Patents

Literature

2554 results about "Gas emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas emissions are any gaseous material released, either naturally or artificially, into the atmosphere. These gas emissions exist in a variety of forms: most notably water vapor, carbon dioxide, methane, nitrous oxide and ozone.

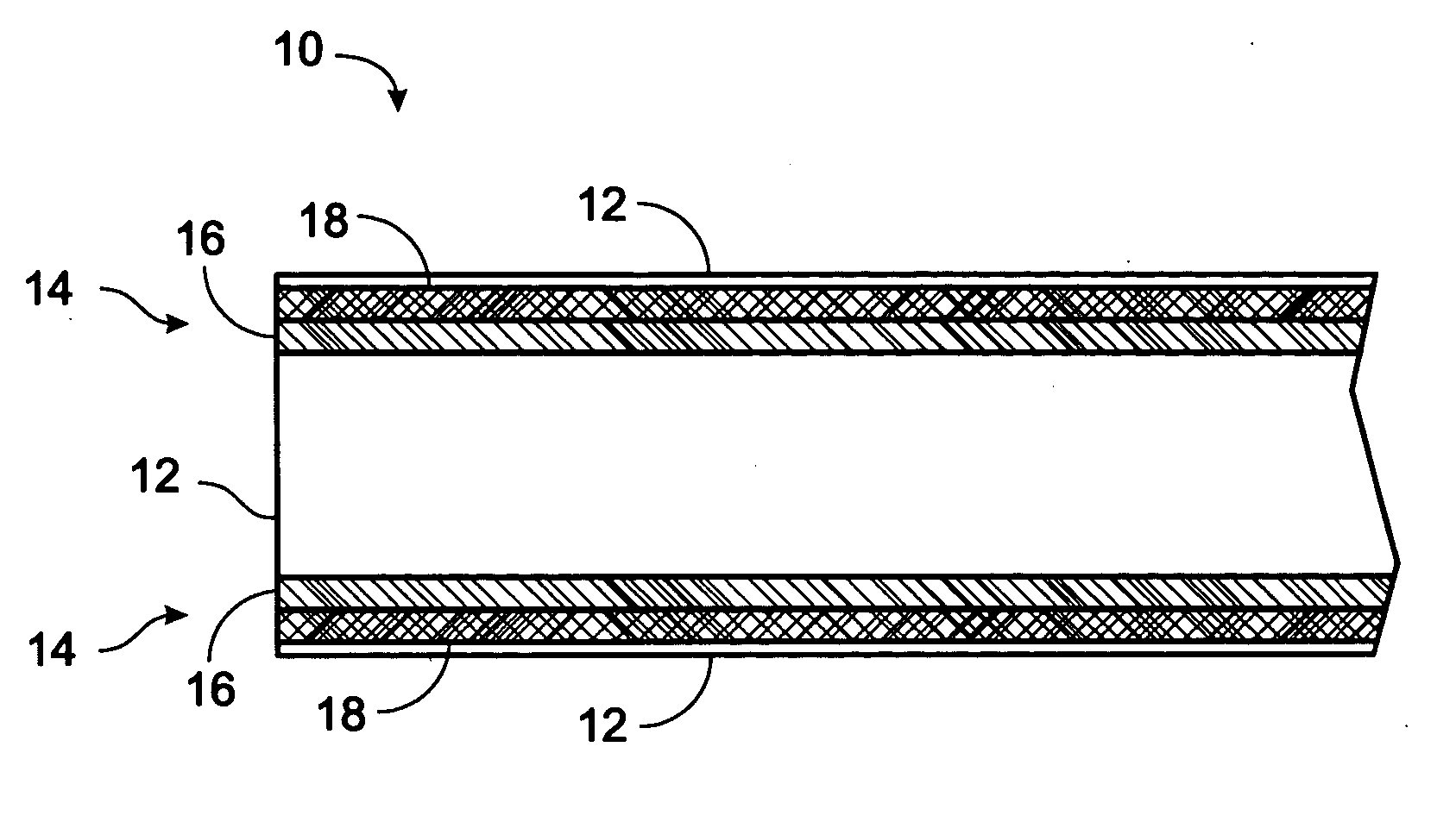

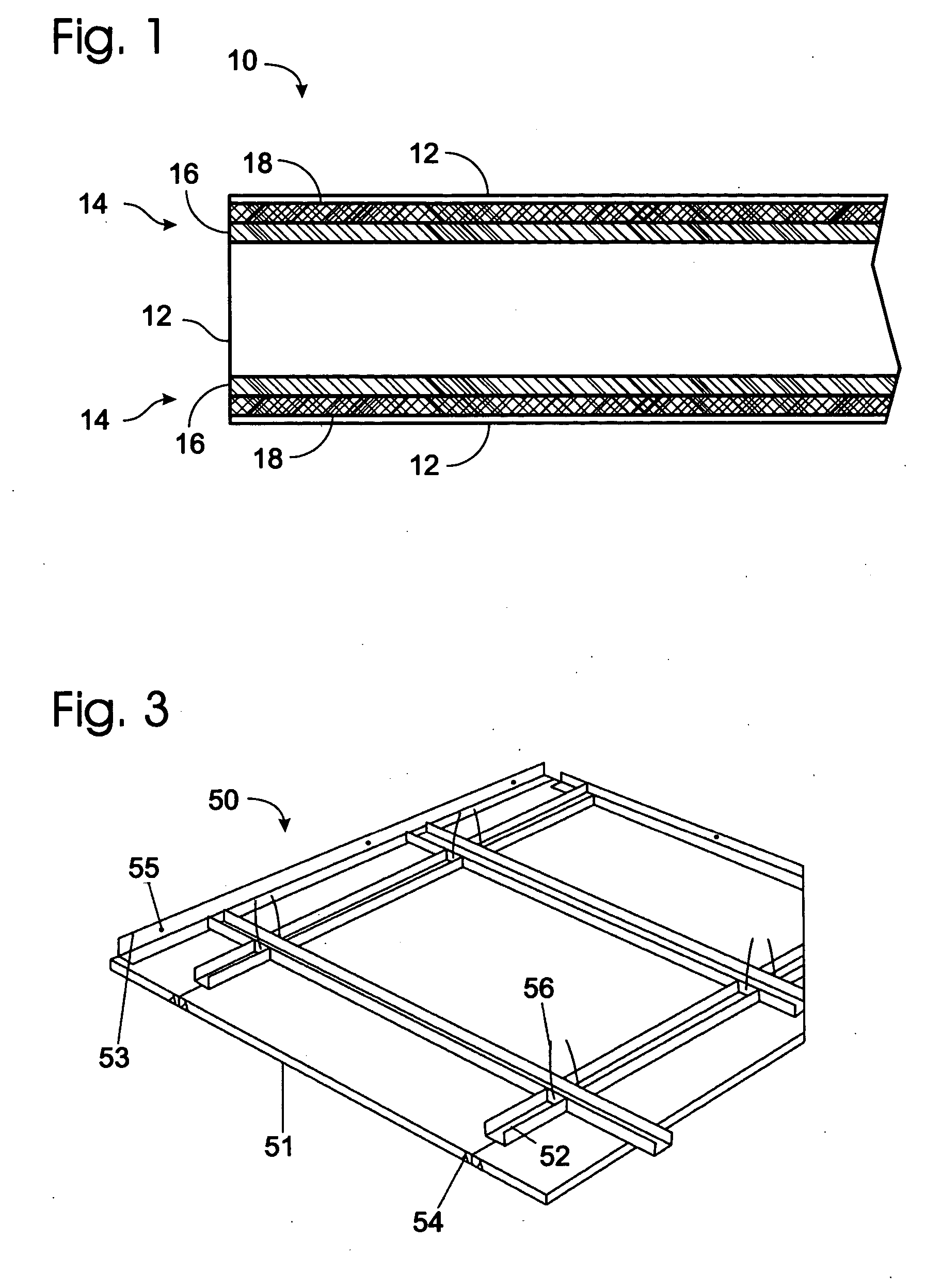

Fire-resistant panel and method of manufacture

A highly fire-resistant and environmentally-friendly panel of 2 mm to 28 mm may be manufactured by a blending of magnesium compounds, sodium silicate, kaolin, fillers, and additives to form the core materials, reinforced by 4 layers of fire-resistant glass fiber meshes and fabrics. Using a proprietary ITC process that accelerates the chemical reactions of the ingredients to generate sufficient heat without external supply of energy, the panels may be completely cured within 24 hours instead of 10 days. The use of waste materials, energy-saving curing system and no gas emission manufacturing process combined to make this panel an eco-friendly product which offers the world's highest-rated fire resistance of 5 hours, high flexural strength, low density, durability and effective water-resistance.

