Patents

Literature

3098 results about "Waste product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste (or wastes) are unwanted or unusable materials.Waste is any substance which is discarded after primary use, or is worthless, defective and of no use. A by-product by contrast is a joint product of relatively minor economic value. A waste product may become a by-product, joint product or resource through an invention that raises a waste product's value above zero.

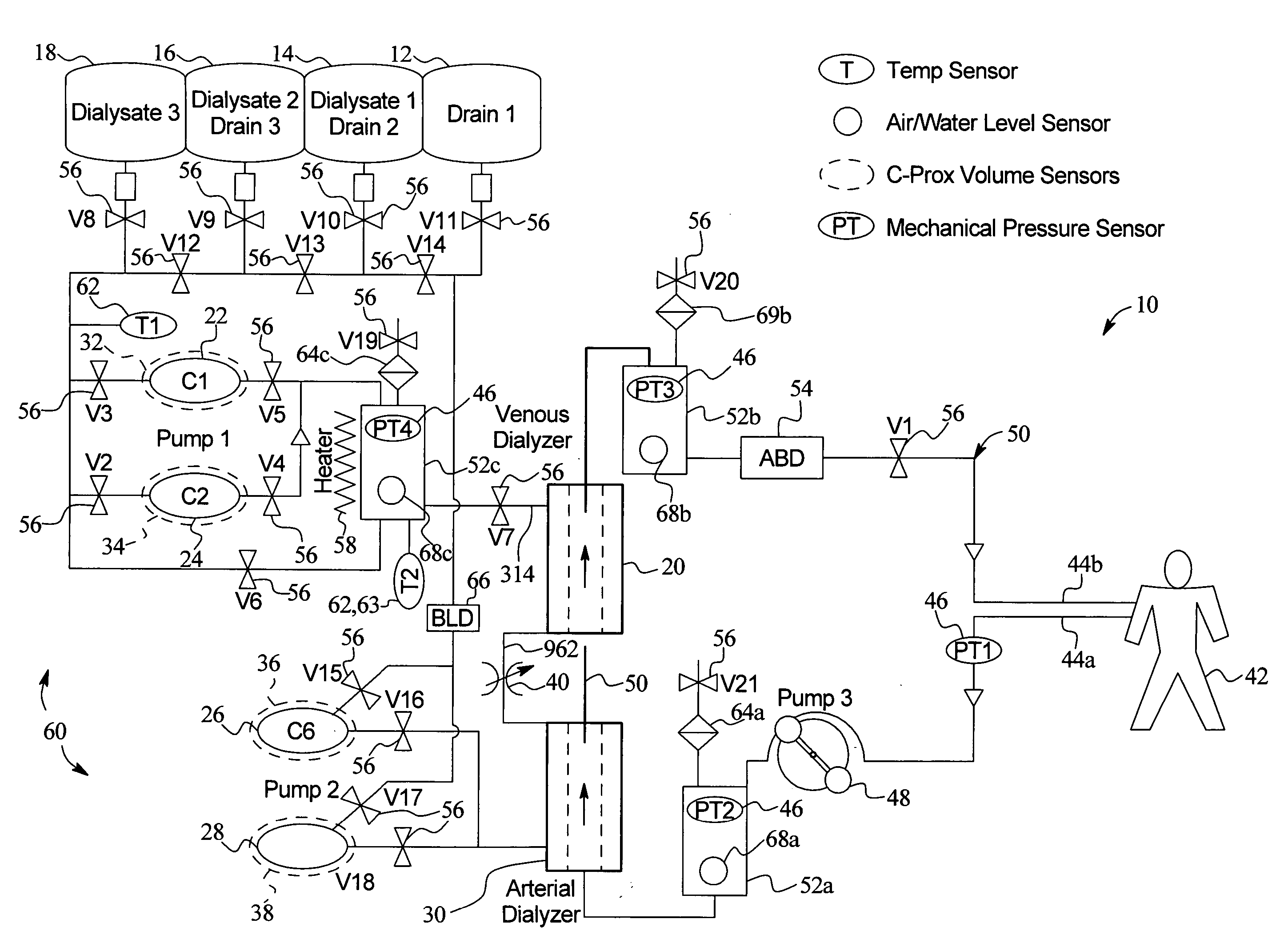

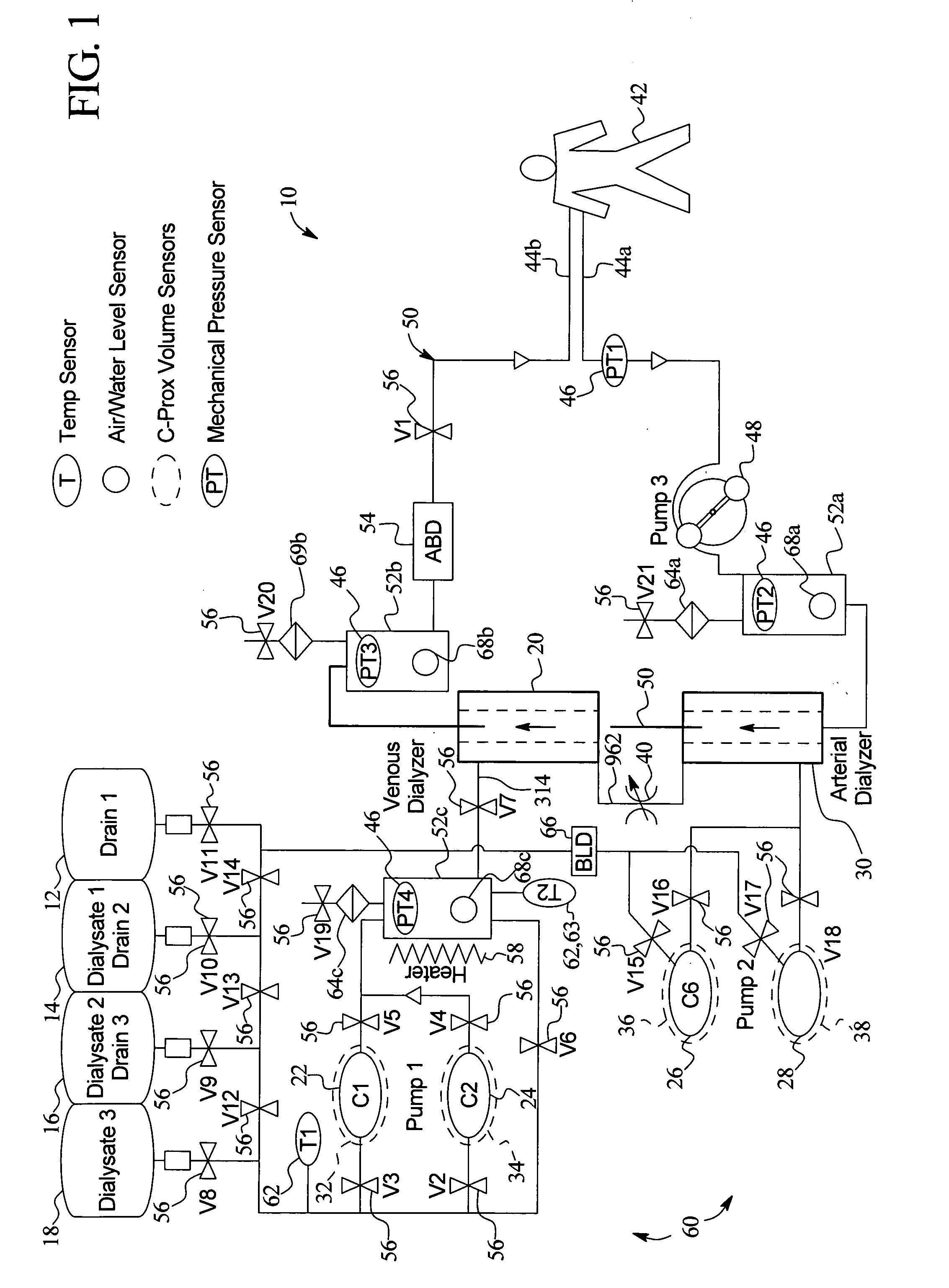

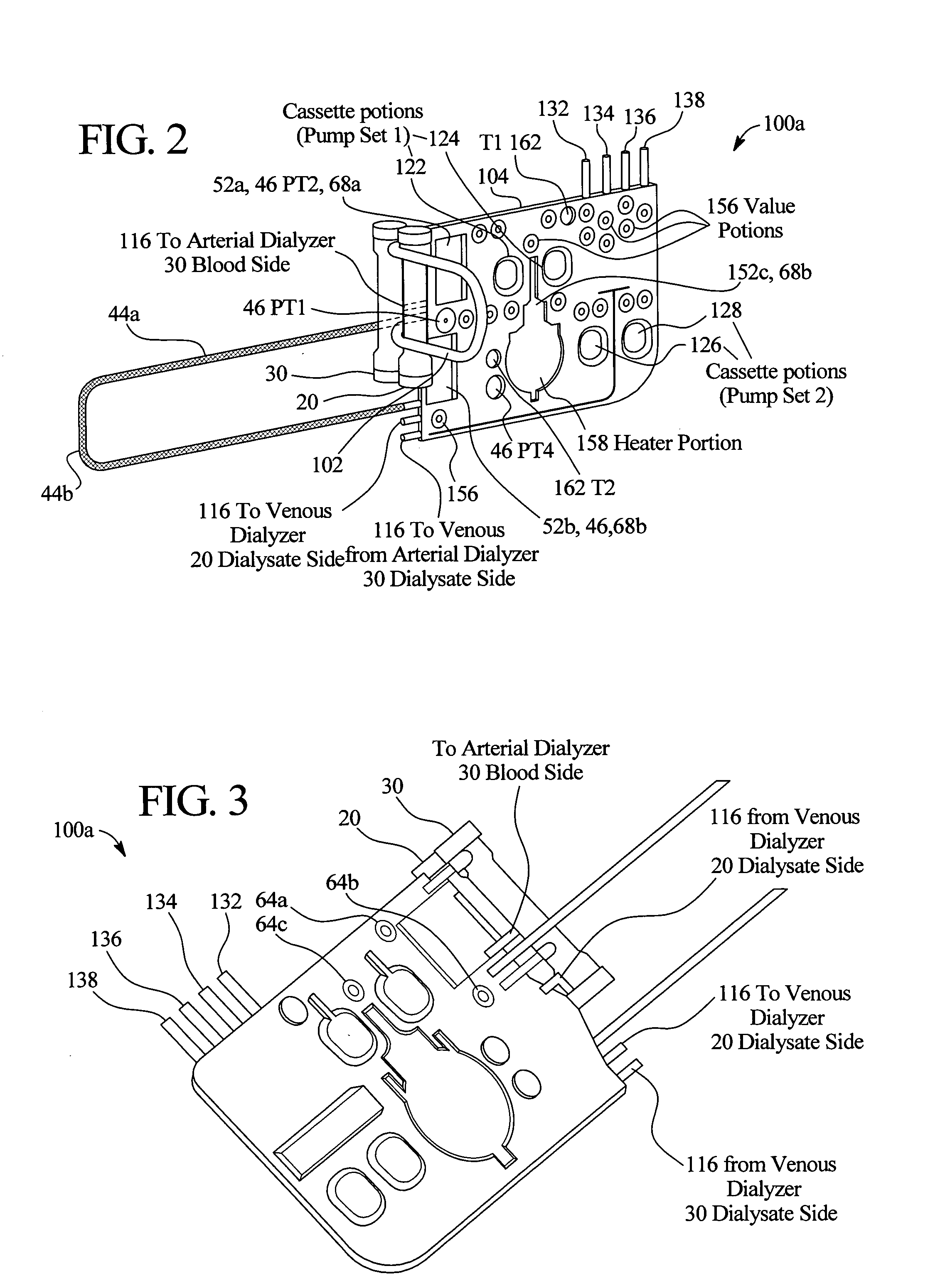

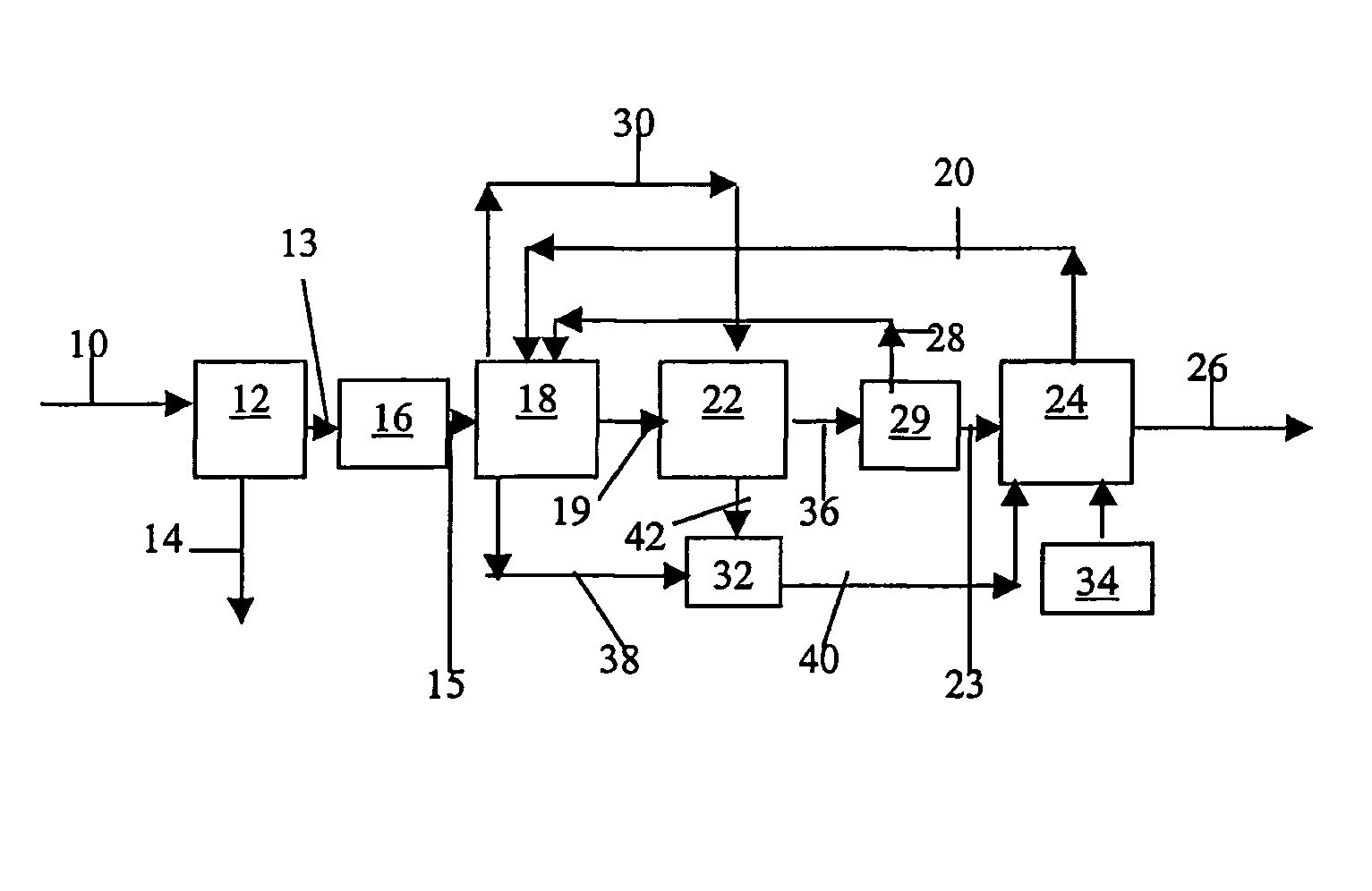

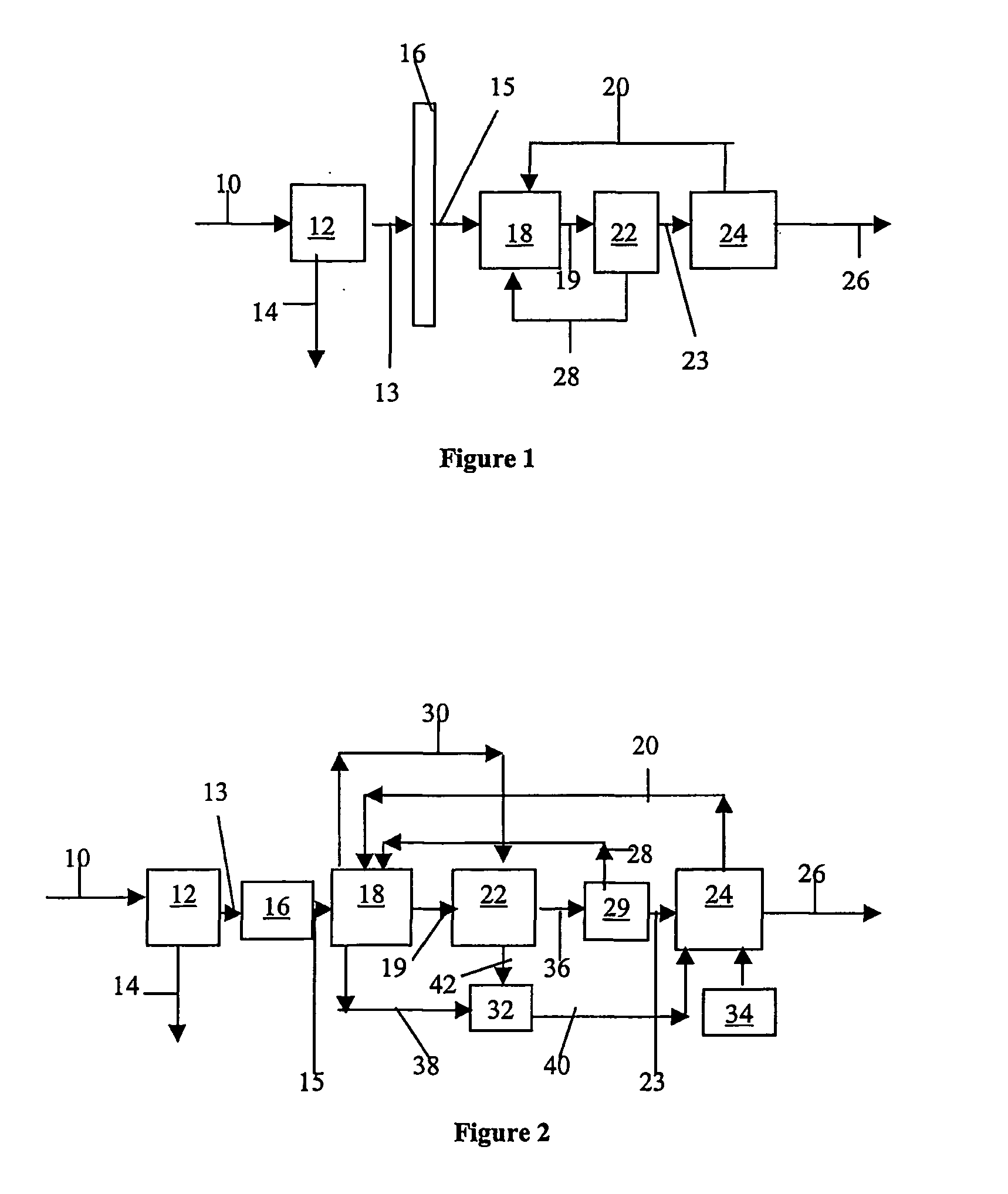

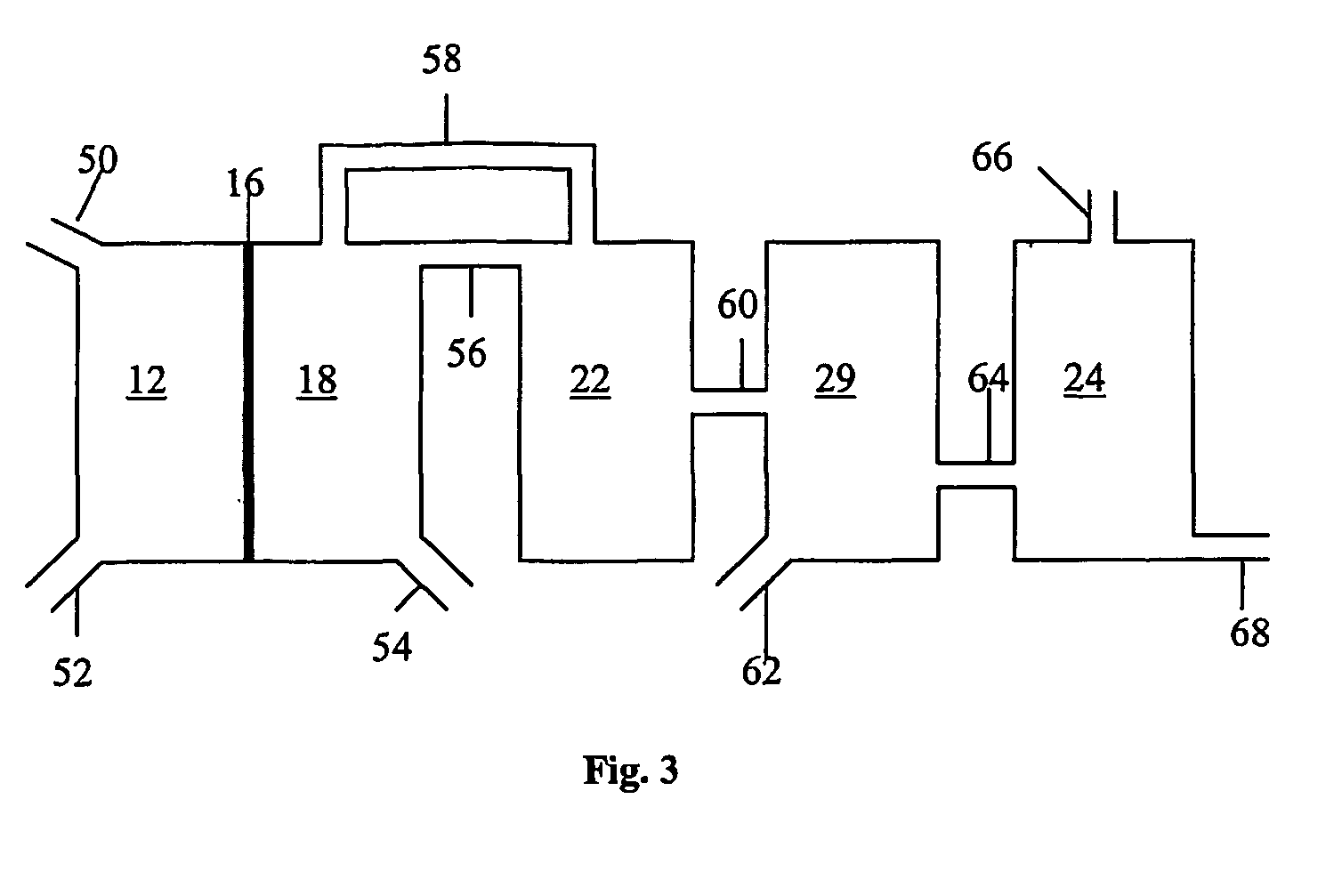

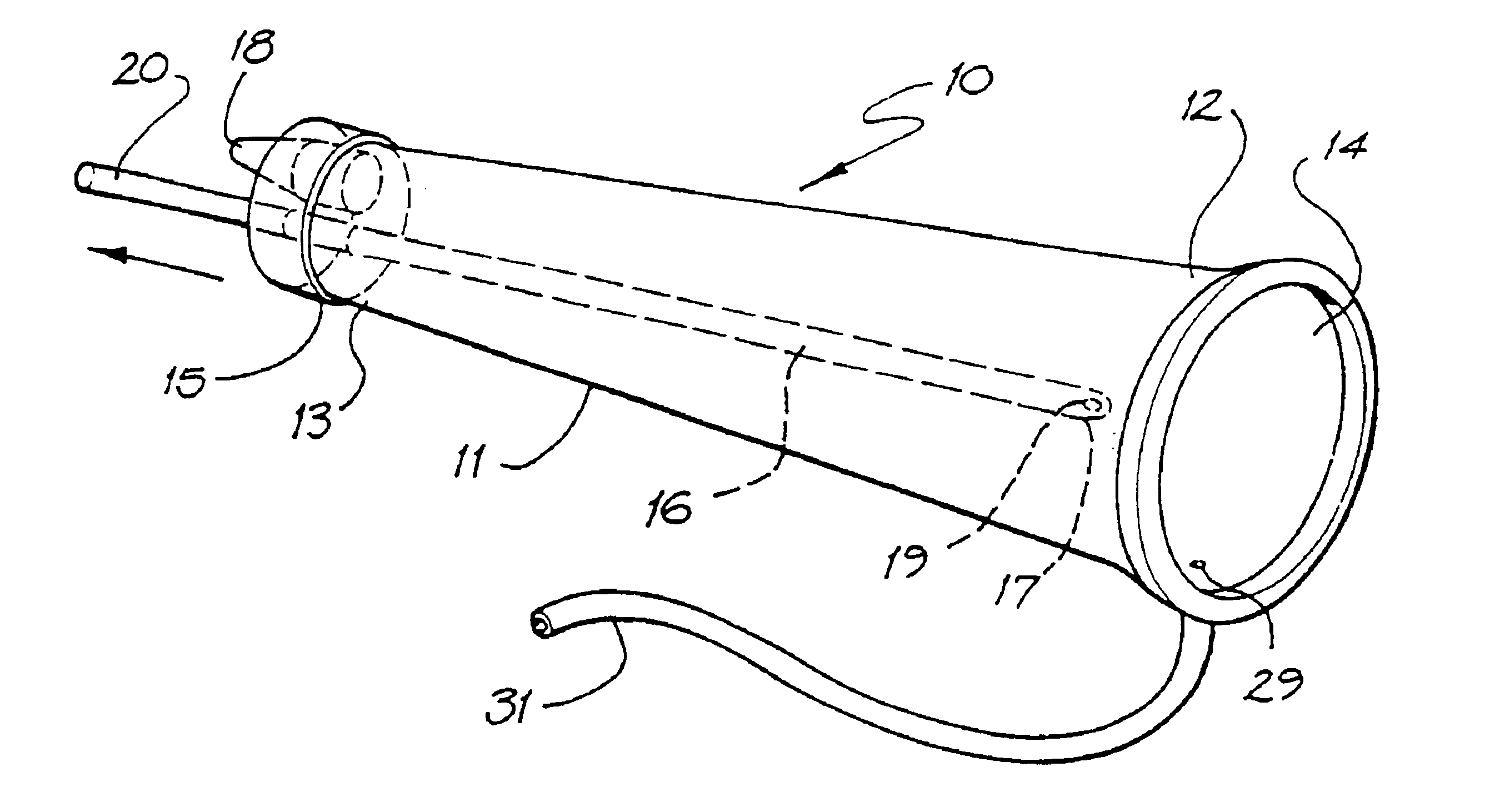

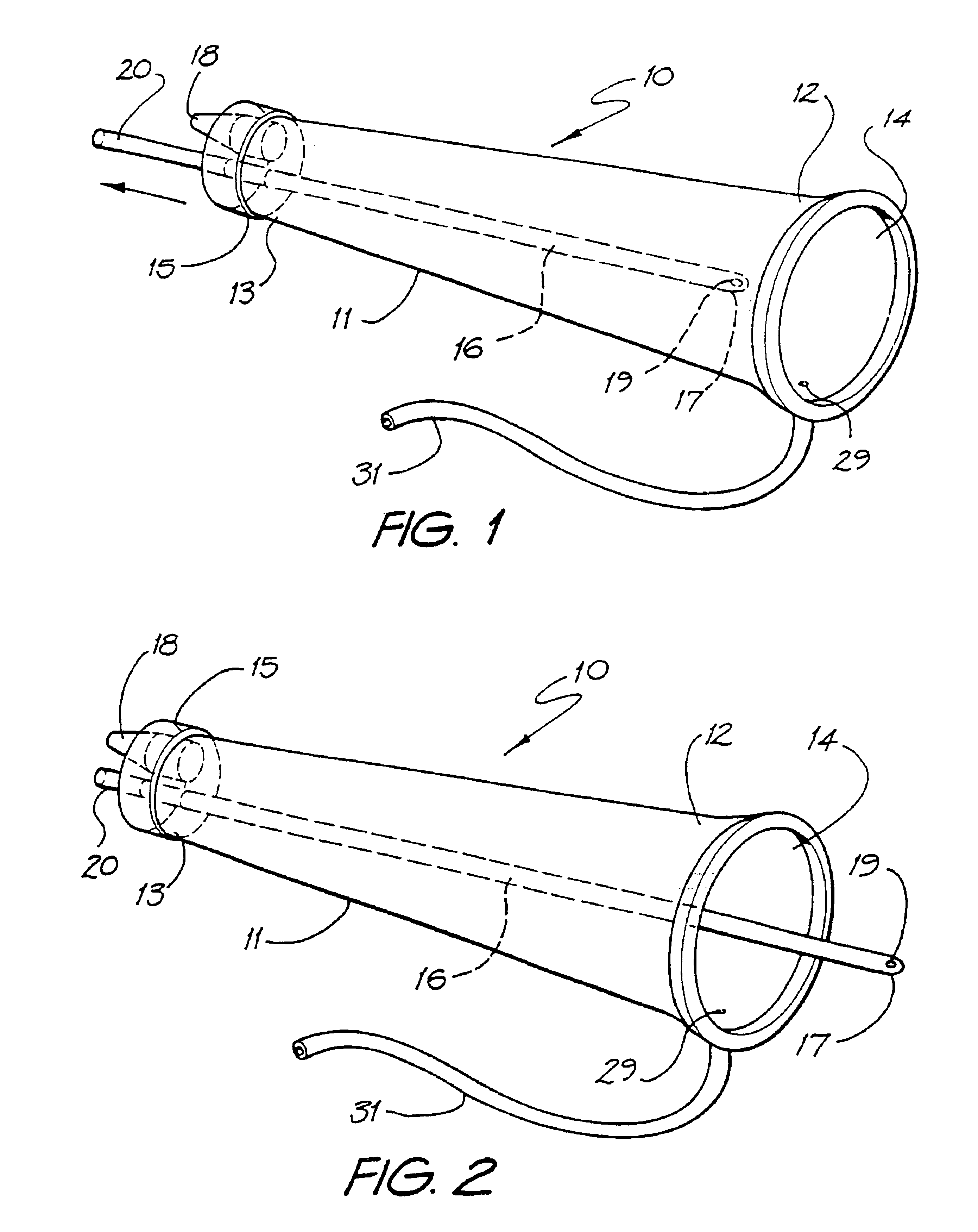

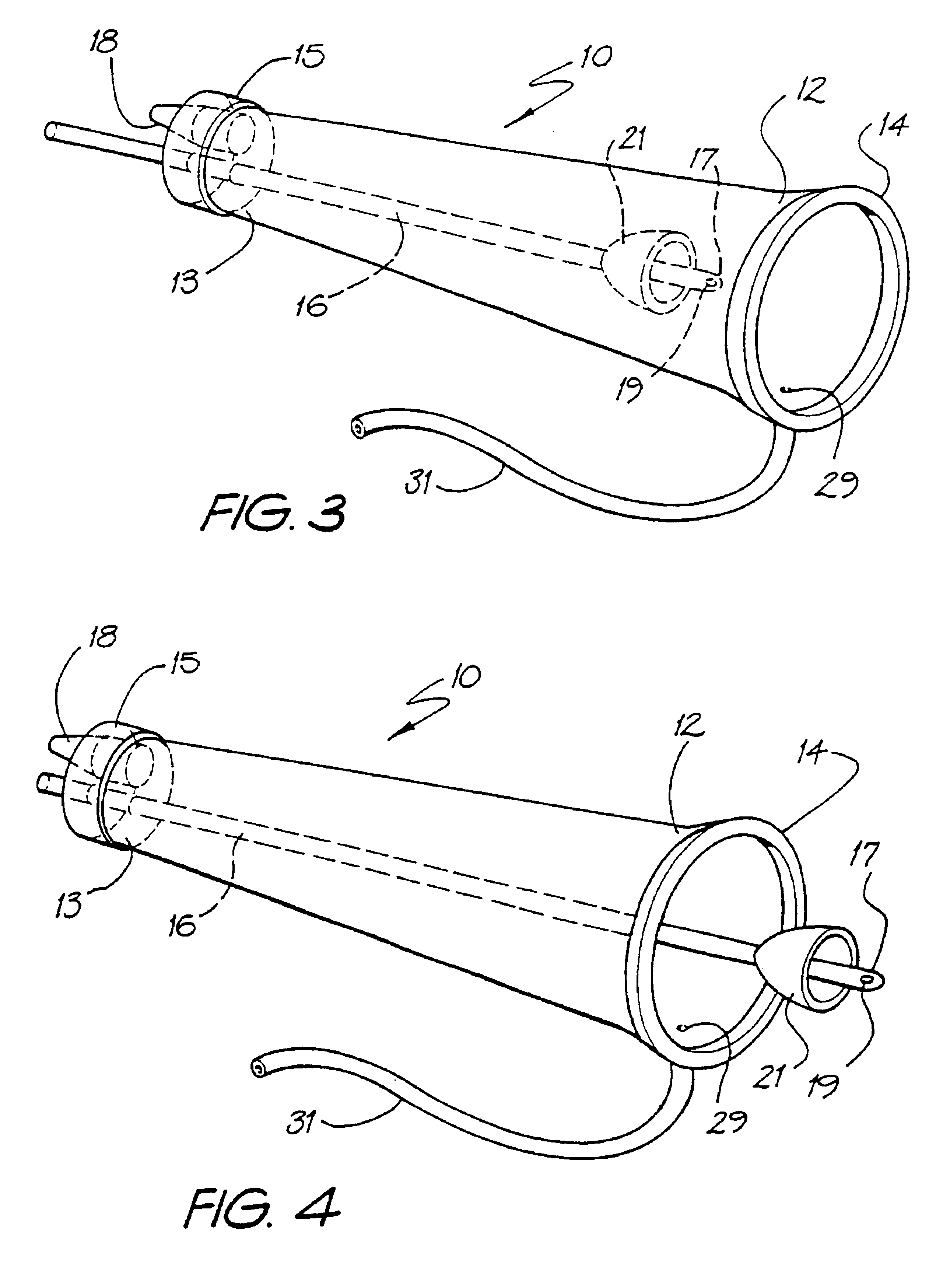

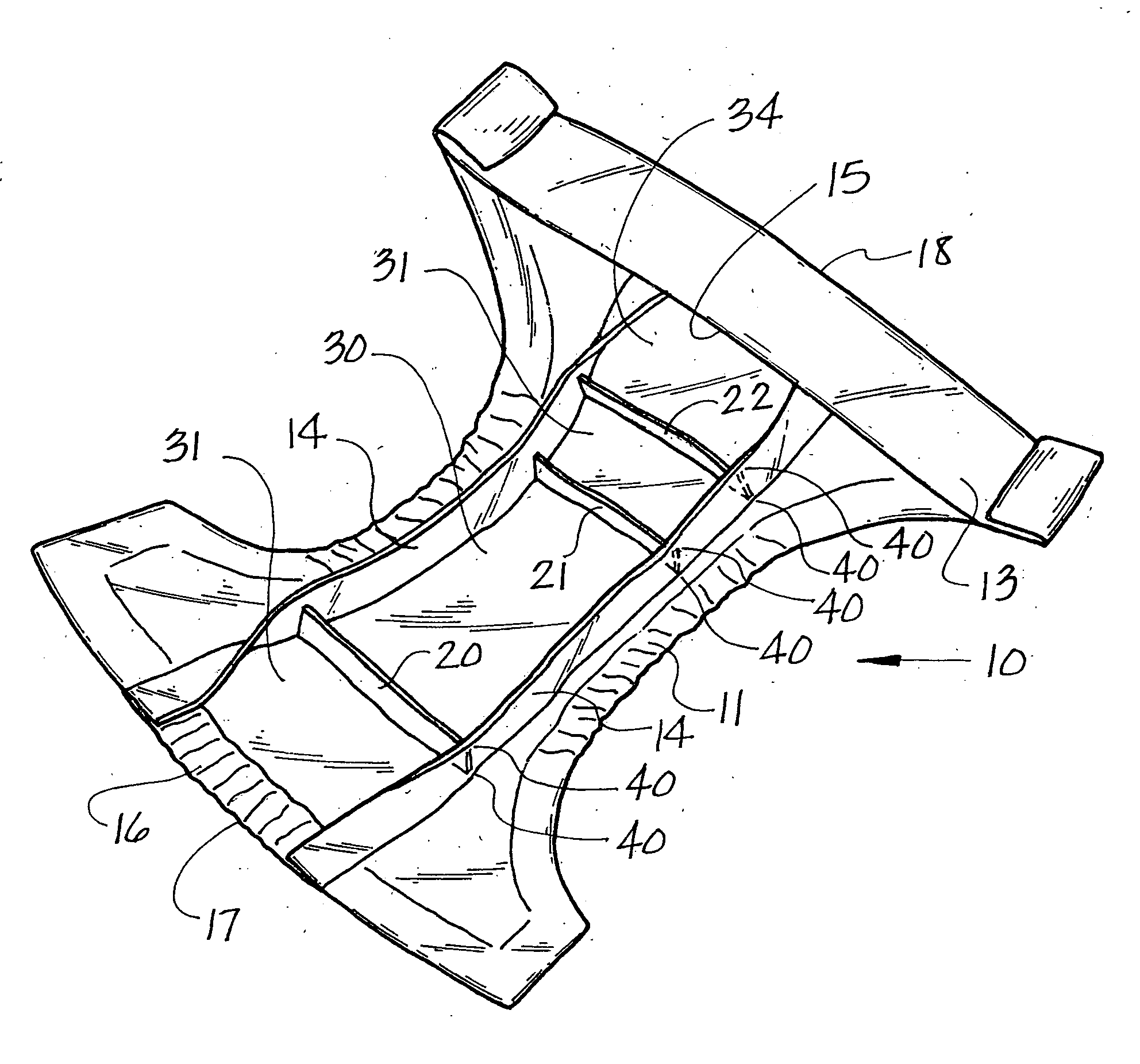

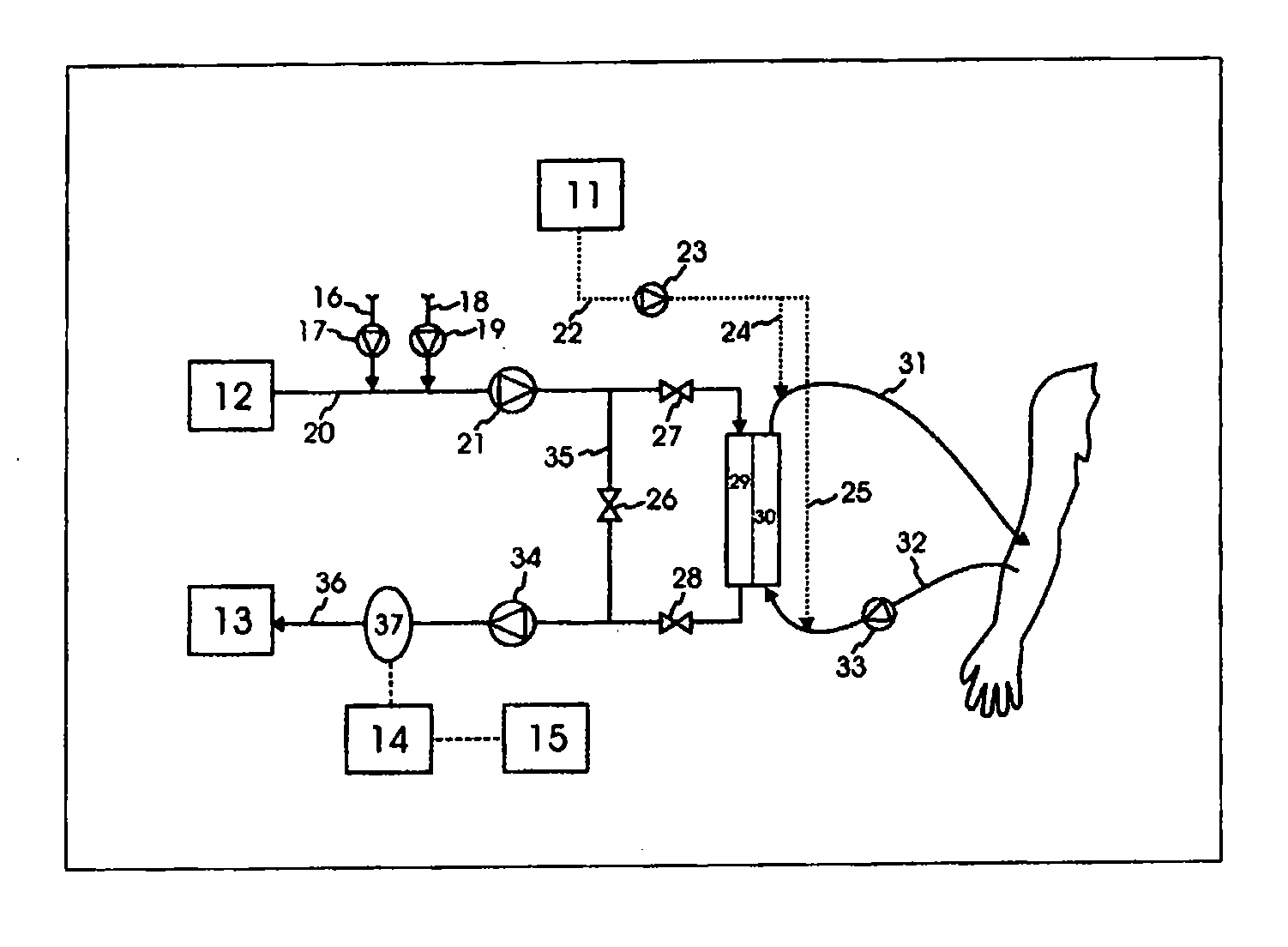

High convection home hemodialysis/hemofiltration and sorbent system

InactiveUS20050131332A1Easily set up sterile blood therapy systemImprove efficiencySemi-permeable membranesHaemofiltrationPositive pressureSorbent

