Patents

Literature

235results about How to "Easy to prepare in large batches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High volume delivery system for gallium trichloride

InactiveUS20090223441A1High manufacturing processEasy to prepare in large batchesPolycrystalline material growthSemiconductor/solid-state device manufacturingHigh volume manufacturingSemiconductor materials

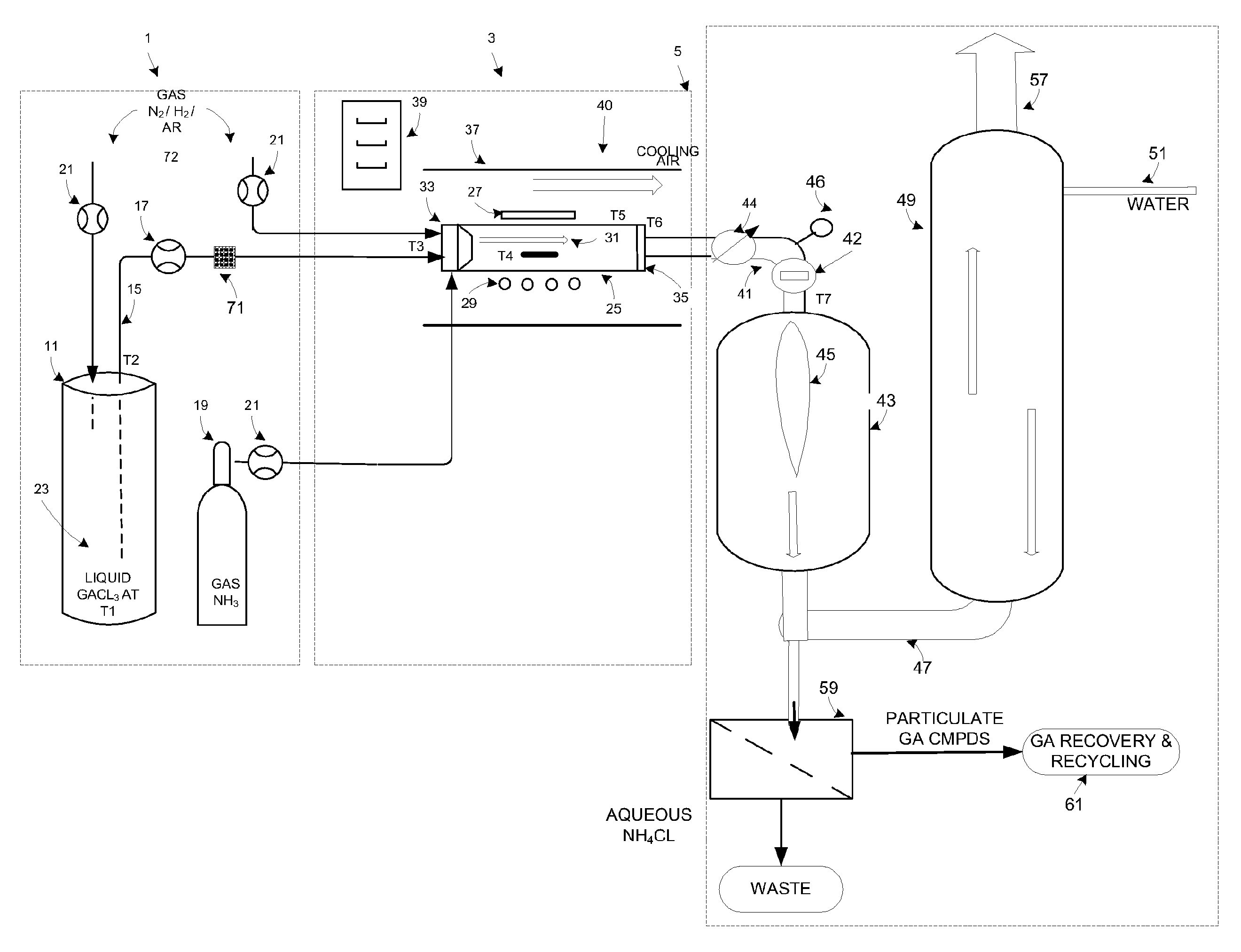

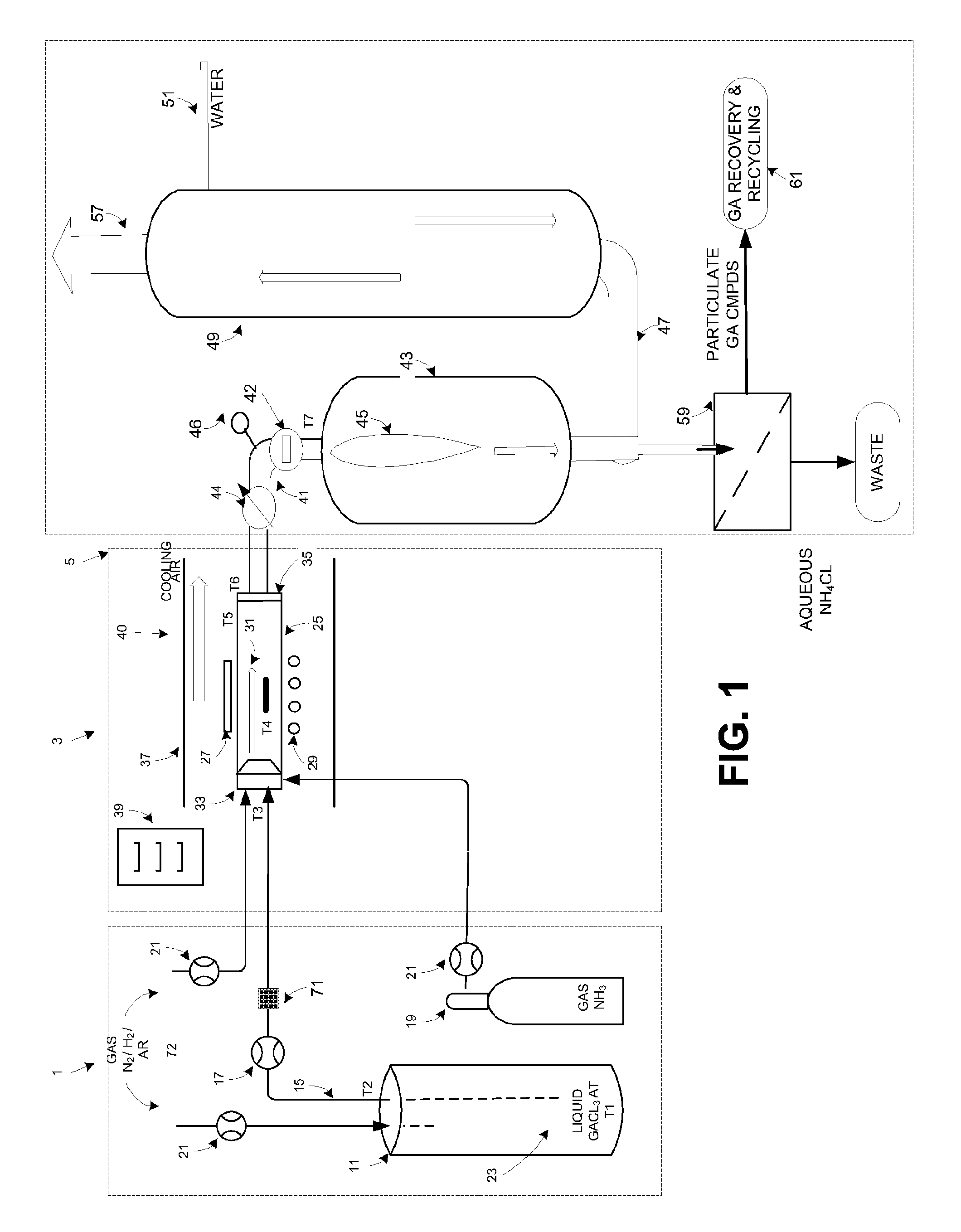

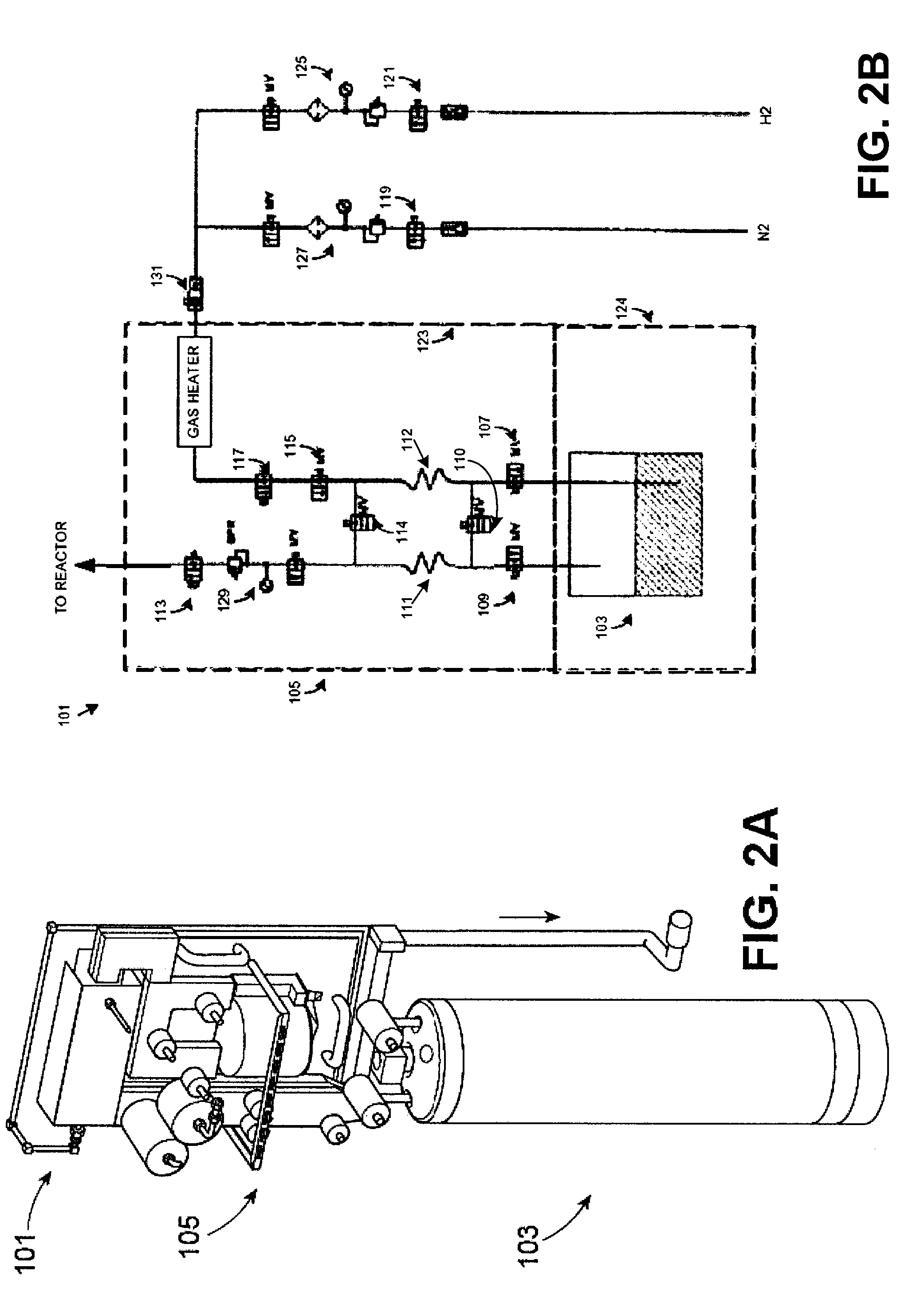

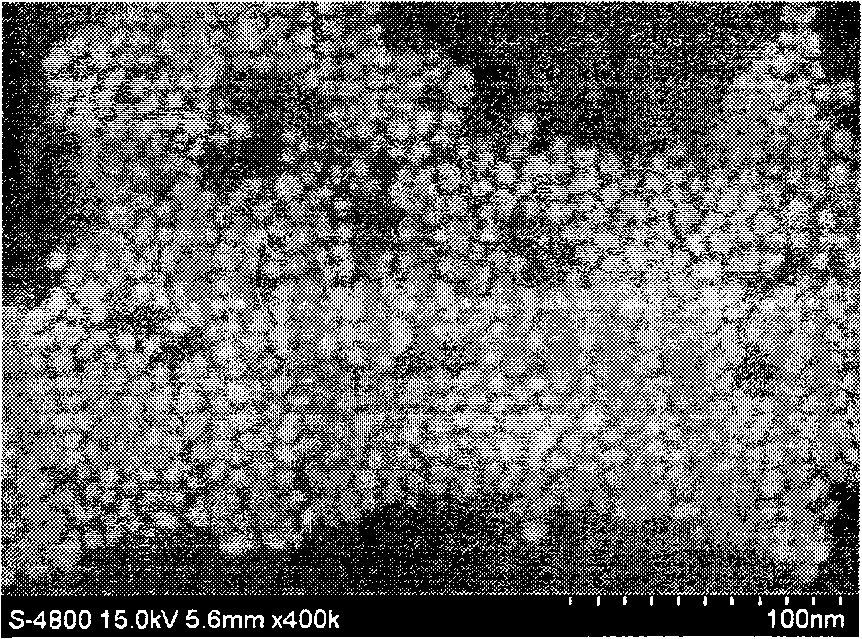

The present invention is related to the field of semiconductor processing equipment and methods and provides, in particular, methods and equipment for the sustained, high-volume production of Group III-V compound semiconductor material suitable for fabrication of optic and electronic components, for use as substrates for epitaxial deposition, for wafers and so forth. In preferred embodiments, these methods and equipment are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the precursor is provided at a mass flow of at least 50 g Group III element / hour for a time of at least 48 hours to facilitate high volume manufacture of the semiconductor material. Advantageously, the mass flow of the gaseous Group III precursor is controlled to deliver the desired amount.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Super-hydrophobic and super-oleophobic surface preparation technology

The invention discloses super-hydrophobic and super-oleophobic surface preparation technology. In the preparation technology, aluminum or aluminum alloy sheets are subjected to two-step electrochemical treatment, and then are modified by using perfluorinated octadecyl trichlorosilane or perfluorinated polymethacrylate to prepare the super-hydrophobic and super-oleophobic surface. The surface has super-hydrophobic property on aqueous solution of which the pH value is between 1 and 14 and super-oleophobic property on various oil drops, wherein a contact angle of the surface on water is 171 degrees, and a rolling angle is less than 1 degree; the surface expresses the super-oleophobic property on various oil drops except for perfluorinated polymer liquid, and all contact angles between the oil drops and the surface are more than 150 degrees, and rolling angles are generally less than 10 degrees; and the surface can also be put in air for a long time and can still maintain the super-hydrophobic property and super-oleophobic property.

Owner:中科润泉(烟台)工业科技有限公司

Method for preparing fluorescent nano material converted on NaYF4

InactiveCN101525540ASmall sizeGood dispersionPolycrystalline material growthFrom normal temperature solutionsSolubilityFluorescence

The invention relates to a method for preparing fluorescent nano material converted on NaYF4, comprising the steps: yttrium nitrate, ytterbium nitrate and erbium nitrate or yttrium chloride, ytterbium chloride, erbium chloride and thulium chloride are dissolved in de-ionized water according to the mixture radio that the mol ratio of rare earth ions which are yttrium ion, ytterbium ion and erbium ion is equal to (70-95): (1-25): (0.5-10), so that the mixed solution is prepared; water soluble polymer having the ligand radical with the rare earth ions is added into the mixed solution for stirring reaction to form complex compound; the pH value of the mixed solution is adjusted to be 2-6; sodium fluoride, ammonium fluoride or hydrofluoric acid can be added into the mixed solution and stirred until colloid solution that is approximately transparent is obtained; then, the colloid solution is put into a high pressure closed reactor and heated at the temperature of 140-200 DEG C; after that the obtained product is cooled to be the room temperature, centrifugated, separated, washed and dried, finally, the fluorescent nano material converted on NaYF4 is obtained. The method can be used for preparing the converted material at lower temperature, the particle size and the appearance can be controlled, and the water-solubility is good.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for preparing graphene-epoxy resin composite material

