Patents

Literature

602results about How to "Meet actual production needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

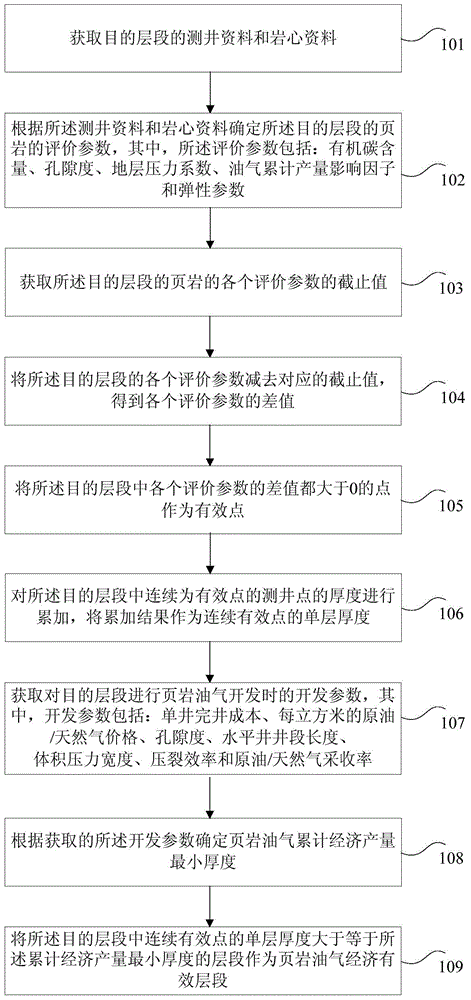

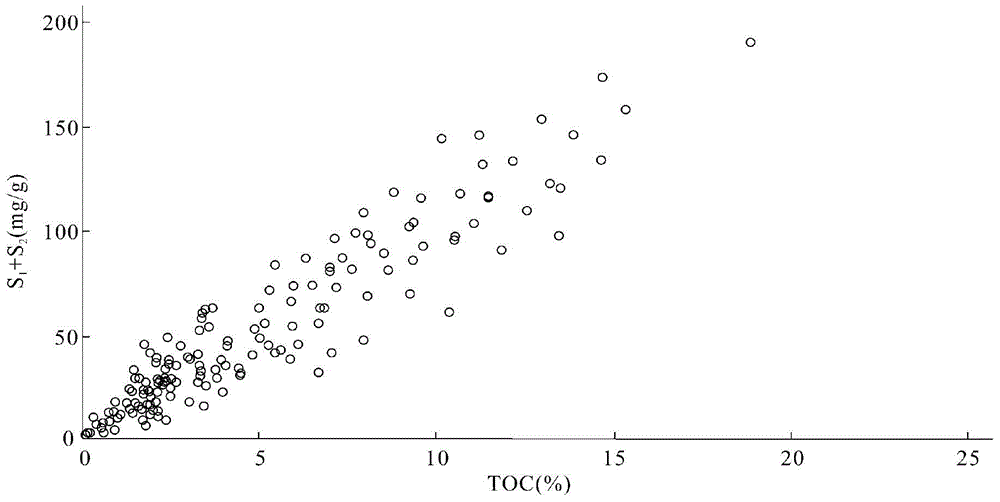

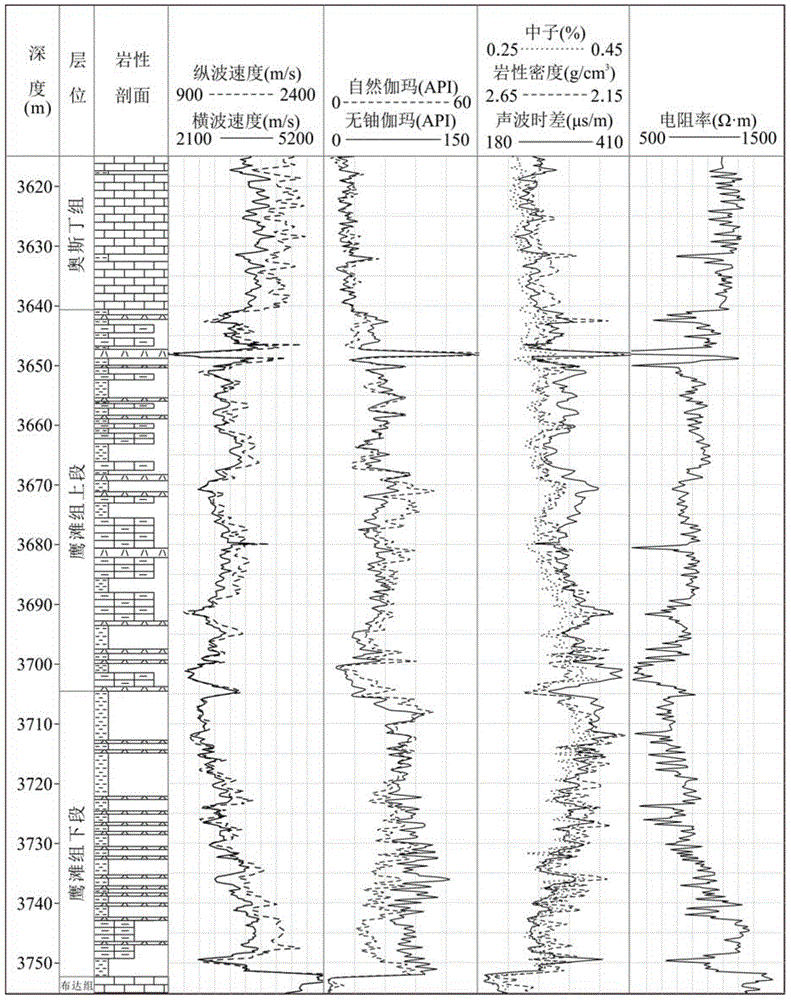

Shale oil-gas economical and effective layer section evaluation method

ActiveCN104453873AImprove development efficiencyEliminate defects with large evaluation errorsBorehole/well accessoriesPorositySlice thickness

The invention provides a shale oil-gas economical and effective layer section evaluation method. The method comprises the steps of determining evaluation parameters of shale of target layer sections according to obtained logging data and core data, wherein the evaluation parameters include the organic carbon content, the porosity, the formation pressure coefficient, the oil-gas accumulative output impact factor and elastic parameters; subtracting a corresponding cut-off value from each evaluation parameter to obtain a difference value of each evaluation parameter; using points with the difference values, larger than 0, of the evaluation parameters as efficient points; adding the thicknesses of logging points which are continuous efficient points in the target layer sections, and using the added result as the single-layer thickness of the continuous efficient points; determining the shale oil-gas accumulated economical yield minimum thickness; using the layer section with the single-layer thickness of the continuous efficient points larger than or equal to the accumulated economical yield minimum thickness in the target layer section as the shale oil-gas economical and effective layer section. According to the shale oil-gas economical and effective layer section evaluation method, the shale oil-gas economical and effective layer section can be accurately and effectively determined, and therefore the shale oil-gas development benefits are improved.

Owner:PETROCHINA CO LTD

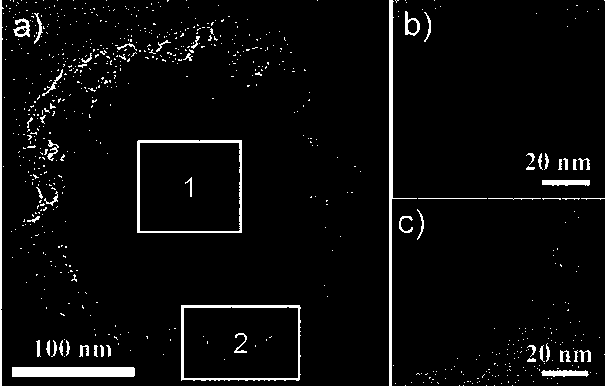

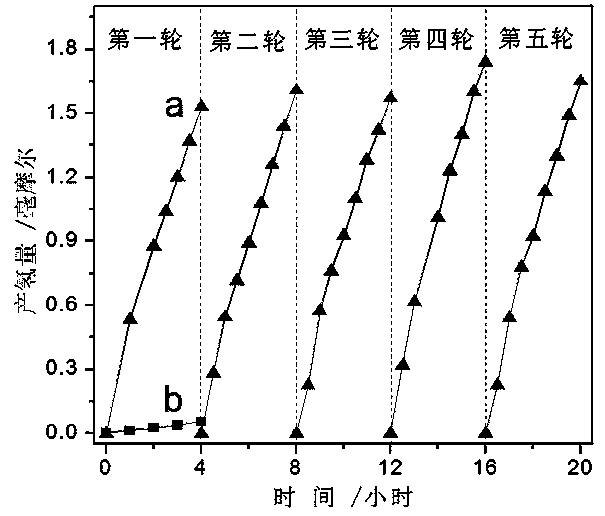

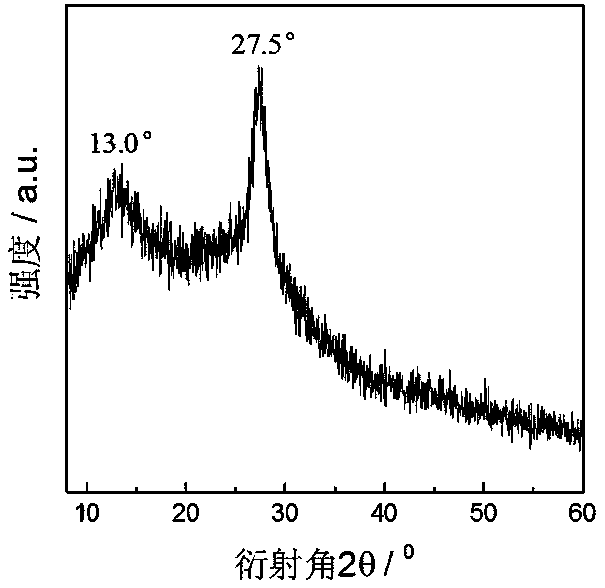

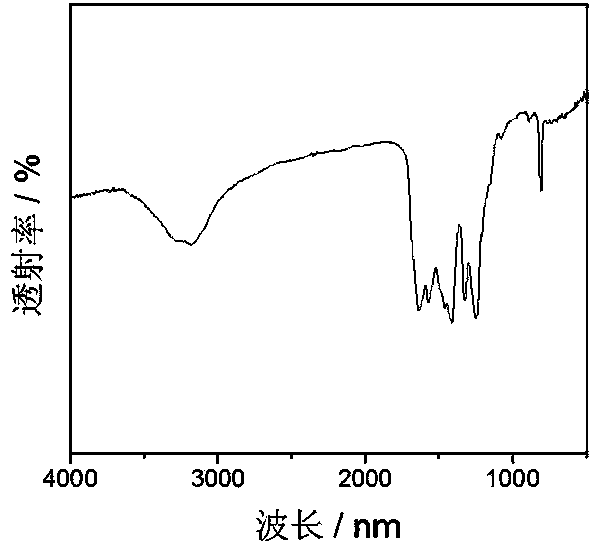

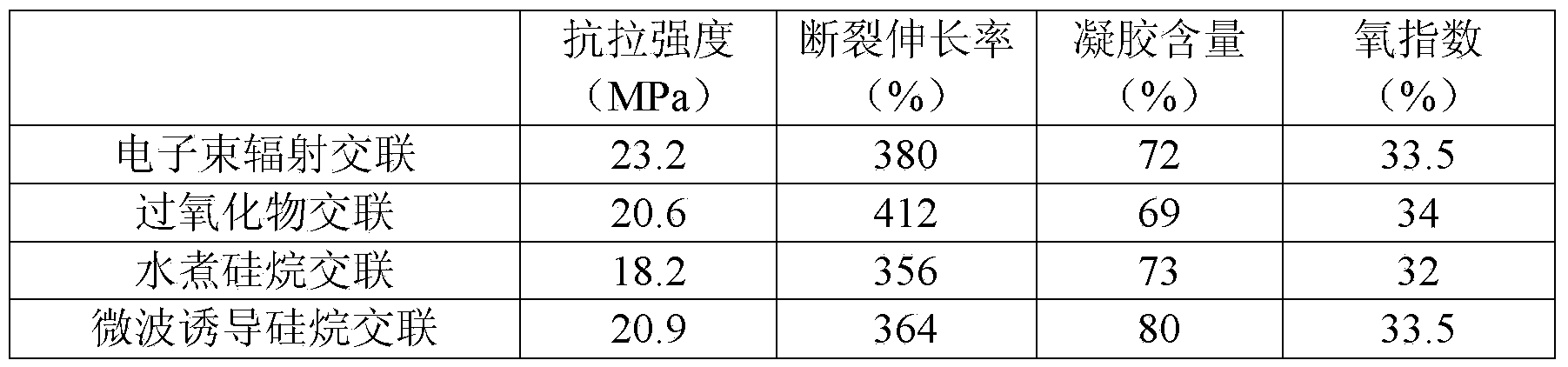

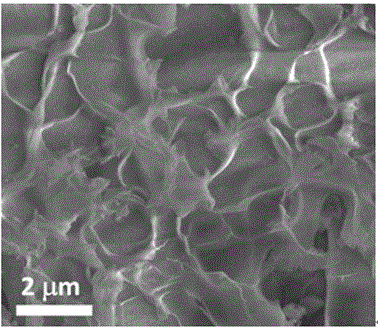

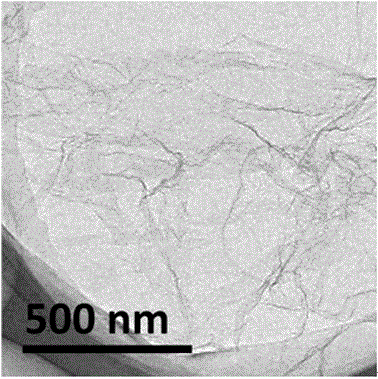

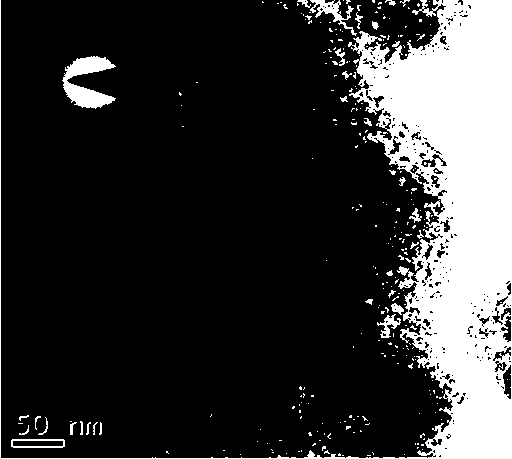

Spherical mesoporous carbon nitride photocatalyst with multistage nano structure

ActiveCN103623856AThe synthesis process is simpleImprove stabilityMaterial nanotechnologyPhysical/chemical process catalystsPhoto catalysisHydrogen production

The invention discloses a spherical mesoporous carbon nitride photocatalyst with a multistage nano structure and a preparation method and application thereof and belongs to the technical field of material preparation and photocatalysis. The spherical mesoporous carbon nitride photocatalyst with the multistage nano structure is prepared by using cyanamide as a precursor, using spherical mesoporous silicon dioxide with a highly open structure as a hard template, carrying out thermal thermal polymerization and removing the hard template. The spherical mesoporous carbon nitride prepared by the preparation method has the characteristic that nanosheet or nanosheet-like small particles are uniformly diffused around from the sphere center to form a spherical micro nano structure of which the surface structure is highly open; compared with conventional bulk phase carbon nitride, the spherical mesoporous carbon nitride photocatalyst can obviously improve the specific surface area and the mass transfer effect and has efficient photocatalytic hydrogen production performance in the visible light. The spherical mesoporous carbon nitride photocatalyst adopts a simple synthetic process, has high catalysis efficiency and has wide application prospect in the field of catalysis / photocatalysis.

Owner:FUZHOU UNIVERSITY

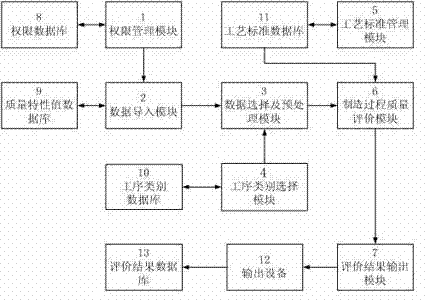

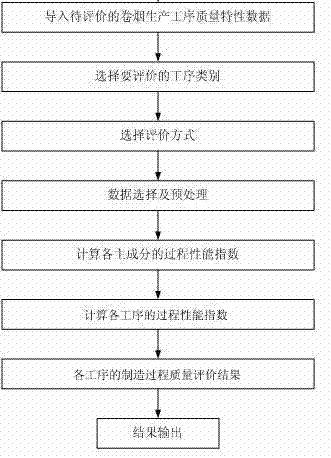

Method and system for evaluating quality in process of manufacturing cigarette

InactiveCN102509243AReflect the processing quality statusImprove quality controlData processing applicationsManufacturing computing systemsProcess qualityPrincipal component analysis

The invention discloses a method and system for evaluating quality in the process of manufacturing batch cigarette products. The method and system are characterized in that on the basis of evaluating the process quality of certain procedure single quality characteristic value, process performance indexes of a multivariable procedure are calculated by a principal component analysis method to obtain the weights of all principal components according to the respective characteristics of the procedures of shredding, wrapping, molding and the like, and the process performance indexes of the procedure are acquired through arithmetic weighted average, so that the quality in the process of manufacturing the cigarette is evaluated. Compared with other evaluation methods, the evaluation method disclosed by the invention has the advantages that: the selection of evaluation indexes more conforms to actual production demands, and the actual application range is wider; the establishment of evaluation standards fully refers to the conventional research results and is more scientific and objective; the quality control conditions of all production procedures of the cigarette can be better known through the evaluation; and more adequate data support is provided for continuously improving the quality in the process of manufacturing the cigarette and the final quality.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

