Patents

Literature

3623results about "Bottle/container closure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

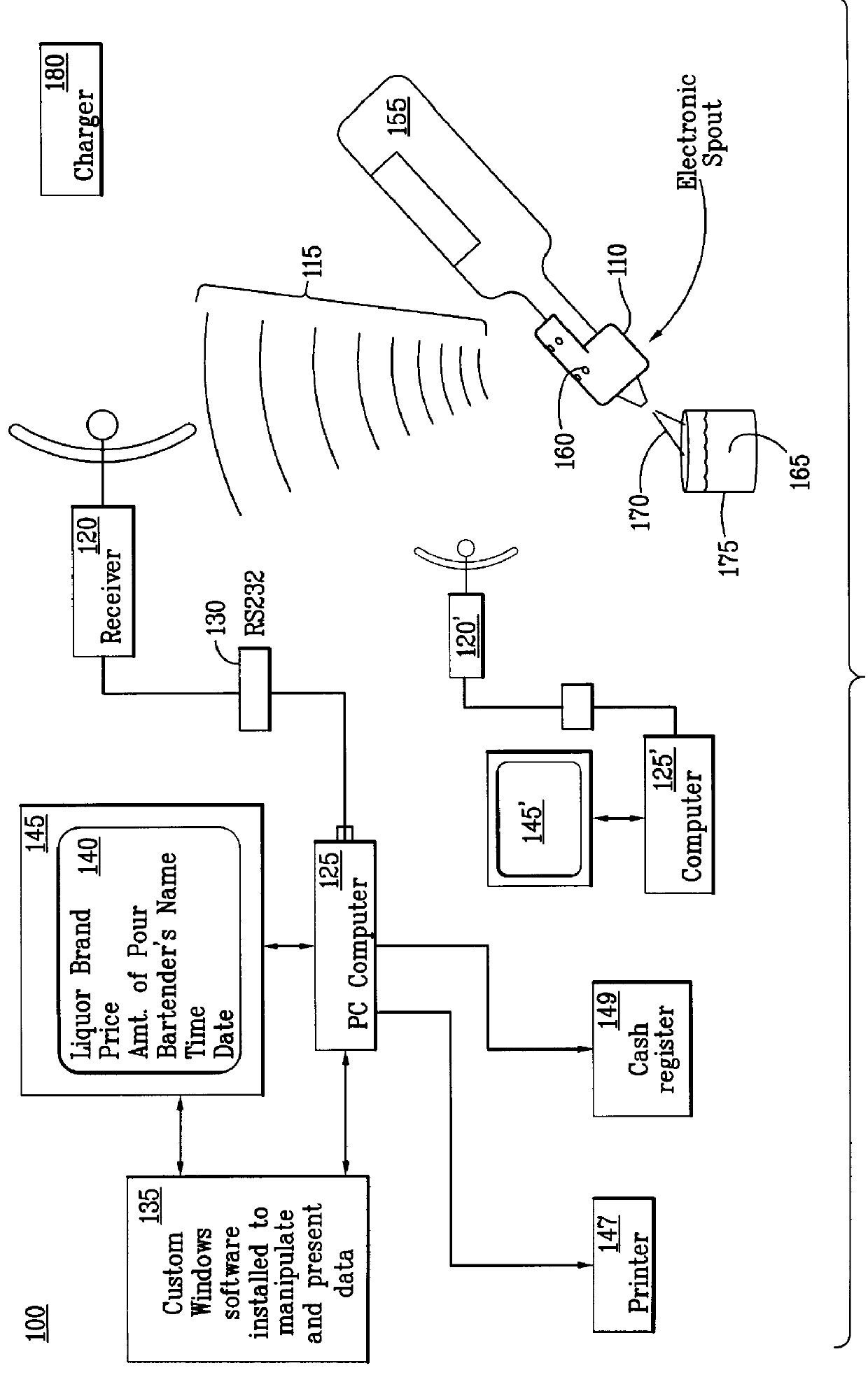

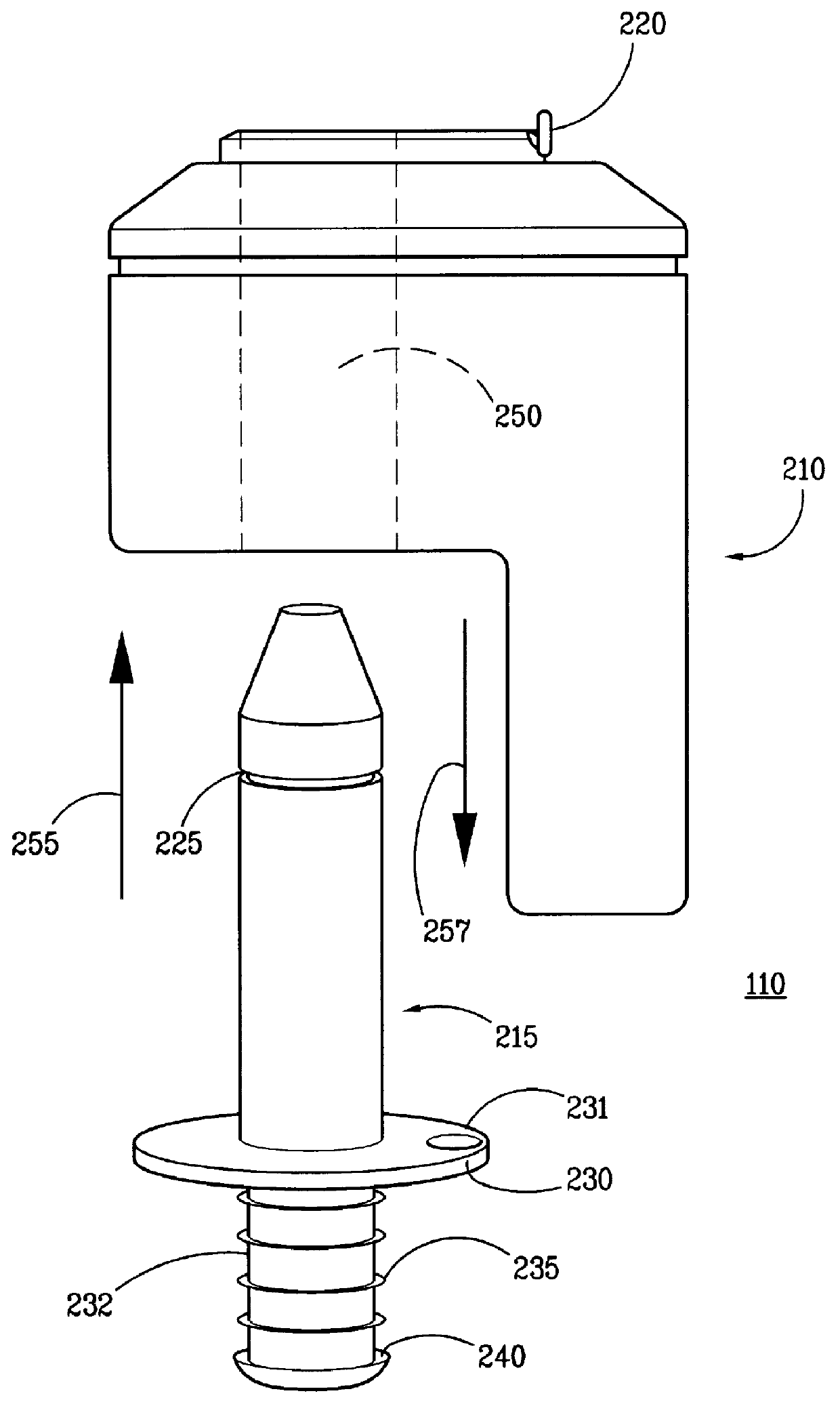

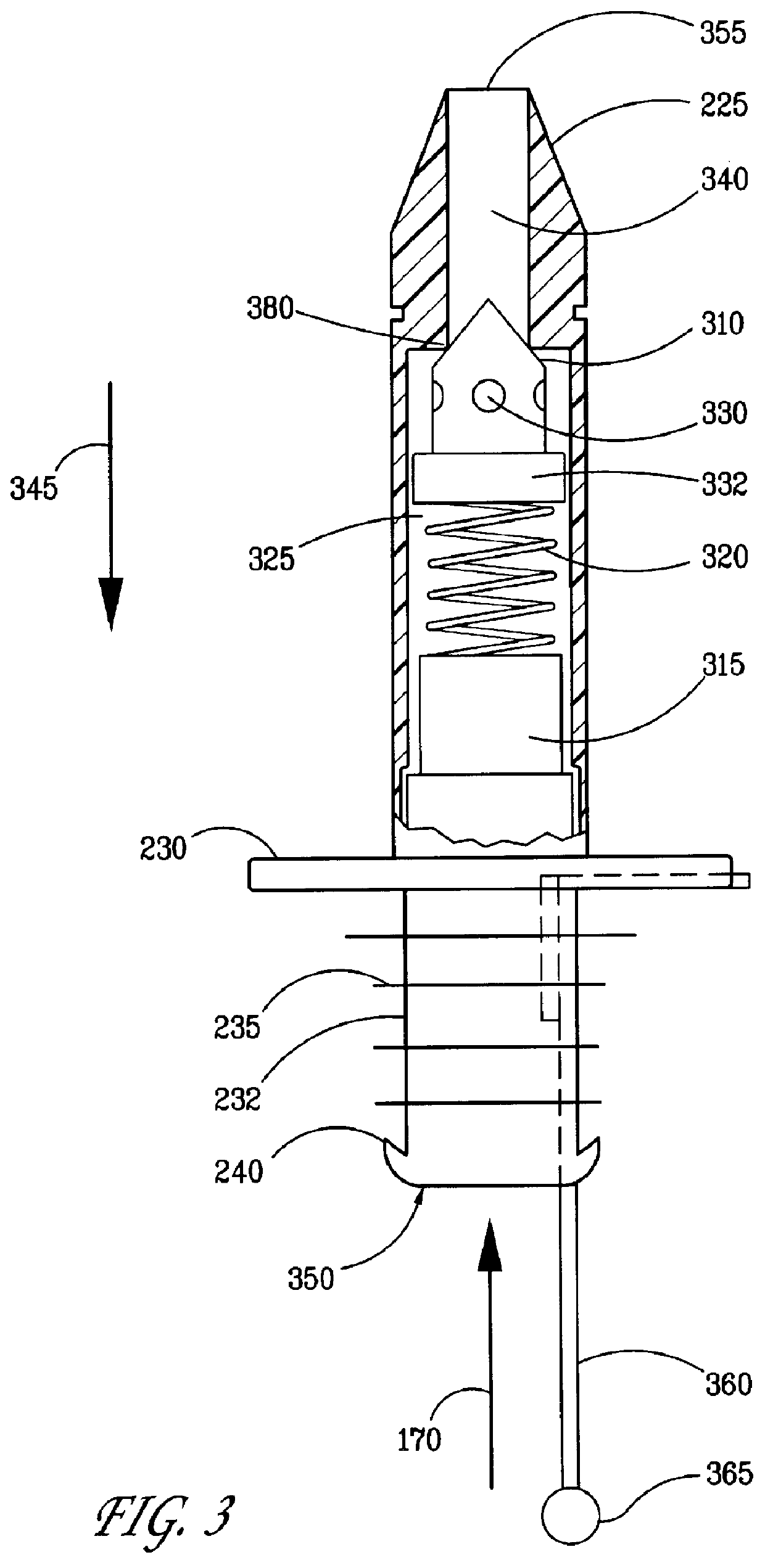

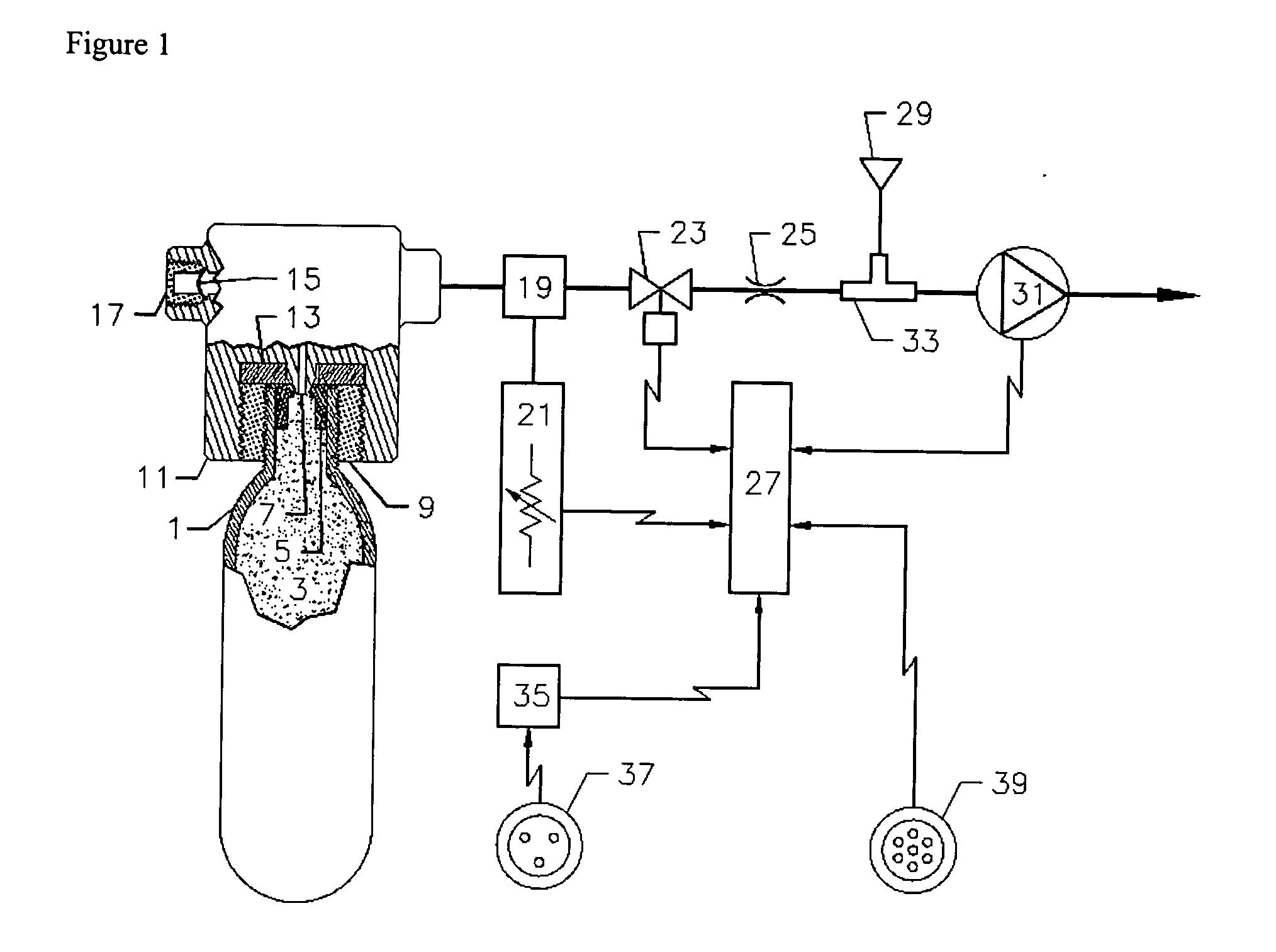

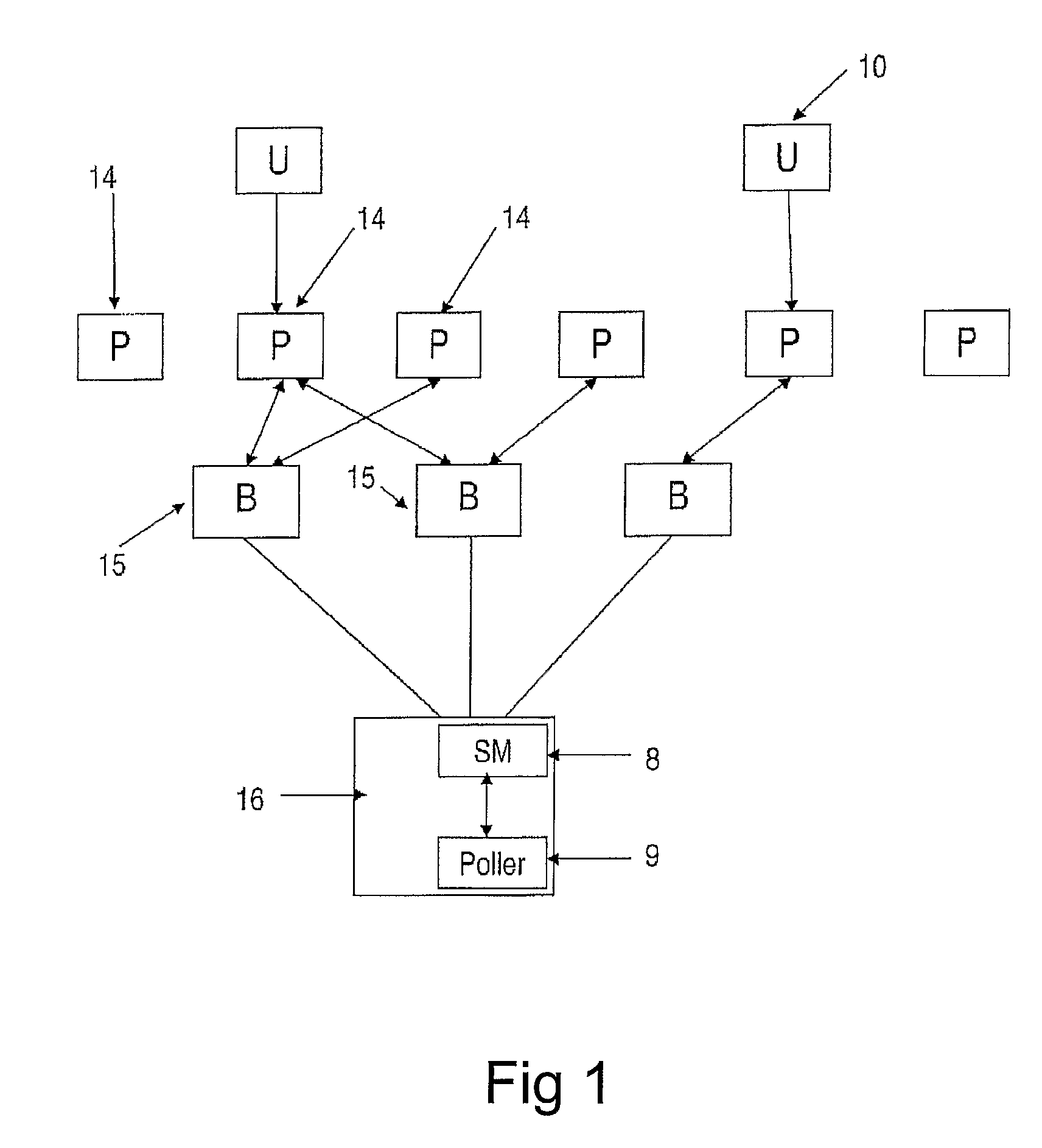

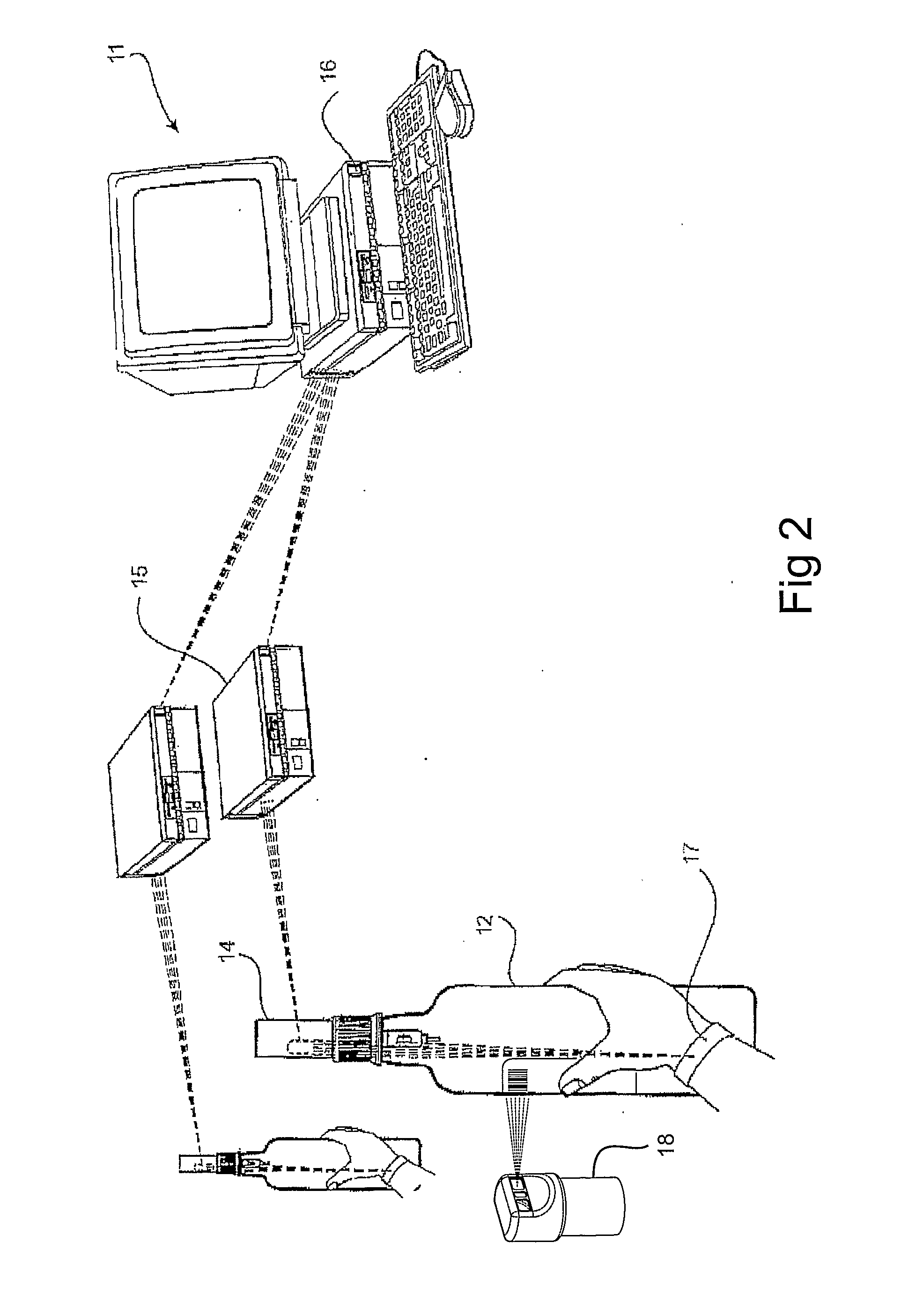

Wireless liquid portion and inventory control system

A system for controlling an amount of liquid poured from a liquid container includes a spout configured for attachment to an opening of a liquid container and for controlling a desired amount of liquid poured from the liquid container. The spout is further configured to emit signals containing activity information. A receiver is configured to receive the signals, and a computer is coupled to the receiver, for processing the signals into text for viewing. The present invention further provides a method of controlling liquid flow from a liquid container, including the steps of: (a) determining an amount of liquid which is to be poured from a liquid container; (b) transmitting activity information signal corresponding to a predetermined activity; (c) remotely receiving the activity information signal of step (b); and (d) processing the activity information signal of step (c) into readable form.

Owner:MOGADAM MASOUD M

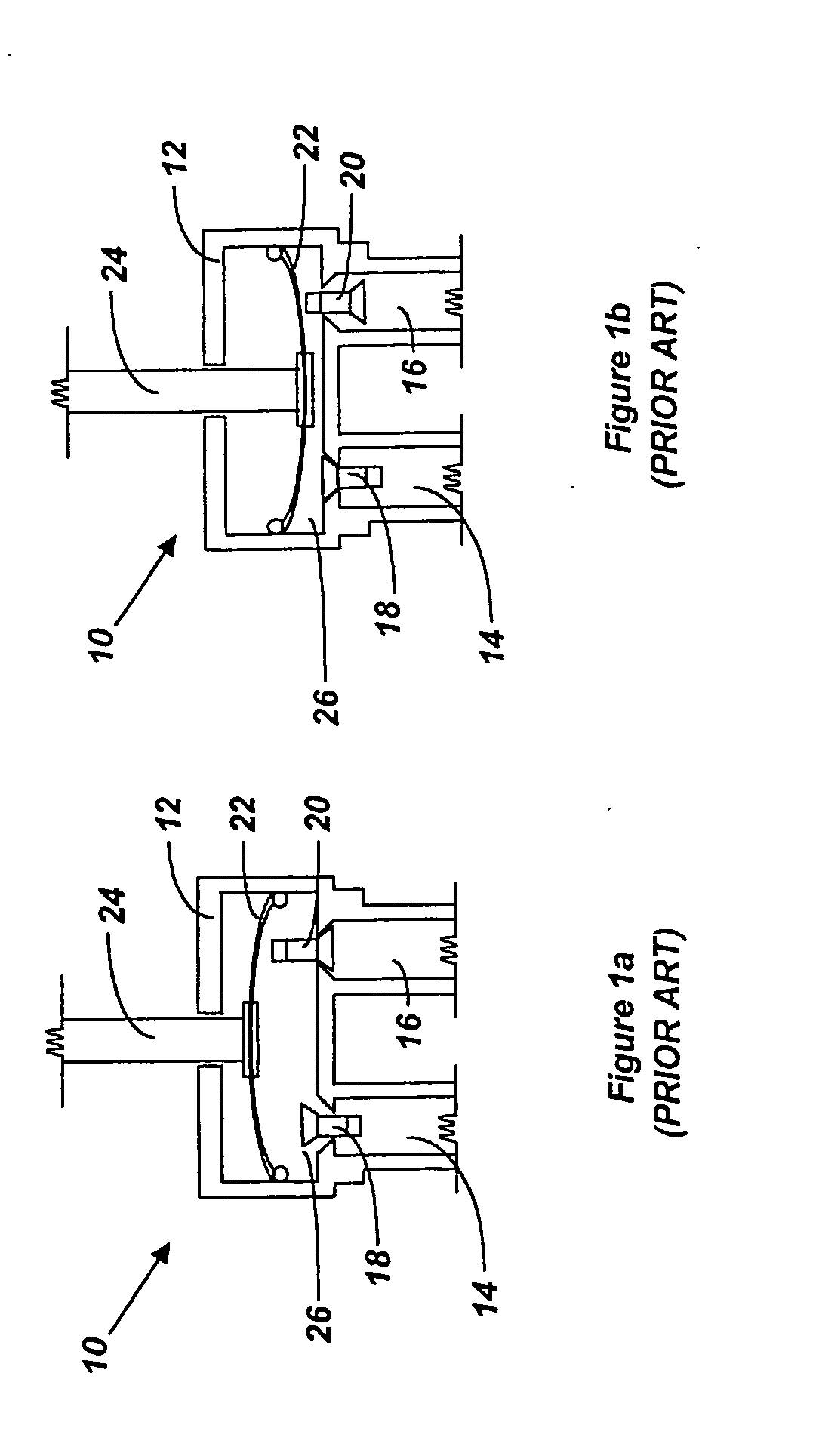

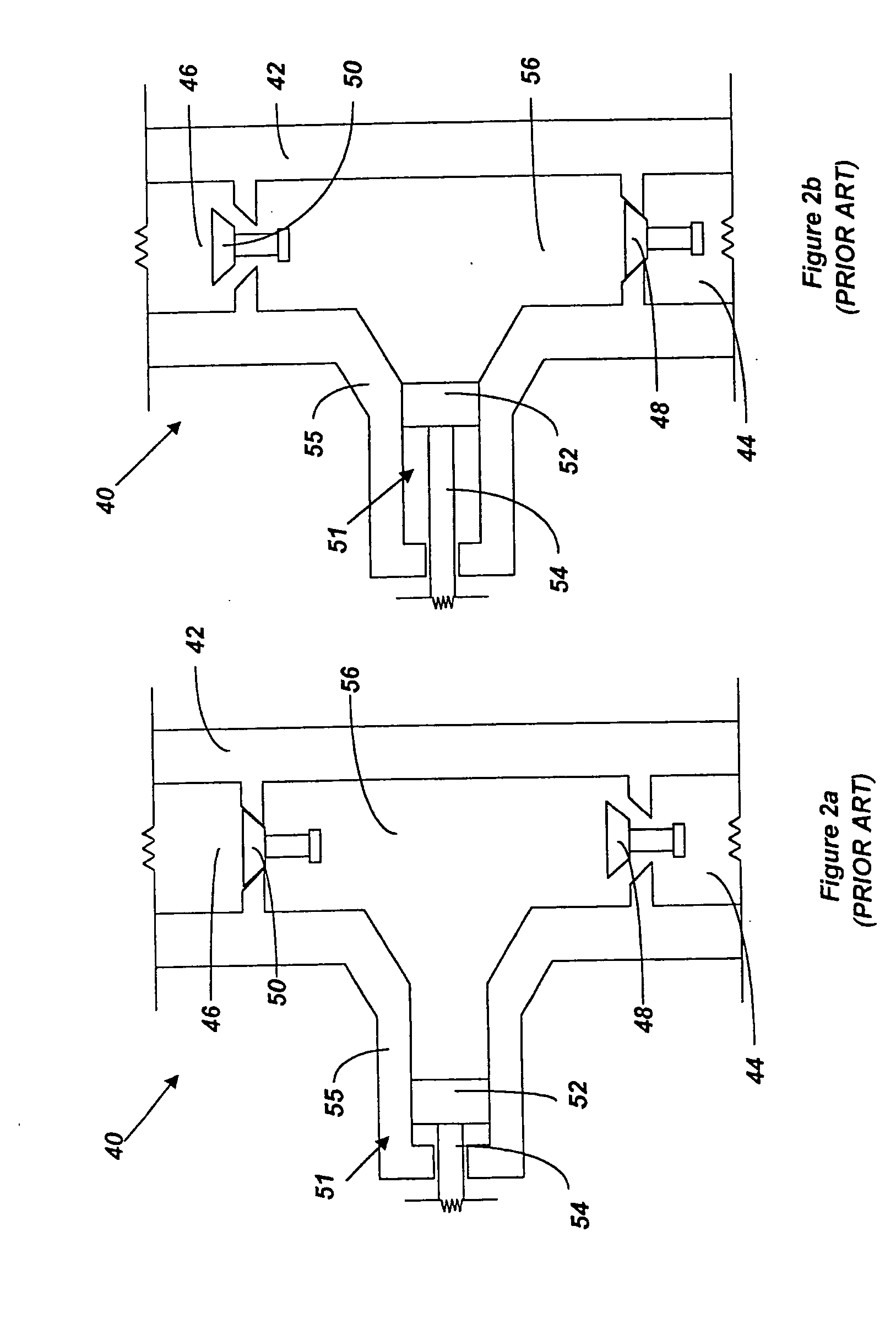

Hazardous material handling system and method

A method and system for handling hazardous materials contained in a vial includes an isolation enclosure having an opening selectively sealable about the vial, a bag body portion, and a cap portion. A latching extraction element is attached to the cap portion and has a preceding engaging member to secure the vial to the isolation enclosure, an extraction member to be inserted into the vial and remove material therefrom, and a primary engaging member to secure the vial to the extraction member. A valve is mounted outside the isolation enclosure and controls the flow of fluid from the vial. An adaptor having a reseal member permits flow when coupled to the valve and restricts flow when uncoupled from the valve. Once uncoupled, the adaptor is removably associated with a second valve located remotely from the isolation enclosure, allowing fluid to pass into the second valve.

