Patents

Literature

599results about "Glass recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

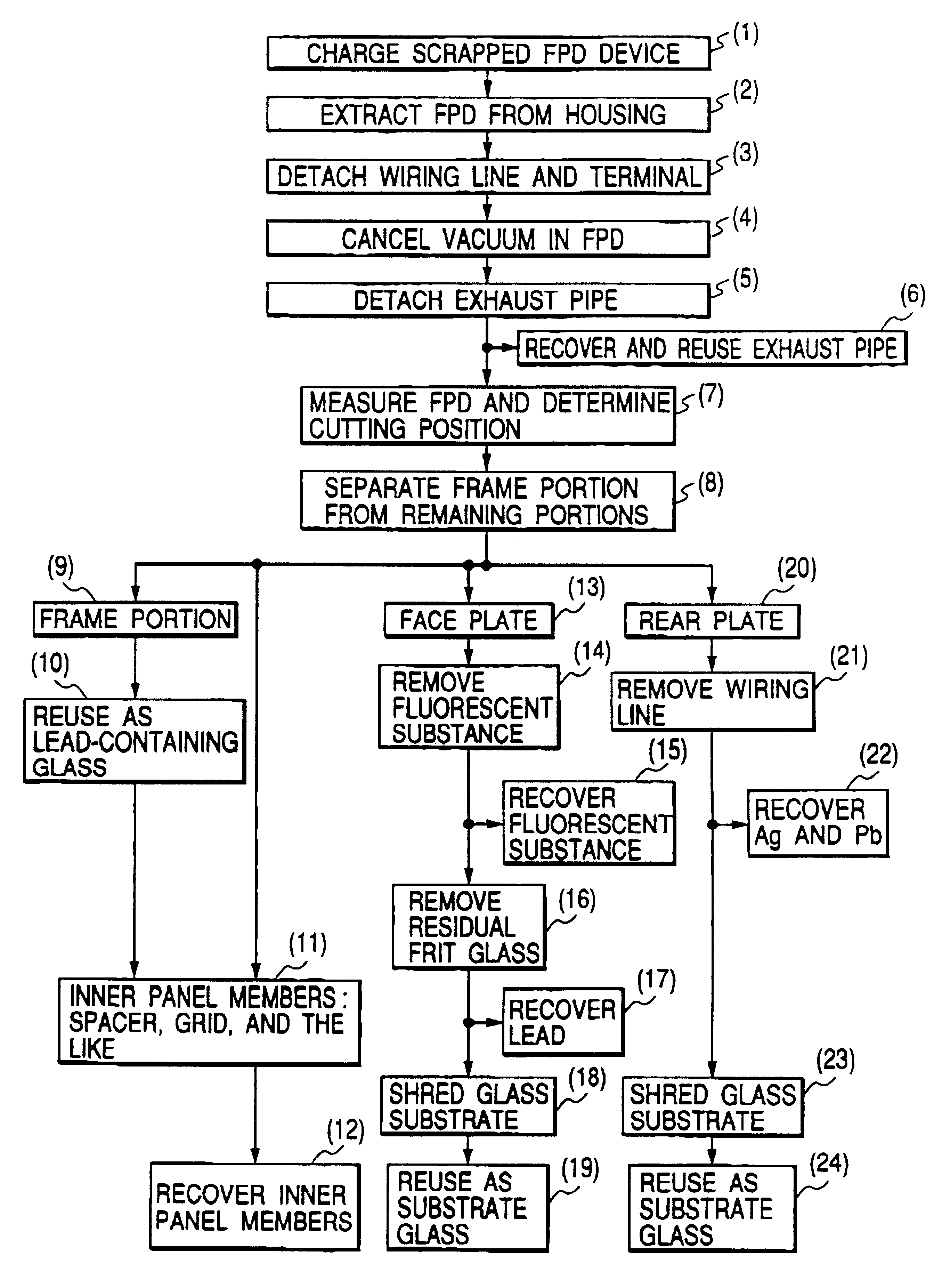

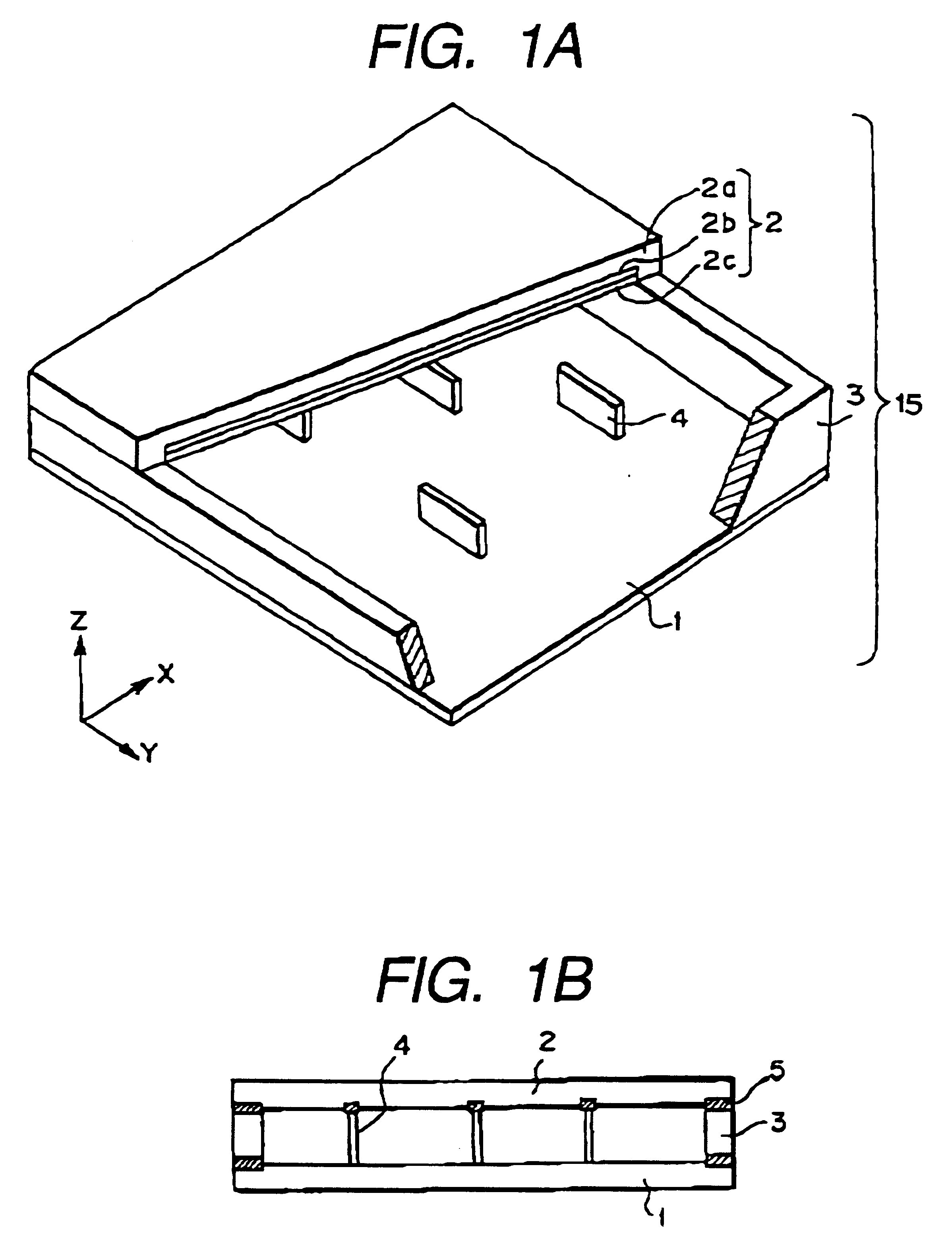

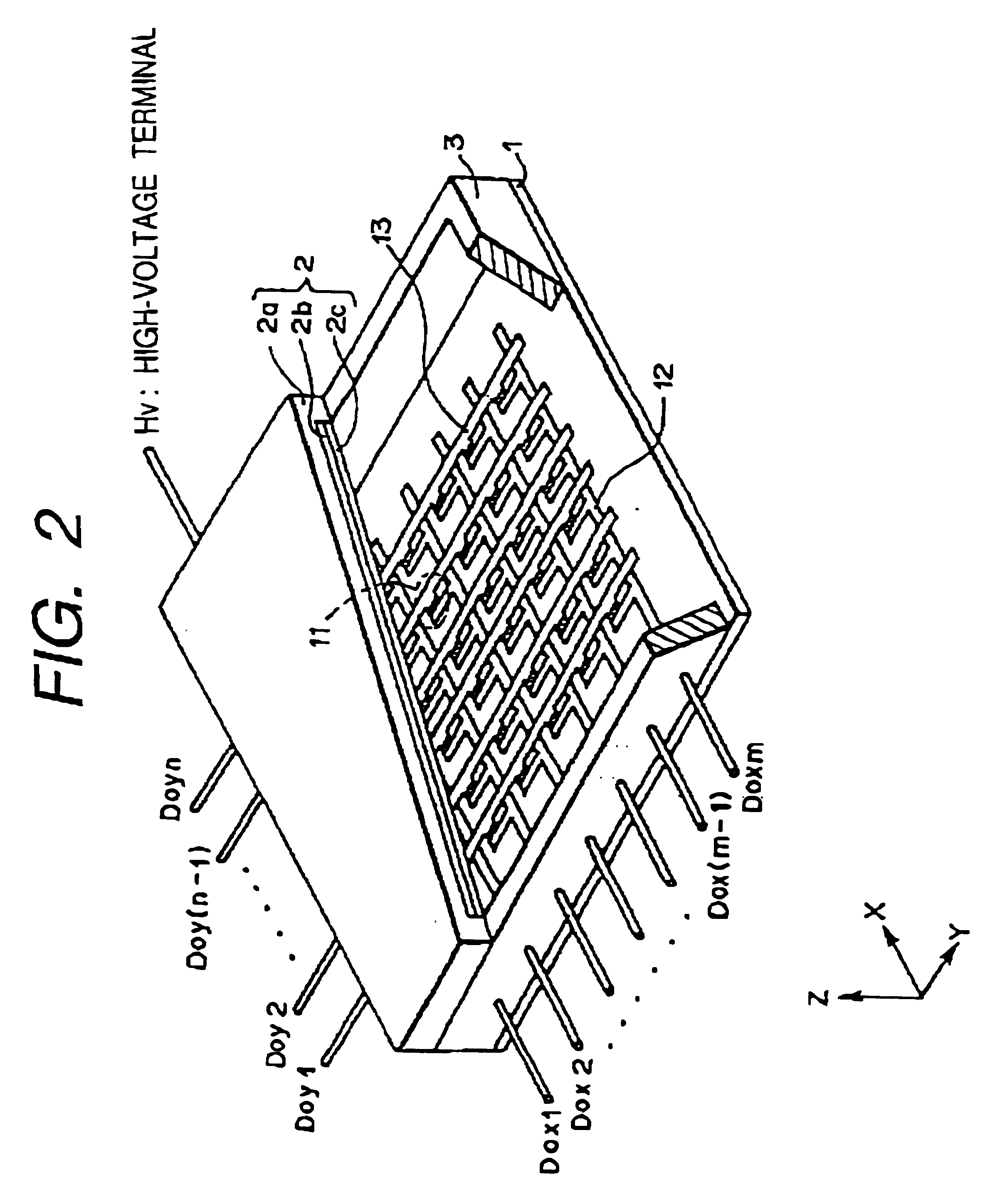

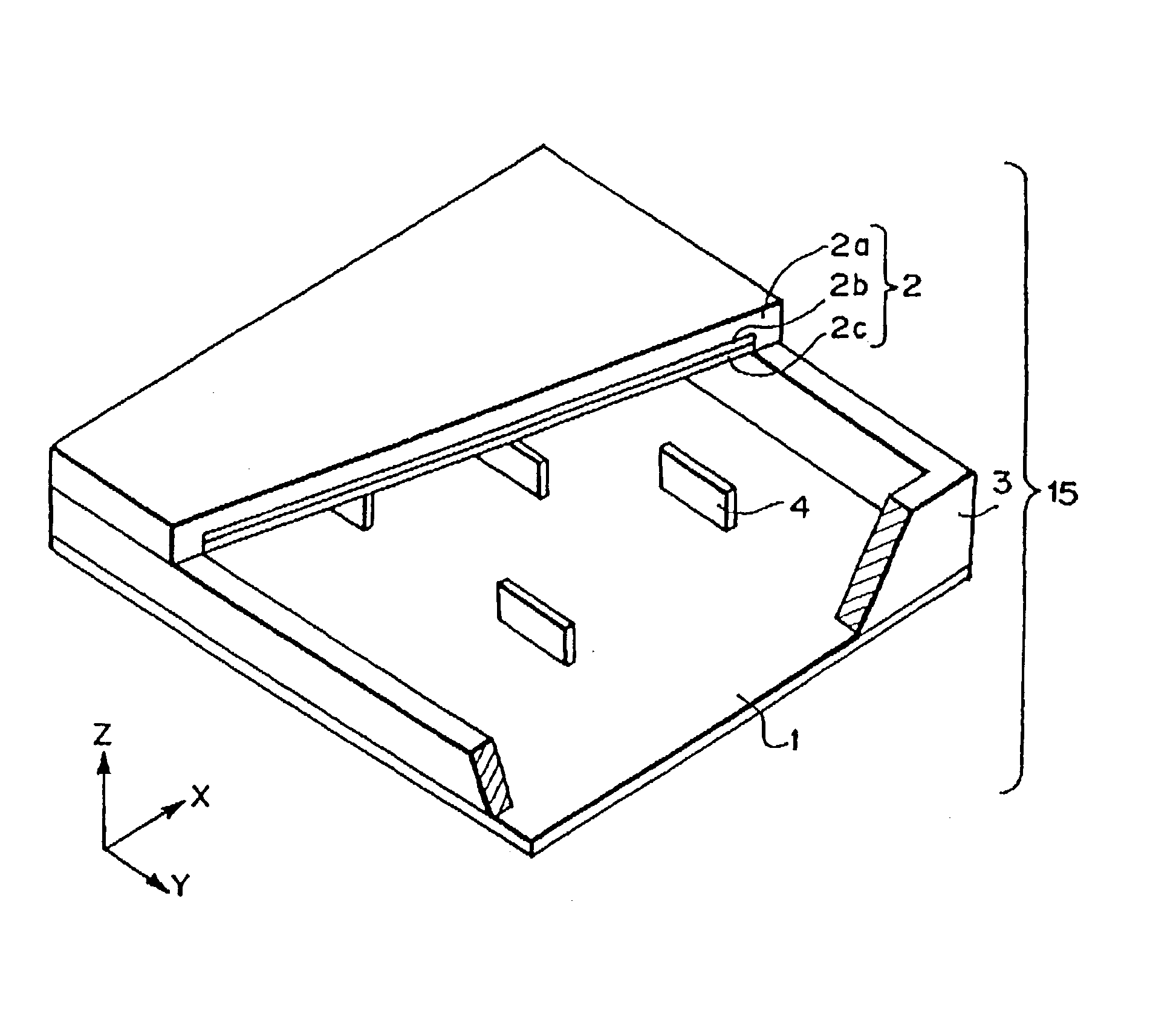

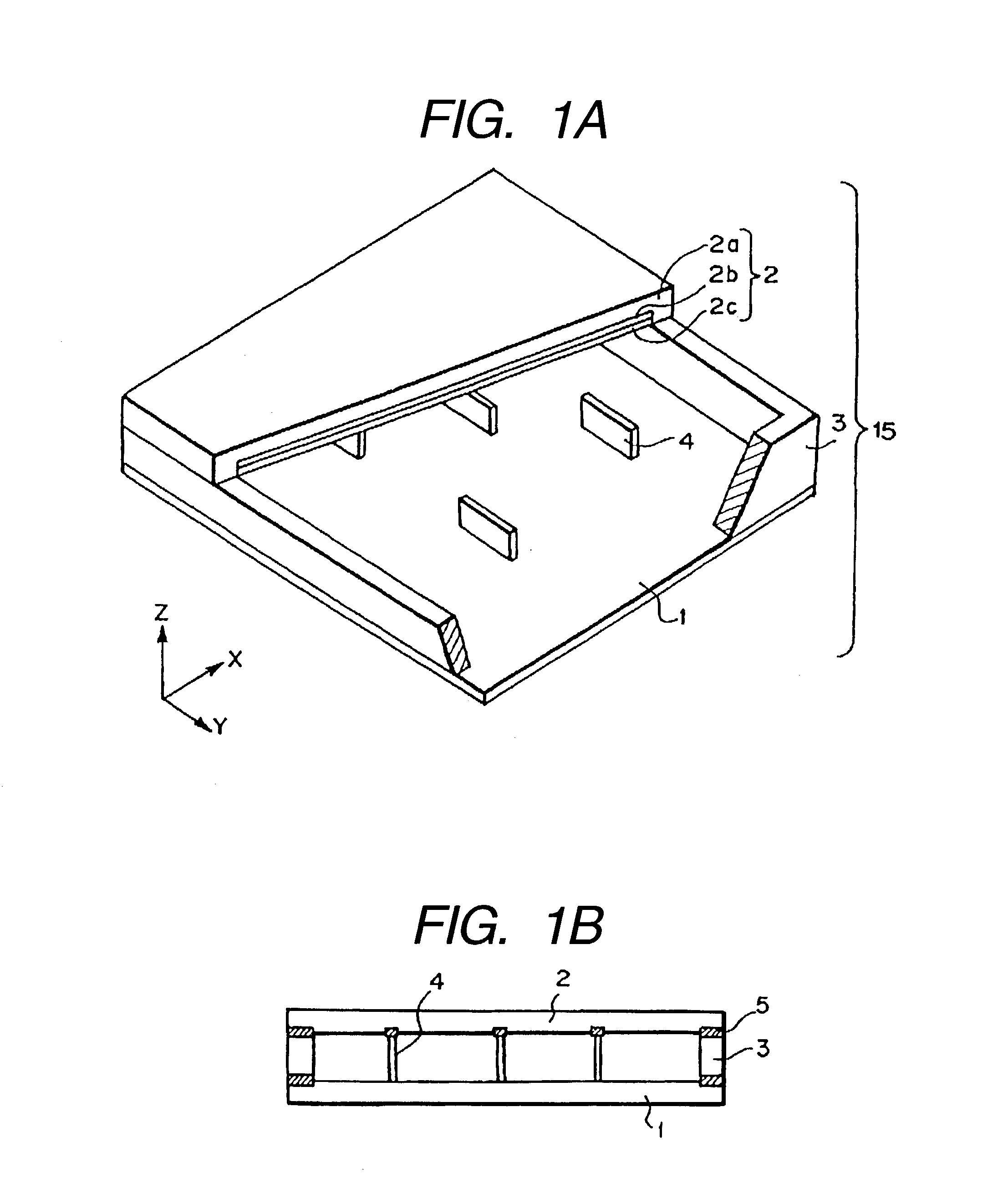

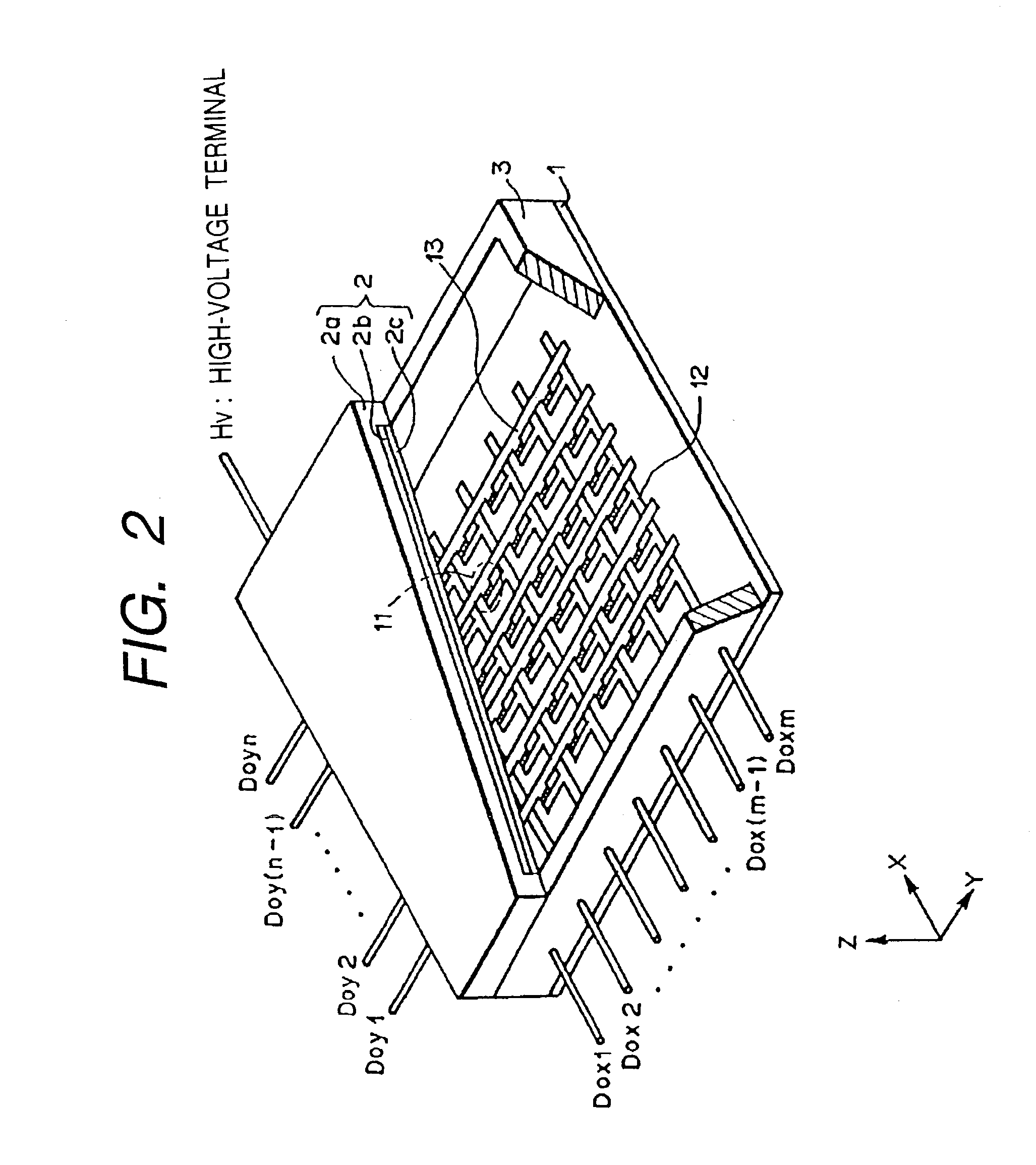

Image display apparatus, disassembly processing method therefor, and component recovery method

InactiveUS6632113B1No pressureAvoid secondary damageElectric discharge tubesGlass recyclingRecovery methodFrit

To reuse glass used in a flat panel display, processing suitable for global environment such as processing of separating a lead component must be realized. A disassembly processing method for a flat panel display having a structure in which a face plate and rear plate mainly containing glass are airtightly joined via a frame with frit glass is characterized by including the step of separating the face plate and rear plate joined with the frit glass. The separation step is characterized by separating the face plate and rear plate by cutting, dissolution, or melting.< / PTEXT>

Owner:CANON KK

Systems and methods for sorting, collecting data pertaining to and certifying recyclables at a material recovery facility

Systems and methods for collecting data pertaining to glass, plastic and / or paper composition within an input stream that includes recyclable material. The data collected can pertain, for example, to the weight and / or volume of the glass, plastic and / or paper within the input stream. The data can be certified for use a third party.