Owner:REP TECH

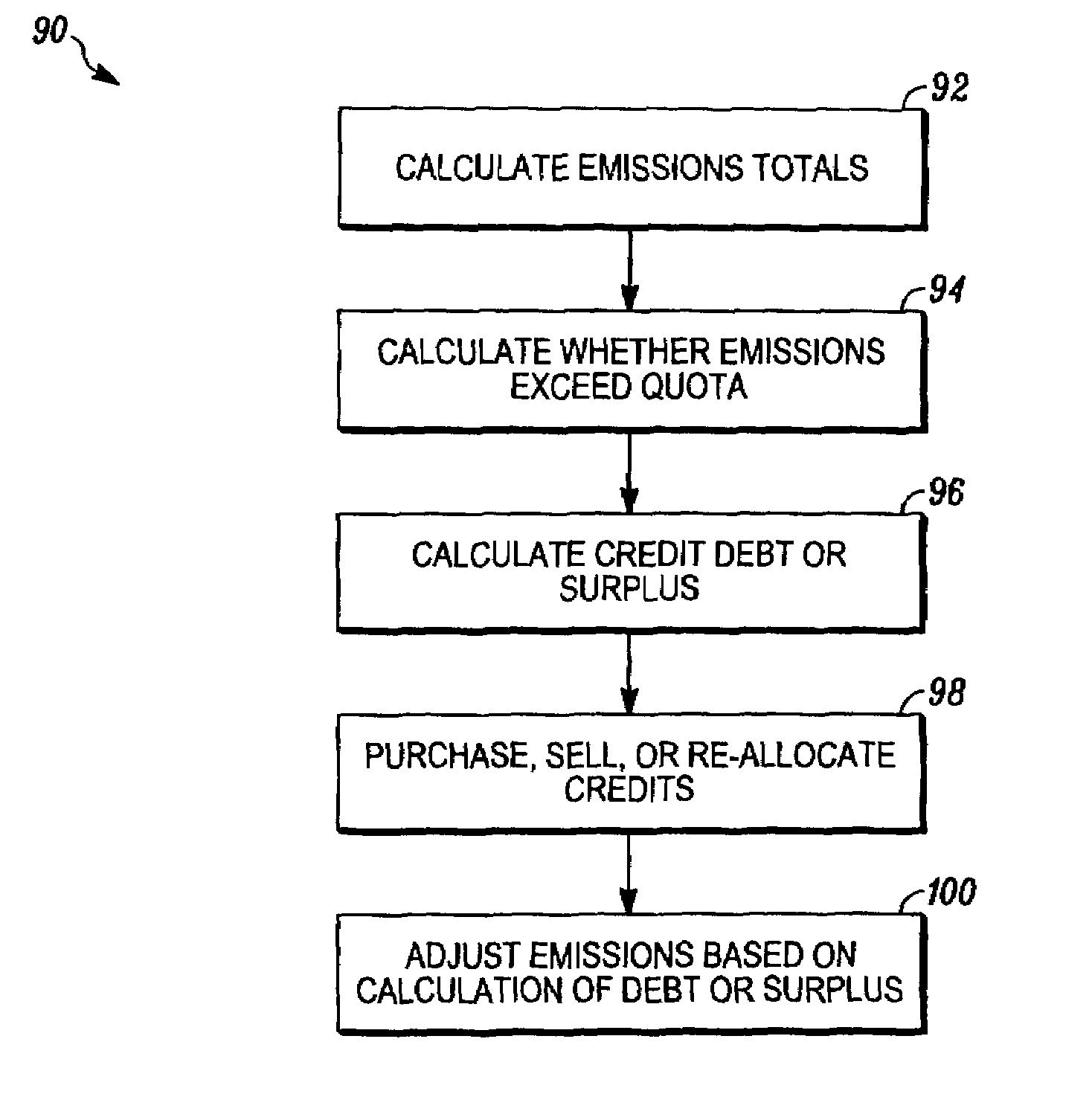

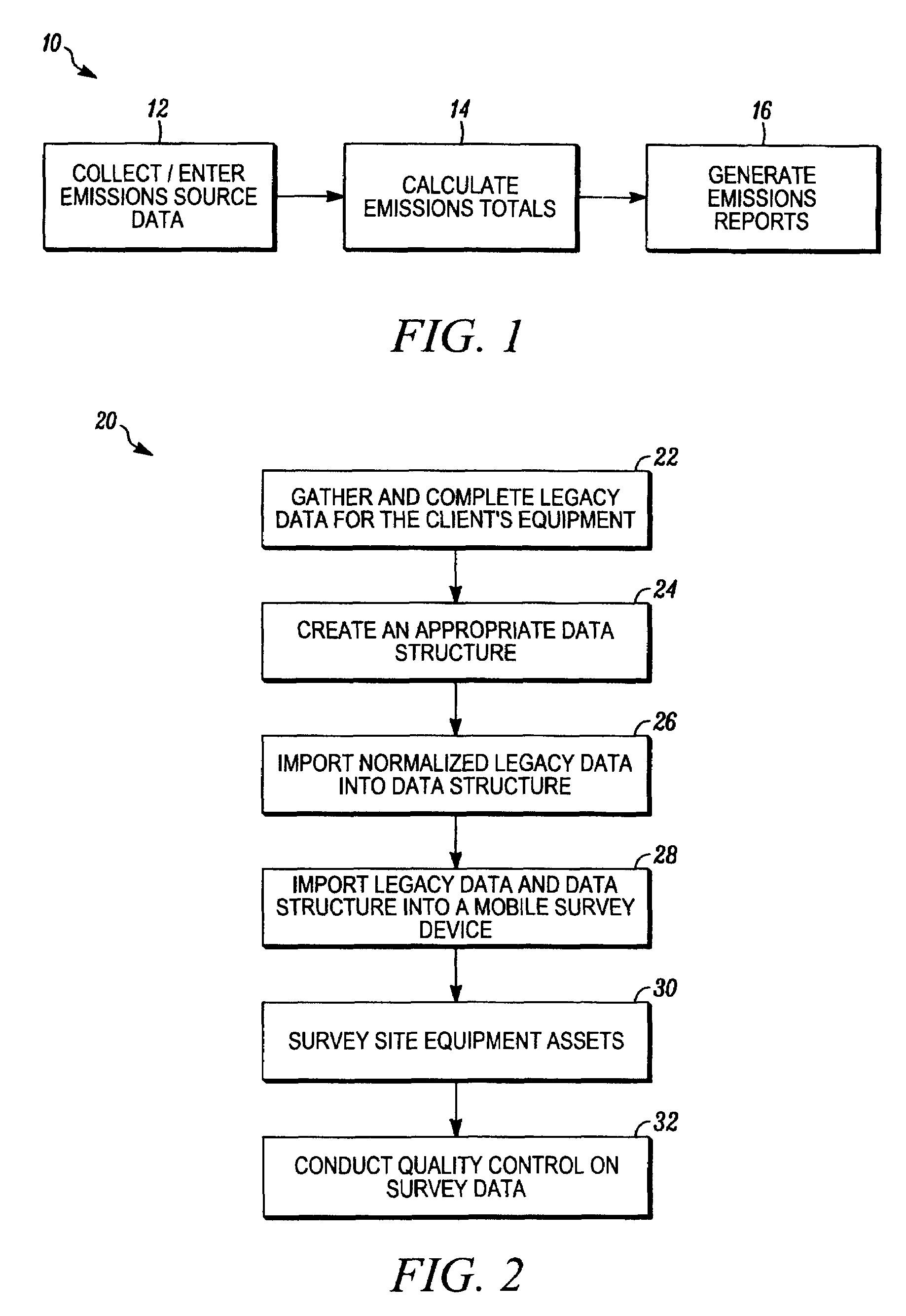

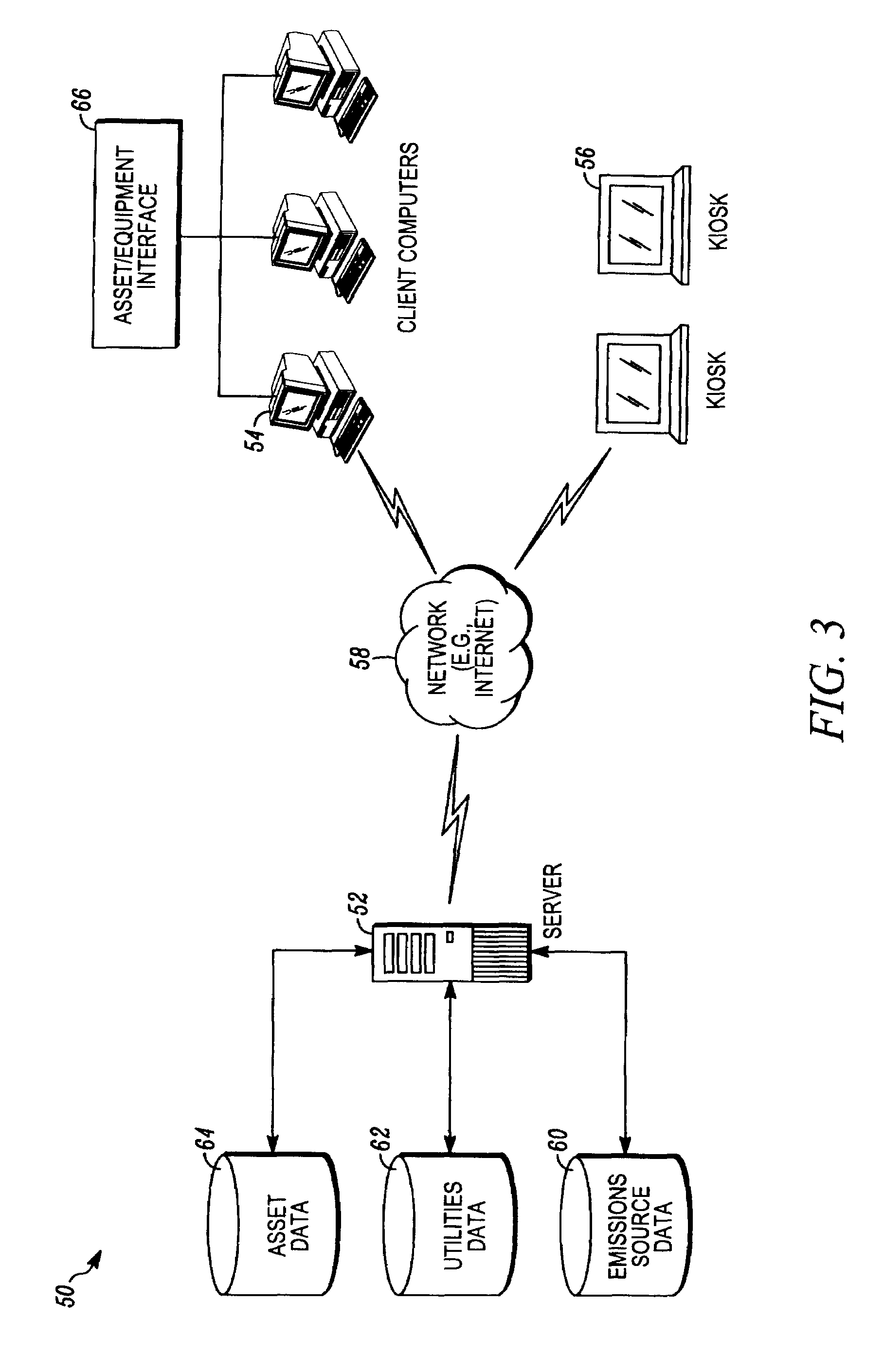

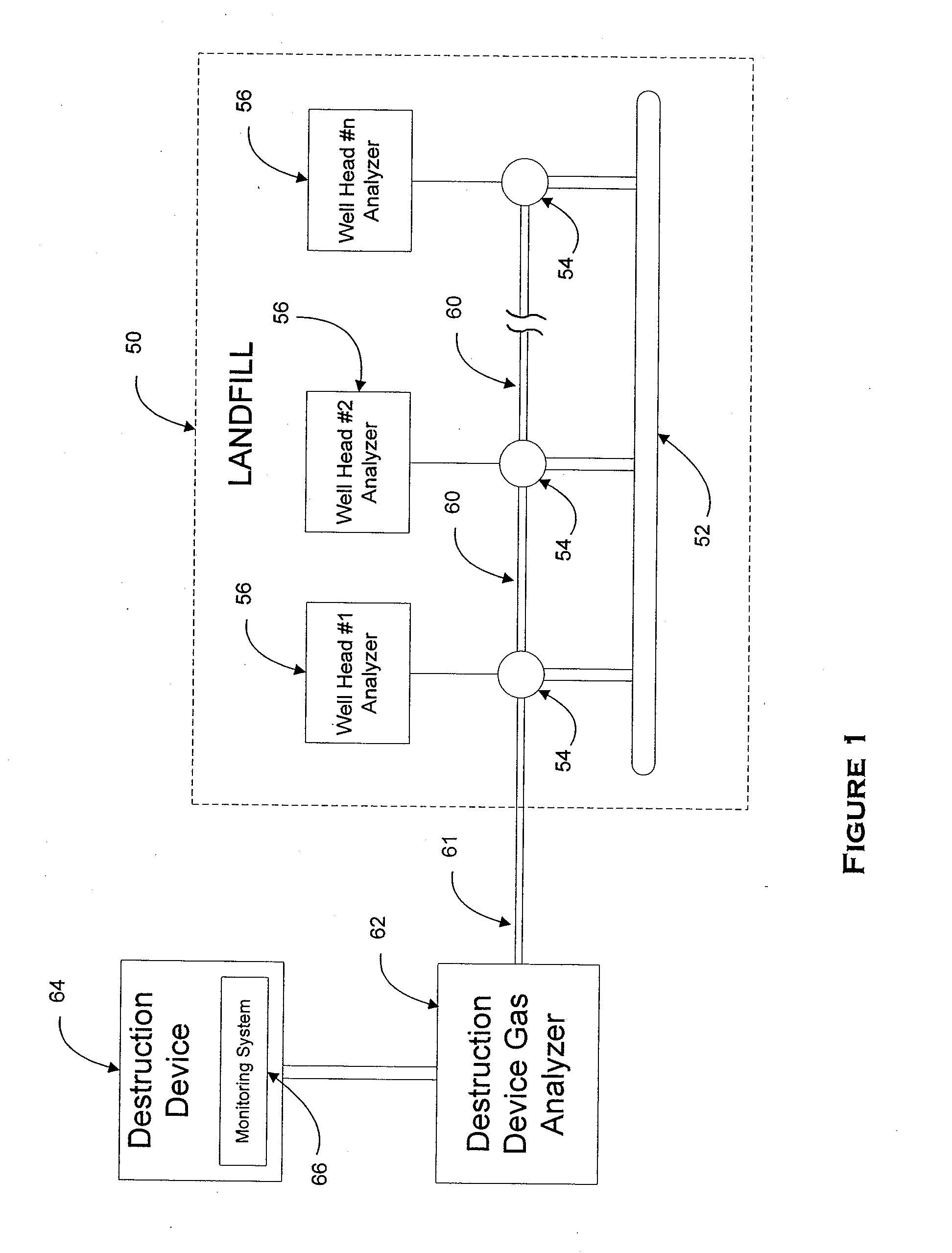

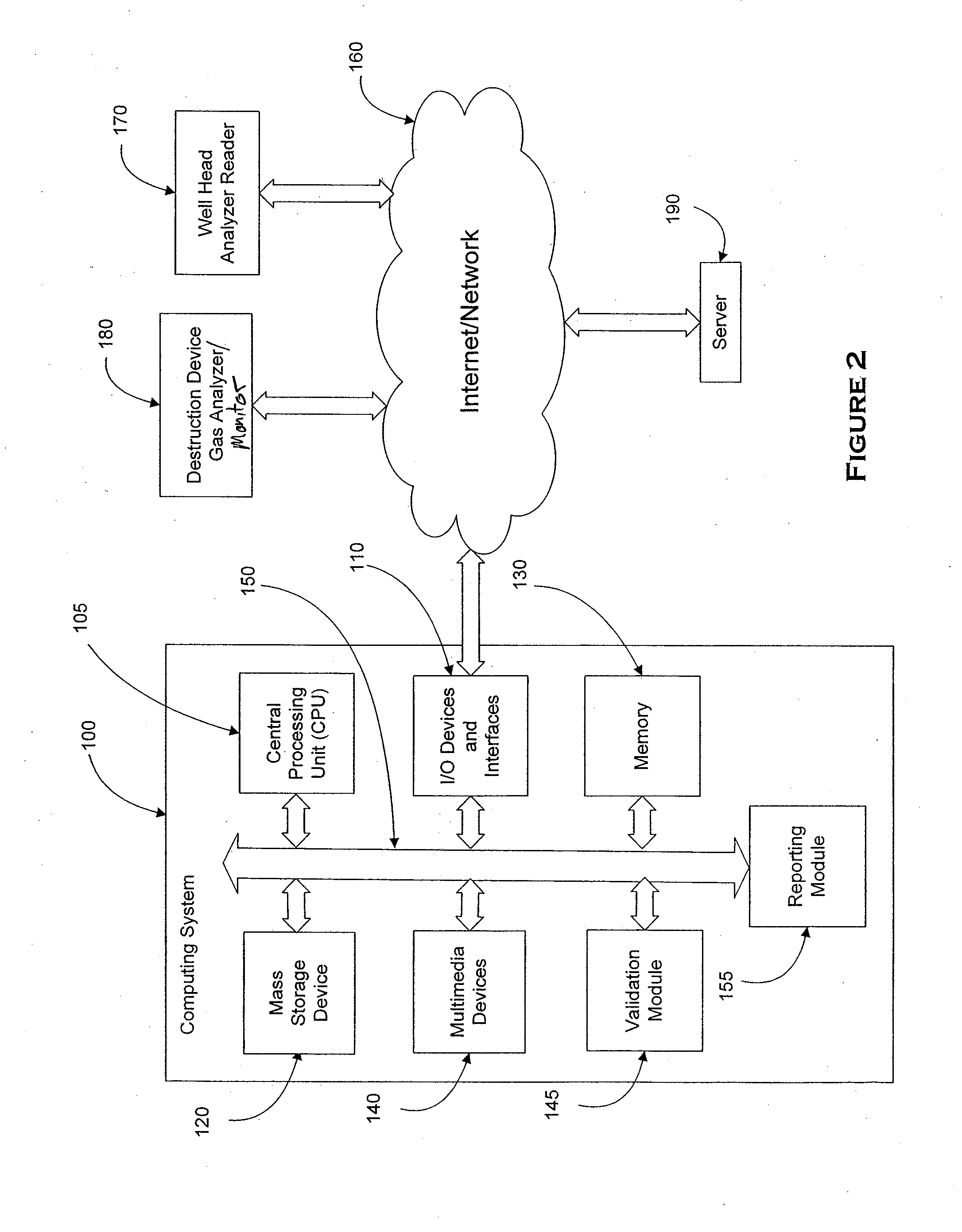

Method and system for tracking and reporting emissions

The present invention relates to methods and systems of tracking enterprise gas emissions such as greenhouse gas emissions. The systems and methods relate to collecting or entering data relating to one or more emissions source of an enterprise or an enterprise location, calculating emissions totals, and, according to certain embodiments, generating emissions reports.

Owner:VERISAE

Methods for hindering formation of tobacco-specific nitrosamines

ActiveUS7650892B1Inhibition formationHindering TSNA formationTobacco preparationTobacco treatmentTobacco-specific nitrosaminesEngineering

Owner:AMERICAN SNUFF CO LLC

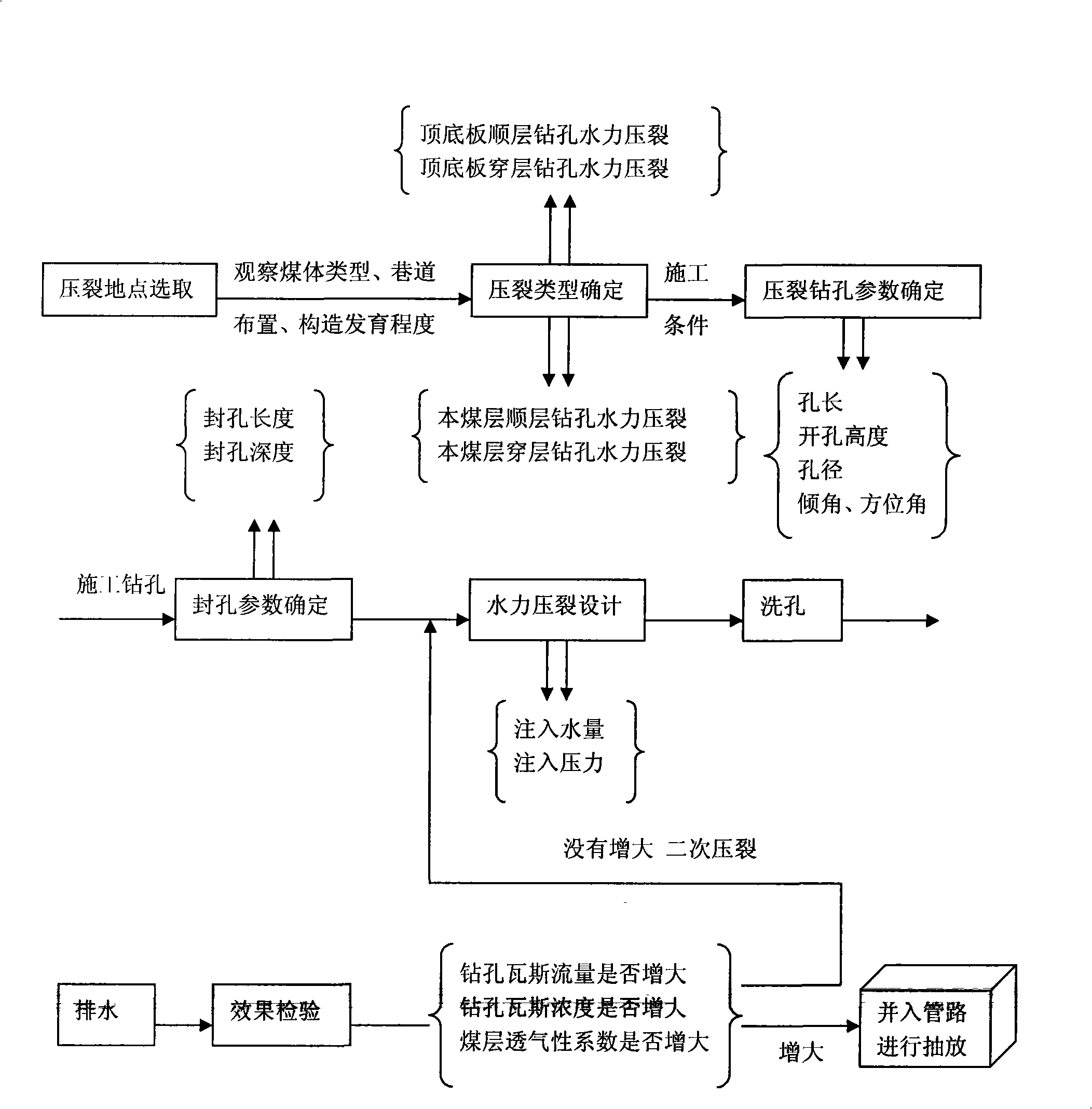

Coal mine down-hole drilling hydraulic fracturing anti-reflection mash gas extraction technique

ActiveCN101403314ALess gushEliminate disastersFluid removalGas removalDischarge efficiencyInjection pressure

The invention relates to a hydraulic fracturing anti-reflection technology for pumping and exploring gas by drilling a hole in a coal mine well, comprising the following steps sequentially: (1) selecting a fracturing location; (2) determining the pressure type according to observed coal type, laneway arrangement and construction development degree, and ways of top soleplate bedding plane borehole hydraulic fracturing, top soleplate translamellar borehole hydraulic fracturing, the coal bed bedding plane borehole hydraulic fracturing or the coal bed translamellar borehole hydraulic fracturing can be adopted; (3) determining borehole parameters for constructing drilling, wherein, the borehole parameters include borehole length, borehole height, aperture, obliquity angle and azimuth angle; (4) designing the hydraulic fracturing, including injected water volume and injection pressure; (5) borehole washing; (6) draining; (7) examining the fracturing effect, if the fracturing effect is in accordance with the requirement, the following step is carried out, if not, turning to step (4); and (8) entering a pipeline for pumping and discharging. The technology enhances the air permeability of the coal bed, reduces the gas emission rate of an excavation working face, and obviously promotes the pumping and exploring capability and the pumping and exploring effect of the single borehole. The pumping and discharging efficiency is improved, the pumping and discharging time is shortened and the damage of the gas is maximally eliminated.

Owner:HENAN POLYTECHNIC UNIV

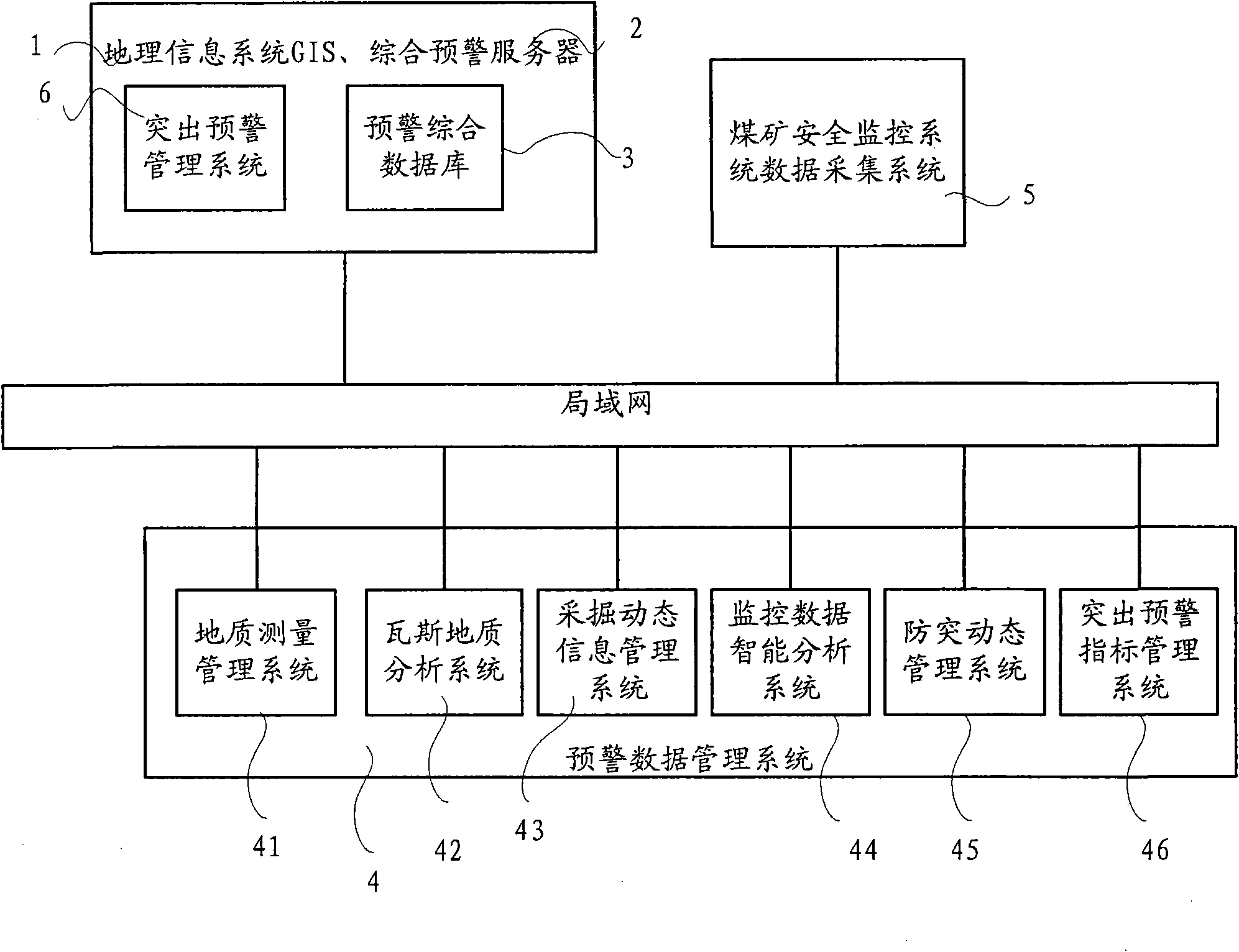

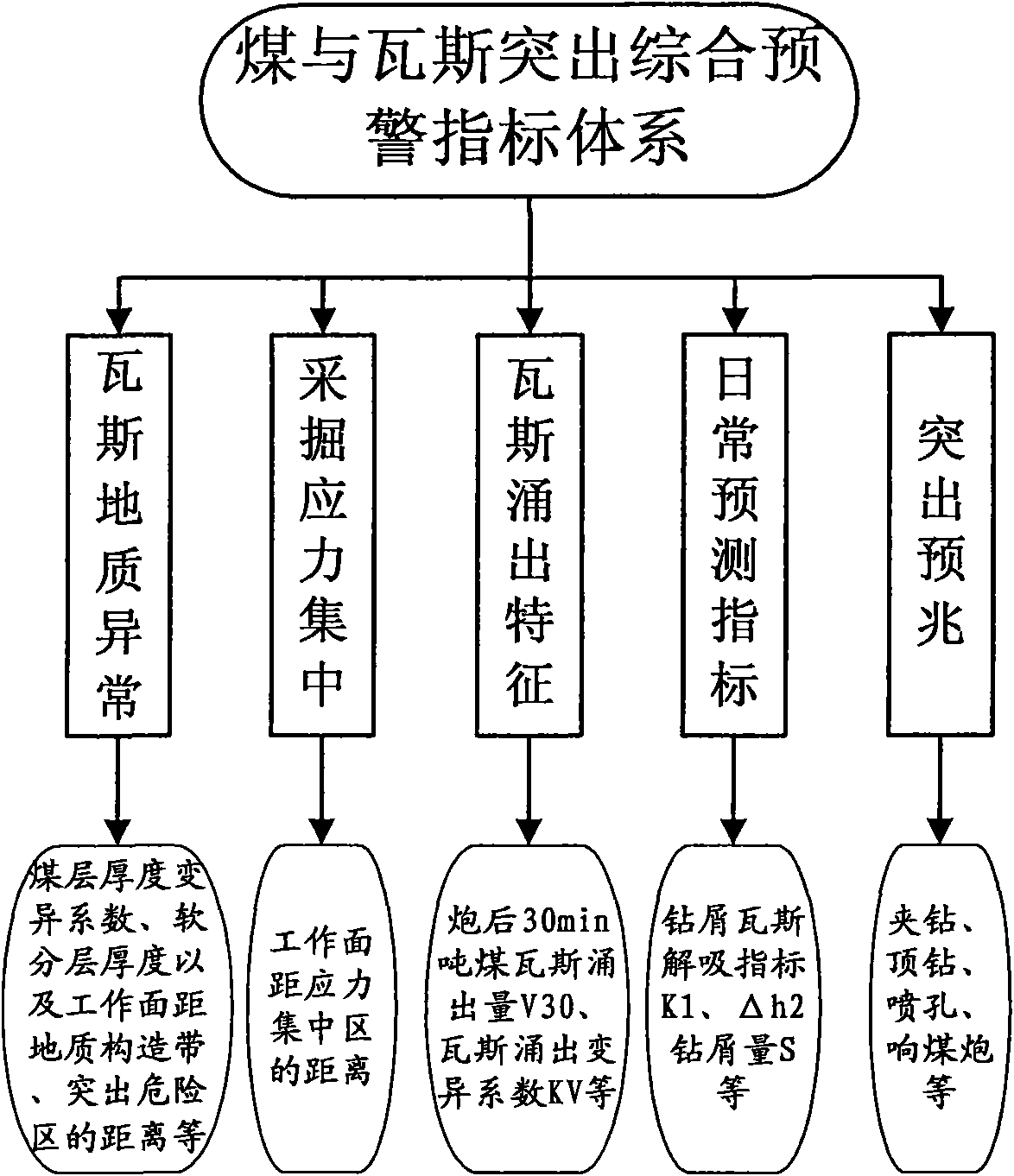

Coal and gas outburst hazard early warning system and early warning method

ActiveCN101550841APrevention of Outstanding DisastersReal-timeMining devicesDust removalForward lookingGeological structure

The invention relates to the field of coal mine safety technique, specifically to a down-hole coal and gas outburst hazard early warning system and early warning method. The coal and gas outburst synthesized early-warning system, uses the existing local area network to connect a synthesized early-warning data server, an early-warning data management system and the existing coal mine safety monitoring system; analyzes the coal and gas outburst early-warning data in the synthesized early-warning data server by an outburst early-warning module; and emits early-warning information based on the analyzed result. The inventive coal and gas outburst synthesized early warning system and early warning method can perform centralized management and comprehensive analysis of the geological structure, coal seam occurrence, gas occurrence, mining production, daily forecast indicators, outburst forecast, gas emission and other security information that originally scatter in various functional sections of coal mine on the geographical information system GIS platform, integrates the existing resources, improves the accuracy of early warning, so that the early warning is both real-time and forward-looking, and can effectively prevent the occurrence of coal and gas outburst in coal mine.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