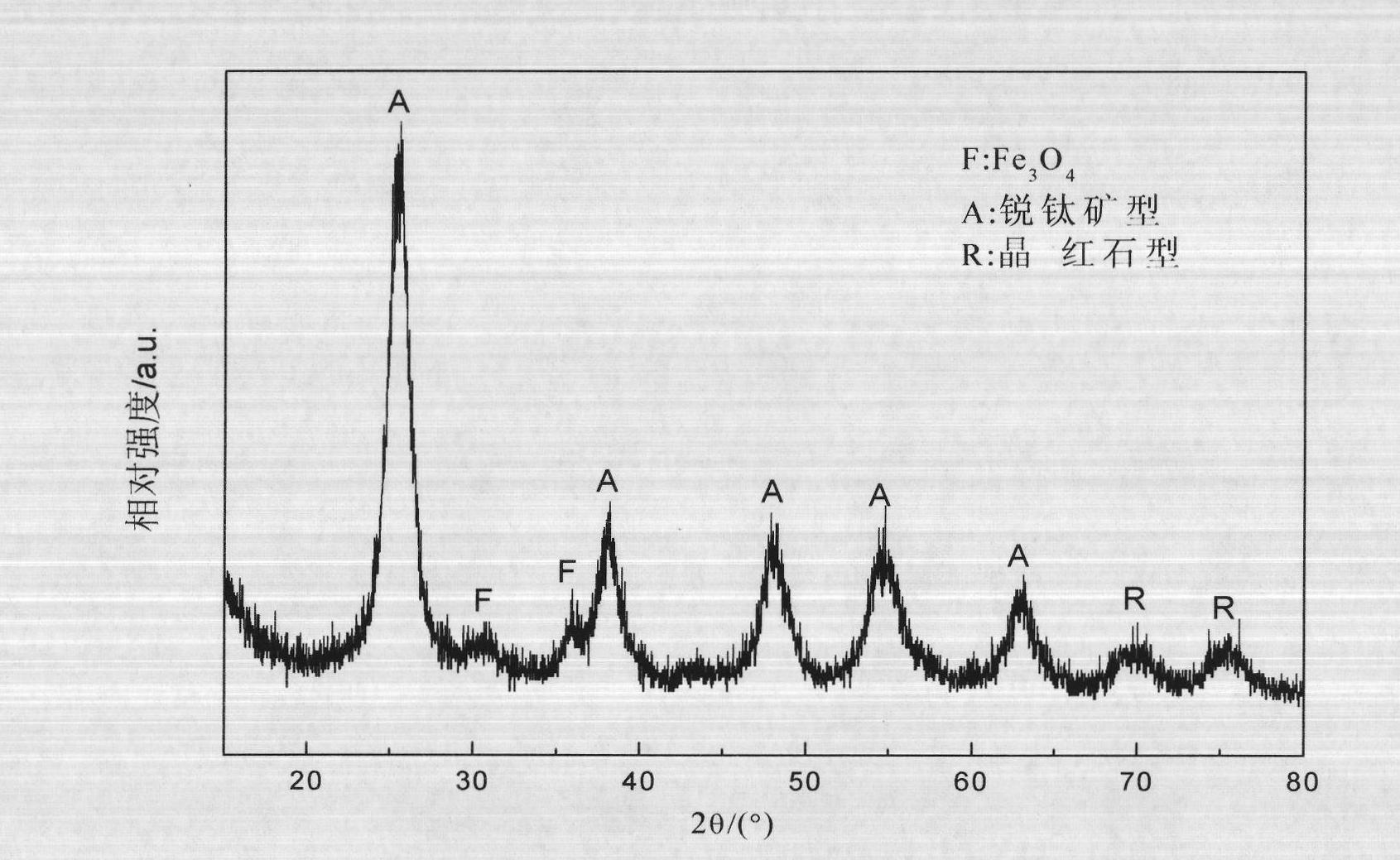

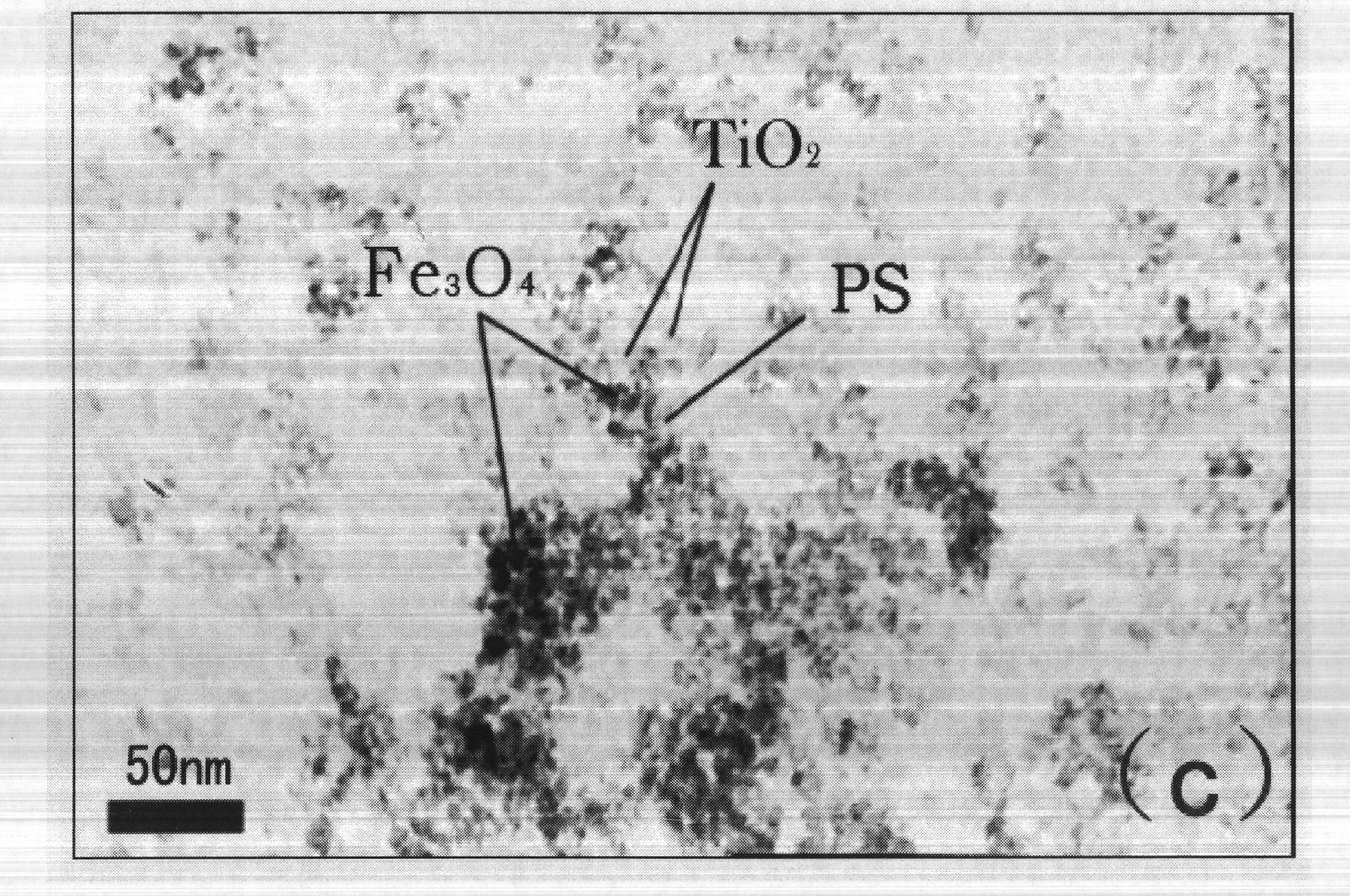

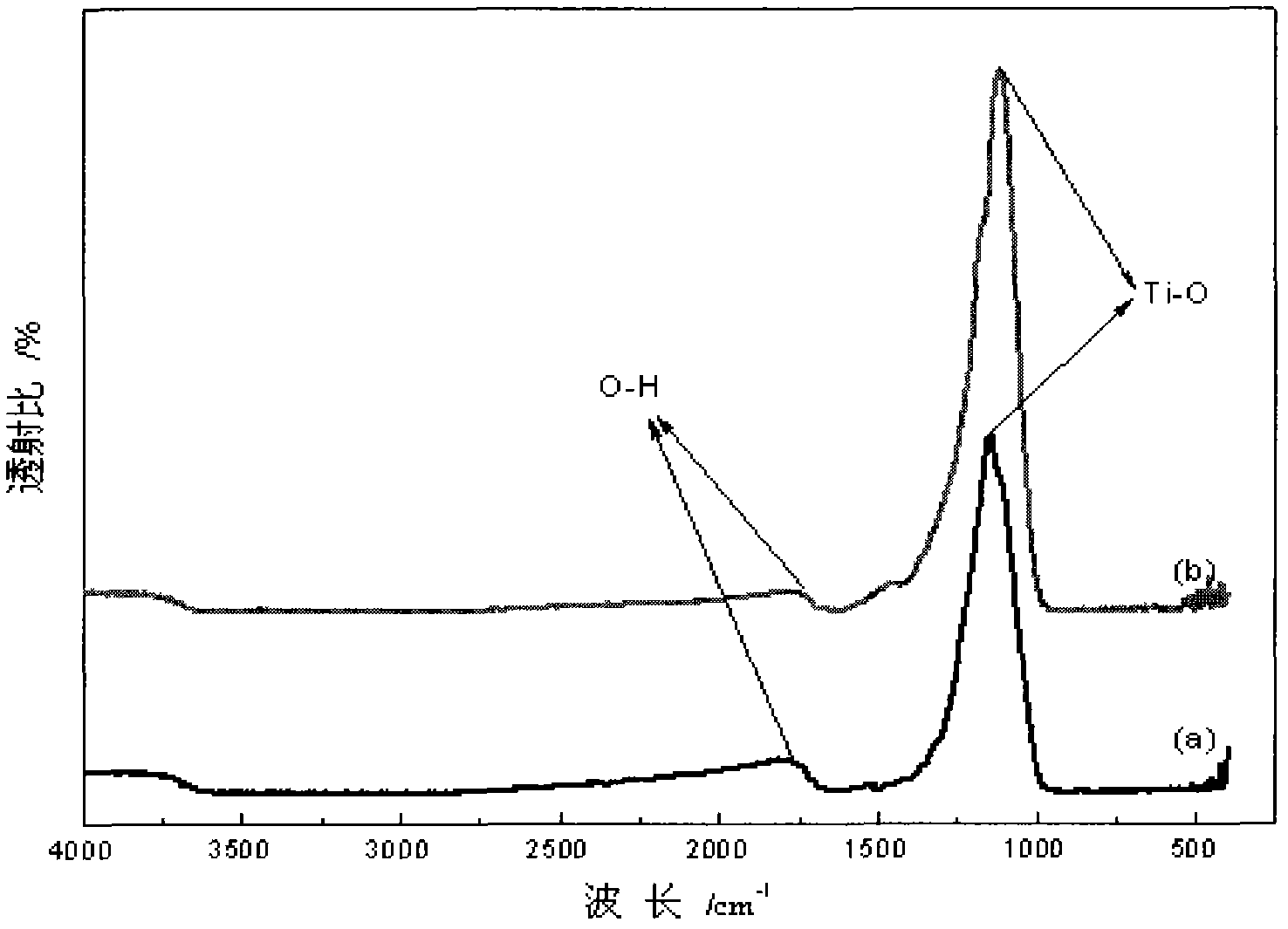

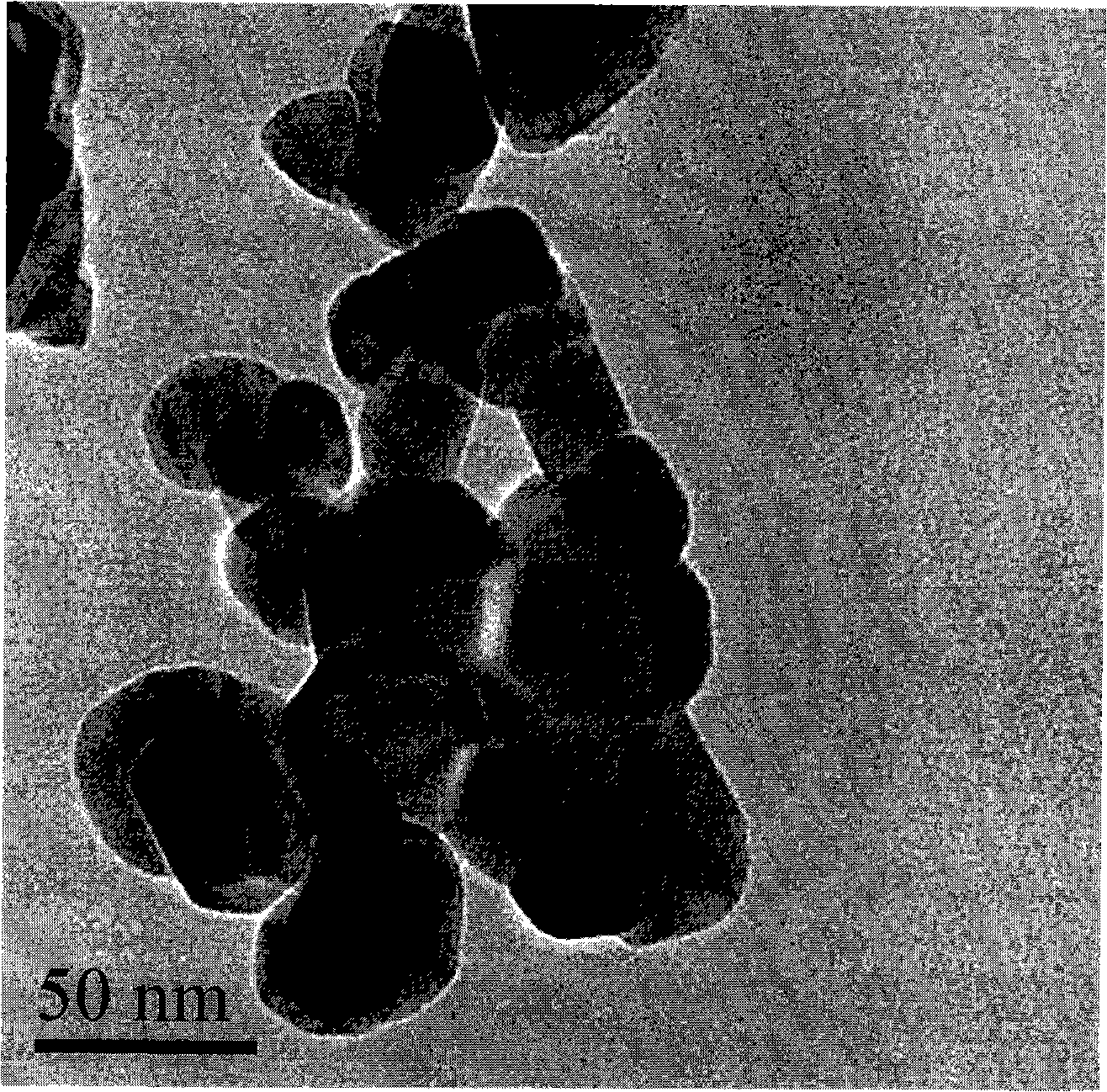

Method for preparing TiO2/PS/Fe3O4 magnetic nanoparticle photocatalyst

InactiveCN102580783ANot corrosiveNo secondary pollutionWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsWater bathsPolystyrene bead

The invention relates to a method for preparing a TiO2 / PS / Fe3O4 magnetic nanoparticle photocatalyst, comprising the following steps of: (1) preparing oleic acid modified Fe3O4 nanoparticles; (2) preparing an aqueous-phase magnetic fluid; (3) preparing styrene miniemulsion; (4) preparing magnetic polystyrene beads PS / Fe3O; and (5) preparing the magnetic photocatalyst TiO2 / PS / Fe3O4, which specifically comprises the following steps of: mixing absolute ethyl alcohol with tetra-n-butyl titanate, and performing magnetic stirring to form a solution A; adding the magnetic polystyrene beads PS / Fe3O to de-ionized water and performing ultrasonic treatment to form a solution B; under magnetic stirring, adding the solution A to the solution B, thereby obtaining sol after 30-40 min, wherein TiO2 covers the PS / Fe3O at the moment; after condensing and refluxing the sol in a water bath, filtering the sol to obtain the TiO2 / PS / Fe3O4, washing the TiO2 / PS / Fe3O4 by using ethanol, filtering, washing by using distilled water and filtering, thus obtaining a solid; and drying the solid until the weight thereof is constant, thereby obtaining the magnetic photocatalyst TiO2 / PS / Fe3O4 with the polystyrene PS as an isolating layer, the Fe3O4 as a magnetic core and the TiO2 as a shell. The product obtained by using the method is low in energy consumption, high in catalytic activity and recyclable.

Owner:LANZHOU JIAOTONG UNIV

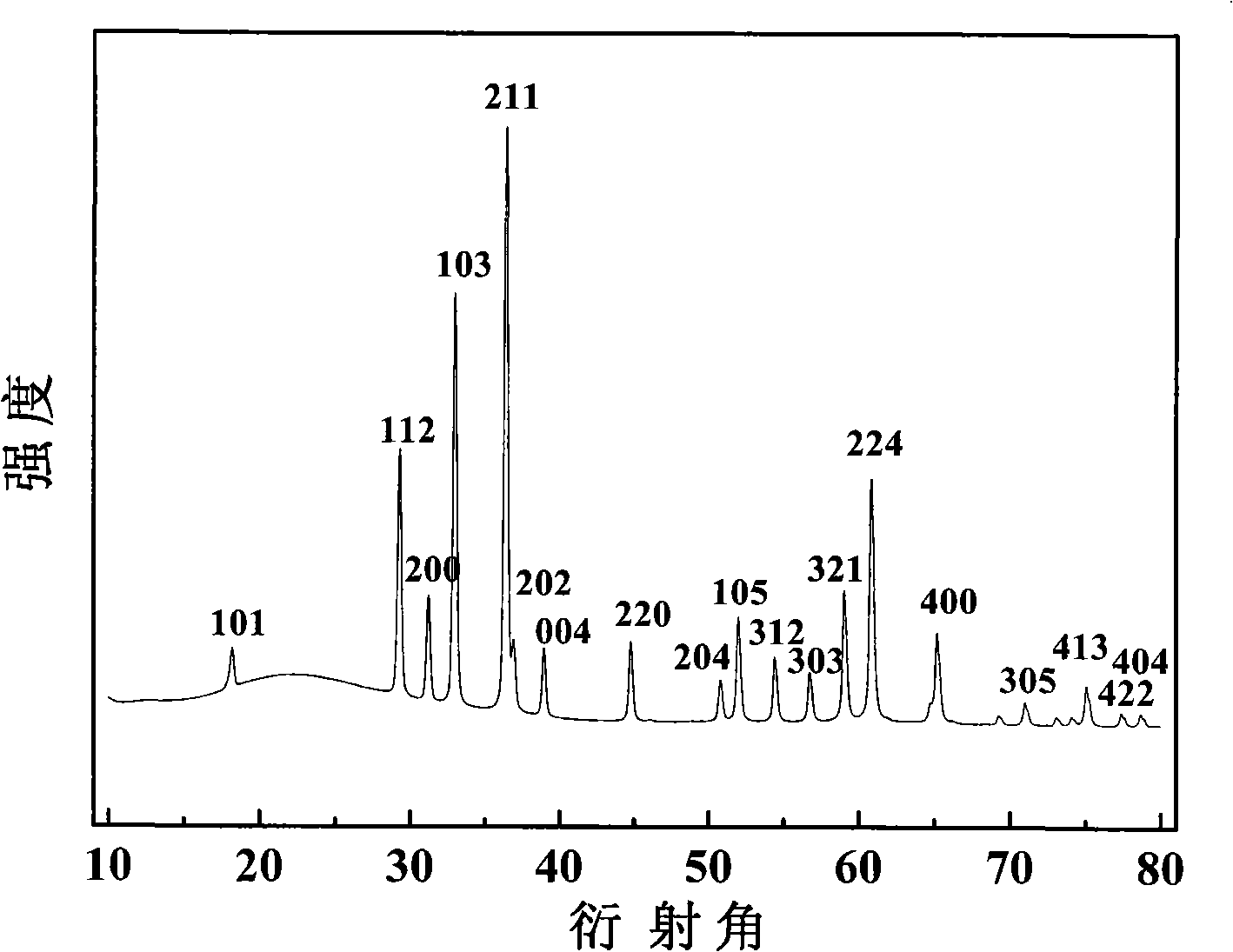

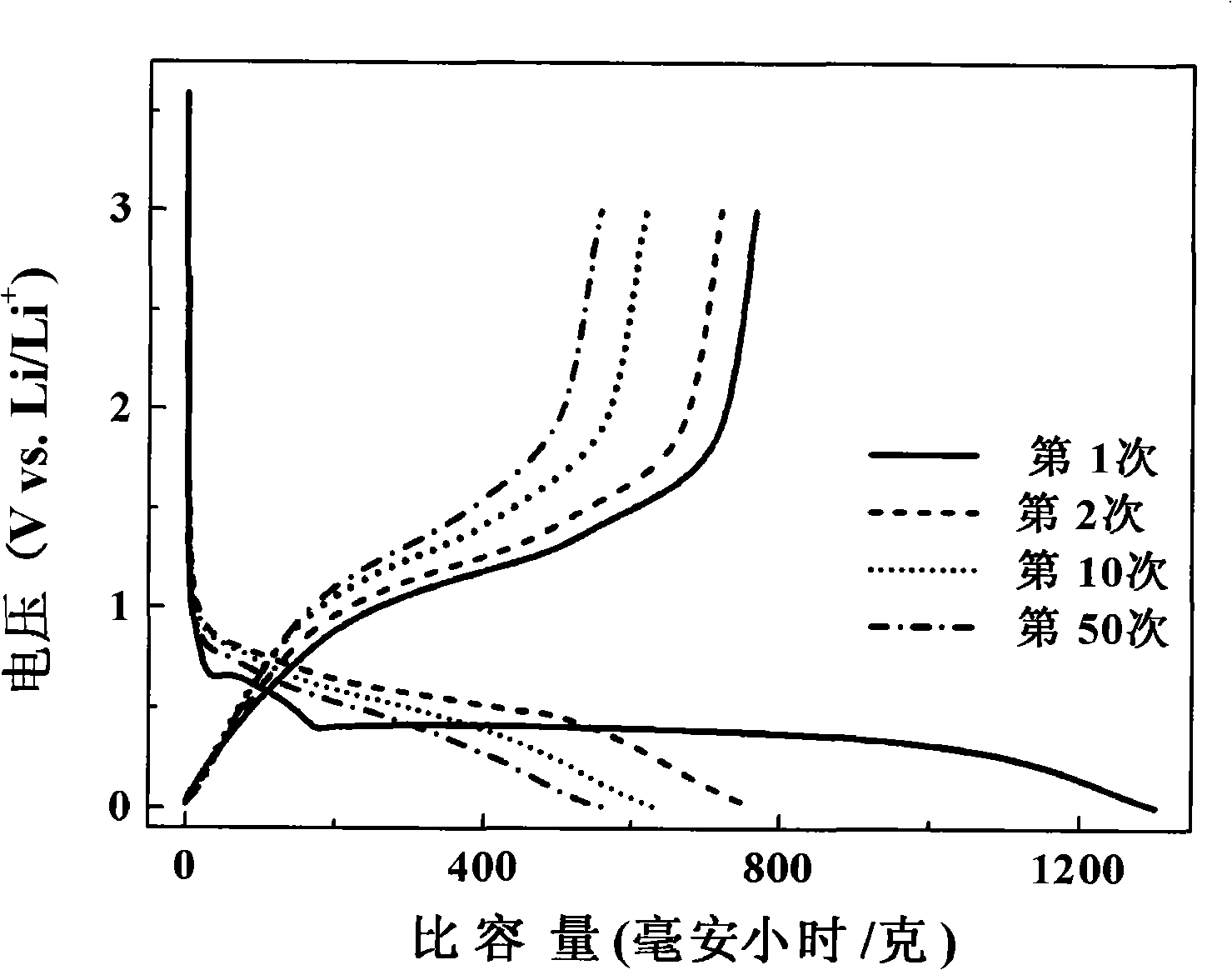

Nano-scaled materials ZnMn2O4 for lithium storage and preparation thereof

The invention provides a nano lithium storage material ZnMn2O4 which is used as the cathode material of lithium ion batteries and pertains to the technical field of high energy batteries. The method is characterized in that: the nano material ZnMn2O4 with the grain size of 30 to 60nm produced by adopting a polymerization and pyrolysis method has high purity and good granule dispersion property. According to an electrochemical performance test, the first cycle charge capacity of the nano material is up to 776mAh / g and the capacity can keep good stability after ten cycles of circulation. The nano lithium storage material ZnMn2O4 has simple technique and low cost, and is environment-friendly and has relatively good electrochemical performance, thereby conforming to actual production needs.

Owner:HUAZHONG NORMAL UNIV

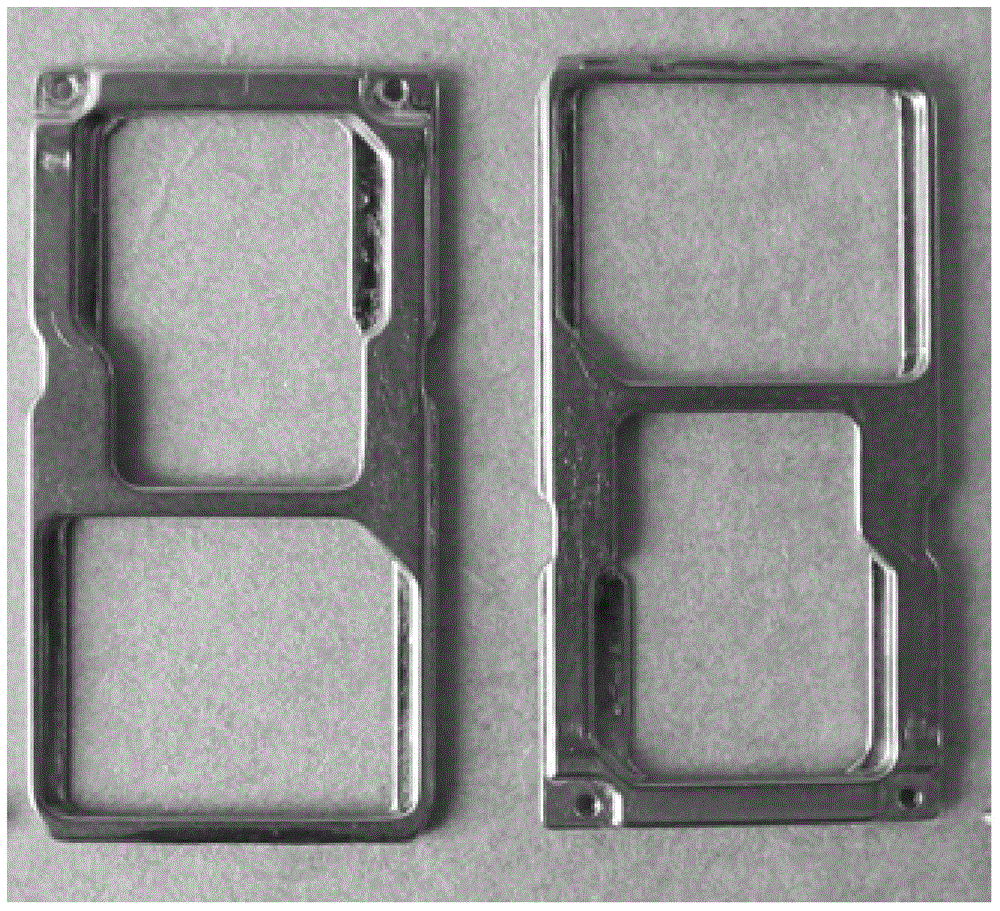

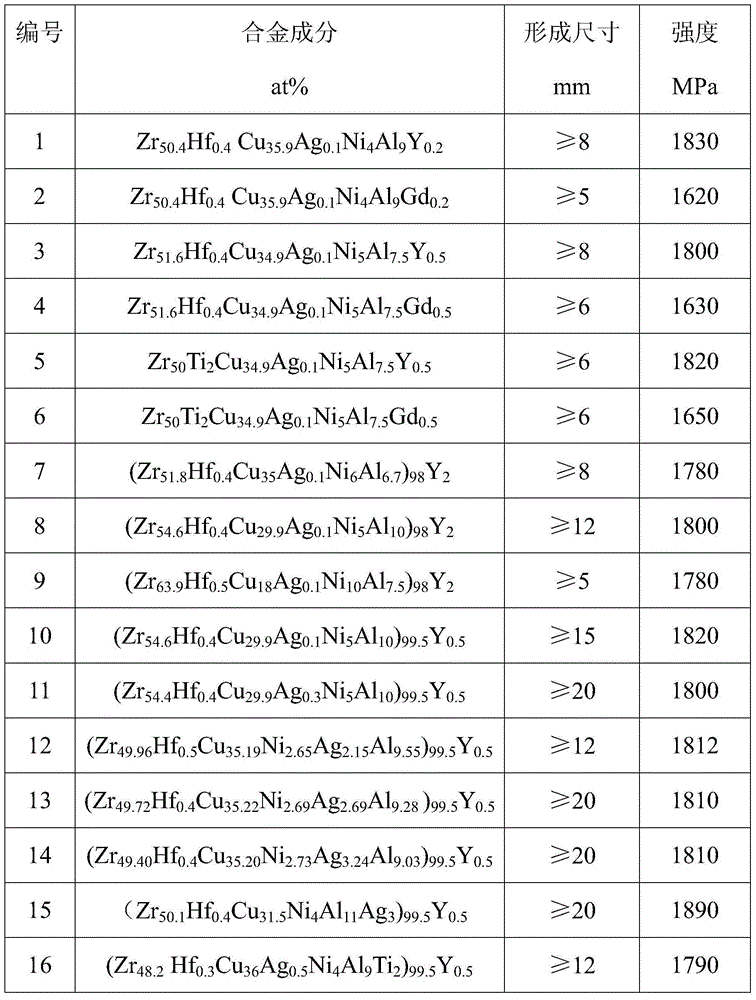

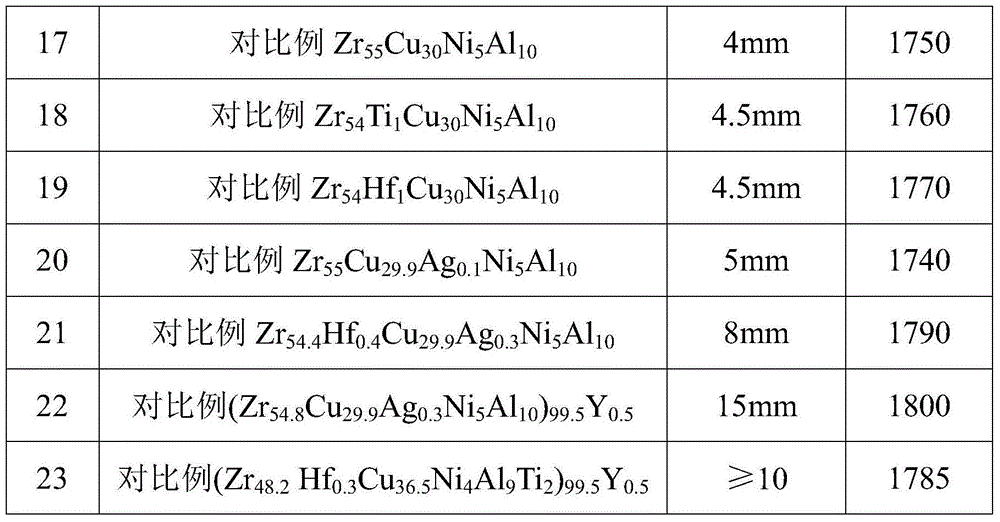

(ZrM)-(CuN)-Ni-Al-(Re) amorphous alloy, and preparation method and application thereof