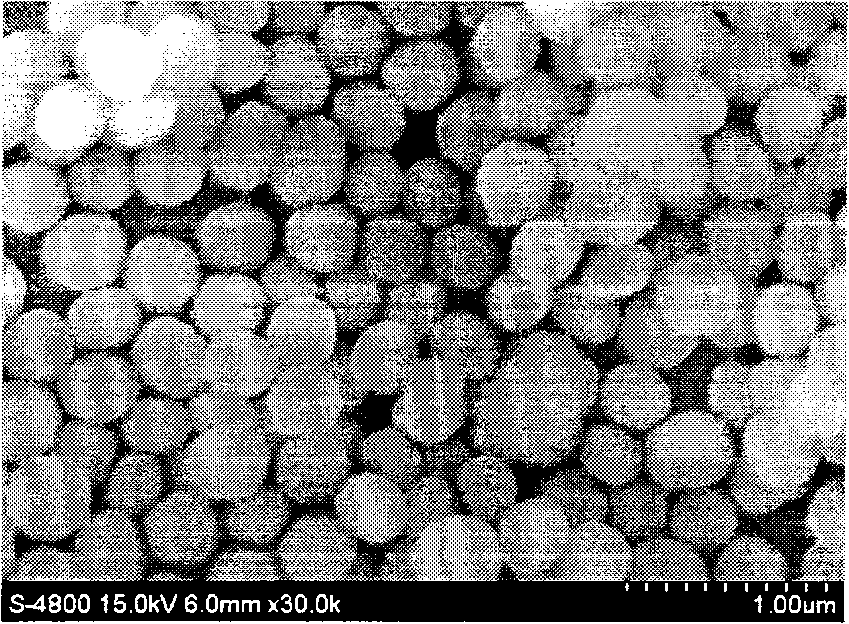

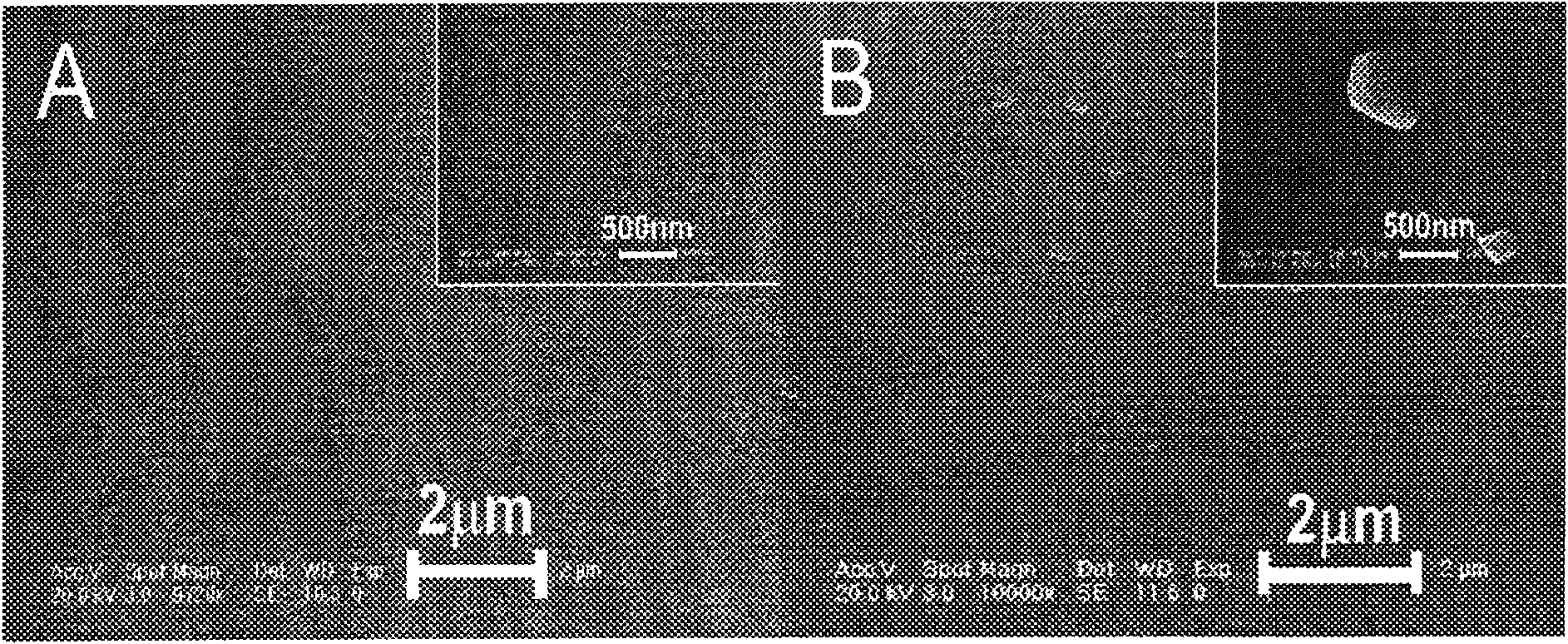

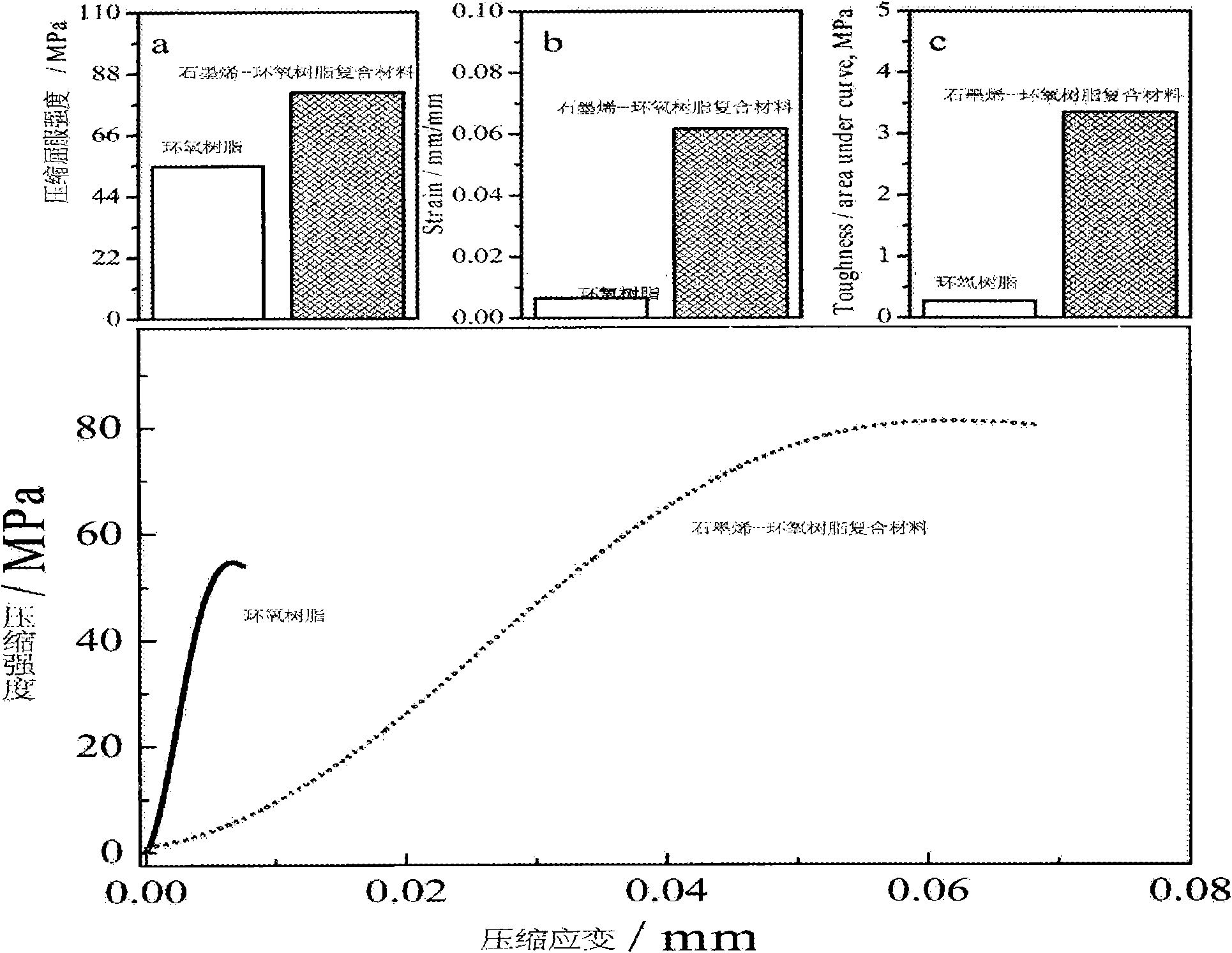

InactiveCN101987908AThe operation process is simple and convenientControllable loadEpoxy resin compositePhase reaction

The invention provides a method for preparing a graphene-epoxy resin composite material, comprising the following steps of mixing epoxy resin and a graphene solution in ratio; controlling the temperature at 60-120 DEG C; stirring for 5-60min; standing for 30min to layer; pouring out an aqueous solution at the upper layer; continuously stirring graphene-epoxy resin at the lower layer at the temperature of 80-150 DEG C and reactng for 2-12h; adding an epoxy resin curing agent, curing for 1h at the temperature of 100 DEG C, and then curing for 2h at the temperature of 150 DEG C, wherein the used epoxy resin is bifunctional bisphenol A epoxy resin or bifunctional epoxy resin. The method has the advantages of no environmental pollution in aqueous-phase reaction, recyclable water at the upper layer, simple operation process and controllable loading and is easy for preparation and synthesis in large scale. The prepared graphene-epoxy resin composite material has good monodispersity. Compared with an epoxy resin composite material, the rigidity of the prepared graphene-epoxy resin composite material is increased by above 50 percent, and the impact resistance is increased by near 12 times.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

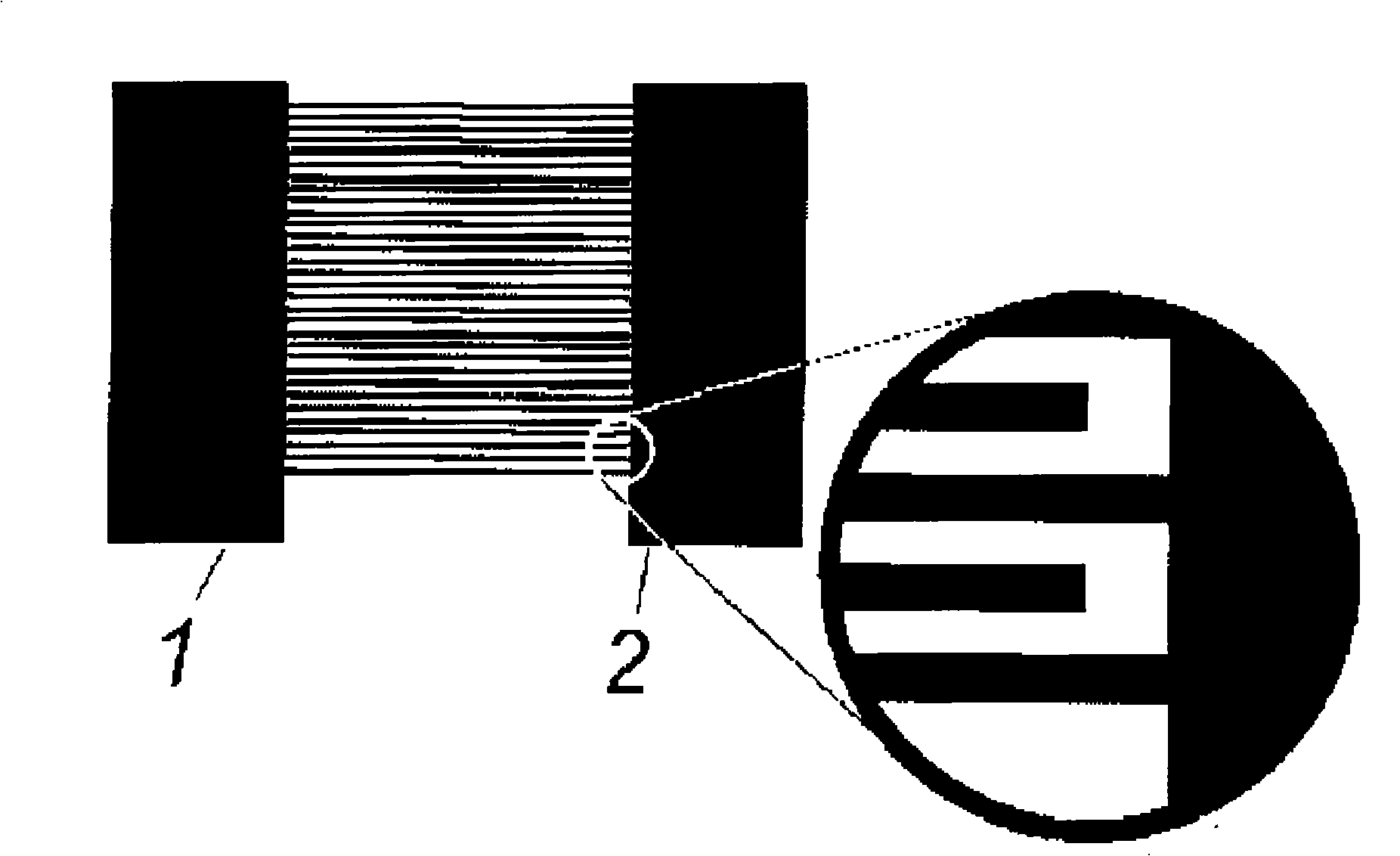

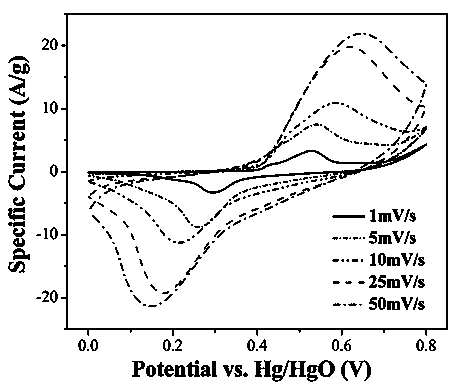

Poly-pyrrole minisize super capacitor based on MEMS technique and method for manufacturing the same

InactiveCN101325130AGood high current discharge performanceIncrease energy densityCapacitor electrolytes/absorbentsSecondary cellsSilicon matrixSolid state electrolyte

The invention discloses a polypyrrole minitype super capacitor in the range of the capacitor manufacturing technology based on MEMS technology and the preparation method thereof. The polypyrrole minitype super capacitor adopts the structure that a metal comb two-dimensional plane structure as a current collector is prepared on the surface of the silicon matrix by utilizing the micro-machining technology; a comb-shaped polypyrrole active electrode is prepared on the surface of the current collector by adopting the method of polypyrrole substance being prepared by the electric precipitation method; a layer of gel solid electrolyte is covered on the surface of the comb-shaped polypyrrole electrode and between a positive electrode and a negative electrode; and a layer of polyimide material is covered on the surface of the structure to accomplish the encapsulation of the minitype super capacitor. The MEMS-based manufacturing technology has the characteristic that the process is simple, and is suitable for mass manufacture. The minitype super capacitor has the advantages of small volume, high energy storage and stable performance, and is widely applicable to micro-robot electronic intelligence systems, chemical sensors, battlefield friend-or-foe identification devices, distributed type battlefield sensors and other fields.

Owner:TSINGHUA UNIV

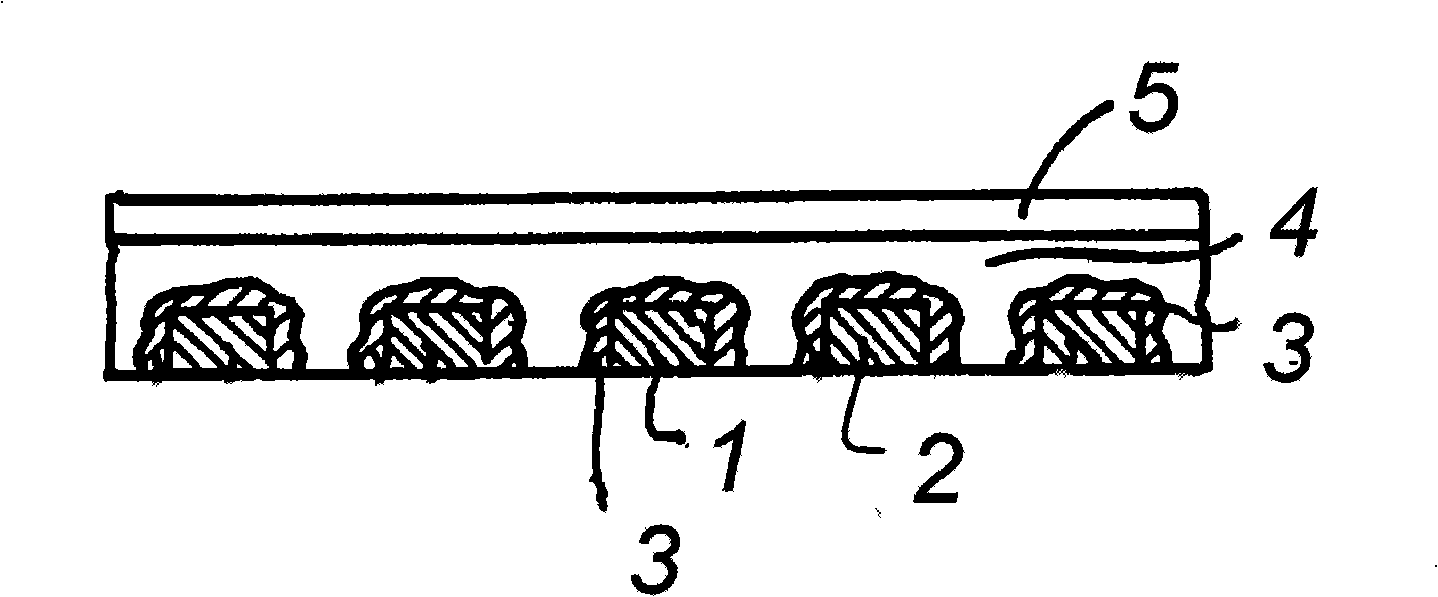

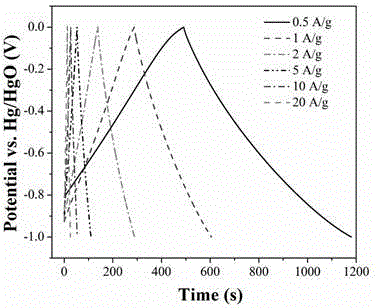

Preparation method of supercapacitor carbon material

ActiveCN104157470AReduce manufacturing costIncrease specific volumeHybrid capacitor electrodesHybrid/EDL manufactureBiomassCyclic stability

The invention provides a preparation method of a supercapacitor carbon material. In the method, cheap and easily available biomass such as pericarp, vegetables and the like is taken as raw materials, and the supercapacitor carbon material is obtained through steps including thiourea hydro-thermal processing, impurity removing processing, freeze drying processing, calcining processing, alkali / microwave activation processing and the like. The material has the characteristics of a layered structure and a large specific surface area. Since a thiourea hydro-thermal step is carried out in a preparation process, S and N in thiourea molecules are introduced, the specific volume of the material is effectively improved, and an electrode prepared by use of the material has the advantages of large specific volume and good circulating stability. According to the invention, wastes such as watermelon peel, shaddock peel and the like and cheap vegetables such as sweet potatoes, radishes and the like are taken as the raw materials, such that the production cost is decreased, and the preparation method also accords with the strategy of sustainable development for environmental protection and has an important popularization value.

