electronic Universal Integrated Circuit Card (eUICC) and client eUICC software comprise a so-called “stack” of software layers. Each software layer is responsible for a set of hierarchical functions which are negotiated with its corresponding peer software layer. The tiered security software protocol is configured for large scale distribution of electronic Subscriber Identity Modules (eSIMs)

Owner:APPLE INC

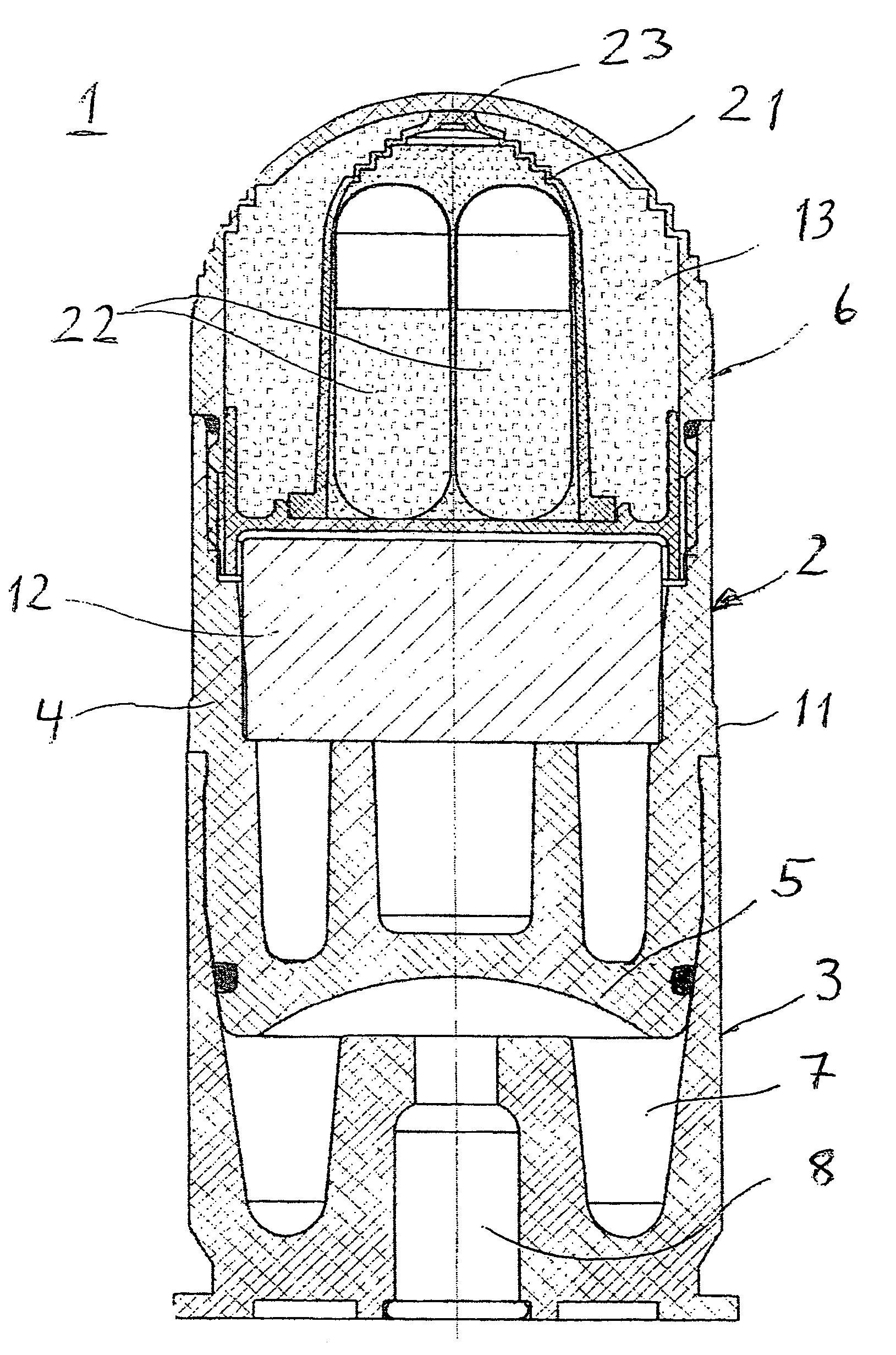

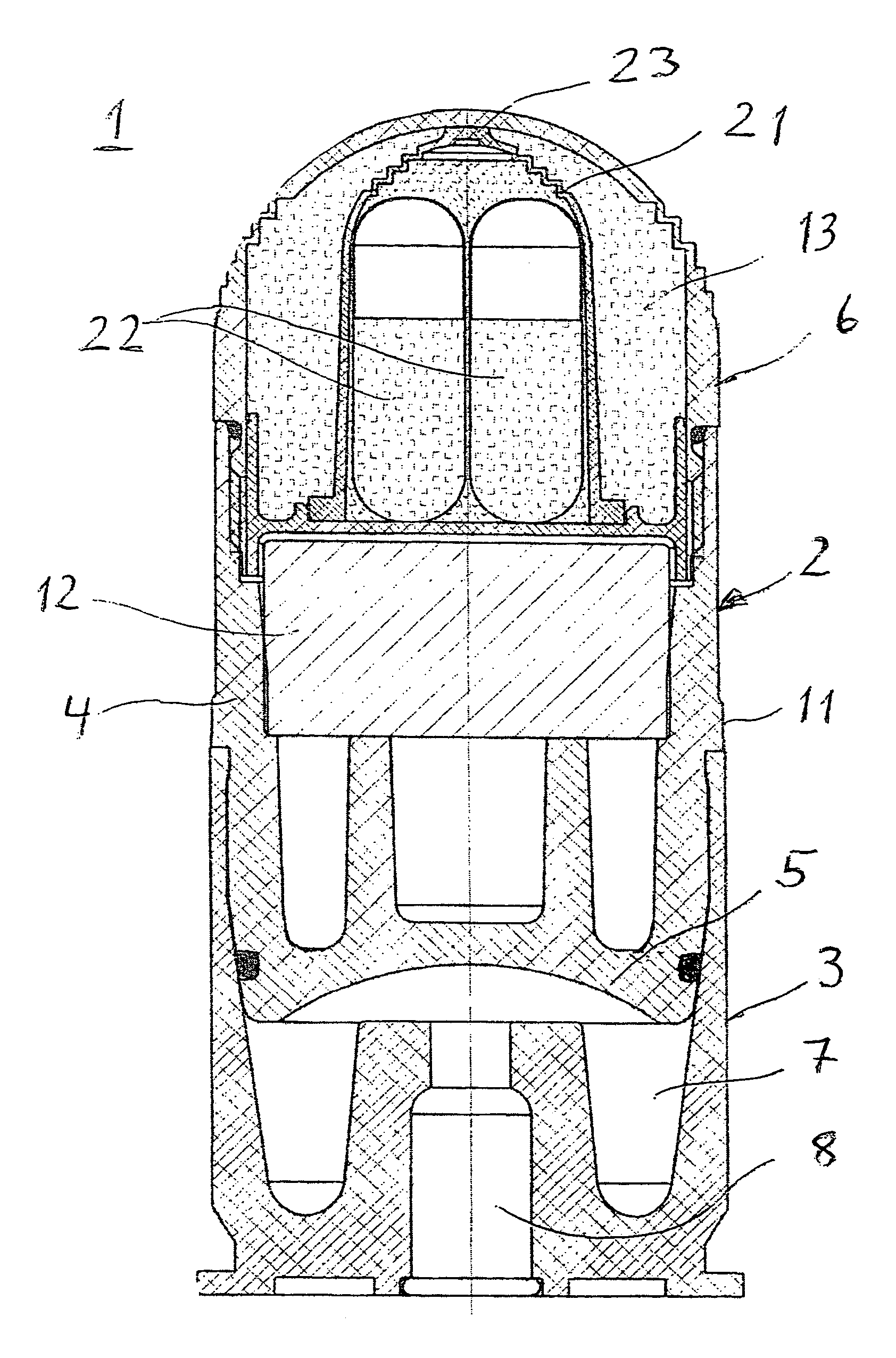

Projectile with means for marking its strike point

ActiveUS7475638B2Good colorClearly visibleAmmunition projectilesTraining ammunitionColor effectEngineering

A training projectile includes at its head a hollow arched cavity or cap that defines a hollow cavity within the head of the training projectile, and that bursts when the projectile strikes a target. Into this cavity are placed a first chemically-inactive marking material and a second chemically-active marking material, whereby both marking materials are released upon bursting of the arched cavity. The first marking material creates, for example, a color effect by means of a colored powder; the second marking material produces a light effect by means of, for example, materials that interact to produce chemo-luminescence.

Owner:NICO PYROTECHNIK HANNS JUERGEN DIEDRICHS GMBH & CO KG

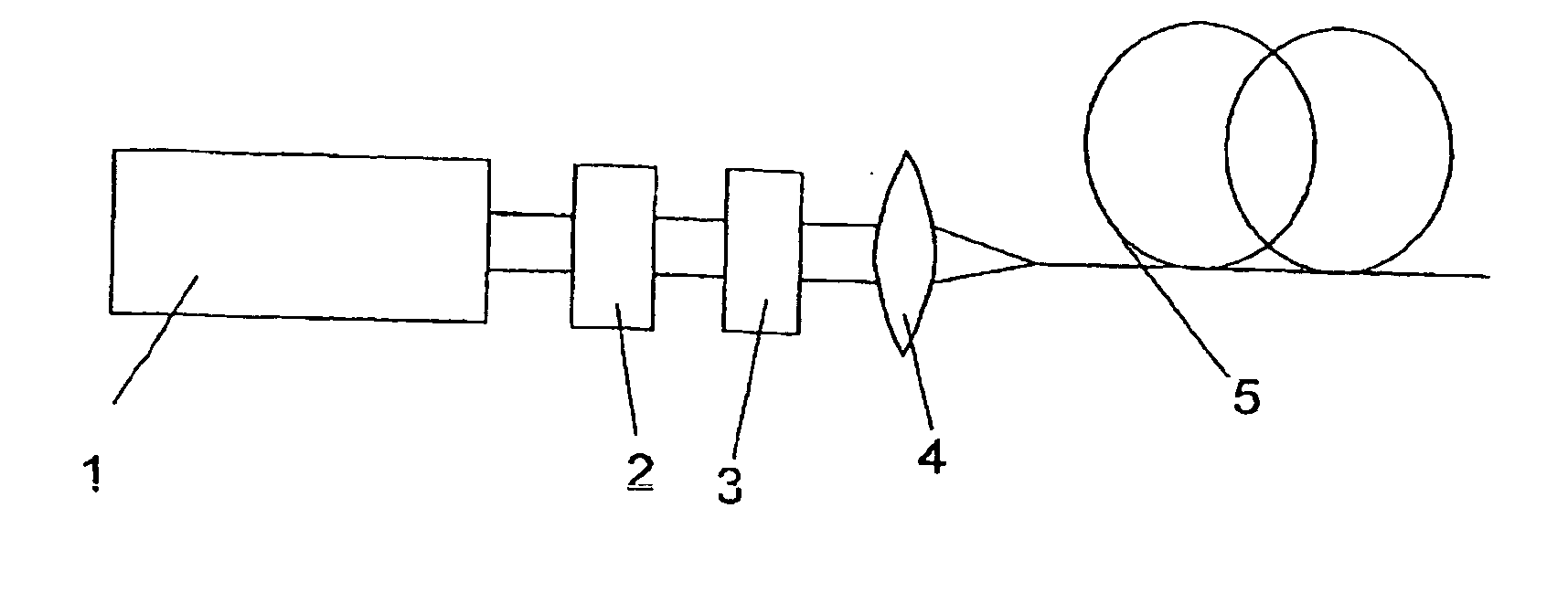

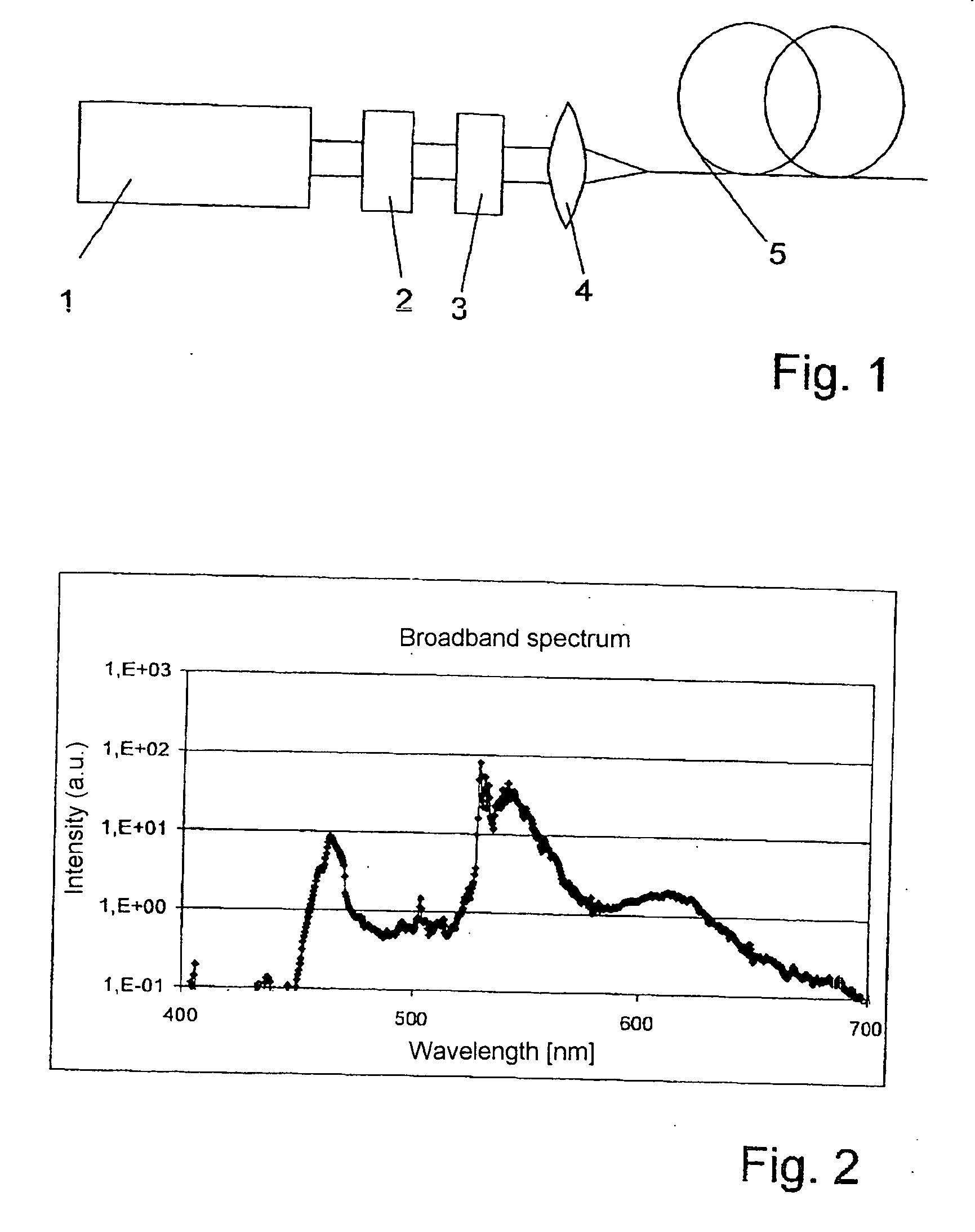

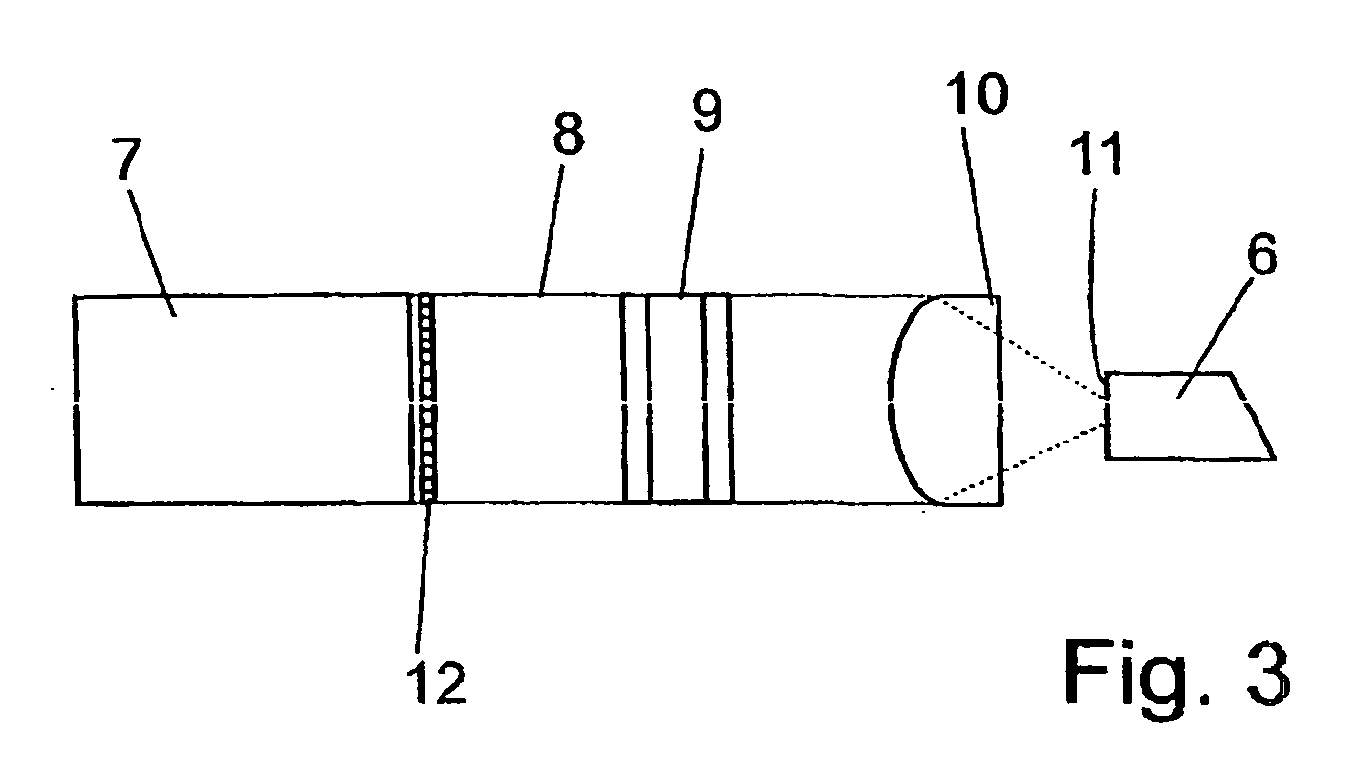

Method and optical arrangement for the generation of a broadband spectrum

InactiveUS20060002437A1Easy to operateEasy constructionLaser detailsNon-linear opticsPicosecond laserPicosecond laser pulse

The invention is directed to a method and an optical arrangement for the generation of a broadband spectrum in which wavelength regions are selected in an application-oriented manner already during spectrum generation in order to provide increased laser power. A passively mode-coupled solid-state laser provides picosecond laser pulses with an infrared output wavelength which is transformed to a secondary wavelength in the visible spectral range by nonlinear optical processes. The picosecond laser pulses are coupled into a nonlinear optical fiber which is optically adapted to the secondary wavelength with respect to dispersion and nonlinear characteristics, so that a radiation output interval comprising a visible wavelength region is selectively generated. The broadband spectrum has high brilliance and can be used, for example, in spectroscopy, microscopy, cytometry or for array readers.

