Patents

Literature

160 results about "Equine Species" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Equus is a genus of mammals in the family Equidae, which includes horses, donkeys, and zebras. Within Equidae, Equus is the only recognized extant genus, comprising seven living species. The term equine refers to any member of this genus, including horses.

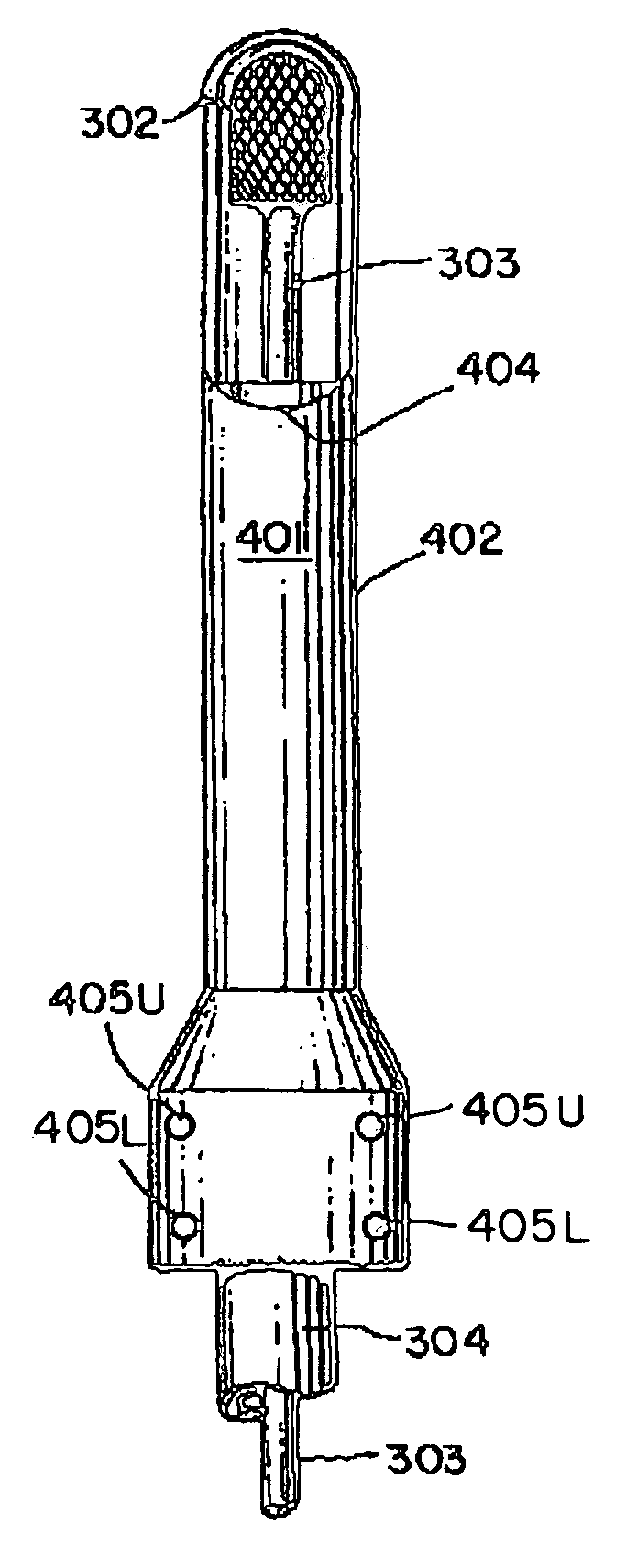

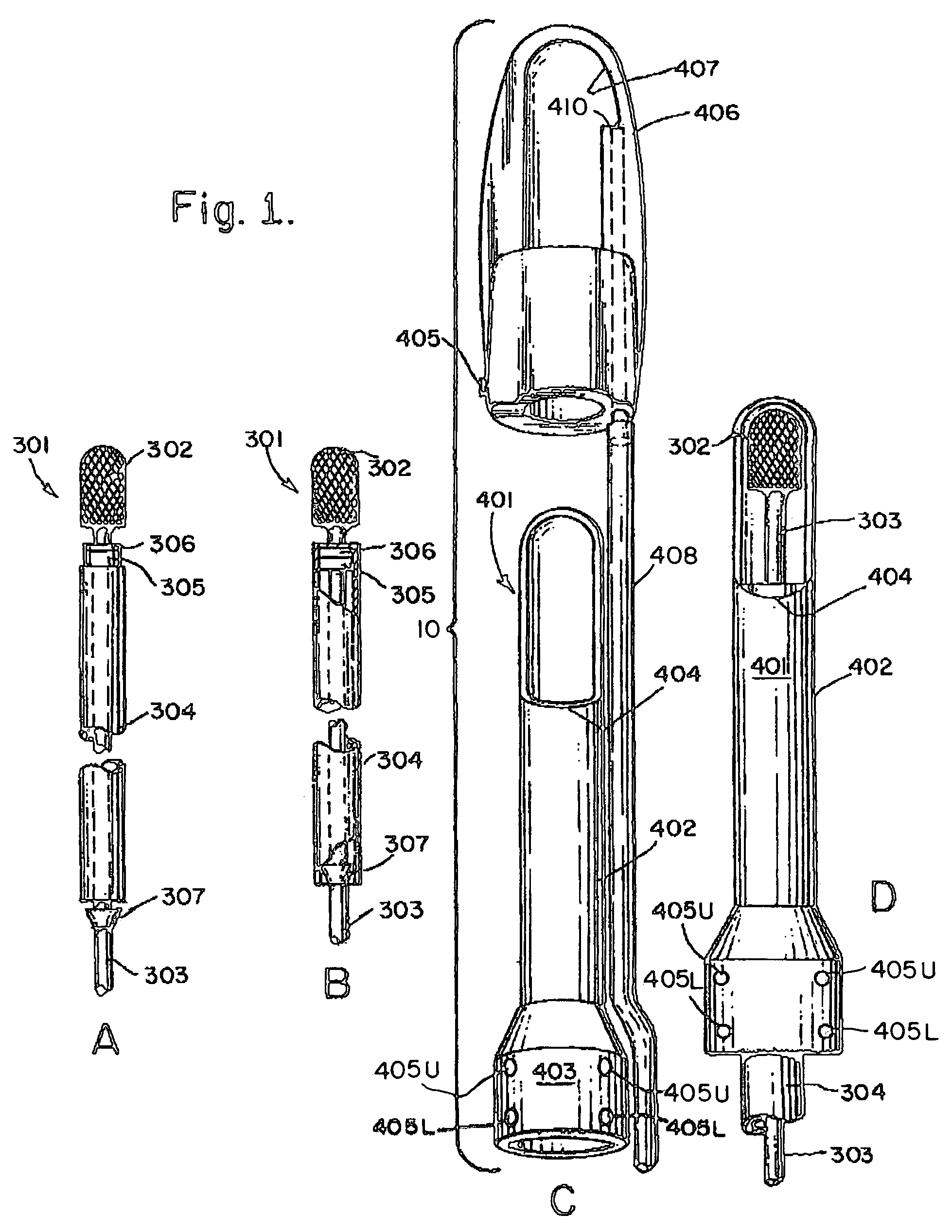

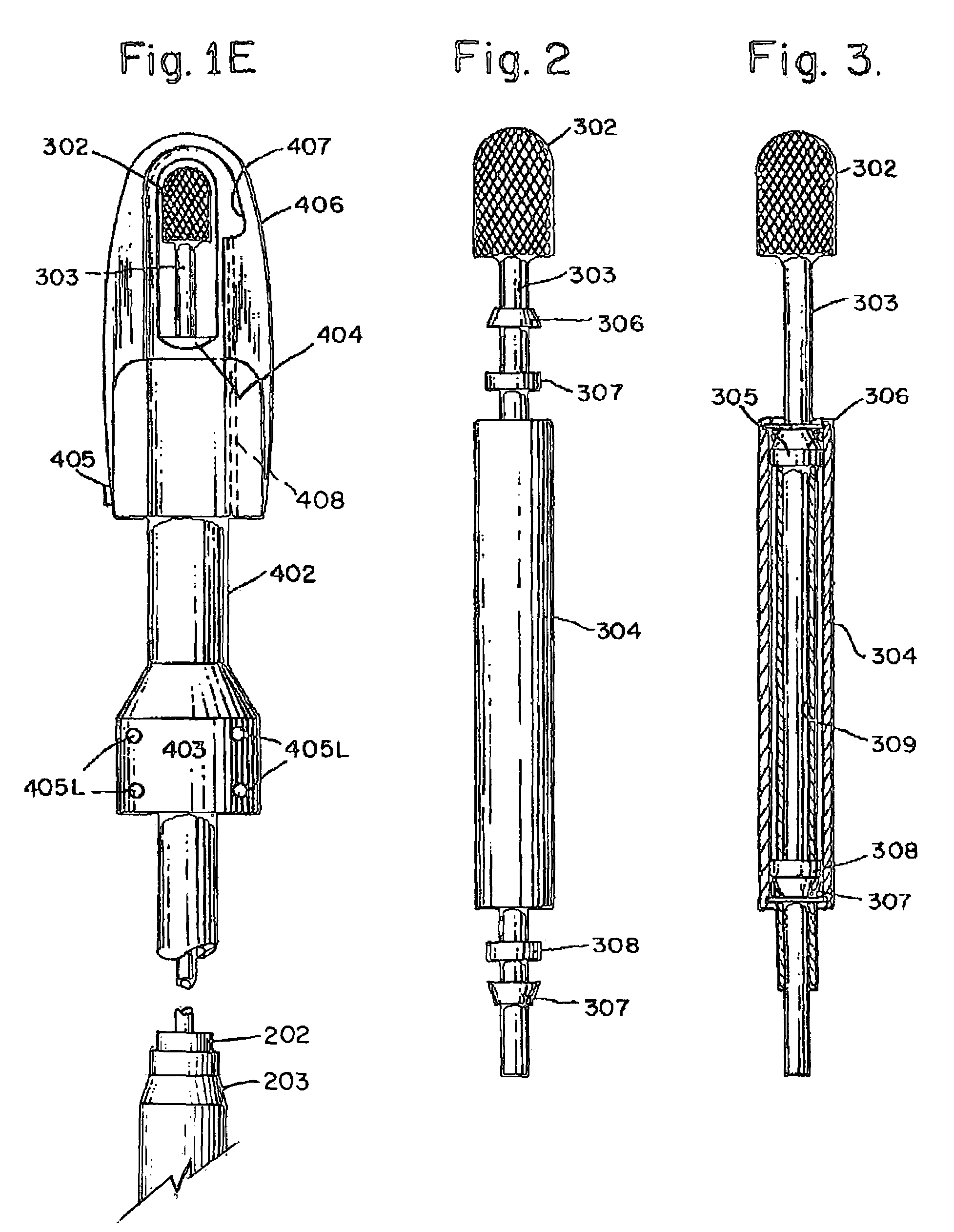

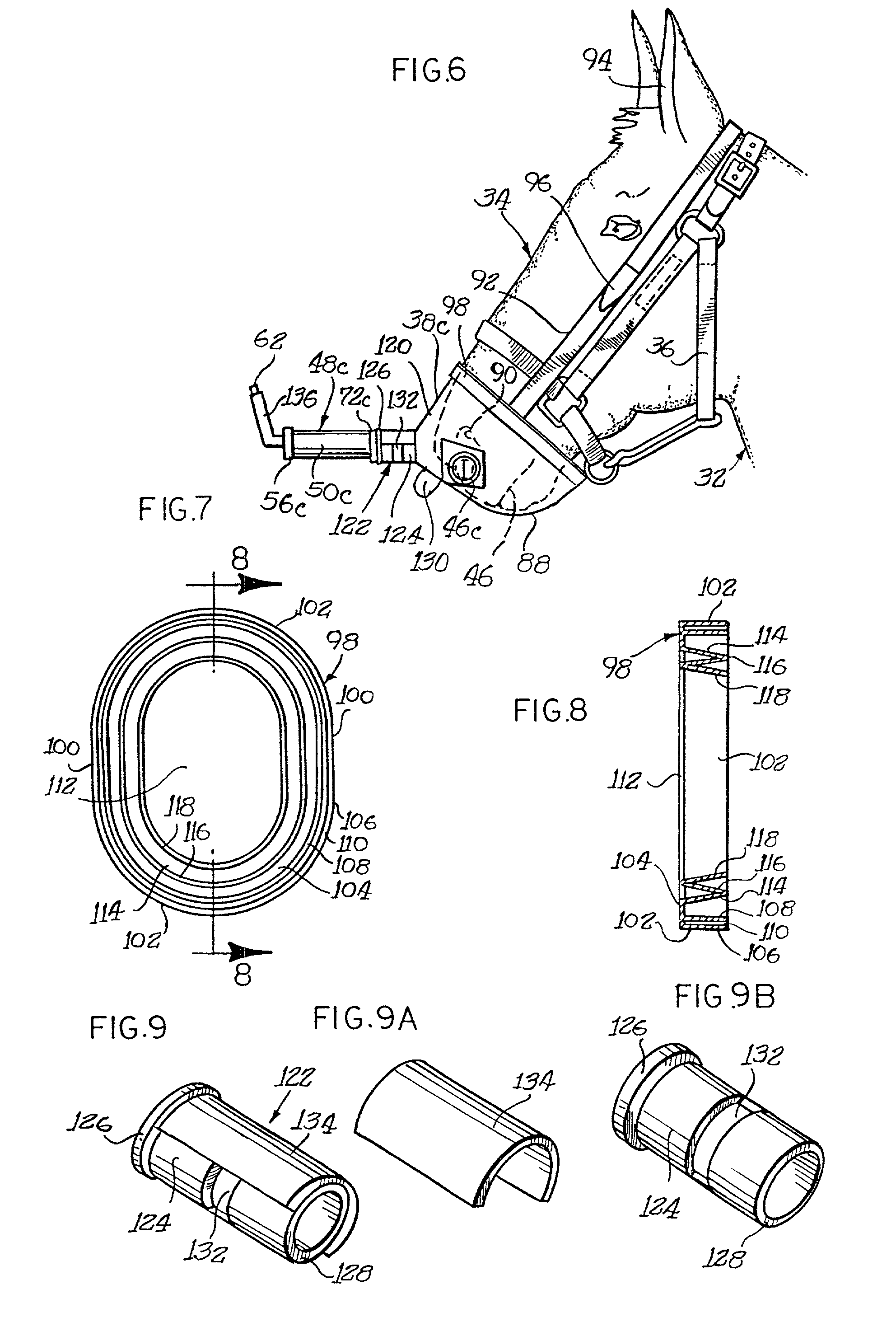

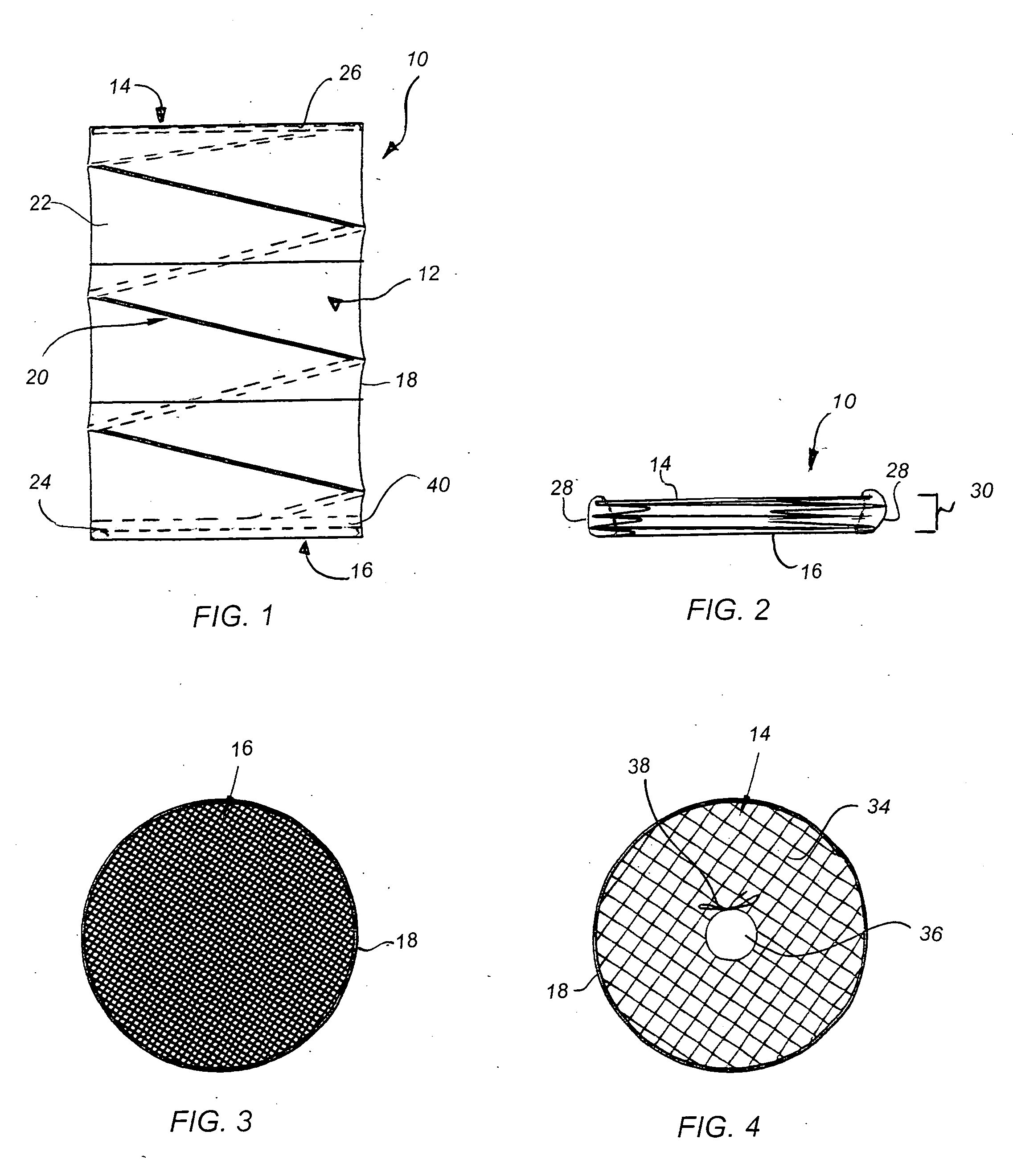

Powered cutting surface with protective guard for equine teeth

InactiveUS7238021B1Quickly reconfiguredSafely and easily performAnimal teeth treatmentBoring toolsReciprocating motionEquine Species

An arrangement that may be used in combination with selected tools having a tooth cutting surface for the care and maintenance such as removing a selected portion of the exposed surface of equine teeth. The selected tool in communication with a source of powered motion and mounted in and supported by a hand piece which is guided into the mouth of the horse. The cutting surface of the powered tool is partially guarded so as to protect fleshy portions of the horse's mouth from being engaged by the cutting surface. The hand piece provides for quick on and off attachment of a selected cutting surface for maintenance of a preselected portion of teeth within the same hand piece or another hand piece sized to ease access to the next selected portion of the horse's mouth. The selected hand piece arrangement may further incorporate a vacuum channel whereby the tooth dust and debris created by the powered cutting surface removing a portion of tooth is sucked out of the mouth of the horse. The motion of the tooth surface removal tool may be changed from rotary to powered reciprocating motion for a selected portion of the teeth or changed to be at a preselected angle. Attaching the powered drive to the rotary cutting surface by means of an adjustable clutch further enhances protection from injury to the inside of the mouth of the horse.

Owner:JOHNSON GARY E

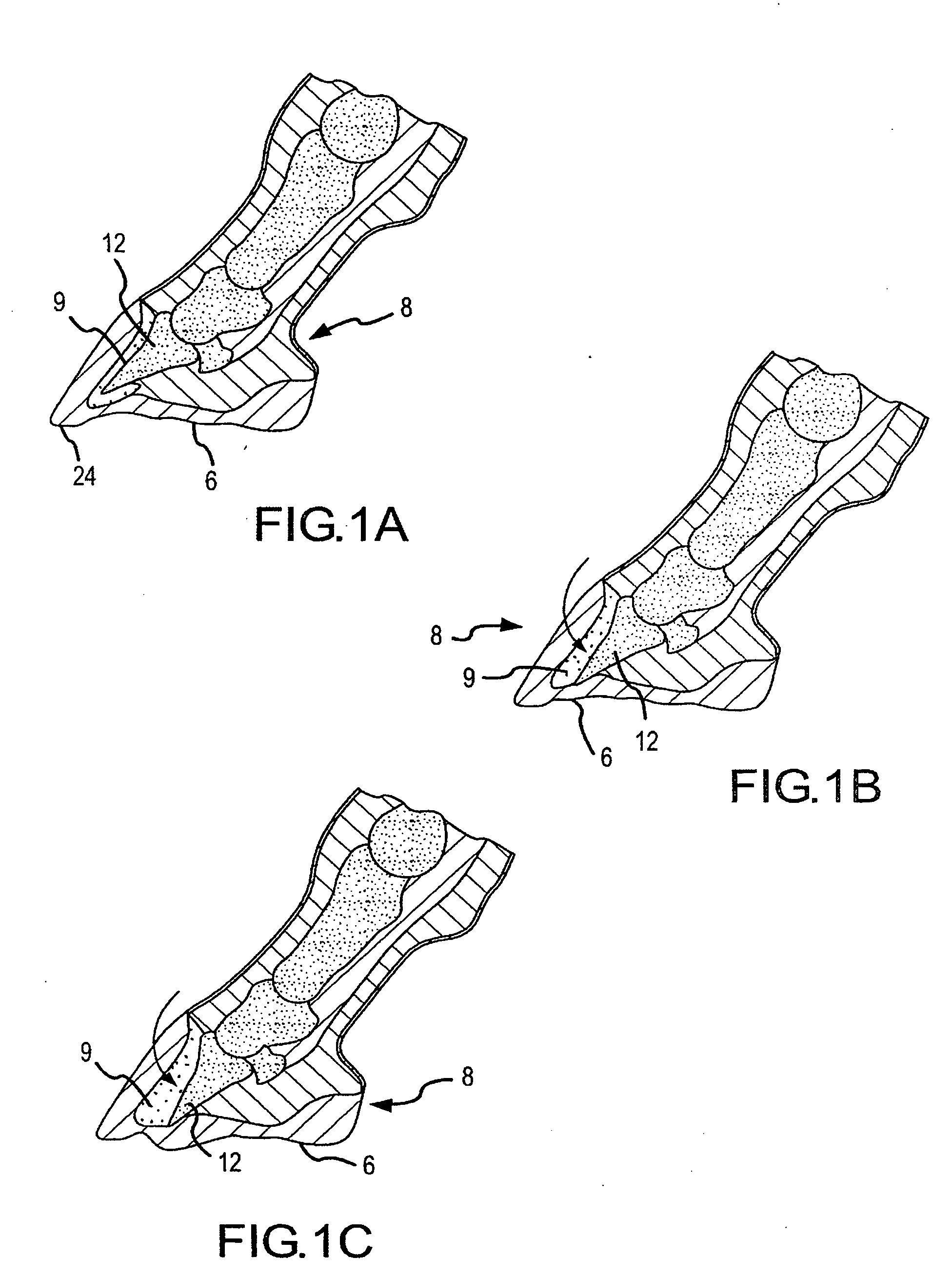

Topical nitric oxide donor compositions

InactiveUS6287601B1Reduced and failing organ functionPoor appetitePowder deliveryBiocideLipid formationEquine Species

Compositions and methods of the topical treatment of equine laminitis are disclosed. In particular, combinations of a fast acting nitric oxide (NO) donor, a sustained acting NO donor and an NSAID mixed in a lipid-based carrier are described. The application of such combinations to the affected areas, e.g., the hoofs and surrounding tissues, of an equine afflicted with laminitis provides relief from the debilitating effects of this painful, often life-threatening condition.

Owner:STREHKEHN INT LTD

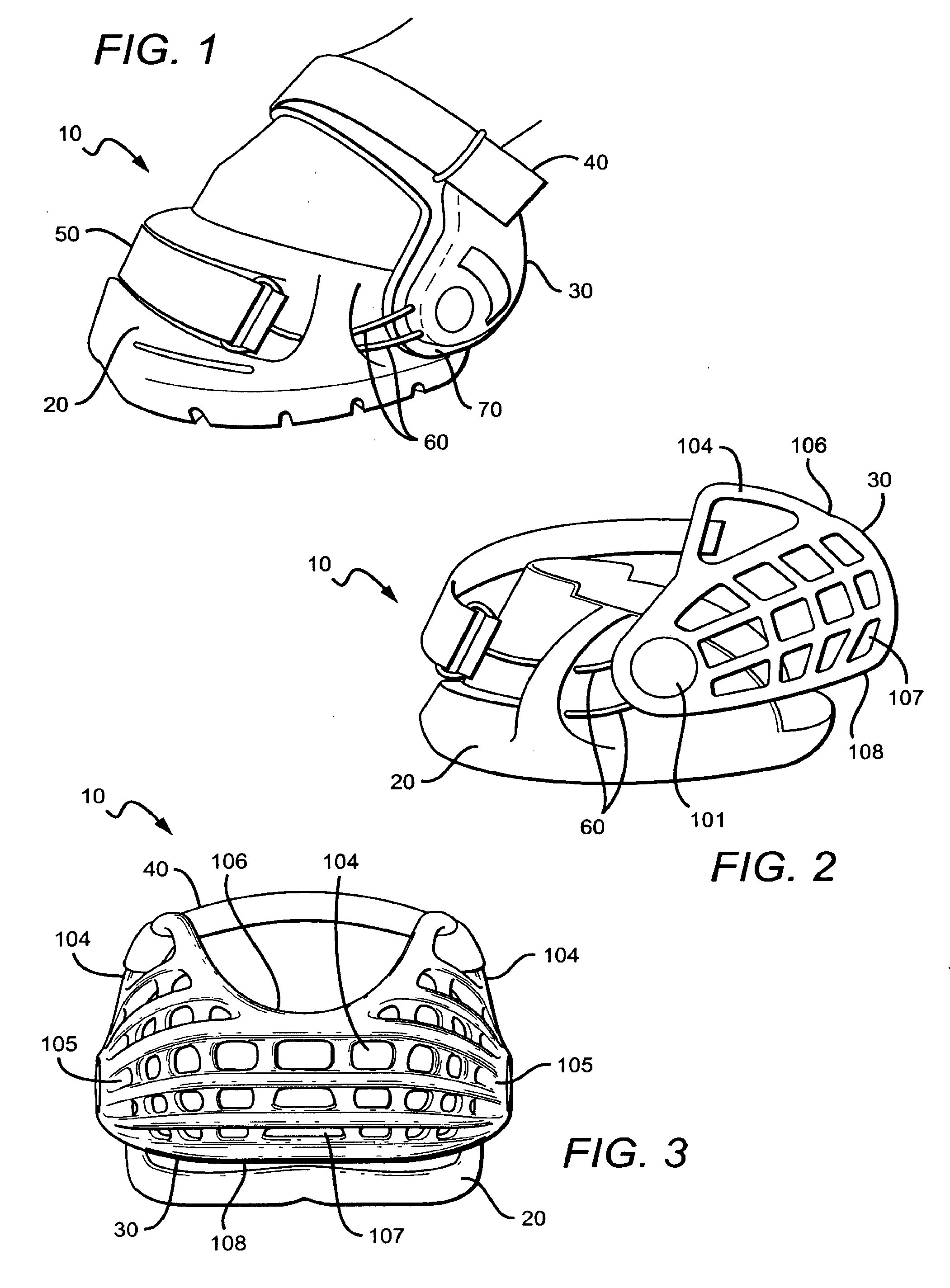

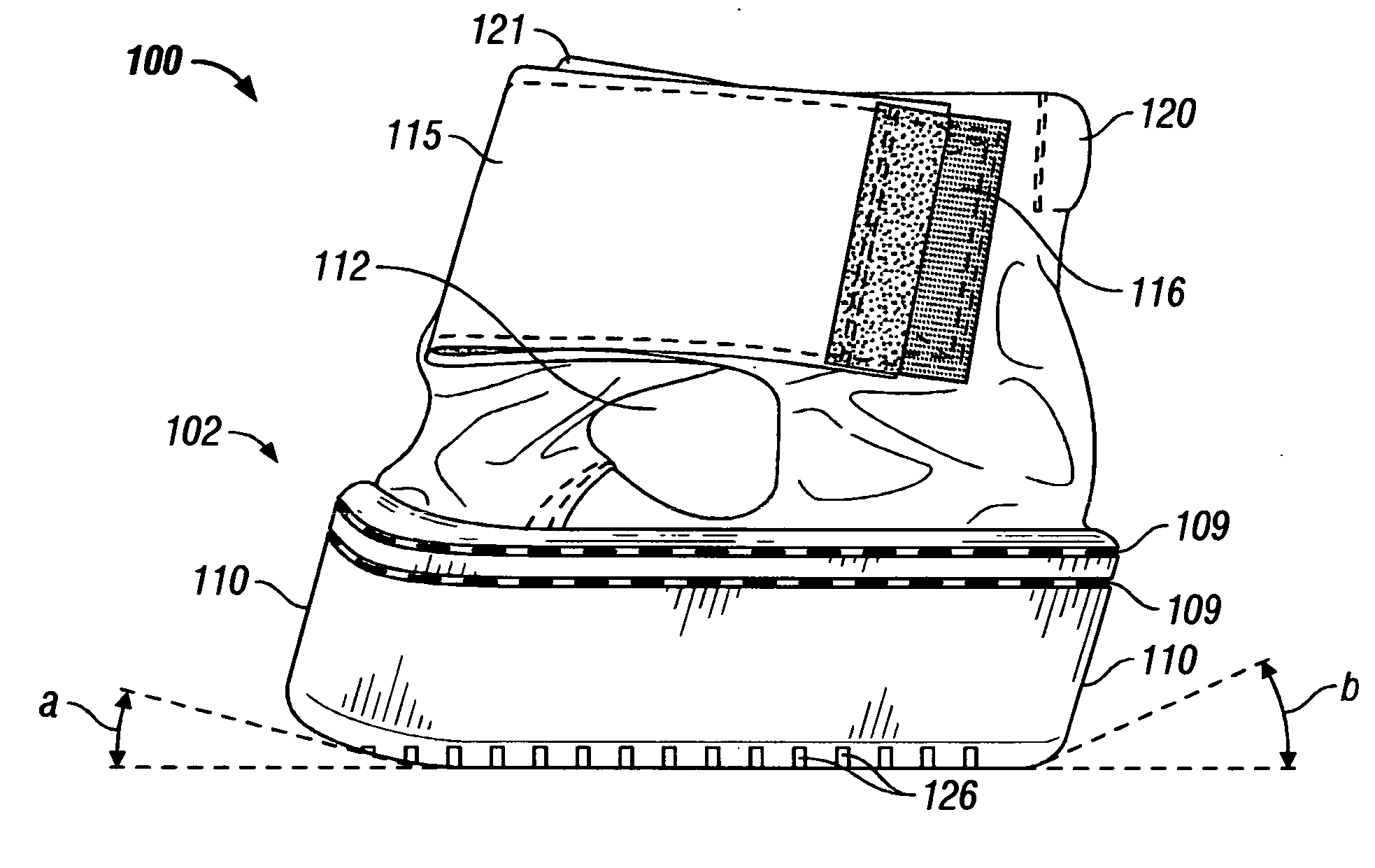

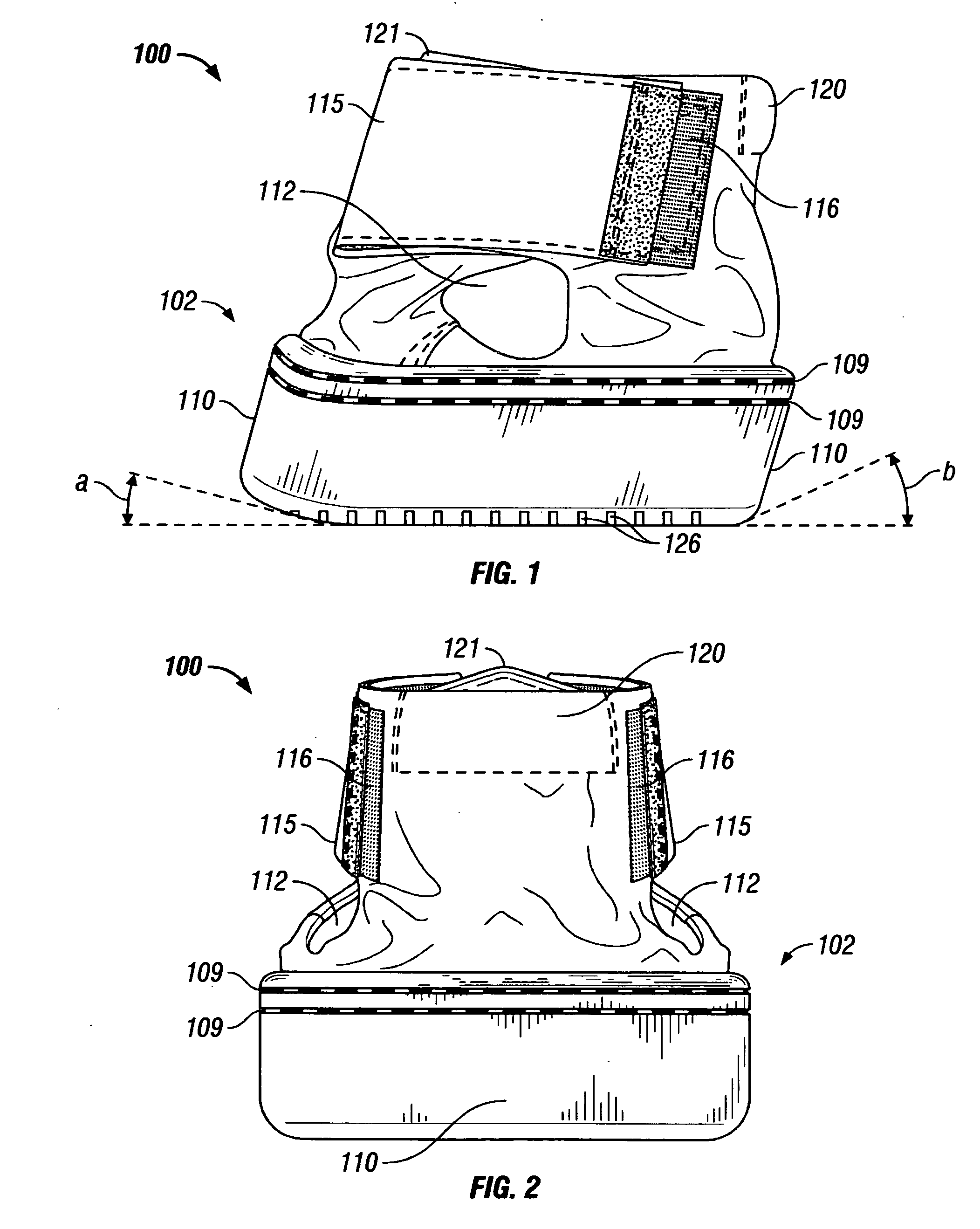

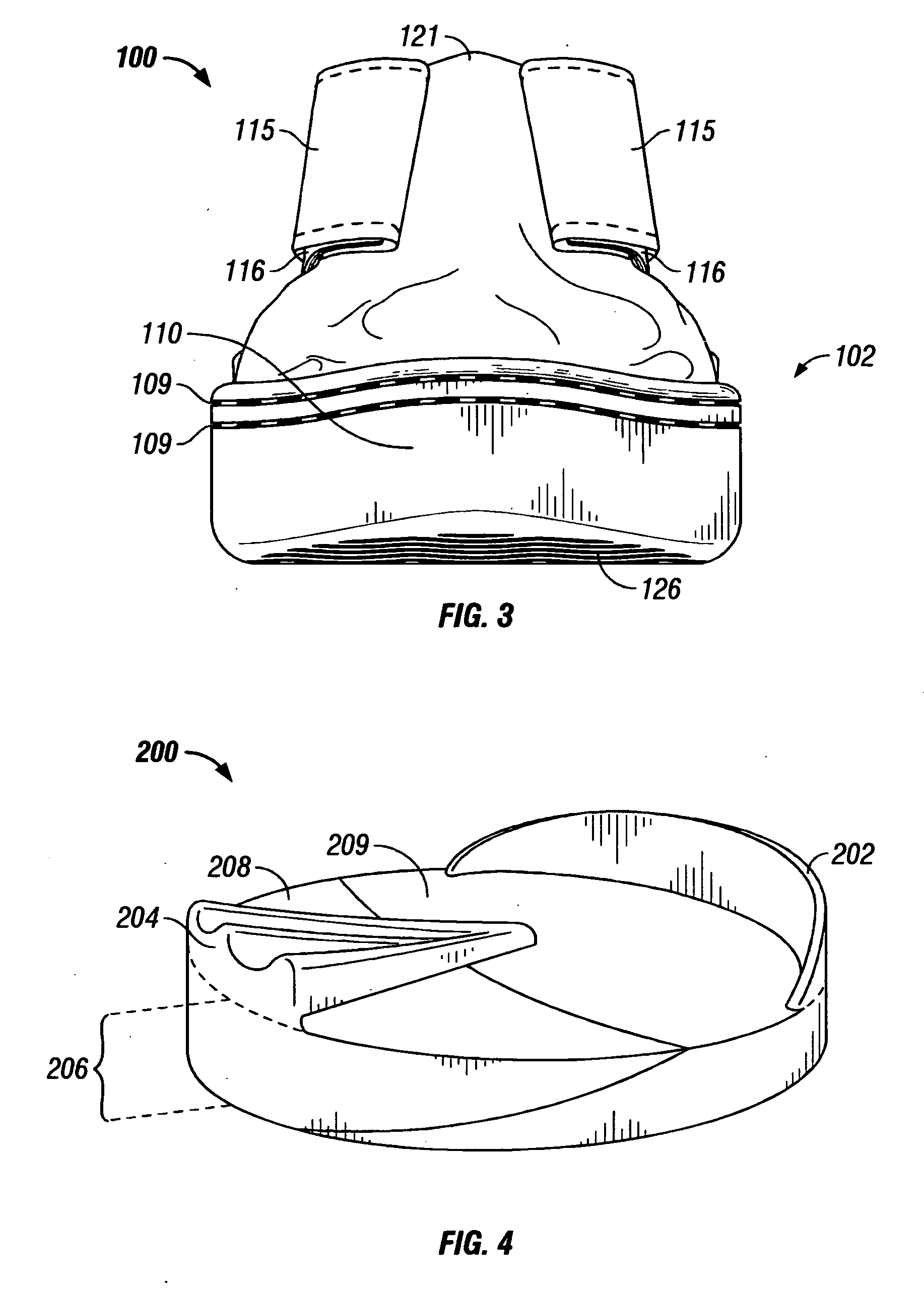

Hoof Boot with Pivoting Heel Captivator

A hoof boot has a base, a heel captivator, and a pivoting mechanism that disposes the heel captivator to pivot relative to the base, preferably in a manner that allows the heel captivator at least three degrees of freedom of movement relative to the base. The heel captivator is preferably low in the rearmost portion, which provides clearance for the pastern bones of the equine lower leg to descend upon weight bearing during movement at various gaits. To reduce the possibility for bruising and chaffing of soft tissue around the pastern bones, and to help eliminate accumulation of debris, preferred heel captivators have an open mesh architecture. Heel captivators can alternatively or additionally be designed with fabric covered neoprene or other liners. Boots are preferably tightened using mechanically advantages laces.

