Patents

Literature

1037 results about "Spray dryer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

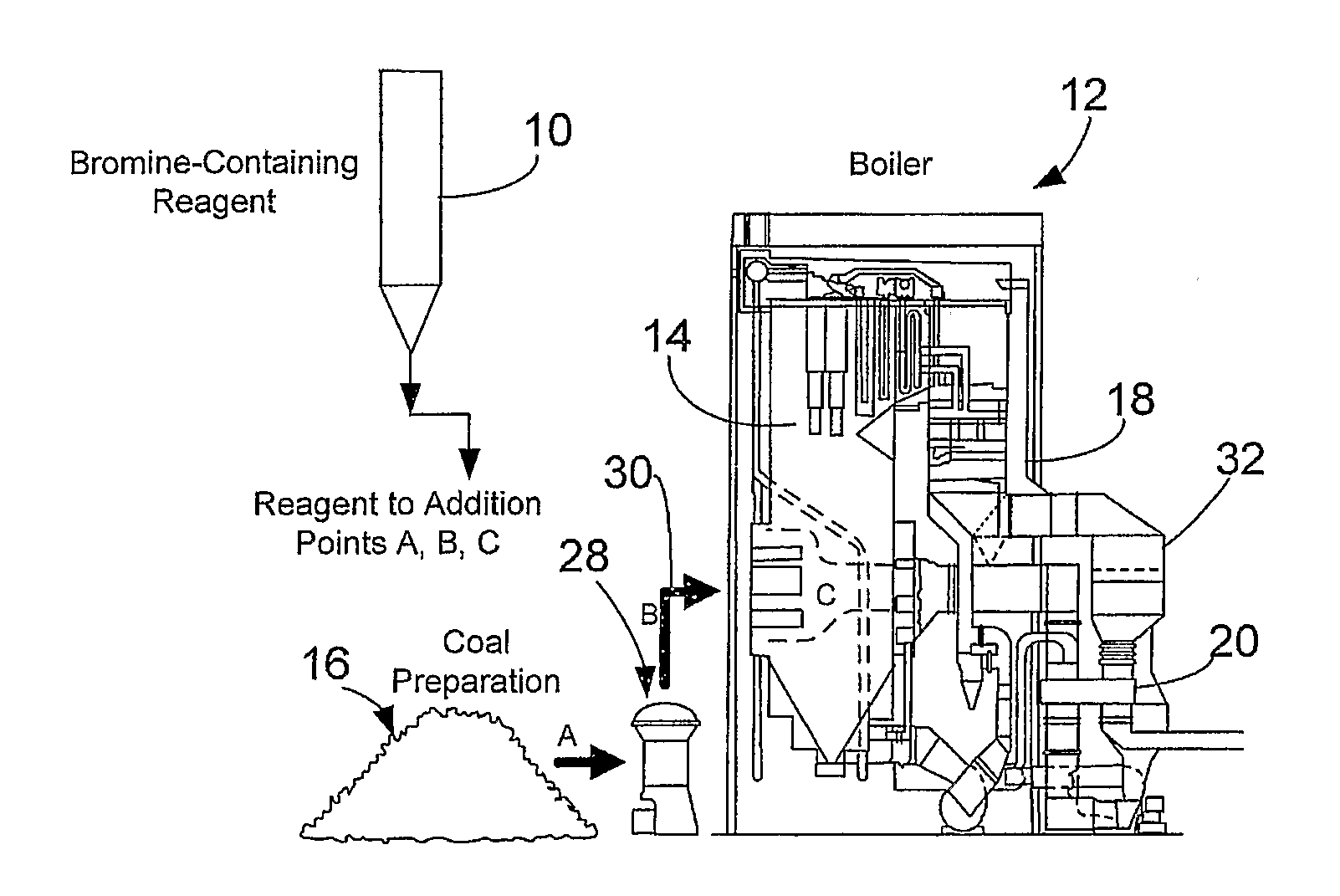

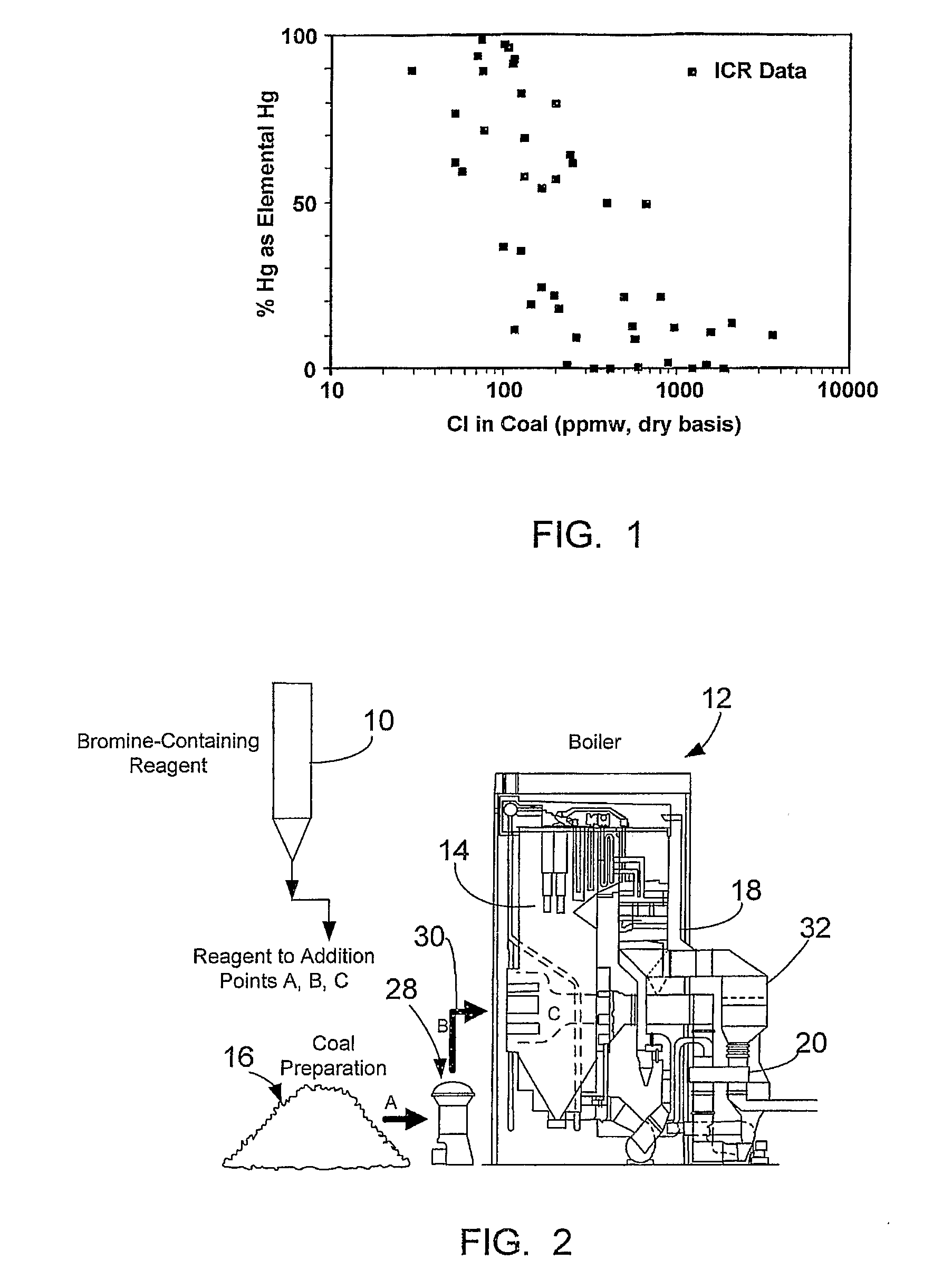

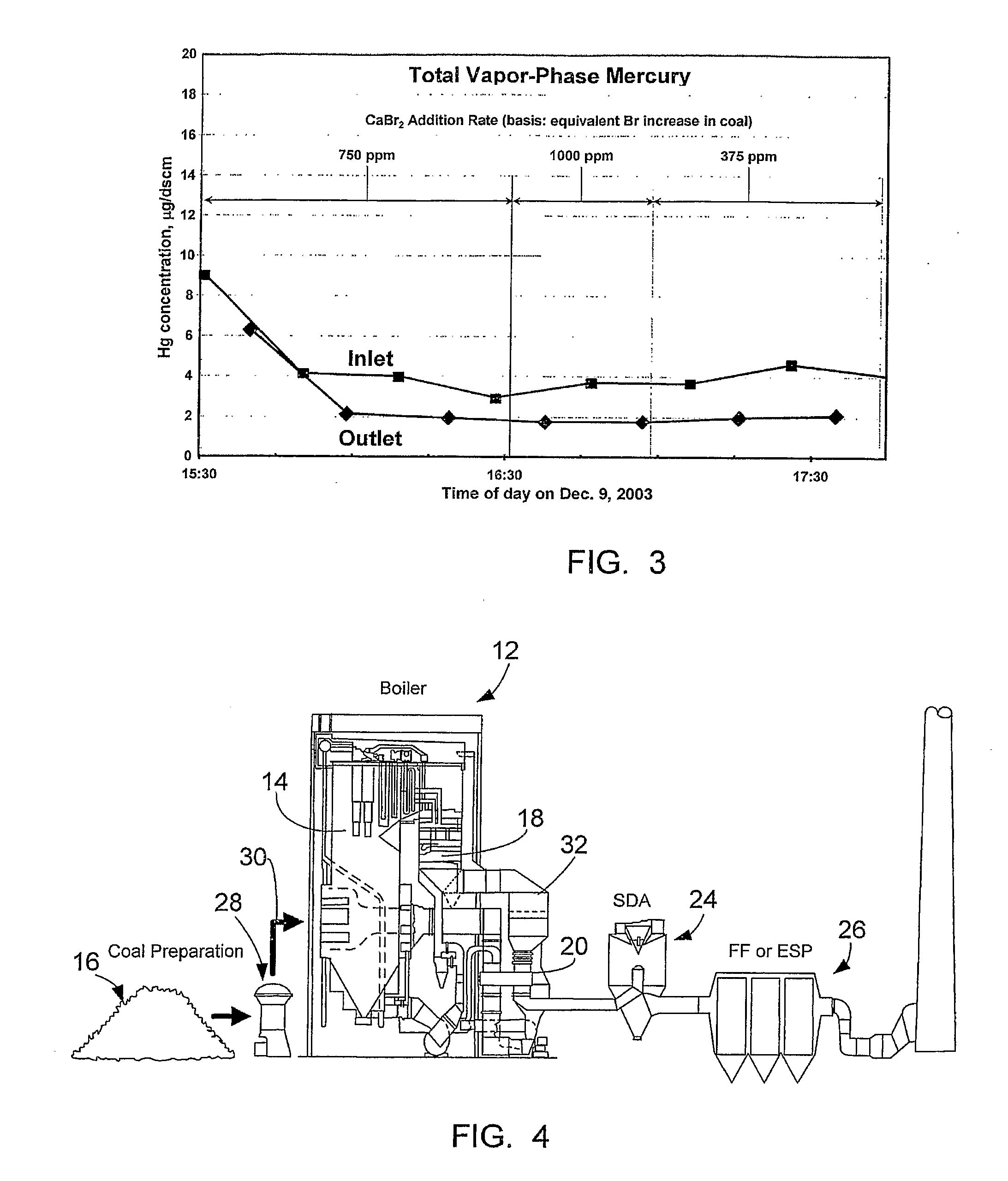

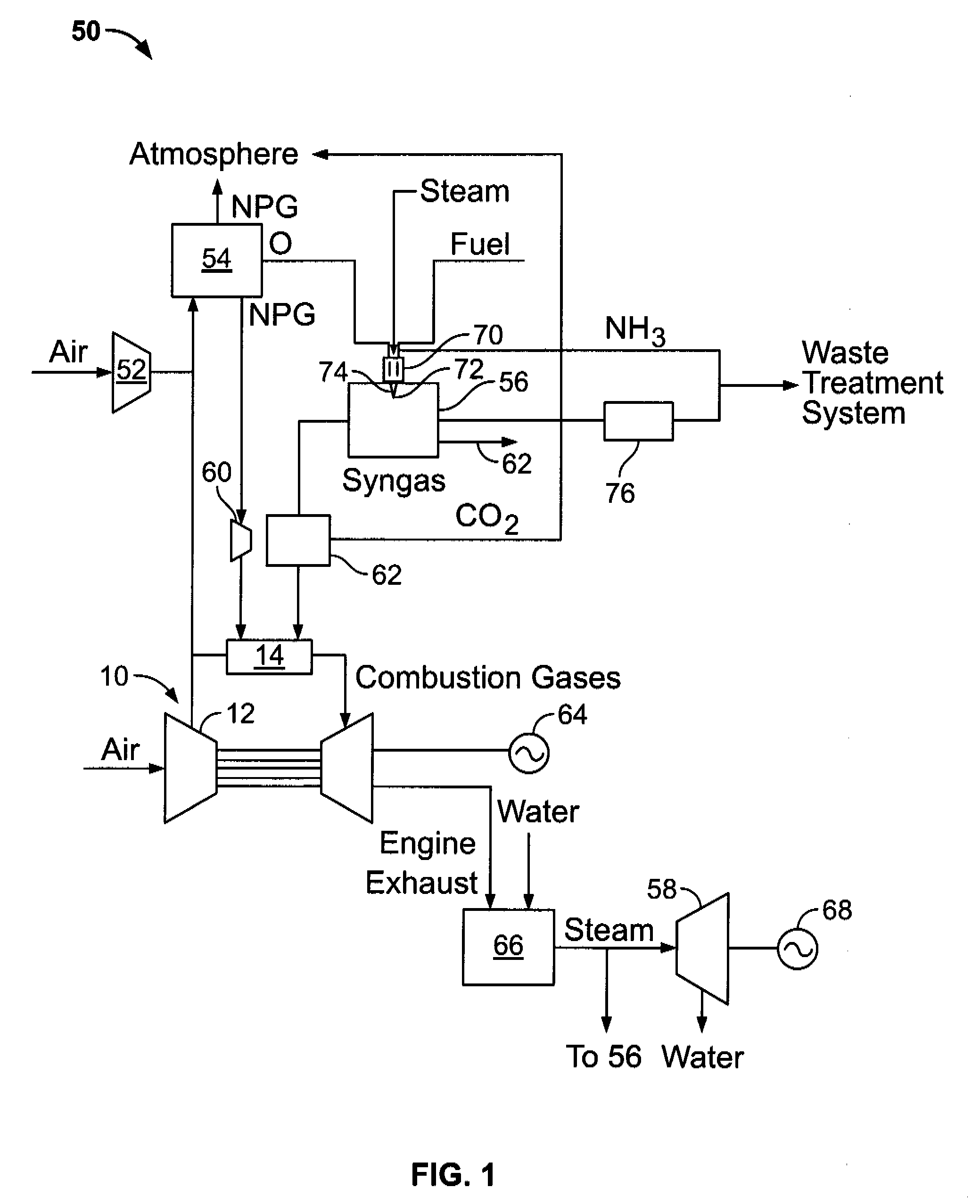

Bromine Addition for the Improved Removal of Mercury from Flue Gas

InactiveUS20080107579A1Significant technicalSignificant commercial advantageGas treatmentUsing liquid separation agentCombustionFlue gas

Bromine-containing compounds, added to the coal, or to the boiler combustion furnace, are used to enhance the oxidation of mercury, thereby enhancing the overall removal of mercury in downstream pollution control devices. The method is applicable to utility power plants equipped with wet FGD systems, as well as those plants equipped with spray dryer absorber FGD systems.

Owner:THE BABCOCK & WILCOX CO

Dry powder which retains savor and flavor and method for producing the same

InactiveUS20050031769A1Avoid and reduce occurrenceLess occurrenceFruit and vegetables preservationFood shapingSolubilityProduct gas

In order to provide a spray dry method capable of producing a dry powder retaining the savor and flavor of a raw material and having solubility without any thermal deterioration, at a mass scale, a method for producing a dry powder keeping savor and flavor from a hydrous liquid material containing a savory and flavorful component and, preferably, a hygroscopic component by spray drying is disclosed, the method including spray drying the hydrous liquid material at the microfine liquid droplet state in gas atmosphere at the outlet temperature of a spray dryer at 20 to 90° C. and the outlet relative humidity of 1% RH to 40% RH, to prepare a dry powder of a mean particle size of 0.1 μm to 15 μm.

