Patents

Literature

442 results about "Tetrahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tetrahydrate is a molecule surrounded by four molecules of water, forming a hydrate. The notation for a tetrahydrate is anhydrous molecule's formula·4H₂O, where the 4 represents tetrahydrate, and the H₂O represents the tetrahydrate. And the molecule's name changes to anhydrous molecule's name tetrahydrate.

Method for inhibiting amine degradation during c02 capture from a gas stream

ActiveUS20090205496A1Induce degradationGas treatmentOther chemical processesHydroxylamineSulfite salt

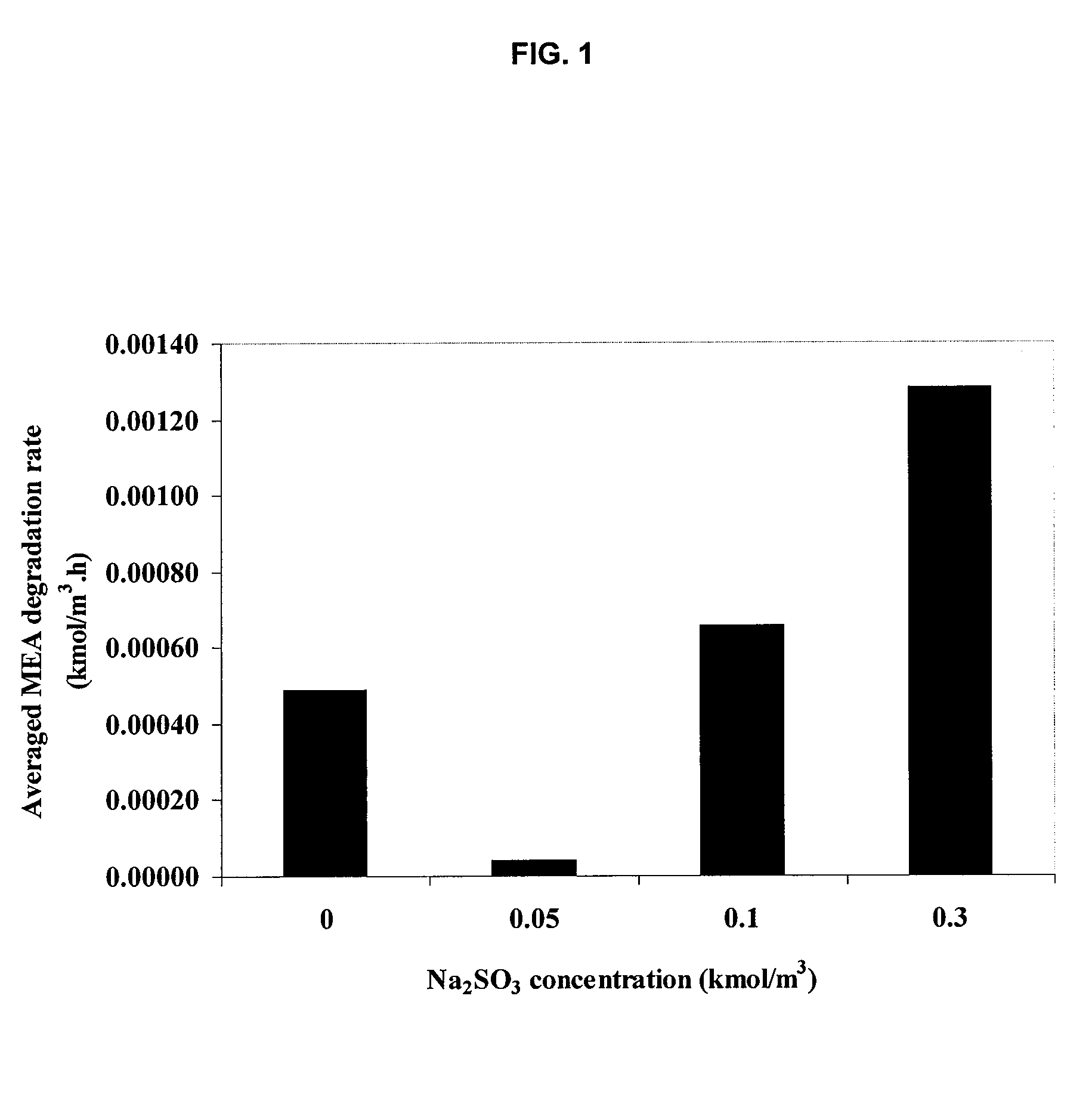

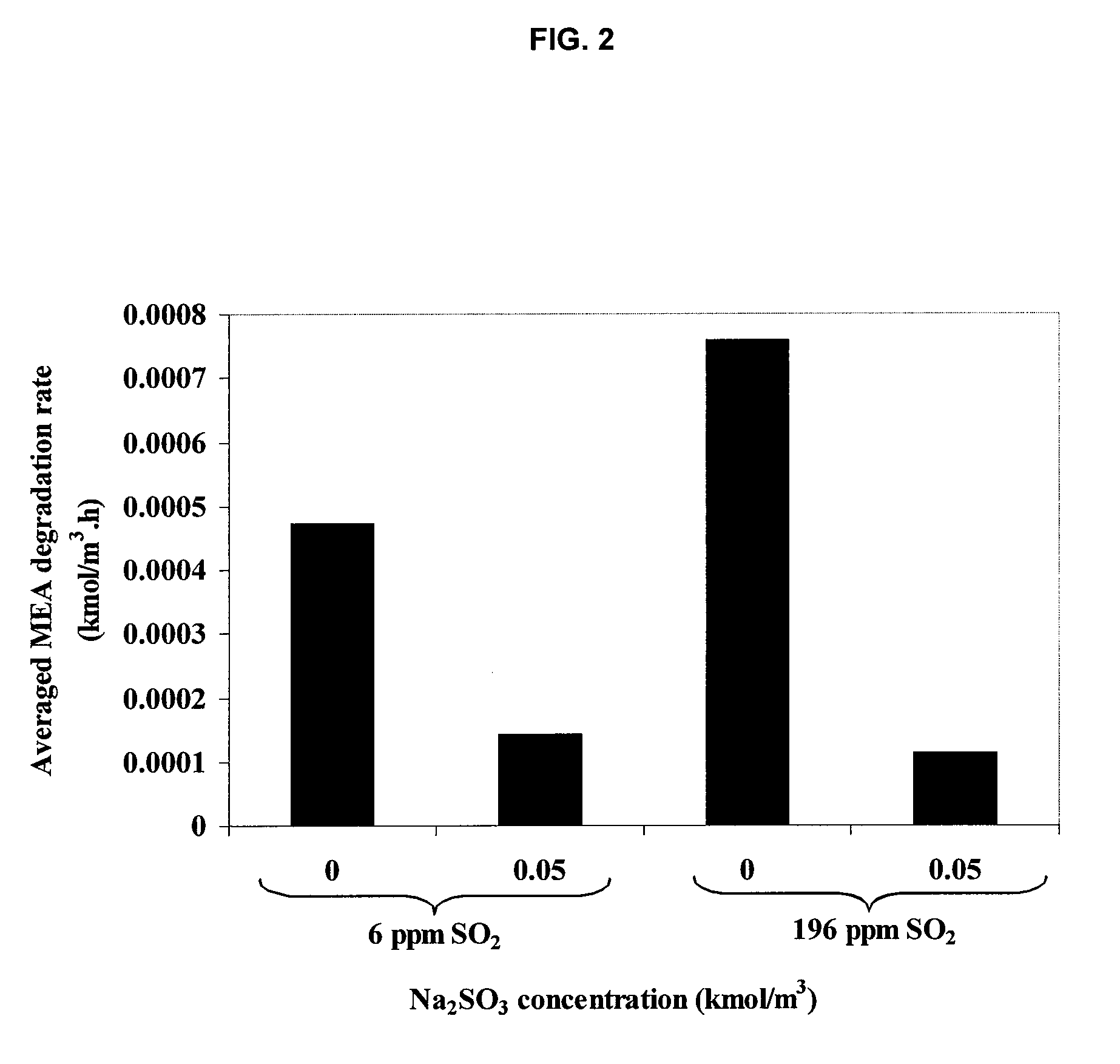

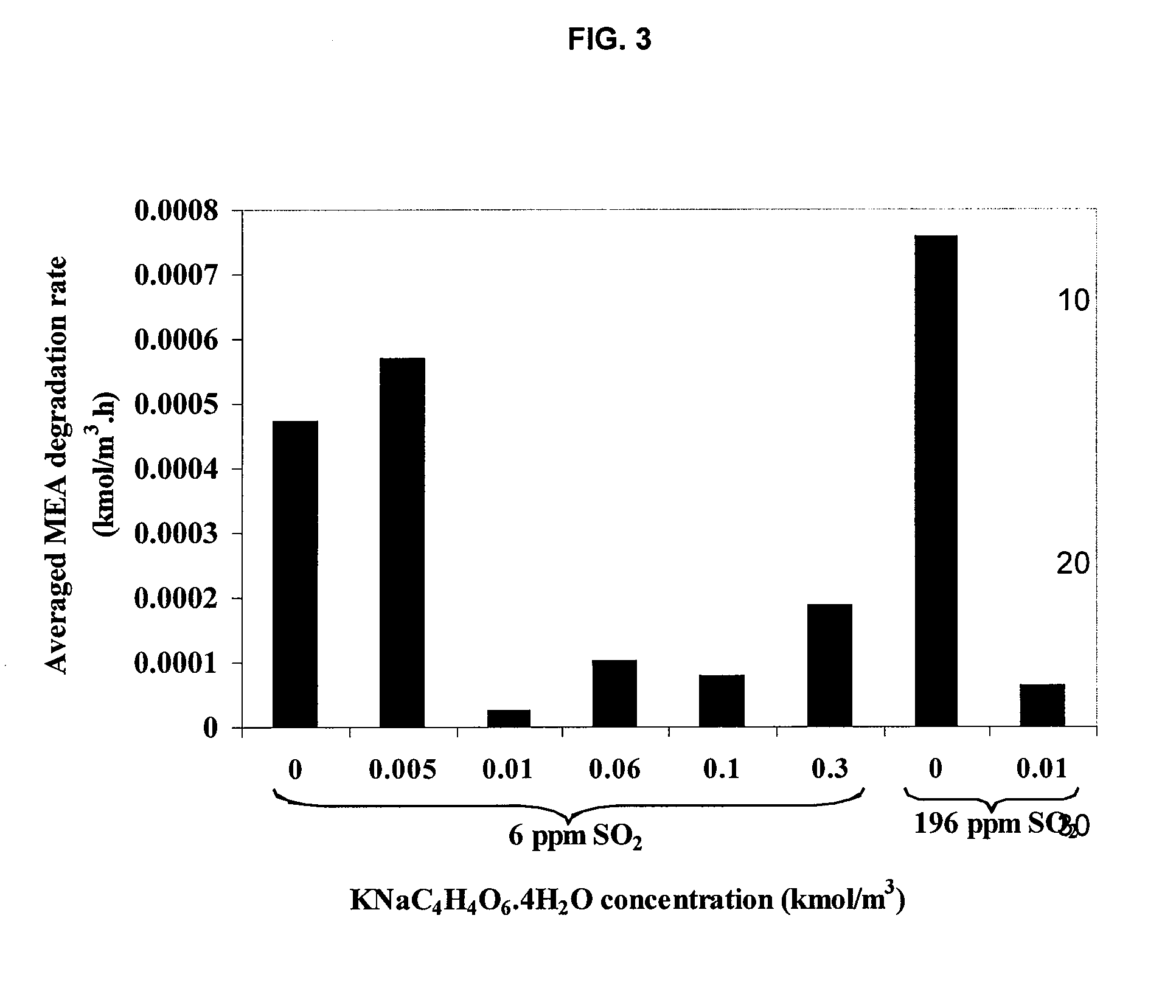

The present application includes a method for inhibiting amine degradation during CO2 capture from flue gas streams. Particularly, the present disclosure relates to a method of inhibiting O2- and / or SO2-induced degradation of amines using sodium sulfite (Na2SO3), potassium sodium tartrate tetrahydrate (KNaC4H4O6.4H2O), ethylenediaminetetraacetic acid (EDTA) or hydroxylamine (NH2OH), or analogs or mixtures thereof during CO2 capture by amines.

Owner:UNIVERSITY OF REGINA

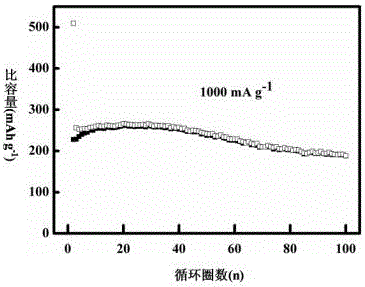

Graphene oxide/metal organic framework composite material and preparation method and application thereof

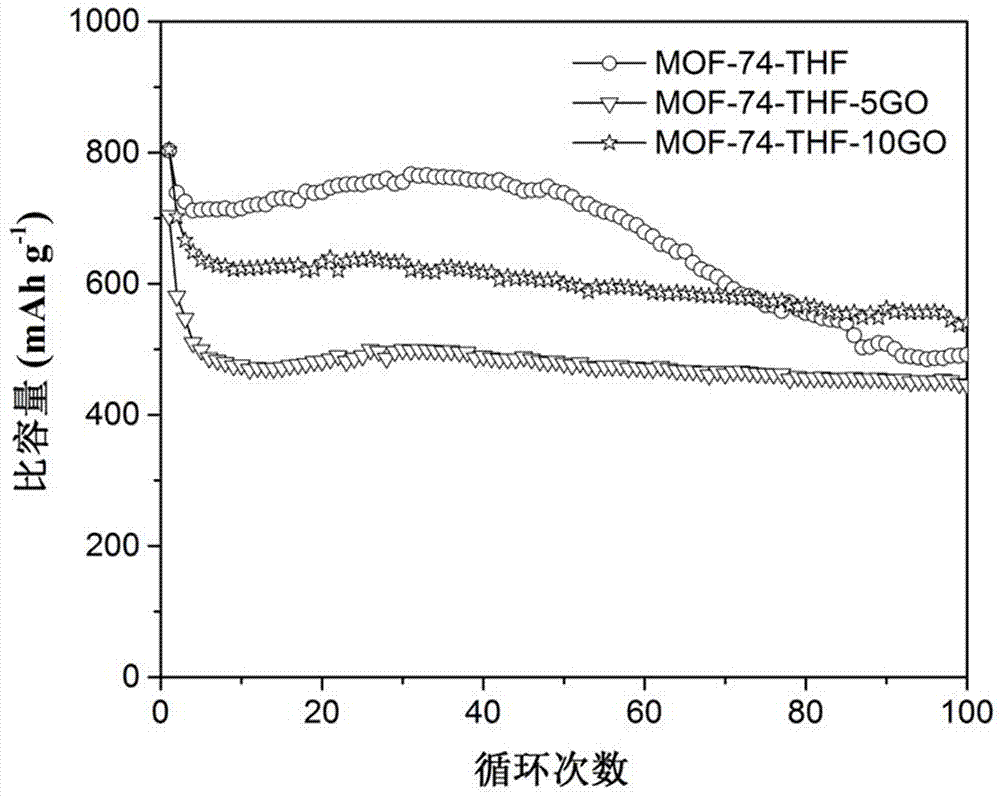

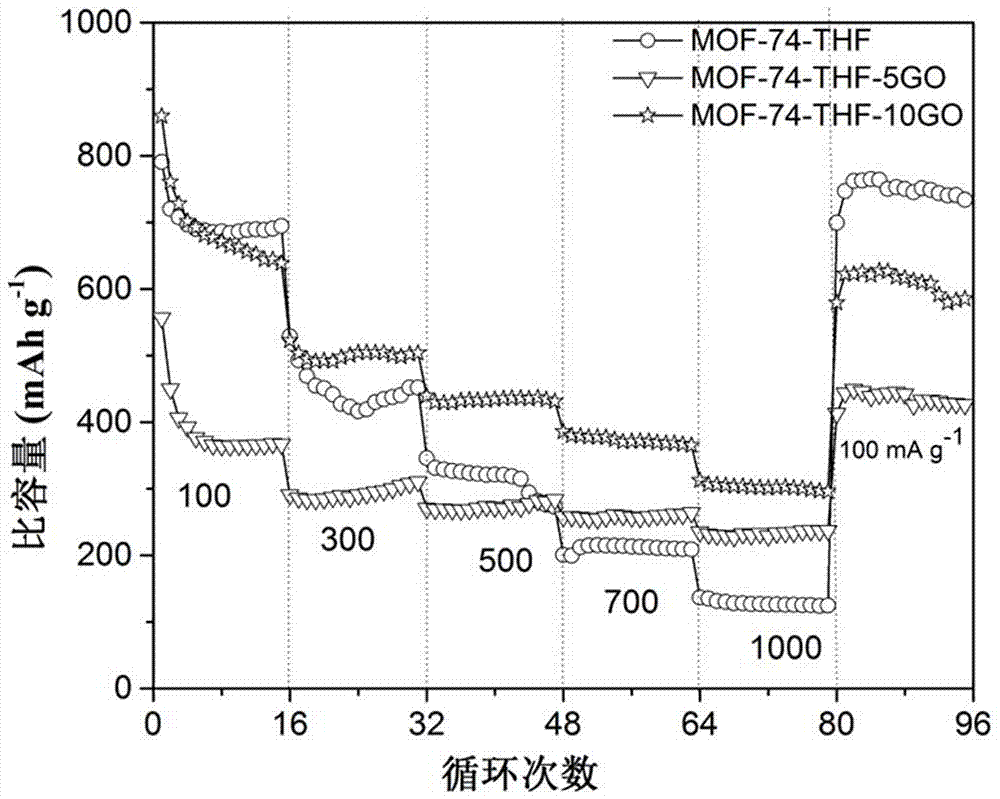

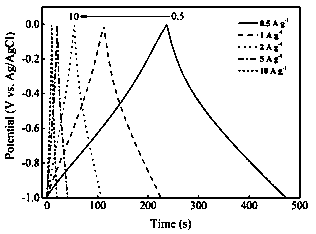

InactiveCN106935825AImprove electrochemical performanceImprove charge and discharge cycle lifeCell electrodesMetal-organic frameworkCharge discharge

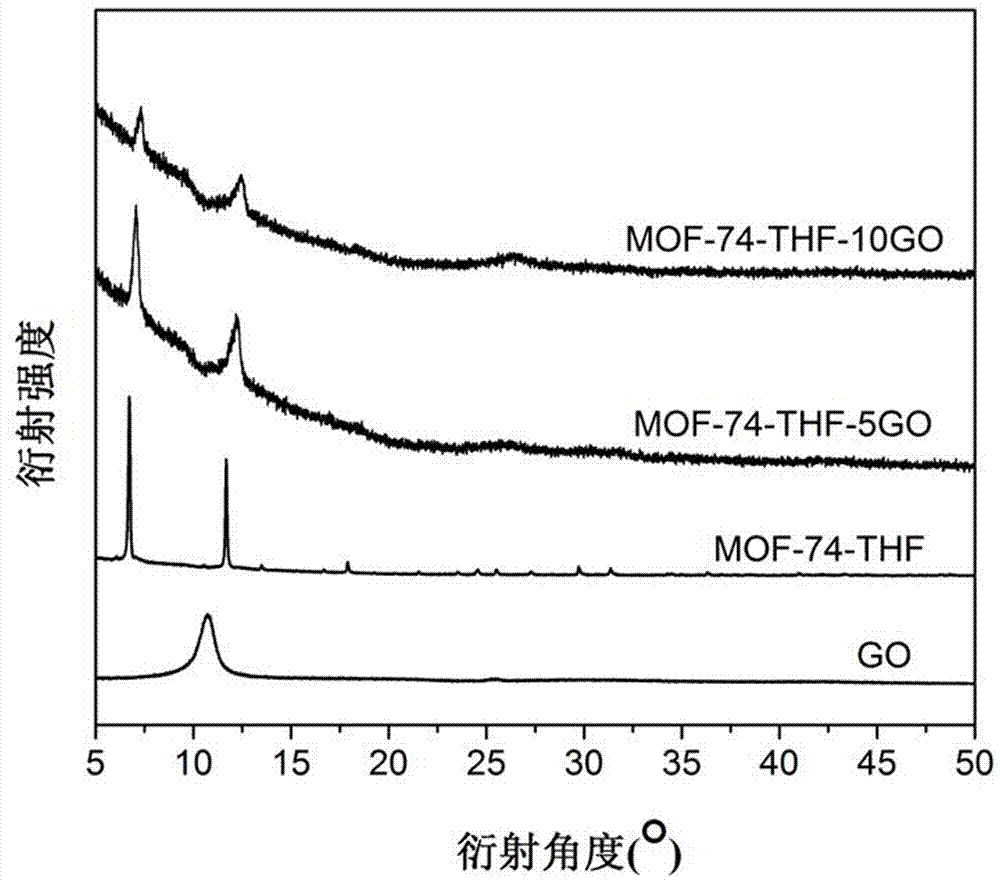

The invention provides a graphene oxide / metal organic framework composite material. The composite material is prepared from graphene oxide, cobalt acetate tetrahydrate and 2, 5-dihydroxyterephthalic acid which are mixed based on a certain proportion through a solvothermal method. The preparation method comprises the steps of (1) dispersing graphene oxide into a solvent to obtain a graphene oxide solution; (2) adding the cobalt acetate tetrahydrate and 2, 5-dihydroxyterephthalic acid into deionized water to form a mixed solution; (3) enabling the obtained mixed solution to be mixed with the obtained graphene oxide solution, and then putting the mixture into a reaction kettle; and (4) performing constant-temperature heating in a drying oven, taking out the product, washing and drying. According to the application of the composite material as a negative electrode material of a lithium ion battery, the specific capacity value can reach 520-600mAh g<-1> at current density of 100mAg<-1> in an electrochemical performance test. The composite material is high in cycling stability, long in charging-discharging service life, and has wide application prospect in the field of the lithium ion battery.