Owner:JENOPTIK OPTICAL SYST

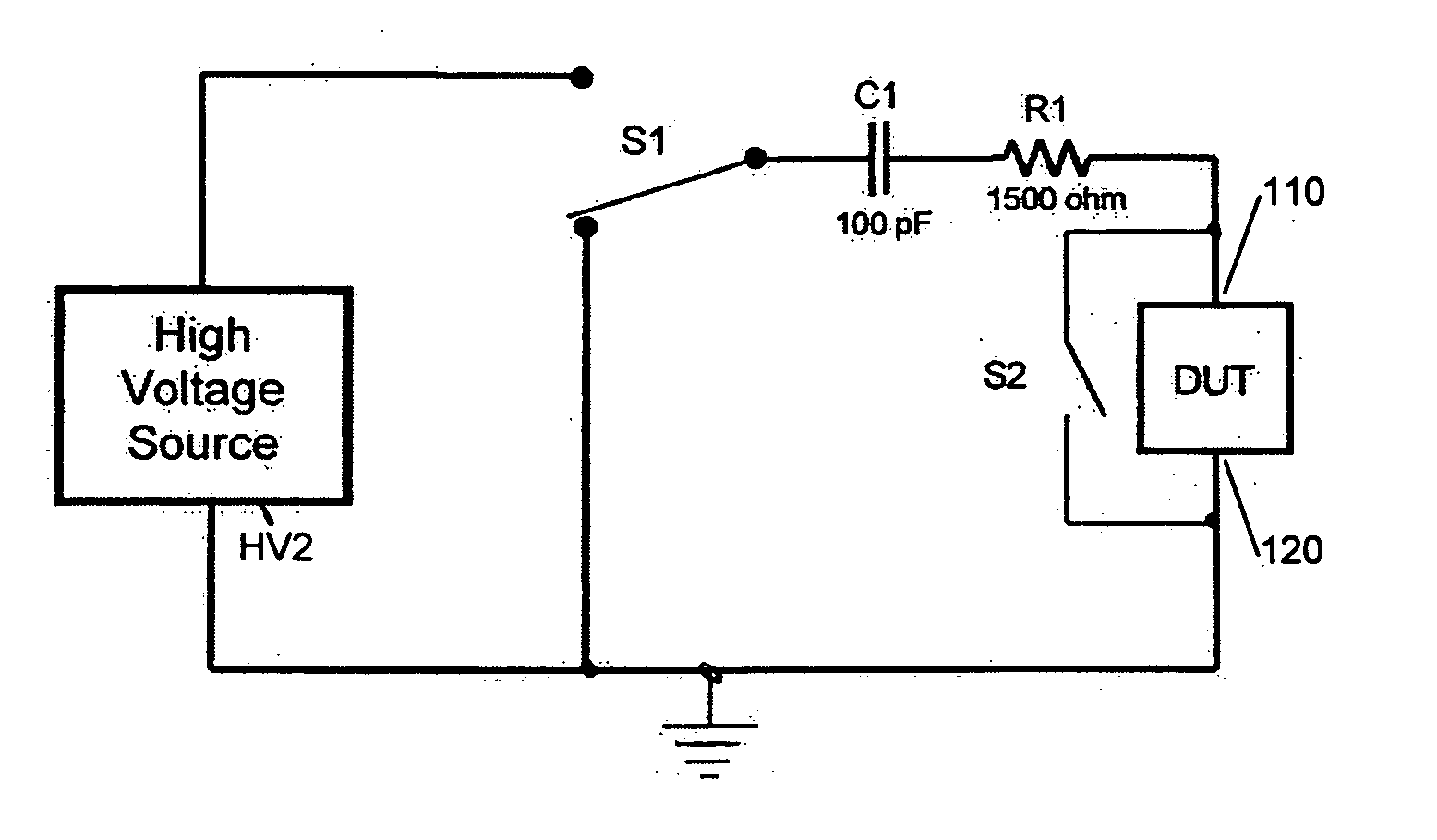

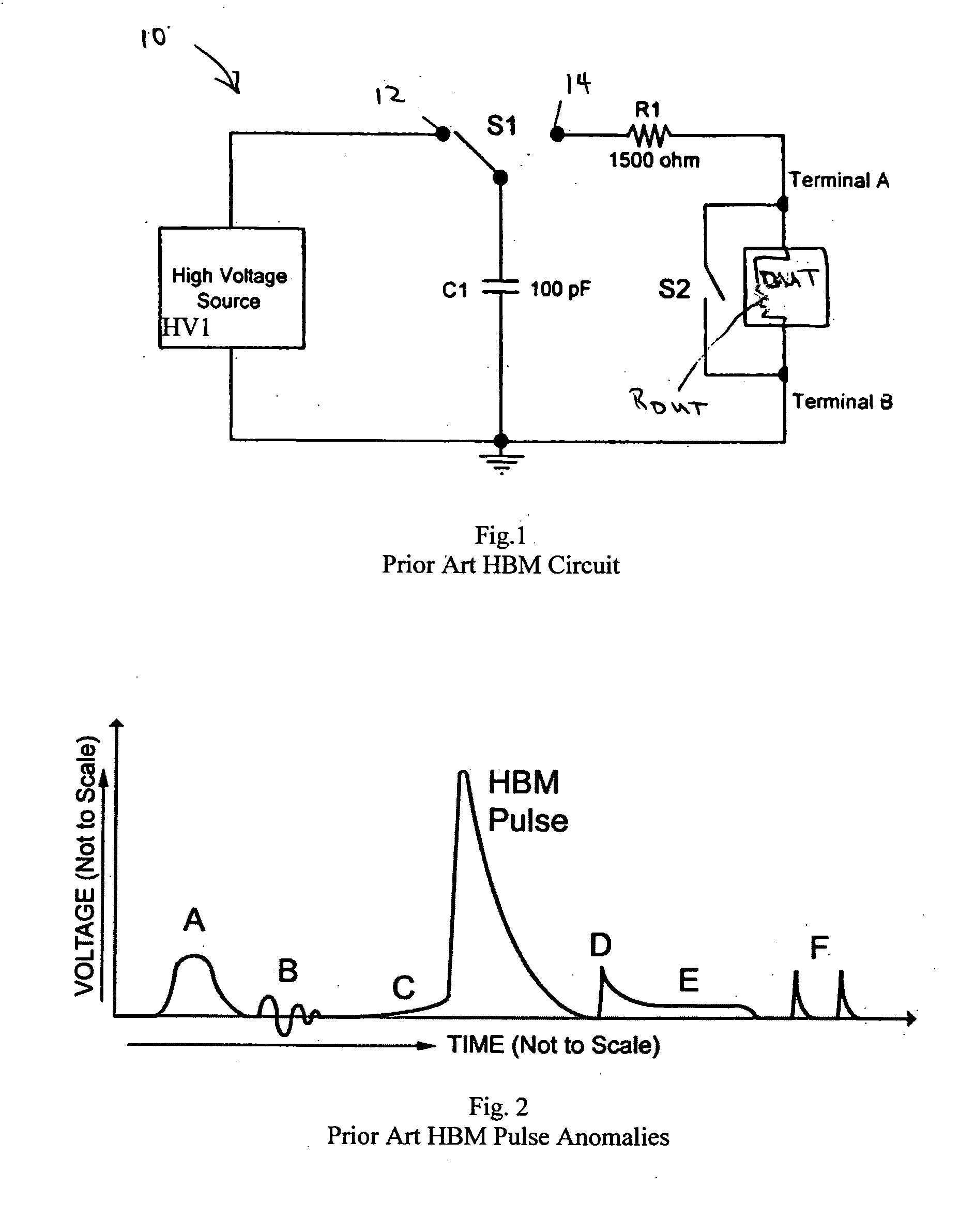

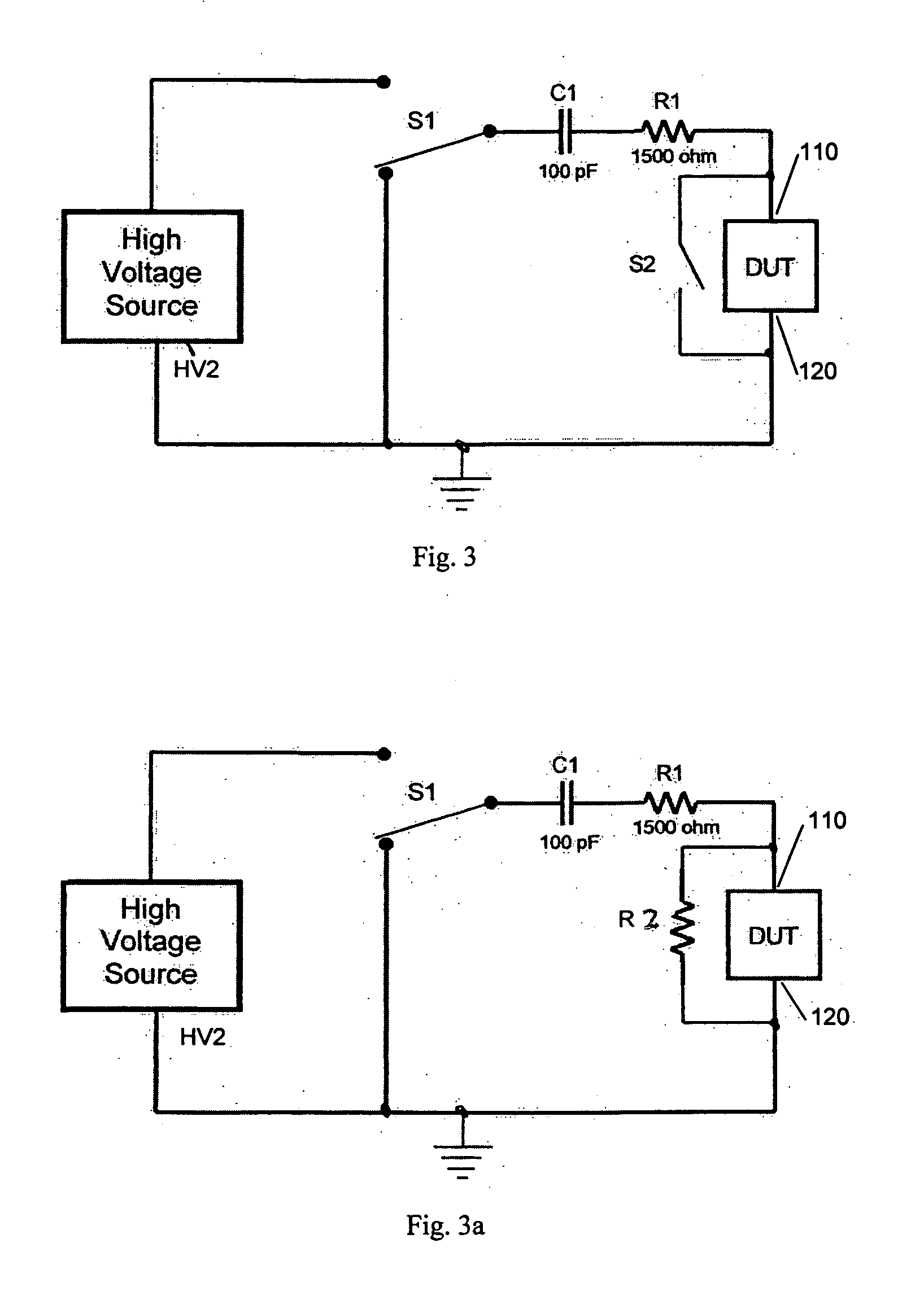

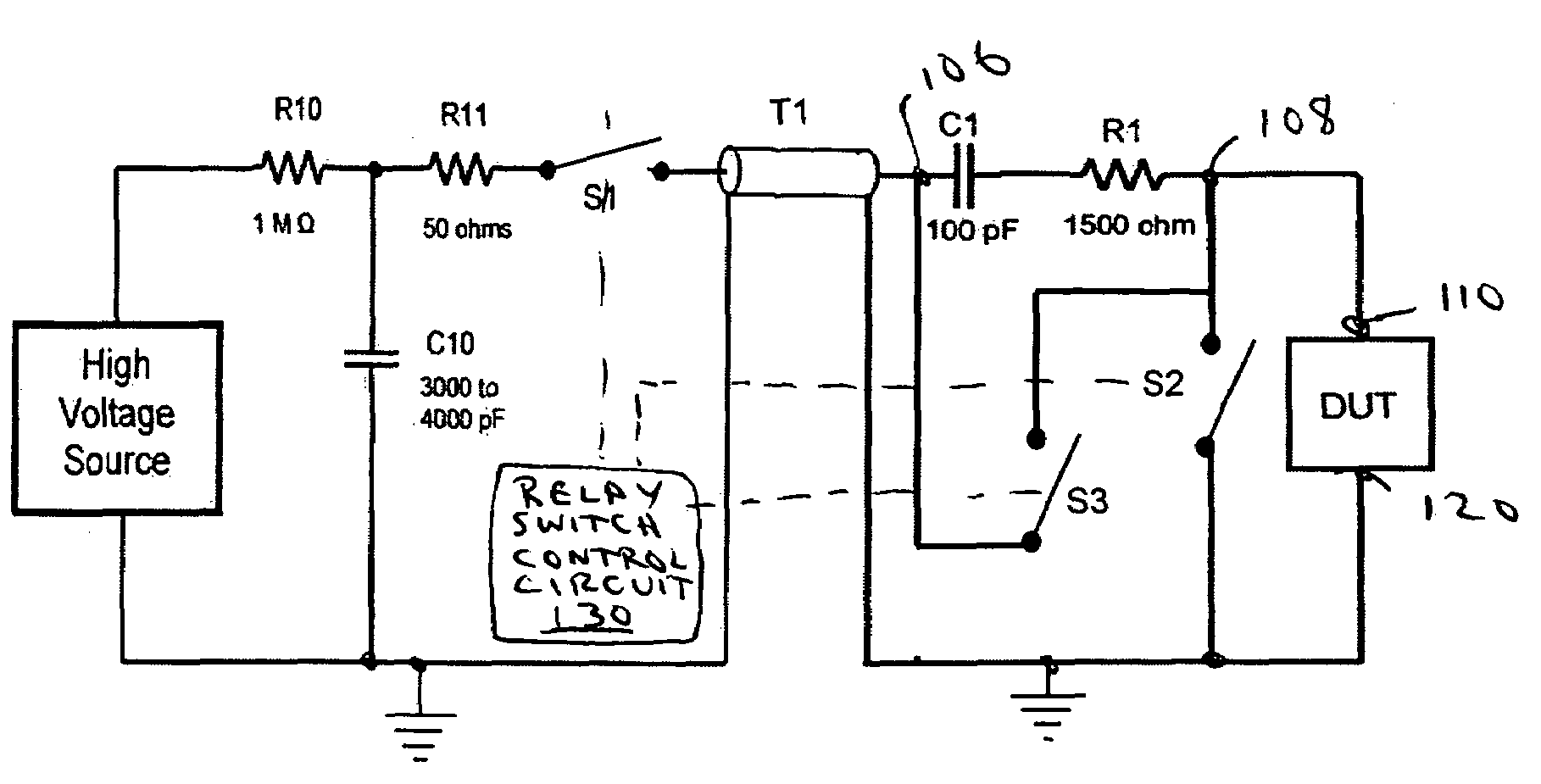

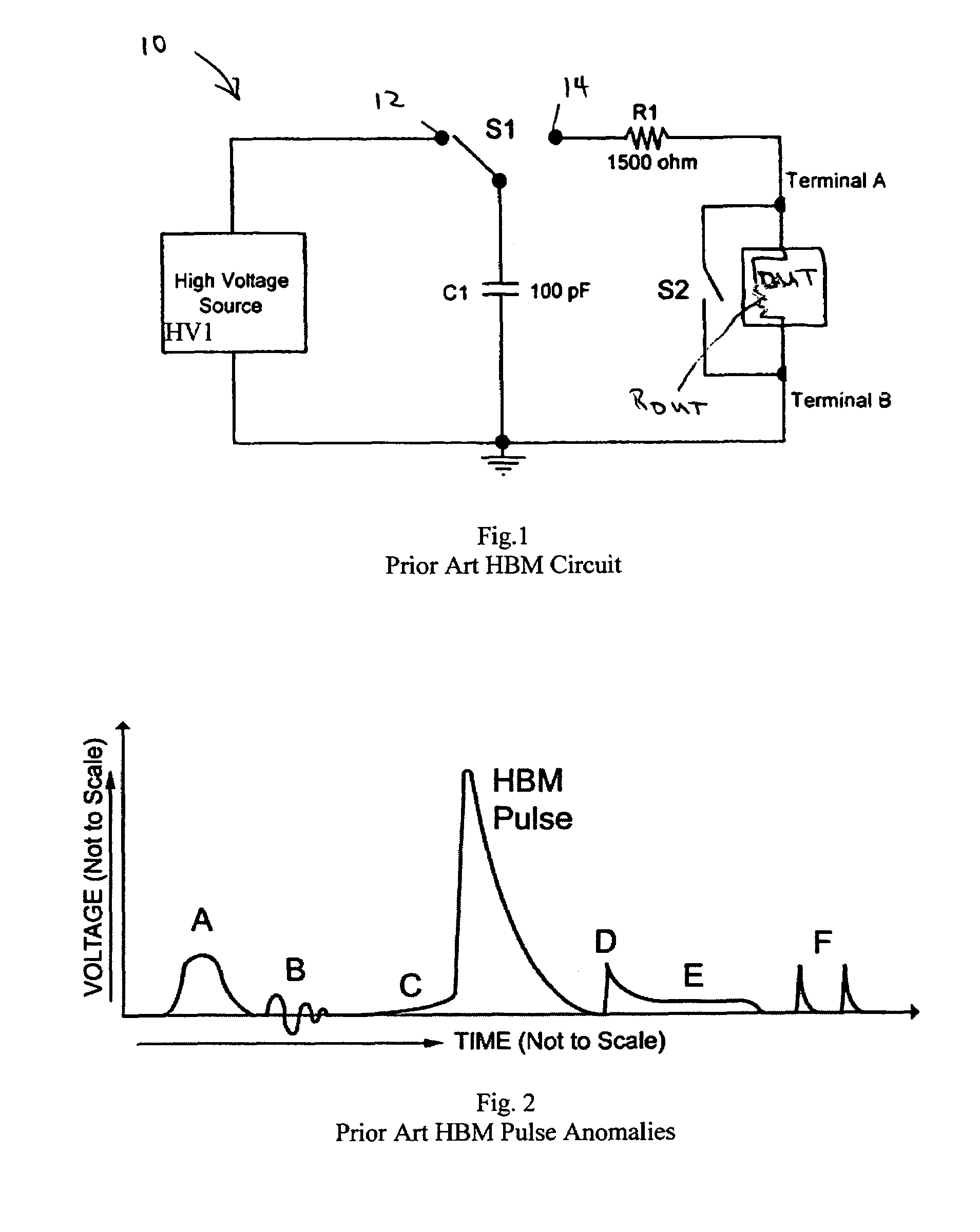

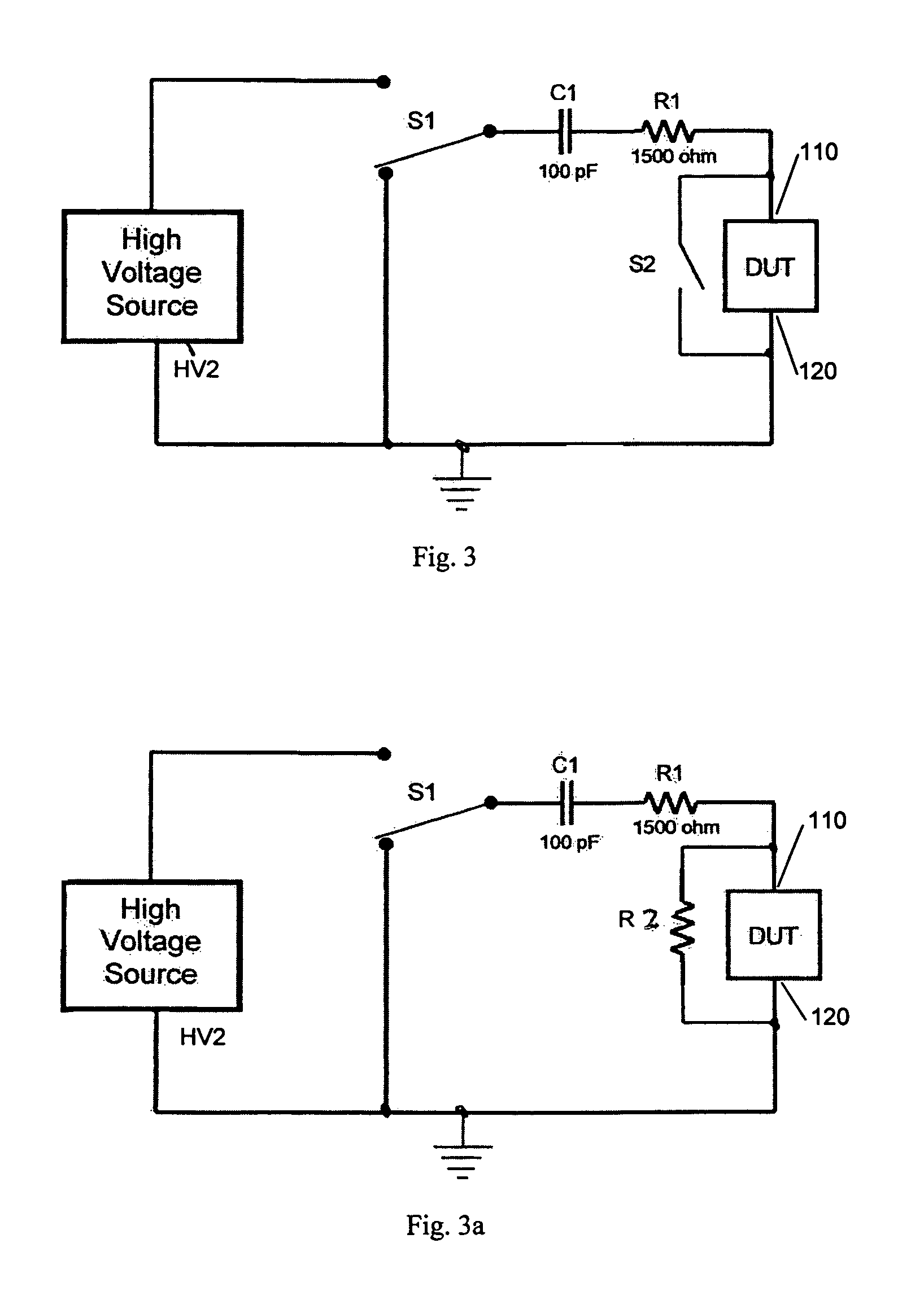

Circuit for minimizing or eliminating pulse anomalies in human body model electrostatic discharge tests

InactiveUS20070159205A1Without unwanted pulse distortionEliminates creationMaterial analysis by electric/magnetic meansMeasuring interference from external sourcesEngineeringElectrostatic discharge

A new circuit for producing simulated electrostatic discharges (ESD) based on the Human Body Model (HBM) is disclosed for testing integrated circuits. HBM ESD test systems provide stress pulses defined by industry standards. The pulses produced by prior art have small imperfections or anomalies. These anomalies can cause incorrect testing to certain devices. The improved ESD HBM test system herein disclosed provides pulses meeting the requirements of industry standards while reducing several anomalies to negligible levels.

Owner:THERMO KEYTEK LLC

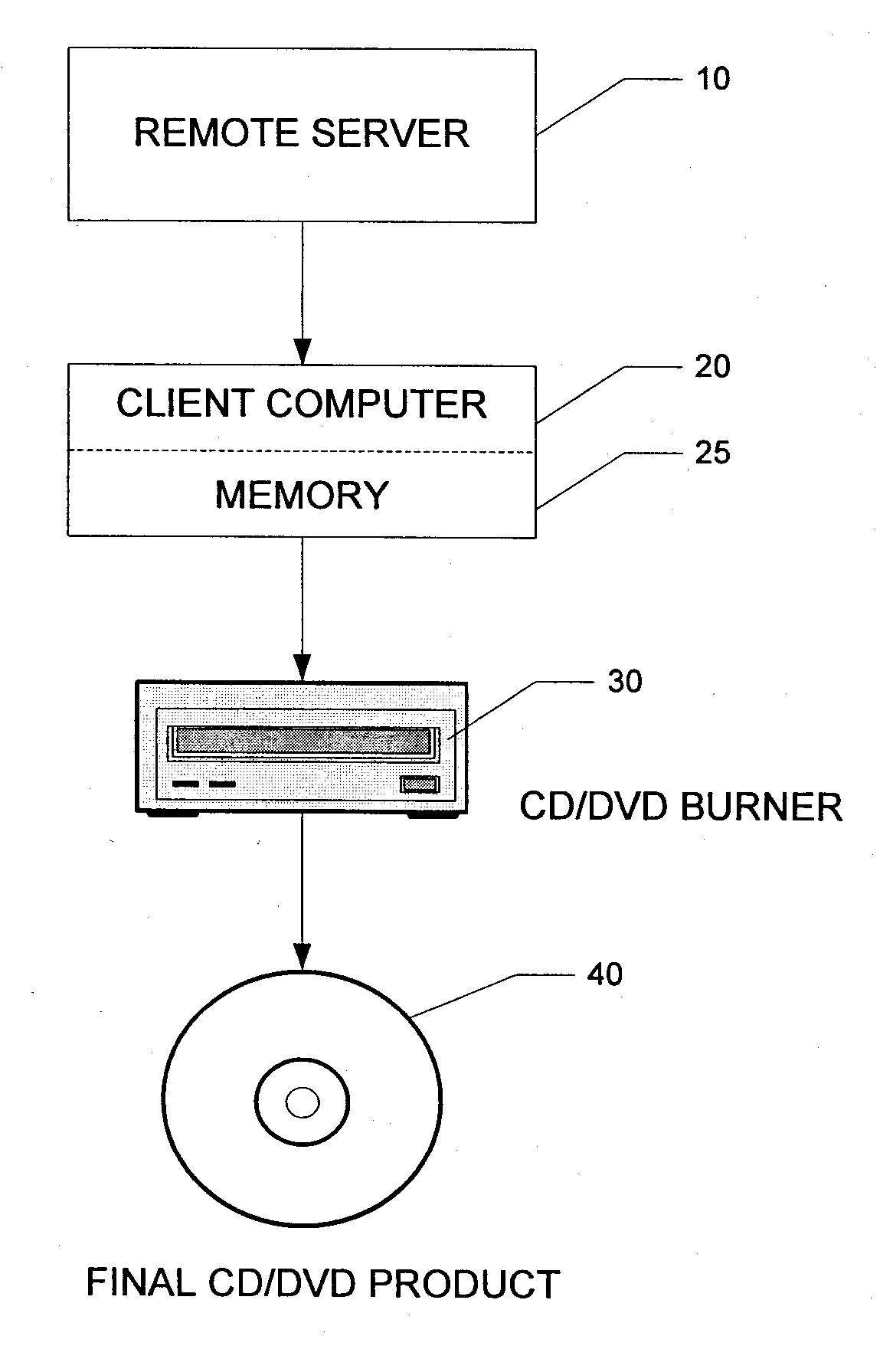

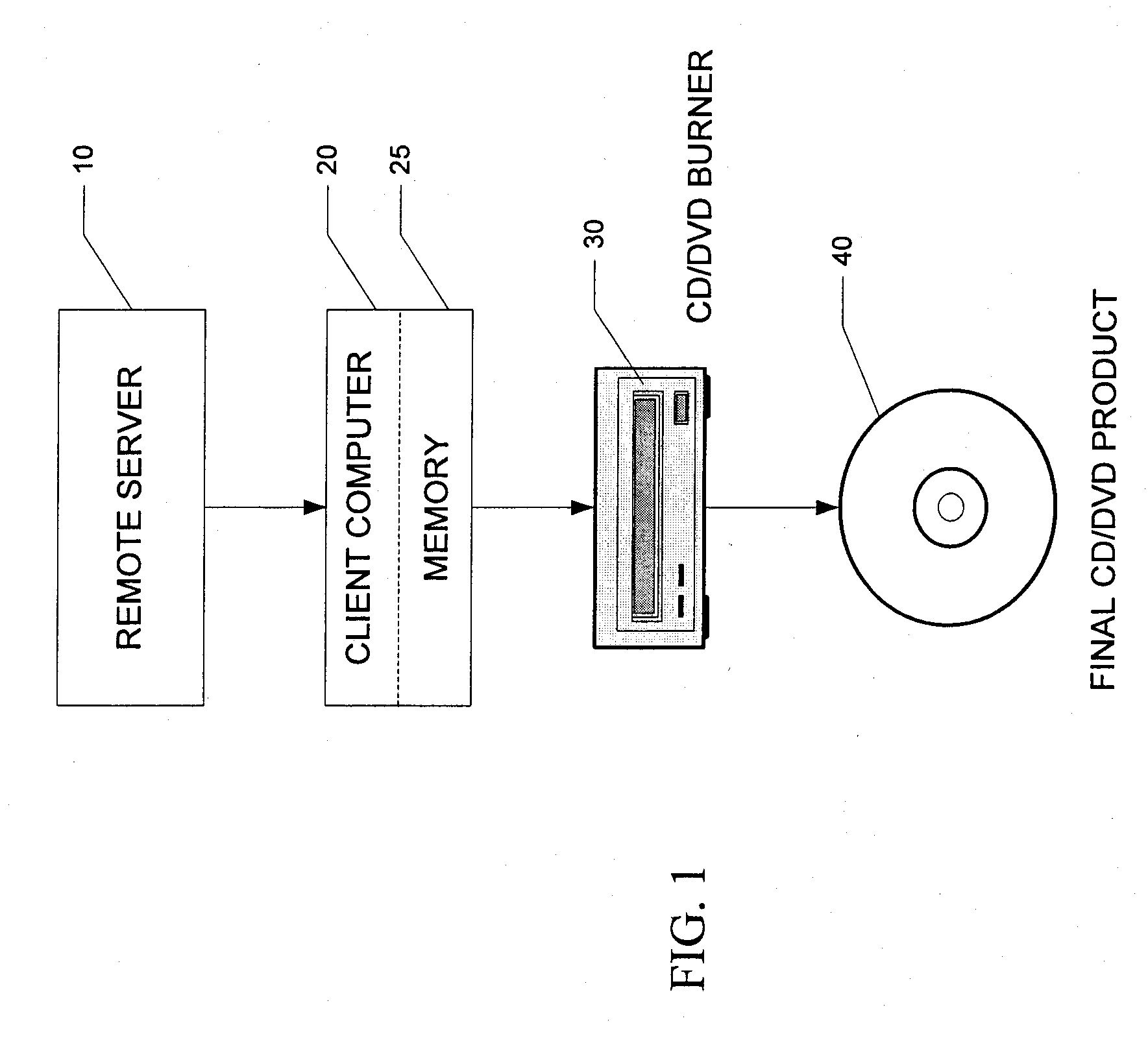

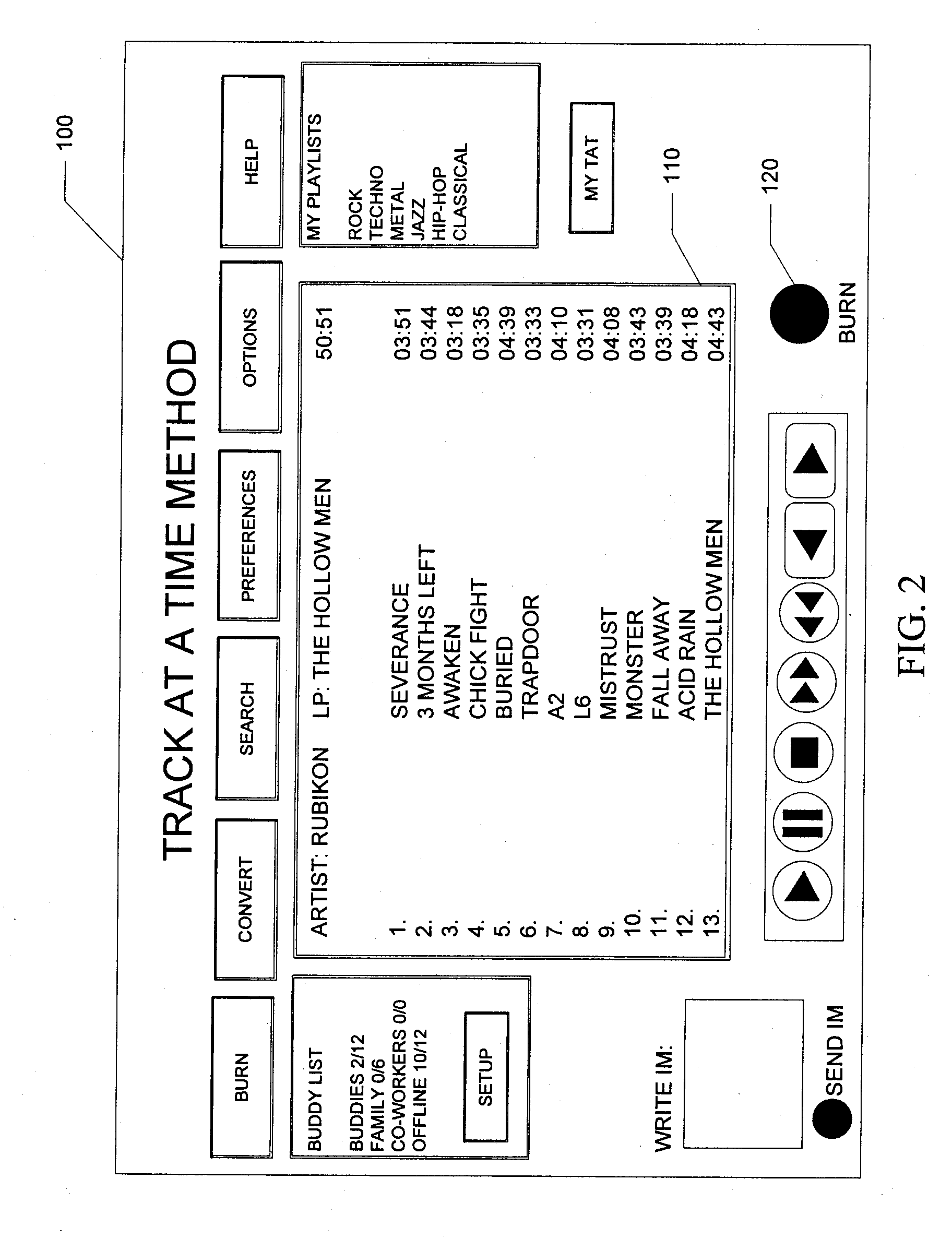

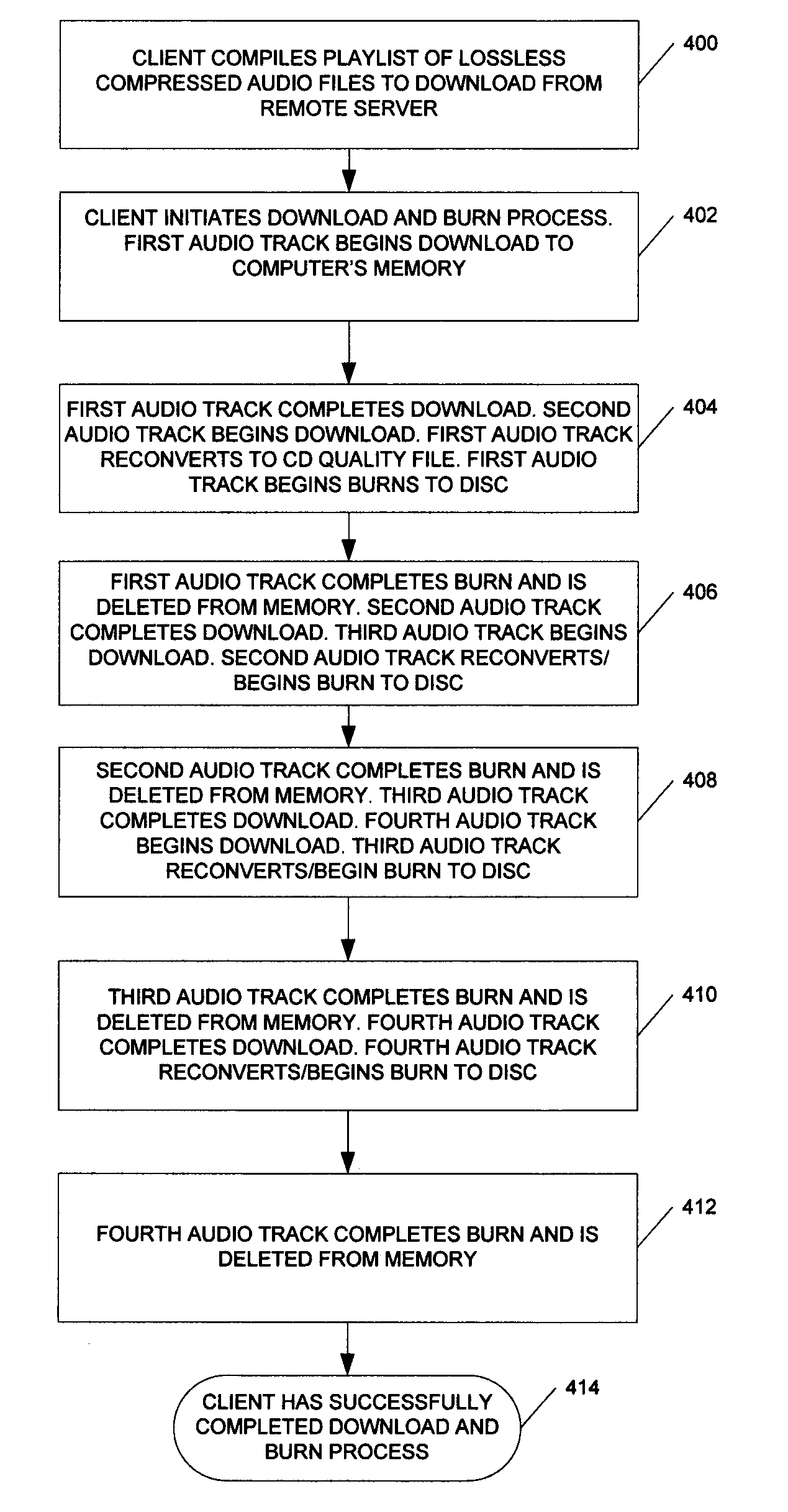

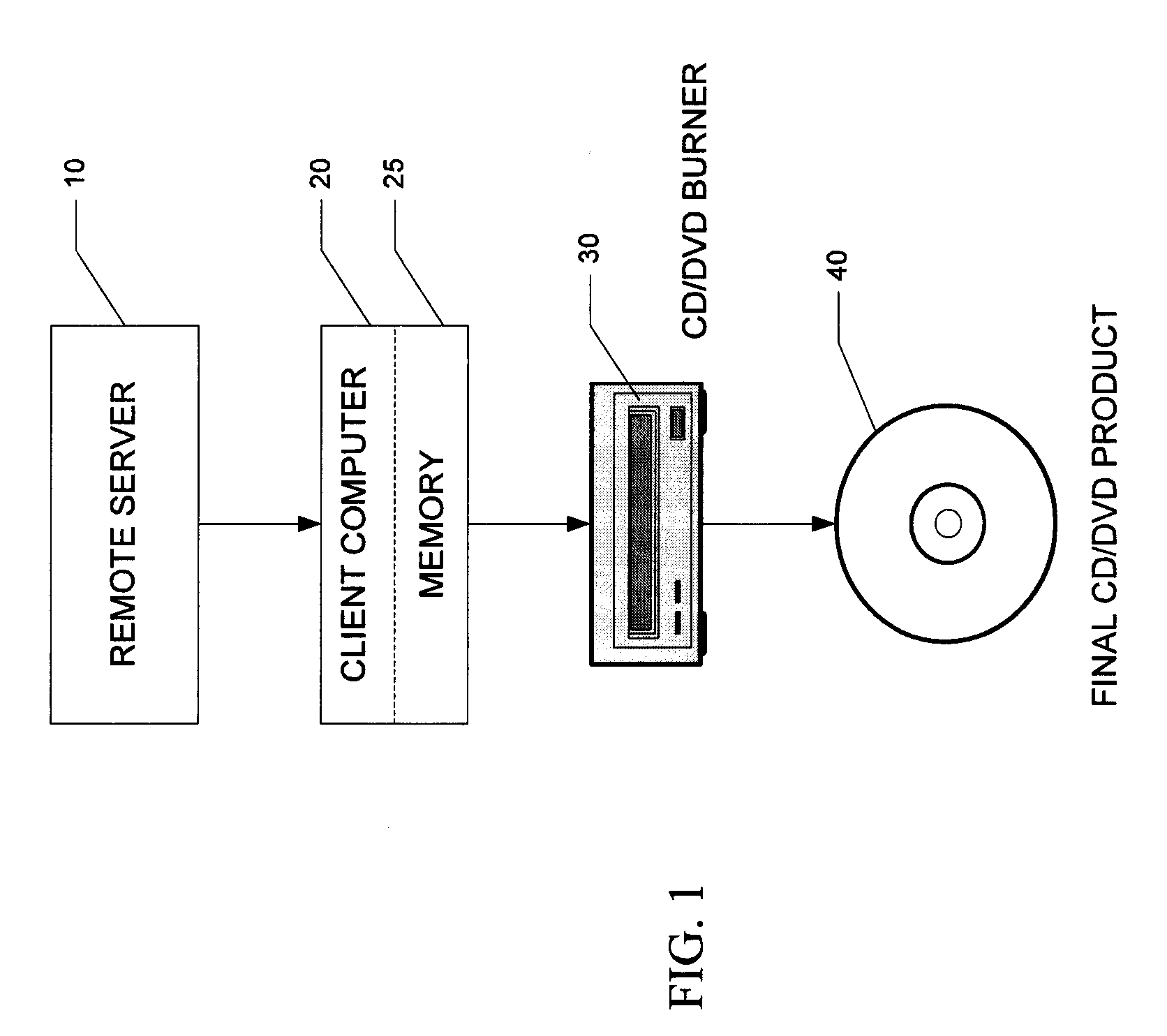

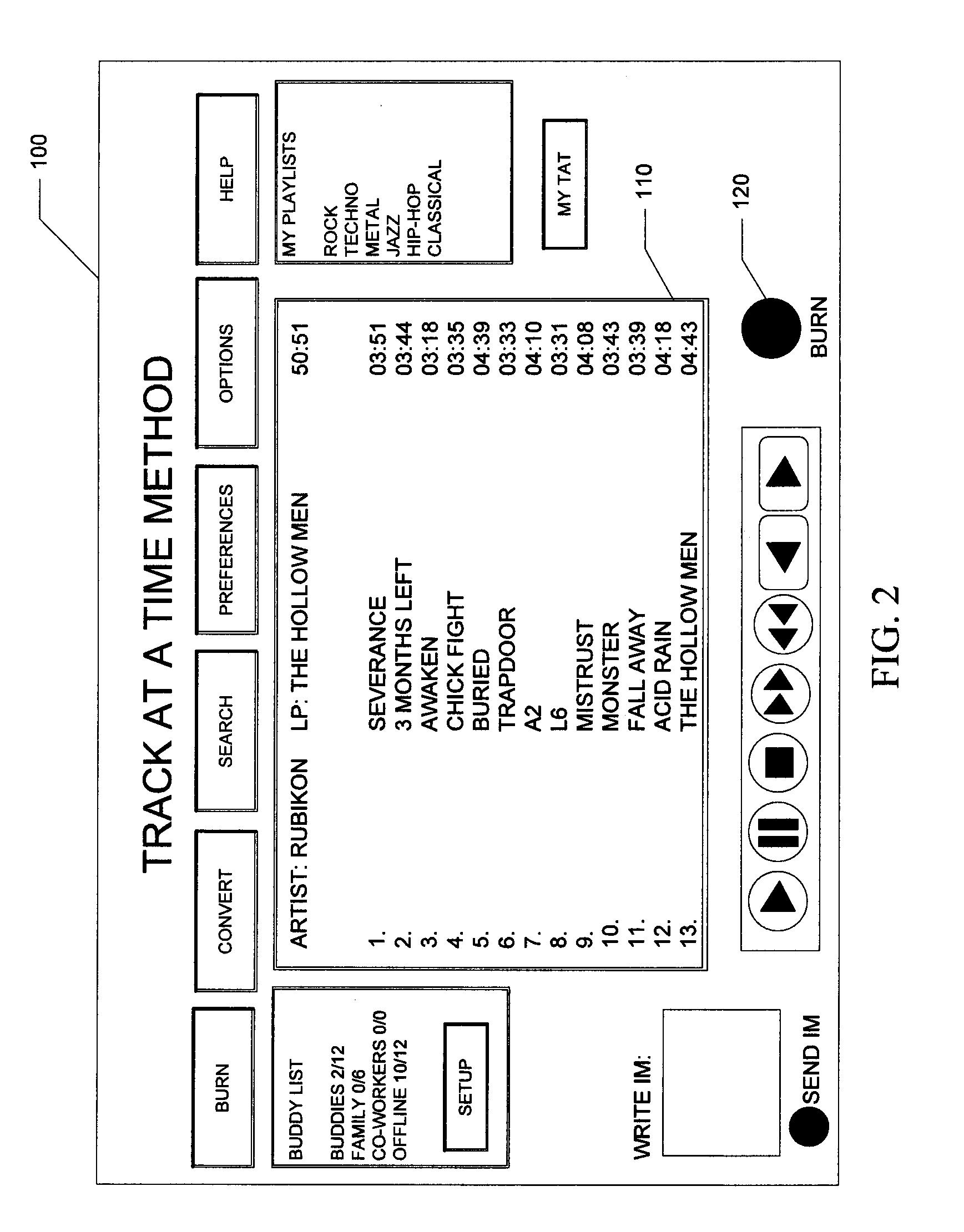

System and Method for Concurrently Downloading Digital Content and Recording to Removable Media

InactiveUS20060294376A1Conveniently burnConveniently obtainTelevision system detailsIndoor gamesThe InternetFile size

A method, system and program product to simultaneously download and burn digital media files via the Internet, including audio, video, video games and other digital content and data, onto removable storage media on personal computer burners. Large media files can be downloaded by pushing files or portions of files to computer memory and simultaneously downloading and burning files selected by a user. Once a file is burned to disc, it is then deleted from the computer's memory. A lossless compression scheme is used for audio files to decrease file size, making the downloading process faster and requiring less hard drive space. Content files other than audio are downloaded and burned through the same one-step process, without using a lossless compression scheme. An alternative method delays the start of the burn process to ensure that the downloaded files are written continuously to the removable storage media.