Owner:AJINOMOTO CO INC

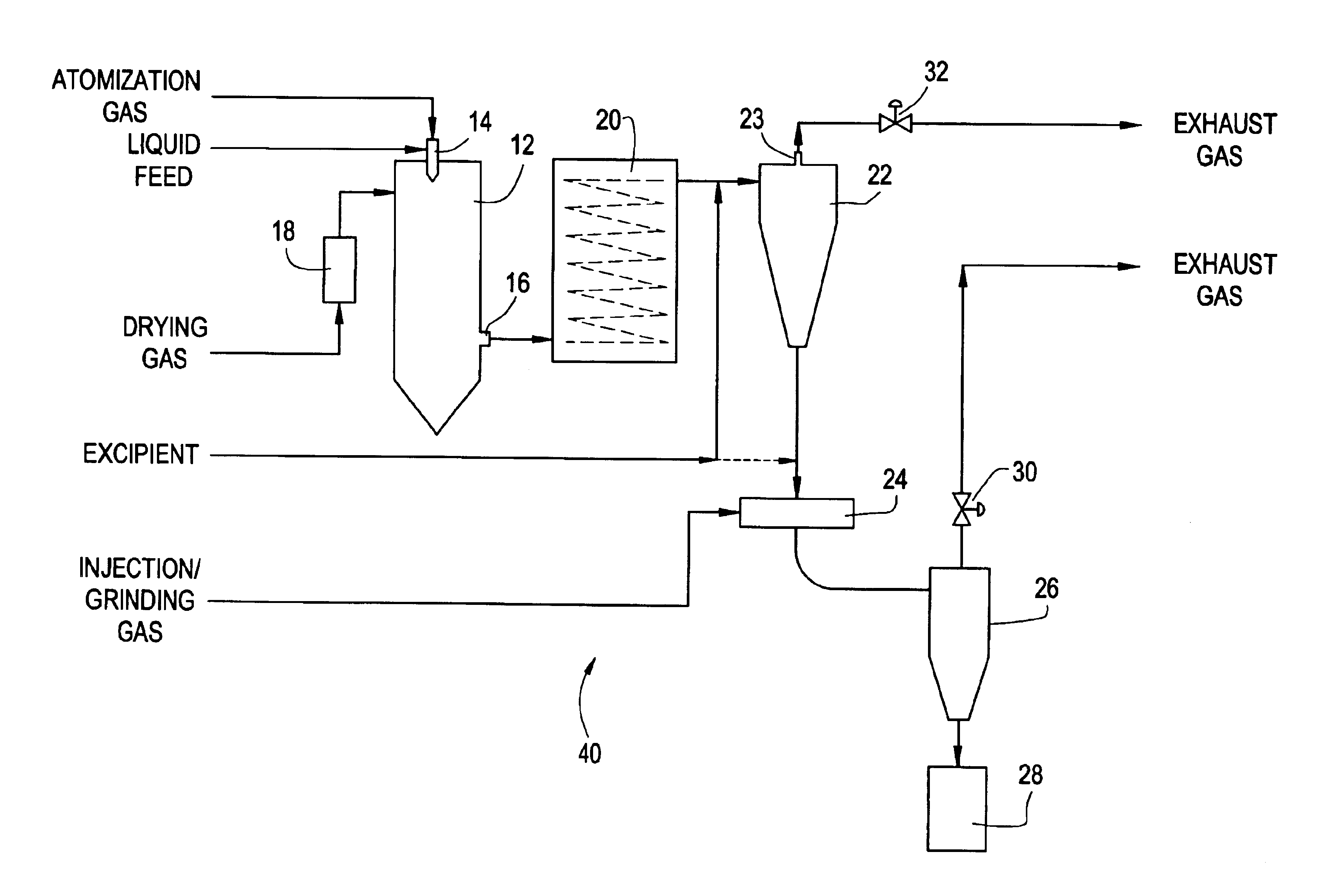

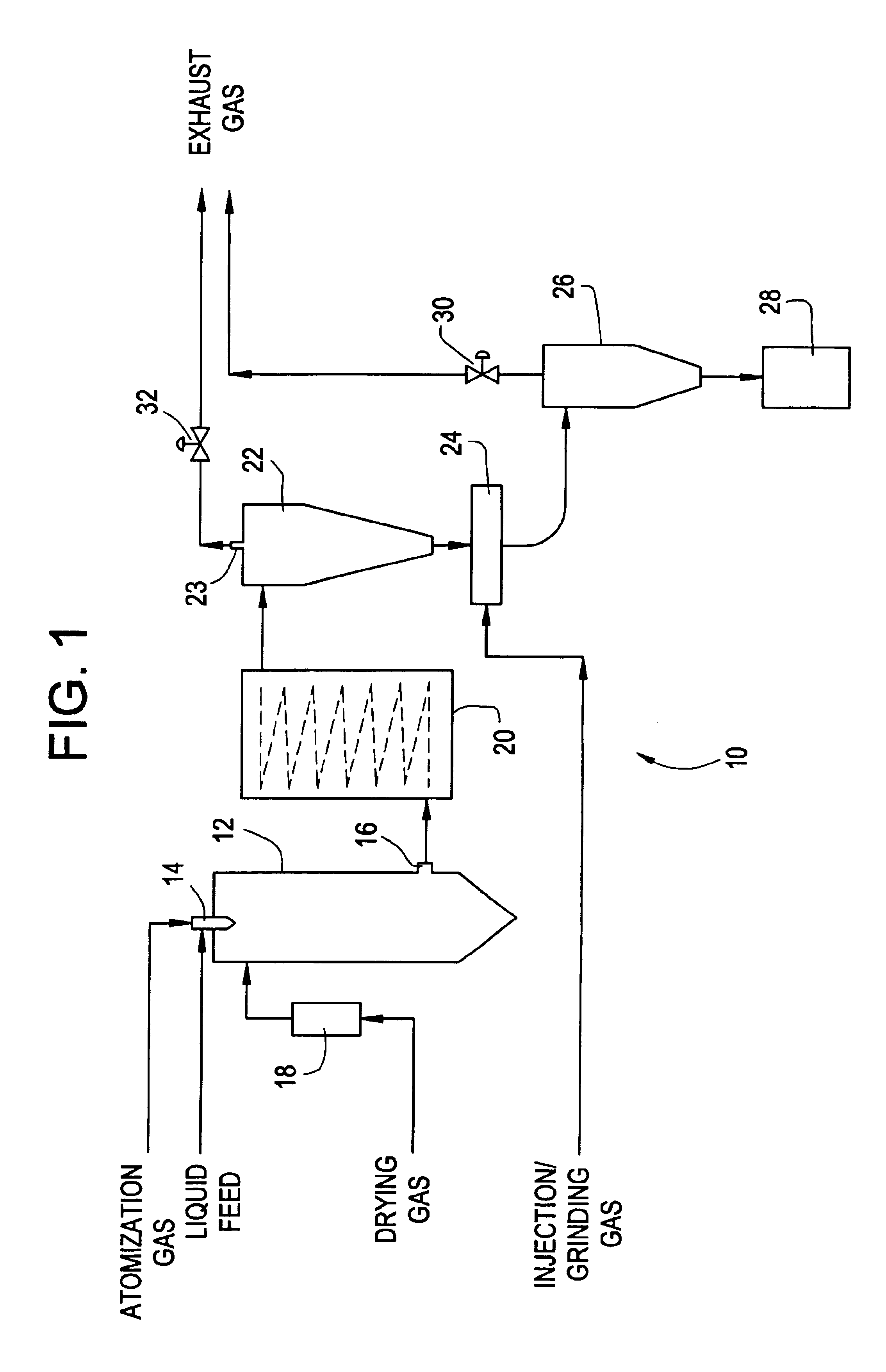

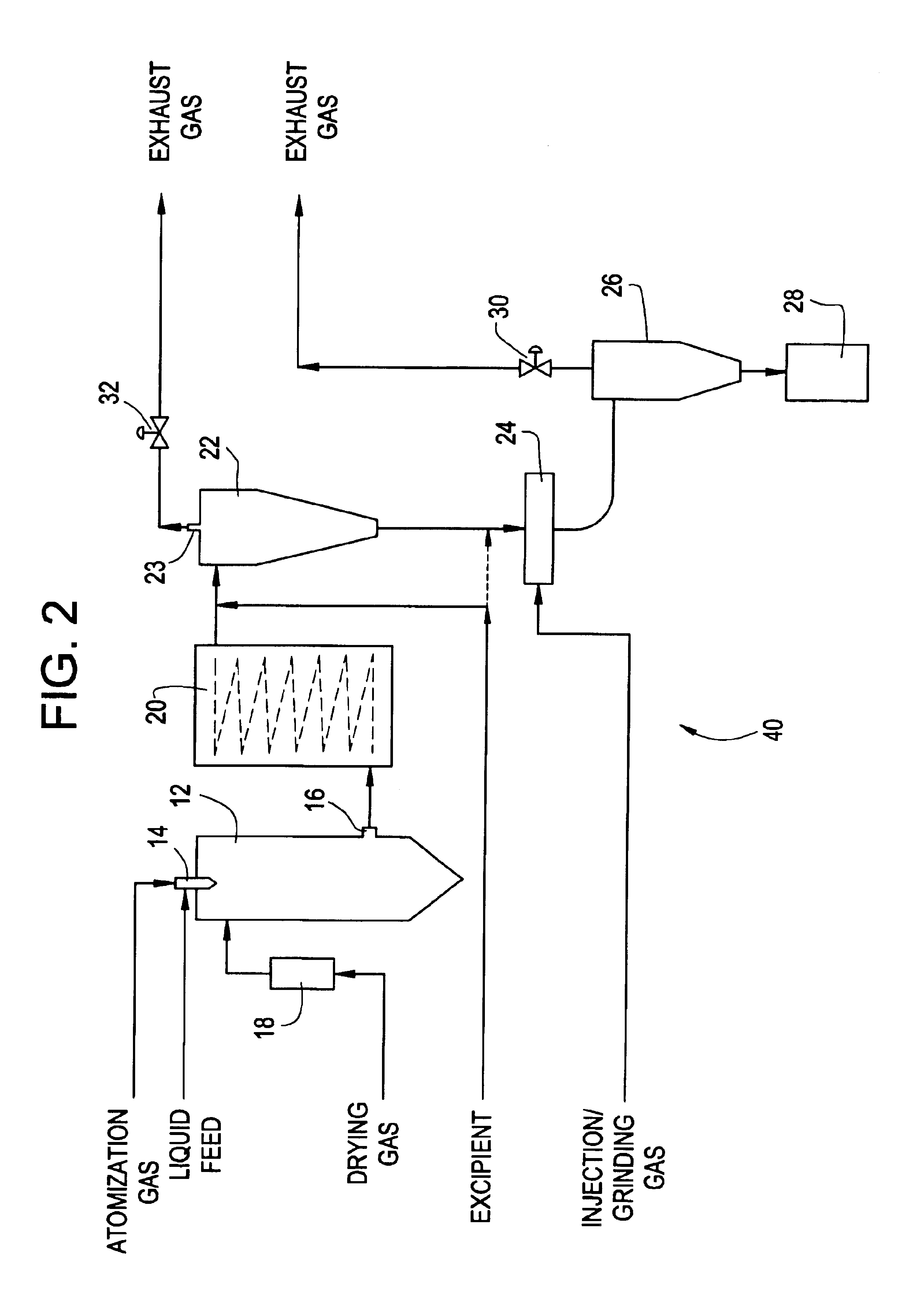

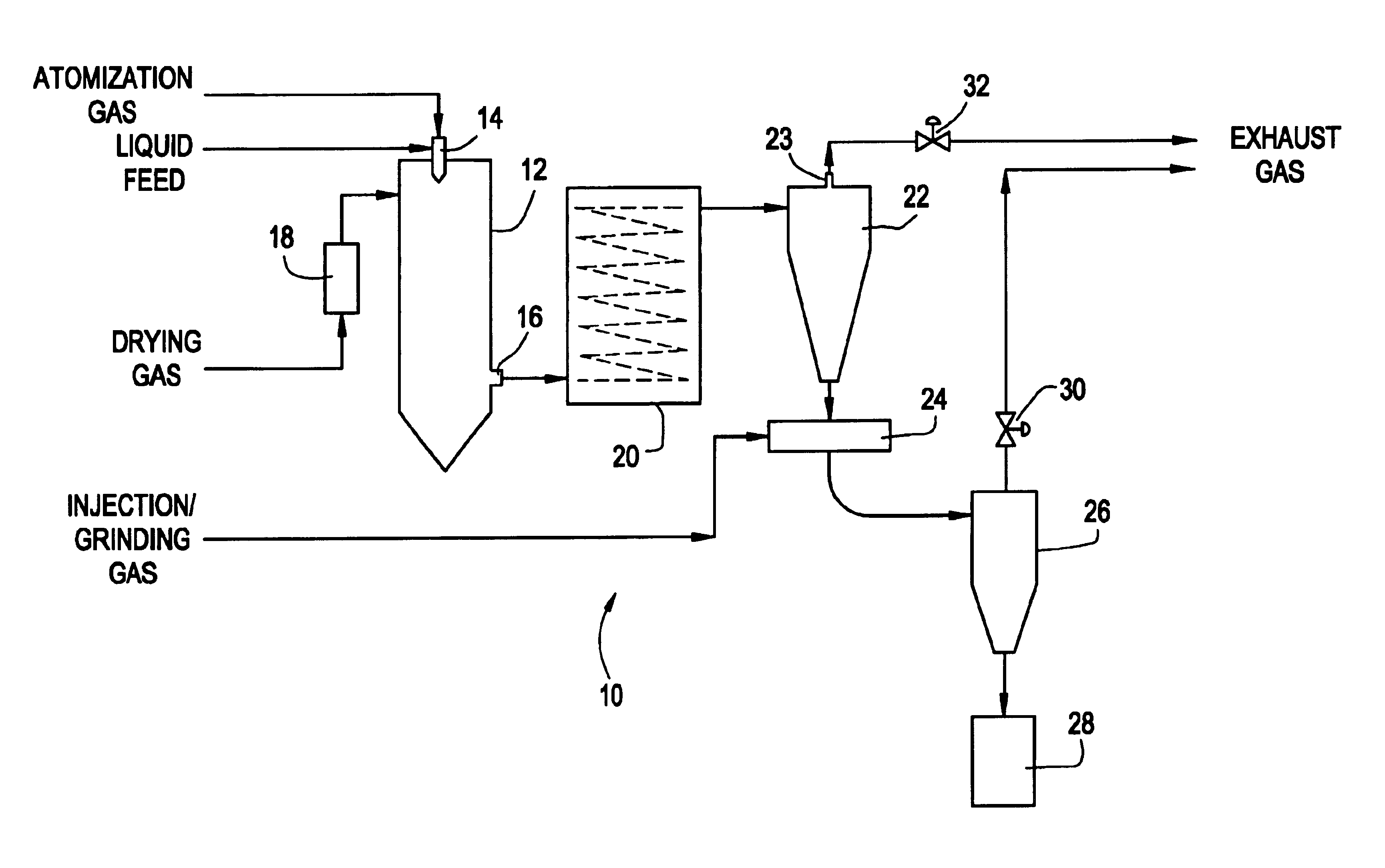

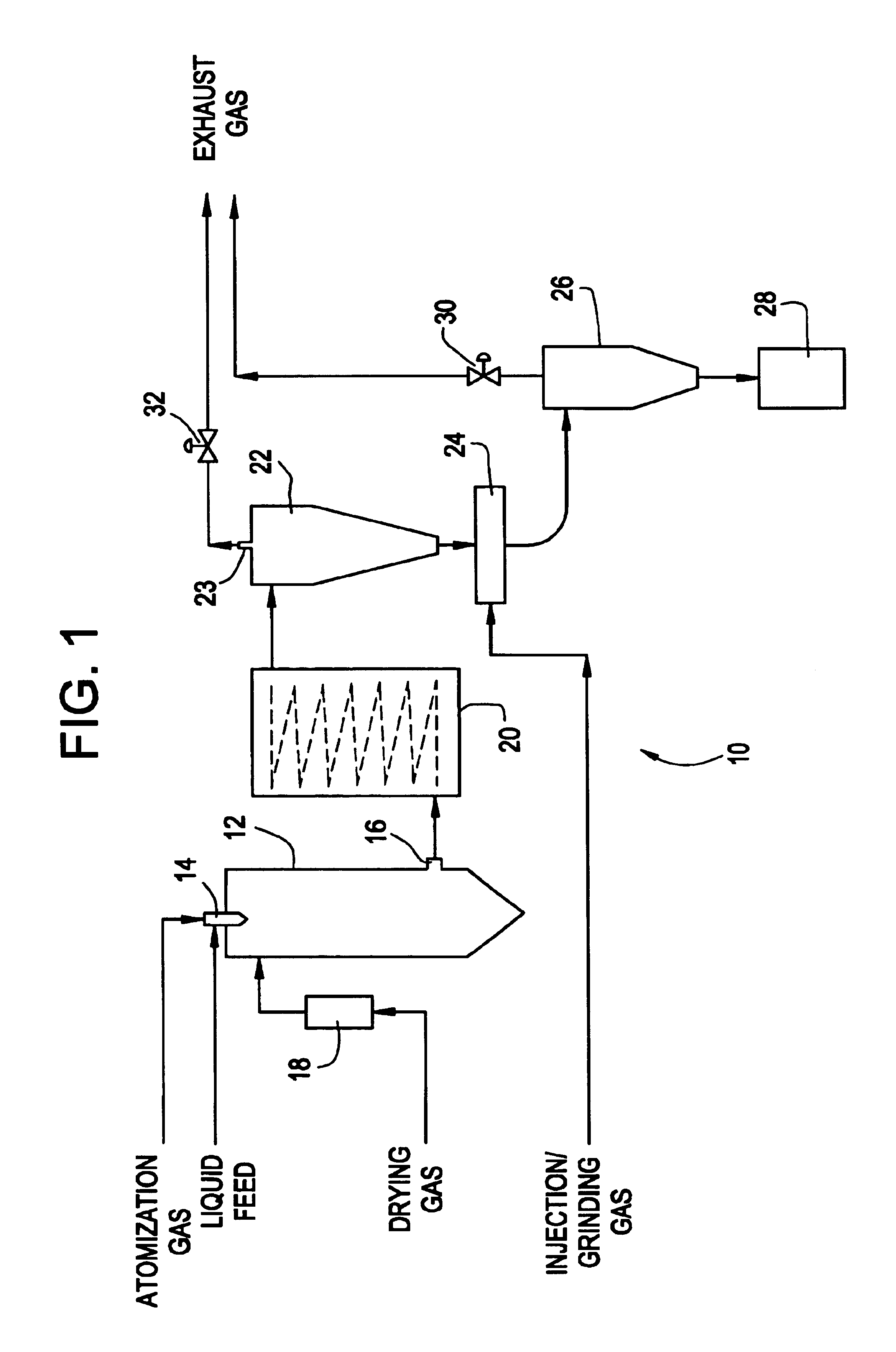

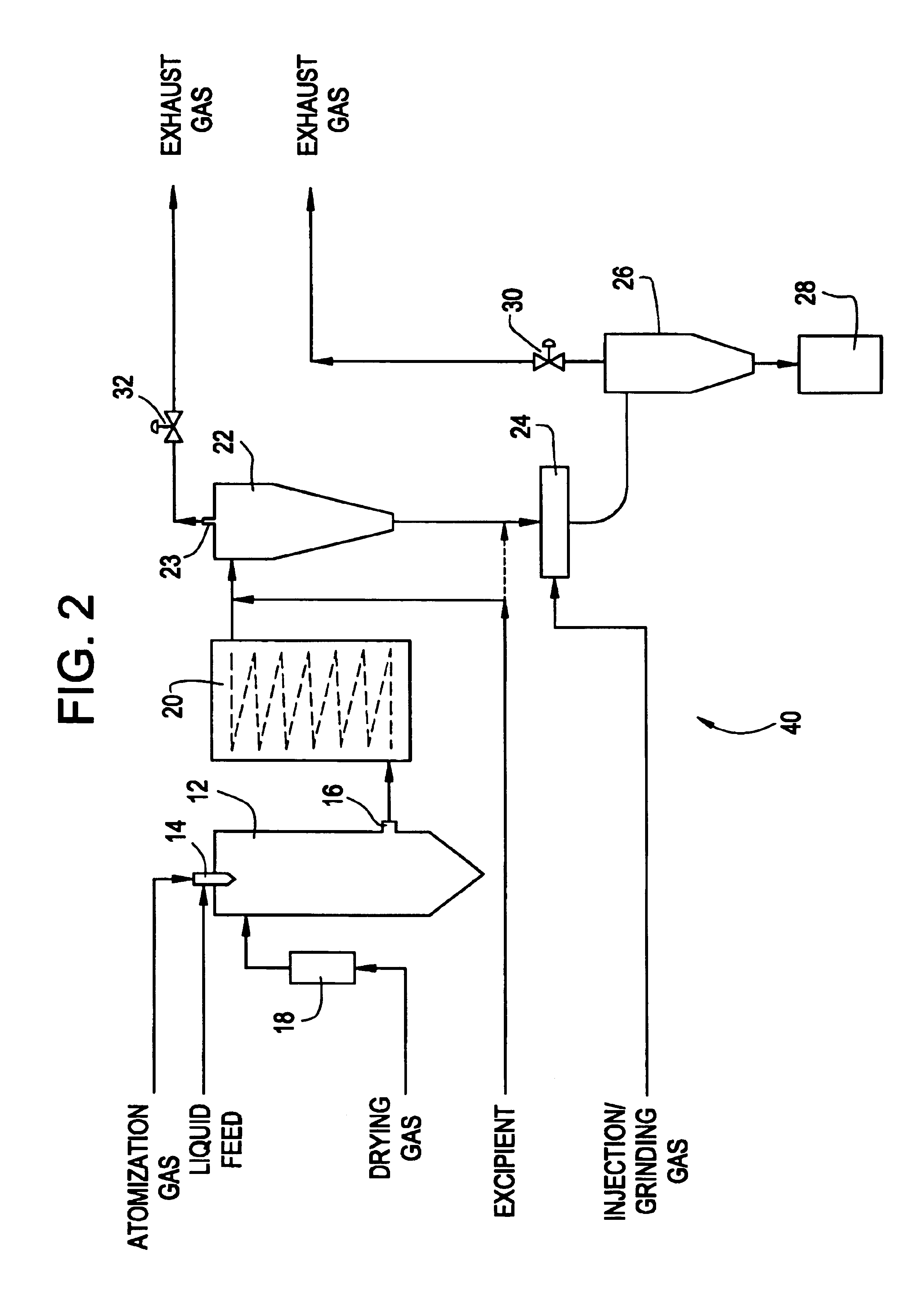

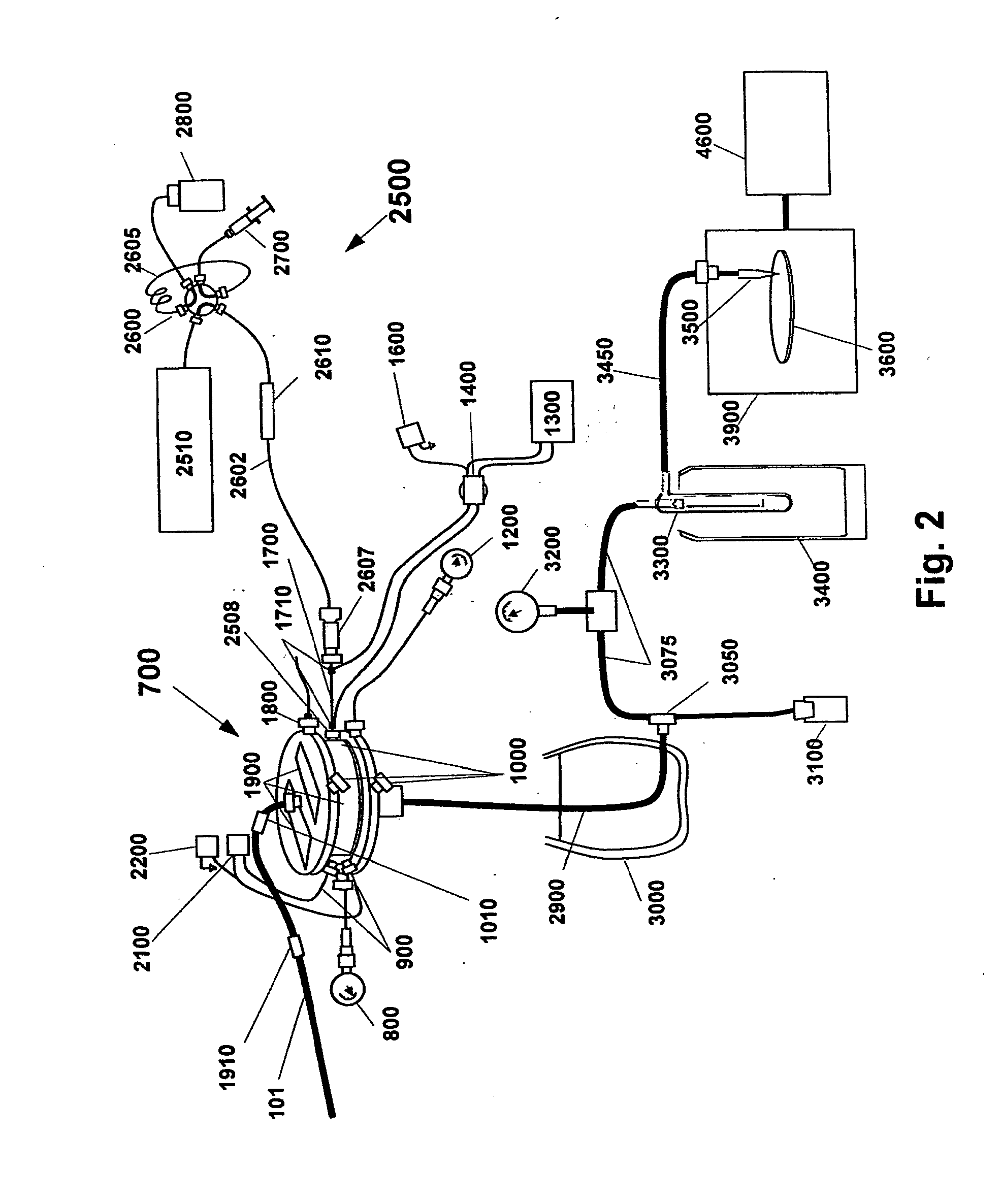

Methods and apparatus for making particles using spray dryer and in-line jet mill

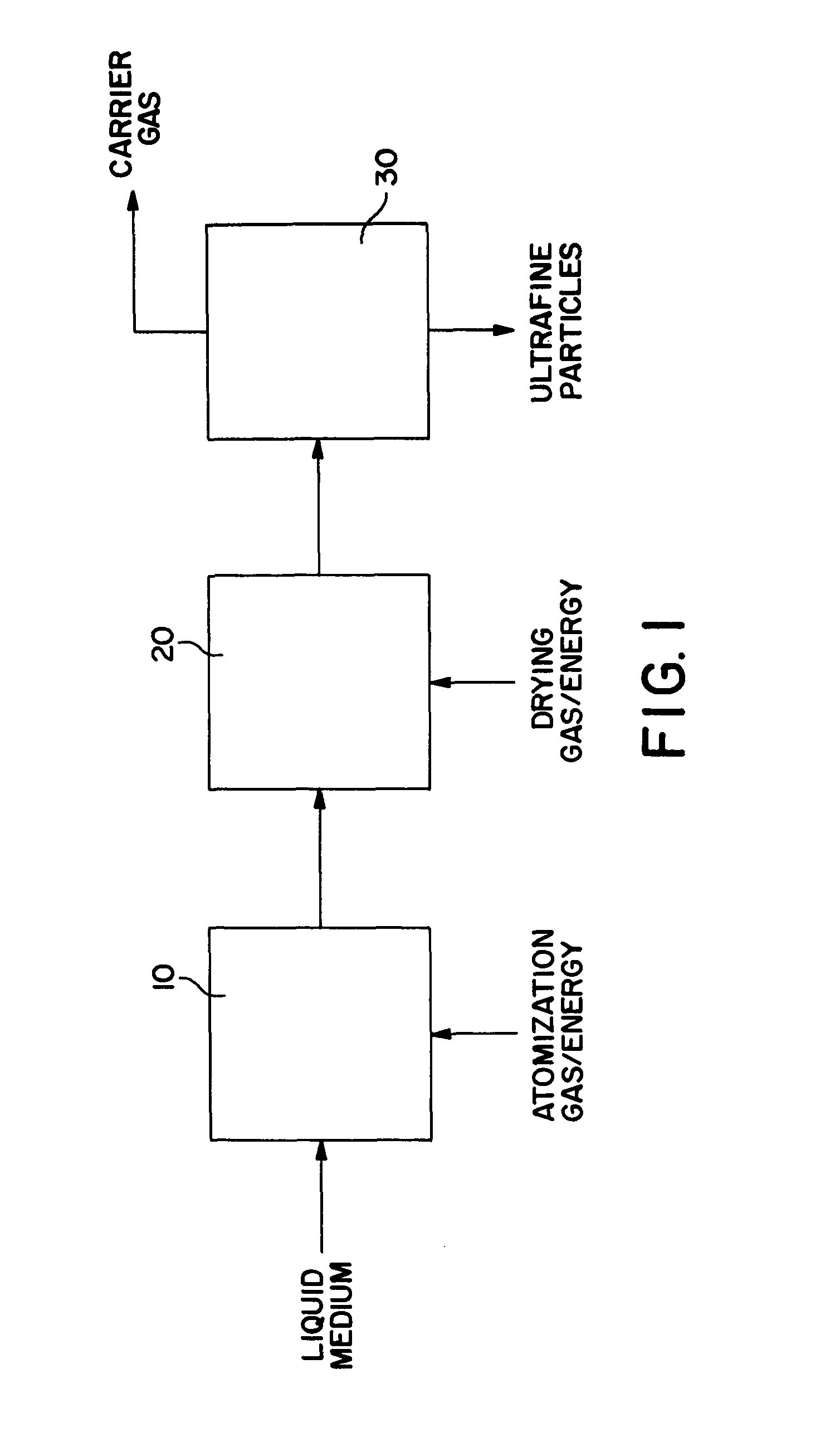

InactiveUS6918991B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6921458B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