Owner:THE CLOROX CO +1

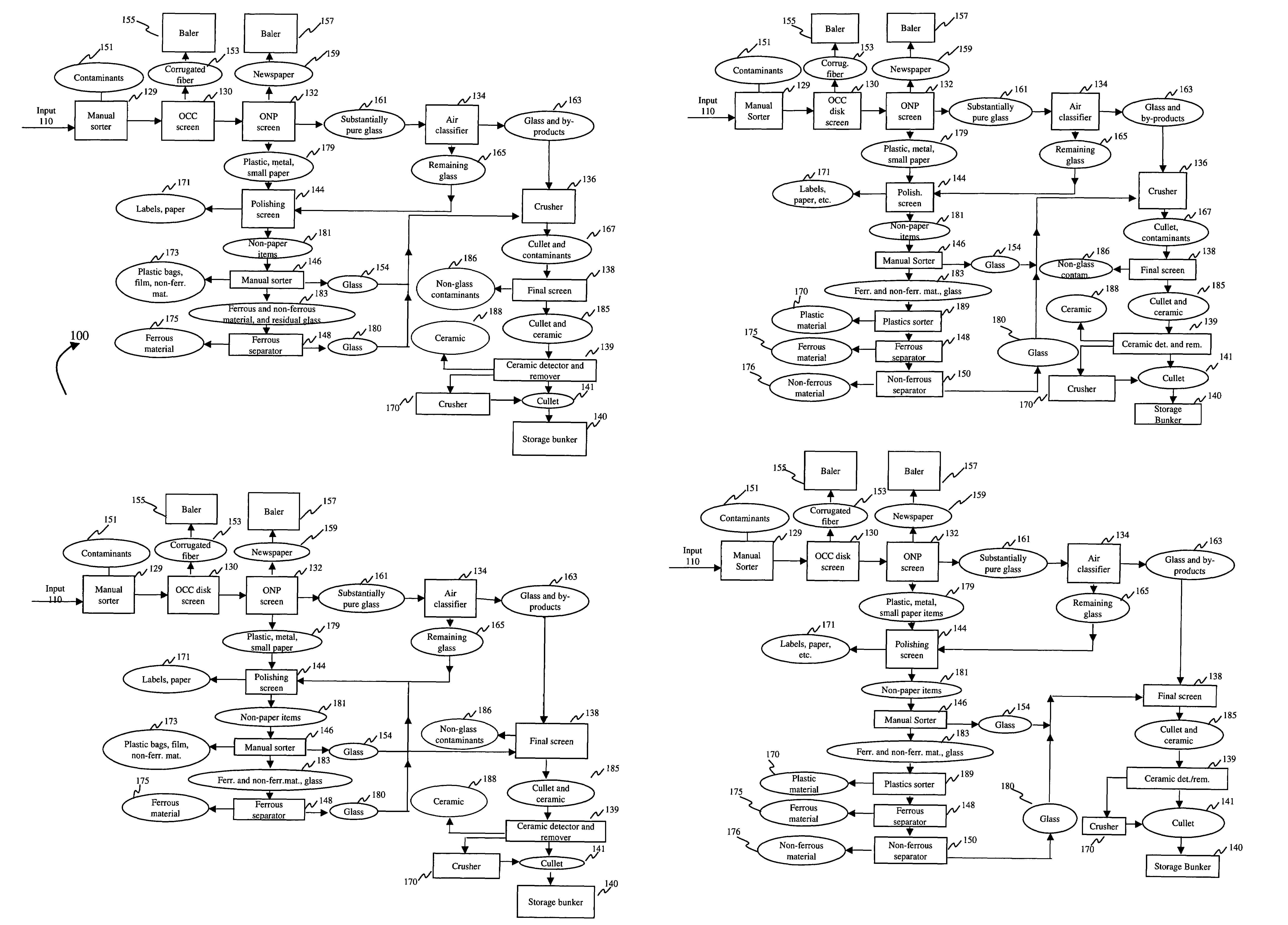

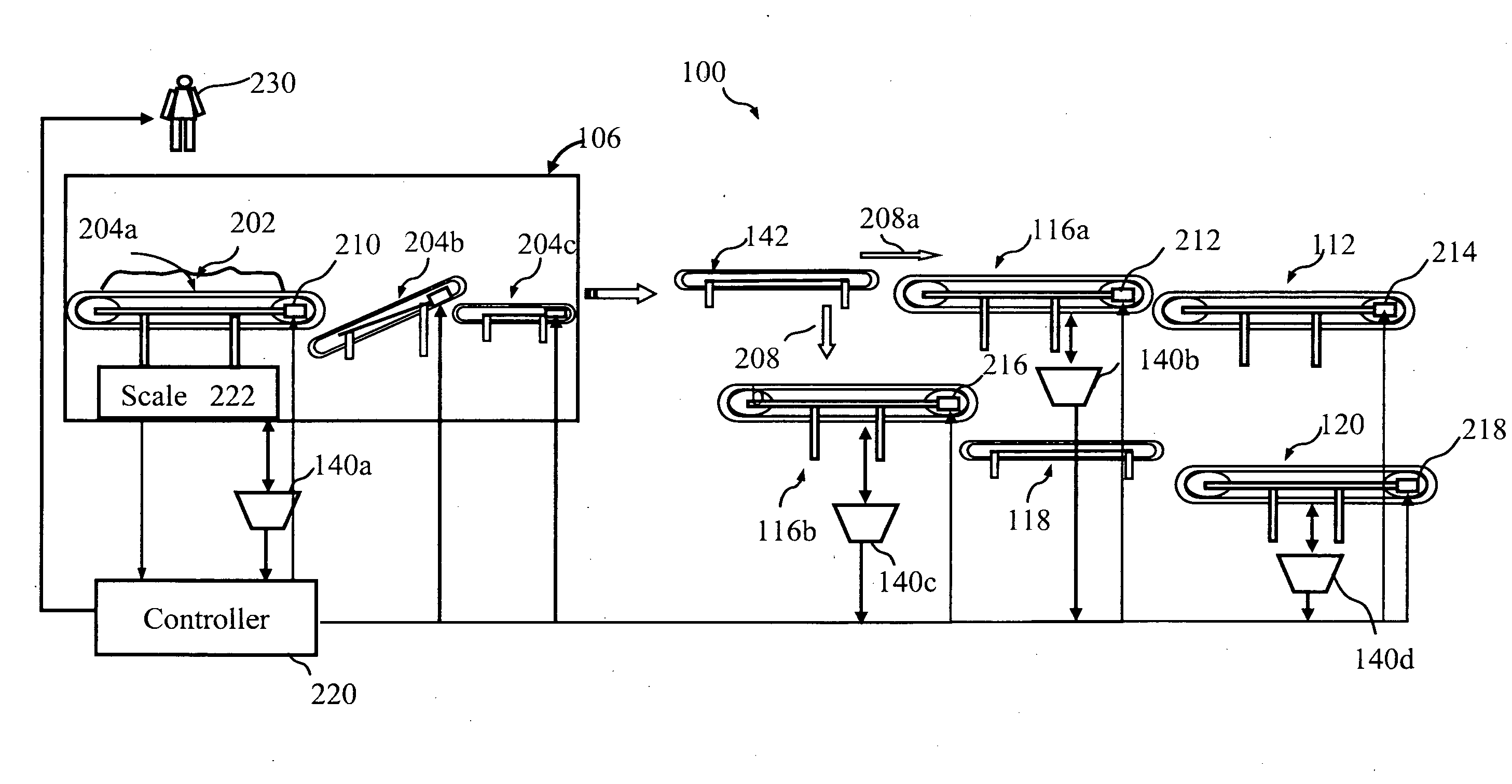

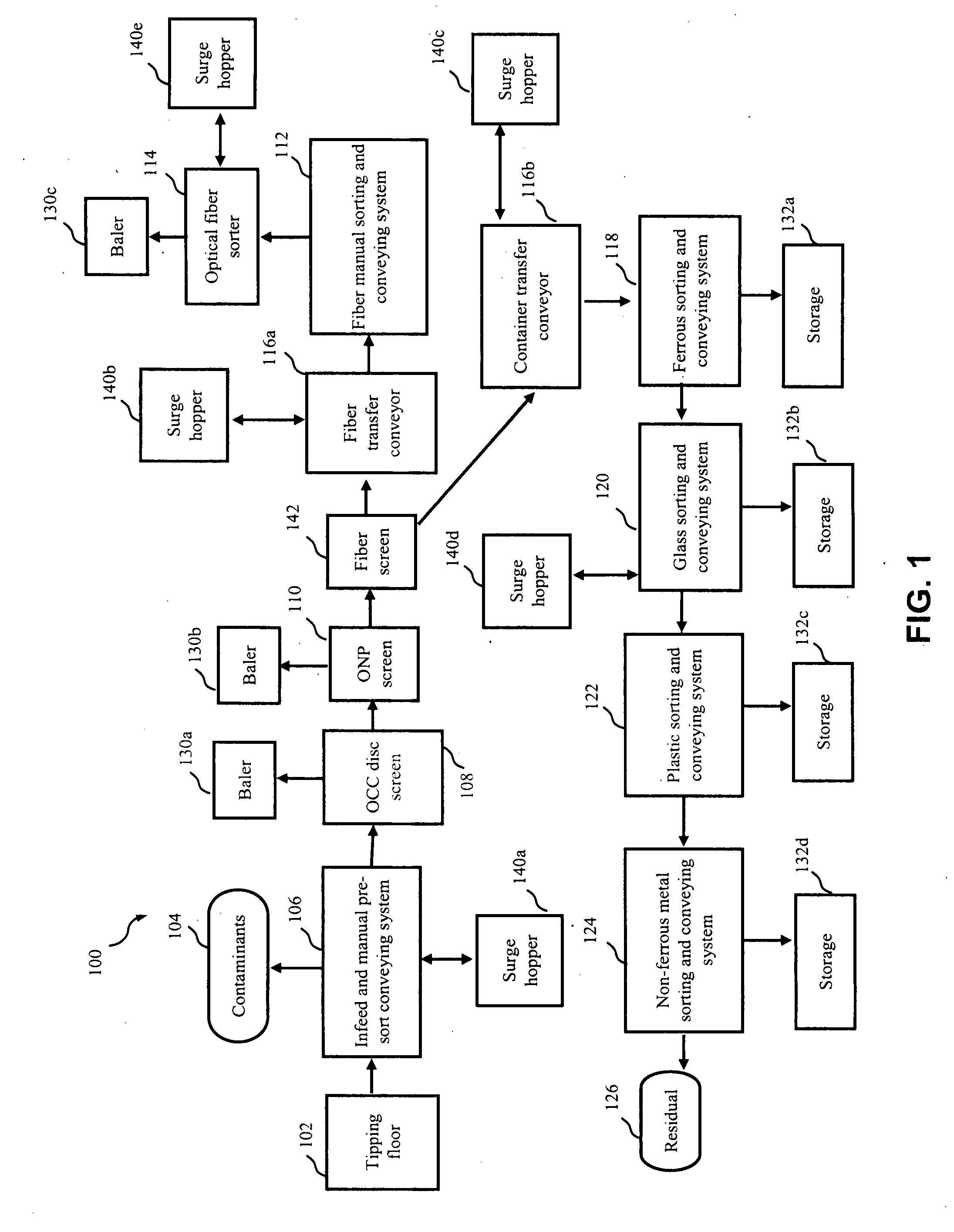

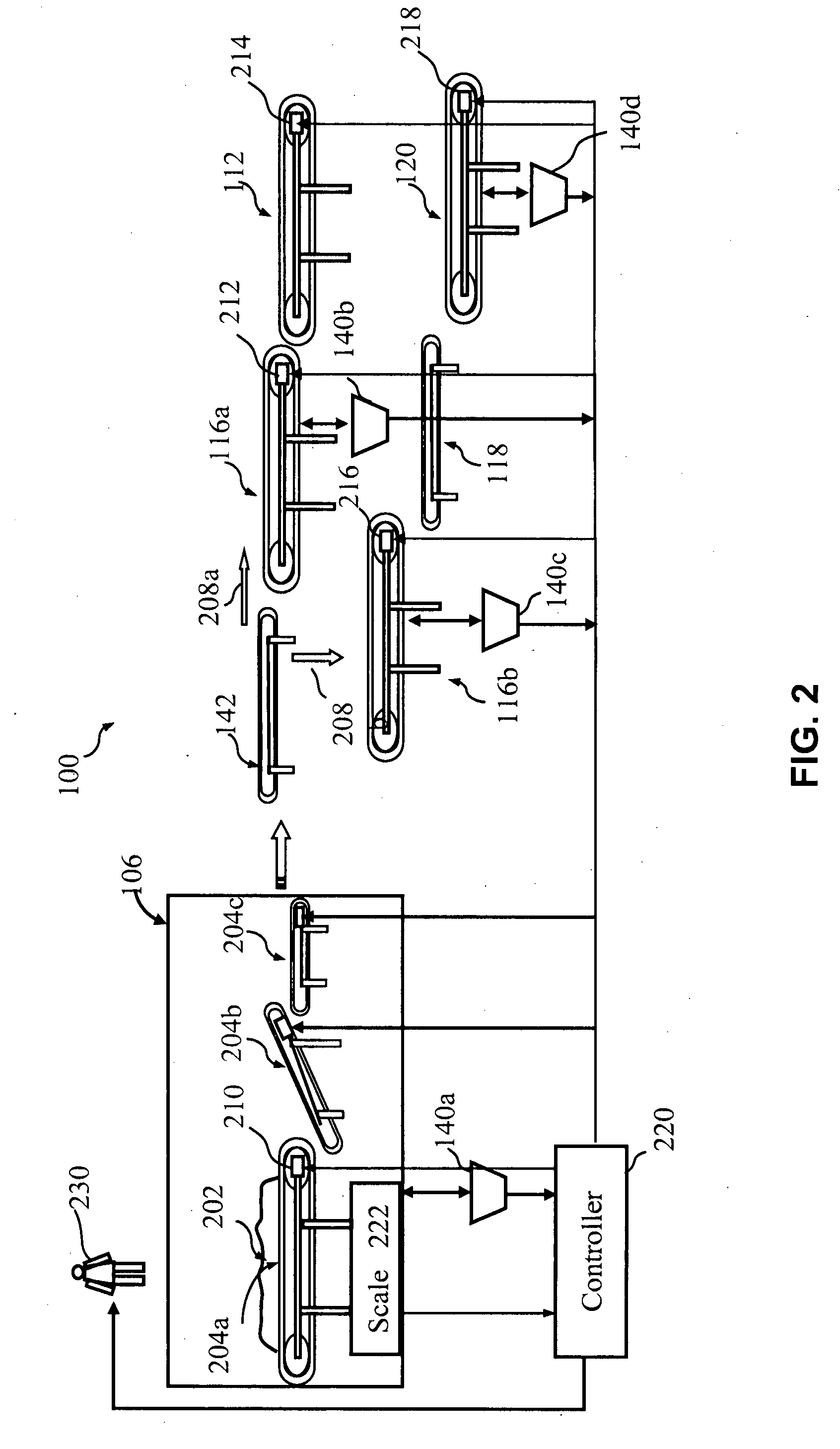

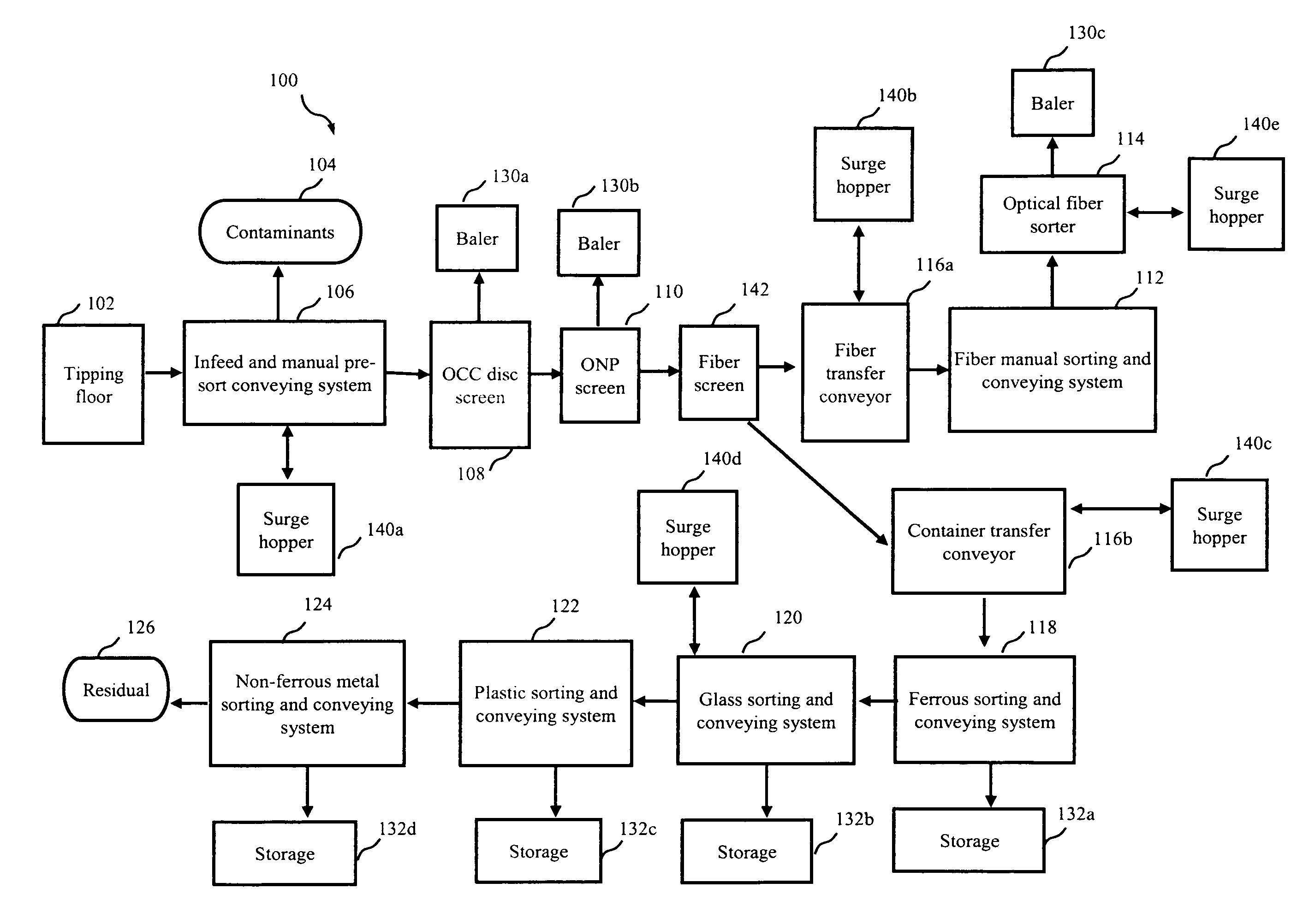

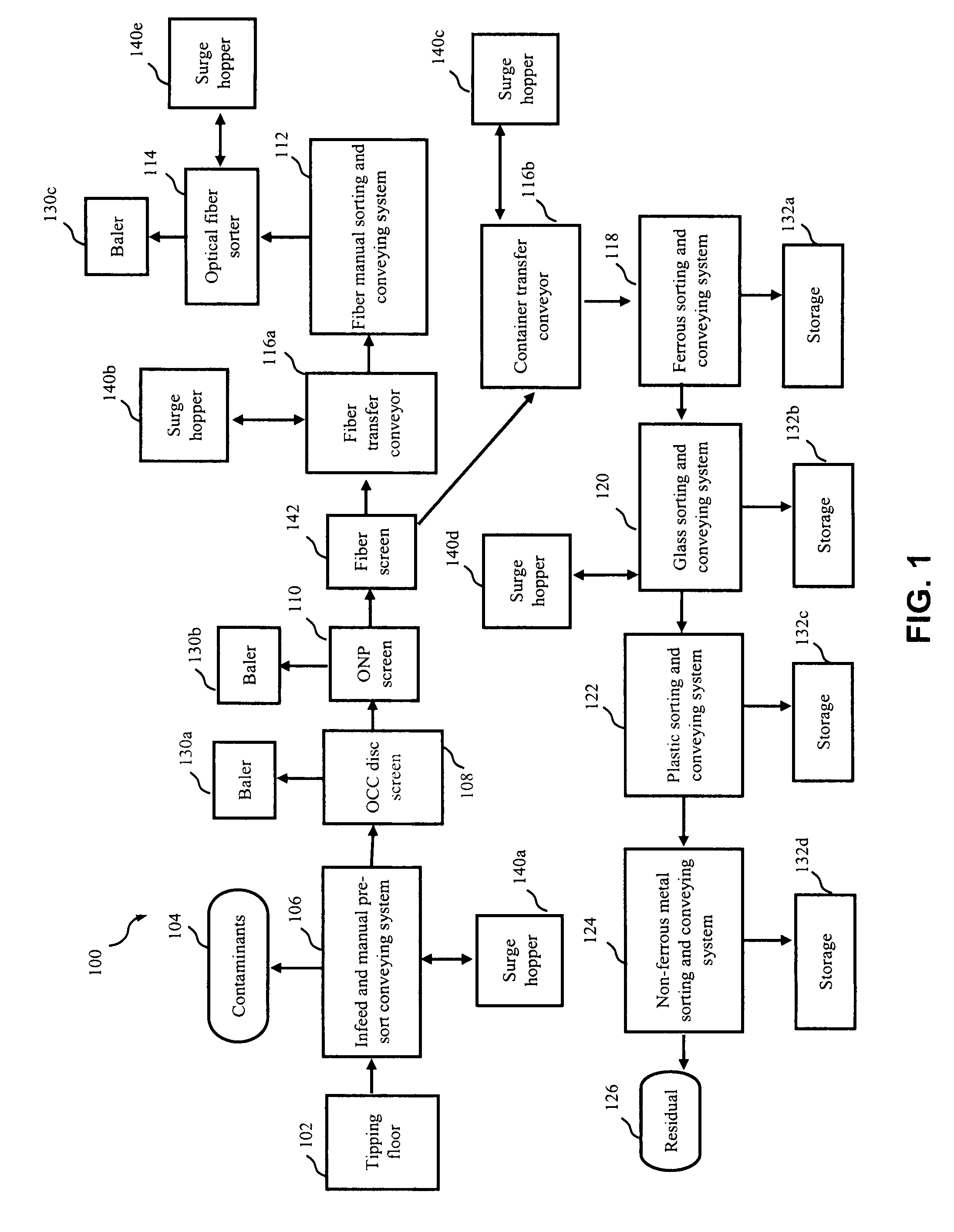

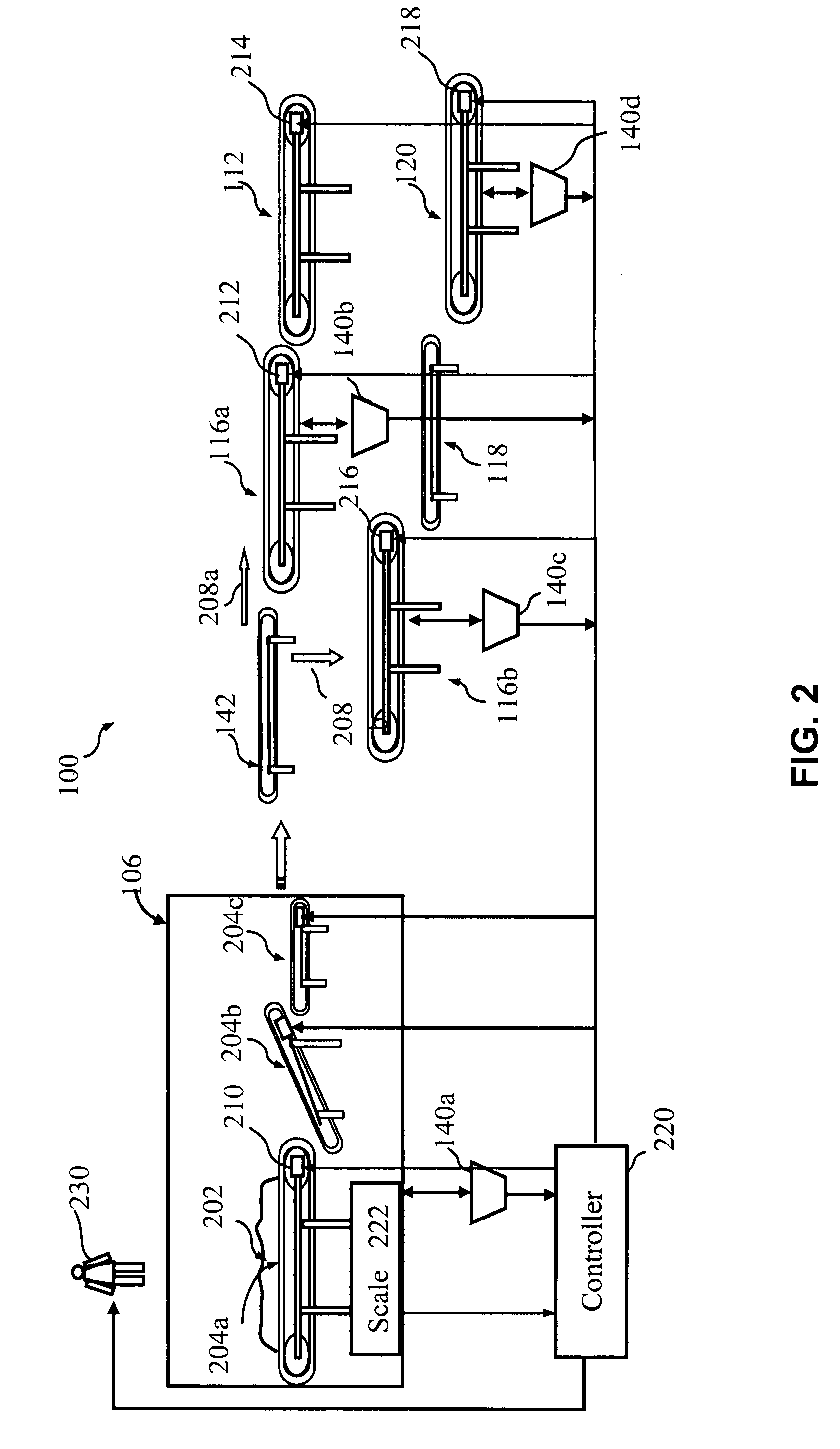

Systems and methods for optimizing a single-stream materials recovery facility

ActiveUS20080290006A1Facilitate manualFacilitate automated removalGlass recyclingCentrifugesFiberControl theory

Systems and methods for sorting a plurality of recyclable items in a single-stream materials recovery facility (SSMRF) are provided. In some embodiments, a system includes an infeed conveying system, a fiber transfer conveyor, a container transfer conveyor, and a glass sorting and conveying system. The system further includes a controller configured to obtain total weight and volume of recyclable items at the infeed conveying system. The controller estimates a percent weight of fiber items and a percent weight of non-fiber items relative to the total weight. Based on the estimates, the controller controls speed of at least one of the infeed conveying system, the fiber transfer conveyor, the container transfer conveyor, and the glass sorting and conveying system.

Owner:RE COMMUNITY HLDG II INC

Systems and methods for sorting, collecting data pertaining to and certifying recyclables at a material recovery facility

Systems and methods for collecting data pertaining to glass, plastic and / or paper composition within an input stream that includes recyclable material. The data collected can pertain, for example, to the weight and / or volume of the glass, plastic and / or paper within the input stream. The data can be certified for use a third party.