Owner:BIG BRAIN HLDG INC

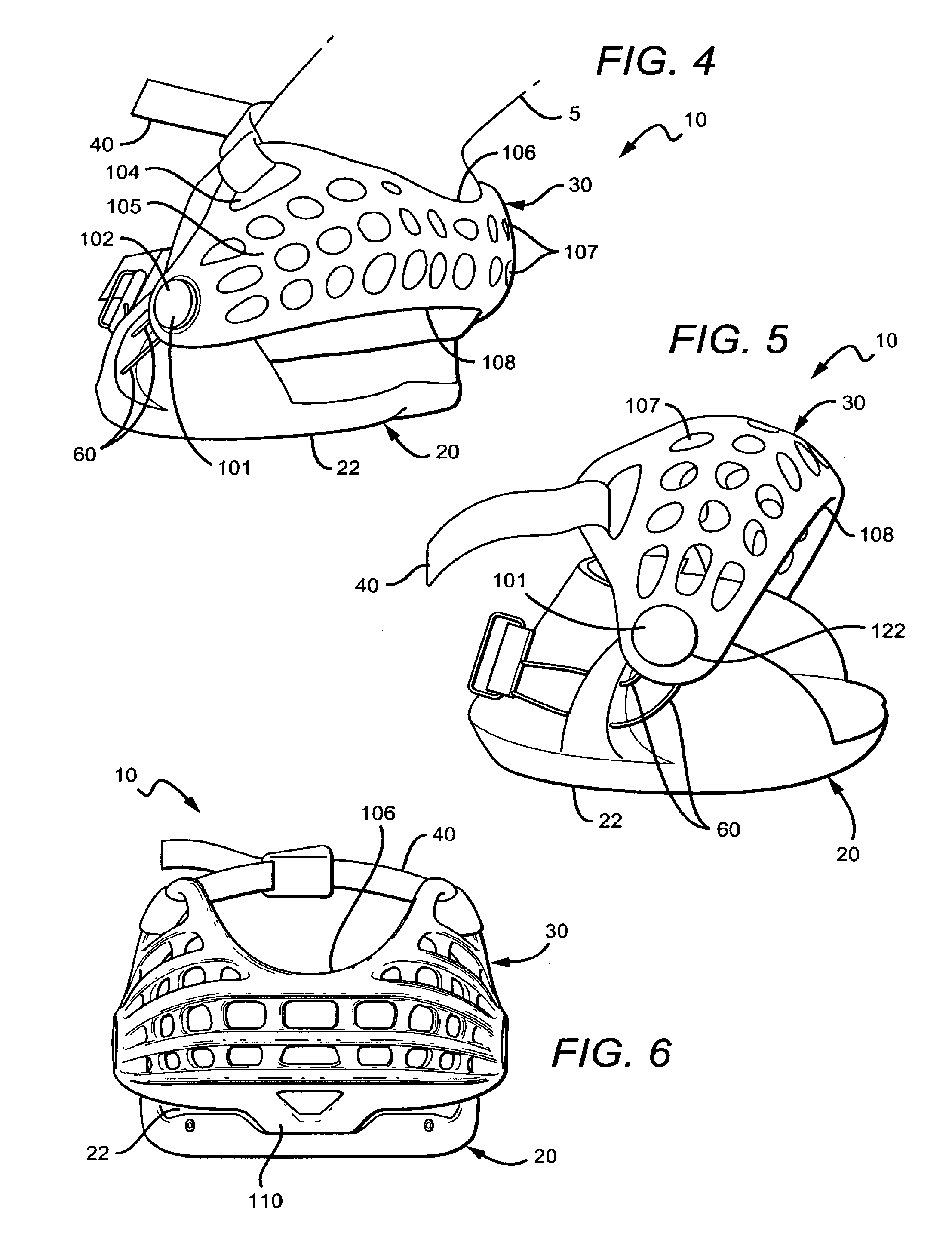

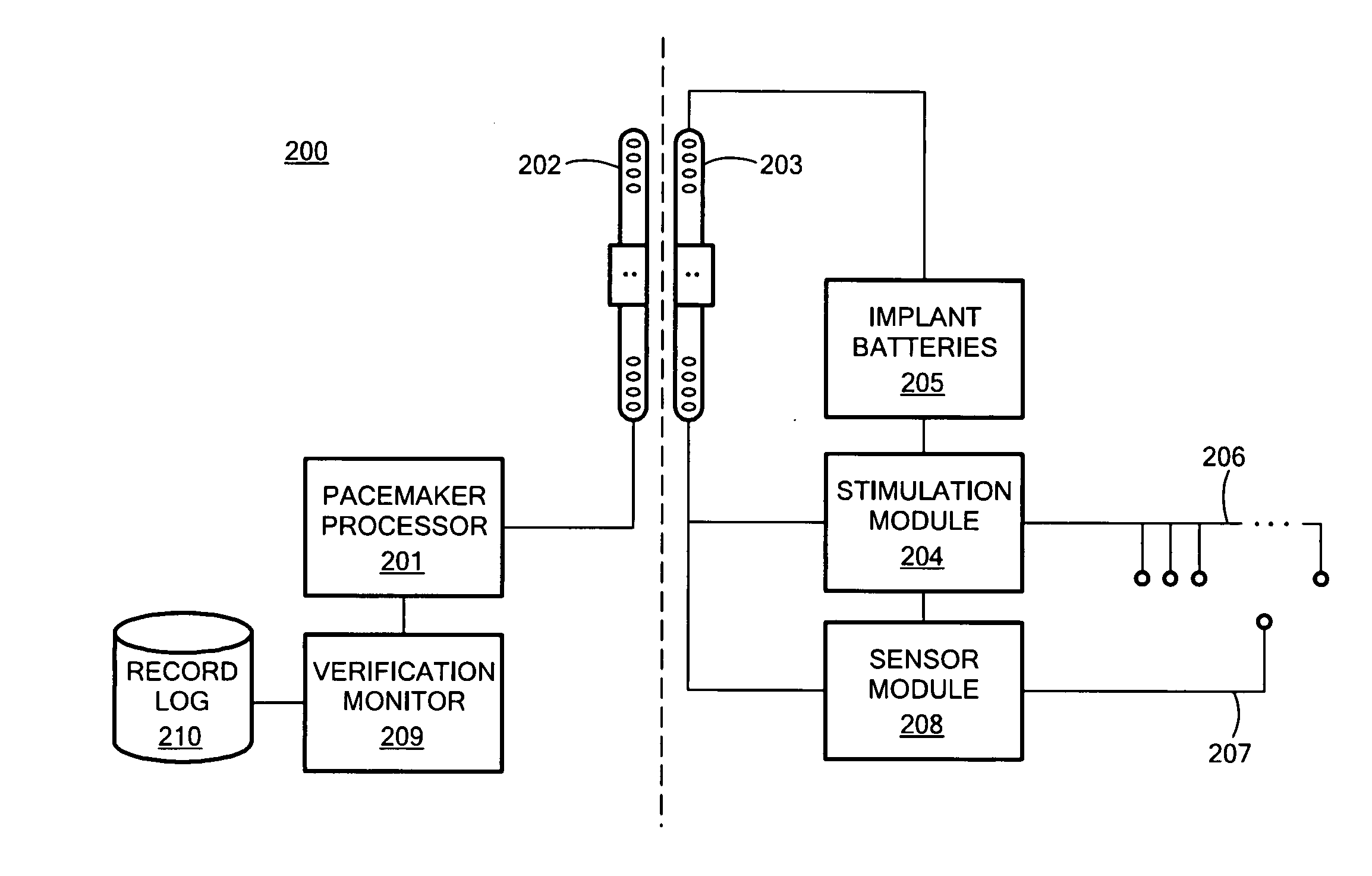

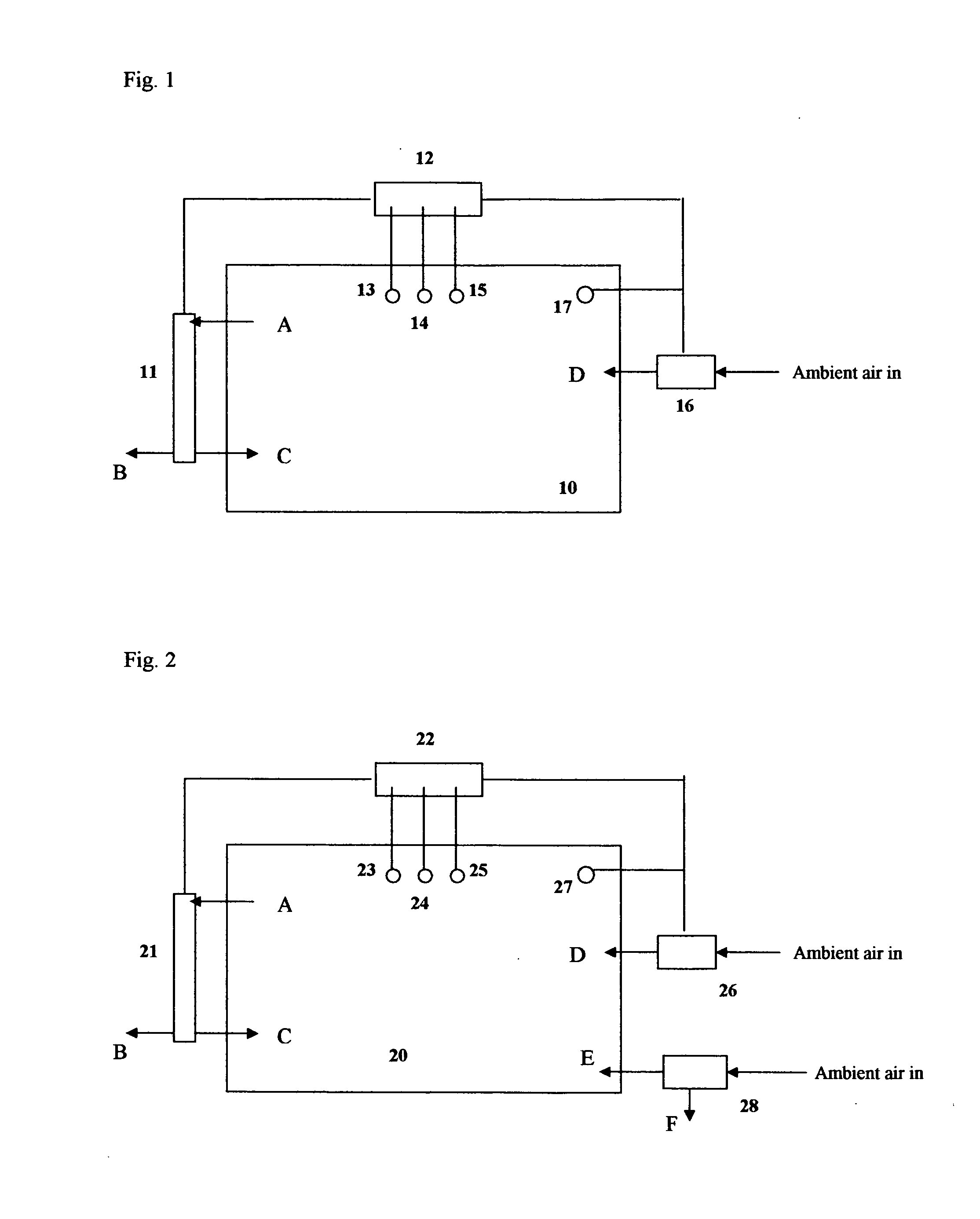

Equine Airway Disorders

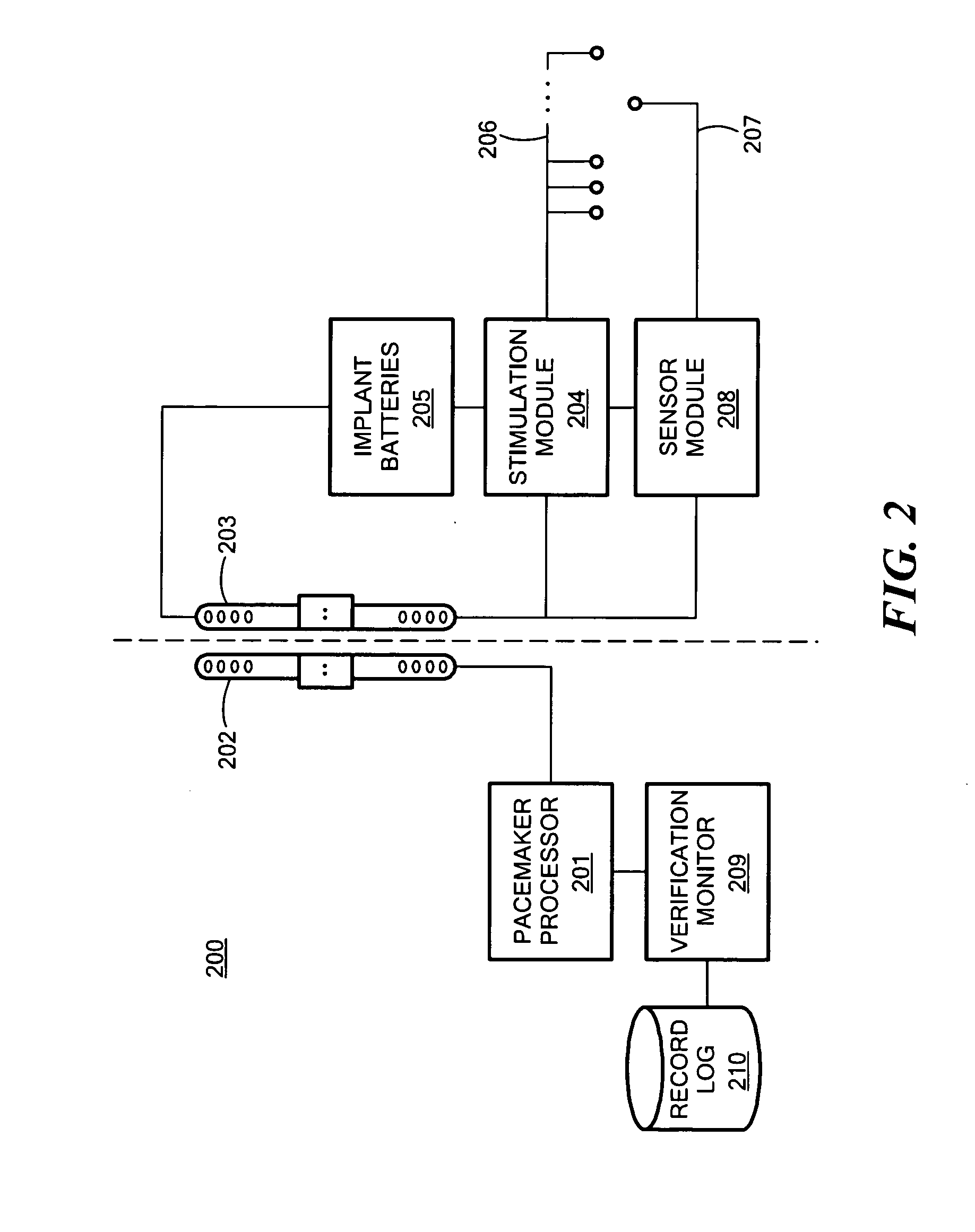

ActiveUS20080208280A1Facilitate axonal regenerationSlow axonal degenerationElectroencephalographySpinal electrodesDiseaseEquine Species

Airway disorders in a horse are relieved by electrical stimulation of the airway tissue. Particular disorders and techniques include electrical stimulation to relieve laryngeal hemiplegia. A pacemaker processor generates an electrical treatment signal to be applied to upper airway tissue of the horse for treating the upper airway disorder. One or more stimulation electrodes interfaces with the upper airway tissue for delivering the treatment signal to the upper airway tissue.

Owner:CORNELL UNIVERSITY +2

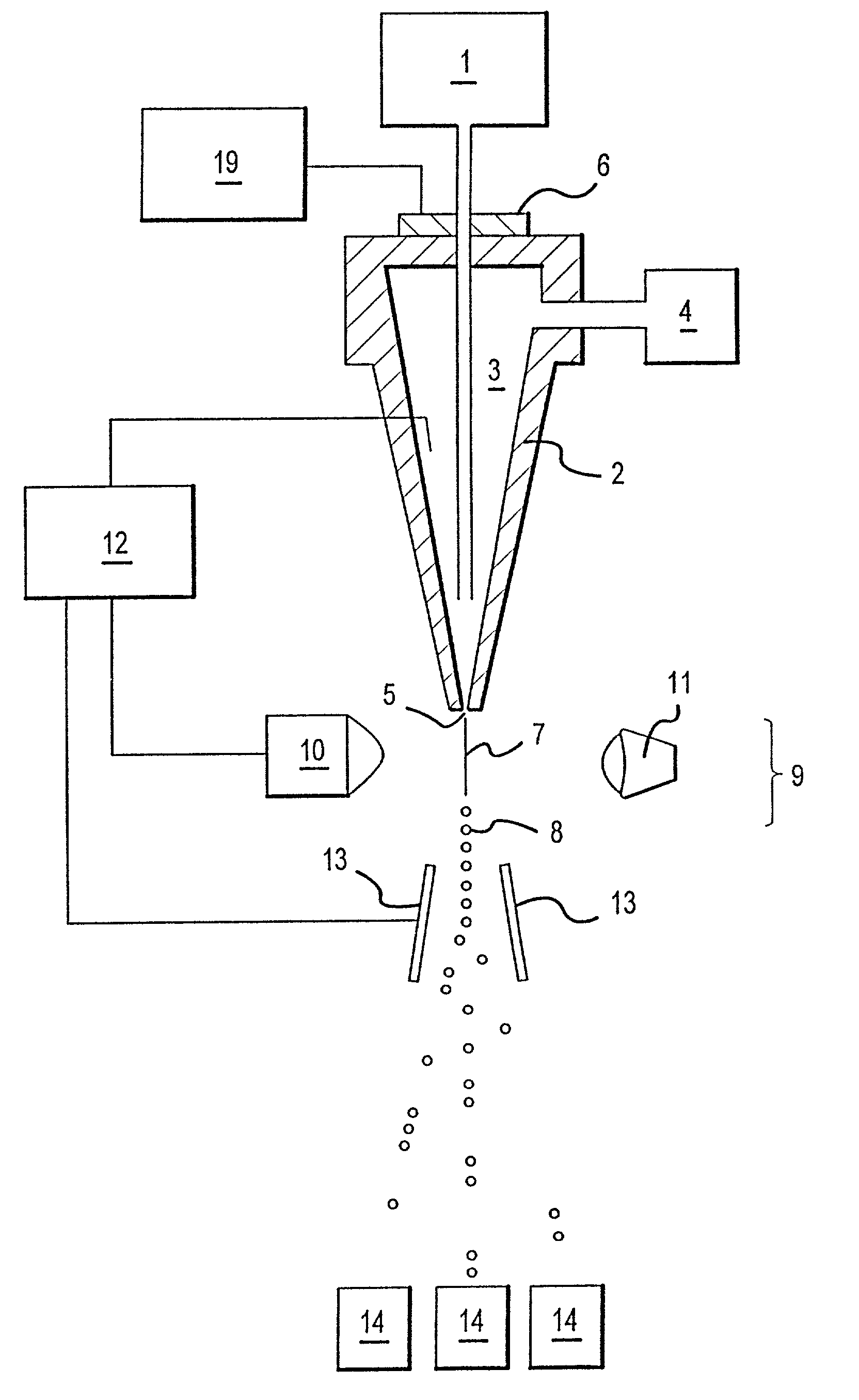

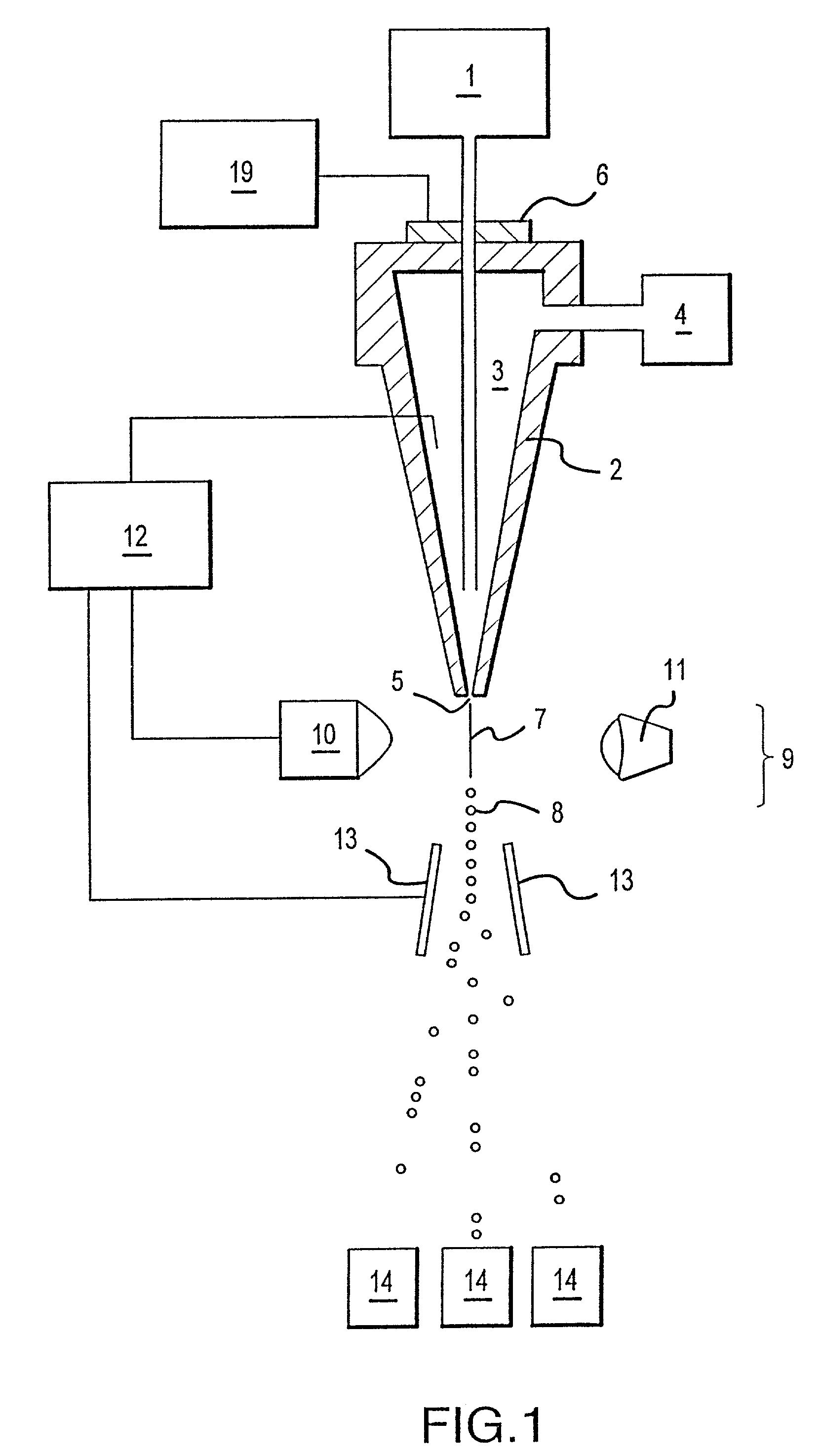

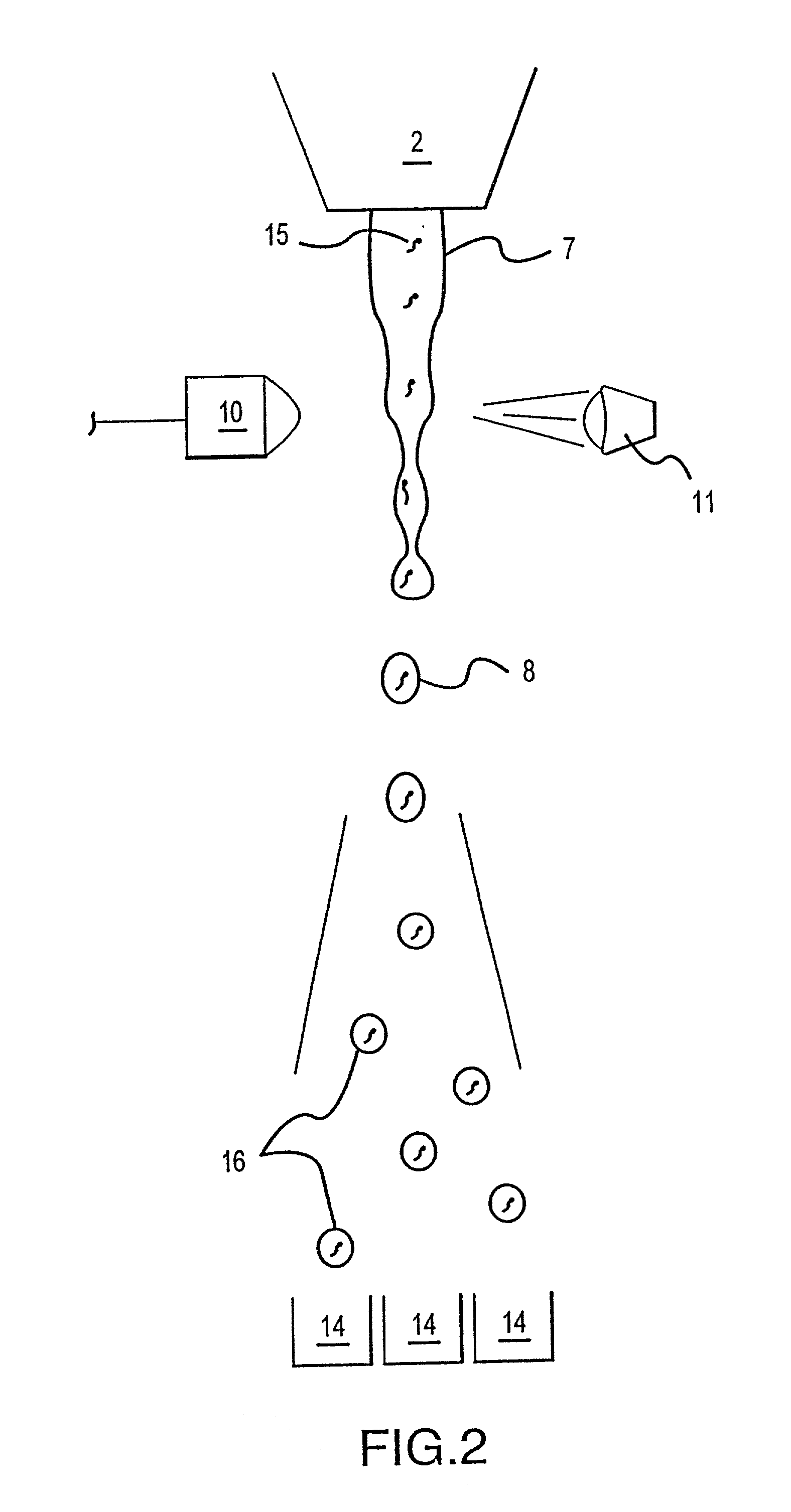

Multiple sexed embryo production system for mammals using low numbers of spermatozoa

InactiveUS20020119558A1Relieve pressureStress minimizationBioreactor/fermenter combinationsAnimal reproductionMammalCollection system

Improved insemination systems particularly adapted to use for sex-selected sperm sorting include systems which achieve superovulation and then multiple embryo production with sexed embryos. These systems combine with other techniques, including techniques for enhanced sheath fluid and other strategies which minimize stress on the sperm cells, and, potentially, a 2.9 percent sodium citrate sheath solution for bovine species and a hepes bovine gamete media for equine species. Improved collection systems and techniques for the process are described so that commercial application of sperms samples as well as the resulting animals may be achieved.