Owner:NOVARC

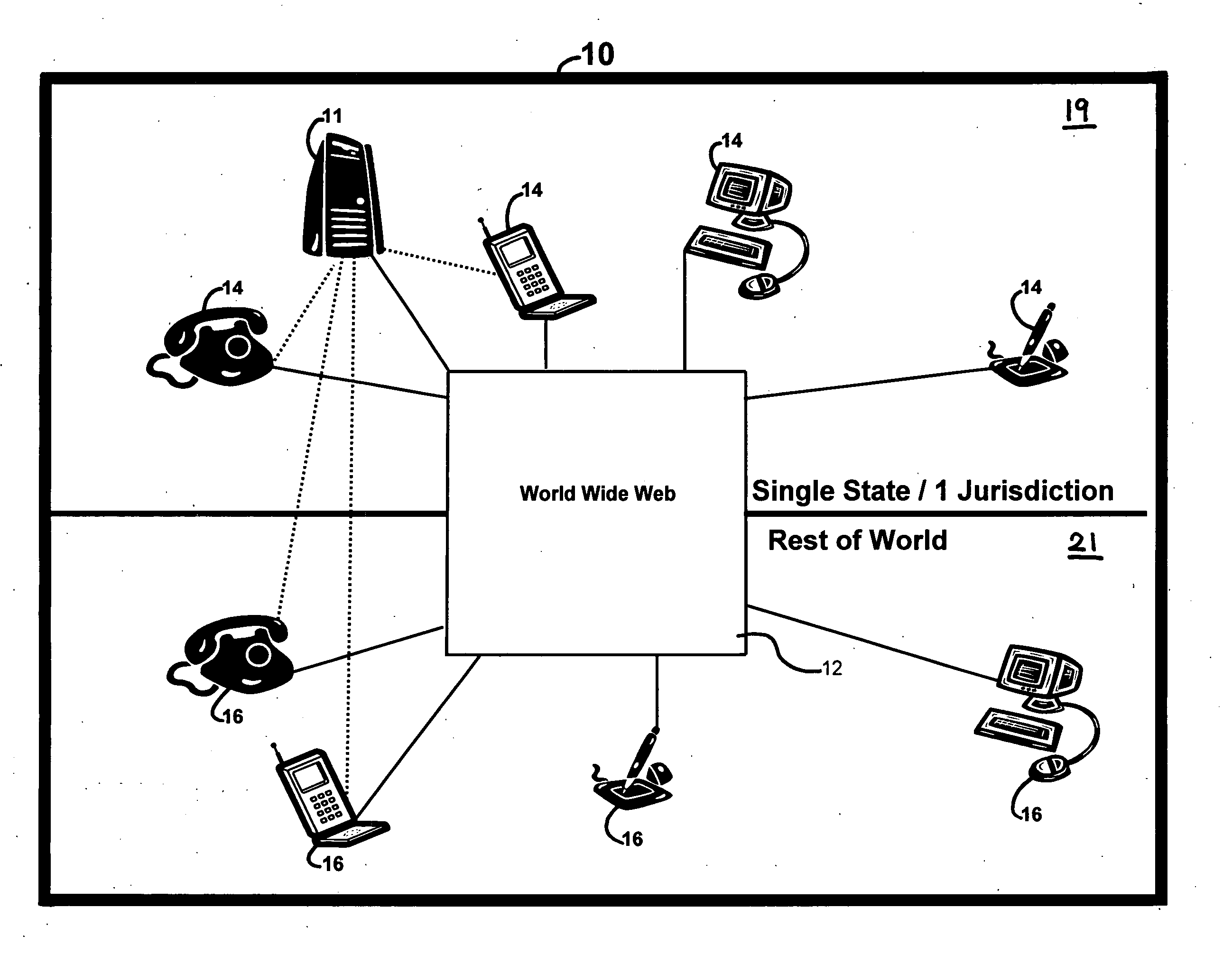

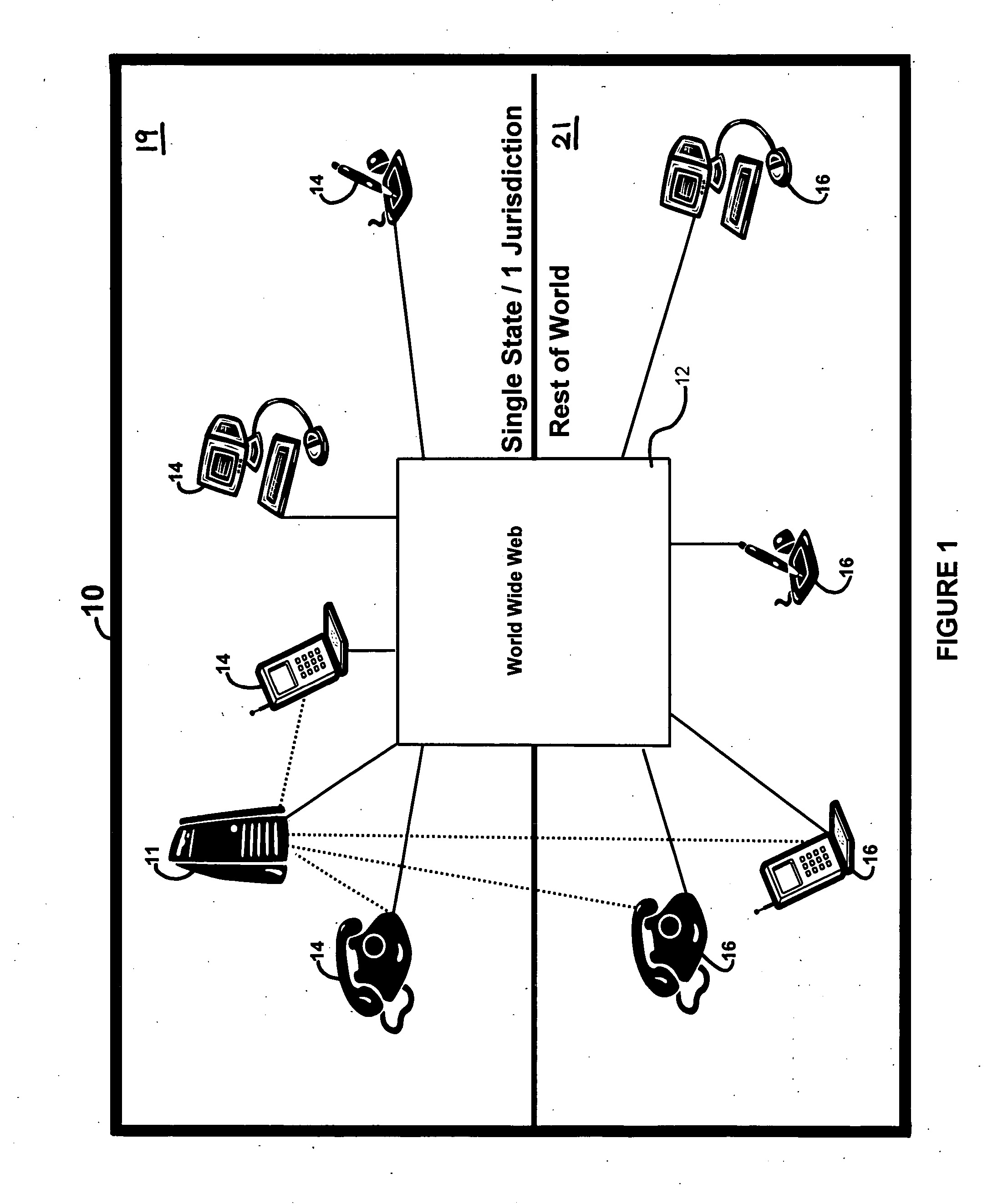

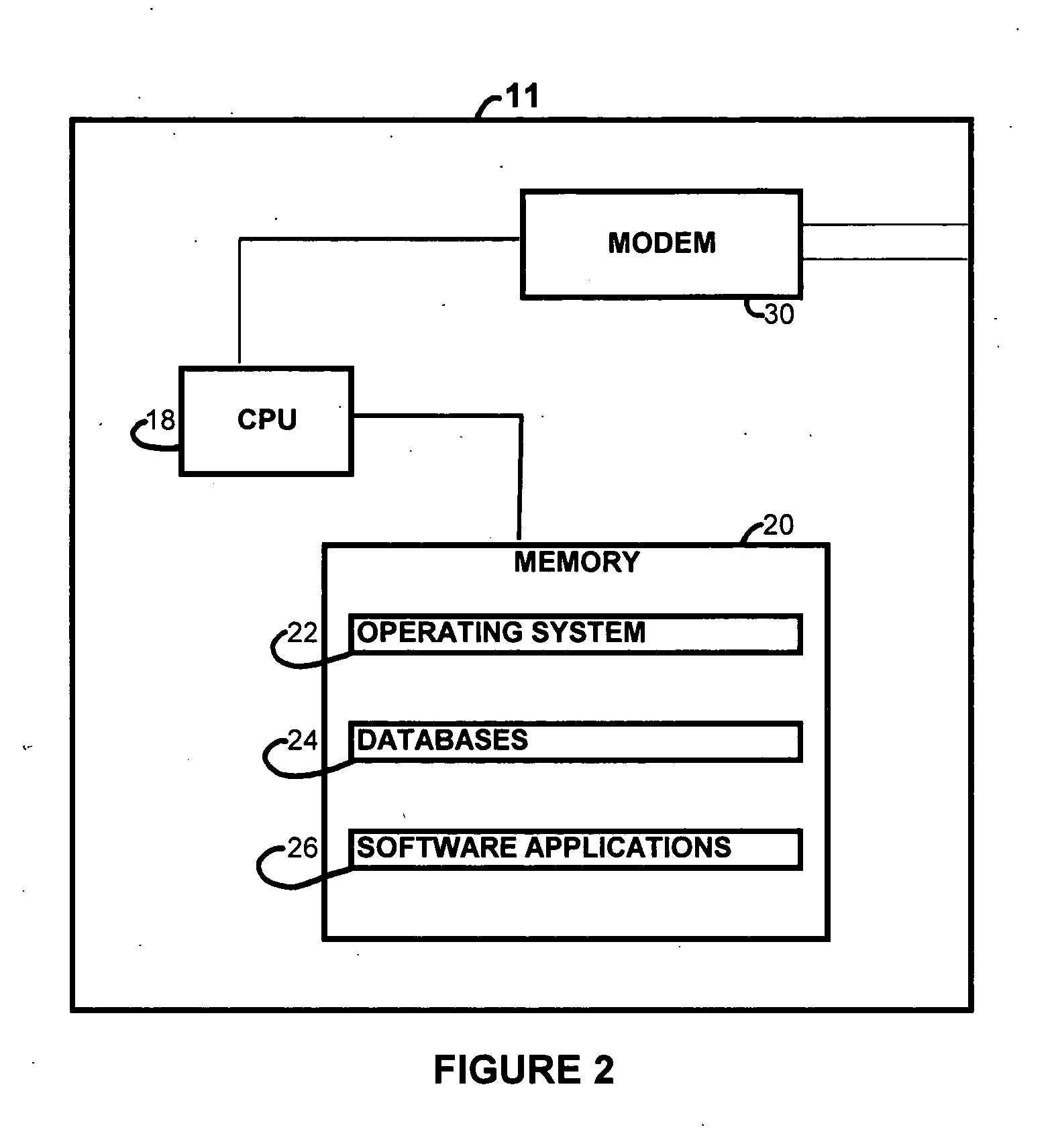

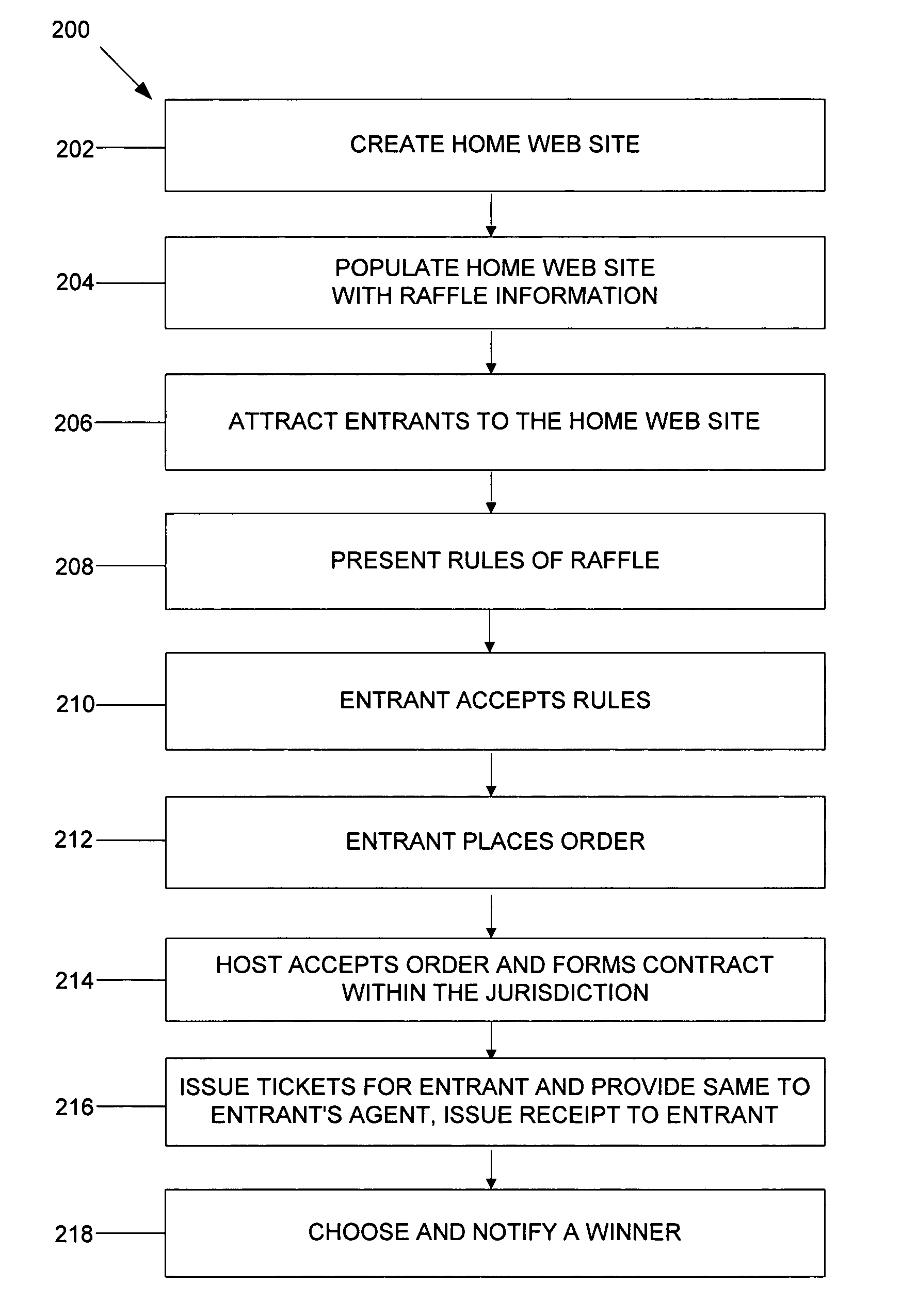

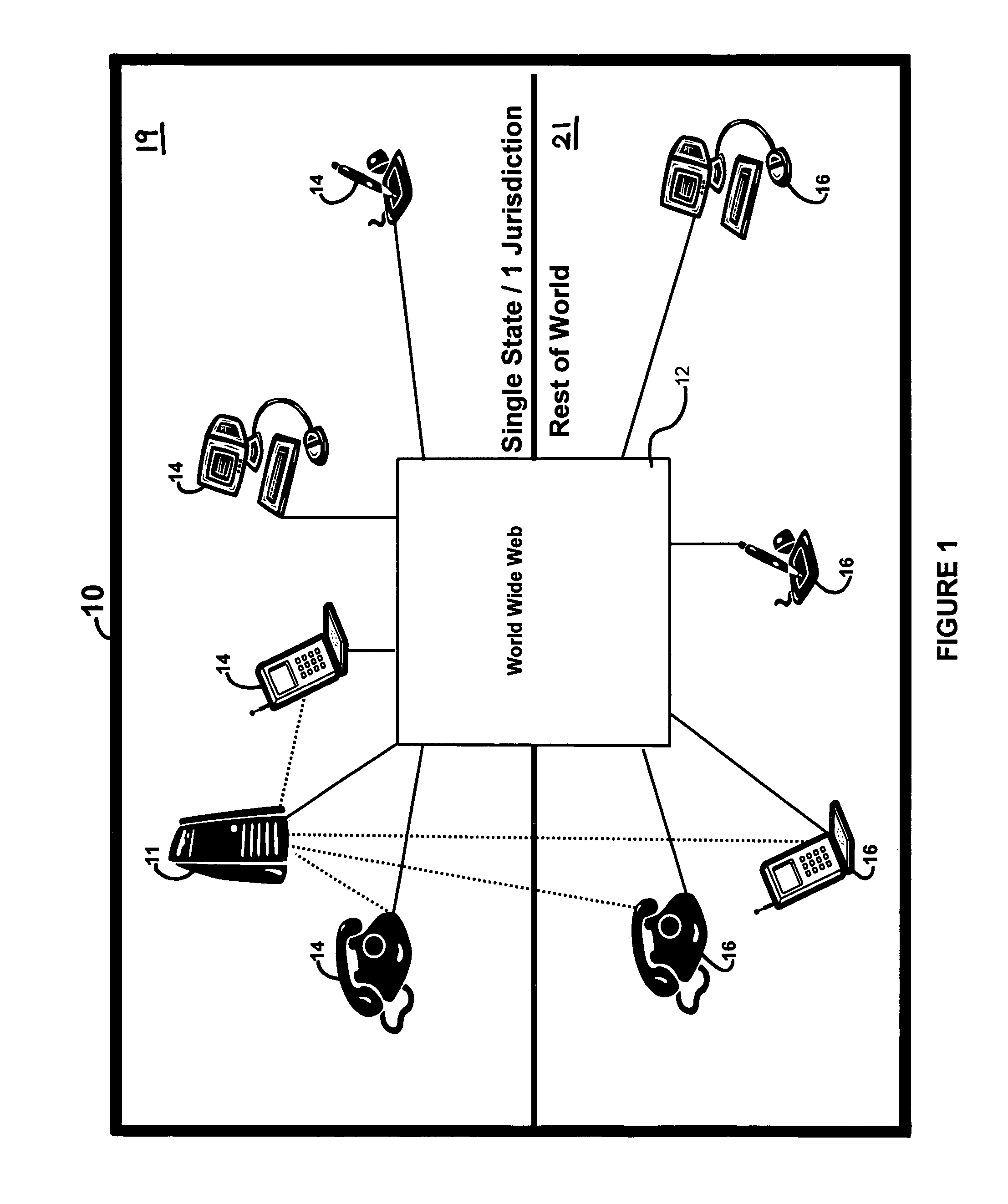

Methods and systems for a single jurisdiction raffle in a distributed computing network

ActiveUS20050187021A1Large distributionIncrease demandApparatus for meter-controlled dispensingVideo gamesWeb siteOperational system

A server facilitates a raffle within a single jurisdiction, wherein the server communicates with clients via a network. The server includes a memory storing an operating system, an instruction set, agent data, sponsor data and Web site data. A processor runs the instruction set and communicates with the memory and the network. The processor is operative to present rules associated with the raffle to entrants, receive acceptance of the rules by entrants, and accept an order for the raffle from entrants. The processor is also operative to associate an entrant agent with each entrant, issue tickets for the raffle to the entrant agent, determine a winner of the raffle and notify the winner to collect a prize associated with the raffle. Preferably, the prize is a high intangible value item.

Owner:MCD ENTERPRISES

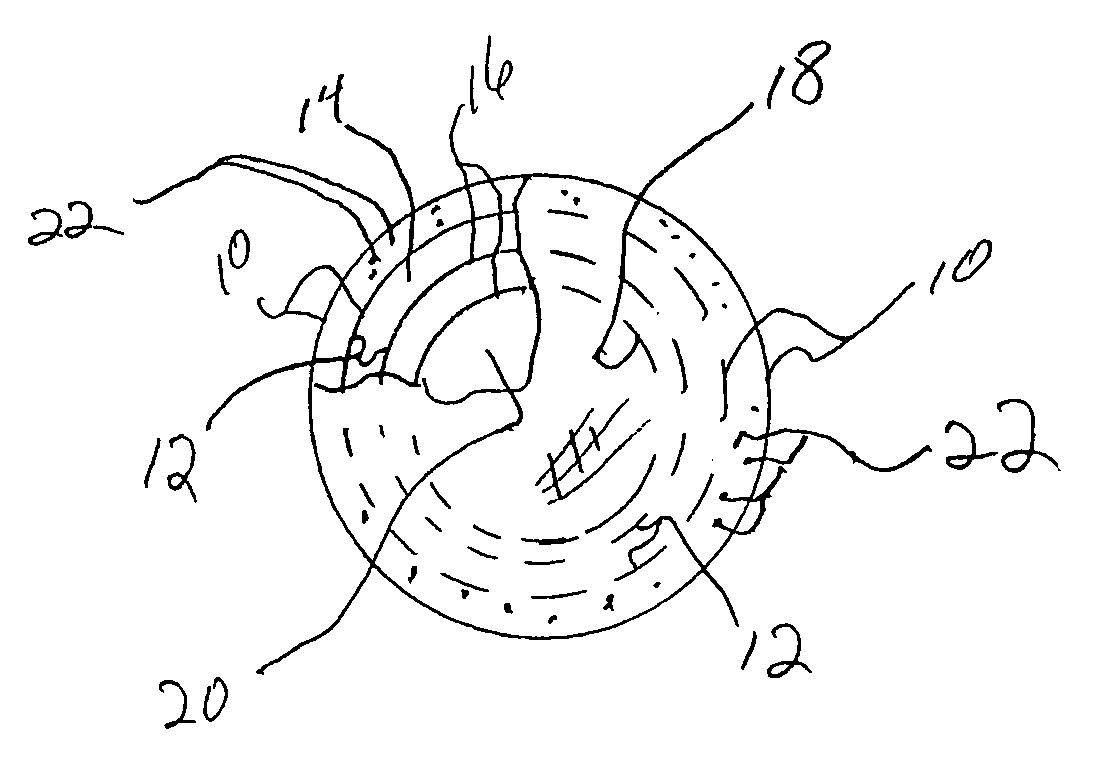

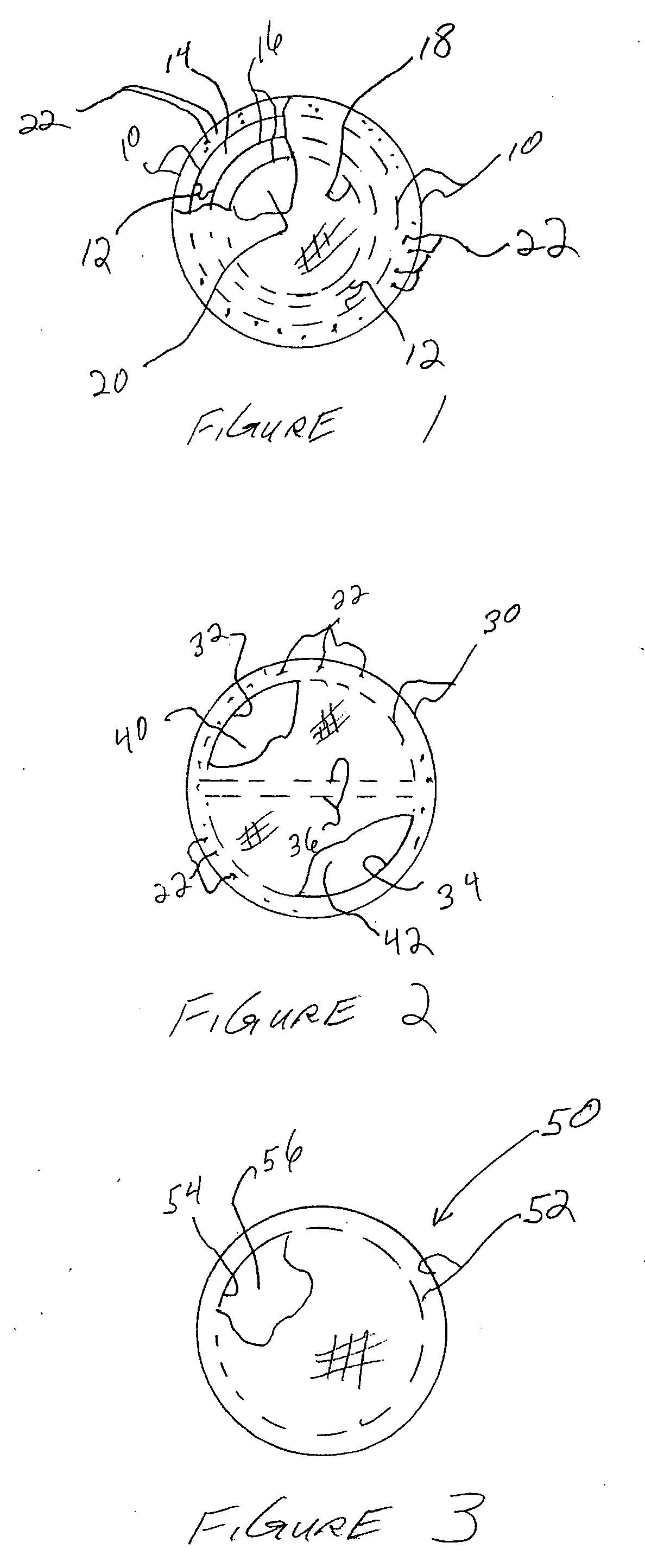

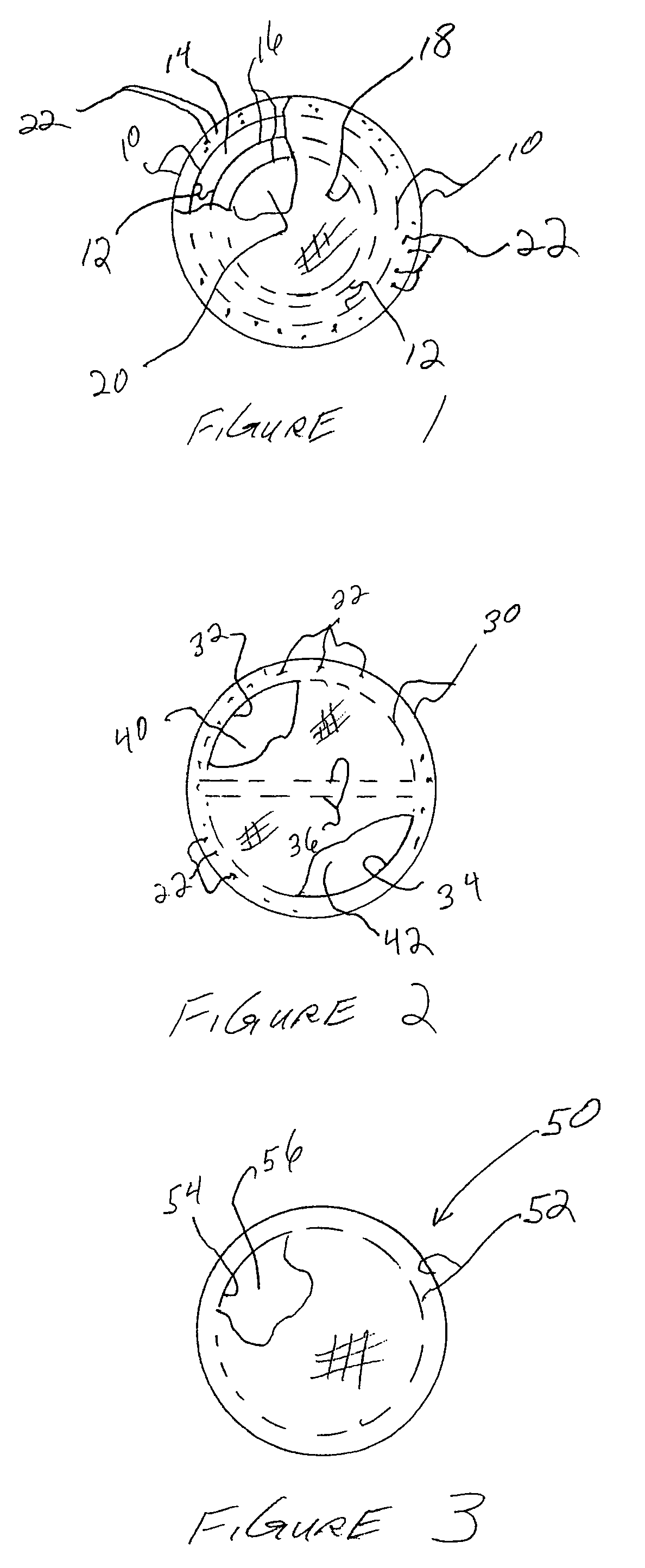

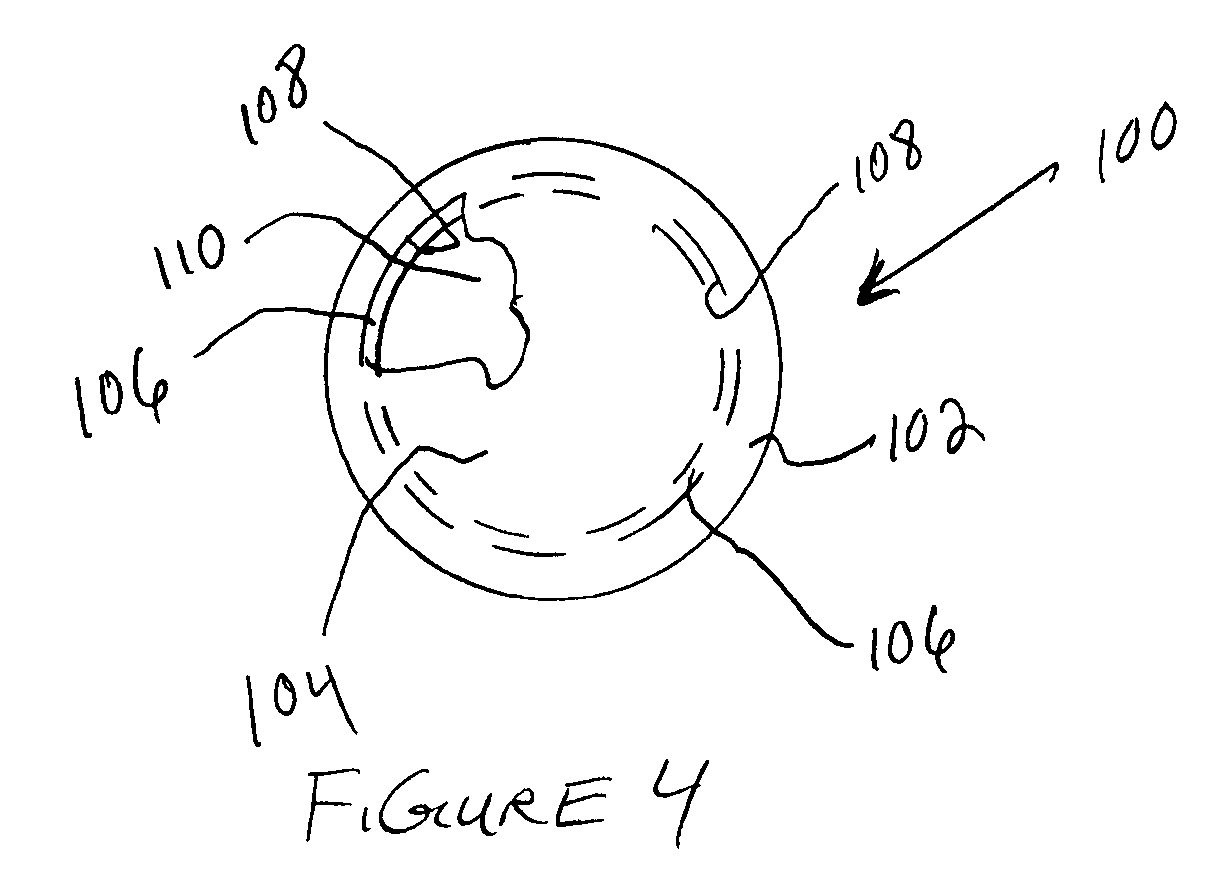

Bioluminescent paintball

ActiveUS20080035006A1Inhibit productionLarge distributionAmmunition projectilesTraining ammunitionPhotoproteinEngineering

A Bioluminescent Paintball 10 includes a shell 12 defining an interior cavity 14, a liquefied substance 16 disposed within the interior cavity 14, a phosphorescent material 18 disbursed throughout the shell 12 for providing a visible “tracing” effect when the bioluminescent paintball 10 is ejected from a paintball discharge device, a neutralizing agent 20 disbursed throughout the liquefied substance 16 for neutralizing calcium disbursed throughout the liquefied substance 16 thereby preventing light emission before the paintball 10 impacts a target, and a photoprotein 22 disbursed throughout the liquefied substance 16 for reacting with calcium disposed upon a target after the bioluminescent paintball 10 impacts the target, thereby rupturing the shell 12 and allowing the liquefied substance 16 to engage the calcium to produce visible light. A paintball 100 includes a shell 102 defining an interior cavity 104, an insoluble coating 106 disposed upon an inner surface 108 of the shell 102, and an aqueous material 110 disposed within the cavity 104 such that the aqueous material 110 engages the insoluble coating 106, thereby preventing the aqueous material 110 from dissolving the shell 102, and promoting the marking of a target via the aqueous material 110 when the paintball 100 forcibly engages the target and ruptures the shell 102.

Owner:HYDRO CAPS

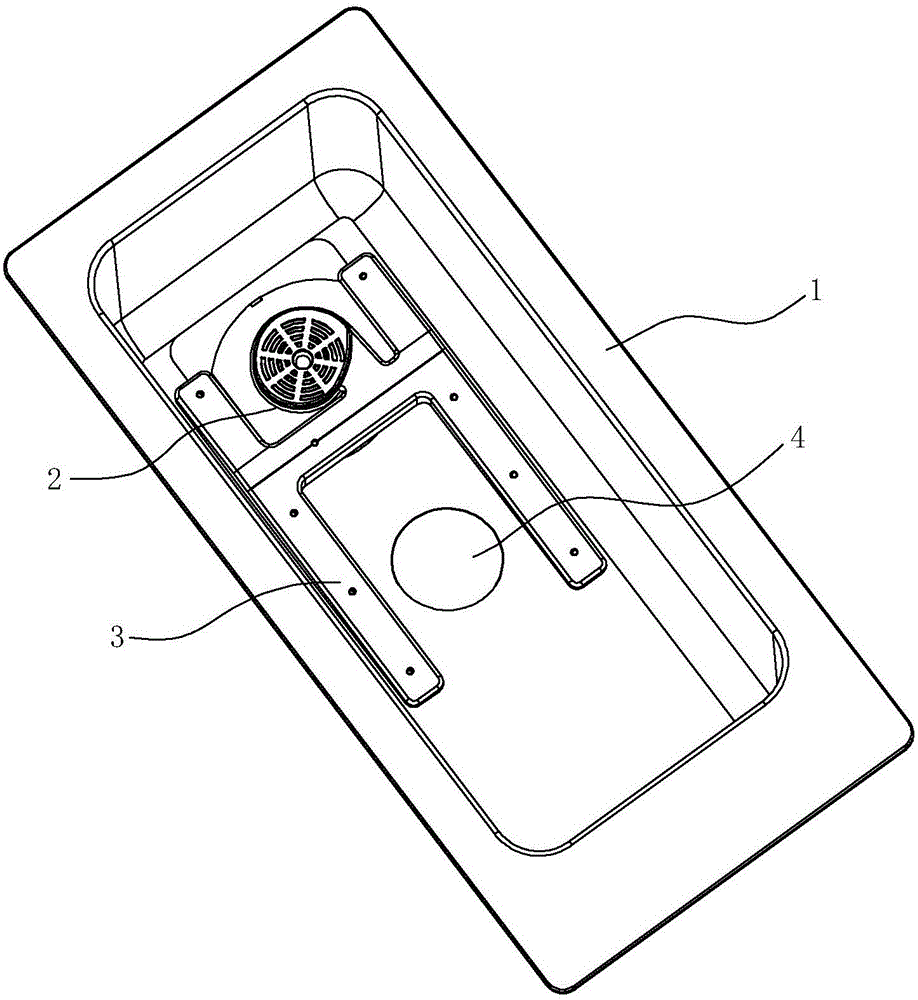

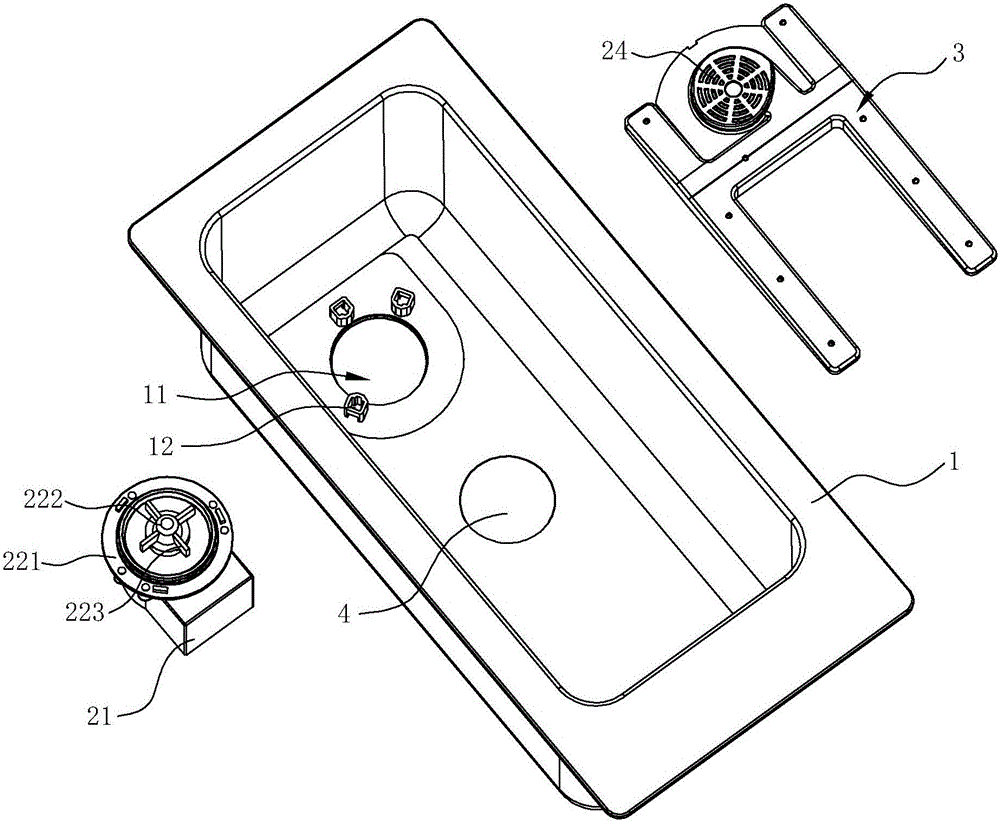

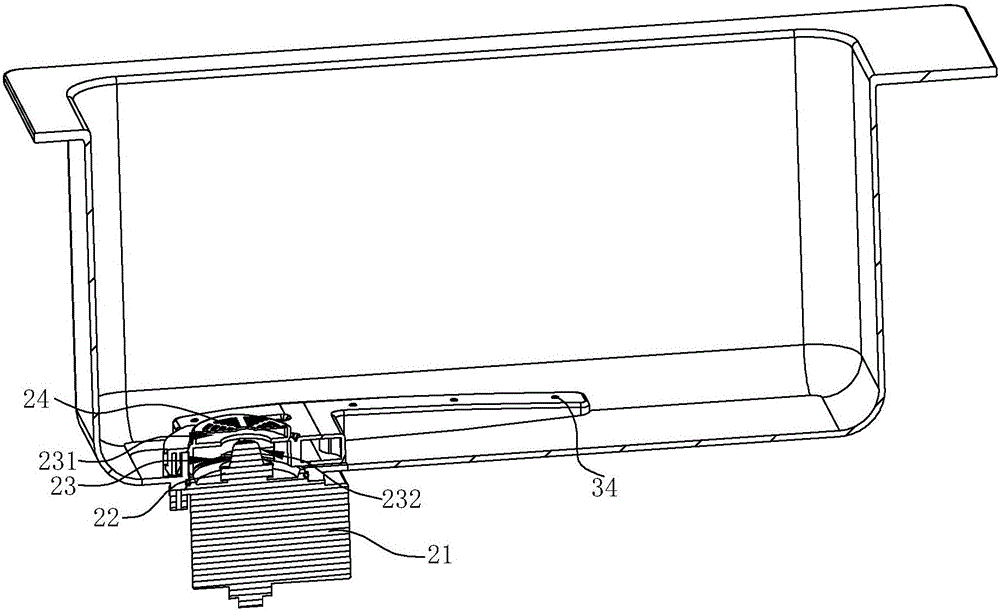

Water tank type cleaning machine

PendingCN105662300AReduce processing requirementsFast water flowTableware washing/rinsing machine detailsKitchen equipmentWater velocityAgricultural engineering

The invention discloses a water tank type cleaning machine which comprises a water tank body, a water pump and a spraying arm; the water pump is arranged at the bottom of the water tank body and comprises a water inlet and a water outlet, the spraying arm is internally provided with a flow splitting channel communicated with the water outlet, and the spraying arm is provided with a plurality of water spraying holes communicated with the inside of the flow splitting channel; the water tank type cleaning machine is characterized in that the water inlet is formed in the top end of the water pump.The water inlet of the water pump is formed in the top end of the water pump, so that a water drainage area does not need to be arranged at the bottom of the water tank body, the machining requirement of the water pump is low, and components of the water tank body and the machining process are simplified; besides, the water inlet of the water pump is small, the water velocity is high, and water pumping efficiency can be high.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Circuit for minimizing or eliminating pulse anomalies in human body model electrostatic discharge tests

InactiveUS7560948B2Without unwanted pulse distortionEliminates creationMaterial analysis by electric/magnetic meansMeasuring interference from external sourcesEngineeringHuman-body model

A new circuit for producing simulated electrostatic discharges (ESD) based on the Human Body Model (HBM) is disclosed for testing integrated circuits. HBM ESD test systems provide stress pulses defined by industry standards. The pulses produced by prior art have small imperfections or anomalies. These anomalies can cause incorrect testing to certain devices. The improved ESD HBM test system herein disclosed provides pulses meeting the requirements of industry standards while reducing several anomalies to negligible levels.