Owner:THE CLOROX CO +1

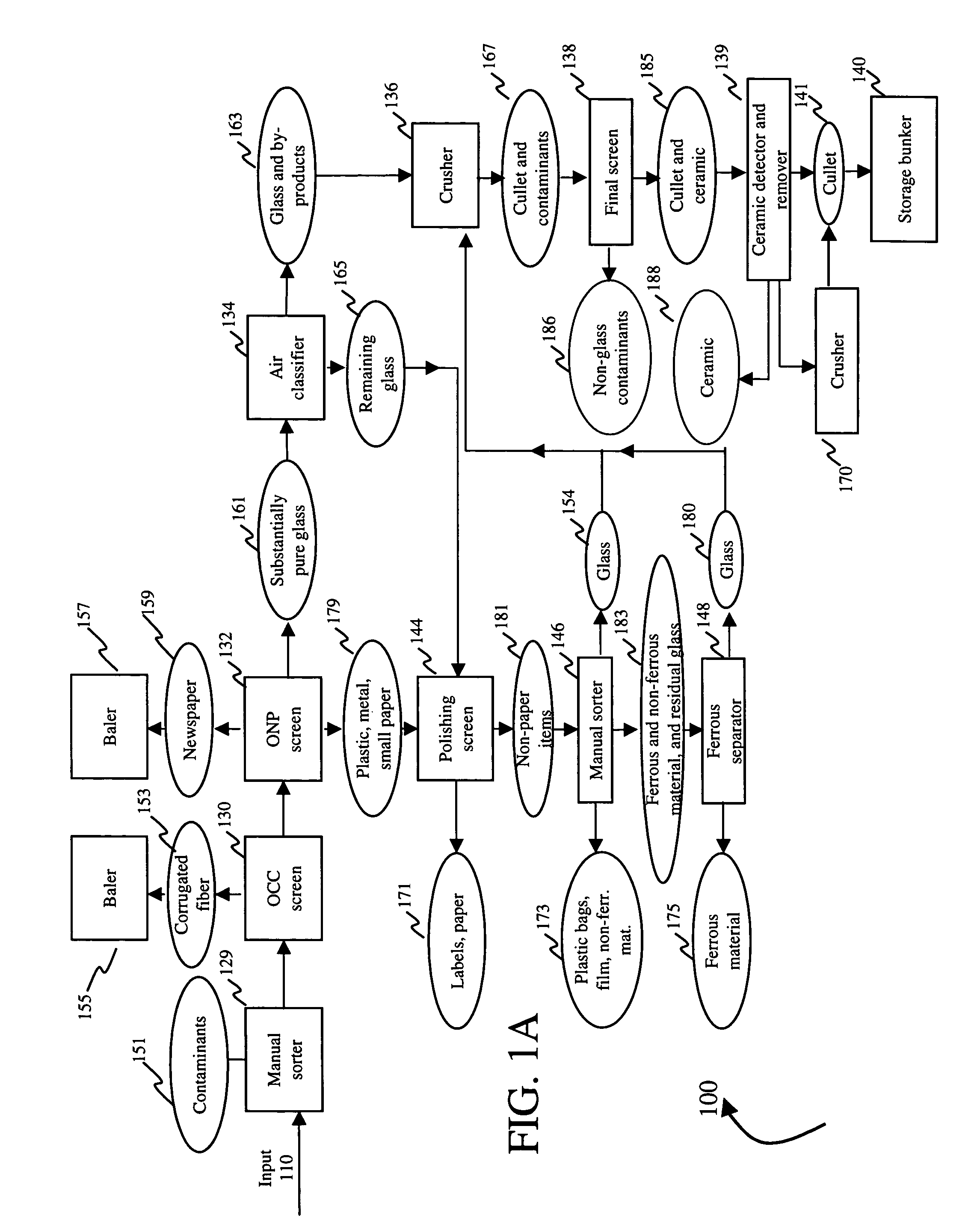

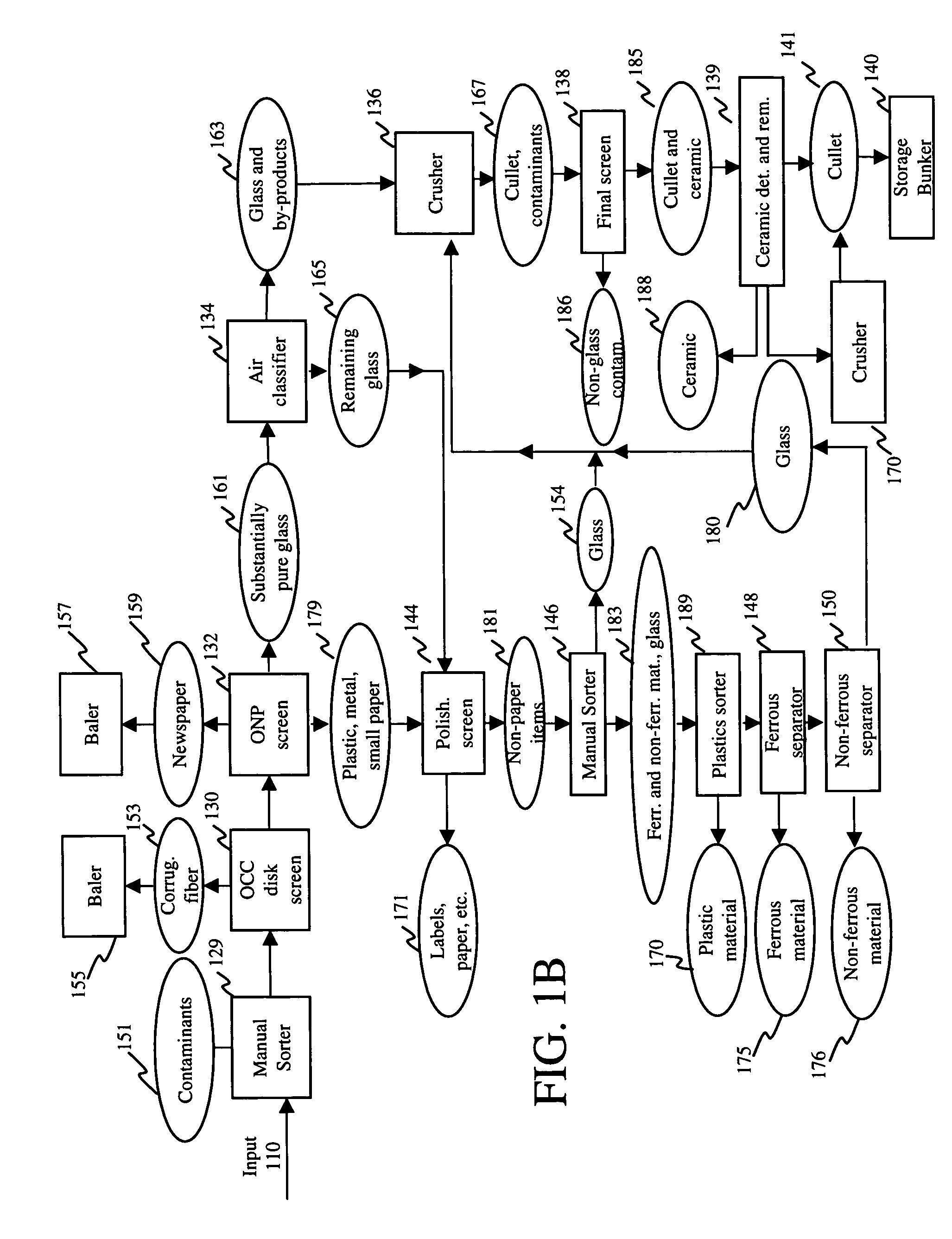

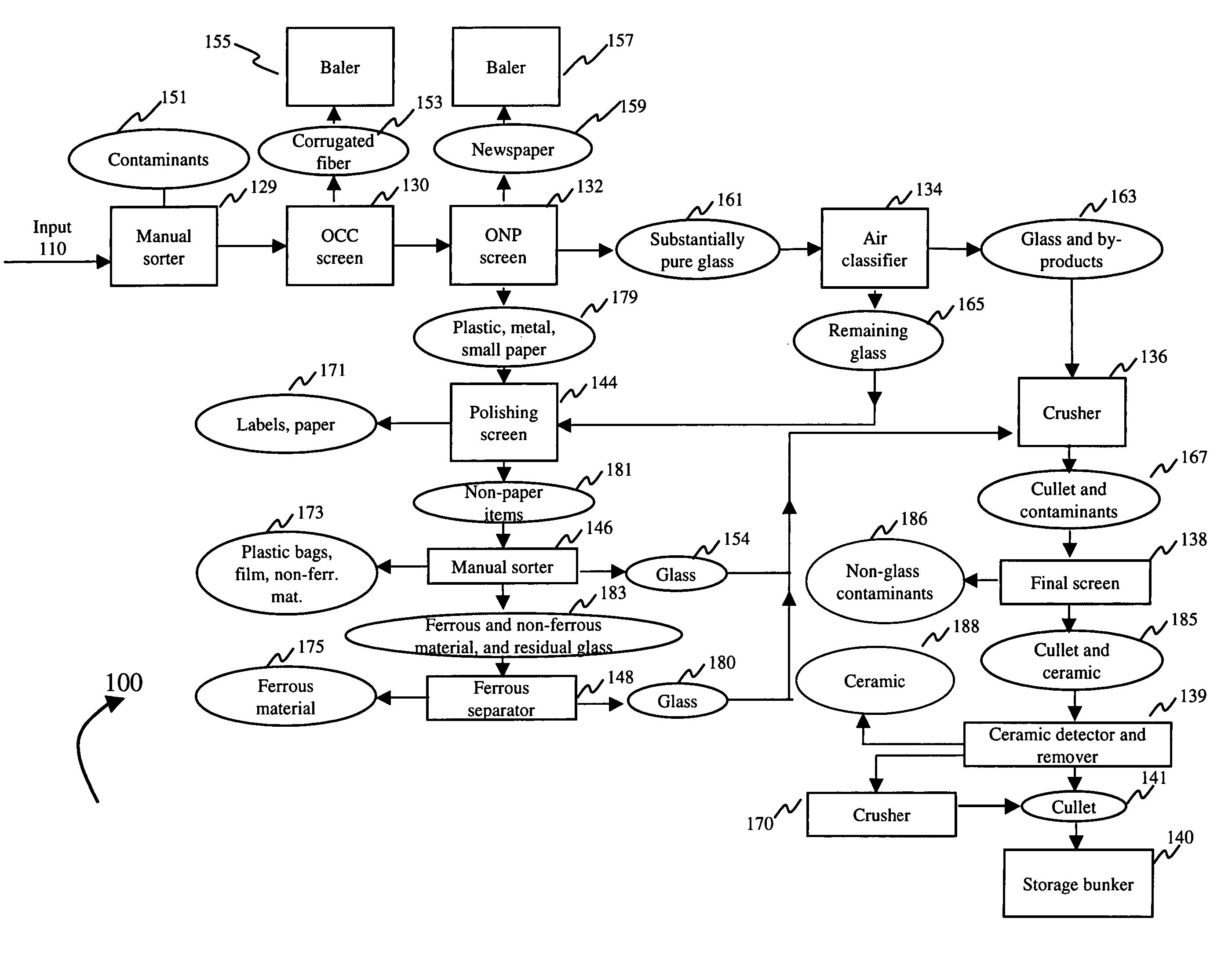

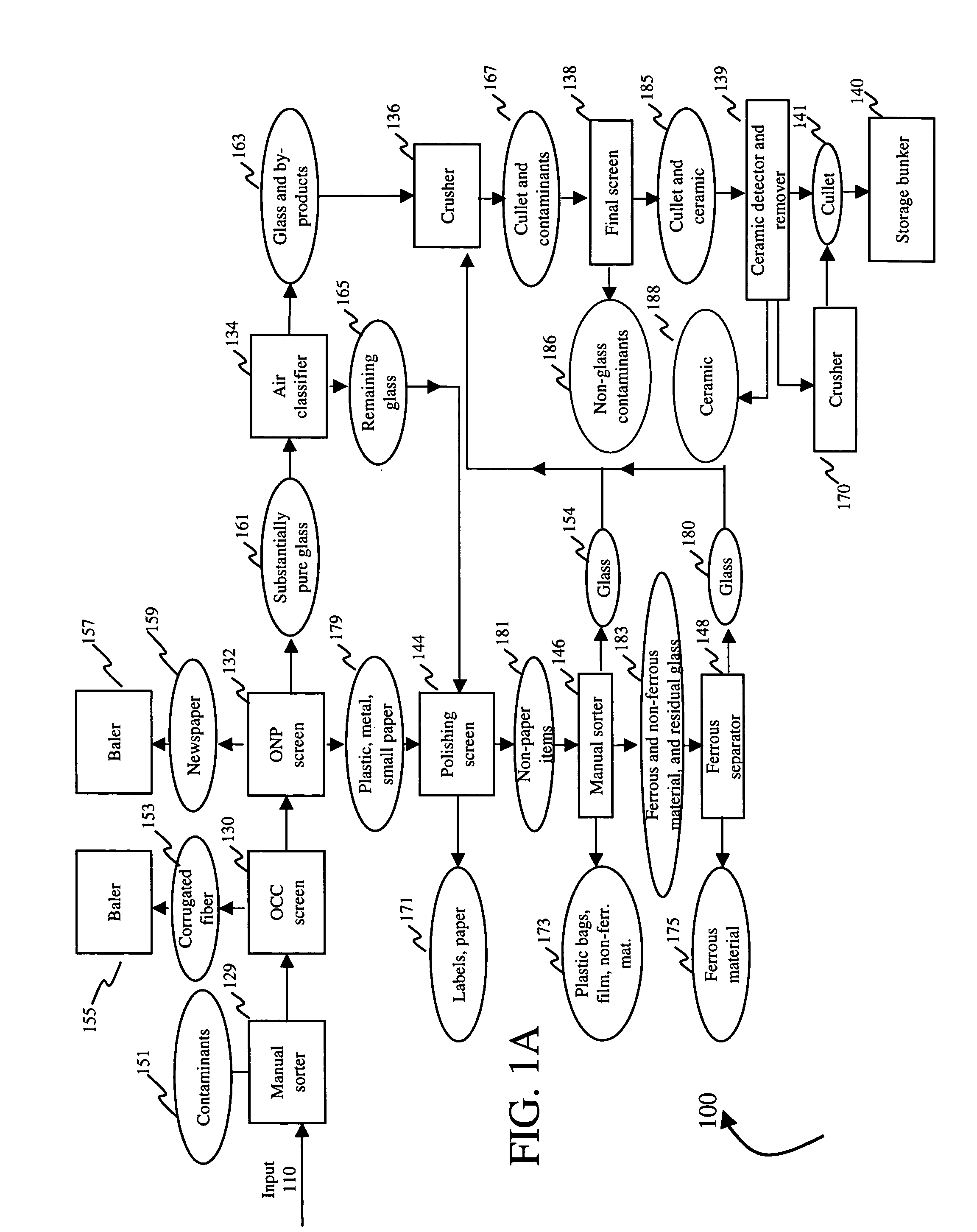

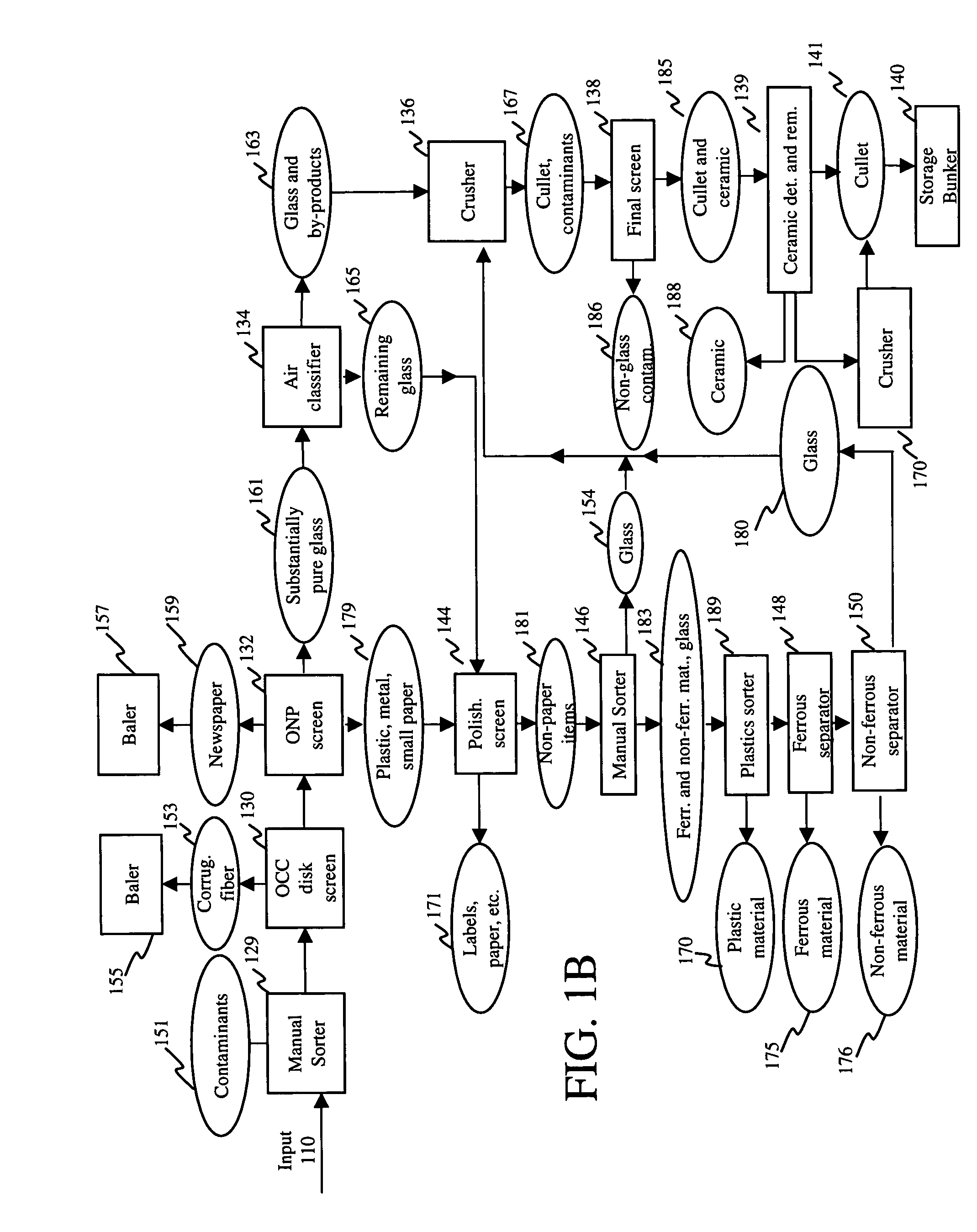

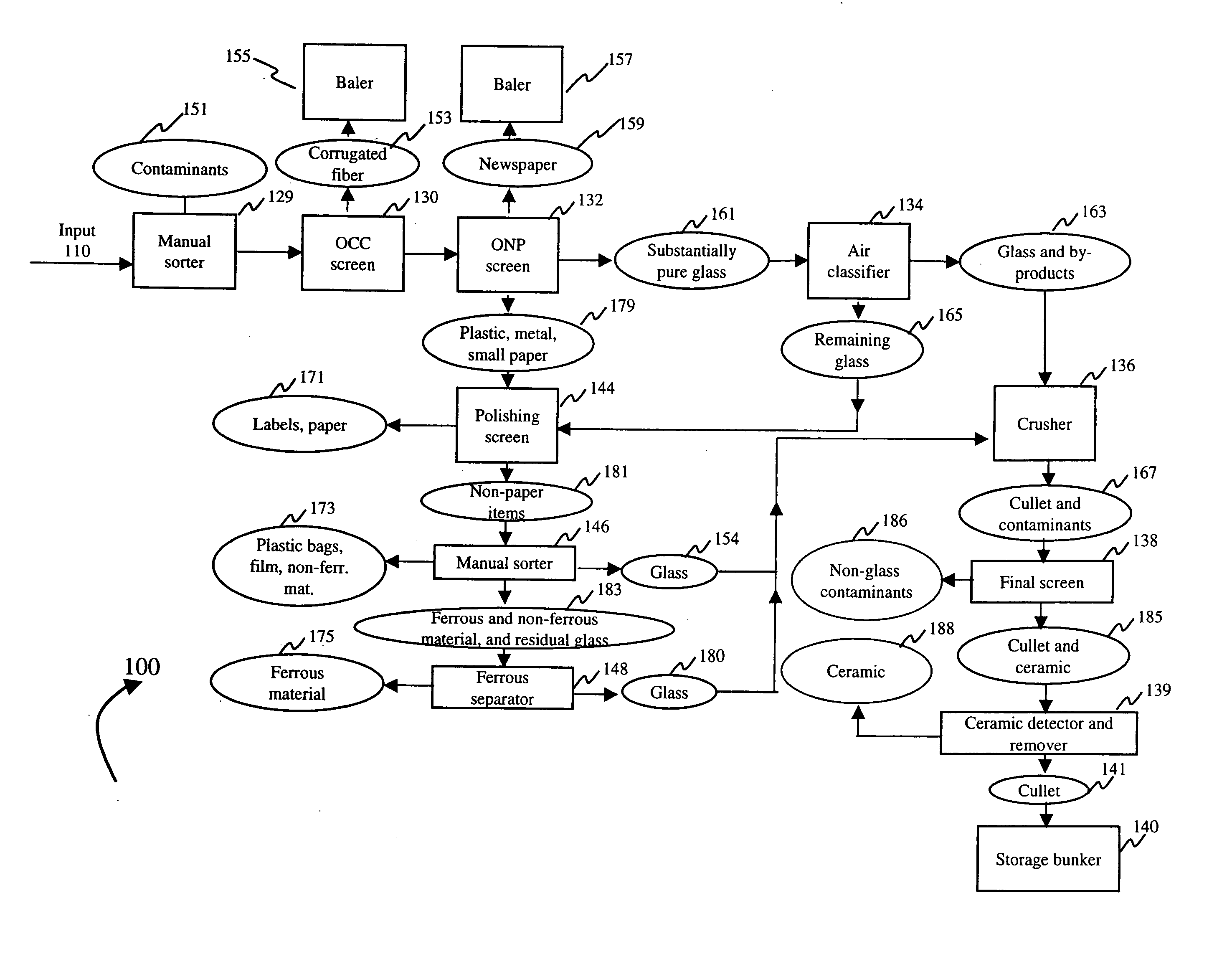

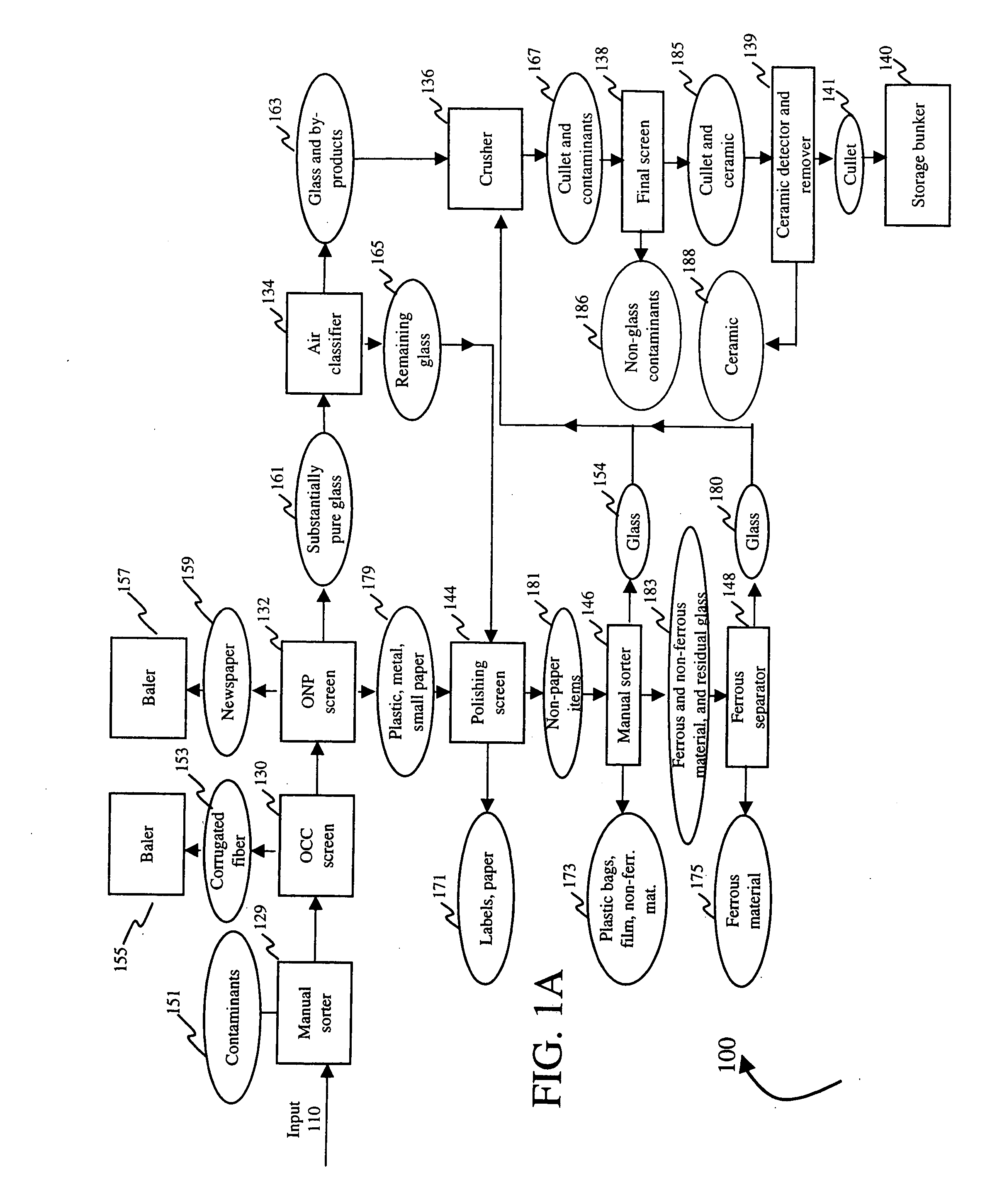

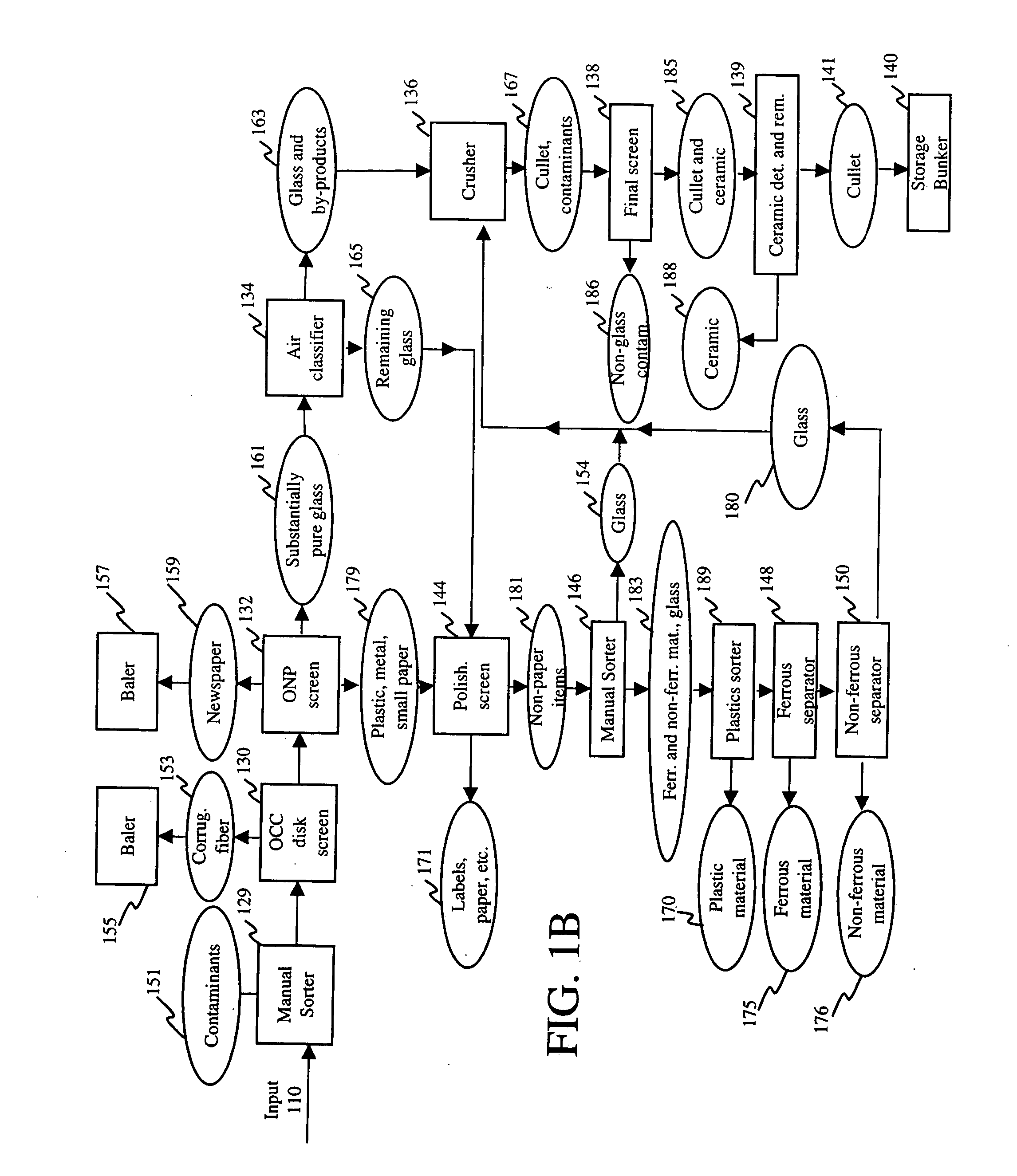

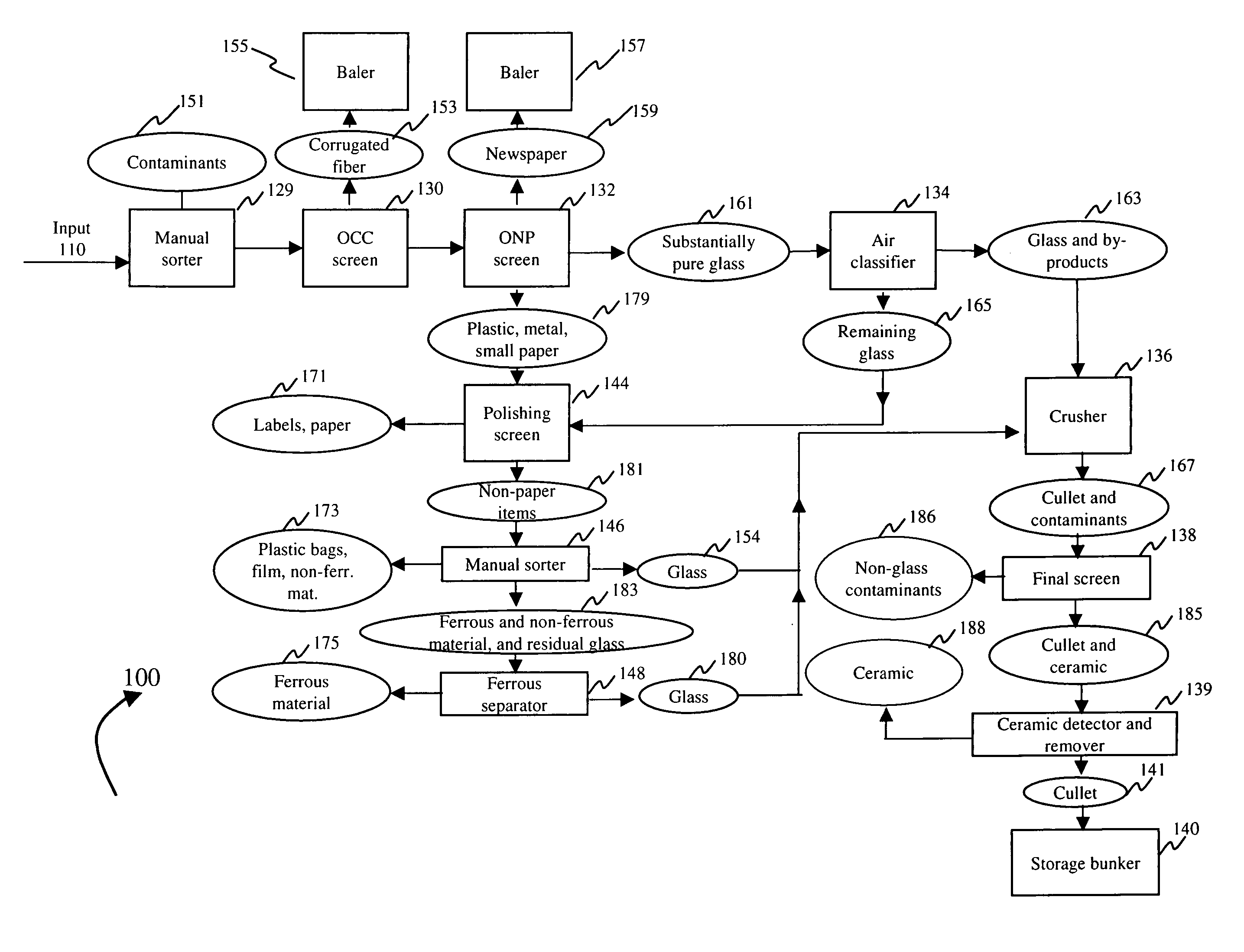

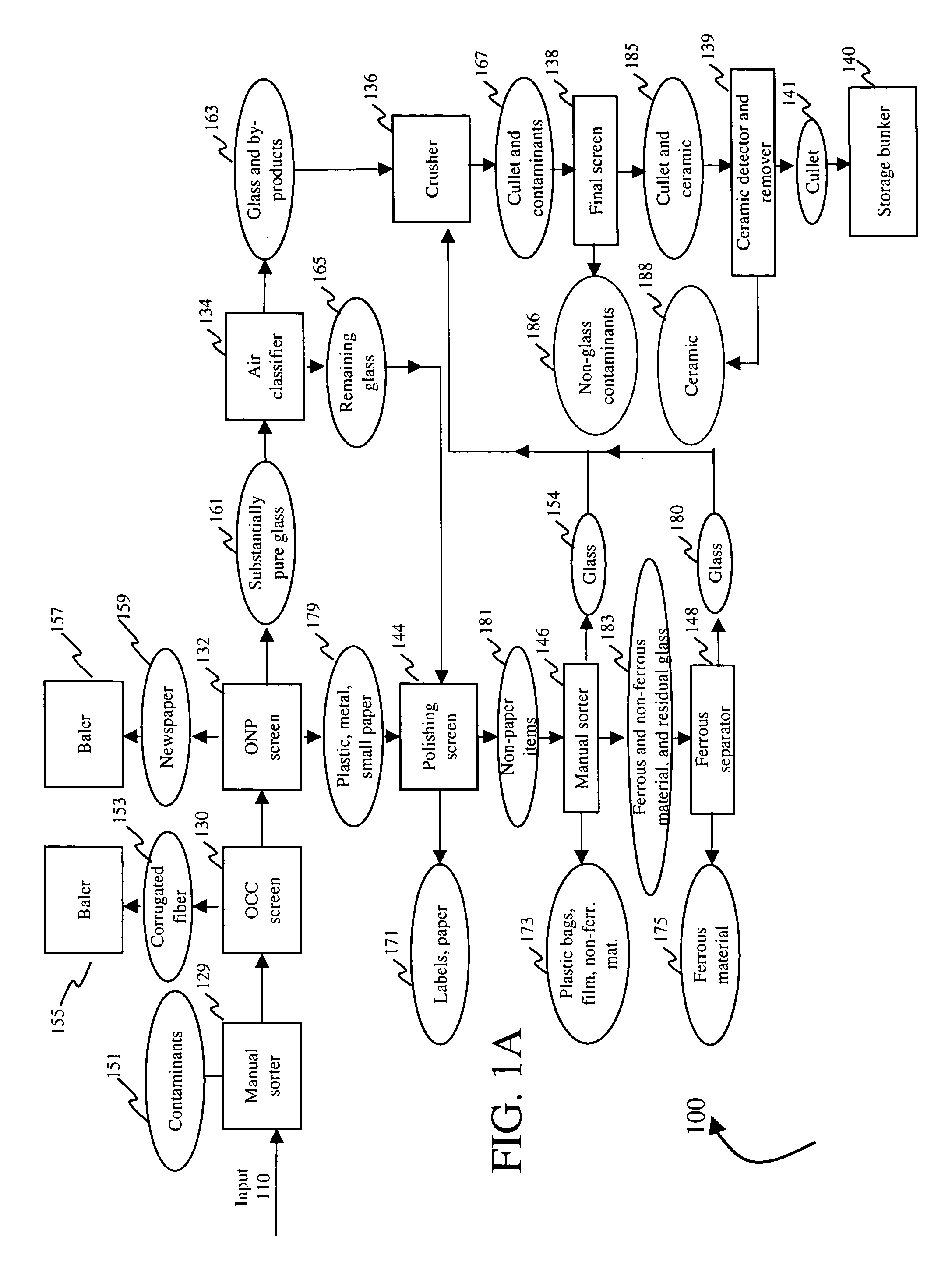

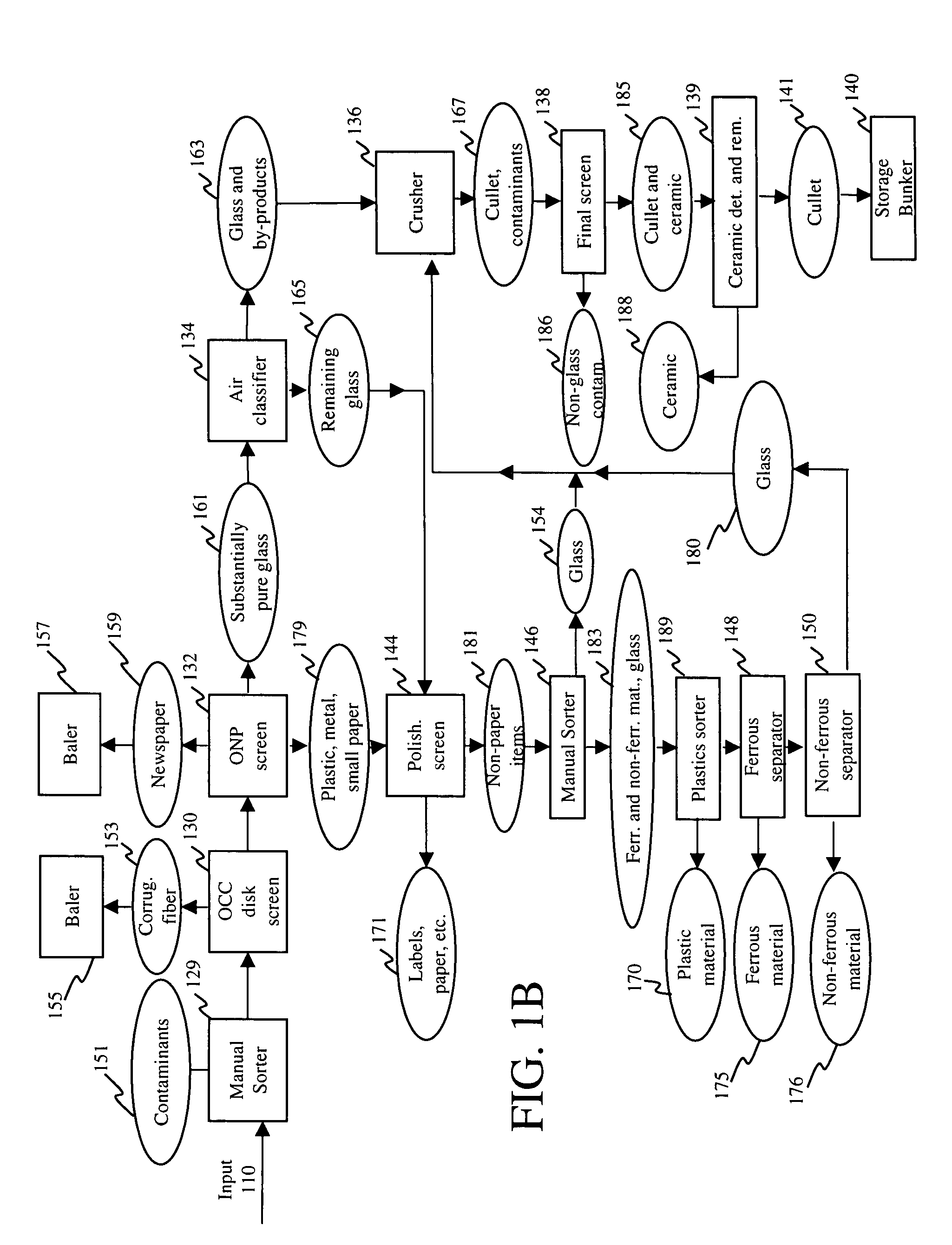

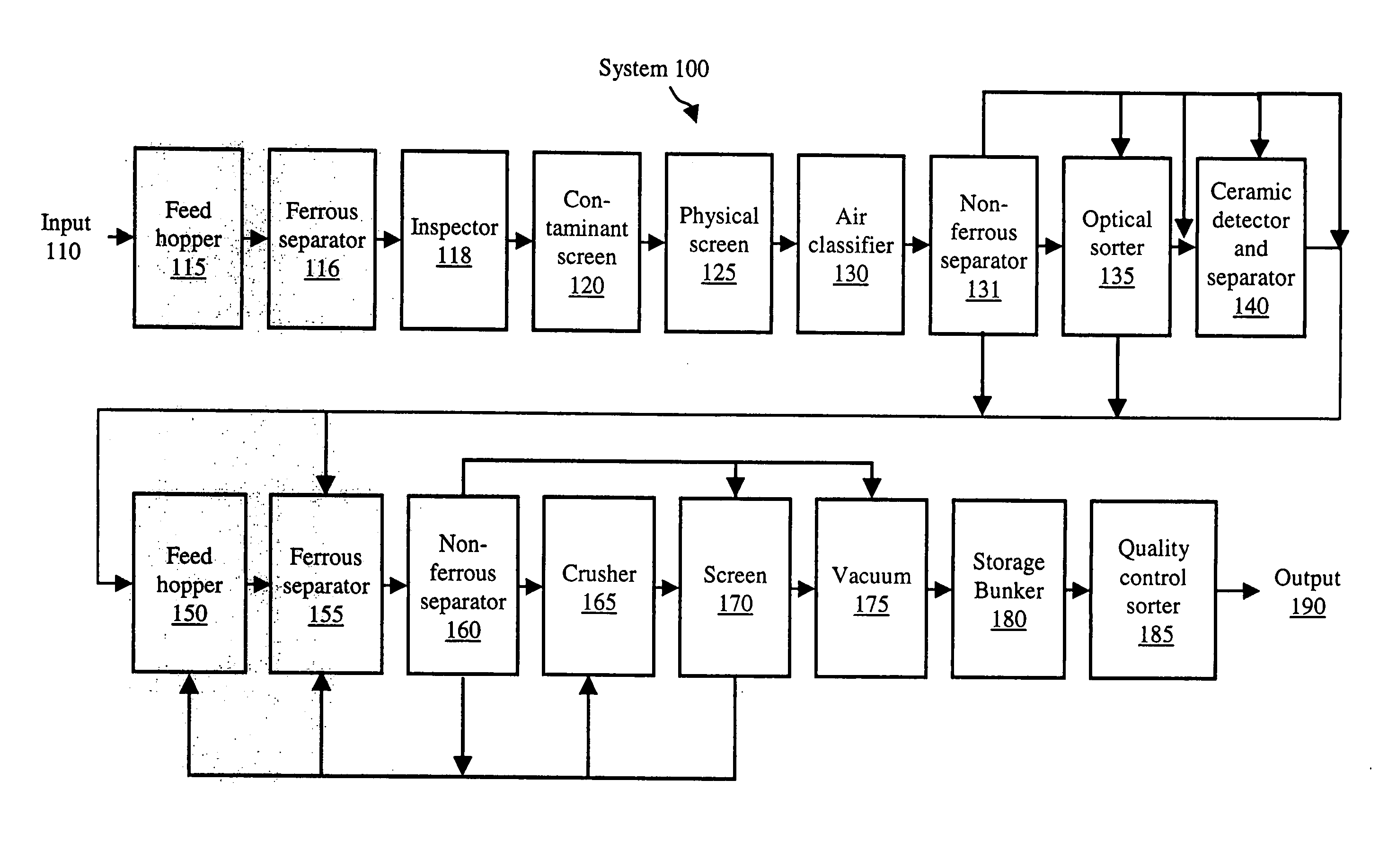

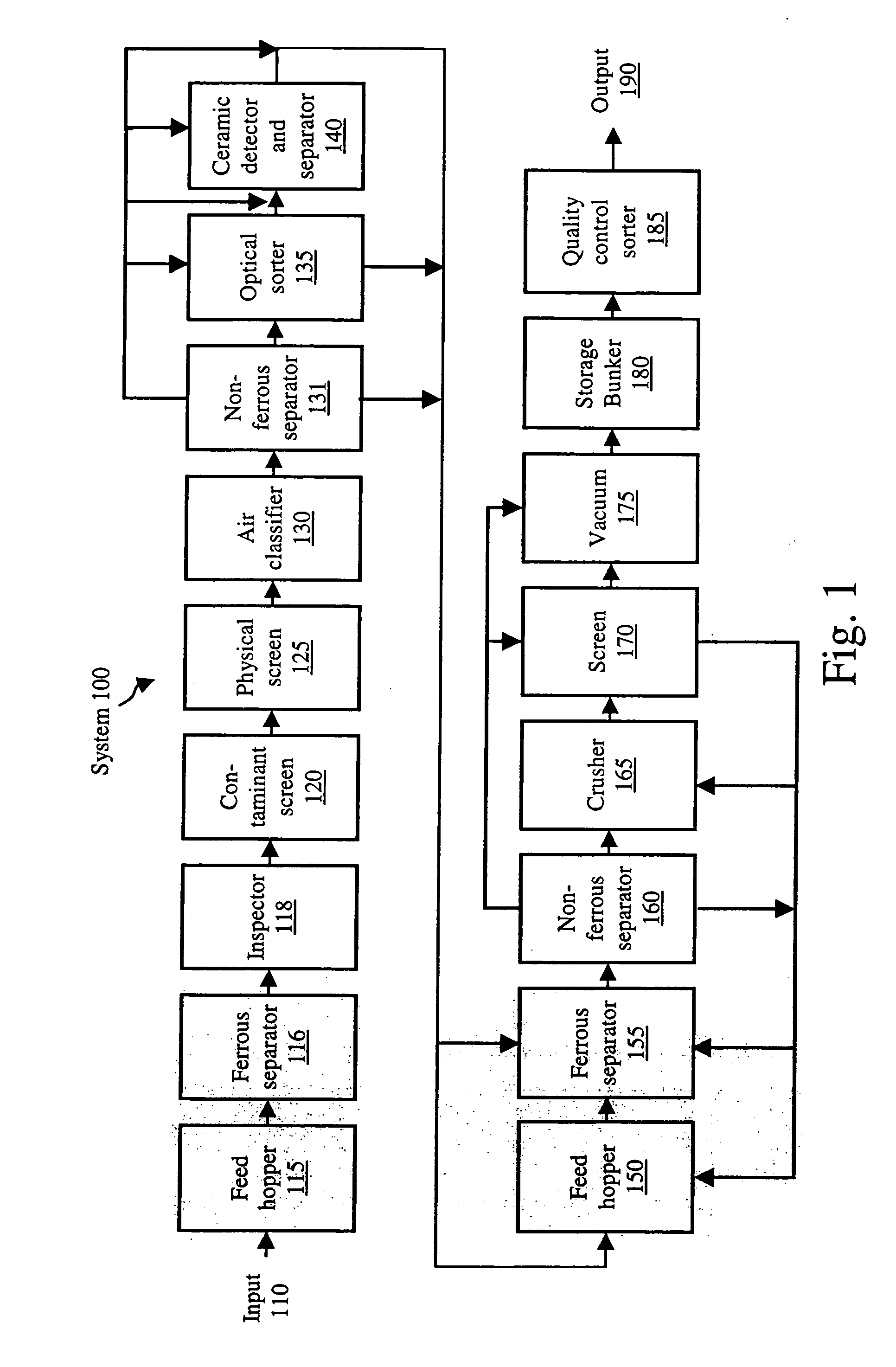

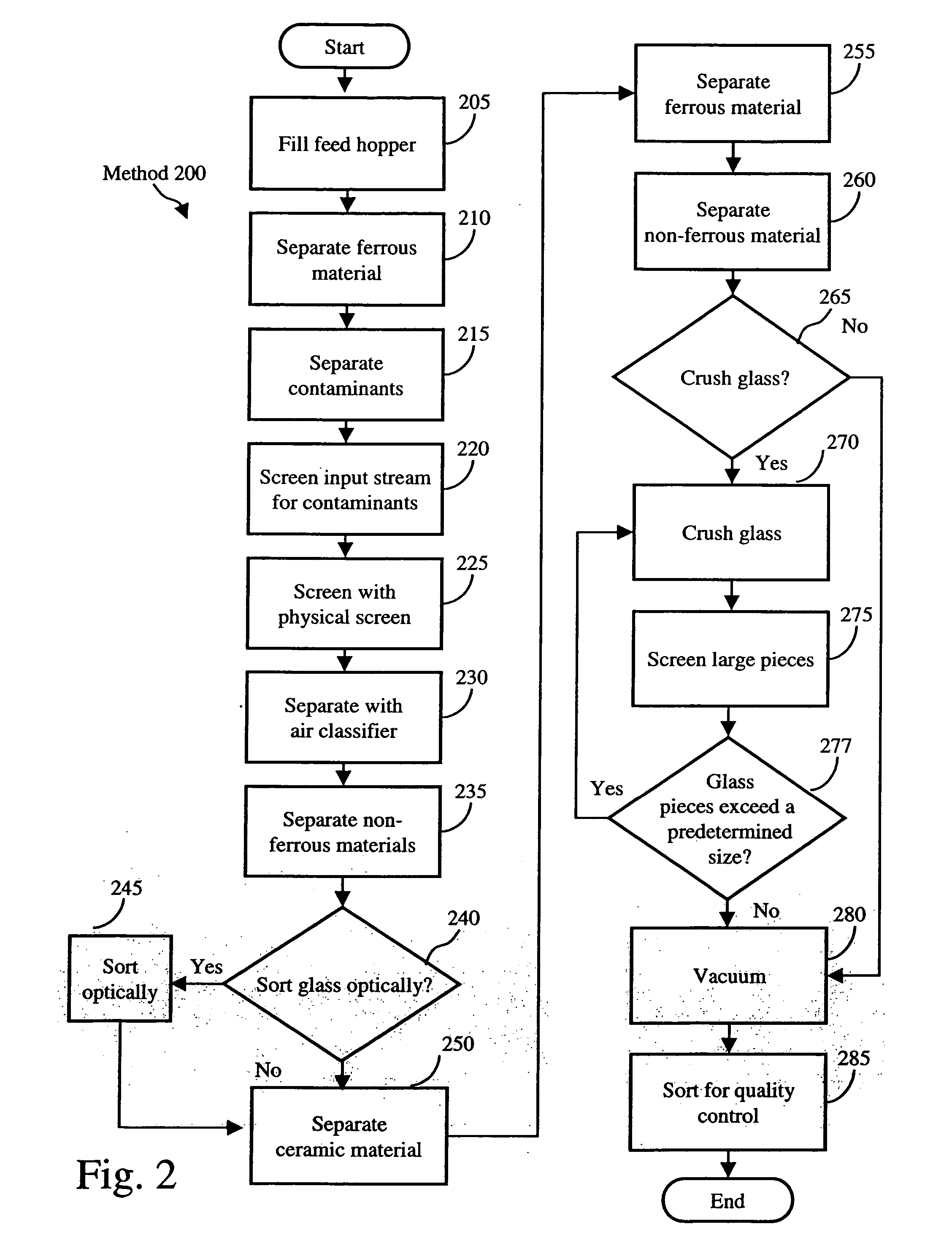

Systems and methods for sorting recyclables at a material recovery facility

InactiveUS20060254957A1Glass recyclingDigital data processing detailsProcess engineeringAir classifier