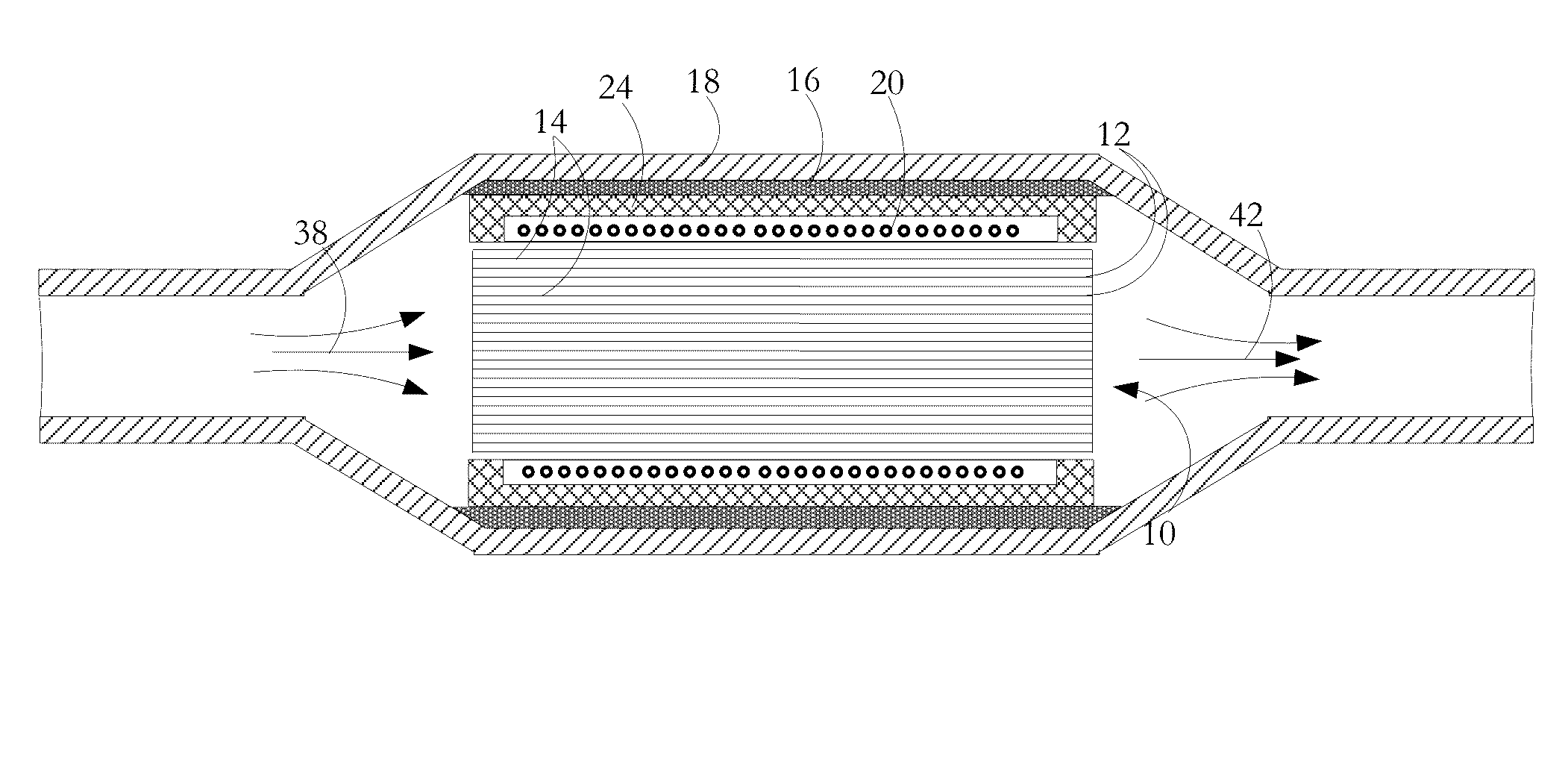

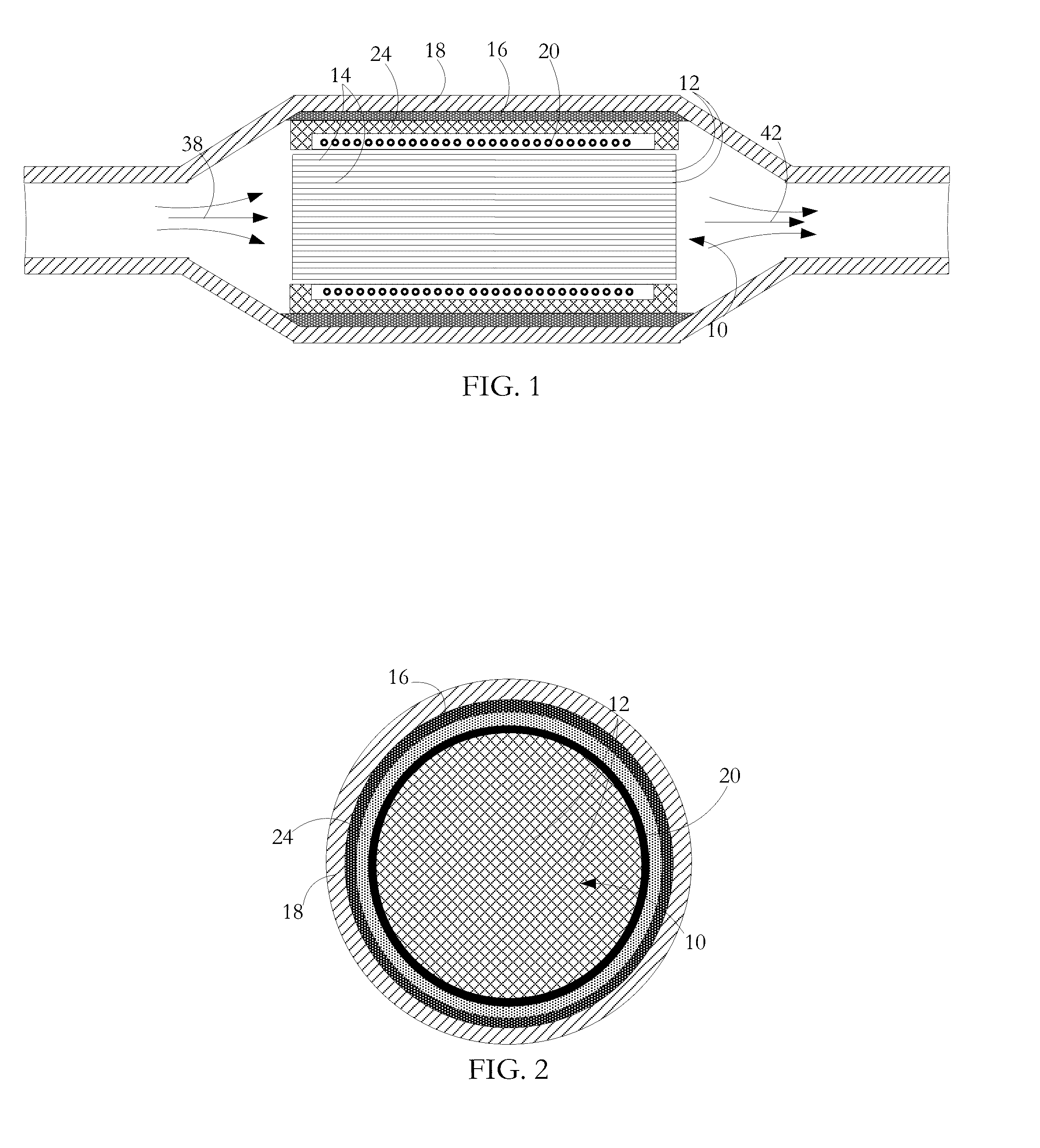

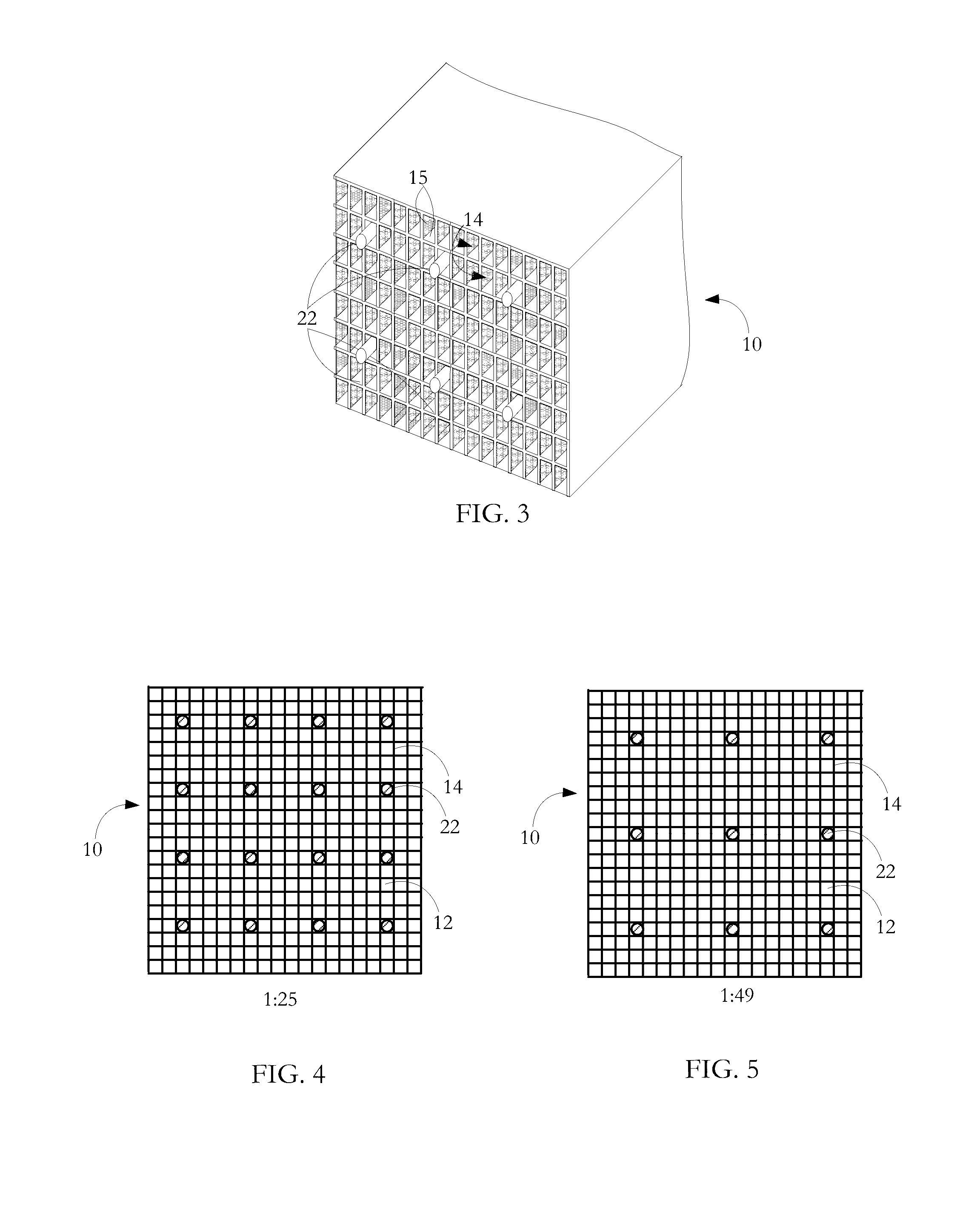

Apparatus and method for gaseous emissions treatment with enhanced catalyst distribution

ActiveUS20170022868A1Reduce back pressurePhysical/chemical process catalystsInternal combustion piston enginesElectromagnetic fieldCell wall

An assembly for treating gaseous emissions includes a substrate body having cells for the passages of emissions gas. Lengths of metal wire are located in selected ones of the cells and an induction heating coil is mounted adjacent the substrate body for generating a varying electromagnetic field for inductive heating of the assembly including gaseous emissions passing along the cells. Within the cells, parts of the cell walls and parts of the wire surfaces are exposed to the passage of the gaseous emissions and both the cell wall parts and the wire surface parts have pollution treating catalyst at their surfaces.

Owner:ADVANCED TECH EMISSION SOLUTIONS

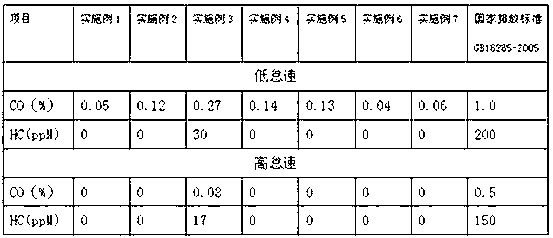

High-cleanness environment-friendly alcohol ether fuel for car

ActiveCN103275769AHigh chemical activityImproves resistance to phase separationLiquid carbonaceous fuelsFuel additivesMechanical engineeringMethanol

The invention provides a high-cleanliness environment-friendly alcohol ether fuel for a car. The fuel provided by the invention consists of the following raw materials: 600-800 parts of methanol, ethanol or a mixture of methanol and ethanol, 100-350 parts of an ether stabilizer, 1-6 parts of an anti-oxygen and anti-gum inhibitor, 2-5 parts of a metal deactivator, 1-3 parts of a corrosion inhibitor, 1-40 parts of a catalytic combustion improver, 2-4 parts of an antistatic agent, 10-100 parts of an antiknock stabilizer, 1-6 parts pf a purification dispersant, 1-6 parts of an anti-wear repair agent, 1-6 parts of a metal corrosion inhibitor, 2-6 parts of a rubber and plastic part corrosion and swelling inhibitor, 10-50 parts of a modified alcohol cosolvent, 0.2-0.8 part of a bactericide and 0.04-0.1 part of a recognition agent. The fuel provided by the invention has the advantages of stable performance, strong power, sufficient combustion, good seismic performance, good acceleration, easiness for starting up, no air lock, no separated layer, reduced fuel consumption, cleaner tail gas emission and no need of changing the structure of a spark ignition engine in the prior art and can be separately used, used instead of regular gasoline or used together with regular gasoline by co-combustion.

Owner:鲁家政

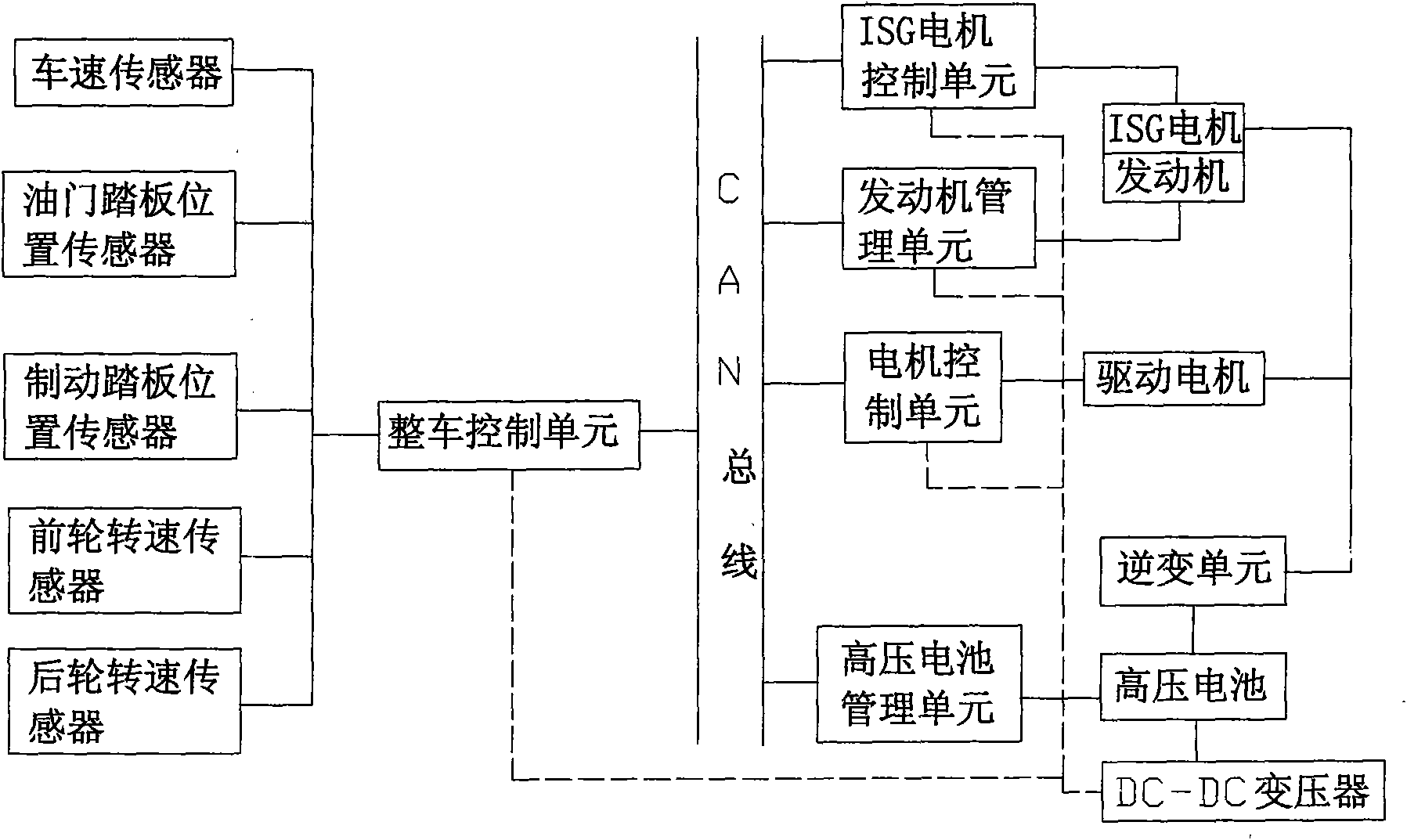

Four-wheel driven hybrid vehicle driving system and driving management method thereof

ActiveCN101570131AUnable to meet torque demandGuaranteed safe electricityGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive motorHigh pressure

The invention provides a four-wheel driven hybrid vehicle driving system capable of meeting the needs of a motor vehicle for torque during running in an urban area and reducing oil consumption and tail gas emission and a driving management method thereof. The driving system comprises an engine driving front wheels, an ISG motor coaxially arranged with the engine and a driving motor driving rear wheels, wherein the engine is connected with an engine management unit; the ISG motor is connected with an ISG motor control unit; the driving motor is connected with the motor control unit; and the ISG motor and the driving motor are connected with a high voltage battery through an inversion unit. The key point is that the driving system also comprises a vehicle control unit and a high voltage management unit connected with the high voltage battery. The vehicle control unit, the high voltage management unit, the engine management unit, the ISG motor control unit and the motor control unit are connected through CAN buses; and the vehicle control unit is also connected with an accelerator pedal position sensor and a vehicle speed sensor.

Owner:CHERY AUTOMOBILE CO LTD

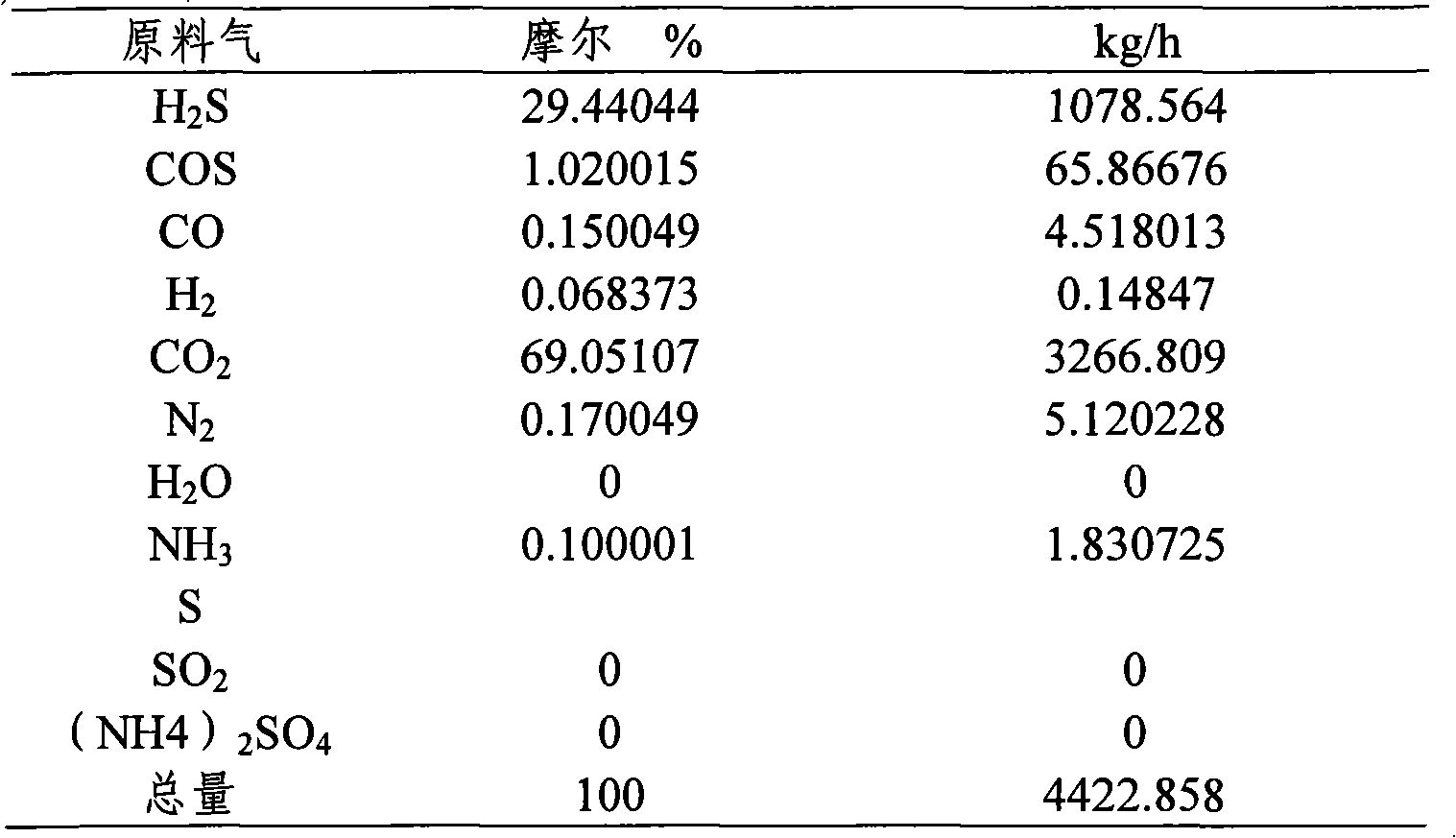

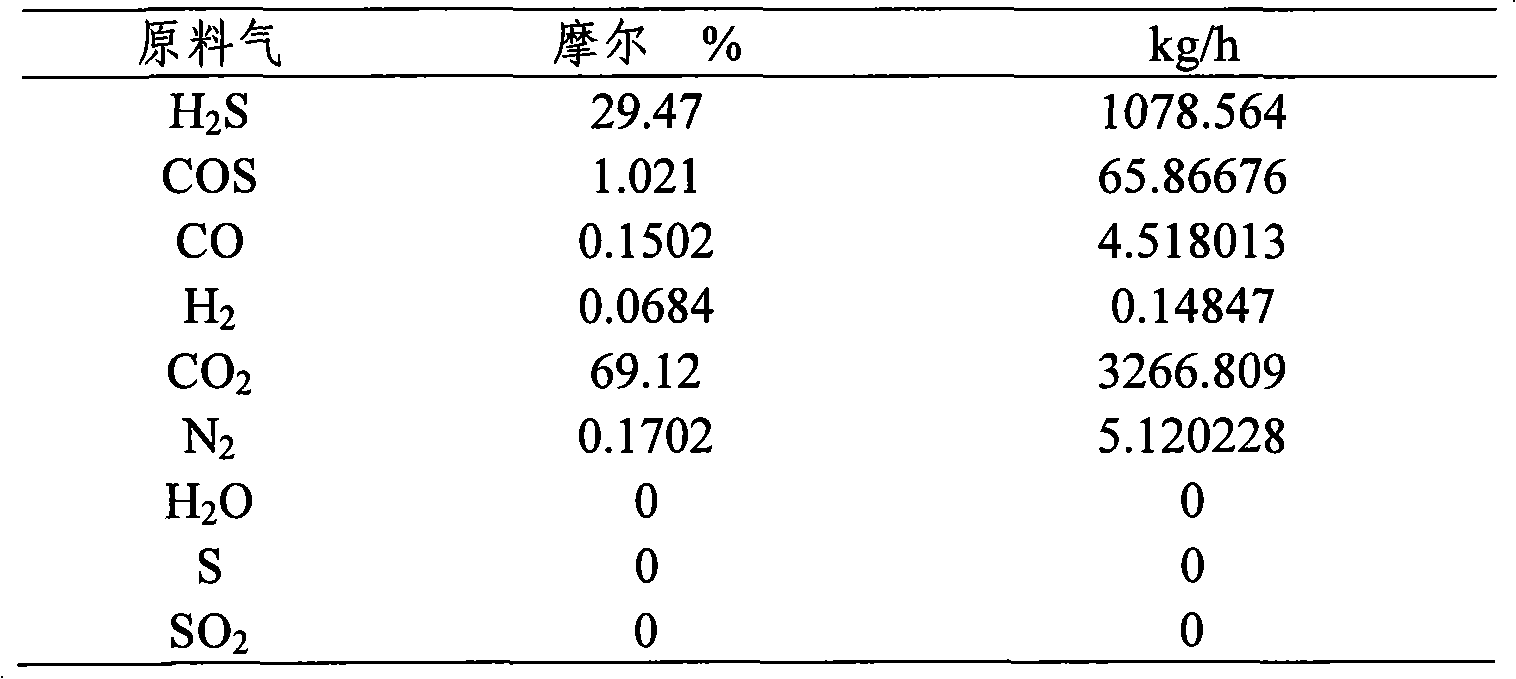

Desulphurization method for acid gas

InactiveCN101574614AEasy dischargeEmissions exceedingDispersed particle separationIncinerator apparatusCombustion chamberEmission standard

The invention provides a desulphurization method for acid gas, which comprises the following steps: firstly, carrying out heat combustion reaction on the acid gas and fuel in a combustion chamber; secondly, carrying out catalytic reduction reaction on the obtained combustion product; thirdly, combusting tail gas obtained by the catalytic reduction reaction; and fourthly, carrying out ammonia elution on sulfur dioxide in gas obtained after combustion to obtain ammonium sulphate. The desulphurization combined process for the acid gas has no strict requirement on the Claus combustion, does not need multistage Claus reaction, and even does not control the Claus reaction strictly; and wastewater subjected to ammonia washing in the acid gas containing ammonia is not discharged to a sewage treatment center of a factory, and a fussy device is not needed to add for ammonium refining and recovery. The method can balance the ammonia and the Clause reaction according to the yield of the ammonium sulphate, and does not have sewage discharge; heat required by the process can be balanced through by-product steam, so that the method greatly saves the investment and operation cost, and has short flow and simple operation; and the gas emission can be far lower than the national emission standard.

