Liquid filling and cover pressing line

A capping and filling technology, applied in liquid filling, liquid processing, packaging, etc., can solve problems such as being unsuitable for large-scale production, and achieve the effect of high production efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

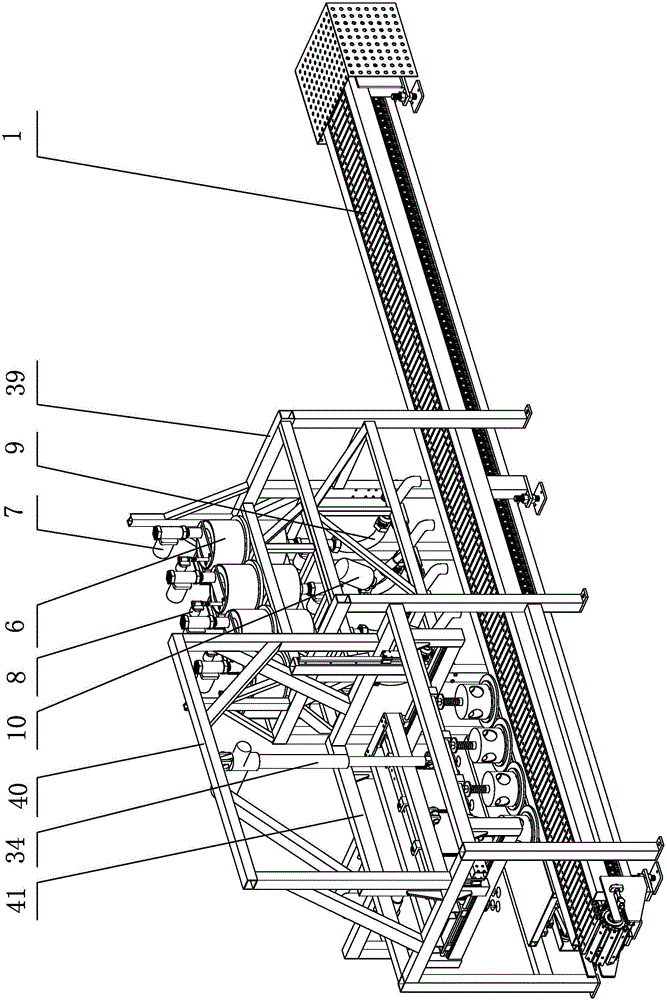

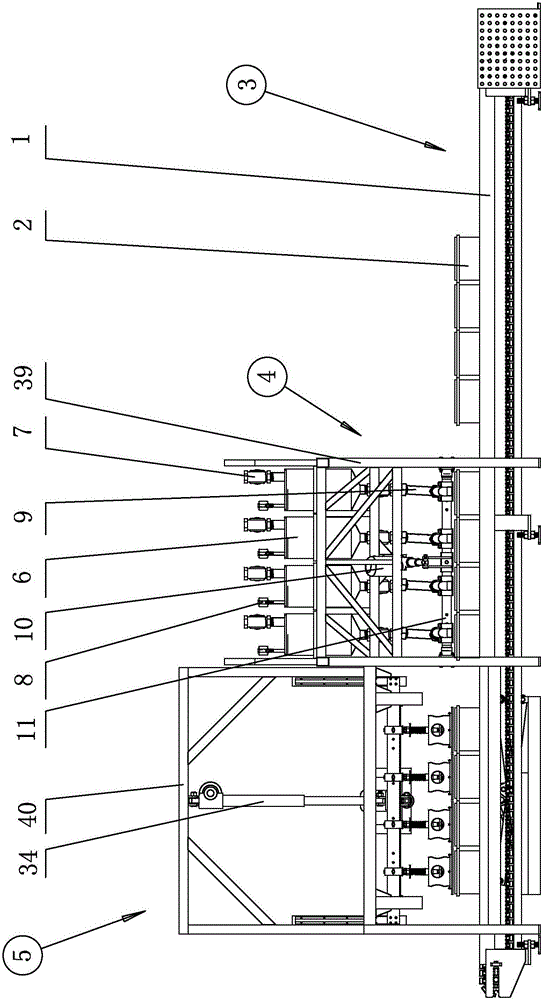

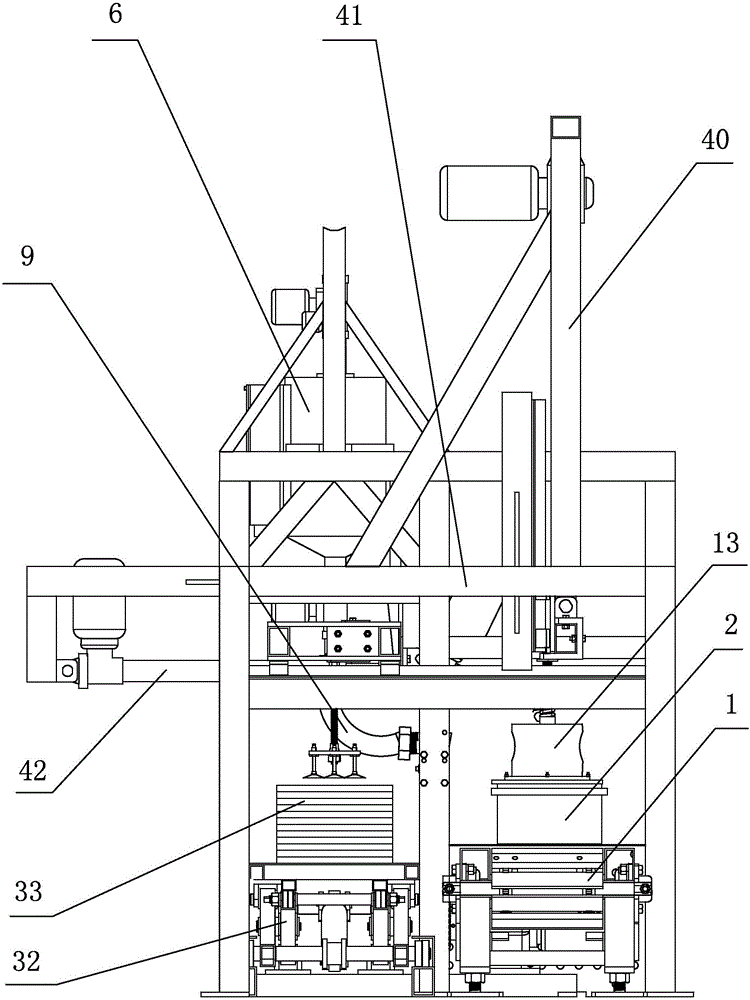

[0029] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0030] The liquid filling and capping line of the present invention includes a chain plate conveyor belt 1, the transmission direction of the chain plate conveyor belt 1 is from right to left (or from left to right), and along the direction of transmission, the chain plate conveyor belt 1 The middle and rear part of the bucket is set as the barrel-releasing station 3, and the barrel-releasing station 3 can place a plurality of liquid-filled barrels 2 in a row along the conveying direction (the number is a multiple of four liquid-filled barrels 2), and the chain plate is transported The middle front part of the belt 1 is set as a quantitative filling station 4 for filling four liquid storage barrels 2 at the same time. The quantitative filling station 4 is provided with a quantitative filling device, and the front part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com