Patents

Literature

112results about How to "Meet the requirements of large-scale production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

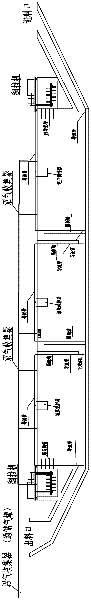

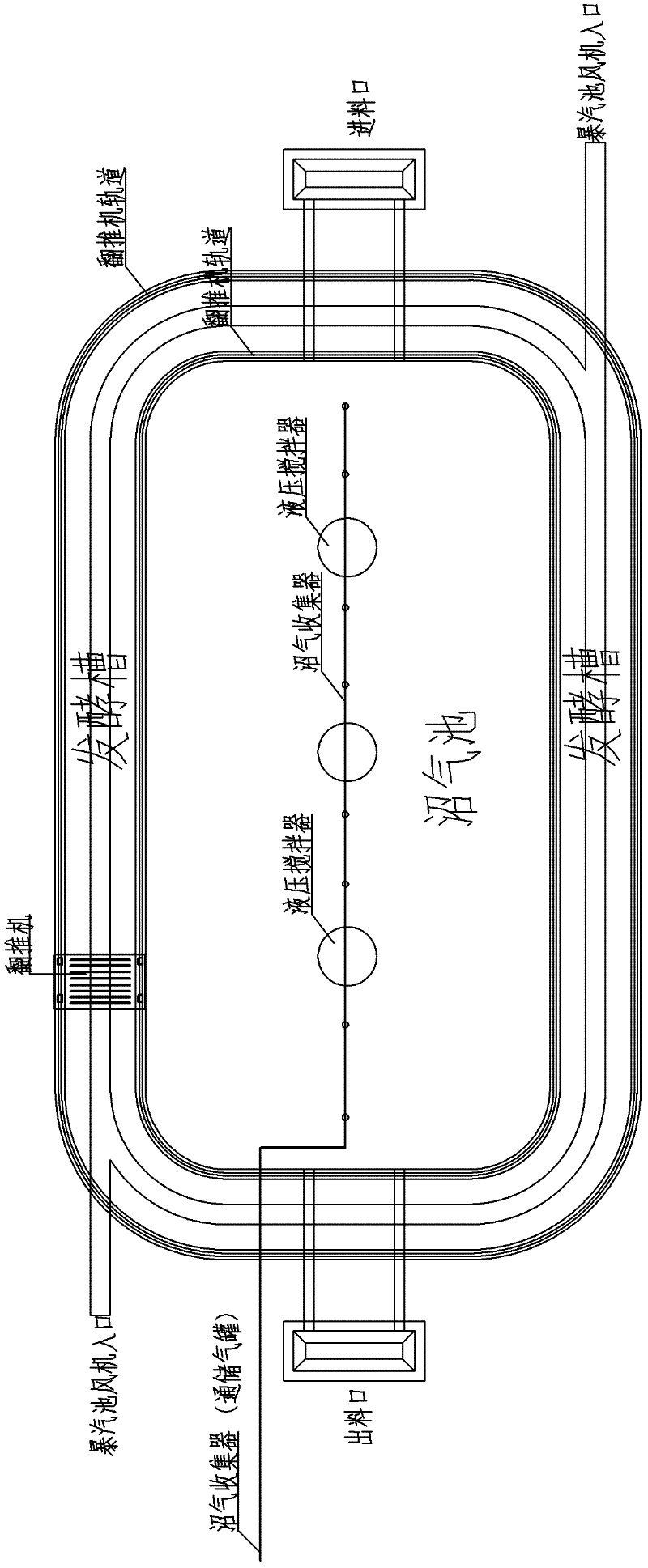

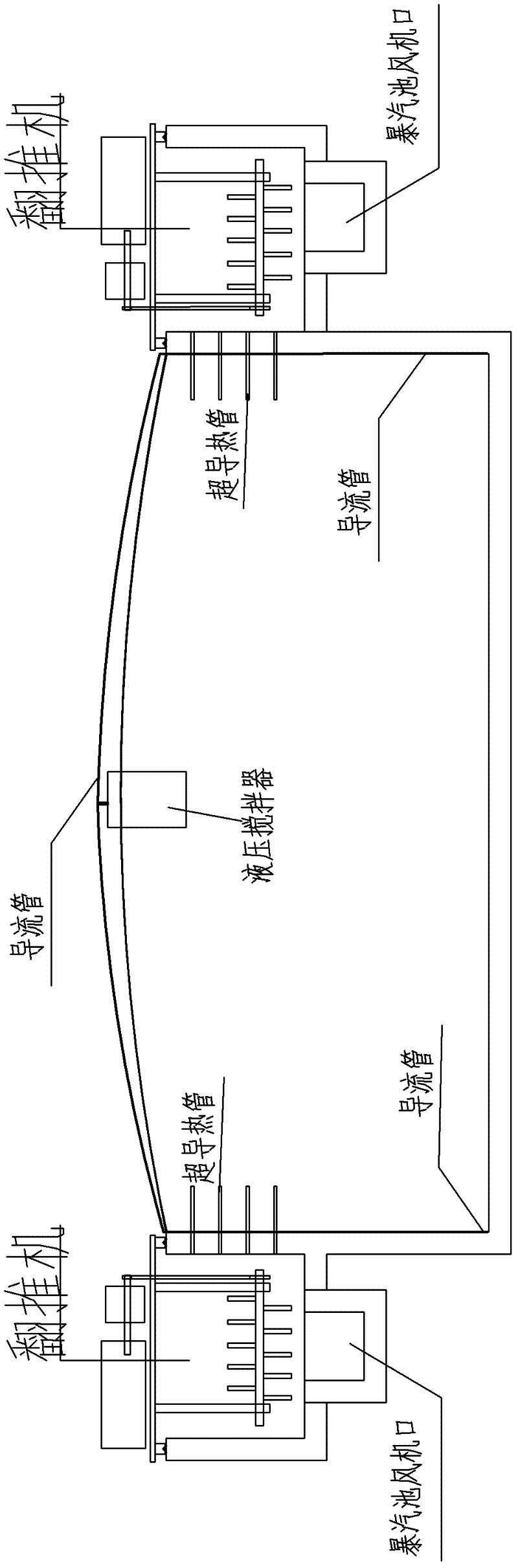

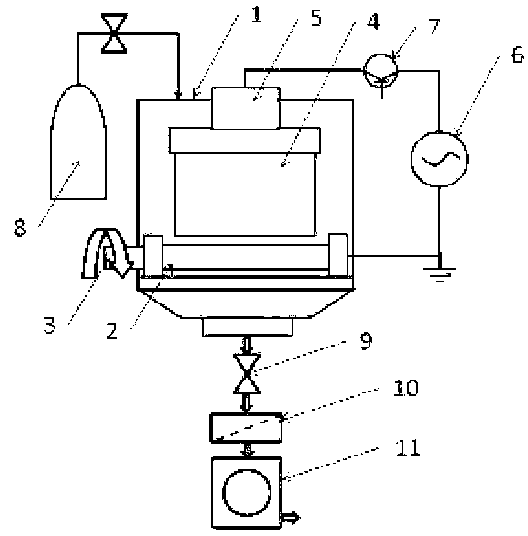

Efficient methane-generating pit using poultry excrement and methane generation process

InactiveCN102531310AReduce moisture contentEasy to produceWaste based fuelBiological sludge treatmentProcess engineeringBiogas production

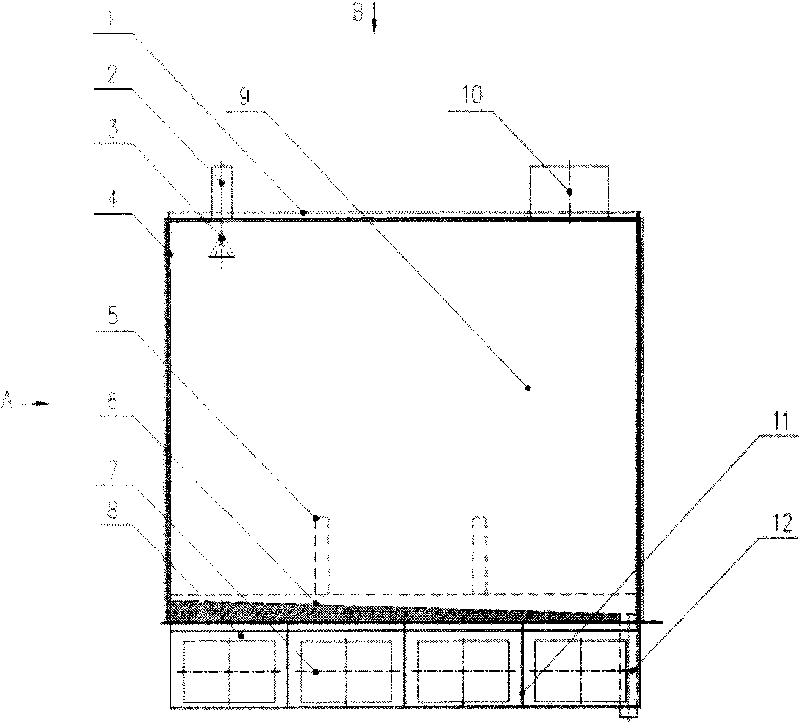

The invention relates to a methane-generating pit using poultry excrement, which is integrally horizontally placed under the water plane. Partition walls are arranged in the middle of the methane-generating pit for dividing the whole methane-generating pit into a plurality of unit methane-generating pits, and medium channels arranged on the partition walls are communicated with each other. An annular fermentation tank is arranged above the periphery of the methane-generating pit, a plurality of superconductive heat pipes are arranged on the inner side of the annular fermentation tank, and the superconductive heat pipes are inserted into the methane-generating pit. A material inlet and a material outlet are respectively arranged at two ends of the methane-generating pit and under the unit methane-generating pits at two ends of the methane-generating pit, a methane collector is arranged above each unit methane-generating pit, and the methane collectors are directly communicated with a gas storage tank through pipelines. The methane-generating pit has the advantages of being high in material concentration, integrating material inlet, deslagging, methane generating, stirring, temperature controlling, regulating and the like, being high in mechanization degree, large in treating quantity, fast in digesting rate and the like and can meet requirements for scale production, and concentration of inlet materials of a continuous methane-generating pit can reach about 15%.

Owner:范立河

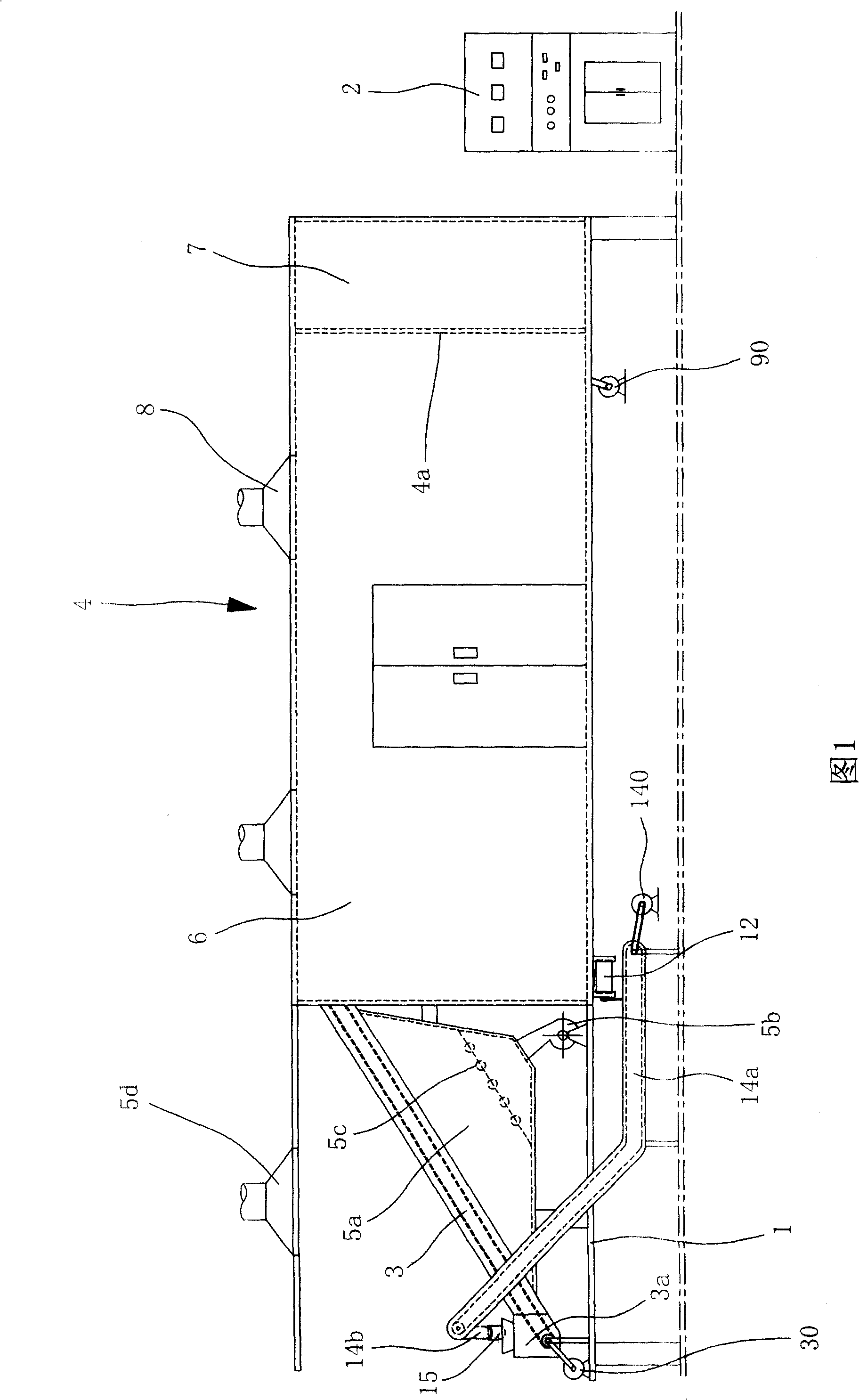

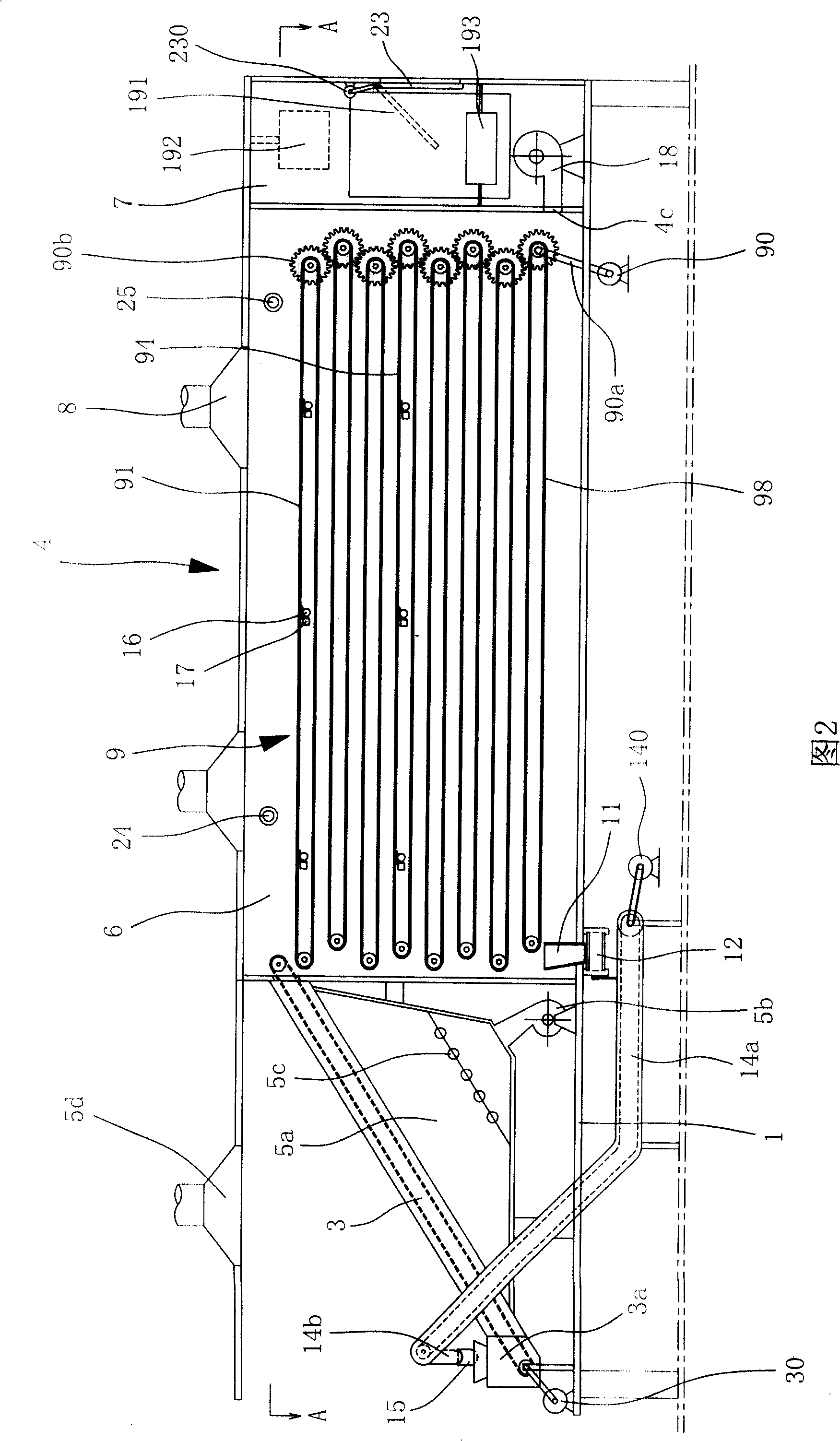

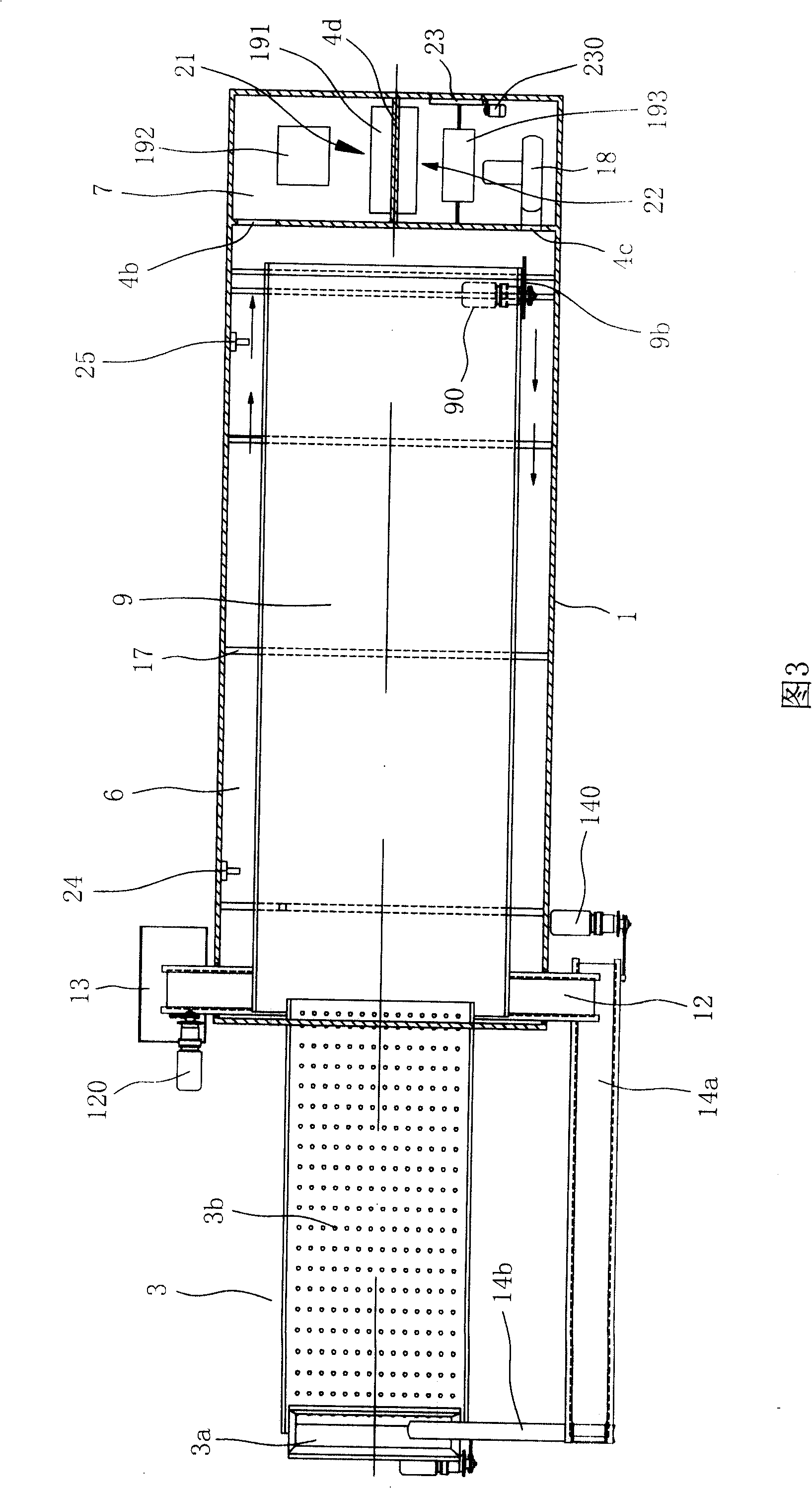

Tea leaf withering process plant

InactiveCN101243817ATimely withering treatmentEvenly dryPre-extraction tea treatmentControl systemAir treatment