A system, method and apparatus for performing a renal replacement therapy is provided. In one embodiment, two small high flux dialyzers are connected in series. A restriction is placed between the two dialyzers in the dialysate flow path. The restriction is variable and adjustable in one preferred embodiment. The restriction builds a positive pressure in the venous dialyzer, causing a high degree of intentional backfiltration. That backfiltration causes a significant flow of dialysate through the high flux venous membrane directly into the patient's blood. That backfiltered solution is subsequently ultrafiltered from the patient from the arterial dialyzer. The diffusion of dialysate into the venous filter and removal of dialysate from the arterial dialyzer causes a convective transport of toxins from the patient. Additionally, the dialysate that does not diffuse directly into the patient but instead flows across the membranes of both dialyzers provides a diffusive clearance of waste products.

Owner:BAXTER HEALTHCARE SA +1

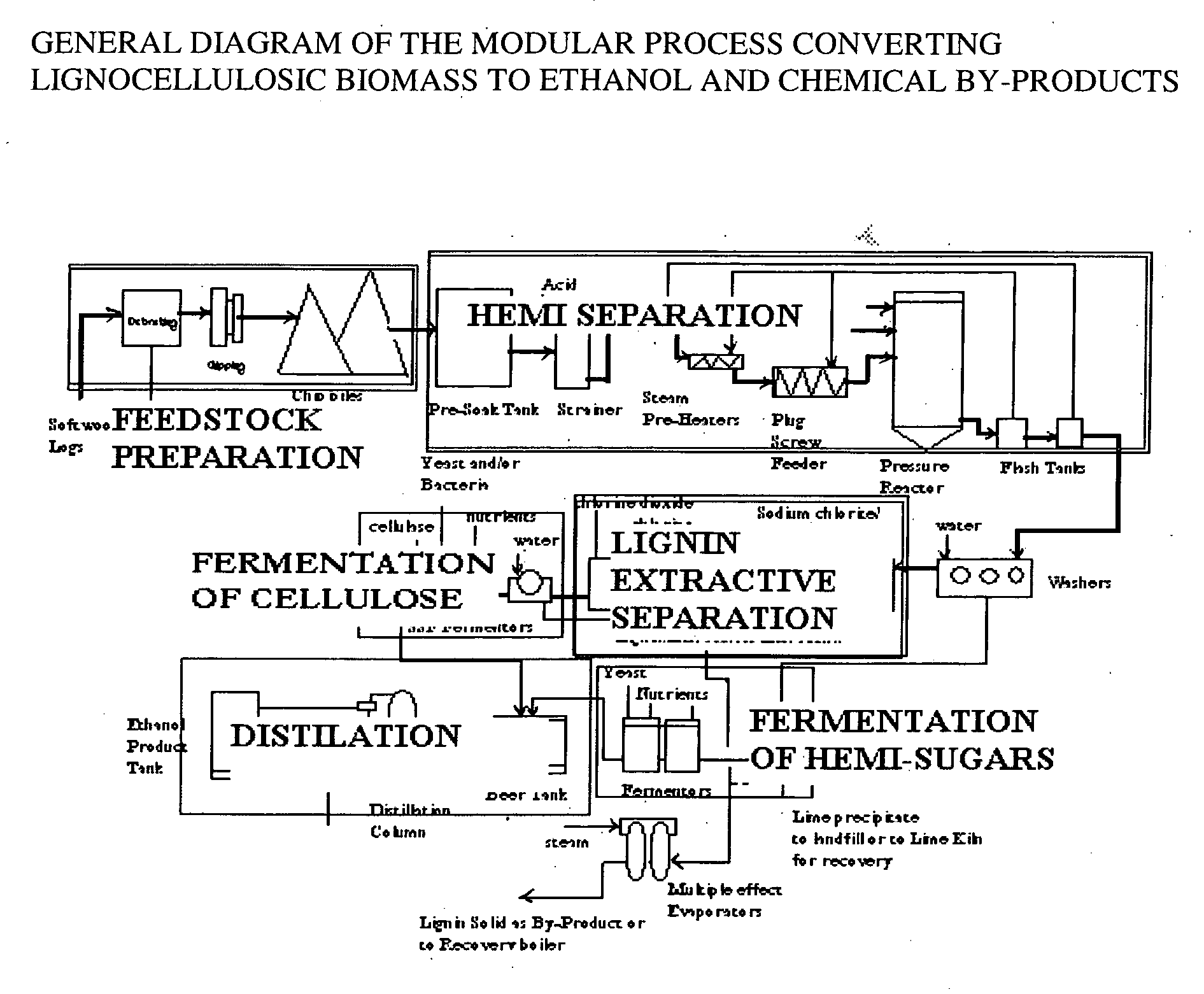

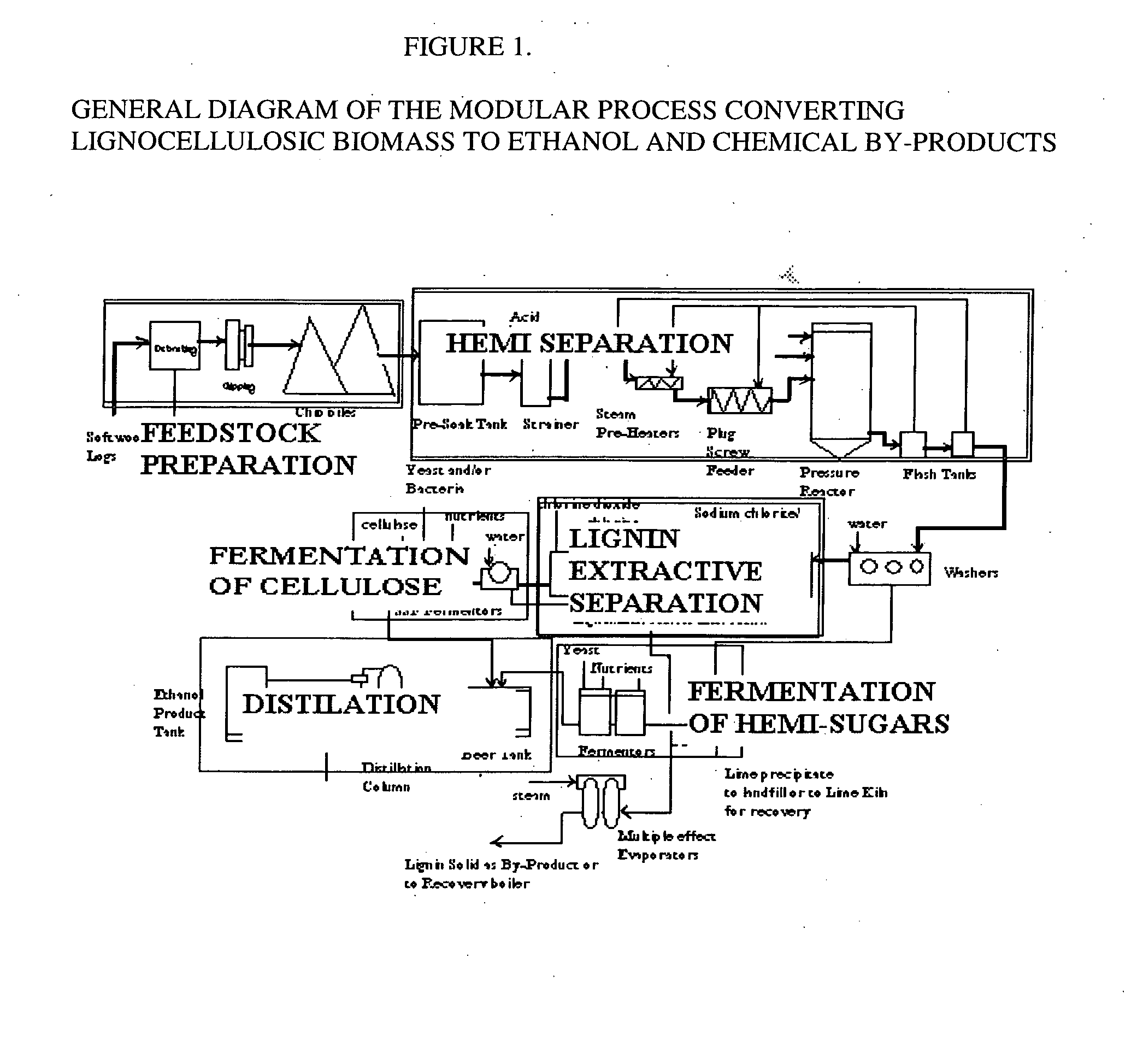

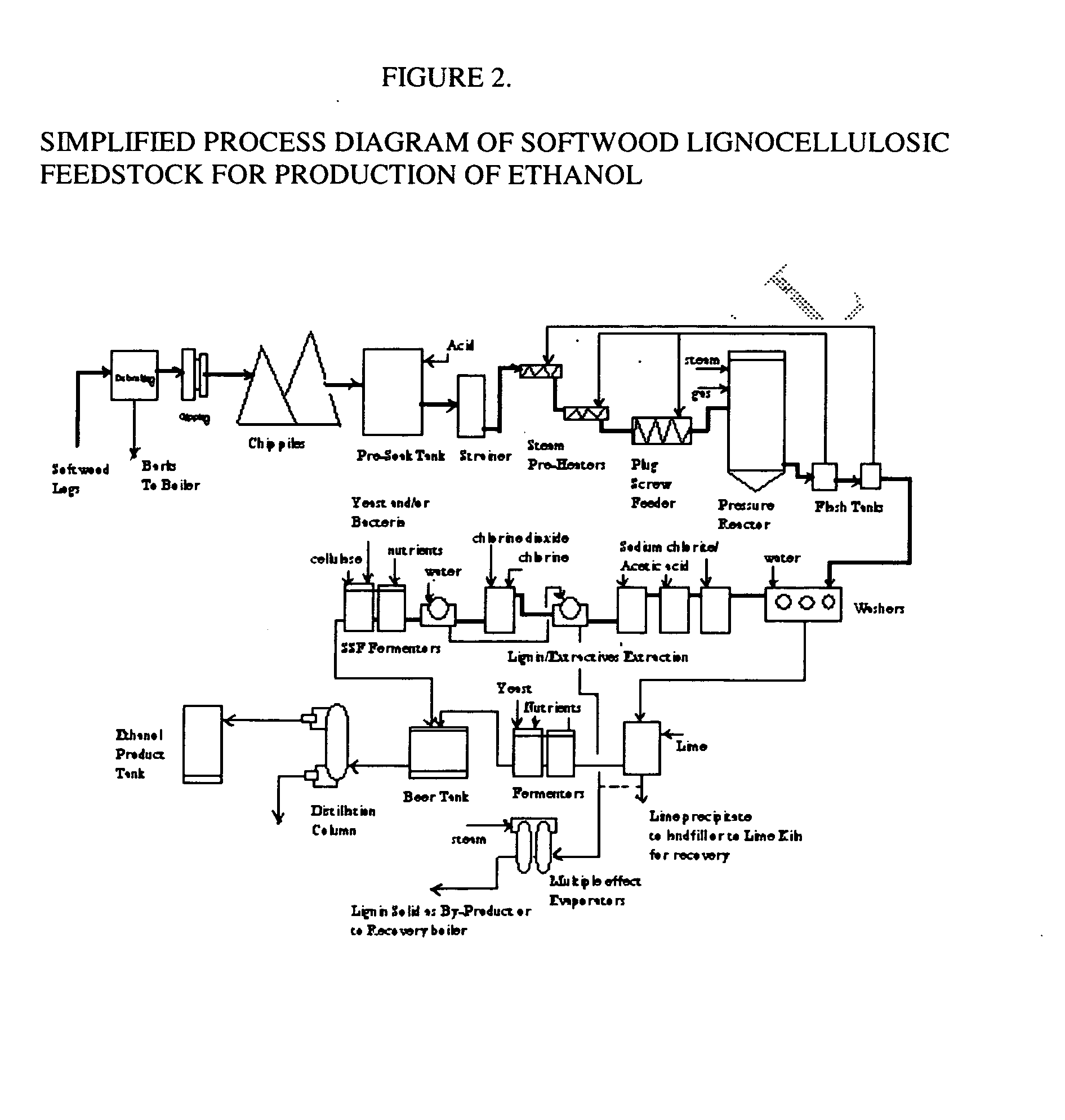

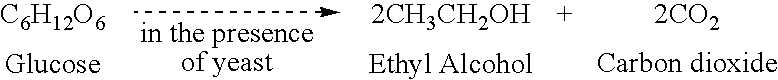

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

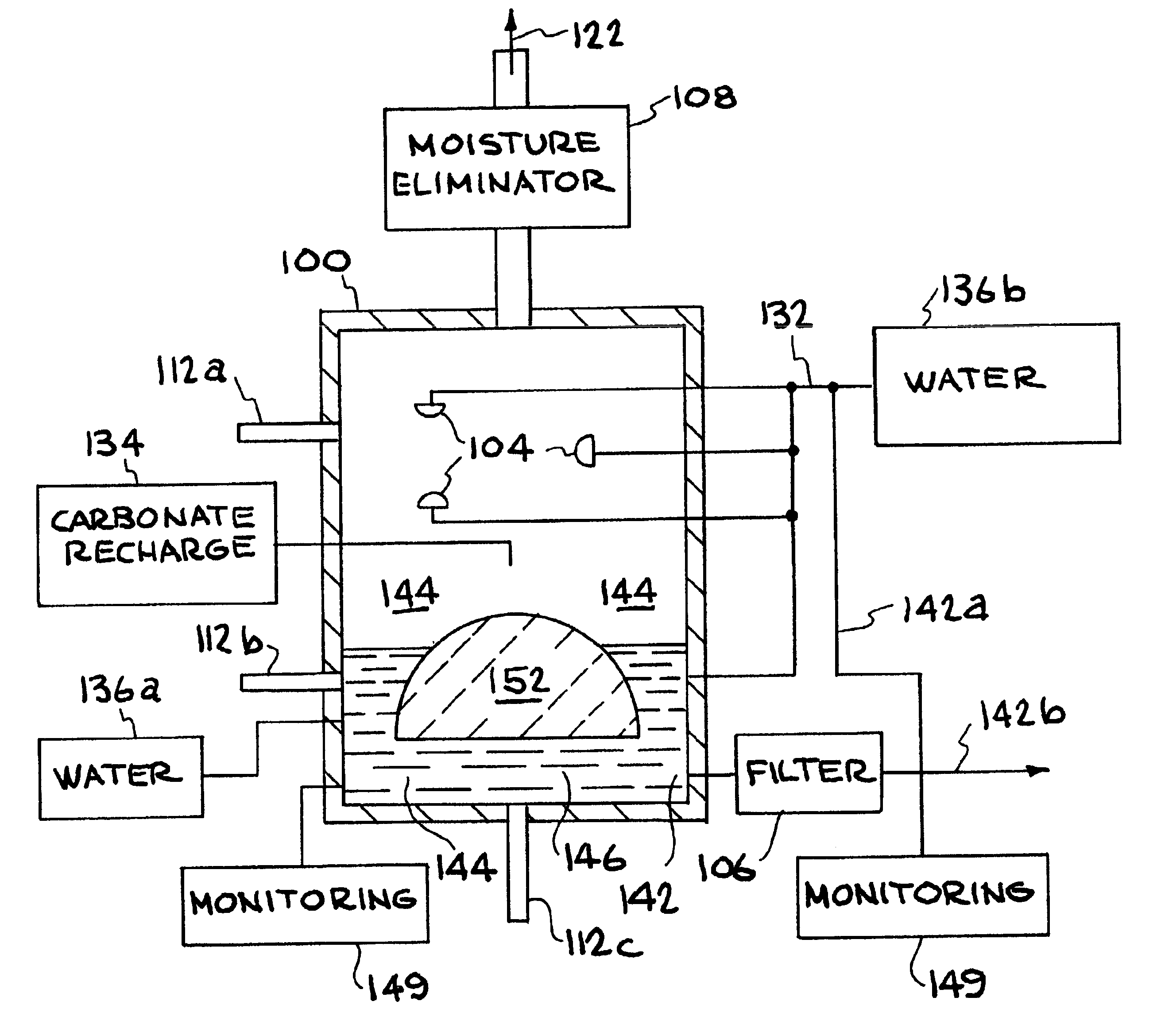

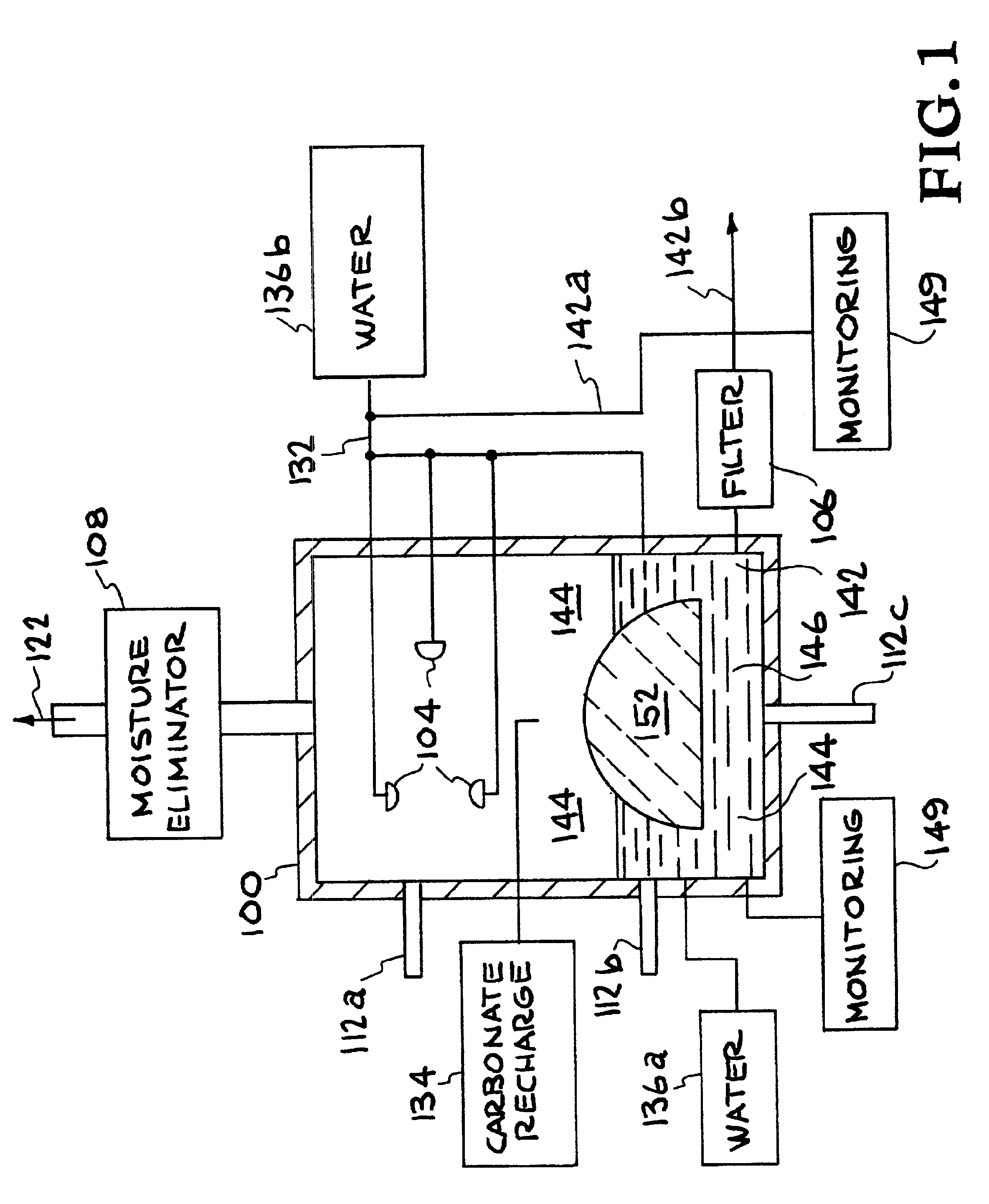

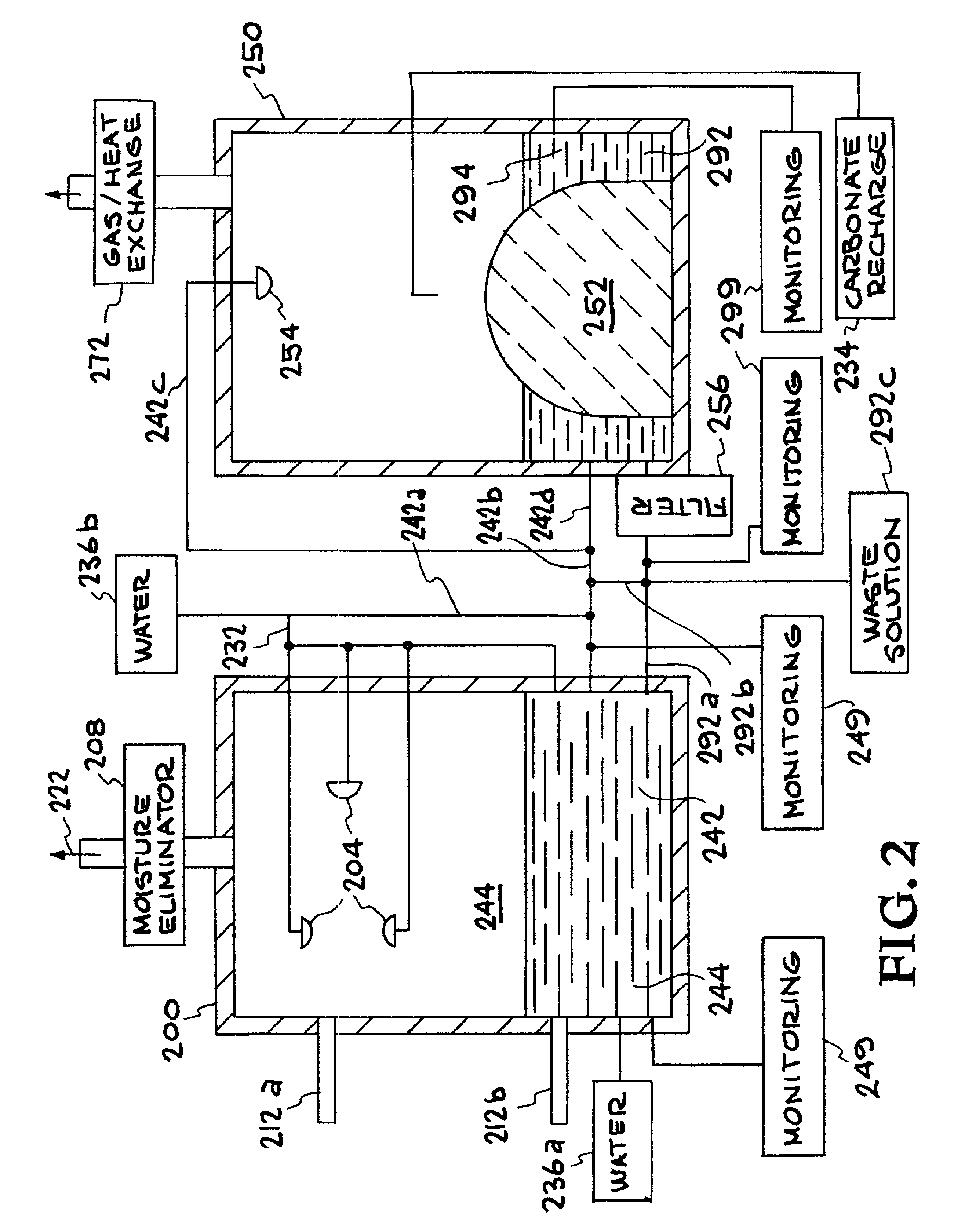

Method for extracting and sequestering carbon dioxide

InactiveUS6890497B2Reduce CO burdenWithout significant expenditureCalcium/strontium/barium carbonatesCombination devicesDicarbonateAlkaline earth metal

A method and apparatus to extract and sequester carbon dioxide (CO2) from a stream or volume of gas wherein said method and apparatus hydrates CO2, and reacts the resulting carbonic acid with carbonate. Suitable carbonates include, but are not limited to, carbonates of alkali metals and alkaline earth metals, preferably carbonates of calcium and magnesium. Waste products are metal cations and bicarbonate in solution or dehydrated metal salts, which when disposed of in a large body of water provide an effective way of sequestering CO2 from a gaseous environment.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

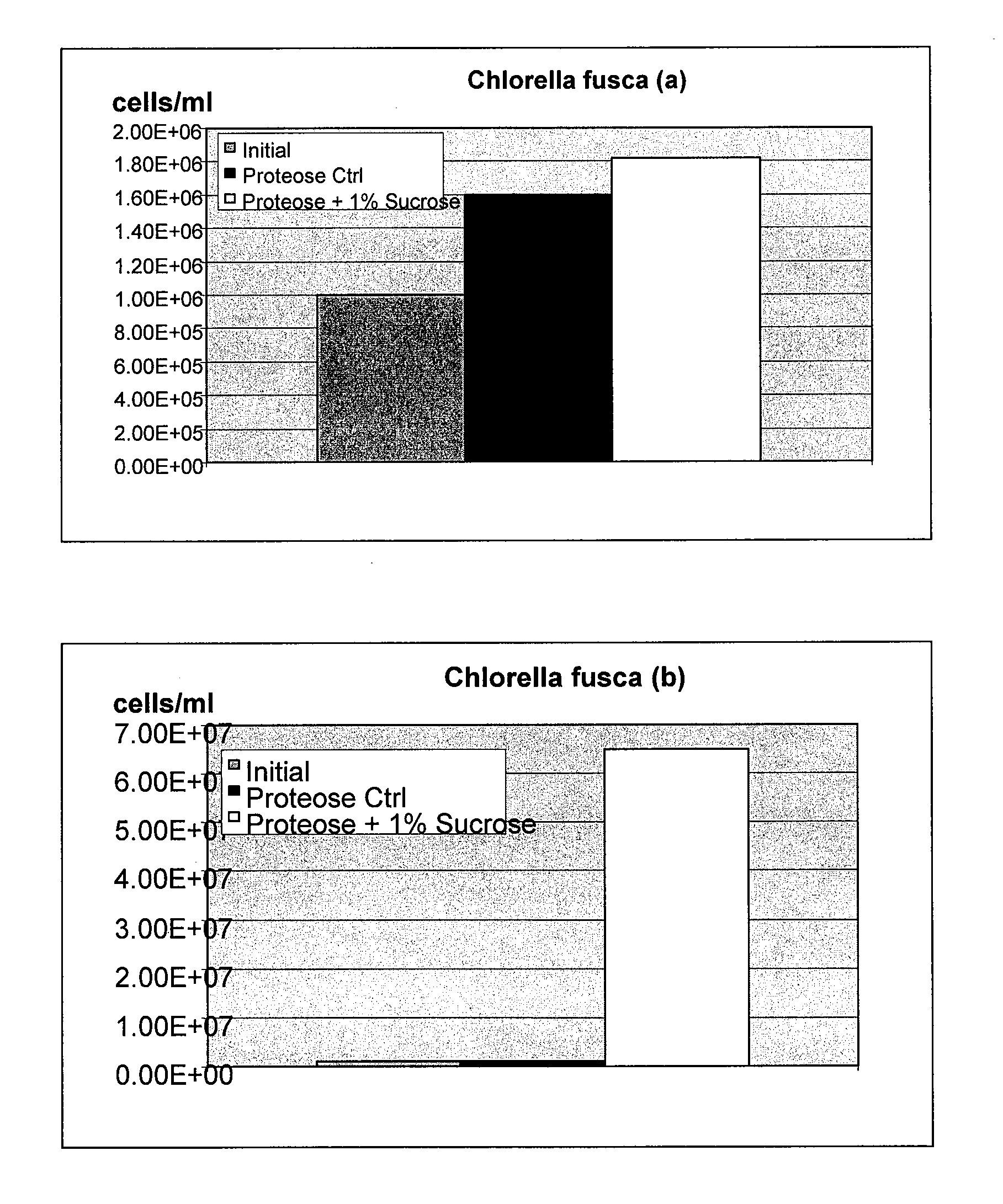

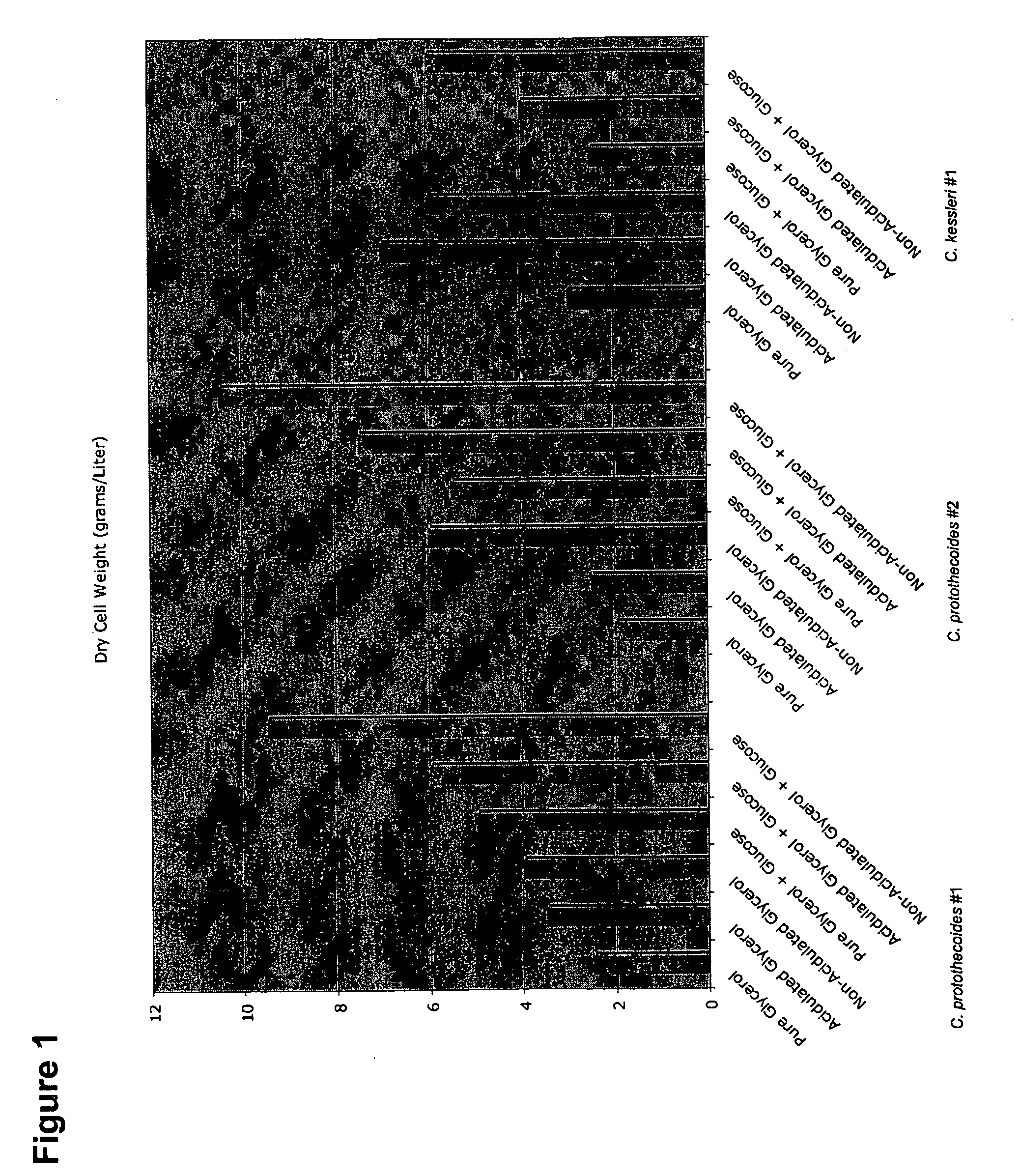

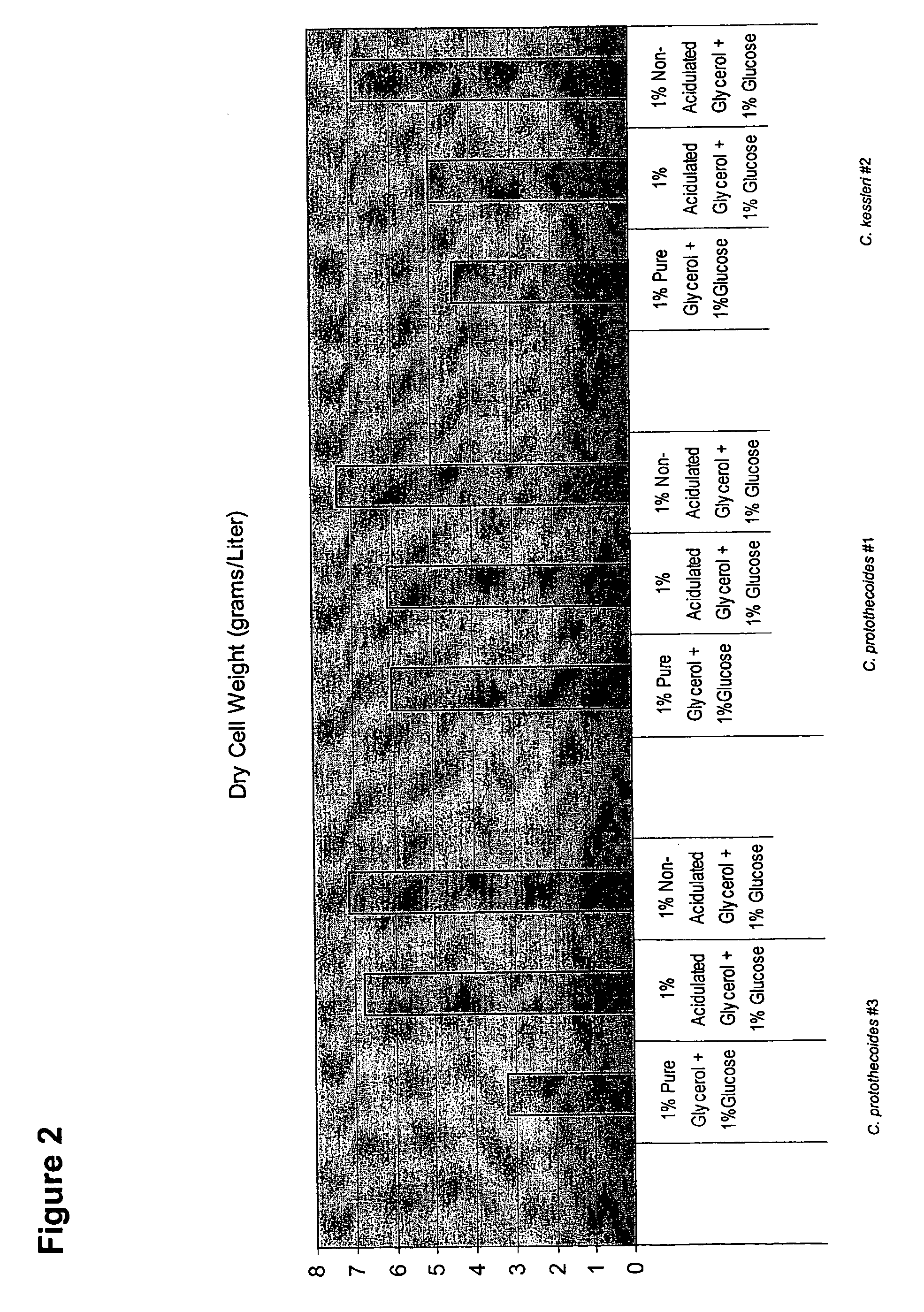

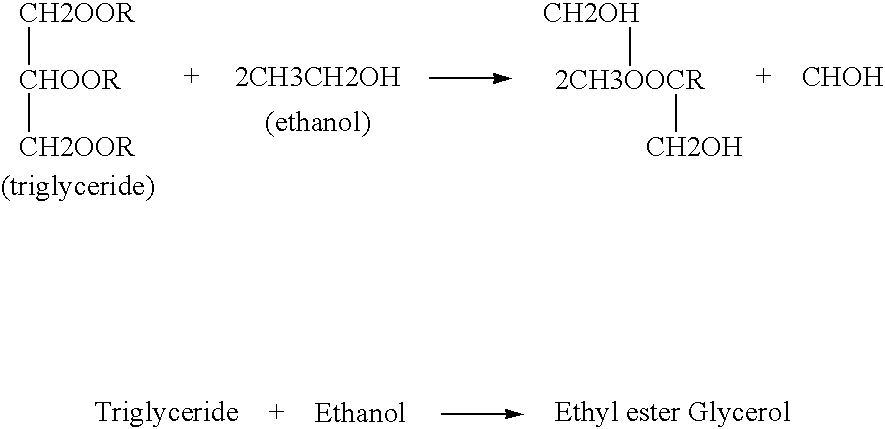

Glycerol Feedstock Utilization for Oil-Based Fuel Manufacturing

InactiveUS20090004715A1Bioreactor/fermenter combinationsFatty acid chemical modificationMicroorganismTransesterification

The invention provides methods of manufacturing biodiesel and other oil-based compounds using glycerol and combinations of glycerol and other feedstocks as an energy source in fermentation of oil-bearing microorganisms. Methods disclosed herein include processes for manufacturing high nutrition edible oils from non-food feedstock materials such as waste products from industrial waste transesterification processes. Also included are methods of increasing oil yields by temporally separating glycerol and other feedstocks during cultivation processes. Also provided herein are oil-bearing microbes containing exogenous oil production genes and methods of cultivating such microbes on glycerol and other feedstocks.