Owner:THERMO KEYTEK LLC

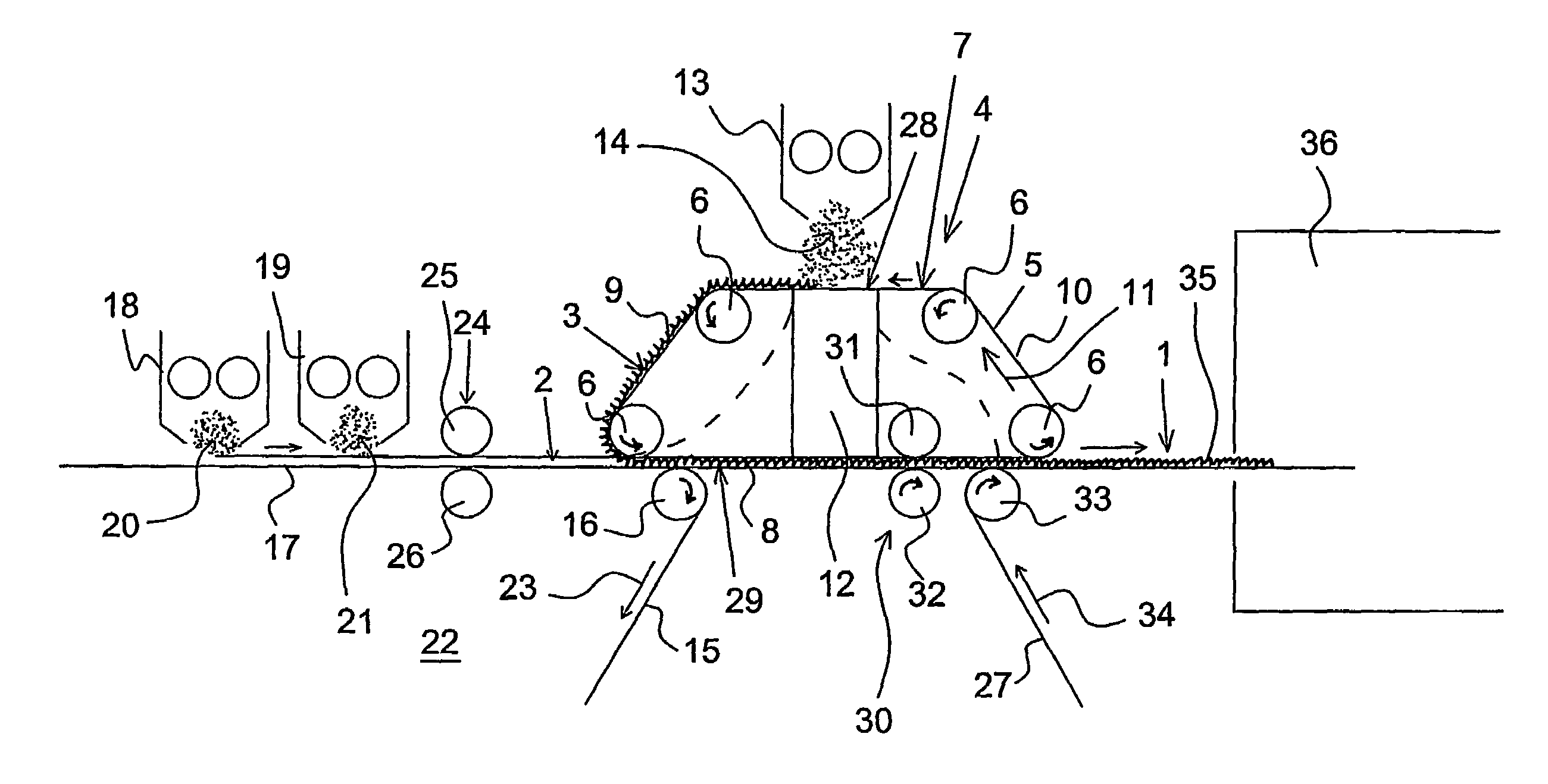

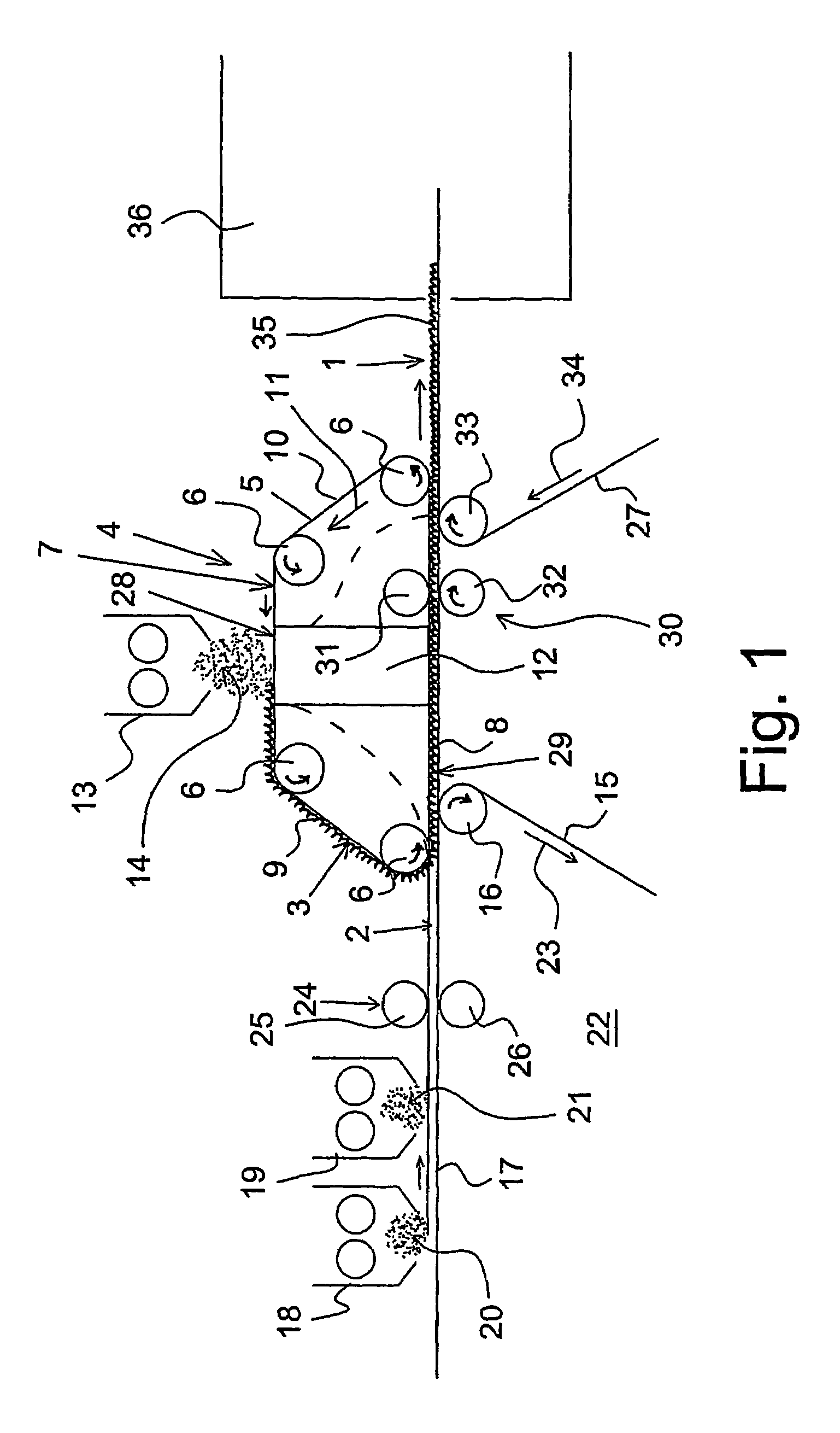

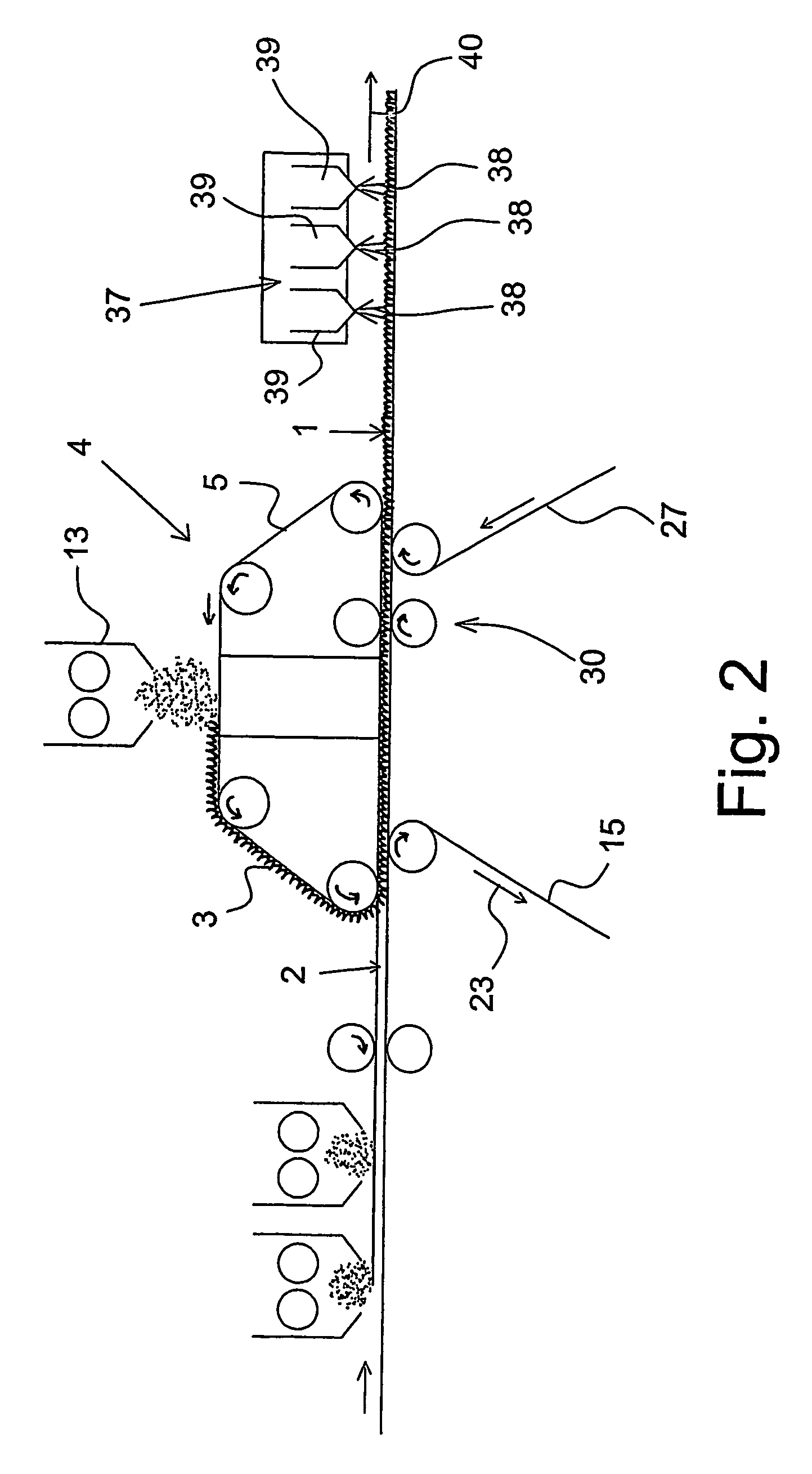

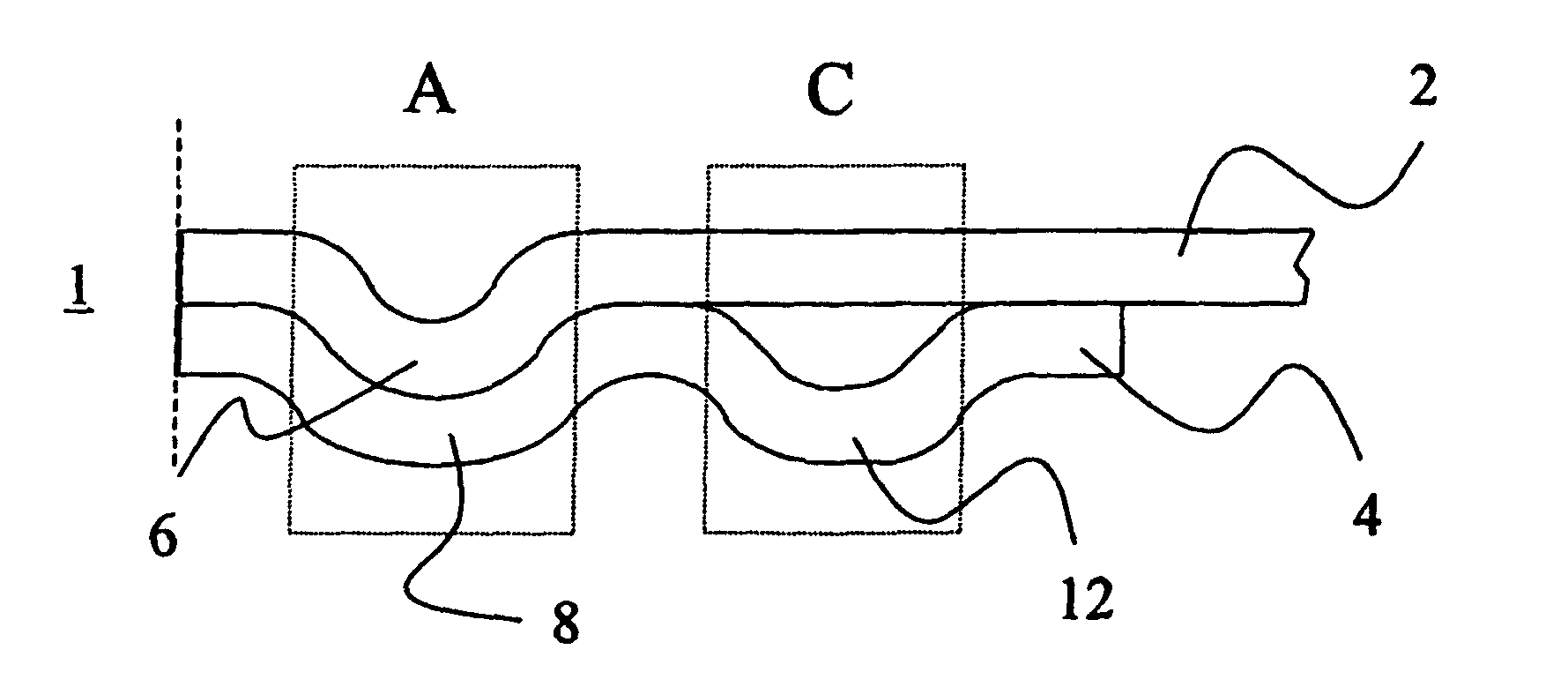

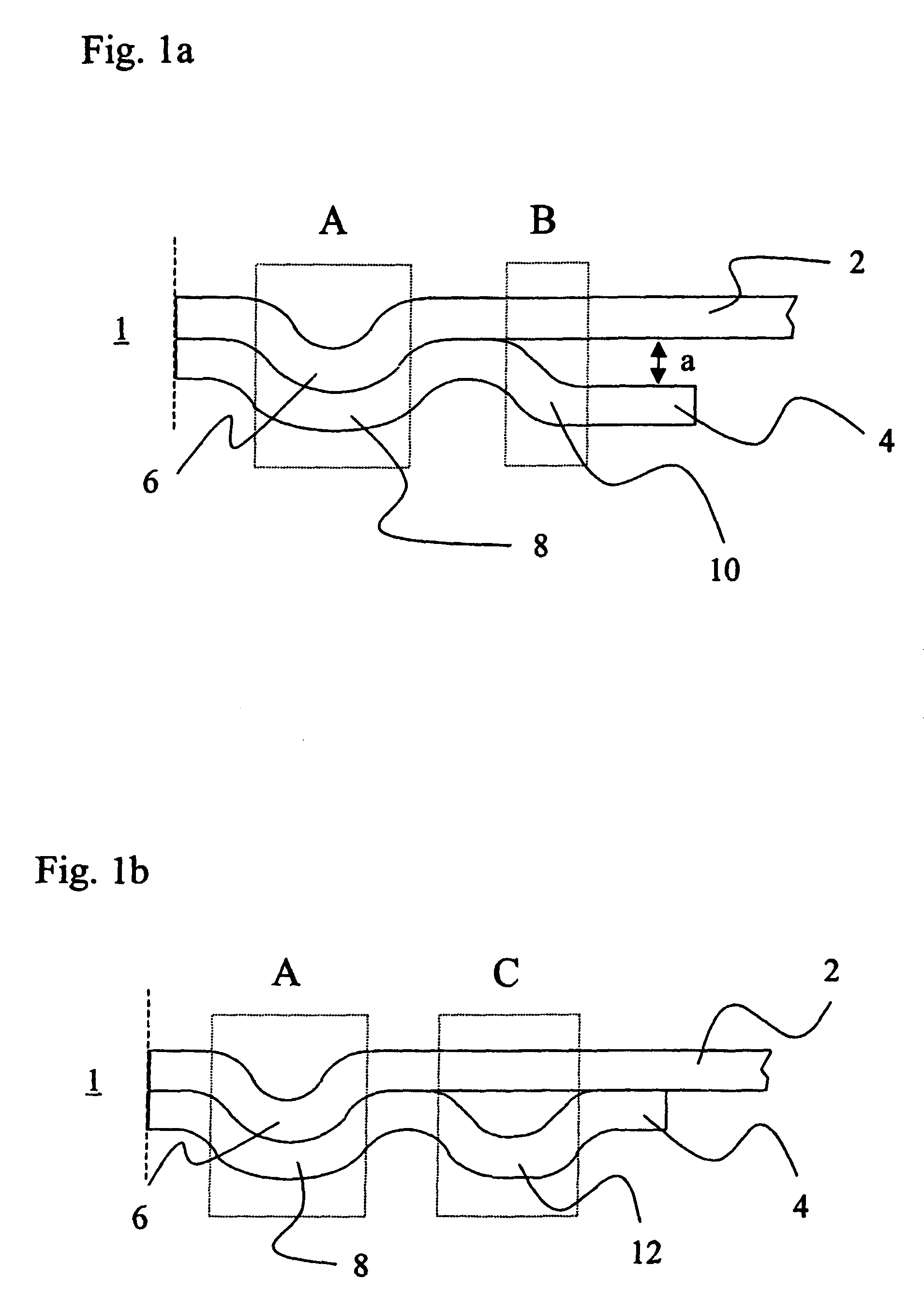

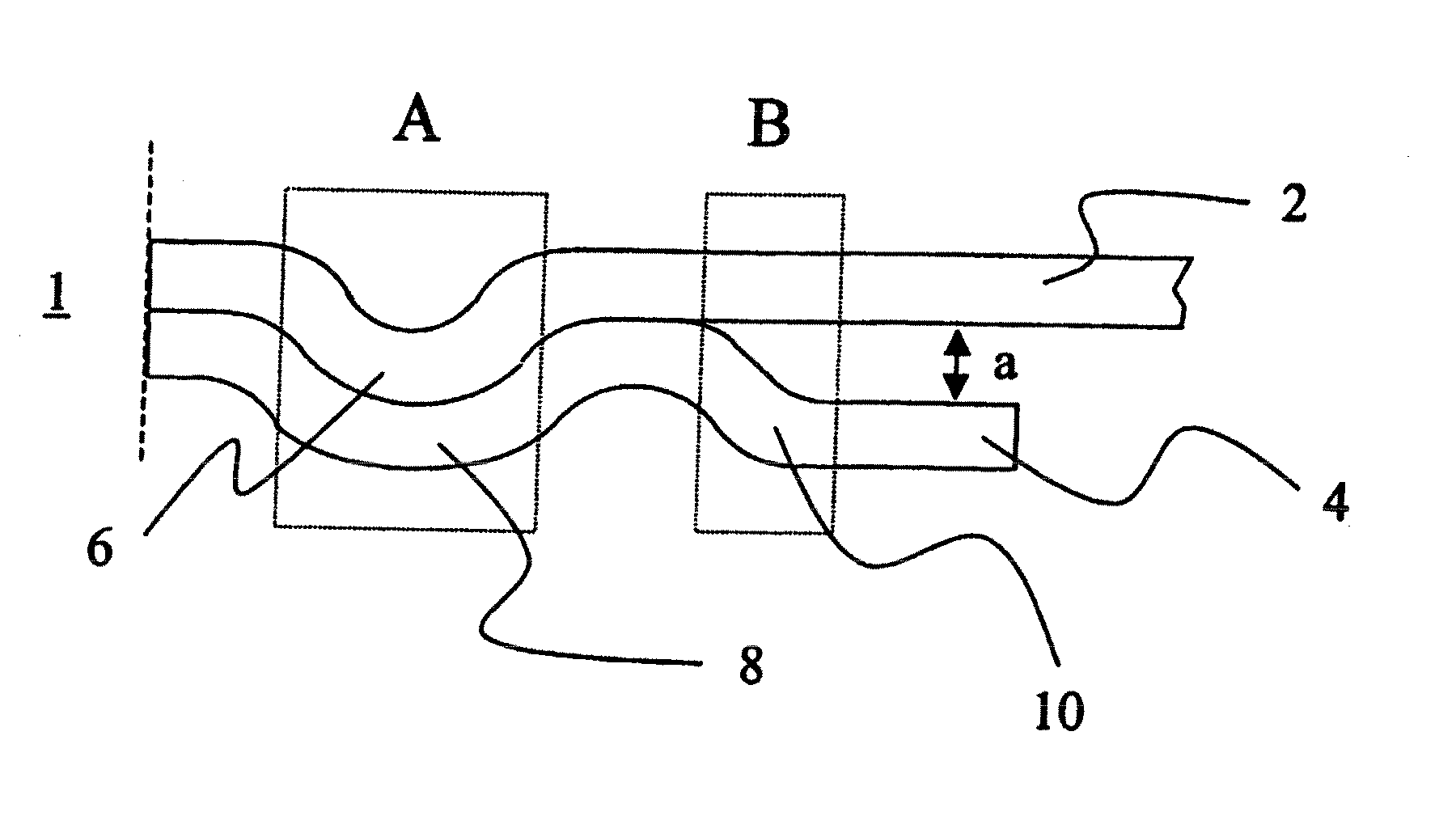

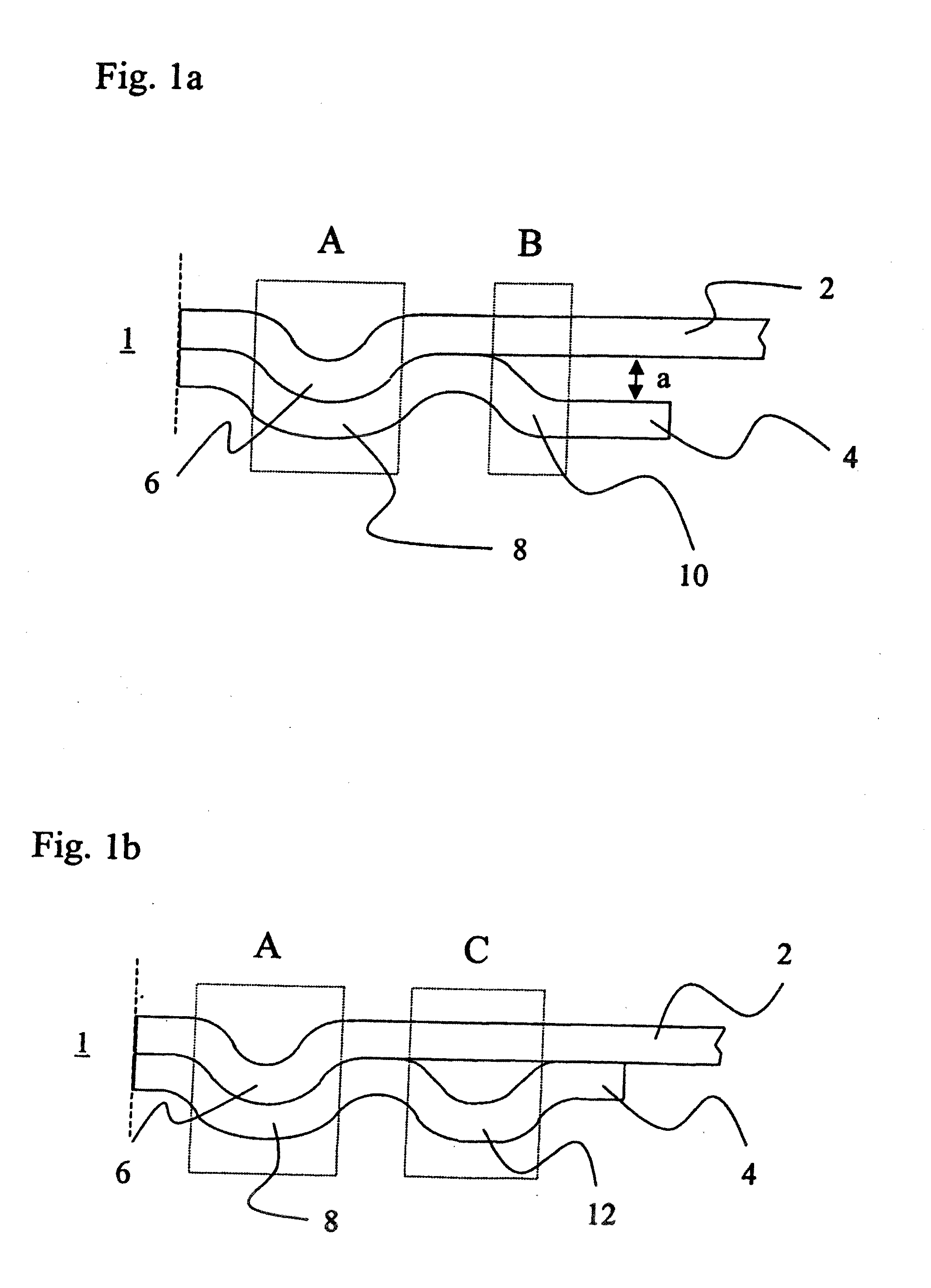

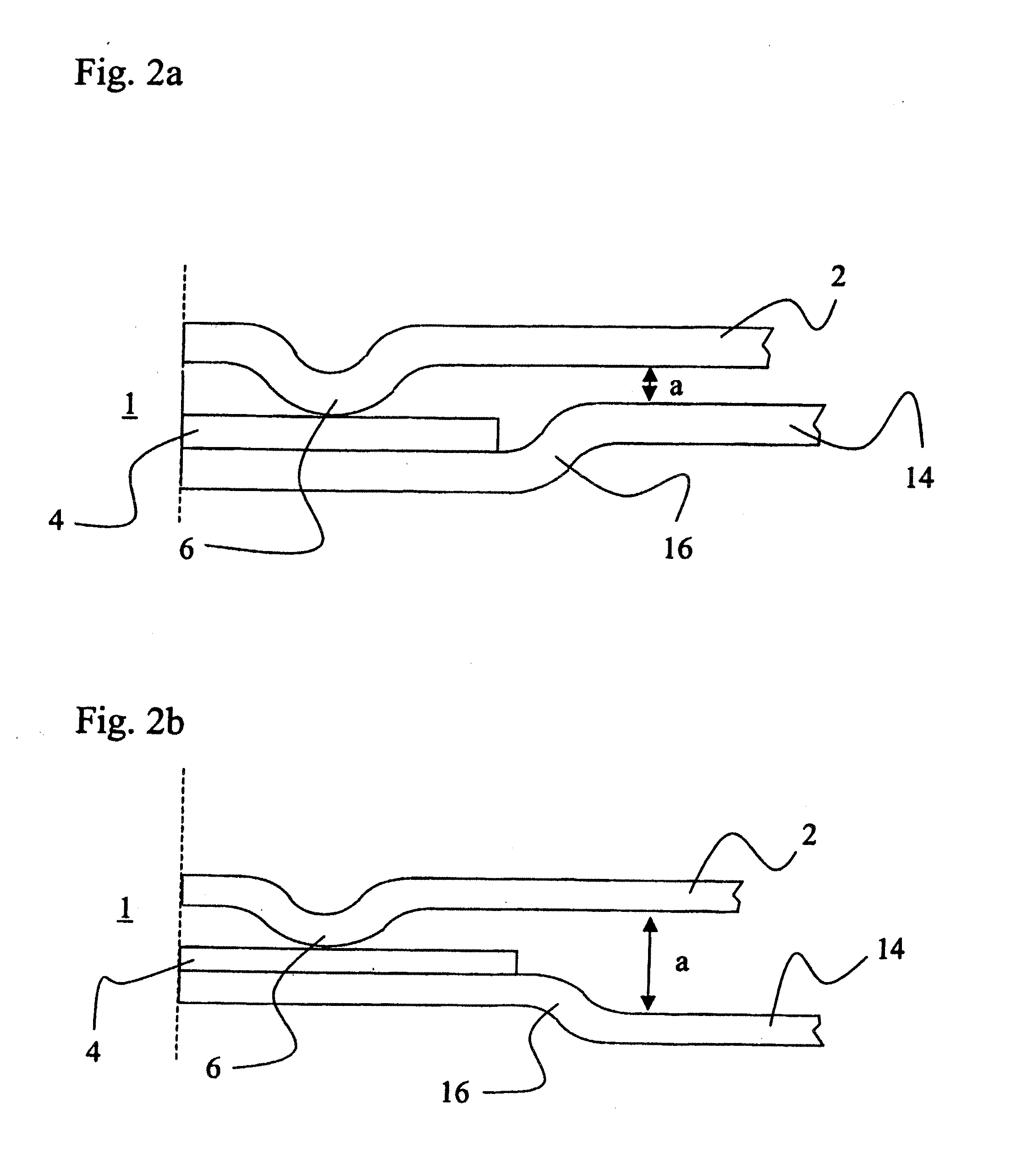

Method and apparatus for dry forming of a fabric

InactiveUS7331089B2Improve relationshipLarge distributionLap forming devicesLap-winding devicesEngineeringNonwoven fabric

A method and apparatus is described for use in dry forming a fabric by at least two non-woven fabrics. The upper run of the transfer wire is used as a forming wire. A forming head is disposed above the transfer wire. An airlaid non-woven fabric is formed on the transfer wire. This non-woven fabric is carried with the transfer wire onto the top side of the first non-woven fabric. The first non-woven fabric is formed on a preceding forming wire and transferred by the transfer wire to a subsequent conveying wire. This subsequent conveying wire can also be a forming wire so further non-woven fabric can be formed before the fabric is consolidated, e.g. by hydroentanglement or latex bonding / fibre bonding.

