Patents

Literature

11113 results about "Oligosaccharide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oligosaccharide (/ˌɑlɪgoʊˈsækəˌɹaɪd/; from the Greek ὀλίγος olígos, "a few", and σάκχαρ sácchar, "sugar") is a saccharide polymer containing a small number (typically three to ten) of monosaccharides (simple sugars). Oligosaccharides can have many functions including cell recognition and cell binding. For example, glycolipids have an important role in the immune response.

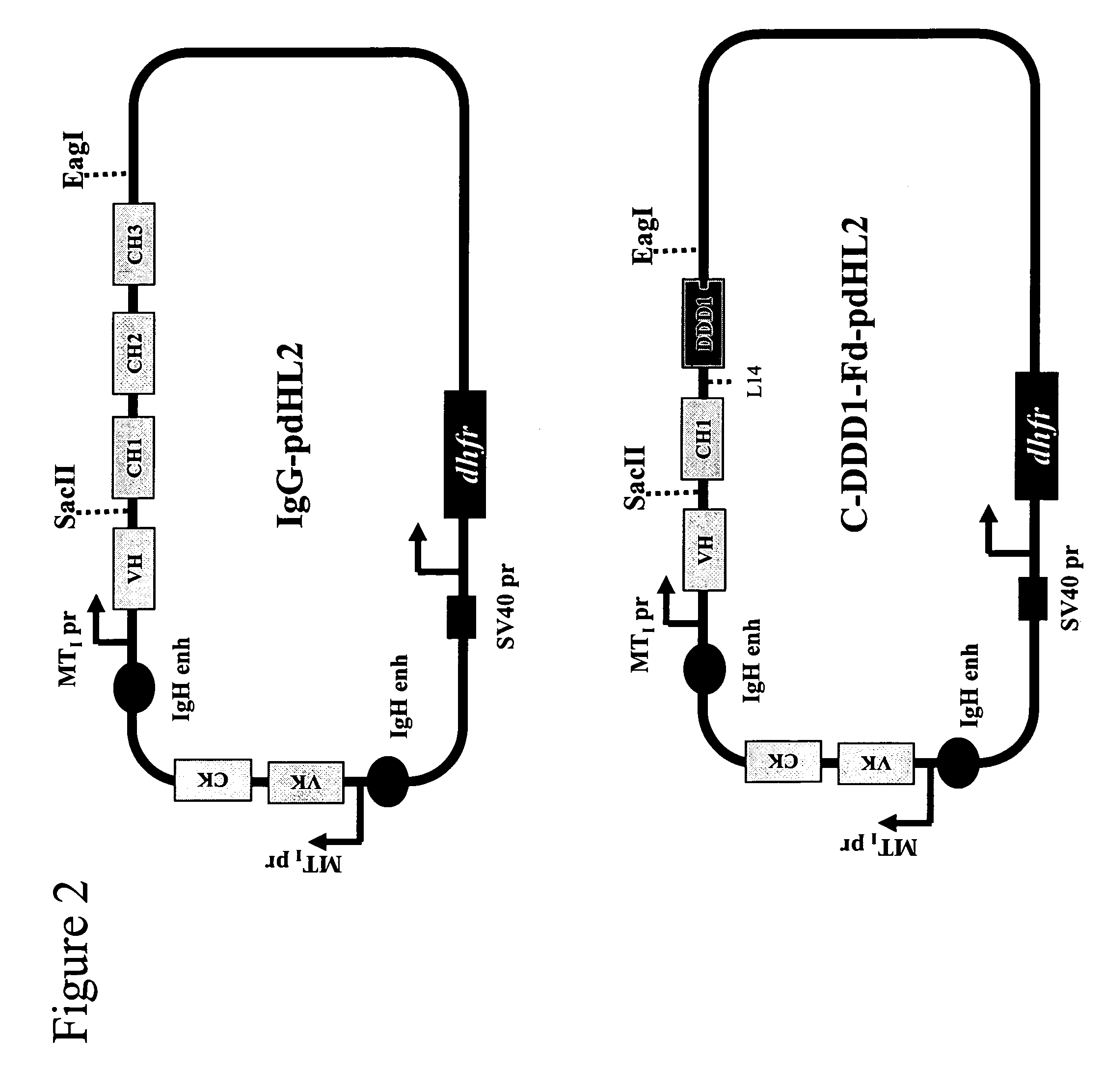

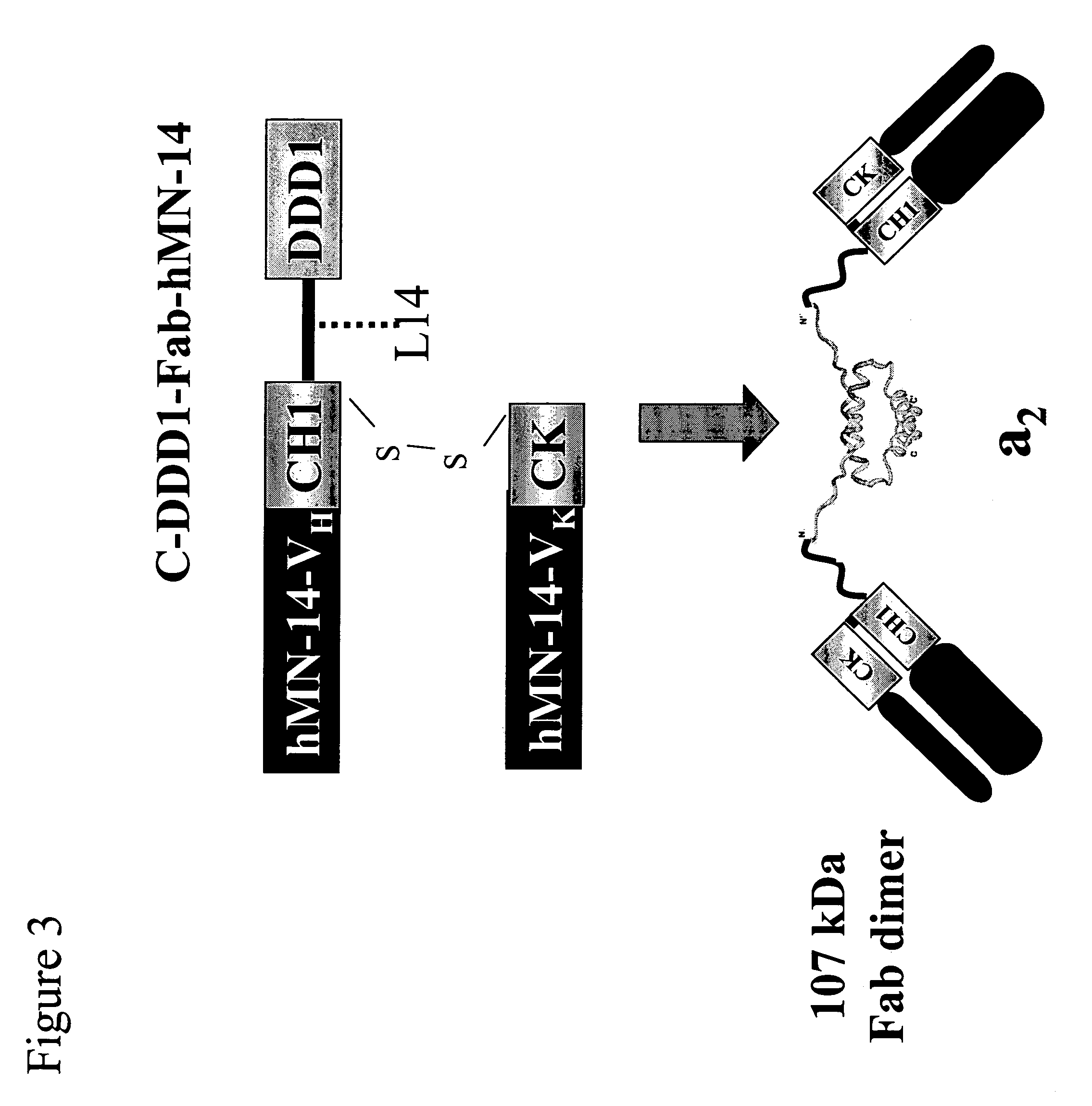

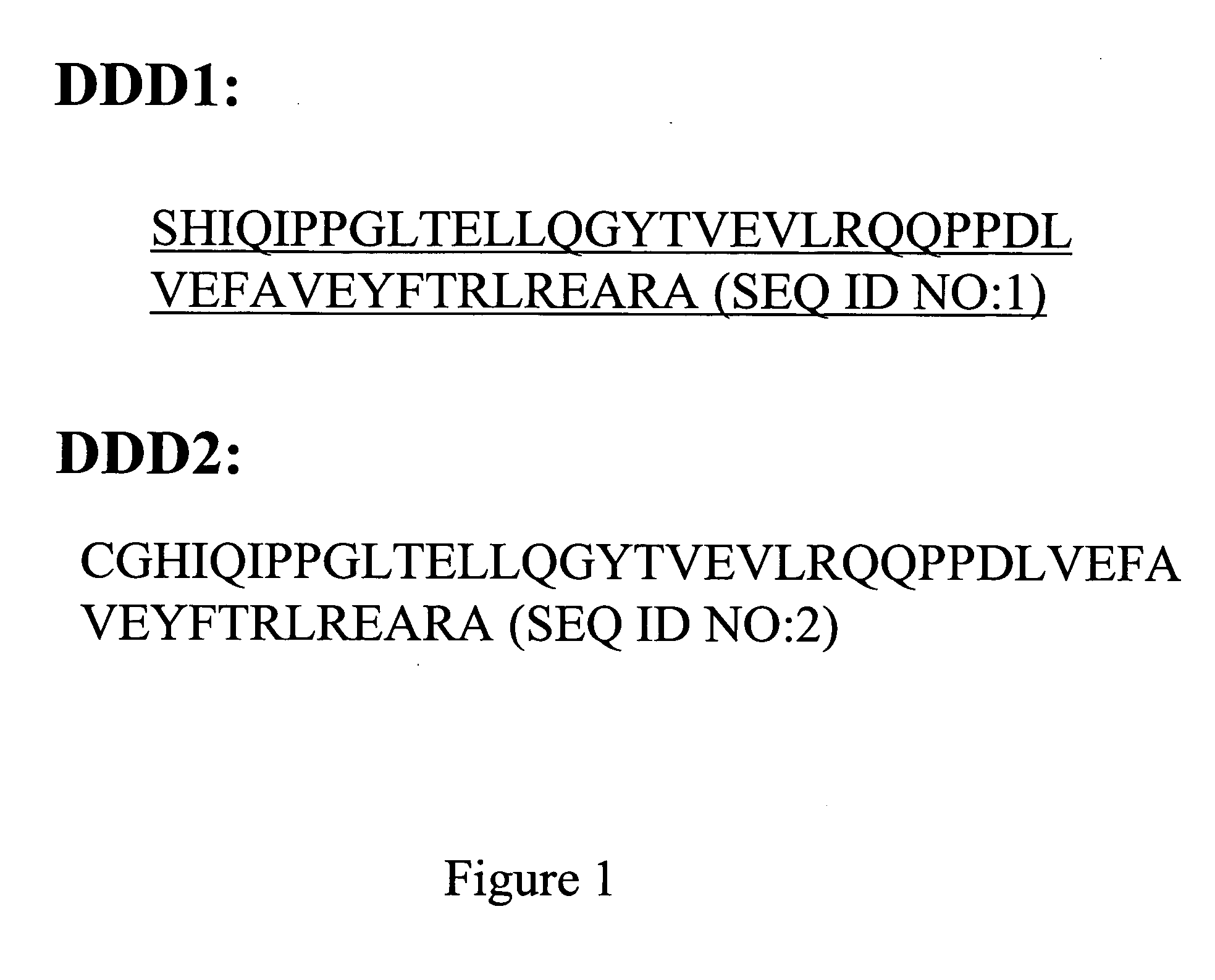

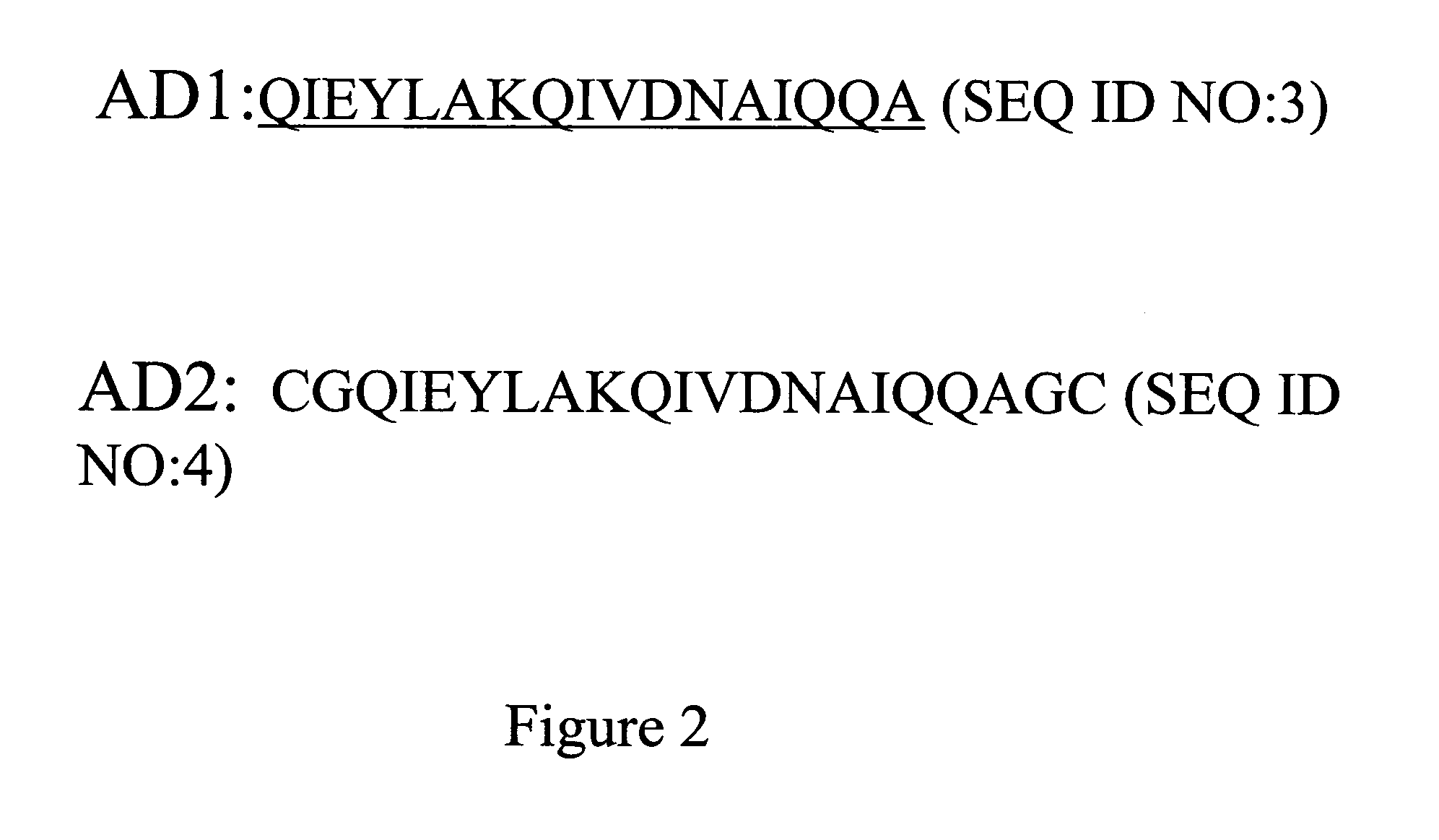

Stably tethered structures of defined compositions with multiple functions or binding specificities

Owner:IBC PHARMACEUTICALS INC

Methods for generating stably linked complexes composed of homodimers, homotetramers or dimers of dimers and uses

ActiveUS7550143B2Improve functionalityStrong specificityPeptide/protein ingredientsAntibody mimetics/scaffoldsHomotetramerAptamer