Owner:TERRAVIA HLDG INC

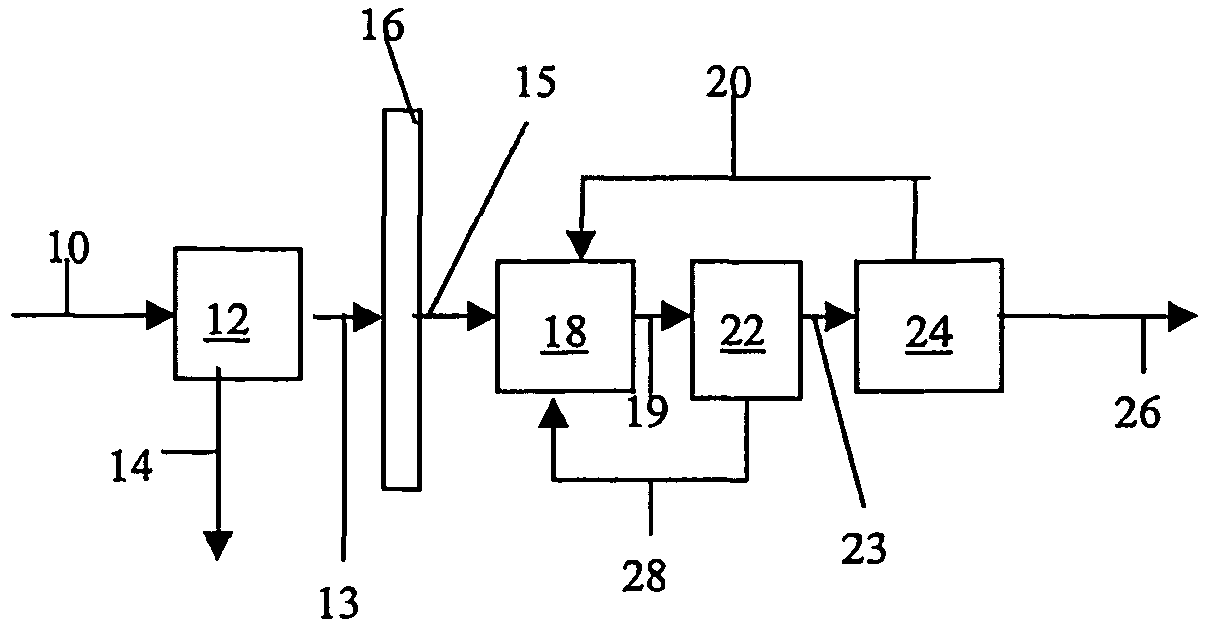

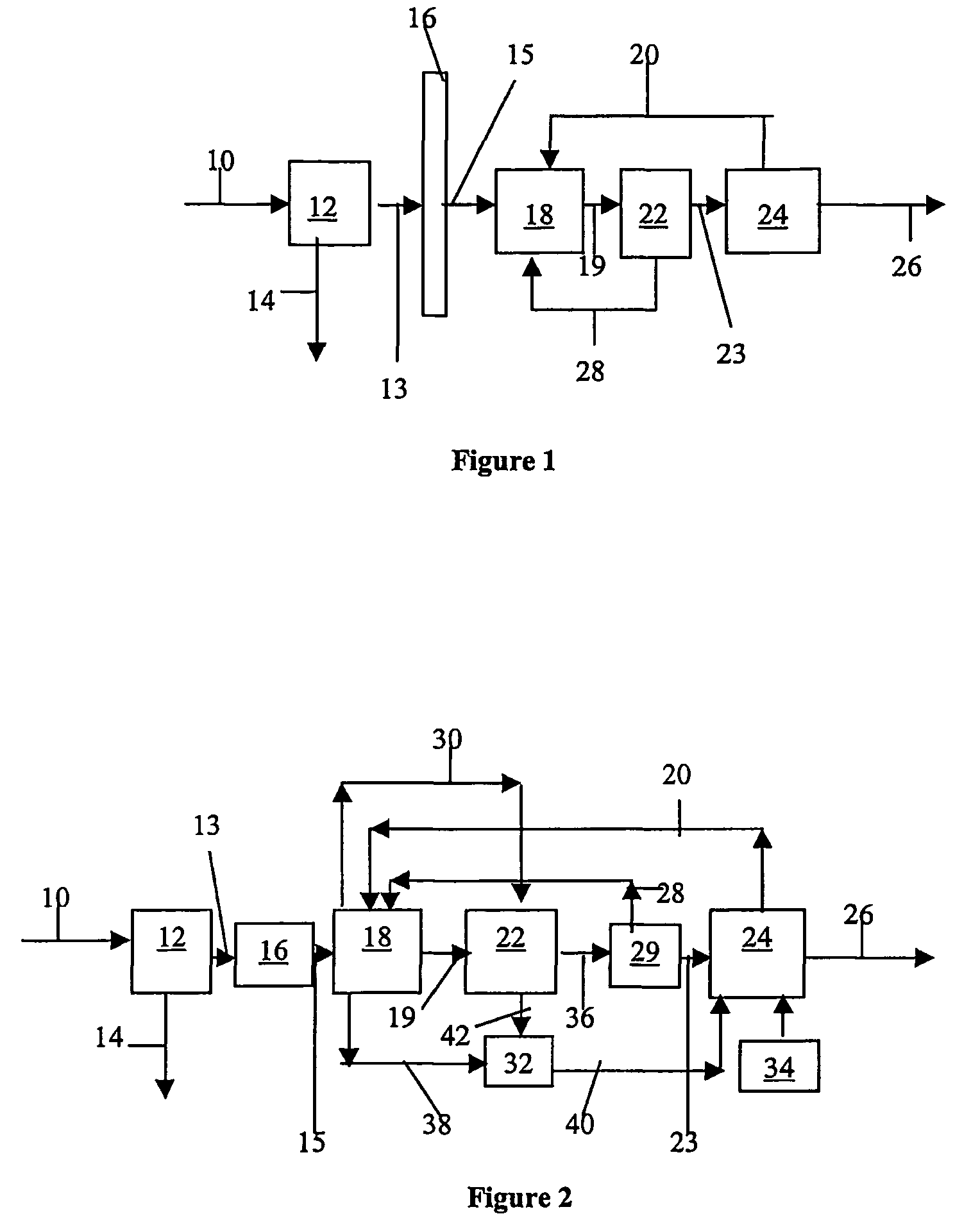

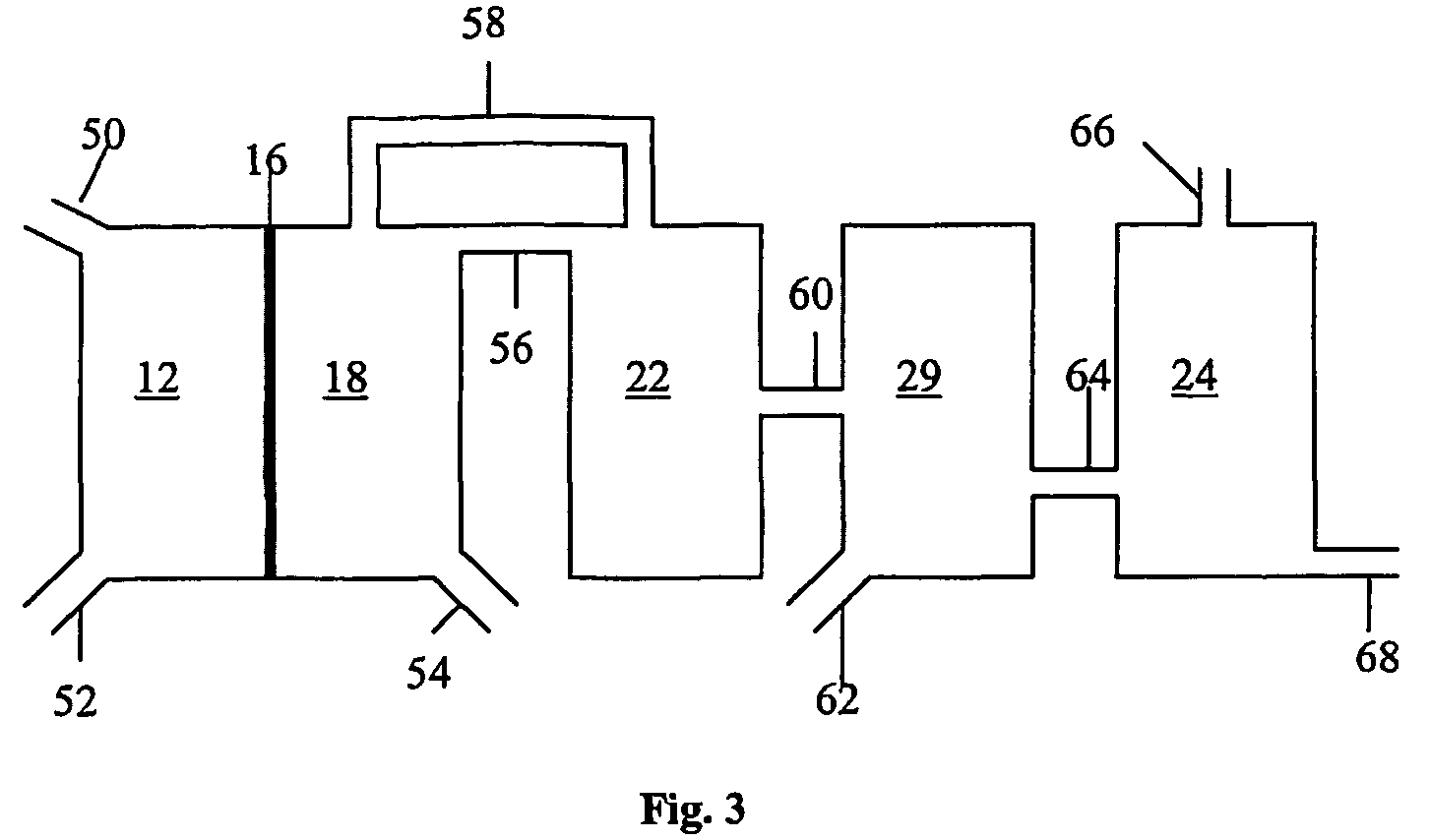

Osmotic desalination process

InactiveUS20050145568A1High yieldImprove concentrationSolvent extractionGeneral water supply conservationPresent methodDesalination

An energy efficient desalination process that does not produce waste products involves the extraction of water from a first solution, such as seawater, by using a second concentrated solution to draw the water from the first solution across a semi-permeable membrane. By manipulating the equilibrium of the soluble and insoluble species of solute within the second solution in favor of the soluble species of the solute, a saturated second solution can be used to generate osmotic pressure on the first solution. Also, by adjusting the equilibrium in favor of the less soluble species after the water has been drawn from the first solution, a portion of the solute can easily be precipitated out. Heating the second solution decomposes the solute into its constituent gasses. The constituent gasses and precipitated solute may be recycled through the process to affect the changes in equilibrium and eliminate waste products. Additionally, by using the waste steam from industrial sources and a heat pump to effectively distribute heat through the present method, the present method exhibits greater energy efficiency than prior art methods.

Owner:YALE UNIV

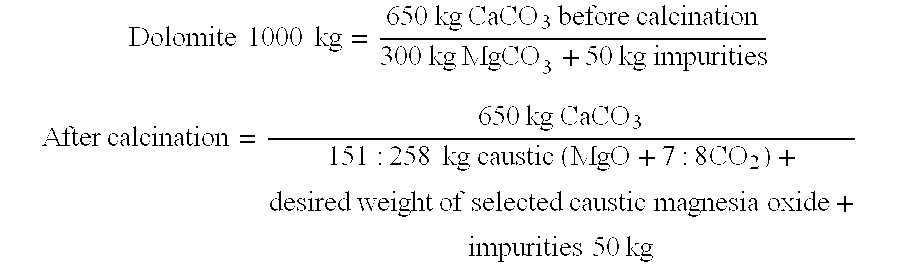

Settable composition and uses therefor

InactiveUS6200381B1Decrease decarbonisation temperaturePromote decompositionSolid waste managementWaste productSlurry

A dry powdered flowable cement composition contains calcium carbonate and a partially decarbonated magnesium carbonate. A slurry of the composition will set hard with various organic fillers including waste products and toxic waste. The composition can be slurried with contaminated water such as sea water, mineral laden ground water and muddy water. A high percentage of filler can be added while still having an acceptable set.

Owner:DOLOMATRIX INT LIMITED ACN 091 340 920

Colostomy pump device

A device for evacuating waste product through an orifice in a mammalian body, the device including a chamber having an irrigating means for introducing an irrigating fluid into the orifice and a suction means for removing the irrigating fluid waste products from the orifice.

Owner:COLOCARE HLDG

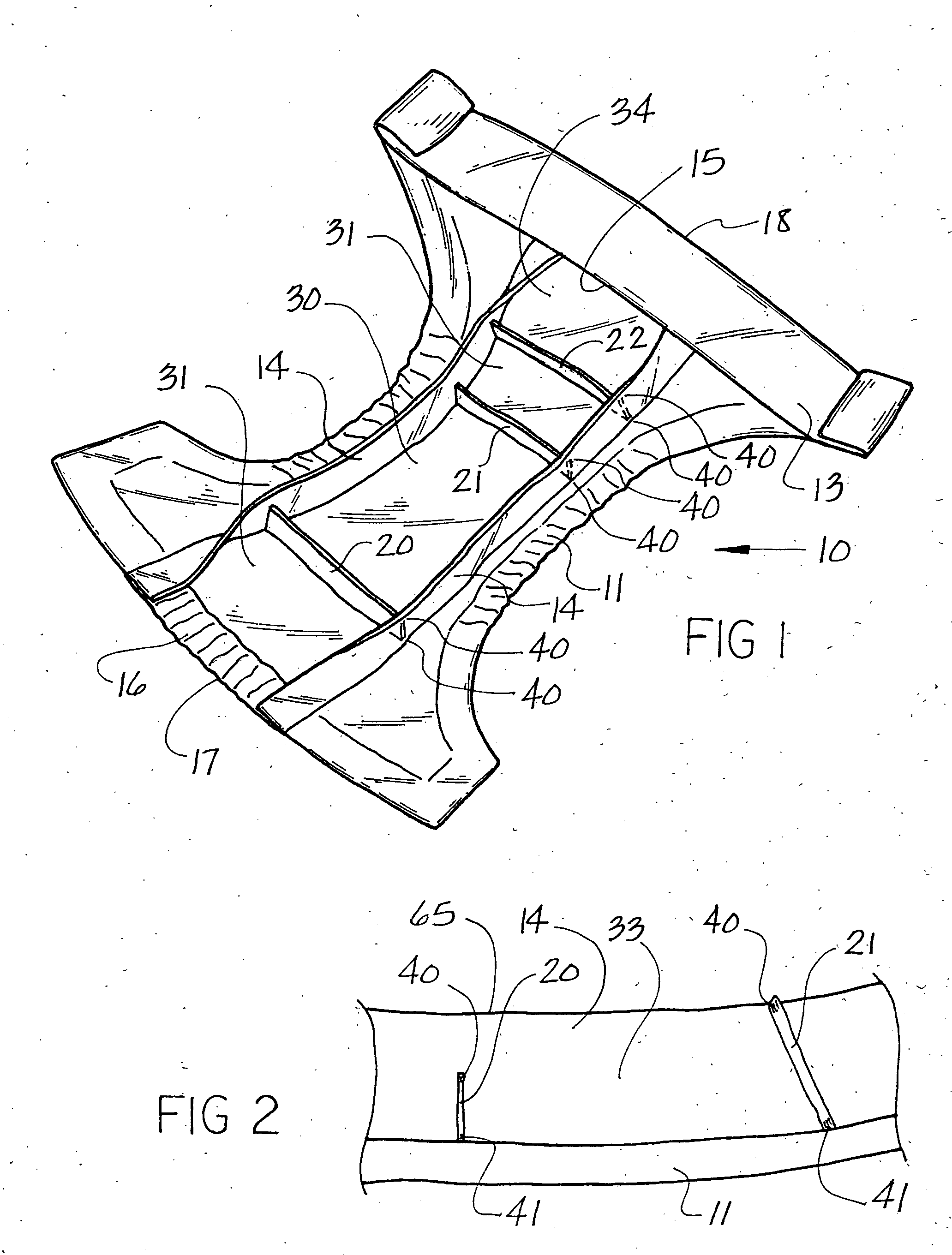

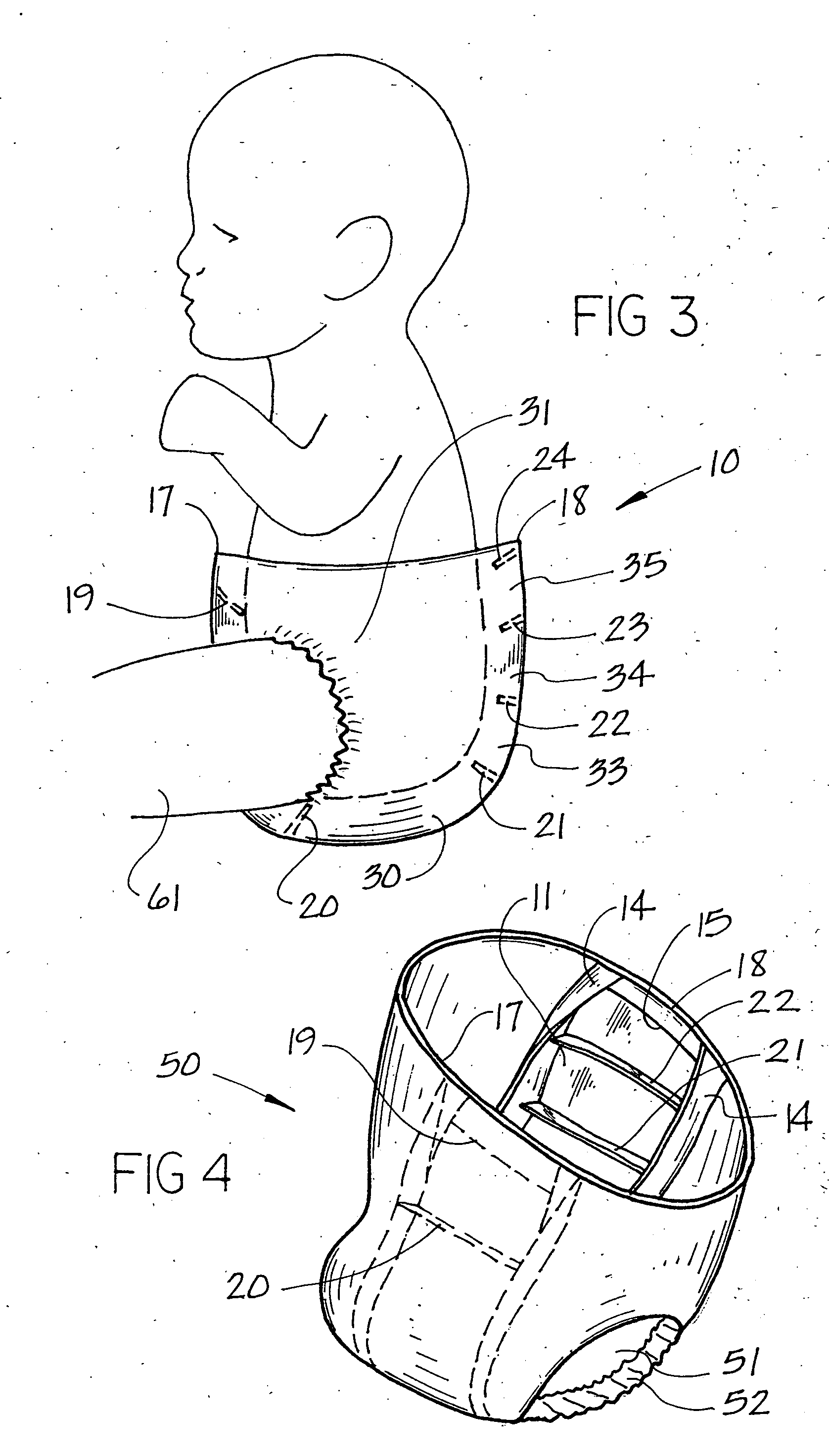

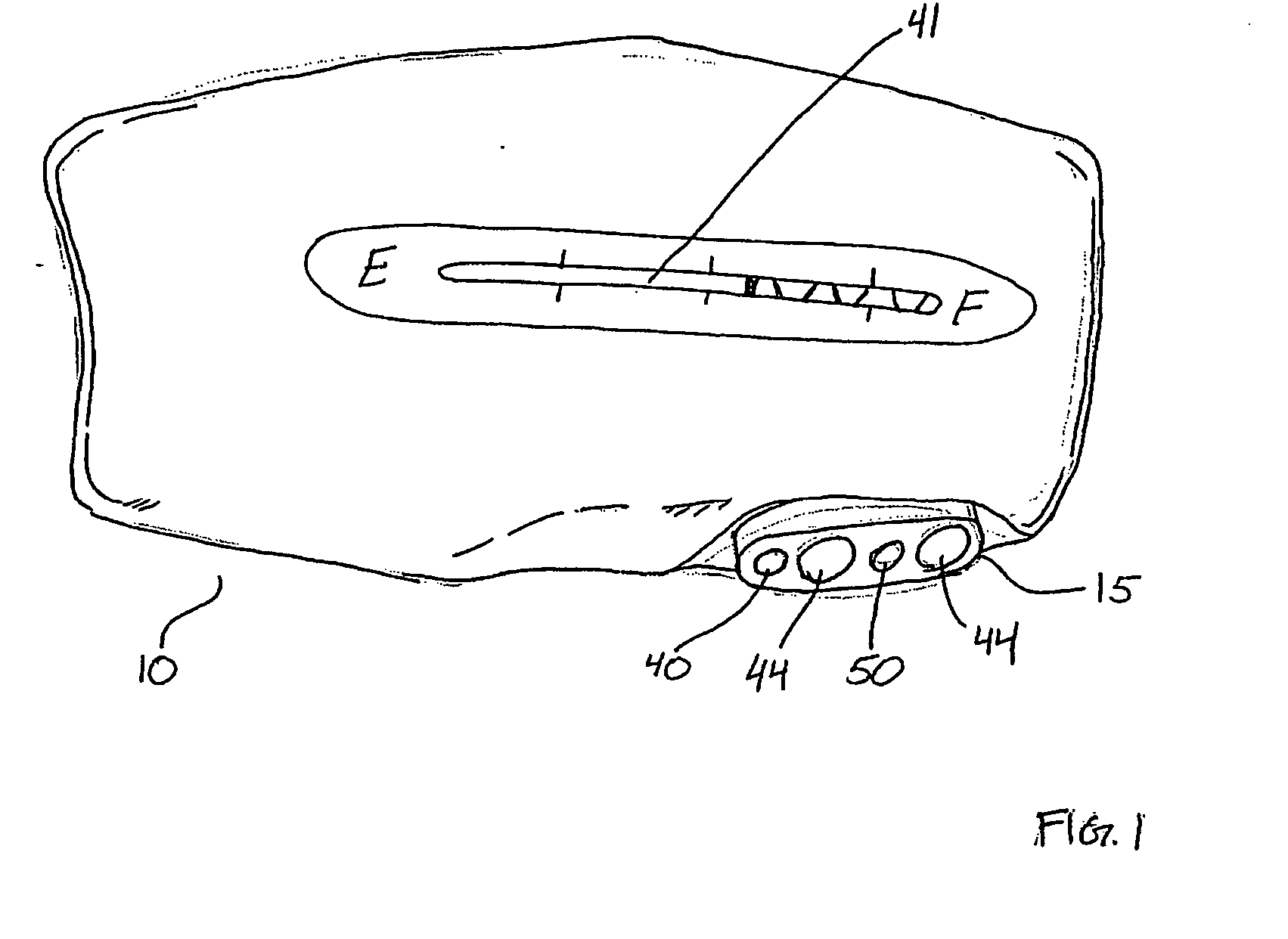

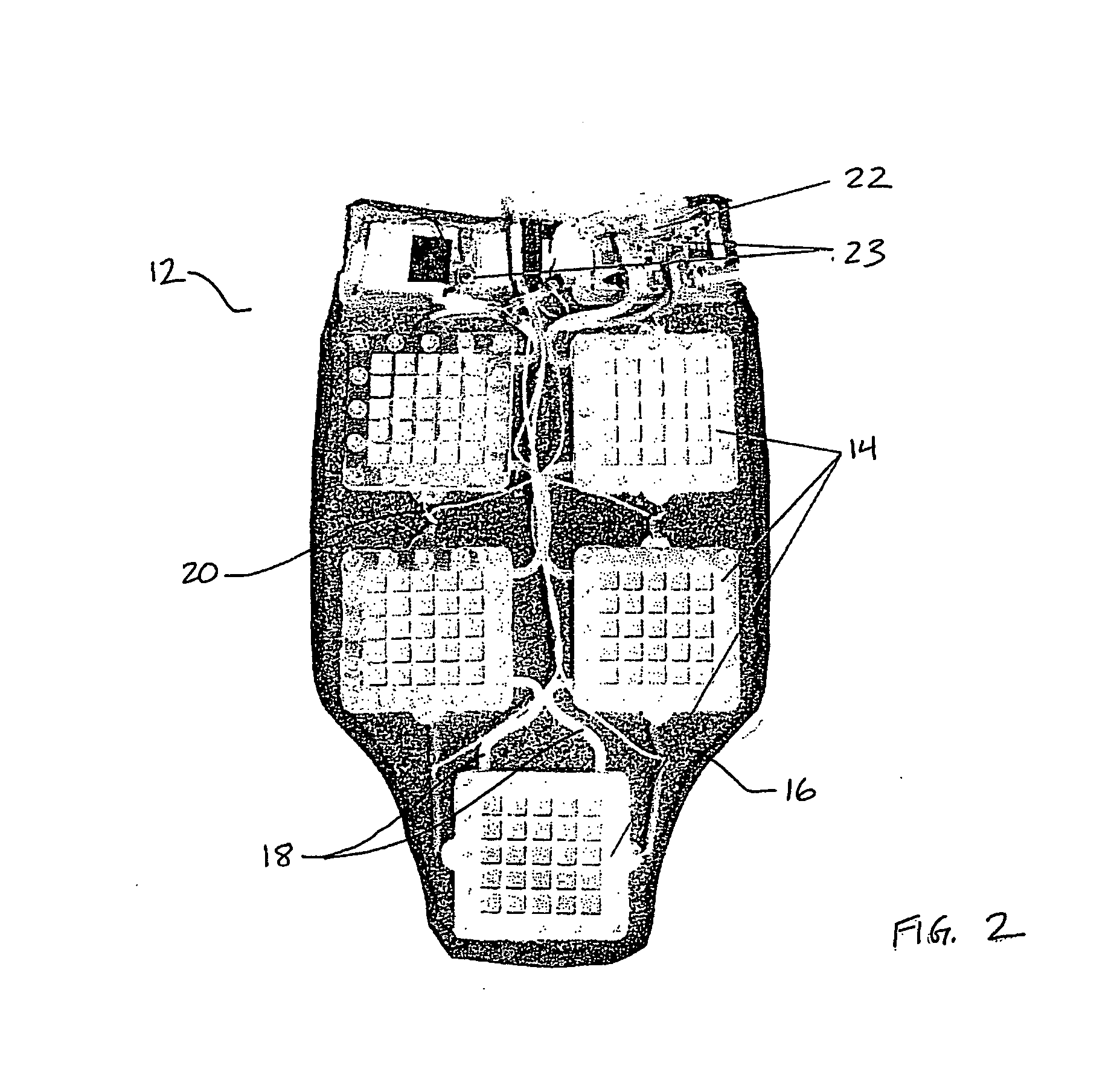

Diaper with baffle overflow protection

InactiveUS20070156110A1Maximum collection capabilityGood prevents leakageBaby linensTamponsWaste productEngineering

An improved diaper or pull up type pant, using attached side walls that are defined from the front to the back of the diaper or pull up type pant, with one or more baffles positioned between said side walls so as to define multiple cavities for the collection and retention of waste. The multiple cavities provide additional barriers, and assist in preventing waste product from moving out of the front top or rear top portion of the pull up type pant or diaper.

