Patents

Literature

1057 results about "Packaging and labeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and personal use.

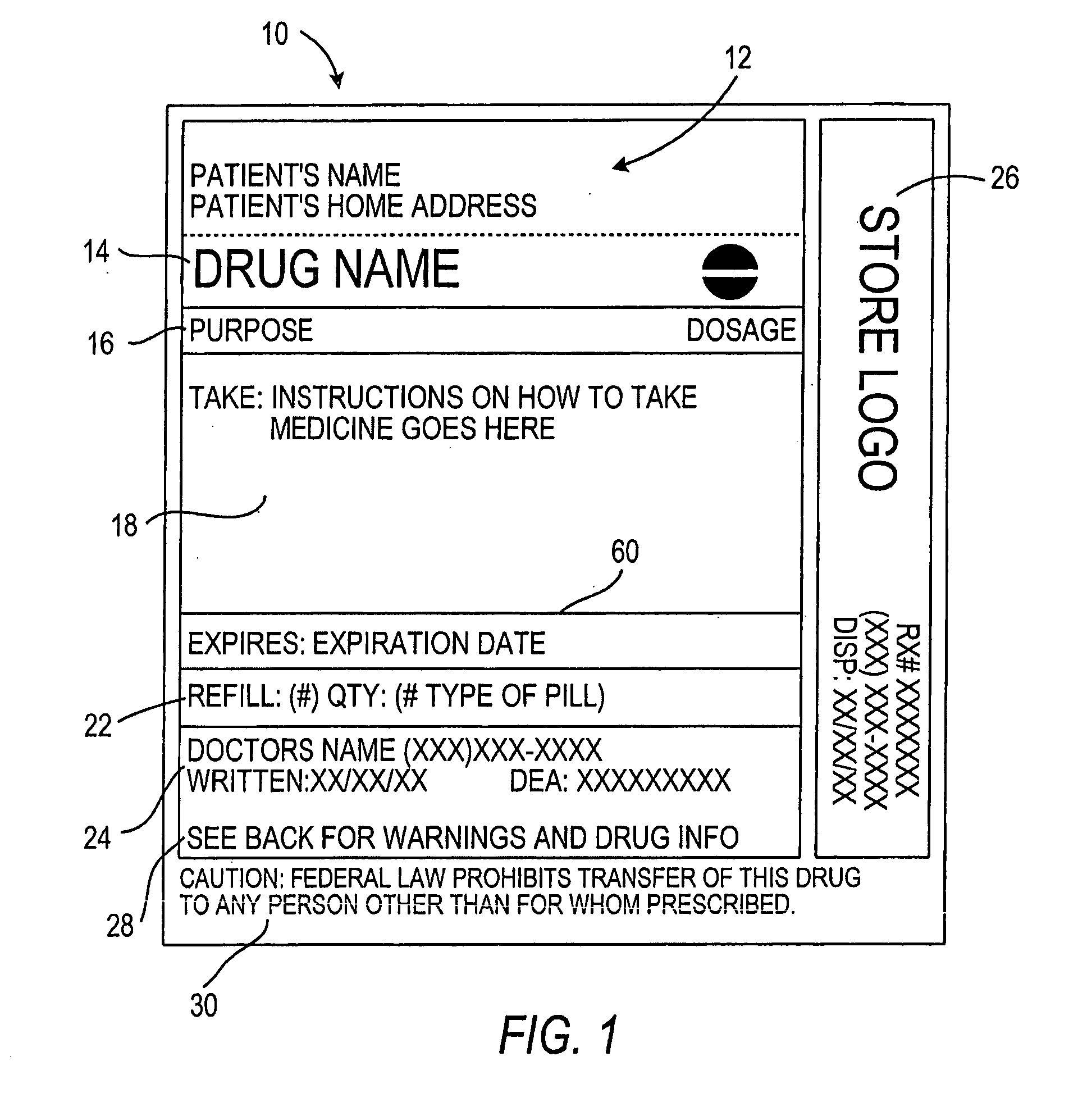

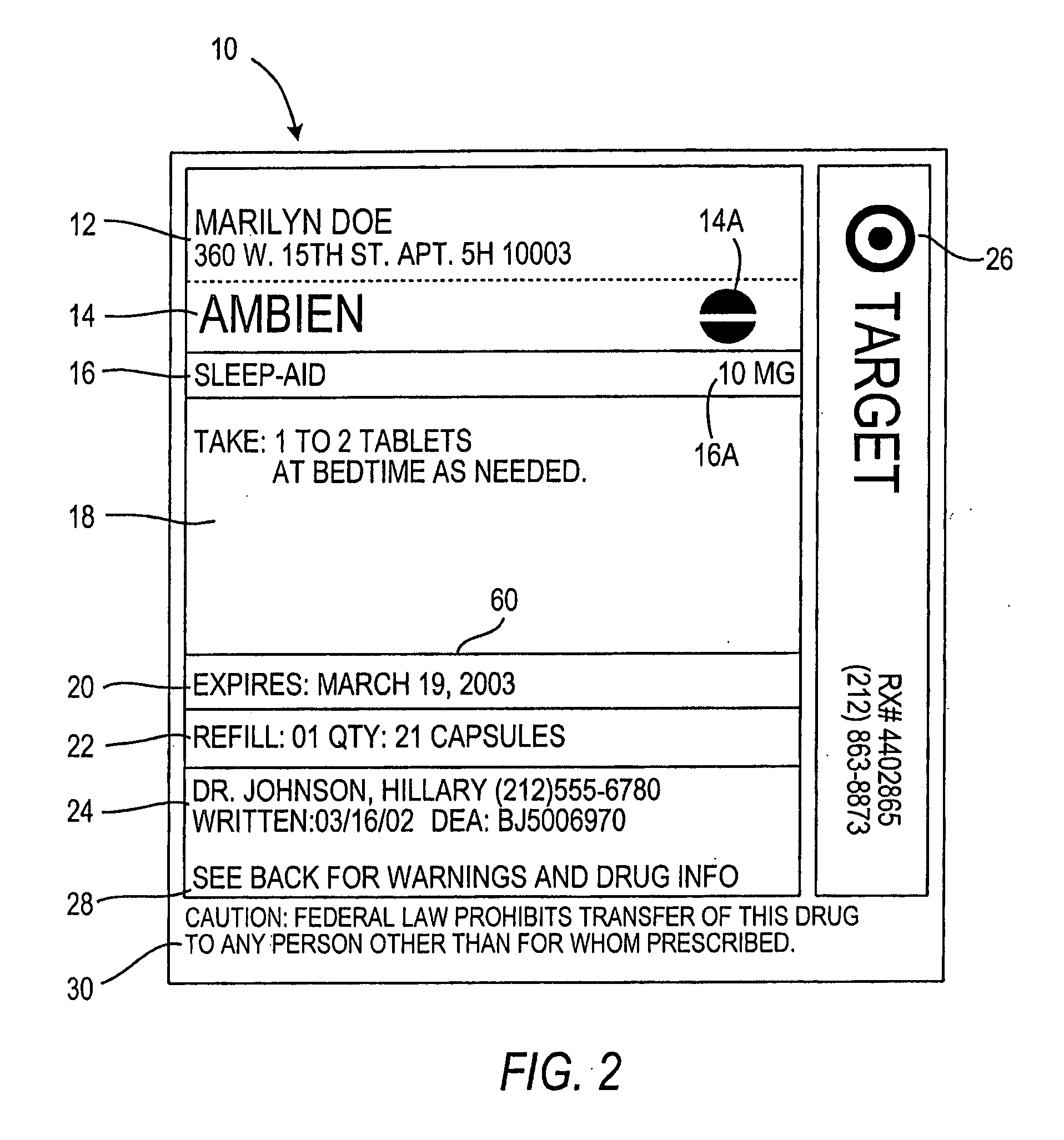

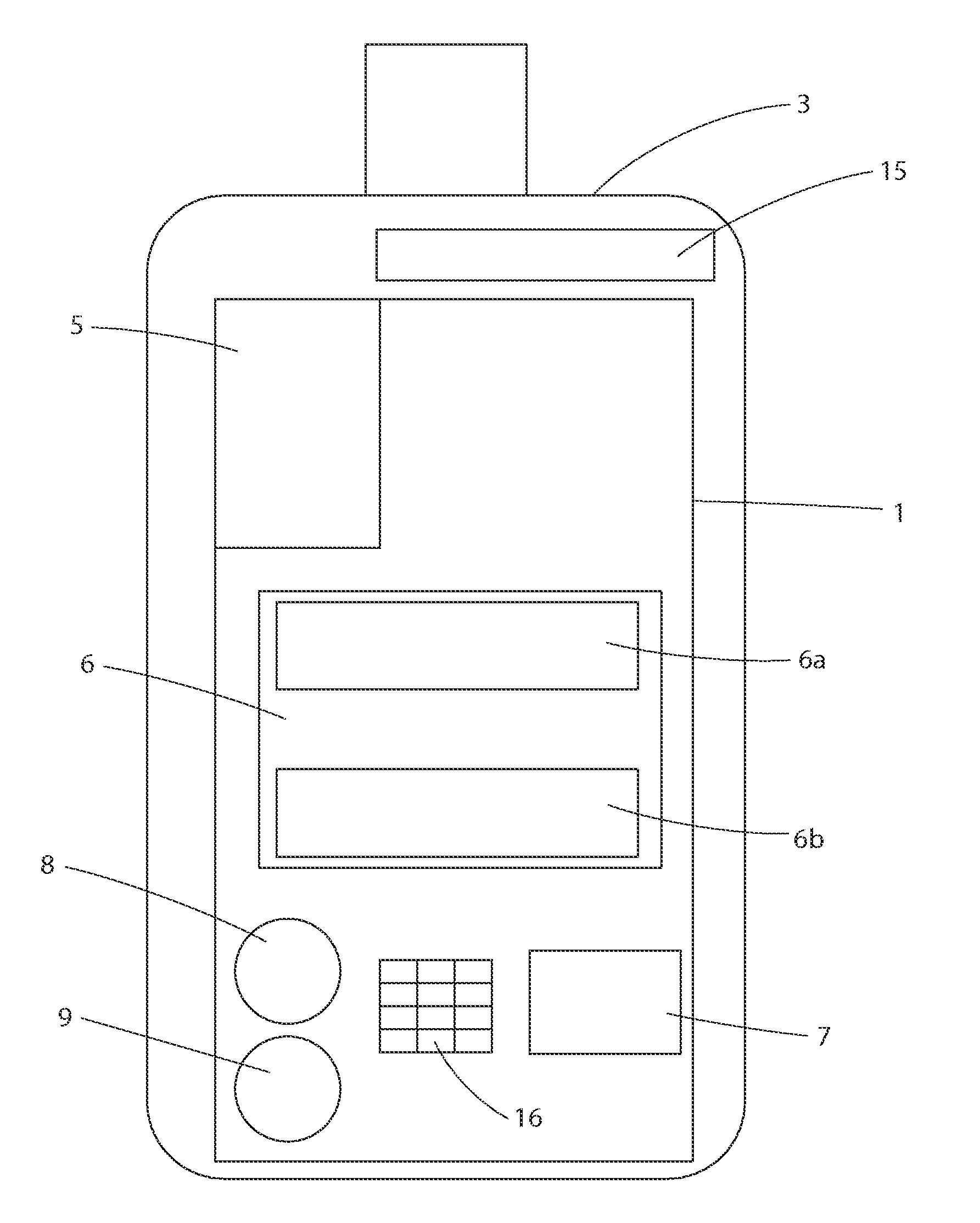

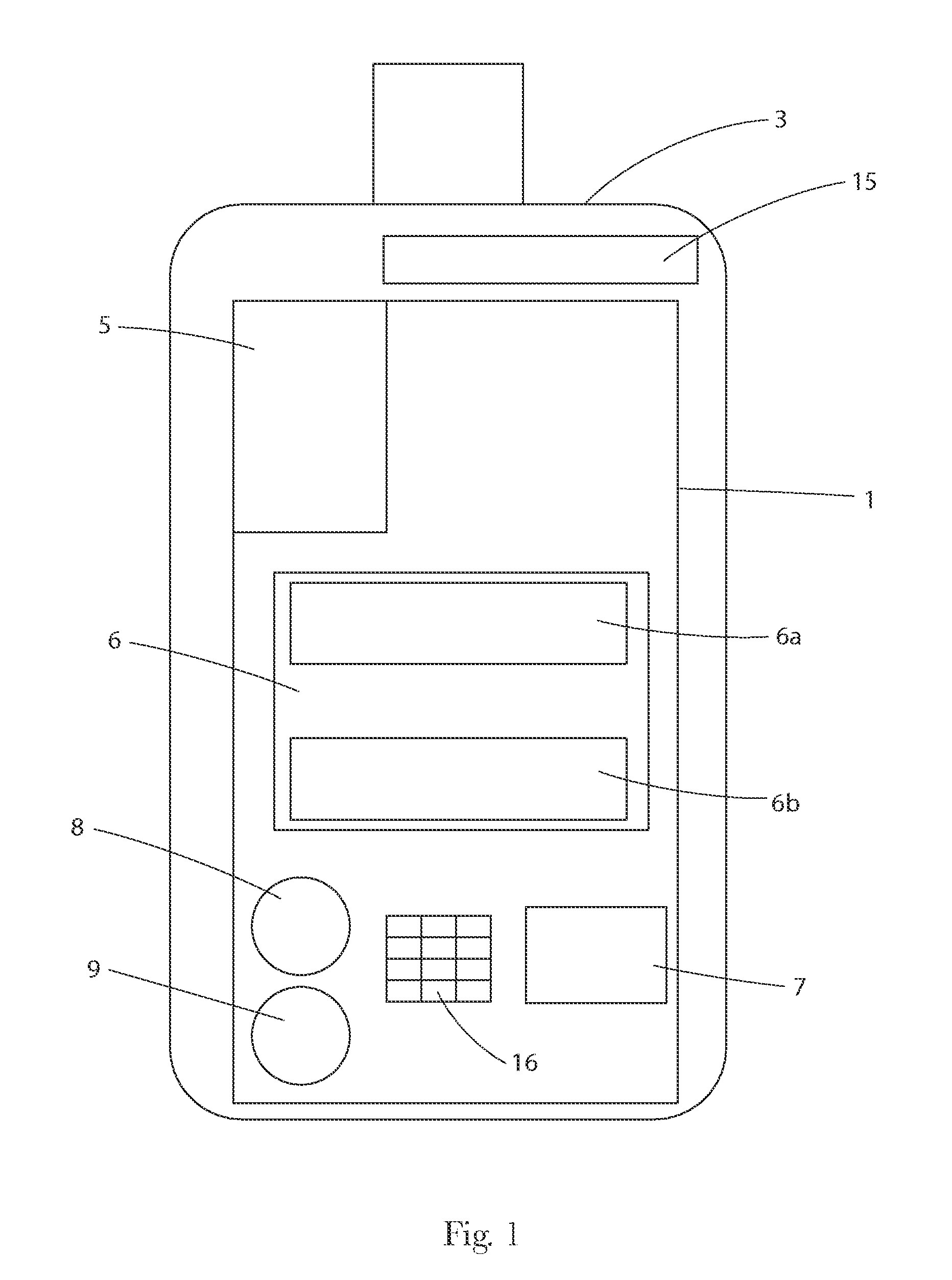

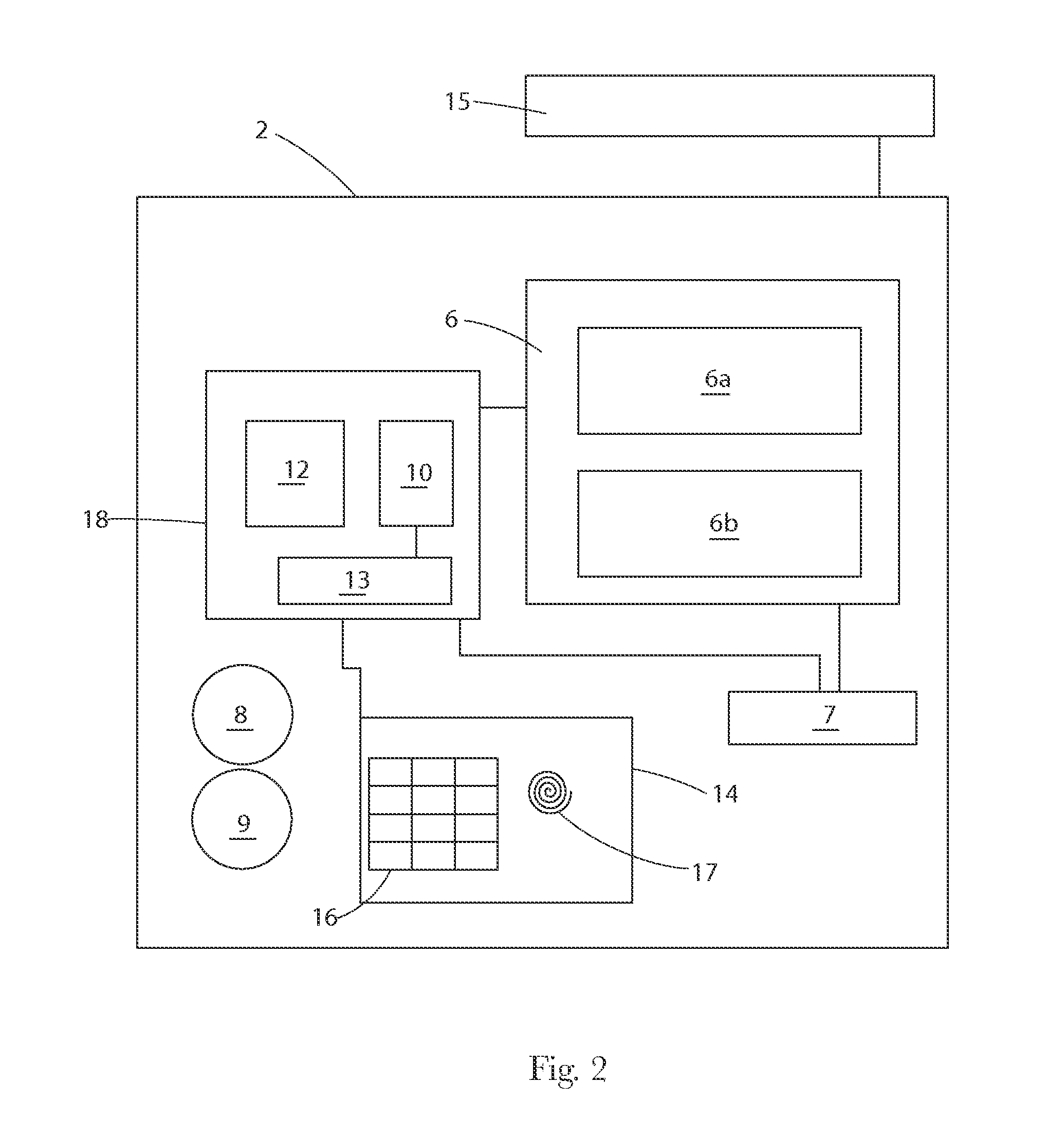

Portable patient devices, systems, and methods for providing patient aid and preventing medical errors, for monitoring patient use of ingestible medications, and for preventing distribution of counterfeit drugs

InactiveUS20080303638A1Easy maintenancePrevent kidney toxicityFinanceDrug and medicationsTransport medicineDrug dispensing

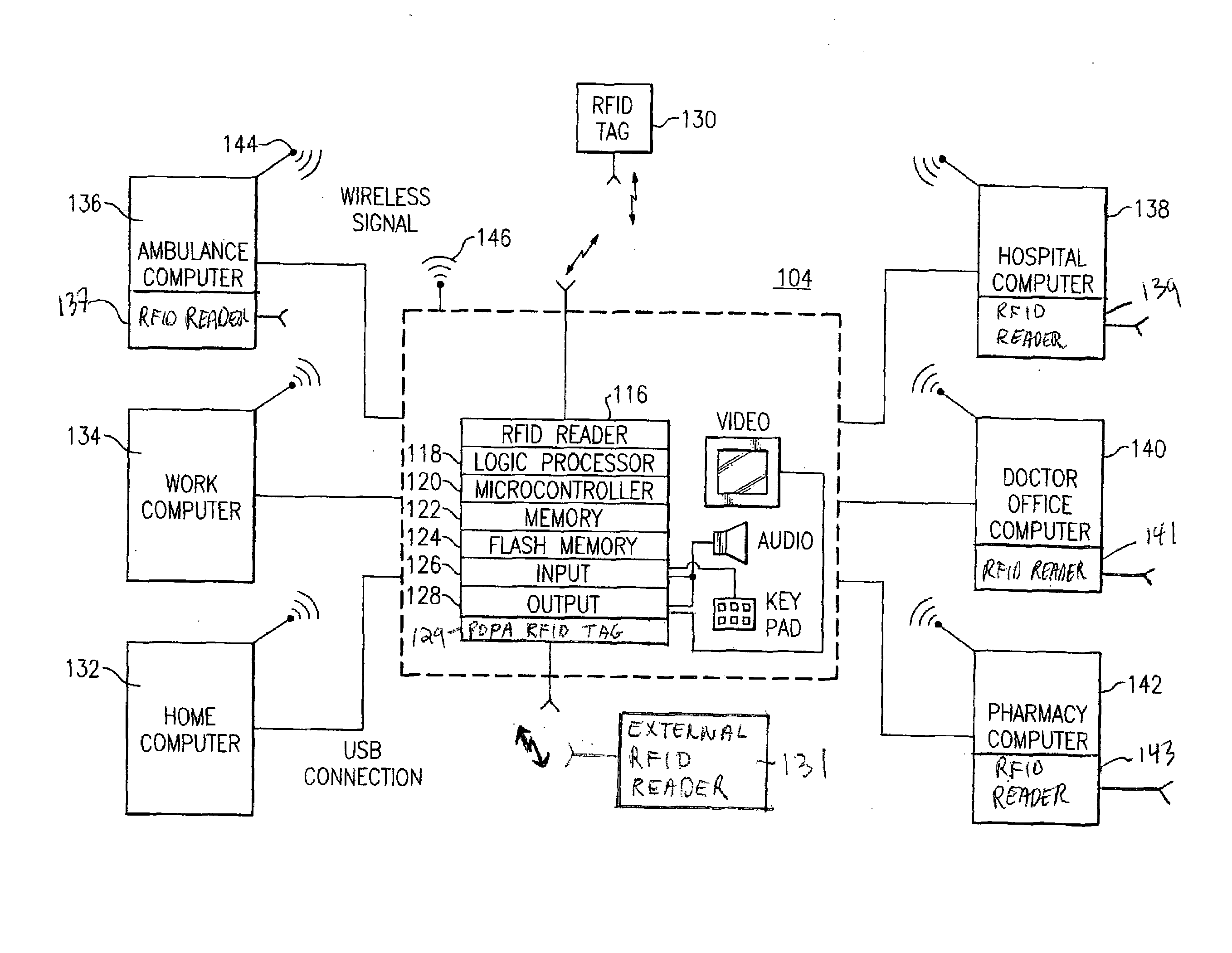

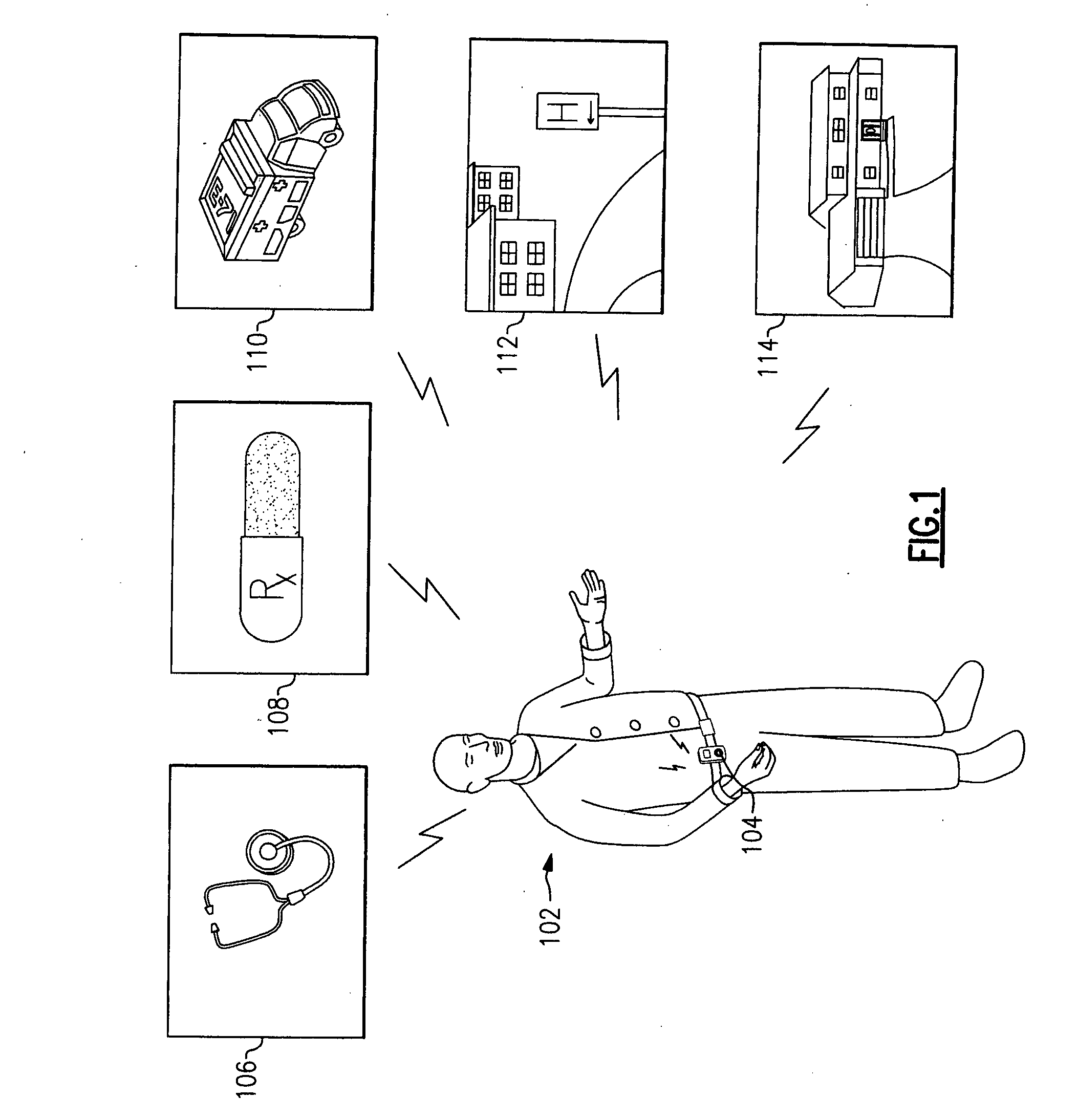

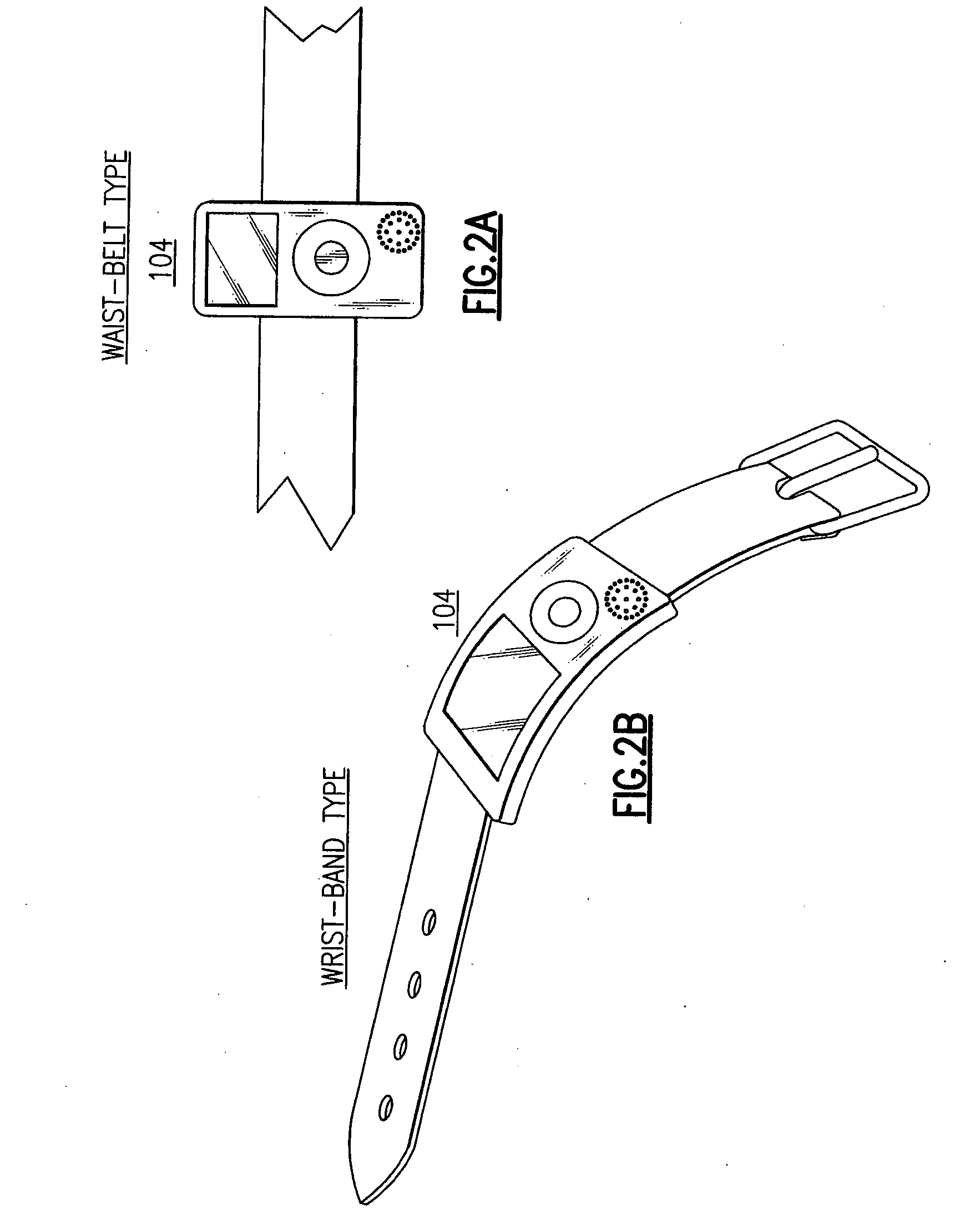

A portable digital patient assistant includes an RFID reader, a central processing unit for processing signals received from the RFID reader, a memory for storing data, and an output operatively linked to the central processing unit for providing output information regarding use of medicinal drugs. Methods for using the portable digital patient assistant include use at the doctor's office, pharmacy, emergency medical vehicle, hospital, home, and use while taking medications to the verify authenticity thereof and prevent drug overdoses. Related methods and systems for manufacturing, packaging, and shipping medicinal drugs to prevent the distribution of counterfeit drugs are also provided. One of the methods includes the steps of preparing a predetermined amount of a specific type of drug for patient end-users; forming discrete individual doses of the specific type of drug; and associating a respective RFID tag with each of the discrete individual doses of the specific type of drug so that when the specific type of drug is distributed to the patient end-users, at least one RFID reader may be employed to read the RFID tags associated with each of the discrete individual doses to thereby verify the authenticity of the doses as they move through a distribution channel from a manufacture to the patient end-users.

Owner:NGUYEN HAP +1

Method and apparatus for efficient package delivery and storage

InactiveUS6974928B2Efficient package creationAuthentication is convenientAcutation objectsDigital data processing detailsComputer scienceSelf-service

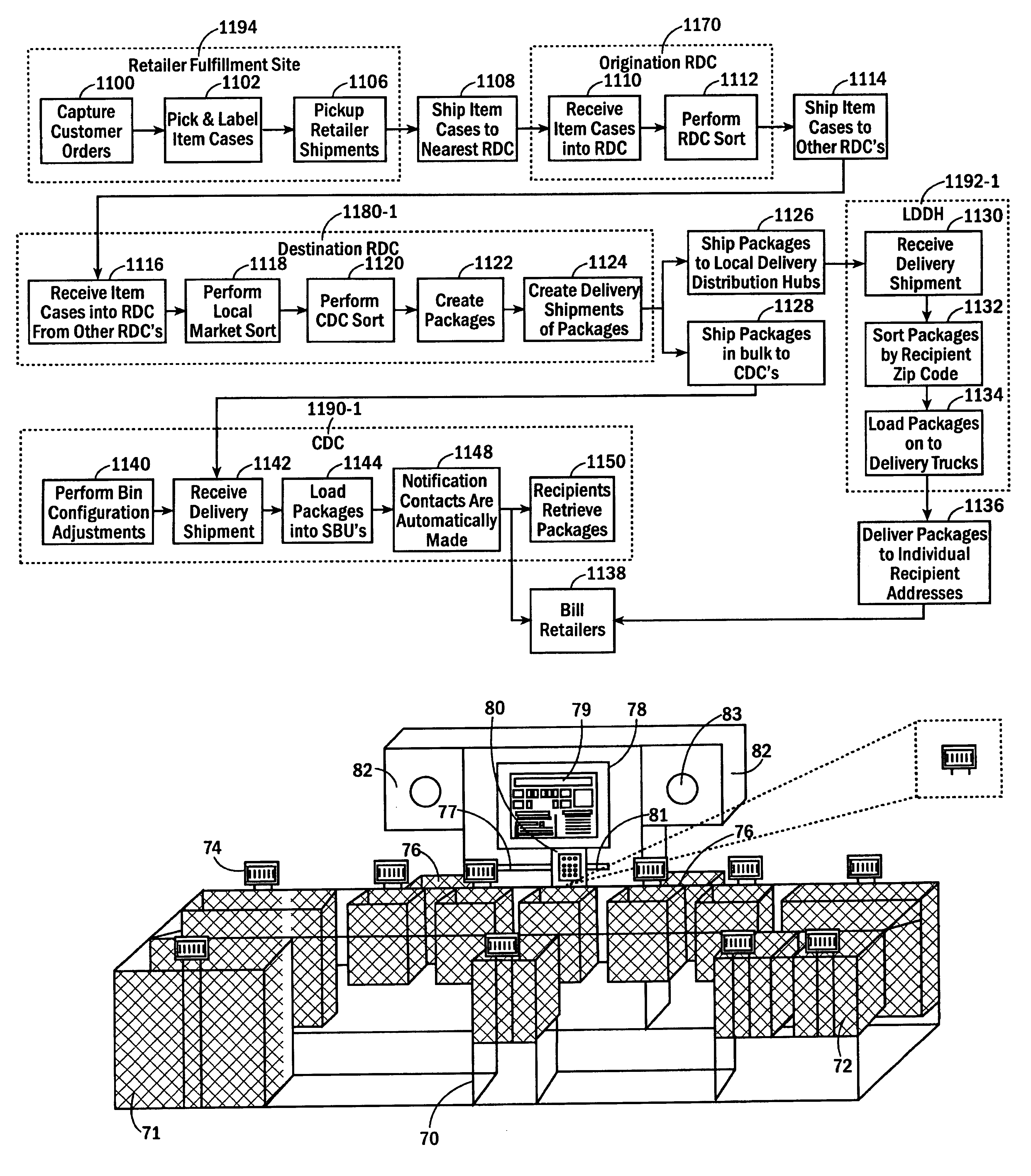

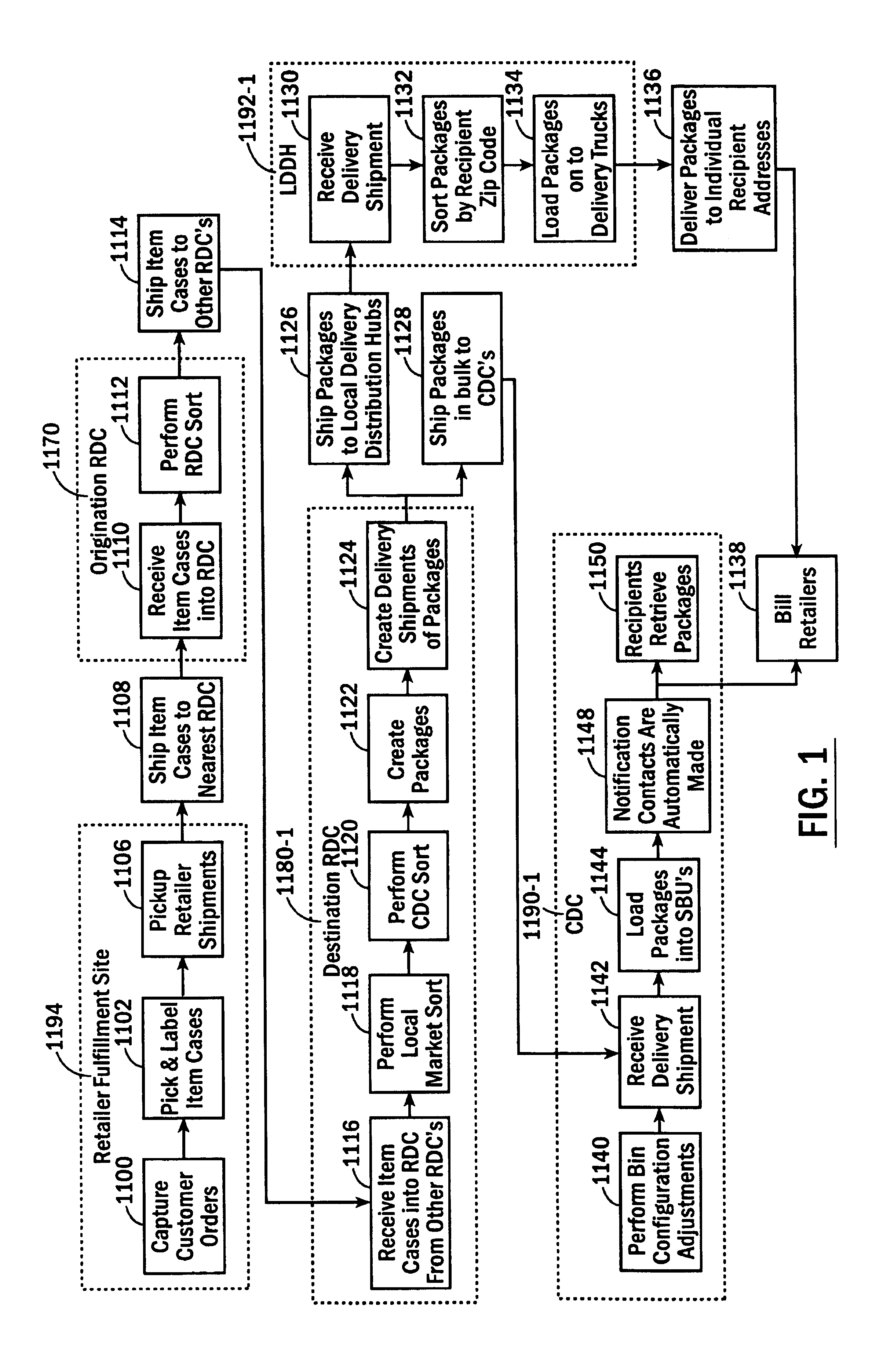

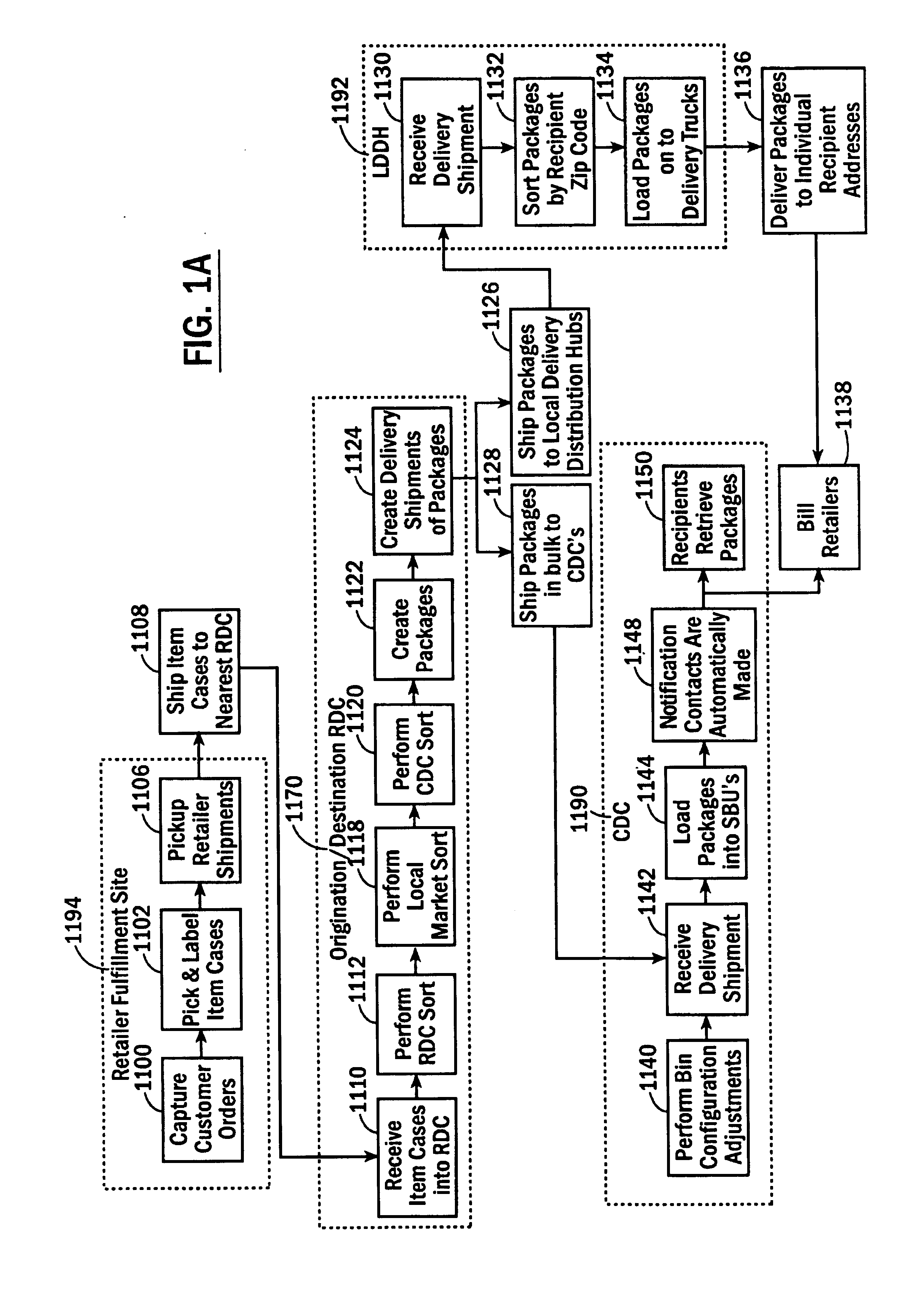

A method and system for the efficient bulk package delivery for recipients. Items ordered by different customers from different retailers, suppliers or manufacturers can be organized by common item identifiers and shipped in bulk from retailers or manufacturers, to an origination regional distribution center. The items can be sorted at the origination regional distribution center in bulk based on the location of destination regional distribution centers that can serve destination centralized pickup locations chosen by the customers placing the orders for those items. Ordered items can be sorted by recipient and the destination centralized pickup location specified in the customer's order and packed into recipient-specific packages at the destination regional distribution center. The packages can be transported in bulk to the destination centralized pickup locations where they can be randomly loaded into any available locker bins in an automated system of stationary and moveable, configurable storage locker bins. During loading, an association can be made between an identifier of the locker bin and an identifier of the bulk delivered package for subsequent self service identification and retrieval. An electronic notification of the delivery can be automatically dispatched to the recipient by the automated system of storage locker bins to alert the recipient of the delivery.