The invention provides a tea withering machine, comprising a frame, an electric cabinet and a case on the rear part of the frame. A feeding and conveying belt for delivering tealeaves into the case is arranged on the frame in front of the case; small vent holes are densely arranged on the conveying belt, and a heating and cooling air supplying device is positioned under the conveying belt; the case is divided into a tealeaves treating chamber and an air treatment chamber by a separating plate with respective air inlets and outlets at both sides; the air treatment chamber is provided with a temperature and humidity treatment device for recirculation air, and a blower; the blower is connected with the air outlets of the separating plate; the tealeaves treating chamber is provided with an air exhausting device and a multi-layer tealeaves distributing and conveying belt; the tealeaves distributing and conveying belt is used to support the tealeaves on the feeding and conveying belt, and deliver downward the tealeaves layer-by-layer; a conveying belt for the discharge tealeaves is arranged at the lower part of a discharge port of the lowest tealeaves distributing and conveying belt; a circulating and back-feeding device for delivering the tealeaves to a hopper is arranged between one end of the conveying belt for the discharge tealeaves and the hopper; a receiving chute is positioned below the other end of the conveying belt for the discharge tealeaves; a temperature and humidity sensor connected with an input end of a control system is arranged in the tealeaves treatment chamber. The tea withering machine has the advantages of saved space and excellent withering effects.

Owner:林清矫

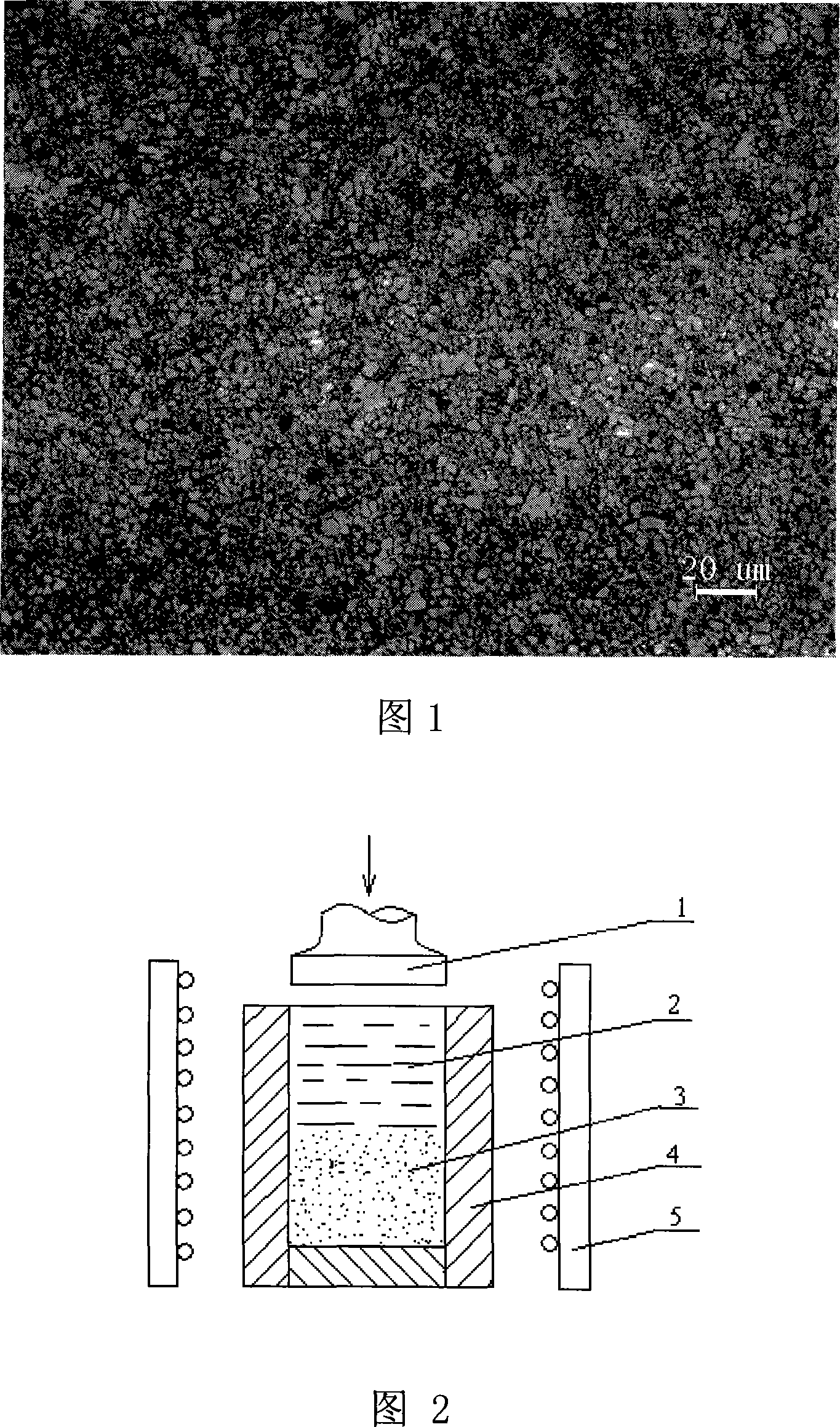

High-strength plasticity aluminum-base composite material employing TiB2 particles and preparation method thereof

The invention provides a high-plasticity aluminum-based composite material containing TiB2 particles and a preparation method thereof, and relates to an aluminum-based composite material and a preparation method thereof. The invention solves the problems of the prior art, such as poor plasticity and toughness and difficulty in secondary processing. The composite material contains (by volume) titanium diboride reinforcement particles 10-25 percent, aluminum particles 25-35 percent, and aluminum alloy matrix in balance. The preparation method comprises: (1) weighing titanium diboride reinforcement particles, aluminum particles and aluminum alloy matrix; (2) mixing by mechanical dry method to obtain a reinforcement powder; (3) placing the reinforcement powder in a die and compression-molding; (4) heating the die; (5) melting aluminum alloy and casting in the die; (6) applying a pressure on the die with molten aluminum and maintaining the pressure for a period of time and cooling; (7) demoulding and taking the cast ingot, that is reinforced aluminum-based composite material. The inventive aluminum-based composite material has high plasticity and good wear resistance and is adapted to secondary processing and machining.

Owner:HARBIN INST OF TECH

Rolling cogging production method of Cr4Mo4V electroslag steel ingot

InactiveCN1586749AThe process is reasonable and simpleEasy to operateMetal rolling arrangementsCarbideTemperature difference

The production process of rolling cogging Cr4Mo4V electroslag steel ingot features the heating in pit heating furnace and cogging in blooming mill to produce 100 mm square bloom. The production process includes heating Cr4Mo4V electroslag steel ingot at 630 deg.c for 90 min, 900 deg.c for 60 min, and 1190 deg.c for 210 min while turning the ingot to make the temperature difference between two opposite sides less than 20 deg.c; and cogging at initial temperature over 1130 deg.c and finishing temperature over 1000 deg.c through 44 gates and final annealing in annealing furnace to eliminate stress. The said production process is simple and has high product quality, raised bloom yield and lowered cost.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

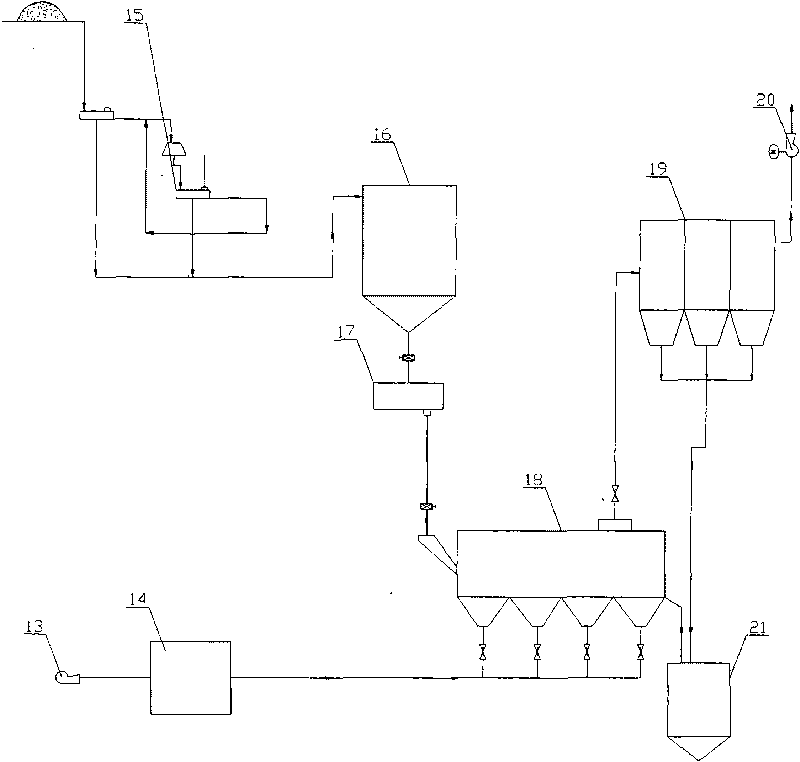

Solid fuel upgrading reaction device and process thereof

InactiveCN101717681ASimple processEasy to operateDrying solid materials with heatDrying gas arrangementsProcess engineeringProduct gas

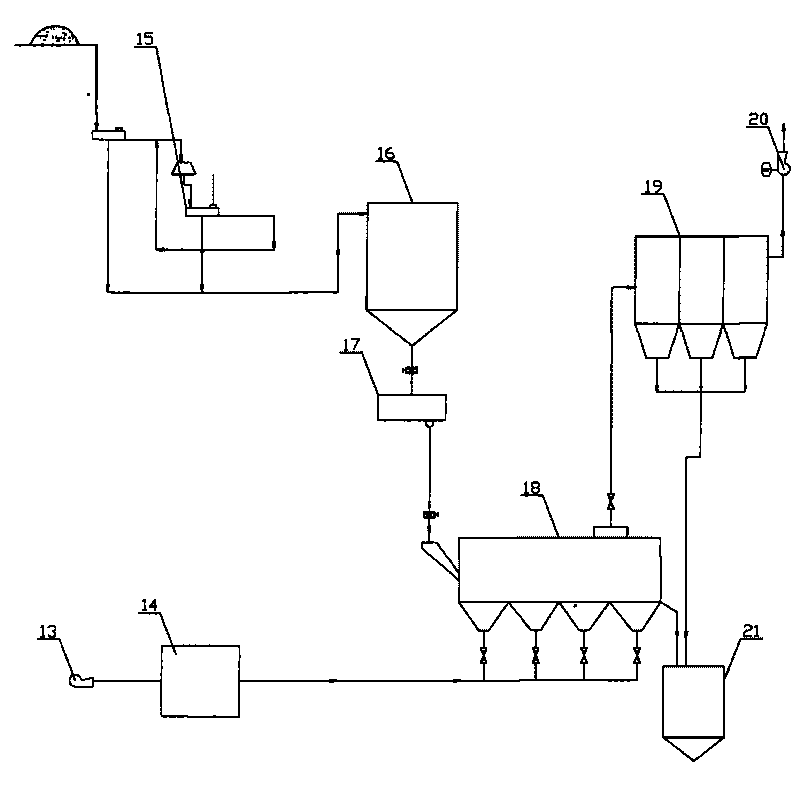

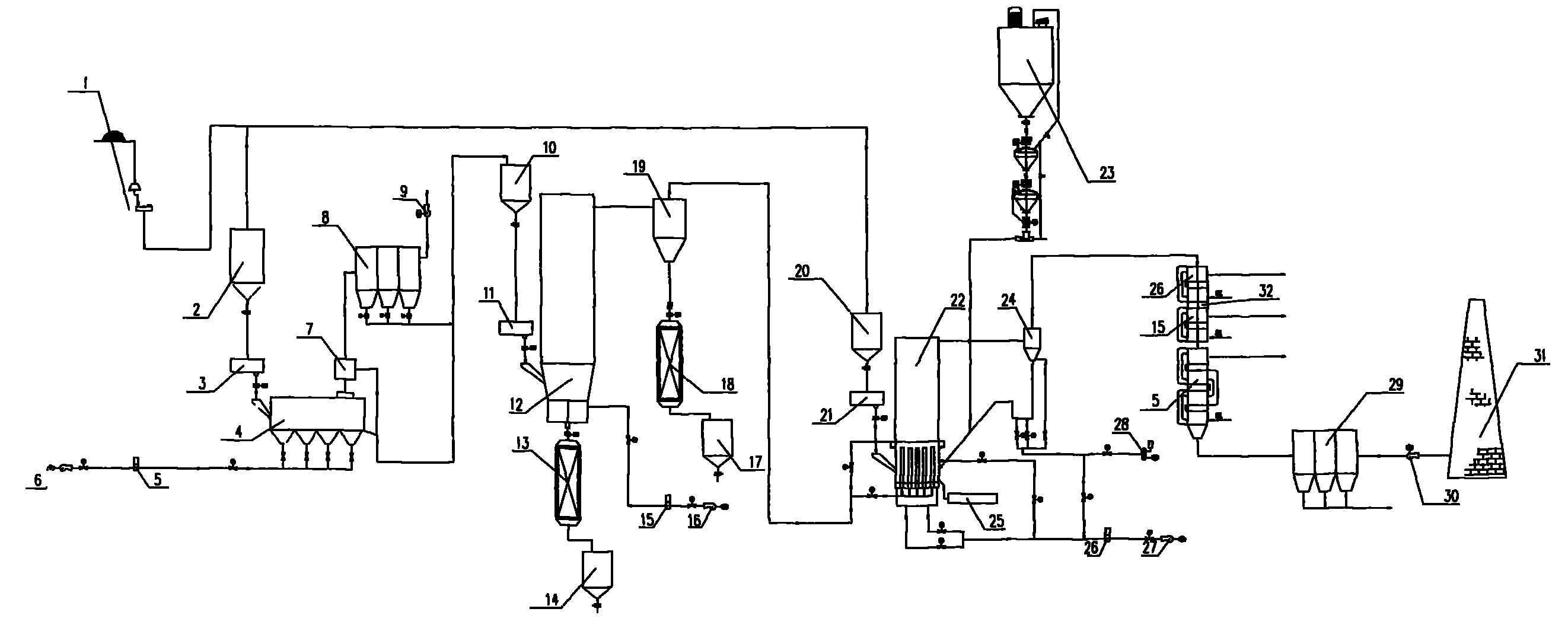

The invention discloses a solid fuel upgrading reaction device and a process thereof. The device consists of a solid fuel crushing system, a fluid-bed solid fuel upgrading device, a ventilator, a thermal smoke furnace, a dust remover and the like. The process adopts fluid bed technology, uses a gas drying medium with certain temperature for keeping brown coal fed into the fluid-bed solid fuel upgrading device in a full fluid state and drying the brown coal, and meanwhile finishes the delivery of the brown coal from a feeding hole to a discharge hole. The process has the characteristics of simple process, convenient operation, low energy consumption, flexible control for moisture content of the dried solid fuel and broad granularity adaptability, and can implement large-scale production without large-scale mechanical equipment.

Owner:XIAN THERMAL POWER RES INST CO LTD

Integrated fluidized bed mild-gasification lignite upgrading system and technology

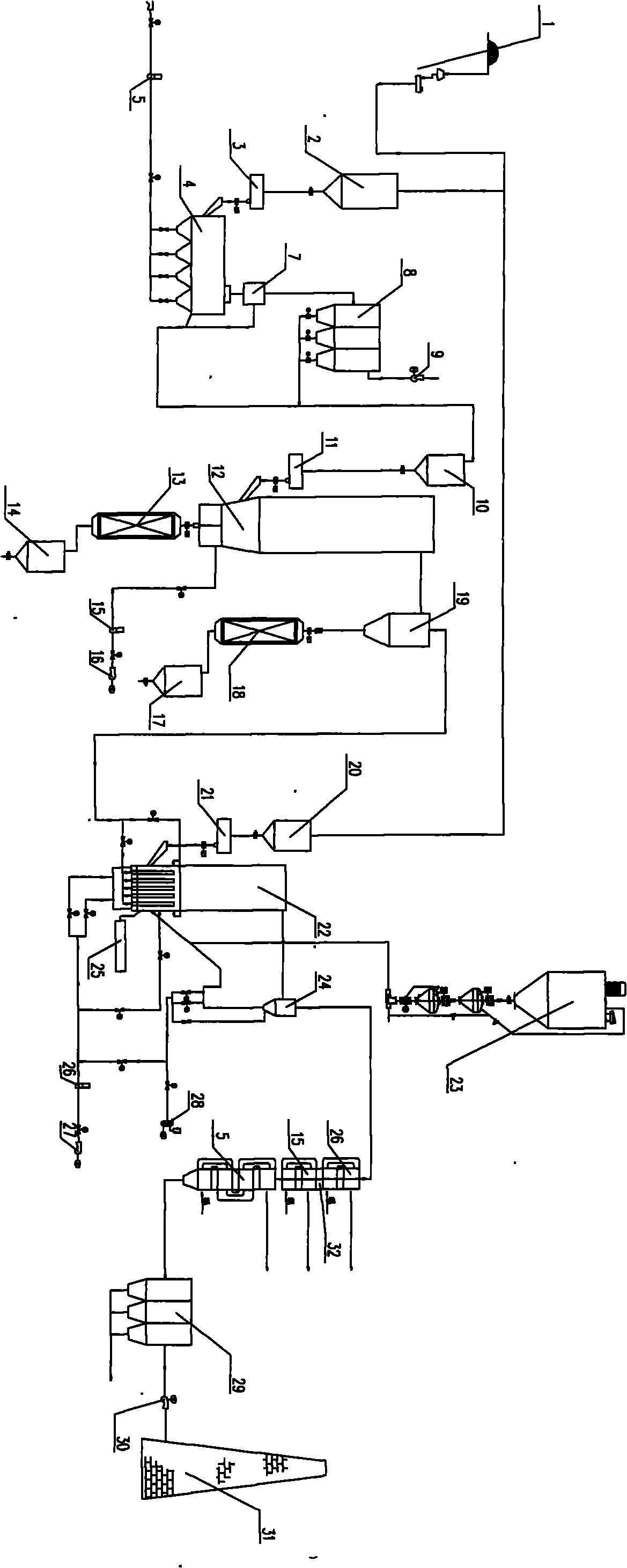

The invention discloses an integrated fluidized bed mild-gasification lignite upgrading system and integrated fluidized bed mild-gasification lignite upgrading technology. The lignite is subjected to pre-drying treatment by using high temperature air generated by a low-value gas-fired incinerator so as to remove part of moisture in the lignite; the lignite is delivered to a fluidized bed mild-gasification lignite upgrading reactor for partial gasification, destructive distillation and combustion reaction, wherein one part of heat generated in the reaction is used for maintaining the temperature in the reactor and the other part of heat is used for removing the moisture in the lignite; and the lignite upgraded by the fluidized bed mild-gasification lignite upgrading reactor is delivered to a finished product cooler for cooling and then delivered to a finished product warehouse, and the generated low-value gas is fed to a subsequent low-value gas-fired incinerator for burning. The system and the technology have the characteristics of simple process, convenient operation, low energy consumption, less pollutant discharge, and no waste water discharge.