Owner:XY

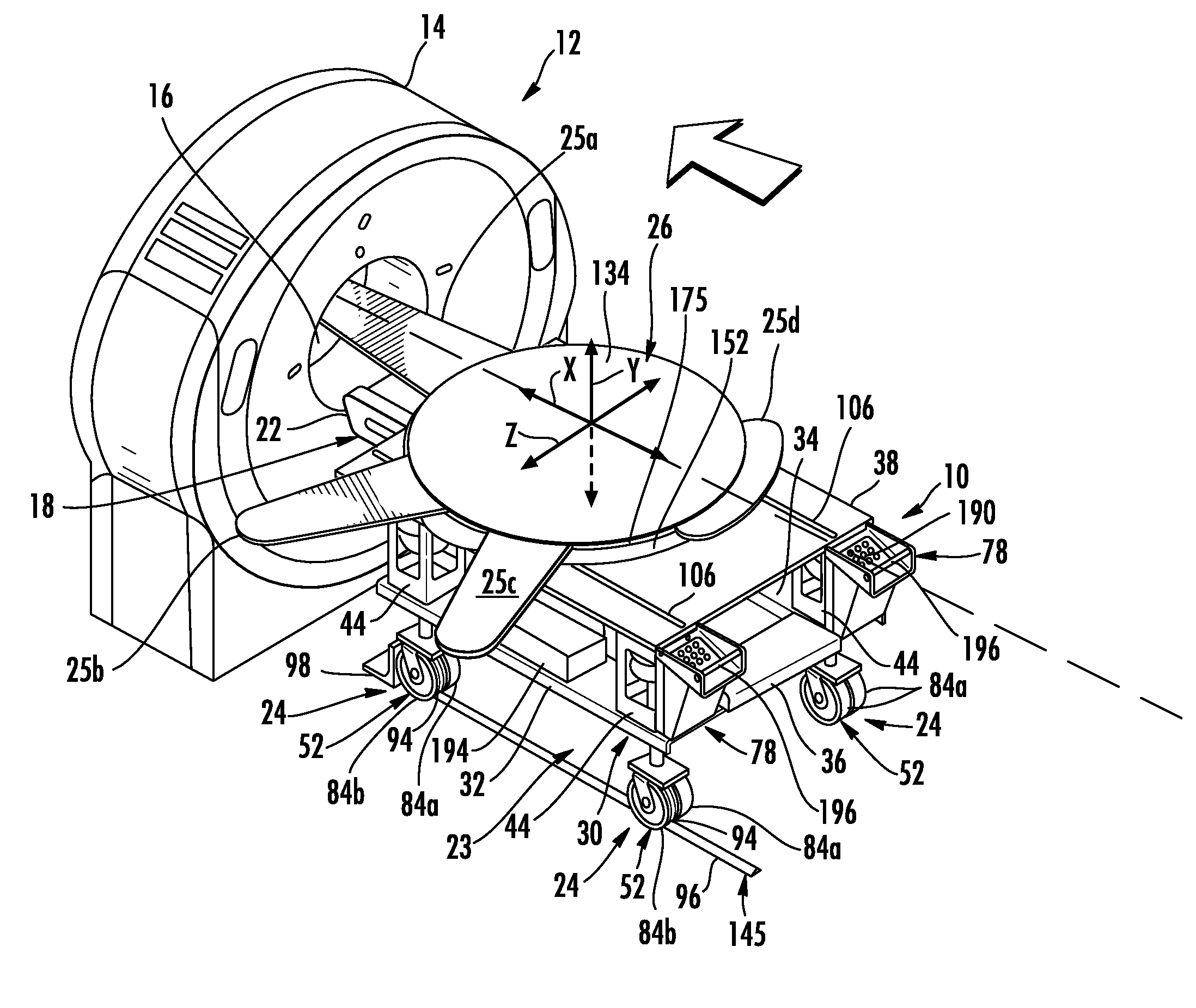

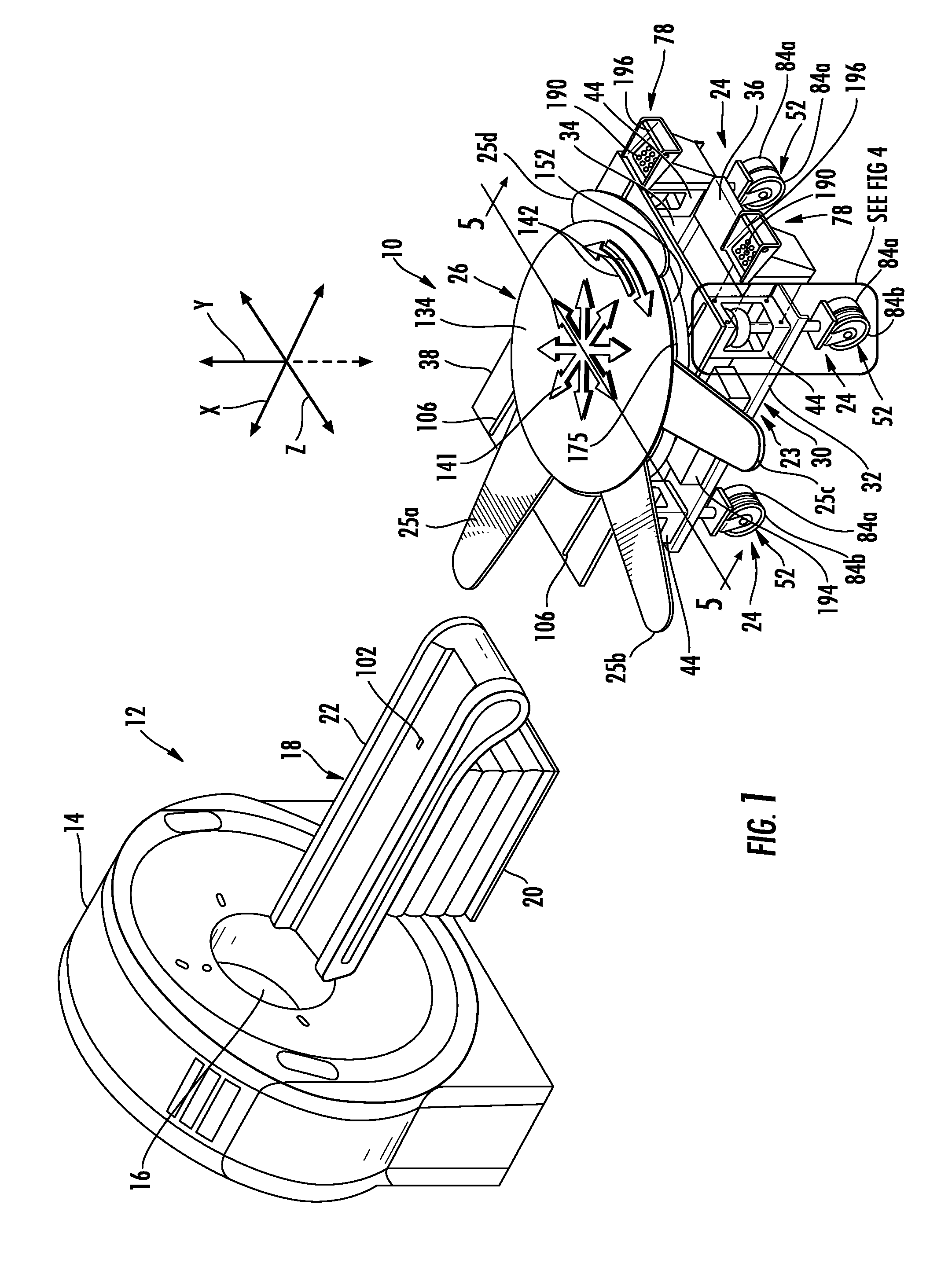

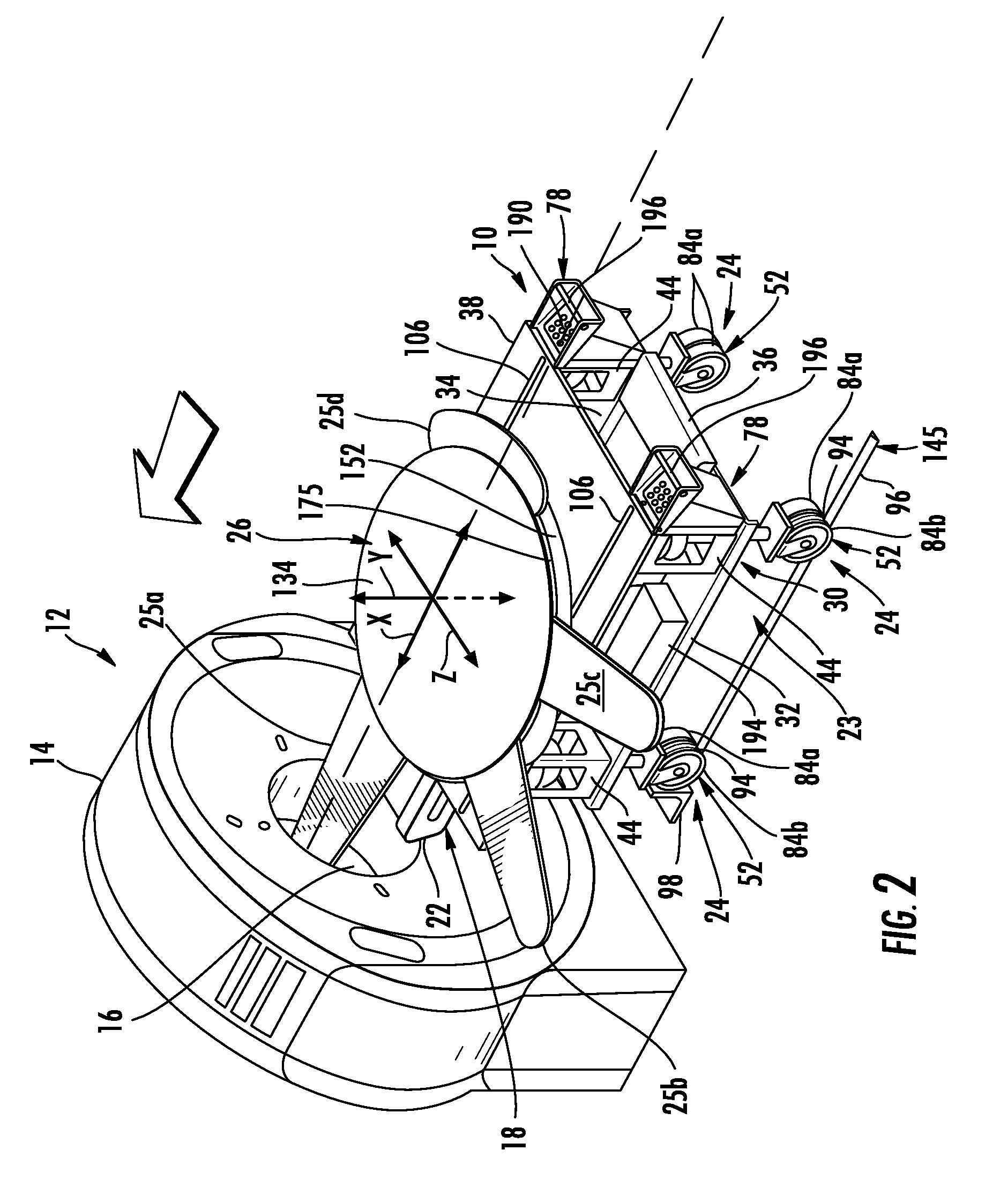

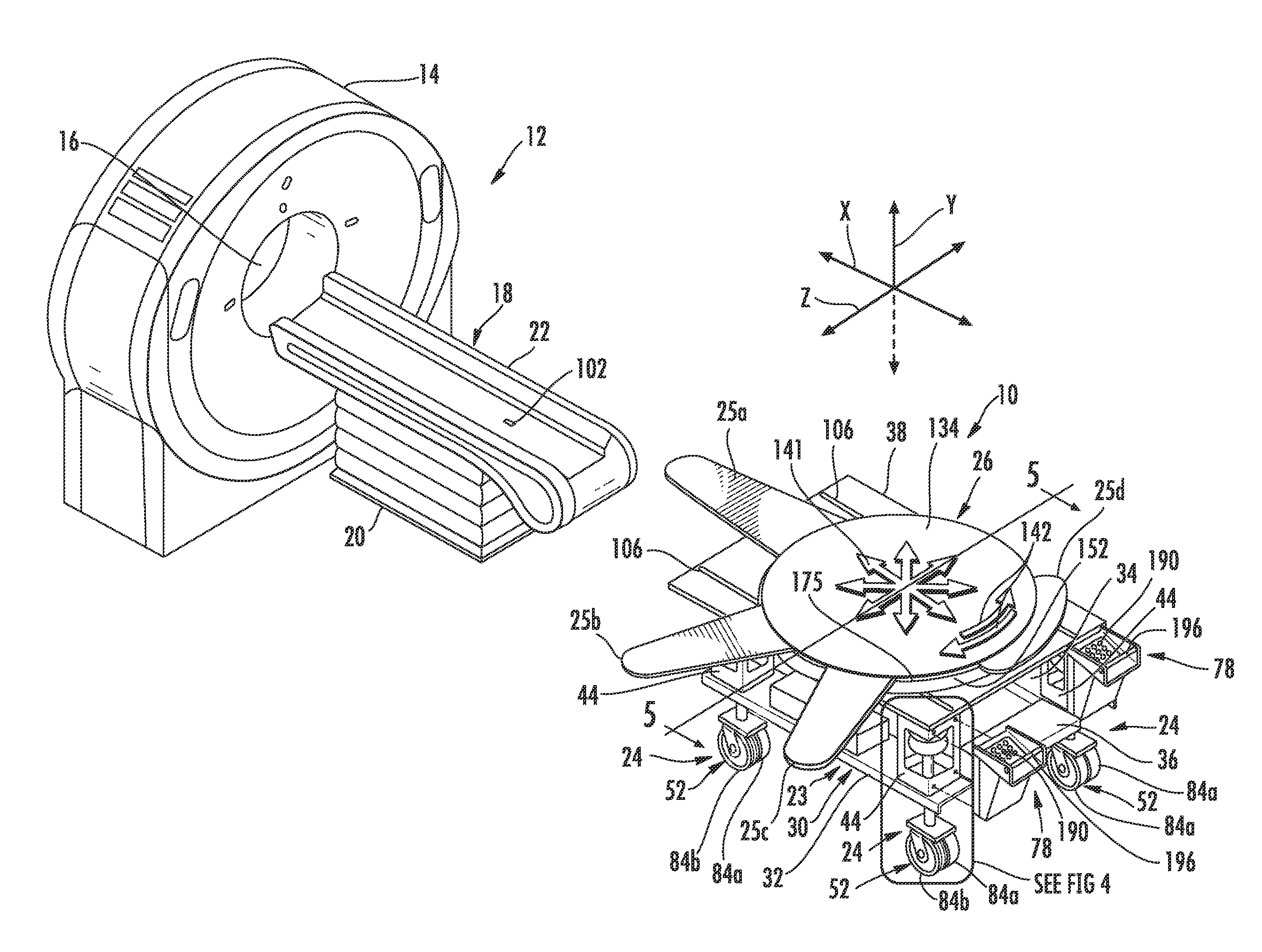

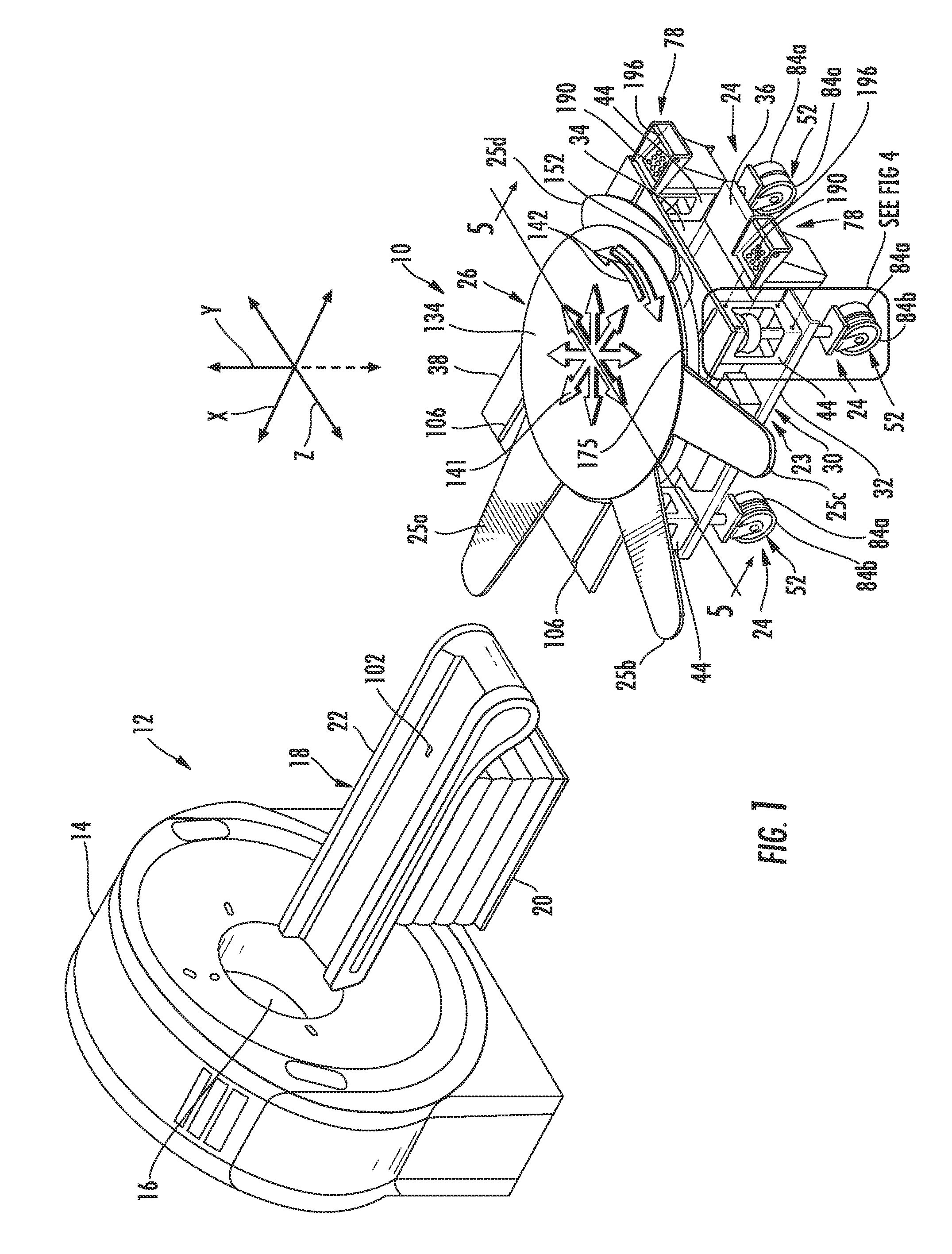

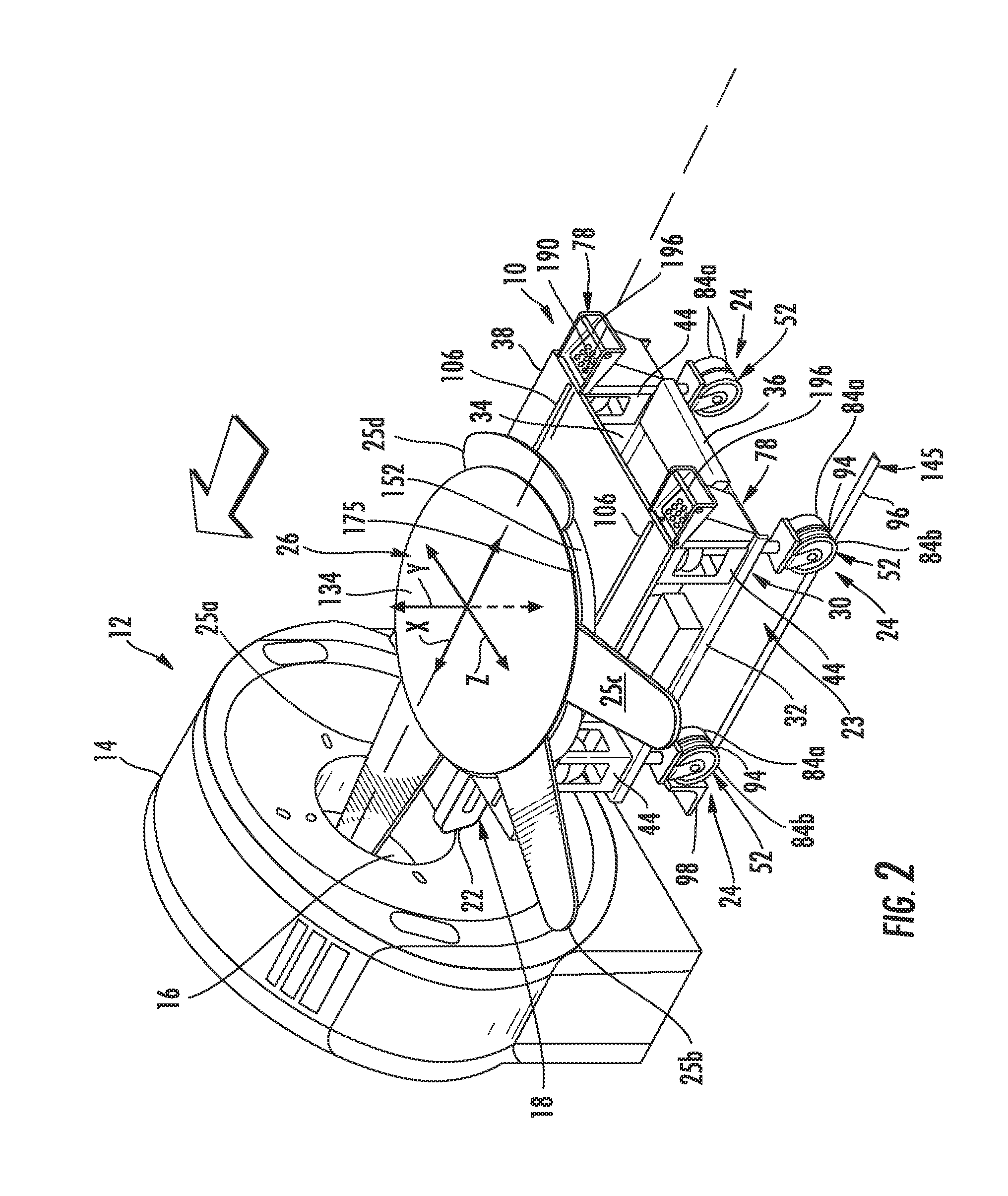

Equine CT Table

InactiveUS20090185663A1Patient positioning for diagnosticsTomographyLinear motionComputed tomography

An equine CT table for positioning a horse during a CT (“computed tomography”) scan. The table is positioned above the patient couch and communicates with the conventional CT system for examination of a horse without requiring mechanical or electrical attachments between the CT system and table. The table includes a frame carrying a tracking system, a linear movement system and a carousal upon which the horse is positioned. Prior to examination, positioning of the horse on the table may be manually adjusted linearly and / or radially in any direction to properly align the horse. Infinitely positional cantilever members are provided to support horse's appendages. The tracking system identifies movement of the CT couch and mimics the movement with the linear movement system to enter and retract the horse from the gantry at predetermined positioning.

Owner:ARTEC IMAGING

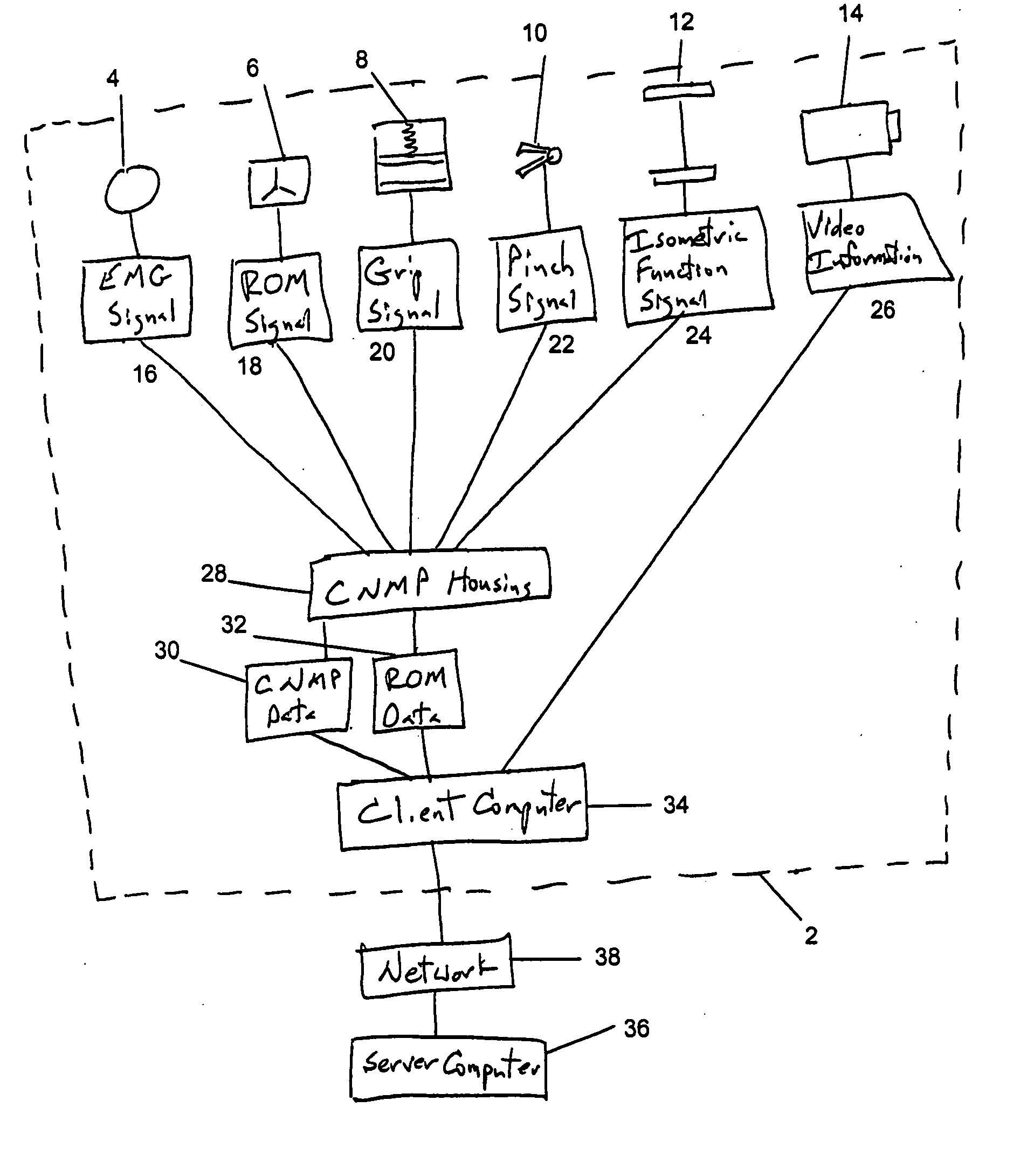

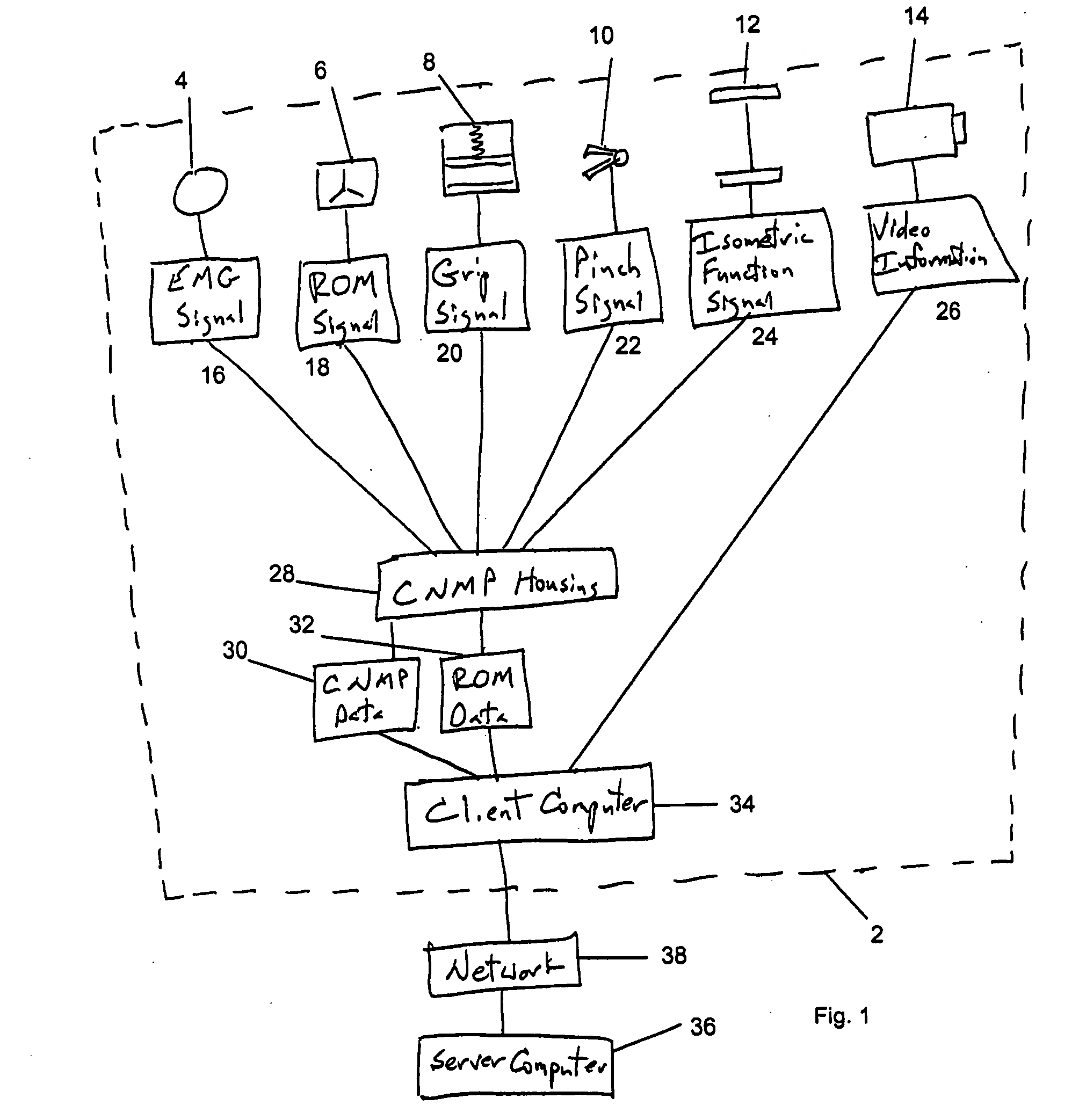

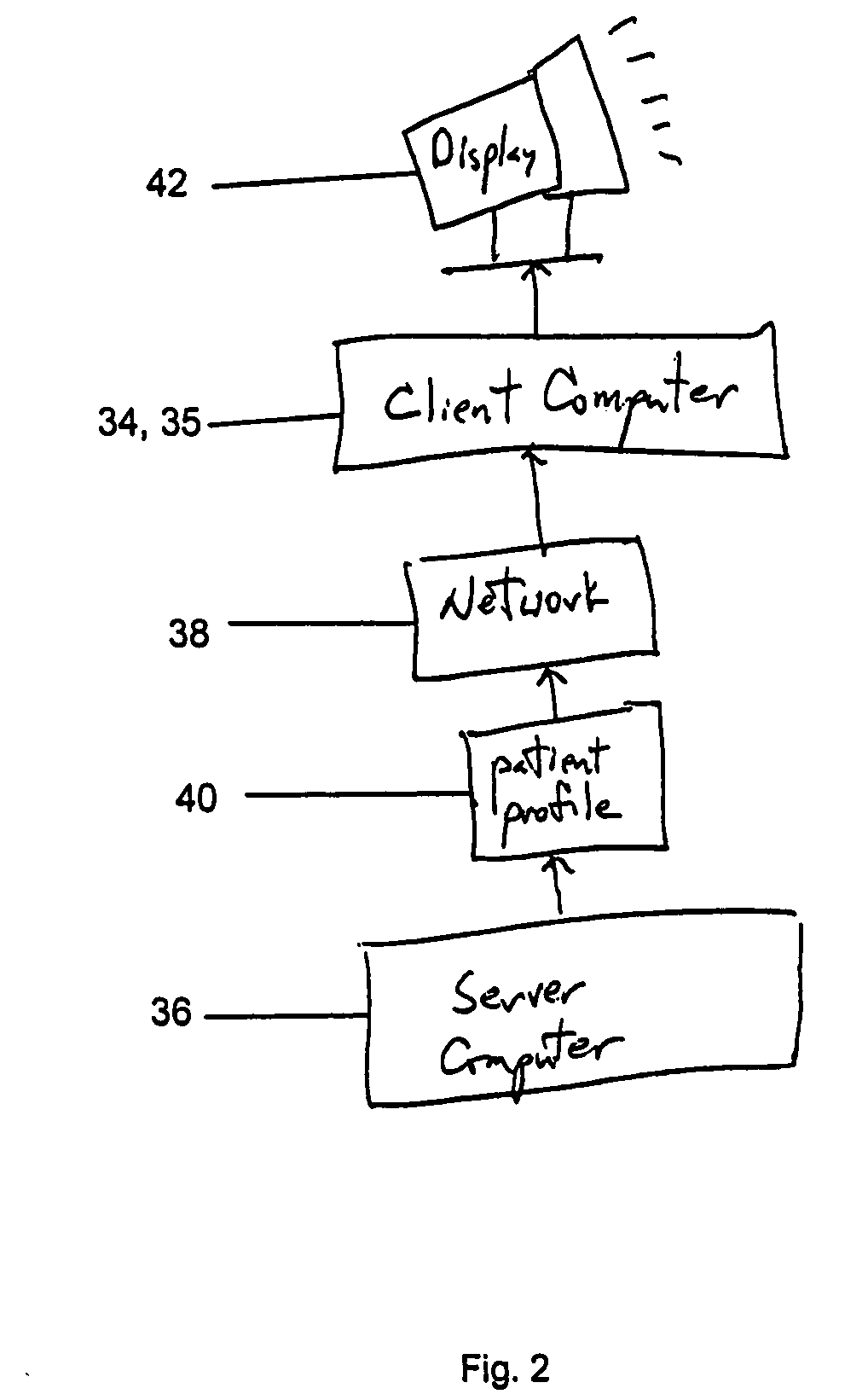

Comprehensive neuromuscular profiler

A Comprehensive Neuromuscular Profiler (CNMP) allows the observation of human and equine muscle functionality and characteristics. The CNMP consists of an integrated system which combines EMG technology, electromagnetic range-of-motion (ROM) technology, and functional capacity sensors. Output signals from the devices are digitized and stored in computer memory. The data may be transmitted to a server computer for further analysis. The server computer examines the data to determine patterns and consults an expert database to determine a diagnosis based on the patterns and combinations of patterns detected.

Owner:MED TEK

Sperm Suspensions For Use in Insemination

InactiveUS20070092860A1Animal reproductionDead animal preservationEquine SpeciesArtificial insemination

The present invention provides a method of cryopreserving sperm that have been selected for a specific characteristic. In a preferred embodiment, the method is employed to freeze sex-selected sperm. Although the cryopreservation method of the invention can be used to freeze sperm selected by any number of selection methods, selection using flow cytometry is preferred. The present invention also provides a frozen sperm sample that has been selected for a particular characteristic, such as sex-type. In preferred embodiments, the frozen sperm sample includes mammalian sperm, such as, for example, human, bovine, equine, porcine, ovine, elk, or bison sperm. The frozen selected sperm sample can be used in a variety of applications. In particular, the sample can be thawed and used for fertilization. Accordingly, the invention also includes a method of using the frozen selected sperm sample for artificial insemination or in vitro fertilization.

Owner:XY

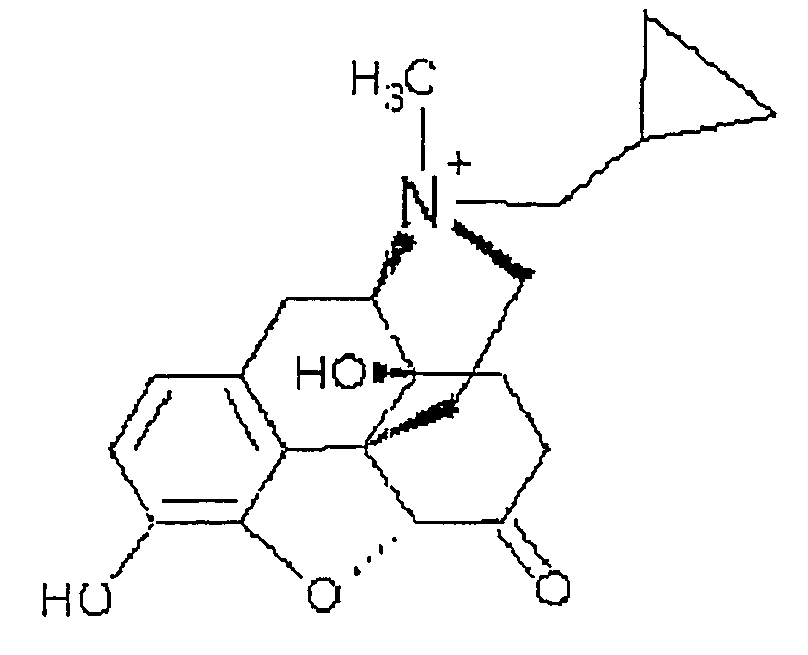

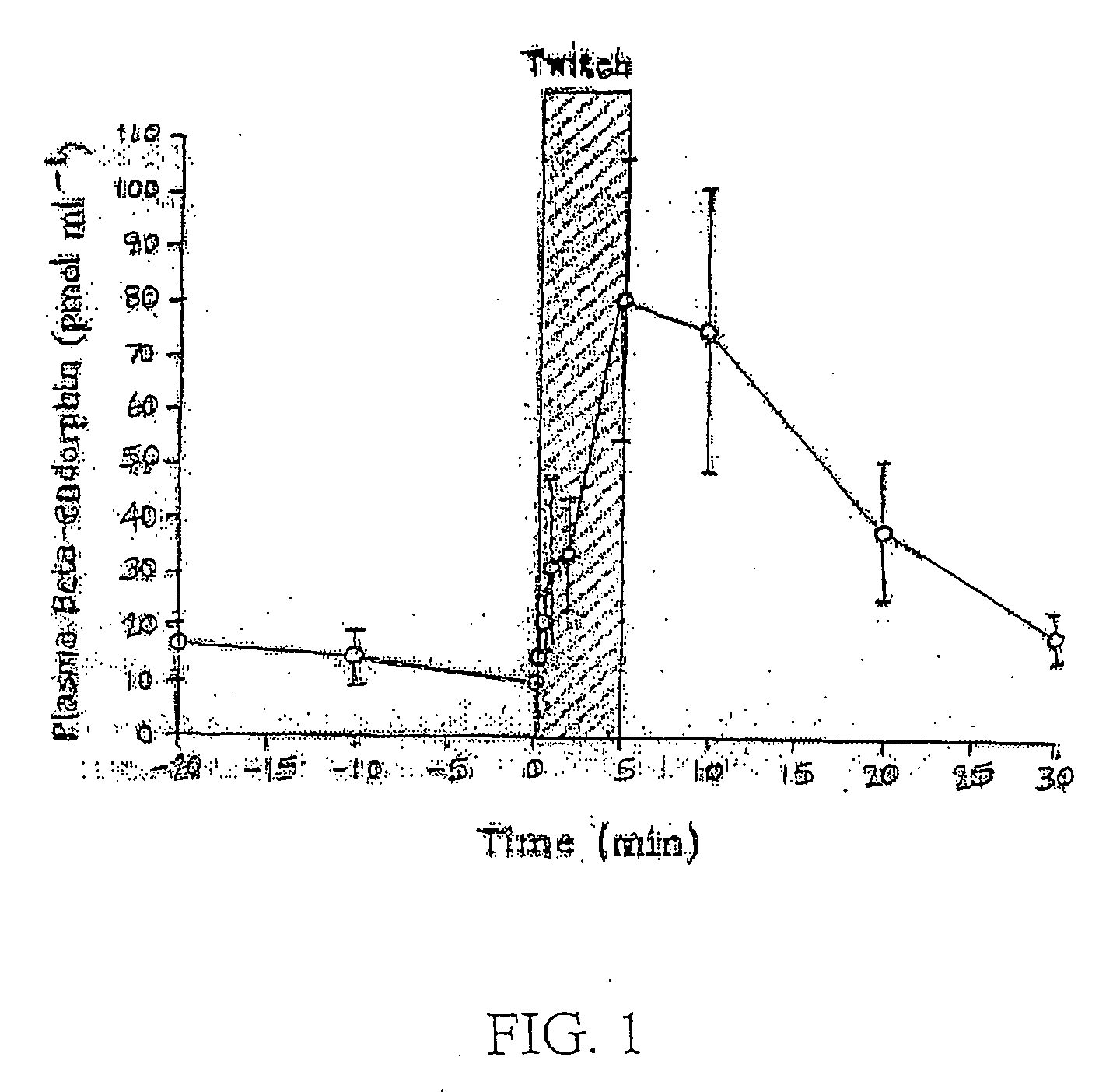

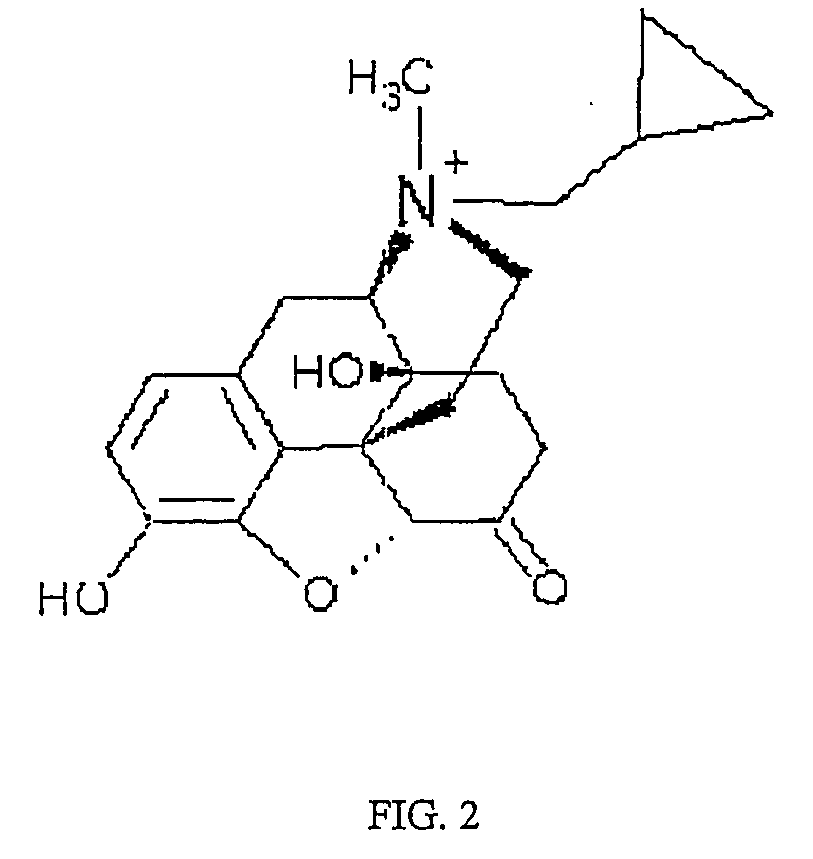

Use of methylnaltrexone in treating gastrointestinal dysfunction in equines

InactiveUS20050011468A1Relieving inhibition of gastrointestinal motilityMaintaining pain-reducing effectOrganic active ingredientsOther apparatusMotilityEquine Species

Systems and methods are described for using methylnaltrexone to treat or prevent inhibition of gastrointestinal motility in equines. A method for preventing or treating opioid-induced and non-opioid-induced gastrointestinal dysfunction includes administering a quaternary derivative of noroxymorphone, preferably methylnaltrexone, to an equine before or after the onset of the gastrointestinal dysfunction.

Owner:PROGENICS PHARMA INC

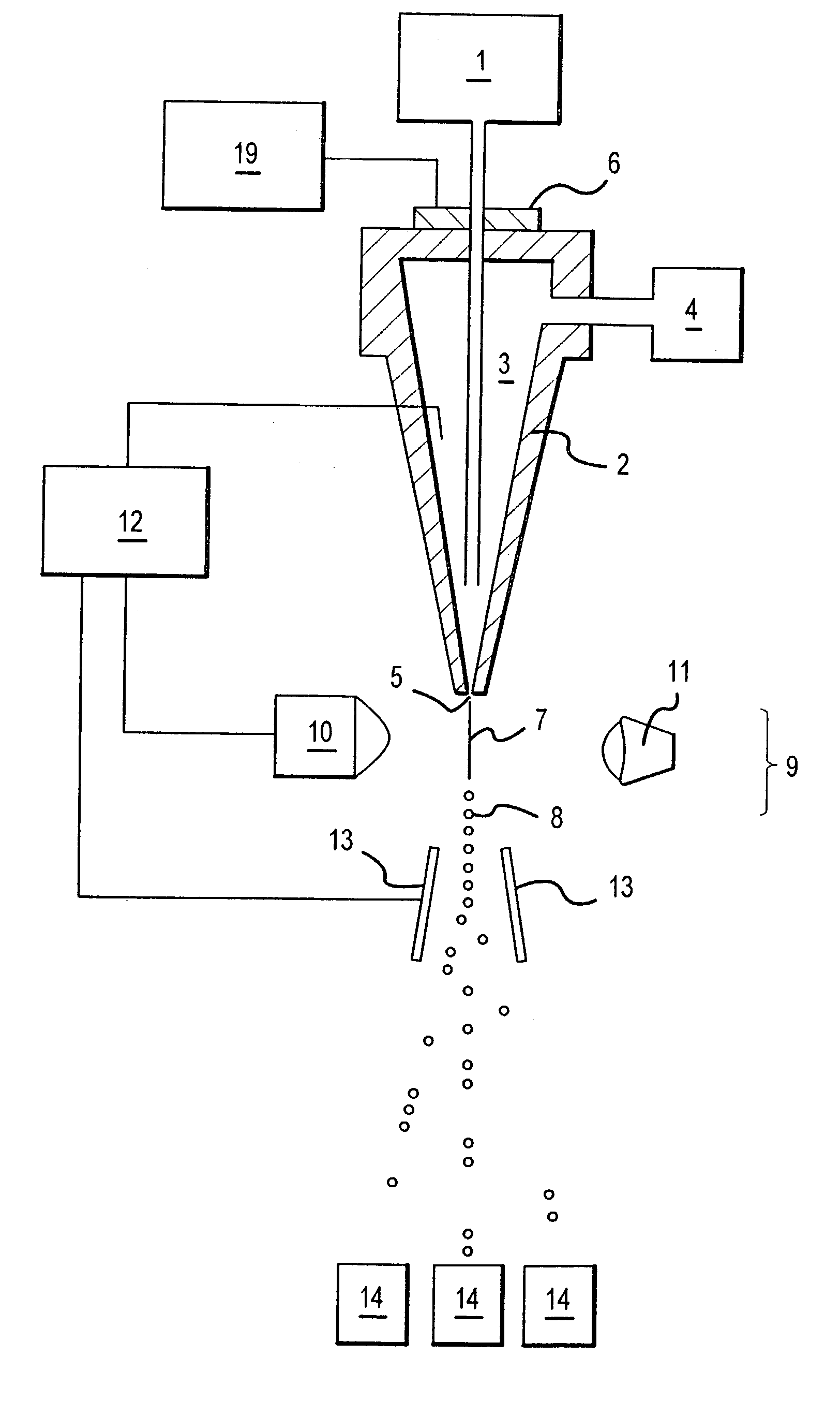

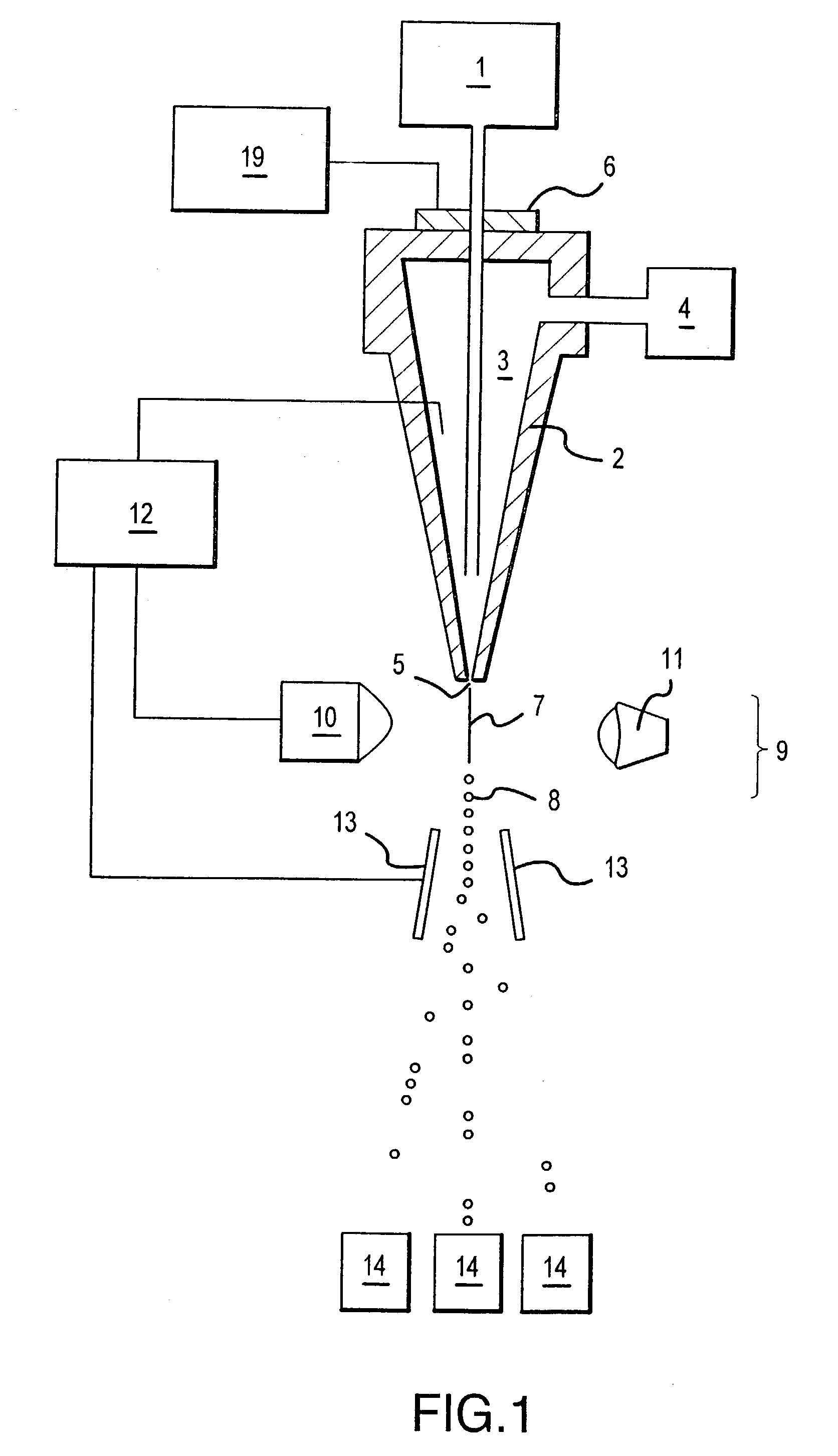

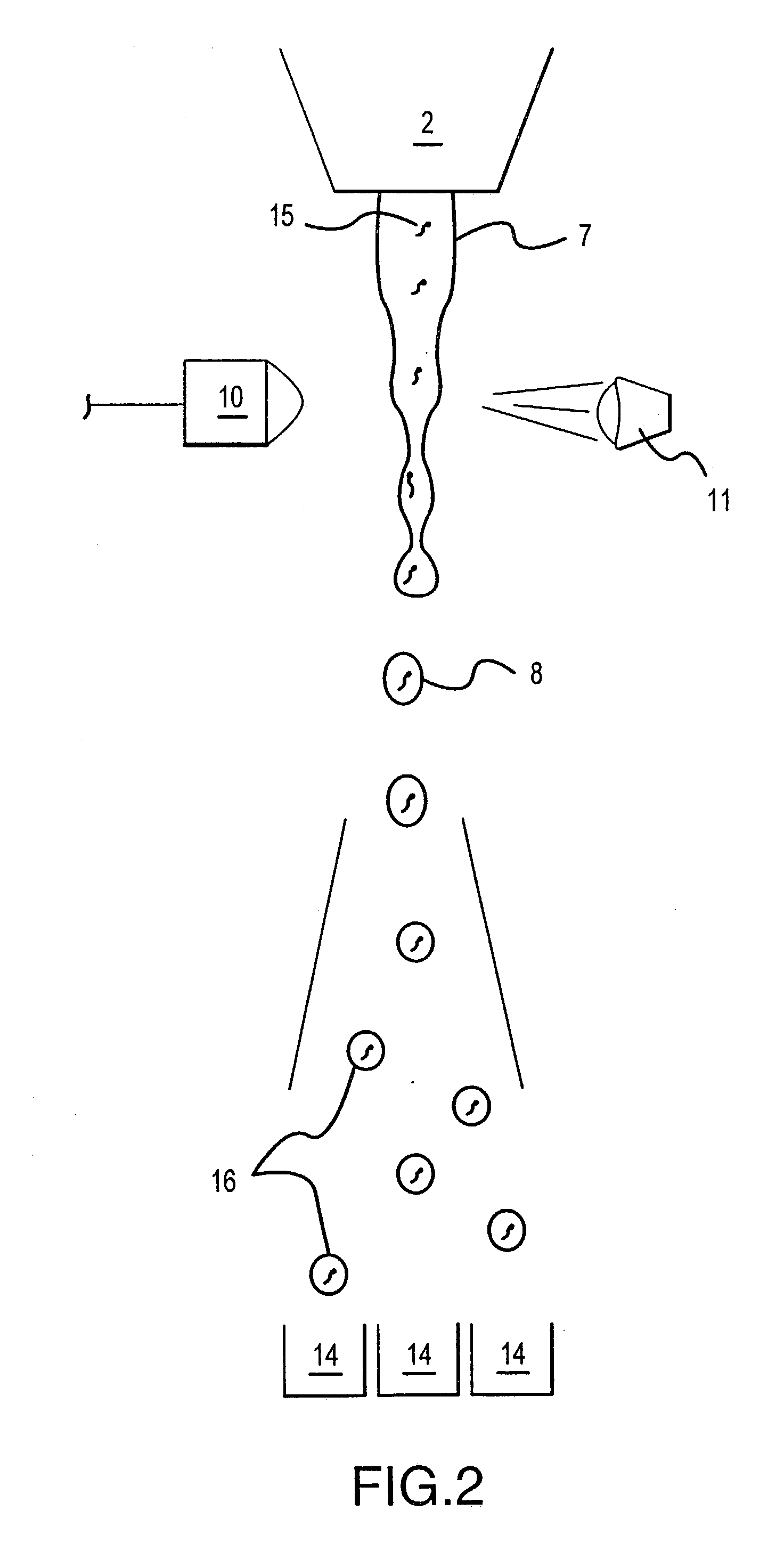

Collection systems for cytometer sorting of sperm

InactiveUS20030129091A1Relieve pressureStress minimizationAnimal reproductionMicrobiological testing/measurementStress minimizationCollection system

Improved flow cytometer system particularly adapted to use for sex-selected sperm sorting include enhanced sheath fluid and other strategies which minimize stress on the sperm cells, including a 2.9 percent sodium citrate sheath solution for bovine species and a hepes bovine gamete media for equine species. Improved collection systems and techniques for the process are described so that commercial applications of sperms samples as well as the resulting animals may be achieved.