Owner:GUILIN UNIV OF ELECTRONIC TECH

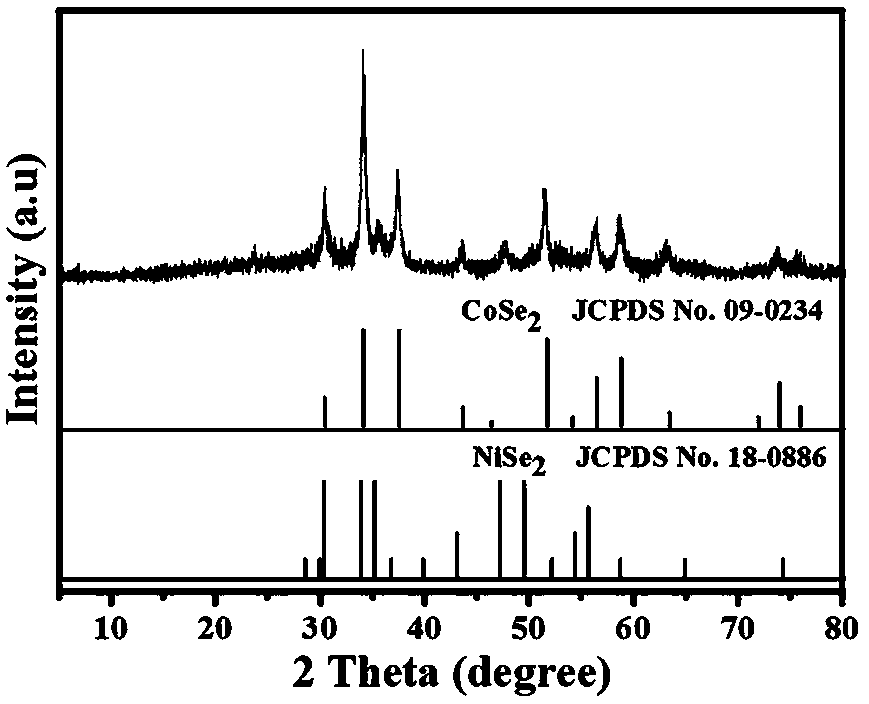

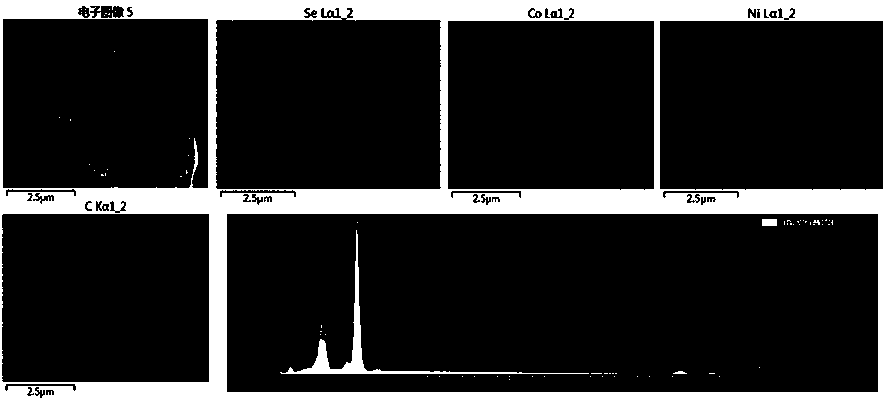

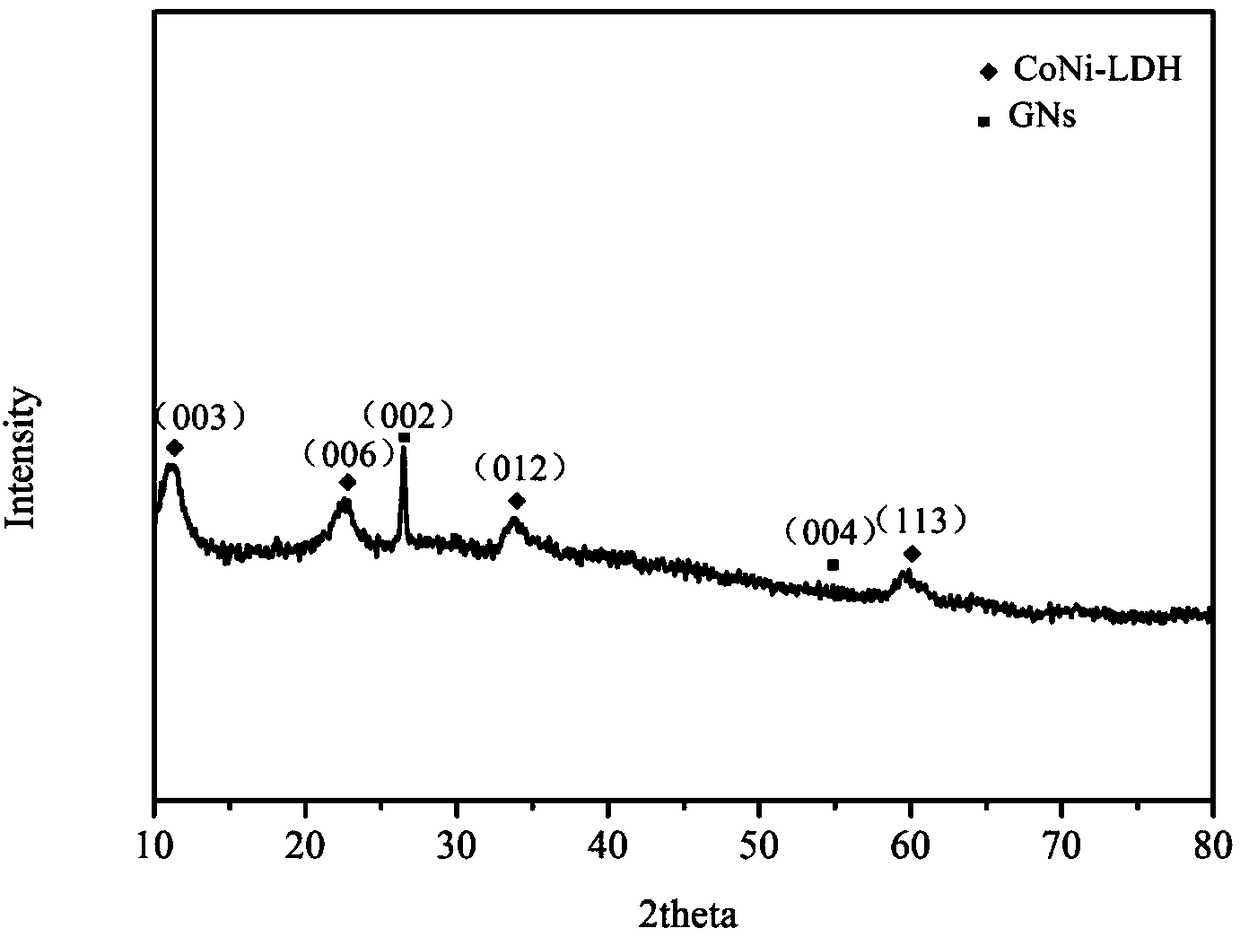

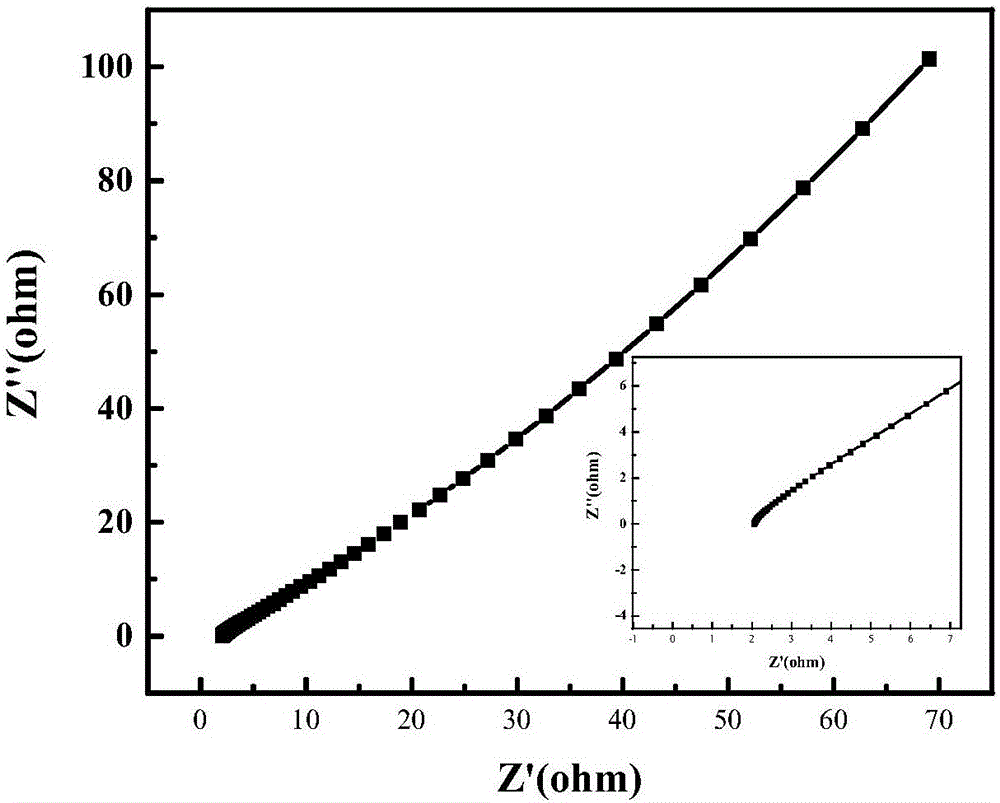

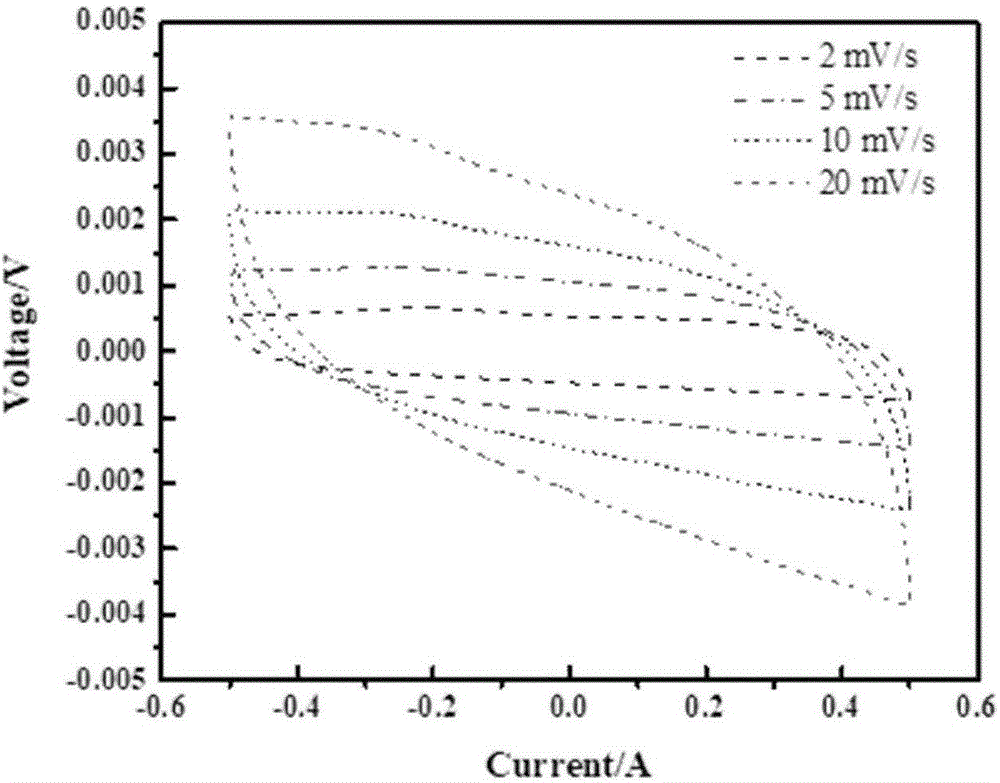

Co-Ni bimetallic selenide/graphene composite electrode material

InactiveCN109243852AAvoid residueHigh purityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel acetate tetrahydrate

The invention discloses a cobalt-nickel bimetallic selenide / graphene composite electrode material, and belongs to the preparation field of electrode material for supercapacitors. A manufacture methodcomprises that follow steps: adding graphene oxide (GO) into ethylene glycol solution, ultrasonic dispersing, and uniformly dispersing GO in the ethylene glycol solution; Adding polyvinylpyrrolidone(PVP), cobalt acetate tetrahydrate and nickel acetate tetrahydrate into the GO dispersion, ultrasonic dispersing and dissolving, transferring it to a round bottom flask for oil bath reaction and centrifugal washing and drying; After centrifugal washing and drying after oil bath, the product was hydrothermally selenized with sodium selenite and hydrazine hydrate to obtain Co-Ni bimetallic selenide / graphene composite electrode material. A large number of uniform size Co-Ni-Se nanosheets were uniformly loaded on graphene substrate, and the prepared electrode materials had high specific capacitance and excellent rate performance.

Owner:FUZHOU UNIV

Oxygen-absorbing compositions and method

An oxygen-absorbing composition including iron and a soluble tartrate. A method of absorbing oxygen from a closed environment including the steps of providing an oxygen-absorbing composition containing iron and a tartrate, injecting water into the composition, and placing the composition into the closed environment. An oxygen-absorbing packet containing iron and a tartrate. All of the foregoing-mentioned compositions preferably include an electrolyte. The tartrates may be selected from the group which may include sodium acid tartrate, potassium acid tartrate, potassium sodium tartrate tetrahydrate and sodium tartrate dihydrate, but are not limited thereto.

Owner:MULTISORB TECH INC

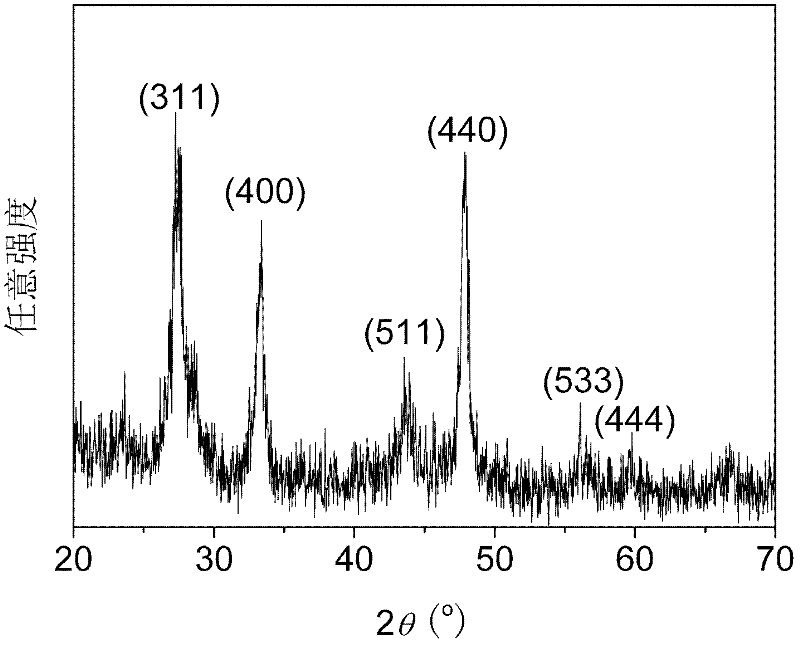

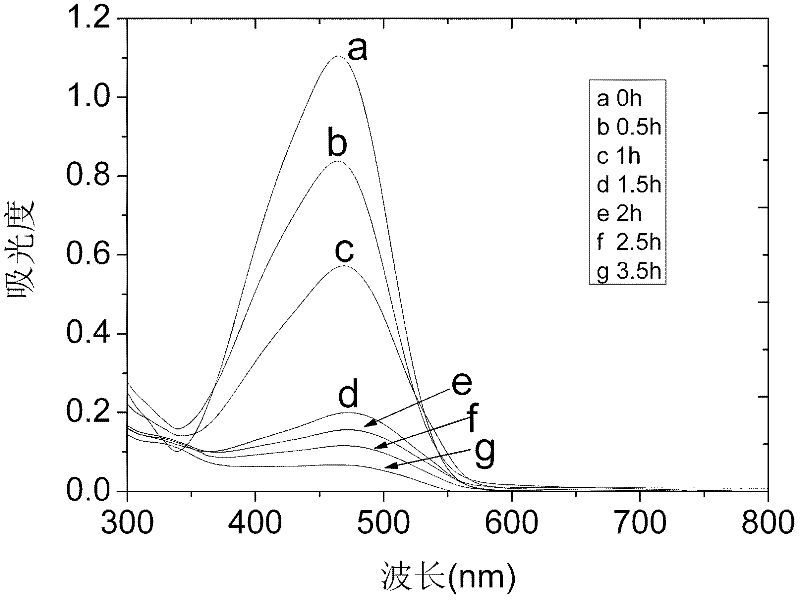

Synthesis method of novel visible-light photocatalyst indium sulfide

InactiveCN102335616APromote degradationSimple processPhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic dyeSynthesis methods

The invention relates to a synthesis method of a novel visible-light photocatalyst indium sulfide, belonging to the technical field of preparation of photocatalysts. The method comprises the following steps: weighing indium chloride tetrahydrate, dissolving the indium chloride tetrahydrate in deionized water, adding acetic acid to regulate the pH value to 1-3, and adding thioacetamide solution, wherein the concentration of indium ions is 0.025 mol / L, and the In / S mol ratio is 1:4-1:10; heating the obtained mixed solution to constant temperature so as to carry out hydrothermal reaction for 4-8 hours while regulating the temperature to 80 DEG C, and cooling at room temperature; and carrying out vacuum filtration under reduced pressure, washing, and drying to obtain the orange indium sulfide powder. The indium sulfide prepared by the method provided by the invention is in a ball-flower shape, and has the advantages of large specific area and uniform size; and the indium sulfide powder is in a cubic structure. The indium sulfide can be used as a visible-light photocatalyst, and has good degradation effect on organic dyes (such as methyl orange).