Owner:RE COMMUNITY HLDG II INC

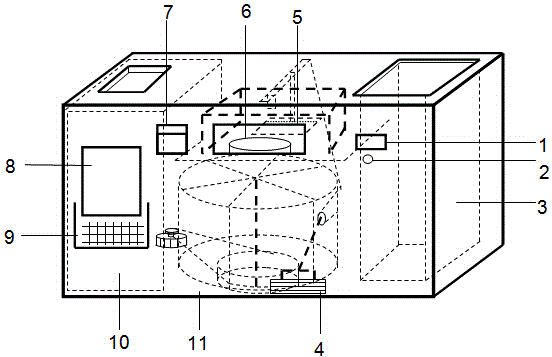

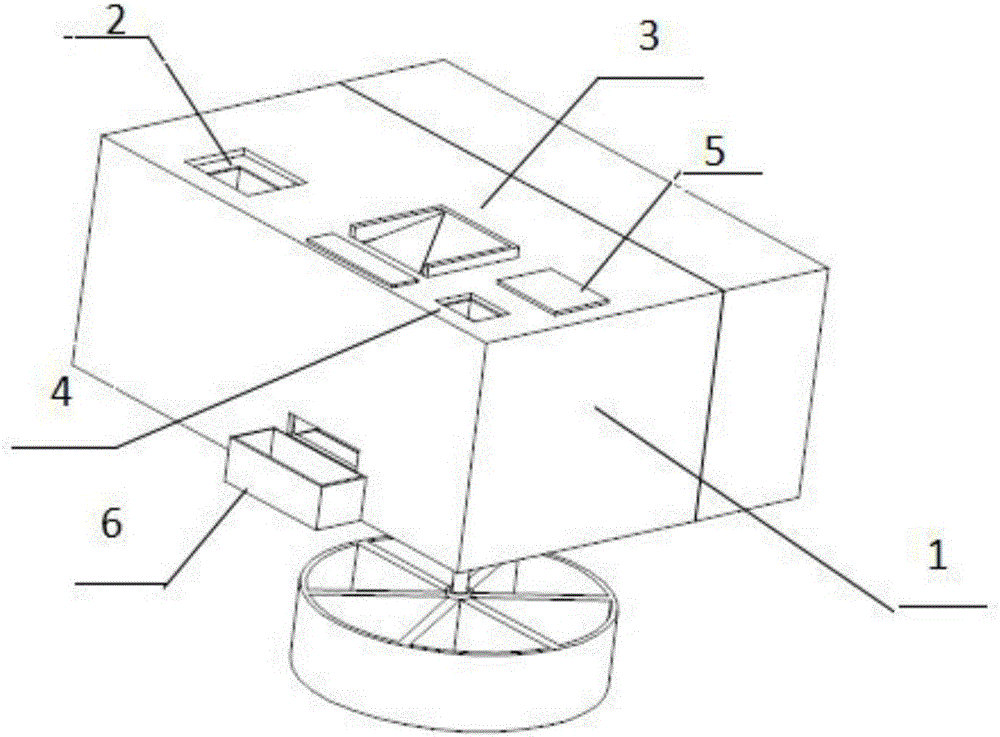

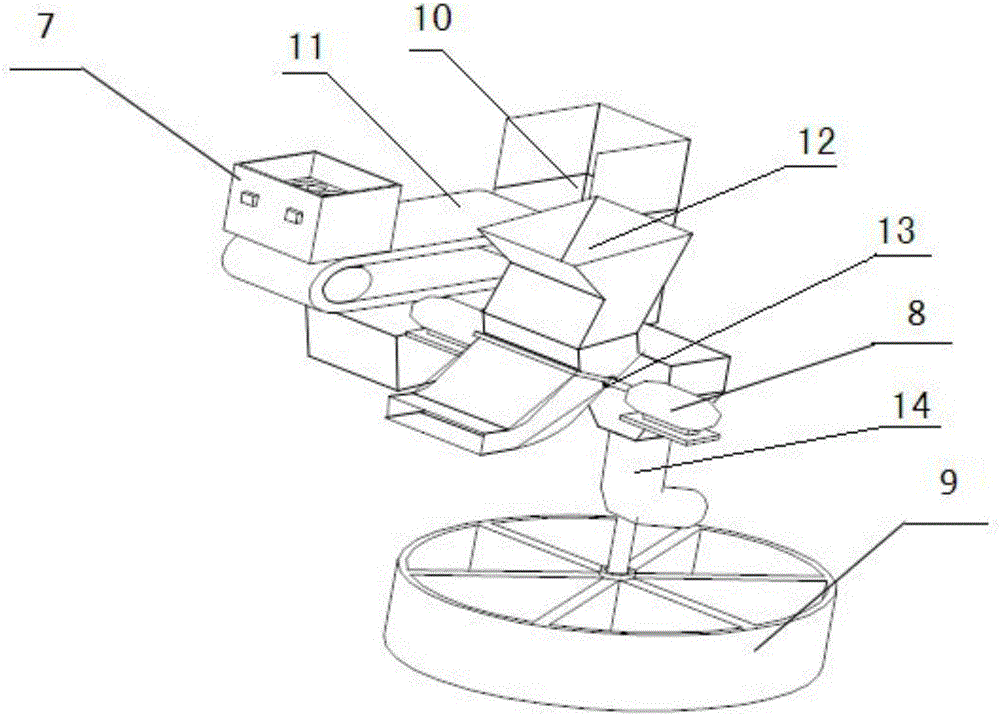

Intelligent identifying card automatic sorting collecting method

ActiveCN104443949AAvoid pollutionSolve the problem of sorting and recyclingGlass recyclingPlastic recyclingWaste productSmart card

The invention discloses an intelligent identifying card automatic sorting collecting method. Classifying recycling of waste paper, waste plastics, waste metal, waste glass, waste batteries and waste electronic products can be achieved, and intelligent point accumulation can be achieved. Meanwhile, recycling, sorting and automatic point accumulation of PET plastic bottles can be achieved. Classifying recycling of unrecyclable garbage such as kitchen garbage can be achieved. Various recycled waste products are converted into accumulated points suitable for daily consumption according to the number, the weight and the value, and the accumulated points are charged into an intelligent card automatically. According to the method, an intelligent identifying card sorting collecting device (11), a PET bottle recycling device (10), an unrecyclable garbage recycling box (3) and an intelligent card sensor (7) in which accumulated points can be recorded are included. The combination structure can carry out classifying recycling on garbage generated in daily life conveniently, practical value is given to household garbage and is converted into the accumulated points for consumption in daily life, garbage classifying is promoted, and people are encouraged to actively participate in the activities of garbage recycling.

Owner:CHANGCHUN UNIV OF TECH

Systems and methods for sorting recyclables at a material recovery facility

Systems and methods for providing a quantity of cullet having at least two colors of glass from an input stream of recyclable material and non-recyclable material. In an embodiment, the system includes a sortation station, a screening apparatus, an air classifier, and a crushing apparatus to provide as output substantially pure cullet having at least two colors.

Owner:RE COMMUNITY HLDG II INC

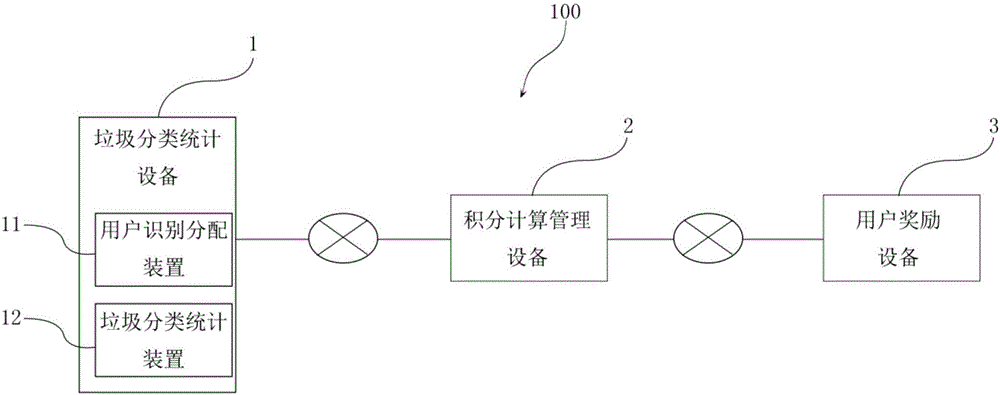

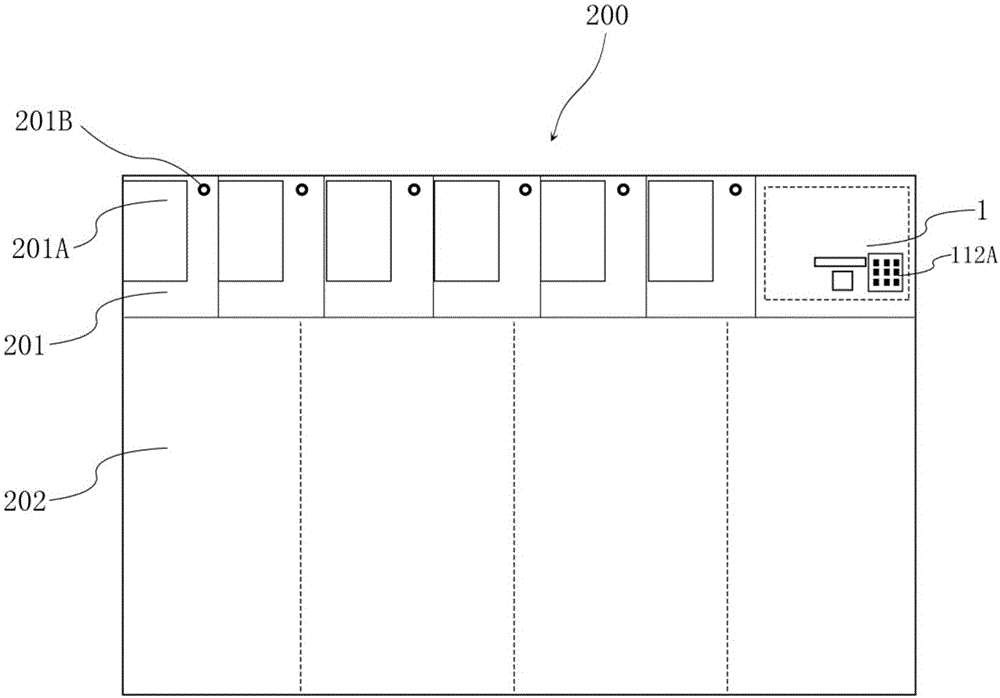

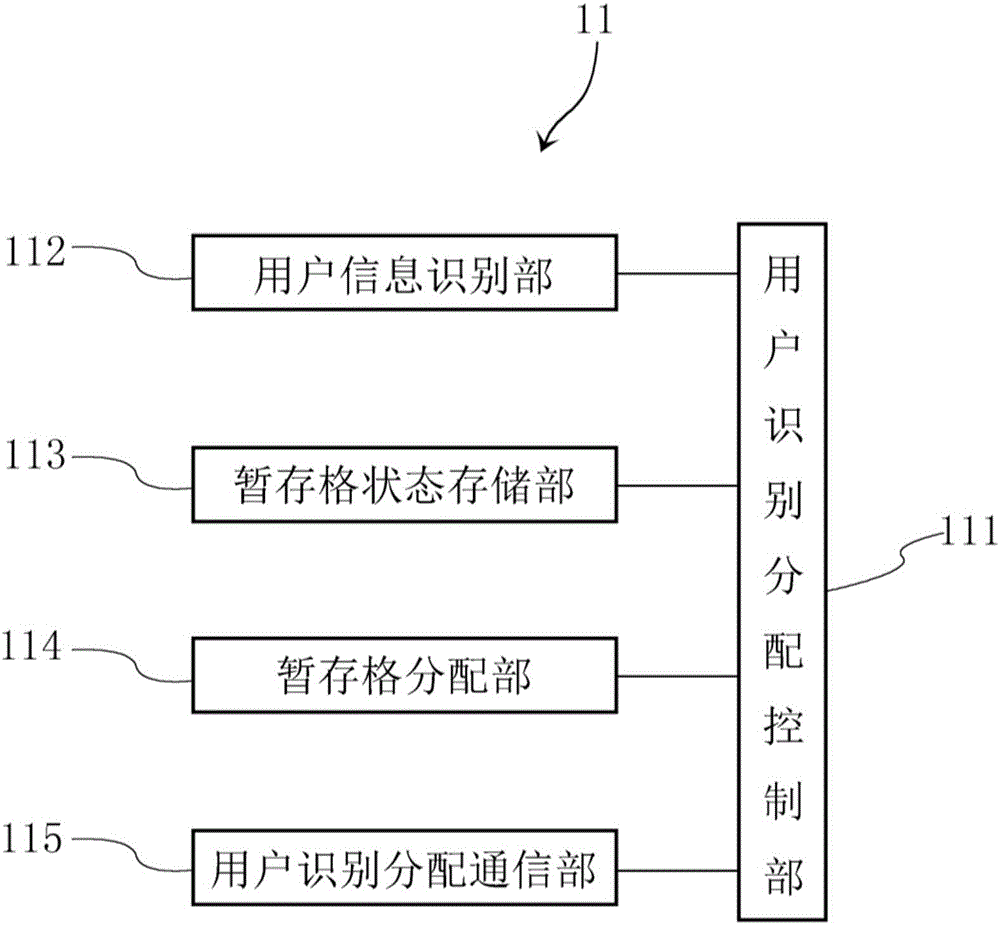

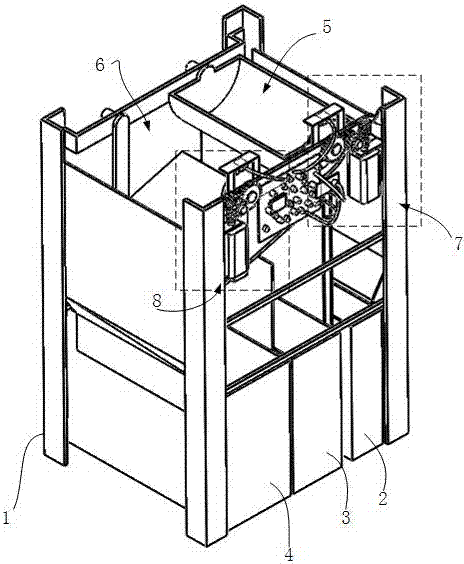

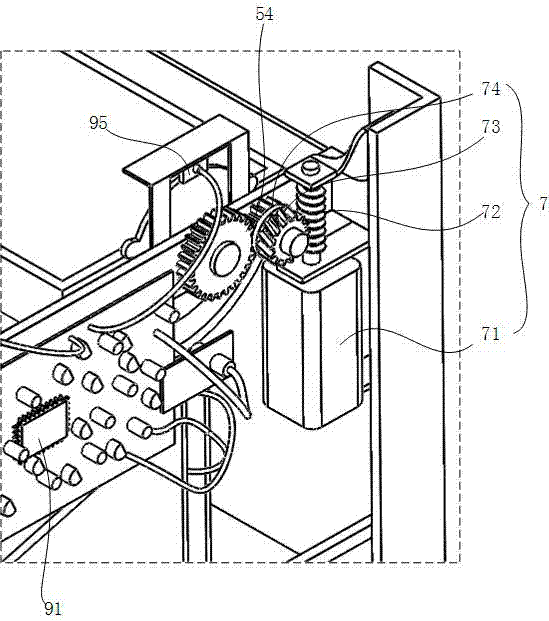

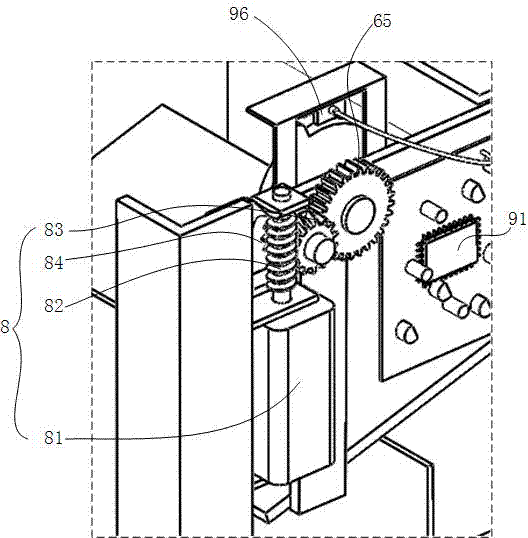

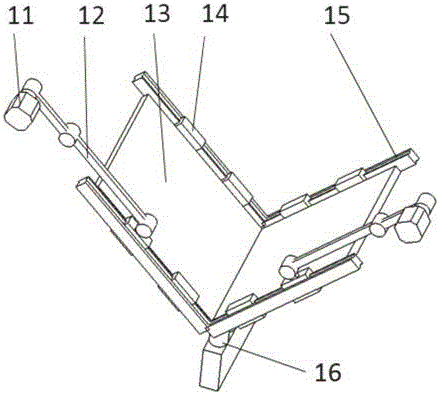

Garbage classifying-counting device, equipment and system

InactiveCN106494789ARealize automatic classification deliveryThe points calculation process is fair and accurateGlass recyclingWaste collection and transferVolumetric Mass DensitySerial code

The invention provides a garbage classifying-counting device and equipment and a garbage classifying-counting and score reward system. The garbage classifying-counting device is mounted on a garbage recovery bin with a plurality of temporary storage compartments and used for classifying and counting recoverable garbage stored in the temporary storage compartments; and the garbage classifying-counting device comprises a temporary storage compartment recognition part used for recognizing and obtaining the serial numbers of the temporary storage compartments, a garbage taking-out part used for taking the recoverable garbage out of the temporary storage compartments one by one, a density value acquiring part used for receiving the recoverable garbage taken out by the garbage taking-out part and acquiring the density values of the recoverable garbage, a garbage class judging and setting part used for judging whether the density values are in preset value ranges of preset classes of garbage and setting the recoverable garbage as the preset categories of garbage, a garbage dumping part used for dumping the recoverable garbage into corresponding types of storage bins, and a counting part used for counting the classes of the recoverable garbage in each temporary storage compartment and the number of the recoverable garbage corresponding to each class according to the serial numbers.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

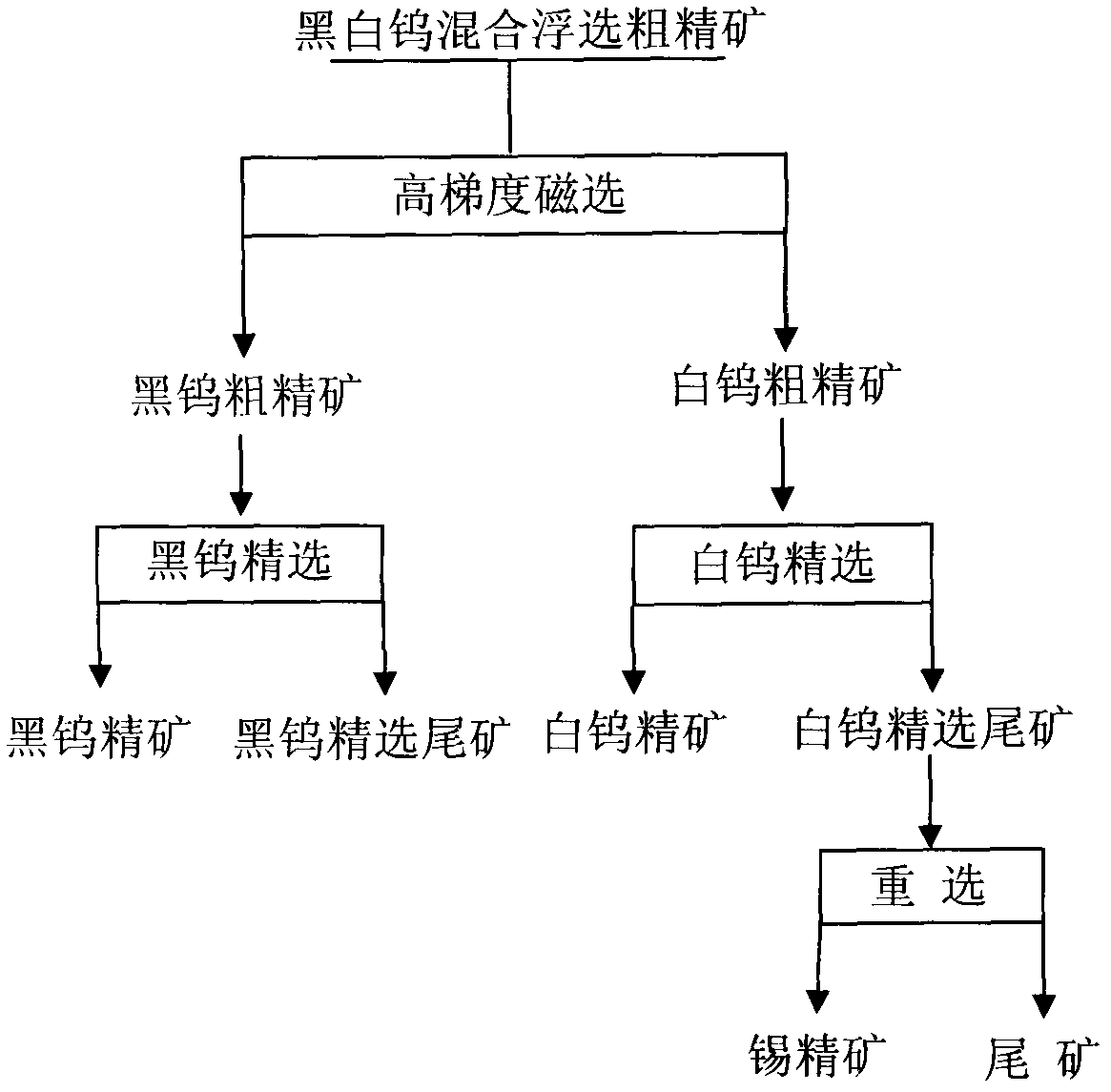

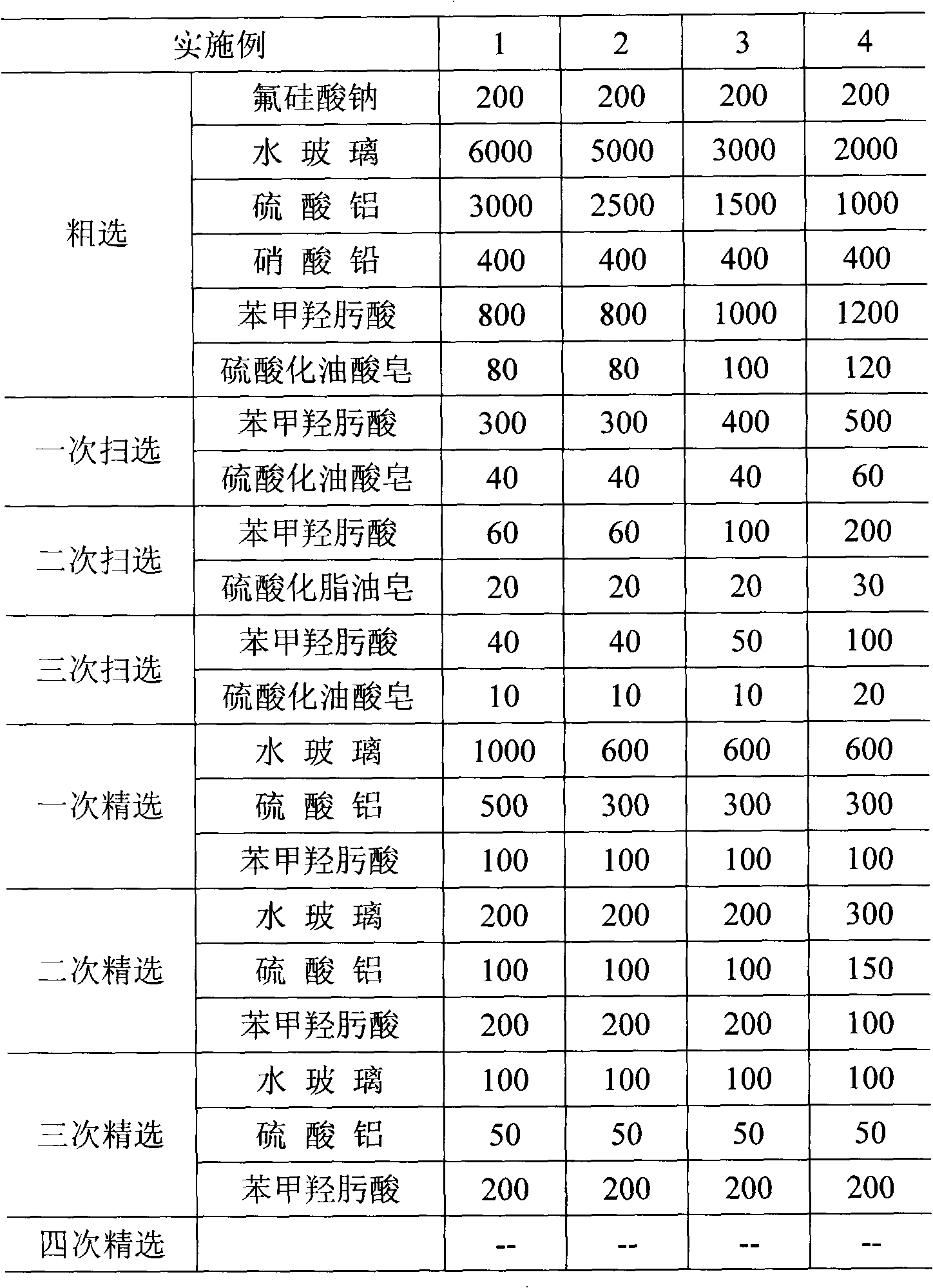

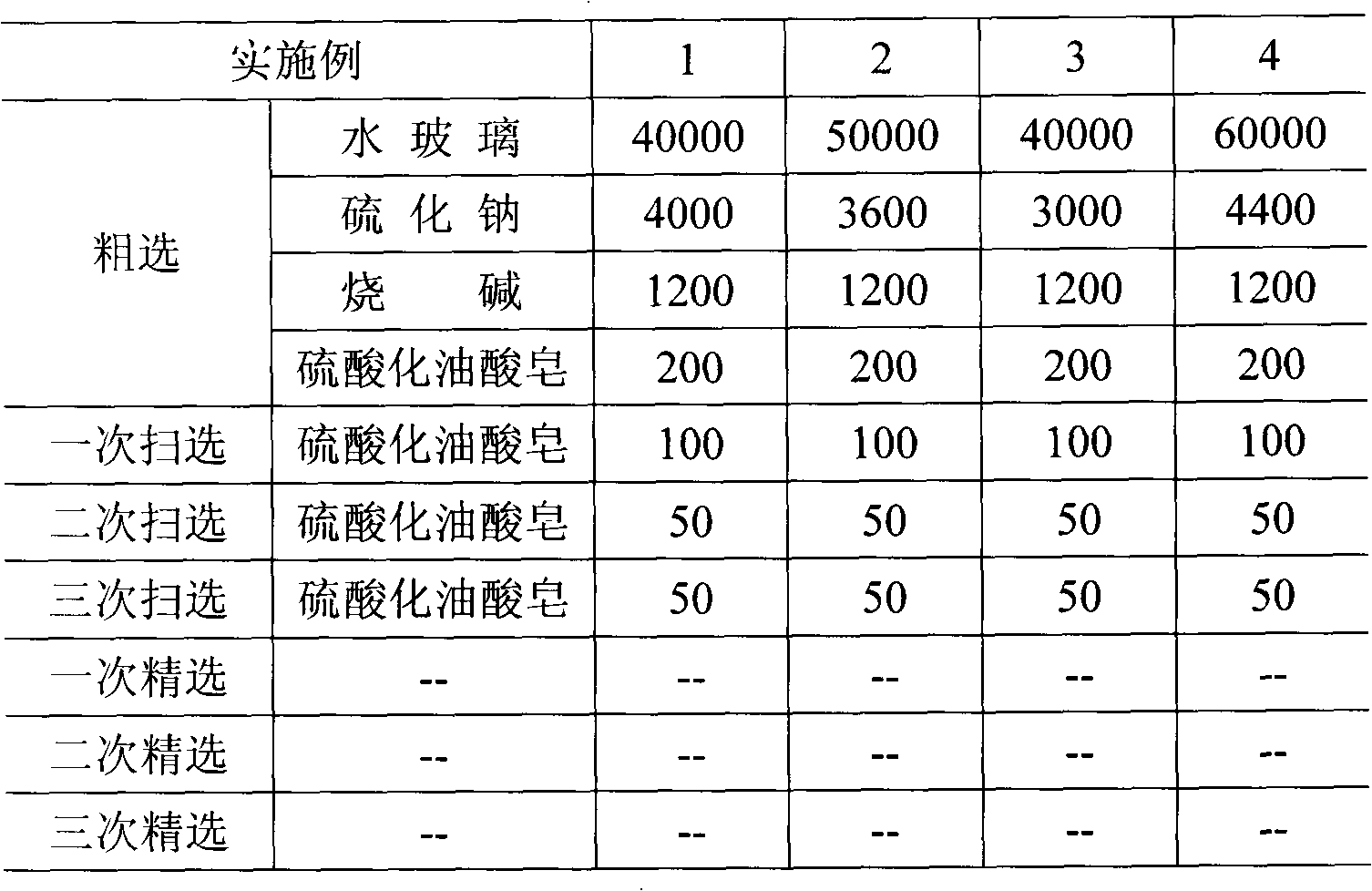

Method for separating black and white tungsten bulk flotation rough concentrates

ActiveCN102211053AHigh recovery rateReduce mutual interferenceGlass recyclingWet separationLead nitrateFatty acid

The invention relates to a method for separating black and white tungsten bulk flotation rough concentrates. The method is characterized in that a black tungsten rough concentrate and a white tungsten rough concentrate are obtained by virtue of high-gradient magnetic separation, roughing or roughing and scavenging; black tungsten concentrates and black tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and four-time concentrating on the black tungsten rough concentrate by utilizing sodium fluosilicate, sodium silicate, aluminum sulfate, lead nitrate, benzohydroxamic acid and sulfated nascent soap; white tungsten concentrates and white tungsten cleaner tailings are obtained via carrying out once roughing, three-time scavenging and three-time concentrating on the white tungsten rough concentrate after the white tungsten rough concentrate is heated up and stirred by utilizing sulfated fatty acid soap, sodium silicate, caustic soda and sodium sulfide; cassiterites in the white tungsten cleaner tailings are recovered by a table concentrator. The method related by the invention has the advantages of small mutual interference of black tungsten ore and white tungsten ore in the black and white tungsten bulk flotation rough concentrates, high recovery ratio of black tungsten ore and high and stable quality of the black tungsten ore; and the method is suitable for the black and white tungsten bulk flotation rough concentrates containing 5-40% of WO3.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI +1