Owner:XIAN THERMAL POWER RES INST CO LTD

Fluid barrier material and preparing method of fluid barrier material

InactiveCN104457429AImprove performanceGood compatibilityPersonal protection gearBiomedical engineeringMaterial technology

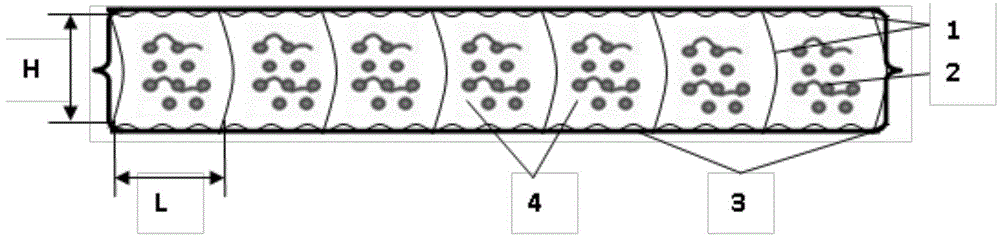

The invention relates to the technical field of bulletproof barrier materials, and particularly discloses a fluid barrier material and a preparing method of the fluid barrier material. The fluid barrier material comprises STF, armored fabric and band adhesive tape. The armored fabric is of a three-dimensional interlayer structure and is provided with cavities, the STF is arranged in the cavities, and the armored fabric is sealed through the band adhesive tape. By means of the fluid barrier material, the compatibility and the stability of the STF and the armored fabric are improved; meanwhile, the technical problem that as the STF has the fluidity and is prone to downwards flowing under the effect of the gravity, the barrier performance at the upper portion of the armored fabric and the barrier performance at the lower portion of the armored fabric have great difference is solved, and the overall barrier performance of the fluid barrier material is improved.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

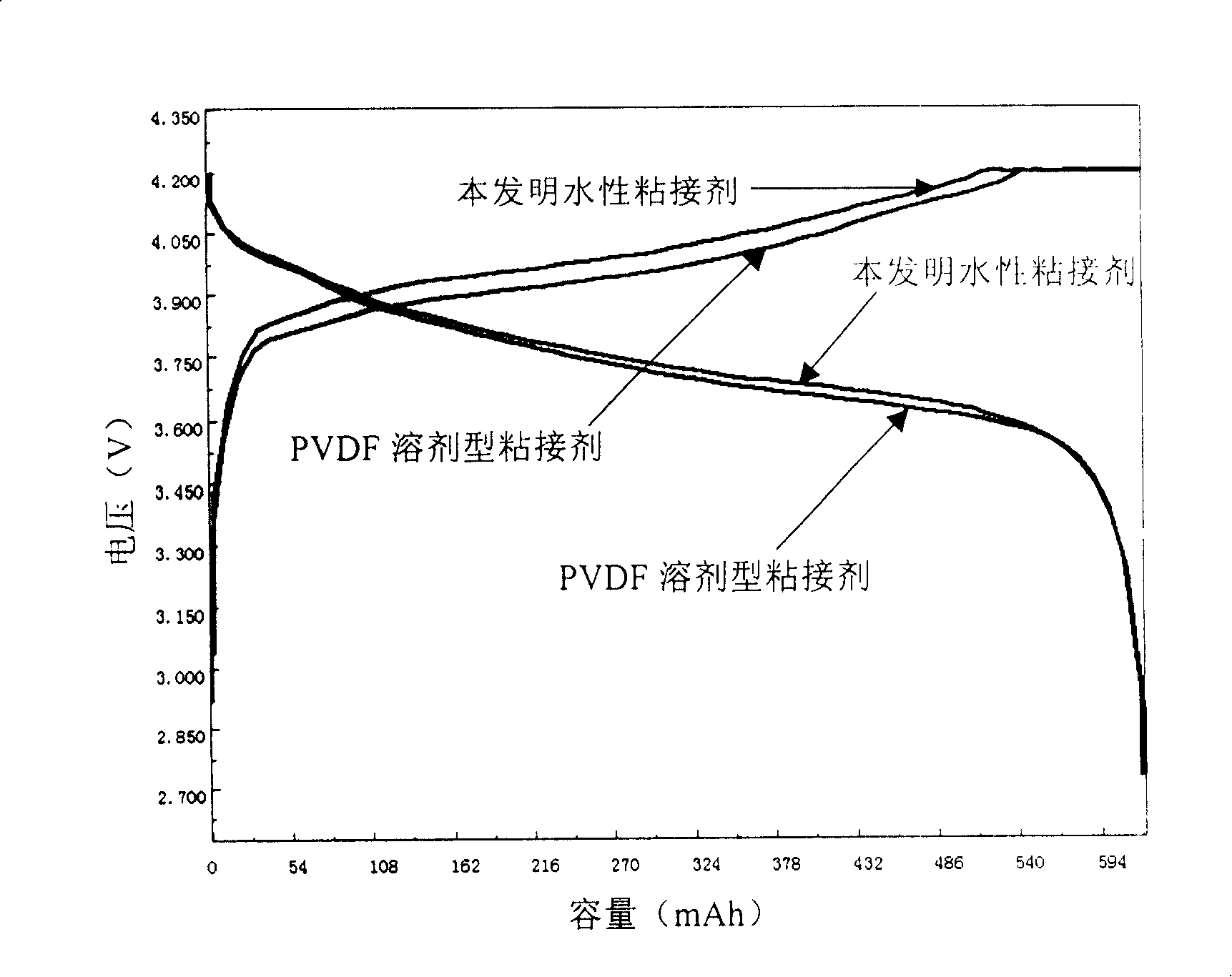

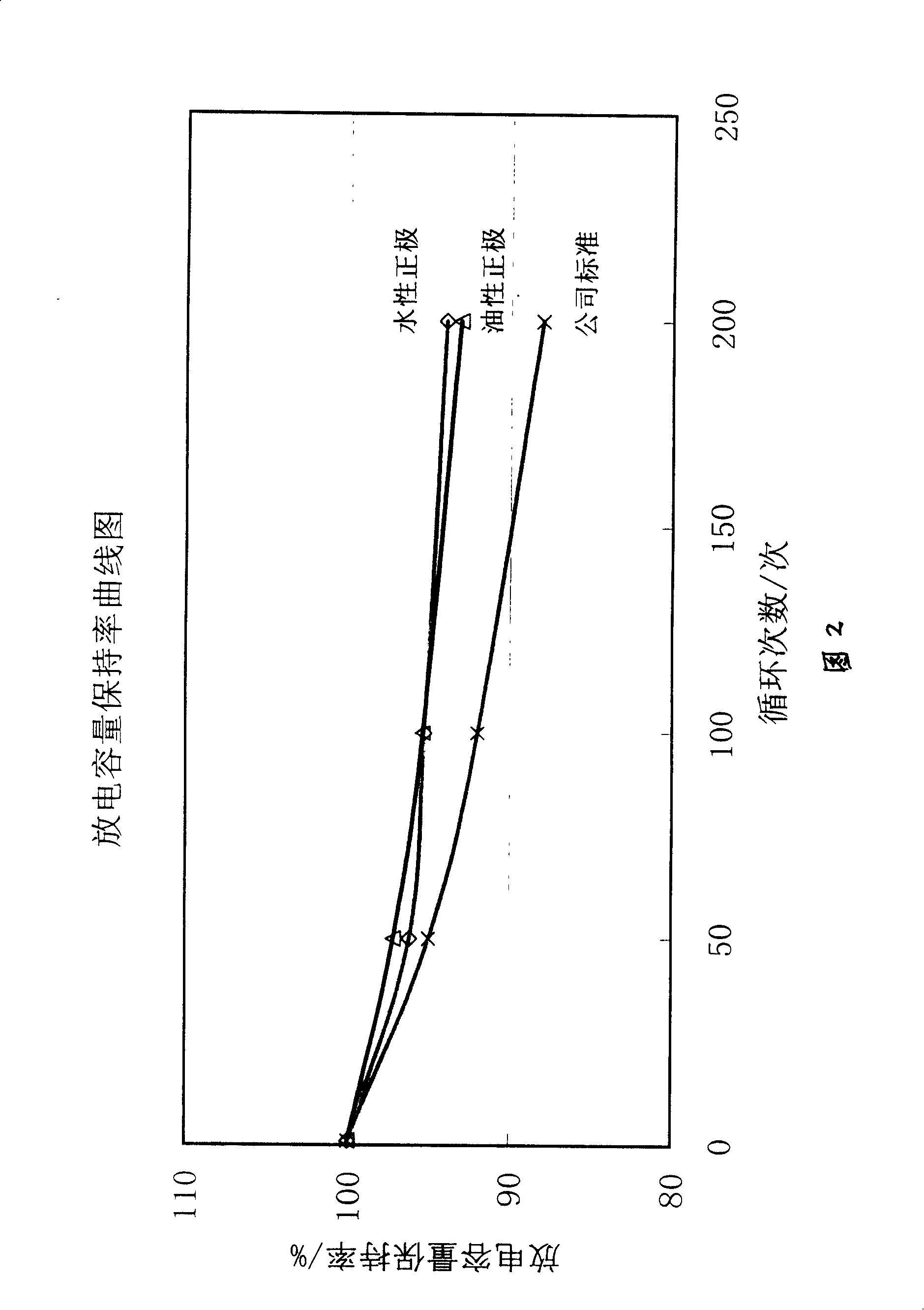

Lithium ion battery positive plate water coating adhesive and preparing method thereof

InactiveCN101210165AGood dispersionEvenly dispersedProtein adhesivesCell electrodesElectrical batteryAdhesive

An aqueous coating adhesive for a positive electrode sheet of a lithium ion battery relates to the field of battery manufacture technique. The adhesive is obtained by mixing and stirring uniformly a main adhesive, a thickening agent, an auxiliary adhesive and an adhesion-enhanced surfactant. The adhesive of the invention has the advantages of strong adhesion, more uniform diffusion of slurry material, and more fresh and beautiful appearance of the coated electrode sheet, thus meeting the requirement for scale production of the positive electrode sheet of the lithium ion battery and achieving water-phase coating manufacture of the positive electrode sheet of the lithium ion battery.

Owner:林云青

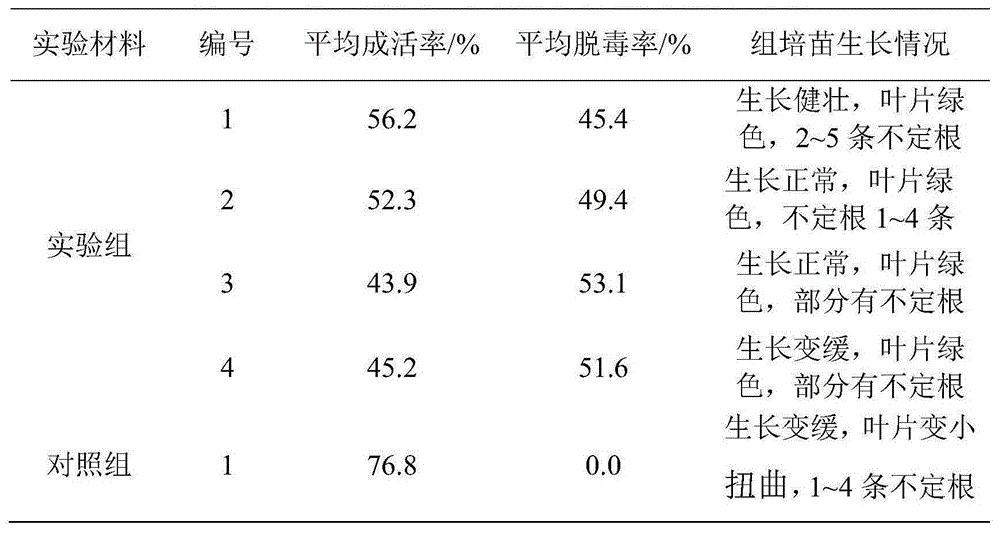

Tissue culture seedling growing process for trichosanthes

InactiveCN1985582AMeet the requirements of large-scale productionAchieve production scalePlant tissue cultureHorticulture methodsCataphyllBud

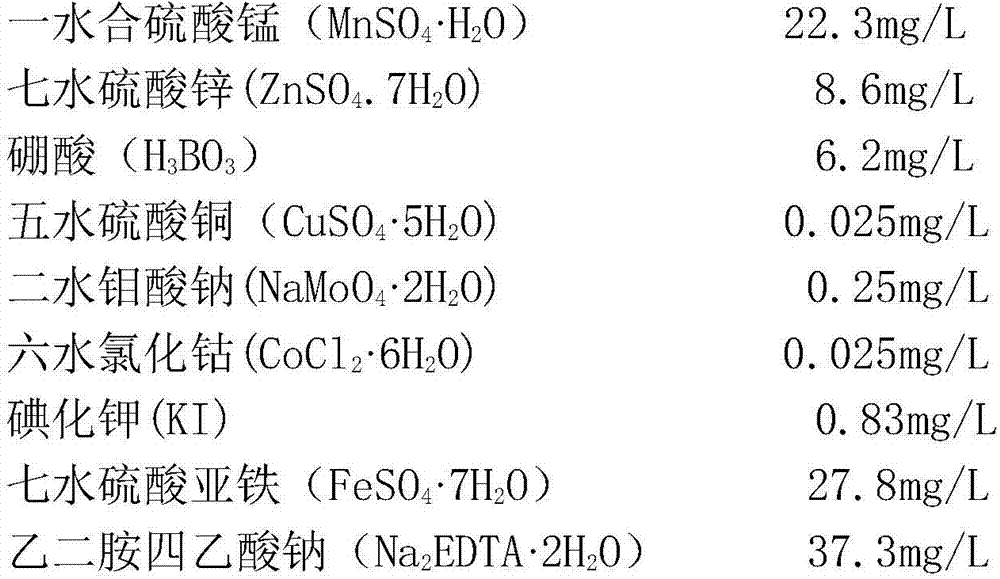

The tissue culture seedling growing process for trichosanthes includes the following steps: 1. taking the bud on tuberous root or stalk of trichosanthes as the explant in summer end or initial summer; 2.cutting bud or stem segment; 3. inoculating the bud or stem segment in culture medium I inside culture bottle; 4. secondary culture in culture medium II inside culture bottle; and 5. rooting culture in culture medium III inside culture bottle for 20-30 days to root. The present invention has short propagation period and high propagation coefficient.

Owner:江苏春辉生态农林股份有限公司

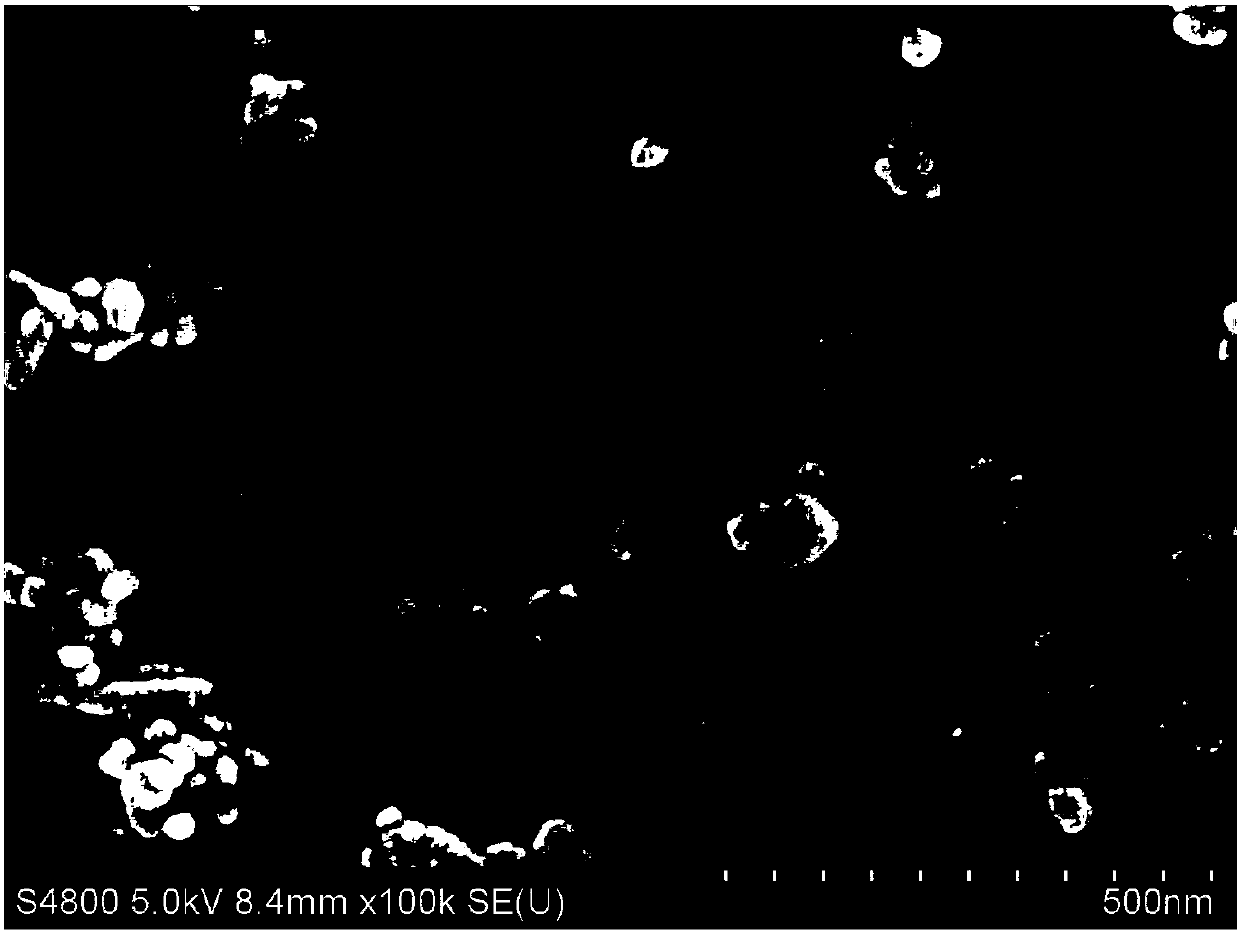

Nanometer hydroxyapatite dispersion body and preparation process thereof

ActiveCN107555406AImprove particle uniformityReduce reunionPhosphorus compoundsOrganic solventNano hydroxyapatite

The present invention discloses a nanometer hydroxyapatite dispersion body and a preparation process thereof. According to the nanometer hydroxyapatite dispersion body, nanometer hydroxyapatite particles are uniformly dispersed in a liquid phase medium, the solid content of the nanometer hydroxyapatite dispersion body is 1-5 wt%, the size of the nanometer hydroxyapatite particles is 40-60 nm, theaspect ratio of the nanometer hydroxyapatite particles is 1-5, and the liquid phase medium is water, an organic solvent, the mixture of a water-miscible organic solvent and water, or the mixture of different organic solvents. According to the present invention, by combining the hydrothermal method and the super gravity technology, the microcosmic mixing effect is strengthened, and the method has advantages of low production cost, simple operation and good repeatability; the prepared nanometer hydroxyapatite dispersion body has advantages of controlled particle size, good dispersion effect andgood stability; and with the technical scheme, the problems of easy agglomeration, poor dispersibility and the like of the nanometer hydroxyapatite particles can be solved, and the product can be endowed with the high application performance and the broad application range.