Owner:HOSPIRA

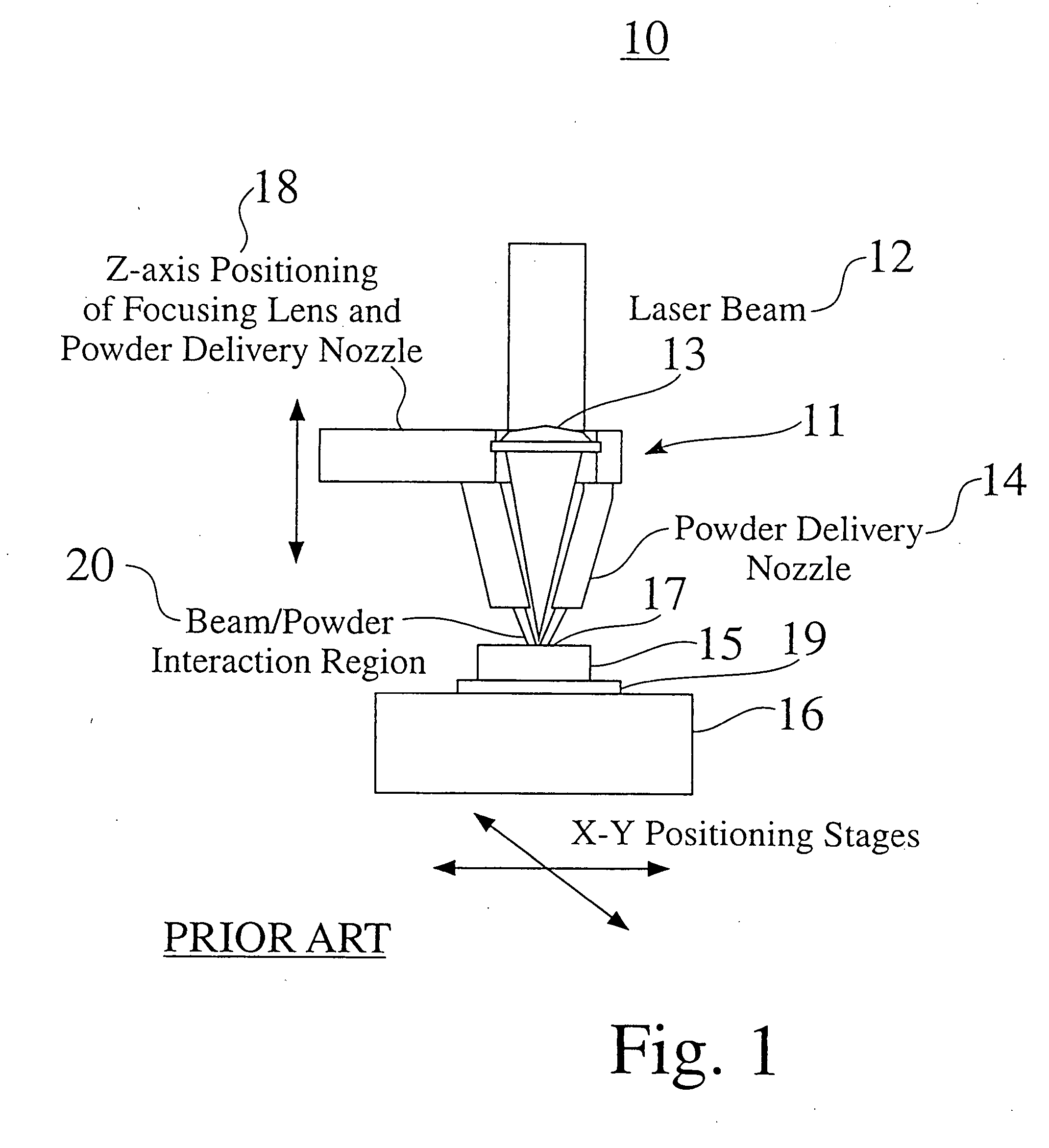

Powder feeder for material deposition systems

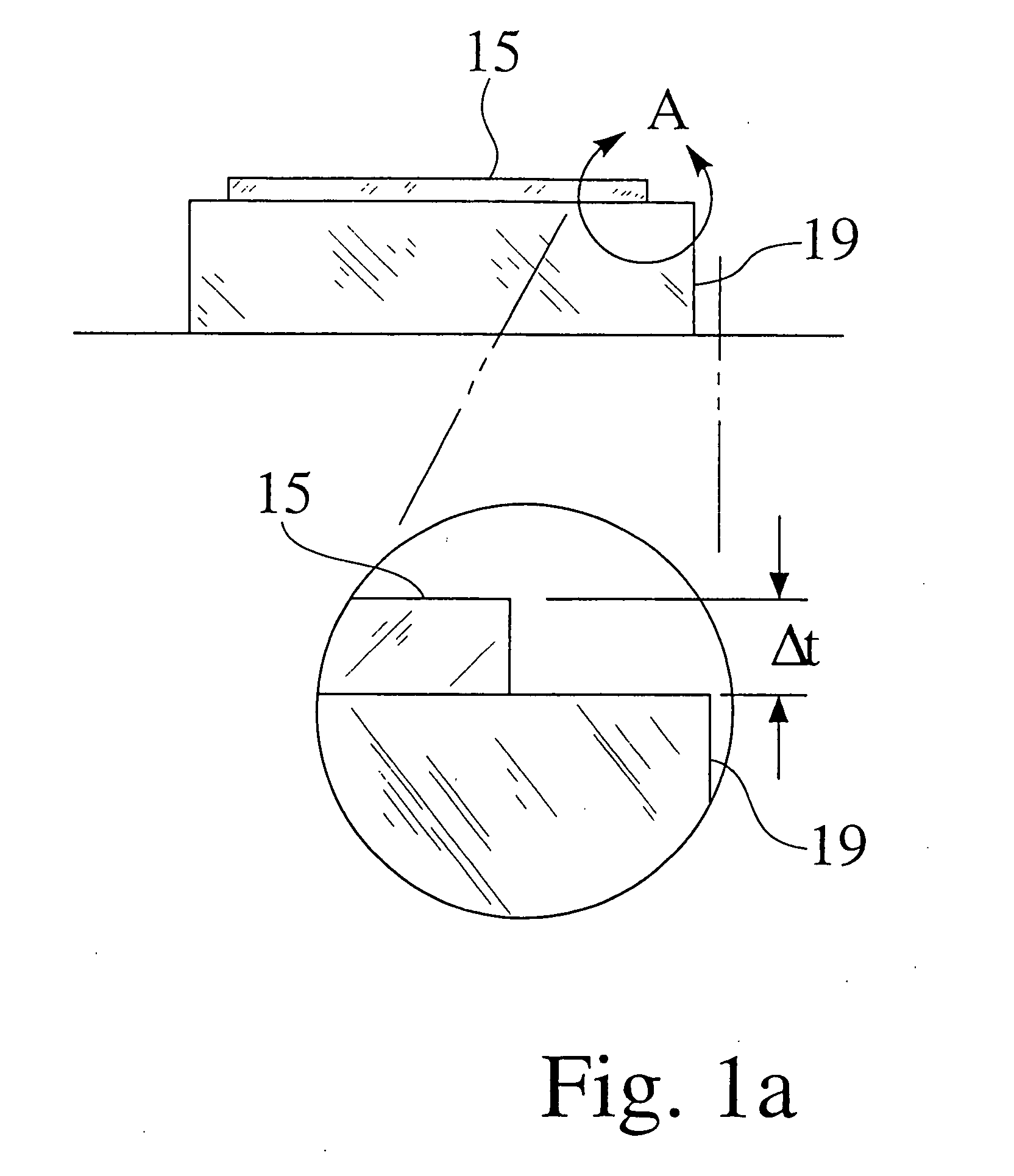

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

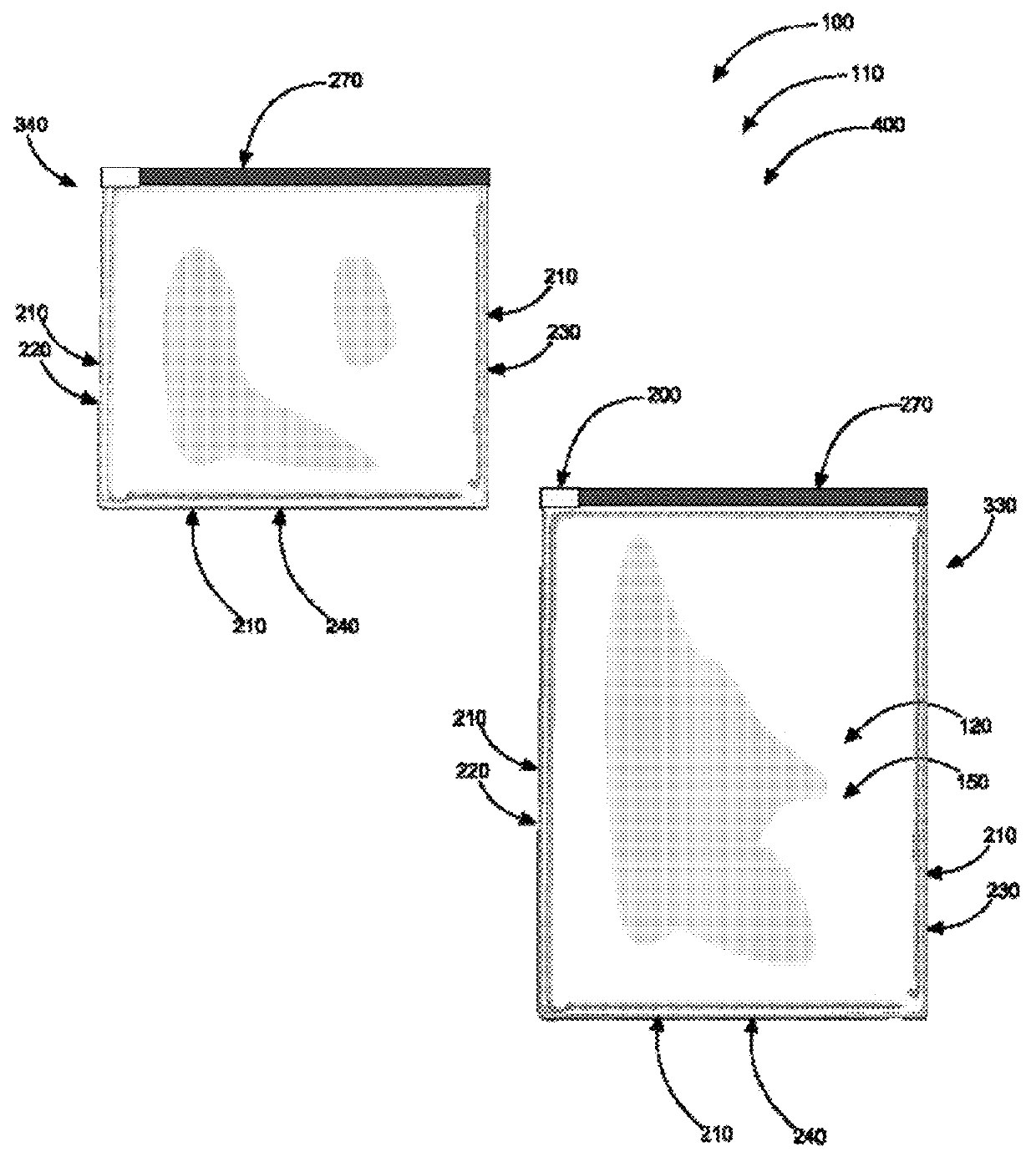

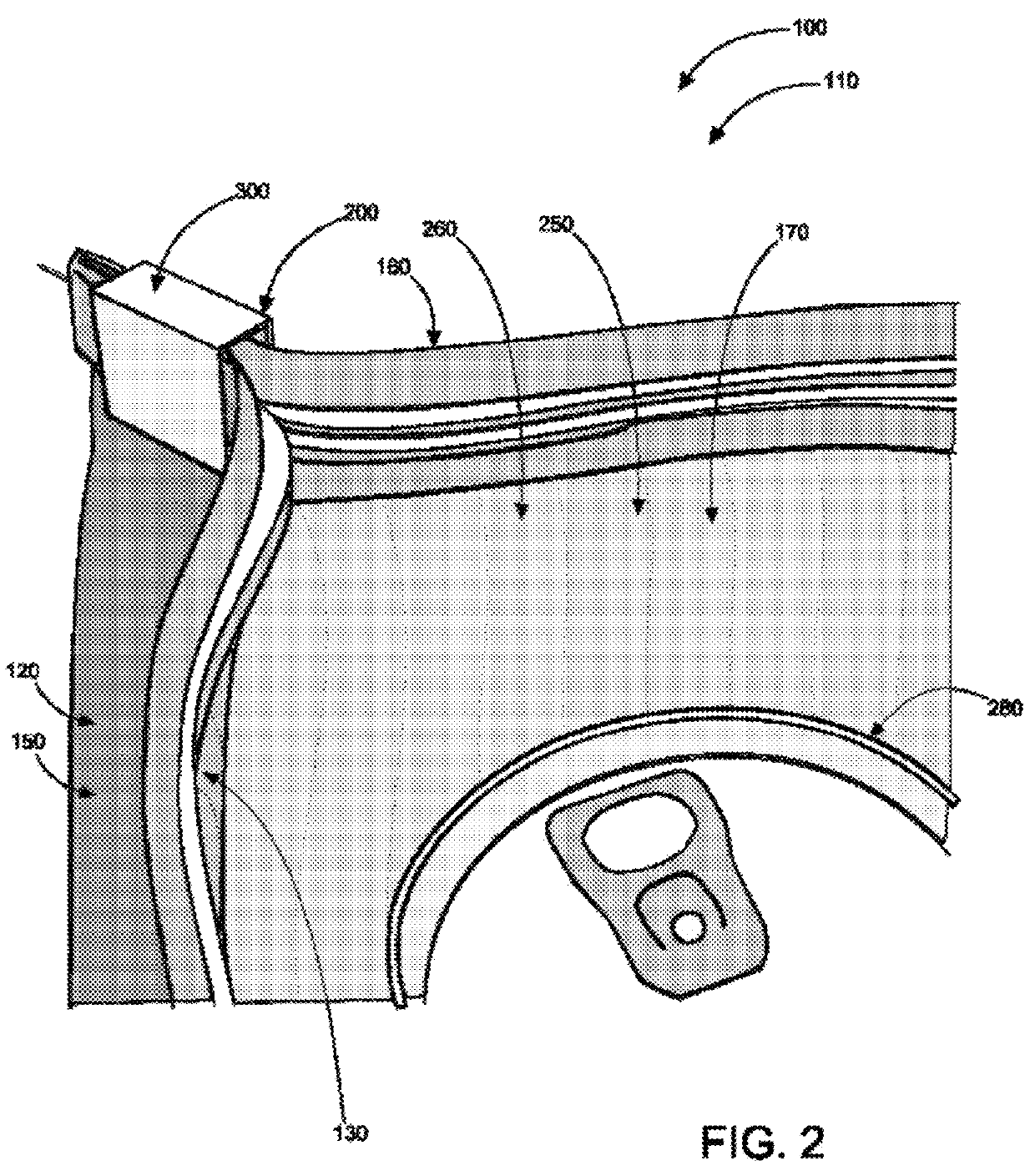

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

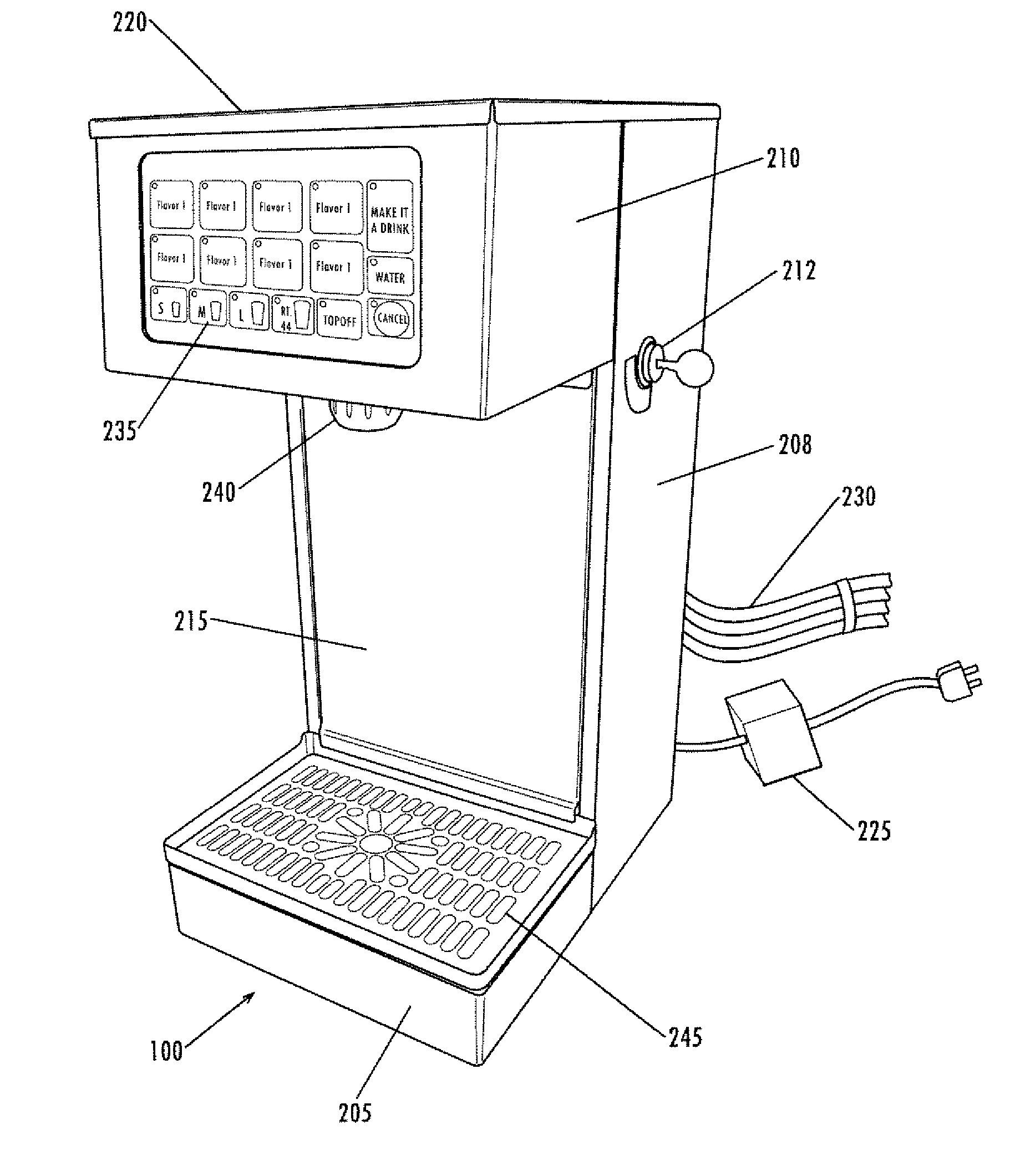

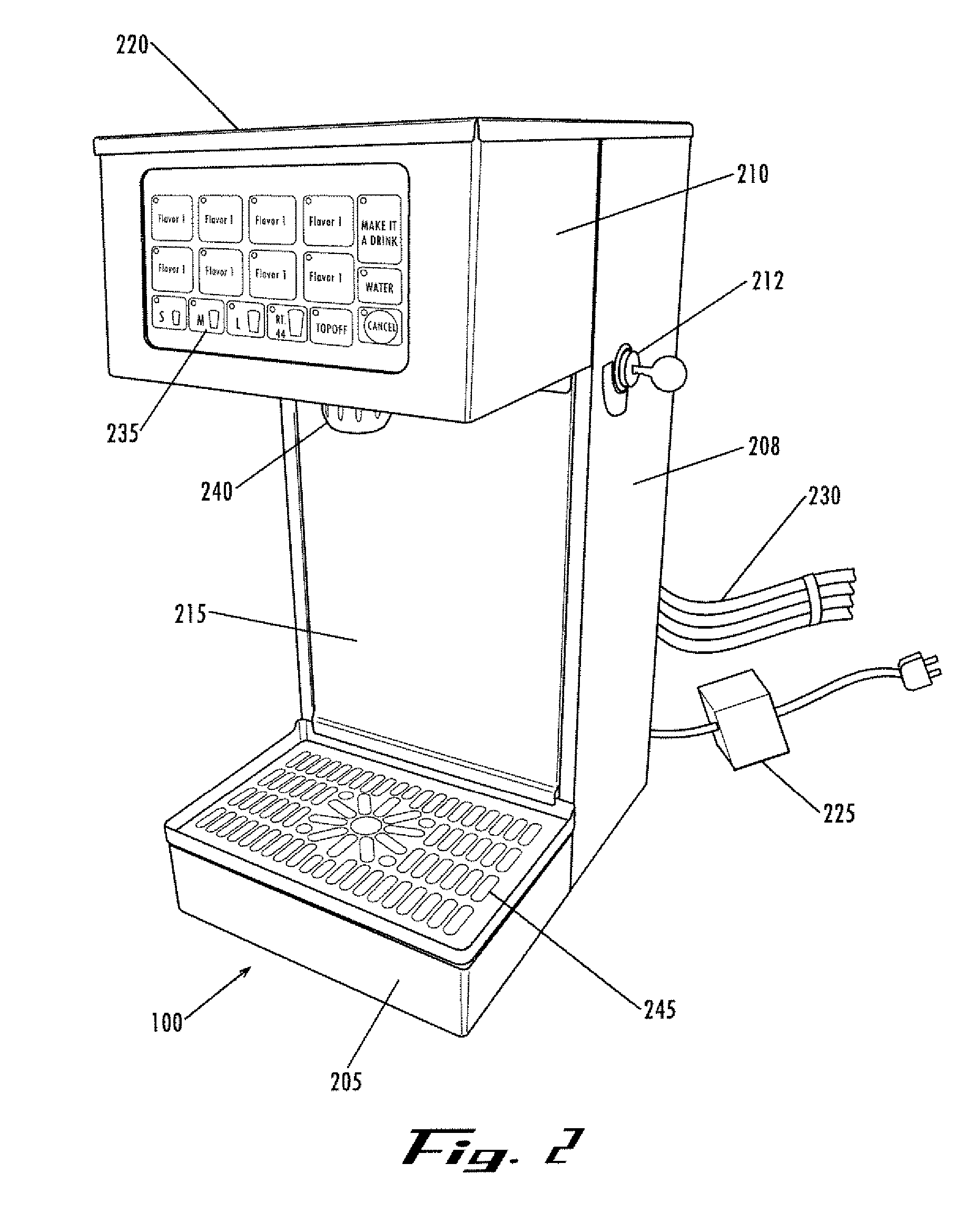

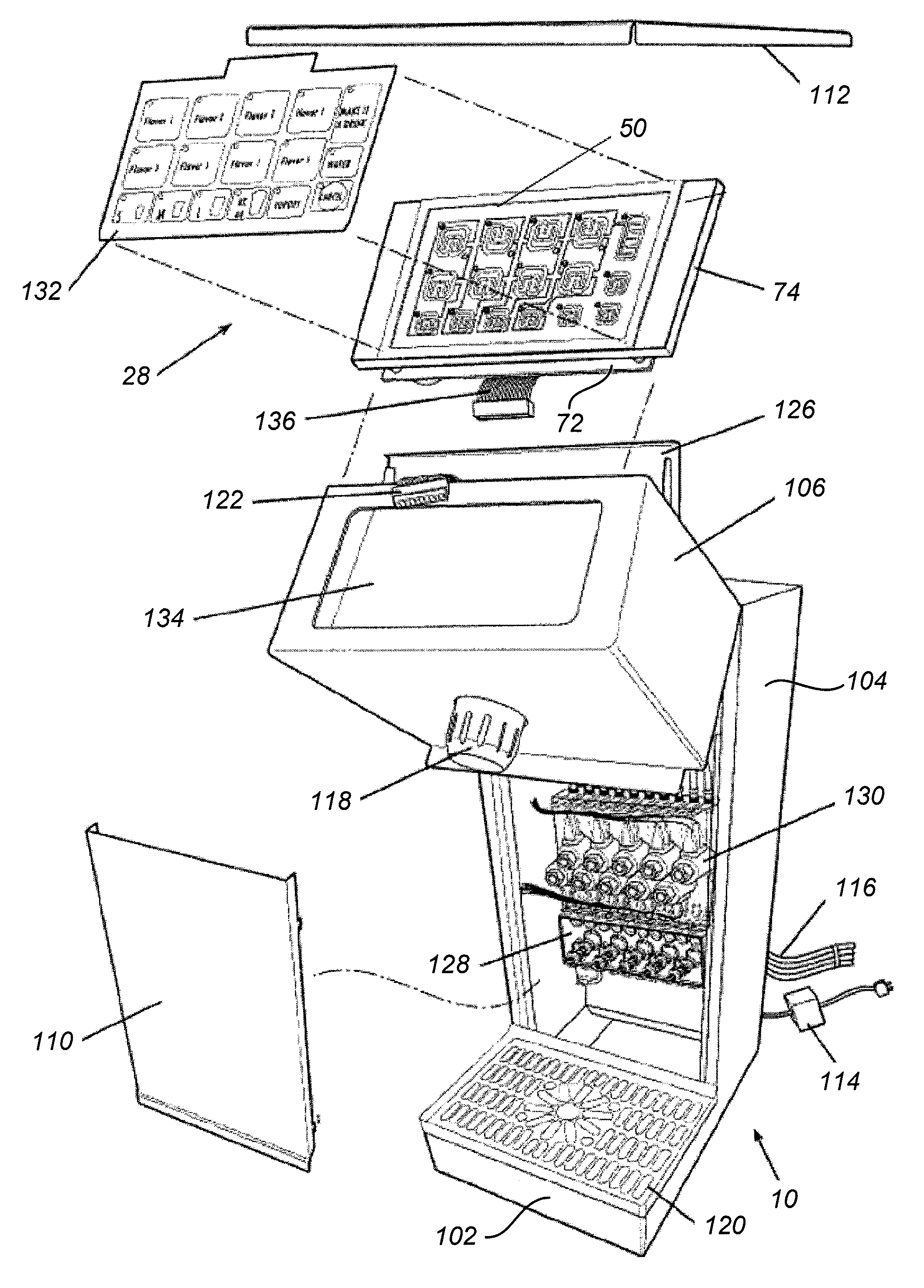

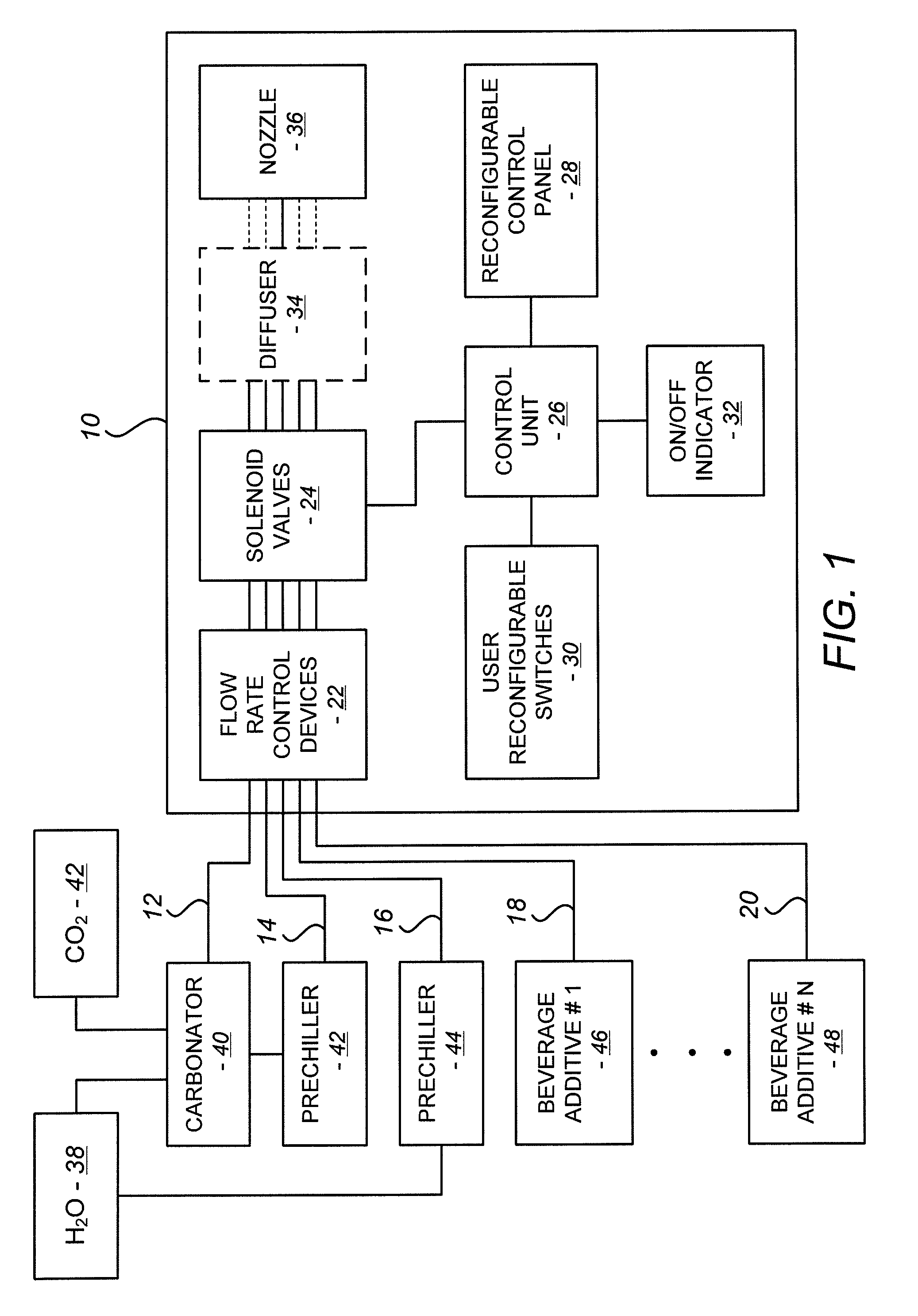

Touch Screen Interface for a Beverage Dispensing Machine

ActiveUS20110315711A1Increase flexibilityAvoid cross contaminationOpening closed containersBottle/container closureEngineeringTouchscreen

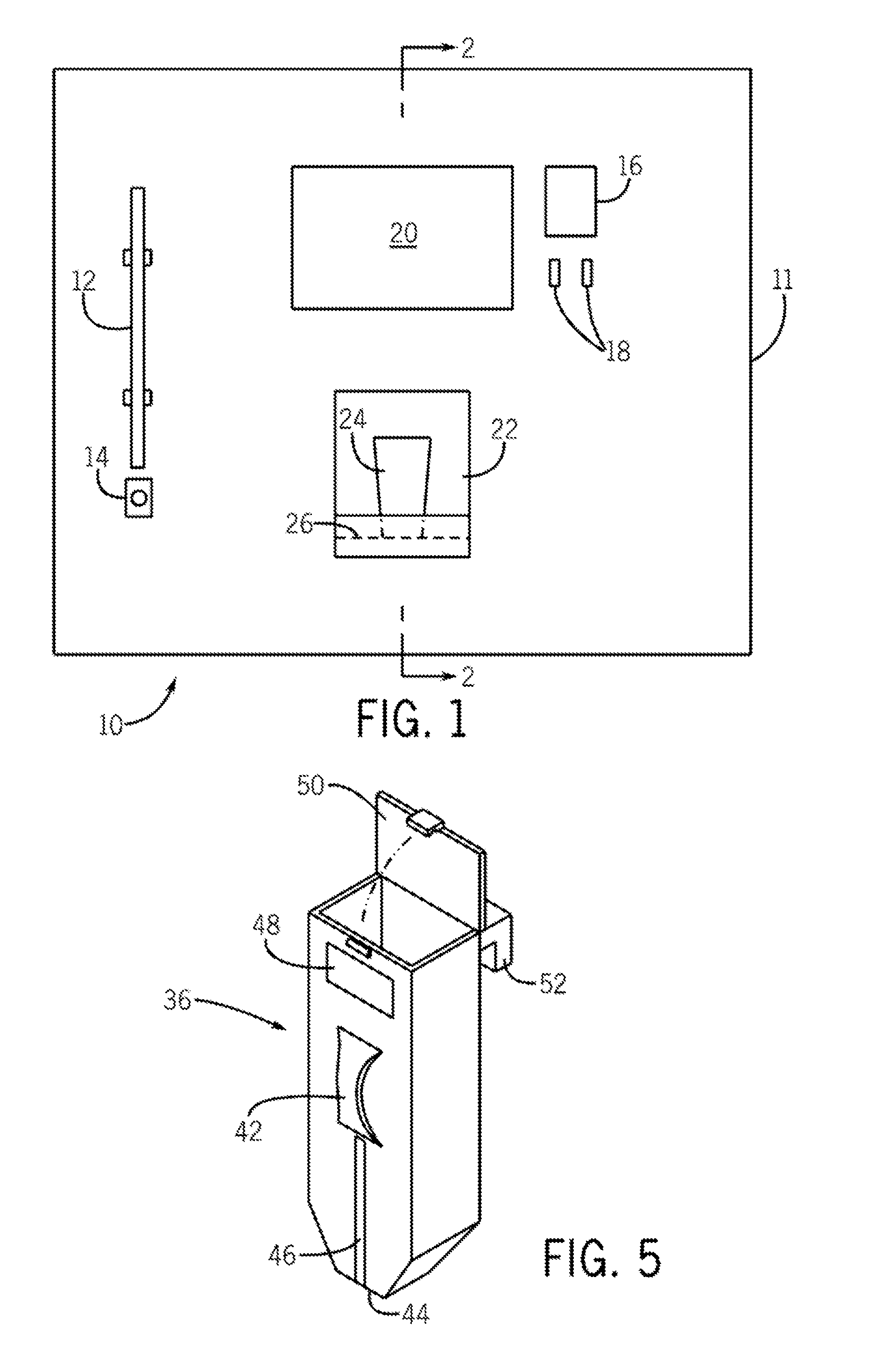

A beverage dispensing system including a control unit and a touch screen. Inputs are made to the touch screen to dispense beverages and apply system adjustments. The control unit controls a plurality of beverage dispensing valves according to inputs made to the touch screen.

Owner:AUTOMATIC BAR CONTROLS

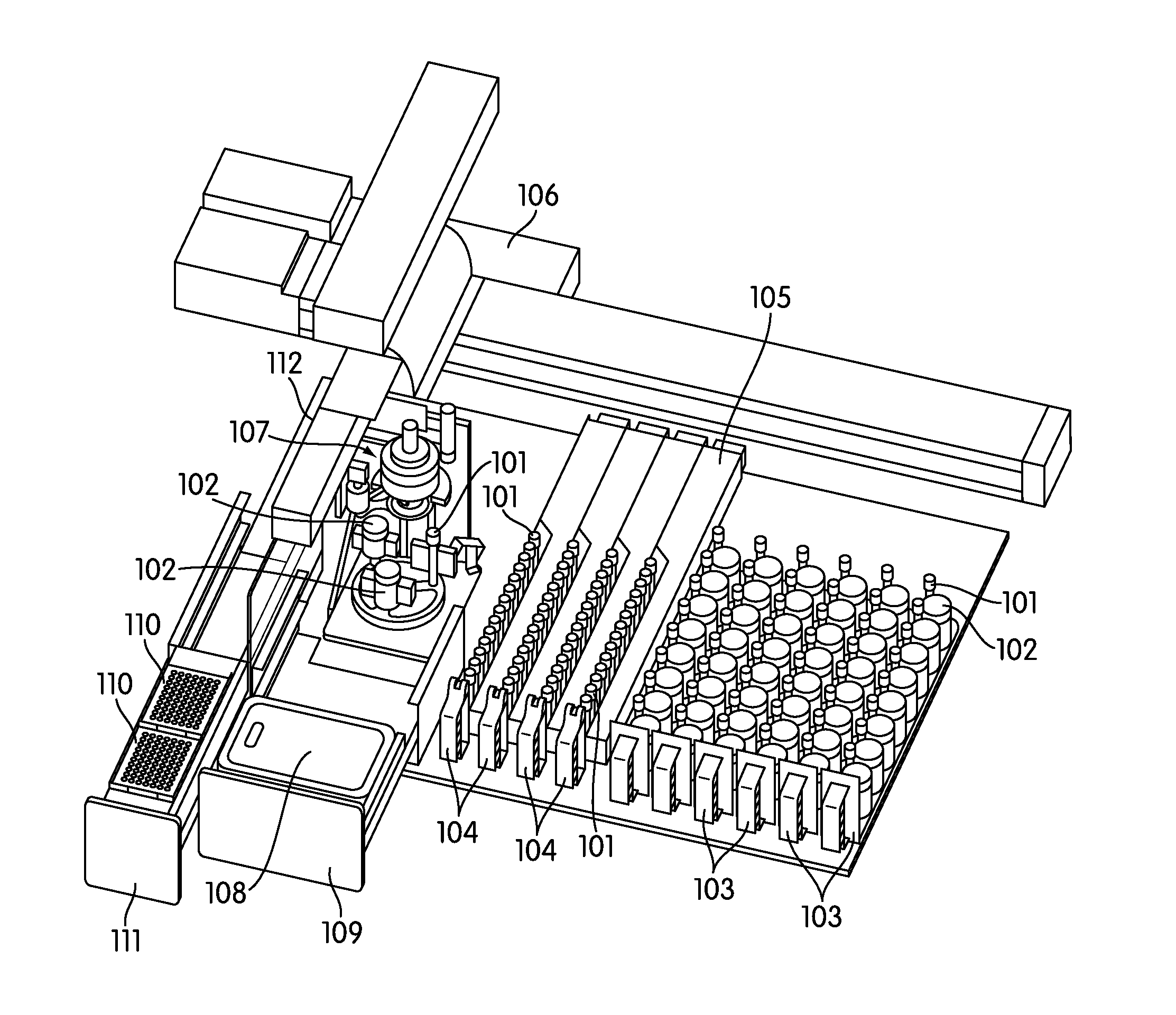

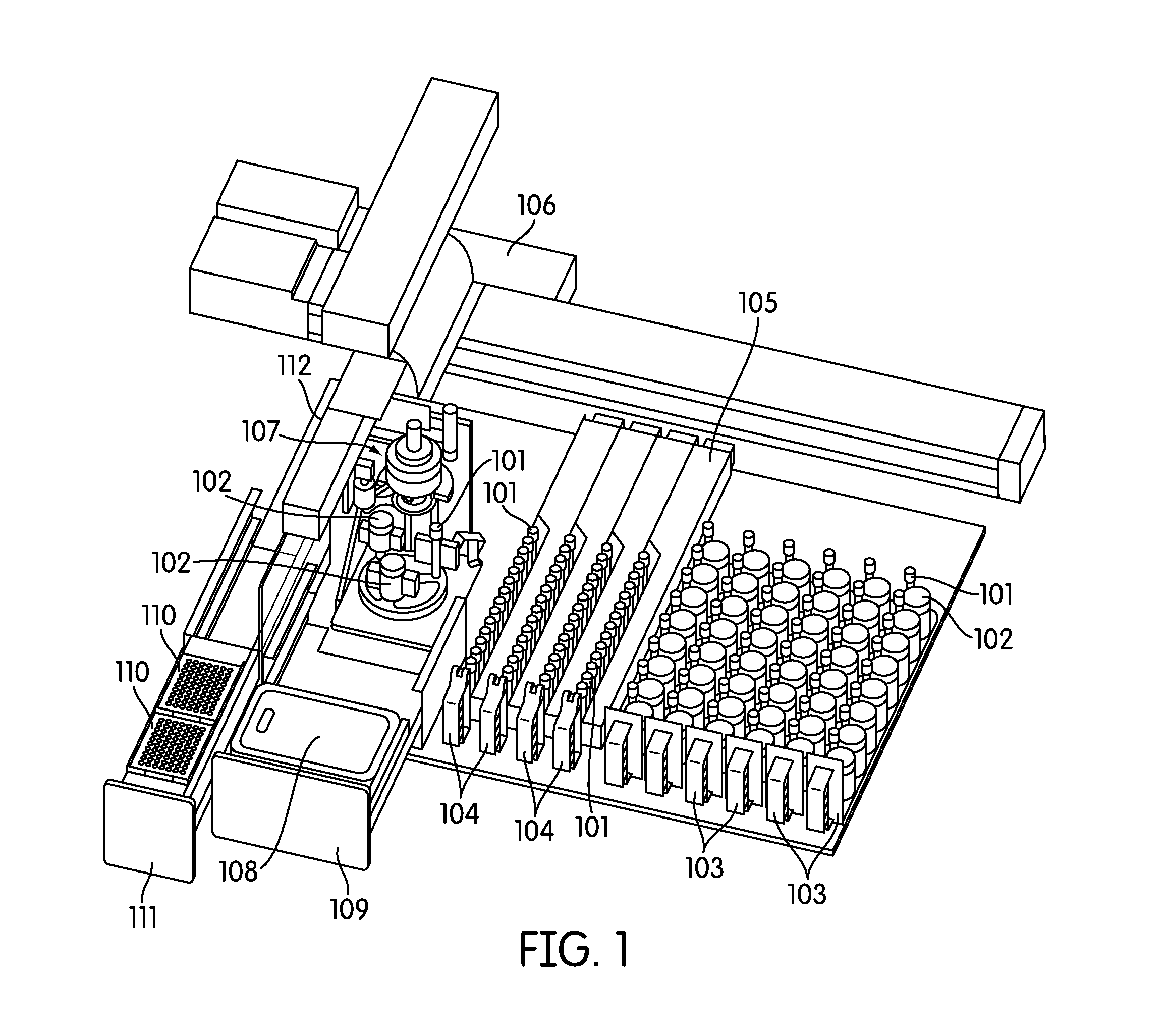

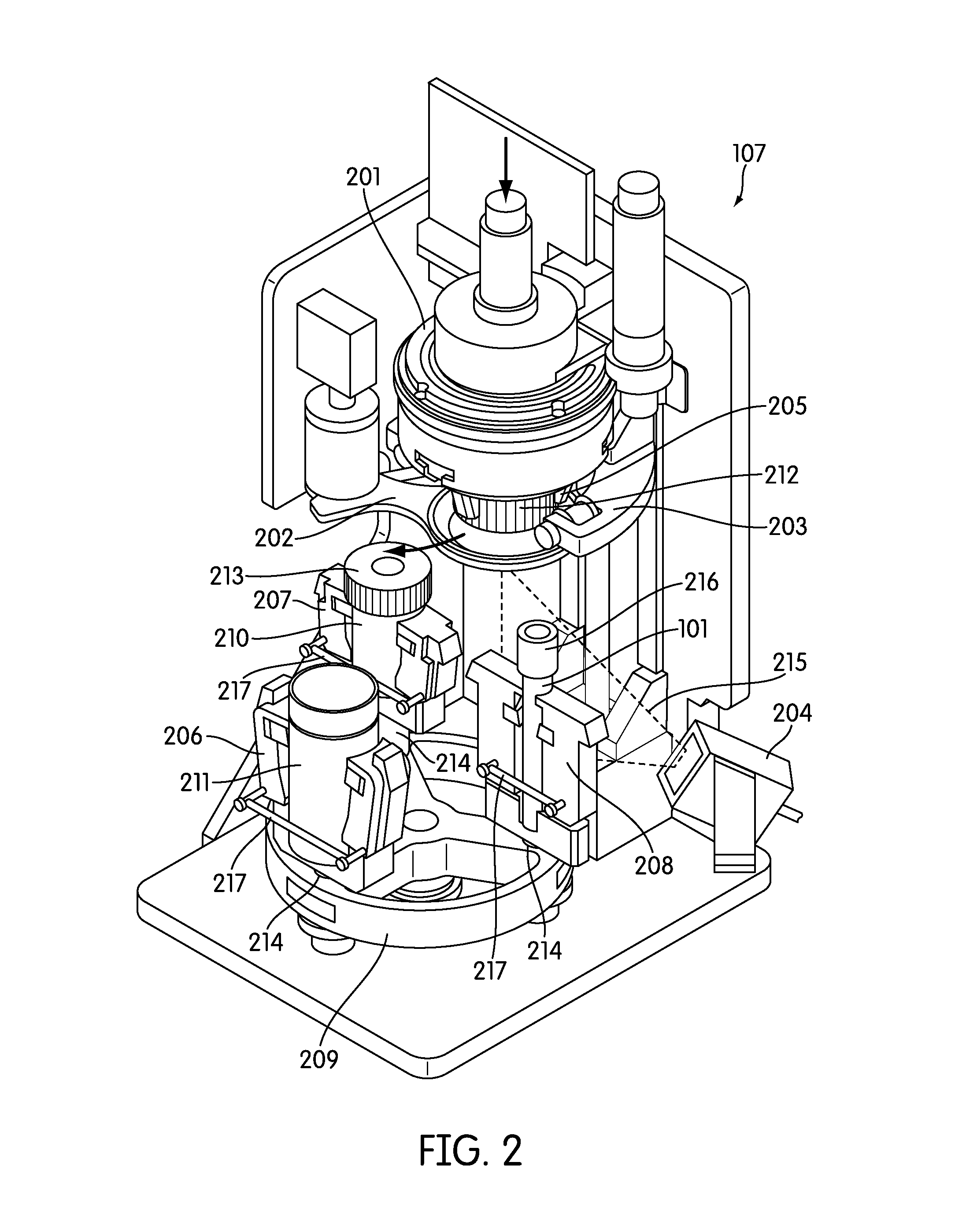

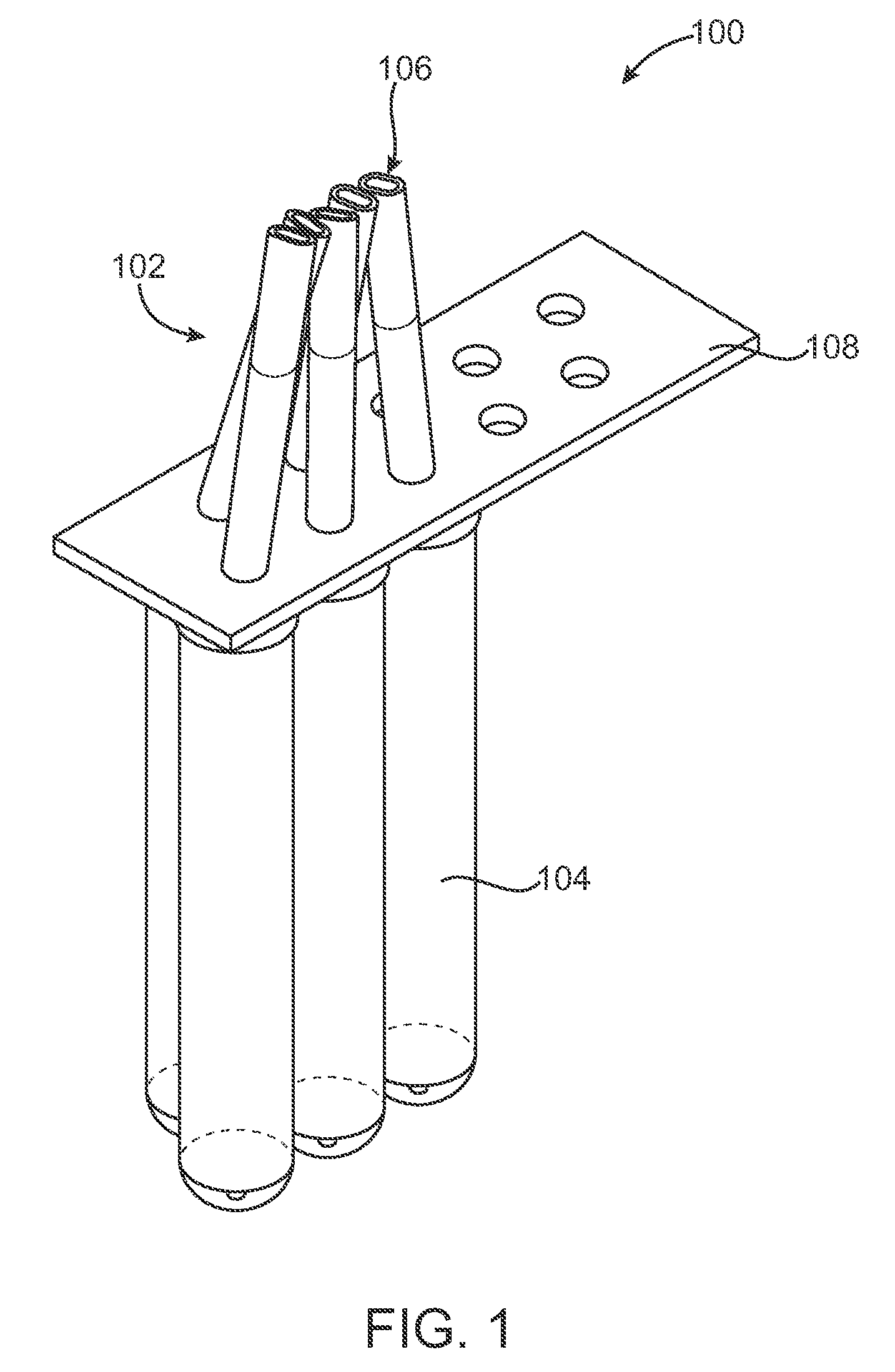

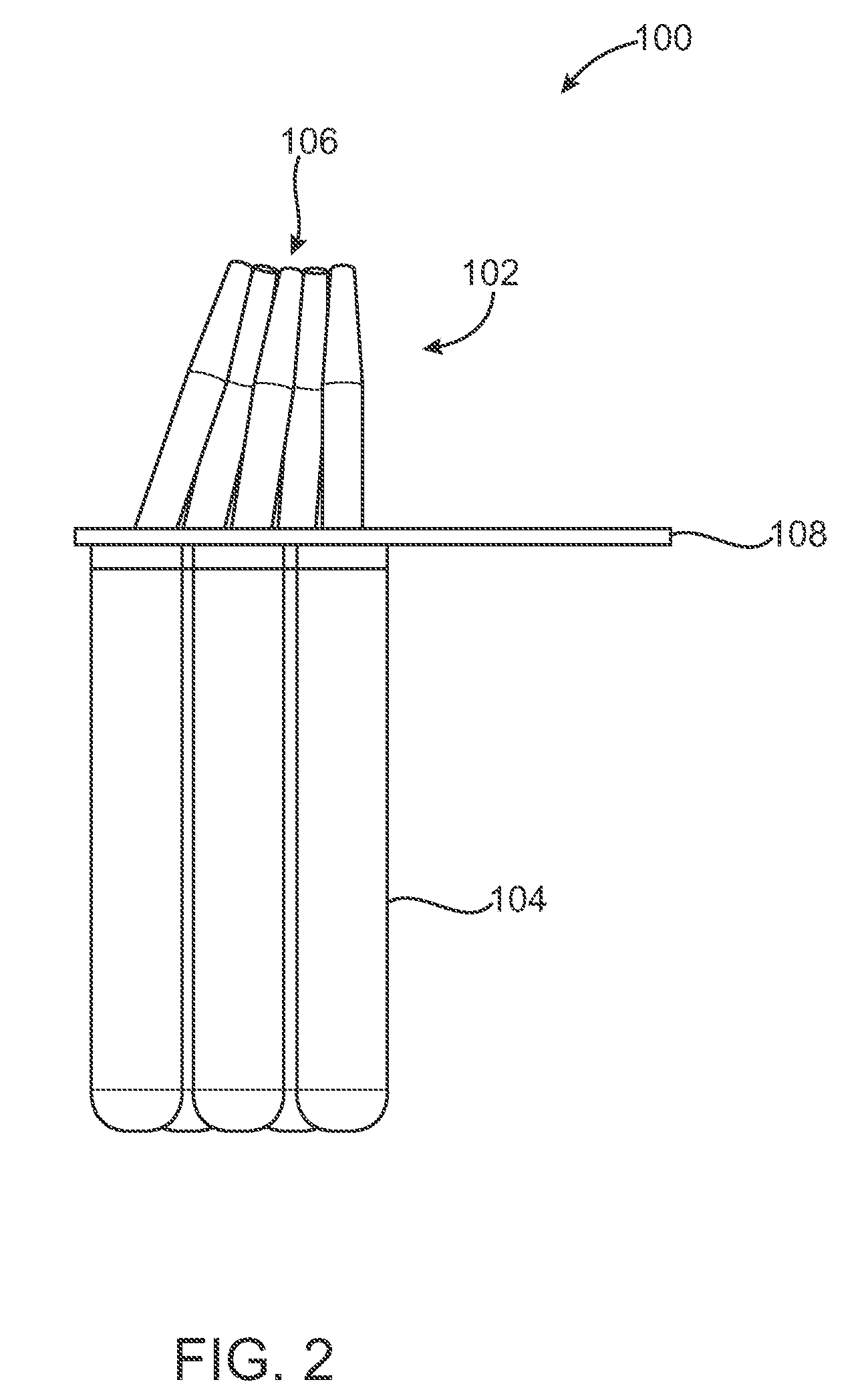

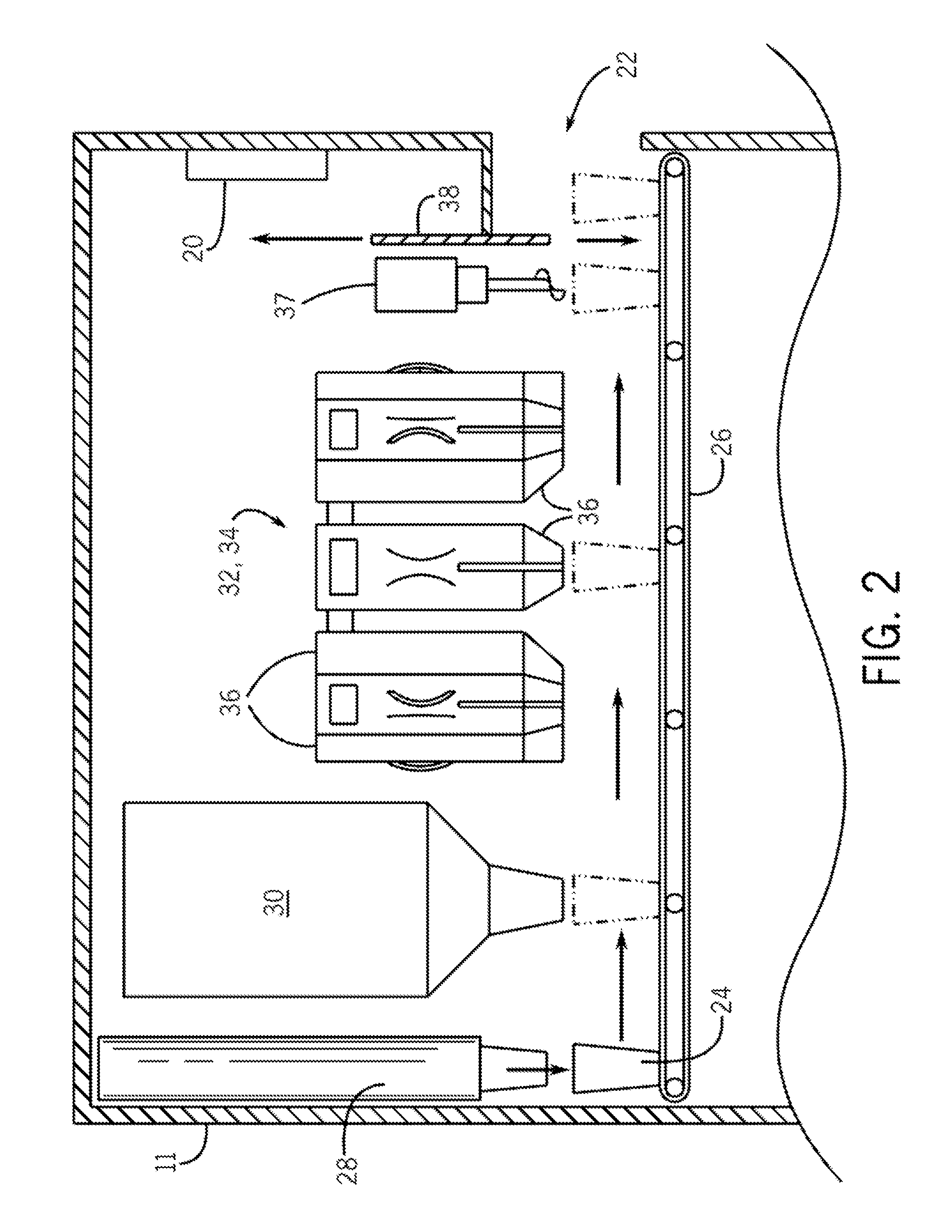

Automated sample handling instrumentation, systems, processes, and methods

The present invention provides a processing station for automatically processing a biological sample, a system for automated real-time inventory control of consumables within a biological sample handling or assay instrument, a high throughput random access automated instrument for processing biological samples, an automated instrument for processing or analysis of a sample, and processes for automated mucoid detection and elimination. Methods of using the disclosed instruments, mucoid detection processes, and systems to process and / or analyze samples are also disclosed.