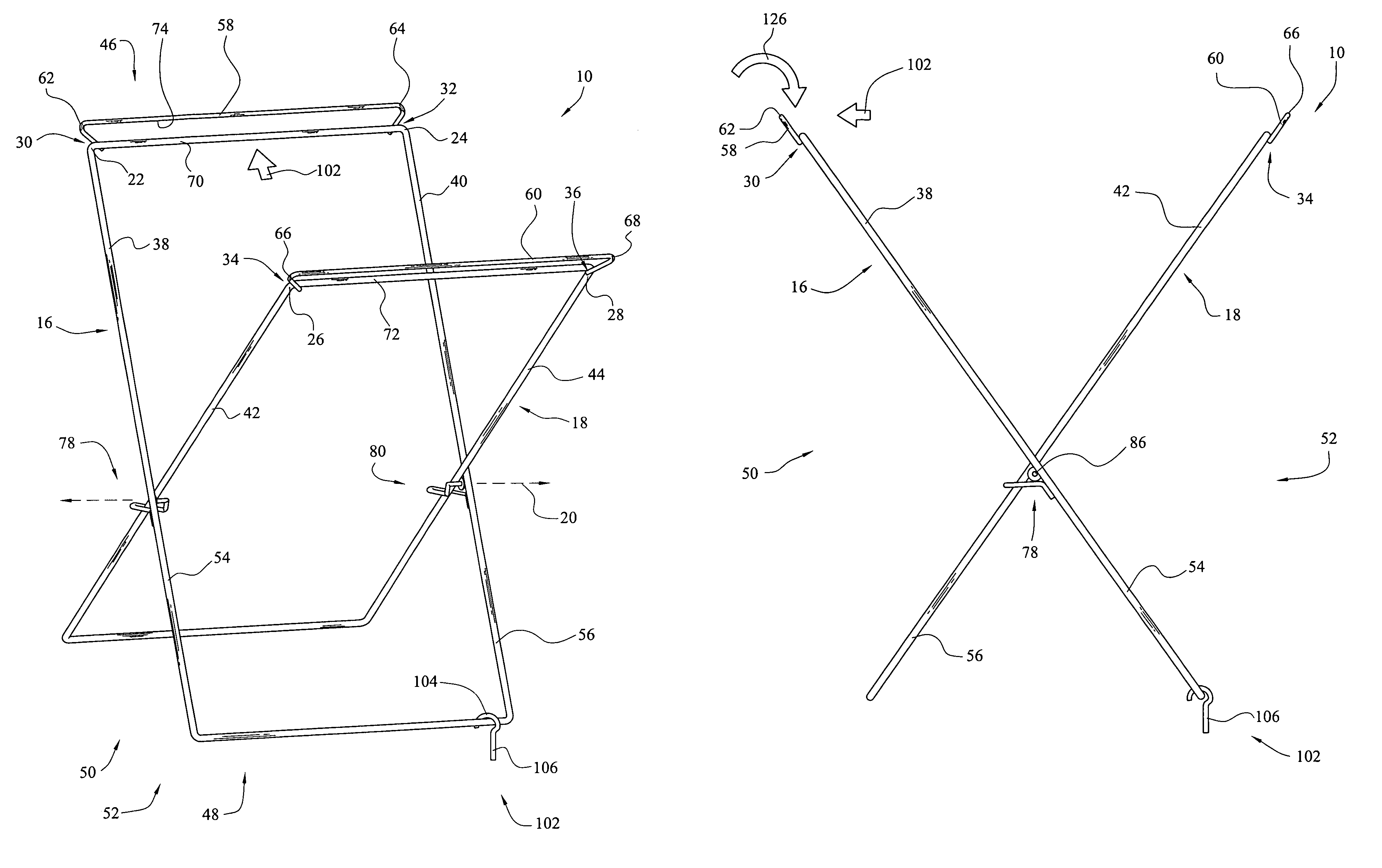

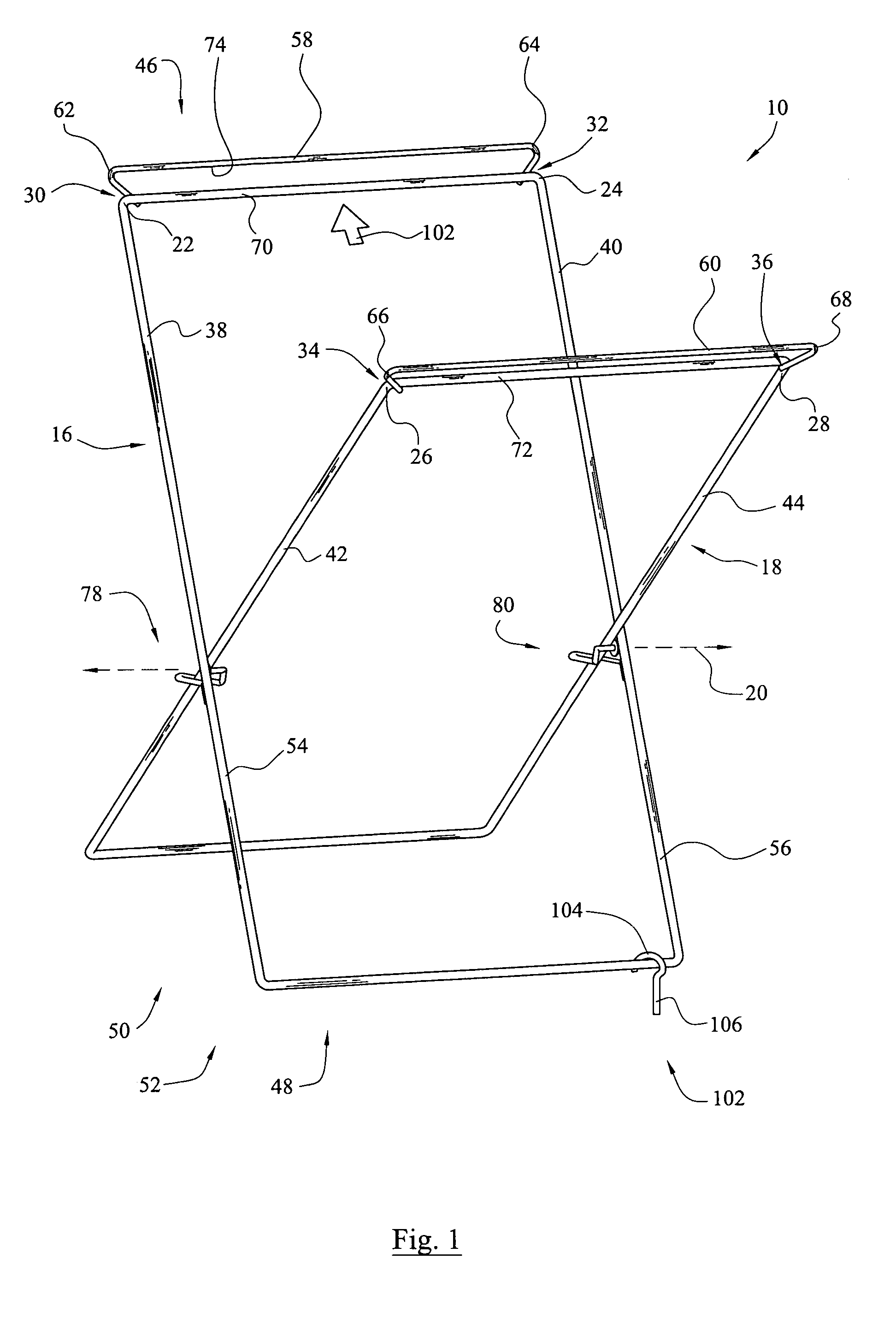

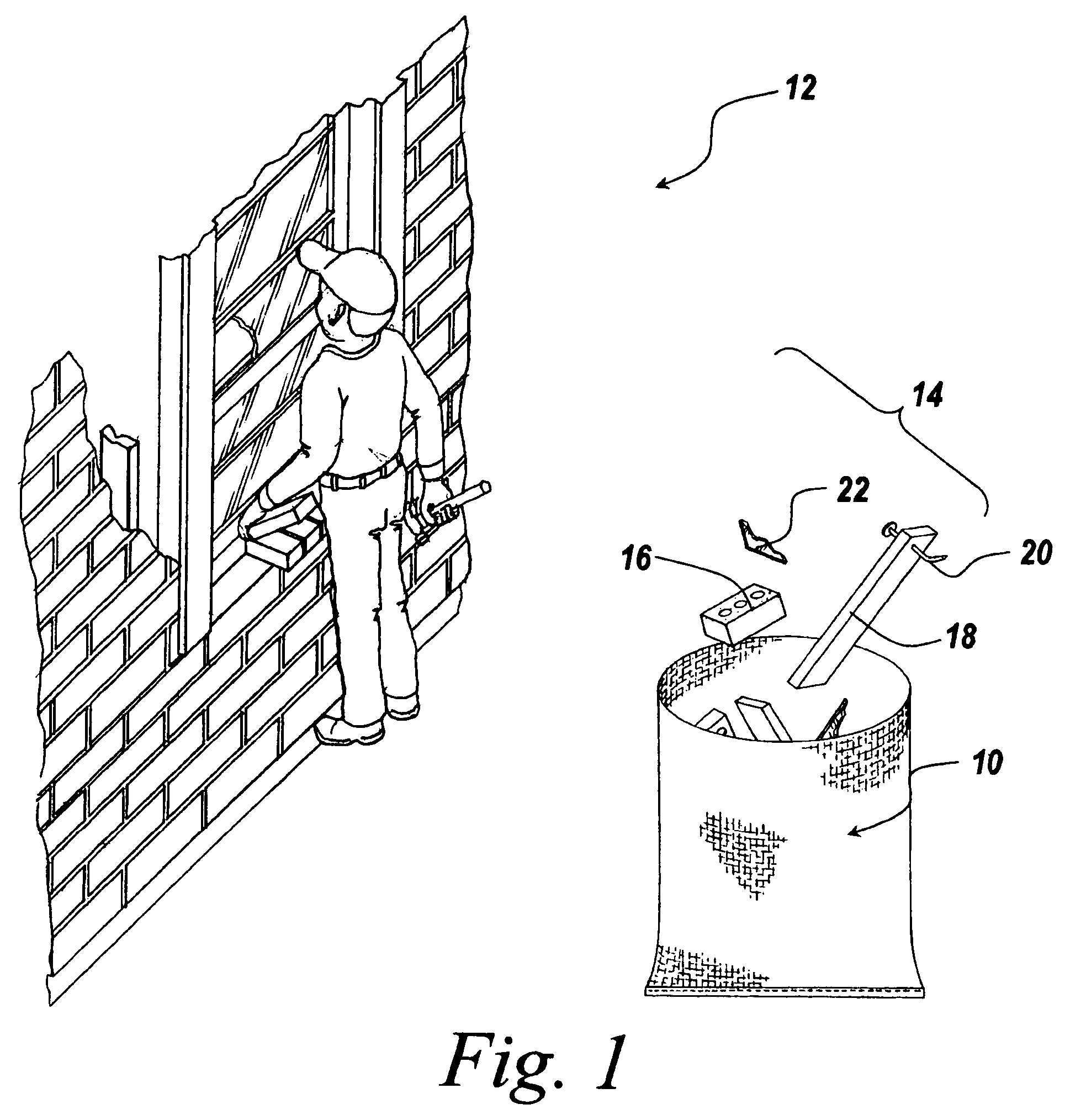

Bag stand

Owner:CLEARSTREAM RECYCLING

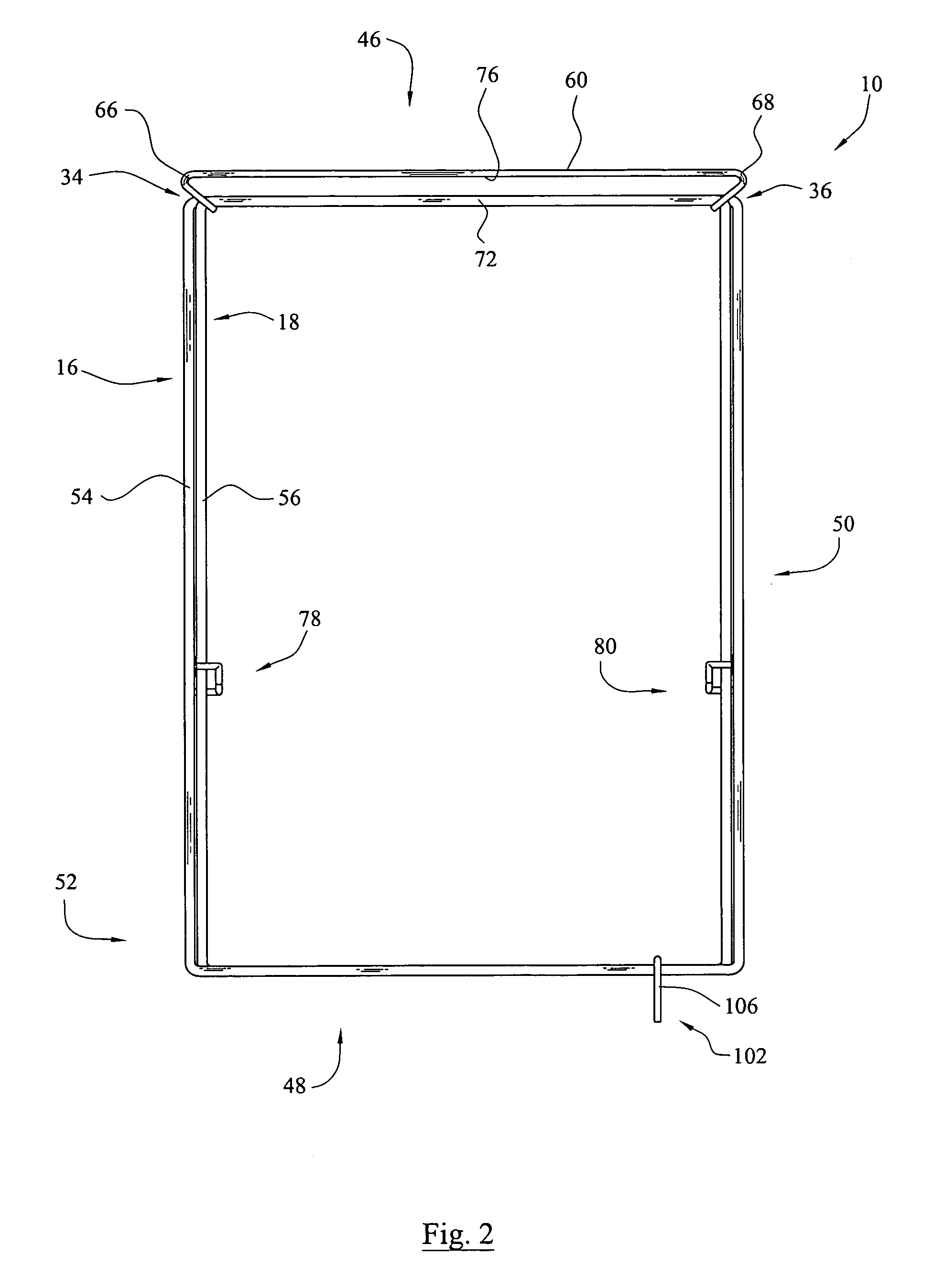

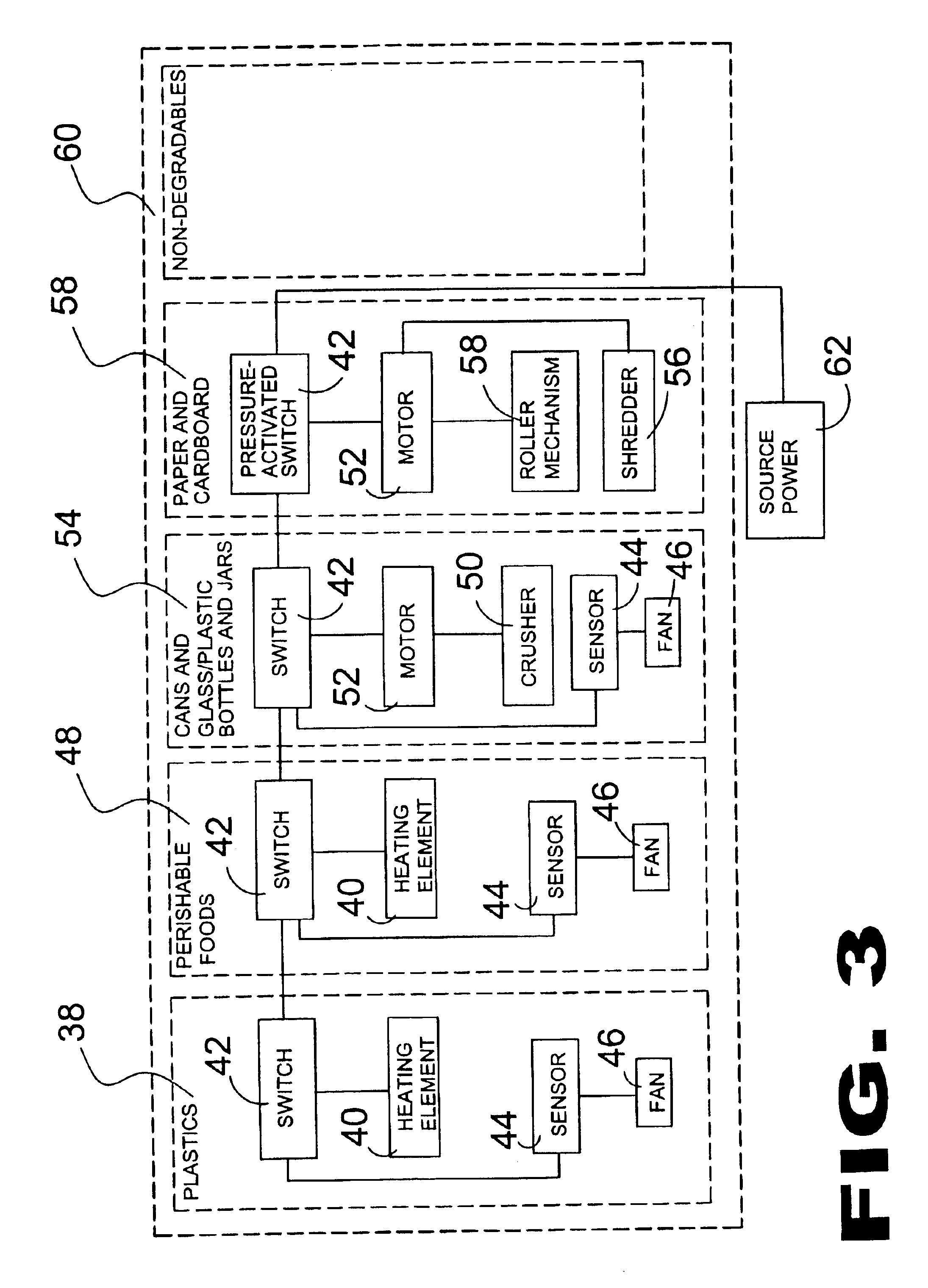

System for sorting and processing a plurality of types of solid waste products for recycling

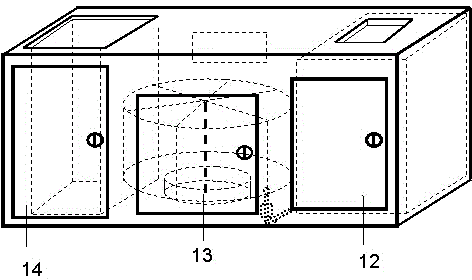

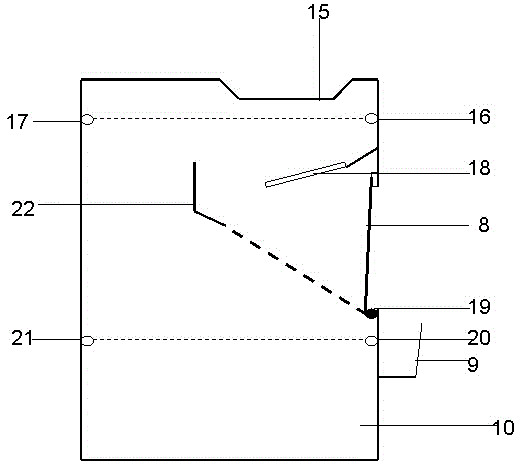

InactiveUS6903142B1Reduce confusionLow costMechanical working/deformationSolid waste disposalCardboardWaste product

The present invention 10 discloses a trash and garbage processing device which may be sized to fit into a kitchen of a home or sized to be used in a multi-family dwelling. The present invention 10 has a plurality of sorting compartments 12 disposed on the top thereof for receiving various types of waste products. There is a compartment for shrinking and palletizing plastics, another compartment for shredding paper and cardboard 58, another compartment for perishable organic waste 48, a crushing compartment for crushing cans and glass / plastic products 54 and a disposal compartment 60 for non-degradable, solid waste such as bones and batteries. After the various types of waste materials are processed, they are transferred to a conduit to a recycling bin 32 for temporary storage and then thereafter removed from the recycling bin and transferred for final disposal. A paper cutting blade 26 is provided for cutting large pieces of cardboard or paper to proper size for placement into a paper shredding compartment 58. The individual openings 12 of the compartments have lids 14 thereon which have safety locks thereon 22 / 34 to prevent children from tampering therewith. A plastic handling compartment also may be coated with a non-stick material and the safety locks may use a touch digital keypad as commonly used. Further, the crusher unit may be equipped with a mechanism for determining the UPC codes of the materials.

Owner:STAUBER CHAIM M

Method for removing oil spills

InactiveUS7041221B2Reduce in quantityPreventing oil spillGlass recyclingSolid separationProcess engineeringOil spill

Owner:GLASS PLUS

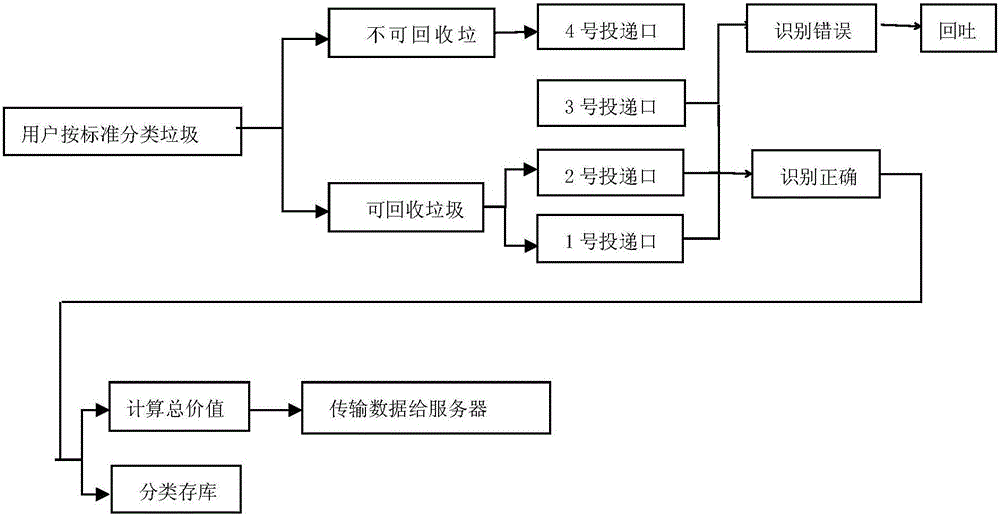

Garbage classification collection system

ActiveCN106185115AEnable smart recyclingEasy to storeGlass recyclingWaste collection and transferCollection systemOperating system

The invention discloses a garbage classification collection system. The garbage classification collection system comprises a garbage collection bin, as well as a user APP, a server and a transmitter which are all based on Internet, wherein the garbage collection bin comprises at least three sets of garbage throw-in openings; each throw-in opening is connected with a garbage storage zone at the bottom of the bin body through a conveying device; one of the garbage throw-in openings allows non-recyclable garbage to be thrown in, and the rest garbage throw-in openings are respectively equipped with various sensors used for identifying the types of garbage to be collected; the server performs information communication with the garbage collection bin through socket communication; and the user APP can be mounted on a user side, performs information communication with the server through socket communication, and is used for garbage collection cash returning and information receiving and releasing. The garbage classification collection system is mainly used for collecting such recyclable garbage as metal, plastics, waste paper, glass and batteries, and can realize intelligent garbage collection and paid cash returning, and the collection efficiency can be higher since all the sensors improve the garbage identification rate.

Owner:王洪林

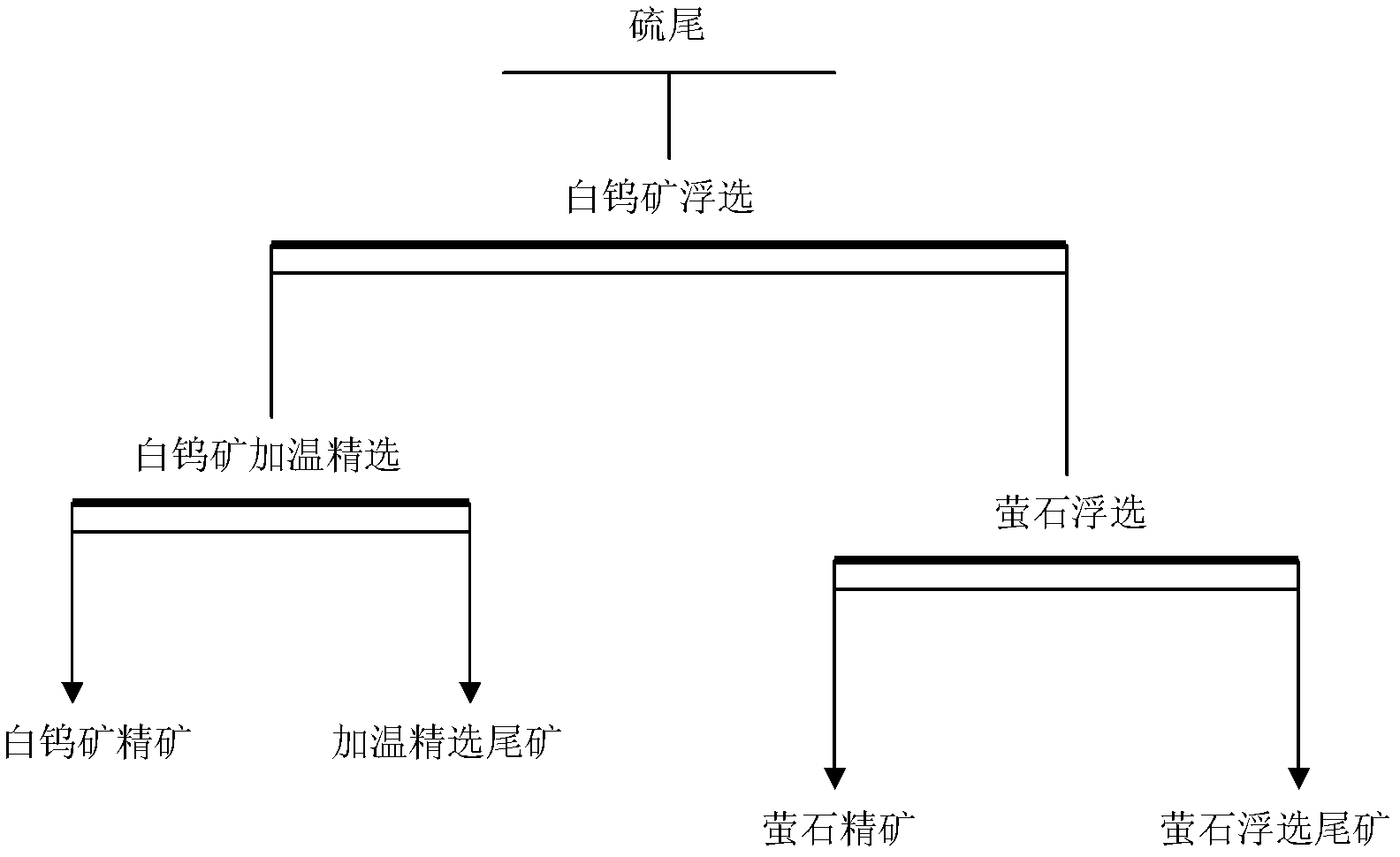

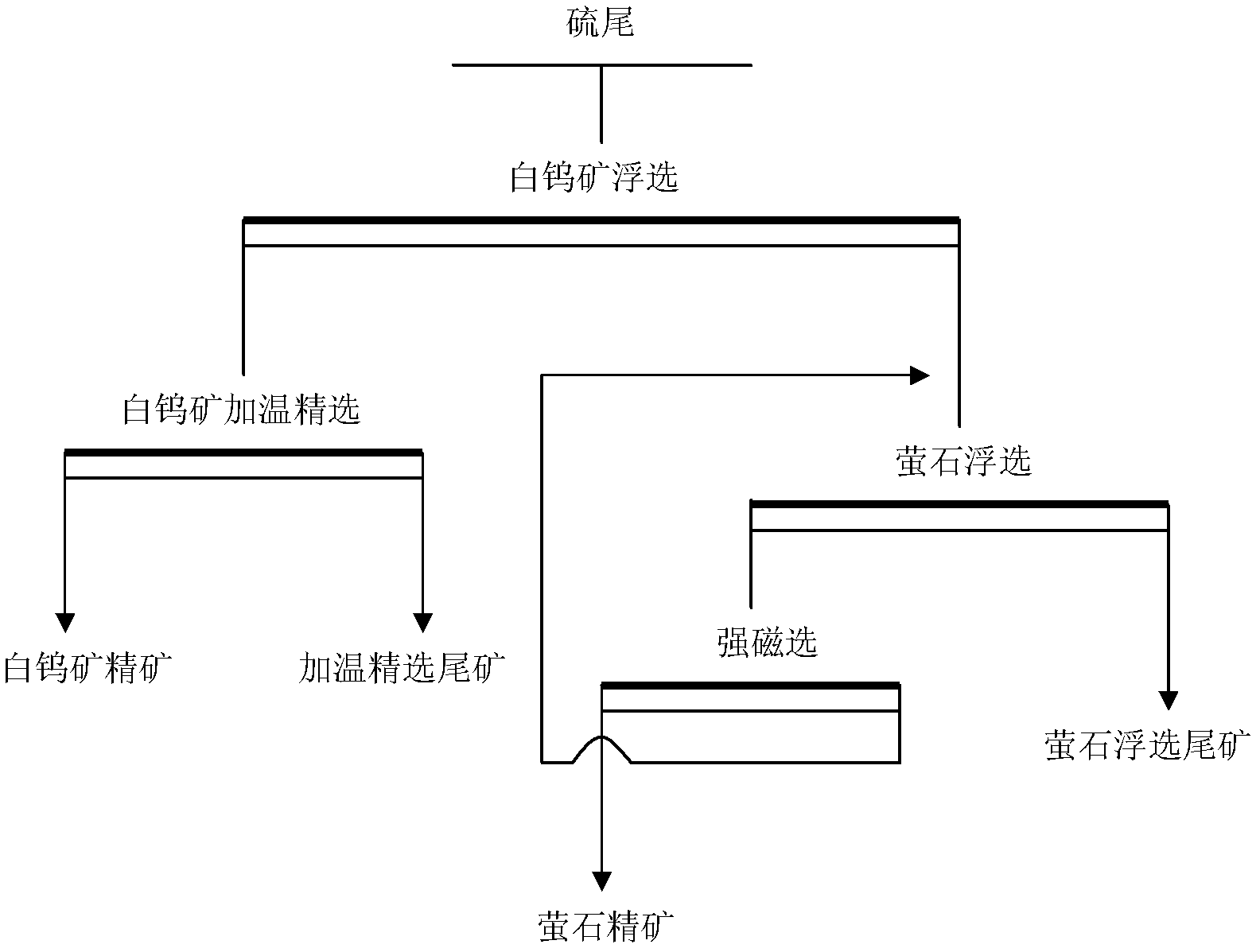

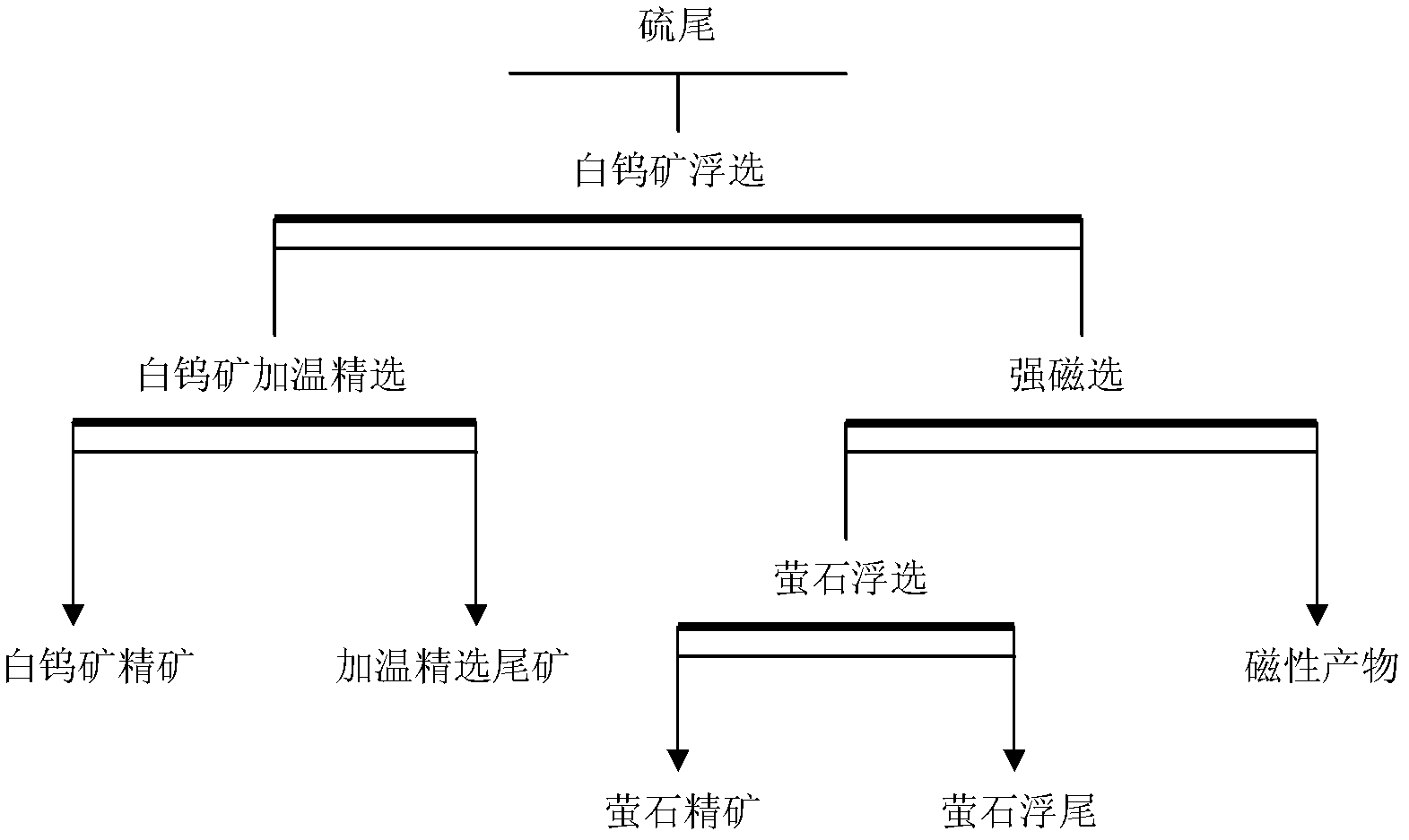

Ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore

InactiveCN102489393AReduce acid consumptionReduce drug consumptionGlass recyclingSolid separationSulfurMaceral