Owner:XY

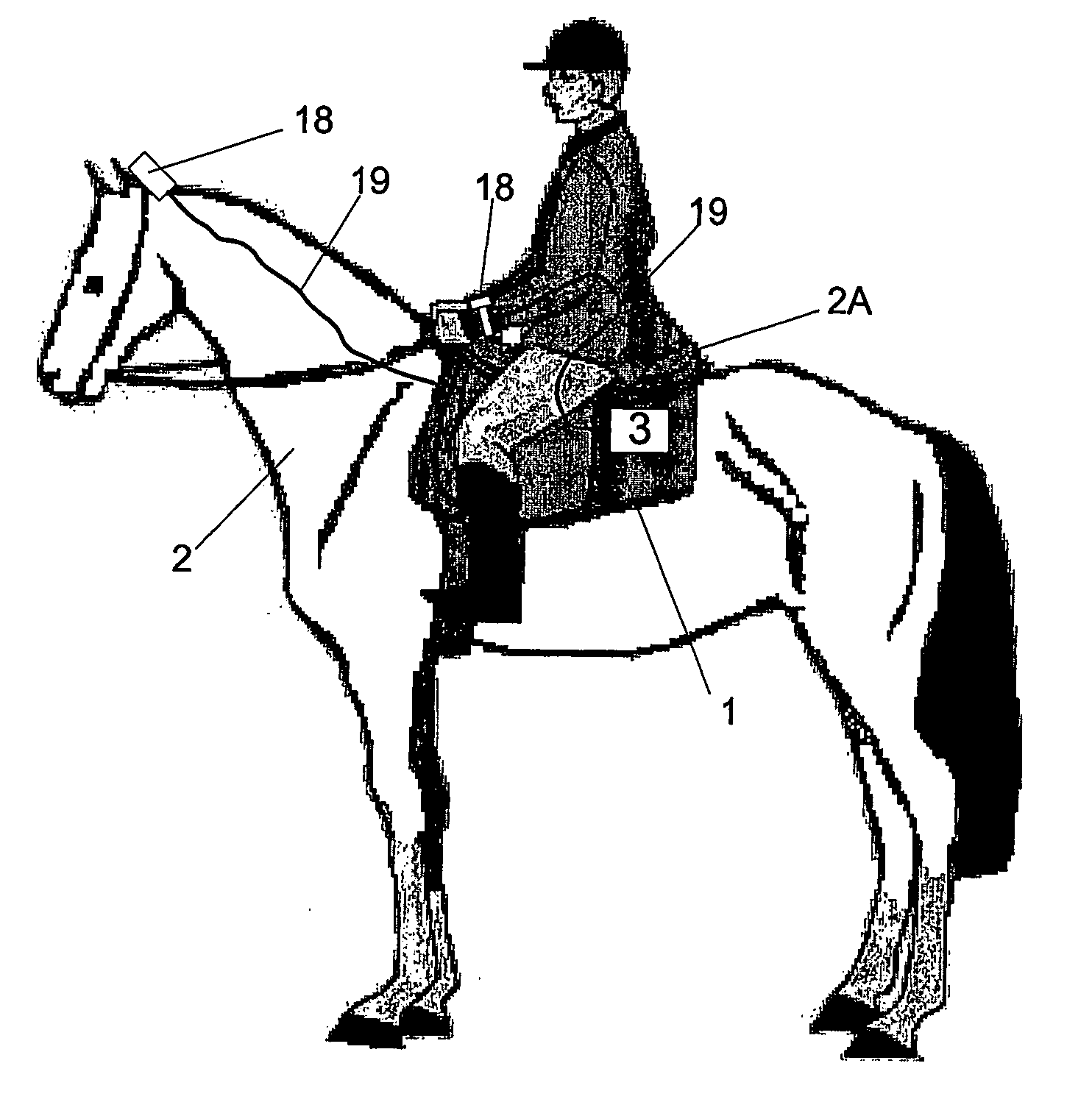

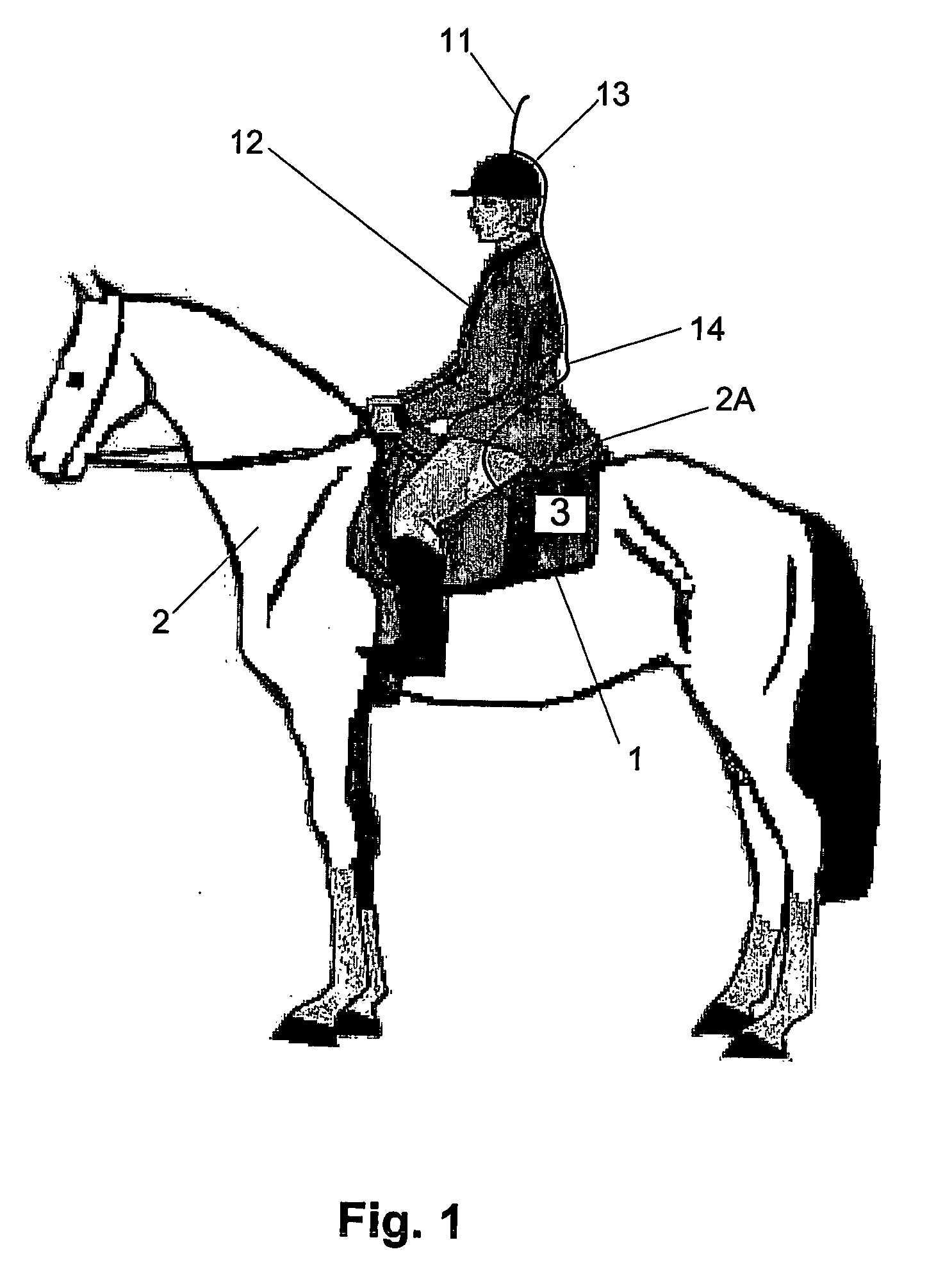

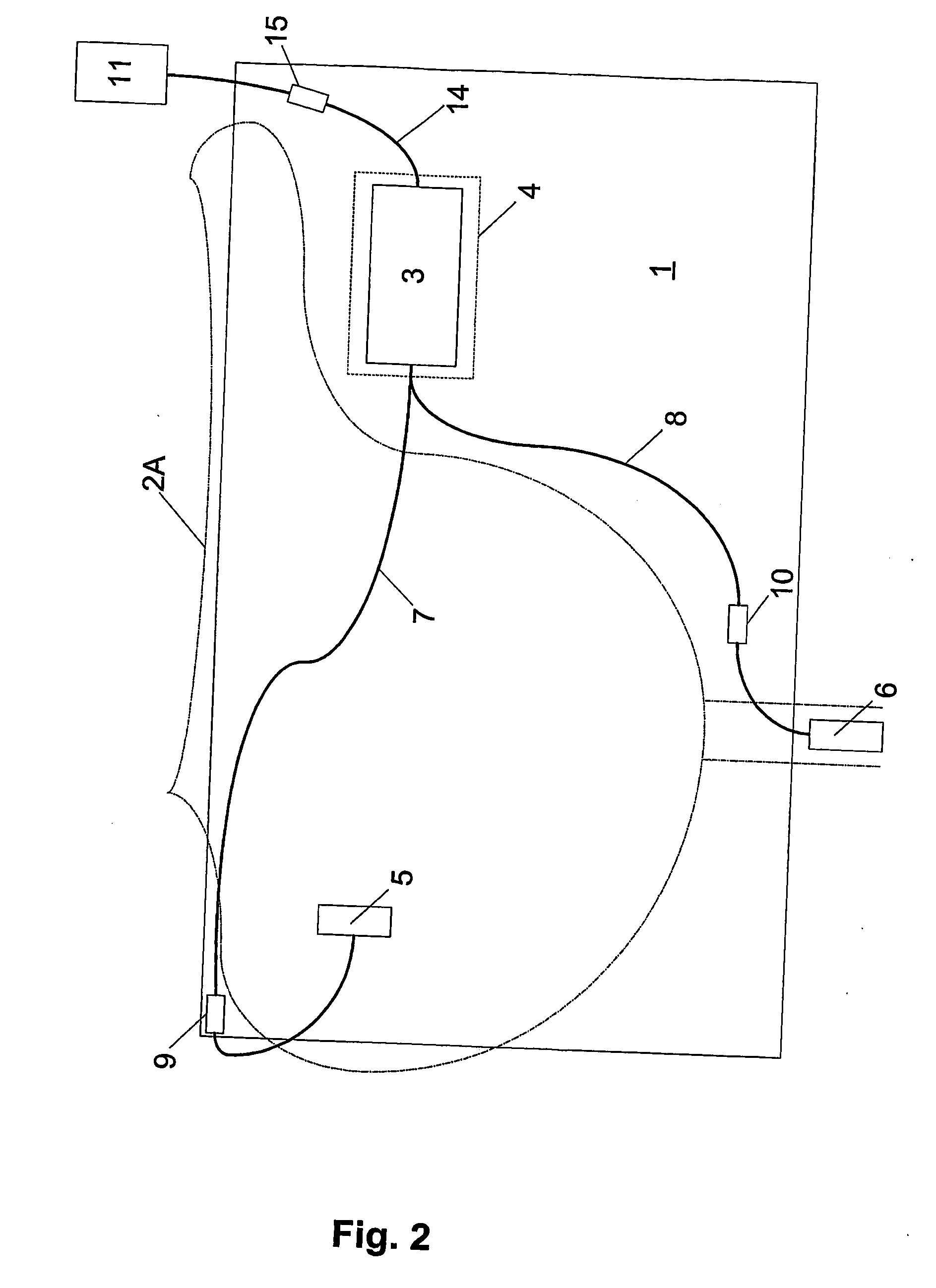

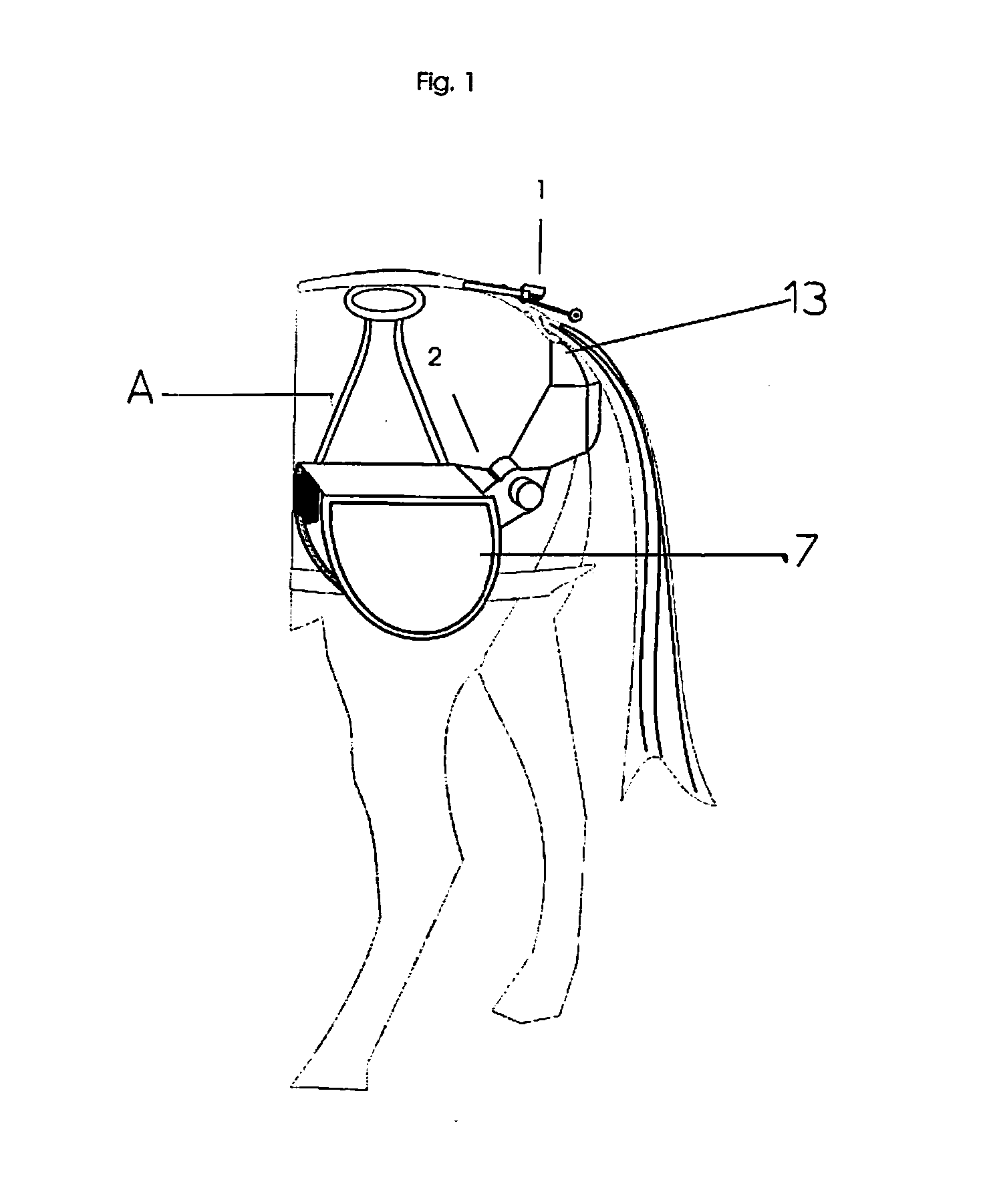

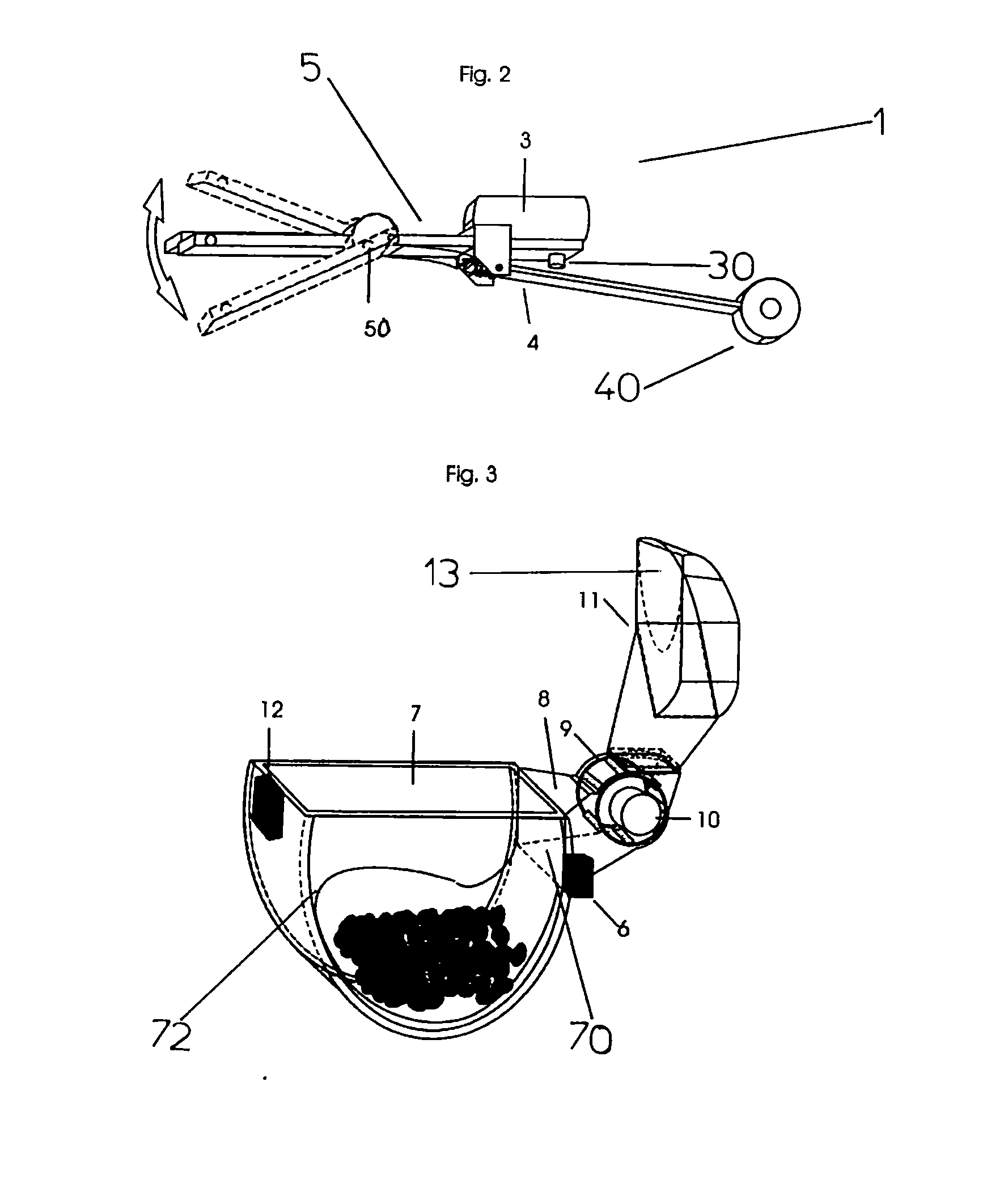

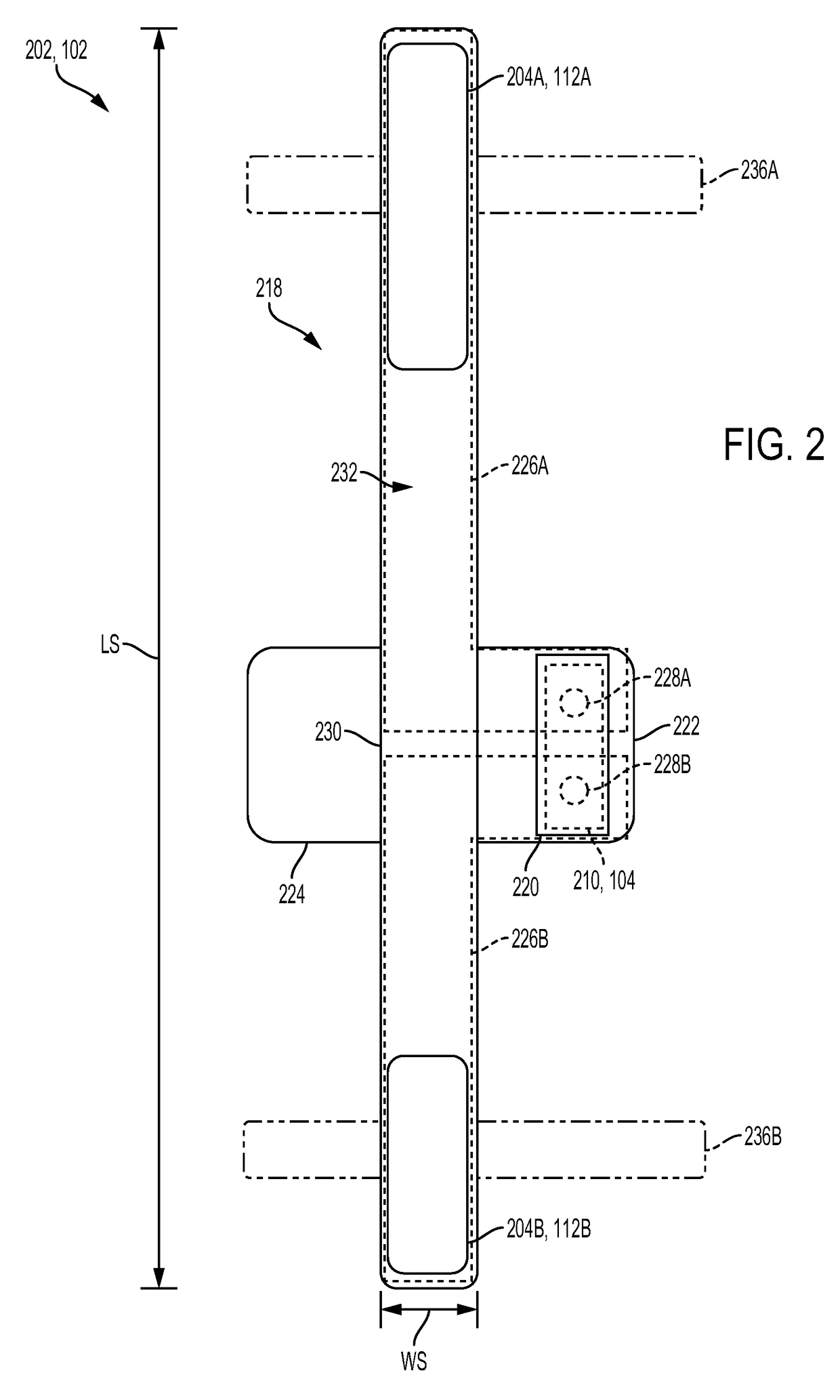

Equine fitness monitoring

Apparatus for determining the health or fitness, under an exercise load, of an animal such a horse comprises: a first sensor (incorporated in module (3) and having electrodes (5, 6)), positioned in blanket (1) under saddle (2a) of a horse, generating physiological data, e.g. breathing or heart rate, blood pressure or flow, temperature, etc; a second sensor, also incorporated in module (3), for generating position data, e.g. a GPS sensor having antenna (11). By using an algorithm, a fitness indicator such as velocity at a heart rate of 200 beats per minute (V-200) can then be derived using data from the sensors. Lameness, disease or poor physiological potential of the animal can thus be identified.

Owner:EQUITRONIC TECH

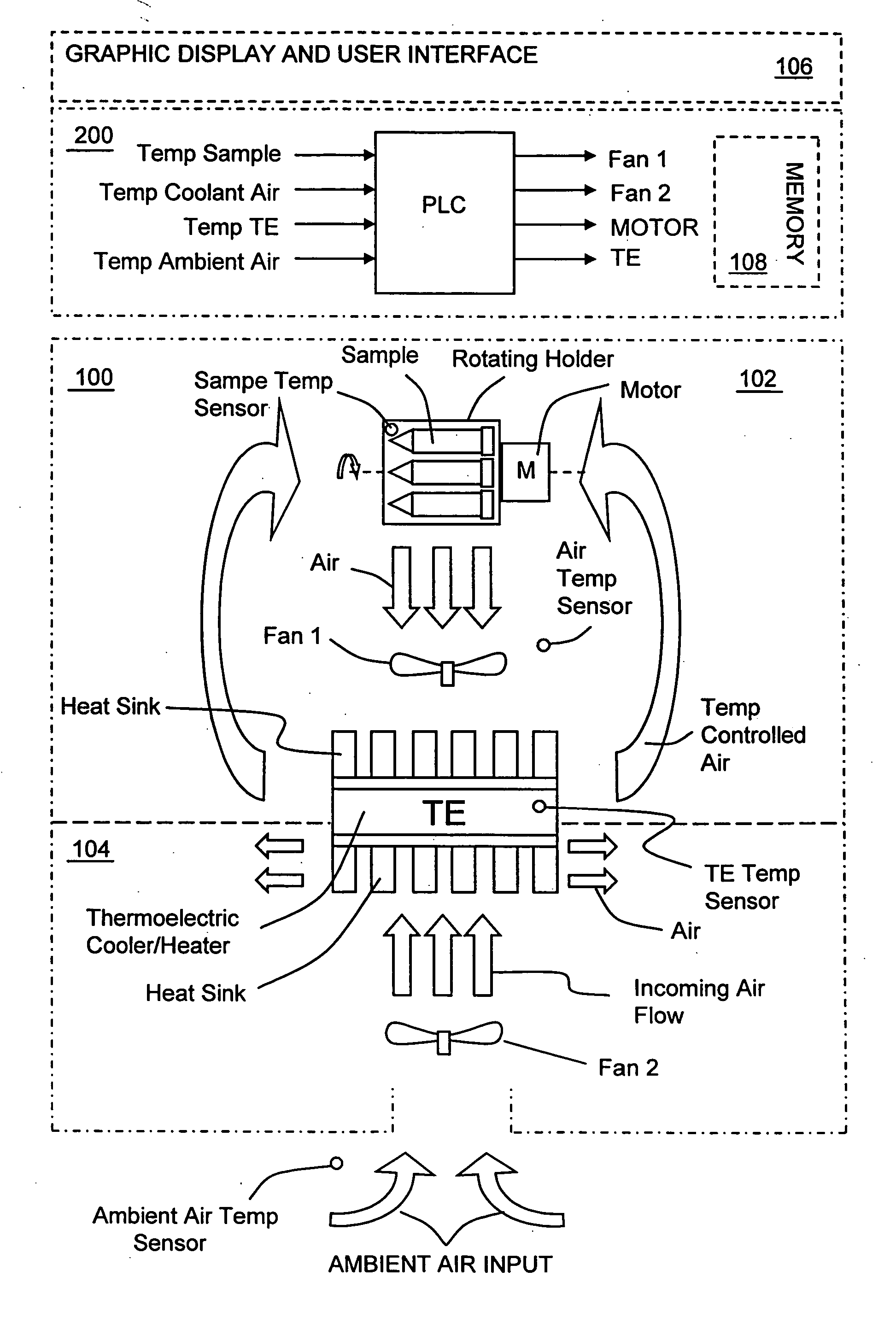

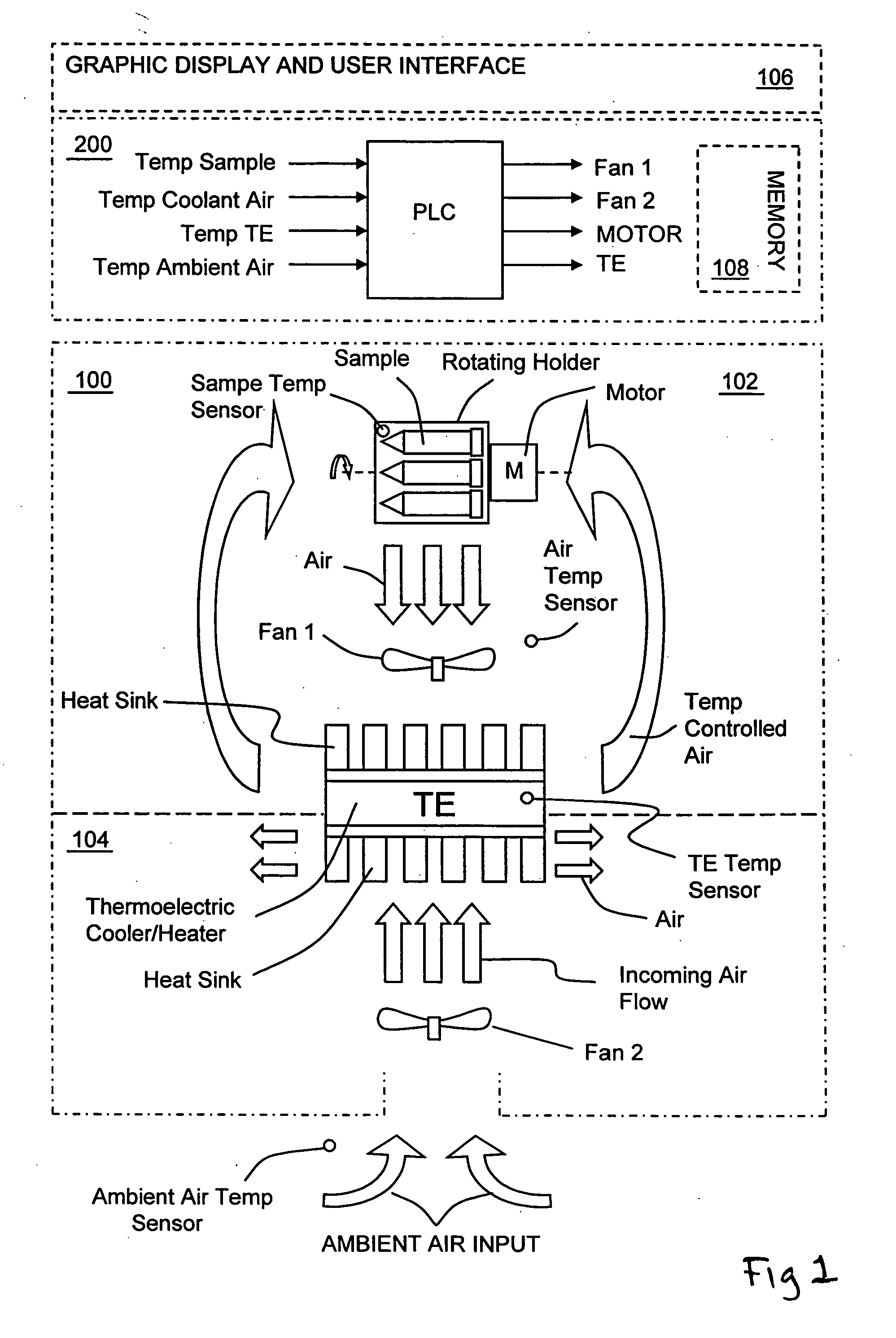

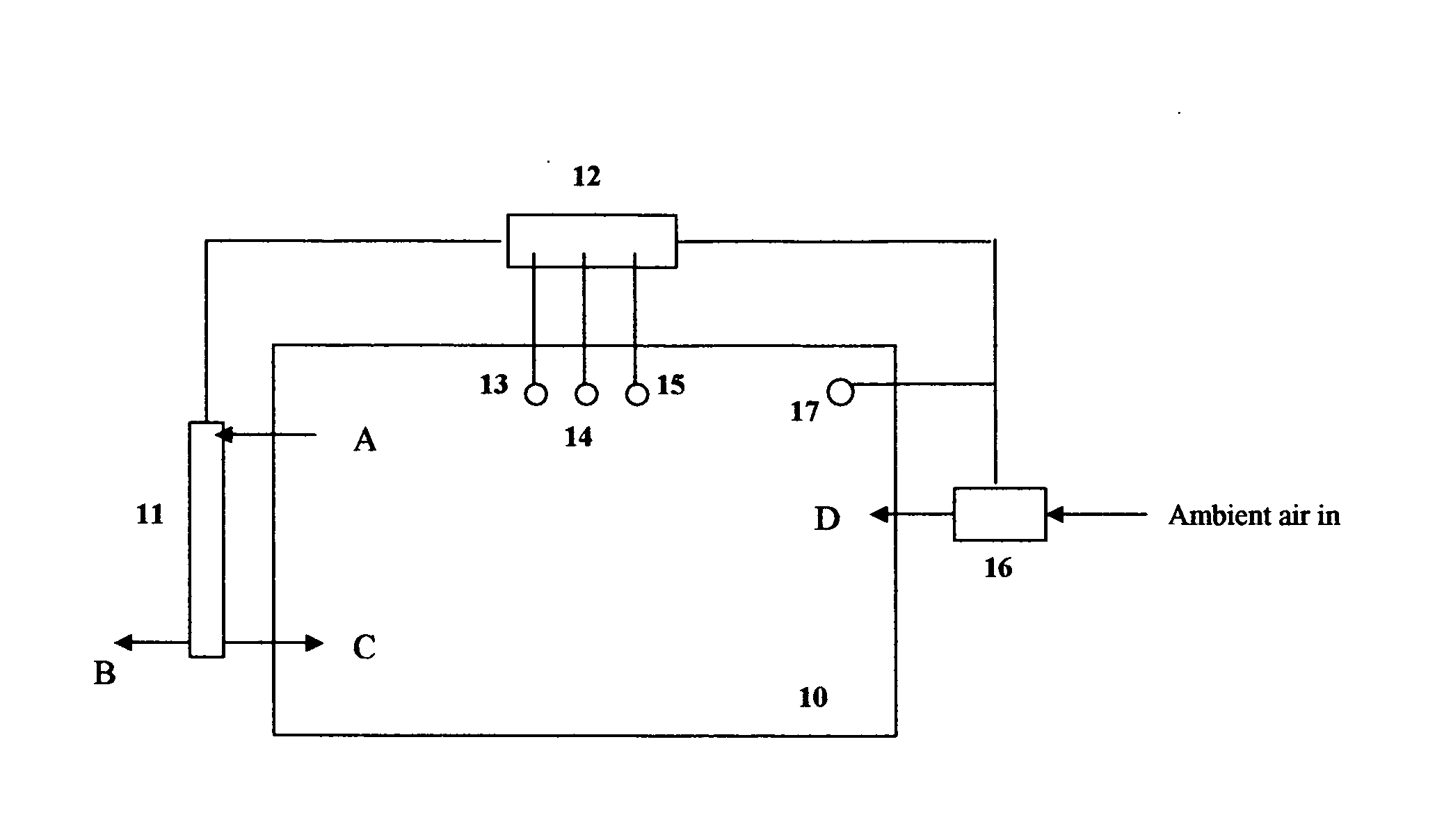

Biological sample preservation, transportation and storage device

InactiveUS20060204950A1Improve survivabilityLower metabolic rateBioreactor/fermenter combinationsHeating or cooling apparatusAir cycleControl system

The biological transport and storage device includes a cooling chamber containing one or more biological samples in a sample holder surrounded by coolant air which is intermittently circulated through the cooling chamber across a thermoelectric unit that can cool or heat the circulating air. A fan is used to circulate air through the cooling chamber, and a separate fan may be used to introduce and circulate ambient air over the thermoelectric unit in incoming air chamber. A sample rotator motor may be used to rotate the samples within the cooling chamber. A control system includes a PLC controller that receives temperature inputs from the sample holder, ambient air within the cooling chamber, and the thermoelectric unit, as well as possibly within the sample. The PLC receives these temperature inputs, and controls the fans, sample rotator motor, and thermoelectric units such that the temperature of the samples within the cooling chamber are cooled at a predetermined and selectable temperature profile. This profile may be selected through the PLC interface based upon a number of factors, such as the type of sample (equine semen, bovine semen, embryo, cardiac tissues, etc.) the expected period for transport or delay until use, for example.