Owner:BREAKTHROUGH LOGISTICS CORP

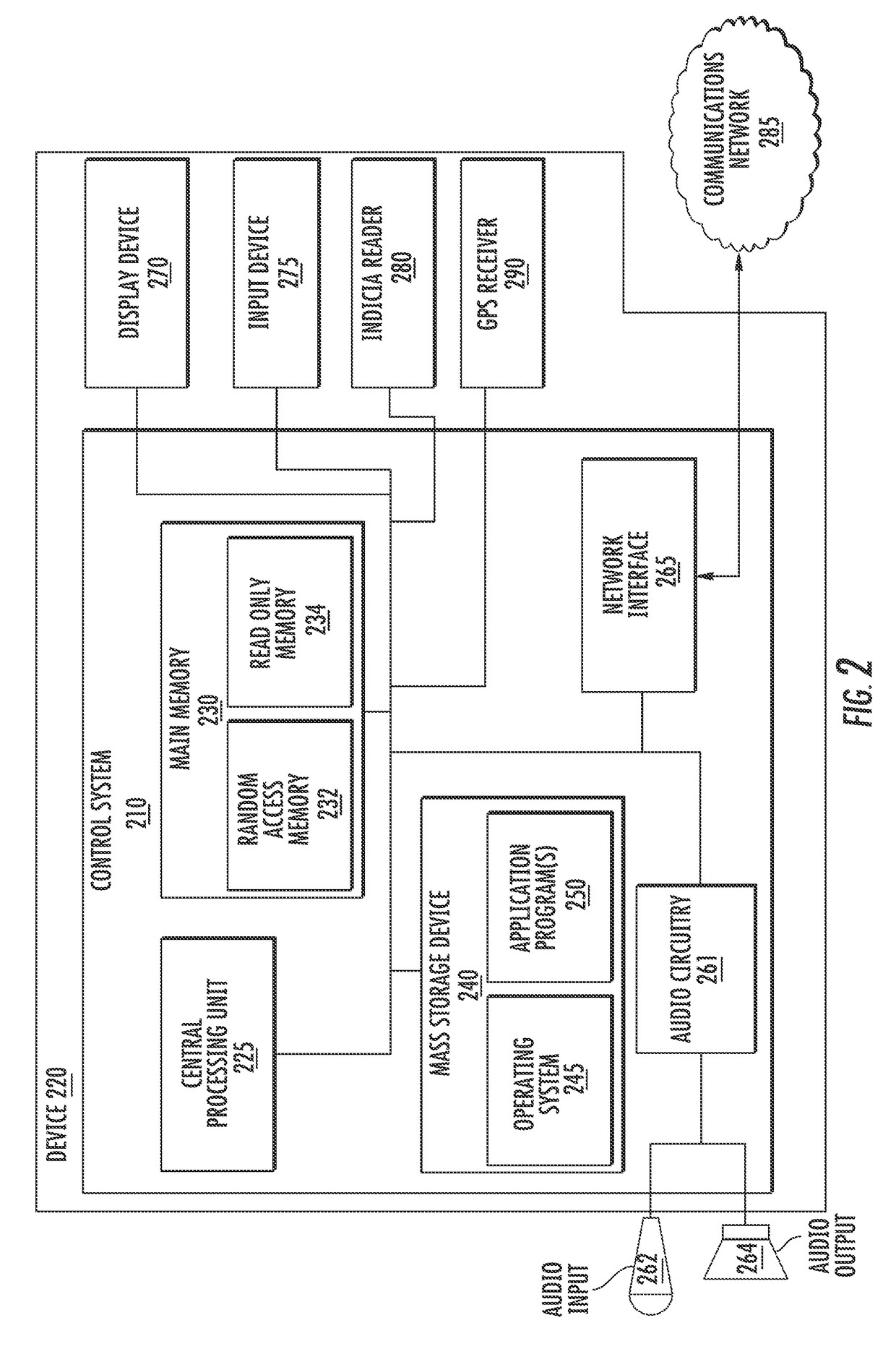

In-vehicle package location identification at load and delivery times

A shelving and package locating system for delivery vehicles includes one or more shelves for storing packages within a delivery vehicle during delivery. Each package is associated with both a geographic delivery address and an assigned location on a particular shelf within the delivery vehicle. A GPS unit determines the location of the delivery vehicle during delivery, and a computer provides the shelf location of a particular package when that package's delivery-location information substantially corresponds to vehicle location information. Several embodiments exist for registering the location of the package in the vehicle at load time, such as scanned location indicia, light sensors on shelves, pressure sensors on shelves, pressure sensors on the floor of the vehicle, and light spot. Several embodiments exist for locating the package in the vehicle at delivery time, such as a pick-to-light system that employs variable length lighting and a light pointer system that generates a light spot.

Owner:HAND HELD PRODS

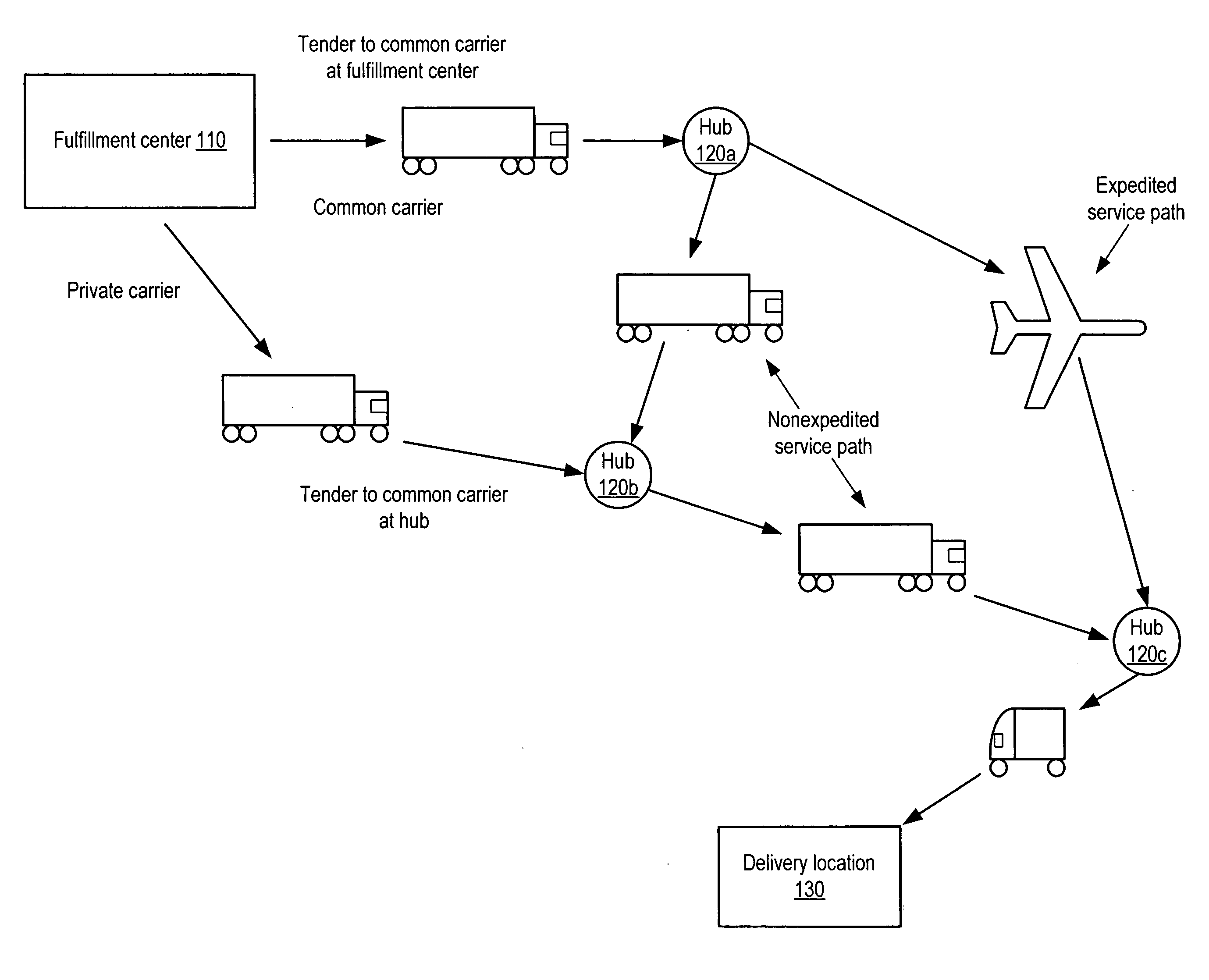

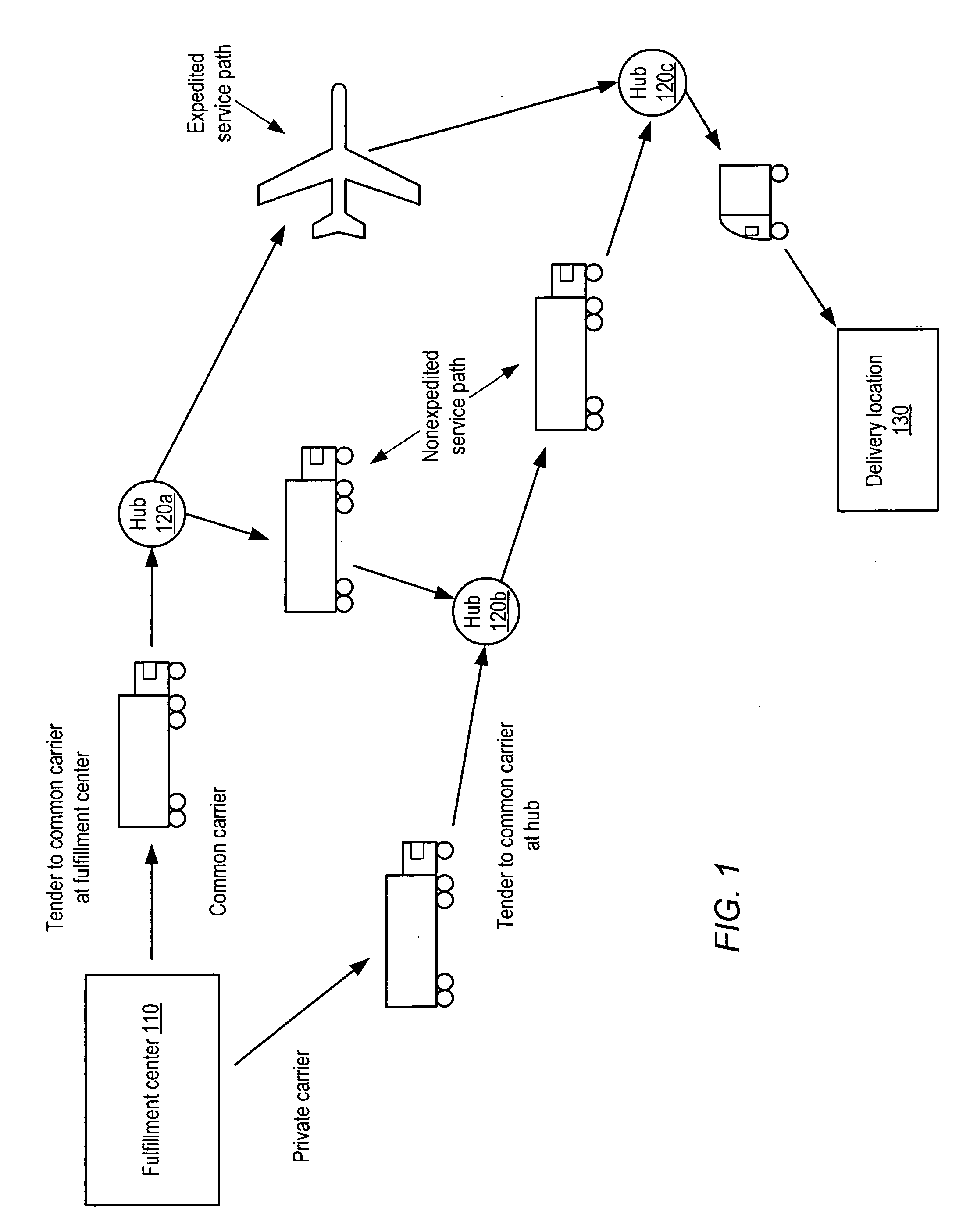

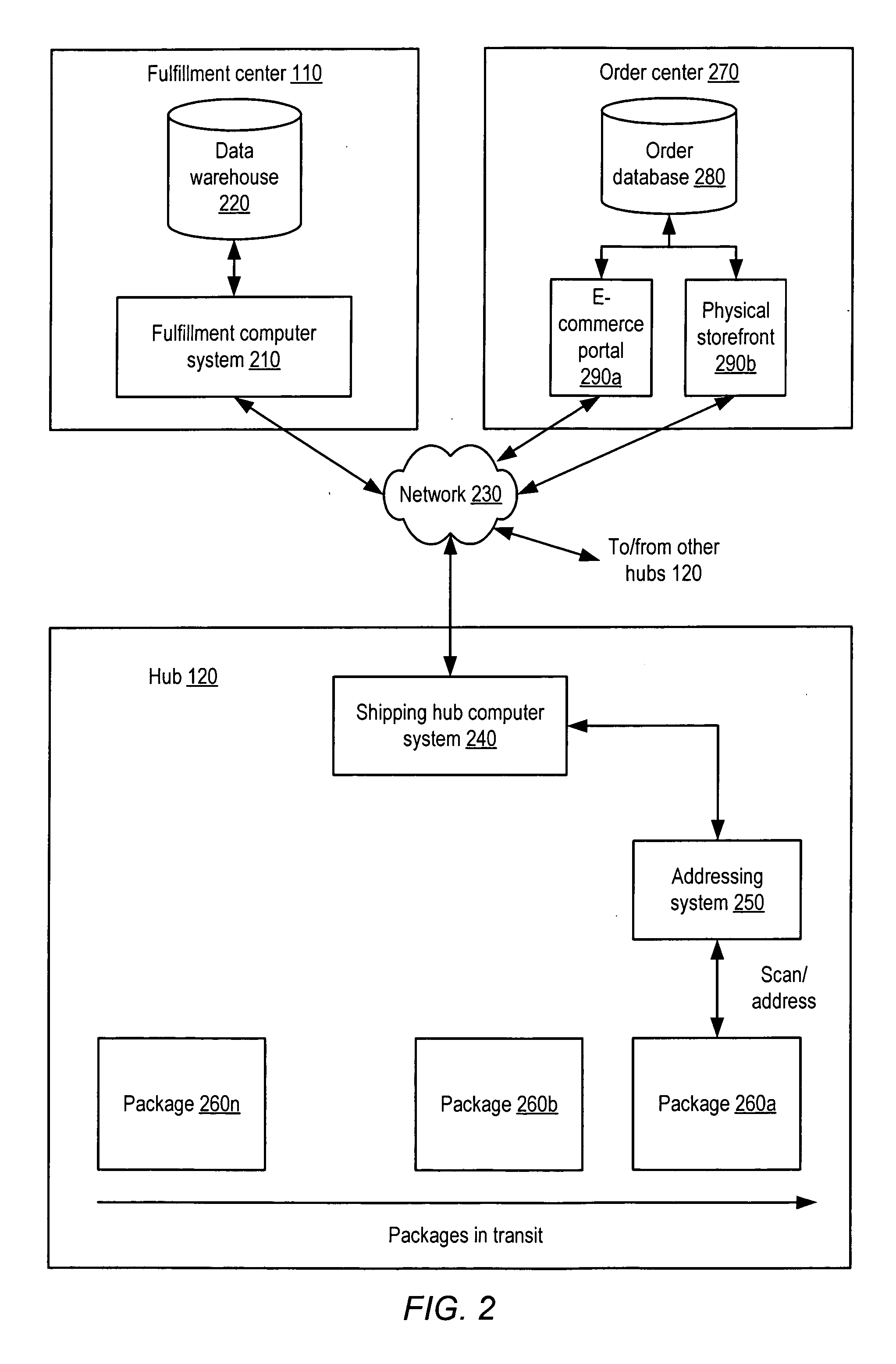

Method and system for anticipatory package shipping

A method and system for anticipatory package shipping are disclosed. According to one embodiment, a method may include packaging one or more items as a package for eventual shipment to a delivery address, selecting a destination geographical area to which to ship the package, shipping the package to the destination geographical area without completely specifying the delivery address at time of shipment, and while the package is in transit, completely specifying the delivery address for the package.

Owner:AMAZON TECH INC

Portable authentication device and method of authenticating products or product packaging

InactiveUS7079230B1Digitally marking record carriersCharacter and pattern recognitionAdditive ingredientEngineering

A portable authentication device and method of authenticating products or packaging by analyzing key ingredients on products or on product packaging is disclosed. Light-sensitive compounds can be used to identify the product or product packaging. The product or product package may include visible or invisible ink containing a particular light-sensitive compound. The ink may be printed in one or more locations on the product or product packaging to produce an authentication mark, such as a bar code. The device includes an assembly for providing a source of light to irradiate the ink containing the light-sensitive compound on the sample product or product package, an optical detector to detect certain spectral properties emitted or absorbed by the irradiated ink and a controller to determine the authenticity of the sample product or product package by comparing the emitted or absorbed properties to a standard.

Owner:SUN CHEMICAL BV

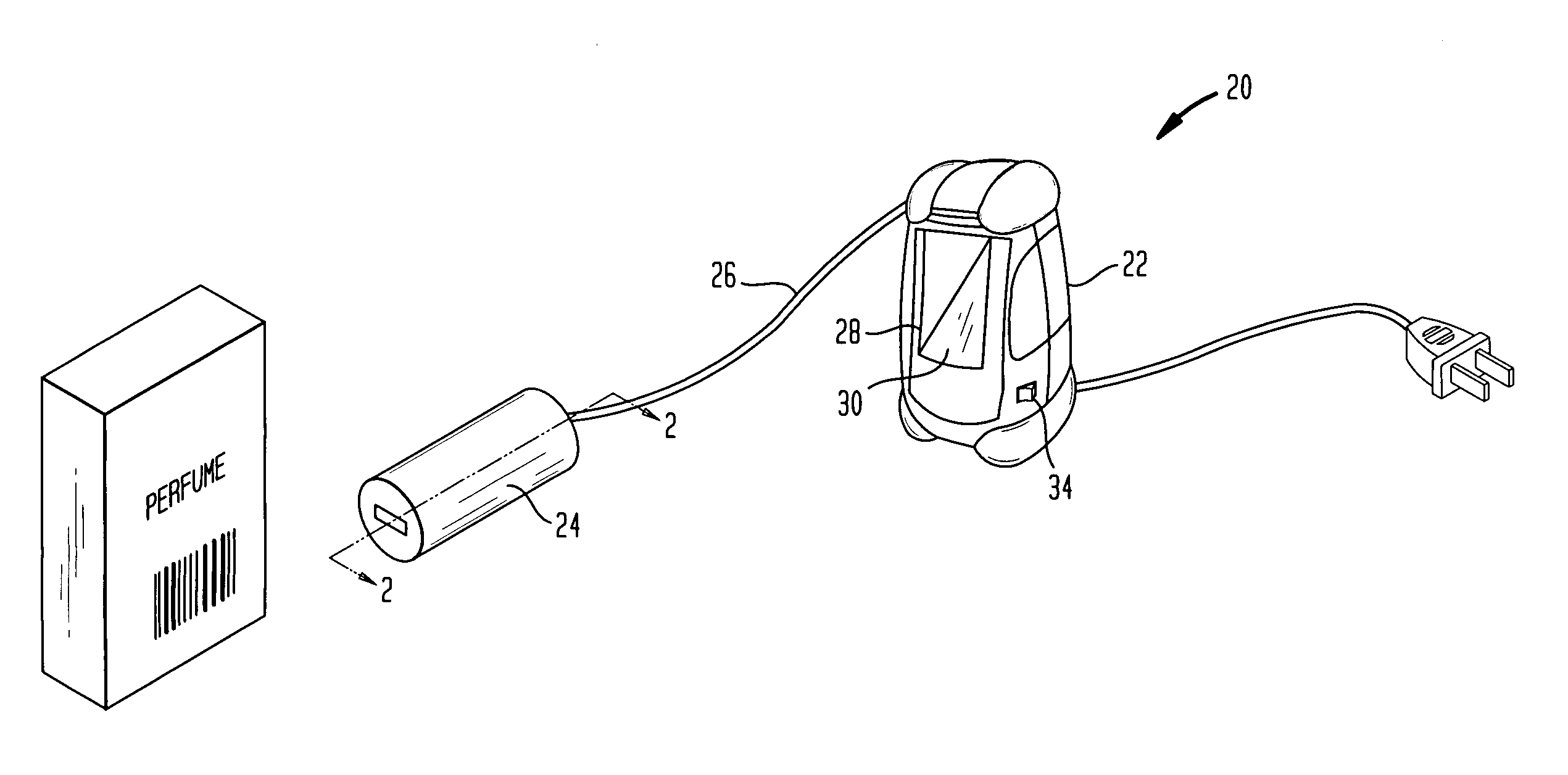

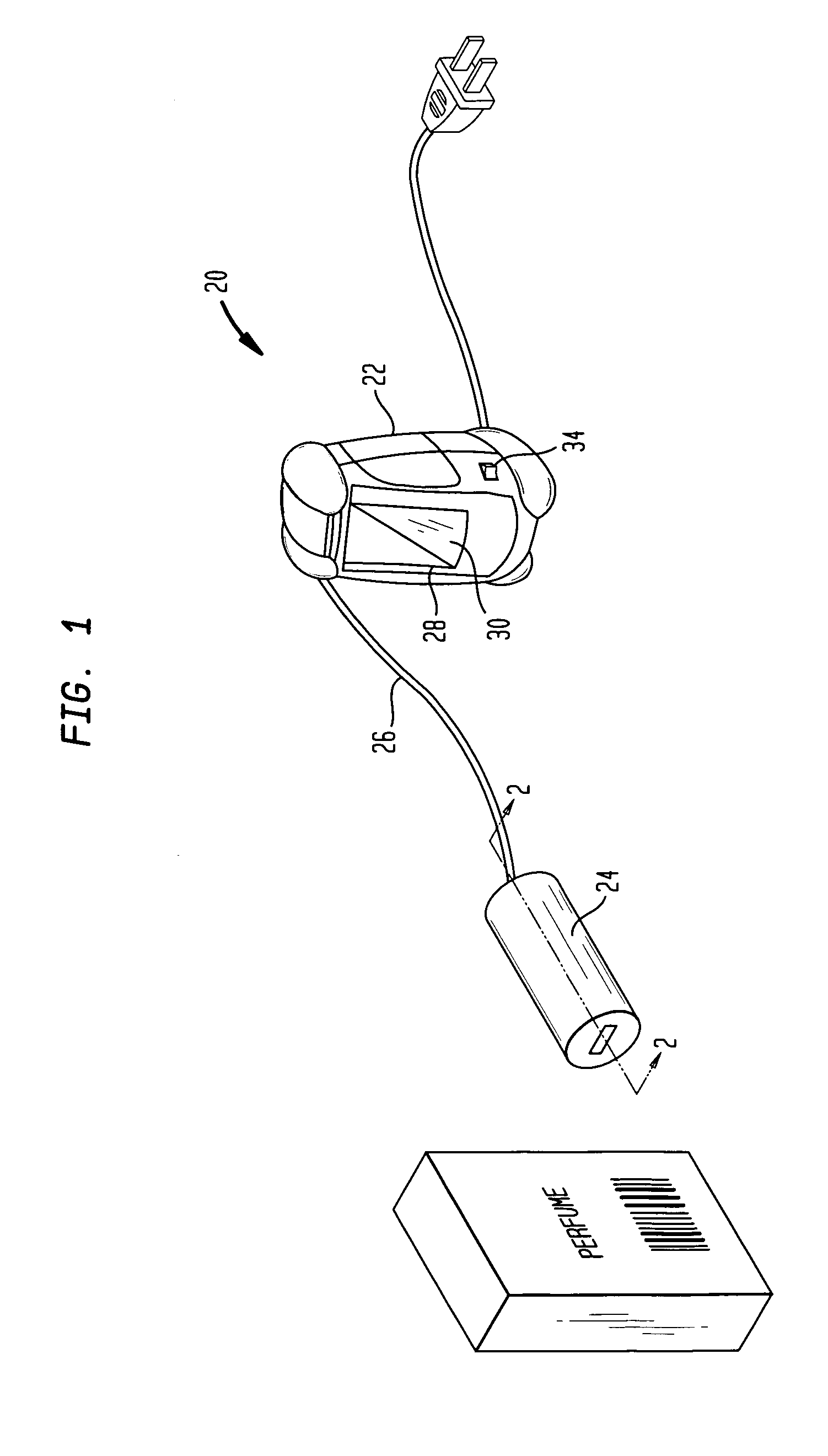

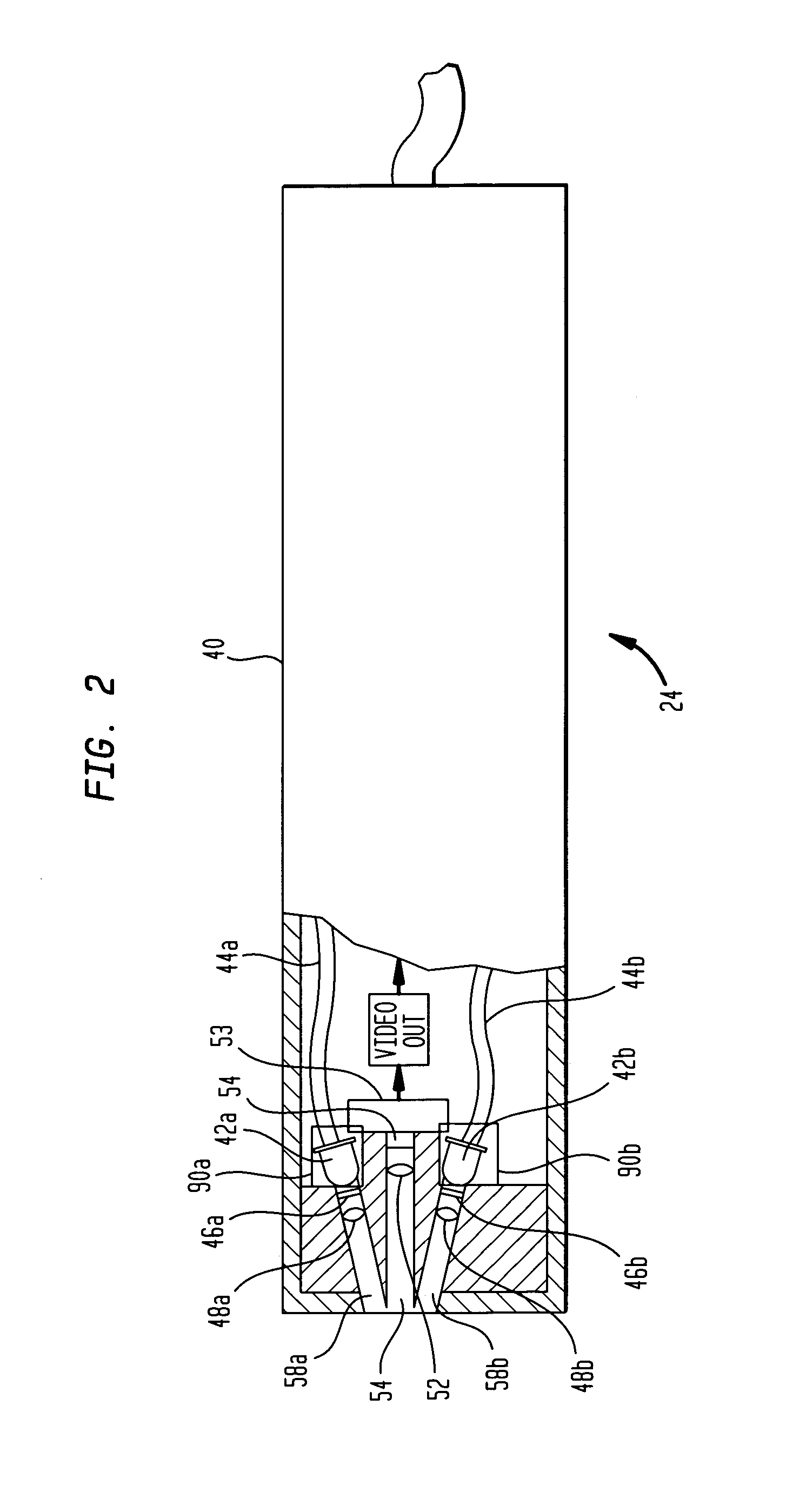

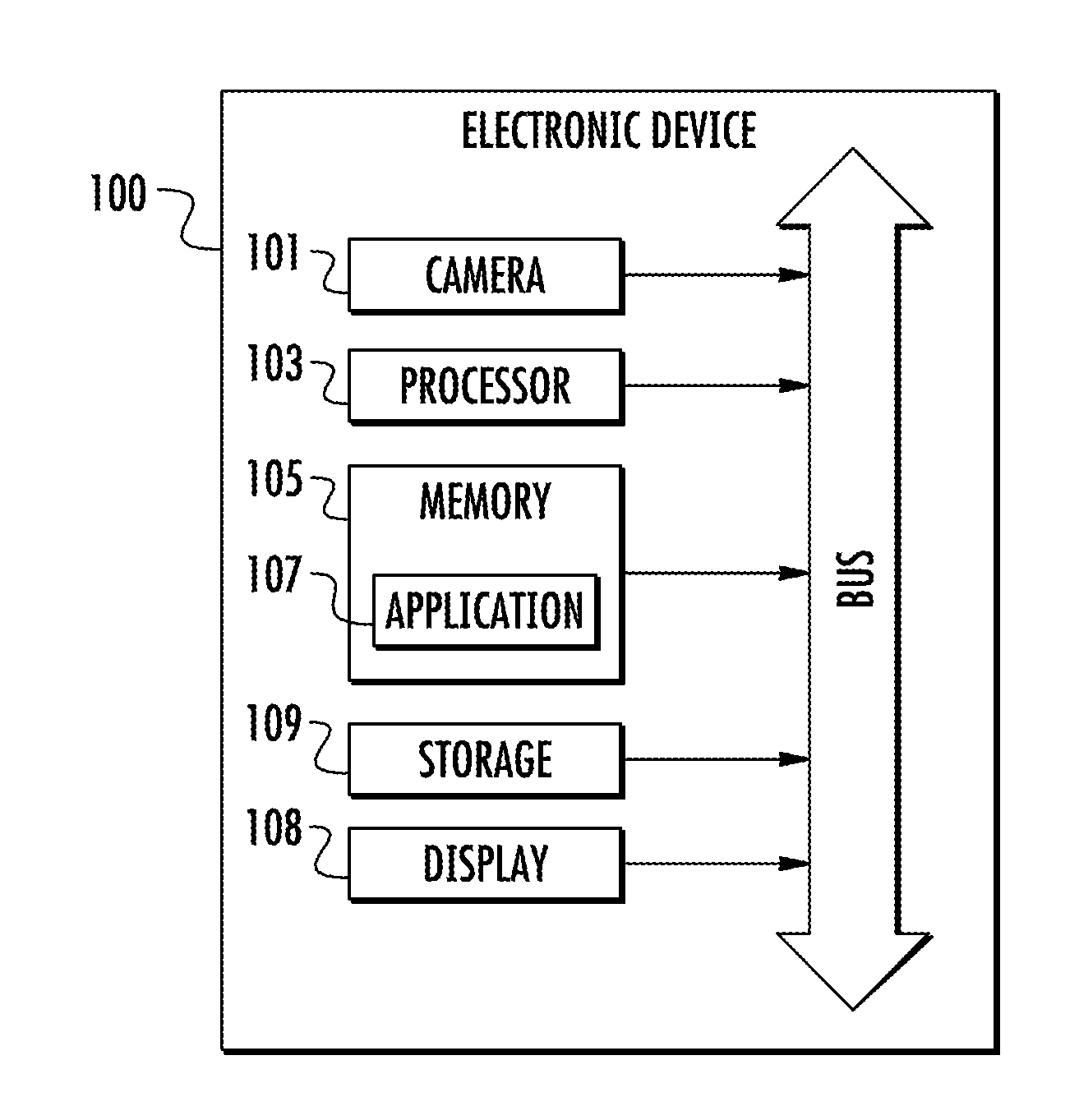

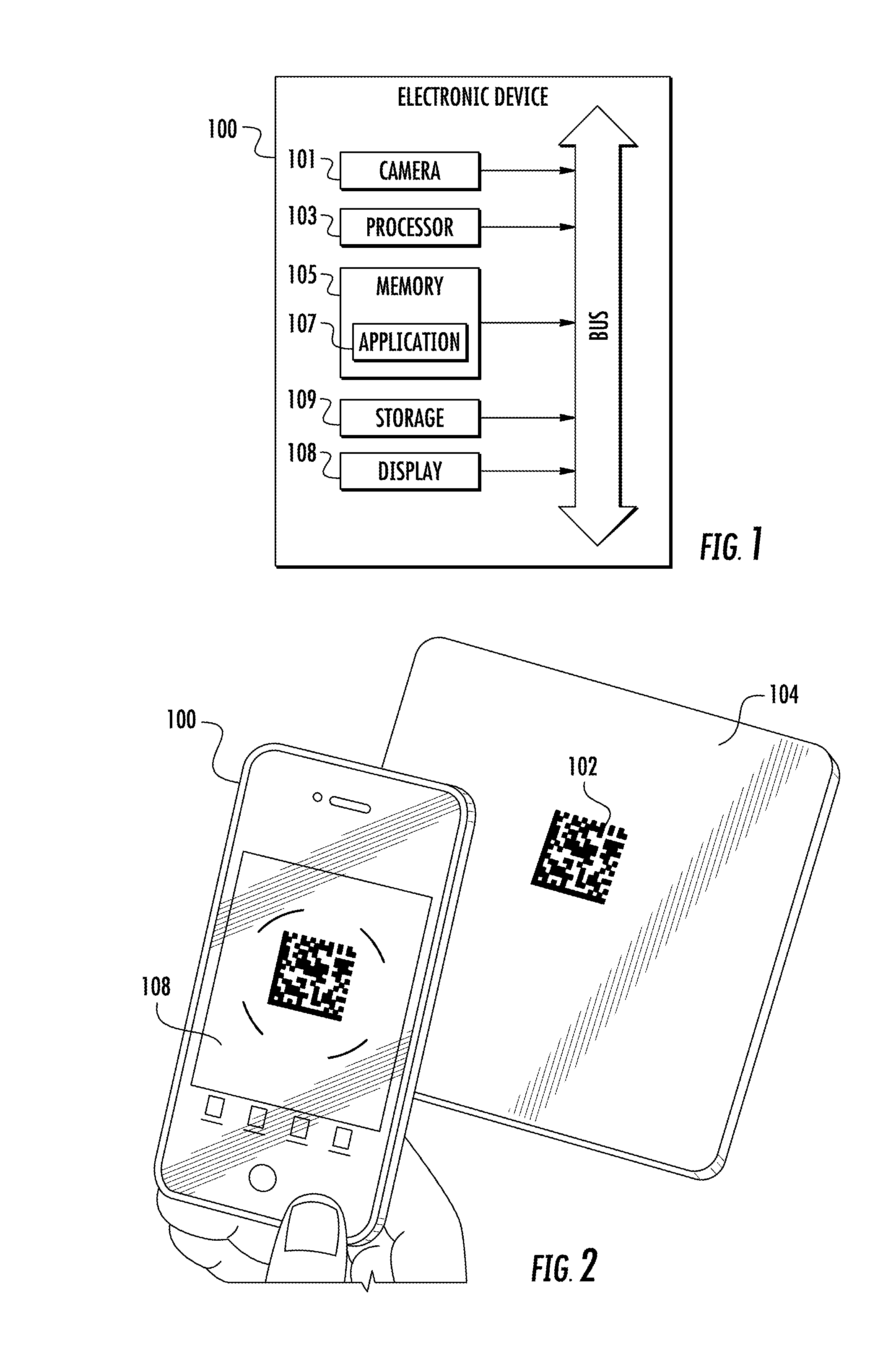

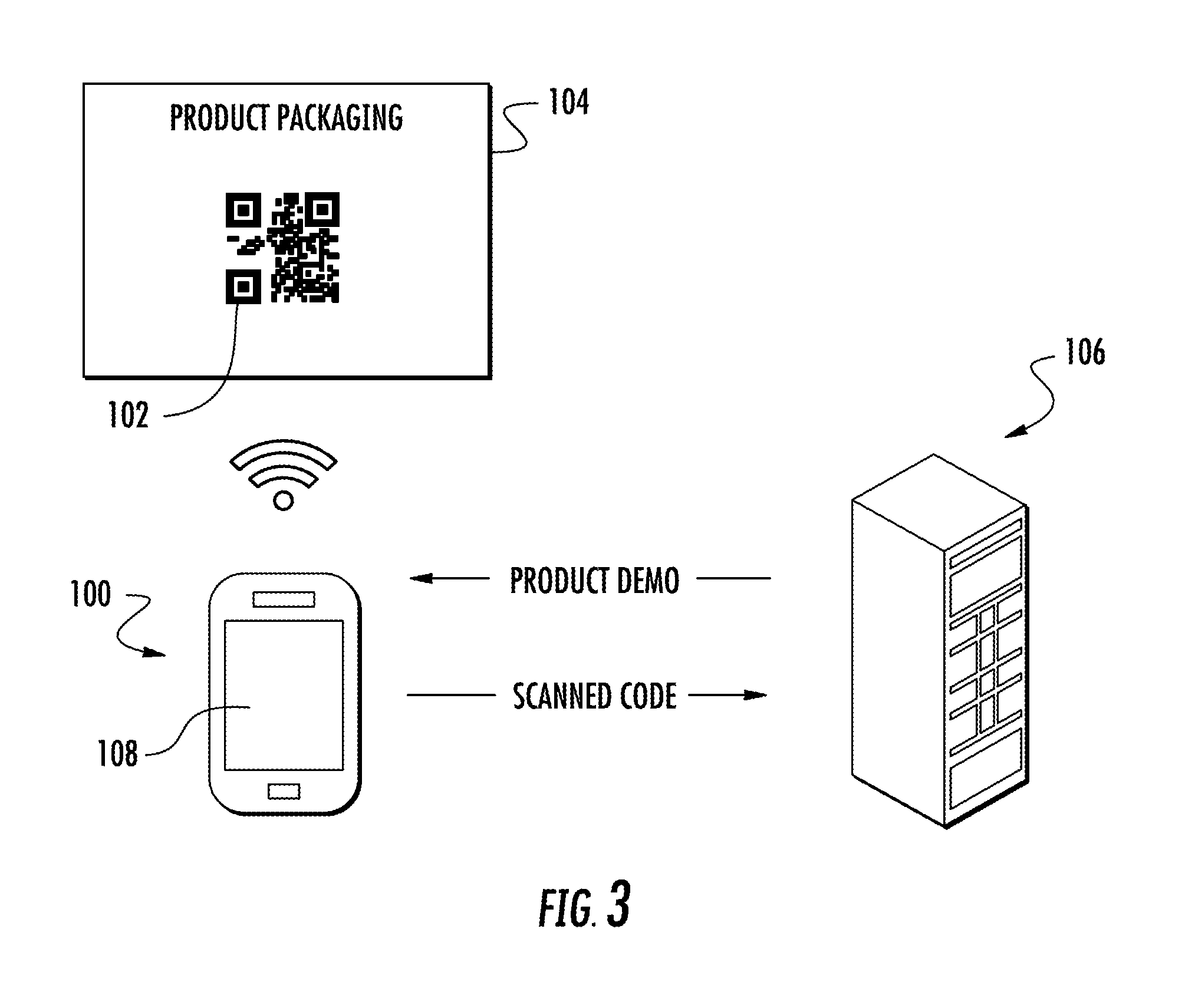

Method of simulating a virtual out-0f-box experience of a packaged product

ActiveUS20160189288A1Buying/selling/leasing transactionsImage data processingComputer graphics (images)Display device

A method of simulating a virtual out-of-box experience of a packaged product with an electronic device is disclosed. The packaging of the product has a computer-readable code which is scanned with a camera on the electronic device. A product demonstration application is retrieved for the product from the internet. Surfaces of the packaging are recognized by the application. An image of a virtual representation of the product is rendered on an image of the packaging to make a combined image, which is displayed to the user on the display of the electronic device wherein the combined image simulates X-Ray vision into the packaging, revealing the product. The method further updates the combined image as the user manipulates the product in front of the camera, revealing different view of the product, a three-dimensional view of the product may further be displayed outside the packaging, and features demonstrated of the virtual product.

