Patents

Literature

302 results about "Calibration gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A calibration gas is a reference gas or gas mixture used as comparative standard in the calibration of analytical instruments, like gas analysers or gas detectors. Therefore, a calibration gas has to be of a precisely defined nature or composition, like zero gas or span gas, for example 500 ppm carbon monoxide in nitrogen.

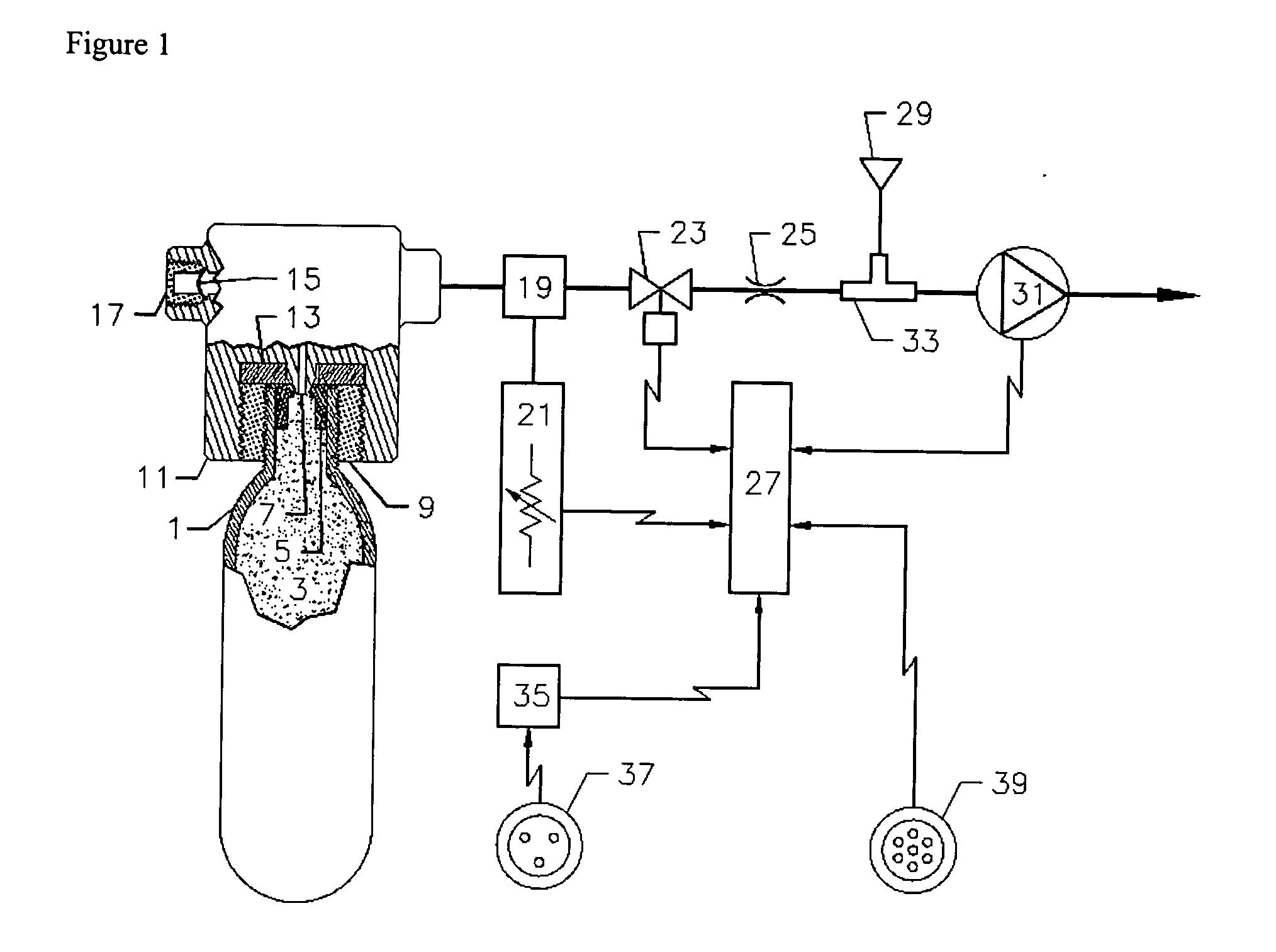

Apparatus and method for generating calibration gas

ActiveUS20050000981A1Low costAccurate concentrationOpening closed containersBottle/container closureDocking stationCalibration gas

An apparatus and method for generating a low concentration of gas within a carrier gas flow employing one or more miniature one-piece cylinders filled under pressure with a pure gas, or a concentrated gas balanced with an inert gas or gas mixture. Released from the cylinder through a pierced or other controlled opening, the flow of the gas is regulated by a pressure regulator and a micro orifice to be blended into a steady stream of diluent gas, typically ambient air, to form a desired gas concentration. No gas is generated if the pressure of the gas in the cylinder, which is monitored constantly by a pressure transducer, is below a predetermined level. The apparatus can be built into a portable device, or an automated docking station (or calibration station) for testing and calibrating gas detection and monitoring instruments, or into a fixed gas detection system for performing such functions.

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

Self-calibrating carbon monoxide detector and method

InactiveUS6948352B2Analysing fluids using sonic/ultrasonic/infrasonic wavesSamplingHydrogenCalibration gas

The self-calibrating carbon monoxide detector and method of the present invention utilize the gas for which the detector was designed to detect as the calibration gas. Specifically, a carbon monoxide gas generator is included in the detector assembly, and is controller to produce a known amount of CO. The sensor response to the quantity of CO generated is monitored, and the calibration thereof adjusted as necessary. The operation of the gas generator is also monitored, and any failures are flagged for user attention. The gas generator specifically suppresses the generation of hydrogen through the materials used in its construction. Temperature effects may also be compensated either through control of gas generation control parameters or compensation of the sensor output in view of the generator temperature effects.

Owner:WALTER KIDDE PORTABLE EQUIP

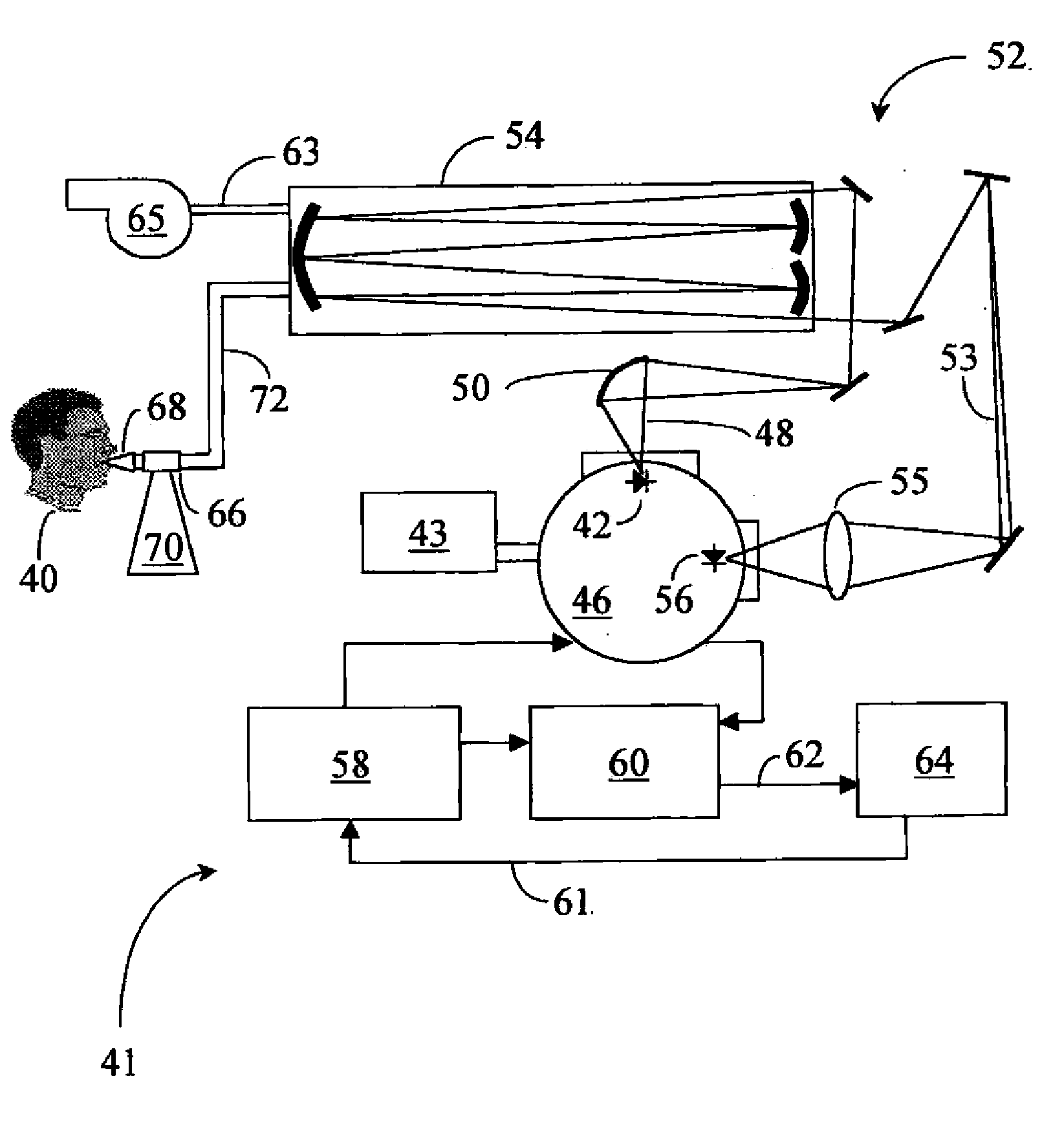

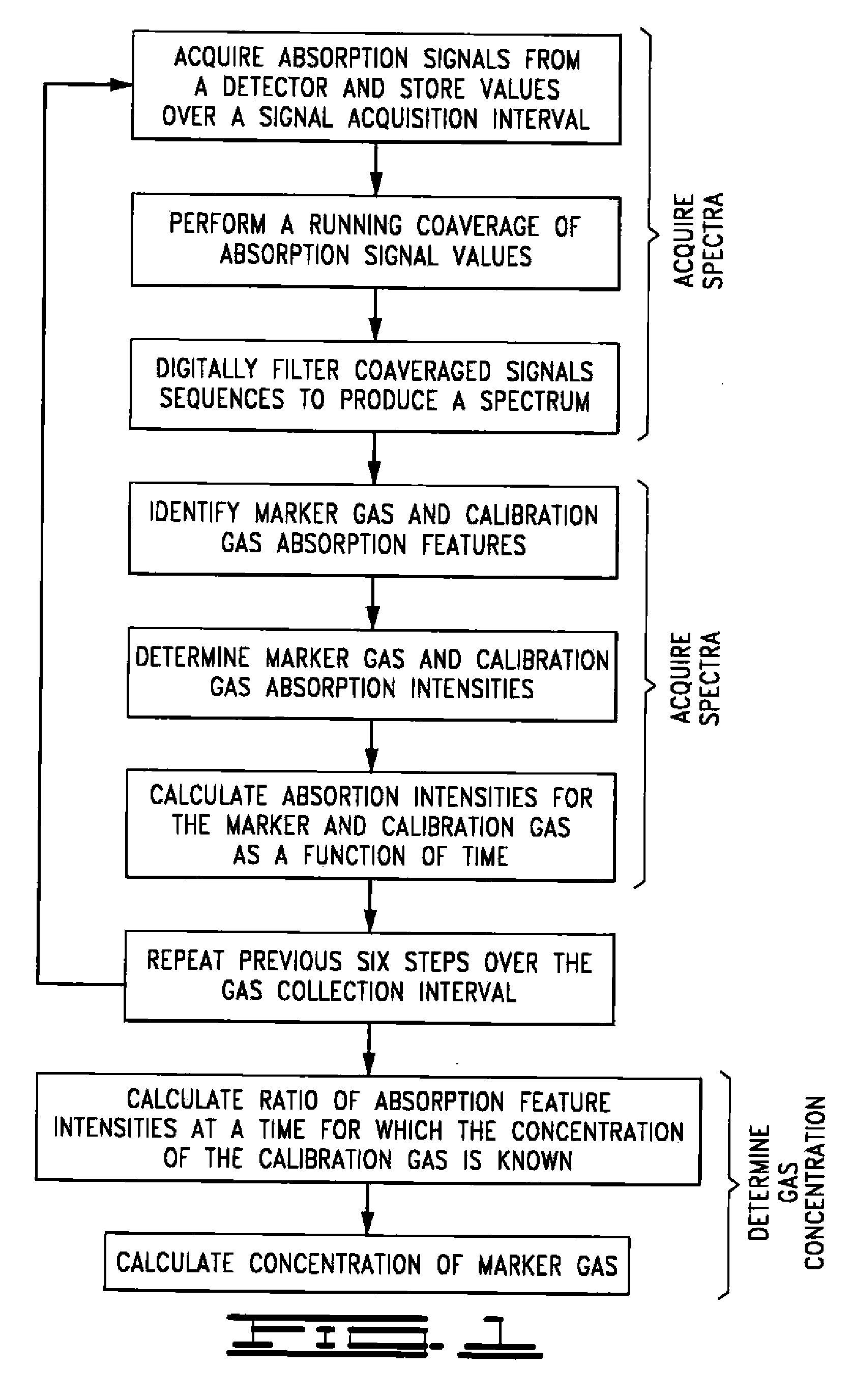

Method And Apparatus For Determining Marker Gas Concentration Using An Internal Calibrating Gas

InactiveUS20070081162A1Diagnostics using spectroscopyTransmissivity measurementsHuman airwayCalibration gas

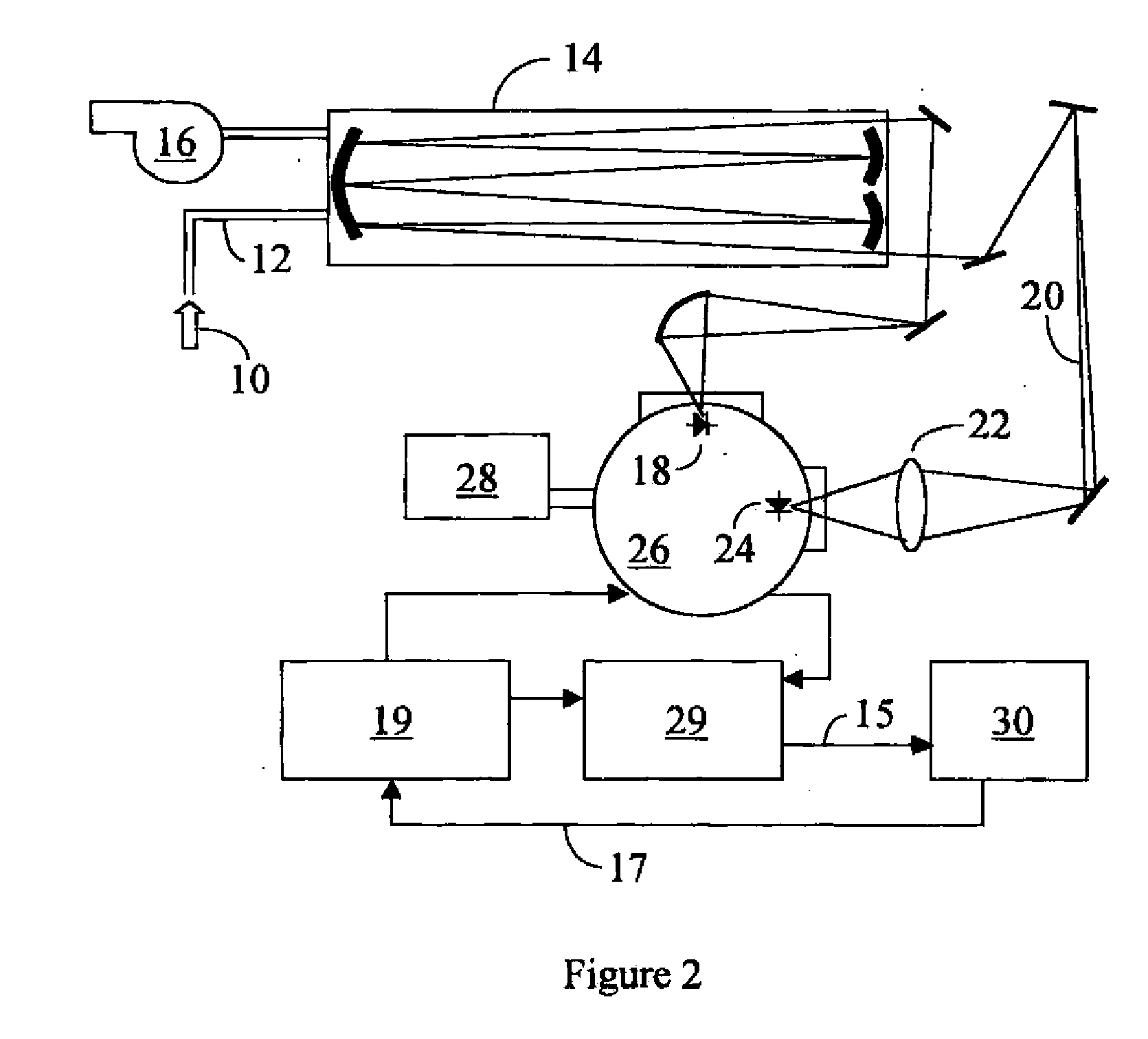

A method and an apparatus for measuring the concentration of a specific gas component of a gas mixture including another gas whose concentration is independently known using light absorption spectroscopy are provided. A method and an apparatus for assessing human airway inflammation by measuring the concentration of exhaled NO and CO2 present in orally exhaled breath using light absorption spectroscopy are also provided. NO concentration is determined at the time during breath sampling corresponding to a known exhaled CO2 concentration. Methods and apparatus are further provided for measuring NO concentration in orally exhaled human breath that analyze breath emanating from the lower airways and lungs, while excluding breath from the nasal cavity. They include steps and apparatus for discarding initially exhaled breath, flowing breath through an analysis chamber using a vacuum pump and flowing breath through an analysis chamber using a vacuum pump at an initial flow rate and later at a flow rate higher than the initial flow rate.

Owner:EKIPS TECH

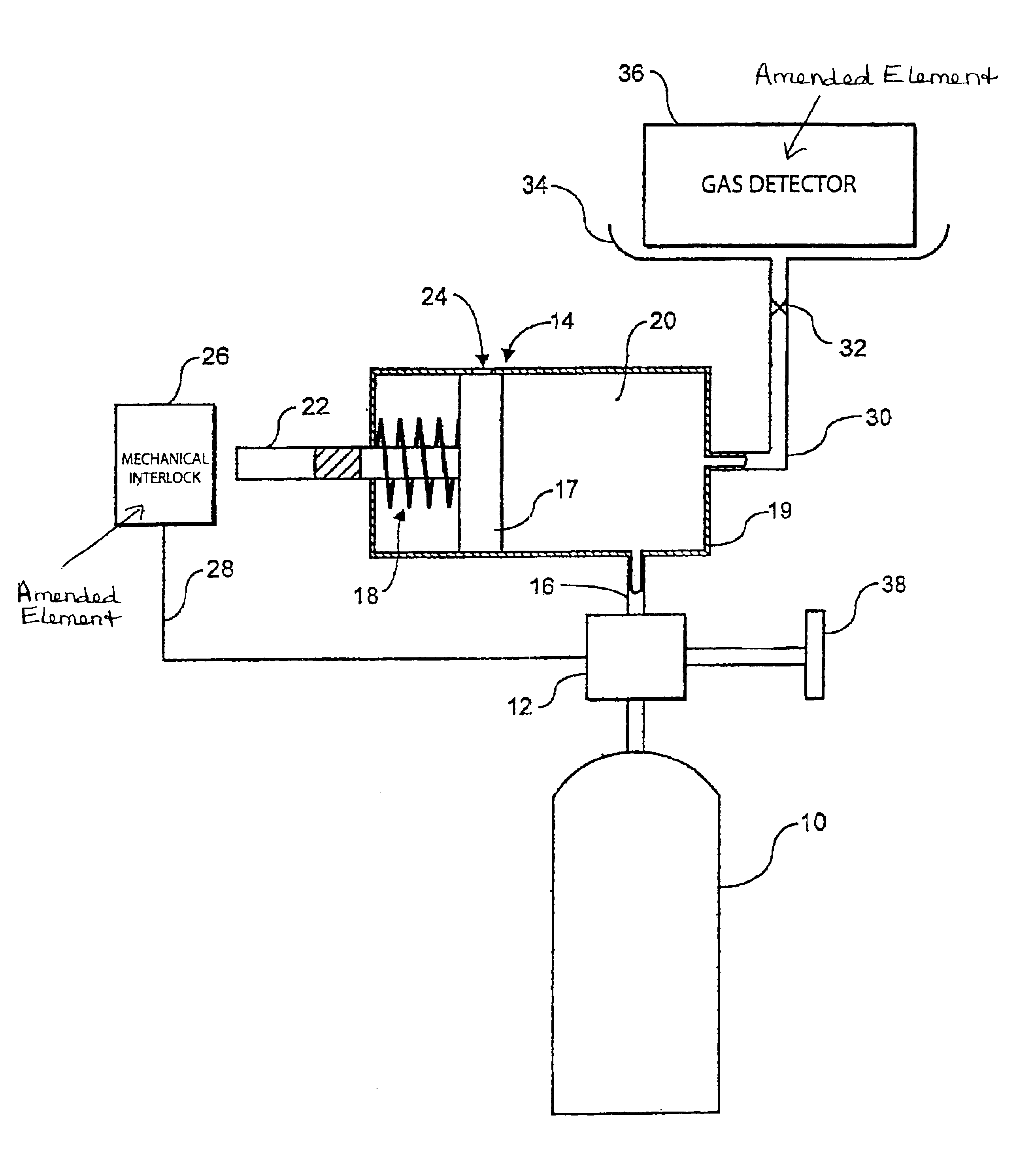

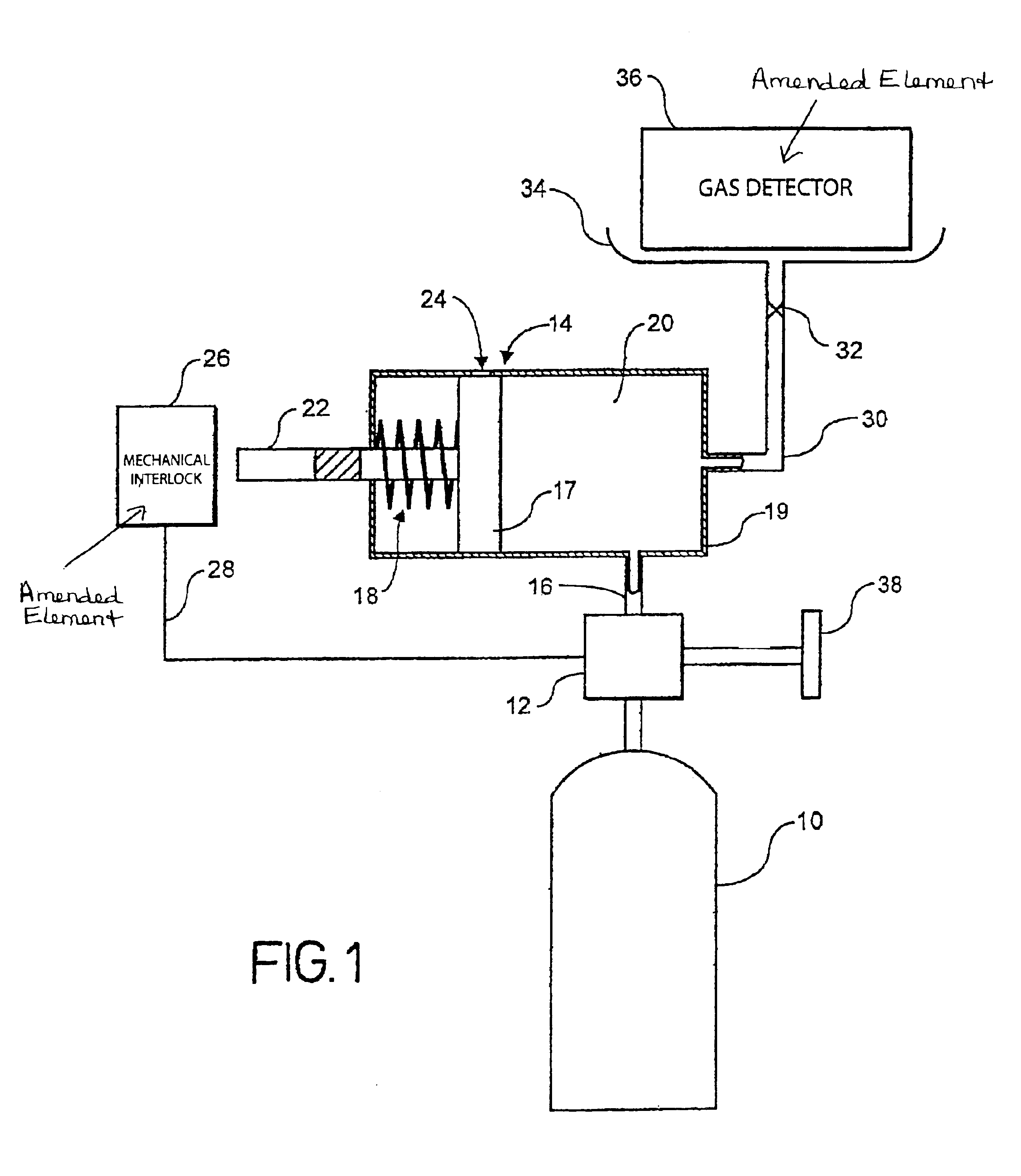

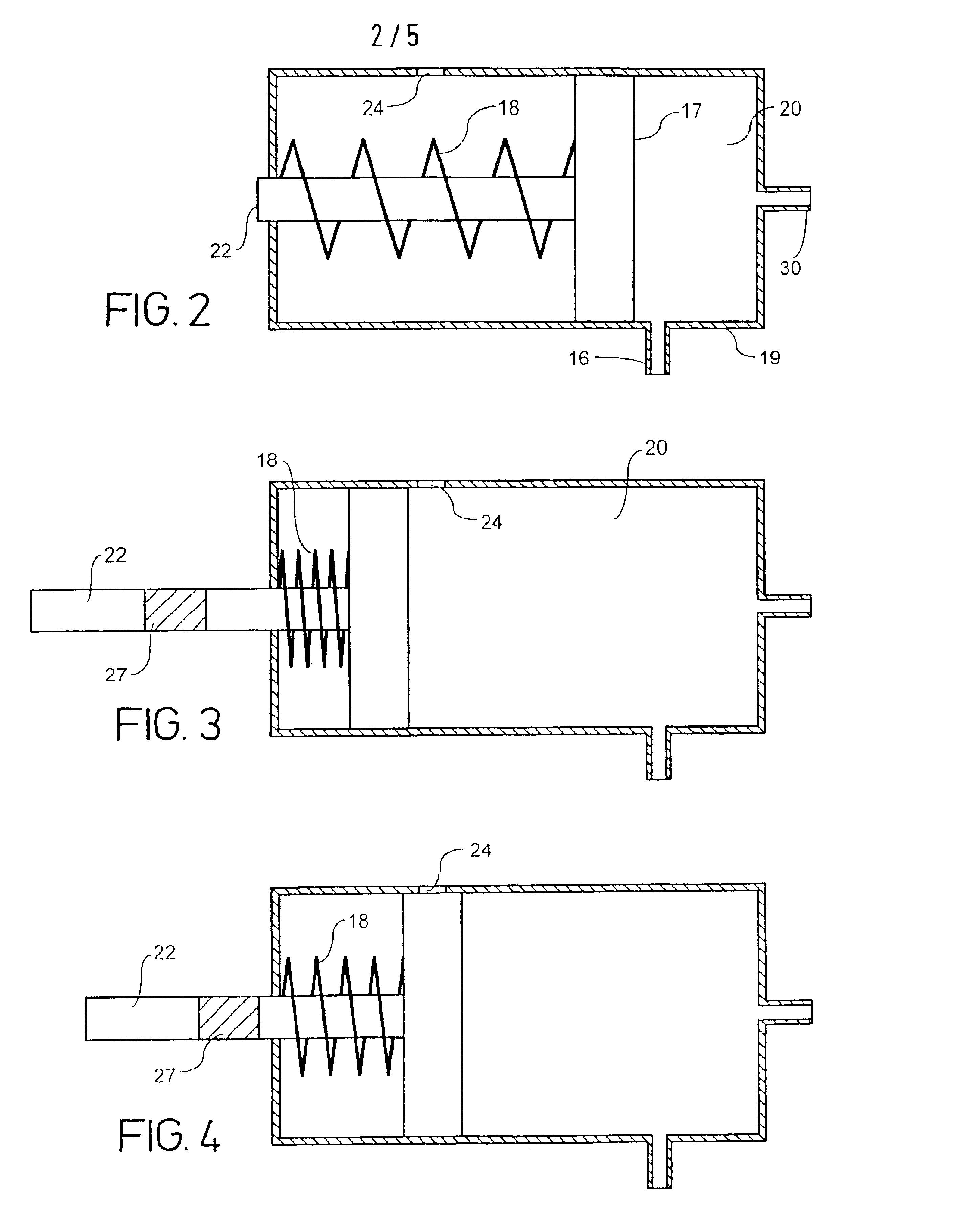

Apparatus and method for generating calibration gas

ActiveUS6997347B2Low costAccurate concentrationOpening closed containersBottle/container closureDocking stationCalibration gas

An apparatus and method for generating a low concentration of gas within a carrier gas flow employing one or more miniature one-piece cylinders filled under pressure with a pure gas, or a concentrated gas balanced with an inert gas or gas mixture. Released from the cylinder through a pierced or other controlled opening, the flow of the gas is regulated by a pressure regulator and a micro orifice to be blended into a steady stream of diluent gas, typically ambient air, to form a desired gas concentration. No gas is generated if the pressure of the gas in the cylinder, which is monitored constantly by a pressure transducer, is below a predetermined level. The apparatus can be built into a portable device, or an automated docking station (or calibration station) for testing and calibrating gas detection and monitoring instruments, or into a fixed gas detection system for performing such functions.

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

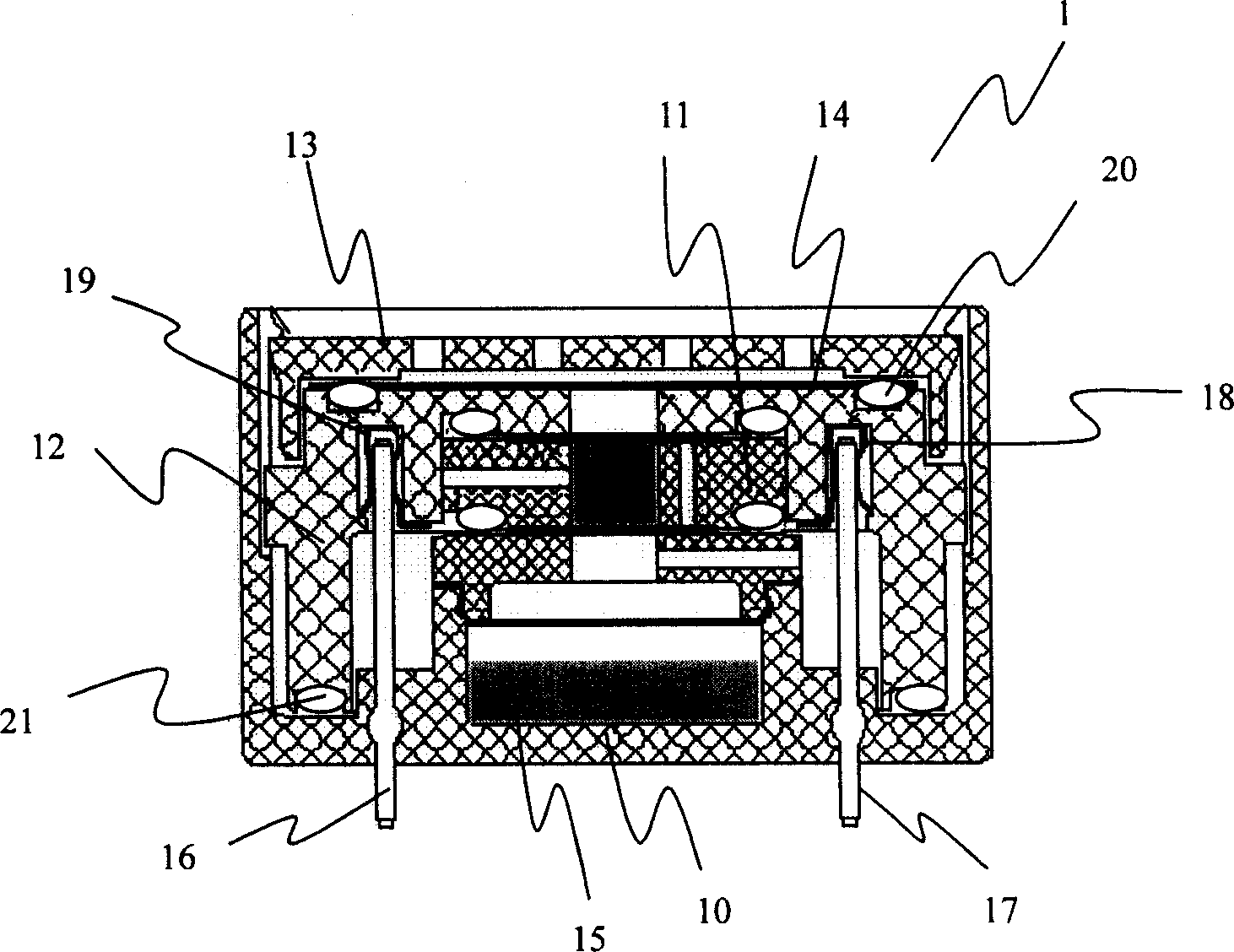

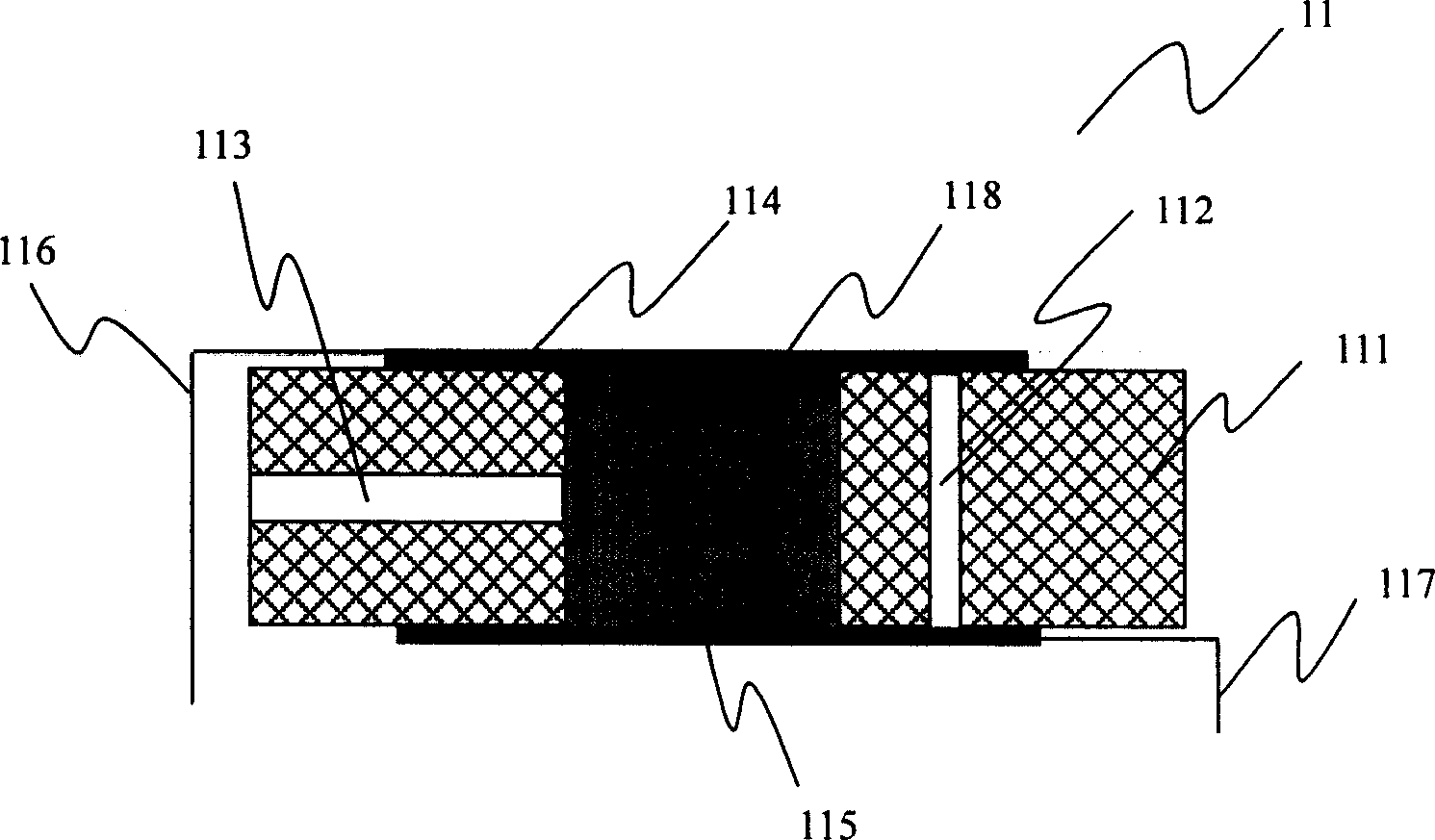

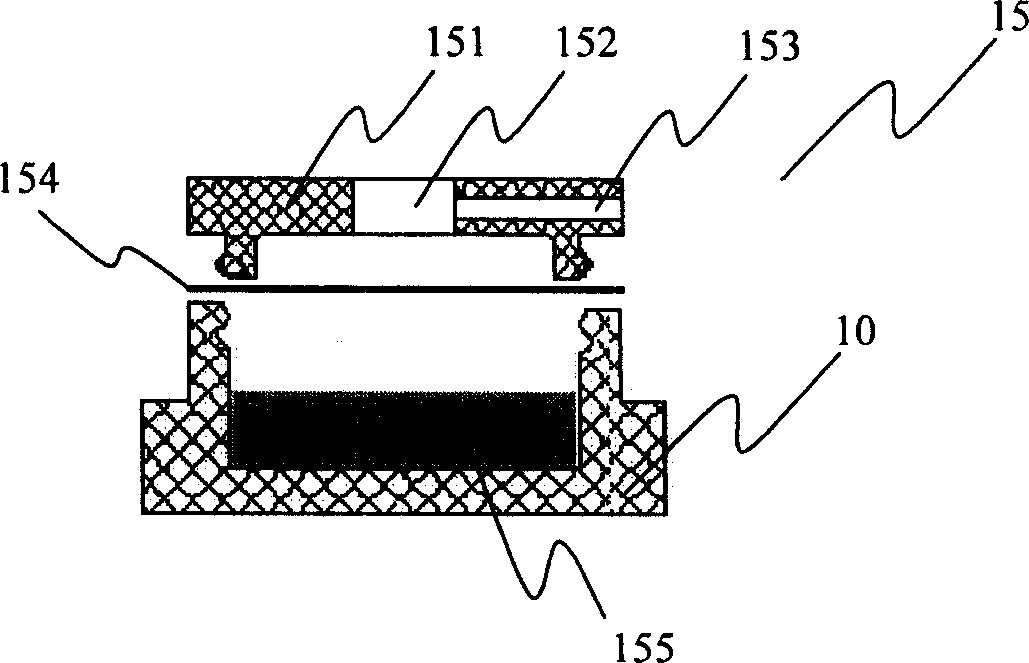

Gas sensor, gas detector, and self-testing and self-correcting method therefor

InactiveCN1865969ASolve the problem of electrolyte leakageExtended service lifeSpecial data processing applicationsMaterial electrochemical variablesGas detectorEngineering

The related gas sensor for fuel cell comprises: based on traditional device, designing a cell core expansion hole and an air hole, using gel electrolyte instead of common liquid, adding a constant moisture device for sensor. It also uses the sensor to prepare a gas detector with self test and adjust function and free to environment effect and calibration gas source. This invention overcomes defects in prior art.