The invention discloses an ore dressing method for separation and recovery of scheelite and fluorite from sulfur flotation tailings of polymetallic ore. The ore dressing method can eliminate the shortcomings caused by a preferential flotation process in the prior art by simultaneously performing bulk flotation on the scheelite and the fluorite and further separating the scheelite from the fluorite, further significantly improve the recovery rate of the scheelite and the fluorite and realize high-efficient recovery of two minerals, namely the scheelite and the fluorite in the polymetallic ore.Furthermore, the scheelite and the fluorite are dressed through a rough concentration bulk flotation and fine concentration separation two-stage process, so that indexes in various stages of operations are convenient to stipulate and control, and quantification of the indexes of the ore dressing process of the scheelite and the fluorite and operation management can be effectively realized.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

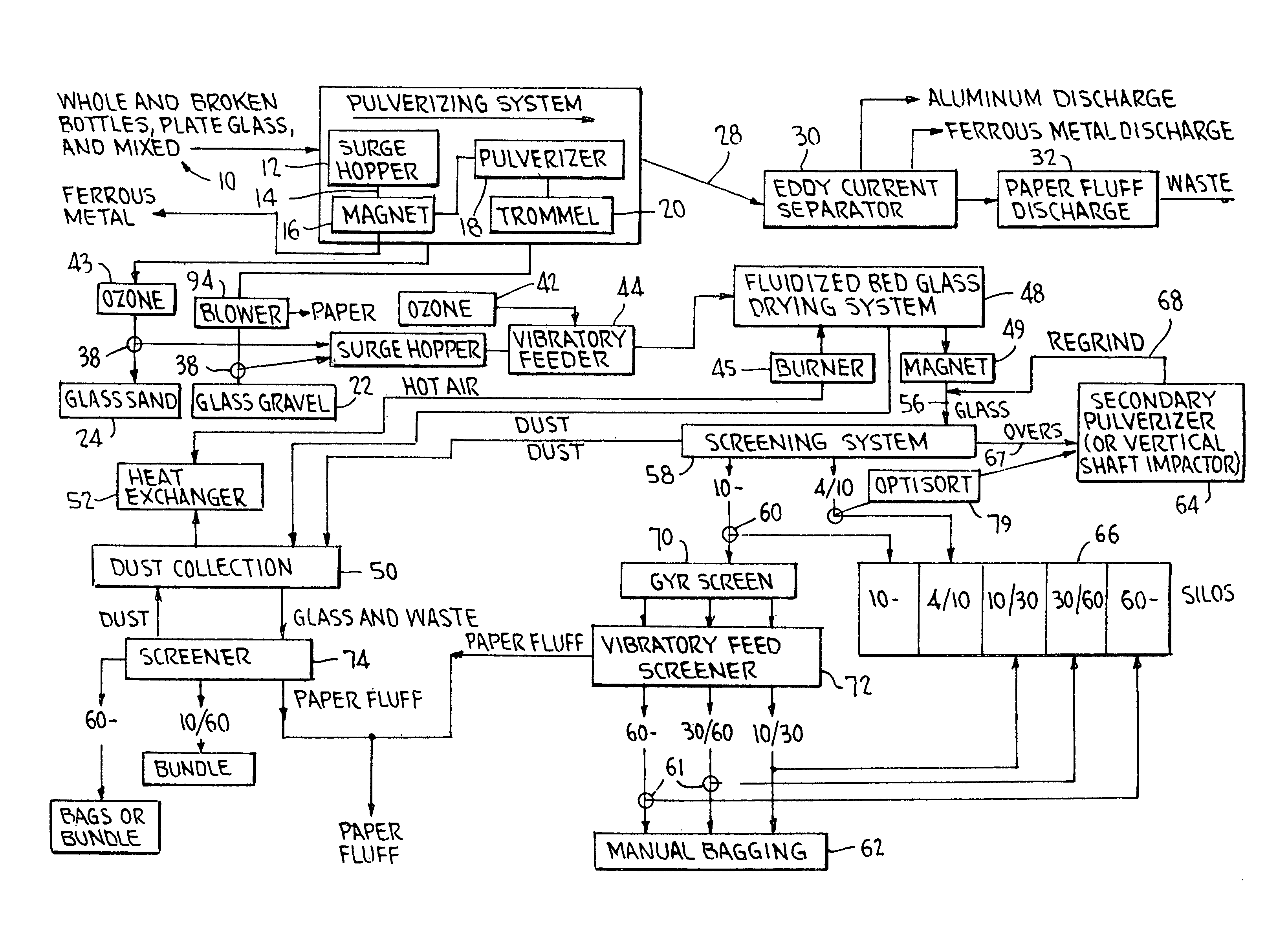

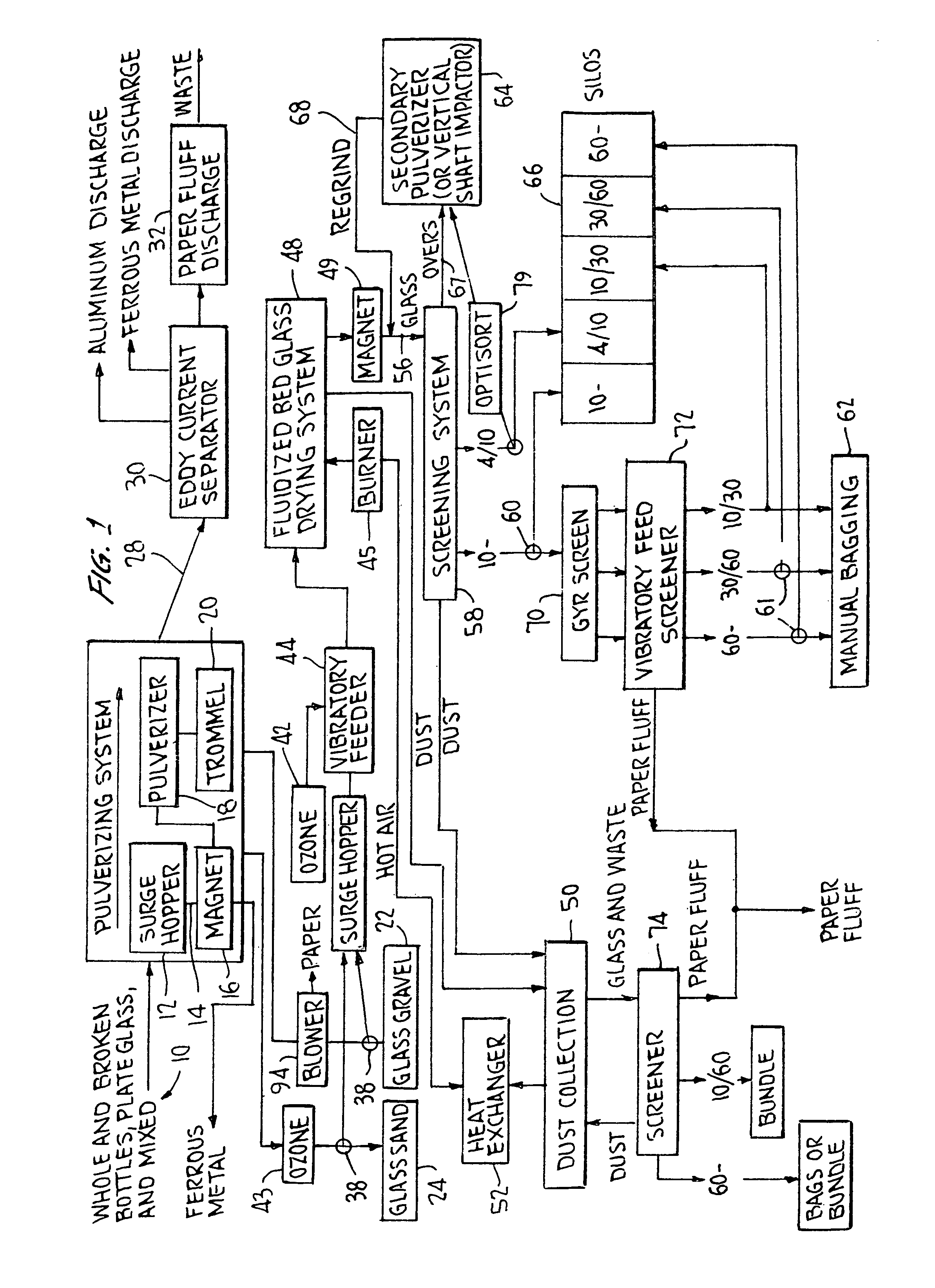

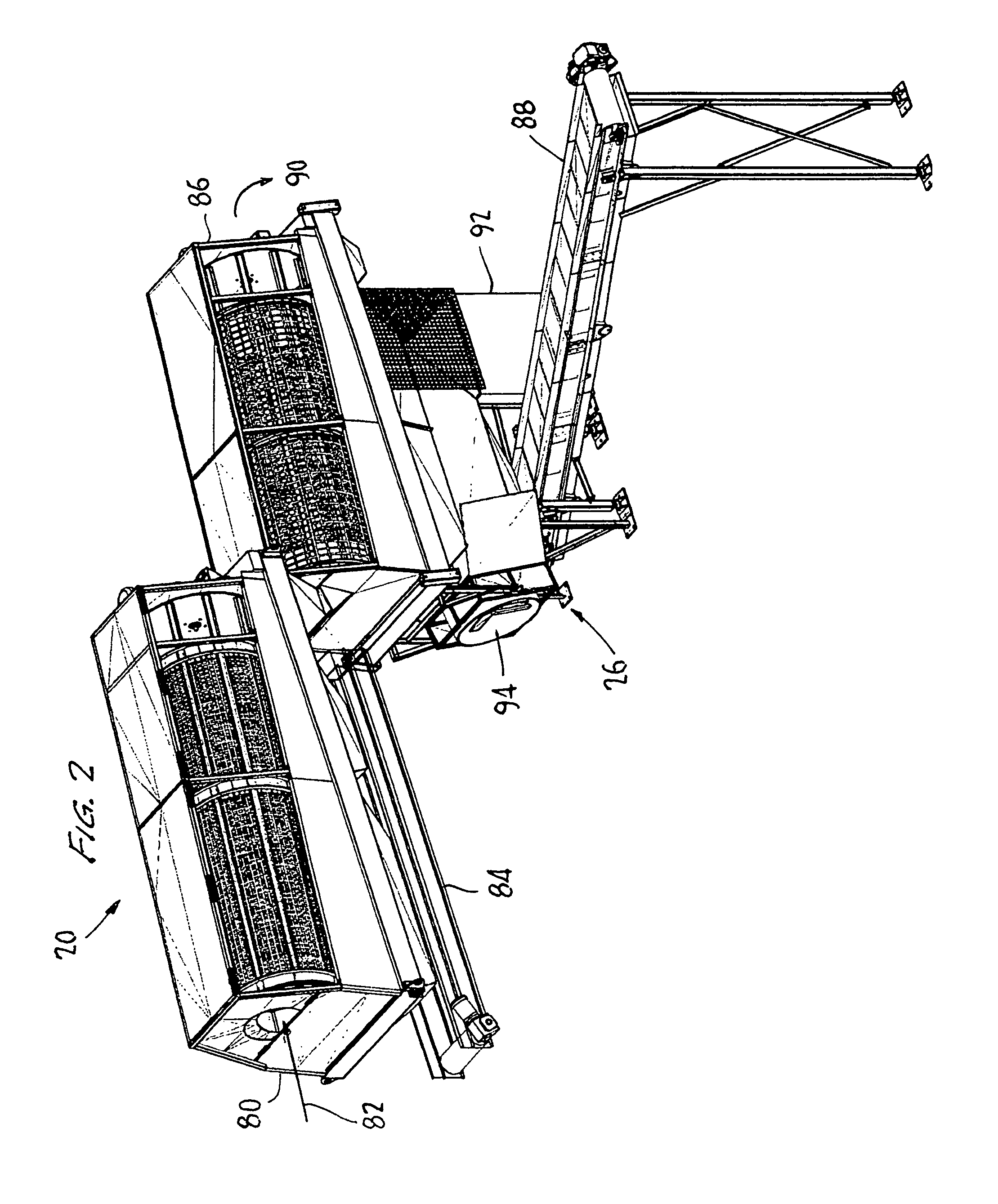

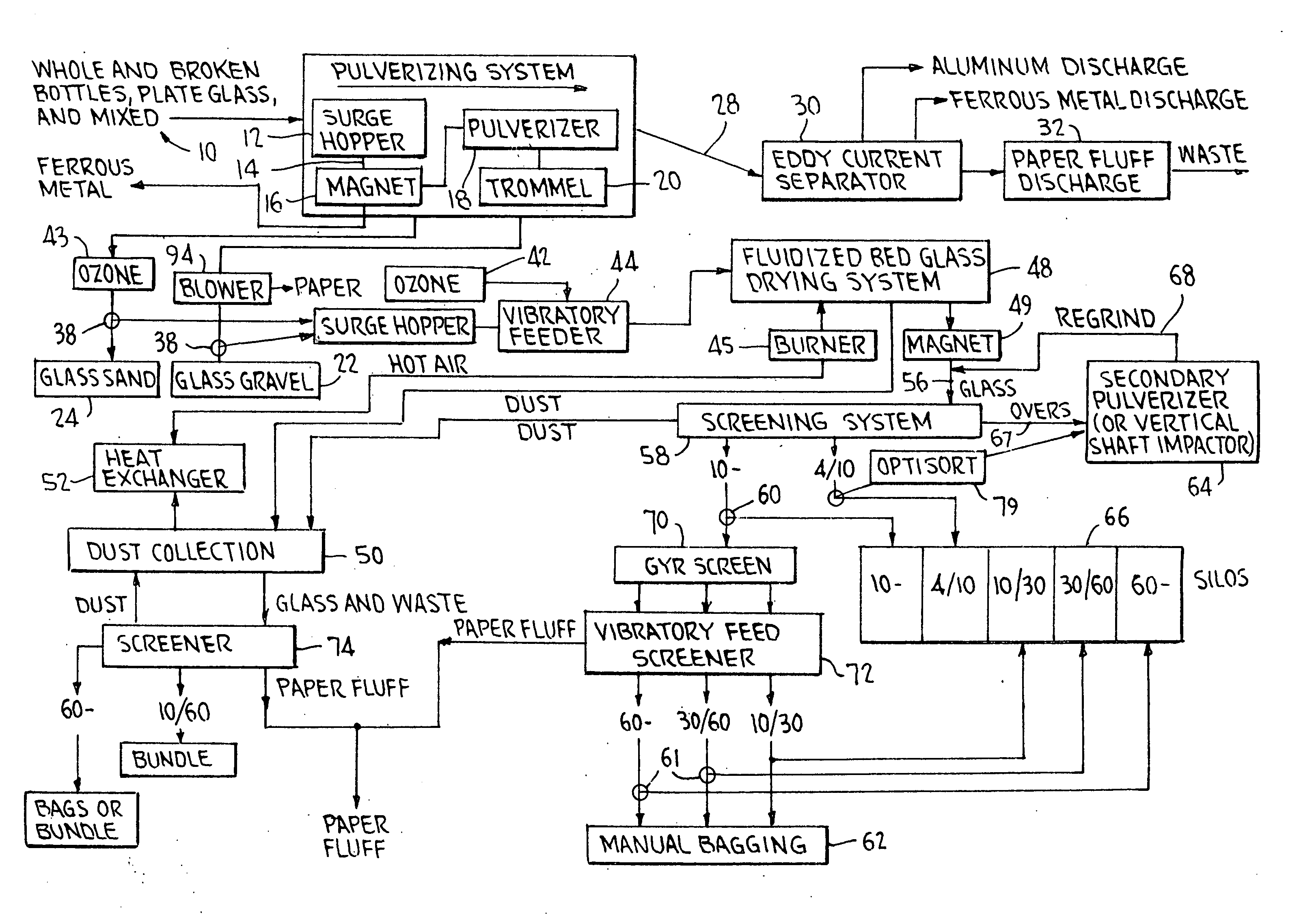

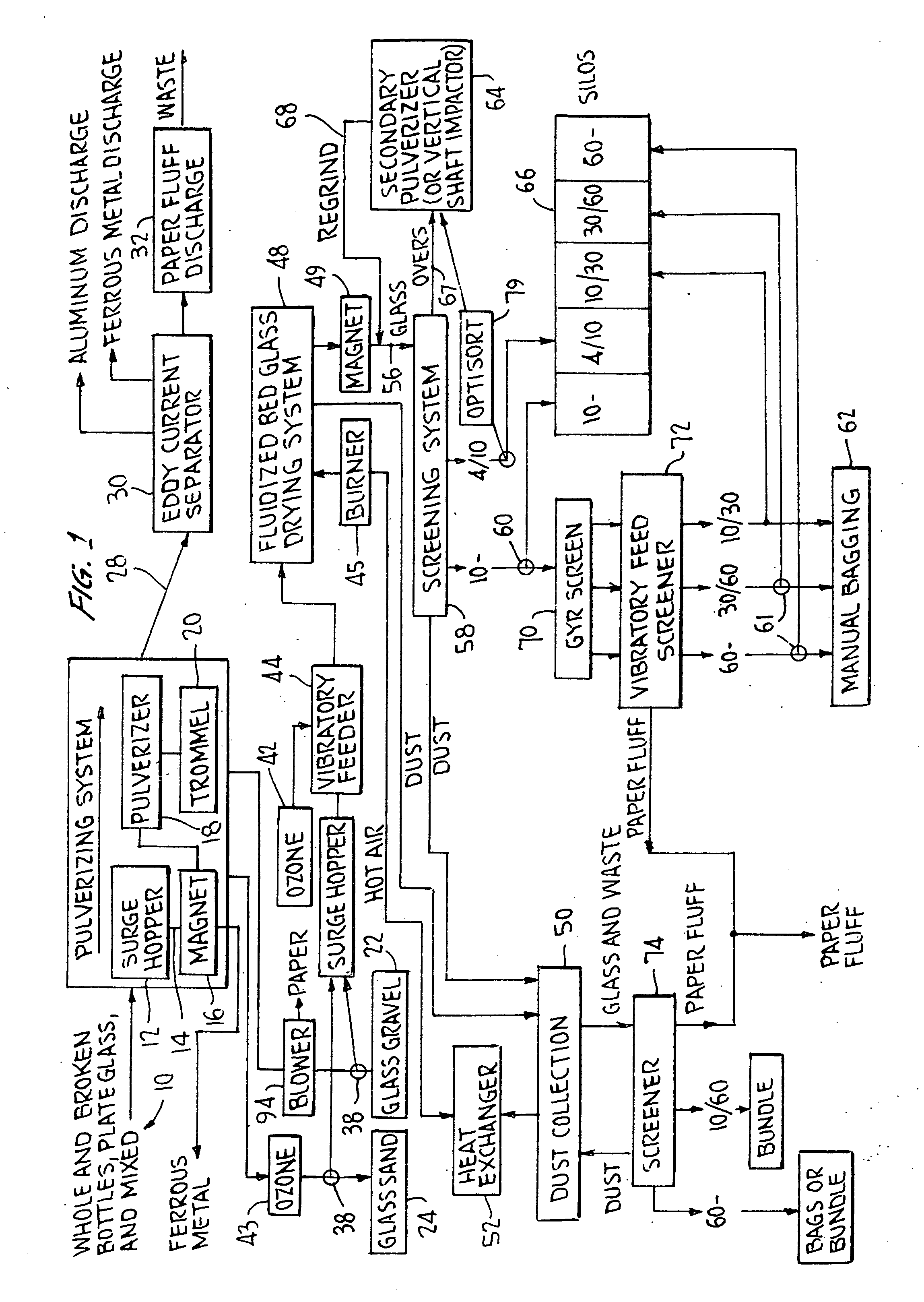

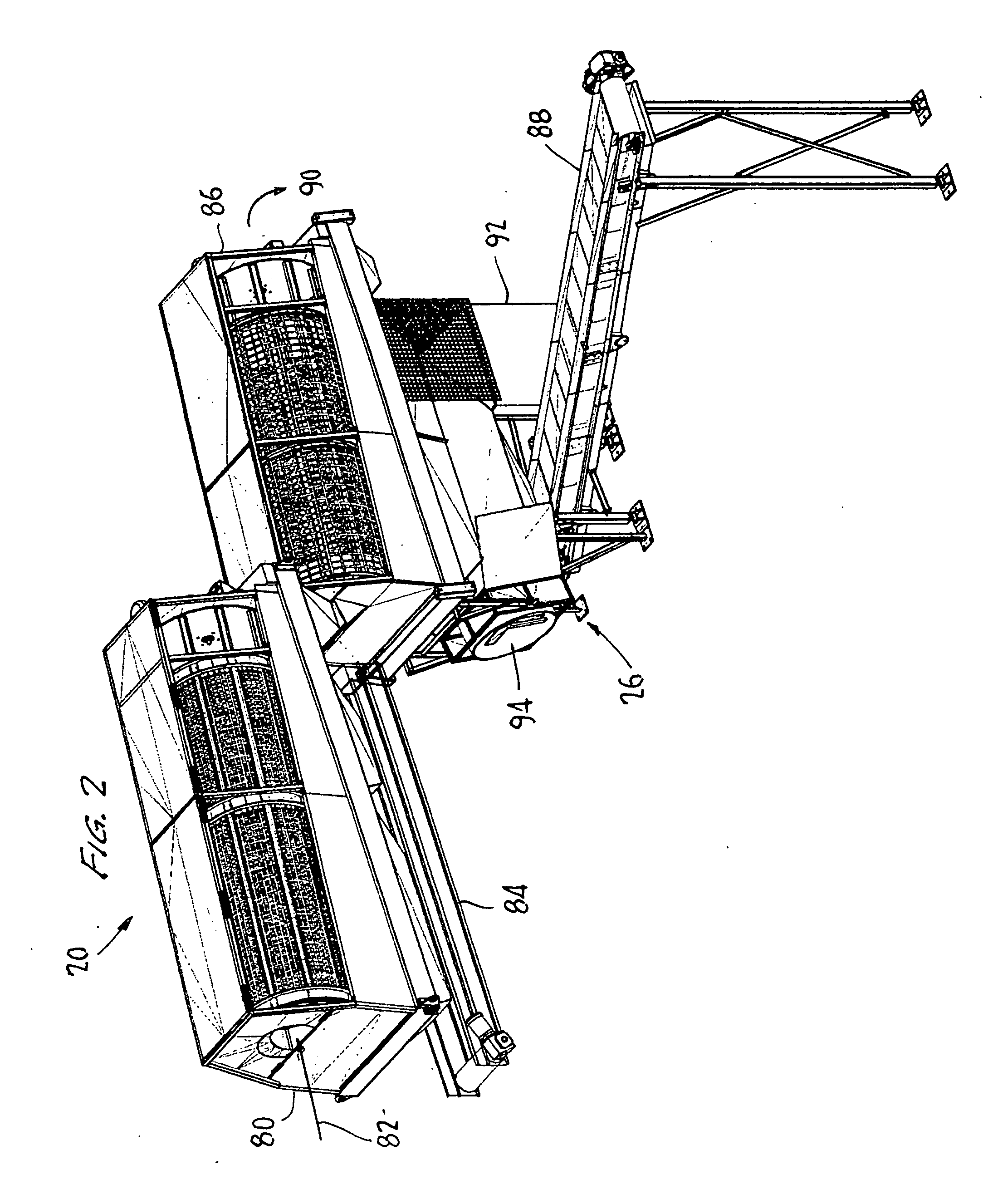

Production of clean glass particles from post-consumer waste

ActiveUS8146841B2Separate cleanInhibit productionMechanical working/deformationGlass recyclingWaste streamPost-consumer waste

Owner:GLASS PROCESSING SOLUTIONS

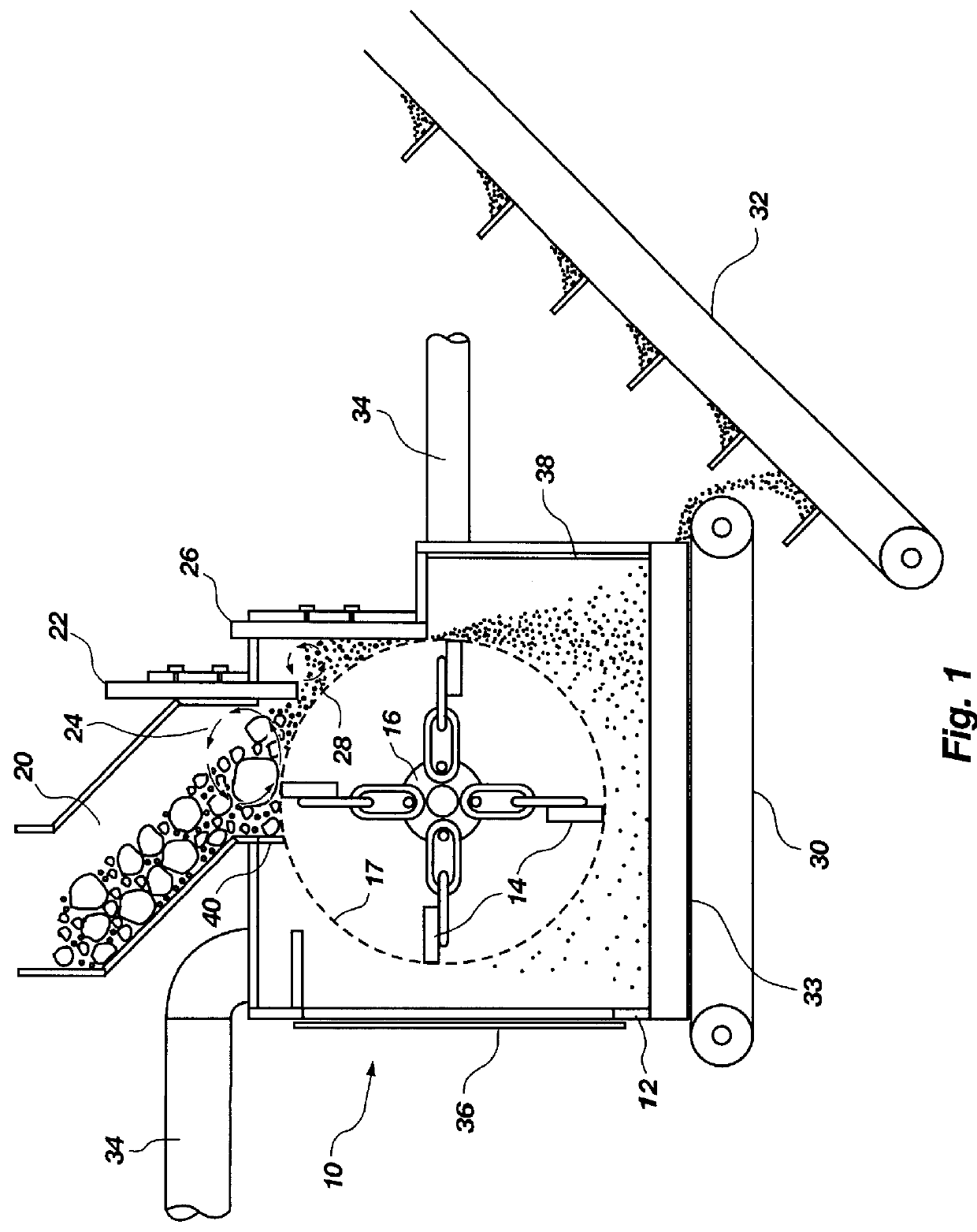

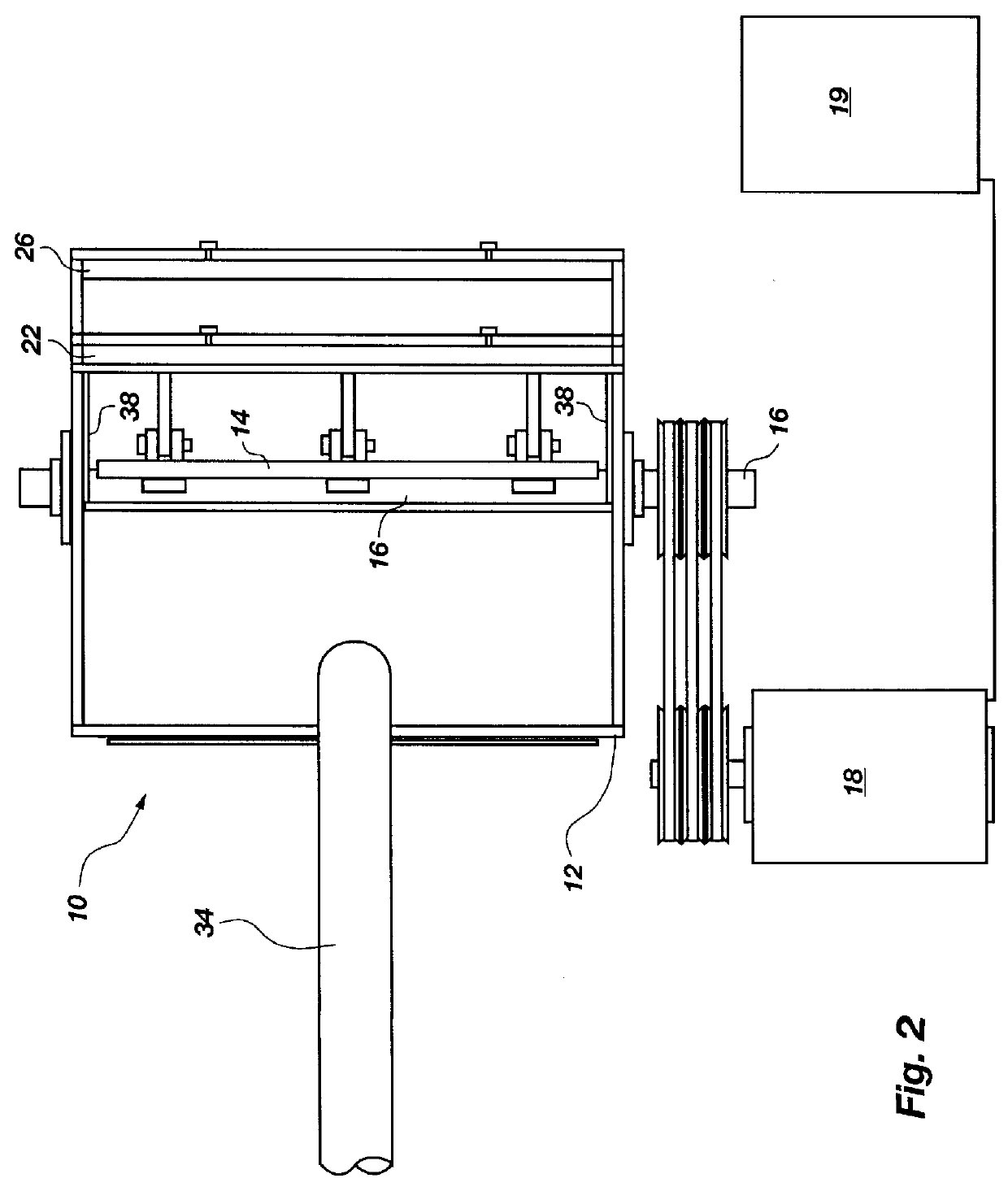

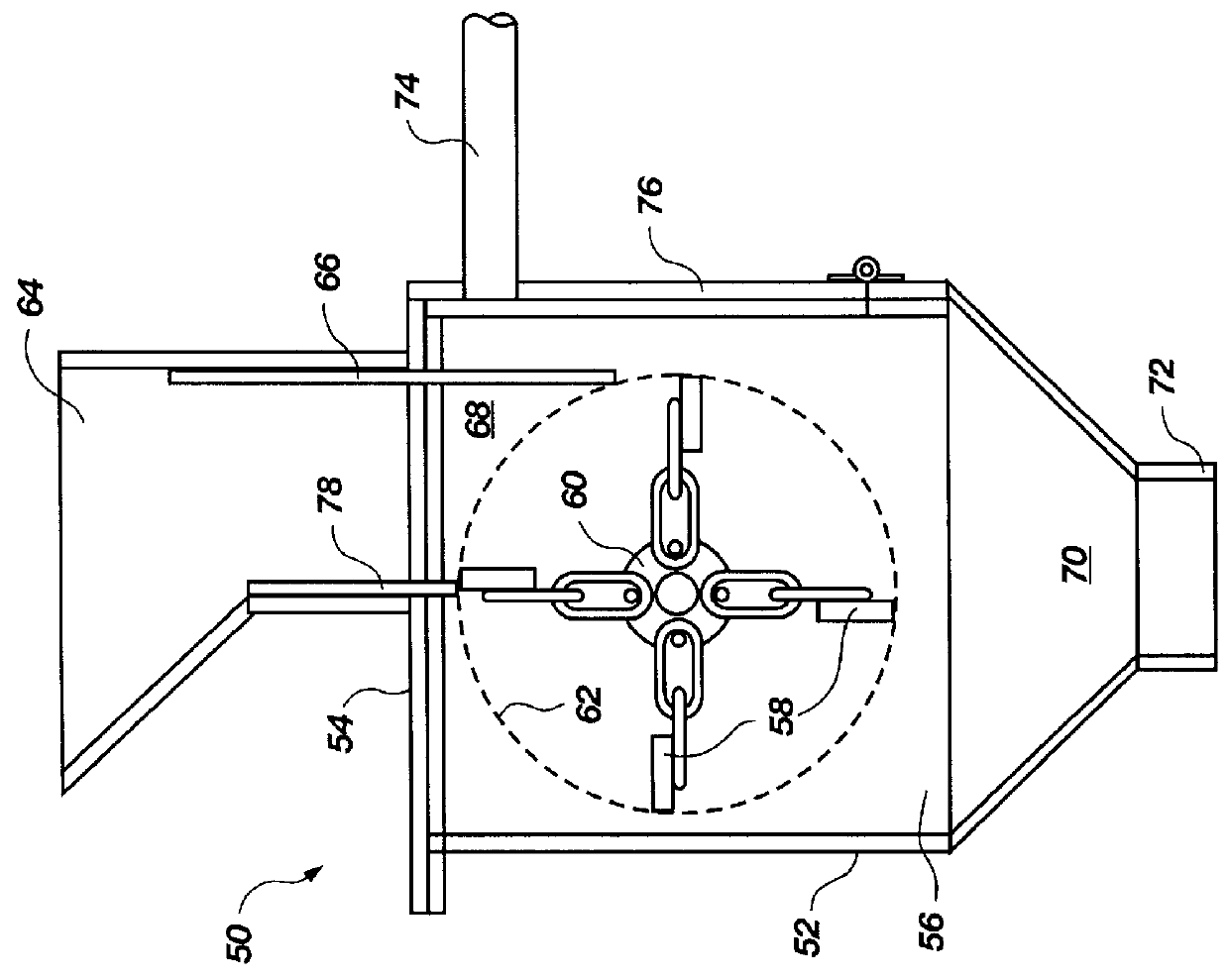

Apparatus and method for comminuting glass fibers

An apparatus for comminuting glass fibers is disclosed. Within a housing are a plurality of weighted members or hammers, flexibly connected to and spaced about a rotatable shaft. A drive member rotates the hammers about the shaft to define a rotation circumference. A glass intake opening located at the top portion of the housing is provided to introduce glass fibers and carrier material into the apparatus. A first adjustable plate is located adjacent the glass intake opening and positioned to provide a space between the first adjustable plate and the hammers' rotation circumference. A first glass suspension chamber is defined by the glass intake opening, the first adjustable plate, and the rotation circumference of the hammers. In operation, a quantity of glass fibers and carrier material is introduced into the apparatus, and spinning weighted members contact the glass, causing the glass to strike the first adjustable plate and other glass particles. Adjusting the space between the first adjustable plate the weighted members' rotation circumference helps control the resulting particle size of the comminuted glass. Controlling the shaft rotation speed affects the resulting particle size of the comminuted glass.