Owner:GEN PROBE INC

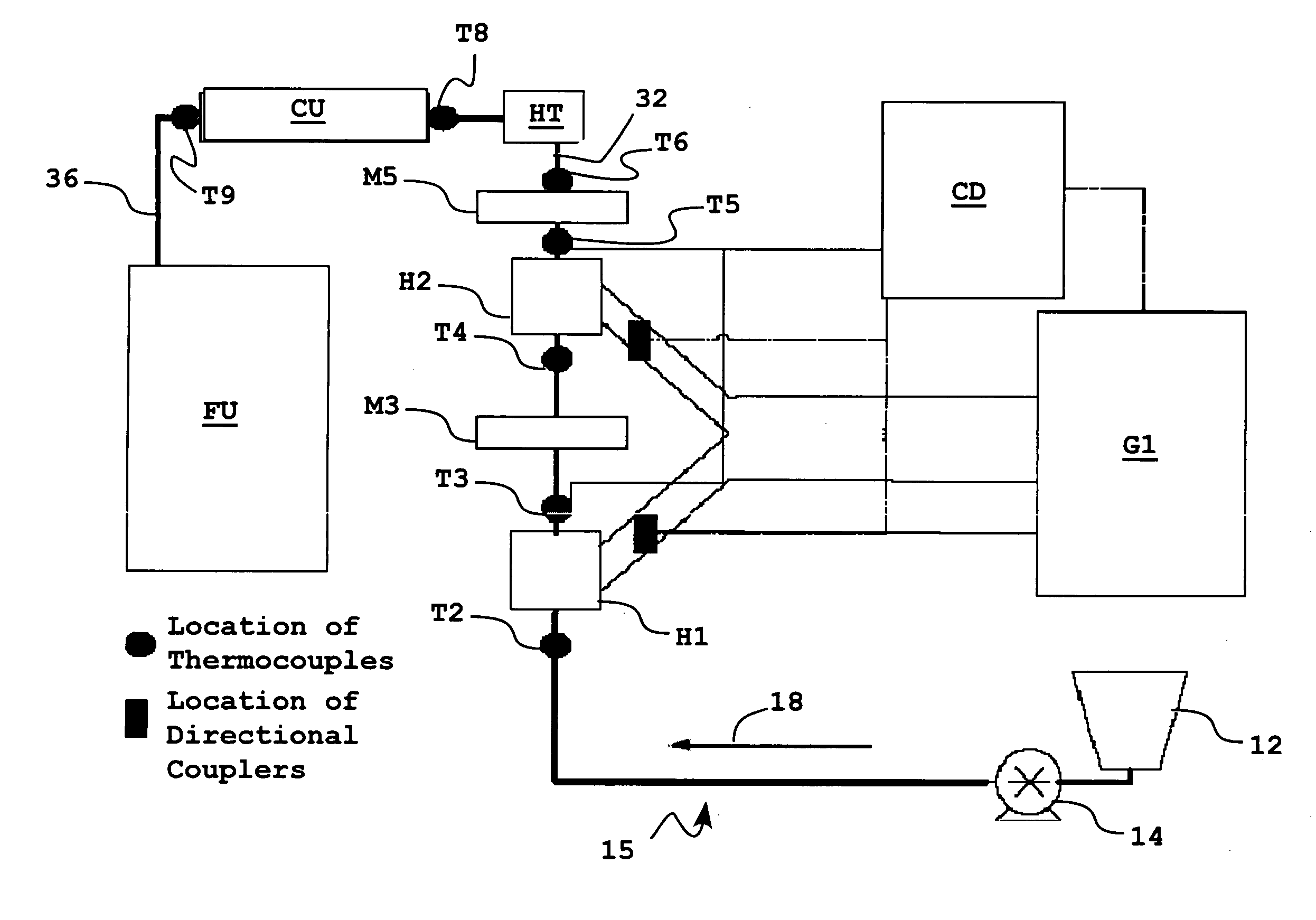

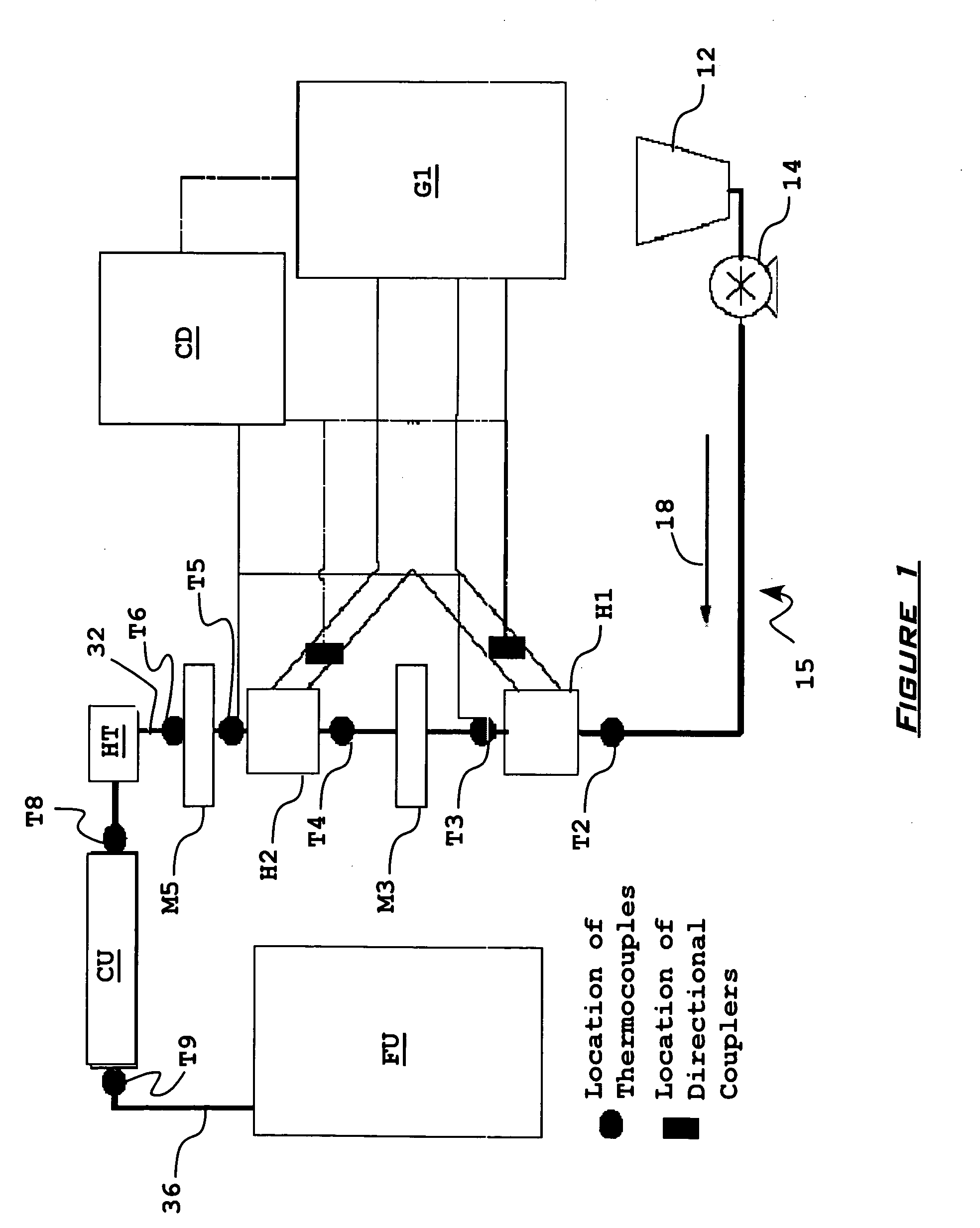

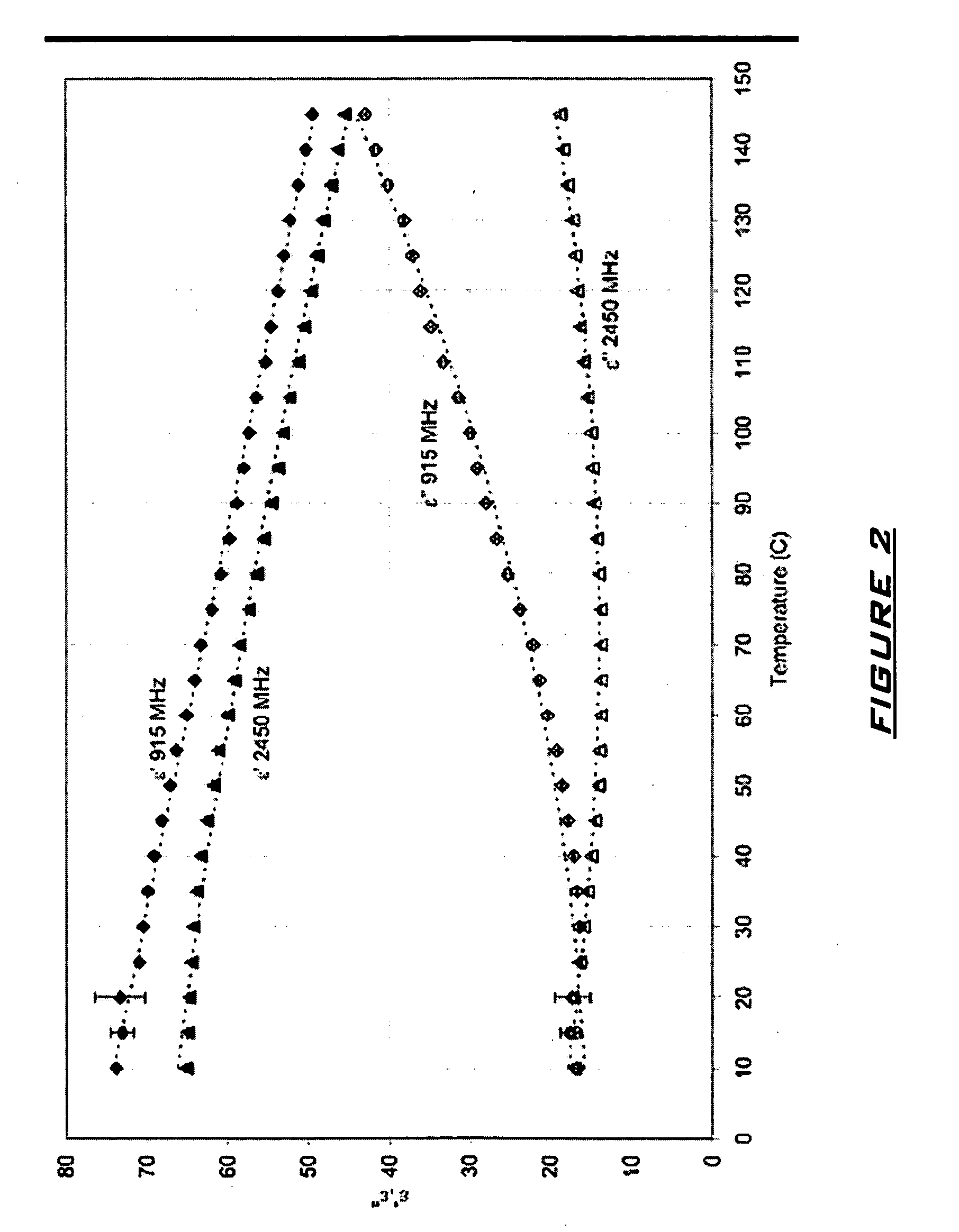

Methods and apparatuses for thermal treatment of foods and other biomaterials, and products obtained thereby

InactiveUS20060151533A1Speed up heat exchangeImproved physical contactOpening closed containersBottle/container closureMedicineContinuous flow

Methods and apparatuses for thermally treating flowable materials using electromagnetic radiation, and foods and materials obtained thereby. Also provided are methods of continuous flow thermal treatment of biomaterials, apparatuses for performing the same, and products prepared using the methods and / or apparatuses.

Owner:SIMUNOVIC JOSIP +6

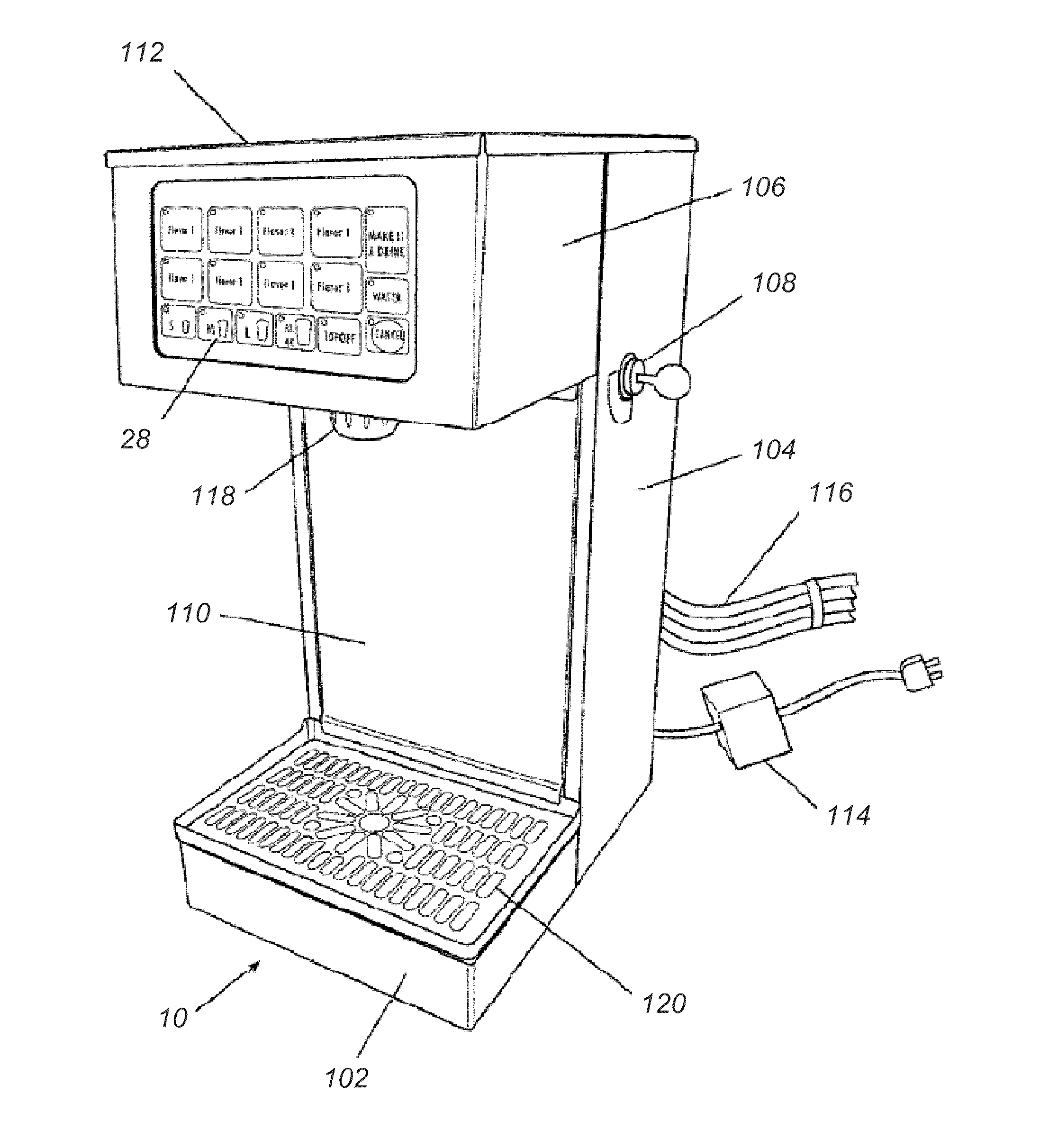

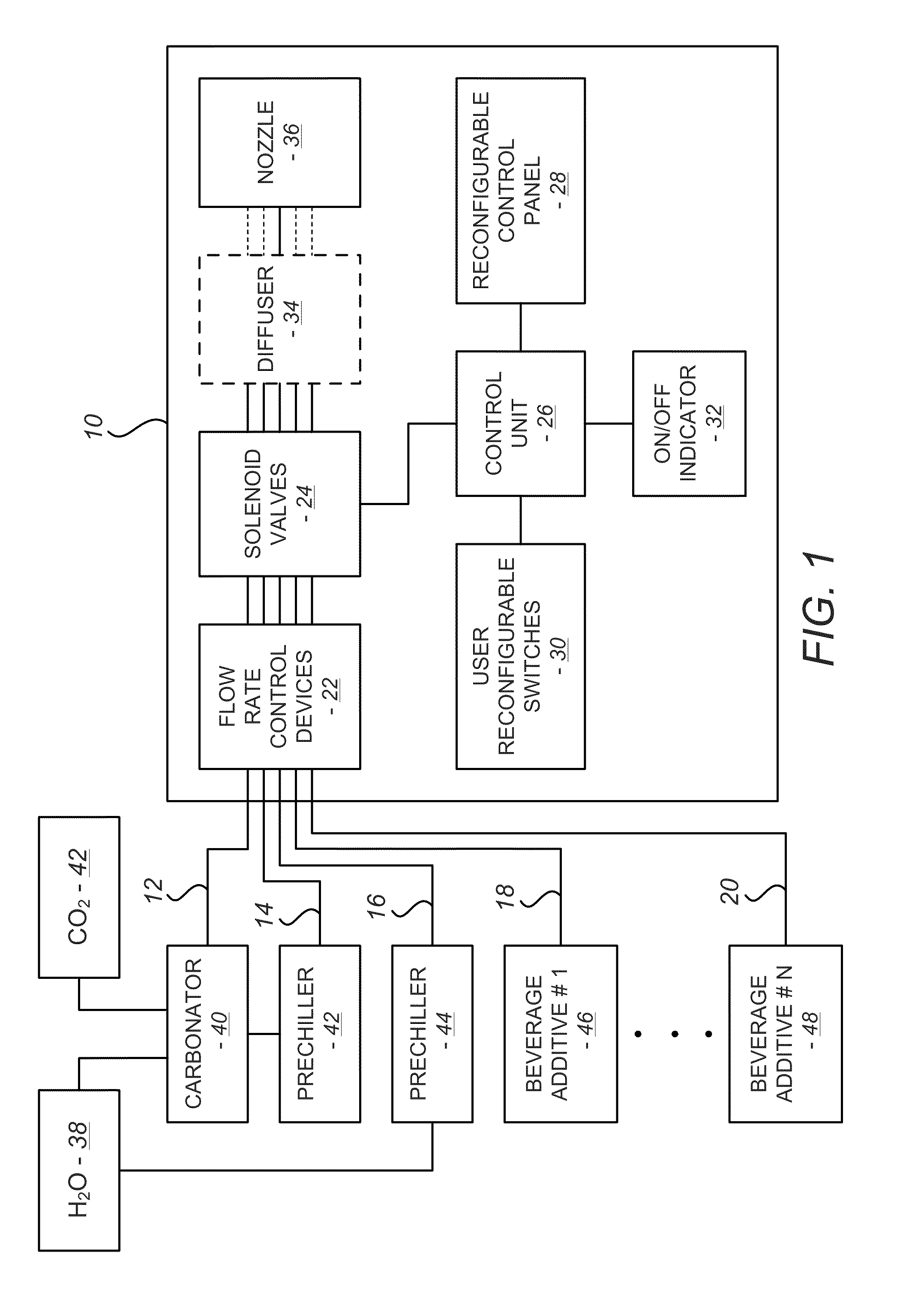

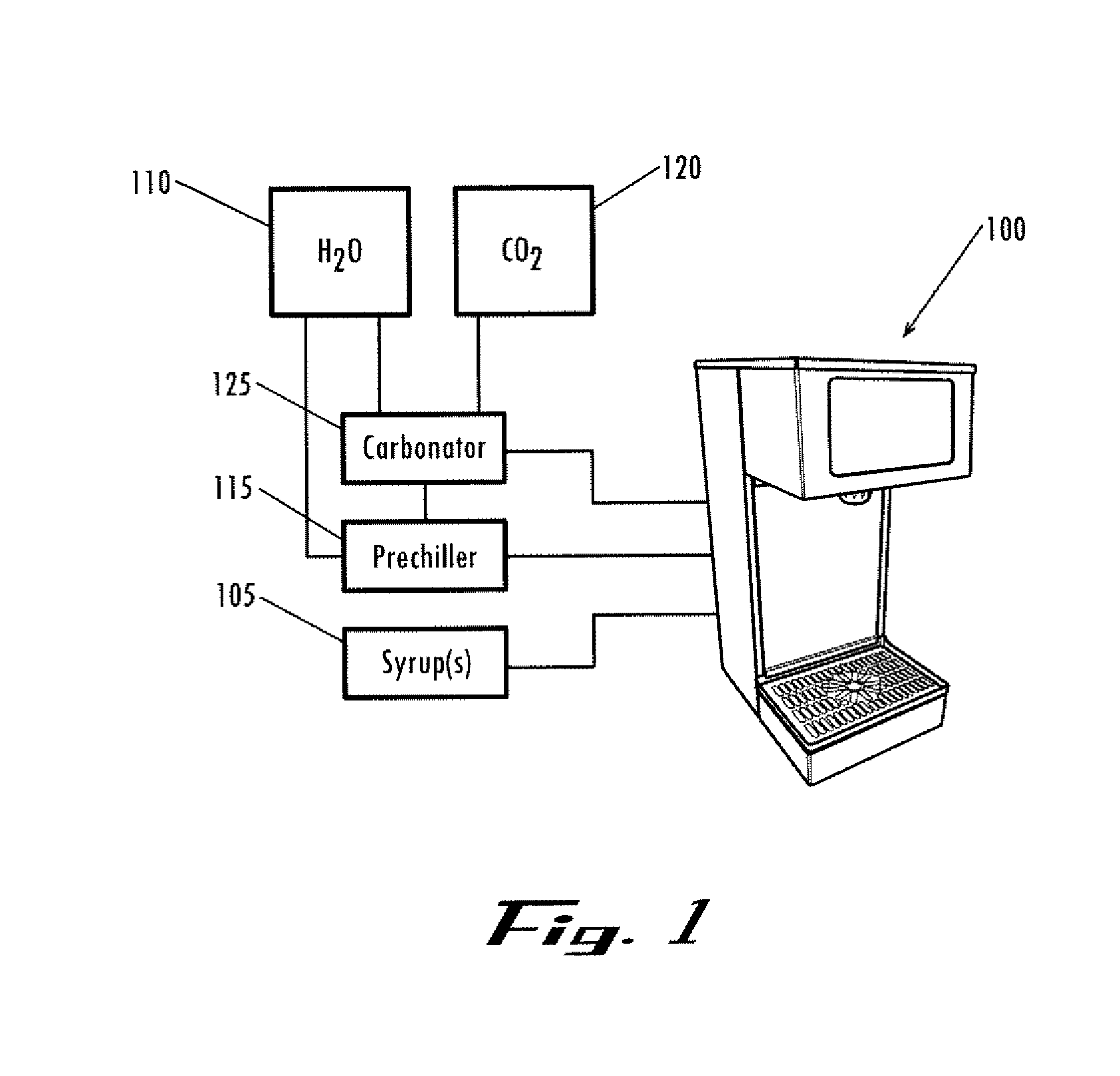

Systems and methods for dispensing flavor doses and blended beverages

ActiveUS20070114244A1Small footprintRich varietyOpening closed containersBottle/container closureUser inputFlavouring agent

Disclosed are systems and methods for dispensing flavor doses and beverages. A beverage tower may be provided that has a small footprint and that is capable of dispensing a wide variety of flavor doses and blended beverages. The beverage tower may include a flow control module that controls the flow rate of beverage additives and water through the beverage tower and a switch module that includes a plurality of switches that may be selectively opened and closed to control the flow of beverage additives and water through the beverage tower to a point of dispense. A flavor dose or blended beverage may be dispensed by the beverage tower in accordance with user input that is provided to the beverage tower via a control panel. The user input may specify a desired beverage additive, a desired cup size, and an indication of whether a flavor shot or a blended beverage is desired. Additionally, a user may define and program into the memory of the beverage tower the various flavor doses and blended beverages that are capable of being dispensed by the beverage tower.

Owner:THE COCA-COLA CO

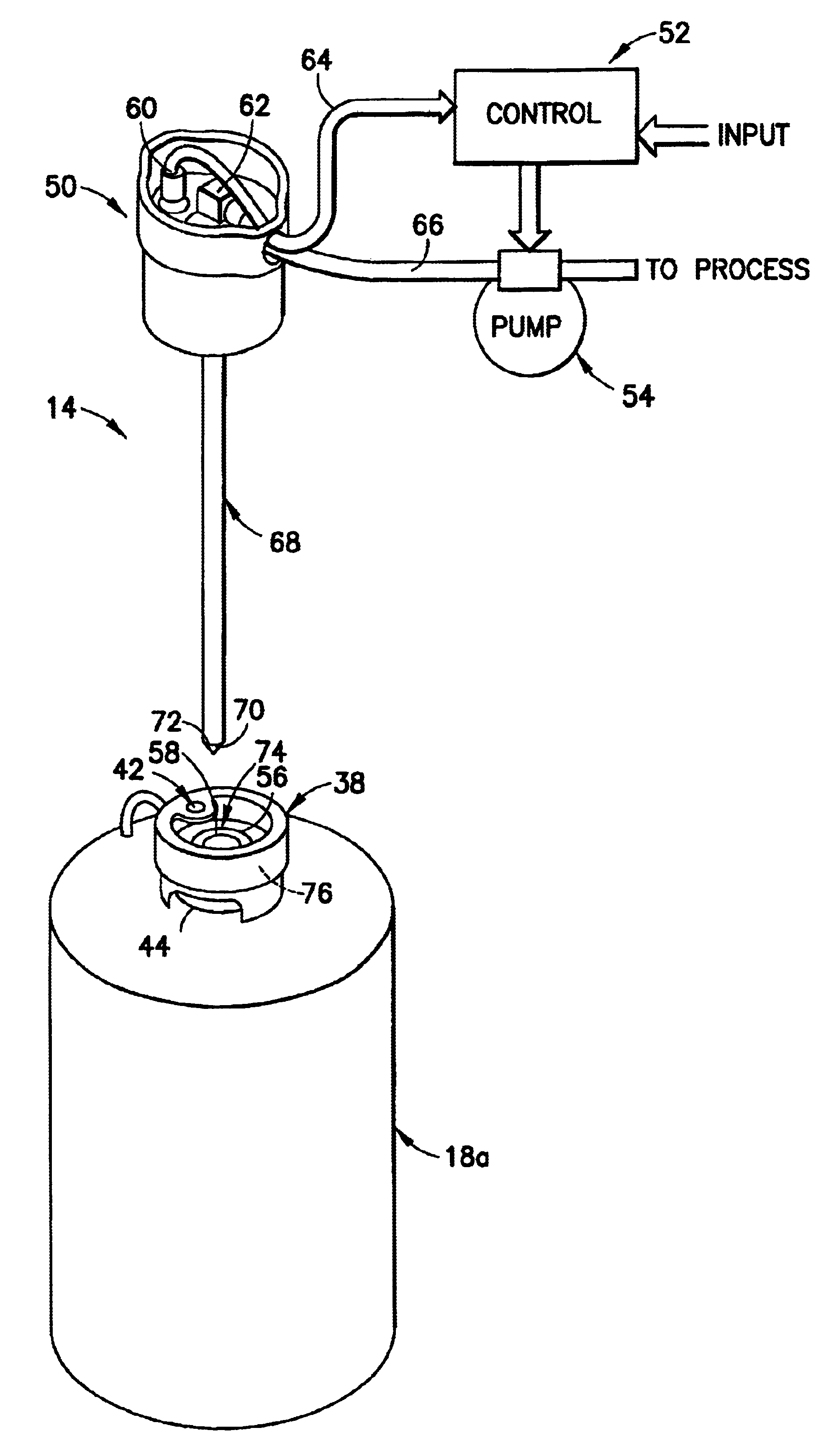

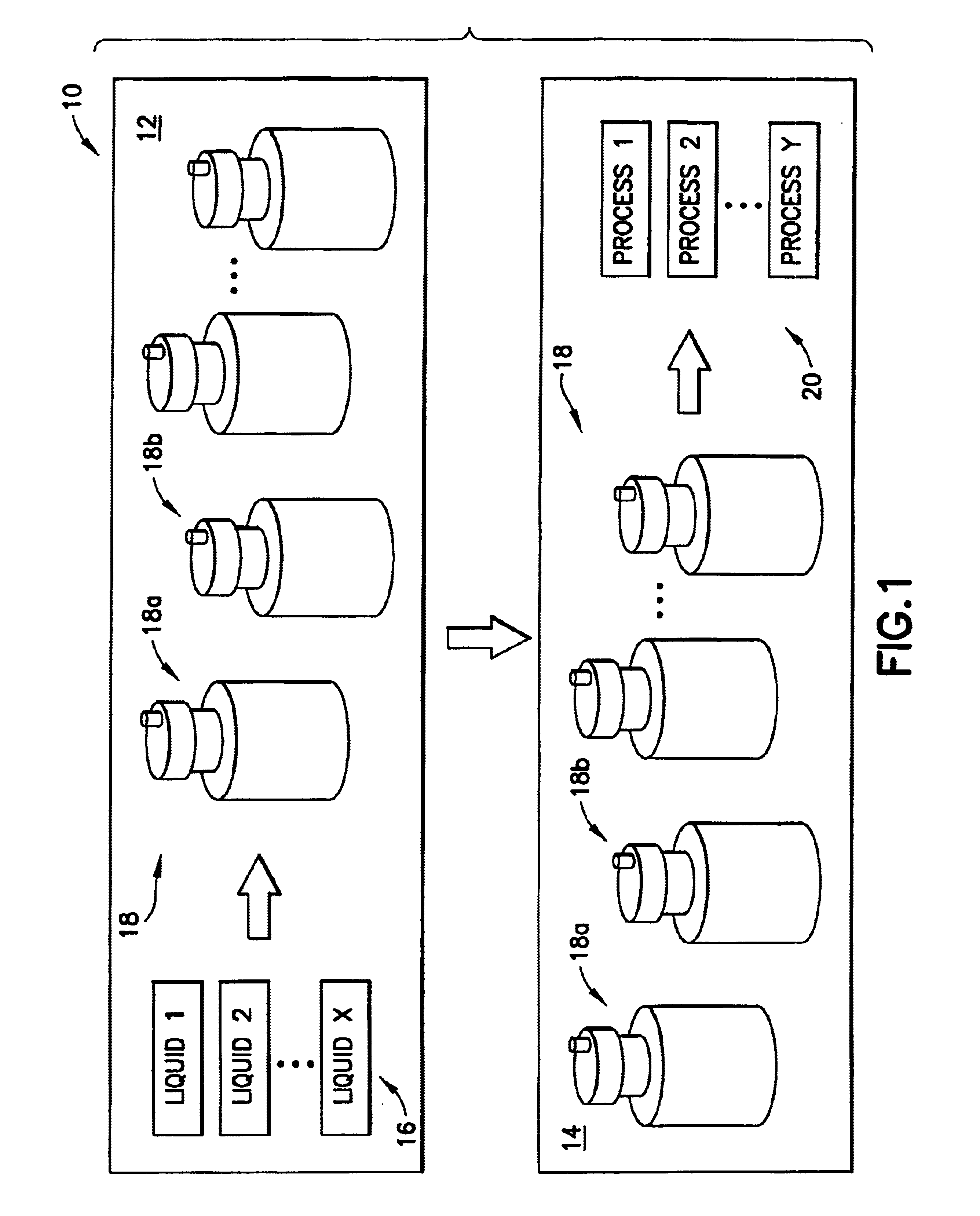

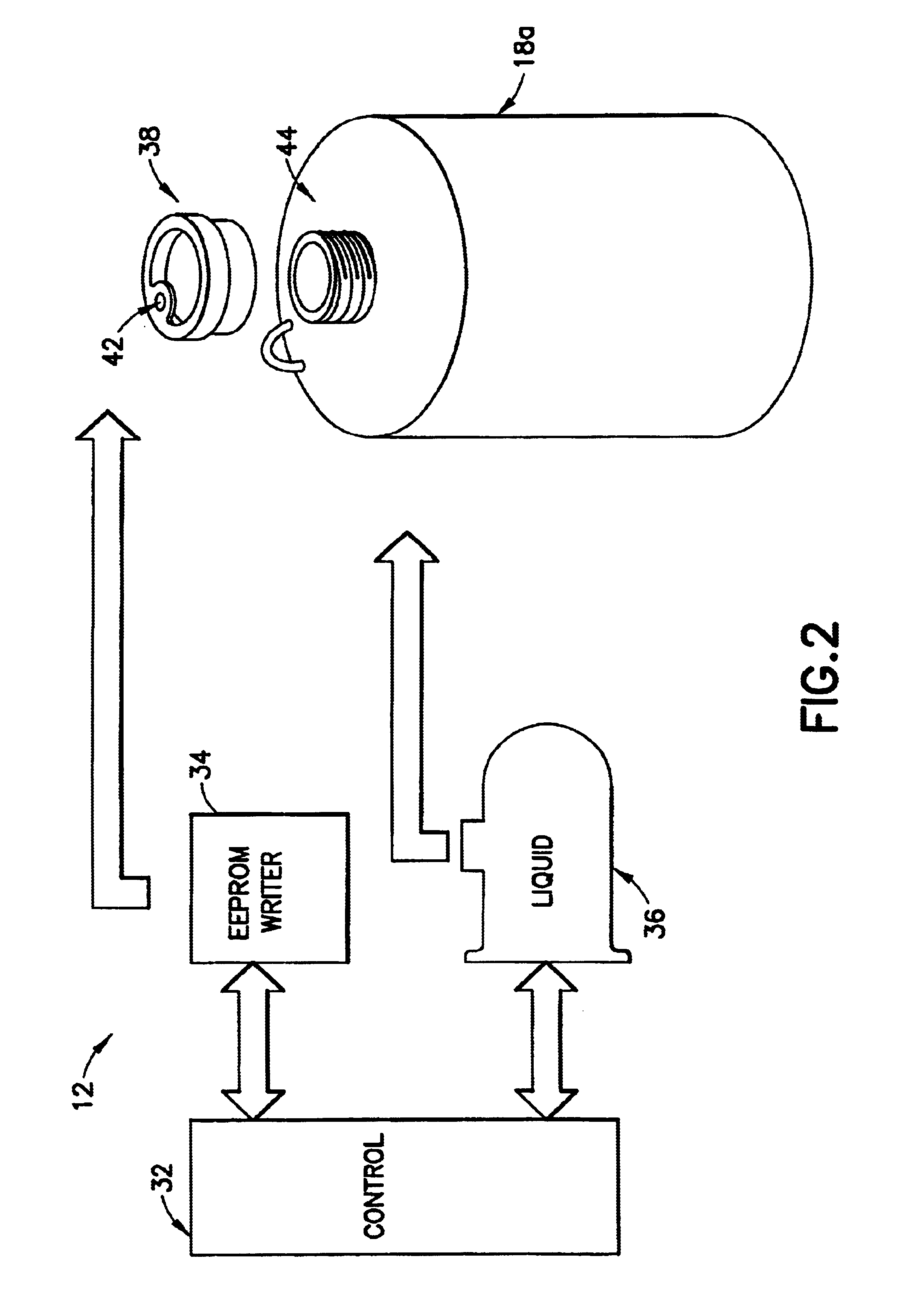

Liquid handling system with electronic information storage

The present invention is a system for handling liquid and a method for the same. The system has a container capable of holding a liquid. An electronic storage device is coupled with the container for electronically storing information relating to the liquid stored in the container. The system also has an antenna, for storing information to and reading information from the electronic storage device. Finally, the system has a microprocessor-based controller, coupled with the antenna, for controlling processing of the liquid based on information read from the electronic storage device by the antenna.

Owner:ENTEGRIS INC

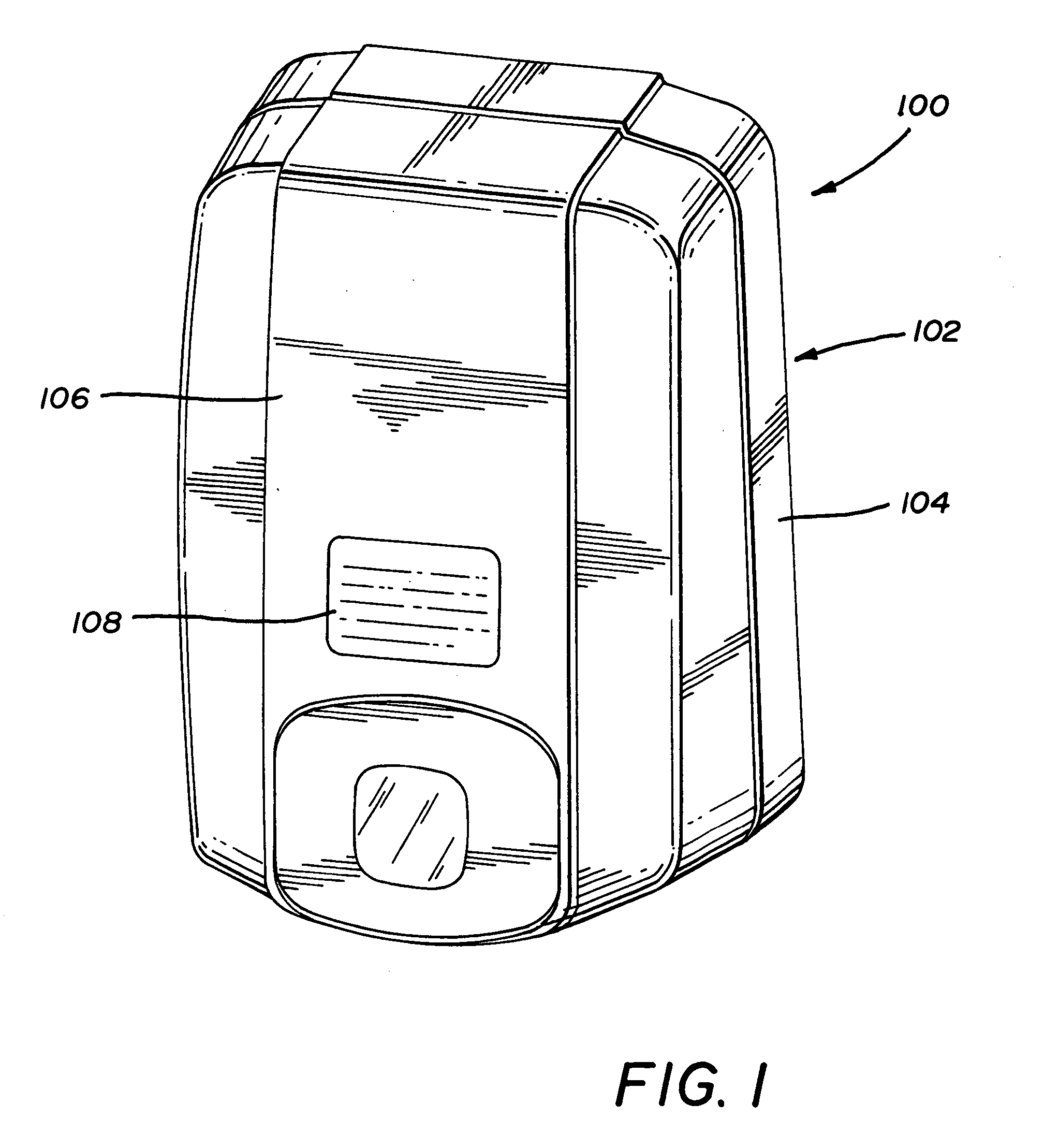

System and method for dispensing soap

InactiveUS6929150B2Smooth rotationEasy to movePower operated devicesLarge containersBiomedical engineeringSOAP

A method of dispensing soap from a fluid dispensing system is disclosed. The method includes the steps of presenting a tube having a tube end disposed at a first position within an indented portion of a spout of the fluid dispensing system, sensing an object below the tube end, in response to sensing the object, expelling said soap from the tube end by drawing the tube end further within the indented portion to a second position, and returning the tube end to the first position.

Owner:RUBBERMAID COMMERCIAL PRODUCTS

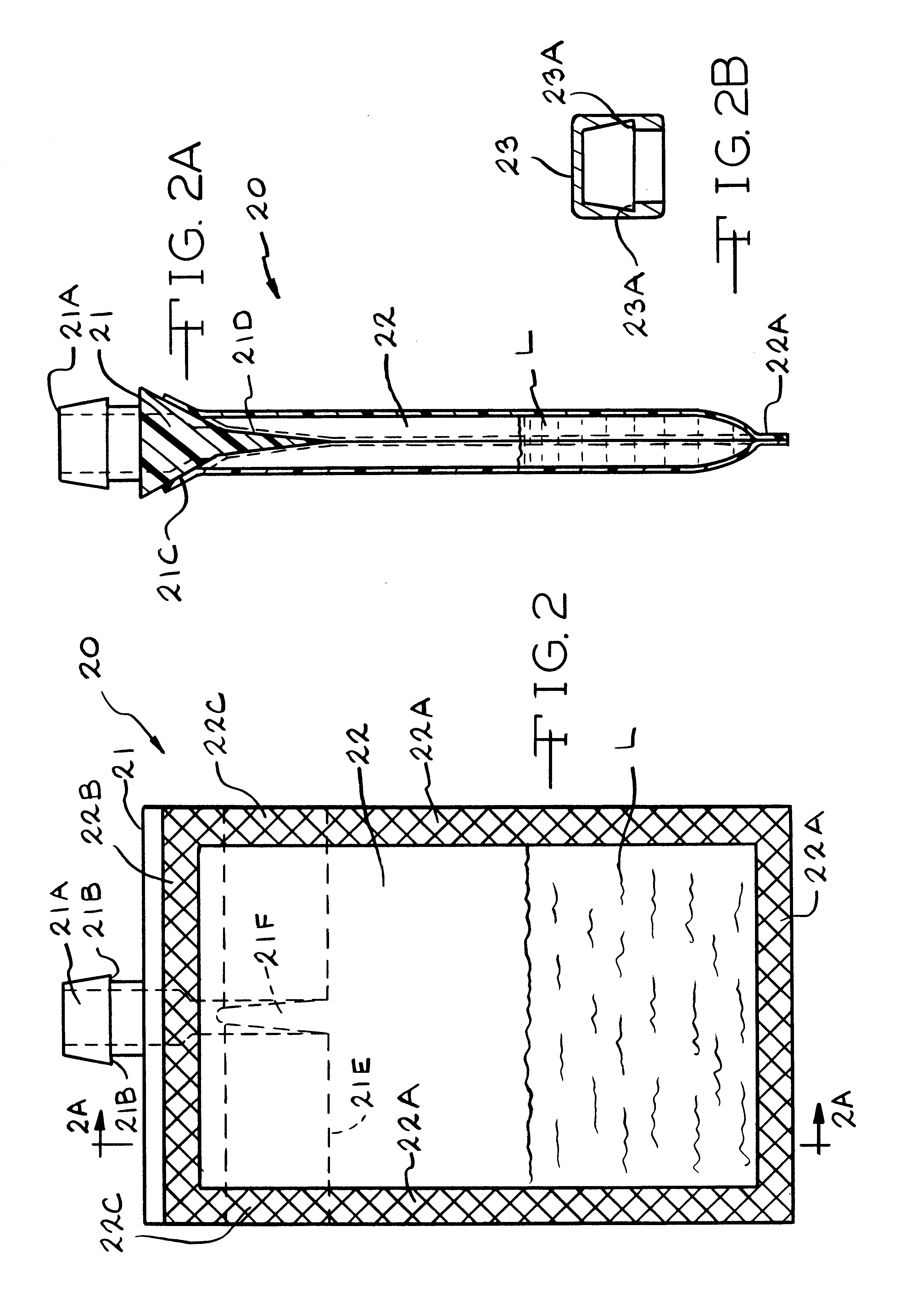

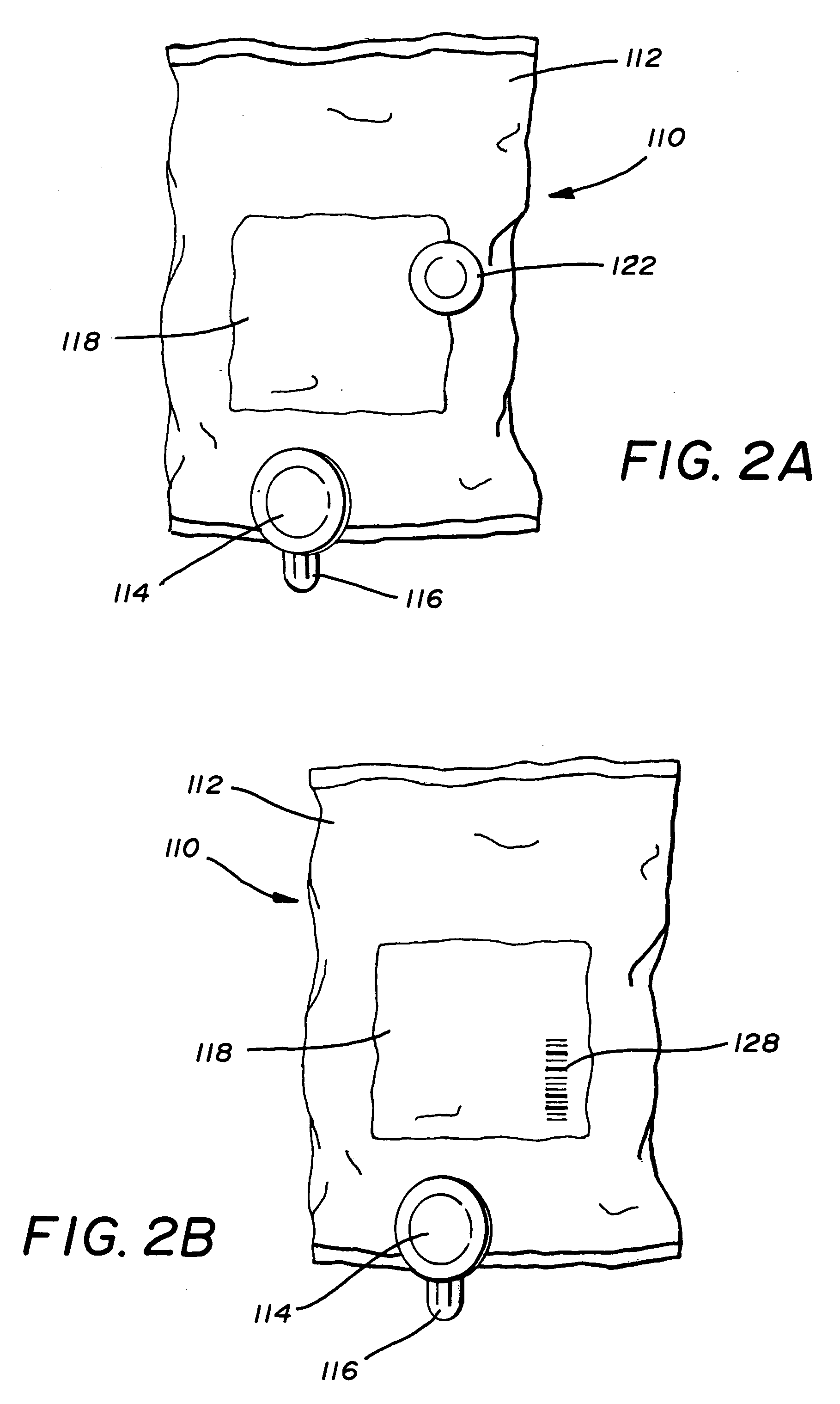

Material storage and dispensing packages and methods

InactiveUS20090212071A1Solve the lack of spaceInhibit productionPower operated devicesShock-sensitive articlesEngineeringParticle generation

Packages and methods for storage and dispensing of materials, e.g., high purity liquid reagents and chemical mechanical polishing compositions used in the manufacture of microelectronic device products, including containment structures and methods adapted for pressure-dispensing of high-purity liquids. Liner packaging of liquid or liquid-containing media is described, in which zero or near-zero head space conformations are employed to minimize adverse effects of particle generation, formation of bubbles and degradation of contained material.