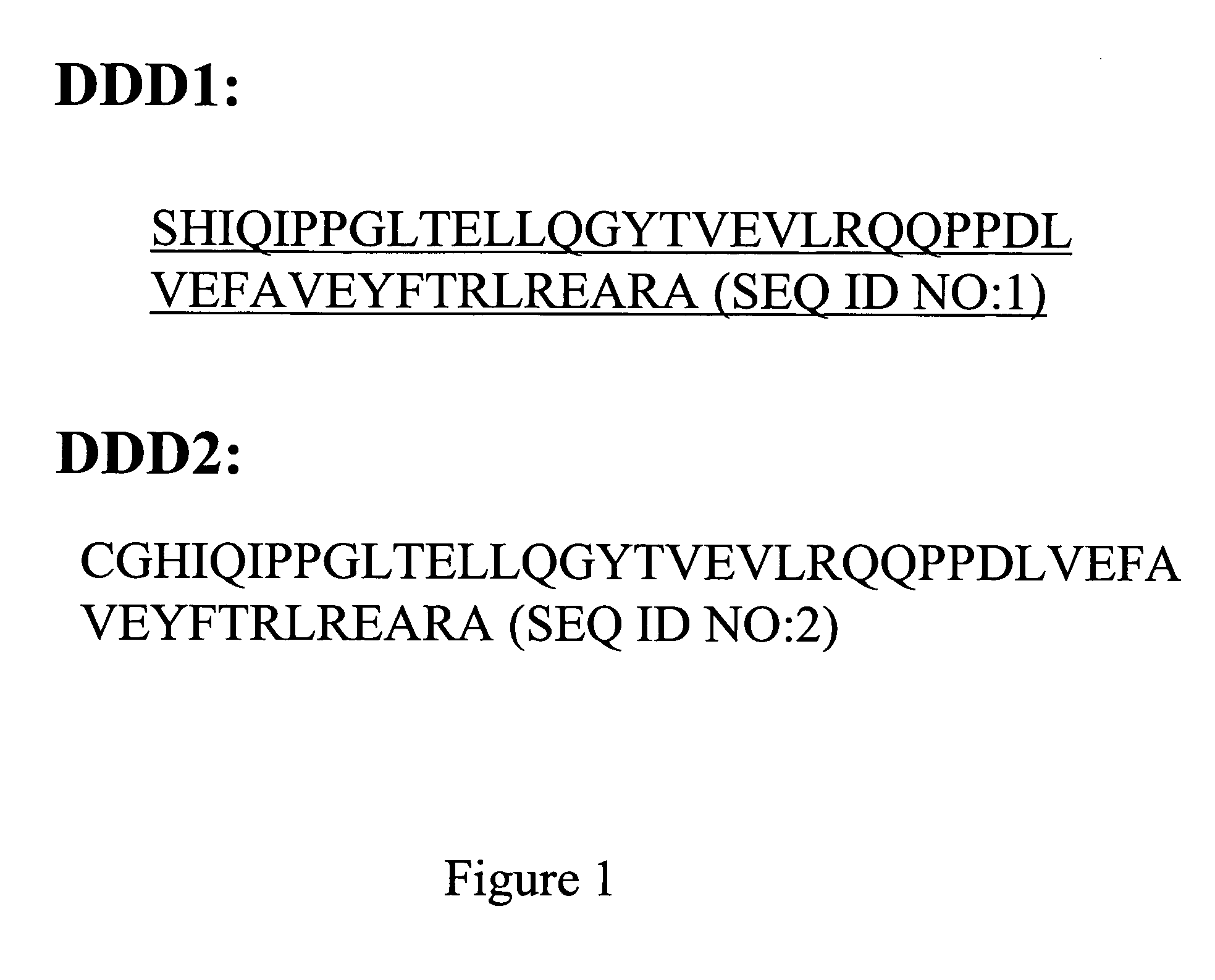

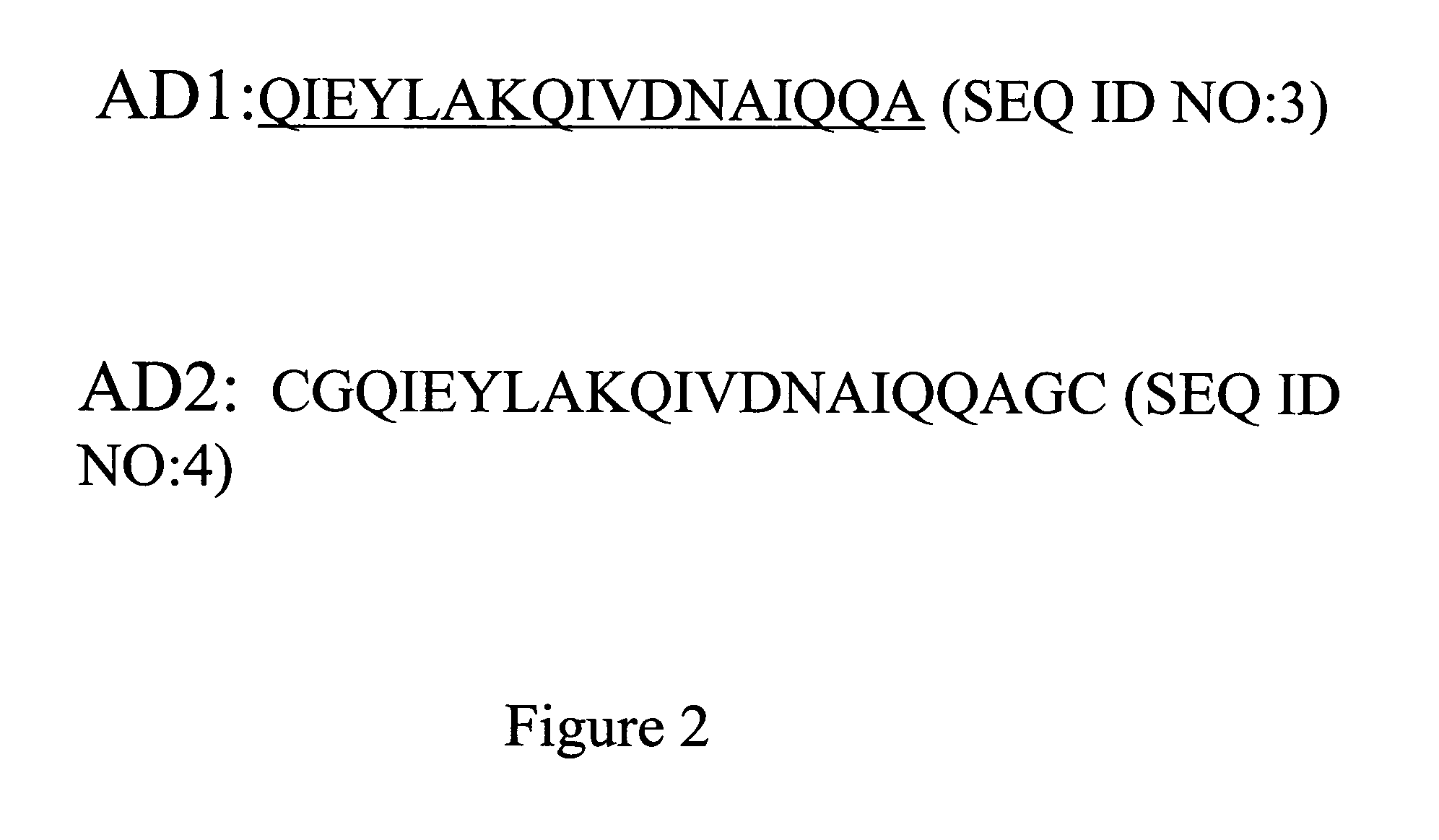

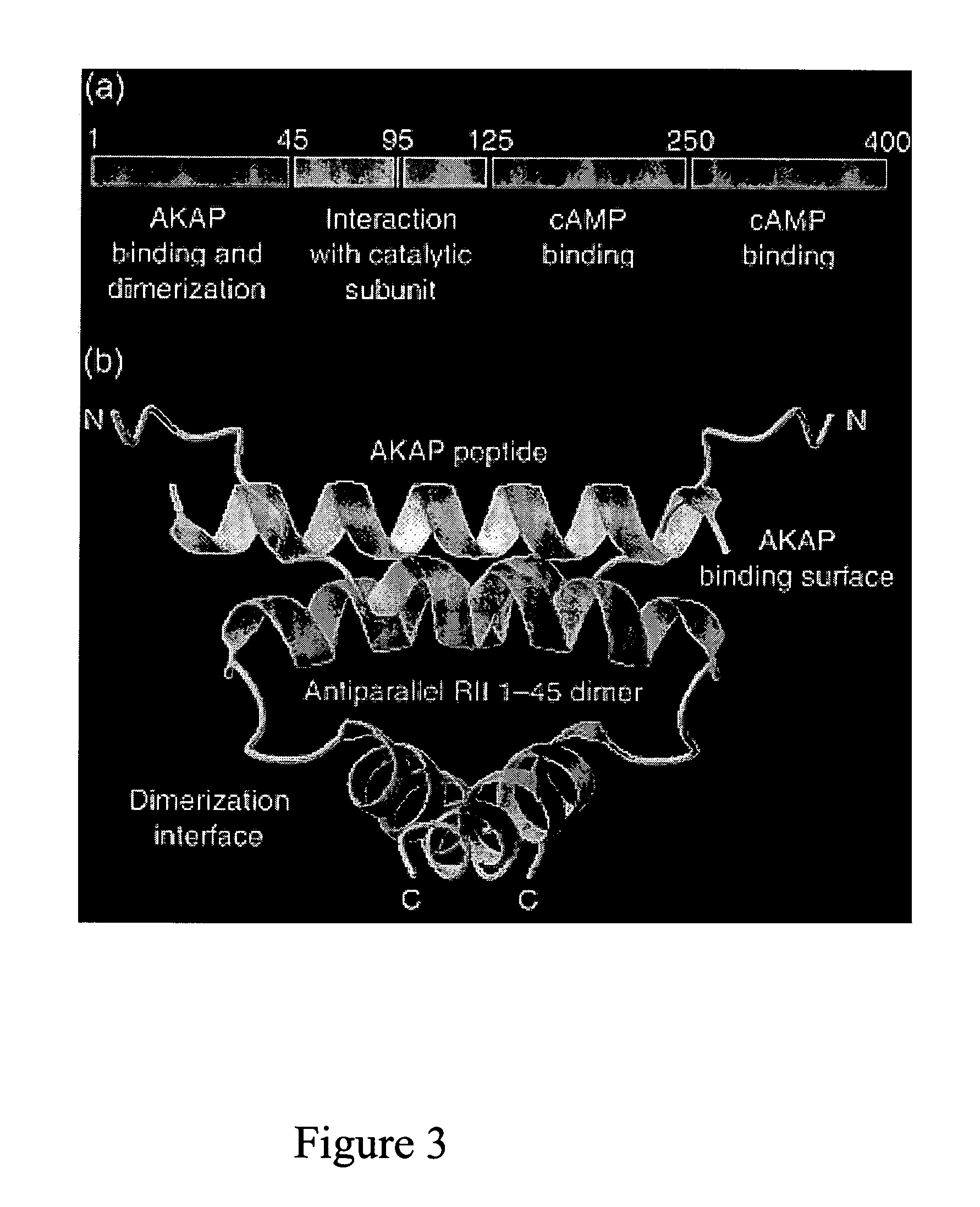

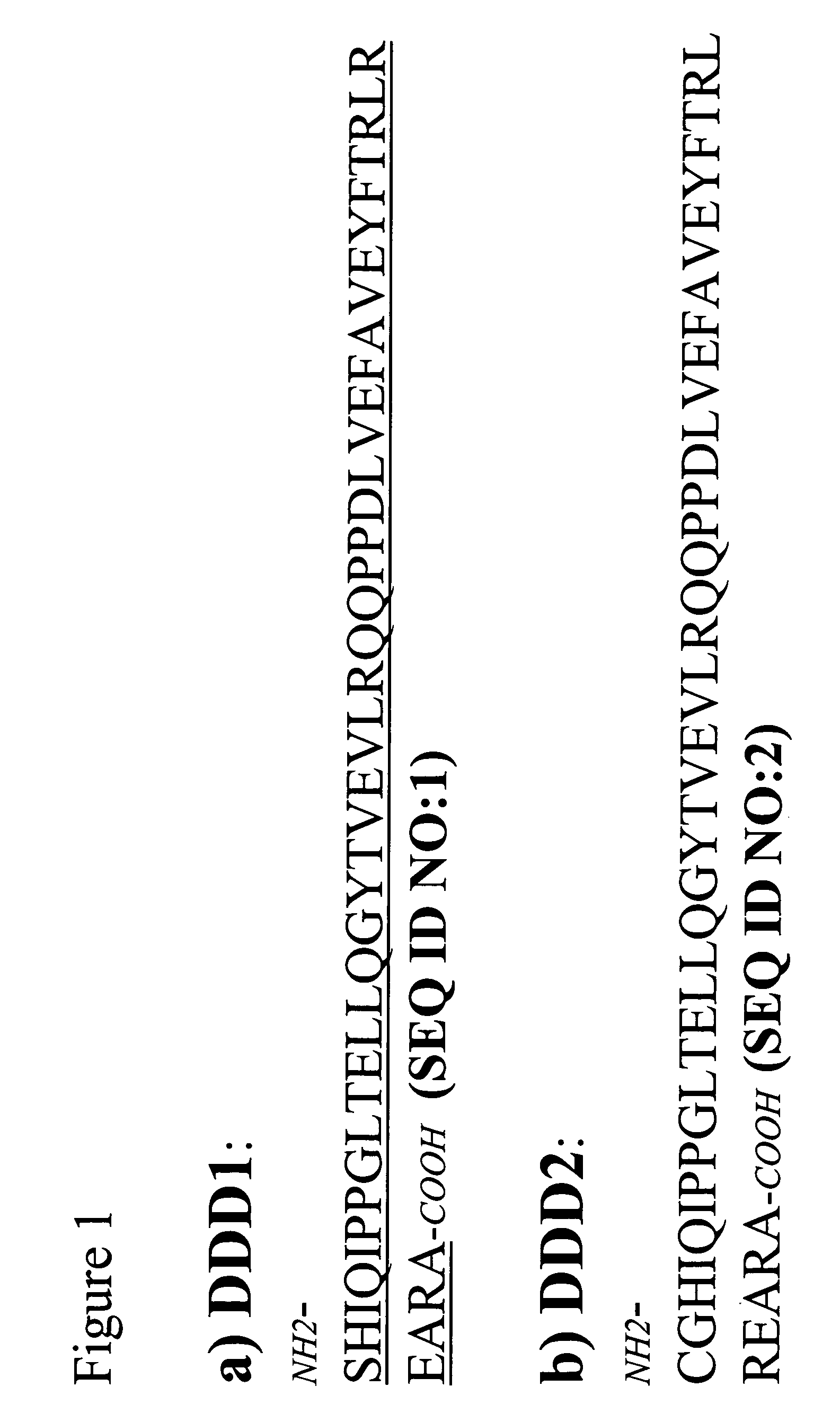

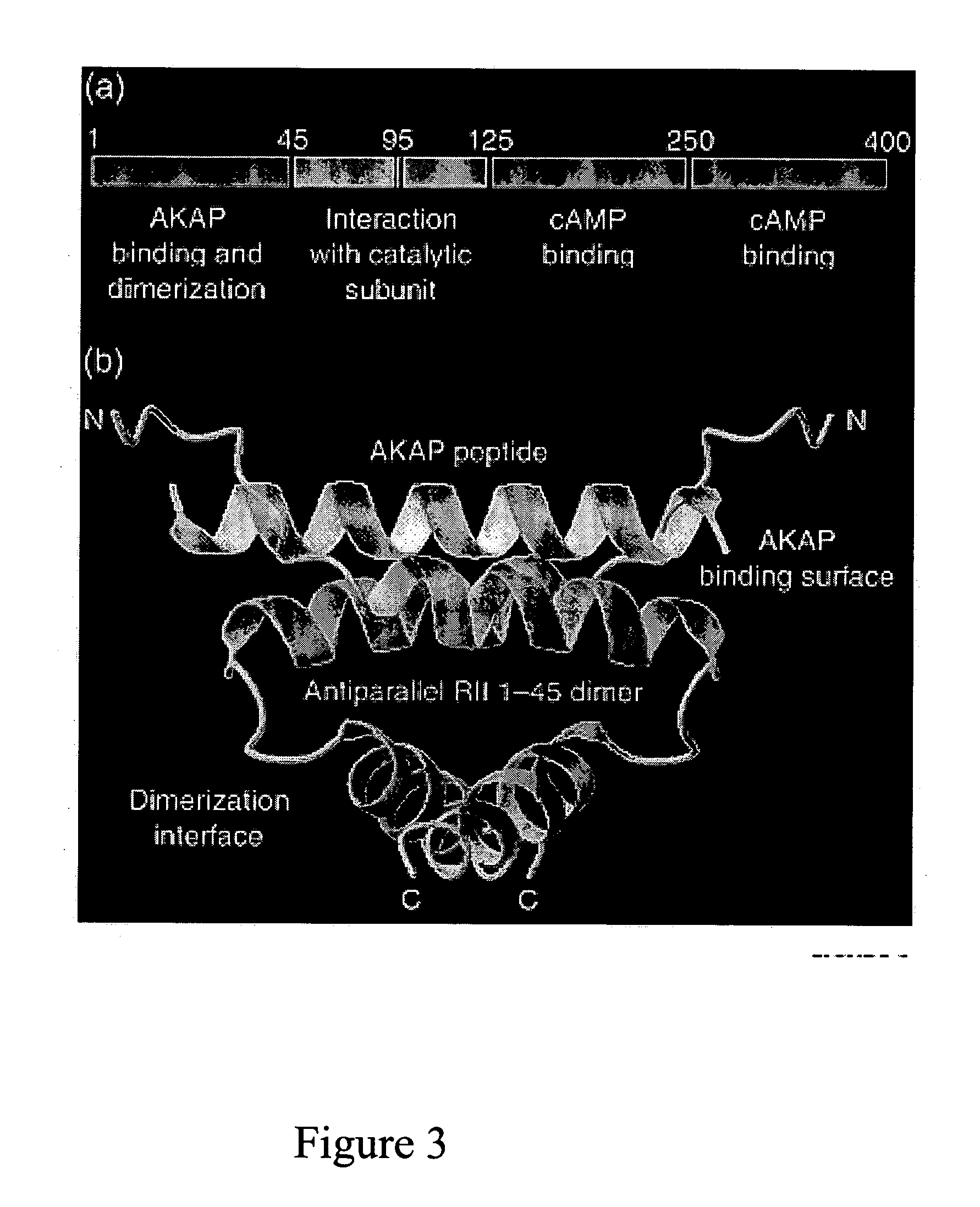

The present invention concerns methods and compositions for stably tethered structures of defined compositions, which may have multiple functionalities and / or binding specificities. Particular embodiments concern homodimers comprising monomers that contain a dimerization and docking domain attached to a precursor. The precursors may be virtually any molecule or structure, such as antibodies, antibody fragments, antibody analogs or mimetics, aptamers, binding peptides, fragments of binding proteins, known ligands for proteins or other molecules, enzymes, detectable labels or tags, therapeutic agents, toxins, pharmaceuticals, cytokines, interleukins, interferons, radioisotopes, proteins, peptides, peptide mimetics, polynucleotides, RNAi, oligosaccharides, natural or synthetic polymeric substances, nanoparticles, quantum dots, organic or inorganic compounds, etc. Other embodiments concern tetramers comprising a first and second homodimer, which may be identical or different. The disclosed methods and compositions provide a facile and general way to obtain homodimers, homotetramers and heterotetramers of virtually any functionality and / or binding specificity.

Owner:IBC PHARMACEUTICALS INC

Stably tethered structures of defined compositions with multiple functions or binding specificities

ActiveUS20060228300A1Reduce exposureReduce deliveryAntibacterial agentsSenses disorderAntibody fragmentsBinding peptide

The present invention concerns methods and compositions for stably tethered structures of defined compositions with multiple functionalities and / or binding specificities. Particular embodiments concern stably tethered structures comprising a homodimer of a first monomer, comprising a dimerization and docking domain attached to a first precursor, and a second monomer comprising an anchoring domain attached to a second precursor. The first and second precursors may be virtually any molecule or structure, such as antibodies, antibody fragments, antibody analogs or mimetics, aptamers, binding peptides, fragments of binding proteins, known ligands for proteins or other molecules, enzymes, detectable labels or tags, therapeutic agents, toxins, pharmaceuticals, cytokines, interleukins, interferons, radioisotopes, proteins, peptides, peptide mimetics, polynucleotides, RNAi, oligosaccharides, natural or synthetic polymeric substances, nanoparticles, quantum dots, organic or inorganic compounds, etc. The disclosed methods and compositions provide a simple, easy to purify way to obtain any binary compound attached to any monomeric compound, or any trinary compound.

Owner:IBC PHARMACEUTICALS INC

Combinatorial DNA library for producing modified N-glycans in lower eukaryotes

InactiveUS7449308B2The overall structure is closedHigh yieldSugar derivativesMicroorganismsHeterologousTherapeutic protein

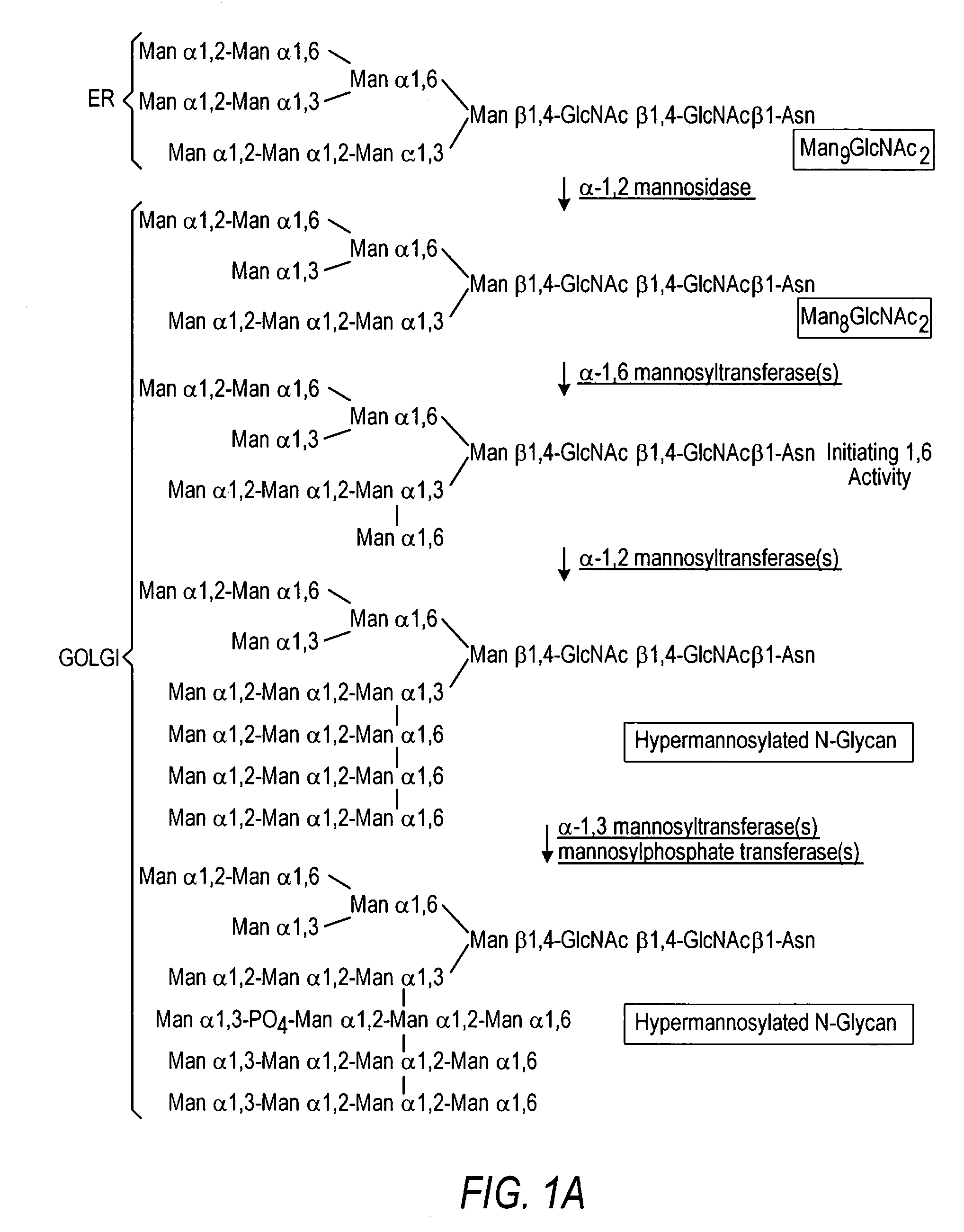

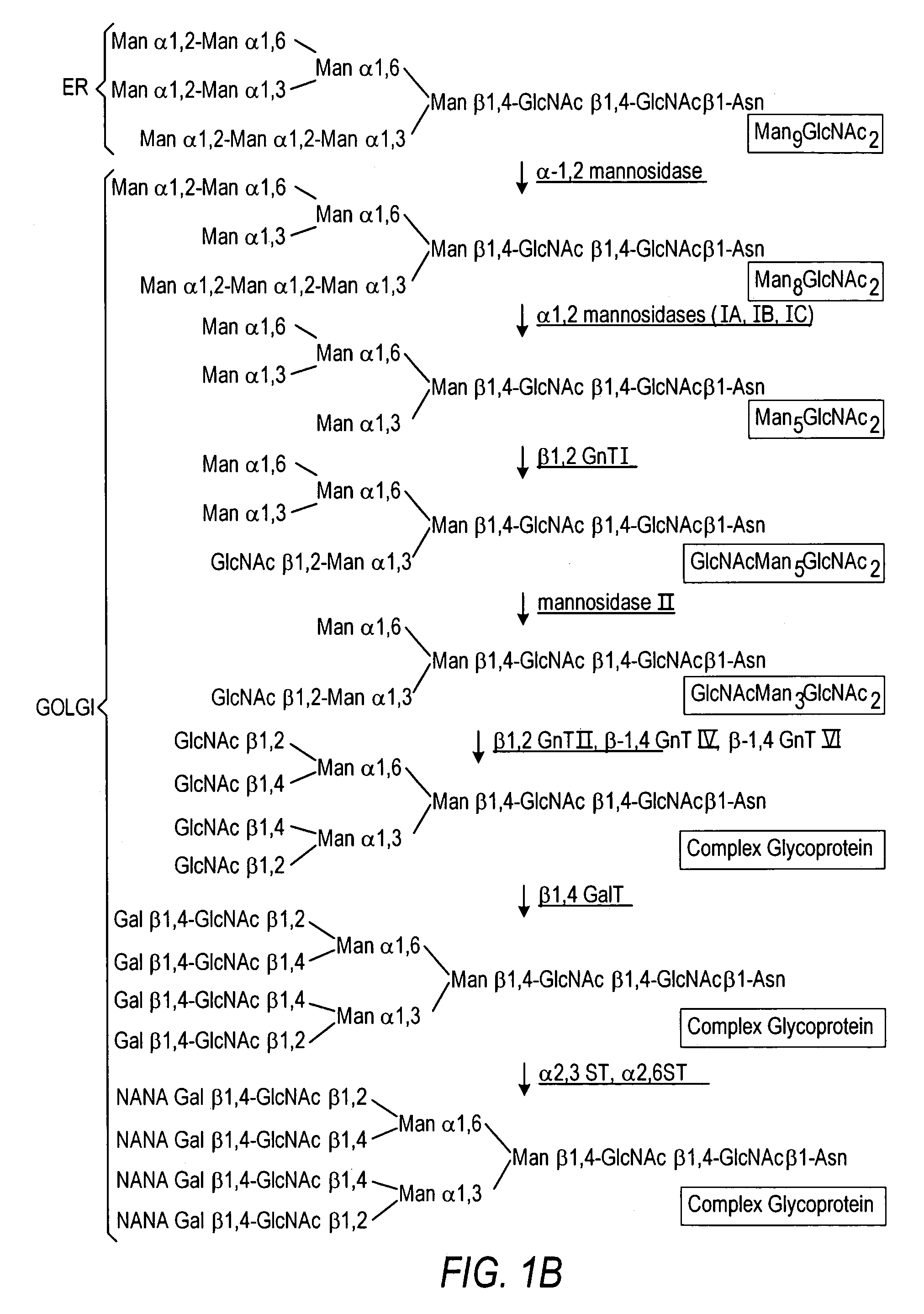

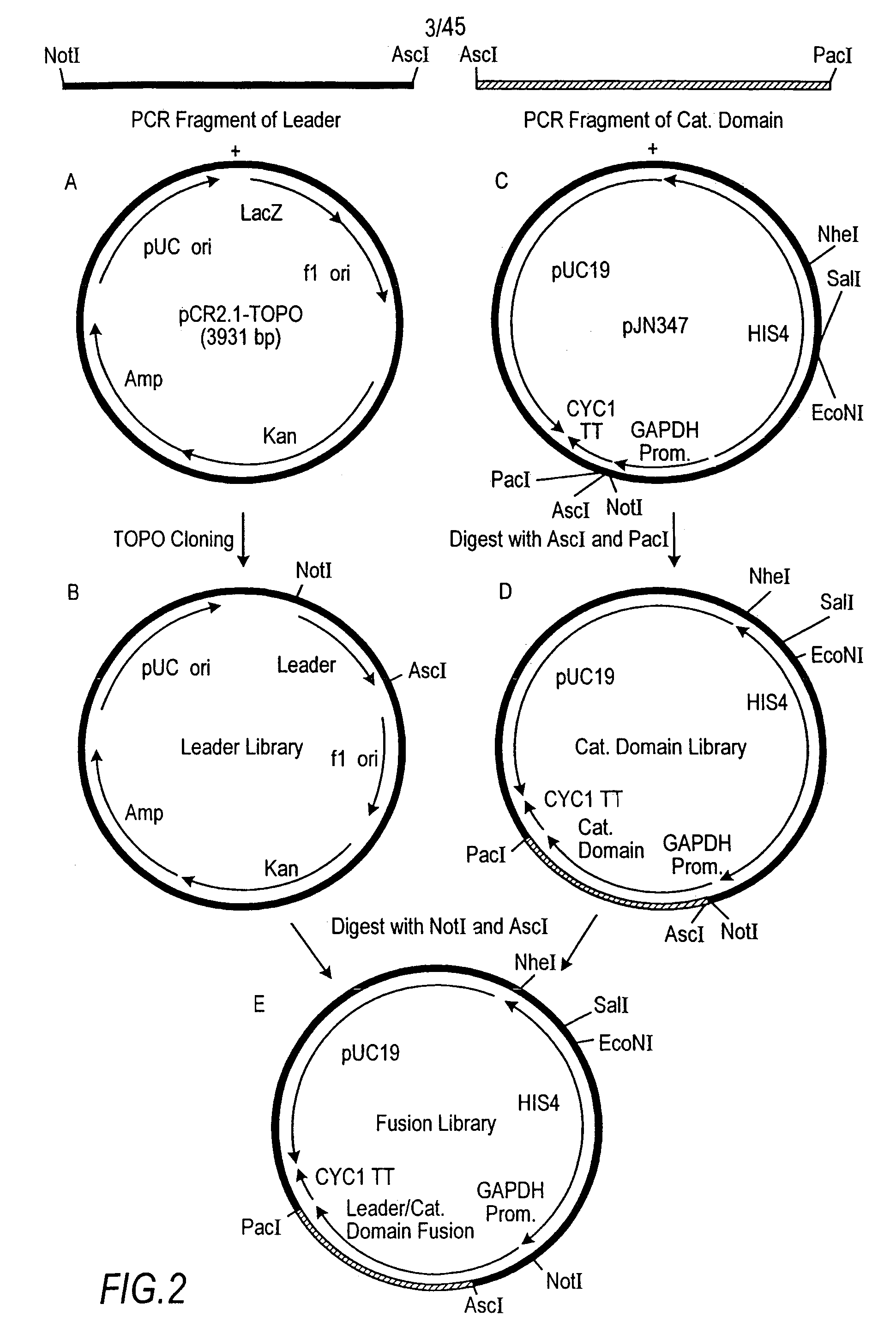

The present invention relates to eukaryotic host cells having modified oligosaccharides which may be modified further by heterologous expression of a set of glycosyltransferases, sugar transporters and mannosidases to become host-strains for the production of mammalian, e.g., human therapeutic glycoproteins. The invention provides nucleic acid molecules and combinatorial libraries which can be used to successfully target and express mammalian enzymatic activities such as those involved in glycosylation to intracellular compartments in a eukaryotic host cell. The process provides an engineered host cell which can be used to express and target any desirable gene(s) involved in glycosylation. Host cells with modified oligosaccharides are created or selected. N-glycans made in the engineered host cells have a Man5GlcNAc2 core structure which may then be modified further by heterologous expression of one or more enzymes, e.g., glycosyltransferases, sugar transporters and mannosidases, to yield human-like glycoproteins. For the production of therapeutic proteins, this method may be adapted to engineer cell lines in which any desired glycosylation structure may be obtained.