Owner:ASENSOR TECH

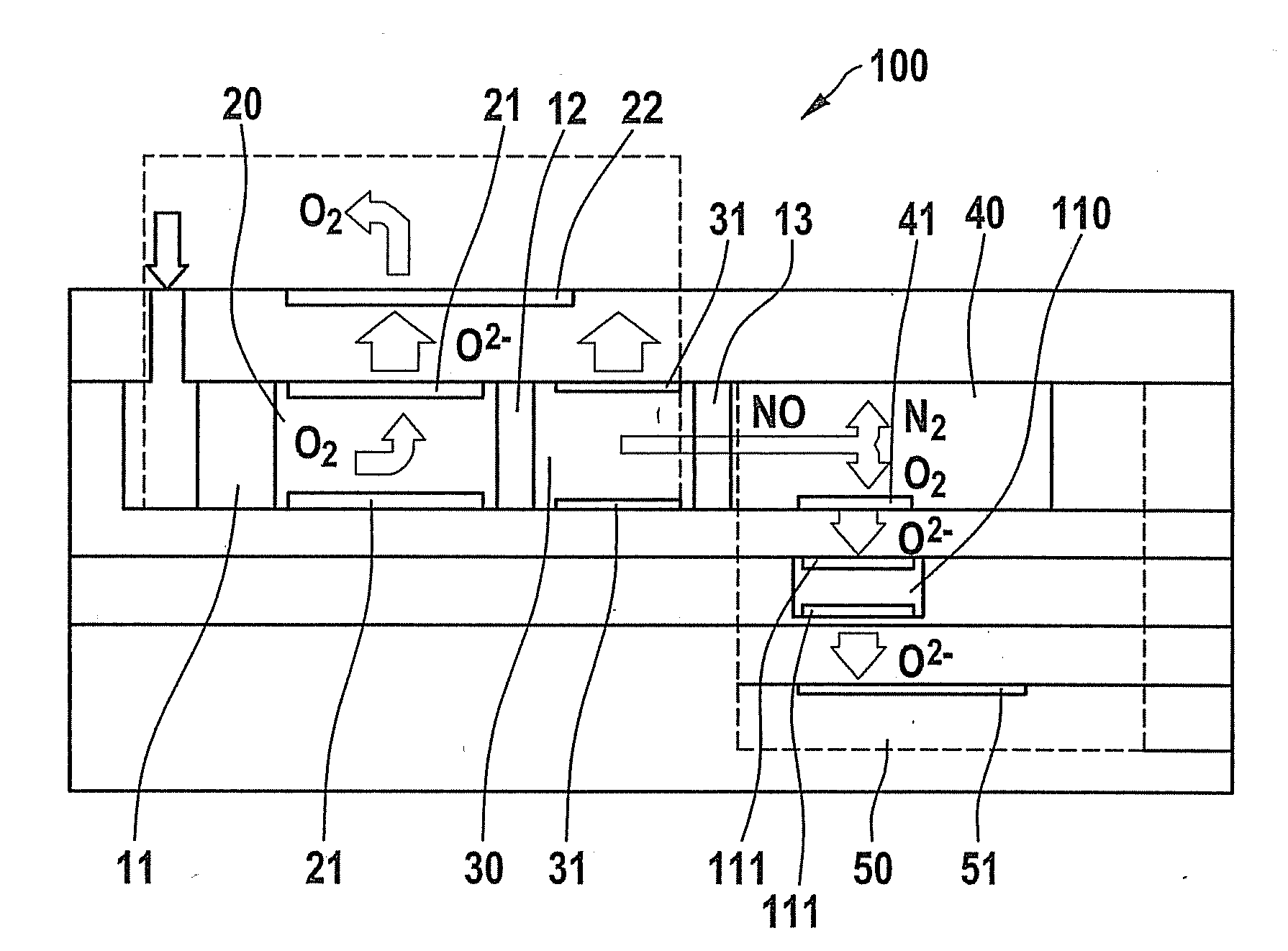

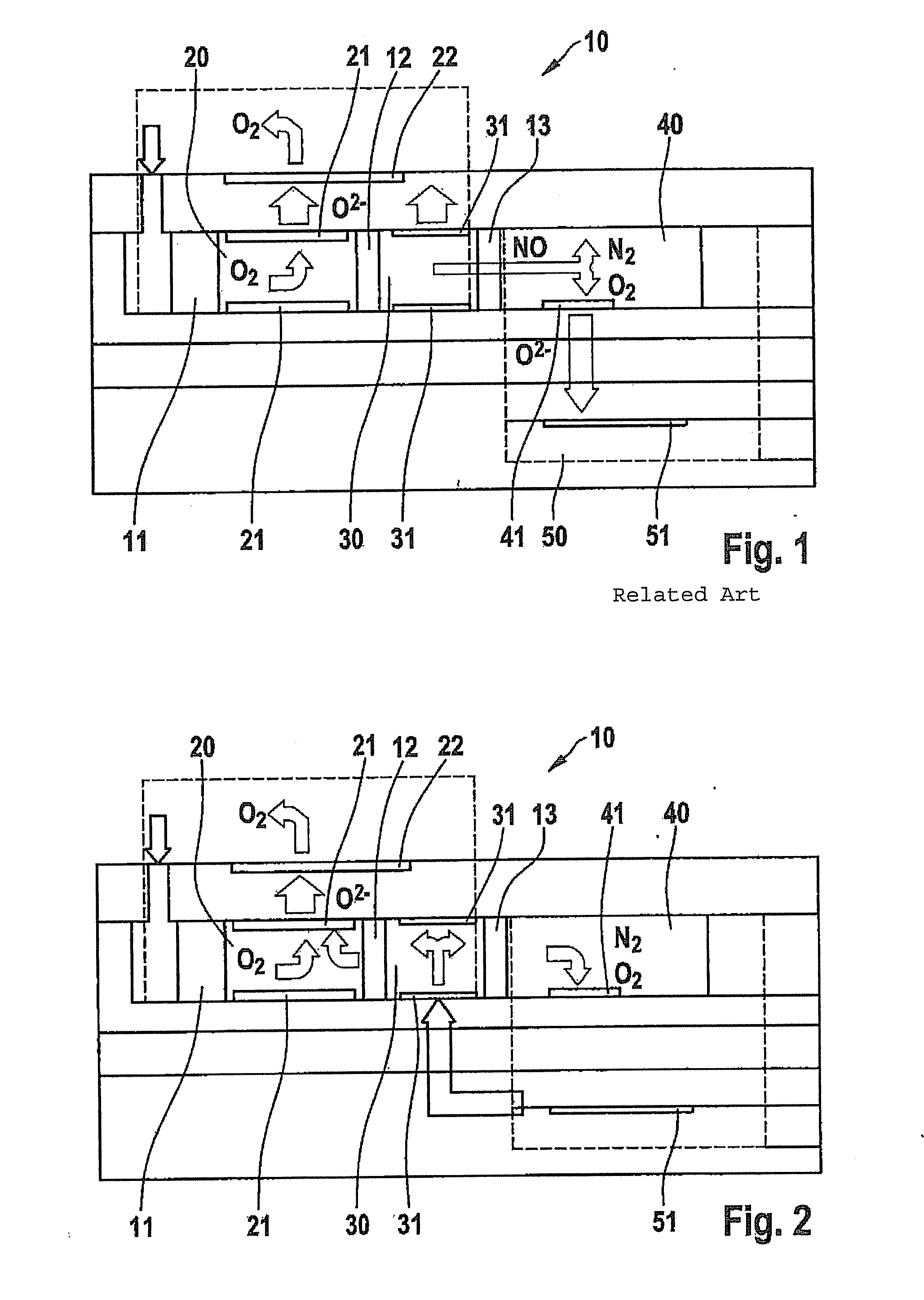

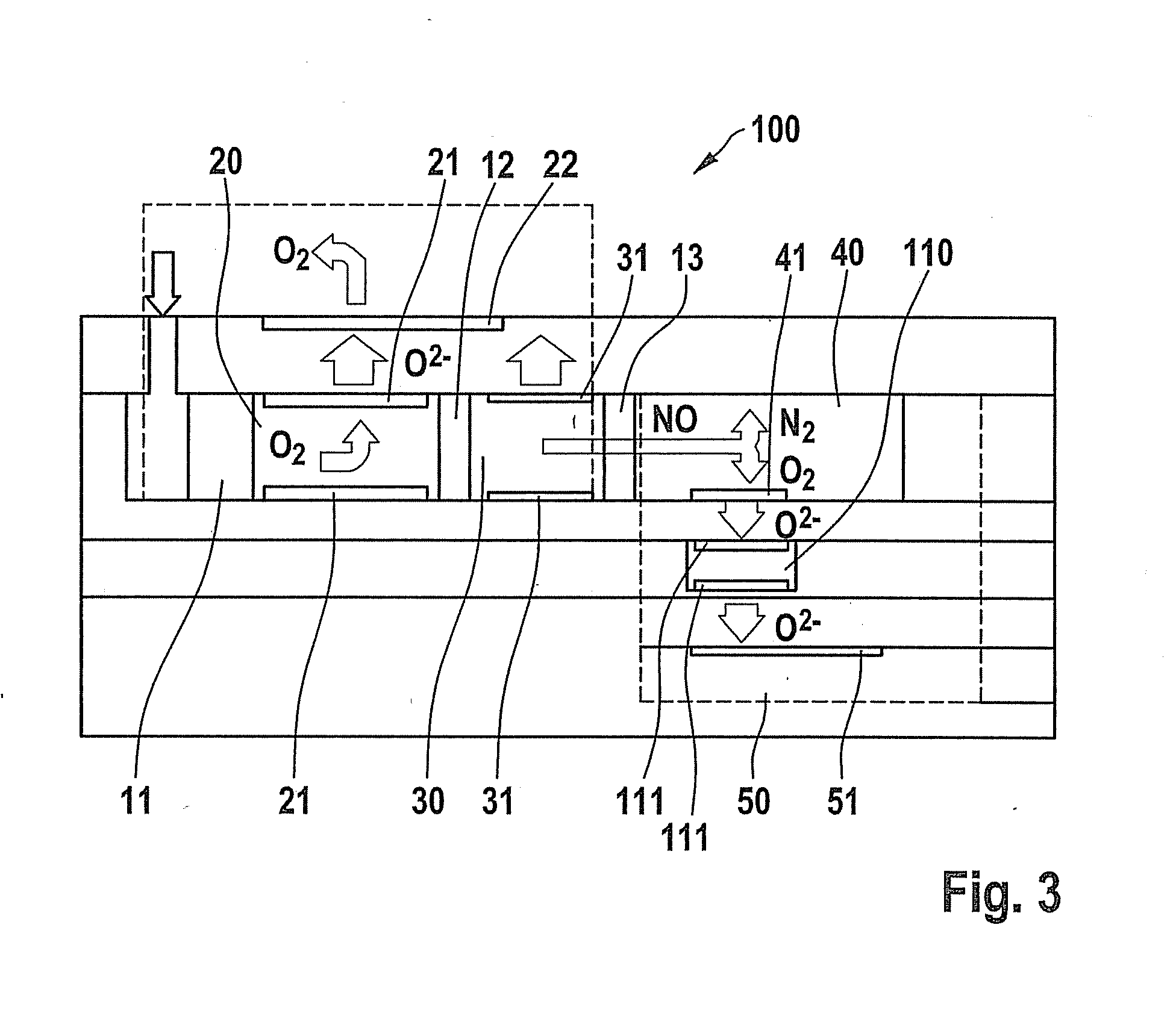

Method for measuring and/or calibrating a gas sensor

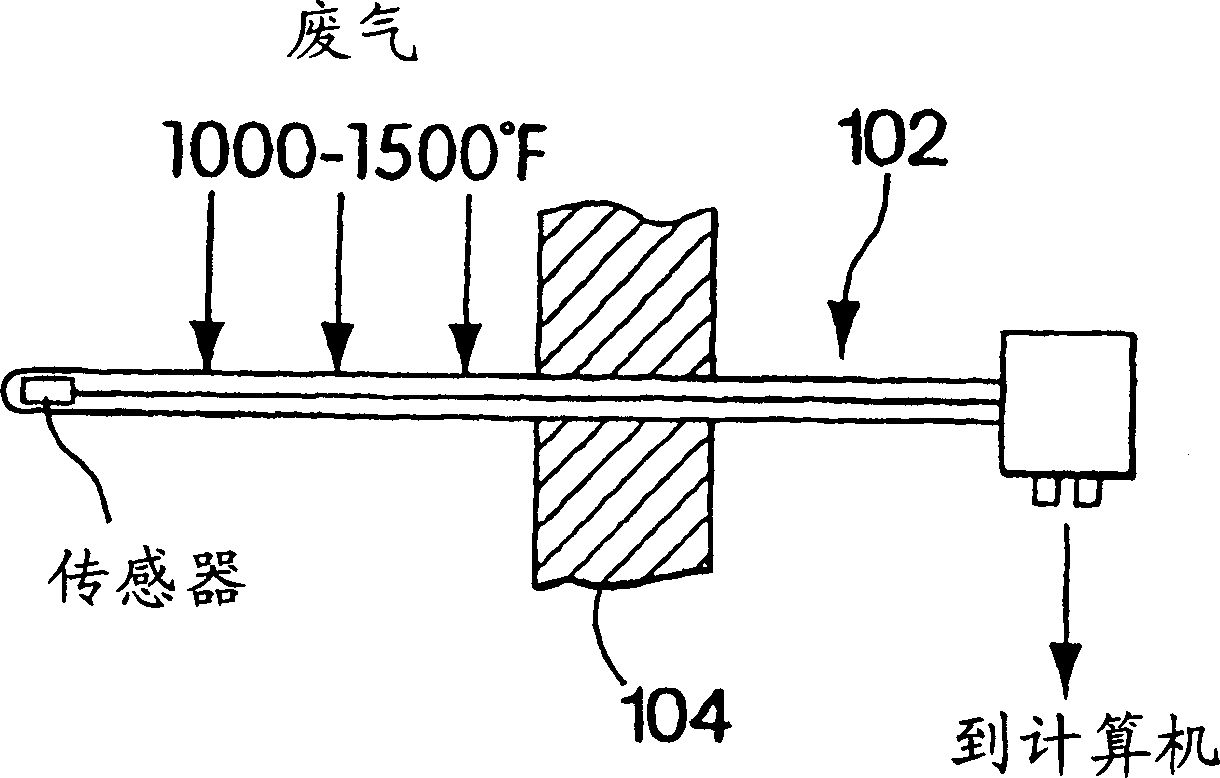

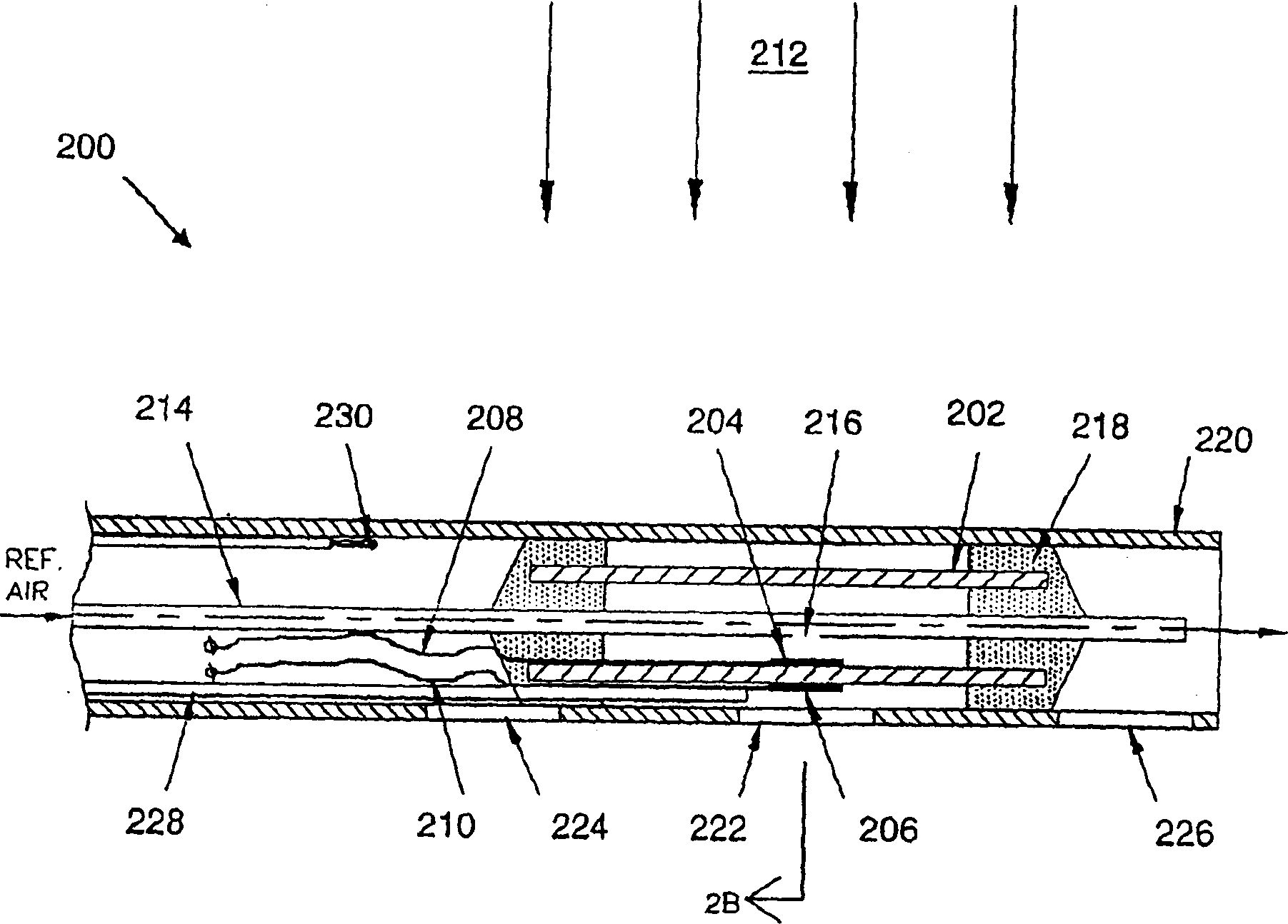

InactiveUS20120097553A1Readily uploaded and usedImprove sensor accuracyInternal combustion piston enginesWeather/light/corrosion resistanceCalibration gasCombustion

A method for measuring and / or calibrating a gas sensor for determining oxygenic gas components in gas mixtures in exhaust gases of internal combustion engines. The gas sensor has one internal pump electrode IPE, one external pump electrode APE and one decomposition electrode NOE. The measurement and / or calibration may be carried out during the ongoing operation of the gas sensor by removing the gas component and / or oxygen from one of the chambers, by introducing oxygen in a controlled manner into one of the chambers with the aid of electrochemical pumping processes. The changes caused by the introduced oxygen are measured against an additional electrode and the gas sensor may be measured and / or calibrated using the measured values.

Owner:ROBERT BOSCH GMBH

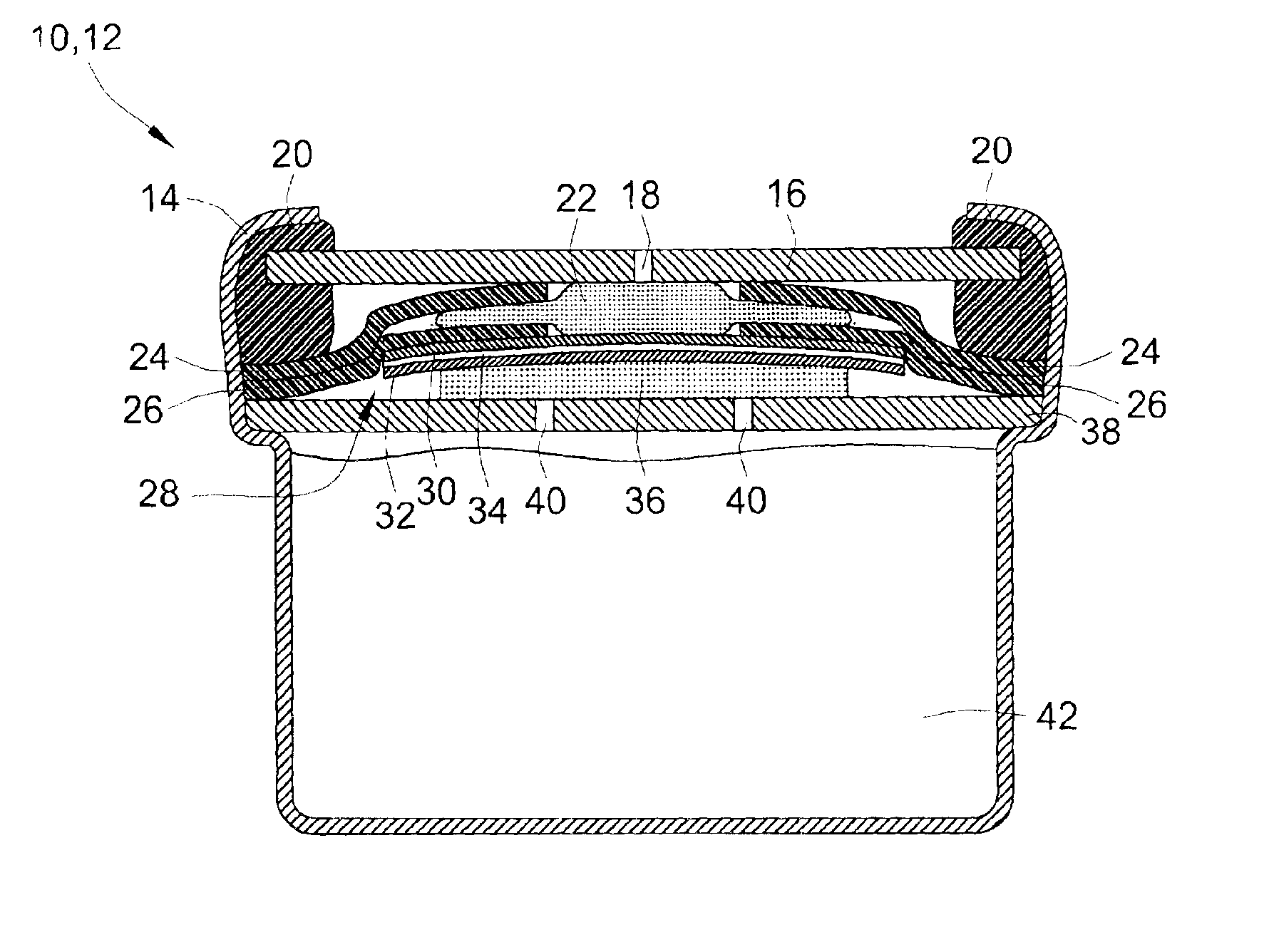

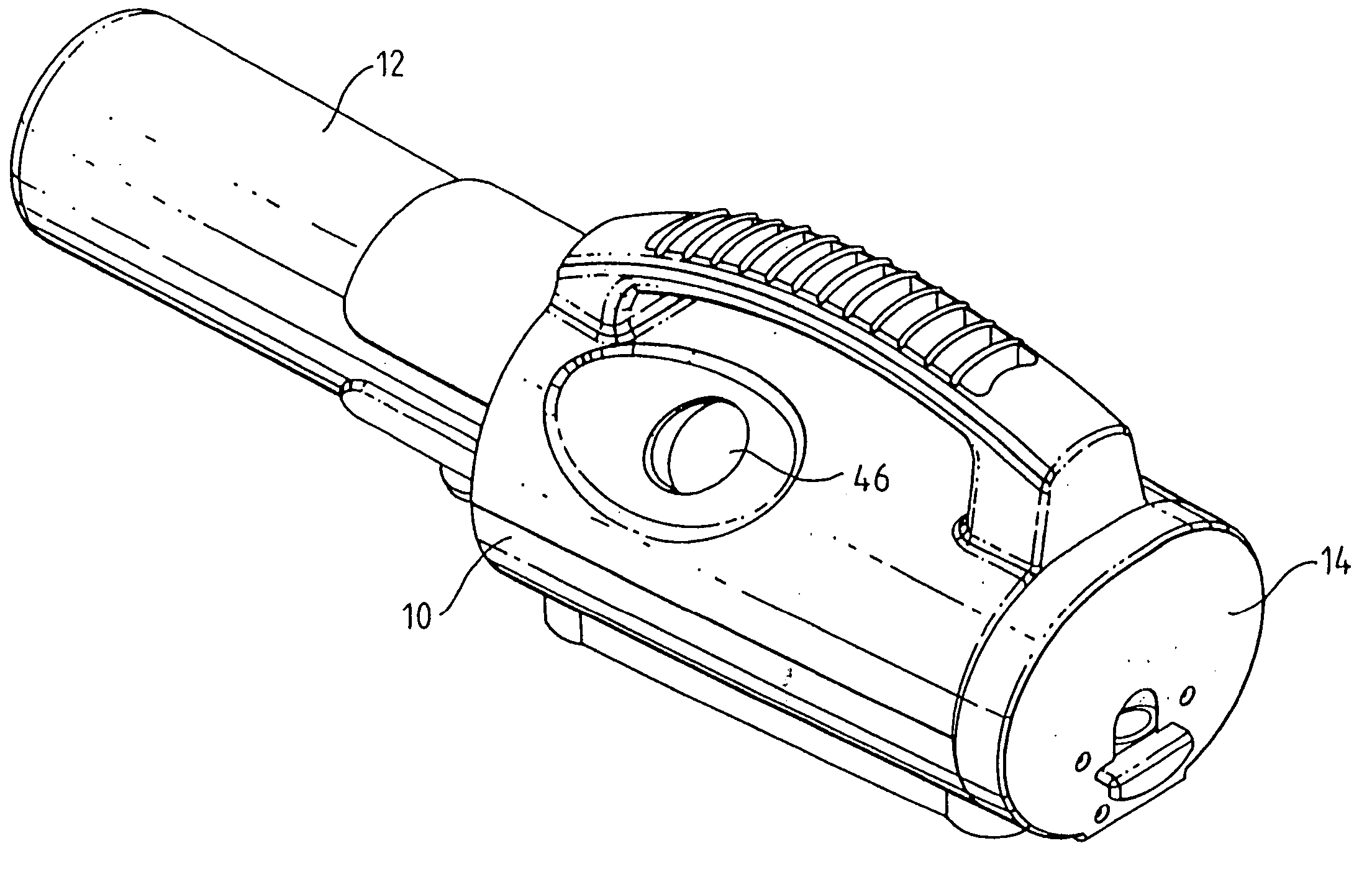

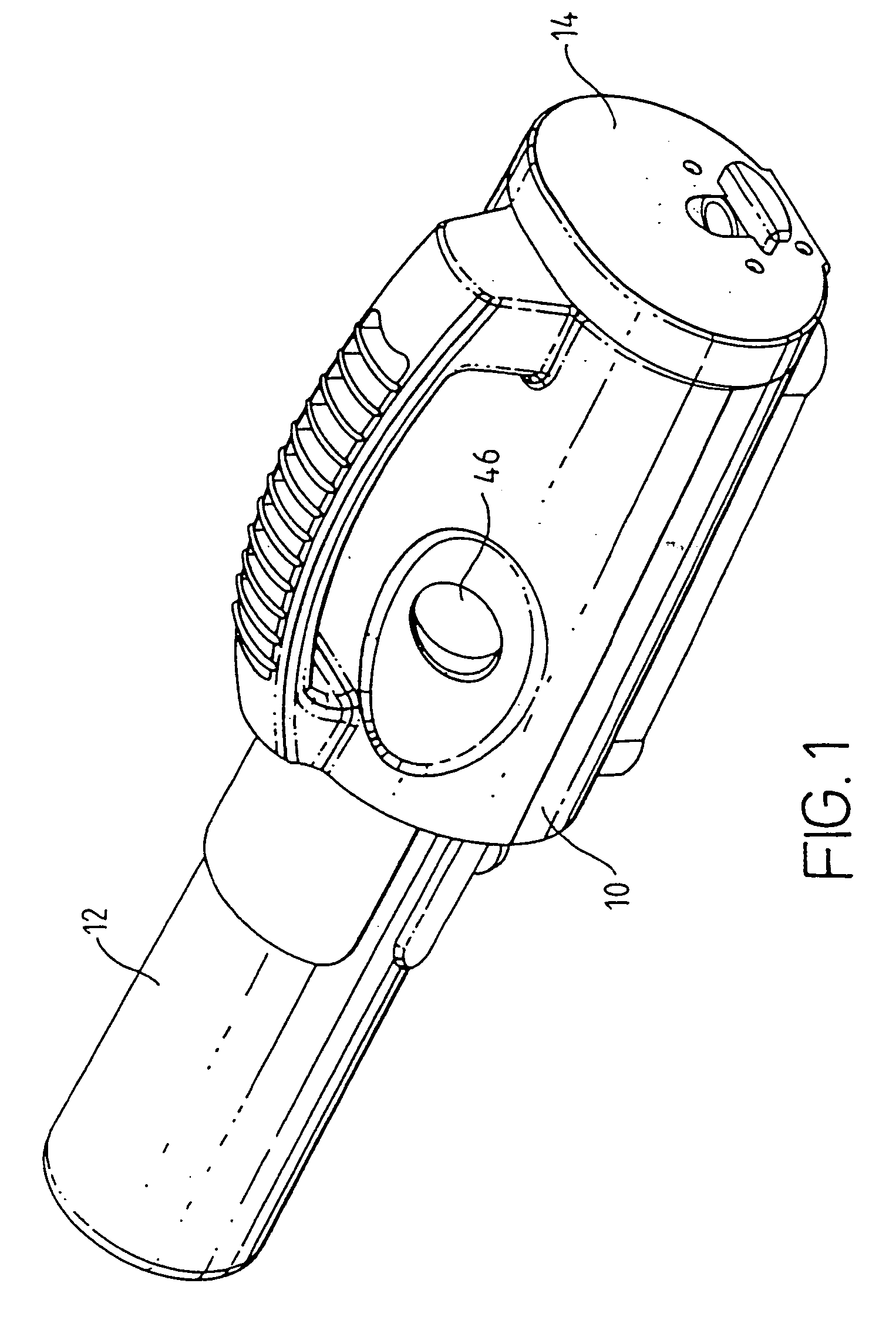

Gas sensor calibration system

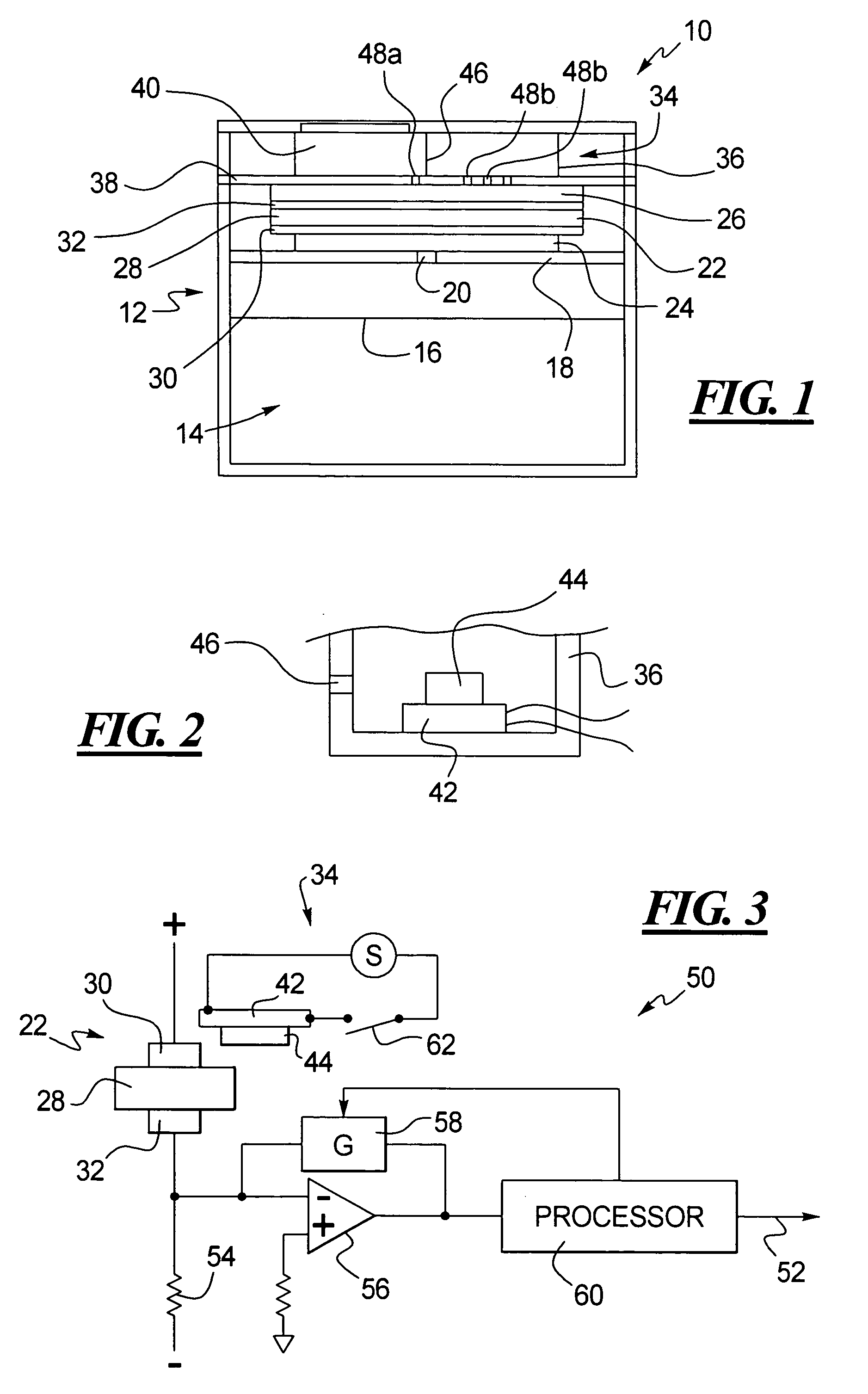

InactiveUS20040074279A1Lower the volumeReduce consumptionTesting/calibration apparatusSamplingElectricityPhase detector