Owner:BEIJING UNIV OF TECH

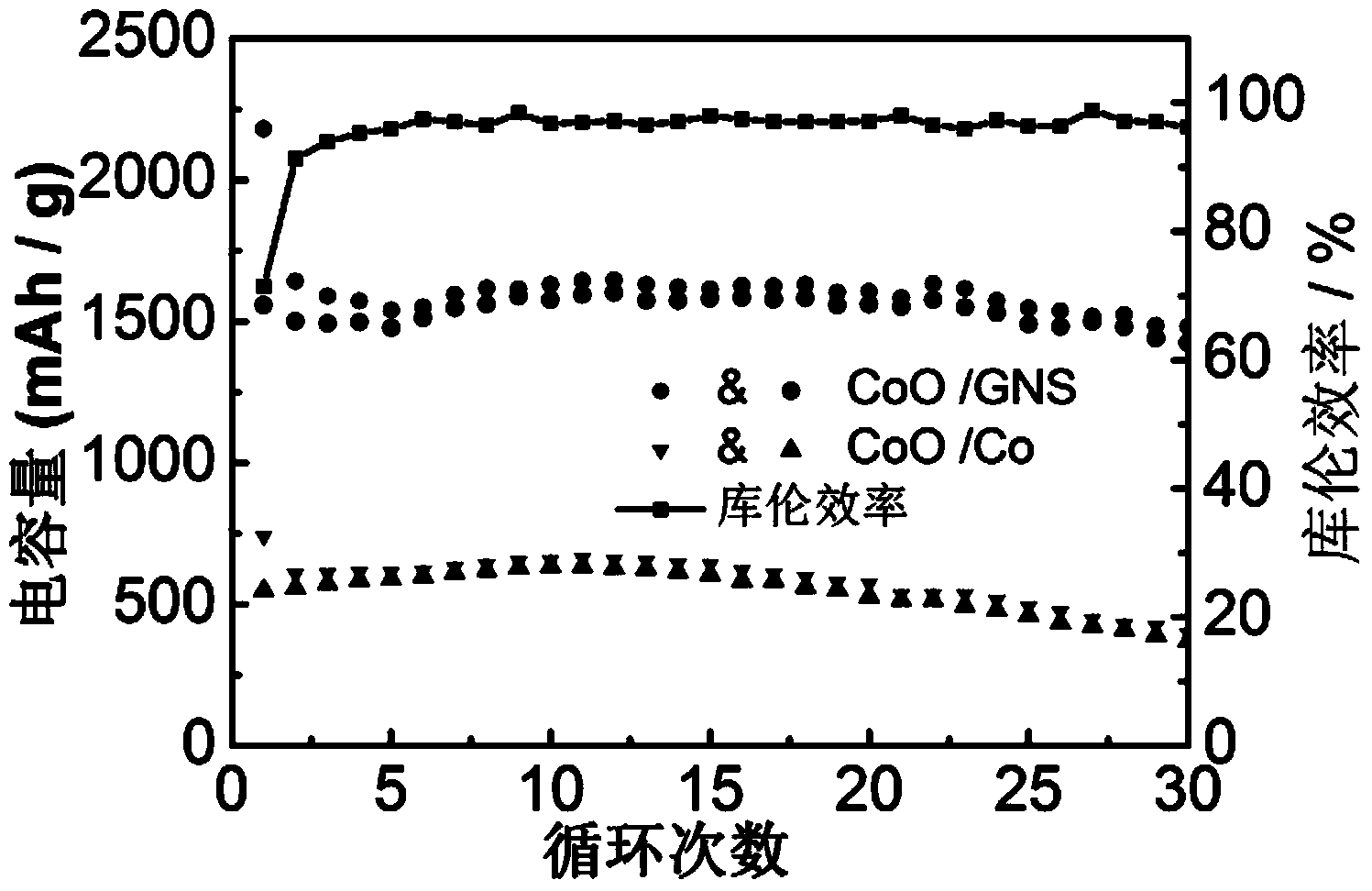

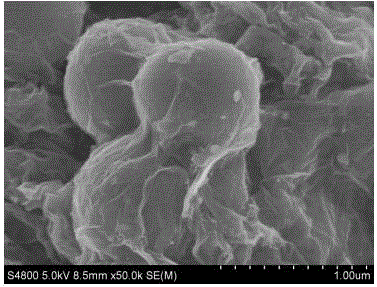

Nano crystalline CoO-graphene composite material as well as preparation and application thereof

ActiveCN104393283AAvoid pollutionThe preparation process is simple and cheapMaterial nanotechnologyCell electrodesCapacitanceSingle layer graphene

The invention discloses a graphene composite material, in particular a CoO and graphene composite material. The invention also relates to a preparation method of the graphene composite material and application of the graphene composite material in a lithium-ion battery. The preparation method comprises the steps of performing low-temperature recrystallization on cobalt acetate tetrahydrate, compositing the recrystallized cobalt acetate tetrahydrate and graphene oxide to obtain a precursor, and performing low-temperature annealing on the precursor under a high vacuum environment to obtain two-dimensional nano crystalline CoO-graphene composite material, wherein single-layer graphene with the thickness of 1-50 micrometers is taken as a carrier frame, and CoO nanocrystals with the average particle diameter of 2-20 nm are uniformly embedded in the upper and lower surfaces of the single-layer graphene. The prepared nano crystalline CoO-graphene composite material can be used as the negative electrode of a lithium-ion battery to effectively improve the capacitance of the lithium-ion battery; the preparation method is simple, the preparation period is short, the preparation efficiency is high, no toxic effect exists, the environment pollution is avoided, and the potential safety hazard is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Human body hard tissue filling renovation material containing calcium citrate

InactiveCN101185772AGood biocompatibilityPromote degradationOrganic chemistryCoatingsTreatment effectCITRATE ESTER

The invention relates to a human hard tissue filling and repair material containing calcium citrate. The invention provides the human hard tissue filling and repair material containing calcium citrate, wherein the calcium citrate is selected from tricalcium citrate, which can be one or any combination of tricalcium citrate tetrahydrate (the molecular formula is Ca3(C6H5O7)2.4H2O), tricalcium citrate dihydrate (the molecular formula is Ca3(C6H5O7)2.2H2O) and tricalcium citrate anhydrous (the molecular formula is Ca3(C6H5O7)2), and the weight percentage content of which in the human hard tissue filling and repair material is 50 to 100 percent. The invention also provides the preparation method of the human hard tissue filling and repair material containing calcium citrate. The human hard tissue filling and repair material containing calcium citrate which is provided by the invention is a reliable hard tissue filling and repair material which is degradable in the body, and the invention has significant treatment effects to bone defects, osteoporosis and bone tumors.

Owner:彭磊

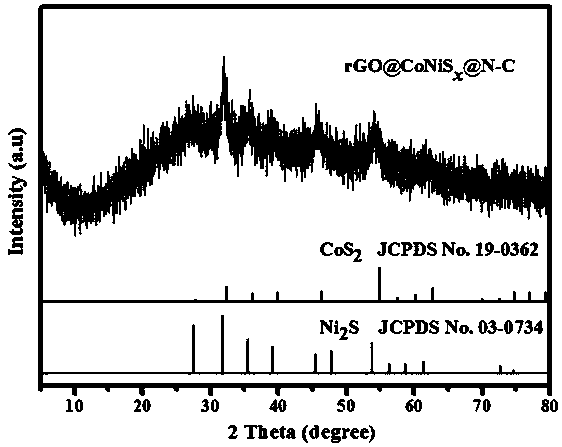

N-doped carbon-coated cobalt-nickel sulfide/graphene composite electrode material

InactiveCN108075128ASimple preparation processImprove controllabilityHybrid capacitor electrodesCell electrodesCapacitanceThiourea

The invention discloses an N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material and a preparation method thereof, belonging to the field of preparation of an electrode material for super capacitors. The preparation method comprises the following processes: adding graphene oxide (GO) into an ethylene glycol solution, and performing ultrasonic dispersion to enable the GOto be uniformly dispersed in the ethylene glycol solution; adding polyvinylpyrrolidone (PVP), cobaltous acetate tetrahydrate and nickel acetate into a GO dispersion solution prepared above, after ultrasonic dispersion and dissolution, transferring to a round bottom flask to perform oil bath reaction and performing centrifugal washing and drying; enabling a product, which is dried via centrifugalwashing after oil bath, to calcine with thiourea to obtain the N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material. According to the prepared electrode material, N-dopedcarbon is coated outside cobalt-nickel sulfide particles which have uniform sizes in microstructure, the electrode material is uniformly loaded on the substrate of graphene, and meanwhile, the electrode material has relatively high specific capacitance, excellent rate capability and cycling stability.

Owner:FUZHOU UNIV

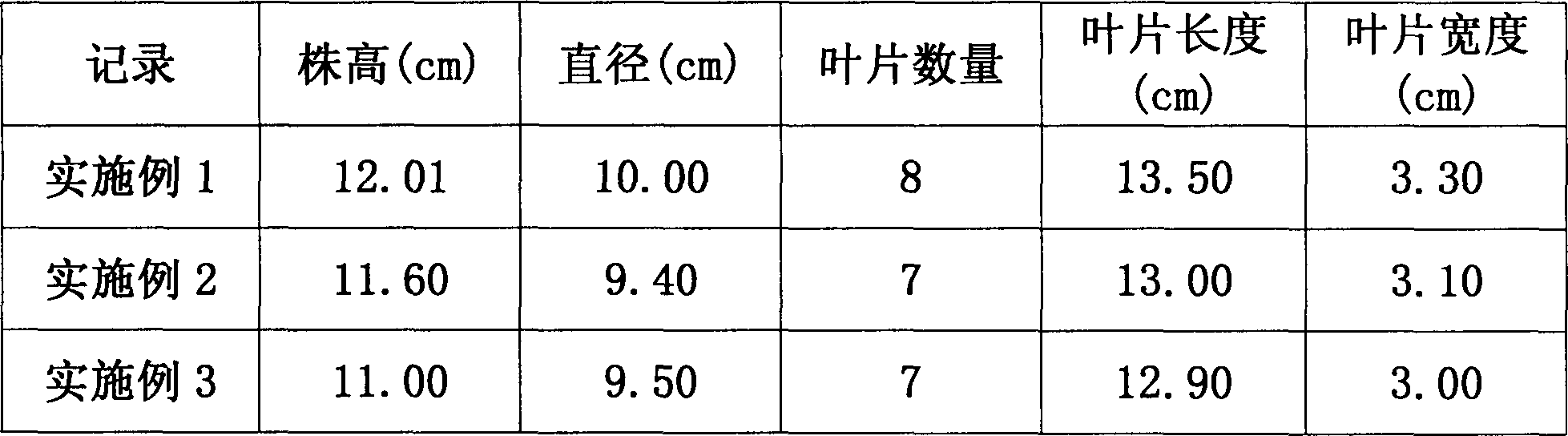

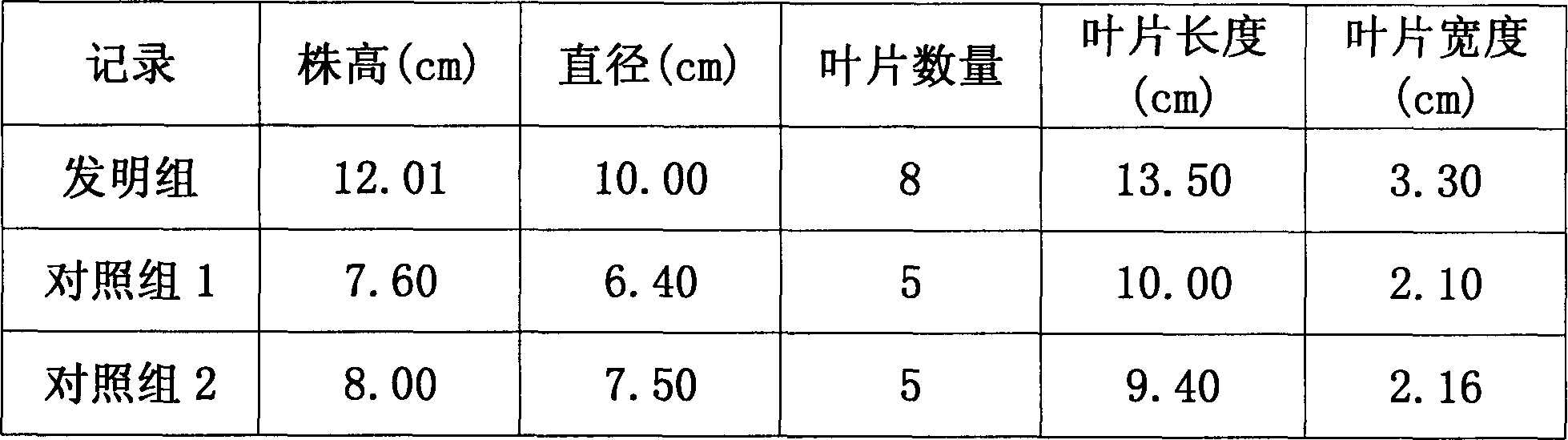

Plant infusion nutrient solution and preparation method thereof

InactiveCN101811909AImprove stress resistanceHigh activityFertilizer mixturesCalcium nitrate tetrahydrateHigh absorption

The invention discloses plant infusion nutrient solution and a preparation method thereof and aims to provide nutrient solution which can be directly infused into the plants, stimulate the tree activity, promote the plants to rapidly take root and sprout, quickly supply nutrition to the trees, and enhance the tree stress resistance, and a preparation method of the nutrient solution. The proportion of the nutrient solution is that: every 1,000ml of deionized water contains 0.05 to 0.1g of monopotassium phosphate, 0.02 to 0.045g of potassium nitrate, 0.15 to 0.3g of calcium nitrate tetrahydrate, 0.11 to 0.2g of magnesium sulfate heptahydrate, 0.03 to 0.06g of ferrous sulphate heptahydrate, 0.07 to 0.15g of disodium ethylene diamine tetraacetate, 0.015 to 0.025g of manganese sulfate tetrahydrate, 0.012 to 0.018g of zinc sulfate heptahydrate, 0.04 to 0.06g of copper sulfate pentahydrate, 0.015 to 0.022g of ammonium molybdate, 0.015 to 0.02g of indolebutyric acid, and 0.008 to 0.015g of 6-benzylaminopurine. The plant infusion nutrient solution satisfies the needed nutrient in the process of transplanting big trees, has high absorption utilization ratio, quick response, stable form, high activity, and is easily absorbed by the plants.

Owner:TIANJIN LVDONG PLANT NUTRITION TECH DEV

Novel catalyst based on metal organic framework material and preparation method and application of novel catalyst

InactiveCN106582887AReact SafeShort reaction timeOrganic-compounds/hydrides/coordination-complexes catalystsCobalt acetateMetal-organic framework

The invention relates to a novel catalyst based on metal organic framework material and a preparation method and application of the novel catalyst, and belongs to the technical fieldo f functional nanomaterial preparation. Ti3AlC2 is taken as a raw material, Ti3AlC2 obtained after ball-milling and screening is corroded with an acid solution, an Al atom layer is removed, and a two-dimensional Ti3C2 nanosheet is generated; the Ti3C2 nanosheet, cobalt acetate tetrahydrate and 1,4-terephthalic acid are taken as precursors, cobalt acetate tetrahydrate and 1,4-terephthalic acid generate a metal organic framework complex (MOF)-cobalt terephthalic acid complex (CoBDC) on the surface of Ti3C2 through an in-situ growth method respectively, the two complexes are compounded, the metal organic framework complex (MOF)-cobalt terephthalic acid complex (CoBDC) and Ti3C2 are compounded, and then a compound Ti3C2-CoBDC of the product titanium carbide-cobalt terephthalic acid complex is obtained. The method is easy and convenient to operate in preparation, safe in preparation operation, short in production cycle, low in production cost, high in yield, basically free of by-products and beneficial for a achieving expanded production and has a very good application prospect.