ActiveCN104651756AImprove the ability to formImprove manufacturabilityRare-earth elementMechanical property

The invention discloses a (ZrM)-(CuN)-Ni-Al-(Re) amorphous alloy which comprises the following components in percentage by atom: 40-65% of Zr, 18-46% of Cu, 2-15% of Ni, 4-15% of Al, 0.1-3% of M(Hf, Ti or Hf+Ti), 0.05-3% of N (Ag) and 0.1-2% of rare-earth element RE (Y, Gd, Sc, Er or composition thereof). By adding small amounts of M, N and RE elements on the basis of the Zr-Al-Ni-Cu amorphous alloy, the alloy has the advantages of higher amorphous formation capacity, excellent manufacturability and favorable mold resistance, maintains the excellent mechanical properties of the Zr-Al-Ni-Cu amorphous alloy, and is an ideal material for preparing complex thin-wall parts in the fields of consumer electronics, medical care, automobiles and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

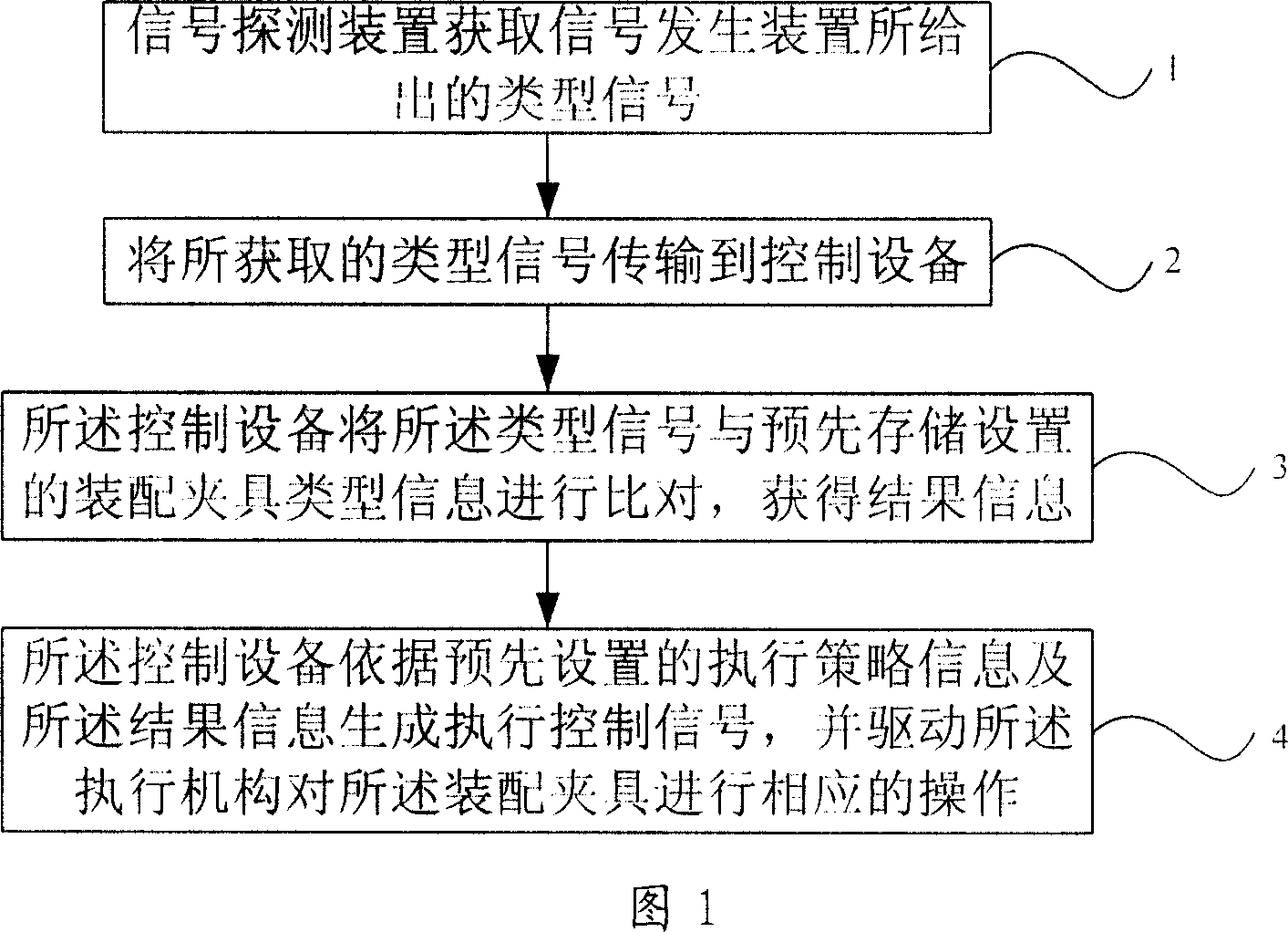

Identifying method of assembling jig of engine

ActiveCN1967416AIncrease productivityMeet actual production needsControl devices for conveyorsElectric programme controlProduction lineExecution control

An engine assembly fixture identification method includes: the signal detection device obtains the type signal sent by the signal generation device of the assembly fixture; sends the received type signal to the control equipment; the said control equipment compares the said type signal and pre-stored assemble fixture type information, to obtain the result information; according to the pre-set execution strategy information and the said result information, the said control equipment generates the execution control signal used to control the execution machine operations, and drive the said execution machine to do the corresponding operation to the said assembly fixture. The invention can improve the efficiency of production for a variety of different type's engine production lines, and meet the actual production demand.

Owner:CHONGQING ZONGSHEN POWER MACHINERY

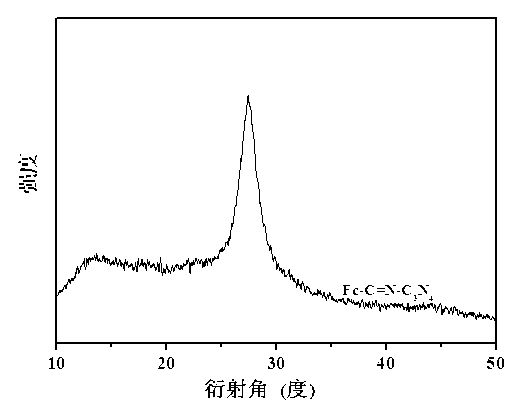

Graphite phase carbon nitride nanosheet visible-light-induced photocatalyst synthesized by promotion of ionic liquid

ActiveCN103752334AImprove migration efficiencyLarge specific surface areaMaterial nanotechnologyPhysical/chemical process catalystsCarbon nitrideGraphite

The invention discloses a preparation method and application of a graphite phase carbon nitride nanosheet visible-light-induced photocatalyst synthesized by promotion of ionic liquid and belongs to the technical field of material preparation and photocatalysis. A graphite phase carbon nitride nanosheet material is formed by using room-temperature ionic liquid of urea and dialkyl imidazolium tetrafluoroborate as a precursor through high-temperature co-polymerization. The graphite phase carbon nitride prepared by the preparation method has a low-dimensional nanosheet layer microstructure and a suitable forbidden bandwidth and shows more efficient photocatalytic hydrogen production performance than that of conventional body phase carbon nitride under the visible light. The graphite phase carbon nitride nanosheet visible-light-induced photocatalyst synthesized by promotion of the ionic liquid is simple in synthetic process, is low in cost, has high photocatalytic efficiency, accords with the actual production requirement and has a wide application prospect in the field of photocatalysis.

Owner:FUZHOU UNIV

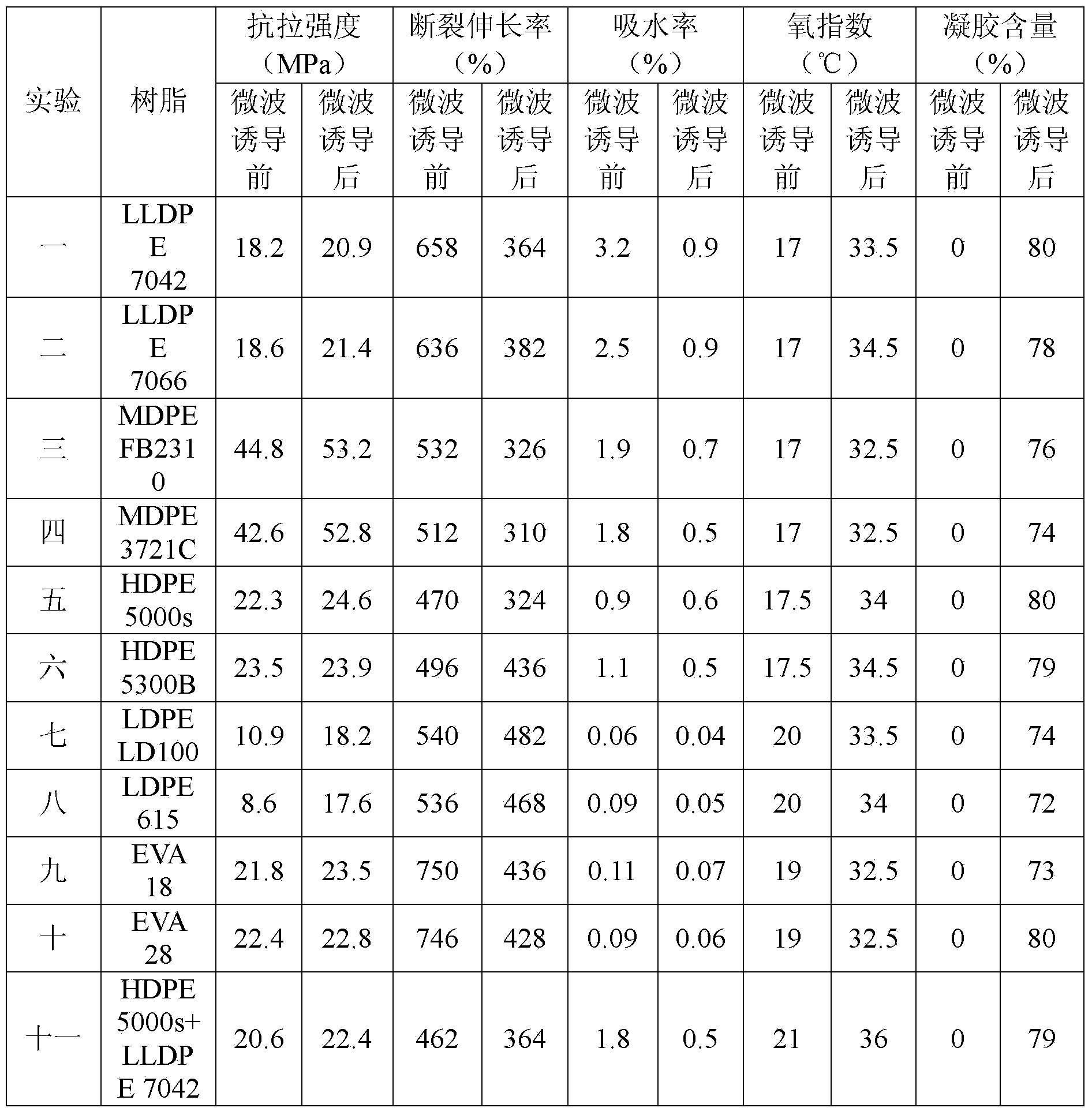

Microwave induced intumescent flame-retardant silane crosslinked polyolefin sheath material for cables and preparation method thereof

InactiveCN103435897ALow costImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesPolyolefinPolymer science

The invention relates to a sheath material and a preparation method thereof and provides a microwave induced intumescent flame-retardant silane crosslinked polyolefin sheath material for cables and a preparation method thereof for solving such technical problems in the existing preparation method of flame-retardant silane crosslinked sheath materials as long-time boiling with water is required, the stability and flame retardant effect of the product are poor. The material is prepared from a polyolefin resin, an intumescent flame retardant, a silane coupling agent, a microwave absorbent, a water bringing agent, a polyfunctional group crosslinking agent, a crosslinking accelerant and an antioxidant. The preparation method comprises the steps of carrying out melt mixing on the polyolefin resin, the intumescent flame retardant, the silane coupling agent, the microwave absorbent, the water bringing agent, the polyfunctional group crosslinking agent, the crosslinking accelerant and the antioxidant, carrying out granulation and tabletting, then carrying out microwave induced crosslinking and putting the product at room temperature, thus preparing the material. The mechanical property of the material prepared by the preparation method is obviously increased, the tensile strength is improved by nearly 20% and the oxygen index is improved by more than 70%. The material and the preparation method belong to the field of preparation of polyolefin sheath materials.

Owner:HONGLONGJIANG ORIENT SCI & TECH

Compounding method for nanometer ultrathin boron carbon nitrogen sheet

ActiveCN106430128AThe synthesis process is simpleGood controllabilityNitrogen and non-metal compoundsOrganocatalysisBoron trioxide

The invention discloses a compounding method for a nanometer ultrathin boron carbon nitrogen sheet and belongs to the technical field of material preparation. The method comprises the following steps: mixing diboron trioxide, melamine, glucose and the mixed salt of NaCl and KCL, then grinding, and performing heat treatment on the acquired powder under the atmosphere of ammonia gas, thereby acquiring the nanometer ultrathin boron carbon nitrogen sheet. According to the invention, the low-cost mixed salt and the boron carbon nitrogen precursor have a heating reaction under the atmosphere of ammonia gas, and the fused mixed salt is utilized as a template of the boron carbon nitrogen sheet, is evaporated at high temperature and is peeled, so that the nanometer ultrathin boron carbon nitrogen sheet characterized by having a graphite like phase crystal structure, the thickness of an atom-level ultrathin sheet, a huge size and a high specific area can be prepared. The compounding method disclosed by the invention is simple in operation; complex and expensive instruments and equipment are not required; the adopted raw materials are low in cost and are easily acquired; the environmental pollution is little; the method is suitable for large-scale production; and the compounding method has significance in boosting the application of the nanometer ultrathin boron carbon nitrogen sheet in the fields of photoelectric materials, organic catalysis, hydrogen storage carriers, detection analysis, and the like.

Owner:FUZHOU UNIV

Welding wire for welding FV520B martensitic stainless steel and manufacturing method thereof

InactiveCN103990918AGood soldering requirementsImprove self-protection performanceWelding/cutting media/materialsWelding/soldering/cutting articlesSlagMartensitic stainless steel

A welding wire for welding FV520B martensitic stainless steel comprises a powder core and an outer skin. The powder core is composed of, by mass, 15 percent to 35 percent of rutile, five percent to 15 percent of zircon sand, two percent to five percent of quartz, four percent to 10 percent of feldspar, two percent to five percent of sodium carbonate, two percent to five percent of aluminum oxide, six percent to 12 percent of aluminum magnesium alloy, five percent to 10 percent of electrolytic manganese metal, 18 percent to 25 percent of chromium powder, six percent to 10 percent of nickel powder, two percent to six percent of ferroniobium and one percent to 10 percent of molybdenum powder, and the sum of the mass percent of all the components is 100 percent. The welding wire is good in arcing and arc stabilizing performance, good in molten pool fluidity, fine in splashed particle and even in postwelding slag coverage, and enables deslagging to be easy, welding joint forming is meticulous and attractive, the welding wire is suitable for large linear energy welding, the organization and performance obtained through the prewelding preheating and postwelding heat treatment process can meet actual production needs, and the welding requirement for FV520B martensitic stainless steel is met.

Owner:XIAN UNIV OF TECH

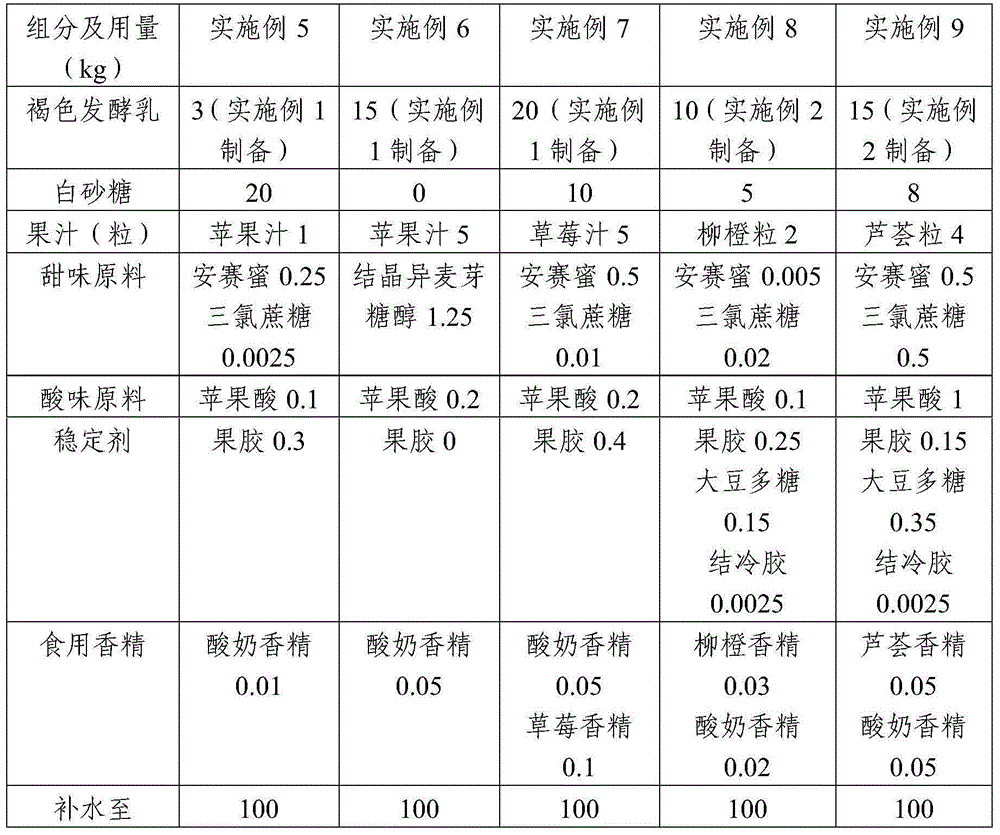

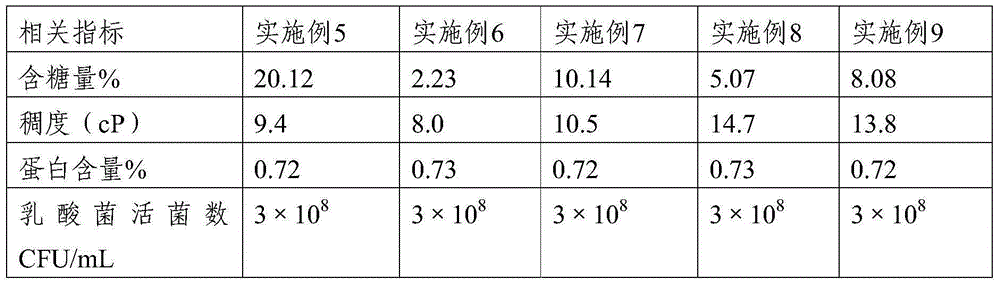

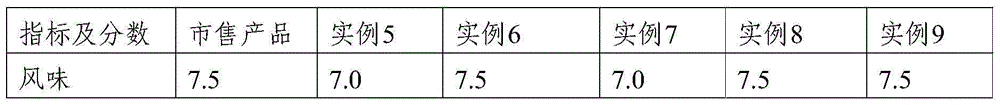

Brown lactobacillus beverage and preparation method thereof

The invention discloses a brown lactobacillus beverage. The brown lactobacillus beverage is prepared from the following raw materials in parts by weight: 3-30 parts of brown fermented milk, 0-20 parts of white granulated sugar, 1-10 parts of fruit juice or fruit granules, 0.01-1.5 parts of sweet material, 0.01-5 parts of sour material, 0-1 part of stabilizer and 0.01-0.5 part of edible essence. In the invention, browning is performed by producing glucose through enzymolysis instead of additionally adding glucose, so that the calorie of the product is effectively reduced. In addition, the sweet material is reasonably added instead of white granulated sugar, so that the calorie of the product is further reduced. The product disclosed in the invention is fresh and cool with low calorie, which meets the requirements of current young groups, and has very good market prospect.