Owner:ILERCIL TY +1

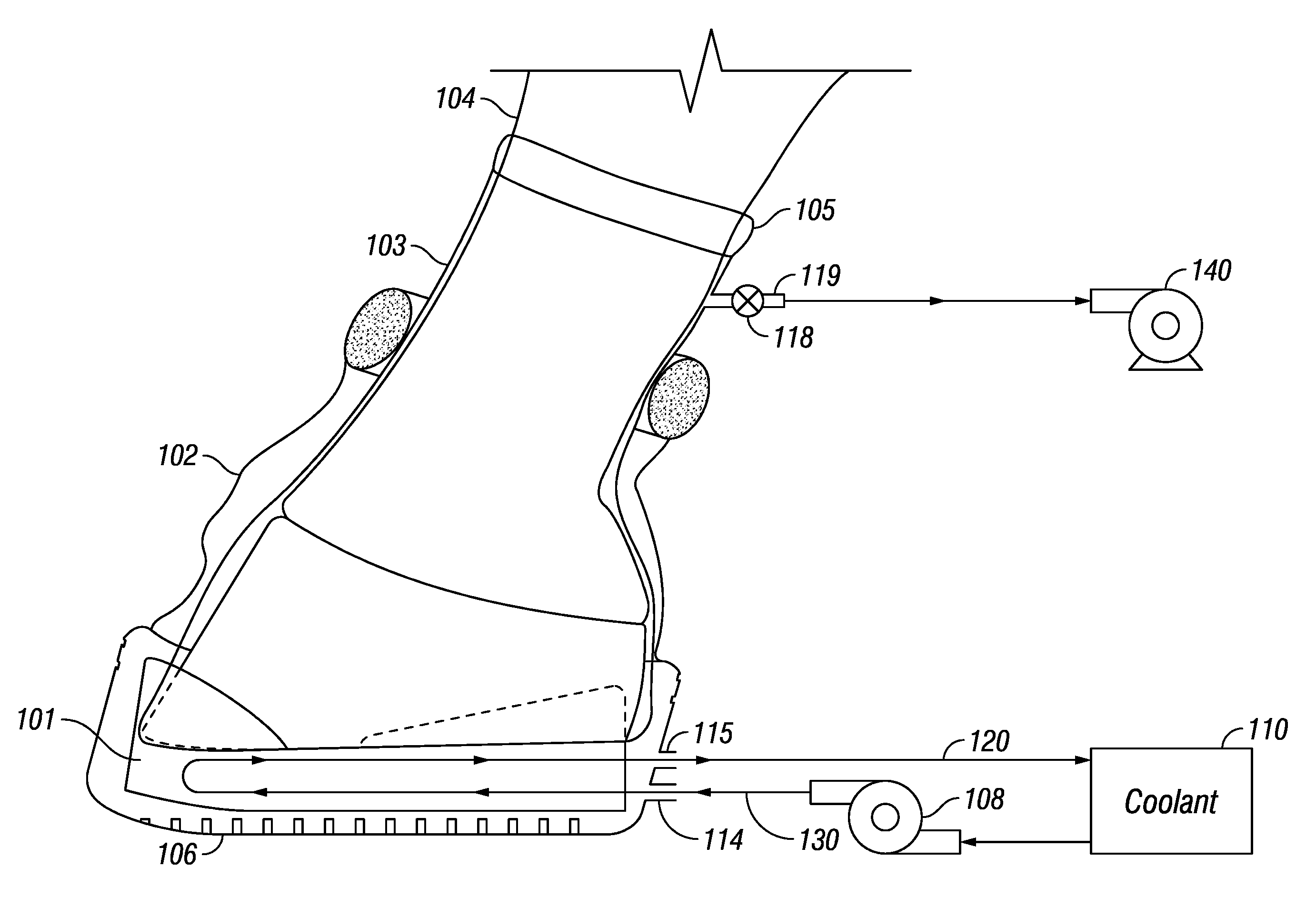

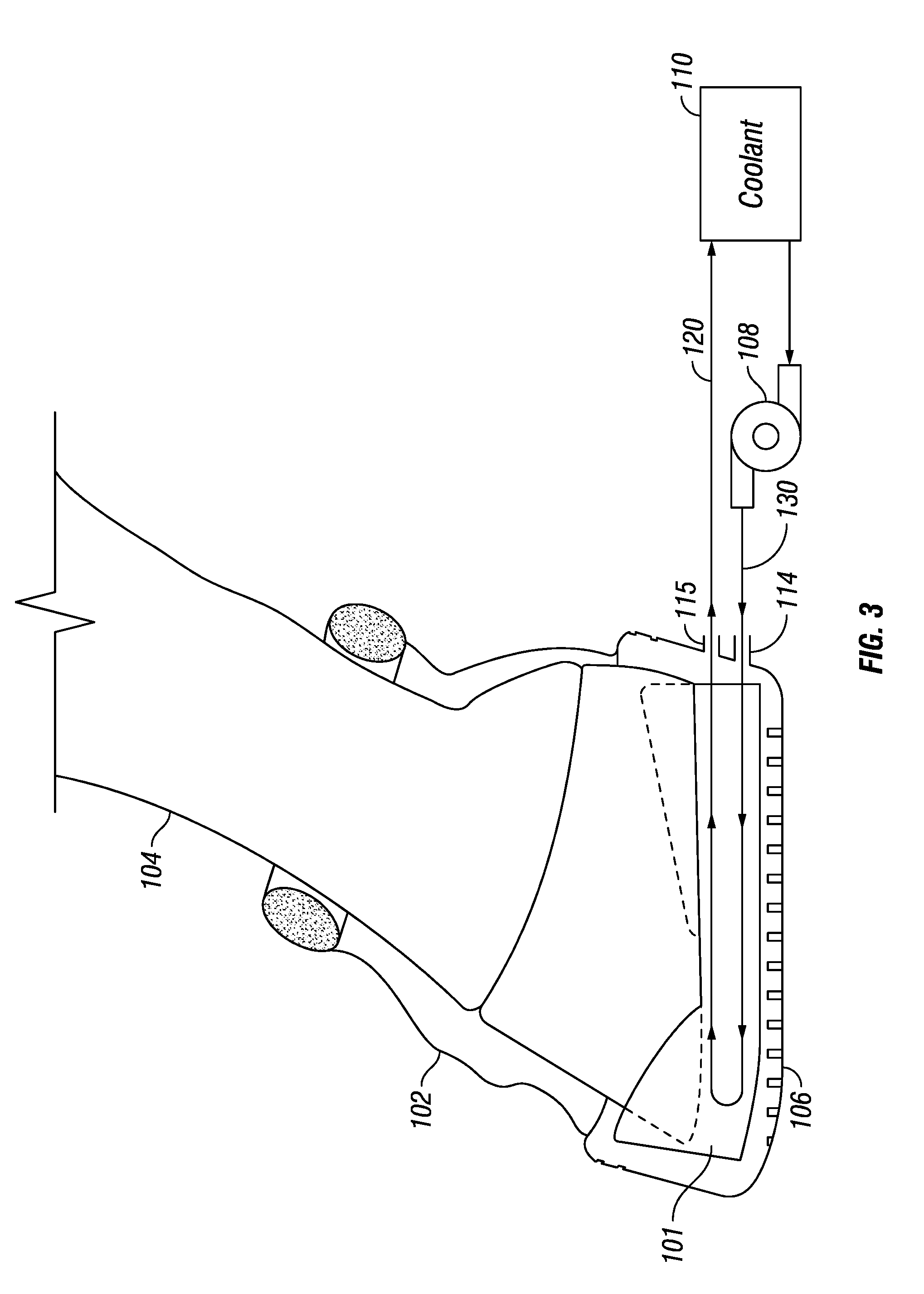

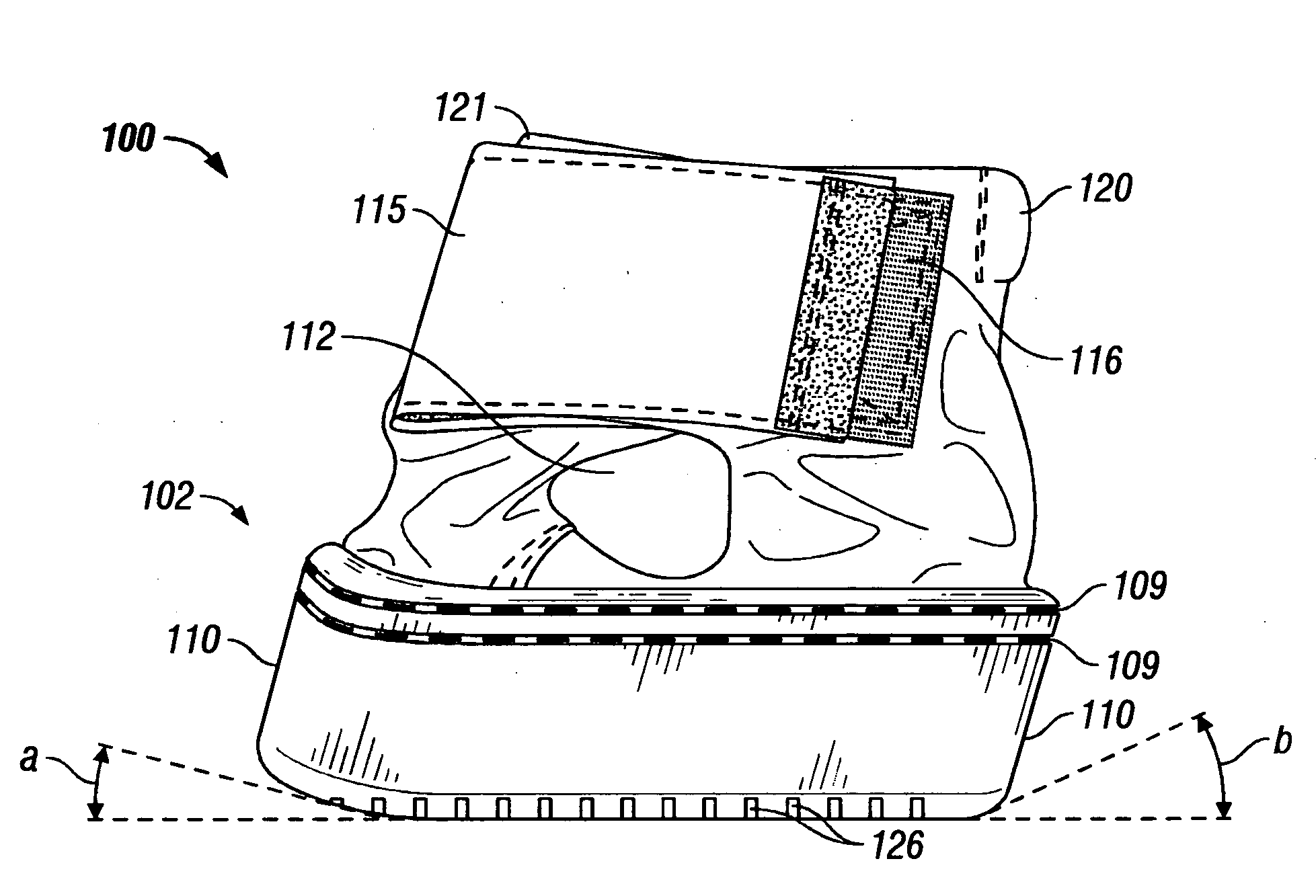

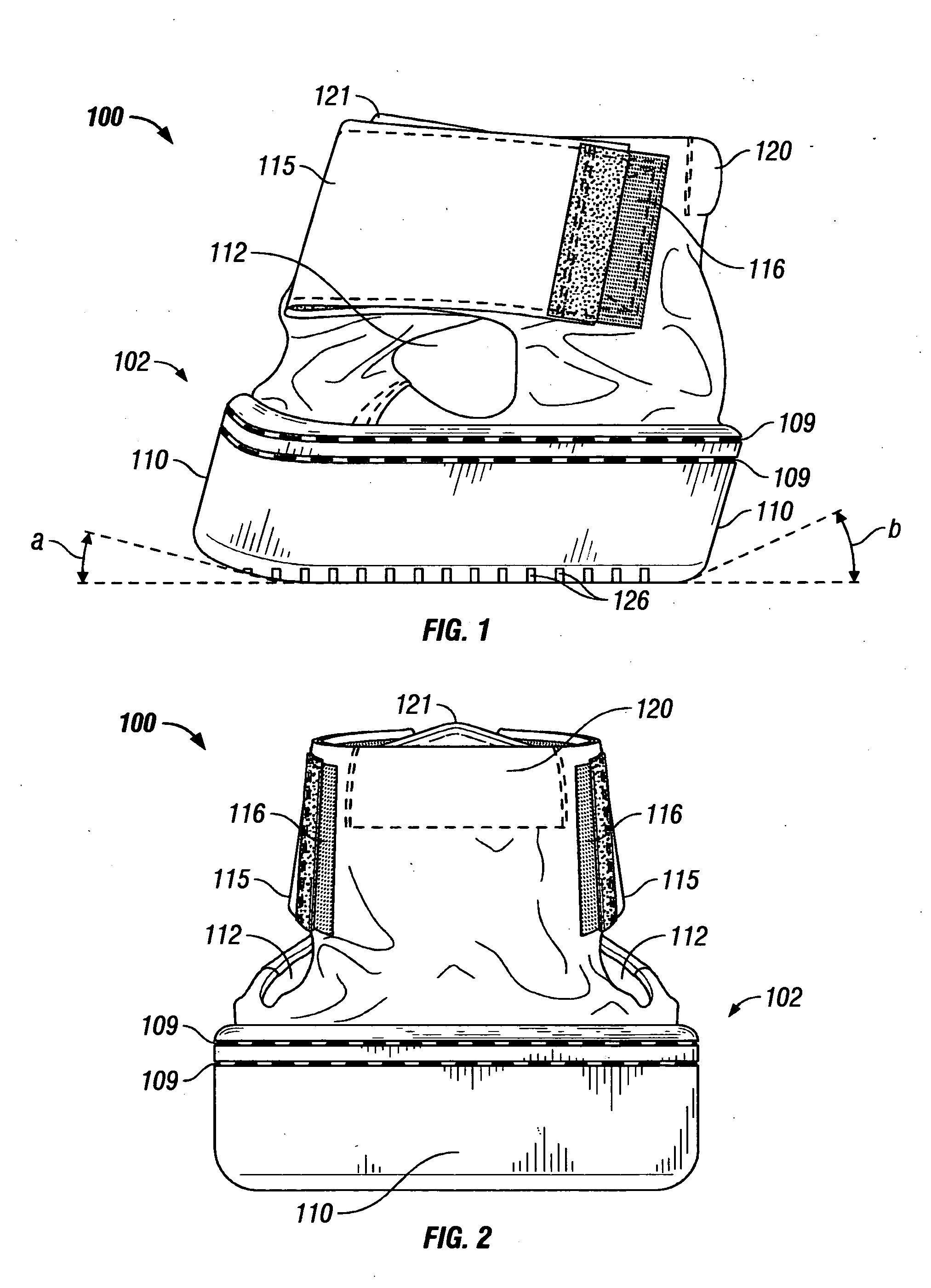

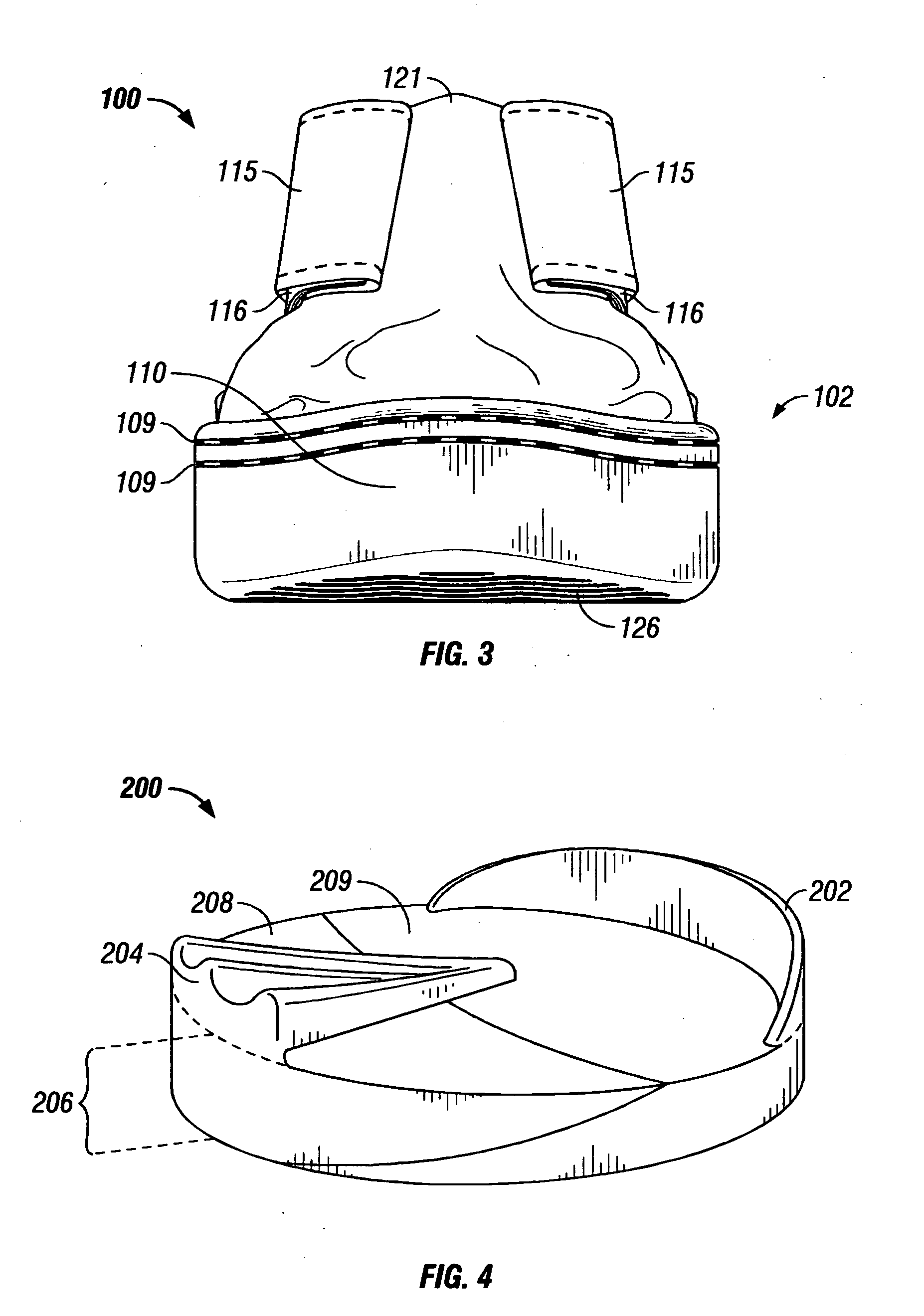

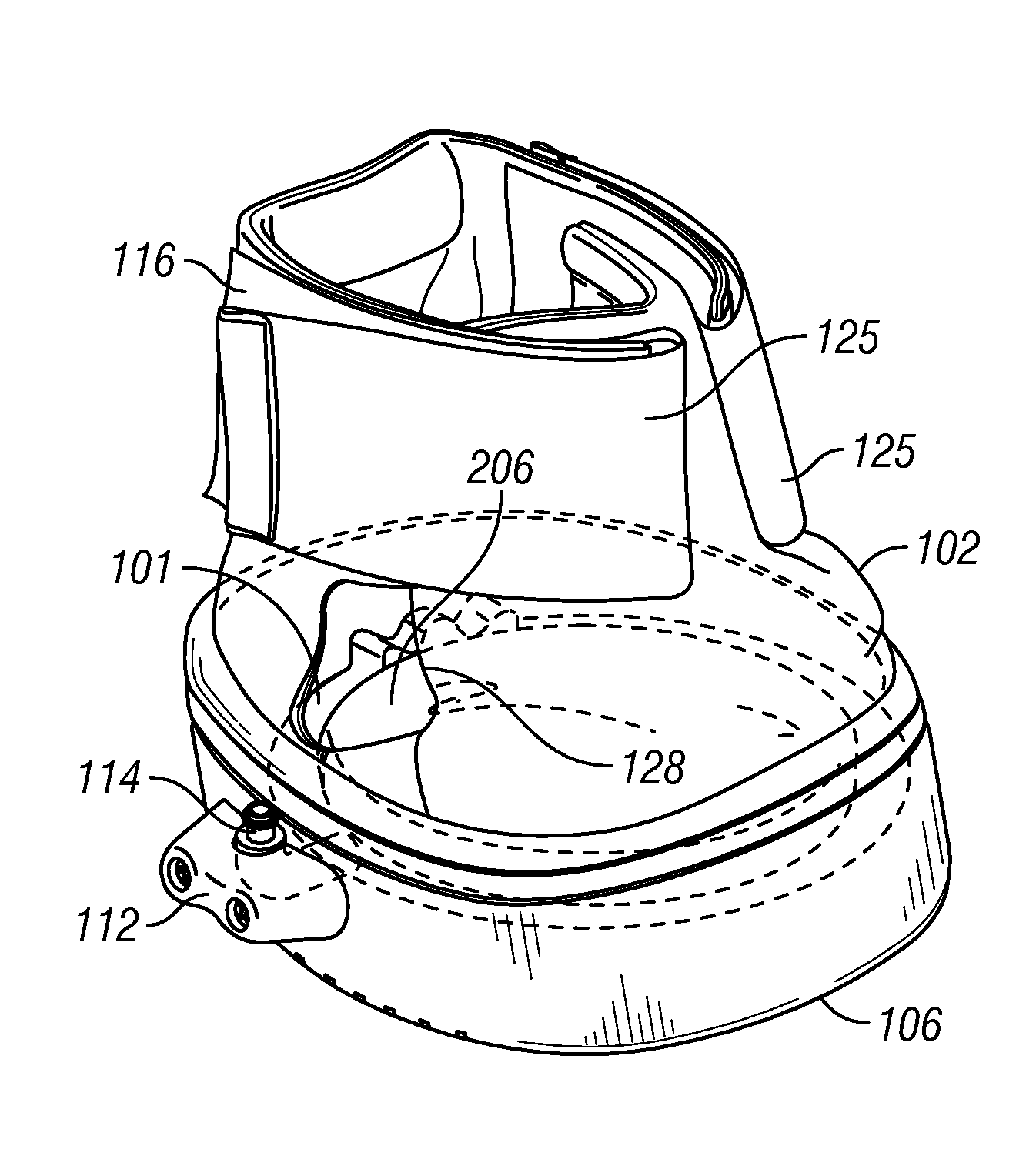

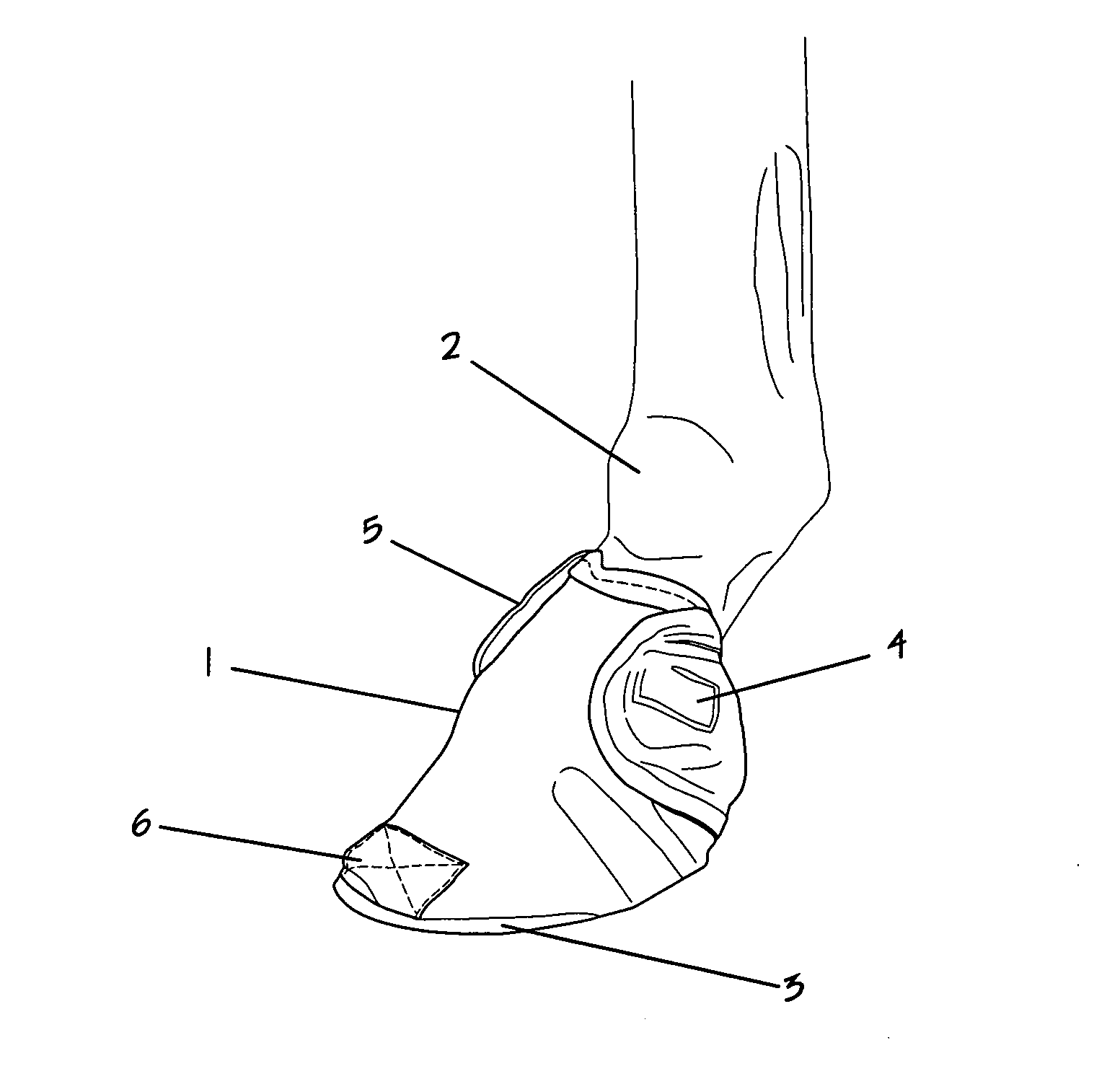

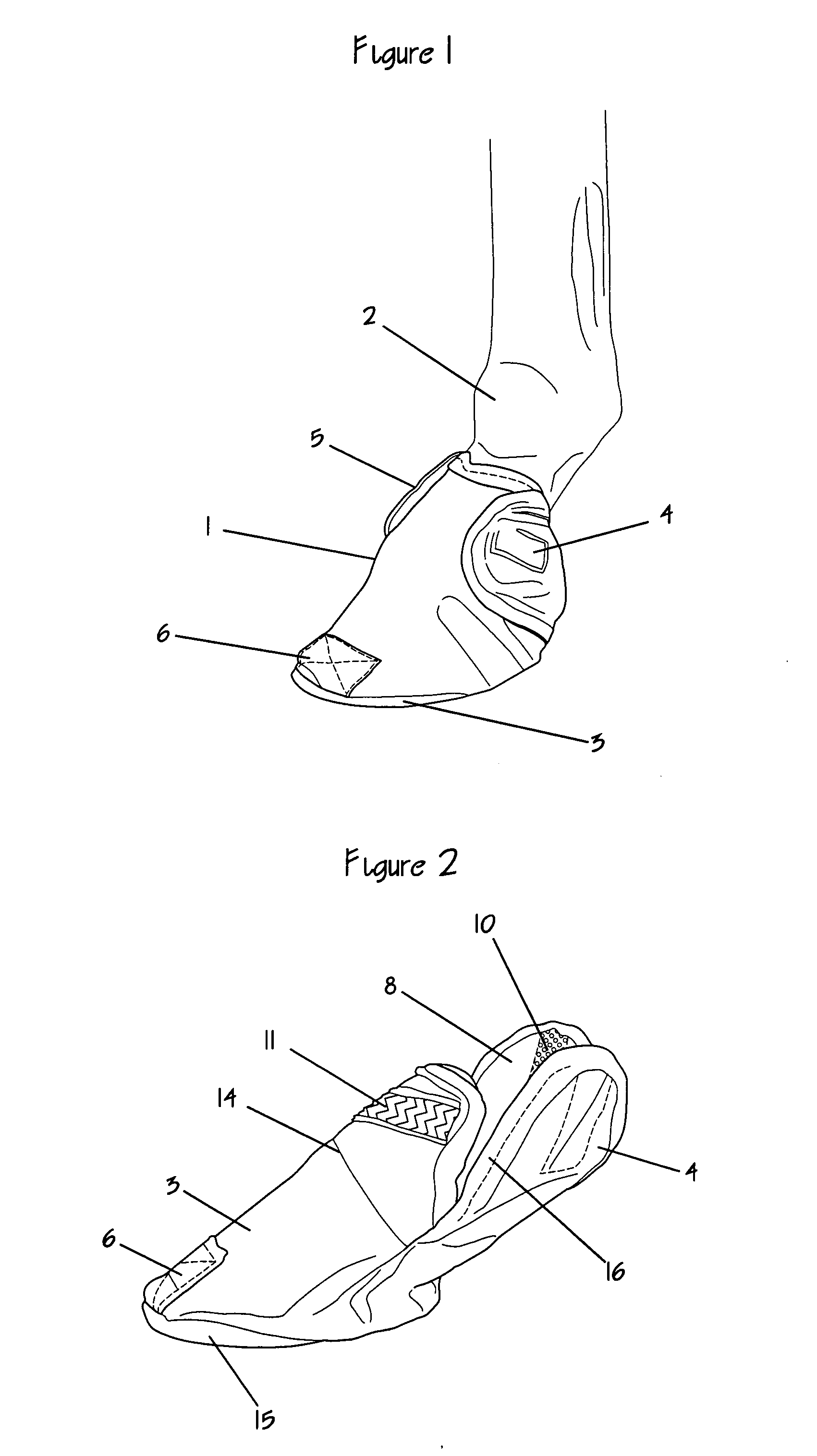

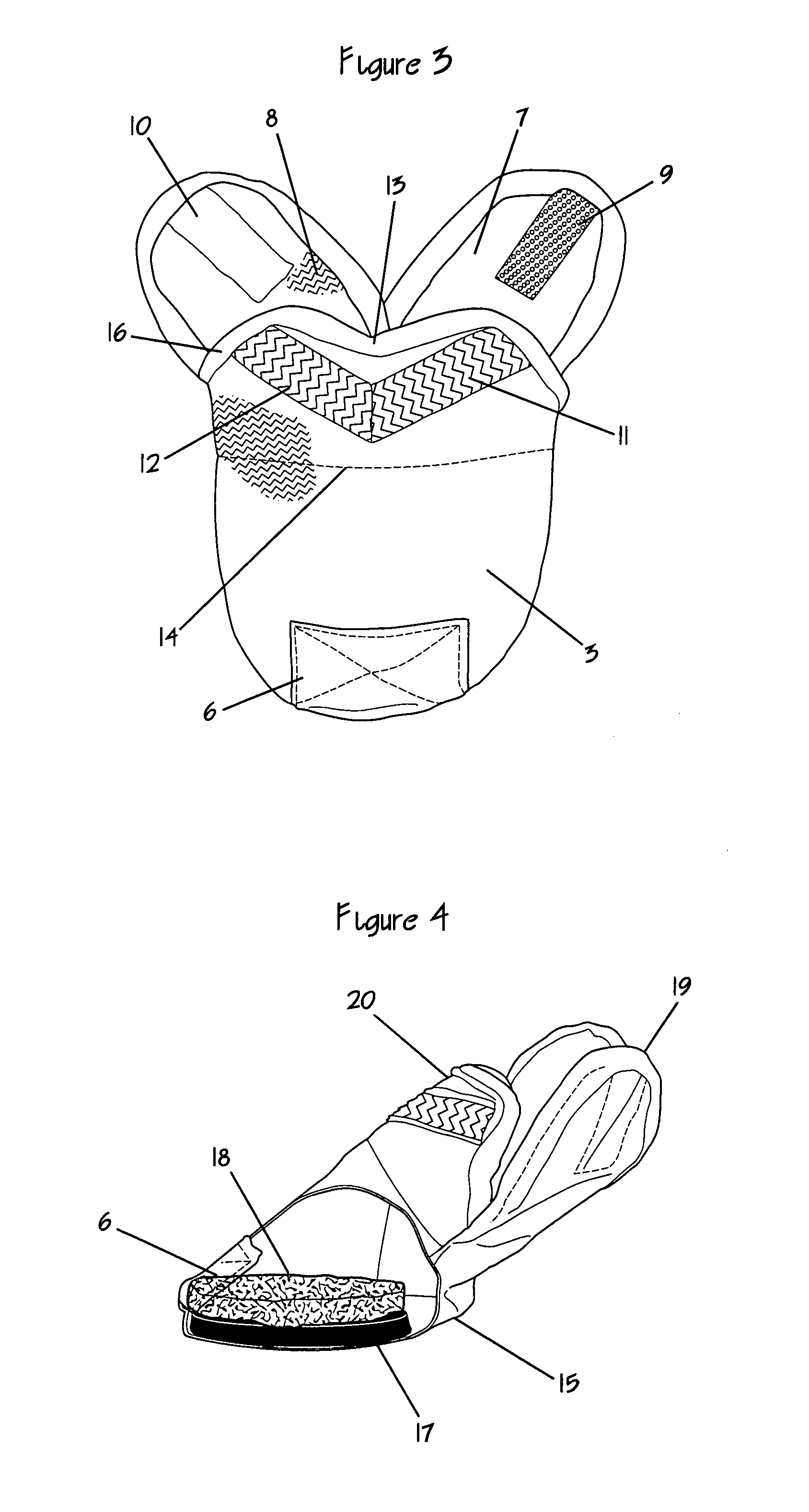

Equine Cold Therapy Apparatus and Method

ActiveUS20100095641A1Heating fastImprove performanceProtection coversVeterinary bandagesEquine SpeciesEngineering

Apparatus for and methods of core cooling the blood of an equine animal. The apparatus is a flexible boot having disposed in it an orthotic pad that has means for circulating coolant so the bottom hoof area of an equine can be cooled. Optionally the pad is designed to allow cooling under vacuum. In some aspects the apparatus also provides means for cooling the lower leg of the equine in a way designed to allow coolant circulated through the boot pad to also be circulated through the leg cooling means while maintaining a controlled temperature against the leg surface. The invention is also a method of core cooling an animal utilizing the apparatus described.