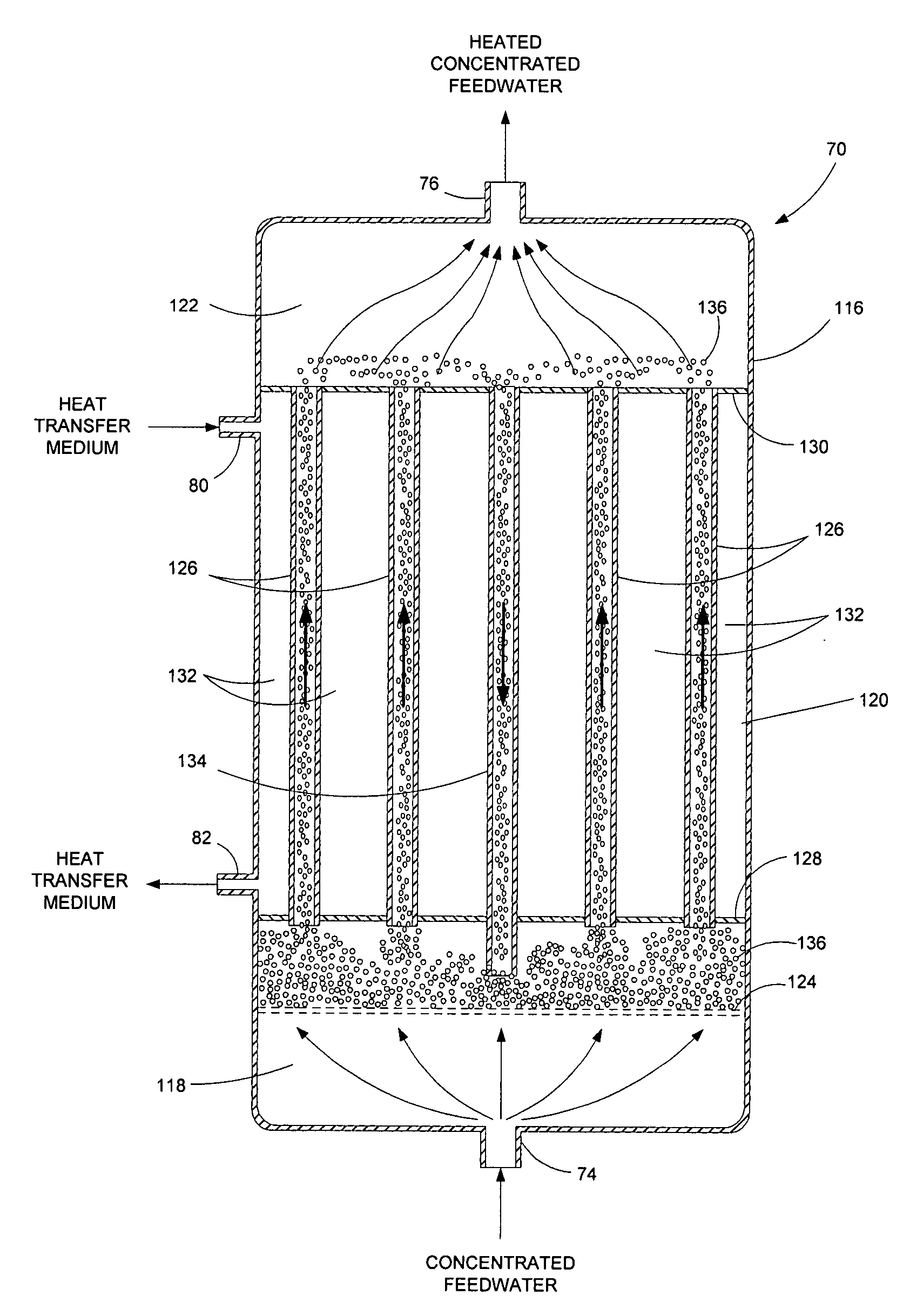

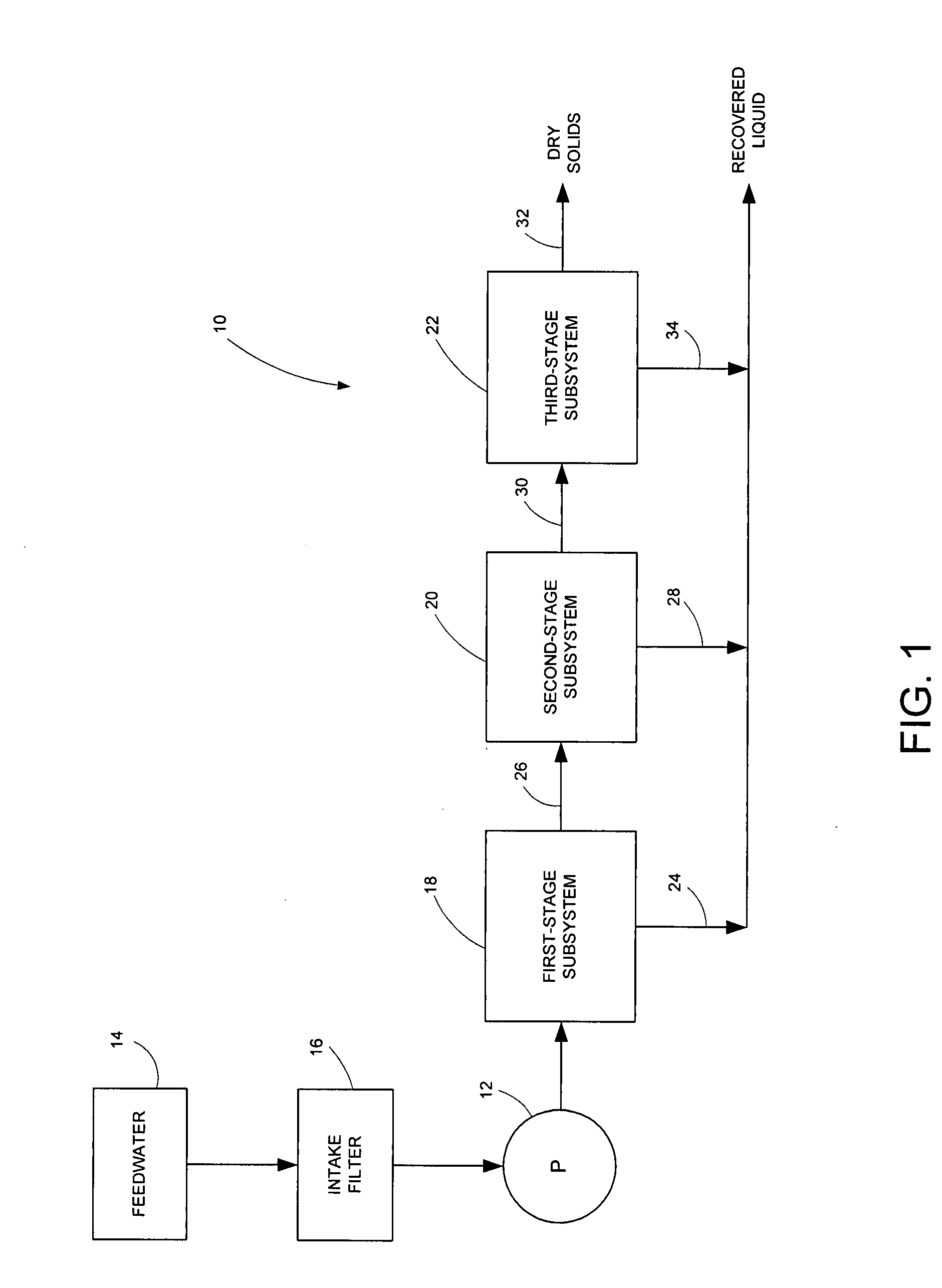

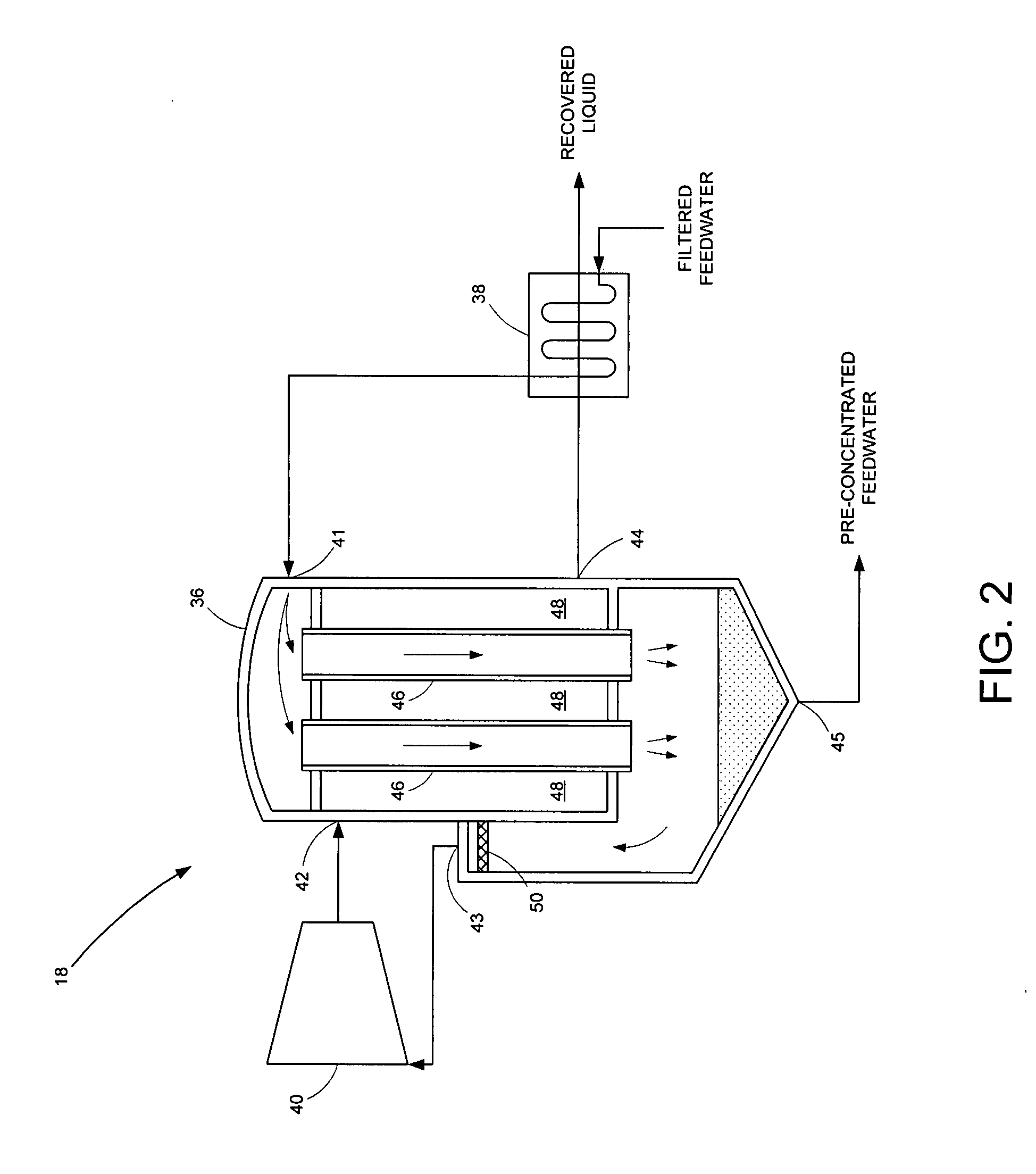

Method and system for treating feedwater

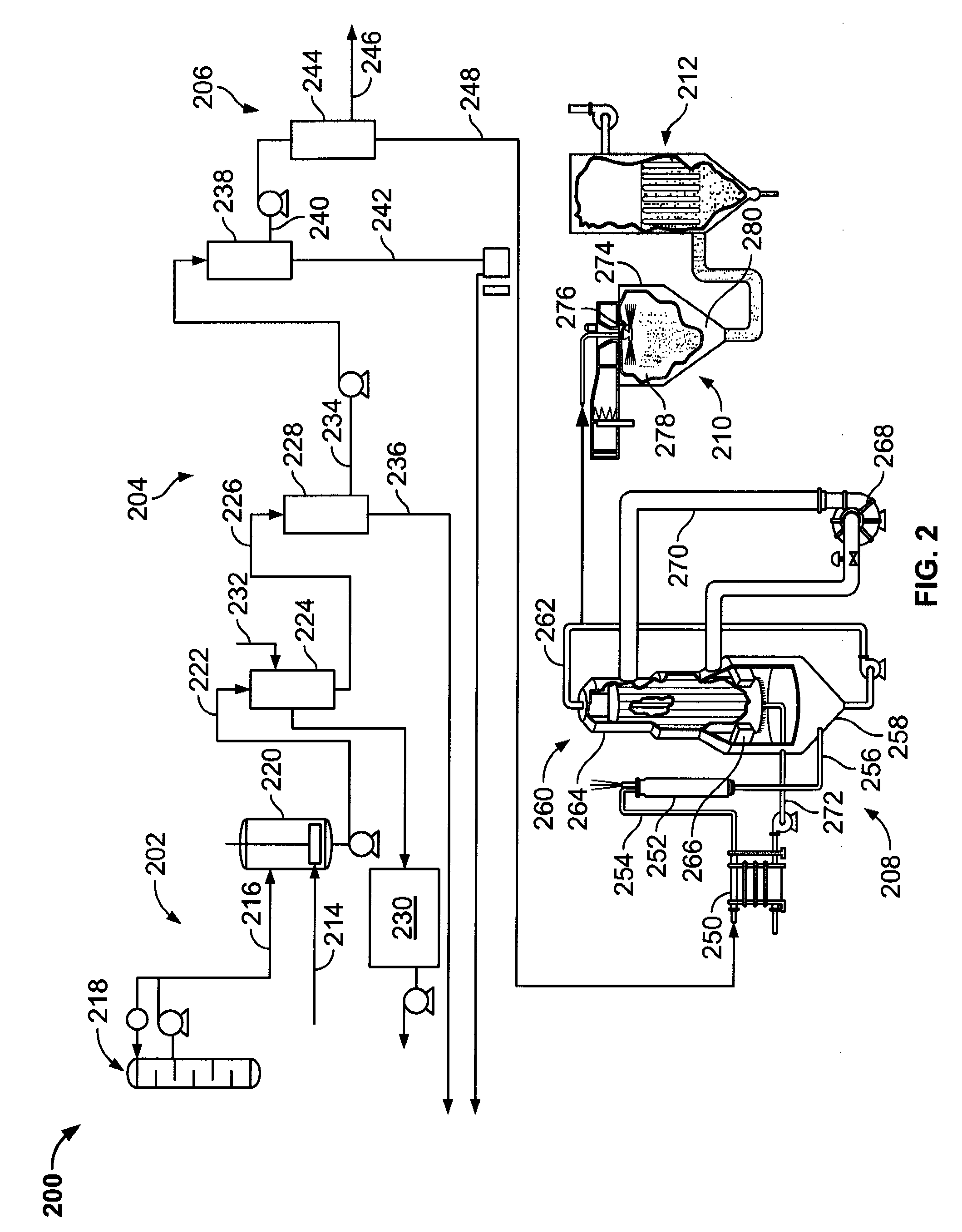

InactiveUS20090020481A1Easy to understandLiquid degasificationSedimentation separationFluidized bedSlurry

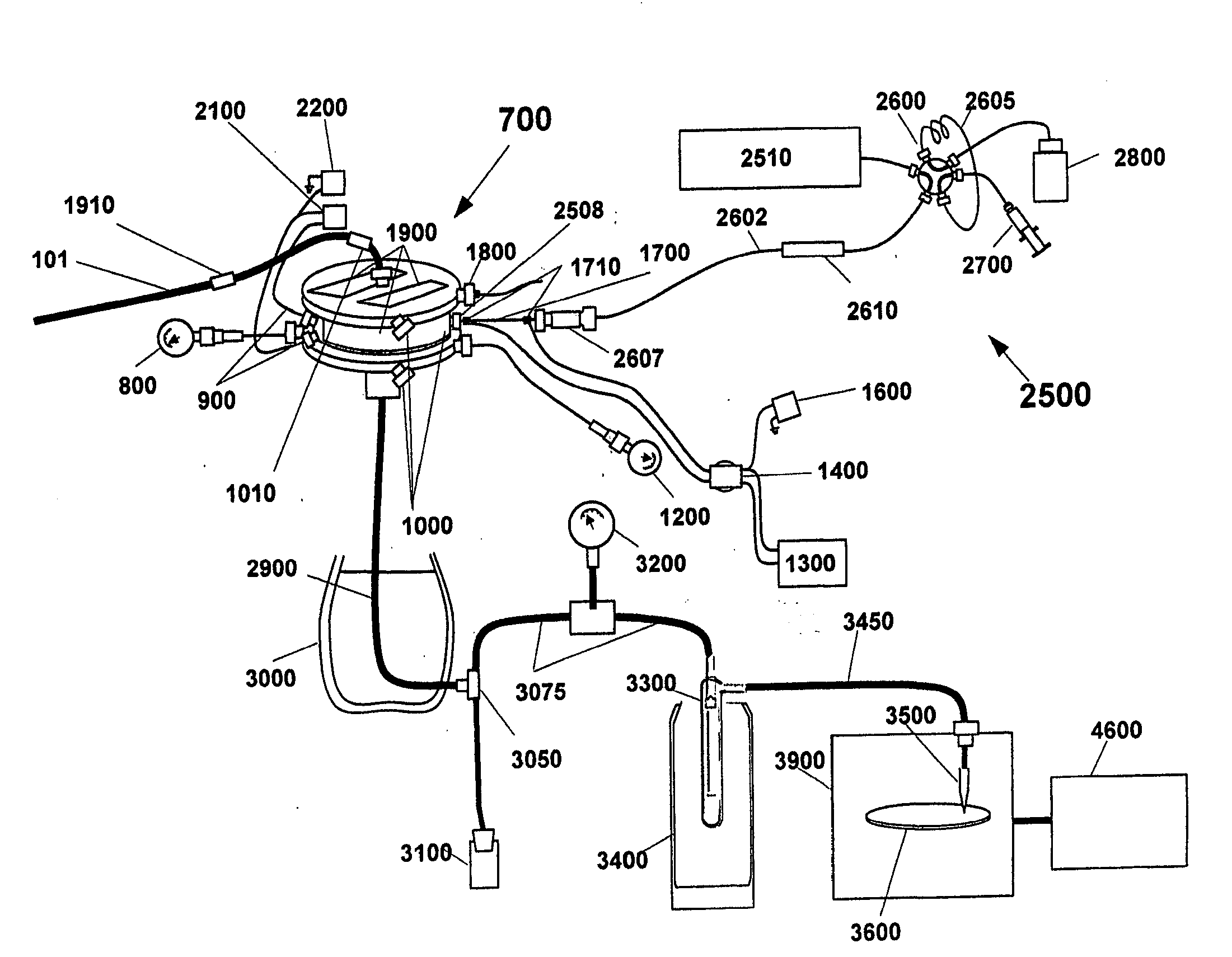

A system for treating feedwater includes a fluidized bed heat exchanger unit connected to receive feedwater and a flash concentrator column connected to receive feedwater discharged from the fluidized bed heat exchanger unit. A spray dryer is provided to receive a solids / liquid slurry discharged from the flash concentrator column. Feedwater can be treated by converting dissolved solids in the feedwater to suspended solids, vaporizing a portion of the feedwater to produce a solids / liquid slurry, and separating solids from the solids / liquid slurry.

Owner:WATERVAP +1

Quick disintegrating tablet in buccal cavity and manufacturing method thereof

InactiveUS6656492B2Good effectDisintegrates quicklyPowder deliveryLiquid surface applicatorsHigh concentrationLow speed

The present invention pertains to a quick disintegrating tablet in buccal cavity, characterized in that drug-containing particles with a mean particle diameter of approximately 50~approximately 250 mum and an apparent specific gravity of approximately 0.5~approximately 1.2 consisting of a bitter tasting drug and / or drug of inferior fluidity and a pharmaceutical preparation carrier and obtained by spray drying are added to a quick disintegrating tablet in buccal cavity comprising a drug and saccharide. Moreover, the present invention pertains to a method for manufacturing drug-containing particles having a specific mean particle diameter and specific apparent gravity by dissolving and suspending a bitter tasting drug and / or drug of inferior fluidity and a pharmaceutical preparation carrier (preferably containing water-insoluble polymer, particularly at least aqueous ethyl cellulose suspension (preferably containing plasticizer)) to a high concentration in terms of solid concentration in a solvent that is pharmaceutically acceptable and then spray drying this liquid using a rotating disk-type spray dryer, with the disk operating at low speed, and a method for manufacturing a quick disintegrating tablet in buccal cavity comprising said particles.

Owner:ASTELLAS PHARMA INC

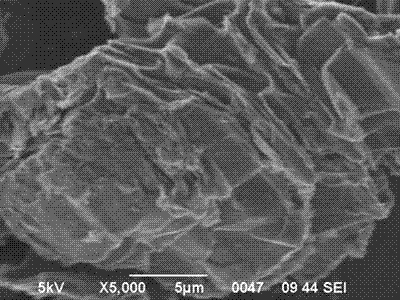

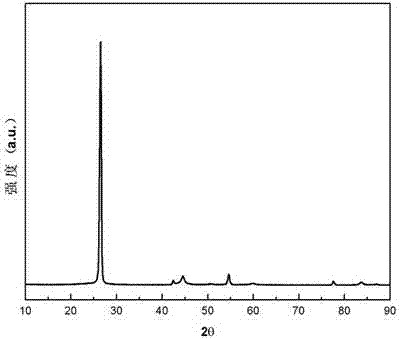

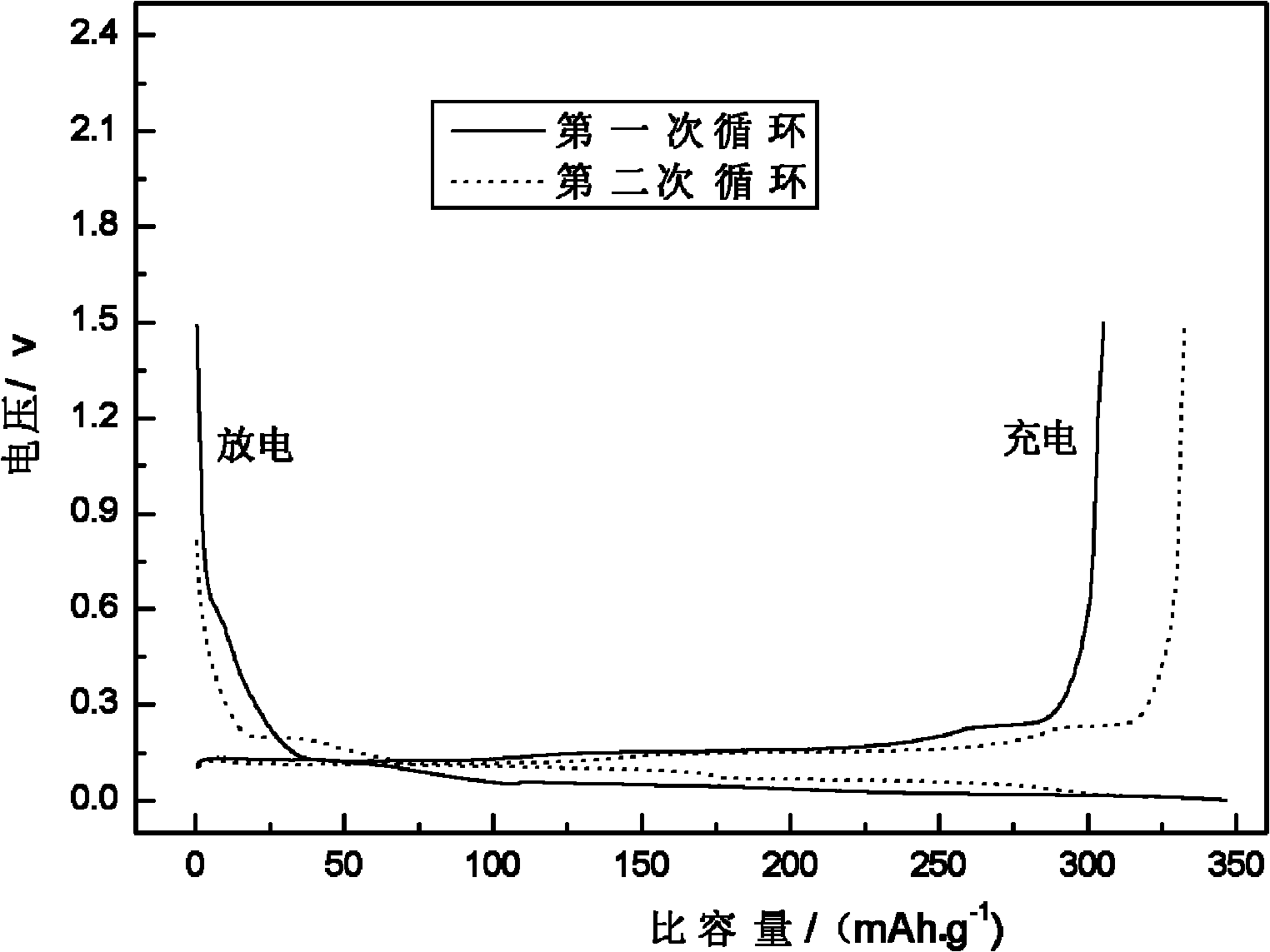

Preparation method of asphalt liquid phase coated modified artificial graphite lithium battery cathode material

ActiveCN103682350AImprove first-time efficiencyHigh specific capacityCell electrodesDischarge efficiencyPhysical chemistry

The invention provides a preparation method and an application of an asphalt liquid phase coated modified artificial graphite lithium battery cathode material. The method comprises the steps of mechanically grinding petroleum coke, mixing with an appropriate amount of (3-8%) asphalt powder after stage treatment, performing reaction for 6-10h in a moderate temperature reaction kettle at 500-650 DEG C, performing reshaping stage treatment again, performing reaction for 36-72h at 2400-3000 DEG C for high-temperature graphitization treatment, finally obtaining an unmodified artificial graphite material through stage treatment, then further dissolving the unmodified artificial graphite material and asphalt in a dispersing agent, stirring to obtain uniform mixing liquid, preparing the uniform mixing liquid into composite powder with a closed cycle spray dryer, heating for 1-5h at 700-1100 DEG C, and finally obtaining the asphalt liquid phase coated modified artificial graphite material. After the asphalt liquid phase coated modified artificial graphite prepared by the method is applied to a lithium battery, the artificial graphite shows excellent electrochemical properties such as high first charge-discharge efficiency, high specific capacity and good cycle performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Method for preparing formaldehyde scavenging agent

InactiveCN102658087ALarge specific surface areaEfficient captureOther chemical processesDispersed particle separationMass ratioNatural mineral

The invention relates to a method for preparing a formaldehyde scavenging agent. The method comprises the following steps of: preparing raw materials such as natural mineral micro powder, water, a binder and amino acid in a mass ratio of 100:(50-1,000):(0.5-5):(1-20), wherein the particle size of the natural mineral micro powder is 0.3 to 5mm; mixing and stirring the natural mineral micro powder and the water at the temperature of between 15 and 30 DEG C for 1 to 3 hours to form suspension; adding the binder, and mixing and stirring at the temperature of between 15 and 30 DEG C for 0.5 to 2 hours to form suspension; adding the amino acid, and mixing and stirring at the temperature of between 15 and 30 DEG C for 0.5 to 1 hour to form suspension; feeding into a spray dryer, and preparing dry porous spherical particle fine powder at the temperature of between 80 and 250 DEG C; and putting the fine powder into a packaging bag, and sealing. The raw materials are cheap and readily available, efficiency is high, energy consumption is low, and the prepared formaldehyde scavenging agent is high in adsorption capacity and long in action time.

Owner:王志勇

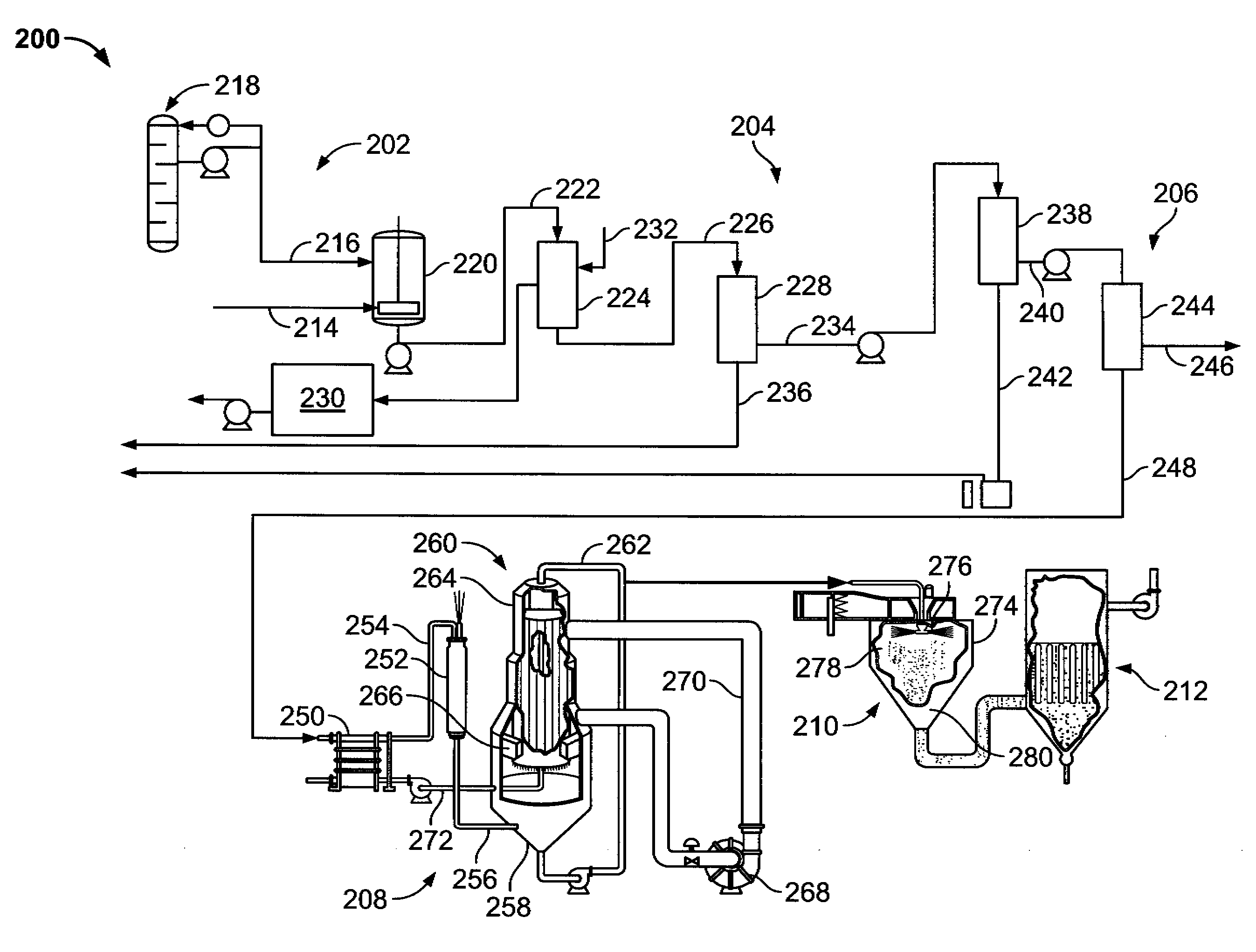

Methods and systems for zero discharge water treatment

ActiveUS20100172819A1Treatment involving filtrationDialysis systemsParticulatesWater treatment system

Methods and systems for a zero discharge waste water treatment system are provided. The system includes a filtration train including filter media having successively smaller diameter filtration elements, a reverse osmosis apparatus including a pump and a membrane coupled in flow communication with said filtration train, a vapor compressor coupled in flow communication with said reverse osmosis apparatus, and a spray dryer coupled in flow communication with said vapor compressor, said spray dryer configured to separate moisture in a brine solution from particulate suspended in the brine solution.