Owner:ADVANCED TECH MATERIALS INC

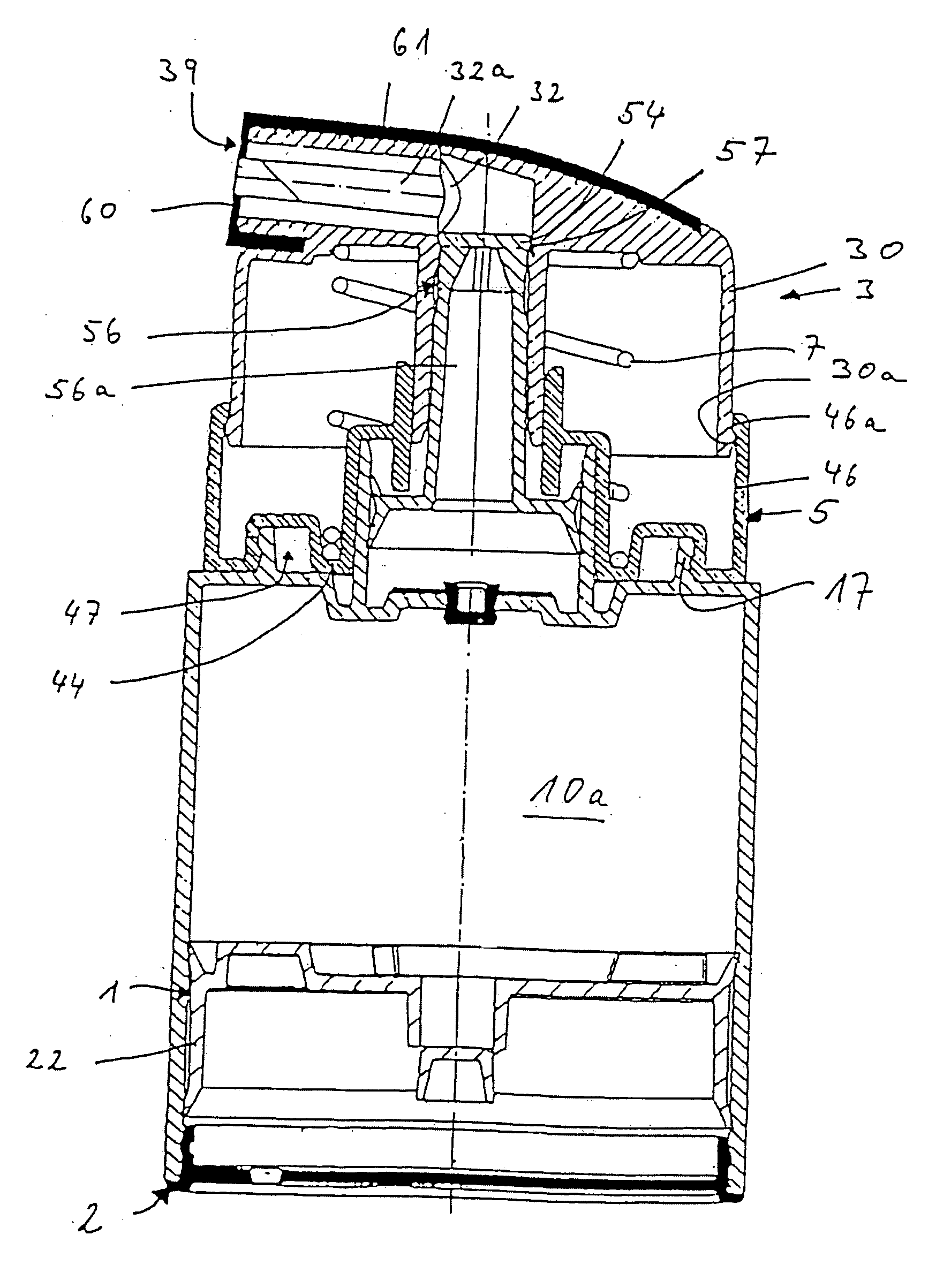

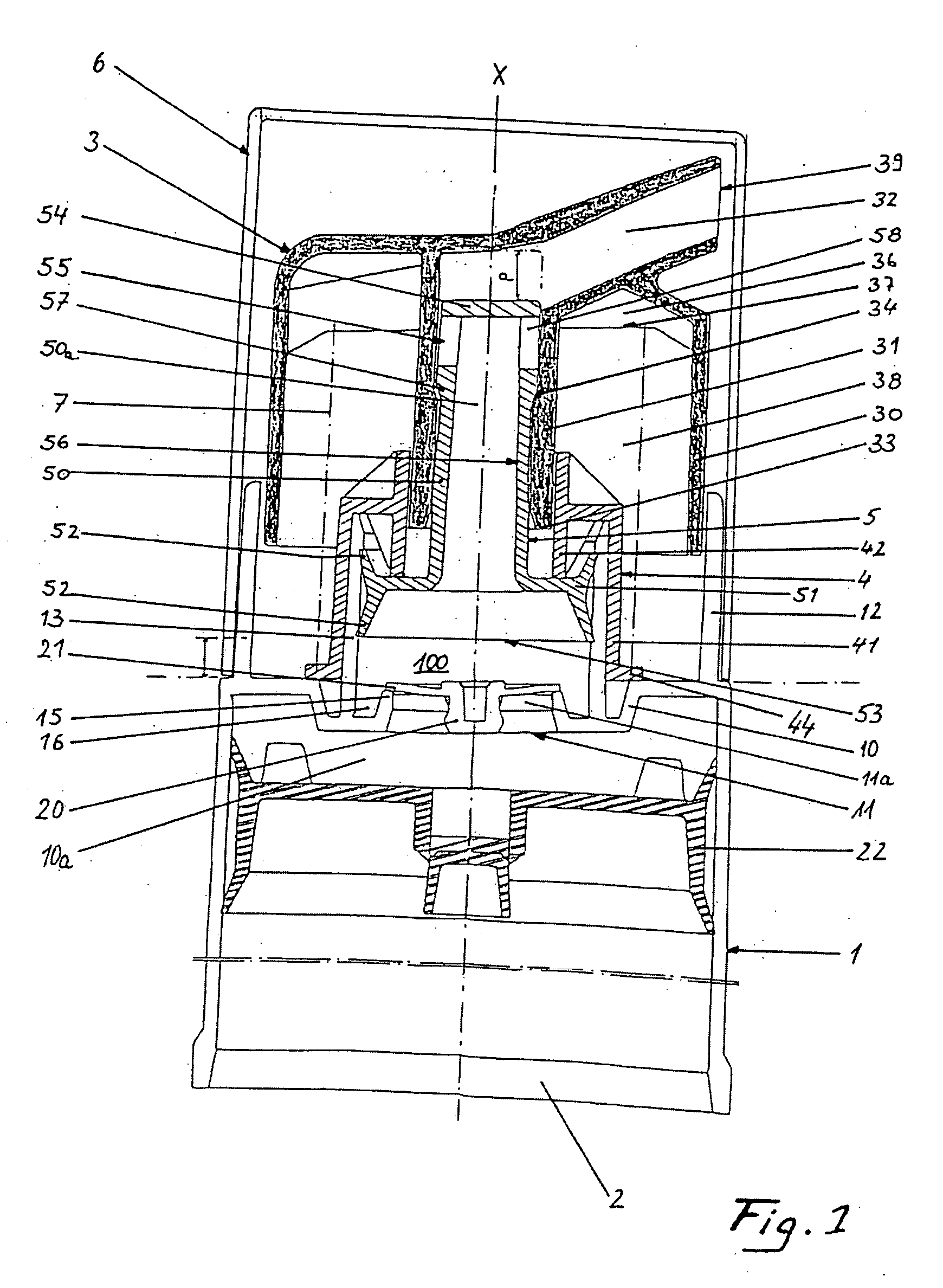

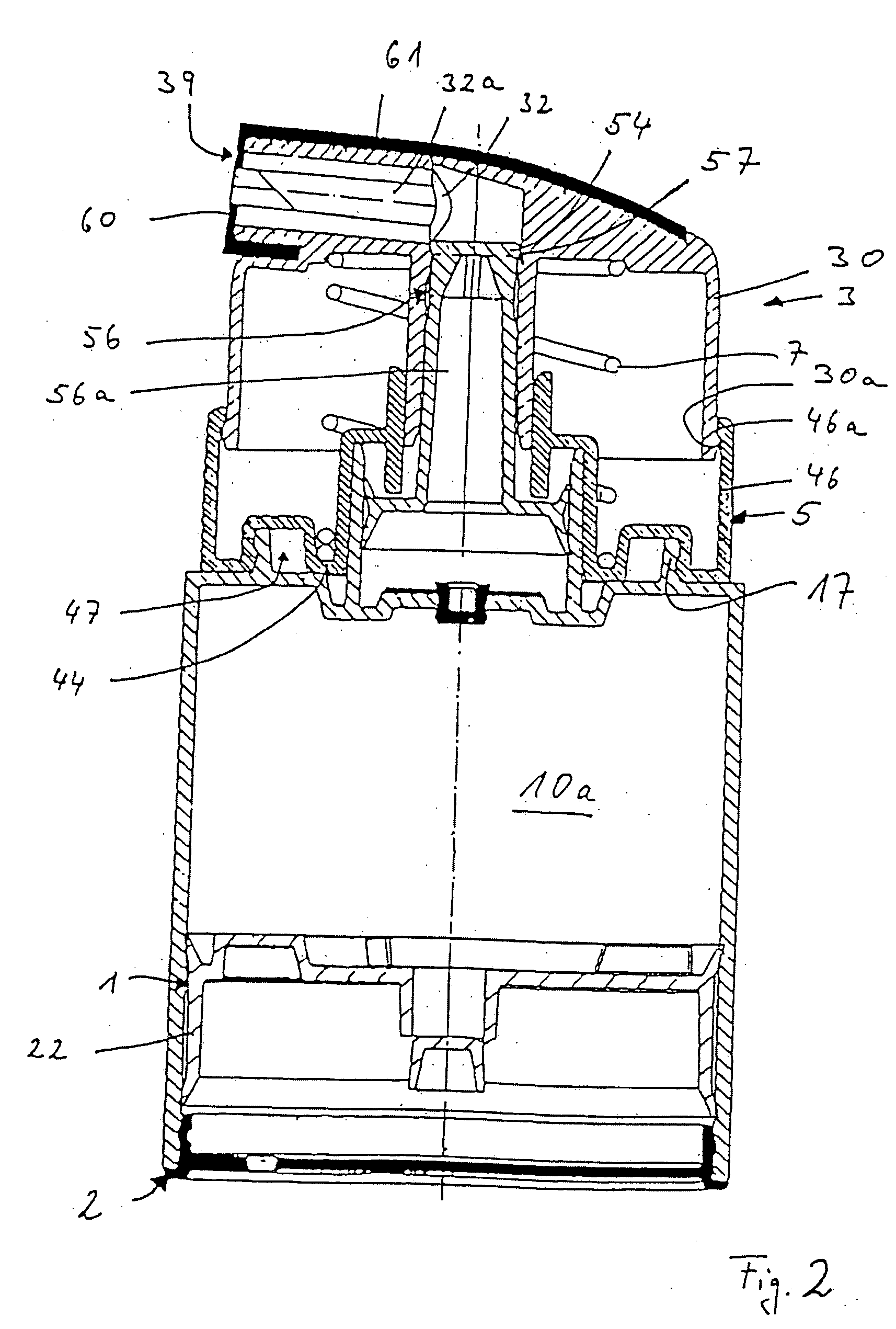

Dispenser and cosmetic or dermatological preparation comprising an auxiliary for use with dispenser

InactiveUS20050189377A1Improves haptic propertyReduce forceCosmetic preparationsPower operated devicesPolyolSURFACTANT BLEND

The present invention is a cosmetic or dermatological preparation for use with a dispenser that includes an auxiliary to keep the dispenser operating smoothly. The auxiliary is selected from the group consisting of (i) polyols having 2 to 6 carbon atoms and 2 to 6 hydroxyl or alkoxy groups and (ii) surfactants that reduce the surface tension of the preparation to less than 30 mN / m. The preparation is particularly suitable with a dispenser comprising a container and an inner container wall for housing a cosmetic or dermatological preparation; a follow-up plunger on a base side of the dispenser, which is capable of being slidably displaced on the inner container wall under the pressure of the ambient atmosphere; a head section on a top end of the dispenser that can be slidably displaced in relation to the container and that comprises a dispensing channel, the dispensing channel capable of being connected in a communicating manner to the container; a manually actuable delivery device comprising a variable-volume delivery chamber, a delivery element that can be displaced longitudinally in relation to the container and the head section, comprising a delivery plunger that can be slidably displaced within the delivery chamber and a delivery stem connected to the delivery plunger, and a delivery channel circumferentially enclosed by the delivery stem and comprising a delivery-channel inlet opening communicating with the delivery chamber and a delivery-channel outlet opening. The delivery channel outlet opening is capable of being moved into an open position relative to the dispensing channel by displacing the delivery element.

Owner:BEIERSDORF AG

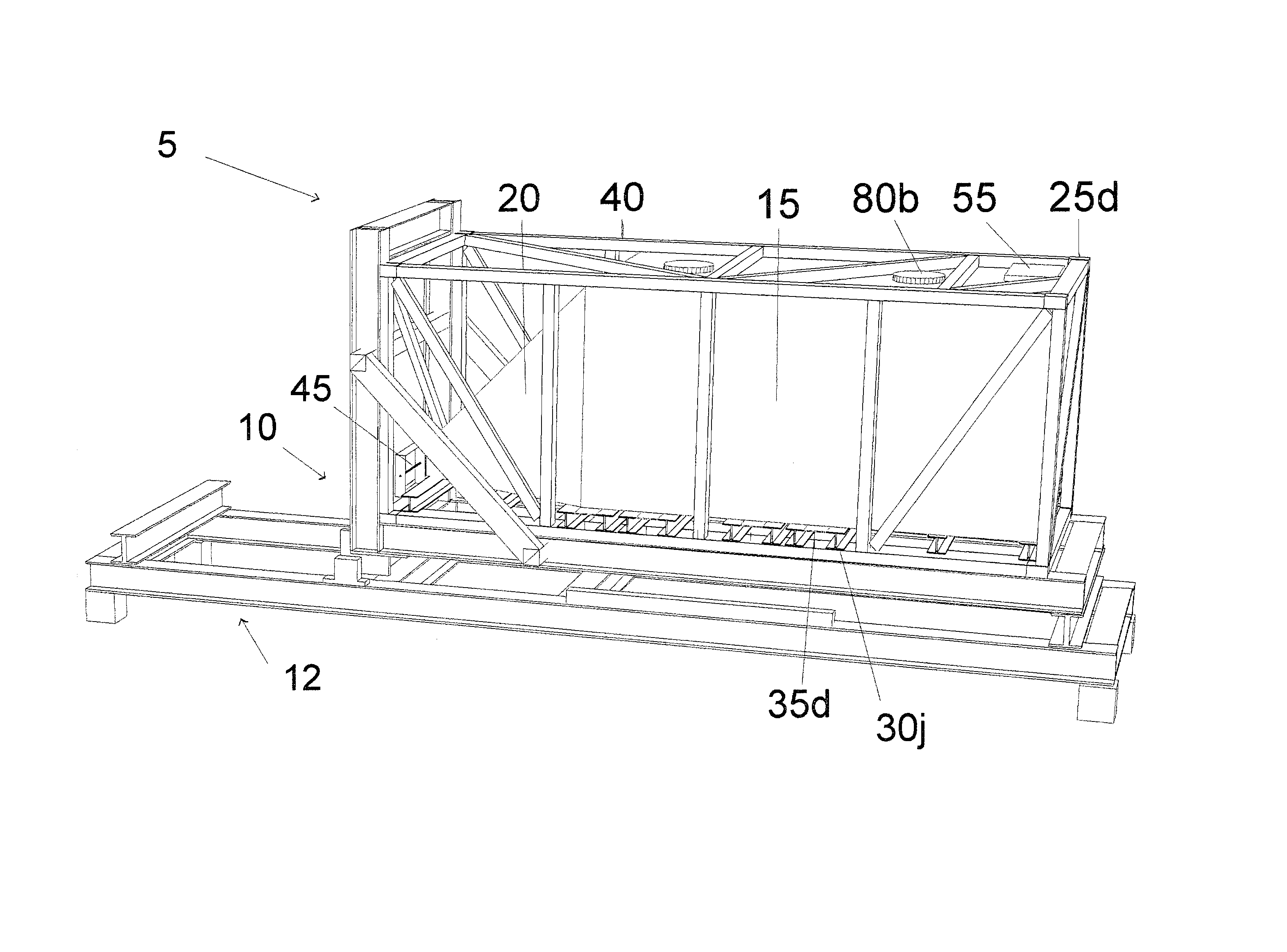

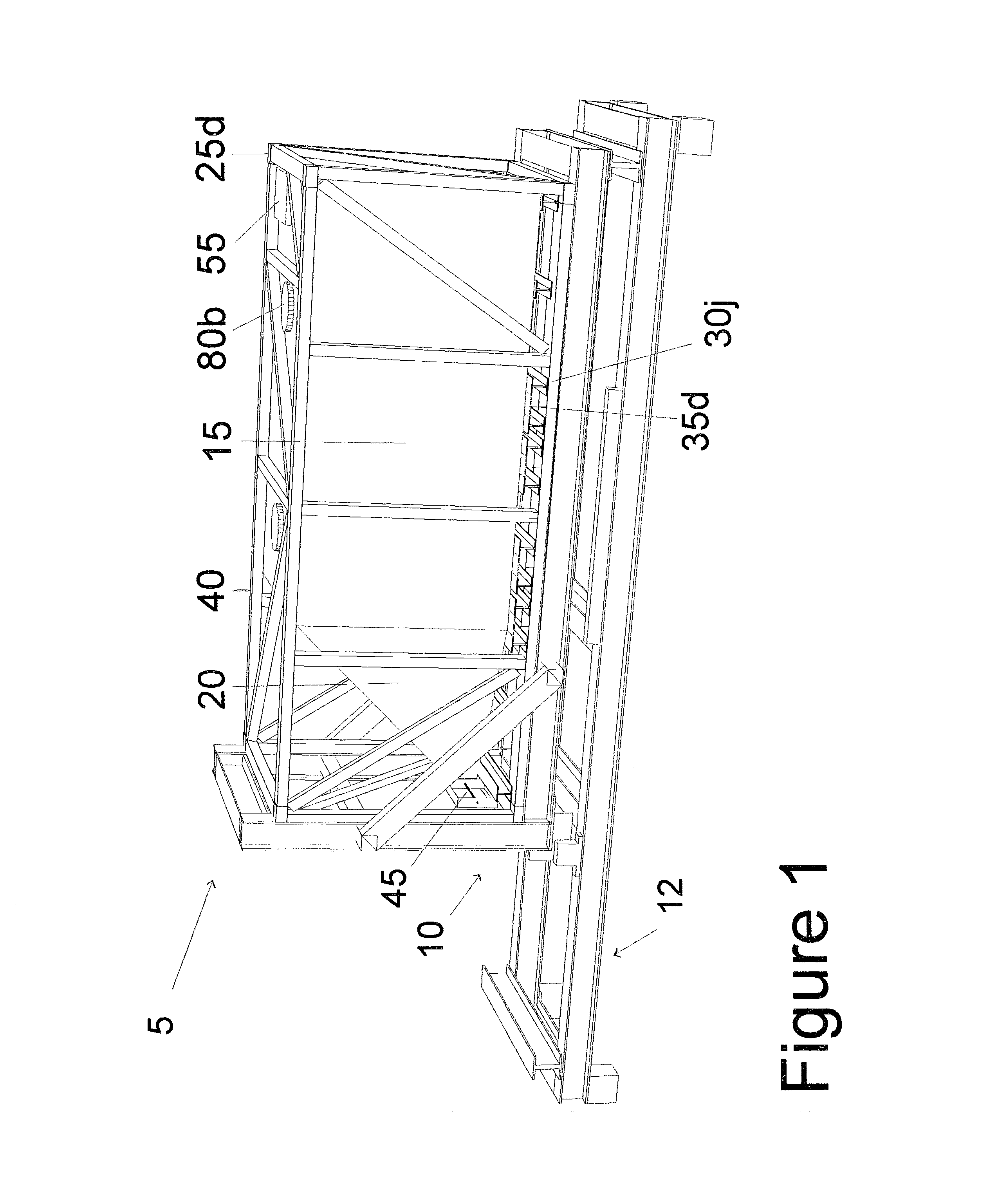

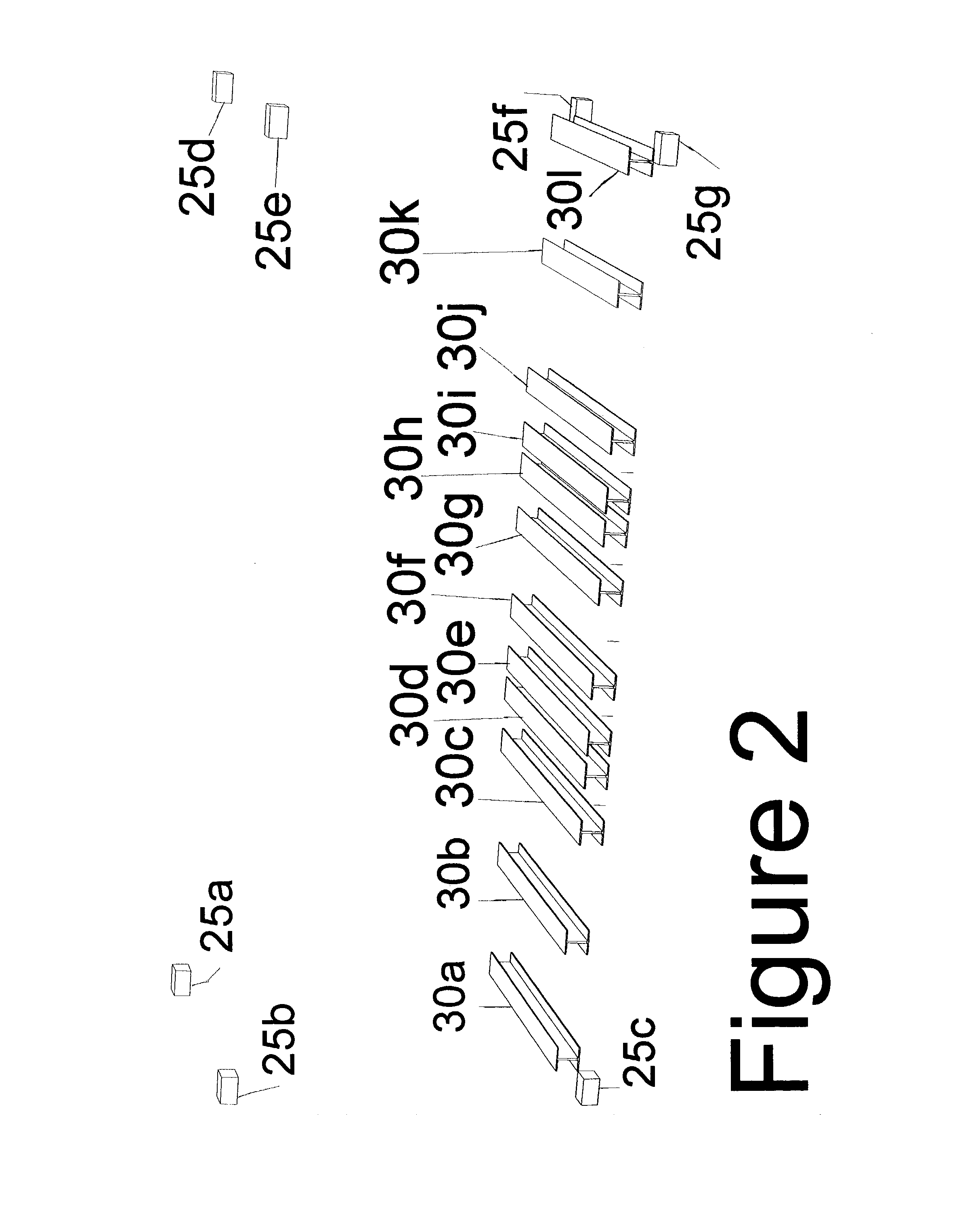

Intermodal bulk dry particulate cargo container and method

A method for loading and unloading of dry bulk freight containers vertically, and a device in the form of an improved intermodal dry bulk freight container for vertical loading and unloading. Standardized corner locks may be used and dimensions may be selected so as to provide a standardized cargo container.The present invention teaches that an intermodal dry bulk freight container may be loaded in either the customary horizontal orientation of such devices, or in a vertical orientation in which one end is opened and elevated. In particular, however, such a container may advantageously be emptied by elevating it into the vertical orientation. The method of the invention is thus to provide only a single hopper and yet allow one hopper to empty the entire container, as well as providing a more efficient gravity feed of bulk cargo as it is off loaded.The present invention furthermore teaches an intermodal dry bulk freight container suitable for this method of operation. In the presently preferred embodiment, the container is loaded conventionally via hatches on the top of the container when it is in a horizontal orientation, but is unloaded via a single hopper located at the lower end when the container is raised into the vertical orientation.

Owner:LE ROY CURTIS W

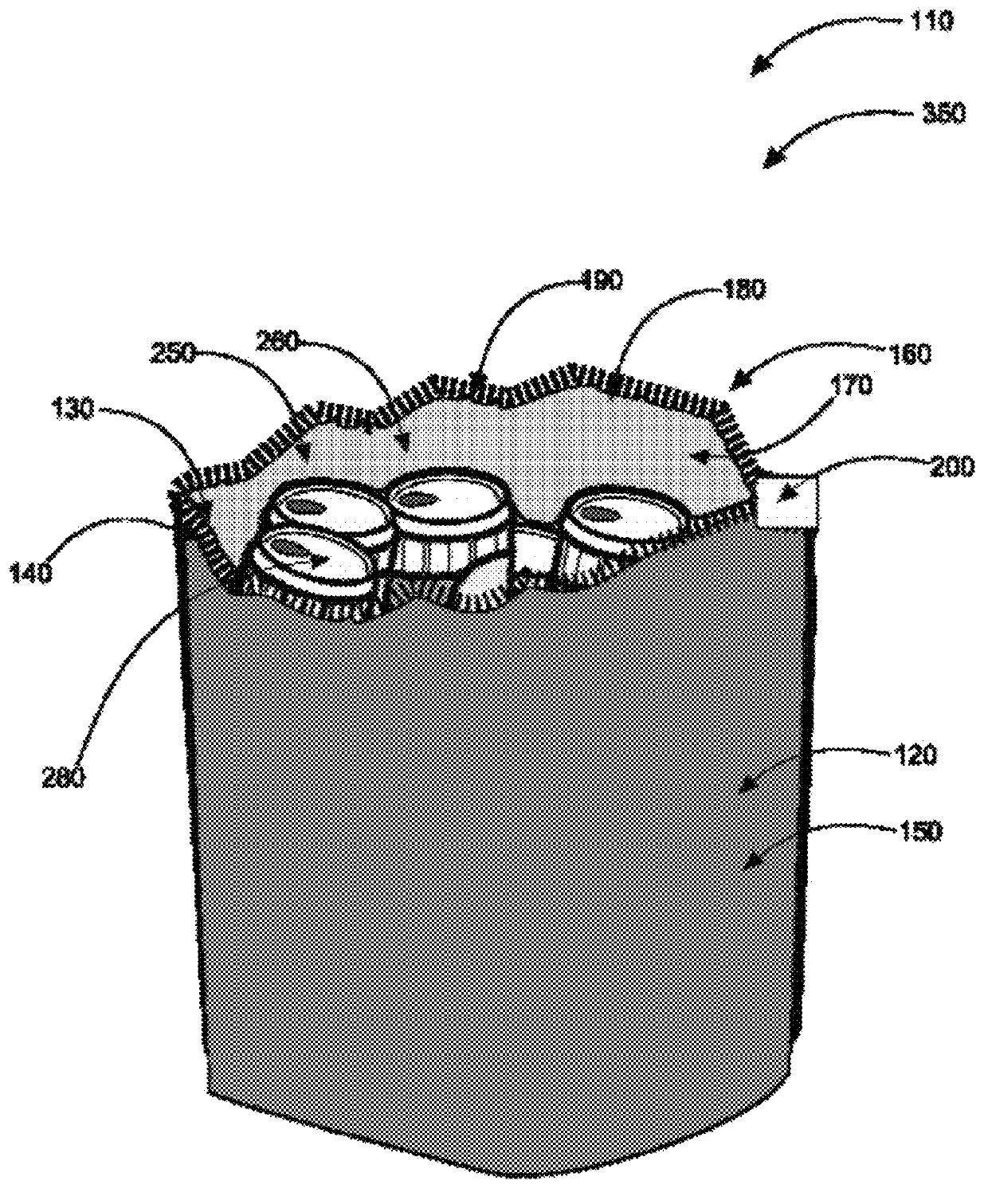

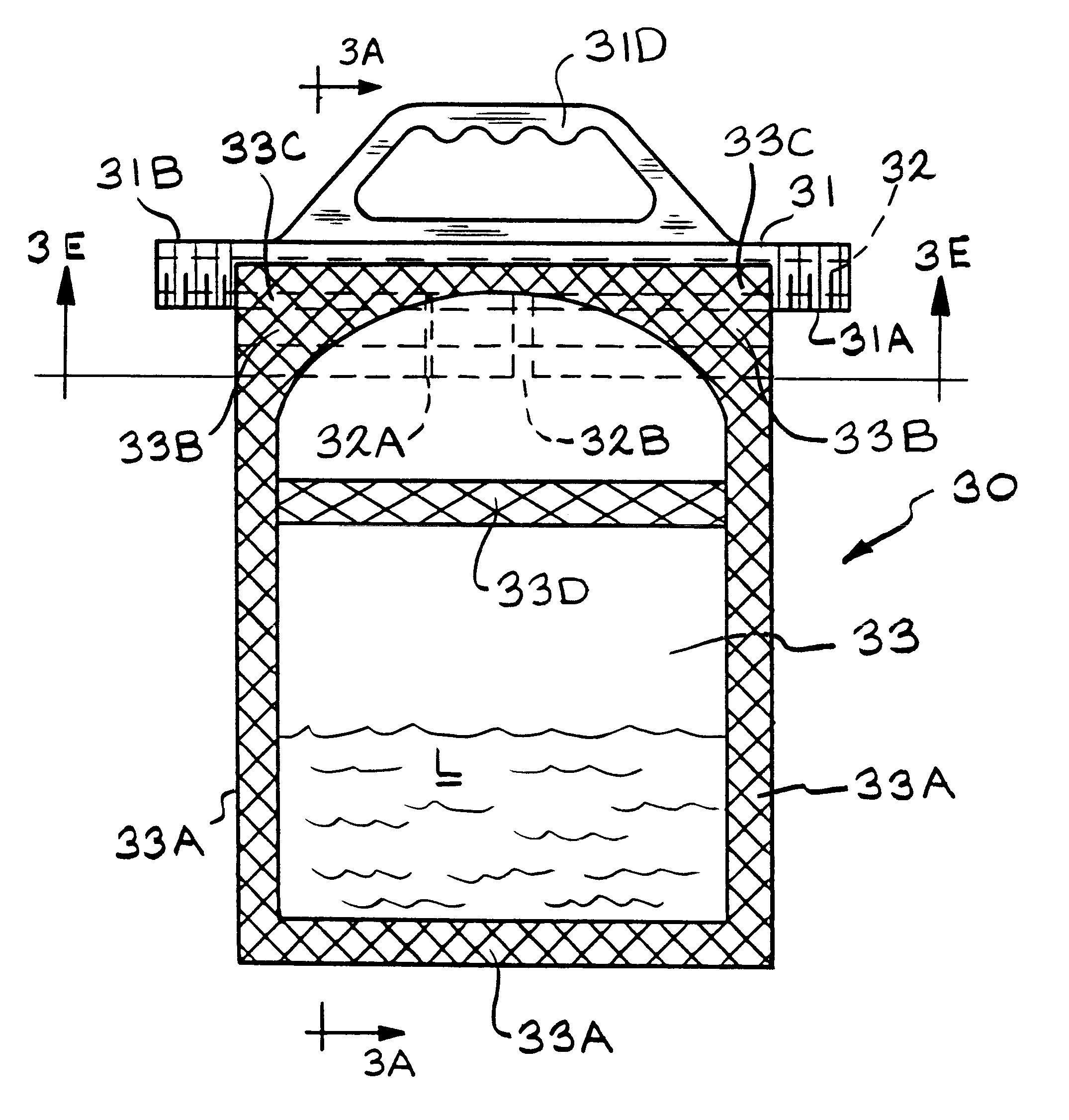

Cool bags systems

A reusable insulated flexible cooler bag comprising: a front wall having a first inner layer, at least one first insulating layer, and a first outer layer of plastic material; a rear wall having a second inner layer, at least one second insulating layer, and a second outer layer of plastic material; and a closure element. The front wall and the rear wall are joined together at their peripheral edges so as to create a pocket-like configuration with an inner volume. The closure element is able to close the pocket-like configuration to substantially ensure an airtight and watertight seal of the inner volume of the reusable insulated flexible cooler bag and is located adjacent a top side of the reusable insulated flexible cooler bag in order to provide access to contents of the reusable insulated flexible cooler bag.

Owner:GILLIS BRENDA

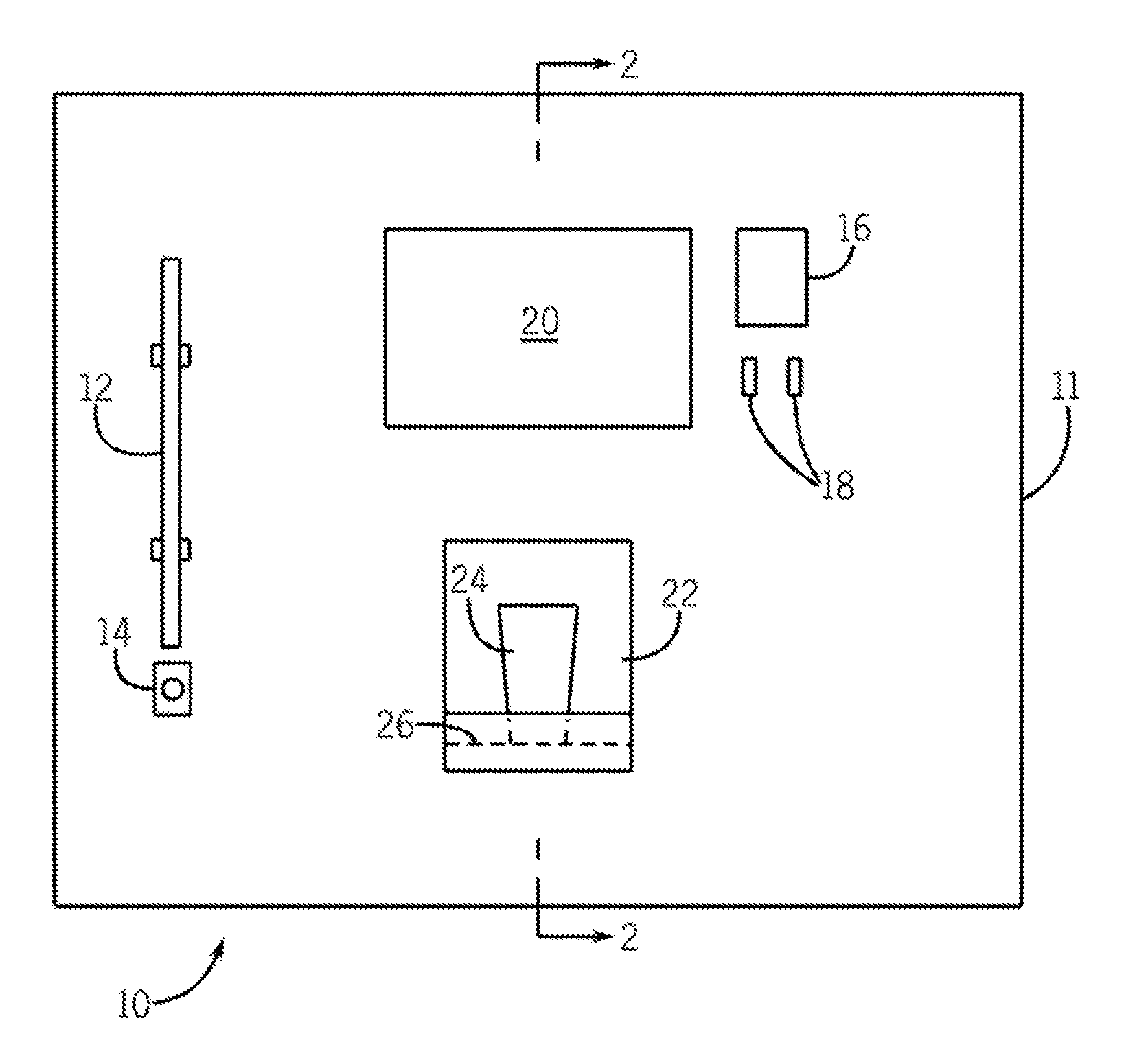

Multi-way sorter system and method

ActiveUS8753573B2Avoid pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsCell sorterEngineering

Provided herein are improved multi-way cell sorter systems and methods. For example, provided are systems and methods for the collection of cells that are sorted in multiple directions. The systems and methods allow for the construction of a multi-way sorter (e.g., a ten-way sorter in the space that currently only allows four-way sorting). In addition the device may actively sense the arrival of drops (with cells of interest) at a sample tube, and trigger an alarm when the drops' arrivals deviate from an expected pattern.