Owner:DAN WEB HLDG AS

Abrasive cutting disk with lateral steel sheets

InactiveUS7115029B2Avoid problemsLarge distributionRevolution surface grinding machinesBonded abrasive wheelsSheet steelAbrasive

Owner:TYROLIT SCHLEIFMITTELWERKE SWAROVSKI KG

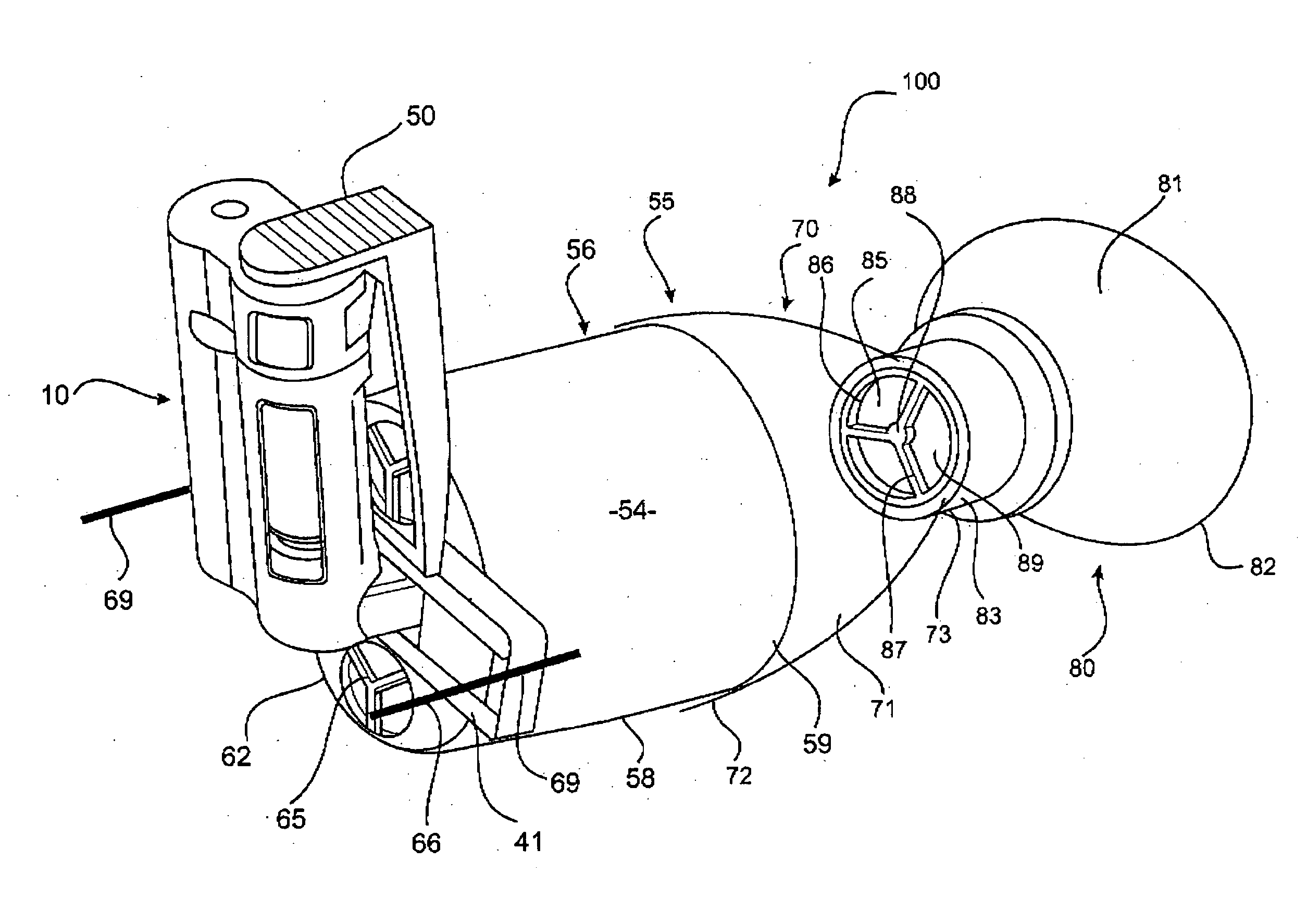

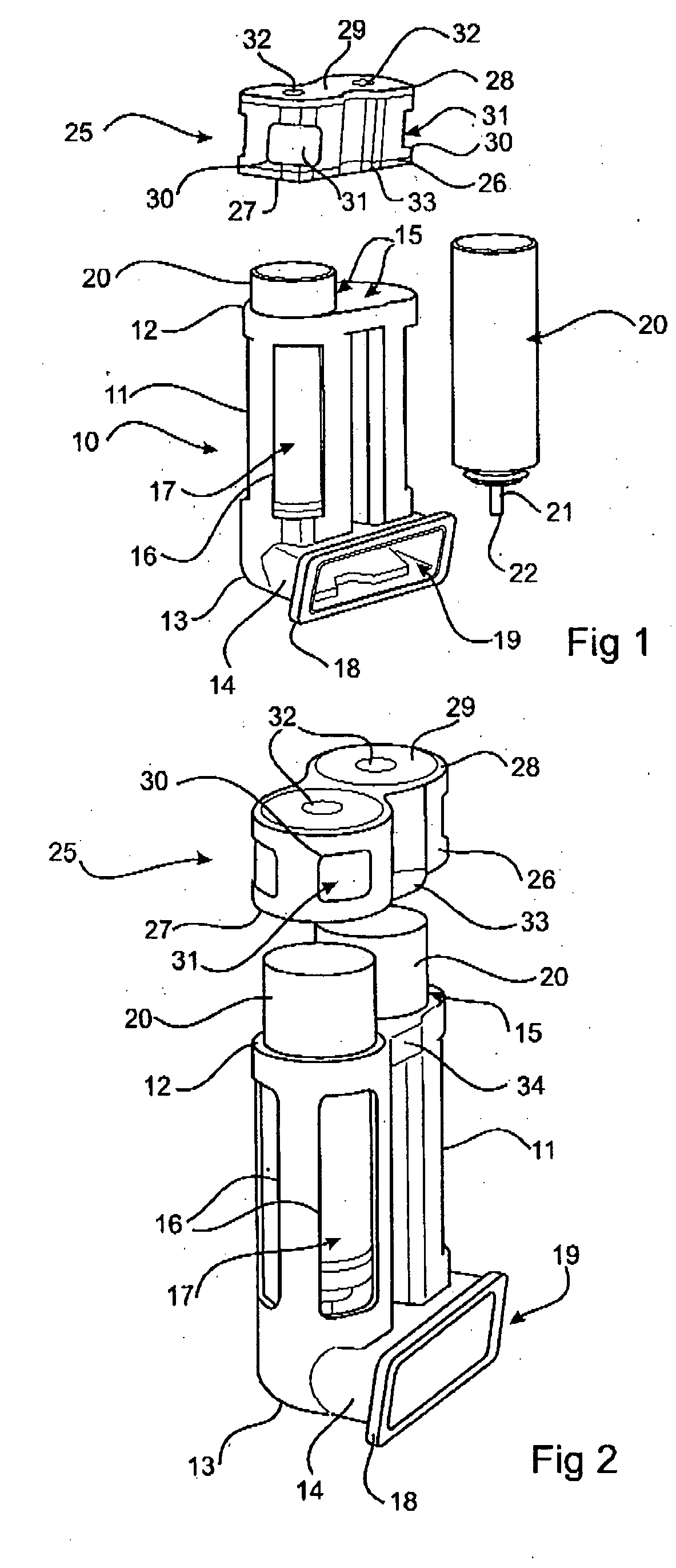

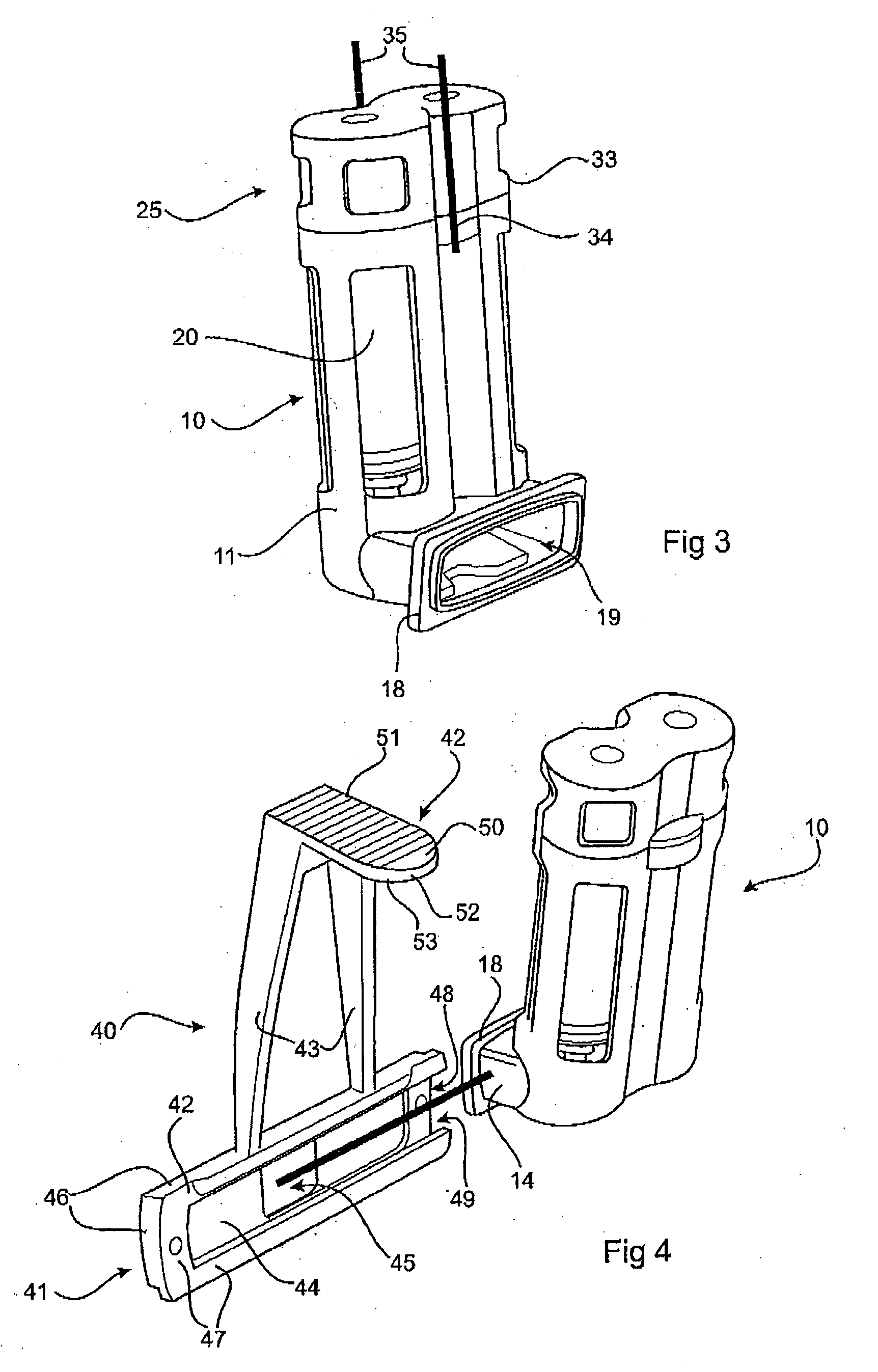

Inhaler assembly

InactiveUS20110214671A1Easy to relaxReduce inflammationRespiratory masksLiquid dispensingEquine SpeciesDrug formulations

The present invention provides an inhaler assembly for providing medications in aerosol form to animals, especially equines. The inhaler assembly comprises a holder adapted to retain at least two diffusion canisters containing either substantially the same or different drug formulations. The canister holder has an outlet in communication with the inlet of a spacer. The spacer, in turn, has an outlet in communication with a mask such that, in use, medication from at least one of the canisters can be dispensed into the spacer for inhalation in aerosol form via the mask.

Owner:PULMOVET

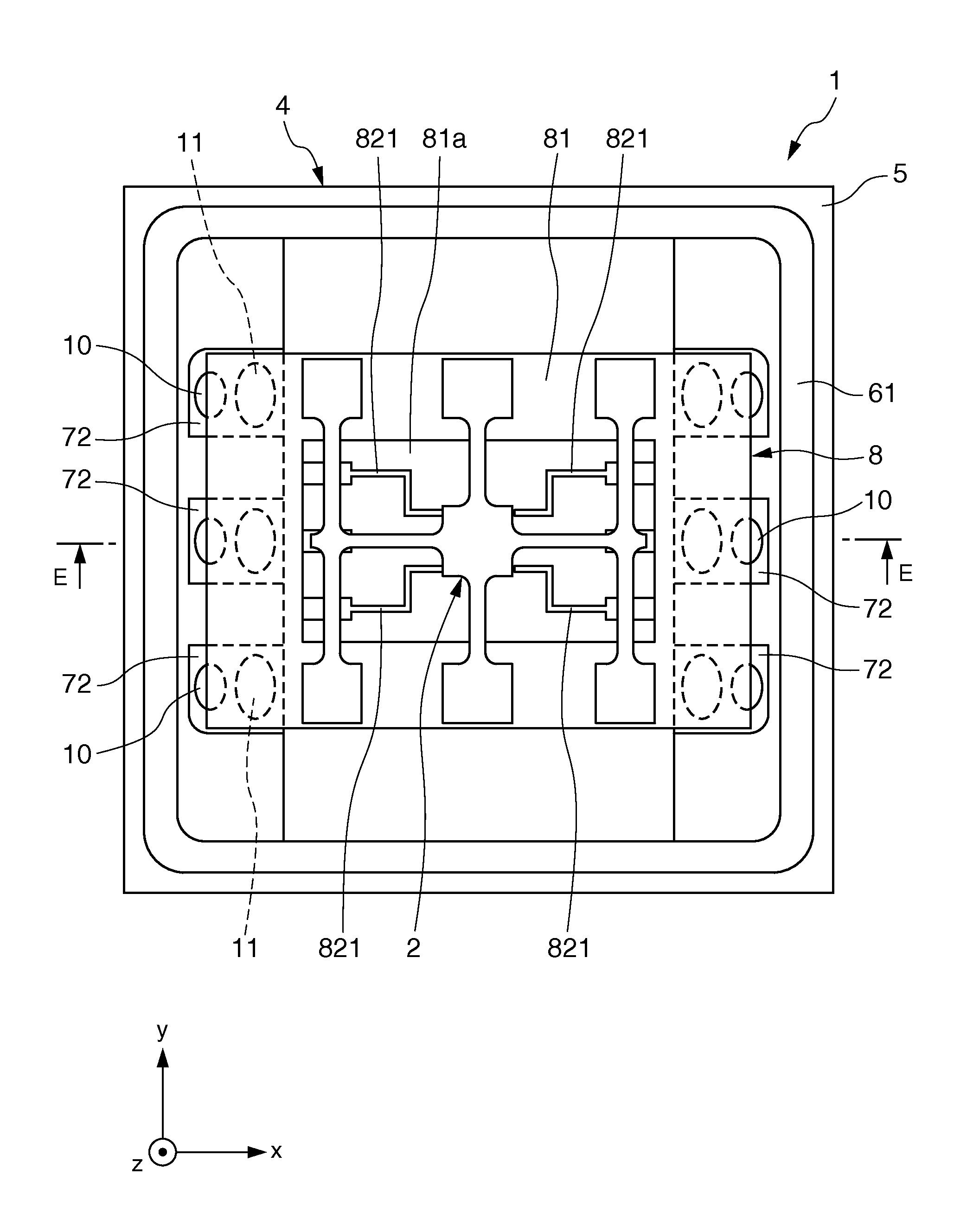

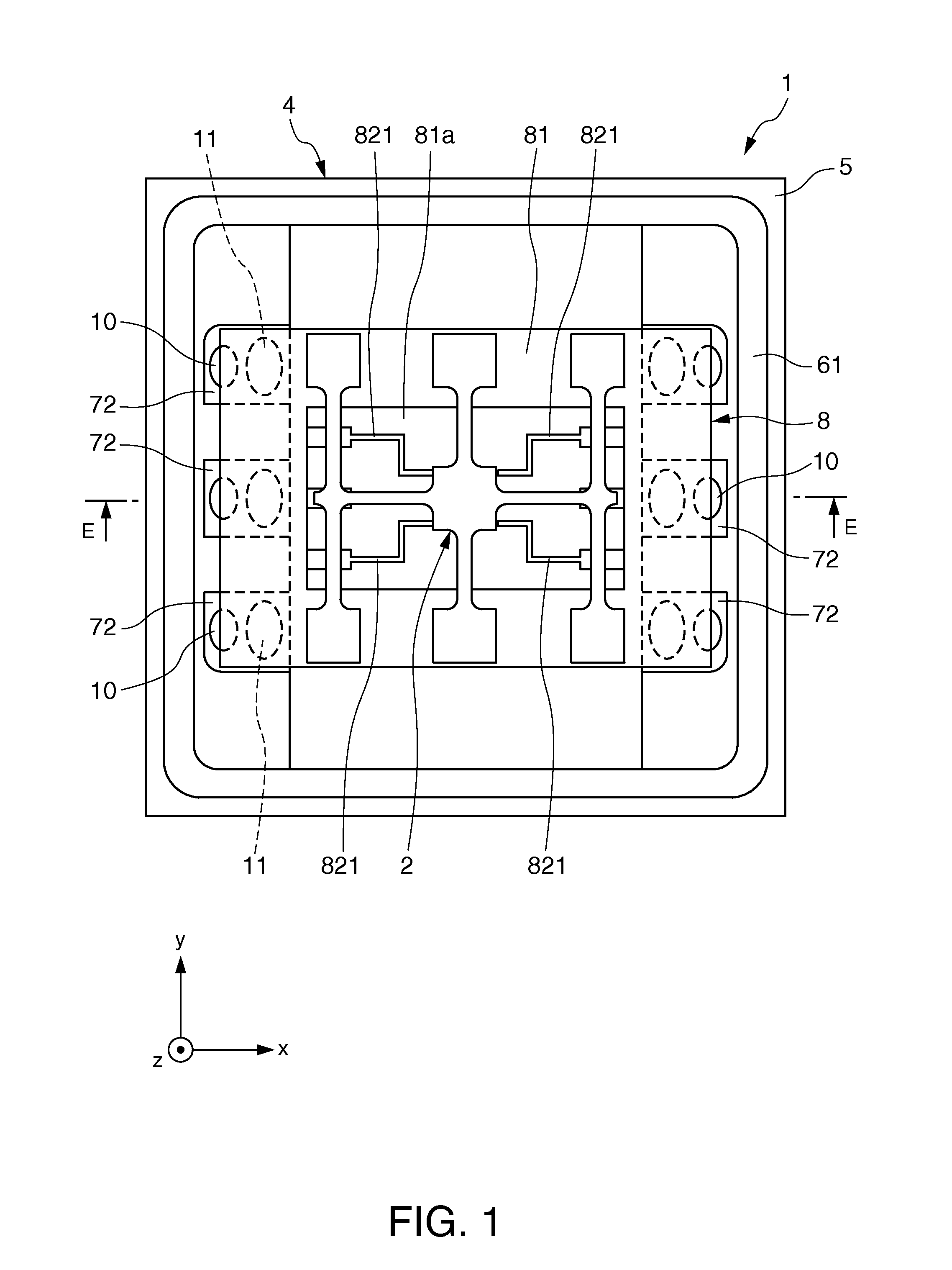

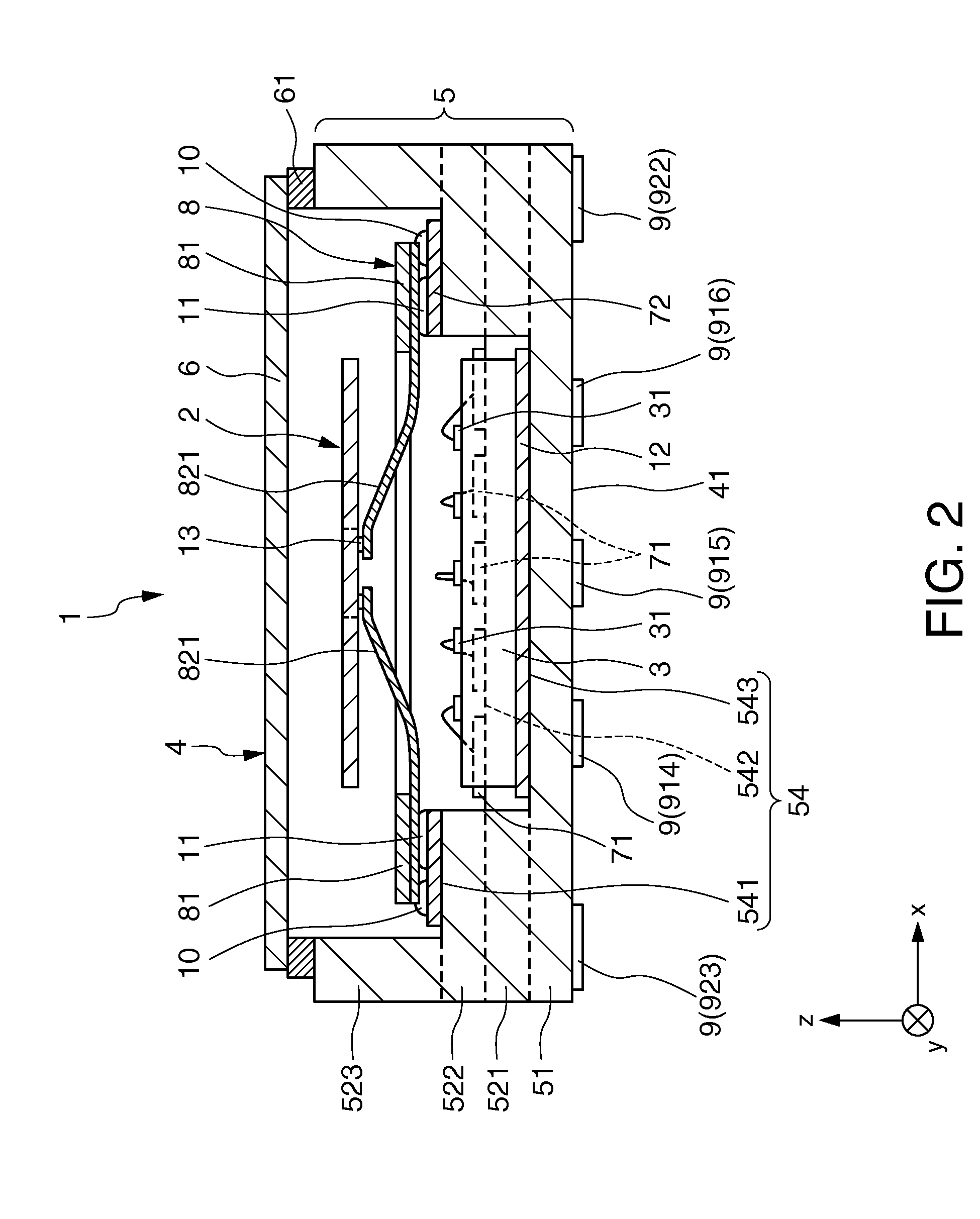

Substrate, electronic device, and electronic apparatus

ActiveUS20130033838A1Prevent and suppress of crackLarge distributionCircuit arrangements on support structuresSemiconductor/solid-state device detailsElectrical and Electronics engineeringElectronic equipment