Owner:GLYCOFI

G-CSF conjugates

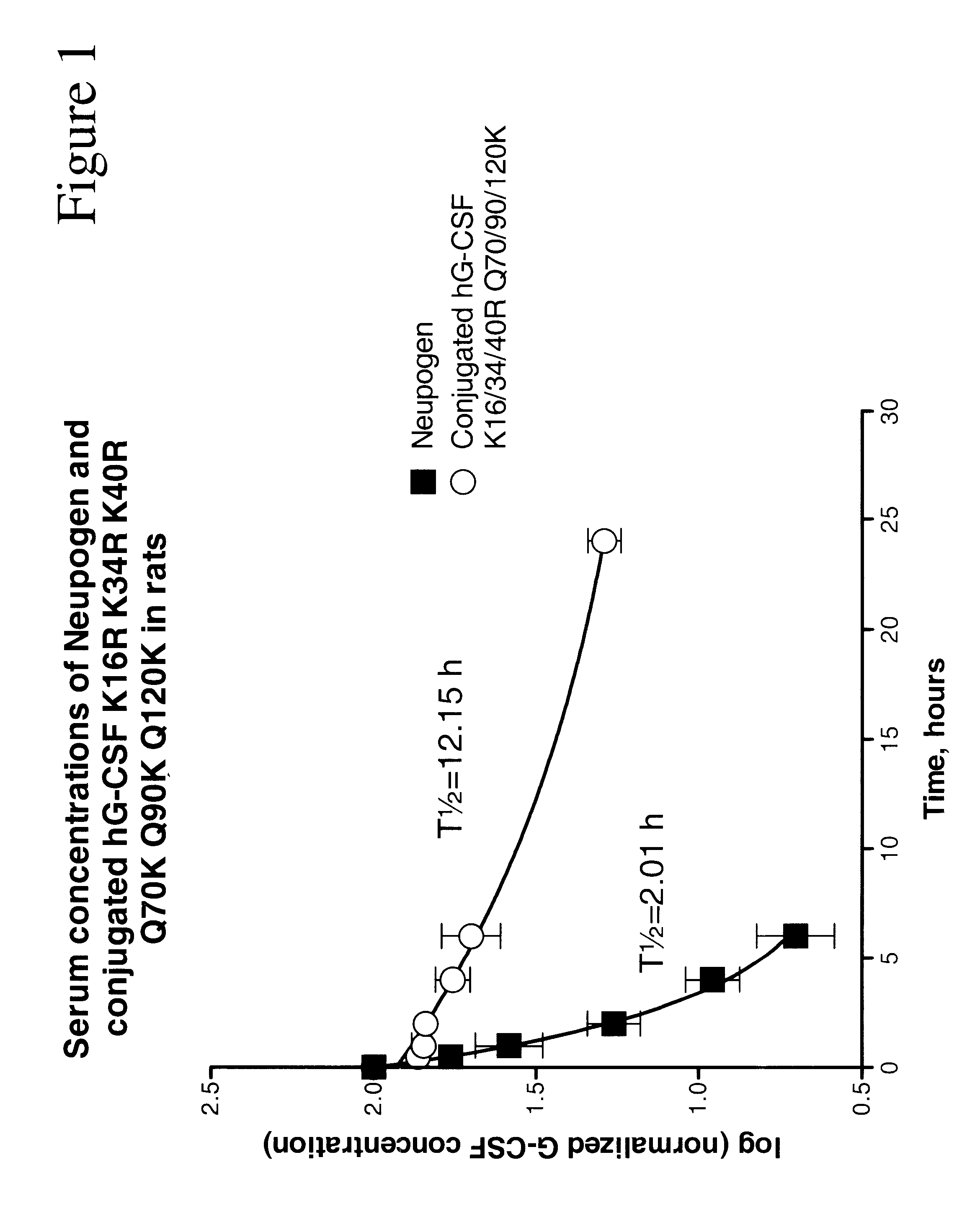

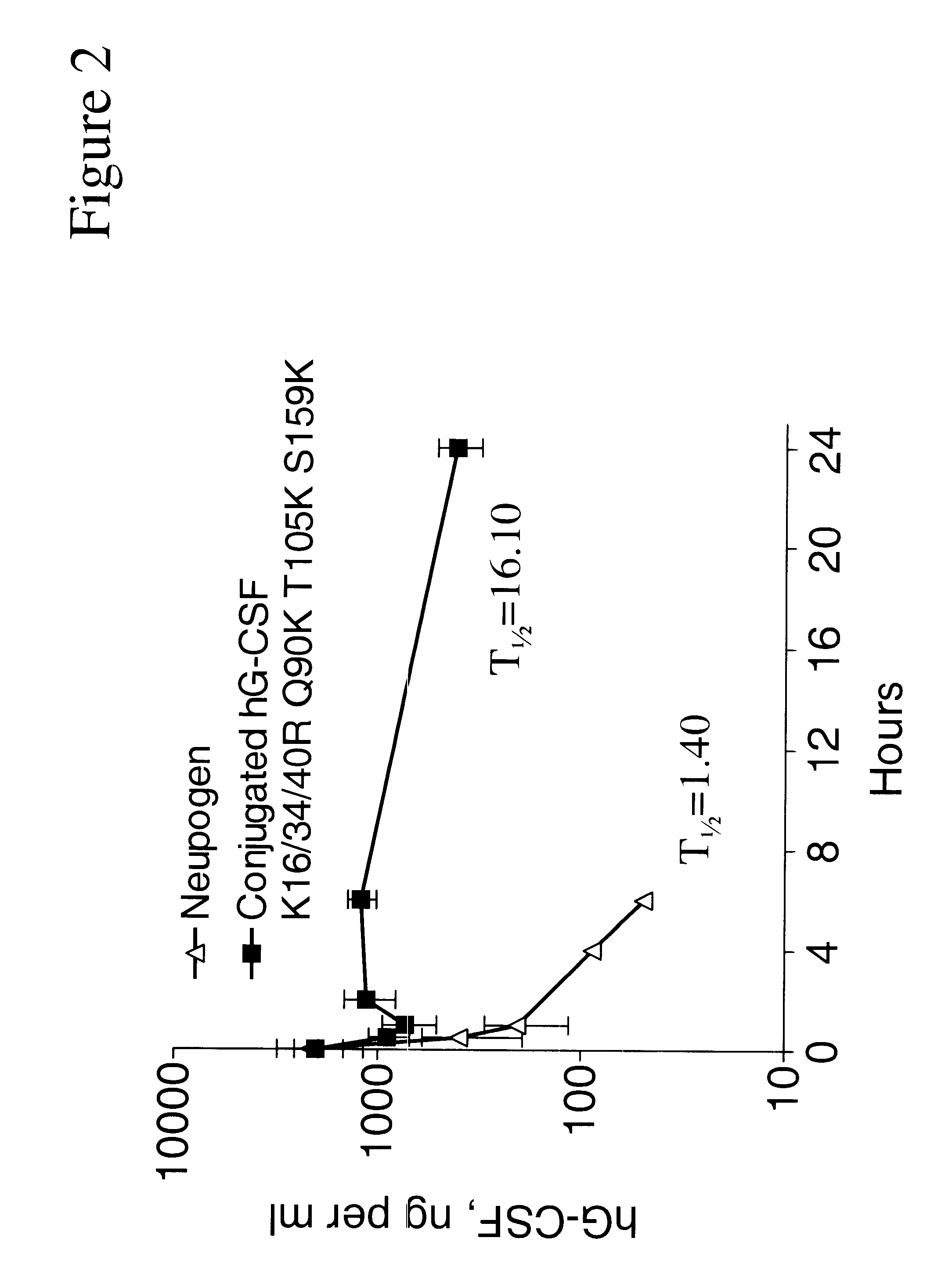

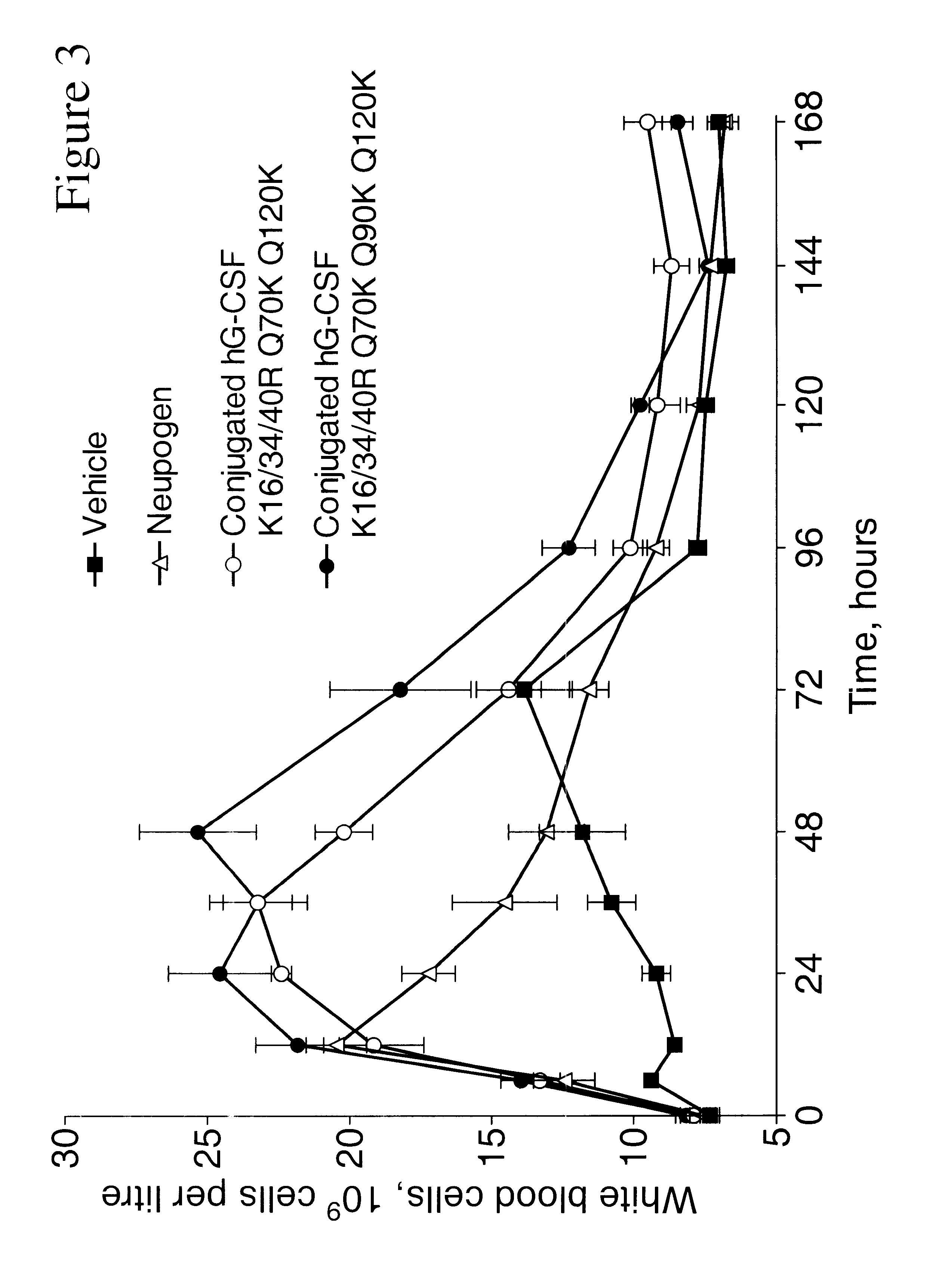

InactiveUS6555660B2Improved propertyReduced in vitroBiocidePeptide/protein ingredientsHalf-lifePolyethylene glycol

The invention relates to polypeptide conjugates comprising a polypeptide exhibiting G-CSF activity and having an amino acid sequence that differs from the amino acid sequence of human G-CSF in at least one specified introduced and / or removed amino acid residue comprising an attachment group for a non-polypeptide moiety, and having at least one non-polypeptide moiety attached to an attachment group of the polypeptide. The attachment group may e.g. be a lysine, cysteine, aspartic acid or glutamic acid residue or a glycosylation site, and the non-polypeptide moiety may e.g. be a polymer such as polyethylene glycol or an oligosaccharide. The conjugate, which has a reduced in vitro bioactivity compared to hG-CSF, has one or more improved properties such as increased biological half-life and increased stimulation of neutrophils.

Owner:MAXYGEN

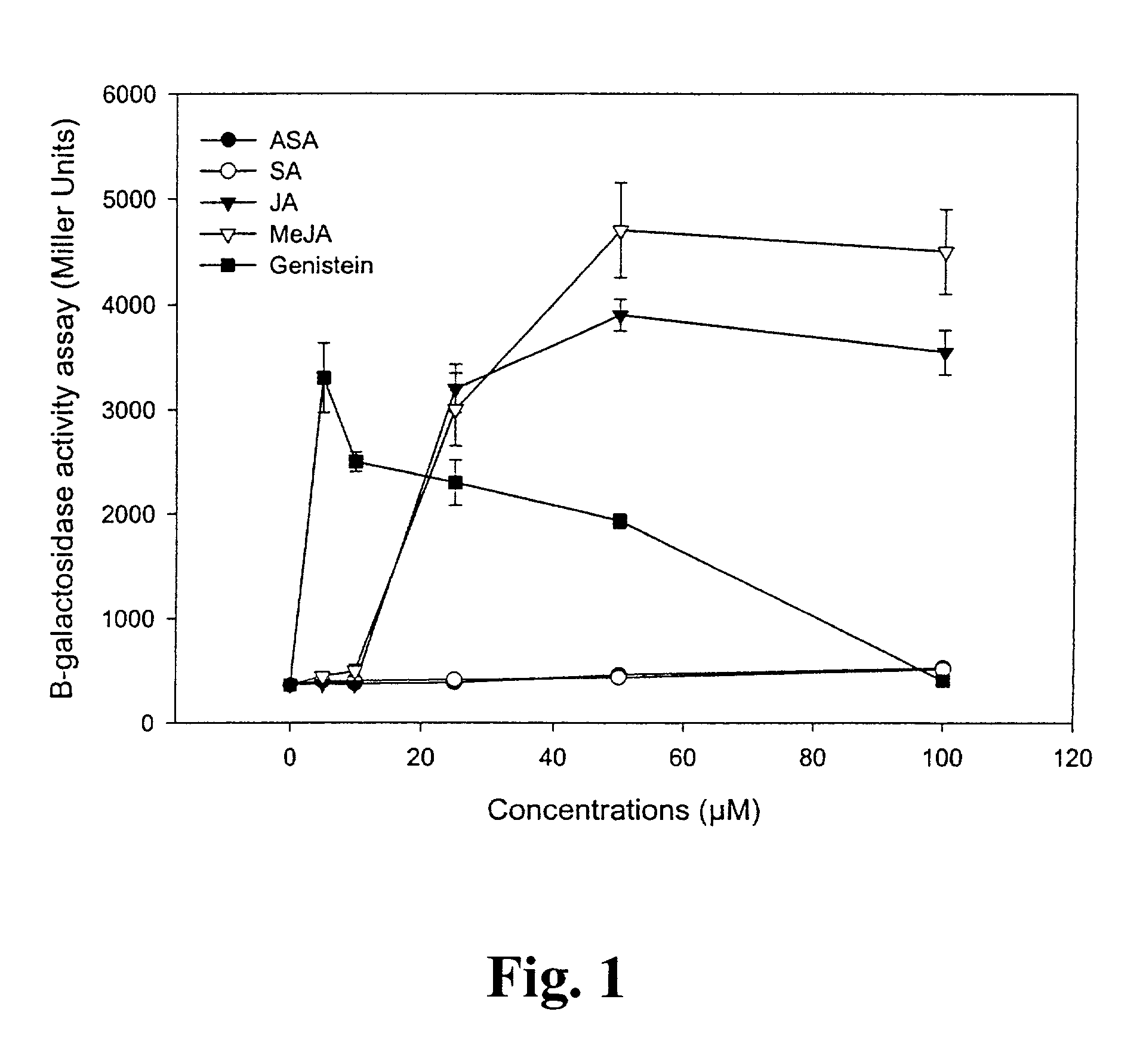

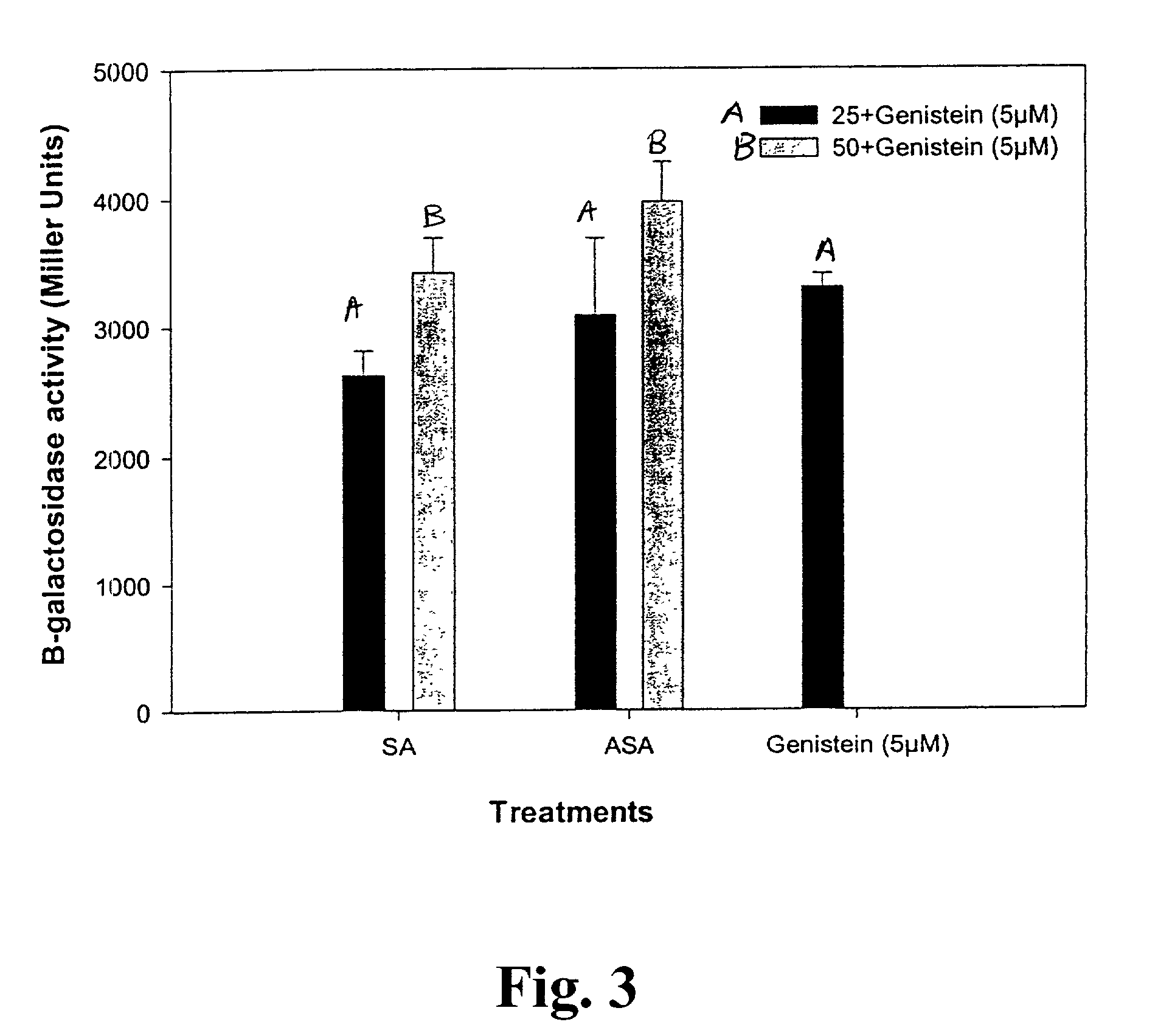

Methods and compositions for production of lipo-chito oligosaccharides by rhizobacteria

Lipo-chito oligosaccharides (LCOs) are produced by culturing rhizobacteria cells in or on a culture medium comprising at least one of: jasmonic acid or a derivative thereof; linoleic acid or a derivative thereof; or linolenic acid or a derivative thereof. Preferably, the rhizobacteria cells are Bradyrhizobium japonicum cells having the identifying characteristics of B. japonicum strain USDA 3. Preferably, the derivative of jasmonic acid is an ester thereof, preferably methyl jasmonate. Also provided are methods for improving LCO production at low temperatures, particularly temperatures below 25° C.

Owner:MCGILL UNIV

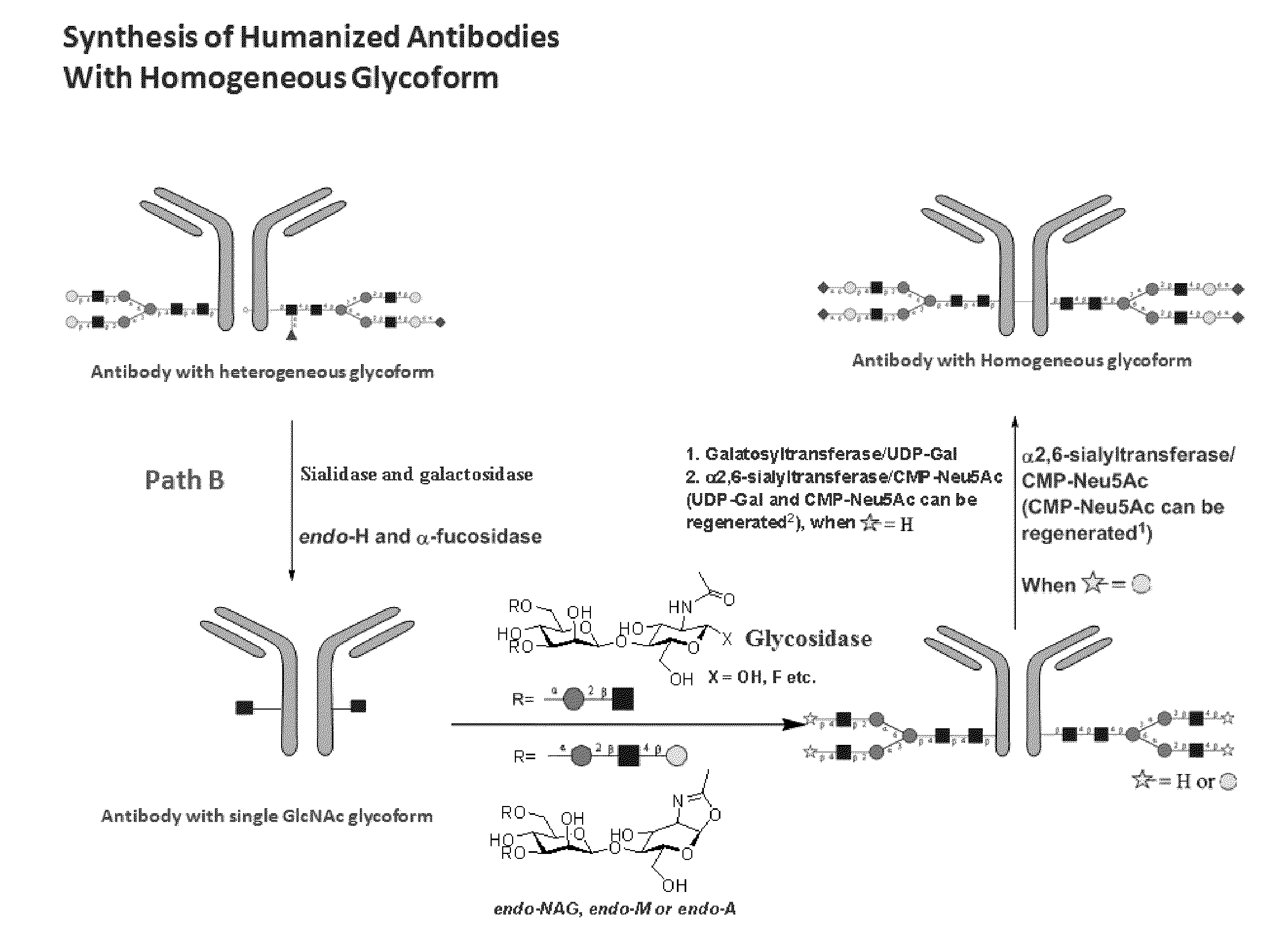

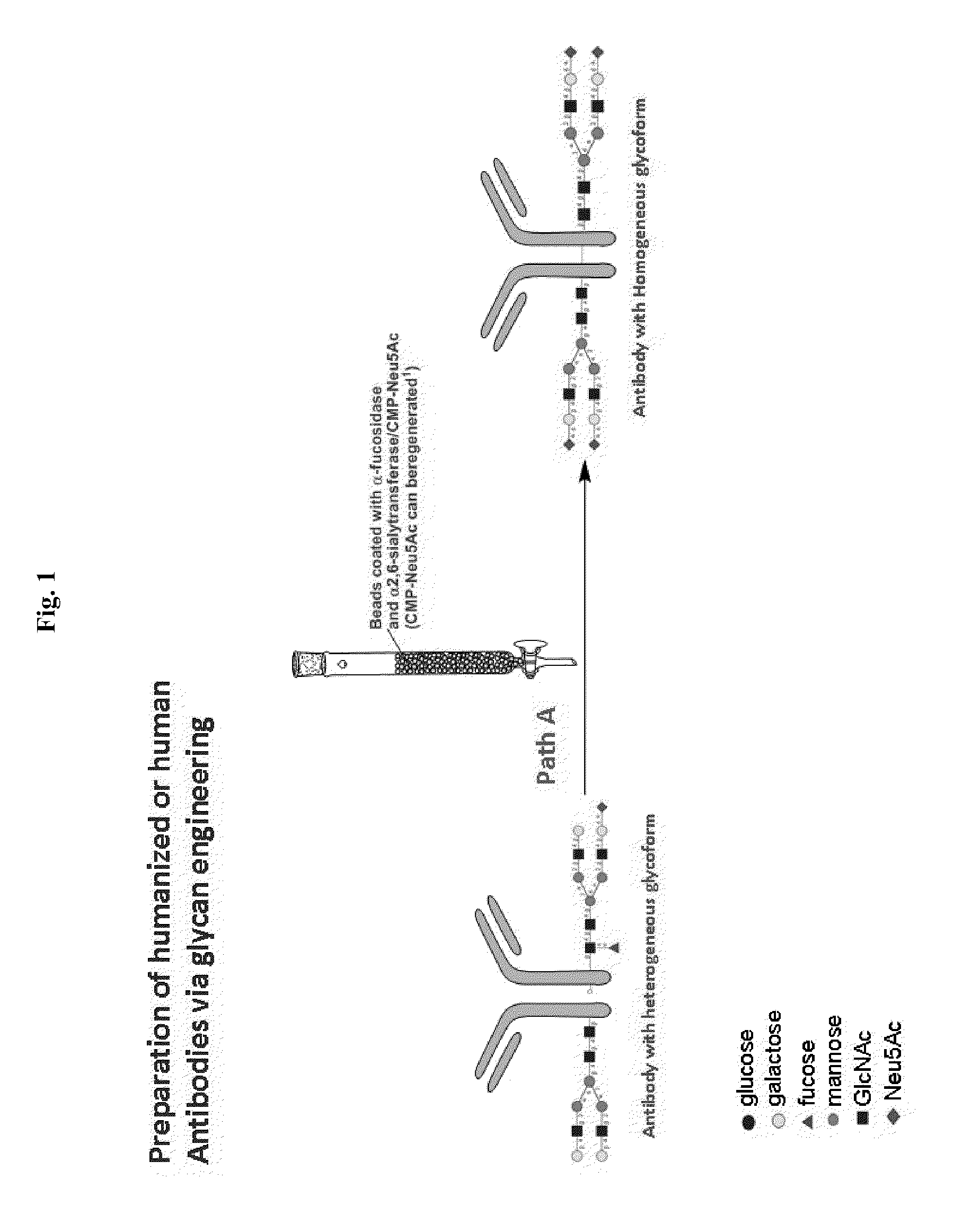

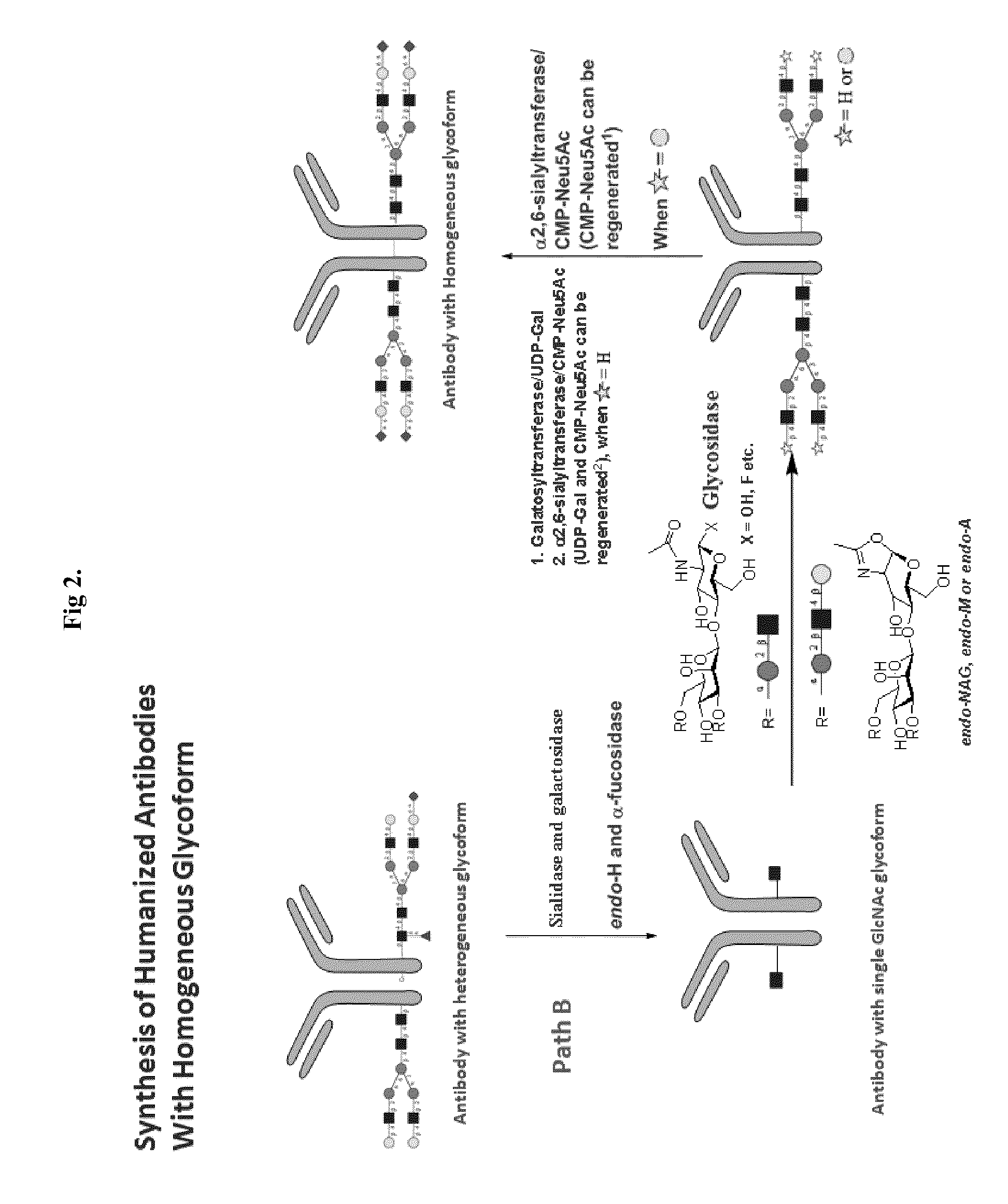

Methods for modifying human antibodies by glycan engineering

ActiveUS20110263828A1Improve efficacyImprove stabilityImmunoglobulinsFermentationGlycanAntibody fragments

Modified Fc regions of antibodies and antibody fragments, both human and humanized, and having enhanced stability and efficacy, are provided. Fc regions with core fucose residues removed, and attached to oligosaccharides comprising terminal sialyl residues, are provided. Antibodies comprising homogeneous glycosylation of Fc regions with specific oligosaccharides are provided. Fc regions conjugated with homogeneous glycoforms of monosaccharides and trisaccharides, are provided. Methods of preparing human antibodies with modified Fc using glycan engineering, are provided.