Owner:HAND HELD PRODS

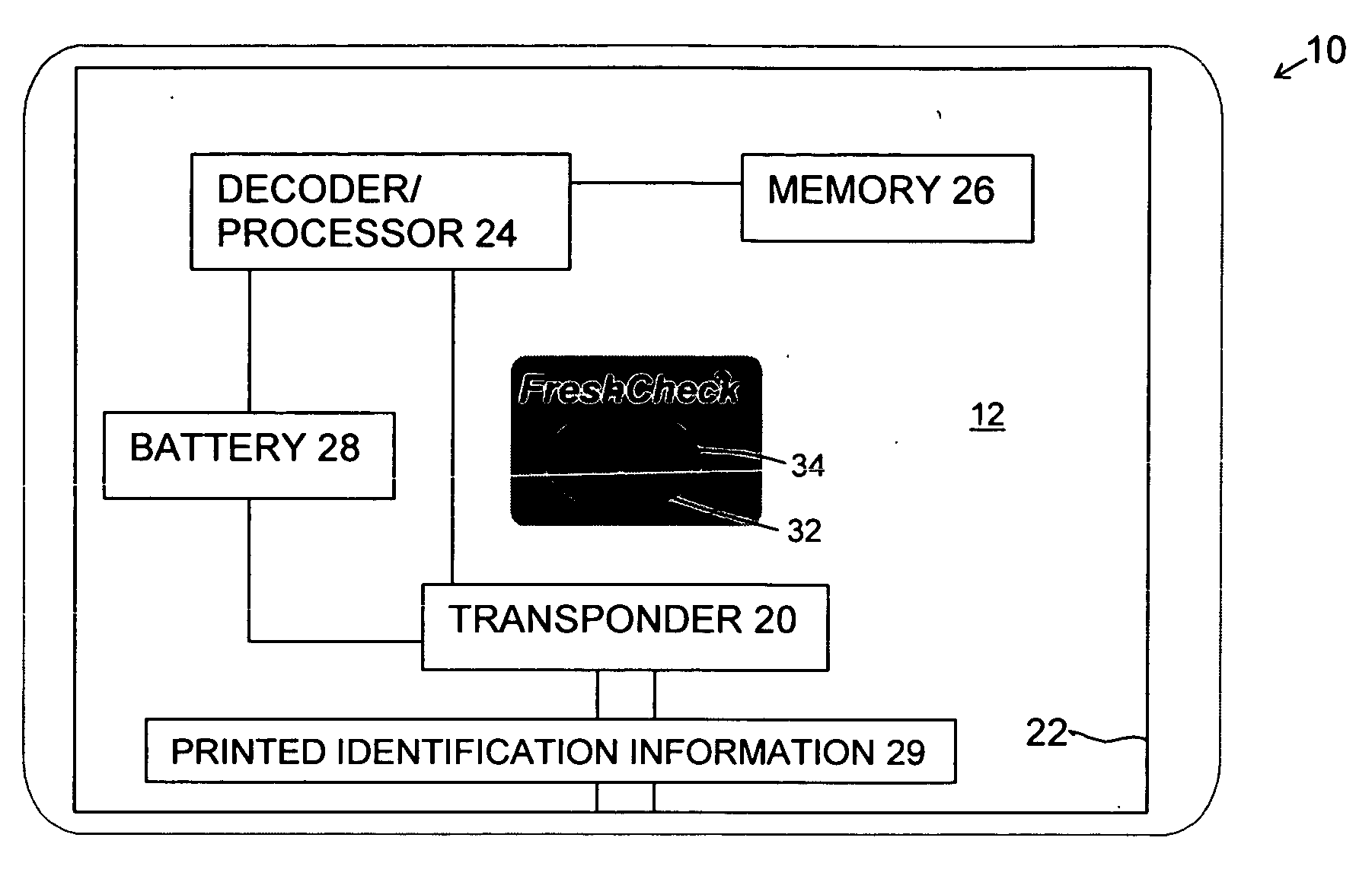

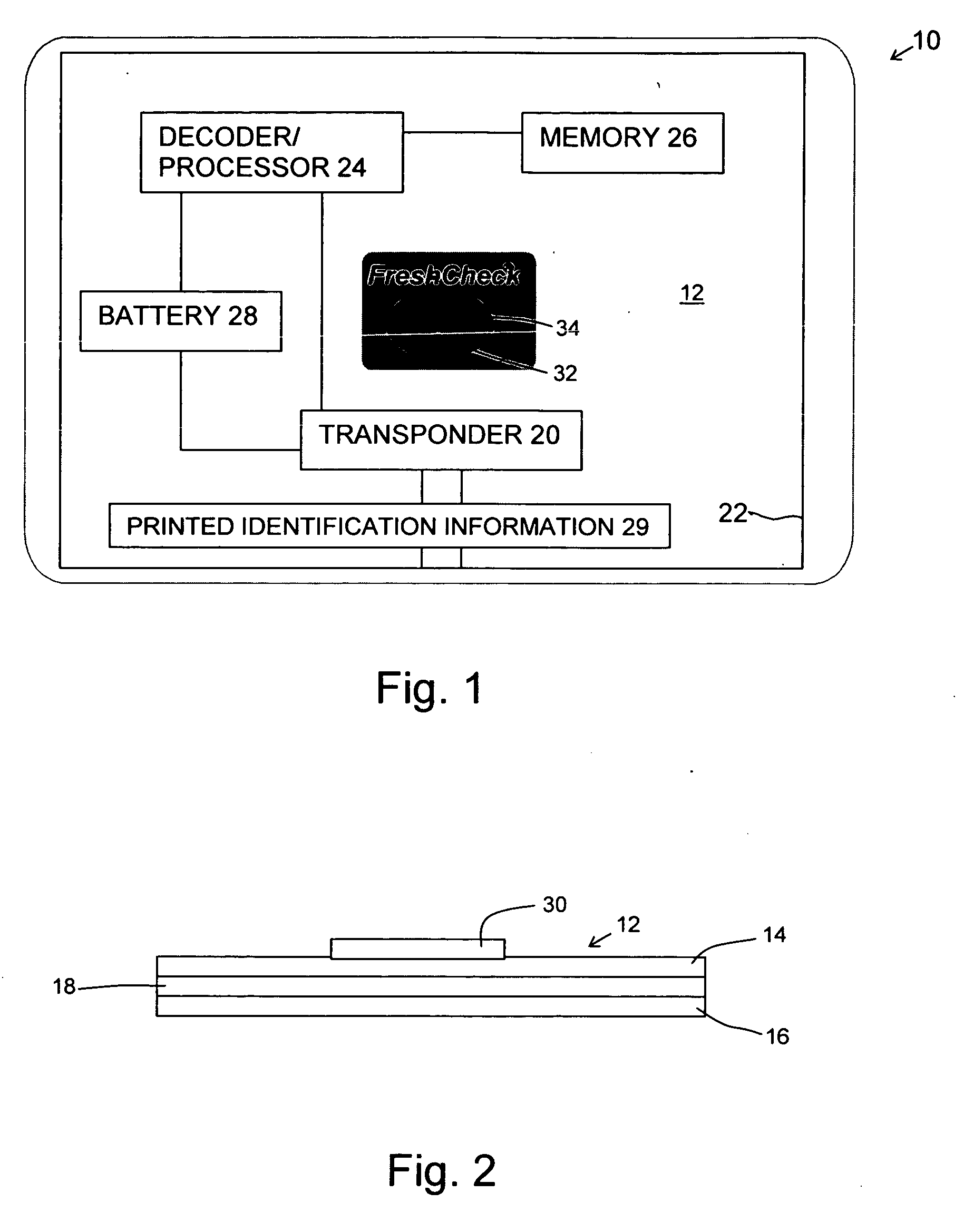

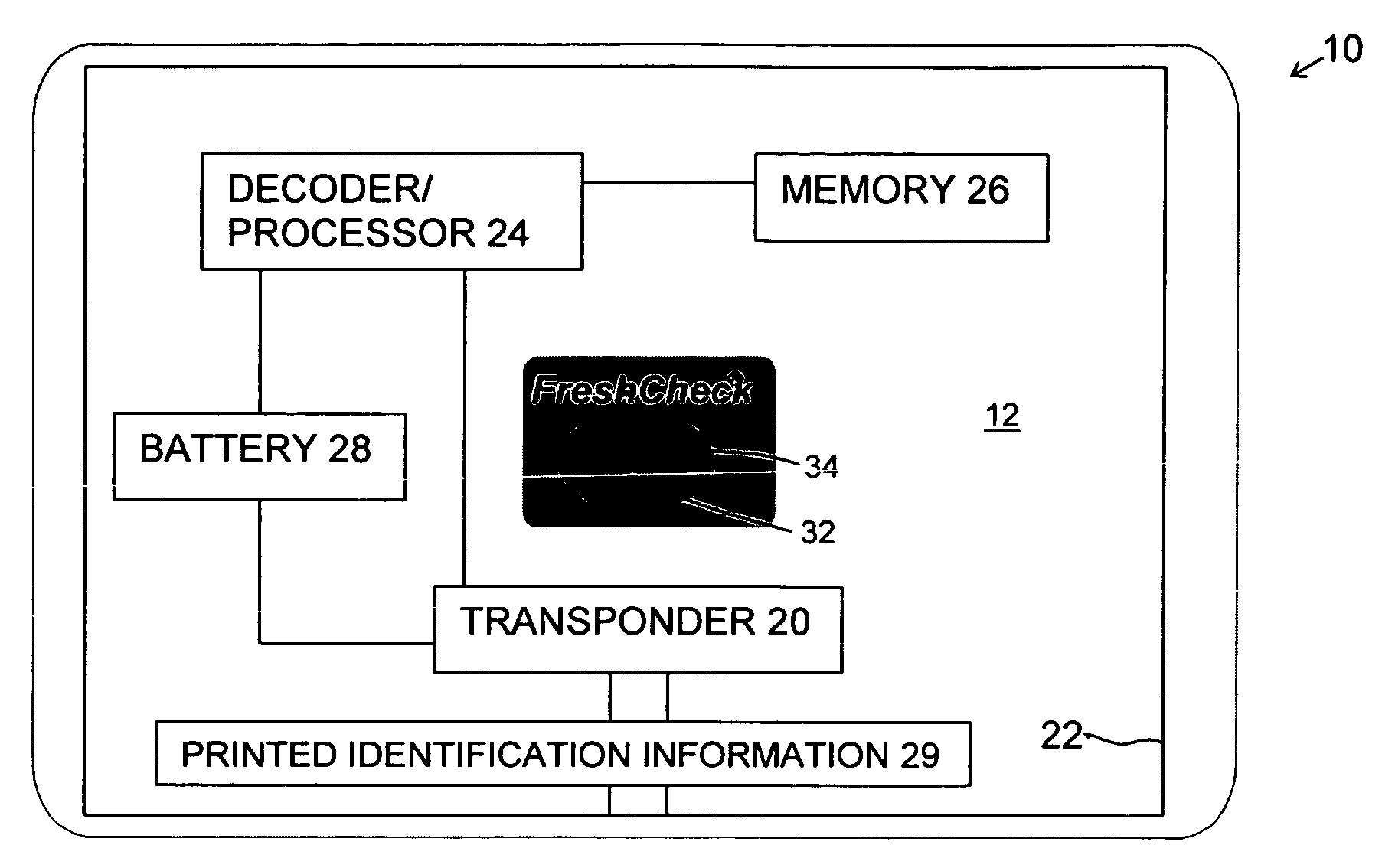

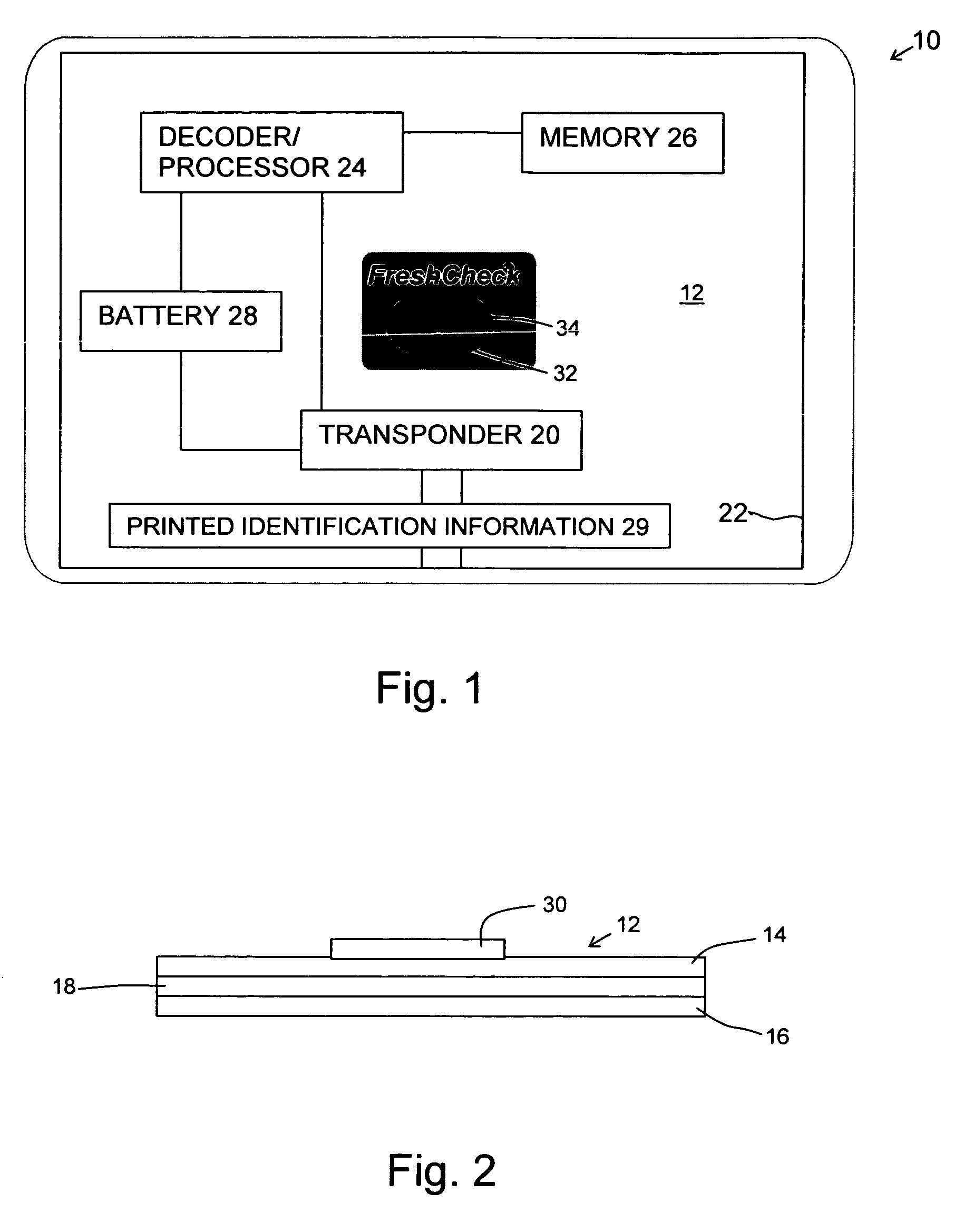

RFID tag with visual environmental condition monitor

ActiveUS20060145863A1Easy to processEasy to readContainer decorationsLevel indicationsStatistical analysisColor changes

A combination RFID tag intended to be associated with a host product, for example by being secured to the outside of a package containing a perishable product, e.g. foodstuffs or vaccines, which RFID tag is provided with a visually readable environmental condition exposure indicator. The visual indicator can sense the exposure of the RFID tag to an environmental condition e.g. temperature, experienced by the host product providing a visual indication, e.g. a color change, readable externally of the RFID tag of the sensed environmental condition. The visual indicator can be chemically active, for example an acetylenic agent, and may be responsive to cumulative temperature excursions over time. The novel RFID tag 11 and tag inspection methods of the invention permit an efficacious harnessing of information about the condition exposure history of a specific inventory item including product identification and related data. The information from multiple items can be compiled into a database that may be audited or statistically analyzed to reveal useful information regarding the handling of the items.

Owner:TEMPTIME CORP

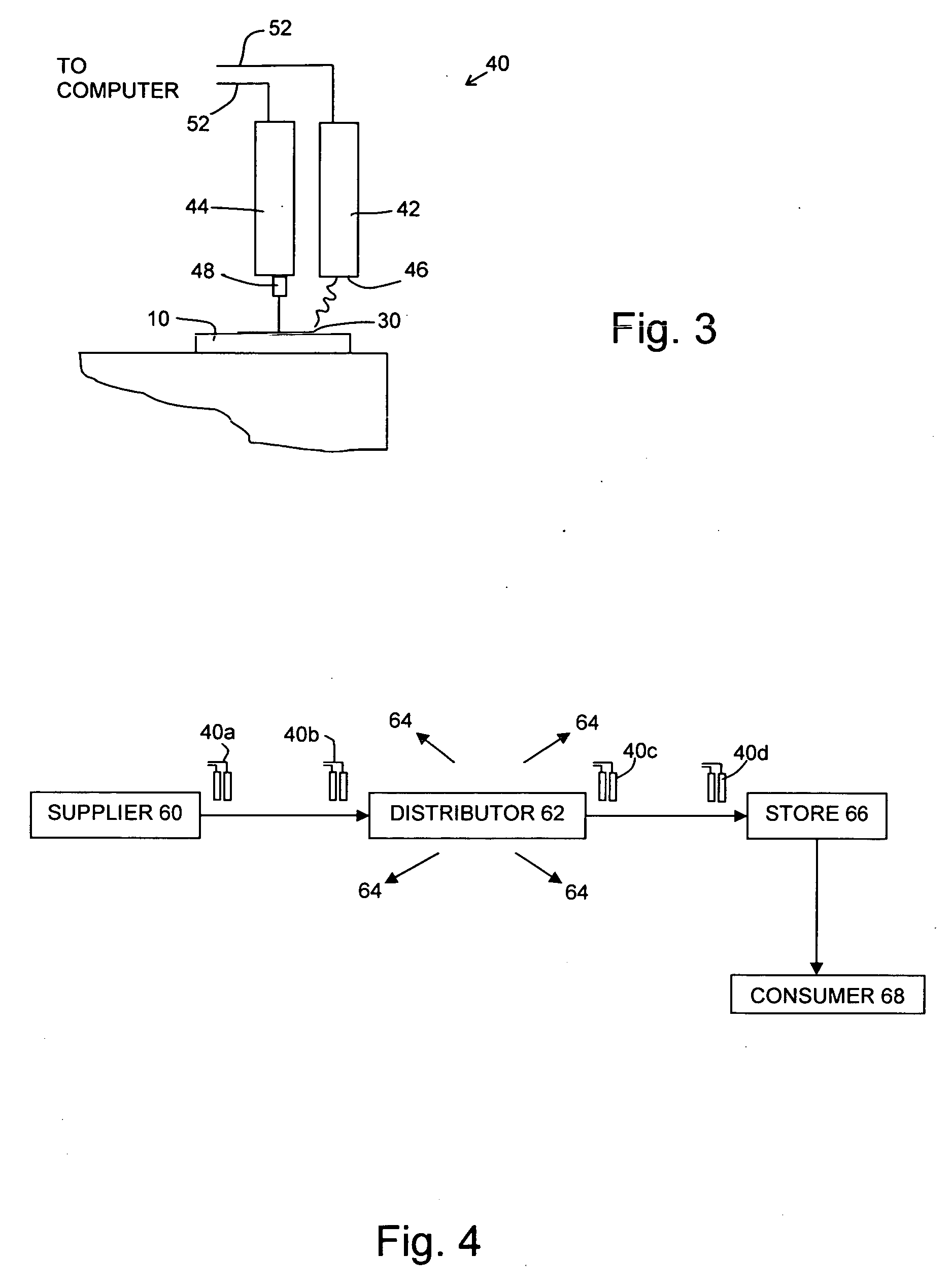

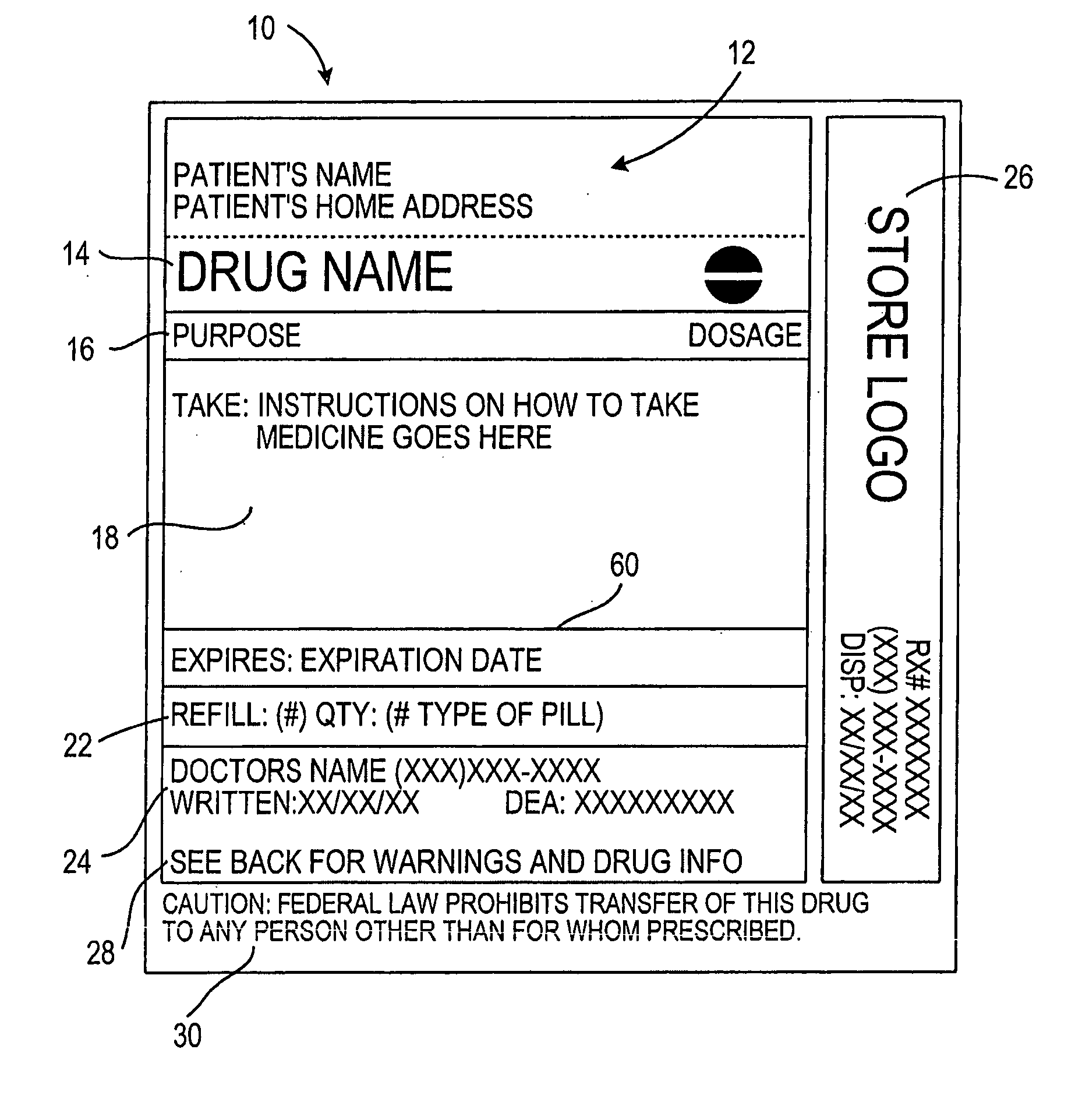

Medication packaging and labeling system

ActiveUS20070029788A1Safe and reliableAvoid misuseStampsSmall article dispensingInformation CardComputer science

Method for generating a label for a medication in which information about the medication is obtained and printed on the label in a hierarchical manner with more important information in a more prominent location or more prominent type relative to other less important information. The information may be divided into primary information and secondary information with the primary information being placed on the label before the secondary information. The label may be used in a container having a curved front wall, a planar rear wall, a substantially planar bottom wall and a cap engaging with the front and rear walls to seal the container. The rear wall is constructed with a device for removably received an information card containing information relating to the medication.

Owner:CVS PHARMACY INC

RFID medical supplies consumption monitoring system and method

ActiveUS7639136B1Accurate confirmationHealthcare resources and facilitiesLogisticsMonitoring systemEngineering

A system and method for tracking supplies, particularly medical supplies, and specifically individual medical items, to the end of the product lifecycle to the point of utilizes. RFID tag technology is utilized. This has the advantage of enabling a system that requires less or no active intervention by the medical services delivery staff, such as nurses and doctors. Nonetheless, the system is applicable to other stand-off identification systems including taggant-based systems. The system provides for the monitoring of items, such as medical items, between the distribution center, facility stock rooms and inventory cabinets, and the procedure rooms in which the items are put into use. In one example, system and method associate stand-off, such as RFID, readers with waste-disposal or refuse containers and / or readers located near the point of usage, such as in or associated with the procedure rooms in order to monitor the endpoint of the product lifecycle. Thus, the knowledge of medical item disposal or disposal of the medical item's packaging is combined with one or more prior detections of the medical item, e.g., at acquisition and when moved to a different location such as storage, to generate a usage history for the item. In all or more cases, this knowledge is acquired with out human intervention by judicious location of readers at the distribution center and / or medical facility.

Owner:WAVEMARK

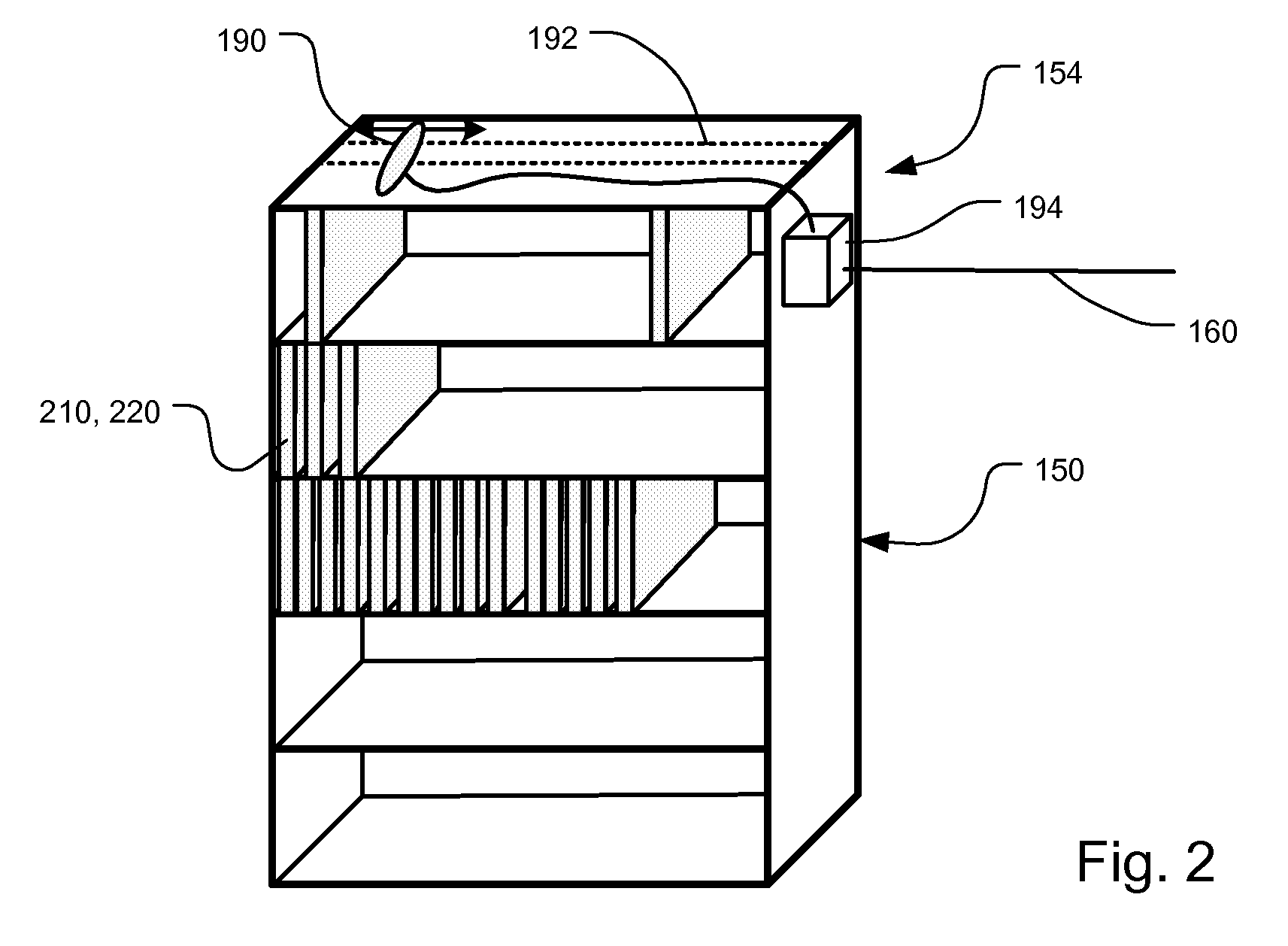

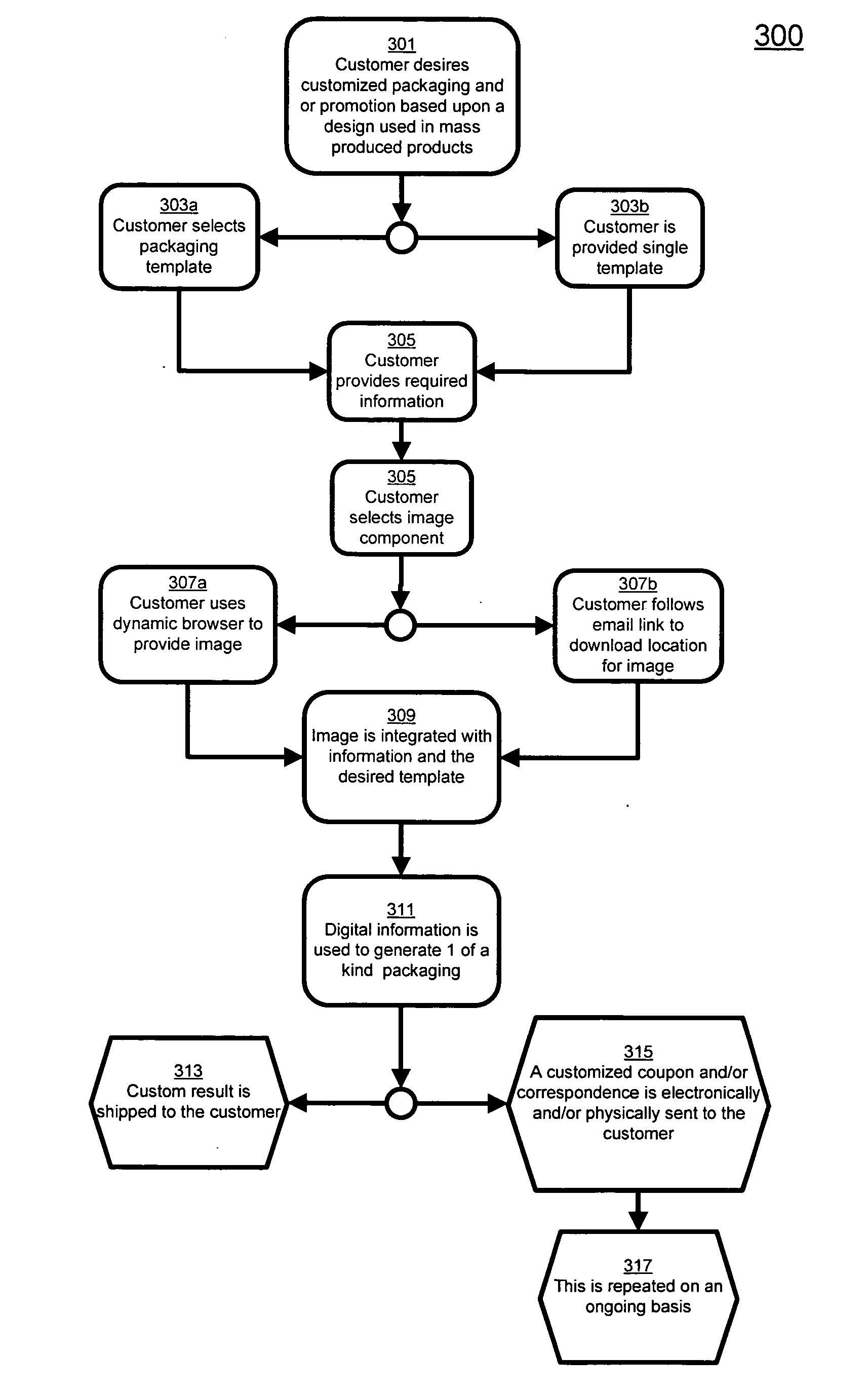

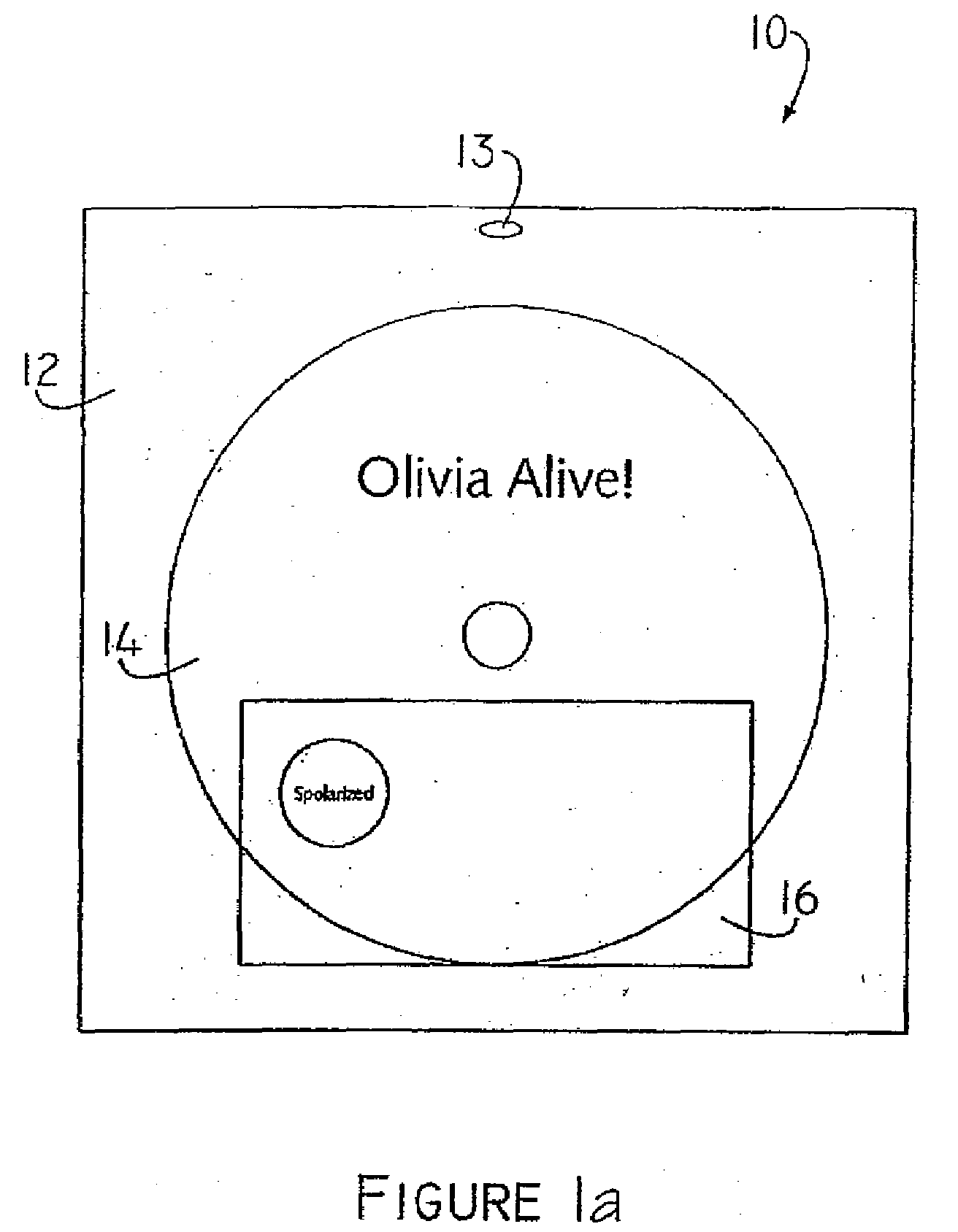

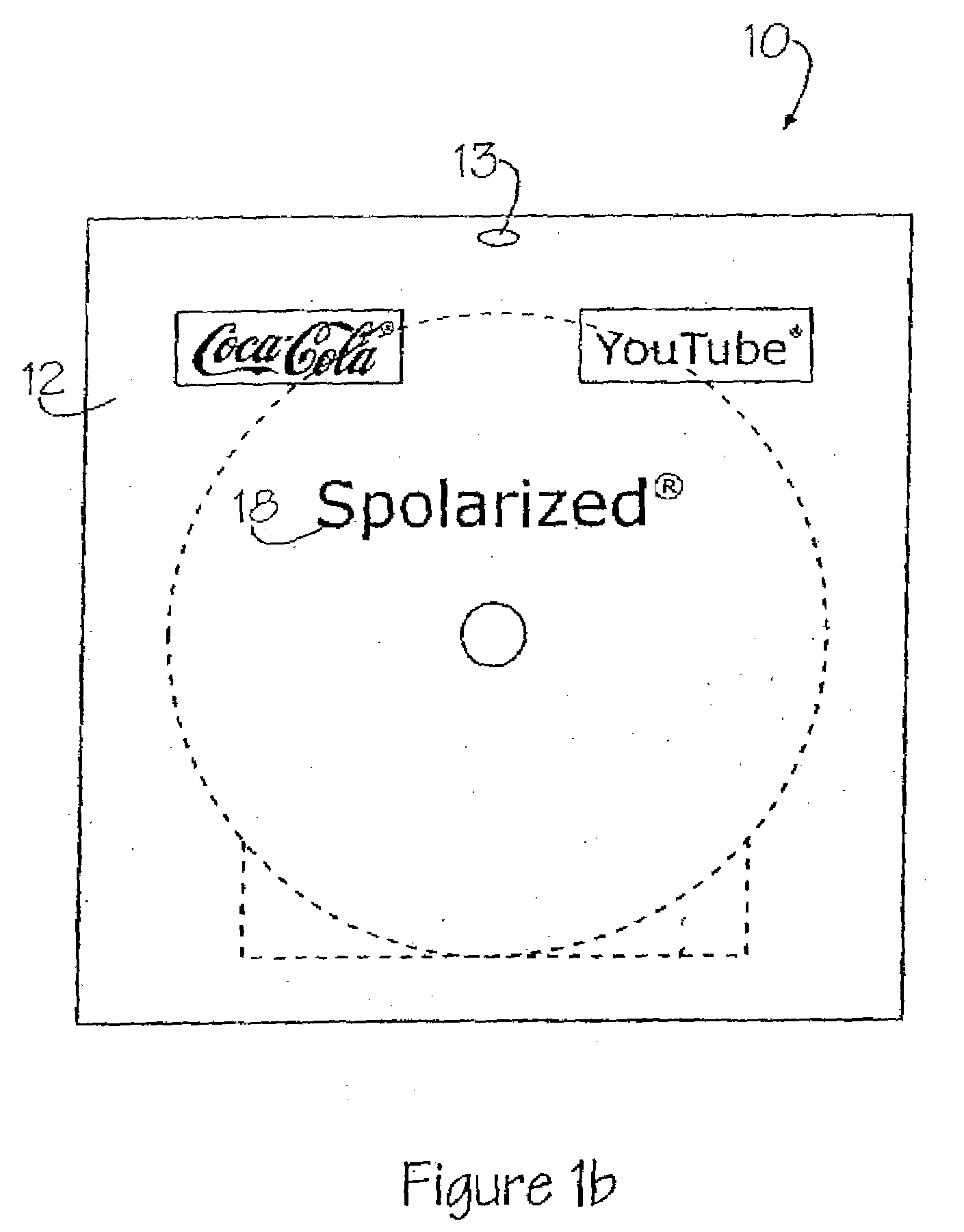

Method and system for facilitating individualized packaging and follow-up capability on a mass scale

Owner:ON THE PACKAGE

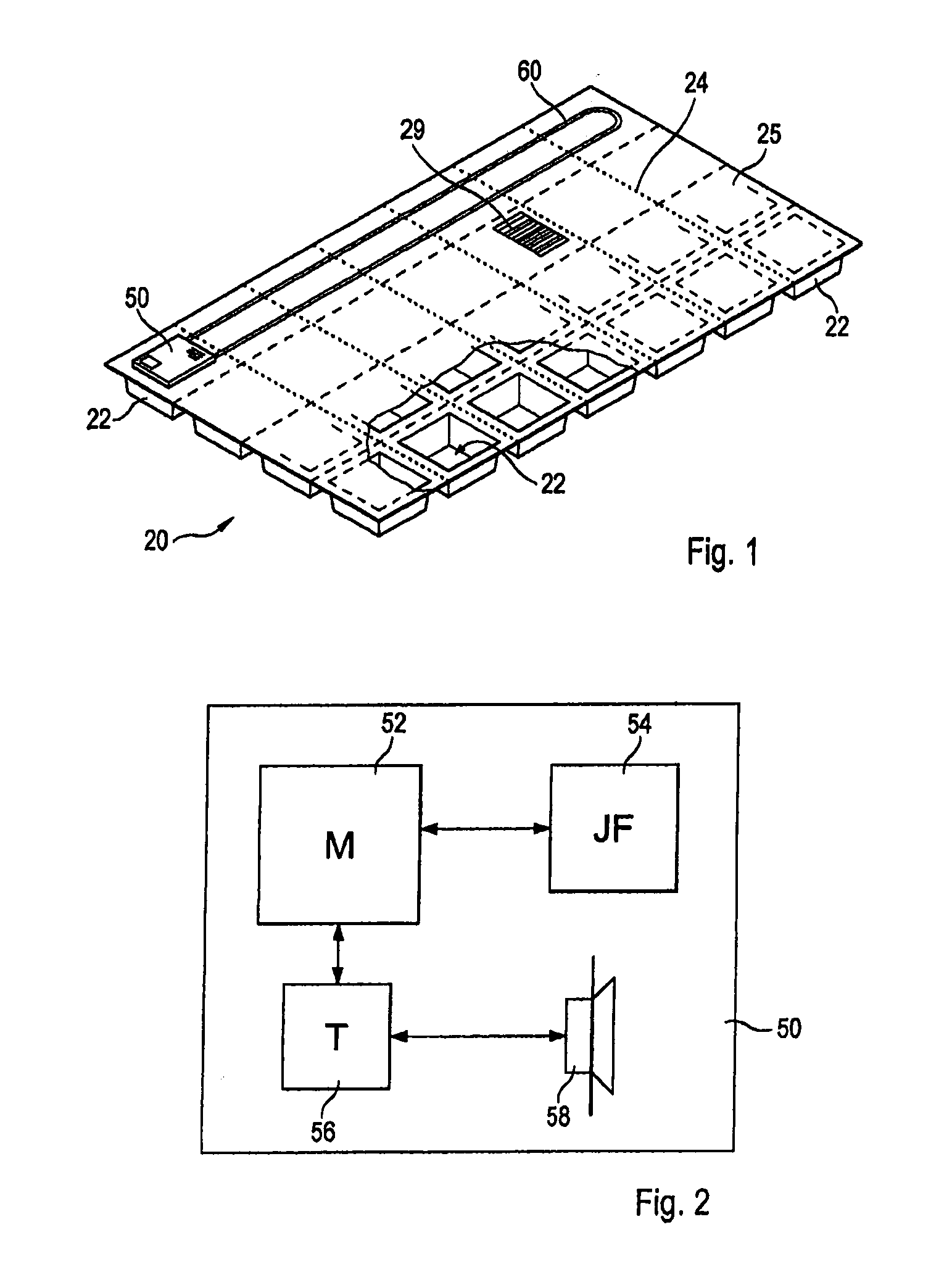

RFID tag with visual environmental condition monitor

ActiveUS7209042B2Easy to processEasy to readContainer decorationsLevel indicationsTime responseStatistical analysis

A combination RFID tag intended to be associated with a host product, for example by being secured to the outside of a package containing a perishable product, e.g. foodstuffs or vaccines, which RFID tag is provided with a visually readable environmental condition exposure indicator. The visual indicator can sense the exposure of the RFID tag to an environmental condition e.g. temperature, experienced by the host product providing a visual indication, e.g. a color change, readable externally of the RFID tag of the sensed environmental condition. The visual indicator can be chemically active, for example an acetylenic agent, and may be responsive to cumulative temperature excursions over time. The novel RFID tag 11 and tag inspection methods of the invention permit an efficacious harnessing of information about the condition exposure history of a specific inventory item including product identification and related data. The information from multiple items can be compiled into a database that may be audited or statistically analyzed to reveal useful information regarding the handling of the items.