Owner:SEIKO EPSON CORP

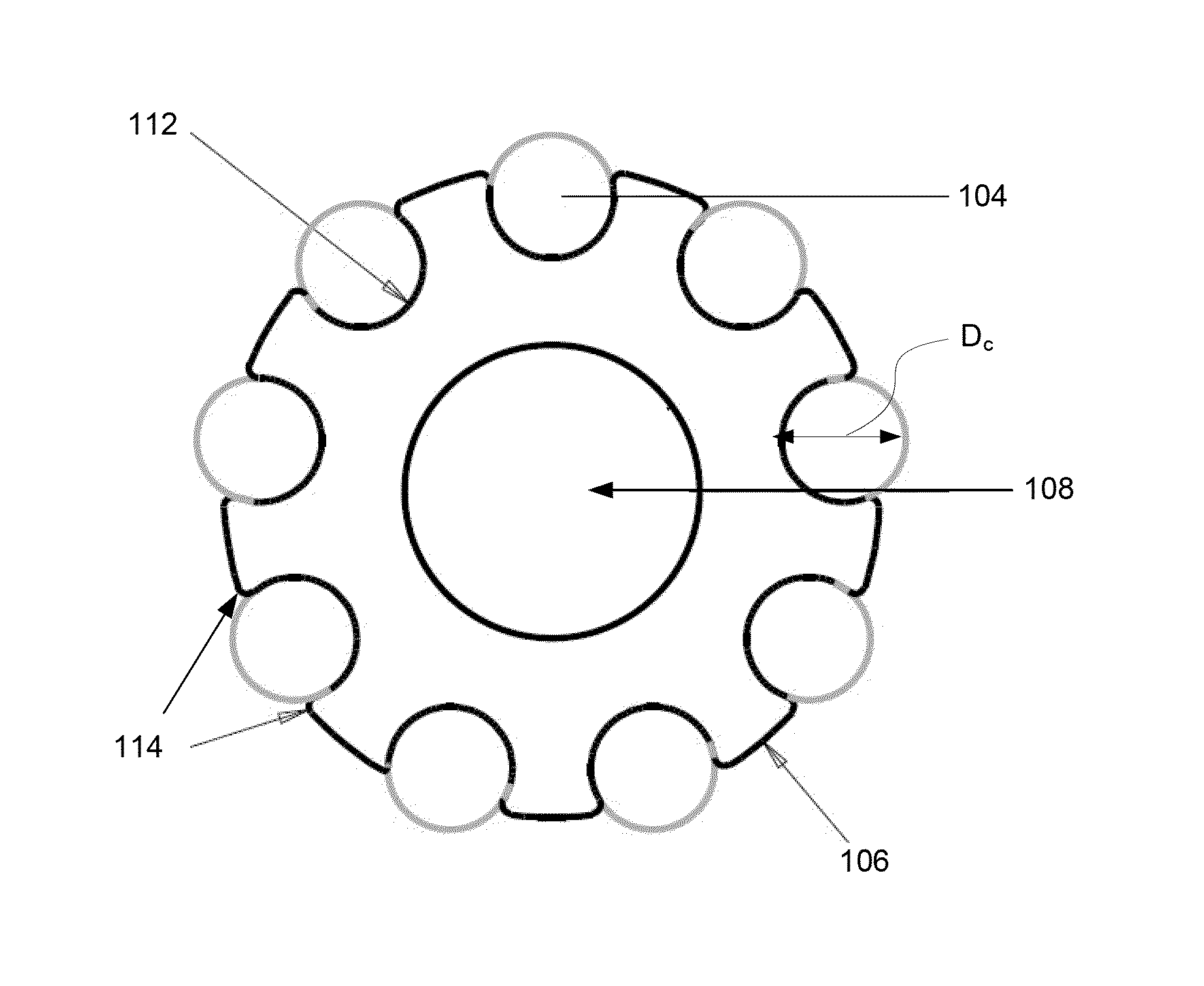

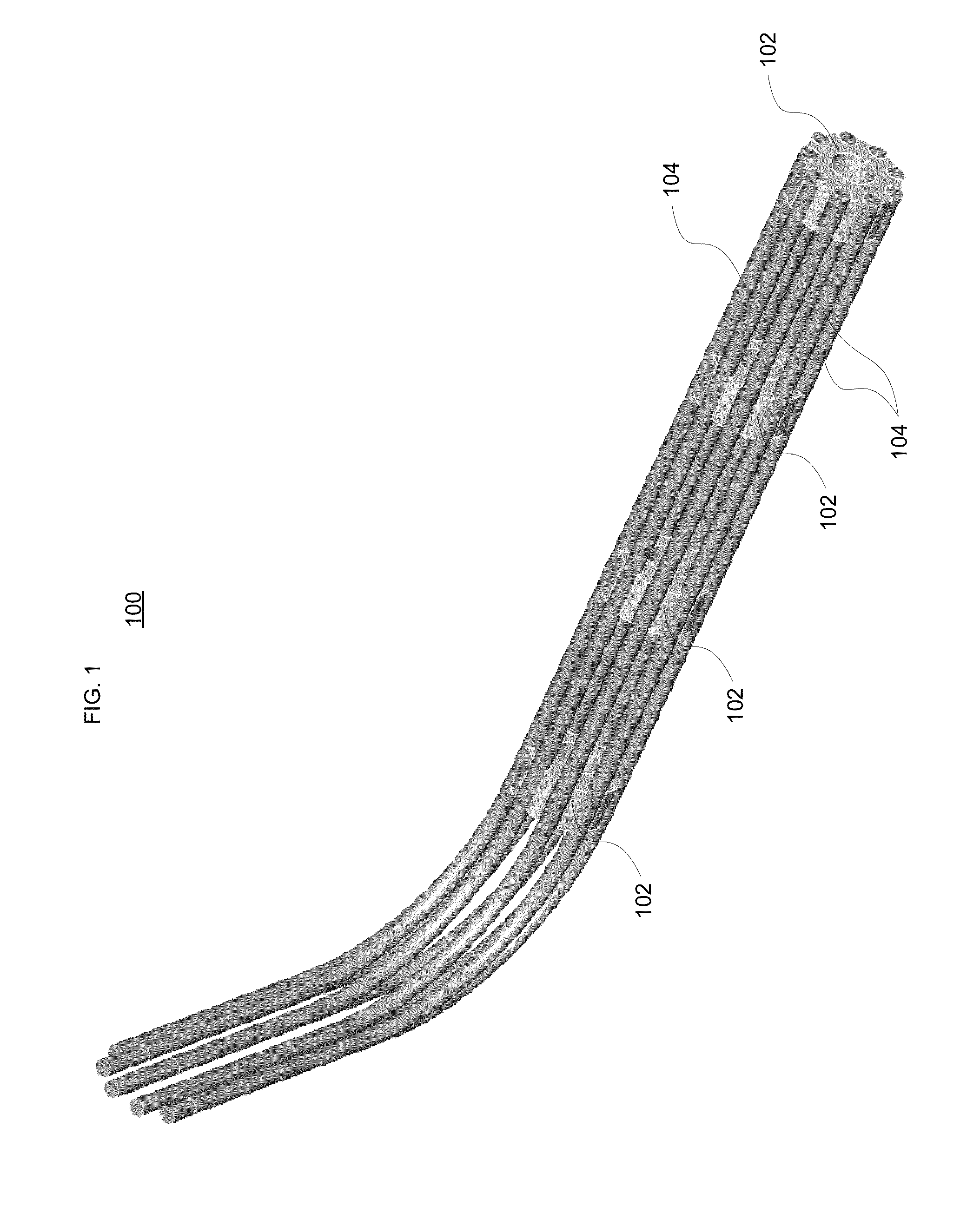

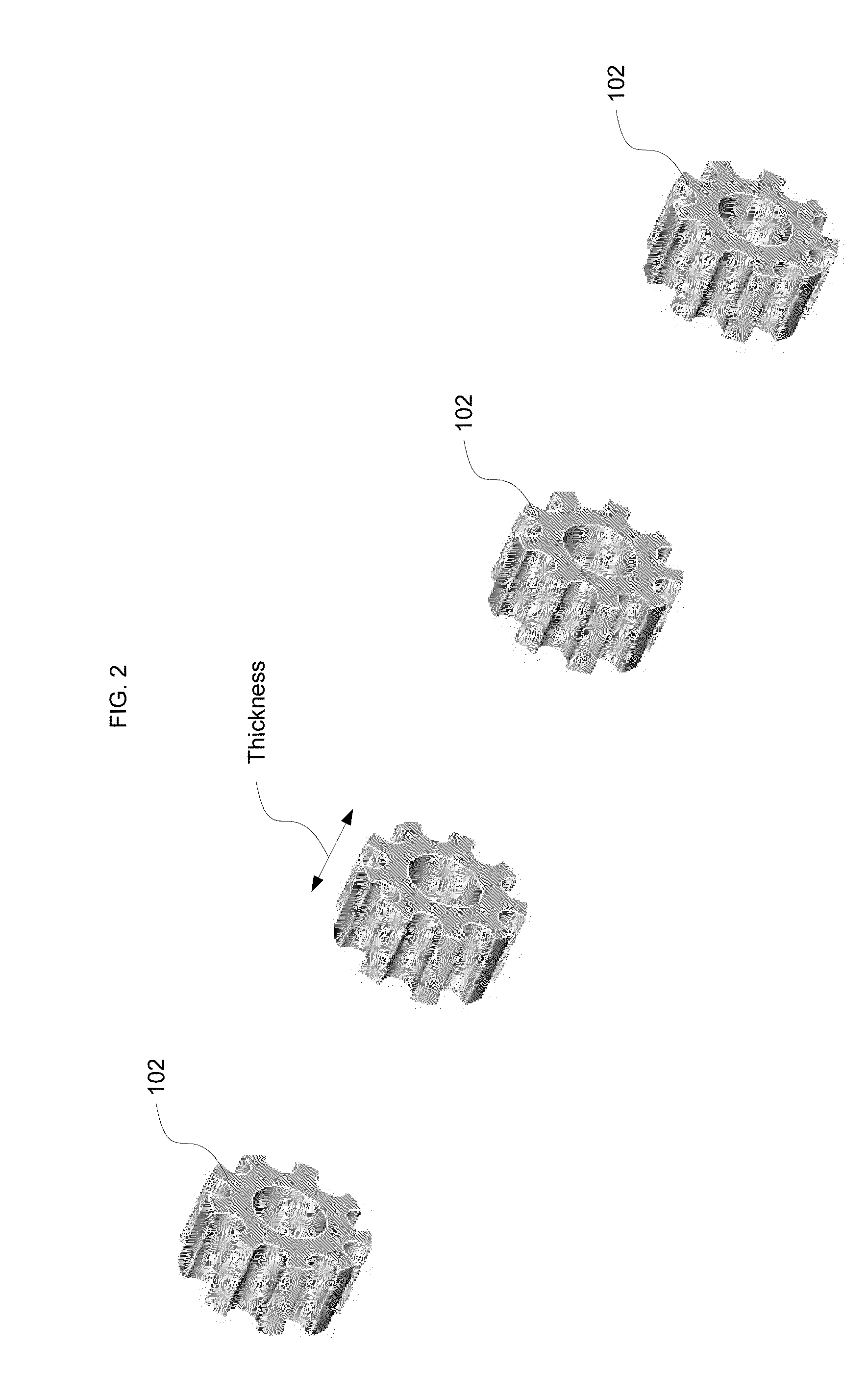

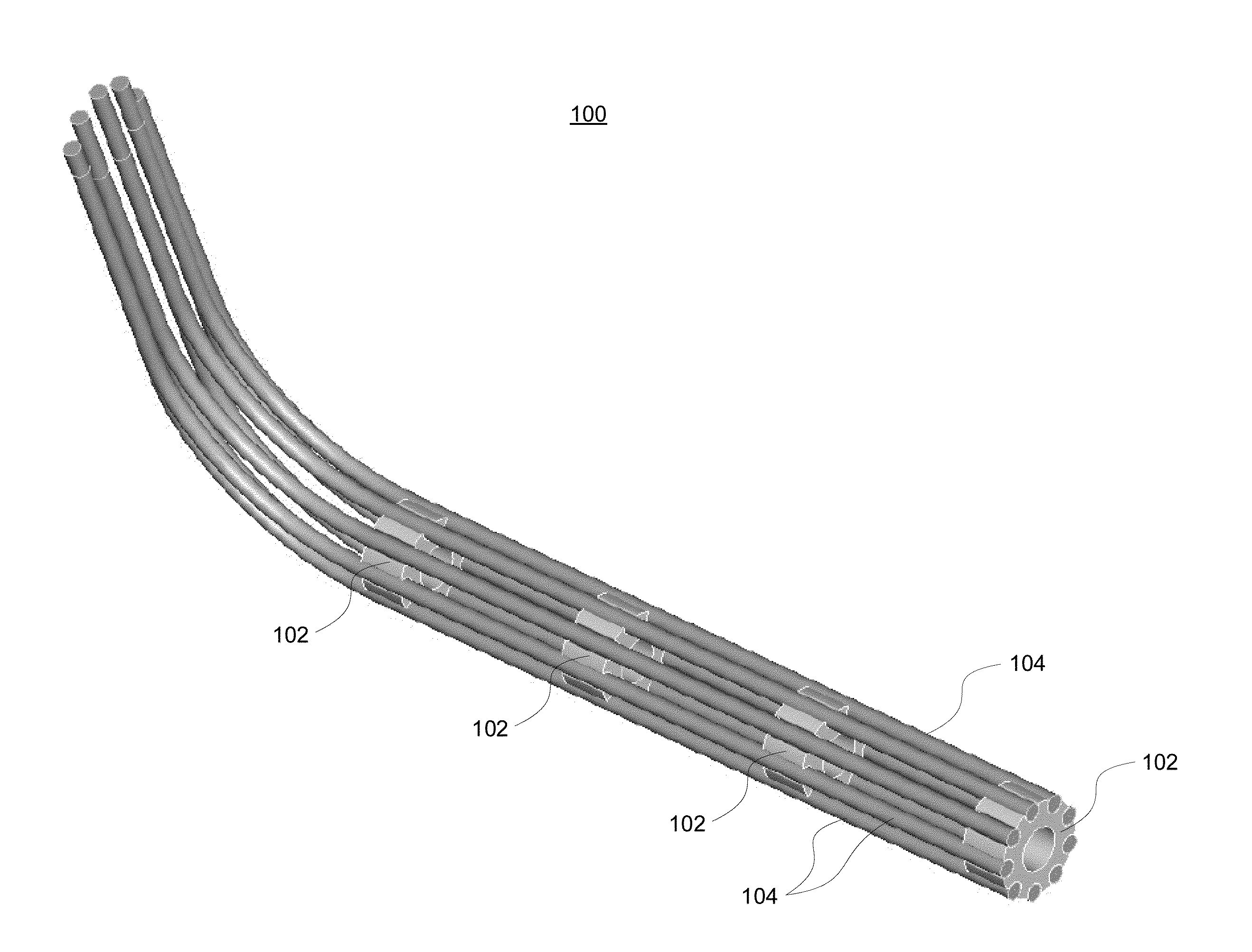

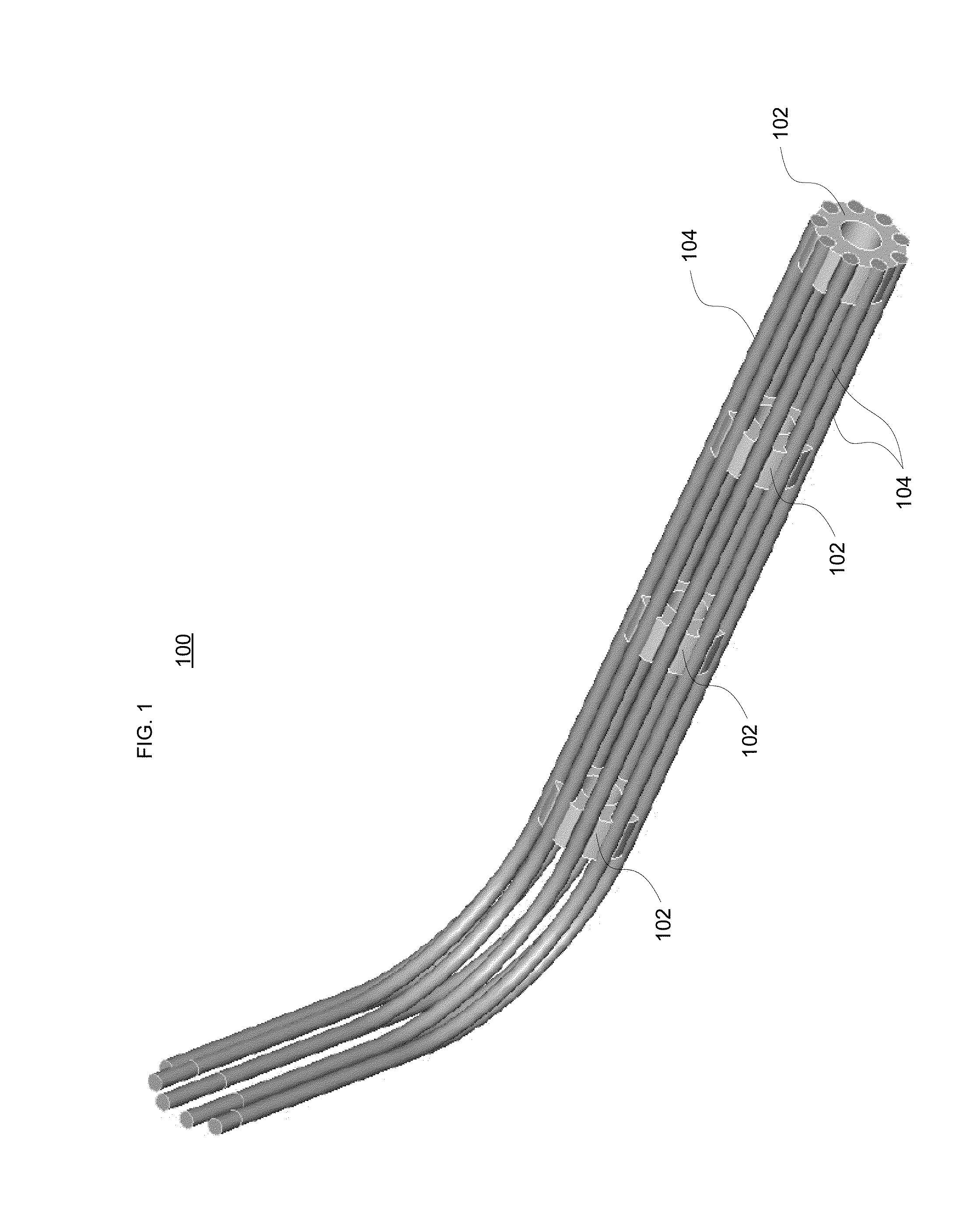

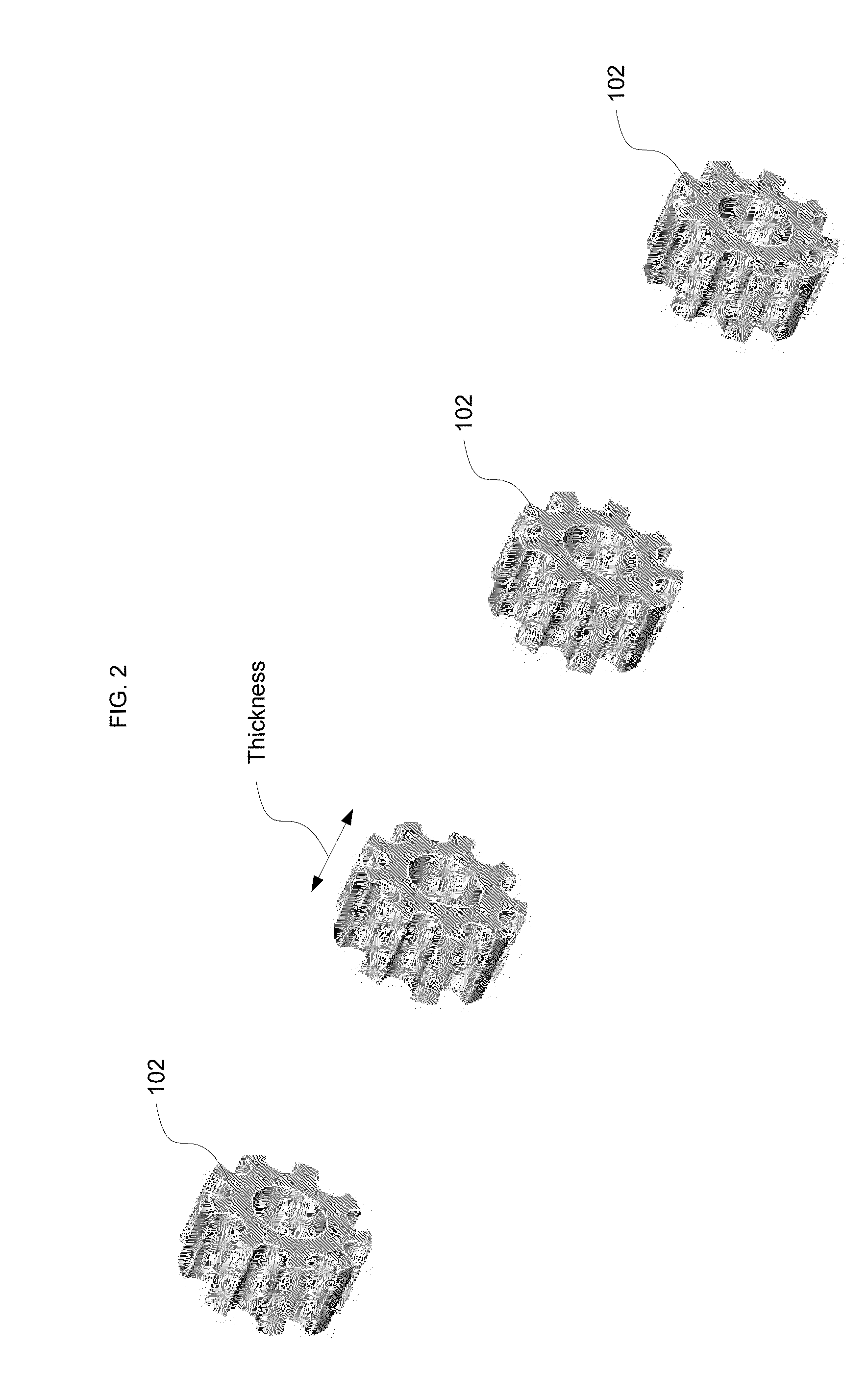

Cooling disc for bundles of current carrying cables

InactiveUS8344246B2Effective spaceImprove cooling effectCoaxial cables/analogue cablesInsulated cablesCurrent loadEngineering

Aspects of the invention pertain to cooling bundles of power distribution cables or other current carrying cables. Such cables give off heat, especially when carrying high current loads. One or more cooling members are used to secure multiple cables. The cables may be placed about a generally circular shaped member which has a central opening. Receptacles are placed along an outer perimeter of the cooling member to secure the cables. The thickness of each cooling member may vary. When multiple cooling members are used, they may be spaced at least 6 inches apart. The cooling members may be fabricated from a nonconductive material such as PVC.

Owner:GOOGLE LLC

Cooling disc for bundles of current carrying cables

InactiveUS20110240341A1Effective spaceImprove cooling effectInsulated cablesInsulated conductorsCurrent loadConductive materials

Aspects of the invention pertain to cooling bundles of power distribution cables or other current carrying cables. Such cables give off heat, especially when carrying high current loads. One or more cooling members are used to secure multiple cables. The cables may be placed about a generally circular shaped member which has a central opening. Receptacles are placed along an outer perimeter of the cooling member to secure the cables. The thickness of each cooling member may vary. When multiple cooling members are used, they may be spaced at least 6 inches apart. The cooling members may be fabricated from a nonconductive material such as PVC.

Owner:GOOGLE LLC

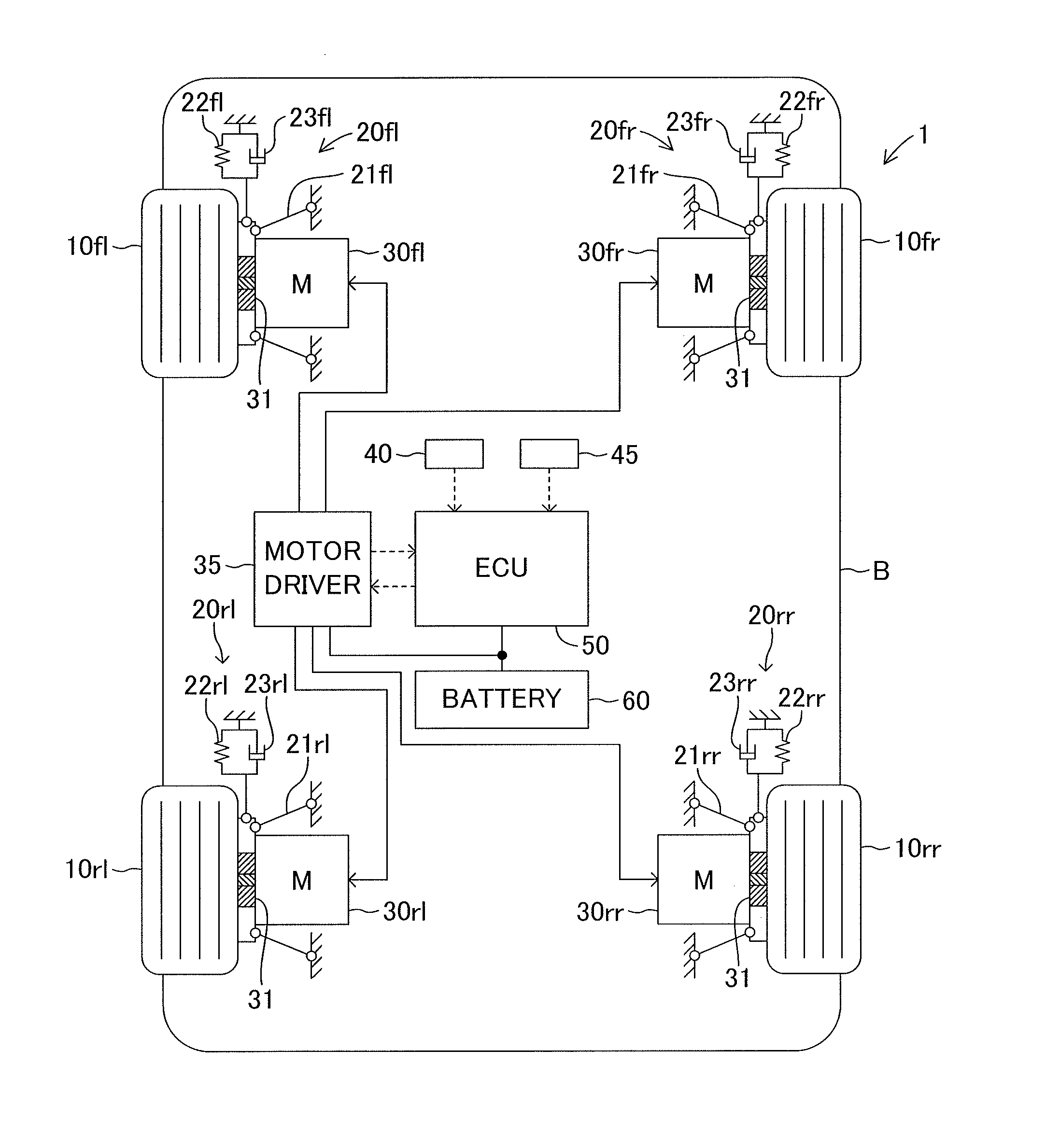

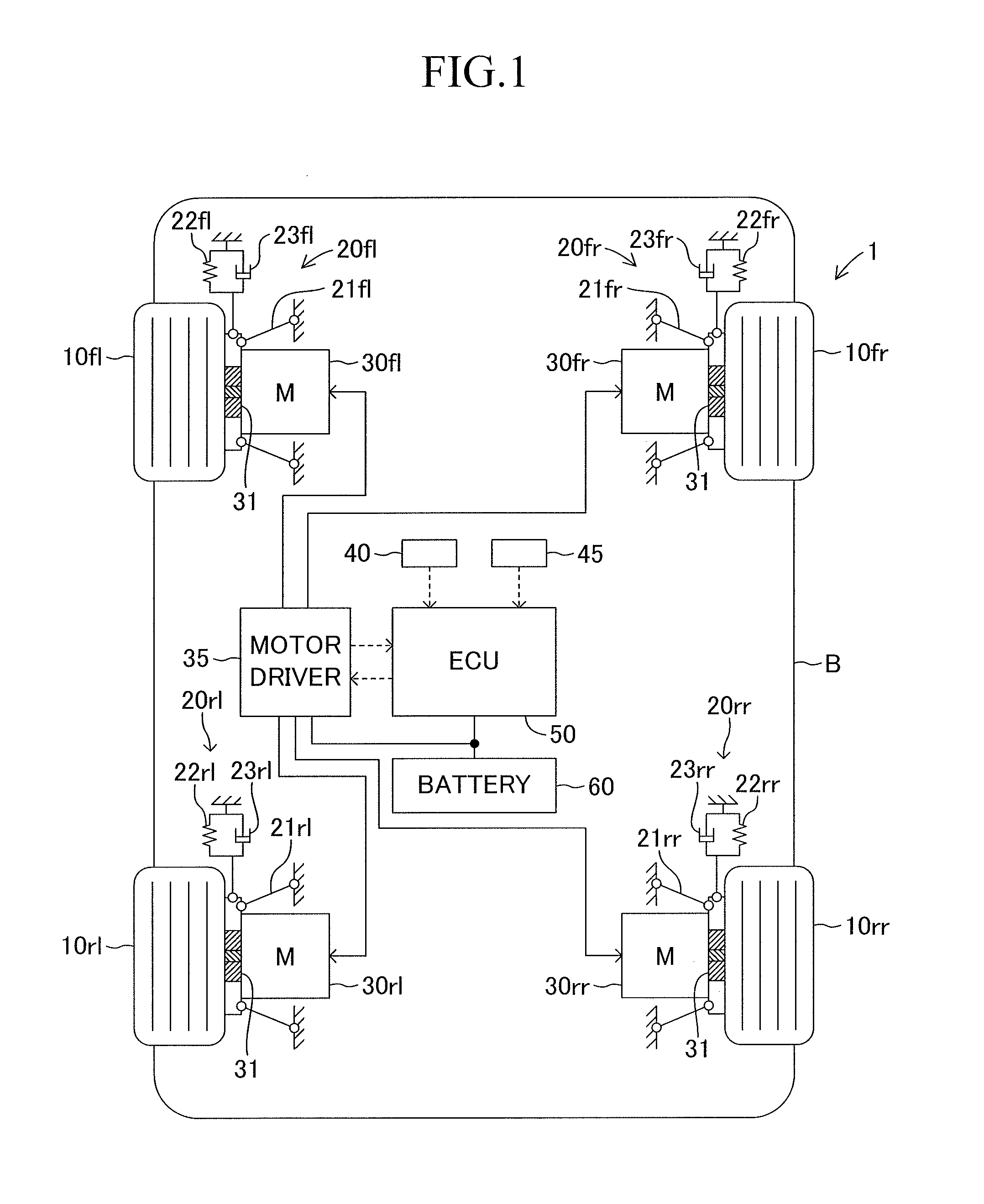

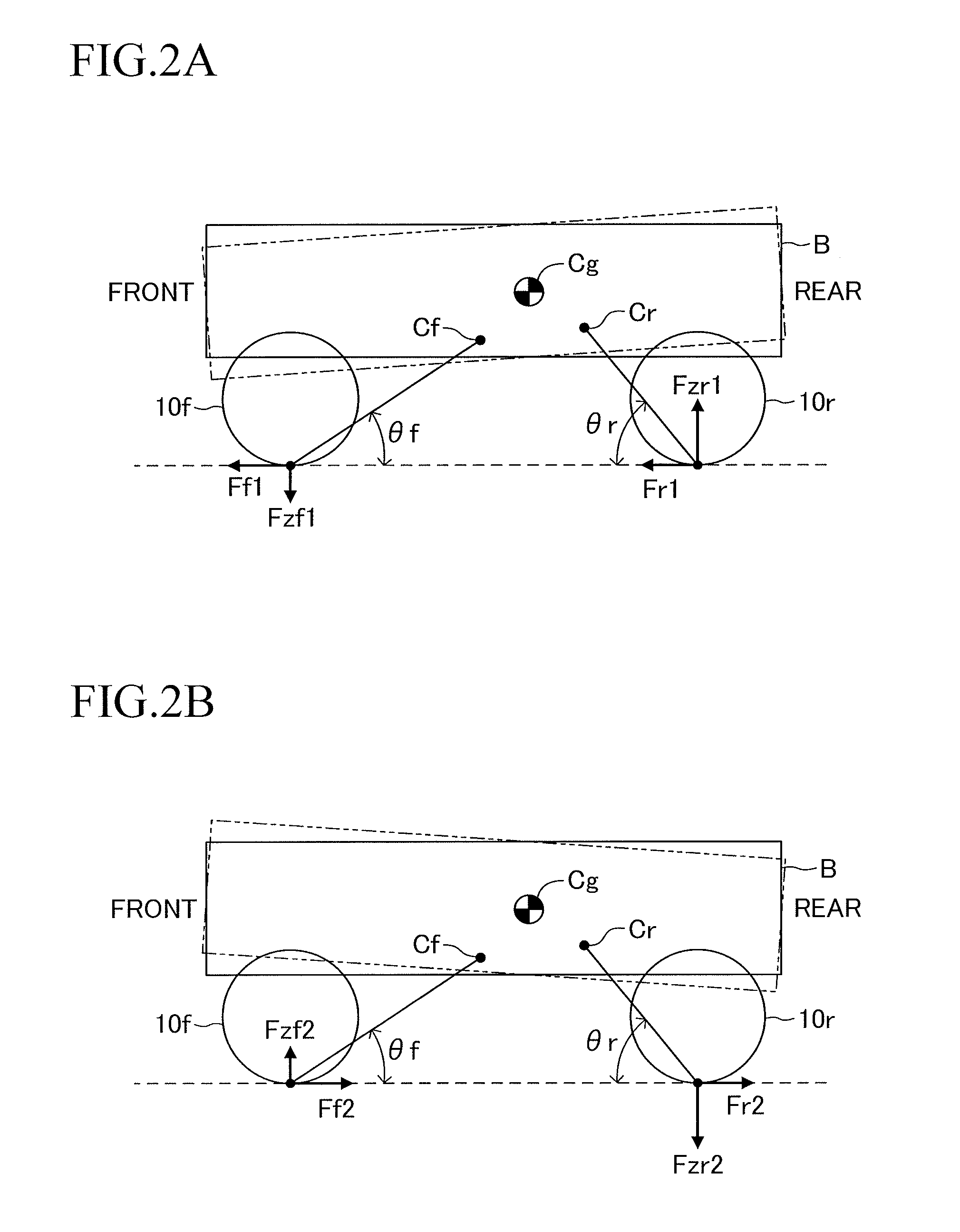

Vehicle braking/driving force control apparatus

ActiveUS20150158493A1Avoid noiseLarge distributionHybrid vehiclesDigital data processing detailsMovement controlSpeed reduction

When a braking / driving force on each wheel is used for vehicle motion control, in order to reduce a noise generated by a zero cross of a motor torque, provided is a distribution setting part, which is to be applied to a vehicle configured so that a conversion rate of converting a braking / driving force on the wheel into a force in a vertical direction of a body by a suspension is different between a front wheel side and a rear wheel side. The distribution setting part sets distributions of a driver-requested driving force to front / rear wheels so as to be larger to the wheels coupled to the suspensions smaller in conversion rate than to the wheels coupled to the suspensions larger in conversion rate. As a result, a zero cross of a motor torque is restrained, resulting in a reduction in generation of a noise caused by a backlash of speed reduction gears.

Owner:TOYOTA JIDOSHA KK

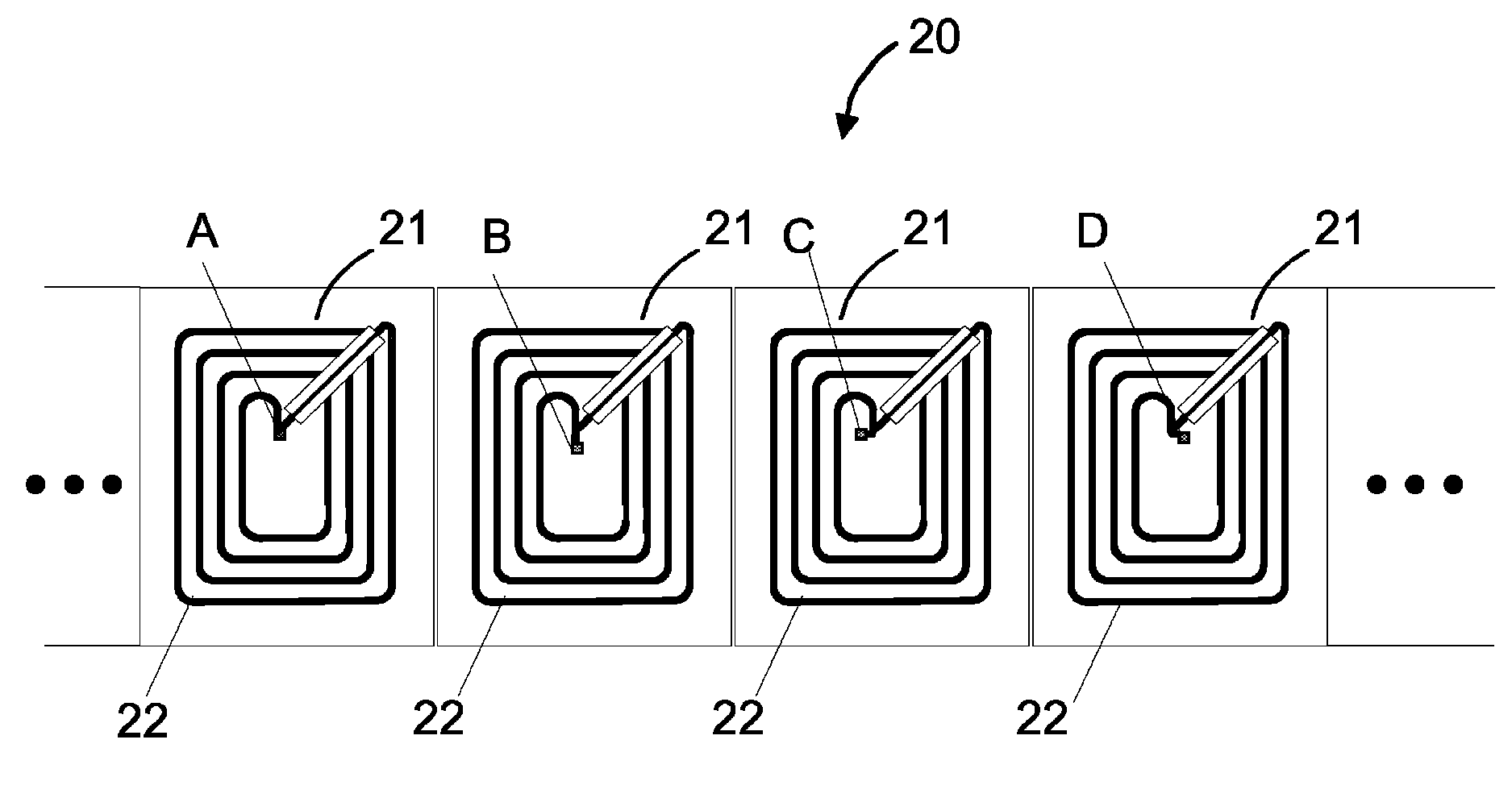

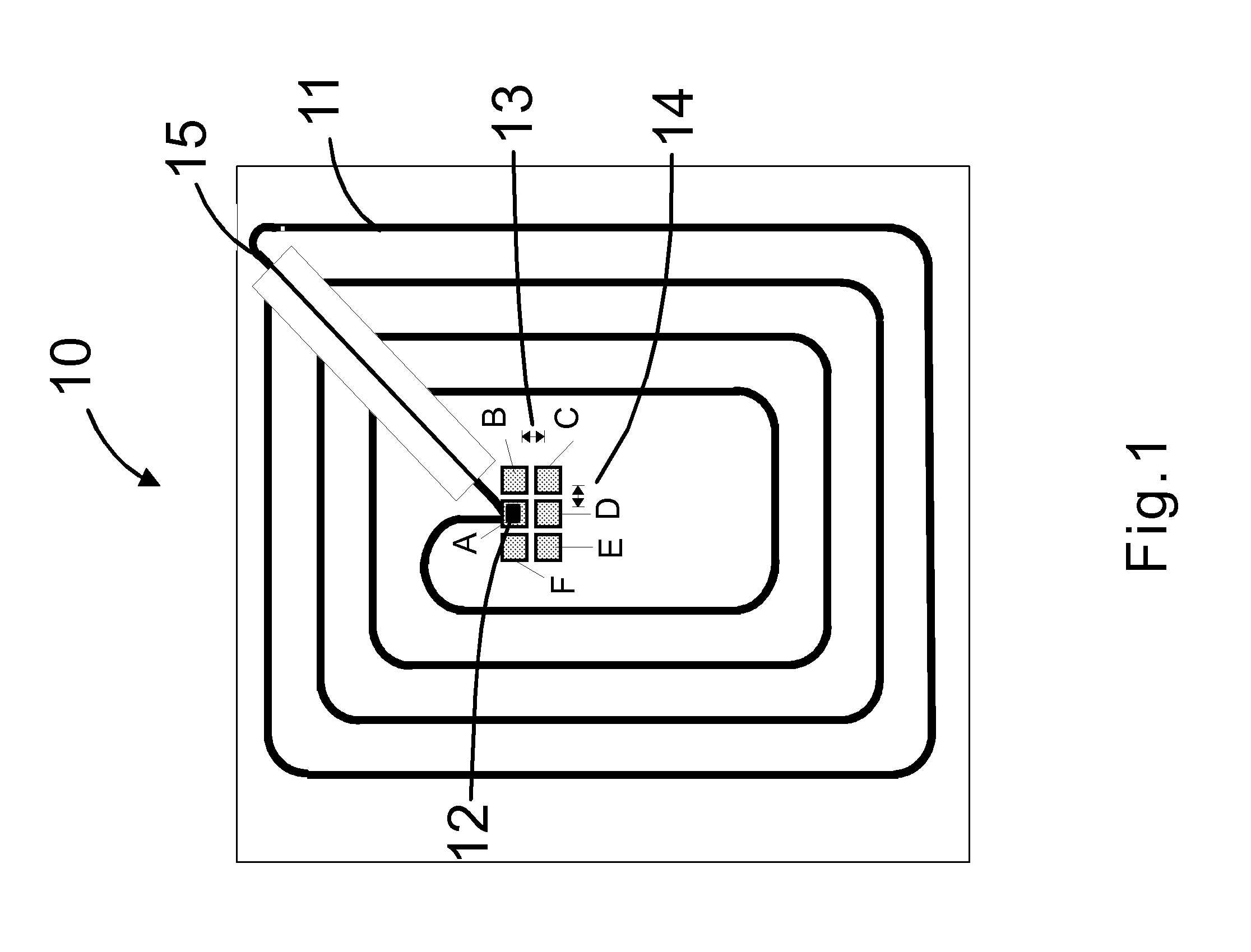

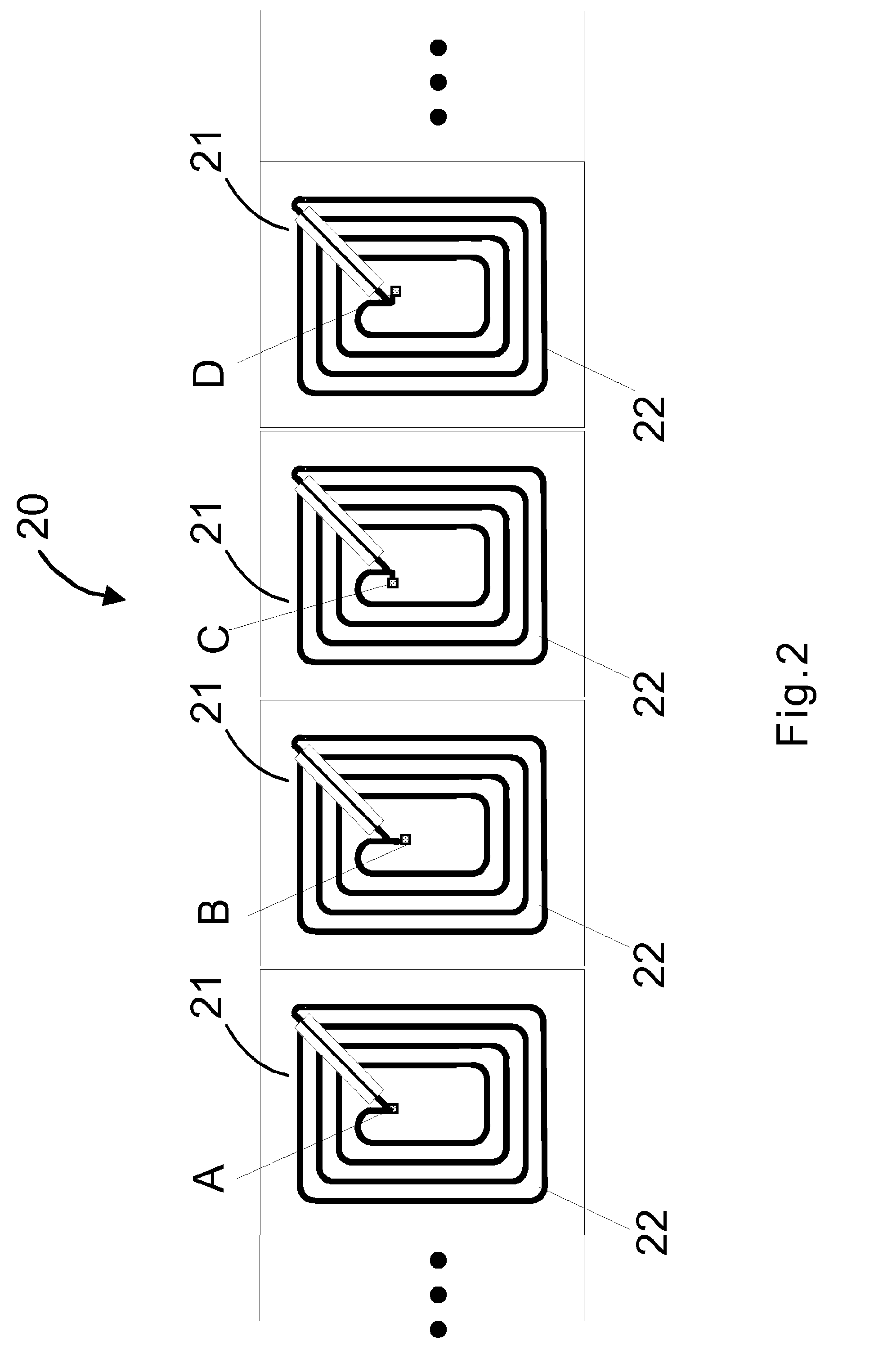

Method for producing a rollable web and a rollable web

InactiveUS8467192B2Eliminate the effects ofReduce stressSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic chip

A method for producing a rollable web with successive antennas, where an electronic chip is attached to an antenna in a predetermined position. The position of an electronic chip changes with respect to the antenna when compared to at least some of the chips within individual and successive antennas. A rollable web includes successive antennas, where electronic chips are attached to antennas in a predetermined position. In the rollable web, the position of a chip changes with respect to the antenna compared to at least some of the chips within individual and successive antennas.

