Melamine aldehyde-based bonding resin and preparation method thereof

A melamine aldehyde-based, adhesive resin technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problem of long curing time and the inability to achieve optimal control of 20°C Tu-4 viscosity Time, small dilution ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

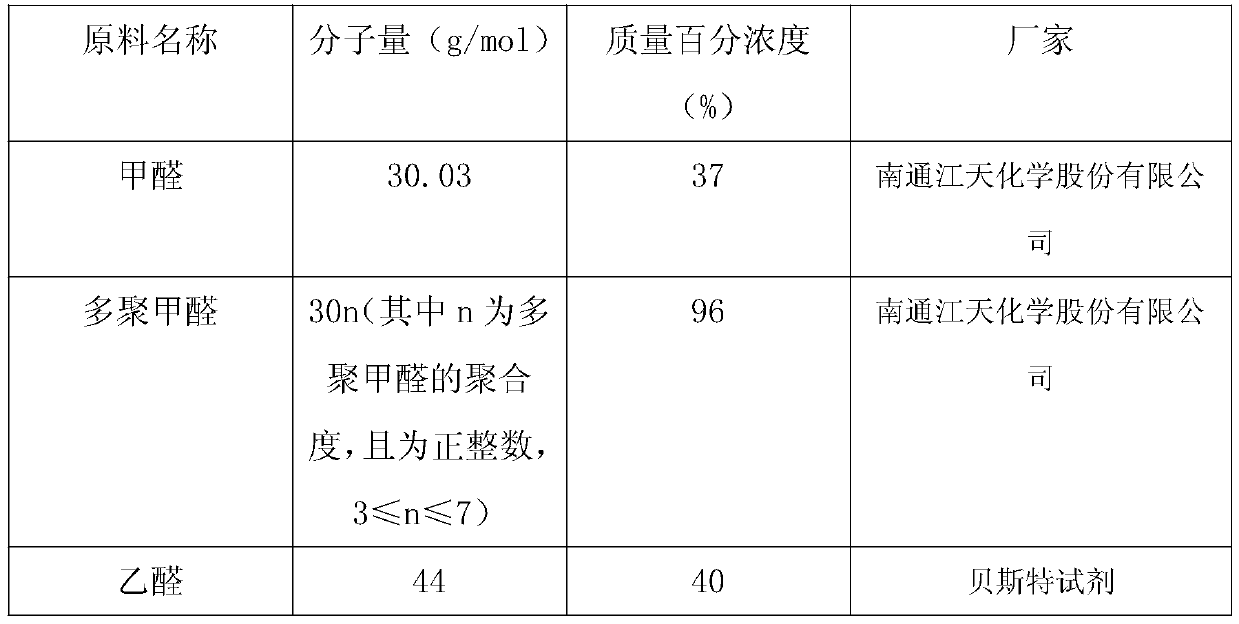

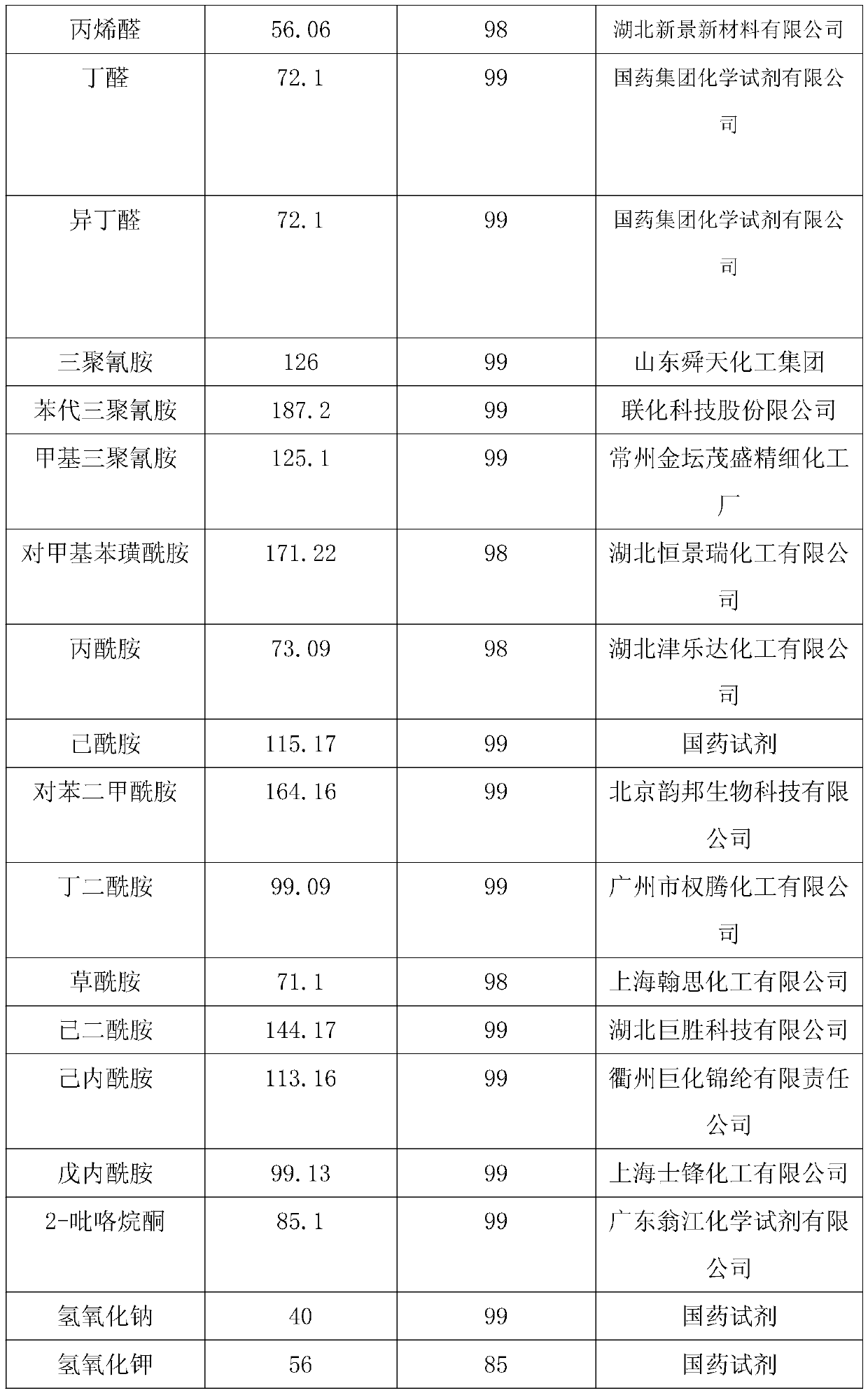

[0026] 1) Add an aqueous solution of formaldehyde with a concentration of 37% by mass to the reaction vessel A: 190.5 g, use 0.4 g of an aqueous sodium hydroxide solution with a concentration of 25% by mass, adjust the PH value of the aqueous formaldehyde solution to 8.5, and add melamine 105 G, 31.5 g of benzo-melamine, heated and stirred to 90°C, until the solution in the reaction vessel A is colorless, clear and transparent, heat preservation and stirring to obtain material I;

[0027] 2) Take out 1ml material I from reaction vessel A and add it to 100ml water at 50℃ and stir evenly. When the reaction product is insoluble in water, reduce the temperature of reaction vessel A to 85℃, add propionamide: 10g, propionamide After being completely dissolved in the reaction vessel A, the temperature is lowered to 40°C, spray-dried, and dried with a spray dryer. The inlet air temperature of the spray dryer is 140°C and the outlet air temperature is 80°C to obtain a white solid of melami...

Embodiment 2 to 5 and comparative example 1 to 2

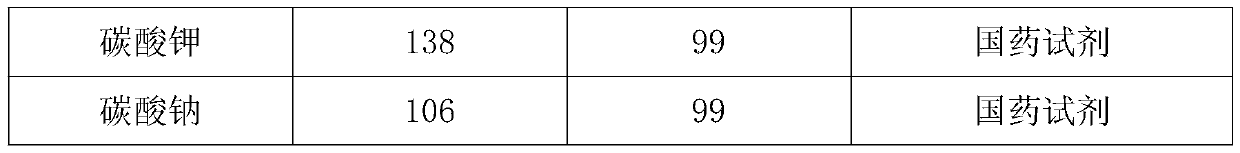

[0029] The experiments of Example 2 to Example 5 and Comparative Examples 1 to 2 were carried out according to the steps of Example 1. The only difference is the type of reaction raw materials, the ratio of raw materials, the reaction time and temperature are different, see Table 2 for details; the prepared melamine The quality inspection data of the aldehyde-based adhesive resin is shown in Table 4.