Owner:THYFAULT KEVIN

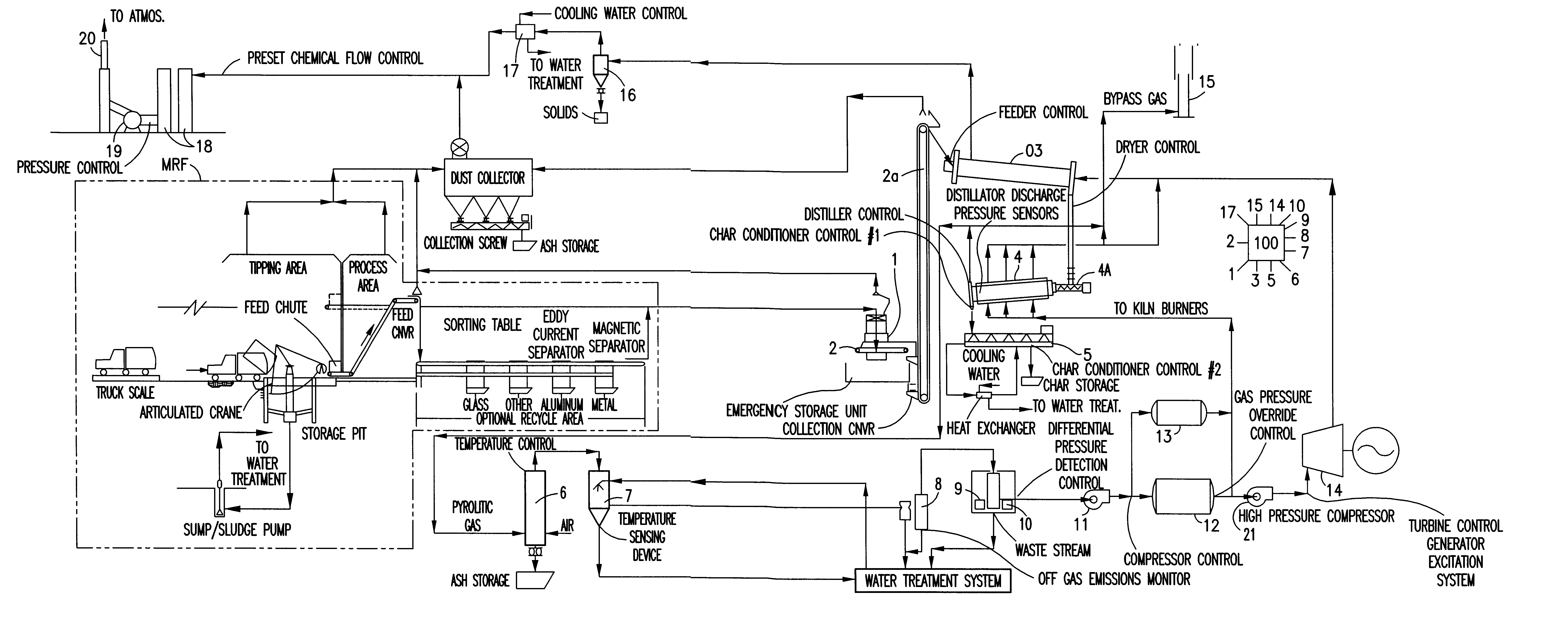

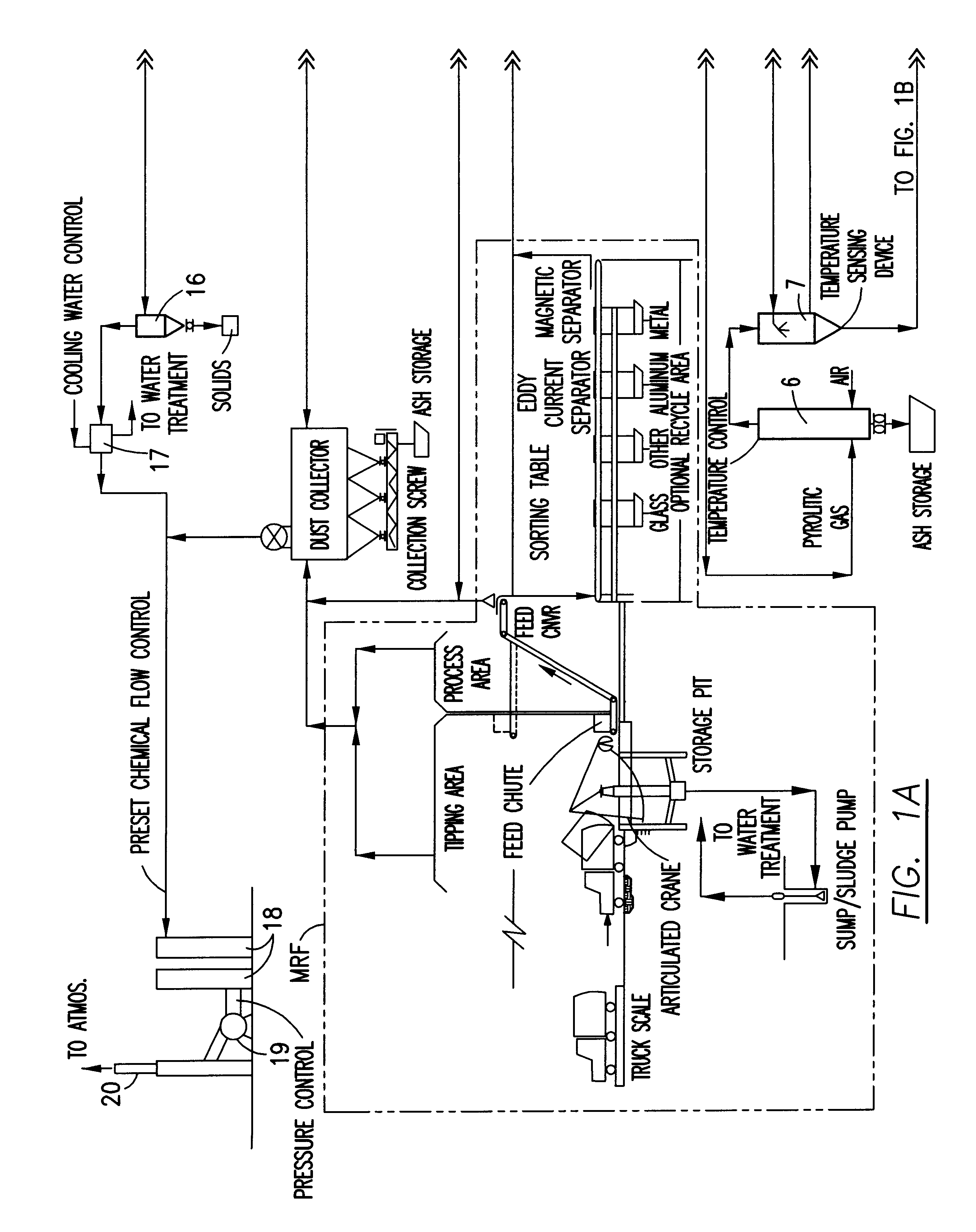

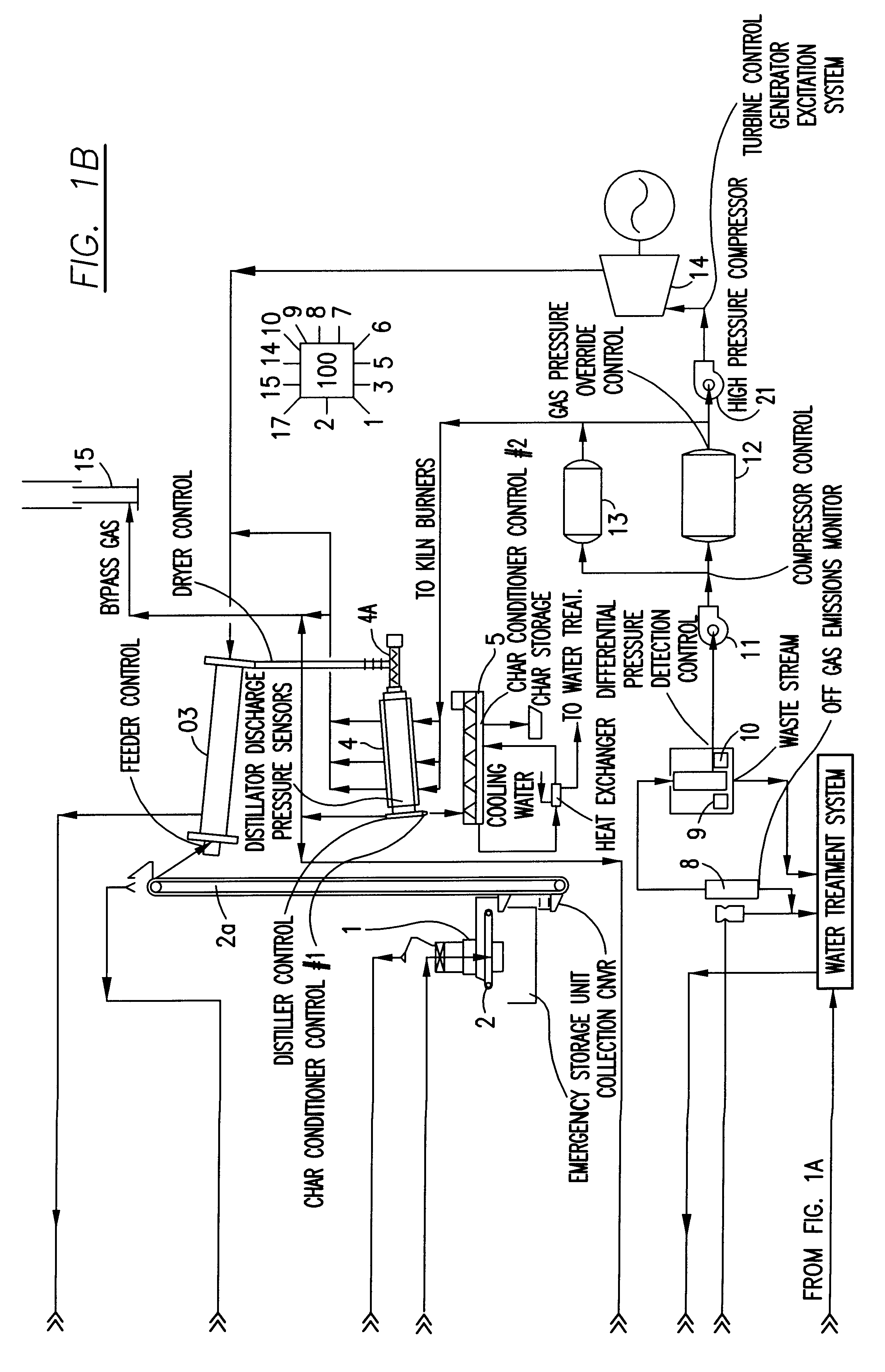

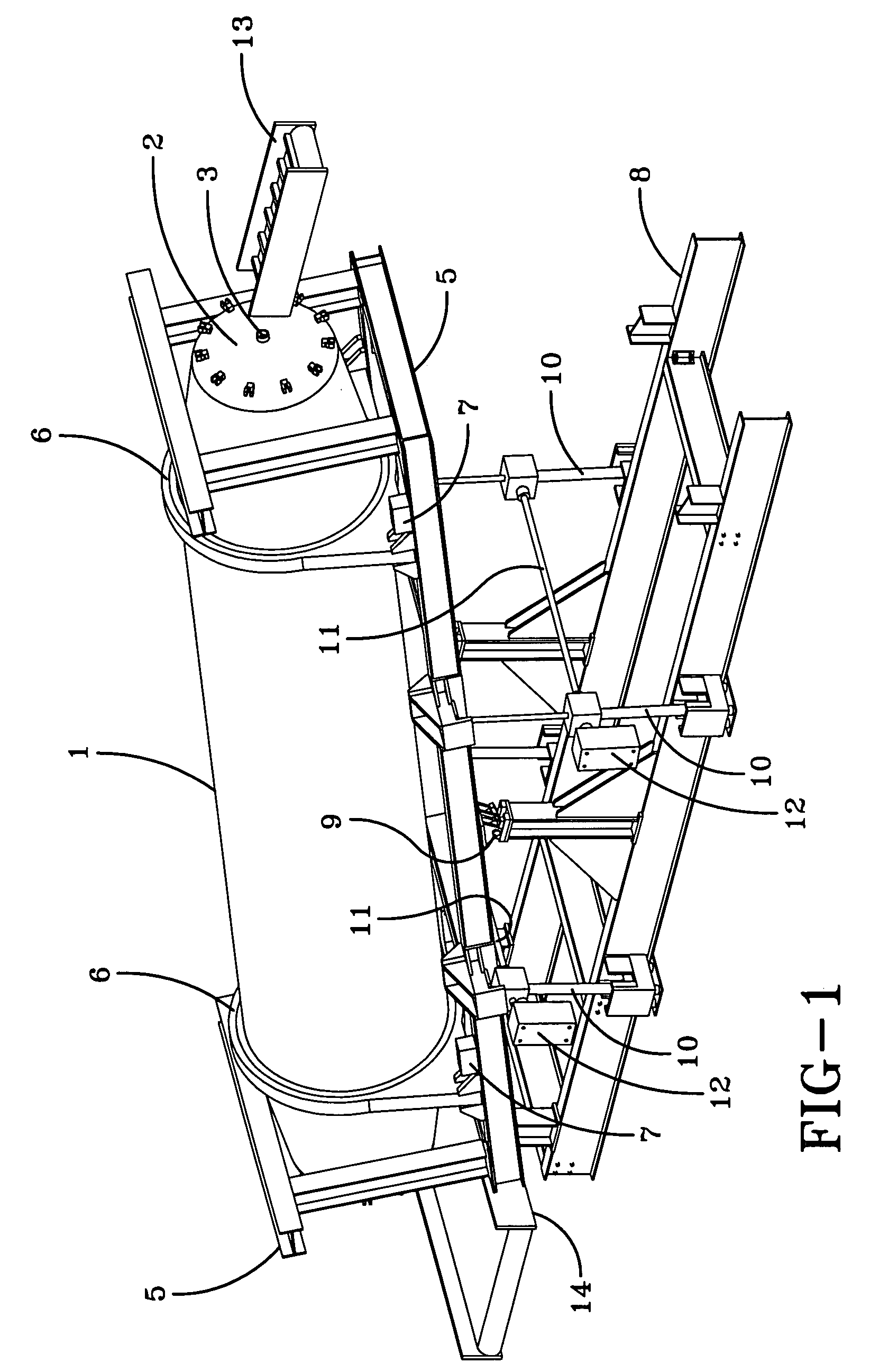

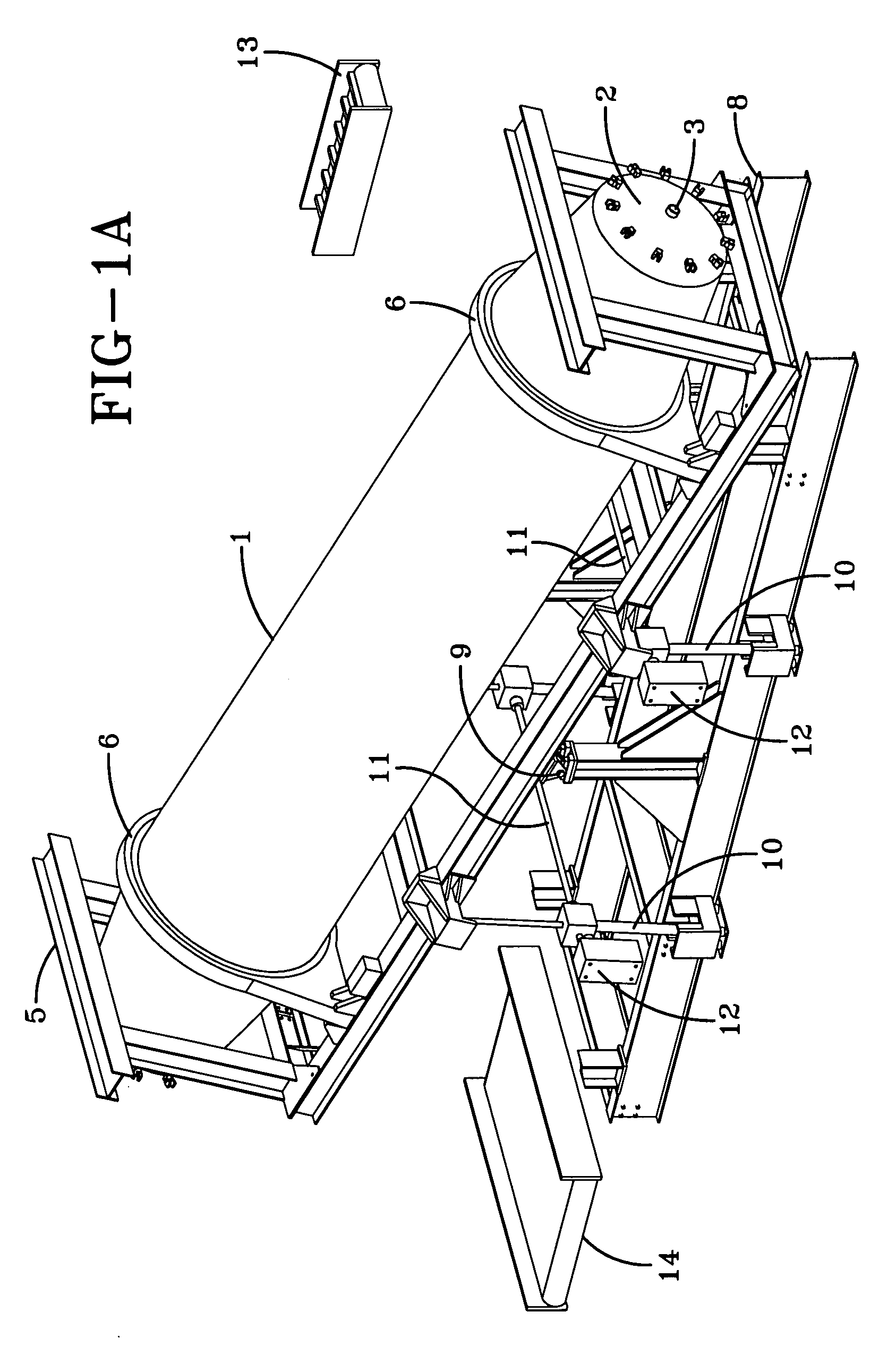

Integrated control and destructive distillation of carbonaceous waste

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

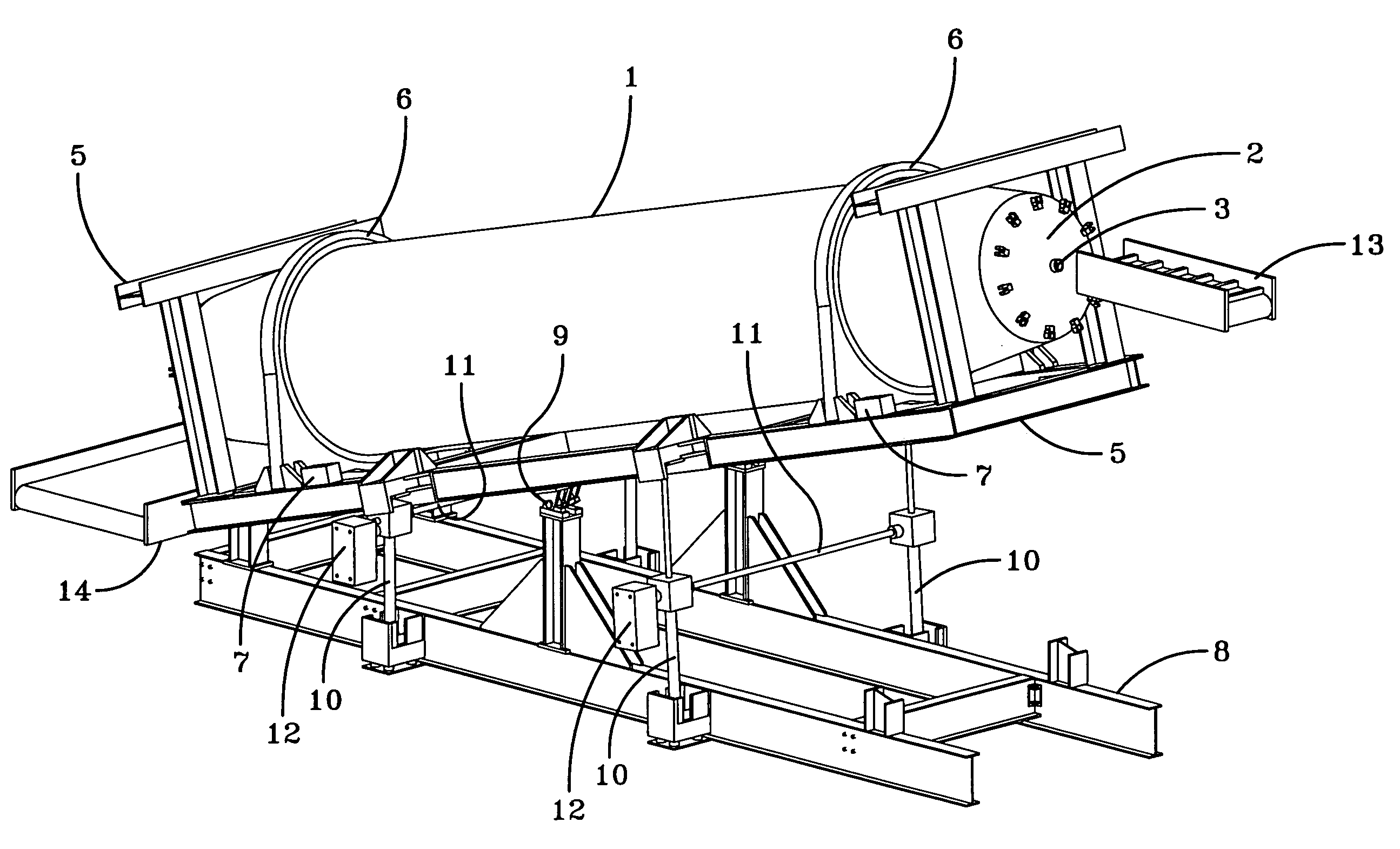

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

Osmotic desalination process

InactiveUS7560029B2High yieldImprove concentrationSolvent extractionGeneral water supply conservationPresent methodDesalination

An energy efficient desalination process that does not produce waste products involves the extraction of water from a first solution, such as seawater, by using a second concentrated solution to draw the water from the first solution across a semi-permeable membrane. By manipulating the equilibrium of the soluble and insoluble species of solute within the second solution in favor of the soluble species of the solute, a saturated second solution can be used to generate osmotic pressure on the first solution. Also, by adjusting the equilibrium in favor of the less soluble species after the water has been drawn from the first solution, a portion of the solute can easily be precipitated out. Heating the second solution decomposes the solute into its constituent gasses. The constituent gasses and precipitated solute may be recycled through the process to affect the changes in equilibrium and eliminate waste products. Additionally, by using the waste steam from industrial sources and a heat pump to effectively distribute heat through the present method, the present method exhibits greater energy efficiency than prior art methods.

Owner:YALE UNIV

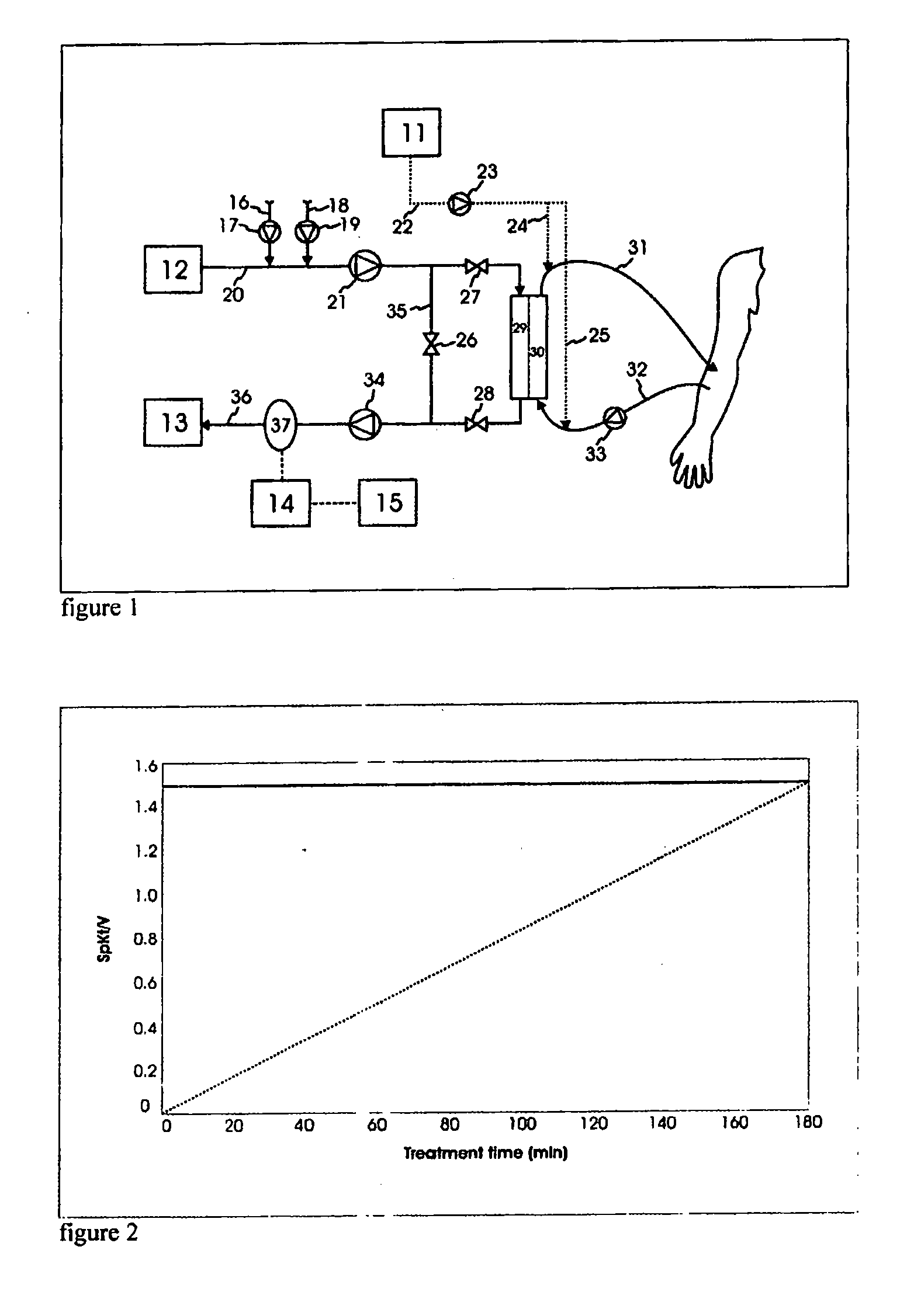

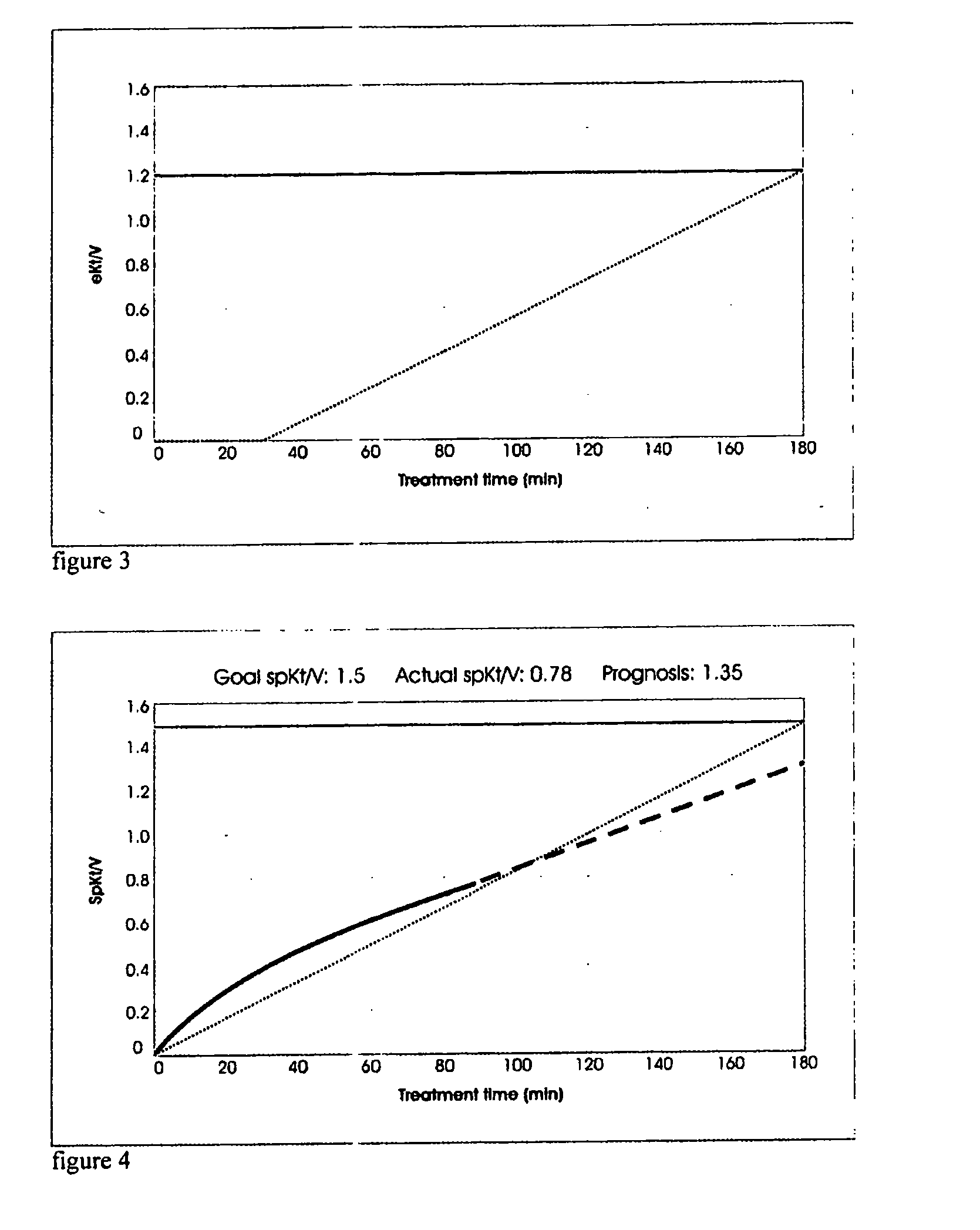

METHOD AND DEVICE TO EARLY PREDICT THE Kt/V PARAMETER IN KIDNEY SUBSTITUTION TREATMENTS

A method for determining or predicting the adequacy parameters that will be achieved at the end of a kidney substitution treatment during said kidney substitution treatment wherein the kidney substitution treatment is provided by a machine, which has an extracorporeal blood system pumping the patient blood through the blood chamber of a dialyzer, wherein the dialyzing fluid collects the waste products from the patient after flowing through the dialyzing fluid chamber of the dialyzer and wherein a device able to measure a adequacy parameter is coupled with the kidney substitution treatment machine and wherein the slope of a preferable linear guideline for the adequacy parameter is compared to the slope of the delivered adequacy parameter and if the slope of both are equal a linearization is performed to determine or predict the adequacy parameter at the end of the kidney substitution treatment.

Owner:B BRAUN AVITUM

In vivo use of water absorbent polymers

InactiveUS6908609B2Reduce the amount requiredReduce the numberBiocideSynthetic polymeric active ingredientsFecesRemove blood

The subject invention is a method and material for removing fluid from the intestinal tract of a host and may be useful in treating animals or human patients suffering from fluid overload states. In one embodiment, the subject method involves ingesting an enterically coated non-systemic, non-toxic, non-digestible, water absorbing polymer which absorbs fluid while passing through the intestinal tract. The polymer is excreted in the feces wherein the polymer and absorbed fluid is removed from the body. Preferred polymers include super absorbent acrylic acid polymers, preferably provided in bead form. The polymers may include functional groups for selectively removing blood borne waste products, e.g. urea, from the G.I. tract.

Owner:RELYPSA INC

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

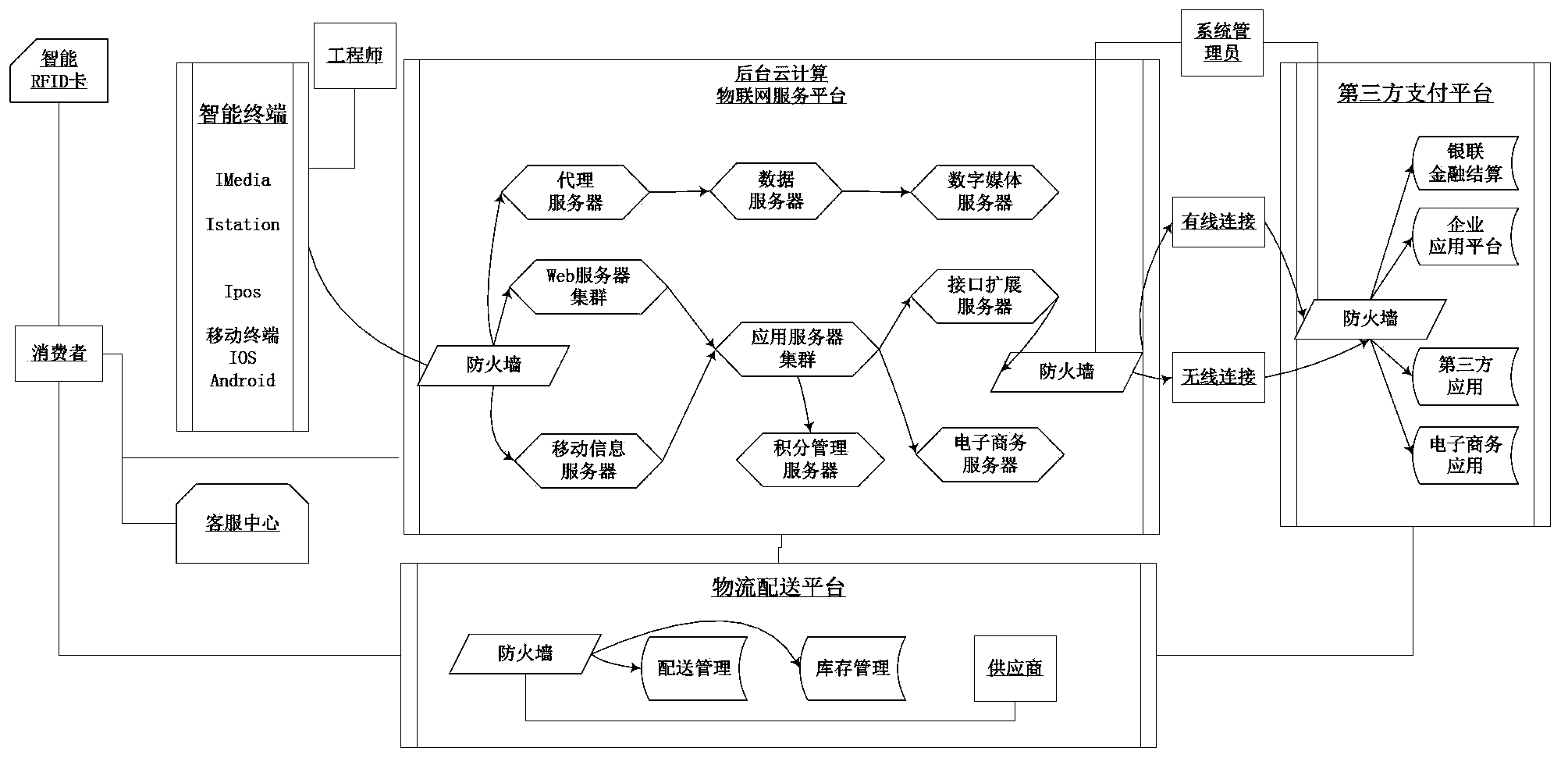

Service platform and method for classifying and intelligently recycling waste and old materials and garbage

InactiveCN103440607AEasy to recycleCommerceCoded identity card or credit card actuationLitterCommunity resident

The invention discloses a service platform and method for classifying and intelligently recycling waste and old materials and garbage. A new technology is adopted, the platform is a new media publicity platform for publicizing garbage classification at the same time, cartoons, video, games and other modes loved by community residents are adopted, the recycling process of the waste and old materials can be fast accepted by all kinds of crowds to the largest extent, the principle of environmental protection and renewable resources enjoys popular support among people, the technology of Internet of Things is adopted, electronic waste and old materials are convenient to recycle, RFID unique labels are attached to the electronic waste and old materials in the production and sale period of the electronic waste and old materials, the labels comprise product classification information, and according to the garbage classification, when the waste of this type is thrown, corresponding garbage recycling and classifying cans can be automatically opened, and other garbage recycling and classifying cans not related to this type cannot be opened.