Owner:ACAD SINIC

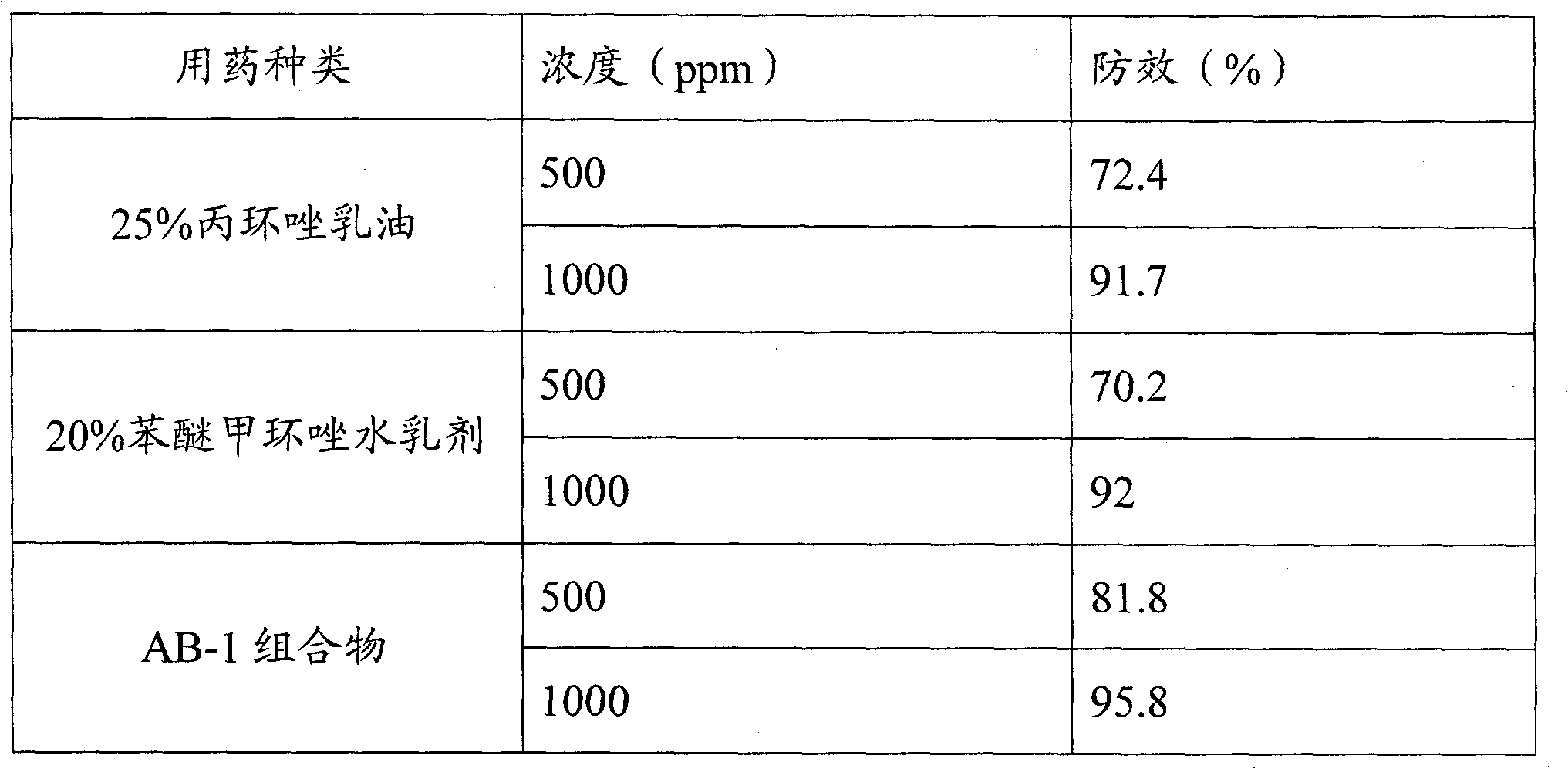

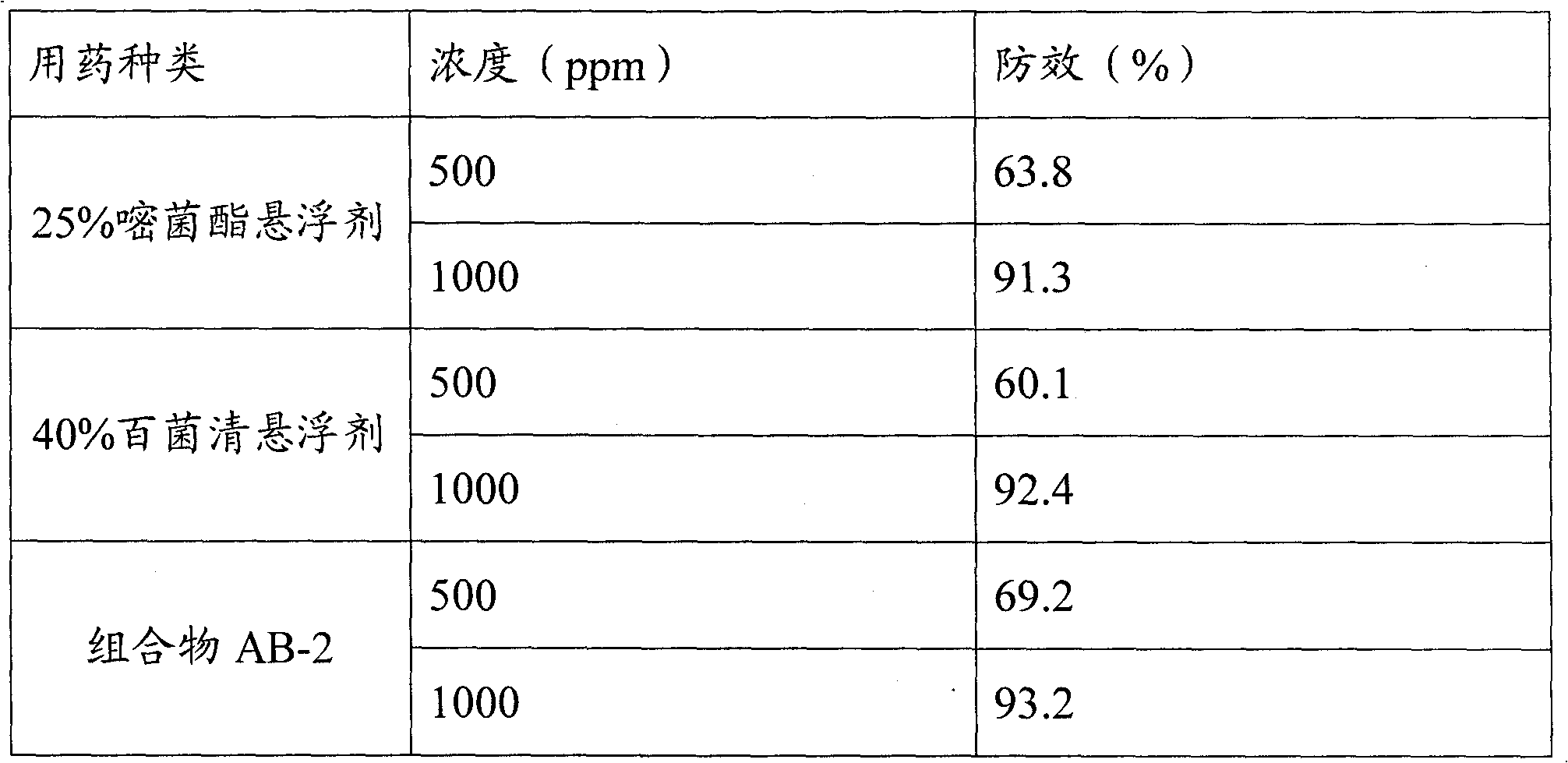

Bactericide pesticide composite containing oligochitosan

InactiveCN101816305AEnhanced application safetyReduce dosageBiocideFungicidesEcological environmentDrug resistance

The invention discloses a bactericide pesticide composite containing oligochitosan, which comprises a component A and a component B, wherein the component A is oligochitosan or a derivative of the oligochitosan; and the component B is one or several of active compounds. The pesticide composition can produce a synergistic action, reduce the dosage of a chemically synthetic bactericide, prevent or delay the medicament resistance of the bactericide, improve crop stress resistance and yield, regulate metabolic balance in plant bodies and improve quality of agricultural products, improve the application safety of the bactericide and is more safe to ecological environmental and human bodies.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