Owner:BEIJING SANYUAN FOOD

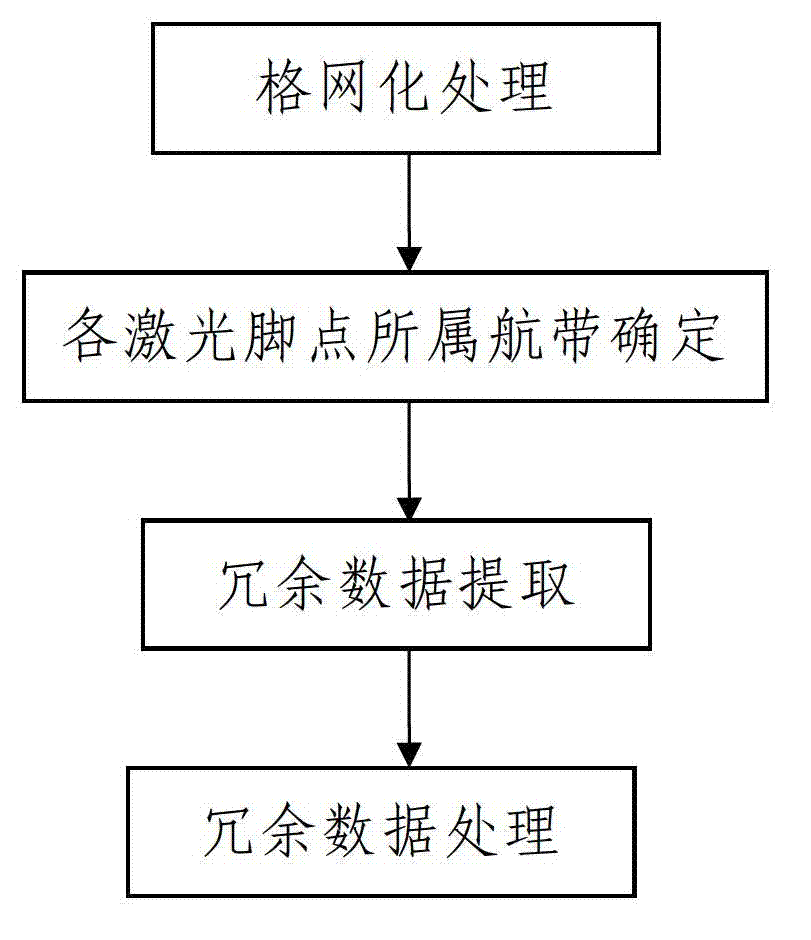

Automatic removal method for redundant data between air strips of airborne laser radar

InactiveCN103033805AThe method steps are simpleSimple and fast operationWave based measurement systemsPoint cloudCloud data

The invention discloses an automatic removal method for redundant data between air strips of an airborne laser radar. The automatic removal method includes the following steps: a first step is gridding processing, wherein a data processor is used for dividing point cloud data to be processed into grids so as to enable the point cloud data to be divided into multiple square grids with the same dimensions; a second step is determination of the air strips where all laser foot points belong; a third step is redundant data extraction, wherein the number of the laser foot points contained in each square grid of the grids and the air strips where all the laser foot points belong are judged, and all redundant data square grids are searched out from the grids; and a fourth step is redundant data processing, wherein the data processor is used, a redundant data elimination module or a redundant data marking module is invoked, and all the searched out redundant data square grids are subjected to the redundant data processing. The automatic removal method for the redundant data between the air strips of the airborne laser radar is simple in procedure, reasonable in design, convenient to realize, simple and convenient to use and operate, good in using effect, and capable of automatically and effectively detecting and eliminating the redundant data in the point cloud data of the airborne laser radar.

Owner:XIAN MEIHANG INFORMATION IND

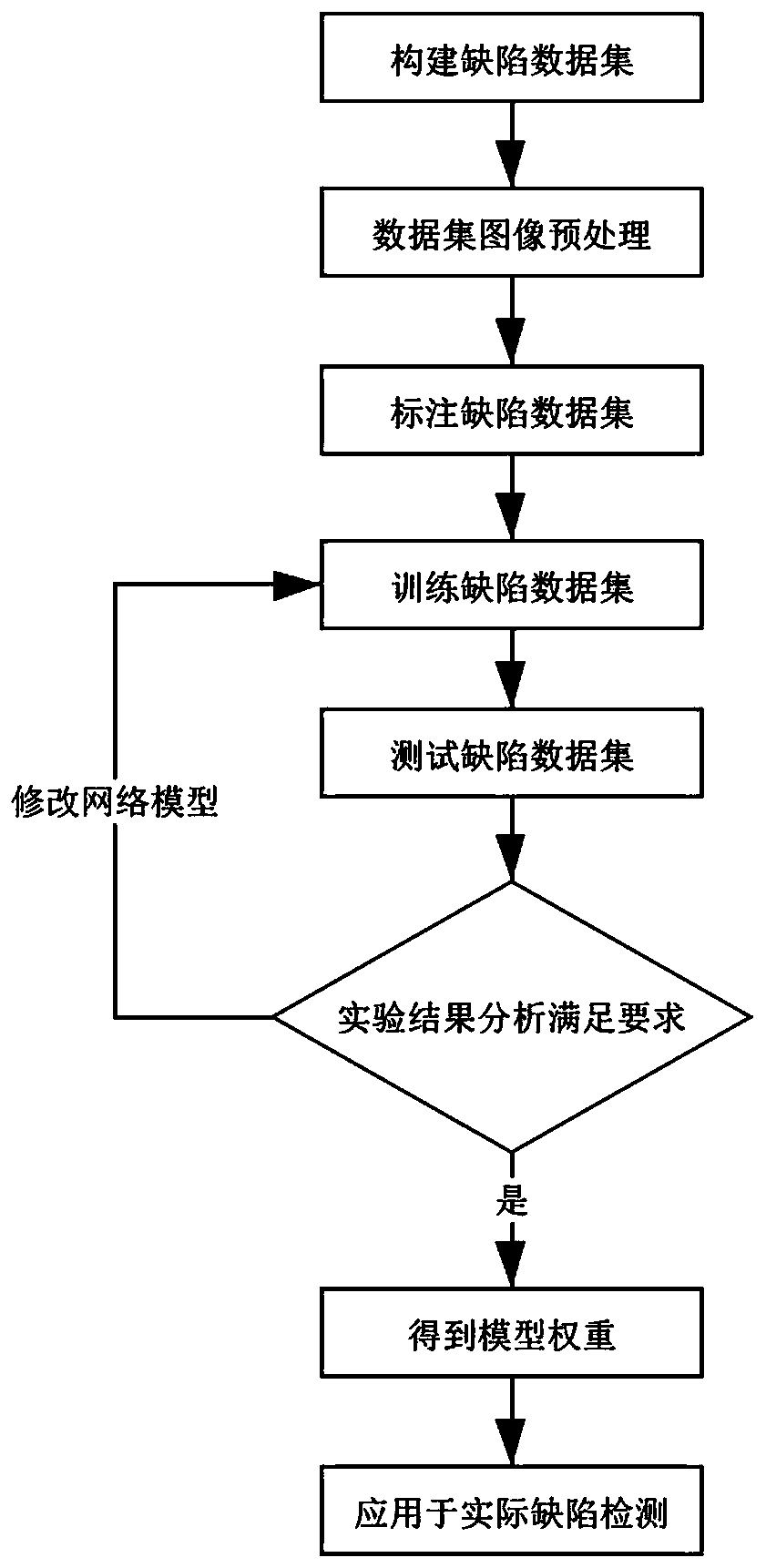

Method for identifying casting DR image loose defects based on improved YOLOv3 network model

PendingCN111476756AIncrease the prediction scaleEasy to detectImage enhancementImage analysisData setEngineering

The invention discloses a method for identifying casting DR image loose defects based on an improved YOLOv3 network model. The method comprises the following steps: 1) performing defect labeling on aloose defect data set by utilizing a rectangular frame of an image labeling tool; and 2) establishing an improved YOLOv3 network model; 3) training the improved YOLOv3 network model by using the loosedefect data training set; 4) testing the trained improved YOLOv3 network model by using the loose defect data test set; 5) improving the improved YOLOv3 network model, and 6) obtaining a DR image ofthe casting to be detected, inputting the DR image into the improved YOLOv3 network model, and judging the defect grade and position coordinates of the casting. According to the invention, detection effects of small target objects by a target detectio network are improved.

Owner:CHONGQING UNIV

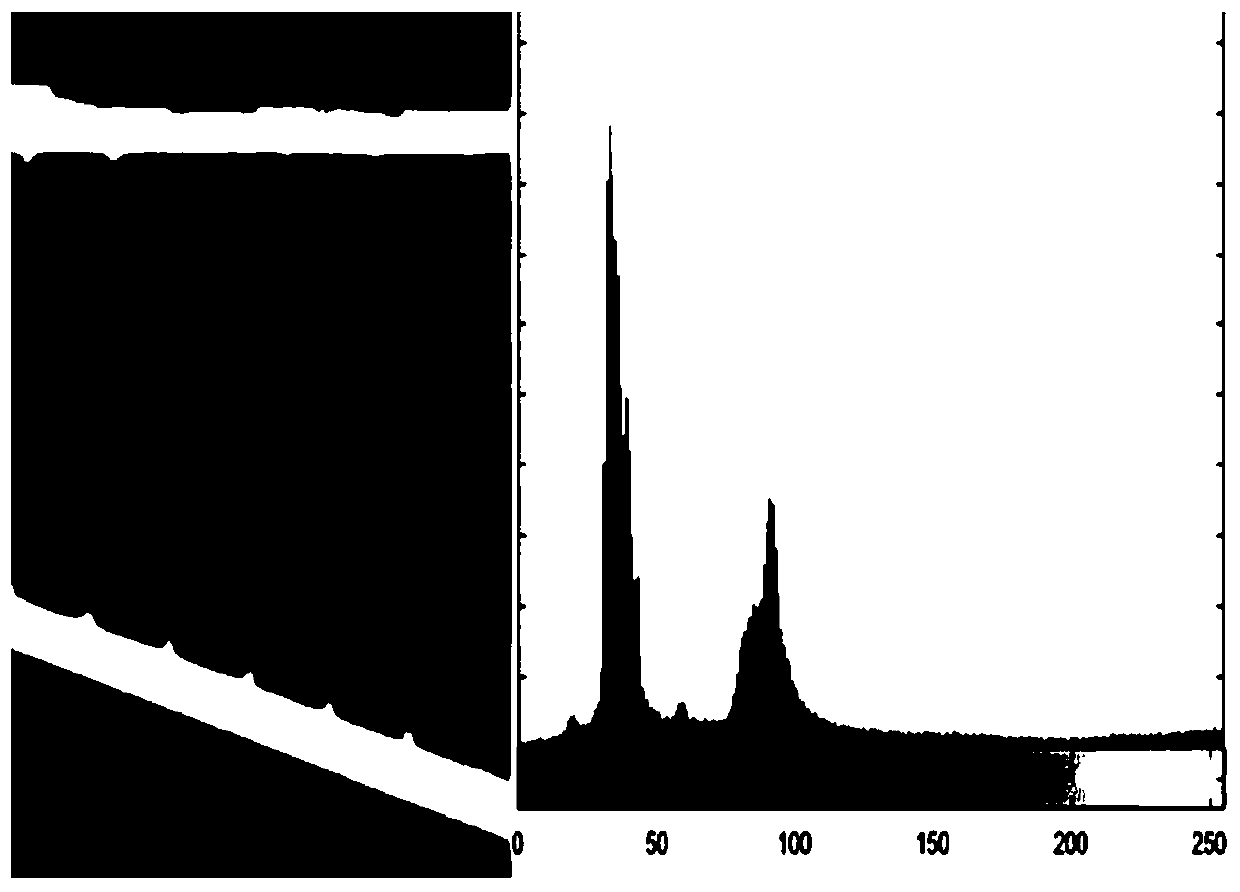

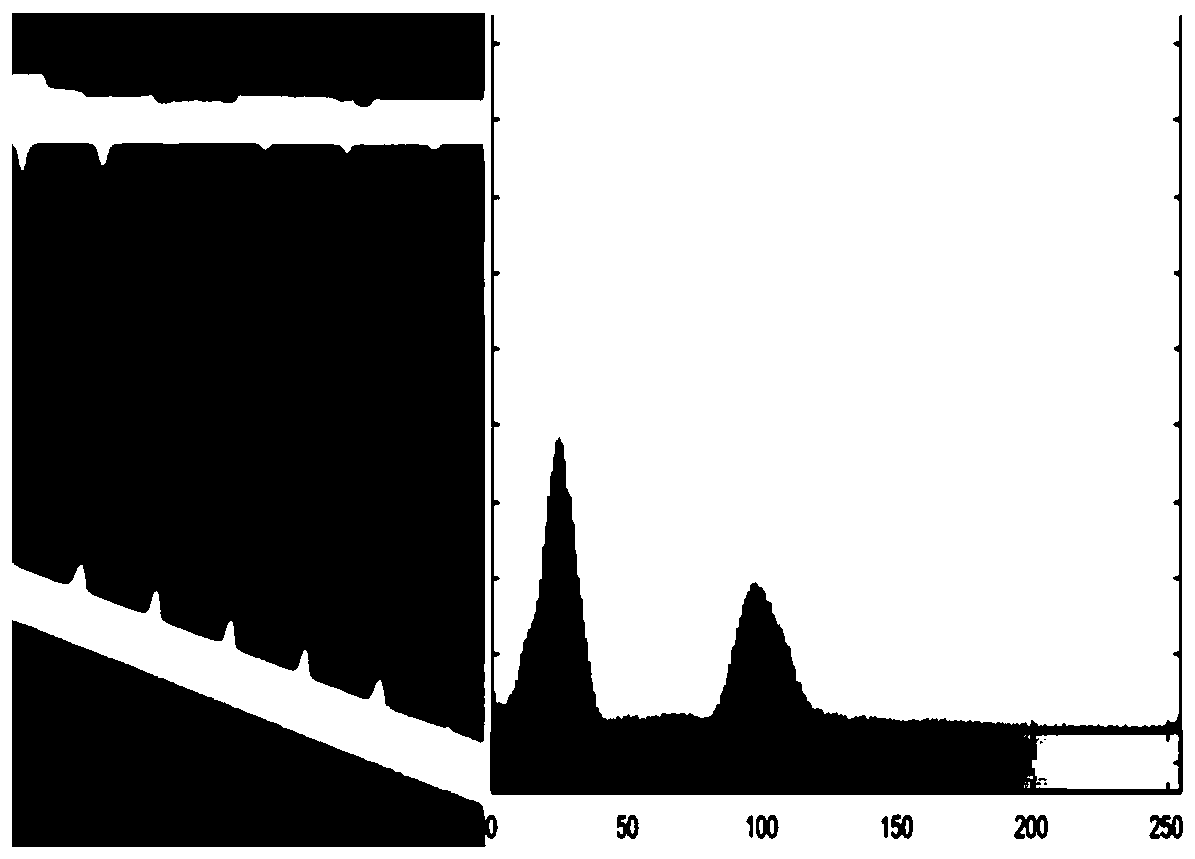

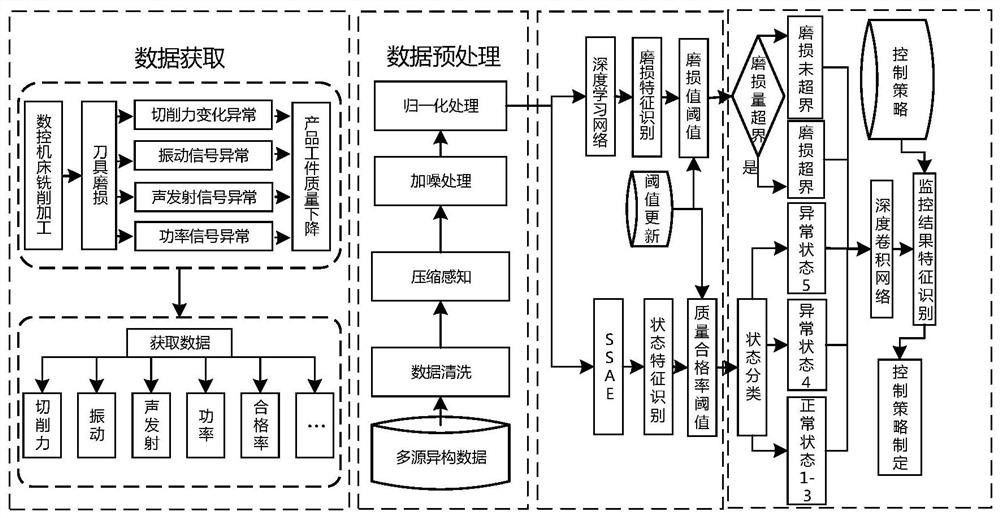

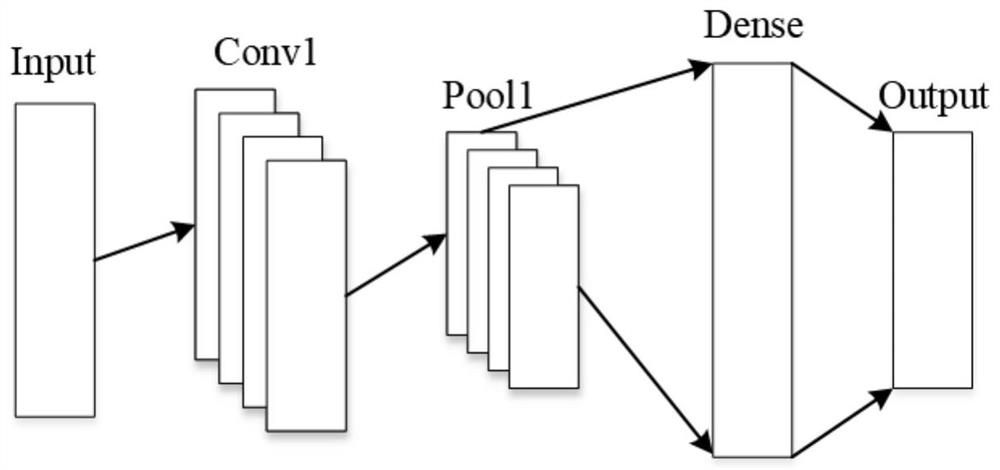

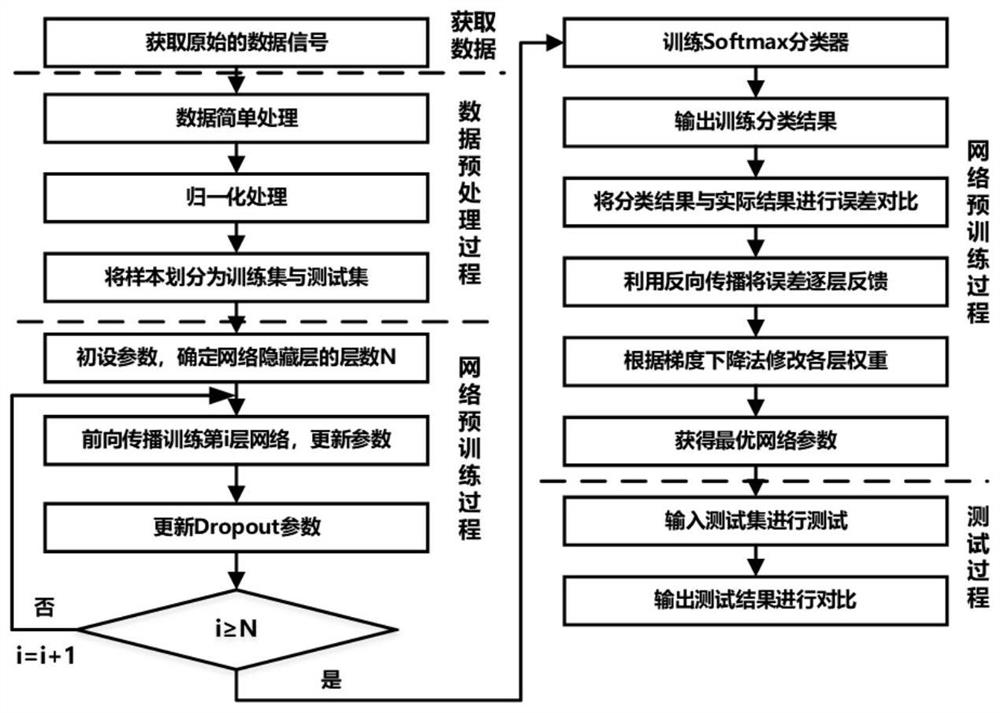

Milling cutter wear state real-time monitoring method based on deep convolutional neural network

PendingCN113664612AImprove accuracyImprove forecast accuracyMeasurement/indication equipmentsNumerical controlMilling cutter

The invention relates to a milling cutter wear state real-time monitoring method based on a deep convolutional neural network, and belongs to the technical field of automatic monitoring and recognition. The milling cutter wear state real-time monitoring method comprises the following steps: collecting multi-source heterogeneous state data generated when a numerical control machine tool mills a workpiece and corresponding milling tool full life cycle abrasion data, and preprocessing and labelling the data; constructing a deep learning network, and achieving accurate regression prediction of a tool abrasion loss result; constructing a deep convolutional neural network, and achieving effective recognition of the tool abrasion loss critical state; and comparing the real-time tool abrasion loss with a corresponding critical state threshold value, and timely taking measures such as tool replacement or parameter change and the like to realize real-time monitoring of the tool abrasion state. The method has the advantages of being complete in network model input signal source, fine in cutter wear critical state category division and high in model prediction accuracy, can accurately monitor the milling cutter wear state in real time, avoids cutter milling in an abnormal state, and guarantees the controllable quality of a machined product.

Owner:SHENYANG POLYTECHNIC UNIV

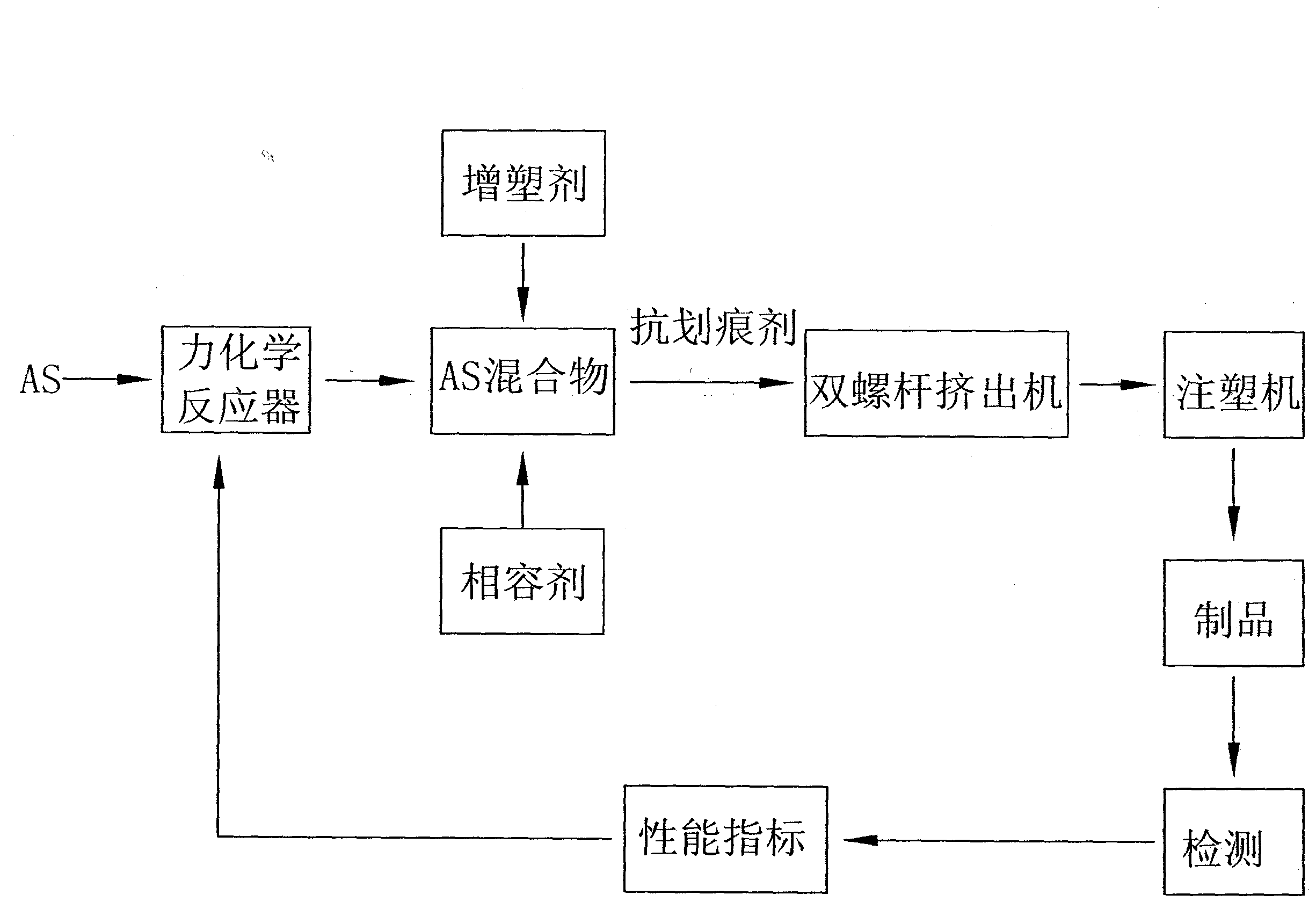

Abrasion-scratch resistant AS modified plastic

InactiveCN103450583AImprove scratch resistanceImprove toughnessInorganic particleInorganic particles

The invention discloses an abrasion-scratch resistant AS modified plastic. The abrasion-scratch resistant AS modified plastic comprises the following components: AS resin, a toughening agent, a compatibilizer, and an inorganic particle packing. Inorganic particles having a scratch resistant function are selected, an scratch resistant chemical agent is employed to modify the inorganic particles, the synergistic effect of the scratch resistance of the inorganic particles and the scratch resistant chemical agent is exerted, and thus the scratch resistant performance is improved; the toughening agent having a certain compatibility with AS is selected, melt blending of the compatibilizer, the toughening agent and AS powder which are different is carried out to prepare an AS modified material with a double-screw extrusion machine, the toughening agent is combined for toughening, and thus the plastic toughness is improved; and at the same time, the dispersion problem of a modifying agent is effectively solved.