Owner:BEIJING FUNGHAN ENG CONSULTING

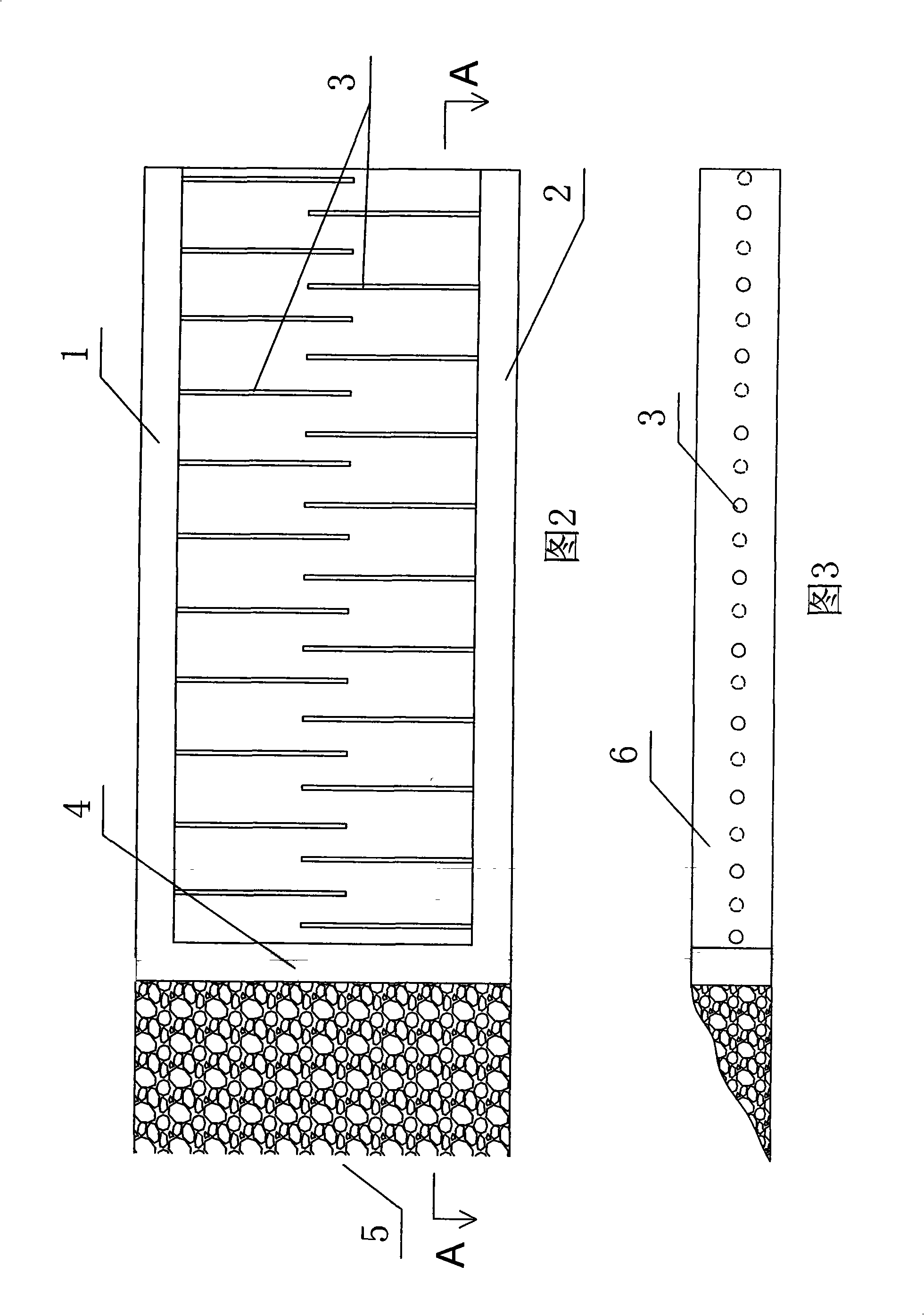

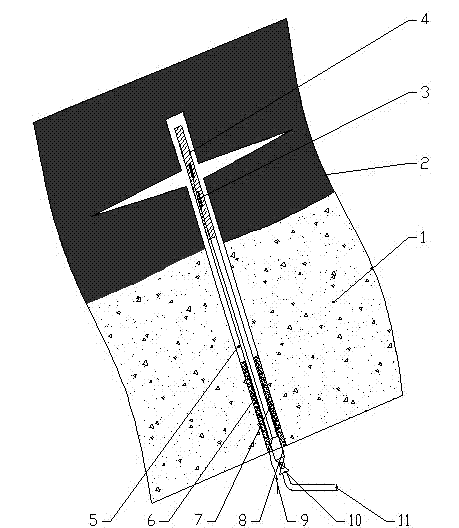

Directional water pressure blasting method for improving coal bed gas permeability

ActiveCN103195466ASolving difficult extraction problemsImprove breathabilityFluid removalGas removalDetonationPore water pressure

A directional water pressure blasting method for improving coal bed gas permeability includes utilizing water pressure blasting splitting to change the structure of the coal and rock mass, firstly drilling holes inside a coal bed, performing high-pressure hydraulic cutting seam, and forming a deep flat slot around the drilling holes of the coal bed after cutting; and filling explosive into the drilling holes of the coal bed, then injecting water and sealing the hole, detonating the explosive to perform water pressure blasting, and enabling the periphery of the drilling holes of the coal bed to generate directional expanding fractures under the function of detonation pressures. Performing water pressure blasting in a high-gas low gas permeability coal bed can organically combine the waterpower and the explosive force of the explosive fully and reasonably, the water pressure blasting enables the cracks generated by hydraulic cutting seam to further expand and a directional expanding cross fracture net is formed on the periphery of the drilling holes of the coal bed, so that the gas permeability of the coal bed is greatly improved, the problem that the gas of the coal bed is hard to extract due to the small number of the cracks can be effectively solved, the concentrated stress of the coal bed is transferred to the deep of the coal mass, and the capacity of gas emission is improved. The directional water pressure blasting method for improving the coal bed gas permeability is simple in process, convenient to operate, safe, reliable, and good in controllability and effects.

Owner:CHONGQING UNIV

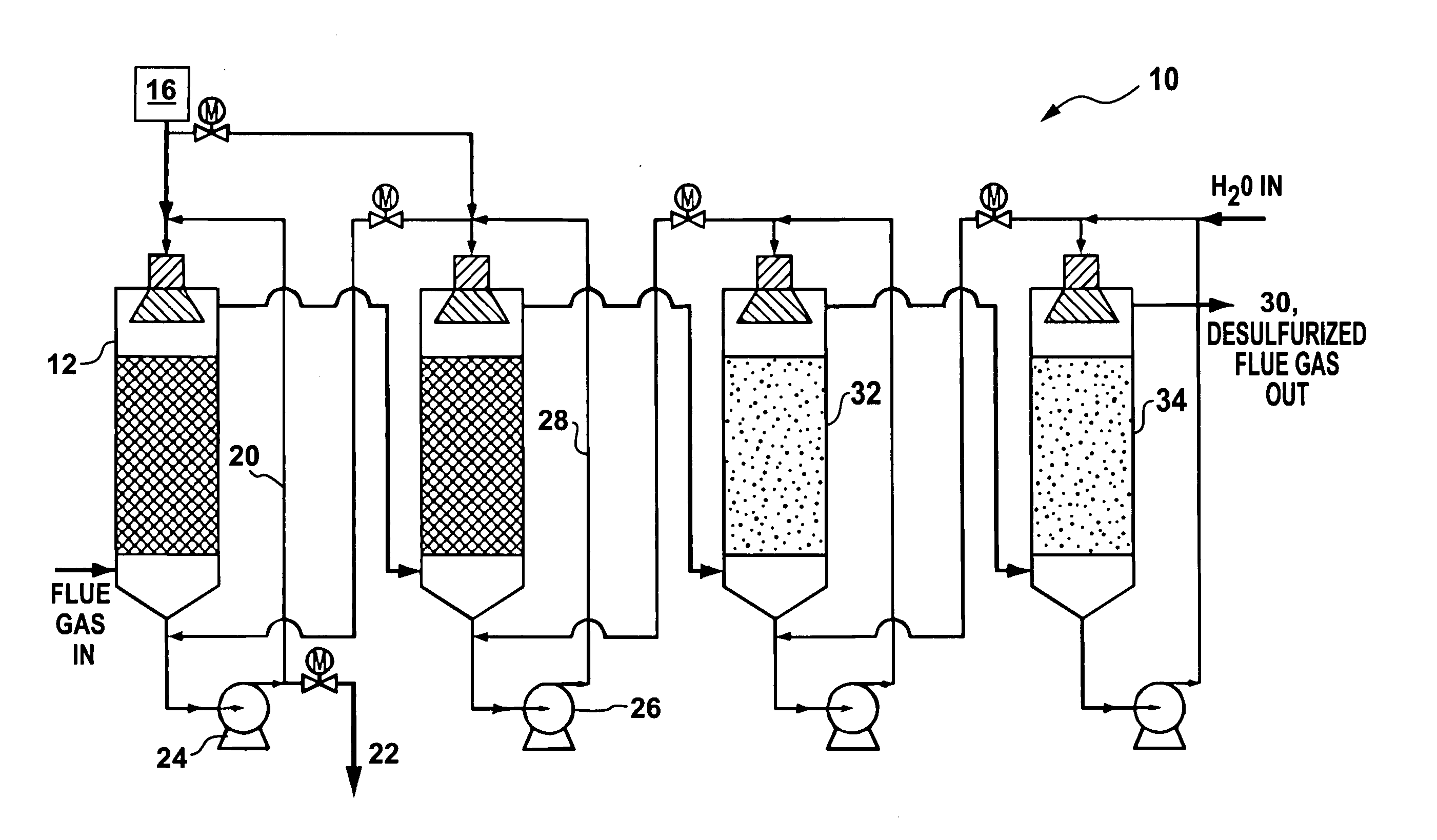

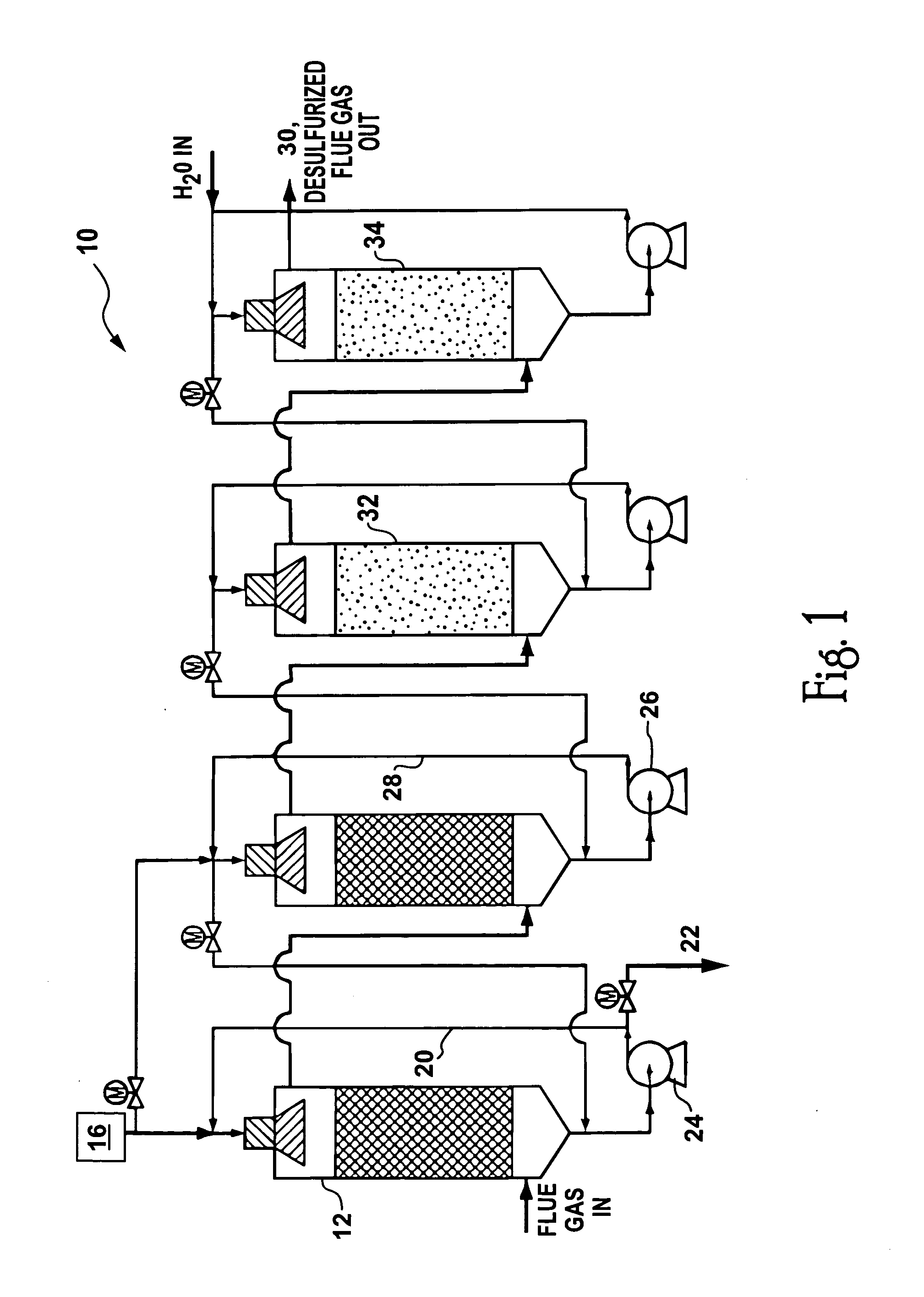

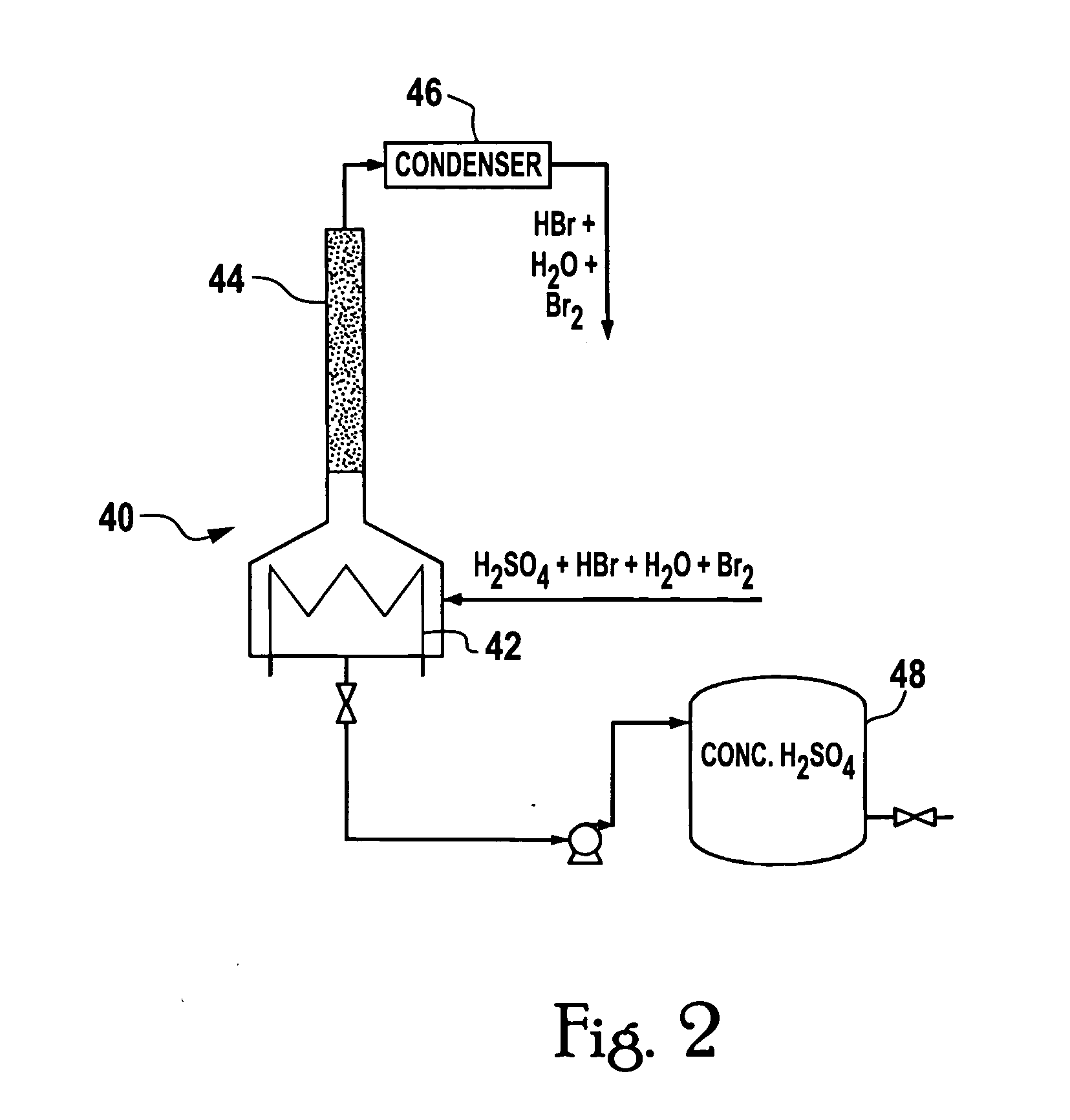

Method for processing stack gas emissions

Apparatus and methods for augmenting the Mark 13a process of Van Zelzen et al., by providing for the addition of dispatchable energy storage and / or additional waste stream treatments. Sulfur-containing stack gas emissions from the burning of fossil fuels for electricity production are cleaned, removing the sulfur by use of the Bunsen reaction. The process produces hydrogen and sulfuric acid as byproducts. The hydrogen output of the process can be used to co-produce electricity in a reversible fuel cell, and optionally can be stored so that electricity can be produced during periods of high demand. Optionally the hydrogen can be reacted with air-nitrogen or nitrogen from the combustion gasses to produce ammonia. The sulfuric acid can optionally be reacted with iron or aluminum to produce iron or aluminum sulphates and additional electricity. In addition, mercury removal from the gas emissions from burning fossil fuels (primarily coal) can be performed.