Owner:BECTON DICKINSON & CO

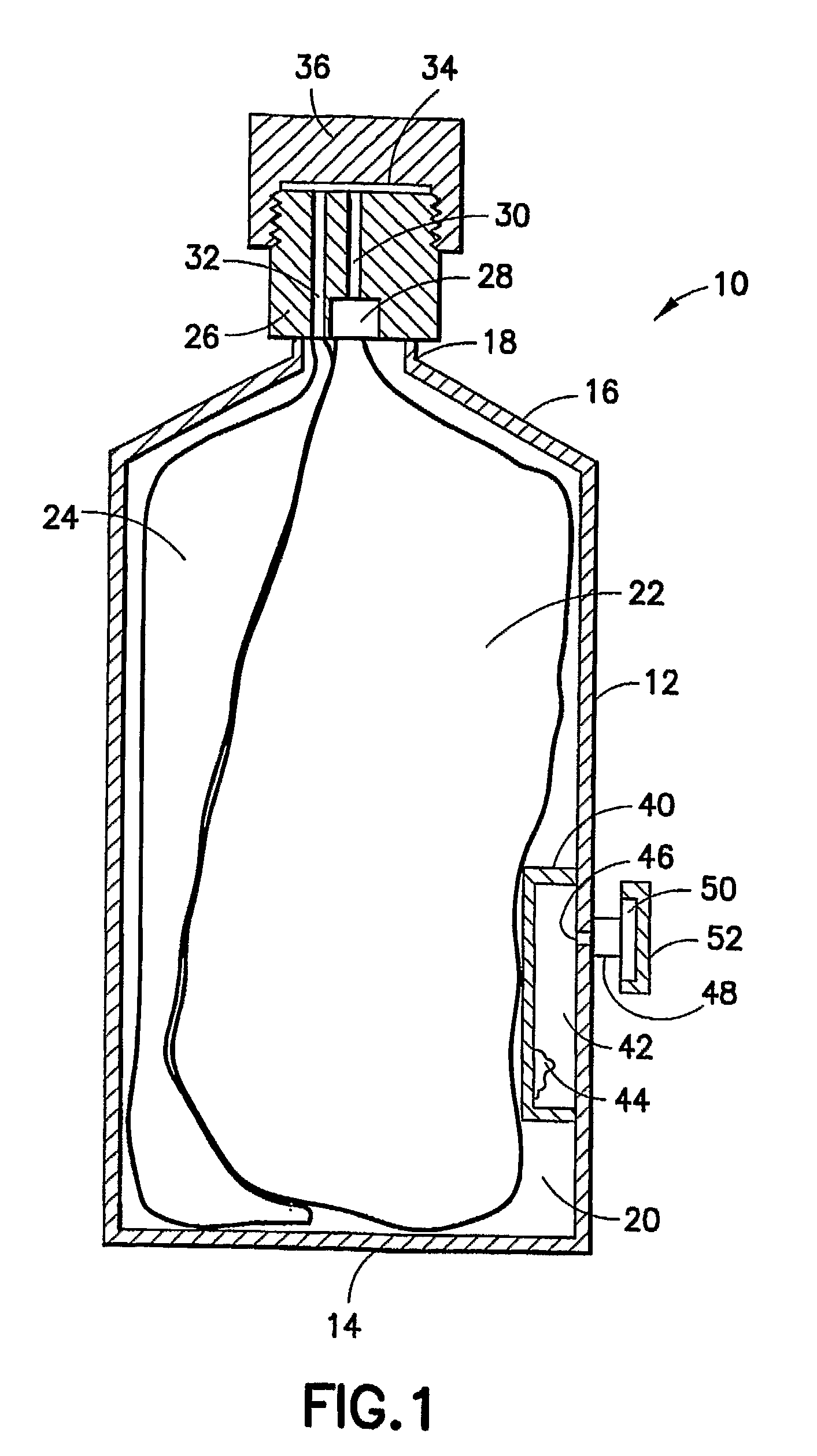

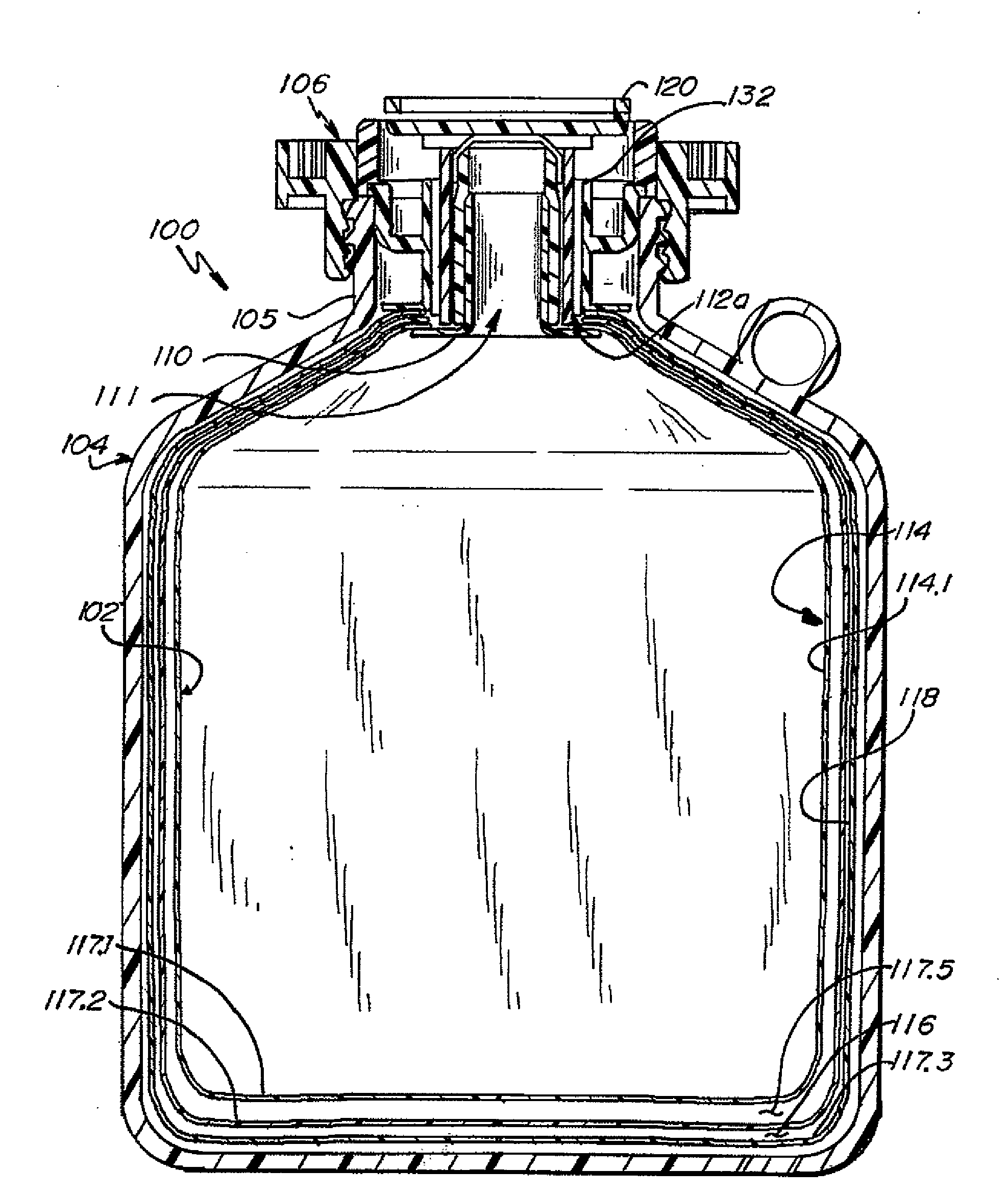

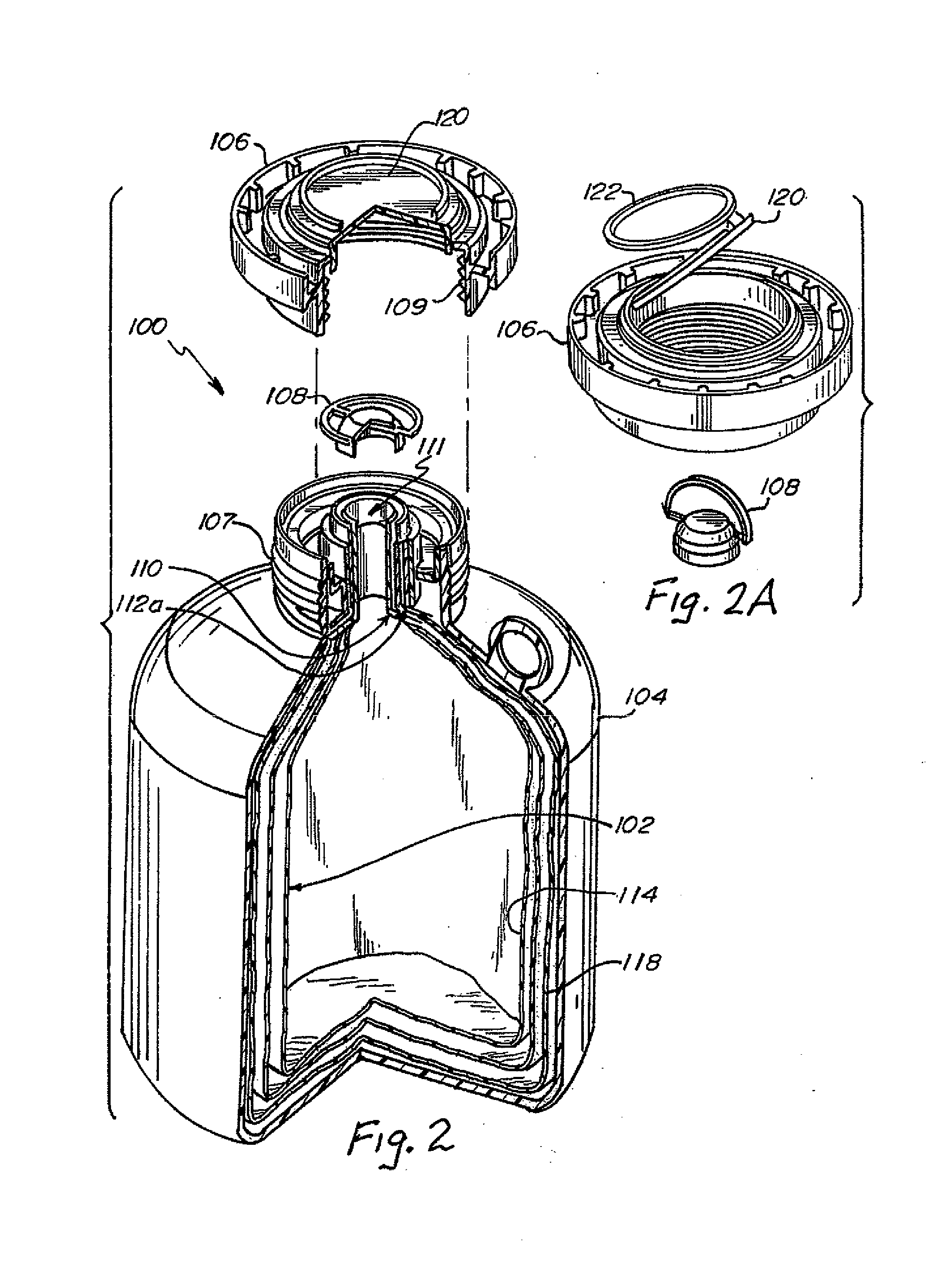

Containers with flexible pouch and closure member

Owner:REES BLAKE M +2

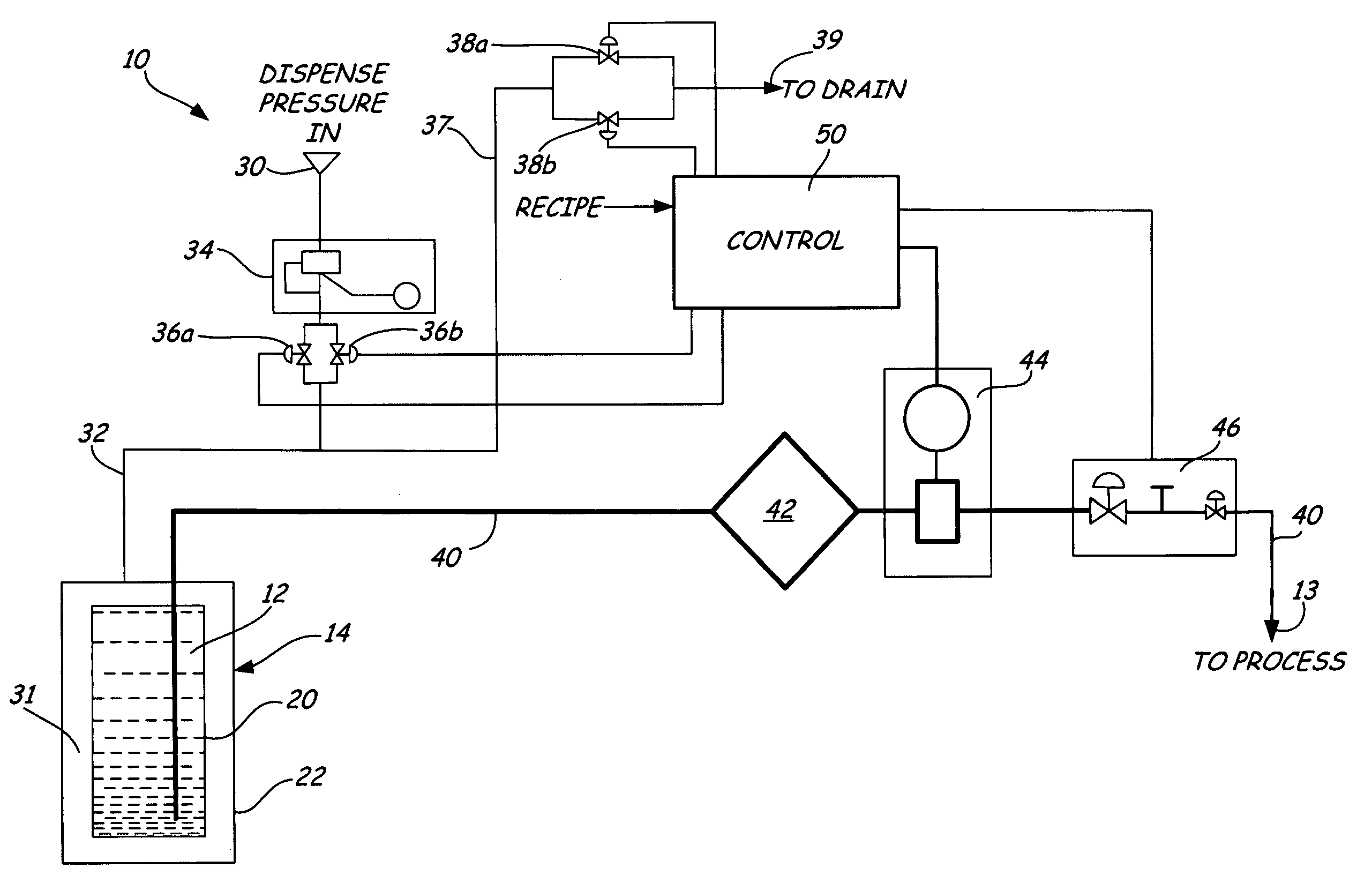

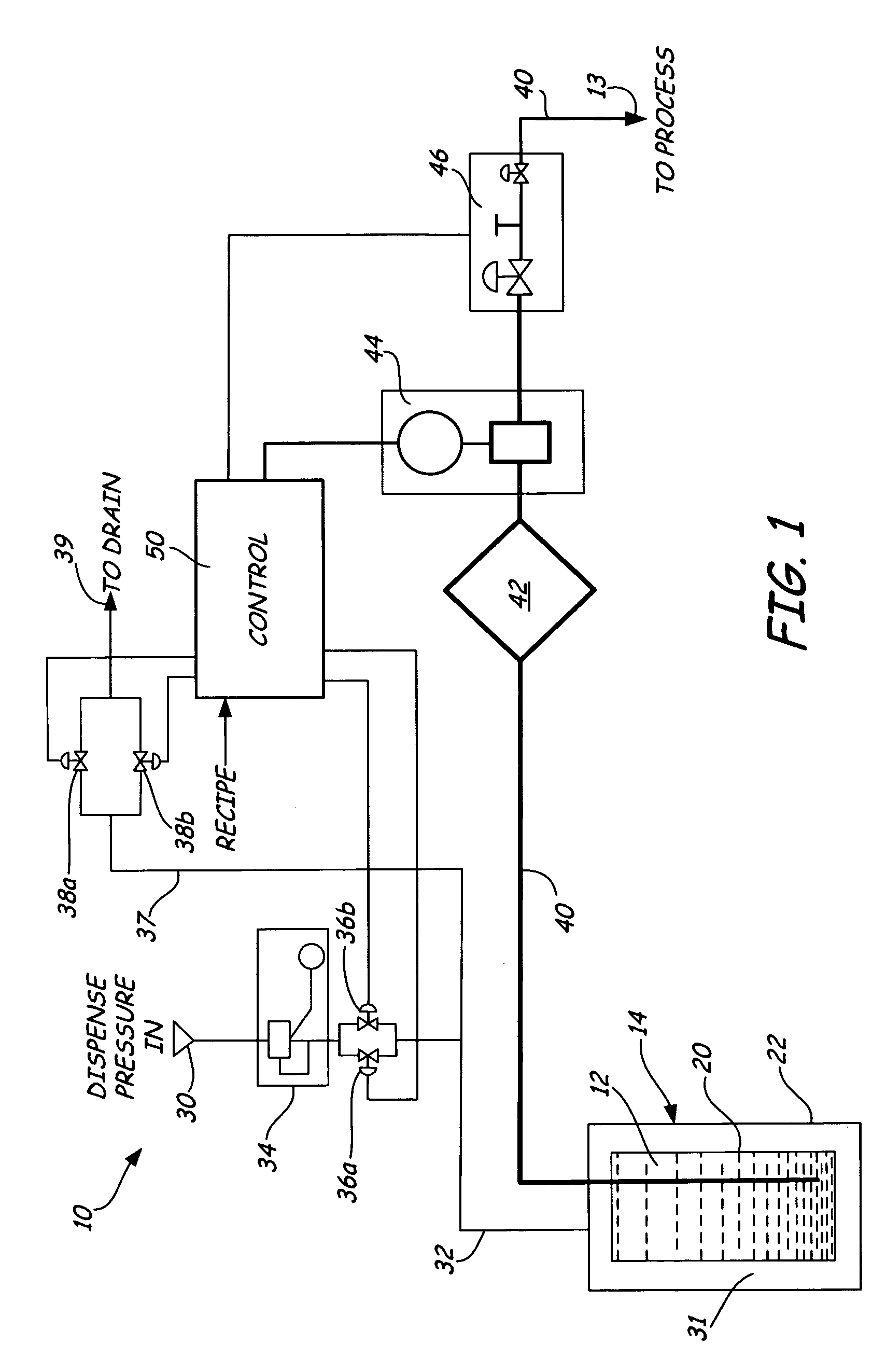

Liquid dispensing system

ActiveUS7172096B2Low costFirmly connectedOpening closed containersBottle/container closureEngineeringForce sensor

Owner:ADVANCED TECH MATERIALS INC

System and method for customized beverages

A system for the automated preparation and delivery of customized beverages is disclosed. The system is deployed as a kiosk or similar device and provides an automated user-customizable drink purchasing experience. The user can select the desired base, add-in ingredients, etc. and receive a drink that has been prepared in accordance with the user preferences. In addition, individual and aggregate user preferences and purchasing habits (e.g., quantity and type of drink purchased, frequency of purchases, location of purchases, etc.) can be tracked, stored, and used to provide targeted marketing messages, including special discounts, promotions, etc.

Owner:IRVIN JASON BRADLEY

Apparatus for hands-free dispensing of a measured quantity of material

InactiveUS20060243740A1Easy to operateHelp positioningOpening closed containersBottle/container closureEffect lightEngineering

An apparatus for automatically dispensing a fluid includes a container adapted to carry a supply of fluid, and a valve connected to said container, wherein actuation of said valve dispenses the fluid. Also included is an apparatus position indicator proximally associated with the container and an object sensor positioned near the valve. The object sensor monitors an area below where the valve dispenses when open and upon detection of an object opens said valve. Initial positioning of the apparatus triggers the apparatus position indicator to generate an appropriate signal until said object sensor is properly positioned. Once positioned the device may be permanently secured. A control circuit within the apparatus also allows programming of lighting indicators, dispense cycle size, and dispense quantities. The control circuit also provides for overload protection, motor braking and RF shielding.

Owner:JOSEPH S KANFER

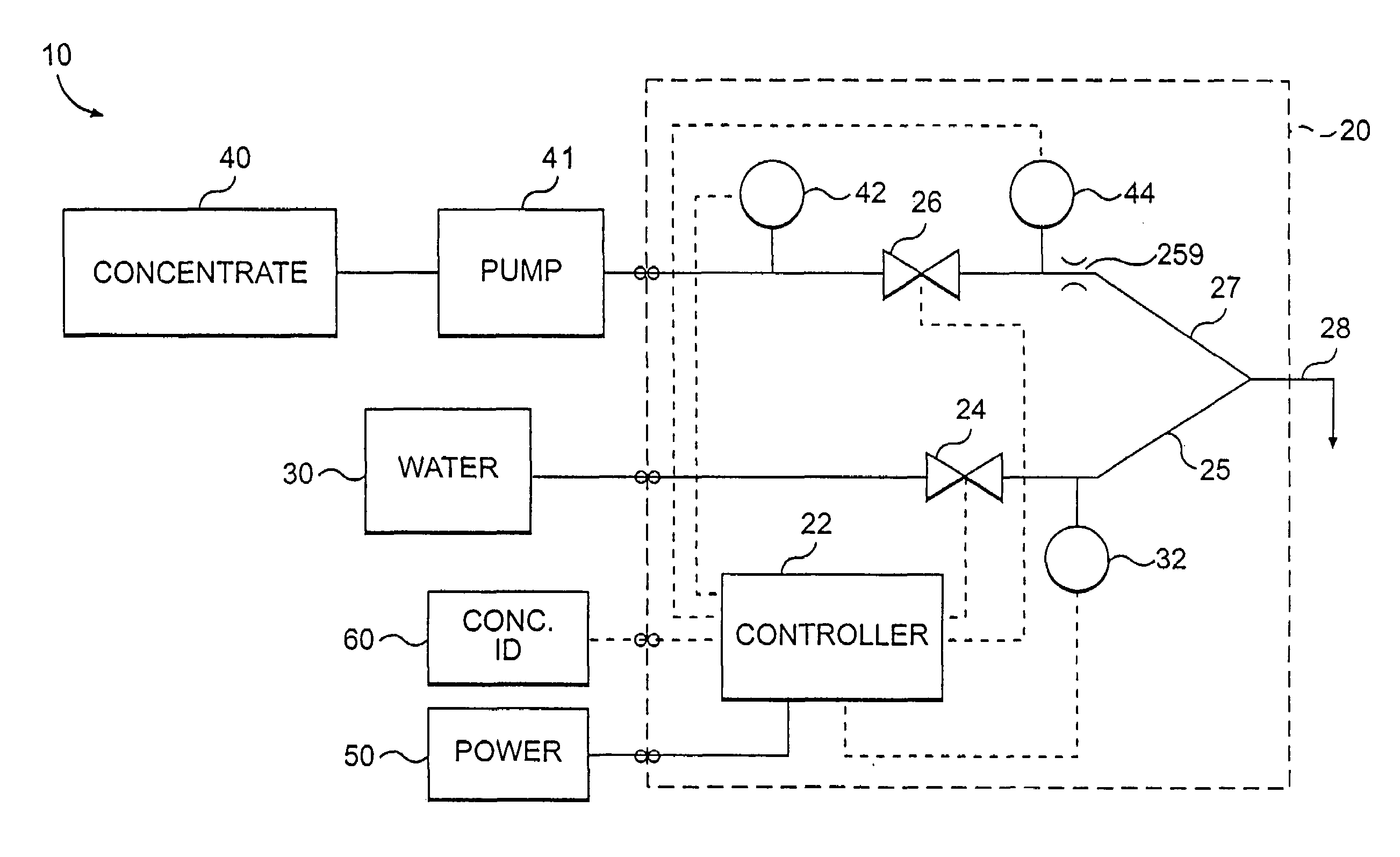

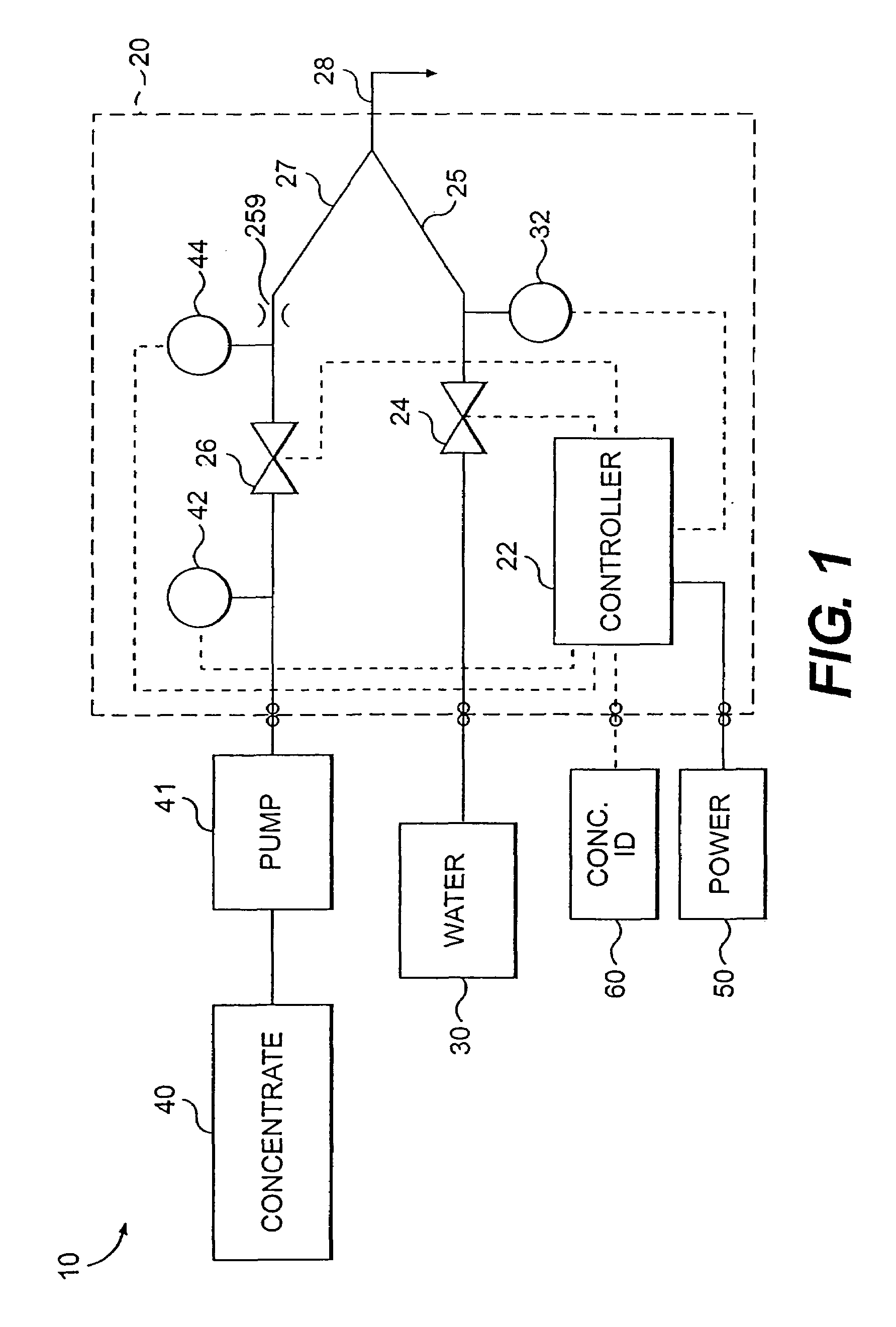

Beverage dispensing system

InactiveUS20050029287A1Precise positioningOpening closed containersBottle/container closureEngineeringIdentification device

A system for dispensing a beverage which is a mixture of stock and water, includes a dispensing apparatus having a water supply thereto, and a container containing the stock, the apparatus further including a controller which in use controls the apparatus to mix water with the stock to make the beverage, and to deliver the beverage to a beverage outlet, and wherein the container includes an identification device which identifies the nature of the beverage to be dispensed, and the dispensing apparatus includes a sensor, which senses the identification device and provides a signal to the controller which identifies the nature of the beverage to be dispensed from the signal.

Owner:SCOTSMAN BEVERAGE SYST

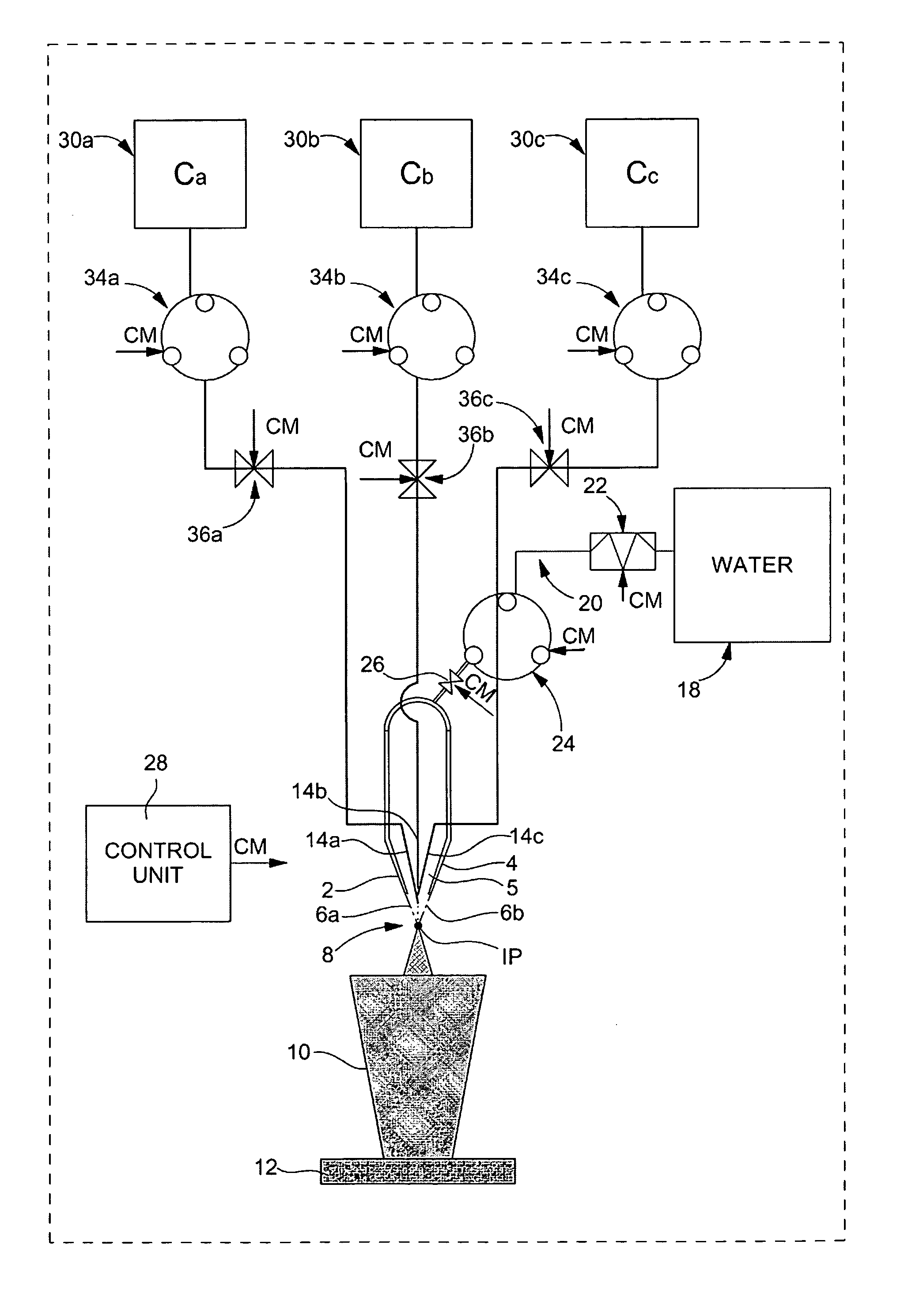

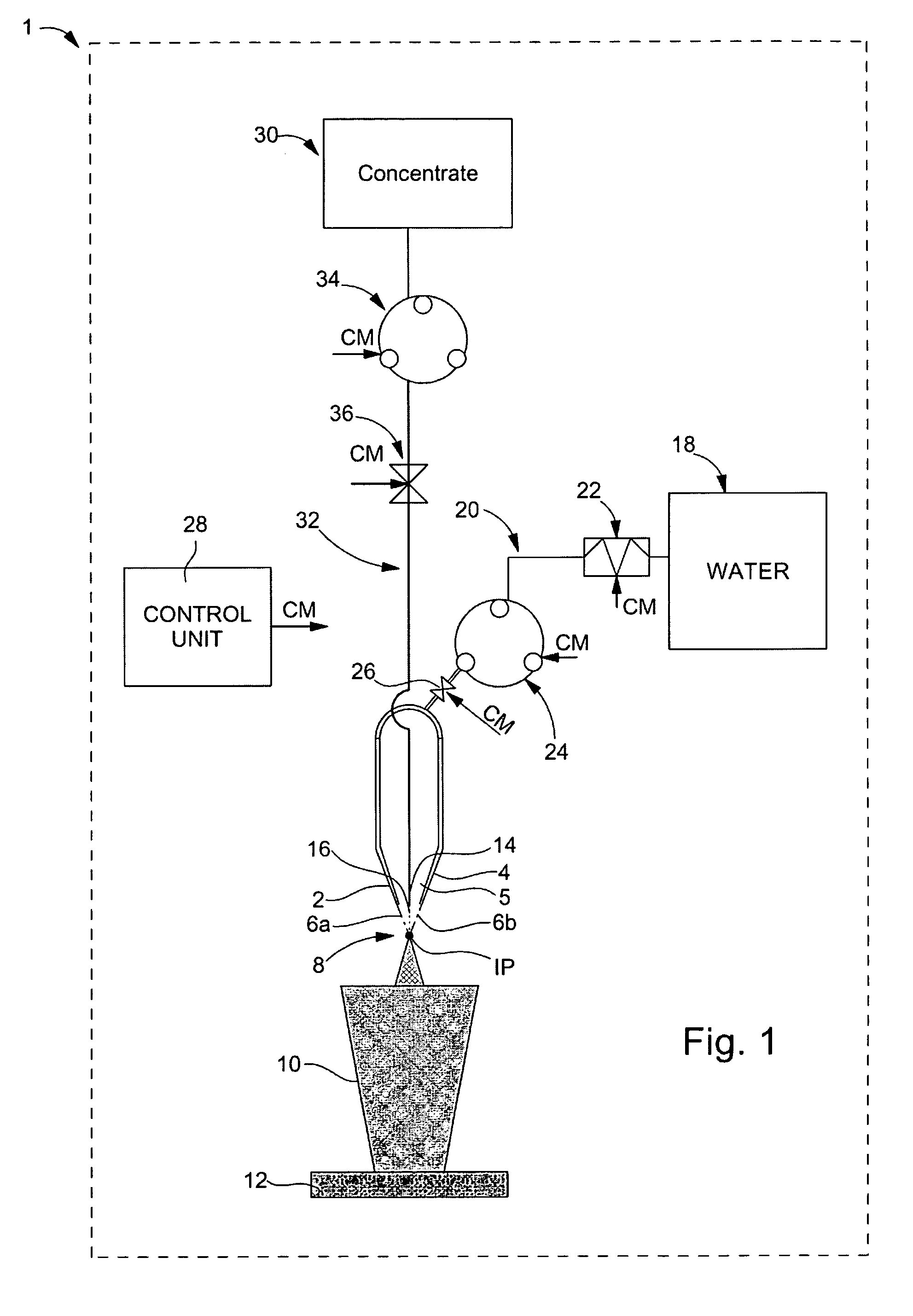

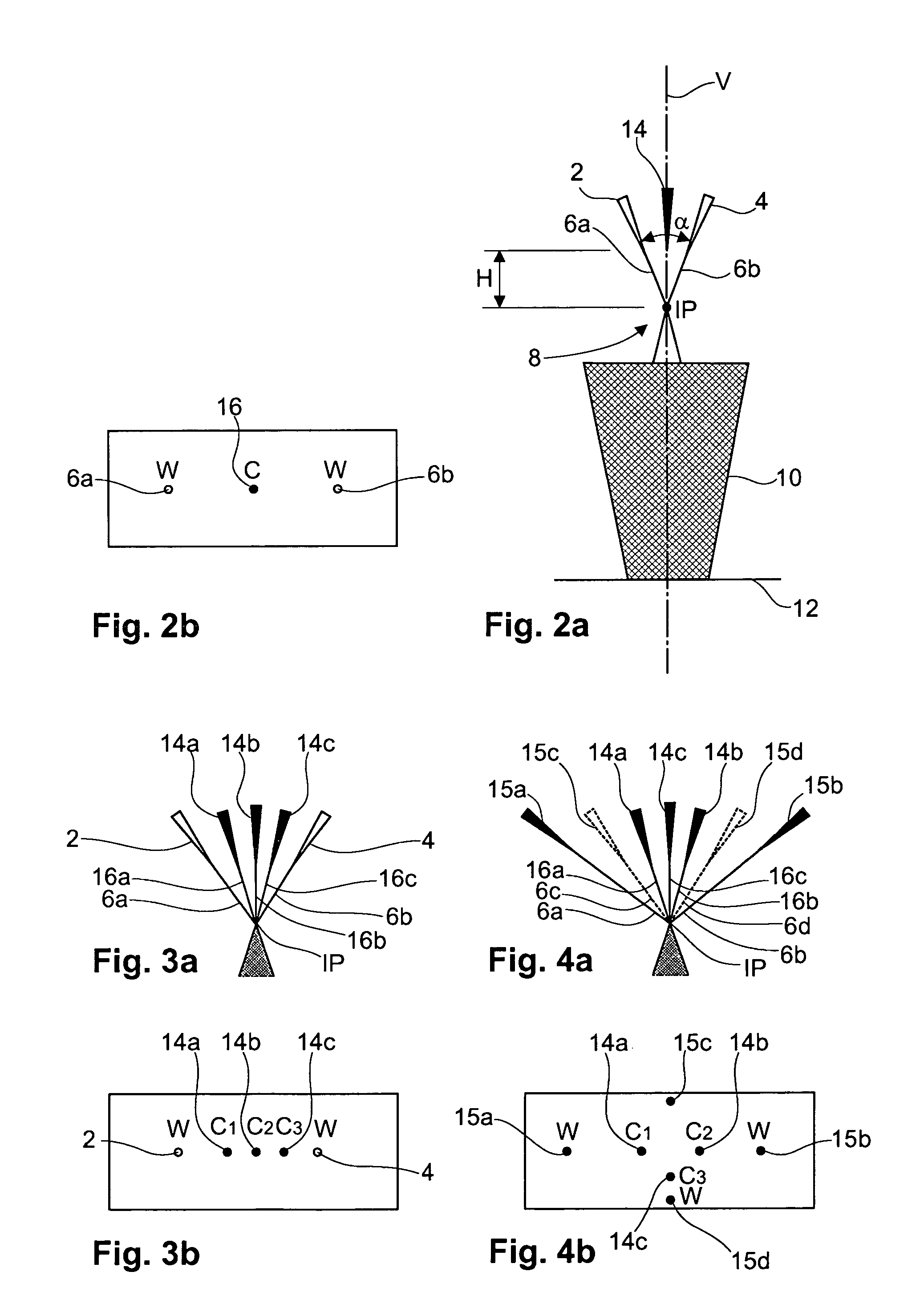

Method and system for dispensing hot and cold beverages from liquid concentrates

InactiveUS7147131B2Reduce complexityHigh quality dispensedOpening closed containersBottle/container closureEngineeringCold drinking

The invention concerns a device for dispensing a beverage comprising a mixture of liquid, e.g. water, and at least one liquid concentrate, comprising at least two liquid nozzles connected respectively to at least one liquid source for producing a first jet of liquid in air along first path and a second jet of liquid in air along a second path, at least one concentrate nozzle connected to at least one liquid concentrate source for delivering a stream of liquid concentrate in air along a third path, wherein the liquid nozzles and the concentrate nozzle are oriented with respect to each other so that the first, second and third paths intersect above a container at a common intersection point, whereby the mixture is formed by collision of the respective jets and the stream(s).

Owner:NESTEC SA

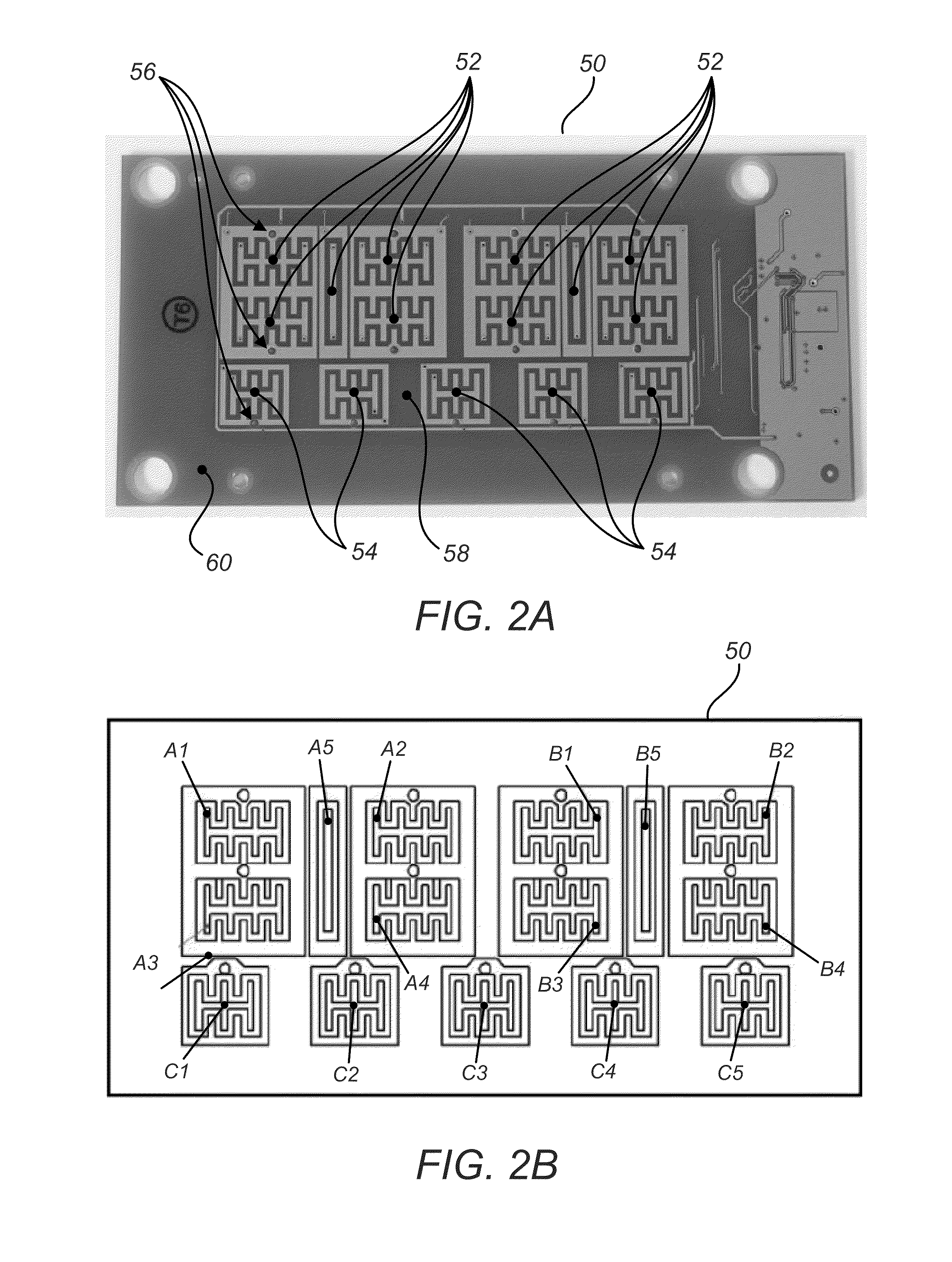

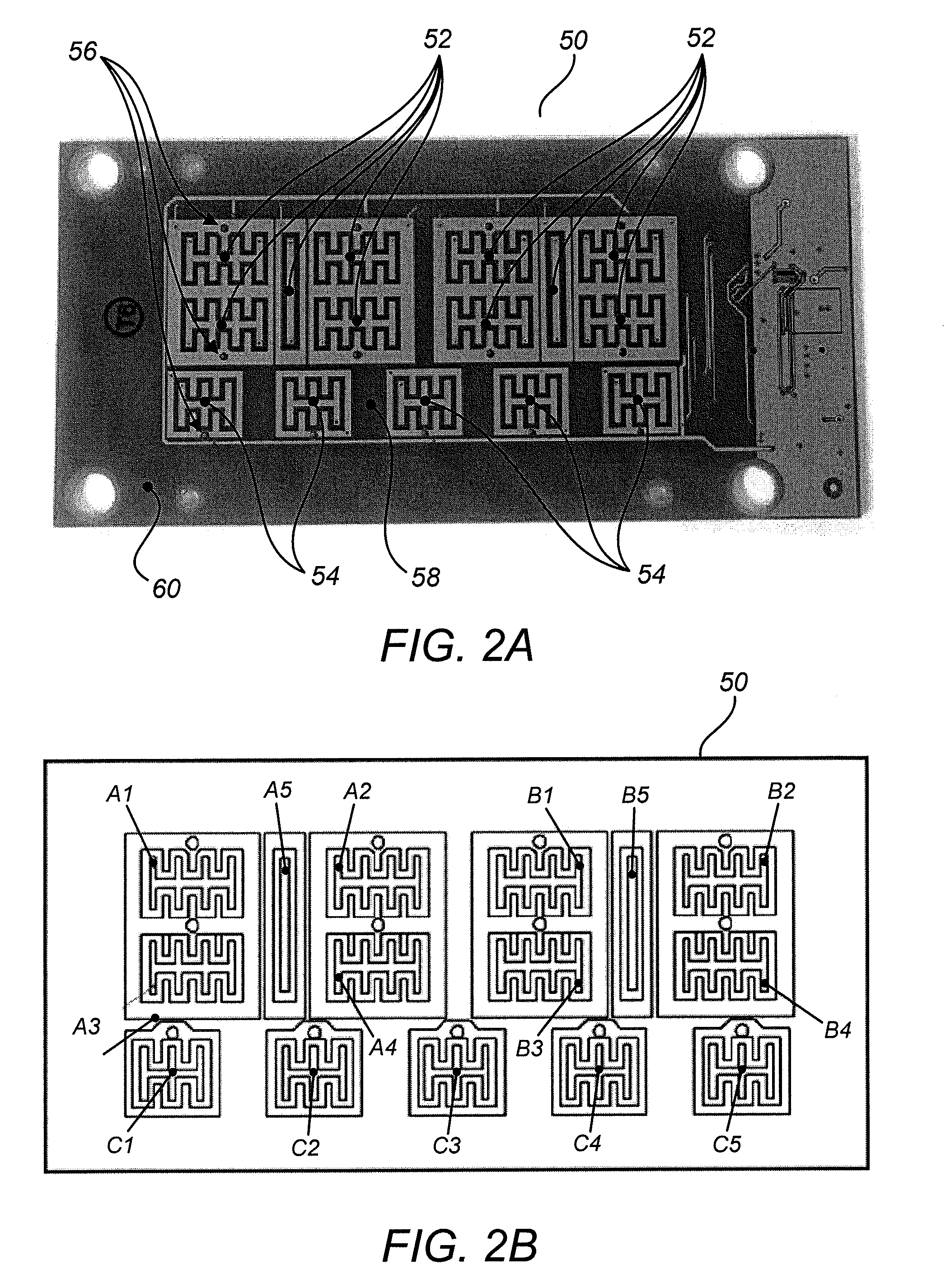

Reconfigurable control panel for a beverage dispenser

InactiveUS20100116842A1Increase flexibilityAvoid cross contaminationOpening closed containersBottle/container closureUser inputControl system

Reconfigurable control systems for beverage dispensers, beverage dispensers with a reconfigurable control panel, beverage dispensers that sequence the dispensing of beverage fluids that make up a selected beverage, beverage dispensers that allow for the dispensing of user customized beverages, and related methods for dispensing a beverage fluid are provided. A reconfigurable control system includes a control panel having multiple sensing regions, user reconfigurable switches used to select a control panel configuration, and a control unit operatively coupled with the control panel and the user reconfigurable switches. Each of the sensing regions is assigned to a key of the selected control panel configuration or deactivated. The keys of the selected control panel configuration receive user input to select a beverage and / or a beverage additive.