Owner:TEMPTIME CORP

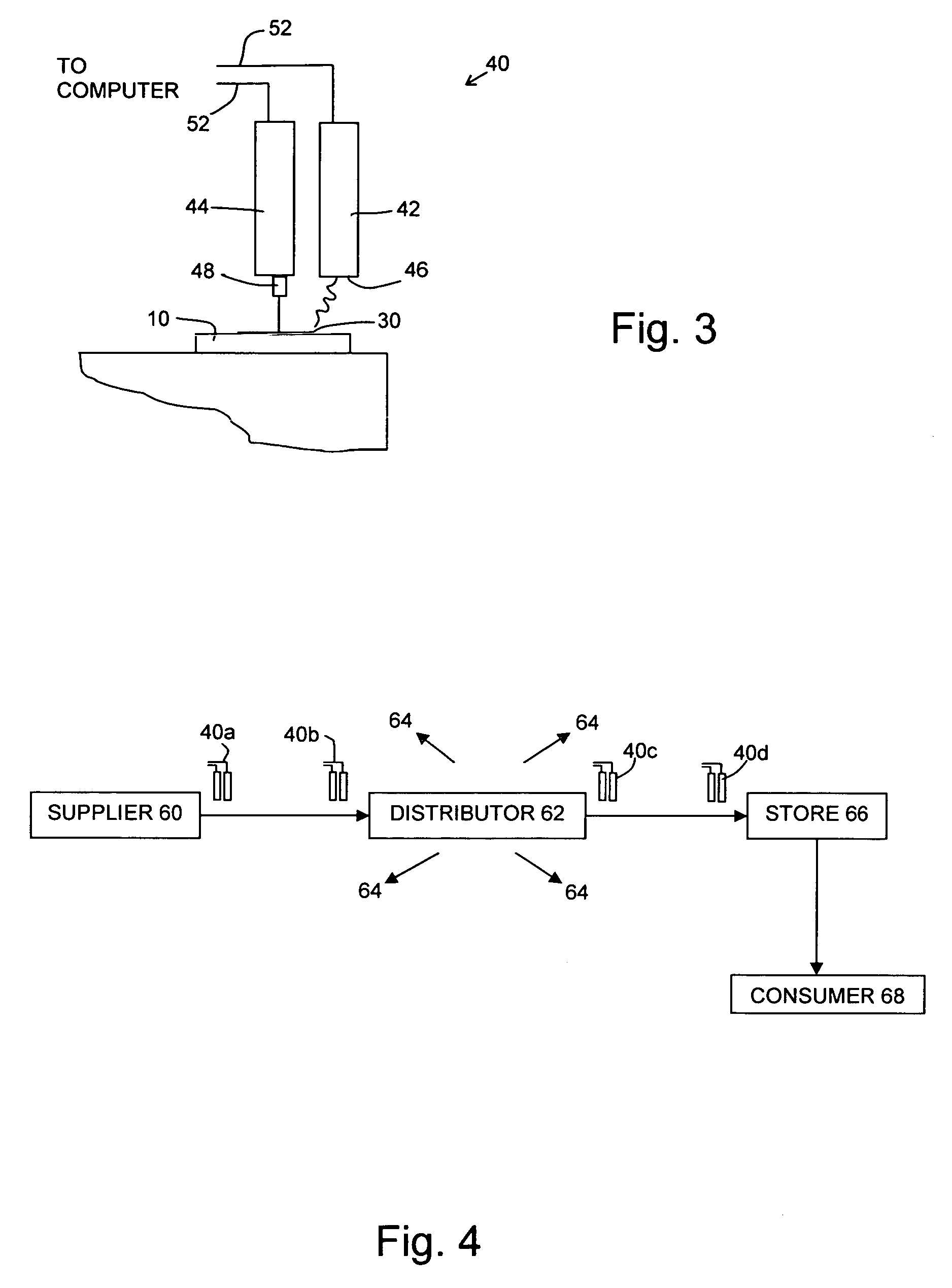

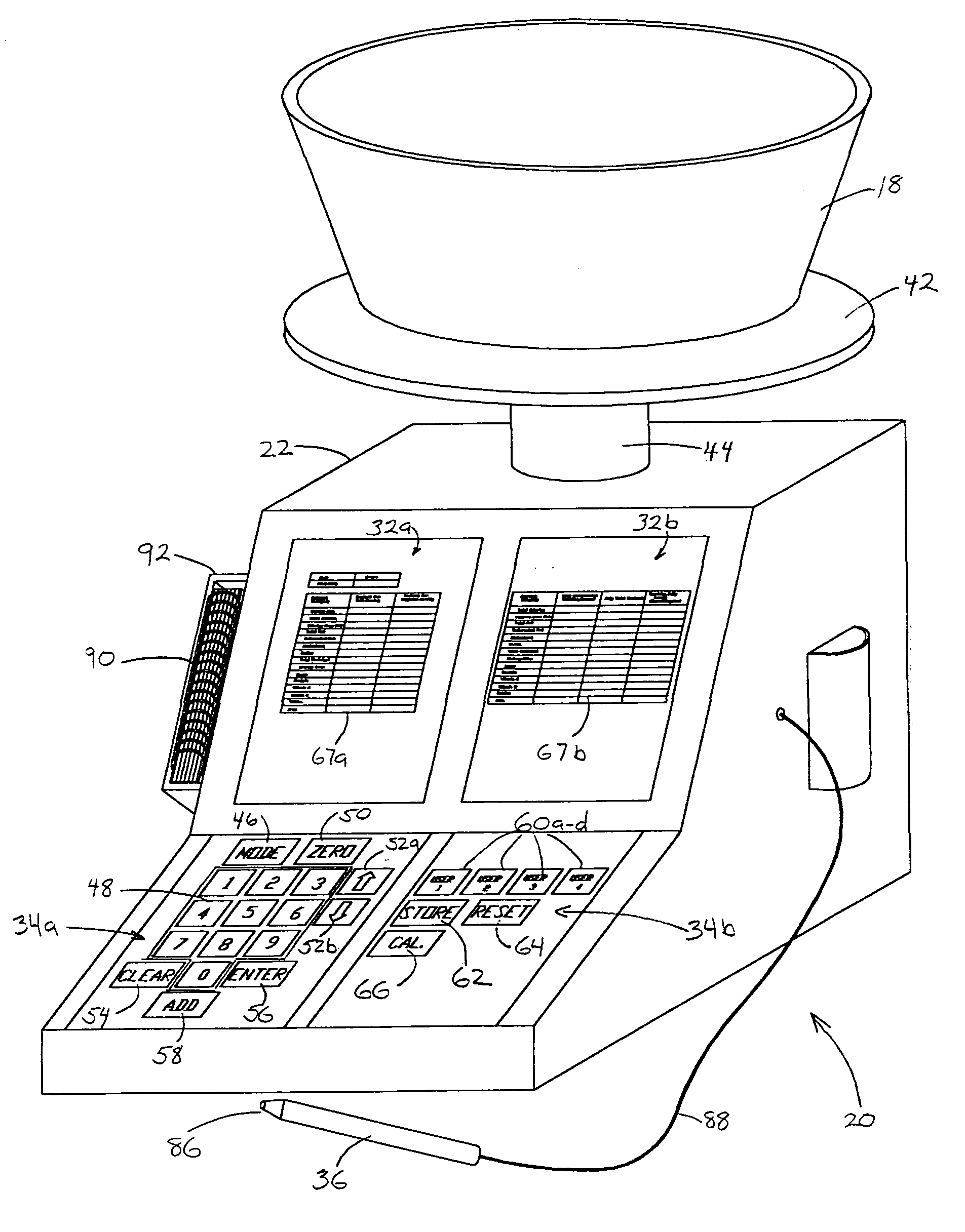

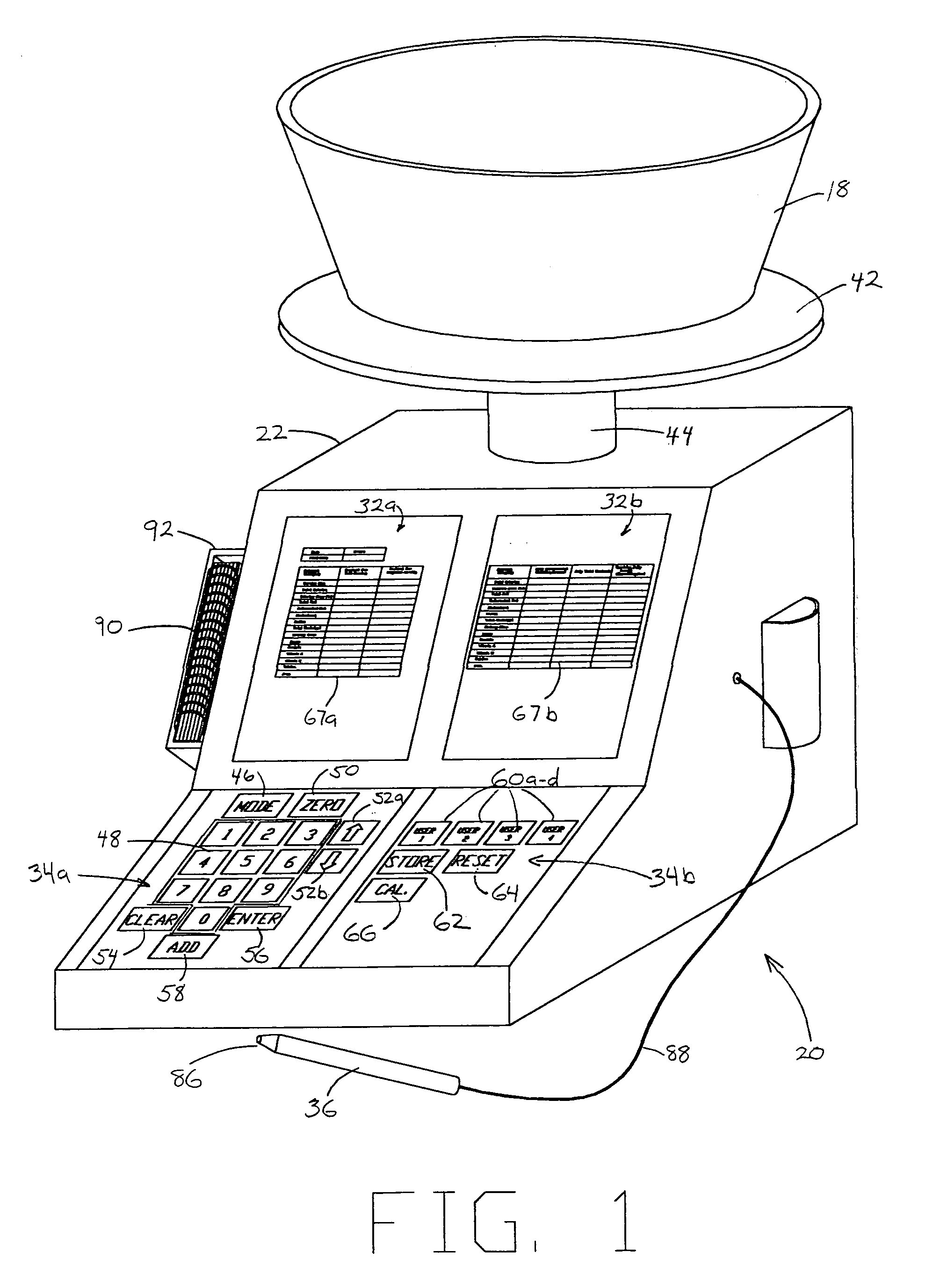

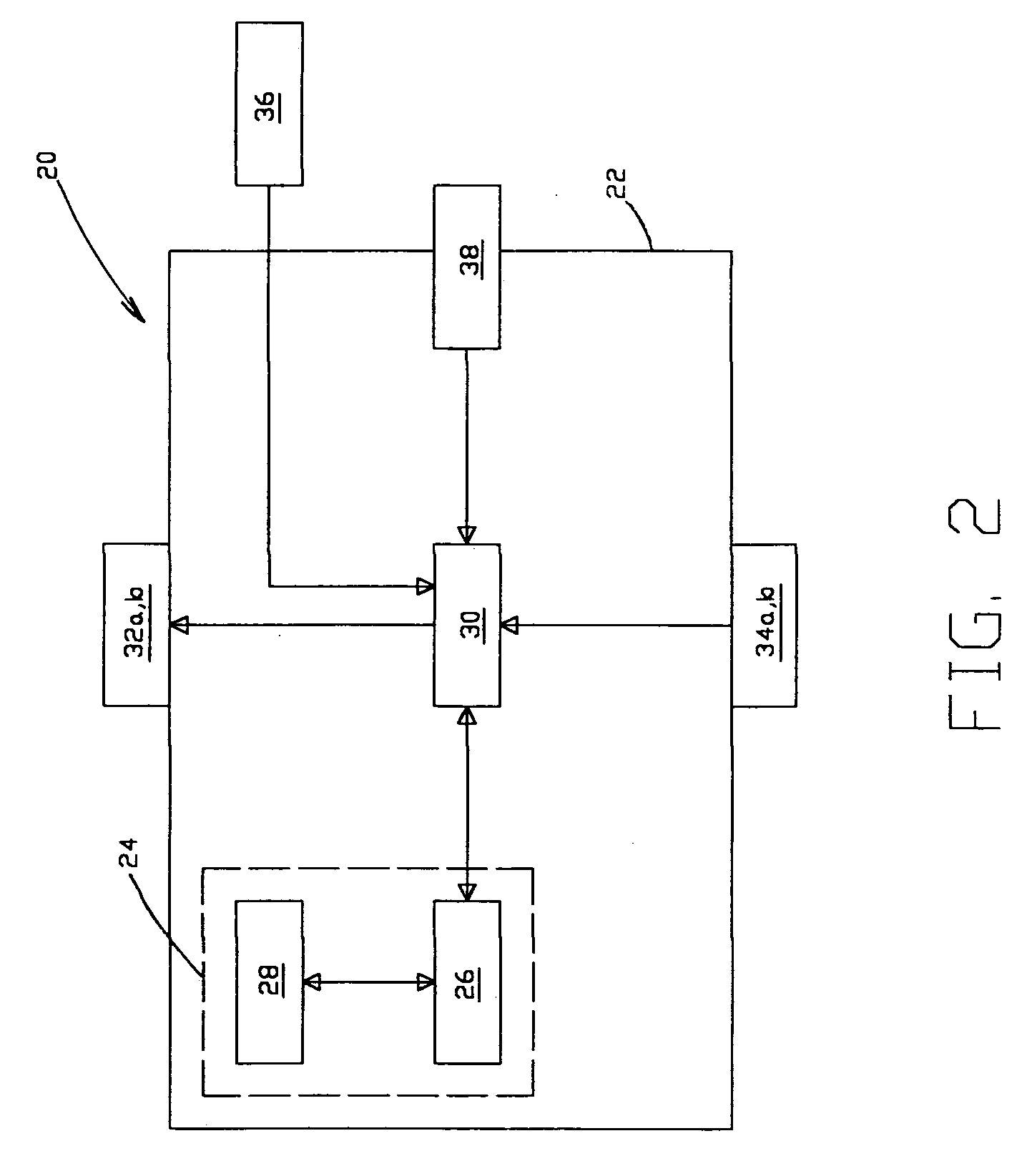

Computerized dietetic scale

InactiveUS6978221B1Convenient and simple and rapid to useEasily compared for accuracyTime indicationSurgeryNutritionBarcode

A dietetic scale and method for calculating and tracking nutritional content information. The scale includes a bar code reader for identifying a food product from its package, with food content data per unit weight of the product being retrieved from a database. The database is a compilation of standardized nutrition facts promulgated by the FDA or other authority for the food products, with the bar code being correlated with the food products by means of their individual UPC numbers. The scale cumulatively sends the nutritional content data for servings of food products consumed over a predetermined interval of time, and then compares the summed values with a predetermined goal that includes minimums and maximums for selected contents. The information may be outputted to a digital flashcard or other electronic storage media for subsequent retrieval and analysis.

Owner:RUDY RICHARD J

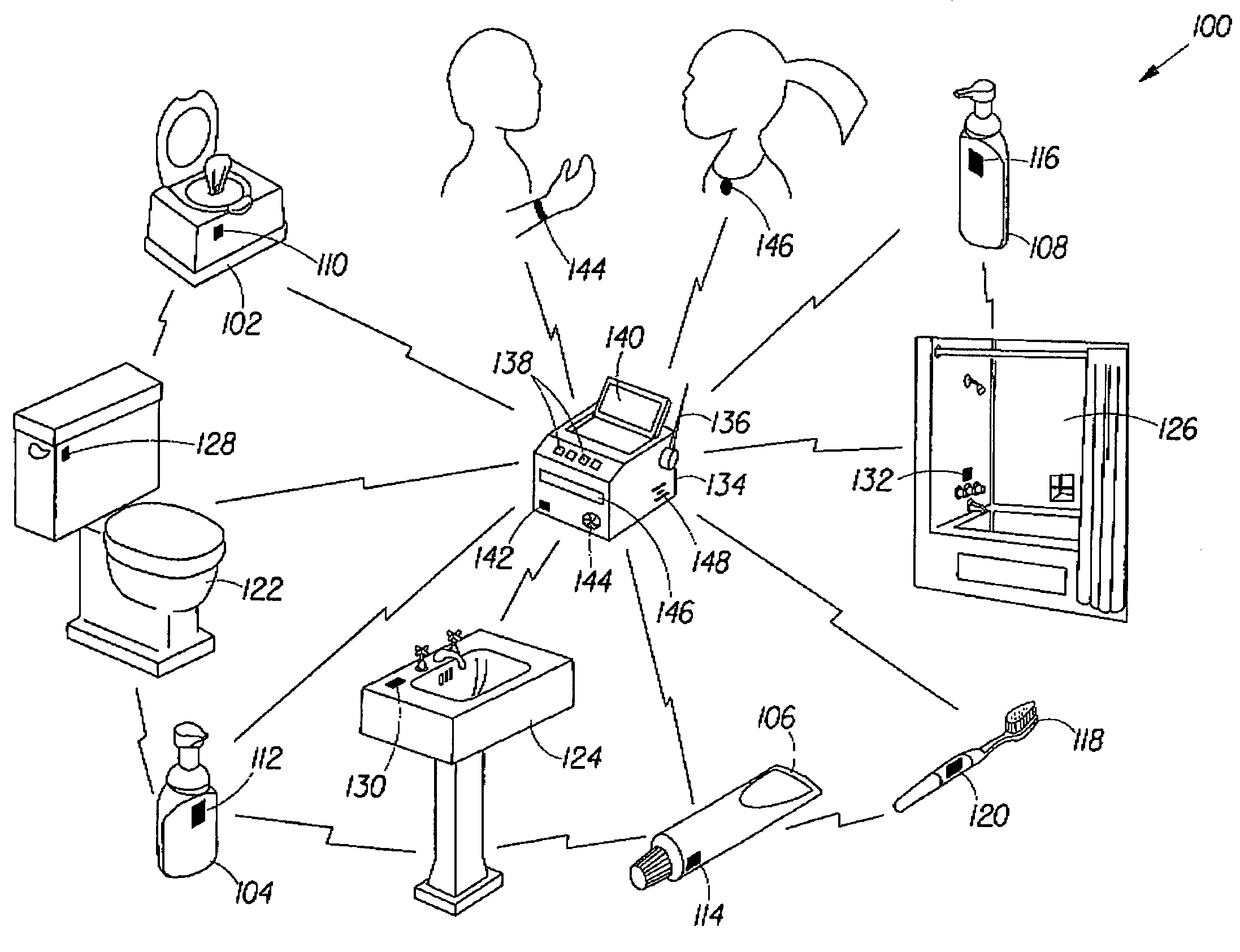

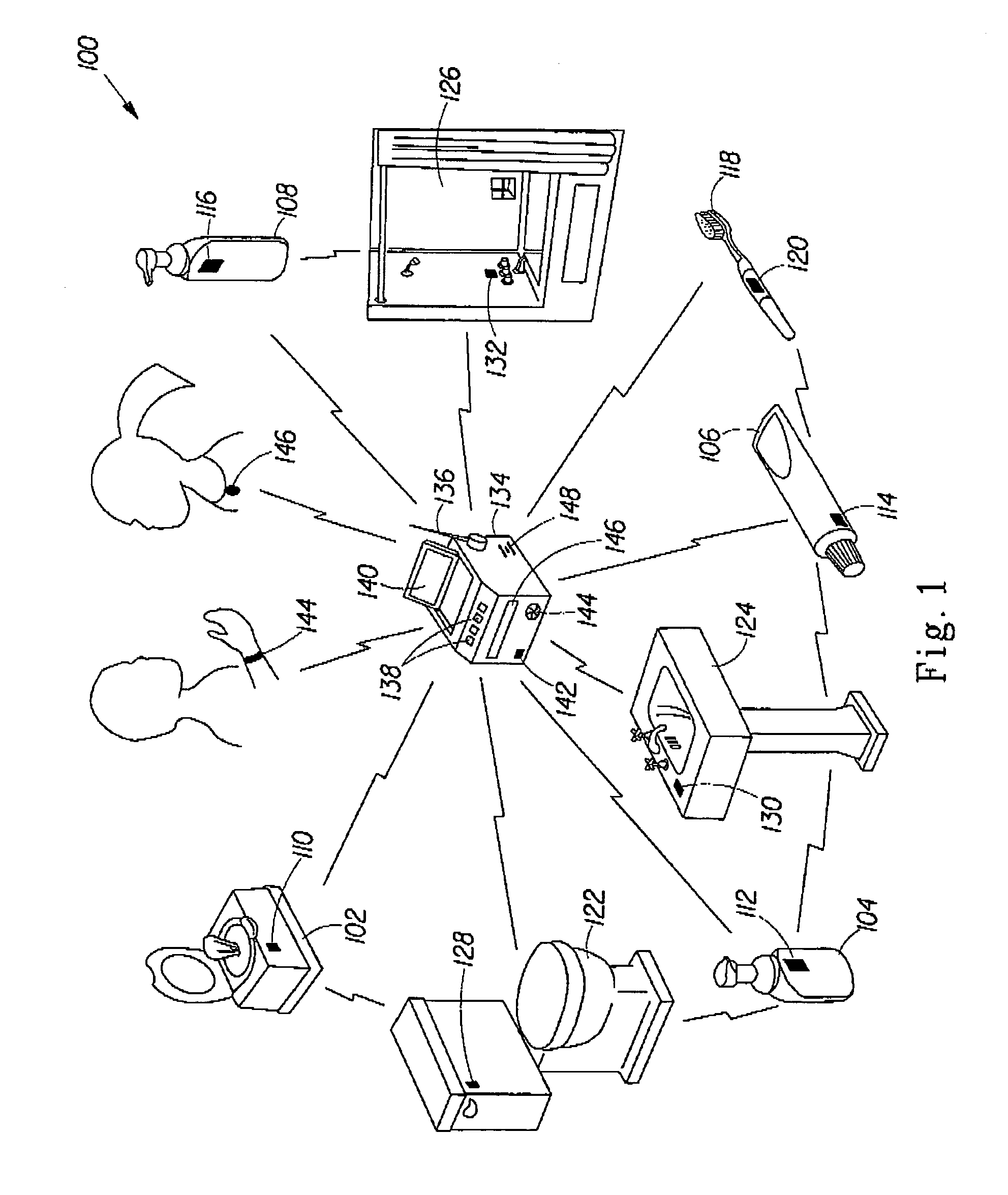

Interactive packaging for development of personal hygiene habits

InactiveUS20070182571A1Registering/indicating working of machinesElectric testing/monitoringHabitEmbedded system

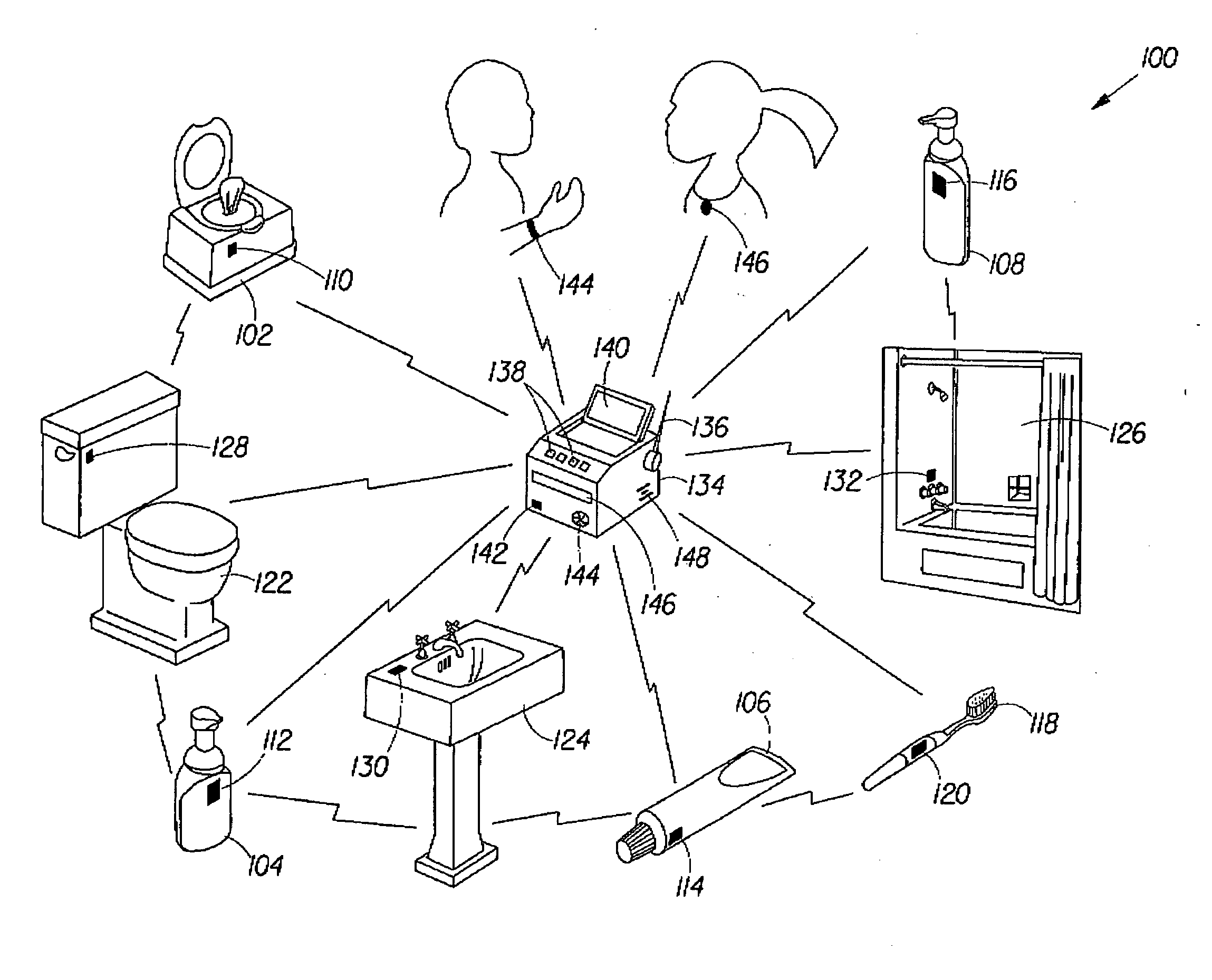

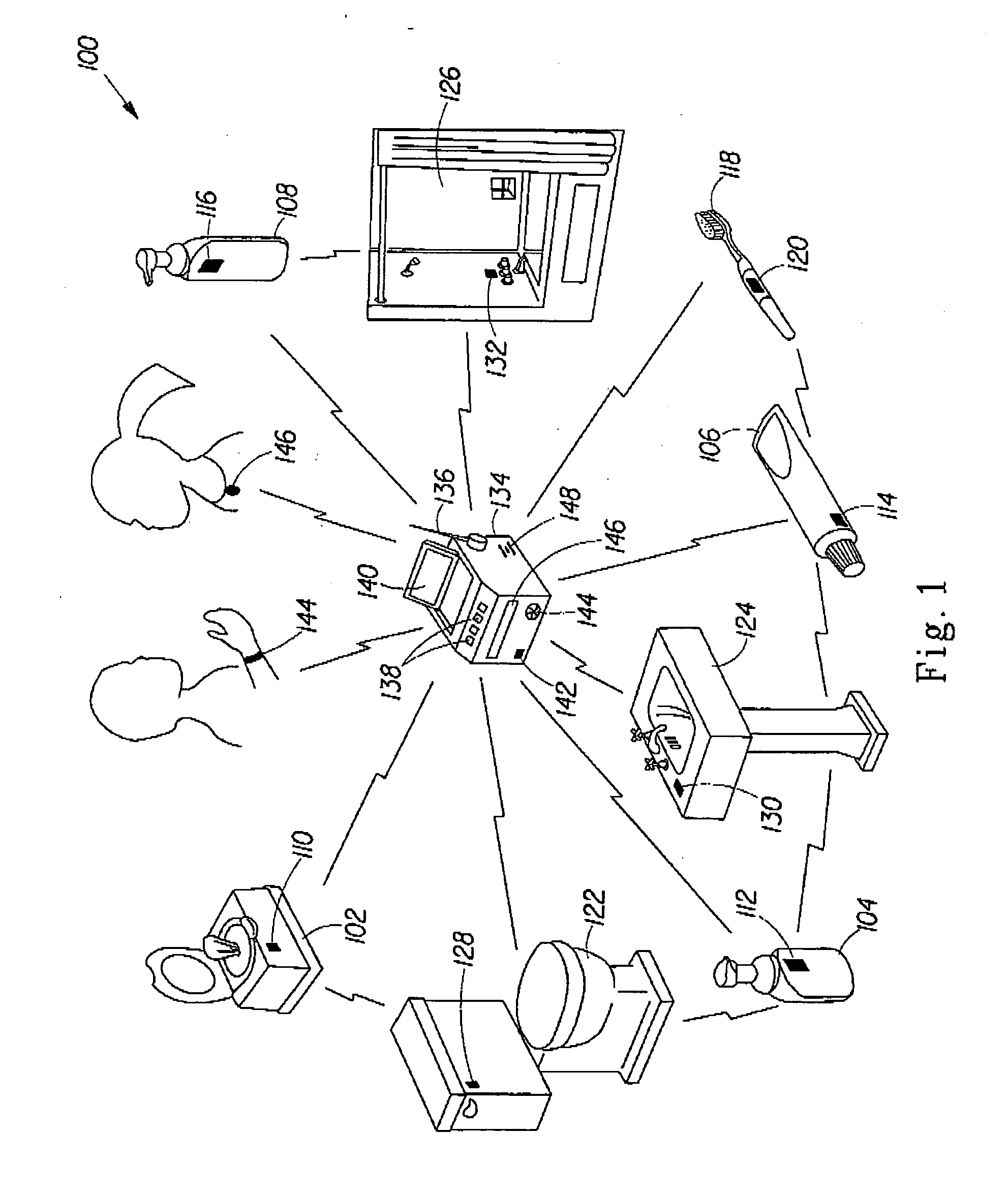

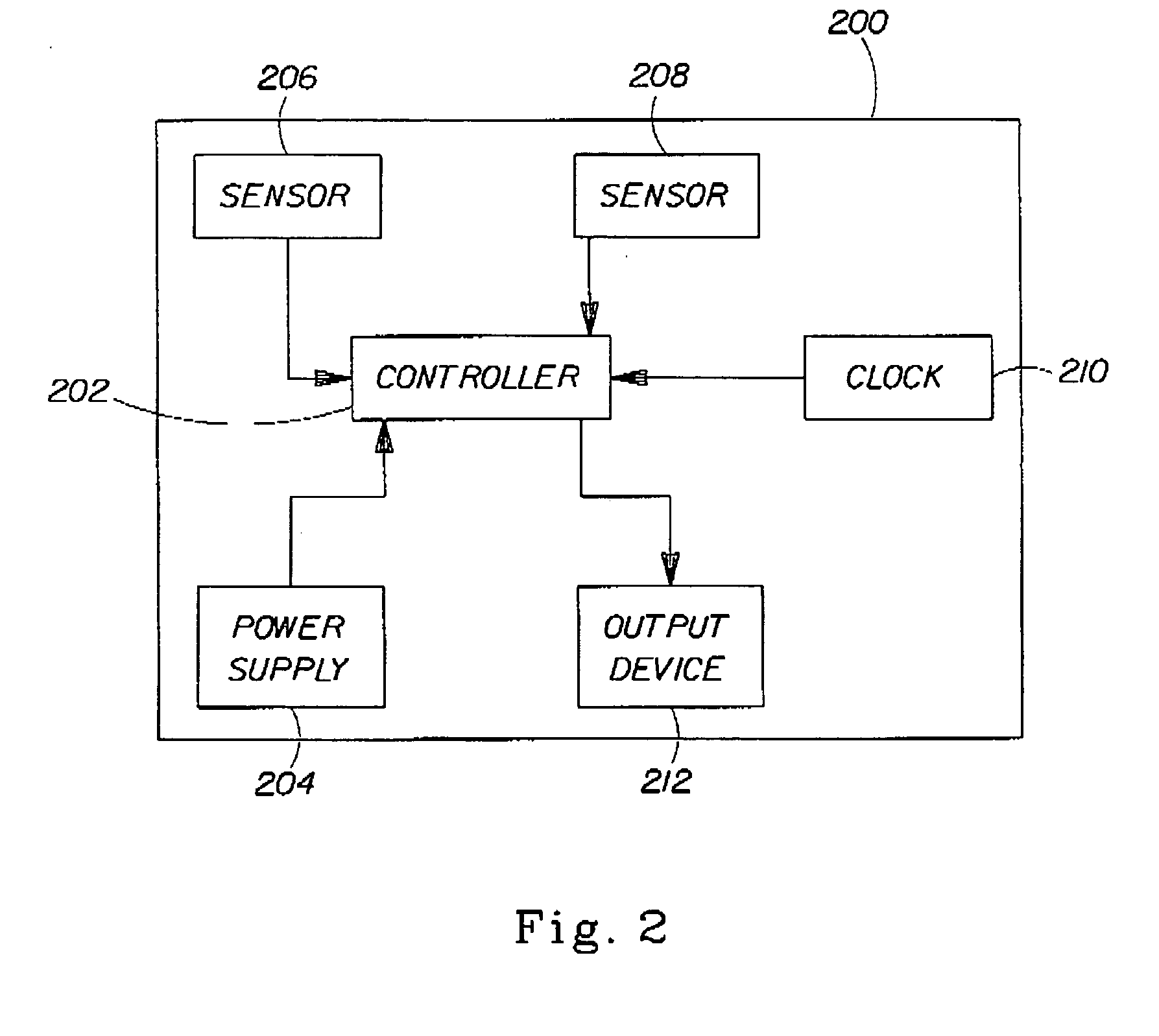

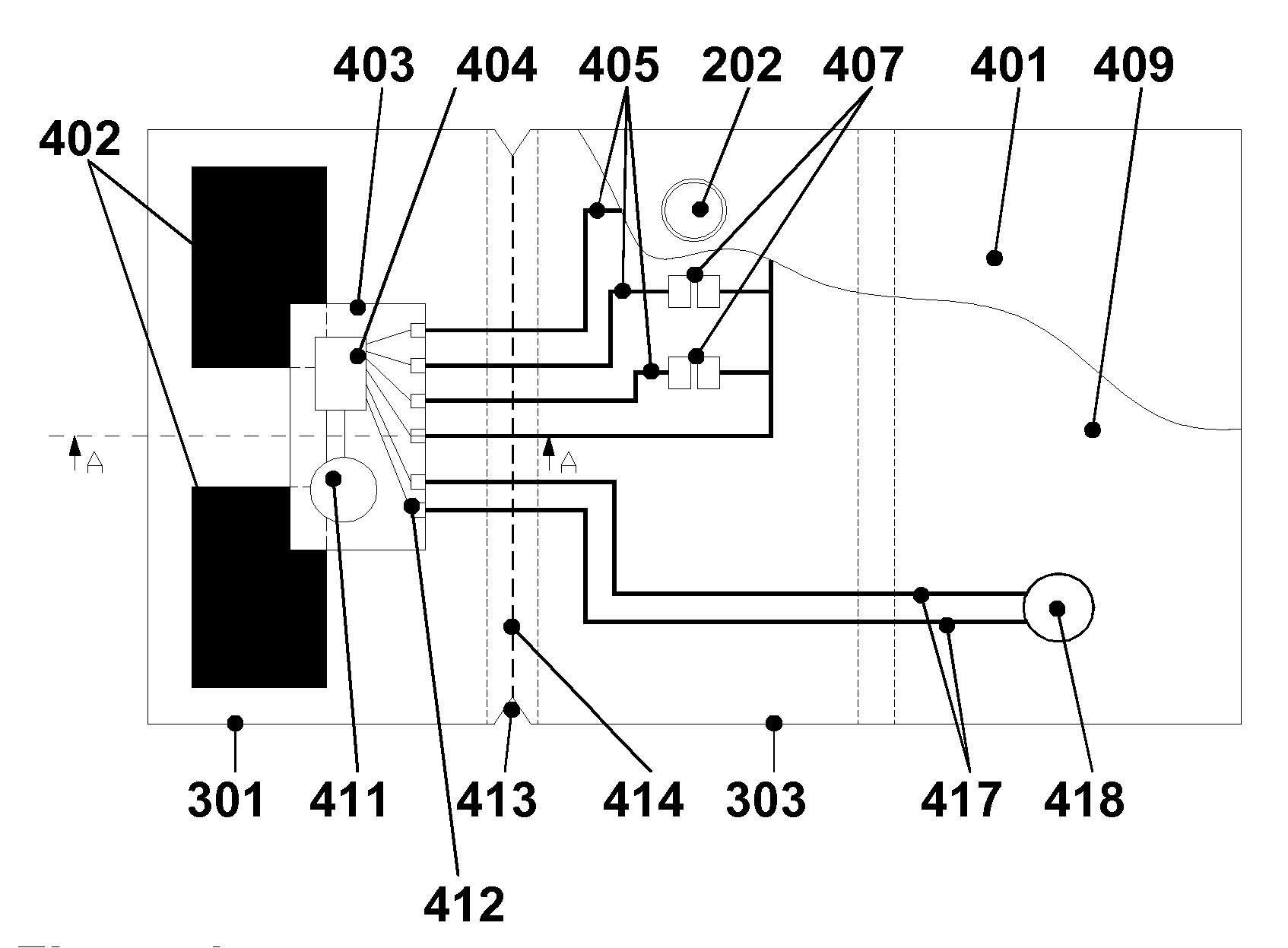

The disclosure is directed to an interactive packaging system for monitoring the usage of personal hygiene products, personal hygiene product packages, and restroom facilities. The interactive packaging system may include a plurality of usage monitoring devices each configured to detect physical stimulus associated with the usage of the product, package or facility with which the usage monitoring device is associate, and to transmit usage messages containing information relating to the detected physical stimulus. The interactive packaging system may further include a base station configured to receive the usage messages transmitted by the plurality of usage monitoring devices and to generate sensory perceptible outputs corresponding to the information contained in the usage messages. Either the usage monitoring devices or the base station may be configured to determine whether the products, packages or facilities are used appropriately based on the detected physical stimulus.