Owner:JIANGSU SUPERBIO LIFE SCI CO LTD

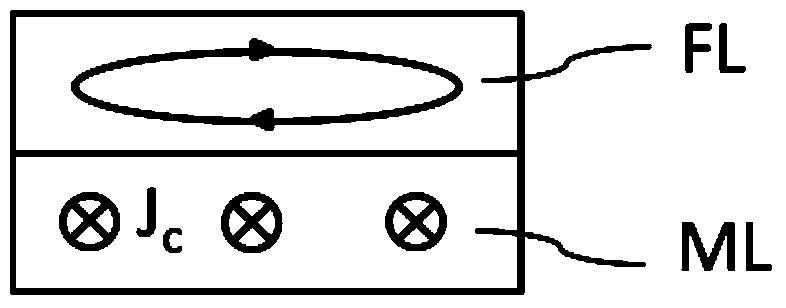

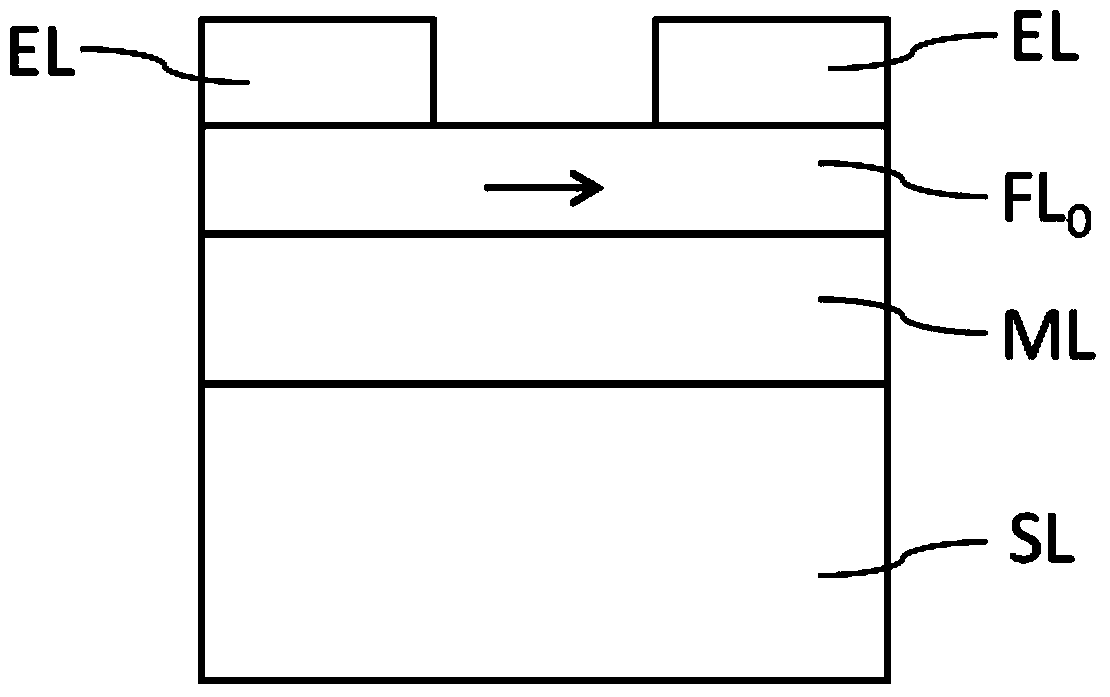

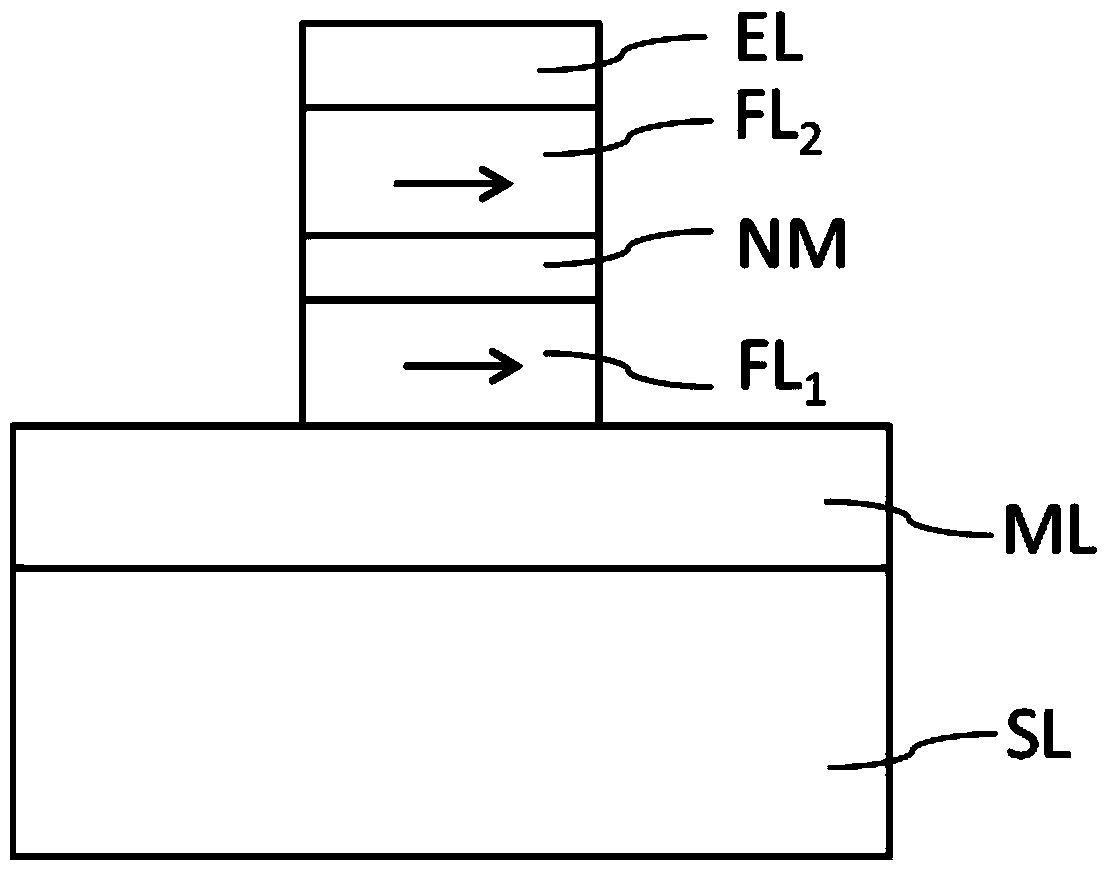

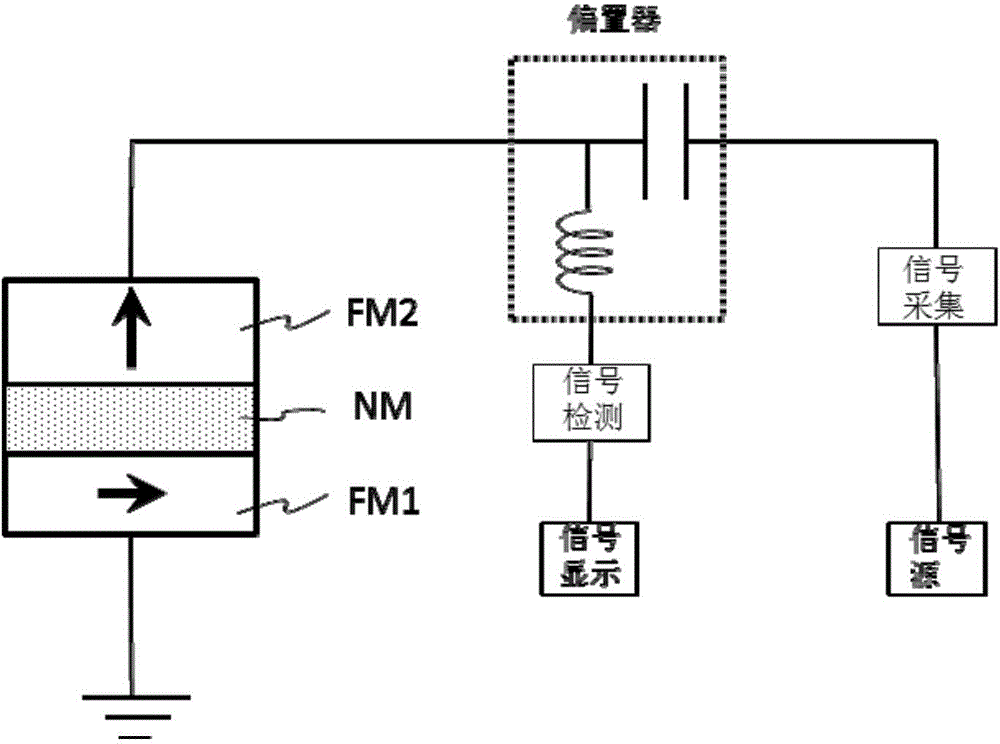

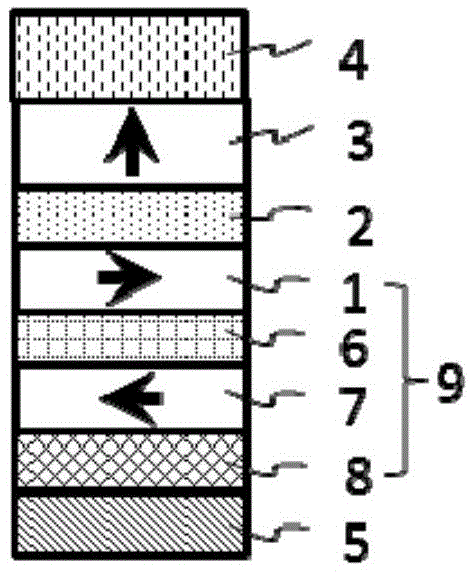

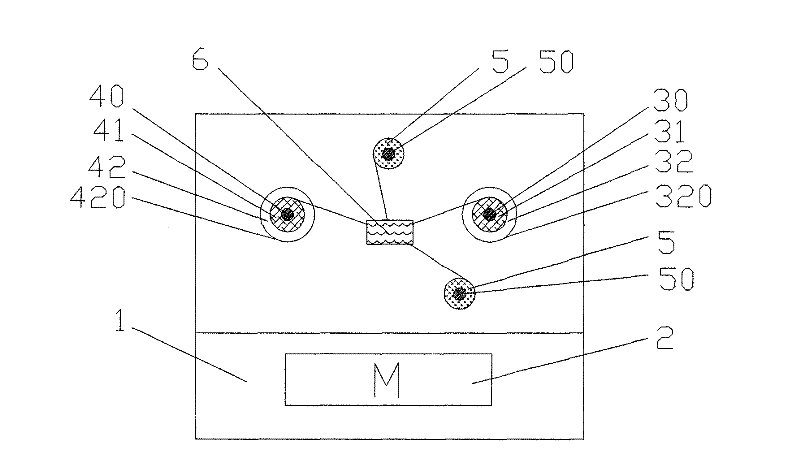

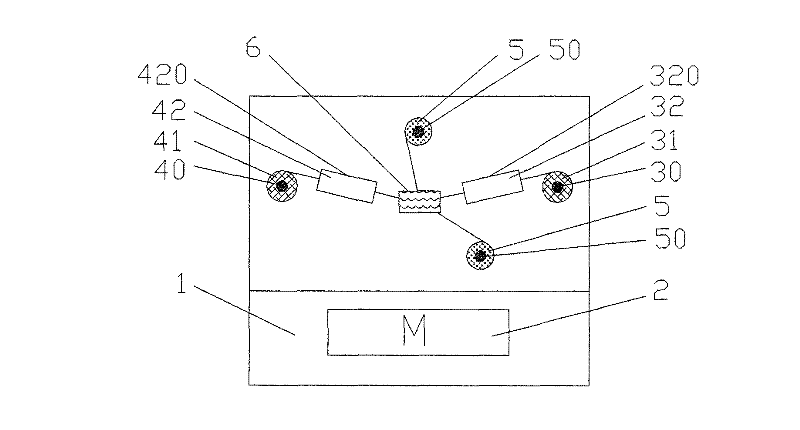

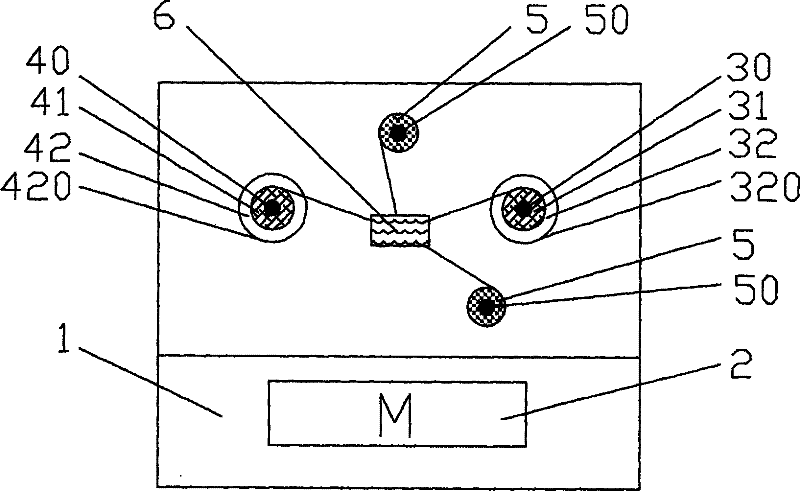

Magnetic element based on spin hall effect, microwave oscillator and manufacturing method thereof

InactiveCN103779495AReduce noiseLarge adjustment rangeMagnetic-field-controlled resistorsGalvano-magnetic material selectionManufacturing technologyMagnetization

The invention discloses a magnetic element based on a spin hall effect, a microwave oscillator and a manufacturing method thereof. The magnetic element comprises a non-magnetic metal film layer (ML) and a magnetic film layer (FL), wherein the non-magnetic metal film layer (ML) can induce electrons to generate spin currents, and the magnetic film layer (FL) is formed on the non-magnetic metal film layer (ML) and can balance magnetization. The microwave oscillator comprises the magnetic element, the magnetic element is formed on a substrate layer (SL), and metal electrodes (EL) are formed on the magnetic element. The microwave oscillator can be formed by using a thin film deposit technology, a photoetching and / or etching technology and the like. The structure of the magnetic element is beneficial to reducing the noise of the microwave oscillator, device microwave frequency is wide in adjustable range under the effect of impressed currents, and output microwave signals are excellent in performance. The microwave oscillator has the advantages of being small in size, simple in structure and the like, and is simple in manufacturing technology, compatible with traditional nano-meter processing technologies, easy to manufacture in a mass mode and capable of serving as a microwave source to be widely applied in the fields of electronics, communication and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for preparing aqueous graphene/epoxy resin nanocomposite material

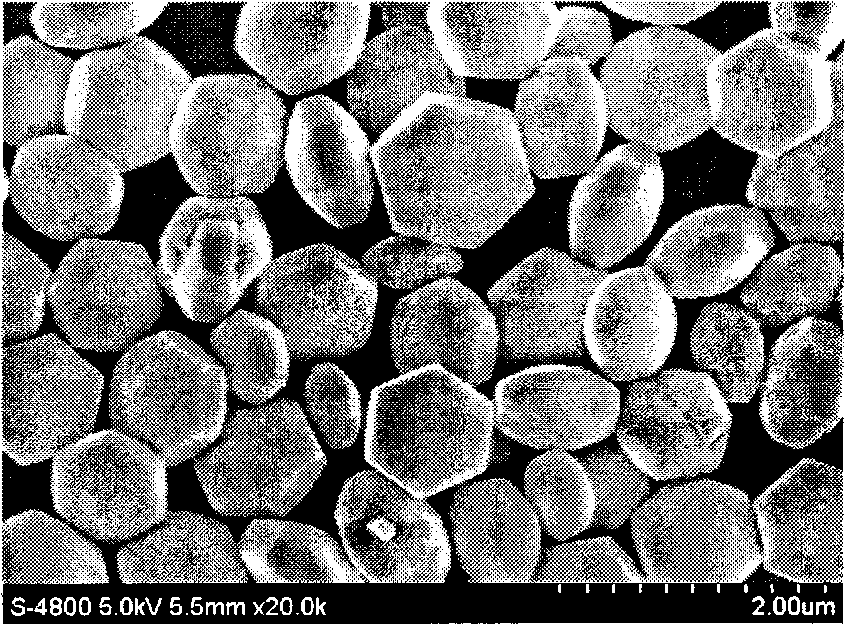

ActiveCN104231547AExcellent interfacial compatibility and binding forceImprove bindingGraphite oxideFirming agent

The invention discloses a method for preparing an aqueous graphene / epoxy resin nanocomposite material. The method comprises the following specific steps: carrying out functional modification and dispersion on graphene oxide obtained through a Hummers method, so as to obtain a high-concentration aqueous graphene dispersion solution; adding epoxy resin into the aqueous graphene dispersion solution, uniformly stirring, then, dewatering under the vacuum condition, adding a curing agent and mixing; carrying out high-temperature curing, thereby obtaining the graphene / epoxy resin nanocomposite material. According to the method, the operating process is simple, convenient and controllable, so that large-batch preparation and synthesis are facilitated; through obtaining the highly-stable aqueous graphene dispersion solution, graphene and epoxy resin can have excellent interface compatibility and adhesion; the matrix adhesion, corrosion resistance and impact resistance of epoxy resin are effectively improved; compared with the conventional aqueous epoxy resin materials, the aqueous graphene / epoxy resin nanocomposite material prepared by the method has the advantages that the hardness is improved by 1.5 times, and the impact resistance is improved by 12 times.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Preparation method of superhydrophobic surface of metal zirconium

ActiveCN101941000AExcellent superhydrophobic propertiesMeet actual needsSurface reaction electrolytic coatingPretreated surfacesAnodizingEtching

The invention provides a preparation method of a superhydrophobic surface of a metal zirconium. The method is as follows: firstly, in site building a nano / micro coarse structure on the surface of the metal zirconium through chemical etching, anodizing and ultraphonic strip membranes; and subsequently, carrying out hydrophobic treatment on the surface through low surface energy substances such as self-assembling siloxane and the like, thereby obtaining the superhydrophobic metal zirconium surface. The metal zirconium surface treated by using the method of the invention has good superhydrophobic property, a contact angle with water-drop reaches 157-163 degrees, and a roll angle is less than 3 degrees, thereby meeting the demand of industry fields on the superhydrophobic surface of the metal zirconium. The method of the invention has the characteristics of simple process, convenient operation, low production cost, easy large-scale preparation, industrial production and the like.

Owner:苏州盛泽科技创业园发展有限公司

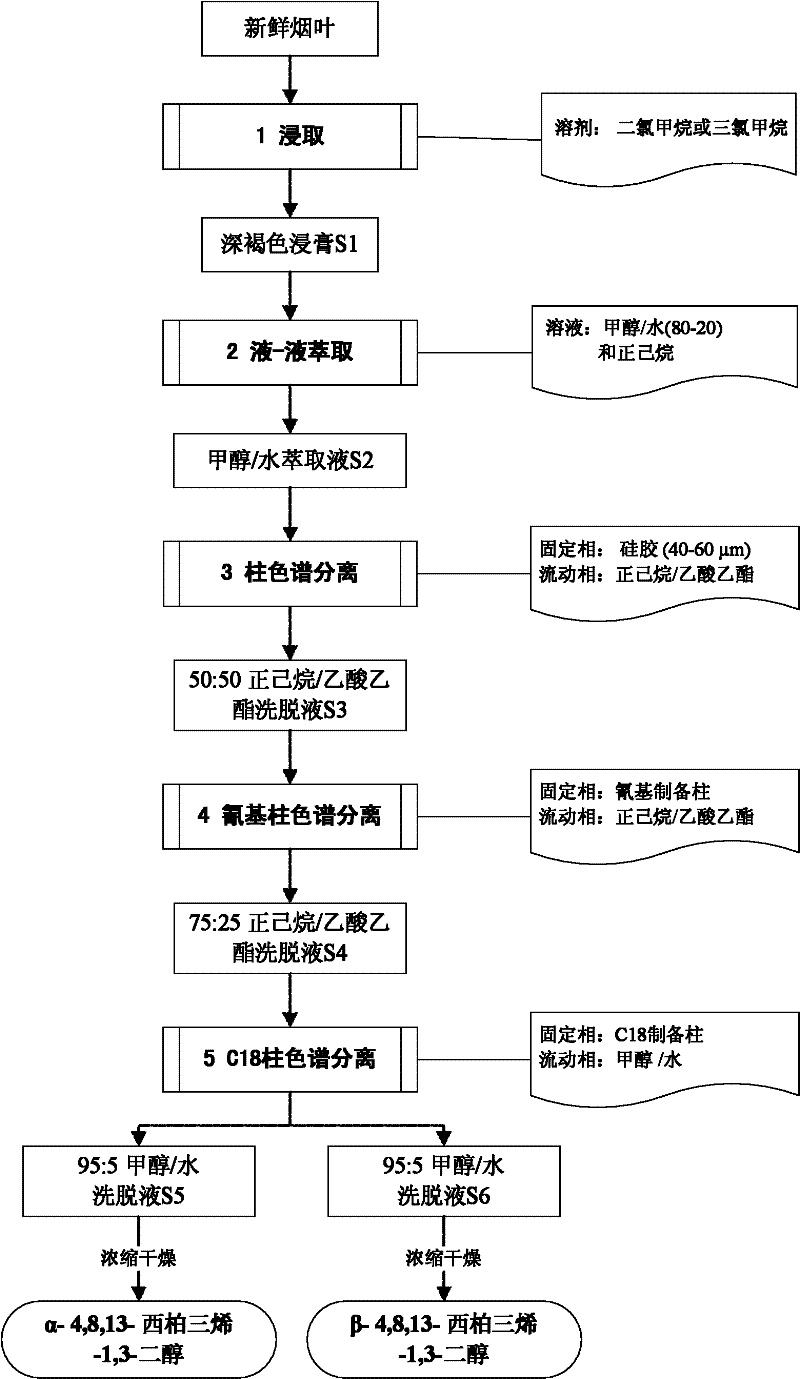

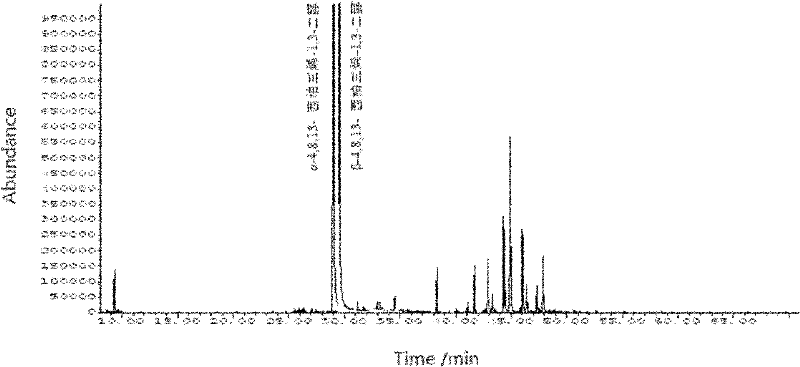

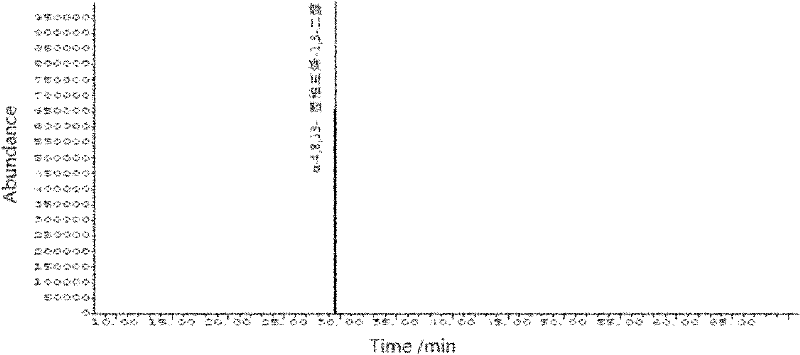

Method for separating and purifying two fragrance precursors from tobacco

ActiveCN102206138AHigh recovery rateEasy to operateOptically-active compound separationOrganic racemisationChromatographic separationPurification methods

The invention belongs to the technical field of separation and purification and relates to a technique for separating and purifying active ingredients in tobacco, in particular to a method for extracting, separating and purifying alpha-4,8,13-duvatriene-1,3-diol and beta-4,8,13-Duvatriene-1,3-diol from fresh tobacco. The separation and purification method disclosed by the method comprises: (1) leaching; (2) liquid-liquid extraction; (3) separating by normal phase silica gel column chromatography; (4) separating by normal phase cyanogen-based column chromatography; and (5) separating by antiphase C18 column chromatography to obtain two fragrance precursors. The purities of the two fragrance precursors obtained by the separation and purification method are both over 99 percent, so that the two fragrance precursors can be used as standard products in related scientific research; and the product recovery rate of the whole separation and purification process, the process operation is simple and convenient, the automation degree is high, and batch production can be realized easily.

