Preparation method for calcium-based CO2 sorbent

An adsorbent, calcium-based technology, applied in the direction of adsorption, chemical instruments and methods, other chemical processes, etc., can solve the problems of long time, high energy consumption, short time consumption, etc., to reduce energy consumption, good cycle adsorption/ The ability to desorb CO2, the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

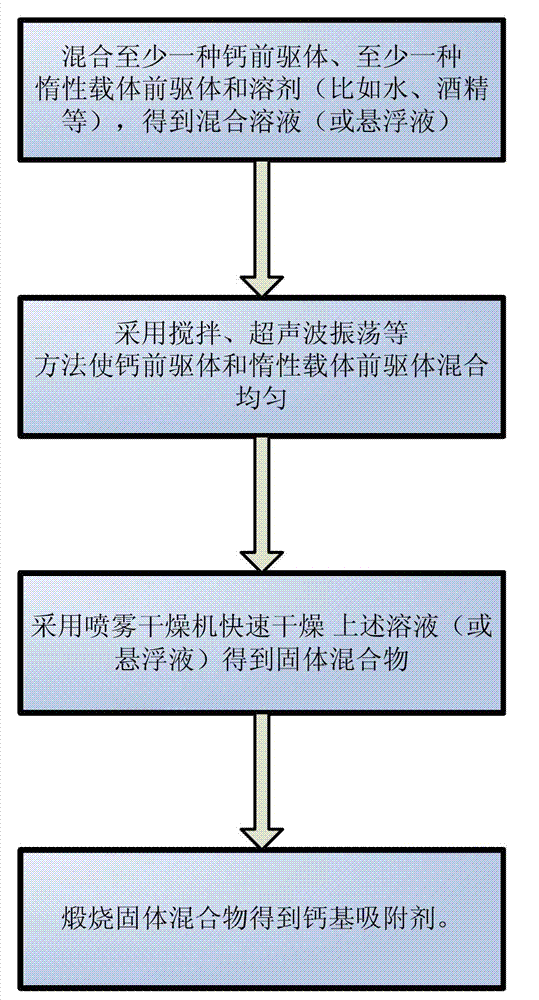

[0029] according to figure 1 As shown in the process, first select 5 kinds of calcium precursors:

[0030] Calcium hydroxide (96%, Ajax Finechem),

[0031] Calcium D-gluconate (calcium D-gluconate monohydrate, 98%, Sigma),

[0032]Calcium L-lactate (calcium L-lactate hydrate, 98%, Fluka),

[0033] Calcium acetate hydrate (99%, Sigma-Aldrich), and

[0034] Nanosized calcium oxide (<160nm, 98%, Aldrich).

[0035] Choose 3 more inert carrier precursors:

[0036] cement,

[0037] Magnesium acetate (magnesium acetate tetrahydrate, >99%, Amresco)

[0038] Magnesium D-gluconate (magnesium D-gluconate hydrate, 98%, Sigma).

[0039] As shown in Table 1, at least one calcium precursor and at least one inert carrier precursor are selected and then mixed with water.

[0040] Among them, D-calcium gluconate, L-calcium lactate, calcium acetate, magnesium acetate, and D-magnesium gluconate are all water-soluble organic acid salts.

[0041] If only these precursors are used, a soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com