Patents

Literature

2545results about How to "Improve digestibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel Insecticidal Proteins and Methods for Their Use

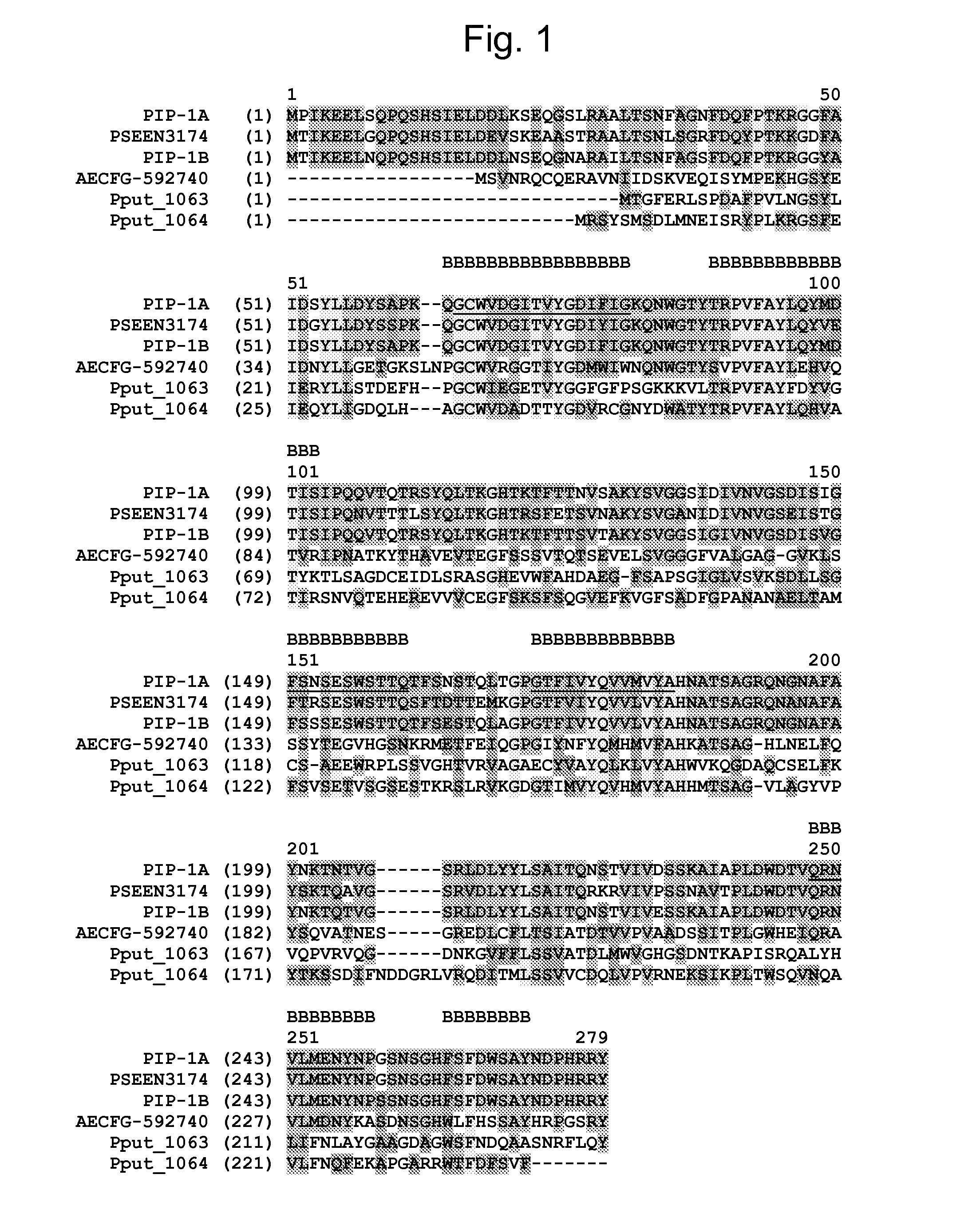

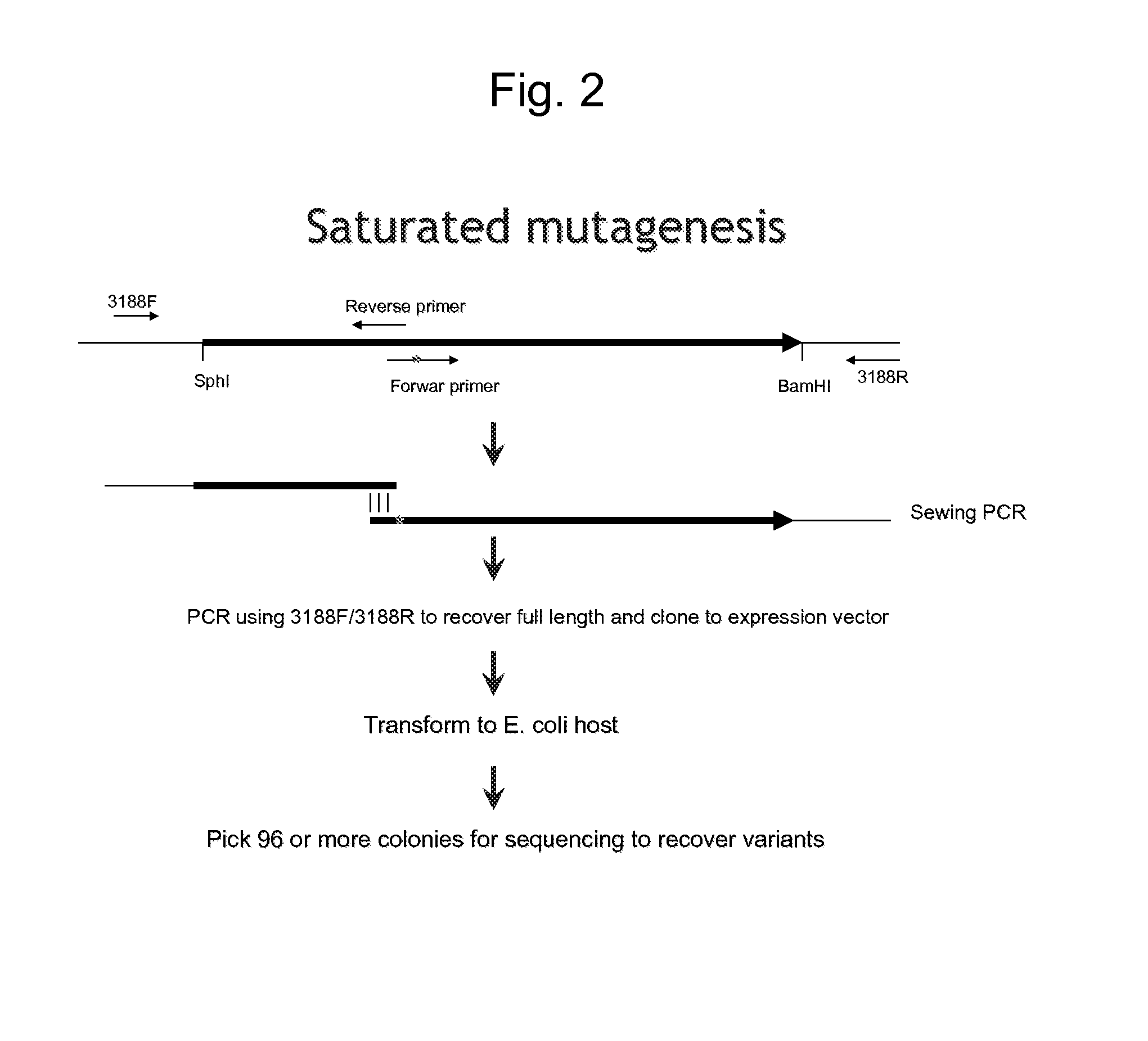

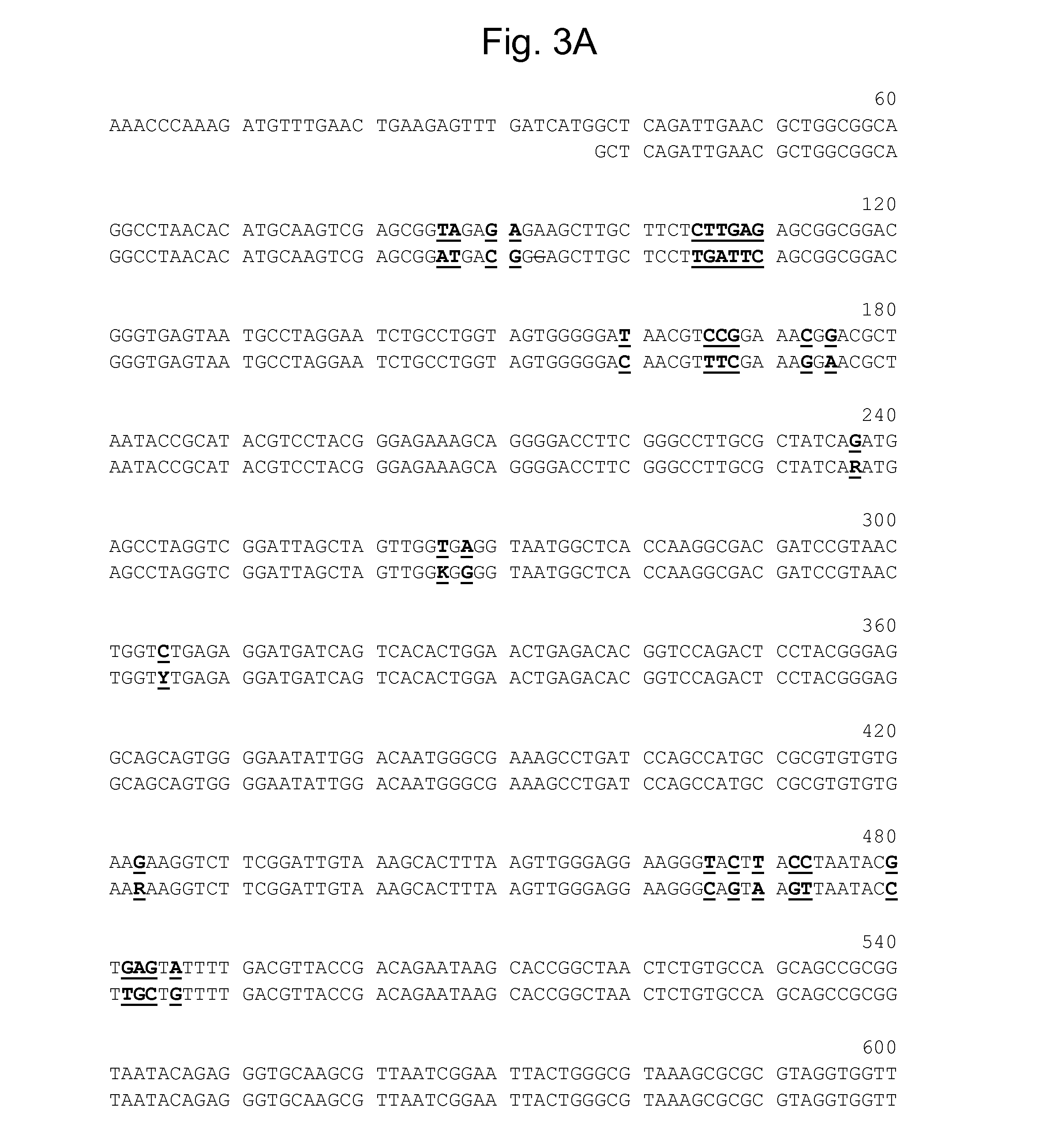

Compositions and methods for controlling pests are provided. The methods involve transforming organisms with a nucleic acid sequence encoding an insecticidal protein. In particular, the nucleic acid sequences are useful for preparing plants and microorganisms that possess insecticidal activity. Thus, transformed bacteria, plants, plant cells, plant tissues and seeds are provided. Compositions are insecticidal nucleic acids and proteins of bacterial species. The sequences find use in the construction of expression vectors for subsequent transformation into organisms of interest, as probes for the isolation of other homologous (or partially homologous) genes. The insecticidal proteins find use in controlling, inhibiting growth or killing lepidopteran, coleopteran, dipteran, fungal, hemipteran, and nematode pest populations and for producing compositions with insecticidal activity.

Owner:PIONEER HI BRED INT INC

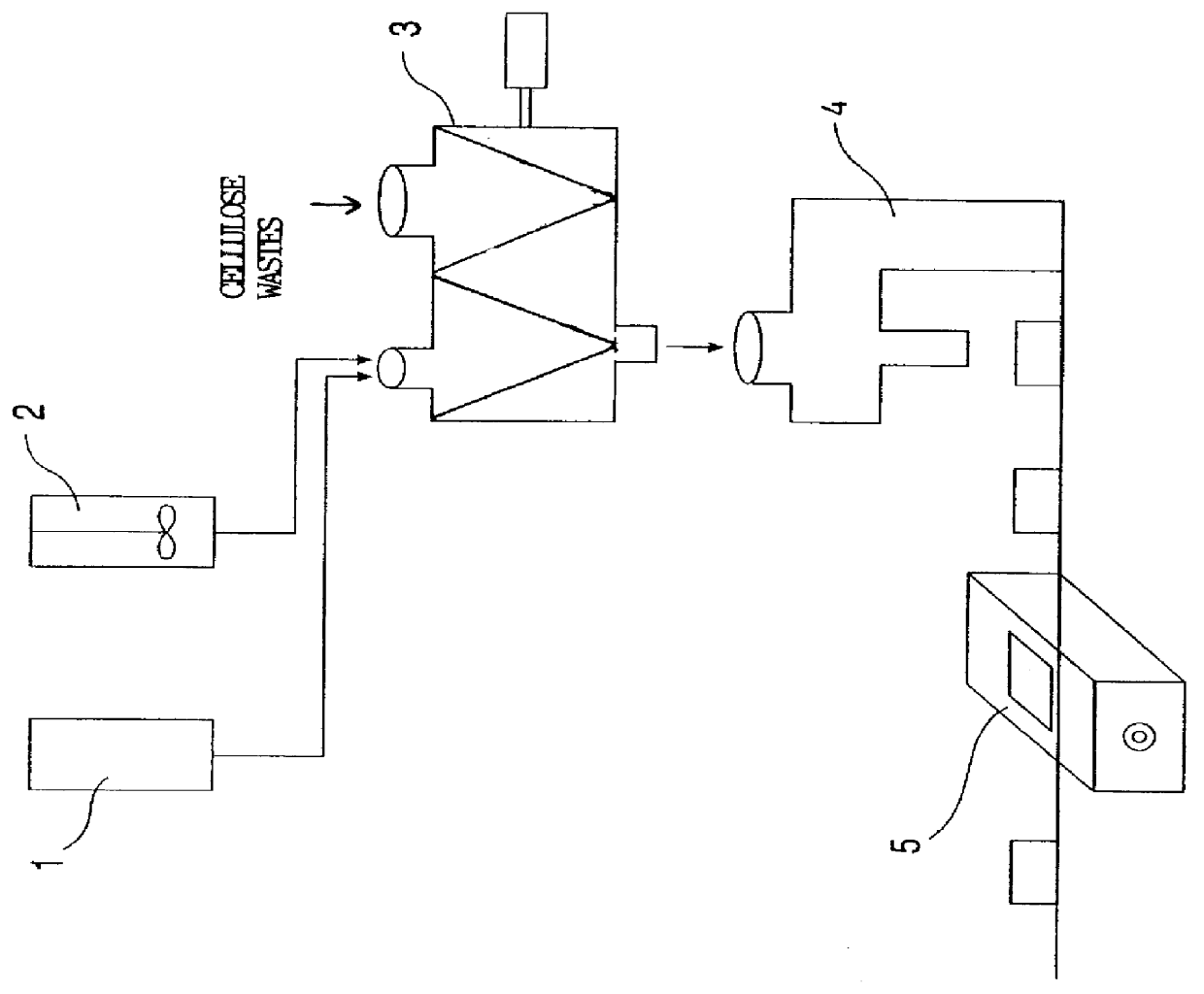

Method of bioconversion of industrial or agricultural cellulose containing wastes

InactiveUS6159510ADrawback mentionedHigh in proteinMilk preparationFood processingCelluloseMicroorganism

PCT No. PCT / IL98 / 00437 Sec. 371 Date Feb. 8, 2000 Sec. 102(e) Date Feb. 8, 2000 PCT Filed Sep. 10, 1998 PCT Pub. No. WO99 / 12429 PCT Pub. Date Mar. 18, 1999A method of bioconversion of organic industrial or agricultural cellulose containing wastes into proteinaceous product. The method comprises comminution of the wastes with moistening and addition of a starting culture inducing their biological degradation and conversion into simple carbohydrates. The carbohydrates are fermented into digestible products. The starting culture comprises cleaving enzymes produced by edible microorganisms such as fungus and bacteria selected from the group consisting of Ilumicola grisea, Trichoderma harzanum, Ruminococcus albus.