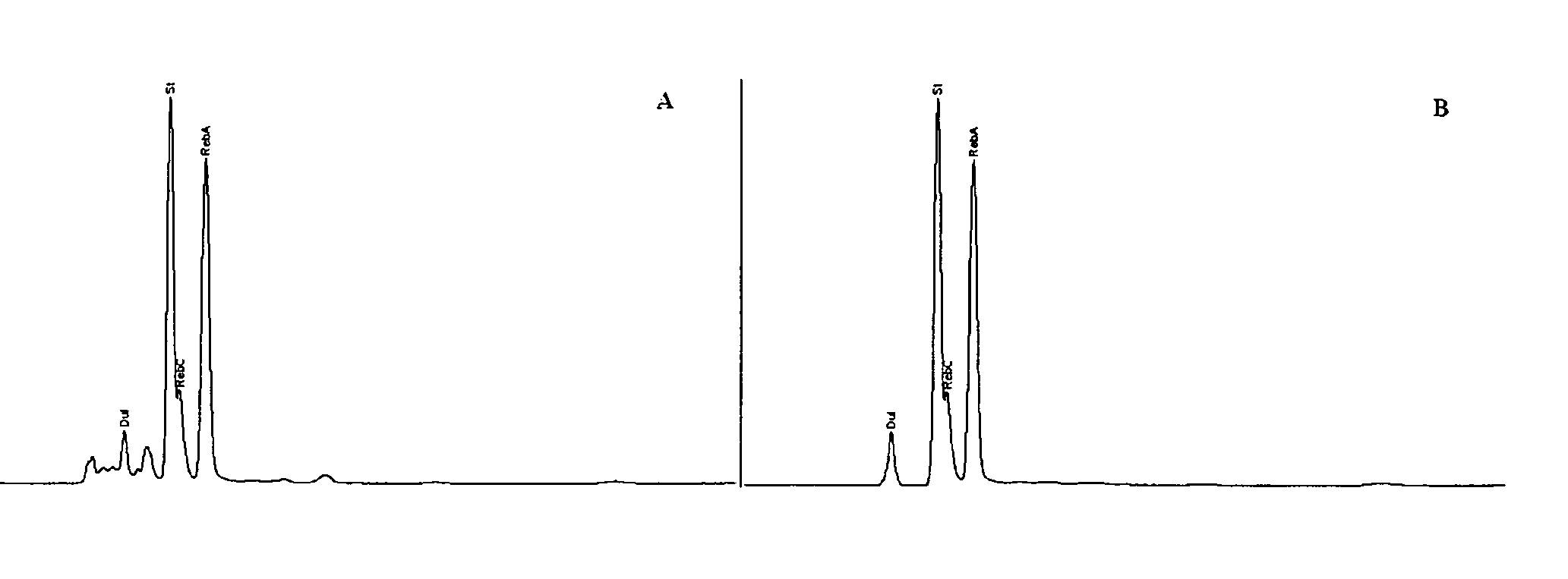

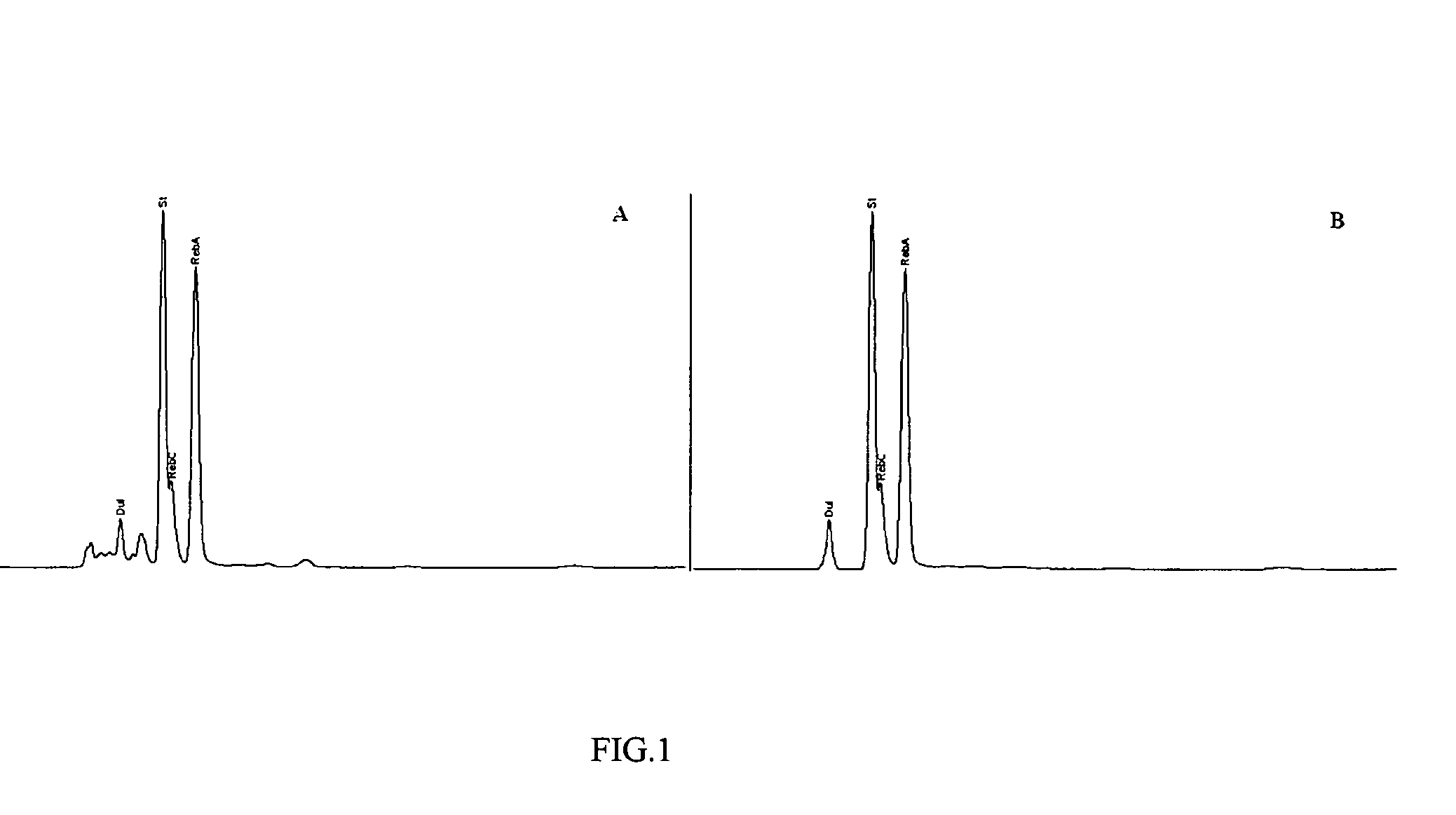

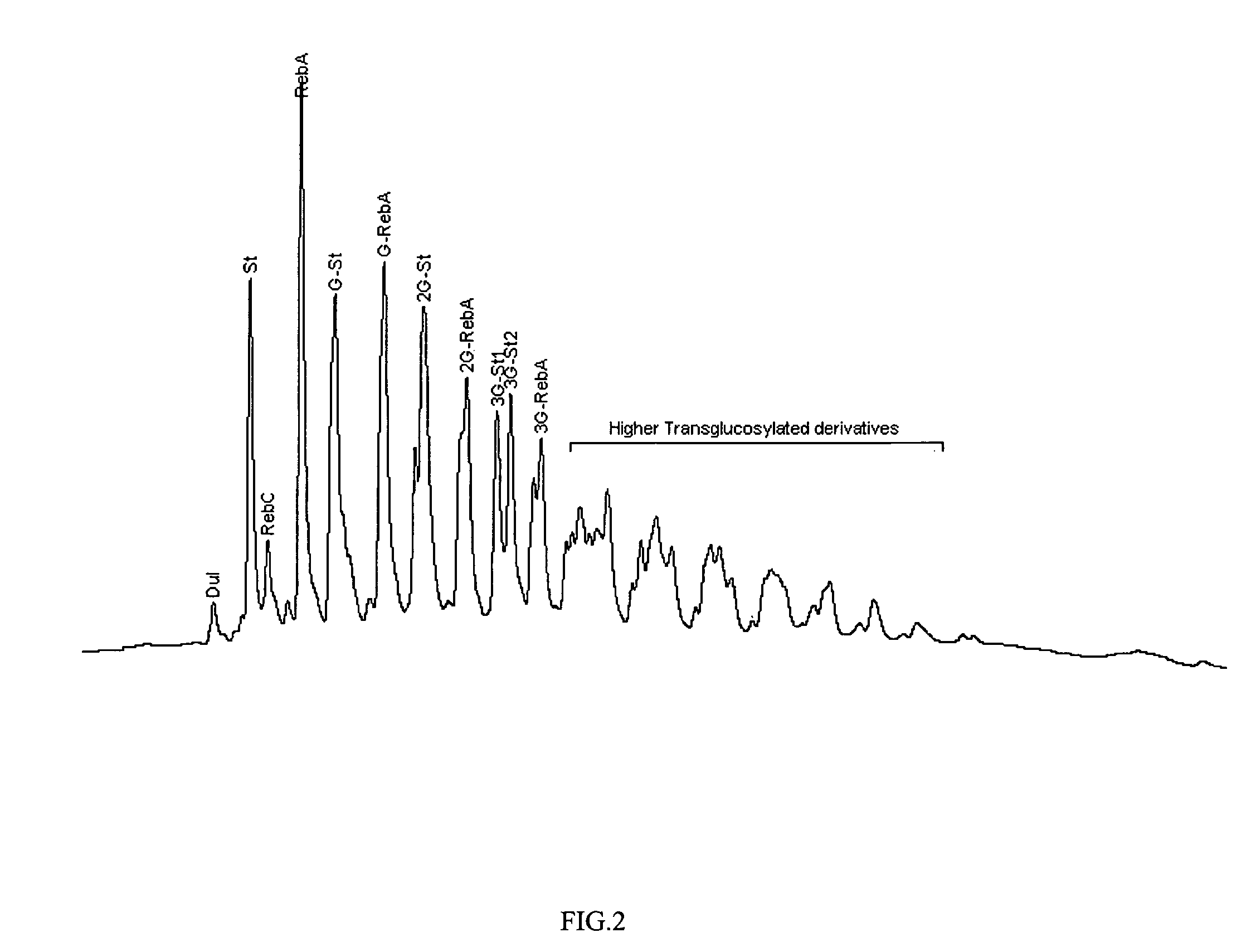

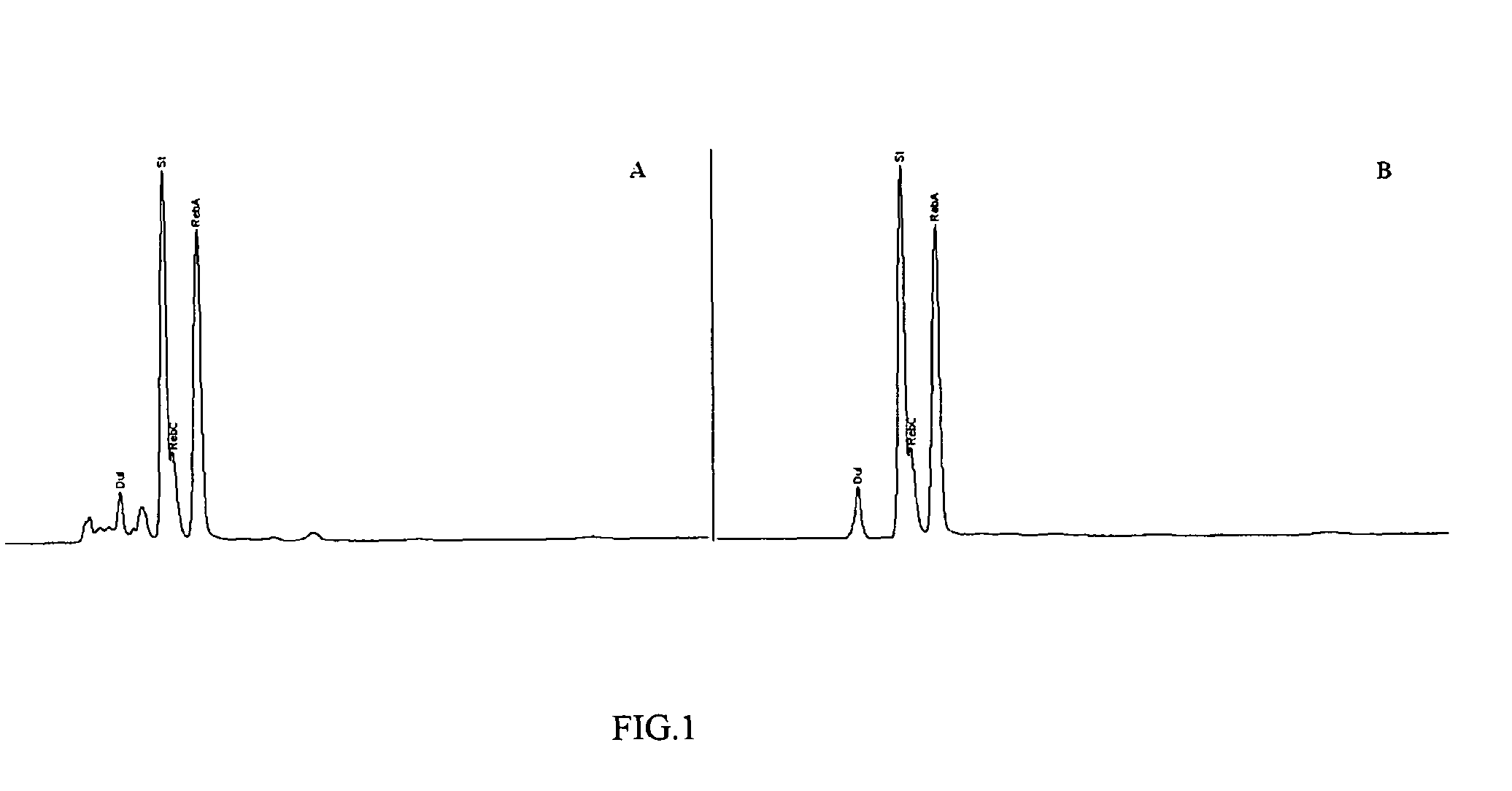

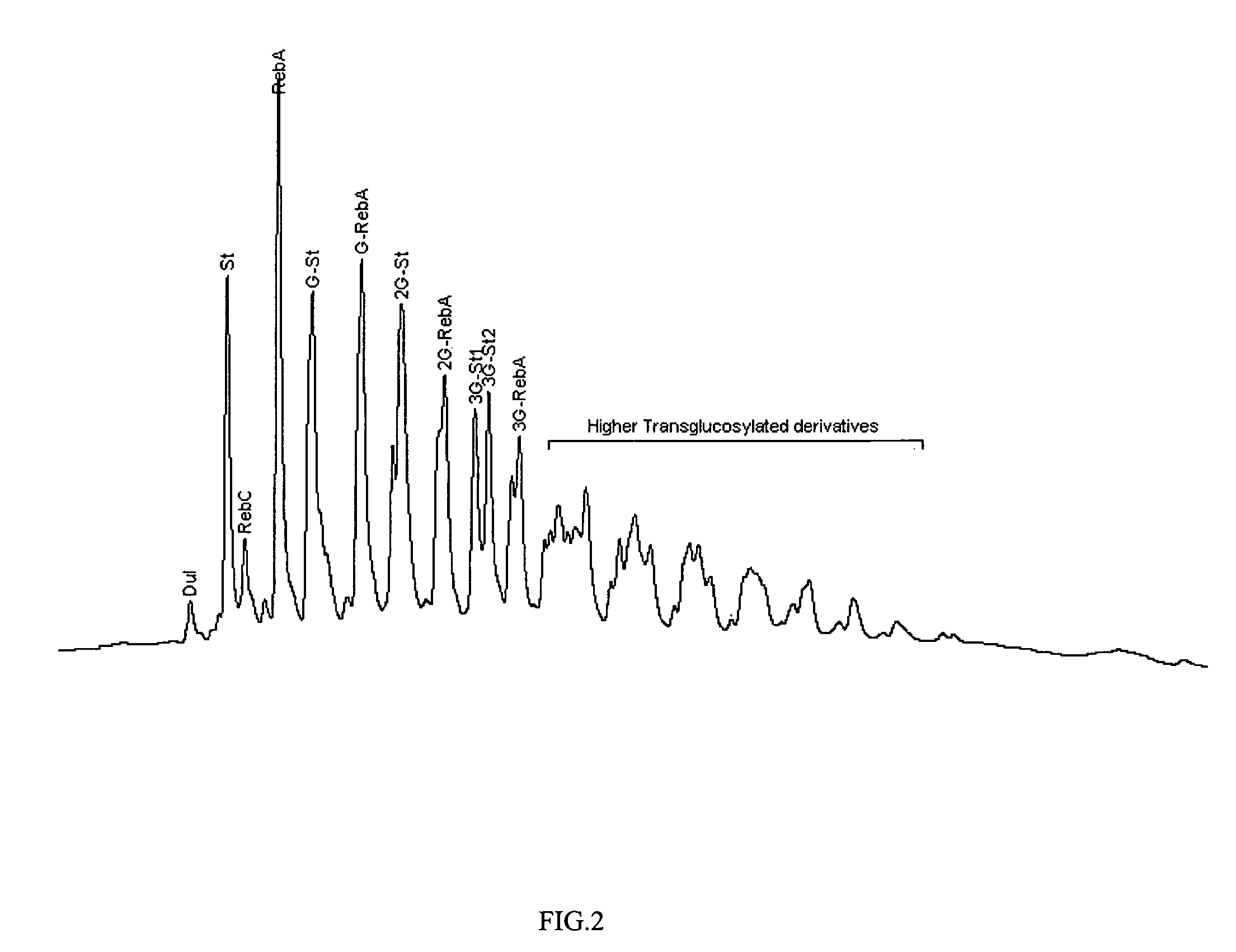

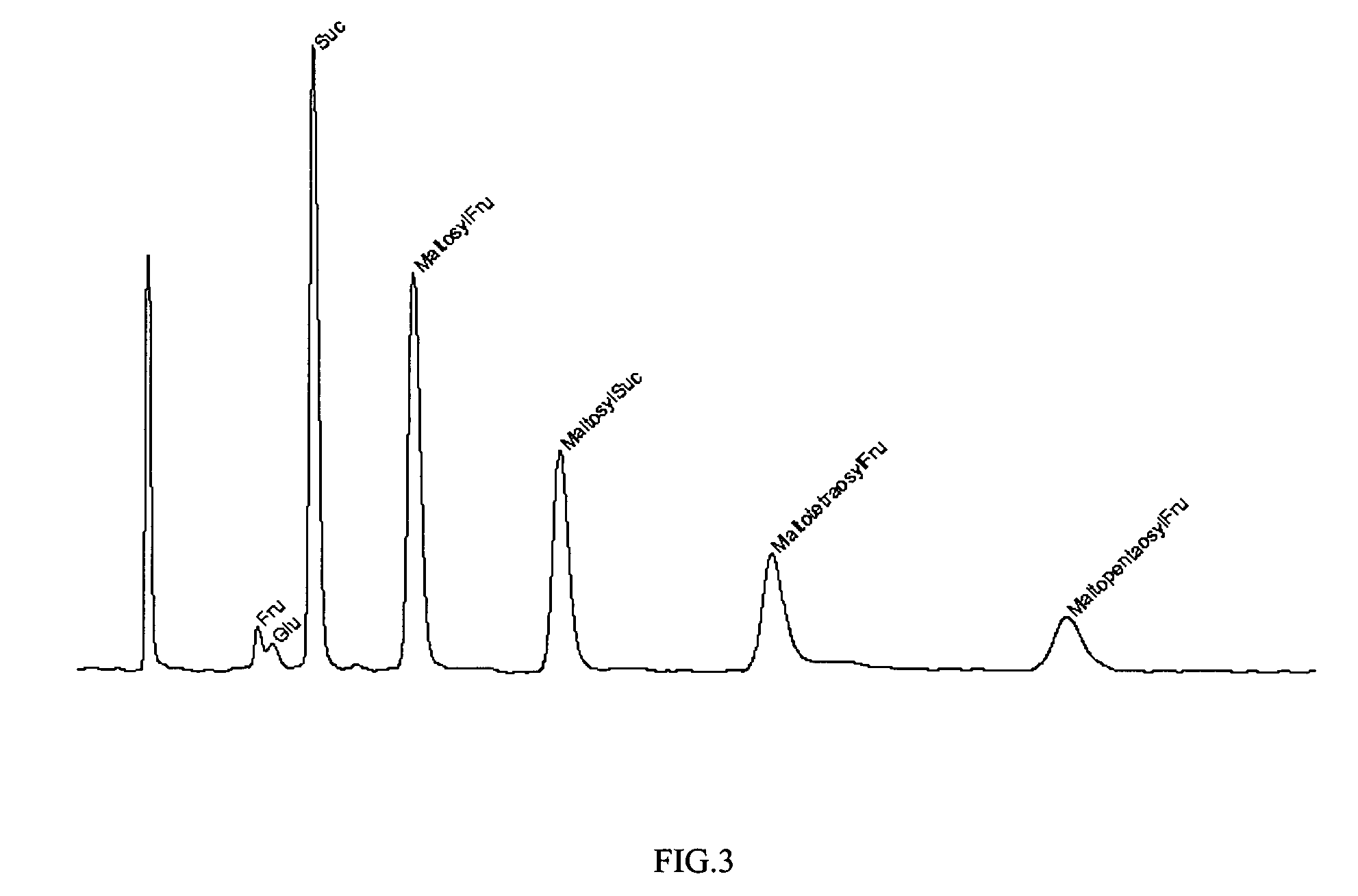

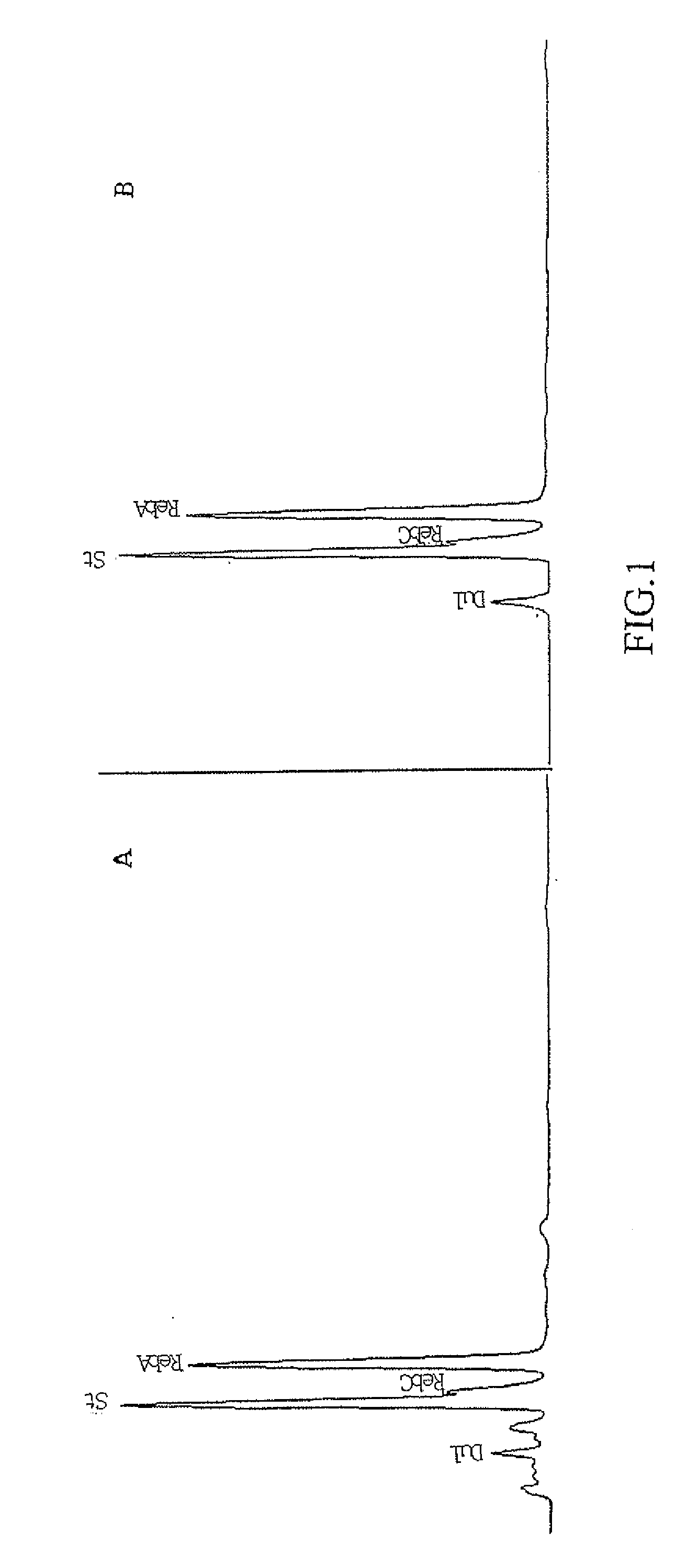

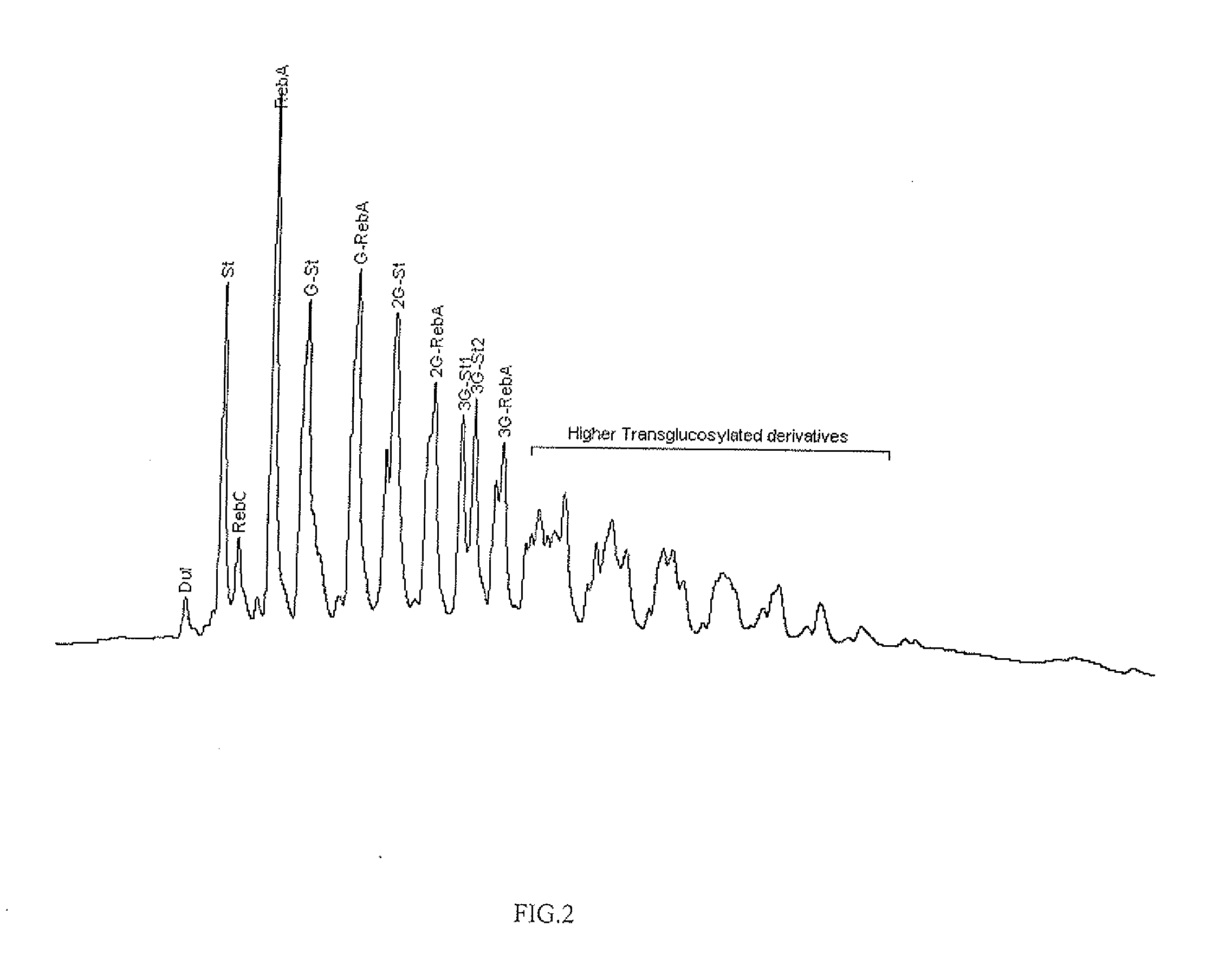

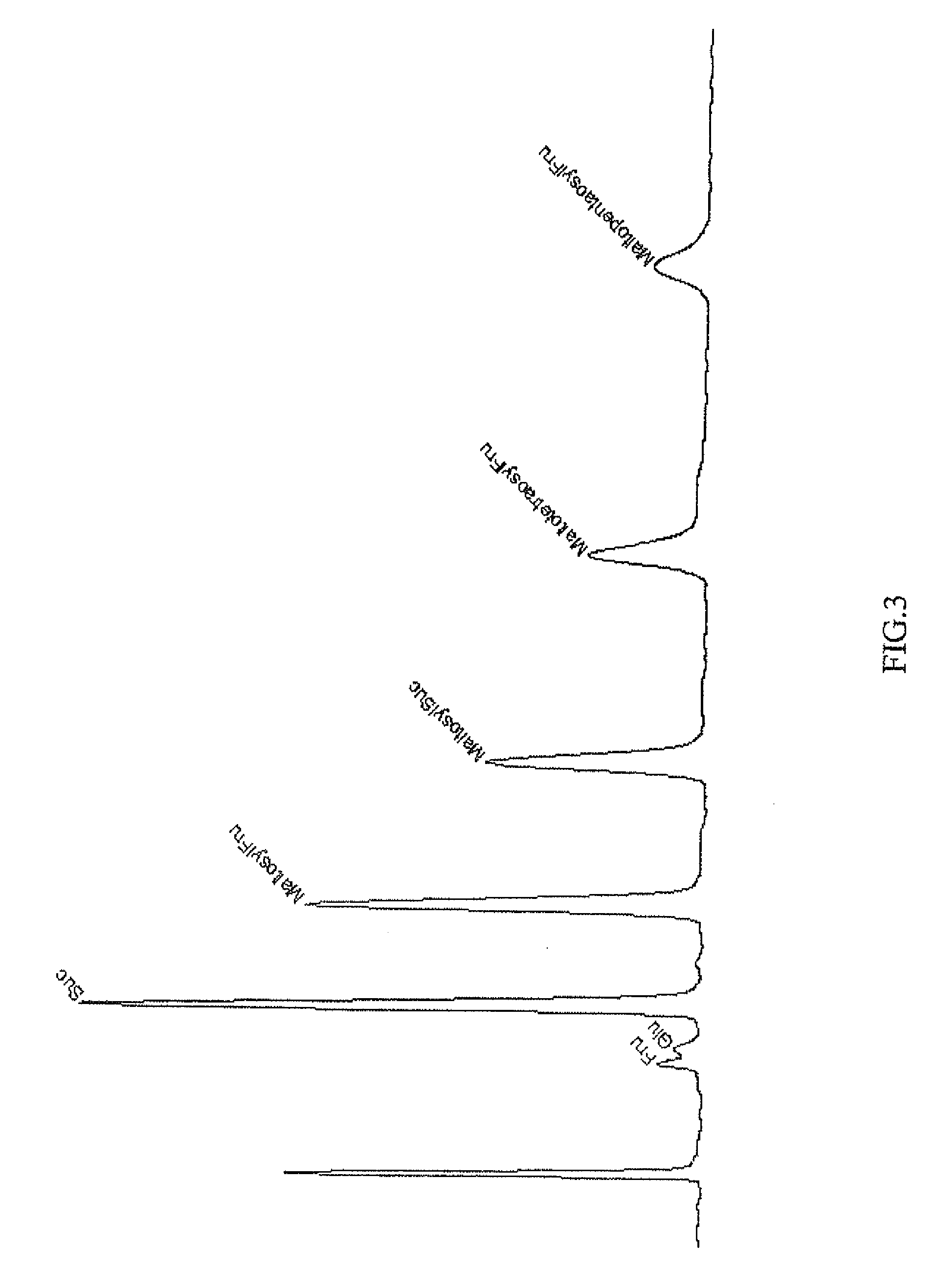

Sweetner and use

Sweeteners on the basis of a simultaneously transglucosylated sweet glycoside mixture of Stevia rebaudiana Bertoni are prepared. The transglycosylation was developed in the presence of starch under the action of cyclodextrin glucanotransferase. The remaining maltodextrins are transferred to the fructose-terminated oligosaccharides. The sweeteners are purified to not less than 98% content of sweet glycosides and derivatives. The preparations are almost non-caloric, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, cosmetics and milk products.

Owner:PURECIRCLE SDN BHD

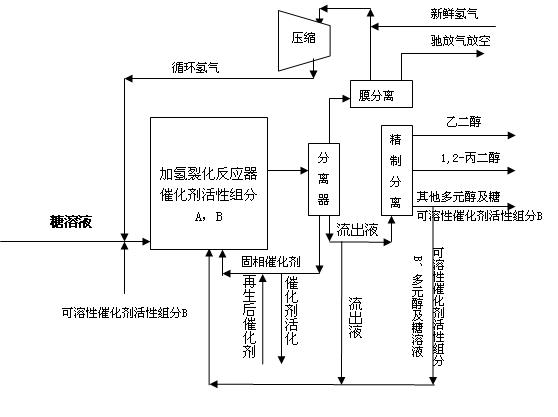

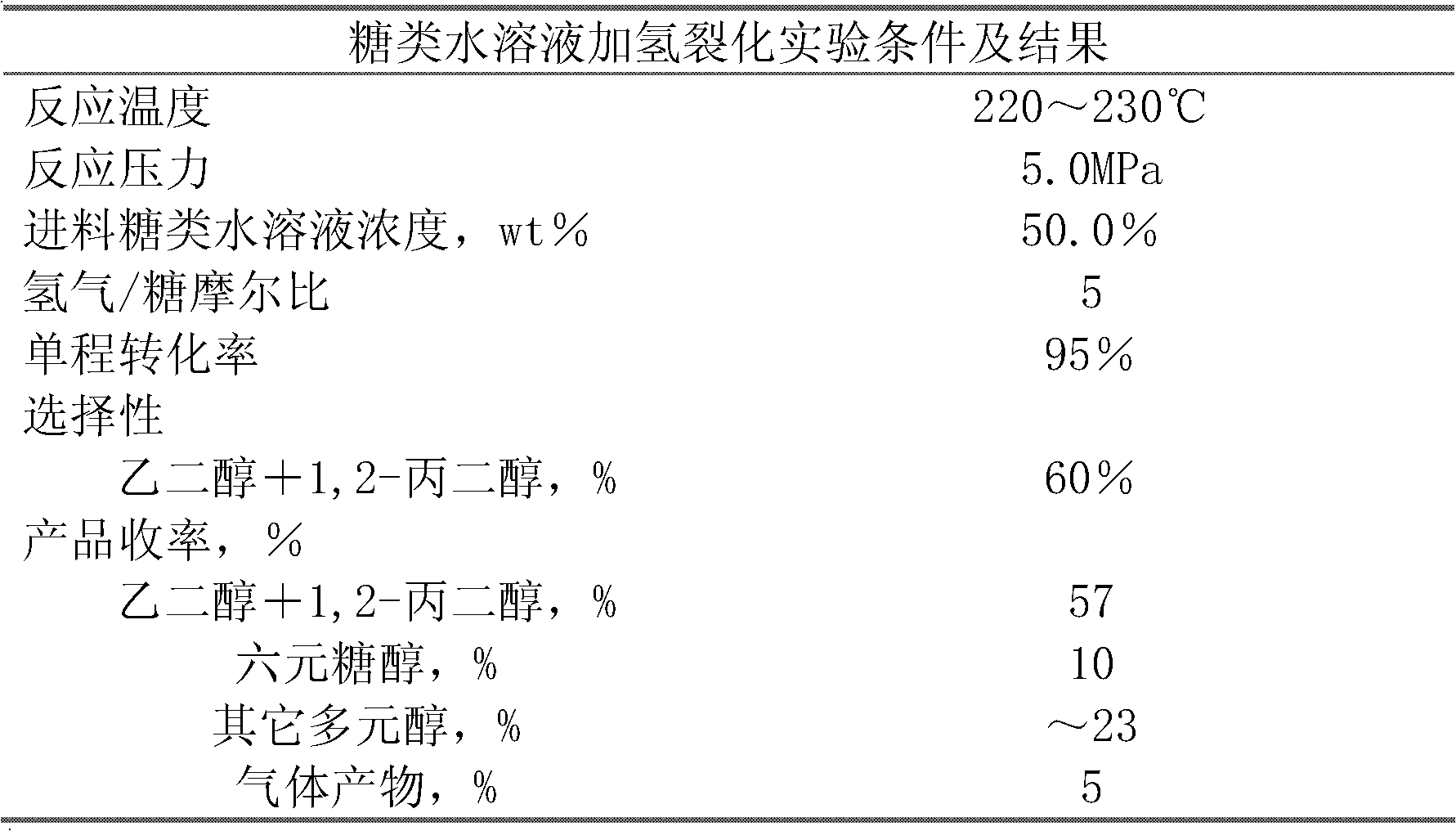

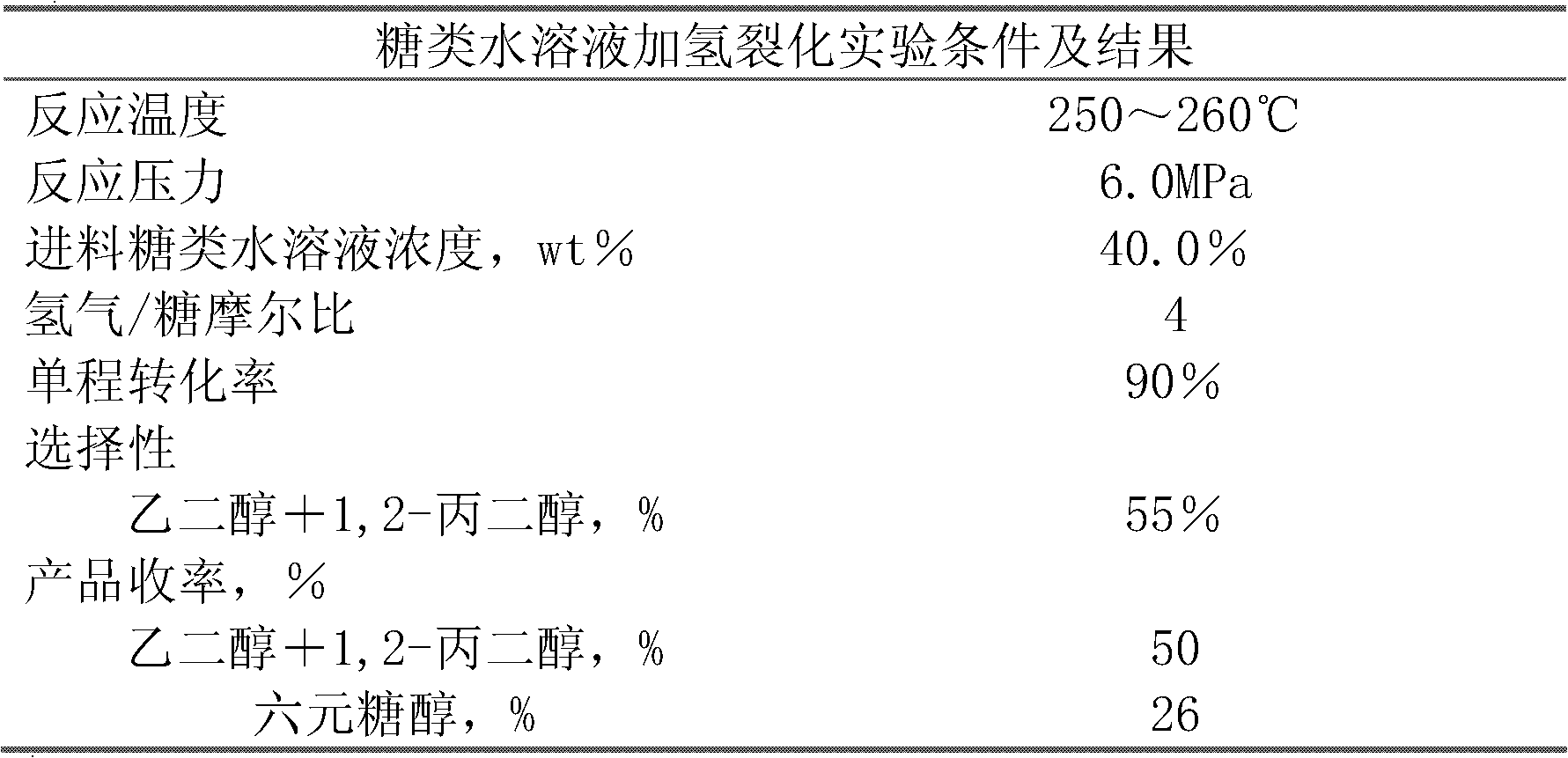

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

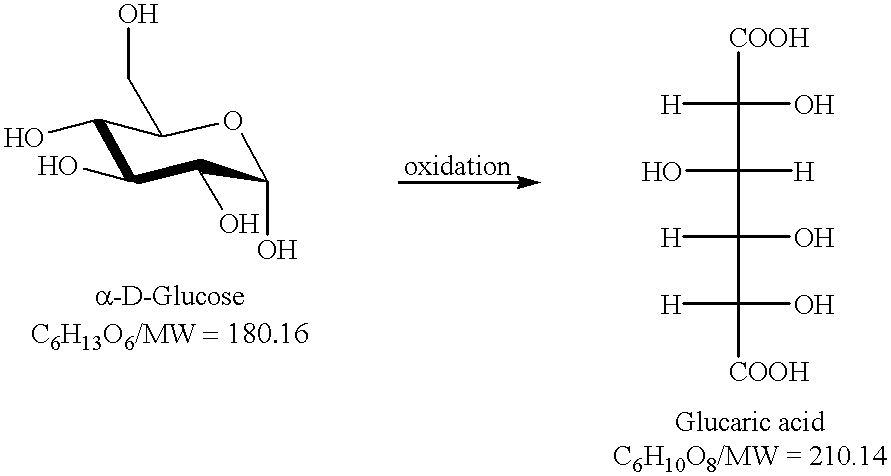

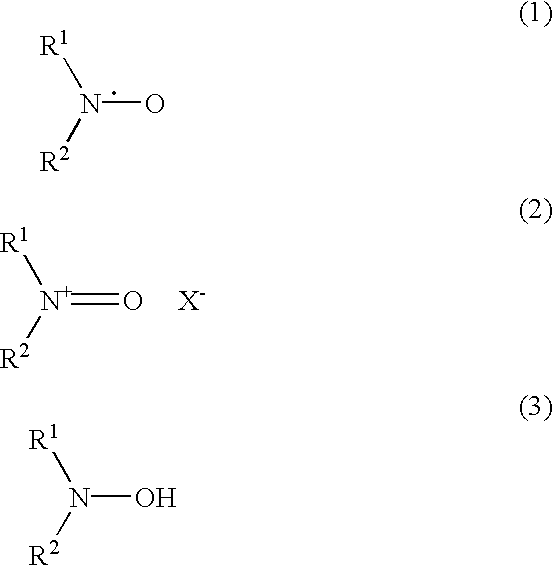

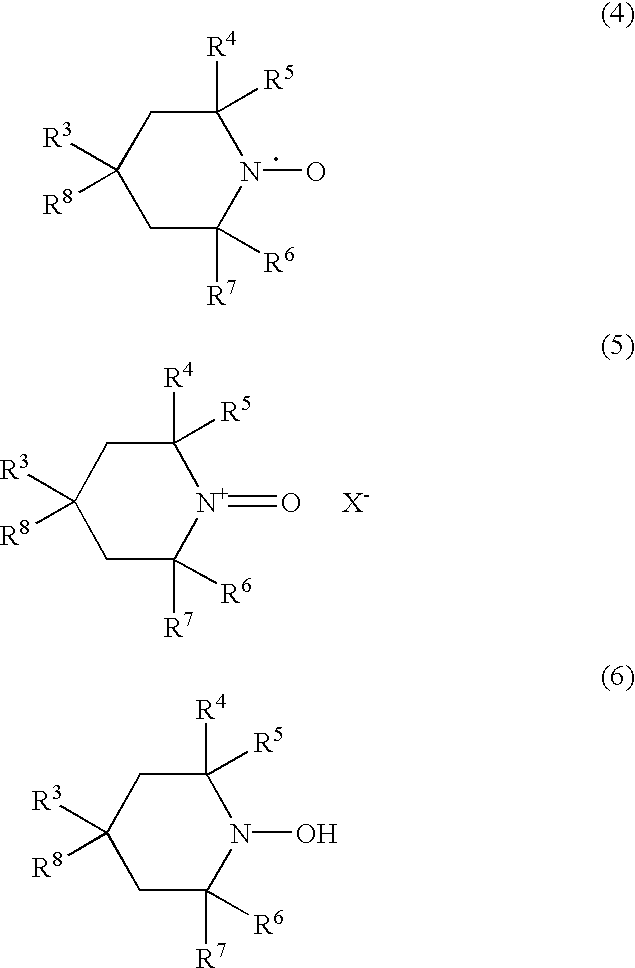

Method for the oxidation of aldehydes, hemiacetals and primary alcohols

InactiveUS6498269B1Economical and effectiveGuaranteed economic efficiencySugar derivativesOrganic compound preparationHalogenBromine

A method for the oxidation of substrates comprising treating an aqueous, basic solution of a substrate having an oxidizable functionality using an elemental halogen as terminal oxidant in the presence of an oxoammonium catalyst / halide co-catalyst system. Use of elemental halogen, preferably chlorine gas or elemental bromine, unexpectedly allows oxidation without significant degradation of the substrate. The substrate is preferably a monosaccharide, oligosaccharide, or polysaccharide, and the oxidizable functionality is preferably an aldehyde, hemiacetal, or a primary alcohol. An effective source of the oxoammonium catalyst is 2,2,6,6-tetramethylpiperidinyl-1-oxy (TEMPO) and a particularly economical and effective catalyst is 4-acetylamino-2,2,6,6-tetramethylpiperidinyl-1-oxy.

Owner:UNIV OF CONNECTICUT

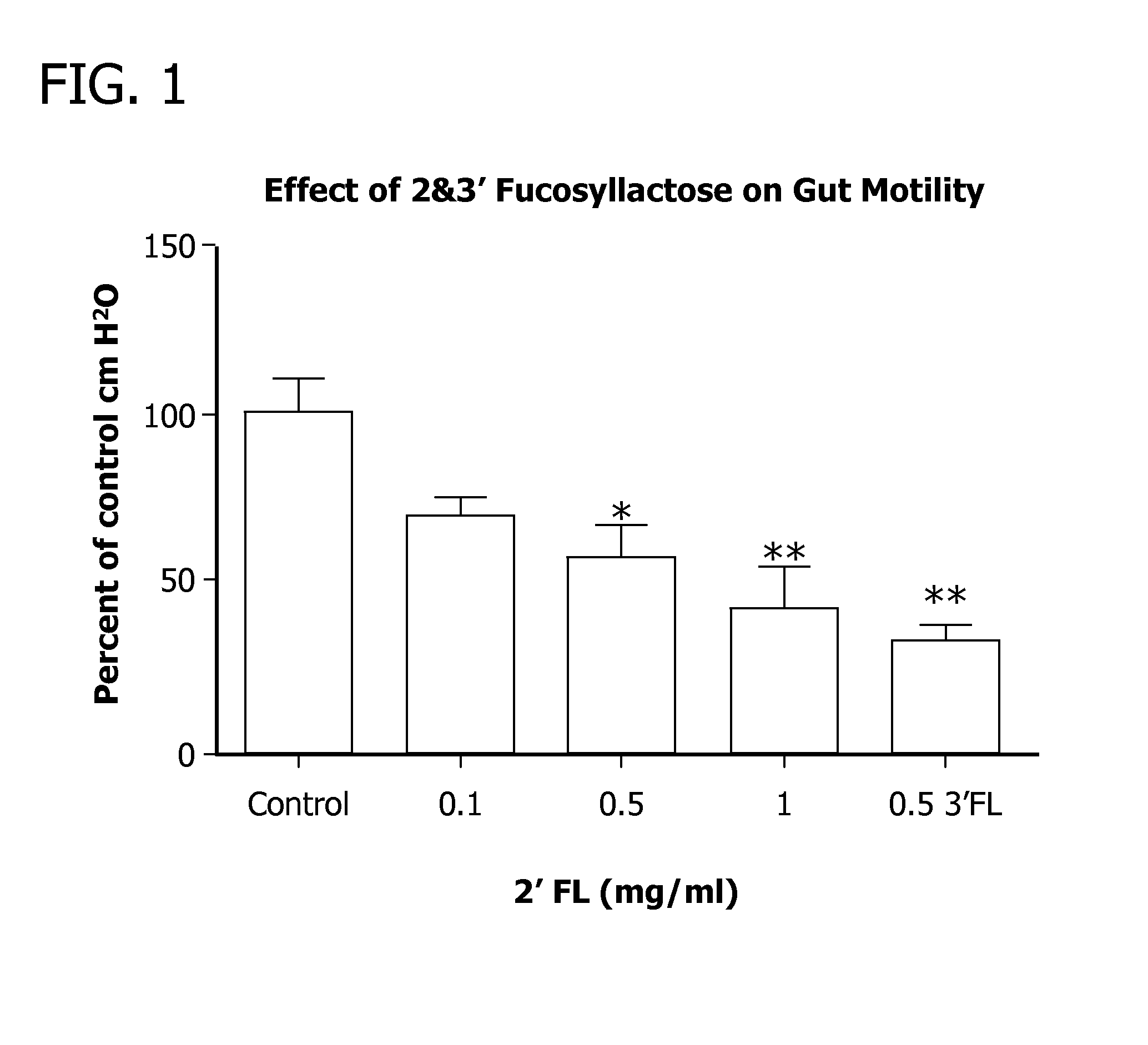

Methods for decreasing the incidence of necrotizing enterocolitis in infants, toddlers, or children using human milk oligosaccharides

ActiveUS20120172319A1Improve immune system systemImprove system enteric nervous systemOrganic active ingredientsBiocideDiseaseMorbidity aspects

Disclosed are methods of reducing the incidence of necrotizing enterocolitis in an infant, toddler, or child using nutritional compositions including human milk oligosaccharides. The nutritional compositions including the human milk oligosaccharides are effective in reducing inflammation and the incidence of inflammatory diseases.