Owner:RUETENIK MONTY L

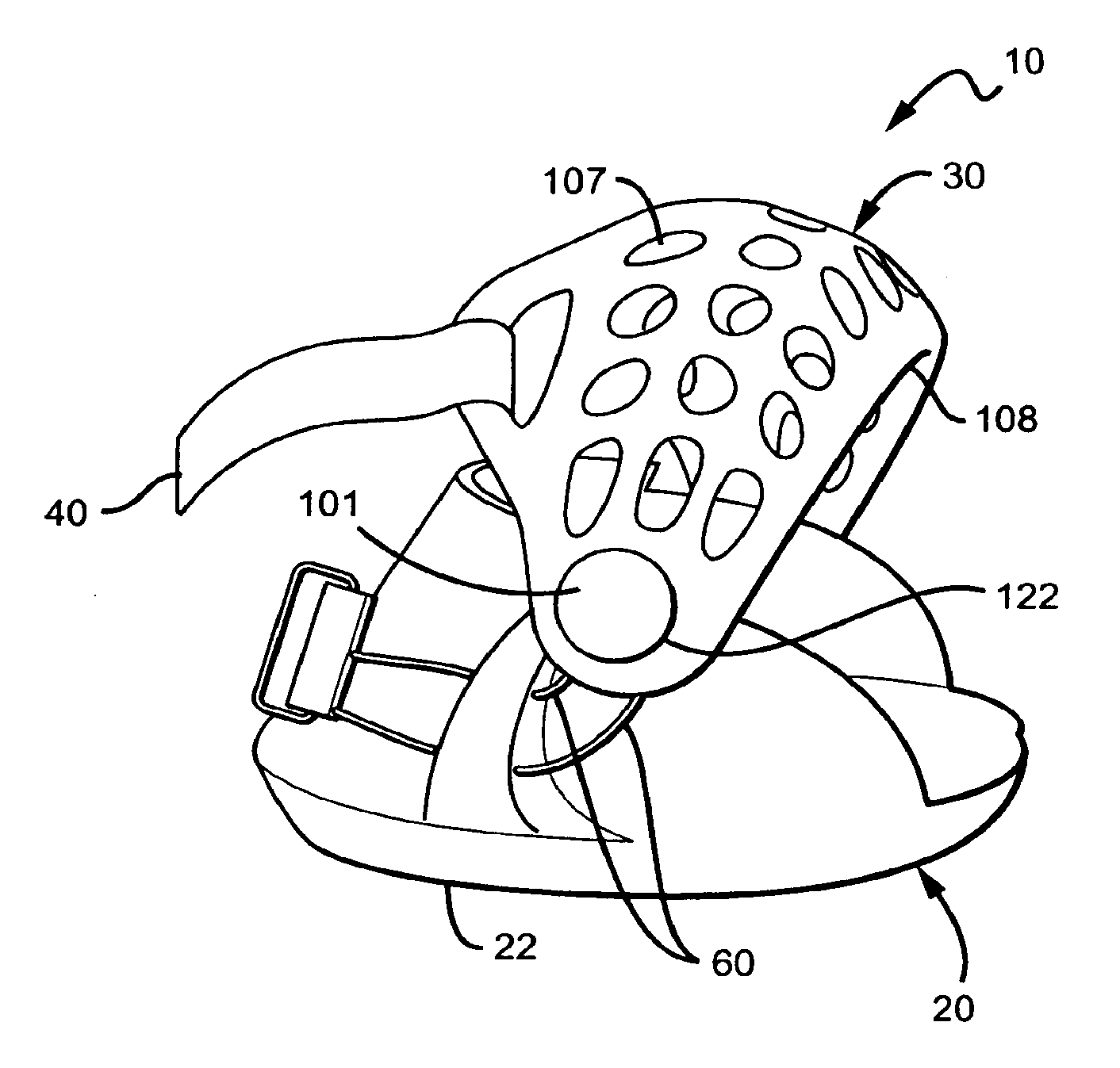

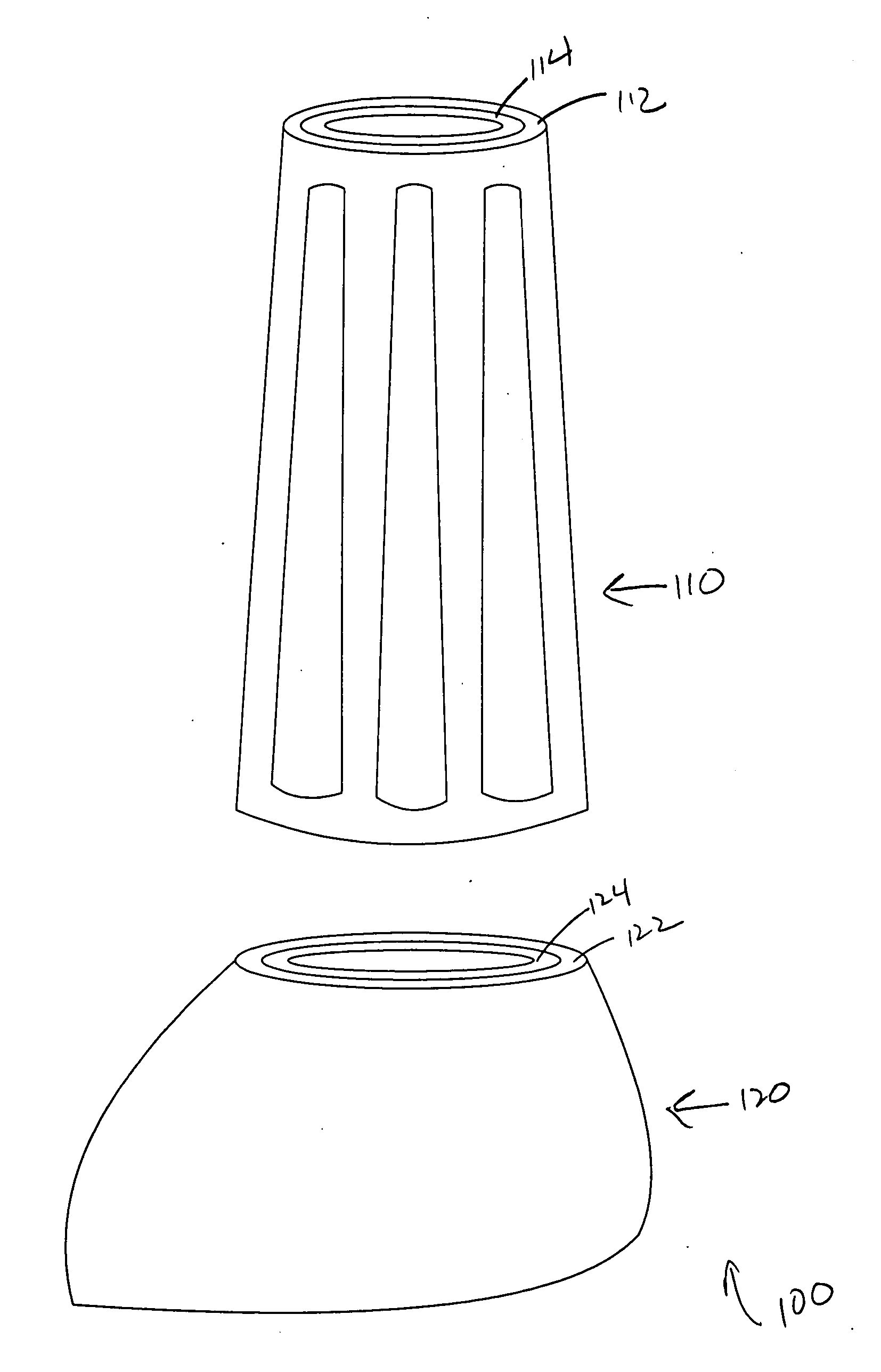

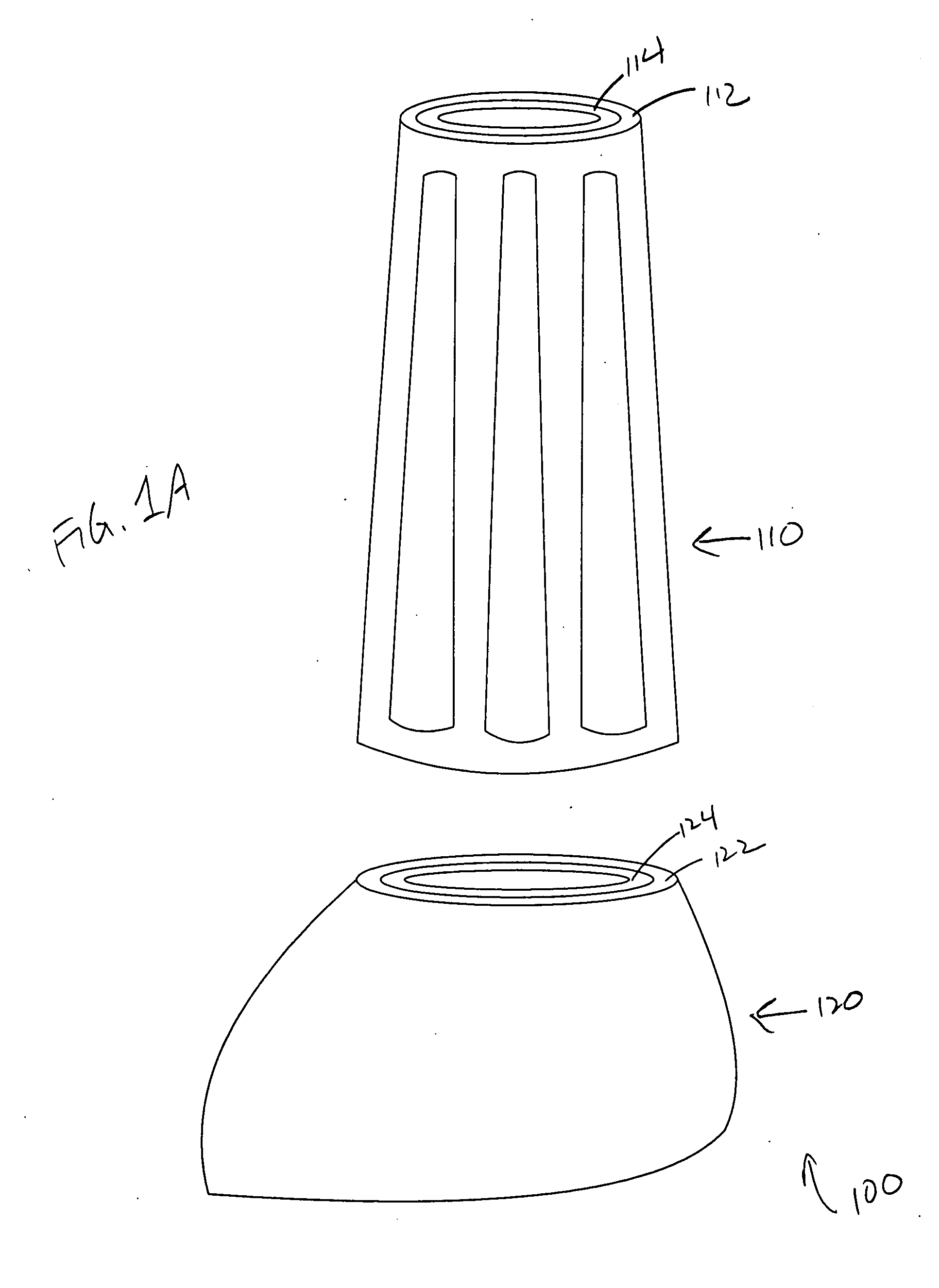

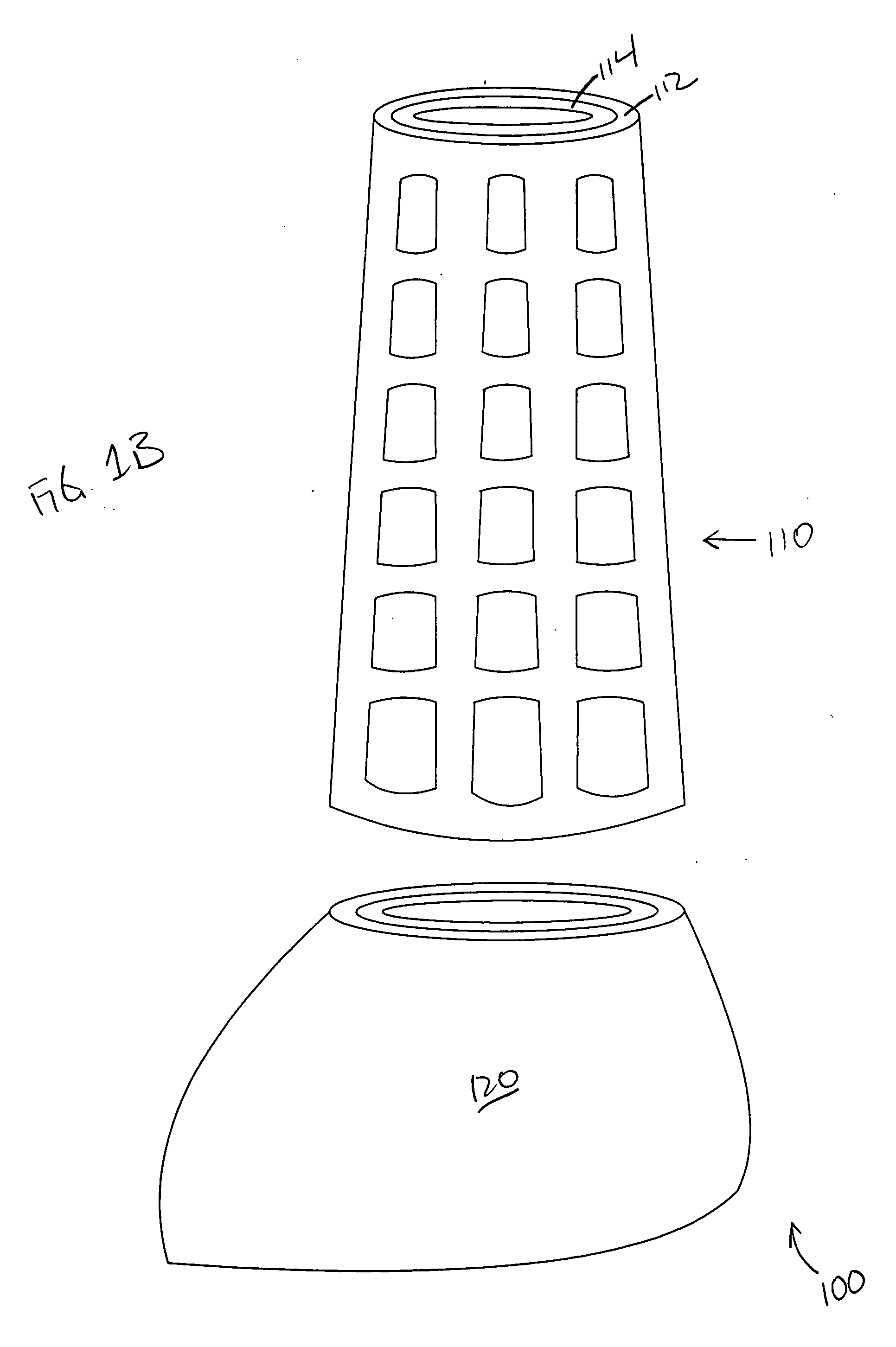

Equine protective device

InactiveUS20060231045A1Taming and training devicesGrooming devicesEquine SpeciesMechanical engineering

An equine protective device is disclosed. The equine protective device comprises a first housing removeably disposable around the lower portion of a horse's leg, wherein that first housing is formed to include a plurality of apertures extending therethrough. Applicant's invention further comprises a hoof liner removeably disposable around the horse's hoof, and a second housing removeably disposable around that hoof liner.

Owner:LINDLEY CAREY

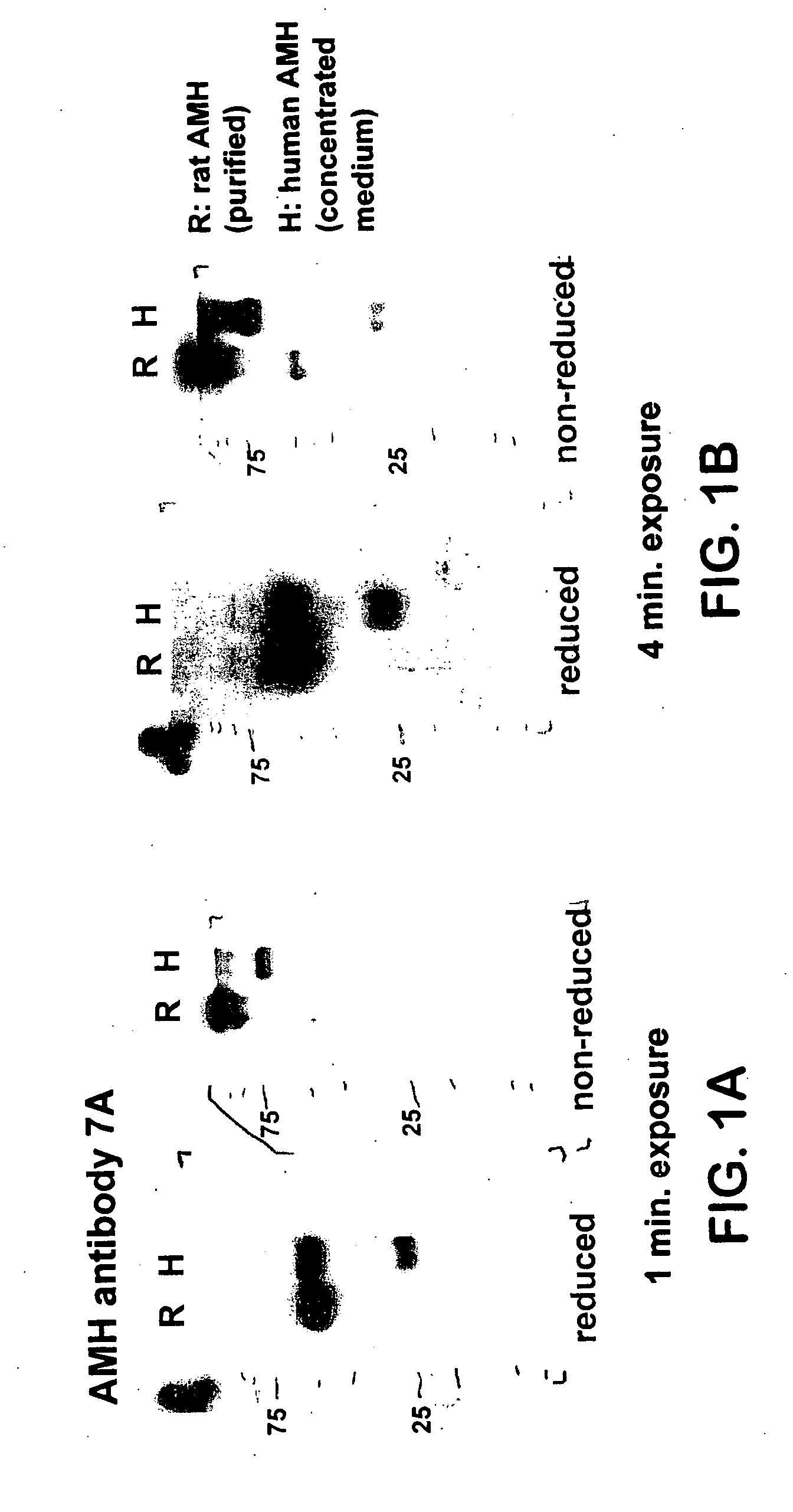

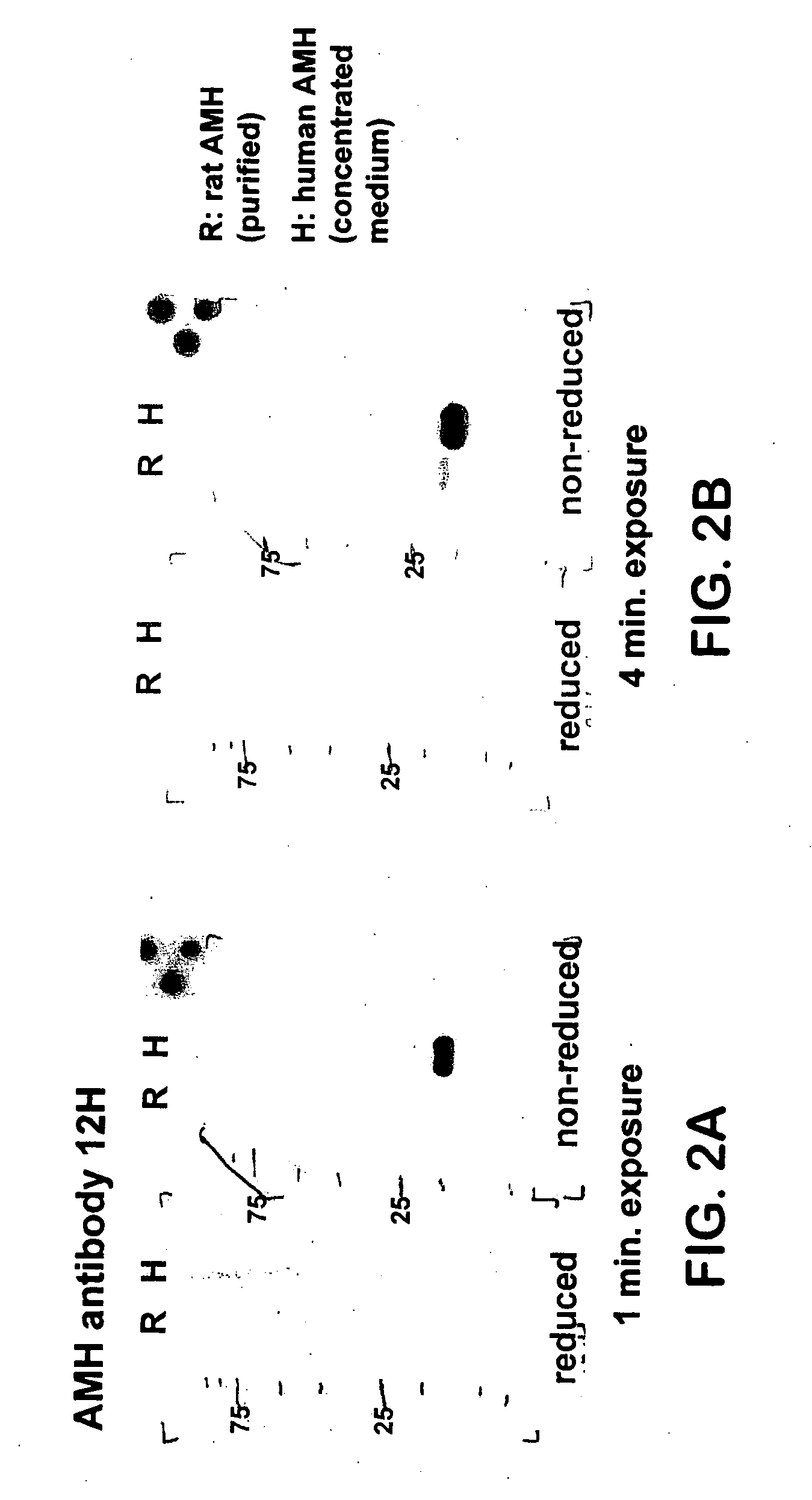

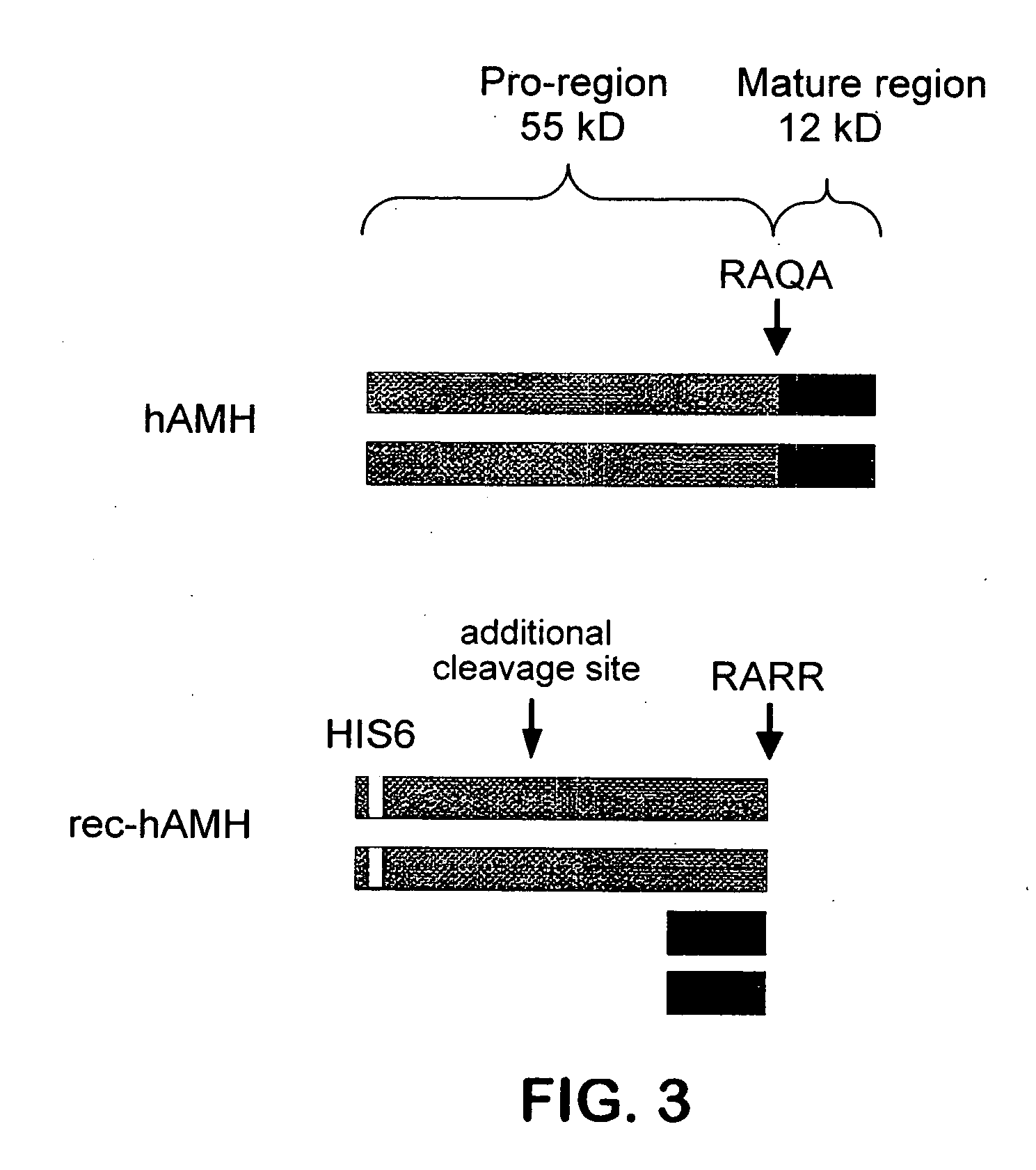

Immunological assay and antibodies for Anti-Mullerian Hormone

The present invention discloses compositions and methods to measure an amount of Anti-Mullerian Hormone (AMH) in a sample, including a mammalian sample such as a primate, rodent, equine, or bovine sample. The compositions and methods herein also provide antibodies that bind to epitopes on AMH that are stable to proteolysis of AMH.

Owner:OXFORD BROOKES UNIVERSITY +1

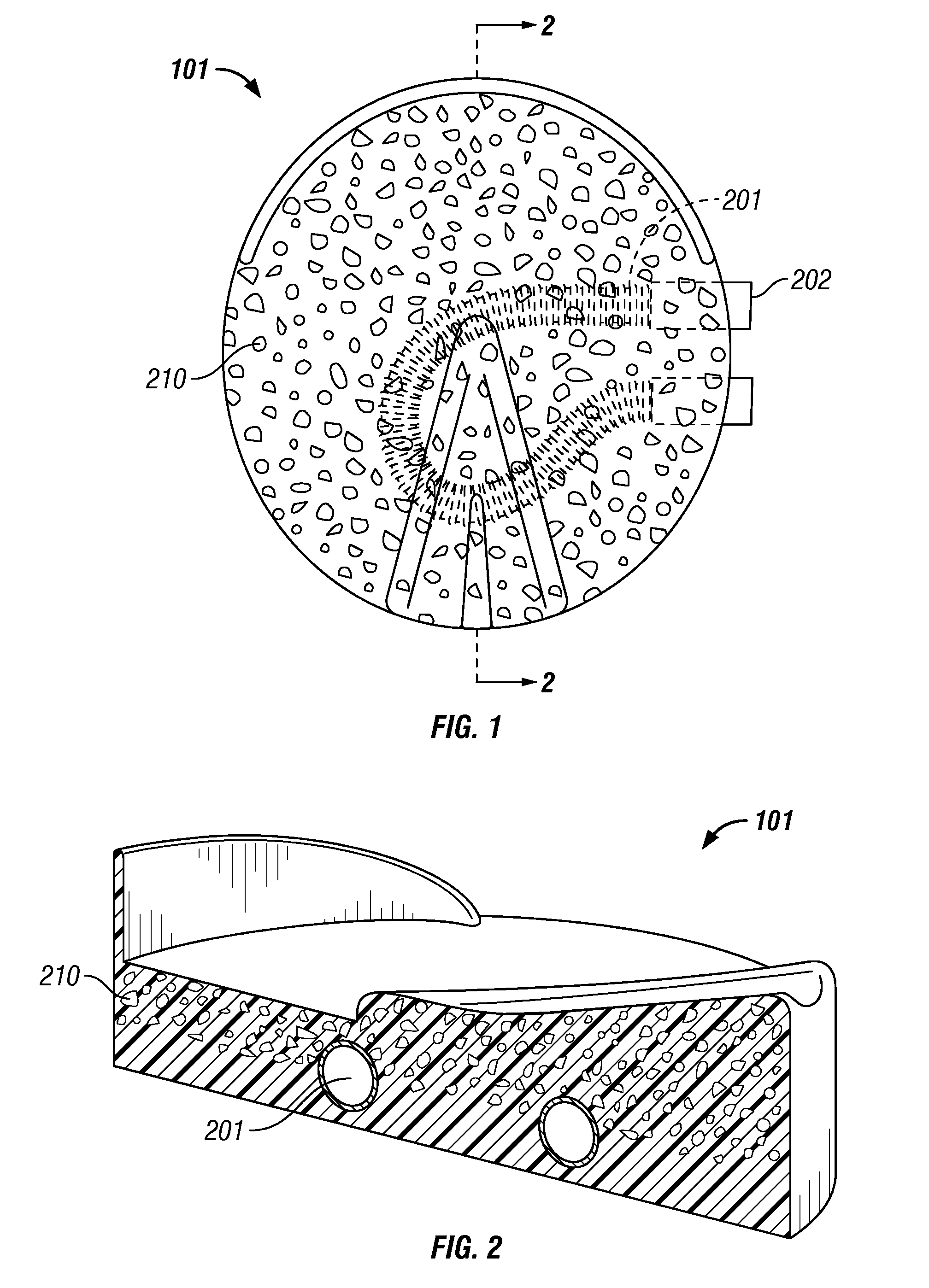

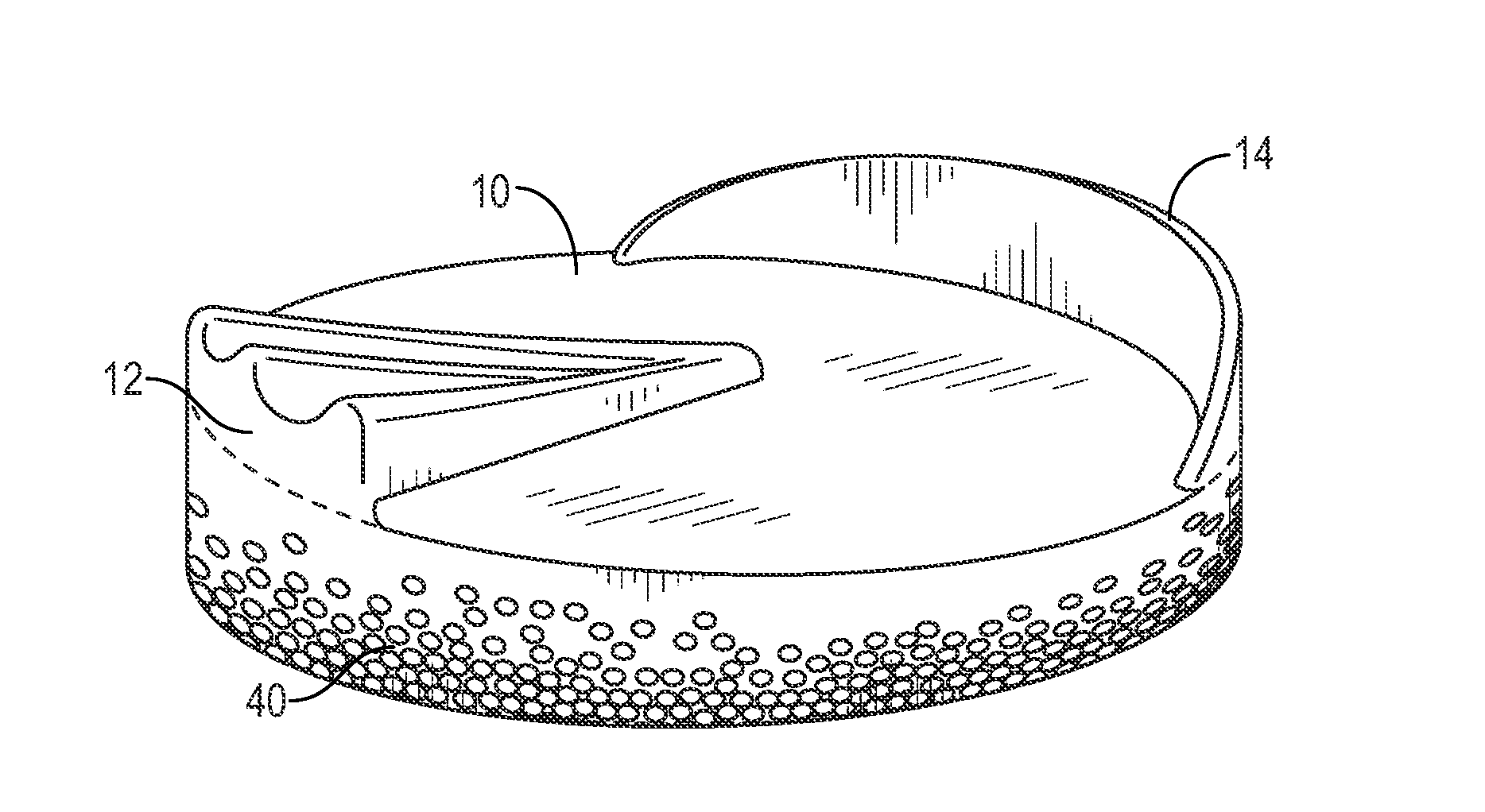

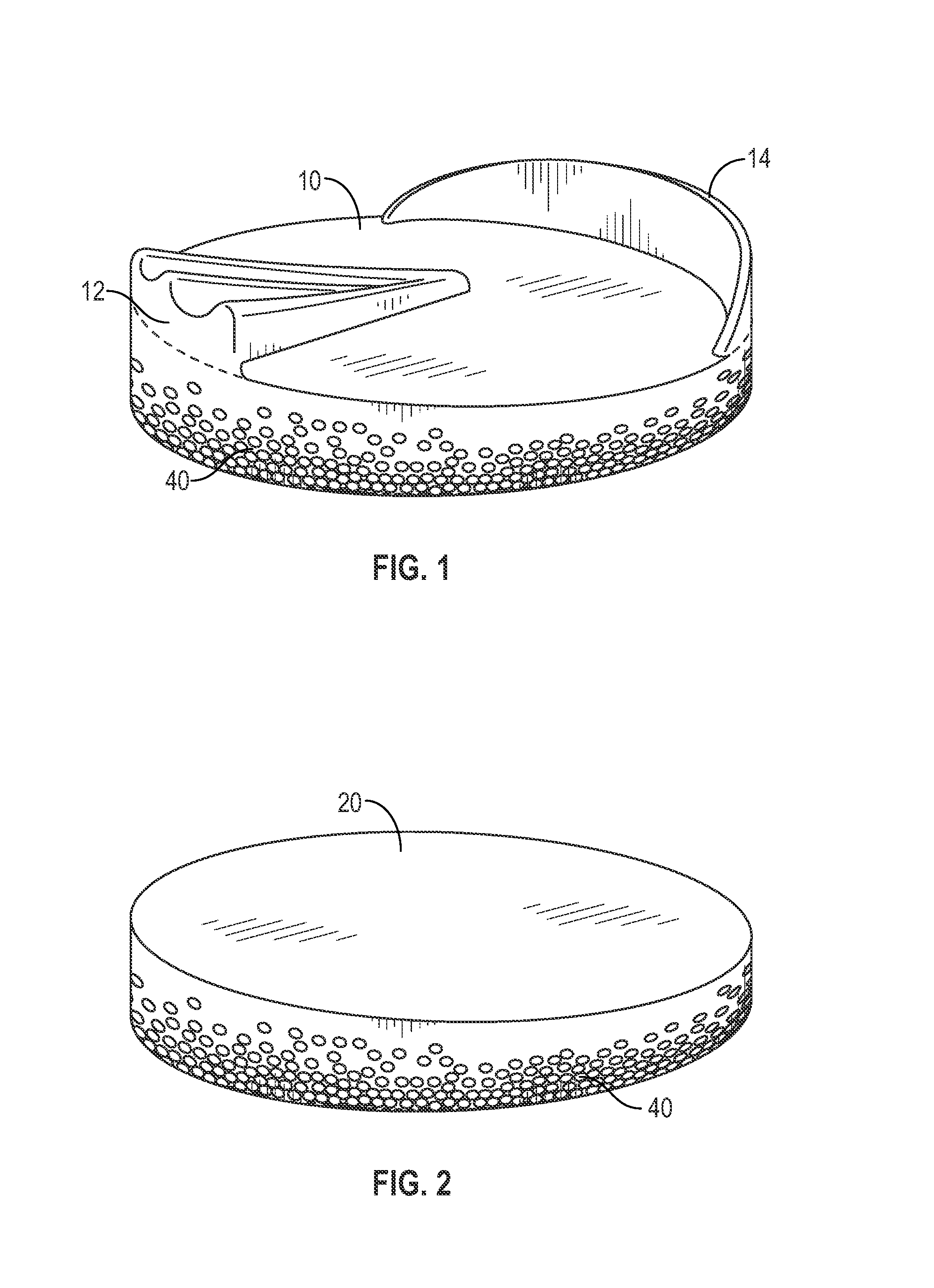

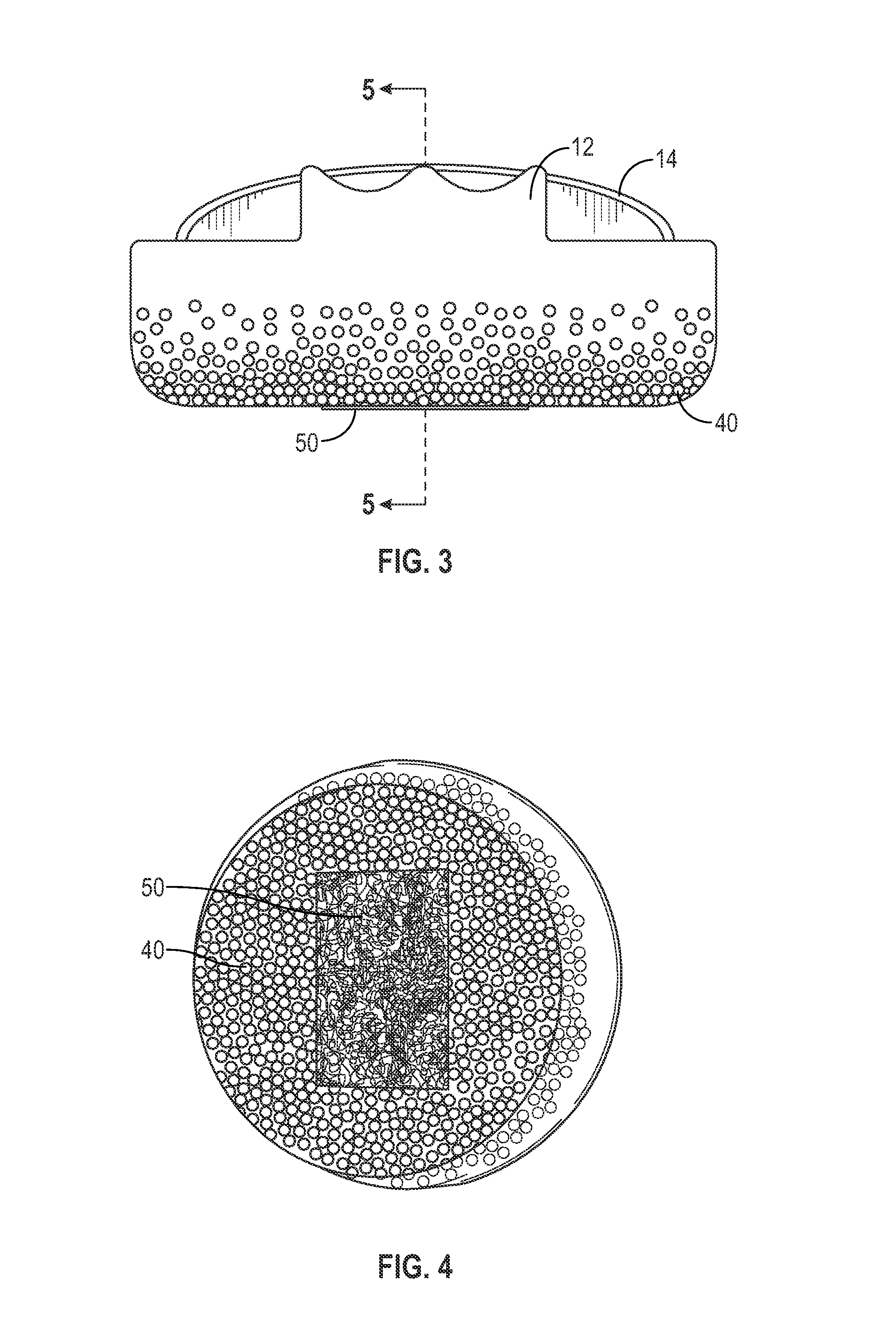

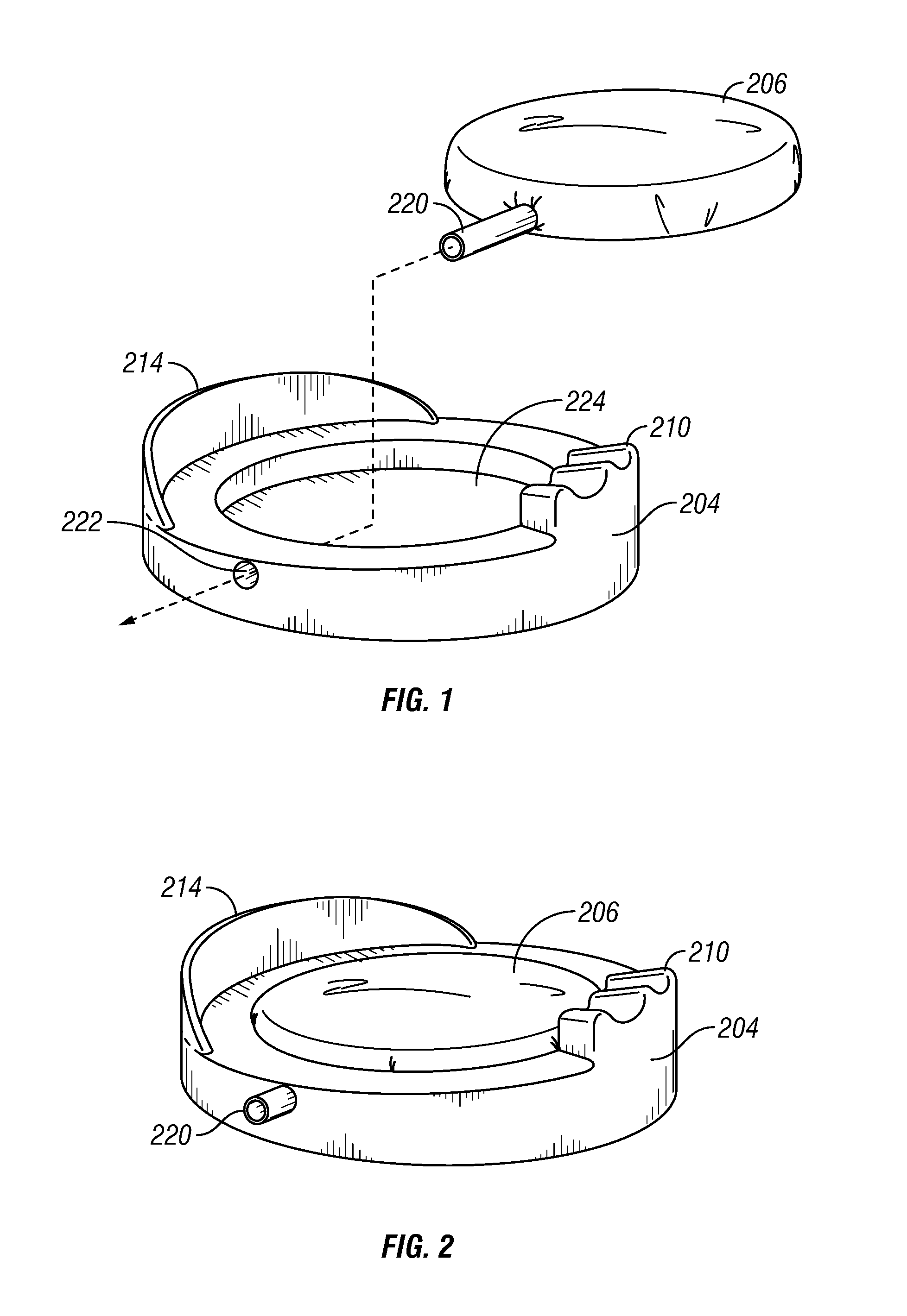

Reduced Weight Equine Orthotic Pad and Method

InactiveUS20140033661A1Reduce weightImprove insulation performanceProtection coversCeramic shaping apparatusElastomerEquine Species