Owner:BIOFEED

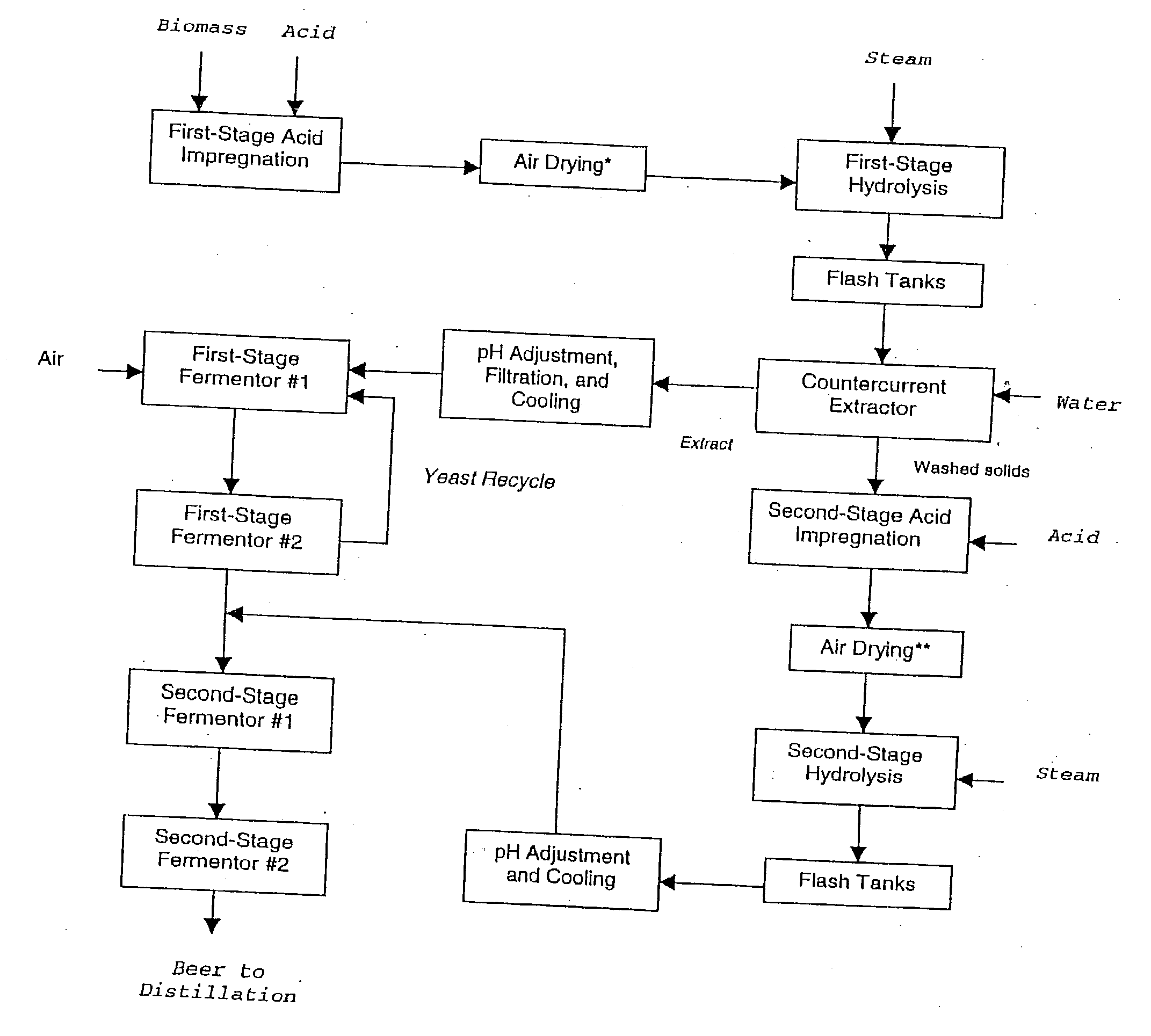

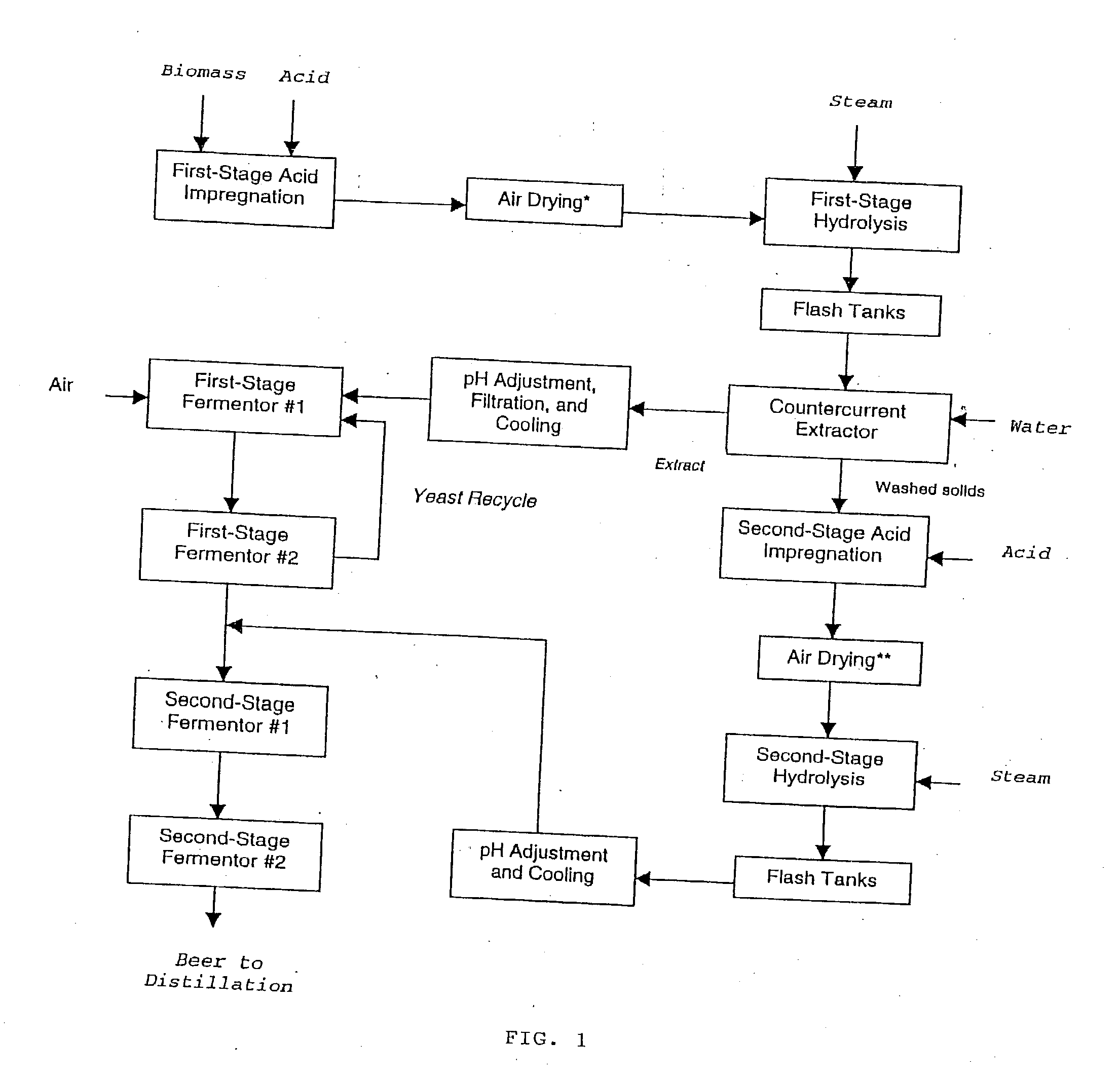

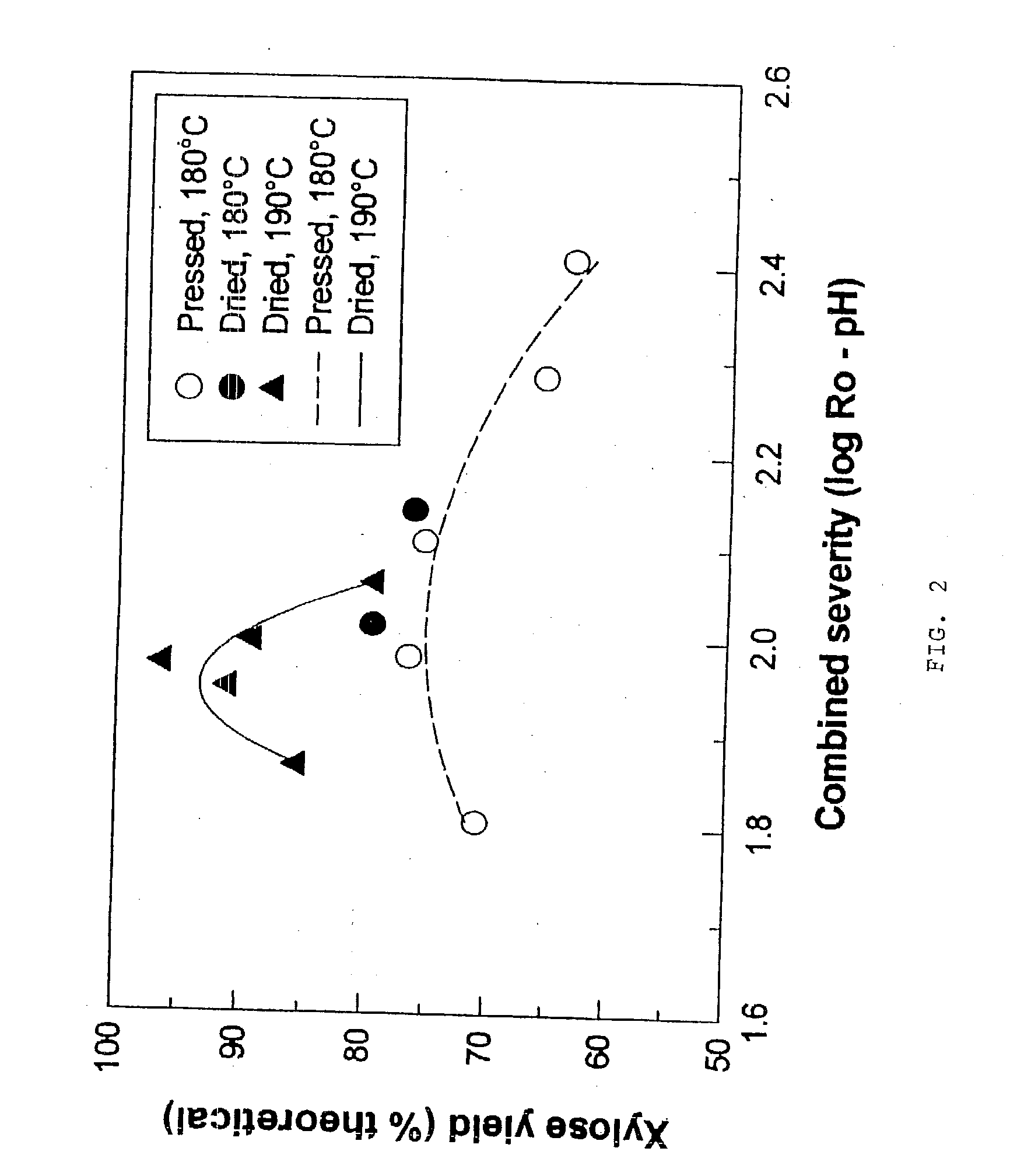

Ethanol production with dilute acid hydrolysis using partially dried lignocellulosics

InactiveUS20030199049A1Increase sugar yieldImprove digestibilityBiofuelsWaste based fuelCelluloseGrowth phase

In a process for converting lingnocellulosic biomass to ethanol, the improvement of obtaining higher fermentable soluble sugar yields by drying acid impregnated biomass particles, comprising: a) feeding moist lignocellulosic biomass into an acid impregnator to render it acid-soaked and draining the acid-soaked biomass to about 30% to 35% by weight solids; b) dewatering the acid-soaked biomass by drying or centrifugation to prevent compaction of the biomass and arrive at about 40% to 60% by weight solids; c) subjecting the acid-impregnated biomass to a first-stage hydrolysis reactor at a temperature of from 130° C. to 220° C. and discharging formed hydrolysate into a flash tank at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars, and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank-the second flash tank serving as a feed surge tank for a counter-current extractor; d) washing the hydrolysate, adjusting the pH of the sugar extract to about 5, and recovering more than 95% of the soluble sugars in the first-stage hydrolysate slurry by a counter-current extractor; e) subjecting remaining washed-first stage solids of pretreated biomass to a second-stage acid and metal salt impregnator and dewatering by drying or centrifugation to prevent compaction of biomass to arrive at 40% to 60% by weight solids; f) subjecting the acid and metal salt-impregnated biomass to a second-stage hydrolysis reactor at a temperature from 190° C. to 240° C. and discharging formed hydrolysate into a flash tank, at about 120° C. to 140° C. to hydrolyze most of the remaining soluble oligosaccharides to monomeric sugars and flashing remaining hydrolysate to a second flash tank at a lower temperature than the first flash tank, the second flash tank serving as a feed surge tank for second-stage fementors; g) cooling pH-adjusted extract from the counter-current extractor, feeding the extract to a first-stage fermentor and air sparging the first-stage fermentor at a rate sufficient to promote enough yeast growth to compensate for loss through second-stage fermentors; h) pH adjusting second-stage hydrolysate slurry to 4.5, cooling the slurry and adding it into the top of the first fermentor of a two-fermentor train in the second stage fermentors, pumping broth from the bottom of the first stage fermentors to the second stage fermentors while the yeast is in the growth phase for a period sufficient to consume over 95% of fermentable sugars; and i) recovering ethanol.