Owner:THE PROCTER & GAMBLE COMPANY

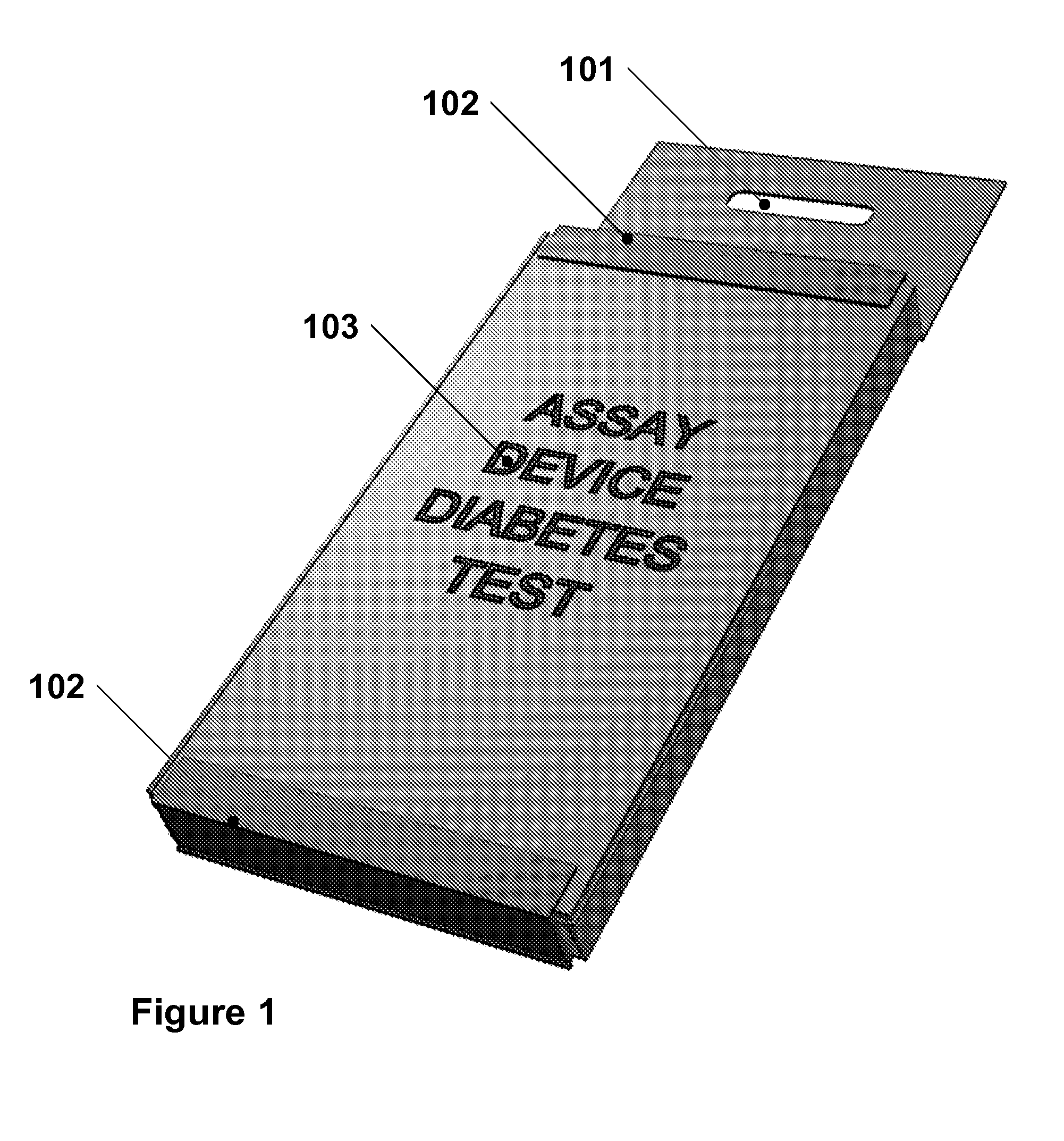

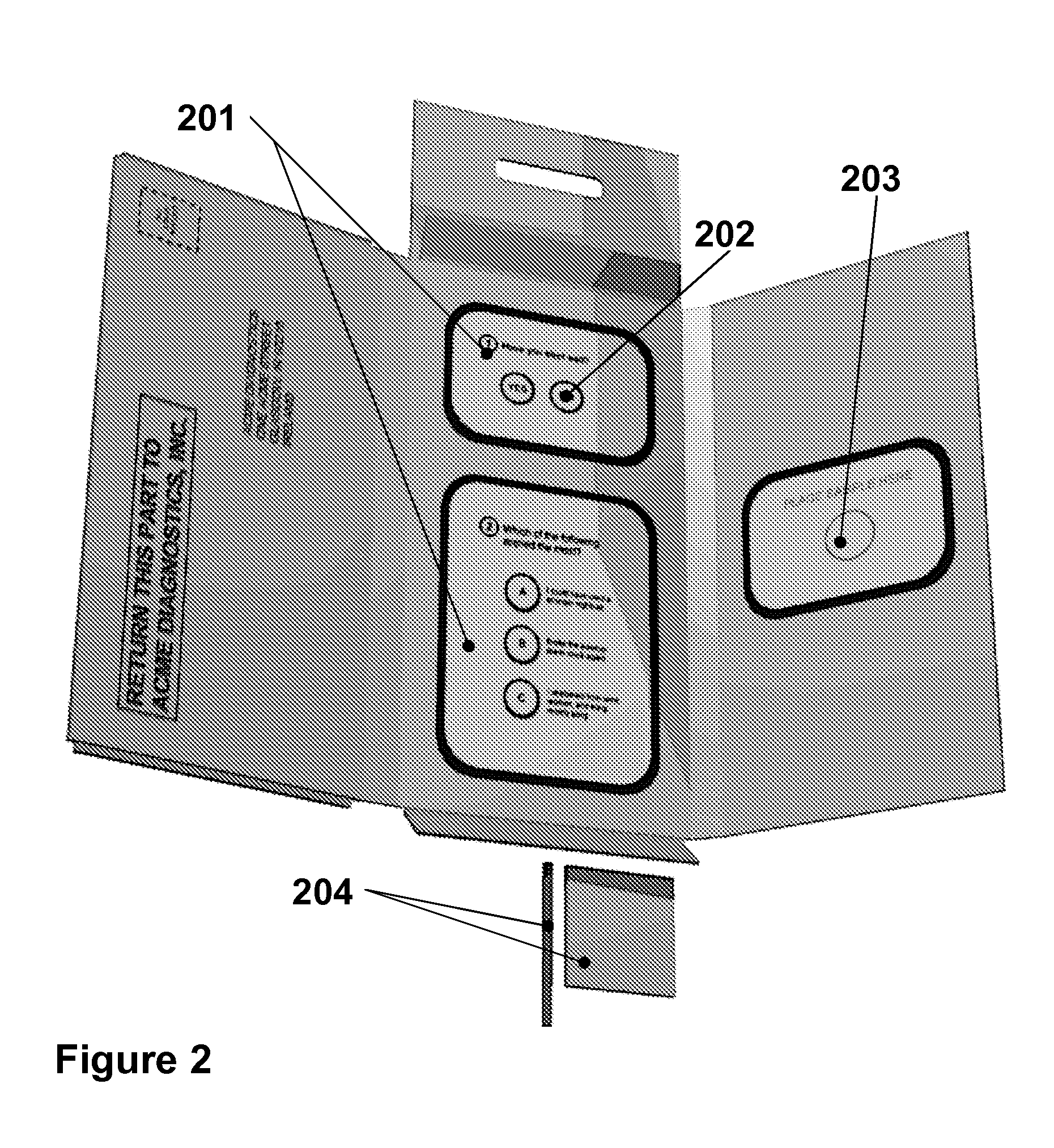

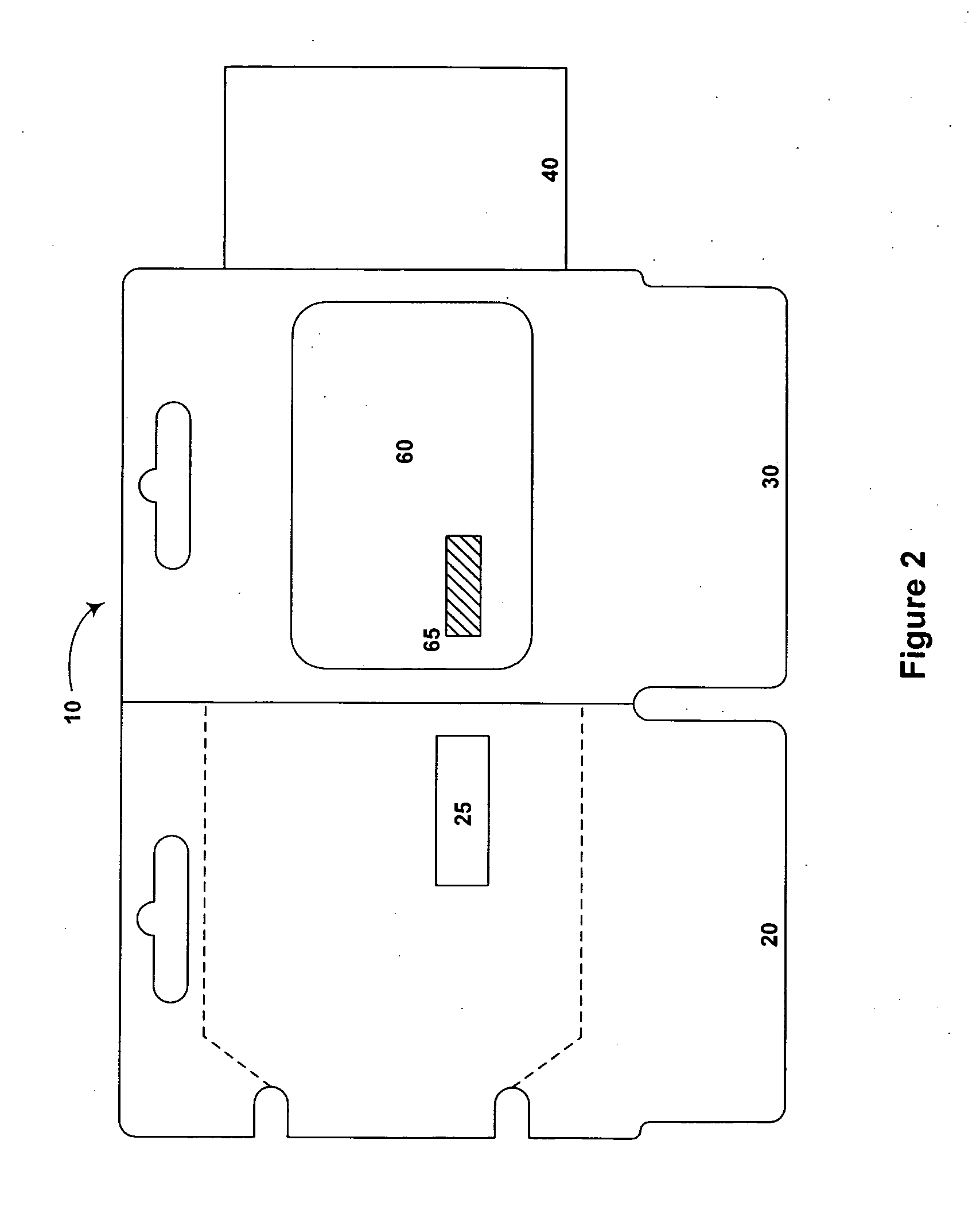

Single use, self-contained assay device for quantitative and qualitative measurements

InactiveUS20080053222A1ConfidenceReliable resultsFluid pressure measurementSpeed/acceleration/shock instrument detailsMeasurement deviceData acquisition

The invention comprises a single-use, self-contained measuring device, comprising a data entry- and sampling part including a sensor for measuring of physical or chemical property of a foreign substance and a data acquisition part including electronic processing- and storage means, where the parts are integral parts of a packaging, formed of a sheet-like, printable and foldable material, the packaging being designed to enclose and protect the parts contained therein. The packaging may also include various instruments needed to perform a test.

Owner:CYPAK +1

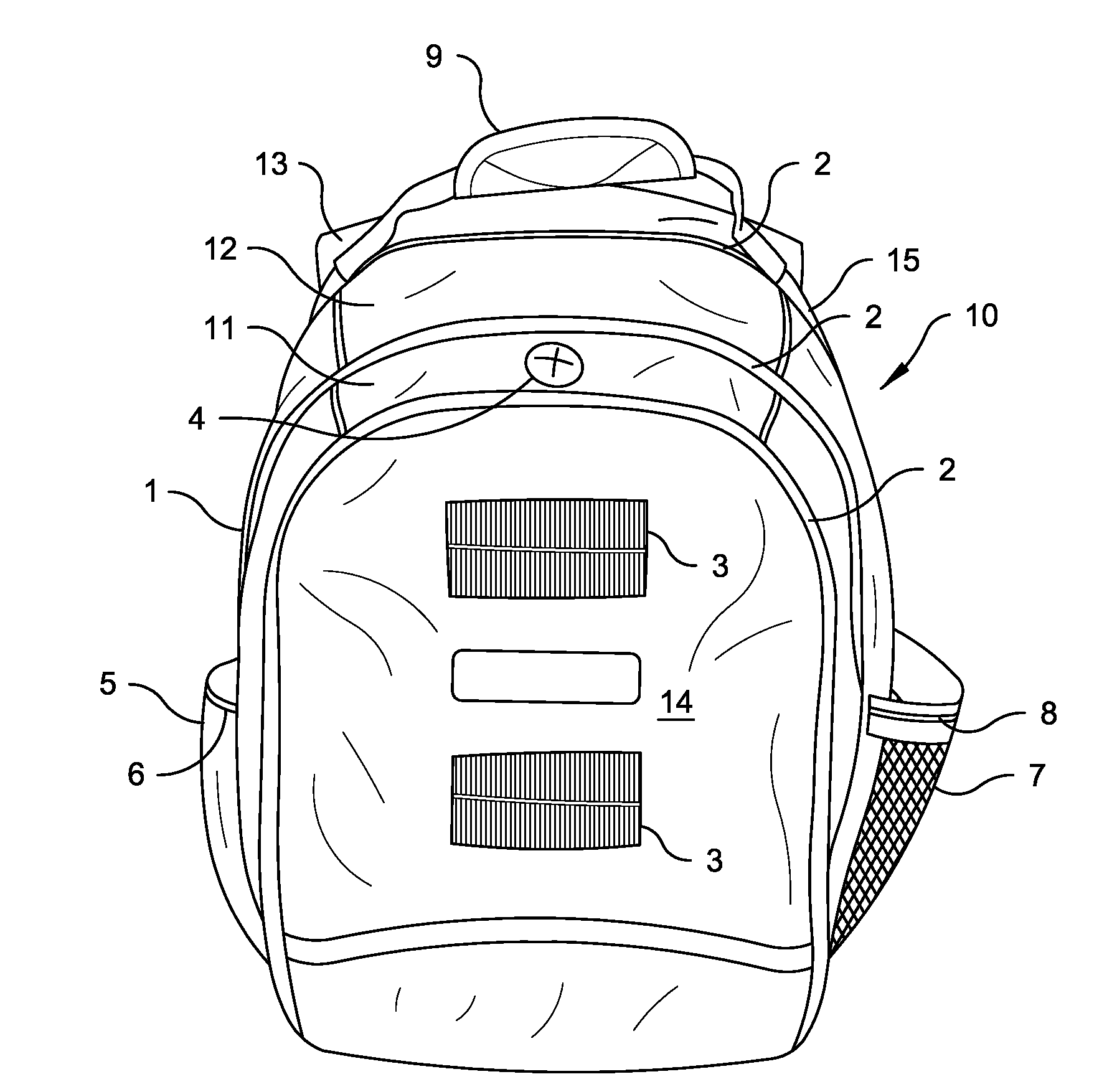

Escape and survival system

A portable, stylish, comprehensively stocked emergency escape and survival package gives the user ability to successfully confront diverse emergency and disaster conditions most likely encountered in the urban or suburban environment. The package is a system of a backpack carrying case and numerous components stored within the case. Each component is a tool, supply or other article selected for use in a particular aspect of an emergency or survival situation. Additionally, the package includes separate stowage capacity for routine business tools, such as files, computer, calculator and the like. Components of the system include, among others, a radiation sensor, a ballistic resistant panel, solar charging station for an included rechargeable battery, and cables and adapters for supplying power to diverse portable electronic devices.

Owner:MILSPRAY

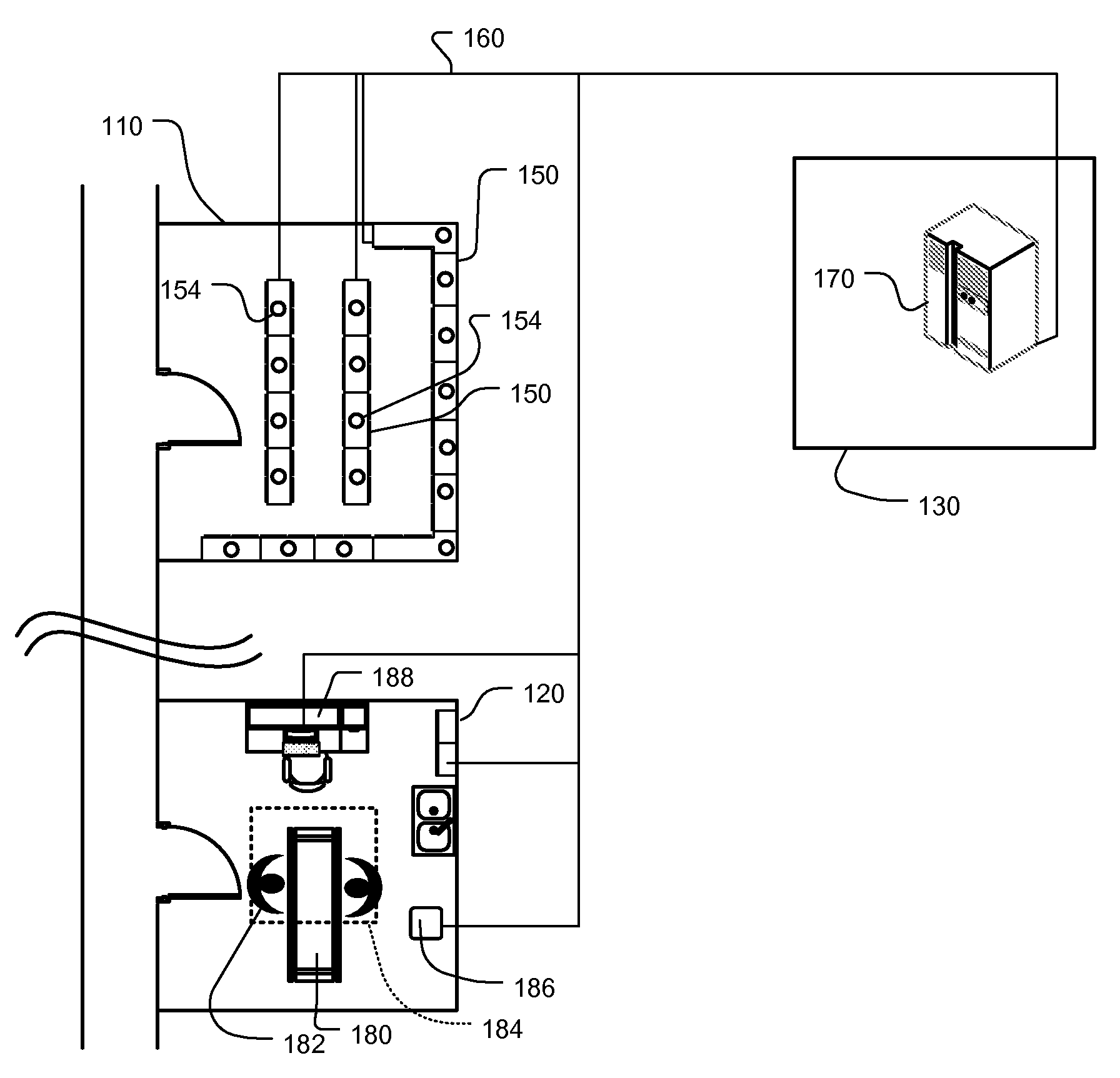

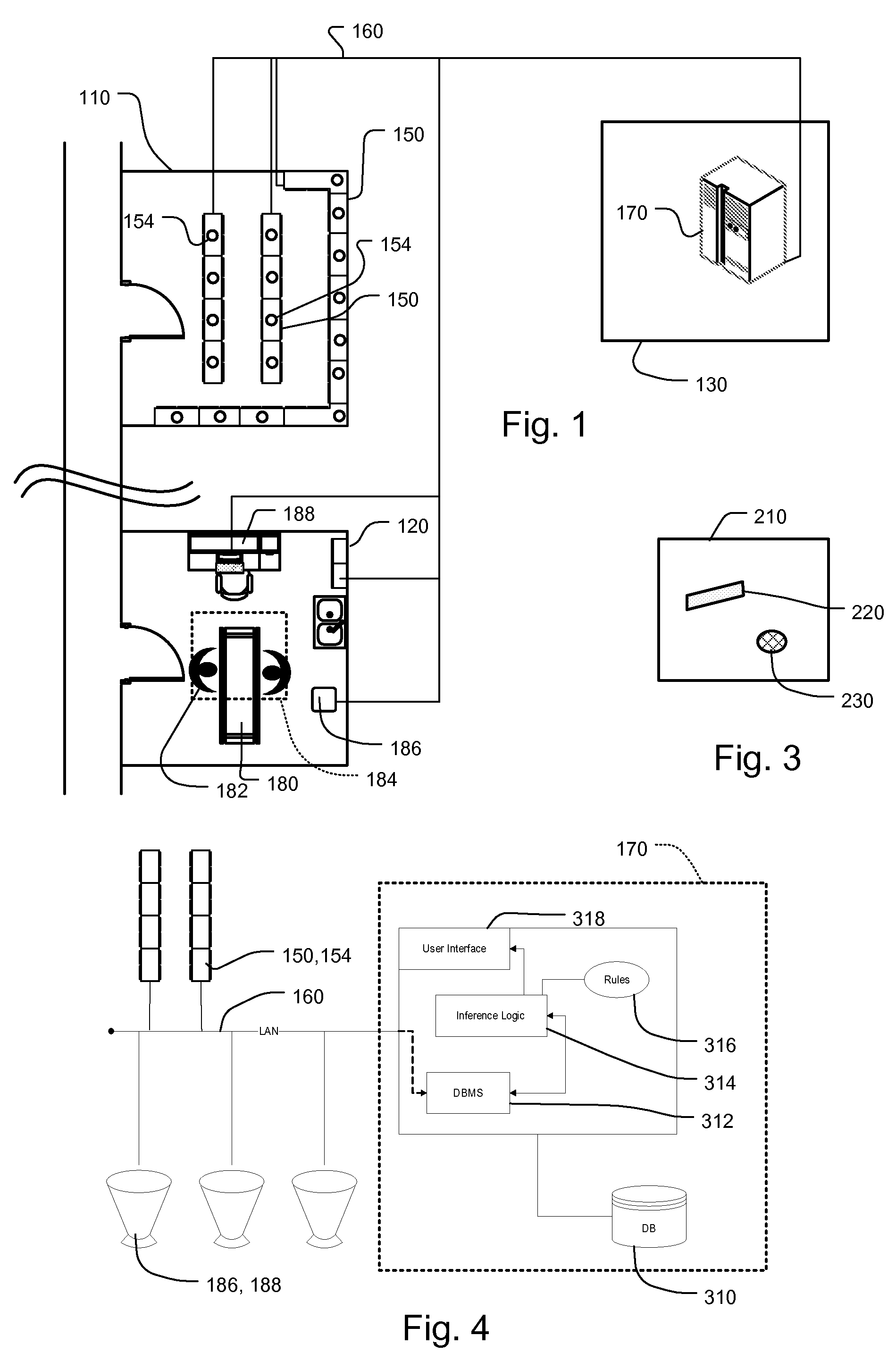

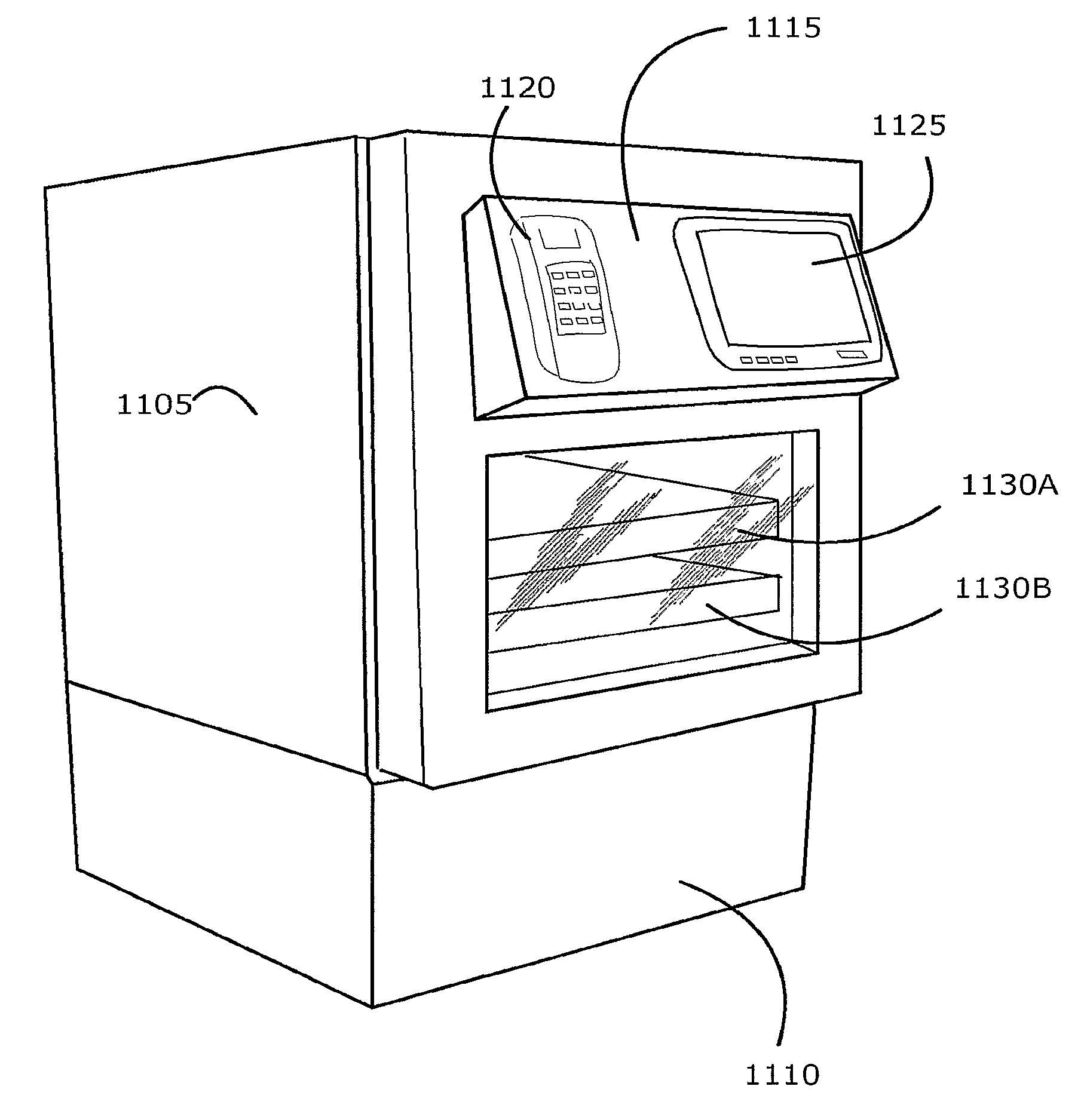

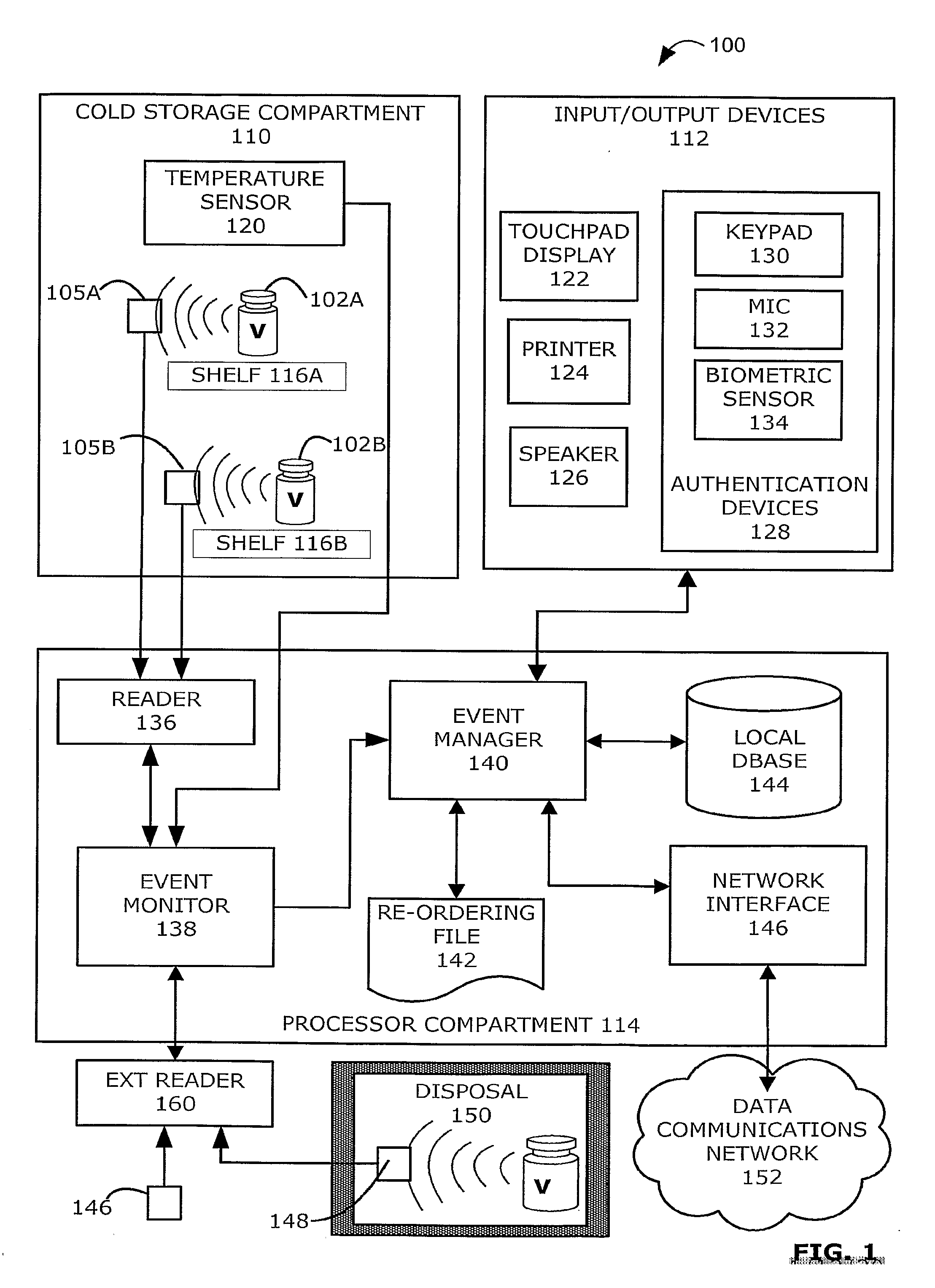

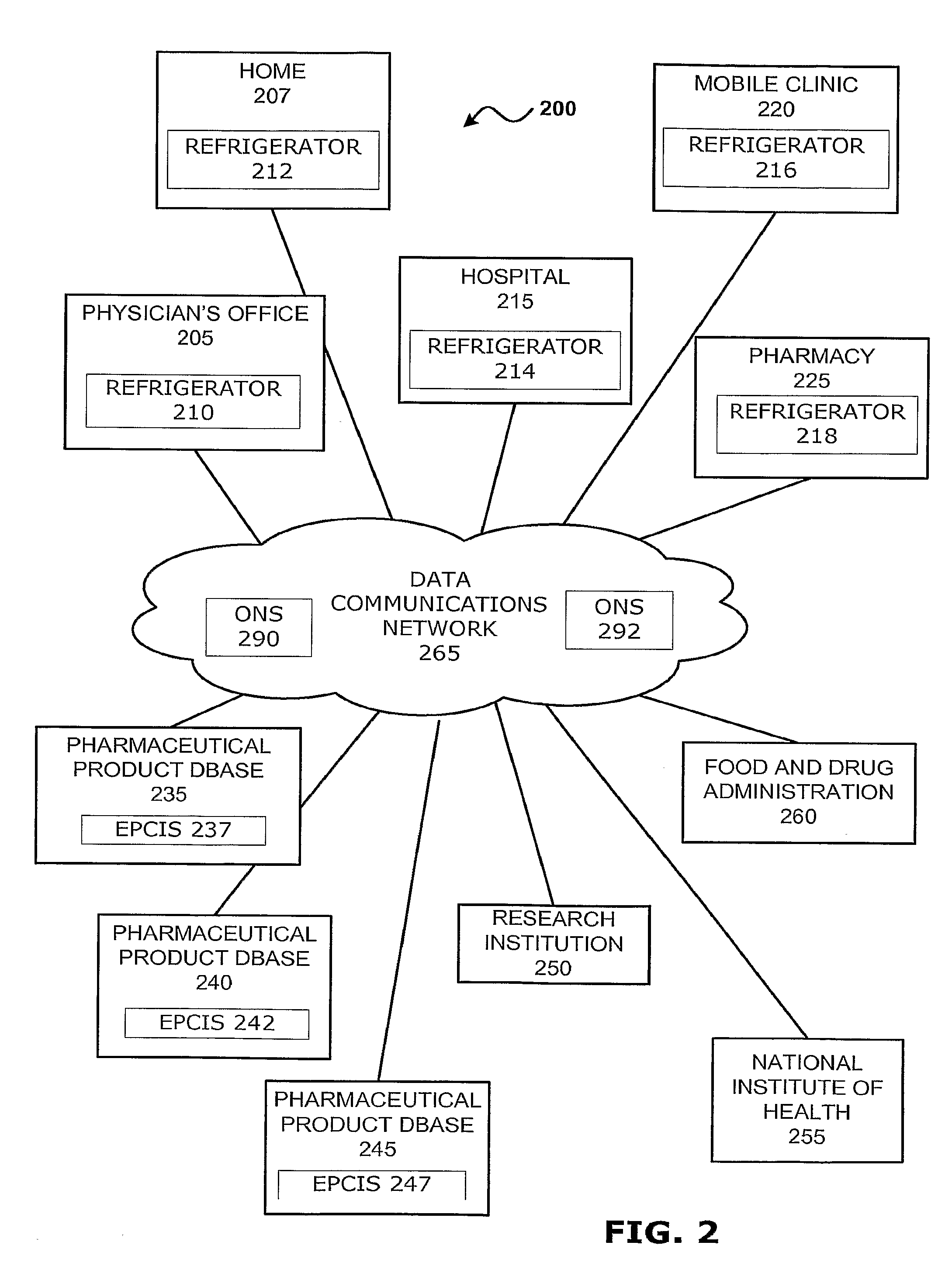

Intelligent Refrigerator for Storing Pharmaceutical Product Containers

Intelligent refrigerator system for storing pharmaceutical product containers, such as vials, ampules, syringes, bottles, medication tubes, blister packs and cartons, at the point of dispensing. Embodiments of the invention use product identification technology, such as radio-frequency identification (RFID) tags and readers, to uniquely identify containers as they are added to or removed from the cold storage compartment of the refrigerator, and automatically retrieve from a local or remote database a variety of details associated with the containers and their contents, such as manufacturing data, expiration dates, time out of refrigeration, inventory levels, safety information, usage statistics, known contraindications and warnings, etc. If the details indicate that there is a problem with a particular pharmaceutical (e.g., that it is counterfeit, expired, suspect, spoiled, recalled or almost depleted), then a message or warning is automatically delivered to a human operator via an attached output device, such as a display screen, speaker or printer. Embodiments of the invention may also be configured to monitor and report temperature faults, power failures and other anomalies associated with the refrigerator or cold storage compartment.