[0030] Wherein, in Example 3, when an acrolein aqueous solution with a mass percentage concentration of 99% is used, water needs to be added to the acrolein aqueous solution to adjust the mass percentage concentration of the acrolein aqueous solution to 55%.

[0031] Wherein, in Example 4, when an aqueous solution of butyraldehyde with a concentration of 99% by mass is used, water needs to be added to the aqueous solution of butyraldehyde to adjust the concentration of the aqueous solution of butyraldehyde to 60% by mass.

[0032] Wherein, in Example 5, when an isobutyraldehyde aqueous...

Embodiment 6 to 10 and comparative example 3

[0039] The experiments of Example 6 to Example 10 and Comparative Example 3 were carried out according to the steps of Example 1. The only difference is the type of reaction raw materials, the ratio of raw materials, the reaction time and temperature are different, see Table 3 for details, the prepared melamine aldehyde group The quality inspection data of the adhesive resin is shown in Table 4.

[0040] Wherein, when an acrolein aqueous solution with a mass percentage concentration of 99% is used in Example 9, water needs to be added to the acrolein aqueous solution to adjust the mass percentage concentration of the acrolein aqueous solution to 55%.

[0041] Table 3 The raw material weight of each component in Example 6 to Example 10 and Comparative Example 3 (unit: g)

[0042]

[0043]

[0044]

[0045] Table 4 Quality inspection data of melamine aldehyde-based adhesive resins in Examples 1 to 8 and Comparative Examples 1 to 3

[0046]

[0047] Among them, the cured product in Compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com