Low-impurity yellow phosphorus production method based on yellow phosphorus production technological process control

A production method and production process technology, which are applied in the production field of low-impurity yellow phosphorus, can solve the problems of high content of yellow phosphorus impurities, high arsenic content, large amount of silica-containing phosphorus mud, etc., and achieve the effect of simplifying the subsequent refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

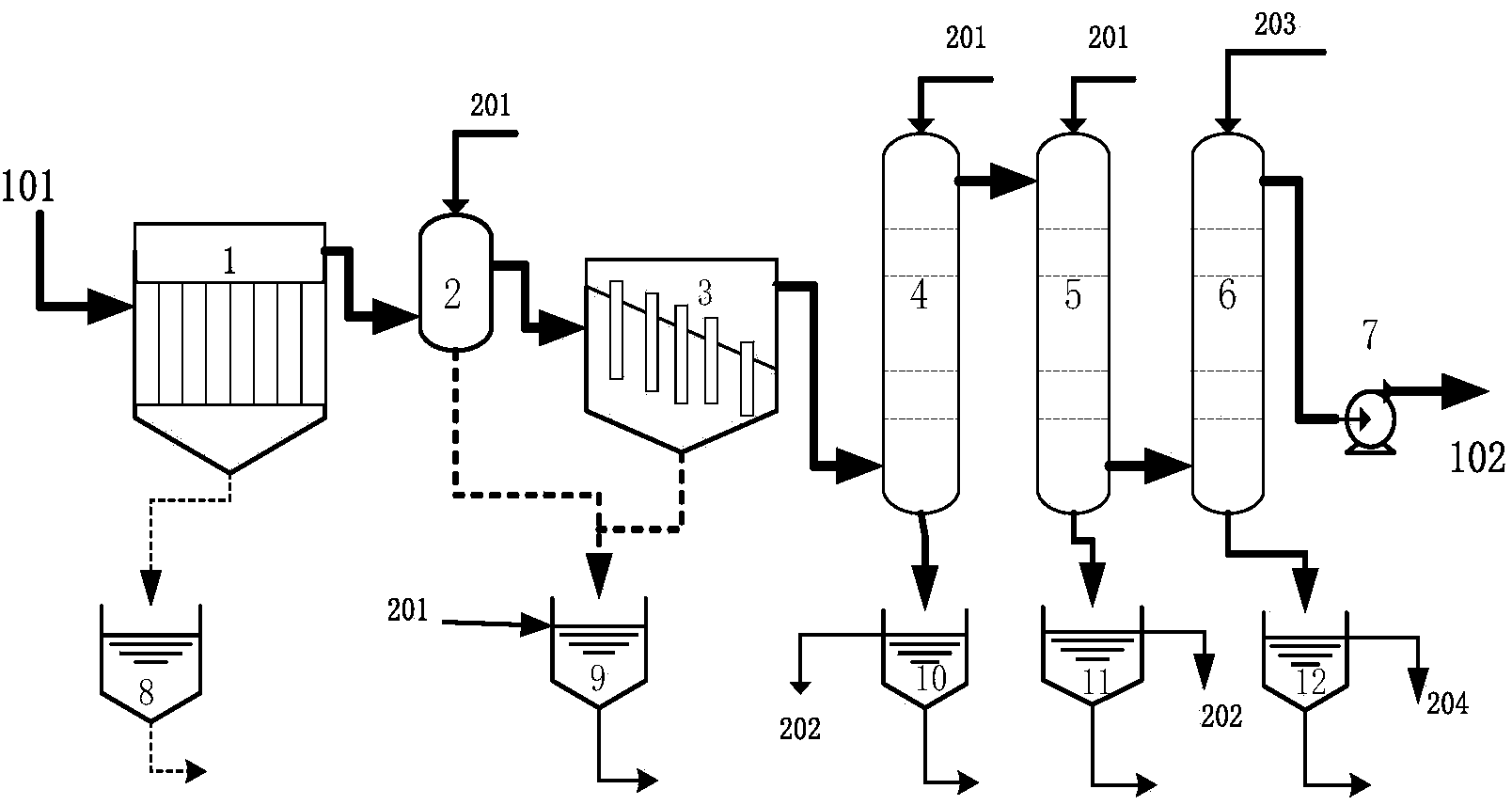

[0049] A production method of yellow phosphorus with low impurities based on the process control of yellow phosphorus production process, aimed at a yellow phosphorus electric furnace (12500KVA) production device with an output of 5000 tons / year (annual operating hours 7200h), in which the phosphate rock into the furnace contains five Phosphorus oxide (P 2 o 5 ) is 30%, the arsenic content is 78mg / kg, the ratio of raw and auxiliary materials and other operating conditions are the same as the conventional operation, and the gas output of the yellow phosphorus electric furnace is about 7100m 3 / h, the temperature is about 230°C. use figure 1 The process technology shown carries out subsequent low-impurity yellow phosphorus production process control, and the specific steps include:

[0050] 1) Remove about 90% of the dust impurities and a small amount of arsenic solid dust from the furnace gas 101 that leaves the yellow phosphorus electric furnace in the yellow phosphorus pro...