Owner:广州市番禺区好友实业有限公司

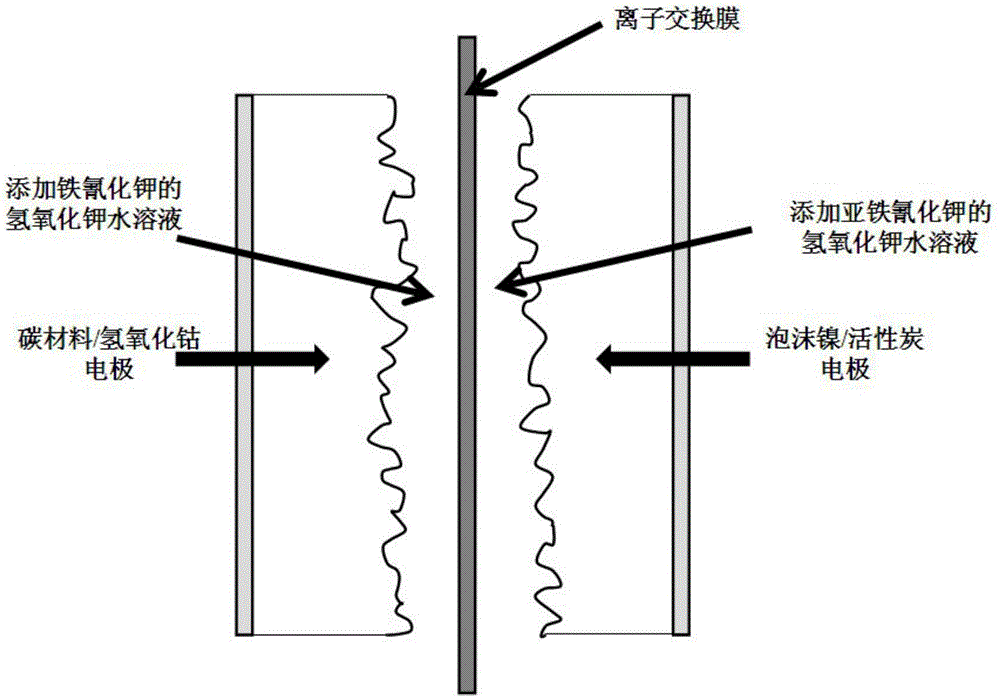

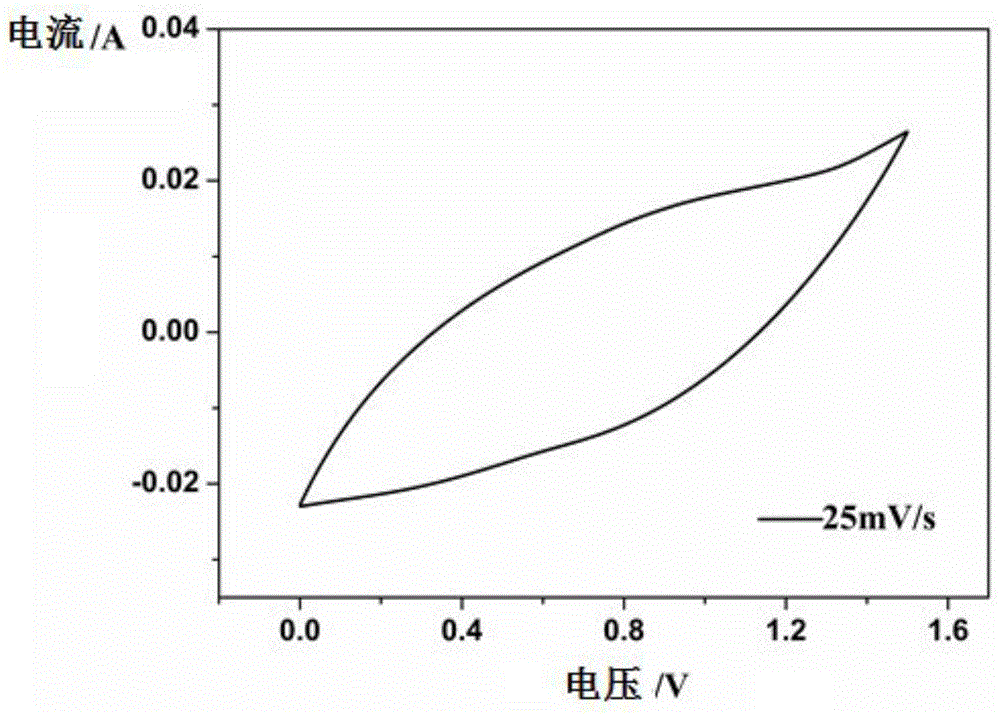

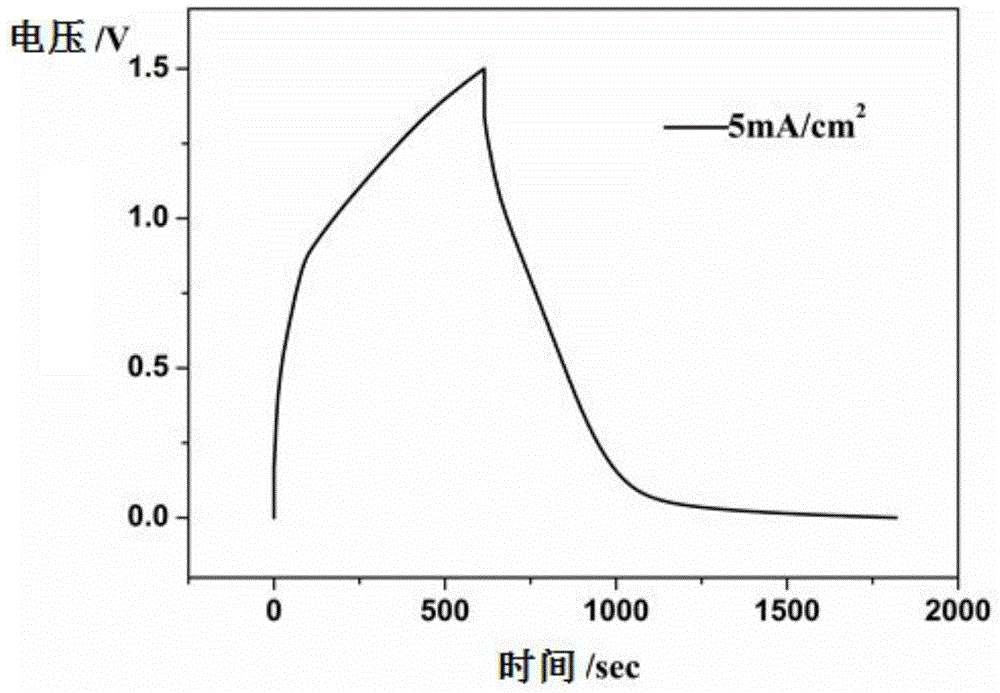

Asymmetric supercapacitor with potassium ferricyanide and potassium ferrocyanide added to two electrode chambers respectively and preparation method thereof

ActiveCN104576082AImprove solubilityNot easy to mixHybrid capacitor separatorsHybrid capacitor electrolytesIon-exchange membranesPotassium ferrocyanide

The invention relates to an asymmetric supercapacitor with potassium ferricyanide and potassium ferrocyanide added to two electrode chambers respectively and a preparation method of the asymmetric supercapacitor. According to the asymmetric supercapacitor and the preparation method of the asymmetric supercapacitor, the potassium ferricyanide is added to the positive electrode chamber, the potassium ferrocyanide is added to the negative electrode chamber, and the positive electrode chamber and the negative electrode chamber are separated by an ion exchange membrane and assembled into a single supercapacitor or a multi-body supercapacitor bank. Solid electrodes and liquid electrolyte provide capacitance simultaneously to achieve organic combination of the supercapacitor and a flow battery. The positive electrode of the capacitor achieves pseudocapacitance overlapping of cobaltous hydroxide and the potassium ferricyanide; the negative electrode of the capacitor achieves pseudocapacitance overlapping of an activated carbon electrical double-layer capacitor and the potassium ferrocyanide. Thus, the asymmetric supercapacitor has quite high energy density. In the negative electrode chamber, K4Fe(CN)6 is selected as a reducing agent, so self discharge is reduced, and the stability of the capacitive performance of the capacitor is improved.

Owner:JILIN UNIV

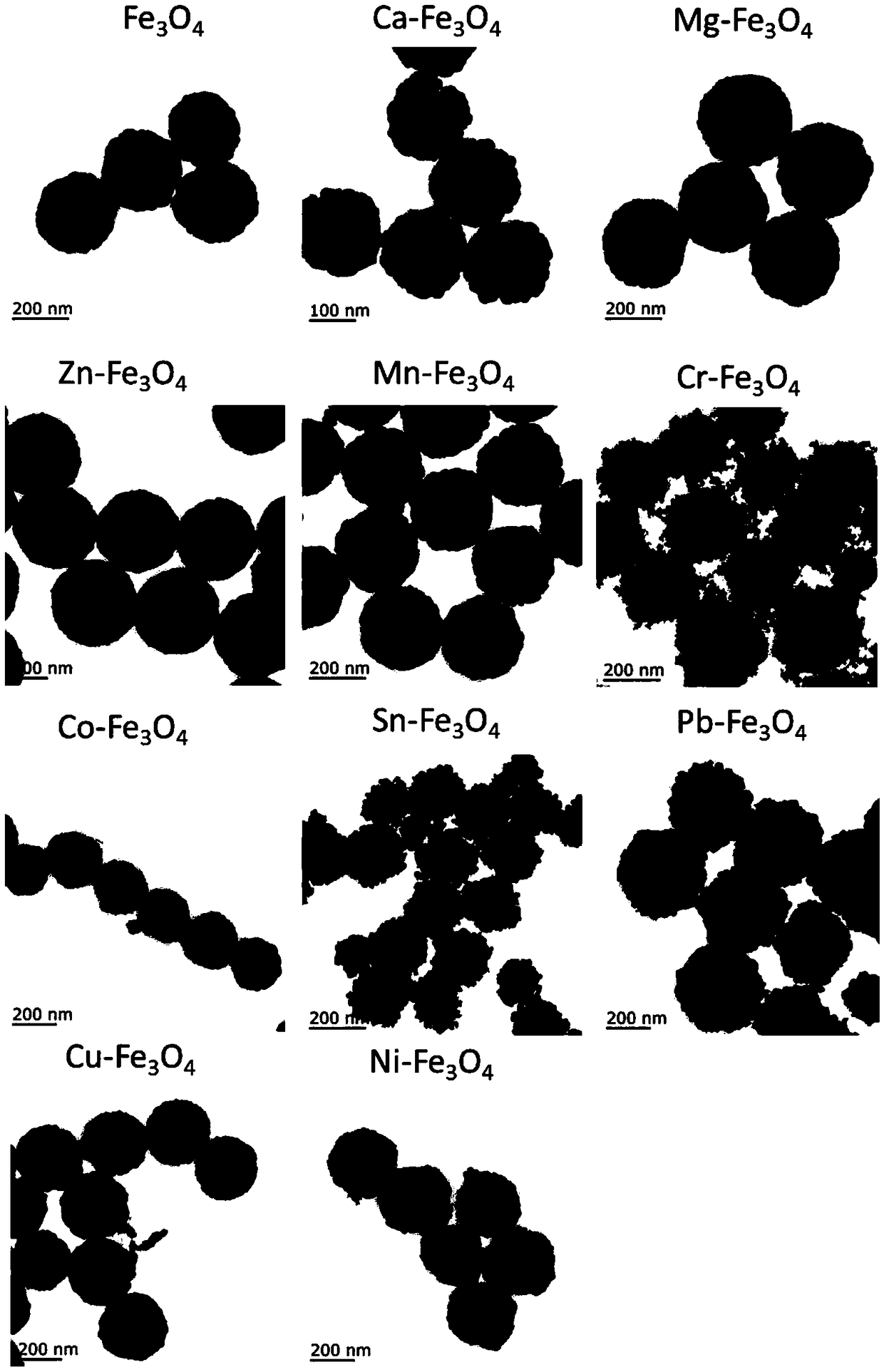

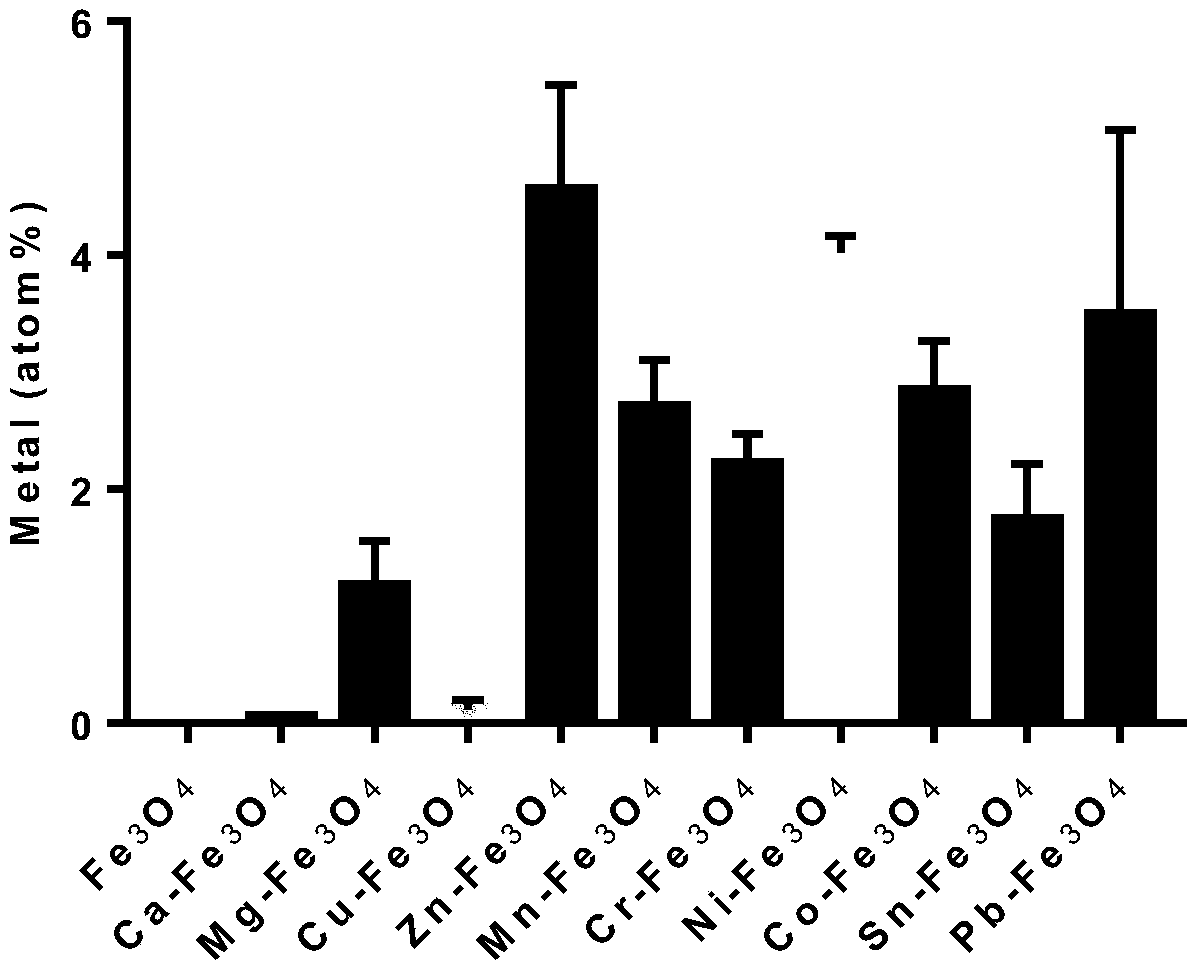

Fe3O4 nanozyme with improved catalytic activity, and preparation method and application thereof

ActiveCN109046360AEasy to prepare in large batchesLow costMetal/metal-oxides/metal-hydroxide catalystsDismutaseSuperoxide

The invention provides a Fe3O4 nanozyme with improved catalytic activity, and a preparation method and application thereof. By doping metal elements in Fe3O4 nanozyme, the dismutase activity of peroxidase, catalase and / or superoxide can be improved; the metal element doped Fe3O4 nanozyme can be prepared in large quantities, has low cost, good stability at room temperature, good safety, and good economic value and application prospect.

Owner:YANGZHOU UNIV

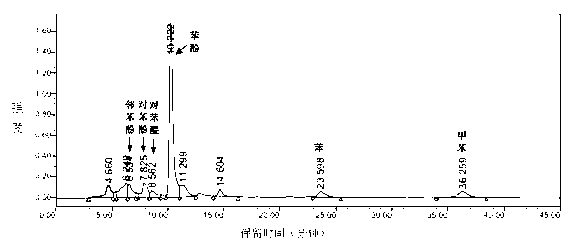

Functionalized carbon nitride photocatalyst capable of performing catalytic oxidization on benzene to synthesize phenol

InactiveCN103191780AEfficient separationLarge specific surface areaOrganic chemistryOrganic compound preparationBenzeneCarbon nitride

The invention relates to a functionalized carbon nitride photocatalyst capable of performing catalytic oxidization on benzene to synthesize phenol, and a preparation method and applications of the functionalized carbon nitride photocatalyst, belonging to the technical fields of material preparation and organic photosynthesis. The chemical formula of the functionalized carbon nitride photocatalyst is Fc-Ch=N-C3N4. The preparation method comprises the steps of: firstly, performing heat condensation to carbon nitride precursor; and synthesizing the functionalized carbon nitride photocatalyst by adopting a solvent reflux method. The prepared photocatalyst has high specific surface area, and the phenol synthesis by efficient catalytic oxidization on benzene can be realized. The functionalized carbon nitride photocatalyst is simple in technique, low in cost, and high in yield, meets the practical production demand and has larger application potential.