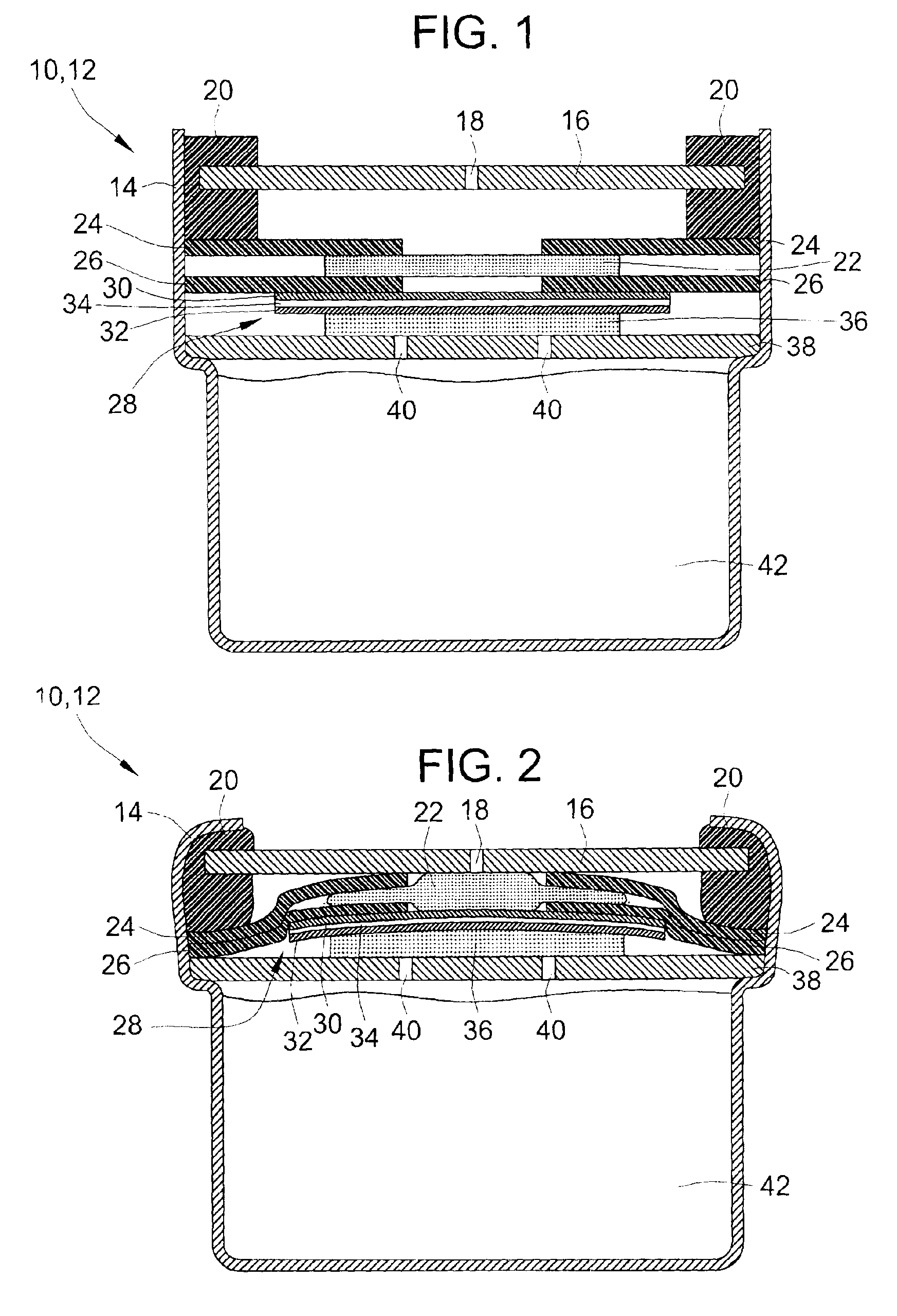

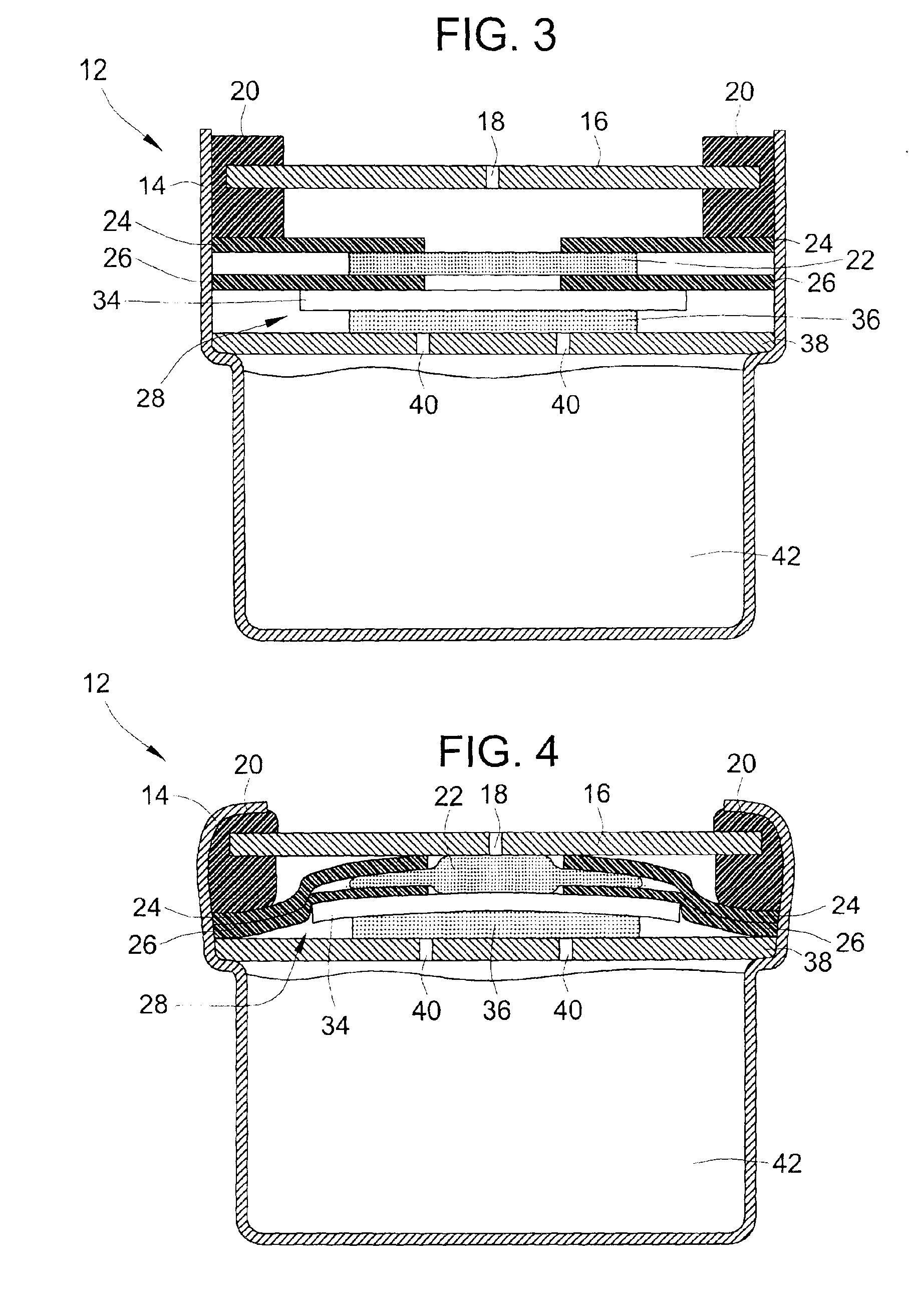

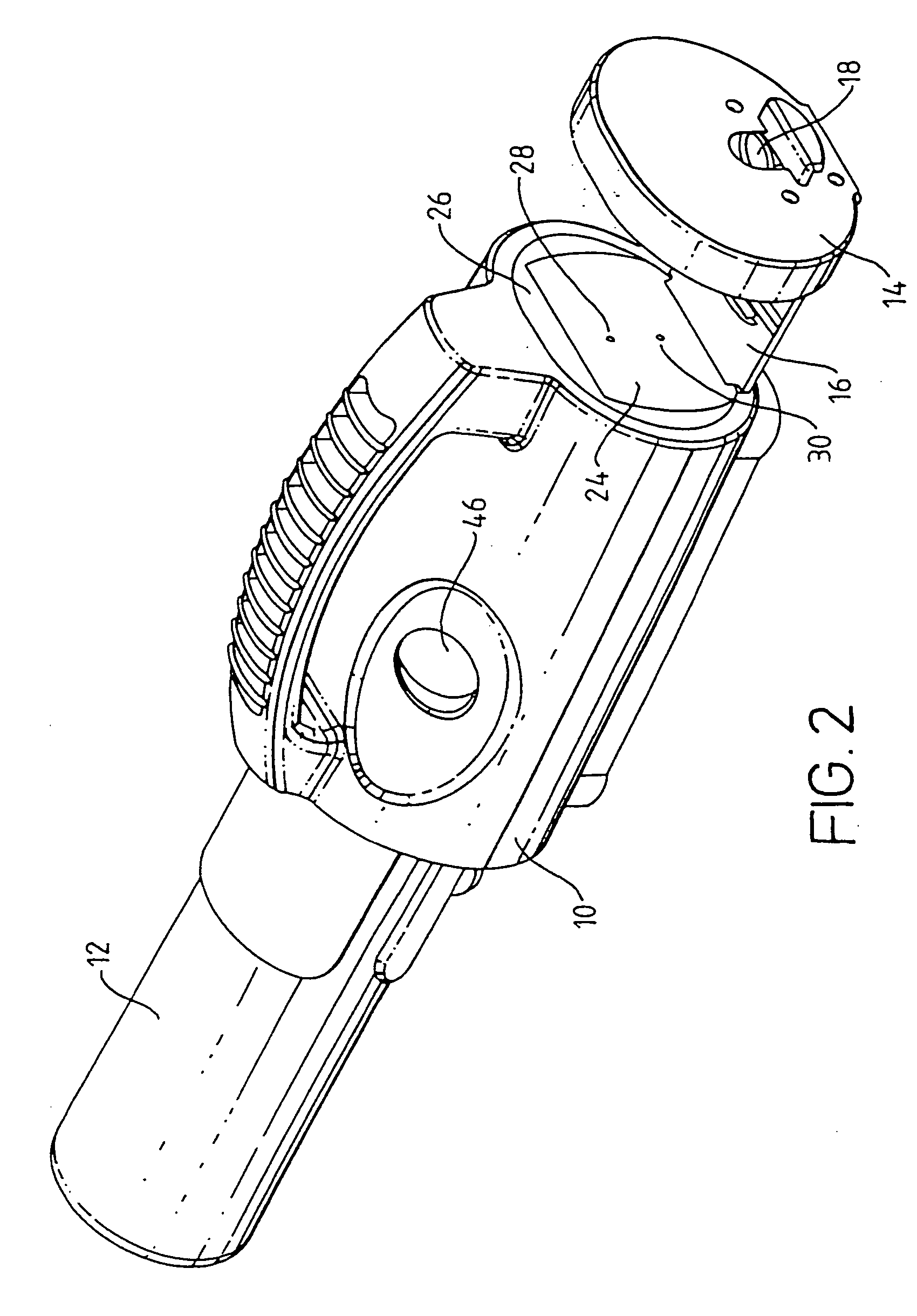

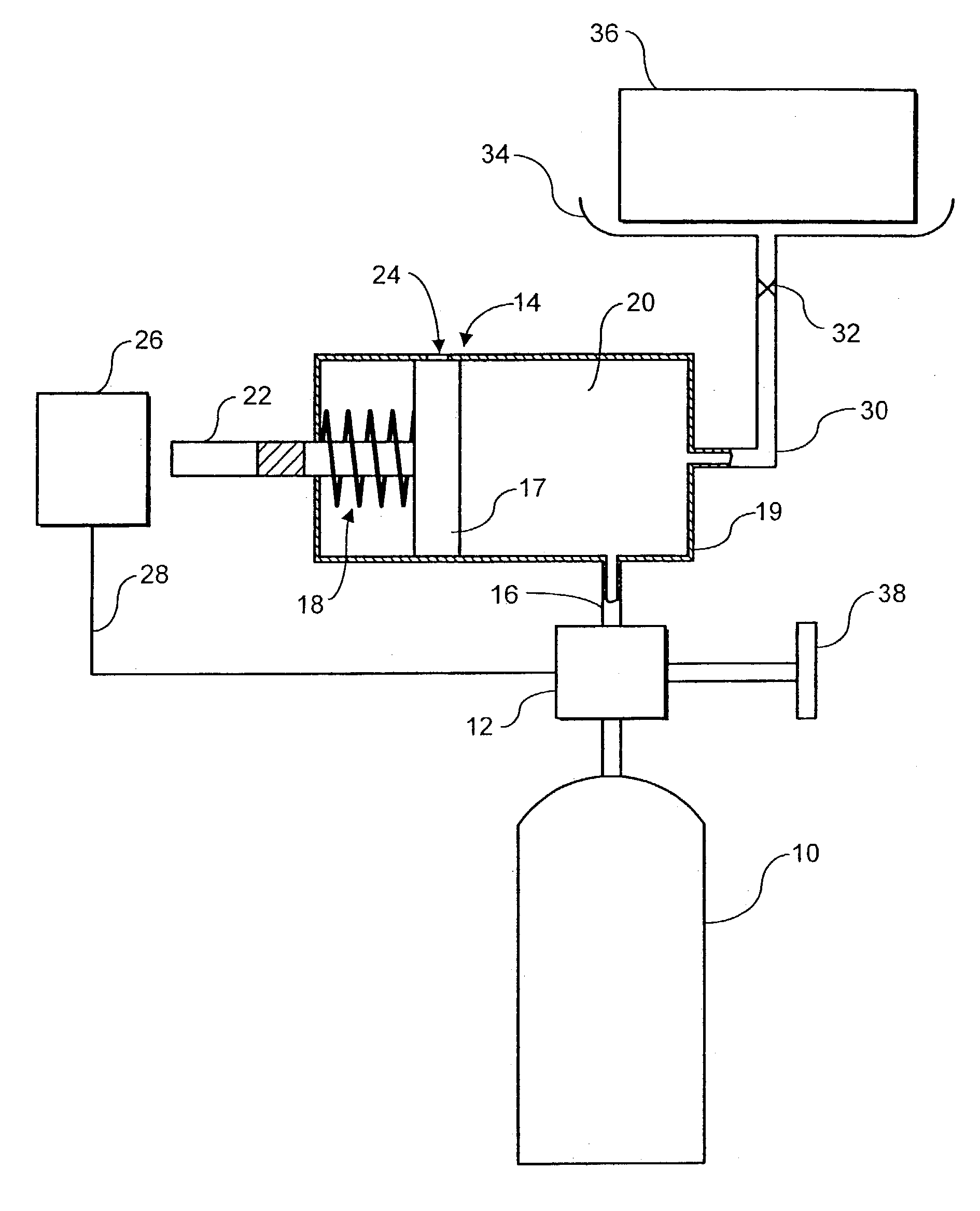

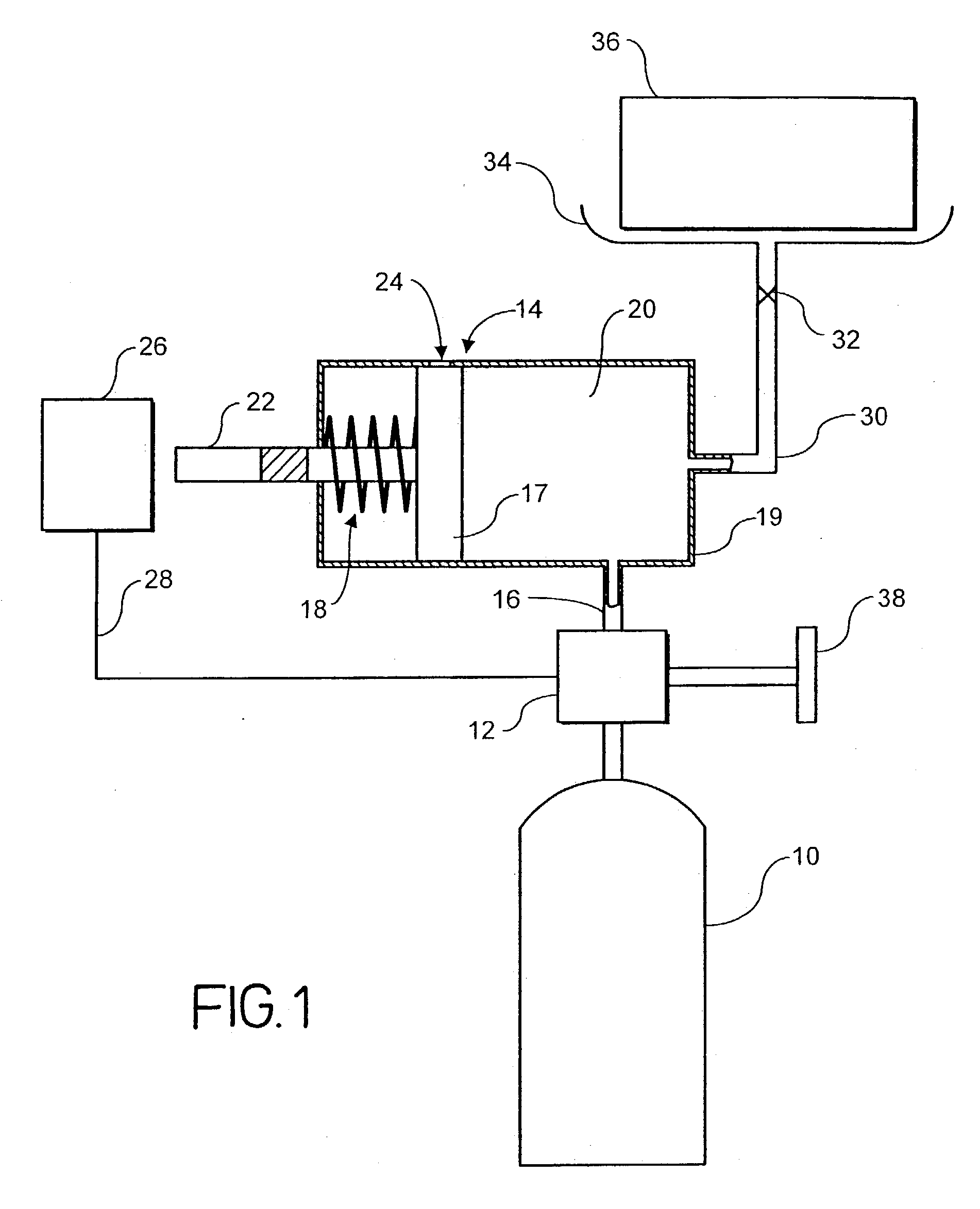

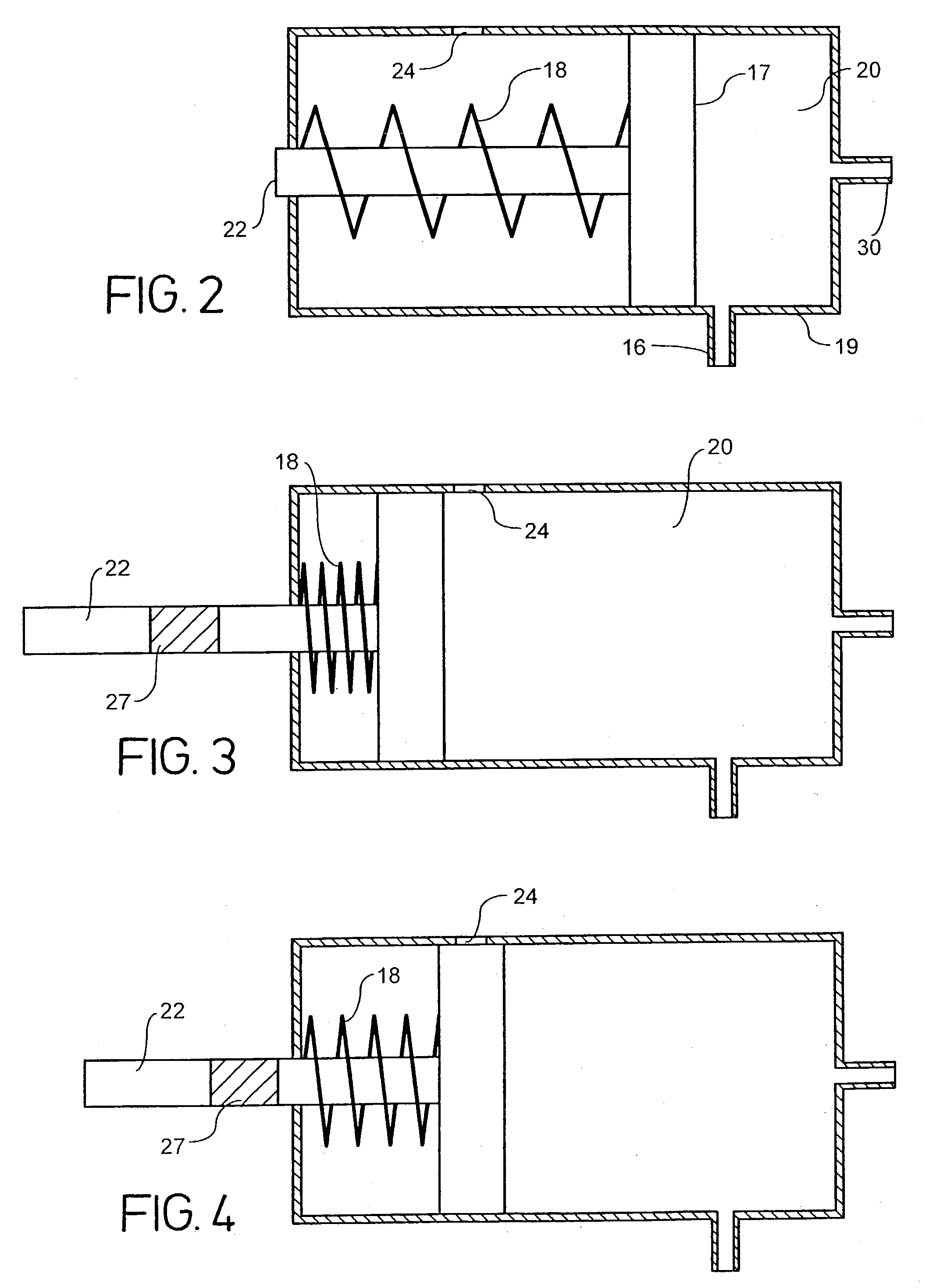

An apparatus is described for calibrating at least one sensor within a gas detector (22), which detector has a gas inlet in fluid communication with the or each sensor, the apparatus comprising a housing (10) that contains: a) a surface (24) for abutting against the detector (22); b) a holder (14) for holding the gas detector (22) with respect to the housing (10) in such a manner that a region of the detector containing the gas inlet abuts against the surface (24) of the housing to form a sealed gas interface between the surface (24) and the detector (22); c) a connector for connecting a source of pressurised calibration gas (12) to the apparatus, d) a conduit (32) for delivering a calibration gas from the connector (34) to the interface between the detector and the apparatus housing, e) electrical connections (40) within the holder for forming electrical connections between the apparatus and a detector held within the holder, and e) a flow controller (34, 36) within the conduit for providing calibration gas at a predetermined level to the interface, the flow controller including an electrically-operated valve (36) being controllable for initiating and terminating the flow of calibration gas through the conduit (32) by means of signals received from the detector via the electrical connections (40). The whole calibration is controlled by he detector and not the calibration apparatus.

Owner:HONEYWELL ANALYTICS LTD

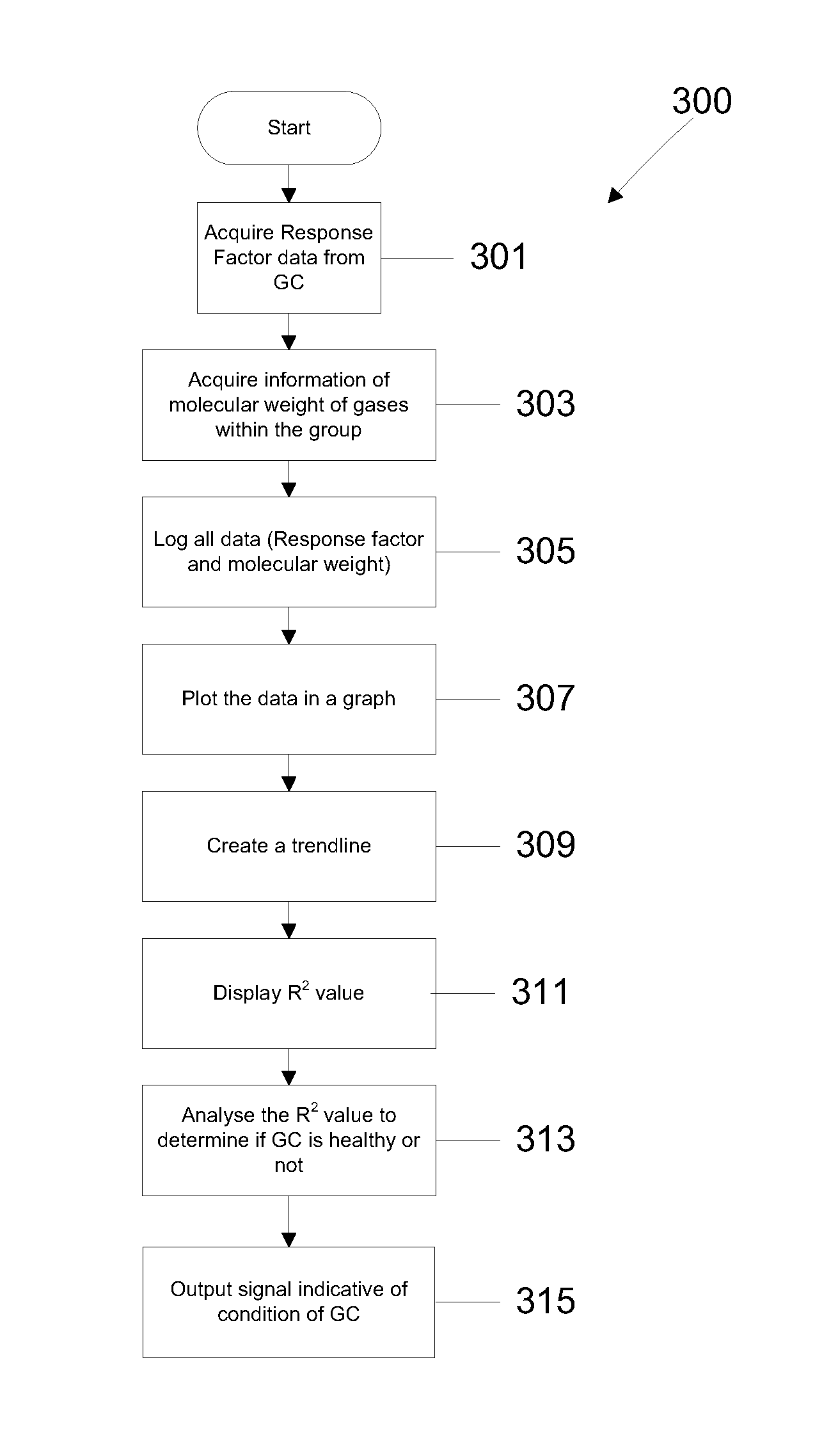

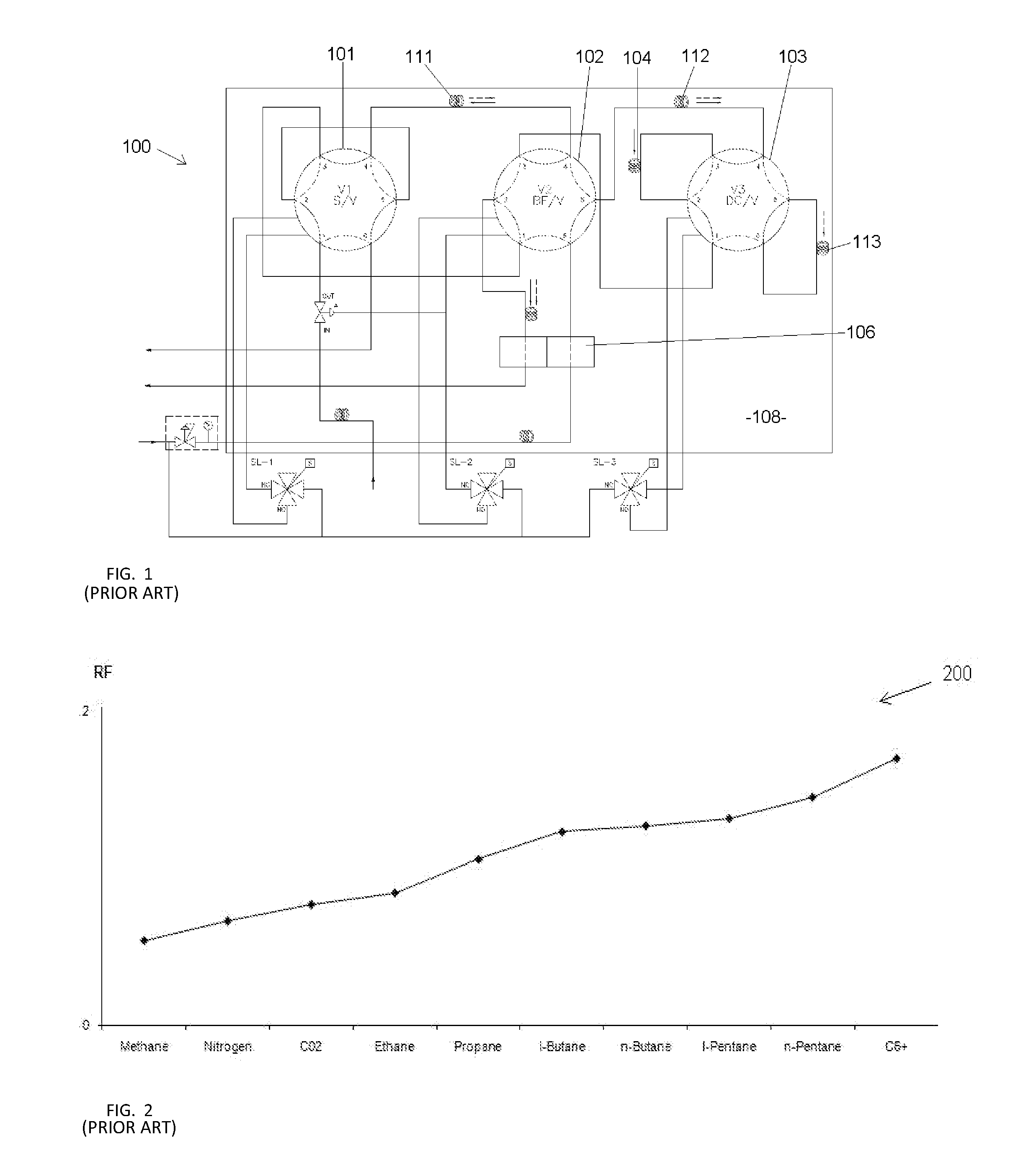

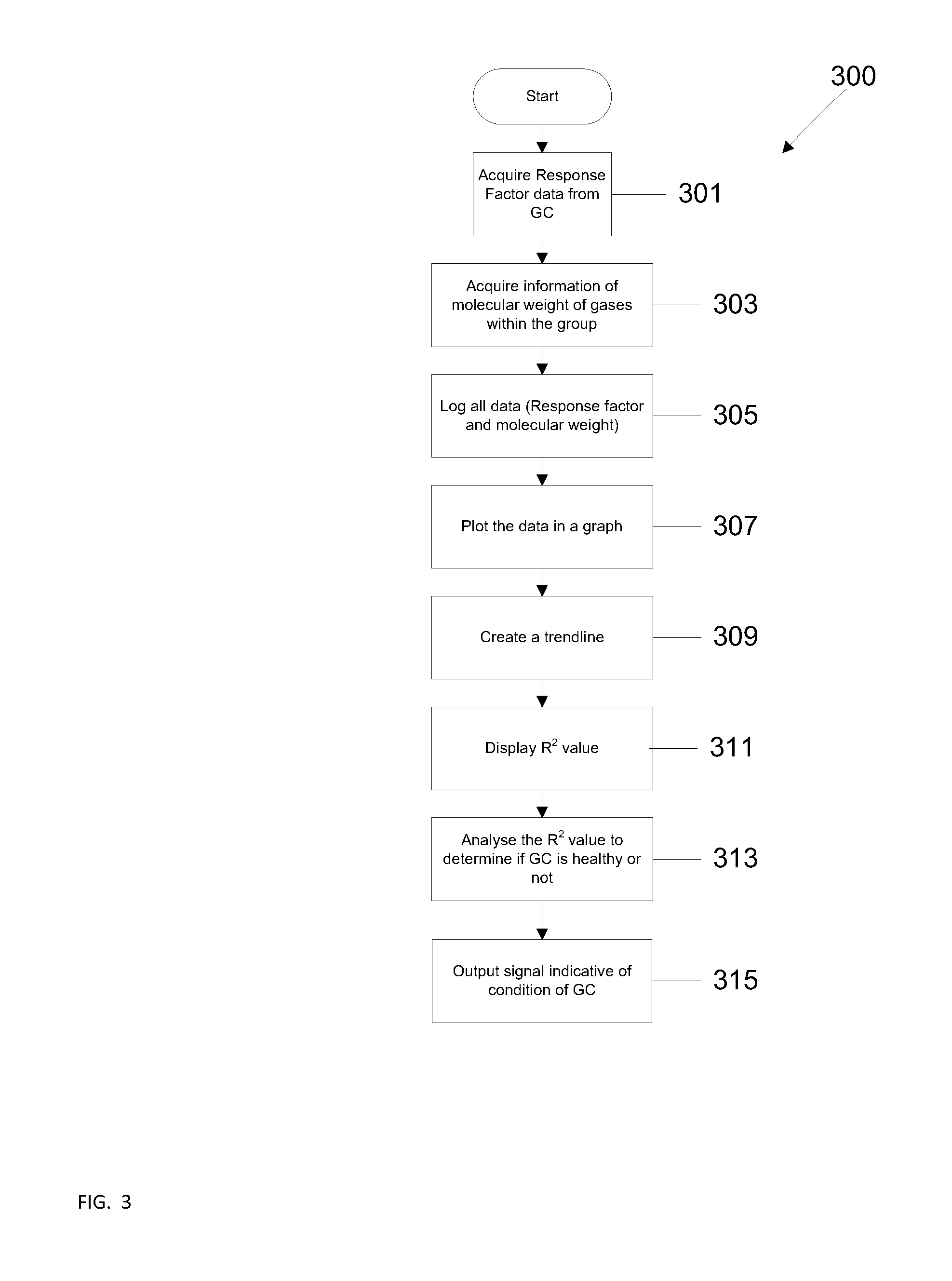

Method for gas chromatgraphy analysis and maintenance

InactiveUS20120016597A1Mitigates one or more drawbacksMitigate one or more drawbacksComponent separationSpecial data processing applicationsCalibration gasResponse factor

A method of analyzing gas chromatography data may include acquiring response factor data for each of a plurality of compounds included in one or more calibration gas samples from a gas chromatograph apparatus, and determining a correlation with molecular weight data for each of the plurality of compounds. The correlation may be analyzed to determine a condition of the gas chromatograph. The method may also determine a correlation for each of a plurality of operating phases of the gas chromatograph, for example, before and after actuation of valves which change the flow rate. The method may also include diagnosing faults, and calibrating and configuring gas chromatographs.

Owner:I VIGILANT

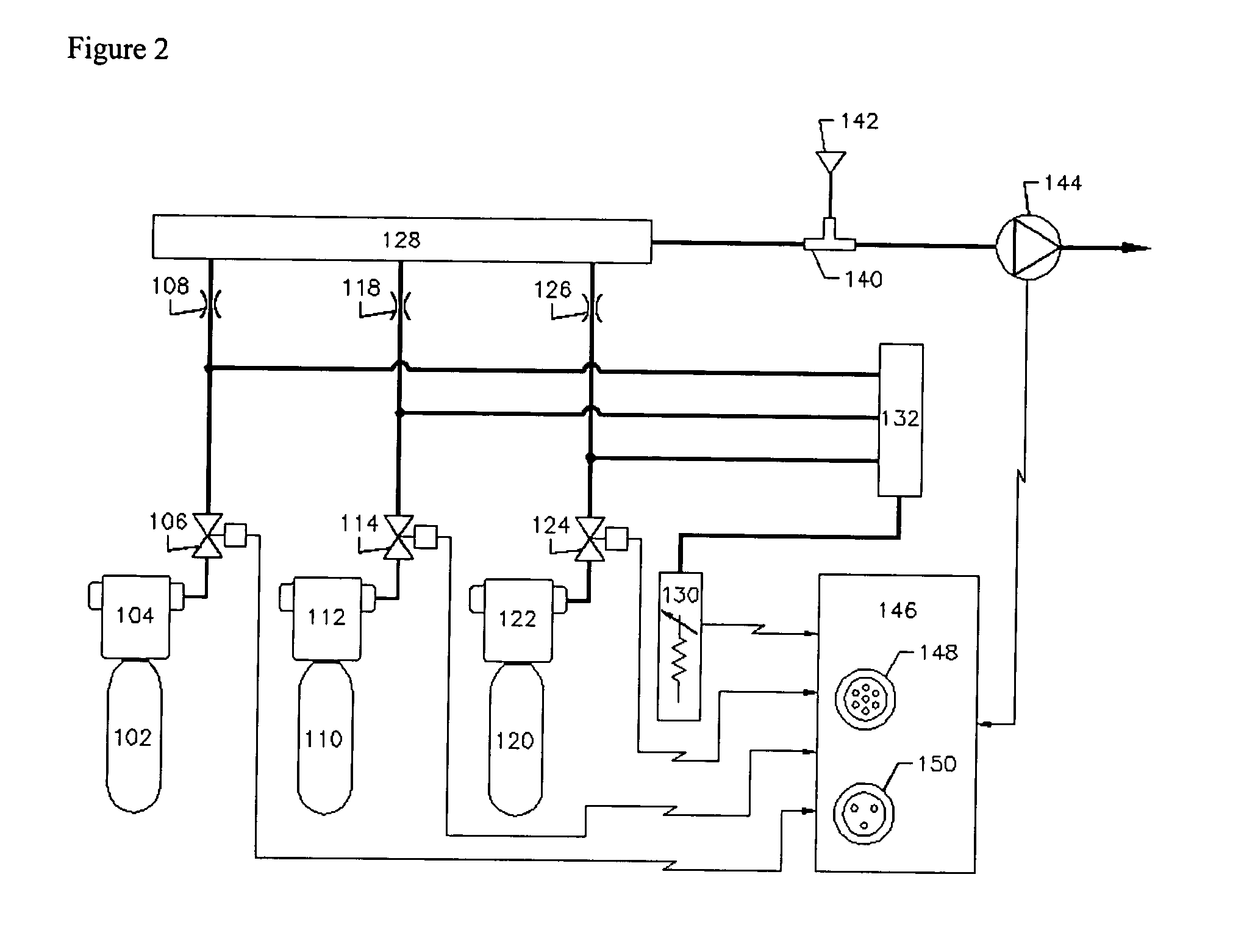

Gas sensor calibration system

InactiveUS6918281B2Reduce wasteCalibrationMaterial analysis by optical meansGas analyser calibrationPhase detectorCalibration gas

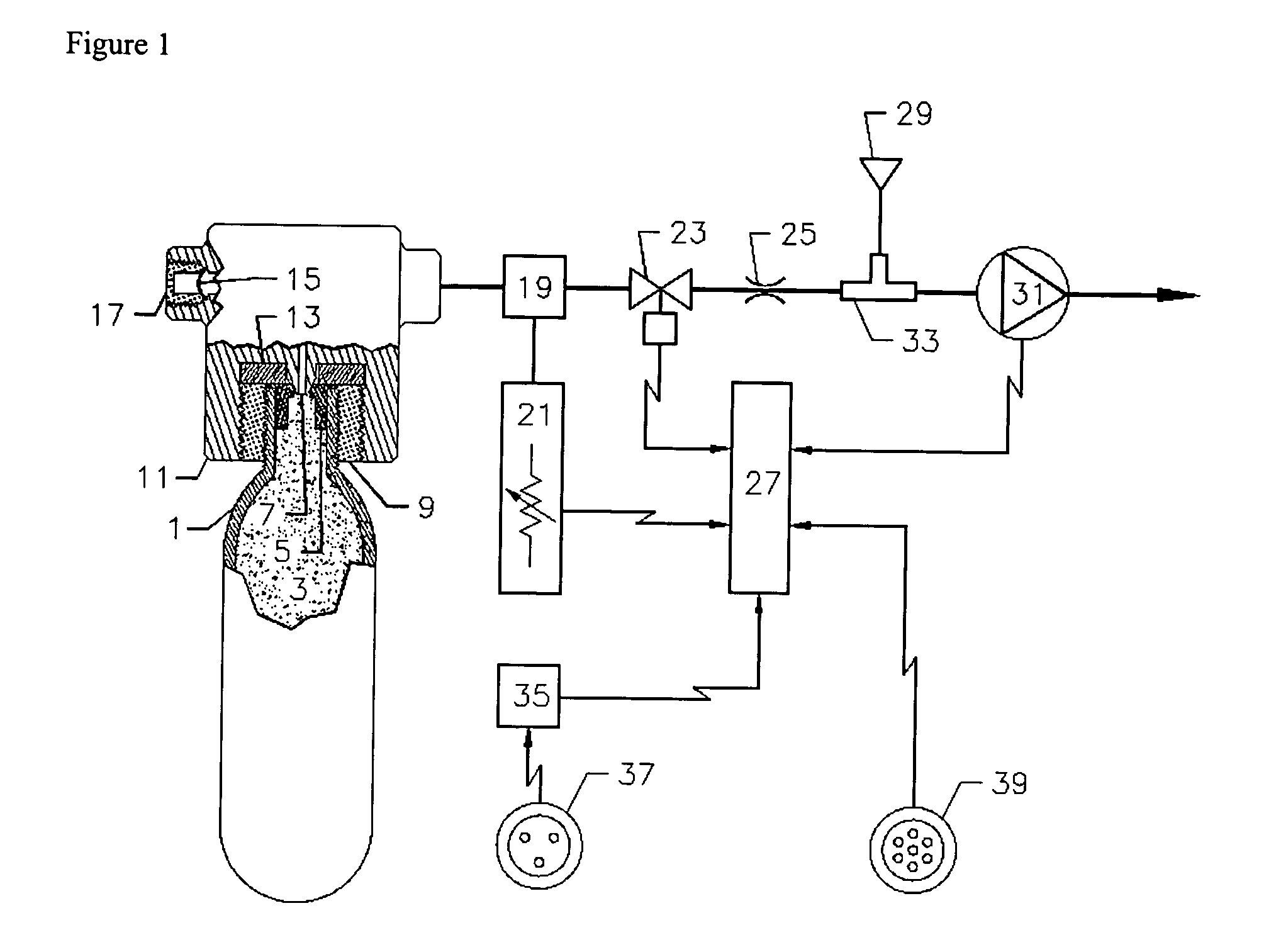

The present invention provides a method of calibrating sensors within a gas detector (36) having a housing containing a gas inlet whereby gas can diffuse from the inlet to the sensors. The gas inlet in the housing is held against part (34) of the calibration apparatus to form a sealed gas interface between the apparatus and the detector; a source (10) of pressurized calibration gas is connected to the apparatus, and a predetermined dose of calibration gas is delivered to the interface between the detector (36) and the calibration apparatus (34) at a predetermined pressure. The source (10) of pressurized calibration gas may contain single or multiple calibration doses and, if the former, the calibration apparatus includes a dosing system such as cylinder (14) for metering individual doses of calibration gas.