Owner:HANGZHOU LANGDUN SCI & TECH CO LTD

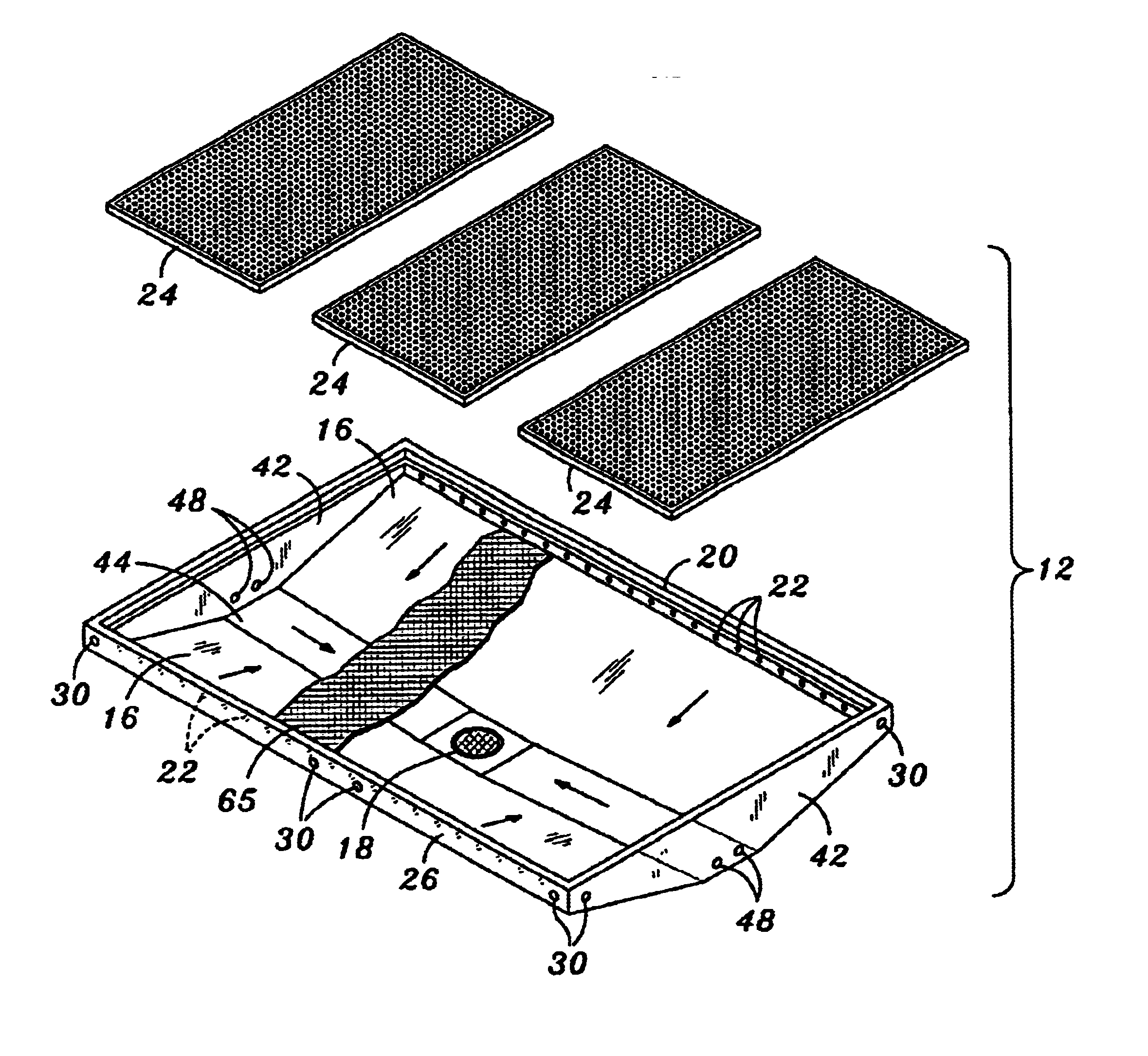

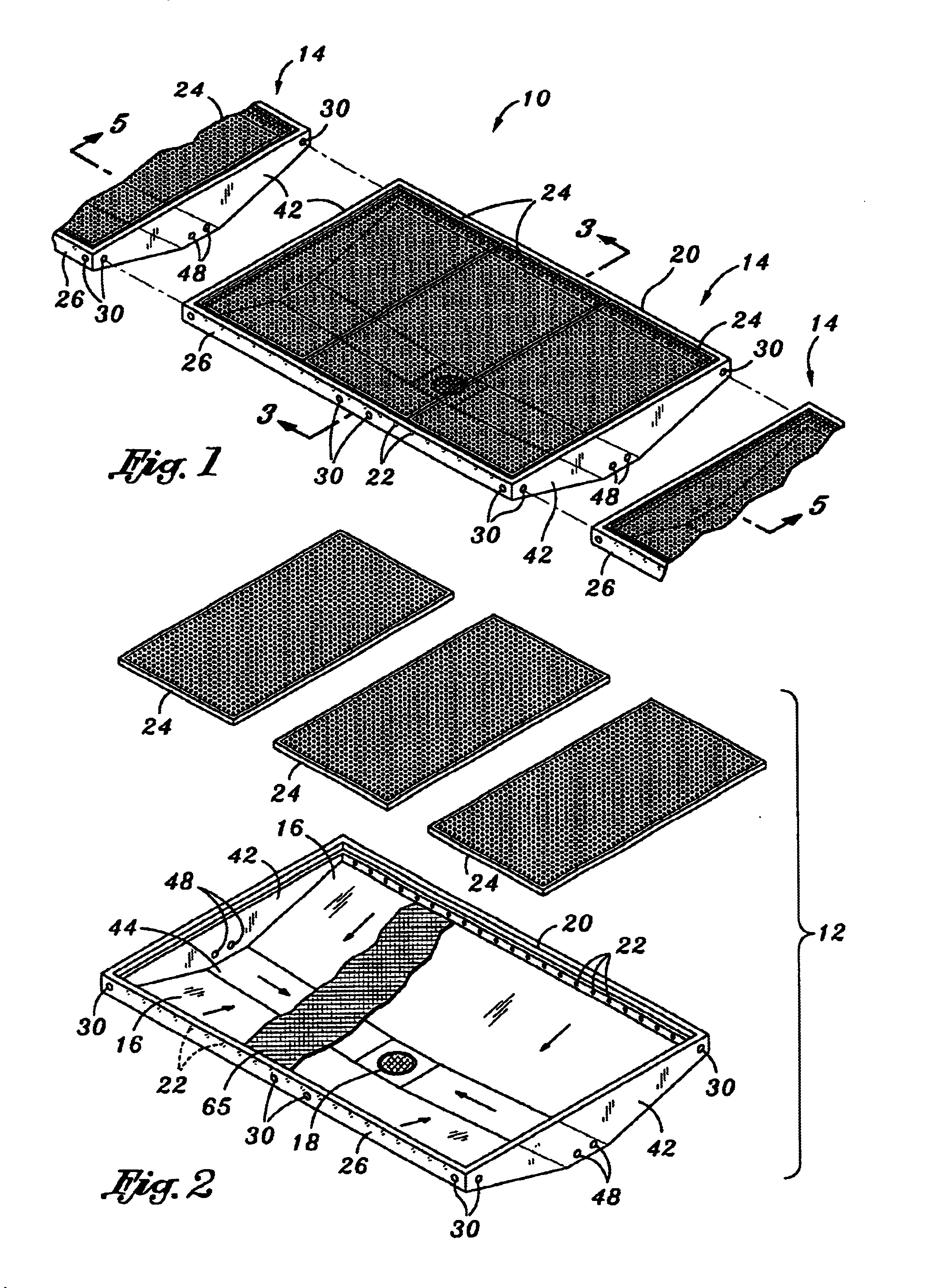

Self-cleaning flooring system

A self-cleaning flooring system for catching waste products has at least one module comprising a drain pan and a floor grid. The drain pan has a ramp and a central drain outlet. The ramp extends around the drain pan defining a drain pan periphery. The ramp slopes downward from the drain pan periphery towards the drain outlet. The drain pan periphery has a plurality of discharge ports spaced therealong for discharge of flushing fluid onto the ramp such that the waste products are washed down the ramp towards the drain outlet. The floor grid extends across the drain pan and is mounted upon the drain pan periphery for supporting personnel standing thereon while permitting waste products to pass therethrough. The module is interconnectable to horizontally adjacent modules to form the flooring system.

Owner:DTS ENTERPRISES INC

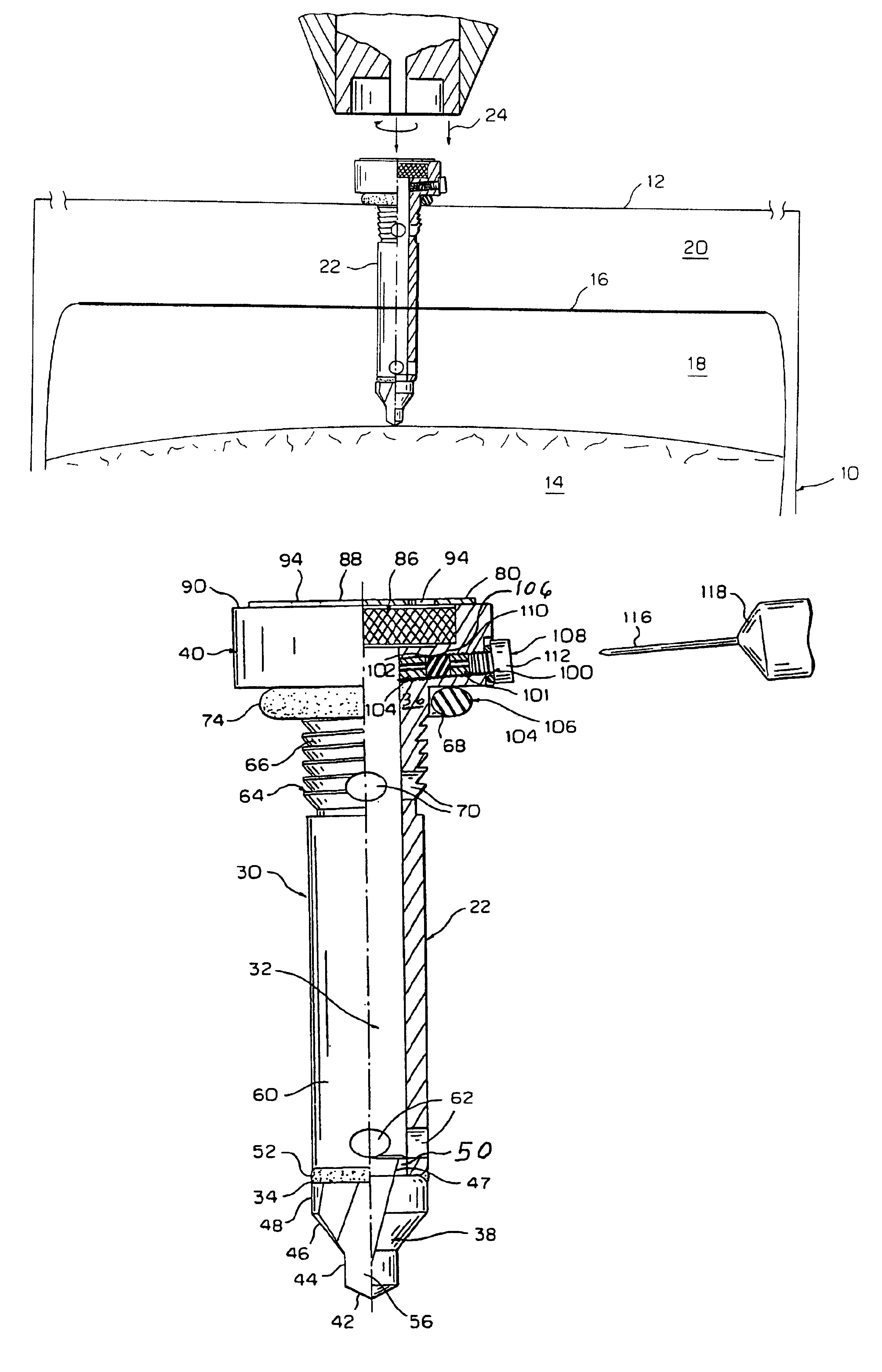

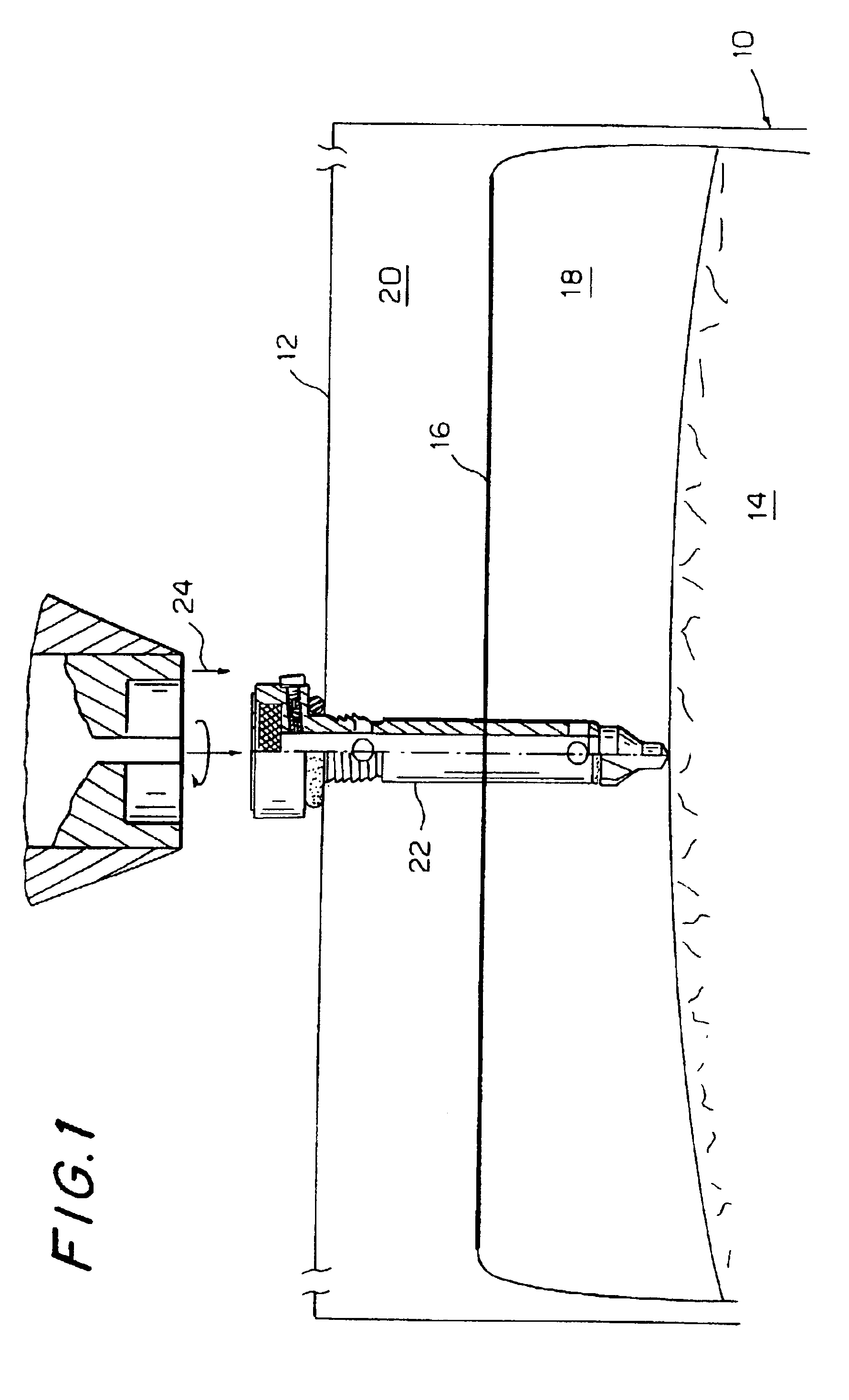

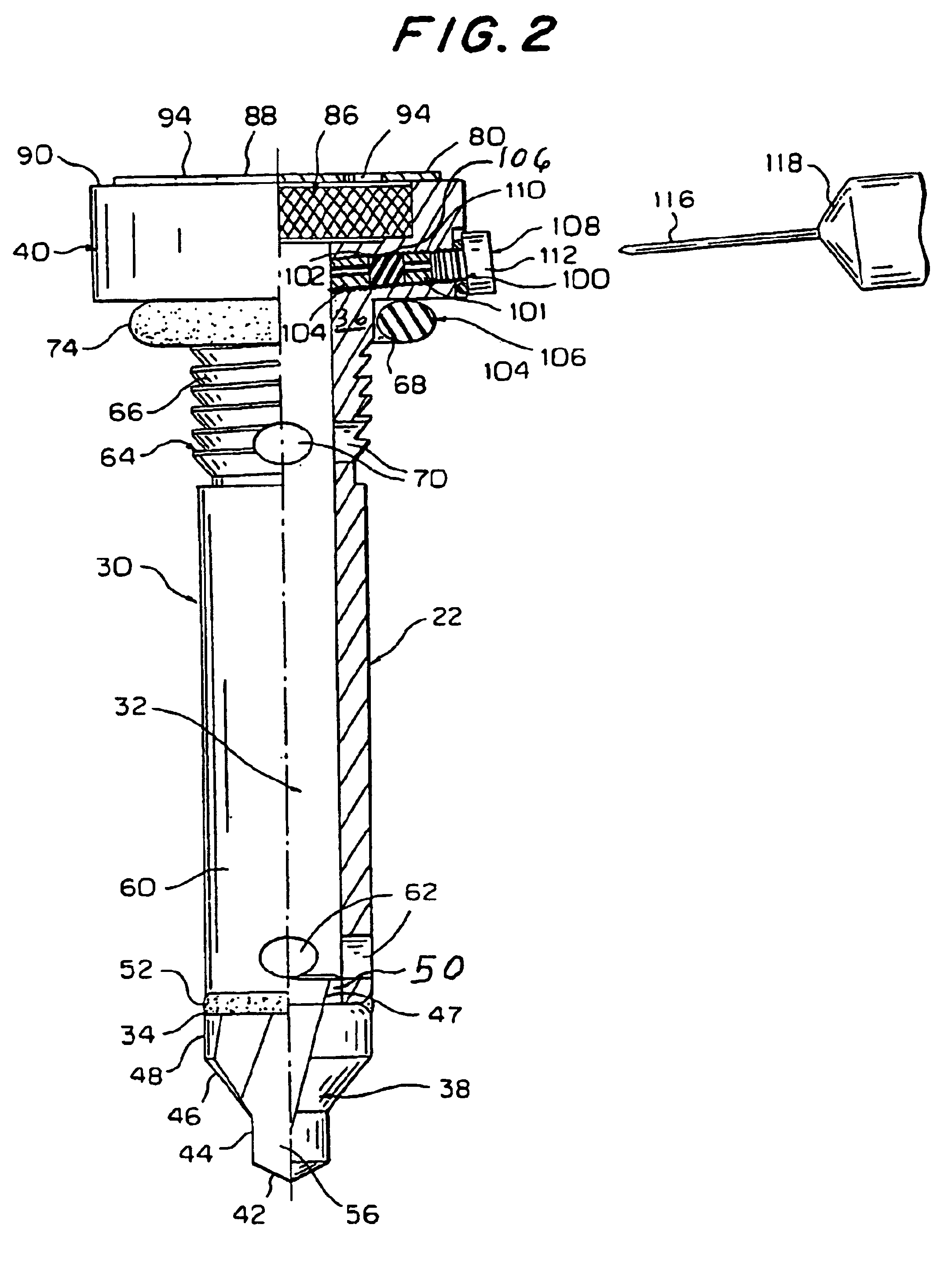

Probe with integral vent, sampling port and filter element

A probe with an integral filtered vent and sampling port has a hollow shaft configured as a drill bit which in use passes through the lid of a drum containing waste products within a liner. The hollow shaft has a penetrating tip and at lest two radial bores, one of which is positioned to open to the space within the liner and the other of which is positioned to open to the space above the liner and between the liner and drum lid. The shaft has a head with a pocket which contains a filter element, the head also having a radial sampling port with a septa seal. In order to sample head space gases, a hypodermic needle is pushed through the septa seal into the longitudinal bore of the hollow shaft, and then withdrawn, allowing the septa seal to close behind the needle. The probe is especially useful for sampling nuclear waste stored within drums having liners. This is because the probe has a first radial port adjacent the penetrating tip thereof which samples gas within the liner and a second radial port disposed between the liner and lid for sampling gas which has escaped past the liner.

Owner:NUCFIL LLC

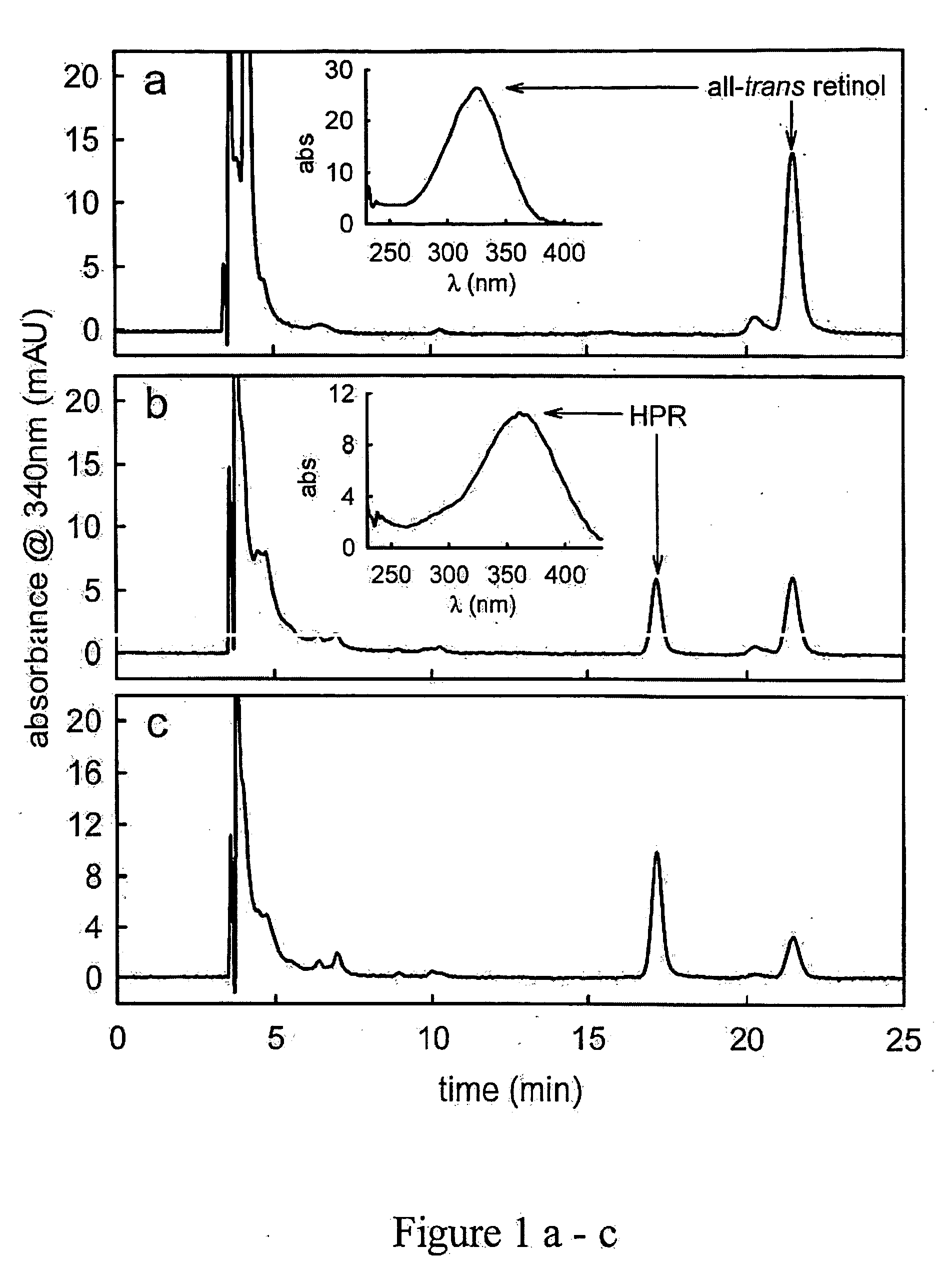

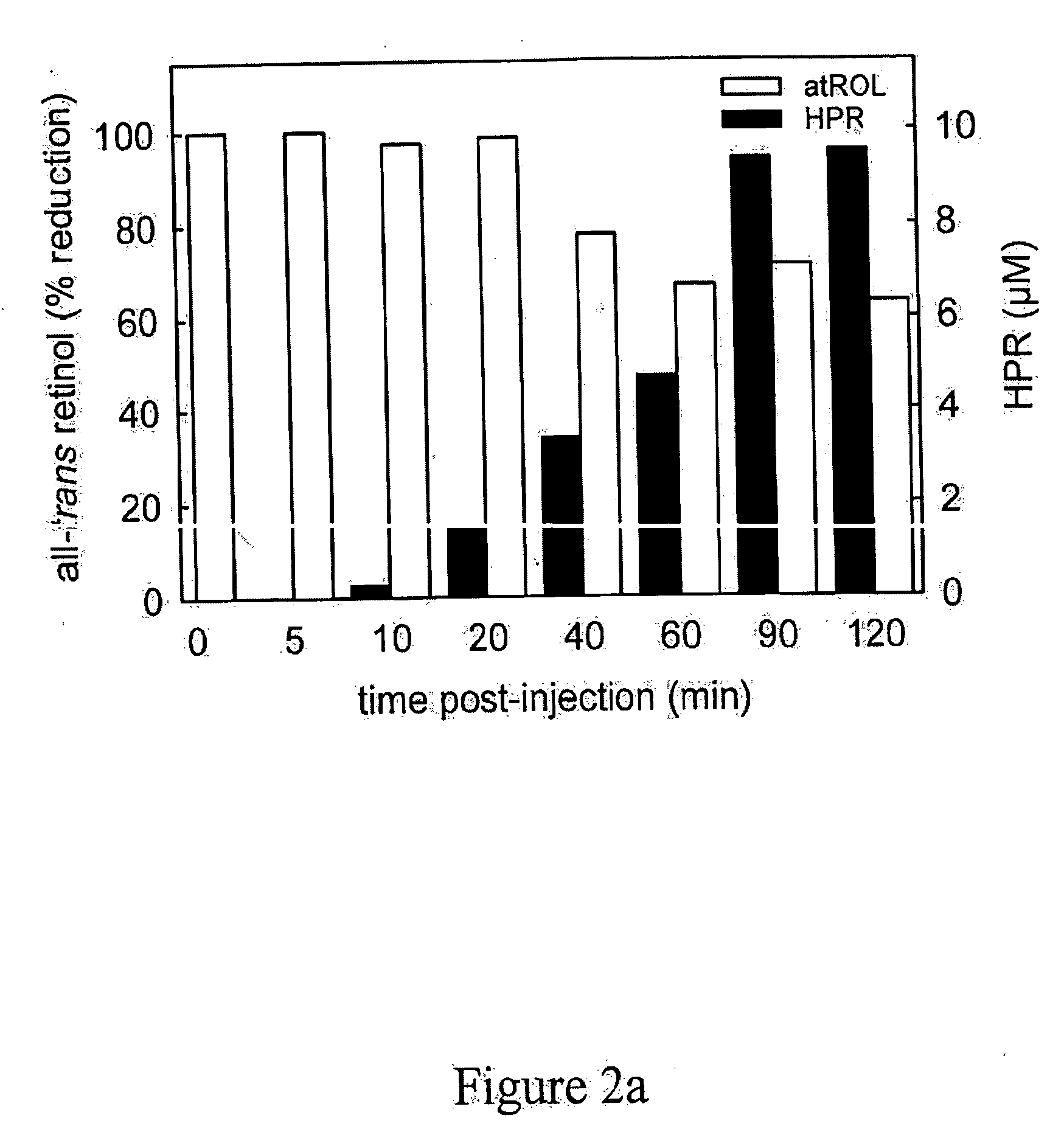

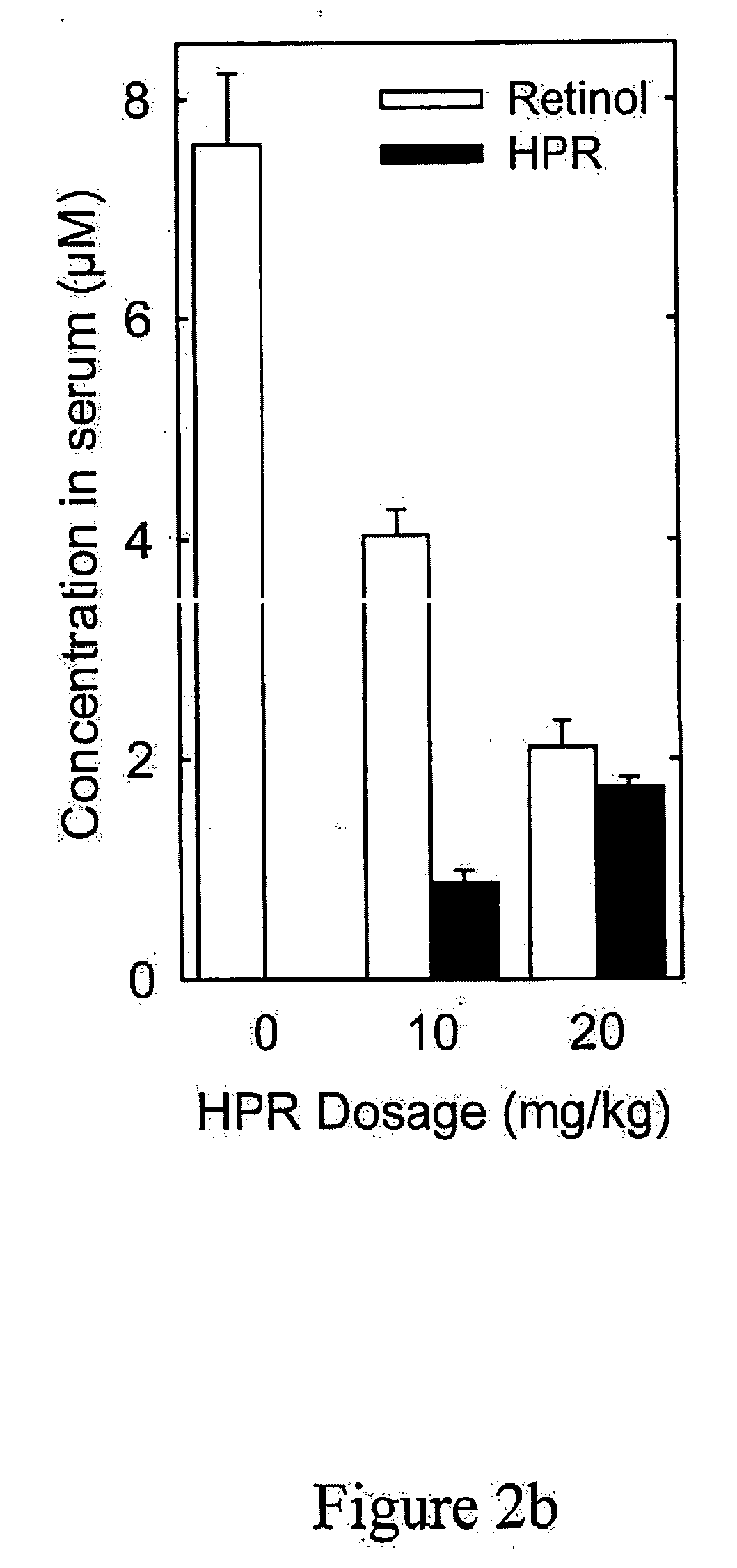

Methods and compositions for treating ophthalmic conditions with retinyl derivatives

Compounds that cause reversible night blindness may be used to treat ophthalmic conditions associated with the overproduction of waste products that accumulate during the course of the visual cycle. We describe methods and compositions using such compounds and their derivatives to treat, for example, the macular degenerations and dystrophies or to alleviate symptoms associated with such ophthalmic conditions. Such compounds and their derivatives may be used as single agent therapy or in combination with other agents or therapies.

Owner:ACUACELA INC

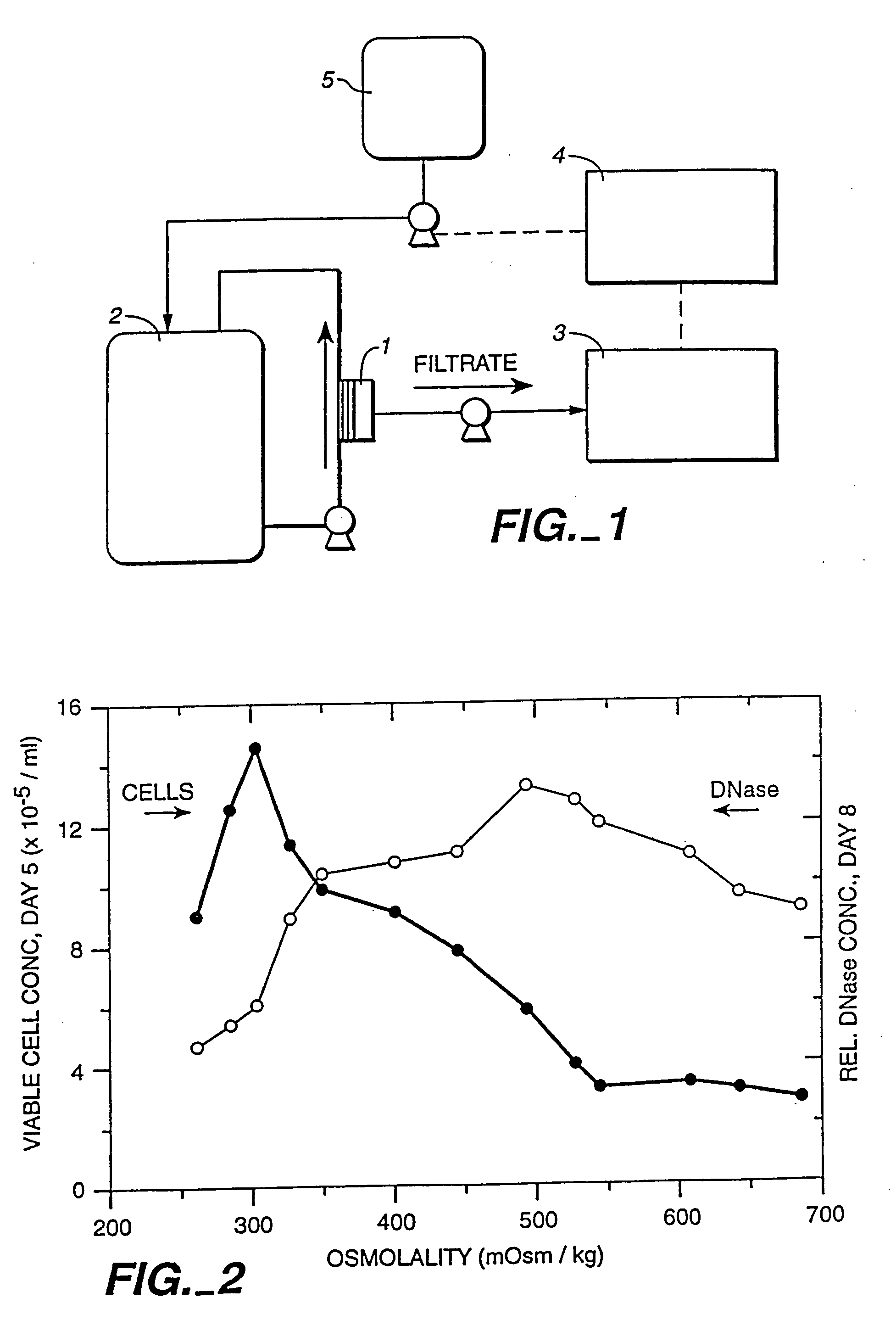

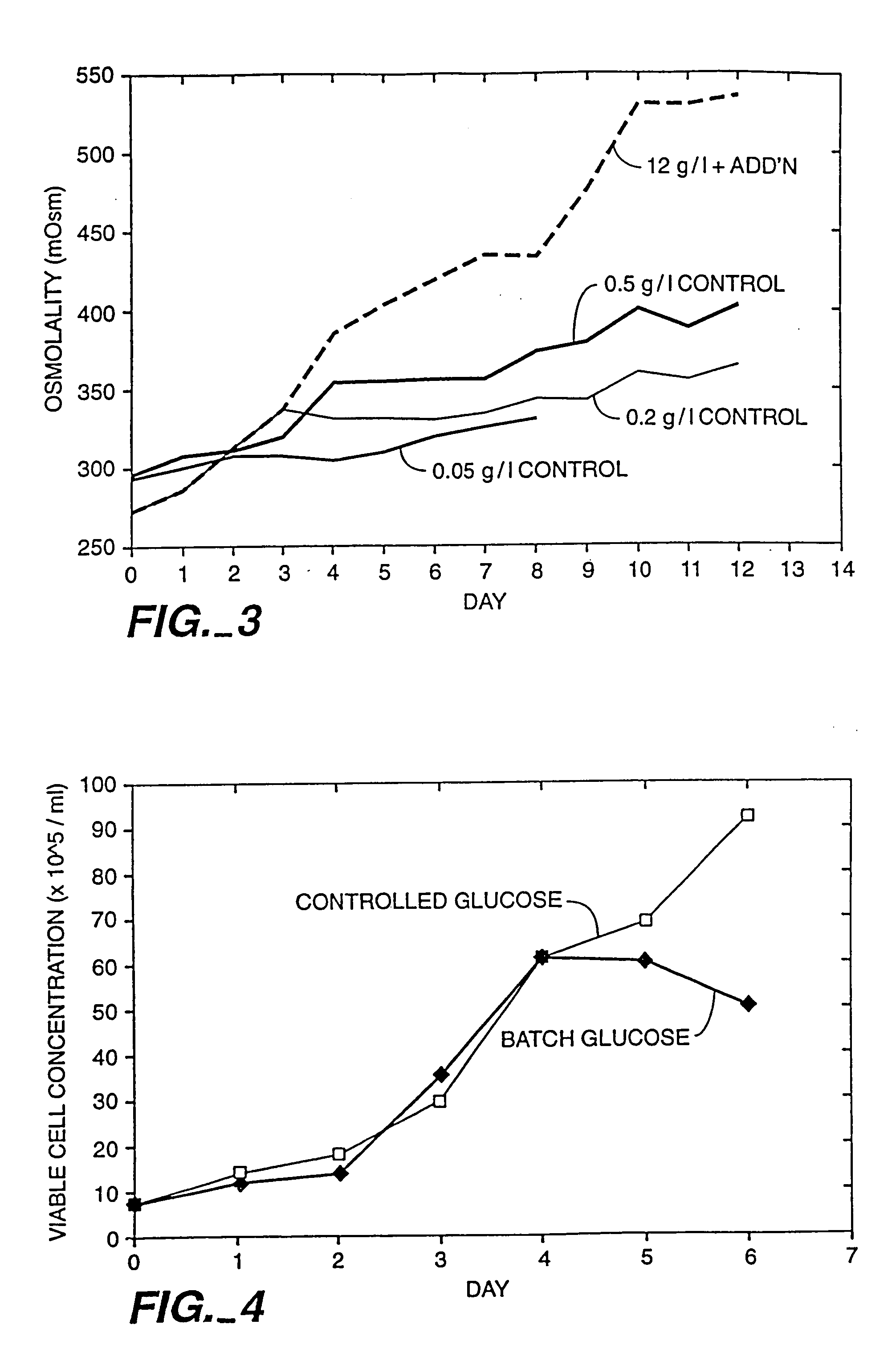

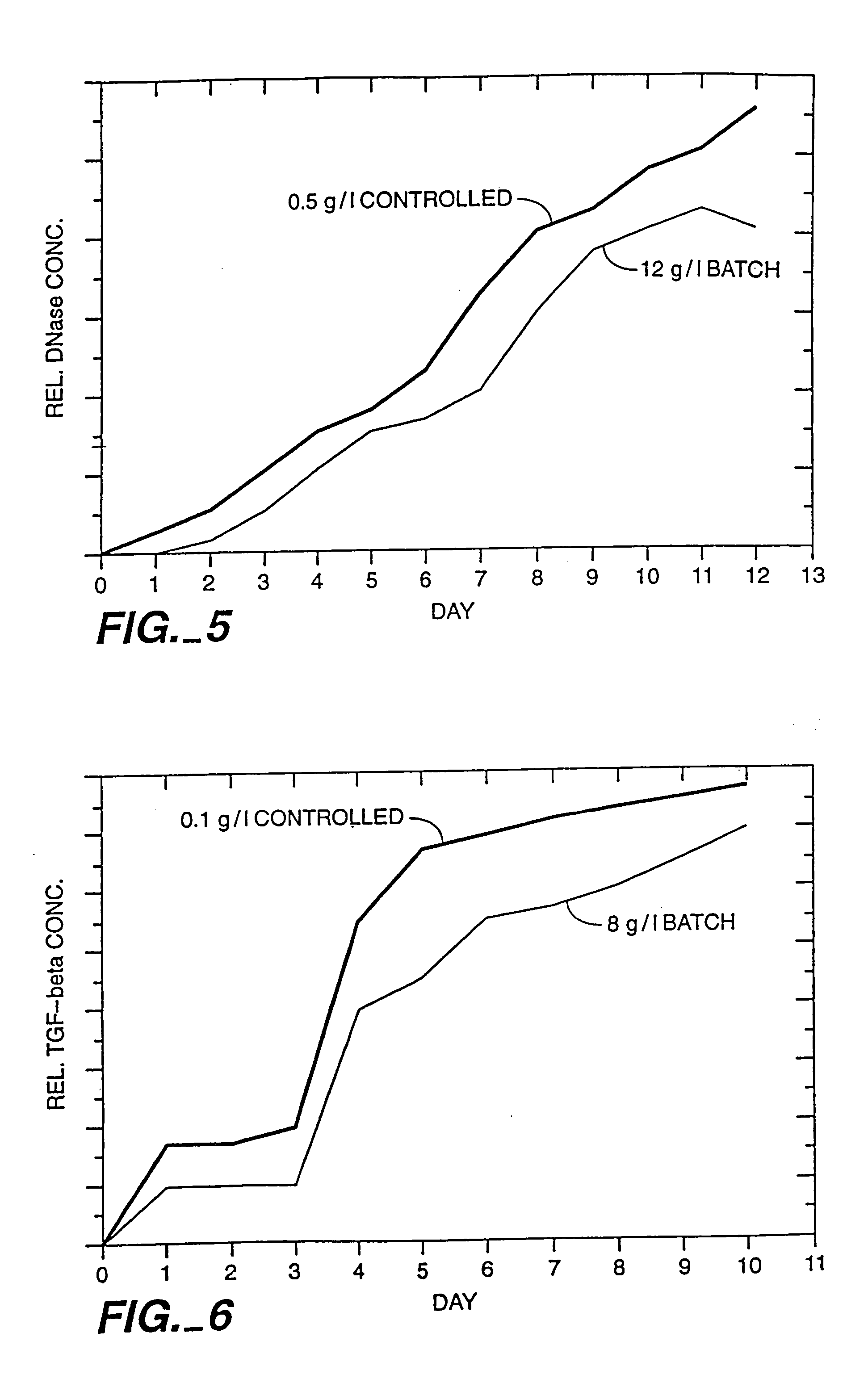

Polypeptide production in animal cell culture

InactiveUS20050272124A1Promote cell growthHigh protein yieldGenetically modified cellsCulture processBiotechnologyGrowth phase

A method of producing a polypeptide in fed batch cell culture is provided which involves an initial cell growth phase and a distinct production phase. In the initial growth stage, animal cells having nucleic acid encoding the polypeptide are cultured at a starting osmolality of about 280-330 mOsm in the presence of a concentration of glucose controlled throughout the culturing to be within a range between about 0.01 and 1 g / L. This is followed by a production phase, where the cultured animal cells of the growth phase are inoculated at a cell seed density of at least 1.0×106 cells / mL and the cells are cultured at a starting osmolarity of about 400-600 mOsm in the presence of a concentration of glucose controlled throughout the culturing to be within a range between about 0.01 and 1 g / L. Preferably, the glutamine concentration in the cell culture medium is simultaneously controlled in order to curtail production of lactic acid and ammonia which result from unnecessarily high glutamine concentrations. During the growth phase, production of potentially detrimental metabolic waste products, such as lactic acid, is controlled thereby curtailing the increase of osmolality due to accumulation and neutralization of waste products. Thus, the cell growth can be improved. In the production phase, the cell culture conditions are modified in order to arrest or reduce cell growth and thereby direct nutrient utilization toward production, as opposed to cell growth. Overall, it is intended that the method results in an improvement in specific productivity, reduction in production run times and / or an increase in final product concentration.