Owner:FUZHOU UNIV

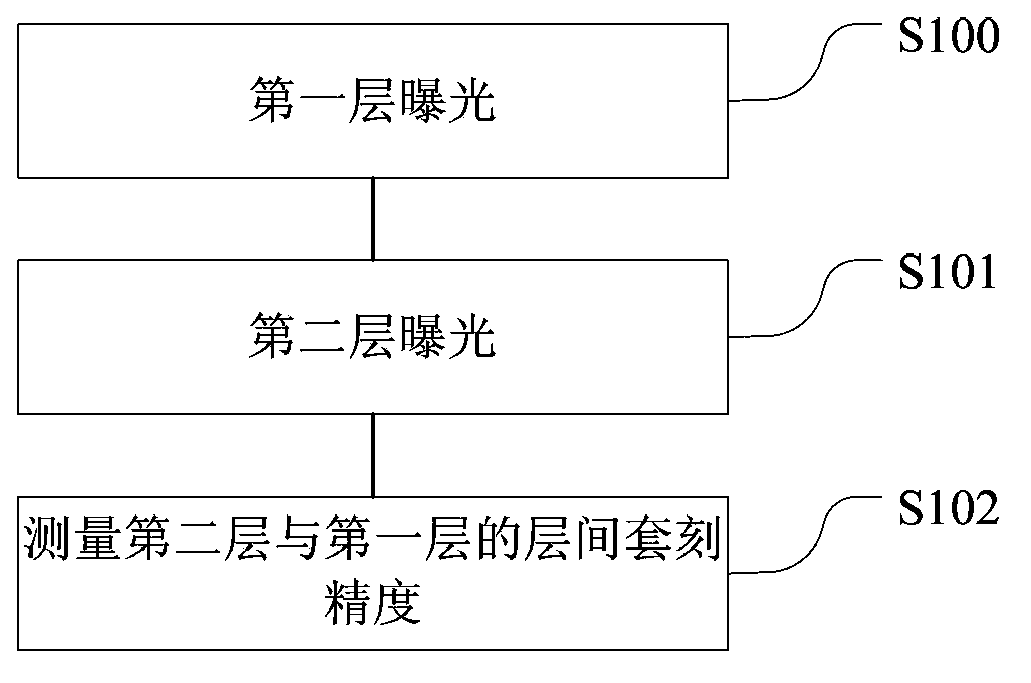

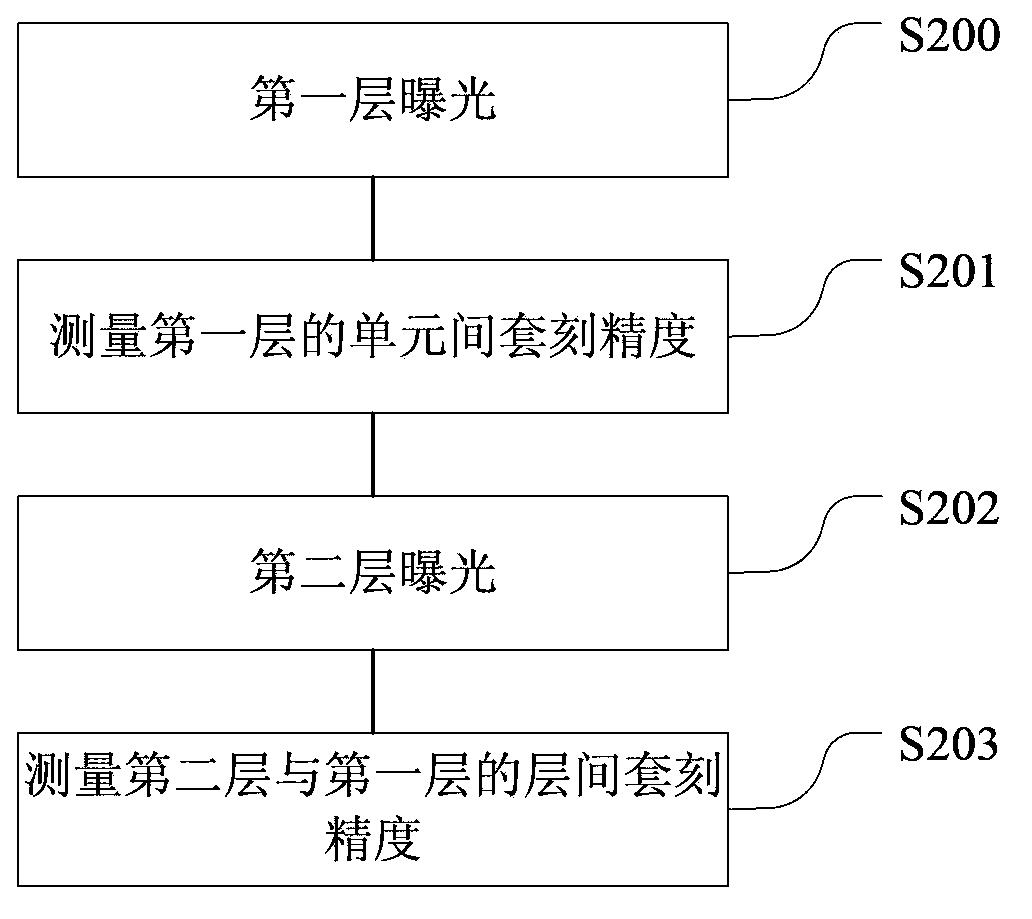

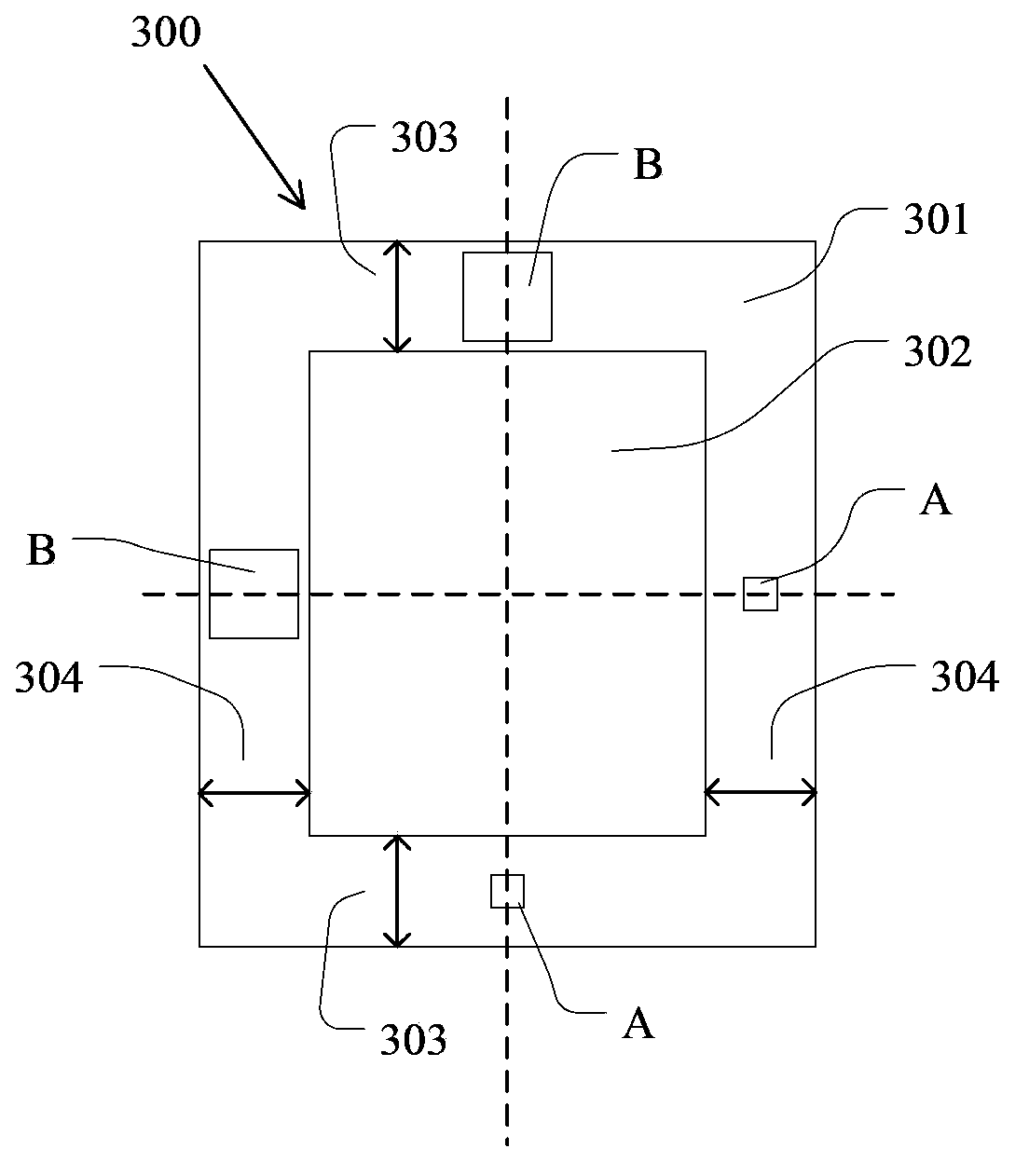

Mask and overlay precision measuring method

ActiveCN103454852AGrasp the initial situationMeet actual production needsSemiconductor/solid-state device testing/measurementPhotomechanical exposure apparatusComputer scienceAdvanced process control

The invention provides a mask and an overlay precision measuring method. The peripheral region of the mask is provided with a plurality of first marks A and second marks B, the peripheral regions of all exposal units can be intersected after the exposure of the whole wafer is ended, the first mark A and the second mark B of one of the exposal units can be respectively nested with the second mark B and the first mark A of the adjacent exposal unit, and on the basis, the relationship between the nested first marks A and the second marks B is measured to determine the overlay precision among the exposal units on the first layer, so that the initial condition of a product is better mastered; the measured overlay precision among the exposal units on the first layer is uploaded to an advanced process control system, so that the overlay precision among the exposal units on all the subsequent layers and the whole condition of the series of products can be mastered, and the actual production requirement is met favorably.

Owner:SEMICON MFG INT (SHANGHAI) CORP

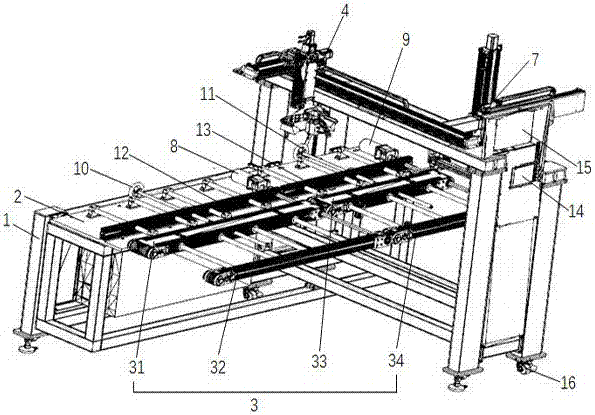

Intelligent production system for wattmeter

The invention discloses an intelligent production system for a wattmeter and solves the technical problems that the conventional electric energy meter calibration and warehouse management system is imperfect and only one type of wattmeter can be operated. The intelligent production system comprises a warehouse inlet / outlet delivery line, a warehouse system and a plurality of calibration systems, wherein the warehouse system comprises a three-dimensional meter library and a stacker for fetching the wattmeter from the three-dimensional meter library; and the intelligent production system is characterized in that: a production scheduling platform system transmits task instructions to the warehouse inlet / outlet delivery line, the warehouse system and the calibration systems; each calibration system comprises a calibrating main delivery line and a plurality of calibration units; and the three-dimensional meter library is lifted through the stacker and is butted with the warehouse inlet / outlet delivery line and the calibrating main delivery lines of various calibration systems respectively. By the system, a monitoring device is integrated, the safety is guaranteed, the system can be adjusted in real time, the whole set of system is operated in order, a plurality of types of wattmeters are warehoused and calibrated simultaneously without interference, and actual production requirements are met.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

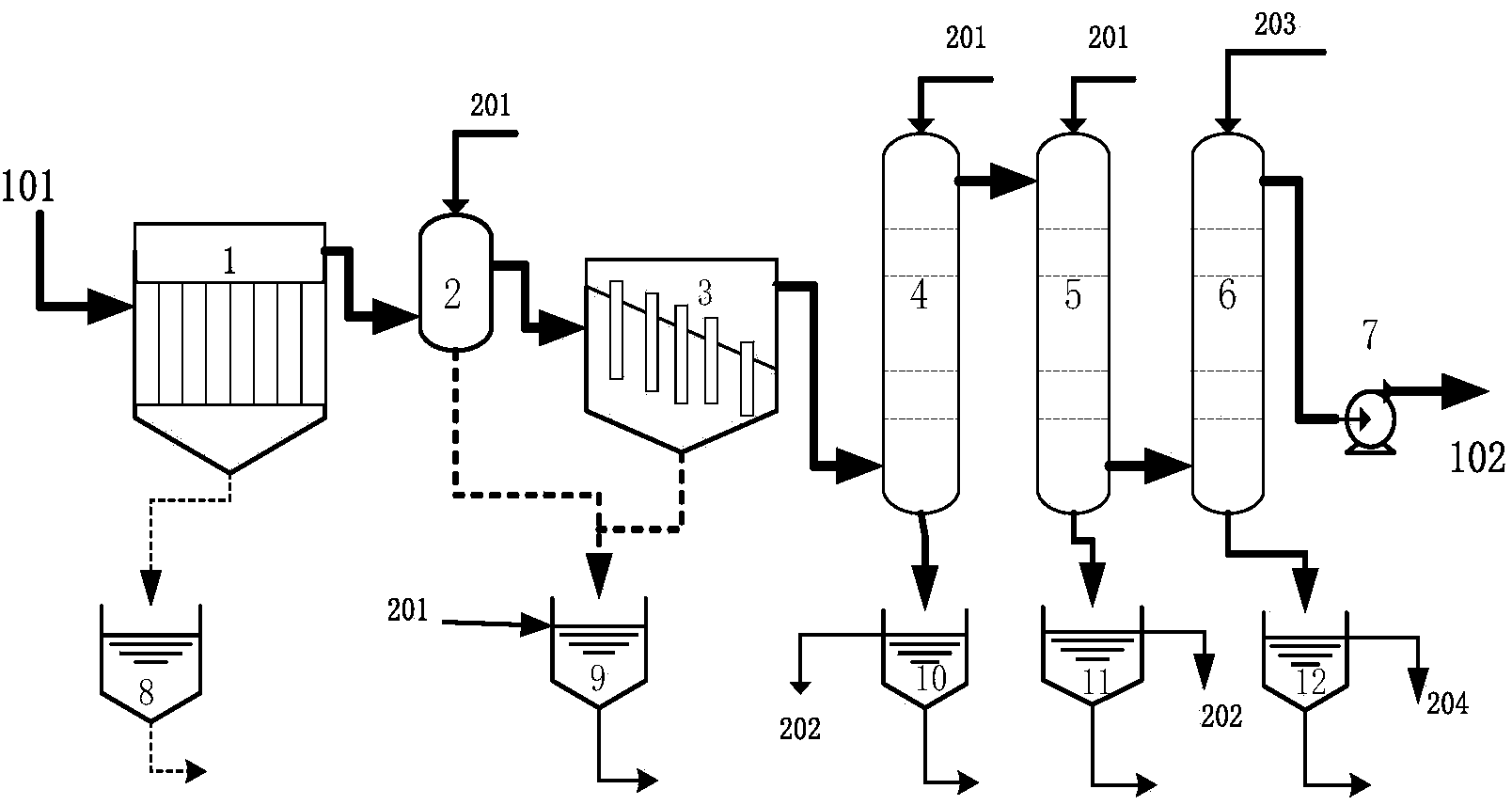

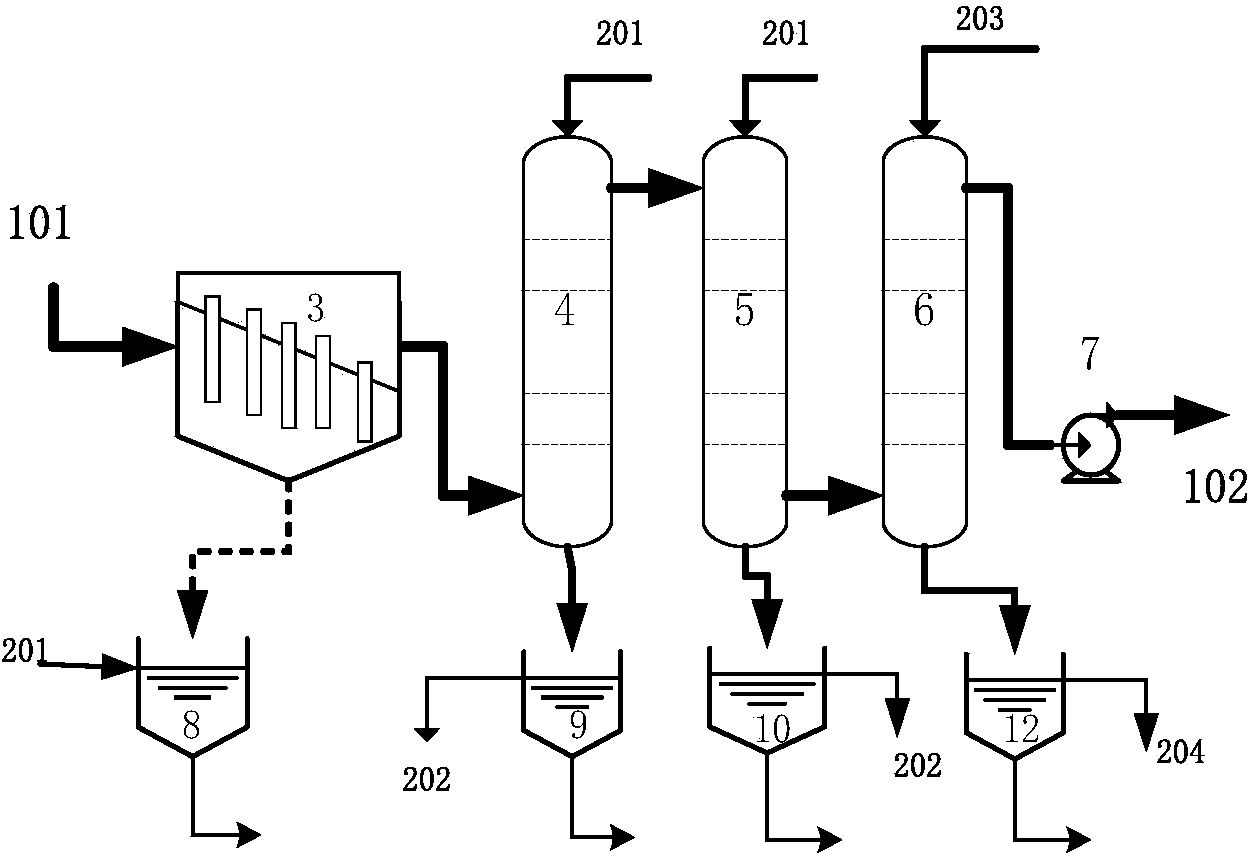

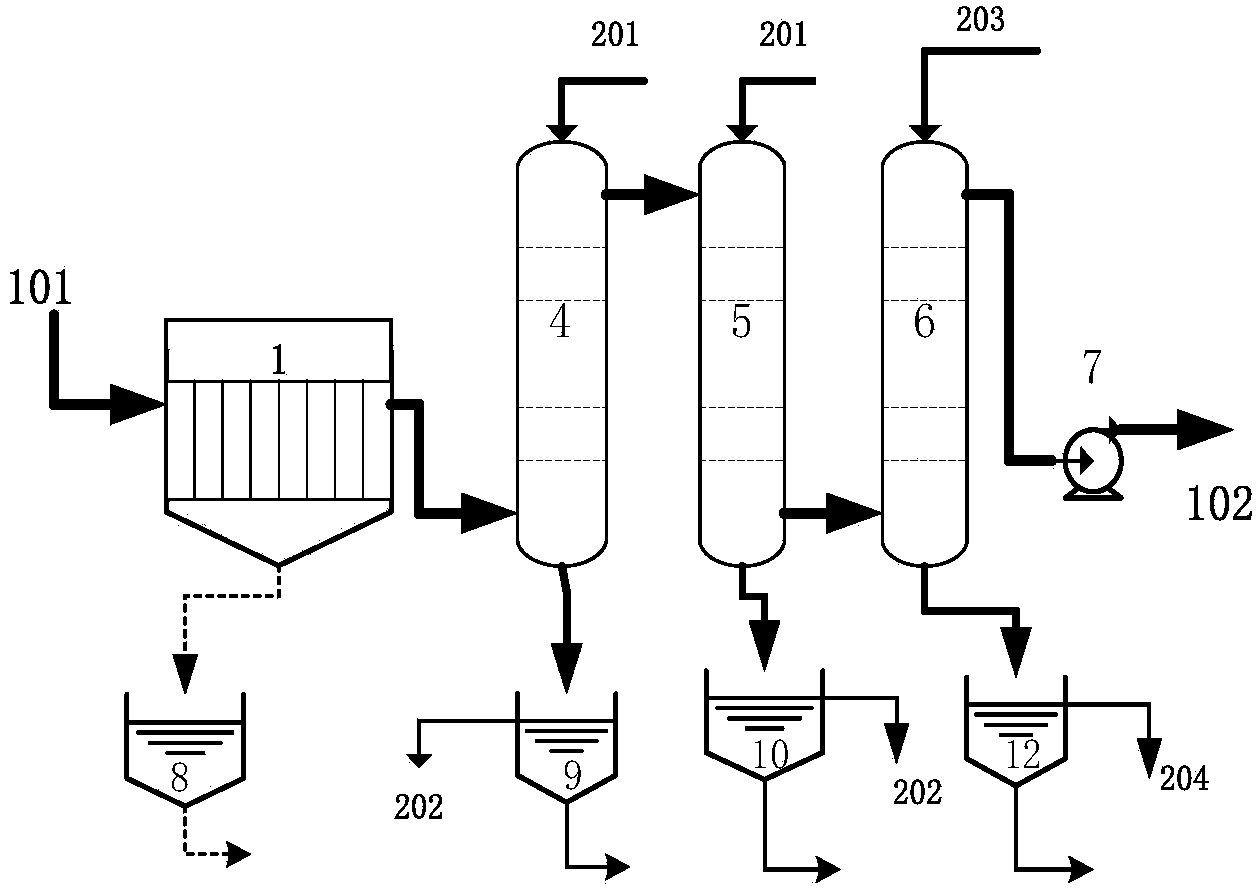

Low-impurity yellow phosphorus production method based on yellow phosphorus production technological process control

InactiveCN104276549AAchieve separationSimplify the subsequent refining processPhosphorus compoundsGas solidDecomposition

The invention relates to a low-impurity yellow phosphorus production method based on yellow phosphorus production technological process control. The low-impurity yellow phosphorus production method is mainly used for solving the problems that yellow phosphorus products produced in the prior art are high in impurity content, especially high in arsenic content. According to the low-impurity yellow phosphorous production method disclosed by the invention, high-temperature furnace gas discharged from a yellow phosphorus electric furnace in the process of yellow phosphorus production is directly subjected to step-by-step impurity removal, and by using the temperature difference between saturated steams of yellow phosphorus and arsenic and the temperature condition limitation of SiF4 and H2O decomposition reactions, the high-temperature furnace gas of the yellow phosphorus electric furnace is subjected to gas-solid (liquid) separation and multistage water washing for cooling, and the like step by step, so that a simple arsenic substance which is sublimated and separated out in advance is separated from yellow phosphorus subsequently separated out, and the separation of ash contents in the high-temperature furnace gas and SiO2 colloids produced by the hydrolysis of SiF4 is also realized, liquid yellow phosphorus crude products separated out by condensing in different temperature stages are respectively collected, and then the crude products are subjected to conventional separation and refining treatment so as to obtain yellow phosphorus products with different impurity contents. The method disclosed by the invention is used for solving the existing quality problem of industrial yellow phosphorus well, and can be applied to the industrial production of yellow phosphorus.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