Owner:SHANGHAI TOBACCO GRP CO LTD

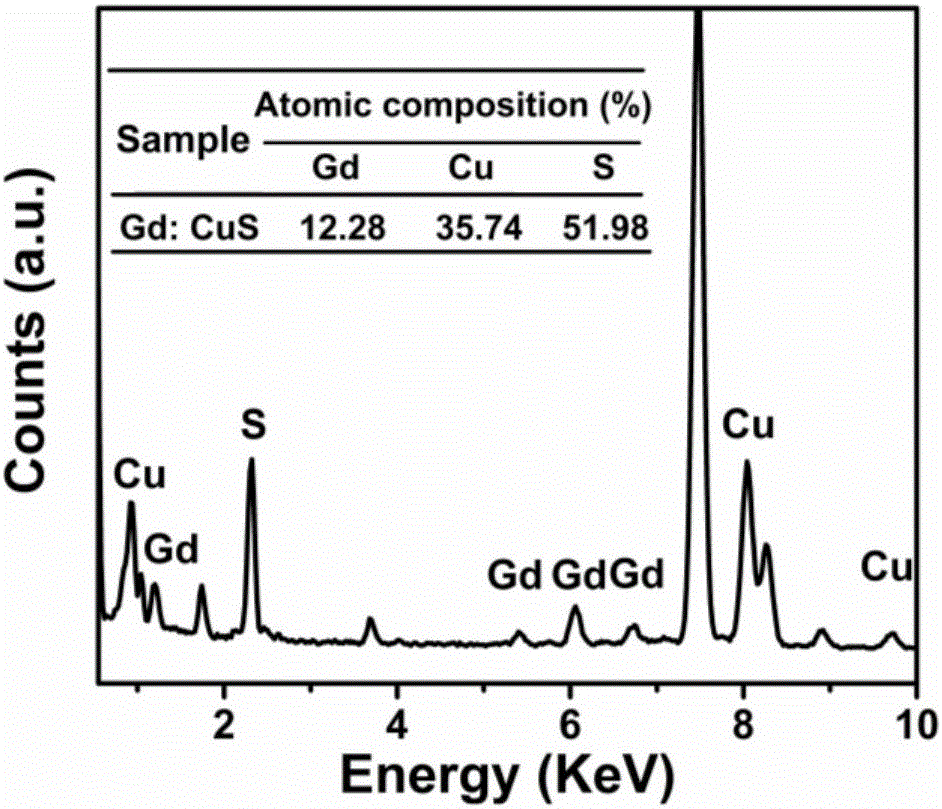

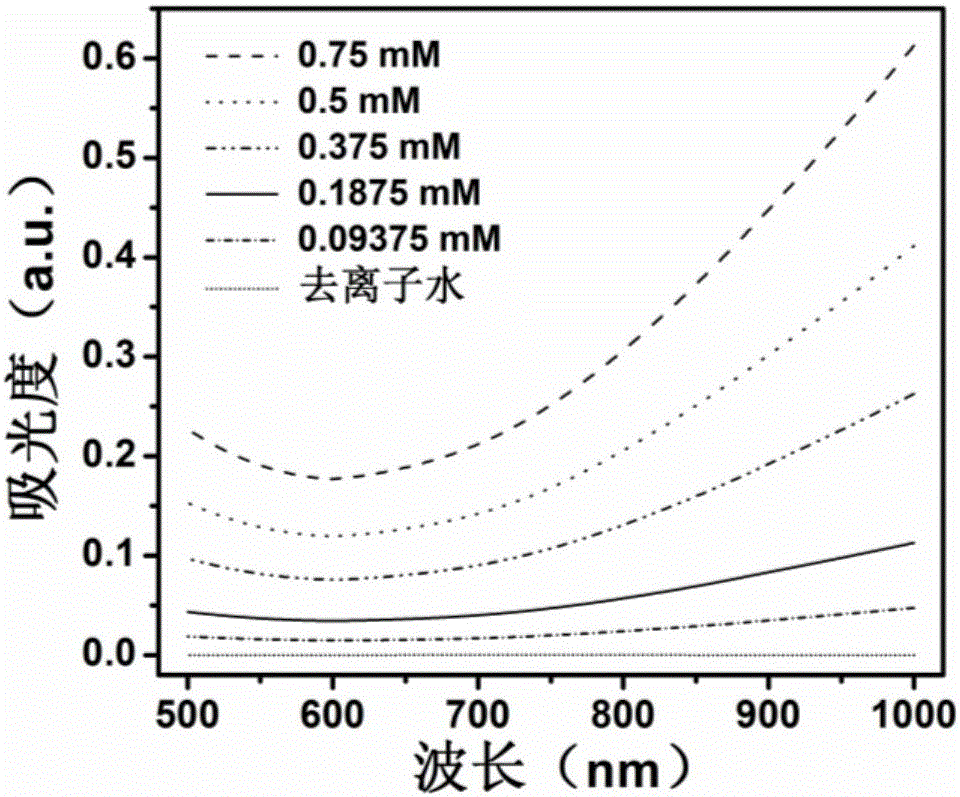

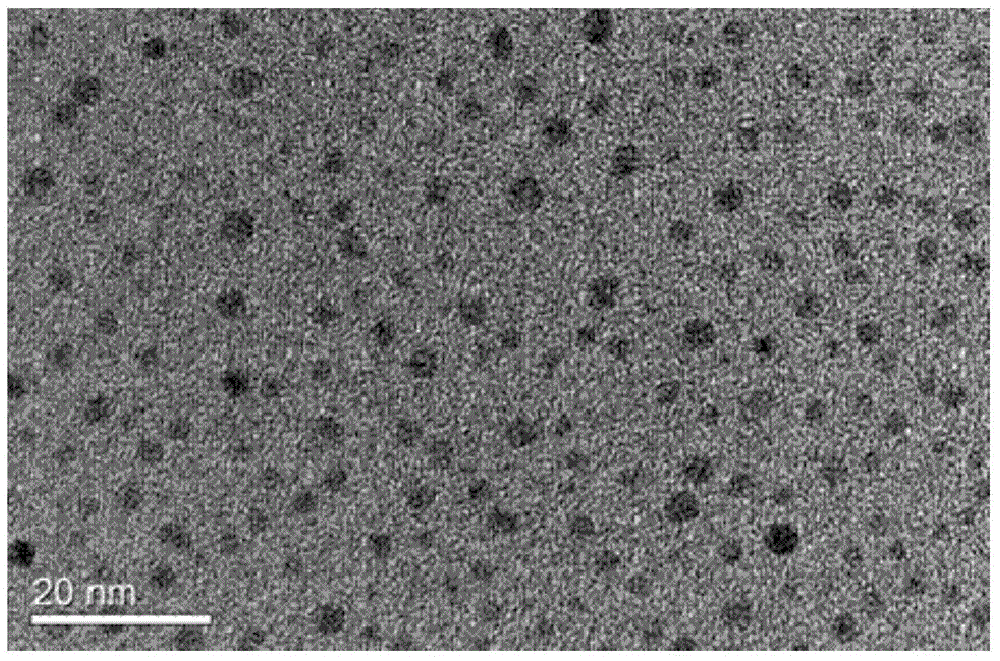

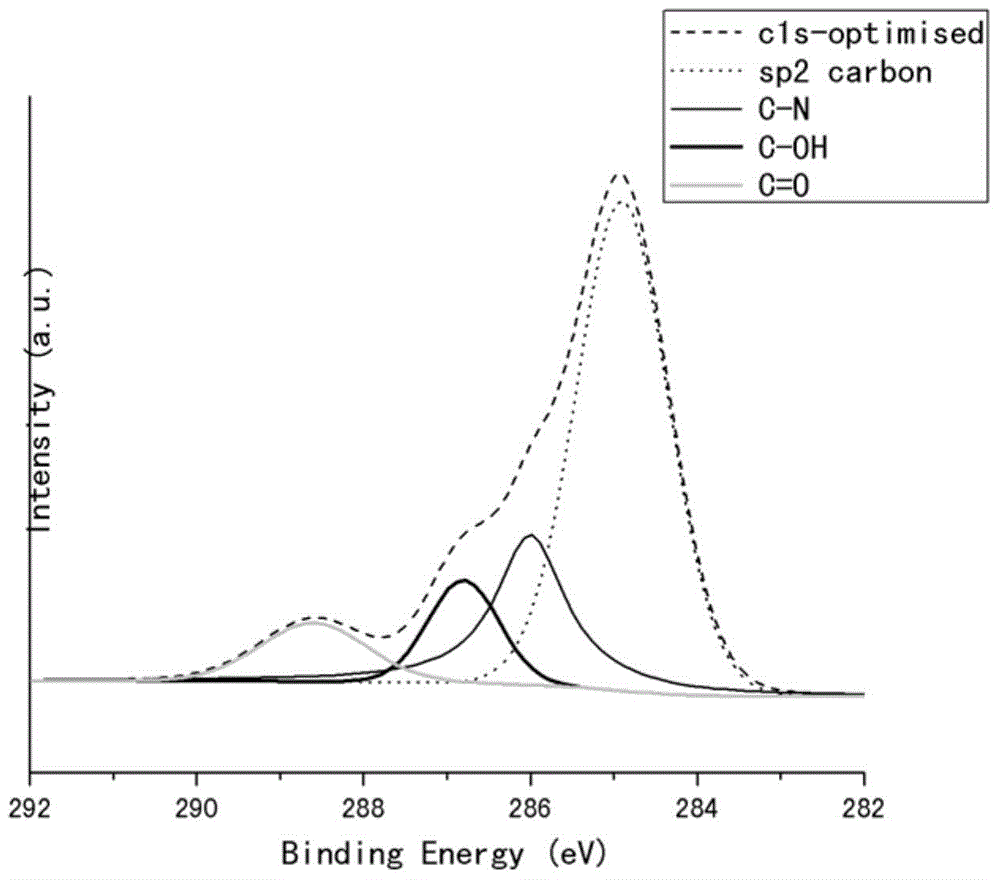

Protein biological template-based gadolinium-doped copper sulfide nano-particles and preparation method thereof

InactiveCN105999309AAvoid practicalityAvoid high temperatureEnergy modified materialsGeneral/multifunctional contrast agentsFreeze-dryingCopper salt

Owner:TIANJIN UNIV

Preparation method of assembly of carbon quantum dots (CQDS)

InactiveCN104531148AOvercome the disadvantage of small sizeHigh reaction yieldLight-sensitive devicesLuminescent compositionsMicrowave methodFreeze-drying

The invention provides a preparation method of an assembly of carbon quantum dots (CQDS). A micromolecule carbohydrate is used as a carbon source, and a one-step microwave method is carried out to synthesize the CQDS with sizes of few nanometers; sodium borohydride is used for treating the CQDS, and after epoxy groups and carbanyl groups of surfaces of the CQDS are reduced to hydroxyl groups, the hydroxyl groups are freeze-dried to obtain yellow powder; then, a micromolecule compound UPy containing -NCO groups reacts with the CQDS in anhydrous NMP, chloroform is used for precipitating a product, and the assembly of the carbon quantum dots is obtained after filtering and drying. The obtained CQDS are uniform in size distribution, the assembly is of a spherical structure, and the assembly of the CQDS has strong fluorescence under ultraviolet light. High temperature or high pressure or high vacuum conditions or specially-made reaction instruments are not needed in the whole process, and the reaction yield is high. The assembly overcomes the defect that monodisperse CQDS are small in size, has important significance in achieving large-scale applications of carbon nanomaterials and is expected to be applied to the fields of solar cells, photovoltaic devices, optoelectronic materials and the like.

Owner:TIANJIN UNIV

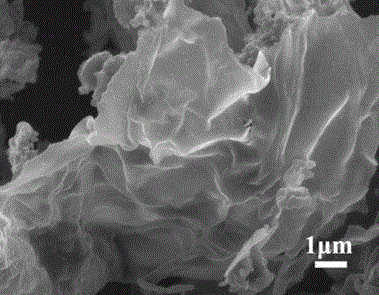

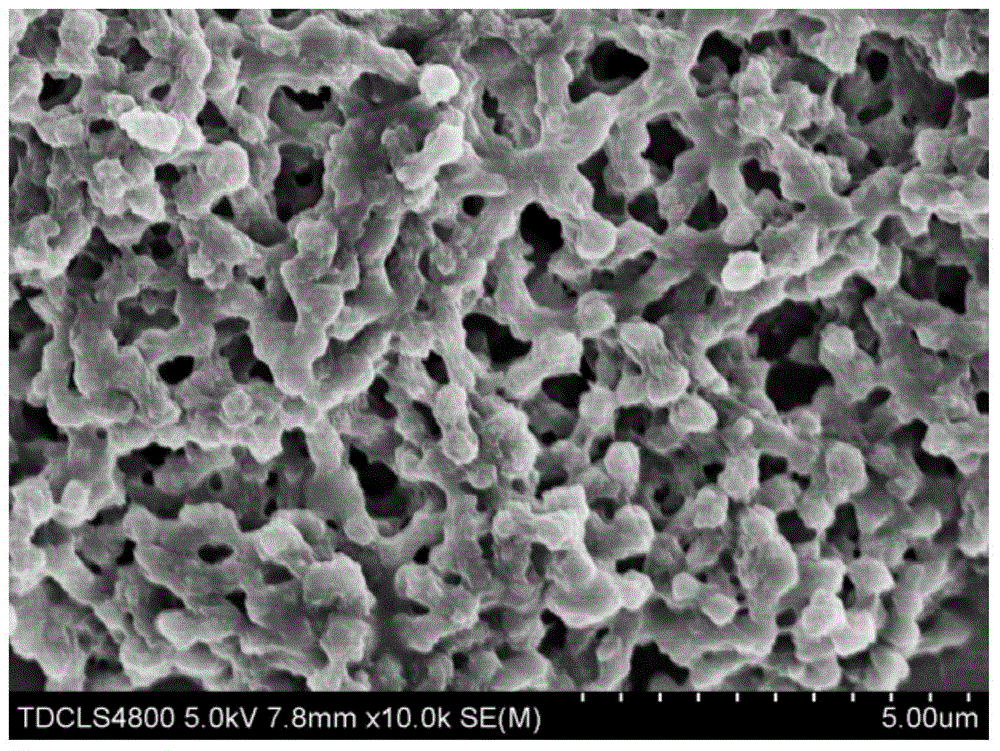

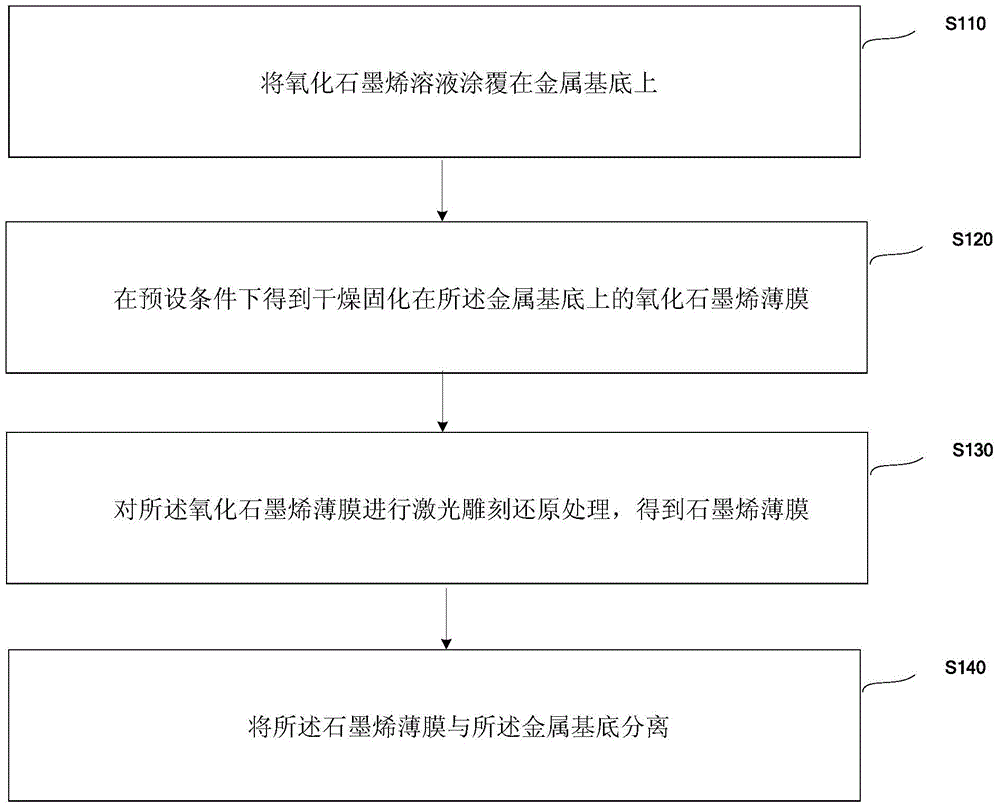

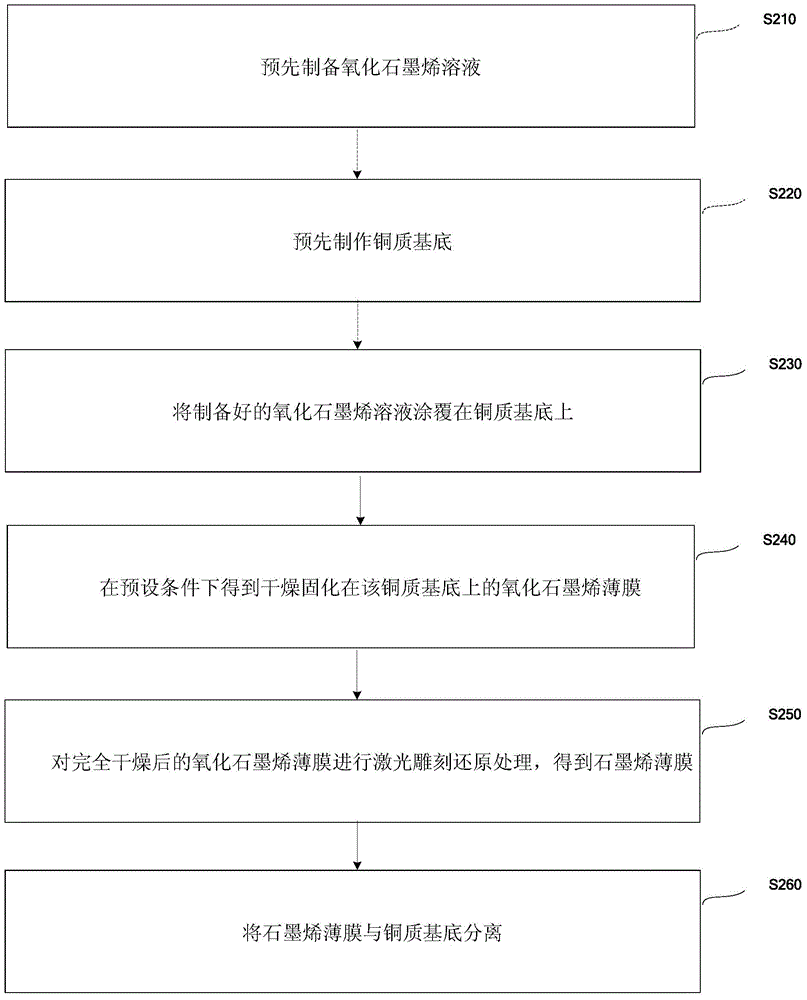

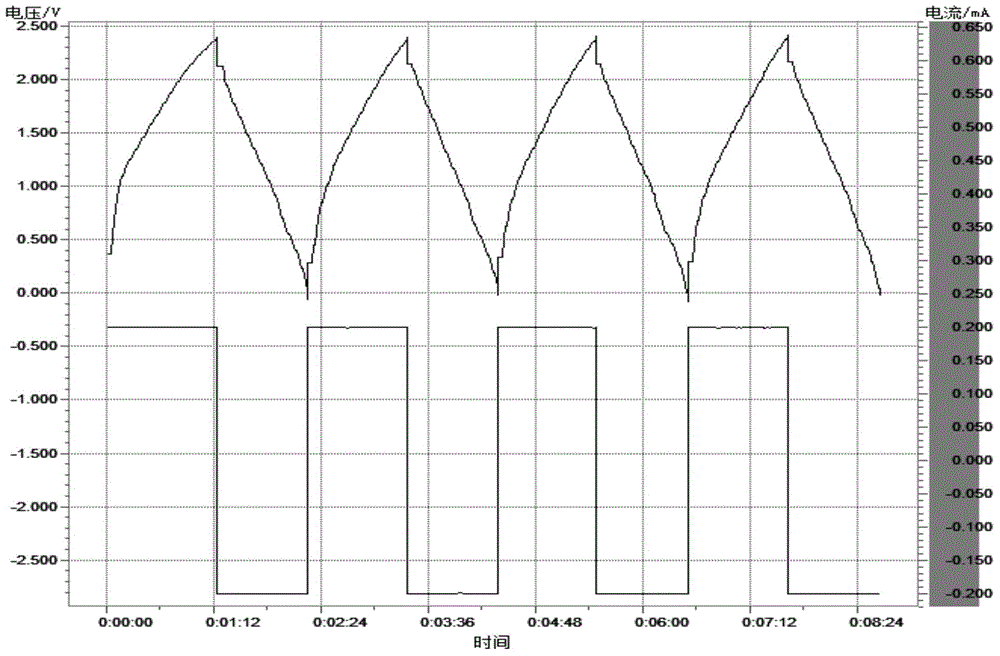

Graphene thin film, graphene super capacitor and preparation method of graphene thin film and graphene super capacitor

ActiveCN104944414AAvoid reunionReunion is not easy to happenHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneHigh energy

The invention discloses a graphene thin film, a graphene super capacitor and a preparation method of the graphene thin film and the graphene super capacitor, and aims at solving the common problems of defects of long time taken, high energy consumption, not easy large-batch preparation and the like of a graphene preparation method in the prior art. The preparation method of the graphene thin film comprises the following steps: coating a metal substrate with a graphene oxide solution; obtaining a graphene oxide thin film dried and cured on the metal substrate under preset conditions; performing laser carving reduction processing on the graphene oxide thin film to obtain the graphene thin film; separating the graphene thin film from the metal substrate.