Owner:SOLAR REACTOR TECH

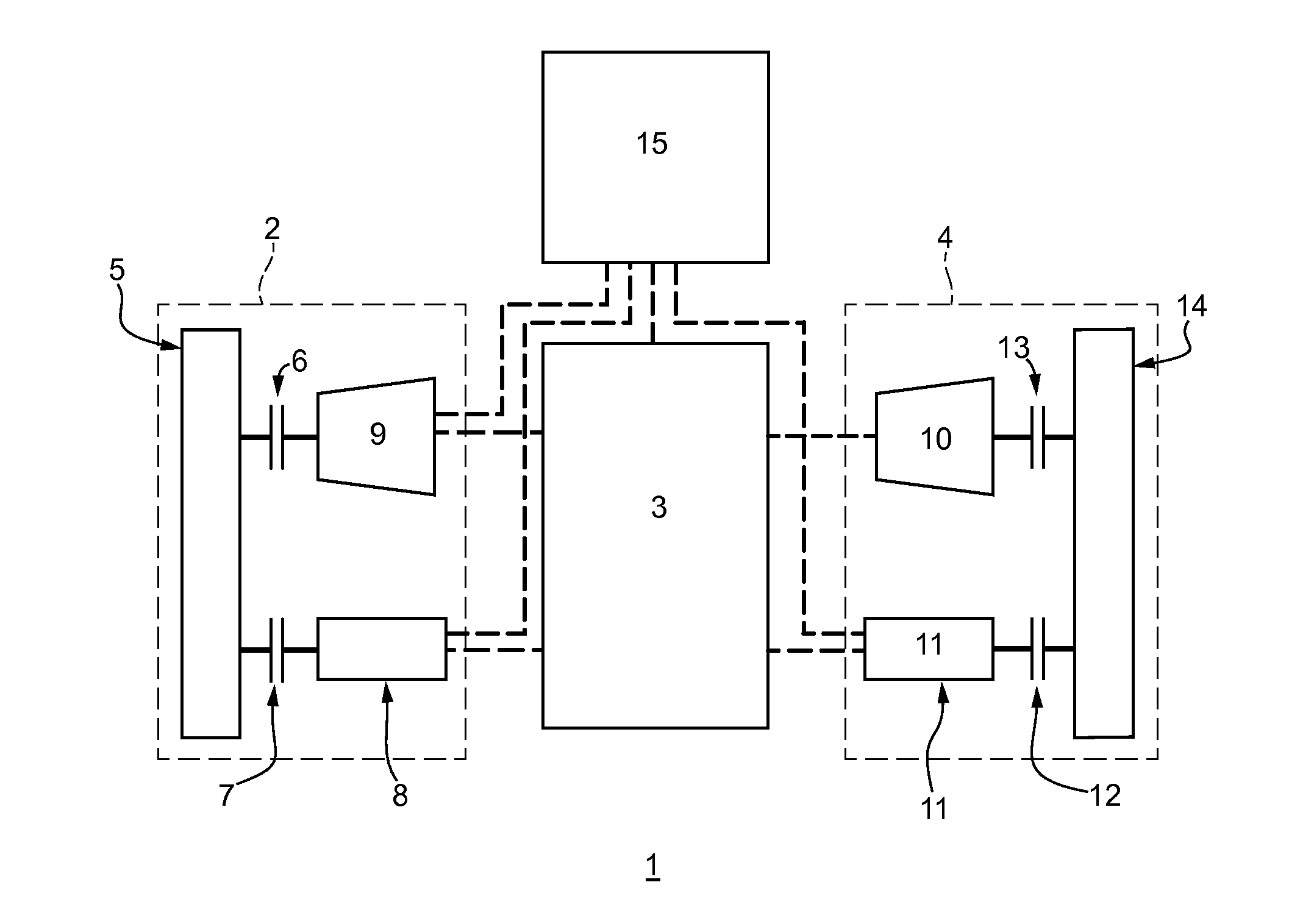

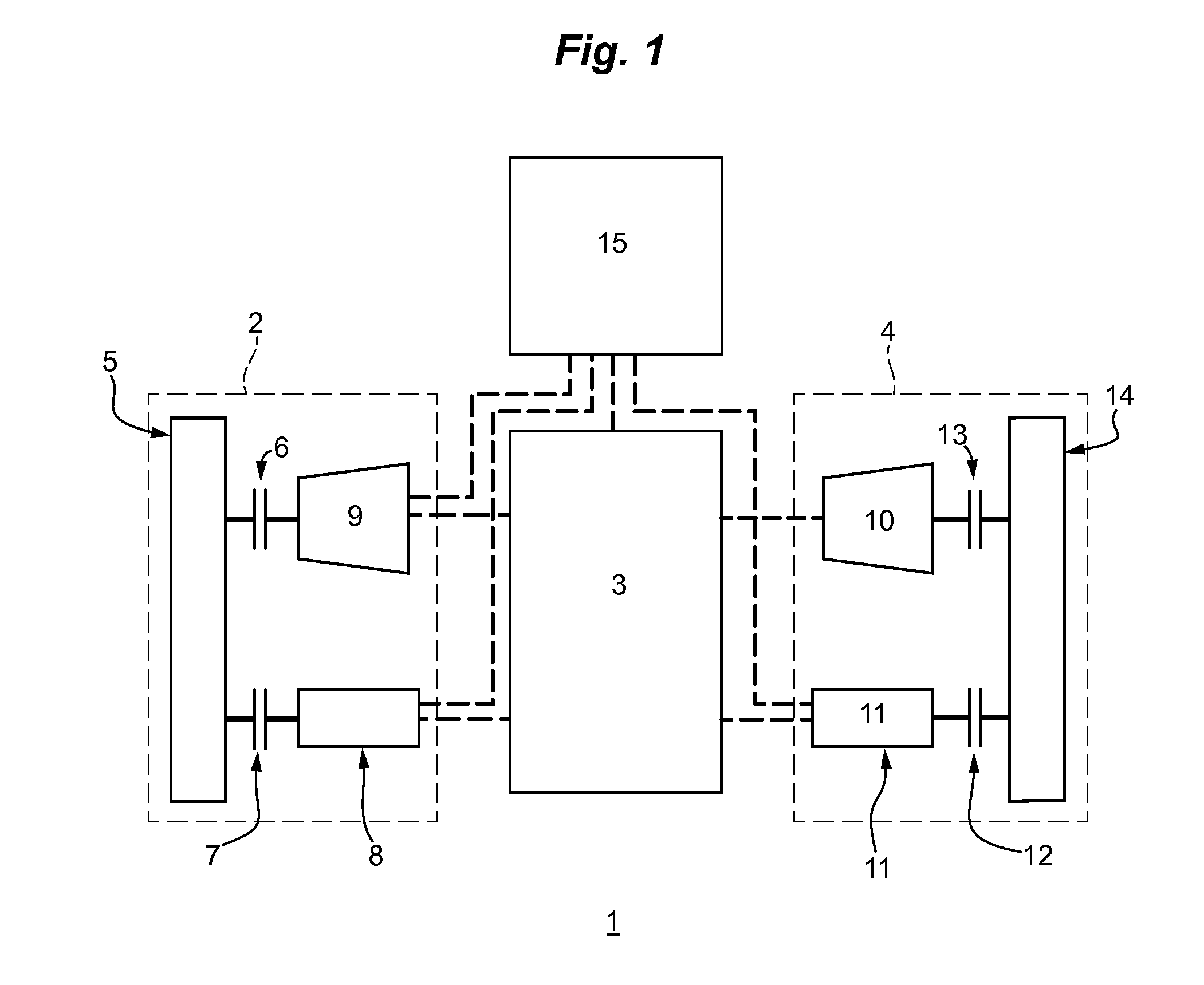

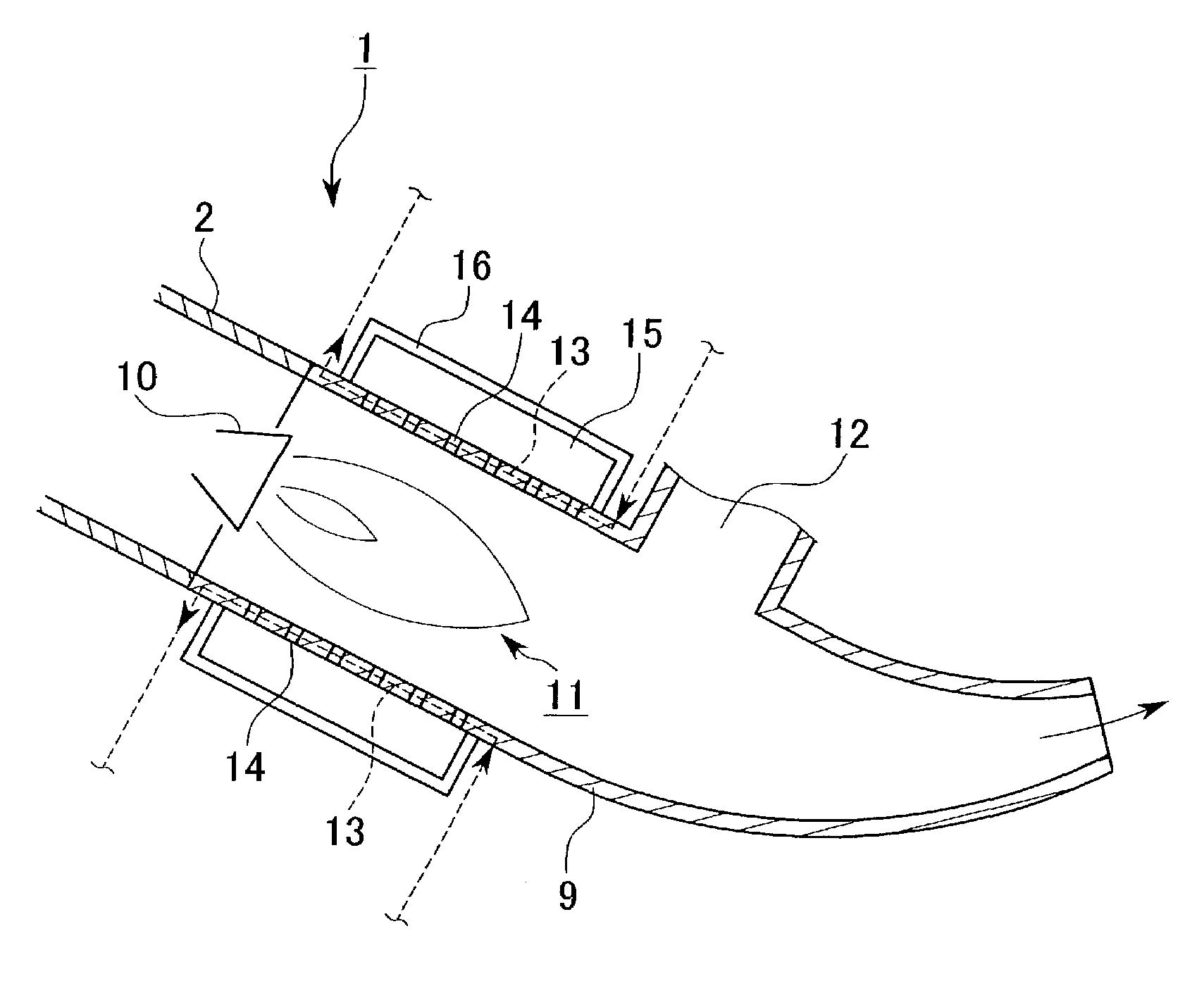

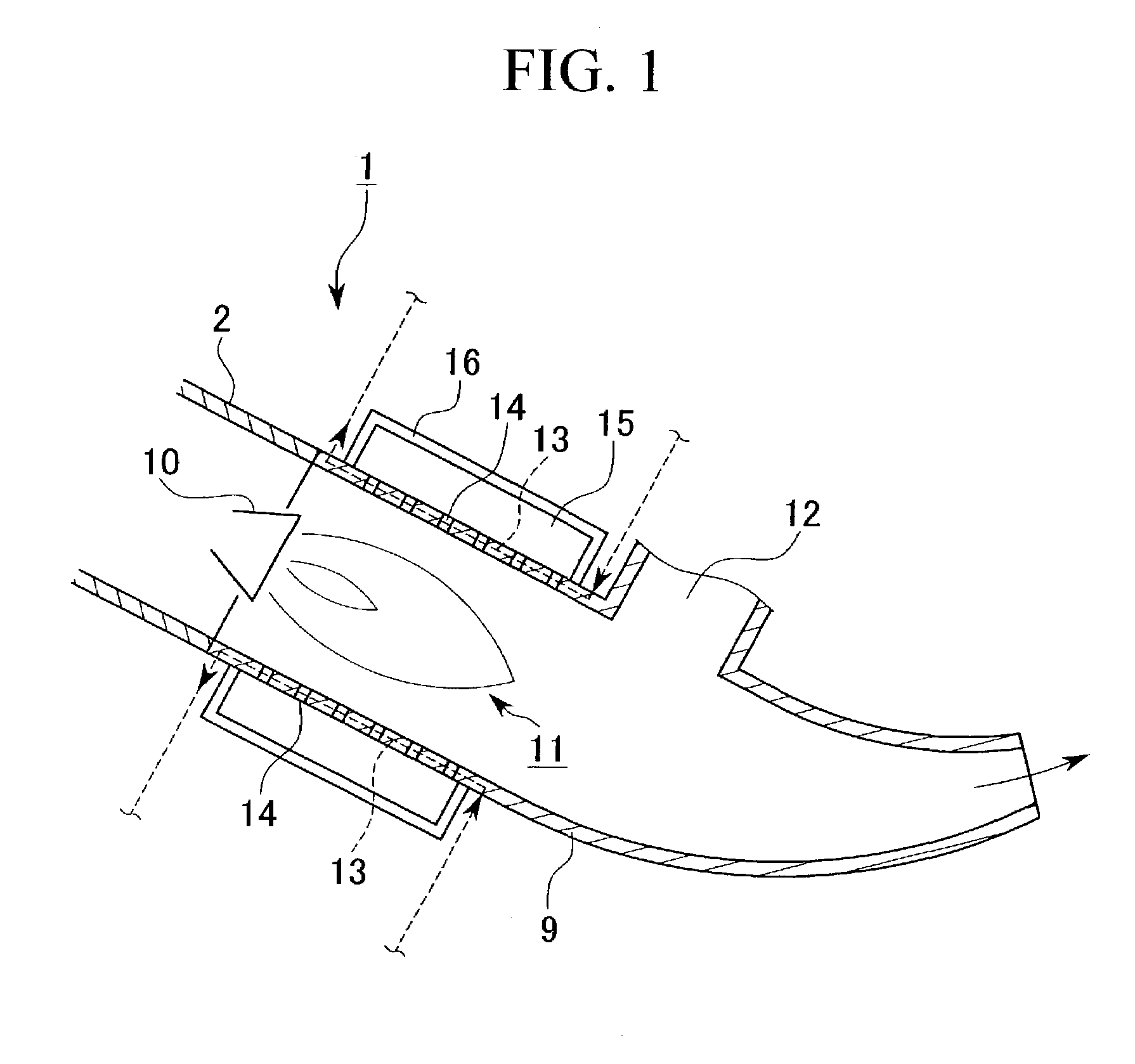

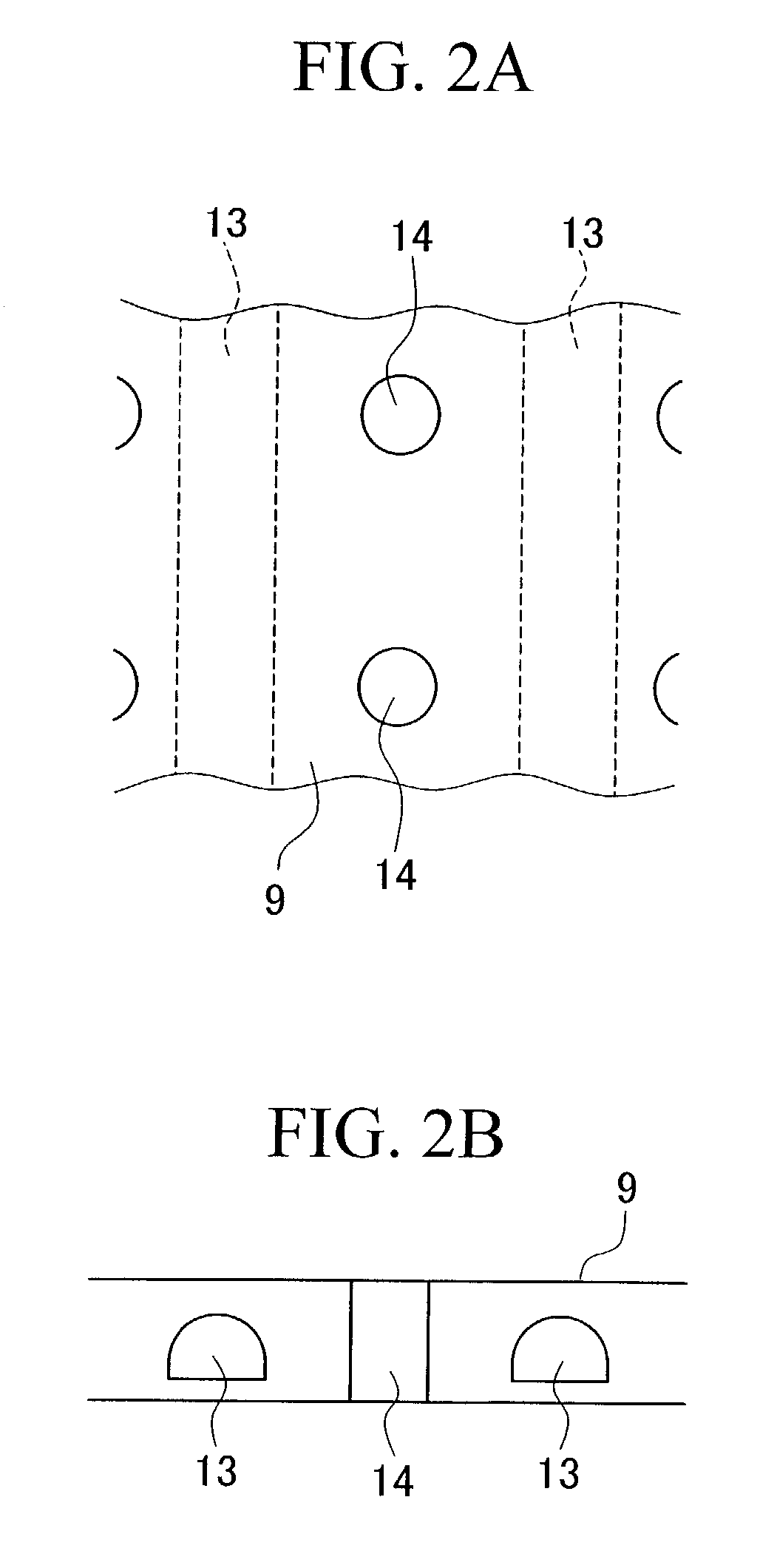

Devices and Methods to Optimize Aircraft Power Plant and Aircraft Operations

InactiveUS20130327014A1Improve fuel efficiencyReduce consumptionEfficient propulsion technologiesJet propulsion plantsPower stationTurbine

Several improvements to optimize aircraft power plant and aircraft operations are disclosed, as well as methods of using these improvements to reduce fuel consumption, gas emission, noise, aircraft weight, maintenance costs, operating costs, aircraft incident and accidents, and improving aircraft performance. The improvements consist of a power plant fitted with a front propulsor, core engine, and aft propulsor. The fan of each propulsor is separated mechanically from the core engine. The front fan is separated mechanically from the aft fan. The aft fan is driven by free turbine that is supplied by exhaust gas of the core engine. If the core engine fails, both propulsors operate and provide thrust and reversed thrust when needed. If one propulsor fails, the other propulsor of the same power plant operates and provides thrust and reversed thrust.

Owner:MOULEBHAR DJAMAL

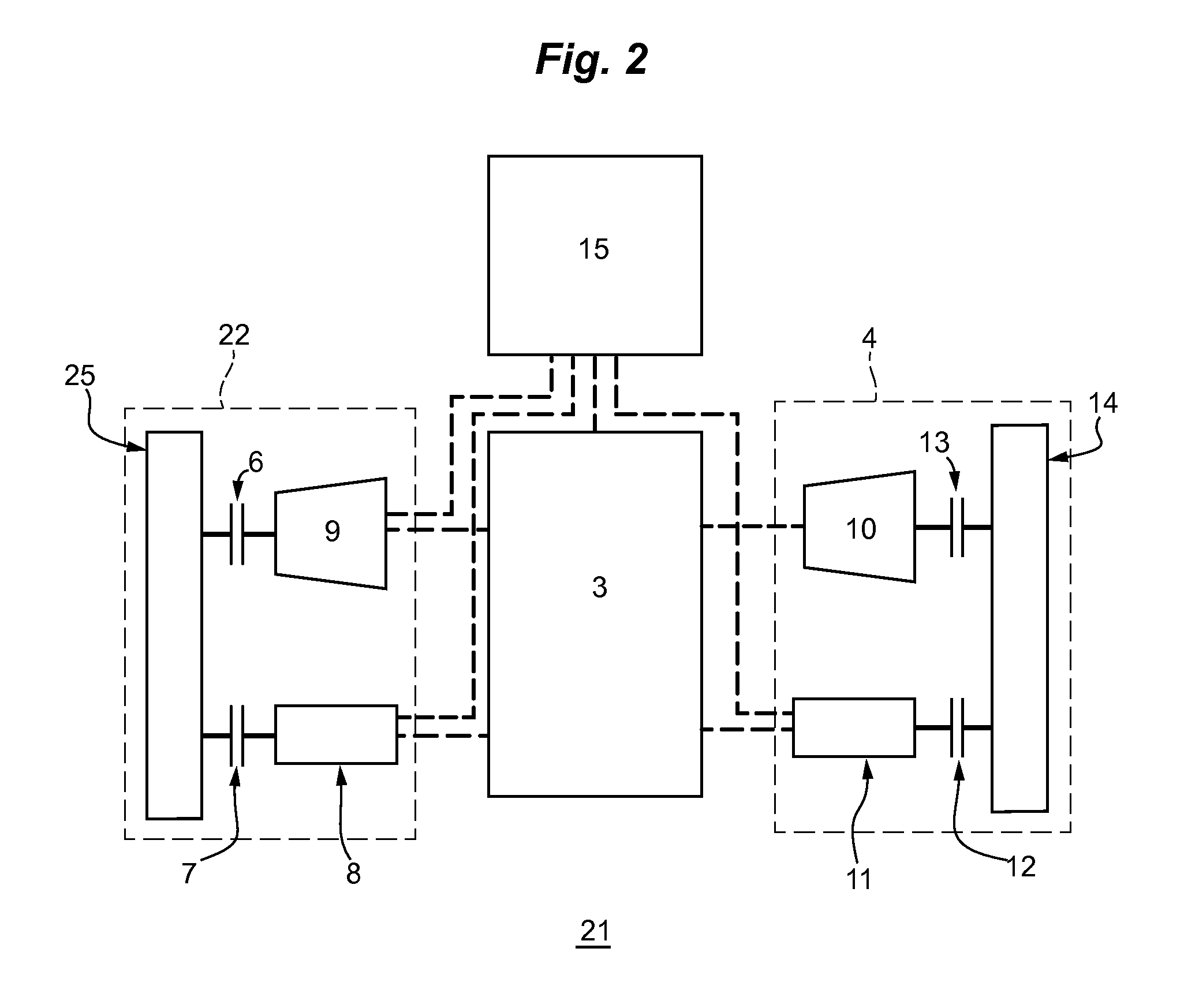

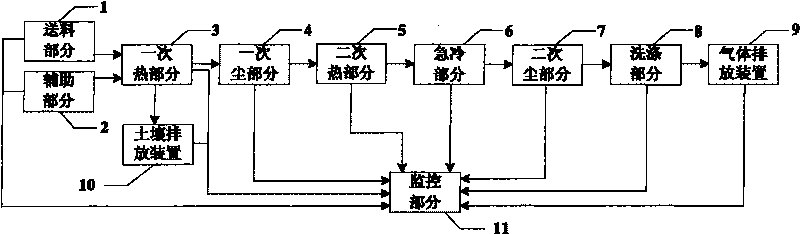

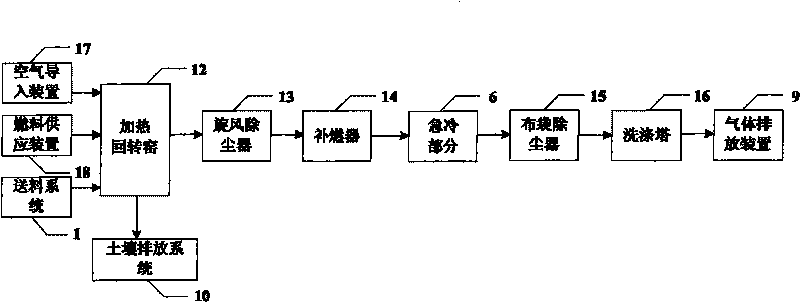

Direct pyrolysis device

ActiveCN101712042AMaintain physical and chemical propertiesEasy to handleCombination devicesDispersed particle filtrationProduct gasEngineering

The invention relates to a direct pyrolysis device. In the direct pyrolysis device, a heating part comprises a primary heating part and a secondary heating part; both a feed part and an auxiliary part are connected with the primary heat part; a dedusting part comprises a primary dedusting part and a secondary dedusting part; an emission part comprises a gas emission device and a soil emission device; the primary heating part is orderly connected with the primary dedusting part, the secondary heating part, a quenching part, the secondary dedusting part, a washing part and the gas emission device; the primary heating part is also connected with the soil emission device; all the components are respectively connected with a monitoring part; the washing part is a washing tower; and the tail end of the washing tower is connected with the gas emission device. The invention has the advantages of high handling capacity, low energy consumption, low handling cost and the like, maintains the advantages of physico-chemical properties of soil and the like, and can effectively separate organic substances from contaminated soil and dispose the contaminated soil.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