Owner:AIR PROD & CHEM INC

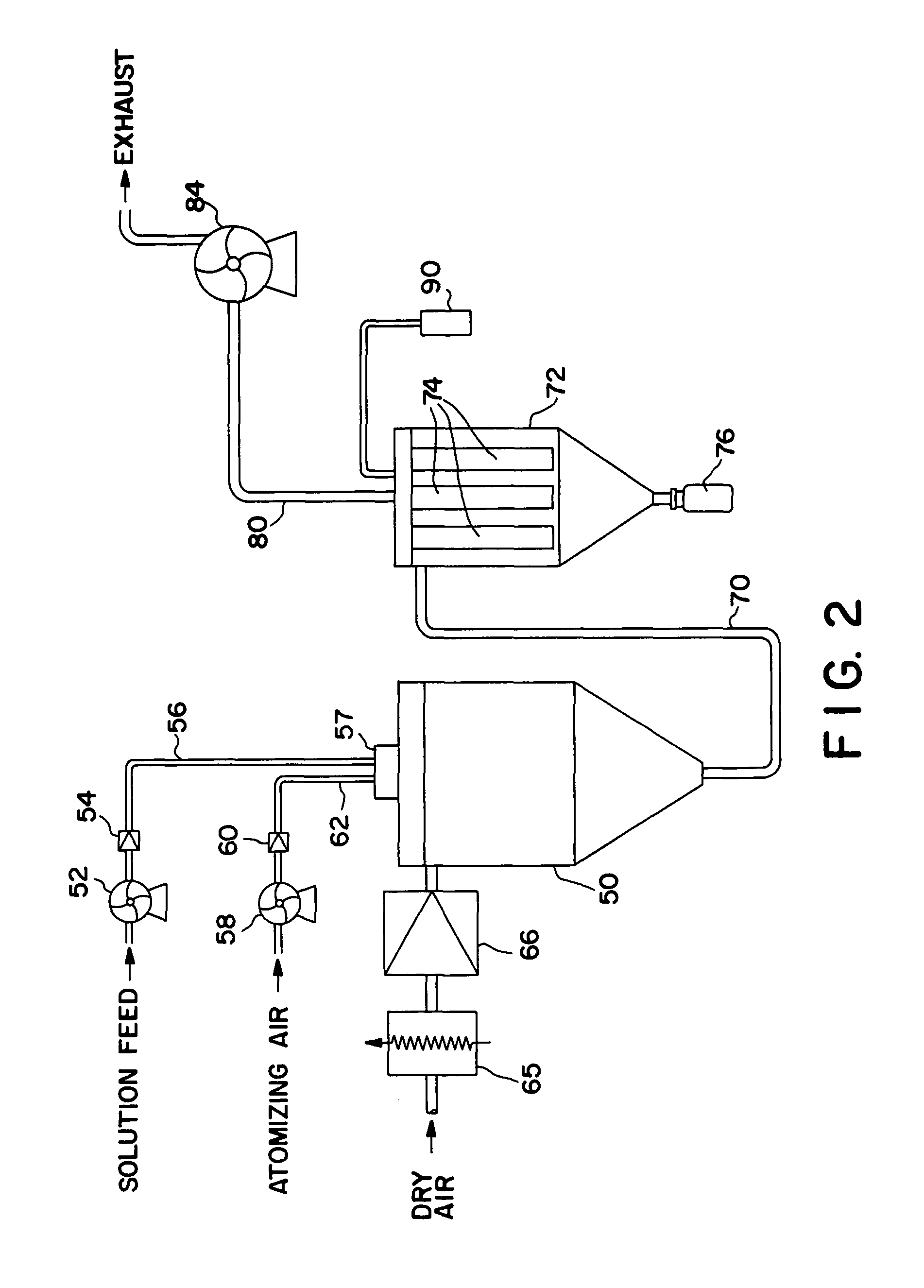

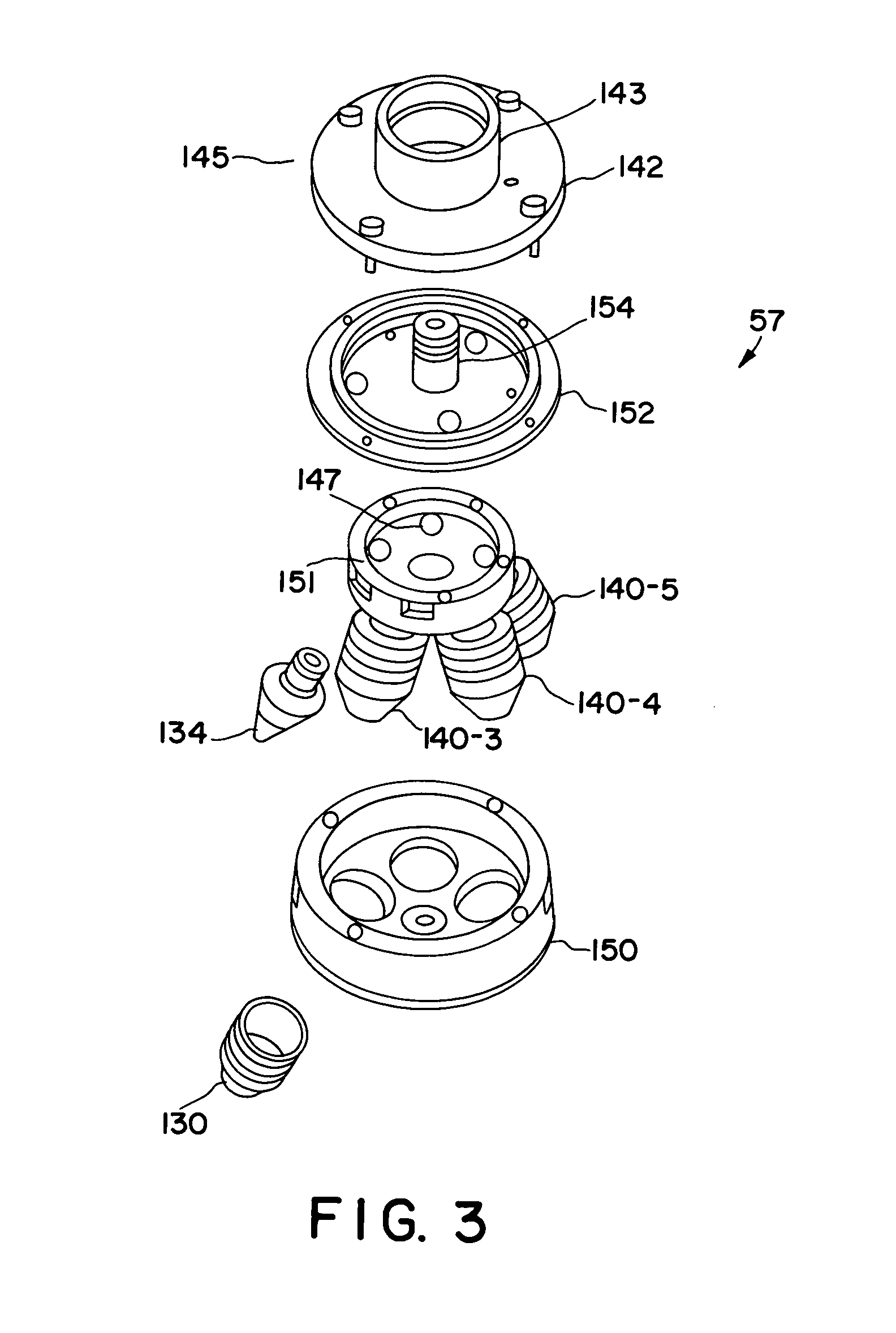

Spray drying methods and related compositions

ActiveUS8524279B2Enabling controlMinimize interactionOrganic active ingredientsPowder deliveryPowder mixtureSpray nozzle

A method and apparatus are provided for atomizing a liquid under dispersal conditions suitable for spray drying at a commercial plant scale. In one embodiment, a liquid atomizer has a structural body adapted for connection with a spray dryer and a plurality of atomizing nozzles. Each of the atomizing nozzles includes a liquid nozzle adapted to disperse a supply of liquid and a gas nozzle adapted to disperse a supply of gas. In another embodiment, a process for producing a powder blend of at least two target substances in a single processing step is provided.

Owner:NOVARTIS AG

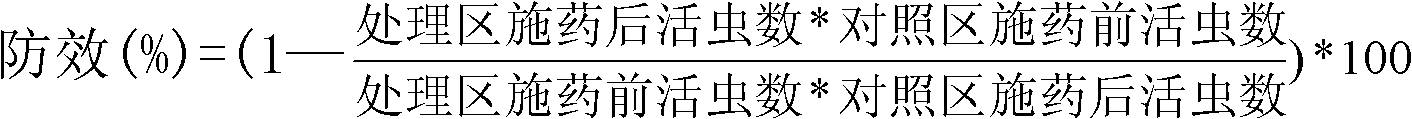

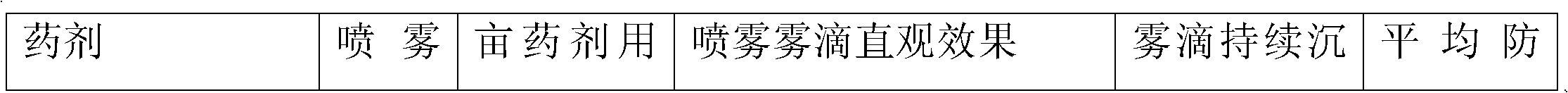

A kind of pesticide adjuvant and preparation method thereof

A pesticide additive of the present invention, by selecting a suitable solvent, cosolvent, viscosity reducer, penetrant type and ratio, the additive system has reasonable volatility, density, flash point, viscosity, and adhesion, and can A certain amount of pesticide active ingredients are fully dissolved, and the preparations of insecticides, fungicides, and plant growth regulators formulated with this adjuvant can be directly used in ultra-low volume without any change or addition of additives. Spraying or spraying with a hot fog machine is used for preventing and controlling pests and diseases on crops or promoting effective tillering of crops; meanwhile, a preparation method of the pesticide adjuvant is also disclosed.

Owner:GAUNGXI TIANYUAN BIOCHEM

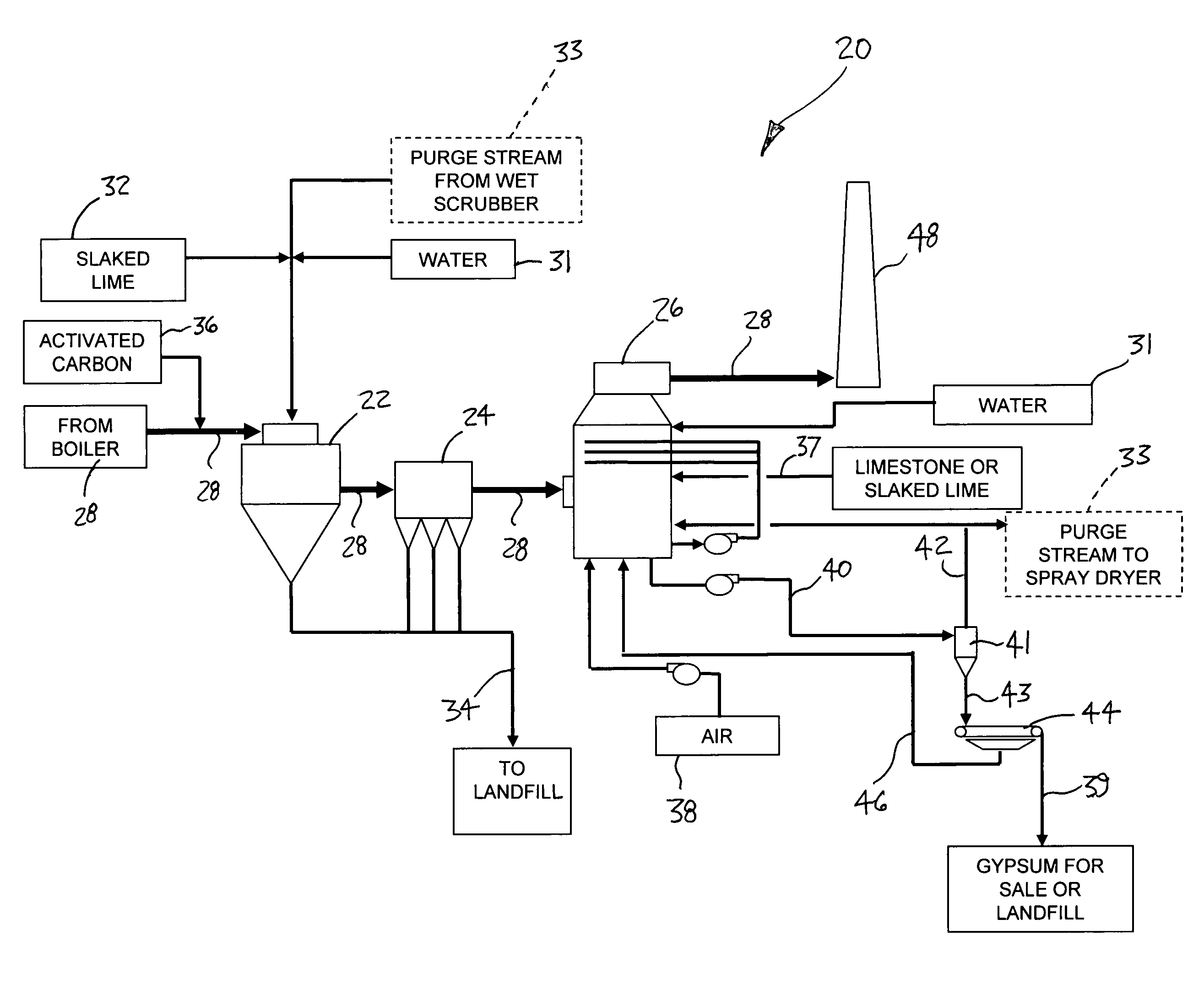

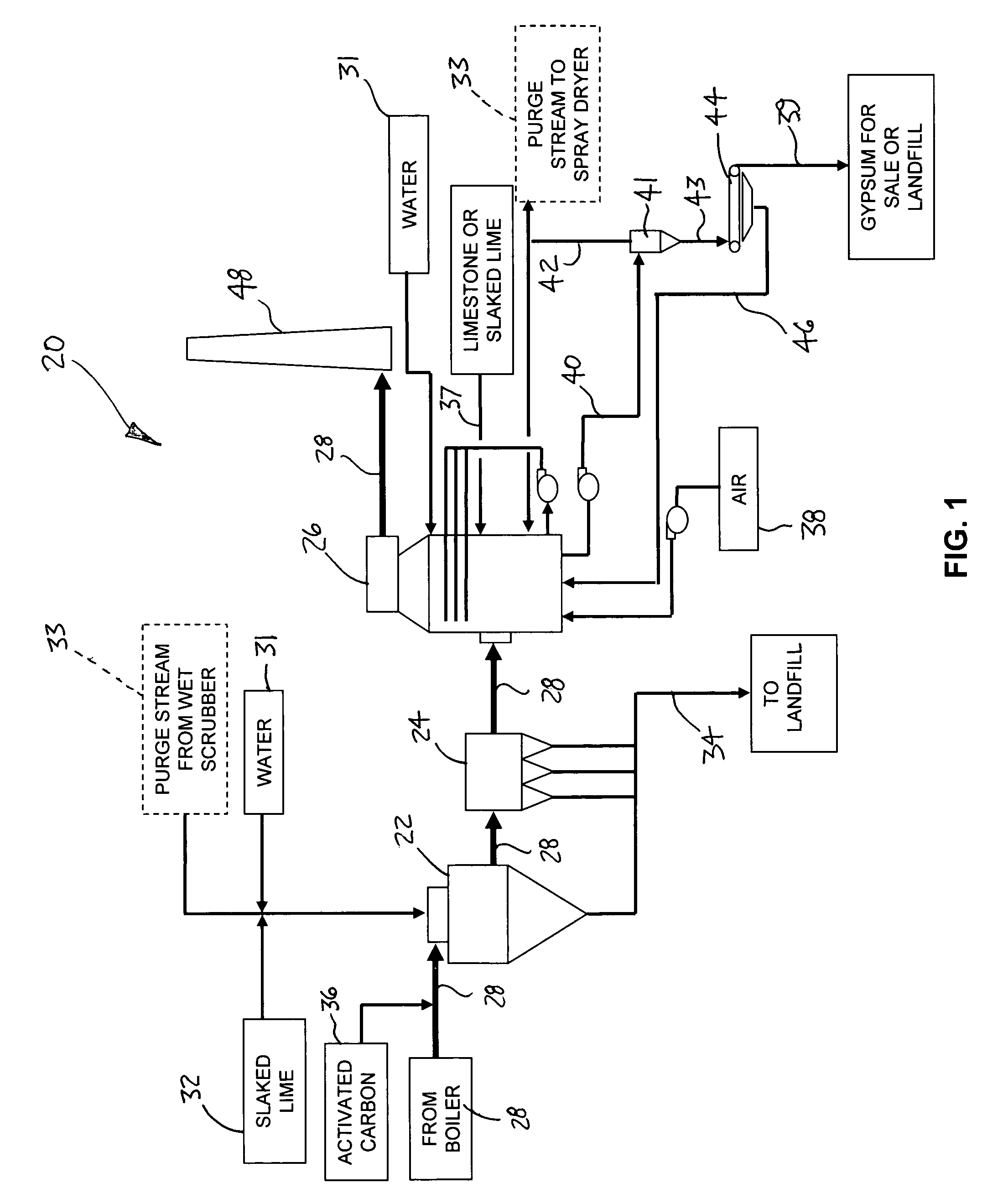

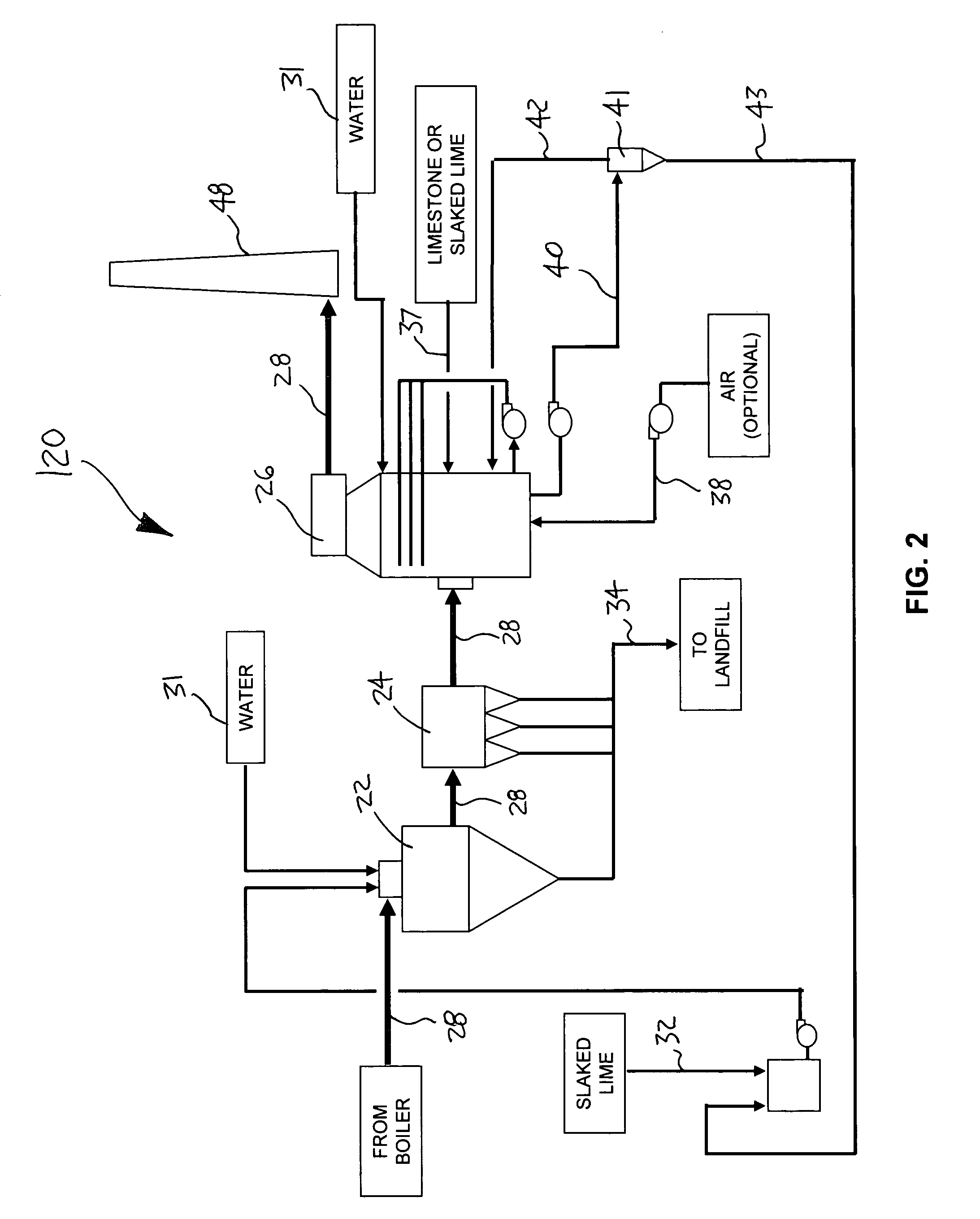

Integrated dry and wet flue gas cleaning process and system

A process and system for removing sulfur oxide, other gases, and particulate from a flue gas. The process includes treating flue gas with a slurry formed from water, an alkaline reagent, and the purge stream from a wet scrubber in a spray dryer, thereby producing a dry by-product. The process further includes filtering the flue gas to remove at least a portion of the dry by-product, wet scrubbing the flue gas exiting the filter in a wet scrubber, adding a lime or limestone reagent to the wet scrubber, and producing gypsum. Activated carbon may be injected into the flue gas upstream of the filtering step and particulate may be removed from the flue gas upstream of the spray dryer.