Owner:NANJING UNIV OF TECH

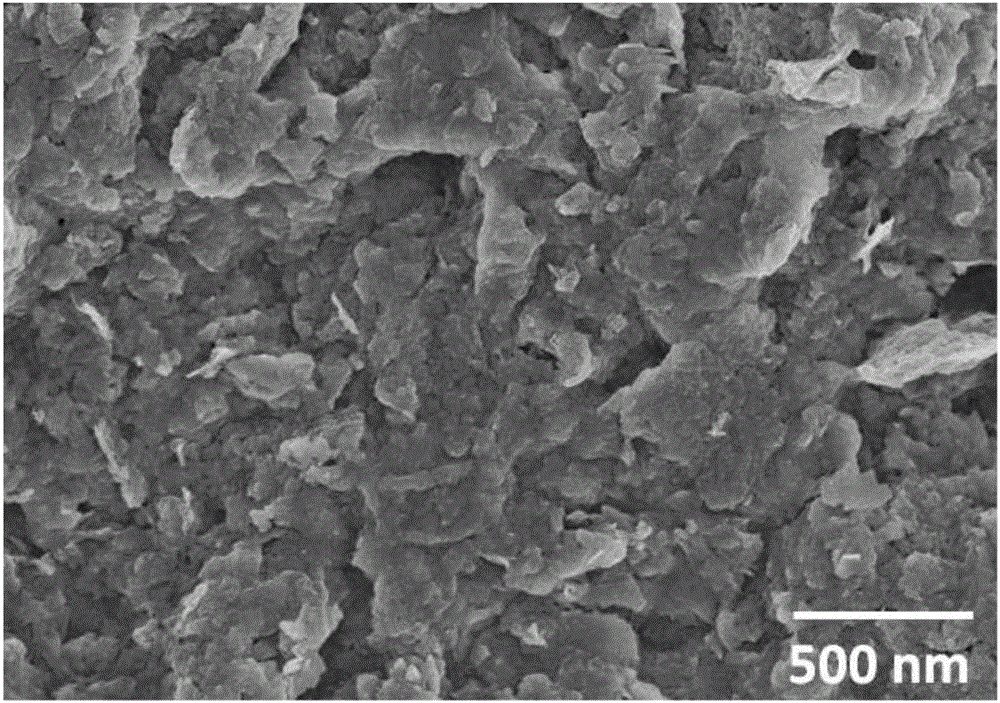

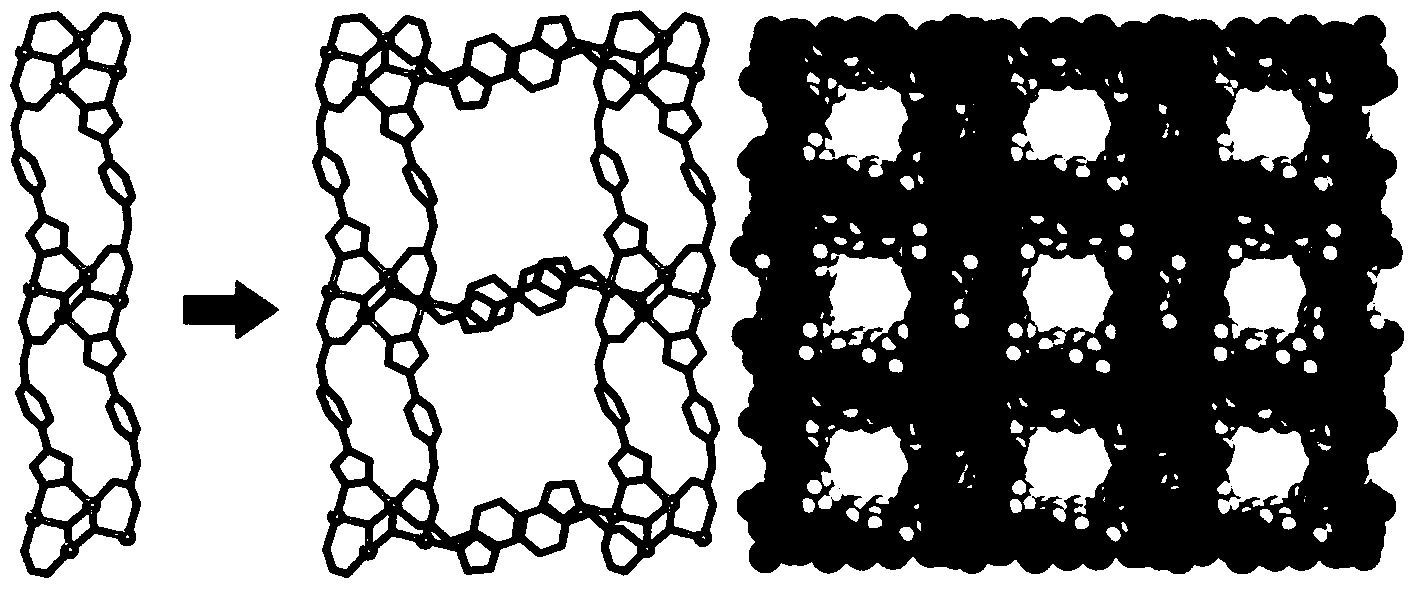

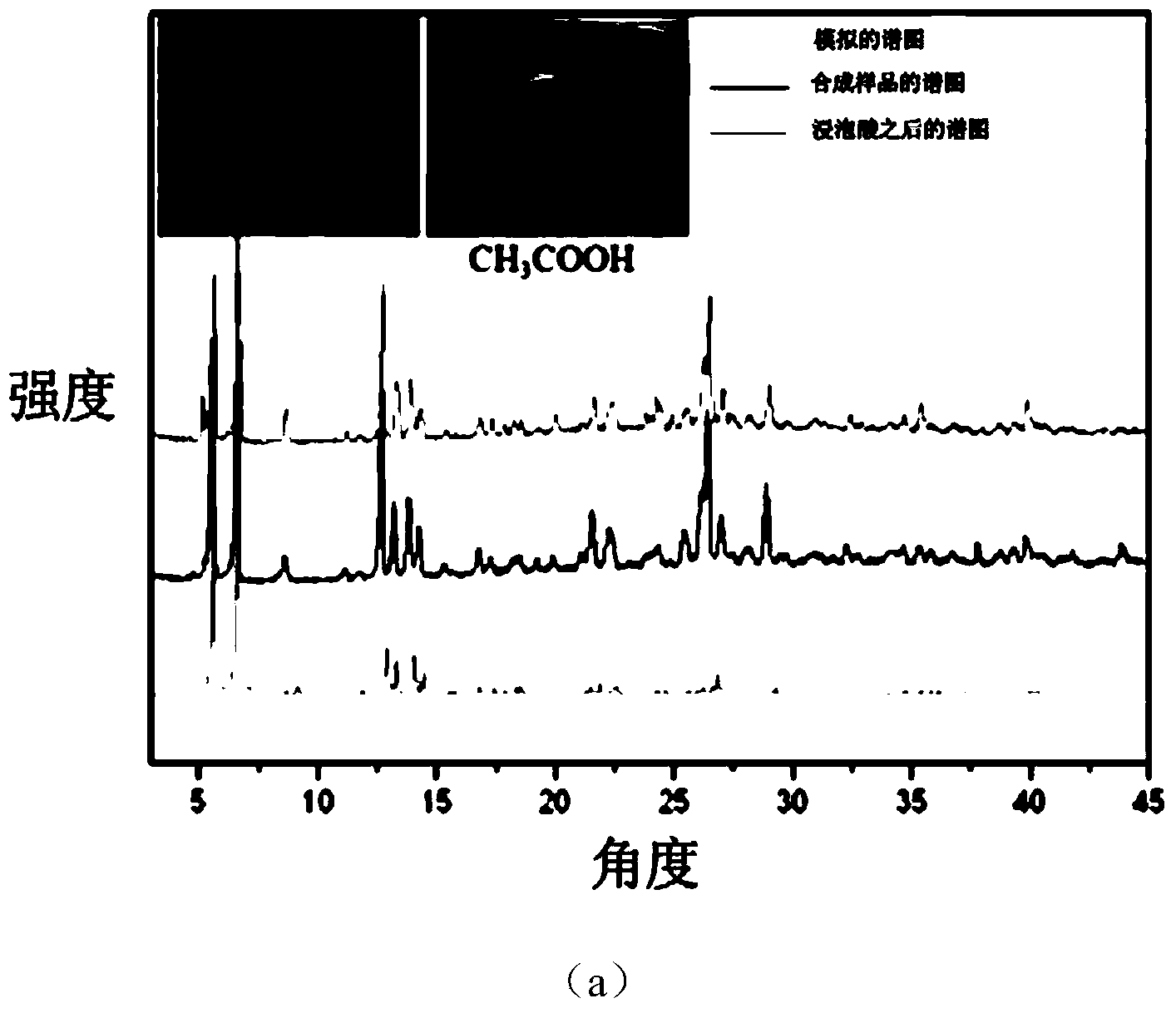

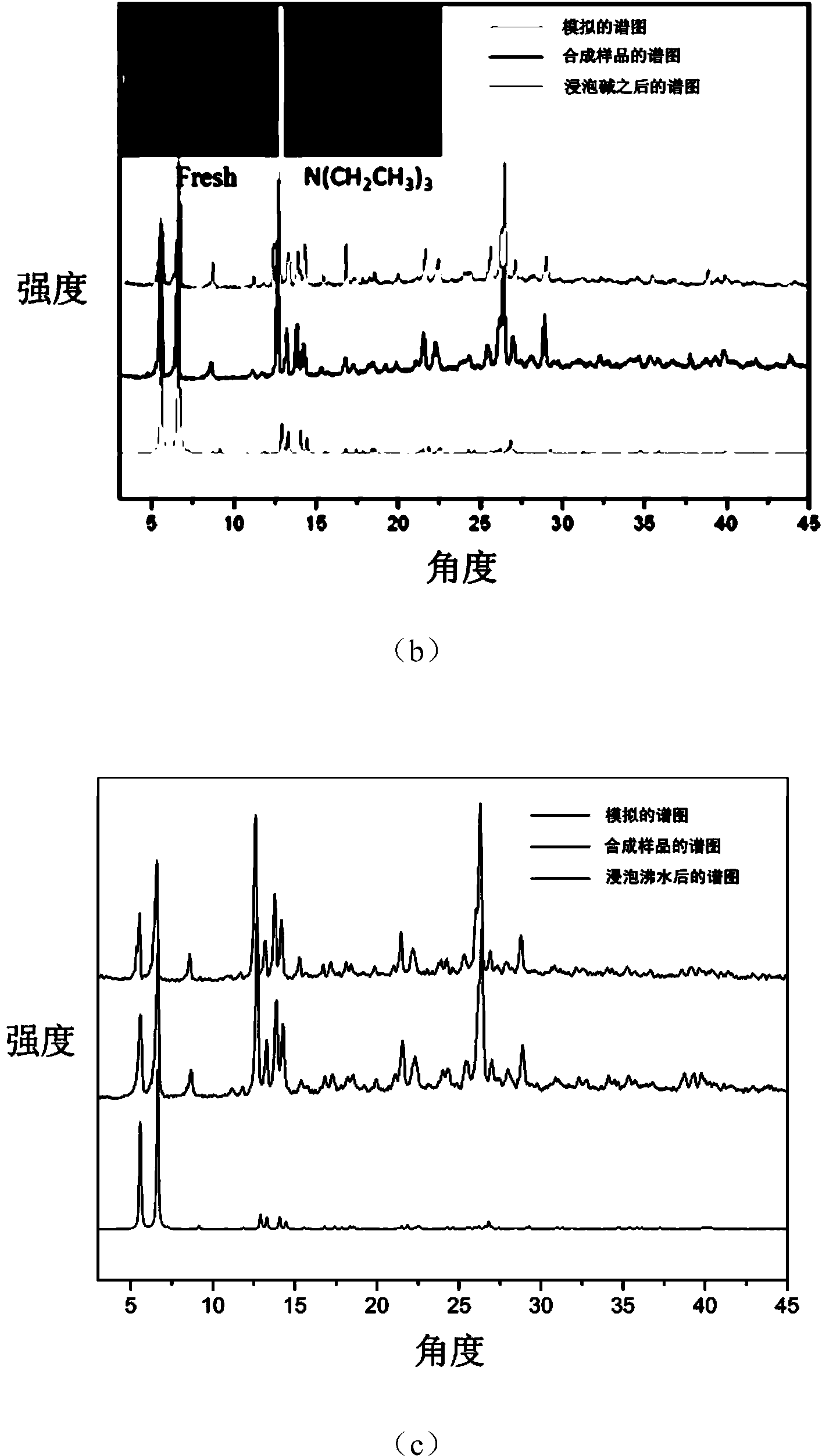

Porous metal-organic framework hybrid material as well as preparation method and application thereof

InactiveCN103665006AMild conditionsEasy to prepare in large batchesOther chemical processesCopper organic compoundsAbsorption capacityCupric nitrate

The invention discloses a porous metal-organic framework hybrid material. A chemical formula of the porous metal-organic framework hybrid material is (Cu4O2(tpa)2)*2NO3*DMA, wherein Htpa adopts 4-(4-benzene acetoxy)-1, 2, 4-triazole, and DMA adopts N, N-dimethylacetamide; and the hybrid material is synthesized by cupric nitrate tetrahydrate serving as metal salt and 4-(4-benzene acetoxy)-1, 2, 4-triazole serving as an organic ligand. The porous metal-organic framework hybrid material has the advantages as follows: 1), raw materials for synthesis are cheap and easy to obtain, the condition is mild, large-scale preparation of the hybrid materials is easy to realize, and the crystal form can be maintained in the large-scale synthetic process; 2), the product has excellent acid resistance and alkaline resistance, and the structure can be maintained in a boiled water environment; and 3), the absorption capacity of the product on CO2 at the temperature of 273K can reach 52 cm<3>g<-1> while the absorption capacity of the product on N2 is only 3.4 cm<3>g<-1>, so that the porous metal-organic framework hybrid material has a good potential application value in the aspect of CO2 preferential absorption.

Owner:NANKAI UNIV

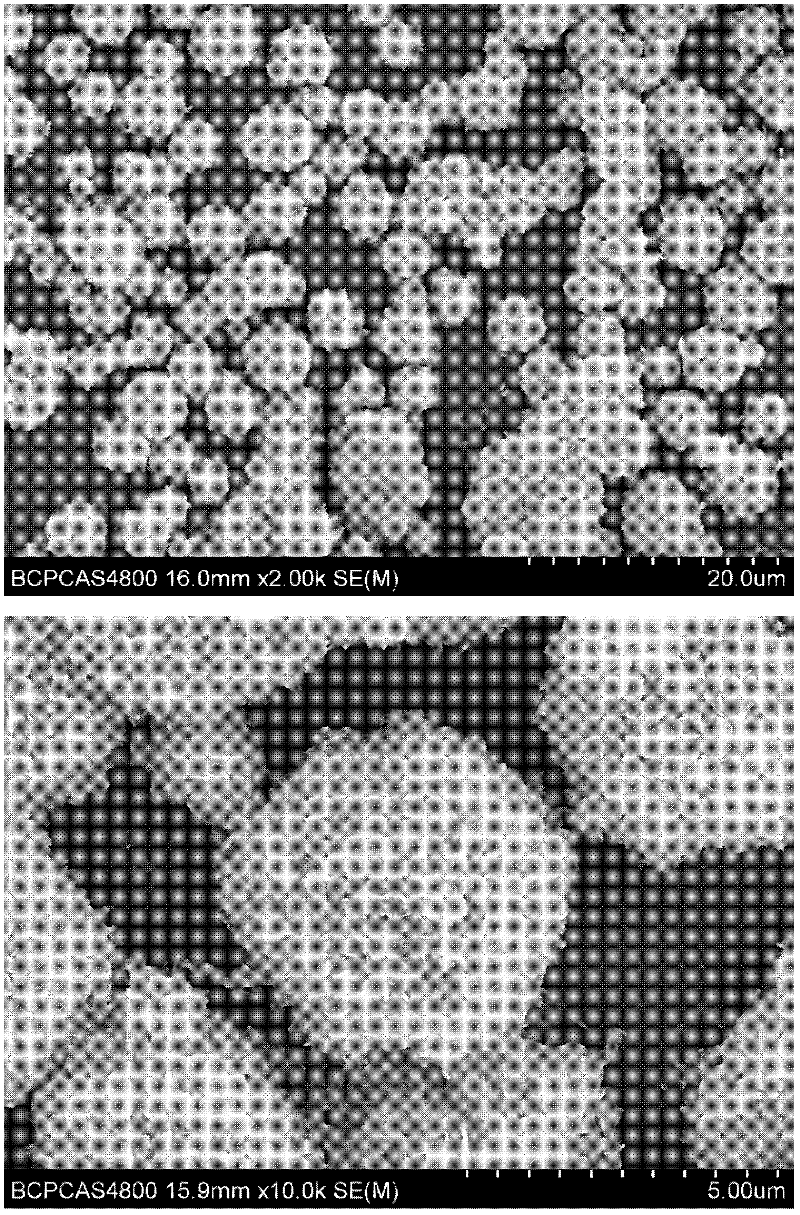

Micro/nano structural ferroferric oxide hollow spheres and preparation method thereof

InactiveCN102153150AEasy post-processingLow reaction temperatureFerroso-ferric oxidesNanotechnologyPolychlorinated biphenylReaction temperature

The invention discloses micro / nano structural ferroferric oxide hollow spheres and a preparation method thereof. The micro / nano structural ferroferric oxide hollow spheres are prepared from ferrous chloride tetrahydrate, urea, ascorbic acid and oleic acid in mixed solution of water and absolute ethanol, and then the synthesized micro / nano structural ferroferric oxide hollow spheres are tested in a removal experiment of durable organic pollutant polychlorinated biphenyl 77 (PCB-77). Substances such as templates and the like do not need to be added in the reaction process of the hydrothermal prepared micro / nano structural ferroferric oxide hollow spheres, the method is environment-friendly, the post treatment is convenient, the reaction temperature is low, and the process is simple; and the prepared micro / nano structural ferroferric oxide hollow spheres have porous hollow structures, have high specific surface area and activity of nano structures, and can effectively prevent agglomeration of granules.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