Owner:R & J HANSEN L L C

Removal of lead from solid materials

InactiveUS20150050199A1Minimal costTin compoundsSolvent extractionMaterials scienceCathode Ray Tube Display

A leaching composition that substantially removes lead from solid materials and a method of using said composition. Preferably, the concentration of lead in the solid materials following processing is low enough that the solid materials can be reused and / or disposed of at minimal cost to the processor. Preferably, the solid materials comprise glass, such as cathode ray tube glass.

Owner:ENTEGRIS INC

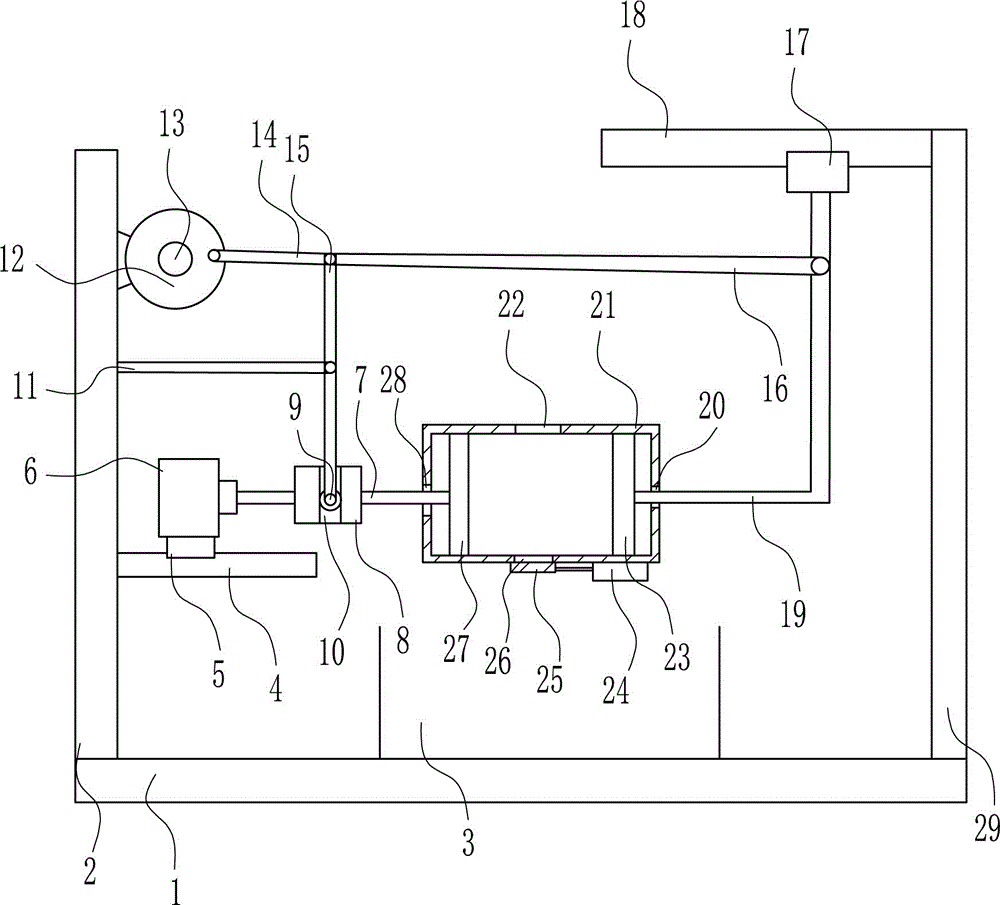

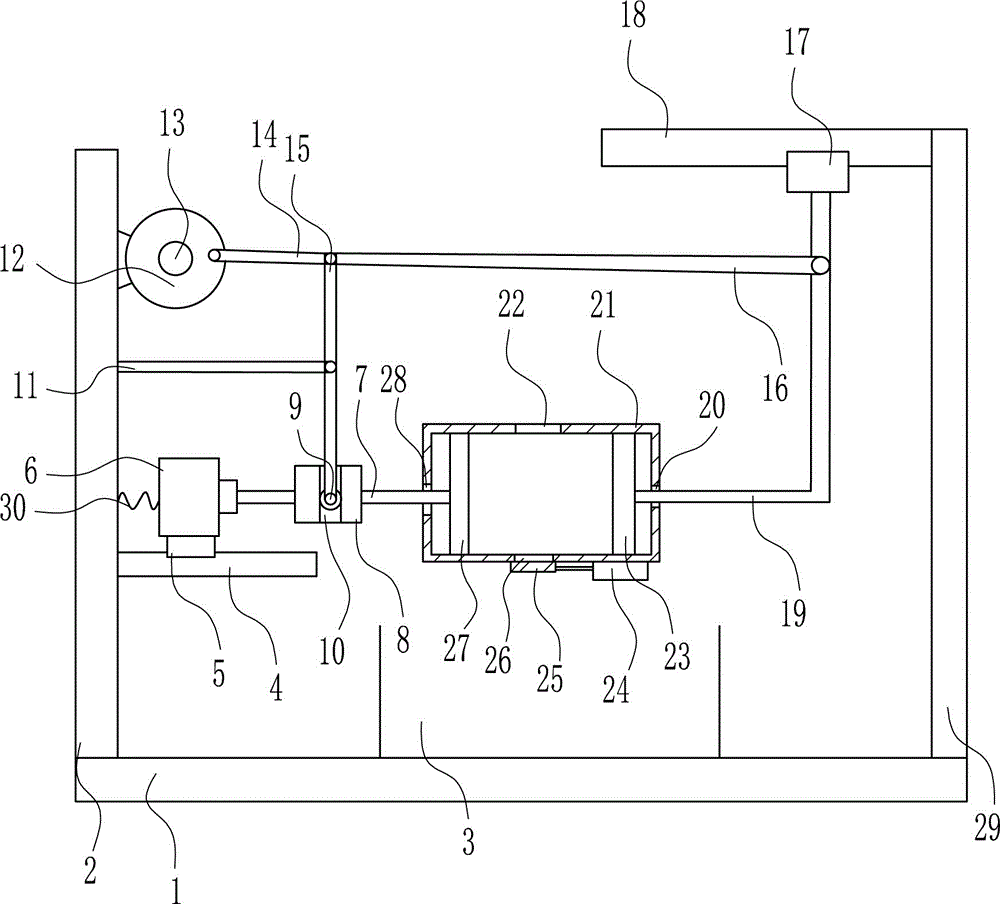

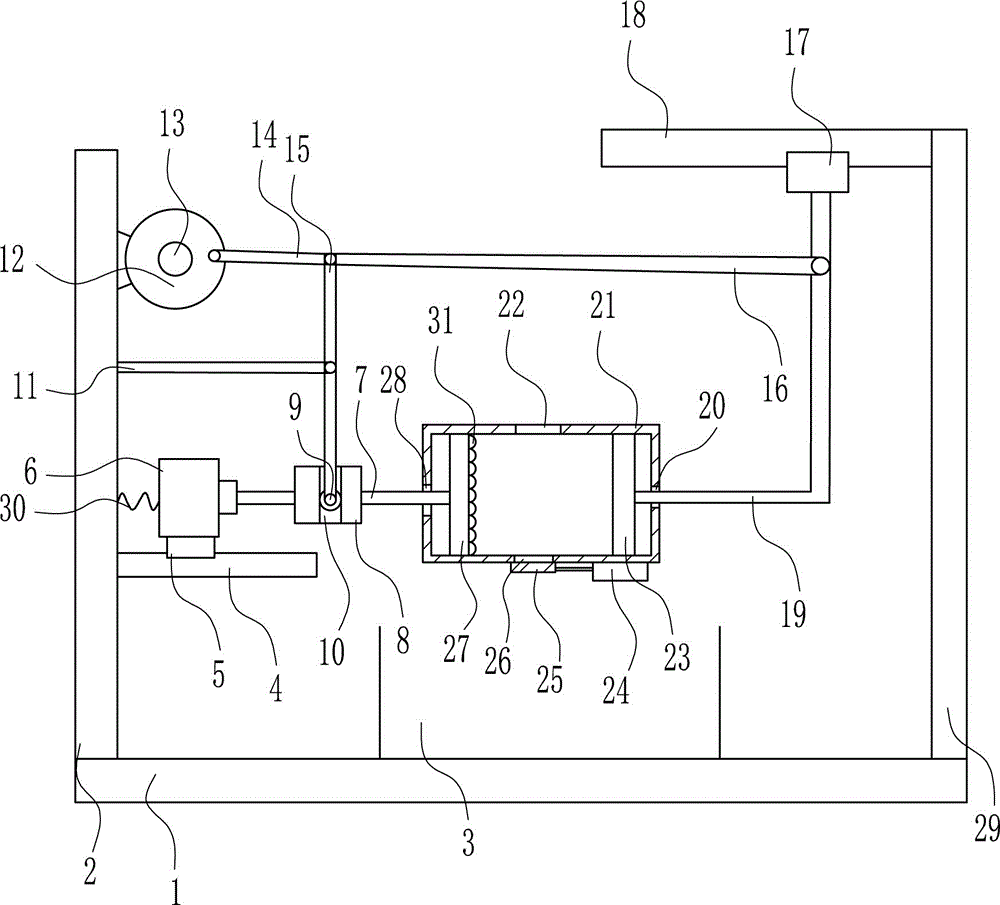

Device for crushing medical glass bottles

The invention relates to a glass bottle crushing device, in particular to a device for crushing medical glass bottles. In order to solve technical problems in the prior art, the device has the advantages that the medical glass bottles can be directly crushed, fragments of the crushed medical glass bottles can be arranged in a united manner, and the effort to recycle the medical glass bottles can be strengthened is provided. The device comprises a baseplate, a left bracket, a collecting frame, a first sliding rail, a first sliding block, a first motor, a rotating shaft, a bearing seat, a rolling wheel, a supporting rod I, a disc, a second motor, a first connecting rod, a swinging rod, a second connecting rod, a second sliding block, a second sliding rail, an L-shaped supporting rod, a compression cylinder, a first crushing plate, an air cylinder, a baffle plate, a second crushing plate and a right bracket. The device provided by the invention achieves the effects that the medical glass bottles can be directly crushed, the fragments of the crushed medical glass bottles can be arranged in a united manner, and the effort to recycle the medical glass bottles can be strengthened.

Owner:陈小方

Systems and methods for optimizing a single-stream materials recovery facility

ActiveUS8459466B2Facilitate manual and automated removalShorten speedGlass recyclingCentrifugesFiberControl theory

Systems and methods for sorting a plurality of recyclable items in a single-stream materials recovery facility (SSMRF) are provided. In some embodiments, a system includes an infeed conveying system, a fiber transfer conveyor, a container transfer conveyor, and a glass sorting and conveying system. The system further includes a controller configured to obtain total weight and volume of recyclable items at the infeed conveying system. The controller estimates a percent weight of fiber items and a percent weight of non-fiber items relative to the total weight. Based on the estimates, the controller controls speed of at least one of the infeed conveying system, the fiber transfer conveyor, the container transfer conveyor, and the glass sorting and conveying system.

Owner:RE COMMUNITY HLDG II INC

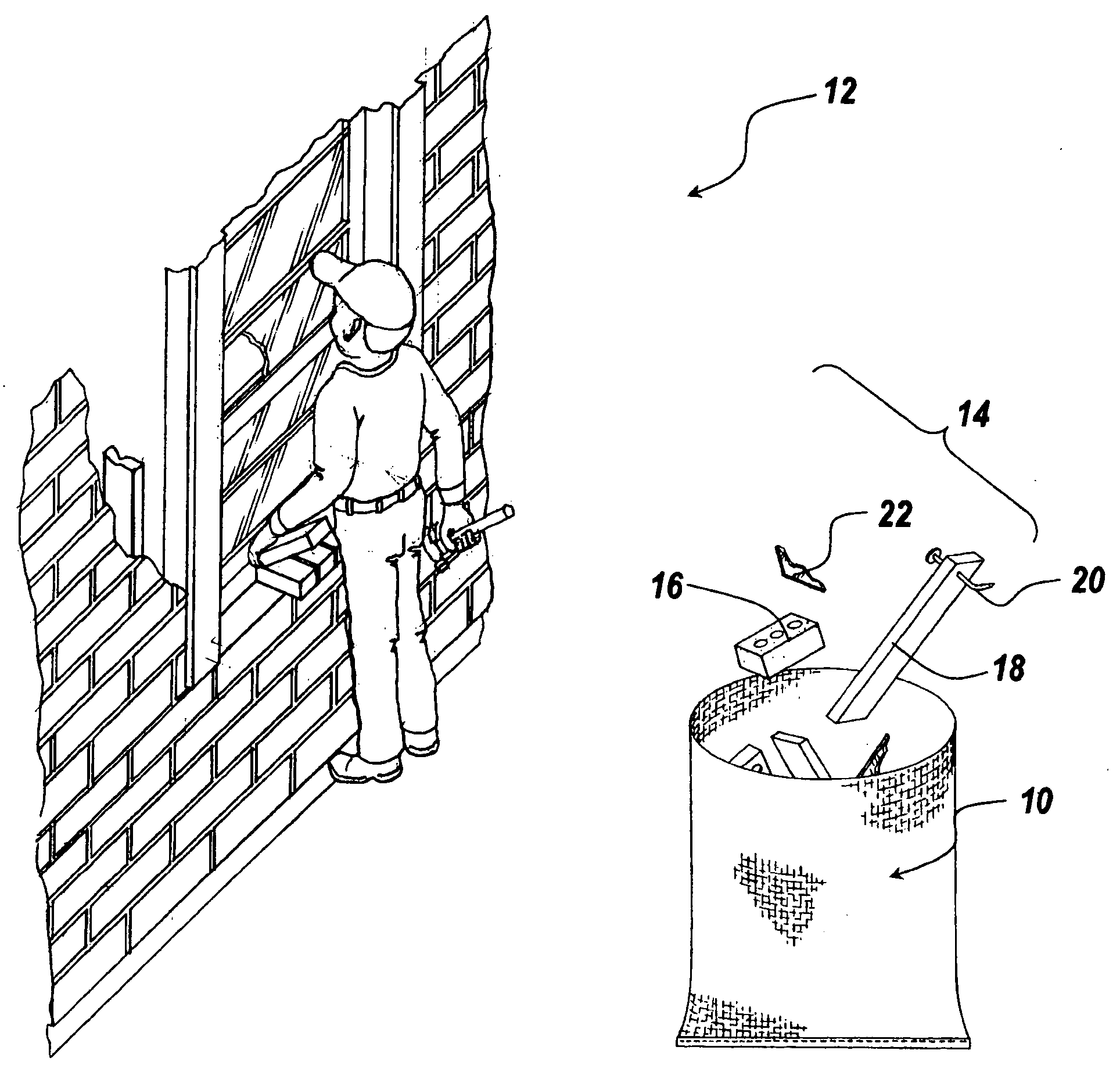

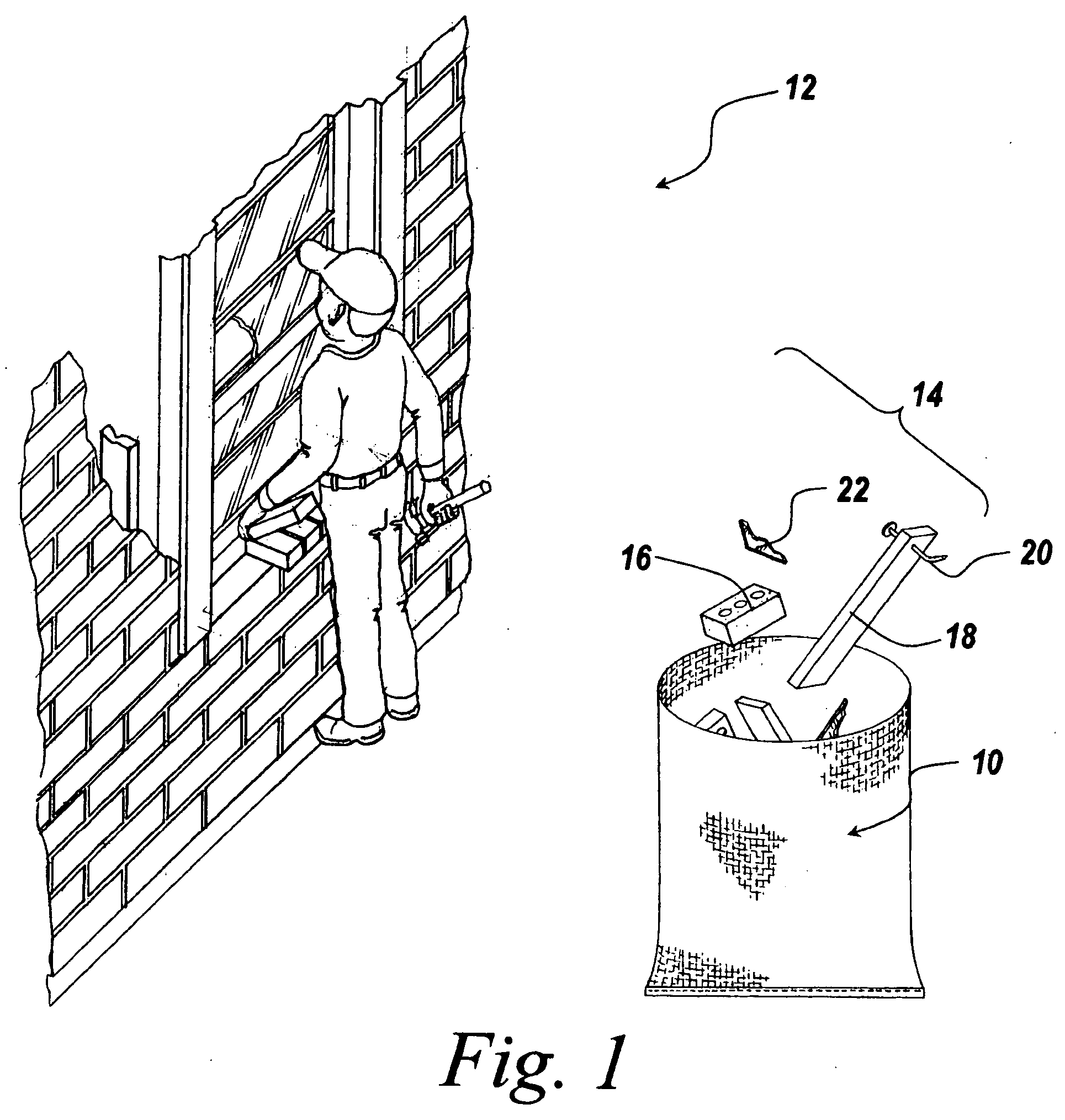

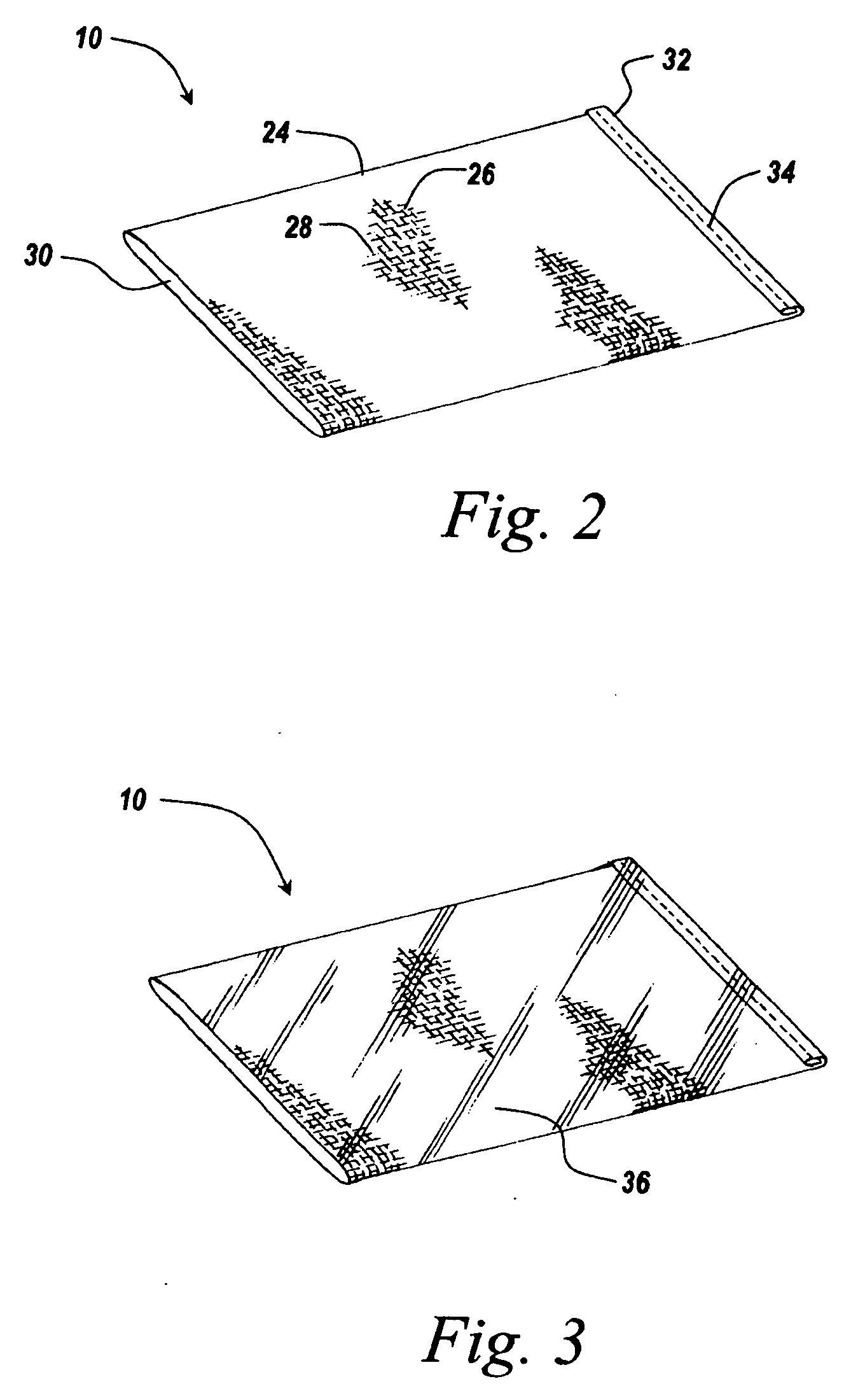

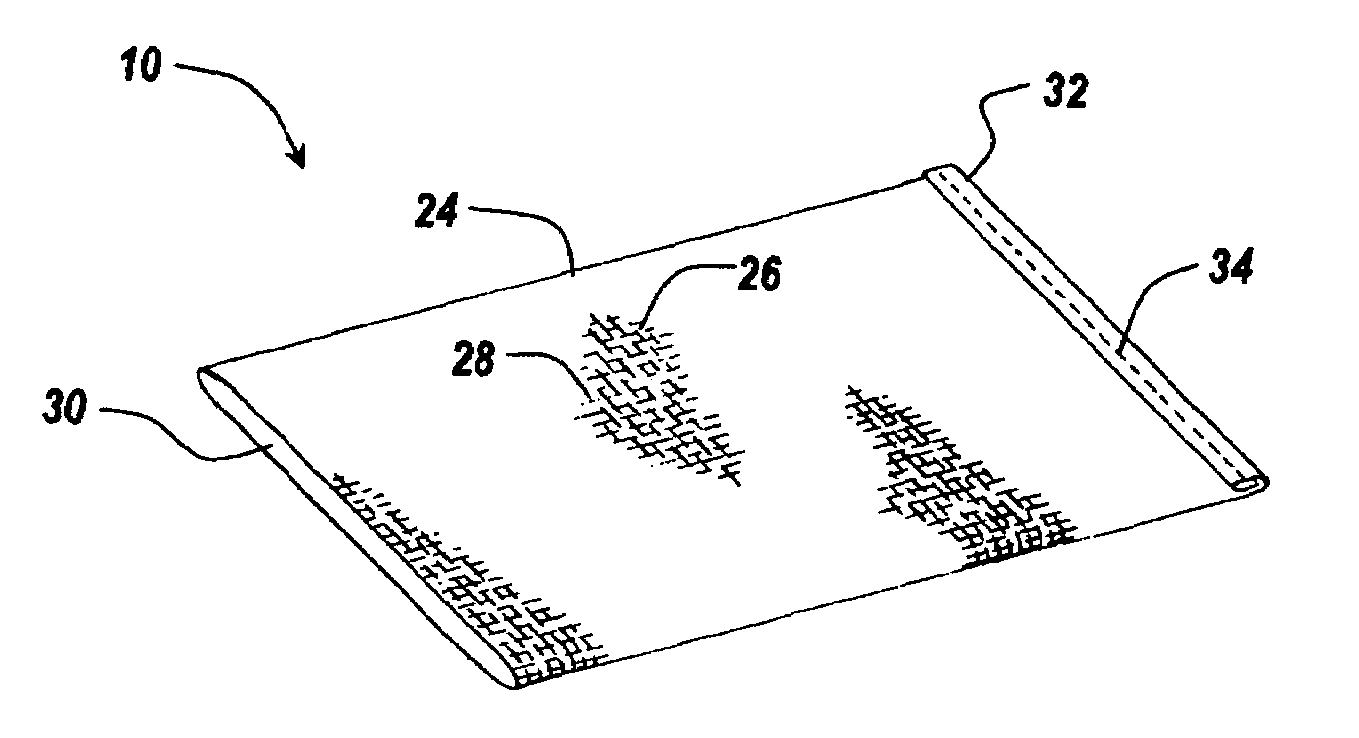

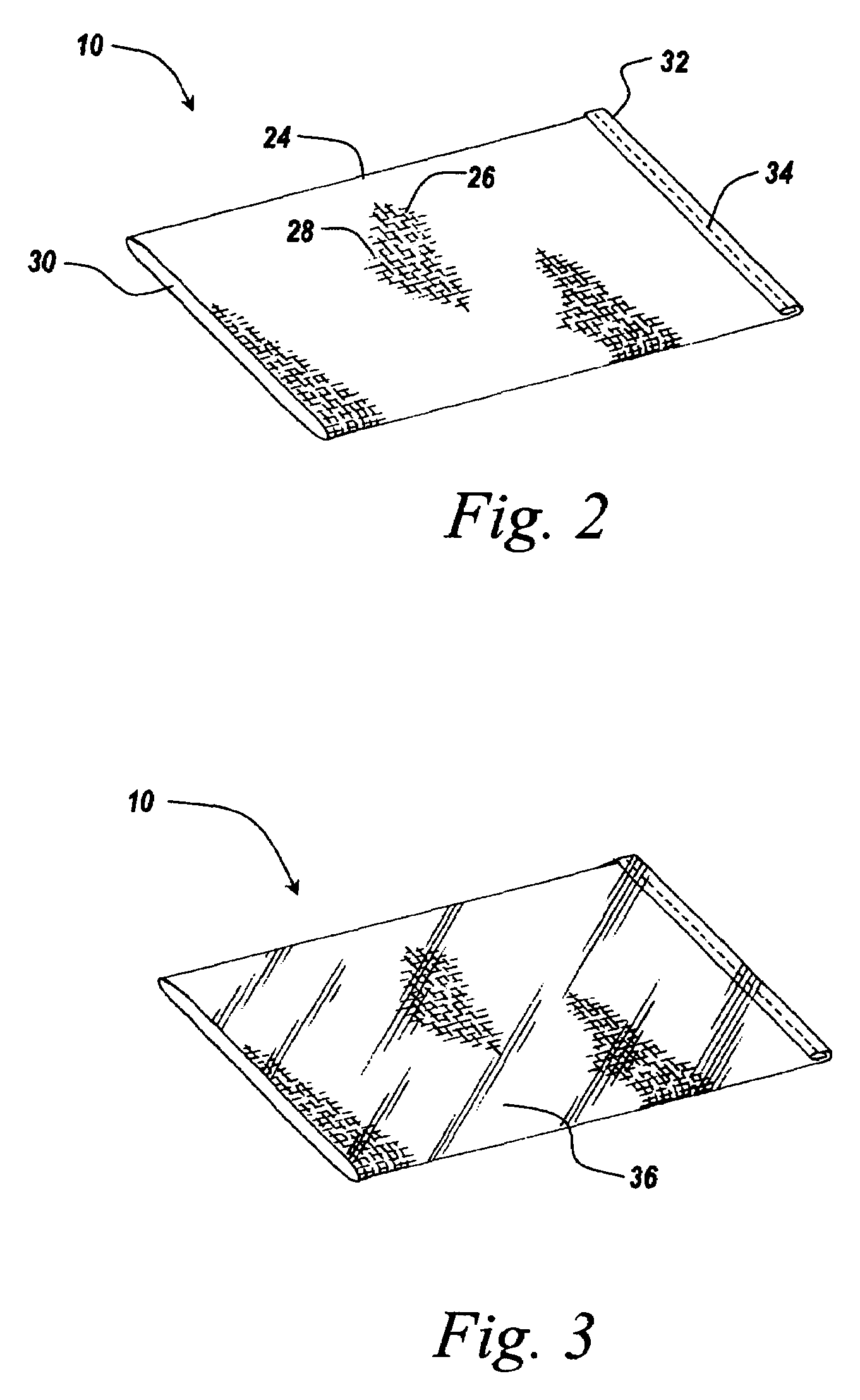

High strength ribbon-woven disposable bag for containing refuse

ActiveUS20060204696A1Reduce manufacturing costHigh strengthGlass recyclingPedestrian/occupant safety arrangementPolymer scienceBin bag

An ultra-strong tear resistant, cut resistant, puncture resistant bag having a high shear strength or modulus is provided by weaving ribbons of flat polypropylene sheet into a bag. The bag is formed by weaving a cylindrically shaped object, cutting the object transversely and sealing up one end to form the bag. The physical properties of the ribbon-woven bag easily accommodate holding refuse including bricks, wood with nails, glass and other refuse in a lightweight disposable bag. In an alternative embodiment, the ribbon-woven bag is overlain with sheets laminated to the exterior of the bag to provide a fluid-tight container.