Owner:ABBOTT LAB INC

Nutritional potato chips and preparation method thereof

InactiveCN103535664AAdd flavorFull of nutritionFood ingredient functionsFood preparationBiotechnologyAdditive ingredient

The invention discloses nutritional potato chips and a preparation method thereof. The nutritional potato chips are characterized by being prepared from the following raw materials in parts by weight: 90-100 parts of potatoes, 25-30 parts of rye flour, 3-4 parts of salt, 4-5 parts of oligosaccharide, 1-2 parts of zinc citrate, 8-10 parts of lily mayonnaise, 10-11 parts of almond, 11-12 parts of peanut, 12-13 parts of sesame, 1-2 parts of burdock, 1.5-1.8 parts of lophatherum gracile, 0.8-1.5 parts of tangerine peel, 1.5-2 parts of cassia seed, 1-1.5 parts of angelica, 2-2.5 parts of broadbean flower, 2-3 parts of apple blossom, 2-3 parts of stellaria media and 3-5 parts of rapeseed oil. The nutritional potato chips have superior flavor, are crisp, refreshing, scientific in proportion of all the ingredients and rich in nutrition, and have the effects of dispelling wind and heat, regulating qi, strengthening spleen, drying dampness, eliminating phlegm, replenishing blood, improving eyesight, cooling blood, detoxifying, maintaining beauty and keeping young.

Owner:ANHUI HUAIYUAN XINTAI CEREAL & OIL

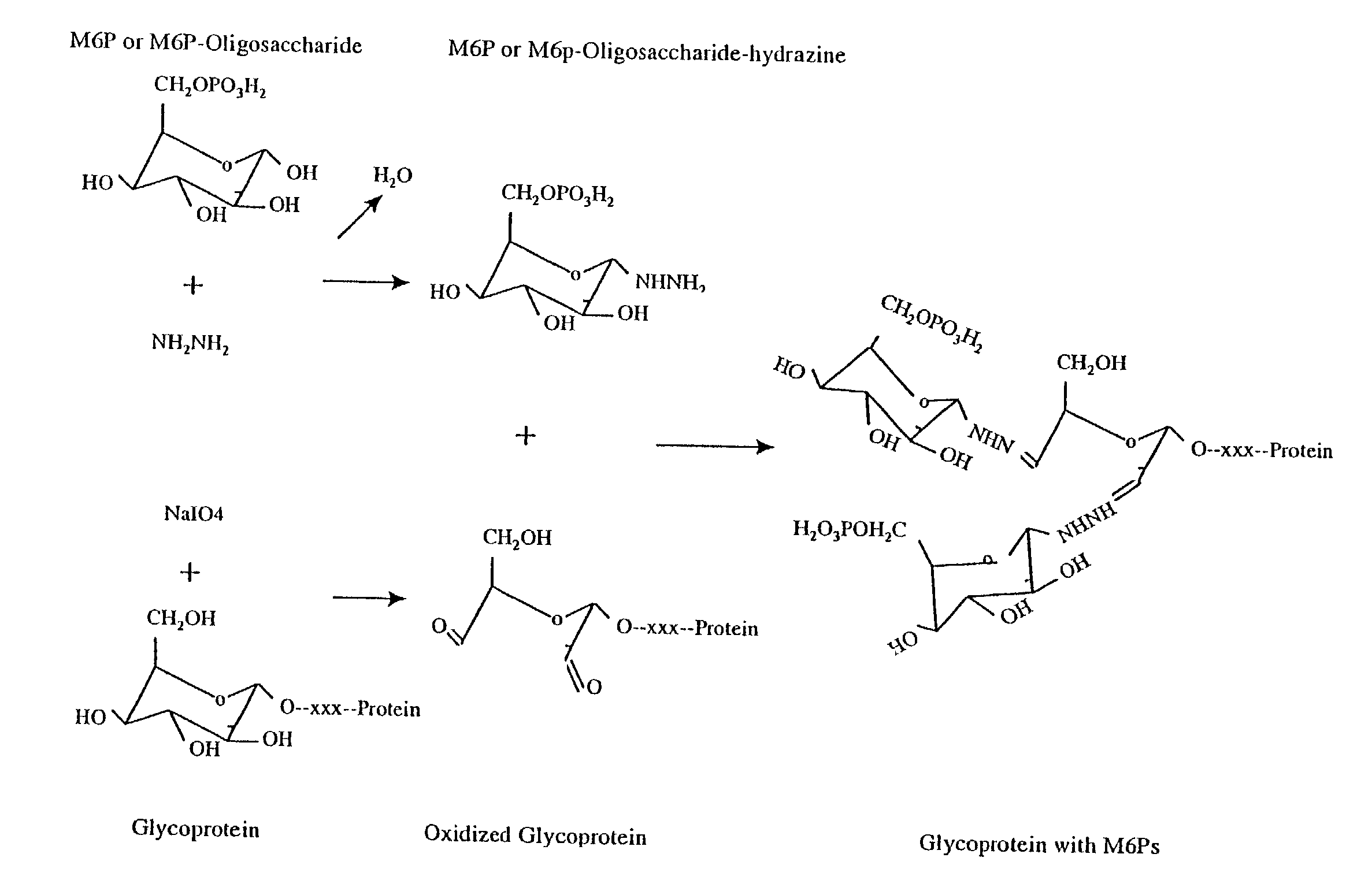

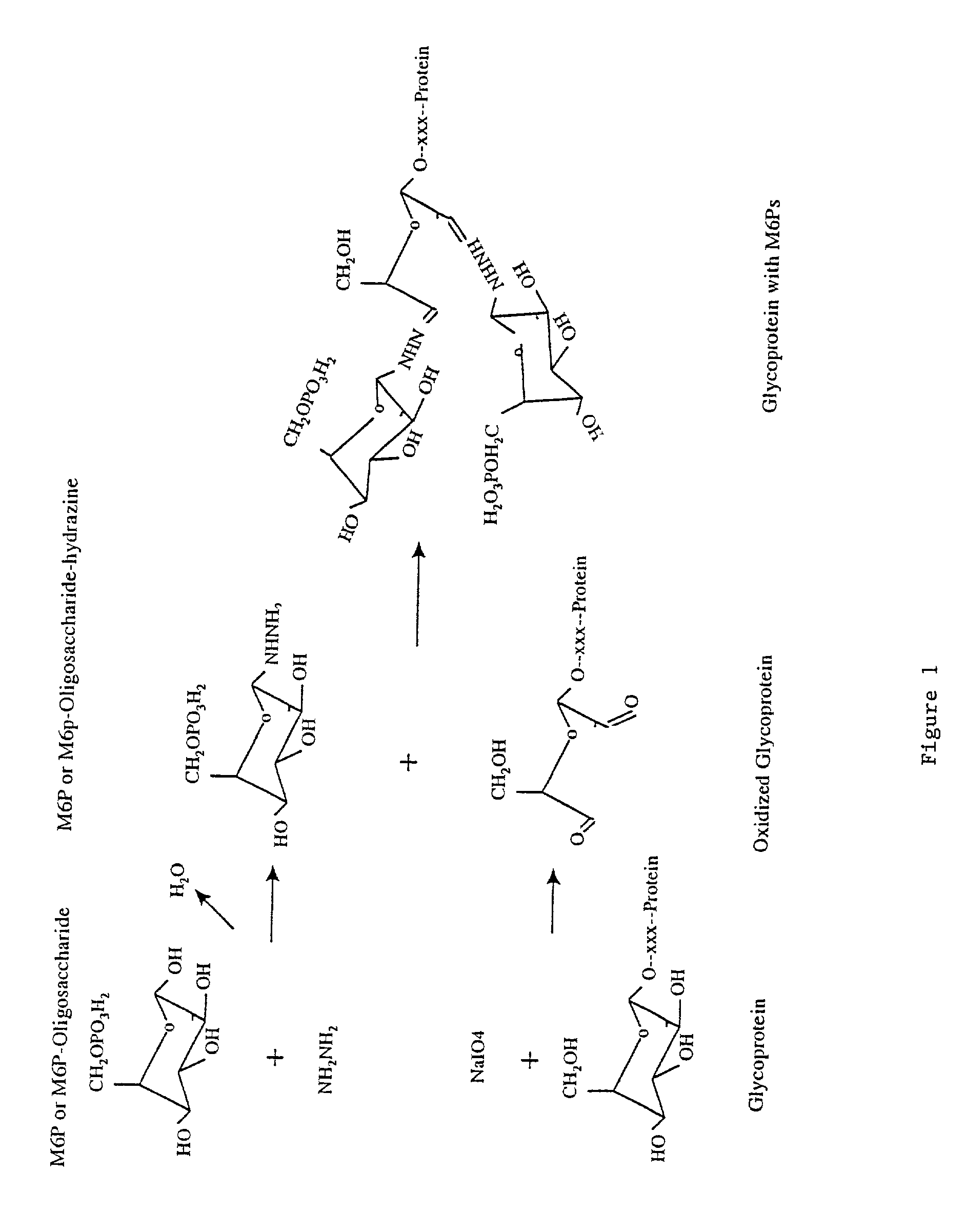

Methods for introducing mannose 6-phosphate and other oligosaccharides onto glycoproteins

InactiveUS7001994B2Well formedIncrease the cellular uptake of lysosomal enzymesHydrolasesPeptide/protein ingredientsPhosphorylationPhosphoric acid

Methods to introduce highly phosphorylated mannopyranosyl oligosaccharide derivatives containing mannose 6-phosphate (M6P), or other oligosaccharides bearing other terminal hexoses, to carbonyl groups on oxidized glycans of glycoproteins while retaining their biological activity are described. The methods are useful for modifying glycoproteins, including those produced by recombinant protein expression systems, to increase uptake by cell surface receptor-mediated mechanisms, thus improving their therapeutic efficacy in a variety of applications.

Owner:GENZYME CORP

Non-maltogenic exoamylases and their use in retarding retrogradation of starch

InactiveUS6667065B1Highly effective in retarding or reducing detrimental retrogradationImprove propertiesDough treatmentHydrolasesAmylosucrase activitySide chain

The present invention relates to a process for making a bread product. The process includes the addition of a non-maltogenic exoamylase that hydrolyses starch to a starch medium, and the application of heat to the starch medium. The non-maltogenic exomylase cleaves one or more linear malto-oligosaccharides, predominantly consisting of from four to eight D-glucopyranosyl units, from non-reducing ends of amylopectin side chains. The non-maltogenic exoamylase has an endoamylase activity of less than 0.5 endoamylase units (EAU) per unit of exoamylase activity.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Human milk oligosaccharides to promote growth of beneficial bacteria

ActiveUS20120171165A1Improve immune system systemImprove system enteric nervous systemBiocideNervous disorderPremature thelarcheBacteroides

Disclosed are nutritional compositions including human milk oligosaccharides that can be administered to individuals including preterm infants, infants, toddlers, and children for improving gastrointestinal function and tolerance, as well as the growth of beneficial bacteria. Additional suitable methods of using the nutritional compositions including the human milk oligosaccharides are also disclosed.

Owner:ABBOTT LAB INC

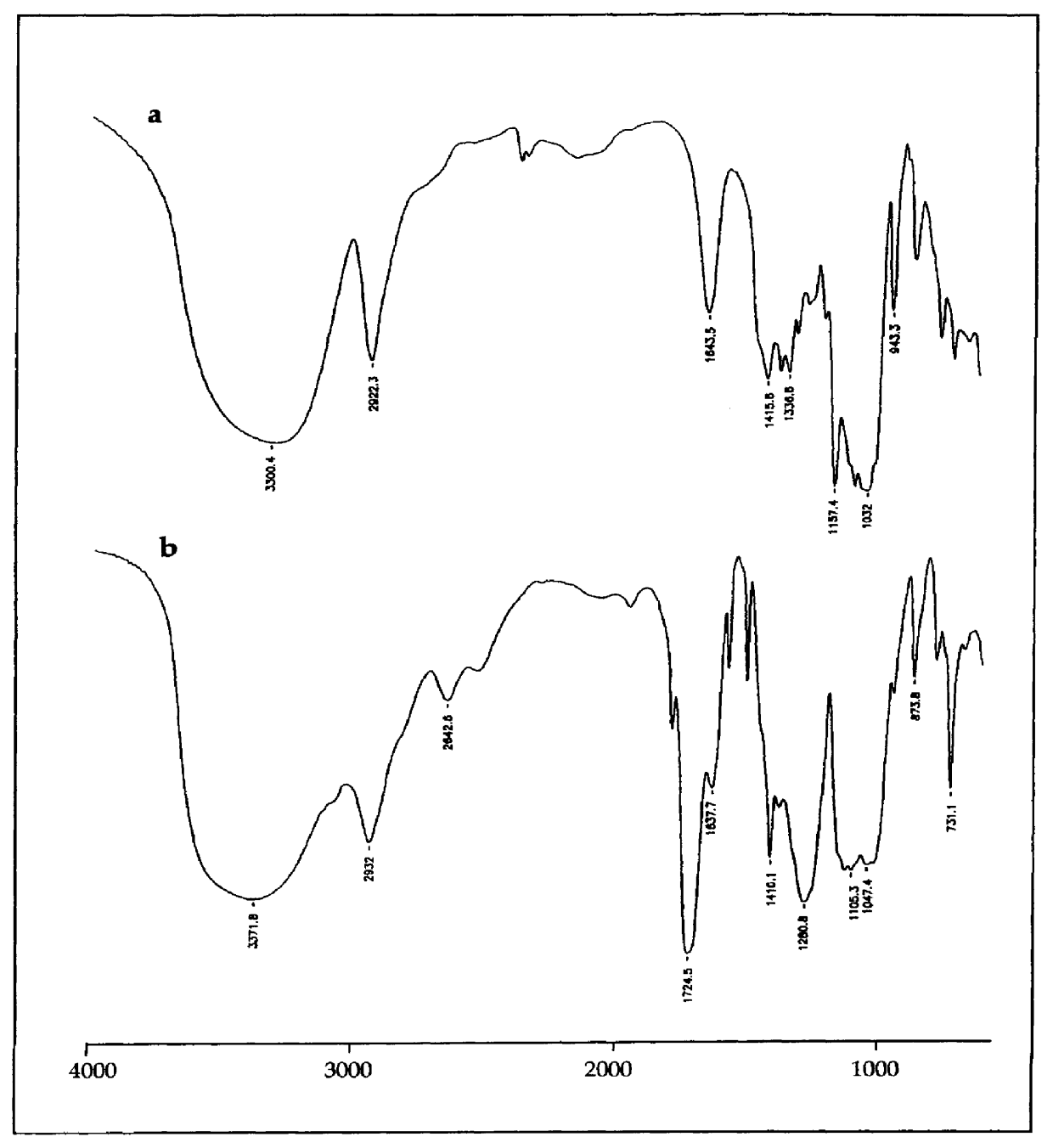

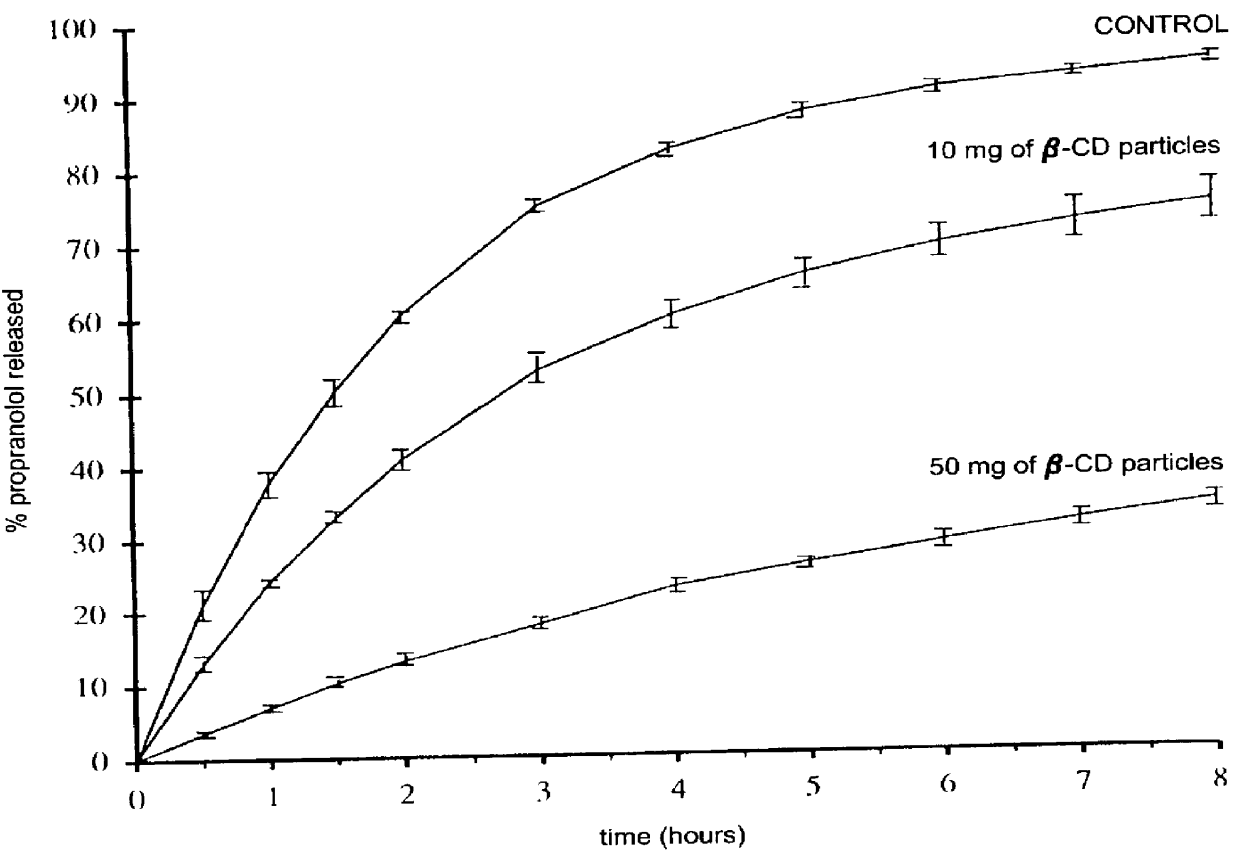

Particles, especially microparticles or nanoparticles, of crosslinked monosaccharides and oligosaccharides, processes for their preparation and cosmetic, pharmaceutical or food compositions in which they are present

InactiveUS6197757B1Demonstrates their biodegradabilityAccurate timingBiocideCosmetic preparationsEmulsionNanoparticle

Particles comprising an outer wall formed of one or more saccharide components selected from the group consisting of monosaccharides and oligosaccharides crosslinked by interfacial crosslinking in emulsion, preferably at room temperature, with a polyfunctional acylating crosslinking agent to produce ester linkages between the acylatable hydroxyl group(s) of the primary alcohol(s) of the saccharide component and the acyl groups of the polyfunctional acylating agent. These particles can be used for the manufacture of cosmetic, pharmaceutical and food compositions.