Owner:MIDWEST RES INST

Glyceride compositions and methods of making and using same

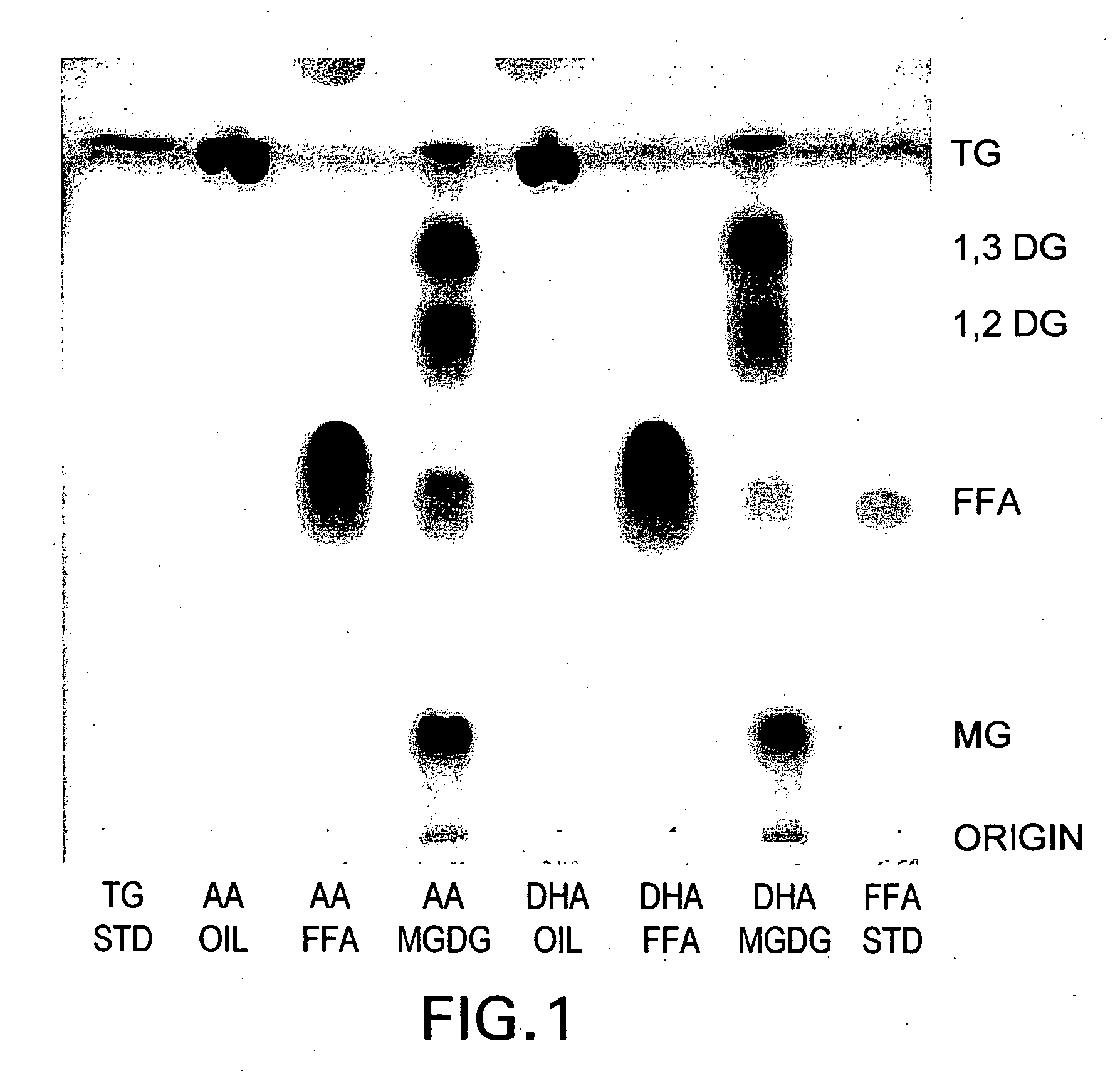

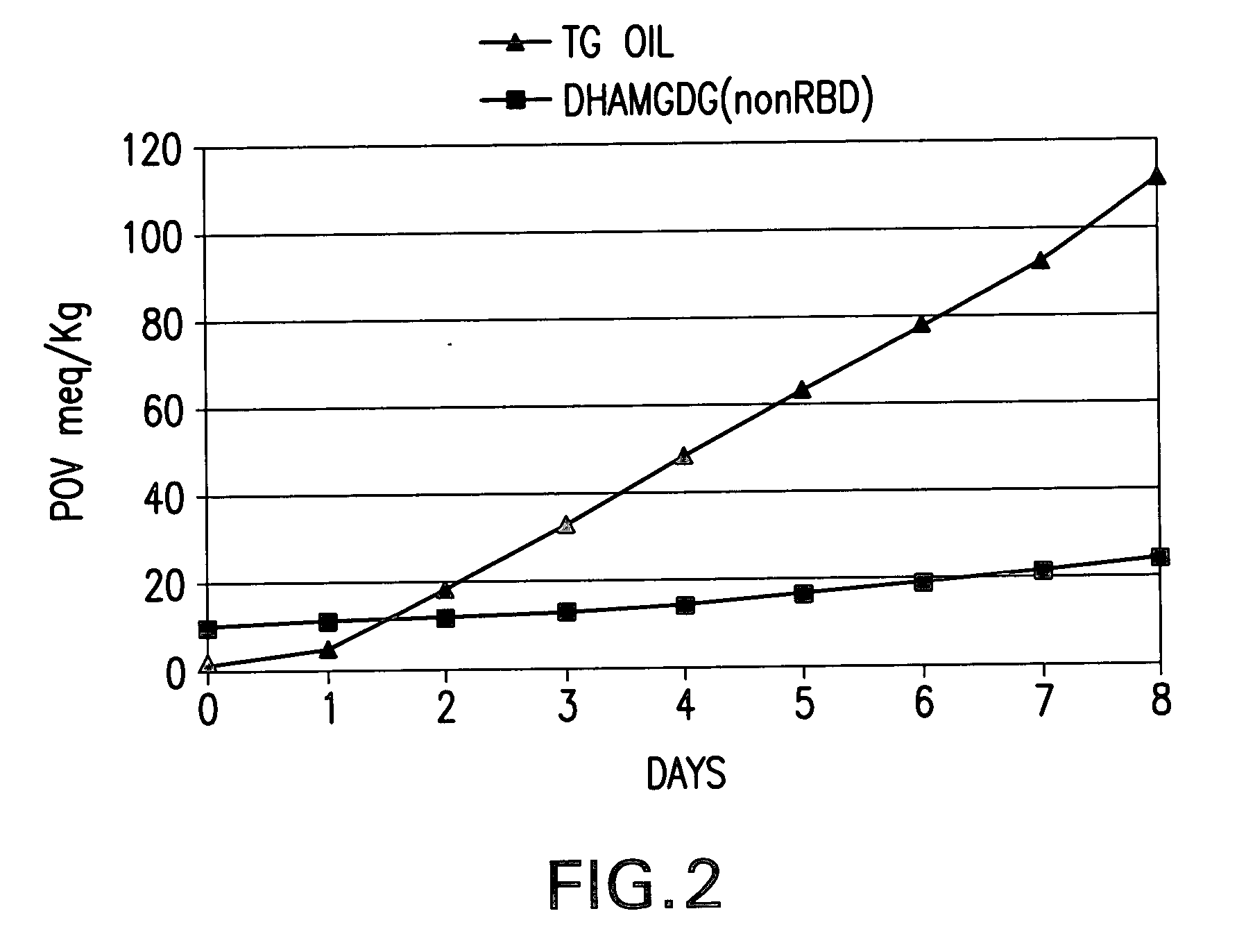

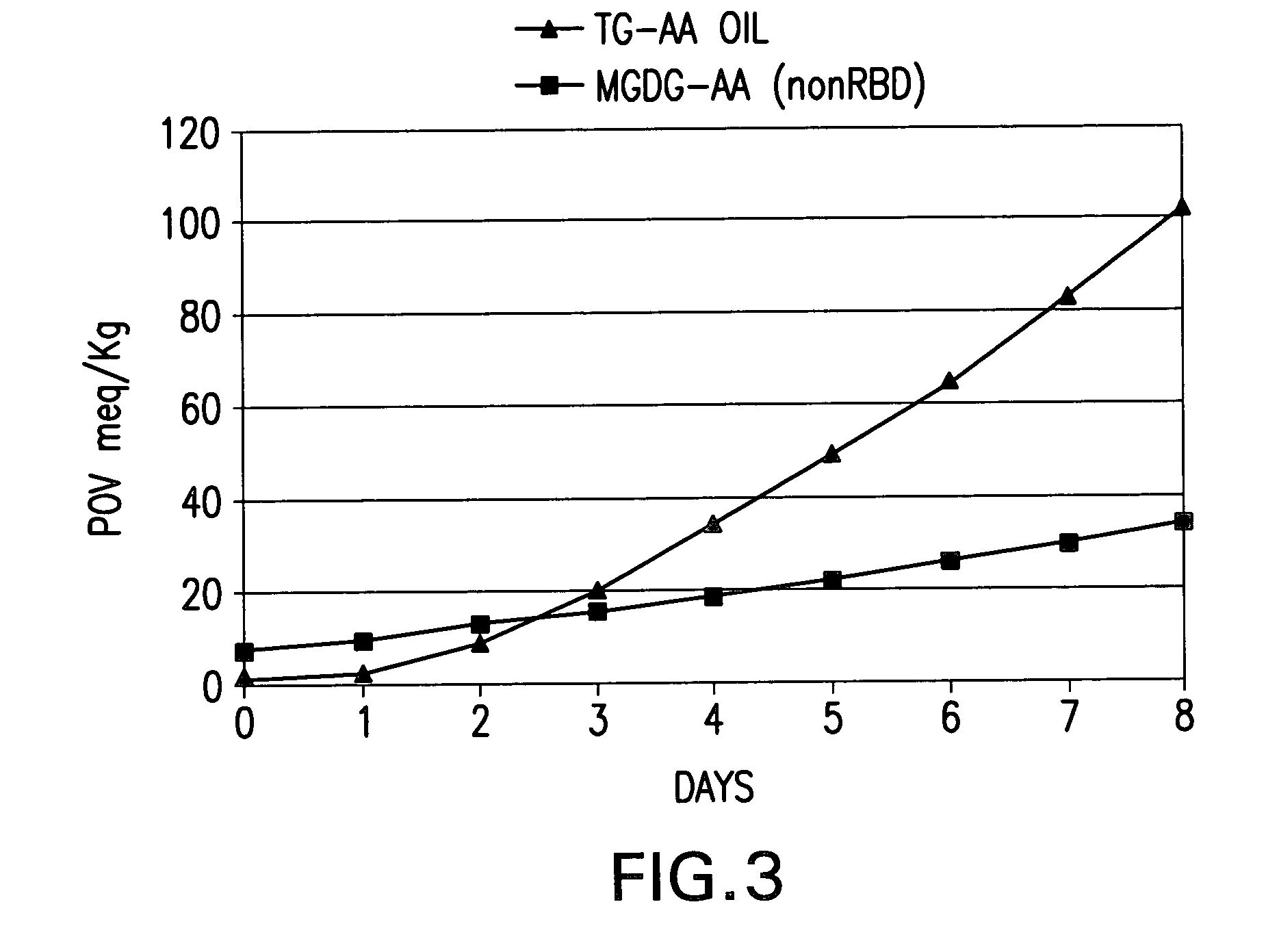

InactiveUS20040209953A1Fast absorptionImprove stabilityOrganic active ingredientsBiocideMonoglycerideDiglyceride

Disclosed are glyceride compositions, methods of making the glyceride compositions, and nutritional formulations containing the glyceride compositions. The glyceride compositions contain predominantly monoglycerides and diglycerides carrying one or more long chain polyunsaturated fatty acids. Also disclosed are methods of using the glyceride compositions and nutritional formulations.