Owner:ZELLWEGER ANALYTICS

Calibration device for gas sensors

ActiveUS7073368B2Material analysis by optical meansGas analyser calibrationPhase detectorCalibration gas

A gas sensor includes a gas detector, a reference gas generator, and a circuit. The reference gas generator includes a heater and a gas releasing material. The gas releasing material is in proximity to the heater such that, when the heater is energized during calibration, the gas releasing material releases an overpressure of a reference gas to the gas detector and such that, when the heater is not energized, the gas releasing material releases no substantial overpressure of the reference gas to the gas detector. The circuit energizes the heater during calibration and is responsive to an output of the gas detector during the period when the gas detector is provided the reference gas so as to calibrate the gas sensor.

Owner:HONEYWELL INT INC

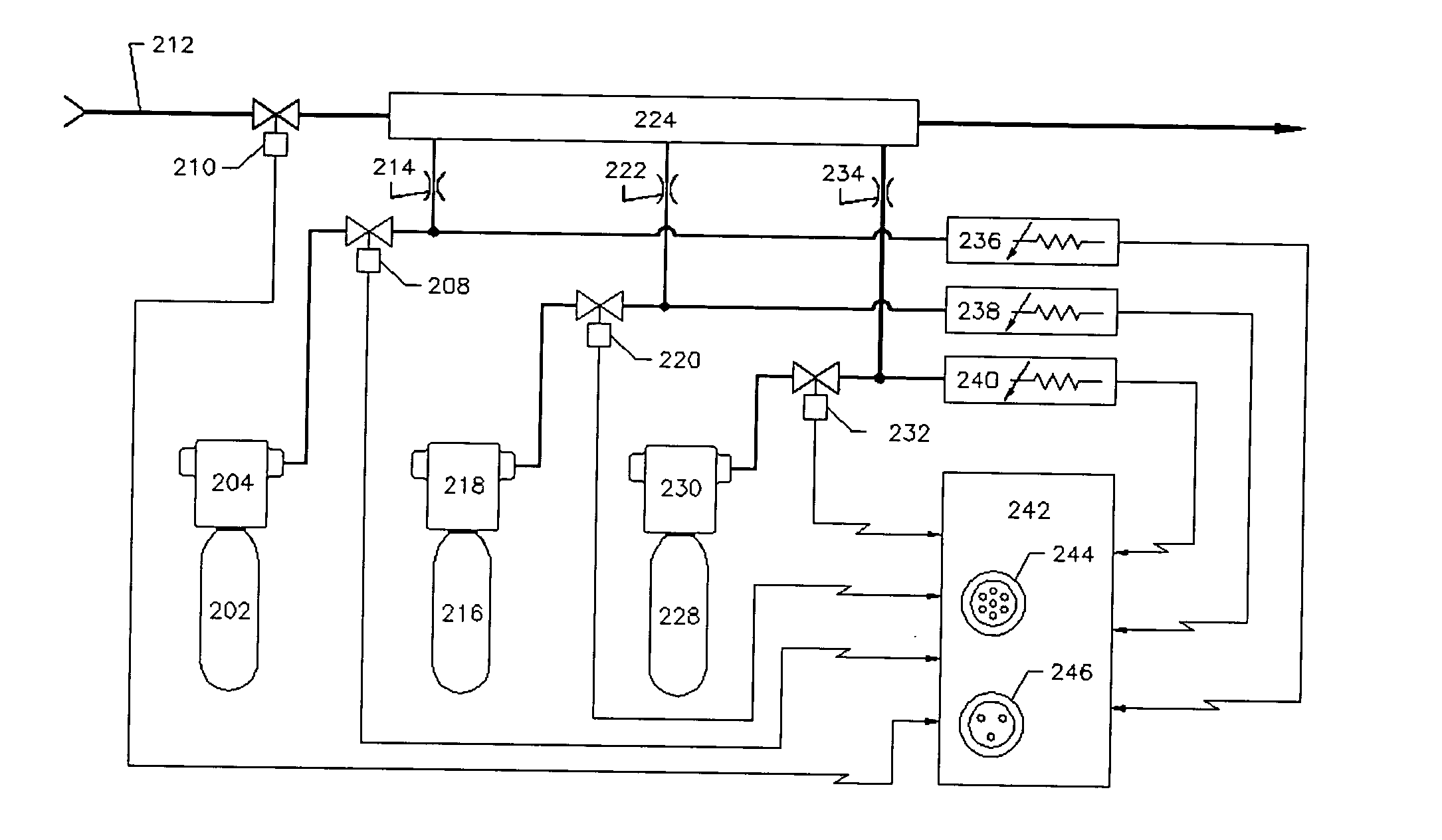

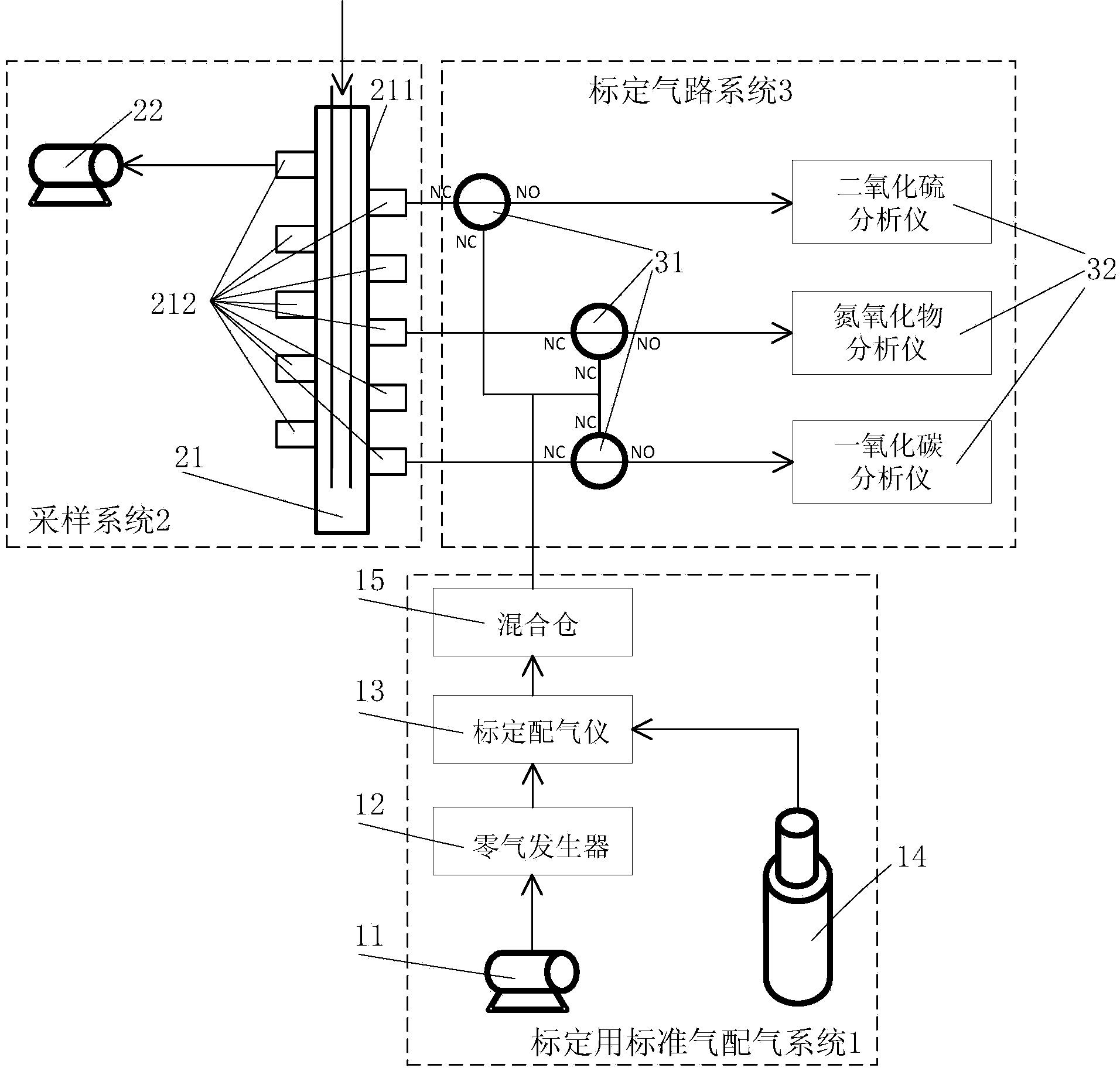

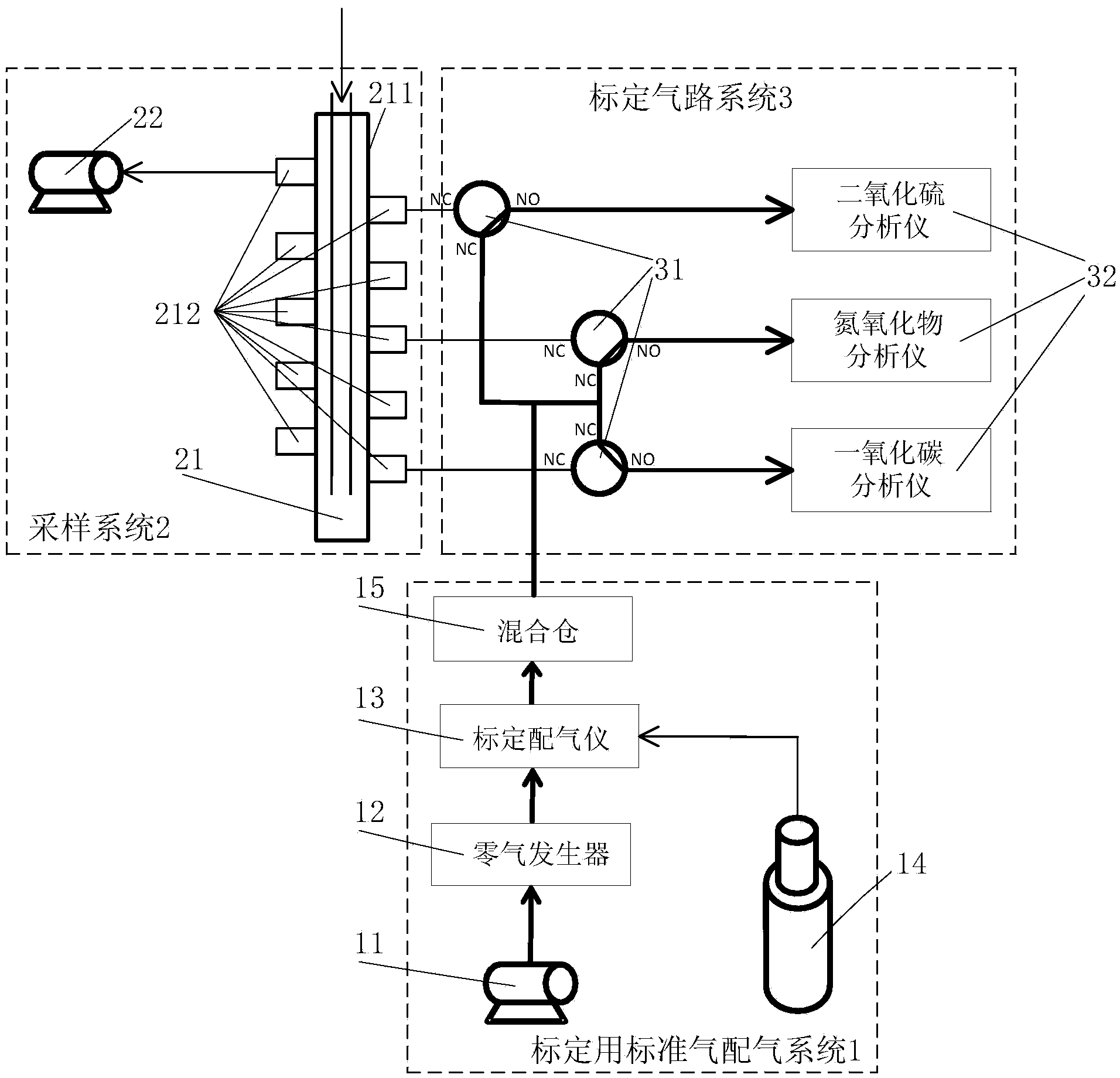

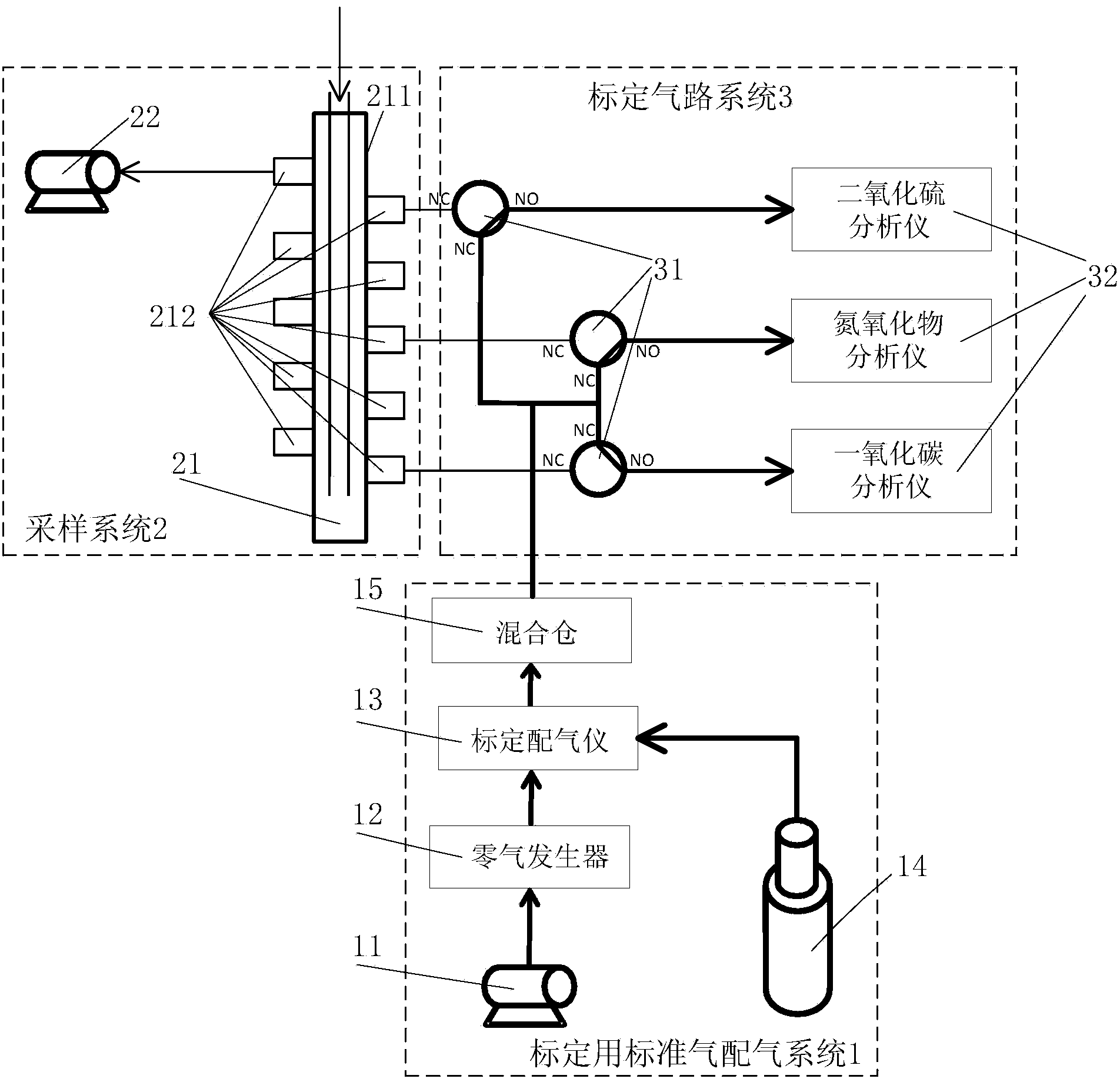

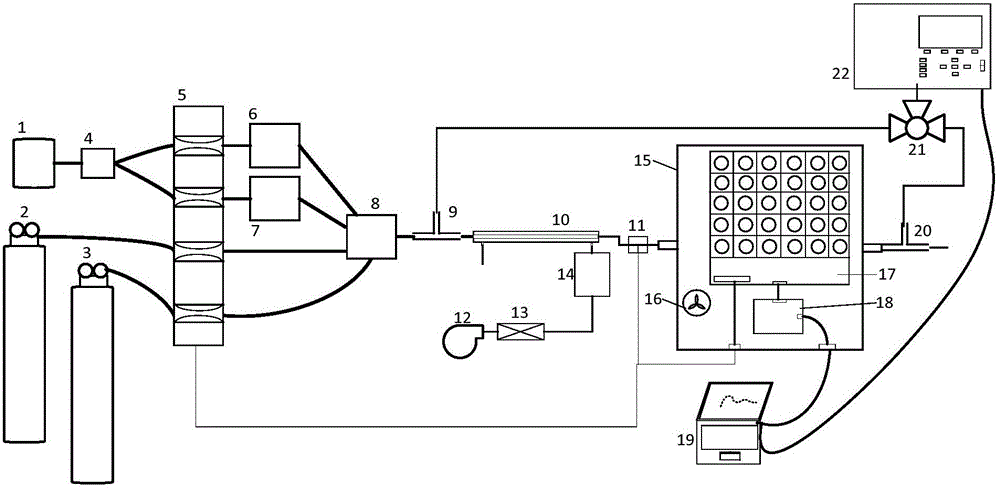

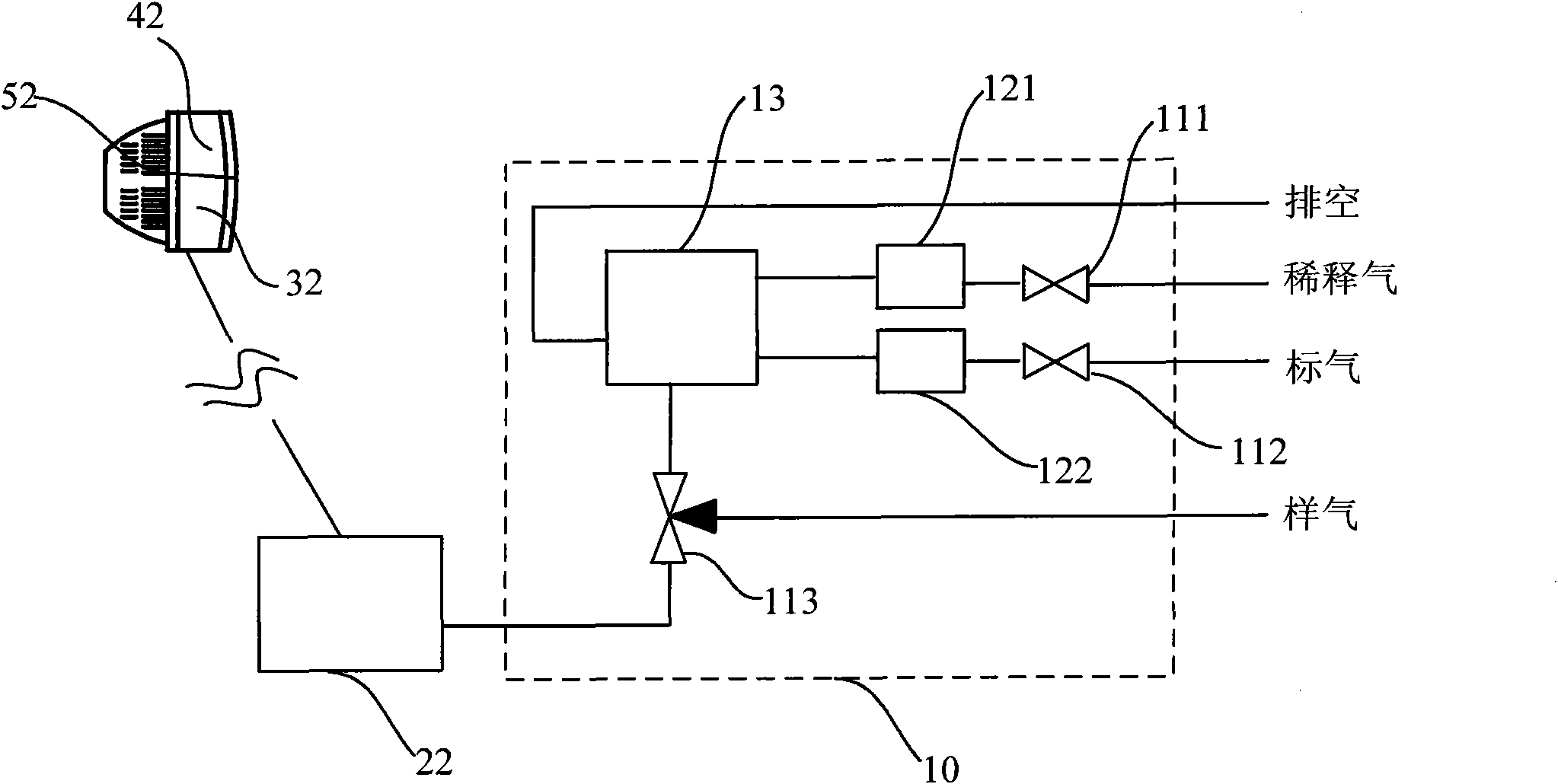

Gas analyzer calibration measurement apparatus and calibration measurement method thereof

ActiveCN103399127AGuaranteed continuityInterference measurement resultsMaterial analysisMeasurement deviceCalibration gas

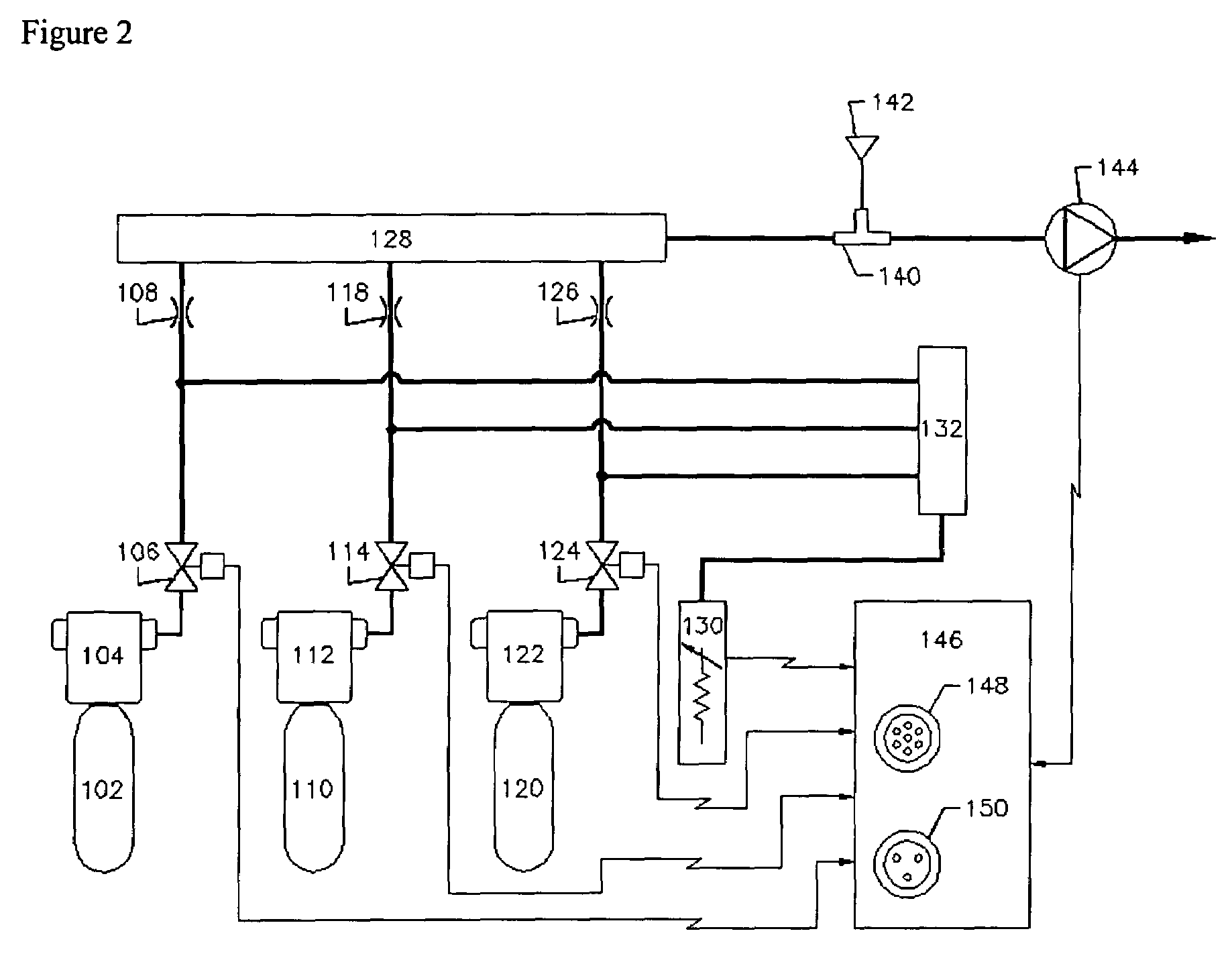

The present invention relates to a gas analyzer calibration measurement apparatus and a calibration measurement method thereof. The gas analyzer calibration measurement apparatus is characterized by comprising a standard gas supply system for calibration, a sampling system and a calibration gas circuit system, wherein the standard gas supply system for calibration comprises an air compressor, a zero air generator, a calibration gas supply device, a standard gas steel cylinder and a mixing bin, the sampling system comprises a gas sampling total pipe and a sampling pump, and the calibration gas circuit system comprises a plurality of three-way valves and a plurality of gas analyzers. According to the present invention, the standard gas supply system for calibration produces zero gas and mixing standard gas, the gases are input into the calibration gas circuit system to perform zero point and span point calibration on the gas analyzer in the calibration gas circuit system, the sampling system inputs the sampled sample gas into the zero point and span point calibration-completed calibration gas circuit system, and the calibration gas circuit system measures atmosphere gas pollutants in the input sample gas. The apparatus and the method can be widely used for atmosphere gas pollutant monitoring processes.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

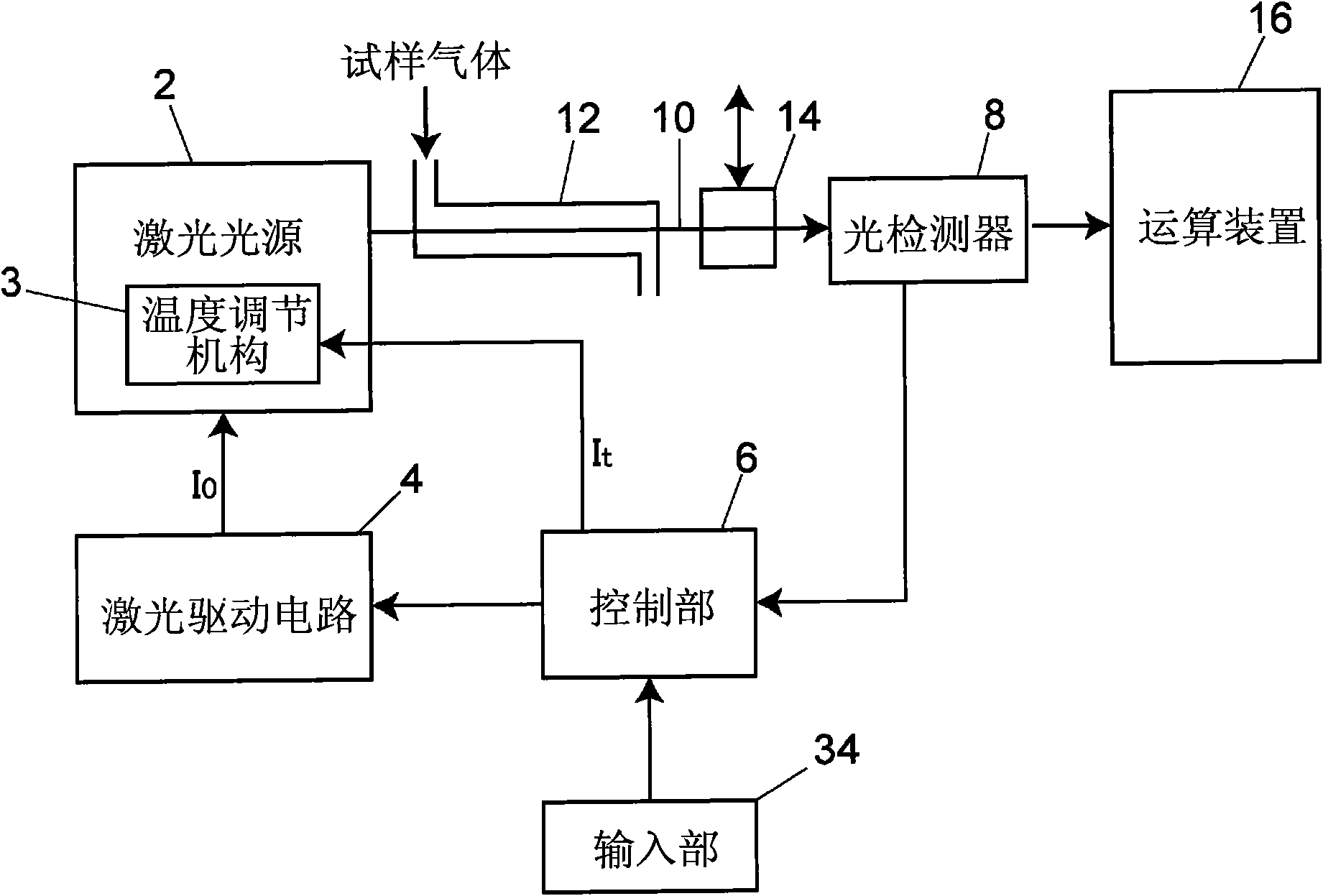

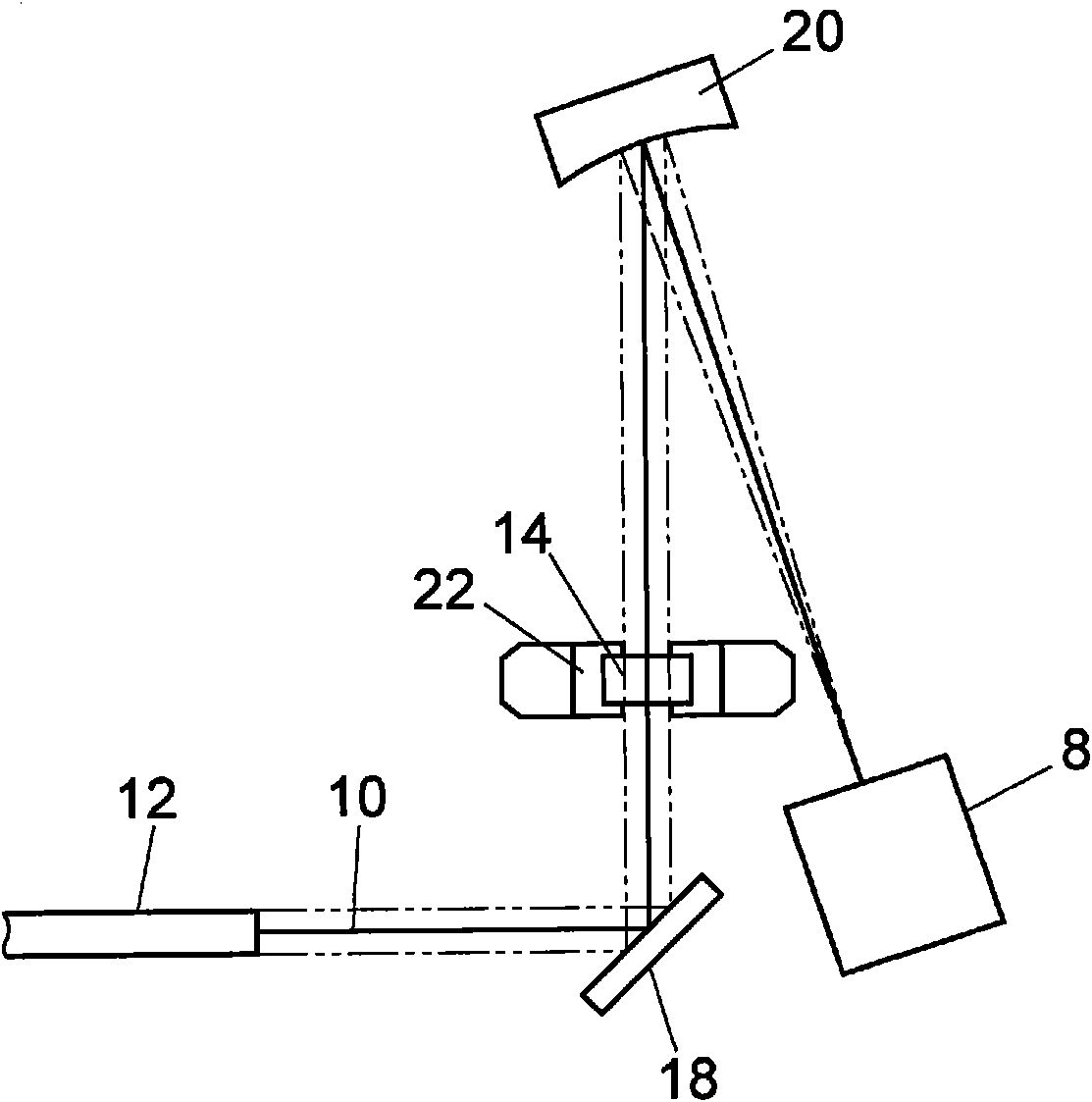

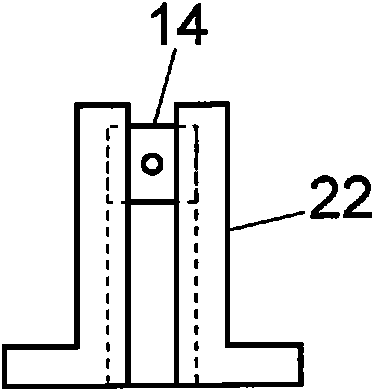

Gas analyzing apparatus with built-in calibration gas cell

A gas analyzing apparatus for laser absorption spectroscopy measurement includes a laser light source to generate laser beam with a specific wavelength absorbed by a component being measured in sample gas, a laser light source drive controller to control driving of the laser light source, an optical detector arranged at a location where the laser beam is received, a gas cell for measurement of the sample gas which is arranged on an optical path of the laser beam going from the laser light source to the optical detector, and a computing unit to calculate a concentration of the component being measured in the sample gas in accordance with a detection signal of the optical detector. Further, the gas analyzing apparatus has at least one calibration gas cell where calibration gas is filled with, and a calibration gas cell mounting mechanism capable of locating one of the calibration gas cells in a removable manner on the optical path of the laser beam.