Owner:BASF BEAUTY CARE SOLUTIONS FRANCE SAS

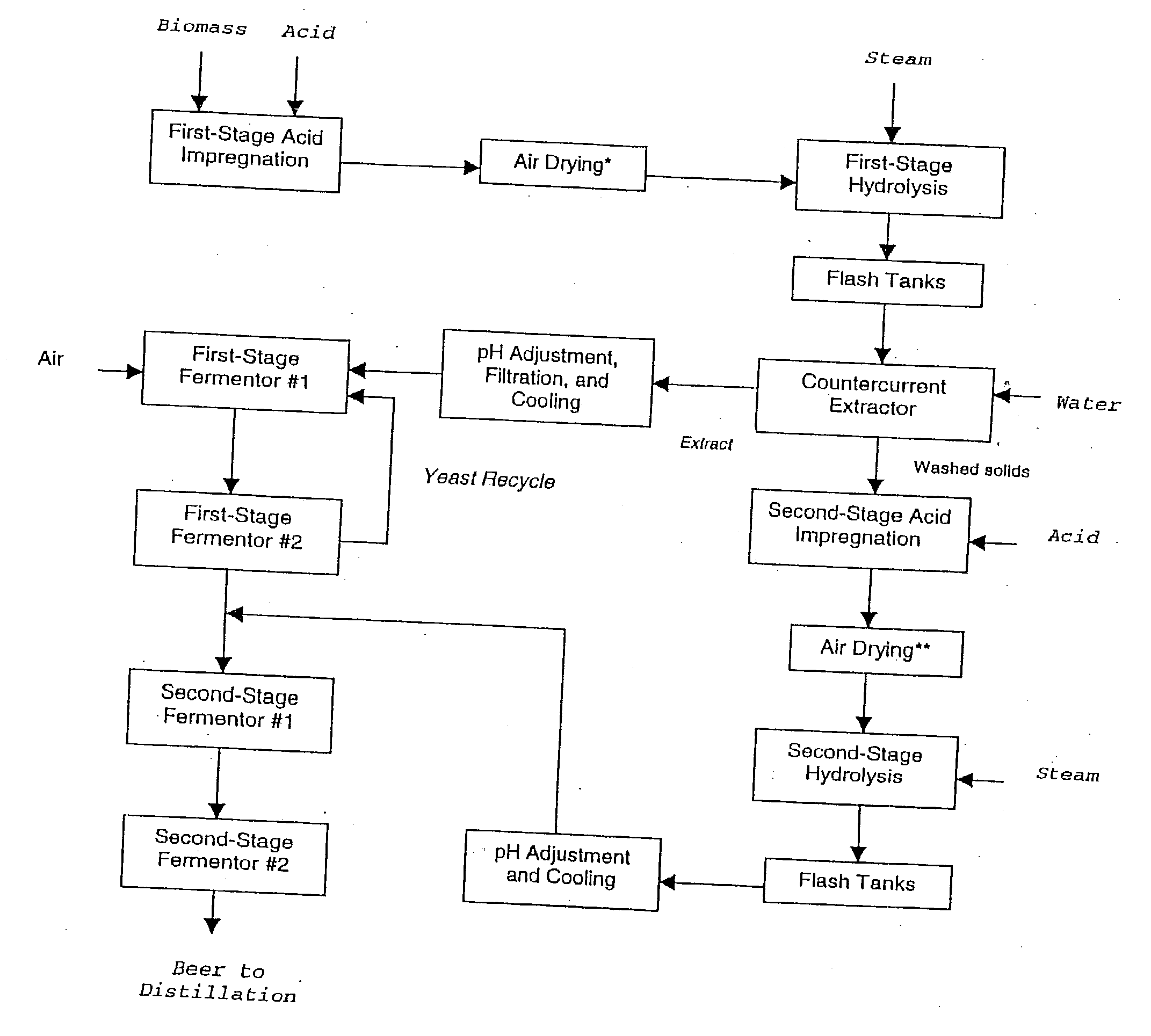

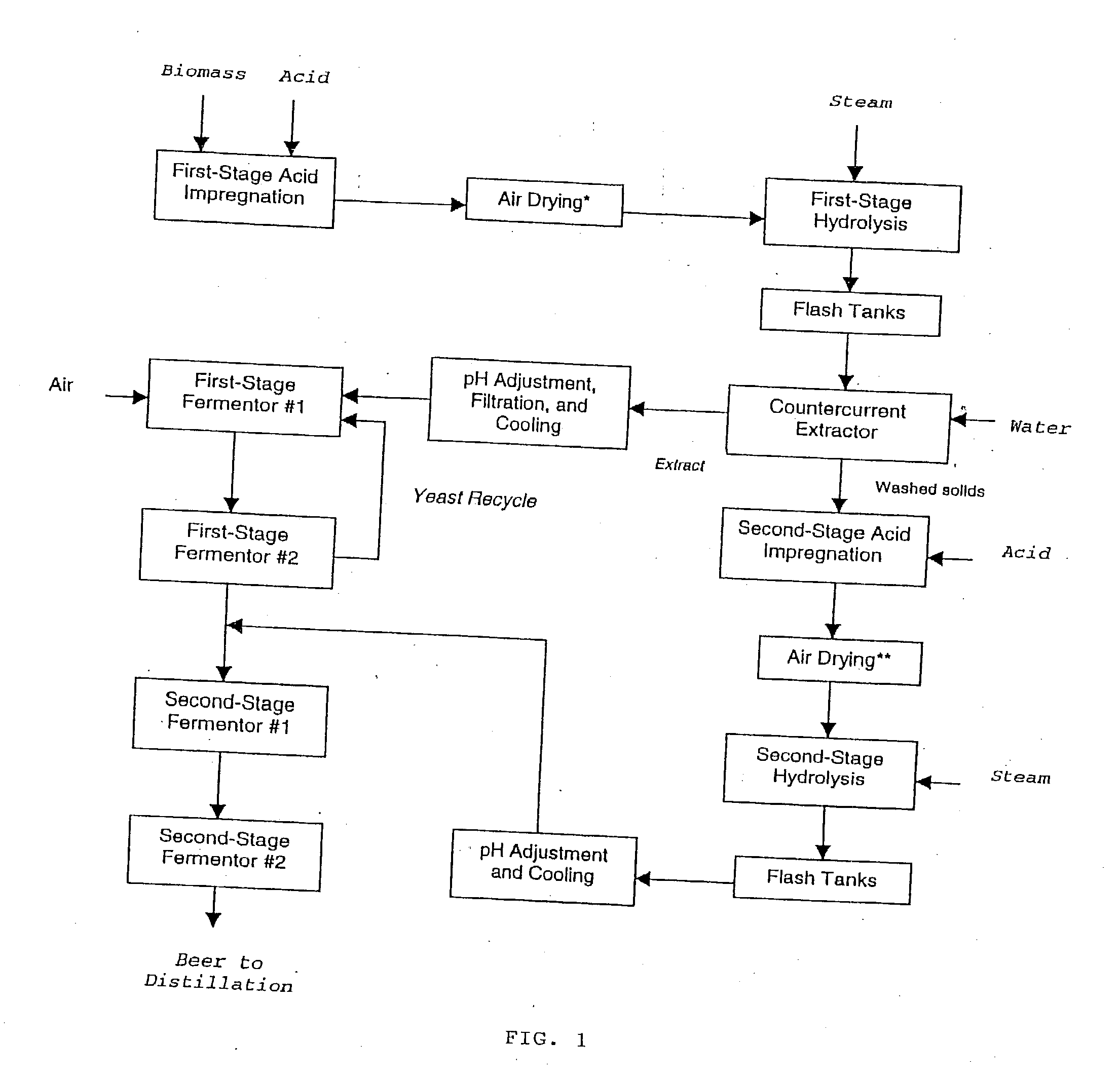

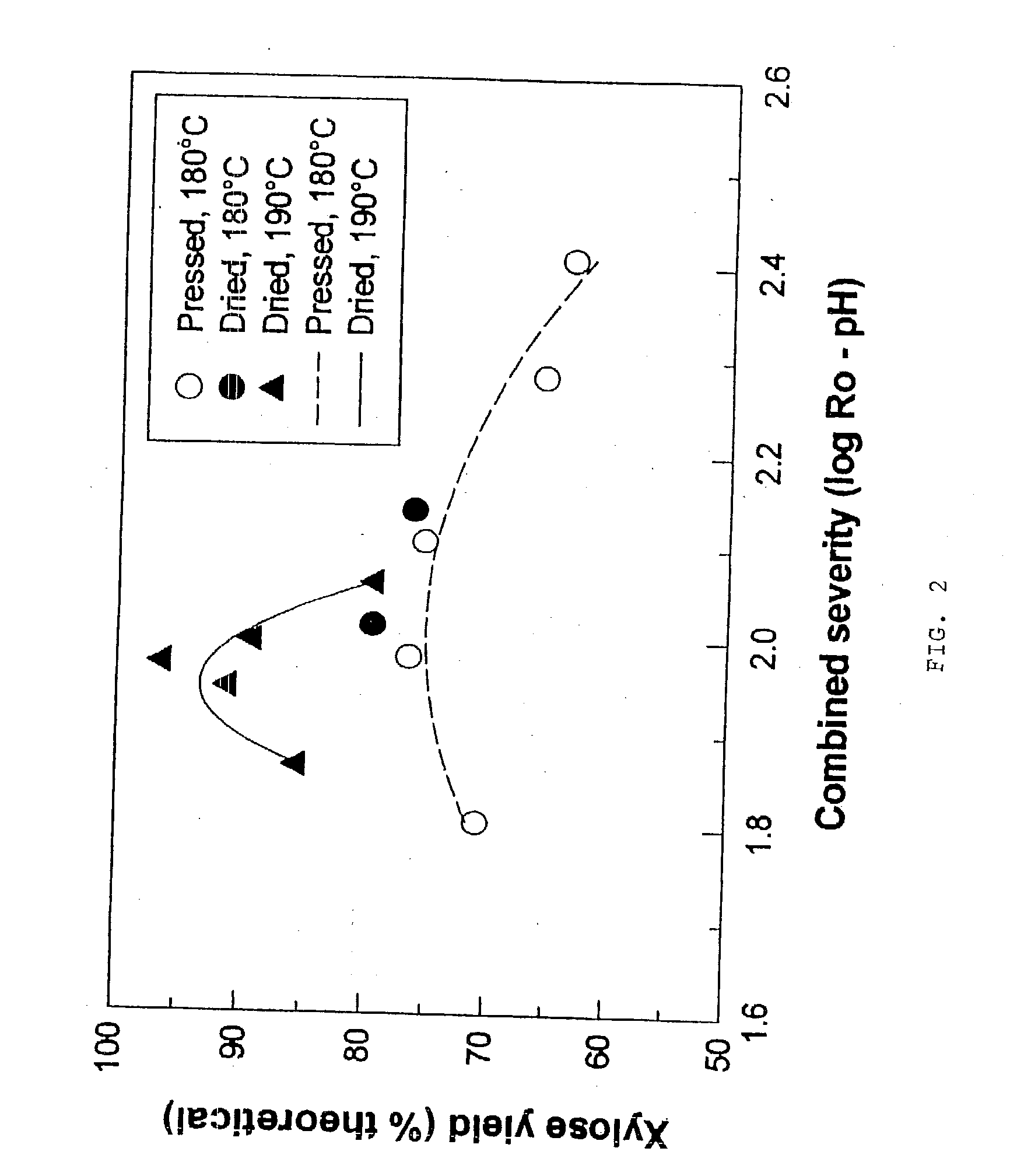

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

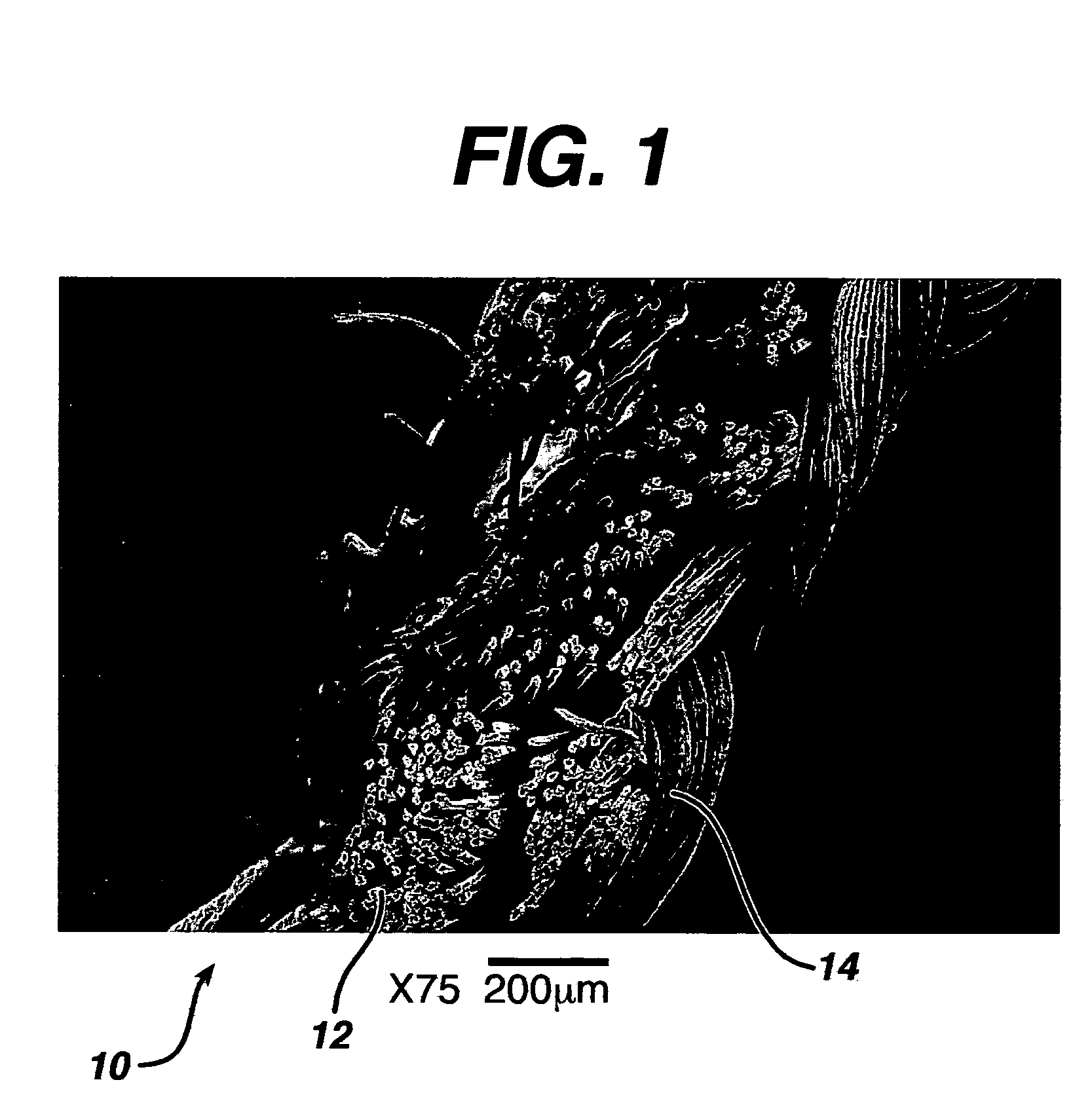

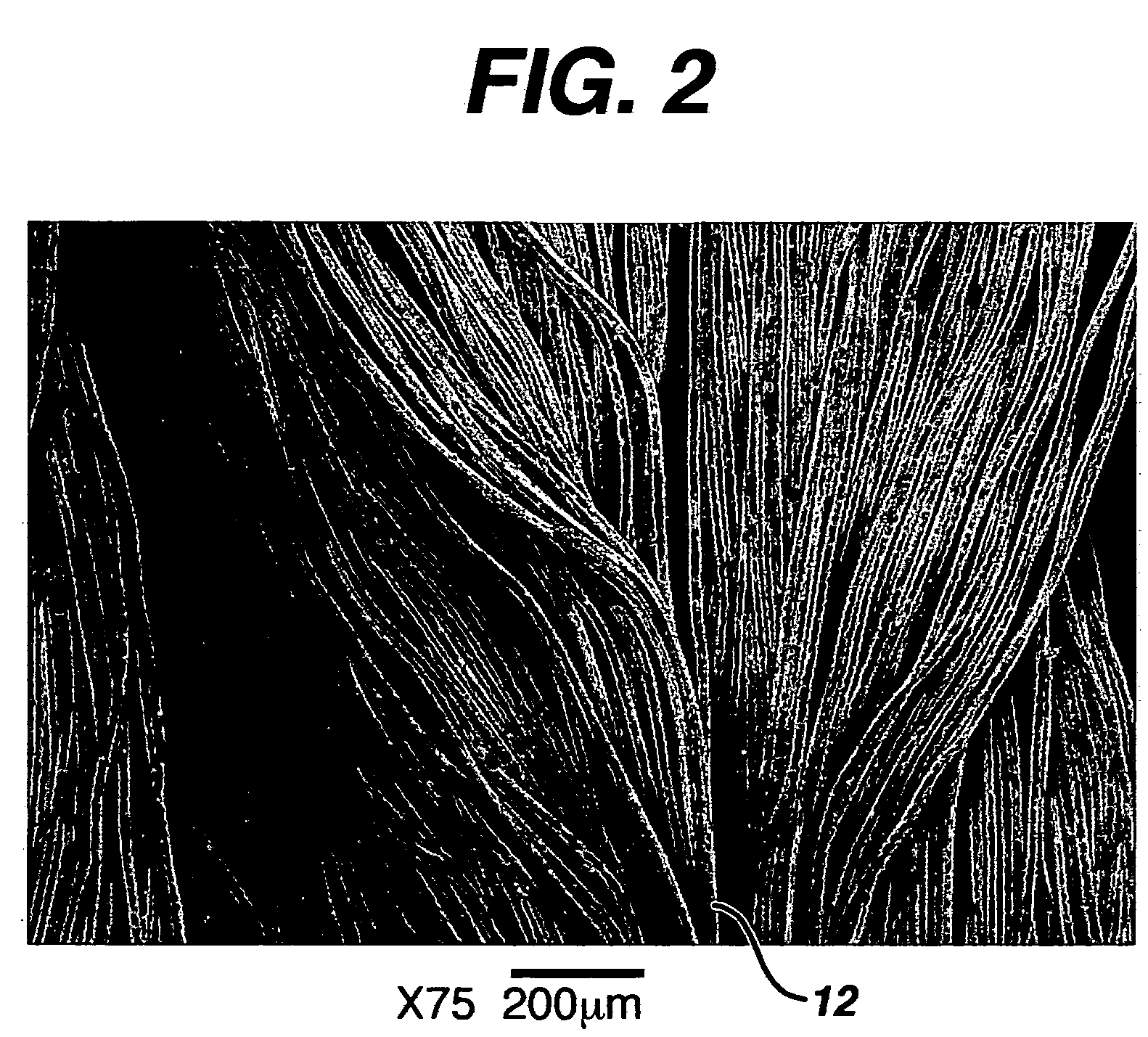

Hemostatic wound dressings and methods of making same

The present invention is directed to a hemostatic wound dressing that utilizes a fibrous, fabric substrate made from carboxylic-oxidized cellulose and containing a first surface and a second surface opposing the first surface, the fabric having flexibility, strength and porosity effective for use as a hemostat; and further having a porous, polymeric matrix substantially homogeneously distributed on the first and second surfaces and through the fabric, the porous, polymeric matrix being made of a biocompatible, water-soluble or water-swellable cellulose polymer, wherein prior to distribution of the polymeric matrix on and through the fabric, the fabric contains about 3 percent by weight or more of water-soluble oligosaccharides.

Owner:ETHICON INC

Sweetner and use

Sweeteners on the basis of a simultaneously transglucosylated sweet glycoside mixture of Stevia rebaudiana Bertoni are prepared. The transglycosylation was developed in the presence of starch under the action of cyclodextrin glucanotransferase. The remaining maltodextrins are transferred to the fructose-terminated oligosaccharides. The sweeteners are purified to not less than 98% content of sweet glycosides and derivatives. The preparations are almost non-caloric, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, cosmetics and milk products.

Owner:PURECIRCLE SDN BHD

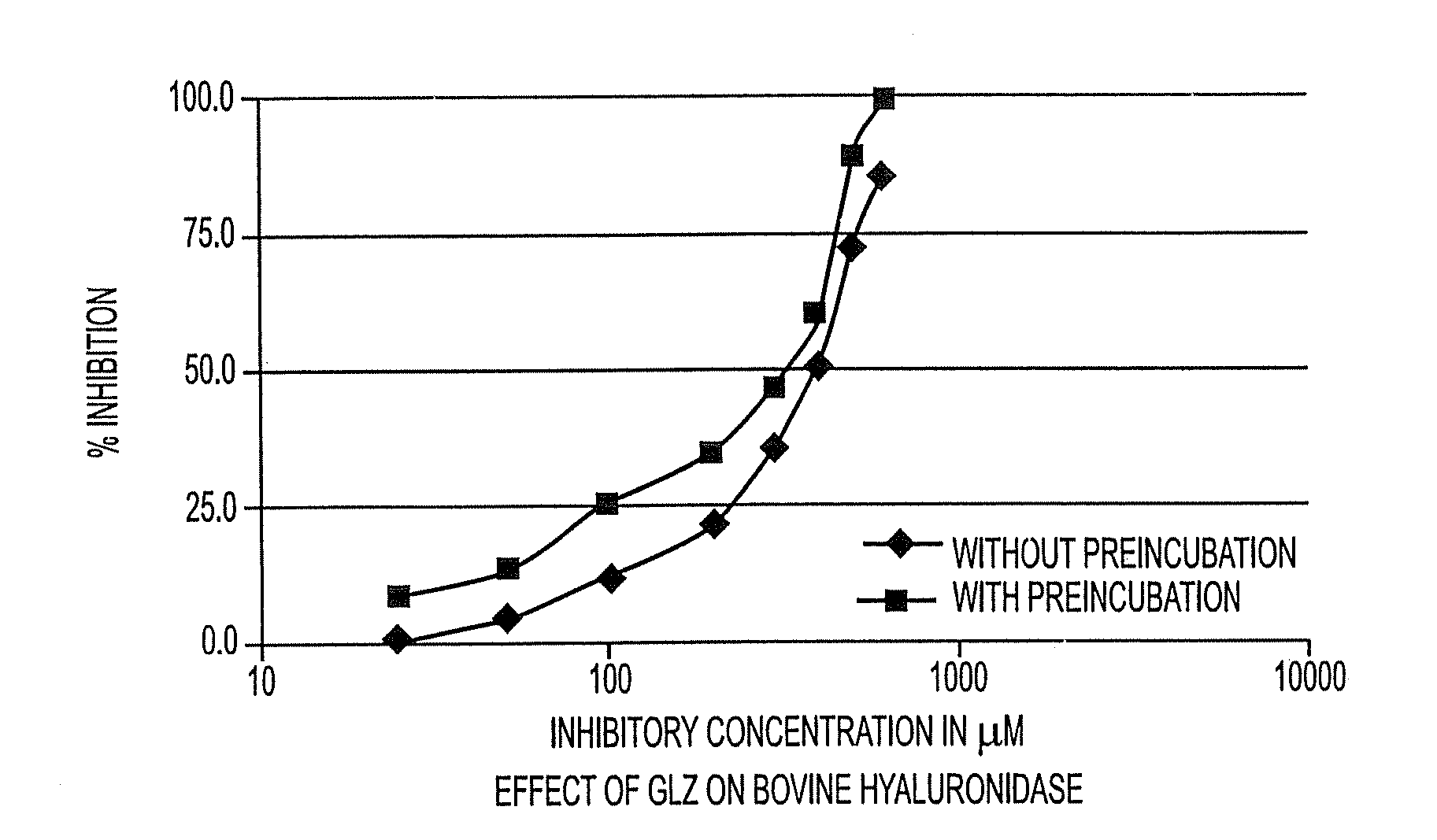

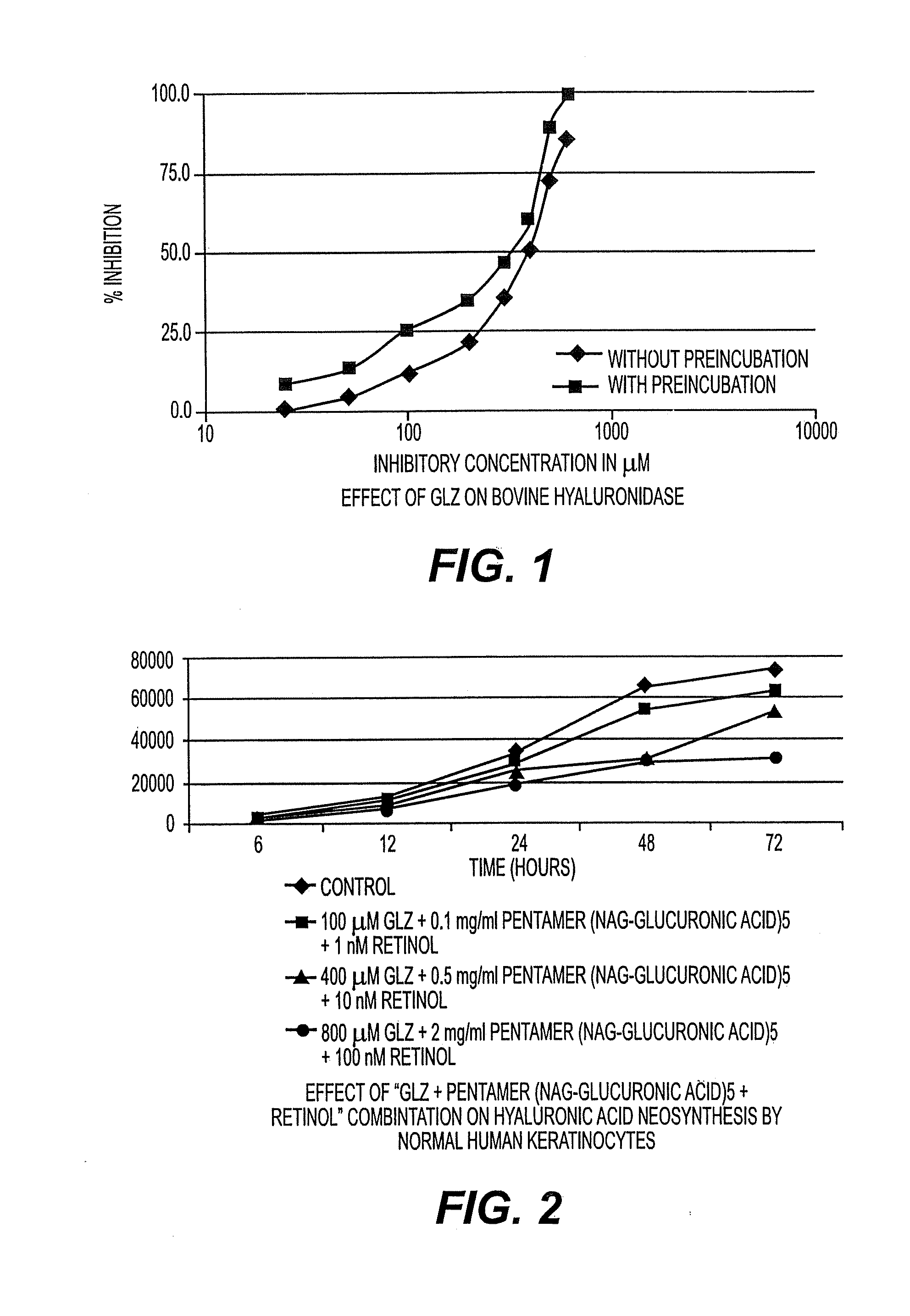

Phamaceutical/cosmetic compositions comprising hyaluronic acid and treatment of dermatological conditions therewith

InactiveUS20090018102A1Improve bioavailabilityReduce in quantityCosmetic preparationsBiocideFine lineWrinkle skin

Pharmaceutical / cosmetic compositions containing a dermatologically effective amount of hyaluronic acid, at least one retinoid and / or salt and / or derivative thereof, at least one oligosaccharide and at least one inhibitor of hyaluronic acid degradation, formulated into a physiologically acceptable medium therefor, are useful for the treatment of wrinkles, fine lines, fibroblast depletions and scars.

Owner:GALDERMA RES & DEV SNC

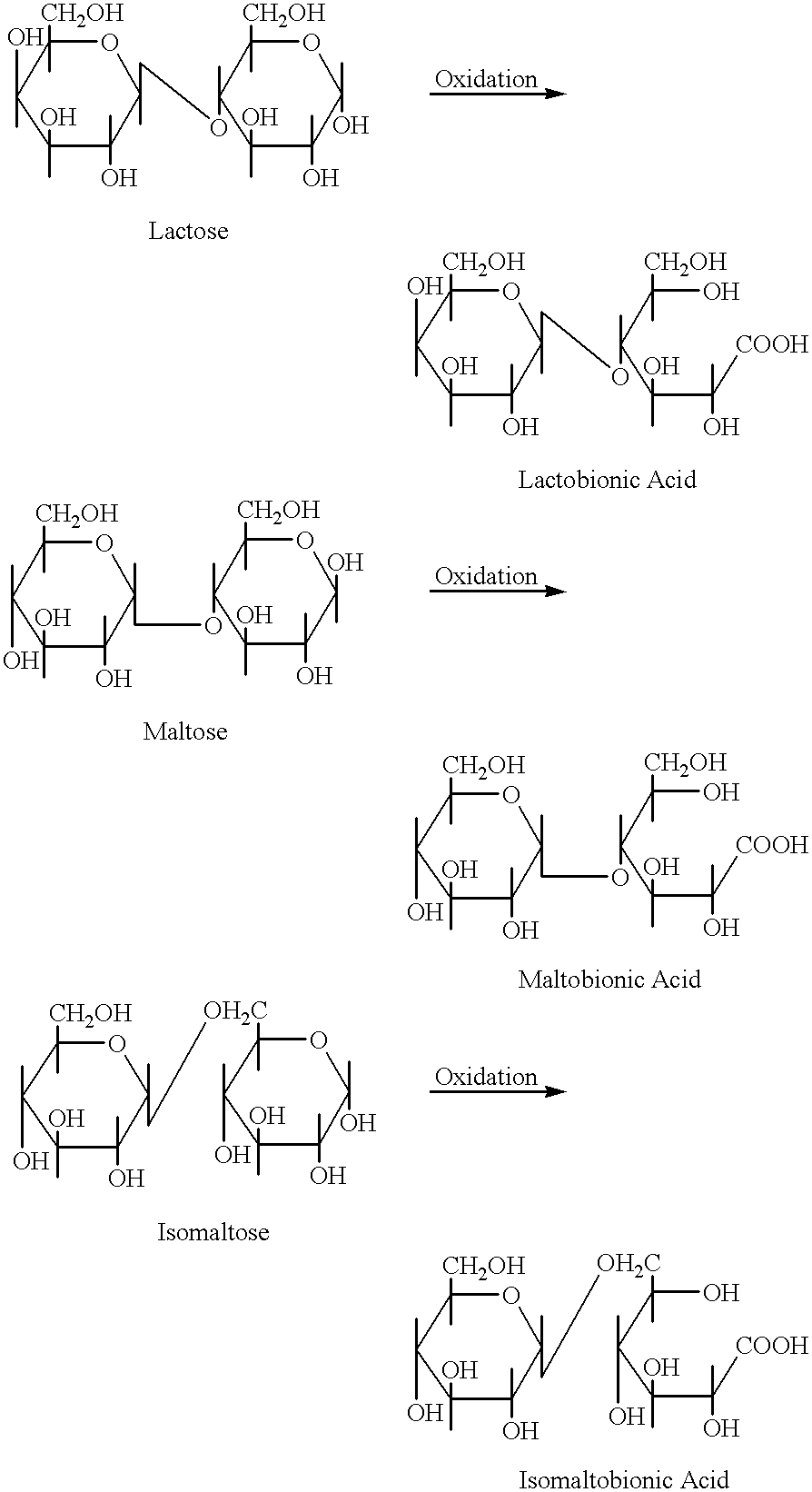

Oligosaccharide aldonic acids and their topical use

Compositions comprising oligosaccharide aldonic acids are useful for general care, as well as for treatment and prevention, of various cosmetic conditions and dermatological disorders, including those associated with intrinsic and / or extrinsic aging, as well as with changes or damage caused by extrinsic factors; general care, as well as treatment and prevention of diseases and conditions, of the oral, and vaginal mucosa; for general oral care, as well as treatment and prevention of oral and gum diseases; and for wound healing of the skin. Compositions comprising oligosaccharide aldonic acids may further comprise a cosmetic, pharmaceutical or other topical agent to enhance or create synergetic effects.

Owner:YU RUEY J +1

Composite probiotics micro-ecological formulation and preparation method

InactiveCN101496822AEnsure balancePromotes the detoxification processBacteria material medical ingredientsDigestive systemDiseaseChronic diarrhea

The invention relates to a composite probiotic bacterium microecological preparation and a preparation method thereof. The preparation is prepared by mixing 1.0 to 20 percent of composite microbial bacterium powder, 5.0 to 50 percent of composite oligosaccharide, 30 to 80 percent of auxiliary protective carrier and 0.1 to 0.2 percent of edible essence. The composite probiotic bacterium microecological preparation is prepared from a beneficial microbial preparation and a microbial growth-promoting factor, namely the oligosaccharide, through special combination and technological recombination. The composite probiotic bacterium microecological preparation has the advantages that beneficial active bacteria and the oligosaccharide promote each other, so that the composite probiotic bacterium microecological preparation has the advantages of obviously improving the microecological environment of the whole intestine and contributing to the digestion, preventing and treating intestine diseases, treating diarrhea, chronic diarrhea, diarrhea which can not be cured by antibiotic, constipation, dyspepsia and abdominal distension which are caused by intestine dysbacteriosis, recovering the intestine flora balance, protecting the liver, reinforcing the functions of detoxication and toxin expulsion of the liver, reinforcing the disease prevention and resistance such as the resistance of human body, and the like.

Owner:上海谱莱生物技术有限公司

Topical anti-wrinkle and anti-aging moisturizing cream

InactiveUS20100098794A1Restoring skinRestoring to stateOrganic active ingredientsBiocideWater basedMedicine

The present invention relates to a topical anti-wrinkle and anti-aging moisturizing cream designed (formulated) to repair and restore human adult skin to its original youthful state. This has successfully been achieved by using a water based molecular mixture of high molecular weight (0.5 to 2.0 million Daltons) hyaluronic acid (HA) and of low molecular weight hyaluronic acid oligosaccharides (small HA fragments less than 12000 Daltons molecular weight) to create this unique anti-aging moisturizer. An equal mixture of high molecular HA and HA-oligosaccharides at concentrations of 0.1-0.2% was found to be essential for providing our moisturizer its unique ability to repair and rejuvenate adult human skin.

Owner:ARMAND GERARD

Sweetner and use

Sweeteners on the basis of a simultaneously transglucosylated sweet glycoside mixture of Stevia rebaudiana Bertoni are prepared. The transglucosylation was developed in the presence of starch under the action of cyclodextrin glucanotransferase. The remaining maltodextrins are transformed to the fructose-terminated oligosaccharides by the addition of sucrose. The sweeteners are purified to not less than 98% content of sweet glycosides and derivatives. The preparations are almost non-caloric, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, cosmetics and milk products.

Owner:PURECIRCLE SDN BHD

Methods for enzymatic hydrolysis of lignocellulose

Compositions and methods for biomass conversion are provided. Compositions comprise novel enzyme mixtures that can be used directly on lignocellulose substrate. Methods involve converting lignocellulosic biomass to free sugars and small oligosaccharides with enzymes that break down lignocellulose. Novel combinations of enzymes are provided that provide a synergistic release of sugars from plant biomass. Also provided are methods to identify enzymes, strains producing enzymes, or genes that encode enzymes capable of degrading lignocellulosic material to generate sugars.