Owner:BEIJING UNIV OF CHEM TECH

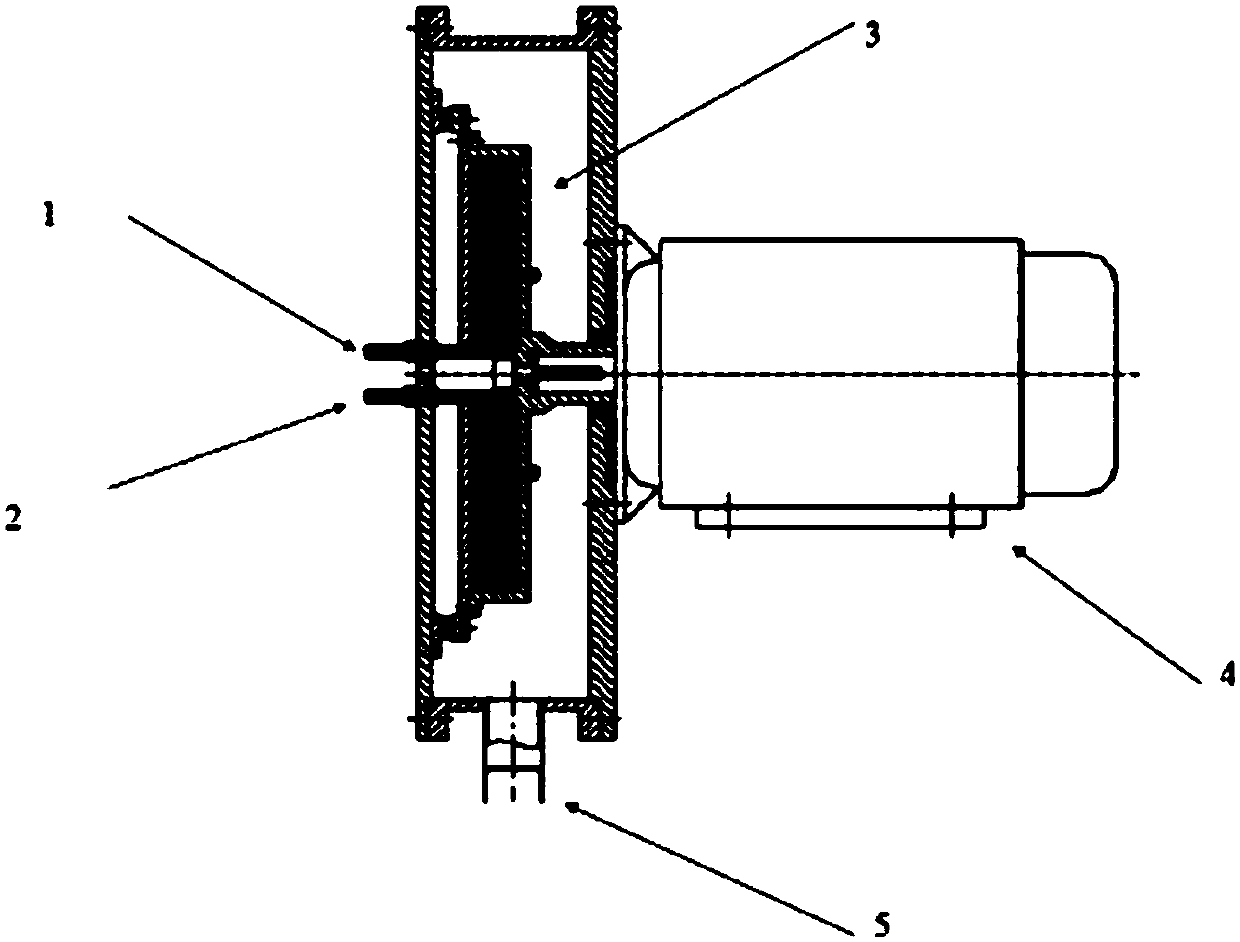

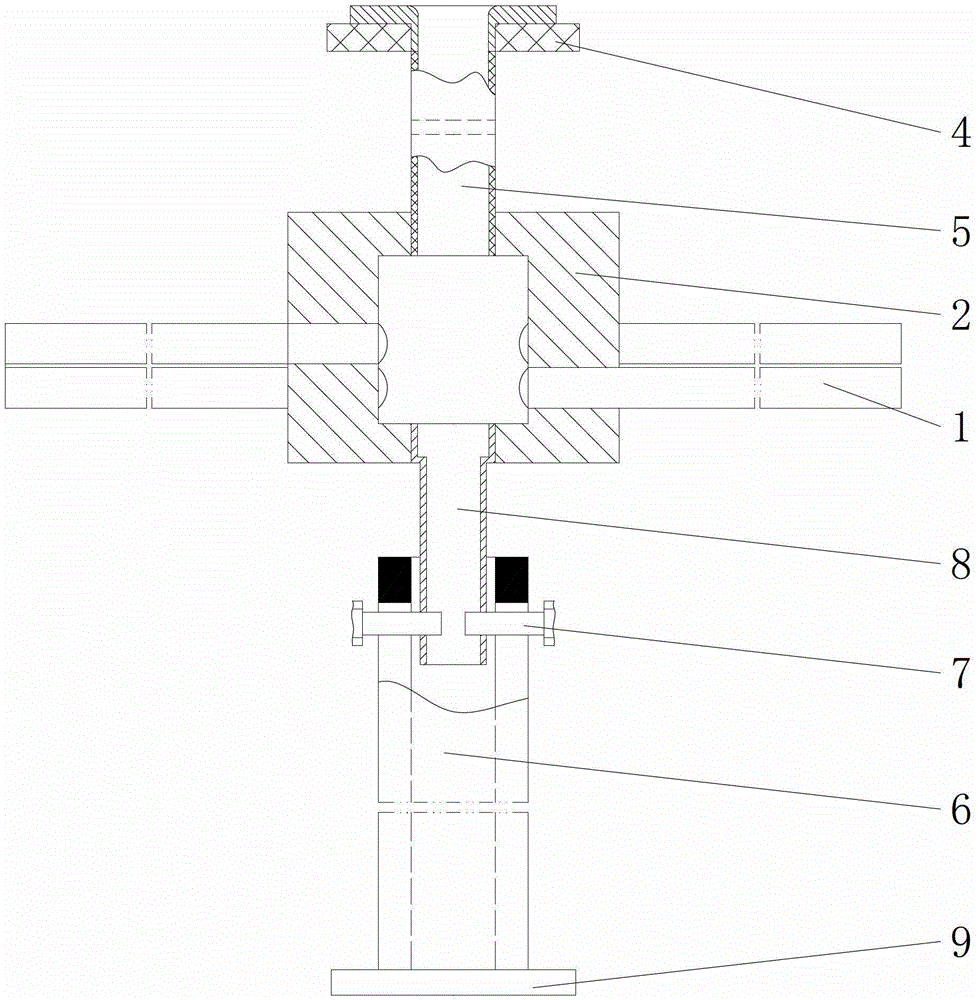

Electrode introduction device

ActiveCN102321877AImprove stabilityAvoid contact disconnectionChemical vapor deposition coatingElectricityEngineering

The invention relates to plasma enhanced chemical vapor deposition equipment, and discloses an electrode introduction device, which comprises two parallel electrodes brackets, wherein one end of each electrode bracket is connected with a furnace door electrode, and the other end of the electrode bracket is a metal contact and is connected with an electrode block on a graphite boat. The electrode introduction device also comprises a connecting rod penetrating through a furnace door, wherein one end of the connecting rod extending into the inner side of the furnace door is connected with a graphite boat supporting rod, and the graphite boat supporting rod is at least two parallel silicon carbide rods. In the invention, the electrode introduction device adopts a lapped joint mode, the metal contacts are directly connected with the furnace door electrodes through the graphite boat supporting rods, two graphite pads on the graphite boat act as the two electrode blocks, and a bulge is arranged on each metal contact at the position contacted with a groove on the electrode block, accordingly, the contact is good, and the degree of automation is high; the silicon carbide dual rods can withstand the temperature of over 1000 DEG C and are not easily deformed, so the stability of electrode contact is improved; and a mechanical mechanism is simple, the cost is low, and the assembly difficulty is reduced.

Owner:北京硅元科电微电子技术有限责任公司

Method for preparing fluorine hydride from acidic mixture of inorganic fluoride and sulphuric acid

InactiveCN101353156AMeet the requirements of large-scale productionFluorine/hydrogen-fluorideChemical industryDistillation

The invention discloses a method for preparing hydrogen fluoride with an acid mixture of inorganic fluoride and sulfuric acid and relates to a fluoride. The hydrogen fluoride gas is prepared by controlling operating conditions of the reaction volatilization, or distillation separation, or rectification separation process of the acid mixture of the inorganic fluoride and the sulfuric acid in a conventional equipment space, especially the pressure condition and the temperature condition, and carrying out a heat and mass transfer process to cause the water and sulfuric acid and sulfate in the acid mixture to be kept on a liquid phase. When the hydrogen fluoride is purified, a 40% hydrofluoric acid or anhydrous hydrogen fluoride is prepared. The method is suitable for recovering and preparing the hydrogen fluorine from the fluorine of the fluorine-containing intermediate materials or 'three industrial wastes' with the fluorine produced in the processes of chemical industry, electronics industry, glass machining industry, aluminum alloy machining industry and the like to make hydrogen. The method is especially suitable for enterprises to recover the materials with fluorine separated from the phosphoric acid, phosphate fertilizer and other phosphate chemical products produced by the wet process and make the hydrogen fluoride, or for the comprehensive utilization of the 'three industrial wastes' with fluorine.

Owner:GUIZHOU RES INST OF CHEM IND

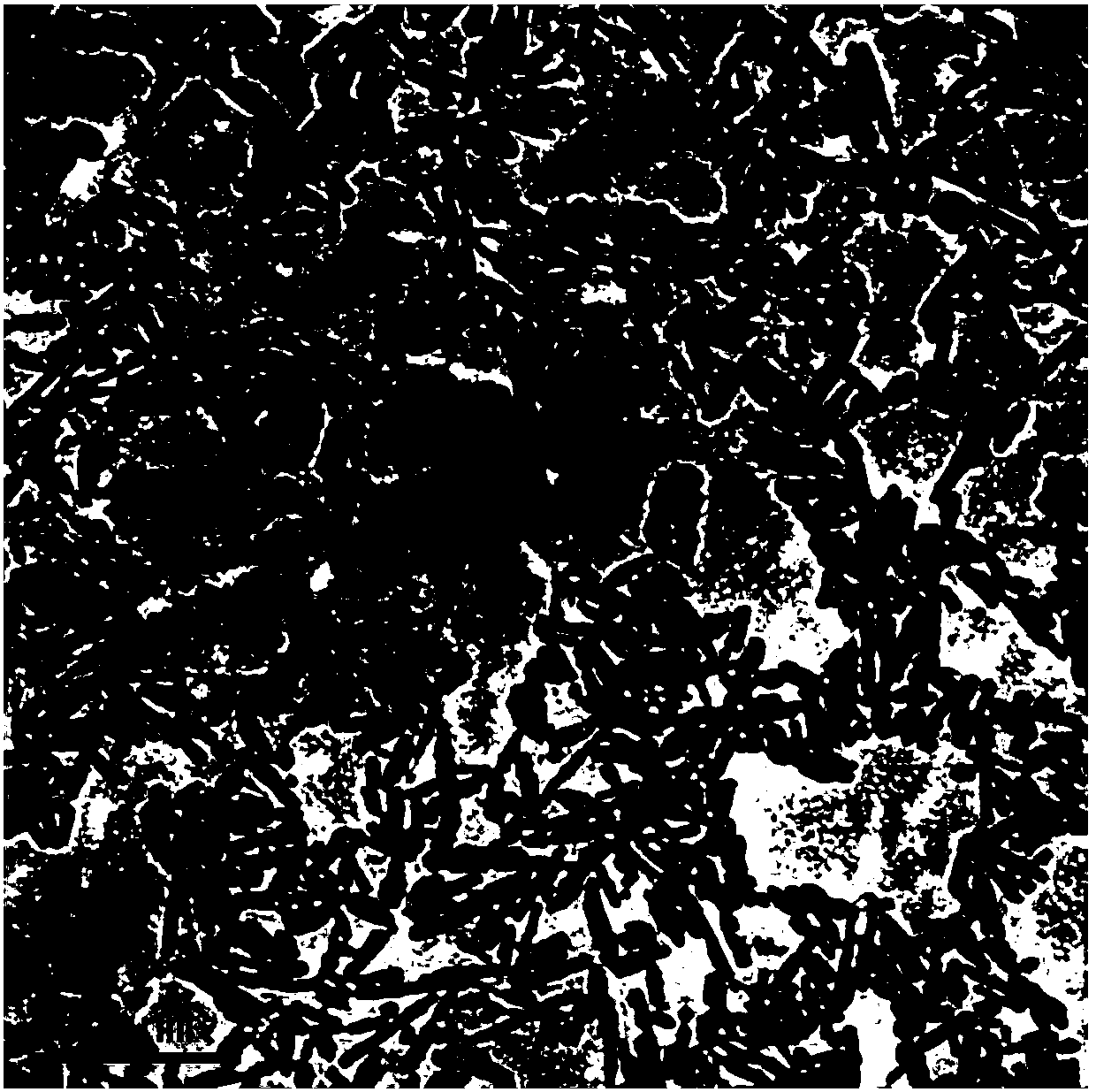

Method and device for preparing boron-doped nano silicon material

InactiveCN103232040AControl spacingReduce sizeMaterial nanotechnologySilicon compoundsNano siliconNanoparticle

The invention discloses a method and a device for preparing a boron-doped nano silicon material. The method comprises the following steps of: placing a rod-like raw material serving as an electrode raw material in a spark discharge chamber; applying a voltage to the electrode raw material by using a pulse power supply and generating sparks under the protection of a dielectric gas or liquid material; partially melting and gasifying the electrode raw material; injecting the molten and gasified electrode raw material into a dielectric gas or liquid to form nanoparticles; and separating and collecting the nanoparticles by using a filter cloth-containing particle collection device. By the method and the device provided by the invention, the spark discharge area of the electrode raw material can be improved, so that the capacity for preparing the nanoparticles is improved; the requirement on scale production is met; and the distance among electrode raw materials can be controlled so as to control the size of the formed nanoparticles and improve the particle size distribution uniformity.

Owner:苏州金瑞晨科技有限公司

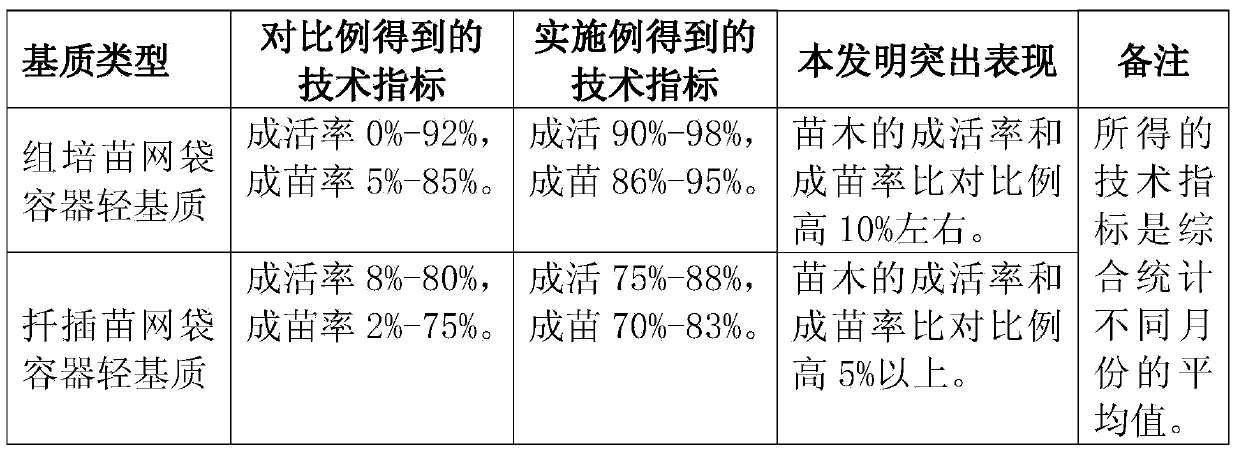

Light matrix for eucalyptus mesh bag seedling culture container

ActiveCN103999751ARoot stretchingStrong seedlingsCultivating equipmentsSoilless cultivationCoirBiology

The invention discloses a light matrix for a eucalyptus mesh bag seedling culture container. The light matrix comprises a eucalyptus tissue culture seeding mesh bag container light matrix and a eucalyptus cuttage seedling mesh bag container light matrix. The eucalyptus tissue culture seeding mesh bag container light matrix of each cubic meter comprises, by volume, 25-35% of peat soil, 25-35% of carbonized chaff and 35-45% of coco coir. The eucalyptus cuttage seedling mesh bag container light matrix of each cubic meter comprises, by volume, 25-35% of peat soil, 35-45% of carbonized chaff and 25-35% of coco coir. The light matrix is more suitable for local seedling culture conditions than mesh bag containers purchased from the market, and the seedling culture survival rate and the seedling rate throughout the year meet the large-scale production requirements.

Owner:钦州市林业科学研究所

Temperature-control controlled-release synergistic fertilizer for biological dwarf

InactiveCN103992180AImprove fertilizer efficiencyIncrease profitAgriculture gas emission reductionFertilizer mixturesPotassiumSoil temperature

The invention provides a temperature-control controlled-release synergistic fertilizer for biological dwarf, belonging to the field of chemical technology. The fertilizer comprises the following components in parts by weight: 0.1-0.2 part of temperature-control stimulin, 3-12 parts of a beneficial microorganism bacterium agent, 0.4-1 part of a chemical fertilizer controlled-release agent, 0.8-1.2 parts of active humus, 0.1-0.2 part of rootone hormone, 18-32 parts of nitrogen, 5-22 parts of phosphorus, 2-20 parts of potassium, 4-15 parts of medium trace elements and 0.1-0.3 part of organic silicon. The temperature-control controlled-release synergistic fertilizer has the advantages of a physical controlled-release agent and a biochemical controlled-release agent, the fertilizer effect can be accurately released according to the change of soil temperature, the effect of reinforcing temperature control and controlled release can be achieved, the growth requirements of crops are met, the fertilizer effect of the temperature-control controlled-release synergistic fertilizer is improved, the utilization rate of the temperature-control controlled-release synergistic fertilizer is increased, the damage caused by diseases is reduced, the cost-saving synergistic effect is very remarkable, and the temperature-control controlled-release synergistic fertilizer has the characteristics of continuous high yield and efficiency, environmental protection and strong adaptability, and has wide market prospect.