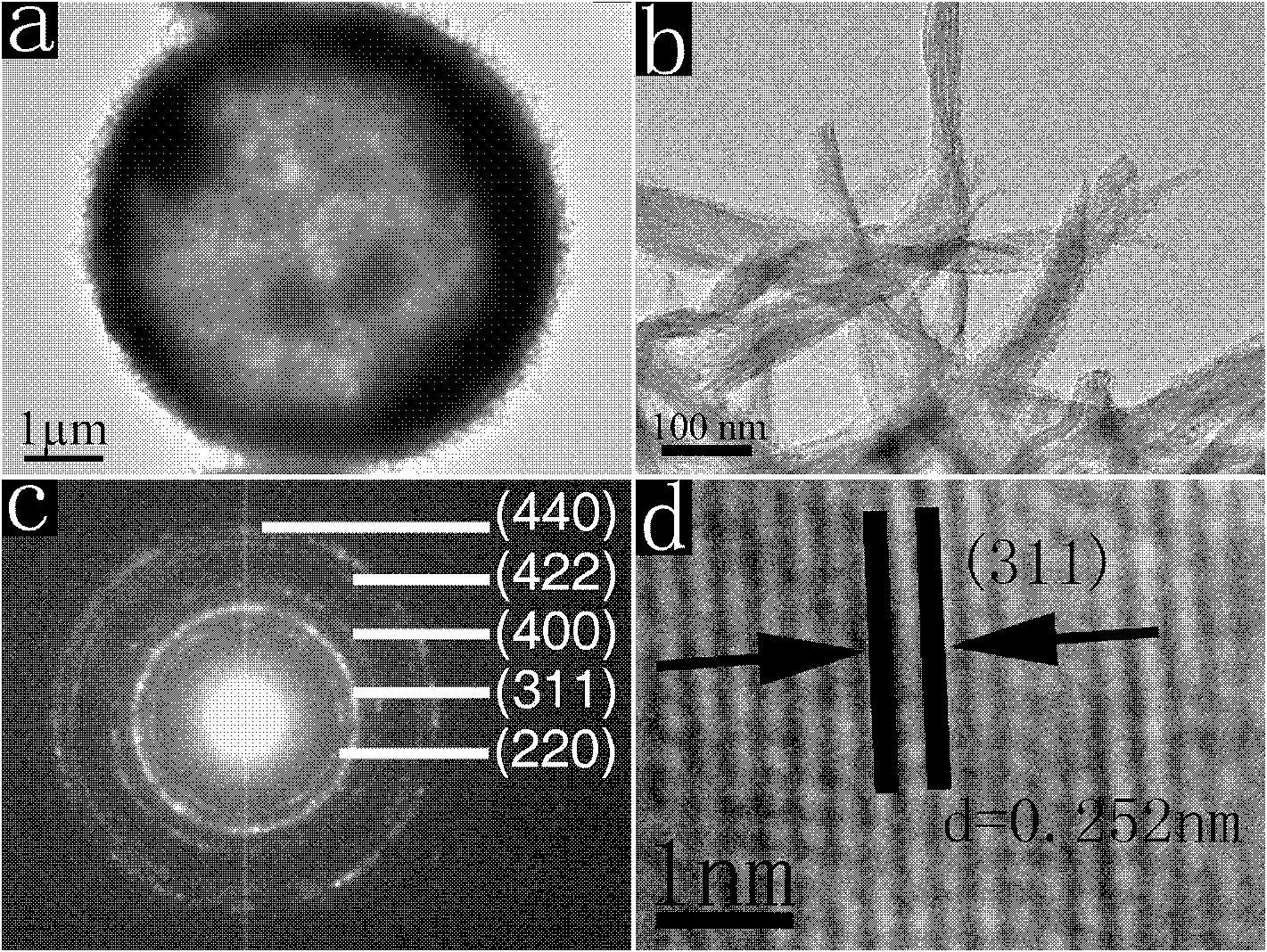

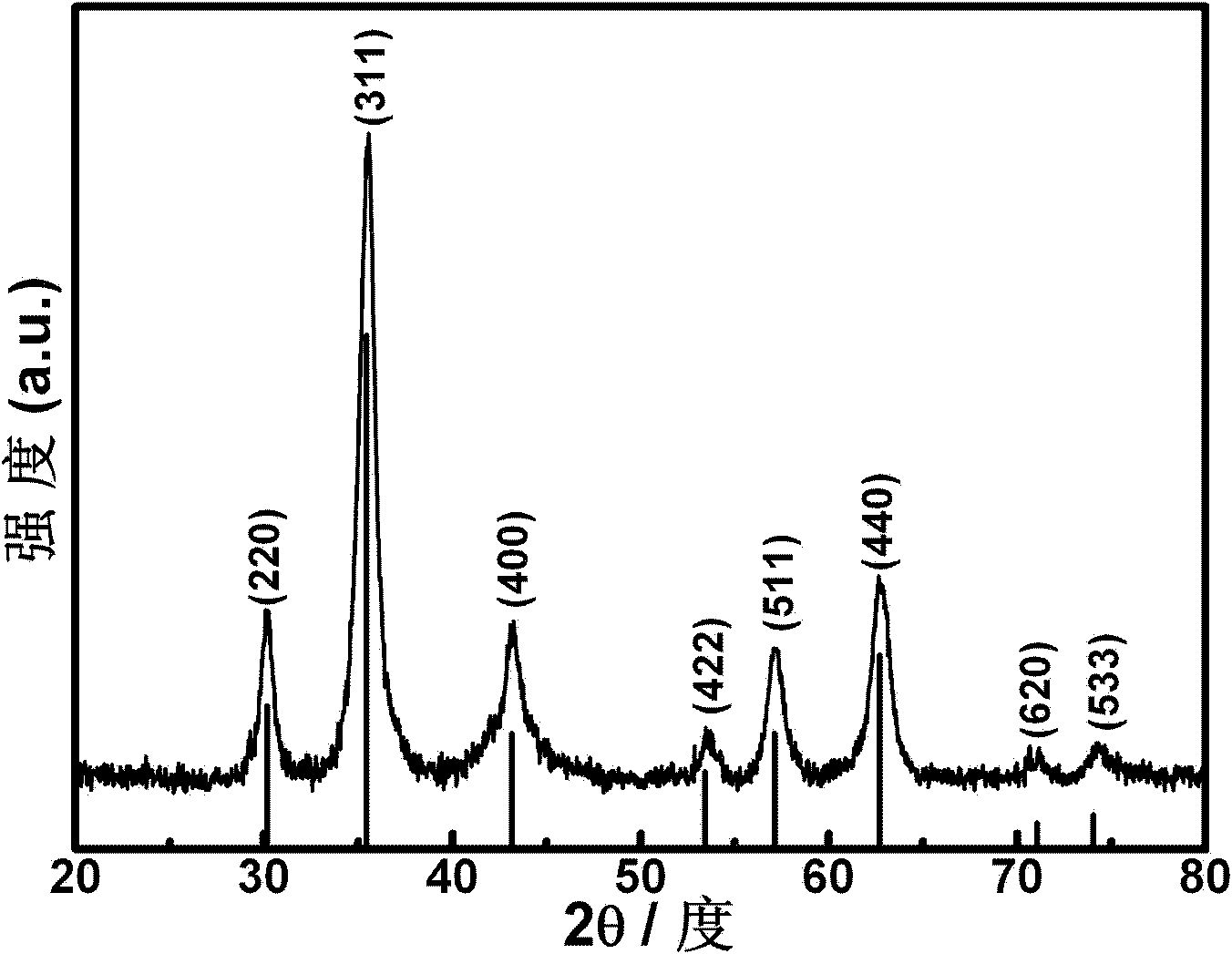

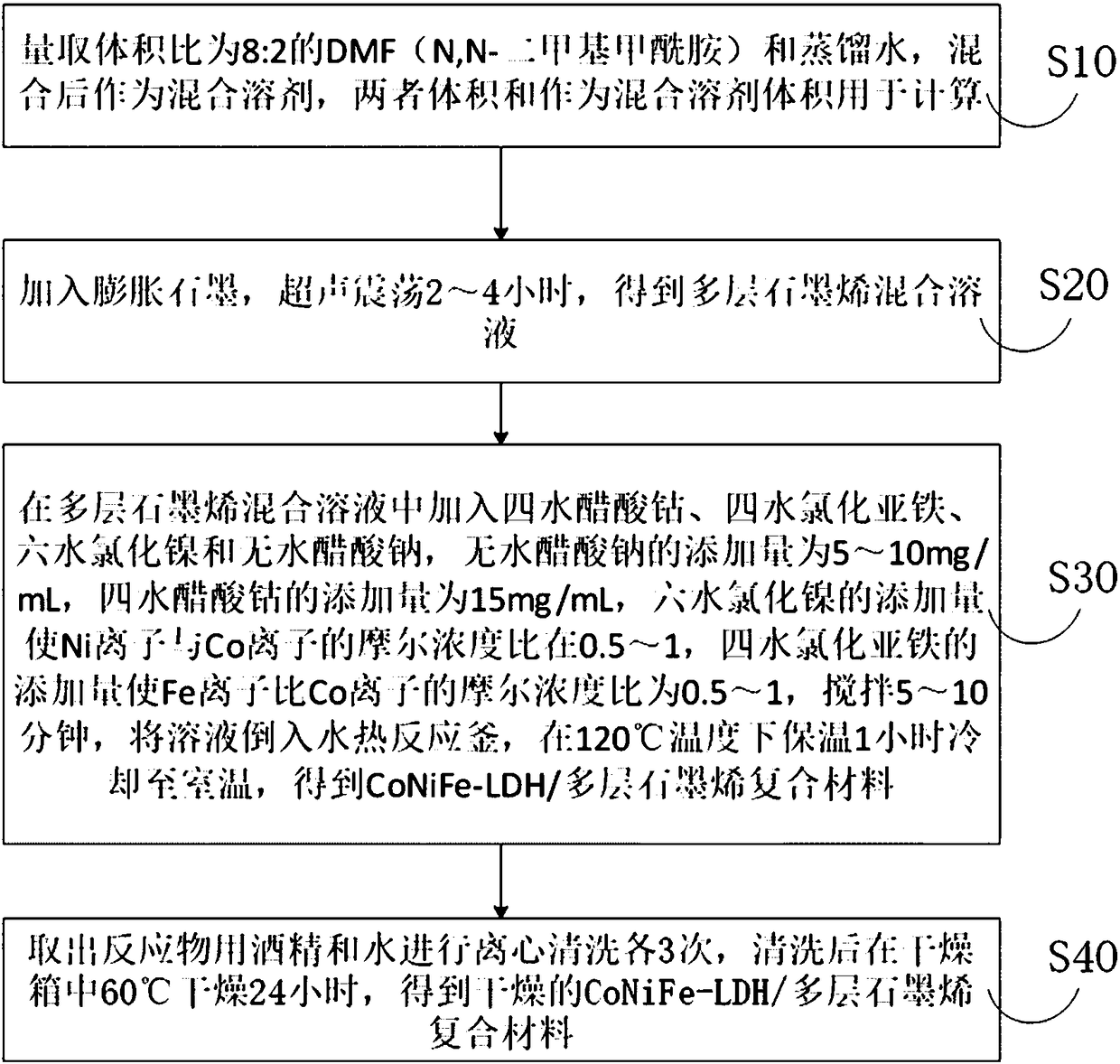

CoNiFe-LDH/multilayer graphene high-performance composite energy storage material and preparation method thereof

ActiveCN108364793AStrong ion capacityEasy to makeMaterial nanotechnologyHybrid capacitor electrodesSolventOxygen

The invention discloses a CoNiFe-LDH / multilayer graphene high-performance composite energy storage material and a preparation method thereof. the preparation method comprises the steps of: measuring DMF and distilled water with a volume ratio of 8:2, and mixing the DMF and the distilled water to serve as a mixed solvent; adding expanded graphite into the mixed solvent, carrying out ultrasonic processing on the solution for 2 to 4 hours to obtain a multi-layer graphene mixed solution; adding cobalt acetate tetrahydrate, ferrous chloride tetrahydrate, nickel chloride hexahydrate and anhydrous sodium acetate into the mixed solution, stirring the solution for 5 to 10 minutes, pouring the solution into a hydrothermal reaction kettle, maintaining the temperature of the solution at 120 DEG C for1 hour, and then cooling the solution to room temperature; taking out a reactant and centrifugally washing the reactant with alcohol and water for three times, and drying the reactant in a 60 DEG C oven for 24 hours to obtain a dry CoNiFe-LDH / multilayer graphene composite material. According to the CoNiFe-LDH / multilayer graphene high-performance composite energy storage material and the preparation method thereof, a method of complexing metal by means of organic molecules is adopted for preparing laminar multi-element metal hydroxide ont eh surface of multilayer graphene which does not containoxygen functional groups, and the process is simple and suitable for production.

Owner:嘉善县国创新能源研究院

Preparation method of porous graphene/polypyrrole electrode material

ActiveCN107522269AImprove conductivityReduce the degree of reunionDispersed particle separationWater/sewage treatmentWater bathsPeristaltic pump

The invention discloses a preparation method of a porous graphene / polypyrrole electrode material. The preparation method of the porous graphene / polypyrrole electrode material comprises dissolving pyrrole in a water-ethanol mixed solution, and then adding in a certain amount of graphene oxide; in an ice-water bath, adding in and uniformly mixing ferrous chloride tetrahydrate, dropwise adding in hydrogen peroxide solution through a peristaltic pump and continuing to stirring the solution for 24 h; then, adding in a certain amount of reducing agent, performing treatment in a thermostatic water bath of 95 DEG C for 12 h; suction-filtering and washing the obtained mixture, and vacuum-drying the washed mixture at 40 DEG C for 12 h to obtain a porous graphene / polypyrrole sample. The prepared porous graphene / polypyrrole sample achieves good effects on the capacitive deionization technology.

Owner:TONGJI UNIV

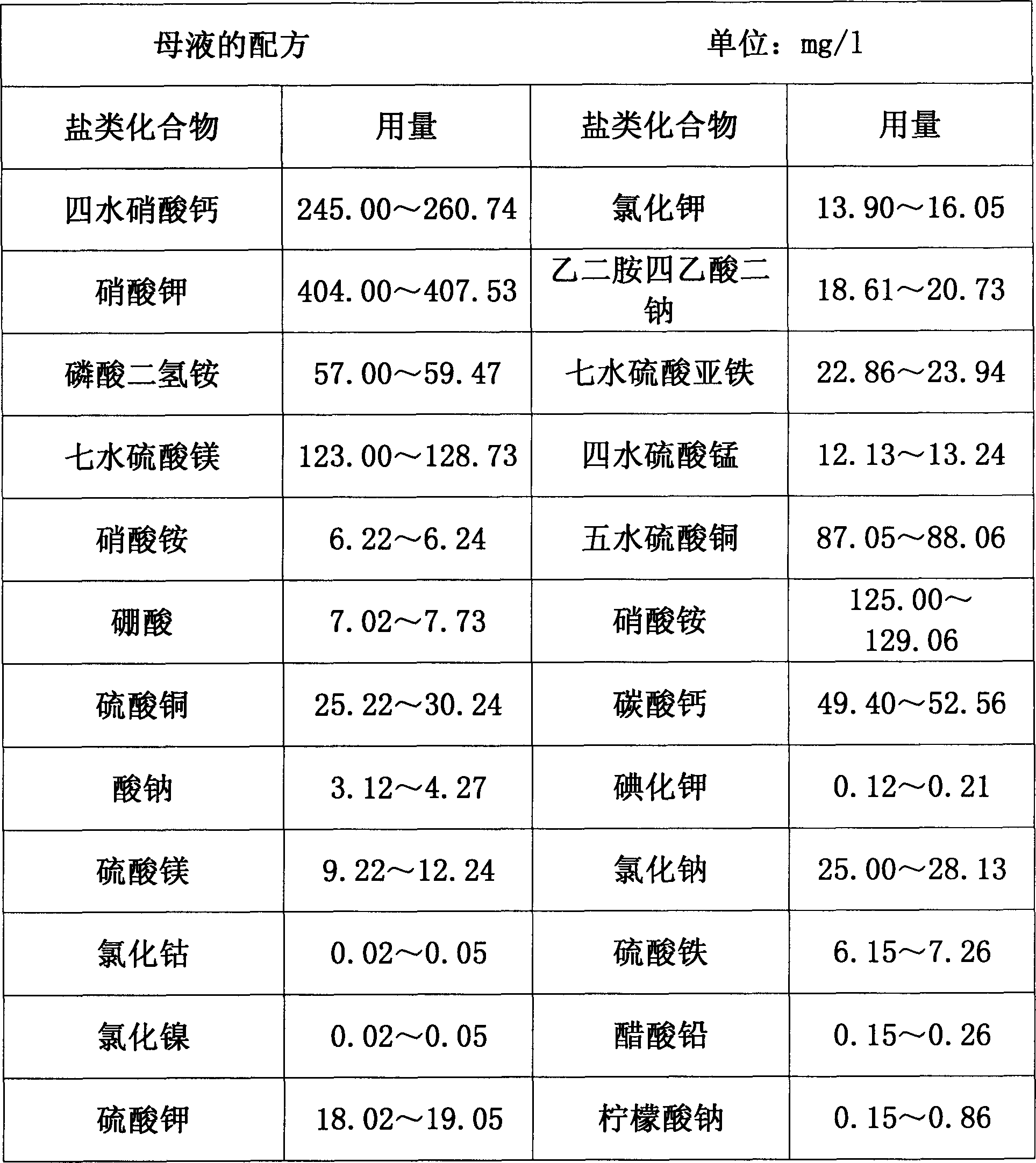

Water culture nutrient solution of spinach beet

InactiveCN103626559APromote growthShorten the growth cycleFertilizer mixturesCalcium nitrate tetrahydrateManganese

The invention discloses a water culture nutrient solution of spinach beet. The water culture nutrient solution comprises macroelements, microelements and water as well as calcium nitrate tetrahydrate, potassium nitrate, ammonium dihydrogen phosphate, magnesium sulfate heptahydrate, ammonium nitrate, boric acid, copper sulfate, sodium silicate, magnesium sulfate, cobalt chloride, nickel chloride, potassium sulfate, potassium chloride, ethylene diamine tetraacetic acid, ferrous sulfate septihydrate, manganese sulfate tetrahydrate, copper sulfate pentahydrate, ammonium nitrate, calcium carbonate, potassium iodide, sodium chloride, ferric sulfate, lead acetate and sodium citrate. According to the water culture nutrient solution of the spinach beet, the absorption utilization rate is high and the waste caused by nutrition excess or deficiency resulted by no pertinence of a water culture nutrient solution of the spinach beet in the past is avoided.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Boric fertilizer water dispersing granule and preparing method thereof

InactiveCN101531550AFast disintegrationDissolve (disperse) completelyFertiliser formsFertilizer mixturesMagnesium phosphatePotassium

The invention belongs to a new boric fertilizer, referring to a boric fertilizer water dispersing granule and preparing method thereof. The invention comprises one or more than one boric fertilizers and at least one surfactant; the materials are processed as the regular or irregular granules water dispersing granule; the weight part of the boric fertilizer is 5-95 parts; the rest is the assistant. The preferable solution of the invention is following: the boric fertilizer comprises one of the boric acid, boron oxide, boric acid ammonium, sodium tetraborate, calcium borate side, partial sodium borate, sodium borate tetrahydrate, magnesium diboride, sodium perborate, zinc borate, boric acid manganese, high-sodium borate, partial acid potassium, boron and magnesium fertilizer, boron and magnesium phosphate and boron mud or the mixture of the two or more than two of the above. The preparing method of the invention is scaling the prescription, mixing, crushing, and granule and drying to obtain the product. The boric fertilizer water dispersing granule of the invention has a fast disintegration, dissolving (dispersing) completely, not plugging the nozzle and the dropping pipe lines, no heating while using, easy to absorb moisture, packaging, storage and transportation, measurement, the use of low cost, widely used in food crops, cash crops, horticulture, lawns and urban greening; the market prospect is very broad.

Owner:SHENZHEN LANGTAI BIOTECH

Cobaltosic oxide coated and modified nickel-doped lithium manganate and preparation method thereof

InactiveCN106356509AInhibition of dissolutionIncrease contentCell electrodesSecondary cellsMANGANESE ACETATE TETRAHYDRATENickel acetate tetrahydrate

The embodiment of the invention discloses modified lithium manganate coated based on a sol-gel method, and a preparation method thereof. The preparation method comprises the steps of preparing a nickel-doped lithium manganate material with the sol-gel method by firstly, weighing lithium hydroxide monohydrate, nickel acetate tetrahydrate, manganese acetate tetrahydrate and citric acid according to a certain stoichiometric ratio, adding deionized water, and uniformly mixing, wherein the citric acid is used as a chelating agent; mixing the prepared nickel-doped lithium manganate with cobalt acetate tetrahydrate; grinding, and calcining in a tube furnace to obtain a cobaltosic oxide coated and modified nickel-doped lithium manganate composite material. The composite material prepared by using the technical scheme has excellent cycling stability, rate capability and high-temperature performance.