Owner:ABBOTT LAB INC

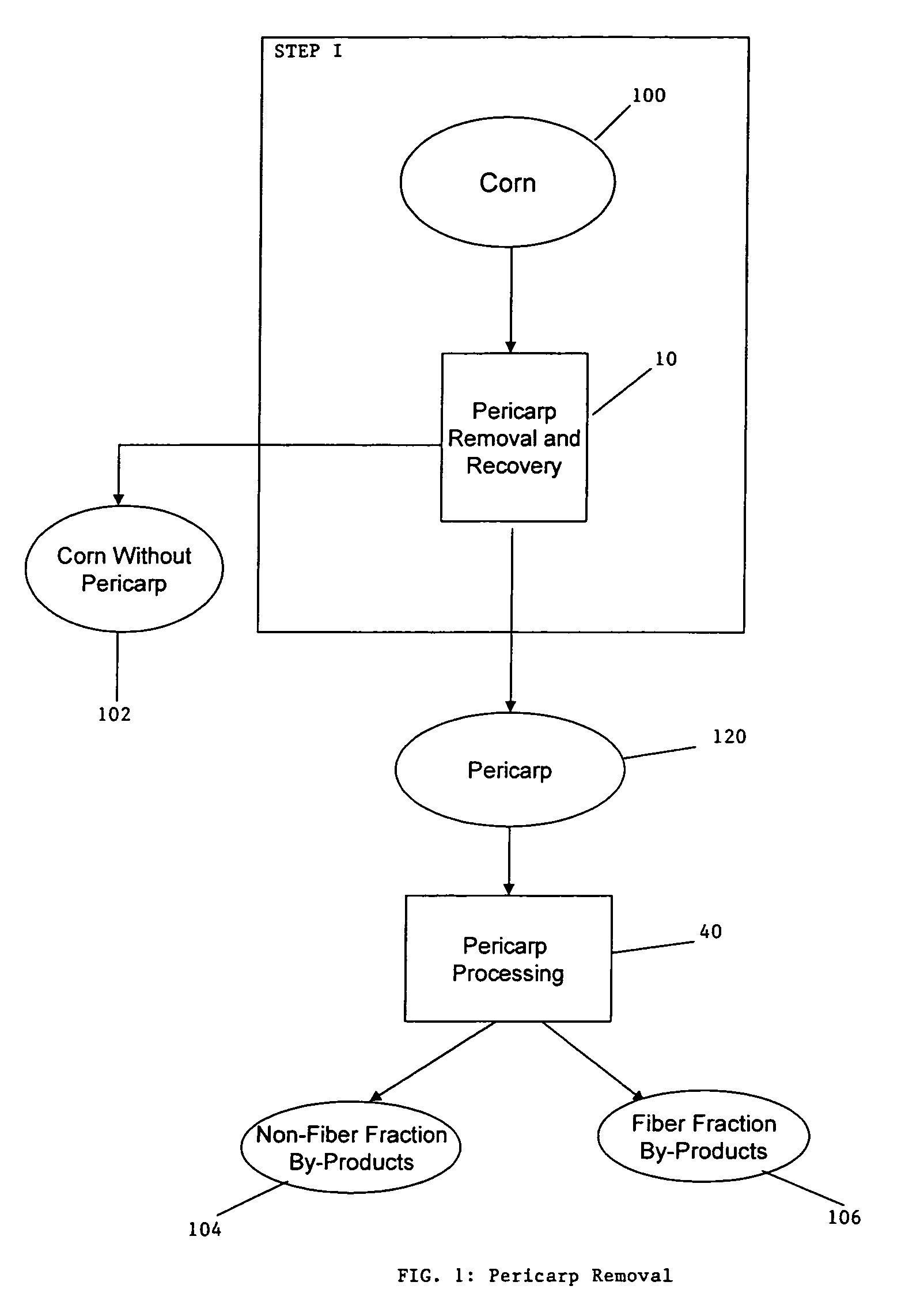

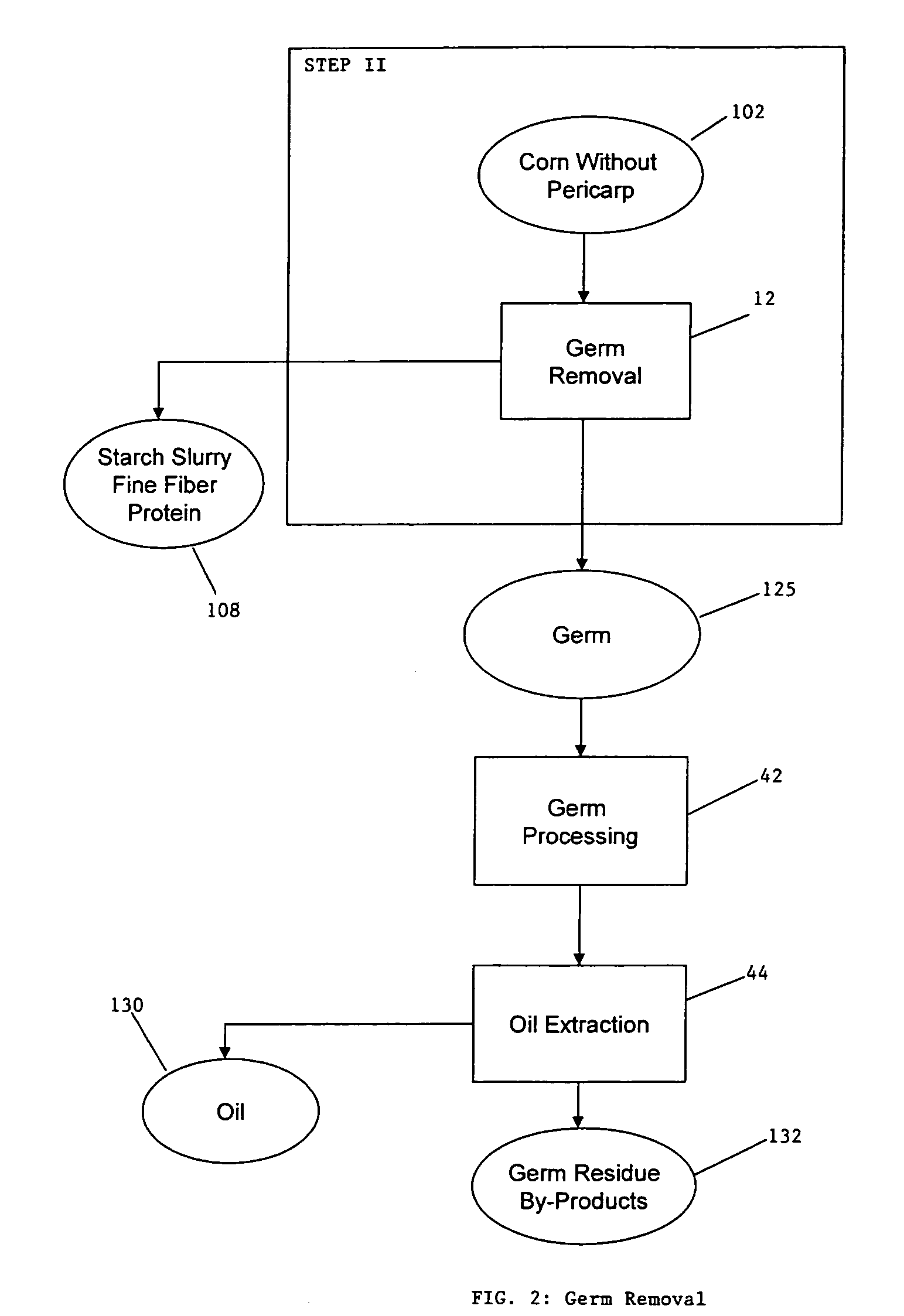

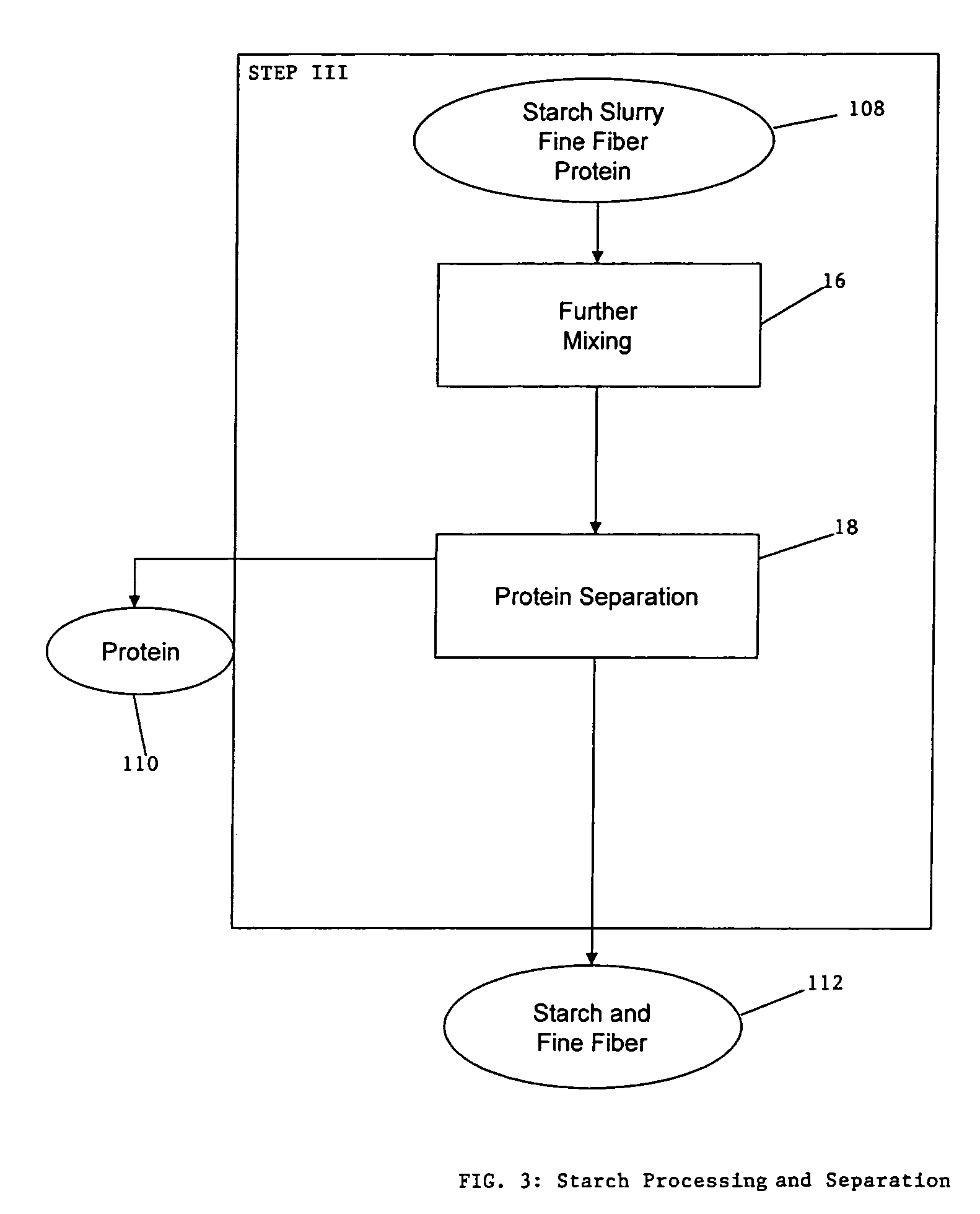

Process for the production of animal feed and ethanol and novel animal feed

A method for the production of ethanol and a modified animal feed is provided. The method replaces the starch in known corn-based animal feed with biomass fiber treated to make it more digestible by animals. The process includes wherein the pericarp and germ are removed from the corn kernel and processed for by-products. The starch and protein are also removed and separated. The starch is then fermented and distilled to ethanol and stillage. The bioavailable modified animal feed comprises the pericarp and germ removed from corn kernels and optionally by-products of the pericarp and germ processing, and lignocellulosic materials. The modified animal feed may optionally include energy materials such as animal and vegetable fats, vegetable soapstocks, or glycerin, and combinations thereof.

Owner:ARCHER DANIELS MIDLAND CO

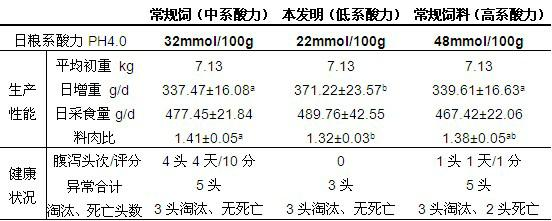

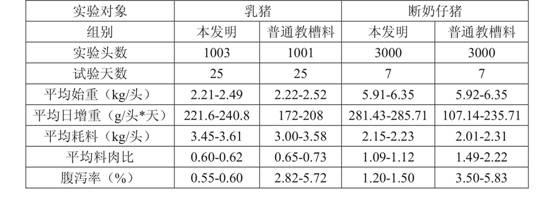

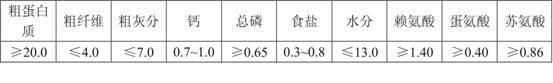

Suckling piglet feed with low acid-binding capacity and preparation method thereof

InactiveCN101999560AReduce acidityGuaranteed healthy growthFood processingAnimal feeding stuffBiotechnologyAnimal science

The invention discloses preparation of a suckling piglet feed with low acid-binding capacity and a production method thereof. The feed is prepared from corn, bean pulp, fermented bean pulp, whey powder, vitamin, microelements and the like which serve as raw materials by special processing modes such as puffing, crushing, low-temperature granulation and the like. Through the feed and the preparation method, the defects of the conventional suckling piglet feed with high acid-binding capacity are overcome, the condition of low digestibility of the suckling piglet is reduced, the palatability of the feed is improved, the health of the intestinal canal of the piglet is improved and the productivity of the suckling piglets is improved.

Owner:TONGWEI

Inbred corn line BB14

ActiveUS7511199B2Improve nutritional qualityModified waxy contentPlant tissue cultureHorticulture methodsGenetic MaterialsTransgene

An inbred corn line, designated BB14, is disclosed. The invention relates to the seeds of inbred corn line BB14, to the plants and plant parts of inbred corn line BB14 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred line BB14 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred BB14.

Owner:KWS SAAT SE +1

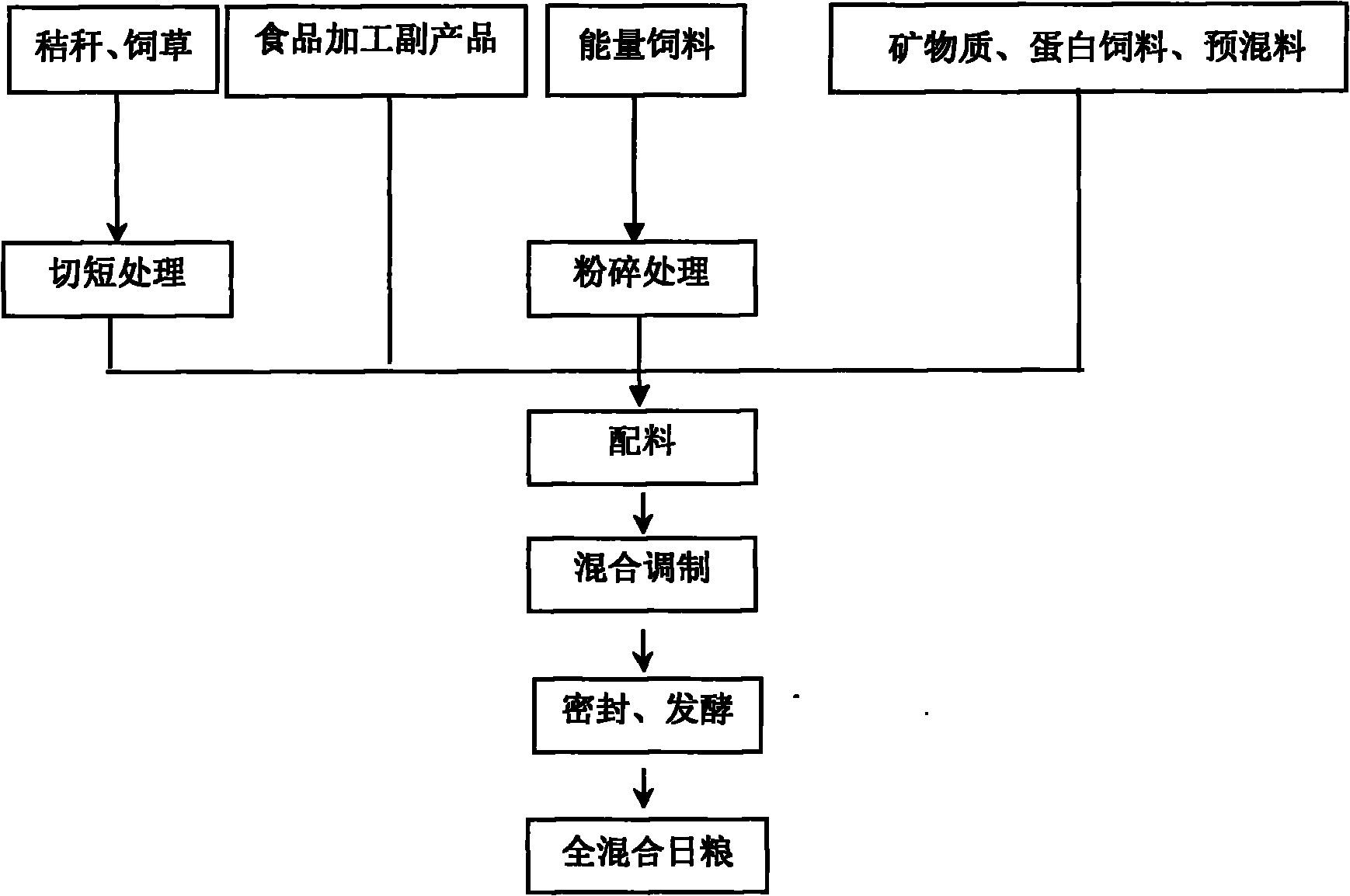

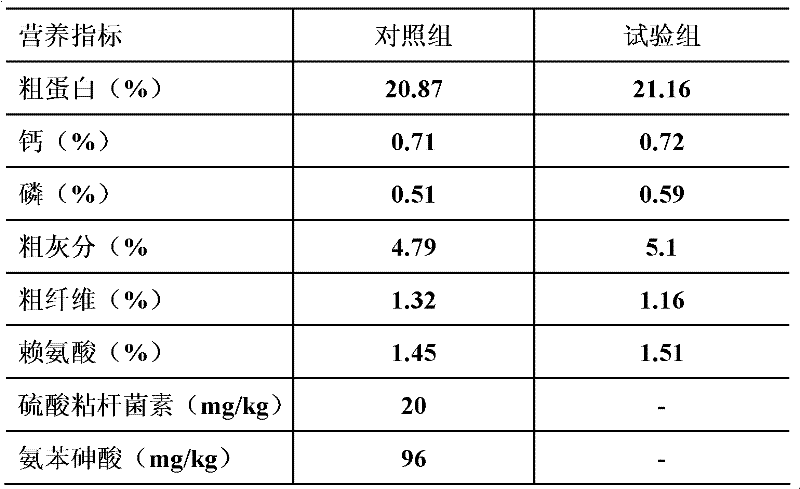

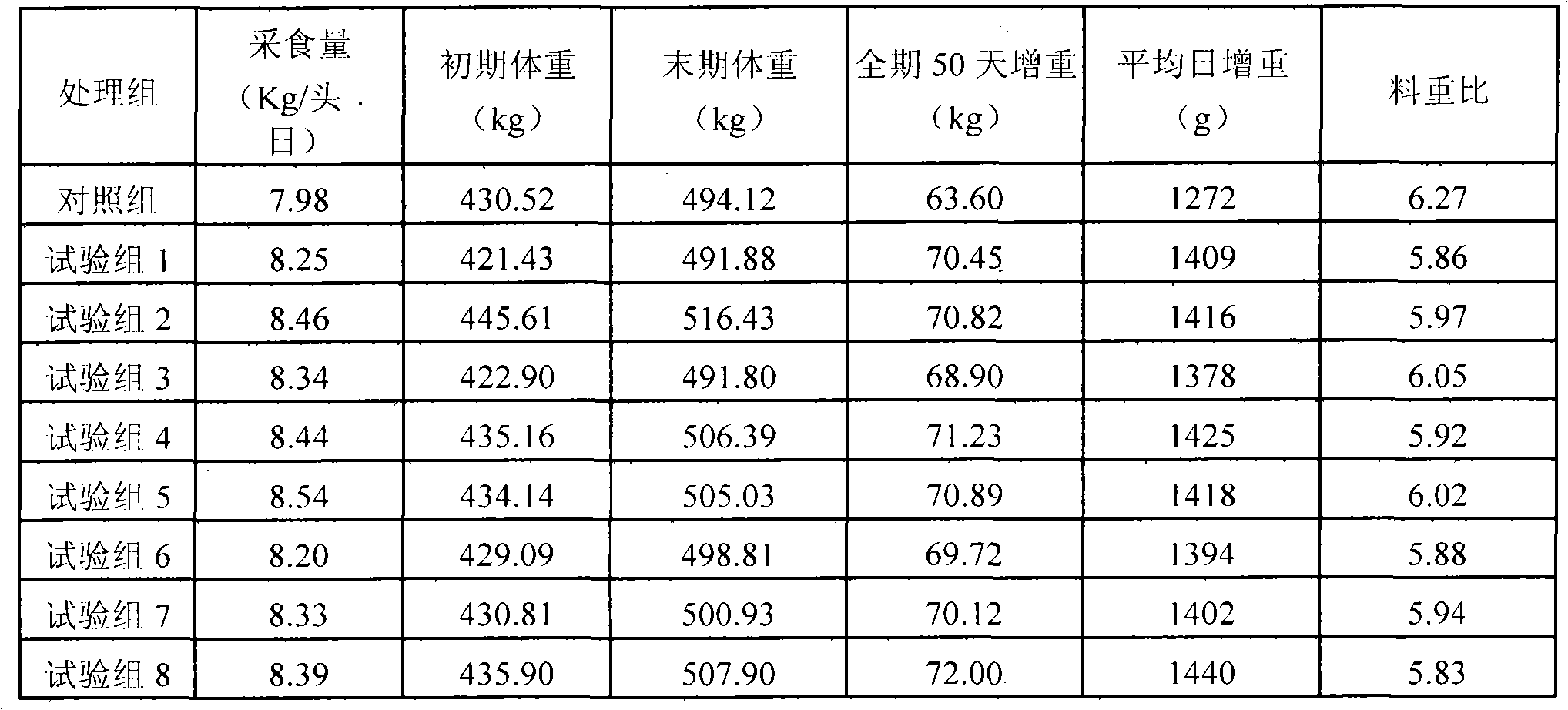

Low-concentrate type fermented total mixed ration for dairy cows and preparation method thereof

InactiveCN101828635ALow costIncrease contentFood processingAnimal feeding stuffAdditive ingredientTrace element

The invention discloses a low-concentrate type fermented total mixed ration (TMR) for dairy cows and a preparation method thereof. The TMR is prepared by the following steps of: (1) mixing the following materials in part by mass to obtain a mixture: 15 to 20 parts of straw, 4 to 8 parts of fodder grass, 6 to 12 parts of protein feed, 25 to 30 parts of energy feed, 3 to 6 parts of minerals and molasses, 40 to 45 parts of food processing by-products and 0.5 to 1 part of premix compound of trace elements and vitamins; (2) adjusting the moisture content of the mixture of the step (1) to be between 40 and 50 percent; and (3) sealing and fermenting the mixture of the step (2) for more than 14 days to obtain the ration for the dairy cows. The TMR of the invention has the following advantages of: low cost; complete nutrition and homogeneous components to avoid animal picky eaters and significantly improve the production performance of animals; and high aerobic stability. The low-concentrate type fermented total mixed ration for the dairy cows opens up a new technique and an effective way for efficient utilization of the resources of the straw and the food processing by-products, and has important practicability and application promotion values.

Owner:CHINA AGRI UNIV

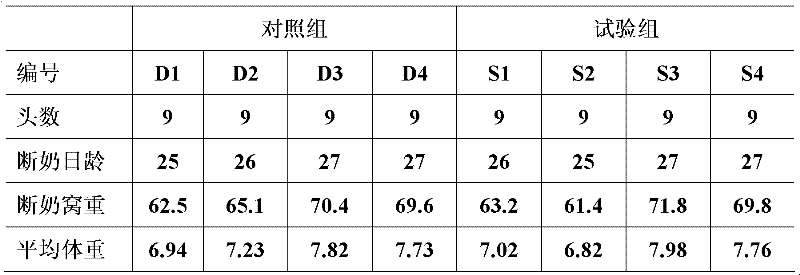

Feed for early weaned suckling pigs

ActiveCN102265984AGood enzyme productionImprove acid resistanceFood processingAnimal feeding stuffWeight gainingAdditive ingredient

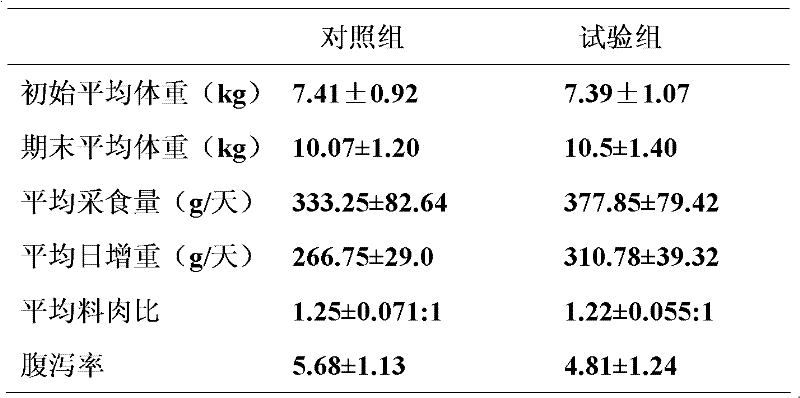

The invention relates to a feed for early weaned piglets, which belongs to the field of the feed. Main ingredients of the feed comprise expanded corn, full-fat soybean, fat powder, steam fish meal, acidified whey powder, fermented soybean meal, a complex enzyme preparation, a micro-ecological preparation, amino acids, complex vitamins, complex trace elements and the like. The digestive physiological characteristics of the weaned piglets are fully considered on the selection and the processing of raw materials, thereby greatly improving the palatability and the digestion rate of the feed; simultaneously, through the synergistic compatibility of an egg yolk antibody, lactein, sodium humate and the complex micro-ecological preparation, the diarrhea rate of the weaned piglets is reduced, the effects are superior to those of adding antibiotics into the feed, and the feed is the green, environmentally-friendly and nuisanceless feed. An animal feeding experiment proves that the feeding effects are ideal, the palatability is good, the piglets after weaning are high in average feed intake, fast in daily weight gain and low in diarrhea rate, and the feed has a good promoting effect for growth and health conditions of the weaned piglets and can meet the demands of most of raisers at present.

