Automatic calibration method and device

An automatic calibration and calibration gas technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low automation, fast consumption of calibration gas, high use and maintenance costs, etc., and achieve high automation, large dilution ratio, and work Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

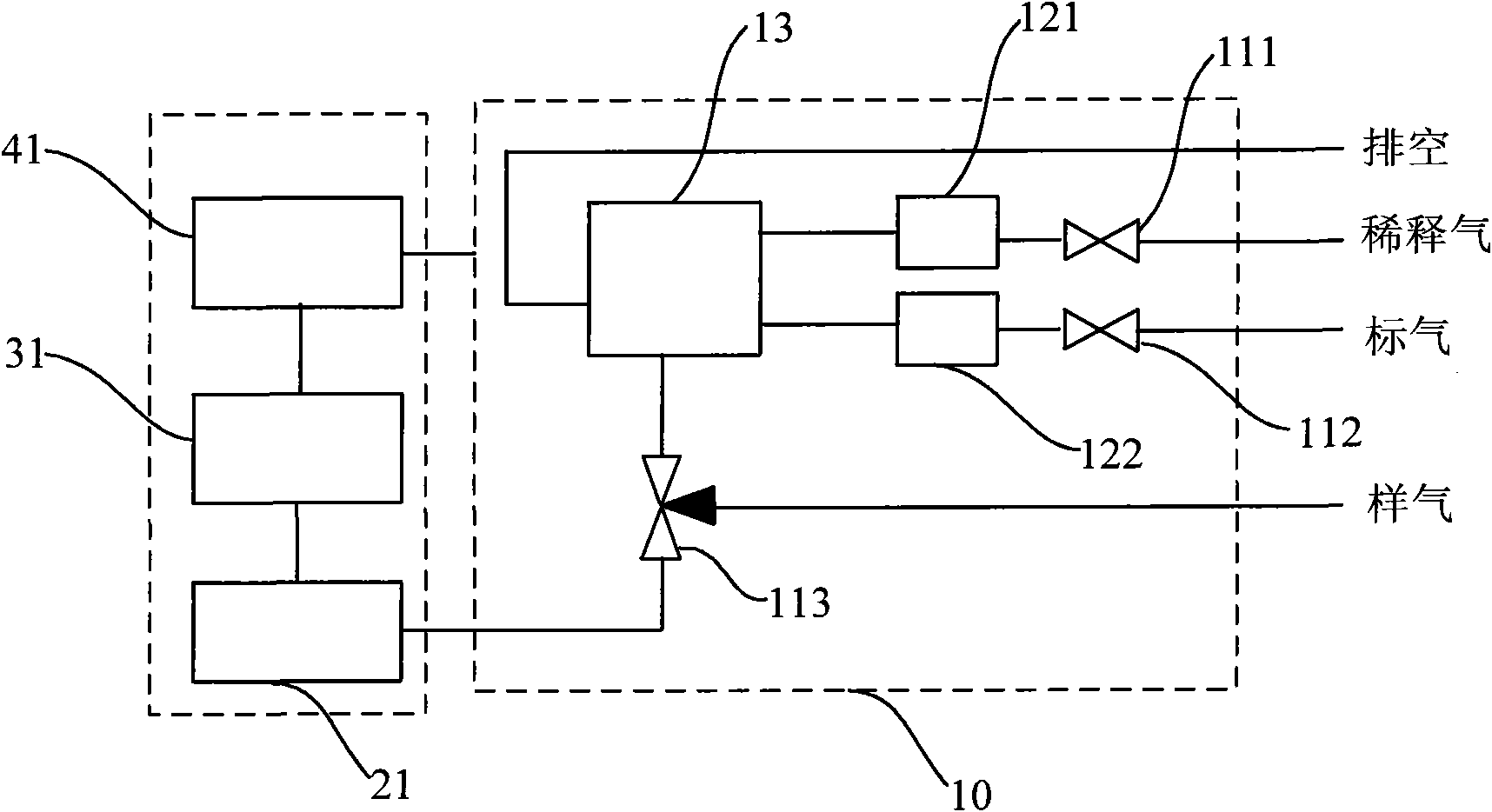

[0055] see figure 1 , an automatic calibration device, comprising an analytical instrument, a calibration unit 10, a measurement unit 21, a processing unit 31 and a control unit 41;

[0056] The calibration unit 10, the measurement unit 21, the processing unit 31 and the control unit 41 are all arranged inside the analytical instrument; the analytical instrument is a chromatography analyzer;

[0057] The calibration unit 10 includes a valve, a flow controller 121, a flow controller 122 and a gas mixing chamber 13;

[0058] The valve includes two two-way normally closed solenoid valves 111, a solenoid valve 112 and a two-position three-way solenoid valve 113;

[0059] The flow controller 121 and the flow controller 122 are mass flow meters MFC or electronic flow controllers EFC, which in this embodiment are EFCs;

[0060] The gas mixing chamber 13 is connected to the dilution gas through a flow controller 121, and connected to the calibration gas through a flow controller 122...