Owner:SMARTRAC INVESTMENT BV

System And Method For Concurrently Downloading Digital Content And Recording To Removable Media

InactiveUS20100106805A1Quicker and convenient experienceLarge distributionTelevision system detailsIndoor gamesDigital contentThe Internet

A method, system and program product to simultaneously download and burn digital media files via the Internet, including audio, video, video games and other digital content and data, onto removable storage media on personal computer burners. Large media files can be downloaded by pushing files or portions of files to computer memory and simultaneously downloading and burning files selected by a user. Once a file is burned to disc, it is then deleted from the computer's memory. A lossless compression scheme is used for audio files to decrease file size, making the downloading process faster and requiring less hard drive space. Content files other than audio are downloaded and burned through the same one-step process, without using a lossless compression scheme. An alternative method delays the start of the burn process to ensure that the downloaded files are written continuously to the removable storage media.

Owner:SANDS IV ALEXANDER P +1

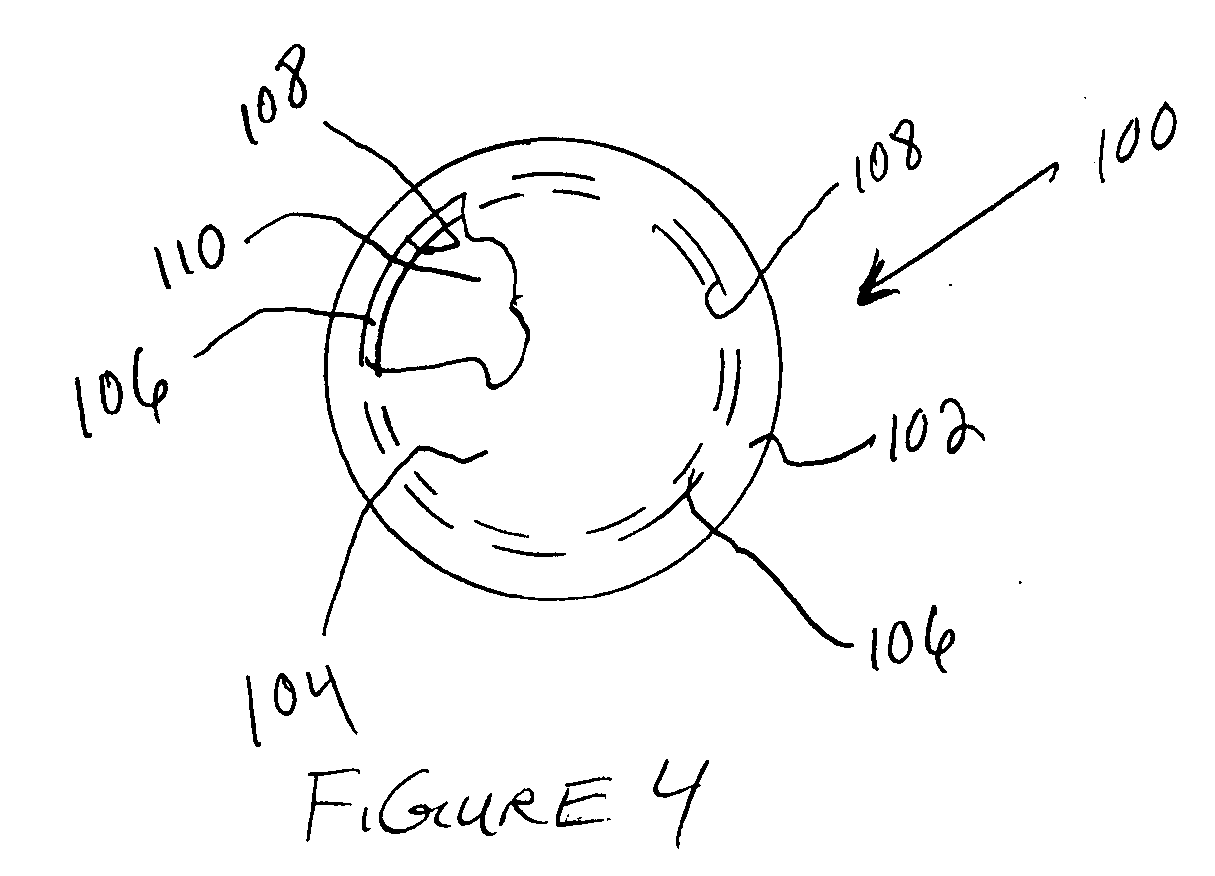

Bioluminescent paintball

InactiveUS7905181B2Inhibit productionLarge distributionAmmunition projectilesTraining ammunitionEngineeringLight emission

A Bioluminescent Paintball 10 includes a shell 12 defining an interior cavity 14, a liquefied substance 16 disposed within the interior cavity 14, a phosphorescent material 18 disbursed throughout the shell 12 for providing a visible “tracing” effect when the bioluminescent paintball 10 is ejected from a paintball discharge device, a neutralizing agent 20 disbursed throughout the liquefied substance 16 for neutralizing calcium disbursed throughout the liquefied substance 16 thereby preventing light emission before the paintball 10 impacts a target, and a photoprotein 22 disbursed throughout the liquefied substance 16 for reacting with calcium disposed upon a target after the bioluminescent paintball 10 impacts the target, thereby rupturing the shell 12 and allowing the liquefied substance 16 to engage the calcium to produce visible light.A paintball 100 includes a shell 102 defining an interior cavity 104, an insoluble coating 106 disposed upon an inner surface 108 of the shell 102, and an aqueous material 110 disposed within the cavity 104 such that the aqueous material 110 engages the insoluble coating 106, thereby preventing the aqueous material 110 from dissolving the shell 102, and promoting the marking of a target via the aqueous material 110 when the paintball 100 forcibly engages the target and ruptures the shell 102.

Owner:HYDRO CAPS

Methods and systems for a single jurisdiction raffle in a distributed computing network

ActiveUS7419426B2Large distributionIncrease demandBoard gamesApparatus for meter-controlled dispensingWeb siteOperational system

Owner:MCD ENTERPRISES

Fluffy and soft skin-friendly medical non-woven fabric and preparation method thereof

InactiveCN111321521ALarge distributionImprove bulkFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention discloses a fluffy and soft skin-friendly medical non-woven fabric and a preparation method thereof. PP and PE are used as spinning raw materials and an elastic copolymer is mixed in theraw materials. The preparation method specifically comprises the following steps that two-component spunbond equipment is adopted for production, and fiber-grade spinning PP slices and spinning PE slices are taken as the spinning raw materials, wherein the PP is taken as a core layer and the PE is taken as a skin layer, the elastic copolymer is uniformly mixed, the PE layer with a lower melting point is melted to generate bonding in a hot rolled reinforcement process, and a melt passing through a spinning box body is distributed to form a double-component filament of a skin-core structure, and is cooled and stretched to form a net on a receiving device; the generated net is subjected to a hot rolling process, a specially designed hot roller is adopted, so that the PE on the surface layerof the net is melted, a bonding point is formed between fibers on the net, and then the net is consolidated to form the non-woven fabric; and the prepared non-woven fabric is subjected to a solvent after-finishing process, and the non-woven fabric is subjected to single-sided coating by adopting an antistatic agent.

Owner:浙江冠诚科技有限公司

Degradable polymers of a cyclic silyl ether and uses thereof

ActiveUS10988491B2Promote degradationImprove applicabilitySilicon organic compoundsPharmaceutical non-active ingredientsPolymer sciencePolymer

Owner:MASSACHUSETTS INST OF TECH

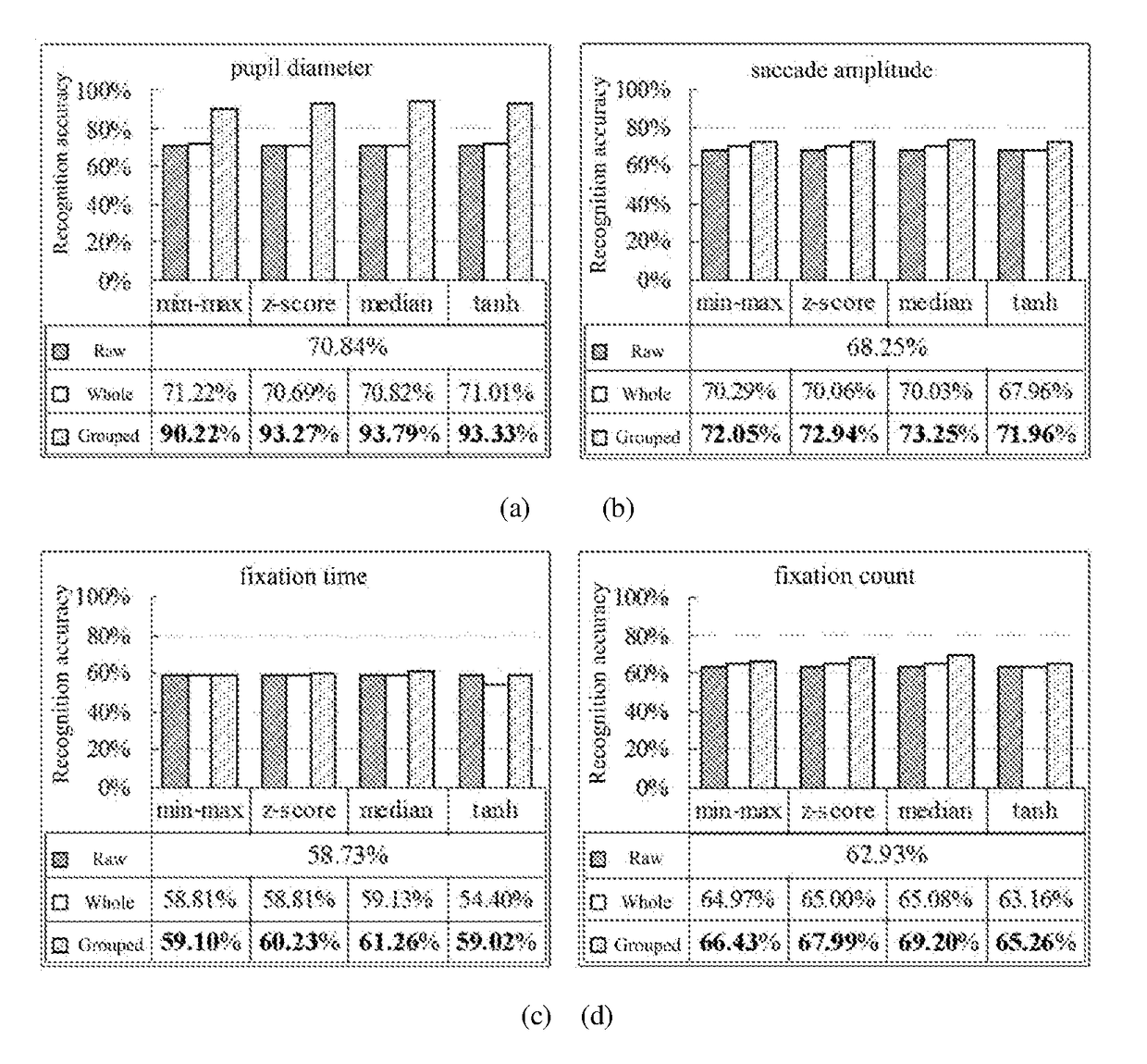

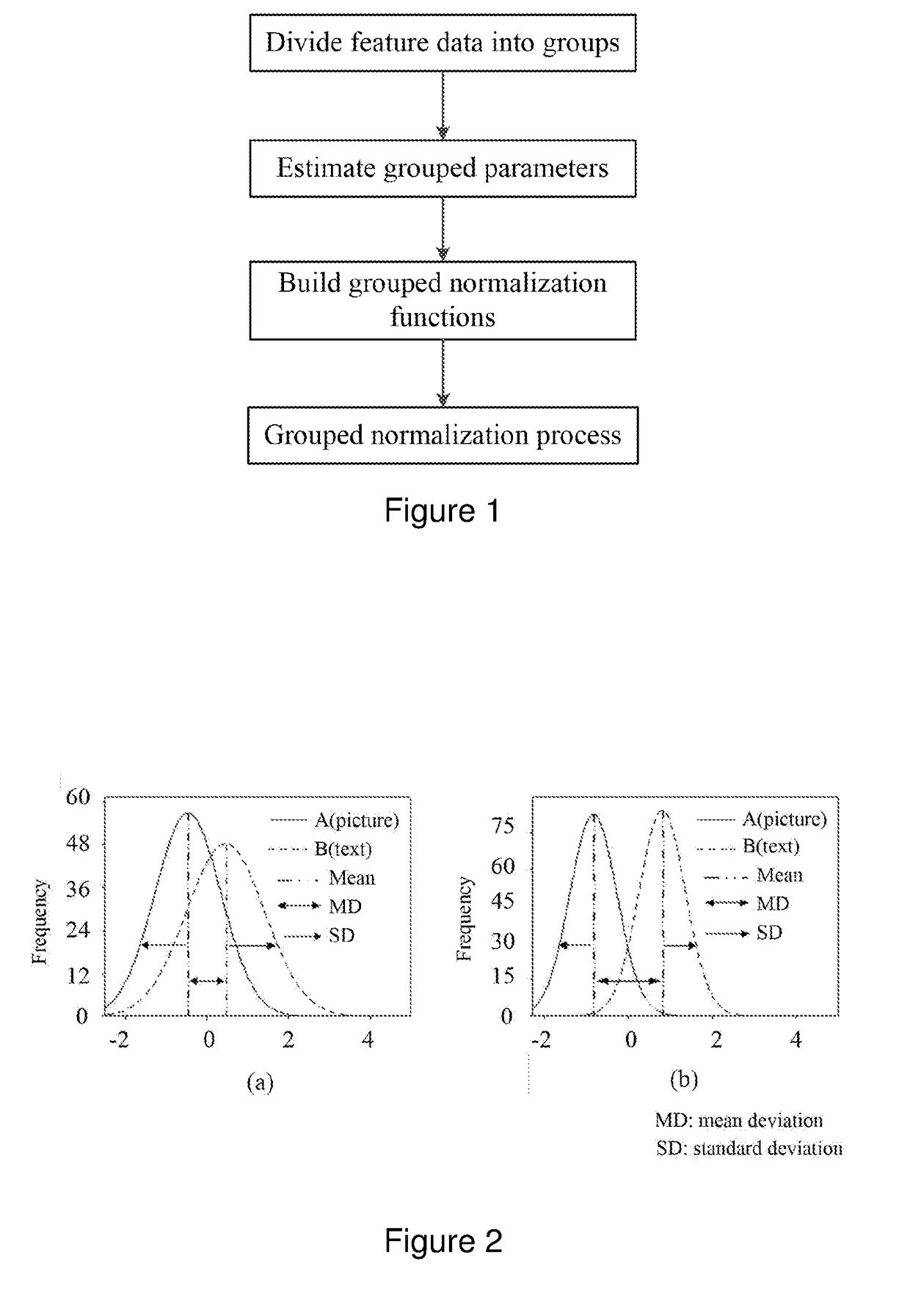

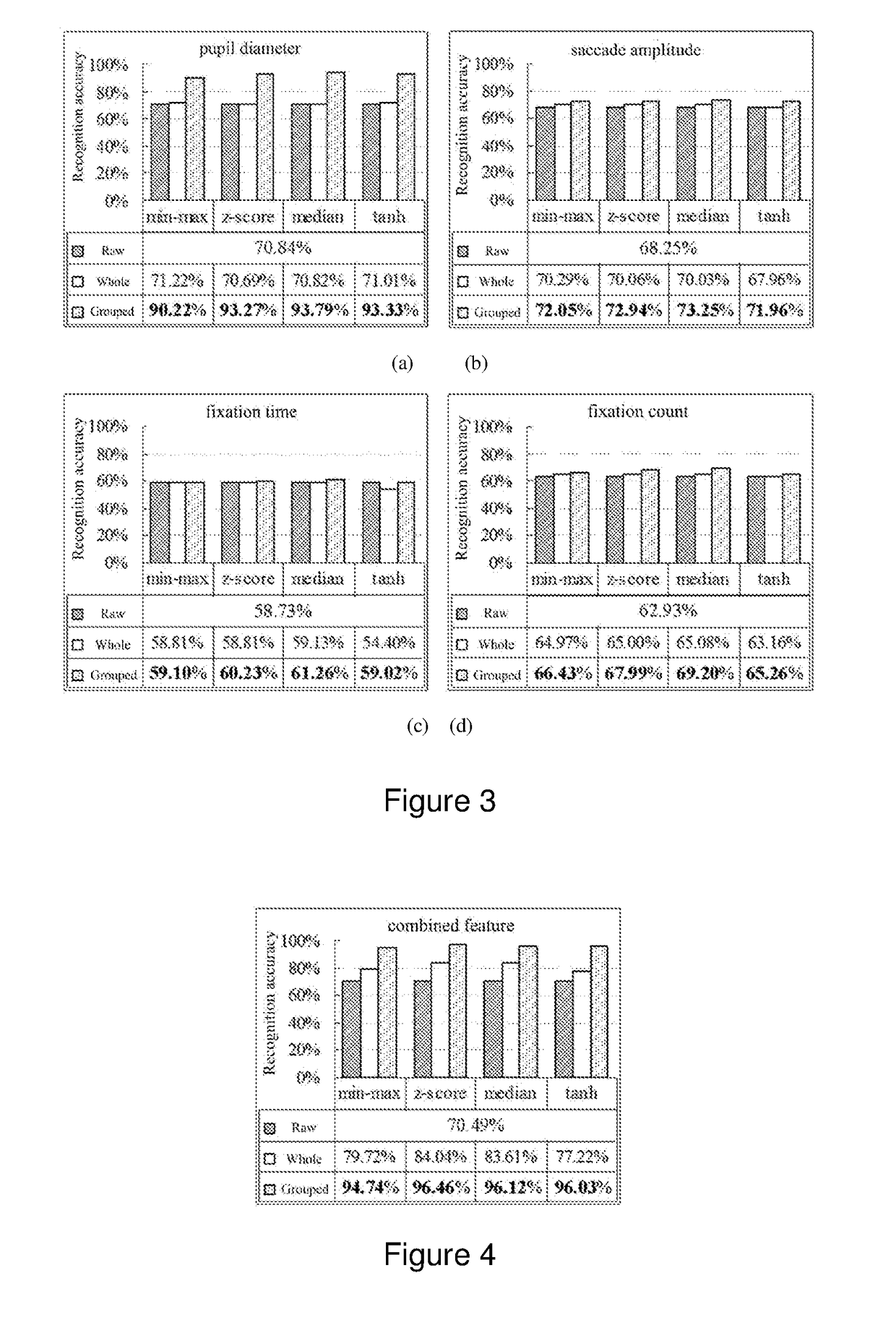

Feature grouping normalization method for cognitive state recognition

InactiveUS20170220905A1Improve cognitive accuracySolve the real problemAcquiring/recognising eyesDiagnostic recording/measuringCognitive statusFeature data

A normalization method in grouped feature data for recognizing human cognitive states, comprising: (1) divide feature data into groups; (2) selecting normalization functions and estimating grouping parameters; (3) building grouped normalization functions, substitute normalization function parameters of each group into its normalization function, the normalization mapping relationship of each group is get; (4) grouped normalization processing, each group uses corresponding normalization function to transfer the feature data to finish feature normalization. The entire feature normalization method can only solve the divers data distribution problem between feature and feature, it can not solve the problem of the large difference of inner data distribution, the grouped normalization methods provided in the invention reserve the advantages of entire feature normalization method, while at the same time, the large inner distribution of feature data is reduced, the accuracy of classification is improved, the grouped normalization method in the invention have strong robustness.

Owner:BEIJING UNIV OF TECH

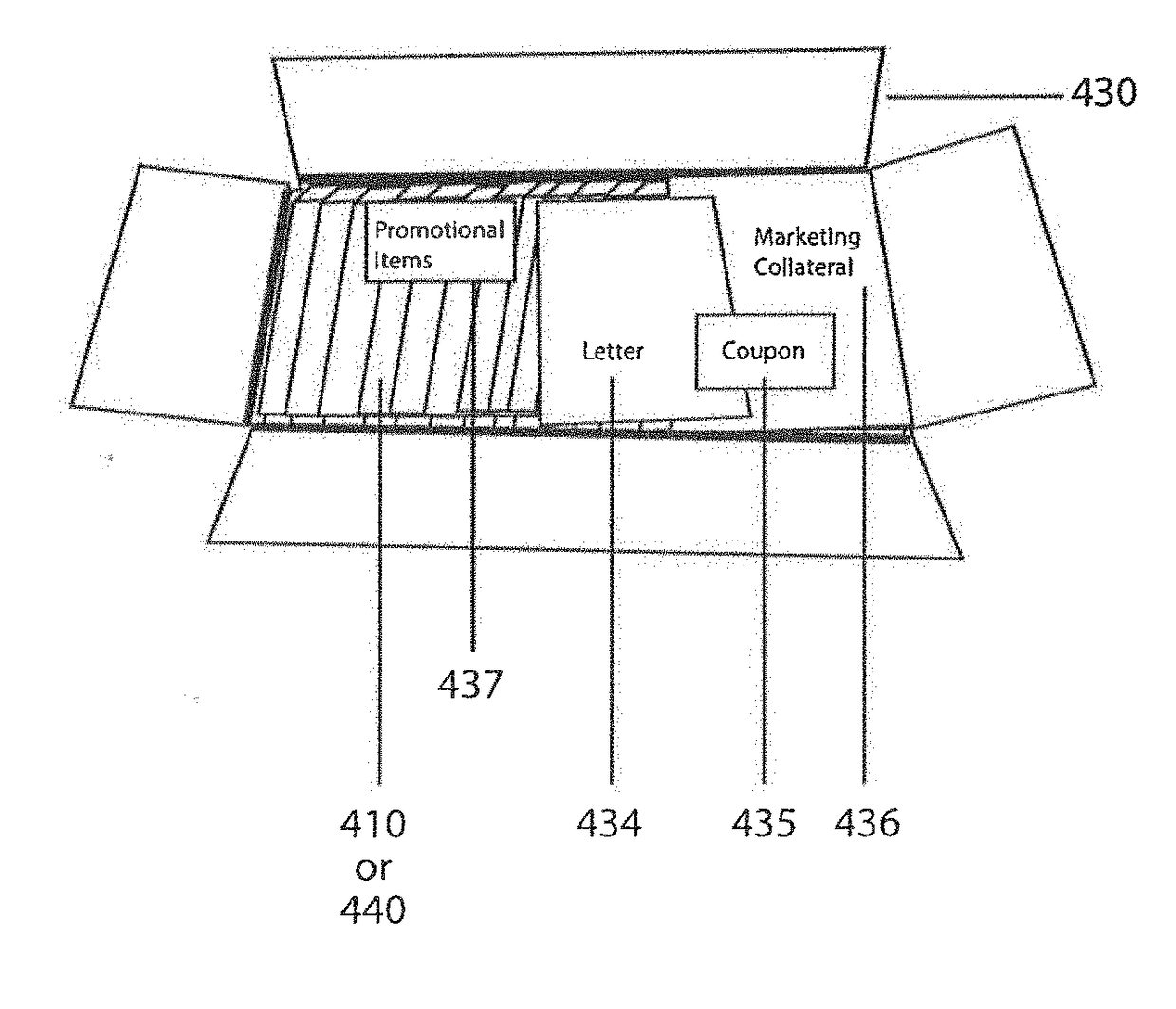

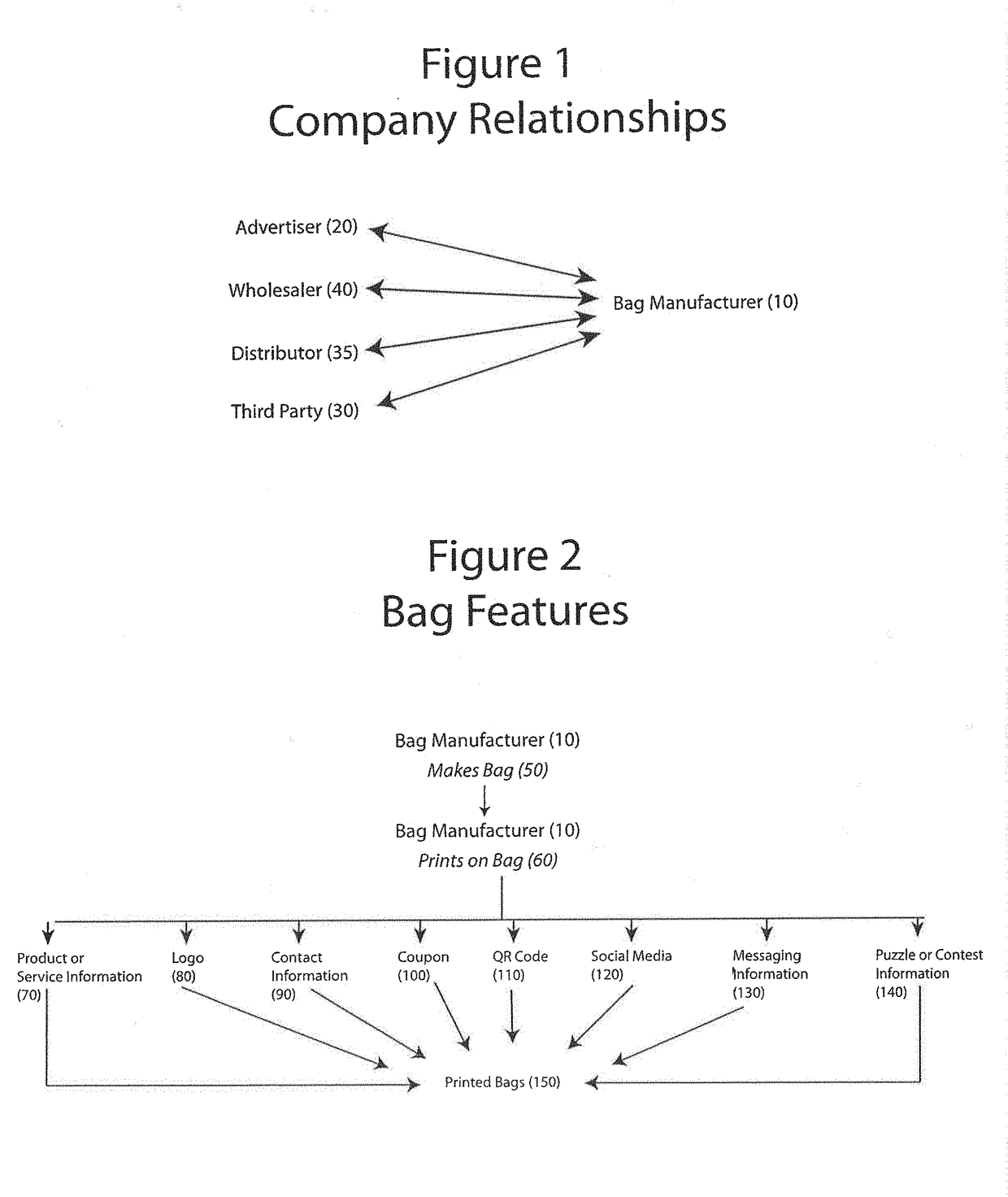

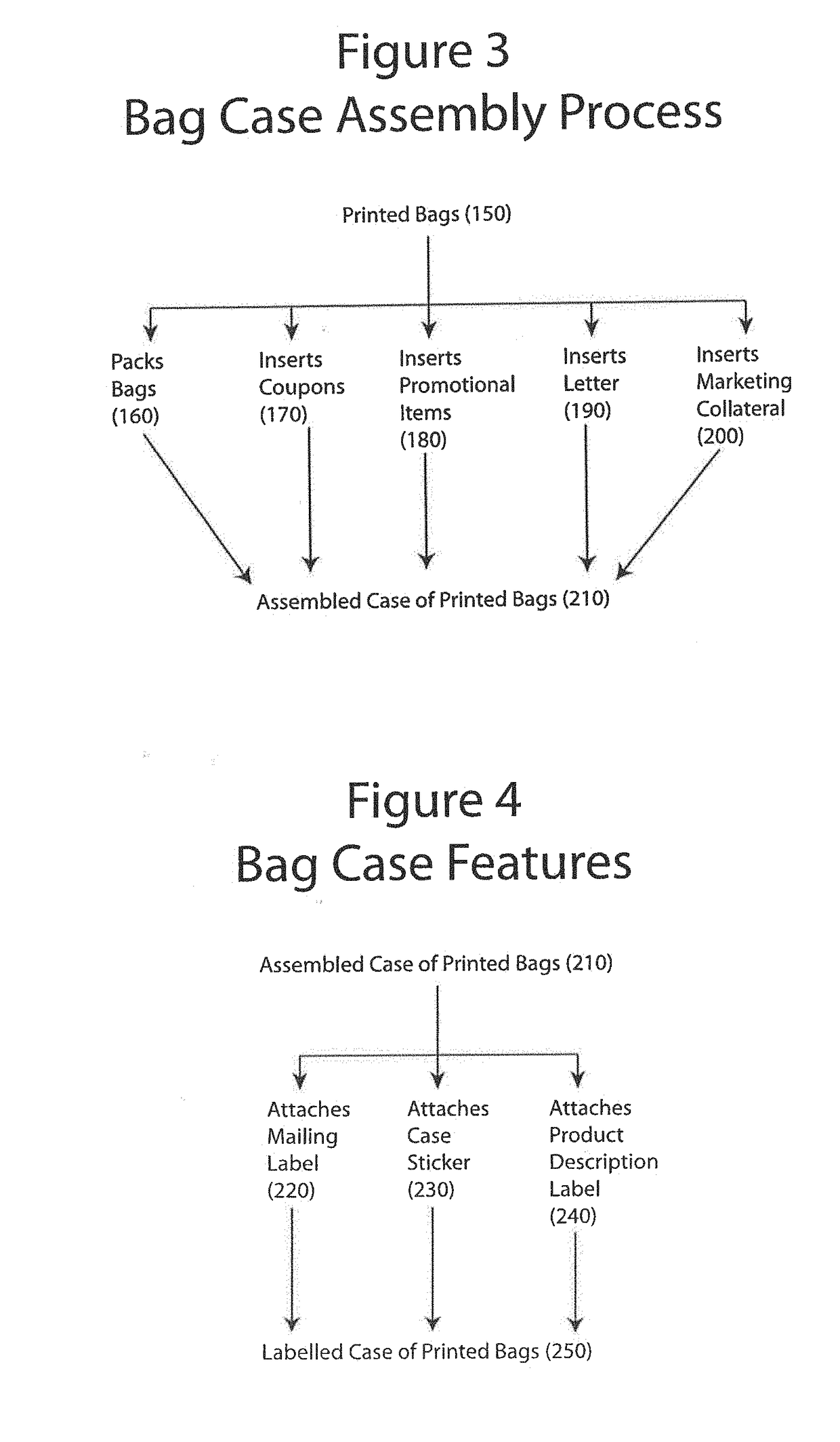

System and method for distributing bags and other packaging and analyzing sales of items promoted on these items

PendingUS20180130163A1Specifically measuring coupon redemptionLarge distributionStampsRecord carriers used with machinesEngineeringPackaging and labeling

A system and method for providing information in and on packaging or packing supplies and for distributing said packaging or packing supplies and for tracking the sales movement of products or services promoted on the packaging or packing supplies.

Owner:BROADWAY HLDG IX LLC

Vehicle braking/driving force control apparatus

ActiveUS9227637B2Avoid noiseLarge distributionHybrid vehiclesRoad vehicle drive control systemsEngineeringMotor torque

When a braking / driving force on each wheel is used for vehicle motion control, in order to reduce a noise generated by a zero cross of a motor torque, provided is a distribution setting part, which is to be applied to a vehicle configured so that a conversion rate of converting a braking / driving force on the wheel into a force in a vertical direction of a body by a suspension is different between a front wheel side and a rear wheel side. The distribution setting part sets distributions of a driver-requested driving force to front / rear wheels so as to be larger to the wheels coupled to the suspensions smaller in conversion rate than to the wheels coupled to the suspensions larger in conversion rate. As a result, a zero cross of a motor torque is restrained, resulting in a reduction in generation of a noise caused by a backlash of speed reduction gears.