Owner:AUTOMATIC BAR CONTROLS

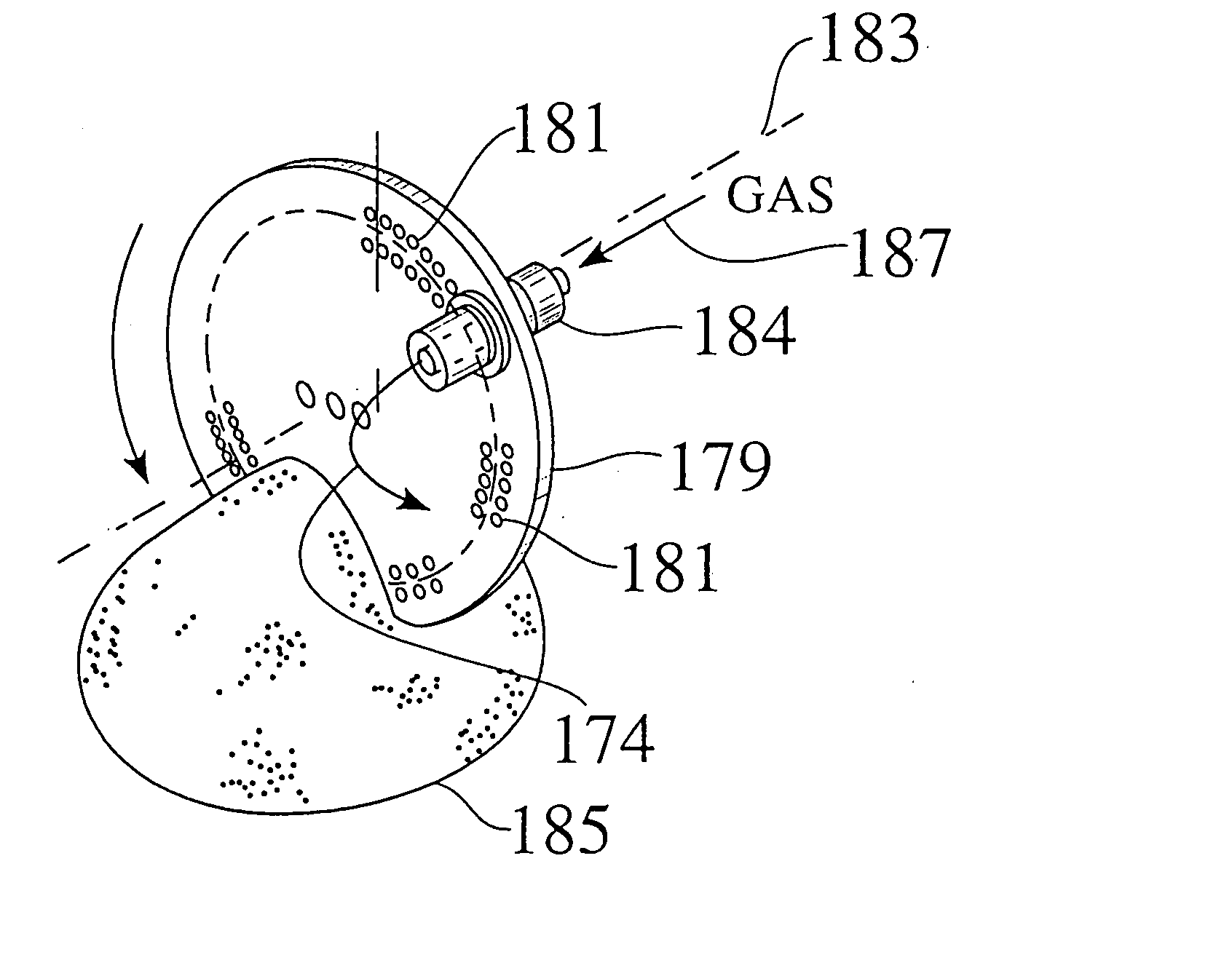

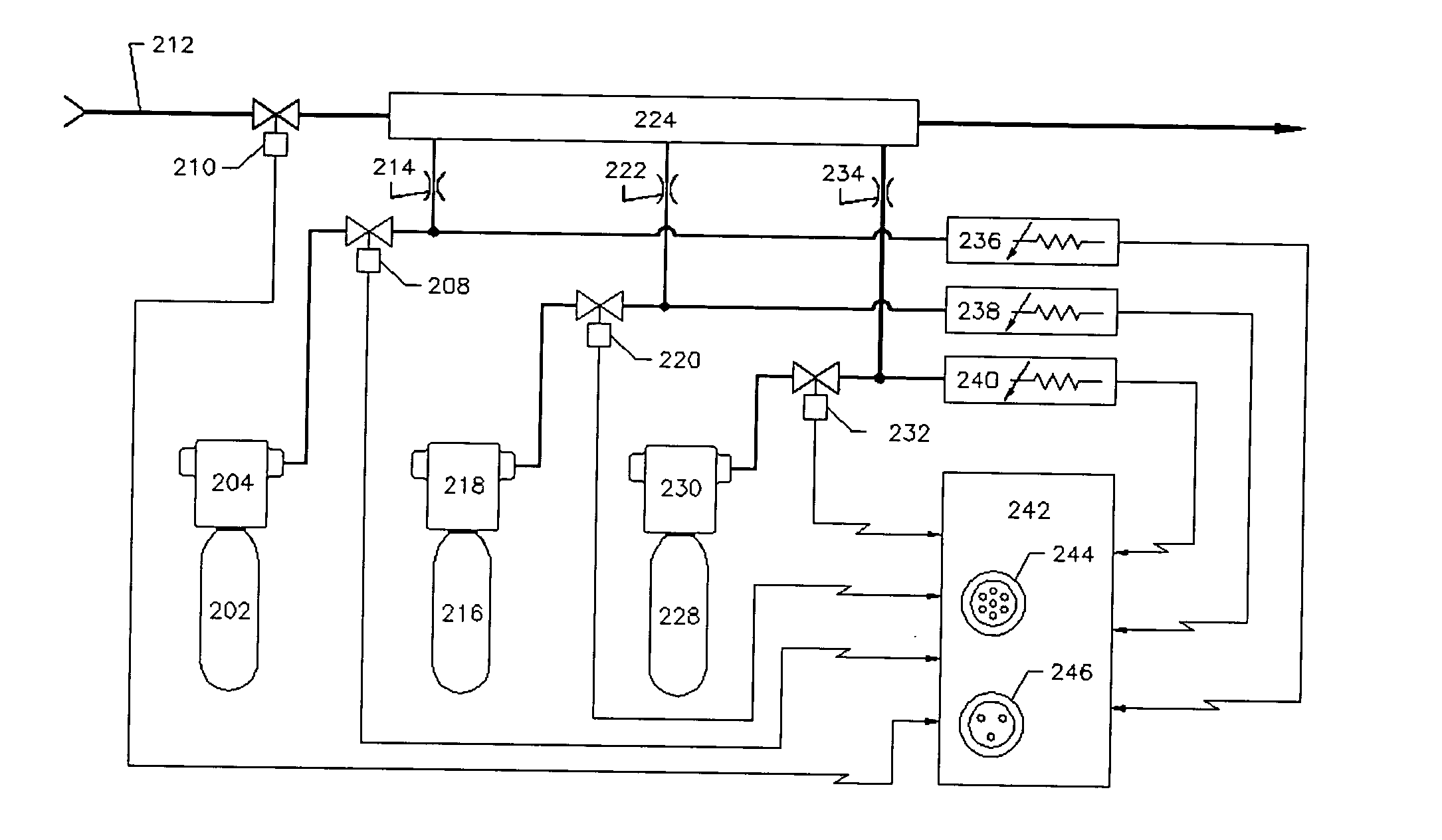

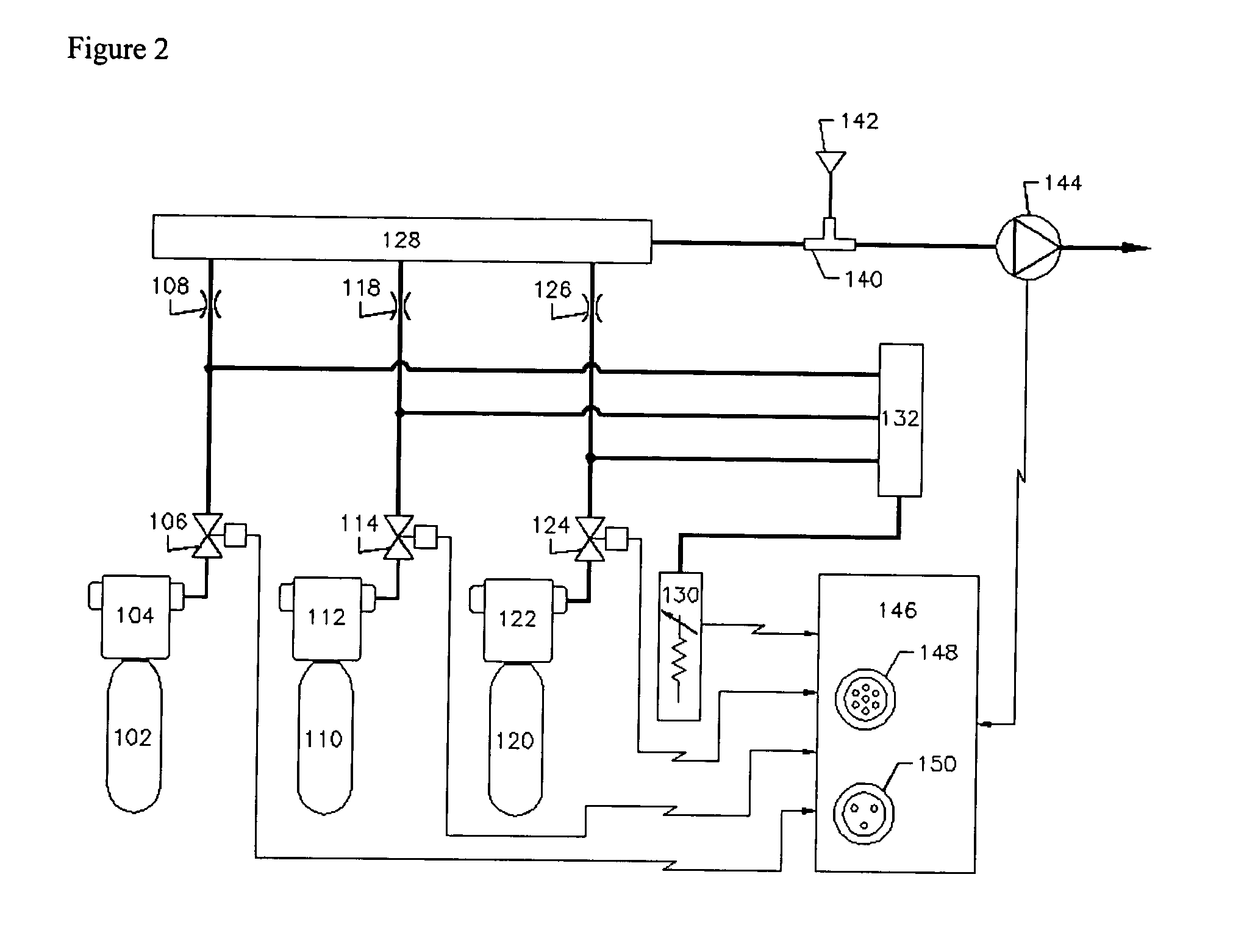

Apparatus and method for generating calibration gas

ActiveUS20050000981A1Low costAccurate concentrationOpening closed containersBottle/container closureDocking stationCalibration gas

An apparatus and method for generating a low concentration of gas within a carrier gas flow employing one or more miniature one-piece cylinders filled under pressure with a pure gas, or a concentrated gas balanced with an inert gas or gas mixture. Released from the cylinder through a pierced or other controlled opening, the flow of the gas is regulated by a pressure regulator and a micro orifice to be blended into a steady stream of diluent gas, typically ambient air, to form a desired gas concentration. No gas is generated if the pressure of the gas in the cylinder, which is monitored constantly by a pressure transducer, is below a predetermined level. The apparatus can be built into a portable device, or an automated docking station (or calibration station) for testing and calibrating gas detection and monitoring instruments, or into a fixed gas detection system for performing such functions.