Owner:SHIMADZU SEISAKUSHO CO LTD

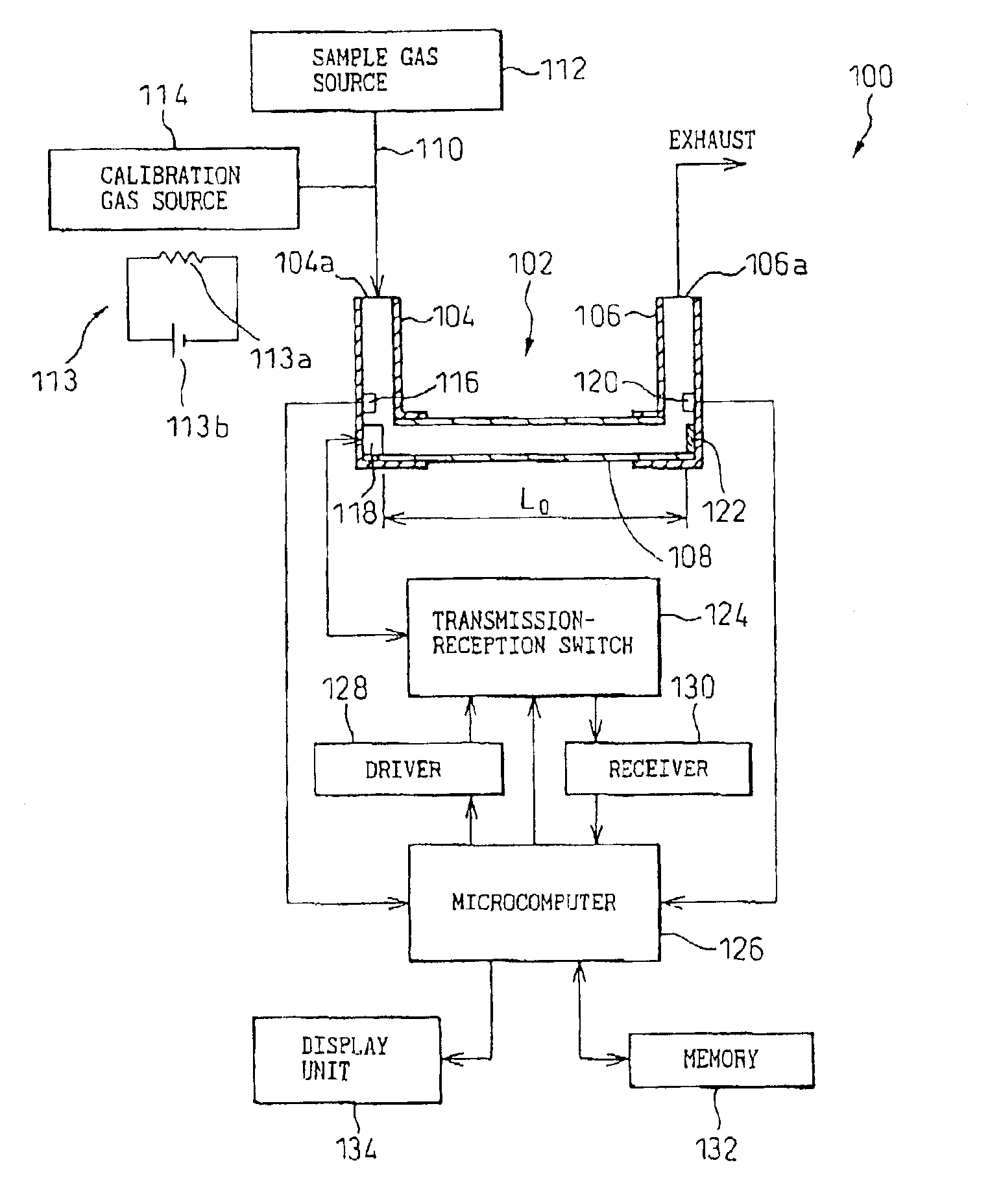

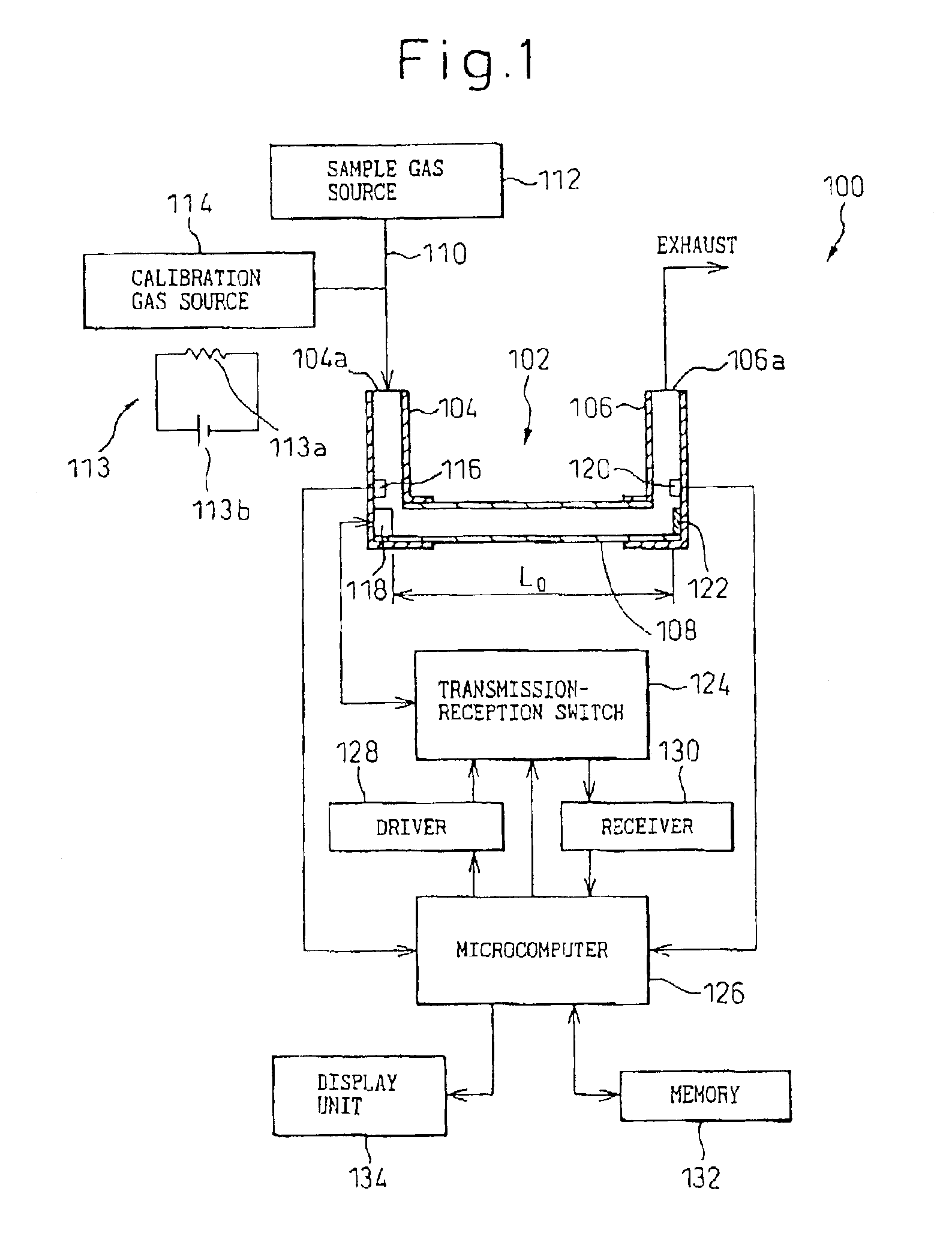

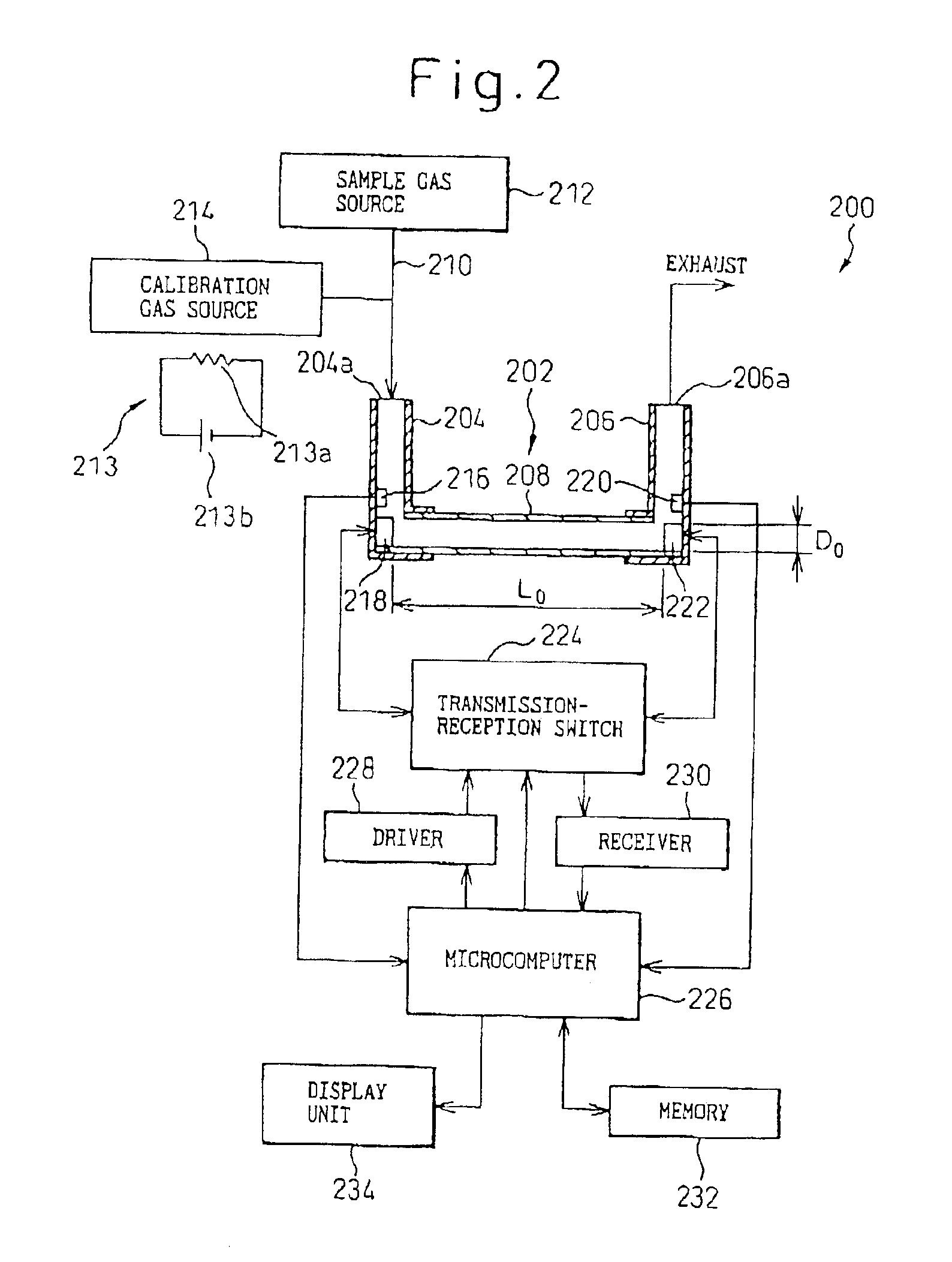

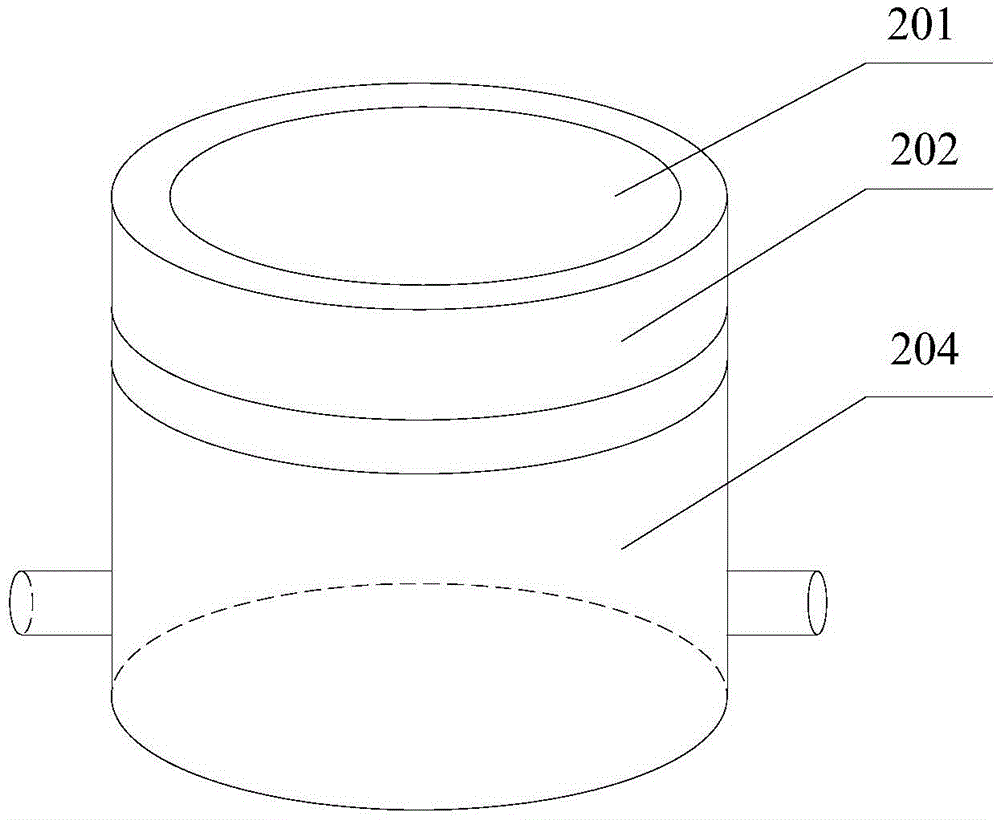

Ultrasonic apparatus and method for measuring the concentration and flow rate of gas

InactiveUS6912907B2Accurate measurementSimple methodAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasound deviceCalibration gas

An apparatus for measuring a gas concentration comprises a conduit through which an objective gas to be measured flows, a ultrasonic transmitting and receiving element fixed in a straight portion of the conduit and a reflecting plate fixed in the straight portion to face to the ultrasonic transmitting and receiving element. The apparatus further comprises a calibration gas source for supplying a calibration gas of which components and component ratio are preliminarily known, temperature sensors for measuring the temperature of the calibration gas flowing through the conduit, a propagation time calculating means for calculating the time period for propagation of the ultrasonic through the calibration gas in the conduit, a calibration means for calibrating the reference distance between the ultrasonic transmitting and receiving element and the reflecting plate based on the calculation results of the propagation time calculating means.

Owner:TEIJIN LTD

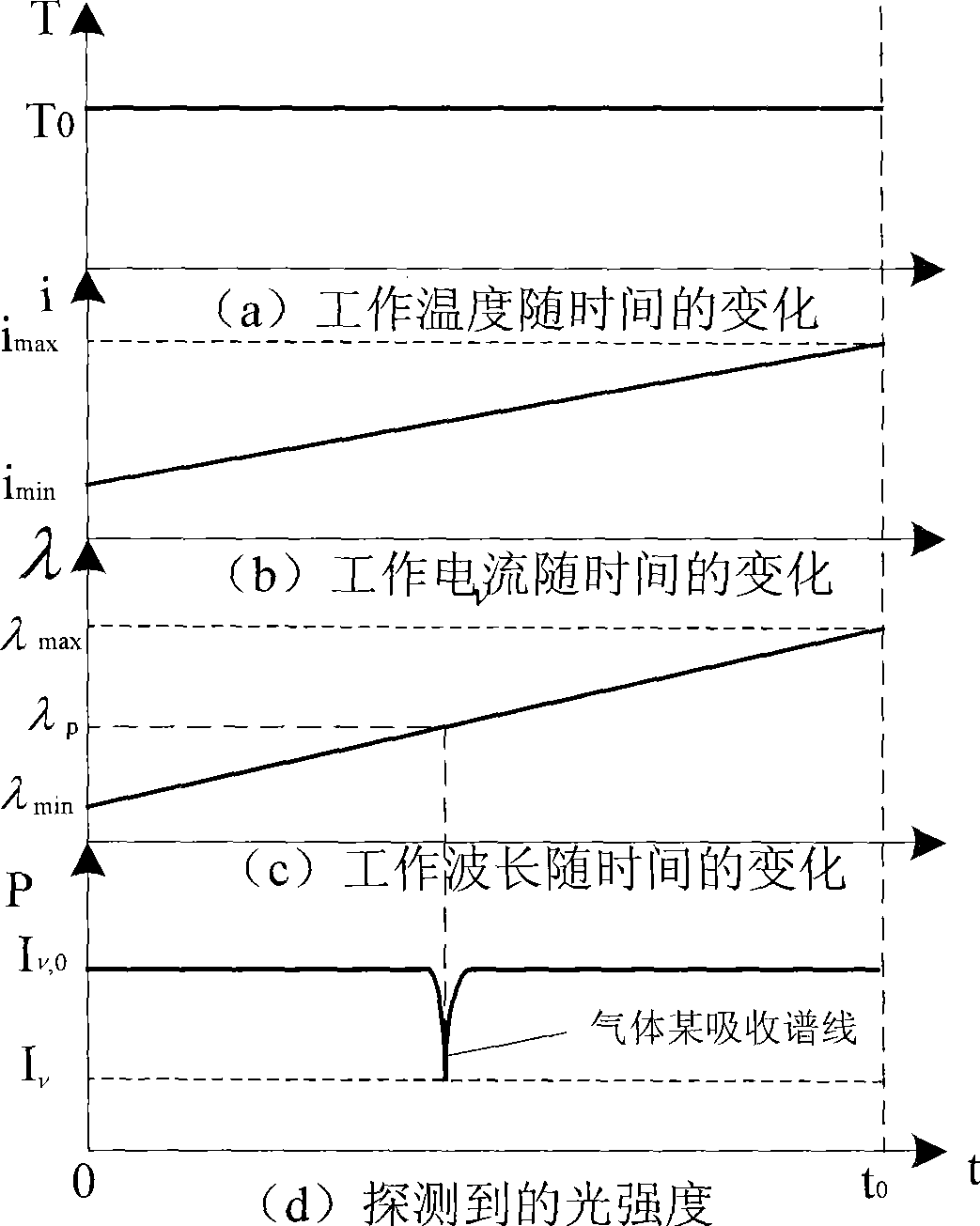

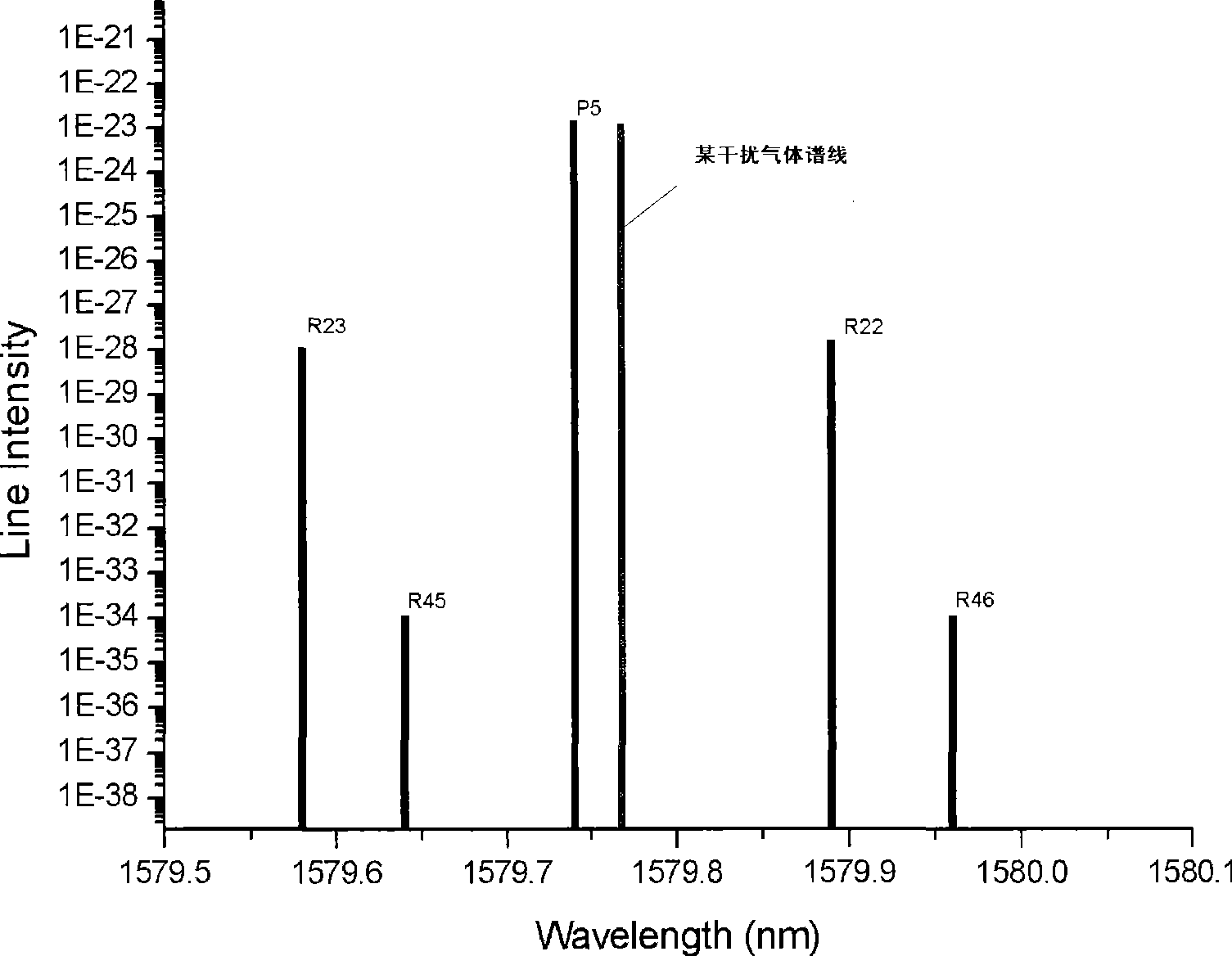

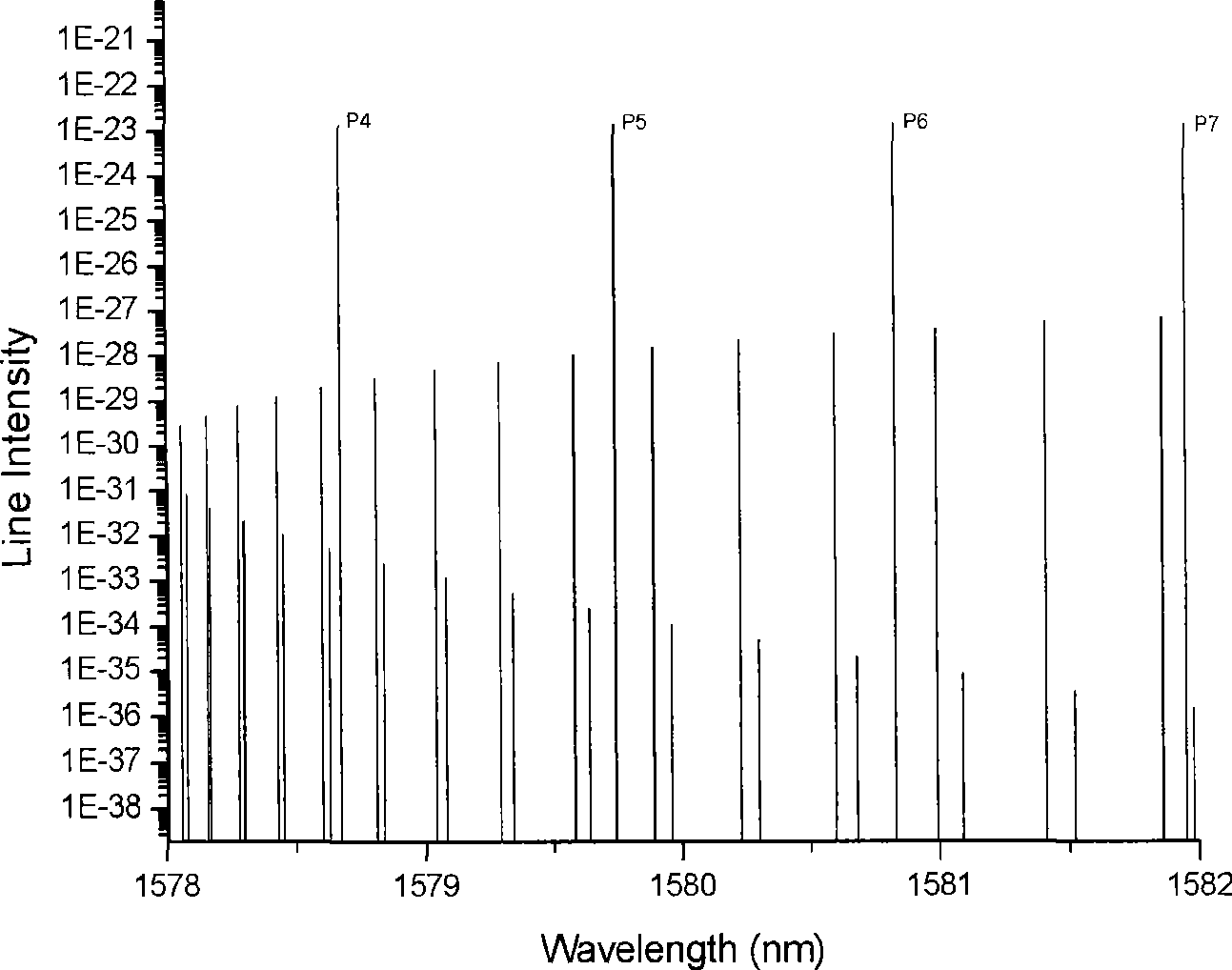

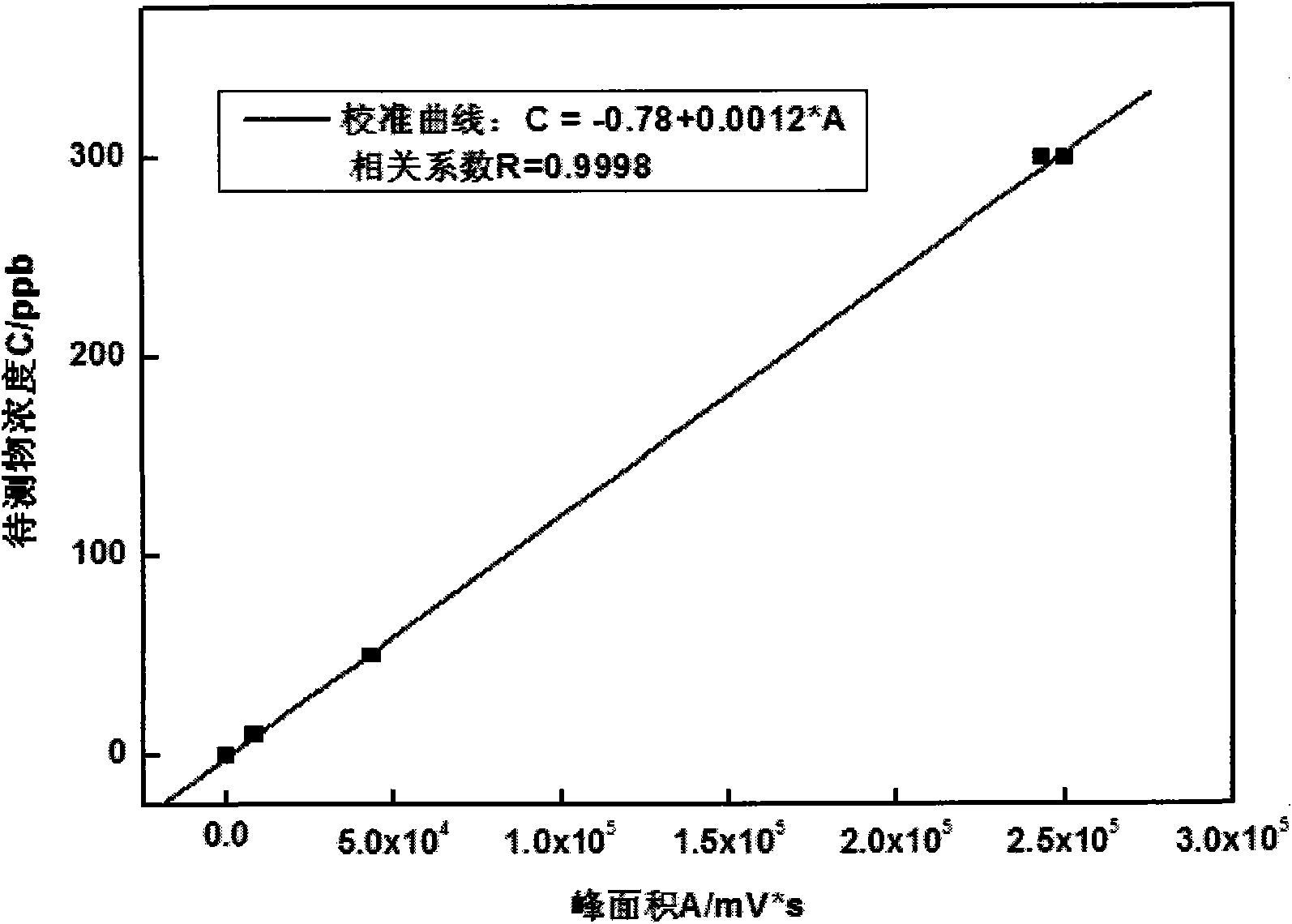

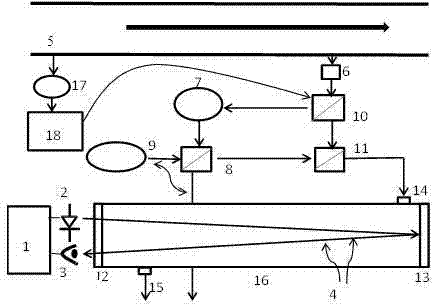

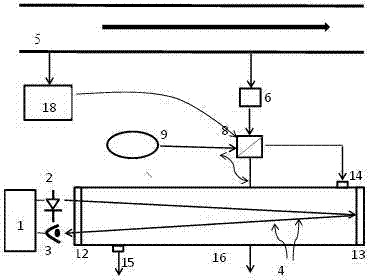

Laser absorption spectrum trace amount gas analysis method and apparatus using the same

ActiveCN101441173AReal-time measurementReal-time calibrationColor/spectral properties measurementsSpecial data processing applicationsGas analysisMeasurement device

The invention relates to an on-line self-calibration laser-adsorption-spectrum trace gas analysis method and the laser-adsorption-spectrum trace gas analysis device employing the method. The method comprises establishing a calibration gas chamber in the measuring light path, adding the standard gas the same as the gas to be measured in the calibration chamber, and calculating the concentration of the gas to be measured by detecting the original light intensity and the line intensity of the measuring light path and the calibration light path irrespective of the gas temperature and the pressure. The method for measuring the concentration of the gas to be measured is simple and accurate, and the device employing the method is also simplified remarkably and can realize real-time self-calibration.

Owner:CHONGQING CHUANYI AUTOMATION +1

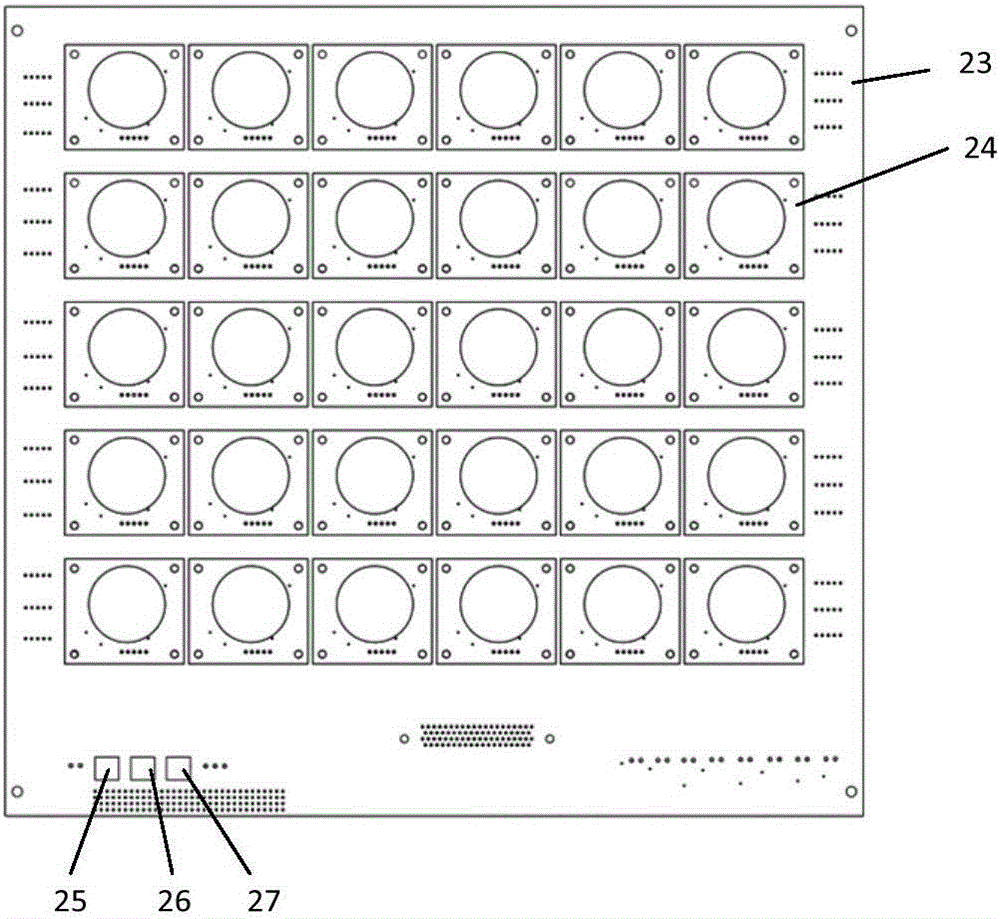

Gas sensor evaluation and calibration system

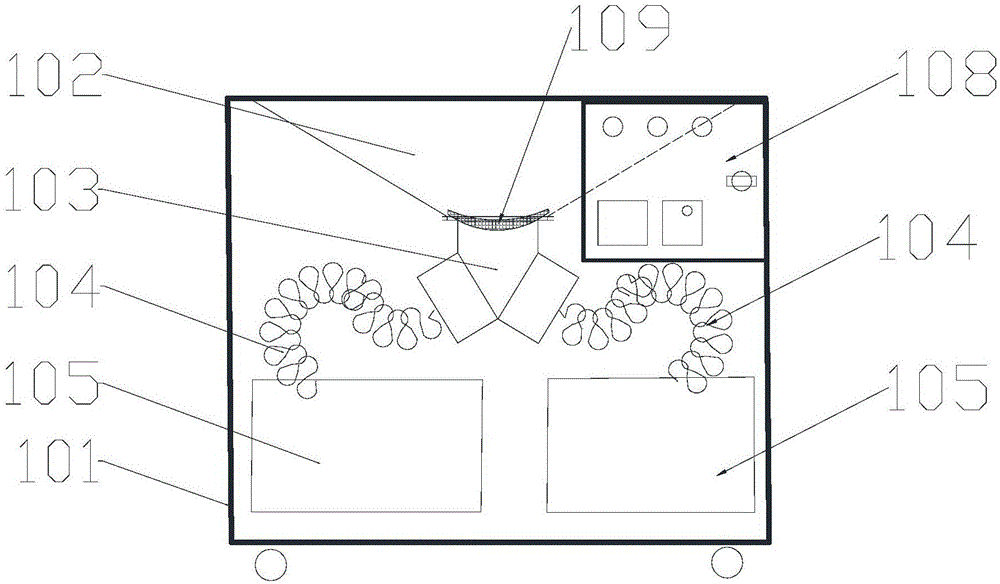

PendingCN106645587AGood humidityEasy to fixGas analyser calibrationGas analyser construction detailsCalibration gasEngineering

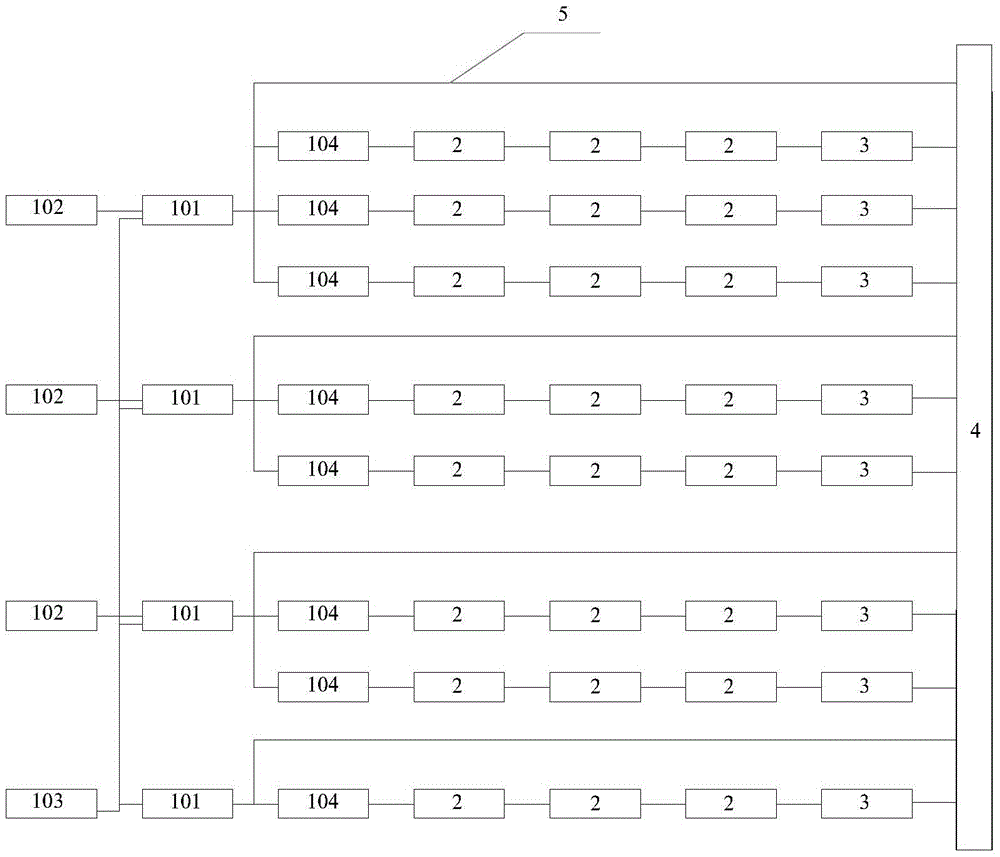

The invention discloses a gas sensor evaluation and calibration system. The gas sensor evaluation and calibration system comprises a gas distribution unit, a conditioning unit, a calibration unit and a reference unit, wherein a gas outlet of the gas distribution unit is connected with the conditioning unit, the gas distribution unit is used for configuring calibration gases of different concentrations, the conditioning unit is used for carrying out humidity control on the calibration gases, the conditioning unit is connected with the calibration unit, the calibration gases passing through the conditioning unit enter the calibration unit and calibrate gas sensors, and the reference unit can be separately connected with a gas inlet of the conditioning unit and a gas outlet of the calibration unit in a switch valve manner and is used for monitoring the concentrations of the gases before entering the calibration unit and after leaving the calibration unit in real time. The gas sensor evaluation and calibration system disclosed by the invention has the advantages of convenient operation, high safety and high extendability, and can be used for evaluating and calibrating the gas sensors in batches.