Owner:MERCK SHARP & DOHME LLC

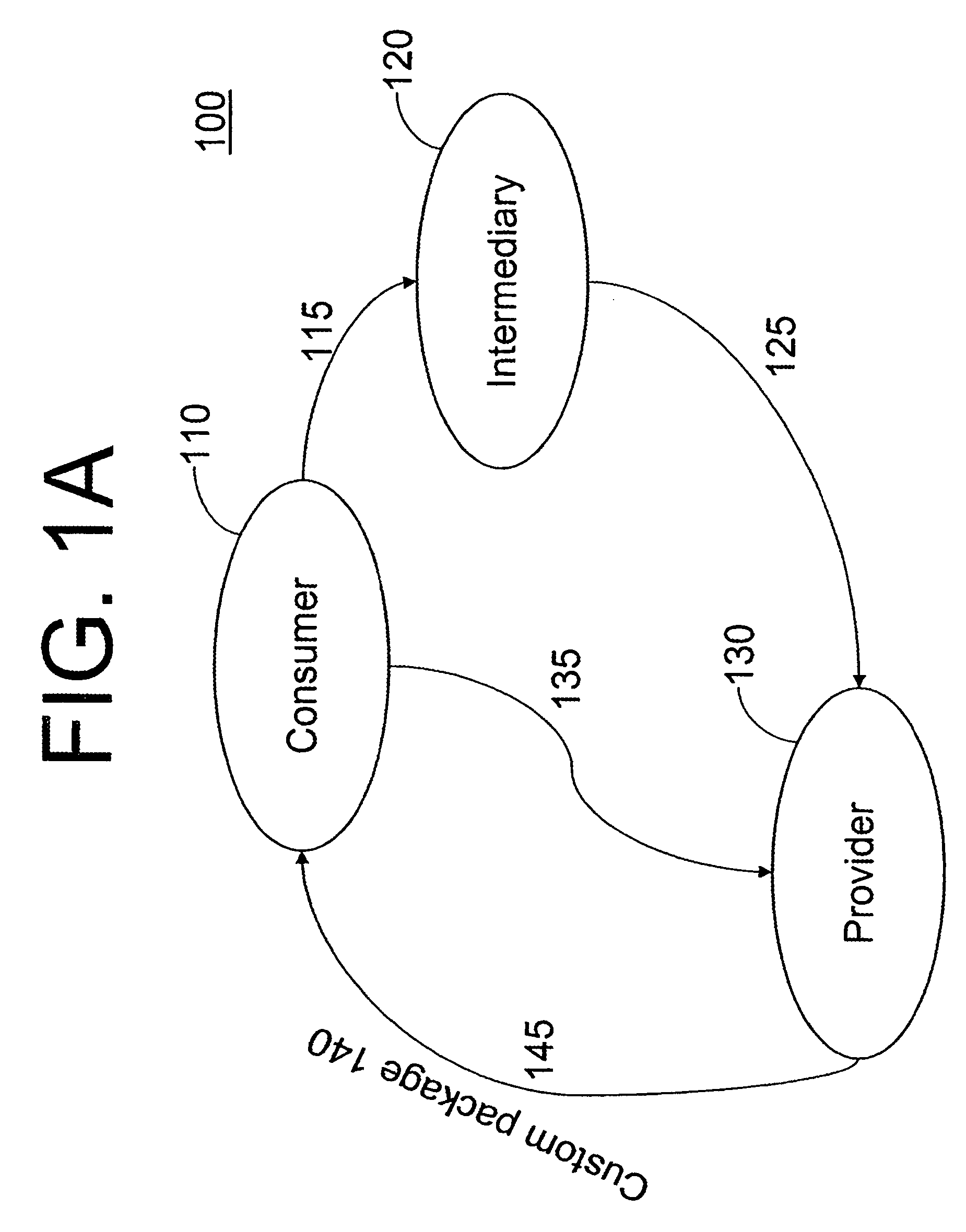

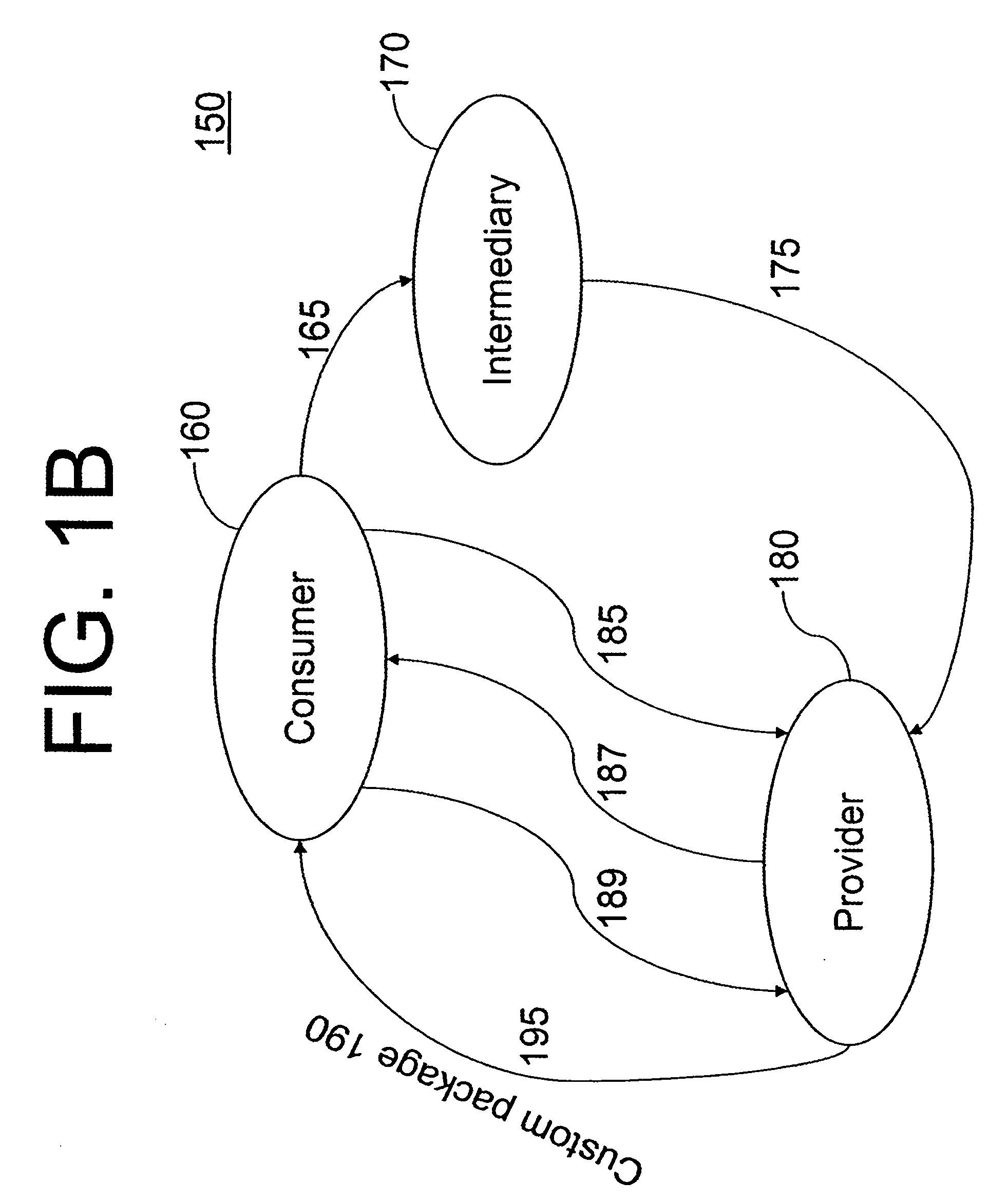

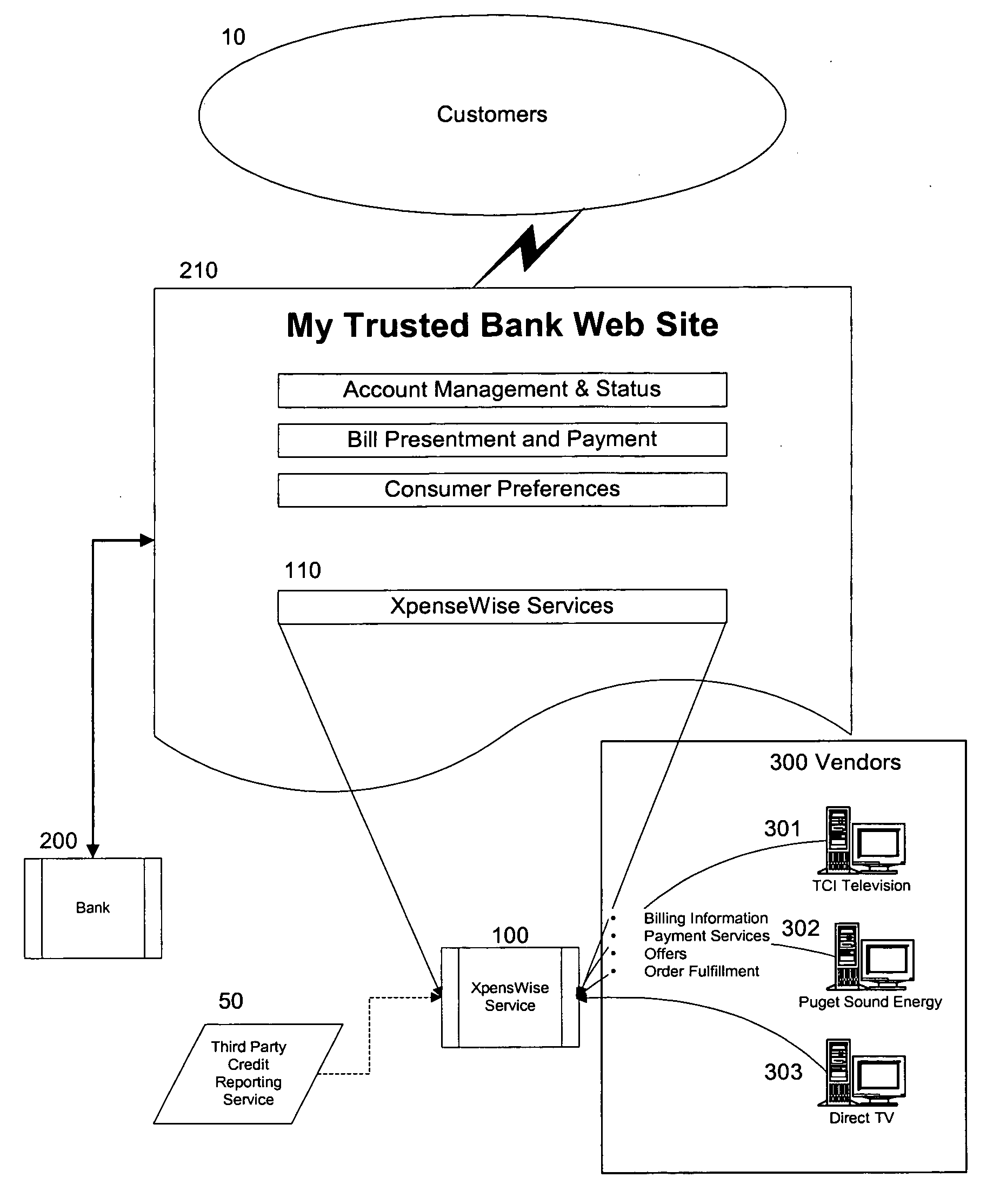

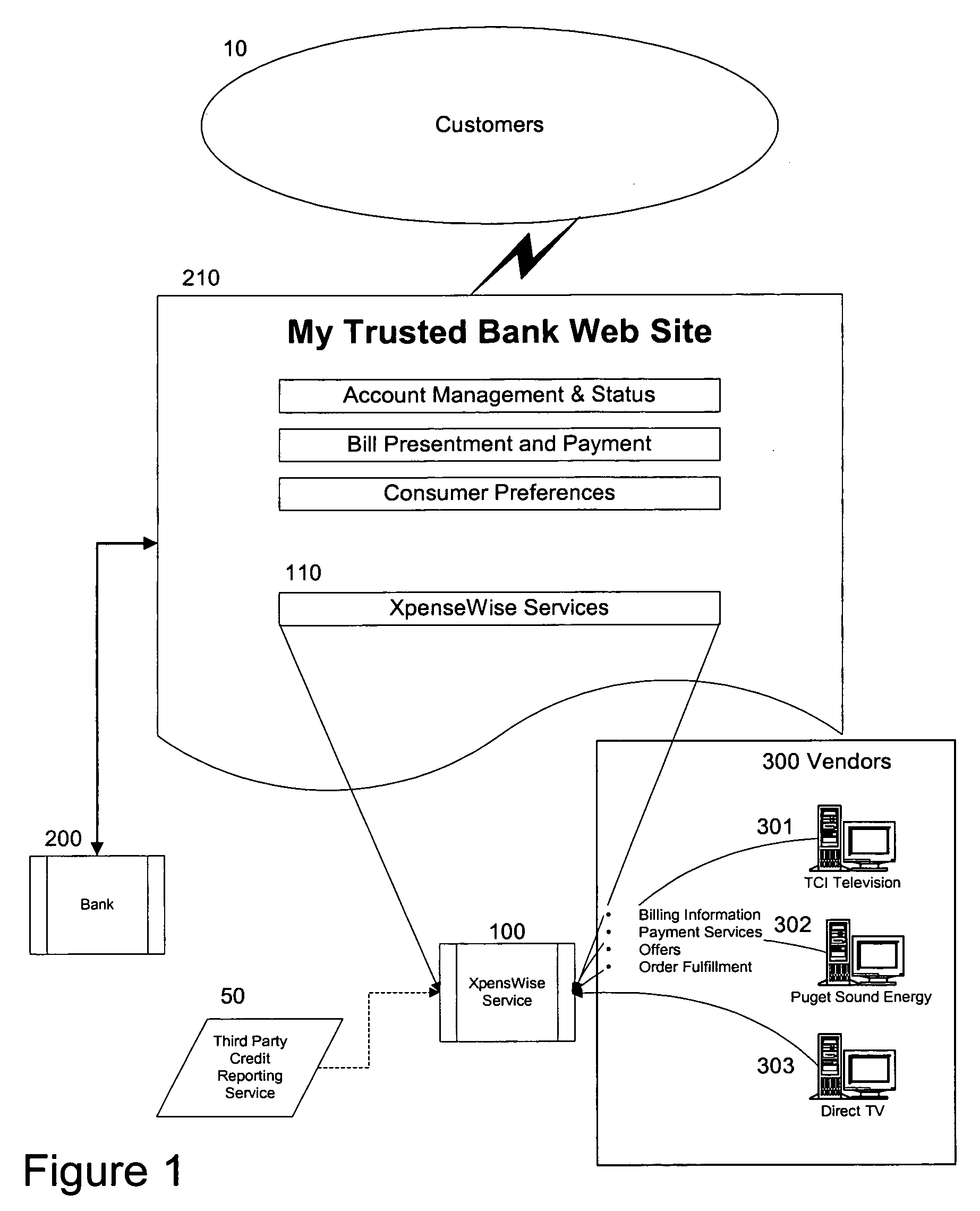

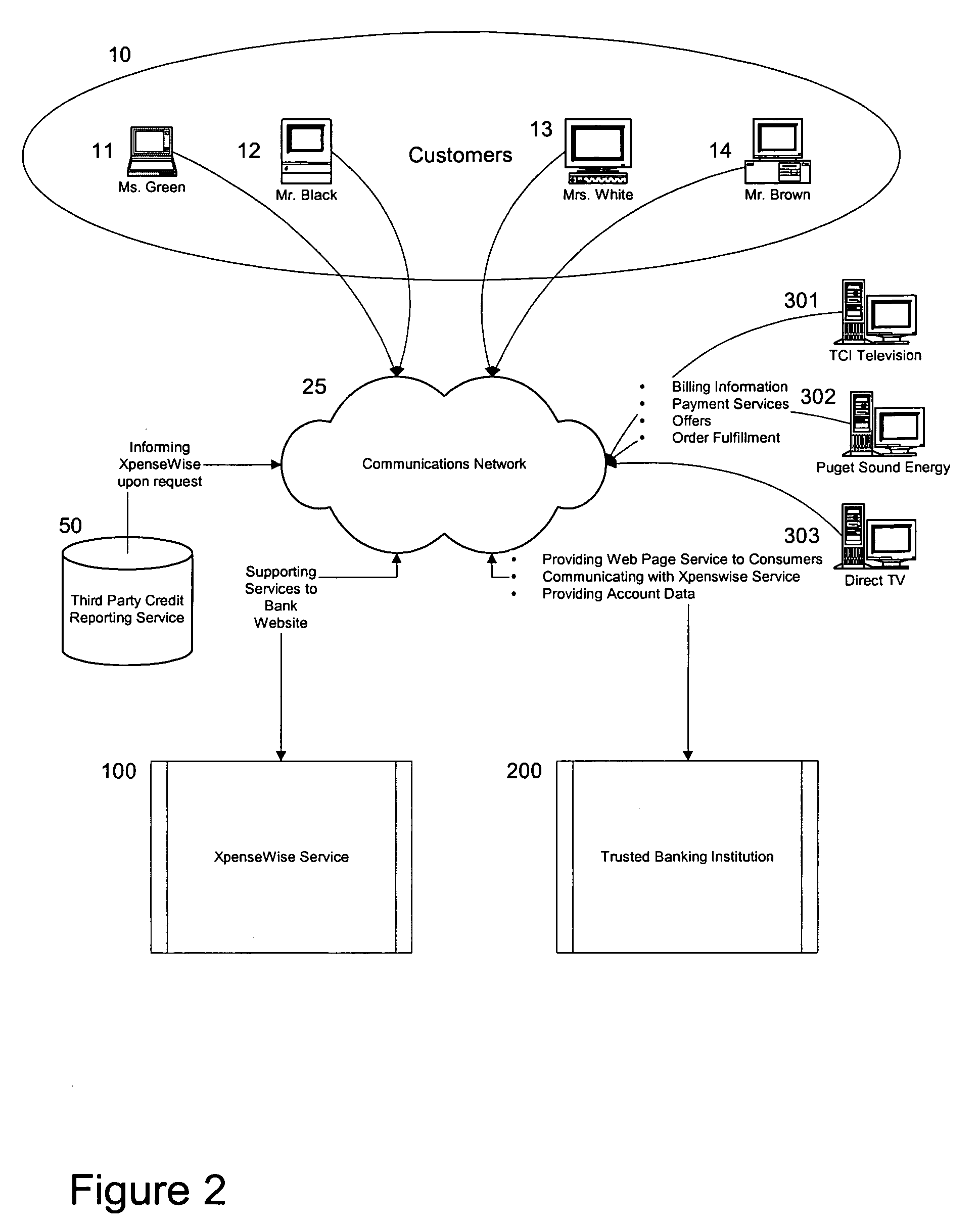

System and method for dynamic price setting and facilitation of commercial transactions

InactiveUS7072858B1Improve efficiencyIncreasing vendor 's competitive lineMarket predictionsAdvertisementsData processing systemHandling system

The present invention provides methods and systems for defining commercial transaction components; defining rules for mapping customer transactions into individual components; market segmentation in light of these individual definitions and bundling individual components of an offer into optimized packages for presentation and sale. A data processing system in accordance with one embodiment of the present invention, examines the commercial behavior of enrolled customers, breaks each of the constituent transactions into purchases of atom-level components; catalogues those components; extracts demographic information from said transactions and other sources; facilitates demographic studies of groups of such customers; optimizes offerings to such groups; and facilitates the consummation of those offers of sale. The processing system may also facilitate customers fiscal management through the communication of data necessary to practice the instant invention.

Owner:XPENSEWISE COM

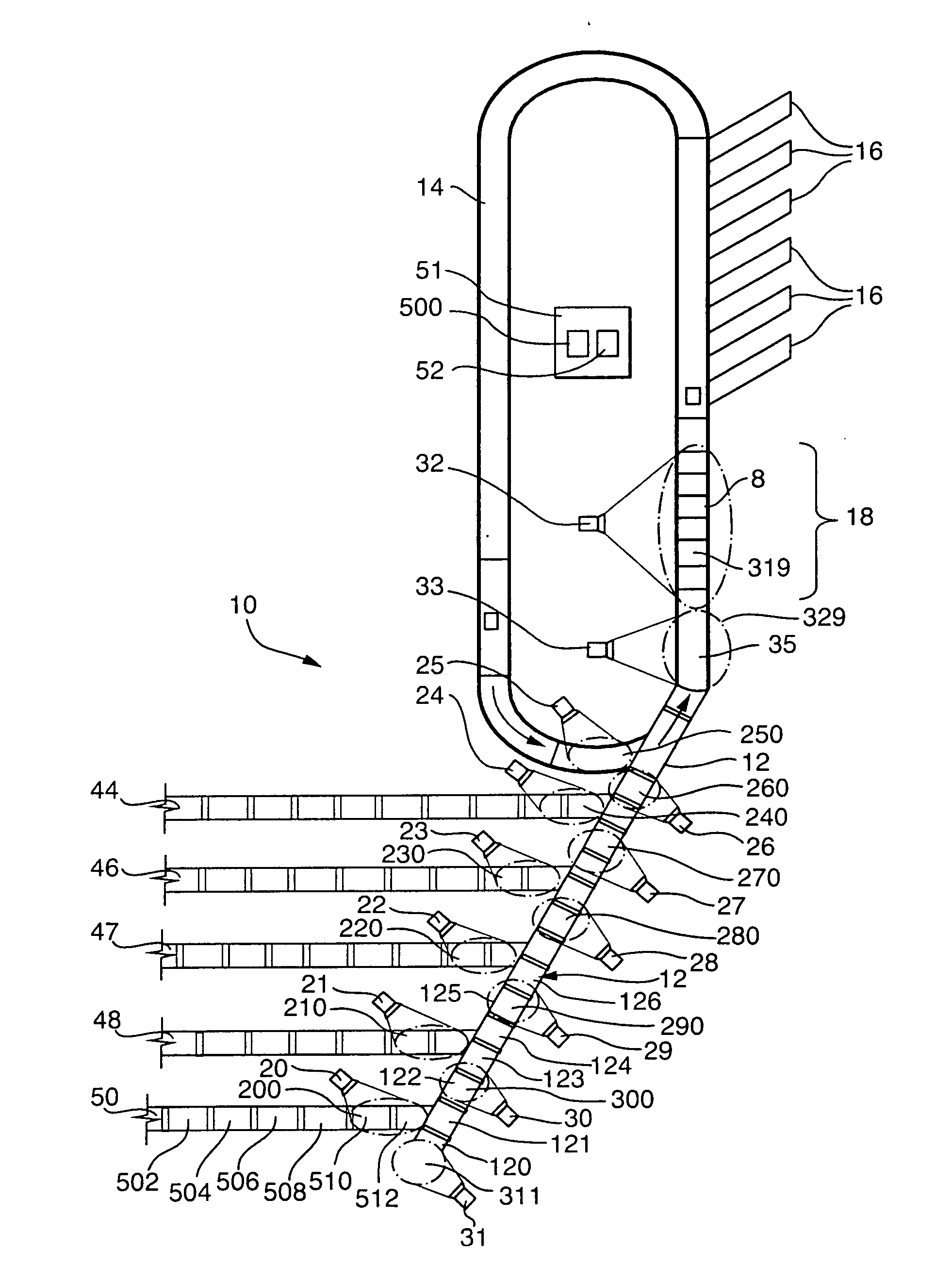

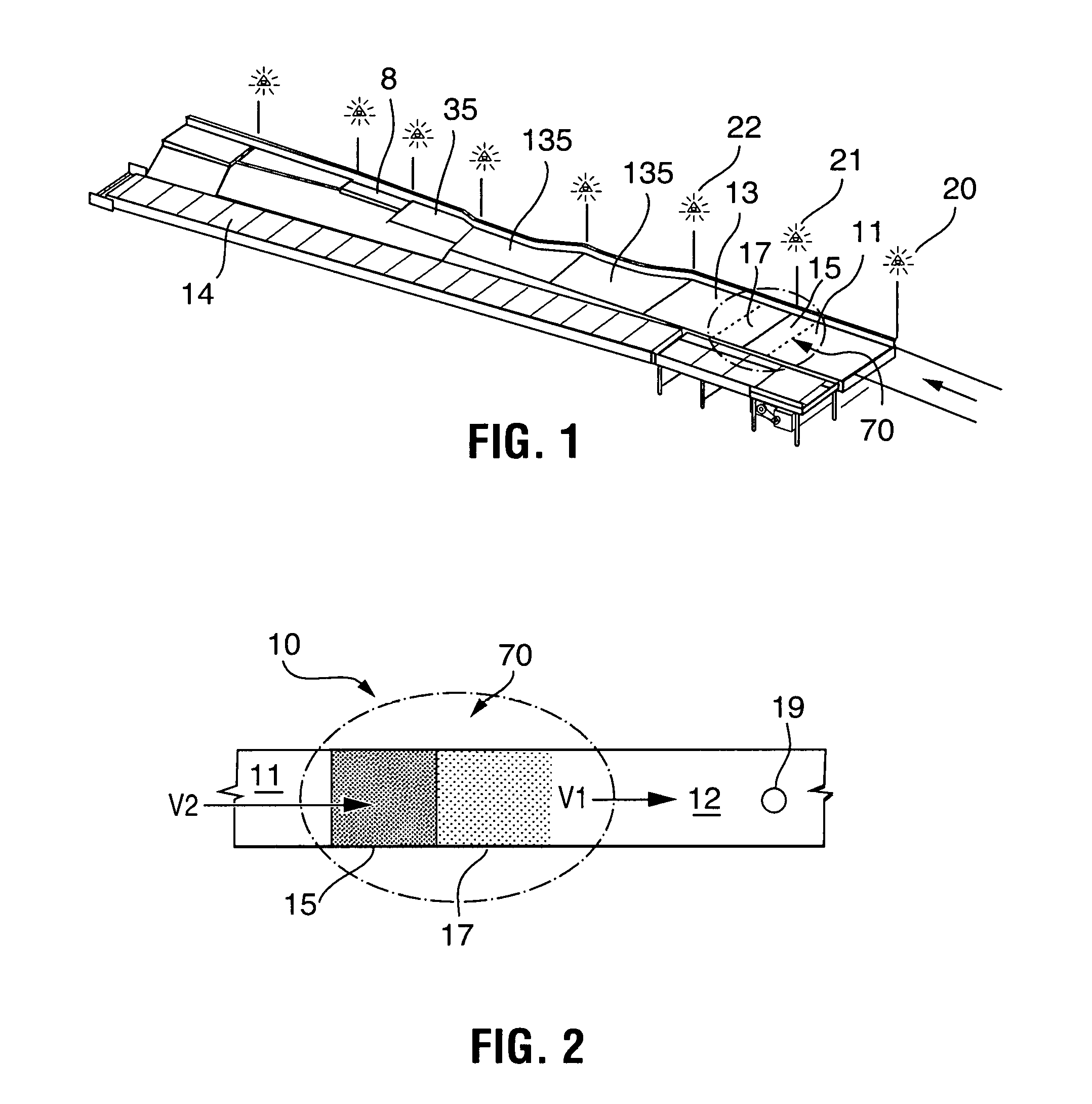

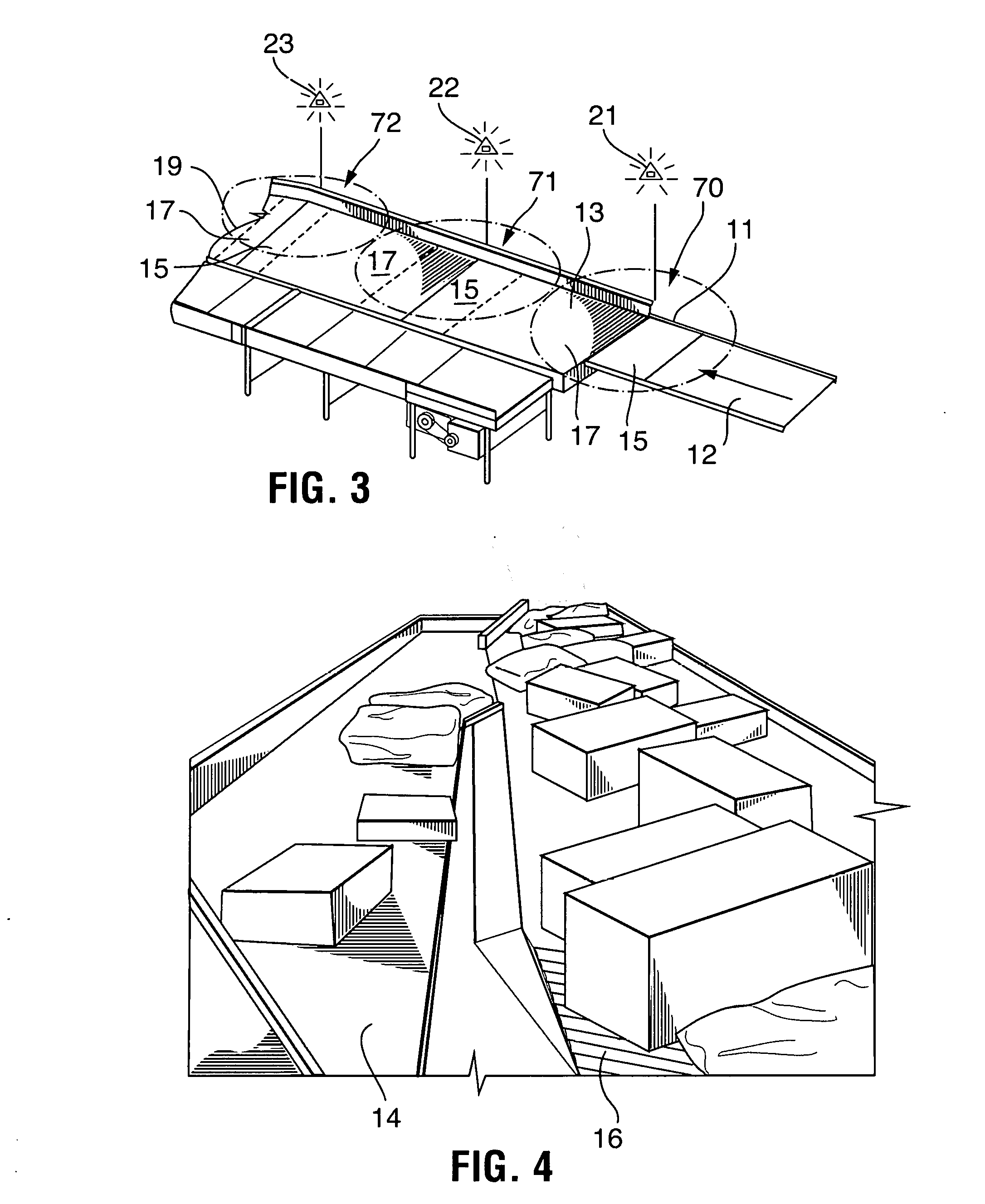

Vision based conveyor package flow management system

ActiveUS20160221762A1Improve efficiencyMaximize packing densityConveyorsControl devices for conveyorsIndividual itemEntry point

A camera based vision system that recognizes and maximizes belt area utilization. A plurality of cameras are positioned at flow entry points of feed conveyors and at the singulator. The control algorithm recognizes individual items area, the rate at which individual objects are passing, and the area utilization of the collector belt. The video camera and computer based conveyor package management system monitor and control the number and size of the packages present on the infeed conveyors, collector conveyor, singulator conveyor and sorting conveyor in a package handling system wherein the camera data is used to measure the available area or space on the conveyors to maintain a desired density of packages on selected conveyor(s). The conveyor speed is controlled as a function of occupancy on a collector or just prior to a singulator or receiver.

Owner:FIVES INTRALOGISTICS SA

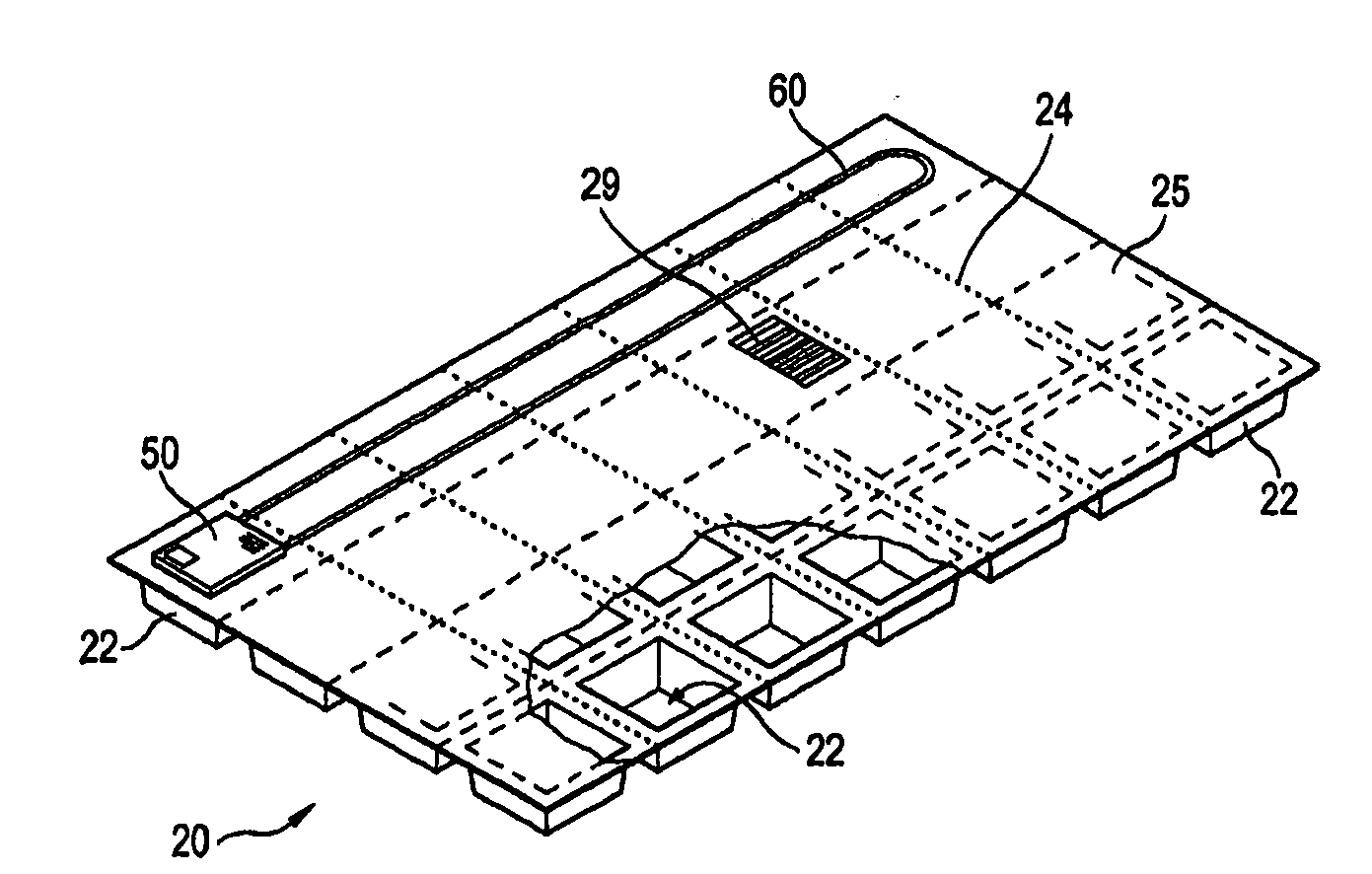

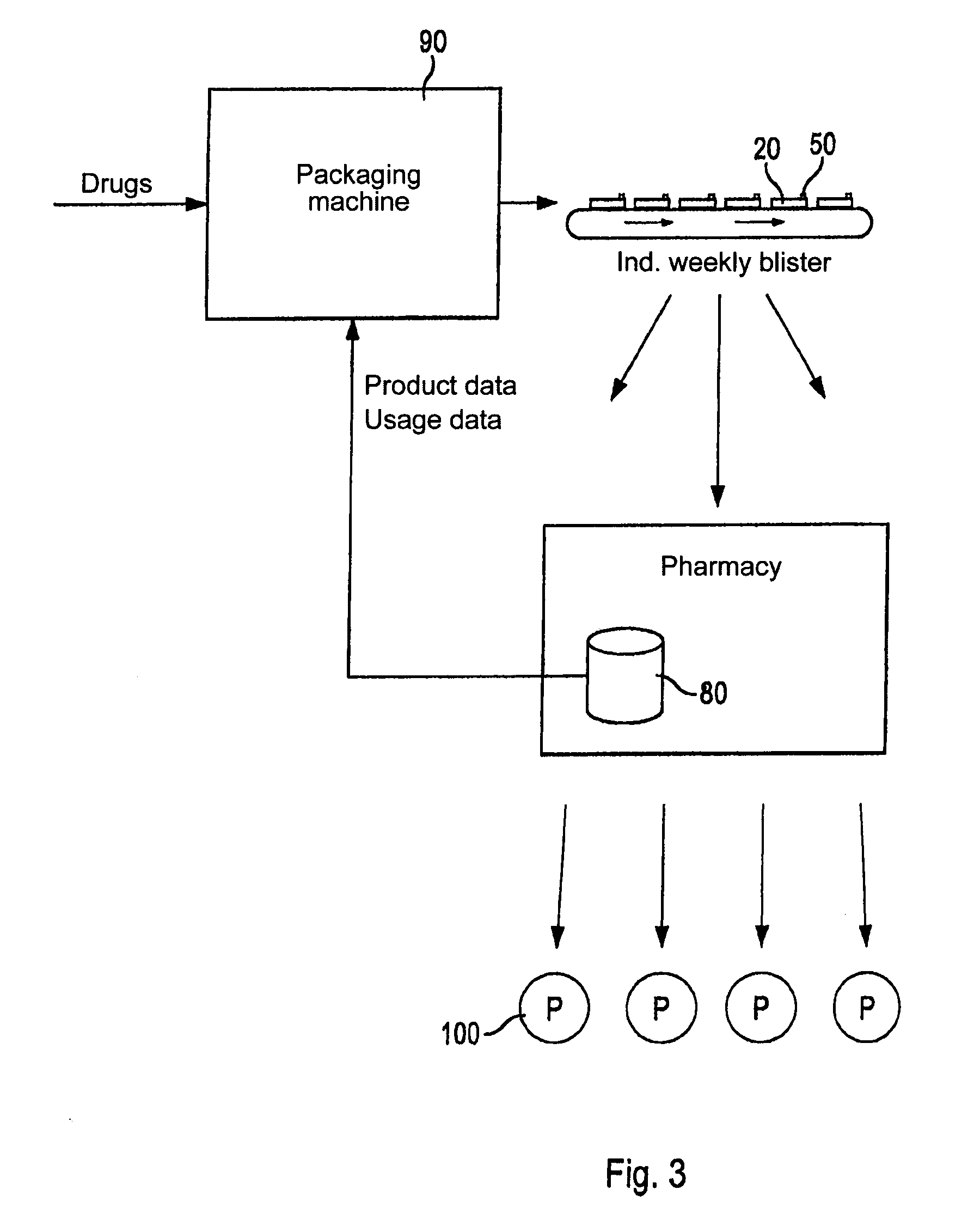

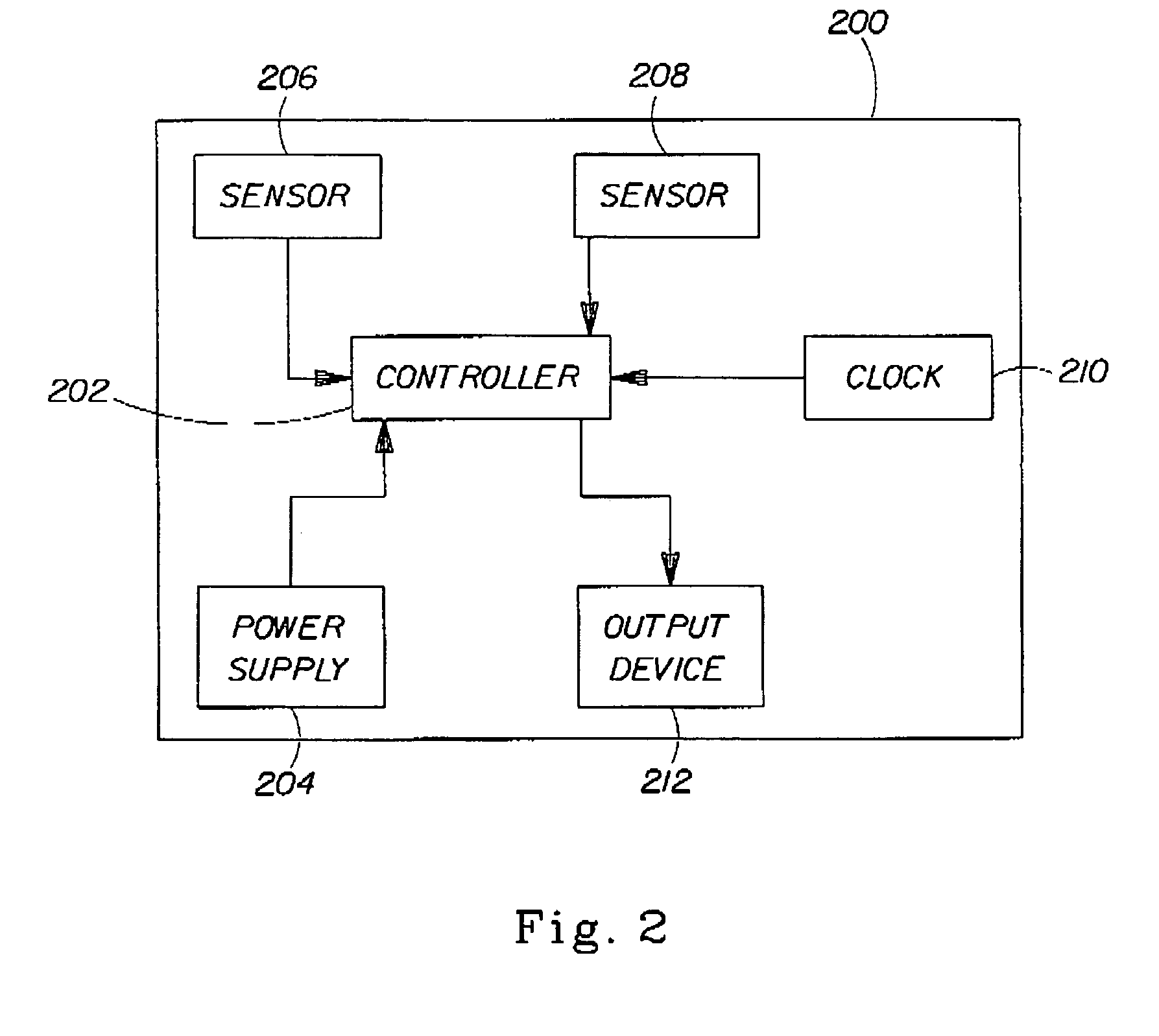

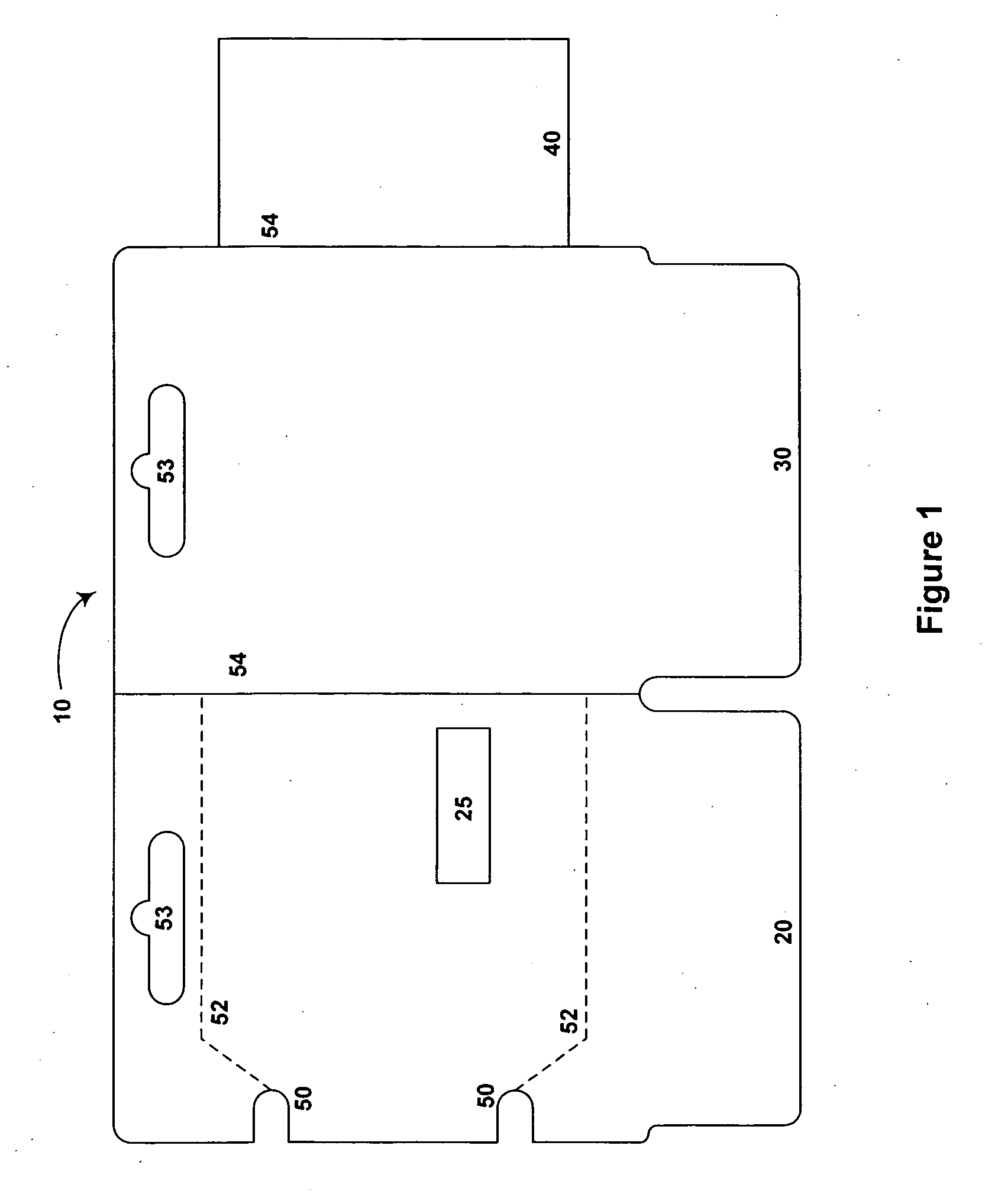

Personalized blister pack

InactiveUS20090277815A1Method securityImprove securitySmall article dispensingContainer/bottle contructionPersonalizationEngineering

A personalized blister pack (20) for the automated packaging of an individually defined product composition, particularly drugs, of a defined person, particularly a patient, for a defined time period comprises a plurality of receiving compartments (22), each closed by a film (25), for the products of the product composition, wherein the receiving compartments (22) are each associated with a defined usage time within the defined time period and disposed in matrix form, comprising a number of lines for usage days and columns for usage times during the day, and a memory device (50) for storing the usage data of the products of the product composition of the defined person for the defined time period, comprising a device (58) for generating a usage reminder signal as a reminder of a defined product usage time based on the stored usage data. The blister pack (20) enables a fast, safe and inexpensive supply of the needs of the person for a defined time period, such as one week, and by means of the memory device, which may comprise a reminder function, supports the planned use of the products.