Owner:GENENTECH INC

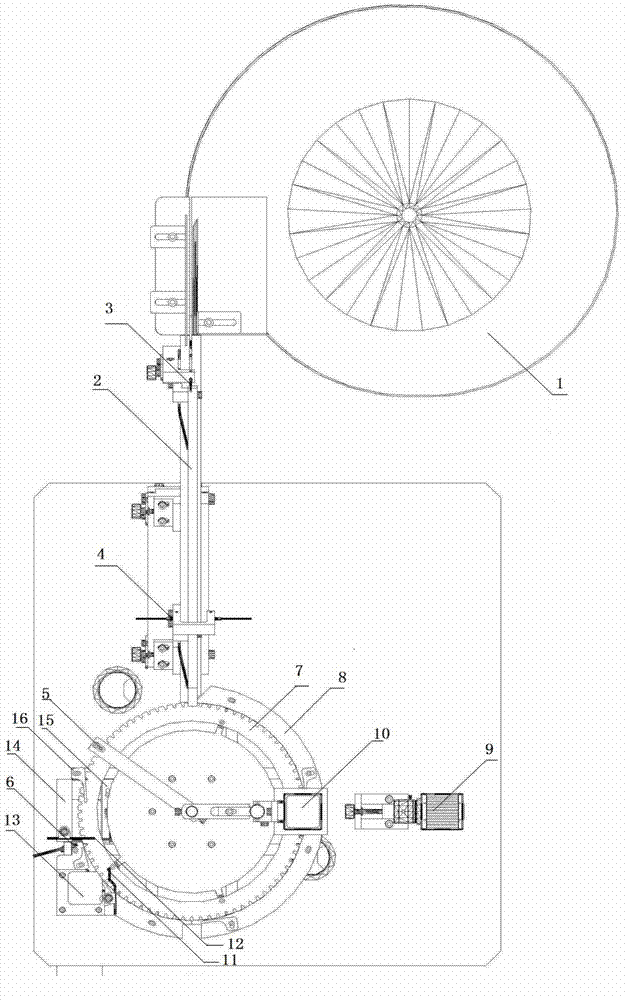

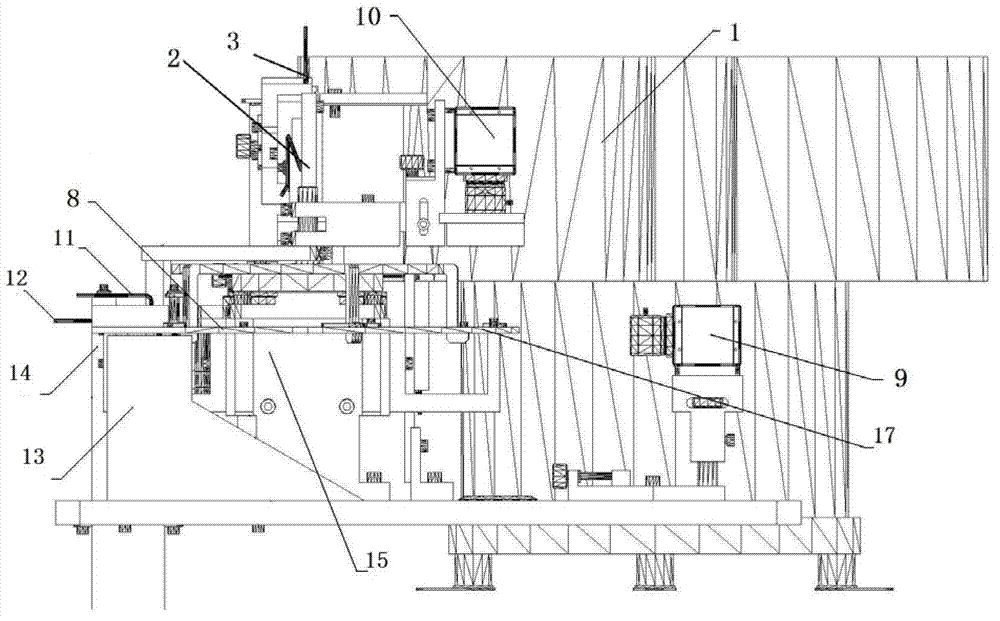

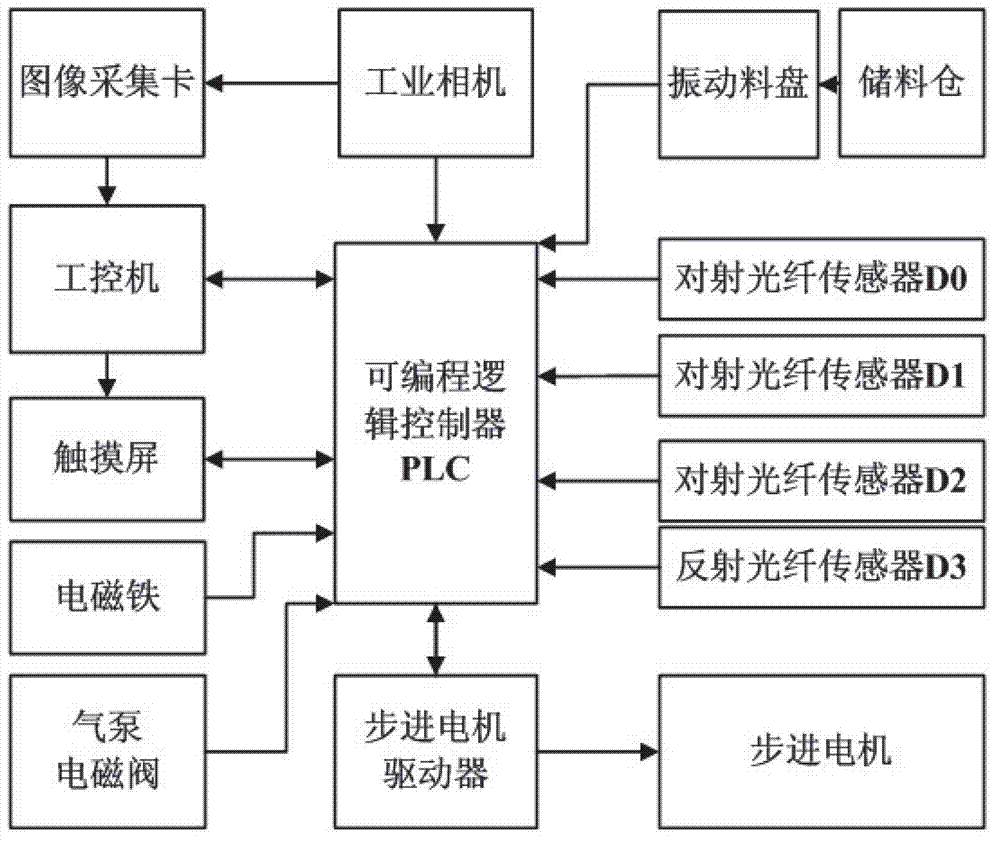

Machine vision automatic detection system for rivets

InactiveCN102829726AImprove the level ofReduce manual inspection costsUsing optical meansSortingVisual perceptionElectromagnetic valve

The invention discloses a machine vision automatic detection system for rivets. The machine vision automatic detection system for rivets comprises a PLC (programmable logic controller), two industrial cameras, a storage bin, a vibration feed plate, a linear rail, a mechanical rotary plate, a waste product blowing pipe, a waste product discharging trough, a salable product blowing pipe, a salable product discharging trough, discharging baffles, an image acquisition card, an industrial personal computer, a touch screen, an electromagnet, a pneumatic electromagnetic valve, an upper sensor, a lower sensor, a hole sensor, a count sensor, a stepping motor drive and a stepping motor. The detection precision of the machine vision automatic detection system for rivets is within + / -0.03mm, and the electromagnetic valve is controlled by the PLC to complete precise waste product blowing and realize separation of salable products from waste products. The final number of the salable products is accurately recorded by a counter, and a discharging port is closed according to time difference to prepare for a subsequent packaging procedure. In addition, all data are recorded in a database, and various production, client, analysis and CPK (complex processing capability index) report forms can be generated by one key.

Owner:SHANGHAI JIAO TONG UNIV

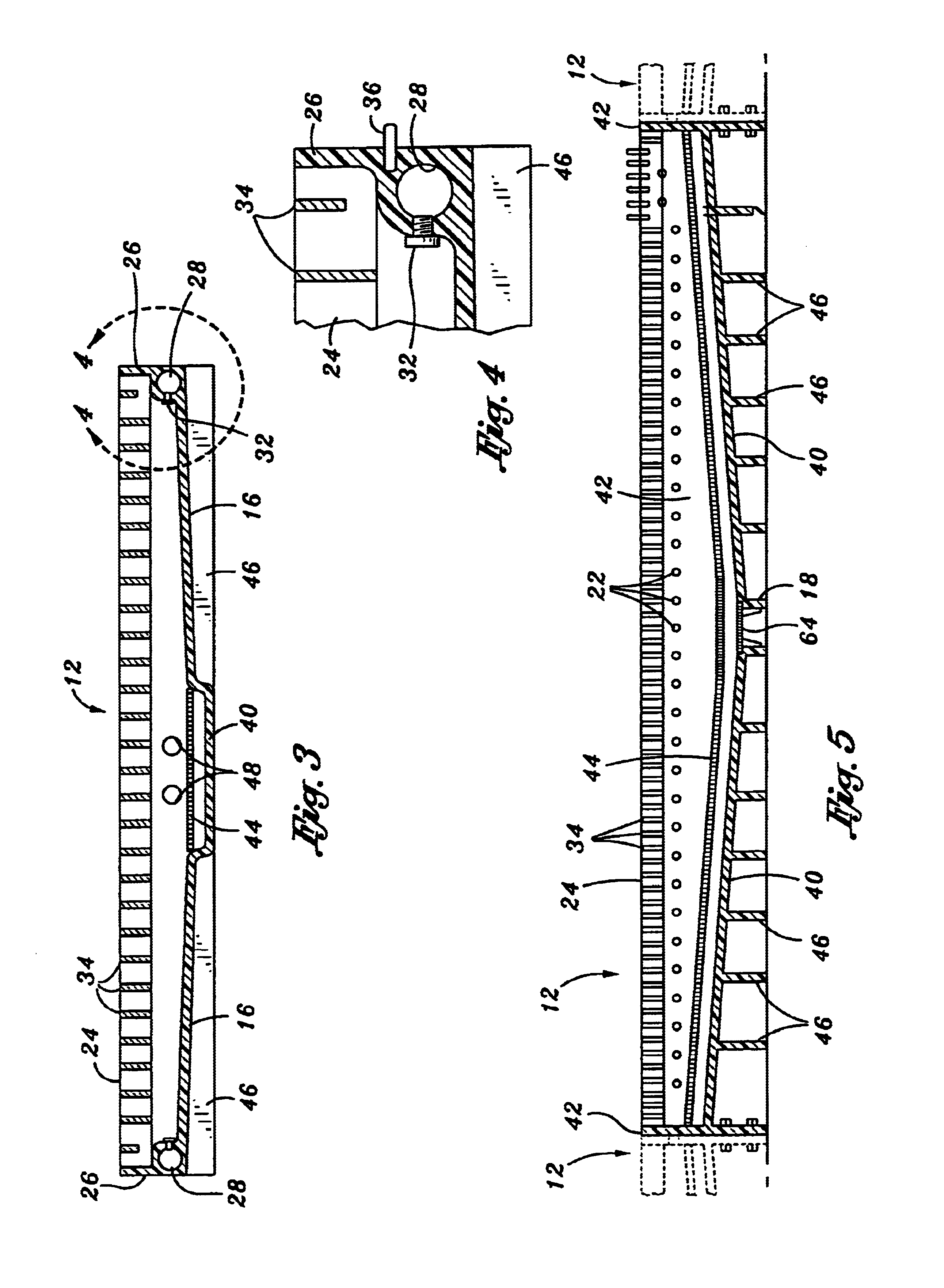

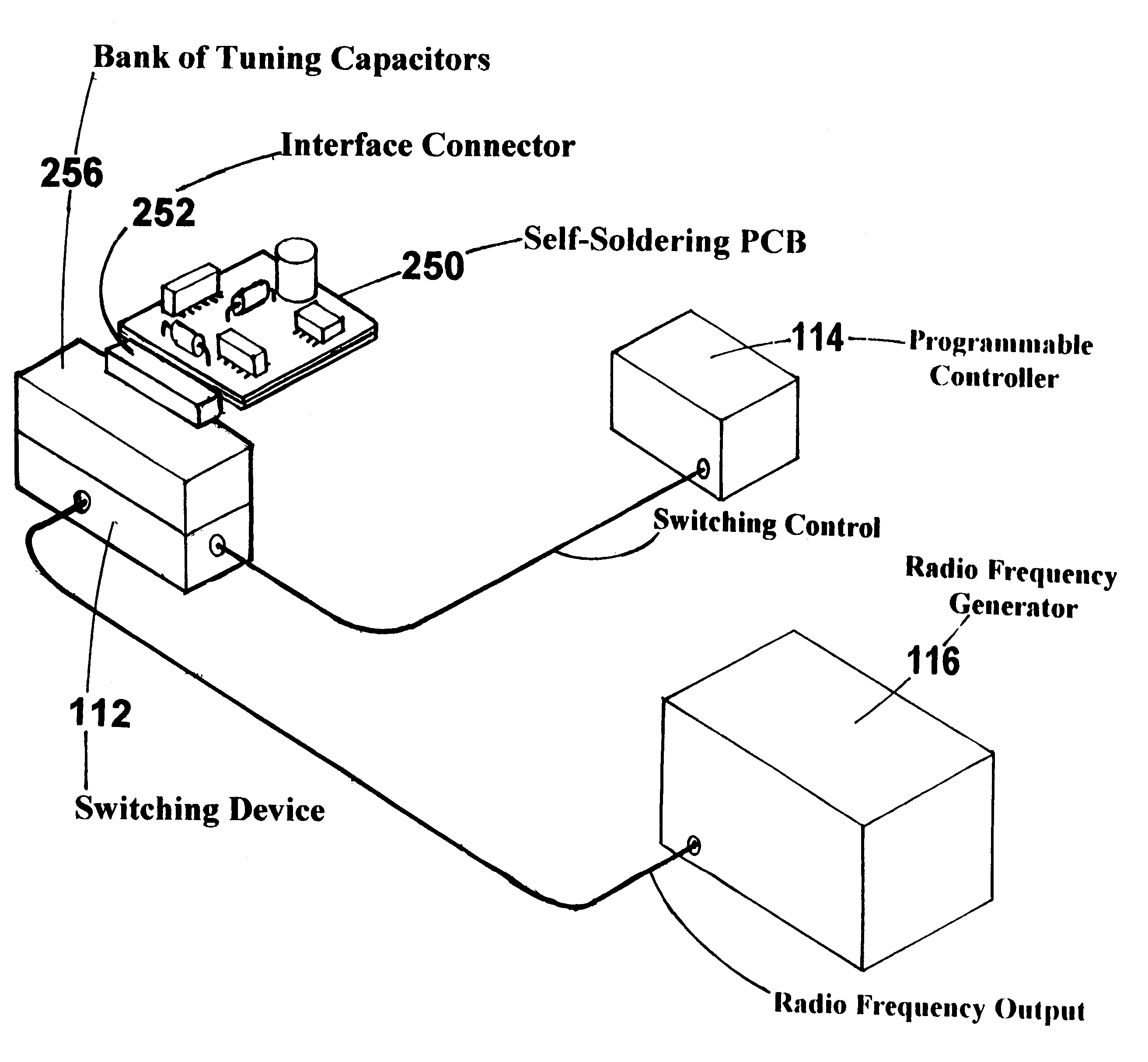

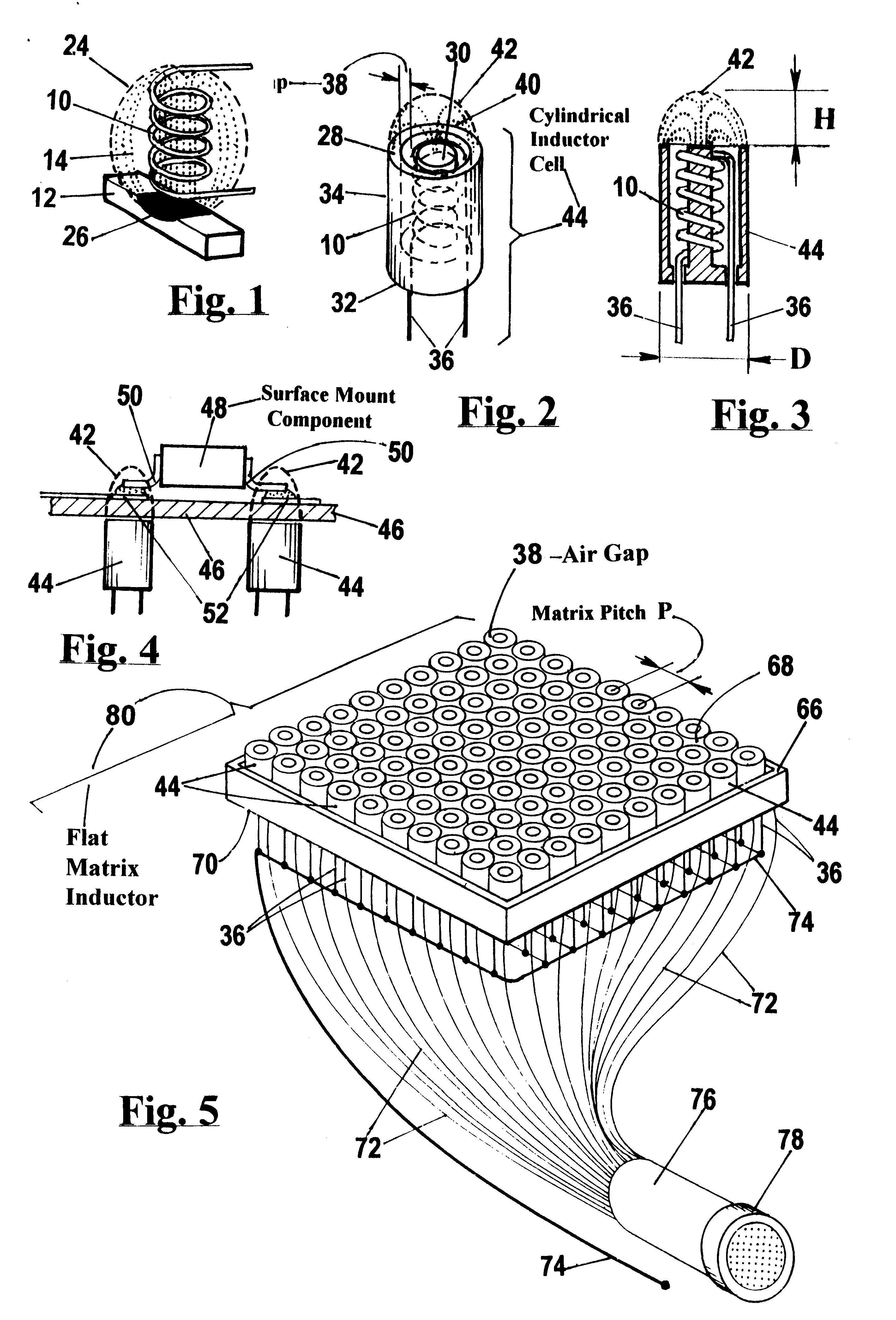

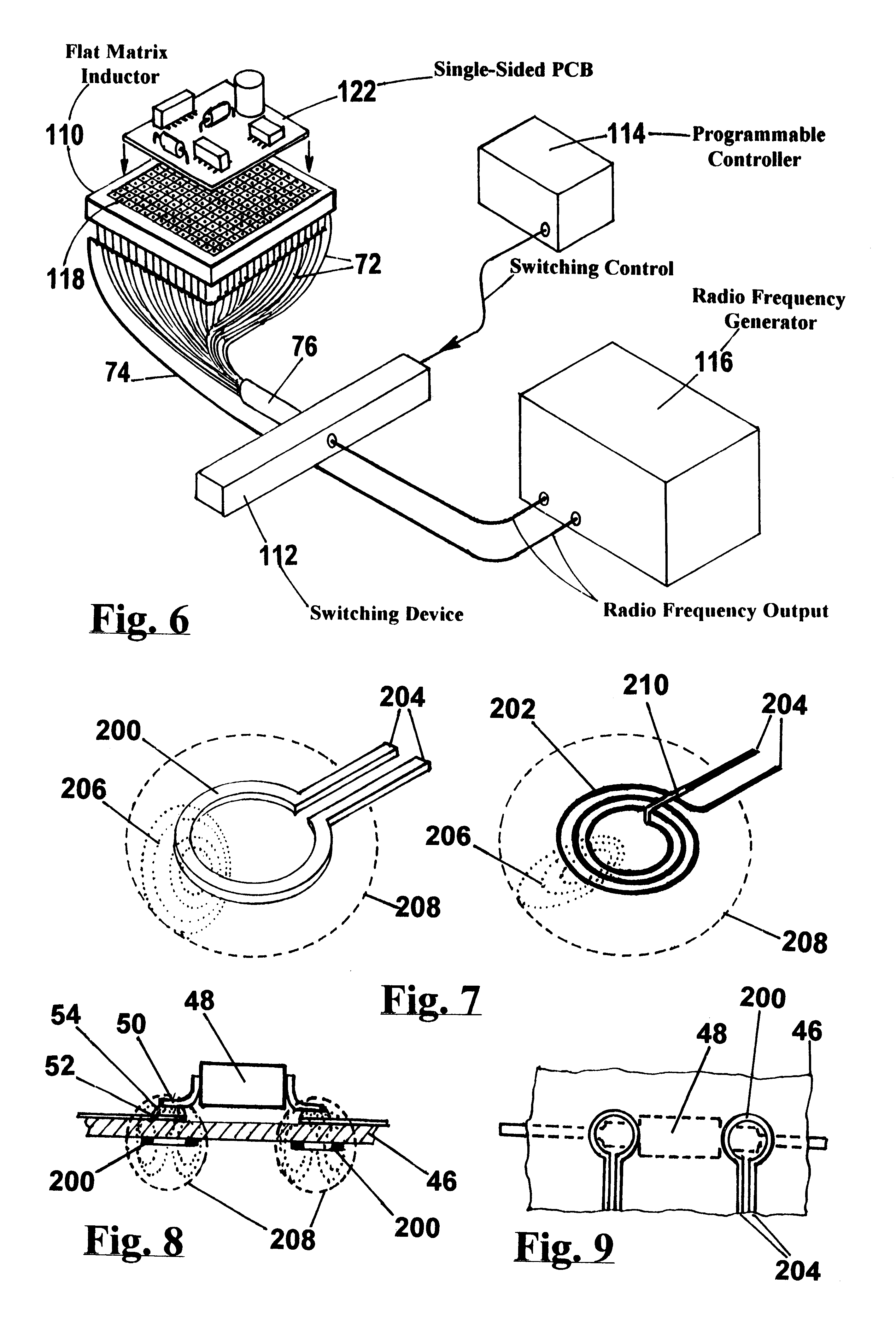

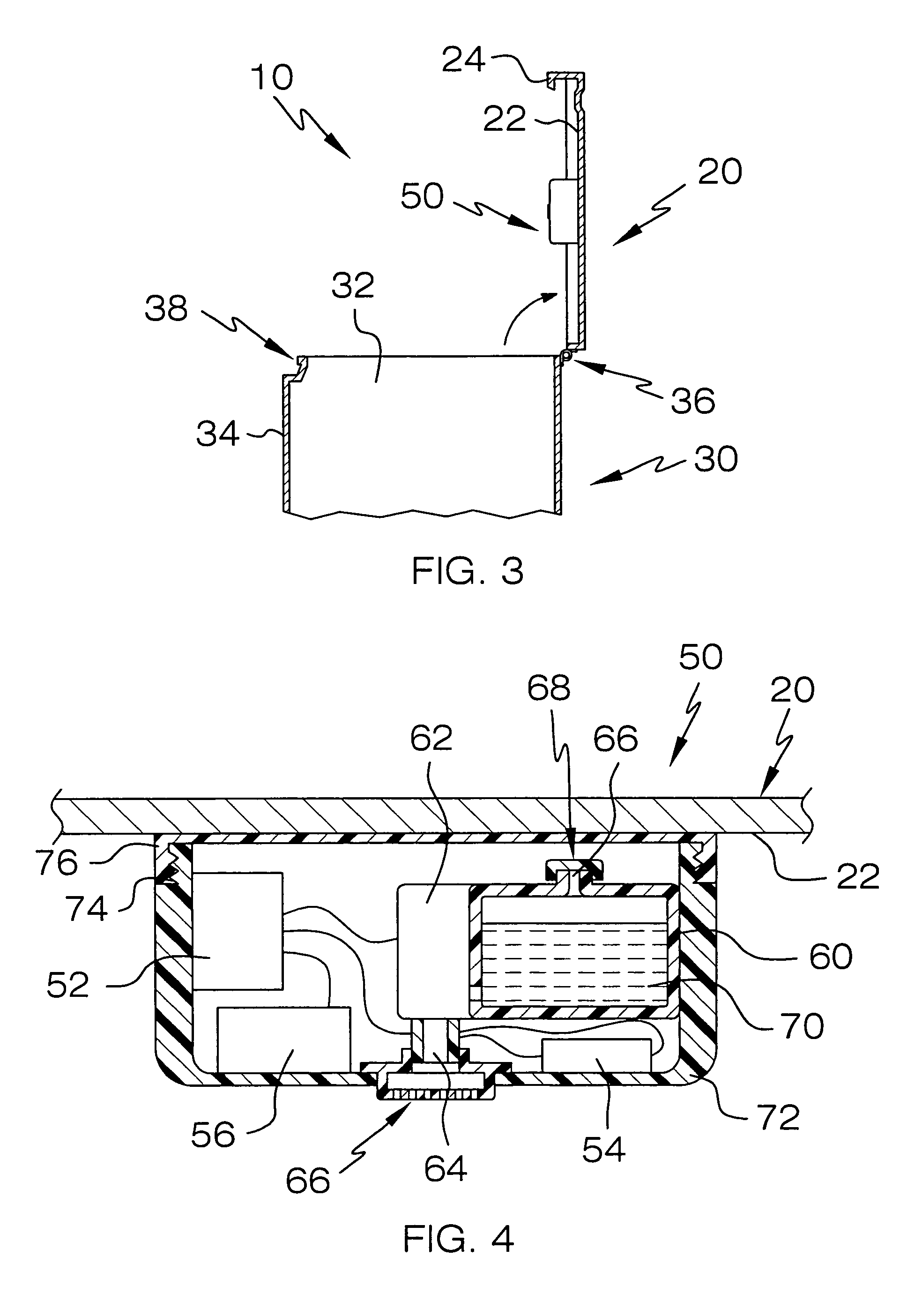

Inductive self-soldering printed circuit board

InactiveUS6229124B1Improve quality and reliabilityReduce formationPrinted circuit assemblingCoil arrangementsManufacturing technologyHeat sensitive

A new apparatus for inductively soldering surface-mount, straddle-mount and through-hole type electronic components into a self-soldering PCB (printed circuit board) in an automated fashion utilizing localized Electromagnetic Induction Heating (E.I.H.). Current manufacture technology for packaging electronic components depends on the reflow and wave soldering processes. Both processes heat up to relatively high temperatures the entire assembly, namely its PCB and all the electronic components being soldered into it. Such harsh high-temperature environment frequently causes components damage resulting in rejects and / or demanding rework. With this invention reflow oven and / or wave soldering equipment is not required. During a soldering operation only the leads and pads being soldered are heated but neither the body of said electronic components nor the dielectric material forming said self-soldering PCB and its interconnecting traces are heated. Because of this selectively localized inductive heating, the invention permits to reduce cost and improve the quality and reliability of manufactured products. The invention consumes about 200 times less energy than the reflow and wave soldering processes. This invention can readily be utilized to complement and / or supplement the reflow and wave soldering processes by providing selective inductive self-soldering of odd-form and / or heat-sensitive components. The invention also allows in-process, and in-situ, testing of soldered joints quality thus permitting rework before final assembly of a self-soldering PCB is completed. This invention also provides for a useful inductive de-soldering apparatus.

