Fe3O4 nanozyme with improved catalytic activity, and preparation method and application thereof

A technology for improving catalytic activity and catalytic activity, which is applied in the field of nanomaterials and biomedical nanotechnology, can solve the problems of low catalytic activity of enzymes and limit practical application value, etc., and achieve high biocompatibility, easy modification and labeling, and storage at room temperature stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

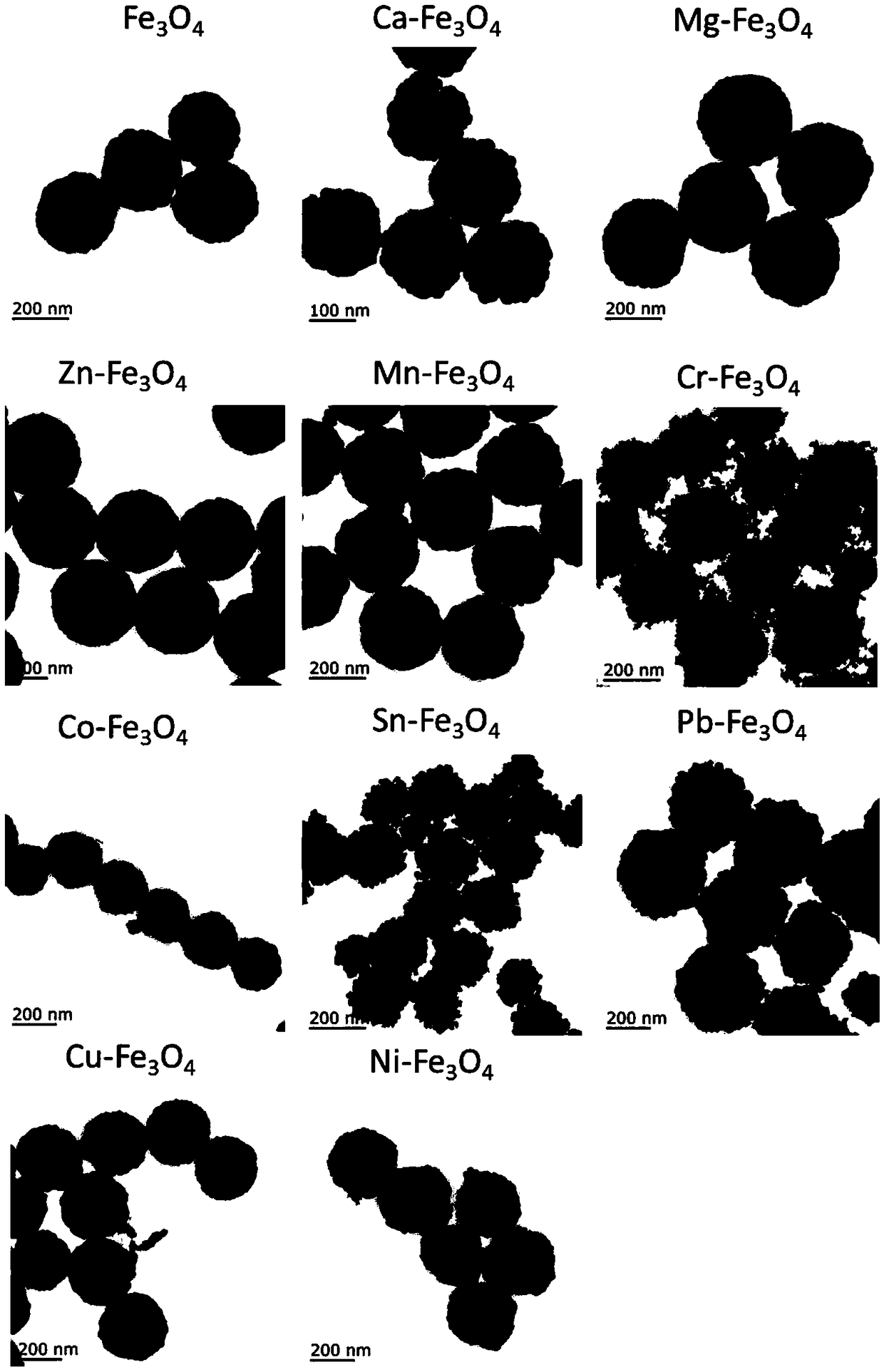

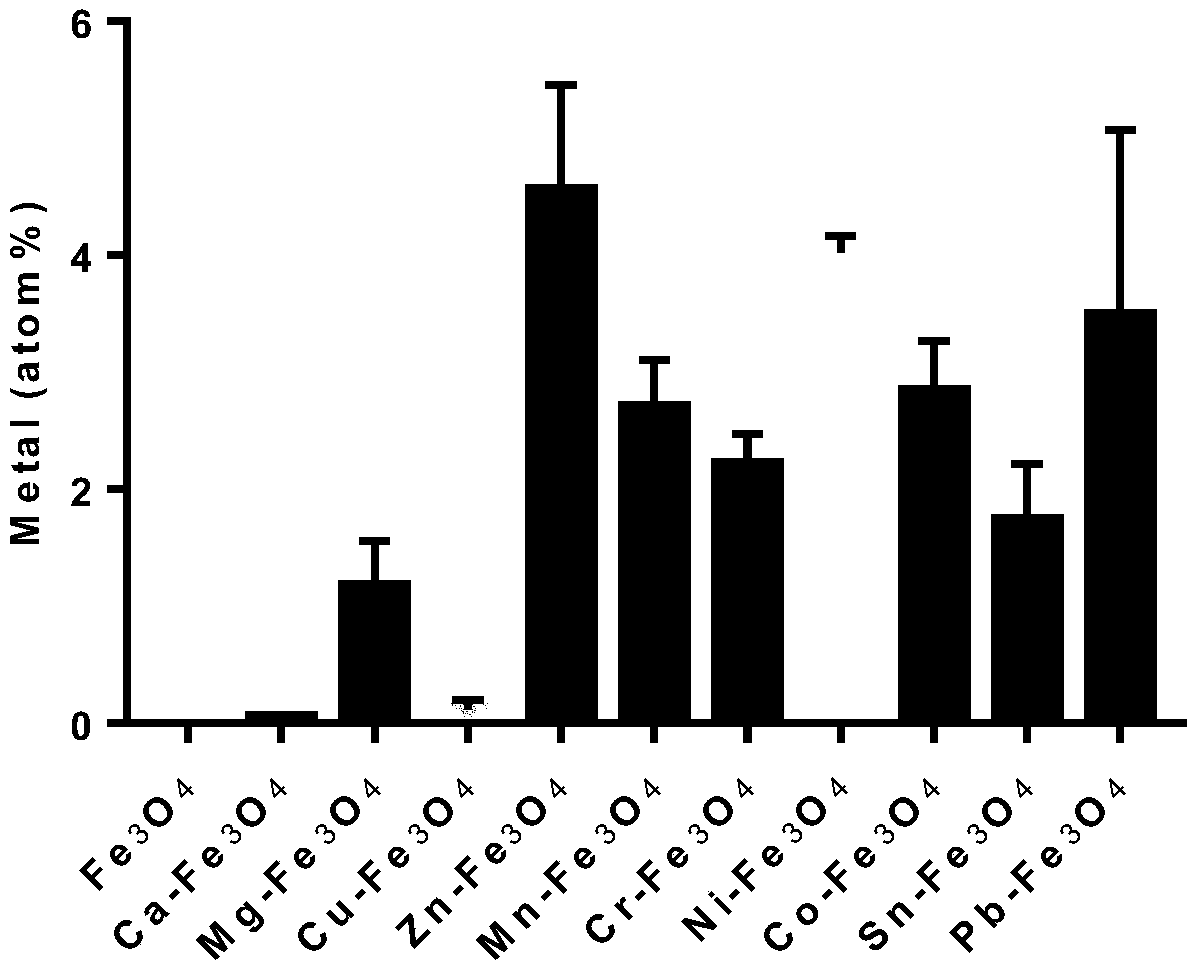

[0037] Embodiment 1: metal element doping improves Fe 3 o 4 Preparation of nanozymes

[0038] Test materials: 3,3',5,5'-tetramethylbenzidine (3,3',5,5'-Tetramethylbenzidine, TMB), ferric chloride, and ethylene glycol were all ordered from Sigma, and kept away from light at room temperature Store for later use. 30%H 2 o 2 , sodium acetate, calcium chloride, magnesium chloride, copper chloride, zinc chloride, manganese chloride, chromium chloride, nickel chloride, cobalt chloride, tin chloride and lead chloride are all ordered from Shenggong Company and stored at room temperature spare.

[0039] experiment method:

[0040] Metal element-doped nanozymes were prepared by hydrothermal synthesis. First, 0.82 g of anhydrous ferric chloride was completely dissolved in 40 ml of ethylene glycol by magnetic stirring to form a clear solution. Next, slowly add 3.6 g of sodium acetate trihydrate, and stir rapidly to form a uniform suspension. Then add 0.1g of inorganic metal salts: ...

Embodiment 2

[0045] Example 2: Metal element doping enhances Fe 3 o 4 Nanozyme peroxidase activity