Owner:KOHL EDWIN

Interactive packaging for development of personal hygiene habits

InactiveUS7411511B2Registering/indicating working of machinesElectric testing/monitoringHabitMonitor equipment

The disclosure is directed to an interactive packaging system for monitoring the usage of personal hygiene products, personal hygiene product packages, and restroom facilities. The interactive packaging system may include a plurality of usage monitoring devices each configured to detect physical stimulus associated with the usage of the product, package or facility with which the usage monitoring device is associate, and to transmit usage messages containing information relating to the detected physical stimulus. The interactive packaging system may further include a base station configured to receive the usage messages transmitted by the plurality of usage monitoring devices and to generate sensory perceptible outputs corresponding to the information contained in the usage messages. Either the usage monitoring devices or the base station may be configured to determine whether the products, packages or facilities are used appropriately based on the detected physical stimulus.

Owner:THE PROCTER & GAMBLE COMPANY

Interactive Product Package that Forms a Node of a Product-Centric Communications Network

A communications-enabled packaged product allows a consumer to partake of communications within a product-centric network. The packaged product performs the functions of a communications node in the network. The packaged product may include two portions, one portion being a reactive label which may be affixed to the packaging and a second part being a “smart communications card” that is separate from the packaging and portable. Each part includes a communications element and an information storage and retrieval element and may include various means for downloading and uploading information into the storage and retrieval elements. In one aspect of its use, the invention allows the consumer to transmit and receive information about the product. In another aspect of its use, the invention allows the consumer to carry information about other similarly enabled products in their possession for use in shopping trips.

Owner:THE PROCTER & GAMBLE COMPANY

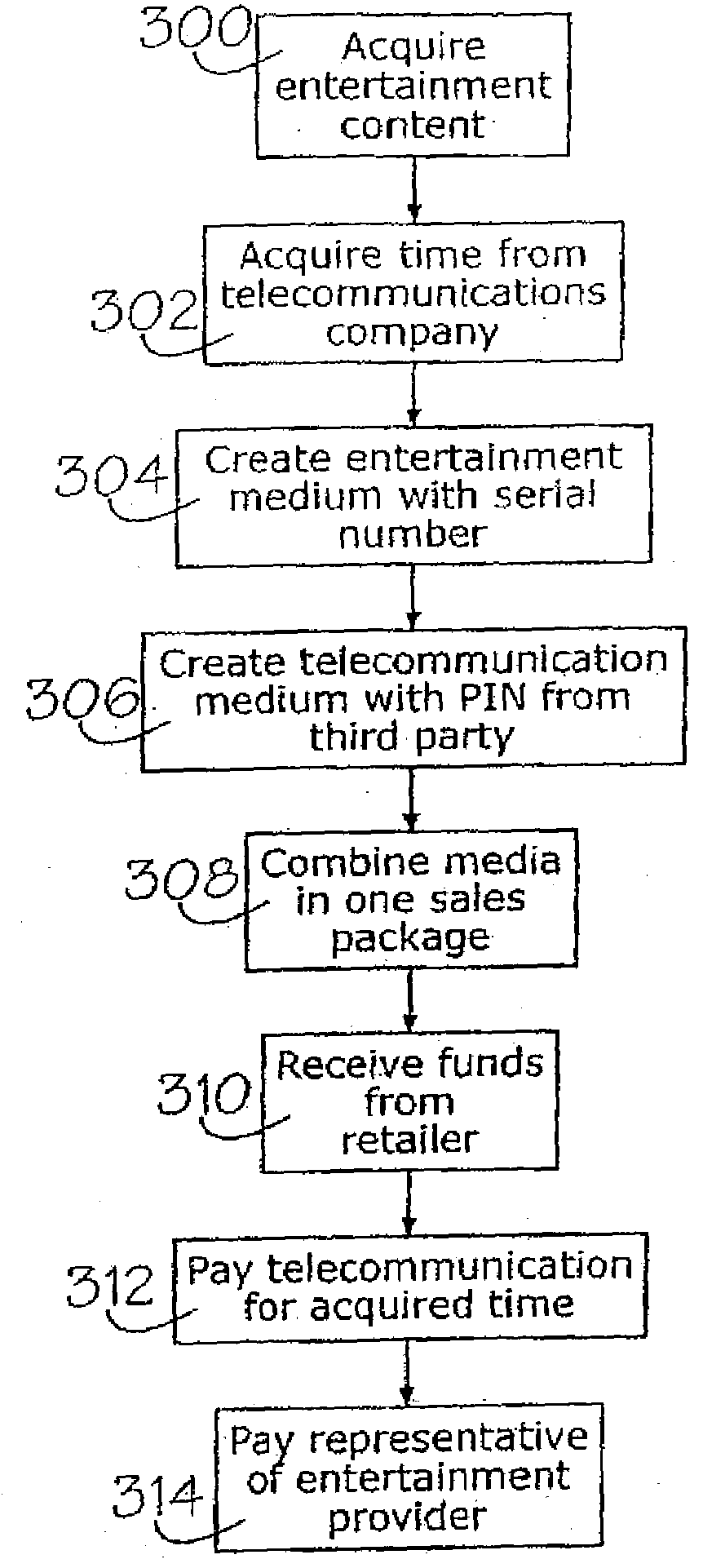

System for combining and bundling commercial products, items having monetary value, business transactions, and entertainment

InactiveUS20100114783A1Payment architectureBuying/selling/leasing transactionsSingle entityMonetary value

A method for acquiring and distributing entertainment items, information representative of monetary funds, and / or commercial products, some or all which maybe combined or bundled in a single package. Goods and services are first identified. Advertising is provided for at least one commercial product. The advertising includes a predetermined code associated with the commercial product. The commercial product is sold and, upon acceptance of the predetermined code, a second commercial product or an entertainment item or a medium containing information representative of monetary funds is provided as a single entity or transaction.

Owner:SPOLAR MARGARET M

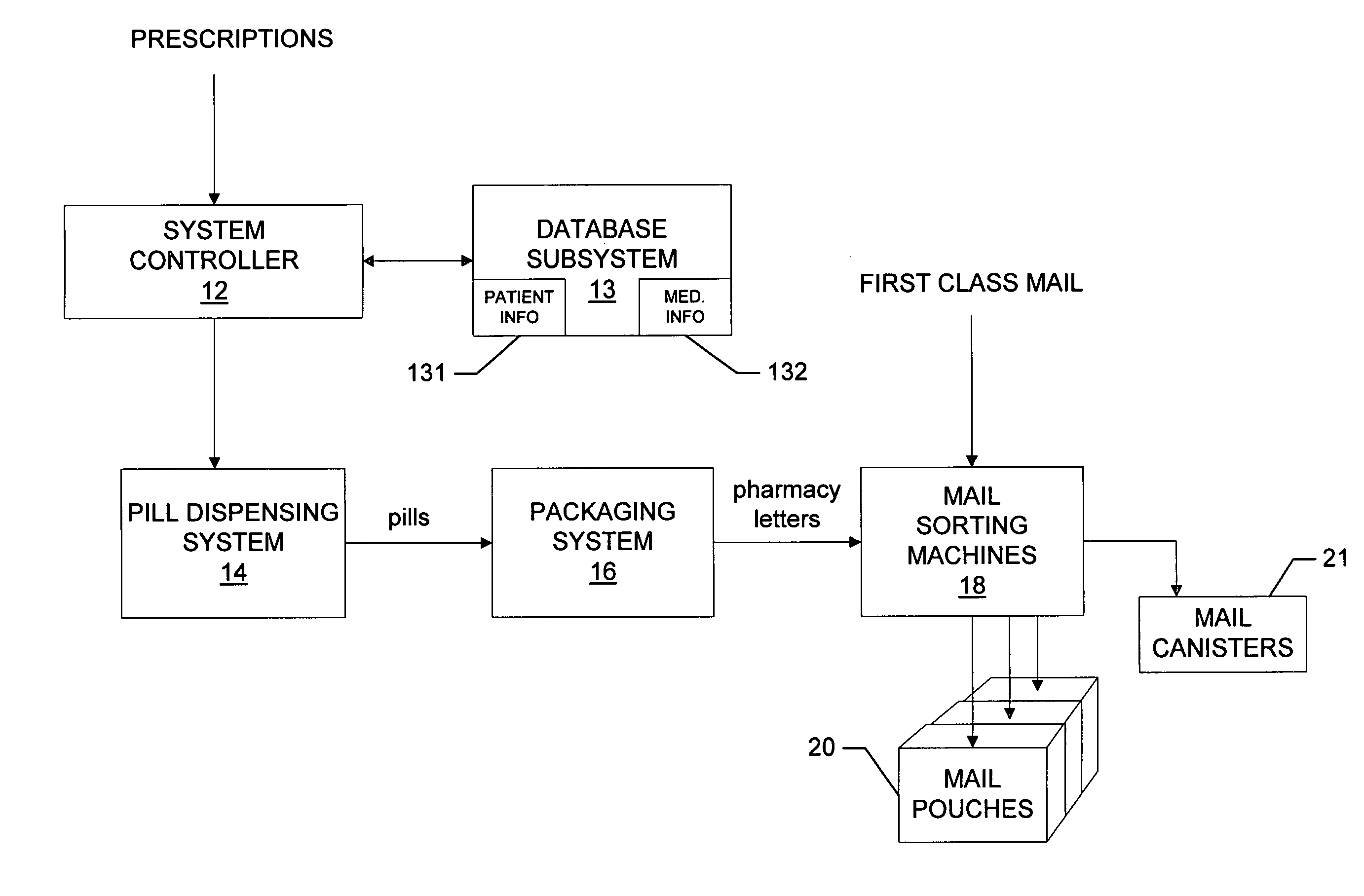

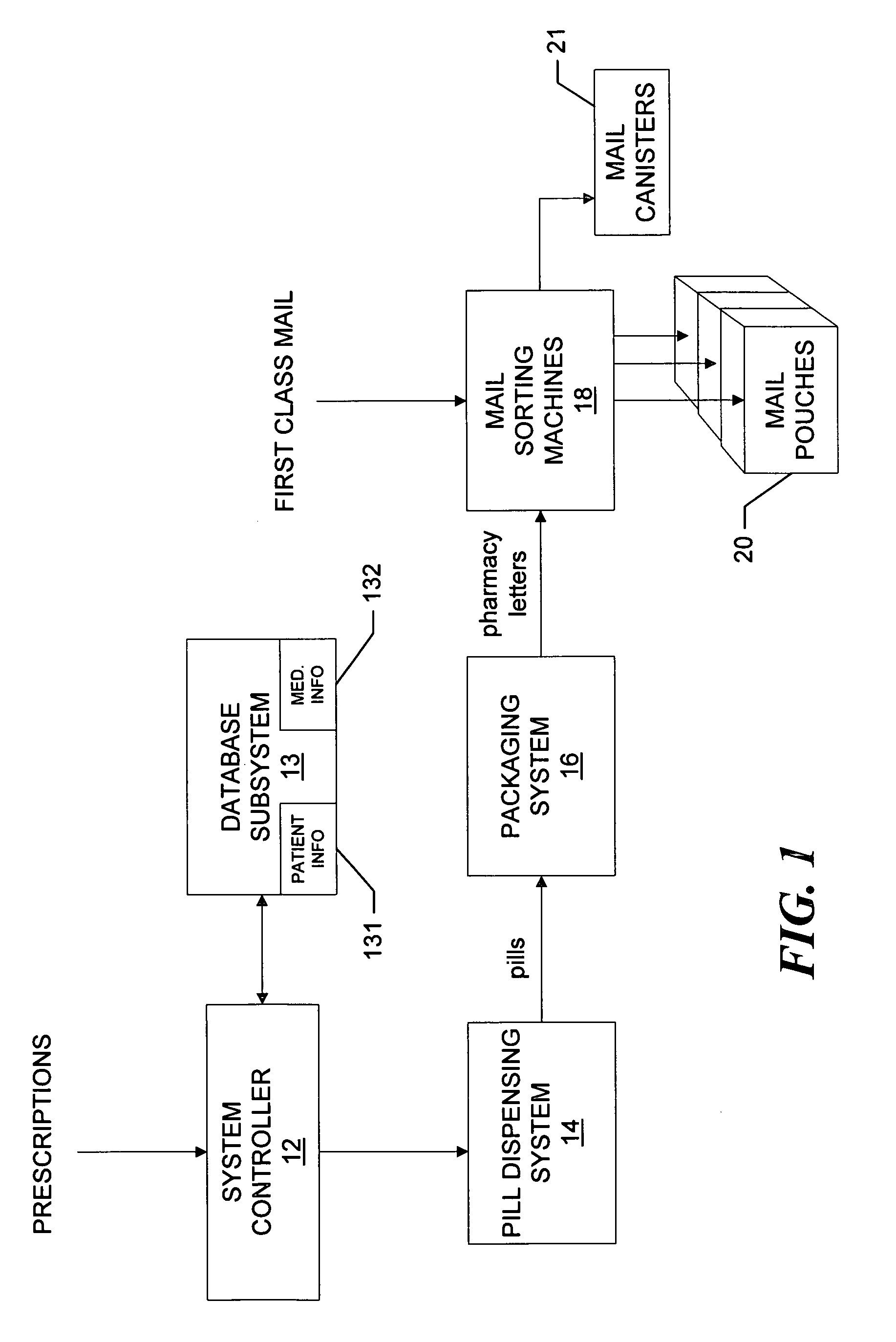

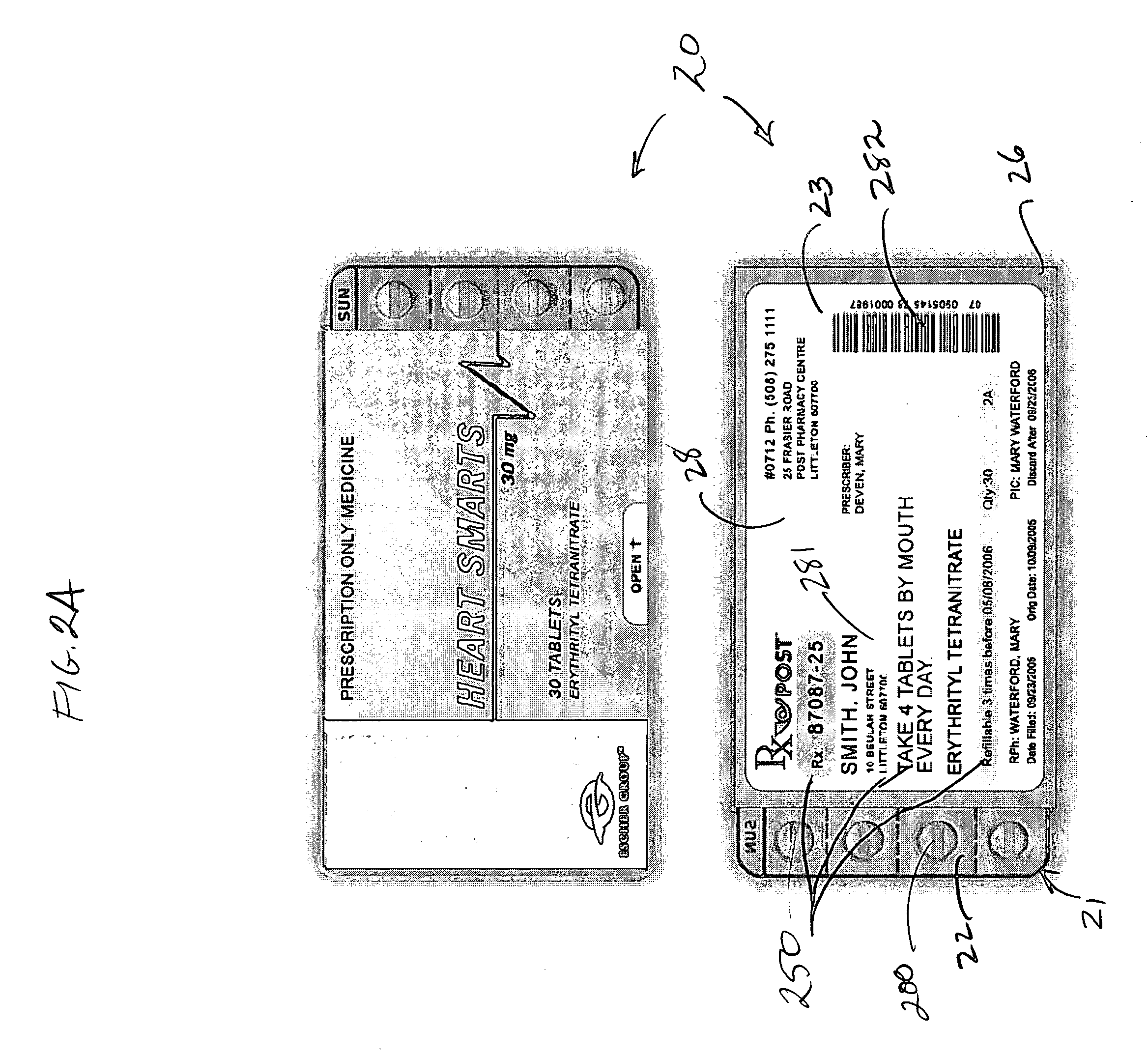

System and method for dispensing, sorting and delivering prescription and non-prescription medications through the post office

ActiveUS20060122729A1Controlling coin-freed apparatusDigital data processing detailsDispensaryNon prescription

Owner:ESCHER GROUP

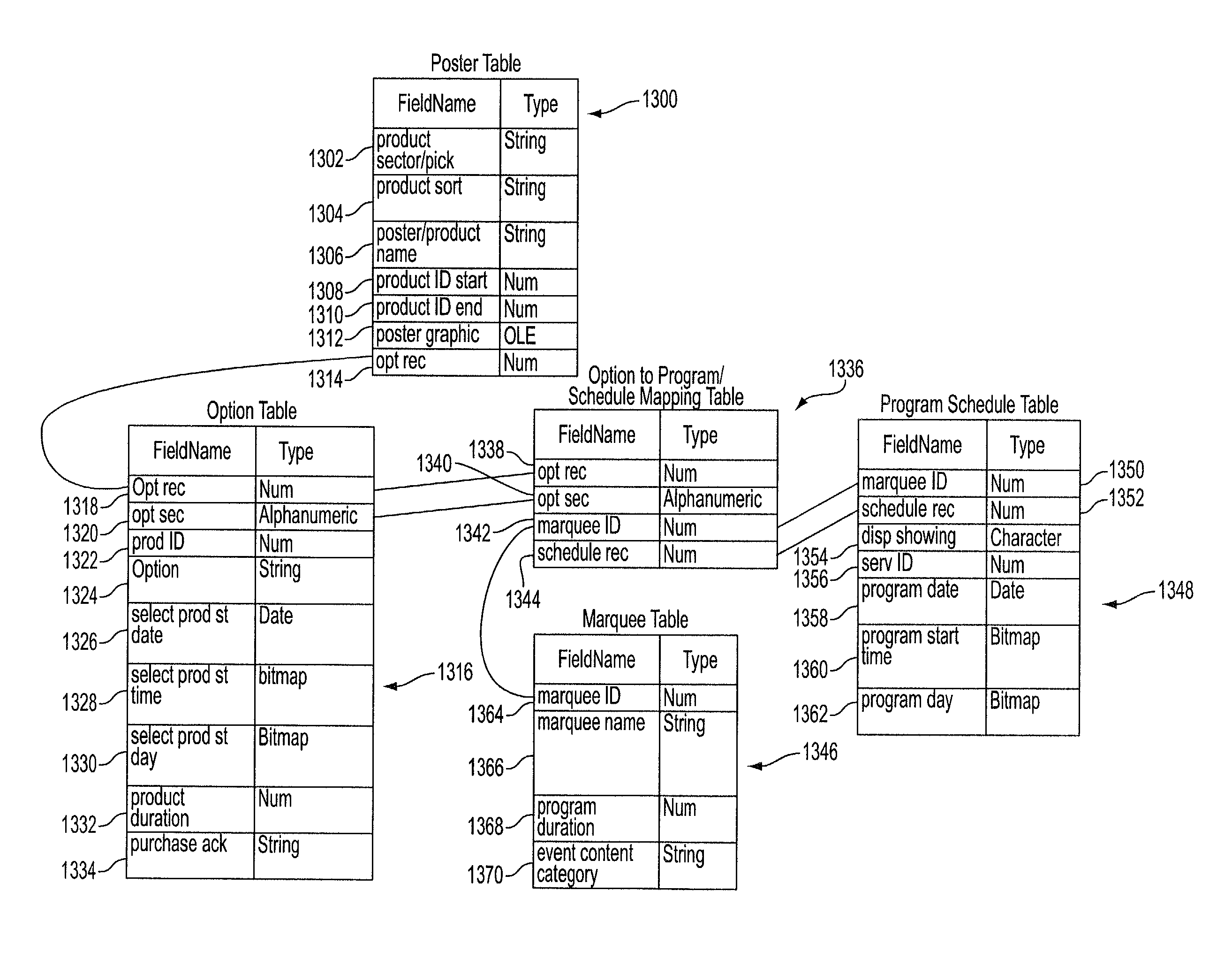

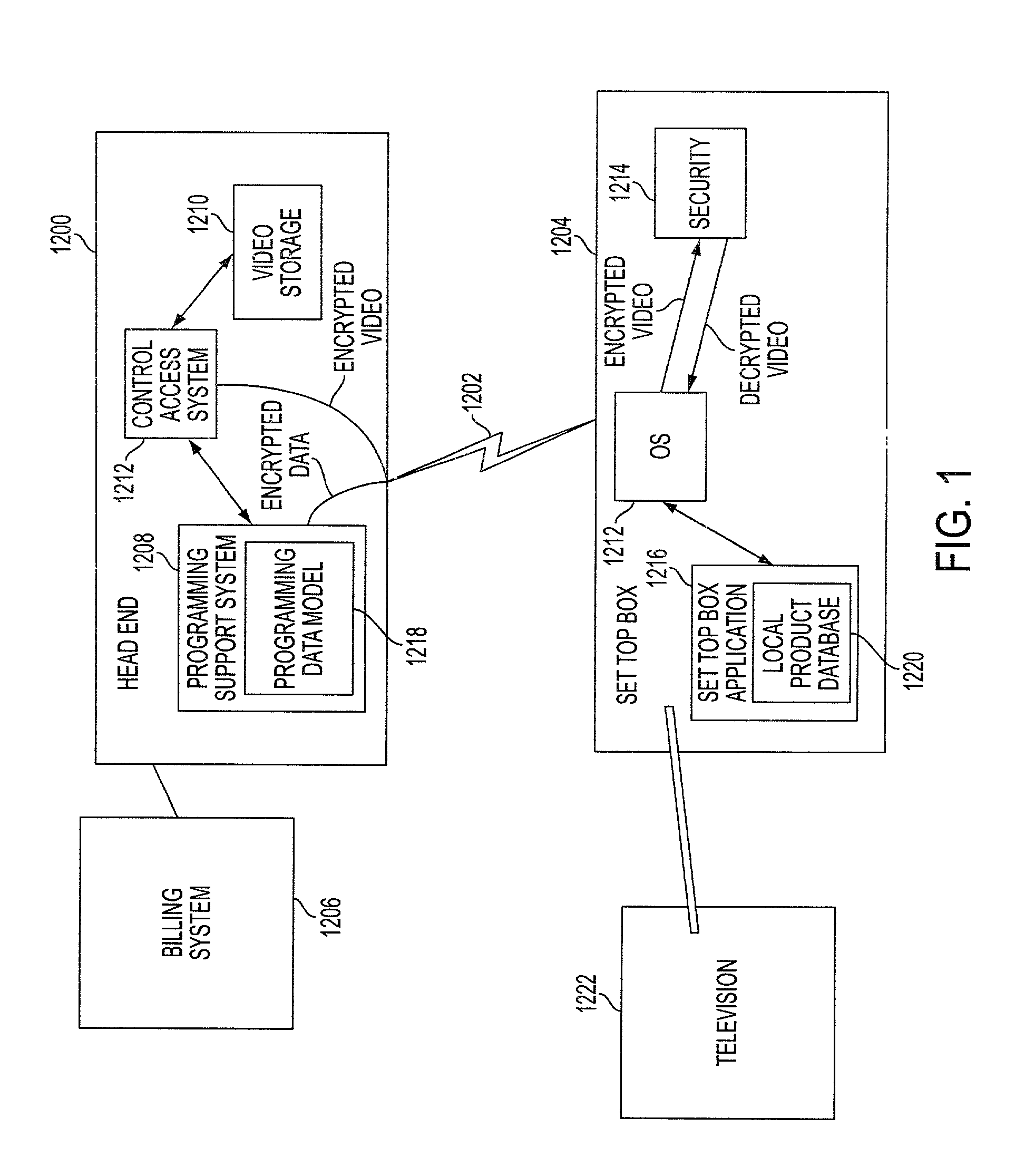

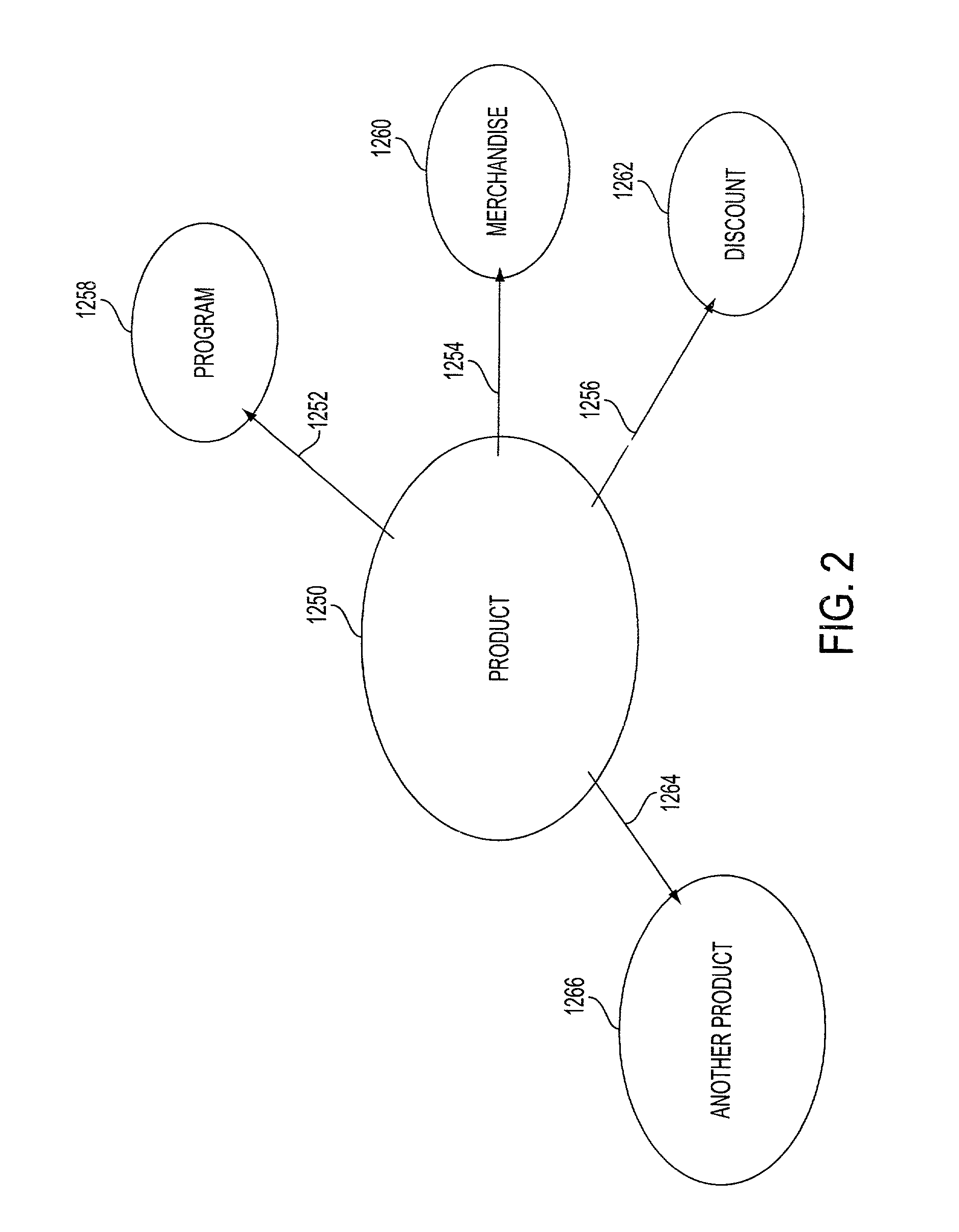

Television program database architecture

ActiveUS8151290B1Good choiceEasy to set upTelevision system detailsDigital data processing detailsData libraryData structure

The present invention provides a data structure for selection of products containing presentable programming as well as a computerized user-interactive system for facilitating allowing a user to select and be provided with deliverable entities including one or more presentable programs. The system and data structure of the invention allow effective, organized, and convenient browsing, selection, conceptual packaging of presentable program-containing products. The system and data structure of the invention further allow efficient structuring and storage of information associated therewith and useful in facilitating effective computerized representation, storage, and delivery of such products. Each product may include multiple deliverable entities, such as multiple programs and merchandize.

Owner:BANBURY TECH

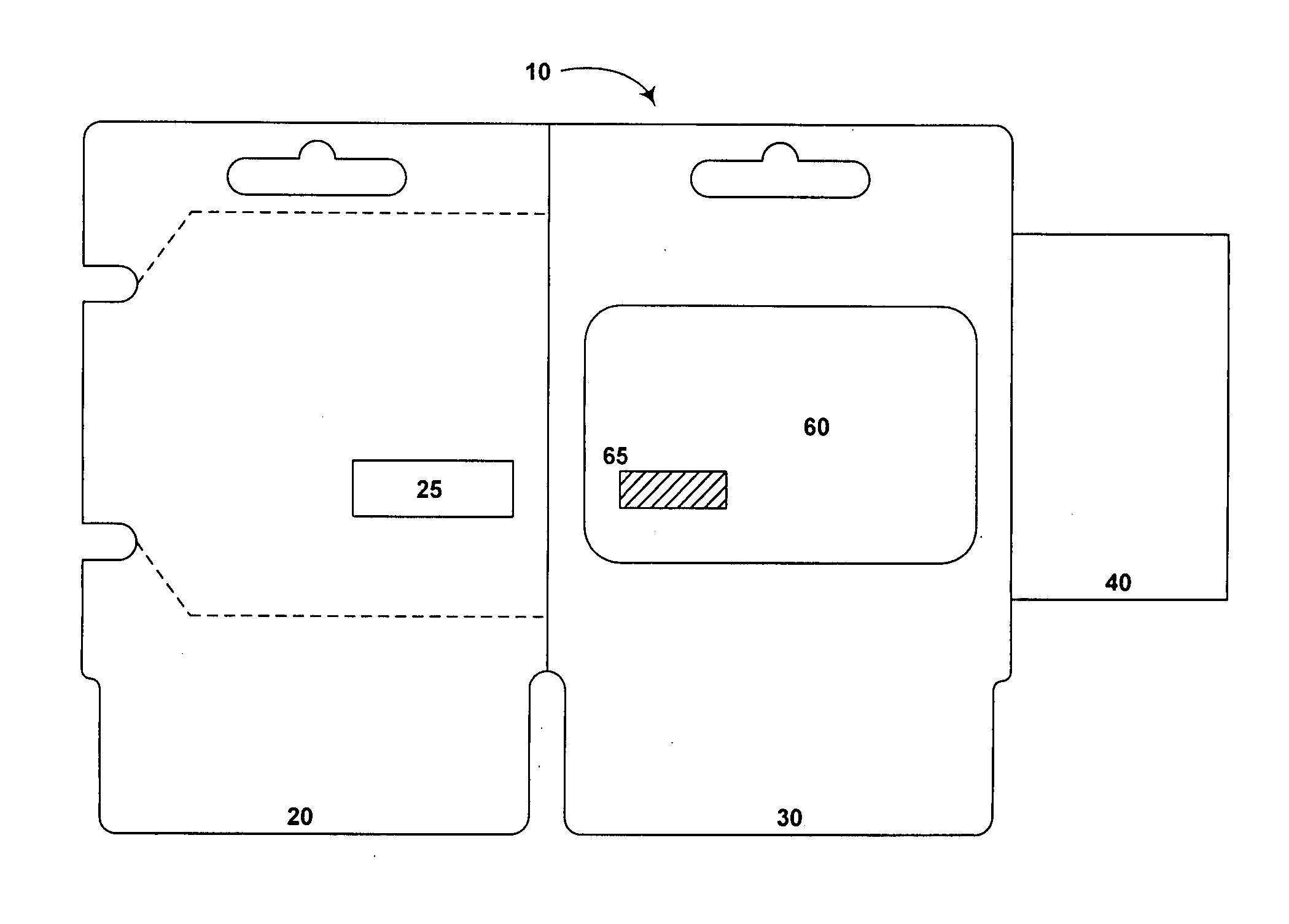

Activation number generation and association

ActiveUS20070063021A1Credit registering devices actuationCard-filingComputer hardwareManufacturing data

The present invention is generally directed to methods of manufacturing data card assemblies. These methods generally comprise manufacturing or purchasing a data card comprising a special number, wherein the special number is associated with a particular data card account; packaging the data cards in a package such that the special number is visible; generating activation information; reading the special number on the data card; recording the activation information on the package; and associating the special number with the particular activation information recorded on the package. Some embodiments of the present invention may further comprise conveying the association between the activation information and the special number to an intermediary managing the data card accounts. Some embodiments of the present invention may further comprise generating a special number associated with a particular data card account; and generating activation information associated with a particular special number.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