Owner:GENERAL ELECTRIC TECH GMBH

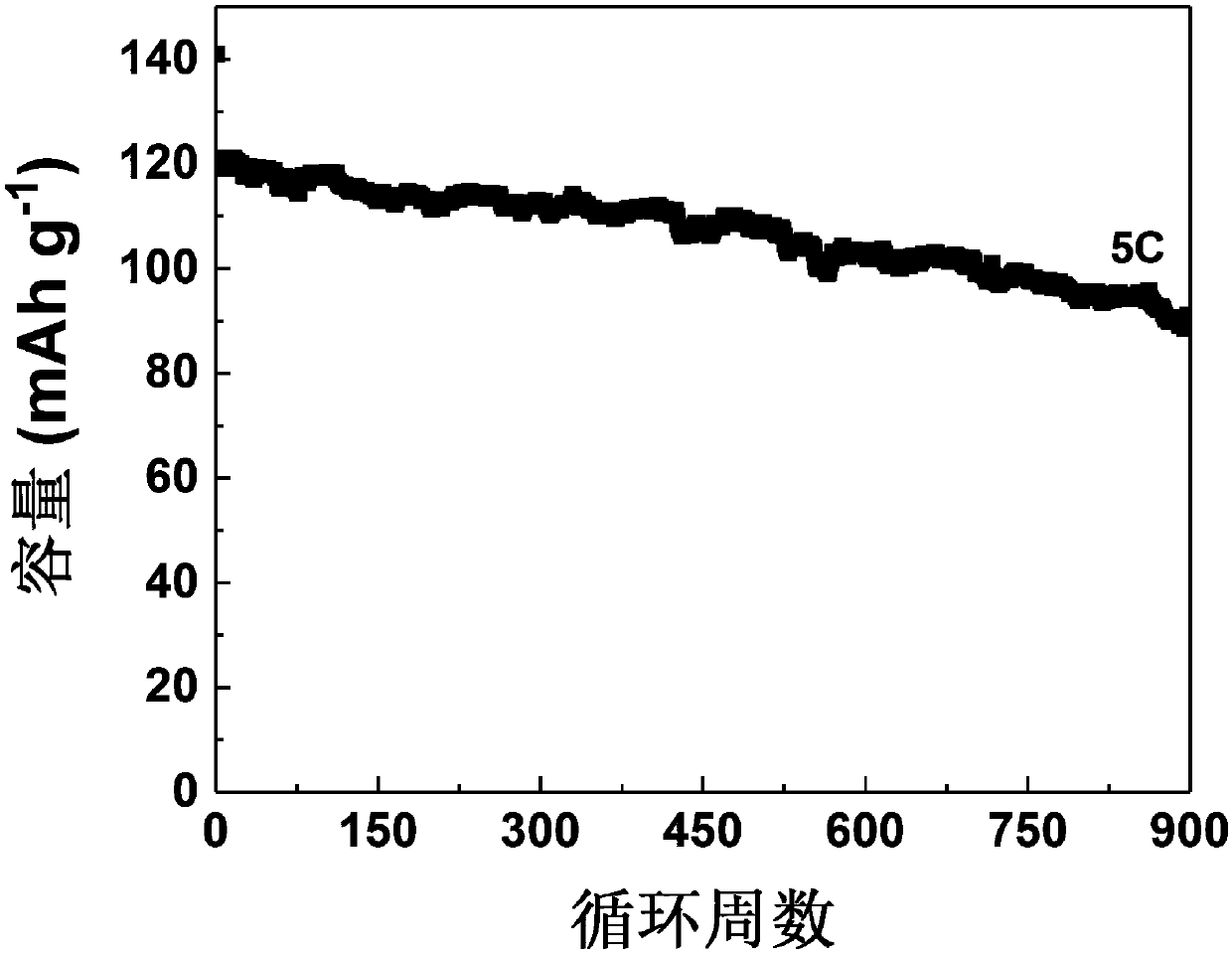

Mxene-coated composite electrode material and preparation method therefor

ActiveCN107706372AReduce voidsImprove conductivityMaterial nanotechnologyCell electrodesElectrolytic agentSolvent

The invention provides an Mxene-coated composite electrode material and a preparation method therefor. The preparation method comprises the following steps of (1) adding an electrode material into a solvent to be stirred uniformly, and then adding Mxene to be stirred to obtain a uniform mixed solution; (2) performing spraying granulation on the obtained mixed solution by a spray dryer to obtain Mxene-coated electrode material powder; and (3) performing sintering on the obtained composite electrode material powder under inert gas protection, and then performing cooling. By adoption of the spraydrying method to enable Mxene to coat the electrode material, and by virtue of Mxene, contact between an electrolyte and the electrode material can be blocked, and ion dissolving in the electrolyte and a self-discharge effect can be lowered; in addition, the Mxene is uniformly distributed among the electrode material particles, so that gaps among the electrode material particles can be reduced and the conductivity of the electrode material can be reinforced; and the method is simple in operation, low in cost and the production efficiency can be improved.

Owner:SHANDONG UNIV

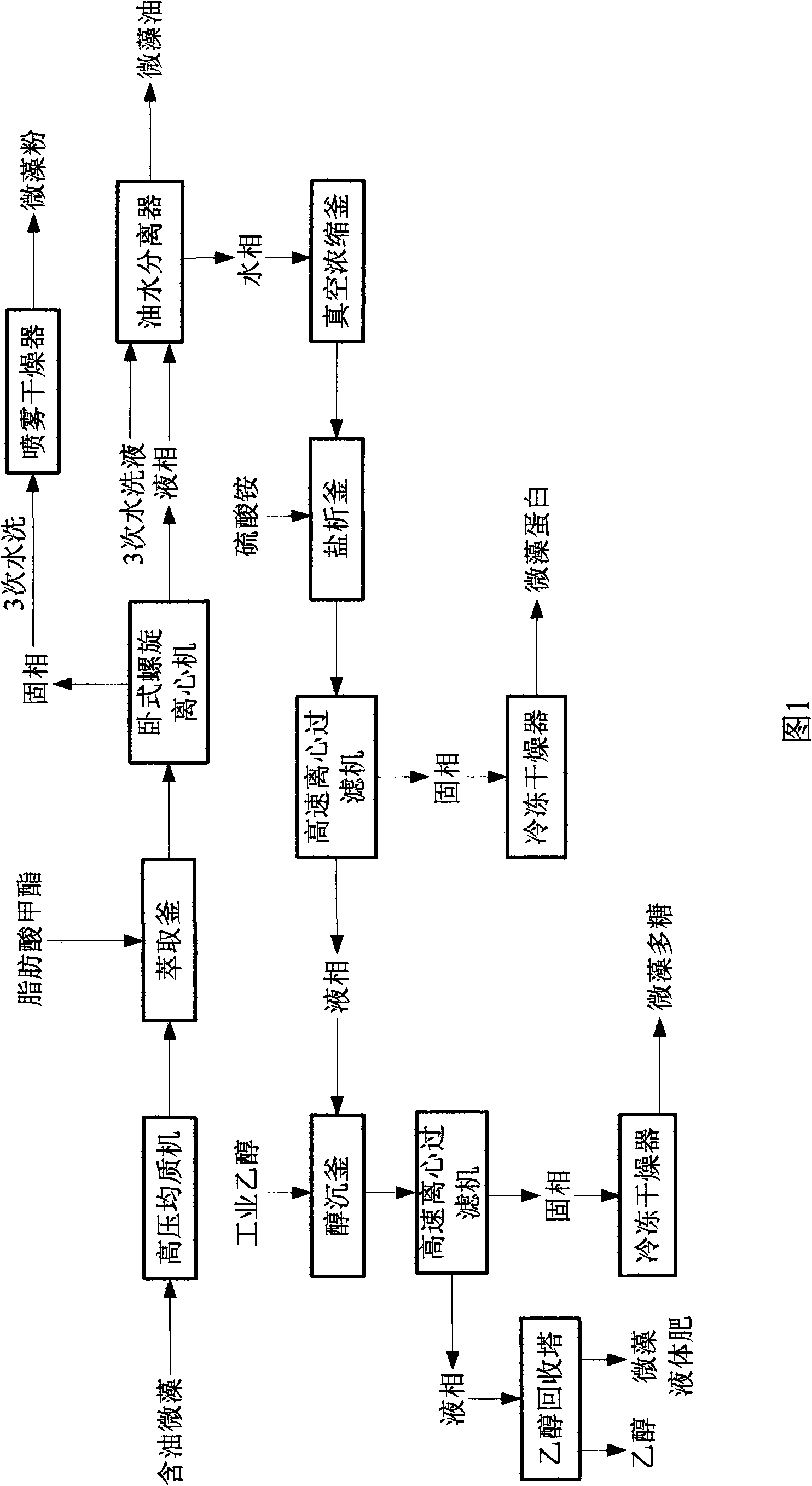

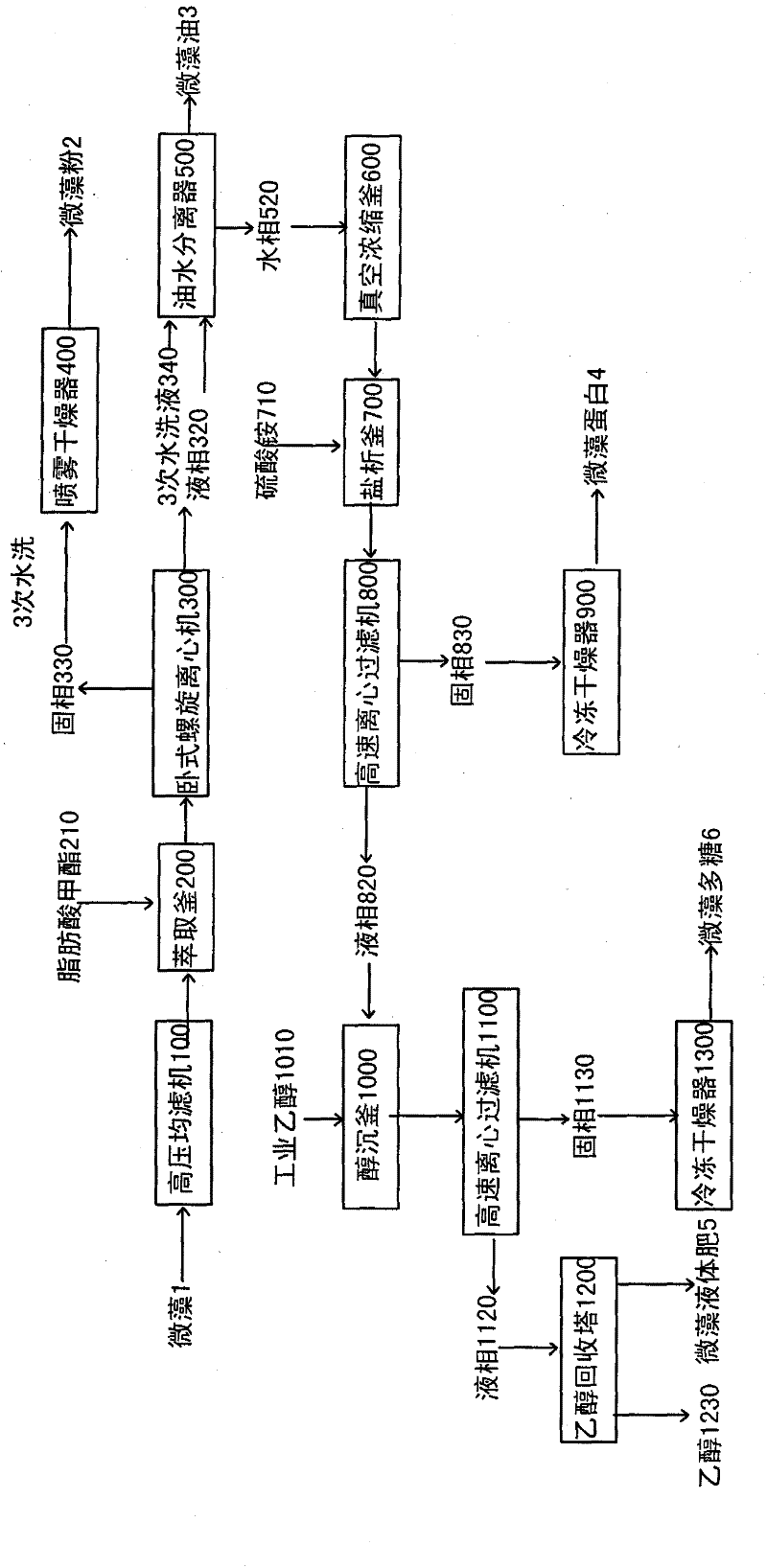

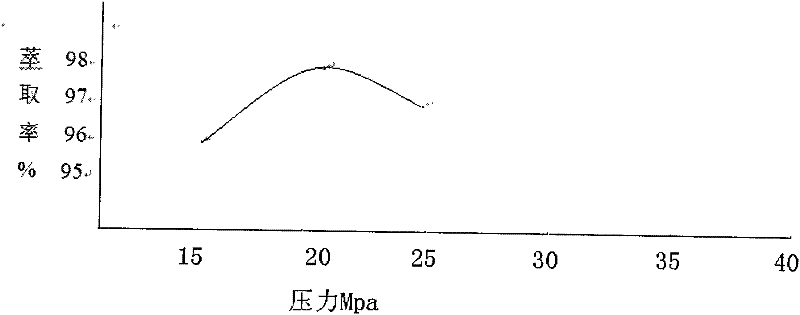

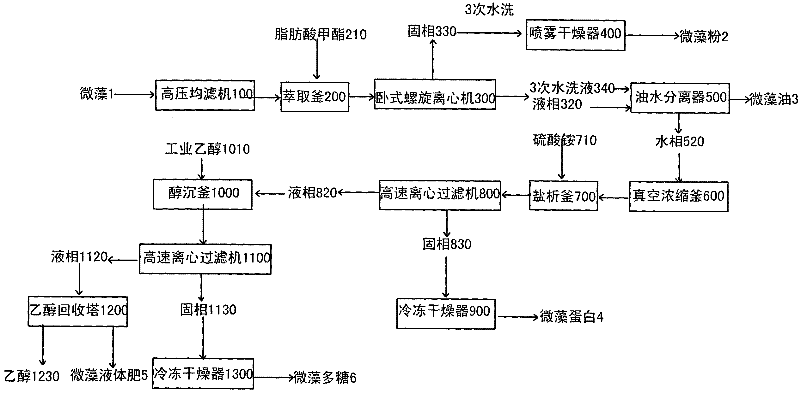

Production method for fully using oil-containing micro-algae

InactiveCN101352249AImprove broken rateSimple production equipmentPeptidesLiquid hydrocarbon mixture productionOil phaseHigh pressure

The invention relates to the filed of microalgae utilization engineering, in particular to a production method for fully utilizing oleaginous microalgae. The method is characterized in that the wall of the microalgae is broken by a high-pressure homogenization method, and the solid phase and liquid phase are separated out by an extraction kettle and a horizontal spiral centrifuge, and microalgae powder is made from the solid phase by a spray dryer. An oil phase and a water phase are separated from the liquid phase by an oil-water separator, and the oil phase is microalgae oil. A solid phase and a liquid phase are separated from the water phase by a vacuum concentration kettle, a salting-out kettle and a high-speed centrifugal filter, and microalgae protein is made from the solid phase by a freeze dryer or a spray dryer. A solid phase and a liquid phase are separated from the liquid phase by an alcohol precipitation kettle and the high-speed centrifugal filter, and microalgae polysaccharide is made from the solid phase by the freeze dryer or the spray dryer, and ethanol and microalgae liquid fertilizer are made from the liquid phase by an ethanol recovery tower. The invention is a good production method which requires low investment, has simple operation and can comprehensively use microalgae on a large scale, and can produce semi-finished products with high added value, such as the microalgae oil, the microalgae powder, the microalgae protein, microalgae polysaccharide, the microalgae liquid fertilizer, etc.

Owner:云南圣草峰生物科技有限公司

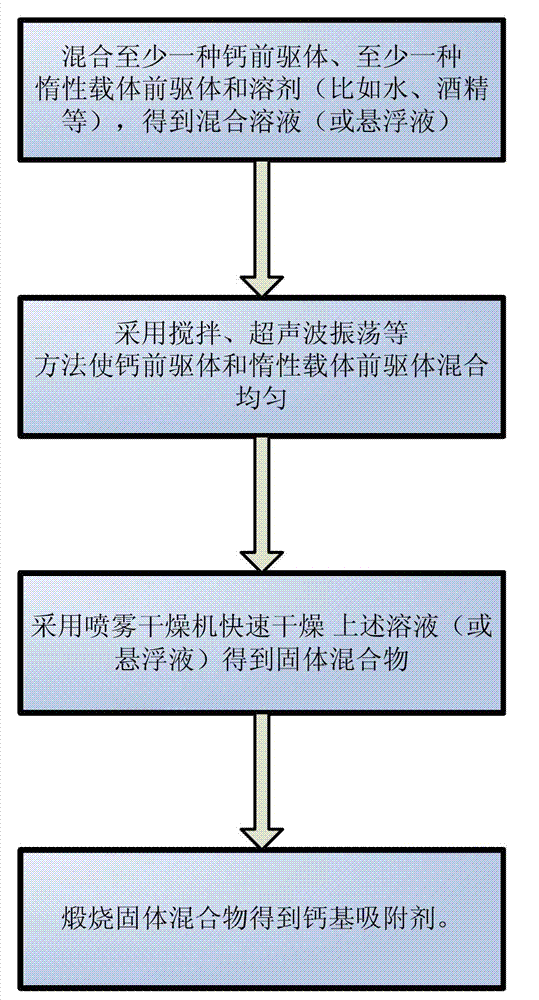

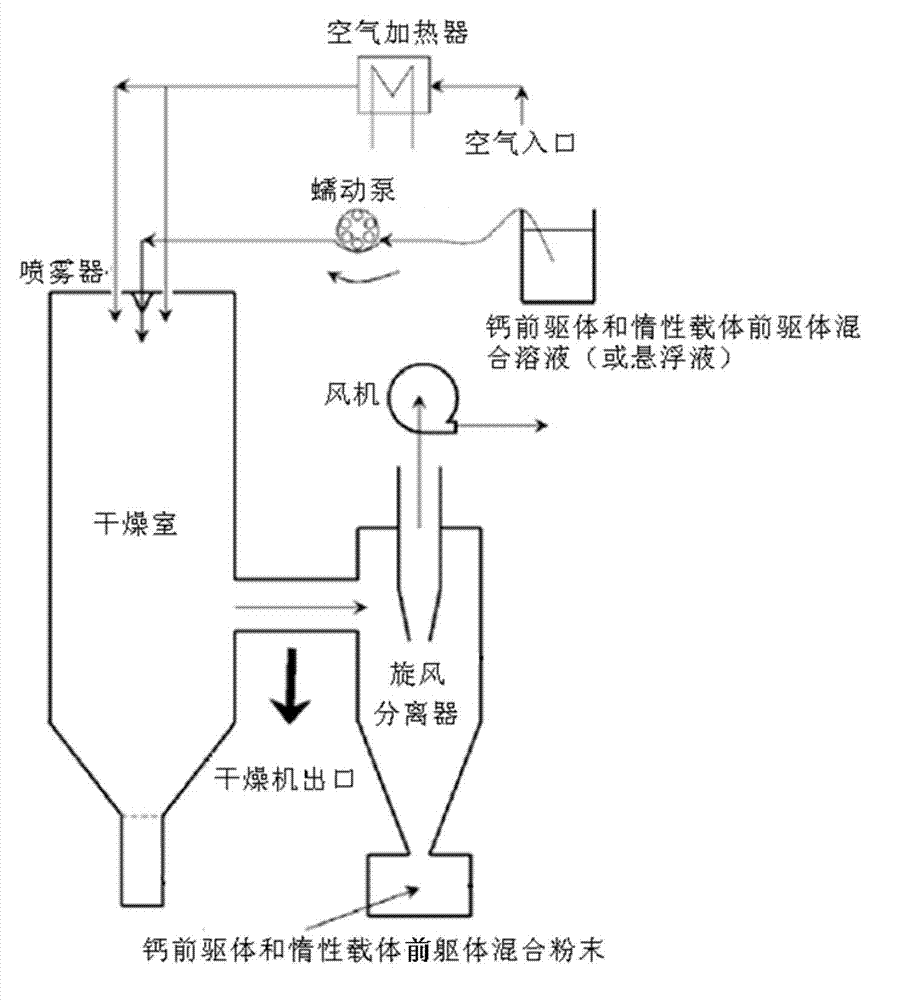

Preparation method for calcium-based CO2 sorbent

InactiveCN102784630AGood cycle adsorption/desorption of CO

<sub>2</sub>

AbilityWell mixedOther chemical processesBy adsorptionSorbentDesorption

The invention provides a preparation method for a calcium-based CO2 sorbent. The preparation method comprises the following steps: mixing calcium precursor and an inert carrier precursor with a solvent so as to obtain a mixed solution containing the calcium precursor and the inert carrier precursor; stirring the mixed solution so as to allow the calcium precursor and the inert carrier precursor to be evenly mixed; then drying the mixed solution with a spray dryer so as to obtain a solid; and finally calcining the solid to obtain the calcium-based sorbent used for capturing CO2. The calcium-based CO2 sorbent prepared by using the method has good cyclic CO2 adsorption / desorption capacity and stability in cyclic adsorption / desorption of CO2 at a high temperature, is suitable for cyclic capture of CO2 at a high temperature, and has the characteristics of low energy consumption and small consumption of time.