Owner:纳米新能源生命科技(唐山)有限责任公司

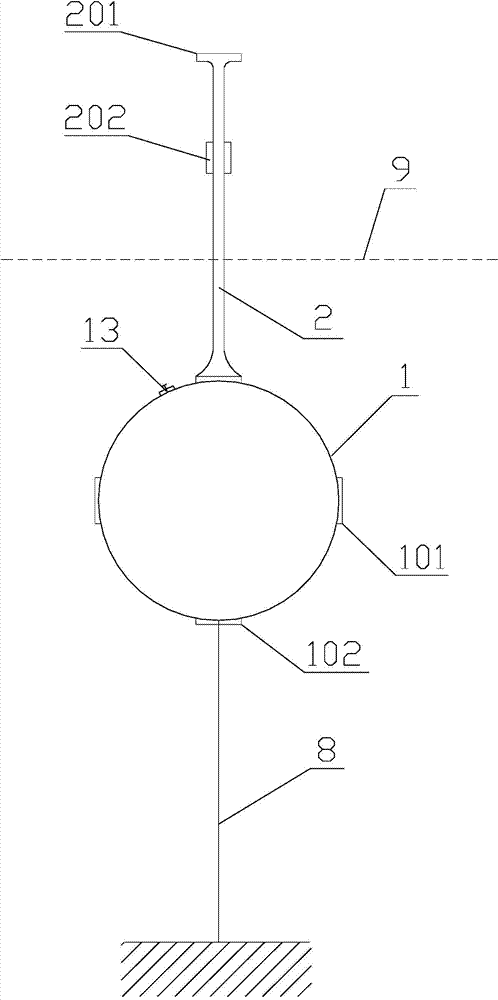

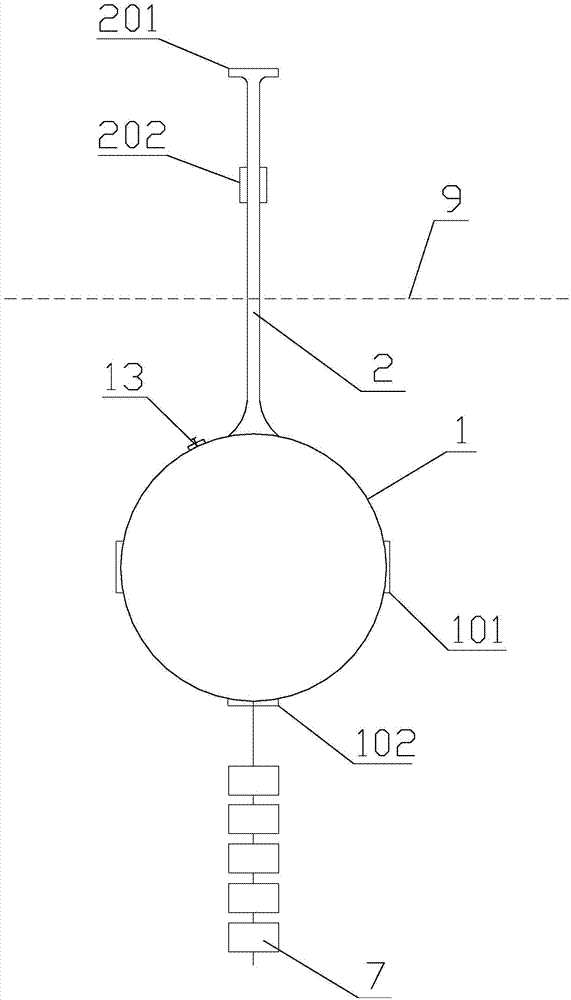

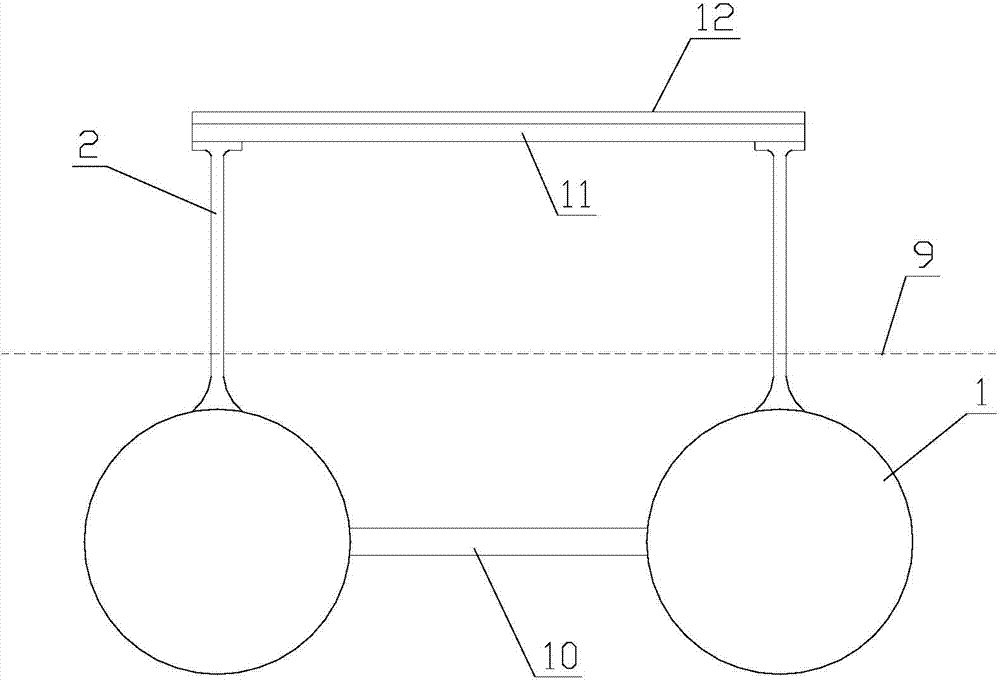

Offshore power generation platform formed by combining floating body units and installation method of offshore power generation platform

InactiveCN104843151AReduce manufacturing costImprove standardizationFloating buildingsSea wavesUltimate tensile strength

The invention relates to an offshore power generation platform formed by combining floating body units and an installation method of the offshore power generation platform. The offshore power generation platform comprises a platform body and the floating body units, wherein the floating body units comprise floating bodies and bearing bodies, and the platform body is connected with the floating bodies through the bearing bodies. The offshore platform enables the floating body units to sink or rise by injecting or draining a proper amount of water into or out of the floating bodies, and thus the height of the platform body can be adjusted; when the floating bodies suspend under water, at least part of the platform body is exposed and maintained above the water surface; the offshore platform is provided with a power generating device. The installation method of the offshore platform comprises the steps that (1) the two or more floating body units are connected in water to form the platform body; (2) the offshore platform is dragged to a predetermined water area, and the platform body is maintained on the water surface all the time. The offshore platform is high in strength and capable of being used for different purposes. The floating bodies suspend under the sea surface and are little affected by sea waves, the swing action of the sea waves can be restrained by the sea wave power generating device, and the capability of resisting severe sea conditions is achieved.

Owner:陈佳宇

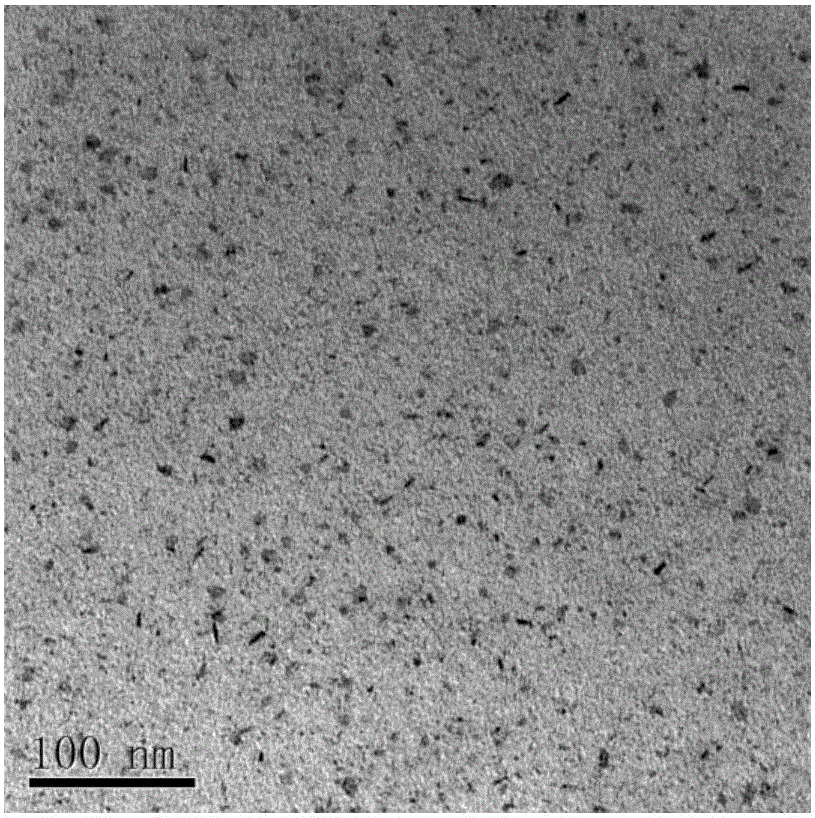

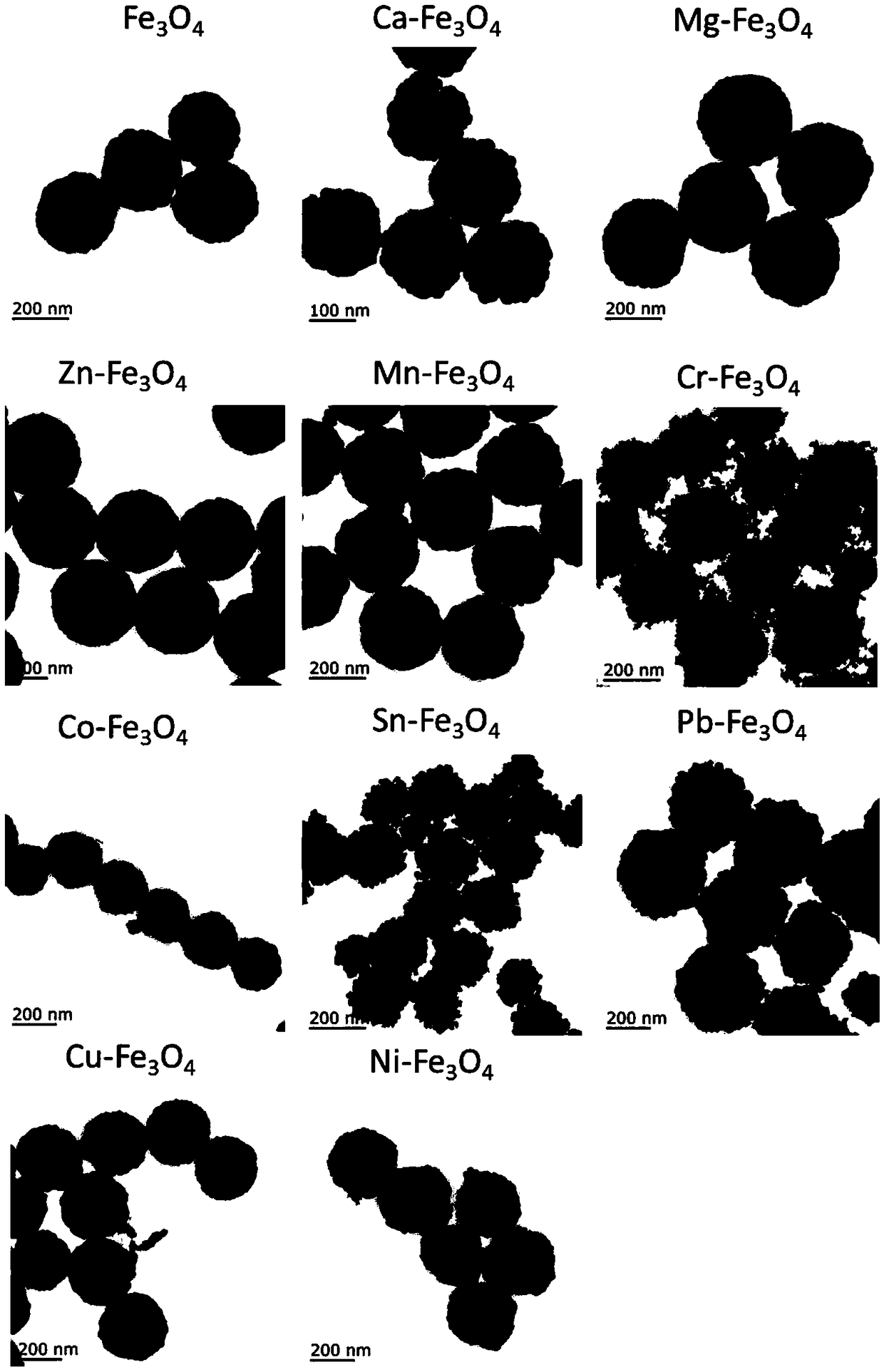

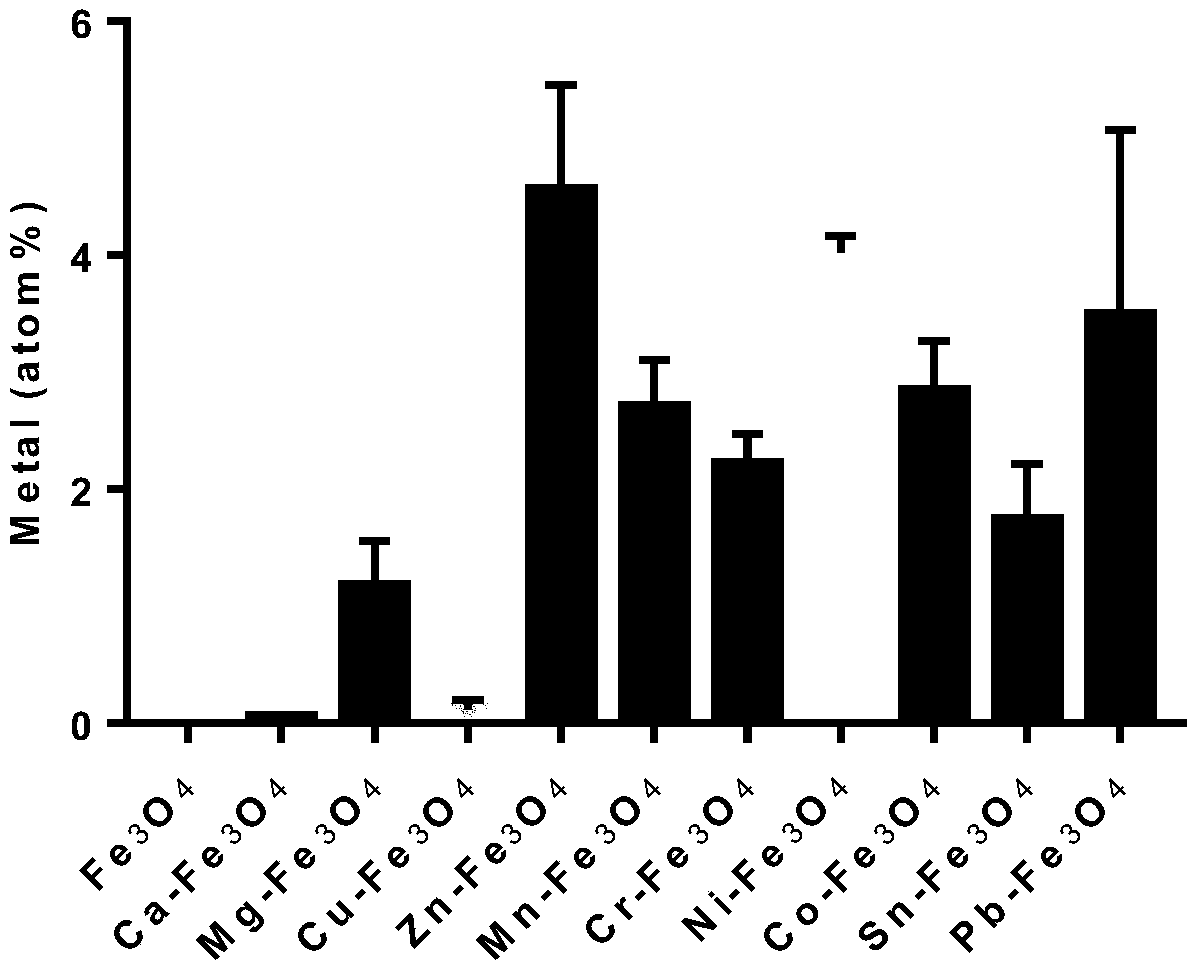

Fe3O4 nanozyme with improved catalytic activity, and preparation method and application thereof

ActiveCN109046360AEasy to prepare in large batchesLow costMetal/metal-oxides/metal-hydroxide catalystsDismutaseSuperoxide

The invention provides a Fe3O4 nanozyme with improved catalytic activity, and a preparation method and application thereof. By doping metal elements in Fe3O4 nanozyme, the dismutase activity of peroxidase, catalase and / or superoxide can be improved; the metal element doped Fe3O4 nanozyme can be prepared in large quantities, has low cost, good stability at room temperature, good safety, and good economic value and application prospect.

Owner:YANGZHOU UNIV

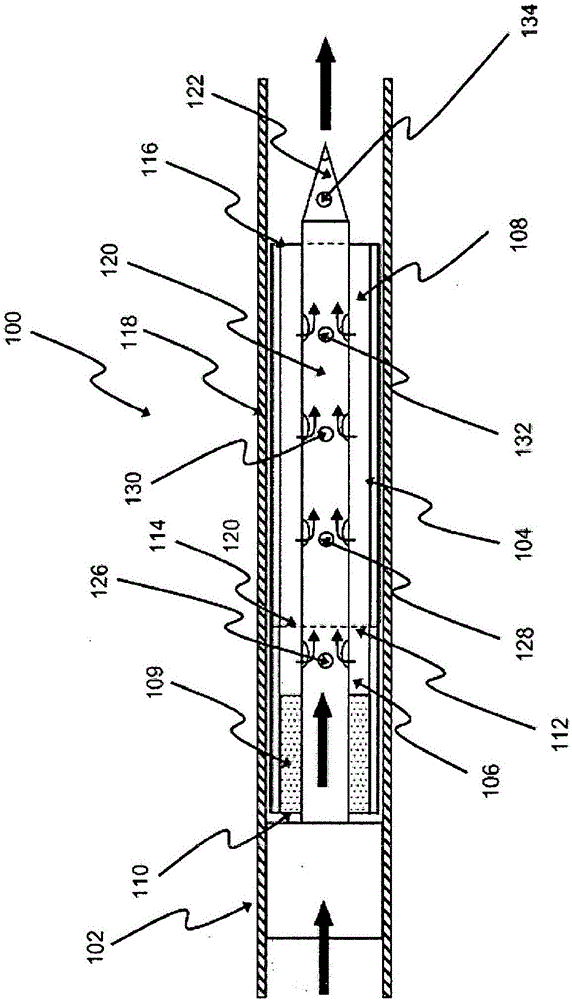

Aerosol-generating system with improved piercing member

ActiveCN106455726AReduce deliveryIncrease costTobacco treatmentTobacco devicesEngineeringMechanical engineering

The present invention relates to an aerosol-generating system (100) comprising an aerosol-generating device (102) in cooperation with an aerosol-generating article (104). The aerosol-generating article (104) comprises at least one container (108) housing a nicotine source and at least two seals (114, 116) sealing the at least one container (108), wherein each seal (114, 116) comprises a deformable material. The aerosol-generating device (102) comprises an outer housing (118) adapted to receive the aerosol-generating article (104) and an elongate piercing member (120) for piercing the at least two seals (114, 116) sealing the at least one container (108). The elongate piercing member (120) comprises a piercing head (122) at a distal end of the elongate piercing member (120) and a hollow shaft portion (124) comprising at least two apertures (128, 130, 132). When the aerosol-generating article (104) is received in the aerosol-generating device (102), at least one aperture (128, 130, 132) is in fluid communication with the at least one container (108).