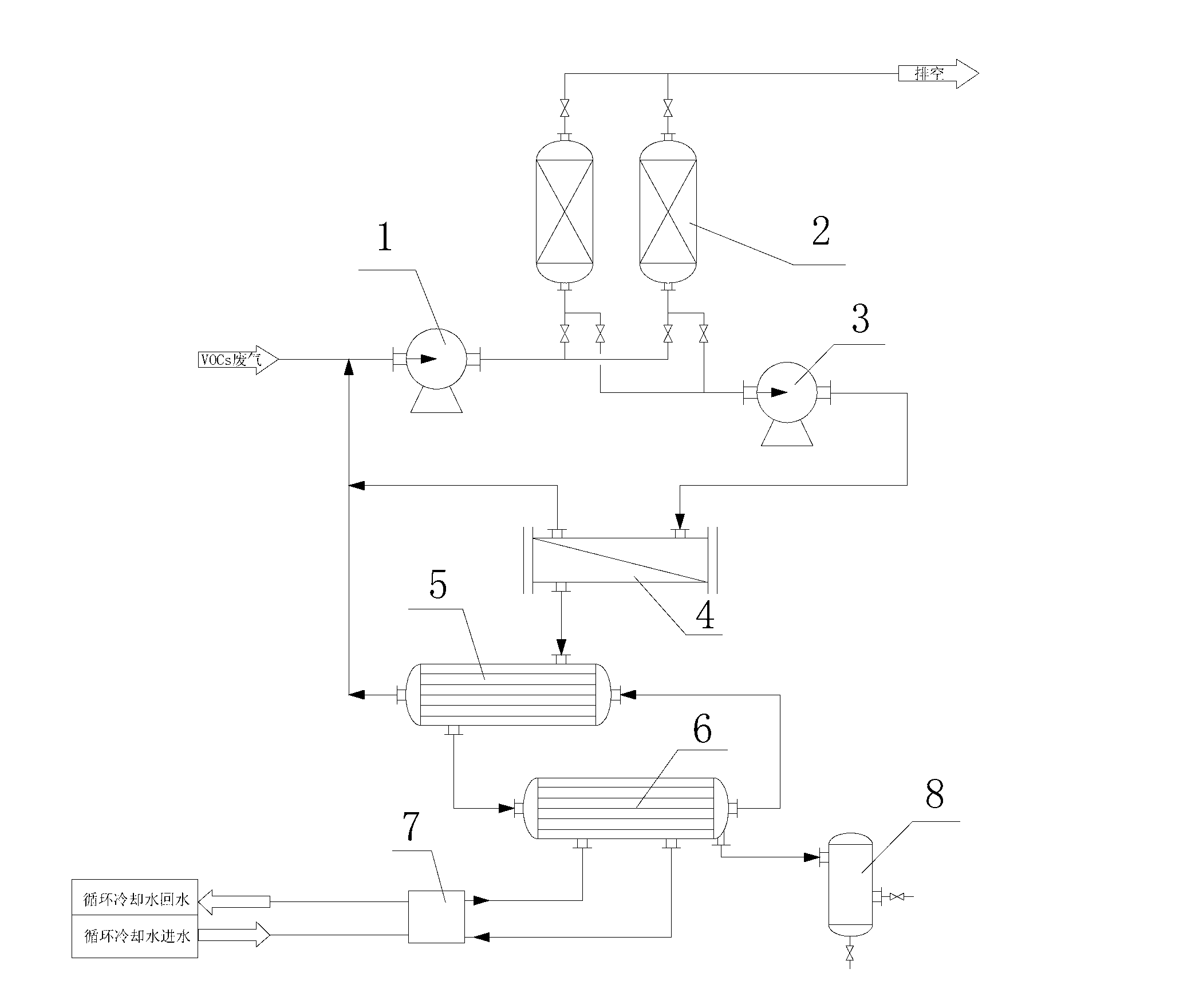

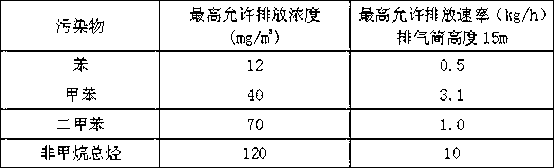

System and technology for processing low-concentration VOCs (volatile organic chemicals) waste gas

InactiveCN102794079AReduce consumptionImprove automationDispersed particle separationVapor condensationSeparation technologySewage

The invention provides a system and technology for processing low-concentration VOCs (volatile organic chemicals) waste gas. In the invention, the adsorption technology, the membrane separation technology and the condensation technology are combined, wherein the VOCs waste gas is subjected to primary concentration by the adsorption technology and secondary concentration by the membrane separation technology, and the VOCs waste gas after concentration is condensed by the condensation technology; and the aim of saturation precipitation of organic components can be achieved with relatively little consumption of cold. The system and technology provided by the invention integrate the adsorption technology, the membrane separation technology and the condensation technology, and are mainly used for processing the VOCs waste gas in the occasions with relatively low concentration such as the truck loading process of oil products and chemical products, storage tanks, sewage pools and the like; and the processed waste gas can meet the requirements of the effluent gas emission standard of the country.

Owner:JIANGSU WISDOM ENG TECH

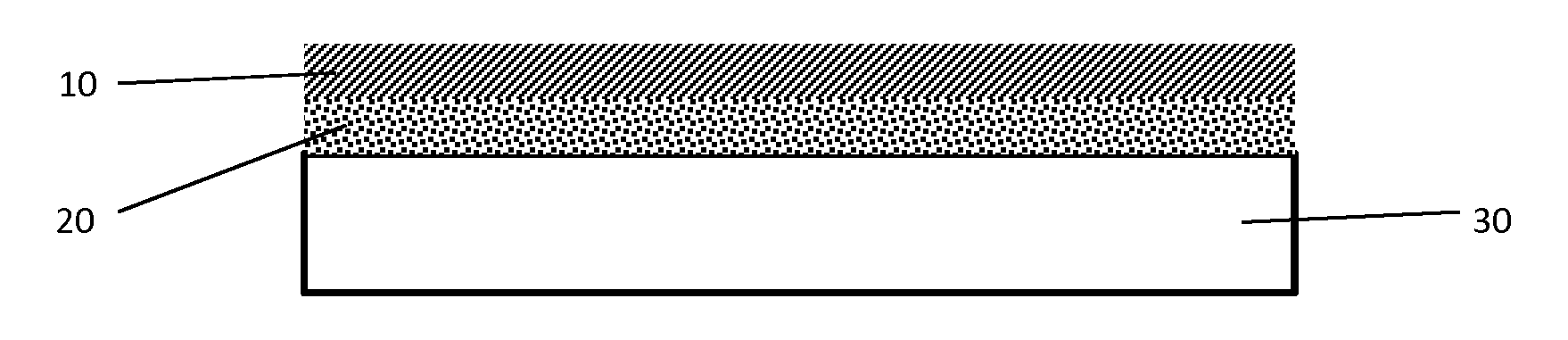

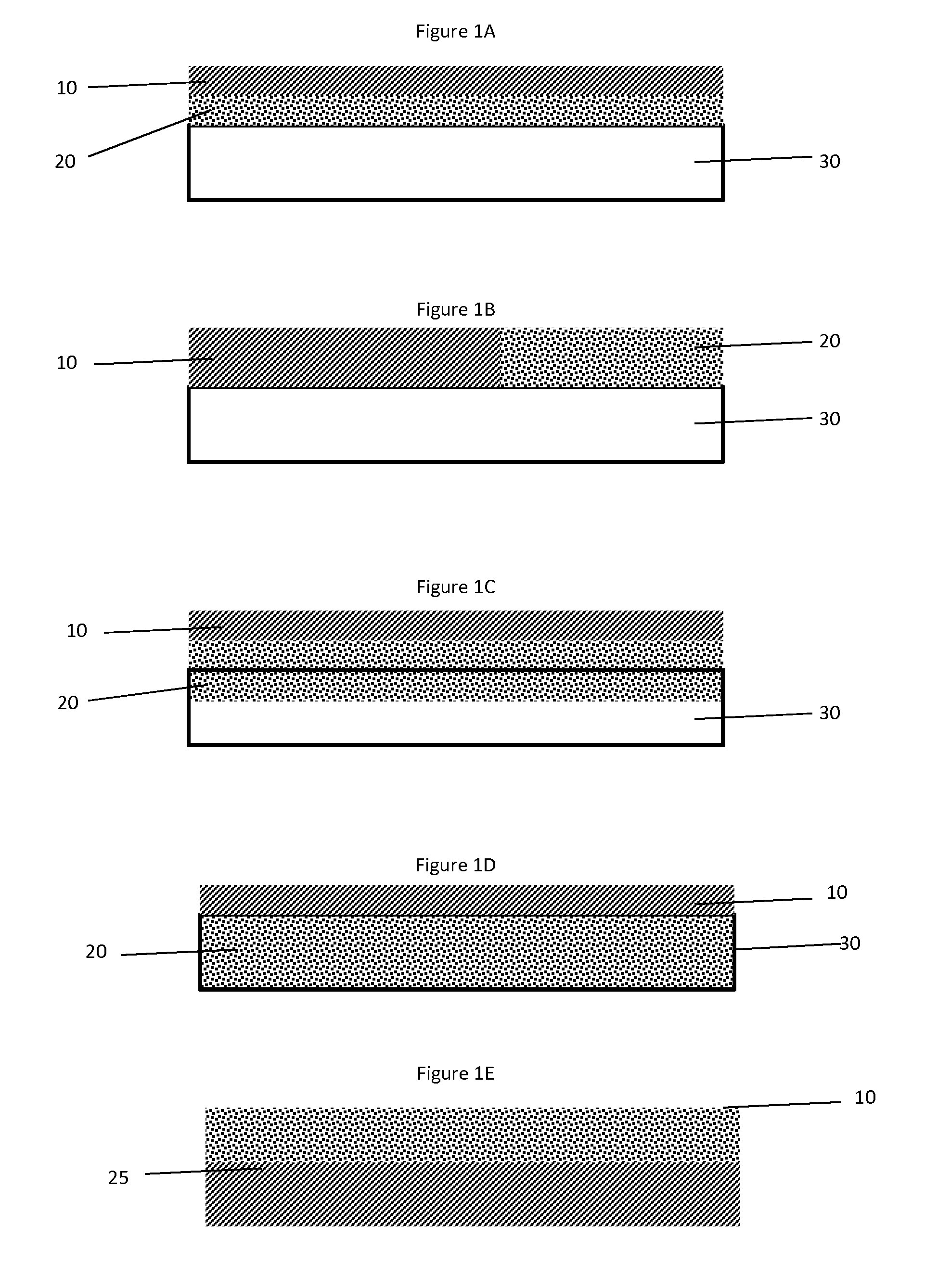

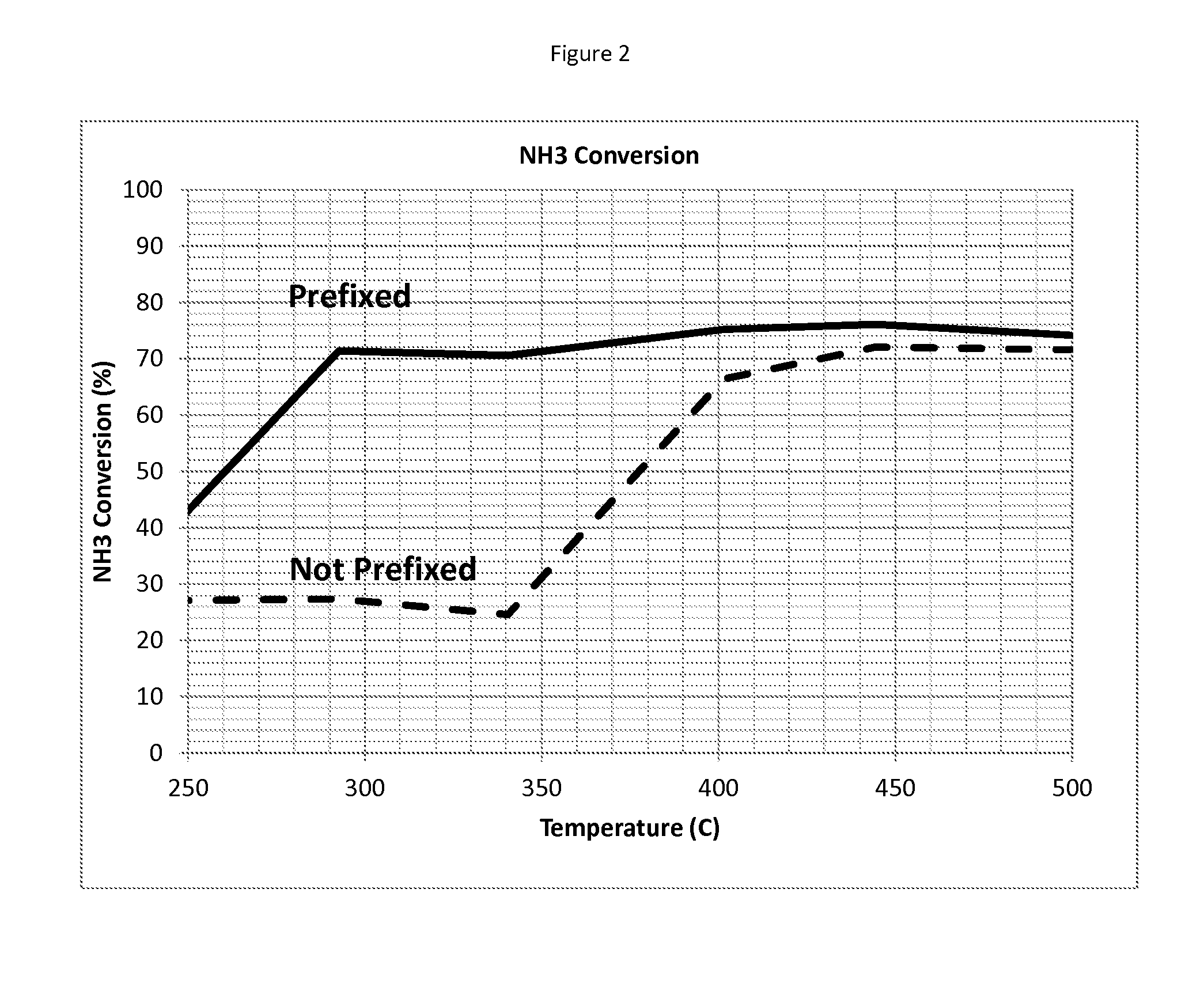

Ammonia oxidation catalyst

ActiveUS20140154163A1High catalytic activityImproving low temperature ammonia conversionCombination devicesCyanogen compoundsPtru catalystSilicon oxide

Provided is a catalyst article for treating an emission gas comprising (a) a noble metal catalyst layer comprising one or more noble metals disposed on a first refractory metal oxide support; and (b) a vanadium catalyst layer comprising vanadium pre-fixed on a second refractory metal oxide support selected from alumina, titania, zirconia, ceria, silica, and mixtures of these, wherein the first catalyst layer is in physical contact with said second catalyst layer. Also provided is a method for making such a catalyst article, a method for treating gas emissions using such an article, and an emission gas treatment system incorporating such an article.

Owner:JOHNSON MATTHEY PLC

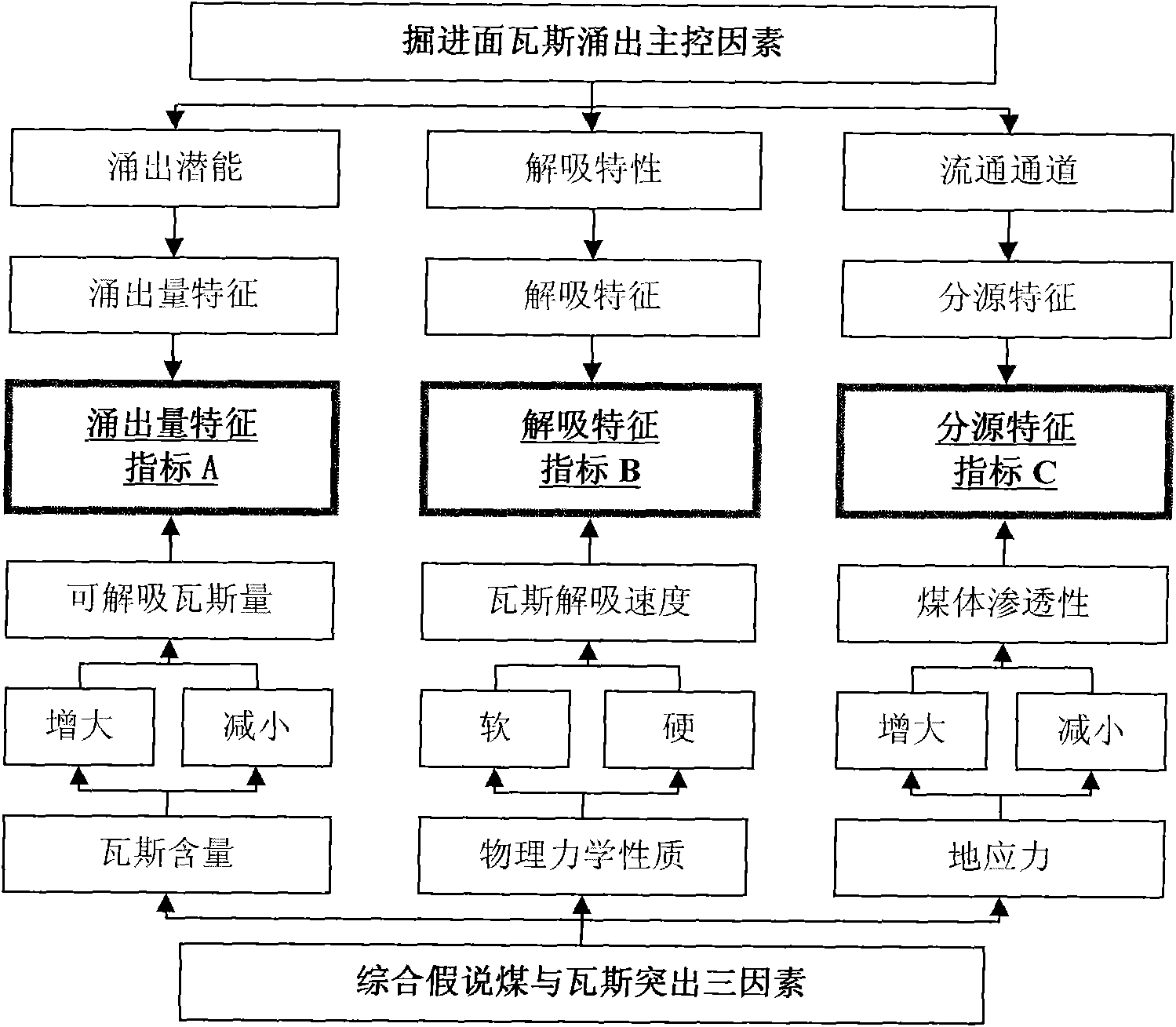

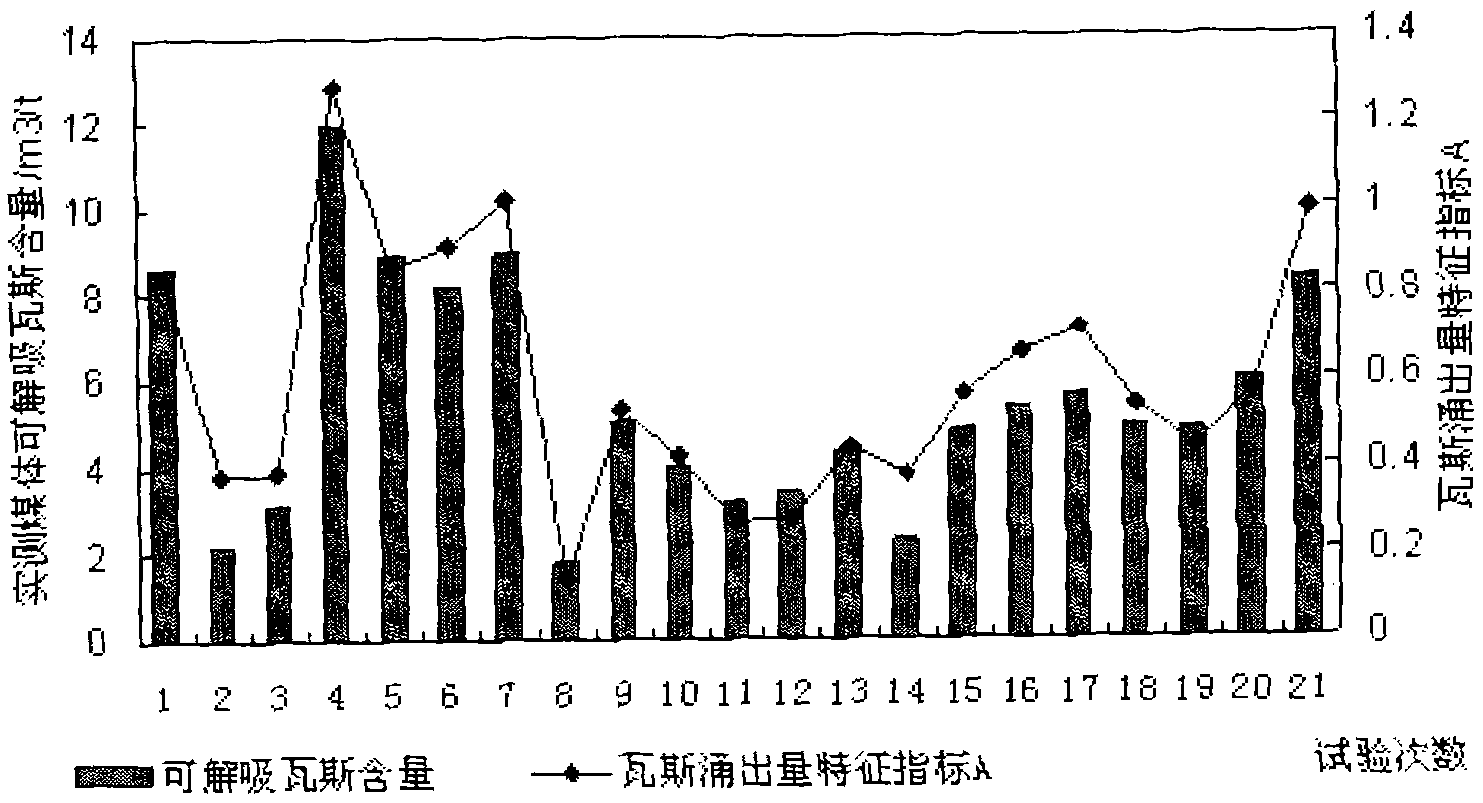

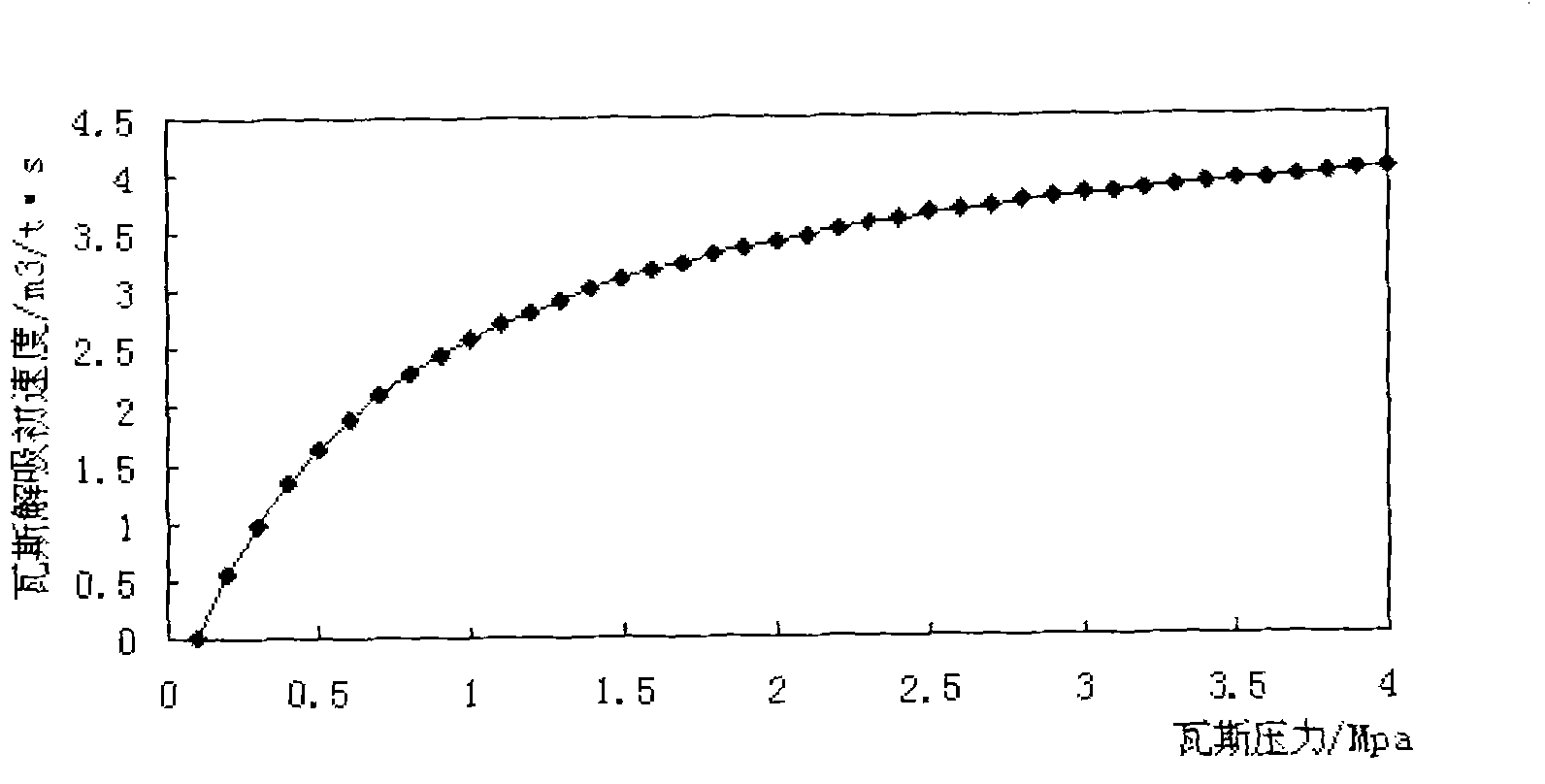

Continuous prediction method of gas emission dynamic characteristic outburst of tunneling surface