Owner:HUAZHONG UNIV OF SCI & TECH

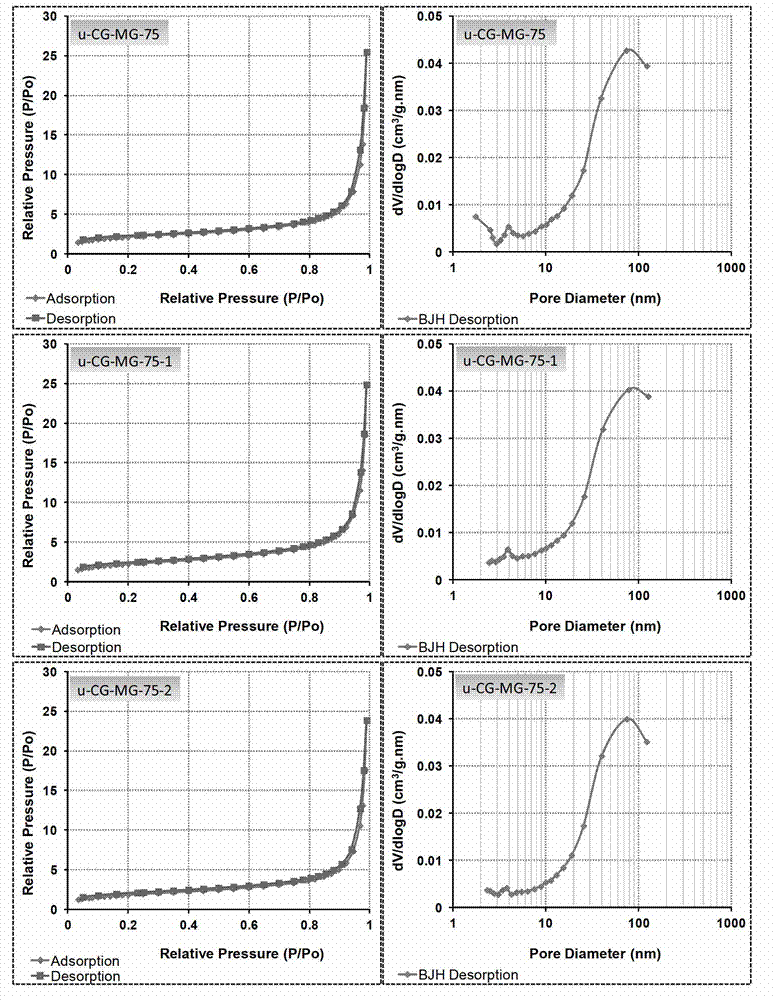

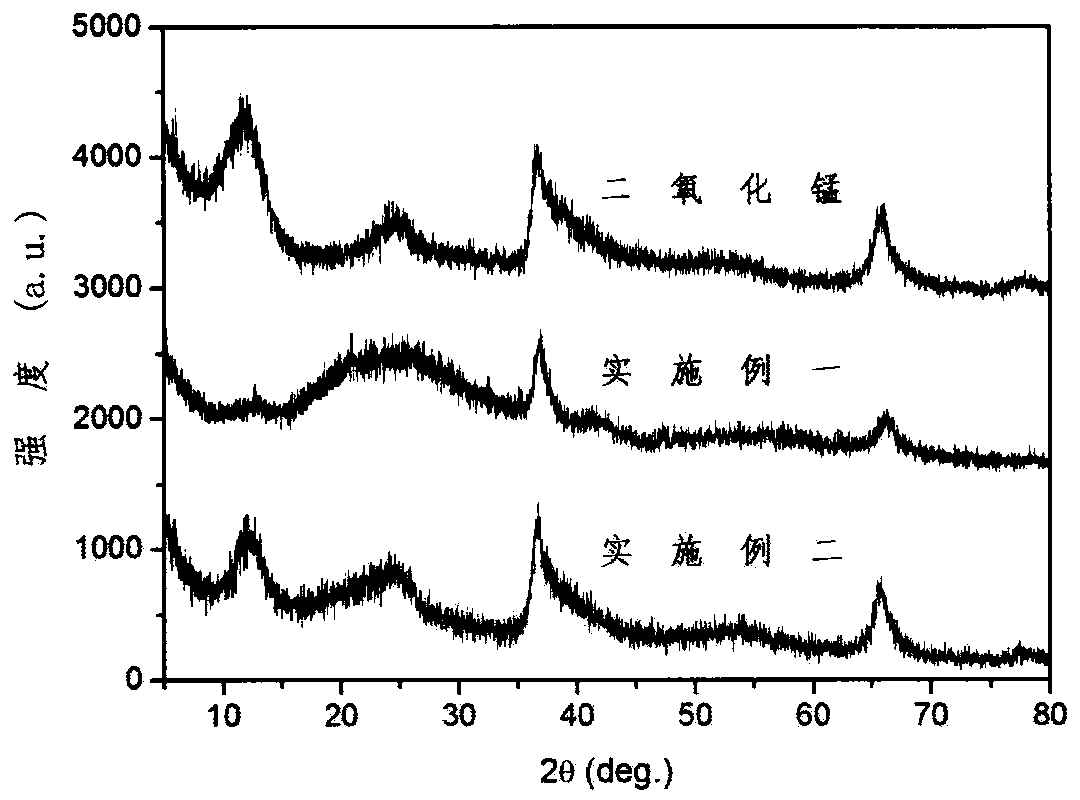

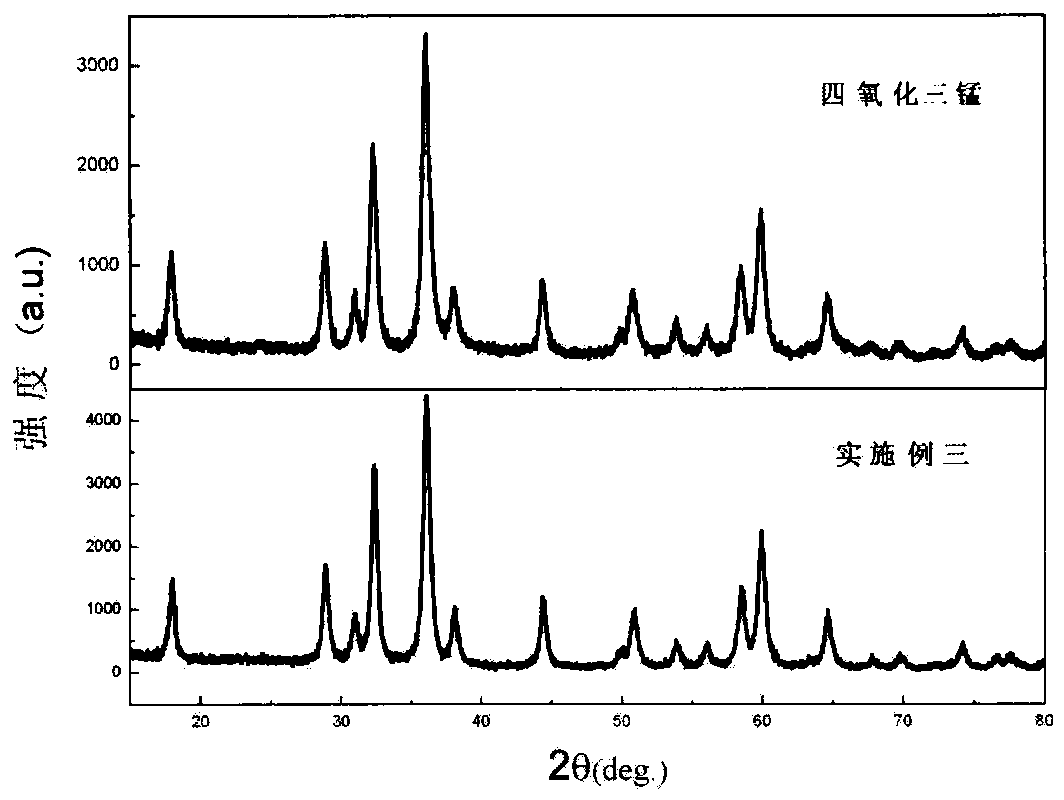

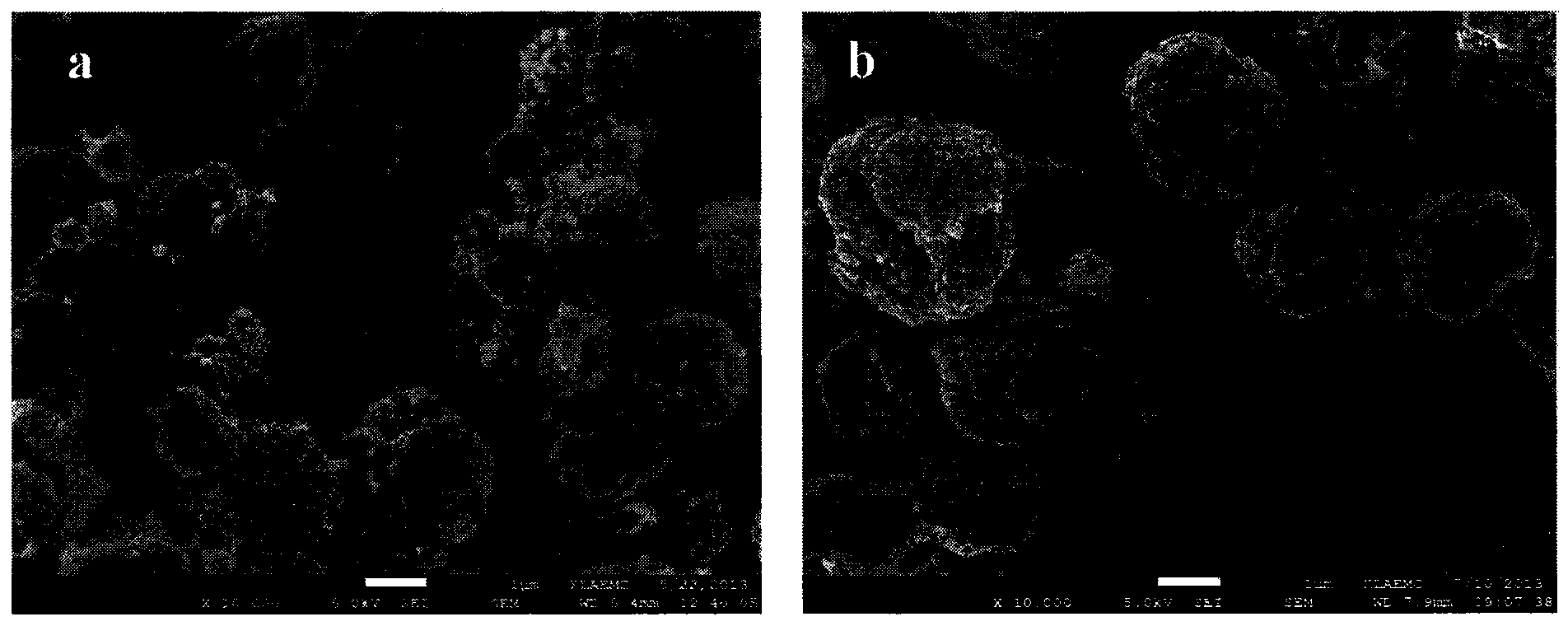

Manganese oxide/graphene porous microspheres, preparation method and energy storage application thereof

The invention discloses a manganese oxide / graphene porous microspheres, a preparation method and energy storage application of the manganese oxide / graphene porous microspheres. The preparation method includes the concrete steps that nano manganese oxide particles or precursor is mixed with aqueous suspension of graphene according to the mass ratio of manganese oxide / graphene 1:10-20:1; after the mixed solution is dispersed evenly through ultrasound or stirring, spray drying is conducted on the mixed solution through a spray drier, temperature at an inlet ranges from 100 DEG C to 280 DEG C, and temperature at an outlet is controlled between 30 DEG C 120 DEG C; after the collected solid powder is heated under 80 DEG C to 350 DEG C, manganese oxide / graphene secondary microsphere structure composite material is obtained. The manganese oxide / graphene composite material prepared through the method has excellent energy storage performance.

Owner:TIANJIN POLYTECHNIC UNIV

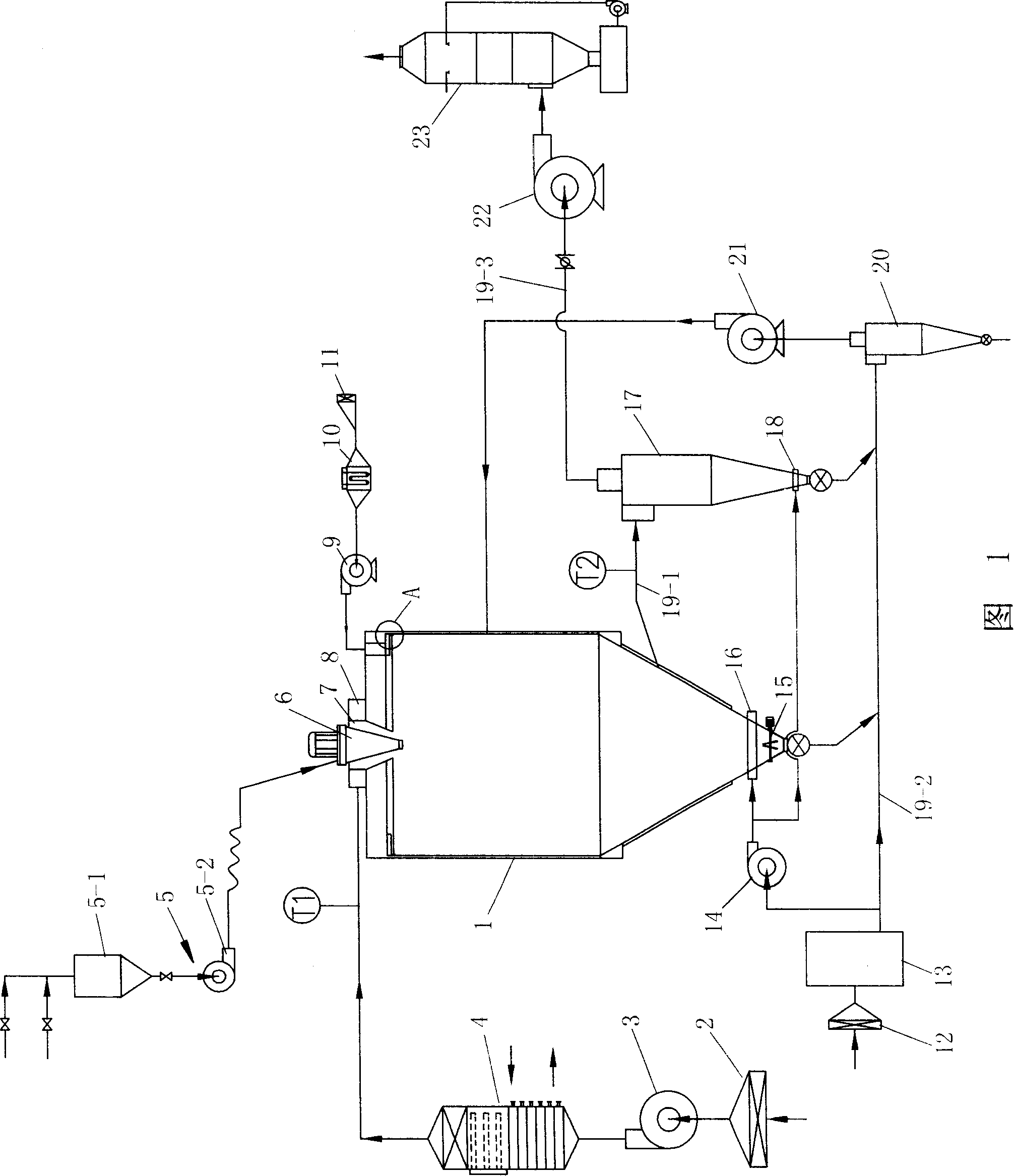

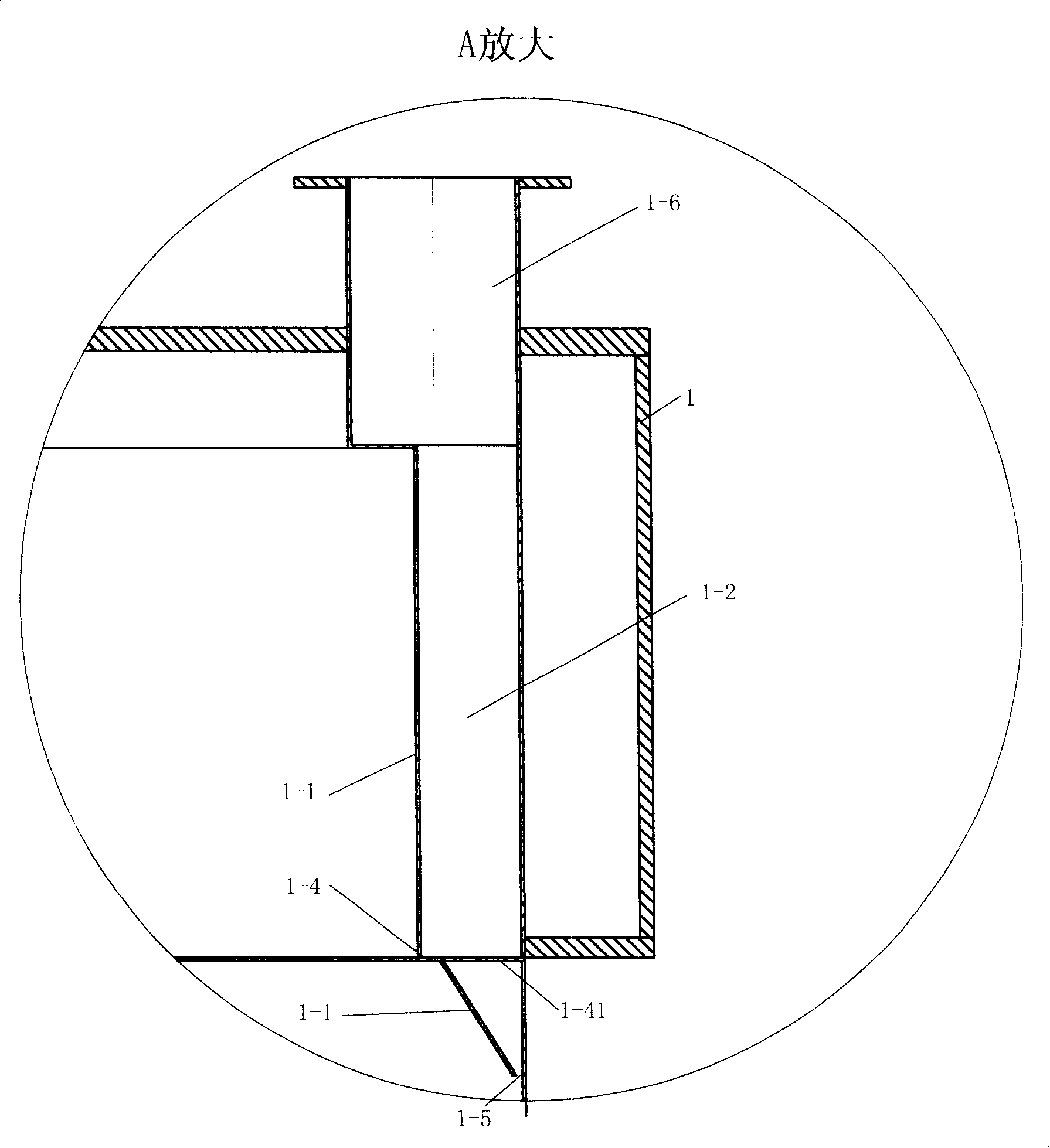

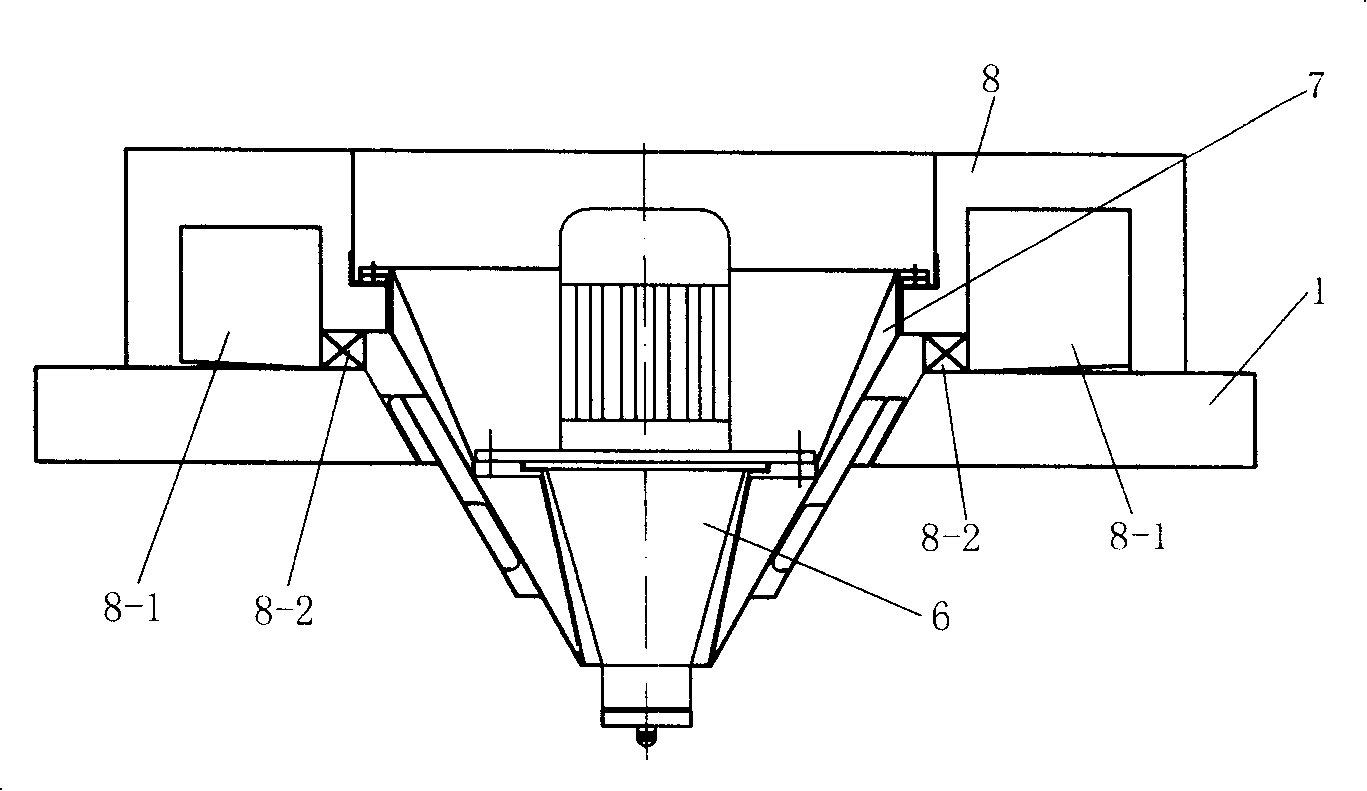

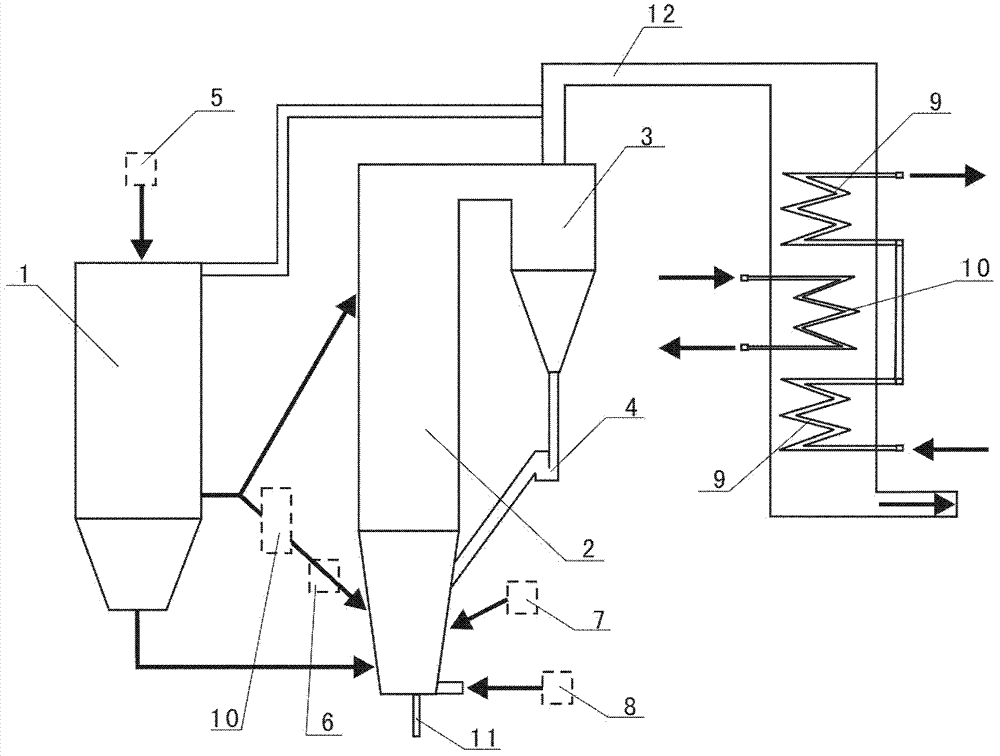

Seasoner sponging drying machine group

InactiveCN101178283AReduce stuck problemsReduce sticky topDrying solid materials with heatHearth type furnacesCycloneFeed technique

The invention comprises a material feeding device, a drying tower, a No 1 fan, a No 1 heater, a first-level cyclone separator and water-membrane dust remover. A hot air distributor and an atomizer which is arranged at the center of the hot air distributor and is connected with the material feeding device are arranged on the top of the drying tower. An air channel disk with a spiral-case shaped air channel is arranged on the top of the drying tower. The inlet of the air channel disk is connected with the output pipeline of the No1 heater, and the outlet of the spiral-case shaped air channel is connected with the inlet of the hot air distributor. A clamp sleeve is arranged in the internal tower body and near the top of the drying tower. A wall-blowing air channel is a space between the clamp sleeve and the inner side wall of the tower body. An annular clearance between the clamp bottom and the inner wall of the tower body is an air vent, and the air forms the wall-blowing air through the annular clearance. The invention adopts the air channel disk spiral air-feeding and wall-blowing feeding technique of the spiral-case shaped air channel, which not only can enhance drying efficiency but also can provide the wall-blowing air to form an air membrane in the drying tower. The air membrane can isolate powder materials from the tower wall so as to avoid a wall-sticking phenomenon.

Owner:JIANGSU XIANFENG DRYING ENG

Method for preparing heat-sensitive moisture-retaining central line filter stick of cigarette

InactiveCN102068038ARelease stabilityReduce sensory stimulationTobacco smoke filtersMolding machineDiluent

Owner:CHINA TOBACCO GUIZHOU IND

Preparation method of soluble easily-digested feed for young livestock and poultry

ActiveCN102845645ALow in Anti-Nutritional FactorsAmino acid balanceAnimal feeding stuffAmylaseHydrolysate

The invention belongs to the technical field of fermentation of feeds, enzymic preparations and microorganism, in particular to a preparation method of a soluble easily-digested feed for young livestock and poultry. Impurity removal and smashing of corn, wheat and broken rice are performed, water is added into cereals to manufacture pulp, and a-amylase and glucoamylase are added to prepare enzymatic hydrolysate. Filtrate, plasma protein, lactose and the like are mixed to prepare dextrin priming. Filter residues, soya bean meal and the water are evenly mixed, then fungi are inoculated to perform anaerobic fermentation and enzymolysis, and small-peptide protein slurry is prepared through superfine grinding and defibrination. A total-nutrition solution is prepared through mixing, and emulsified liquid is prepared through filter pressing and homogeneity of a high-pressure homogenizer. The emulsified liquid is directly packed into a paste or liquid feed, or is manufactured into a powder feed through absorption of extruded corns and drying of a tube bundle dryer, or is manufactured into a small-pellet feed through the drying of a spray dryer after tempering is performed by adding the water. The feed is rich in short-chain dextrin, glucose, oligosaccharide, small peptide, lactic acid and probiotics and has the advantages of being balanced in amino acid, high in nutrition, easy to digest, good in palatability, low in antinutritional factor content and the like.