Owner:BEIJING DABEINONG TECH GRP CO LTD +2

Inbred corn line BC5

ActiveUS7605310B2Improve nutritional qualityModified waxy contentImmunoglobulinsFermentationGenetic MaterialsTransgene

An inbred corn line, designated BC5, is disclosed. The invention relates to the seeds of inbred corn line BC5, to the plants and plant parts of inbred corn line BC5 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred line BC5 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred BC5.

Owner:KWS SAAT SE +1

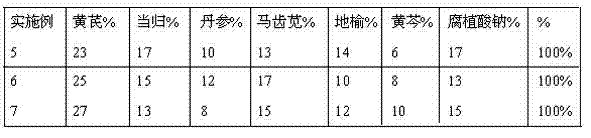

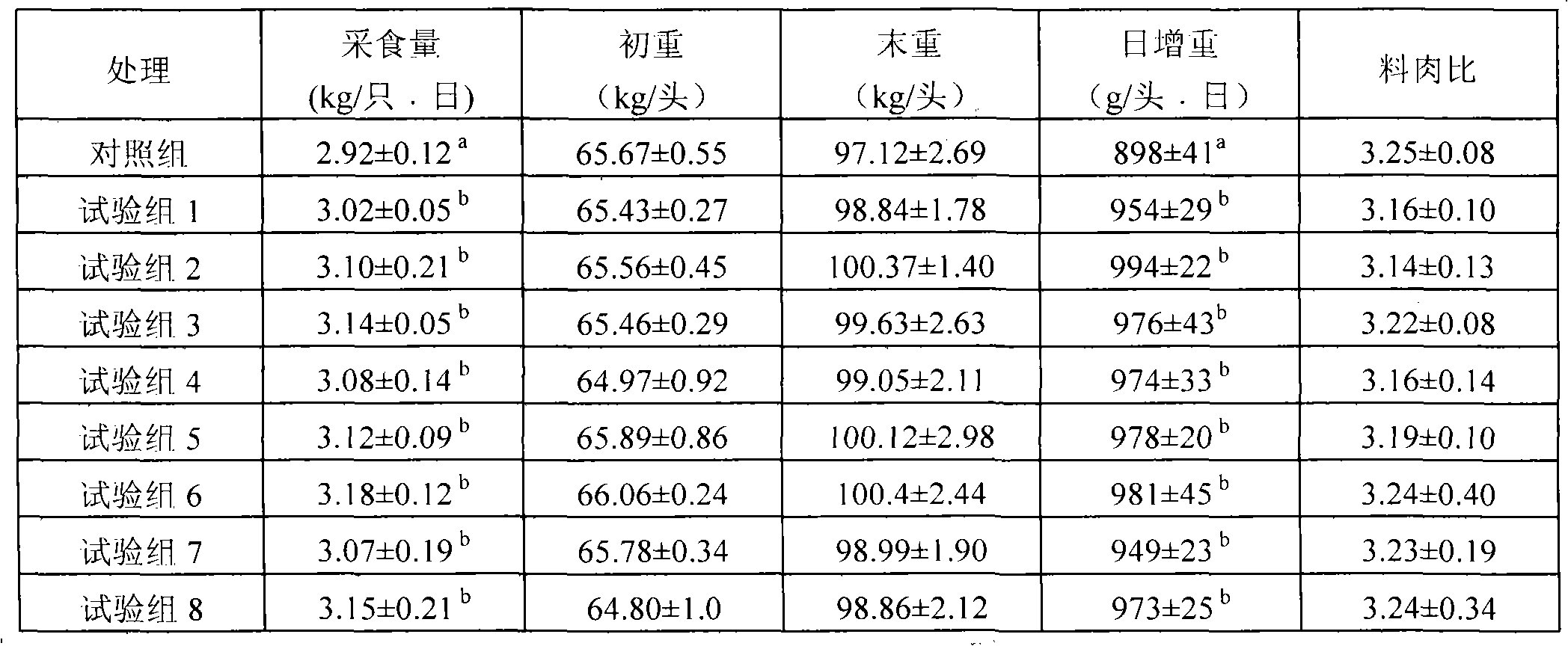

Green safe feed for fleshy poultry and preparation method

The invention relates to green safe feed for animals in the field of animal husbandry and veterinary medicine, in particular relates to a recipe and a production process of the feed. Green safe feed for fleshy poultry is mainly characterized by comprising the following raw materials: corn, wheat, bean pulp, corn protein powder, cotton seed meal, mixed oil of bean oil and poultry oil, common salt,calcium hydrophosphate, mountain flour, lysine, methionine, mineral feed additives, choline chloride, composite vitamins, coated sodium butyrate, composite Chinese herbal medicine feed additives, emulsifying agents, antioxidants and mycotoxin absorbing agents. The green safe feed has the advantages that the current conditions of high medicine residue content in the poultry meat and poor flavor caused by the abuse of various antibiotics and chemical additives in broiler raising are changed, the feed cost is saved, the economic benefits are improved, and the sustainable development of the animal husbandry is promoted.

Owner:GANSU AGRI UNIV

Inbred corn line IV2

ActiveUS7696417B2Improve nutritional qualityModified waxy contentOther foreign material introduction processesFermentationGenetic MaterialsTransgene

An inbred corn line, designated IV2, is disclosed. The invention relates to the seeds of inbred corn line IV2, to the plants and plant parts of inbred corn line IV2 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred line IV2 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred IV2.

Owner:KWS SAAT SE +1

Inbred corn line BB38

ActiveUS7687688B2Improve nutritional qualityModified waxy contentOther foreign material introduction processesFermentationGenetic MaterialsTransgene

An inbred corn line, designated BB38, is disclosed. The invention relates to the seeds of inbred corn line BB38, to the plants and plant parts of inbred corn line BB38 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred line BB38 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred BB38.

Owner:LIMAGRAIN EURO +1

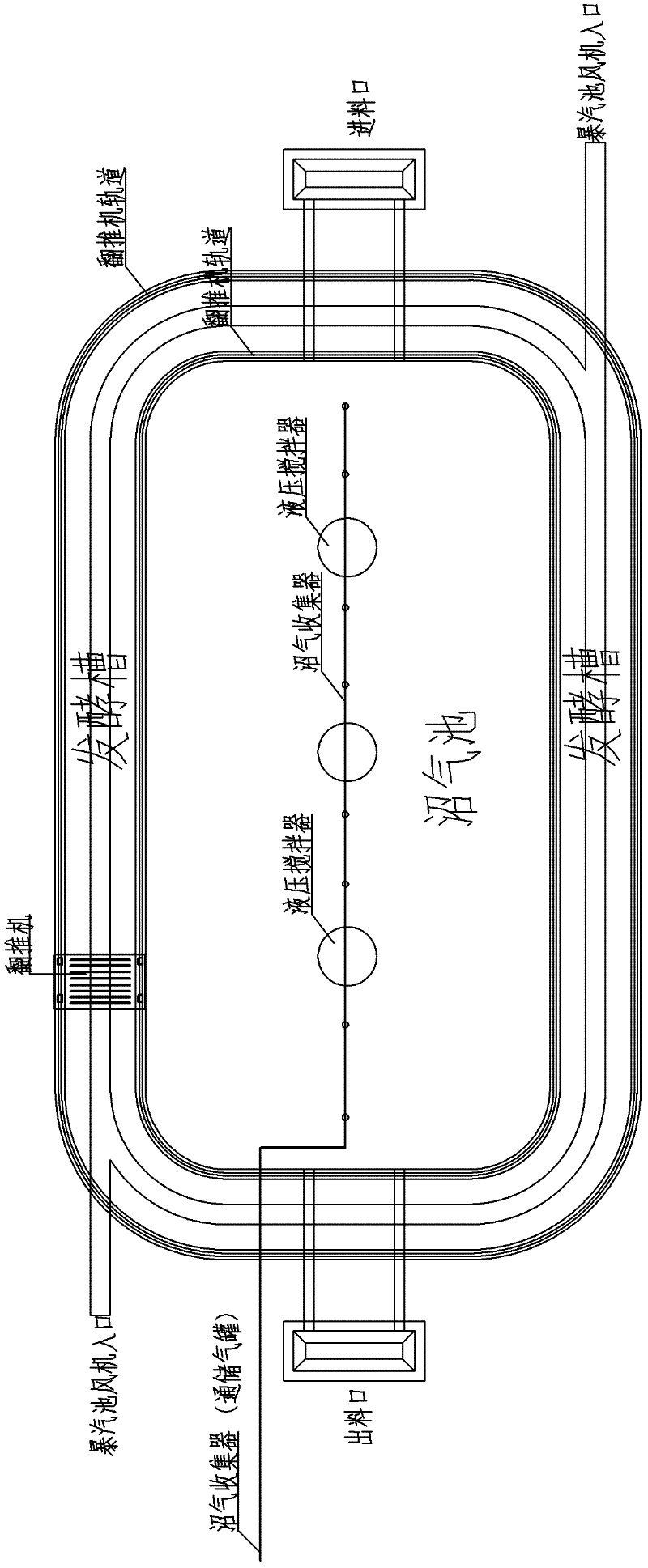

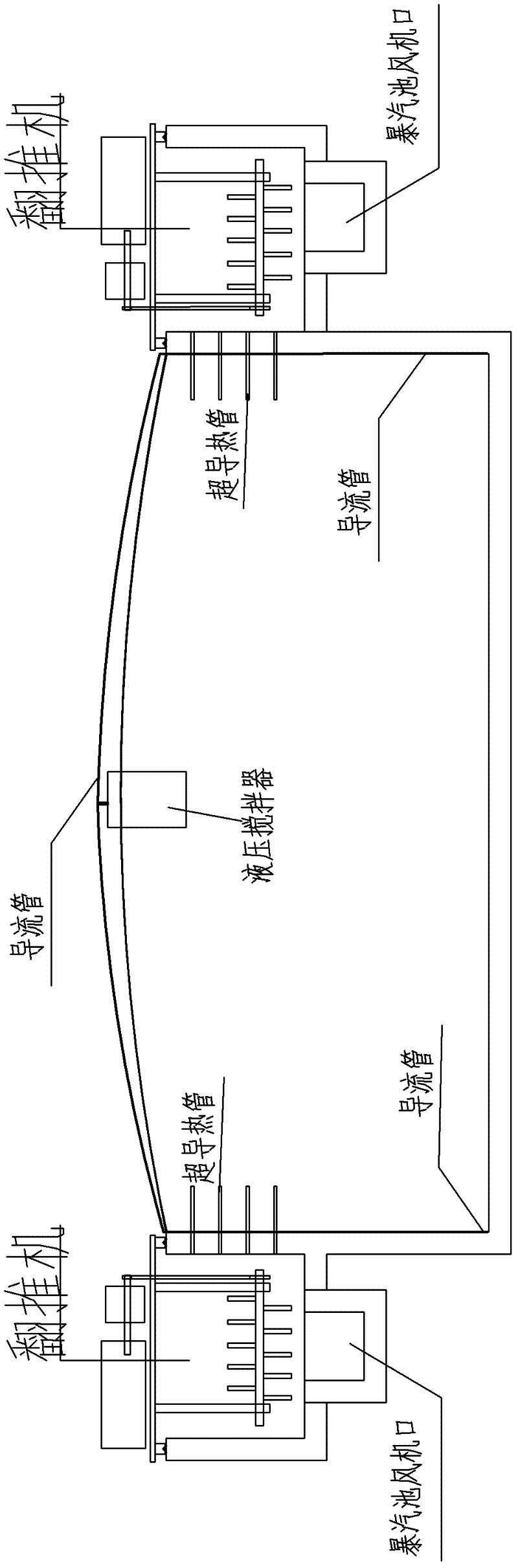

Efficient methane-generating pit using poultry excrement and methane generation process

InactiveCN102531310AReduce moisture contentEasy to produceWaste based fuelBiological sludge treatmentProcess engineeringBiogas production

The invention relates to a methane-generating pit using poultry excrement, which is integrally horizontally placed under the water plane. Partition walls are arranged in the middle of the methane-generating pit for dividing the whole methane-generating pit into a plurality of unit methane-generating pits, and medium channels arranged on the partition walls are communicated with each other. An annular fermentation tank is arranged above the periphery of the methane-generating pit, a plurality of superconductive heat pipes are arranged on the inner side of the annular fermentation tank, and the superconductive heat pipes are inserted into the methane-generating pit. A material inlet and a material outlet are respectively arranged at two ends of the methane-generating pit and under the unit methane-generating pits at two ends of the methane-generating pit, a methane collector is arranged above each unit methane-generating pit, and the methane collectors are directly communicated with a gas storage tank through pipelines. The methane-generating pit has the advantages of being high in material concentration, integrating material inlet, deslagging, methane generating, stirring, temperature controlling, regulating and the like, being high in mechanization degree, large in treating quantity, fast in digesting rate and the like and can meet requirements for scale production, and concentration of inlet materials of a continuous methane-generating pit can reach about 15%.

Owner:范立河

Safe efficient environment protection type feedstuff

InactiveCN101380056AImprove digestibilityReflect environmental protectionFood processingAnimal feeding stuffAnimal scienceSide effect

A safe and high-efficient environment-friendly feed comprises the following raw materials in terms of weight percentage: 6 to 20 percent of corn gluten feed, 3 to 25 percent of soybean meals, 1 to 20 percent of powder, 0 to 15 percent of rice bran, 0 to 40 percent of corn, 3.5 to 10 percent of rapeseed dregs, 1 to 5 percent of cotton seed meals, 1 to 5 percent of bone meals, 2 to 6 percent of fish meals, 1 to 6 percent of meat meals, 3 to 15 percent of wheat and right amount of additives. According to the required amounts of all nutritional components of the livestock in different growing stages, the invention combines energy feed, protein feed and various additives in equilibrium according to certain percentages by adopting a scientific method, thus leading various livestock to obtain the largest feed digesting rate and leading the livestock to absorb the feed to the largest degree; the excrement after the digestion of the livestock have no obvious smell and cause no pollution to the surrounded environmental sanitation and the environment protection after the feed being eaten is shown; moreover, no banned substances are added in the process of the feed processing and the feed is processed from natural products, which have no residue side effects on the livestock.

Owner:罗喜华

Inbred corn line UNW1

ActiveUS7482517B2Improve nutritional qualityModified waxy contentBryophytesOther foreign material introduction processesGenetic MaterialsTransgene

An inbred corn line, designated UNW1, is disclosed. The invention relates to the seeds of inbred corn line UNW1, to the plants and plant parts of inbred corn line UNW1 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred line UNW1 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred UNW1.

Owner:LIMAGRAIN EURO +1

Complex enzyme preparation for feeding piglets

InactiveCN102119768AImprove metabolic energyReduce chyme viscosityAnimal feeding stuffAccessory food factorsPectinaseDisease

The invention discloses a complex enzyme preparation for feeding piglets. The complex enzyme preparation for feeding piglets comprises the following seven enzymes: acid protease, amylase, xylanase, beta-glucanase, cellulase, pectinase and phytase; and the enzymatic activity ratio of the seven enzymes is 1: 1: (8-10): (3.3-4): 1: (0.5-0.55): (0-0.02). By applying the complex enzyme preparation disclosed by the invention, various anti-nutritional factors in feed can be degraded, the viscosity of chyme in an intestinal tract can be reduced, and the metabolic energy of the feed can be improved; the protein and starch digestibility of the piglets can be improved; excessive reproduction of harmful microorganisms in the intestinal tract can be reduced, damage to the intestinal wall can be reduced, and the microecological balance of the intestinal tract can be regulated; the survival rate and disease resistance of the piglets can be improved, the diarrhea rate can be reduced, and the overall uniformity is improved; and the weight gaining of the piglets can be promoted, and the cultivation cost is reduced.