Embodiment 2

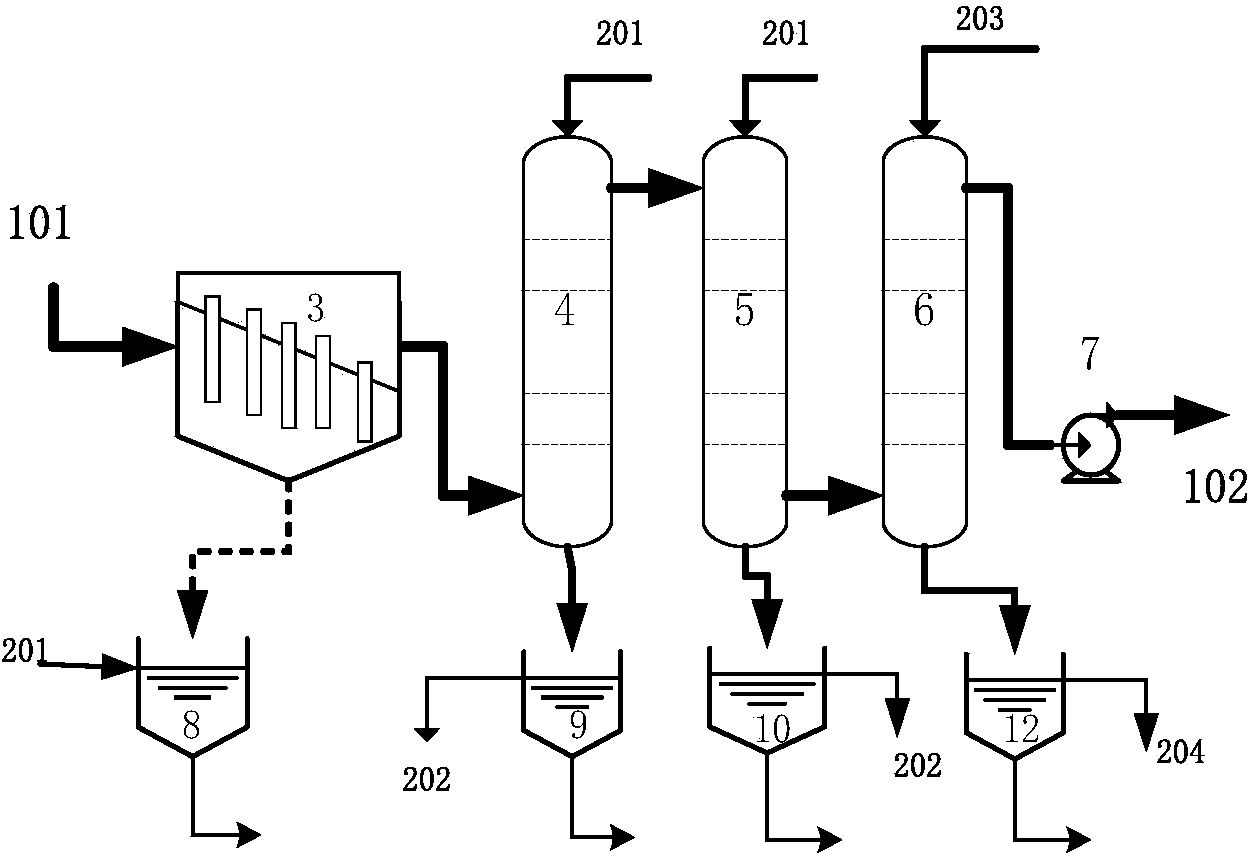

[0054] A production method of yellow phosphorus with low impurities based on the process control of yellow phosphorus production process, aimed at a yellow phosphorus electric furnace (15000KVA) production device with an output of 7500 tons / year (annual operating hours 7200h), in which the phosphate rock contained in the furnace contains pentoxide diphosphorus (P 2 o 5 ) is 30.5%, the arsenic content is 76mg / kg, the ratio of raw and auxiliary materials and other operating conditions are the same as those of conventional operation. The output gas volume of the yellow phosphorus electric furnace is about 11000m 3 / h, the temperature is about 235°C. use figure 2 The process technology shown carries out subsequent yellow phosphorus production process control, and specific steps include:

[0055] 1) The furnace gas 101 leaving the yellow phosphorus electric furnace passes through the multi-tube cyclone dust collector 3 to remove solid dust. In order to ensure that the dust col...

