Efficient methane-generating pit using poultry excrement and methane generation process

A technology for livestock and poultry manure and biogas digesters, which is applied in biological sludge treatment, waste fuel, etc., can solve the problems of incomplete digestion, poor feed and slag discharge process, and low gas production efficiency, so as to reduce production costs and The effect of labor, meeting the requirements of large-scale production, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

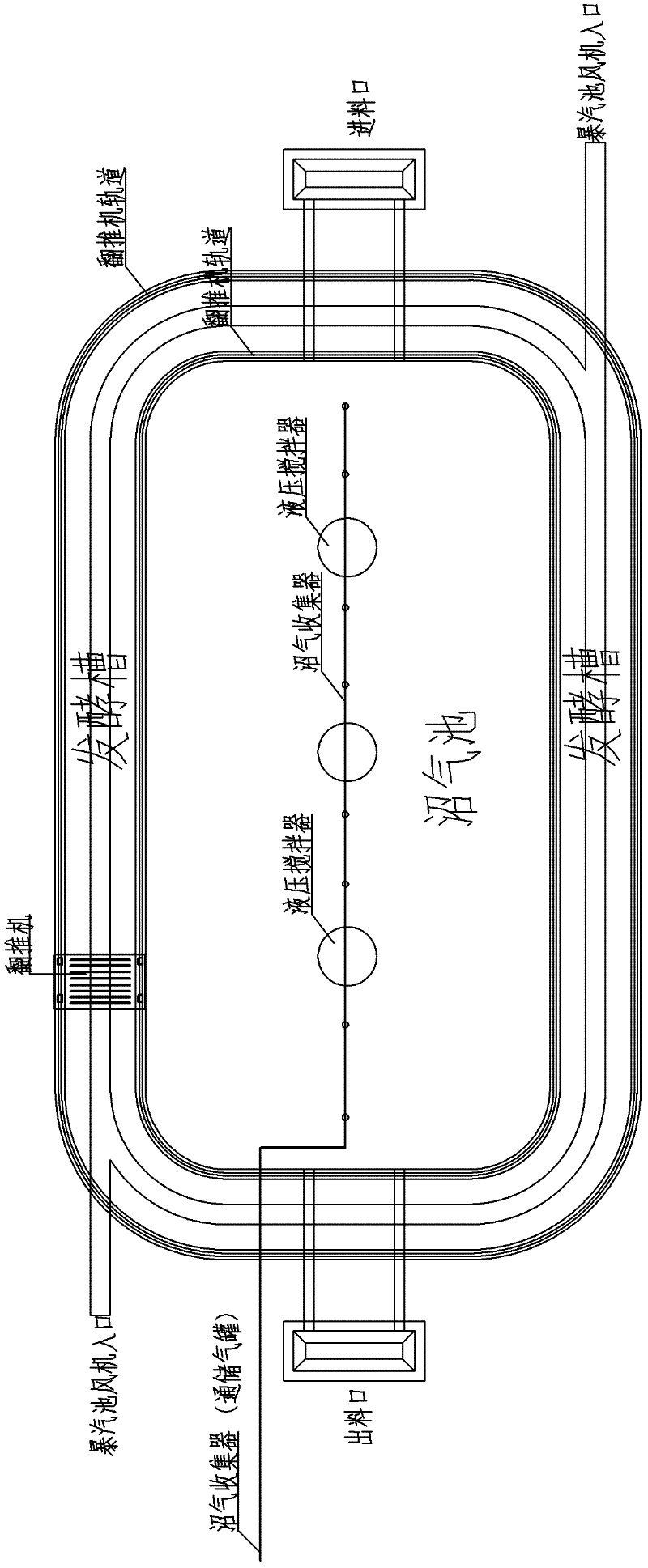

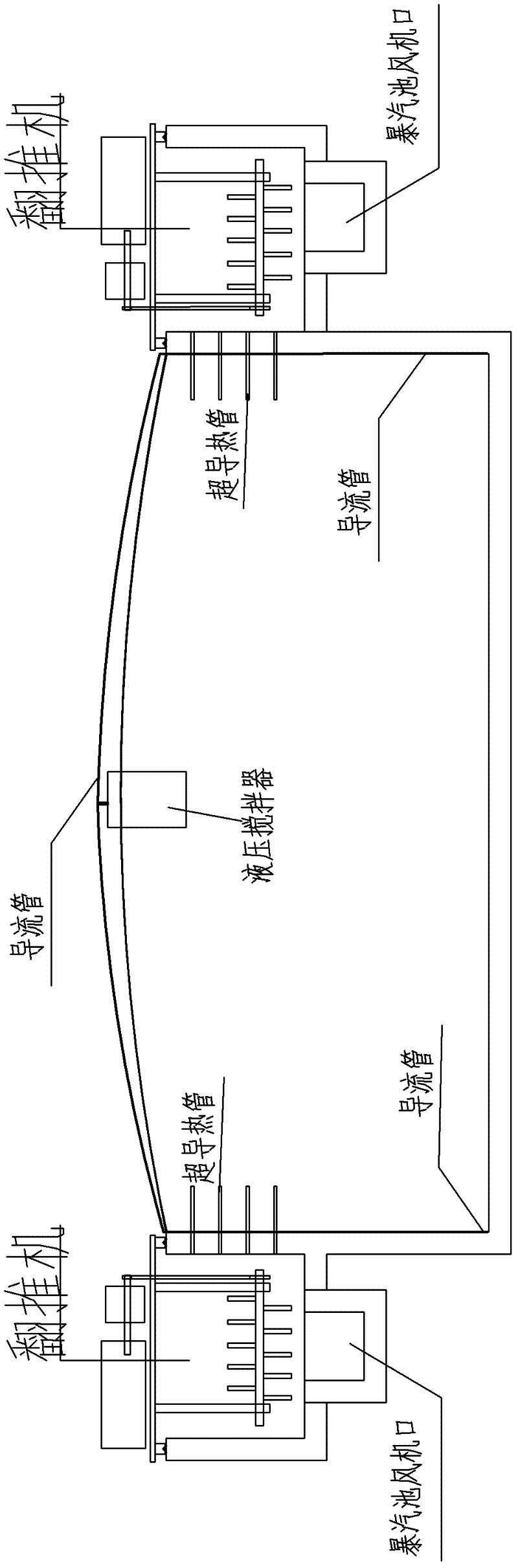

[0065] (1) Production scale. Processing 300M per day 3 The scale of livestock and poultry manure is the design target. If the manure concentration is 20%, the solid matter is 60 tons, and each ton of solid matter can produce 300M biogas 3 , the daily biogas production is 18,000 M 3 , with an annual output of 6.48 million M of biogas 3 .

[0066] (2) Number of biogas digesters: 10 unit biogas digesters are designed to process 300M of livestock and poultry manure per day 3 , the material concentration is 20%, the solid weight is 60 tons, and the material concentration is 15%, it is 400 tons, and 20 days is a cycle, the total material volume is 8000M 3 , the volume of each pool is 800M 3 .

[0067] (3) The loss of biogas residue is calculated as 30% of the total amount, which is 60×70%=42T. According to the formula of organic compound fertilizer, the amount of biogas residue accounts for 50%, and the daily production of organic compound fertilizer is 84T, and the annual out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com