Owner:郑军岭

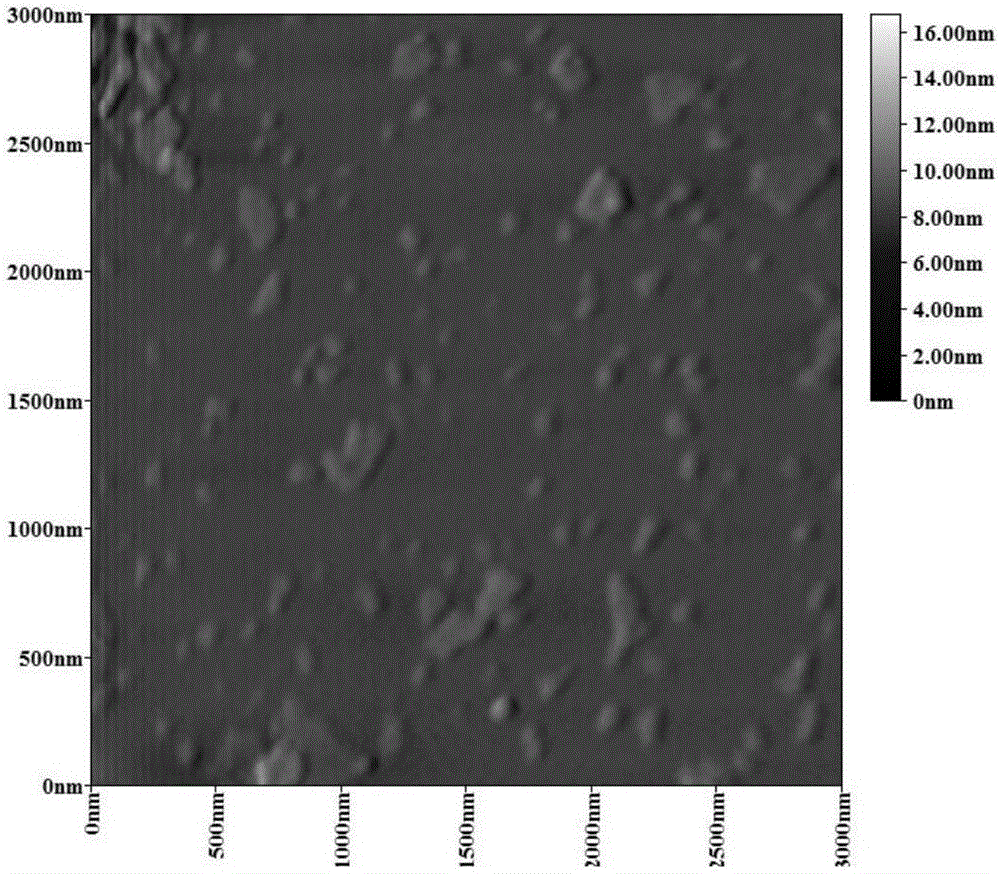

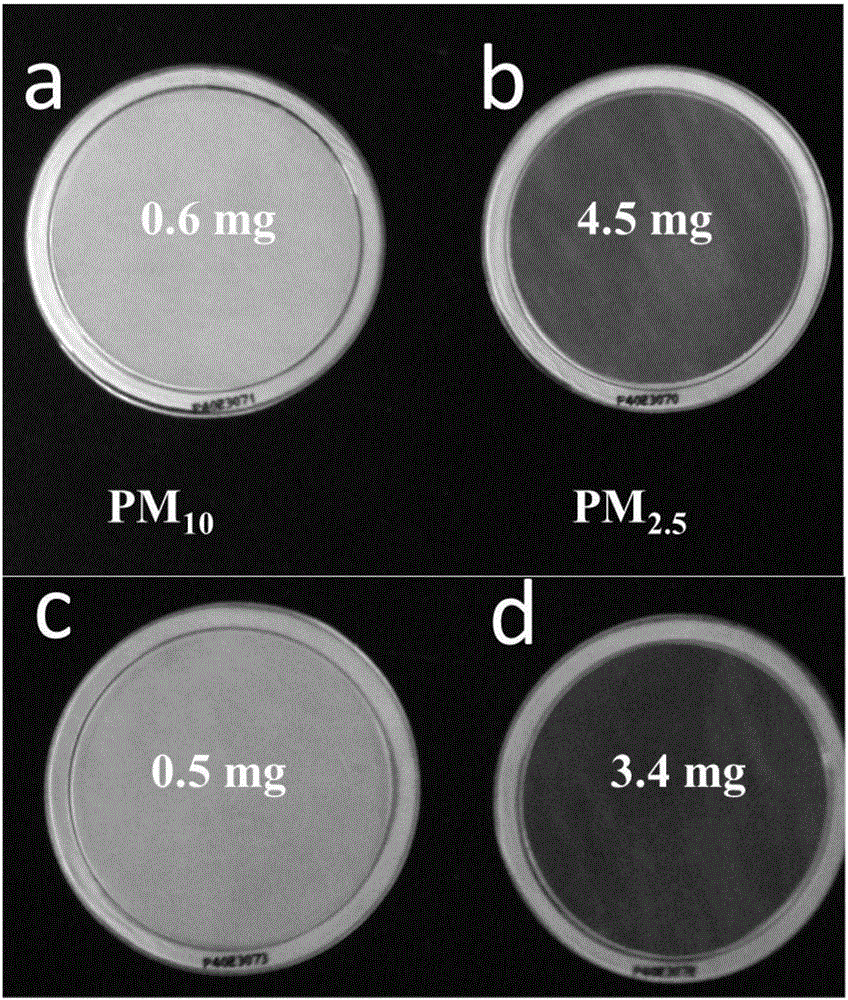

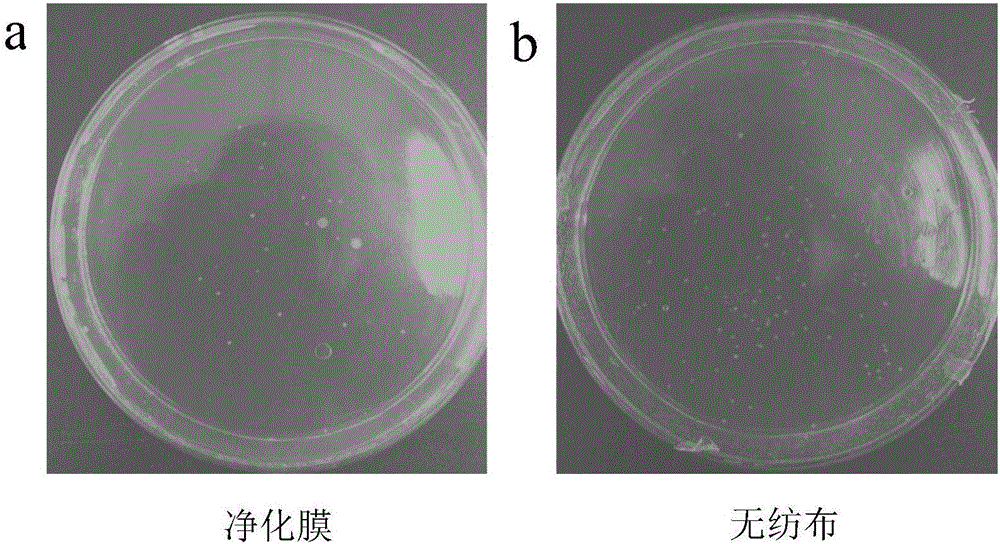

Multifunctional air purification film and method for preparing same

ActiveCN106268705AExtended use timeHigh removal rateOther chemical processesDispersed particle separationMolecular materialsNonwoven fabric

The invention relates to a multifunctional air purification film and a method for preparing the same. The multifunctional air purification film is one of the following two types: a first type of air purification film which comprises a base film and a multifunctional layer coated on the base film, wherein the multifunctional layer is mixture of nanometer graphene oxide and a fluorescent conjugated polymer, and the base film is a nonwoven fabric; a second type of air purification film which is obtained through spray melting after mixing an organic high-molecular material, nanometer graphene oxide and a fluorescent conjugated polymer, wherein the aperture of the used purification film is 0.2mu m to 12mu m, and the thickness is 500mu m to 5000mu m. As compared with a traditional antibacterial film, the antibacterial air purification film which is obtained by the invention and can eliminate PM2.5 has the characteristics such as high efficiency, good antibacterial performance and long service life.

Owner:河北凯尔威生物技术有限公司

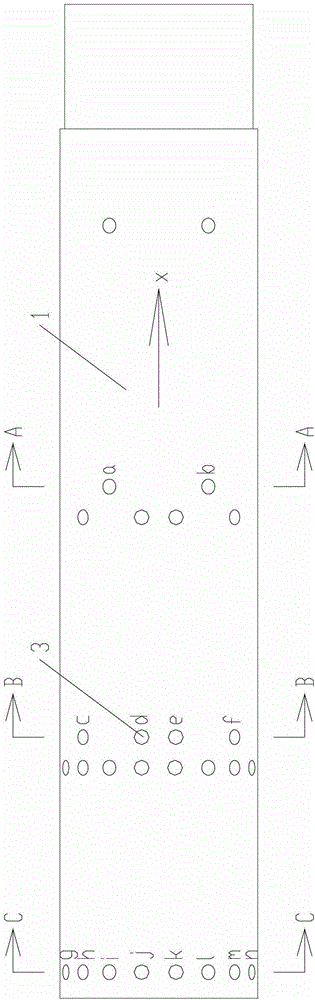

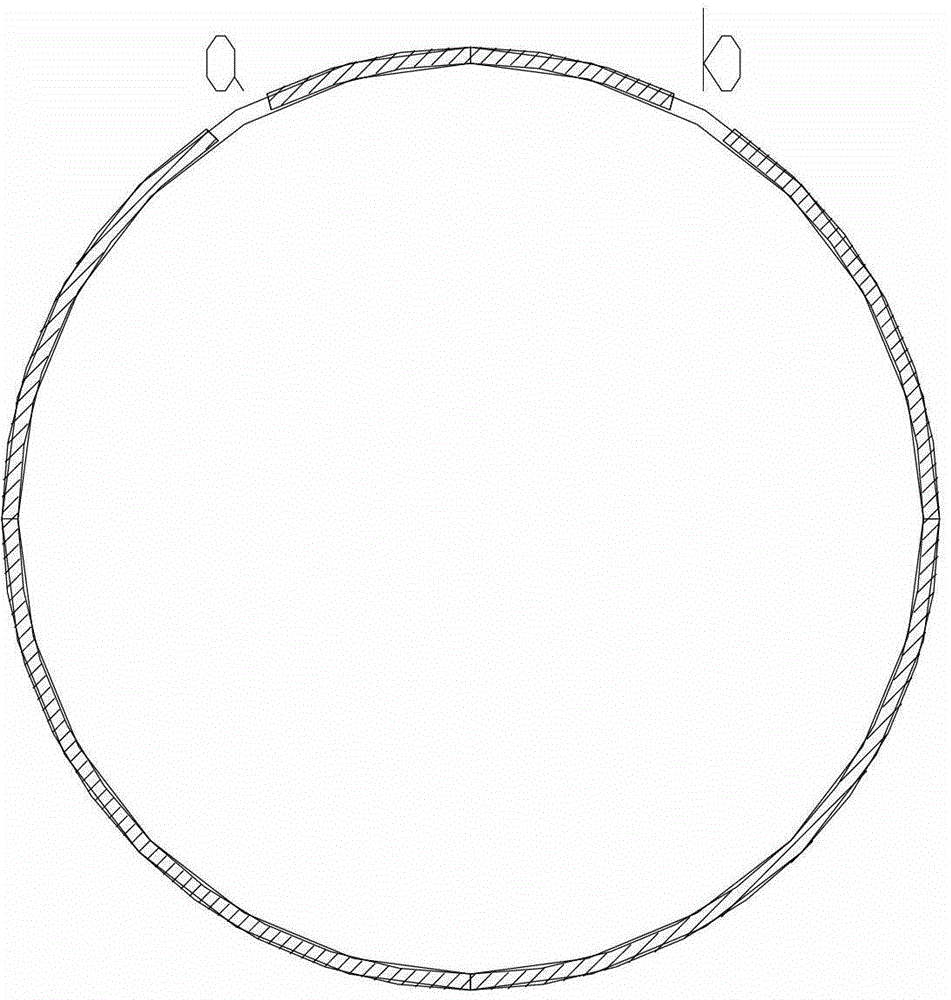

Process for producing chloroactic acid by large chlorinated kettles and chlorinated kettles for reaction

InactiveCN102875357ALessen the effects of absorptionReduce consumptionOrganic compound preparationChemical/physical/physico-chemical stationary reactorsAcetic acidChemical industry

The invention discloses a process for producing a chloroactic acid by large chlorinated kettles. Three chlorinated kettles of 'two main chlorinated kettles and one auxiliary chlorinated kettle' are utilized, a tail gas which is discharged after main chlorinated kettles are subjected to a chlorination reaction is fed into the auxiliary kettle for the chlorination reaction, after the chlorination reaction, a chlorinated liquid is obtained, the chlorinated liquid is subjected to crystallization and separation to obtain the chloroactic acid, an acetic acid and a catalyst are added into the main kettles, the main kettles are jacketed and heated to 85 DEG C, and a chlorine gas is fed into the main kettles in three stages for the continuous chlorination reaction. The invention simultaneously discloses the chlorinated kettles used for the process. The process for producing the chloroactic acid by the large chlorinated kettles and the chlorinated kettles used for the process have the advantages that a reasonable production process is provided for chloroactic acid production by the large chlorinated kettles, the structure of the chlorinated kettles is improved, thereby the chlorination reaction can be fully and uniformly performed, the reaction time is shortened, a large-scale production requirement is met, the productivity and the product quality are improved, the amplification effect of chemical industry production is avoided, the product purity can reach to above 98%, the yield coefficient based on the acetic acid can reach to 91%, and the product quality reaches to the export product standard.

Owner:江苏省格林艾普化工股份有限公司

Method for preparing sulfobutyl ether-beta-cyclodextrin

The invention discloses a method for preparing sulfobutyl ether-beta-cyclodextrin. By using water as a solvent, beta-cyclodextrin and 1,4-sulfobutyrolactone, which are used as raw materials, undergo a substitution reaction in the presence of a catalyst quaternary ammonium base with double functions of strong basicity and phase-transfer catalysis; and then operations such as ultrafiltration, decolouring with active carbon, freeze-drying, etc. are successively carried out to finally obtain sulfobutyl ether-beta-cyclodextrin with high yield and high quality. The quaternary ammonium base used in the method can be recovered and recycled after a simple treatment. The preparation method of sulfobutyl ether-beta-cyclodextrin is suitable for industrial production.

Owner:SHIJIAZHUANG UNIVERSITY

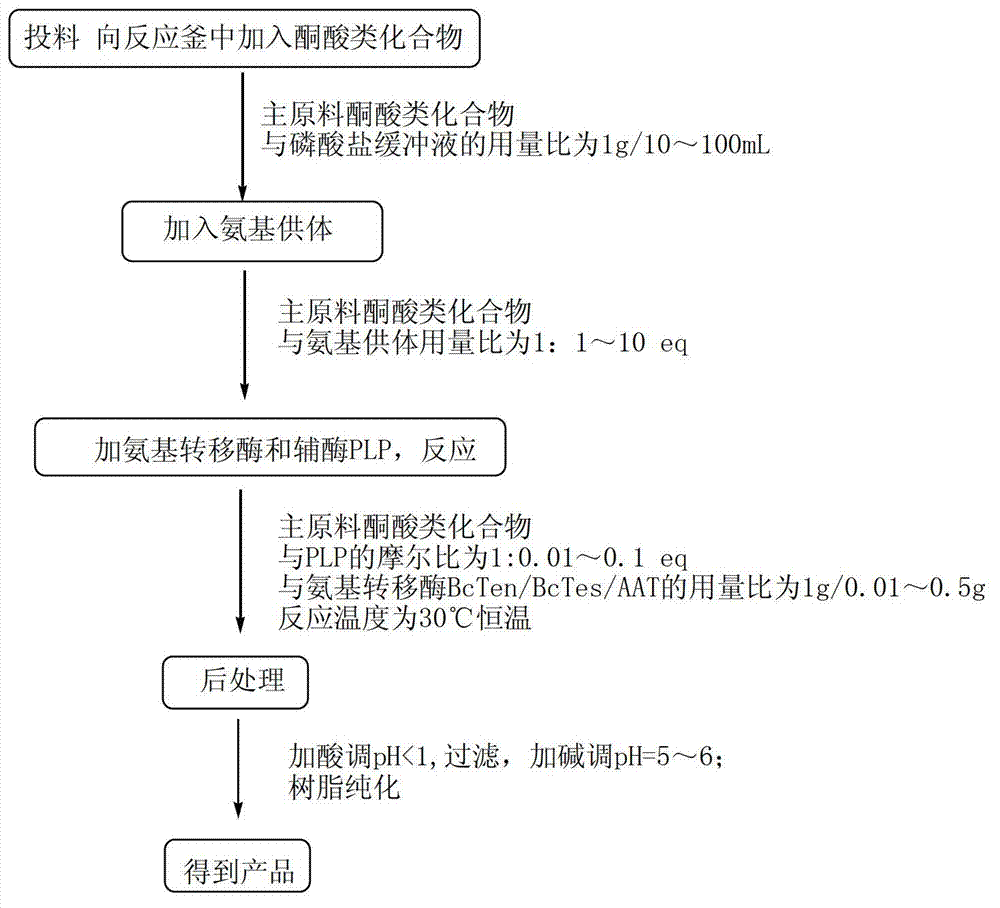

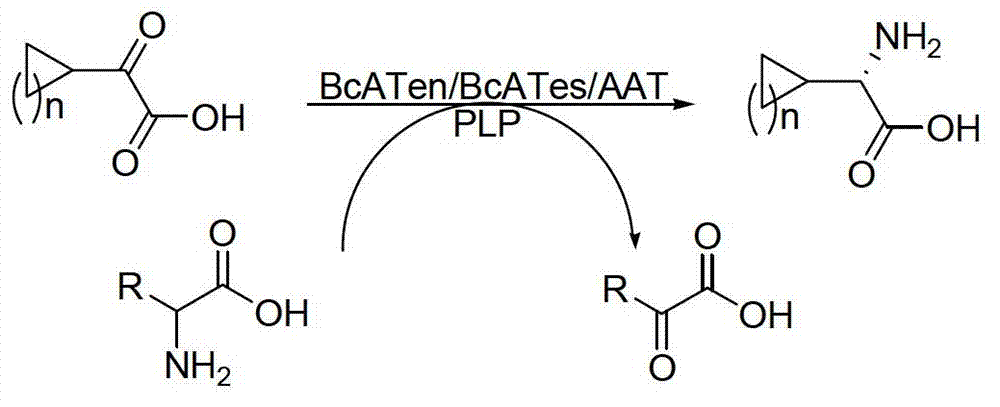

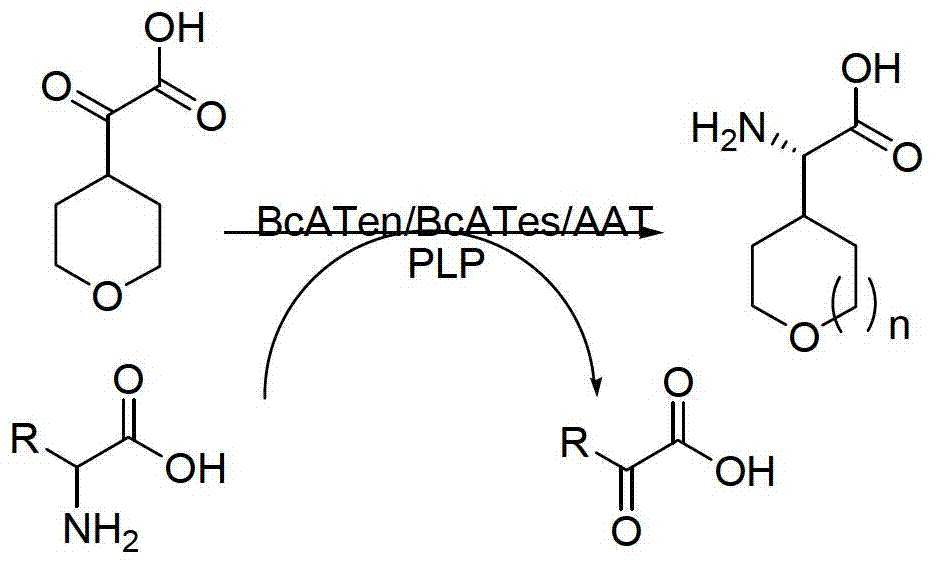

Method for synthetizing chiral cyclic alkyl amino acid by amino transferase

The invention discloses a method for synthetizing chiral cyclic alkyl amino acid by amino transferase. The commercialized material ketonic acid or corresponding soluble ketonic acid salt compound in the market is selected as an initial material; the initial material is dissolved into phosphate buffer, and added to an amino supply body; pyridoxal phosphate (PLP) and amino transferase main enzyme are added to a system containing the amino supply body and main material ketonic acid or corresponding soluble ketonic acid salt compound to react under constant temperature, and obtaining a product with a high ee value, wherein n is equal to 1, 2, 3, 4, 5, or obtaining a product wherein n is equal to 0 and 1. The method is stable in technological condition, simple to operate, high in yield, low in cost, and suitable for large-scale production, and beneficial for environmental protection; and a novel train of thought and a method are provided for the preparation of chiral cyclic alkyl amino acid compound.