Owner:EAST CHINA UNIV OF SCI & TECH

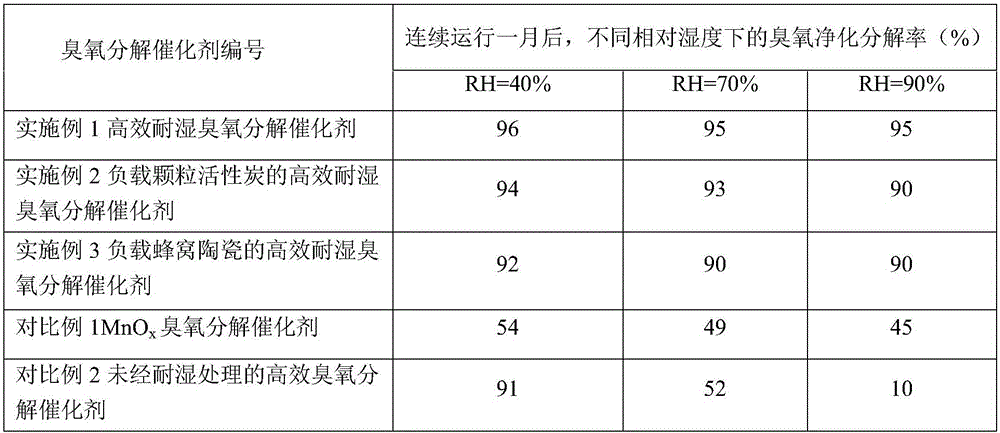

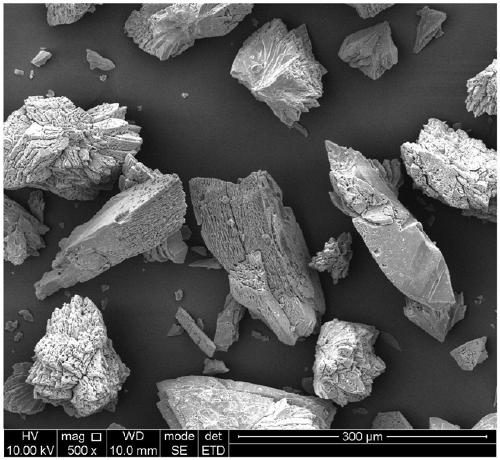

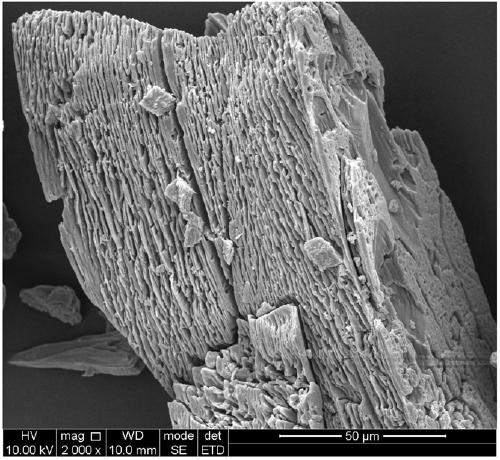

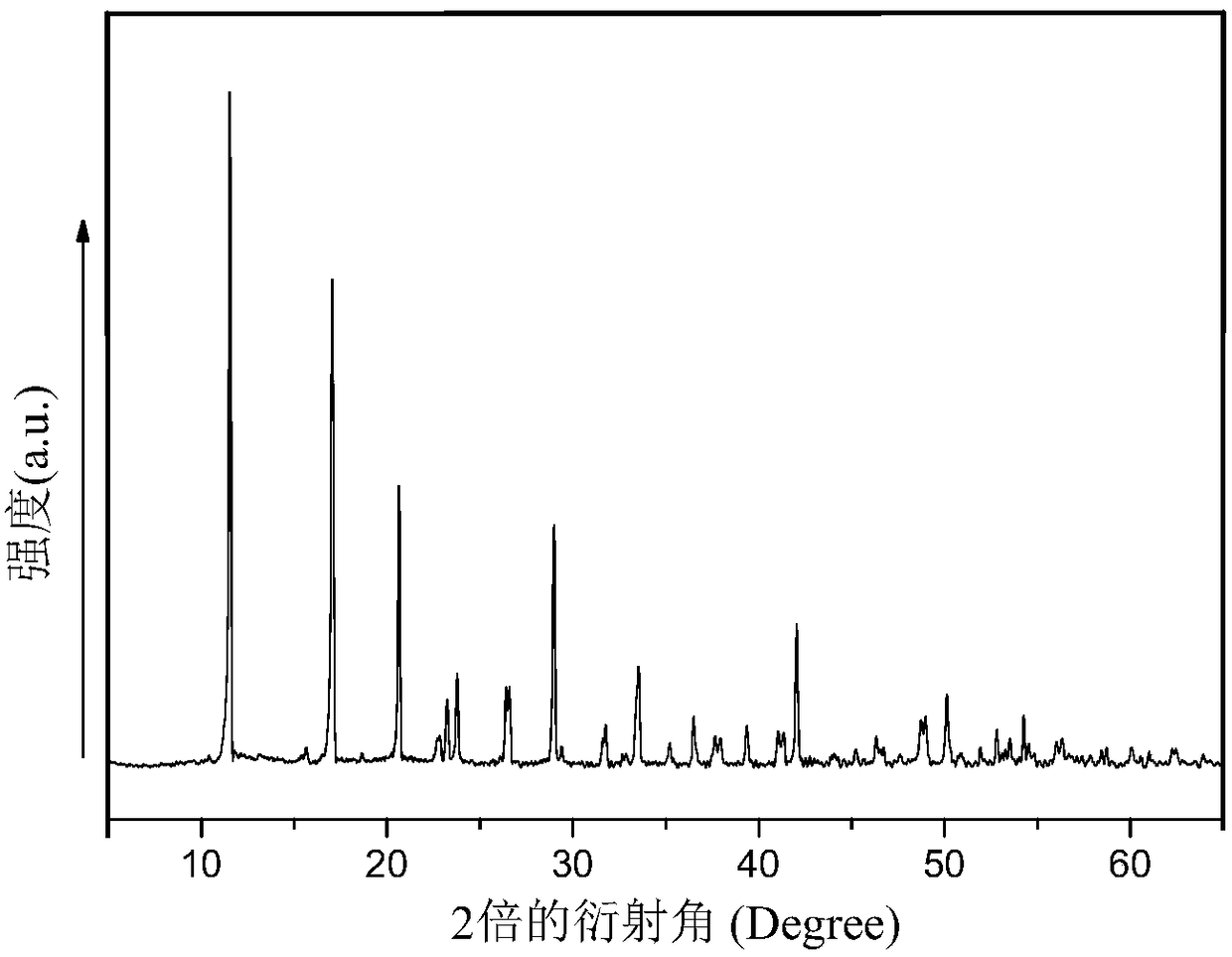

High-efficiency moisture-proof ozonolysis catalyst and preparation method thereof

ActiveCN106824218AHigh Ozone Decomposition EfficiencyImprove moisture resistanceHeterogenous catalyst chemical elementsDispersed particle separationCopper nitrateSurface-active agents

The invention discloses a high-efficiency moisture-proof ozonolysis catalyst and a preparation method thereof, belonging to the technical field of ozone purification catalysts. According to the high-efficiency moisture-proof ozonolysis catalyst disclosed by the invention, the oxides of manganese, copper, nickel and cobalt are taken as active components; the preparation method of the high-efficiency moisture-proof ozonolysis catalyst is a sol-gel method; in the preparation process, manganese nitrate tetrahydrate, copper nitrate trihydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate are dissolved in deionized water to obtain a nitrate solution; the nitrate solution is slowly added in a mixed solution of citric acid and a cationic surface active agent; after the pH value of the mixed solution is adjusted with ammonium hydroxide, constant temperature stirring is performed to obtain gel; and after the gel is dried, calcination is performed to obtain the ozonolysis catalyst. The preparation method disclosed by the invention is simple and low in costs, solves the problem that the ozonolysis catalyst is relatively poor in moisture-proof performance, and meanwhile, improves the ozonolysis efficiency; and the ozonolysis catalyst is long in service life, and the ozonolysis efficiency is not lowered when the ozonolysis catalyst is continuously used for a month.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

Iron/cobalt duplex-metal organic framework material as well as preparation method and application thereof

ActiveCN109054033AEasy to prepareMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsSulfate radicalsPersulfate

The invention relates to an iron / cobalt duplex-metal organic framework material as well as a preparation method and application thereof. The preparation method comprises the steps: dissolving cobalt nitrate hexahydrate, iron dichloride tetrahydrate and terephthalic acid into N,N dimethyl formamide to obtain a precursor solution; performing hydrothermal reaction on the precursor solution for 14 to27 h under the temperature of 110 to 170 DEG C; cooling, washing and drying to obtain the iron / cobalt duplex-metal organic framework material. Duplex transition metal coordination sites which are highly dispersed in the prepared iron / cobalt duplex-metal organic framework material disclosed by the invention can enhance effective contact between the iron / cobalt duplex-metal organic framework material and persulfate and can efficiently catalyze the persulfate to generate sulfate radicals; thus, persistent organic pollutants in wastewater can be removed. The iron / cobalt duplex-metal organic framework material is suitable for treating varieties of organic wastewater and has the advantages of high activity, small use amount, wide application pH range, good durability, convenience in operation and environmental friendliness and wide prospect in treating toxic and harmful organic wastewater which is difficult to biodegrade.

Owner:HANGZHOU DIANZI UNIV

Fireproofing and insect-proofing modifying liquid for collection tools of files and cultural relics and application of modifying liquid

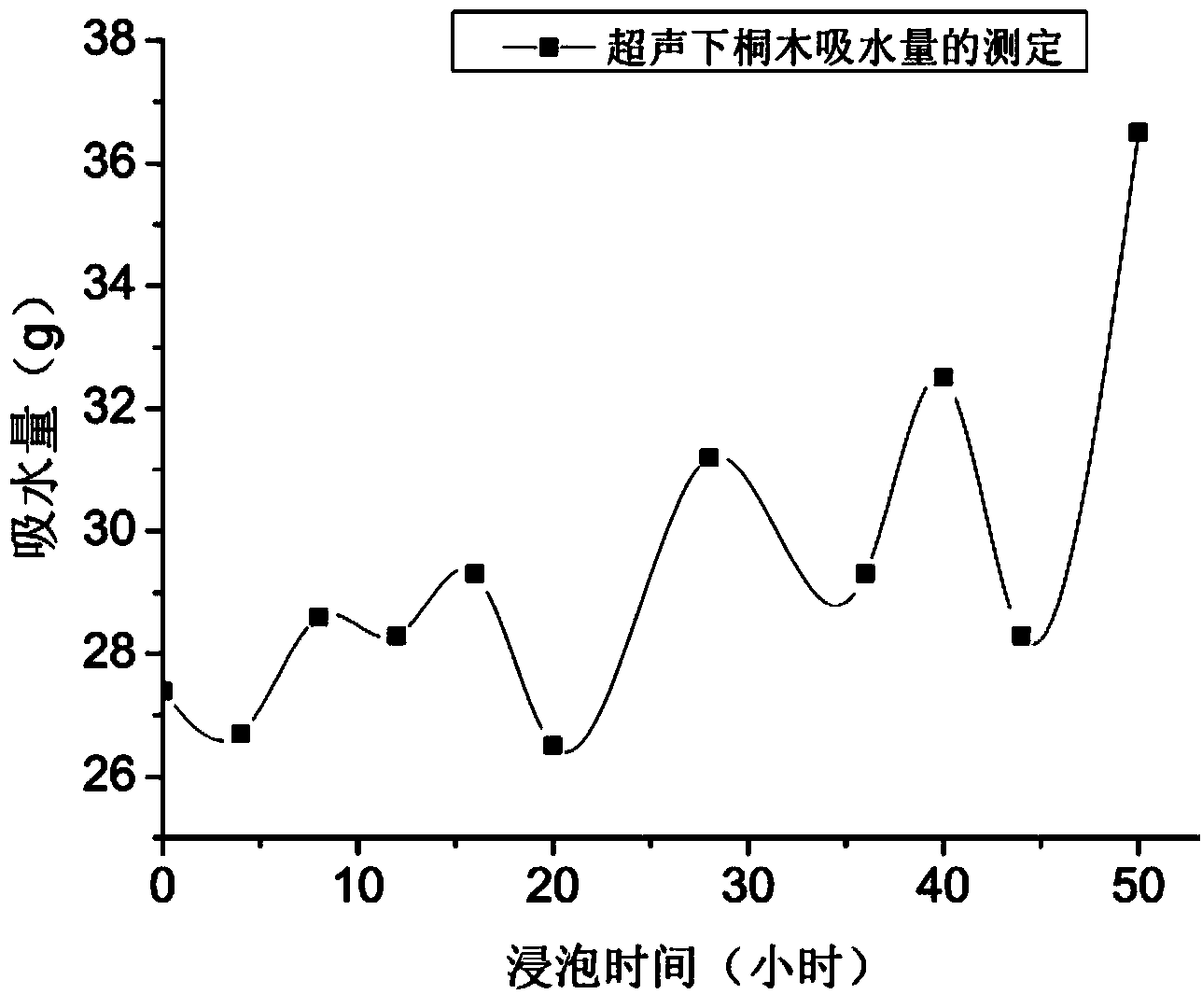

ActiveCN103612305AImprove flame retardant performanceGood pest controlWood impregnation detailsFireproofingEvery Four Hours

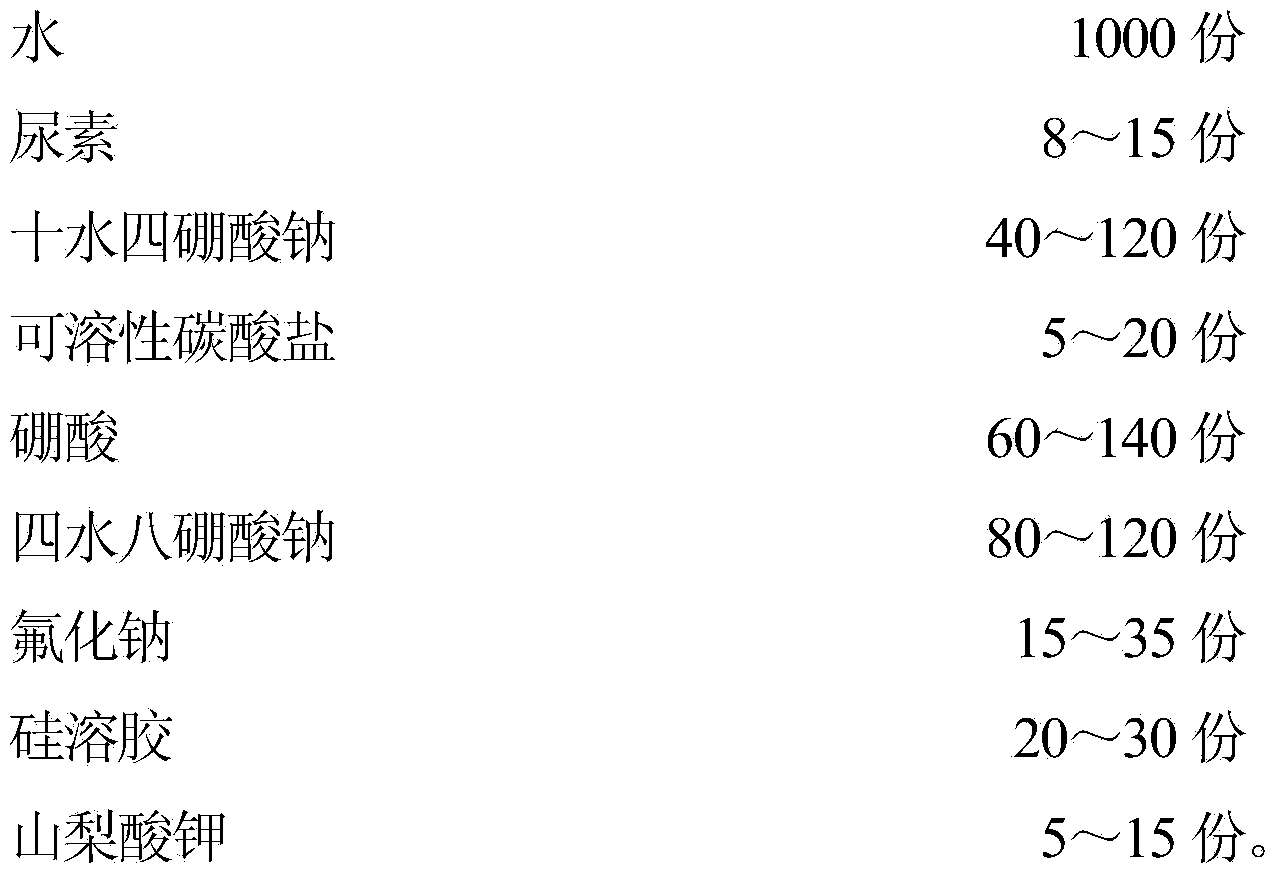

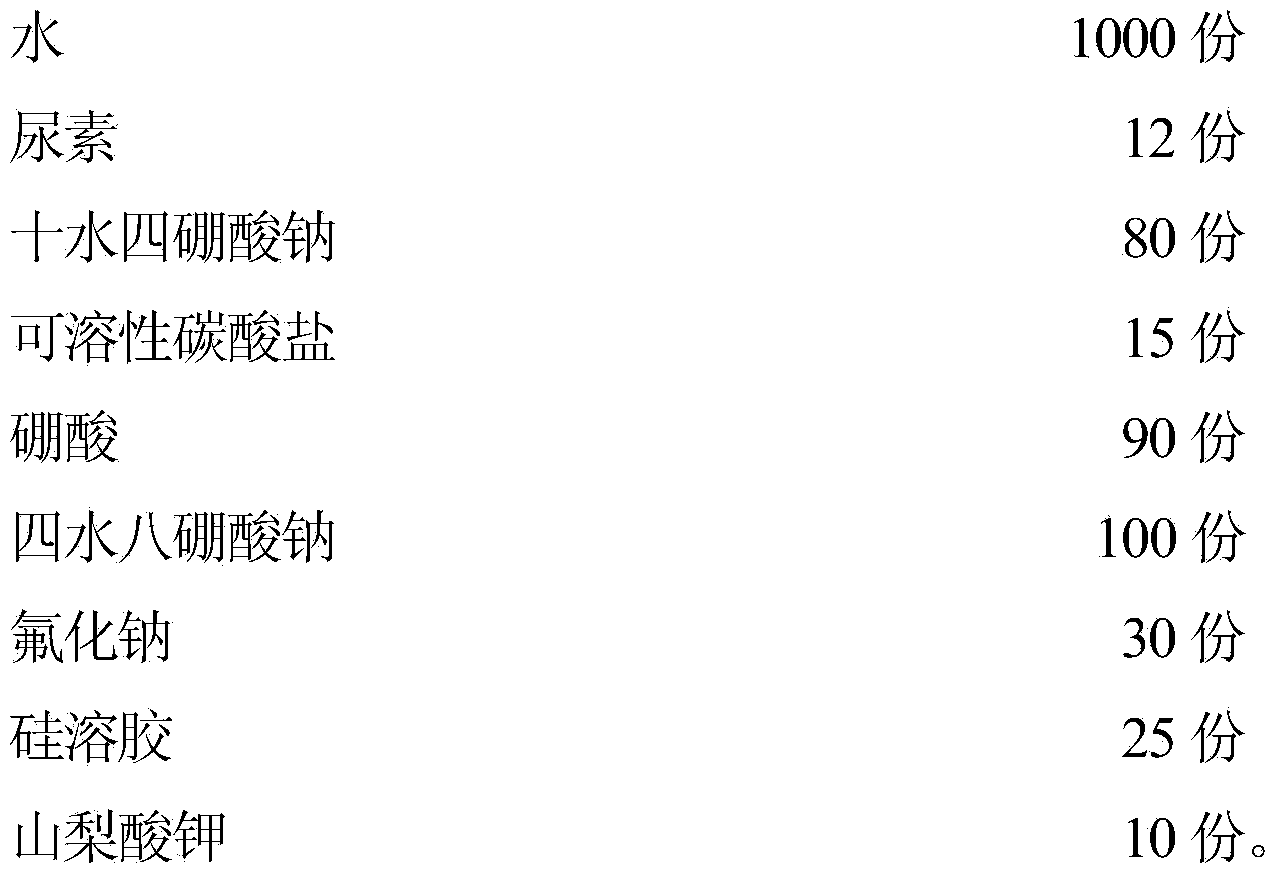

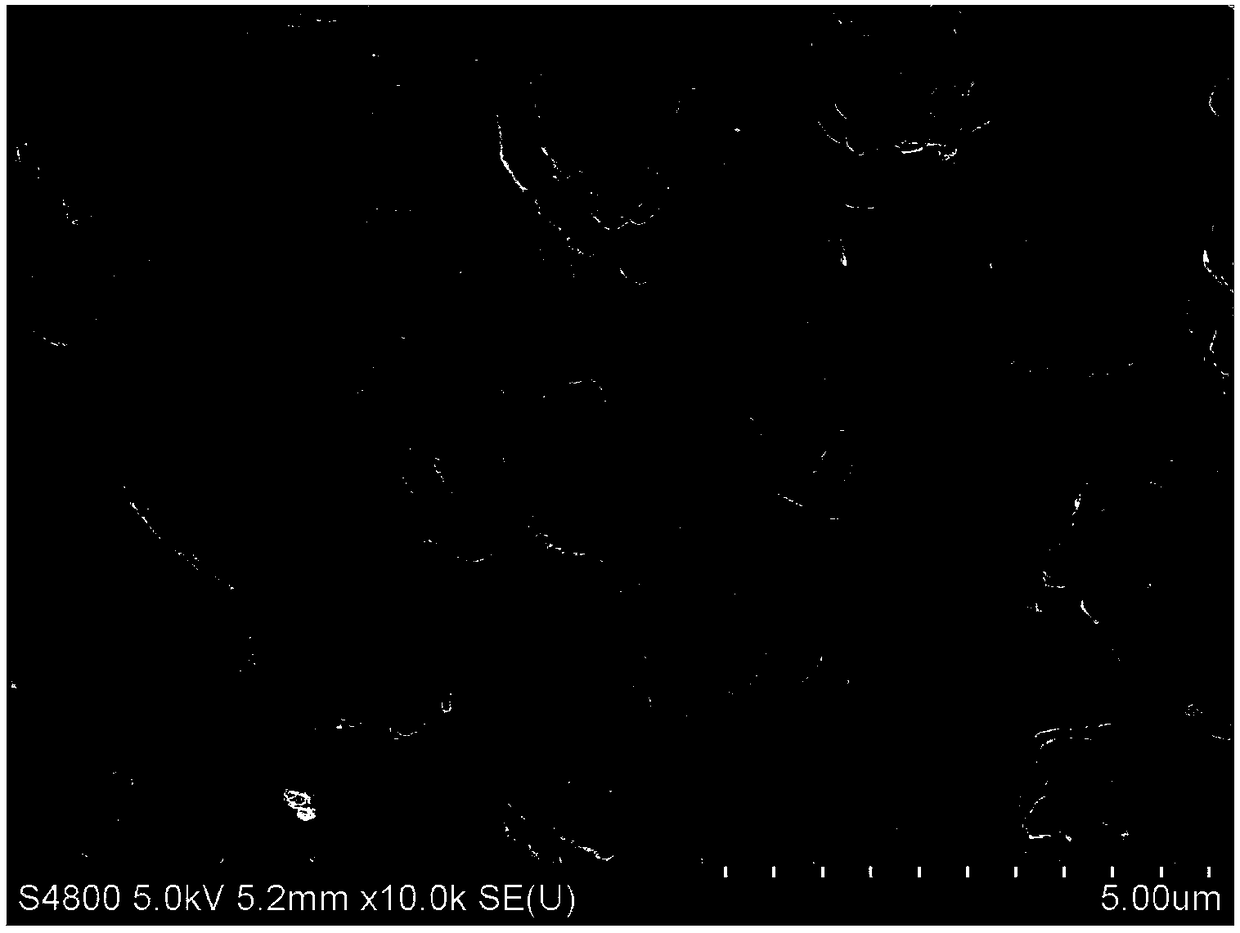

The invention provides a fireproofing and insect-proofing modifying liquid for collection tools of files and cultural relics and an application of the modifying liquid. The modifying liquid is composed of a solution A and an alum aqueous solution with a mass fraction of 15%-25%, wherein the solution A is composed of the following components in parts by weight: 1000 parts of water, 8-15 parts of urea, 40-120 parts of sodium tetraborate decahydrate, 5-20 parts of soluble carbonate, 60-140 parts of boric acid, 80-120 parts of sodium octoborate tetrahydrate, 15-35 parts of sodium fluoride, 20-30 parts of silica sol and 5-15 parts of potassium sorbate. The application method of the fireproofing and insect-proofing modifying liquid comprises the steps: soaking wood in water until the moisture content of the wood is above 66%; next, soaking the wood in the solution A, and in the soaking process, applying ultrasonic treatment every four hours; and finally, soaking the wood in the alum solution with the mass fraction of 15%-25%. The modifying liquid provided by the invention is low in price, non-volatile and non-toxic; the wood treated by using the modifying liquid does not generate toxic gases, has a good flame retardant effect, and is resistant to insects and good in leaching resistance; as a result, the wood can be used for fabricating the collection tools of files and cultural relics.