Owner:PHILIP MORRIS PROD SA

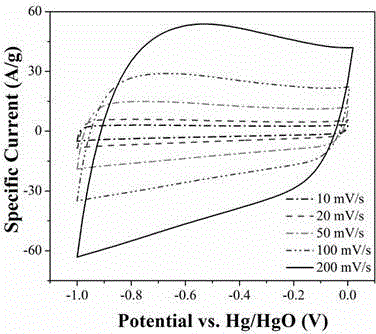

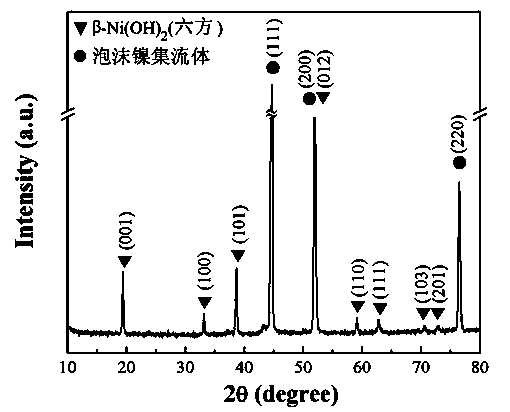

Self-collecting supercapacitor electrode material and preparing method thereof

ActiveCN103762090AReduce productionIncrease specific volumeHybrid capacitor electrodesNanotechnologyMaterials scienceHydrogen peroxide

The invention provides a self-collecting supercapacitor electrode material and a preparing method thereof. The electrode material is composed of a foamed nickel current collector and a b-nickel hydroxide hexagonal nanosheet grown on the surface of the foamed nickel current collector in an in-situ mode. According to the preparing method of the electrode material, the conductive current collector foamed nickel is immersed into a hydrogen peroxide solution for low-temperature hydrothermal oxidation, and then the b-nickel hydroxide hexagonal nanosheet is directly grown on the conductive current collector in the in-situ mode. The electrode material has the advantages of being large in specific volume and good in circulating stability. Due to the fact that the active material nickel hydroxide is directly grown on the foamed nickel current collector, the electrode material can be used directly without extra current collectors, or conductive additives or binding agents, complicated electrode preparing processes are omitted, and self-collecting is achieved. The electrode material preparing method only relates to the cheap hydrogen peroxide solution, other chemical reagents are not needed, and then zero pollution and low cost are guaranteed. The preparing processes only relate to hydrothermal oxidation and vacuum drying, operation is easy and convenient, reproducibility is good, and bulk preparation and industrialized production are facilitated.

Owner:CHONGQING UNIV

Preparation method of composite cavity microfibers based on micro-fluidic technology

ActiveCN108149342AStable growthPrecise Density ControlConjugated cellulose/protein artificial filamentsArtificial cell constructsCell adhesionAdhesion process

The invention relates to a preparation method of composite cavity microfibers based on a micro-fluidic technology. The preparation method is characterized in that in the preparation process of cavitymicrofibers, a modified material capable of promoting the cell wall adhesion growth is introduced in a microfiber inner cavity; while the cavity is formed, the modified material is adhered onto the cavity to form a modified coating layer, so that a promoting effect on late cell adhesion and culture is provided. By utilizing the micro-fluidic technology, a micron-sized channel capable of generatinga coaxial laminar flow pattern is formed, the flow pattern control on a sample fluid is realized, and the sample fluid is finally solidified into a micron-sized hollow fiber material with a specificinner coating structure. The microfiber material can simulate a microstructure in a human body tissue, and a new method and a new concept are provided for tissue engineering and organ regeneration. The preparation method provided by the invention is simple and reliable to operate, high in efficiency and excellent in technical effect; convenient conditions are provided for the modification of the microfibers; an internal finish coating is uniform, stable, simple and controllable to facilitate the cell wall adhesion growth.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

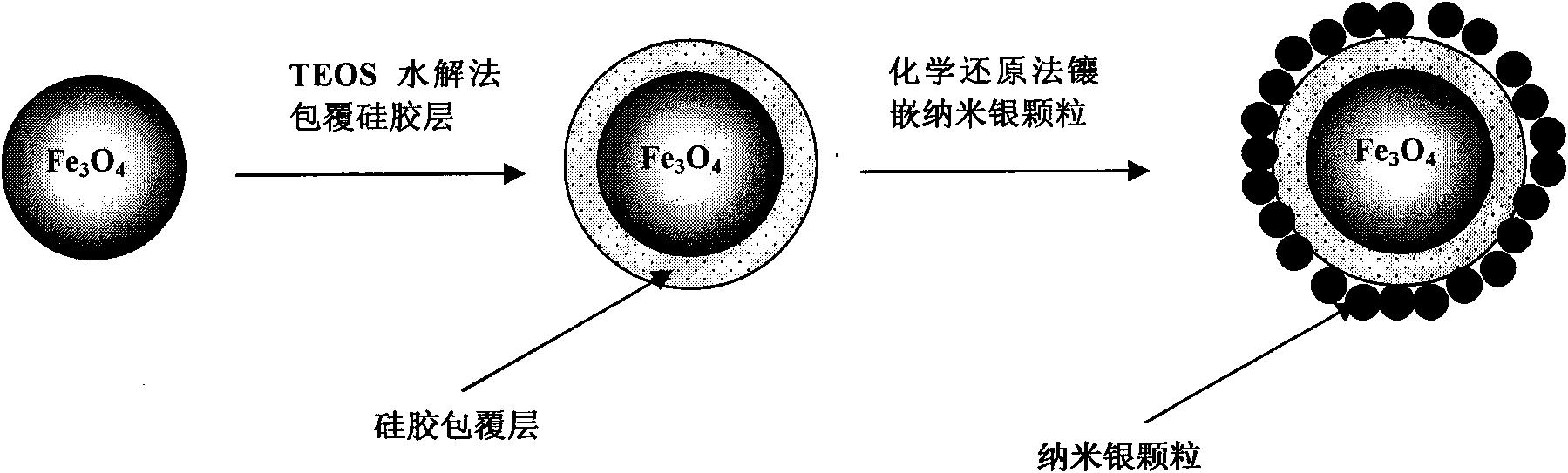

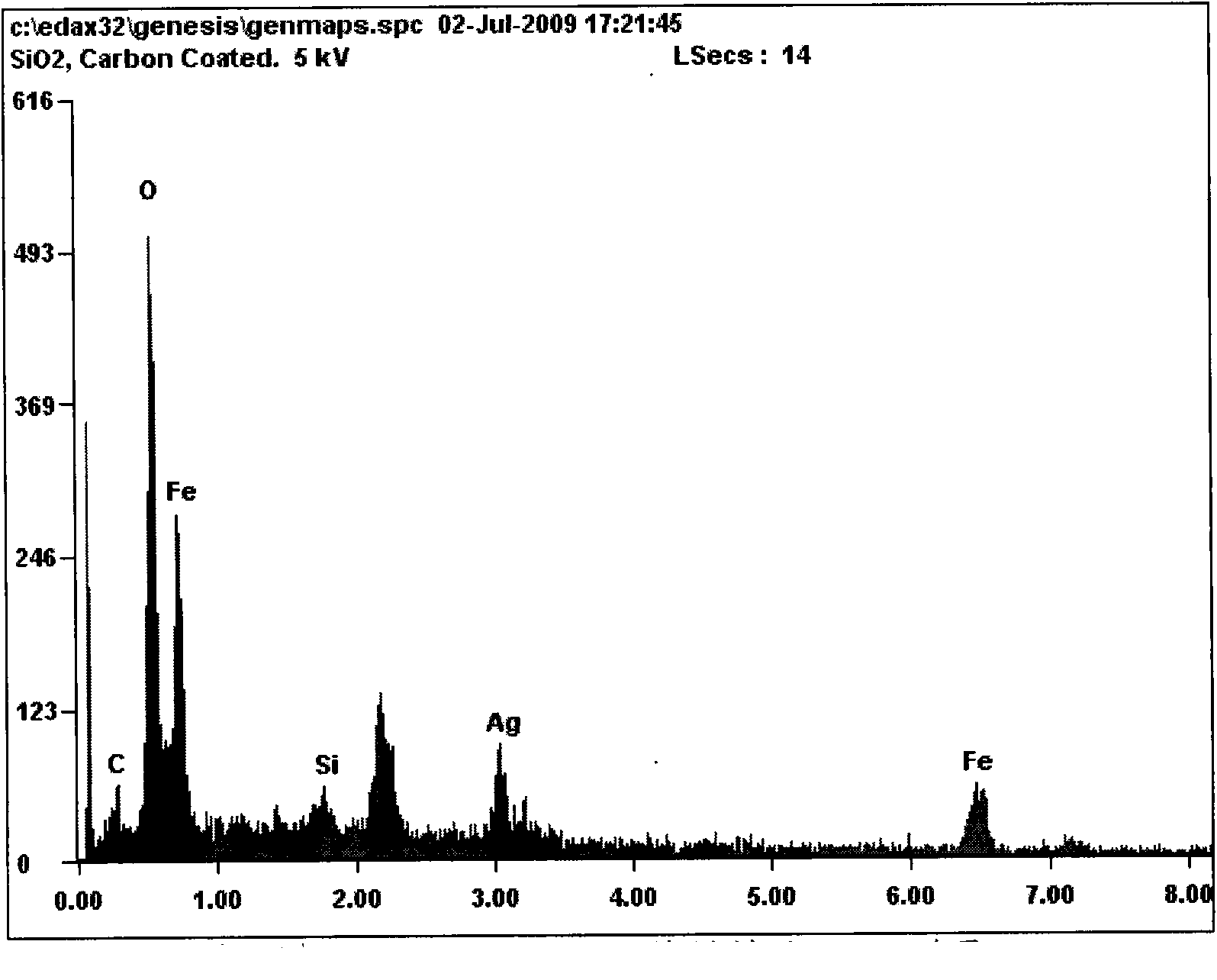

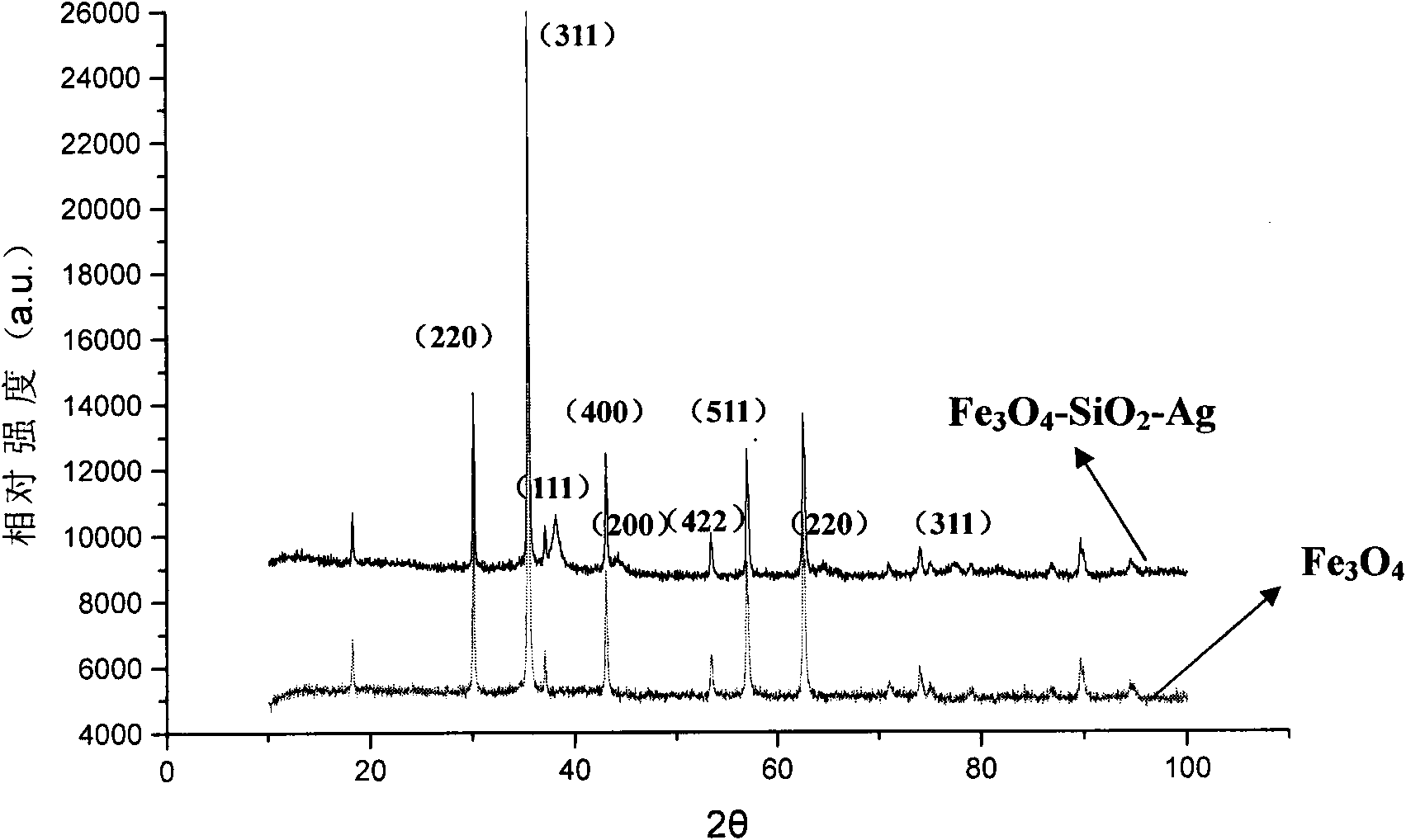

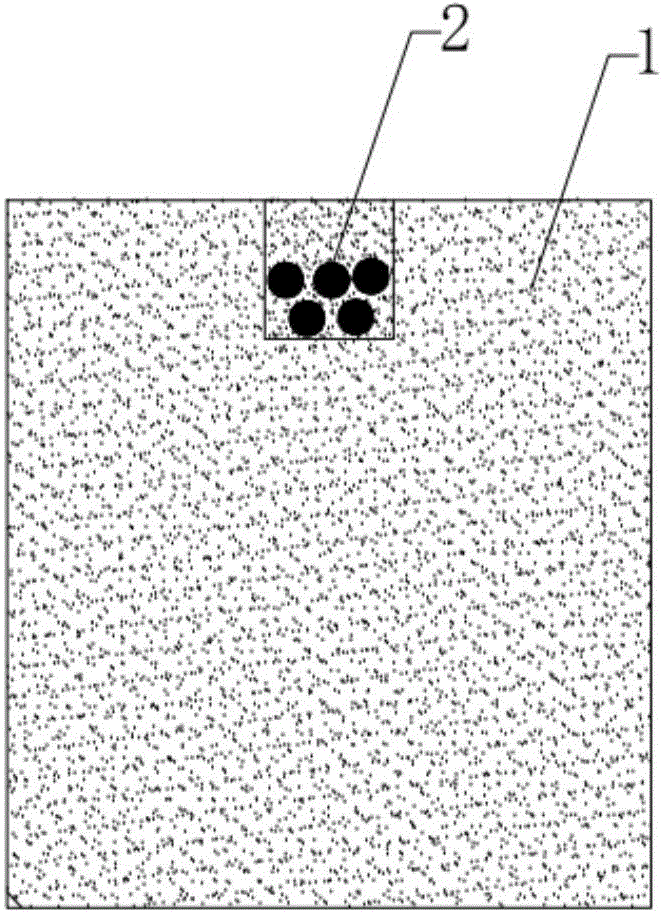

Magnetic nano silver antibacterial material and preparation method thereof

InactiveCN101664044AImproved antioxidant and anti-dissolution capacityGood for magnetic retentionBiocideDisinfectantsNanometreMagnetite Nanoparticles

The invention provides a magnetic nano silver antibacterial material for sterilization treatment in medical treatment and / or drinking water and a preparation method thereof. An antibacterial agent provided by the invention takes magnetic nanoparticles coated with silica gel as a core and inlaid with antibacterial particles on the outer layer, is preferably a Fe3O4 magnetic nano antibacterial material which is inlaid with silver nanoparticles and coated with silica gel. The antibacterial agent simultaneously has large special surface area of nano material, magnetic separation capacity and magnetic target of magnetic material, dispersant effect of a silica gel coating layer, protection action on the core and strong antibacterial ability of nano silver. In addition, the antibacterial agent issimple to prepare and convenient to operate and can realize directional sterilization, thereby having wide application prospect in medical care and food sanitation sterilization treatment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Limestone stony desertification area vegetation growth base and manufacturing method thereof and vegetation planting method

ActiveCN104396620ALight in massLoose structureBio-organic fraction processingExcrement fertilisersPlant rootsEvaporation

The invention discloses a limestone stony desertification area vegetation growth base and manufacturing method thereof and a vegetation planting method. The limestone stony desertification area vegetation growth base is rich in organic content, good in water and nutrient retention performance, wide in raw material source and low in cost and has an ability in absorbing moisture in rack mass cracks and the air. The vegetation planting method enables the plant survival rate to be high, the plant root system to be developed and the vegetation greening effect to be good. The growth base is formed by biology base materials, modifier and water in a mixing mode. The manufacturing method comprises the following steps of (1) mixing the biology base materials and adding water; (2) fermenting, turning piles and after ripening; (3) air drying; (4) adding the modifier, pressing the biology base materials and the modifier into cylinders and naturally drying; the planting method comprises the following steps of (1) drilling growth base arranging holes; (2) drilling root system holes in rock surfaces at the bottom and the periphery of the growth base arranging holes; (3) filling disperse system growth base into the root system holes; (4) arranging the integral growth base into the growth base arranging holes and sowing seeds; (5) covering evaporation proof covers on the growth base.