Owner:ASYMCHEM LAB TIANJIN +5

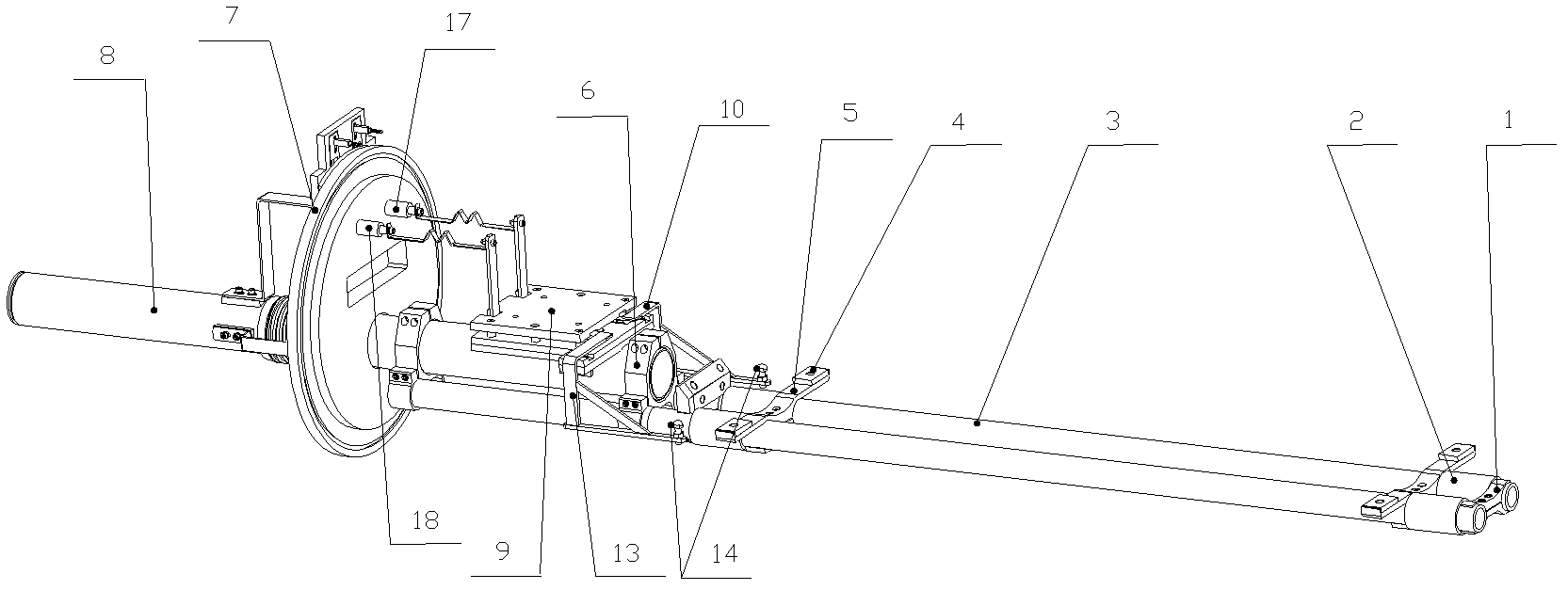

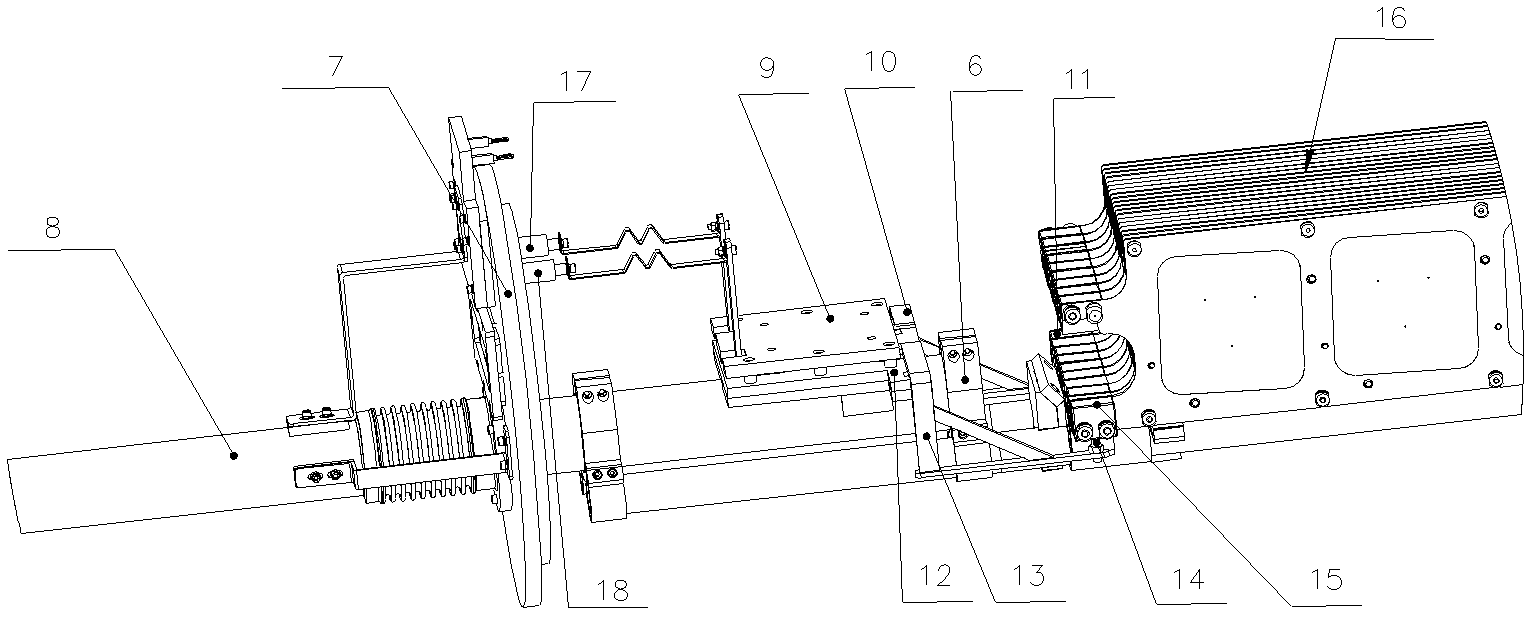

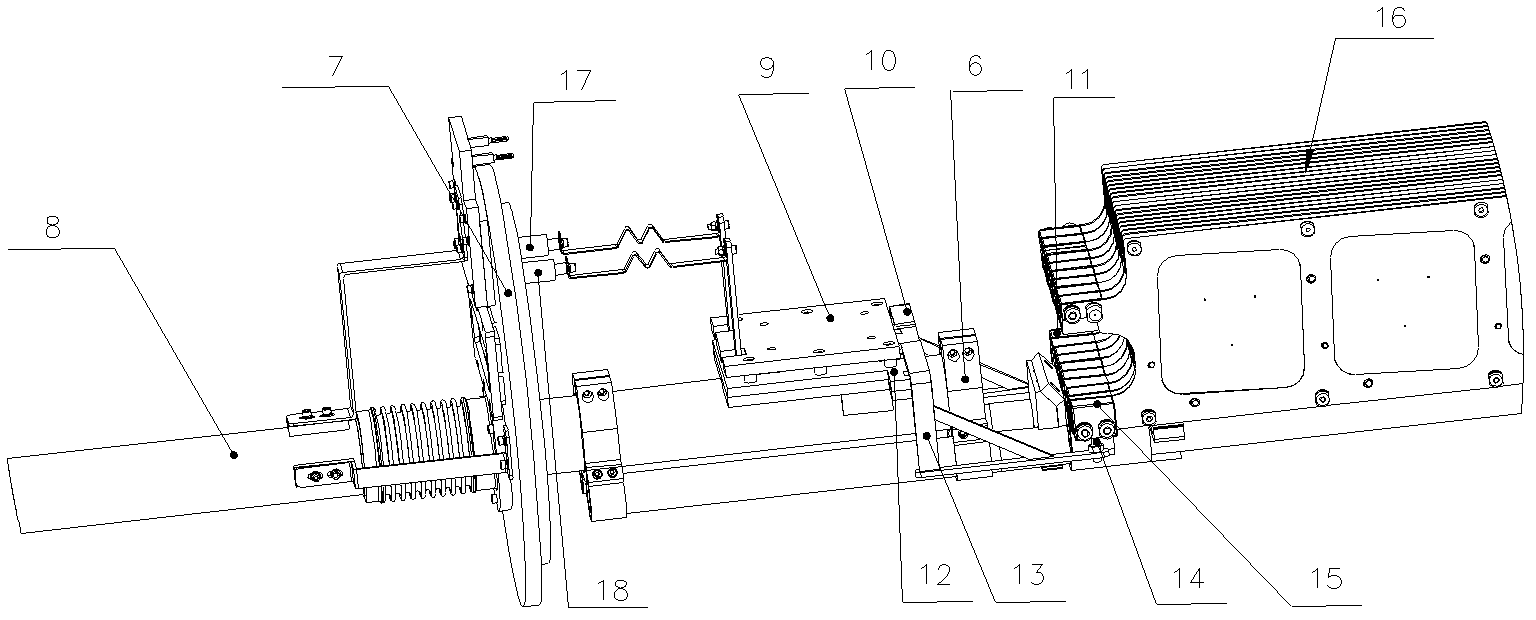

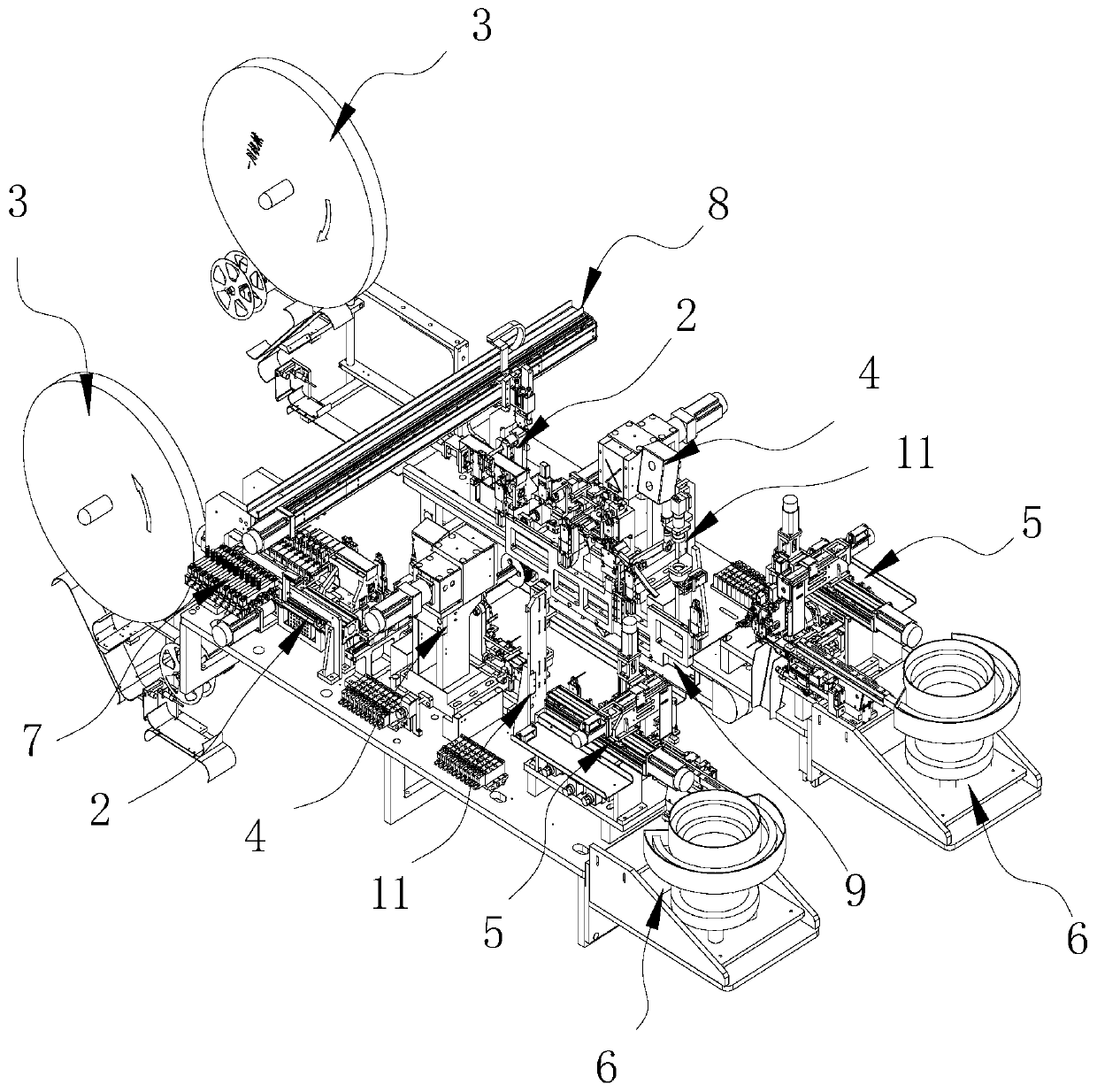

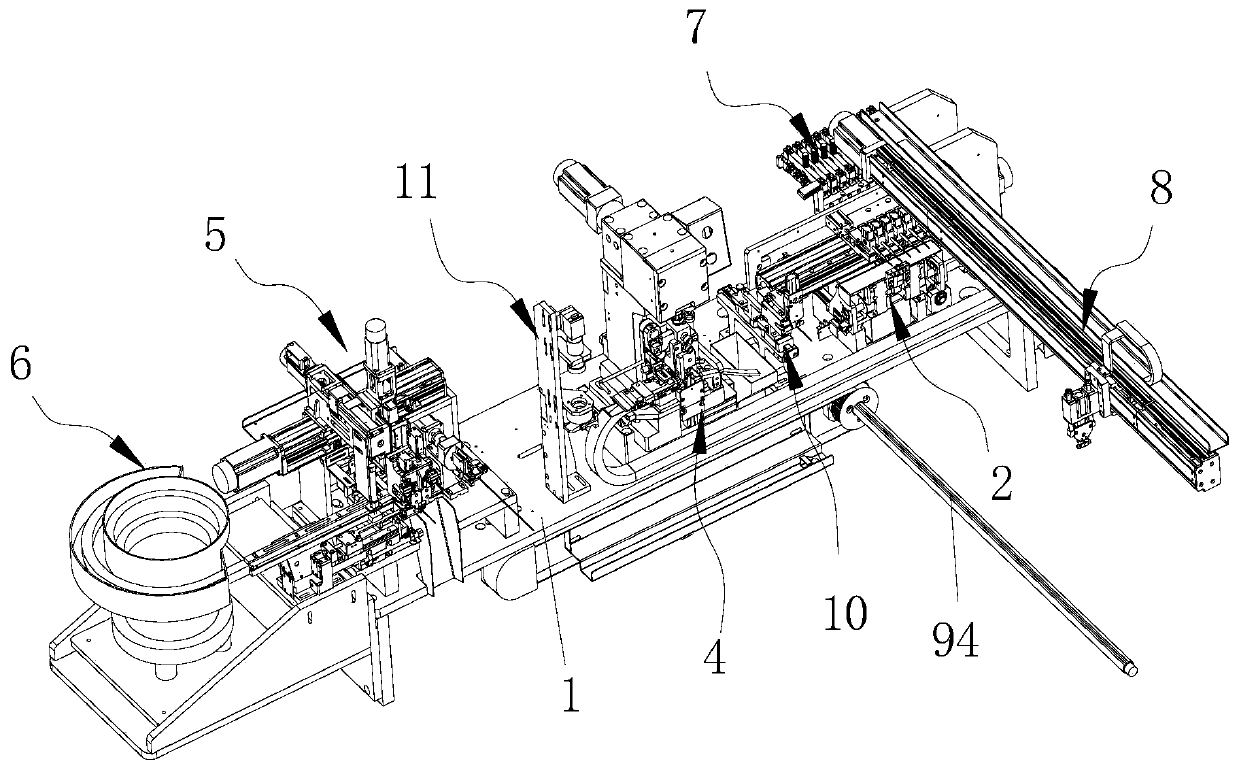

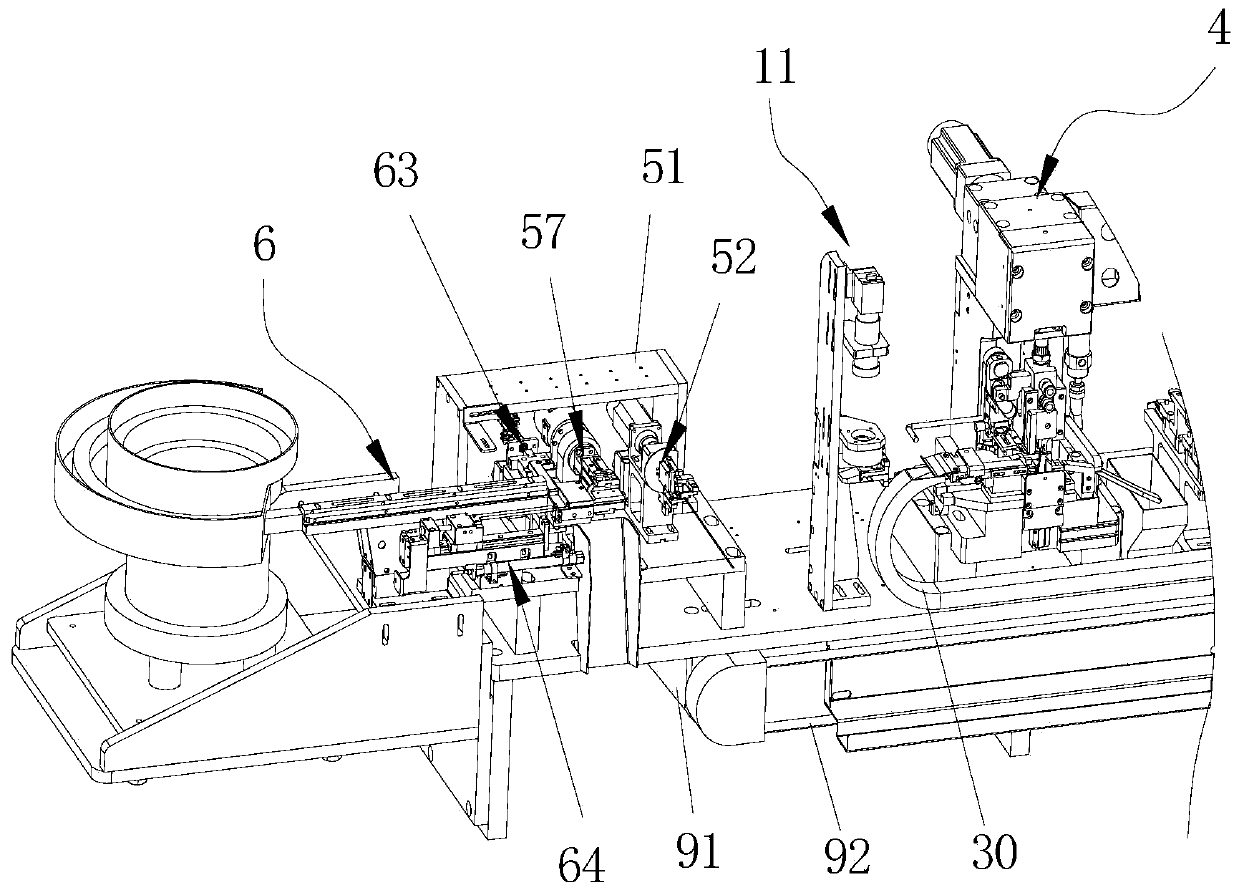

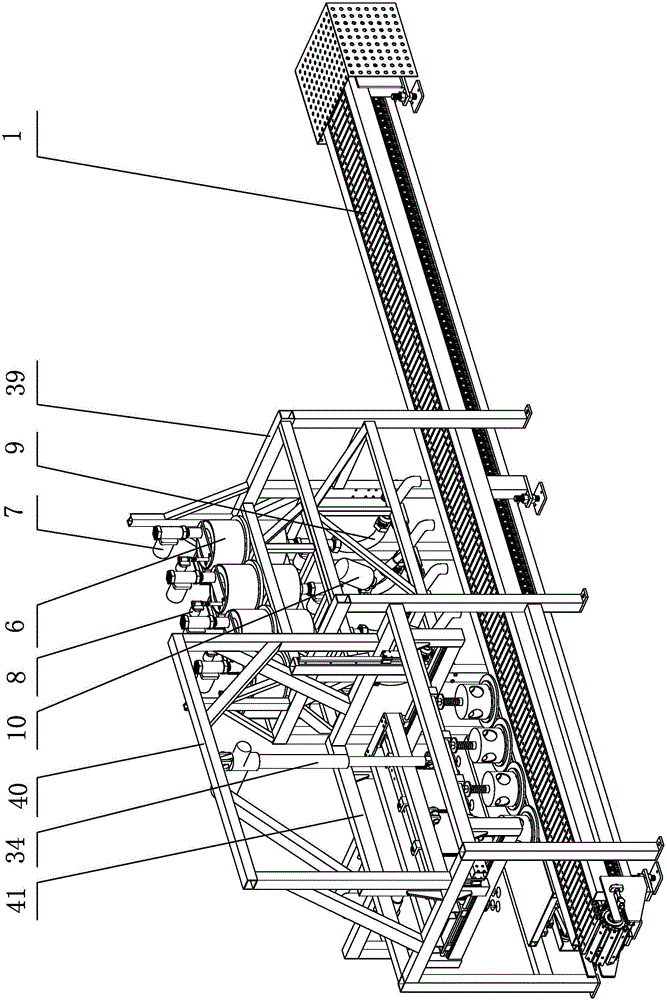

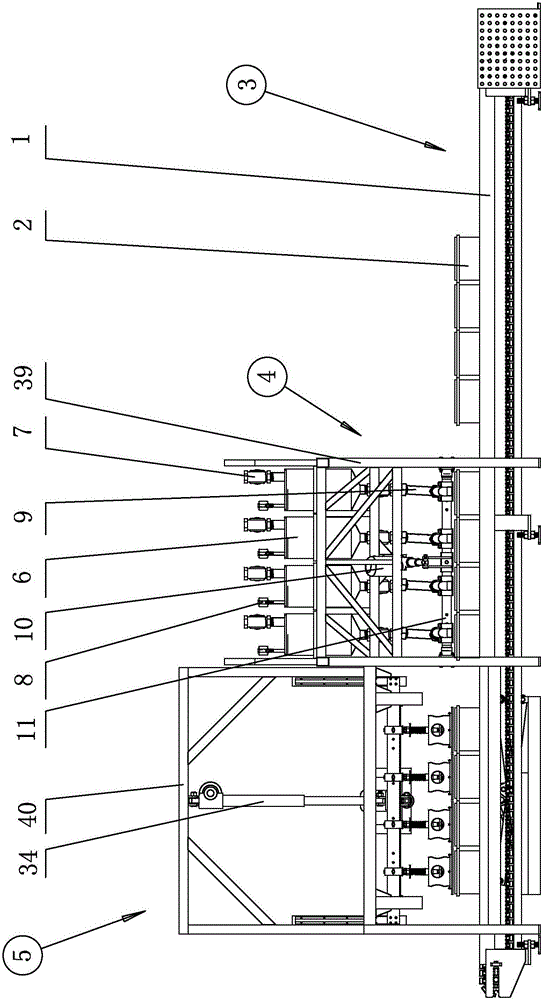

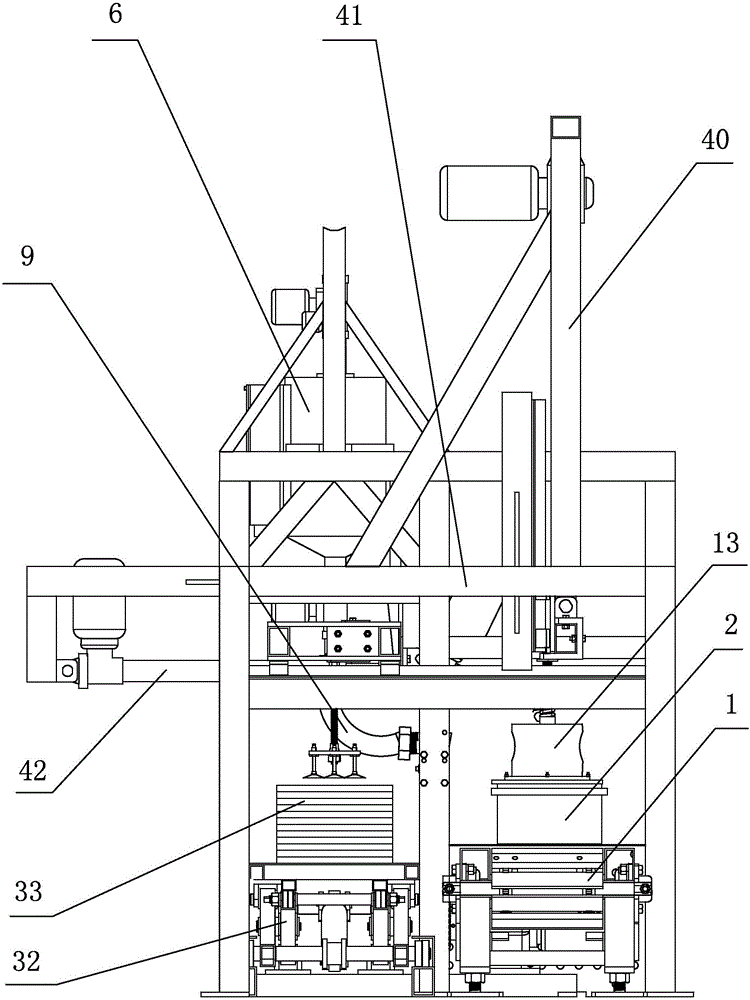

Double-end terminal-pressing and housing-inserting machine for automatically assembling wire harness

PendingCN109888591ARealize automated assembly operationsMeet the requirements of large-scale productionContact member manufacturingContact member assembly/disassemblyPunchingAutomation

The invention discloses a double-end terminal-pressing and housing-inserting machine for automatically assembling a wire harness. The double-end terminal-pressing and housing-inserting machine comprises a wire harness front end assembly unit and a wire harness rear end assembly unit; each of the two units comprises a bracket, a stripping mechanism, a terminal feeding mechanism, a terminal punchingassembly mechanism, a wire-inserting housing mounting mechanism, and a plastic housing feeding mechanism; the terminal feeding mechanism, the stripping mechanism, the terminal punching assembly mechanism, the wire-inserting housing mounting mechanism and the plastic housing feeding mechanism are orderly arranged on the bracket; the wire harness front end assembly unit is further provided with a wire feeding mechanism; and a wire drawing mechanism and a station switching wire shifting mechanism are arranged between the wire harness front end assembly unit and the wire harness rear end assemblyunit. The double-end terminal-pressing and housing-inserting machine provided by the invention integrates the functions of wire feeding, wire drawing, double-head wire stripping, double-head terminalfeeding, double-head terminal punching and wire mounting, double-head plastic housing feeding and double-head wire-inserting housing mounting and the like; the action coordination of various mechanisms can realize the automatic assembly operation of a double-head wire harness, the degree of automation is high the speed is fast, the operation is stable and reliable, the precision is high, and theproduction efficiency and the product quality are improved.

Owner:湖北一川金品机械有限公司

Liquid filling and cover pressing line

ActiveCN105692535AIncrease productivityReduce labor intensityBottle/container closureBarrels/casks fillingEngineeringAssembly line

Disclosed is a liquid filling and cover pressing line. The liquid filling and cover pressing line comprises a chain plate conveyer belt. A barrel placement station, a quantitative filling station and a cover taking, releasing and pressing station are arranged on the conveying path of the chain plate conveyer belt, wherein a plurality of liquid containing barrels can be placed on the barrel placement station in rows, the quantitative filling station can conduct filling operation on the liquid containing barrels at the same time, and the cover taking, releasing and pressing station corresponds to one-time cover taking, releasing and pressing operation of the liquid containing barrels. A quantitative filling device is arranged on the quantitative filling station. The cover taking, releasing and pressing station comprises a cover pressing device and a cover taking and releasing device, wherein the cover pressing device is arranged above the