[0046] Test materials: 3,3',5,5'-tetramethylbenzidine (3,3',5,5'-Tetramethylbenzidine, TMB) was ordered from Sigma, and stored at room temperature in the dark for future use. 30% H2O2 and sodium acetate were ordered from Shenggong Company and stored at room temperature for future use.

[0047] Method: The enzymatic kinetic parameters of the catalytic substrate H2O2 are measured. The detection method is to take an appropriate amount of nanozyme, dissolve it in 200 μl of 0.1M sodium acetate buffer (pH 4.5), add 4 μl of TMB solution (10mg / ml, dissolve in DMSO), adjust H 2 o 2 The microplate reader detects the light absorption value at 652nm, the time scan is 300s, and the reaction temperature is 37°C. For nanozyme, the concentration gradient of adding H2O2 is 0, 18.625, 37.125, 74.25, 148.5, 297, 594, 1188mM. GraphPadPrism7 software was used to statistically analyze the experimental data...

Embodiment 3

[0049] Example 3: Metal element doping enhances Fe 3 o 4 Nanozyme catalase activity

[0050] Test materials: 30% H2O2 and sodium acetate were ordered from Shenggong Company and stored at room temperature for future use.

[0051] Method: Determination of the enzymatic kinetic parameters of the catalytic substrate H2O2. The detection method is to take an appropriate amount of nanozyme, dissolve it in 5ml of 0.1M sodium acetate buffer solution (pH 7.4), add different amounts of H2O2, and use a dissolved oxygen meter to detect oxygen. generated speed. GraphPad Prism7 software was used for statistical analysis of experimental data, and Michaelis-Menten kinetics was used to analyze catalytic parameters and compare catalytic efficiencies.

[0052] Using a dissolved oxygen meter to detect the effect of metal doping on Fe 3 o 4 effects on catalase-like activity. Such as Figure 6 As shown, with Fe 3 o 4 Compared to Co-Fe 3 o 4 The catalase activity of Mn-Fe was significantly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com