Owner:CHONGQING JIAOTONG UNIVERSITY

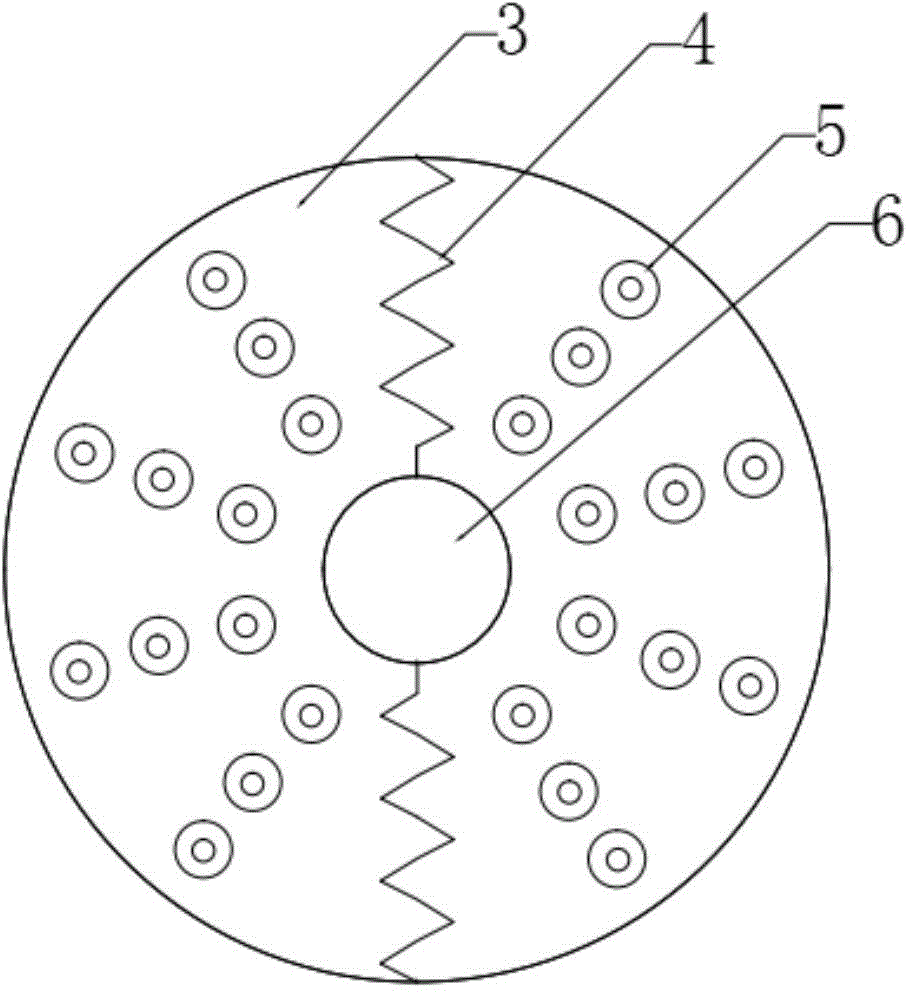

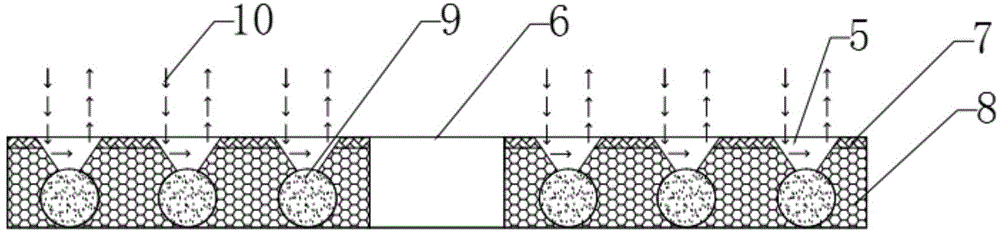

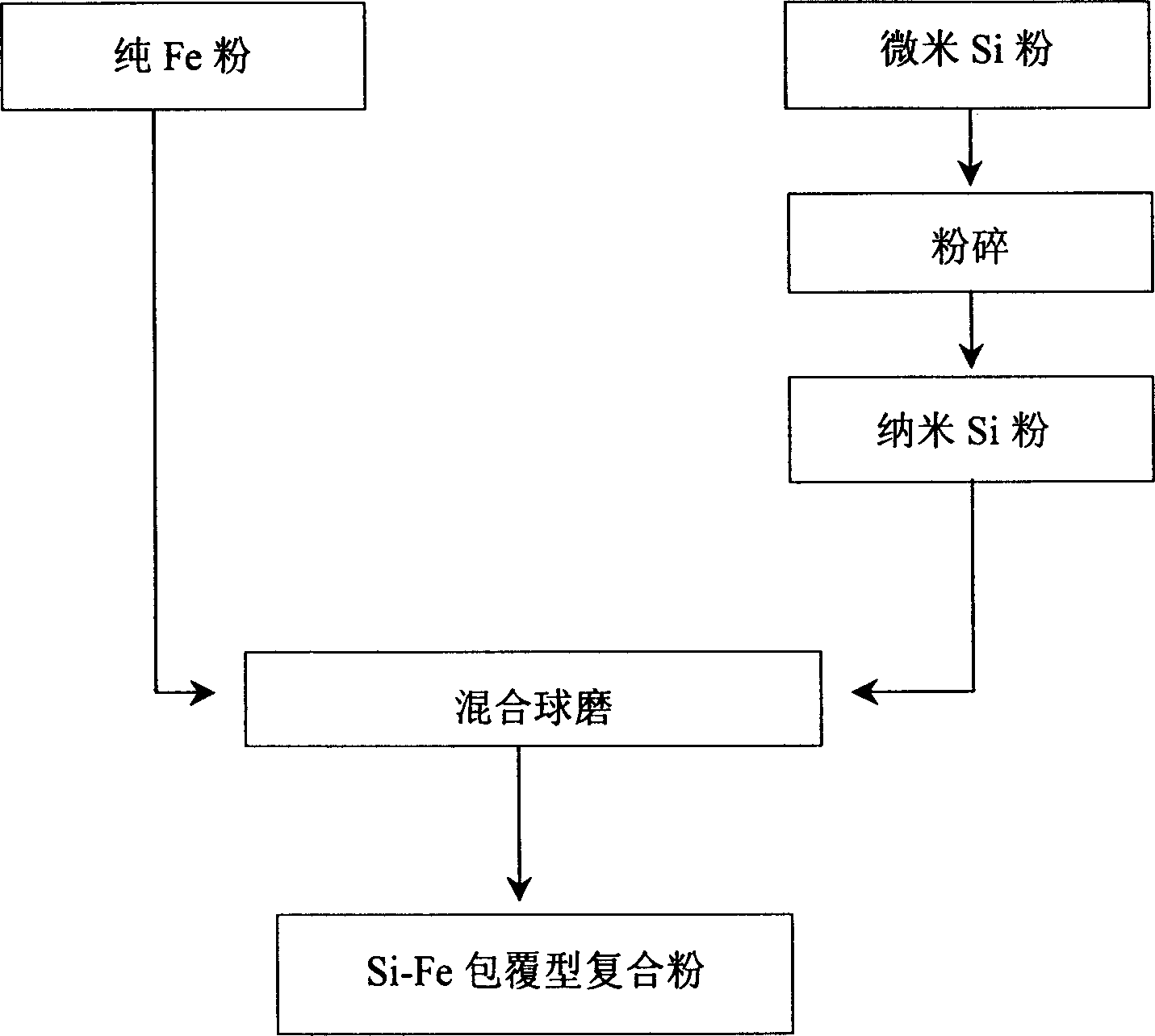

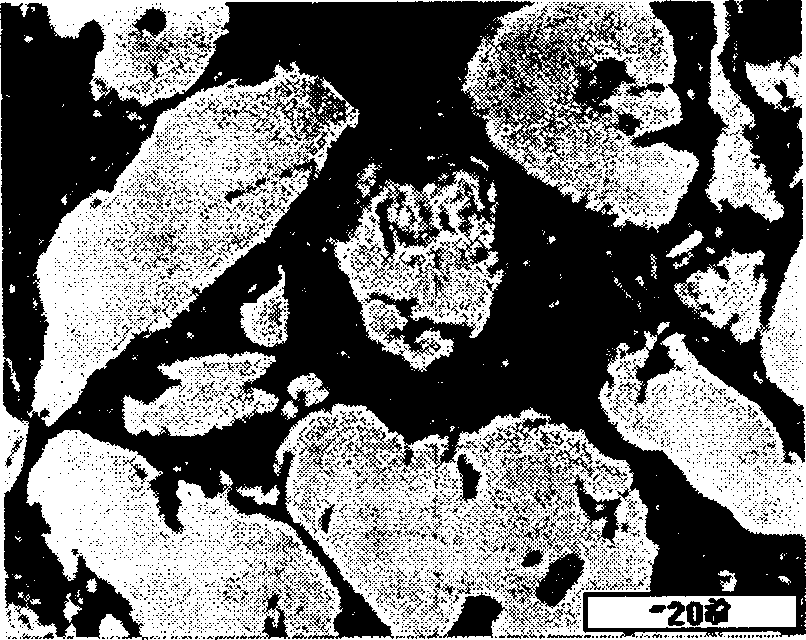

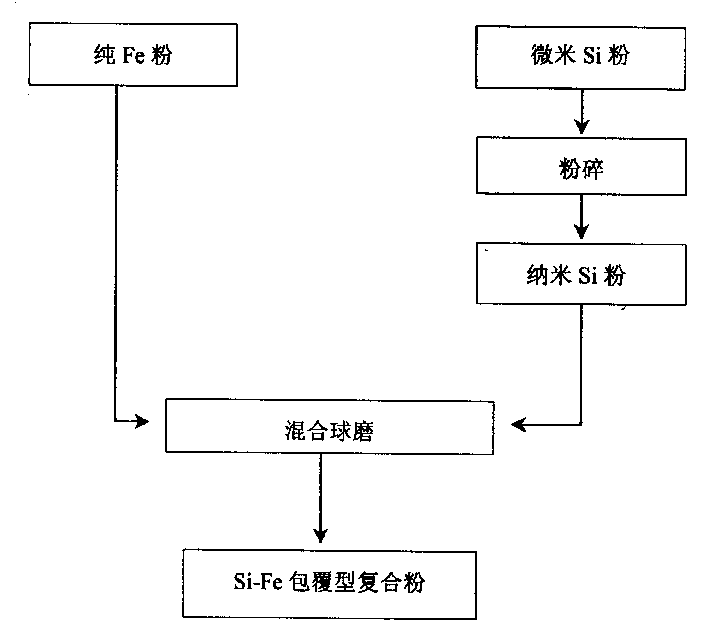

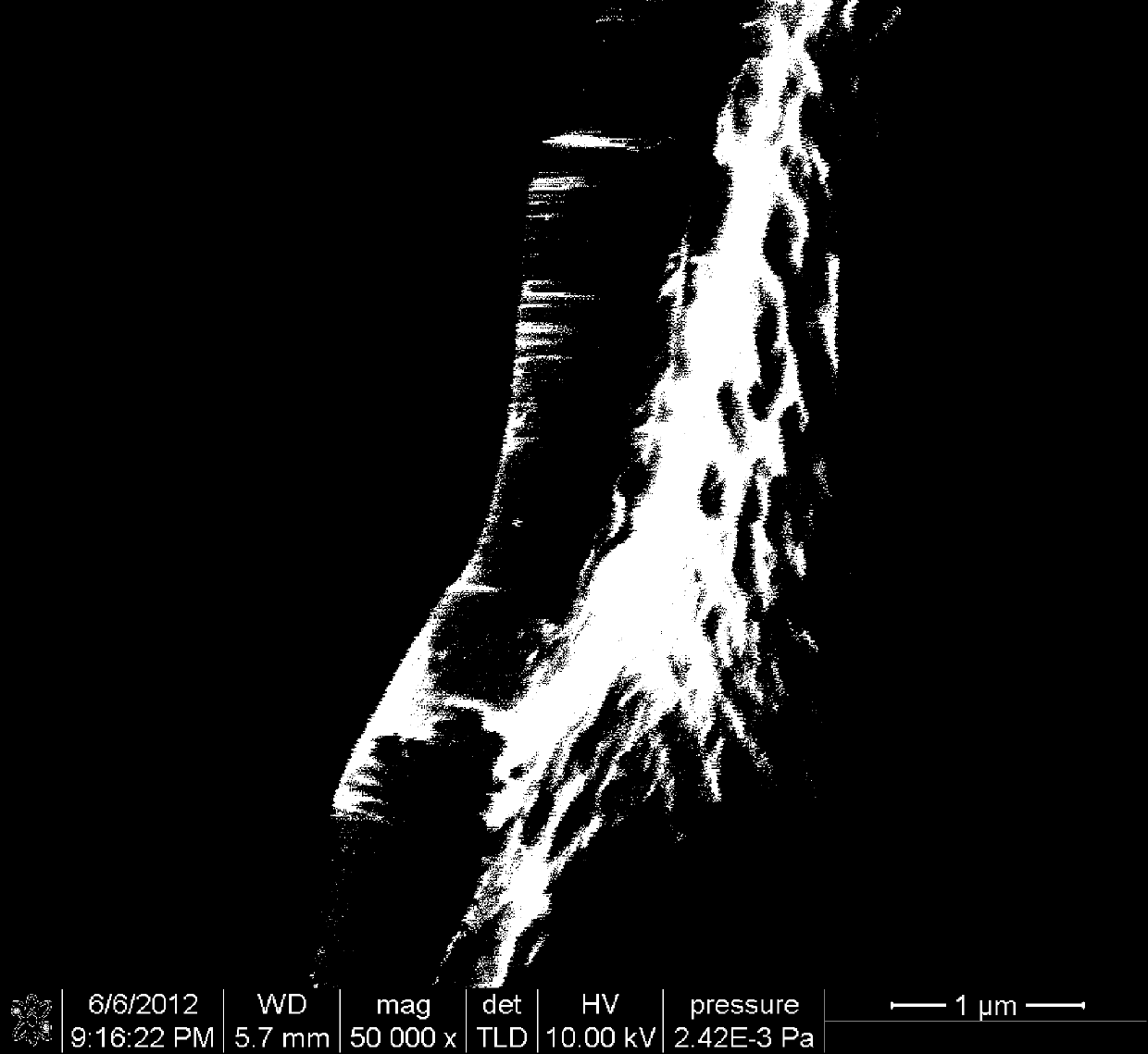

Method for preparing silicon-iron coating type composite powder

The method for preparing silicon-iron uniformly-covered composite powder includes the following steps: (1). utilizing high-energy pulverizing equipment to pulverize micrometer-grade Si powder into nano-grade Si powder; (2). mixing 6-7 wt% of nano-grade Si powder and 93-94 wt% of micrometer-grade Fe powder, ball-grinding, ball and material ratio is 4:1, ball grinding time is 1-2 hr, so as to make the Si be uniformly distributed on the surface of Fe granules and can obtain the Si-Fe uniformly-covered composite powder. Said covered composite powder retains the original plastic deformation capability of alpha-Fe, so that it can provide acceptable material for preparing high-silicon silver-steel sheet.

Owner:WUHAN UNIV OF TECH

Method for preparing photoelectrocatalysis electrode material capable of efficiently degrading organic pollutants

InactiveCN103132120AGood electrical conductivityLight in massSurface reaction electrolytic coatingChemistryAnodic oxidation

The invention provides a method for preparing a photoelectrocatalysis electrode material capable of efficiently degrading organic pollutants. The photoelectrocatalysis electrode material is a TiO2 nano porous film which takes titanium sponge as a substrate, and the method comprises the following preparation steps: performing anodic oxidation on the titanium sponge piece subjected to ultrasonic oil removal and cleaning to obtain a highly orderly arranged TiO2 nano porous film, wherein the film is converted into an anatase structure from an undefined structure through annealing treatment, and the film can be used for degrading organic pollutants through photoelectrocatalysis. The material has the characteristics of light weight, low cost, high conductive property and high stability, the organic pollutants can be efficiently degraded, and the material can be applied to the fields such as photoelectrocatalysis water-splitting hydrogen production. The preparation method has the characteristics of simple process, convenient operation, low production cost and easy industrial production.

Owner:佛山市顺德区荣骏盛塑料有限公司

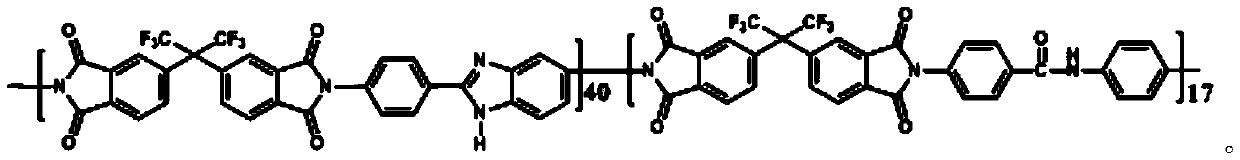

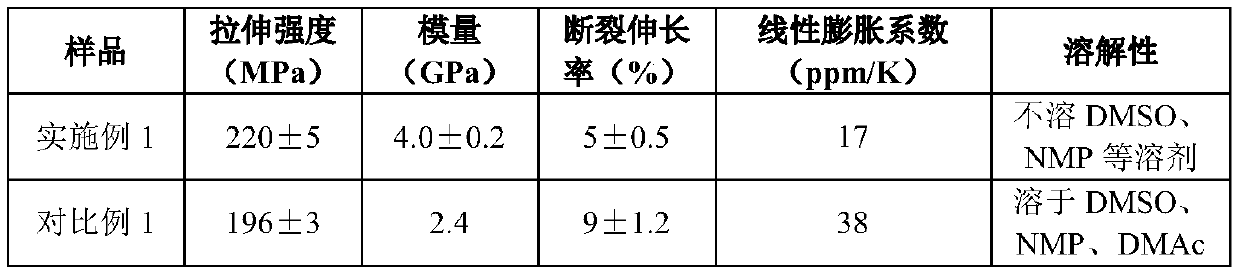

Preparation method of self-crosslinking polyimide film

The invention relates to a preparation method of a self-crosslinking polyimide film. The method comprises the following steps of: adding a benzimidazole heterocyclic diamine monomer and a halogen substituent-containing diamine monomer into a polar aprotic solvent, adding a dianhydride monomer for reaction, performing coating, drying and curing on the obtained polyimide solution to obtain a polyimide film, and performing heat treatment. The method is simple to operate, environmentally friendly in process, beneficial to large-scale preparation, and has a good industrialization prospect. And theobtained crosslinked film has excellent heat resistance, solvent resistance, radiation resistance and corrosion resistance, can be applied to extreme environments or special environments, and furtherexpands the application range of the materials.

Owner:DONGHUA UNIV

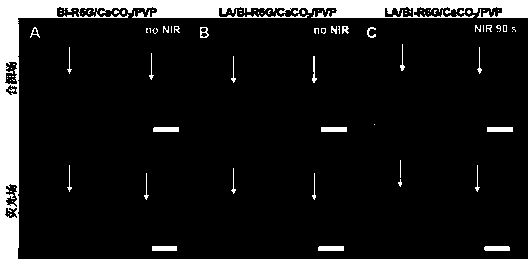

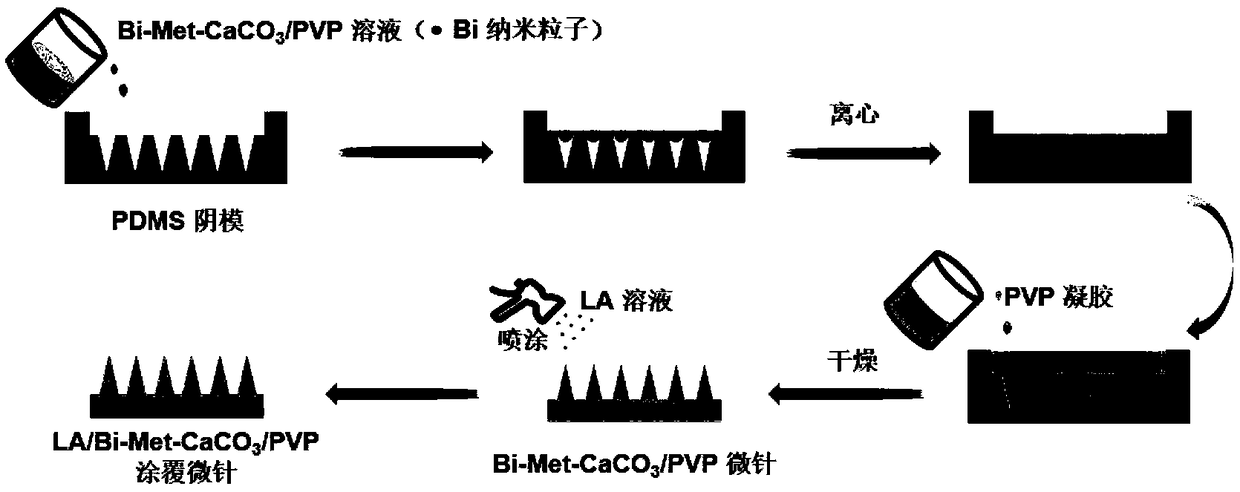

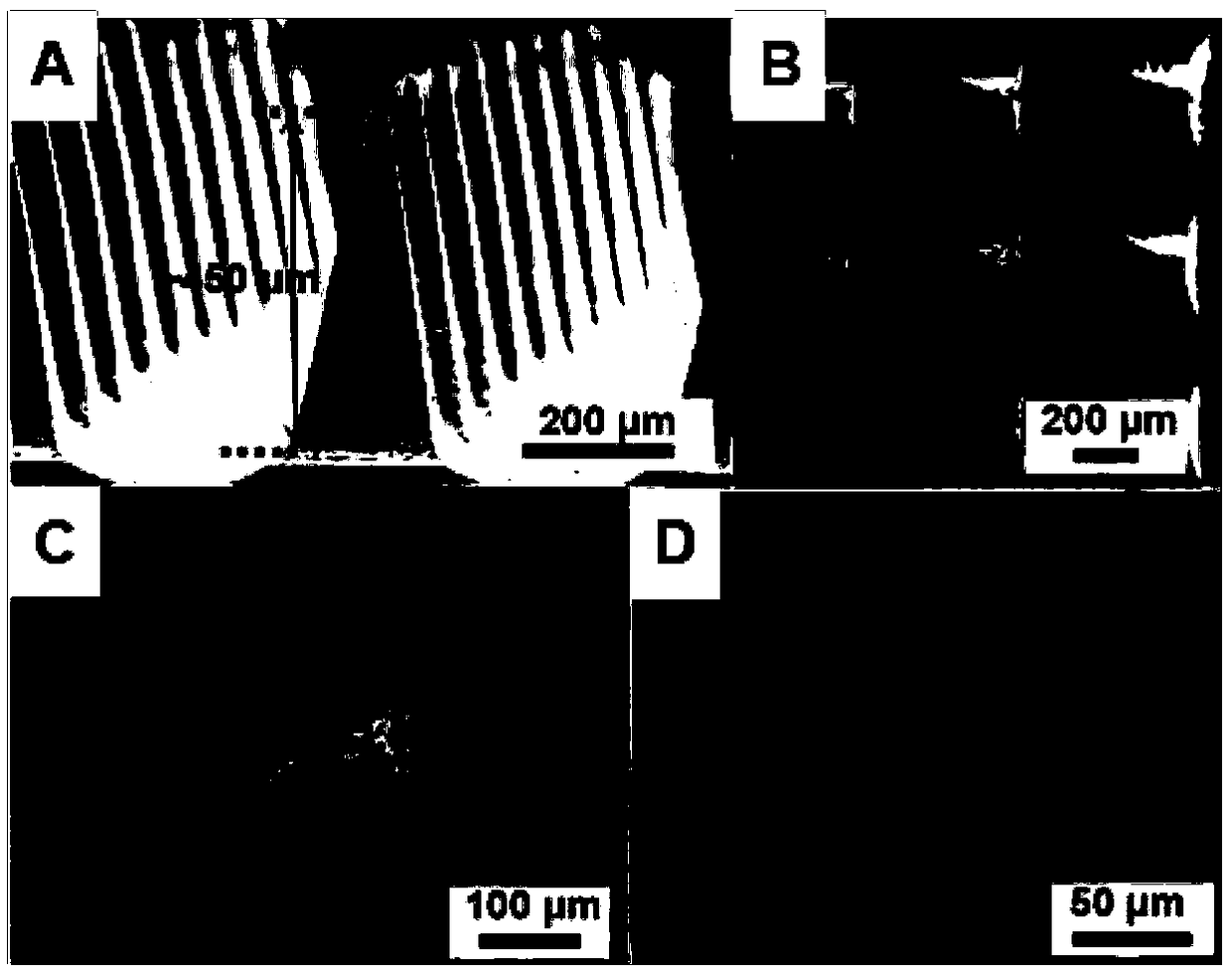

Photosensitive micro-needle, preparation method for same and controlled release method implemented by aid of photosensitive micro-needle

InactiveCN108619081AEasy to prepareSimple methodOrganic active ingredientsMetabolism disorderControlled releaseConversion factor

The invention belongs to the technical field of micro-needle transdermal medicine administration, and particularly relates to a photosensitive micro-needle, a preparation method for the same and a controlled release method implemented by the aid of the photosensitive micro-needle. The photosensitive micro-needle comprises a matrix and a plurality of needles. The needles are attached to the matrixand comprise main materials, medicine factors and photo-thermal conversion factors, and the main materials are mixed with the medicine factors and the photo-thermal conversion factors and are solidified; phase transformation materials with low melting points are coated on the needles. The photosensitive micro-needle, the preparation method and the controlled release method have the advantages thatthe phase transformation materials with the low melting points are used as surface coatings of the needles, near-infrared light can be absorbed by the photo-thermal conversion factors in the needlesand can be transformed into heat, accordingly, the coatings on the surfaces of the needles can be melted, body fluid can be absorbed by the needles and can be gradually dissolved or degraded, and themedicine factors embedded in the needles can be released.