Owner:GLOBAL STRATEGIES INC

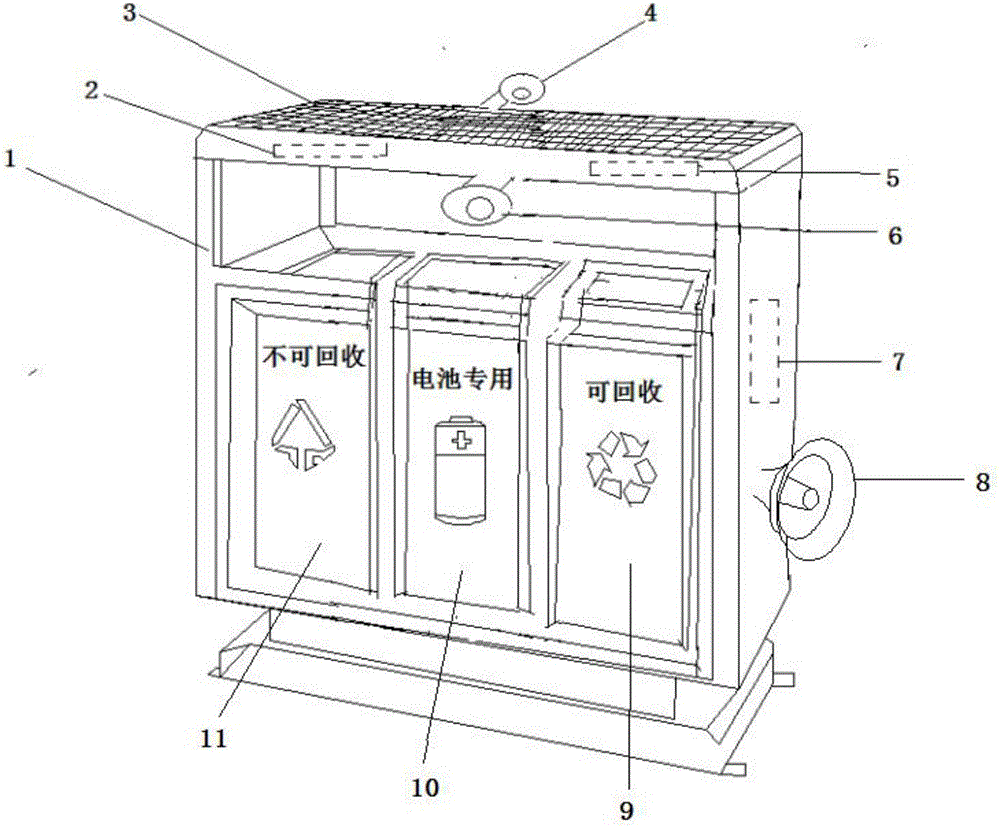

Intelligent classification trash can

InactiveCN106742960AEasy to classifyGlass recyclingWaste collection and transferElectricitySolar cell

The invention provides an intelligent classification trash can which comprises a trash can body and further comprises a power module, a controller module, a camera recognition module, a storage module and a voice module. The trash can body comprises a recyclable trash bin, a battery dedicated bin and an unrecyclable trash bin. The power module comprises a solar cell panel and a storage battery. The controller module comprises a controller. The solar cell panel is controlled by the controller to charge the storage battery. The storage battery is controlled by the controller to discharge electricity to a camera and a loudspeaker. A storage stores recyclable trash photos, battery photos and unrecyclable trash photos. The controller module controls the camera recognition module to compare trash to be thrown with the recyclable trash photos, battery photos and unrecyclable trash photos stored in the storage to recognize which classification the trash to be thrown belongs to, and the voice module reminds that the trash is thrown into the corresponding bin according to the classification.

Owner:SHENZHEN SAIYI TECH DEV

Resource recycle method for waste tubes

InactiveCN101604606AEfficient recyclingLow costGlass recyclingSolid waste disposalRecovery methodReverse current

The invention relates to a resource recycle method for waste tubes, and the technique method is as follows: pouring the waste tubes into a crusher for crushing under the negative pressure; delivering the mixture after crushing into a material receiving box; sucking the waste gas into a condensing system by an exhaust fan arranged on the top of the material receiving box for separating mercury and fluorescent powder; wherein, mercury can be recycled by a vacuum heater; the glass after crushing and the metal materials are sent to a magnetic separator for separating the glass from the metal; the separated metal is sent to a washing machine for recycling the metal by third-stage reverse current spraying washing. The invention can effectively recycle the fluorescent powder, mercury and metal, thus realizing up-to-standard discharge of waste water, waste liquid and waste gas.

Owner:HUIZHOU DINGCHEN IND DEV

Production of clean glass particles from post-consumer waste

ActiveUS20120018548A1Separate cleanInhibit productionGlass recyclingGrain treatmentsWaste streamPost-consumer waste

Owner:GLASS PROCESSING SOLUTIONS

High strength ribbon-woven disposable bag for containing refuse

ActiveUS7510327B2High modulusStrength highGlass recyclingPedestrian/occupant safety arrangementBrickBand shape

Owner:GLOBAL STRATEGIES INC

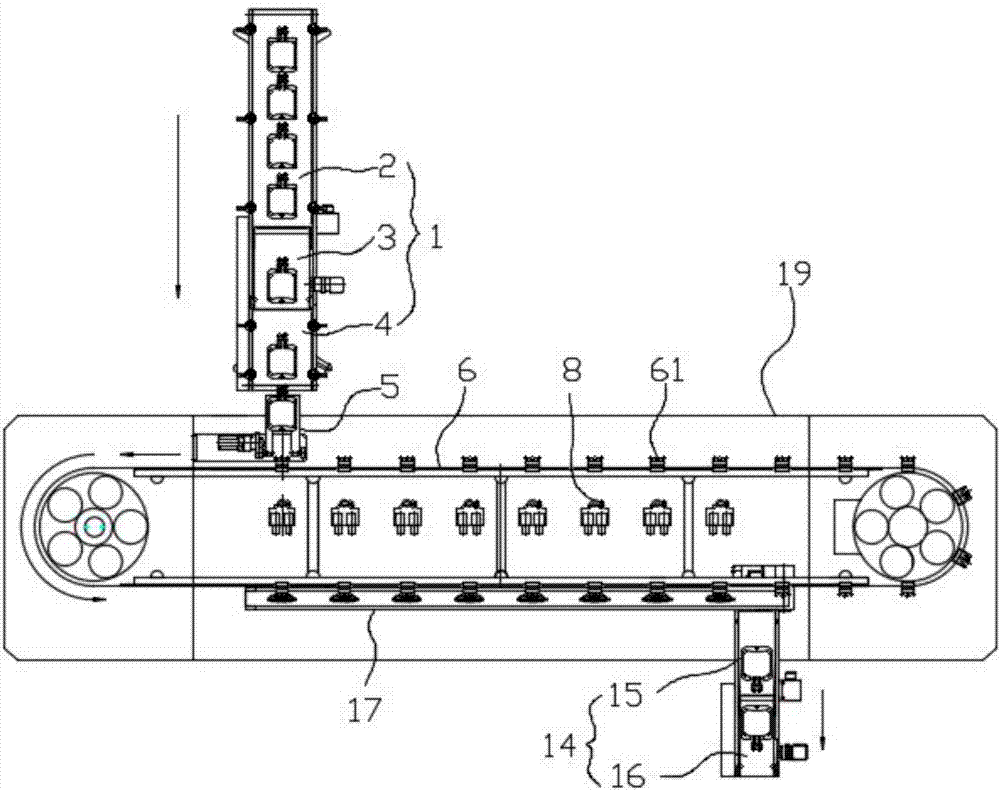

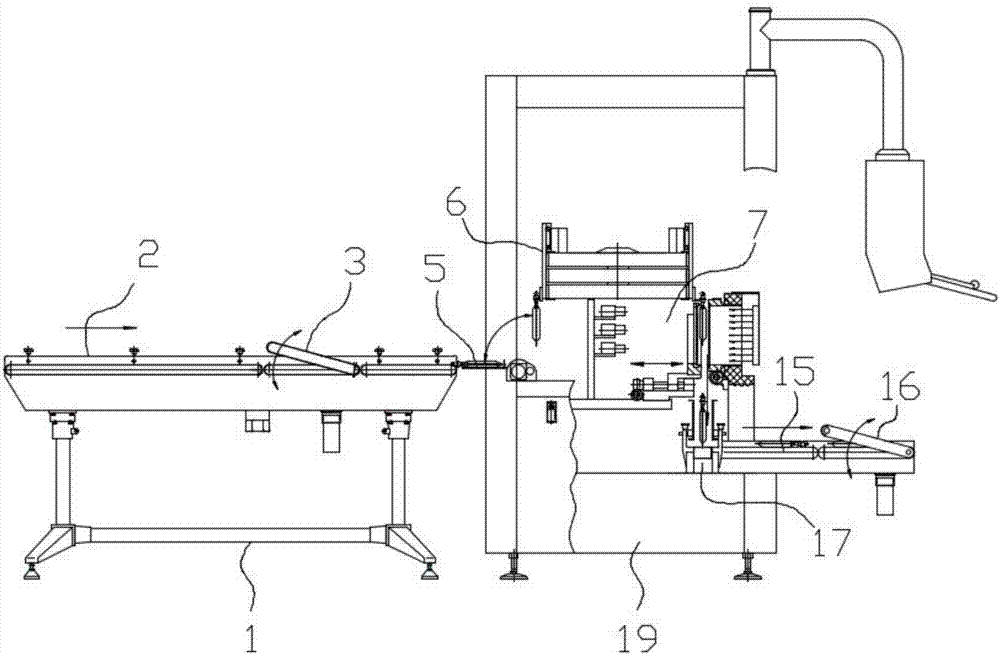

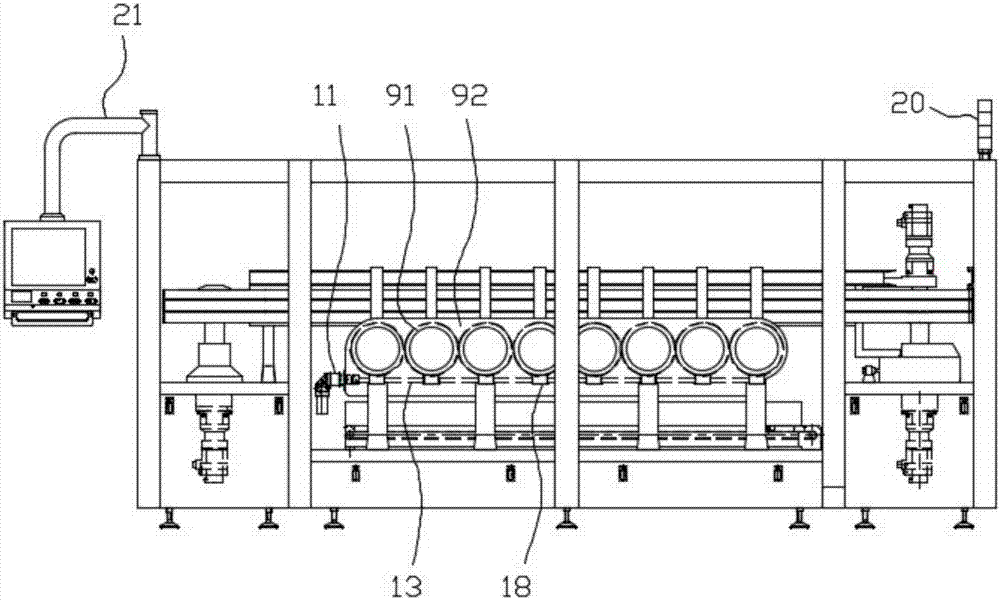

Automatic apparatus used for detecting foreign matters in soft-bag infusion

PendingCN107228863AImprove versatilityAutomatic and efficient detectionOptically investigating flaws/contaminationGlass recyclingForeign matterEngineering

The invention discloses an automatic apparatus used for detecting foreign matters in soft-bag infusion. The frame of the apparatus is provided with three cyclically-conveying synchronous belts; all the cyclically-conveying synchronous belts are provided with material hanging plates; a bag feeding and conveying device is connected with a bag receiving disc; the frame of the apparatus is provided with a detection device; the detection device comprises a clamping and turning unit; a light source group is arranged before the clamping and turning unit, and a camera group is arranged behind the clamping and turning unit; a bag receiving conveyer belt is arranged below the clamping and turning unit and connected with a bag discharging and conveying device; the clamping and turning unit comprises a sleeve mounting plate; the sleeve mounting plate is provided with a circular hole; a rotary sleeve is arranged in the circular hole; transparent glass is arranged in the rotary sleeve; a reciprocatingly-moving pressure plate is arranged in front of the rotary sleeve; a rotary circular ring is arranged in the circular hole in the reciprocatingly-moving pressure plate; transparent glass is arranged in the rotary circular ring; and the reciprocatingly-moving pressure plate is connected with a linear reciprocating mechanism. The automatic apparatus provided by the invention can accurately and efficiently detect whether soft-bag preparations have foreign matters or not and is fast in detection speed, high in precision and good in versatility.

Owner:HUNAN ZHENGZHONG PHARMA MACHINERY

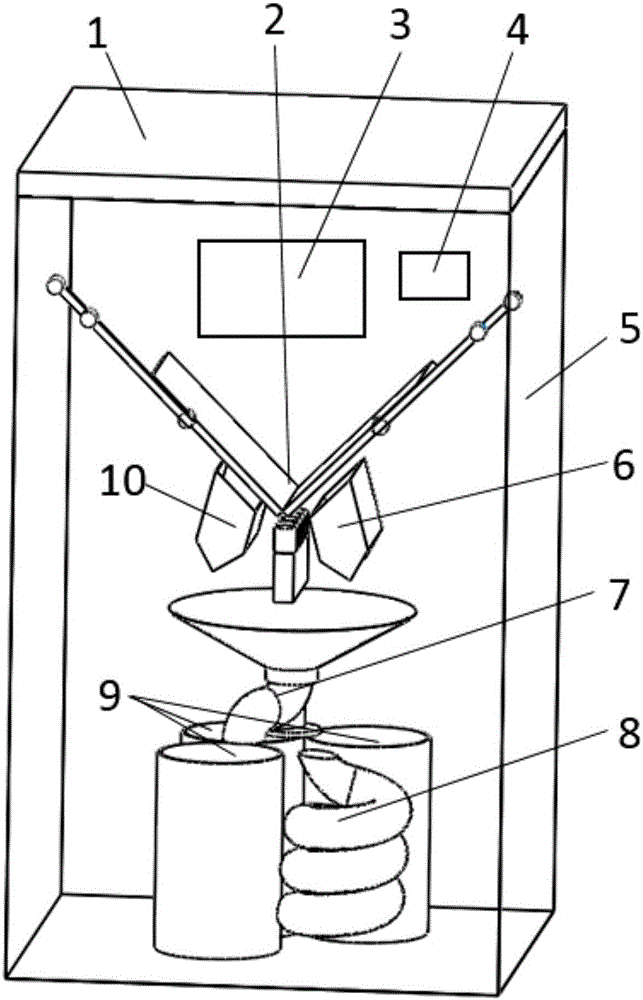

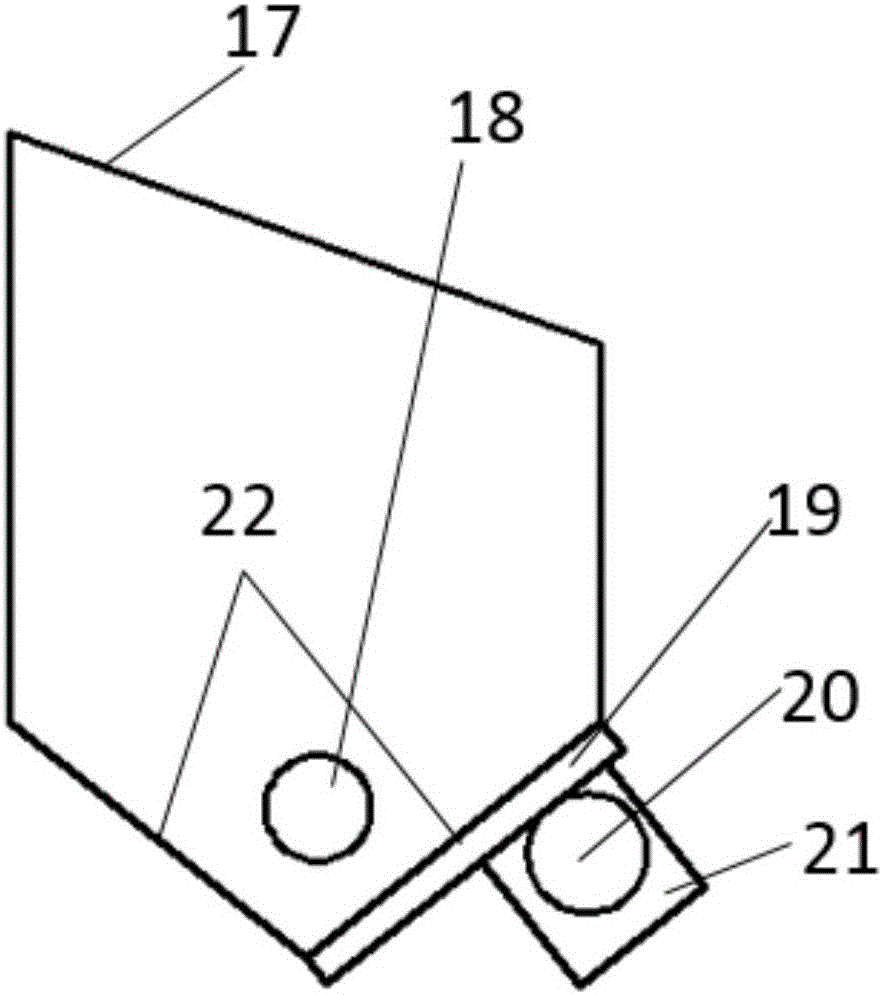

Intelligent sorting device for recycling beverage bottles

ActiveCN107444800ARealize automatic sorting and recyclingSave resourcesGlass recyclingWaste collection and transferState of artPublic place

The invention discloses an intelligent sorting device for recycling beverage bottles. The intelligent sorting device for recycling the beverage bottles comprises a rack, a put-in opening is formed above the rack, and a sorting mechanism is arranged in the rack and corresponds to the put-in opening; and after the beverage bottles are put in the device, the beverage bottles are intelligently sorted according to metal, plastic and glass and are put in a storage barrel for plastic bottles, a storage barrel for glass bottles and a storage barrel for metal bottles correspondingly. Compared with the prior art, the intelligent sorting device for recycling the beverage bottles can be put beside a beverage vending machine in a large public place, automatic sorting and recycling for rubbish with high recycling value such as beverage bottles are achieved, regeneration granulation or alcoholysis can be conducted on the plastic bottles, remelting can be conducted on the metal bottles for reproducing, the glass bottles can be sent back to a beverage factory for rewashing and filling, and a great deal of petroleum, coal and metal resources can be saved.

Owner:青州市圣鑫化工有限公司

Intelligent bottle classified recycling machine

InactiveCN105857992AEfficient and accurate resolutionCompact structureGlass recyclingRefuse receptaclesEngineeringBottle

The invention discloses an intelligent bottle classified recycling machine. The intelligent bottle classified recycling machine comprises a first movable baffle, a second movable baffle, a metal sensor, a metal bottle collecting cavity, a magnetic sensor, a non-metal bottle collecting cavity, a photoelectric sensor, bottle storage containers and a guiding conveying module, wherein the second movable baffle and the first movable baffle form a metal detecting cavity with the upper portion wide and the lower portion narrow so that bottles entering the metal detecting cavity can be concentrated at the bottom; the metal sensor is installed at the bottom of the metal detecting cavity; the metal bottle collecting cavity is located below the first movable baffle; the magnetic sensor is installed at the bottom of the metal bottle collecting cavity; the non-metal bottle collecting cavity is located below the second movable baffle; the photoelectric sensor is installed at the bottom of the metal bottle collecting cavity and used for detecting whether the bottles are made of a glass material or not; and the four bottle storage containers are located below the non-metal bottle collecting cavity and the metal bottle collecting cavity, and bottle inlets are formed in the tops of the bottle storage containers. According to the recycling machine, four kinds of bottles can be distinguished through two-stage detection and can be stored in a classified manner, a reasonable structural layout is combined with a sensor technology, material distinguishing is efficient and accurate, the overall structure is compact, and the occupied space is small.

Owner:ZHEJIANG UNIV

System and methods for glass recycling at a beneficiator

Owner:RE COMMUNITY HLDG II INC

Image display apparatus, disassembly processing method therefor, and component recovery method

InactiveUS20040002276A1Easy to useEfficient reuseElectric discharge tubesGlass recyclingRecovery methodFrit

To reuse glass used in a flat panel display, processing suitable for global environment such as processing of separating a lead component must be realized. A disassembly processing method for a flat panel display having a structure in which a face plate and rear plate mainly containing glass are airtightly joined via a frame with frit glass is characterized by including the step of separating the face plate and rear plate joined with the frit glass. The separation step is characterized by separating the face plate and rear plate by cutting, dissolution, or melting.

Owner:CANON KK

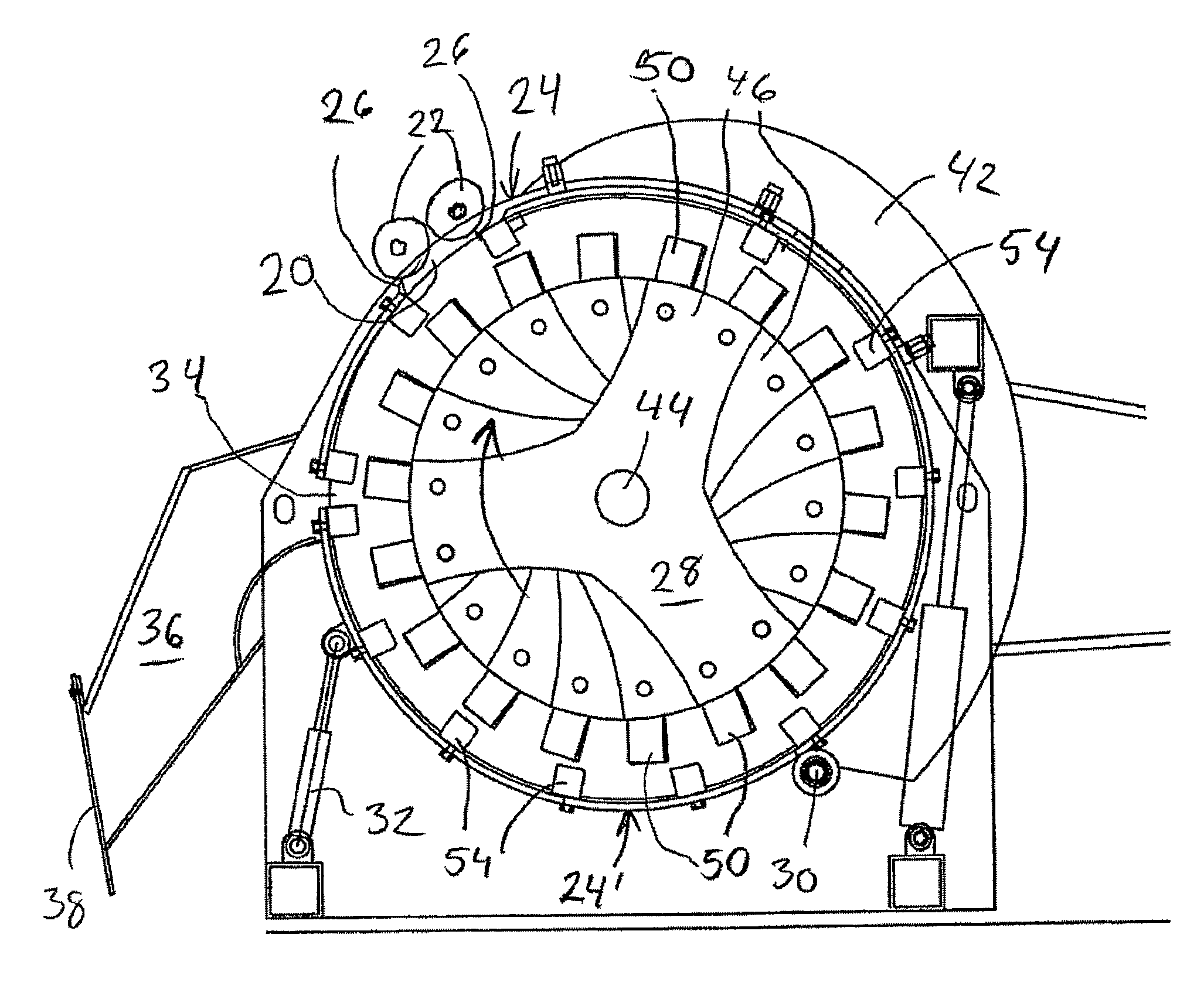

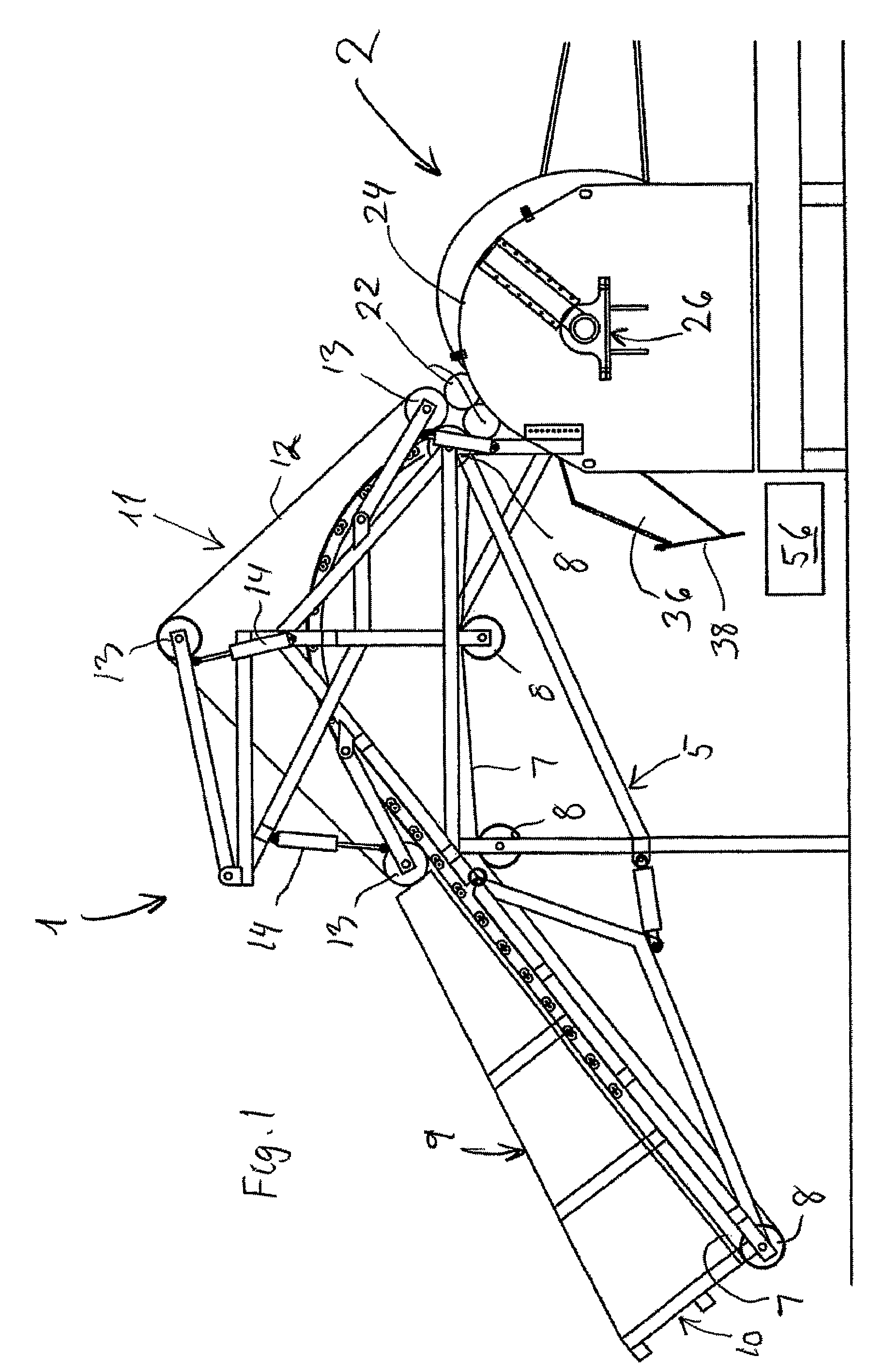

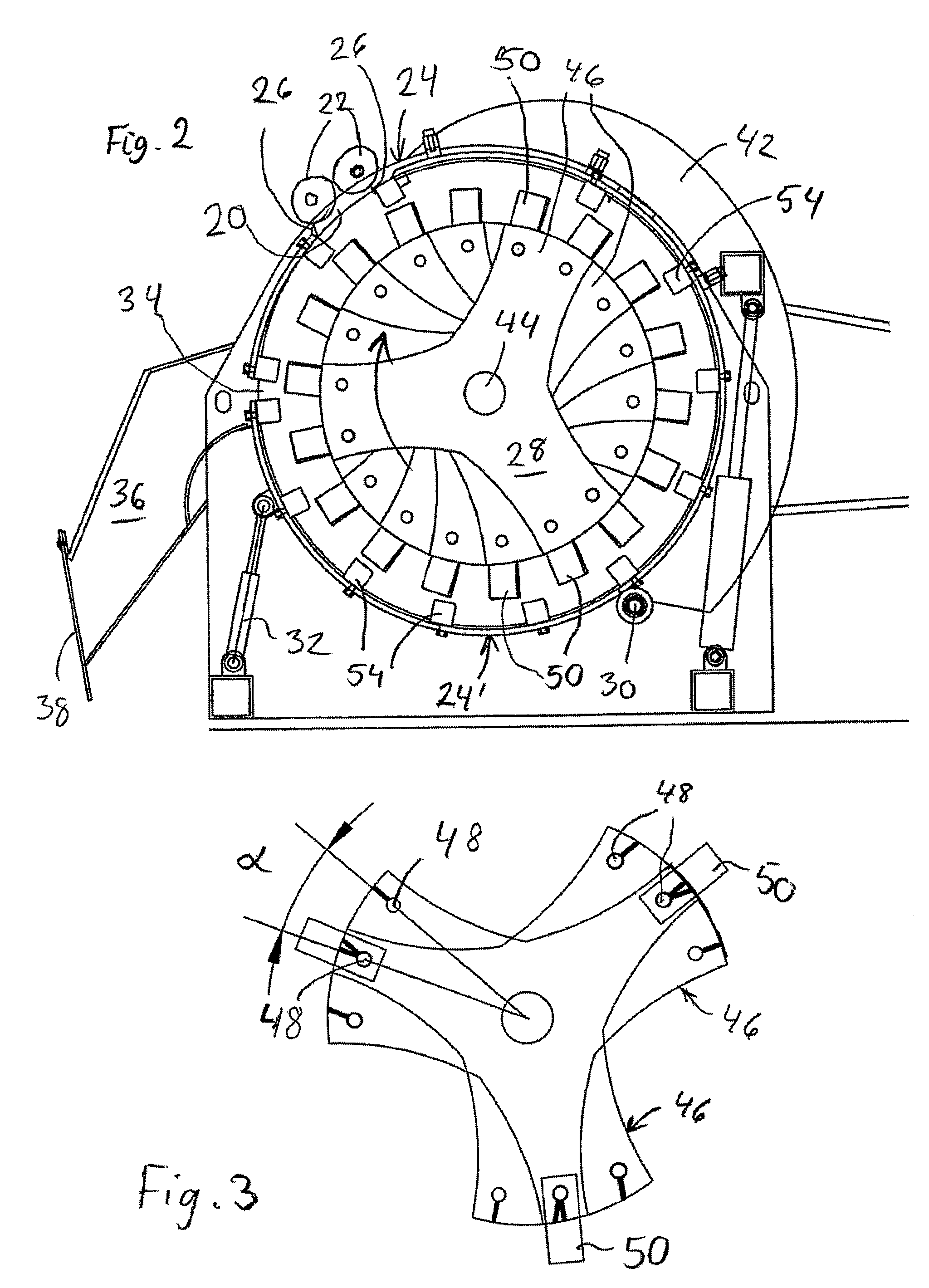

Crushing machine for comminuting laminated glass

ActiveUS7861959B2Sure control of the air flow through the discharge opening may be attainedSturdy designGrinding machine componentsGlass recyclingContinuous flowEngineering

A crushing machine for comminuting laminated glass, particularly windshields for cars, consists of a chamber with cylindric wall (24) in which is suspended a rotor (28) with pivotably beaters (50). Plural layers of laminated glass are fed through a feeding opening (20) through rubber rollers (22) which form an almost airtight lock into the crushing chamber. At the inner side of its wall (24), the chamber is provided with a number of evenly distributed ribs (54) to be impacted by laminated glass pieces, which are subsequently further comminuted by the beaters (50). The crushing chamber is provided with a slot-formed discharge opening (34) which may be varied in width. Outside the discharge opening (34), there is mounted a collecting containing (36) provided with subpressure. Due to naturally occurring leaks in the wall (24) of the crushing chamber, including the feeding opening (22), there will be a continuous flow of air out through the opening (34), why the material will eventually be conducted therethrough and collected in a container (36). From here, the material may leave the container (36) through an aperture closed by a flap (38). With the crushing machine according to the invention, there may be achieved a complete comminution of laminated glass material and separation of glass from the plastic film in one step and so that the finest glass particles have a size in the order of 0-3 millimeters.

Owner:SHARK SOLUTIONS APS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com