There is disclosed an improved shock absorbing, light-weight, thermally insulative orthotic pad designed for use in a pad and boot assembly for hoofed livestock. The pad is comprised of a mixture of small particles, preferably spheroids, and elastomeric materials. In a preferred embodiment, elastomeric material generally is more concentrated at the top portion of the pad, and particles dispersed in a matrix of elastomeric material concentrated at the bottom section of the pad. The particles have a lower density than the elastomeric materials and possess better thermally insulative properties, and in a particularly preferred embodiment, at least some of the particles are comprised of closed-cell polypropylene foam. A method of making the light weight pad is also disclosed

Owner:RUETENIK MONTY L

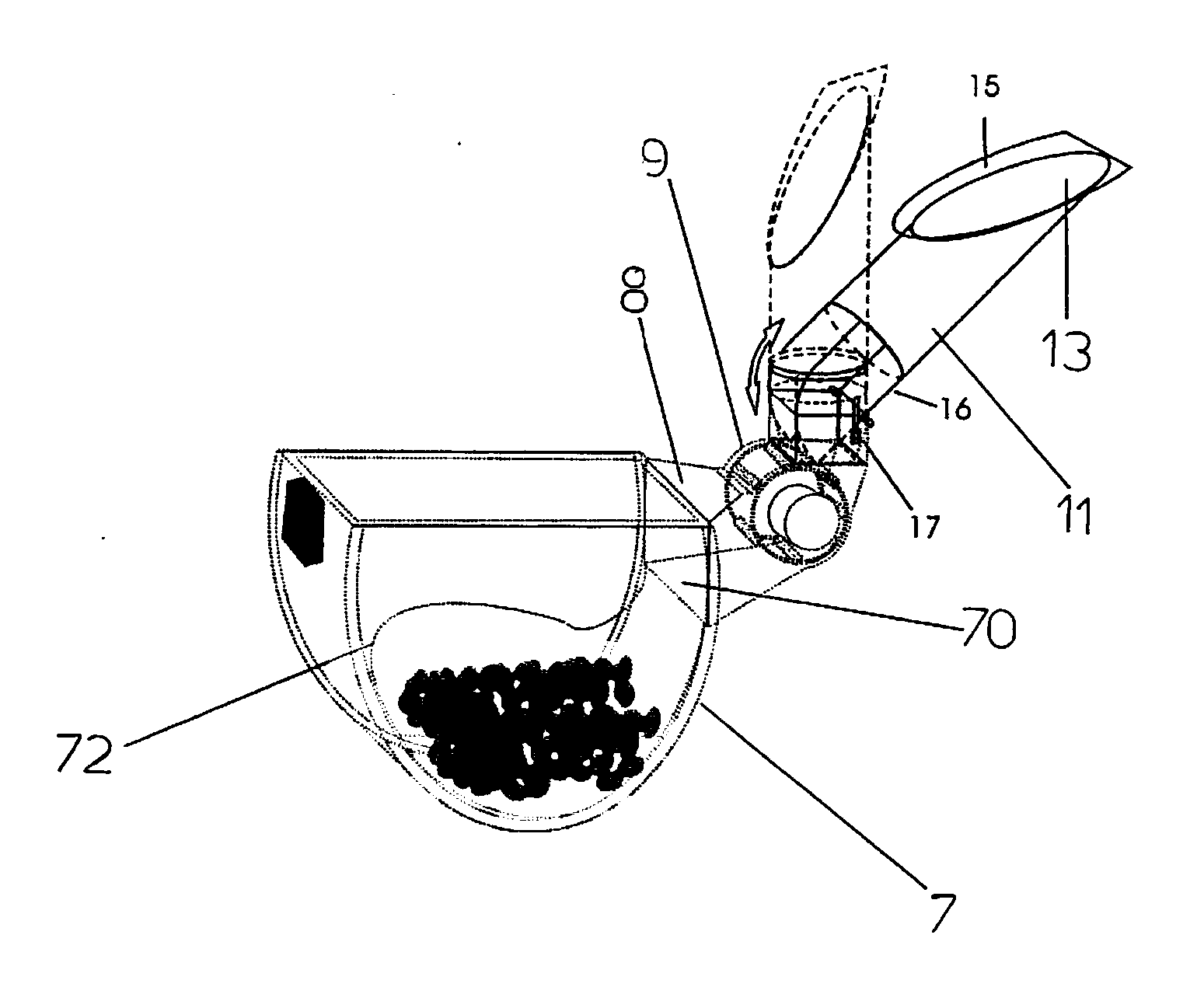

Equine faeces collection system

The equine faeces collection system includes a tubular excrement collection device (2) with a faeces outlet (70) connected to the collection deposit intake (7) and an intake mouth (13) adapted to face the animal's anal area directing the excrement towards the deposit. The collection device (2) has a first collection area (8) with an outlet mouth connected (70) to the collection deposit intake (7), and a second collection area (11) with an intake mouth (13) which is coupled to the first area (8) to move from a rest position to a collection position in which the intake mouth (13) is facing the animal's anal area, where the intake mouth is located over the outlet mouth so that the excrement falls towards the faeces deposit by gravity. In addition, a turbine (9) moved by an electrical motor (10) could be mounted inside the first collection area (8) to help drag the faeces towards the deposit (7).

Owner:HERNANDEZ RAMIREZ JOSE

Equine CT table

An equine CT table for positioning a horse during a CT (“computed tomography”) scan. The table is positioned above the patient couch and communicates with the conventional CT system for examination of a horse without requiring mechanical or electrical attachments between the CT system and table. The table includes a frame carrying a tracking system, a linear movement system and a carousel upon which the horse is positioned. Prior to examination, positioning of the horse on the table may be manually adjusted linearly and / or radially in any direction to properly align the horse. Infinitely positionable cantilever members are provided to support horse's appendages. The tracking system identifies movement of the CT couch and mimics the movement with the linear movement system to enter and retract the horse from the gantry at predetermined positioning.

Owner:ARTEC IMAGING

Method of producing hypoxic environments in occupied compartments with simultaneous removal of excessive carbon dioxide and humidity

A method and a system for providing a hypoxic environment inside an enclosed compartment with simultaneous removal of carbon dioxide and moisture produced by occupants; said method and system designed for fire prevention and for simulated altitude training, wellness and hypoxic therapy, including equine and other animal applications.

Owner:KOTLIAR IGOR K

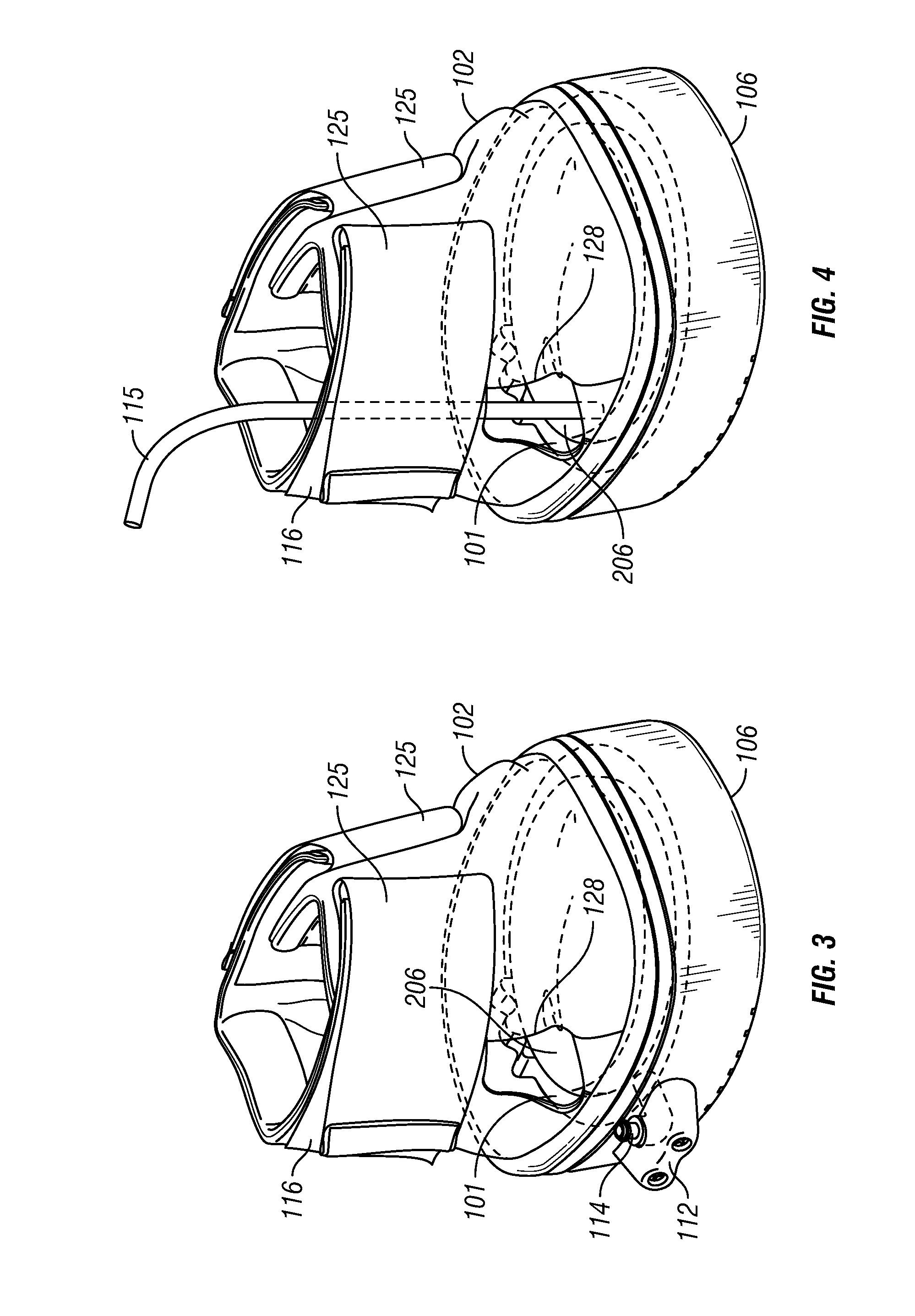

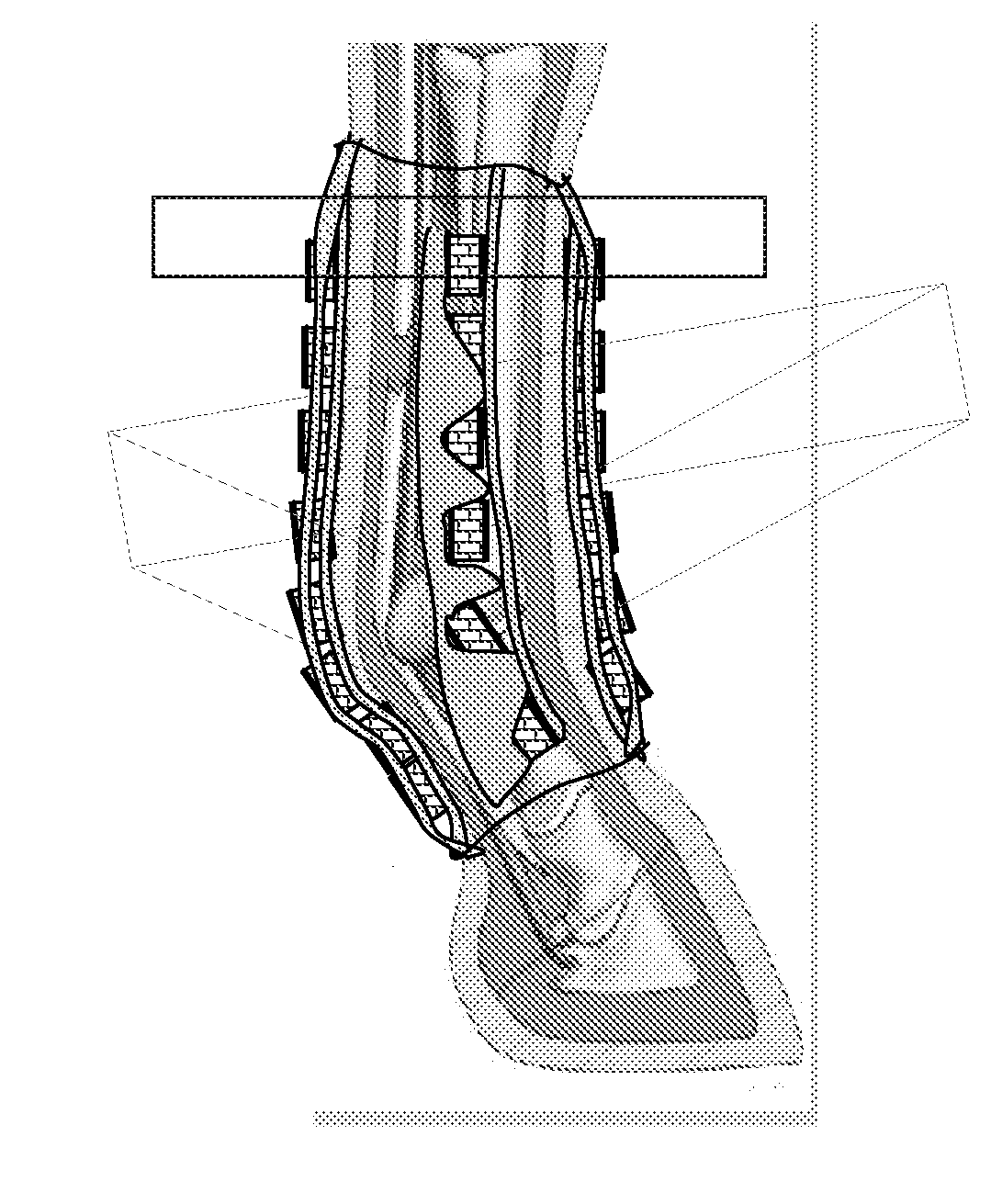

Equine Exercise Boot Assembly and Method

A boot assembly and method that simulates in a static equine animal (stalled or hauled) the natural mechanical action of walking, or other gaited exercises. The assembly has a boot, containing a pad that is fitted with a pulsing means of expanding and contracting against the underside of an equine hoof. Pressuring and relaxing the pulsing means in the bottom of the boot rhythmically pushes against the sole and frog in much the same way that the hoof is exercised when the animal is moving. The pulsing action helps stimulate blood flow through the hoof, and is beneficial to shod, injured, and transported horses. The assembly may be fitted on one or more hooves, and may be automated to provide timing and sequencing to simulate different gaits of the animal. The fluid for the pulsing means may be gas or liquid and the liquid may be a coolant for cooling the hoof sole. The boot base may be fitted with a rocker attachment.

Owner:RUETENIK MONTY L

Therapeutic equine hoof sock

InactiveUS20080156503A1Prolonged and comfortable treatmentFlexibilityBiocideProtection coversEquine SpeciesAbsorbent material

A flexible hoof sock for use with horse's comprising a sole portion and body portion both made of a flexible and durable material to enable the hoof sock to be worn in the field or in the stall. Further, comprising two flexible closure flaps attached to the upper portion of the body having VELCRO™ attachments at the distal ends of each closure flap and the opposing point of connection on the upper anterior portion of the body, or the tongue. The body, sole and closure flaps when attached to the tongue create a pocket or opening to encase an equine's hoof. Inside this opening one or both of two pads can be inserted, parallel to the sole portion of the hoof sock. The first pad is the cushion pad which is a circular pad that is made of rubberized material to provide cushioning to the horse's hoof. The second pad is a therapeutic pad which is also circular in shape and is made of a felt or similar absorbent material. Treatments and medications are releasably applied to the therapeutic pad, and then the equine's hoof is placed inside the hoof sock in contact with the therapeutic pad to allow for continued treatment of the equine's hoof aliment.

Owner:PENN EQUINE GEAR

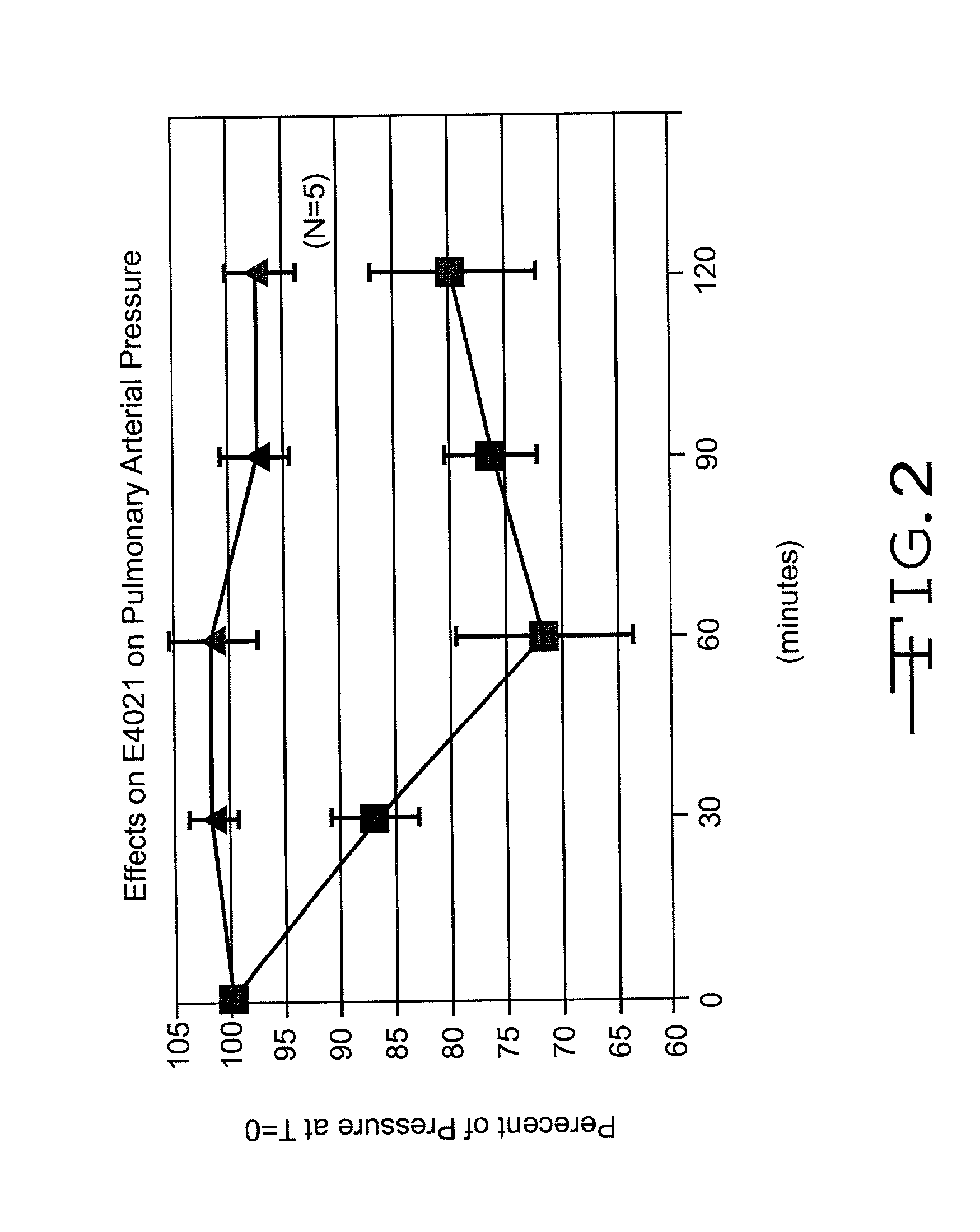

Use of aerosolized compounds in the treatment of exercise induced pulmonary hemorrhage in an equine

InactiveUS20030070674A1Prevent exercise induced pulmonary hemorrhageReduce pressureRespiratorsMedical devicesVeinTreatment modality

The administration of aerosolized nitric oxide donors or type V phosphodiesterase inhibitor in controlled doses to horses during high intensity exercise is described. Aerosolized nitric oxide donors (in conjunction with intravenous type V phosphodiesterase inhibitor) and type V phosphodiesterase inhibitor are beneficial to prevent exercise induced pulmonary hemorrhage by reducing transmural pulmonary artery pressure with a concomitant decrease in pulmonary capillary stress failure. The administration of aerosolized nitric oxide donors and type V phosphodiesterase inhibitors is viewed as a novel therapeutic modality in the alleviation of capillary stress failure and EIPH in performance horses.

Owner:PULMONOX TECH

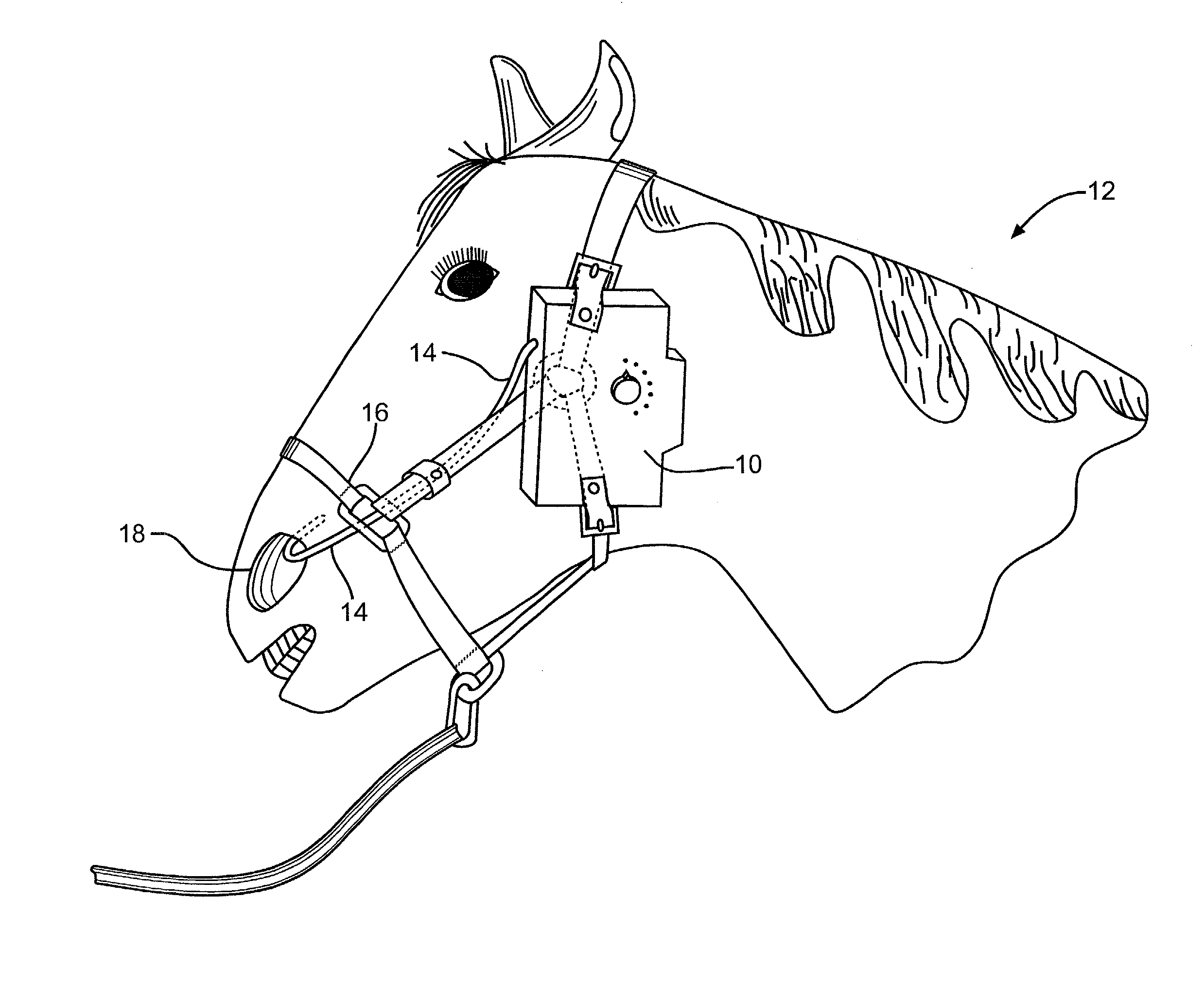

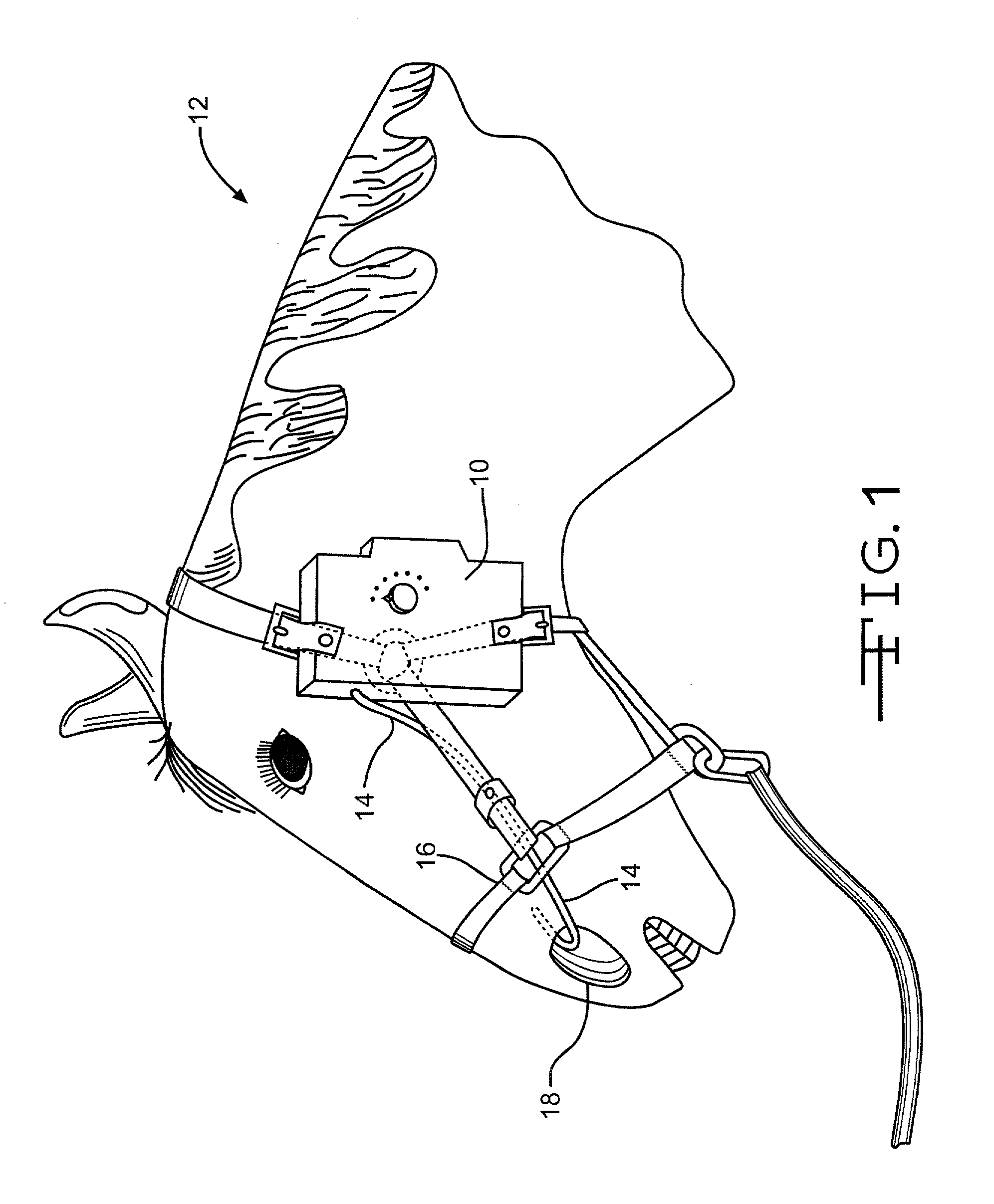

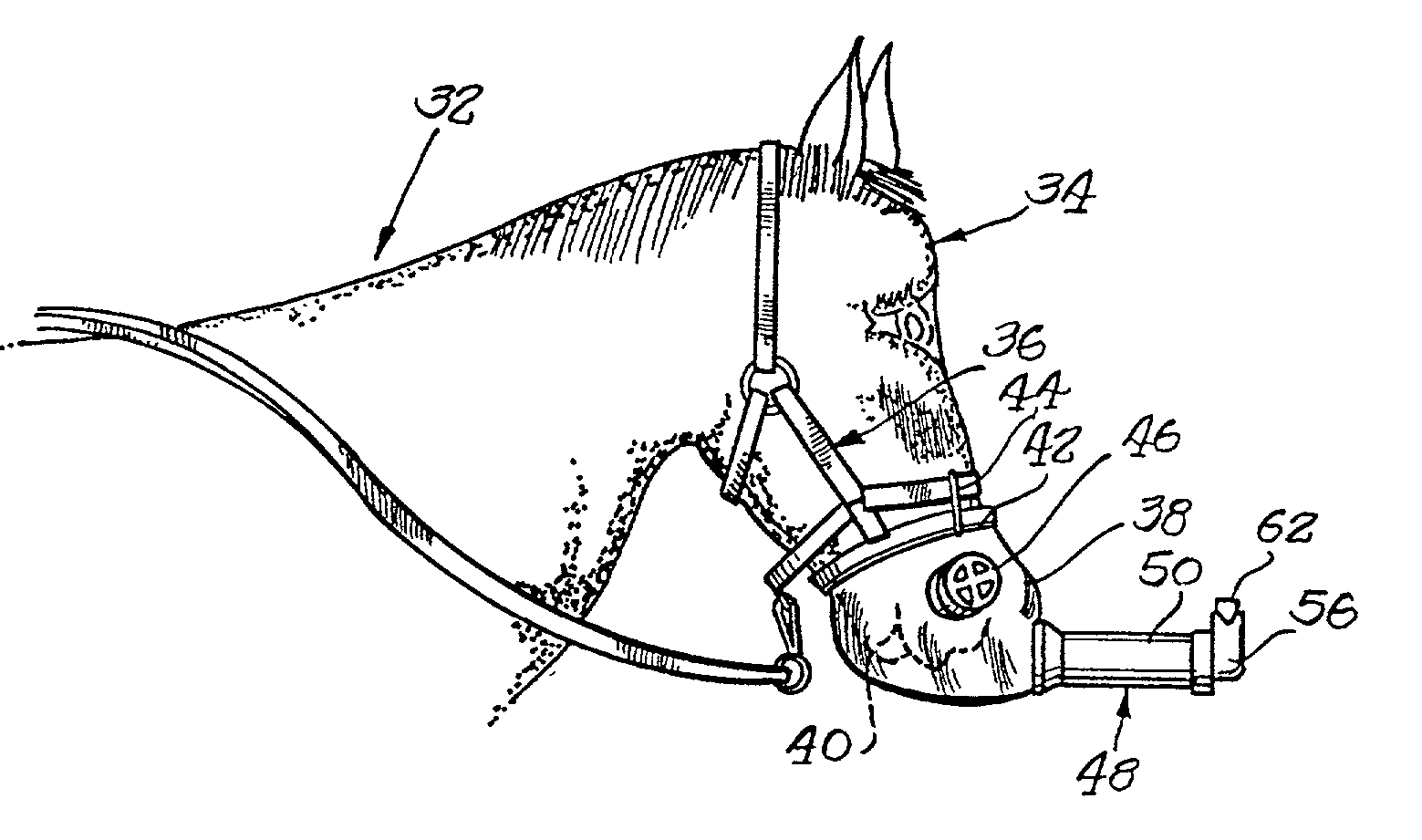

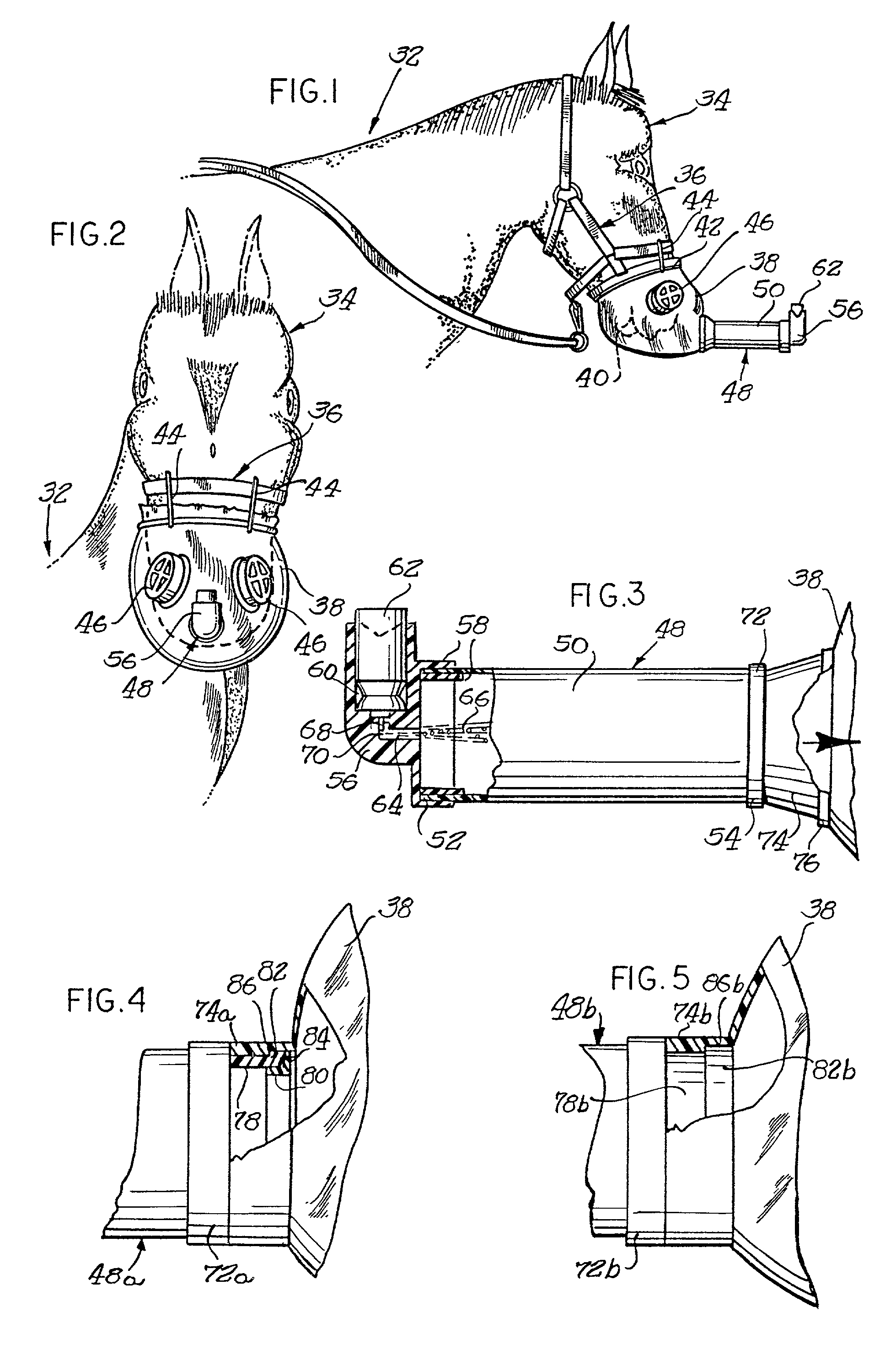

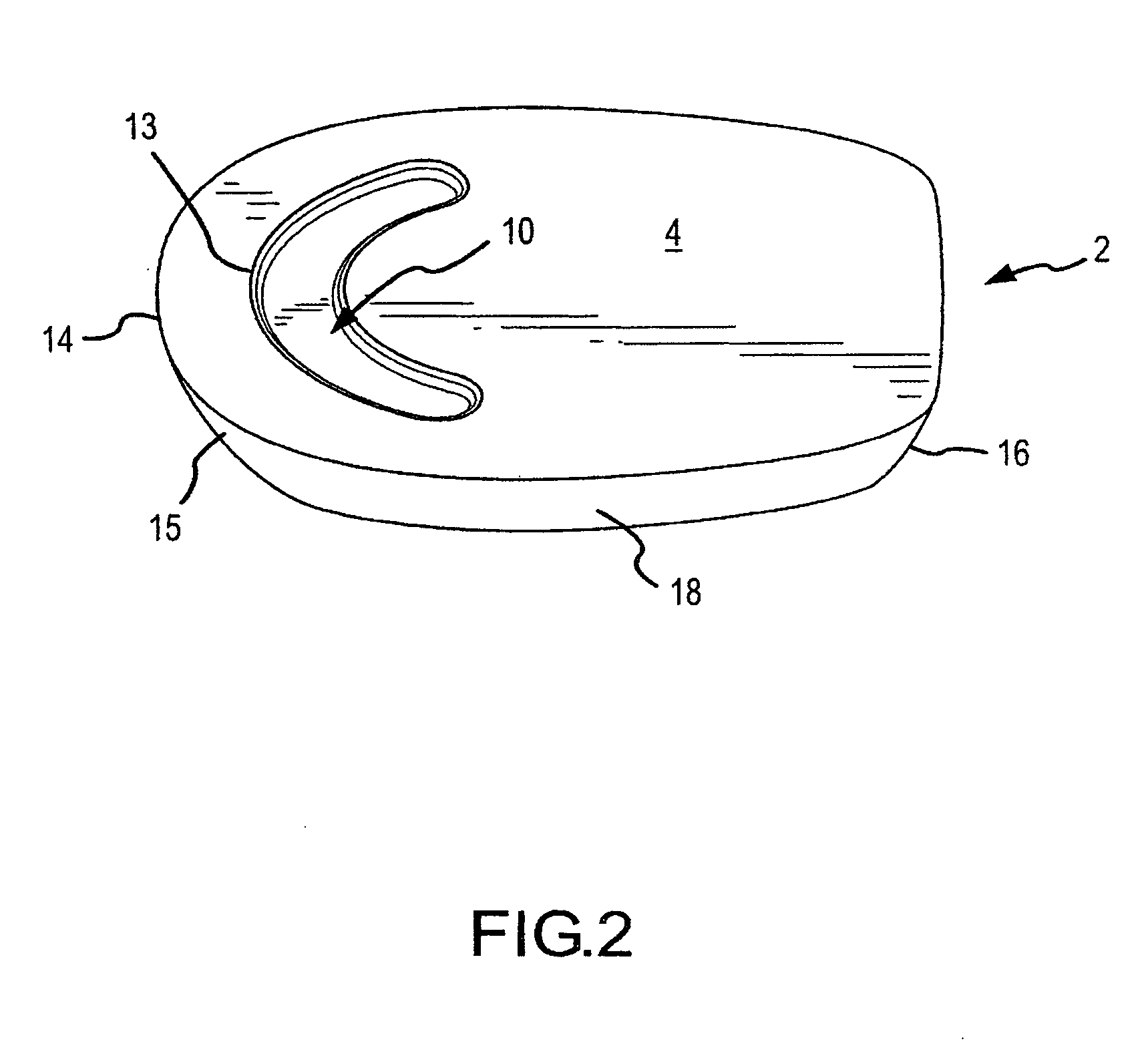

Equine mask

A mask is provided for administering medication, particularly asthmatic medication, to equine animals, particularly horses. The mask has a body that fits over the nostrils of the horse. An aerosolization chamber is secured to the body and opens into the interior thereof, and is supplied with misted medications such as from a metered dose inhaler, for inhalation by the animal. The mask and body is also provided with one or more exhalation ports, and a strap or band or the like for securing the body to the animals face overlying the nostrils.