chain plate conveyer belt, and the cover taking and releasing device is arranged above one side of the chain plate conveyer belt, and is lower than the cover pressing device. The liquid filling and cover pressing line is applicable to assembly line operation, the working procedures of quantitative filling, cover taking, cover releasing and cover pressing operation except manual barrel placement are automatically accomplished, the production efficiency is high, the labor intensity is low, and the requirement of large-scale production is met.

Owner:LINGSHAN JIAOFENG CHEM

Rapid propagation method of cassava virus-free seedlings

PendingCN104823849AEfficiently obtainedReproduce fastHorticulture methodsPlant tissue cultureDiseasePropagule

The invention relates to a rapid propagation method of cassava virus-free seedlings. The method comprises the following steps: step one, collecting explants and carrying out a detoxification pretreatment; step two, disinfecting the surfaces of explants and taking off the stem tips; step three, inducing the stem tips to obtain seedlings; step four, subjecting the seedlings to subculture multiplication culture; step five, carrying out virus detection through a semi-quantitative RT-PCR method; step six, domesticating and transplanting the virus-free tube seedlings. The provided method can effectively remove various viruses and bacteria taking cassava stems as the nutrient source, and obtains virus-free cassava seedlings. The healthy planting, purification and rejuvenation of cassava seedling can be achieved. The occupied space for propagation is small, the propagation speed is quick, and the survival rate of transplanting is high. The provided method can be applied to safe species exchange among different countries and areas, can provide healthy cassava seedlings, reduces the happening and spreading of diseases, and provides technical guarantees for sustainable development of cassava.

Owner:TROPICAL CORP STRAIN RESOURCE INST CHINESE ACAD OF TROPICAL AGRI SCI

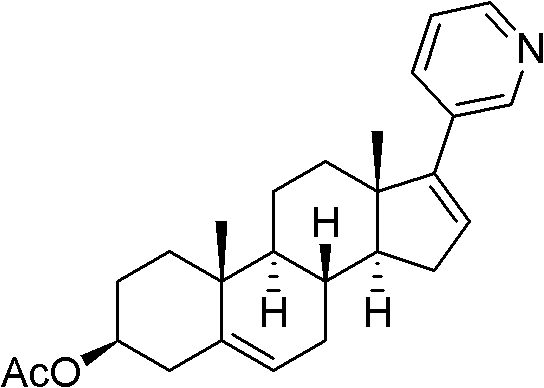

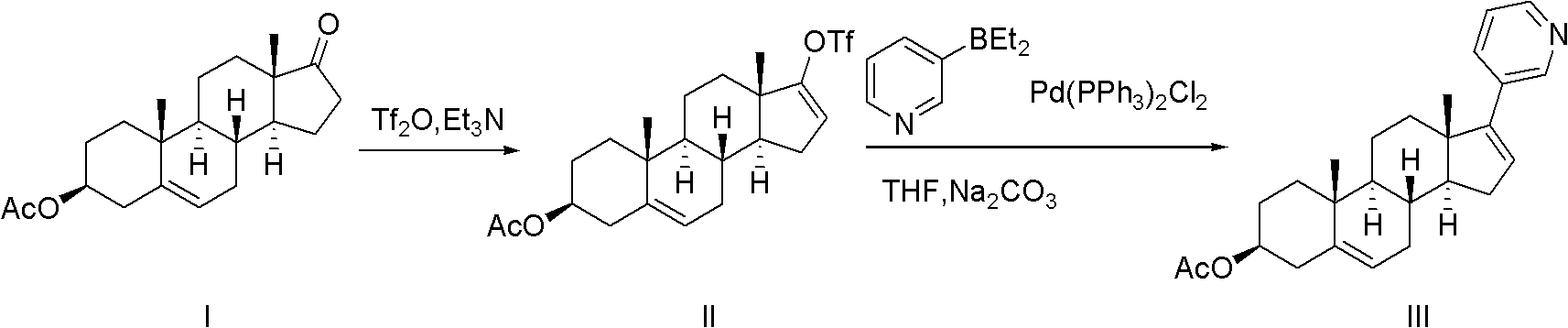

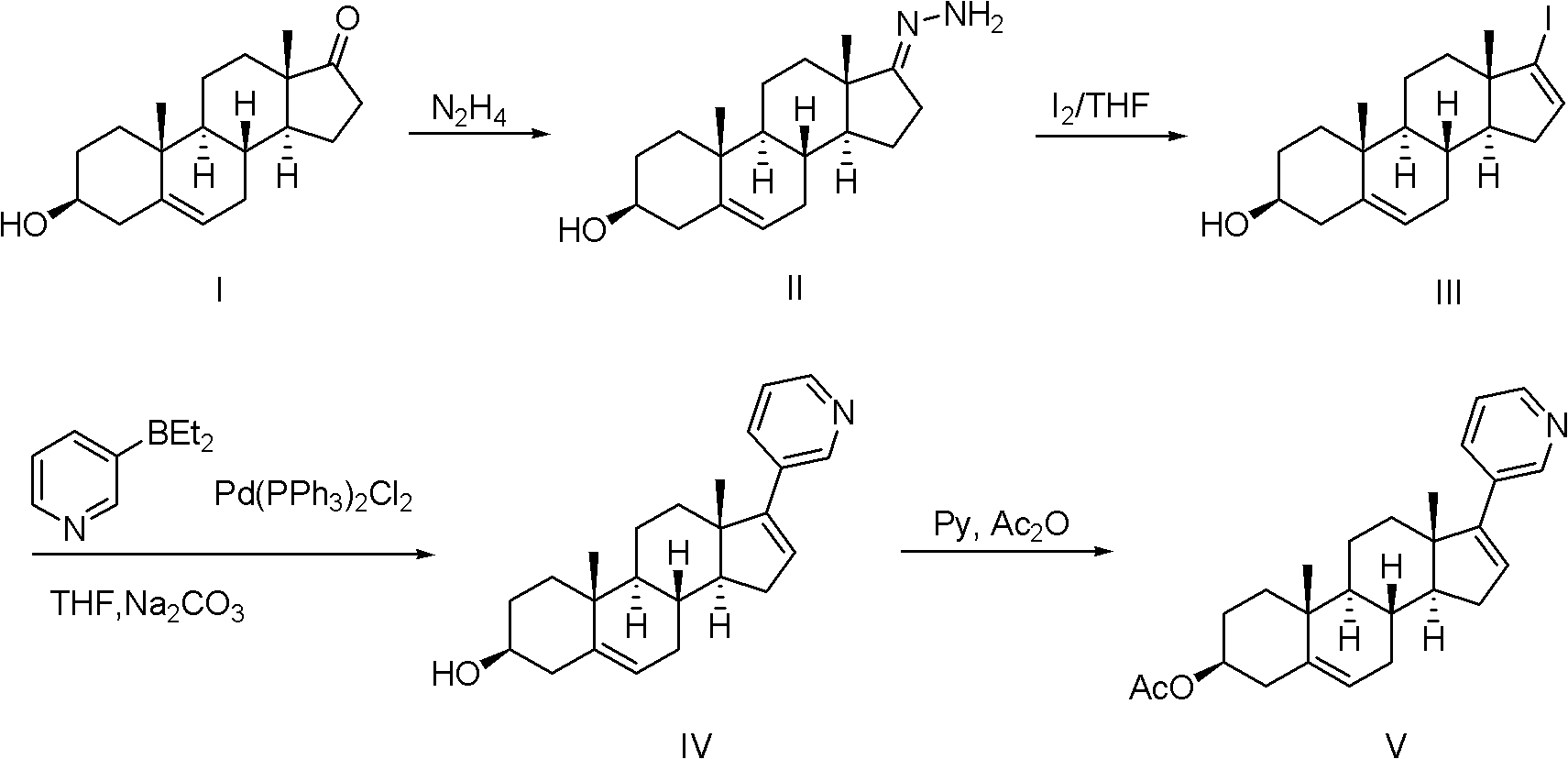

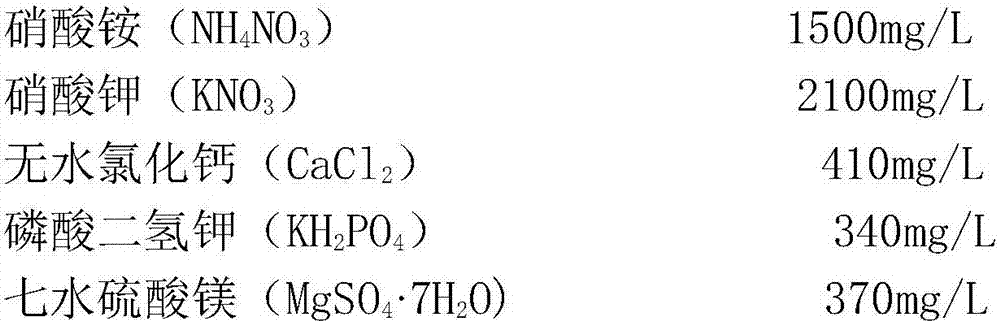

Abiraterone acetate trifluoroacetate, and preparation method and application thereof

ActiveCN103254265AHigh purityMeet the requirements of large-scale productionSteroidsCarboxylic acid salt preparationTrifluoroacetic acidSelf purification

The invention discloses abiraterone acetate trifluoroacetate, and a preparation method and an application thereof. The trifluoroacetate is obtained by a salt formation reaction of abiraterone acetate and trifluoroacetic acid. The abiraterone acetate trifluoroacetate provided by the invention is solid, and can be subjected to self purification through re-crystallization. Medical-standard abiraterone acetate with purity higher than 99.5% and single impurity lower than 0.1% can be easily obtained by ionizing and re-crystallizing the purified abiraterone acetate trifluoroacetate. With the method provided by the invention, a defect of the requirement on abiraterone acetate column chromatography purification of prior art is solved, and the salt formation reagent is cheap. Salt formation and purification operations are simple and feasible, yield is high, and quality is stable. The purpose for producing high-purity abiraterone acetate with low cost and simple process is realized, and abiraterone acetate large-scale production requirement can be satisfied.