Owner:TRUCCO HORACIO ANDRES

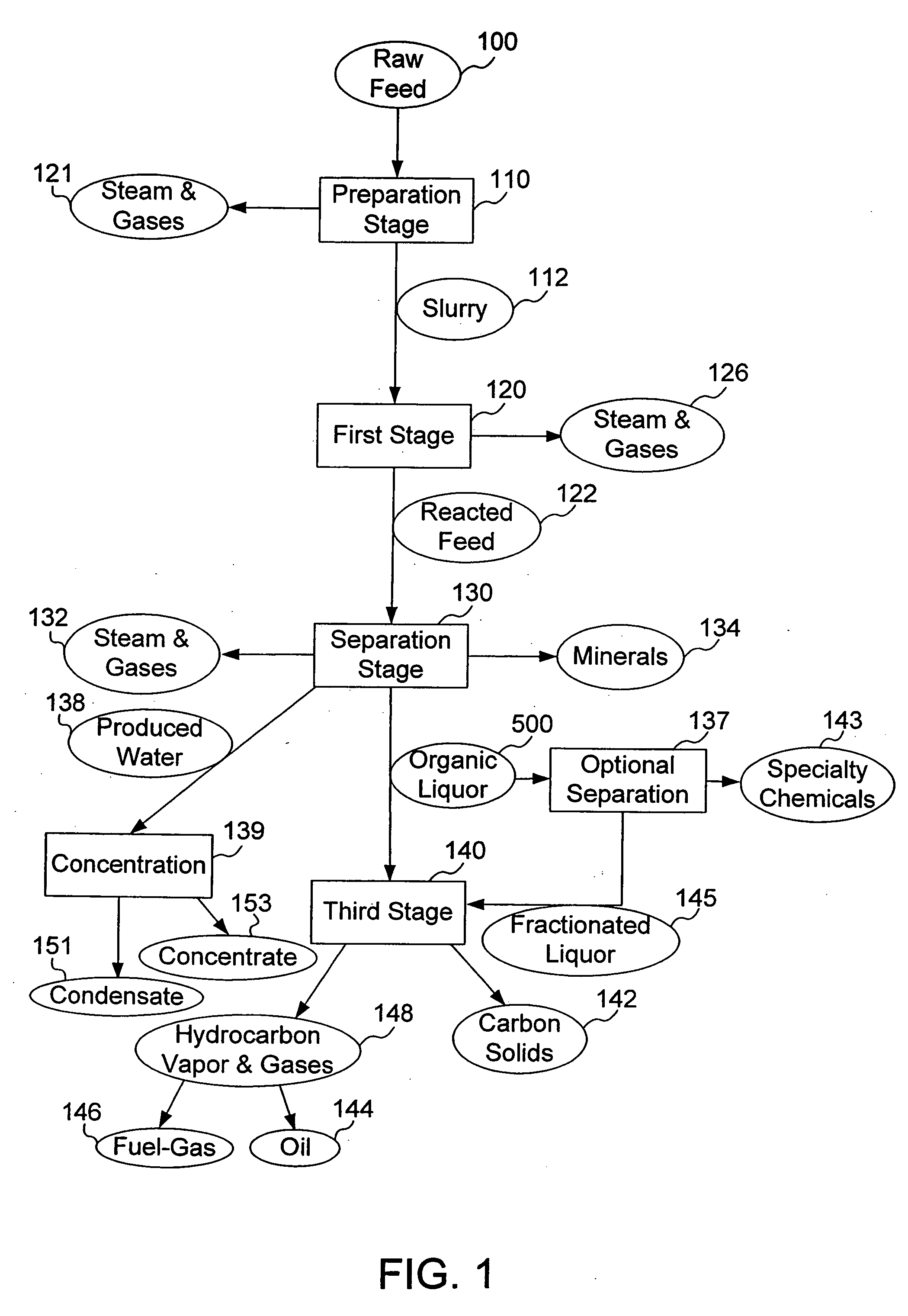

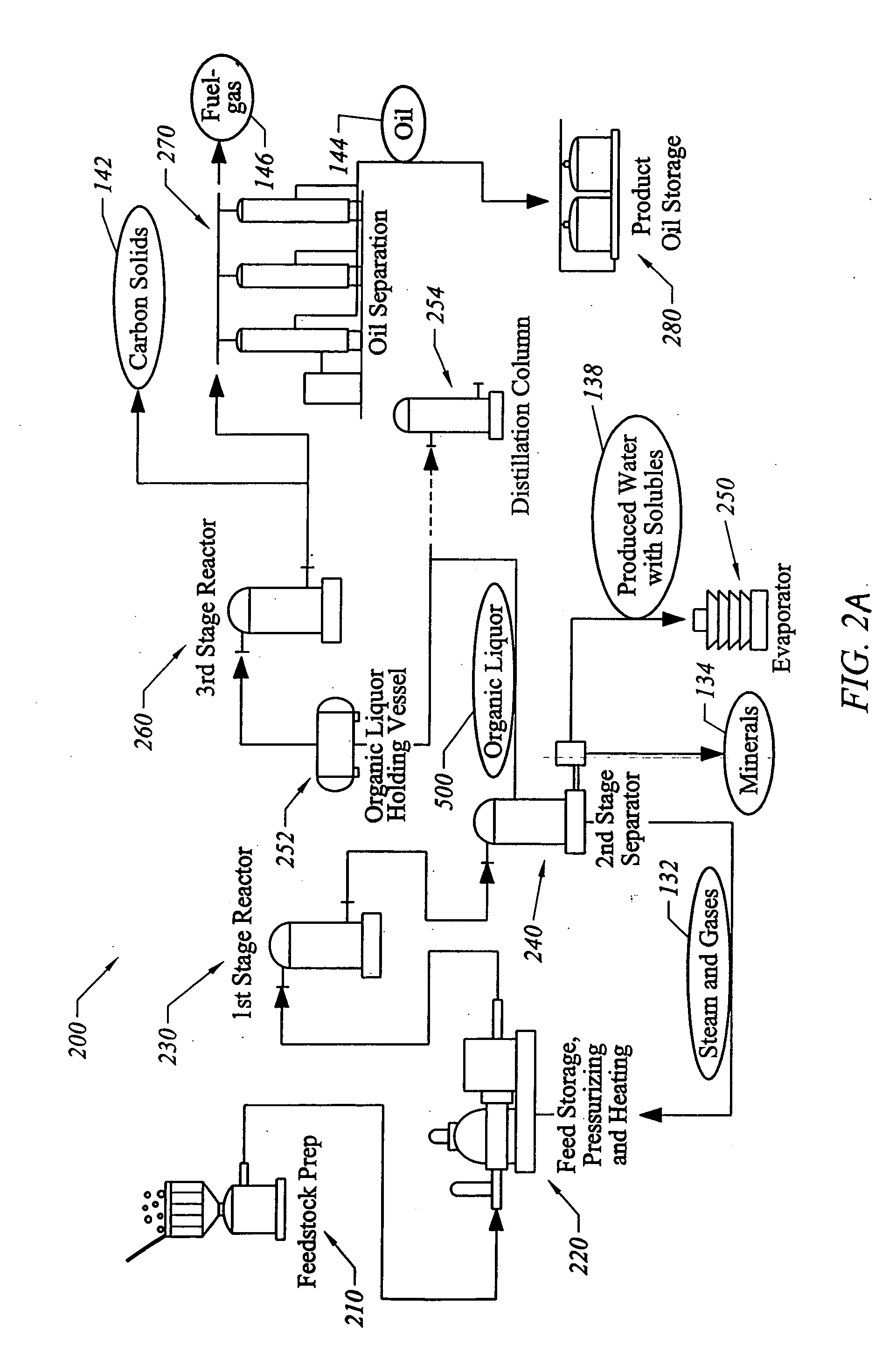

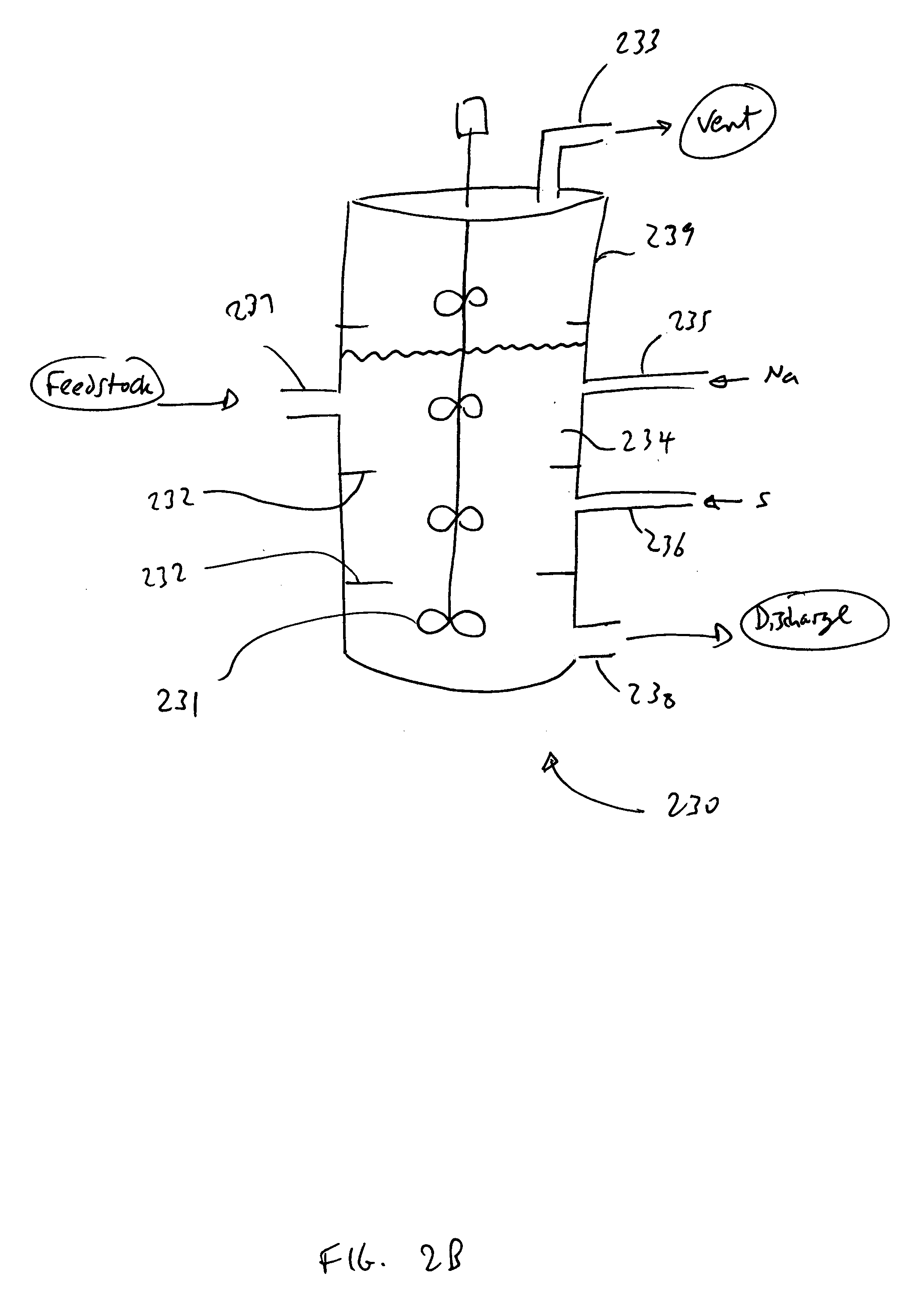

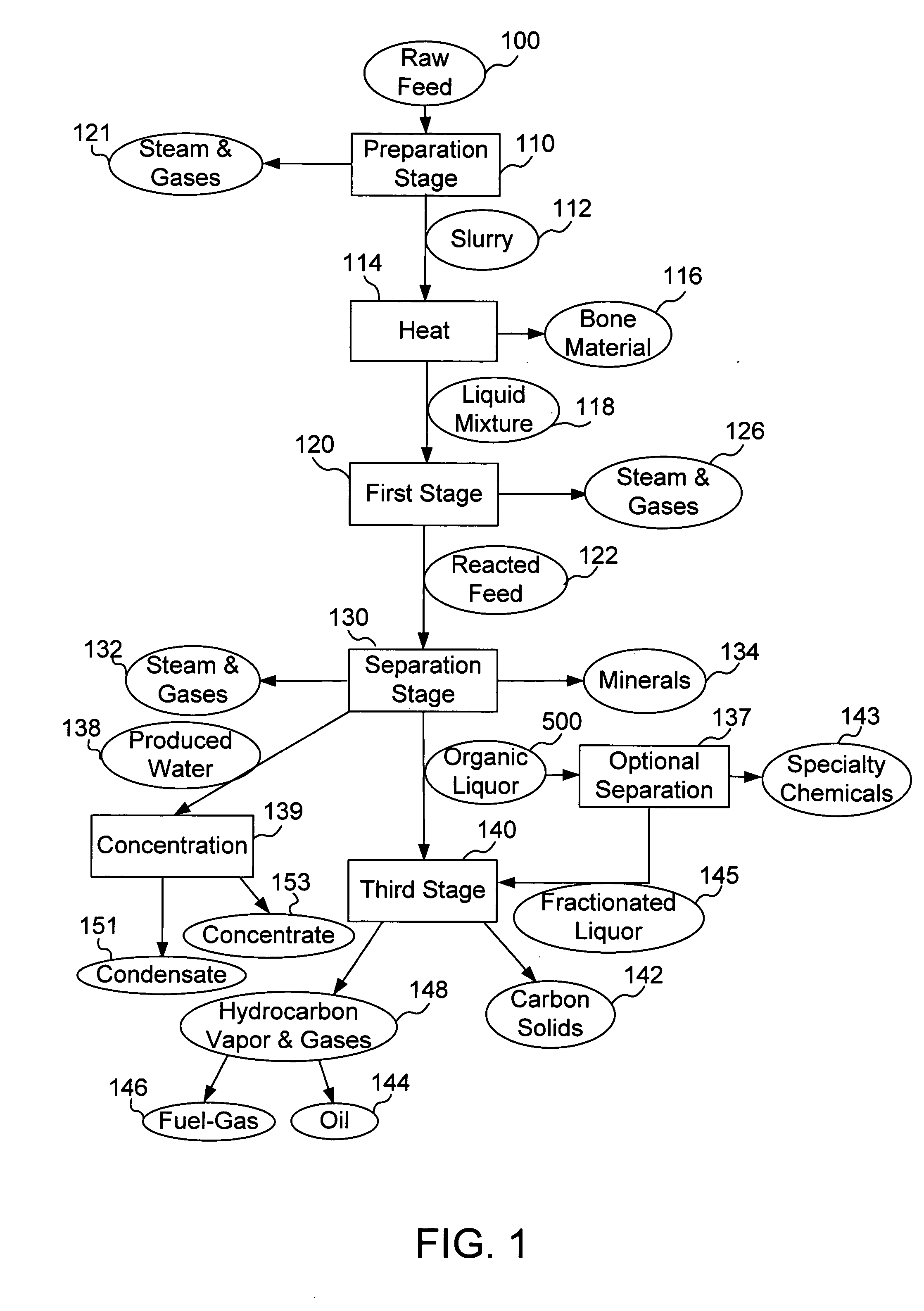

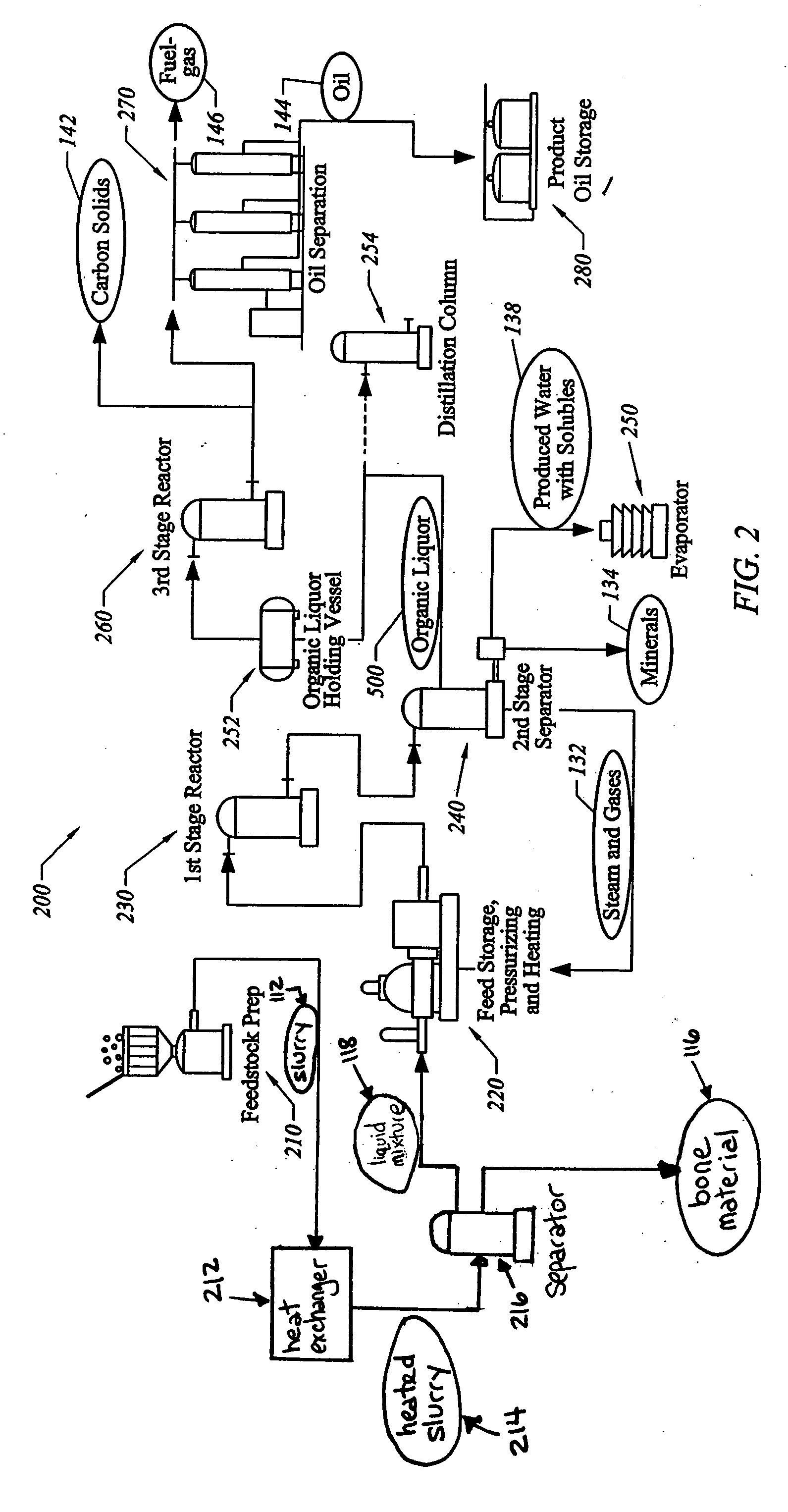

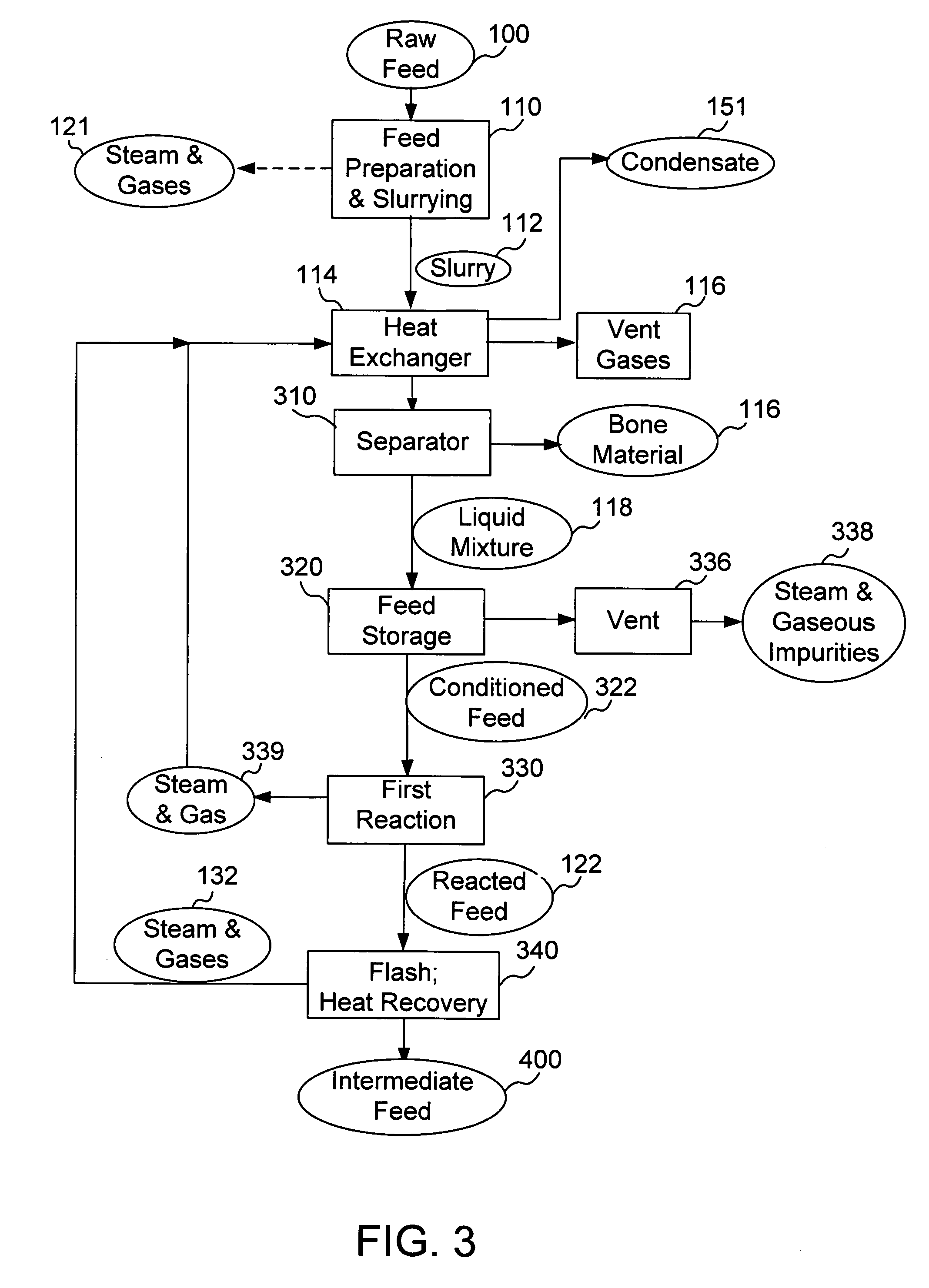

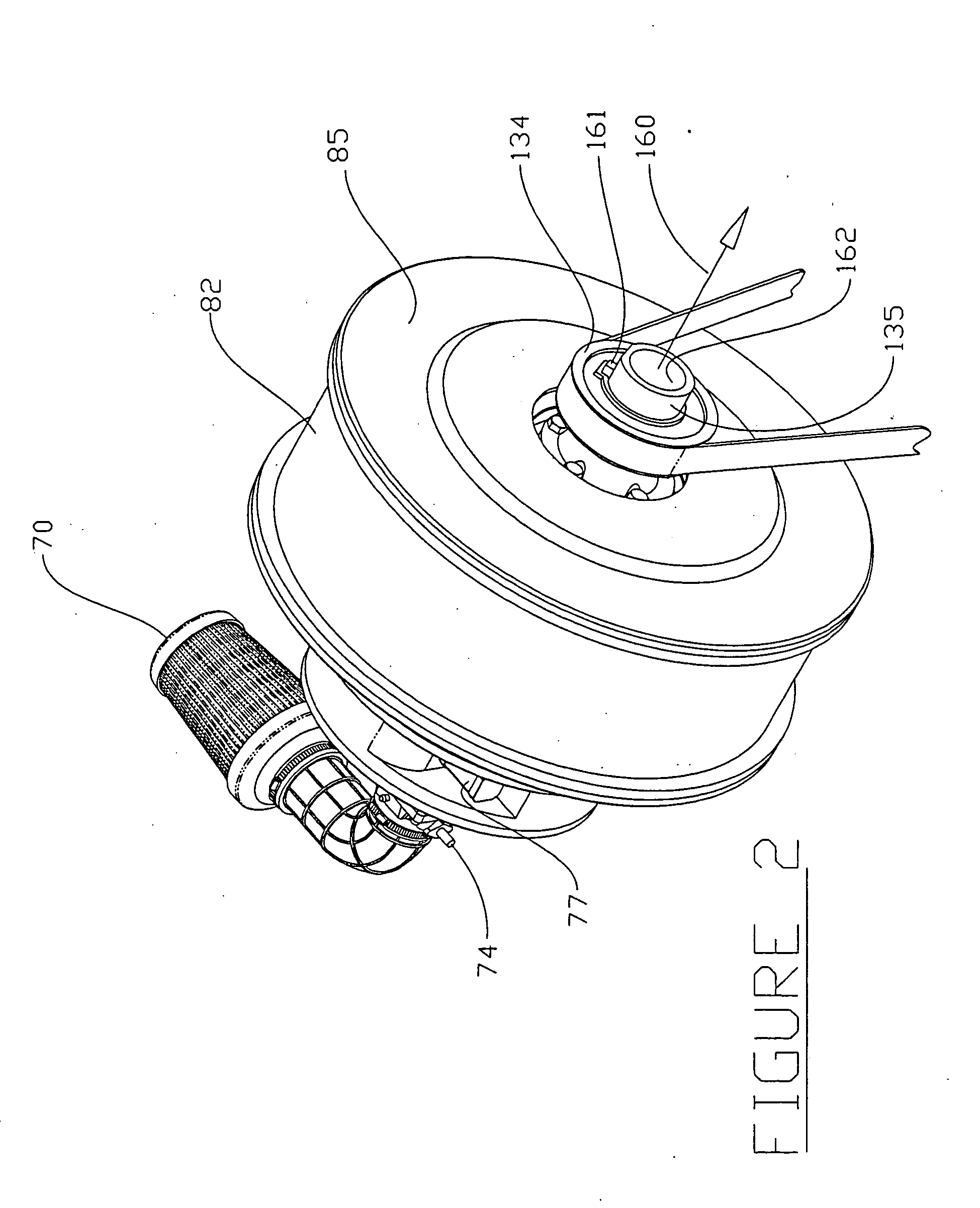

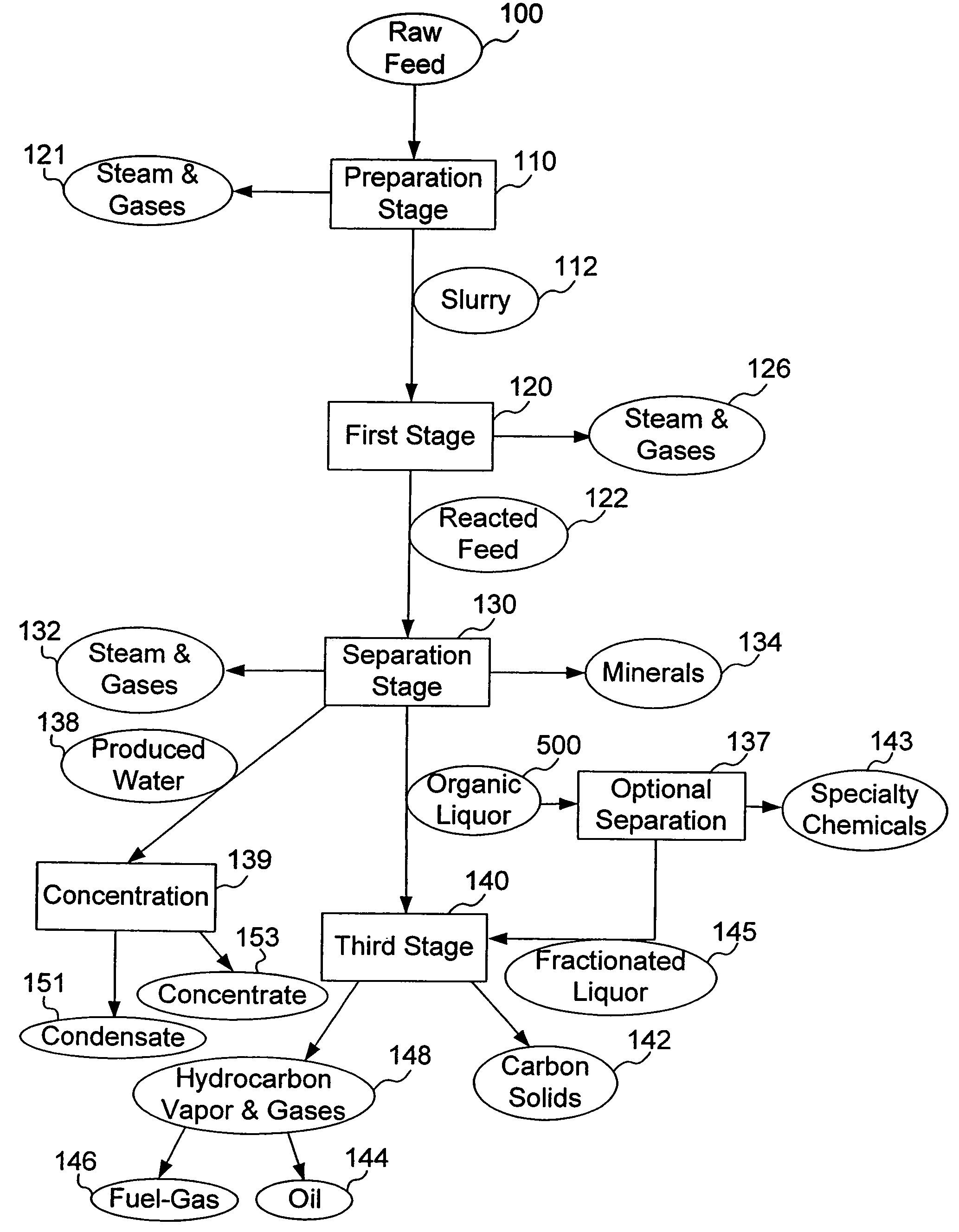

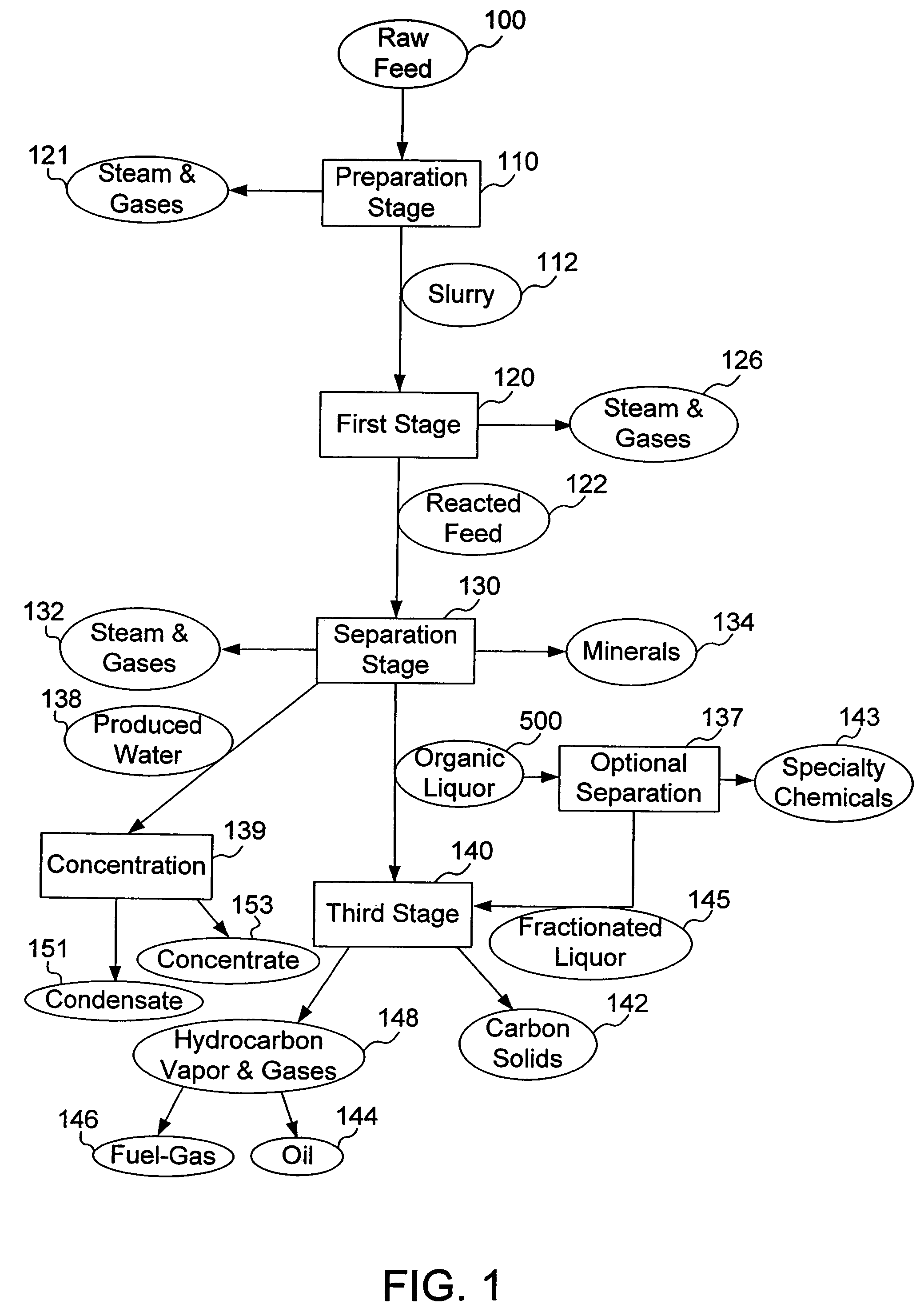

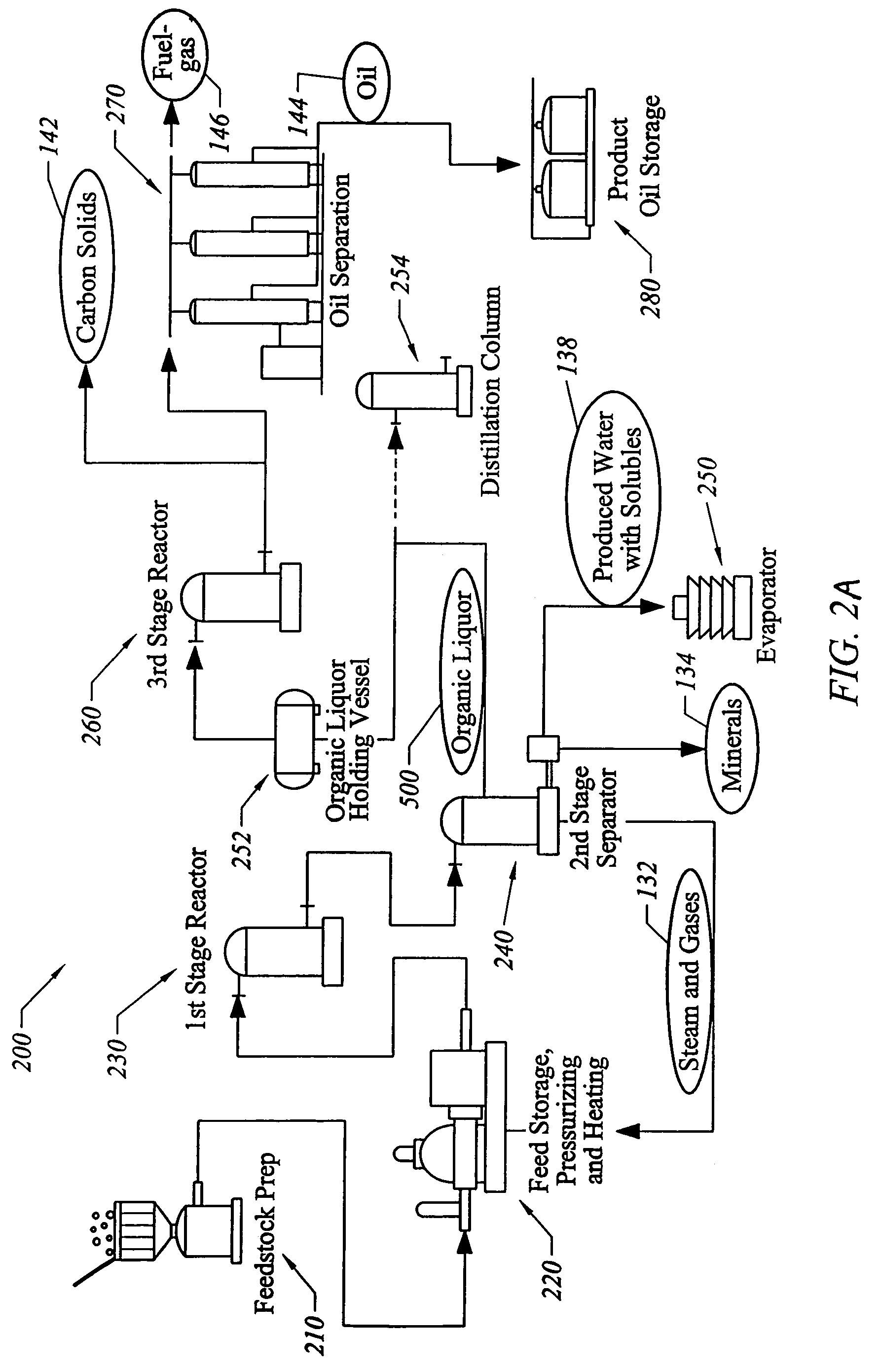

Process for conversion of organic, waste, or low-value materials into useful products

ActiveUS20060004237A1Low viscosityHydrocarbon purification/separationIndirect and direct heating destructive distillationHigh energySulfur

The present invention addresses the processing of waste and low-value products to produce useful materials in reliable purities and compositions, at acceptable cost, and with high energy efficiency. In particular, the invention comprises a multi-stage process that converts various feedstocks such as offal, animal manures, municipal sewage sludge, that otherwise have little commercial value, to useful materials including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure in a reducing environment accomplished by controlled addition of sulfur and sodium, separates out various components, then further applies heat and pressure to one or more of those components. The invention further comprises an apparatus for performing a multi-stage process of converting waste products into useful materials, and at least one oil product that arises from the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