Owner:ATHENIX

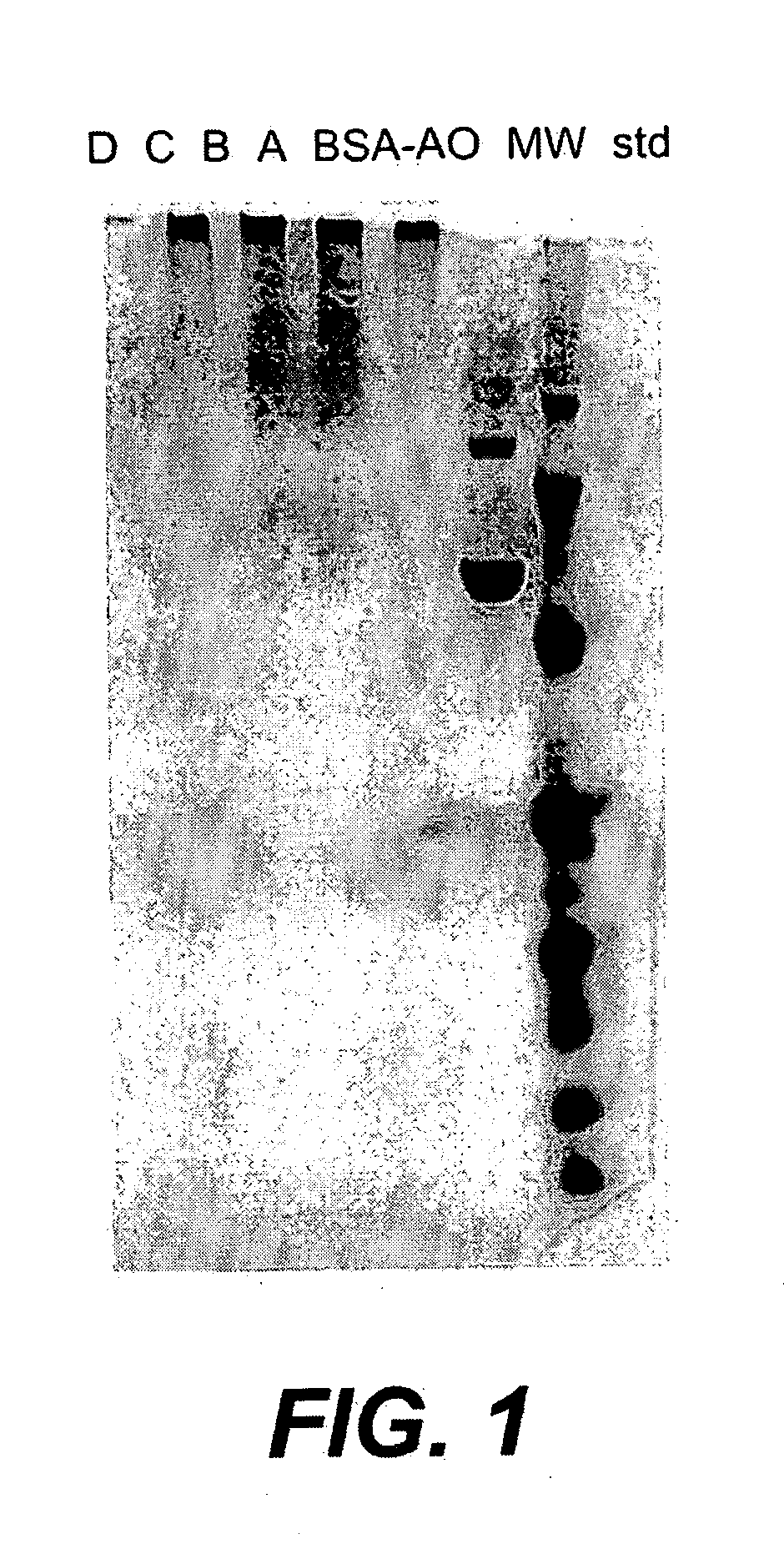

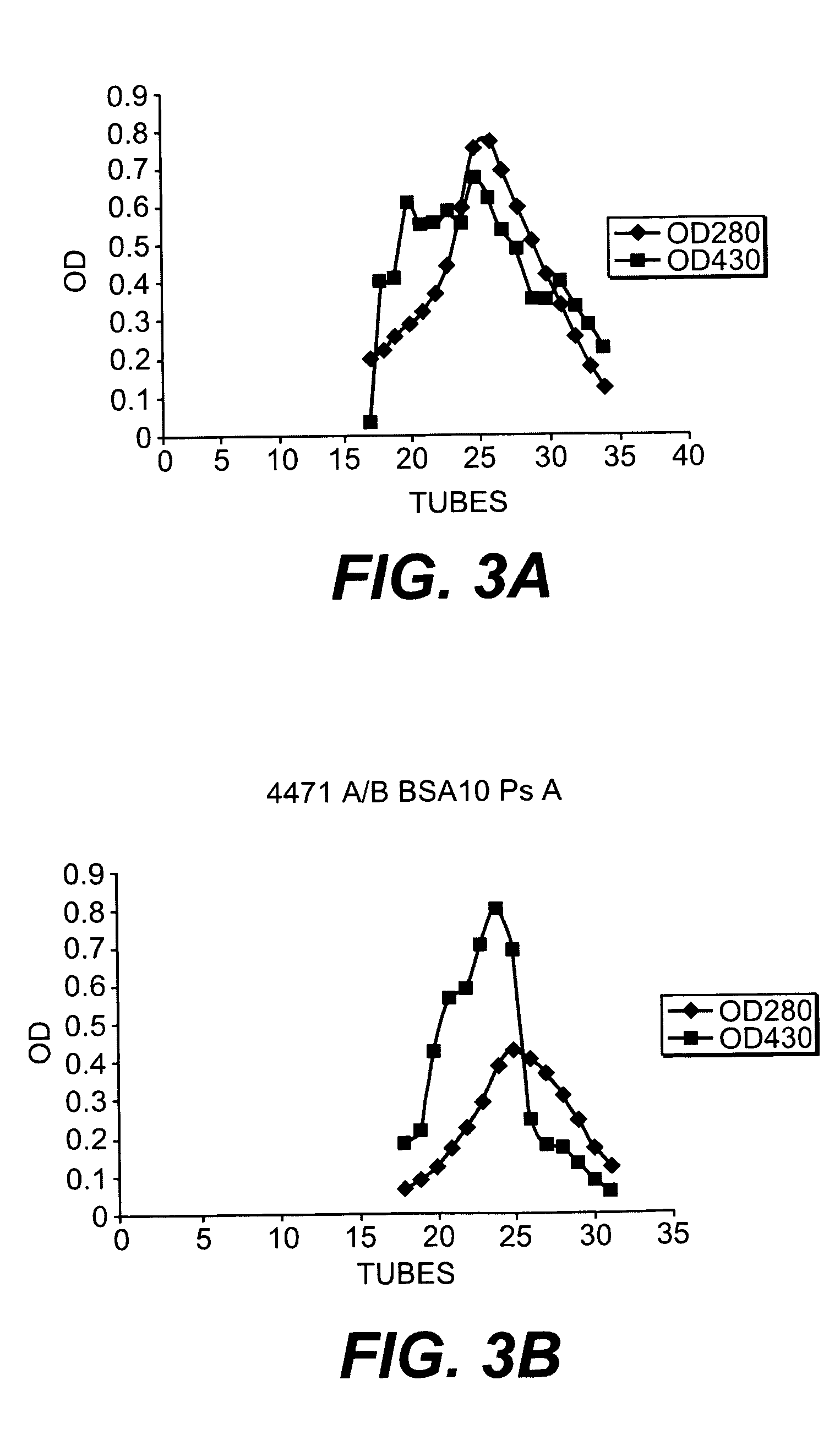

Use of amino-oxy functional groups in the preparation of protein-polysaccharide conjugate vaccines

InactiveUS20050169941A1Antibacterial agentsBacterial antigen ingredientsConjugate vaccineCompound (substance)

The invention relates to a process for preparing a conjugate comprising combining an amino-oxy homofunctional or heterofunctional reagent with an entity chosen from polysaccharides, oligosaccharides, carbohydrates, and carbohydrate-containing molecules containing at least one carbonyl group, to form a polysaccharide, oligosaccharide, carbohydrate, or carbohydrate-containing molecule functionalized via at least one oxime linkage. The functionalized compound is then reacted either directly or indirectly with a protein moiety to form a protein-carbohydrate conjugate that may be used as a vaccine.

Owner:FINA BIOSOLUTIONS

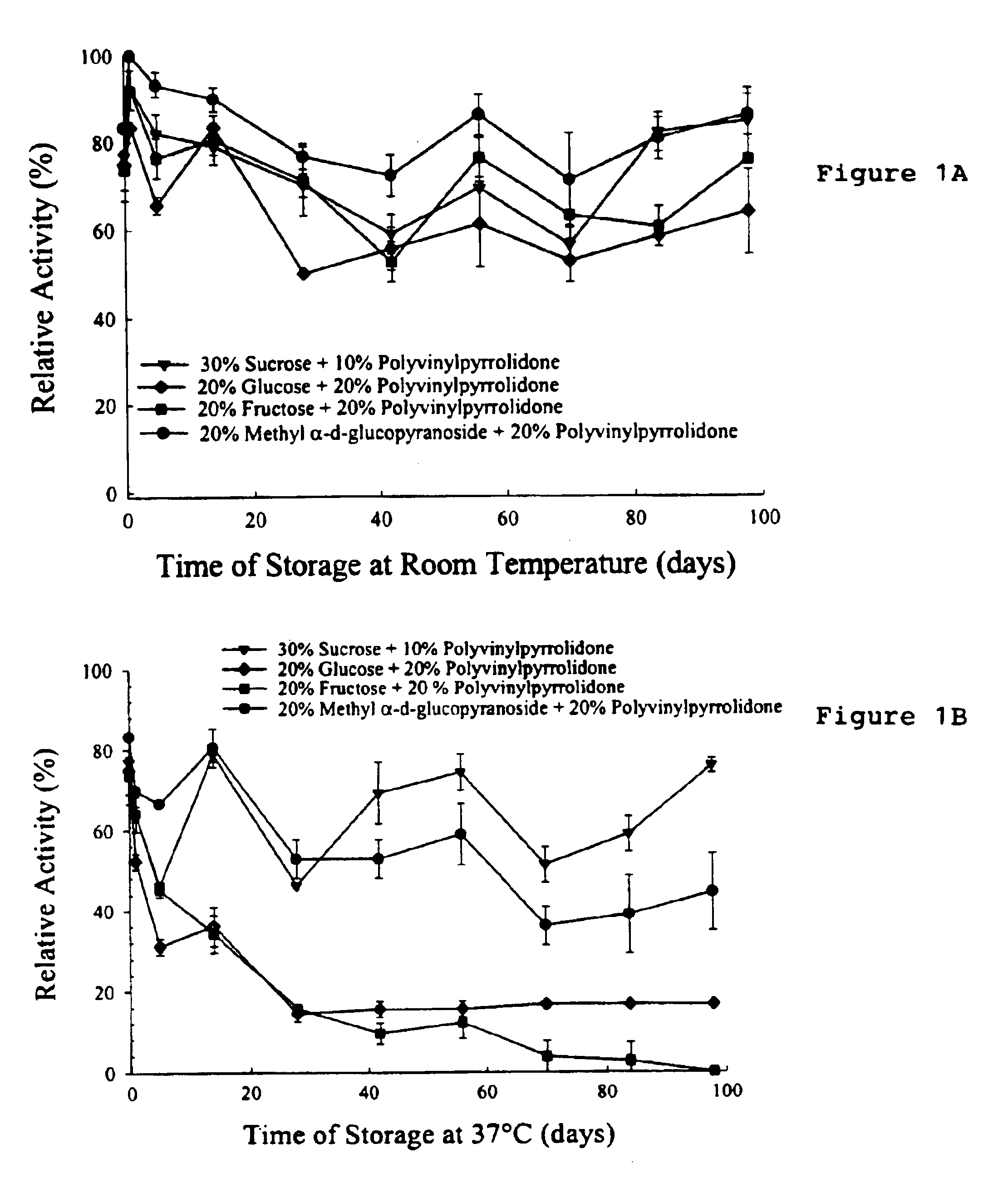

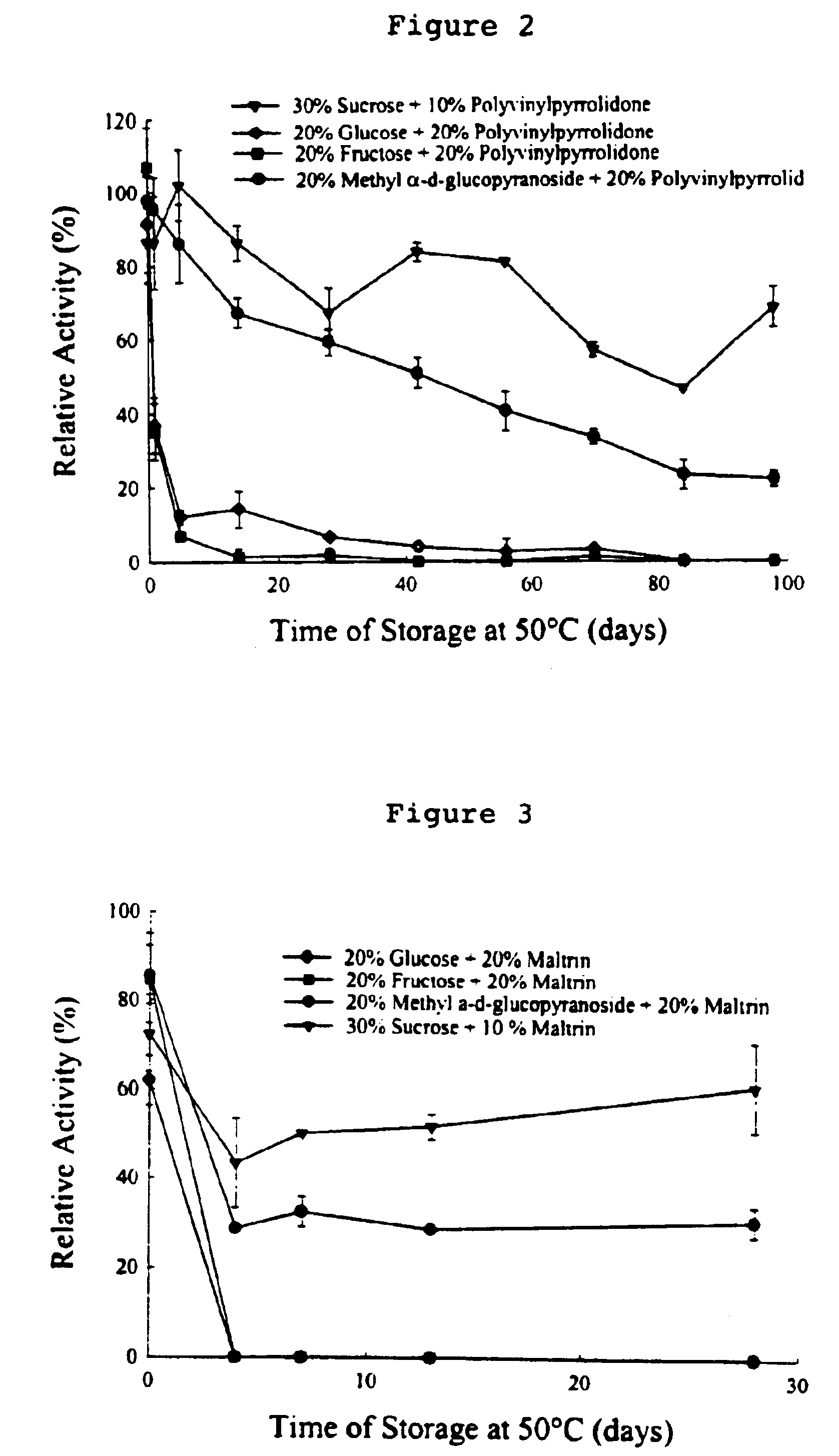

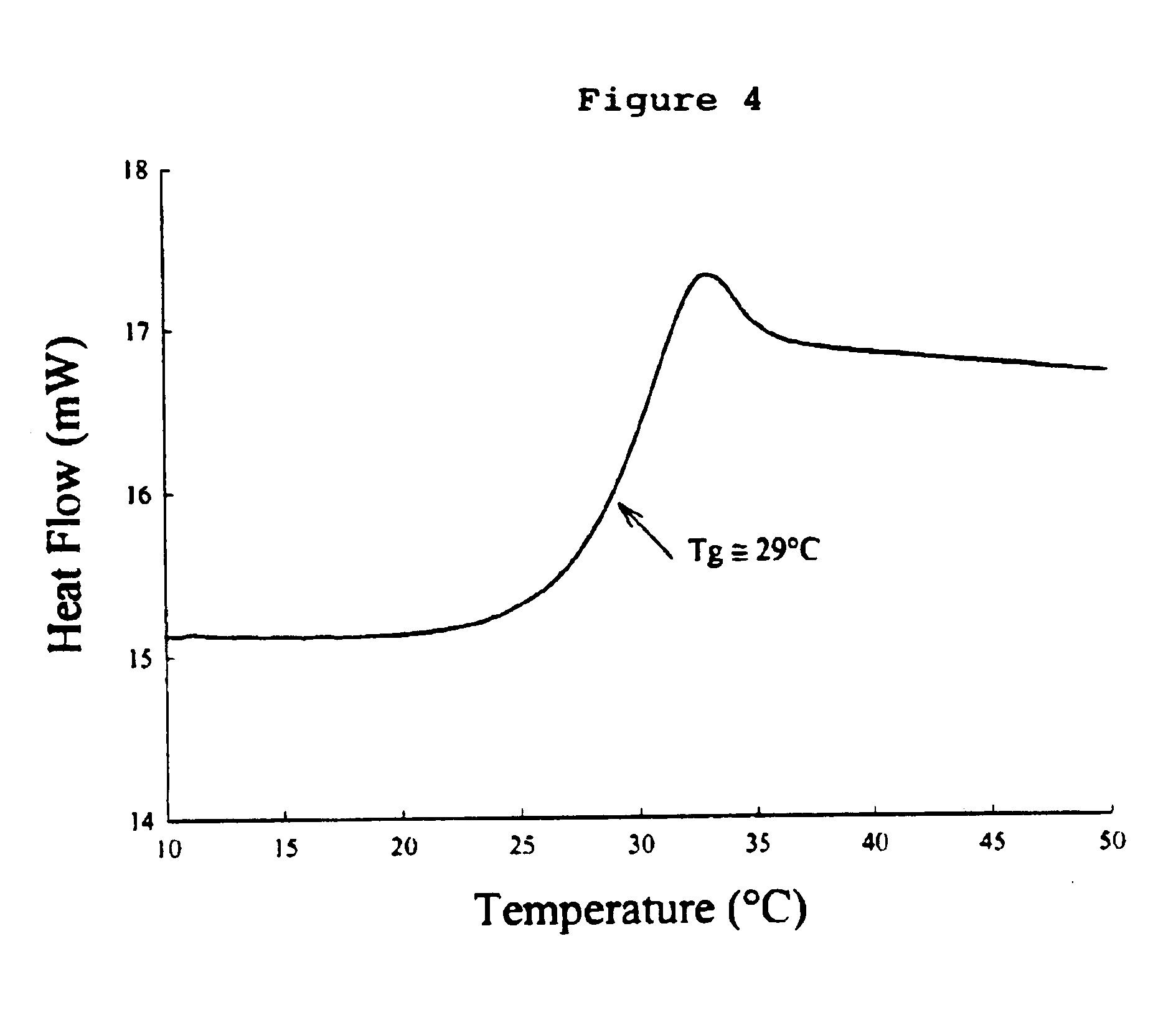

Formulation of preservation mixtures containing sensitive biologicals to be stabilized for ambient temperature storage by drying

This invention relates to formulations and methods for preserving sensitive biologicals, viruses, bacteria and eukaryotic cells by drying. More particularly, the invention relates to preservation mixtures containing viruses or cells and protectants, including a combination of a methylated monosaccharide and a disaccharide, or oligosaccharide, wherein the mixtures are adapted to stabilize these during dehydration and subsequent storage at ambient and higher temperature.

Owner:AVANT IMMUNOTHERAPEUTICS

Nutritional composition for treating an immune condition

InactiveUS6929793B2Treat conditionPrevention or inhibition of diarrheaOrganic active ingredientsBacteriaVitamin CPhysiology

A nutritional composition is described for prevention or treatment of an immune condition. The composition includes at least vitamin E, vitamin C, vitamin B6, folic acid, vitamin B12, copper, zinc, selenium, fructo-oligosaccharides and / or gum acacia, a probiotic lactic acid bacterium. For example, in an embodiment it comprises per 300 g: 150 IU Vitamin E, 120 mg Vitamin C, 2 mg Vitamin B6, 400 ug Folic acid, 3.8 ug Vitamin B12, 1.5 mg Copper, 15 mg Zinc, 100 ug Selenium, 3 g Fructo-oligosaccharides and / or gum acacia, 10E10 cfu ST11 lactobacillus. Also disclosed are a method for making the nutritional composition, a method for manufacturing a functional food or medicament; and a method of prevention or treatment of an immune condition by administering an effective amount of the composition, functional food or medicament.

Owner:SOC DES PROD NESTLE SA

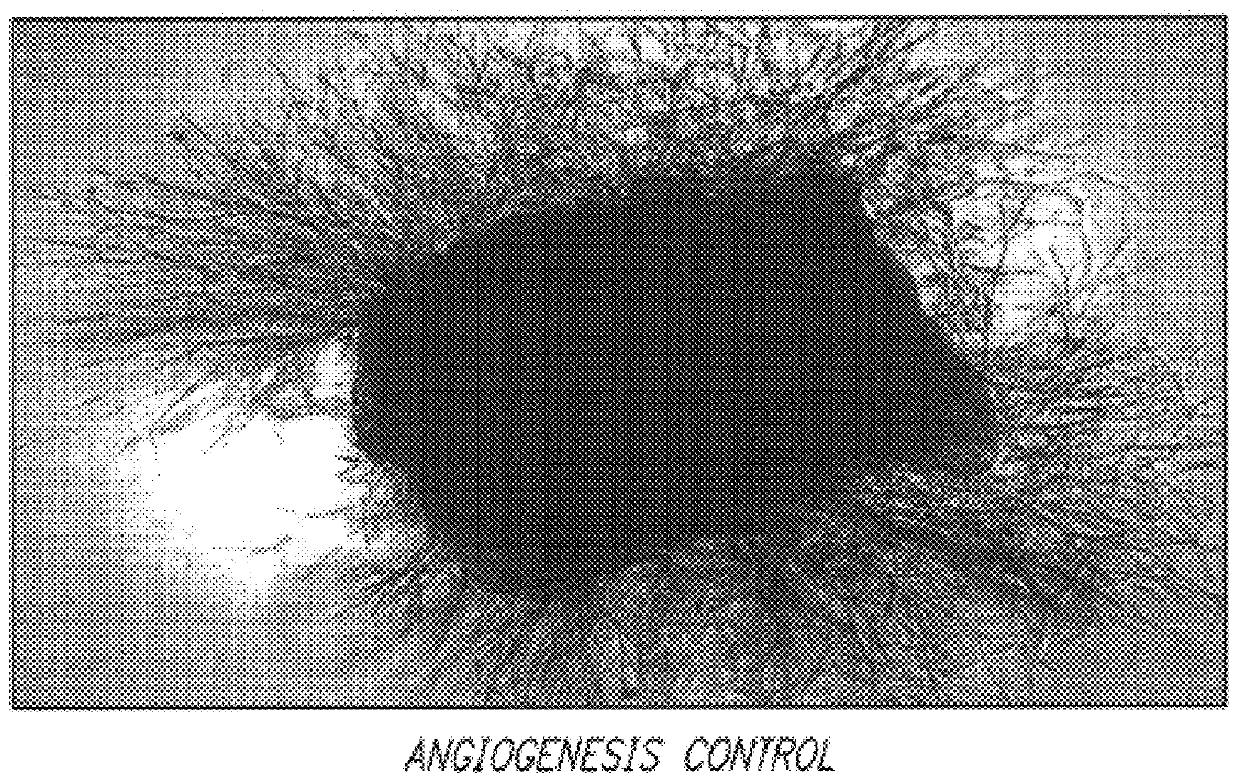

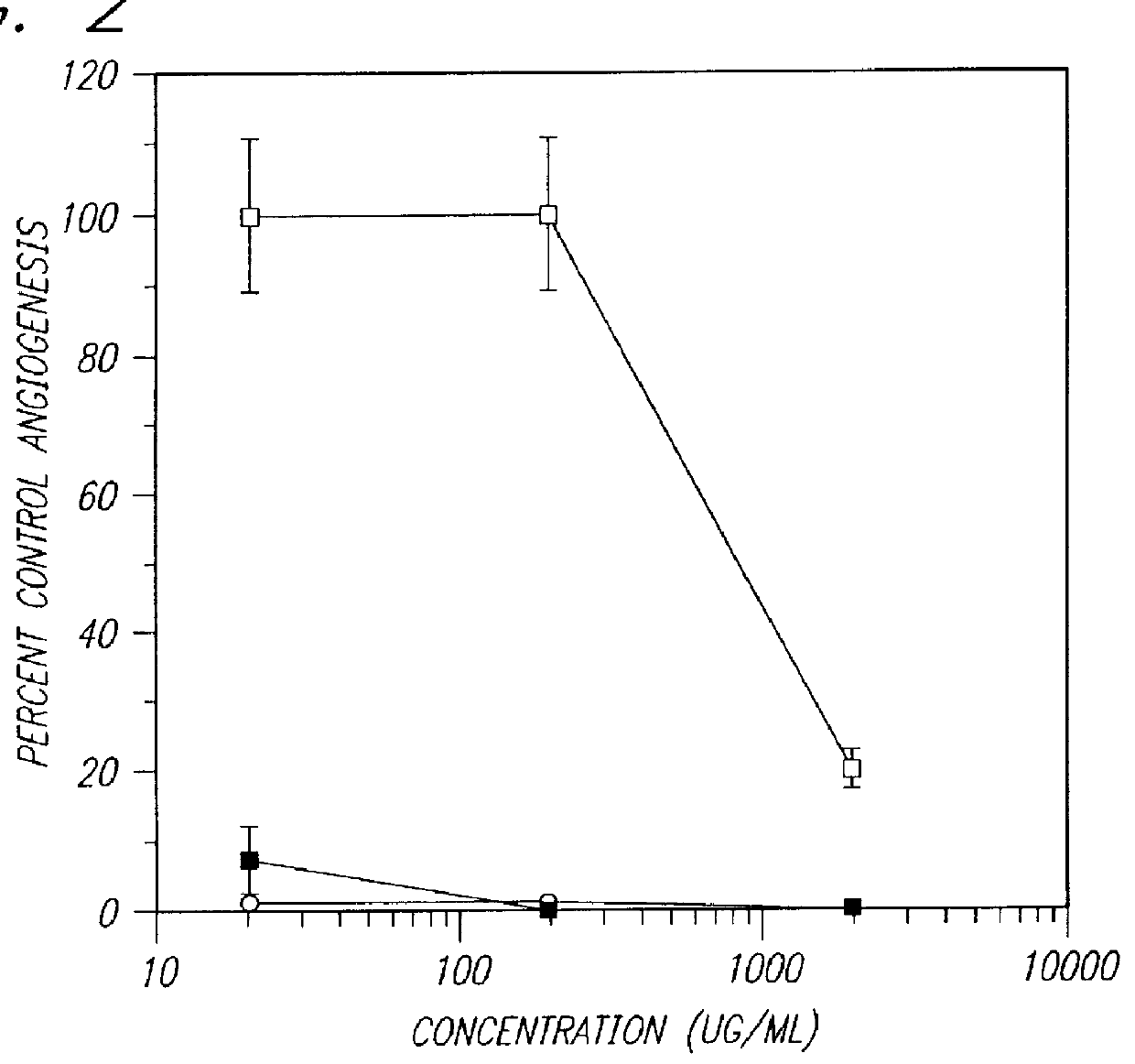

Preparation and use of sulfated oligosaccharides

PCT No. PCT / AU96 / 00238 Sec. 371 Date Oct. 28, 1997 Sec. 102(e) Date Oct. 28, 1997 PCT Filed Apr. 24, 1996 PCT Pub. No. WO96 / 33726 PCT Pub. Date Oct. 31, 1996Sulfated oligosaccharides, wherein the oligosaccharide has the general formula I:R1-(Rx)n-R2(I)wherein R1 and R2 and each Rx represents a monosaccharide unit, all of which may be the same or different, adjacent monosaccharide units being linked by 1->2, 1->3, 1->4 and / or 1->6 glycosidic bonds and n is an integer of from 1 to 6, and use thereof as anti-angiogenic, anti-metastatic and / or anti-inflammatory agents.

Owner:AUSTRALIEN NAT UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com