Owner:FOLEY MARTIN P +1

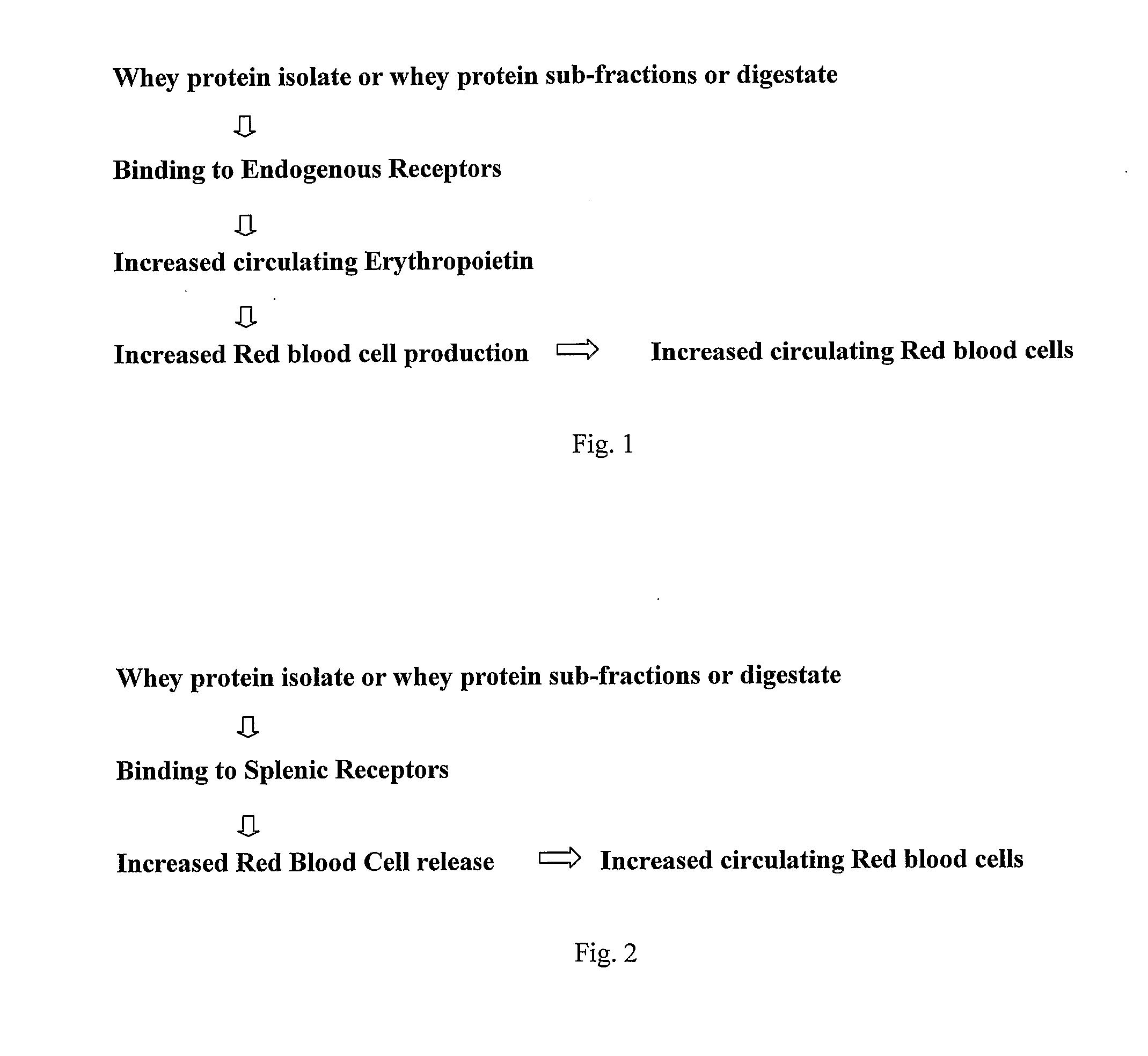

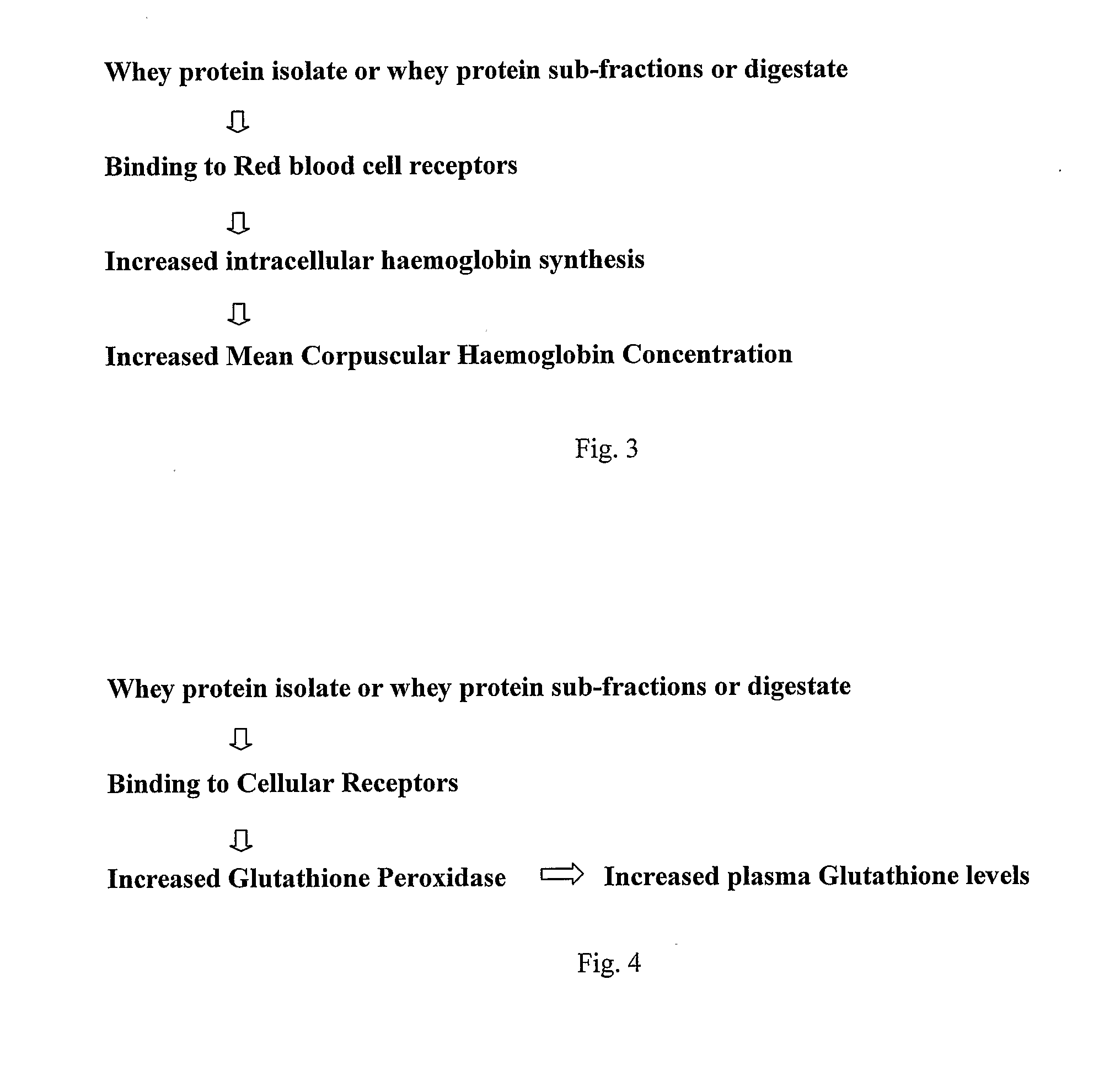

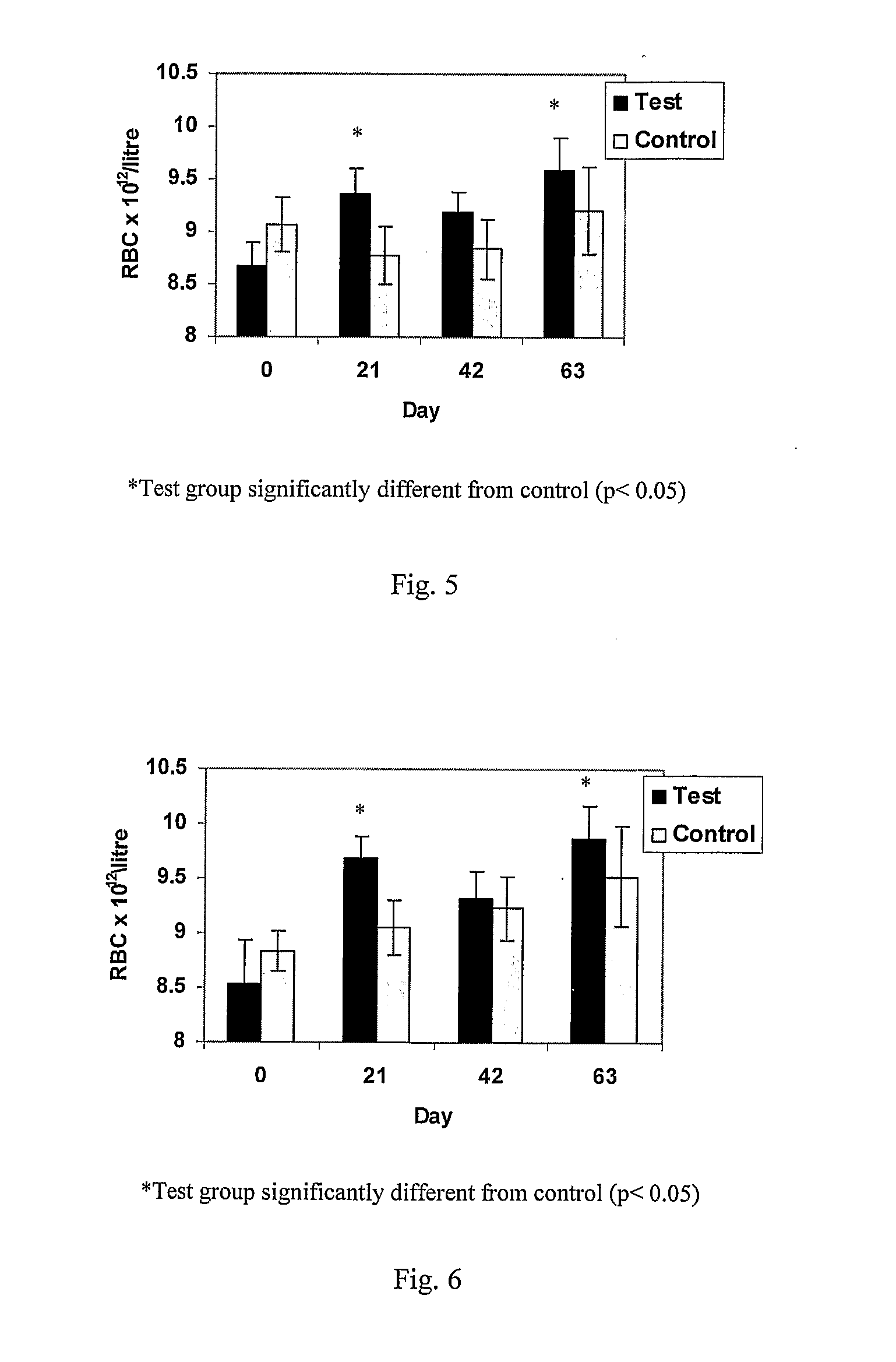

Composition for increasing stamina

InactiveUS20100196352A1Increasing mean aerobic capacityMaintain standardBiocideOrganic active ingredientsErythrocyte productionInulin

Use of whey protein isolate in the preparation of a composition for increasing mean aerobic capacity, enhanced haemoglobin production, enhanced red blood cell production and increased mean corpuscular haemoglobin concentration in competitive species, such as equine species, involved in strenuous activity. The composition may further comprise a prebiotic such as a fructo-oligosaccharide for example inulin.

Owner:BOPA IRELAND

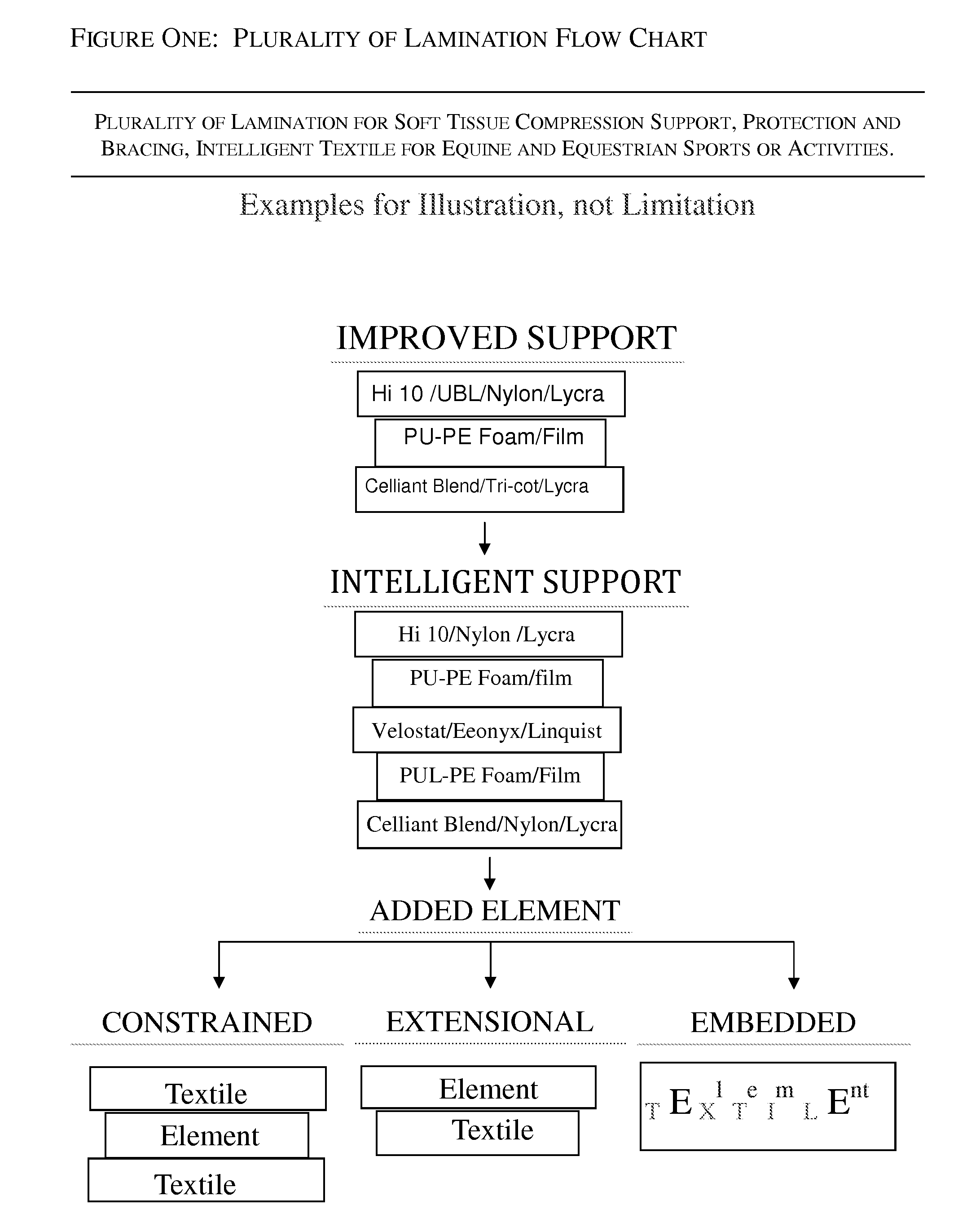

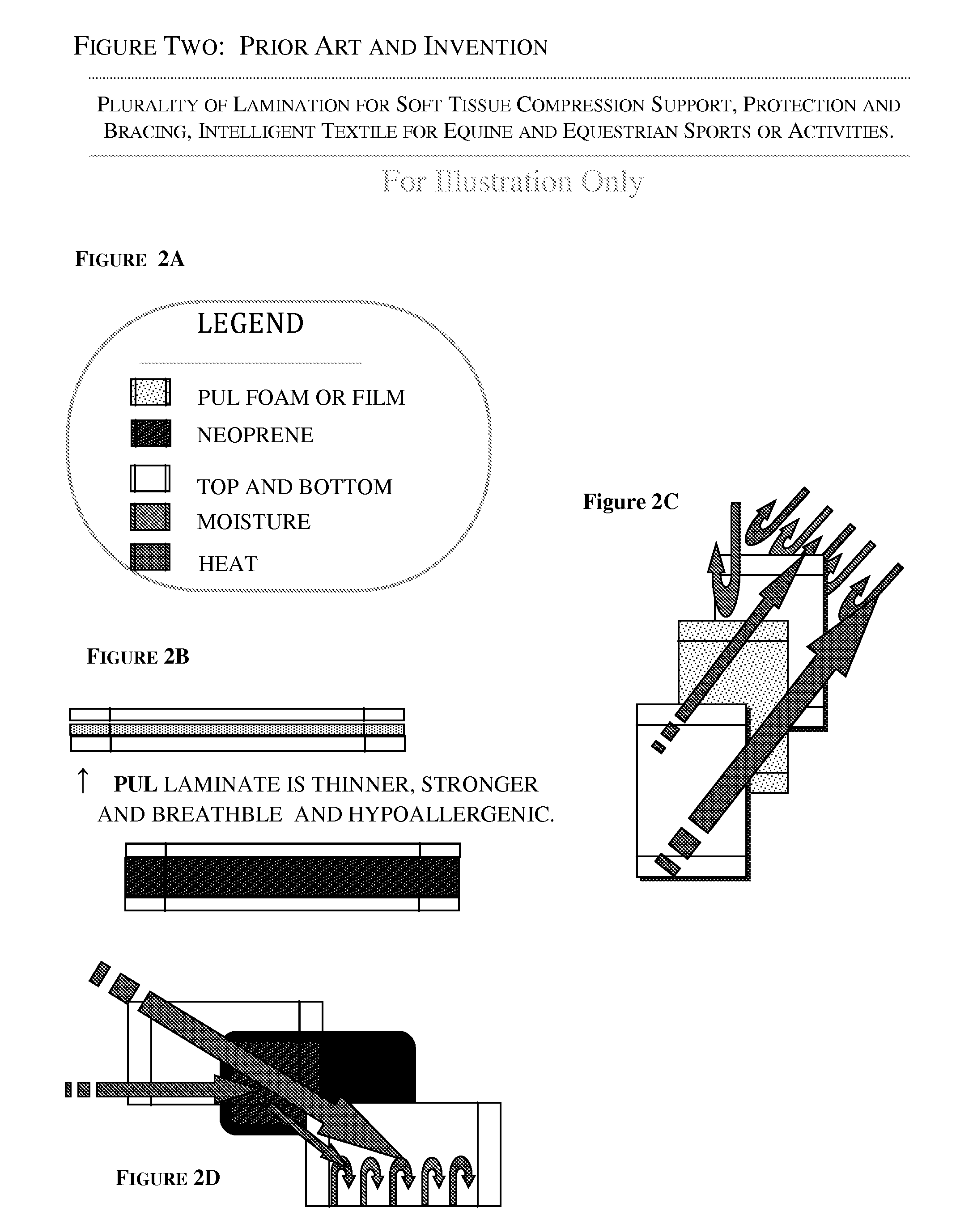

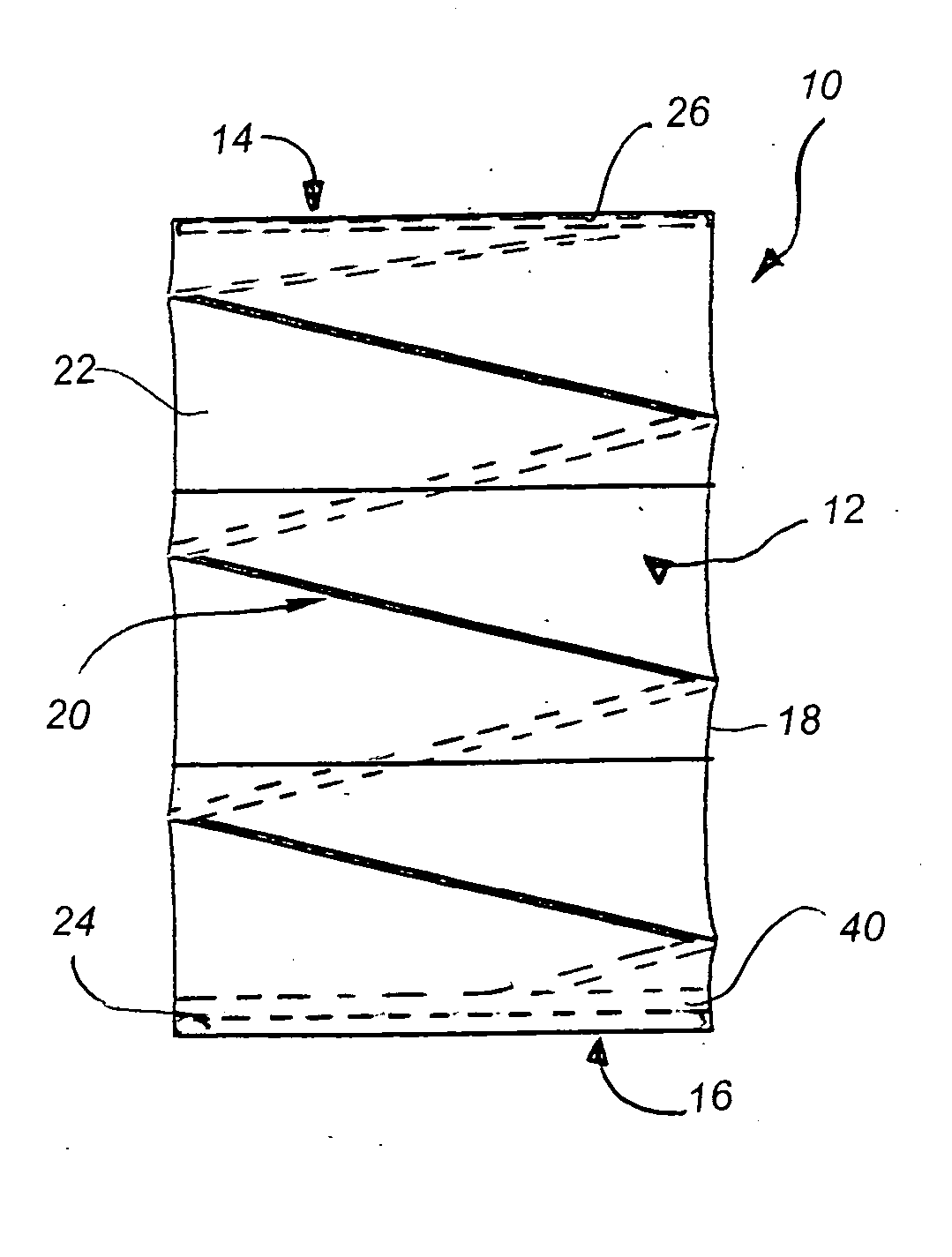

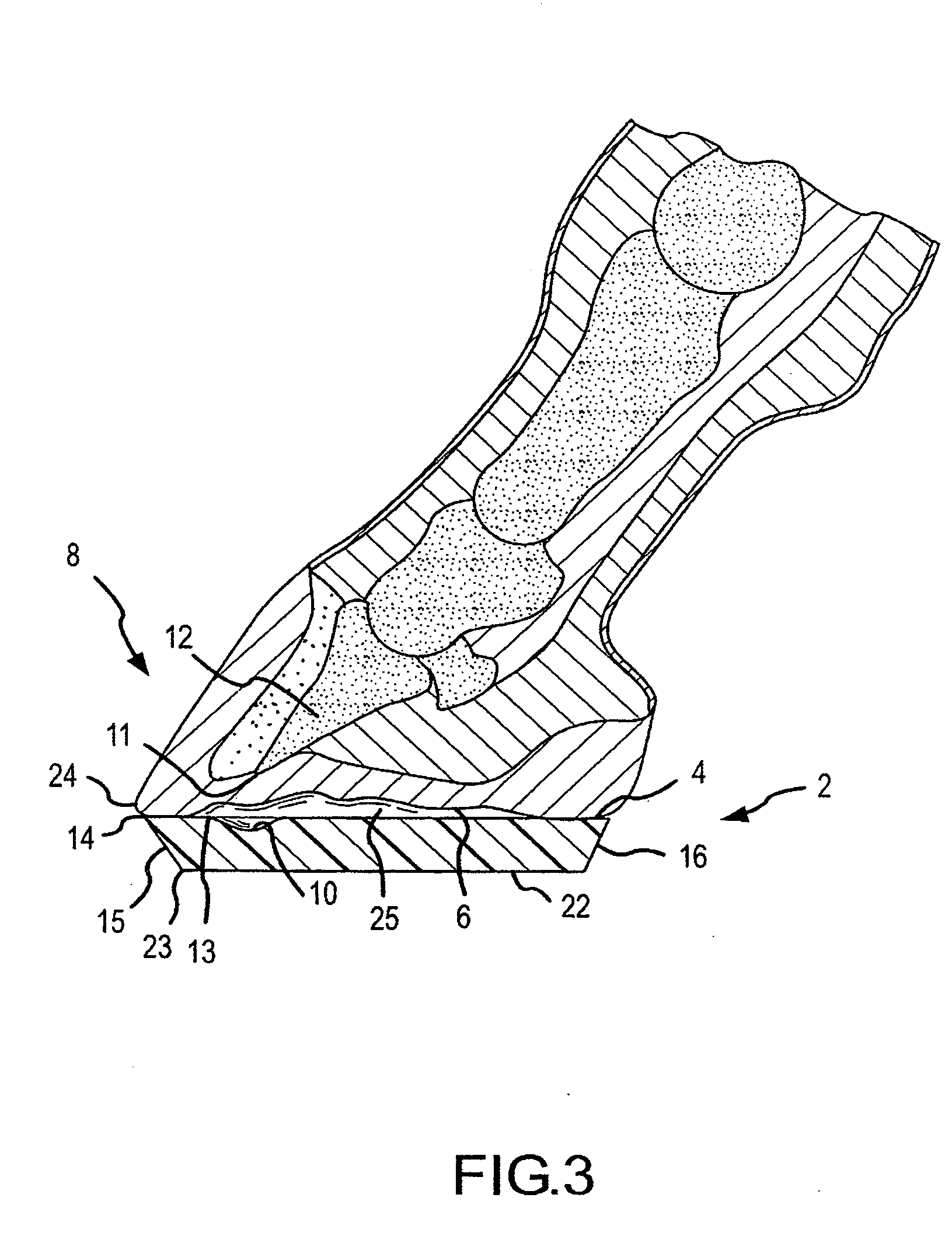

Plurality of Lamination for Soft Tissue Compression Support, Protection and Bracing; Intelligent Textile for Equine and Equestrian Sports or Activities

ActiveUS20140288383A1Reduce riskReadily conformsGarment special featuresNon-adhesive dressingsEquine SpeciesEngineering

Described here is a plurality of laminations and elements for constructing an improved Equestrian soft tissue compression support and intelligent textile for Equine, Equestrian Sports or Activities including but not limited to bracing. Scientific research and testing cites the inherent flaws to Prior Art which may make them undesirable to use. Prior Art has been shown to introduce allergies, heat damage, mechanical injuries and joint interference from material binding, bunching and migrating. Due to inherent flaws of Prior Art, they are not suitable for the plurality of laminations and elements to include fibertronics; organic electronics and other forms of e-textiles. Intelligent textiles can aid in expanding the working knowledge of equine or human sports related, repetitive use, occupational and mechanical injuries, rehabilitation treatment and prevention. The intelligent textile pertains generally to monitoring of joint and soft tissues that support a joint of a human or animal body.

Owner:VANSCOY BARNETT KELLY ANNETTE

Collapsible practice barrels for equine barrel racing

A collapsible barrel is provided for use in training for equine barrel racing. The collapsible barrel is configured and sized to approximate the dimensions of a conventional barrel used in the sport of equine barrel racing, but is constructed of sturdy, lightweight materials that enable the barrel to be transformed between a fully deployed state and a collapsed state. The collapsible barrel of the present invention is sufficiently lightweight and dimensioned, when in a collapsed state, to be easily transported, deployed for training and later stored. The flexibility of the collapsible barrel makes training ideal because it eliminates injury to the legs of the rider and the body of the horse.

Owner:SEVENTEENFLAT COM

Equine hoof pad for break over modification

A hoof pad for treatment of equine lower limb pathology comprising, a pad formed of rigid material having an upper hoof contacting surface spaced apart from a lower flat surface that is adapted for ground contact or for mounting of a supplemental pad, the anterior, posterior, medial and lateral side surfaces being sloped and curvilinearly interconnected and where the anterior and posterior side surfaces have a lesser slope than the medial and lateral side surfaces, said pad having a plan view shape substantially similar to that of the ground contacting surface of a horse's hoof, but laterally wider.

Owner:OVNICEK EUGENE D +1

Equine boot

An improved equine hoof boot, boot pad and boot and pad assembly that consists of a fabric boot and dimensioned elliptical shock absorbing pad disposed inside at the bottom of the boot, the pad optionally a combination of soft and harder components and also optionally having a triangular raised frog support at the rear of a hoof stop at the front.

Owner:RUETENIK MONTY

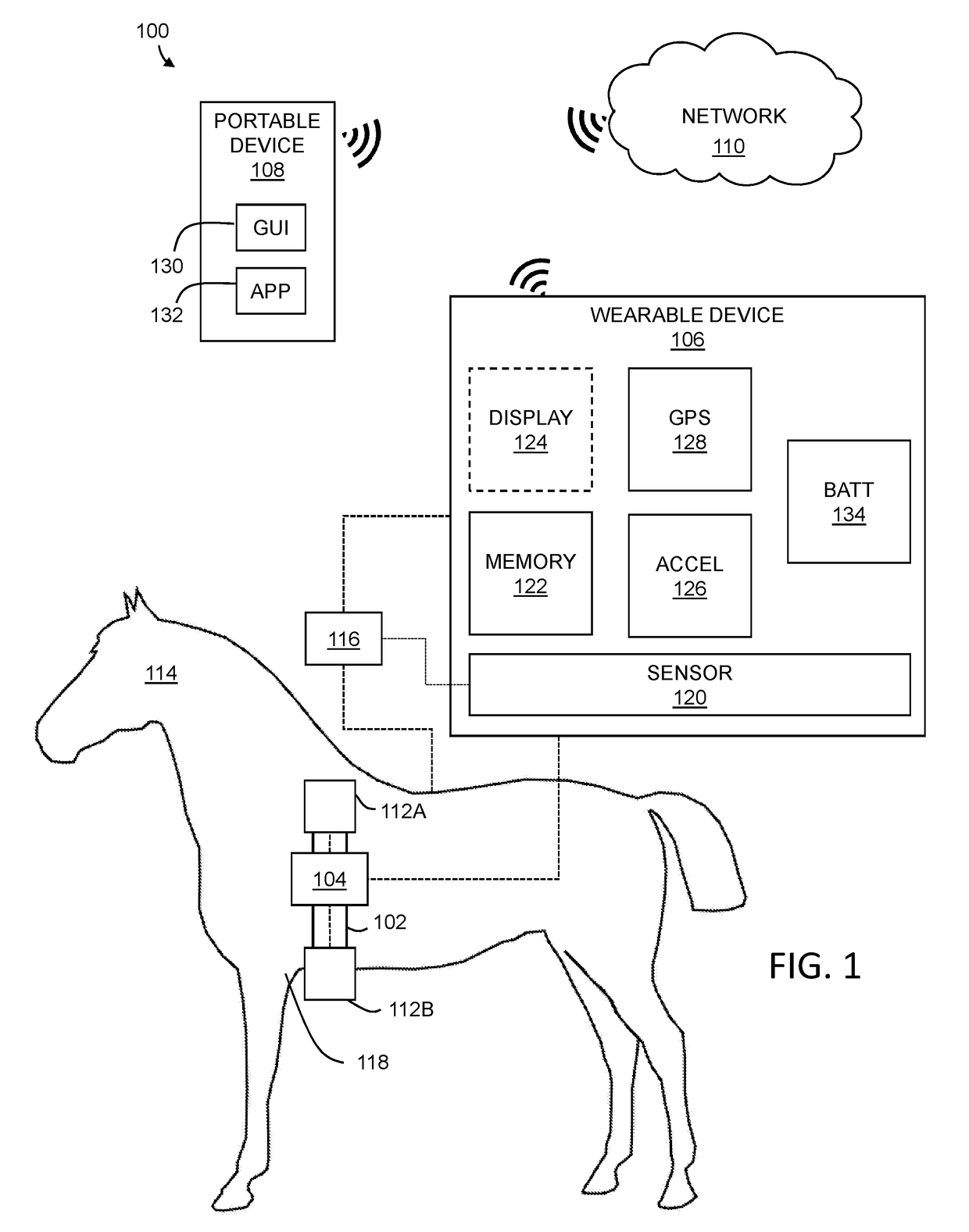

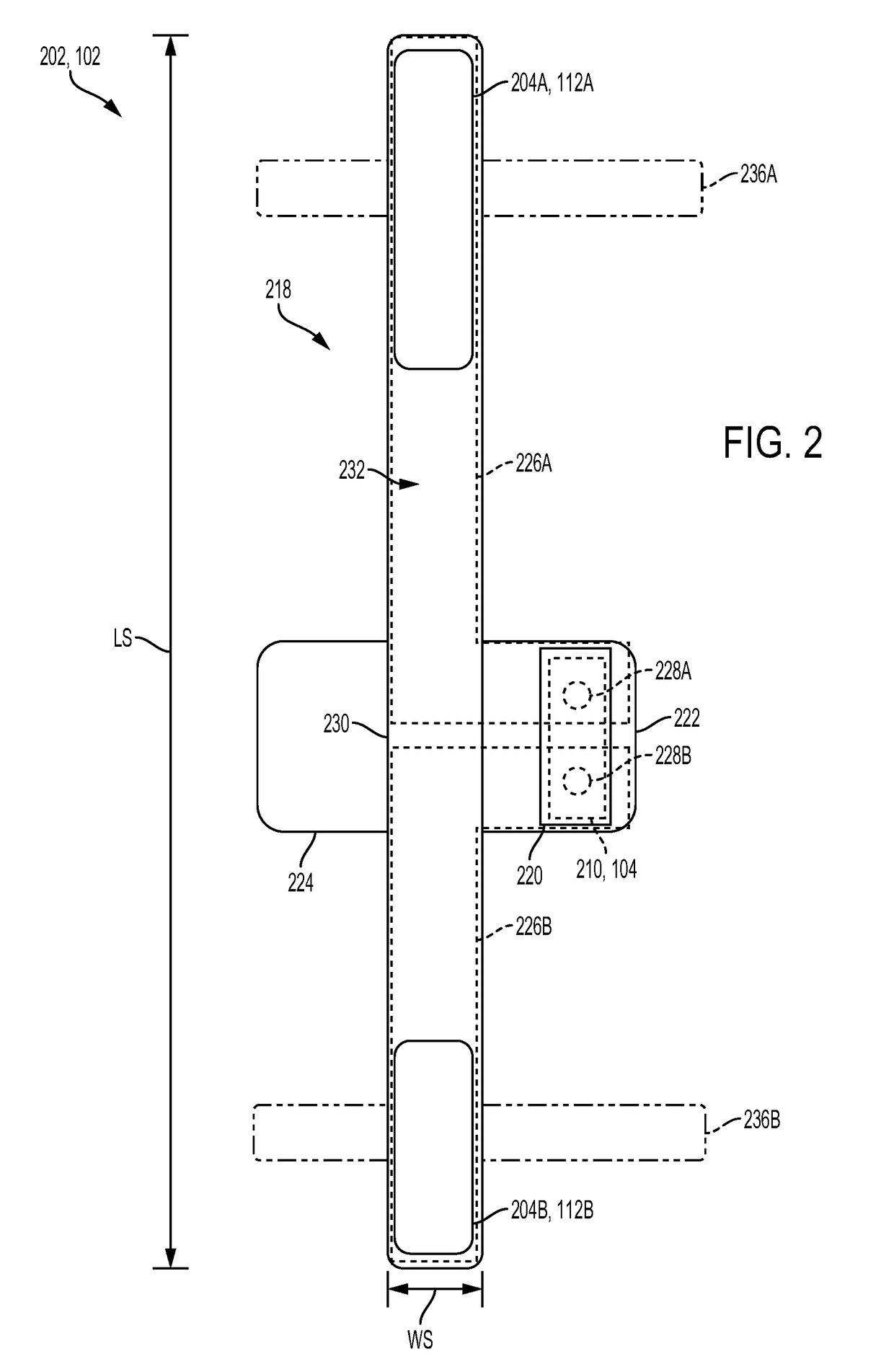

Equine performance tracking and monitoring system

An equine performance tracking and monitoring system having real-time feedback may include a horse heart rate monitoring strap configured to be secured against a portion of a horse while extending only part of the way around the horse. To measure the horse's heart rate, the disclosed systems may utilize such a discrete-length horse heart rate monitoring strap having electrodes, one of which is positioned behind the left elbow of the horse. The horse's heart rate may be transmitted to a wearable device work by a rider. The wearable device may include a sensor configured to measure the heart rate of the rider. The heart rate of the horse and the heart rate of the rider may each be presented to the rider, for example, via a display of the wearable device.

Owner:HYLONOME LLC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com