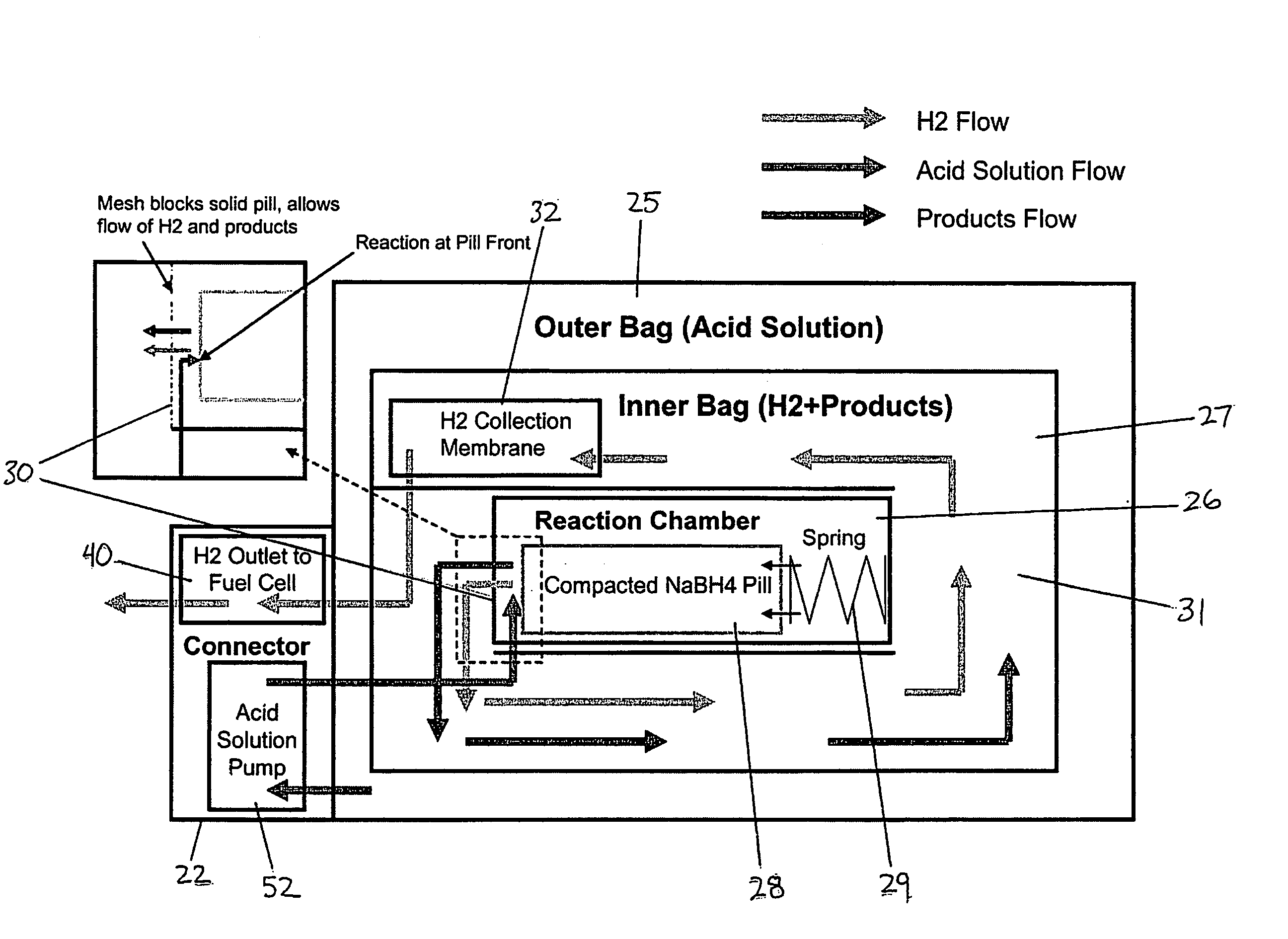

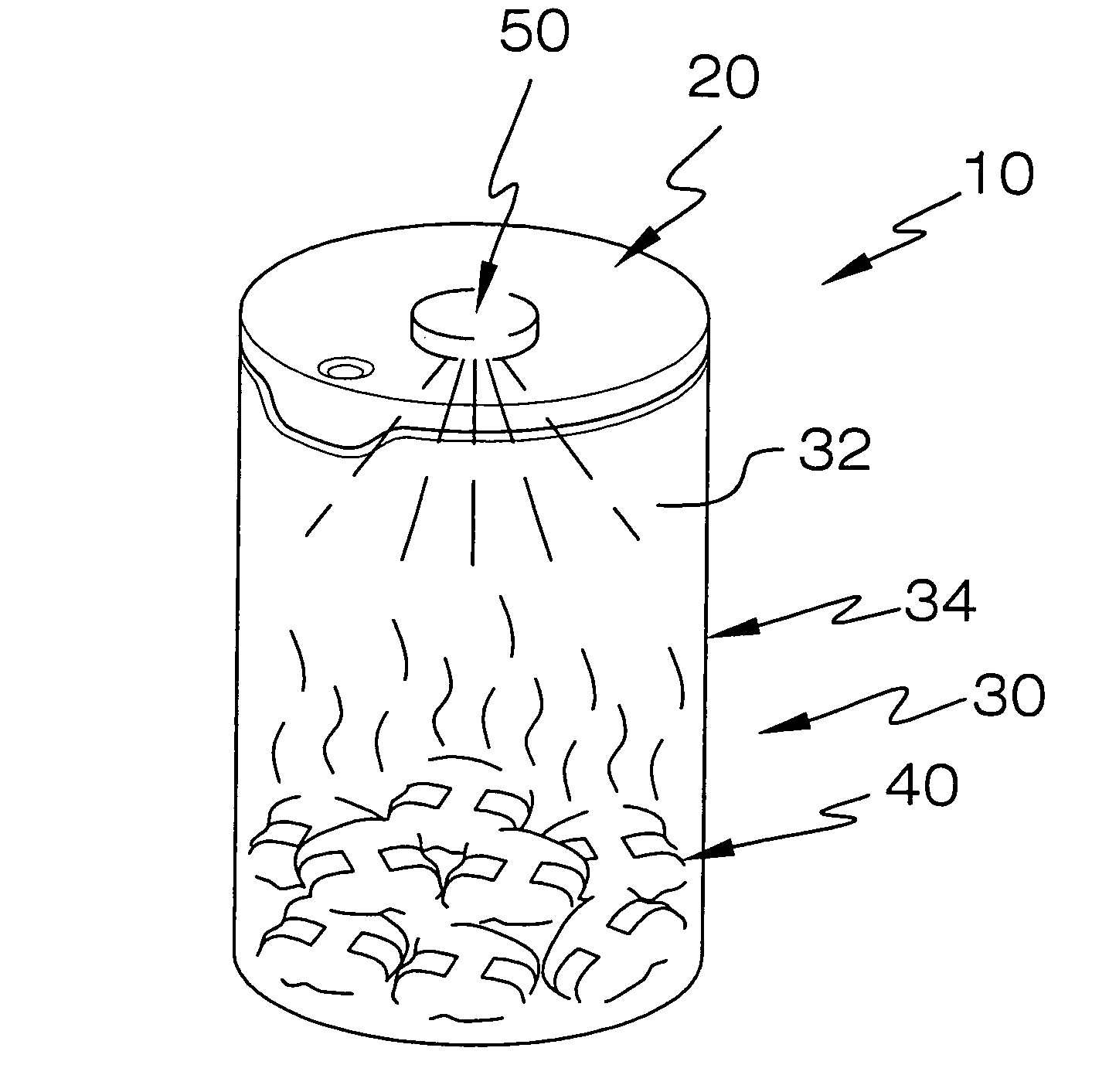

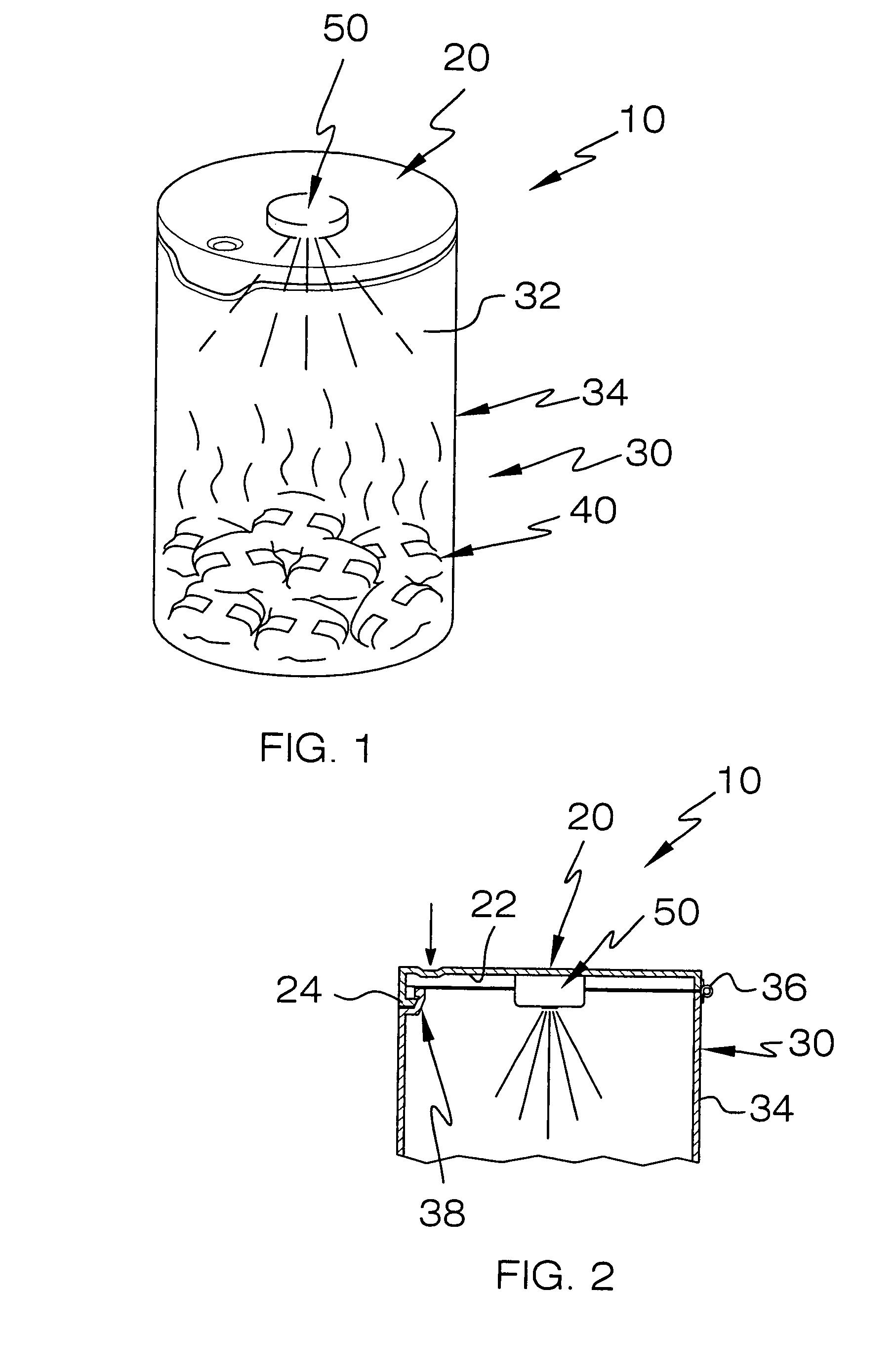

Hydrogen generator

A hydrogen gas generator generates hydrogen gas by mixing two reactants. The generator has a reaction chamber for receiving a solid reactant. The chamber has a reaction product separator impermeable to the solid reactant and a biasing means for biasing reactant products against the separator. The generator also has a liquid reactant dispenser for storing a liquid reactant and is fluidly coupled to the reaction chamber, such that dispensed liquid reactant reacts with the solid reactant in the reaction chamber to produce hydrogen gas and a waste product that are substantially permeable through the separator. The generator also has a product collector coupled to the reaction chamber for collecting hydrogen gas and waste product that have passed through the separator.

Owner:ARDICA TECH

Deodorized waste receptacle

Owner:PIERRE REGINALD

Apparatus and process for separation of organic materials from attached insoluble solids, and conversion into useful products

InactiveUS20050113611A1Efficient removalReduce slurry viscosityMechanical conveying coke ovensSolid waste disposalHigh energyWaste product

The present invention addresses the processing of waste and low-value products that contain bone material to produce useful materials in reliable purities and compositions, at acceptable cost, and with high energy efficiency. In particular, the invention comprises a process that converts various feedstocks such as offal, animal manures, and municipal sewage sludge, to useful materials including gas, oil, specialty chemicals, and carbon solids. The process heats the feedstock in order to breakdown proteins and separate organic material from bone material, applies further heat and pressure to the resulting liquid mixture, separates out various components, then further applies heat and pressure to one or more of those components. The invention further comprises an apparatus for performing a process of converting waste products into useful materials, and an oil product that arises from the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

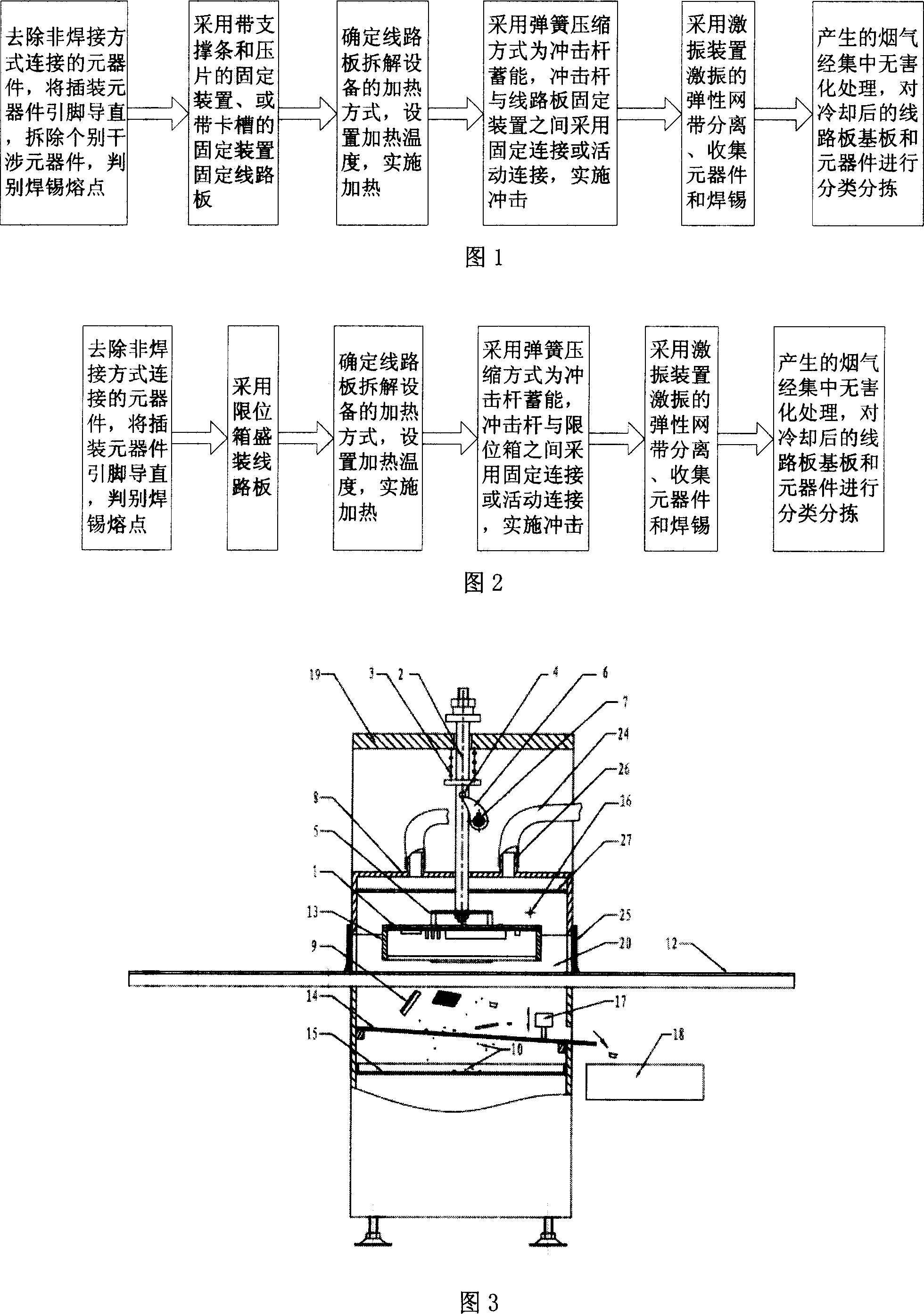

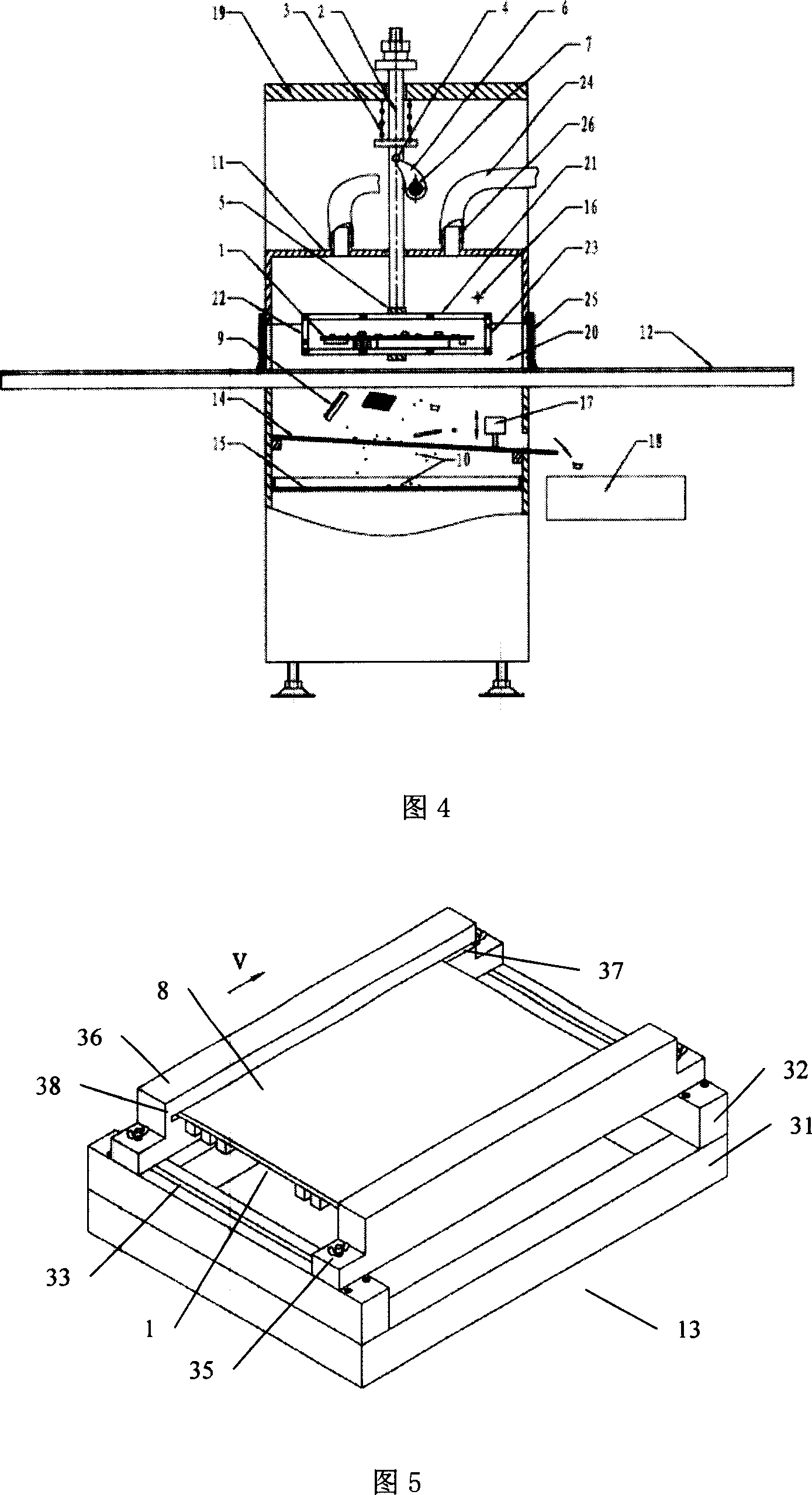

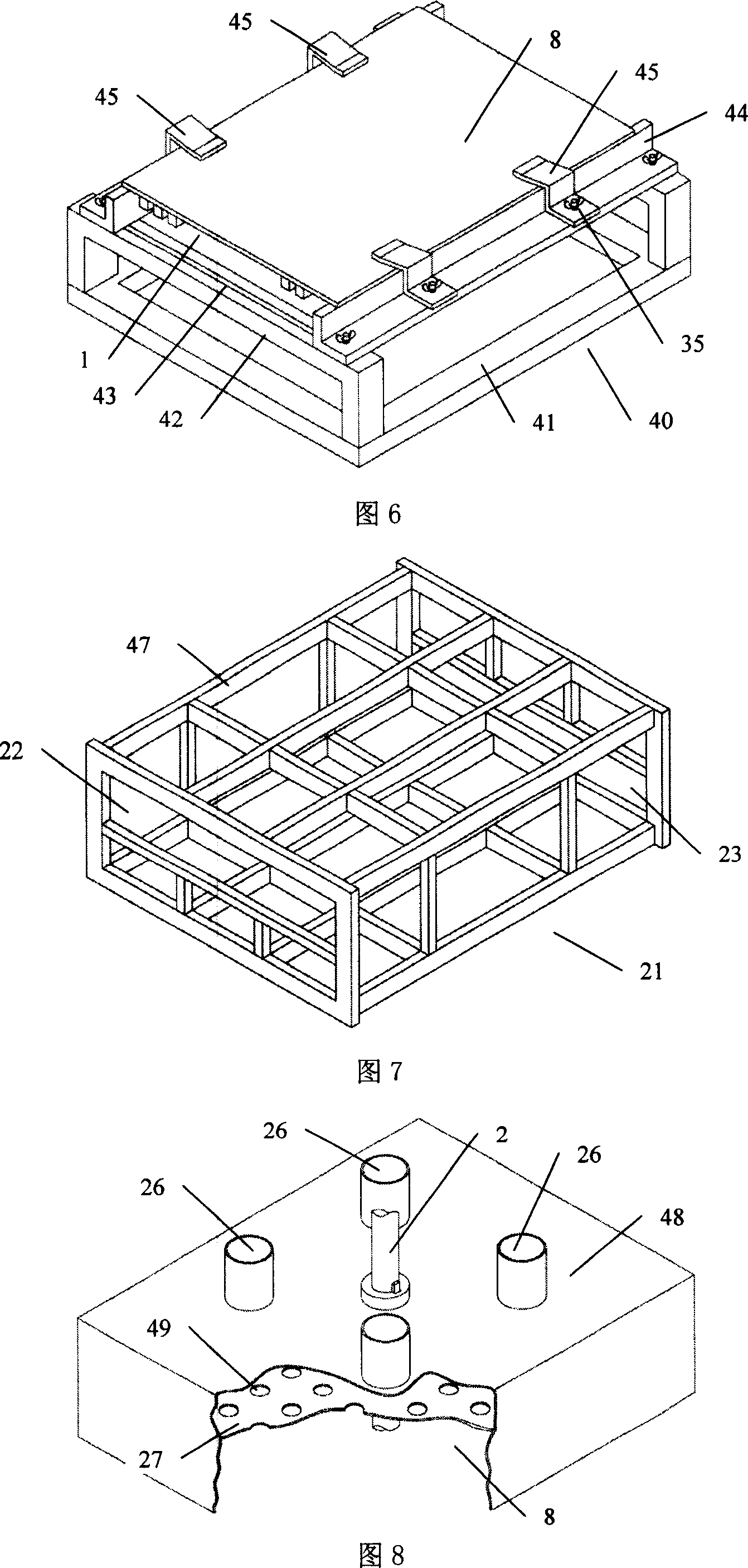

Method and equipment for disassembling components entirely from waste circuit board

InactiveCN101014229AImprove efficiencyGuaranteed functionSoldering apparatusPrinted circuit manufactureWaste productPrinted circuit board

The invention relates to one method and device to disable elements from old circuit board, which comprises the following steps: fixing circuit board or using limit box container circuit board; heating; fixing or connecting impact lever and circuit board fix device for impact; using oscillation device spring network band isolation, collection part and welding; after cooling to sort the circuit base board and element. The device comprises impact lever, compression spring, circuit board fix device, protruding wheel, guide rail, spring net band, and hot wind entrance hole.

Owner:TSINGHUA UNIV

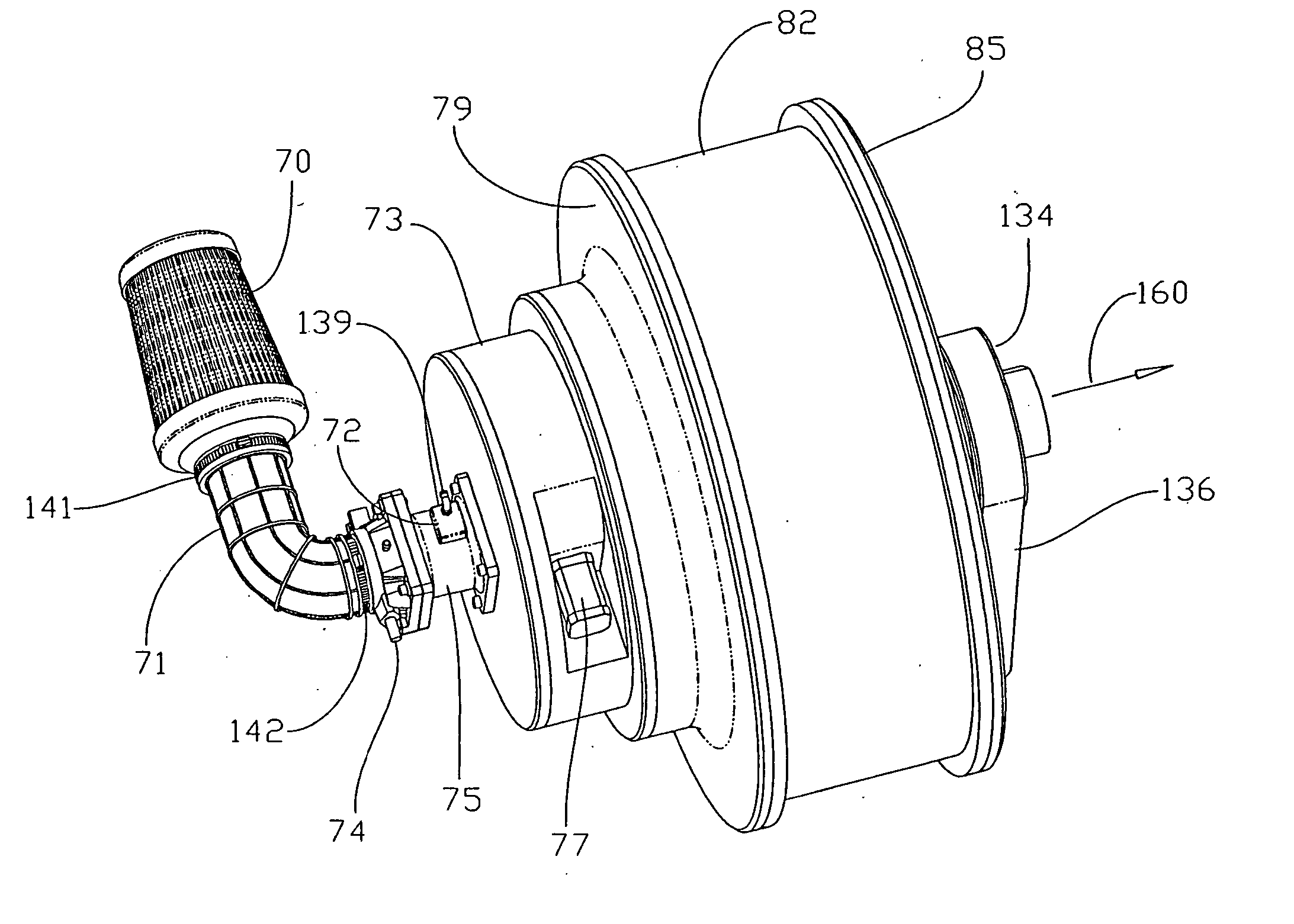

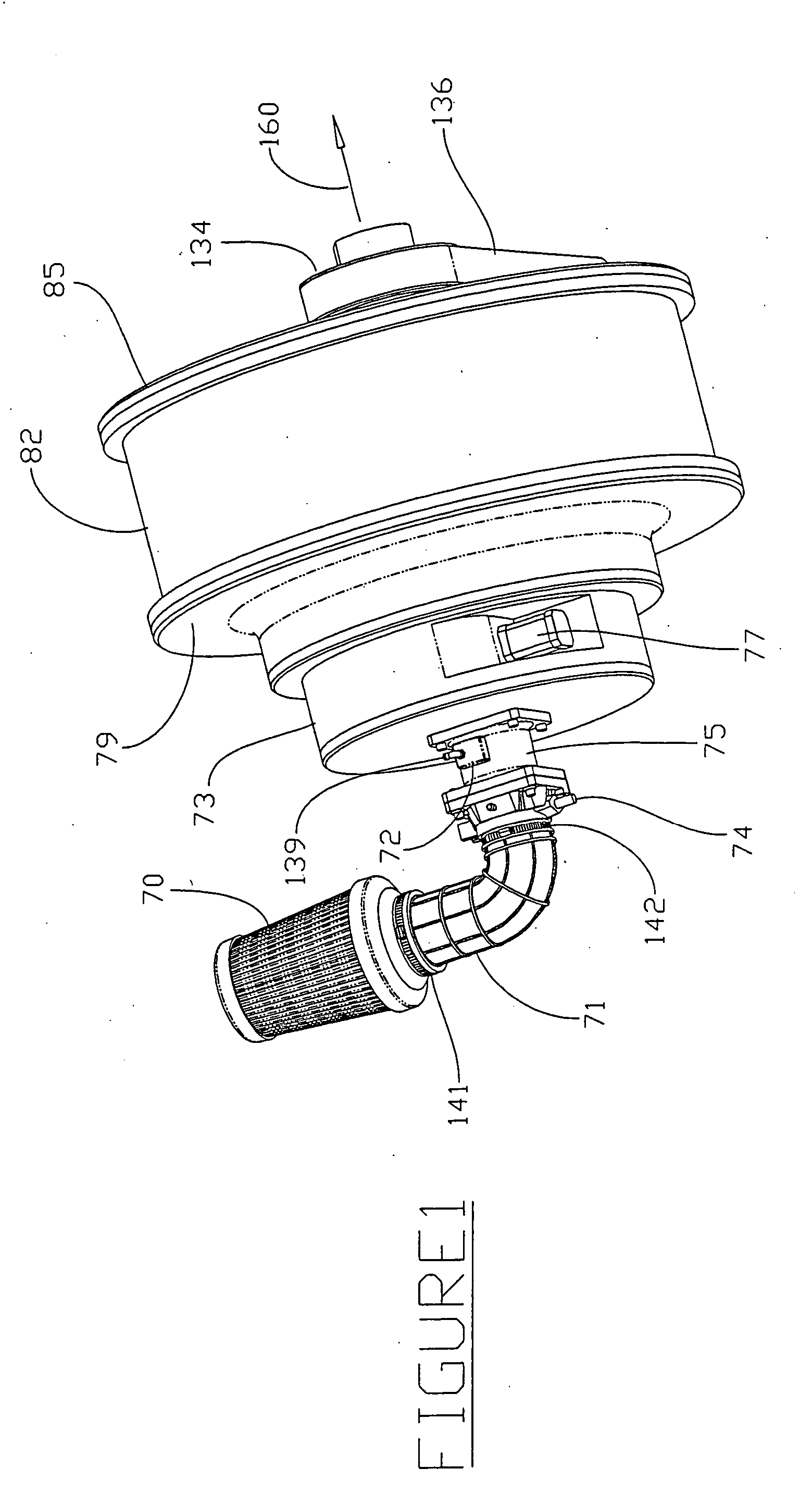

Waste processing apparatus and method featuring water removal

ActiveUS20080217444A1Easy to separateSimple treatmentRotating receptacle mixersTransportation and packagingWaste productWastewater

The present invention includes an apparatus and method for processing solid waste products. The invention features periodic removal of water preferably while the contents are under pressure. The apparatus comprises a rotatably mounted cylindrical vessel having a first end, a second end and an interior surface, at least one end terminating in a hatch that may be opened to allow access to the interior of the vessel and sealably closed to allow pressurization of the vessel; a steam inlet for injecting stem disposed at one or both ends; and one or more valves for exhausting water periodically as the waste mass is being processed.

Owner:ESTECH

Method of processing waste product into fuel

InactiveUS20050142250A1Efficient conversionControlled and adjustable resistanceMilk preparationSolid fuelsWaste streamWaste product

Fuels used may be derived from existing waste streams such as animal wastes and streams of discarded or unwanted animal byproducts generated at animal slaughterhouses. A method of processing organic waste products into fuel includes homogenizing the waste products. The waste products are heated and pressurized. Water is removed from the waste products. Selected constituent of the waste products are separated from the waste products into a waste stream. The waste stream is blended with a fuel to form a bio-fuel mixture.

Owner:STONE MICHAEL

In vivo use of water absorbent polymers

InactiveUS20050036983A1Improving fluid absorbing performanceLess interferenceMetabolism disorderDigestive systemMedicineRemove blood

The subject invention is a method and material for removing fluid from the intestinal tract of a host and may be useful in treating animals or human patients suffering from fluid overload states. In one embodiment, the subject method involves ingesting an enterically coated non-systemic, non-toxic, non-digestible, water absorbing polymer which absorbs fluid while passing through the intestinal tract. The polymer is excreted in the feces wherein the polymer and absorbed fluid is removed from the body. Preferred polymers include super absorbent acrylic acid polymers, preferably provided in bead form. The polymers may include functional groups for selectively removing blood borne waste products, e.g. urea, from the G.I. tract.

Owner:SORBENT THERAPEUTICS

Process for conversion of organic, waste, or low-value materials into useful products

ActiveUS7301060B2Low viscosityHydrocarbon purification/separationIndirect and direct heating destructive distillationSpeciality chemicalsHigh energy

Owner:SYNPET TEKNOLOJI GELISTIRME

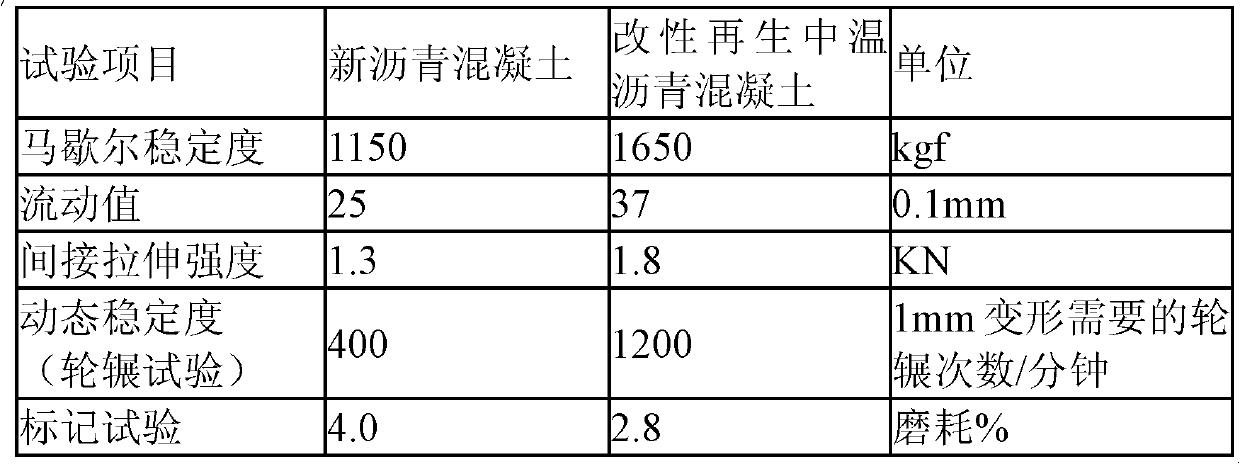

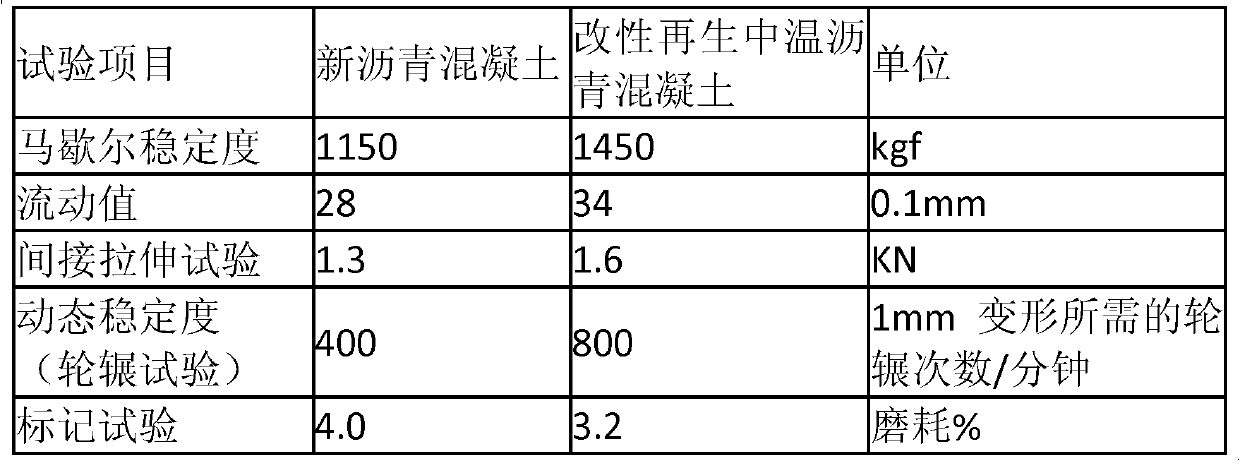

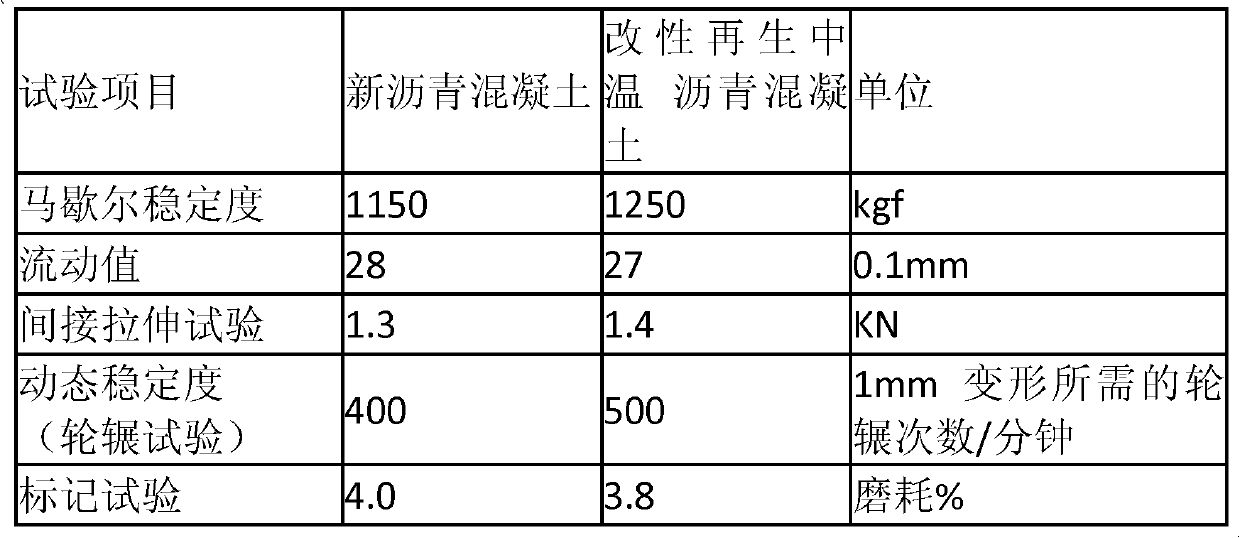

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com