Owner:TSINGHUA UNIV

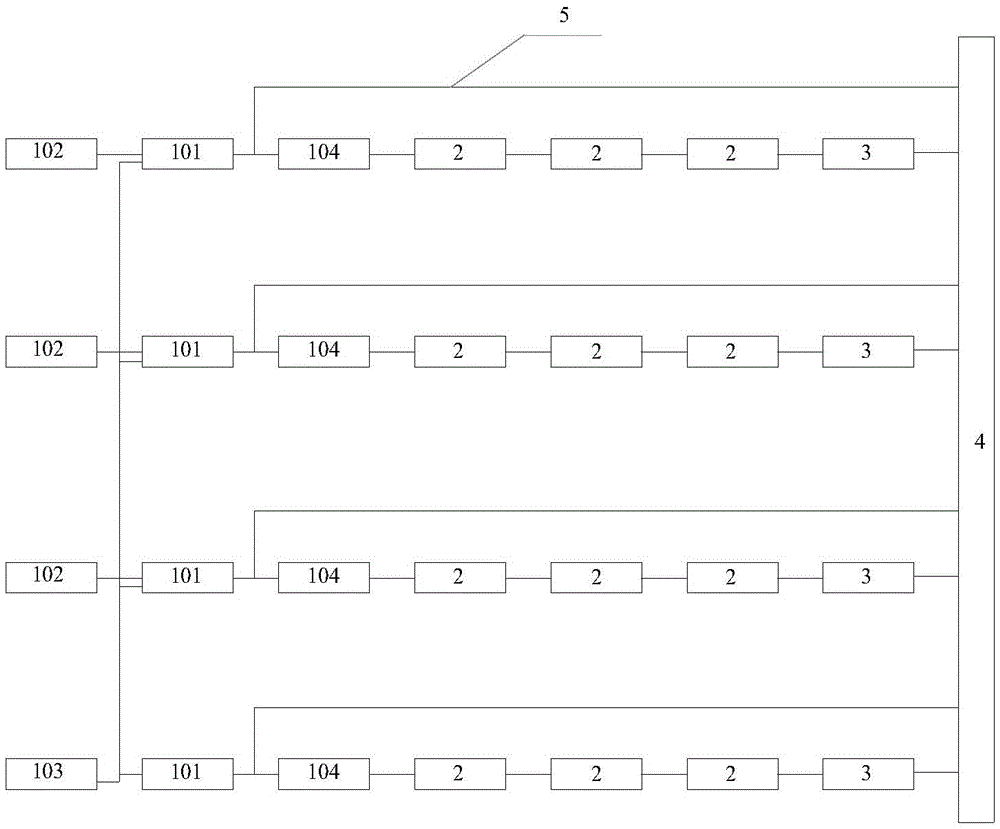

Calibration tool for gas sensors and calibration method

ActiveCN105572307AImprove accuracyImprove consistencyGas analyser calibrationCalibration gasProcess engineering

The invention discloses a calibration tool for gas sensors, and belongs to the technical field of gas sensor testing. The calibration tool comprises a calibration gas generating device and a gas analyzer which are connected with gas intakes and gas exhaust openings of the gas sensors through pipelines respectively. The calibration tool is arranged in groups, each group comprises a sensor set formed by the gas sensors arranged in series, and the gas intakes and the gas exhaust openings of the sensor sets are connected with the calibration gas generating device and the gas analyzer respectively. The invention further provides a calibration method of the calibration tool. According to the calibration tool and the calibration method, different sensors can be calibrated at the same time, and the sensors of the same kind can be calibrated in batch.

Owner:HEBEI SAILHERO ENVIRONMENTAL PROTECTION HIGH TECH

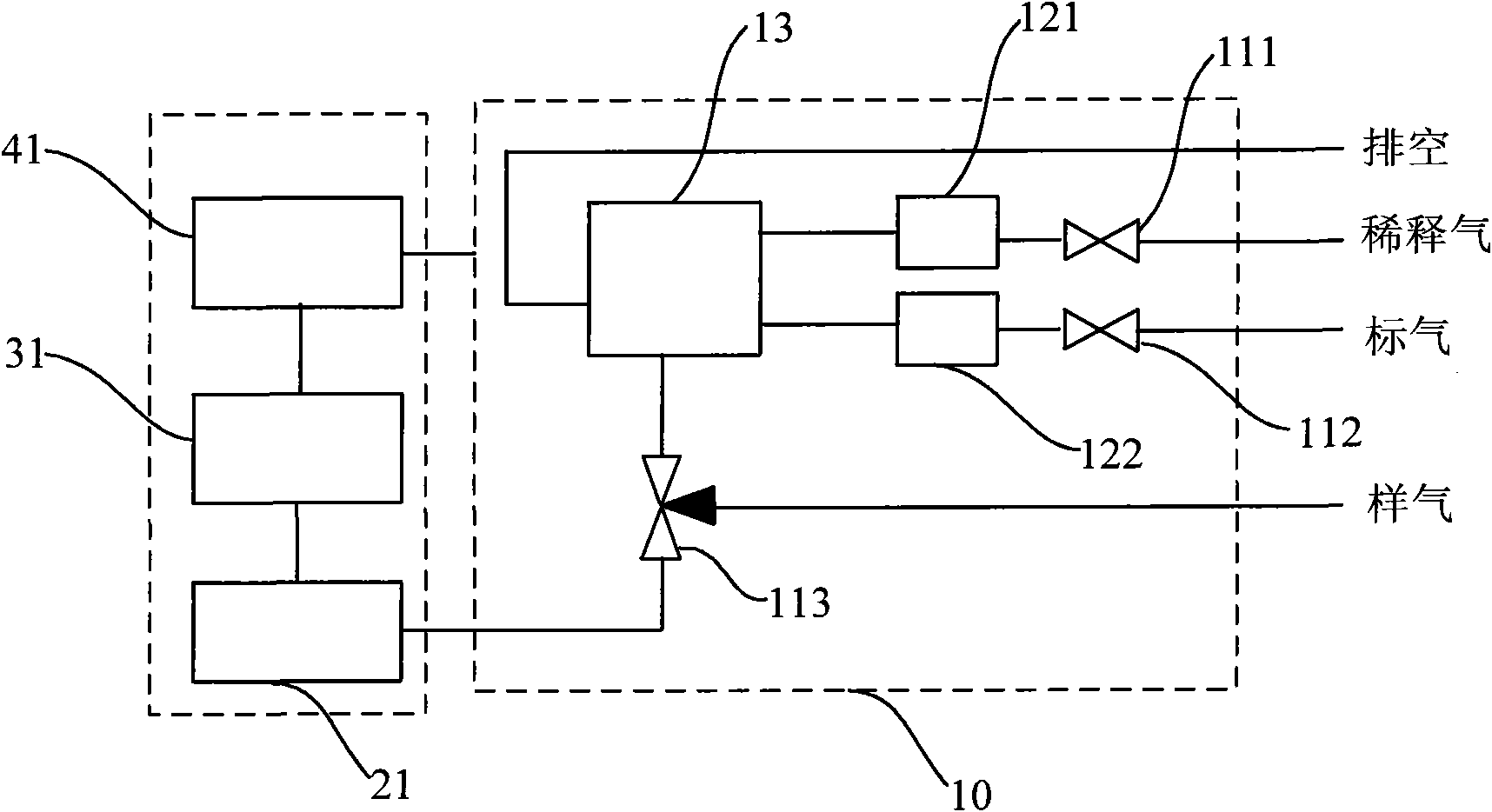

Automatic calibration method and device

The invention relates to an automatic calibration method. The method comprises the following steps of: a, introducing a gas sample into an analytical instrument and continuously analyzing the gas sample; b, when calibration is needed, switching a gas flow path to a calibration flow path by a control unit, controlling the flow of standard gas and diluent gas by the control unit, preparing calibration gas with specified concentration, and introducing calibration gas into the analytical instrument to obtain calibration data; and generating a new calibration result according to the calibration data; and c, switching the gas flow path to a gas sample flow path by the control unit, and continuously analyzing the gas sample by using the new calibration result until calibration is needed. The invention also provides an automatic calibration device. The invention has the advantages that: a dilution ratio range is wide, the volume is small, remote control and automatic calibration can be realized and the like.

Owner:杭州谱育检测有限公司

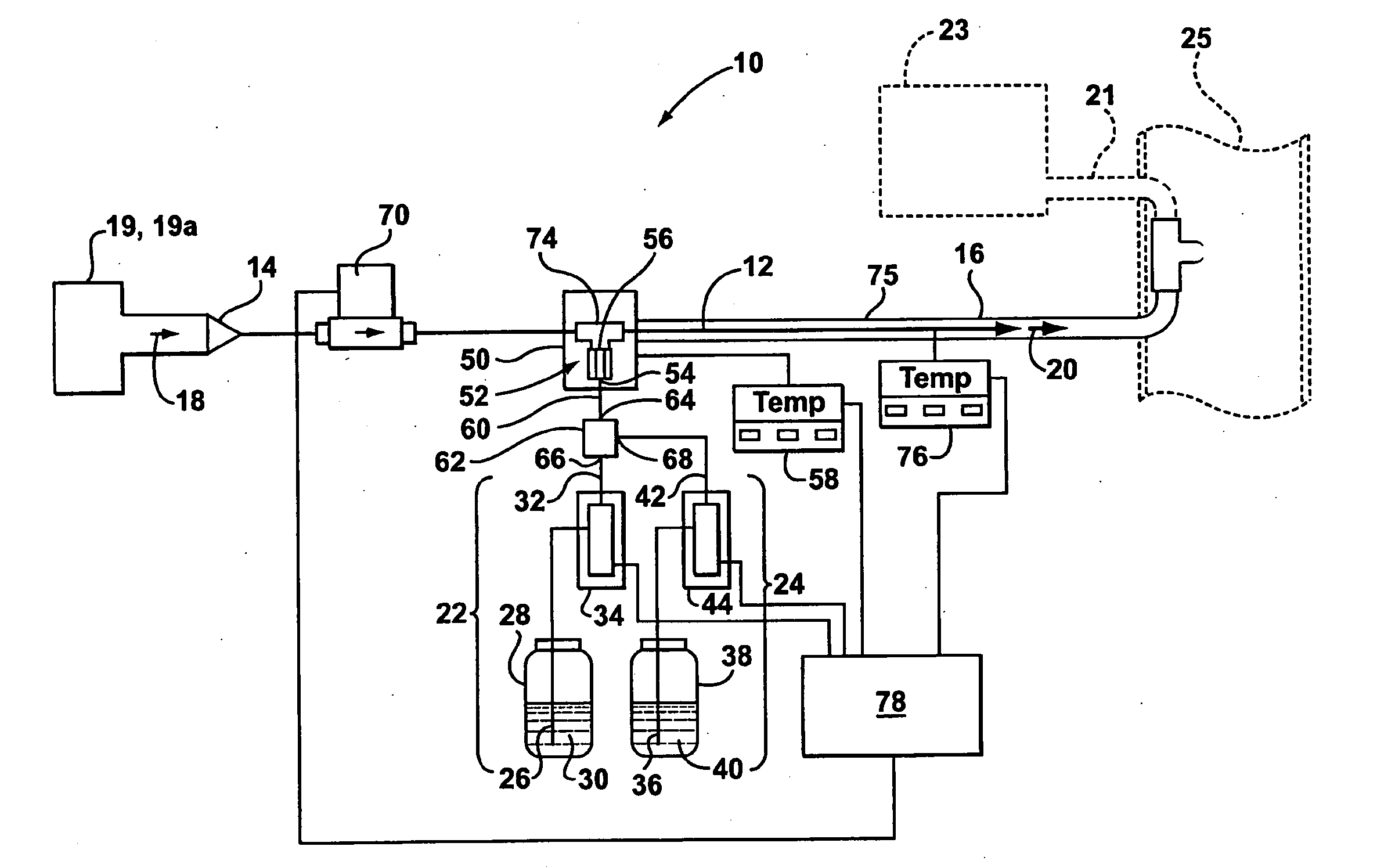

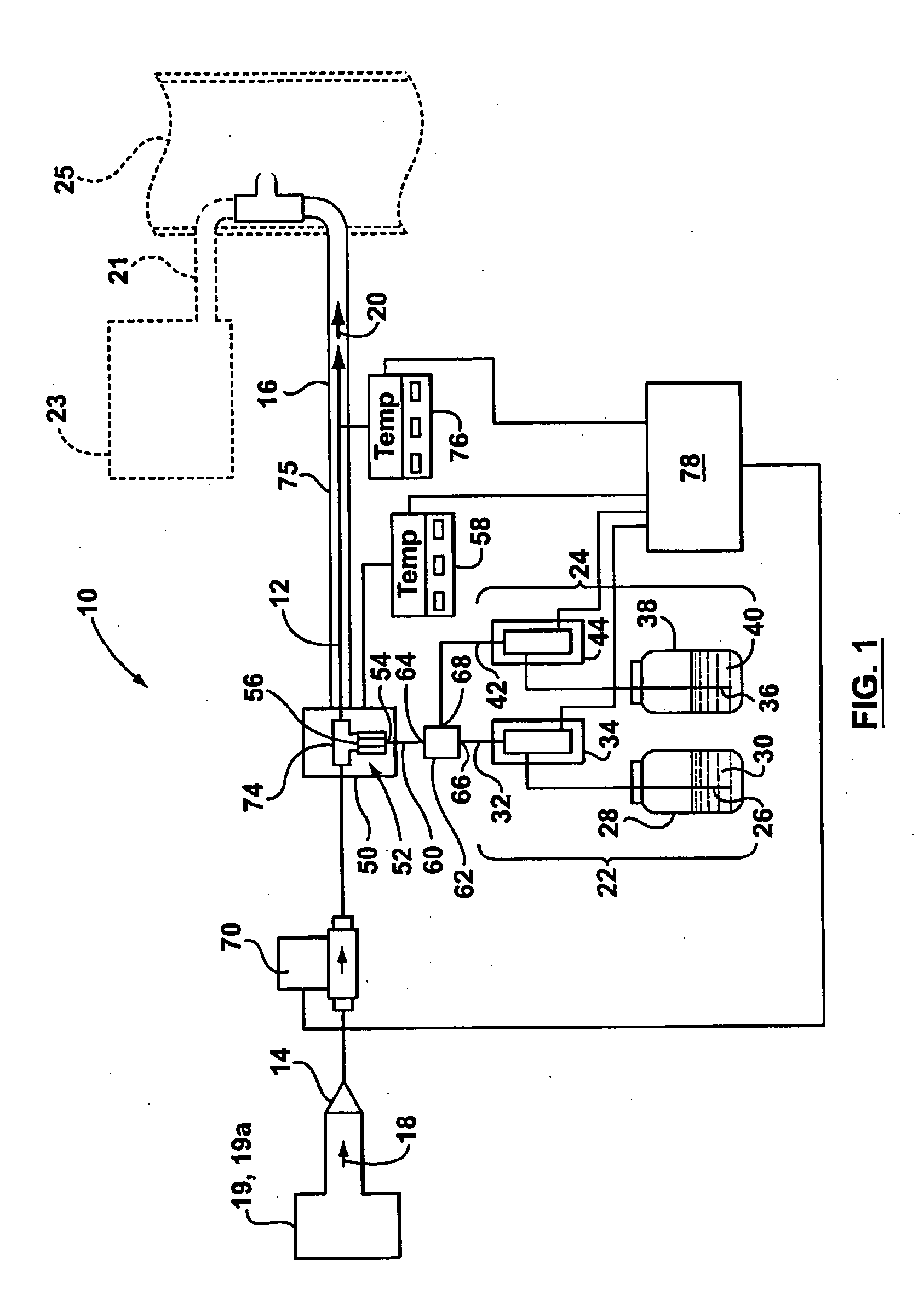

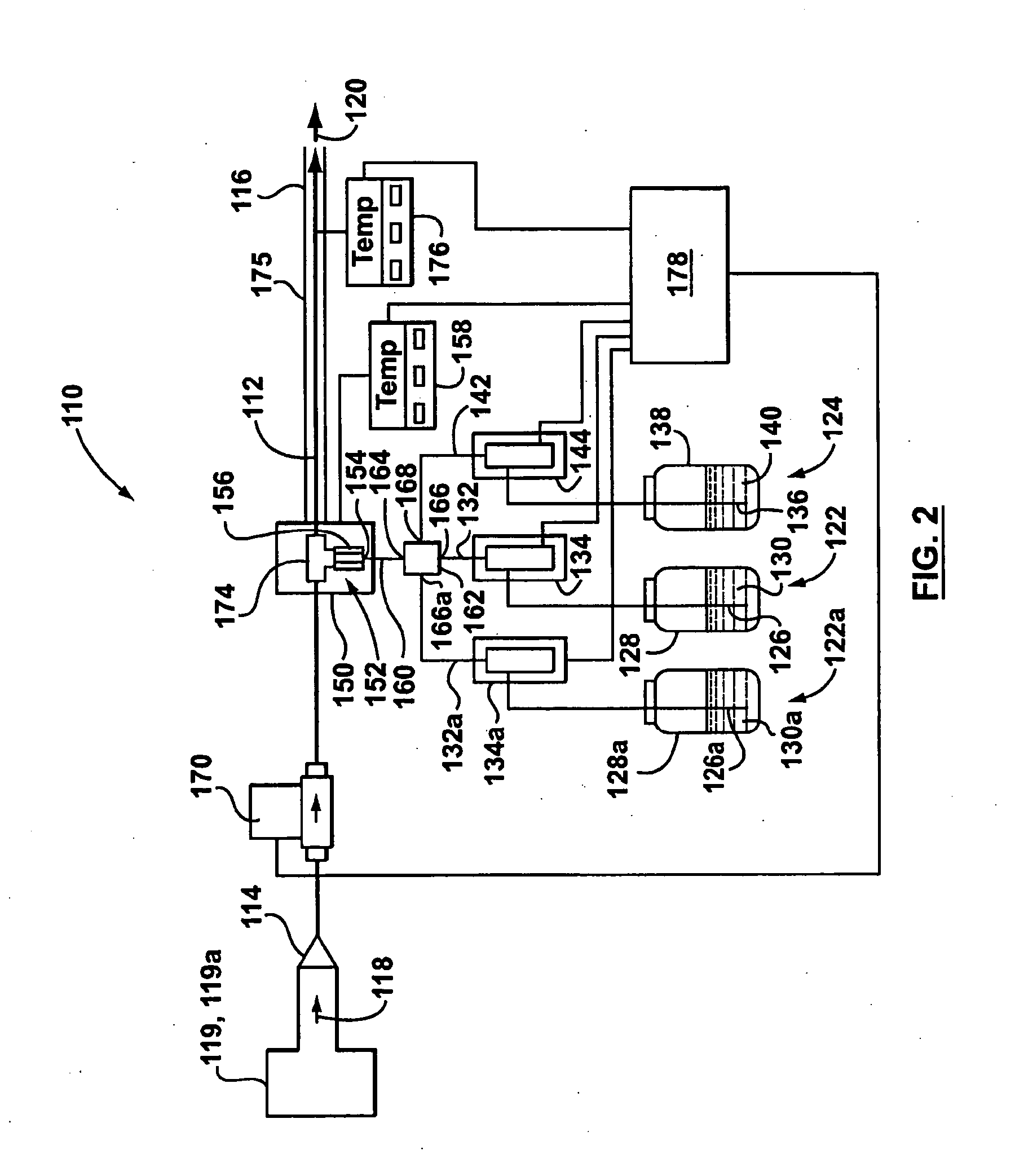

Calibration gas delivery apparatus

ActiveUS20070178015A1Economical and simpleFully automatedMaterial analysis by electric/magnetic meansMaterial analysis by optical meansCalibration gasAnalyte

A calibration gas generation method and apparatus for generating a selectively humidified calibration gas to a measurement probe includes a delivery conduit having a conduit inlet adapted to receive a carrier gas stream and a conduit outlet for delivering a calibration gas stream. The apparatus is provided with a first injection unit having a first intake in fluid communication with a first reservoir and a first outlet in fluid communication with the delivery conduit, the first reservoir being adapted to hold a first analyte in liquid form, and a second injection unit having a second intake in fluid communication with a second reservoir and a second outlet in fluid communication with the delivery conduit, the second reservoir being adapted to hold a humidificant in liquid form. The apparatus further includes at least one vaporizer downstream of the first and second outlets and upstream of the conduit outlet for converting the analyte and humidificant liquids to vapor form and delivering a calibration gas including the carrier gas, analyte vapor, and humidificant vapor to the conduit outlet.

Owner:TEKRAN INSTR CORPORTION

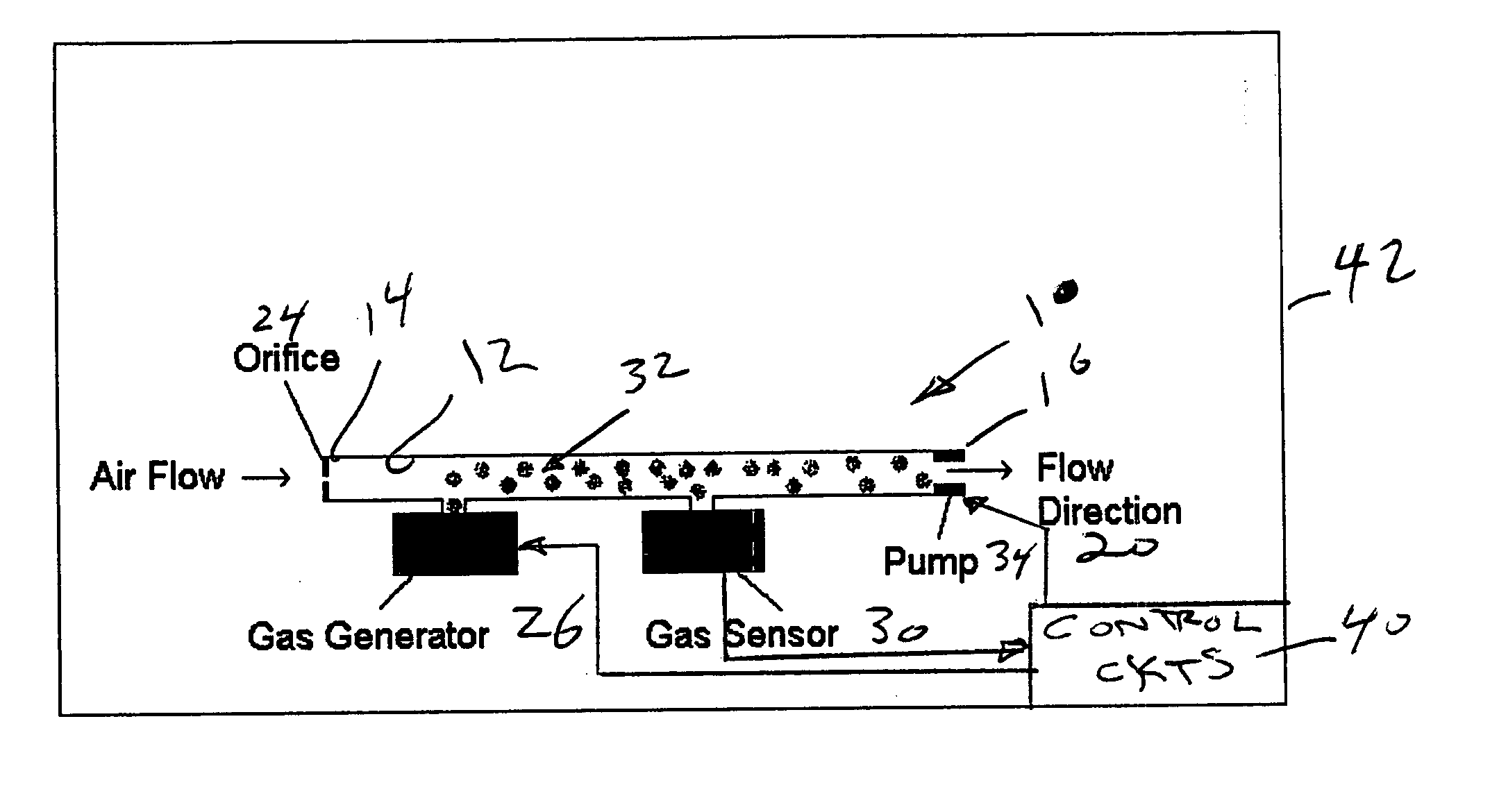

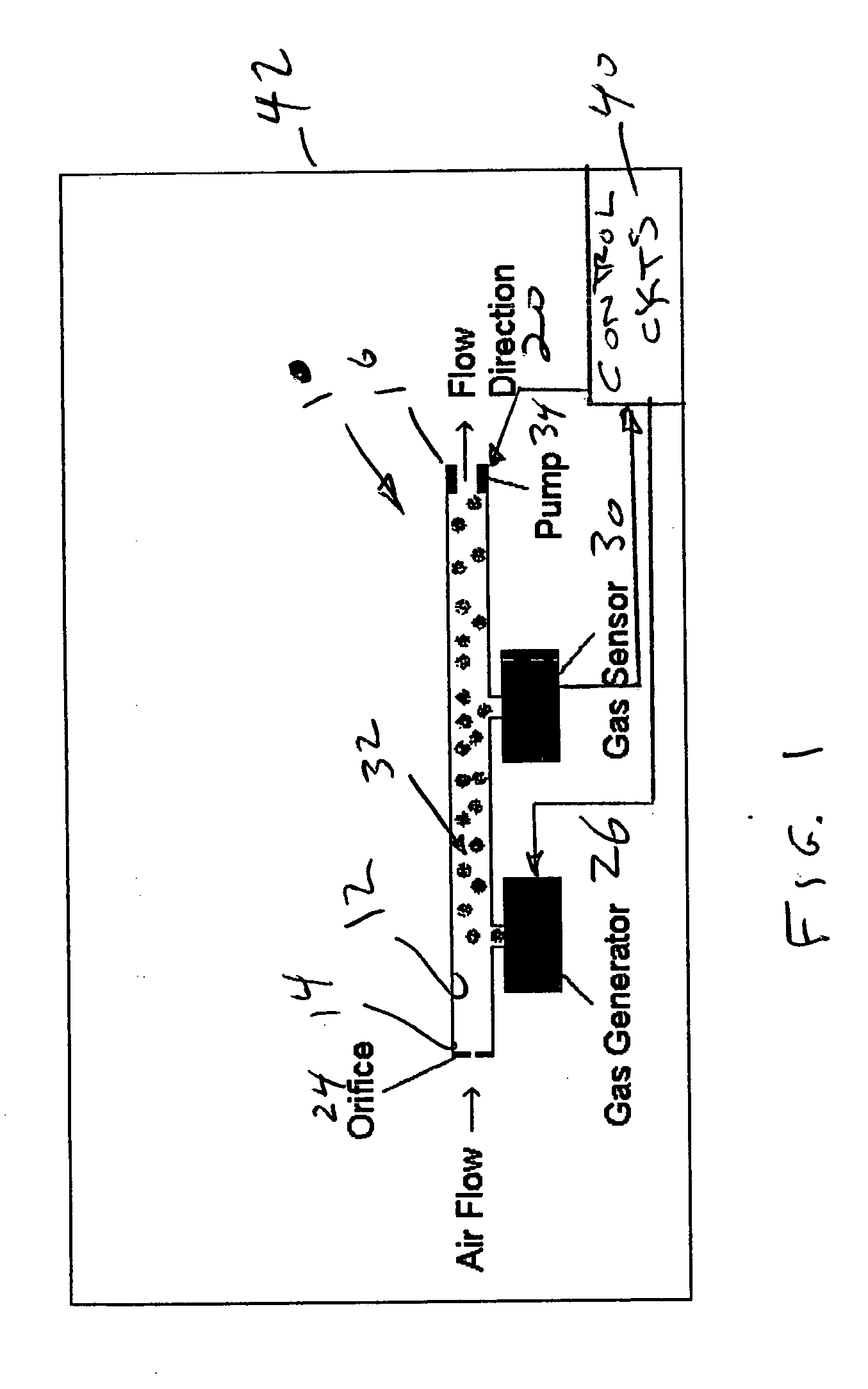

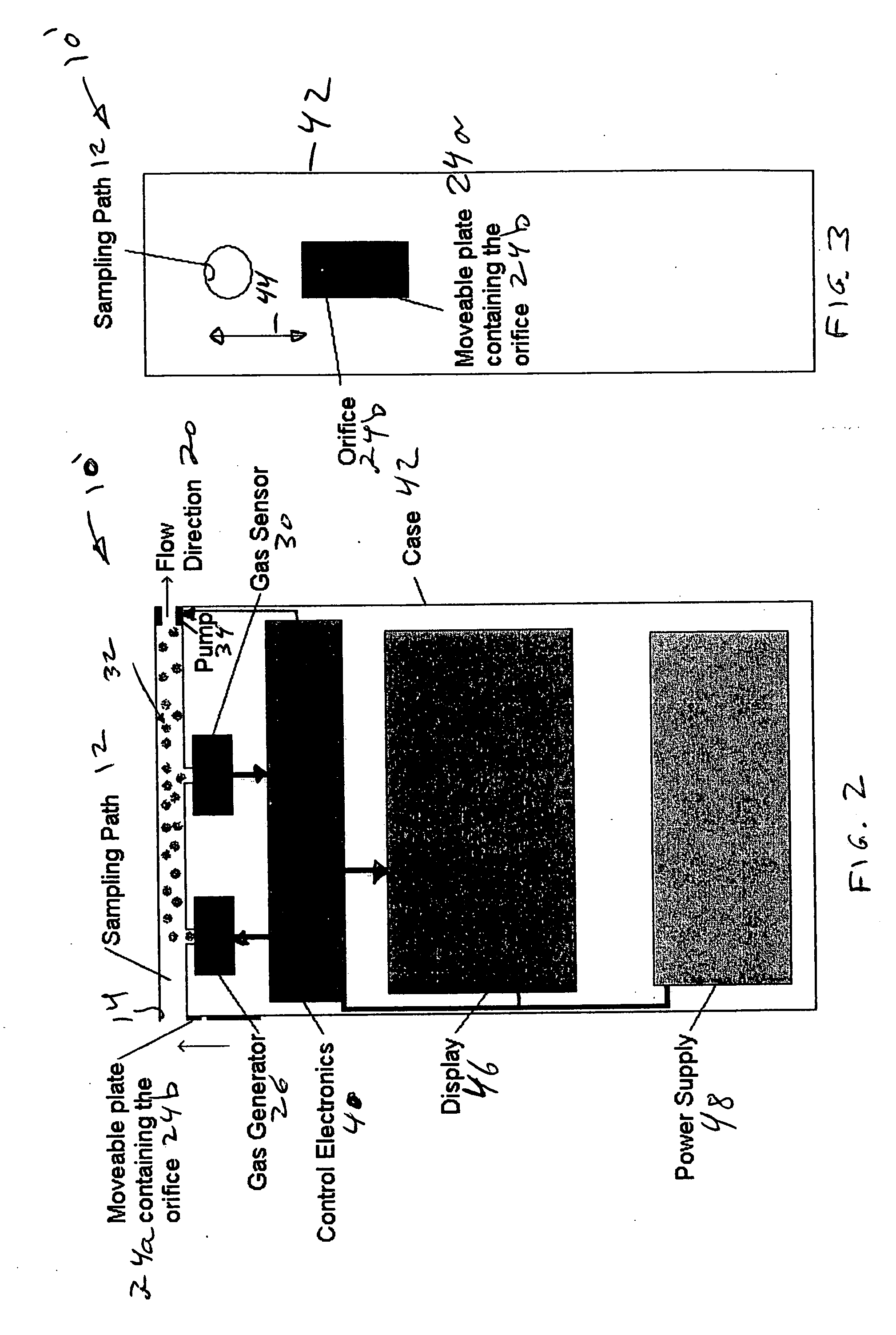

Self-calibrating gas detector and method

InactiveUS20060266097A1Easy CalibrationPrevent inflowMaterial analysis by electric/magnetic meansMaterial analysis by optical meansCalibration gasGas detector

A portable, calibratible gas detector includes a multi-position gas inflow limiting orifice. When this orifice is in a calibrating position, a source of calibrating gas can be activated to provide a quantity of gas that diffuses into ambient atmosphere flowing through the orifice. The calibration gas can then be sensed.