Owner:SHAANXI NORMAL UNIV

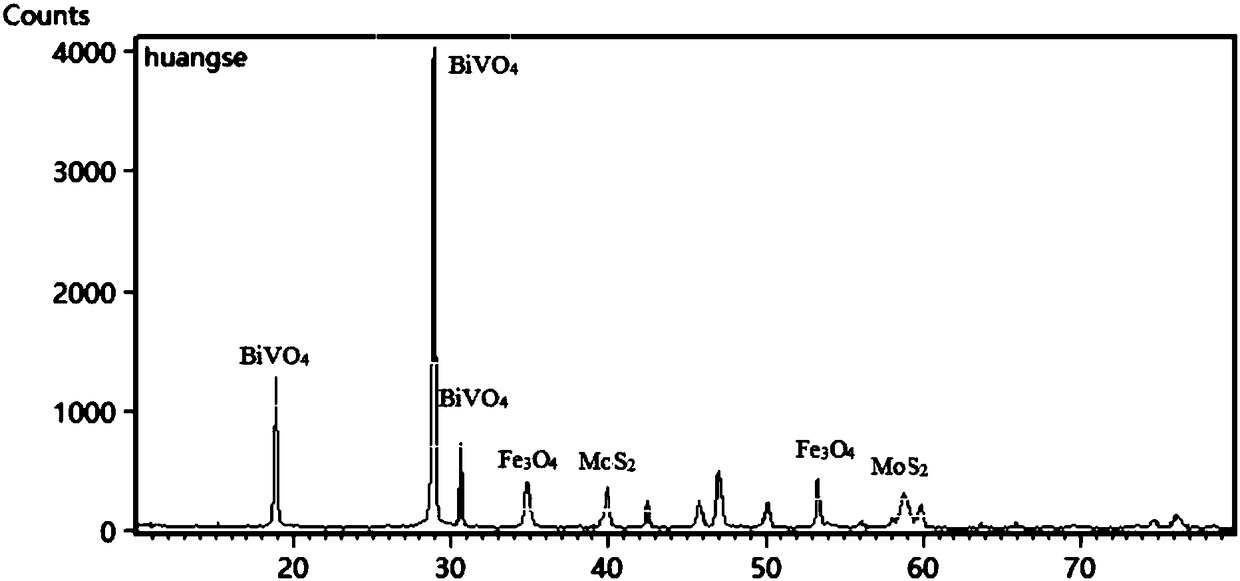

Fe3O4/MoS2/BiVO4 material preparing method, product and application of product

InactiveCN108355679AHigh reuse rateEasy to recycleWater/sewage treatment by irradiationWater treatment compoundsSodium acetateThiourea

The invention discloses a Fe3O4 / MoS2 / BiVO4 material preparing method, a product and an application of the product. The method comprises the steps: firstly, dissolving ferric chloride hexahydrate, sodium acetate and polyethylene glycol in ethylene glycol, carrying out a reaction at the temperature of 180-200 DEG C for 8-9 h, and thus obtaining ferric oxide; then, mixing sodium molybdate dehydrate,sodium molybdate tetrahydrate and thiourea evenly, adding ferroferric oxide, and carrying out a reaction for 22-24 h at the temperature of 180-200 DEG C, to obtain a Fe3O4 / MoS2 material; finally, dissolving bismuth nitrate pentahydrate and ammonium metavanadate in deionized water, adding the Fe3O4 / MoS2 material, mixing evenly, carrying out a reaction for 15-17 h at the temperature of 160-170 DEG C, and thus obtaining a Fe3O4 / MoS2 / BiVO4 composite material. When the composite material is used as a photocatalyst for treating tetracycline hydrochloride wastewater, the degradation rate can reach 90% or more, and the photocatalytic efficiency can be improved. At the same time, because of the presence of Fe3O4, the photocatalyst can be recovered more conveniently and simply for repeated experiments, the recovery cost of the photocatalyst is reduced, and the repeated utilization rate of the photocatalyst is improved.

Owner:CHANGAN UNIV

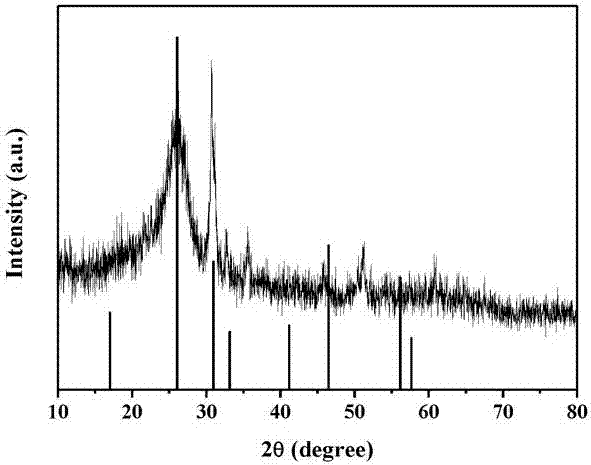

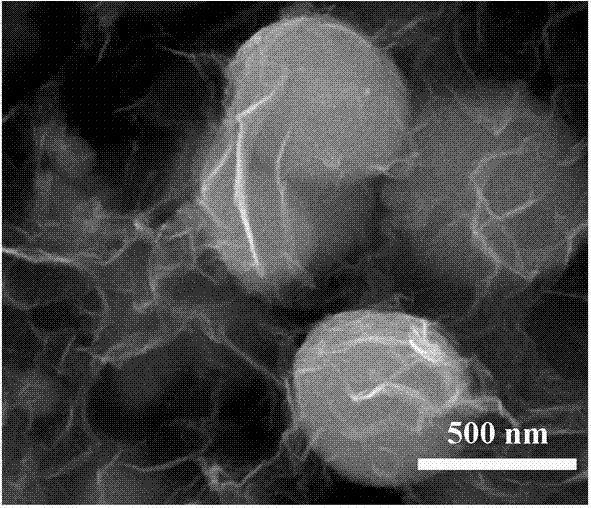

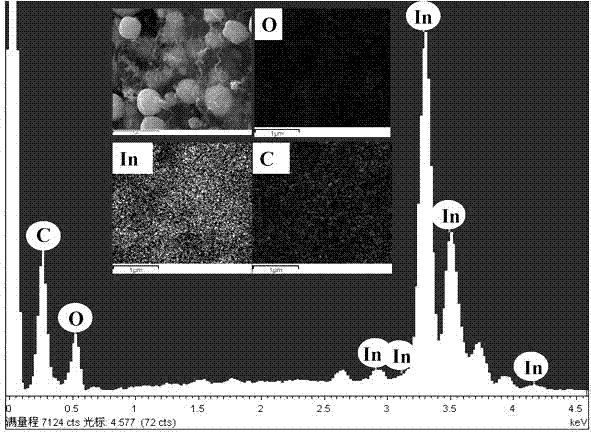

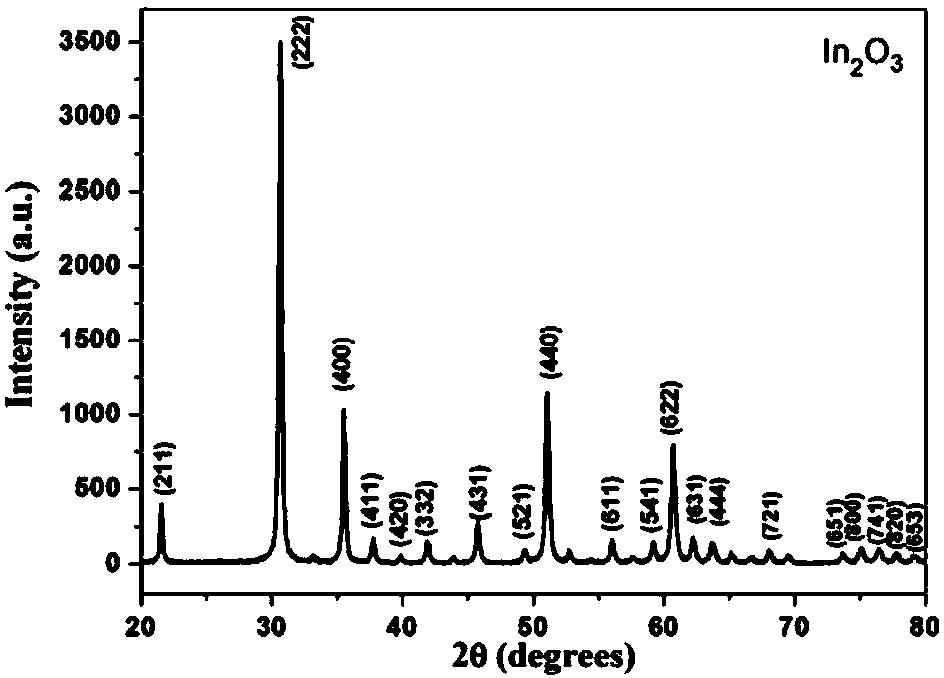

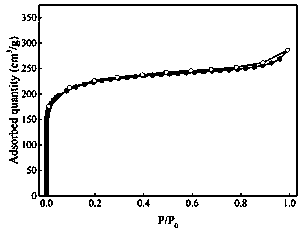

Method for preparing rGO-In2O3 nanoparticle composite

InactiveCN107381622ALow costSimple production processMaterial nanotechnologyGallium/indium/thallium compoundsSemiconductor materialsMicrosphere

The invention provides a method for preparing an rGO-In2O3 nanoparticle composite. The method particularly comprises the following steps: performing a hydrothermal reaction on indium(III) chloride tetrahydrate and lauryl amine which are taken as raw materials and performing calcination treatment to obtain indium oxide nanoparticles; then processing the surface of indium oxide by use of aminopropyl triethoxysilane (APTES) to ensure that the surface of indium oxide carries positive charges; and dispersing indium oxide carrying the positive charges and graphene oxide in deionized water to ensure mutual combination, and finally, performing reduction on graphene oxide by a hydrothermal method to obtain the rGO-In2O3 nanoparticle composite at last. The method is simple in production process, and the obtained rGO-In2O3 nanoparticle composite adopts a p-n heterogeneous structure and combines the advantages of large specific area of rGO and an In2O3 semi-conductor material. The method is suitable for an rGO and metal semi-conductor oxide combining process, so that the material with favorable performance is obtained.

Owner:UNIV OF JINAN

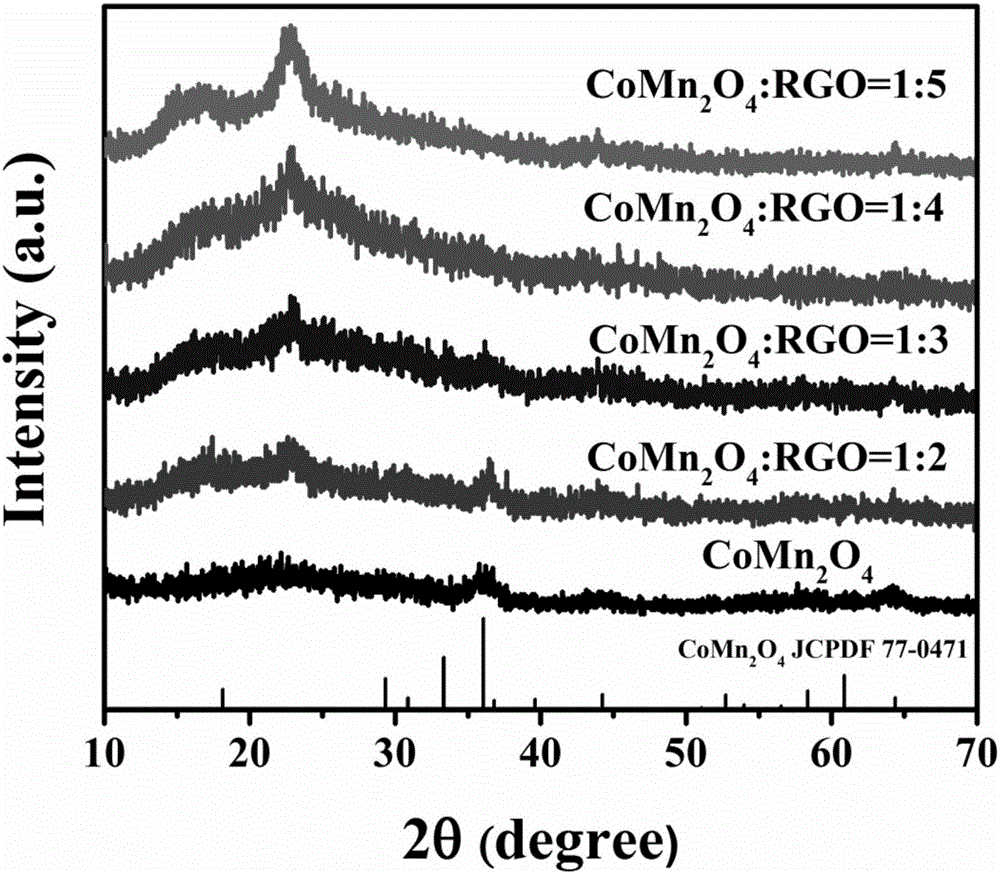

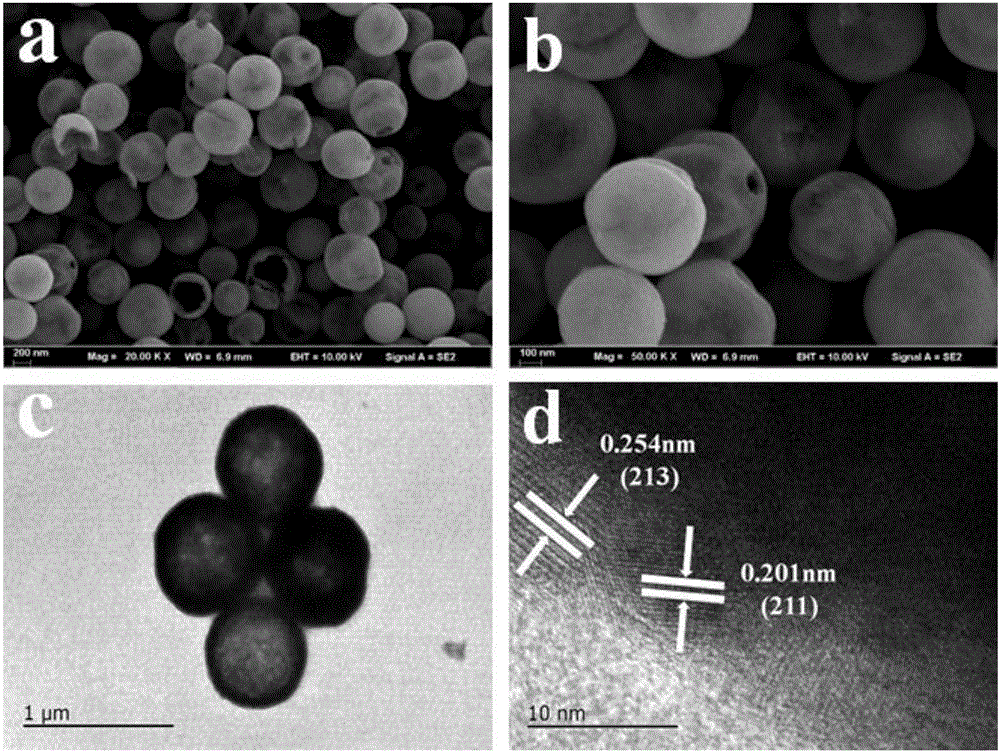

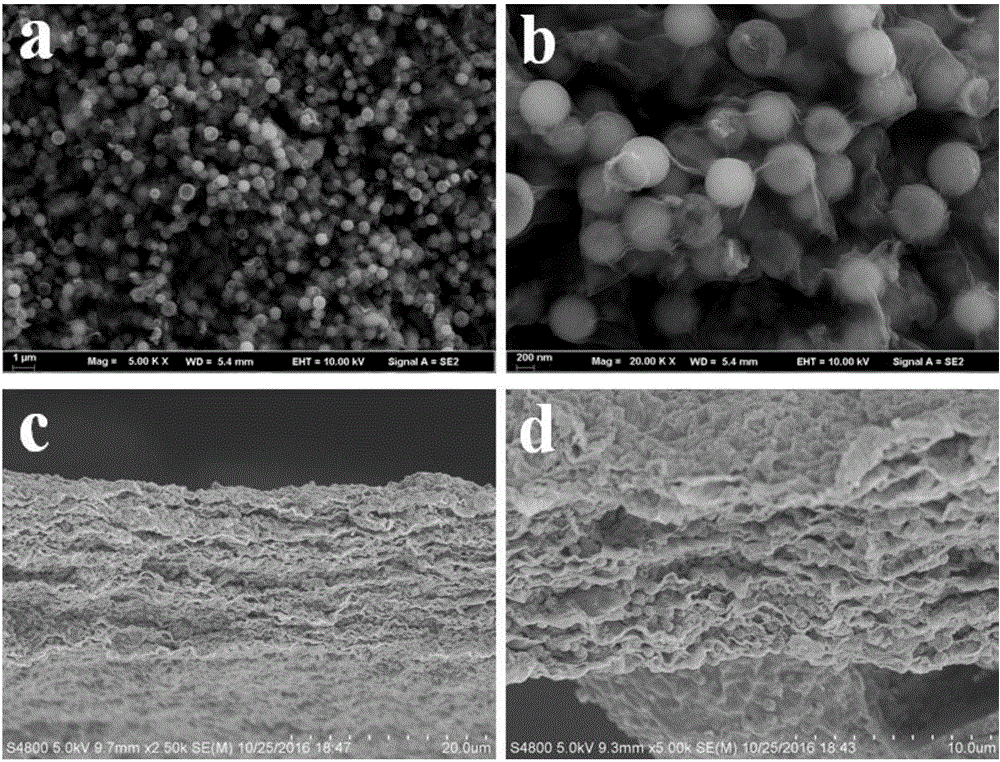

Preparation method of hollow CoMn2O4-RGO flexible super capacitor material

ActiveCN106803464AImprove electrochemical performanceConducive to infiltrationMaterial nanotechnologyHybrid capacitor electrodesElectrolysisFiltration

The present invention relates to the super capacitor technology field, in particular to a method which uses the manganese nitrate tetrahydrate, the cobaltous nitrate hexahydrate, the glycerinum, the isopropyl alcohol and the graphene oxide as the raw materials to prepare the hollow CoMn2O4-RGO flexible super capacitor material, and is simple in preparation technology and low in cost. According to the present invention, by adopting the CoMn2O4 and GO materials of the hollow core-shell structures and by a vacuum filtration method, a CoMn2O4-RGO sandwich structure composite material is prepared for the first time, on one hand, the CoMn2O4 of the hollow core-shell structure has a larger specific area, and the hollow structure is more conducive to the permeation and transfer of an electrolyte; and on the other hand, a CoMn2O4 spherical structure also can support the intervals between the graphene layers, a channel for the flow of the electrolyte is provided, and the flow of the electrolyte in the interior of the material also can be accelerated. By the structure, the electrochemical performance of the material can be improved effectively.