Embodiment 3

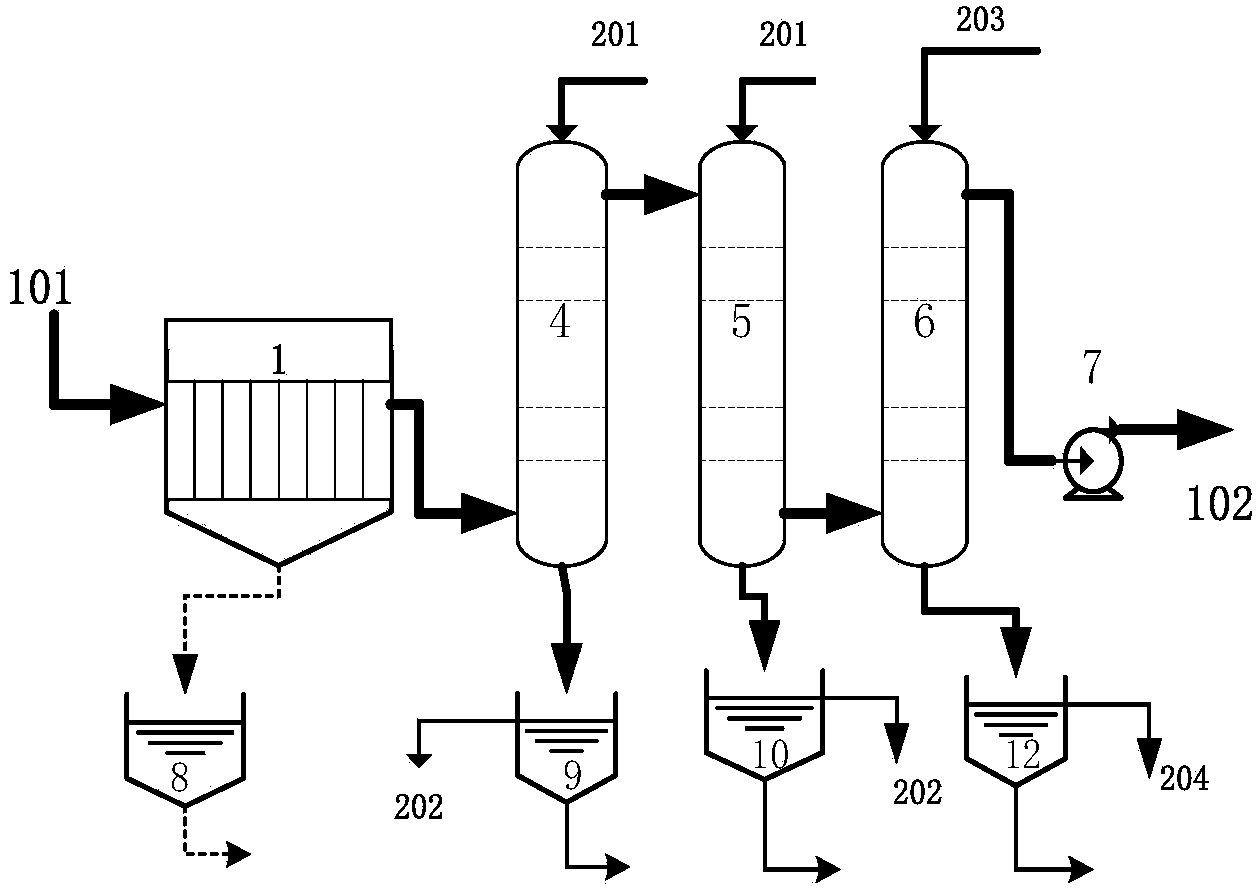

[0059] A production method of yellow phosphorus with low impurities based on the process control of yellow phosphorus production process, aimed at a yellow phosphorus electric furnace (15000KVA) production device with an output of 7500 tons / year (annual operating hours 7200h), in which the phosphate rock contained in the furnace contains pentoxide diphosphorus (P 2 o 5 ) is 30%, the arsenic content is 78mg / kg, the ratio of raw and auxiliary materials and other operating conditions are the same as the existing conventional operation. The output gas volume of the yellow phosphorus electric furnace is about 11000m 3 / h, the temperature is about 240°C. use image 3 The process technology shown carries out subsequent yellow phosphorus production process control, and specific steps include:

[0060] 1) The furnace gas 101 leaving the yellow phosphorus electric furnace passes through the electrostatic precipitator 1 to remove solid dust. In order to ensure that the dust collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com