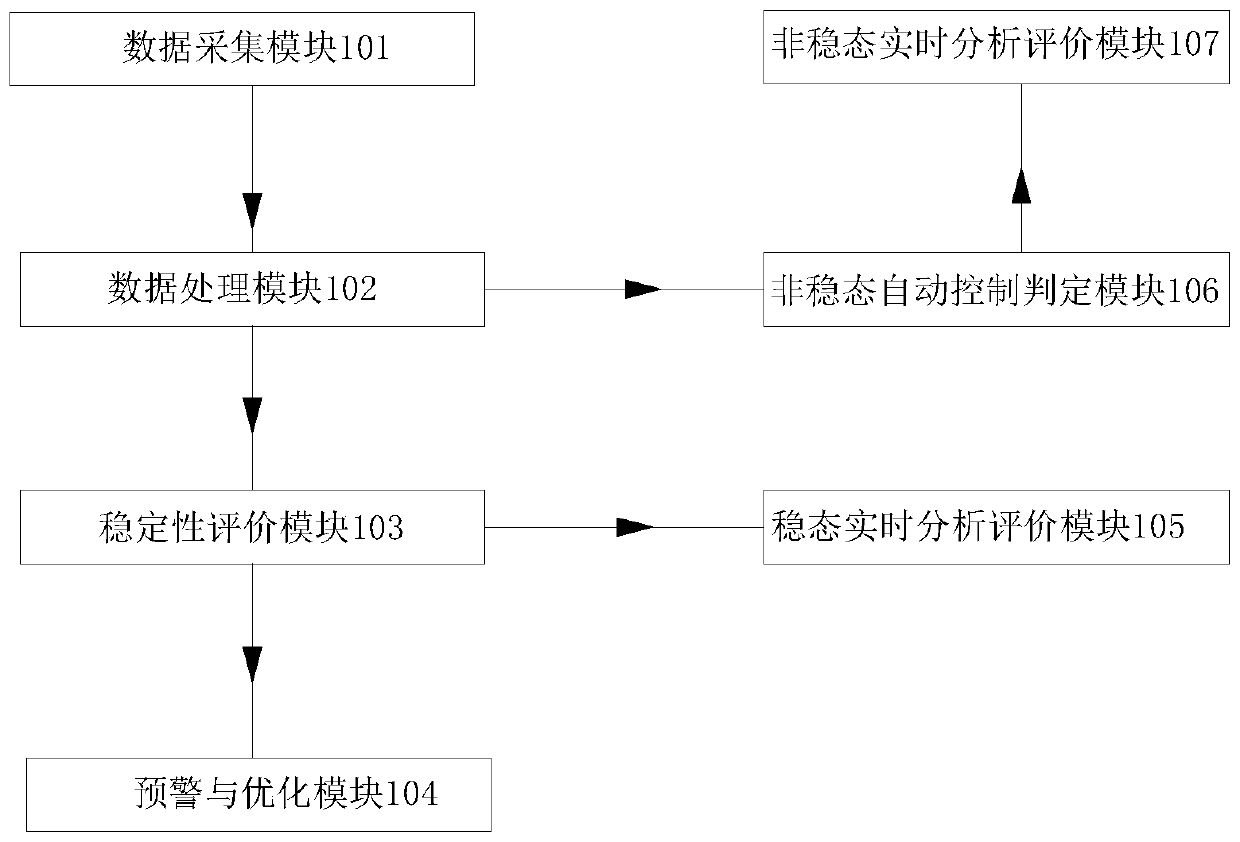

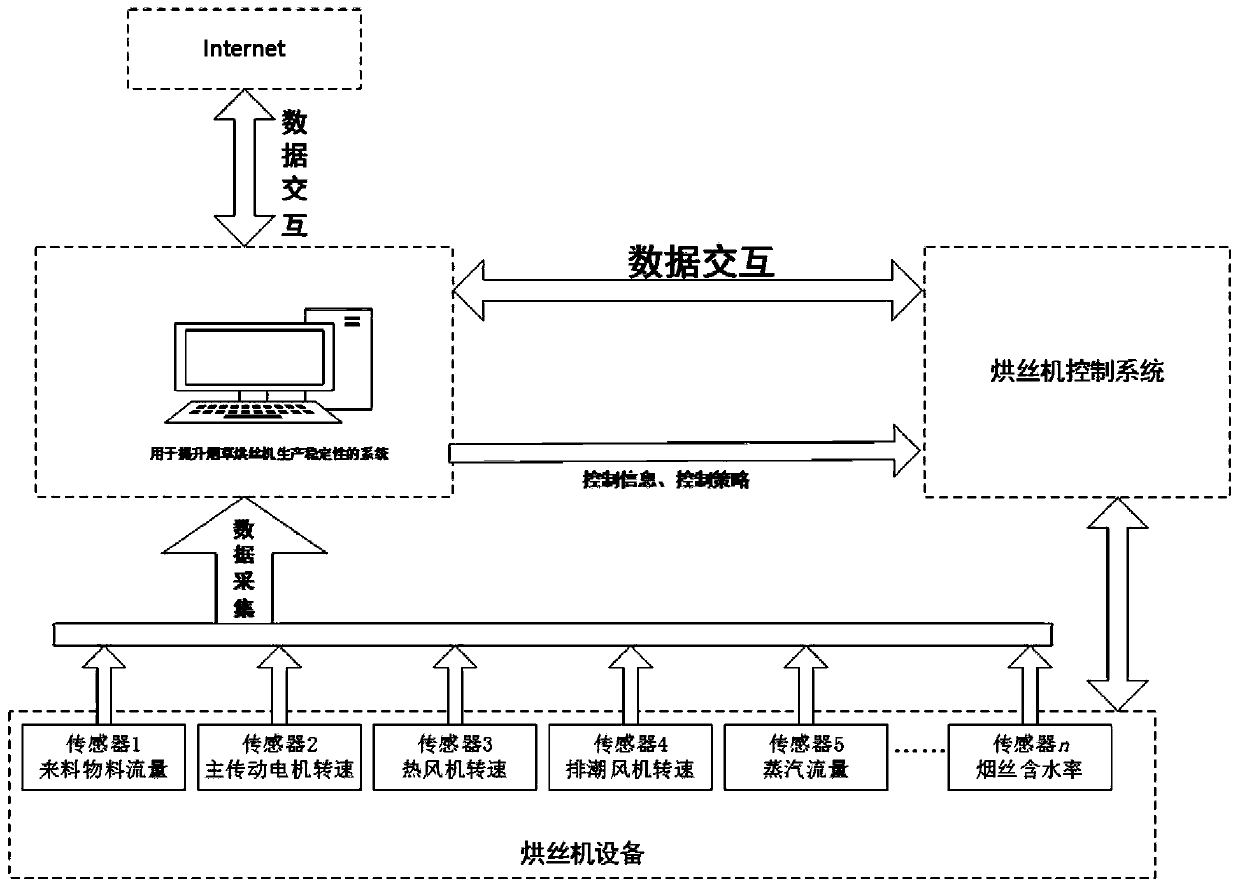

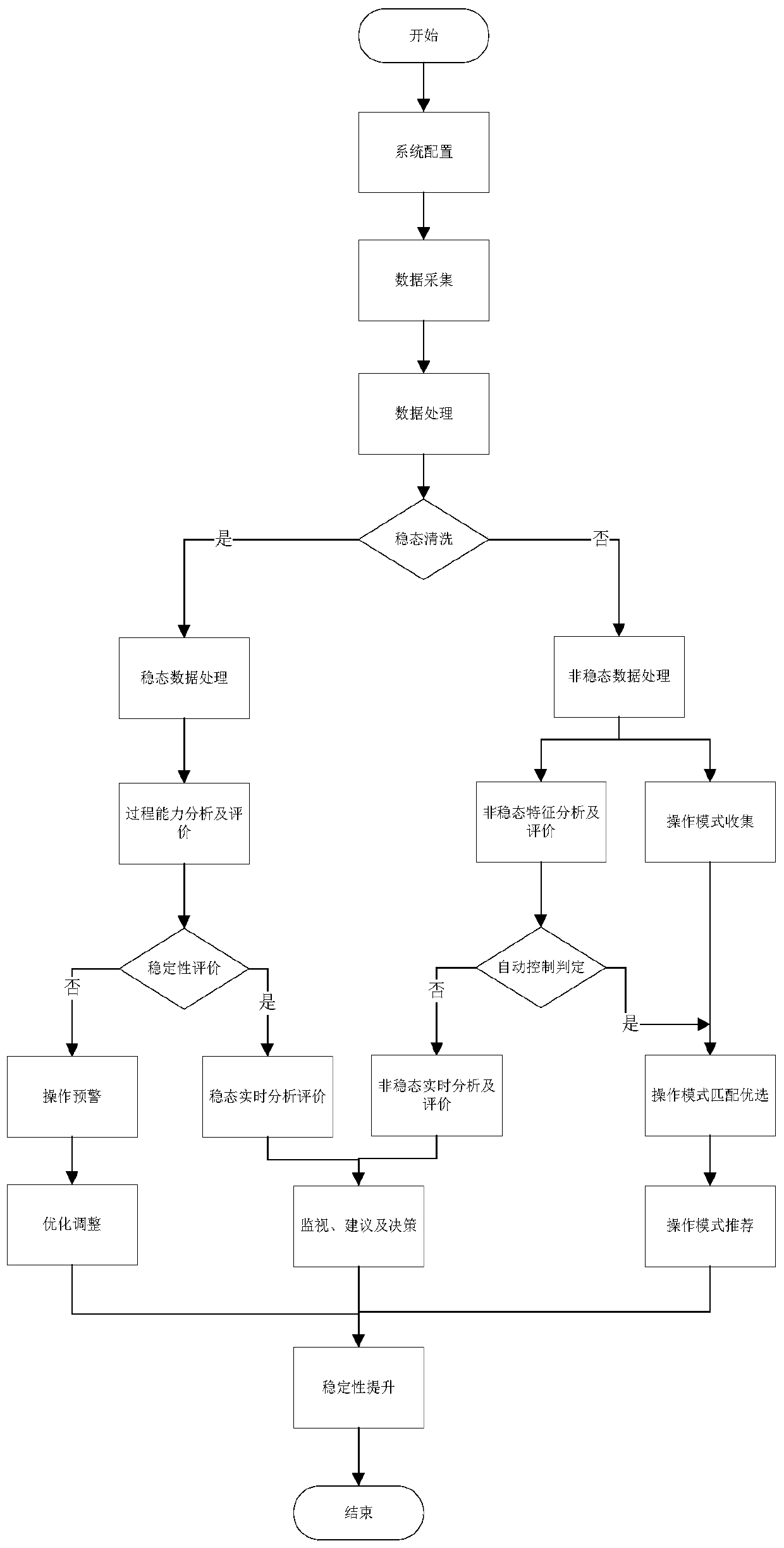

System and method for improving production stability of cut tobacco dryer

PendingCN111103854AAvoid control varianceImprove quality stabilityTobacco preparationProgramme total factory controlAutomatic controlProcess engineering

The invention relates to a system and a method for improving the production stability of a cut tobacco dryer, and belongs to the technical field of cut tobacco production. The system comprises a dataacquisition module, a data processing module, a stability evaluation module, an early warning and optimization module, a steady-state real-time analysis and evaluation module, an unsteady-state automatic control judgment module, an unsteady-state real-time analysis and evaluation module and the like. According to the system, new-generation information technologies such as industrial big data and artificial intelligence are used as supports, the unsteady-state time is shortened, the steady-state control quality is improved, then the quality stability of the whole production process of the cut tobacco dryer is effectively improved, and the system is easy to apply and popularize.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

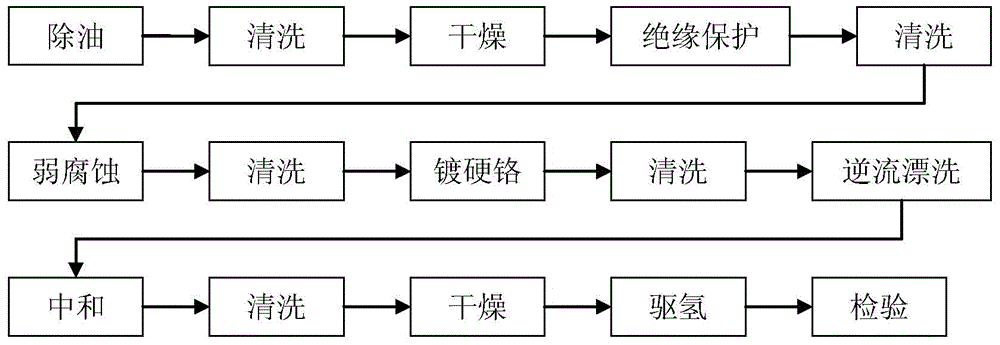

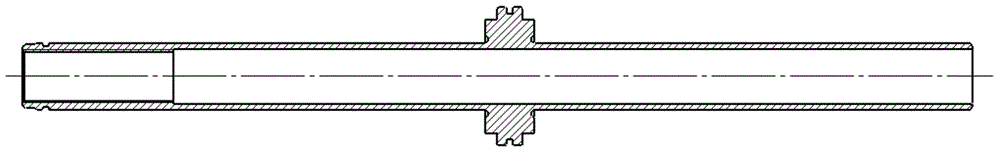

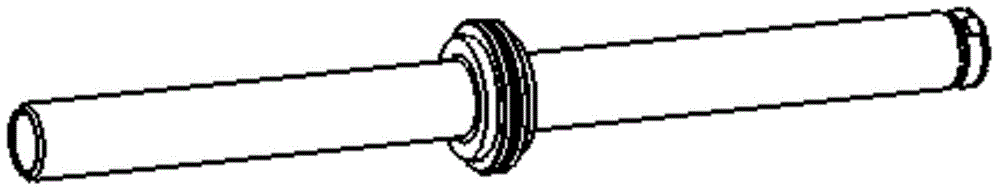

Hard chromium plating method and solution formula for piston rod class parts

The invention belongs to the field of chemical engineering and particularly relates to a hard chromium plating method and solution formula for piston rod class parts. The objective is to solve the problem that when a piston rod is produced, the quality of a hard chromium coating produced by a traditional electric chromium plating technology is not ideal, and the current efficiency is low. The method comprises the following steps: first, removing oil; then, washing, drying and carrying out insulation protection; after washing, carrying out weak corrosion; washing, and then, plating hard chromium; after washing, carrying out backflow bleaching, after neutralization, washing and drying; and after removing hydrogen, carrying out test. The hard chromium plating solution formula comprises 200-225g / L of CrO3, 2.3-2.5g / L of H2SO4 and 3-6g / L of Cr3+. The hard chromium plating method and solution formula are more suitable for piston rod class parts, particularly the production of hard chromium films of 30GrMnSiA materials. Moreover, the CrO3 content in the formula is reduced, so that the cost is reduced, and environmental pollution is reduced.

Owner:北京实验工厂有限责任公司 +1

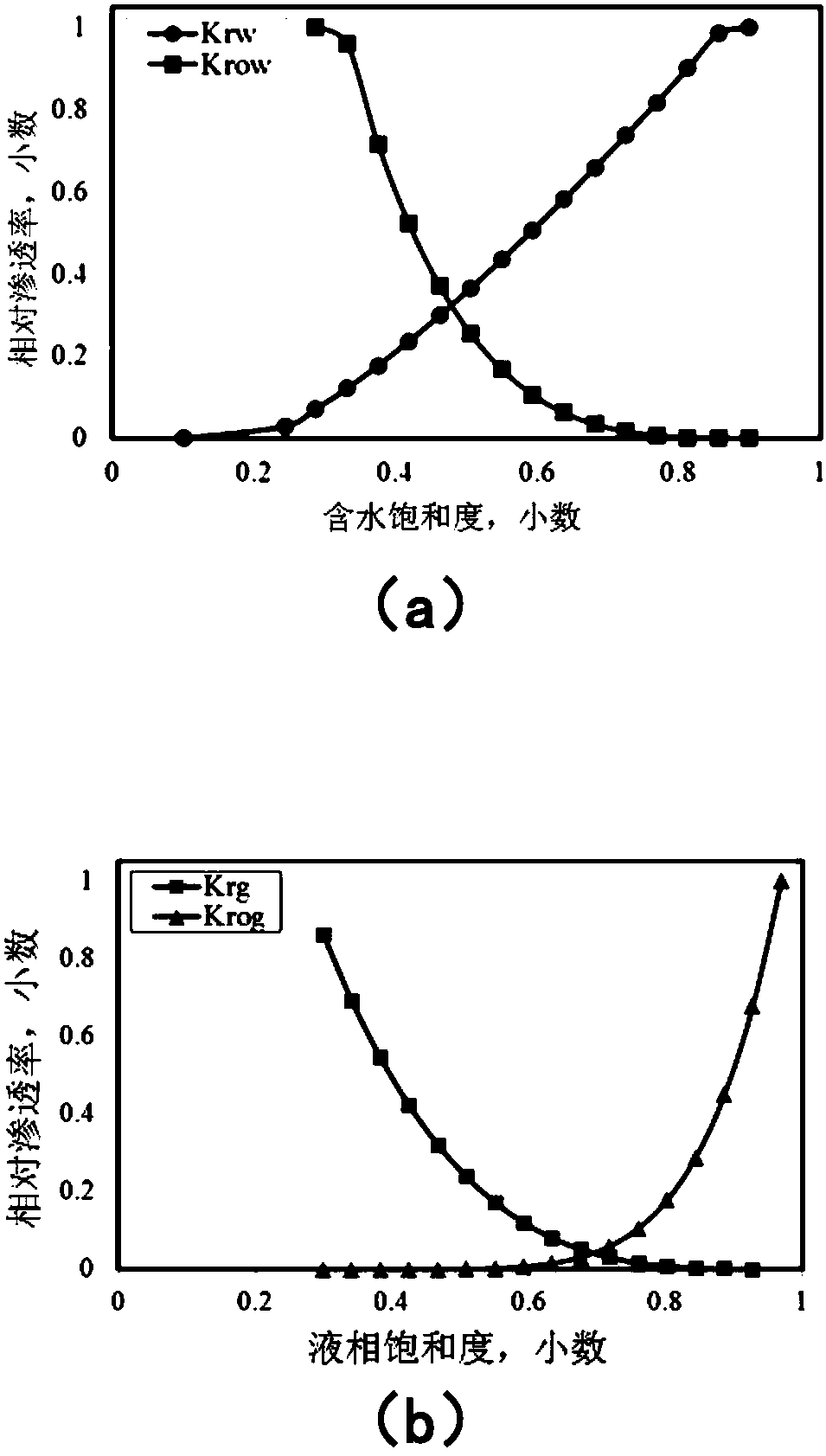

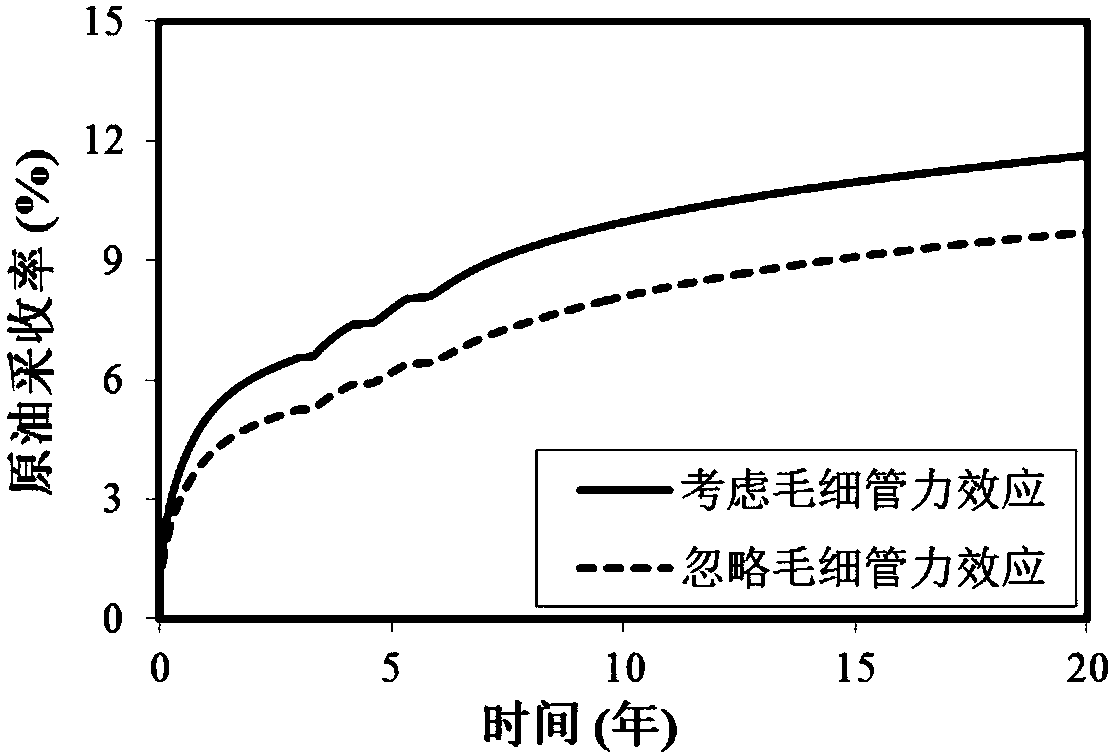

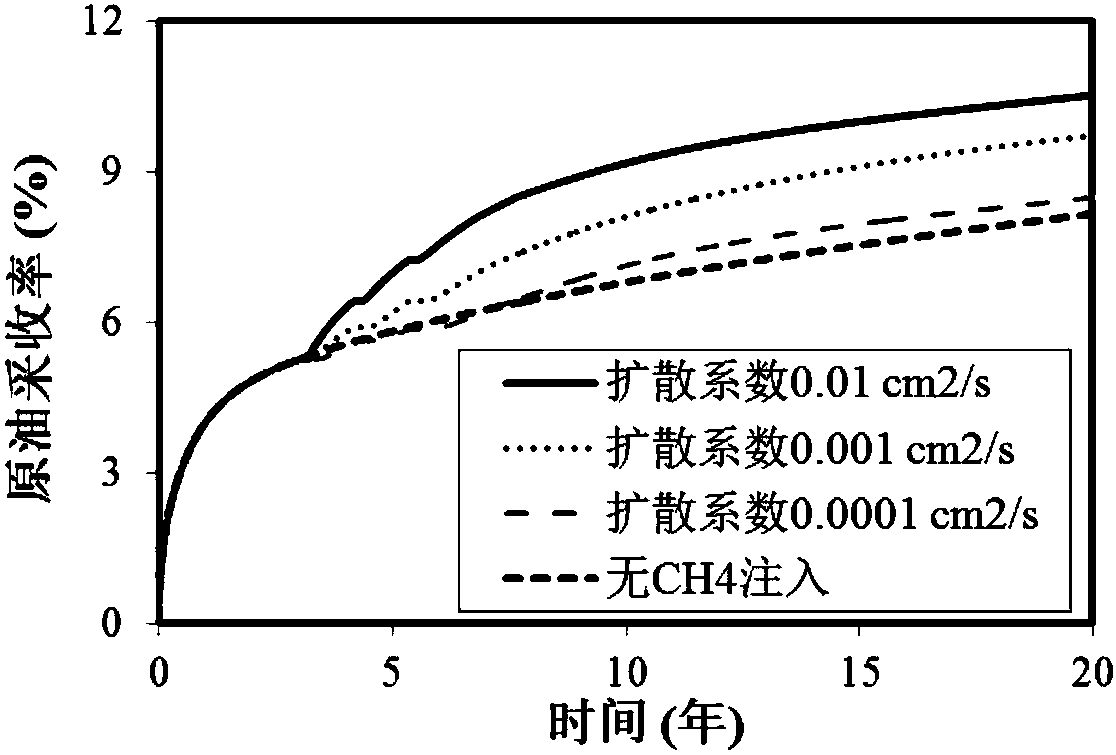

Method for analyzing yields of cyclic gas injection wells of shale oil reservoir and application thereof

InactiveCN108460203AImprove development efficiencyCircular Gas Injection GuidanceFluid removalDesign optimisation/simulationInjection wellPhase state

The invention belongs to the technical field of simulation of shale oil reservoir development, and relates to method for analyzing yields of cyclic gas injection wells of shale oil reservoir and an application thereof. The method for analyzing yields of cyclic gas injection wells of shale oil reservoir comprises the following steps of: establishing a shale oil reservoir phase state theoretical model; establishing an oil reservoir model; obtaining production history data of an oil reservoir; combining the shale oil reservoir phase state theoretical model and the oil reservoir model to carry outsimulative calculation on influence factors of a well yield by utilizing a numerical simulation technology, wherein the influence factors comprise capillary force effect, molecular diffusion effect,cyclic period and the like; and respectively determining influences, on a recovery ratio, of each factor under different numerical values through comparing the simulative calculation result, and analyzing or evaluating an influence degree, on improving the well yield via cyclic gas injection, of each factor. According to the method, the problem that the reservoir oil displacement process of shaleoil reservoir cyclic gas injection and particularly cyclic CH4 injection is lack of systematic study in the prior art is relieved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

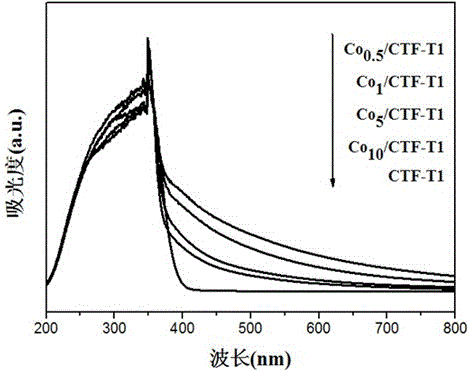

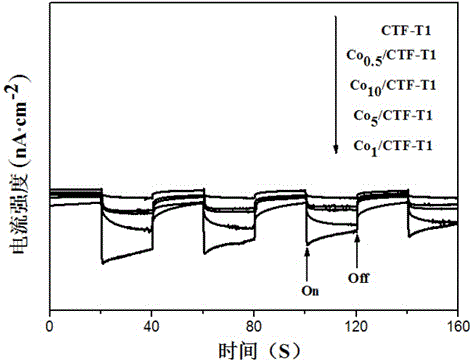

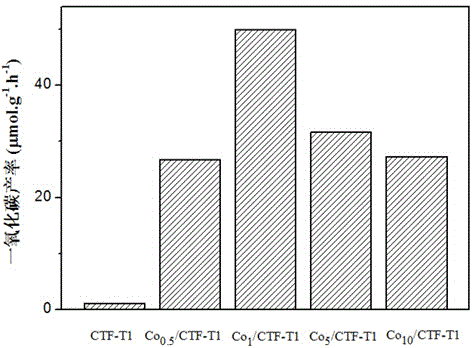

Covalent organic polymer based visible-light photocatalyst capable of efficiently reducing CO2

ActiveCN106732796AResponsive to visible lightSimple processGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceSolid reaction

The invention discloses a covalent organic polymer based visible-light photocatalyst capable of efficiently reducing CO2 and an application of the visible-light photocatalyst. The visible-light photocatalyst is a Co-doped covalent organic polymer, and is synthesized by introducing transition metal Co into a covalent organic polymer based on a triazine structure with a solid-phase reaction sintering method. The solid-phase reaction sintering method is simple to operate and lower in production cost and meets actual production requirements; besides, the obtained photocatalyst has good visible-light response, can efficiently catalyze CO2 reduction under visible light and has great application prospect.