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

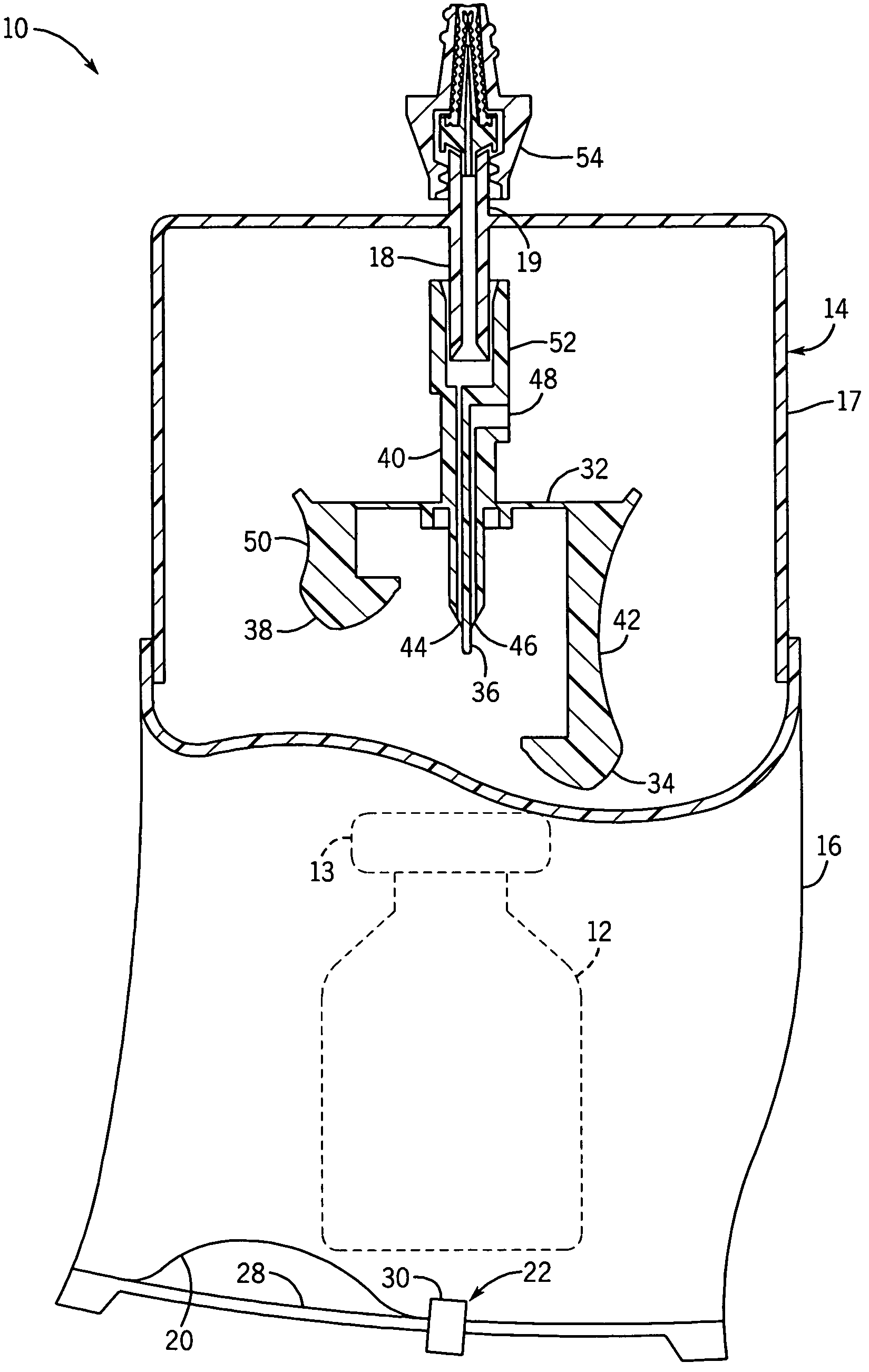

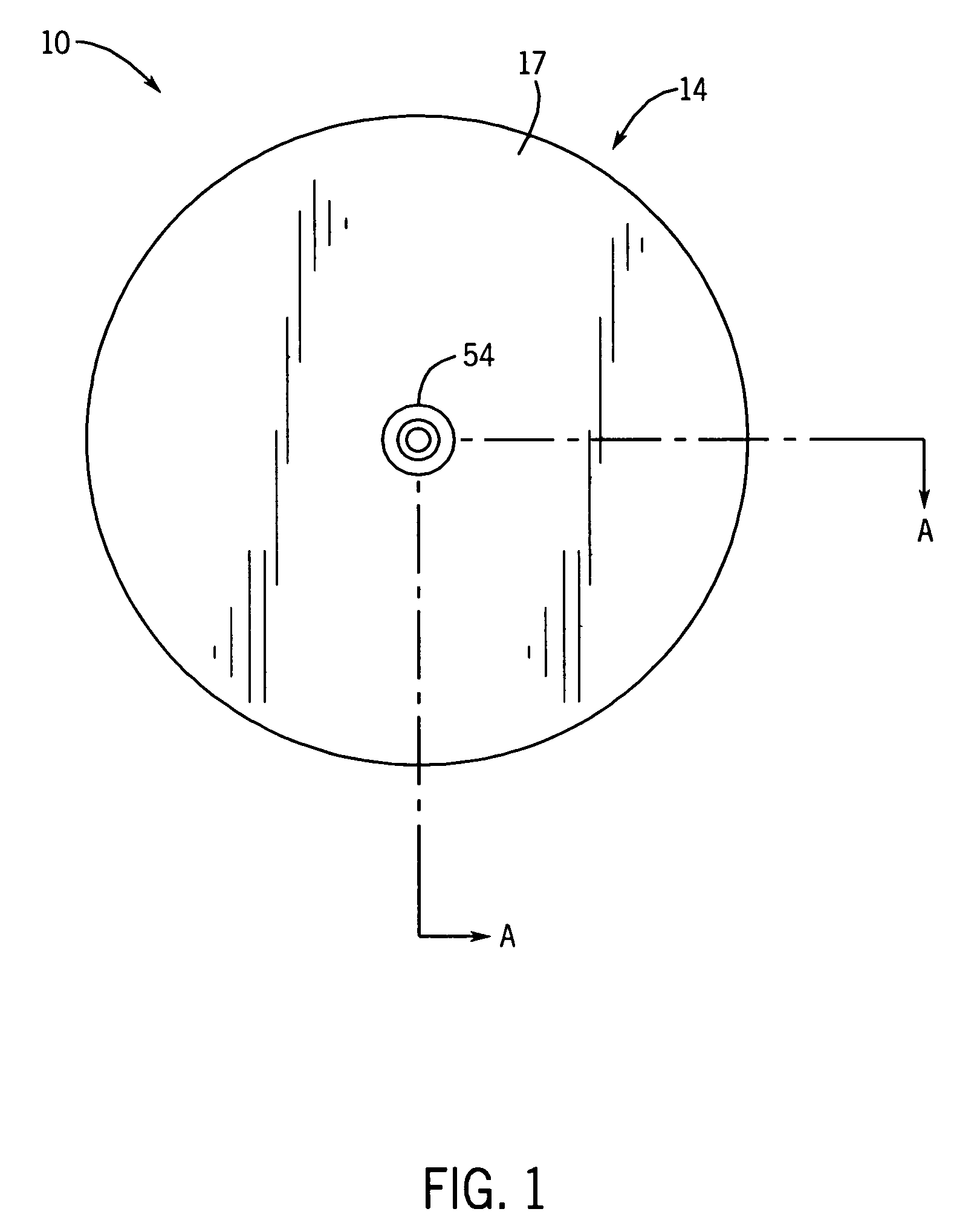

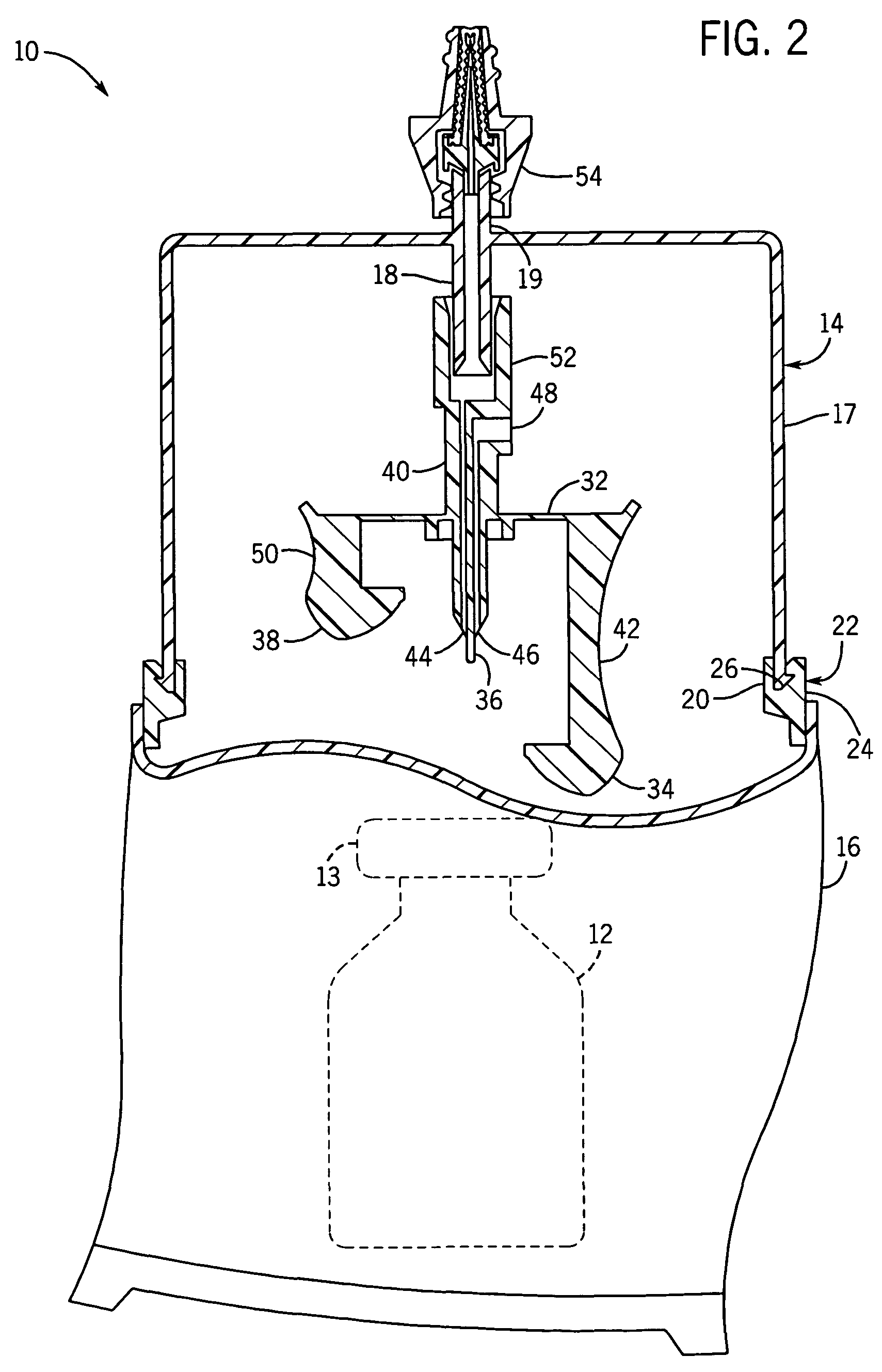

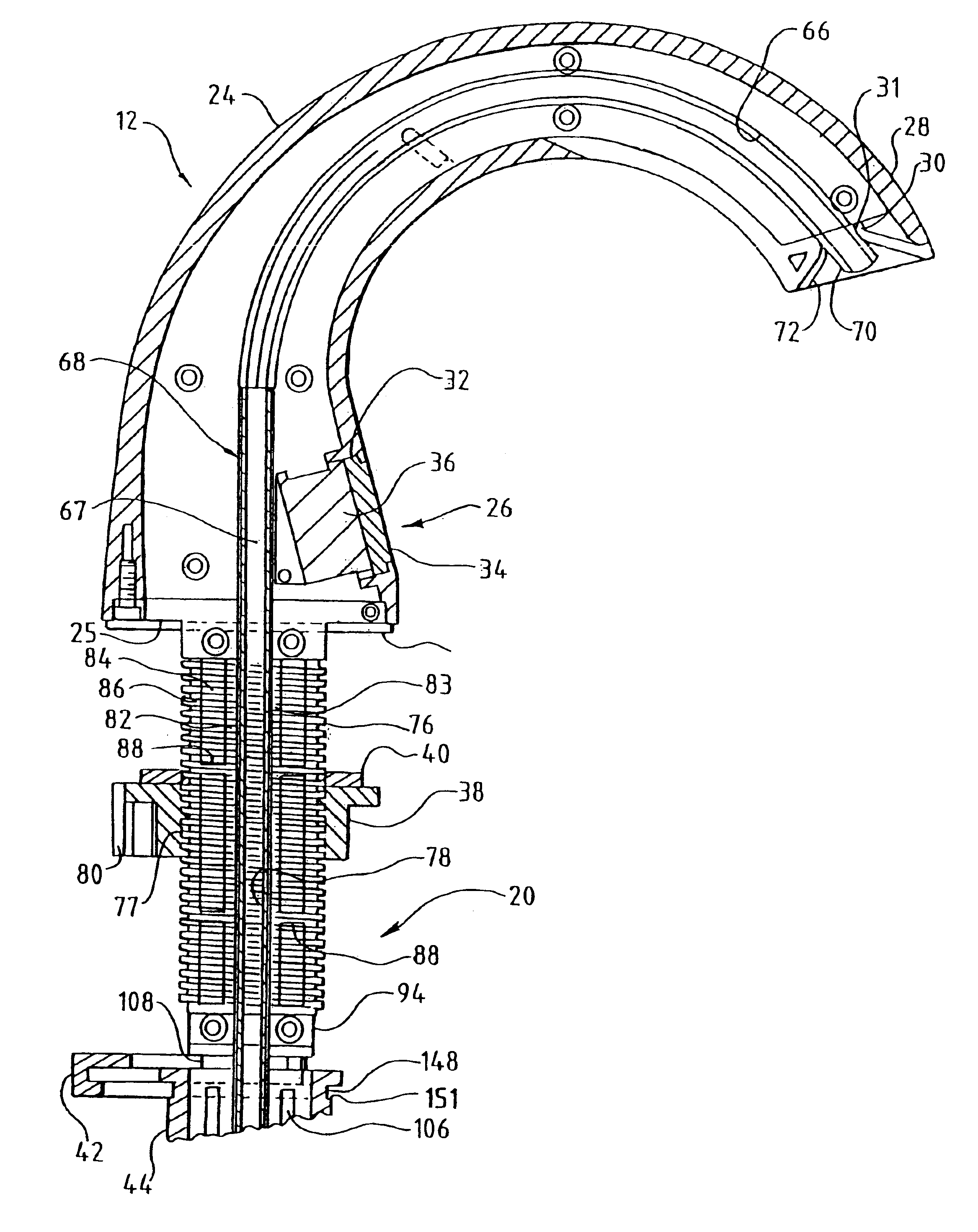

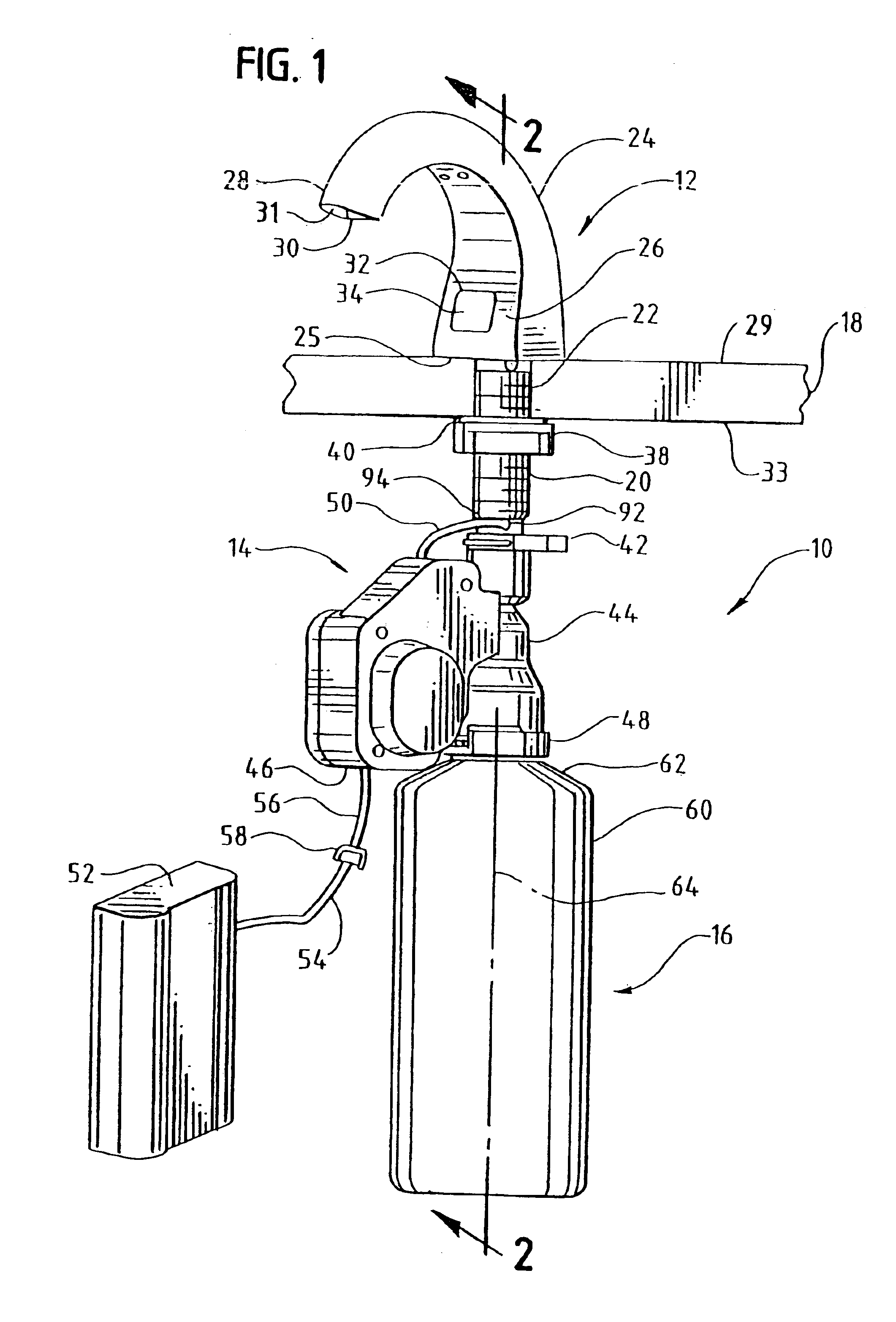

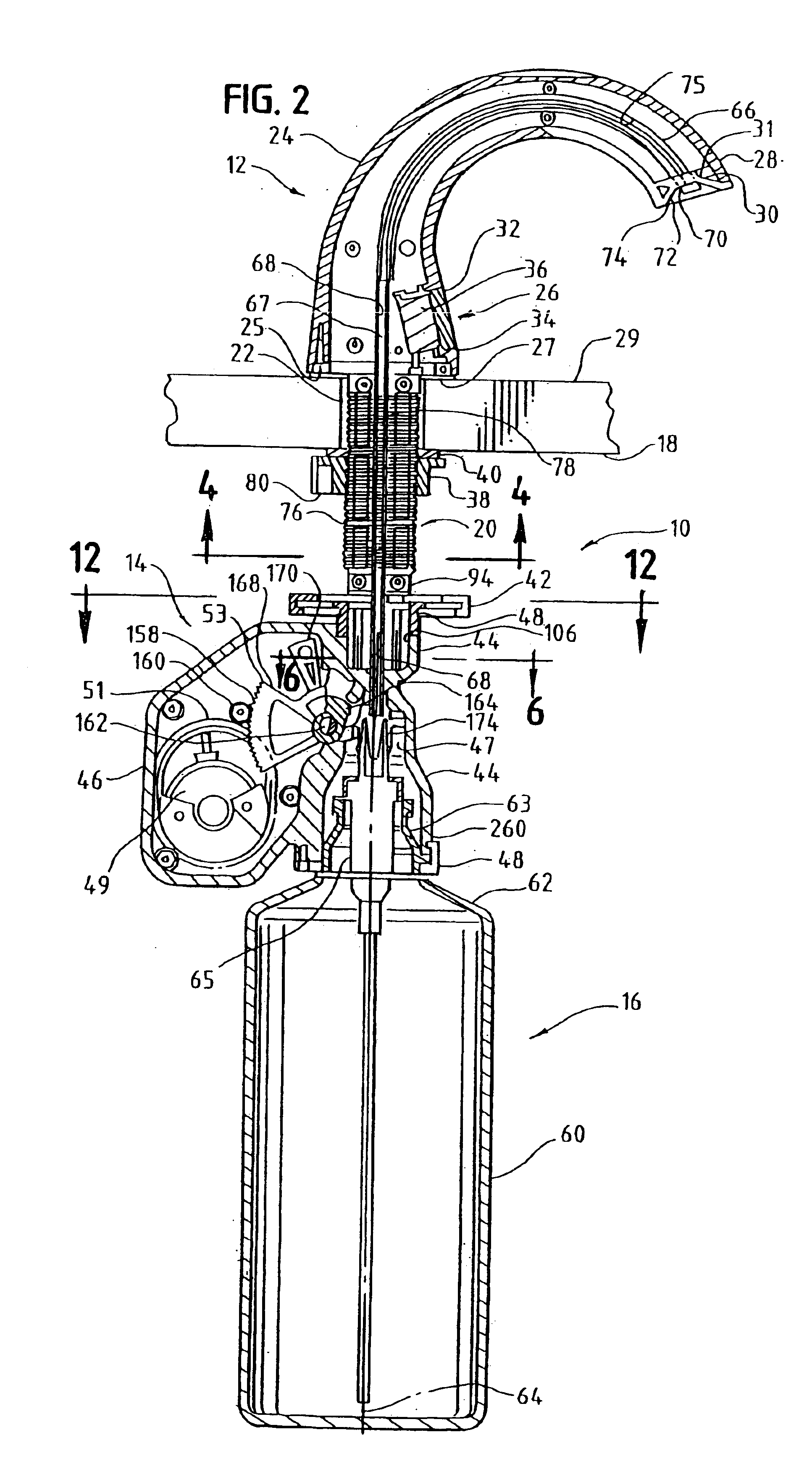

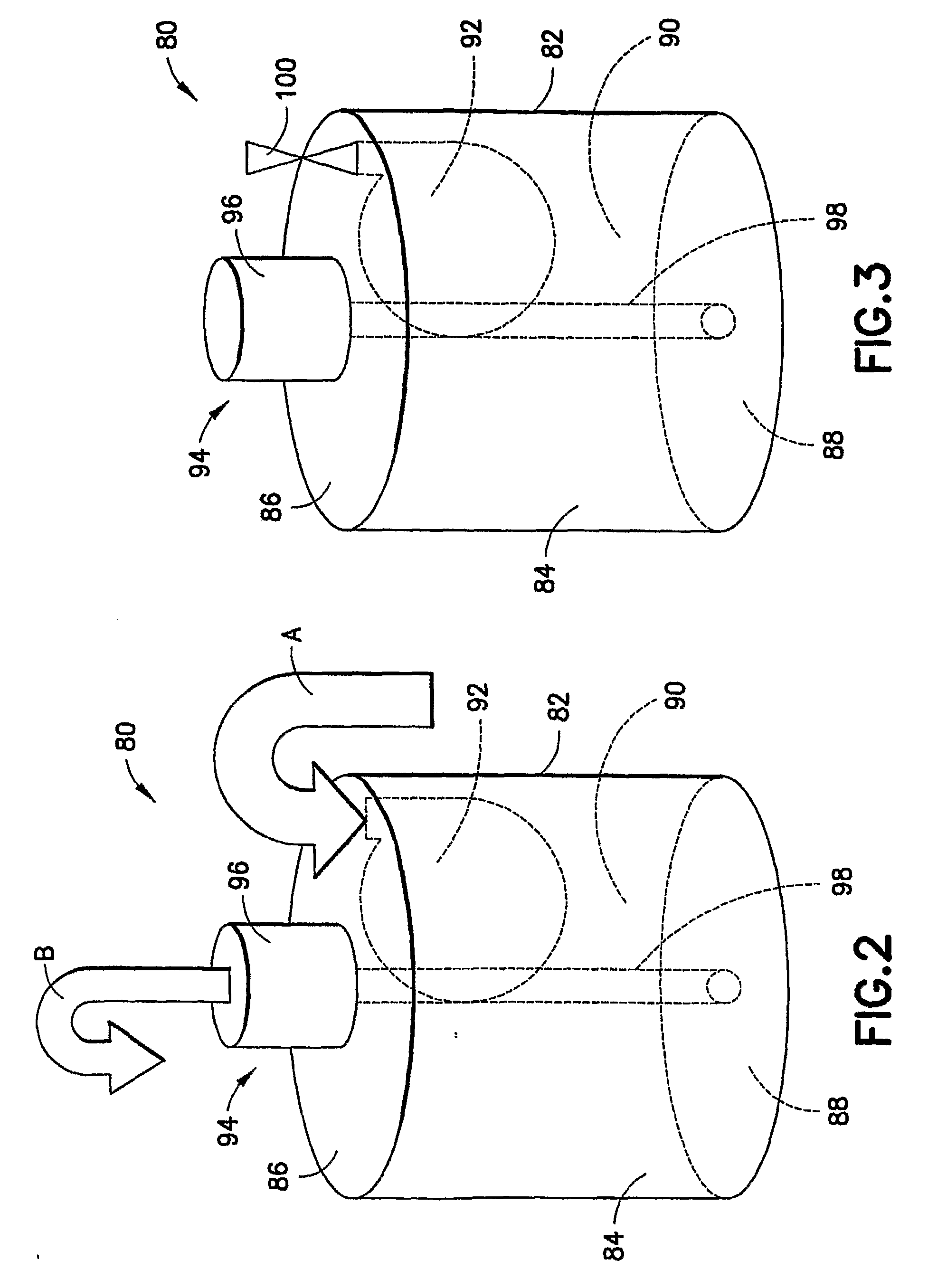

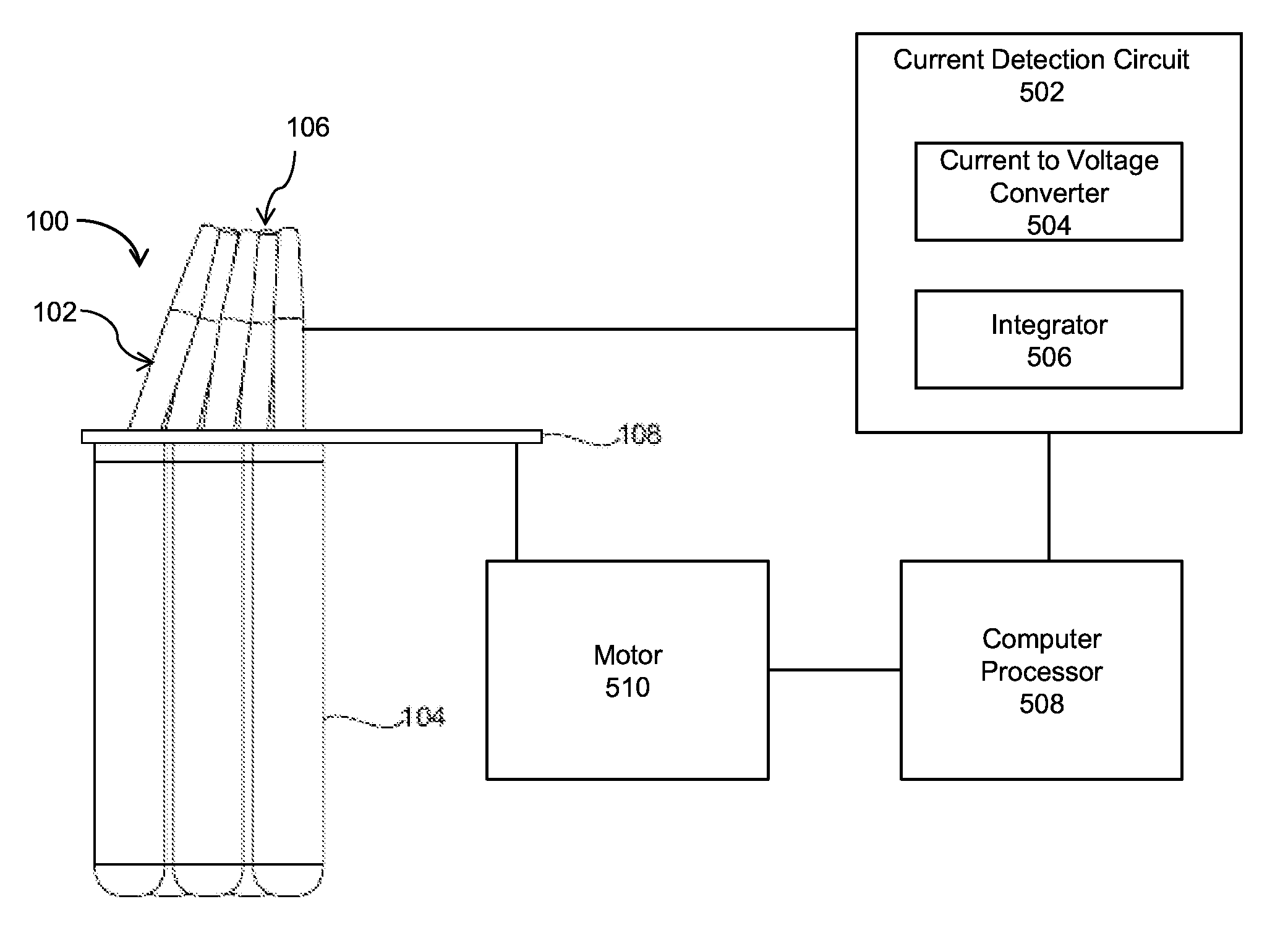

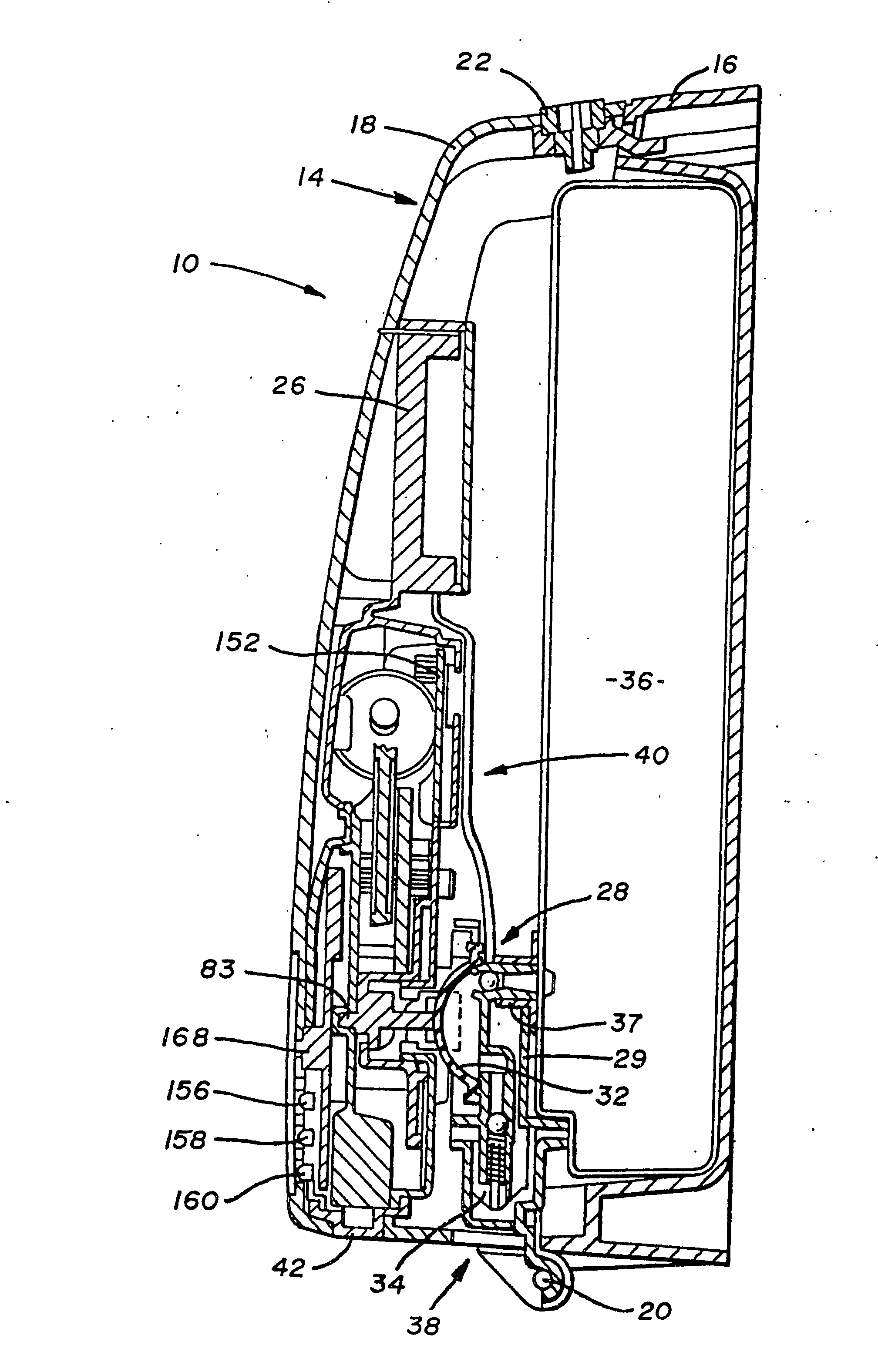

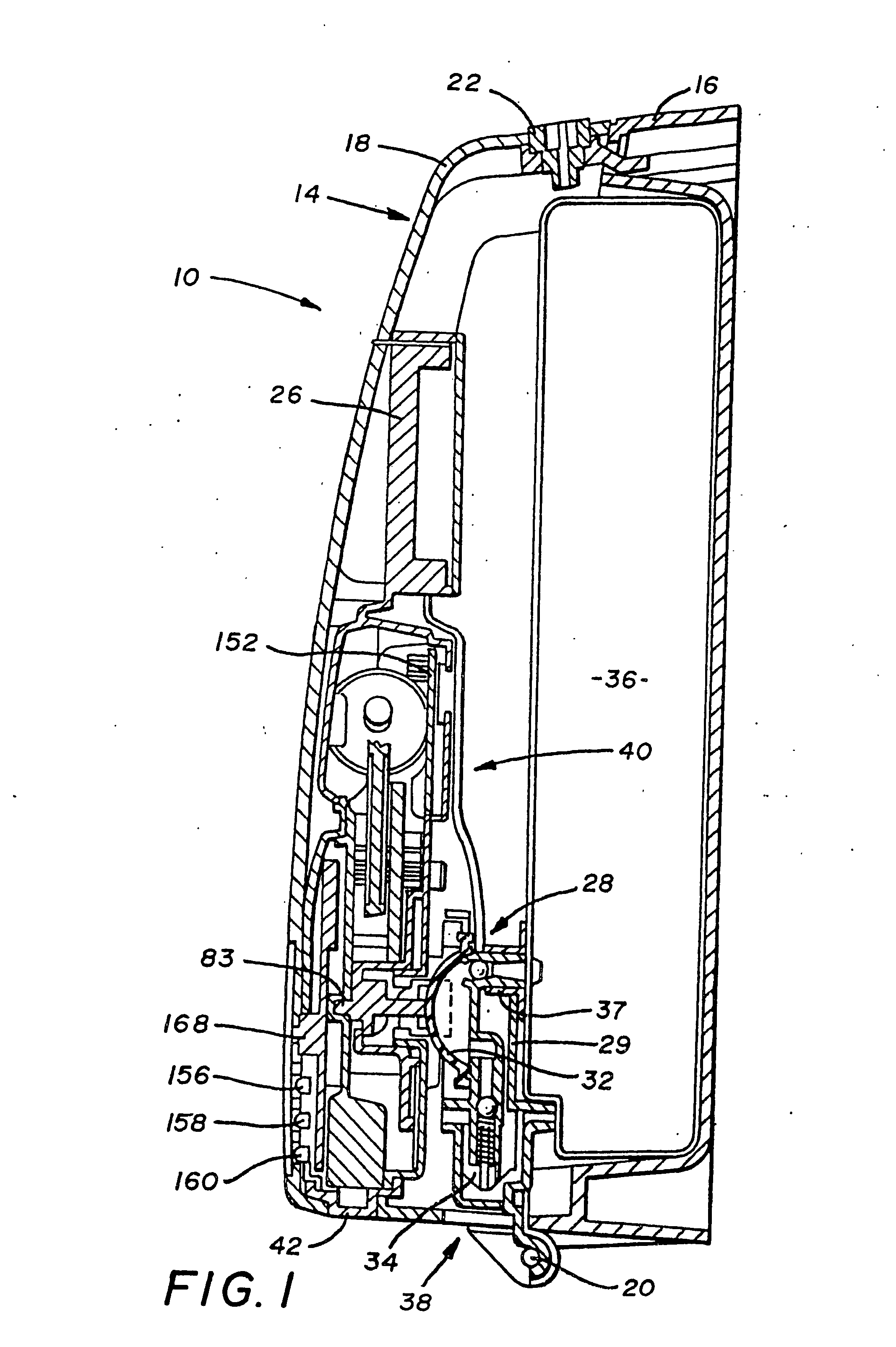

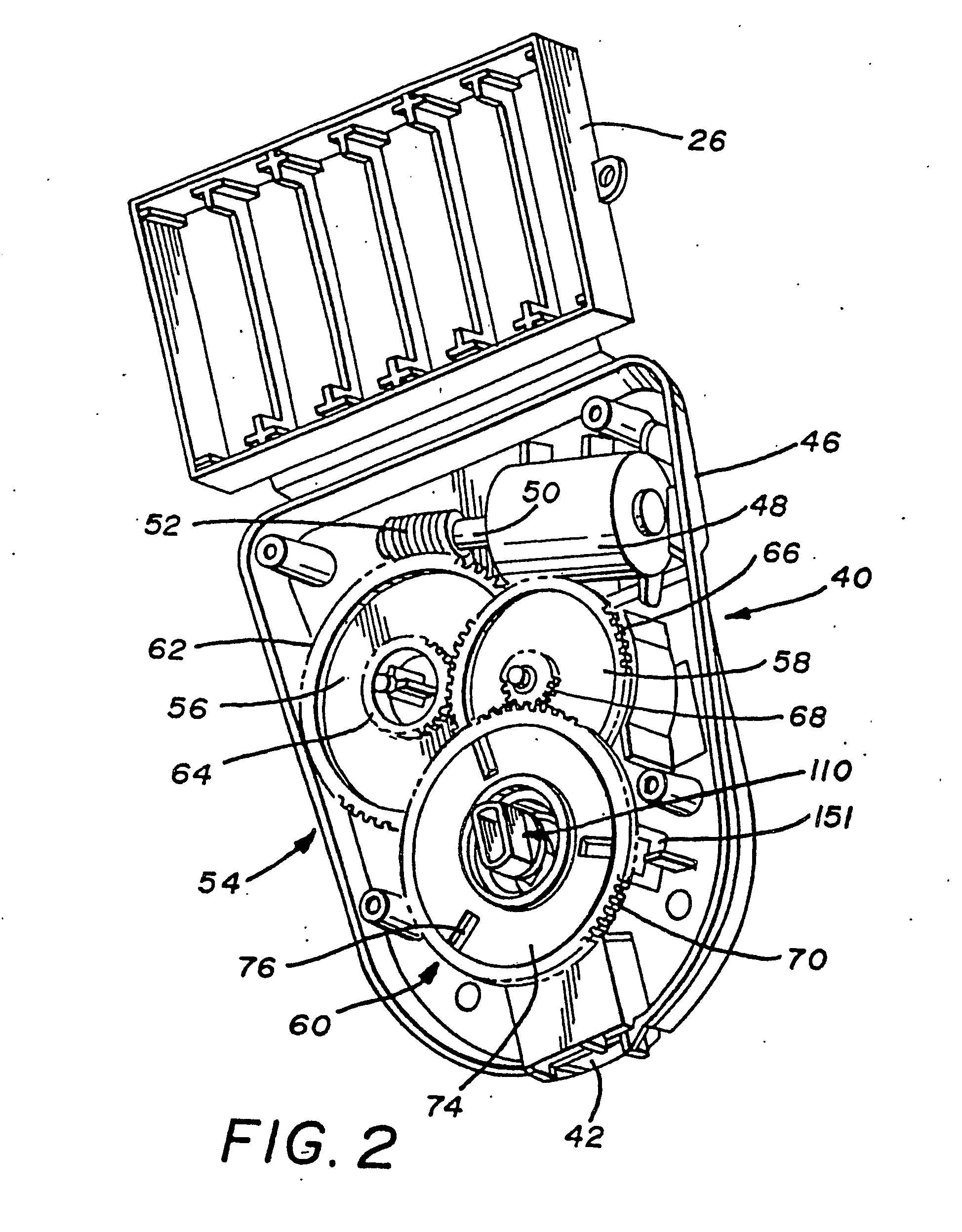

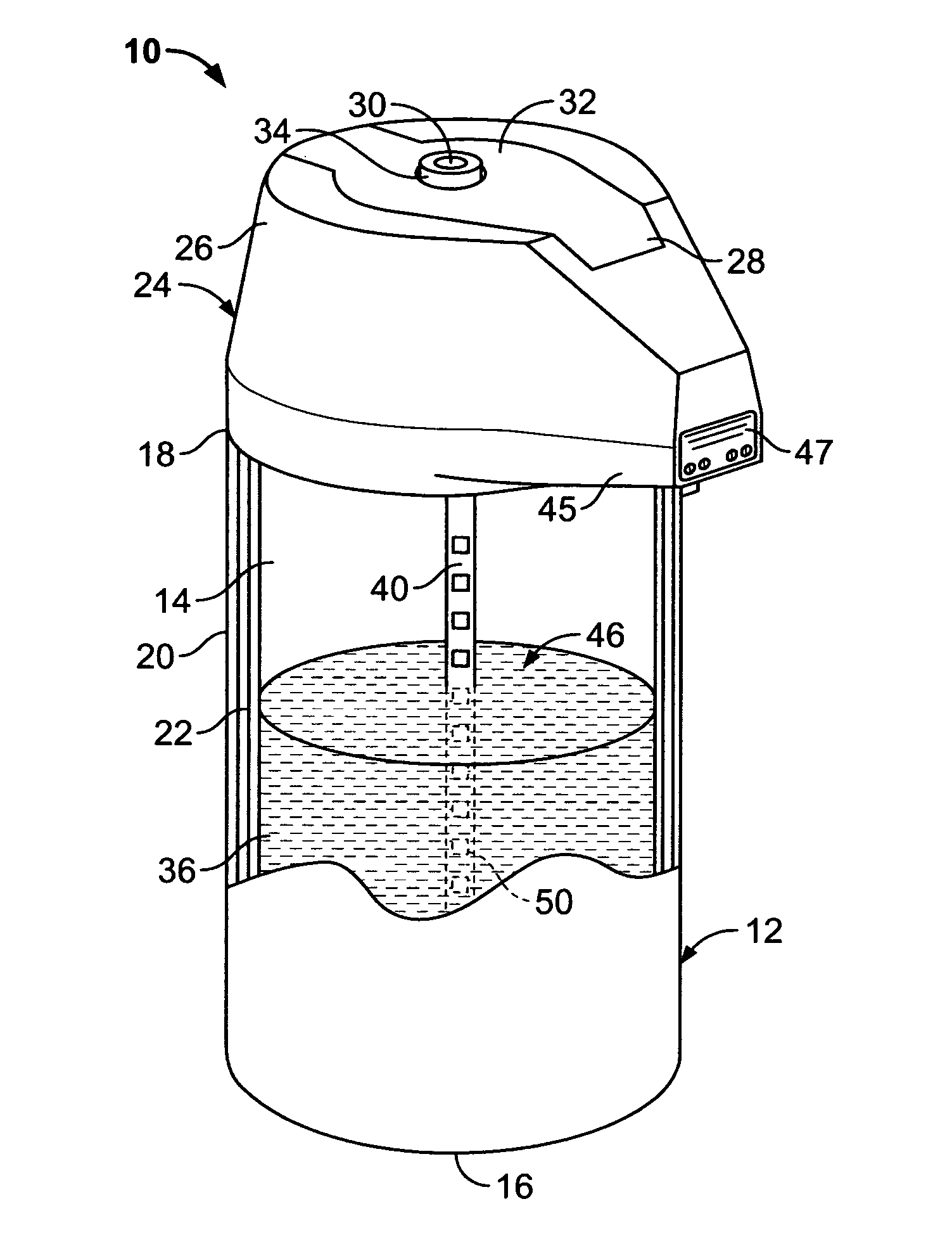

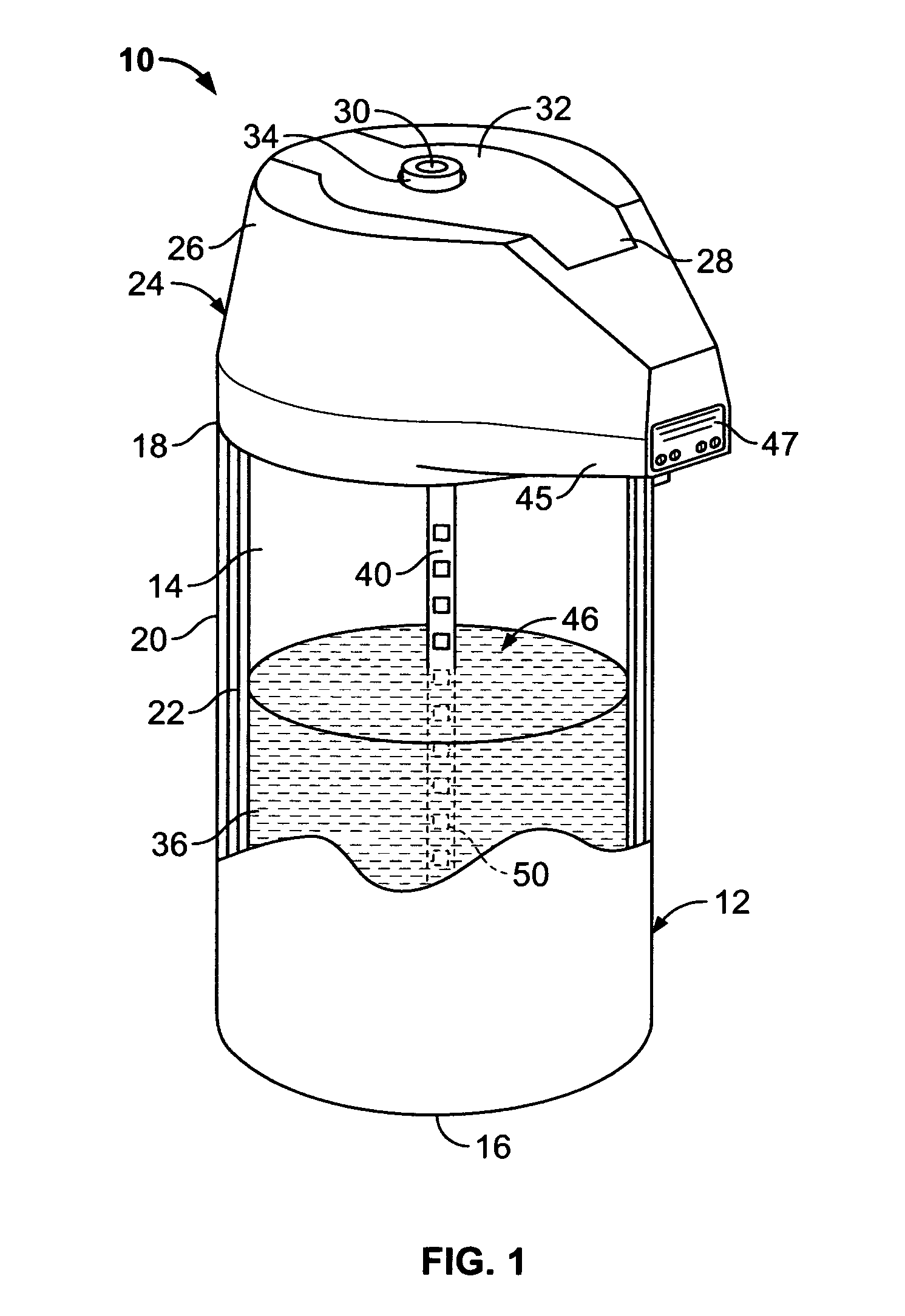

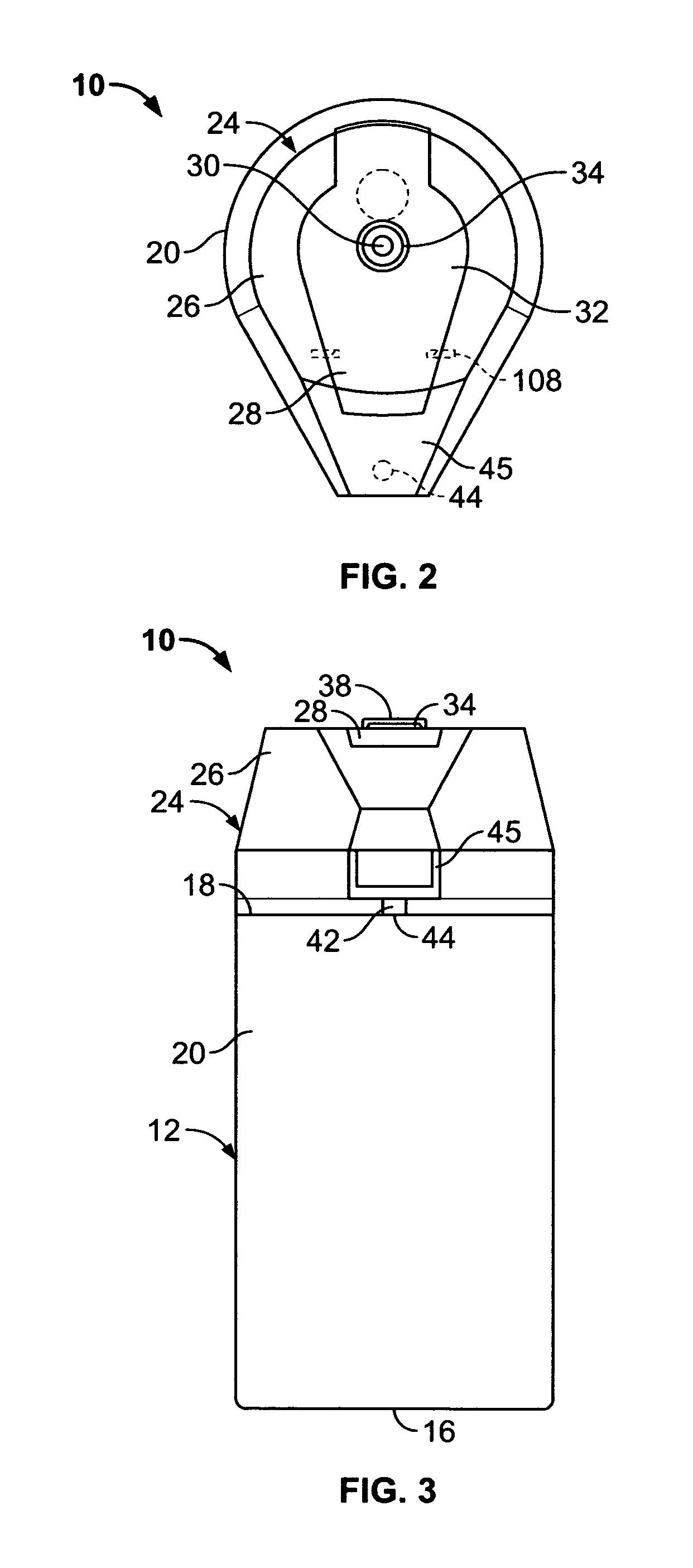

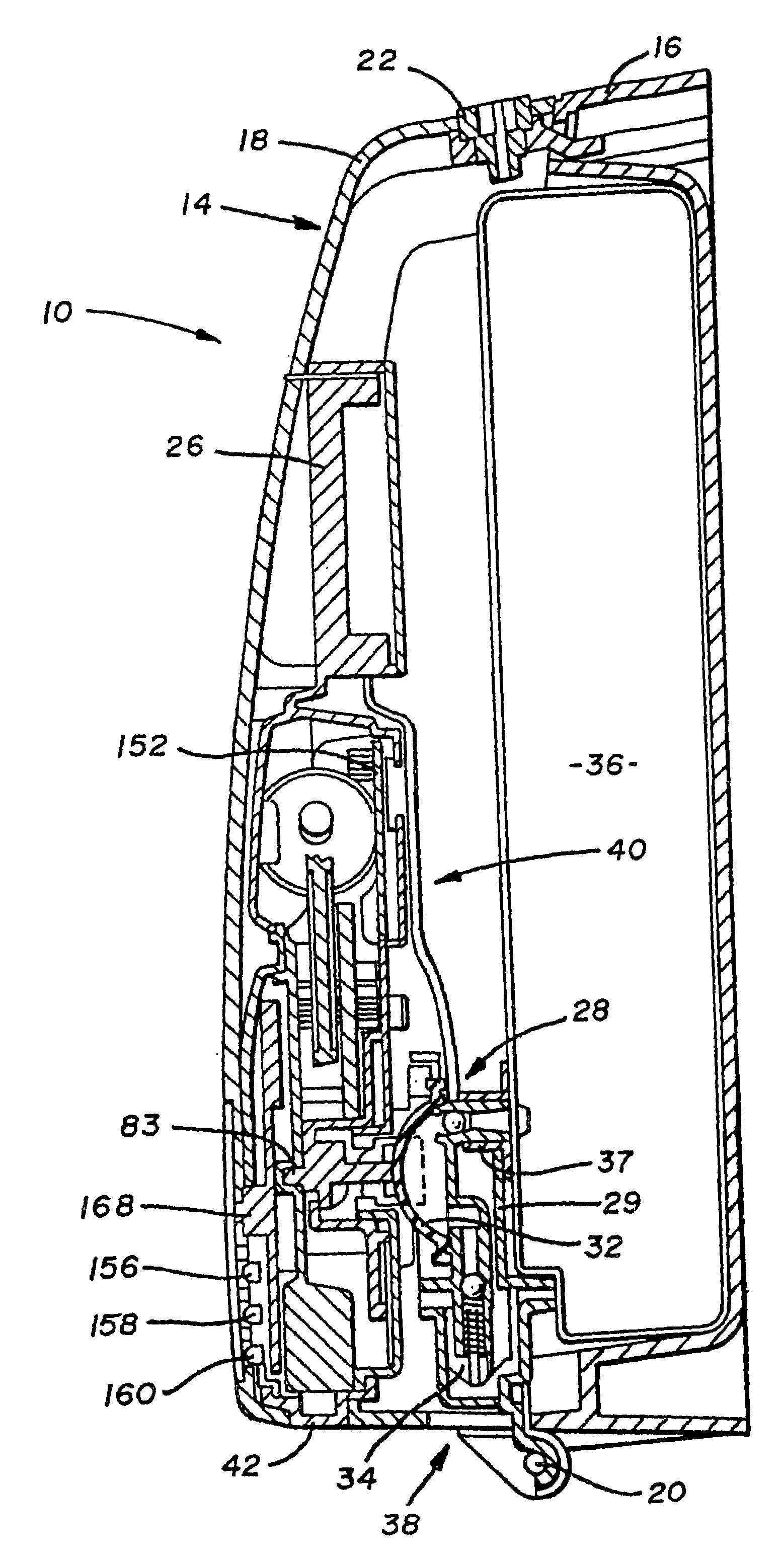

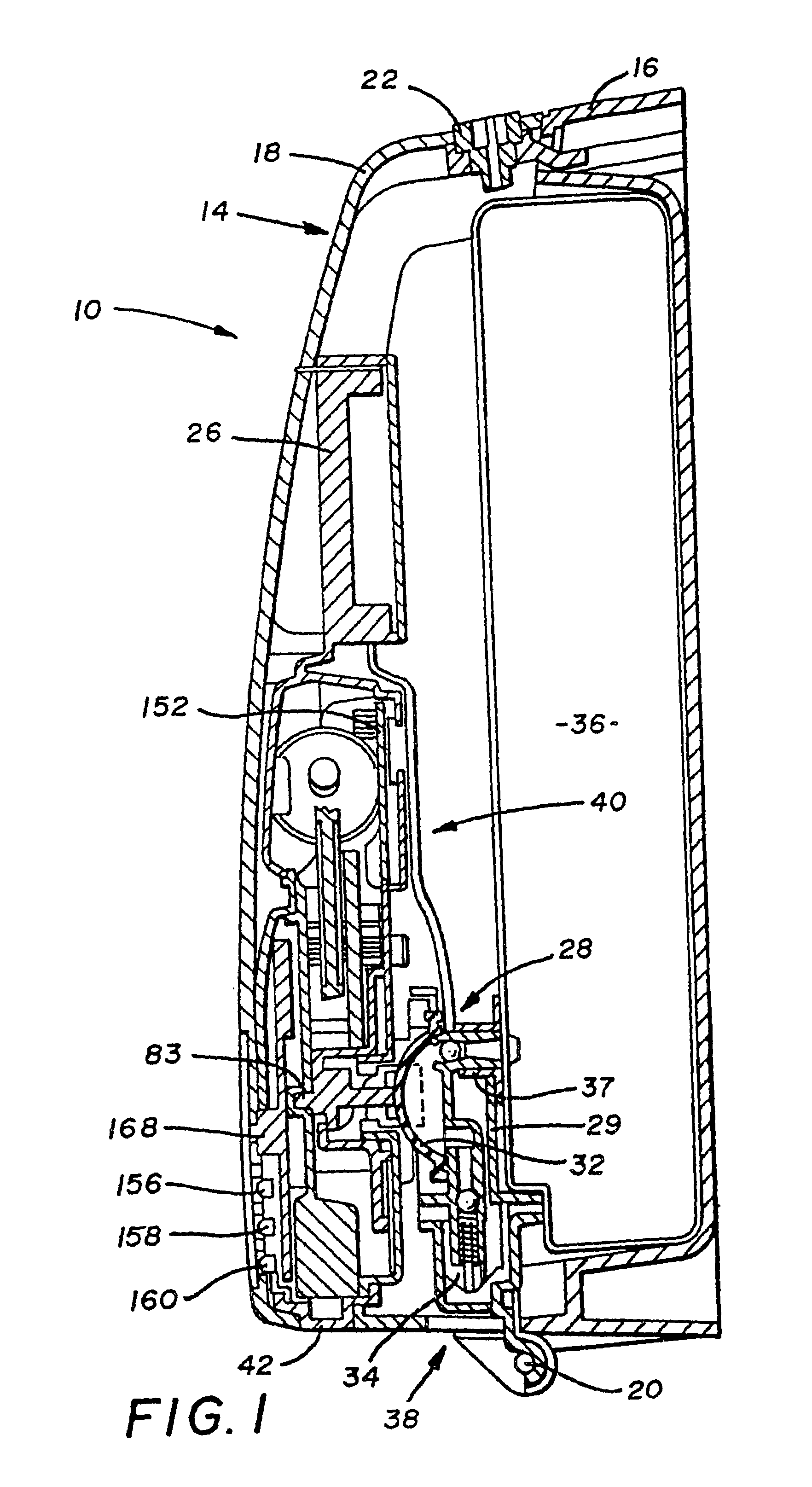

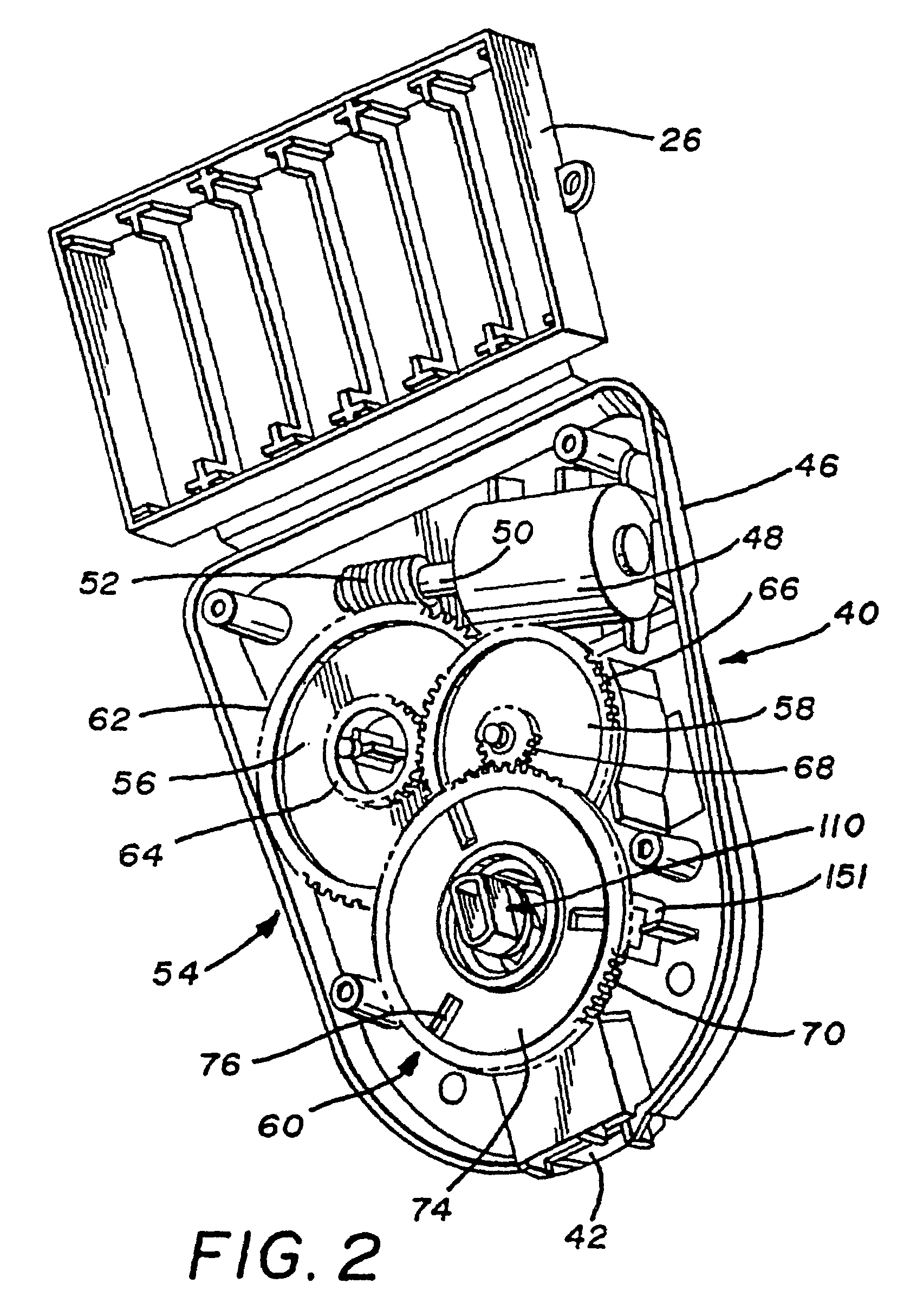

Airpot beverage dispenser and method

ActiveUS7798373B1Opening closed containersBottle/container closureCapacitanceElectrical resistance and conductance

An airpot beverage dispenser (10) having a composite dispense tube (40) with an exterior outlet (44) adjacent a top of a hollow body (20) and an interior inlet (110) located adjacent a bottom (16) for passing beverage (36) from adjacent the bottom (16) to the outlet when the interior of the hollow body (20) is pressurized has a brew-through assembly with a cover body (24) for substantially closing the open top (18) except for a centrally located brew-through passageway (95) substantially smaller than the open top (18) and extending between an upwardly facing exterior brew-through inlet (30) and an interior outlet (102) that passes through a central passageway extending through a double-walled bellows (74) or extends past a plurality of bellows (FIG. 16, 114) that are laterally spaced from the passageway has an electronic display (48) for indicating a plurality of levels of the beverage (36) within the hollow body and a resistive (FIGS. 11-14) or capacitive (FIG. 21) electronic level sensing assembly carried by the dispense tube (40) for sensing a plurality of different levels of beverage (36) within the hollow body and electrical leads (170, 172) printed on the dispense tube to pass the sensing signals to a display controller (127). The display, controller and portable power source (123) are protectively contained within a plastic watertight compartment (126) integrally formed with the cover body (24) is vented (FIG. 20) to prevent the accumulation of moisture within the compartment (126).

Owner:FOOD EQUIP TECH

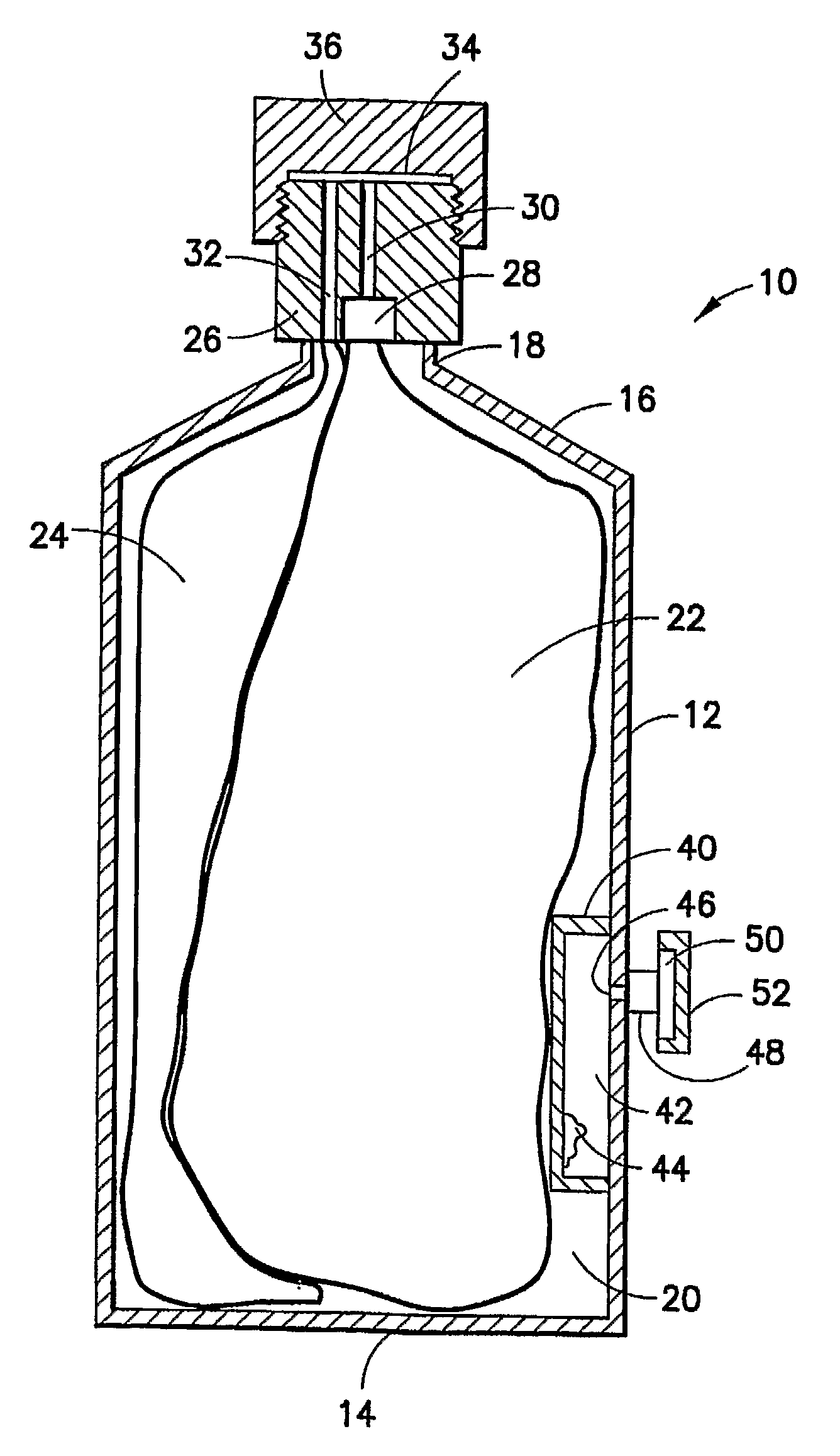

Method and apparatus for dispensing fluids

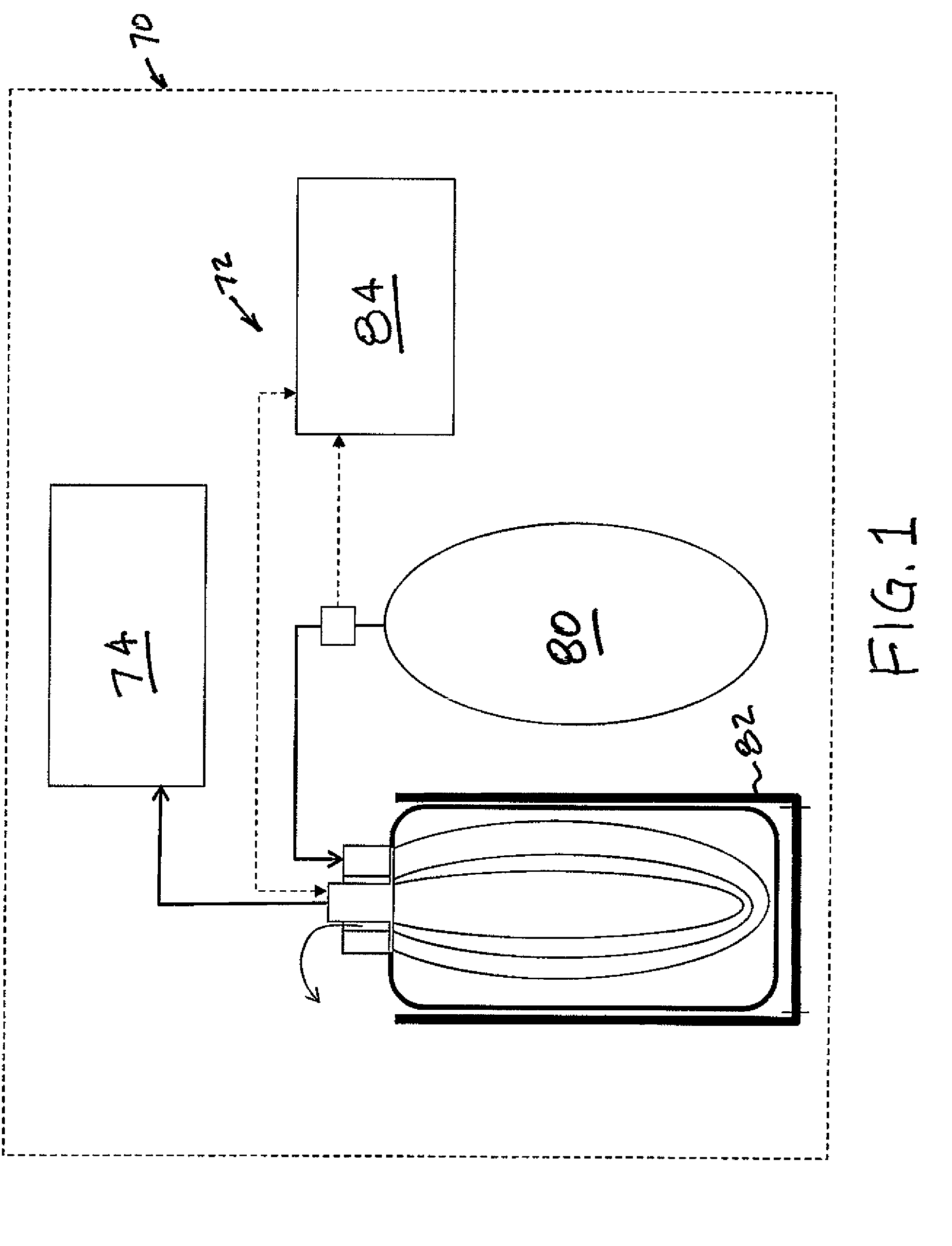

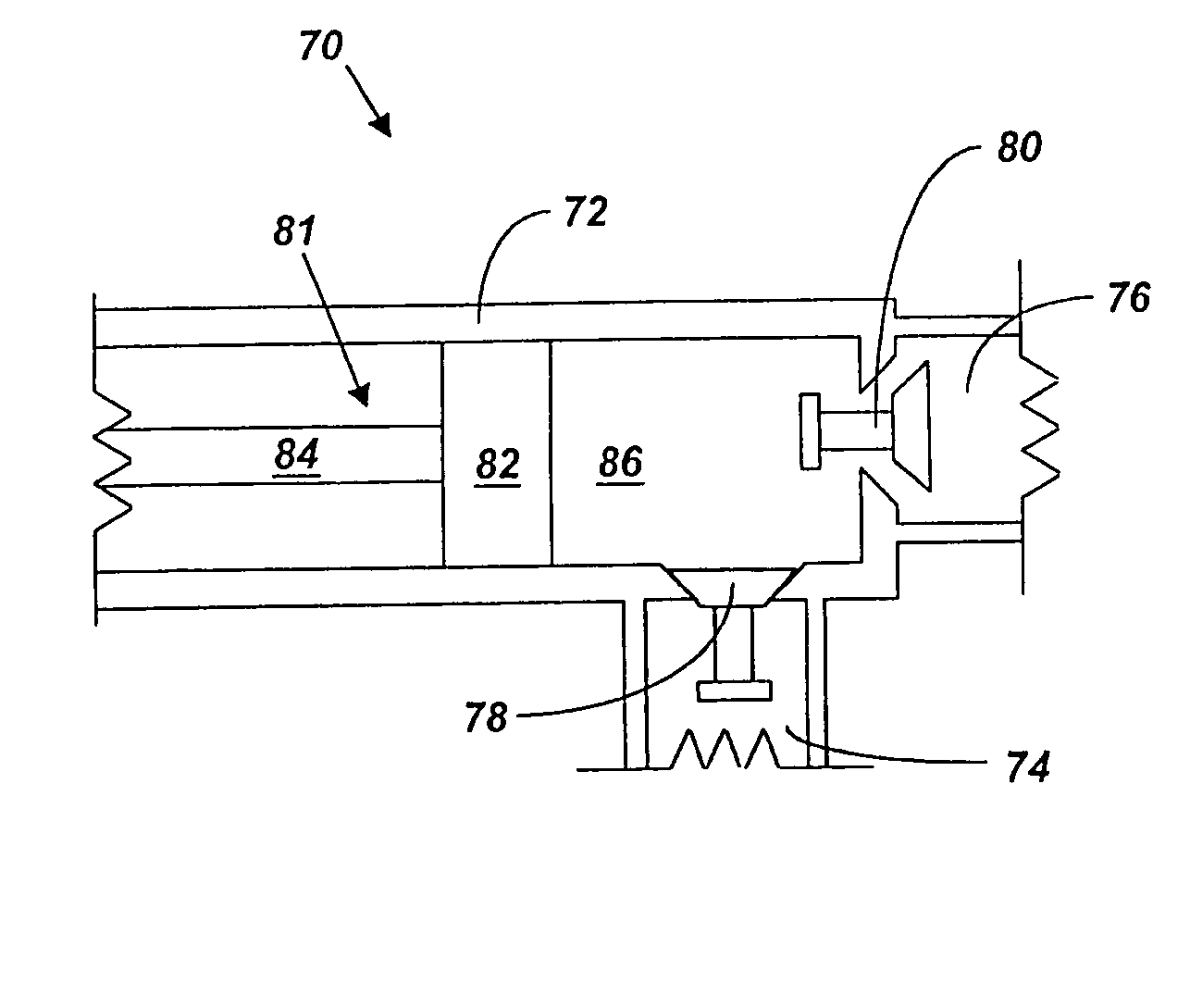

ActiveUS20090057347A1Quick and easy engagementQuick and easy and releaseOpening closed containersBottle/container closureCouplingEngineering

A bag-in-bag-in-bottle assembly formed by a flexible dispensing container with a dispensing fitment. The dispensing container is positioned adjacent or sandwiched between one or more flexible pressurization containers having a separate inlet / outlet path through a second fitment. The bag-in-bag assembly can then be placed in a containment vessel with the fitments mounted such that it is accessible on the vessel. A liquid can be extracted from the dispensing container by introducing a fluid into the pressurization container(s) with enough pressure to force the liquid out through the dispensing fitment. A contoured dispensing head may be coupled to the bag-in-bag-in-bottle assembly using a earn actuation arrangement for simultaneously locking the pressurization, vent and fluid extraction couplings.