Owner:合肥五粮泰生物科技有限公司

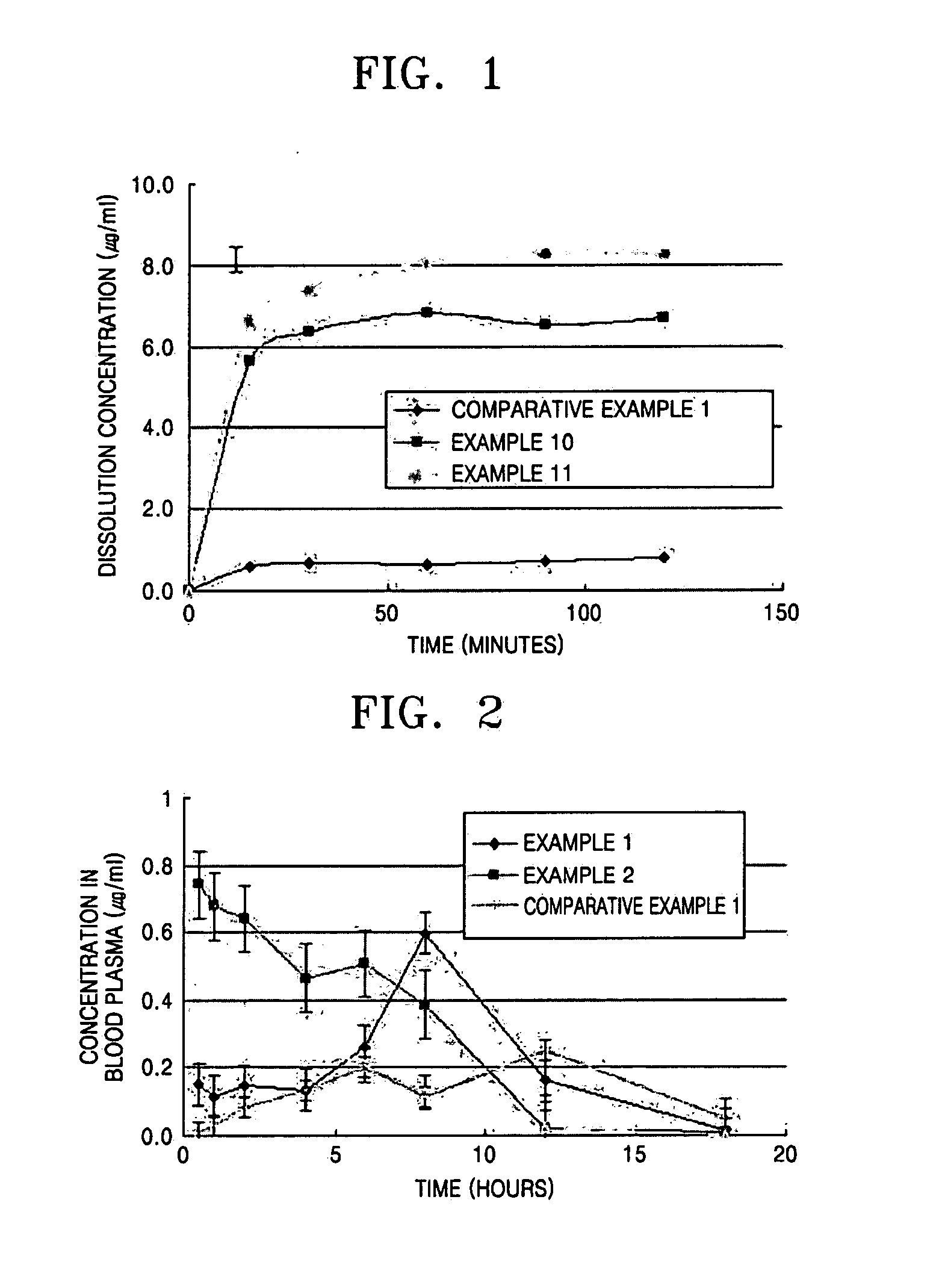

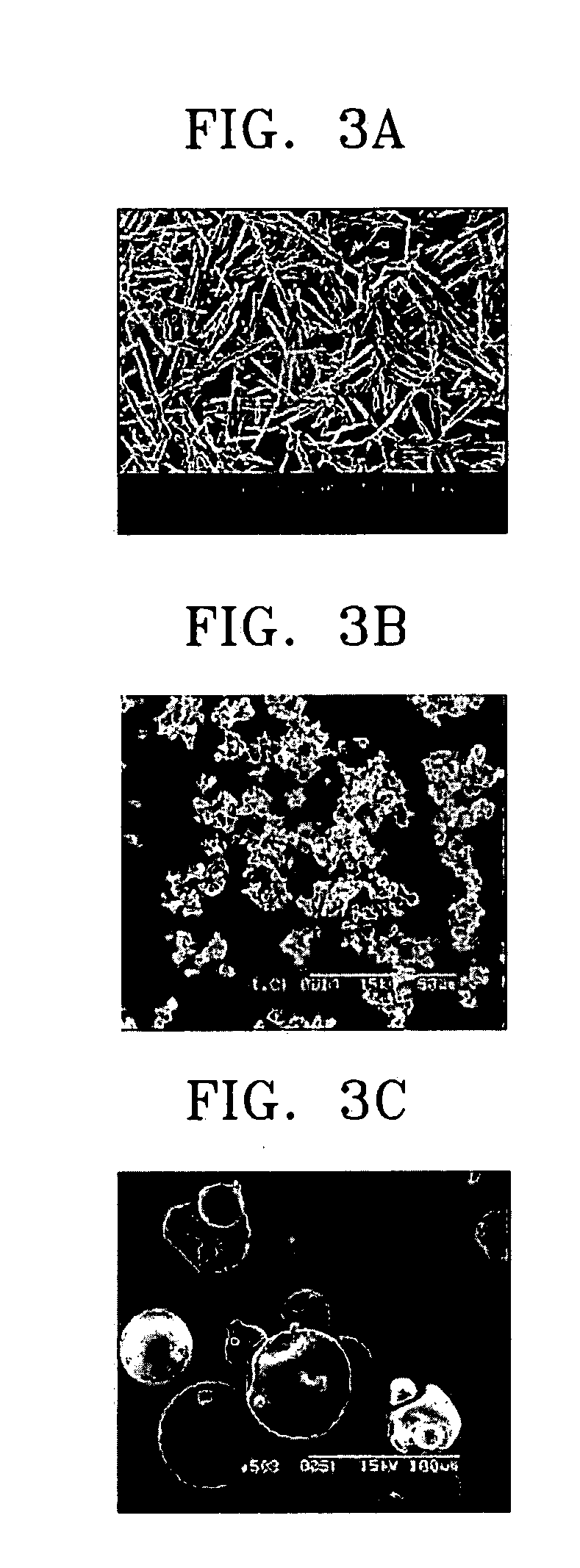

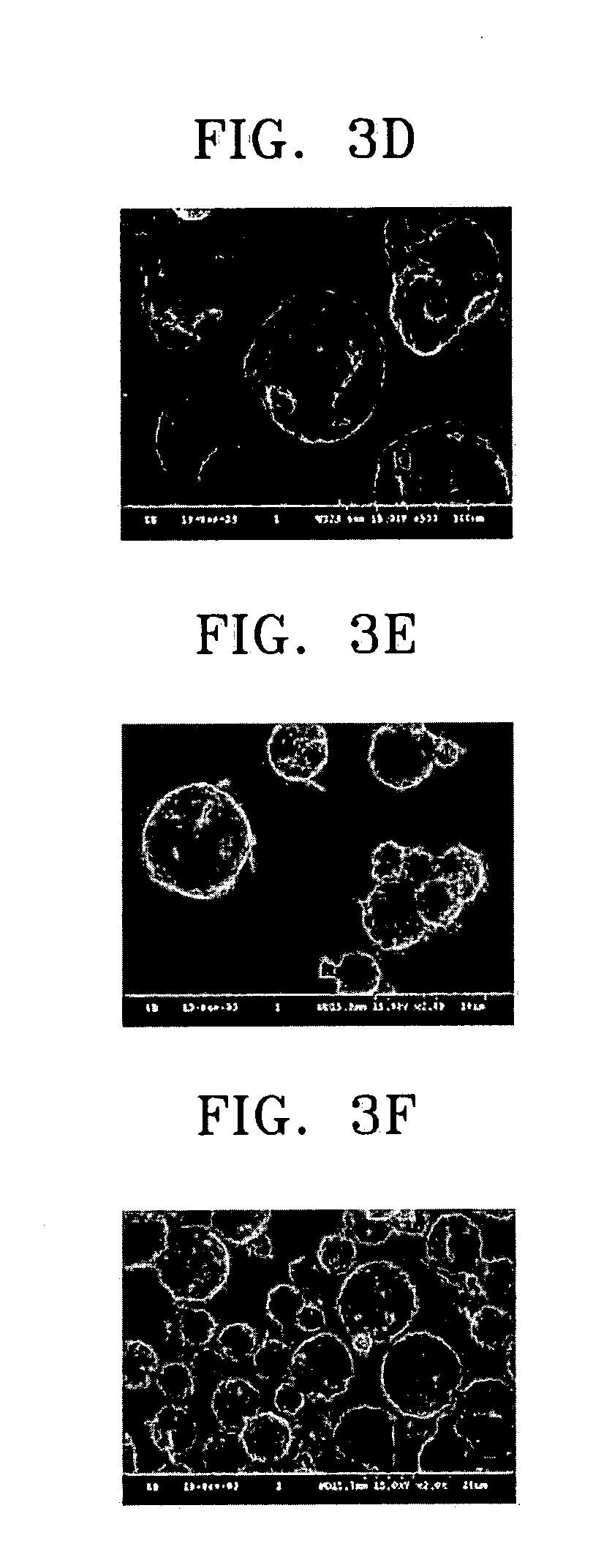

Method of preparing low-crystallinity oltipraz or amorphous oltipraz

InactiveUS20050163855A1Improve solubilityImprove bioavailabilityPowder deliveryOrganic active ingredientsOrganic solventWater insoluble

Provided is a method of preparing low-crystallinity oltipraz or amorphous oltipraz. The method includes: obtaining a mixed solution containing oltipraz and a water-soluble polymer or a water-insoluble polymer in a solvent, the solvent being an organic solvent or purified water; and solid-dispersing the oltipraz in the polymer. In the solid-dispersing, the mixed solution may be spray dried using a spray dryer or granulated using a fluid bed granulator.

Owner:CJ CHEILJEDANG CORP

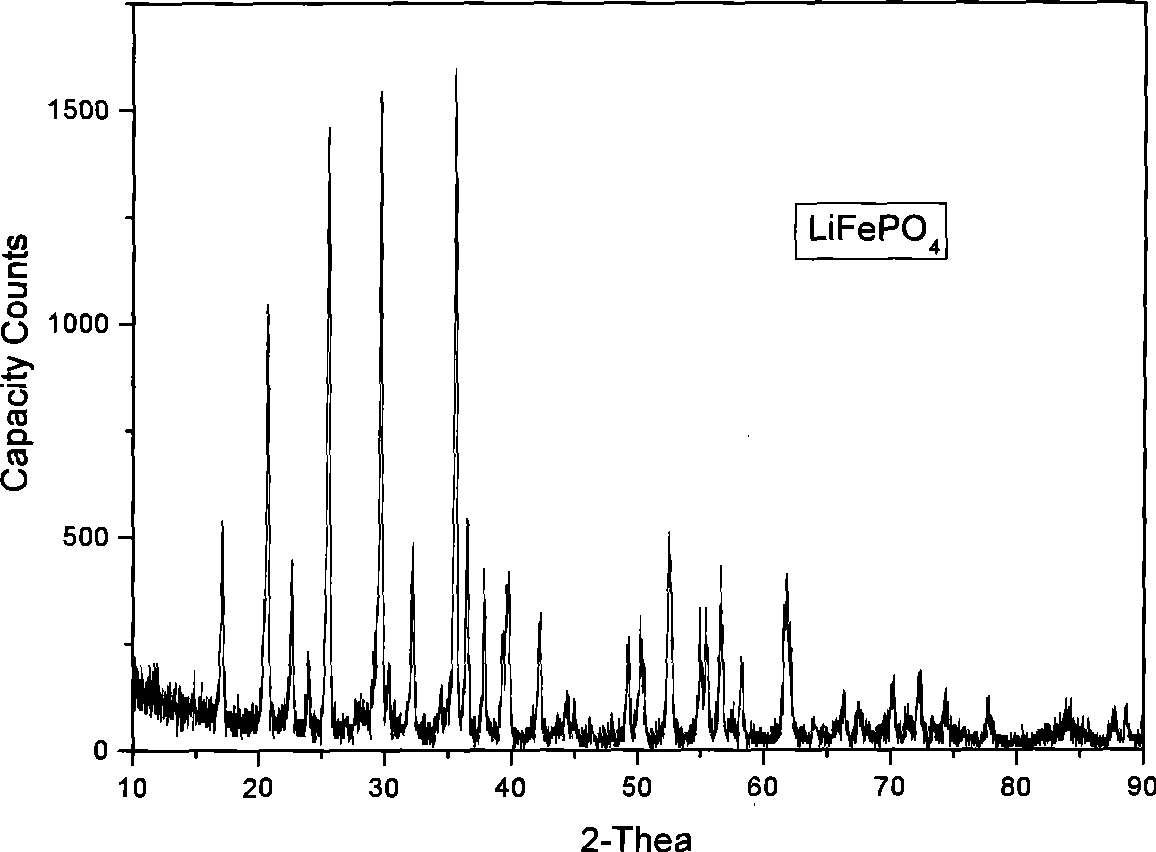

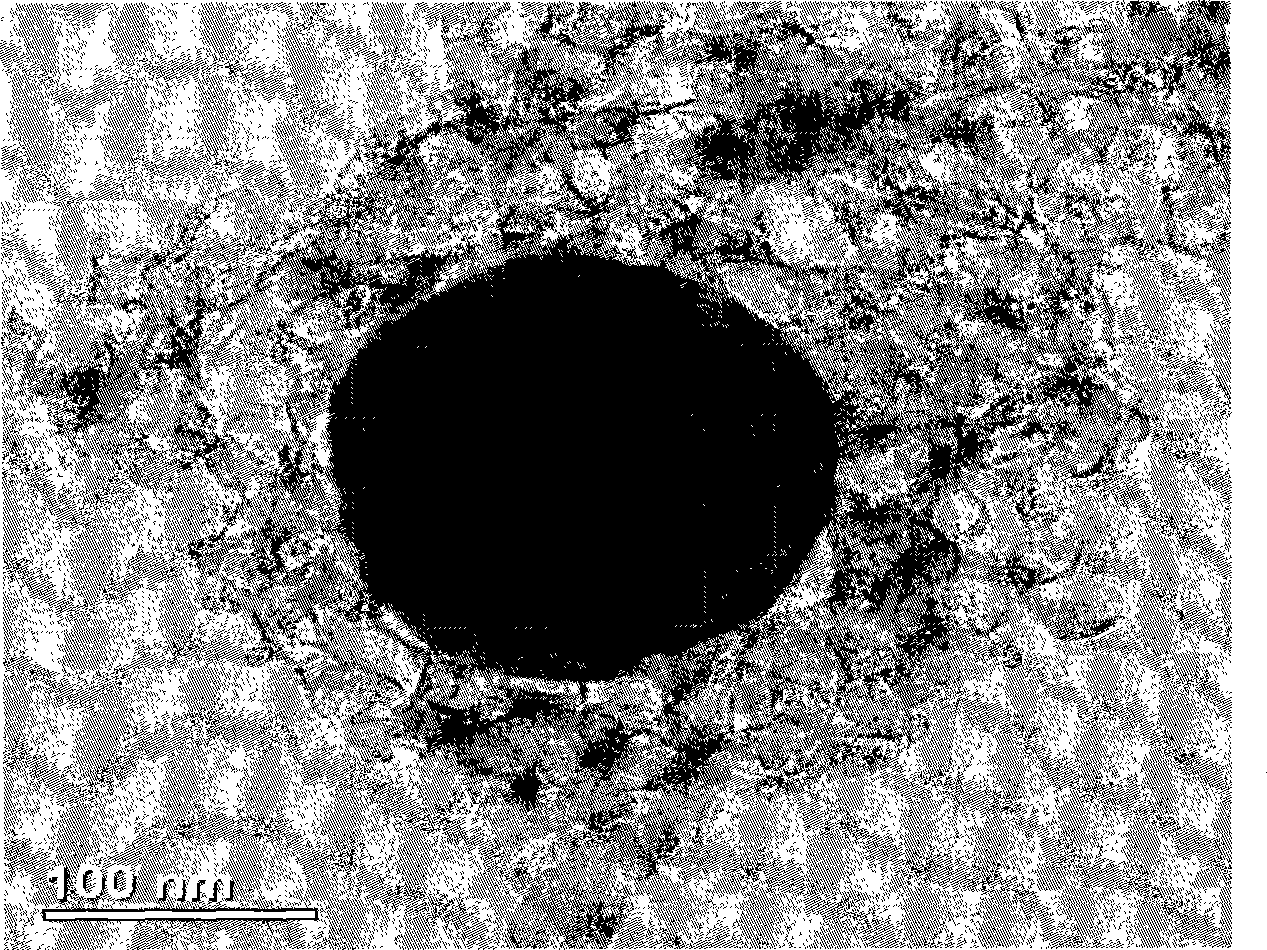

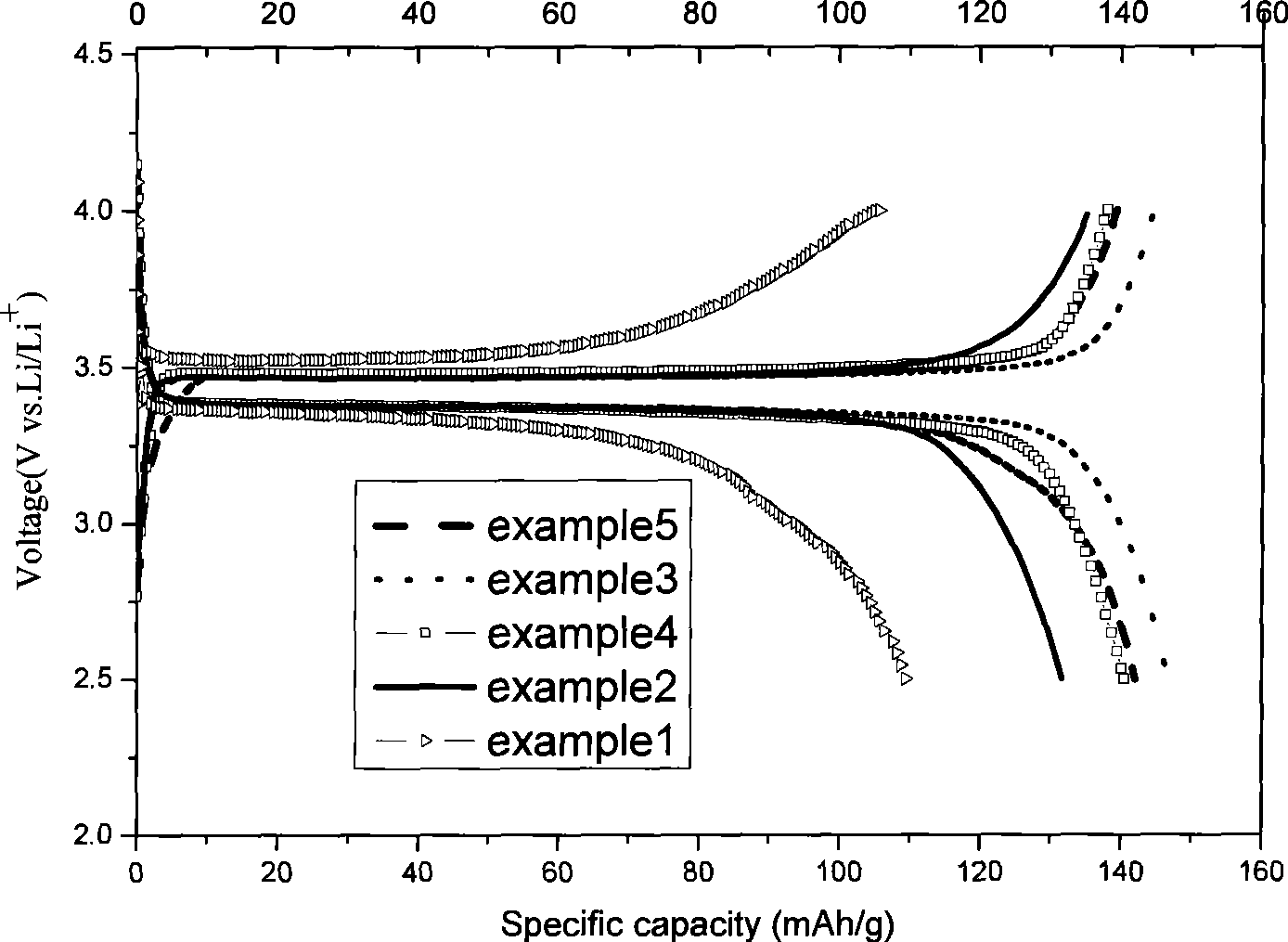

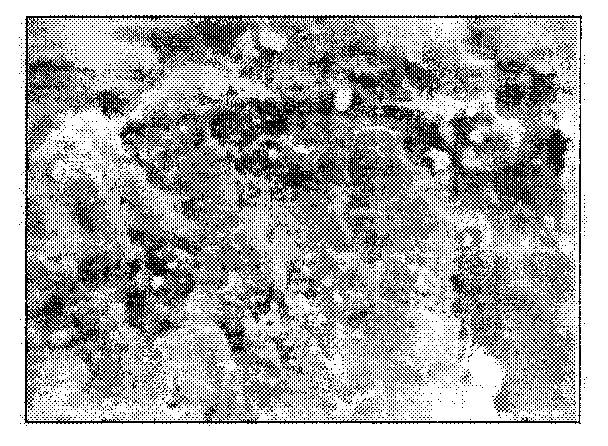

Method for preparing carbon-coating ferric phosphate lithium

ActiveCN101442117AImprove surface structureImprove electrochemical performanceElectrode manufacturing processesPhosphateNon oxidative

The invention discloses a method for preparing carbon-coated lithium iron phosphate (LiFePO4 / C). The method comprises the following steps: a, LiOH.H2O, reduced Fe powder and H3PO4 are weighed according to the molar ratio of 1:1:1 and are stirred in an aqueous solution so as to react for 2 to 10 hours under nitrogen protection; a carbon source is added to a reaction system, and an obtained suspension as a reaction product is subjected to spray drying through a high-speed centrifugal spray drying machine, so as to obtain a LiFePO4 / C precursor; and b, the LiFePO4 / C precursor is transferred to a tubular furnace in inert or non-oxidative atmosphere and treated for 6 to 24 hours at a temperature of between 200 and 750 DEG C, so as to obtain the LiFePO4 / C. As the method adopts the Fe powder as a raw material, the specific discharge capacity of a LiFePO4 / C anode material prepared by a coprecipitation method under the multiplying power between 0.1 and 2C is obviously improved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

Method for preparing polyurethane-polyurea coated fertilizer

InactiveCN101747123ARegular structureHigh strengthFertiliser formsFertilizer mixturesPolyolAtmospheric pressure

The invention relates to a method for preparing polyurethane-polyurea coated fertilizer, comprising the following steps: dehydrating polyether polyol to obtain dehydrated polyether polyol, adding polyisocyanate to the dehydrated polyether according to the molar ratio of NCO to OH of 2-5, heating the temperature of the mixture of the dehydrated polyether and the polyisocyanate to 70-90 DEG C, making the mixture of the dehydrated polyether and the polyisocyanate react until the mass of NCO being 5-9 percent of the mass of the product of reaction, defoaming the product of reaction in vacuum to obtain -NCO-ended polyurethane prepolymer, filling fertilizer in a spray dryer, heating the fertilizer to 60 DEG C, mixing the polyurethane prepolymer with amine chain extender according to the mass ratio of 7-8:1 to obtain spraying liquid by controlling the fan frequency at 45 Hz, the nozzle atomization air pressure at 0.7-1.2 MPa, the inlet air temperature at 20-80 DEG C and the spray rate at 0.4-0.6 Kg / h, spraying the spraying liquid whose mass is 7-10 percent of the mass of the fertilizer on to the fertilizer, and curing the coating film to obtain the polyurethane-polyurea coated fertilizer.

Owner:晋盾防护(山西)科技有限公司 +1

Carbon nanotube-metal composite enhanced copper-based composite material and preparation method thereof

The invention relates to a carbon nanotube-metal composite enhanced copper-based composite material and a preparation method thereof, and belongs to the field of preparation of composite materials. The preparation method comprises the following steps: preparing colloidal sol by using soluble salts containing metallic elements and copper ions and carbon nanotube as raw materials, carrying out spray granulation by using the colloidal sol through a spray dryer so as to obtain nanoscale mixed powder, calcining the mixed powder in an oxygen-free atmosphere so as to obtain black powder, reducing the black powder in a hydrogen atmosphere so as to obtain carbon nanotube-metallic element composite enhanced copper-based powder, carrying out isostatic press moulding on the mixed powder, and then sintering in the hydrogen atmosphere so as to obtain the carbon nanotube-metallic element composite enhanced copper-based composite material, wherein the content of a metallic element X in the composite material is 0.1-2wt%, and the content of the carbon nanotube in the composite material is 0.1-2wt%. The preparation method has the advantages that corresponding carbides can be formed, the problem of reinforcement agglomeration caused by poor interface bonding between reinforcement and a copper matrix is solved, and the copper-based composite material with excellent combination properties can be obtained.

Owner:NINGBO CPX ELECTRONICS TECH

Method for preparing precipitated white carbon black with controllable specific surface area

The invention relates to a preparation method of a chemical raw material, namely a method for preparing precipitated white carbon black with controllable specific surface area. The raw materials comprise water glass with modulus of 3.3-3.5 and water solution proportion of 1.085+ / -0.001 and 15 percent of sulphuric acid. The method comprises the following steps: reaction: when the quantity of bottom material and the water glass is 30-80 percent of the total inventory rating, stirring, and rising the temperature to 84+ / -1 DEG C, beginning to add the 15 percent of sulphuric acid for reaction, then adding the water glass and the sulphuric acid and keeping the pH value constant when the pH value of a suspending liquid reaches 9-10, finishing the addition of the left 70-20 percent of water glass within 55min, continuously adding the sulphuric acid to enable the water glass to completely react and adjusting the pH value to be 2-3; washing with water and drying: filtering the suspending liquid by a filter and drying by a spray dryer. The preparation method can be used for preparing the white carbon black with the specific surface area of 50-250 m<2> / g, which is particularly suitable for being used as rubber reinforcing filler.

Owner:通化双龙化工股份有限公司

Method and apparatus for desolvating flowing liquid

ActiveUS20100000943A1Quick releaseAvoid contactLiquid degasificationComponent separationTemporal resolutionSolvent vapor

Methods and apparatus for desolvating flowing liquid streams while retaining temporal resolution of dissolved substrates are disclosed. A novel small-scale self-regulating spray dryer preserves temporal resolution while desolvating a liquid chromatography eluent stream and depositing the solute onto an optical surface for infrared spectrographic analysis. The liquid eluent is pumped through a heated nebulizer to create a high-speed jet of solute containing liquid and solvent vapor. This jet is directed circumferentially inside a hot cylindrical cavity. Centrifugal force causes the larger liquid droplets to travel along the outer diameter of the cavity. The cavity surface is heated to cause the droplets to film boil. Film boiling reduces droplet contact with the cavity surface thereby retaining the solute in the droplets. The solute temperature is limited by controlling the pressure into which the solvent evaporates from the droplets. When the droplets are sufficiently small, Stokes drag from the exiting solvent vapor carries the droplets out through the center of the cylindrical cavity. After exiting, the superheated solvent vapor further dries the droplets. Solvent vapor is removed by condensation onto a cooled surface. A freezing point reducing agent may be added to improve removal of solvent condensate. Stokes drag from a non-condensable gas maintains the dried droplets in suspension. This suspension travels through an orifice that focuses the impaction of the dried droplets onto the optical surface for infrared analysis. The deposition surface is in an evacuated chamber and is temperature controlled to freeze liquid solutes yet allowing sublimation of residual solvent.