Owner:HONEYWELL INT INC

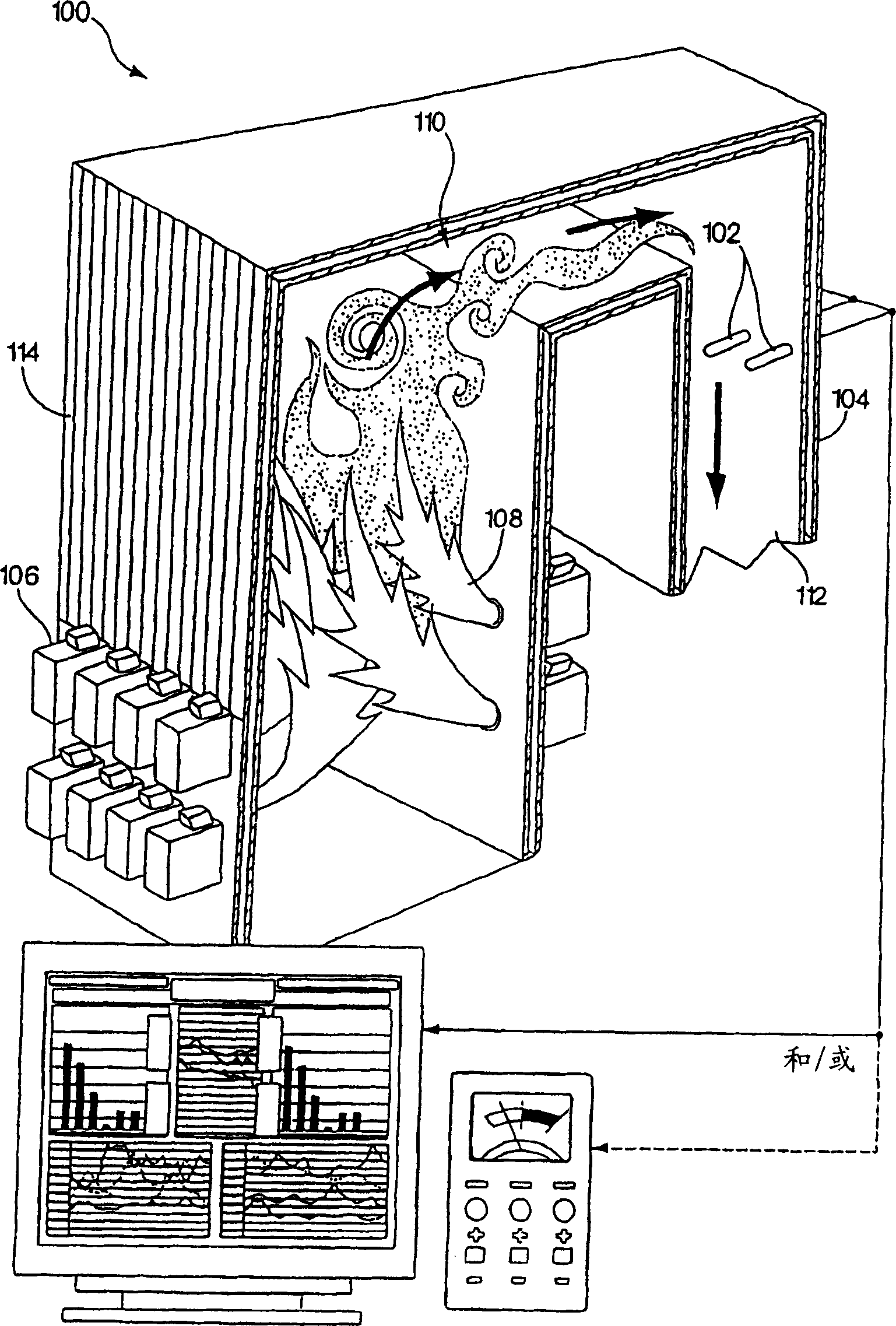

Method and equipment for monitoring gas in combustion system

InactiveCN1434293AOptimization of the combustion processMaterial analysis by electric/magnetic meansCombustion regulationElectrical batteryNitric oxide

Owner:GENERAL ELECTRIC CO

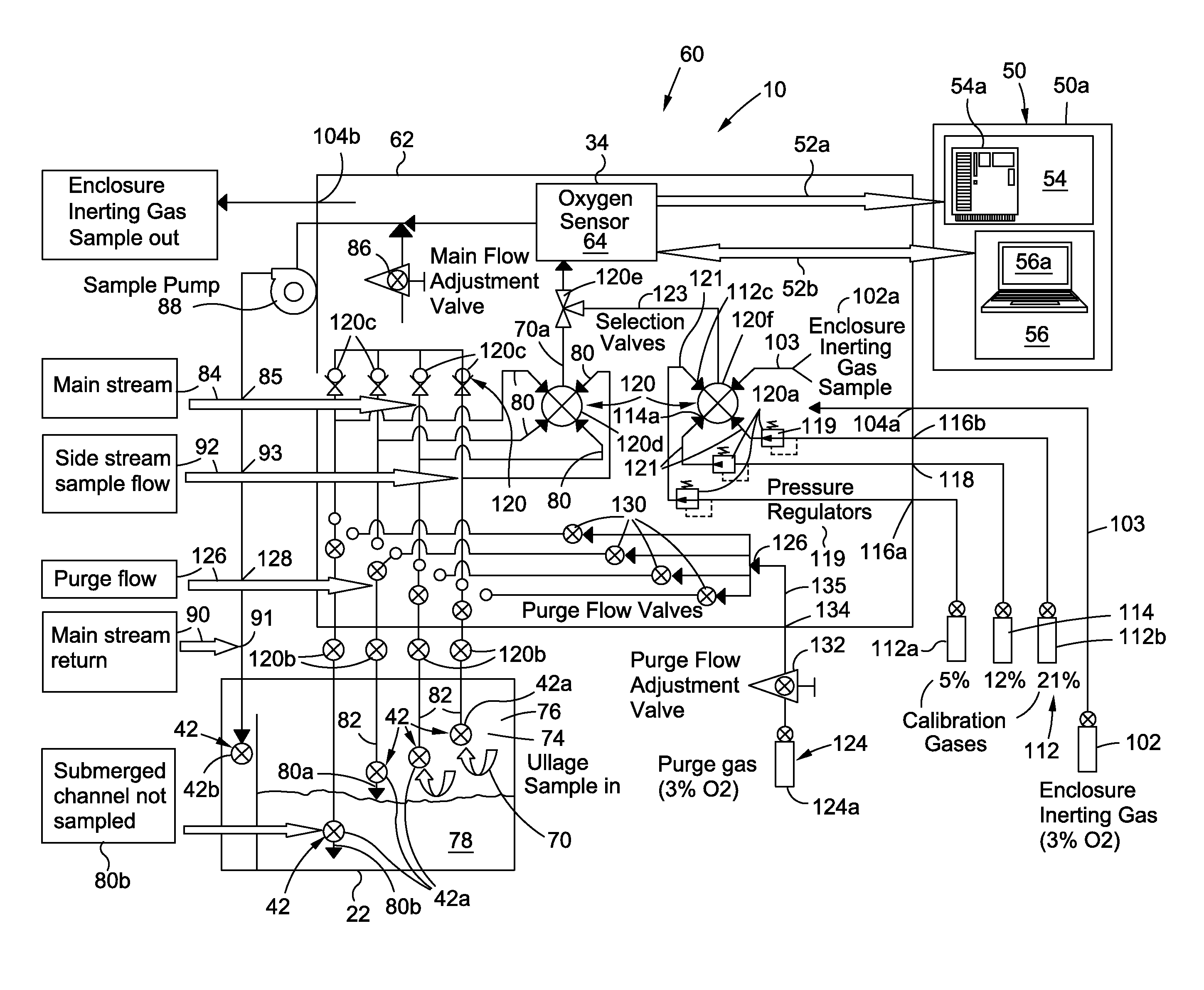

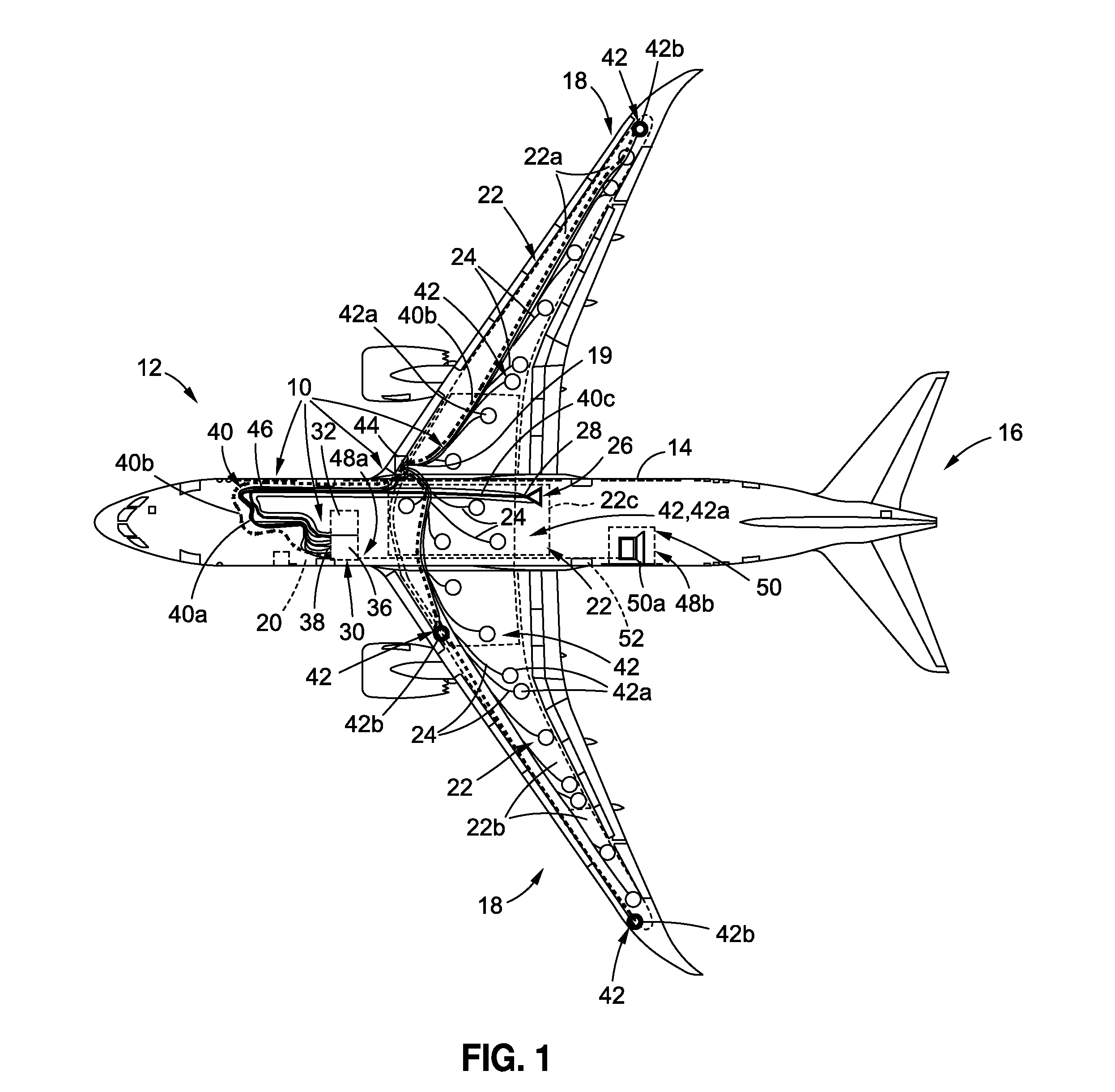

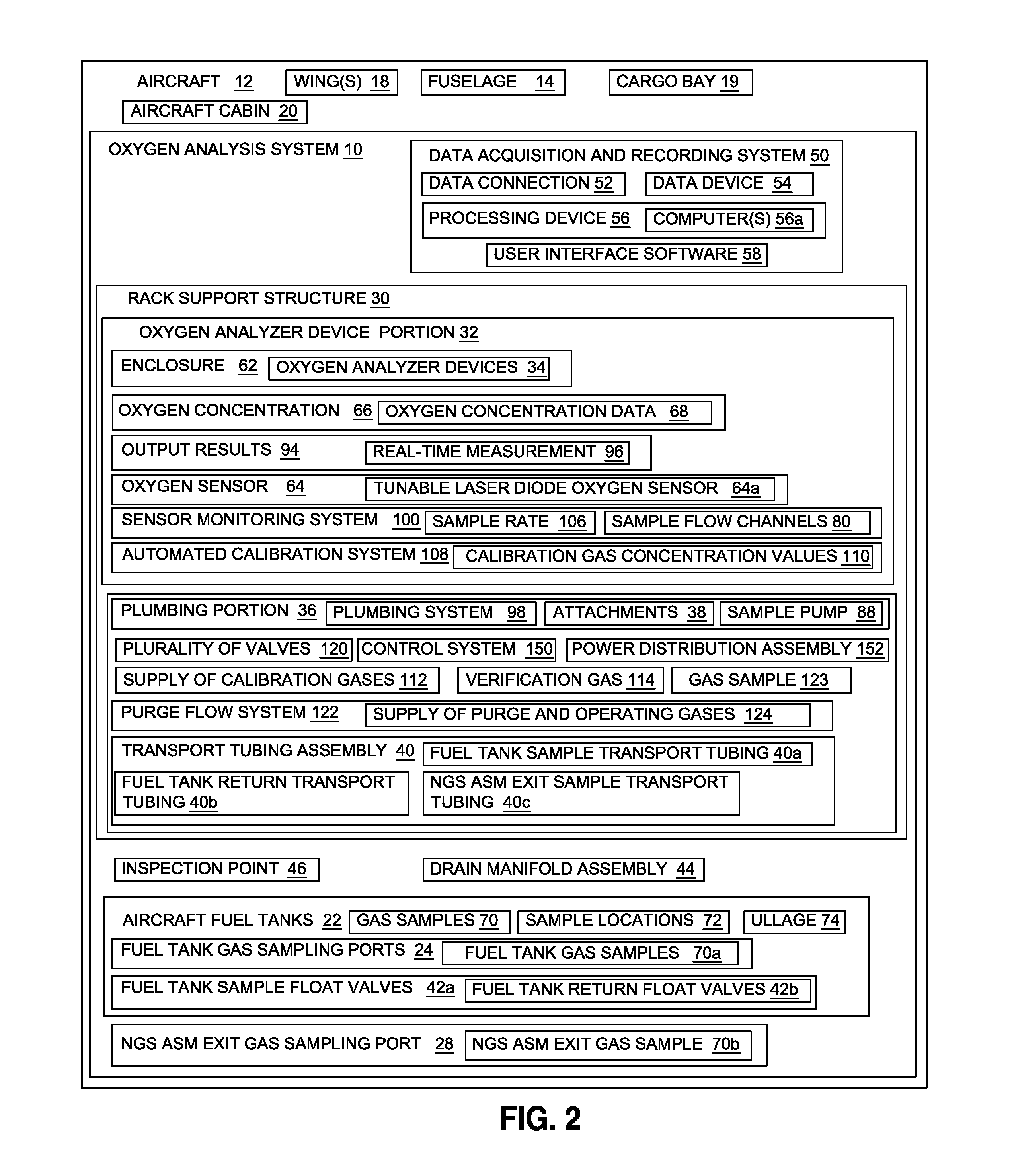

Oxygen analysis system and method for measuring, monitoring and recording oxygen concentration in aircraft fuel tanks

ActiveUS20150219554A1Meet actual needsPower plant fuel tanksFuel tank safety measuresCalibration gasNacelle

An oxygen analysis system (OAS) for measuring, monitoring and recording oxygen concentration in aircraft fuel tanks. The OAS has a rack support structure installed in an aircraft cabin with a plurality of oxygen analyzer devices mounted in the rack support structure. Each oxygen analyzer device has an oxygen sensor to measure oxygen concentration in gas samples continuously drawn from sample locations in aircraft fuel tanks and at an aircraft NGS ASM exit. The OAS further has a plurality of valves, a supply of calibration gases, a supply of purge and operating gases, and a power distribution assembly, all coupled to the rack support structure. The OAS further has a transport tubing assembly, a plurality of fuel tank gas sampling ports, an NGS ASM exit gas sampling port, a drain manifold assembly, and a data acquisition and recording system having a user interface software to monitor and control the OAS.

Owner:THE BOEING CO

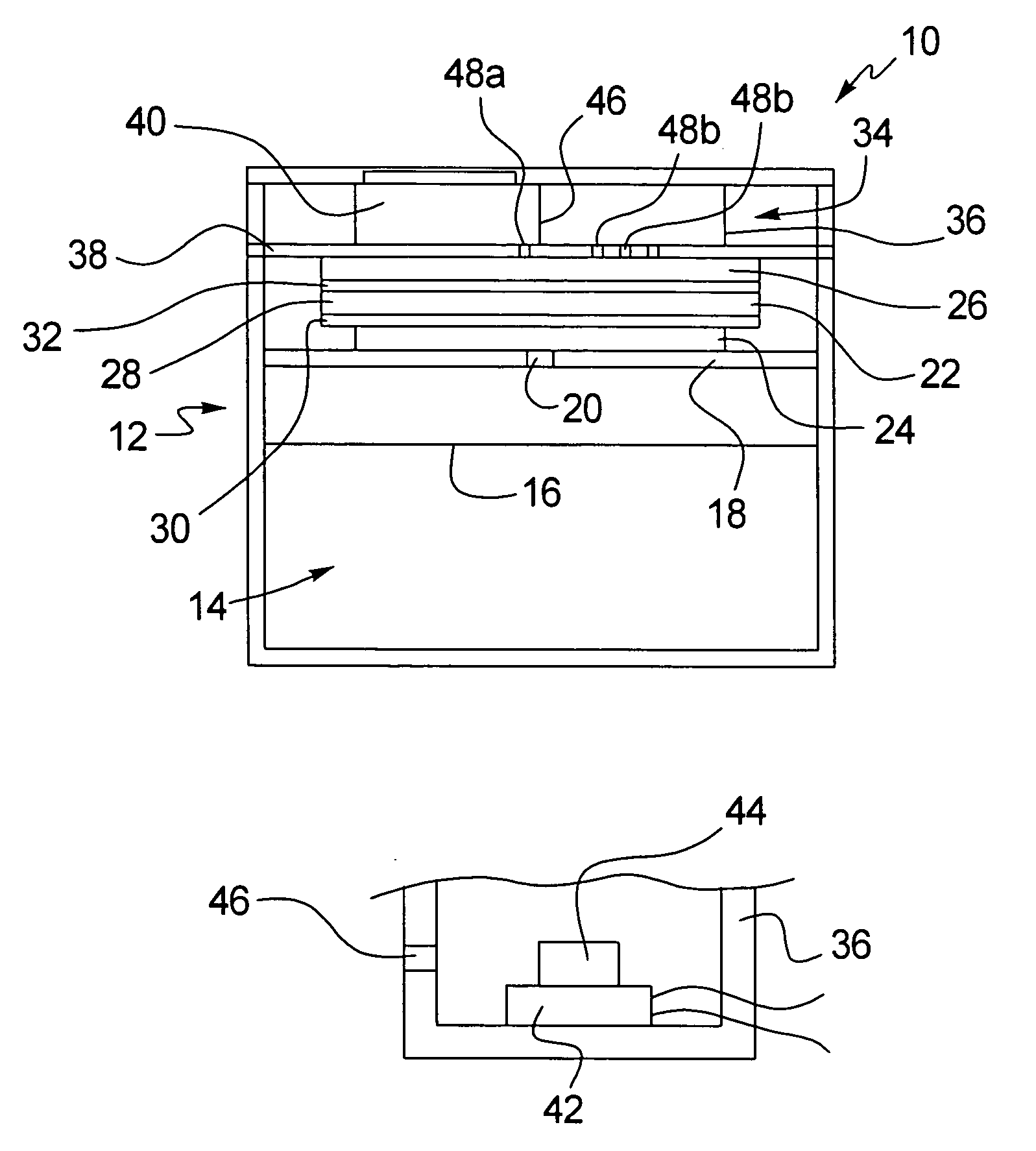

Gas sensor calibration system

InactiveUS20030167821A1Reduce wasteCalibrationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansPhase detectorCalibration gas

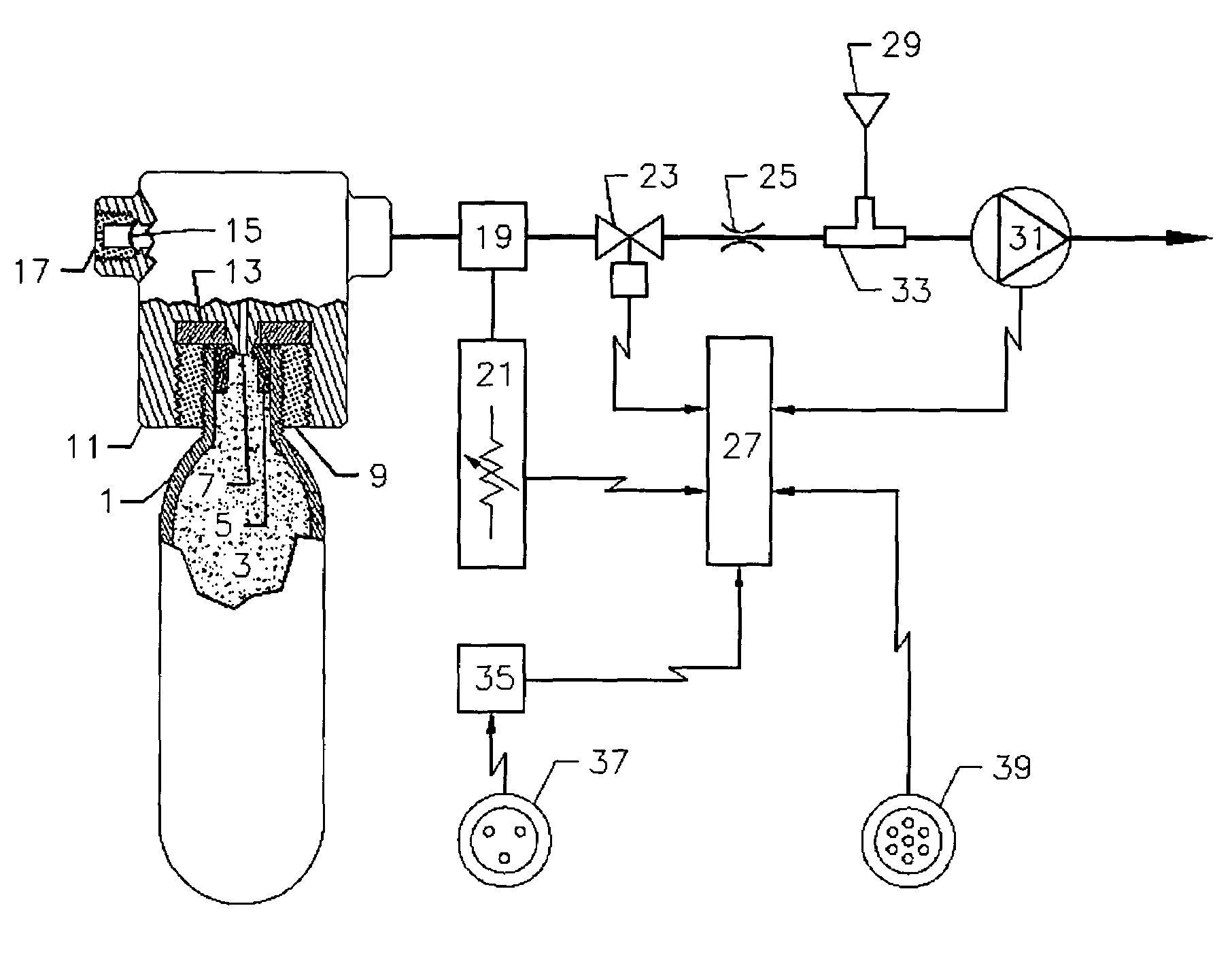

The present invention provides a method of calibrating sensors within a gas detector (36) having a housing containing a gas inlet whereby gas can diffuse from the inlet to the sensors. The gas inlet in the housing is held against part (34) of the calibration apparatus to form a sealed gas interface between the apparatus and the detector; a source (10) of pressurised calibration gas is connected to the apparatus, and a predetermined dose of calibration gas is delivered to the interface between the detector (36) and the calibration apparatus (34) at a predetermined pressure. The source (10) of pressurised calibration gas may contain single or multiple calibration doses and, if the former, the calibration apparatus includes a dosing system such as cylinder (14) for metering individual doses of calibration gas.

Owner:ZELLWEGER ANALYTICS

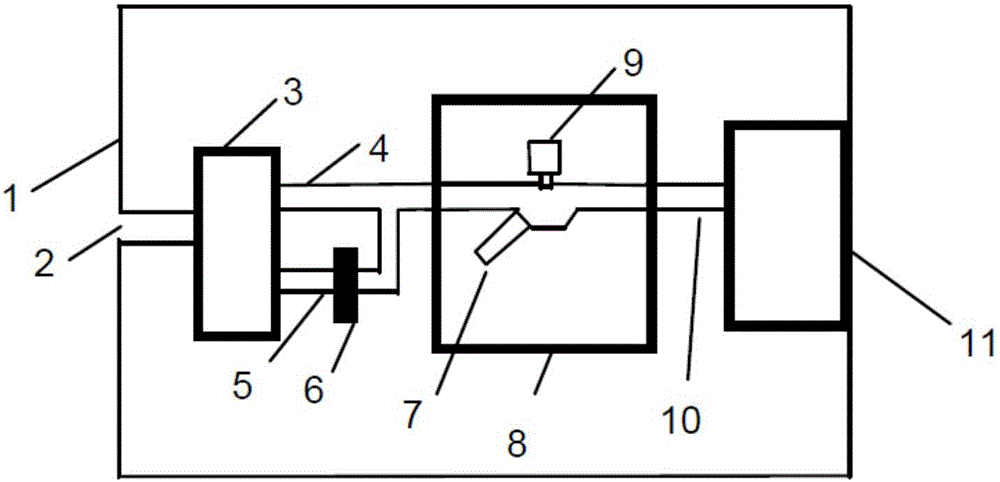

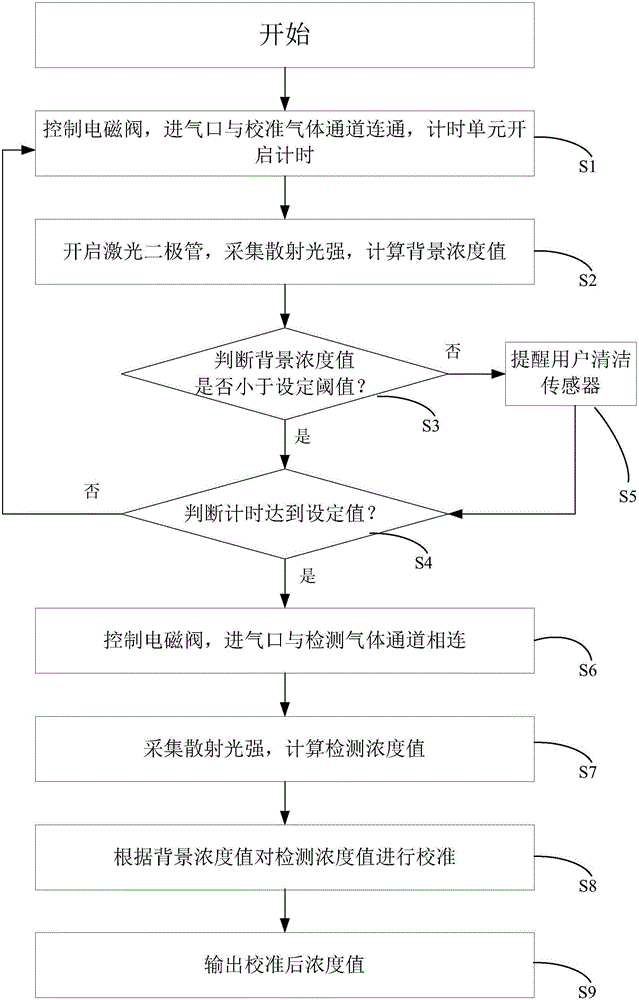

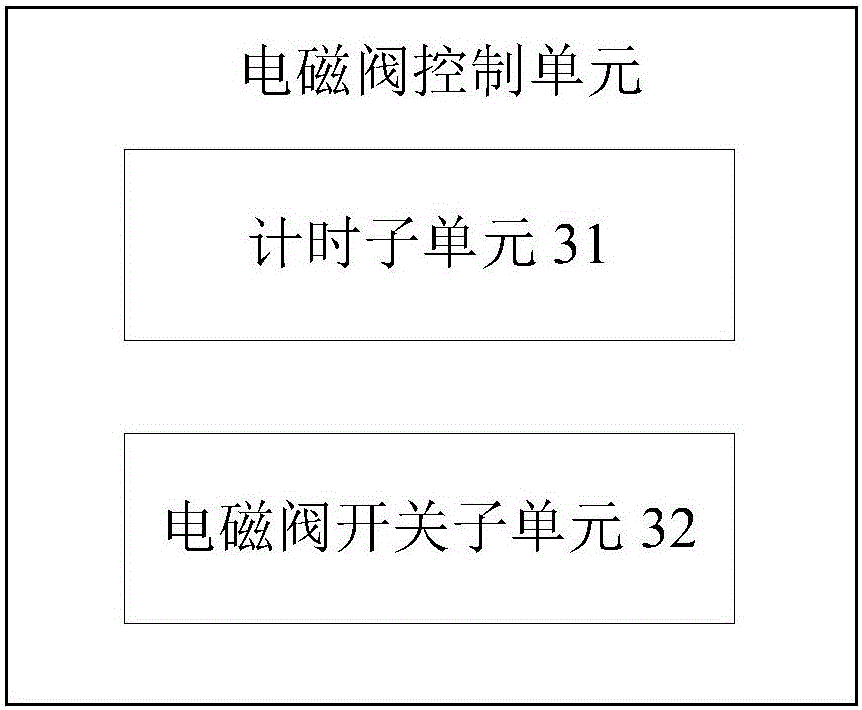

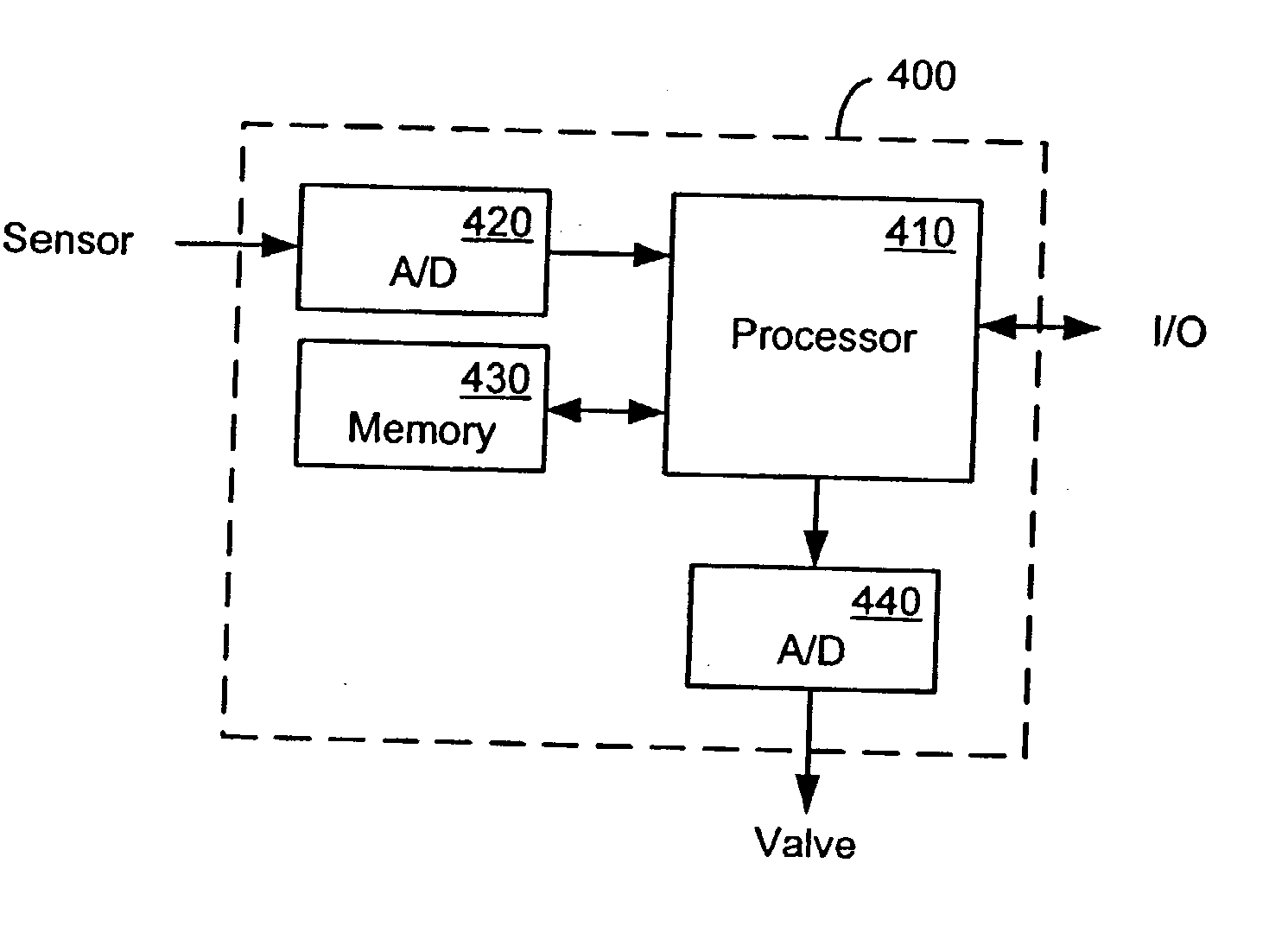

PM 2.5 (particulate matter 2.5) sensor and automatic calibration method thereof

InactiveCN106053309AReasonable designSimple structureParticle suspension analysisBackground concentrationsParticulates

The invention discloses a PM 2.5 (particulate matter 2.5) sensor and an automatic calibration method thereof. By automatically calibrating detection results of a sensor through clean air, the error due to particulate matter accumulation is overcome and it is ensured that detection results of the sensor are highly accurate within a service cycle. A technical scheme of the invention refers to the PM 2.5 sensor, comprising a detection gas passage, a calibrating gas passage, a detection light source unit, a light receiving unit, a signal processing unit, an electromagnetic value, an electromagnetic valve unit and a detection chamber; by dividing a detection chamber intake passage into the detection gas passage and the calibrating gas passage and using outside air and filtered clean air respectively, PM 2.5 detection concentration and background concentration are obtained, thus enabling the detection centration to be calibrated with the background concentration.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

System and method for mass flow detection device calibration

InactiveUS20040030522A1Low costHigh yieldVolume/mass flow by thermal effectsVolume flow proportion measurementCalibration gasTraffic volume

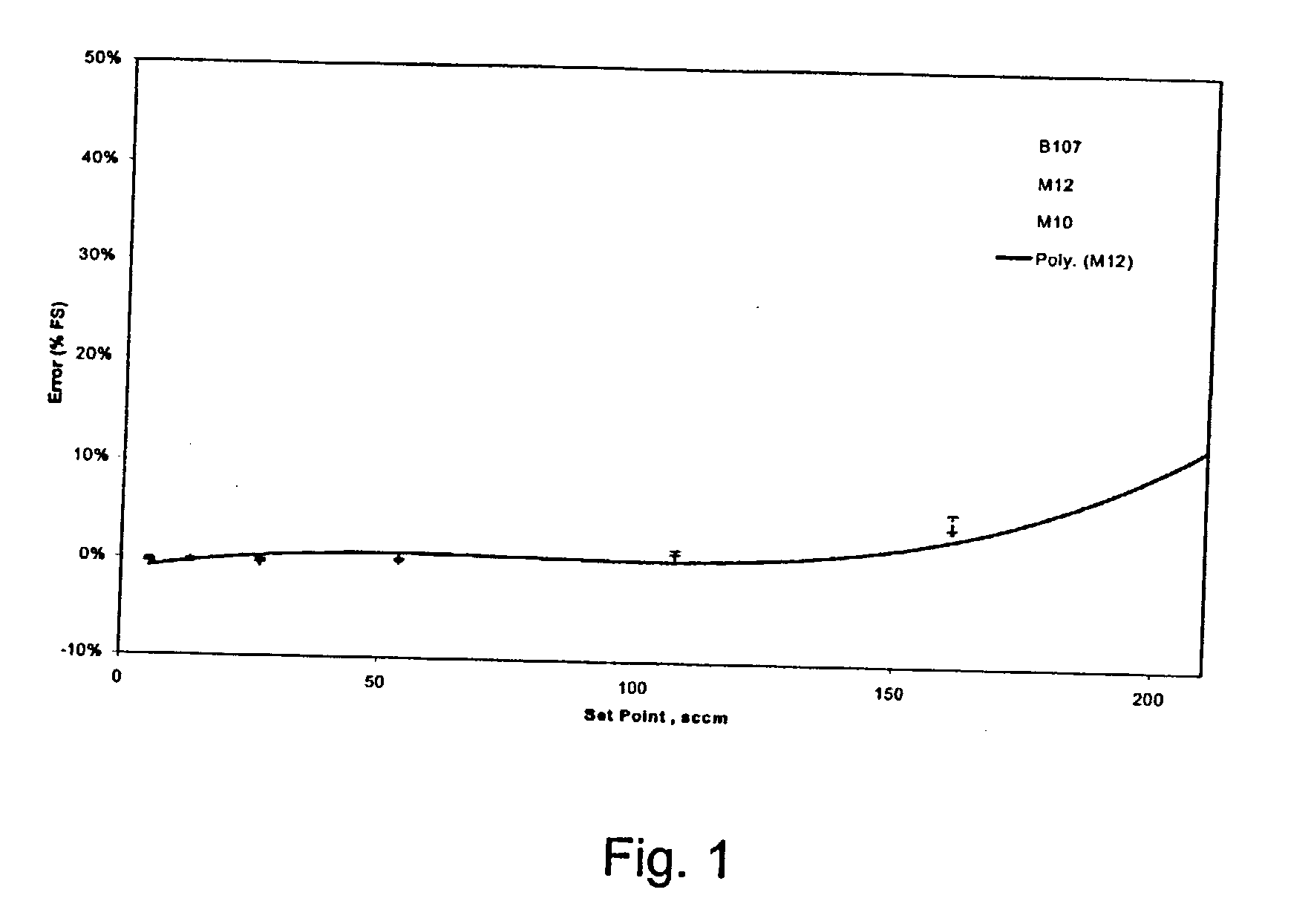

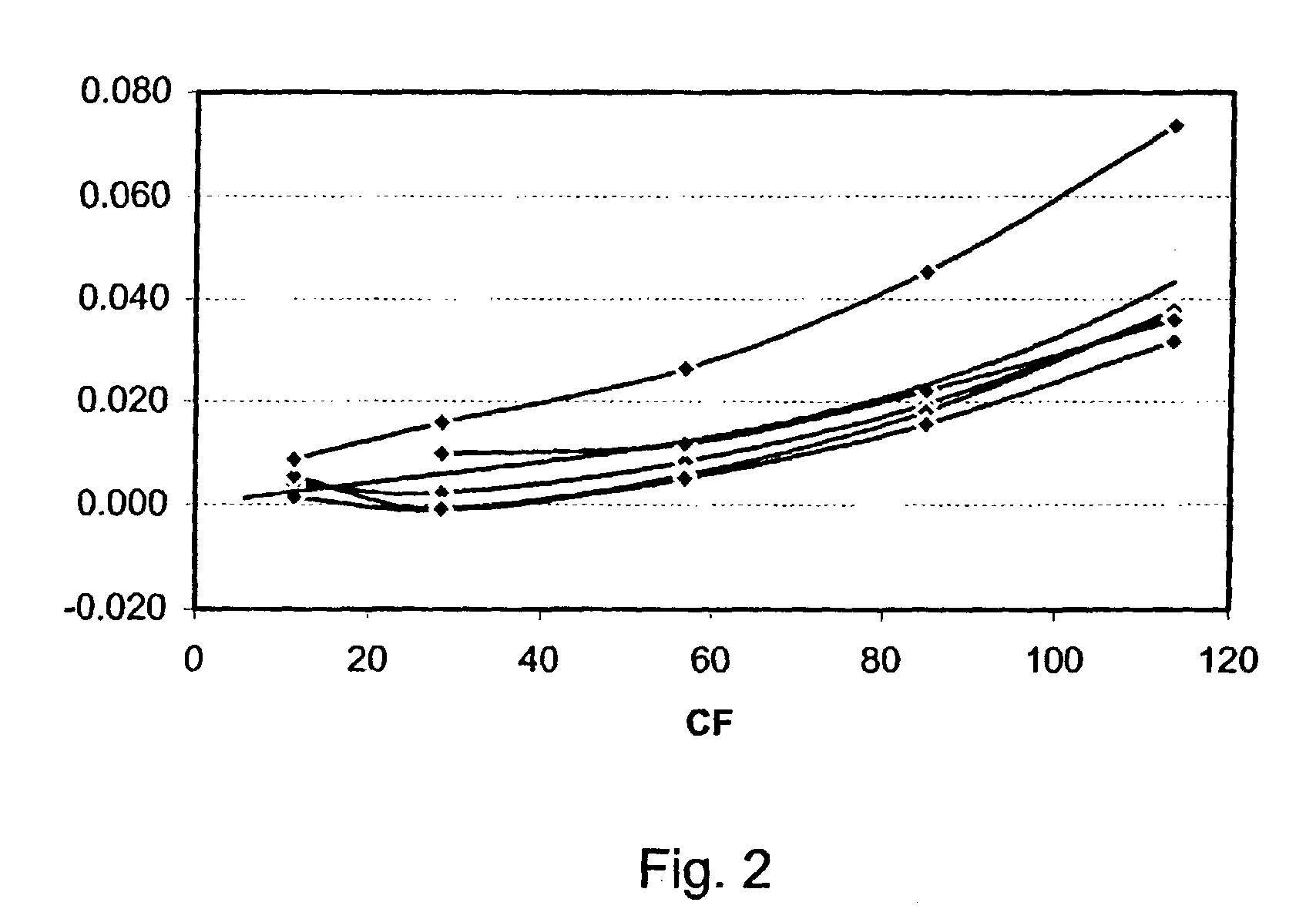

Systems and methods for correcting measurements of fluid flow using device-specific information to compensate for differences between individual devices of the same design. In one embodiment, a method comprises providing device-specific calibration data; sensing a fluid flow; computing a measured fluid flow based on the sensed fluid flow, and correcting the measured fluid flow based on the device-specific calibration data. More particularly, the fluid flow measurement is corrected using correction factors that compensate for the use of a gas that is different from the calibration gas (CF0(1+aF+bF<2>+cF<3>)), for device variations in sensor sensitivity (1+alphaDeltaR), and for variations in the split flow of fluid through the flow meter (1-betaDeltaADC(Sp / 100)<2>). The sensor and split flow correction factors may be used independently of each other in some embodiments.