Owner:BEIJING CHALLENGE AGRI SCI & TECH CO LTD

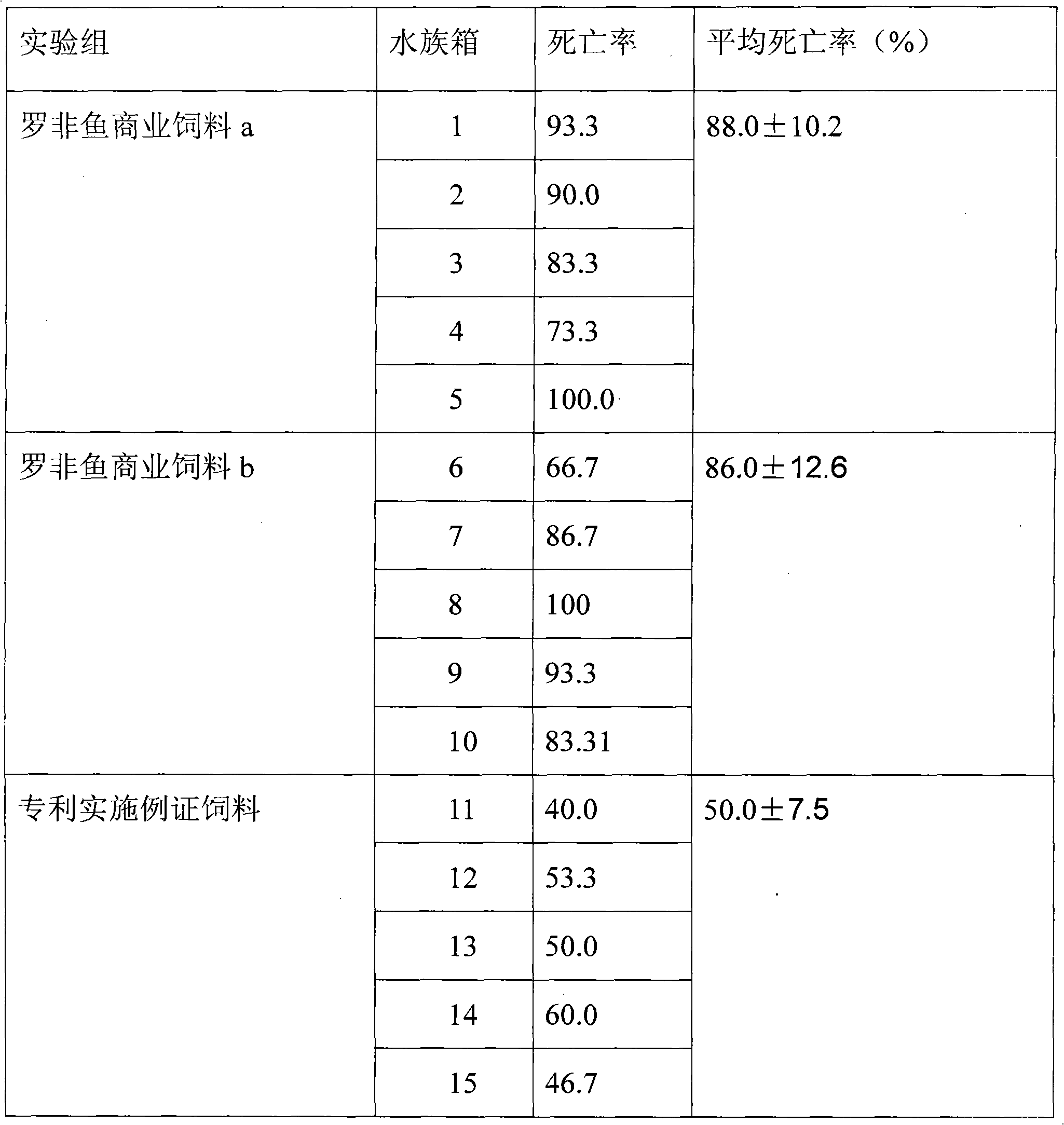

Artificial compound feed with function of preventing tilapia mossambica streptococcicosis

ActiveCN101971928AImprove digestibilityImprove antibacterial propertiesFood processingClimate change adaptationSodium BentoniteAntioxidant

The invention relates to a tilapia mossambica feed, in particular to an artificial compound feed for tilapia mossambica. An artificial compound feed with function of preventing tilapia mossambica streptococcicosis comprises the following components in percentage by mass: 5 to 10 percent of fish meal, 20 to 30 percent of bean pulp, 20 to 30 percent of rape pulp, 10 to 15 percent of cotton pulp, 10 to 15 percent of DDGS (maize alcohol lees and residual liquid dry substance), 5 to 10 percent of rice bran, 15 to 20 percent of flour, 5 to 10 percent of maize, 1 to 2 percent of soybean oil, 0.5 to 1.5 percent of phospholipid oil, 1 to 2 percent of calcium hydrogen phosphate, 1 to 10 percent of bentonite, 0.5 to 1 percent of multi-dimensional multi-mineral premix, 0.1 to 0.5 percent of choline chloride, 0.01 to 0.05 percent of antioxidant, 0.1 to 0.5 percent of mildew-proof agent and 1 to 5 percent of composite Chinese medicinal additive. Multiple antibacterial Chinese medicinal herb additives are added into the feed, so the feed improves the antibacterial capability of the tilapia mossambica and can prevent the tilapia mossambica streptococcicosis.

Owner:GUANGZHOU PANYU DACHUAN FEED

Compound feed for teaching piglets to eat foods other than breast milk

InactiveCN102178115AHealthy micro-ecological balance environmentAvoid damageFood processingAnimal feeding stuffDiseaseSucrose

The invention provides compound feed for teaching piglets to eat foods other than breast milk, which is used for weaning piglets and teaching the piglets to eat foods other than breast milk, and comprises the following components in part by weight: 212.4 parts of corn starch, 154.0 parts of bulked corn, 100.0 parts of 46 percent of bulked bean pulp, 40 parts of fish meal, 100 parts of wheat flour, 5 parts of calcium powder, 21 parts of calcium hydrophosphate, 2 parts of table salt, 20 parts of soybean oil, 5 parts of lysine, 2 parts of threonine, 1.5 parts of choline chloride, 10 parts of premix, 0.2 part of complex enzyme, 0.3 part of pig Duowei, 0.2 part of sweetener, 0.3 part of flavouring agent, 3 parts of baking soda, 20 parts of cane sugar, 30 parts of glucose, 50 parts of egg powder, 70 parts of soy protein concentrate, 50 parts of fermented bean pulp, 6 parts of acidizer, 100 parts of whey powder, 0.5 part of mould removing agent, 0.3 part of antioxidant and 0.3 part of mildewpreventive. In the invention, the problems of incomplete immune functions, low disease resistance, inadequate digestive ferment, incomplete upper gastrointestinal development, low digestion and absorption ability, susceptibility to diarrhea and the like of piglets.

Owner:AGRI SCI & TECH INST CO LTD OF CHENGDU WEST HOPE GRP

Novel efficient and natural attractant

ActiveCN102217713APromote secretionEliminate gasFood processingAnimal feeding stuffAquatic animalFeed additive

The invention relates to natural attractants, belonging to the field of feed additives. One natural attractant is mainly composed of a dried tangerine peel crushed substance, a hawthorn crushed substance, a cinnamon crushed substance, a mugwort leaf crushed substance, and composite microbial powder. The other natural attractant is mainly composed of a dried tangerine peel extractive, a hawthorn extractive, a cinnamon extractive, a mugwort leaf extractive, and composite microbial powder. The attractants provided by the invention has the advantages of promoting the ingestion of livestock, poultry and aquatic animals, increasing the ingestion speed and feed intake of the livestock, poultry and aquatic animals, avoiding the indigestion caused by overfeeding, increasing the feed intake and digestibility of the animals to the feeds hard to digest, expanding the application range and usage amount of unconventional feed materials, enhancing the immunity and anti-stress capability of the animals, resisting diseases, promoting growth, decreasing the production cost of the animal feeds and increasing the production benefits; the attractants contain no antibiotic and chemical medicine as well as drug residue, can be used for a long time without causing drug resistance, and have safety and high efficiency.

Owner:BEIJING KEEPYOUNG TECH

Nursery pig concentrated feed

ActiveCN101606639AImprove orderImprove immunityFood processingAnimal feeding stuffAdditive ingredientThreonine

The invention relates to a pig feed, in particular to a nursery pig concentrated feed, comprising the following raw materials by weight proportion: 30-50 of sucking pig composite vitamin, 30-50 of low copper mineral element, 60-100 of peeled soybean meal, 100-180 of fermented soybean meal, 100-150 of extruded soybean, 110-180 of steam fish meal, 50-100 of dried porcine soluble, 60-120 of acid whey powder, 80-90 of glucose powder, 5-10 of glutamine, 80-100 of chyle fat powder, 40-49 of calcium carbonate, 12-14 of basic zinc chloride, 4-6 of salt, 55-60 of calcium biphosphate, 6-10 of sodium butyrate, 12-15 of lysine, 6-8 of threonine, 4-6 of TP-100 enzyme, 4-5 of cysteine, 5-7 of se-enriched yeast and 6-10 of copper chloride hydroxide. The nursery pig concentrated feed has the advantages of milk nutrition composition simulation, good palatability, high digestibility, large feed intake because the baby pigs like to eat and improvement of survival rate as well as immunity of the nursery pigs.

Owner:江西大佑农生物科技有限公司

Inbred corn line BB36

ActiveUS7834256B2Improve nutritional qualityModified waxy contentImmunoglobulinsFermentationGenetic MaterialsTransgene

An inbred corn line, designated BB36, is disclosed. The invention relates to the seeds of inbred corn line BB36, to the plants and plant parts of inbred corn line BB36 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred line BB36 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred BB36.

Owner:LIMAGRAIN EURO +1

Inbred corn line MN7

ActiveUS7829770B1Excellent plant healthImprove nutritional qualityImmunoglobulinsFermentationBiotechnologyGenetic Materials

An inbred corn line, designated MN7, is disclosed. The invention relates to the seeds of inbred corn line MN7, to the plants and plant parts of inbred corn line MN7 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred corn line MN7 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred corn line MN7.