Owner:ENTEGRIS INC

Fluid dispensing system suitable for dispensing liquid flavorings

InactiveUS20050103799A1Opening closed containersBottle/container closureEngineeringMechanical engineering

A fluid dispensing apparatus includes a pulse generator coupled to a pump that operates in discrete cycles. Each cycle includes a first part in which fluid is drawn into the pump through an inlet, and a second part in which fluid is expelled from the pump through an outlet. Each cycle results in a discrete, consistent volume of fluid being expelled. The pulse generator transmits discrete pulses to the pump, causing the pump to operate for a set number of cycles per pulse. The total number of cycles is a multiple of the number of pulses transmitted, so that the number of pulses determines the volume of fluid dispensed. Alternatively, the pump is driven through increments of the second part of the cycle, with the number of pulses supplied to the pump determining the proportion of the second part of the cycle completed, and therefore the volume of fluid dispensed.

Owner:ZAVIDA COFFEE

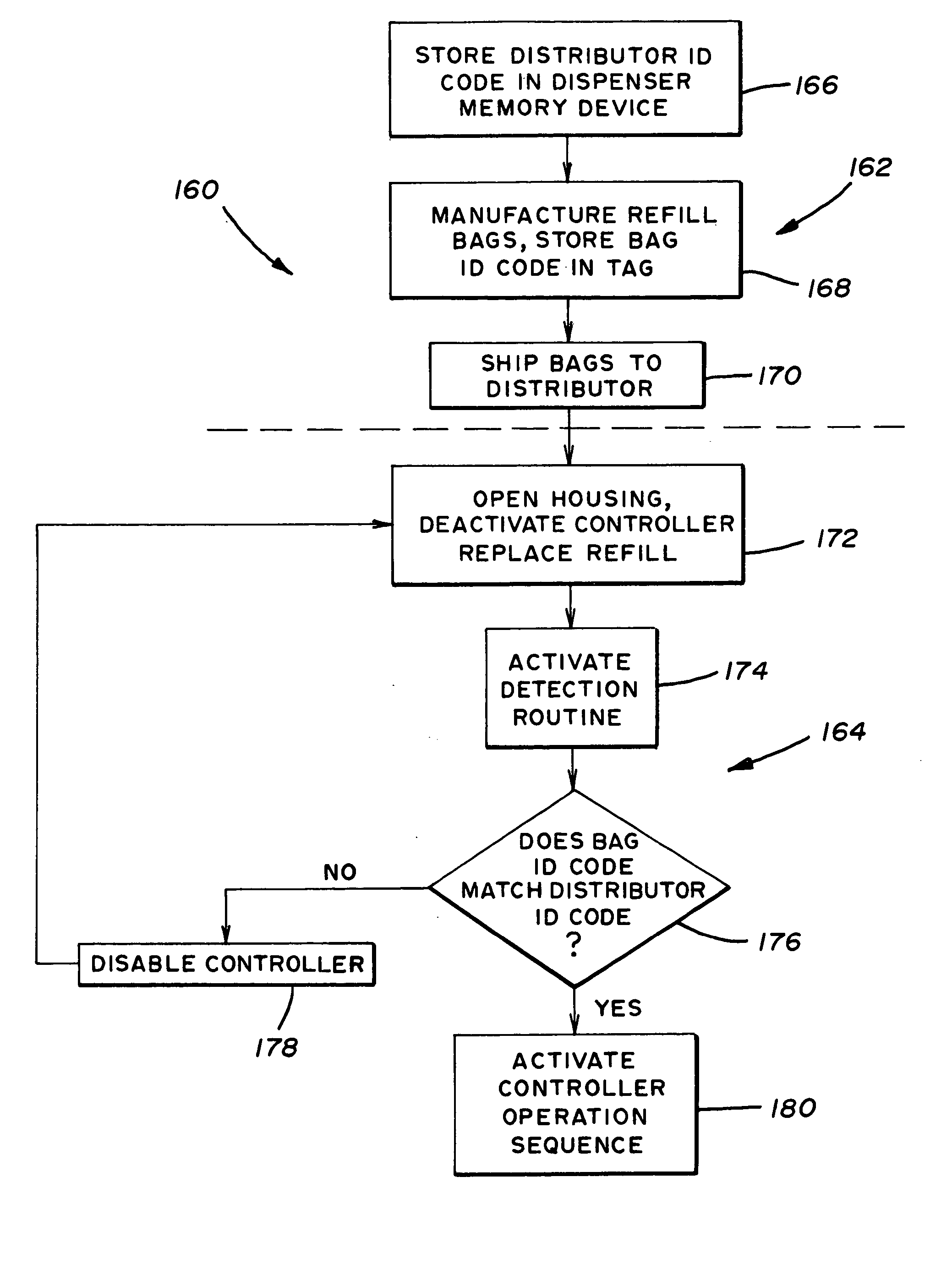

Electronically keyed dispensing systems and related methods of installation and use

Dispensing systems are disclosed which utilize electronically powered key devices and / or identification codes associated with a refill container to preclude the need for mechanical keys. A first embodiment of the device utilizes a matching code stored in a radio frequency identification tag or bar code associated with a fluid refill container and an identification code associated with the dispenser housing. Matching of the codes by a controller allows for continued use of the dispenser via some type of operational mechanism. Another embodiment employs a key which carries the matching code wherein matching of the codes allows for actuation of a motor actuated pumping device. Yet another embodiment employs a blocking mechanism to prevent use of a dispenser's push bar if a key and dispenser housing do not have matching codes. And yet another embodiment requires the use of a key that has a matching code that matches the dispenser's identification code in order to permit initial access to the dispenser housing.

Owner:JOSEPH S KANFER

Apparatus for hands-free dispensing of a measured quantity of material

InactiveUS7611030B2Easy to operateHelp positioningOpening closed containersTime indicationEngineeringHands free

An apparatus for automatically dispensing a fluid includes a container adapted to carry a supply of fluid, and a valve connected to the container, wherein actuation of the valve dispenses the fluid. An apparatus position indicator is associated with the container and an object sensor is positioned near the valve. The object sensor monitors an area below where the valve dispenses when open and upon detection of an object opens the valve. Initial positioning of the apparatus triggers the apparatus position indicator to generate an appropriate signal until the object sensor is properly positioned and permanently secured. A control circuit in cooperation with a hidden switch allows programming of lighting indicators, dispense cycle size, and dispense quantities. The control circuit also provides for overload protection, motor braking and RF shielding. And an anti-vandal feature prevents excessive use of the apparatus.

Owner:JOSEPH S KANFER

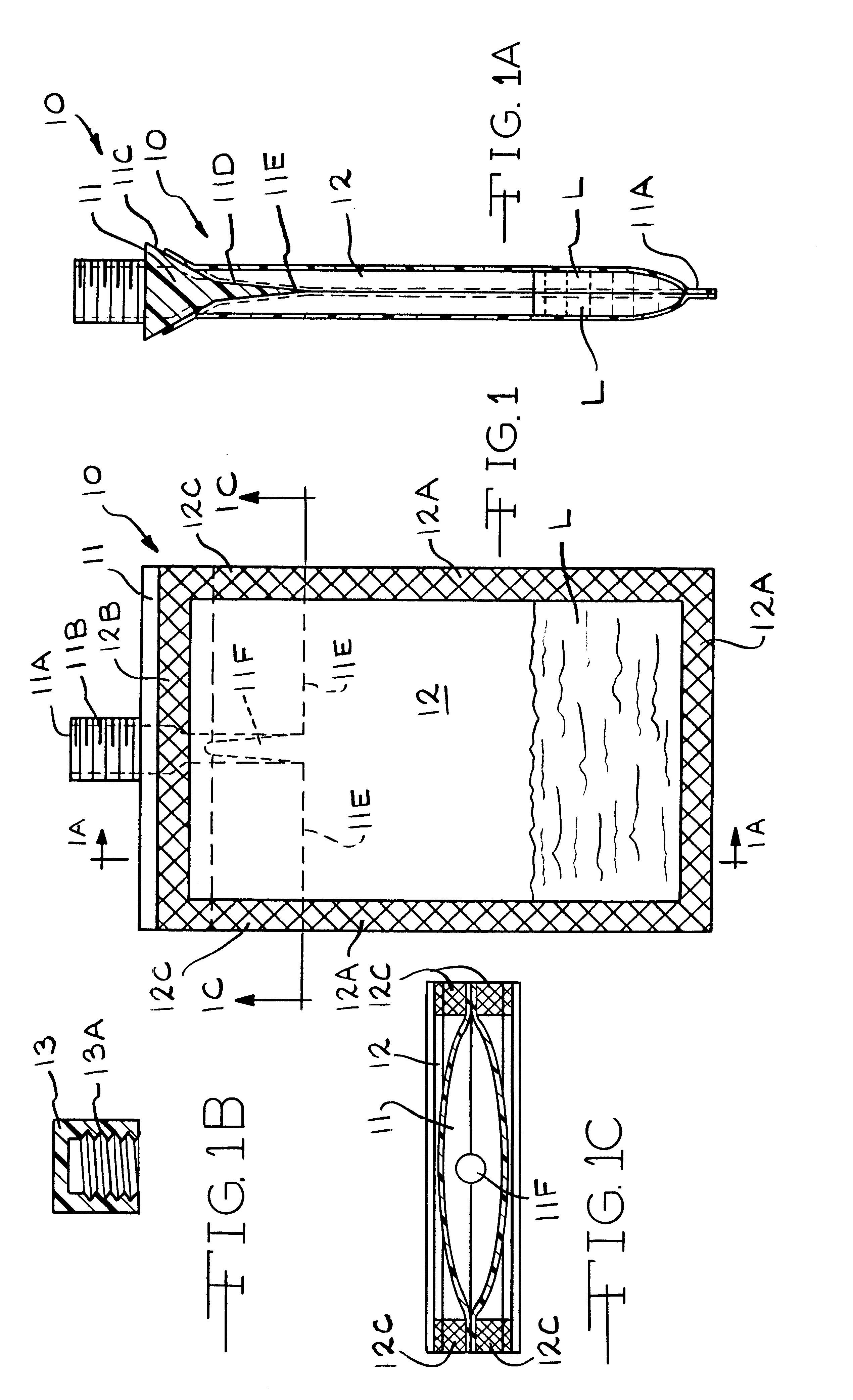

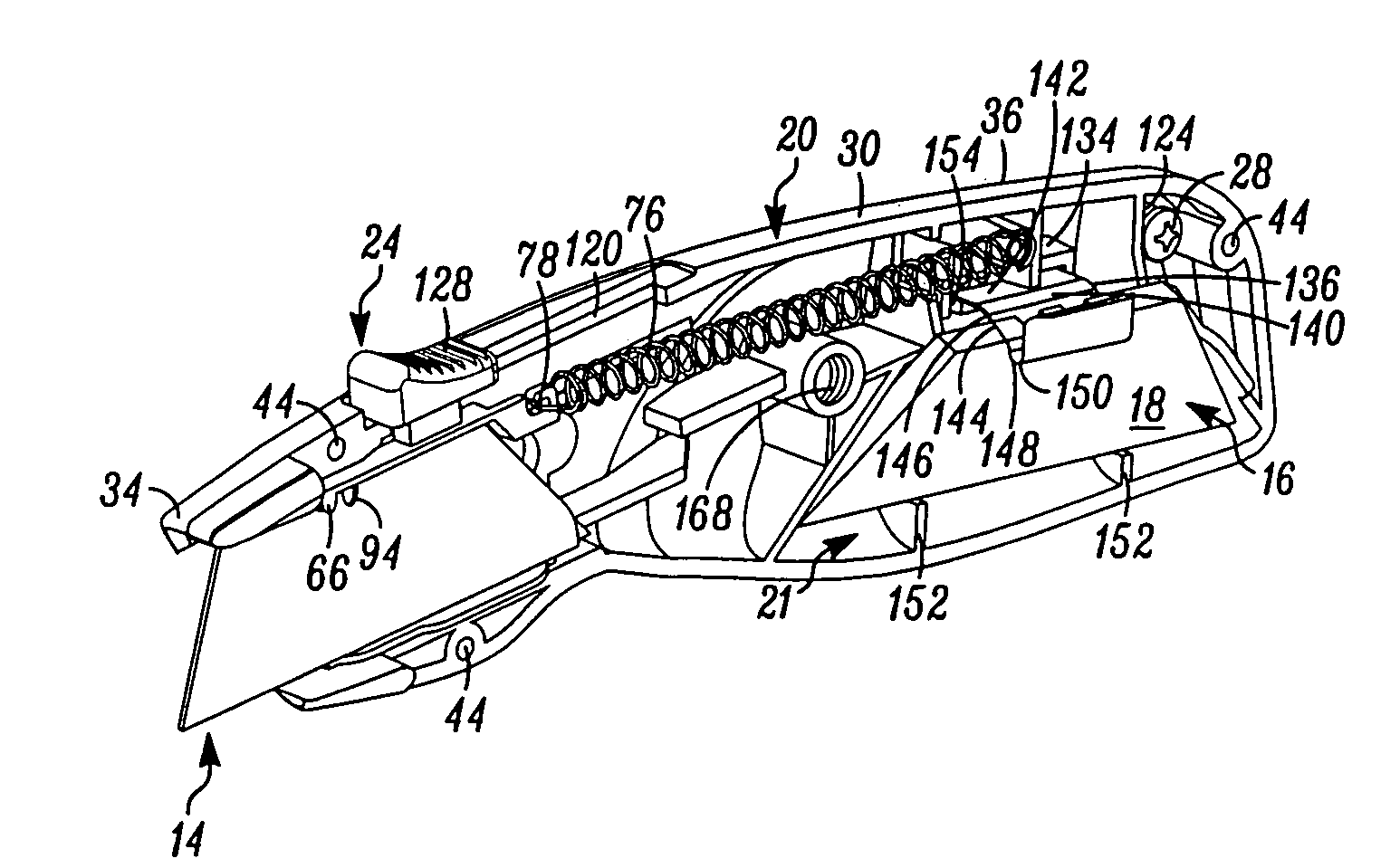

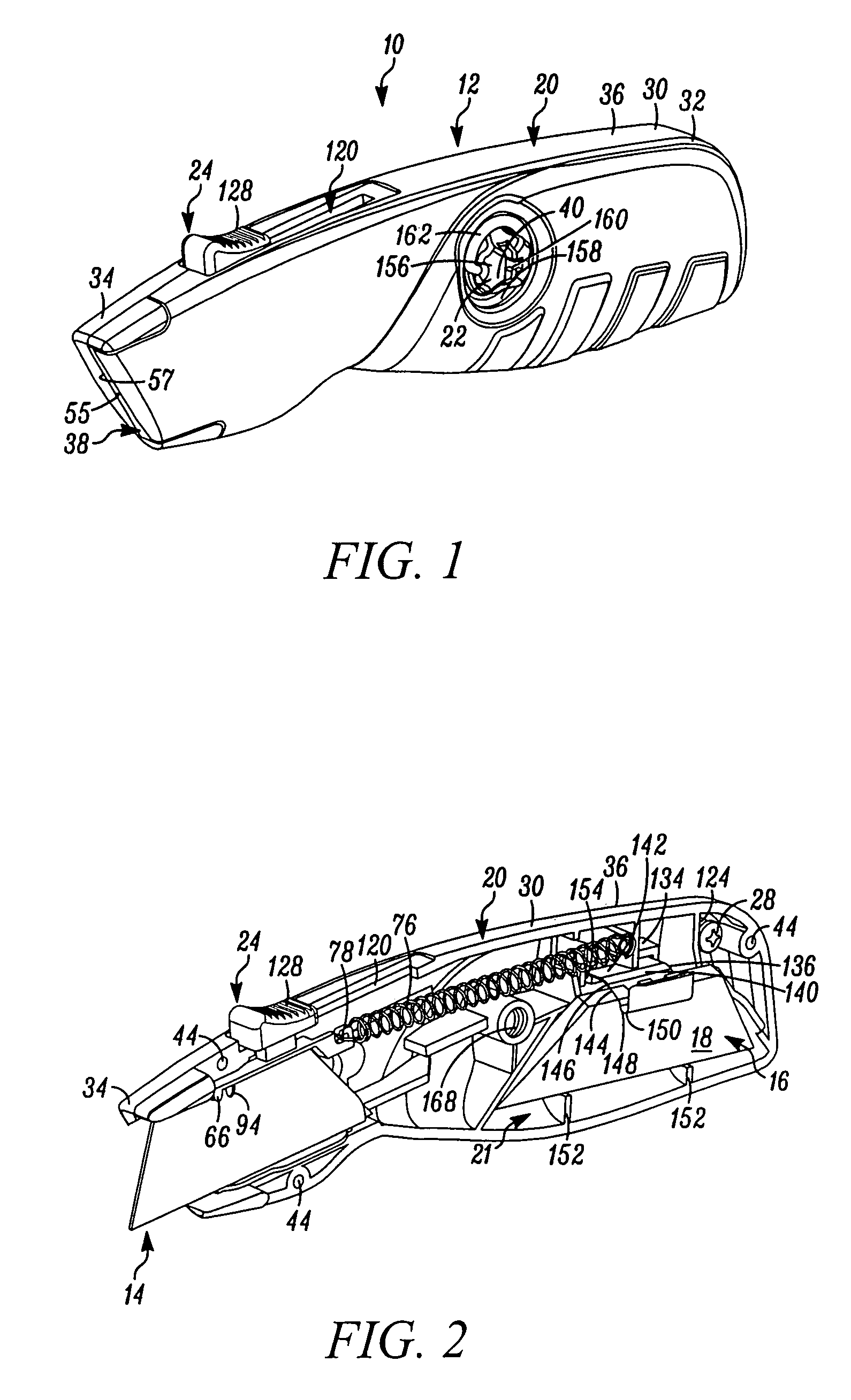

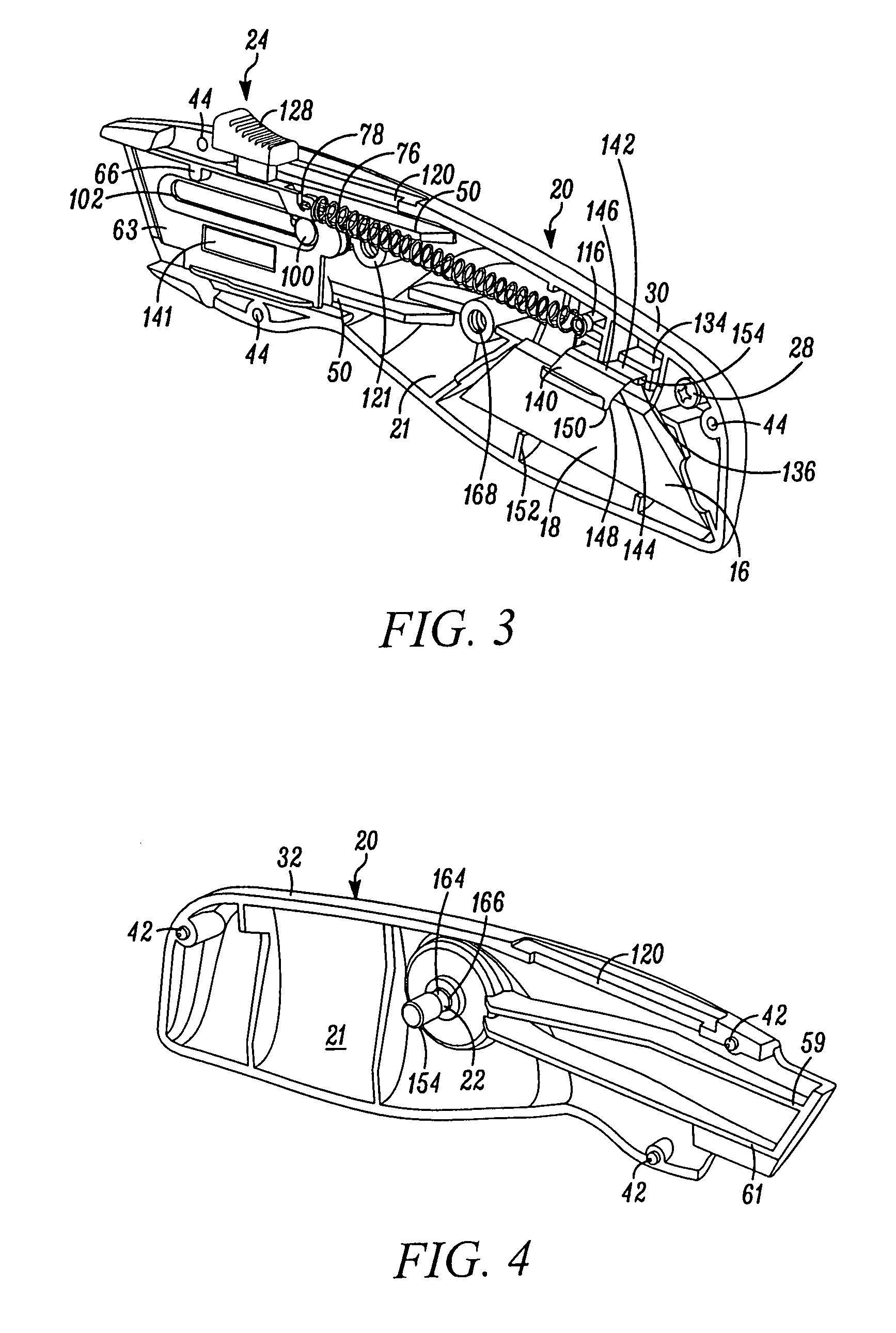

Self-retracting utility knife

ActiveUS7316070B2Avoid the needNarrow handleOpening closed containersBottle/container closureActuatorSupport surface

A utility knife includes a housing and a blade carrier movably mounted to the housing. The blade carrier includes a blade supporting surface for supporting a blade, wherein the blade carrier is movable between a retracted position with at least a substantial portion of the blade retracted in the housing, and a first extended position with at least a portion of the blade extending outwardly of the housing. An actuator is operably connected to the blade carrier and is operable to move the blade carrier between the retracted and extended positions to, in turn, move a blade located on the blade carrier between the retracted and extended positions. A biasing member biases the blade carrier toward the retracted position. A stop member is movable between a first position and a second position. In the first position, the stop member is engagable with the blade carrier to thereby limit extension of the blade carrier and blade located thereon to a second extended position spaced inwardly on the housing relative to the first extended position. In the second position of the stop member, the stop member is spaced away from the blade carrier to thereby permit movement of the blade carrier and blade located thereon to the first extended position.

Owner:BLACK & DECKER INC

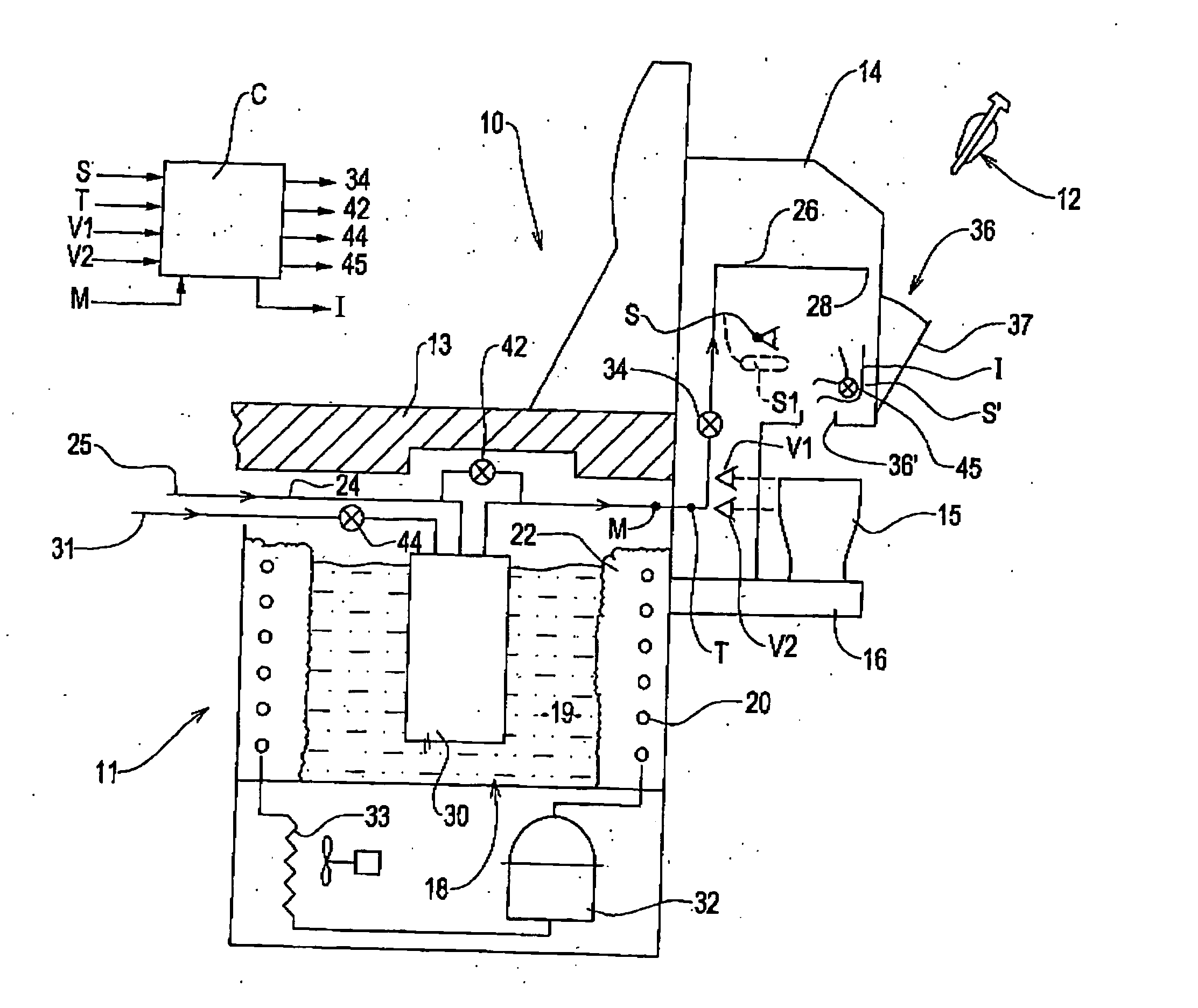

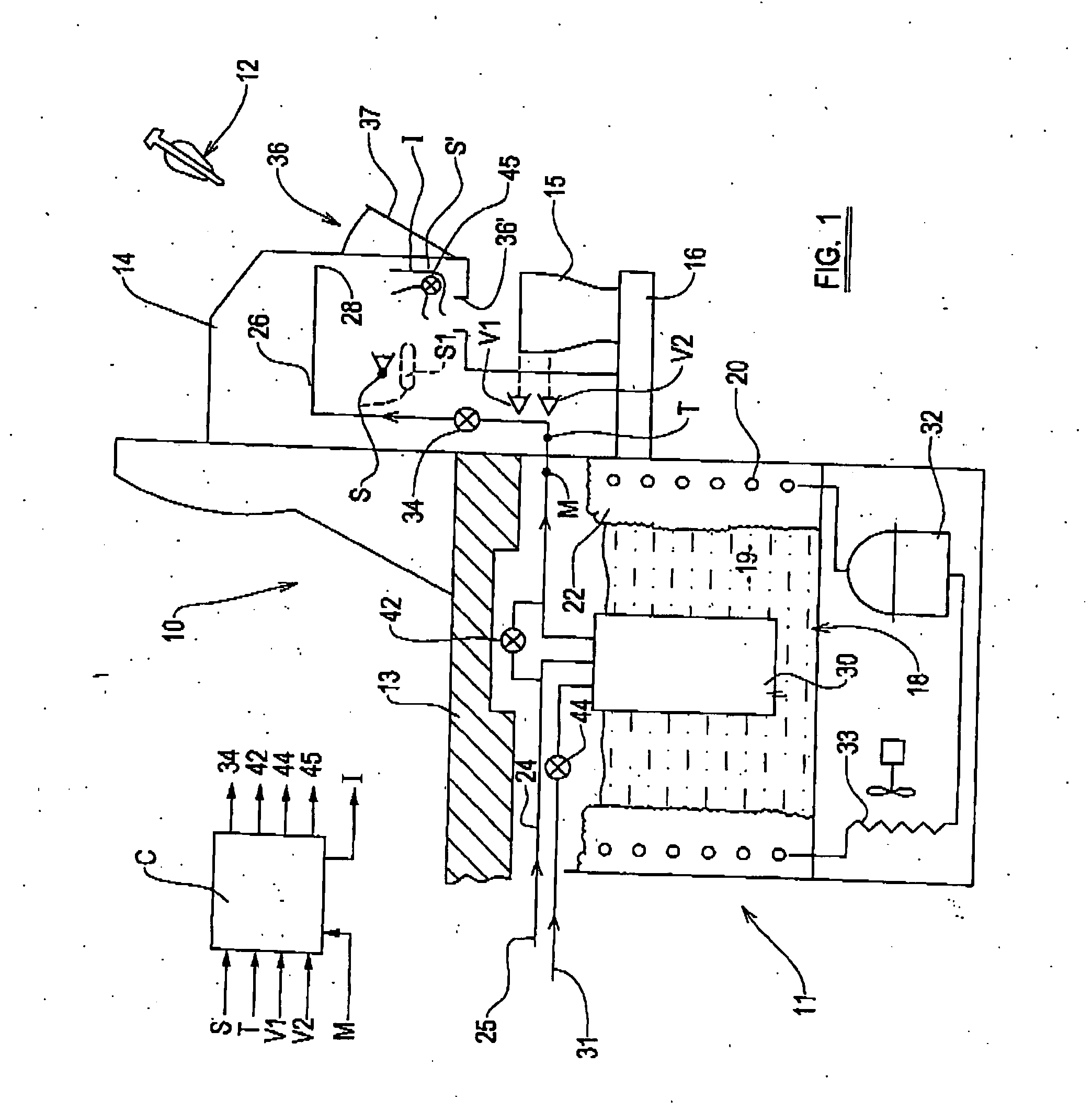

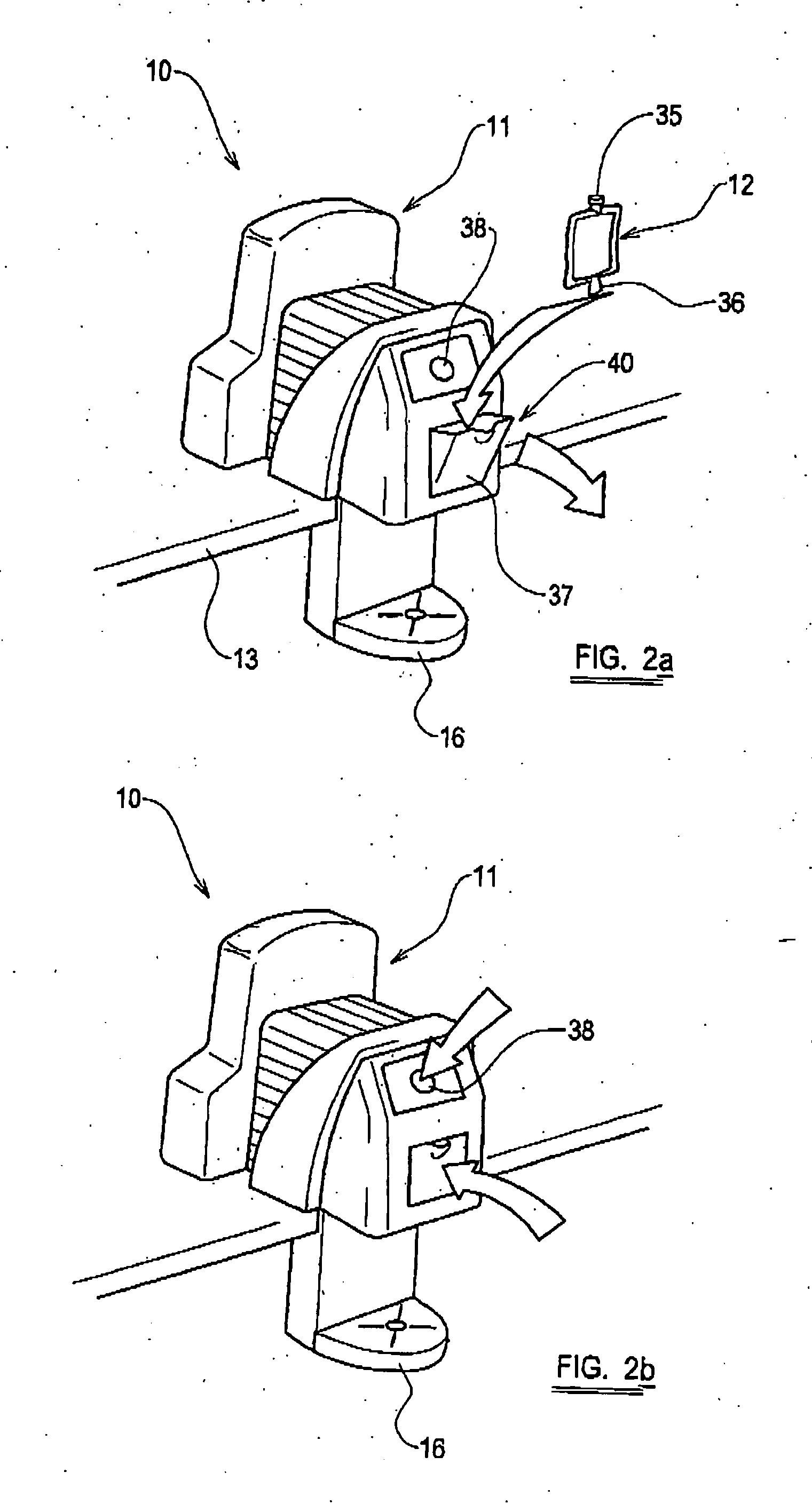

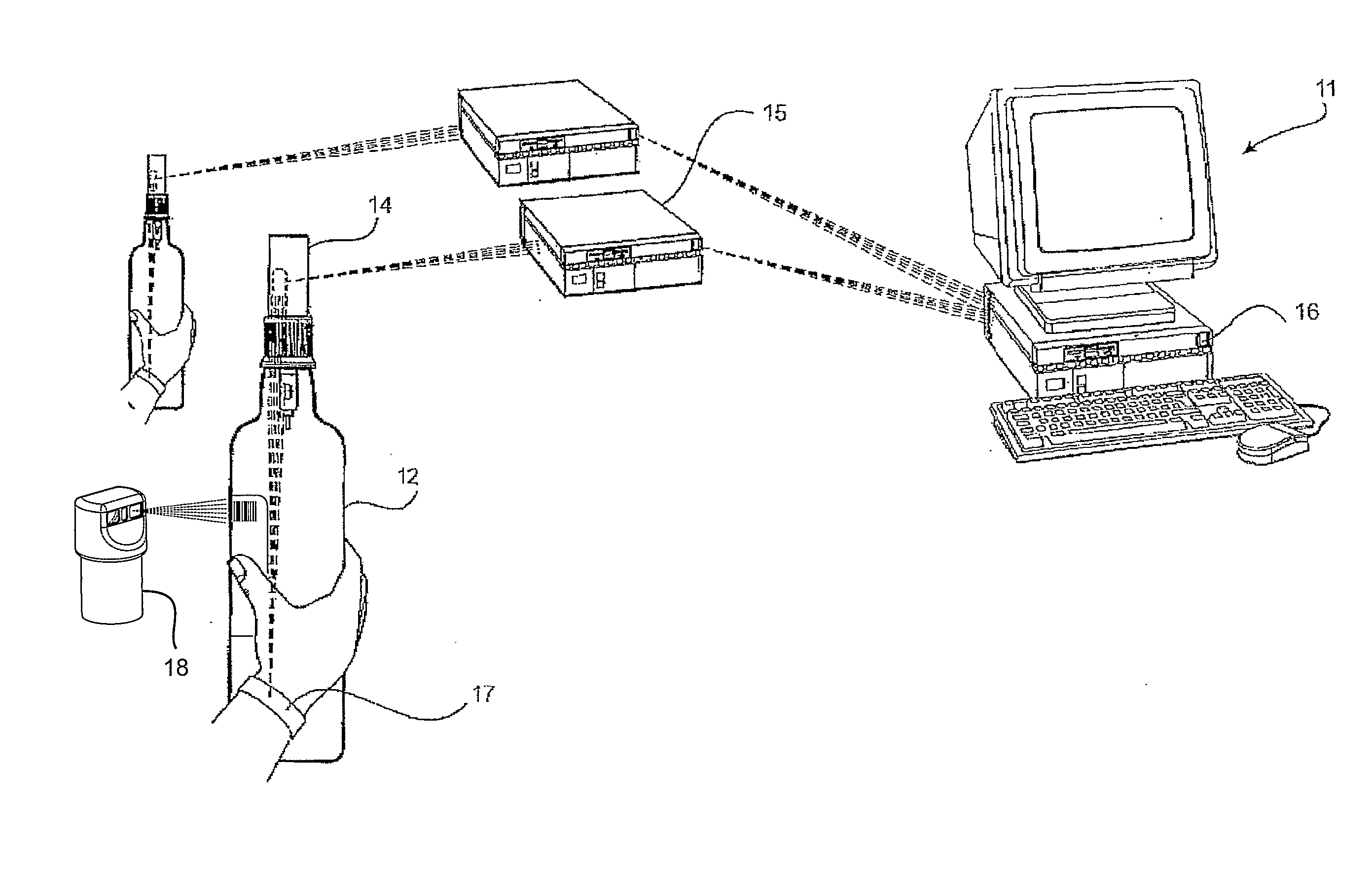

Beverage Control System

InactiveUS20080195251A1Prevent rotationOpening closed containersBottle/container closureDistribution controlPinch valve

Pourer (14) including a beverage dispensing controller (23) including a pinch valve solenoid (40, 83) to control the dispensing of a beverage; a cap (21) includes a locking system to releasably secure the cap to a beverage container (12). The cap has a cap body (31) having an outer duct (43), and the locking system includes a collar (32) with a central aperture for receiving and allowing the collar (32) to pass over the outer duct, and a locking tab located on the cap body. A clamp (34) is engaged by a slide (33) to thereby secure the cap to the container (12) and a locking pin (38) which when engaged acts to prevent rotation of the collar (32). Also, disclosed is a system (FIG. 2) that includes the pourer (14) having a unique identification (ID) and can trasmit wireless signals to a base station (15) about the amount of beverage dispensed; a personal identification unit (17) such as a passive RFID tag to identify the barman pouring the beverage; and an infra-red sensor (7) to allow the pourer (14) to communicate with a container scanner (18) that reads the barcode on the container.

Owner:MILNER ANDREW

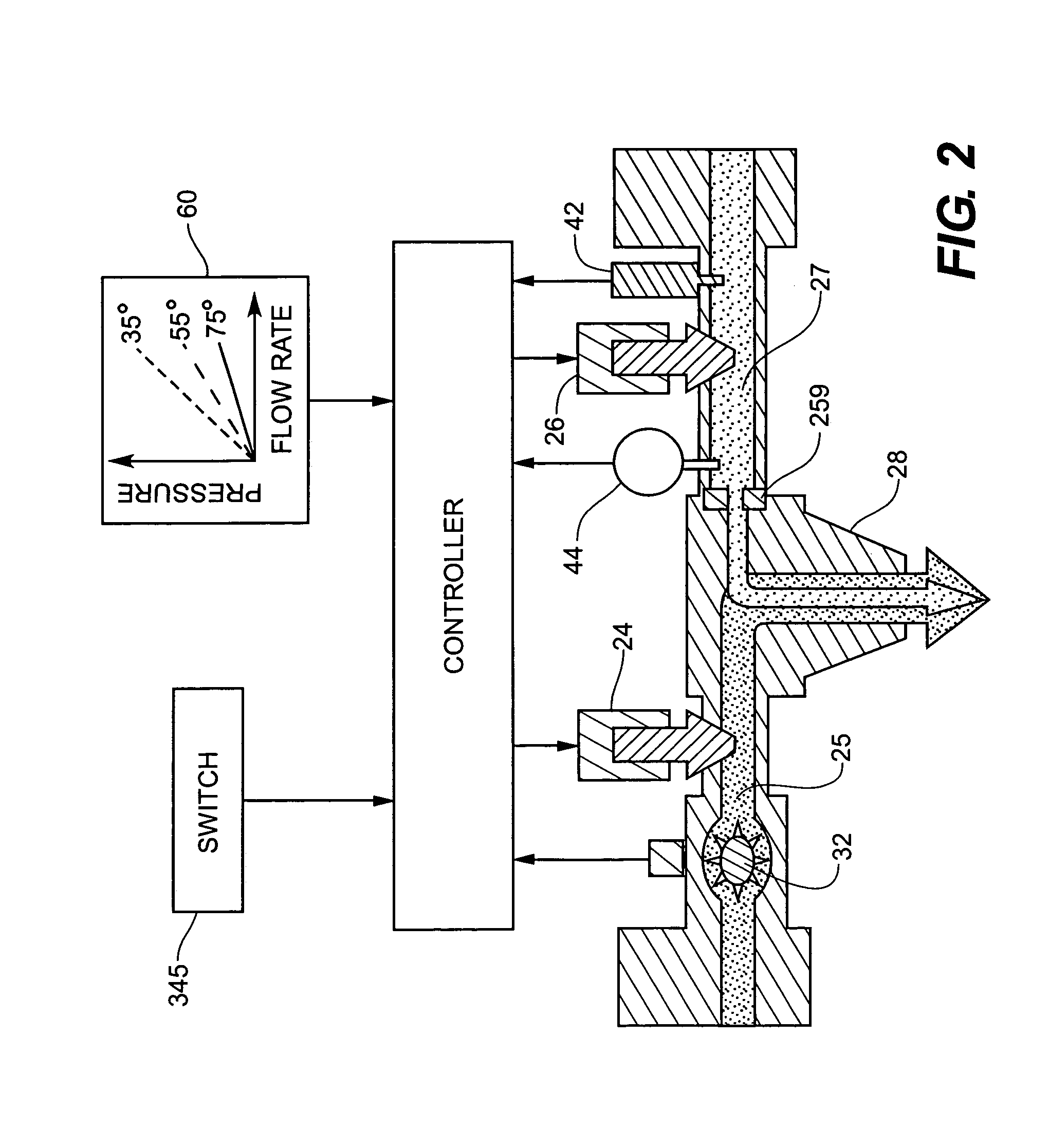

Beverage forming and dispensing system

InactiveUS7077290B2Quality improvementOpening closed containersBottle/container closureDiluentEngineering

A beverage dispensing system includes separate valves for controlling the flow rate of a diluent and a concentrate. Various concentrates of different viscosities can be used and the selected concentrate is identified. The flow rate of the concentrate is determined based on temperature and pressure and on information related to the identified concentrate. The valves are controlled so that the concentrate and diluent reach target flow rates. The target flow rates satisfy a target ratio of diluent to concentrate. If the actual flow rates cannot reach the target flow rates, then the target flow rates are modified to satisfy the target ratio. The structure of the concentrate valve is designed to accommodate proportional metering of any one of the various concentrates.

Owner:PEPSICO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com