Owner:SPECTRA ANALYSIS INSTR

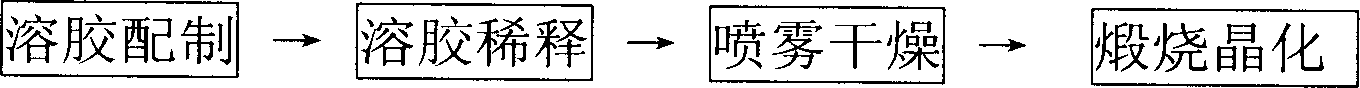

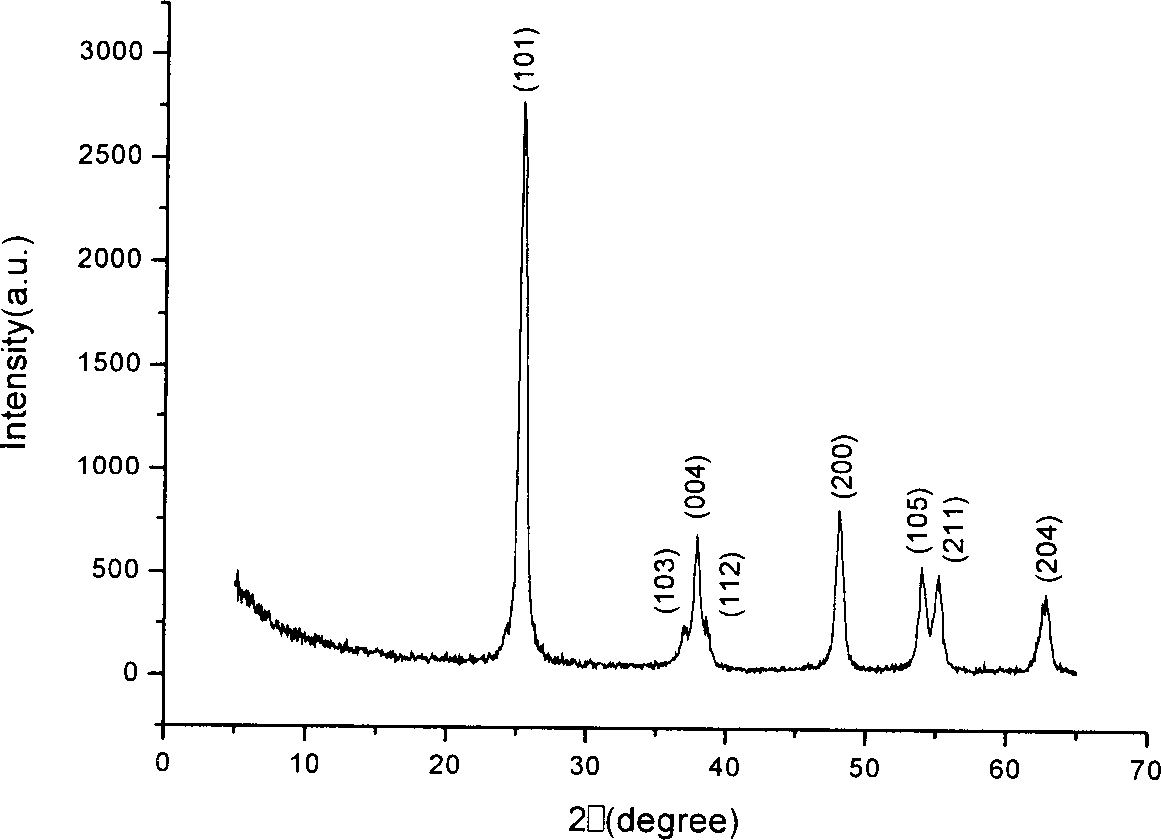

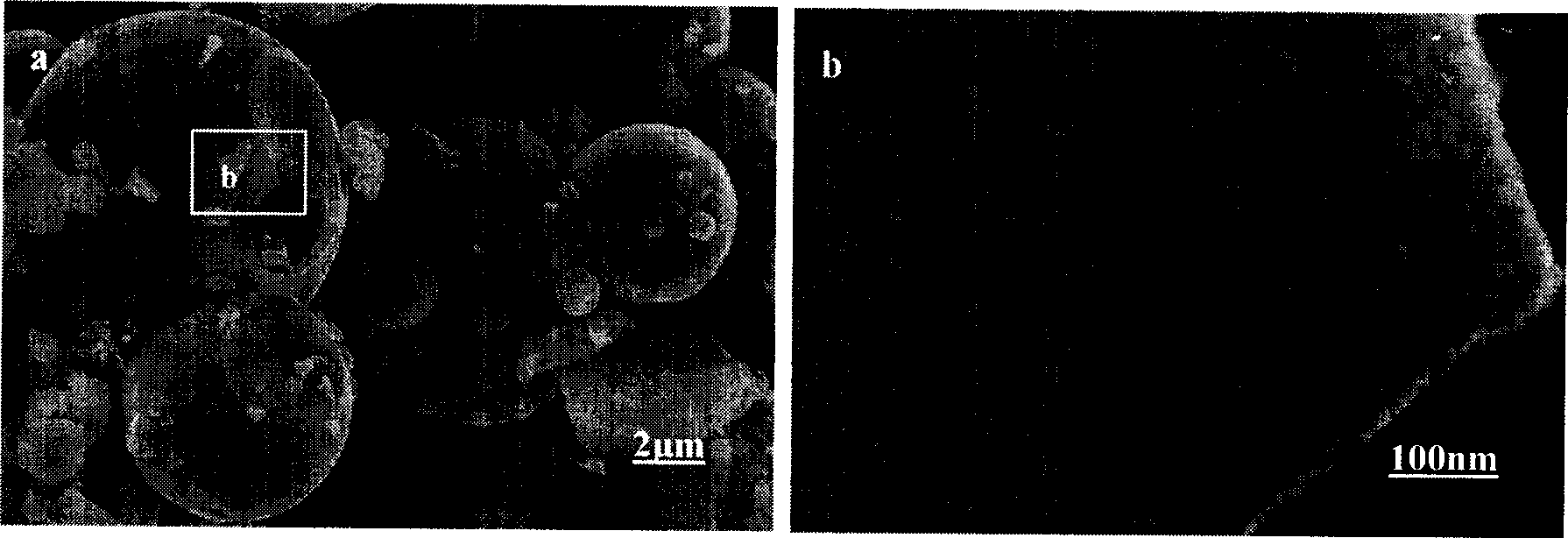

Prepn. process of mesic hole hollow ball-shape titania powder

This invention relates to a method to prepare mezoporous empty-centered titanium dioxide powders, which comprises following steps: titanium chloride is made into hydrosol with pure water, diluted and introduced into a spray dryer for spray drying. The subsequent product is empty-centered ball-shaped powder made up of nanosized titanium dioxide particles and the preceding titanium chloride is titanium tetrachloride or titanium trichloride. The titanium dioxide particles prepared in this invention all have mezoporous empty-centered ball-shaped structure and the empty-centered wall is made up of nanosized titanium dioxide particles and mezopores, on the surface of which titanium atoms possess a fraction of as high as 70%. As only titanium tetrachloride is adopted as precursor and no other reagent is necessary, the product is highly pure and has excellent photocatalytic properties. This method has the advantages of high yield, low cost, easily controlled technique and convenience for magnification experiment. Besides, there are not severe requirements for facilities and this method is suitable for industrial production.

Owner:ZHEJIANG UNIV OF TECH

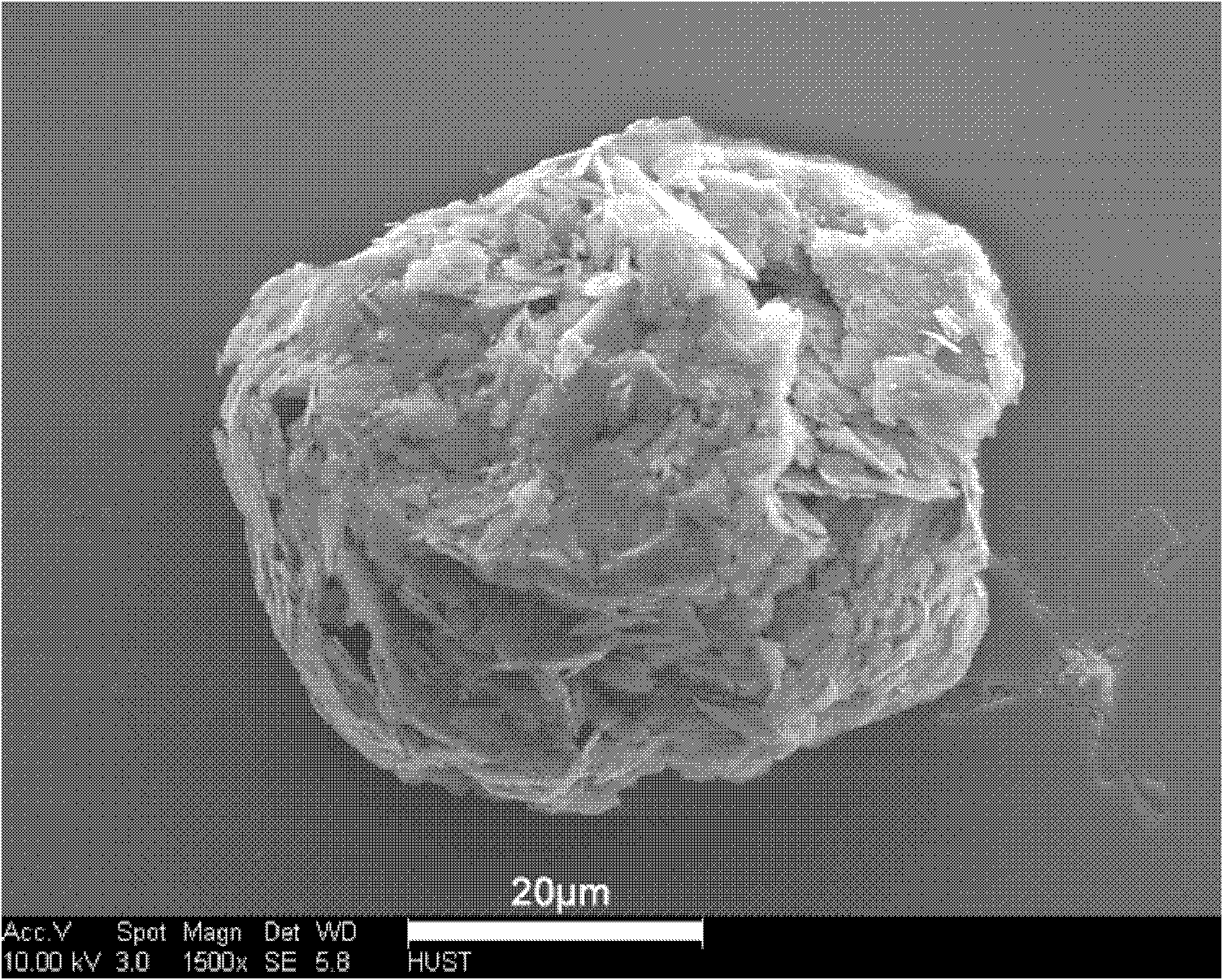

Different-orientation spherical natural graphite negative electrode material and preparation method thereof

ActiveCN101800304AHigh specific capacityImprove cycle stabilityCell electrodesNitrogen gasFlake graphite

The invention relates to a different-orientation spherical natural graphite negative electrode material and a preparation method thereof. The method comprises the following steps: mixing natural crystalline flake graphite micro powder and dispersion medium; adding deflocculants for regulating the solid content; then, placing materials and bonding agents into a pulp mixing machine to be stirred; carrying out atomization, drying and granulation on the pulp on a spraying drying machine to obtain powdery materials; carrying out heat treatment on the powdery materials in nitrogen gas atmosphere through a revolving furnace; and cooling the obtained powder to obtain the different orientation spherical natural graphite negative electrode material. The graphite negative electrode material consists of a plurality of layered graphite crystalline flakes, and the layered graphite crystalline flakes are glued and have different orientations. The graphite negative electrode material prepared by the method of the invention has the obvious characteristics that the specific capacity of the material is high, the circulation stability is high, the micro spheres formed by the graphite flakes of the graphite with different orientations can effectively inhabit the layer flake peeling caused by deep lithium insertion, the graphite flake adhesion and the carbon coverage can be realized at the same time, the powder agglomeration can be avoided through dynamic sintering, and the invention is favorable for obtaining the spherical natural graphite micro powder with uniform granularity.

Owner:CHINA THREE GORGES UNIV +1

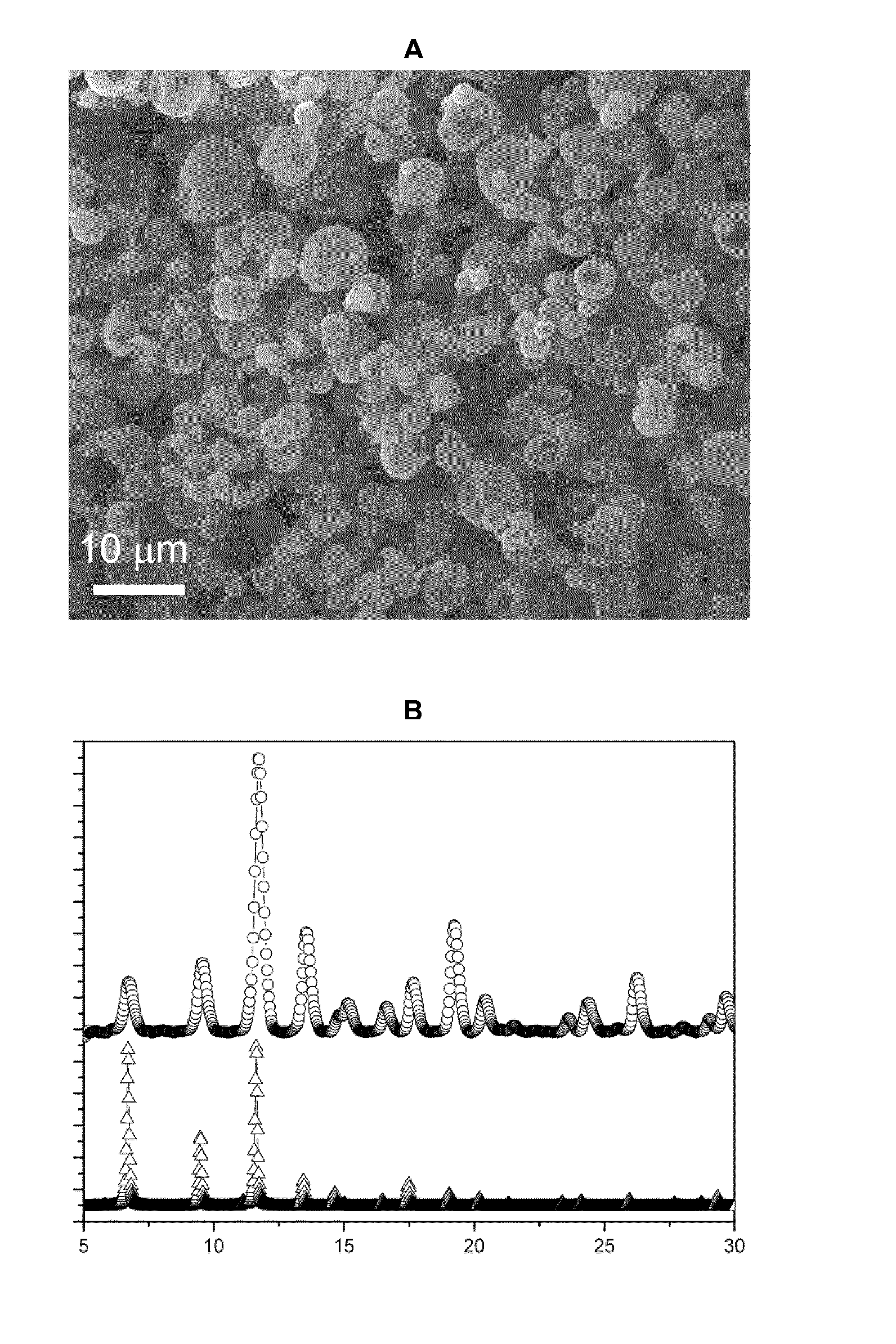

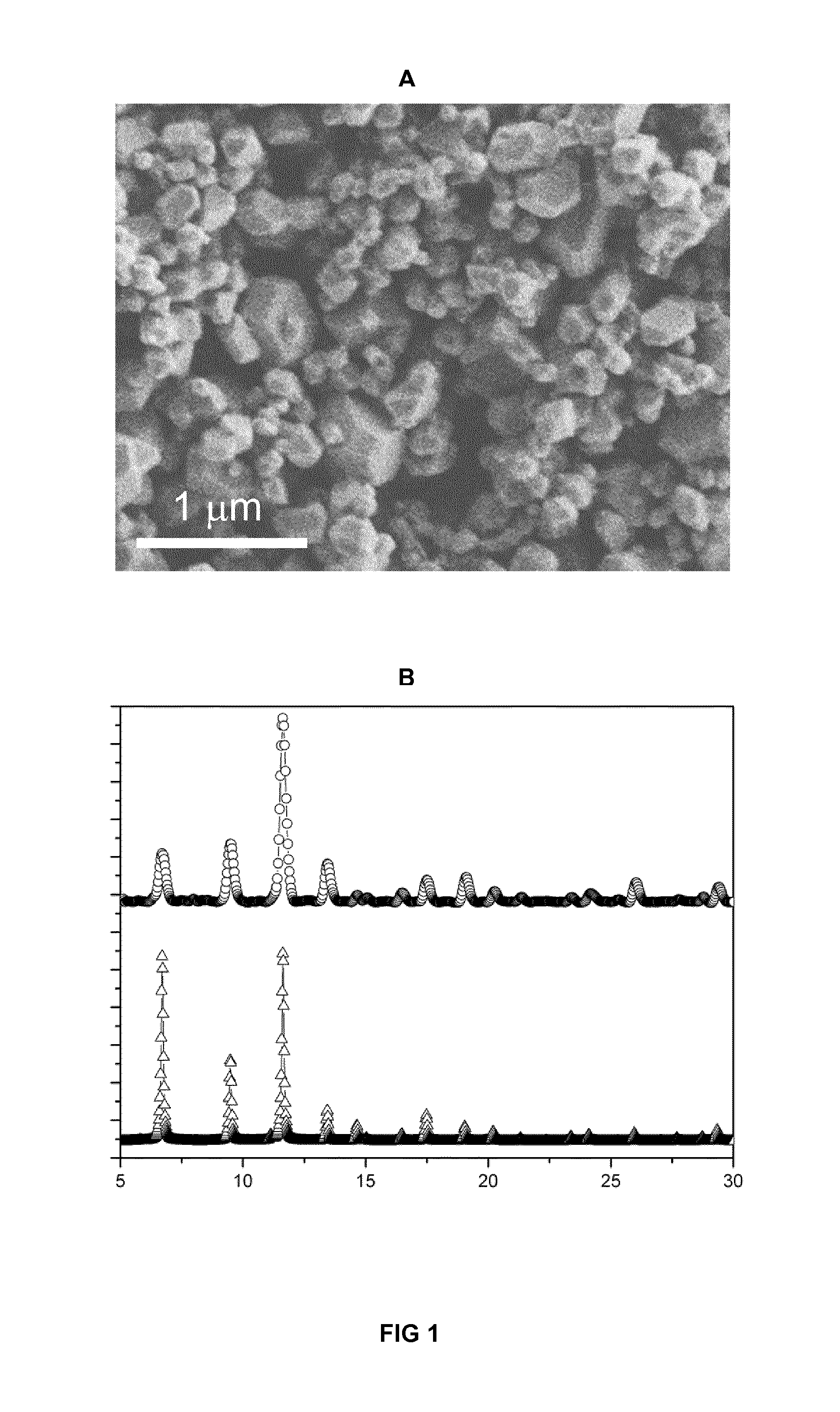

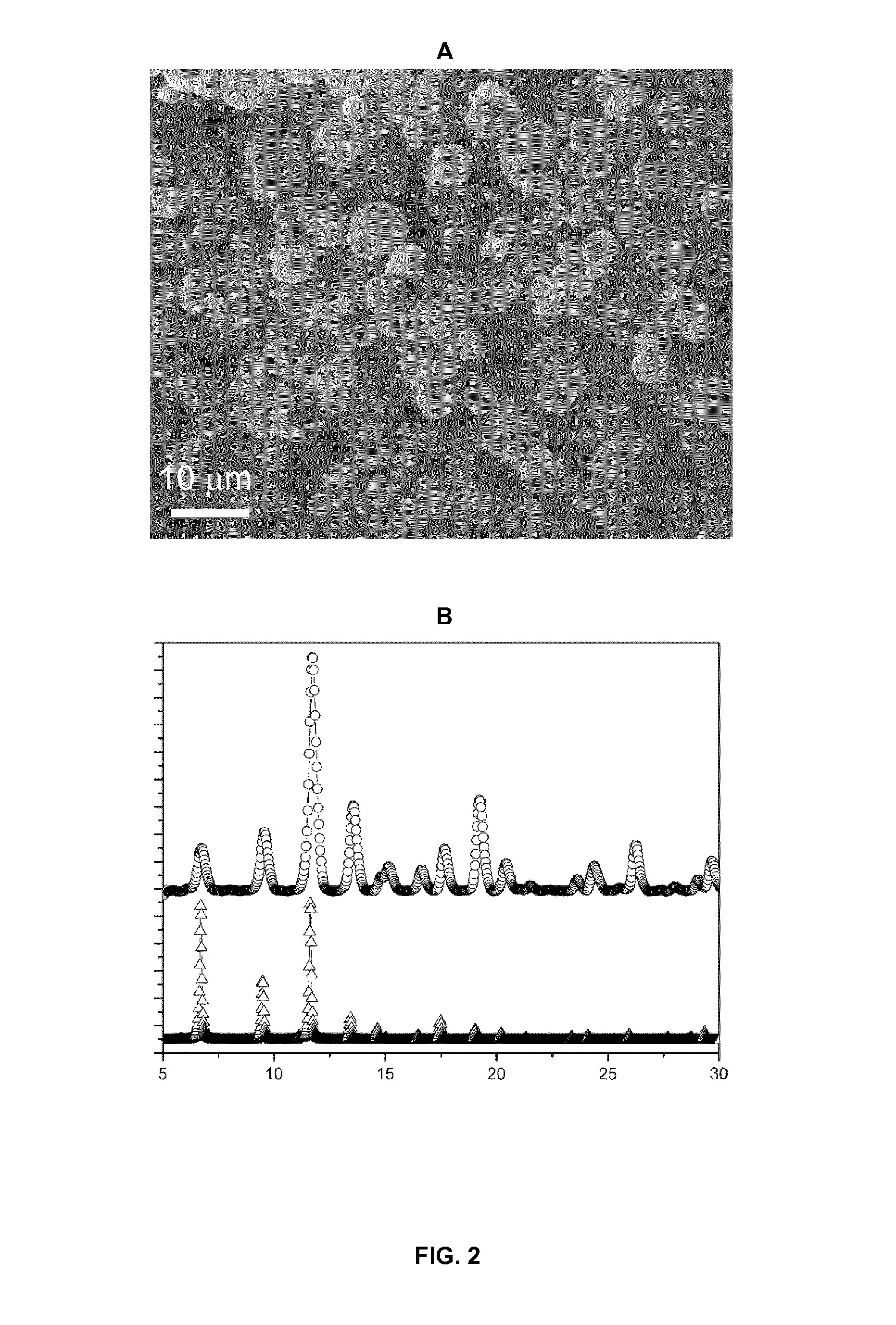

Method for the preparation of metal organic frameworks

ActiveUS20140284829A1Delayed reaction timePrevent steppingGroup 1/11 organic compounds without C-metal linkagesOrganic compound preparationMetal-organic frameworkSolvent

A process for the preparation of a dry crystalline metal organic framework which comprises: a) spray drying at least one metal ion and at least one organic ligand which is at least bidentate into a spray dryer in the presence of a solvent, wherein the reaction of the at least one metal ion with the at least one organic ligand to yield the metal organic framework and the drying of the obtained metal organic framework take place simultaneously inside the spray dryer, and b) collecting the formed dry crystalline metal organic framework.

Owner:FUNDACIO PRIVADA INST CATALA DE NANOTECNOLOGIA

Integral treatment method for drying and incinerating sludge

InactiveCN103244957ALow costReduce pollutionSludge treatment by de-watering/drying/thickeningIndirect carbon-dioxide mitigationSludgeSlag

The invention discloses an integral treatment method for drying and incinerating sludge. The integral treatment method includes steps of treating the original sludge by a dehydrator so that the moisture content of treated sludge ranges from 70% to 90%; atomizing the sludge with the moisture content ranging from 70% to 90%, treating atomized sludge by a spray dryer to obtain dry sludge and feeding tail gas generated by the spray dryer into a fluidized bed incinerator; feeding the dry sludge into fluidized bed incinerator to incinerate the dry sludge; and feeding flue gas generated in an incineration procedure of the fluidized bed incinerator into a flue after ash is separated from the flue gas by a separator, discharging a part of the flue gas in the flue, feeding another part of the flue gas into the spray dryer, enabling the ash to return the fluidized bed incinerator via a return feeder, and discharging slag generated in an incineration procedure of the fluidized bed incinerator via a slagging pipe. The integral treatment method has the advantages that a drying process and an incineration process which are independent from each other originally are organically combined with each other, waste heat generated in a drying procedure is effectively utilized, waste water and odor treatment systems are omitted, the cost is saved, pollution is obviously reduced, and the integral treatment method is favorable for environmental protection.

Owner:四川宇阳环境工程有限公司

A kind of production method of comprehensively utilizing oleaginous microalgae

InactiveCN102295983ALess investmentEasy to operateClimate change adaptationBioloigcal waste fertilisersOil phaseHigh pressure

A production method for comprehensively utilizing oil-containing microalgae, comprising: using a high-pressure homogenizer to homogenize and break the wall of the microalgae at room temperature and high pressure. Transfer to the extraction tank, extract the microalgae oil under agitation, separate the liquid phase and the solid phase after centrifugation, wash the solid phase with water three times, add it to a spray dryer for drying to obtain microalgae powder. The liquid phase and the three times of washing liquid are added to the oil-water separator to separate into an oil phase and a water phase, and the oil phase is microalgae oil. The separated water phase is separated and purified to extract bioactive substances such as microalgae protein, microalgae polysaccharide, and microalgae liquid fertilizer. The invention has the advantages of low investment, simple operation, large-scale utilization of microalgae production method, and can produce microalgae oil, EPA, DHA, microalgae powder, microalgae protein, microalgae polysaccharide, microalgae liquid fertilizer and other high added value Semi-finished products.

Owner:上海辰浩生物技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com