Owner:KWS SAAT SE +1

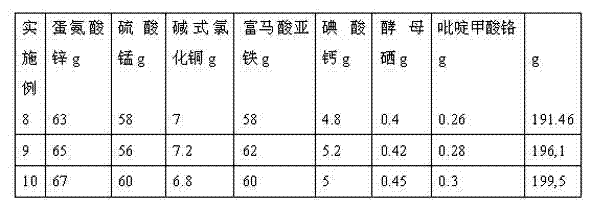

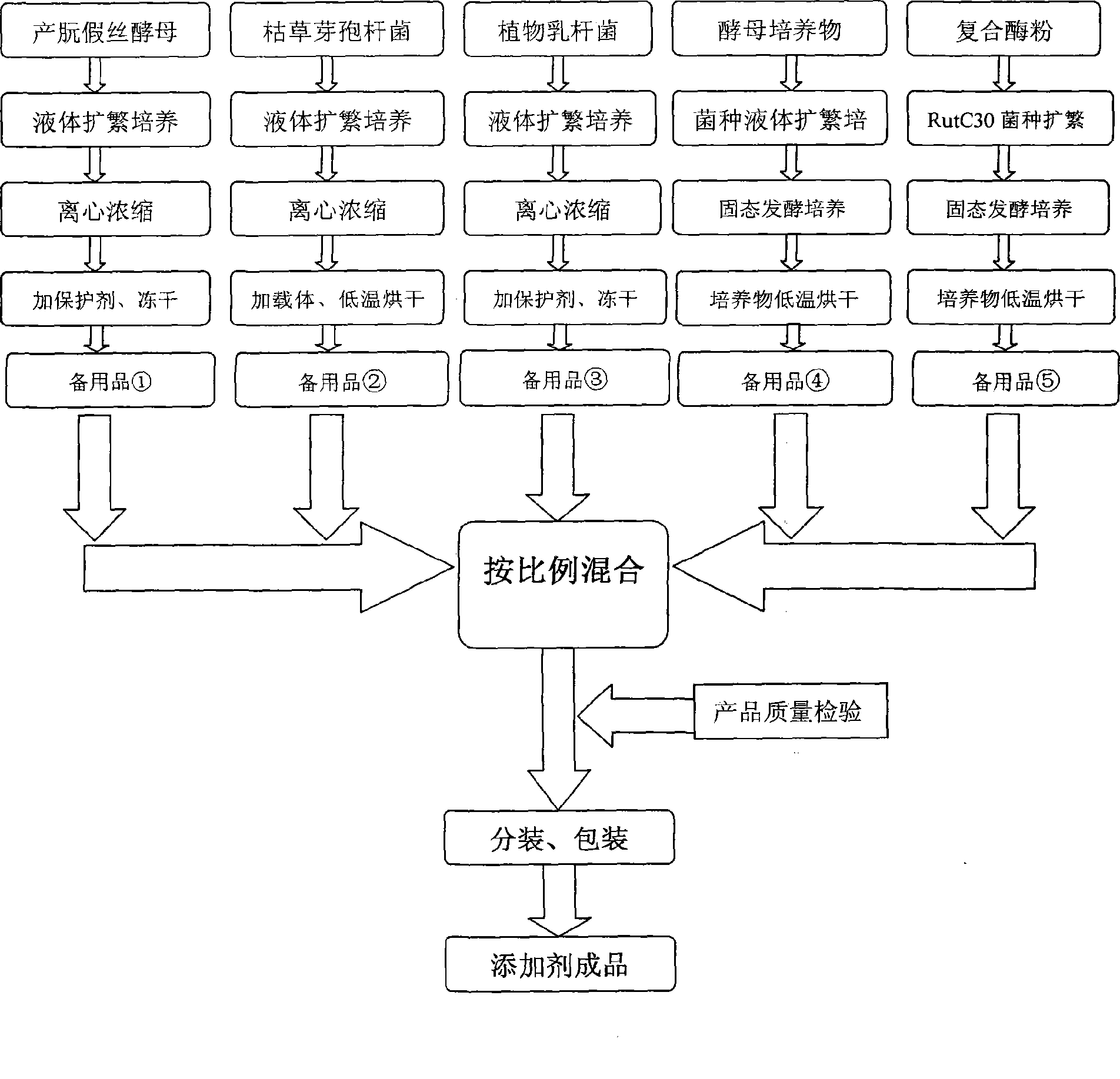

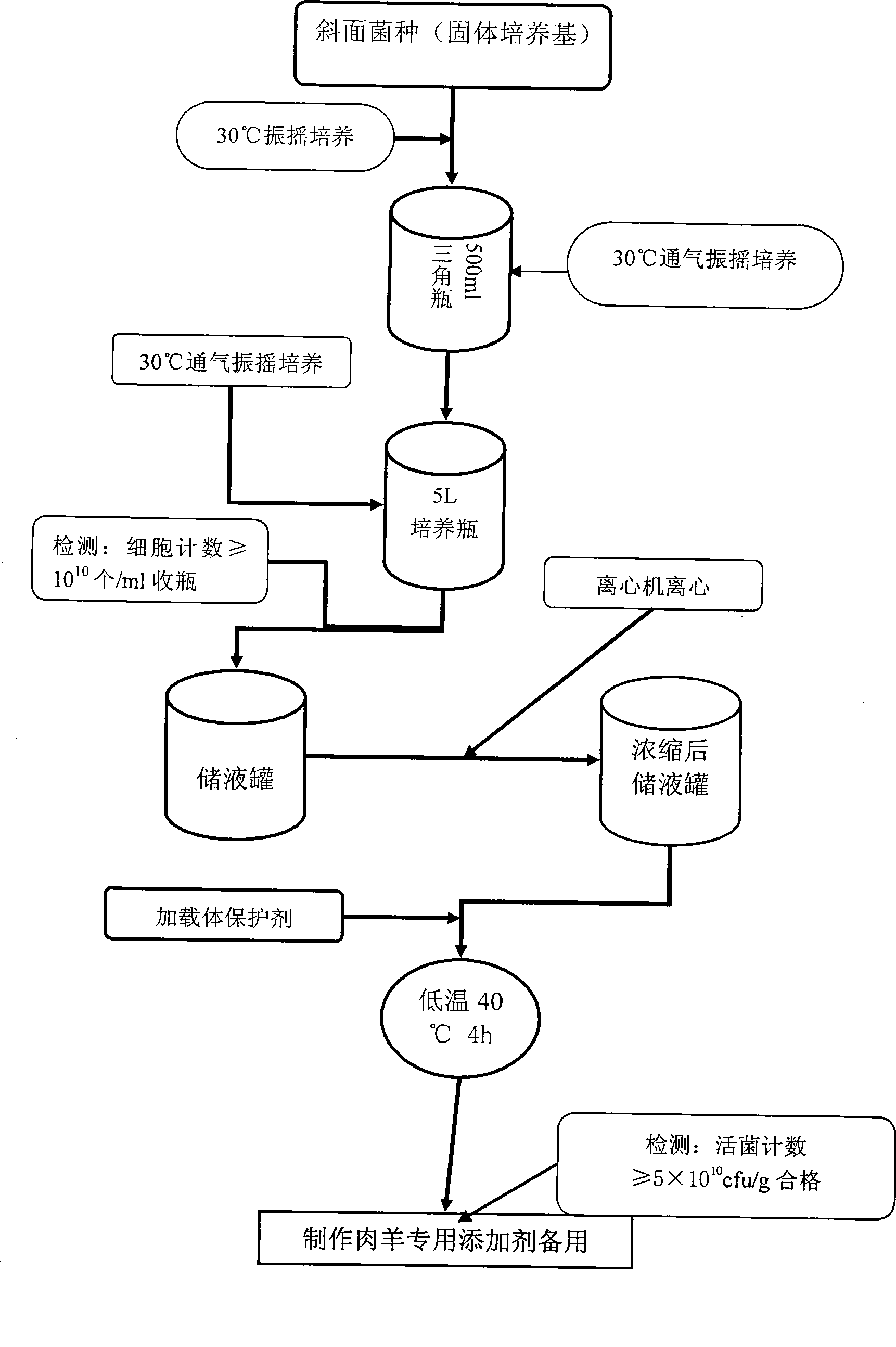

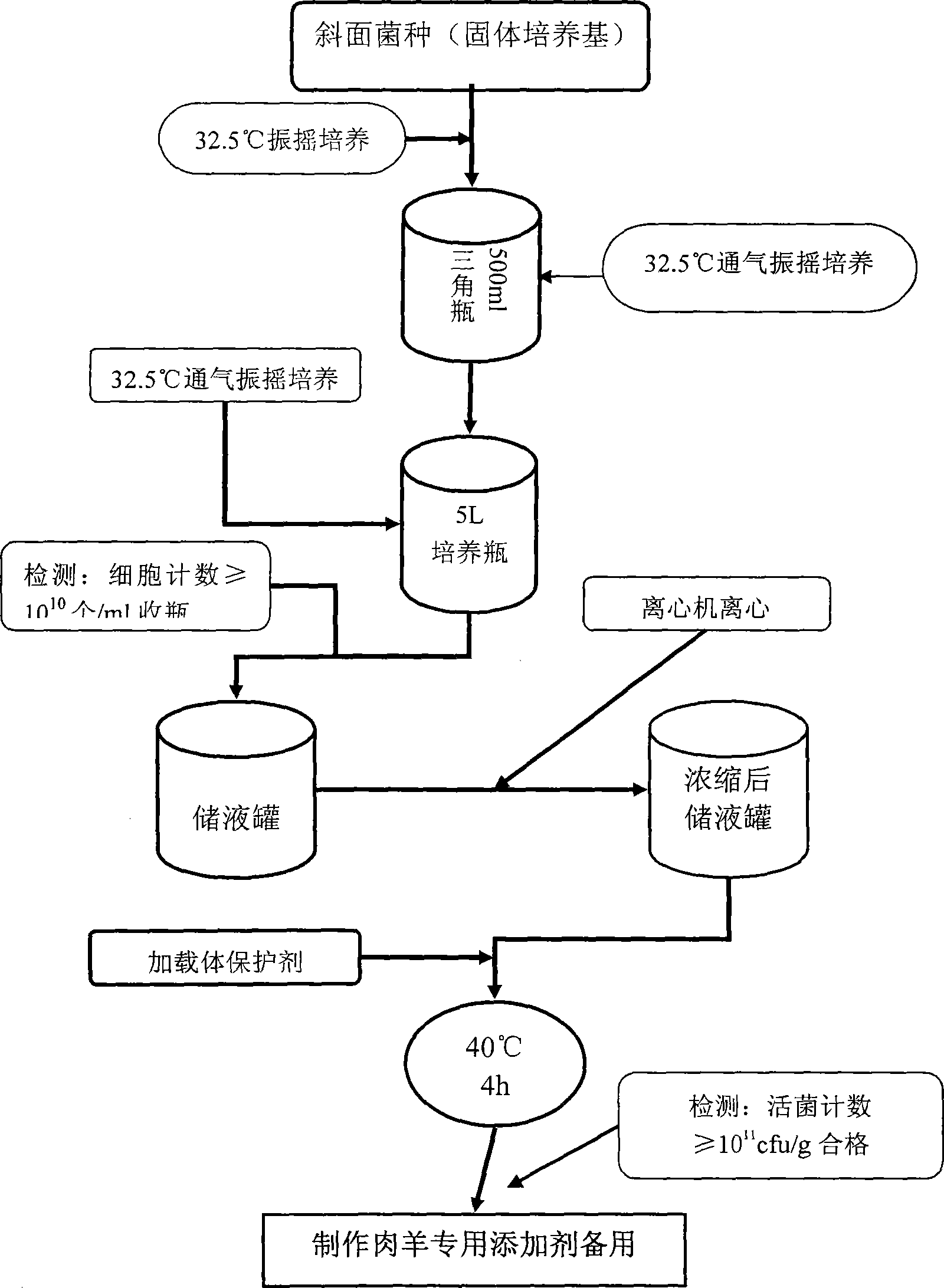

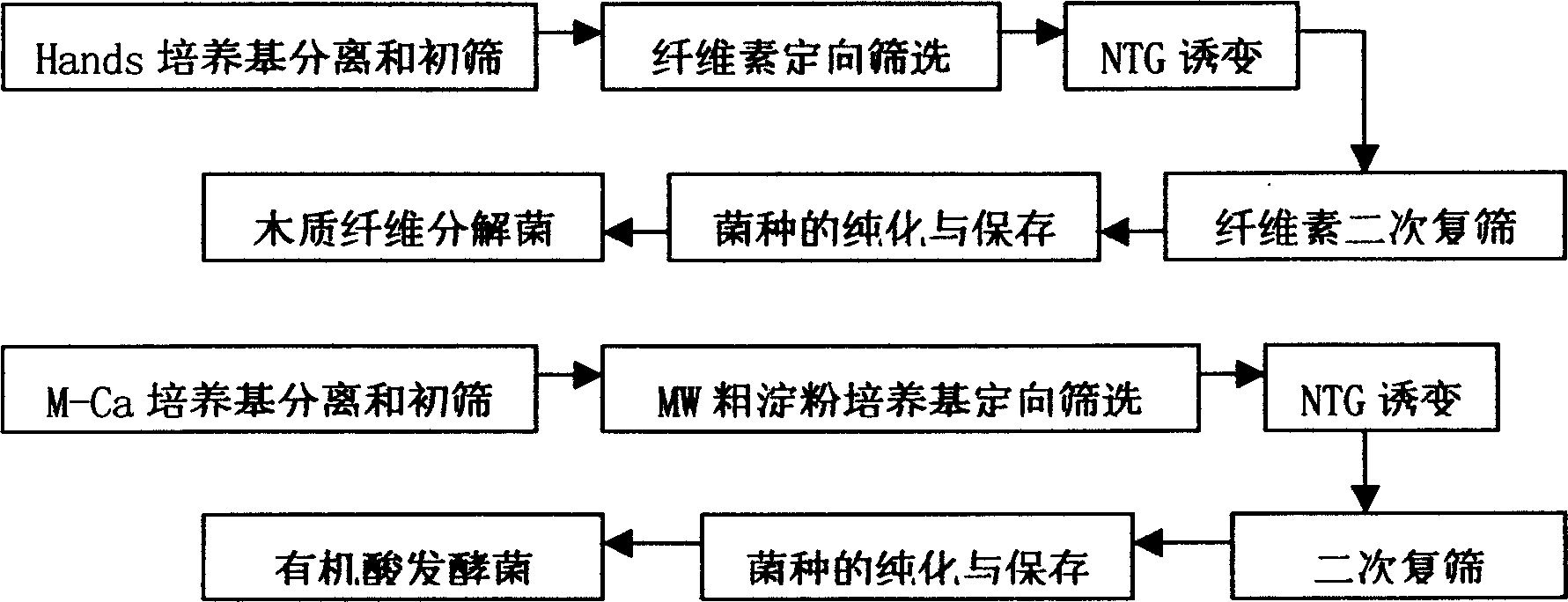

Composite biological feed additive agent for fattening early weaning mutton sheep

InactiveCN101485402AImprove developmentIncrease weightAnimal feeding stuffEcological environmentMicrobial agent

The invention relates to an early weaning meat sheep fattening compound biological feed additive, which belongs to the technical field of animals feeding by feed. The feed additive comprises prebiotics consisting of candida utilis, bacillus subtilis and a lactobacillus plantarum microbial agent, non-starch polysaccharide enzyme containing cellulase, xylanase, beta-dextranase, beta-mannase and pectinase and a yeast culture formed by using saccharomyces cerevisiae to completely ferment bean pulp. The additive is specially used for fattening period ration of the early weaning(the weaning lunar age is less than or equal to 2 ages of the moon) meat sheep, and the adding percentage for the full-mixing ration of the fast-fattening meat sheep in 3 to 5 ages of the moon is 1 percent. The additive can provide functional nutrients such as digestive enzyme, B group vitamins and growth promoting factors, and the like which are inadequately produced and insufficient for the early weaning baby sheep and simultaneously contains probiotics for adjusting the micro-ecological environment in intestinal canals, thereby improving the immunity and the healthy level of the baby meat sheep; and after weaning, the daily gaining in weight is more than 10 percent in the prior period and later period of fattening, and the economic benefits are obviously improved.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Low-salt liquid state fermented soy sauce production process

The invention discloses a low-salt liquid state fermented soy sauce production process, comprising the following main processes: preparing koji in a koji-maker machine; mixing the wheat which is fried and smashed with koji, inoculating the mixture in soybean meal and bran which are cooked; preparing finished koji in a koji making disc machine; mixing the finished koji with brine, sending the mixture in a fermenting vat for fermentation; preparing the finished soy sauce through soaking, pouring oil, filtrating, mixing, sterilizing and filling to obtain the finished soy sauce. The soy sauce is characterized in that materials containing zygosaccharomyces Rouxii 2.180 accounting for 1.5-2.5% of the total weight of materials and torulopsis candida 2.202 accounting for 1.5-2.5% of the total weight of materials are added during the medium term of the fermentation process and the raw materials--soybean meal and bran are cooked by high temperature short-time continuous cooking process. Compared with the prior art, the raw material digestion rate can reach 88-90%, the protein utilization rate can reach 83%, the activity of neutral protease of the finished koji can reach 2000mu / g, the enzymesystem is complete, the defects such as long period of high-salt liquid state fermentation (180 days), burnt flavour and heavy bitter taste of low-salt solid state fermentation and the like are overcame and the produced soy sauce is characterized by strong soysauce-like aroma, alcohol-like aroma and ester-like aroma and the like.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Inbred corn line BB46

ActiveUS8026432B2Improve nutritional qualityModified waxy contentBryophytesPlant genotype modificationBiotechnologyGenetic Materials

An inbred corn line, designated BB46, is disclosed. The invention relates to the seeds of inbred corn line BB46, to the plants and plant parts of inbred corn line BB46 and to methods for producing a corn plant, either inbred or hybrid, by crossing inbred corn line BB46 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from inbred corn line BB46.

Owner:KWS SAAT SE +1

Inbred corn line BB59

ActiveUS7989682B2Improve nutritional qualityModified waxy contentBryophytesPlant genotype modificationBiotechnologyGenetic Materials

An inbred corn line, designated BB59, is disclosed. The invention relates to the seeds of inbred corn line BB59, to the plants and plant parts of inbred corn line BB59 and to methods for producing a corn plant, either inbred or hybrid, by crossing inbred corn line BB59 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from inbred corn line BB59.