Owner:BROOKS INSTRUMENT

Low-cost calibration system for multiple air quality monitoring sensors

ActiveCN106226483ACost-effectiveImprove performanceGas analyser construction detailsCalibration gasEngineering

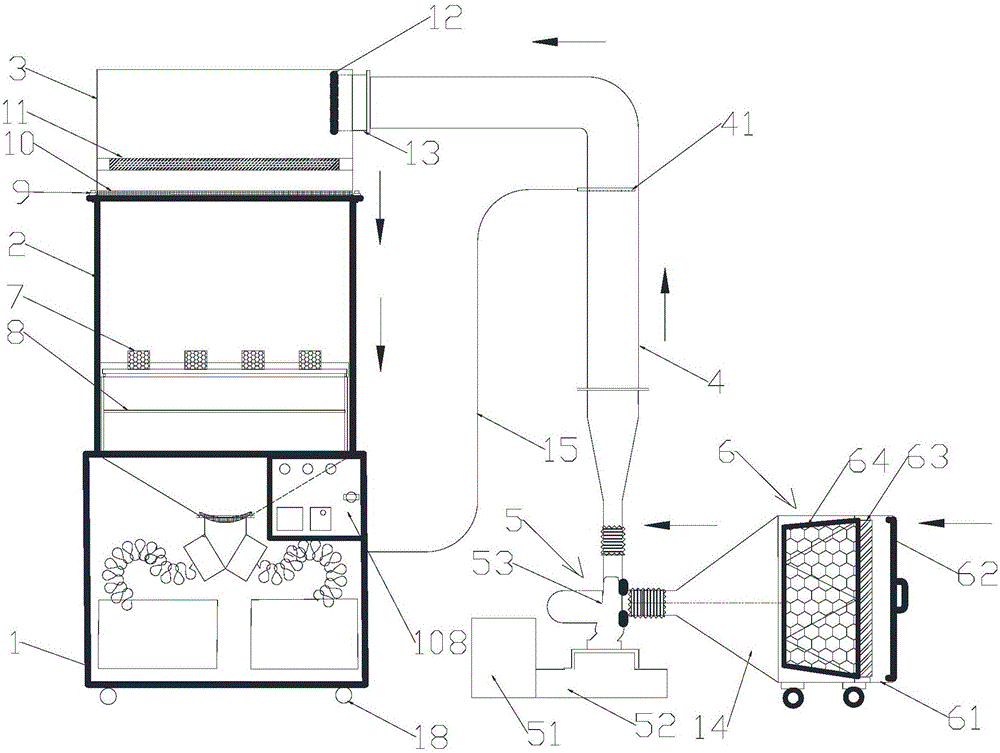

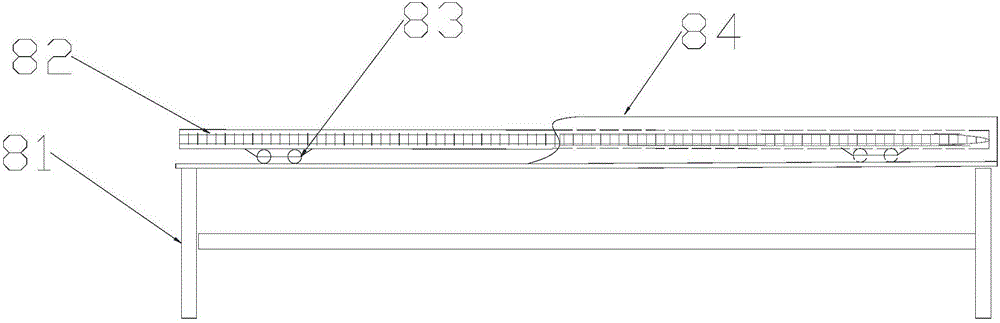

A low-cost calibration system for multiple air quality monitoring sensors comprises a machine cabinet, a calibration cabin and a static pressure box, wherein the machine cabinet is used for providing polluted gas with set concentration and controlling the speed of calibration gas, the calibration cabin is arranged at the upper end of the machine cabinet, communicated with the machine cabinet and provided with the calibrated sensors, and the static pressure box is connected with the upper end of the calibration cabin through a first flange; a flow equalizing film is arranged in the static pressure box, one side of the static pressure box is connected with one end of an air feeding pipe through a second flange, the other end of the air feeding pipe is connected with an air outlet of an air feeding regulation device, an air inlet of the air feeding regulation device is connected with a filtering device through an air director, a polluted gas filling pipeline used for guiding polluted gas with set concentration into the air feeding pipe from the machine cabinet is arranged between the machine cabinet and the air feeding pipe, and a stainless steel flow equalizing net used for equalizing airflow is arranged on a channel between the calibration cabin and the static pressure box. The system mainly aims to achieve scientific calibration of cheap sensors, performances of cheap sensors can be improved remarkably, and cost performance of sensors can be improved exponentially.

Owner:天津中天环境科技有限公司

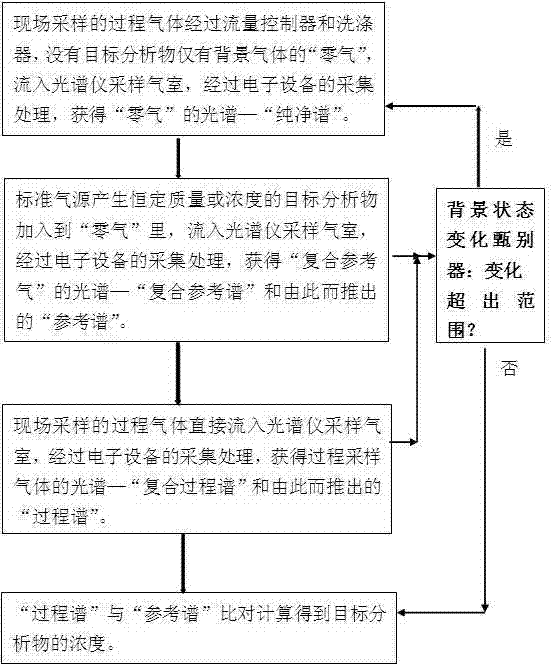

Self-calibration analyzer design method and device

InactiveCN104713841AEfficient removalGuaranteed validityColor/spectral properties measurementsTarget analysisAnalyte

The invention relates to a self-calibration analyzer design method and device, wherein the method includes the following steps: generating zero gas, and acquiring a pure spectrum; generating composite reference gas, and acquiring and calculating a reference spectrum; controlling a flow path of real-time process sampling gas, and acquiring and calculating a process spectrum; comparing the process spectrum with the reference spectrum, and calculating to obtain the concentration of a target analyte. Through new technical design scheme, the method and device can be applied to completely different backgrounds, and a saturation effect is not caused as long as the spectra of the sampling gas and the composite reference gas are in a linear response region of an electronic device; the device does not need pre-calibration before leaving a factory, moreover, does not need to store reference curves for the process sampling gas and the calibration gas according to different groups, and of course, also does not need to adopt different reference curves in the process sampling measurement and calibration measurement; and a built-in standard gas source is adopted for real-time self calibration.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

System for on-line detection of dioxin type trace organic pollutants in actual smoke

ActiveCN105954441ARespond quicklyRapid and timely discharge concentrationComponent separationBottleMass spectrometric

The invention relates to a trace organic pollutant detection technology and aims at providing a system for on-line detection of dioxin type trace organic pollutants in actual smoke. A sampling device of the system is connected with a thermal desorption instrument and a sampling pump module respectively through a pipeline, and a heat tracing pipeline is arranged on the pipeline. A laser device can simultaneously output two types light beams of deep ultraviolet wavelength and tunable ultraviolet visible waveband, an optical lens set is arranged between a flight time mass spectrometer and the laser device, two beams of laser are combined and then enter a laser window of the flight time mass spectrometer. A sample inlet pipeline of the flight time mass spectrometer is connected with a calibration gas storage bottle and the thermal desorption instrument respectively. The system integrates a thermal desorption technology and flight time mass-spectrometric technique, overcomes the shortcomings of a sample detection technology, can rapidly reflect the dioxin discharge concentration of smoke in time and is high in precision and large in information amount. The system composition can be adjusted according to actual demands, the adaptation can be improved. Detection results can represent the combustion conditions in a furnace, and the incineration process control can be optimized.

Owner:浙江富春江环保科技研究有限公司

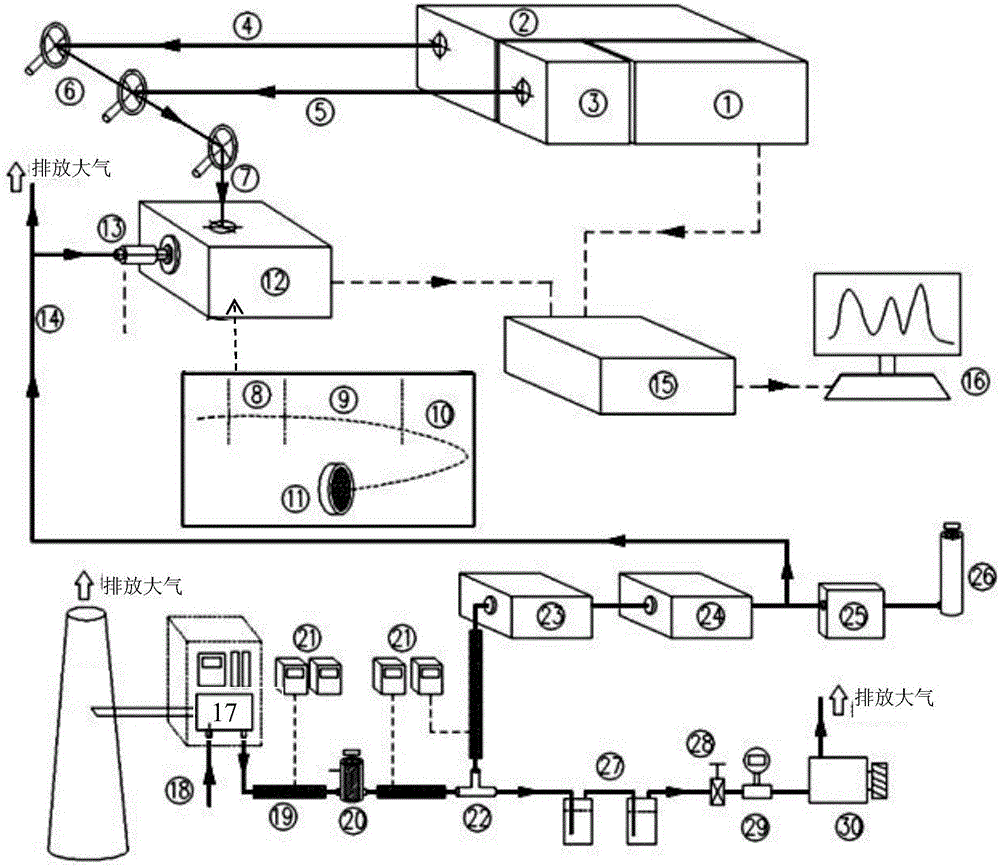

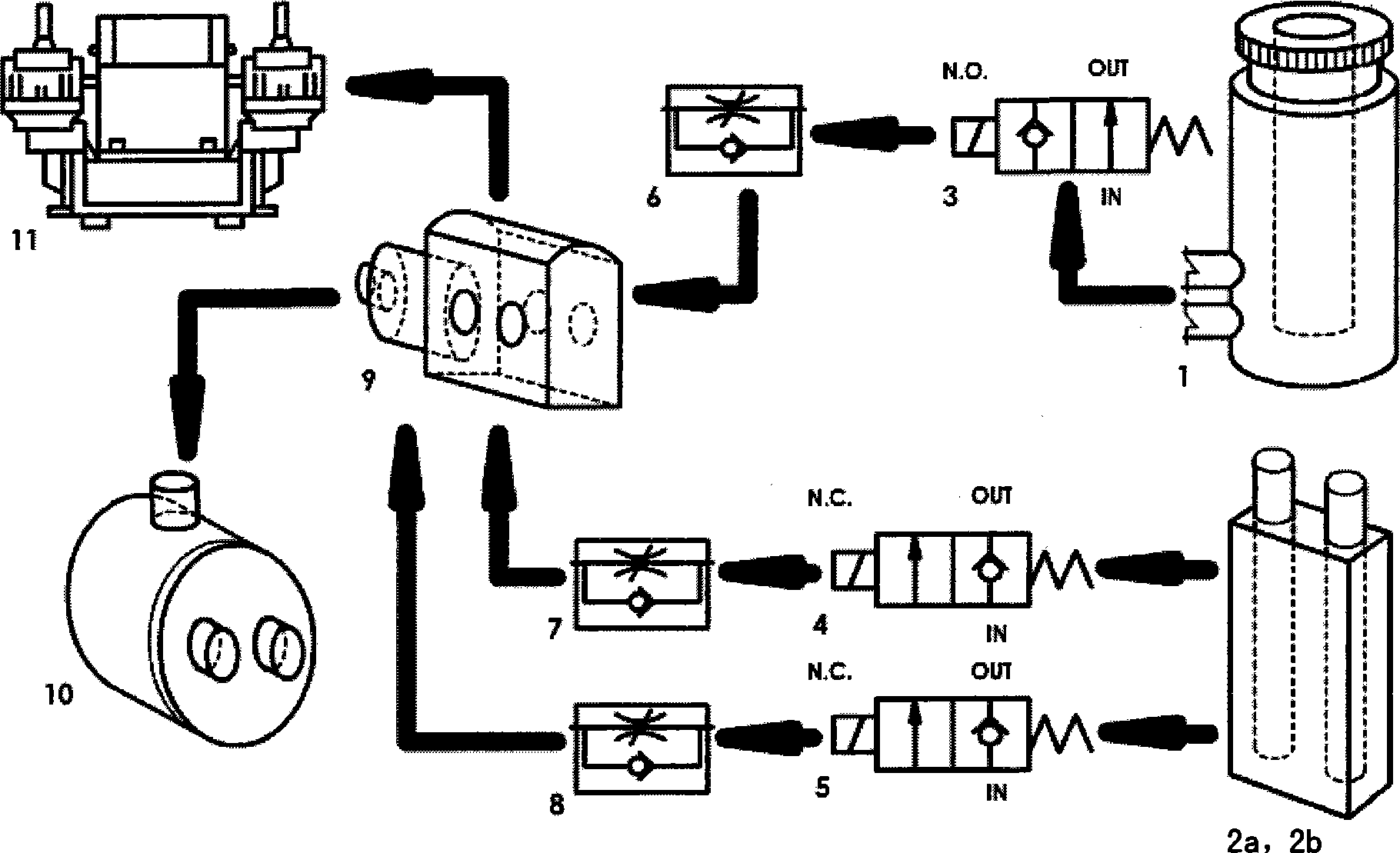

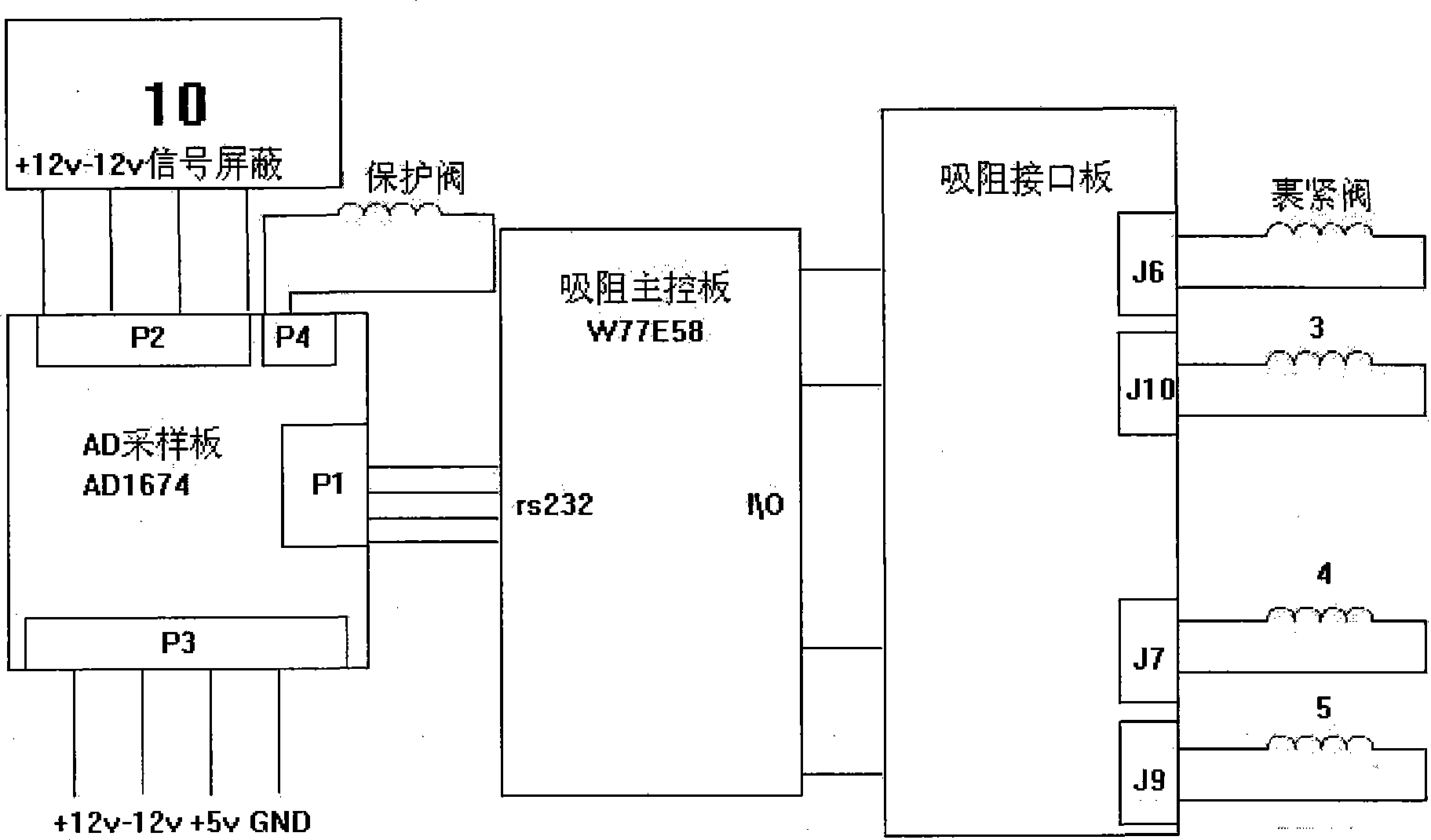

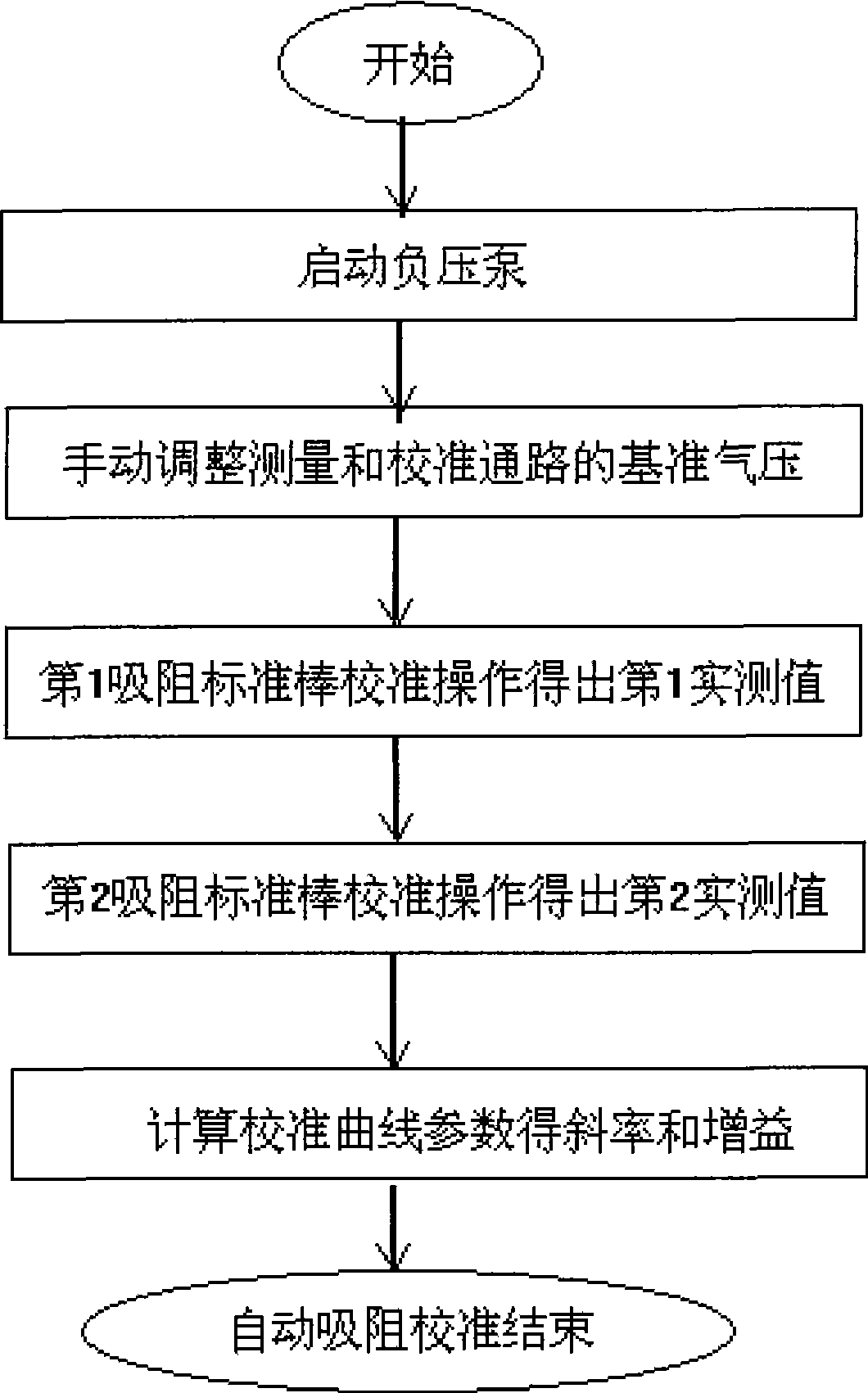

Automatic calibration system and method of resistance absorbing instrument

InactiveCN101413869AAvoid human interferenceReal-time calibrationPermeability/surface area analysisSample MeasureAutomatic control

The invention relates to an absorbing resistance instrument automatic calibration system, which is provided with a gas circuit device and an electric control gear. The gas circuit device comprises a calibration gas circuit and a measuring gas circuit. The calibration gas circuit is provided with two absorbing resistance rod gauge measuring heads. The measuring gas circuit is provided with a sample measuring head. The calibration gas circuit and the measuring gas circuit respectively pass through a motorized valve and a hand-operated valve, and then are connected with a negative pressure vacuum air pump by the same constant flow element and a surge chamber. The constant flow element and the surge chamber are internally provided with a gas differential pressure pickup. The electric control gear is provided with a drawing resistance main control panel, the output end of which is respectively connected with the motorized valve in each gas circuit by a drawing resistance interface board; a serial communication interface of the drawing resistance main control board is connected with a drawing resistance sensor by an AD sampling panel. The method is as follows: the negative pressure vacuum air pump is started; the benchmark pressure of the measuring gas circuit and the calibration gas circuit are regulated; a first drawing resistance rod gauge is calibrated; a second drawing resistance rod gauge is calibrated; the calibration cure parameter is calculated to obtain the rate of slope of the specification curve and the gain. The system avoids artificial interference, realizes automatically controlled real time calibration, and is suitable for batch test.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

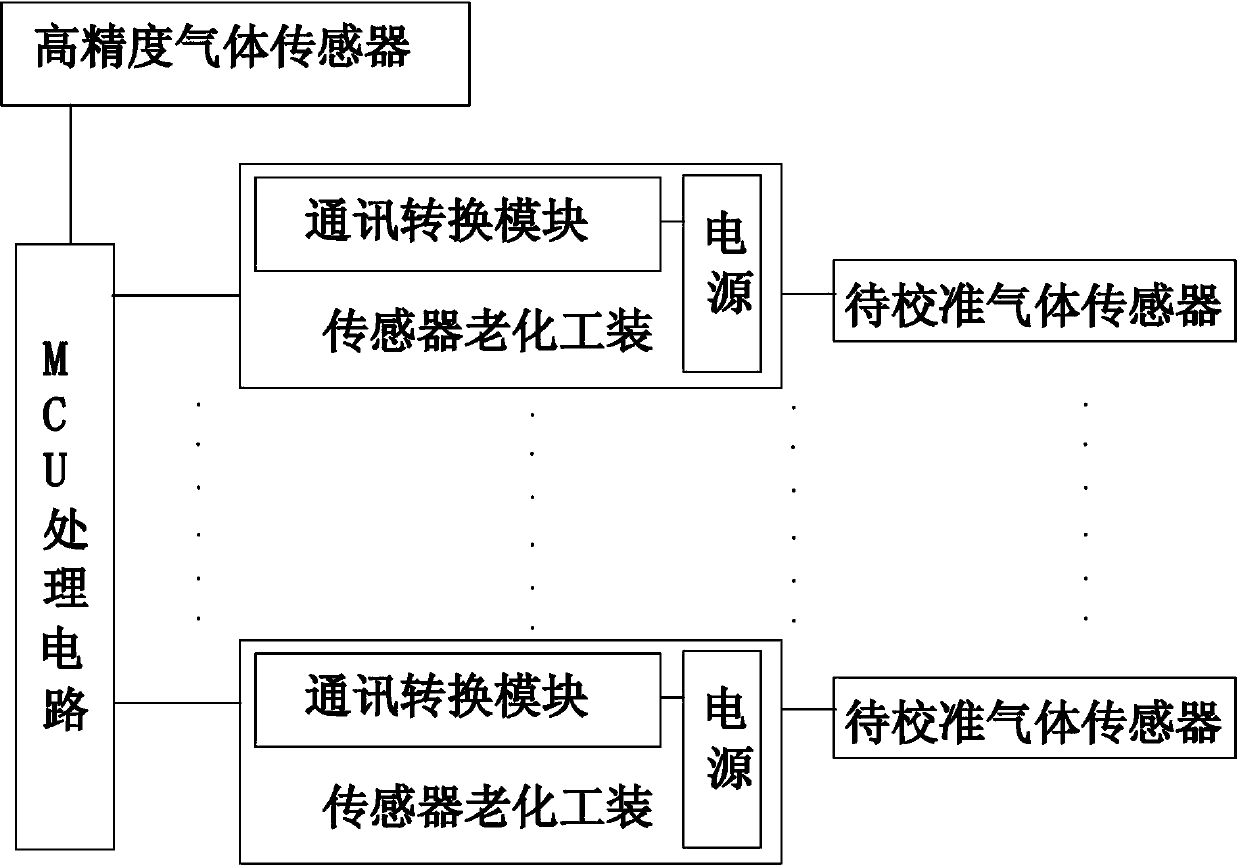

Automatic gas sensor calibration system and gas sensor calibration method thereof

The invention provides an automatic gas sensor calibration system. The automatic gas sensor calibration system comprises at least one sensor aging tool provided with a communication conversion module, and further comprises a microprocessor circuit and a high-precision gas sensor, wherein a gas concentration sampling input end of the microprocessor circuit is connected with the output end of the high-precision gas sensor; the communication conversion module is provided with an input end and an output end communicated with a gas sensor to be calibrated; a calibration signal output end of the microprocessor circuit is connected with the input end of the communication conversion module. The invention further relates to a gas sensor calibration method. When the automatic gas sensor calibration system provided by the invention is used, a precise gas distribution system is not used any more, so that the structure is simple, the construction cost is low and the calibration is convenient.

Owner:HENAN HANWEI ELECTRONICS

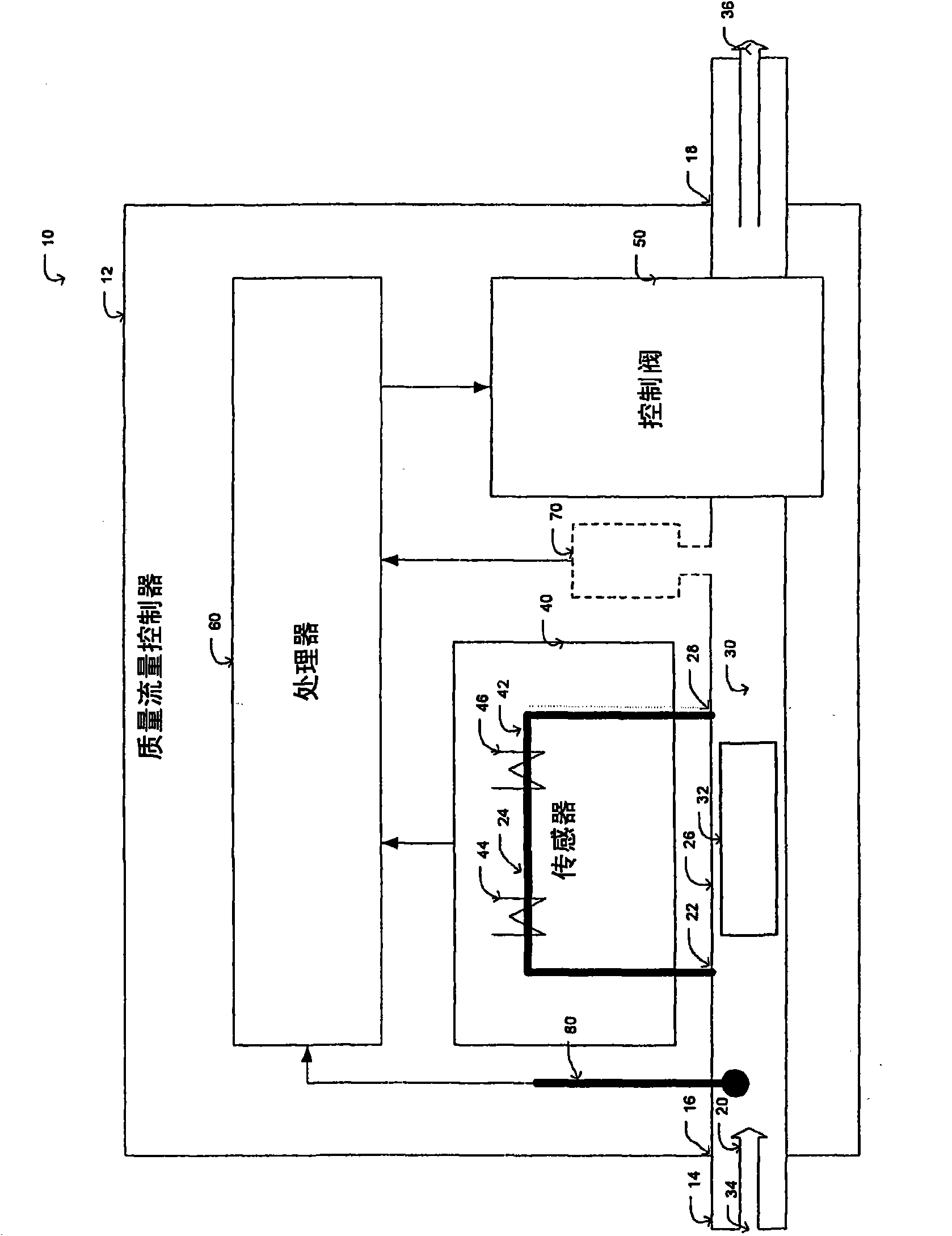

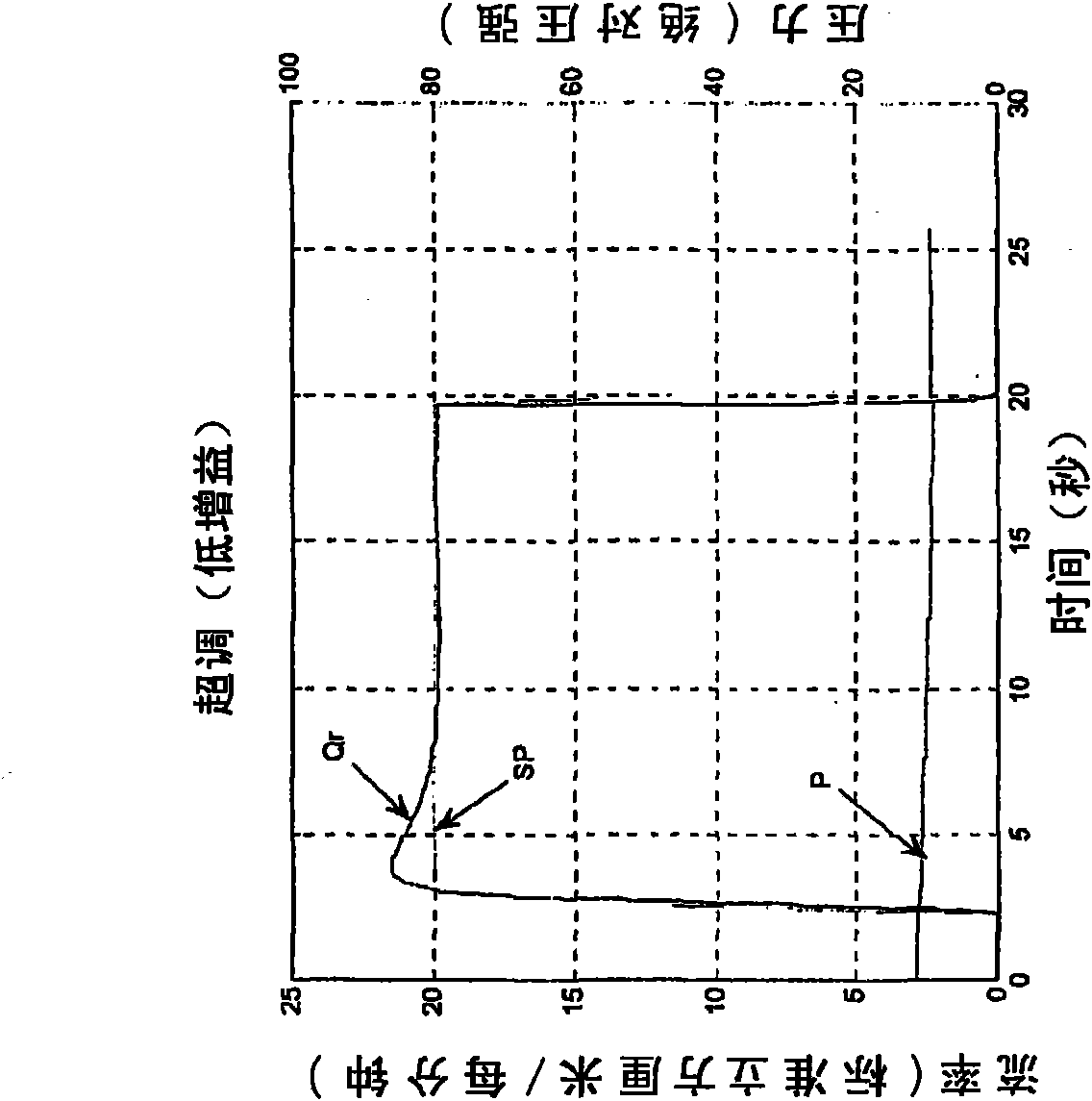

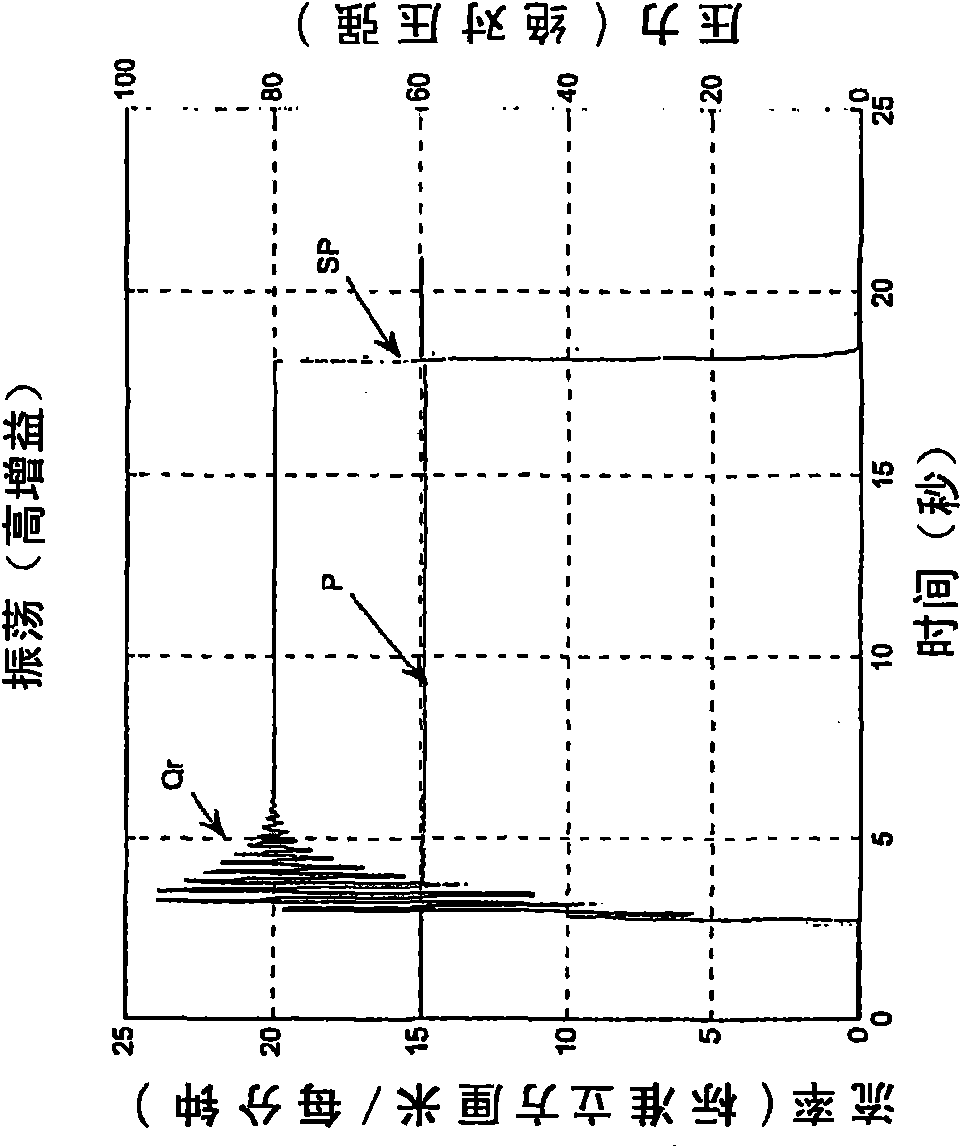

Controller gain scheduling for mass flow controllers

ActiveCN101636641AVolume/mass flow by thermal effectsFlow control using electric meansCalibration gasFeedback controller

A mass flow controller having a feedback controller gain, comprises: a sensor configured so as to sense the flow of fluid through controller; a valve arranged so as to adjust the flow of fluid through the controller; and a processor configured so as to controlling the valve as a function of the flow of fluid sensed by the sensor. The sensor and valve are arranged within a feedback system, and the processor updates the feedback controller gain in real time based on the ratio of at least one calibration gas parameter to at least one operating gas parameter, such that the closed loop transfer function of the feedback system remains substantially constant regardless of operating conditions so as to have a consistent control performance at different operation conditions from the calibration condition.

Owner:MKS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com