Owner:FUZHOU UNIV

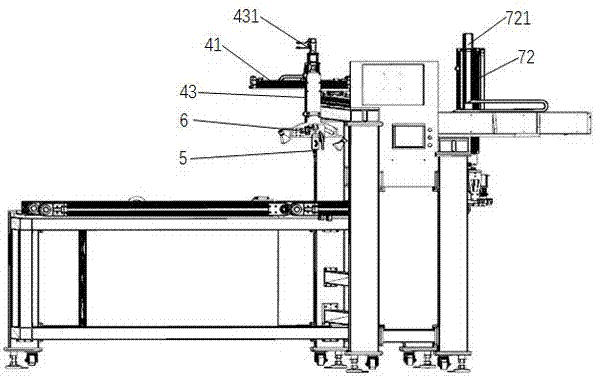

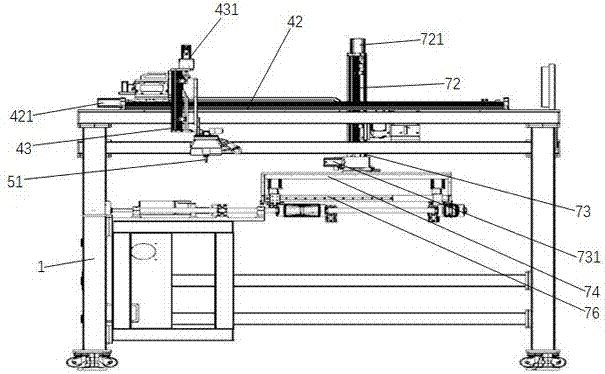

Vision guiding type automatic dispensing system and operating method thereof

InactiveCN107199151AReduce volumeHigh precisionLiquid surface applicatorsCoatingsEngineeringManual handling

The invention relates to the technical field of dispensing equipment, and particularly relates to a vision guiding type automatic dispensing system. A visual scanning and recognition mechanism and a dispensing device are arranged on the lower end of a first Z-axis platform of an XYZ platform, a three-dimensional model of a to-be-dispensed workpiece is designed and typeset by a computer, a dispensing area is determined, information is transferred to the visual scanning and recognition mechanism so as to scan and recognize the to-be-dispensed workpiece, then the information is transferred to the dispensing device so as to generate a dispensing path to dispense the workpiece, and the dispensed workpiece is rotated and taken out from a processing flow channel section and is put at a specified point by an XZR platform after being dispensed, so that an output flow channel section is omitted, and the length of a flow channel is shortened, thereby reducing the size of the dispensing system. The vision guiding type automatic dispensing system has the advantages of high degree of automation, high dispensing accuracy and good quality, the problems of nonuniformity in dispensing and large error caused by manual operation are solved, the working efficiency is greatly improved, practical production requirements of enterprises are satisfied, and additionally, equipment has the advantages of small size and reasonable structure.

Owner:苏州欧康诺电子科技股份有限公司

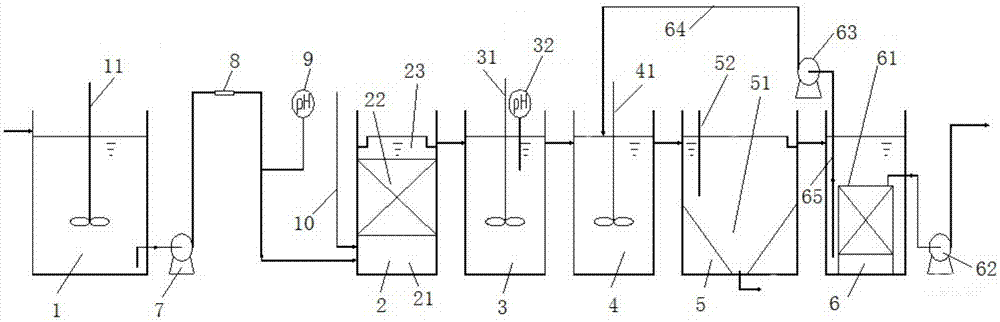

Chemical copper precipitation wastewater copper removing treatment process and chemical copper precipitation wastewater copper removing treatment system

ActiveCN105439335AReduce doseLow costWater contaminantsWaste water treatment from metallurgical processElectrolysisSludge

The present invention provides a chemical copper precipitation wastewater copper removing treatment system, which comprises an adjustment tank, a micro-electrolysis reaction tank, a pH value adjustment tank, a flocculation tank, a buffer tank and a MCR tank, wherein the adjustment tank, the micro-electrolysis reaction tank, the pH value adjustment tank, the flocculation tank, the buffer tank and the MCR tank are sequentially connected through pipelines. The present invention further provides a chemical copper precipitation wastewater copper removing treatment process, which comprises steps such as adjustment, acidification, micro-electrolysis reaction, neutralization, flocculation, physical sedimentation, and MCR treatment. According to the present invention, the micro-electrolysis reaction is used to replace the traditional additionally-added complexing breaking agent, the traditional additionally-added complexing breaking agent is not required, the stability and the complexing breaking effect are excellent; the MCR tank is used to replace the sedimentation tank, such that the effluent effects is extremely stable and is not affected by the water fluctuation, the poor reaction effect and other factors, and the addition of a lot of the flocculant is not required; the sludge of the MCR tank refluxes to the flocculation tank so as to reduce the addition of the flocculant and save the agent cost; and the problems of poor stability, high agent addition amount and poor load impact resistance of the conventional treatment process are avoided, the labor intensity is substantially reduced, the treatment efficiency is improved, and the actual production needs are met.

Owner:GUANGDONG SHUIQING ENVIRONMENTAL PROTECTION TECH CO LTD

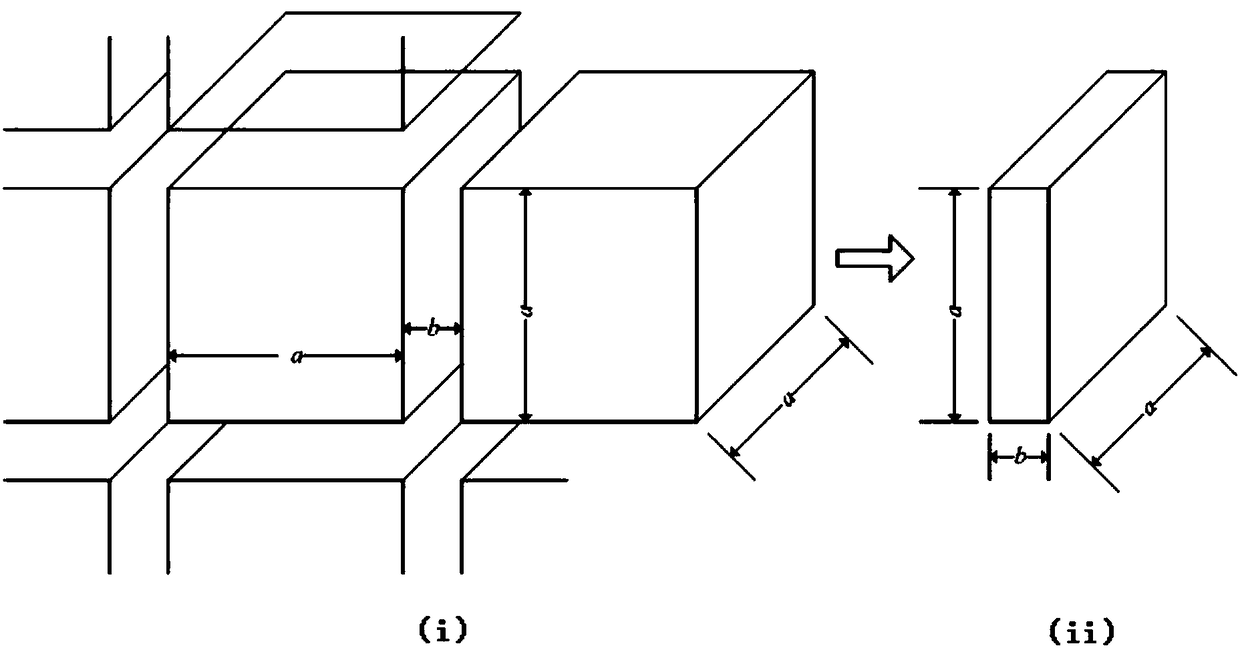

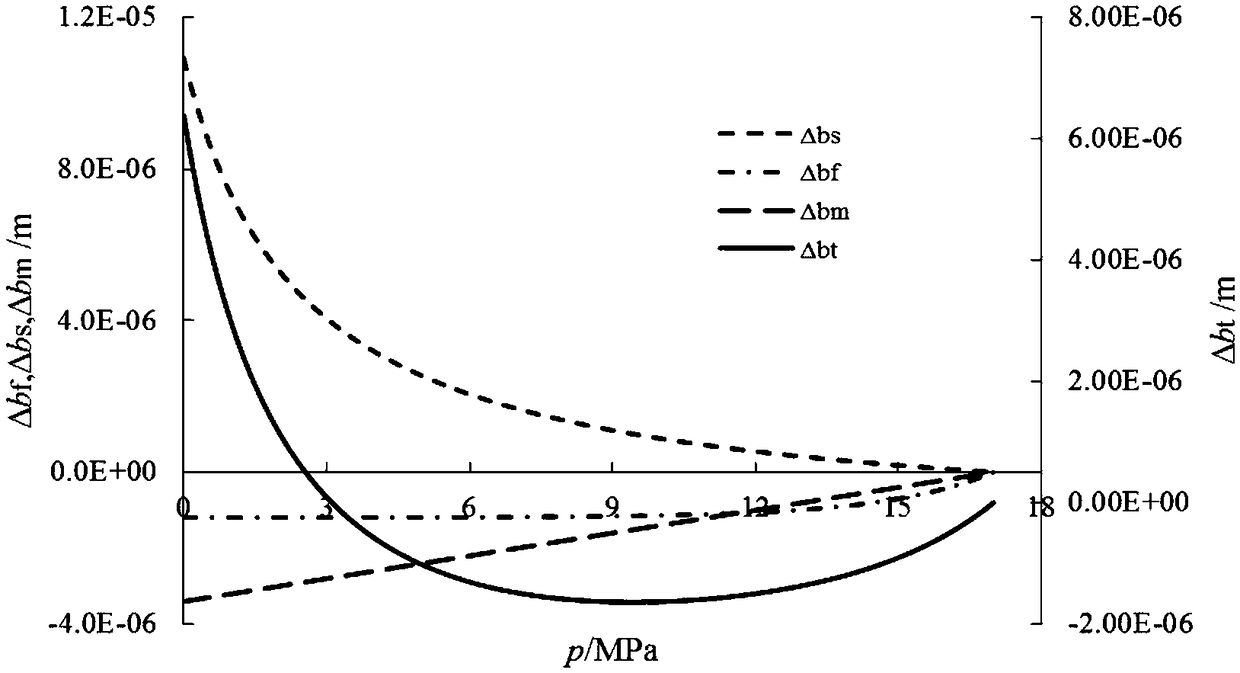

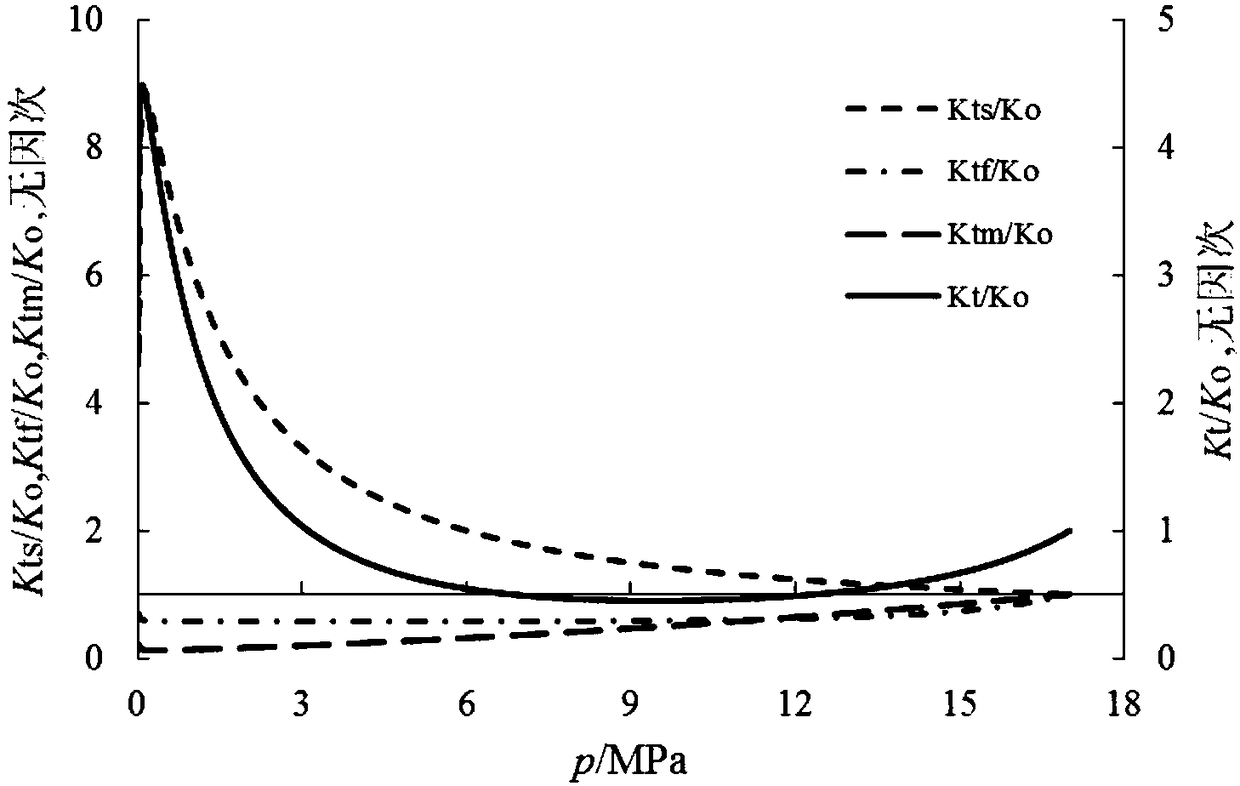

Method for calculating gas mass transmission parameters under shale microcrack crack width variation

ActiveCN108343433AStrong noveltyComprehensiveDesign optimisation/simulationSpecial data processing applicationsDesorptionMass migration

The invention discloses a method for calculating gas mass transmission parameters under shale microcrack crack width variation. The method comprises the following steps that the reservoir pressure, the microcrack initial size, rock mechanics parameters, and reservoir gas-related parameter basic data are collected; according to the influence of microcrack compressibility, matrix compressibility andgas desorption on the microcrack width, a crack width variation equation under stress sensitivity is established; aiming at different transmission mechanisms, a mass migration equation describing theflow state corresponding to continuous flowing, slippage flowing, Knudsen flowing and the surface diffusion effect under consideration of shale crack width dynamic variation is established; and a unified equation describing mass migration of the different transmission mechanisms under consideration of shale crack width dynamic variation is established. The gas mass transmission parameters in shale microcracks can be calculated, crack width dynamic variation under the stress sensitivity is considered, and the characteristics of novelty, comprehensiveness and the like are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

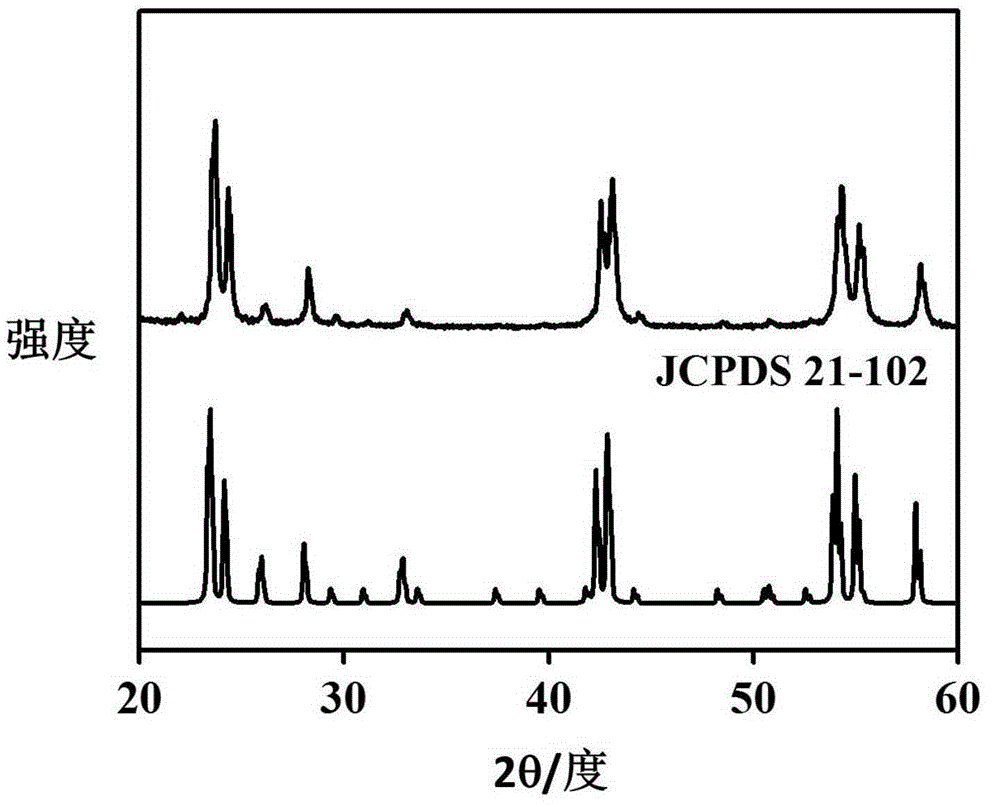

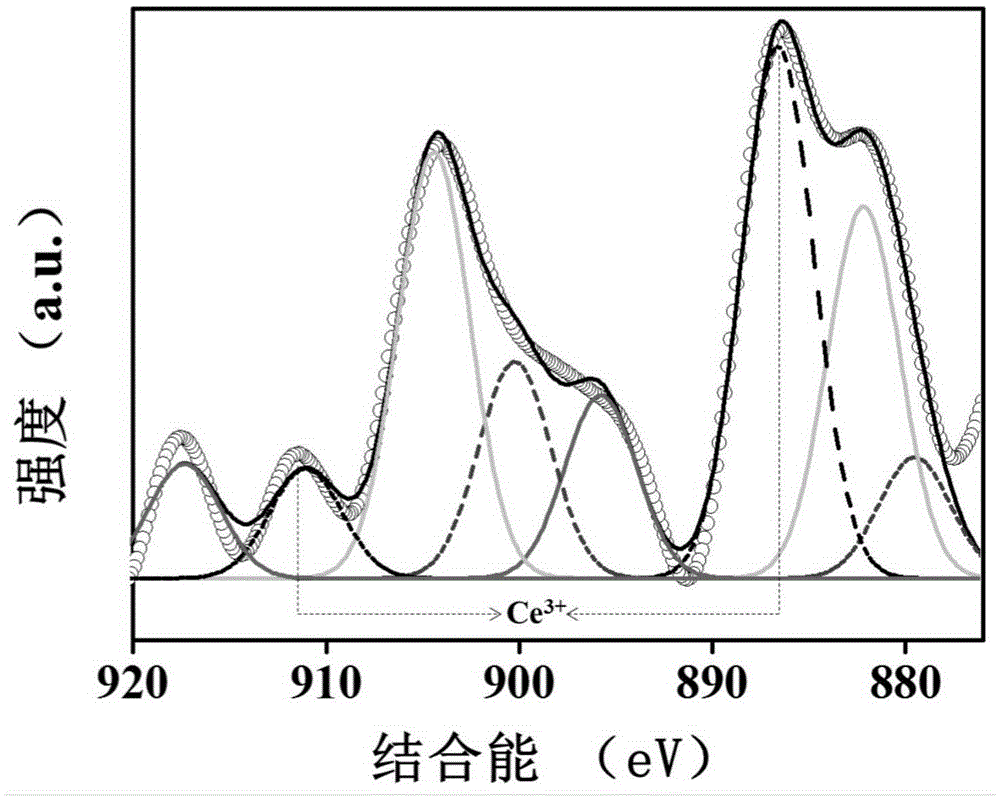

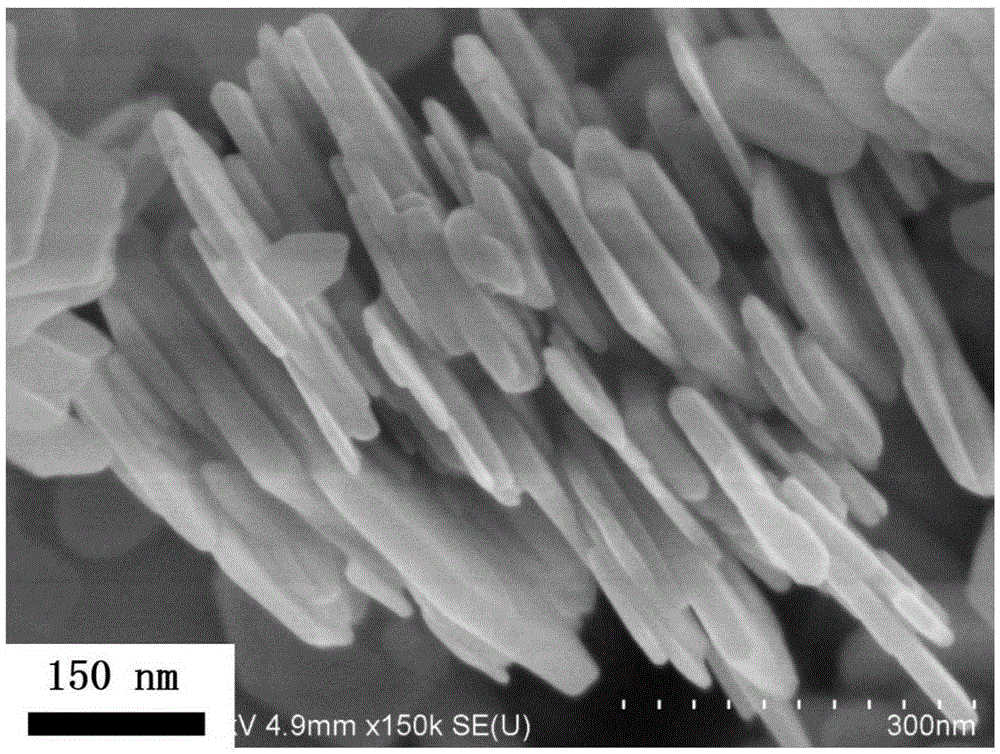

Nanometer flake cerium-doped bismuth molybdate catalyst, as well as preparation method and application thereof

InactiveCN105289579AEffective thickness controlSimple preparation processBiocideMaterial nanotechnologyDyeing wastewaterLight response

The invention discloses a preparation method of a nanometer flake cerium-doped bismuth molybdate catalyst. A simple one-step hydrothermal method is adopted; the PH of reaction liquor is free from being adjusted; the method is green and is free from acid-base pollution. A nanometer flake cerium-doped bismuth molybdate material can be served as a visible light response photocatalyst and has a uniform flake appearance with the average thickness being 20-30nm; a relatively thin flake structure and cerium ions are introduced, so that the absorption for photons is promoted, the high-efficient separation for a photon-generated carrier is realized and the ultrahigh photocatalytic performance is shown under the irradiation of visible light; the catalyst has relatively high catalytic activity at the aspects of degradation of dye wastewater and killing of water bacteria; the application prospect is wide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com