Owner:ZHEJIANG SCI-TECH UNIV

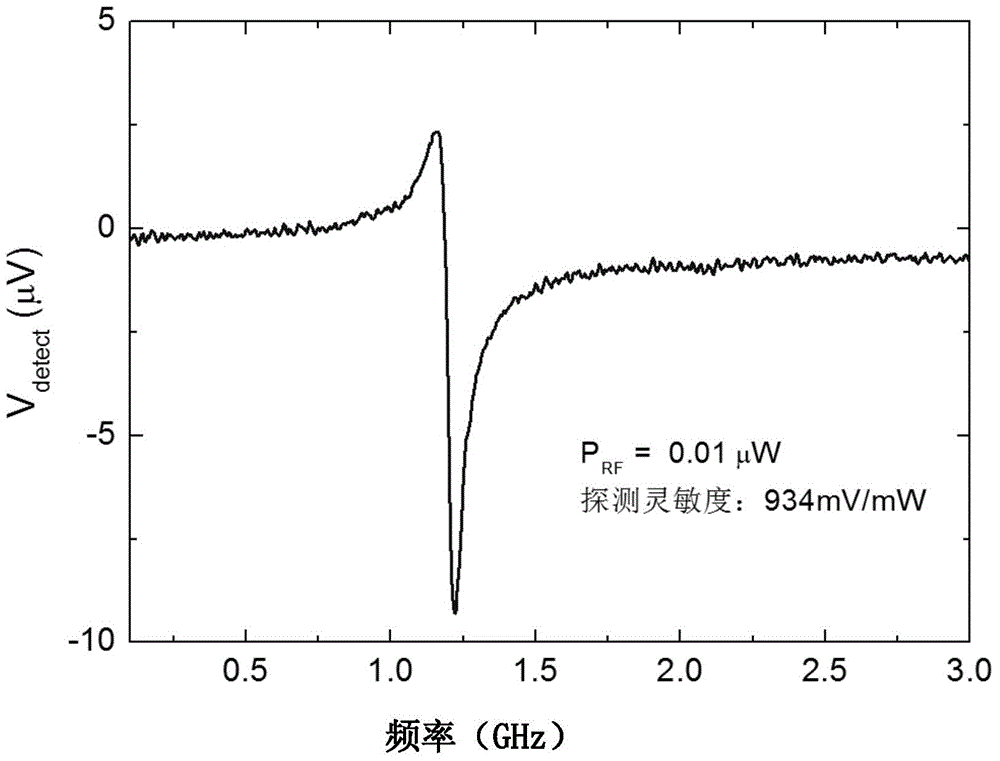

Novel microwave detector with high sensitivity

ActiveCN105223414AHigh detection sensitivitySmall sizeElectric devicesElectric power measurementIn planeMagnetization

The present invention discloses a novel microwave detector with high sensitivity. The novel microwave detector comprises a signal acquisition module, a rectifier module, a signal detection module and a signal display module, which are connected in turn, wherein the rectifier module comprises a fixed magnetic layer with in-plane balanced magnetization, a non-magnetic isolating layer formed on the fixed magnetic layer, and a magnetism free layer formed on the non-magnetic isolating layer and having vertical magnetocrystalline anisotropy. The microwave detector provided by the present invention has the characteristics of being small in size, high in sensitivity and simple in structure; and the preparation technology is compatibility with the prior art, easy for mass production, and widely applicable to fields such as high-speed multichannel communication, week signal detection and microwave power transmission.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Perovskite solar cell with conducting polymer as back electrode and preparing method of perovskite solar cell

ActiveCN104319348AReduce manufacturing costSimple processFinal product manufactureSolid-state devicesNanowirePerovskite solar cell

The invention provides a perovskite solar cell with a conducting polymer as a back electrode and a preparing method of the perovskite solar cell and relates to solar cells. The perovskite solar cell is provided with a transparent conducting glass substrate, an isoelectronic transmission layer, a light absorption perovskite material layer and a conducting polymer back electrode layer from bottom to top in sequence. The preparing method comprises the steps that the transparent conducting glass substrate is preprocessed; the isoelectronic transmission layer is prepared on the preprocessed transparent conducting glass substrate; a DMF solution of PbI2 is prepared, the isoelectronic transmission layer is coated with the DMF solution of the PbI2 in a spinning mode, and a yellow PbI2 thin film is obtained; the yellow PbI2 thin film is coated with a polyaniline nanowire ethanol solution in a spinning mode, and a loose porous thin film, namely the conducting polymer back electrode, is obtained; an isopropanol solution of methylamine is added on the conducting polymer back electrode, standing and heating are conducted, and the perovskite solar cell with the conducting polymer as the back electrode is obtained. The conducting polymer prepared at the lower temperature is used as the back electrode, evaporation is not needed, the technology is simple, the preparation cost is low, and mass preparation is easy.

Owner:KUNSHAN GCL OPTOELECTRONIC MATERIAL CO LTD

Battery cell winding method and equipment

ActiveCN102683736AEvenly heatedImprove deformationFinal product manufactureSecondary cells manufacturePole pieceBattery cell

The invention discloses a battery cell winding method and equipment. According to the method, a positive pole piece and a negative pole piece are heated before winding, so the stress of the pole pieces is sufficiently released, the pole pieces are lengthened to a certain degree under the tensile action during winding, after the winding is finished, the pole pieces contract along with an isolation film in the cooling process, and the deformation of the battery cell is accordingly improved. The equipment comprises a machine frame, a motor arranged in the machine frame, a positive pole piece feeding mechanism, a negative pole piece feeding mechanism, an isolation film feeding mechanism and a winding mechanism which are fixedly connected with the machine frame respectively, wherein the machine frame is also connected with a positive pole piece heating mechanism and a negative pole piece heating mechanism. The beneficial effects of the technical scheme are as follows: the method is simple and practical, and can be applicable to automation continuous production; and the equipment is simple to operate, the heating mechanisms are easy, and the large-scale manufacturing is facilitated.

Owner:NINGDE AMPEREX TECH +1

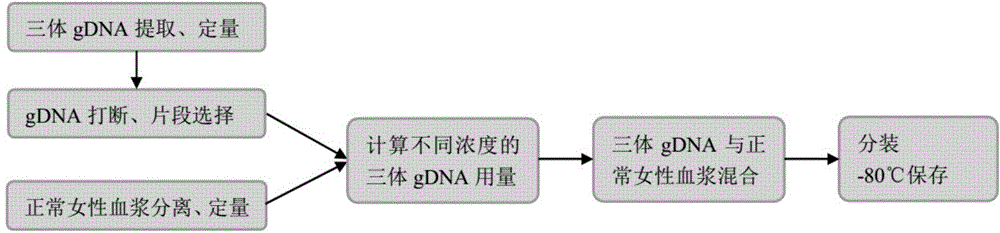

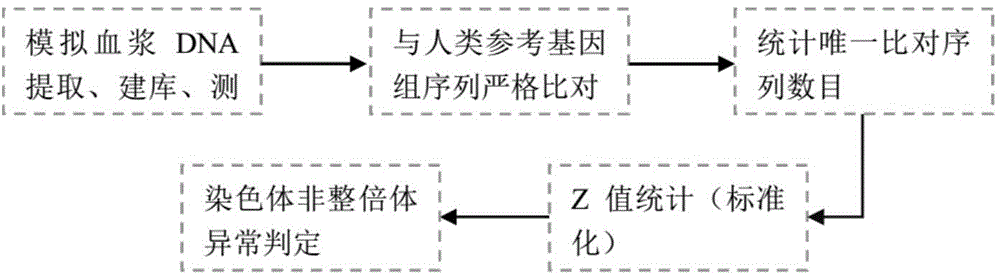

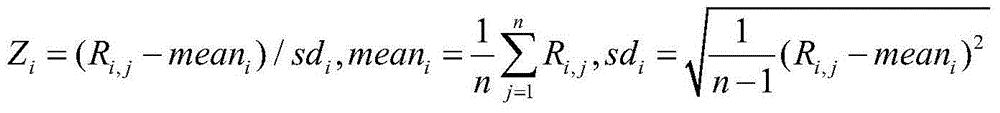

Standard product for polyploid chromosome detection and preparation method thereof

ActiveCN105821117ARich sourcesEasy to operateMicrobiological testing/measurementNormal femaleBlood plasma

The invention provides a standard product for polyploid chromosome detection and a preparation method thereof. The standard product comprises a first standard, a second standard and an optional third standard which are respectively positioned inside a separate container, wherein the first standard contains 3.5+ / -0.2% of polyploid chromosome gDNA fragments and residual normal female plasma on the basis of total mass (mass) of DNA in the standard; the second standard contains 4-6% of polyploid chromosome gDNA fragments and residual normal female plasma on the basis of total mass (mass) of DNA in the standard; and the first standard contains 8-12% of polyploid chromosome gDNA fragments and normal female plasma on the basis of total mass (mass) of DNA in the standard.

Owner:海南华大基因科技有限公司

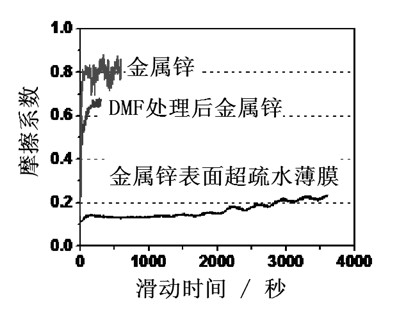

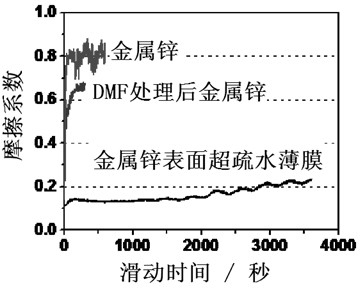

Preparation method of zinc or zinc alloy super hydrophobic surface with antifriction and wear-resisting property

InactiveCN102133572AWith anti-frictionWith wear resistanceSpecial surfacesCoatingsN dimethylformamideAlcohol

The invention discloses a preparation method of zinc or zinc alloy super hydrophobic surface with antifriction and wear-resisting property. The method comprises the following steps: firstly cleaning the surface of metal by absolute ethyl alcohol and deionized water; then dipping the metal in N,N-dimethylformamide solution for 8-24 hours with constant temperature, cleaning and drying, wherein the volume ratio concentration of N,N-dimethylformamide is 2-5%, and the temperature is 40-80 DEG C; and finally, dipping the metal in fatty acid ethanol solution with the concentration being 0.001-0.01M and the temperature being 20-60 DEG C for 8-24 hours, taking out the metal, then cleaning the metal by absolute ethyl alcohol, and drying the metal by nitrogen, thus obtaining super hydrophobic surface. The zinc or zinc alloy super hydrophobic surface can be stable for long time, and can keep good super hydrophobicity, antifriction and wear resistance performances after the mechanical bending deformation.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

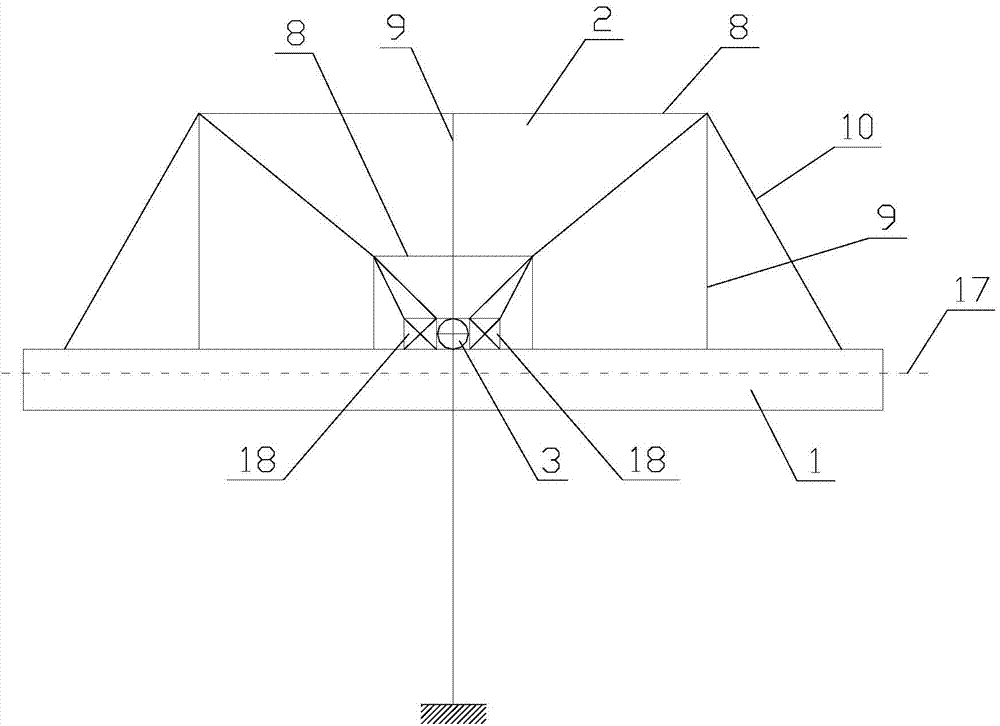

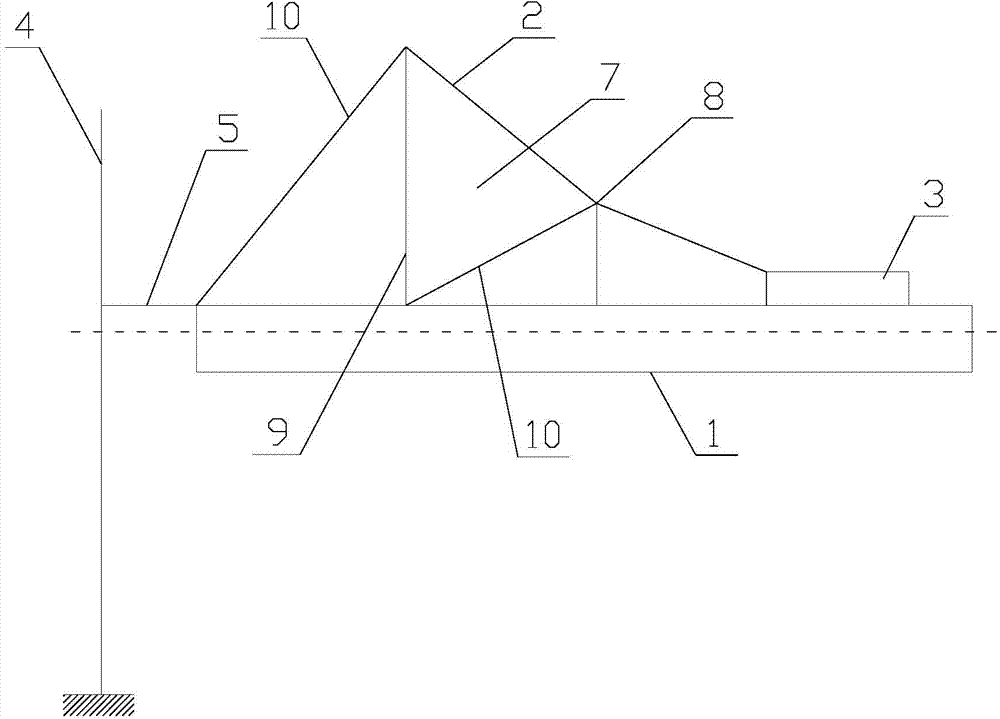

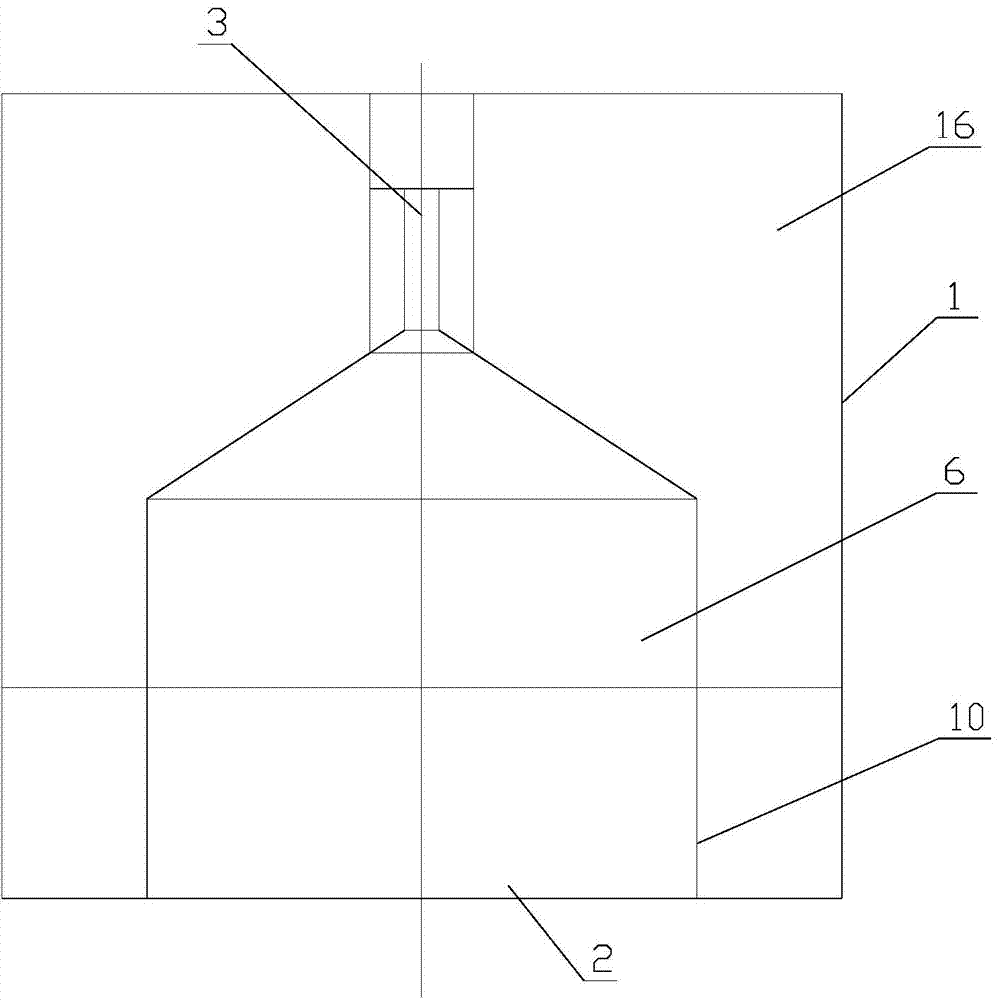

Self-adapted wind collection type overwater wind power station

InactiveCN104763595AHigh strengthReduce the impactWind motor with solar radiationPV power plantsSea wavesWind wave

The invention relates to a self-adapted wind collection type overwater wind power station. The self-adapted wind collection type overwater wind power station comprises a wind collection device and a wind power generator set, wherein the wind collection device is provided with a wind collection opening and a wind outlet; the wind outlet is formed towards the wind power generator set; the wind collection device and the wind power generator set are arranged on a floating body; the floating body is floated on the water and is rotationally connected with a mooring body through a connection piece; when the wind direction is changed, the wind collection device and the wind power generator set rotate around the mooring body along the floating body on the water surface, so that the wind collection opening is automatically adjusted to a direction facing incoming wind; the size of the wind collection area can be adjusted; the floating body is composed of a plurality of floating body units; each floating body unit comprises a body of the floating body and a supporting column; the body of the floating body is suspended under the water. The self-adapted wind collection type overwater wind power station can be automatically adapted and integrates wave energy and solar power generation devices along the change of a wind direction, so that the comprehensive economic benefits are improved. The self-adapted wind collection type overwater wind power station has high strength; the body of the floating body is suspended under the water and the influences by wind are small; the wave energy power generation device can inhibit the swinging effect of sea waves, and has the capability of resisting strong wind waves.

Owner:陈佳宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com