Owner:TOYOTA JIDOSHA KK

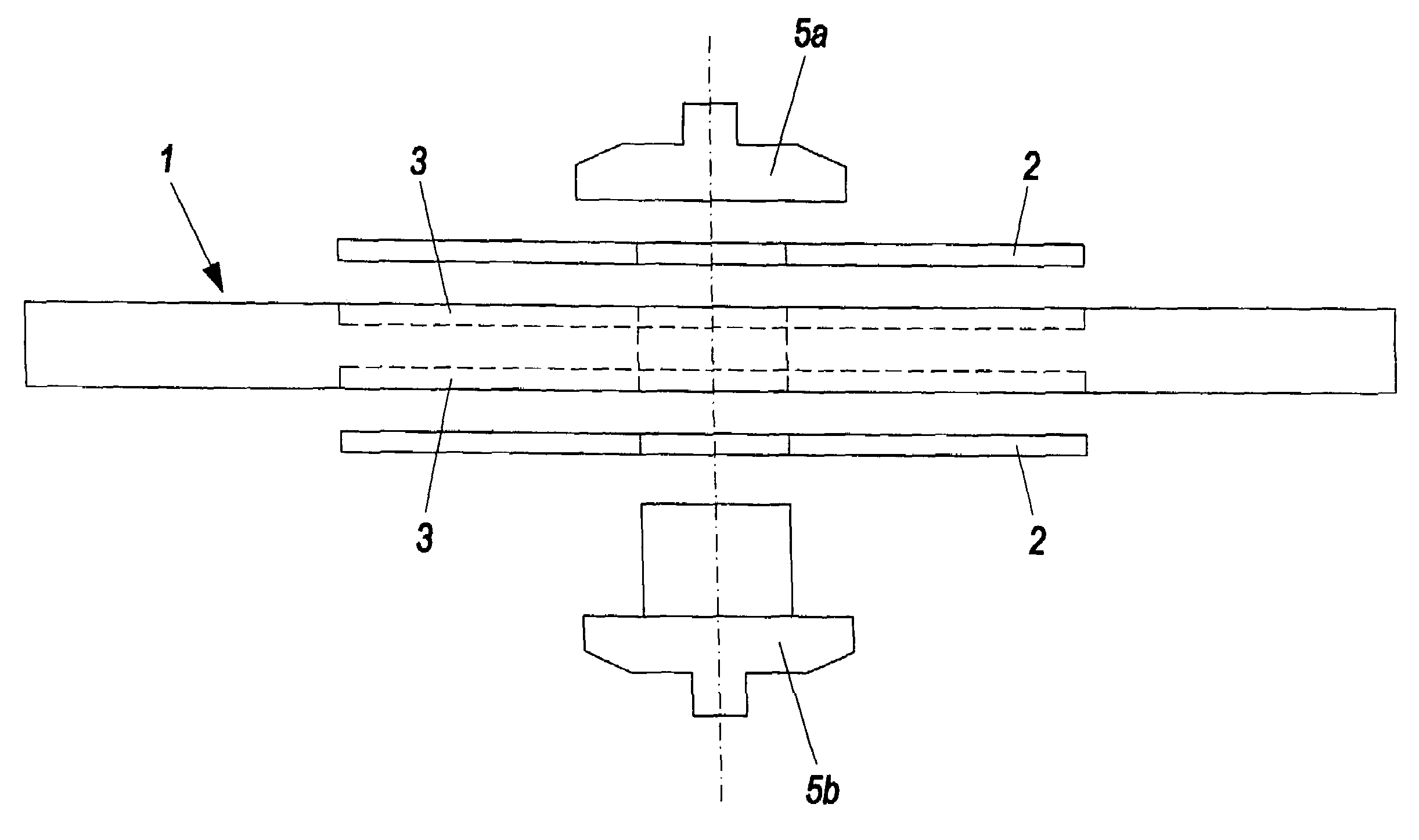

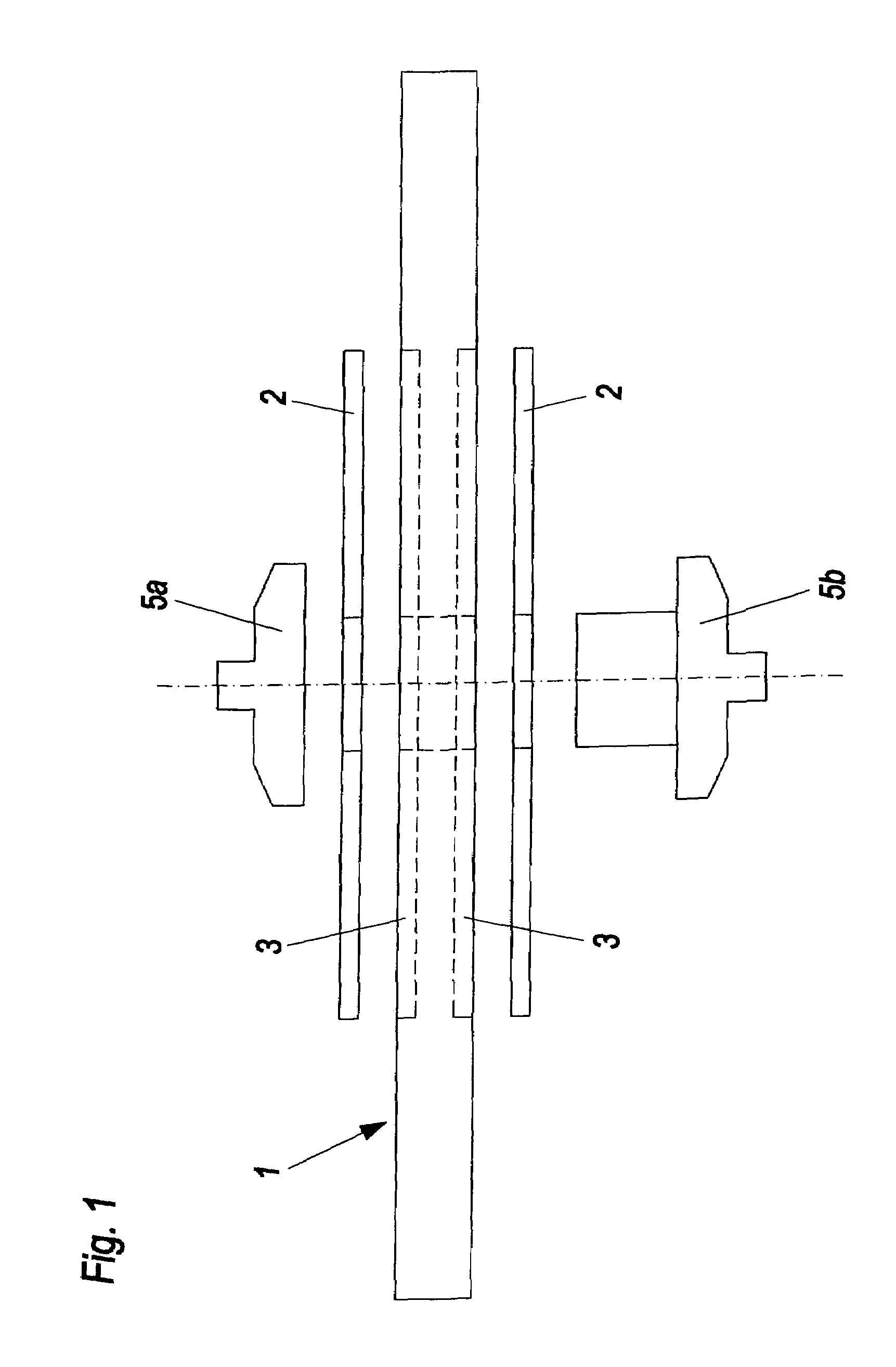

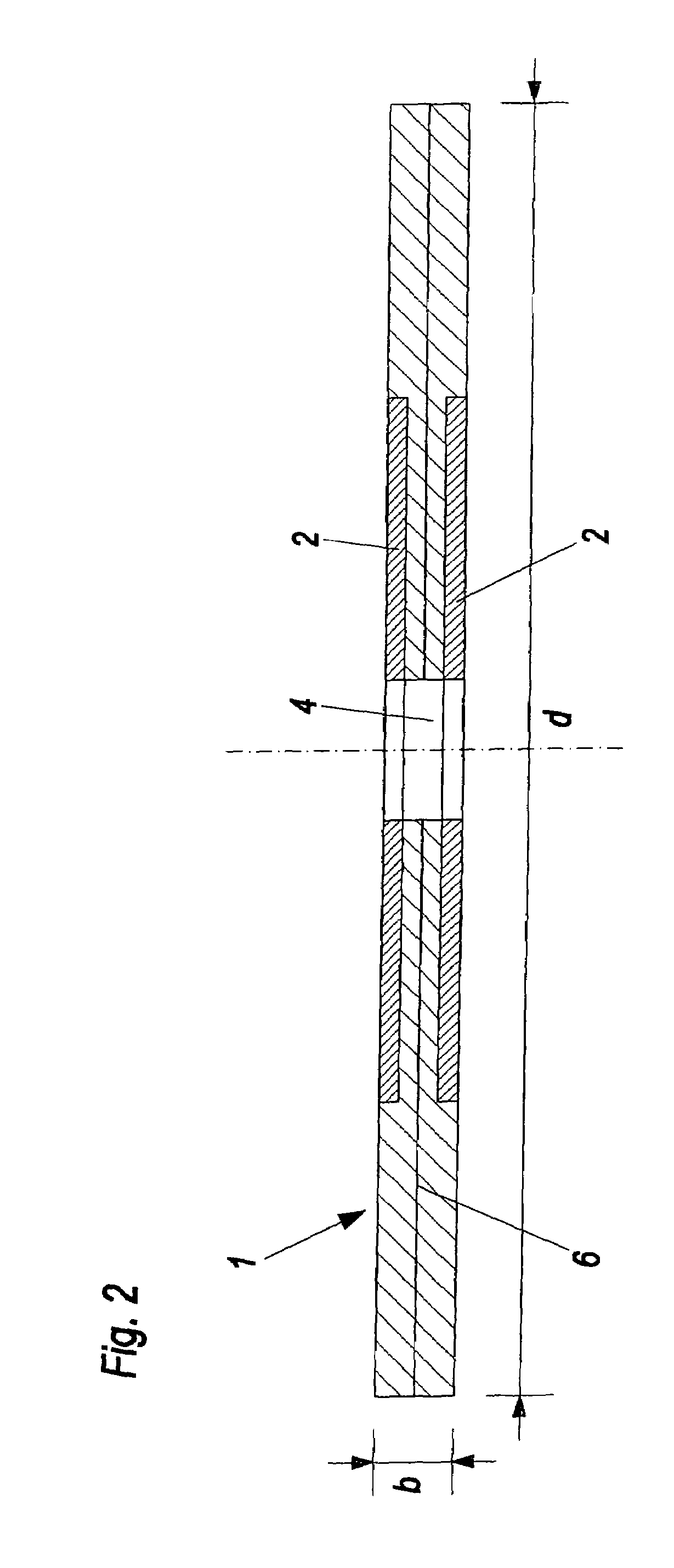

Metal cylinder head gasket without a spacing layer

InactiveUS8382123B2Improve rigidityLarge distributionEngine sealsSealing arrangements for enginesEngineeringMetal cylinder

The invention relates to a metal cylinder head gasket provided with at least one opening corresponding to a combustion chamber of an internal combustion engine, comprising a function layer and an annular support arranged thereon. The functional layer comprises one full bead. The cylinder head gasket is characterized in that the annular support comprises one full bead which is defined on the functional layer, and the annular support comprises one bead which is arranged on the side of the full bead which is oriented away from the combustion chamber The invention also relates to a metal cylinder head gasket provided with at least one opening corresponding to a combustion chamber of an internal combustion engine, comprising an upper functional layer, an annular support and a lower functional layer. The annular support is arranged between the upper functional layer and the lower functional layer and is adjacent to the lower functional layer. The upper functional layer comprises one full bead which is adjacent to the annular support. The cylinder head gasket is characterized in that the lower functional layer comprises one bead which is arranged on the side of the full bead which is oriented away from the combustion chamber.

Owner:FEDERAL MOGUL SEALING SYST

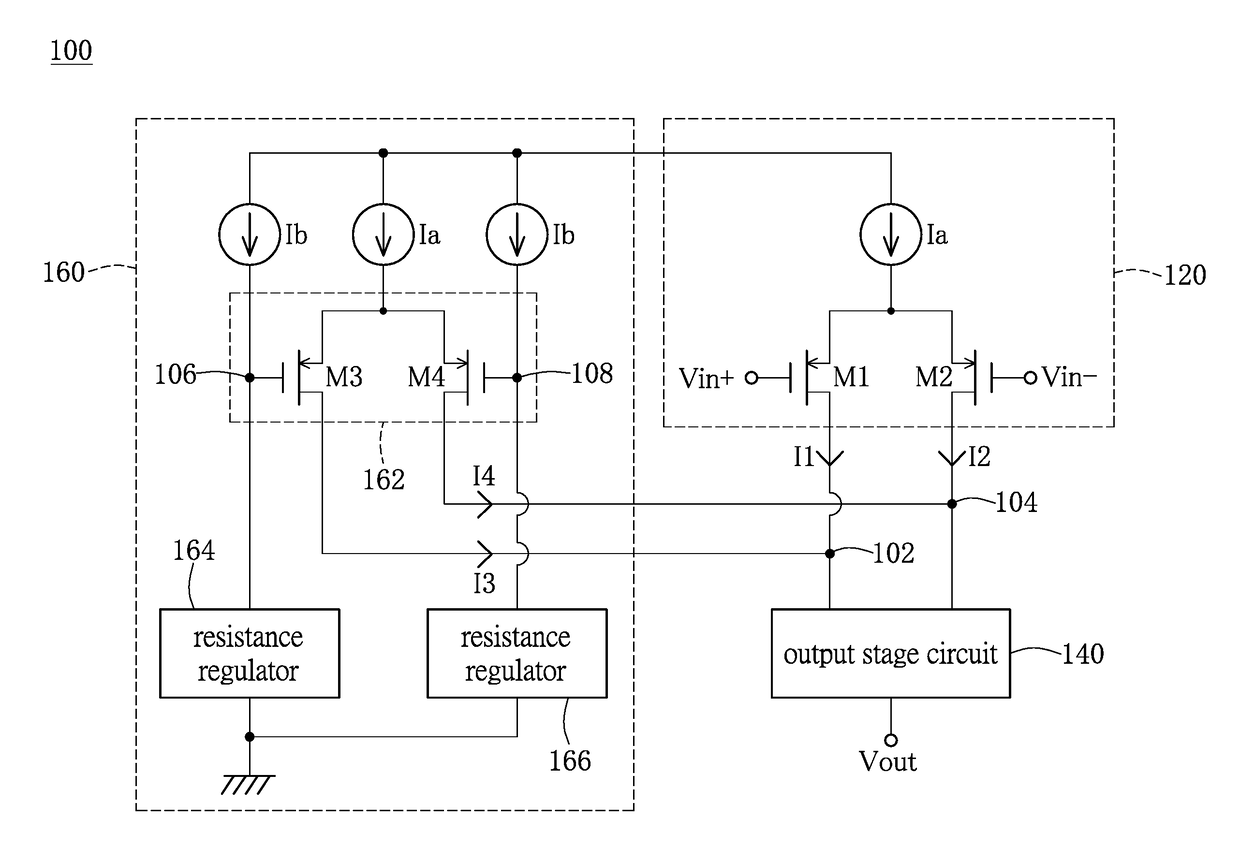

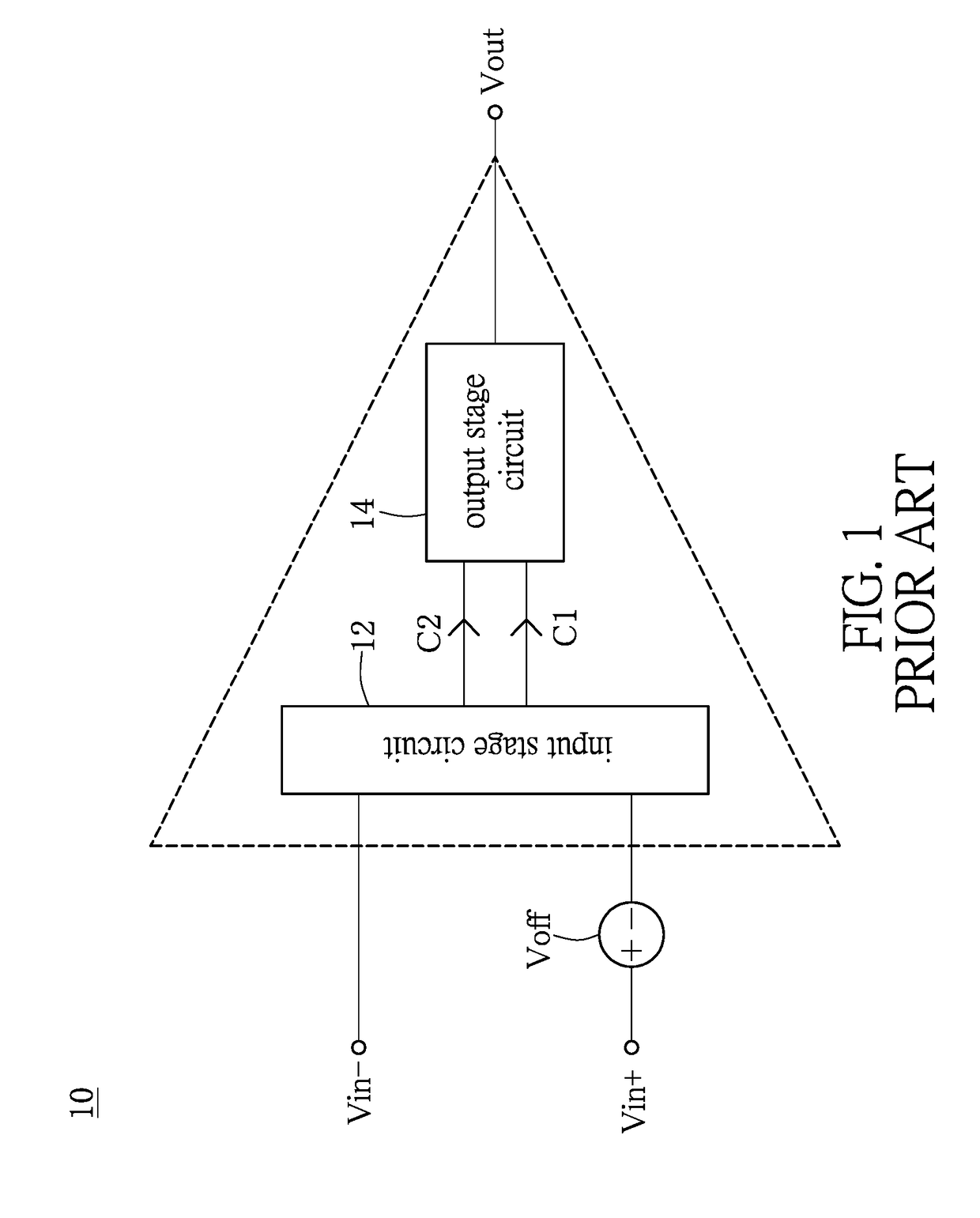

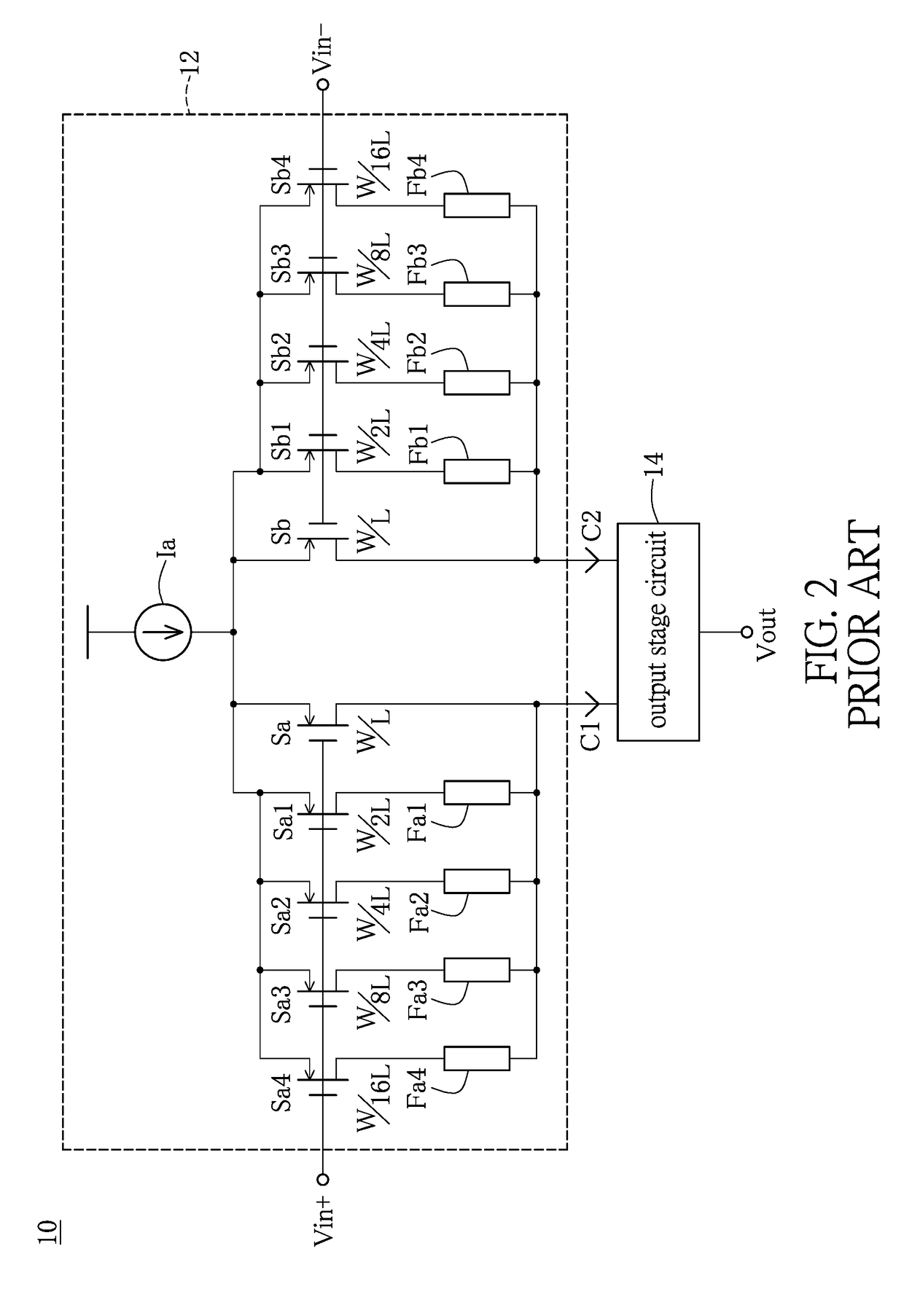

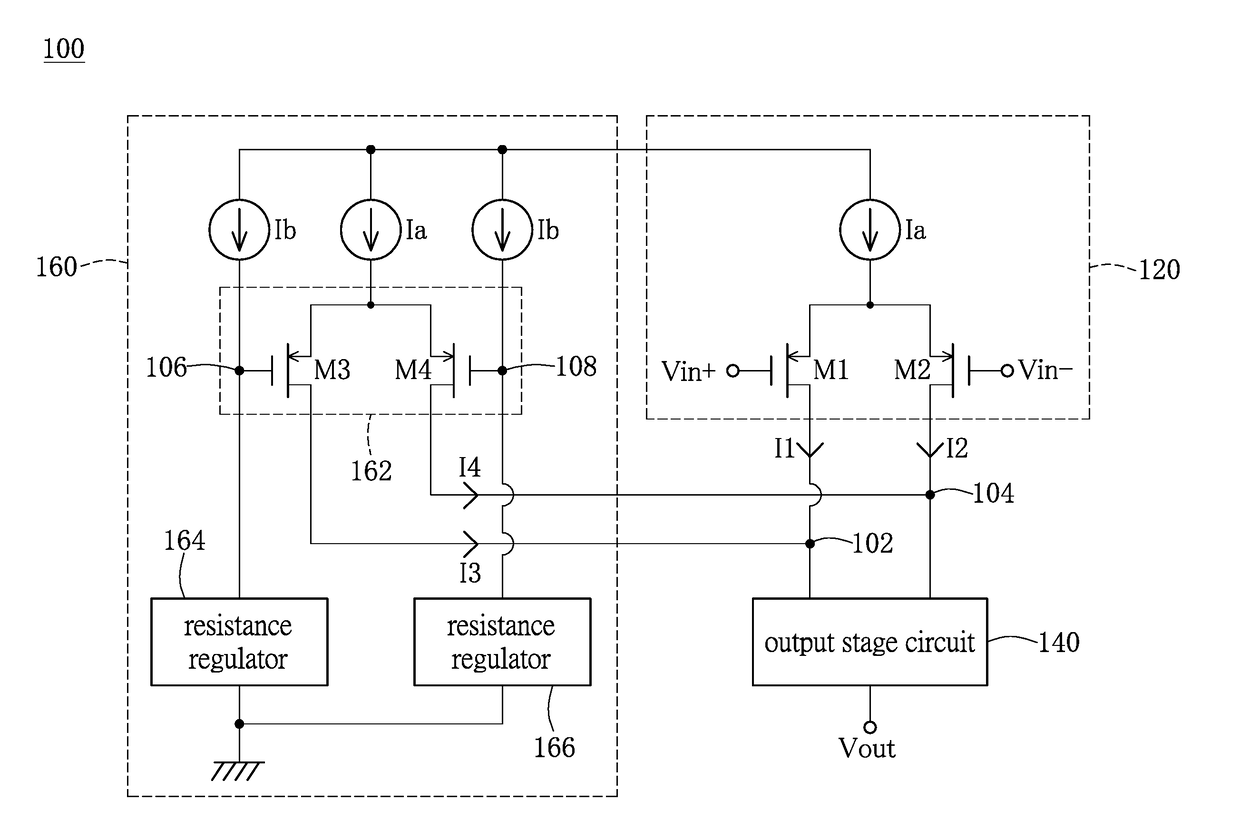

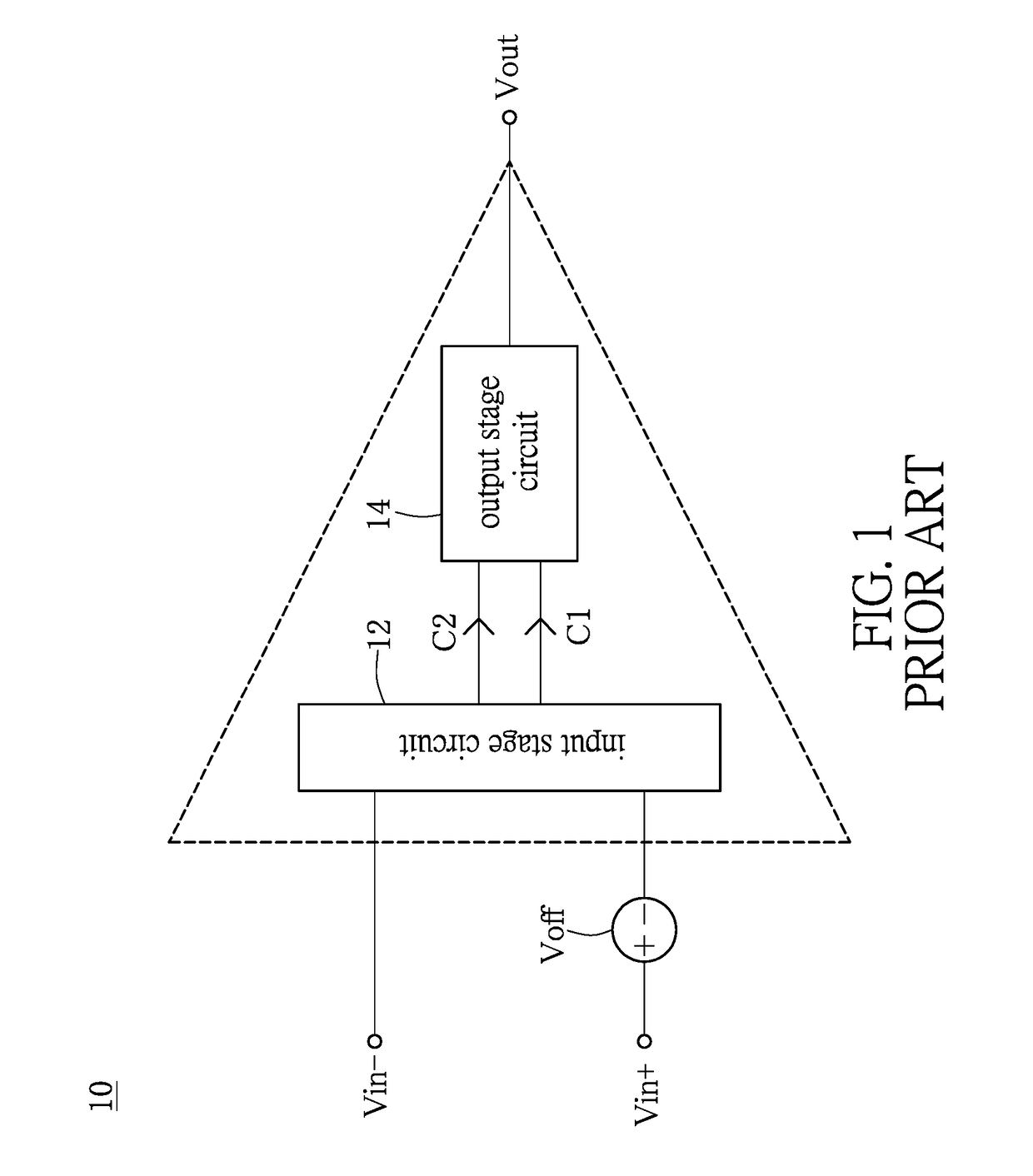

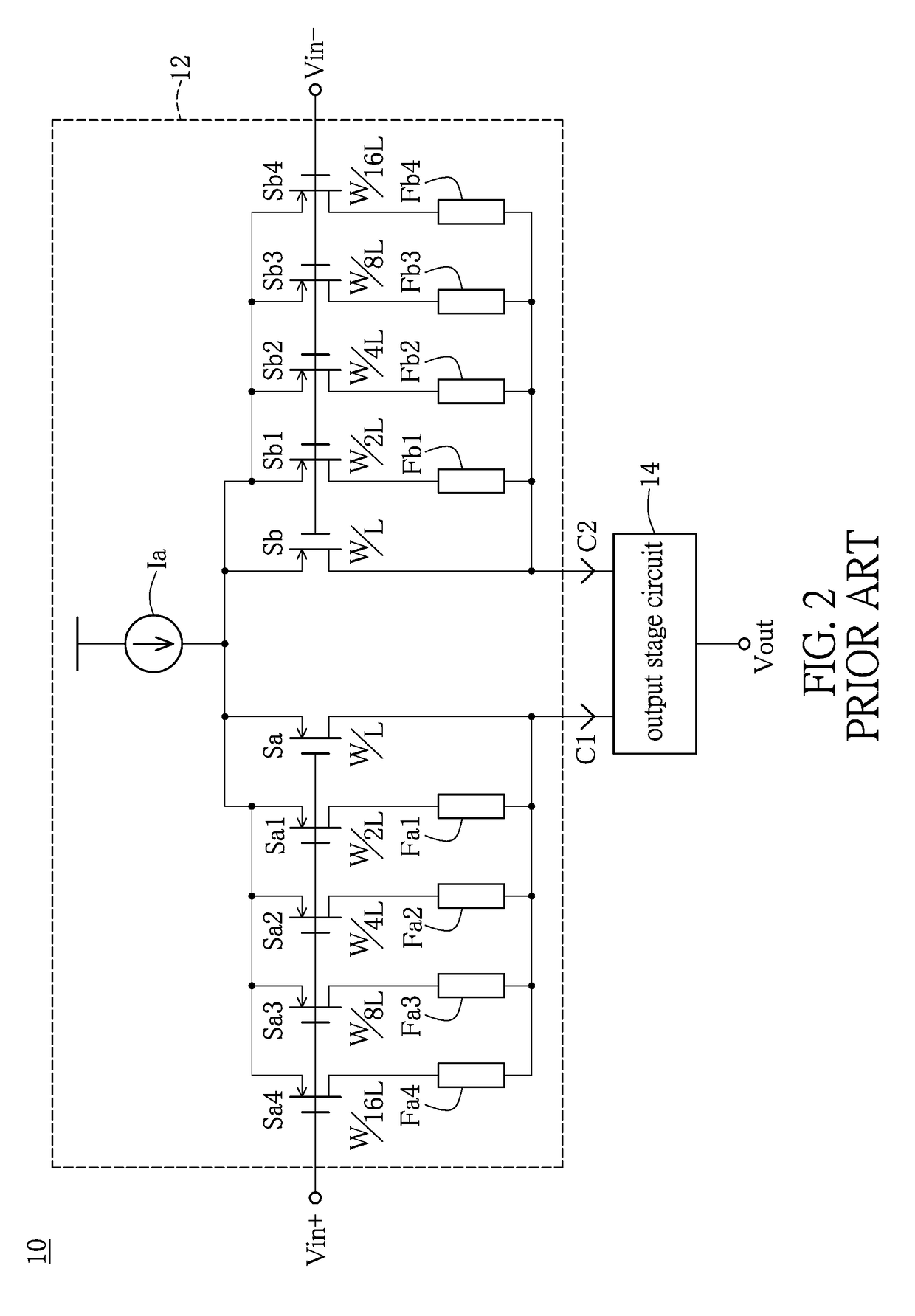

Operational amplifier and method for reducing offset voltage of operational amplifier

ActiveUS20180131328A1Improve accuracyLower Offset VoltageAmplifier modifications to raise efficiencyDifferential amplifiersPower flowLeast significant bit

Disclosed are an operational amplifier and a method for reducing an offset voltage of the operational amplifier, which control an auxiliary circuit to generate a first auxiliary current and a second auxiliary current by adjusting the resistance of a resistance regulator, thereby adjusting a first current and a second current outputted from an input-stage circuit and further adjusting the offset voltage of the operational amplifier. Therefore, the operational amplifier and the method for reducing the offset voltage of the operational amplifier use the resistors to adjust the offset voltage so as to reduce the Least Significant Bit (LSB) distribution, thereby enhancing the accuracy of the offset voltage.

Owner:ANPEC ELECTRONICS CORPORATION

Metal cylinder head gasket without a spacing layer

InactiveUS20120228835A1High rigidityLarge distributionEngine sealsSealing arrangements for enginesMetal cylinderHead gasket

One aspect of the invention relates to a cylinder head gasket provided with at least one opening corresponding to a combustion chamber of an internal combustion engine. The gasket has a function layer with a full bead and an annular support with a bead. The bead of the annular support is arranged on the side of the full bead which is oriented away from the combustion chamber. Another aspect of the invention relates to a cylinder head gasket having an upper functional layer, an annular support and a lower functional layer. The annular support is arranged between the upper and lower functional layers and is adjacent to the lower functional layer. The upper functional layer comprises one full bead, and the lower functional layer has a bead arranged on the side of the full bead which is oriented away from the combustion chamber.

Owner:FEDERAL MOGUL SEALING SYST

Operational amplifier and method for reducing offset voltage of operational amplifier

ActiveUS10003304B2Improve accuracyLower Offset VoltageAmplifier modifications to raise efficiencyDifferential amplifiersAudio power amplifierLeast significant bit

Disclosed are an operational amplifier and a method for reducing an offset voltage of the operational amplifier, which control an auxiliary circuit to generate a first auxiliary current and a second auxiliary current by adjusting the resistance of a resistance regulator, thereby adjusting a first current and a second current outputted from an input-stage circuit and further adjusting the offset voltage of the operational amplifier. Therefore, the operational amplifier and the method for reducing the offset voltage of the operational amplifier use the resistors to adjust the offset voltage so as to reduce the Least Significant Bit (LSB) distribution, thereby enhancing the accuracy of the offset voltage.

Owner:ANPEC ELECTRONICS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com