Owner:SHANGHAI ACEBRIGHT PHARMA CO LTD +1

Preparation method of water-soluble chitosan-oligosaccharide

InactiveCN102786607AControl weight average molecular weightControl the degree of degradation reactionHydrolysateWater soluble

A preparation method of water-soluble chitosan-oligosaccharide comprises the following steps: (1) dissolving chitosan in an acetic acid solution to prepare a chitosan acetic acid solution with a concentration of 2.0-4.0 g / ml; (2) heating to 55-65 DEG C, adding a 1-5% H2O2 solution according to a molar ratio of the chitosan to hydrogen peroxide of 1:1.5-1:2.5, adjusting the pH to be 5.5-6.5, continuously stirring for hydrolyzation to obtain a hydrolysate; (3) sampling, adding strong alkali liquor till no flocculent precipitate is generated so as to determine the hydrolysate; (4) continuously performing hydrolyzation for not more than 2 hours; (5) adding a degradation reaction terminator to obtain a preliminary product; (6) processing the preliminary product by a spray-drying process to obtain the water-soluble chitosan-oligosaccharide. Compared with the prior art, the invention has the advantages that: the degradation reaction terminator is used for controlling the degree of the degradation reaction so as to control the weight average molecular weight of the obtained chitosan-oligosaccharide; real production requirements are met; and large scale production requirements are met.

Owner:ZHEJIANG OCEAN UNIV

Culture medium for tissue culture of dragon fruits

ActiveCN106857255ASimplified induction procedureSimplify the breeding processHorticulture methodsPlant tissue cultureMicrobiologyEnrichment culture

The invention discloses a culture medium for tissue culture of dragon fruits. The culture medium not only can be used for culturing subculture plantlets, but also can be used for inducing rooting seedlings, i.e., culture steps are simplified, subculture enrichment culture and rooting induction culture are completed by one step, the production period is greatly shortened, and cost is saved. The invention provides the efficient culture medium for the tissue culture of the dragon fruits so as to solve the problems of long production period and high production cost in the dragon fruit cultivating process.

Owner:钦州市林业科学研究所

Chinese medicine for treating chronic nephritis and its preparation method

InactiveCN1442165AShort exposure timeSmall weight differenceUnknown materialsUrinary disorderClinical therapyKidney

A Chinese medicine in the form of capsule, tablet and particle for treating chronic nephritis is prepared from 10 Chinese medicinal materials including rehmannia root, dogwood fruit, yam, tuckahoe, etc. through extracting volatile, nonwater-soluble and alcohol-soluble active components respectively, spray drying and granulating. Its advantages are high curative effect, low dosage, and low toxic by-effect.

Owner:ZHONGJING WANXI PHARMA CO LTD

Dehumidification reel and preparation method thereof

ActiveCN103585862AGood hygroscopicityImprove appearanceDispersed particle separationEngineeringAqueous solution

The invention provides a dehumidification reel which comprises a reel and a silicon dioxide-aluminum oxide gel film which is compounded on the surface of the reel. The invention further provides a preparation method of the dehumidification reel. The invention further provides a real dehumanization machine which adopts the reel which is the dehumidification reel provided by the technical scheme of the invention or the dehumidification reel which is prepared by using the method provided by the technical scheme of the invention. According to the dehumidification reel, silica sol is directly generated from a sodium silicate solution and a carbon dioxide gas, and reaction in the solution is prevented, so that non-uniform deposition effect of the silica sol caused by solution diffusion is prevented, and the dehumidification reel which is uniform in surface, compact and dense in structure and good in appearance is obtained. Meanwhile aluminum oxide sol which is subjected to concerted reaction with the silica sol is introduced into the dehumidification reel, so that the moisture adsorption property of a moisture adsorption medium is improved. In addition, the method provided by the invention is simple in step, the industrial degree is high, and the in-scale production requirement can be met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

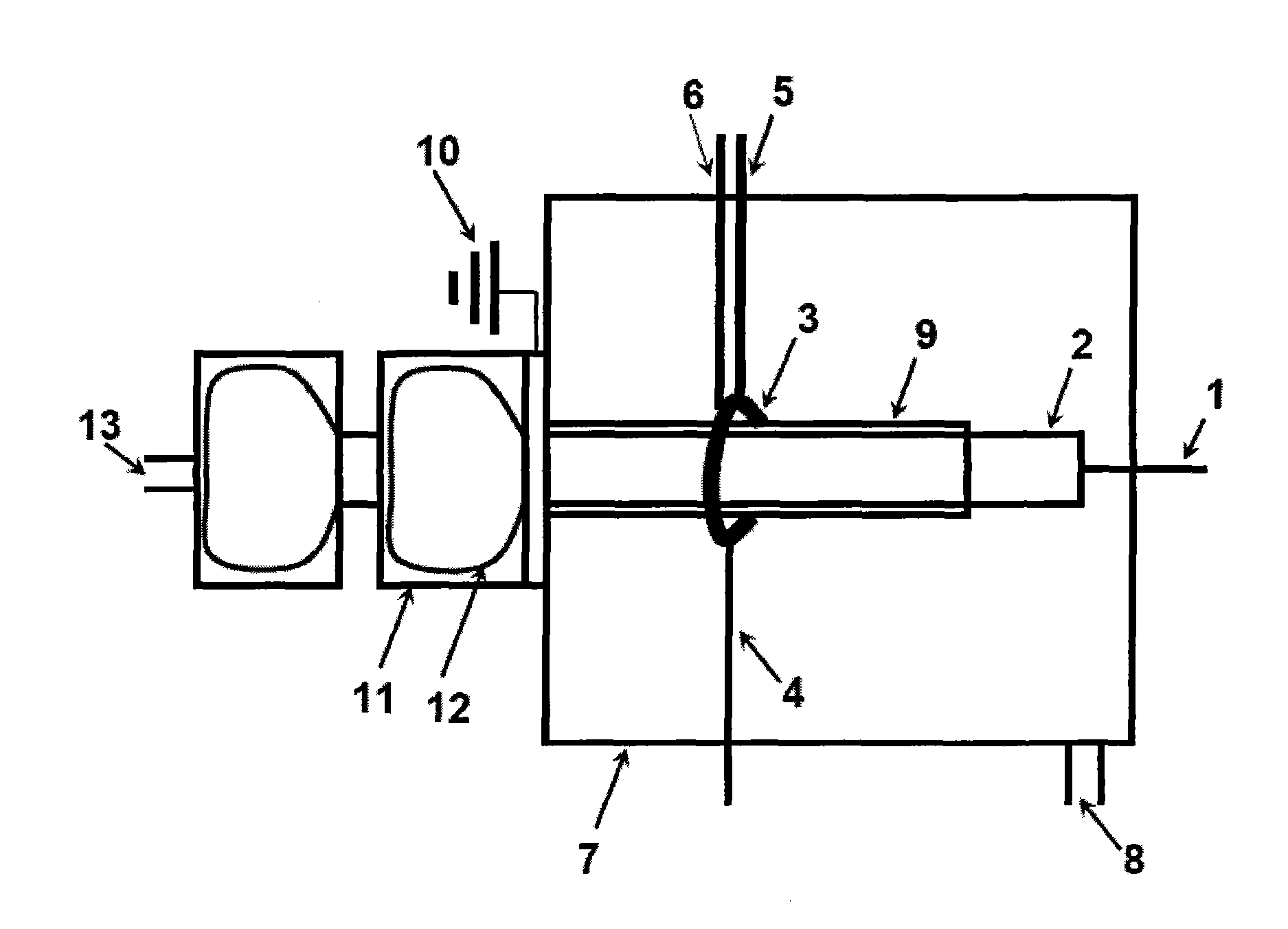

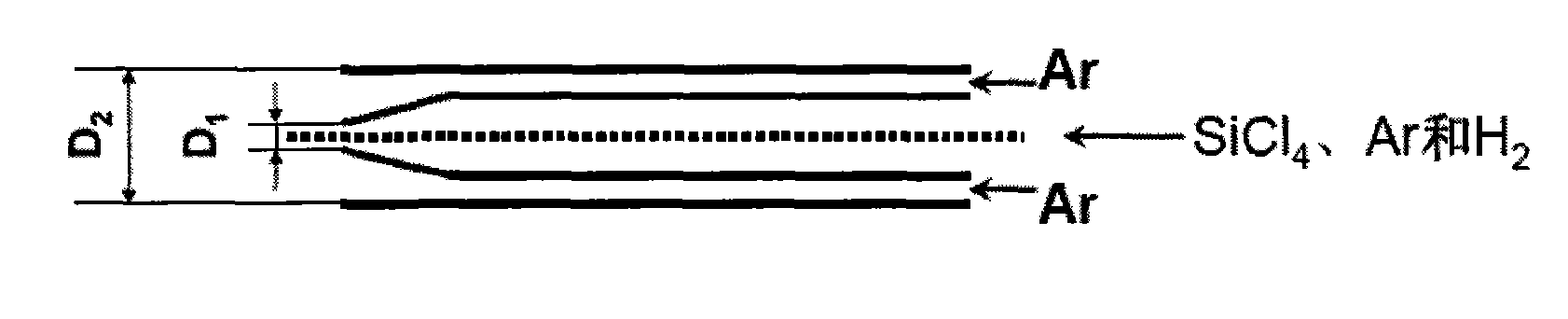

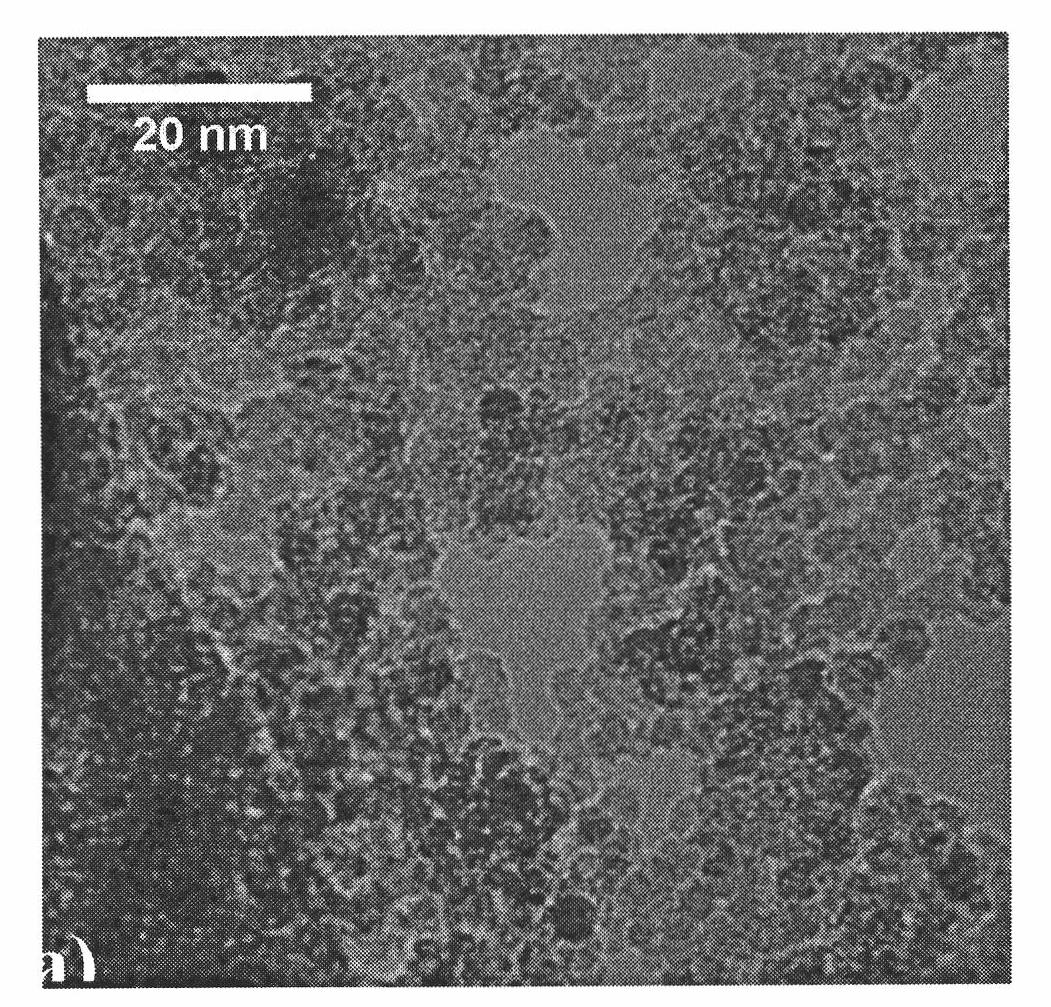

Method and device for preparing silicon nanoparticles by utilizing plasma body

The invention discloses a method and a device for preparing silicon nanoparticles by utilizing a plasma body. The method comprises the following steps: introducing mixed gas containing a silicon-containing air source and inert gas into a plasma body cavity; exciting the gas in the plasma body cavity to make the silicon-containing air source converted into the silicon nanoparticles; and collectingthe silicon nanoparticles by the collection device after the silicon nanoparticles are taken out of the plasma body cavity by air current. The method can use the high-power plasma body in the processof preparing the silicon nanoparticles, simultaneously avoids depositing the silicon nanoparticles on the inner wall of the plasma body cavity, and improves the collection of the silicon nanoparticlesin a gas phase. The method and the device ensure that the preparation of the silicon nanoparticles meets the requirements of large-scale production.

Owner:ZHEJIANG UNIV +1

Preparation method and device of phosphorus-doped nano silicon material

The invention discloses a preparation method and device of a phosphorus-doped nano silicon material. The method comprises the following steps: arranging a bar-shaped raw material used as an electrode material in a spark discharge chamber; under the protection of a dielectric gas or liquid material, applying a voltage onto the raw material of the electrode through a pulse power source, and generating a spark to locally melt and gasify the raw material of the electrode; injecting the molten and gasified raw material of the electrode into the dielectric gas or liquid to form nano particles; and then, separating and collecting through a particle collecting device containing a filter cloth. According to the method and device, the spark discharge area of the raw material of the electrode can be increased, so that the productivity of the nano particle preparation is increased and meets the requirements for large-scale production; and the spacing between raw materials of electrodes can be controlled, thereby controlling the size of the formed nano particles and enhancing the uniformity of particle size distribution.

Owner:苏州金瑞晨科技有限公司

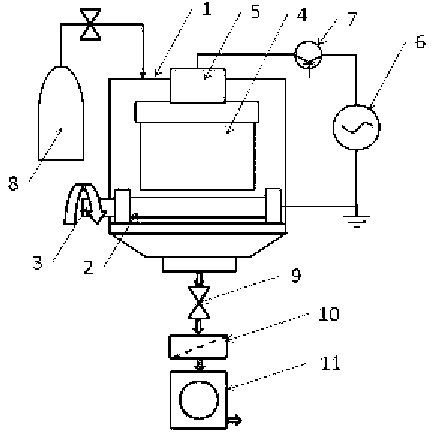

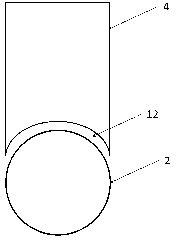

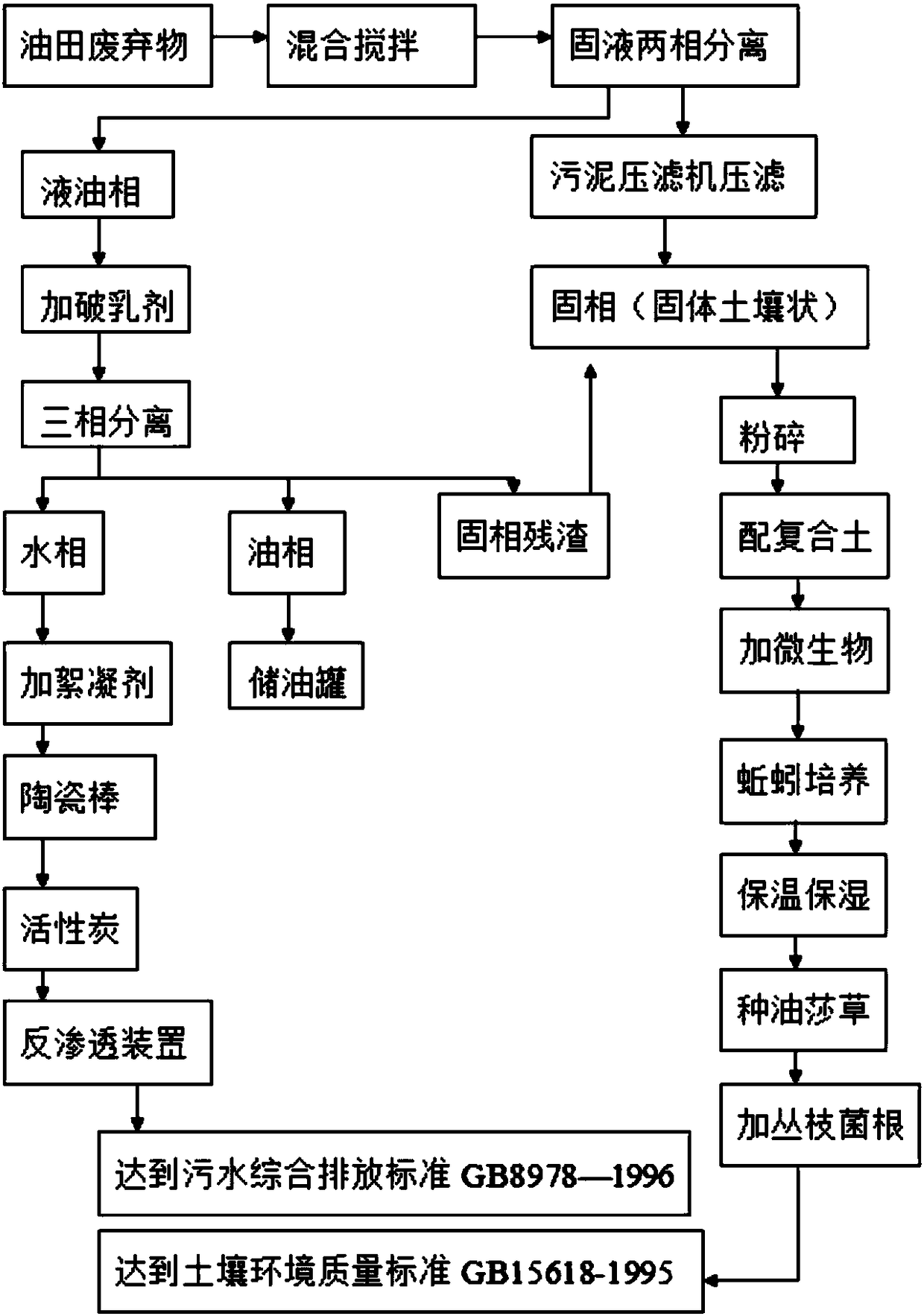

Method for comprehensively treating oil field waste by using physicochemical and biochemical technologies

InactiveCN108455762ASolve the use problemSolve pollutionWaste water treatment from quariesWater/sewage treatment by centrifugal separationOil fieldThree-phase

The invention relates to treatment and utilization technologies of oil field waste, in particular to a method for comprehensively treating oil field waste by using physical-chemical and biochemical technologies. The method aims to provide a low-cost and convenient operation method for comprehensively treating oil field waste by using physical-chemical and biochemical technologies. The method comprises the following steps of: solid-liquid separation; three-phase separation; oil phase treatment; water phase treatment; solid-phase residue treatment. The method solves the problem of oil field waste disposal and utilization, utilizes separation treatment to separate water, mud and waste oil, disposes a lot of oil field waste by using intergrowth of microorganism, earthworm, mycorrhiza and plant, and meets the requirements of large-scale production; The pollution problem of oil field waste is solved, and the practical requirements of oil field operation and environmental protection are met.

Owner:陈淡宁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com