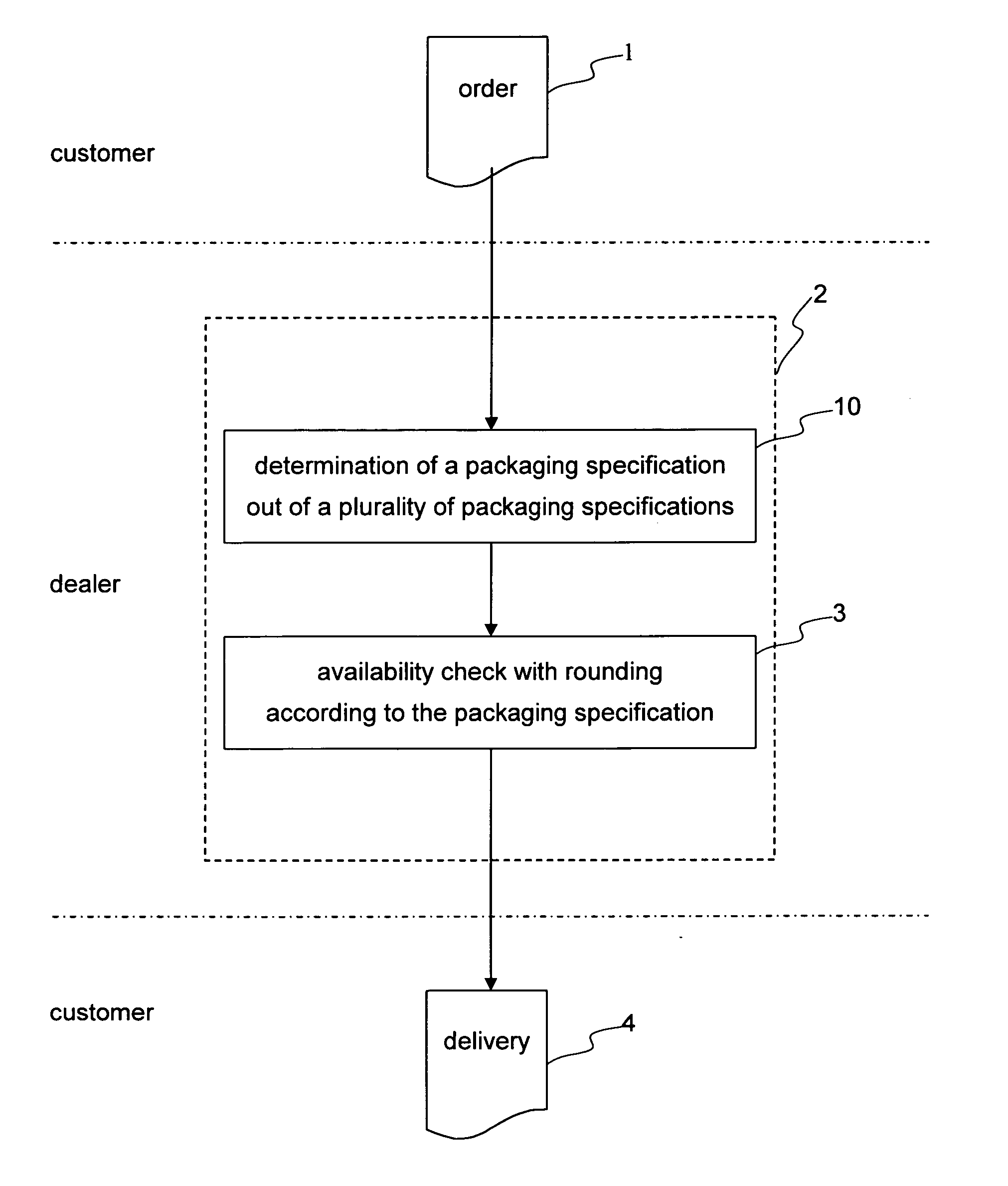

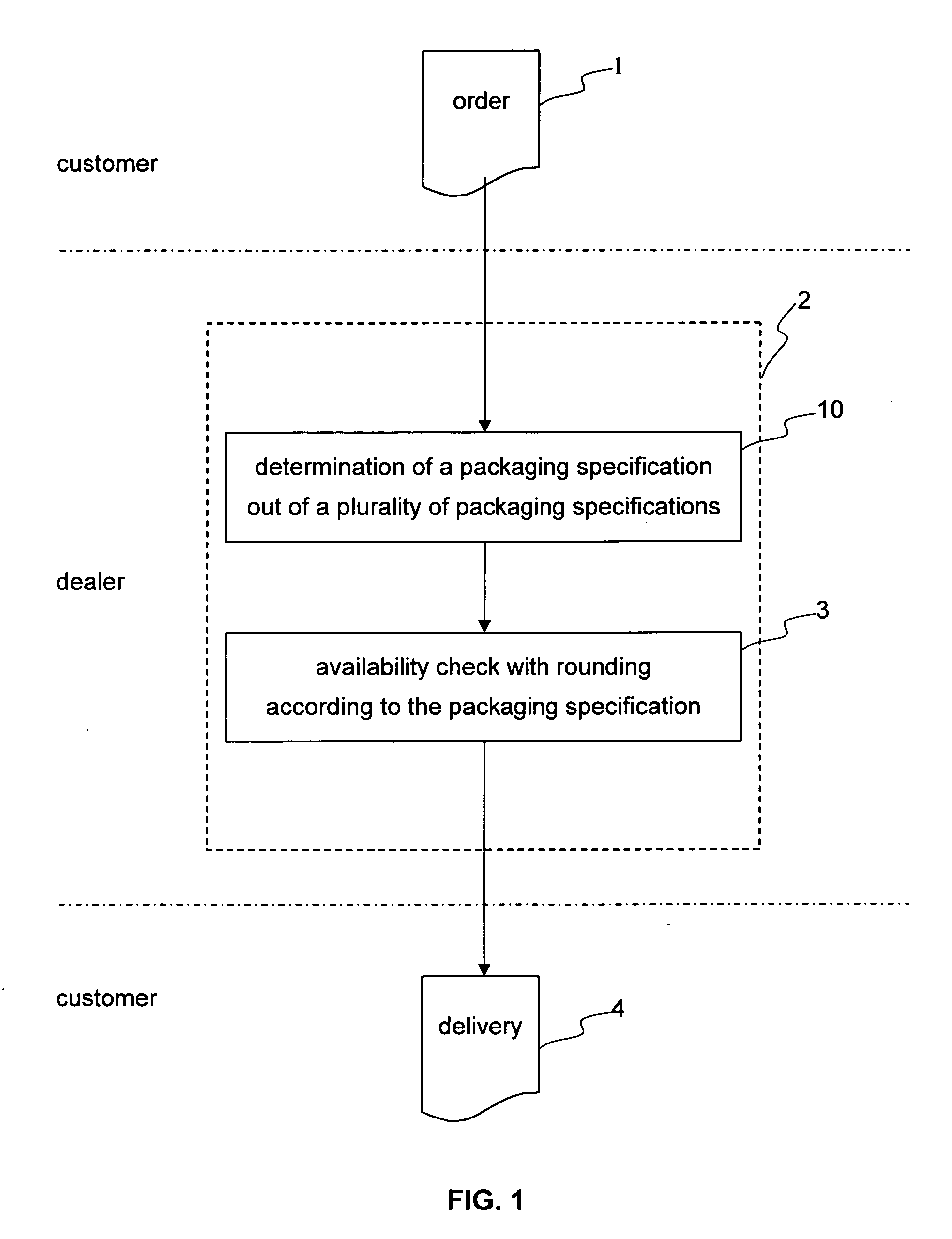

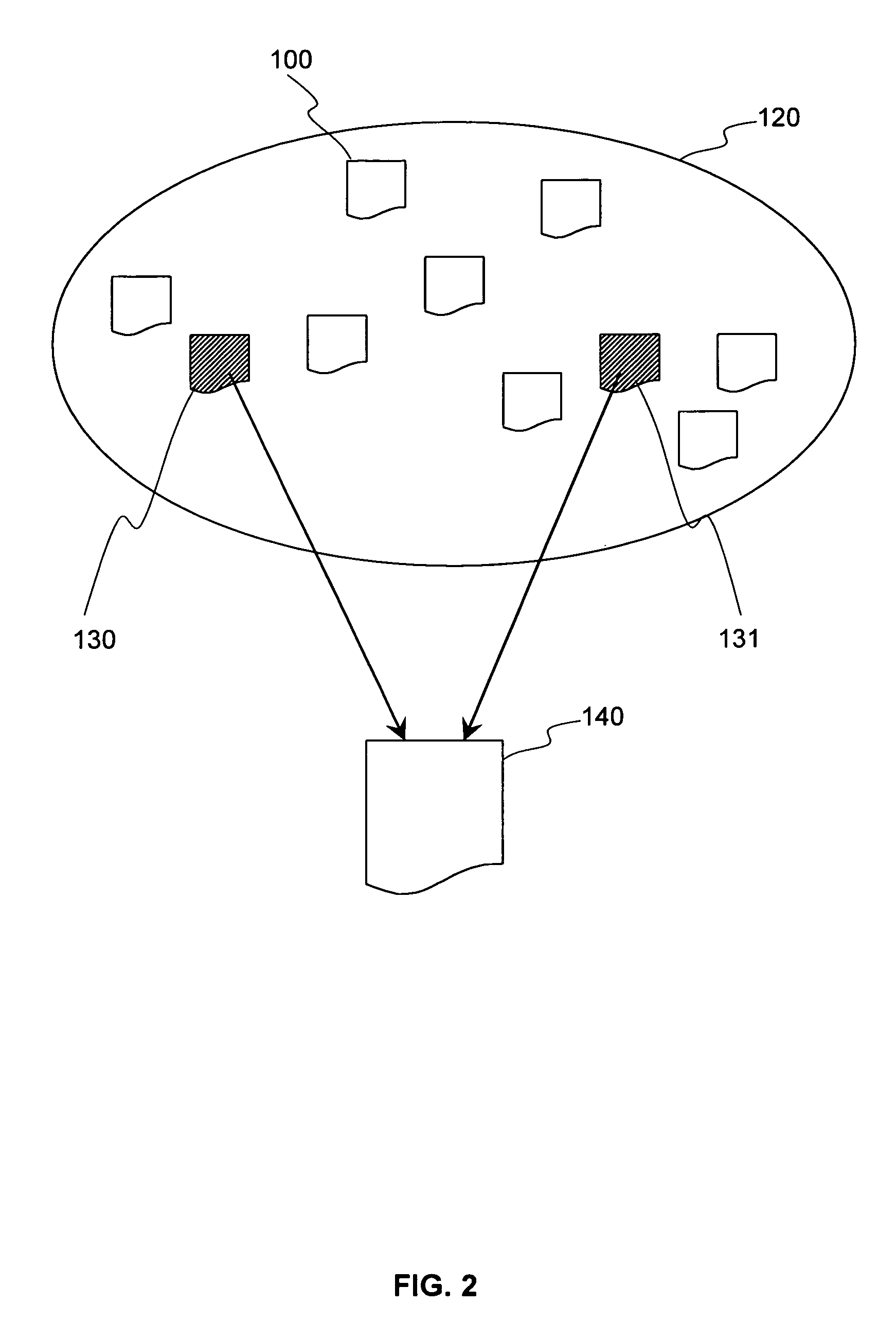

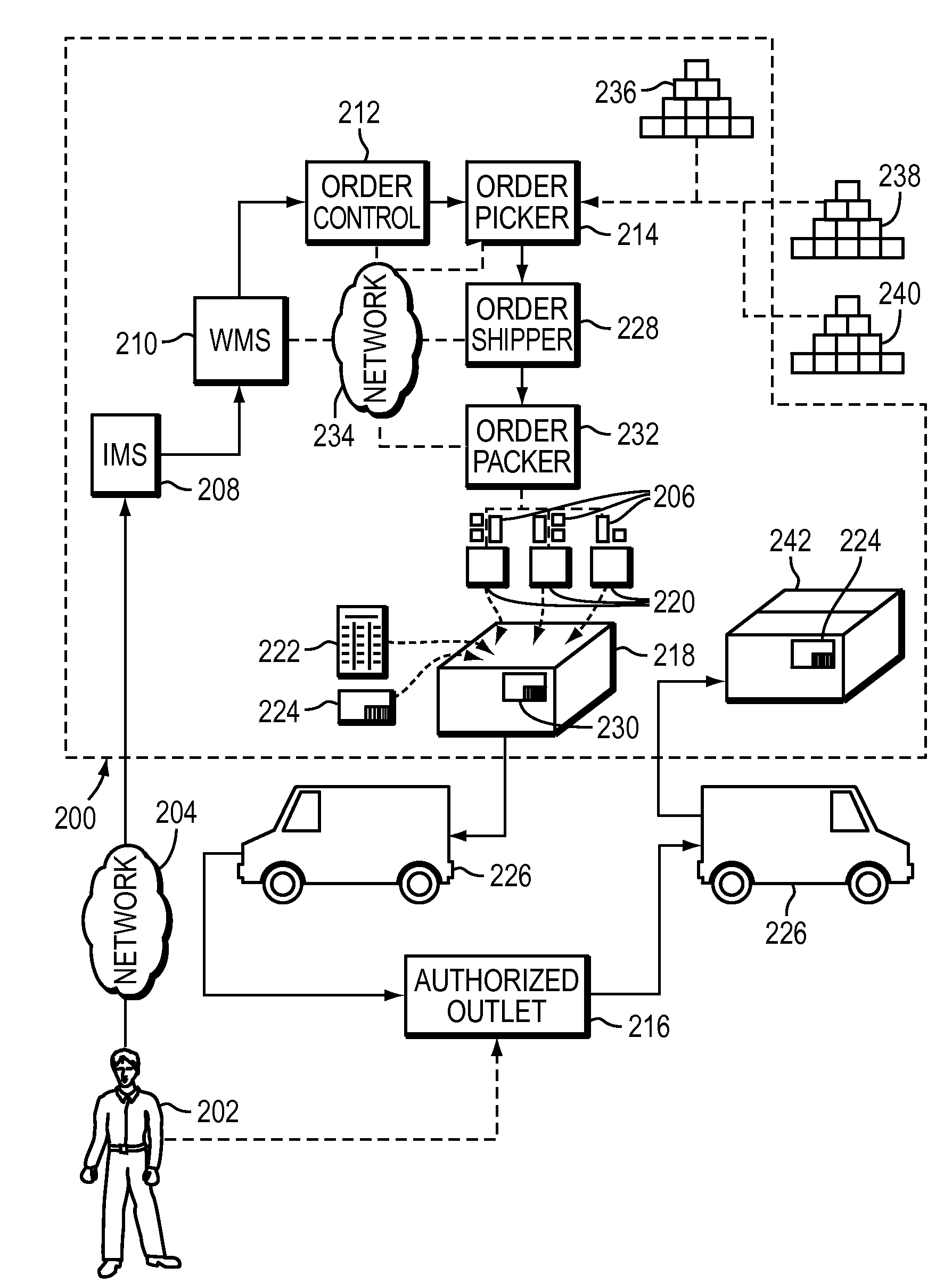

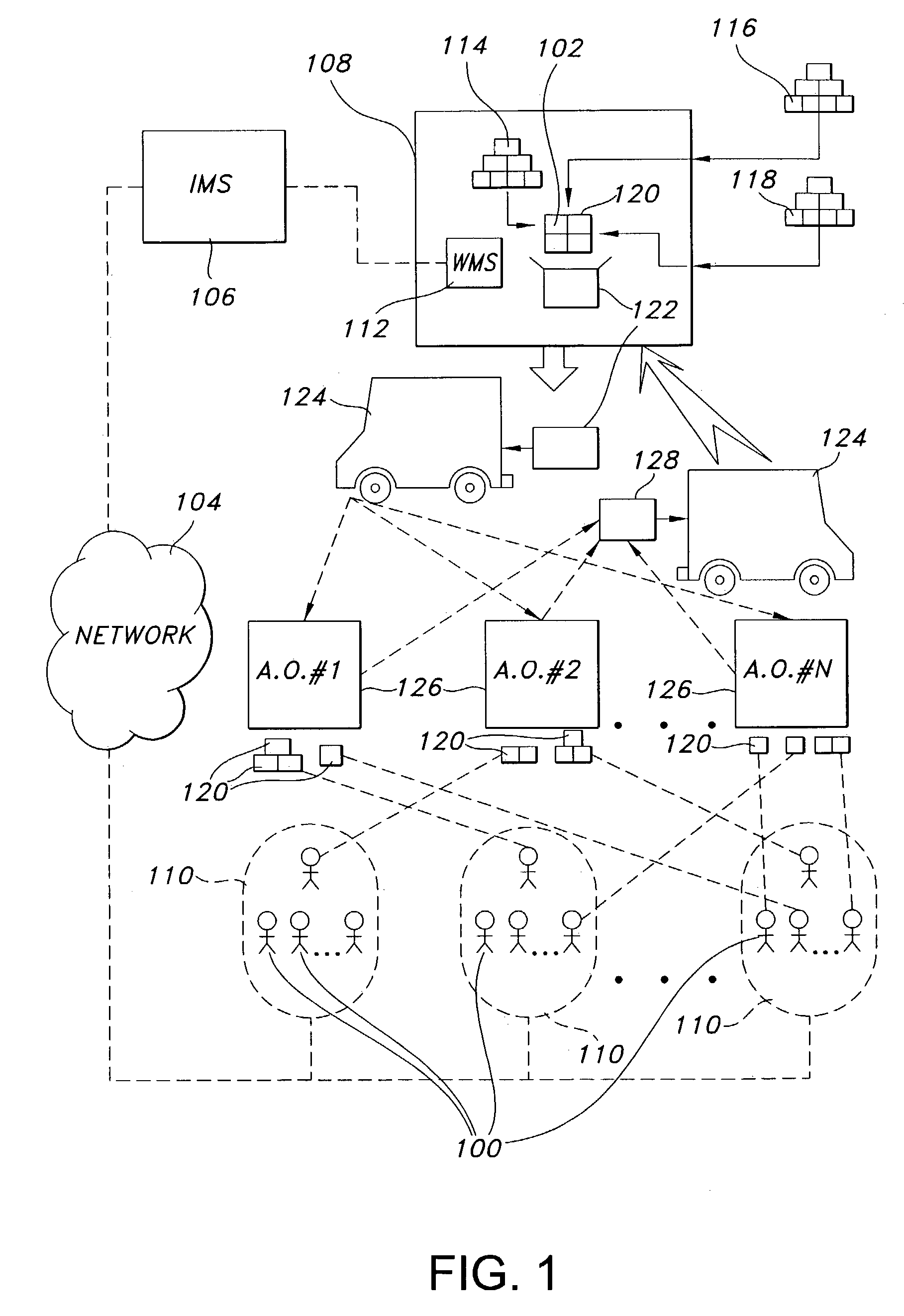

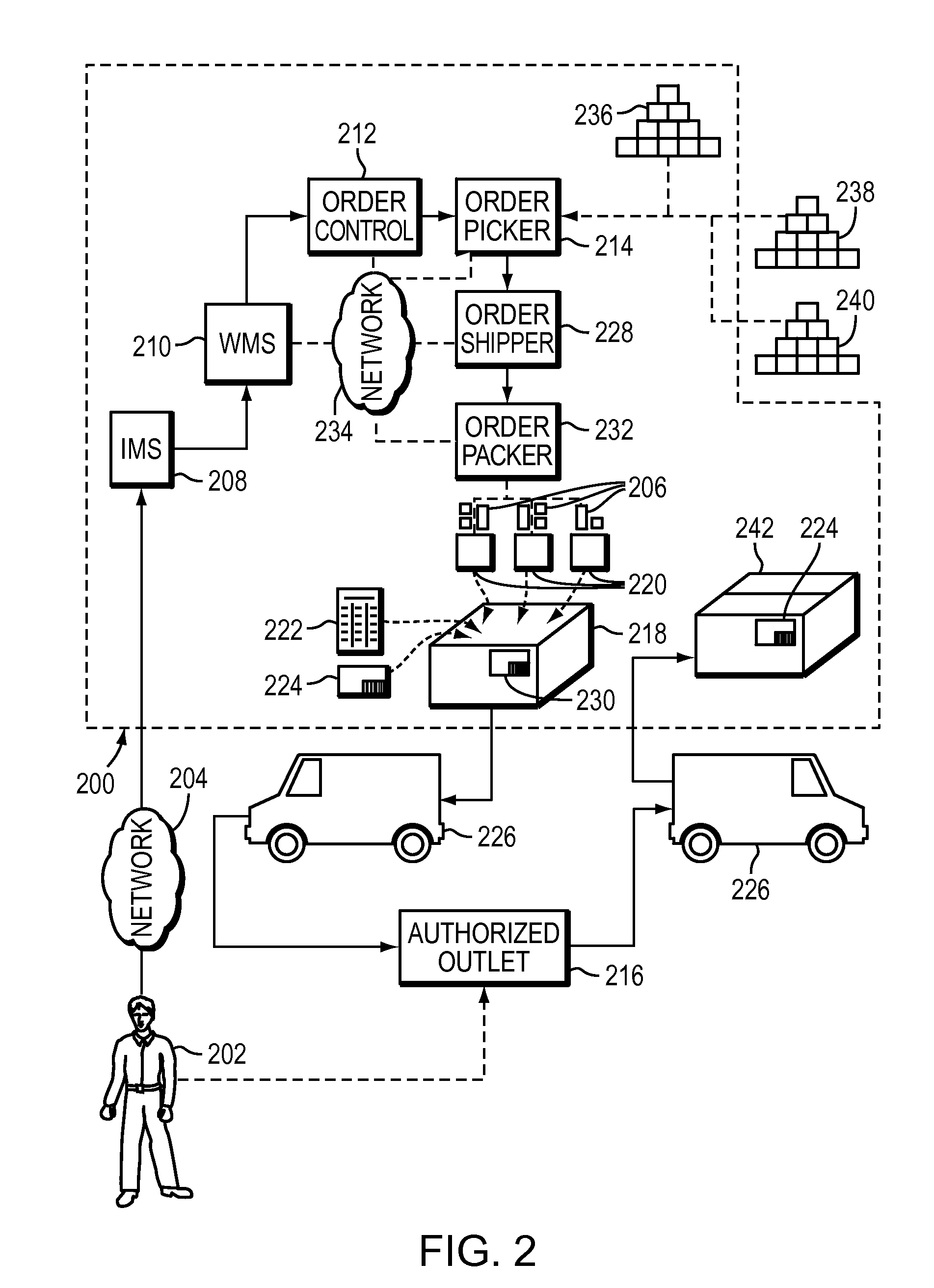

Consolidated shipping and distribution of multiple orders with returns

ActiveUS7426484B2Reduce frequencyLow costElectric signal transmission systemsHand manipulated computer devicesInventory managementEngineering

The present invention provides systems and methods of consolidating, shipping and distributing items comprising multiple orders to multiple customers. The orders are received by an inventory management service, filled and packaged at a centralized distribution center in fewer containers than there are orders. For instance, if there are N orders destined for a particular authorized outlet, then the N orders will be consolidated and shipped in at most N−1, or fewer, containers. However, each order is individually packaged, controlled, tracked and received as an individual order. The consolidated containers are shipped to an authorized outlet and the individual orders are distributed to the customers. Also provided are systems and methods for returning orders that are not picked up at the authorized outlet to a central location. The items may be, for example, service parts, wireless communication devices, etc. Warehousing, shipping and transportation costs are reduced by this invention.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

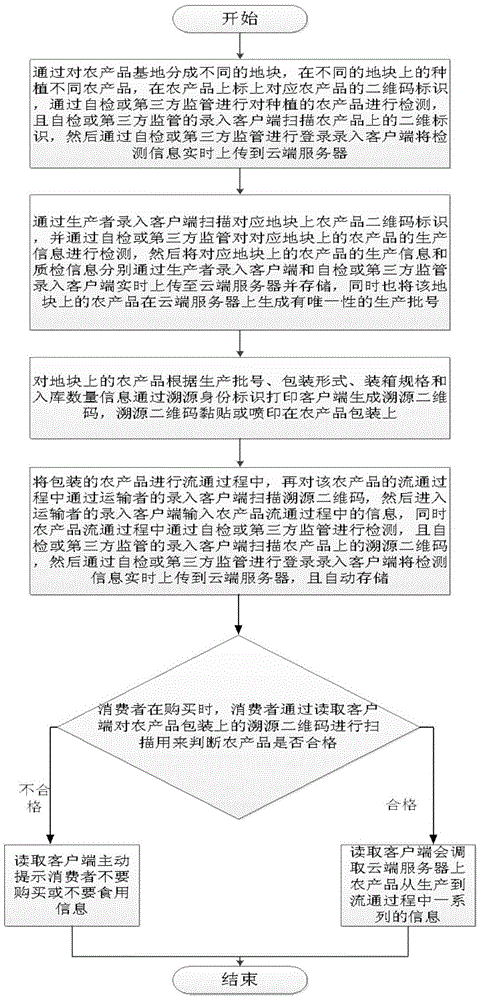

Agricultural product whole process traceability method and system

The invention discloses an agricultural product whole process traceability method and system, comprising the steps of: S1, marking a two-dimensional code identification corresponding to an agricultural product on the agricultural product on a land block; S2, a producer logging client scanning the agricultural product two-dimensional code on a corresponding land block, and uploading agricultural product production information to a cloud server in real time; S3, generating a traceablility two-dimensional code for the agricultural product on the land block, and adhering or printing the two-dimensional code on an agricultural product package; S4, in a circulation process, a transporter logging client scanning the traceablility two-dimensional code, and uploading agricultural product circulation information to the cloud server; and S5, when purchasing the agricultural product, a consumer employing a reading client to scan the traceablility two-dimensional code on the agricultural product package to determine whether the agricultural product is qualified, the reading client acquiring the agricultural product information from production to circulation if qualified, and otherwise actively promoting the consumer. The agricultural product whole process traceability method and system can conveniently upload agricultural product information in an on-line real-time mode, facilitate timely updating data, and improve security.

Owner:浙江甲骨文超级码科技股份有限公司

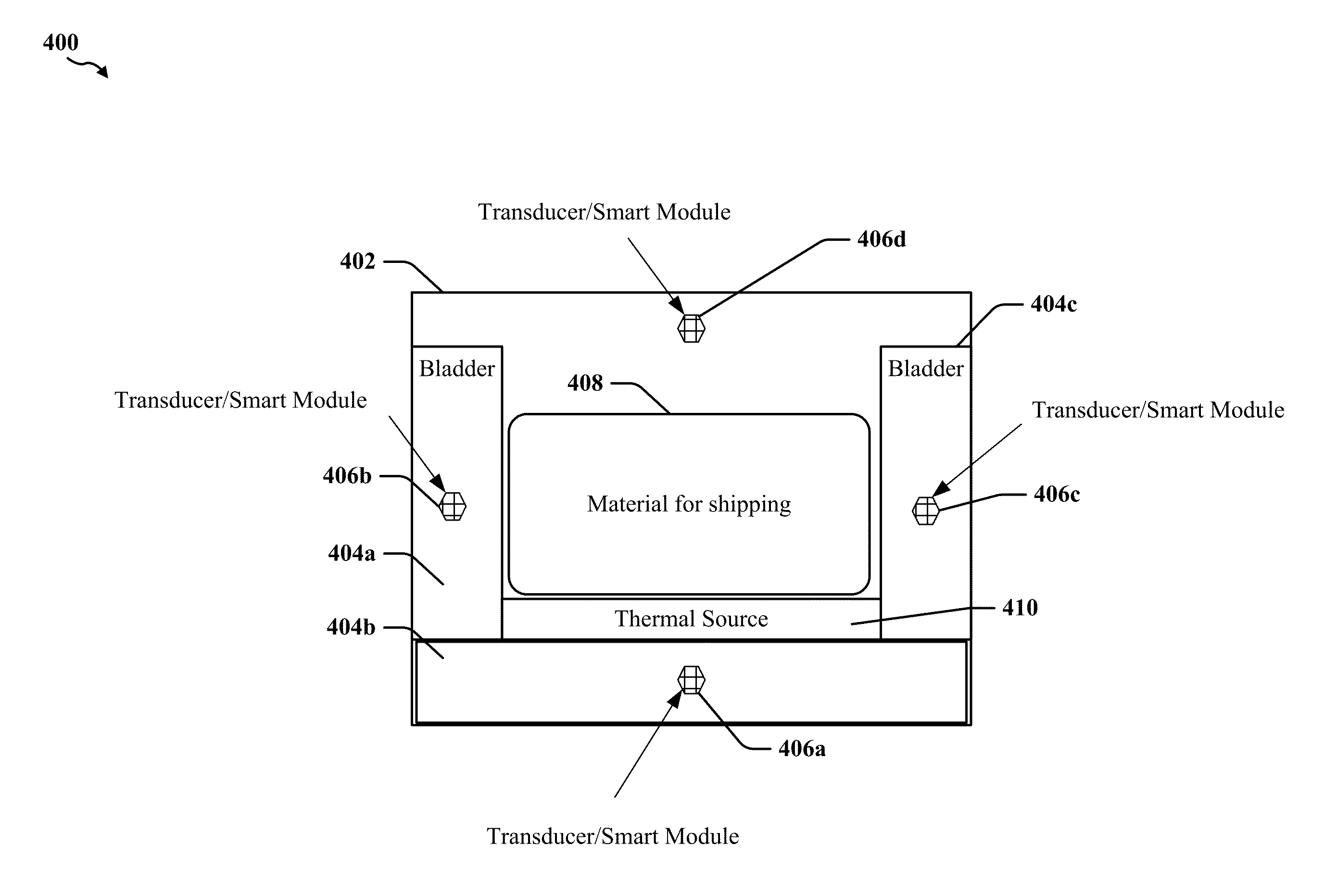

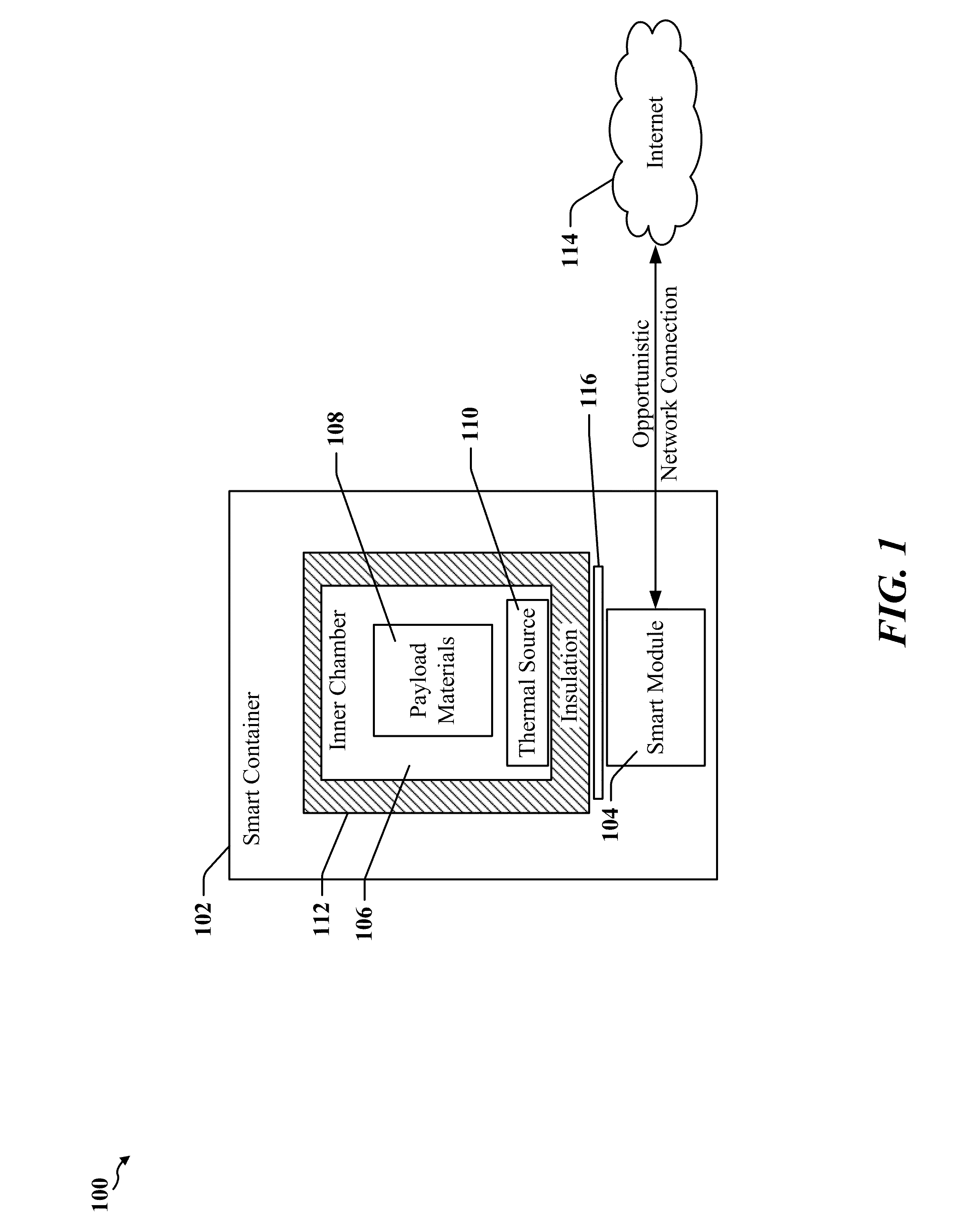

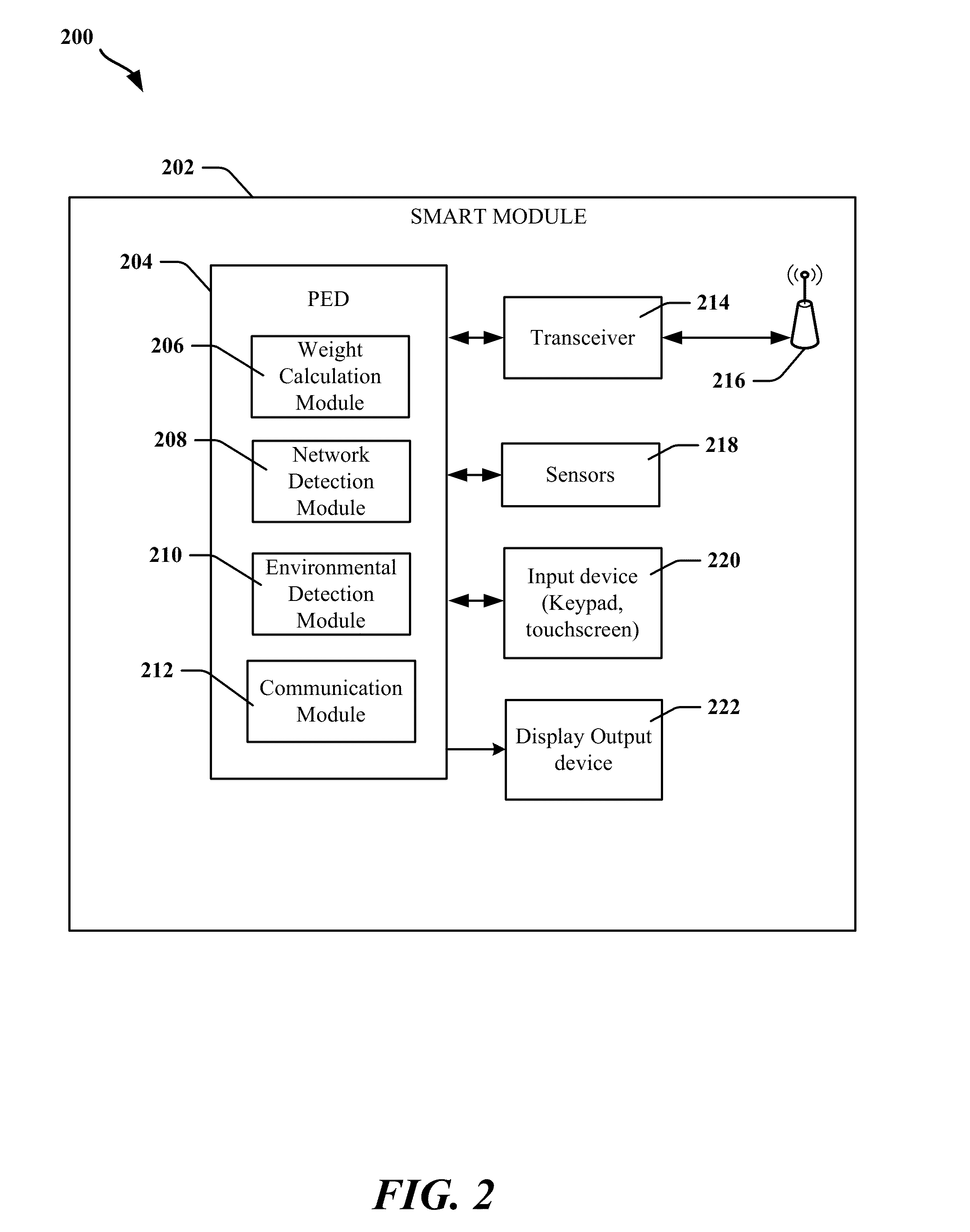

Method for determining the remaining life of a thermal mass in a shipping package while in transit

InactiveUS20130245991A1Data processing applicationsLighting and heating apparatusTemperature controlTransducer

A shipping container is described for use with methods for monitoring and controlling shipment of a temperature controlled material and determining the remaining useful life of a Thermal Source contained within the shipping container. The container comprises an inner enclosure adapted to carry one or more commodities during shipment, a bladder conformed to the inner surface of the inner chamber, or a plate upon which commodities are place, and instrumented with at least one transducer and at least one processing device configured to receive measurements from the at least one transducer. The processing device communicates the measurements to a networked device upon detecting the presence of a network. The networked device may transmit commands to the processing device that causes the processing device to adjust a configuration parameter.

Owner:KLATU NETWORKS

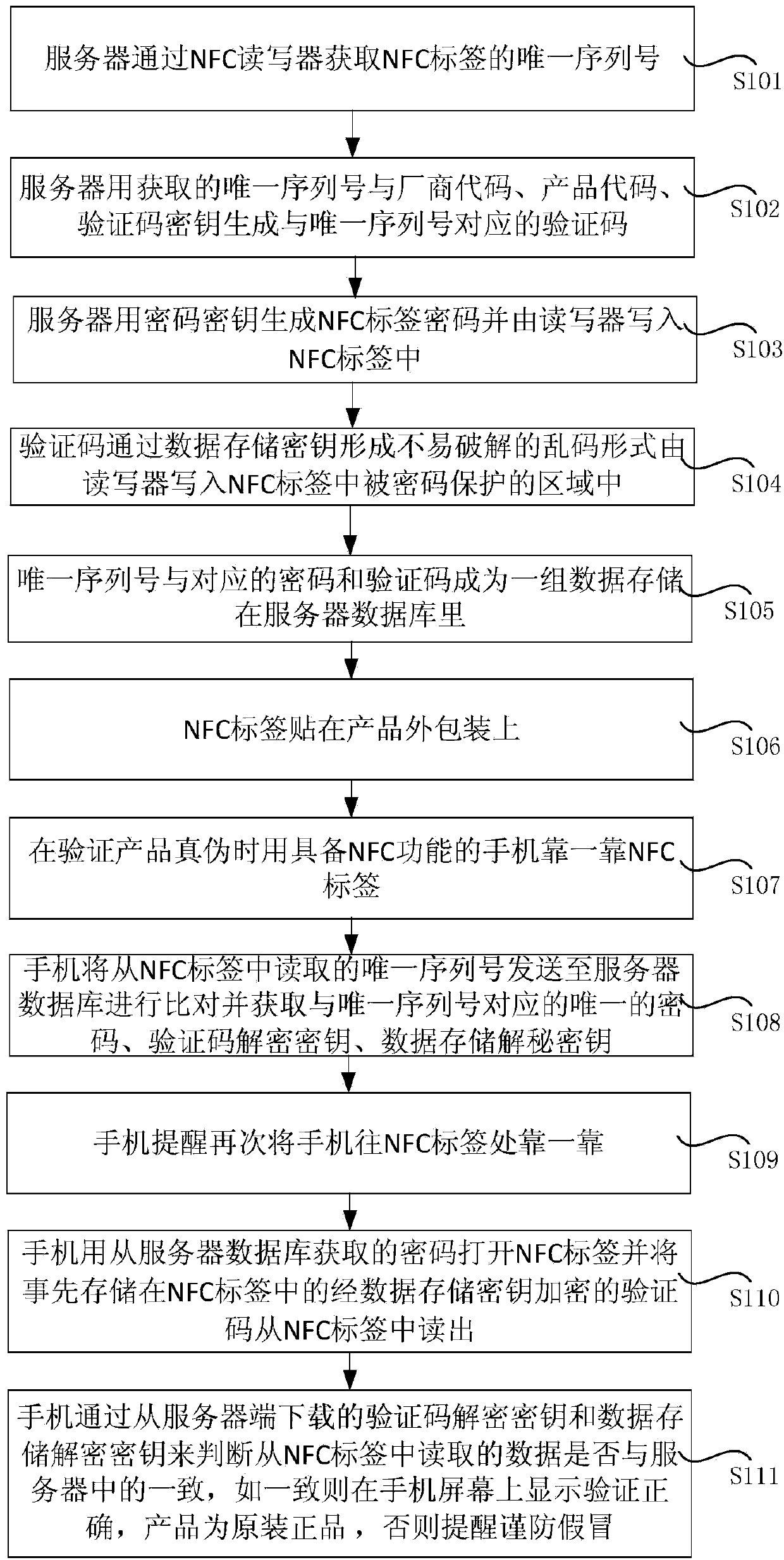

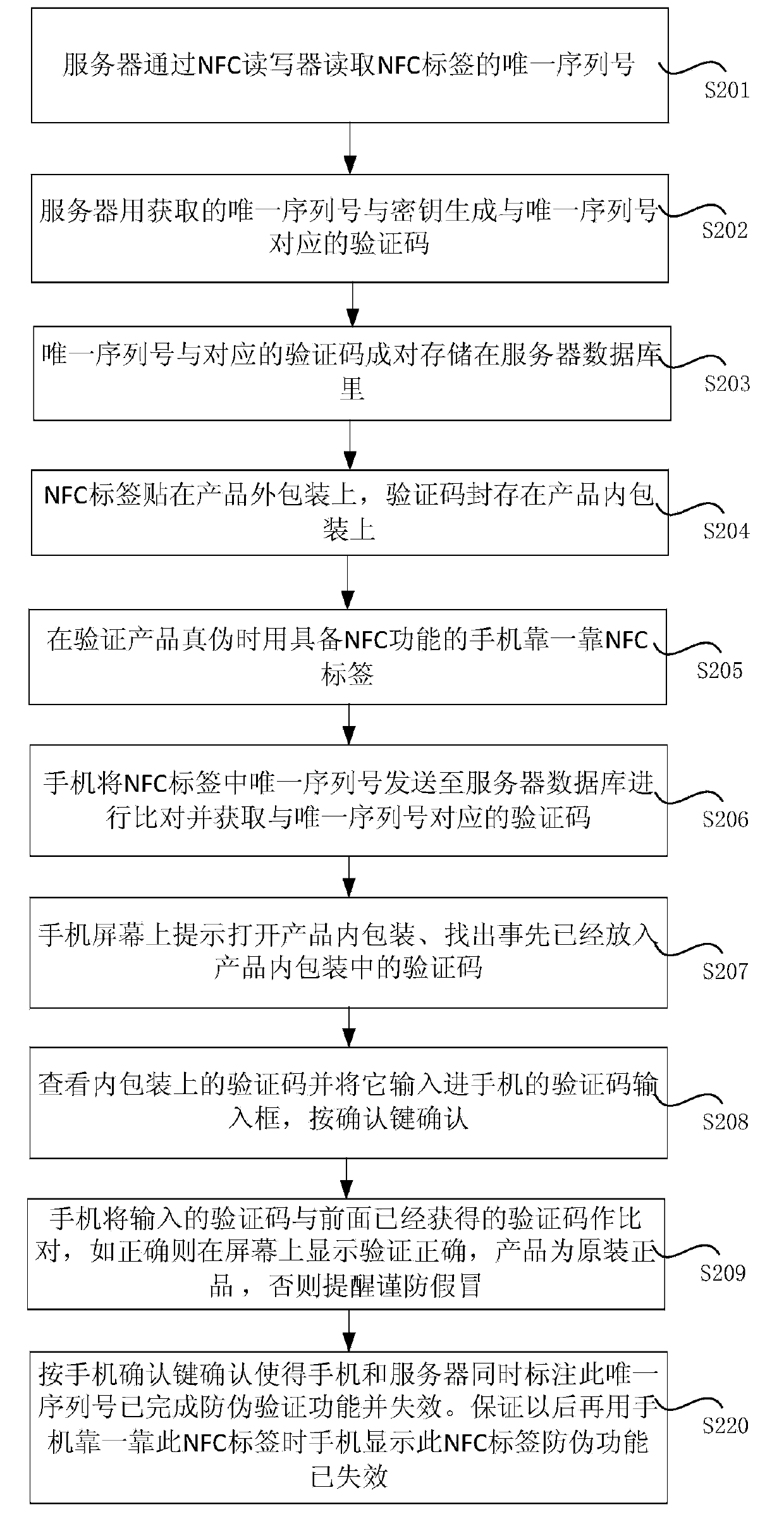

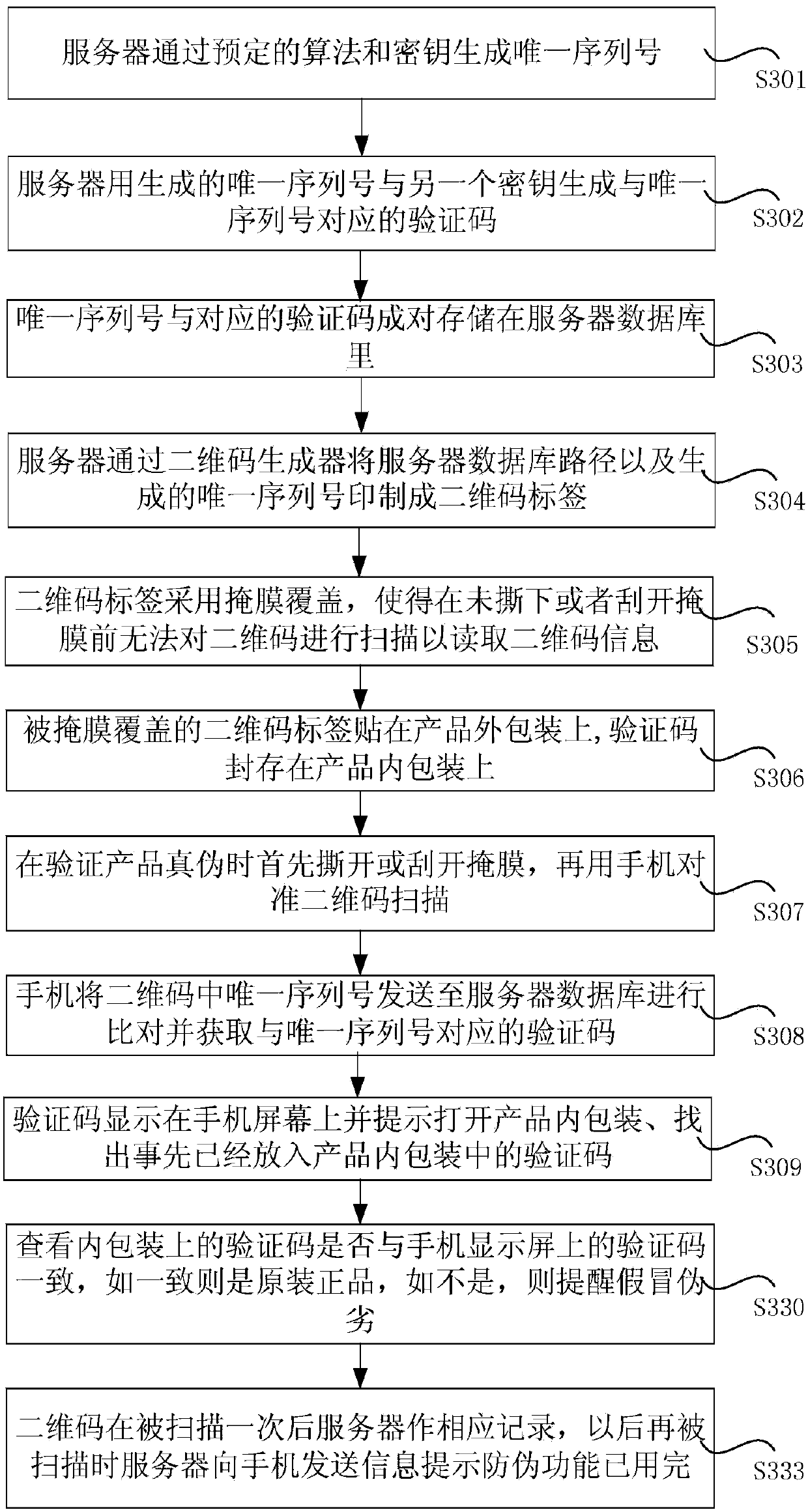

Anti-counterfeiting method for product

The invention provides an anti-counterfeiting method for a product. The anti-counterfeiting method includes the steps that a unique serial number is generated through a preset algorithm and a secret key; a verification code corresponding to the unique serial number is generated; a path of a server database and the generated unique serial number are printed to form a two-dimension code label through a two-dimension code generator; the two-dimension code label covered with a mask is attached to an outer package of the product, and the verification code is stored on an inner package of the product in a sealed mode; when the authenticity of the product is verified, the mask is torn off or scraped off, and then a mobile phone is used for being aligned to and scanning the two-dimension code; the unique serial number in the two-dimension code is sent to the server database and compared, and the verification code corresponding to the unique serial number is obtained; the verification code on the inner package is checked and input into a verification code input box of the mobile phone, and a confirming key is pressed for confirming; the mobile phone compares the input verification code with the verification code obtained before. The anti-counterfeiting method for the product facilitates the anti-counterfeiting verification operation on the product, improves the verification efficiency, and is practical.

Owner:上海高研明鉴信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com