Owner:LIMAGRAIN EURO +1

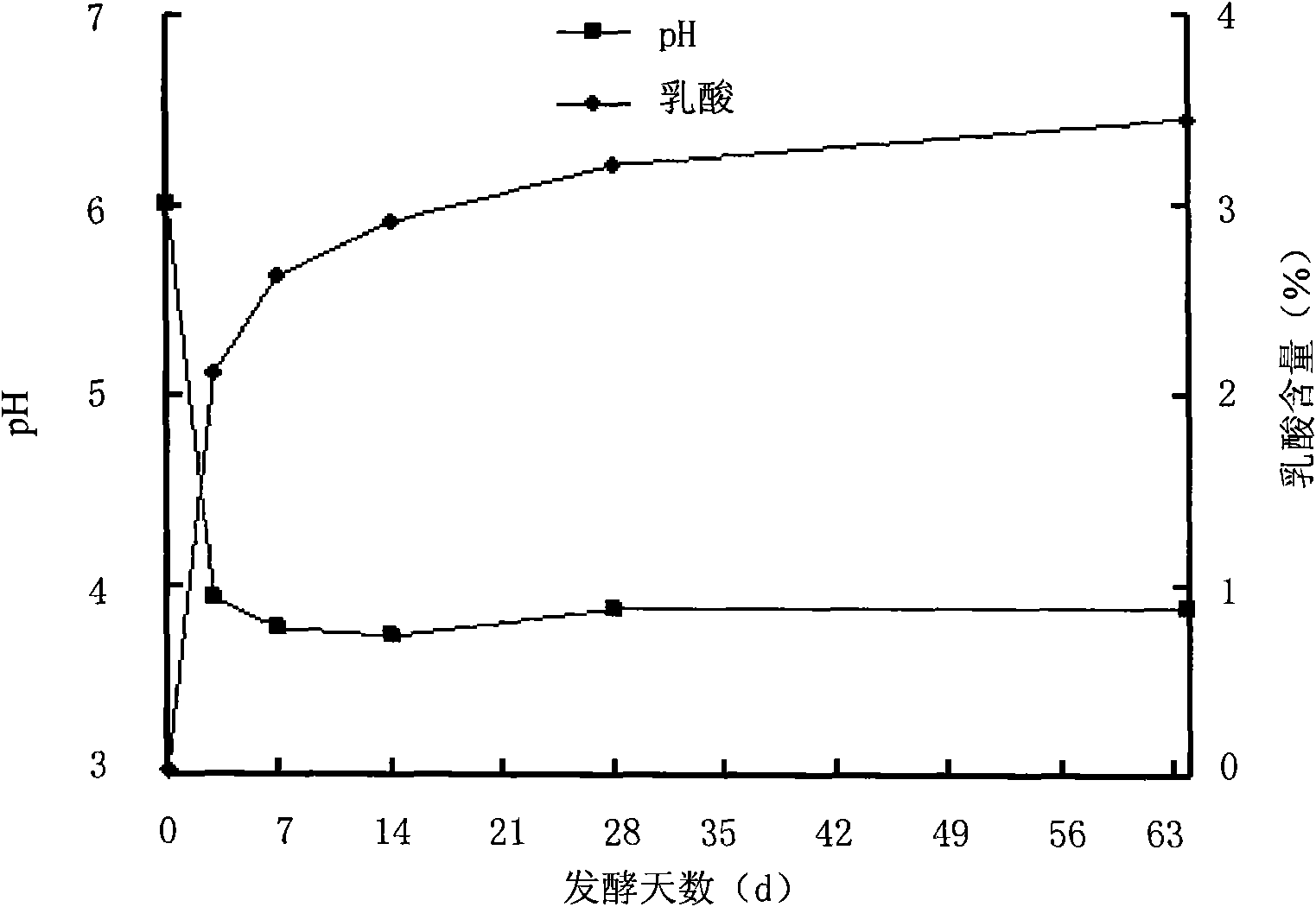

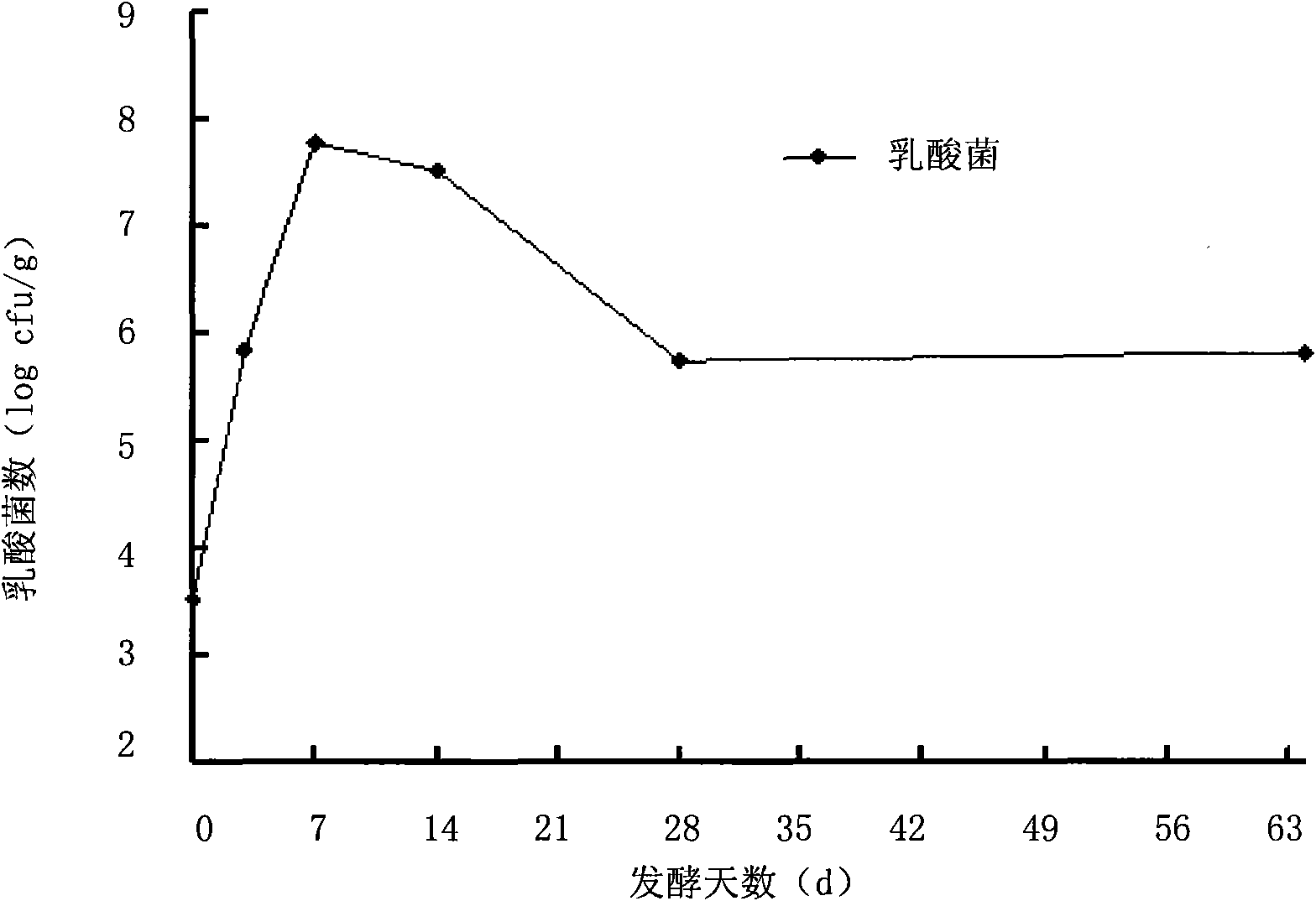

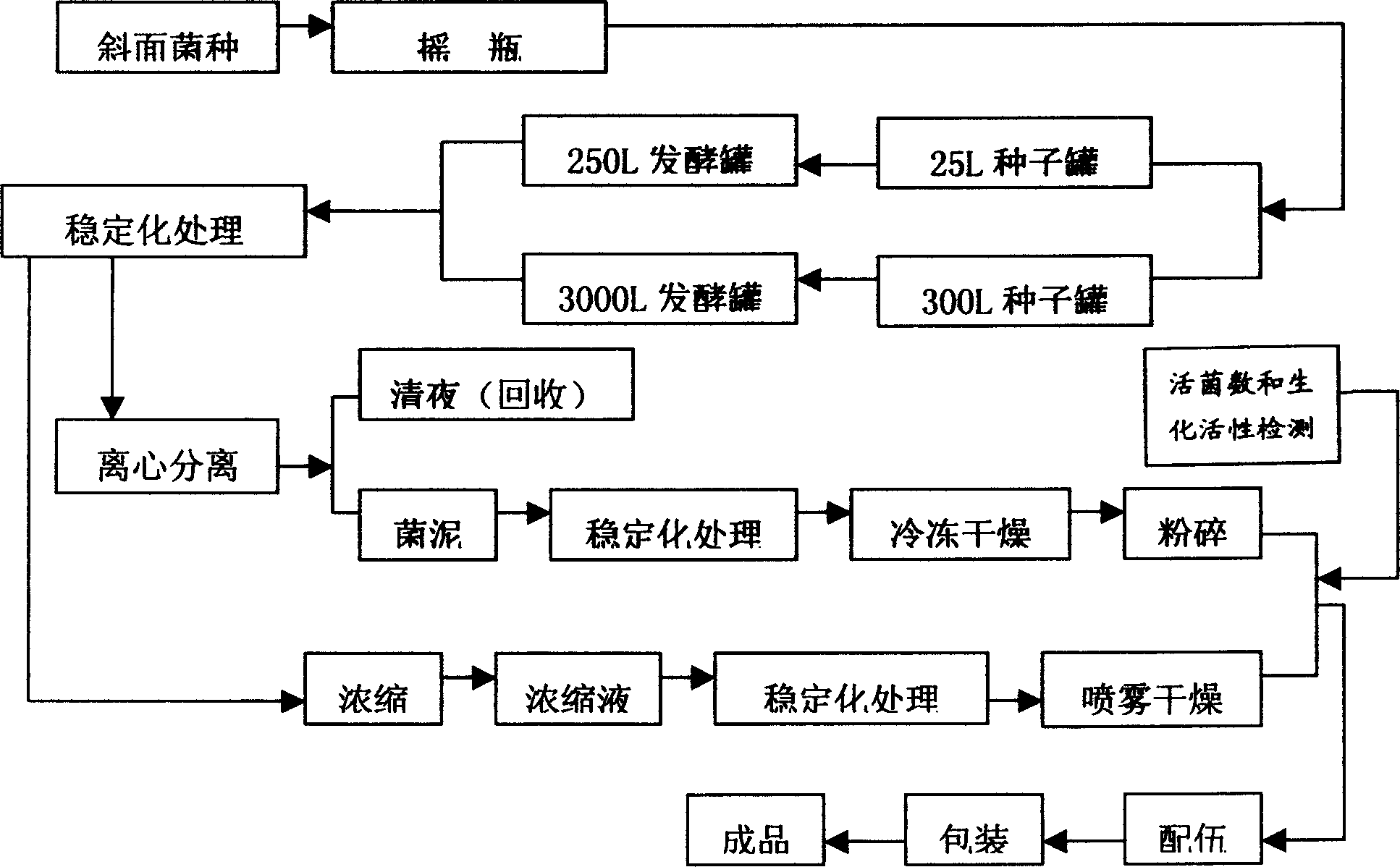

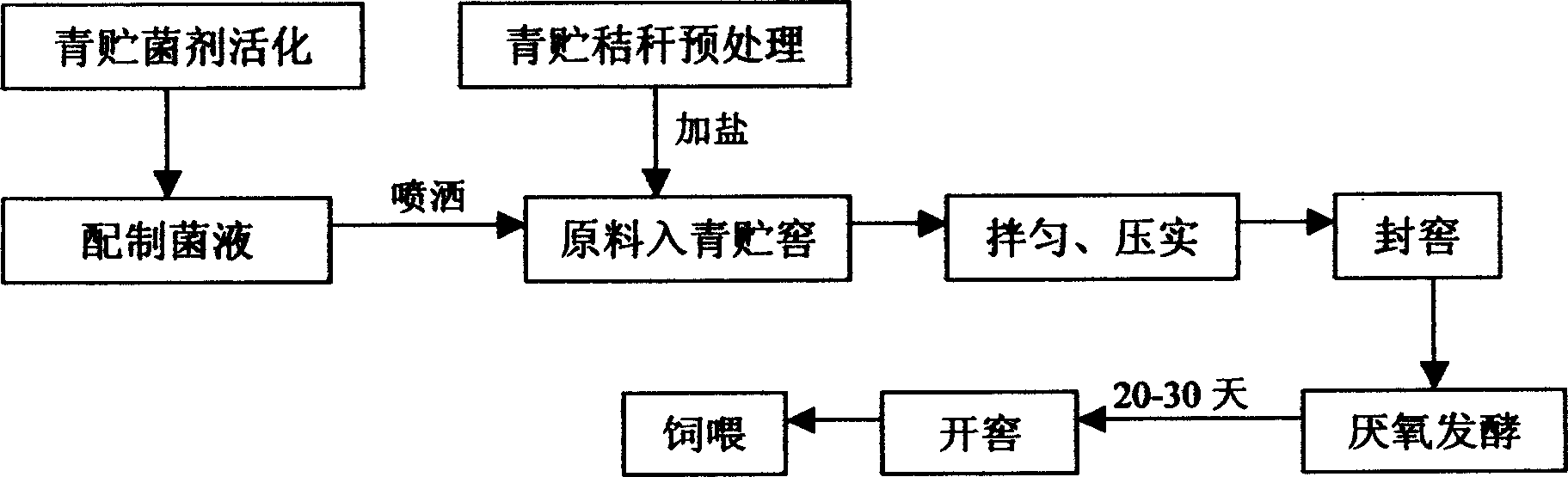

Microbial ensiling strain and composite fungus, method for producing silage

A high-activity composite microbial product for ensilage is composed of the streptococcus lactis and other 3 bacterial strains. After it is added to the raw materials of ensilage, such as corn plant, alfalfa, straw, stalk and pasturage, their pH value can be quickly lowered and the cellulose and semi-cellulose can be decomposed to obtain excellent feed.

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI +1

Inbred corn line CC1

ActiveUS7858853B2Improve nutritional qualityModified waxy contentHorticulture methodsPlant tissue cultureGenetic MaterialsTransgene

An inbred corn line, designated CC1, is disclosed. The invention relates to the seeds of inbred corn line CC1, to the plants and plant parts of inbred corn line CC1 and to methods for producing a corn plant, either inbred or hybrid, by crossing the inbred line CC1 with itself or another corn line. The invention further relates to methods for producing a corn plant containing in its genetic material one or more transgenes and to the transgenic plants produced by that method and to methods for producing other inbred corn lines derived from the inbred CC1.

Owner:LIMAGRAIN EURO +1

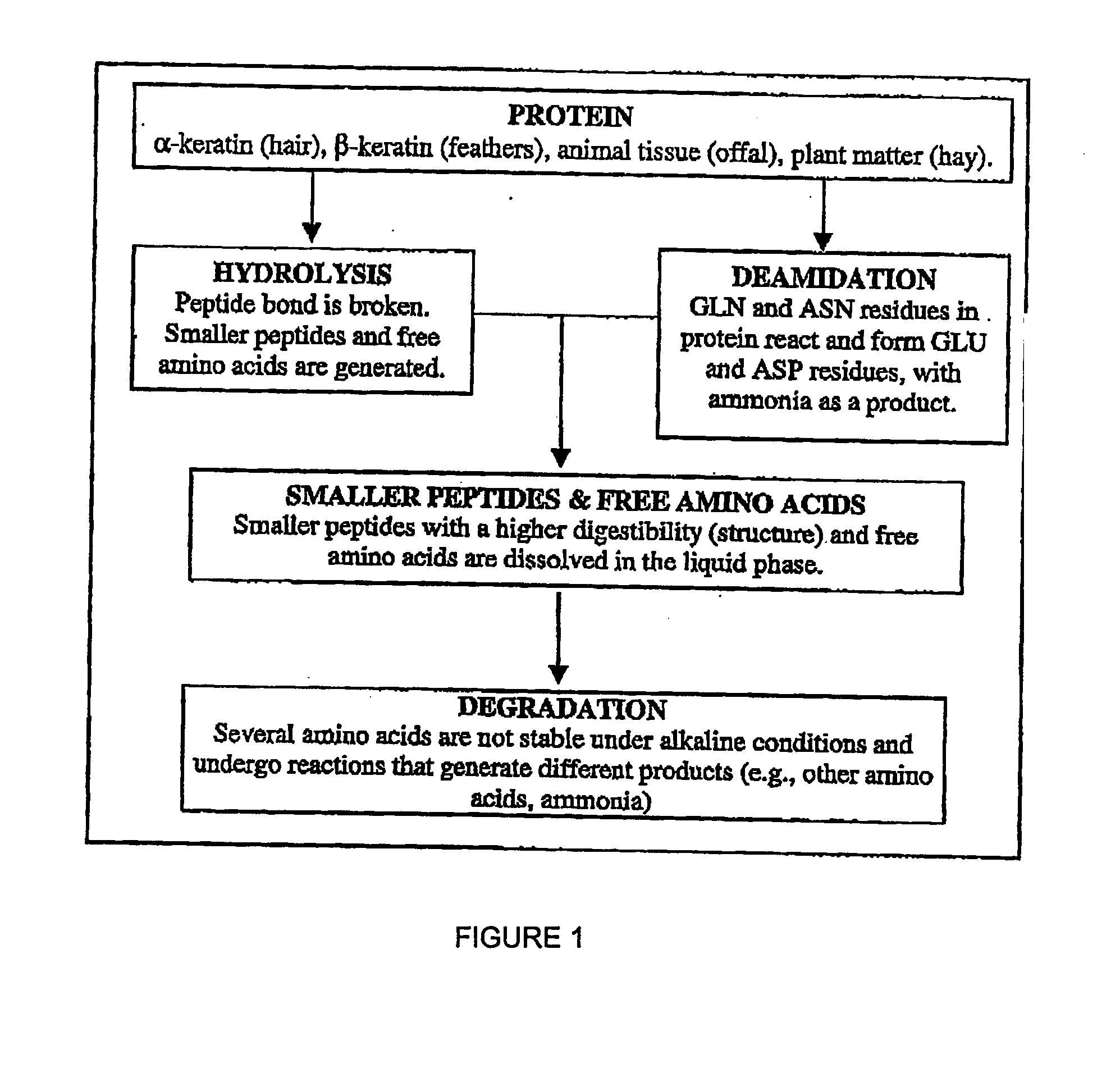

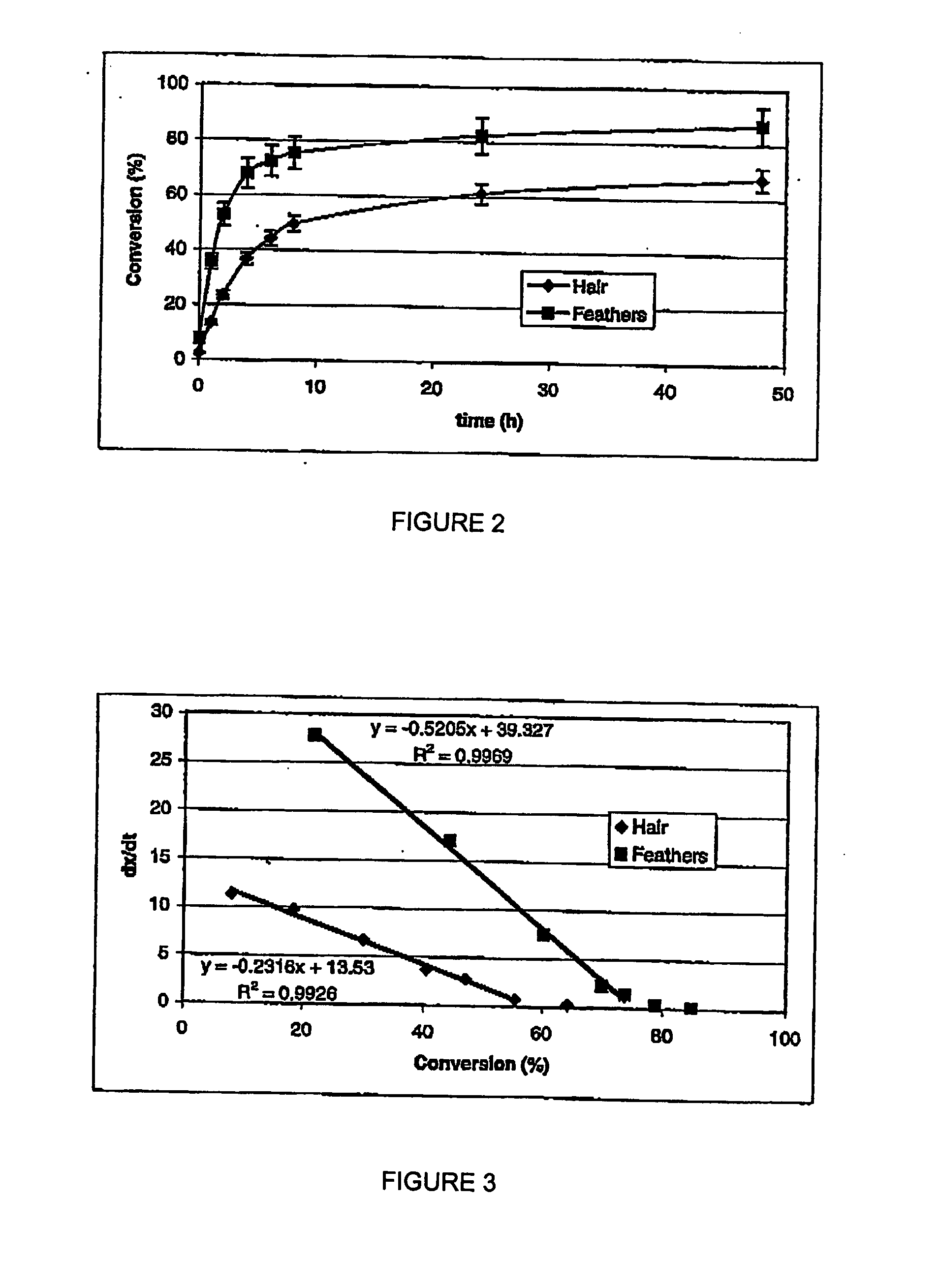

Method and system for solubilizing protein

InactiveUS20060069244A1Improve digestibilityRecovery of some componentPeptide/protein ingredientsPeptide sourcesSingle stagePolymer science

A process for solubilization of protein including application of an alkali, such as lime, and heating. The process may also involve lime recovery and may be accomplished in a single stage or two stages to separate protein solubilized from labile and recalcitrant sources. Systems and devices for use in such process, including a continuous stirred tank reactor and a plug flow reactor are also involved.

Owner:TEXAS A&M UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com