Owner:JIANGSU UNIV

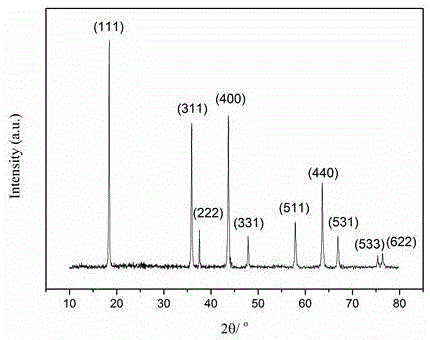

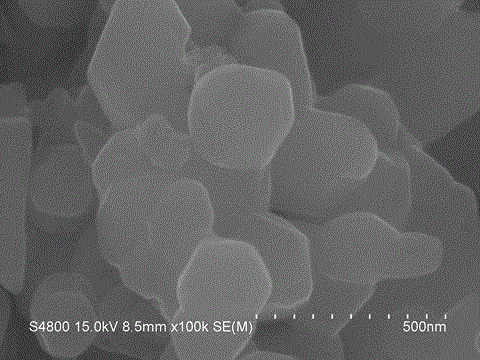

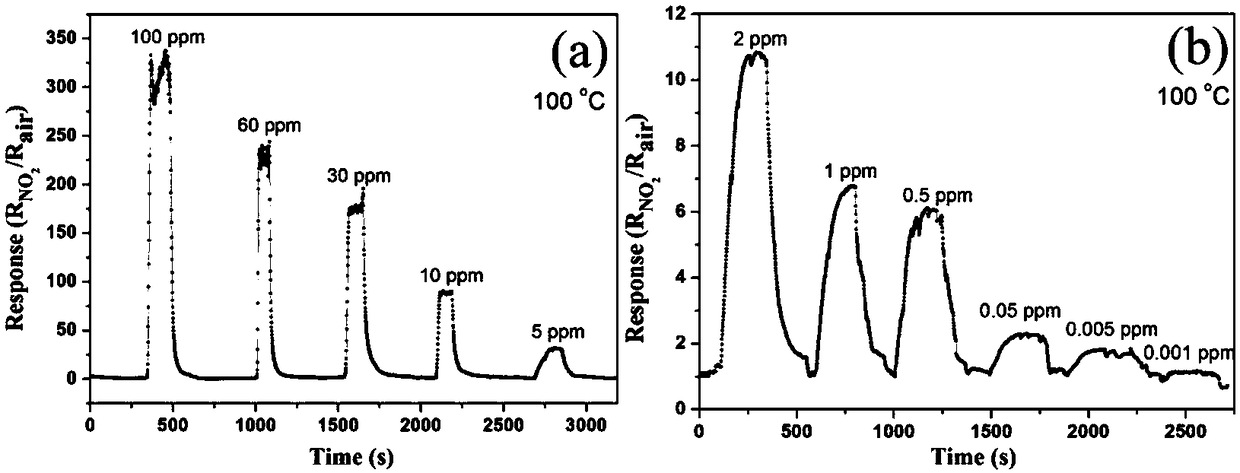

Preparing method of nano-rod-shaped indium oxide gas-sensitive material

ActiveCN108455659AGood sensor detection performanceLower working temperatureMaterial nanotechnologyGallium/indium/thallium compoundsIndium TrichlorideWorking temperature

The invention relates to a preparing method of a nano-rod-shaped indium oxide (In2O3) gas-sensitive material, and belongs to the technical field of preparation of inorganic nanometer functional materials. The preparing method comprises the steps of with indium(III) chloride tetrahydrate being an indium source, by adopting hexadecyl trimethyl ammonium bromide as surface active agent, conducting a hydrothermal reaction under the alkaline condition of sodium hydroxide to prepare indium hydroxide and finally, conducting thermal roasting to obtain the indium oxide gas-sensitive material of a nano-rod-shaped structure. Finally prepared indium oxide is In2O3 with the cubic phase and of the nano-rod-shaped structure, has very good performance of sensing and detecting both nitrogen dioxide gas andhydrogen sulfide gas and is insensitive to other gases (carbon monoxide, ethyl alcohol, ammonia, hydrogen, formaldehyde and the like); the indium oxide also has low working temperature, a quick response and restoration, very high sensitivity, a low detection limit, high selectivity and high stability. Besides, the indium oxide gas-sensitive material can also be used in the fields of catalyst, battery materials, photoelectric materials and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing boron-nitrogen-doped porous carbon material applied to super capacitor under microwave hydrothermal assistance

InactiveCN109251031AHigh nitrogen contentHigh specific capacitanceHybrid capacitor electrodesCeramicwareMetallurgyPorous carbon

The invention relates to a method for preparing a boron-nitrogen-doped porous carbon material applied to a super capacitor under microwave hydrothermal assistance. The method is characterized in thatChinese fir bark is taken as a raw material, and ammonium pentaborate tetrahydrate is taken as a boron source and a nitrogen source. The method comprises the following steps: firstly, performing boron-nitrogen heteroatom doping under microwave hydrothermal assistance; performing high-temperature pyrolysis to obtain the boron-nitrogen-doped porous carbon material, which is 10.19 to 13.05 percent byweight in boron content, is 15.13 to 19.5 percent by weight in nitrogen content, and can be up to 820 to 955m<2> / g in specific surface area. By adopting method, heteroatom doping is realized under microwave hydrothermal assistance through high-temperature pyrolysis, and a carbon material with a large specific surface area is prepared. The method is easy and convenient to operate, and the preparation time of the carbon material is shortened greatly. Meanwhile, strong acid, strong alkali and toxic reagents are not used in the preparation process, so that the process is environmentally friendly,and the prepared boron-nitrogen-doped porous carbon material has a certain application prospect in the field of super capacitors.

Owner:FUJIAN AGRI & FORESTRY UNIV

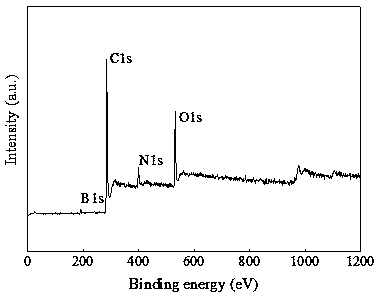

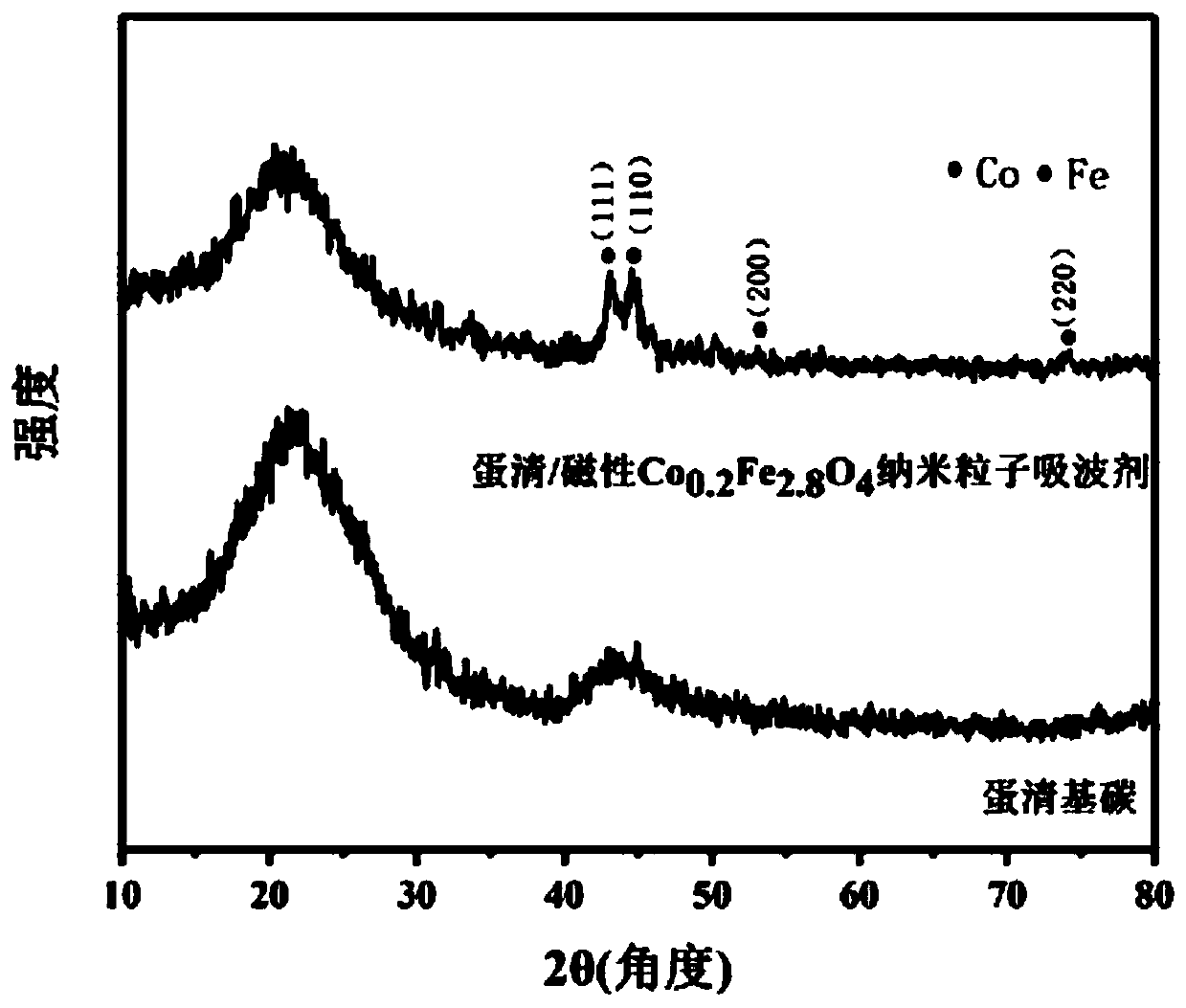

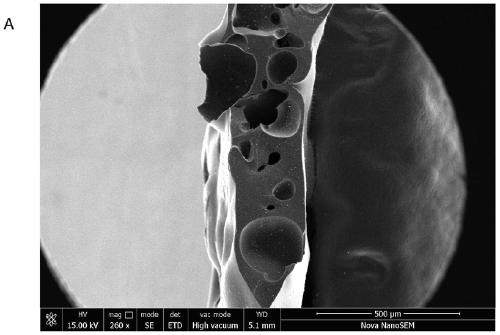

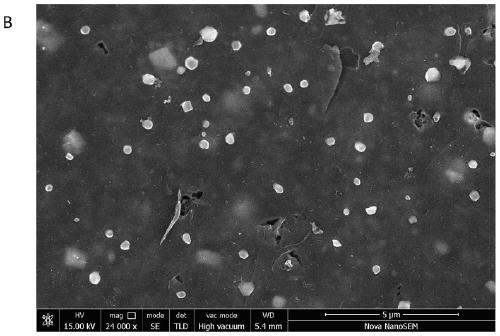

Protein-based carbon/magnetic Fe Co nanoparticle composite wave-absorbing agent and preparation method and application thereof

ActiveCN110079271AImprove absorbing performanceAbsorbing frequency bandwidthMaterial nanotechnologyOther chemical processesMagnetite NanoparticlesLarge applications

The invention provides a protein-based carbon / magnetic Fe Co nanoparticle composite wave-absorbing agent and a preparation method and application thereof, and belongs to the technical field of wave-absorbing materials. The preparation method of the protein-based carbon / magnetic Fe Co nanoparticle composite wave-absorbing agent comprises the following steps: 1) mixing water, ferric chloride hexahydrate, ferrous chloride tetrahydrate and cobalt chloride hexahydrate, and reacting for 1-2 h at the temperature of 70-100 DEG C to prepare magnetic nanoparticles; 2) mixing the magnetic nanoparticles with egg white liquid, and curing to obtain a protein-magnetic nanoparticle compound; 3) carbonizing the protein-magnetic nanoparticle compound obtained in the step 2) to obtain the protein-based carbon / magnetic Fe Co nanoparticle composite wave-absorbing agent. The material prepared by using the composite wave-absorbing agent has strong wave-absorbing performance, meanwhile has the characteristicsof wide wave-absorbing frequency band, small matching thickness of an absorber and the like, and has a large application prospect in the field of wave-absorbing materials.

Owner:JILIN UNIV

Microelement-rich liquid urea ammonium nitrate solution fertilizer and preparation method thereof

ActiveCN104262064AImprove securityAvoid corrosionMagnesium fertilisersAmmonium nitrate fertilisersPolyethylene glycolManganese

The invention discloses a microelement-rich liquid urea ammonium nitrate solution fertilizer, which comprises 20-25 parts of urea, 20-30 parts of ammonium nitrate, 0.1-2 parts of liquid ammonia, 0.01-0.1 part of magnesium nitrate, 1-3 parts of sodium polyaspartate, 0.01-0.1 part of any one or a mixture of any more than two of ammonium carbonate, ammonium thiocyanate and ammonium bicarbonate, 0.02-0.08 part of an urease inhibitor, 1-2 parts of edta-2nacu tetrahydrate, 1-3 parts of ferric-sodium edentate, 1-3 parts of magnesium-disodium edetate, 1-3 parts of manganese-disodium edetate, 1-3 parts of zinc-disodium edentate, 1-3 parts of disodium octaborate tetrahydrate, 0.01-0.1 part of ammonium heptamolybdate, 1-3 parts of citric acid, 1-3 parts of an antifreezing agent PX-60 or polyethylene glycol PEG-200, and 16.5-41 parts of water. A product disclosed by the invention is high in safety, and pH value is 6-7; and due to the addition of an anticorrosive antiscale agent, the corrosion of products on production, storage, transportation and application facilities is effectively prevented.

Owner:中化(临沂)作物营养有限公司

Aerogel hybrid microsphere grafted silicon composite coating and preparation method thereof

The invention discloses an aerogel hybrid microsphere grafted silicon composite coating which is prepared from the following raw materials in parts by weight: 3-5 parts of superfine silicon dioxide aerogel, 7-9 parts of ferric chloride hexahydrate, 10-12 parts of ferrous chloride tetrahydrate, 2-3 parts of citric acid, 1-2 parts of methylacryloyloxypropyl trimethoxy silane, 100-130 parts of tetraethoxysilane, 5-7 parts of hexafluorobutyl acrylate, 0.1-0.4 part of azodiisobutyronitrile, 0.1-0.2 part of sp800, 1-2 parts of chlorthal-dimethyl, 2-4 parts of hydrolyzed polymaleic anhydride, 0.6-1 part of polyacrylamide, 1-2 parts of casein, 0.3-1 part of zinc cyanurate, 0.1-0.2 part of ethyl naphthol, 3-5 parts of calcium phosphate and appropriate absolute ethyl alcohol and dimethyl formamide. In the invention, the added silicon dioxide aerogel can effectively improve the packing dispersity in resin, and the stability and impact strength of the finished product of coating are enhanced.

Owner:TONGLING JINGWEI FLUID SCI & TECH

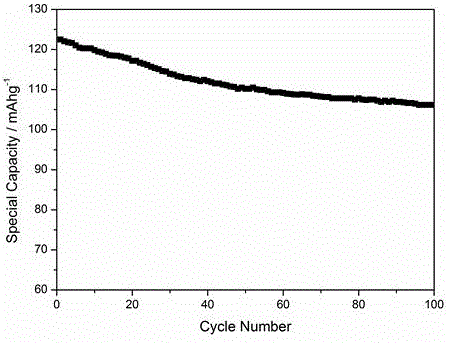

Preparation and application of graphene coated spherical cobalt disulfide composite material

InactiveCN106558690AUnique shapeSimple processCell electrodesSecondary cellsAcetic acidCobalt acetate

The invention relates to the technical field of sodium-ion batteries and particularly relates to preparation and application of a graphene coated spherical cobalt disulfide composite material. The preparation mainly includes the steps of: dissolving 0.2-0.5 g of cobalt acetate tetrahydrate in 5-15 ml of deionized water, and when the cobalt acetate tetrahydrate is dissolved completely, adding the solution to 25 ml of a graphene oxide solution, stirring the mixture for 10 min and adding 0.3-0.6 g of L-cysteine, stirring the mixture, and adding 10 ml of ethylene glycol with stirring, and moving the solution to a 40 ml reaction kettle, performing a reaction in a drying box at 120-180 DEG C for 6-18 h, washing a product with water for 3 times and drying the product to obtain the graphene coated spherical cobalt disulfide composite material. The material, when being used as a negative pole of a sodium-ion battery, is high in specific capacity and cycling stability. The preparation is simple process, is low in cost and has good repeatability.

Owner:FUZHOU UNIV

Potato spray culture nutrient solution and preparation method thereof

InactiveCN101781148AMeet the needs of growth and developmentIncrease productionFertilizer mixturesEthylenediamineCalcium nitrate tetrahydrate

The invention discloses potato spray culture nutrient solution and a preparation method thereof. The potato spray culture nutrient solution comprises mother solution A, mother solution B, mother solution C, mother solution D and mother solution E. The mother solution A comprises the following raw materials in weight volume ratio: 30 to 40 g / L of potassium nitrate, 20 to 30 g / L of monopotassium phosphate, 4.0 to 5.0 g / L of ferrisodium ethylenediamine tetracetate trihydrate, 3.0 to 4.0 g / L of sodium ethylenediamine tetracetate dehydrate, and the balance of water. The mother solution B comprises the following raw materials in weight volume ratio: 45 to 55 g / L of calcium nitrate tetrahydrate, and the balance of water. The mother solution C comprises the following raw materials in weight volume ratio: 0.8 to 0.9 g / L of potassium iodide, 6.0 to 7.0 g / L of boric acid, 22 to 23 g / L of manganese sulfate tetrahydrate, 8.0 to 9.0 g / L of zinc sulfate heptahydrate, 0.2 to 0.3 g / L of sodium molybdate dehydrate, 0.025 to 0.03 g / L of cobalt chloride hexahydrate, 0.02 to 0.03 g / L of copper sulfate pentahydrate, and the balance of water. The mother solution D comprises the following raw materials in weight volume ratio: 100 to 200 g / L of urea, and the balance of water. The mother solution E comprises the following raw materials in weight volume ratio: 100 to 200 g / L of monopotassium phosphate, and the balance of water.

Owner:庞淑敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com