Embodiment 2

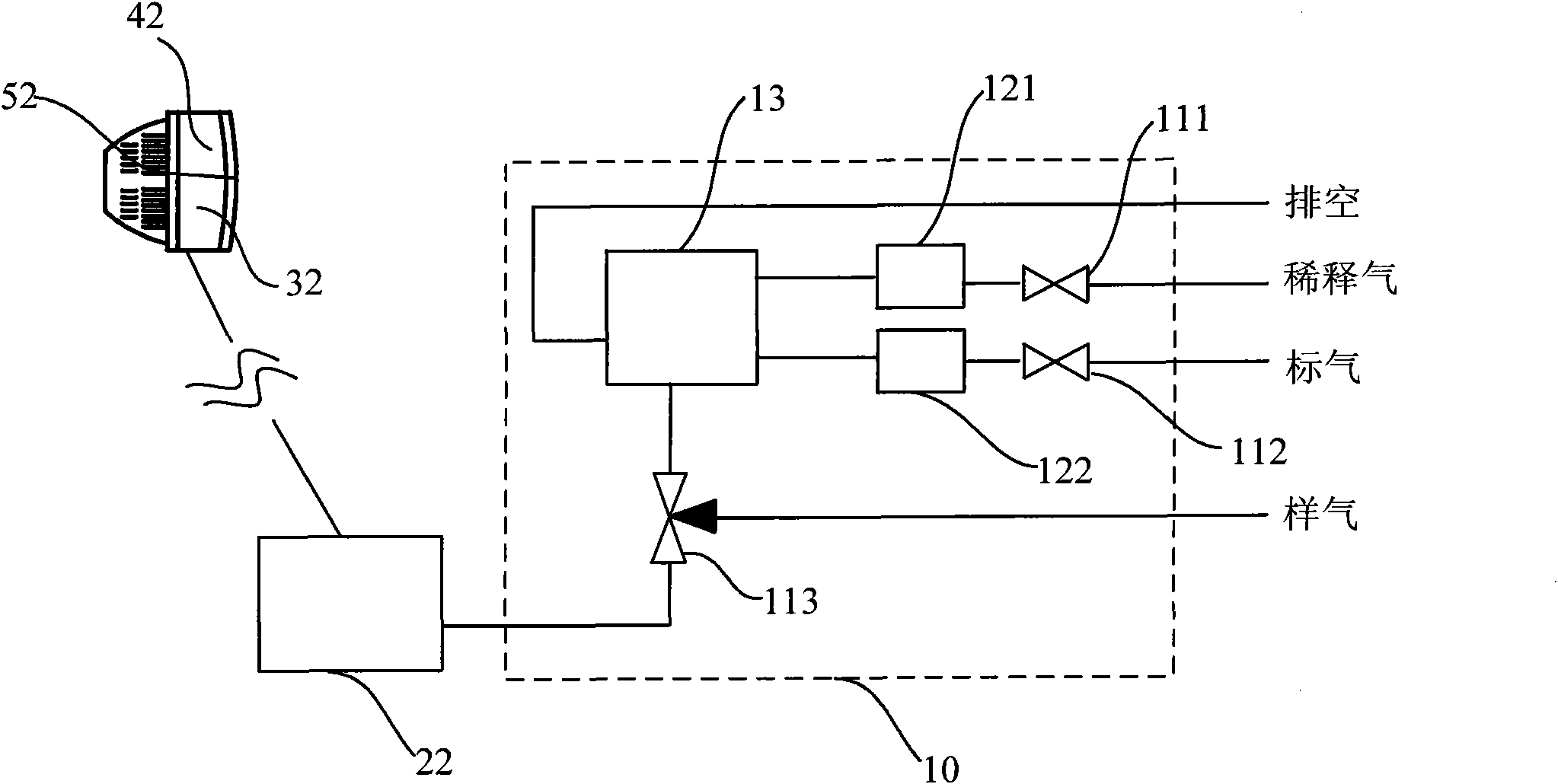

[0086] see image 3 , an automatic calibration device, different from the automatic calibration device described in embodiment 1 is:

[0087] The automatic calibration device also includes a remote server 52, and the control unit and the analysis unit can be arranged in the analytical instrument one, and one in the remote server; they can also be arranged in the analytical instrument; they can also be arranged in the remote server;

[0088] In this embodiment, the control unit 42 and the processing unit 32 are set in the remote server 52;

[0089] The automatic calibration device is equipped with flow controllers of different flow ranges to realize the ratio of different dilution concentrations of standard gas and dilution gas;

[0090] An alarm module is set in the processing unit 32, and the processing unit 32 judges whether the flow rate of the calculated standard gas and / or dilution gas exceeds the range range of the flow controller for controlling the corresponding gas f...

Embodiment 3

[0105] see Figure 4 , an automatic calibration device, different from the automatic calibration device described in embodiment 2 is:

[0106] There are multiple analytical instruments, wherein the calibration unit 10 is built into one analytical instrument, and the solenoid valve and the flow controller are controlled by the control unit 43 in the remote server 53; the exhaust air of the gas mixing chamber 13 In this embodiment, the analytical instruments are four chromatographic analyzers, and the calibration unit 10 is built in the chromatographic analyzer 1.

[0107] An automatic calibration method, different from the calibration method described in embodiment 2 is:

[0108] In step a, the automatic calibration device described in this embodiment is provided;

[0109] In step b, the processing unit 43 calculates the flow rate of the diluent gas and the standard gas, and when measuring each concentration point, at least one chromatographic analyzer performs calibration and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com