The invention relates to the technical field of coal mine safety, in particular to a continuous prediction method of gas emission dynamic characteristic outburst of a tunneling surface, which utilizes the development state and the development trend of three factors of outburst comprehensive hypothesis of the tunneling surface of gas emission dynamic characteristic reaction of the tunneling surface and realizes the non-contact type continuous prediction technology of coal of the tunneling surface and gas outburst; and the method comprises the following steps: acquiring real-time gas emission monitoring data of an underground gas sensor from a coal mine gas monitoring system; extracting dynamic characteristics of gas emission of the tunneling surface, including average value of frequency ofthe monitoring data of the gas emission, the maximum value of the frequency per minute of the monitoring data of the gas emission and the movement minimum value of the frequency per t minutes of the gas emission; and acquiring the shape design characteristic parameters of a lane, the original desorbable gas content of a coal layer, wind rate and frequency time, sequentially acquiring characteristic index of the gas emission rate of the tunneling surface, gas desorption index and gas dividing source characteristic index, and carrying out real-time prediction and forecast of outburst risk of a working surface according to the states and the trends of the three characteristic indexes.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

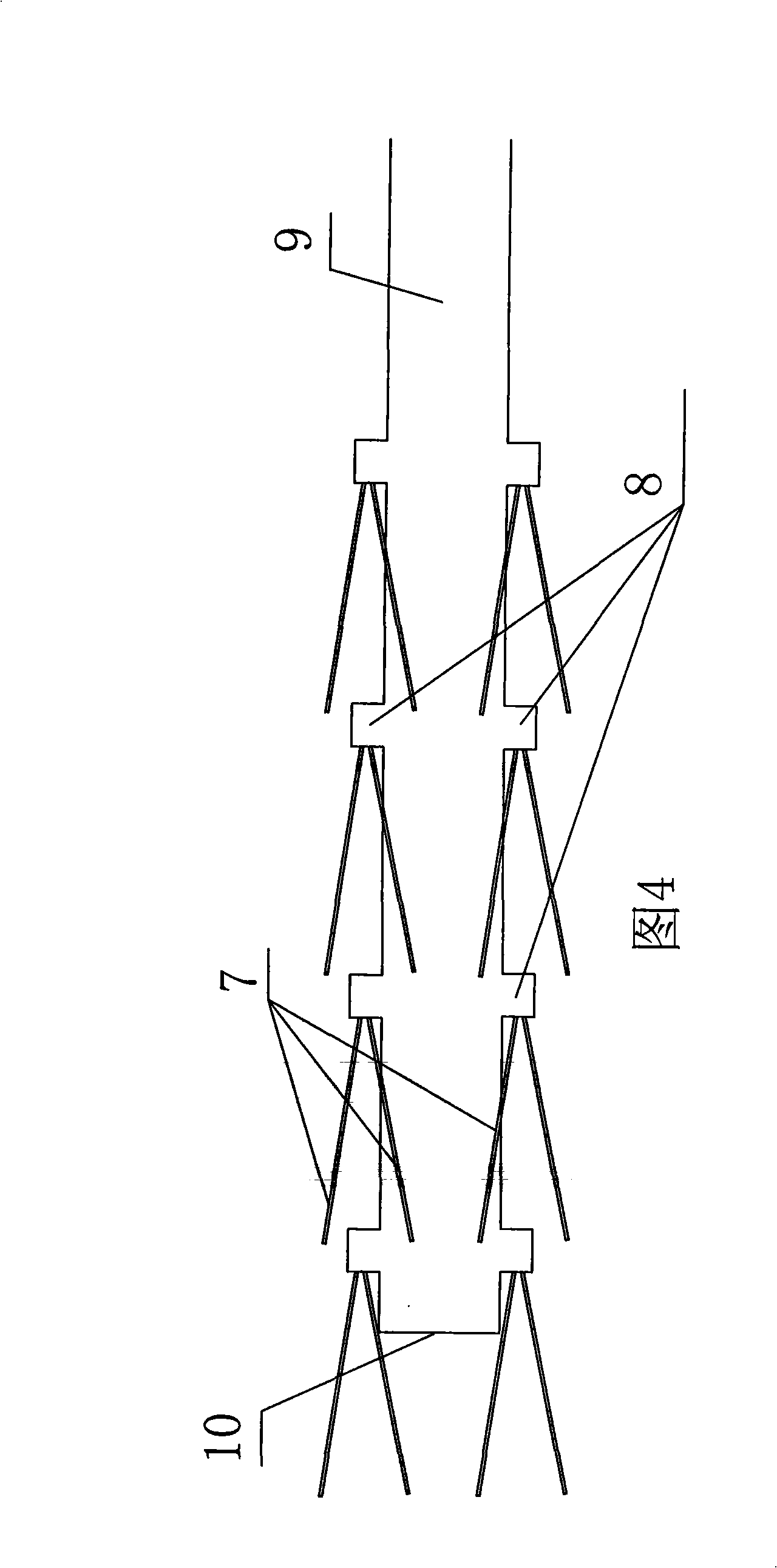

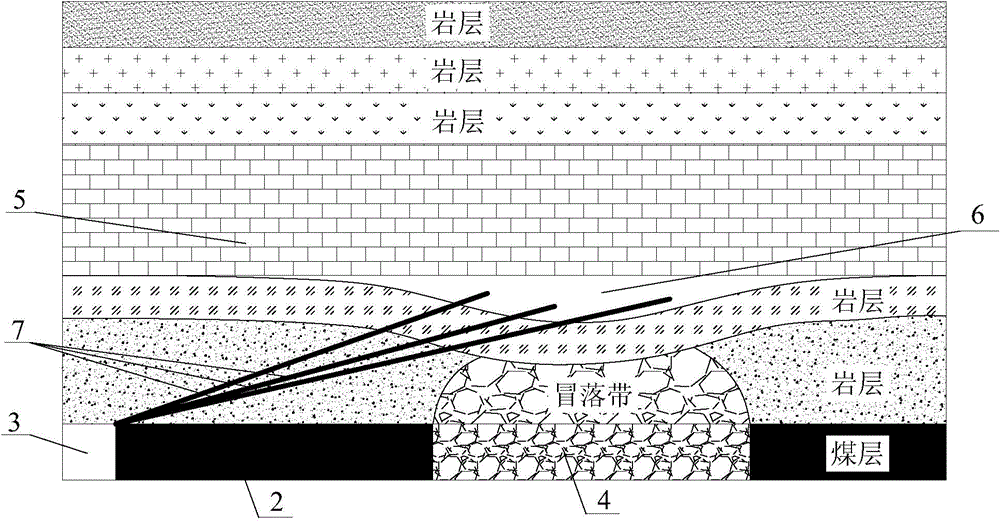

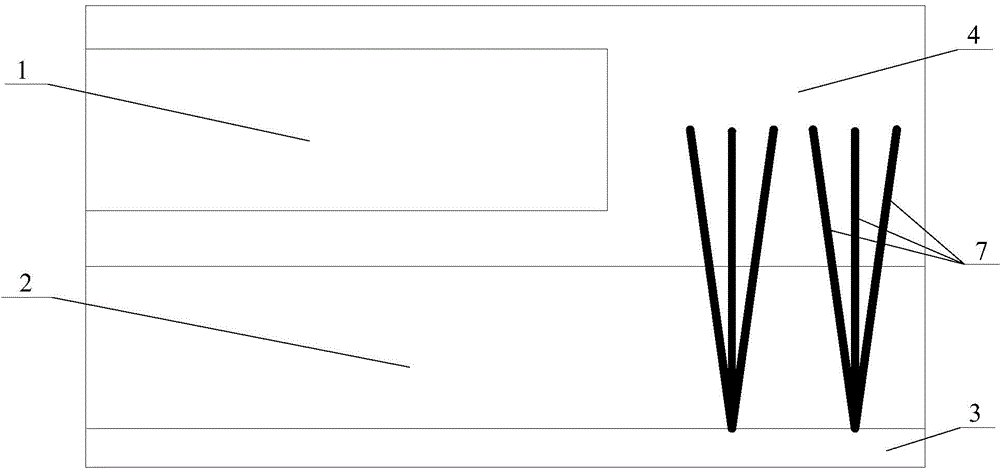

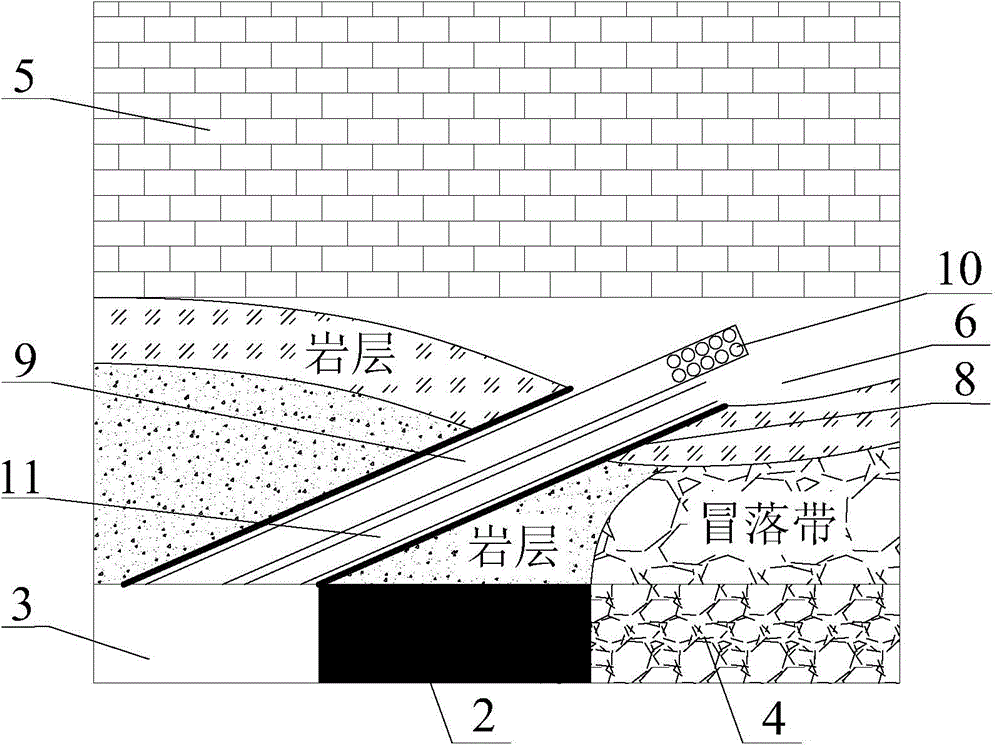

Method for extracting gas from separation layer below overlying strata, draining water and grouting through combined drill hole

ActiveCN104863629AHigh extraction rateImprove grouting effectMaterial fill-upDrainageDrill siteCement paste

The invention discloses a method for extracting gas from a separation layer below an overlying strata, draining water and grouting through a combined drill hole and belongs to a mine disaster prevention method. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole includes that installing a drill site at a transportation roadway of a preparatory work face adjacent to a coalface, constructing the combined drill hole in the part about to generate the separation layer below the overlying strata above the gob of the coalface in a mode of keeping away from a caving zone, wherein the combined drill hole is composed of an inside gas extraction pipe and a water draining-grouting pipe; after the separation layer is generated, preventing the mine disaster according to the stages that firstly, draining water from the separation layer through the combined drill hole; secondly, after the gas is gathered in the separation layer after the water in the separation layer is emptied, using the primary combined drill hole to extract the gas from the separation layer; finally, after the water and gas are completely drained and extracted from the separation layer, filling cement paste to the separation layer through the primary combined drill hole. The method for extracting gas from the separation layer below the overlying strata, draining water and grouting through the combined drill hole is capable of solving the mine disasters of water bursting in mine, gas outburst (gas emission), rock burst, surface subsidence and the like through the combined drill hole, the separation layer water and gas extraction rate is high, and the grouting effect is good.

Owner:CHINA UNIV OF MINING & TECH

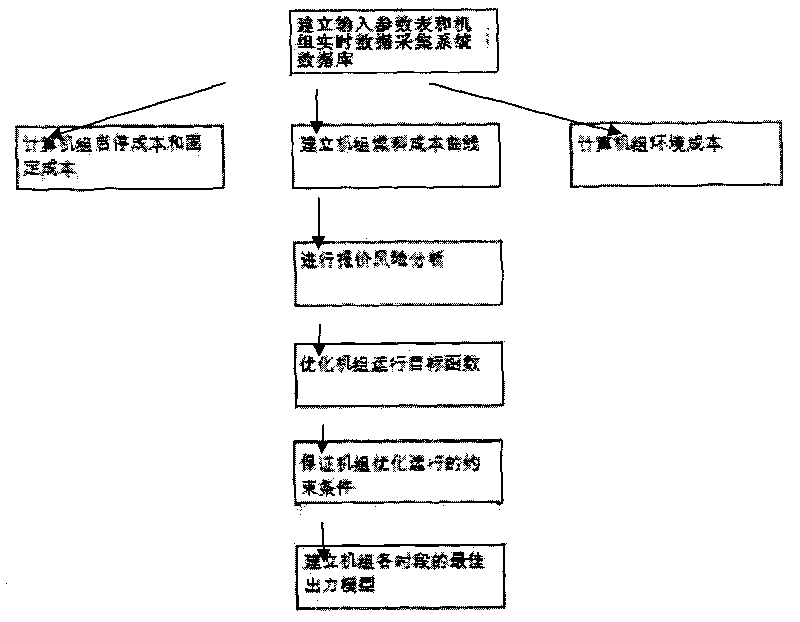

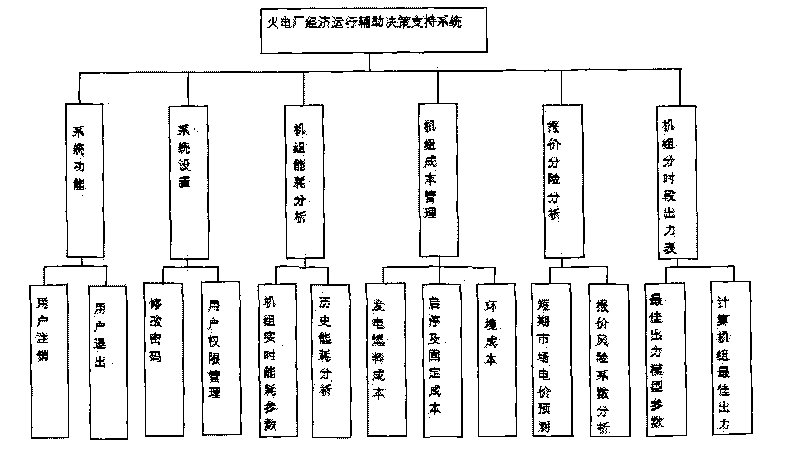

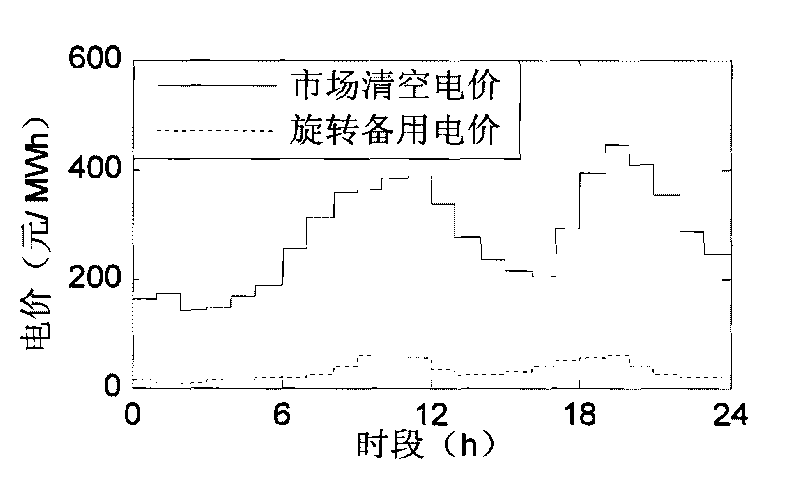

Output optimal operation method of thermal power unit based on electricity marketization environment

InactiveCN101763089AEmission reductionProof of validityTechnology managementTotal factory controlElectricity priceStart stop

The invention discloses an output optimal operation method of a thermal power unit in the environment of ensuring electricity price bidding marketization, and the method comprises the following steps: establishing a manual input cost parameter table and a unit production real-time system database; establishing a generating fuel cost curve of the unit; calculating the start-stop cost and the fixed cost of the unit; calculating the environment cost of the unit, internalizing the environment cost and calculating the environment cost directly according to harmful gas emission and a discount standard; analyzing bidding risk; establishing an objective function of a mathematical model of economic operation of a single unit based on profit maximization; guaranteeing constraint conditions of optimal operation of the unit; and establishing the best output model table of the unit at various periods. The method considers the factors of environmental protection cost and bidding risk comprehensively, thus reducing harmful gas emission of the power plant when a generation company does not add environmental protection equipment, and moreover, reasonable analysis of the bidding risk can realize price bidding of low risk and high profit.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO

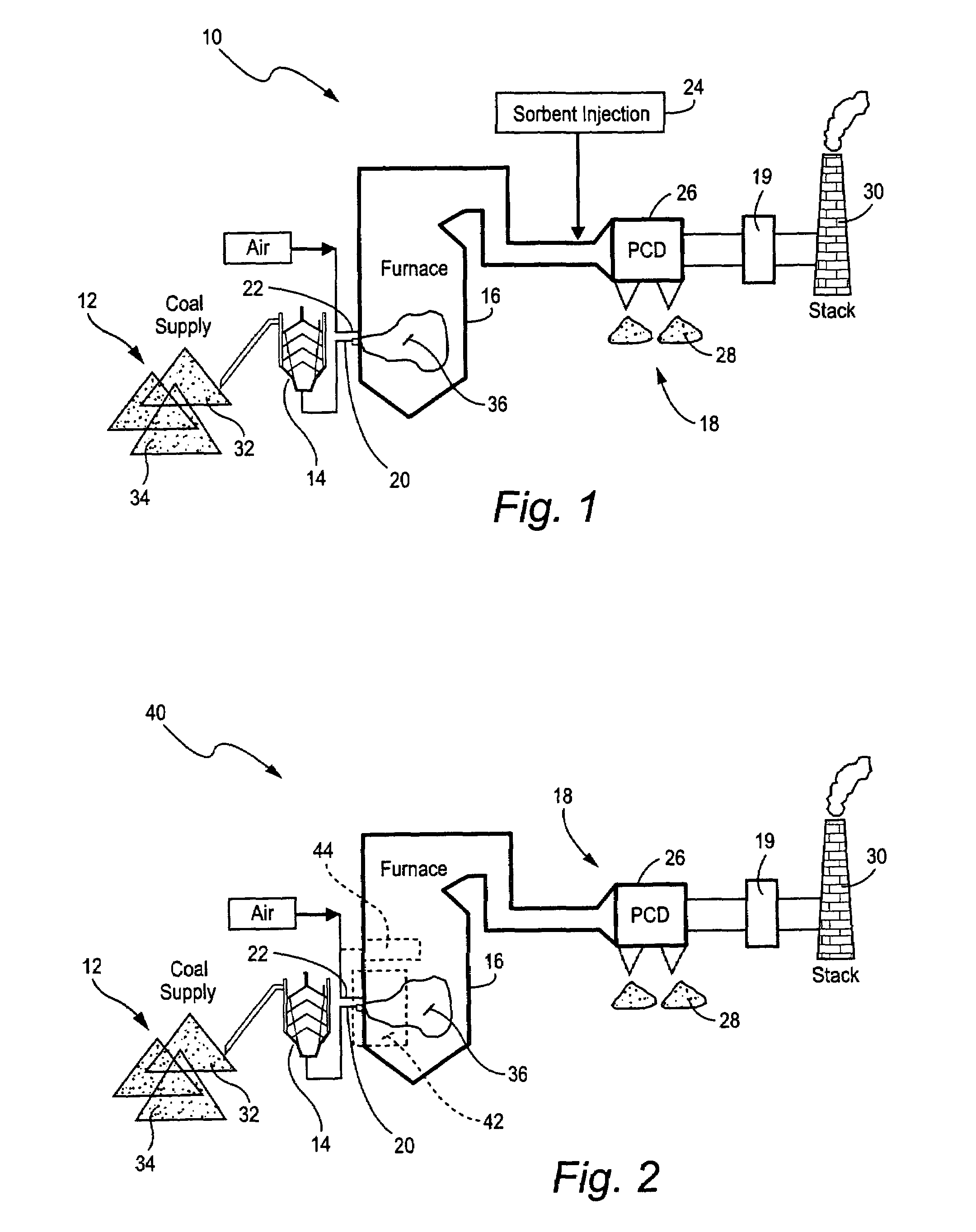

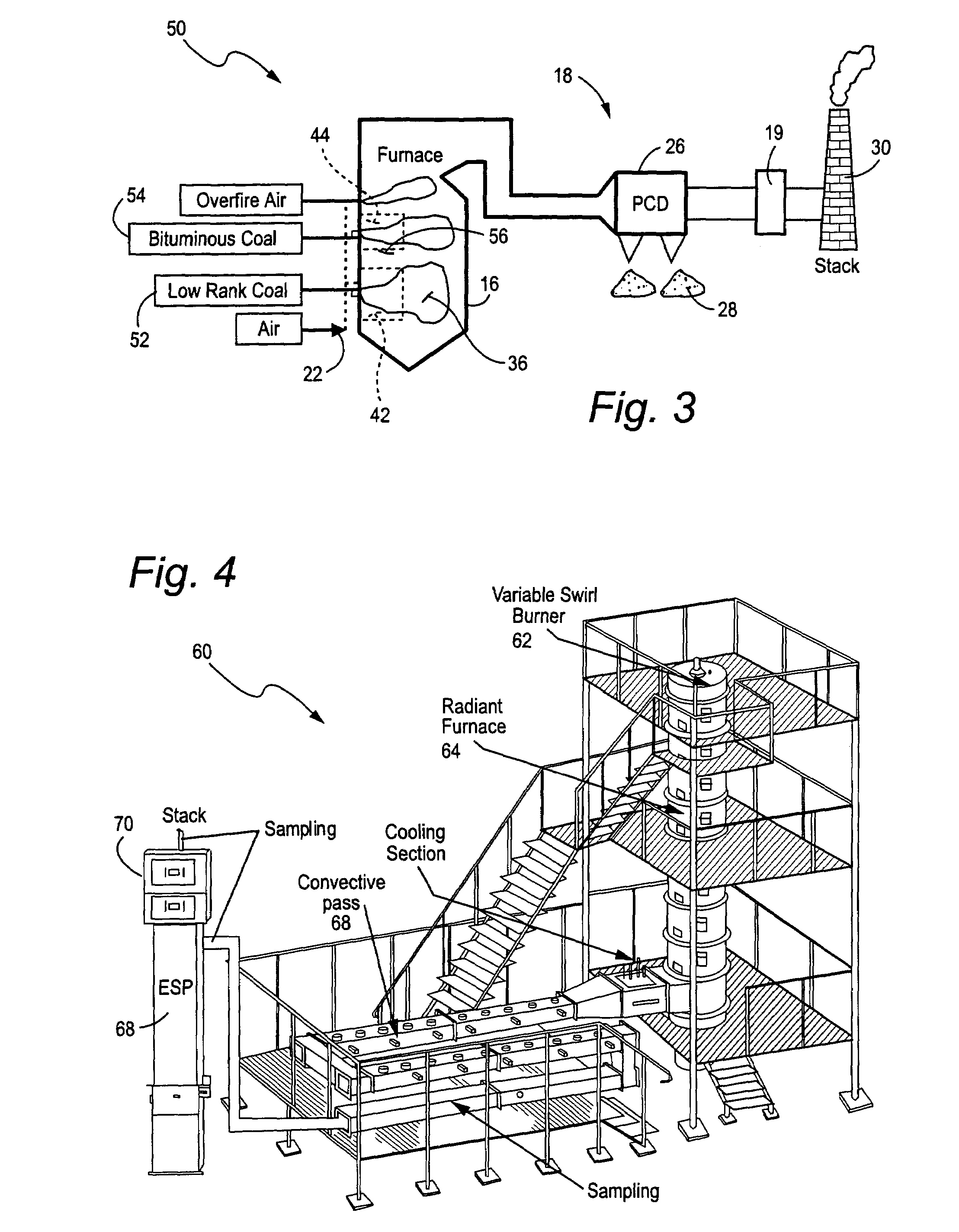

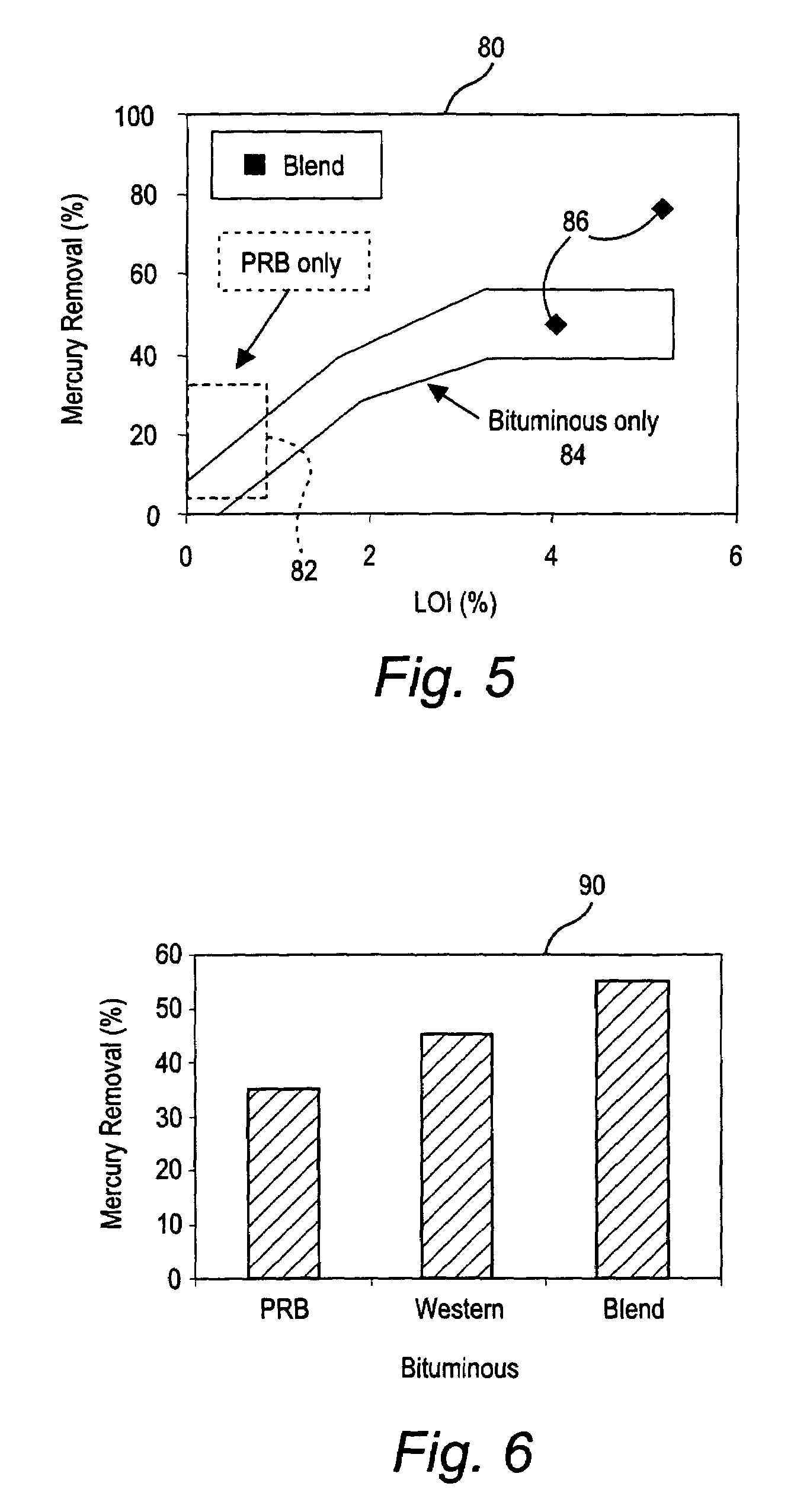

Mercury reduction system and method in combustion flue gas using coal blending

ActiveUS7381387B2Reduce gas emissionsGas treatmentUsing liquid separation agentCombustion systemCombustion

A method to reduce mercury in gas emissions from the combustion of low rank coal in a combustion system including: combusting coal having a low chlorine content in the combustion system, wherein elemental mercury (Hg0) is released in the flue gas produced by the combustion of the low rank coal; releasing chlorine into the flue gas by combusting a coal having a high chlorine in the combustion system; reacting the elemental mercury and released chlorine in the flue gas to oxidize the mercury; adsorbing at least a portion of the oxidized mercury generated by the combustion of the coal with an adsorbent in the flue gas, and collecting the adsorbent with the oxidized mercury in a combustion waste treatment system.

Owner:GENERAL ELECTRIC CO

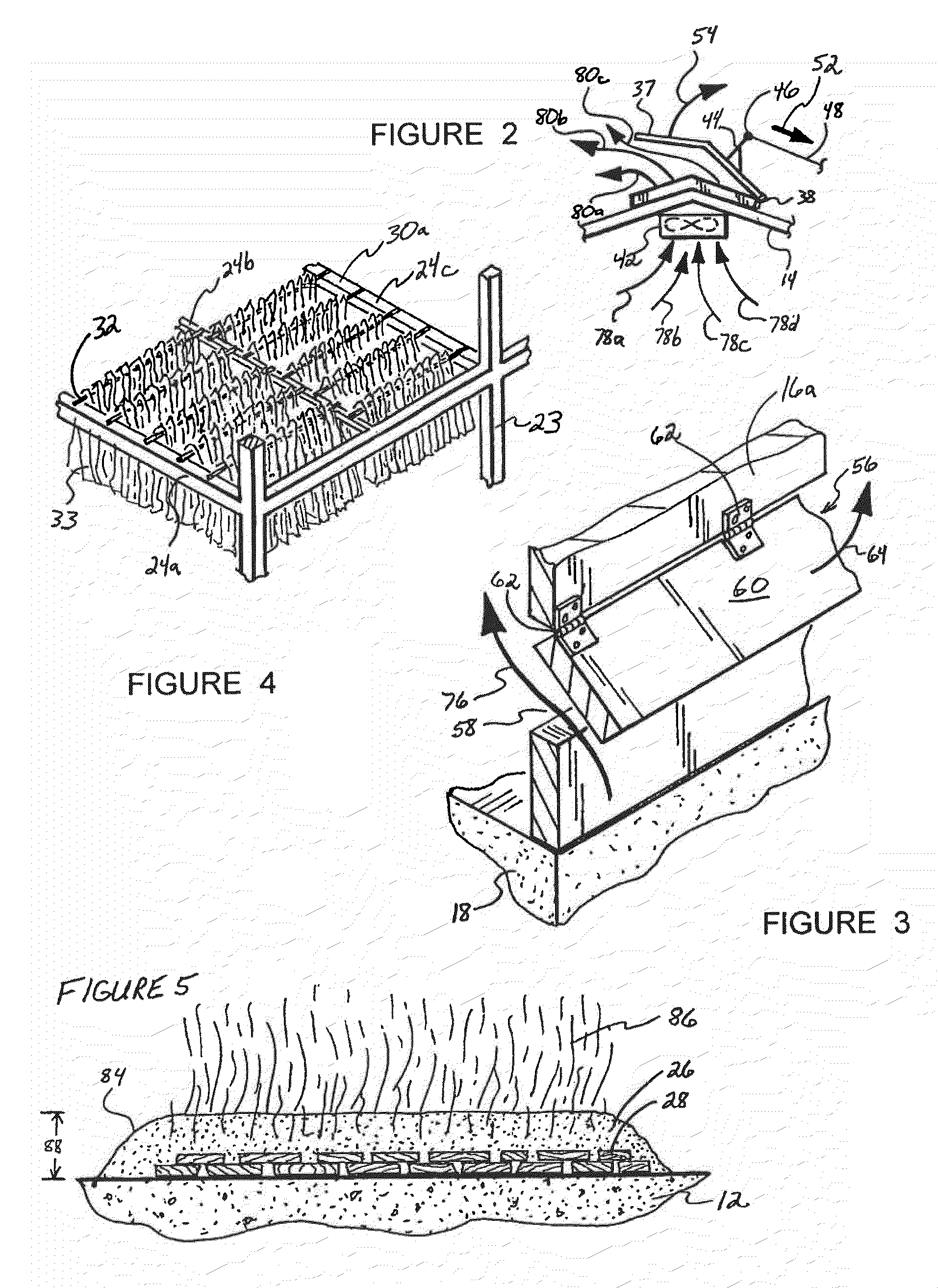

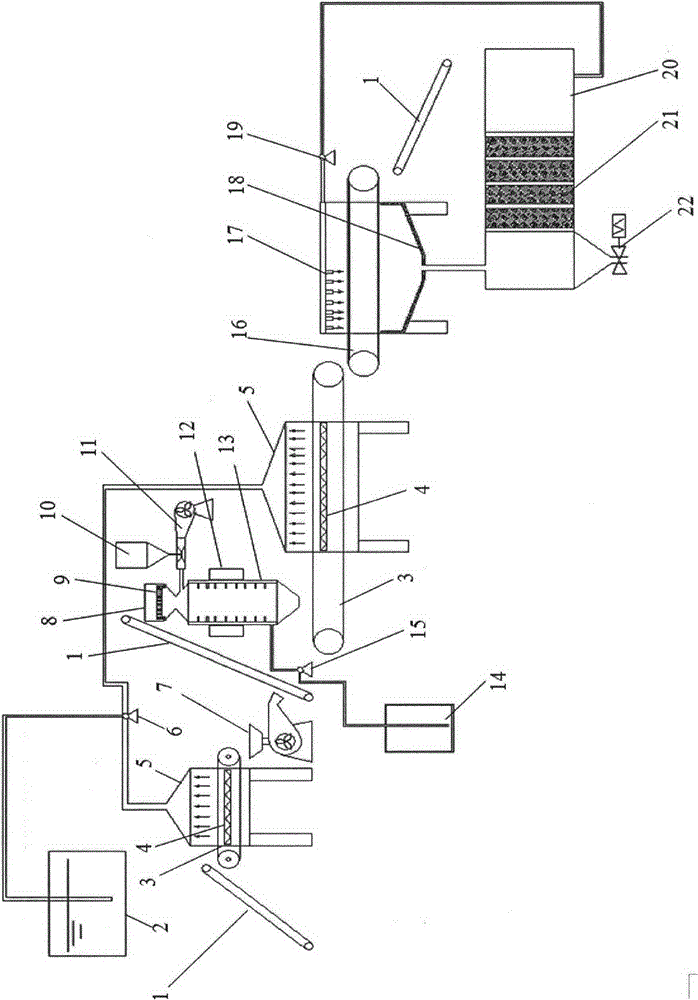

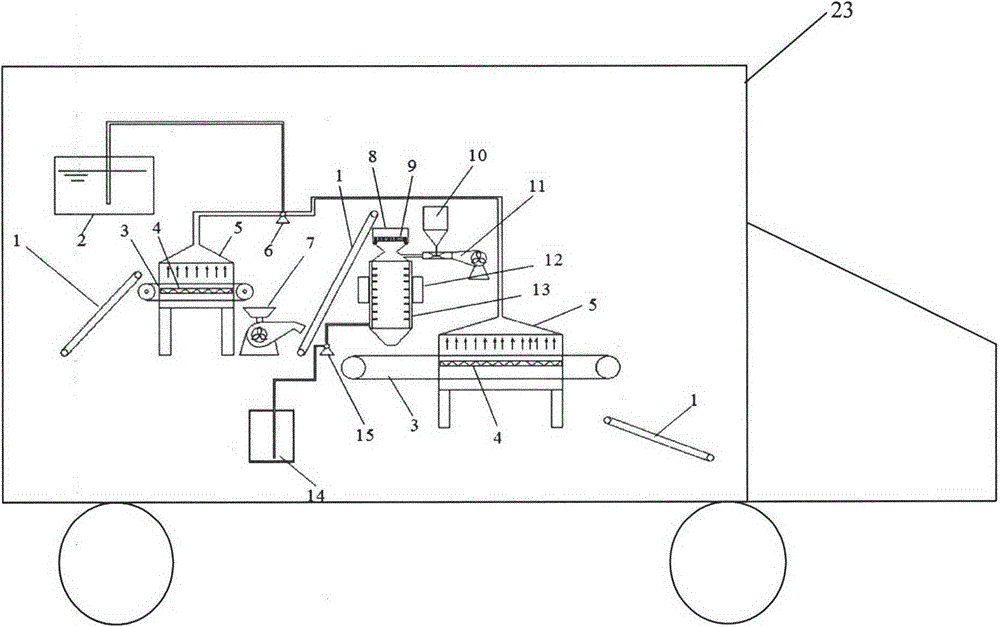

Integrated and comprehensive soil in-place position-changing combined remedying equipment

ActiveCN105013806AAchieving Heterotopic Continuous Joint RepairImprove repair efficiencyContaminated soil reclamationEnvironmental resistancePeristaltic pump

The invention discloses integrated and comprehensive soil in-place position-changing combined remedying equipment, and belongs to the technical field of soil remedying. The equipment mainly comprises feeding and discharging machines, heating baking channels, conveying belts, a vacuum pump, a smashing device, a mixer, a solid chemical adding tank, a Venturi conveying pump, an ultrasonic atomizer, a peristaltic pump, a liquid chemical storage tank, a drip washing device, an activated carbon adsorption purification tank, a mud discharging electromagnetic valve and an absorbent storage tank. The modularized design is adopted for the whole set of remedying equipment, flexible matching and combining can be performed according to different types of polluted soil to be remedied, and therefore the cost is lowered. The whole set of equipment can be installed on a trailer to achieve moving operation. The equipment has the multiple remedying functions of thermal desorption treatment, chemical oxidation / restoration, chemical drip washing and others, can achieve in-place position-changing combined remedying on soil containing organic pollutants and heavy metal combined pollution, and is high in remedying efficiency, wide in range, free of harmful gas emissions, safe and environmentally friendly.

Owner:南京康地环保科技有限公司

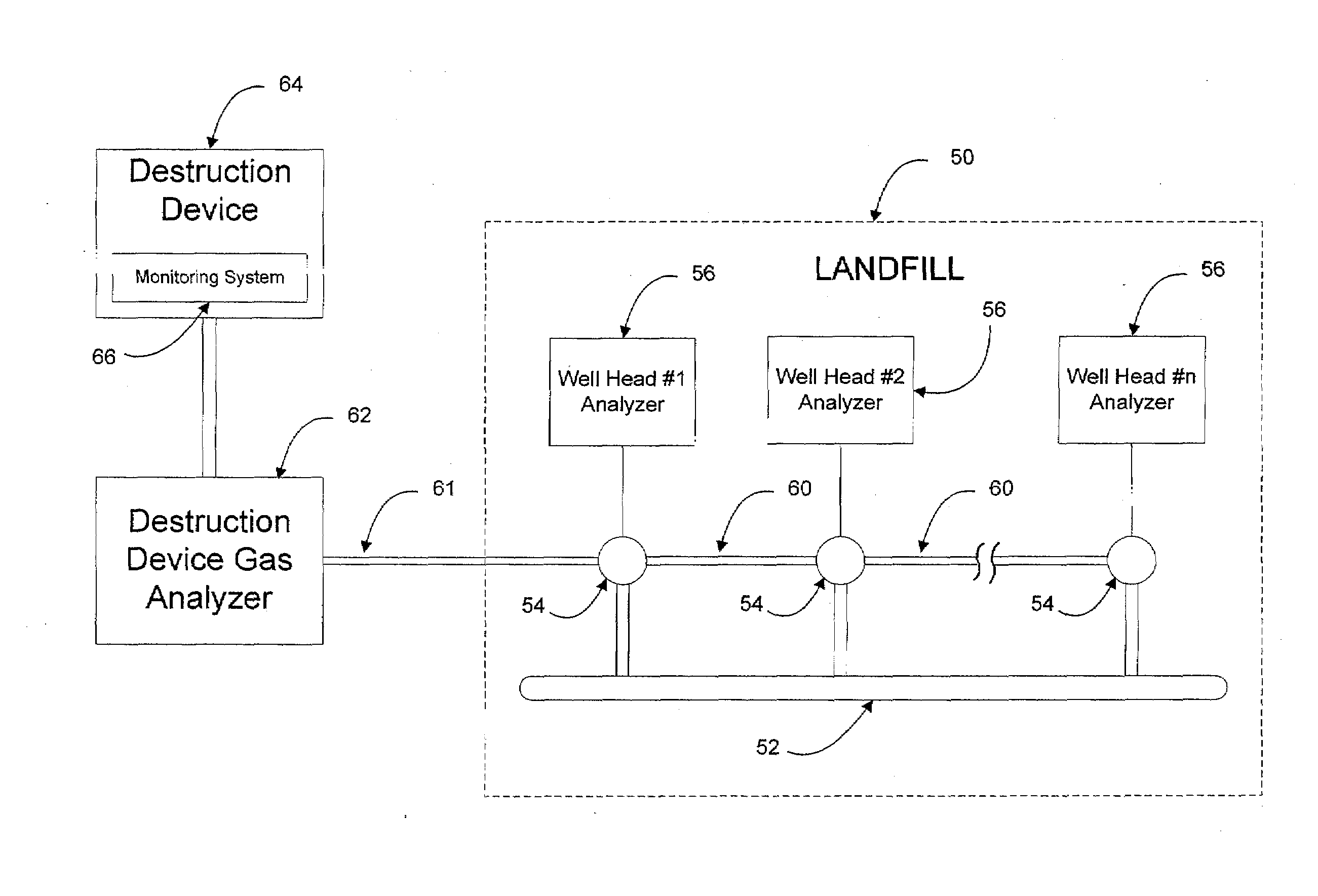

System and methods for assisting businesses in compliance with gas emissions requirements

ActiveUS20070224085A1More confidenceGreat confidenceCombination devicesSampled-variable control systemsData miningAtmosphere

A system and method for calculating a value indicative of the amount of an undesirable constituent of a volatile gas stream that is removed from the atmosphere. Data received at a higher sampling rate is subjected to a plurality of validation processes and data that is determined to be faulty is then quarantined. Quarantined data can be replaced, however, an audit trail is generated to indicate what data has been replaced and the underlying rationale for the replacement data.

Owner:ECOTEC SOLUTIONS

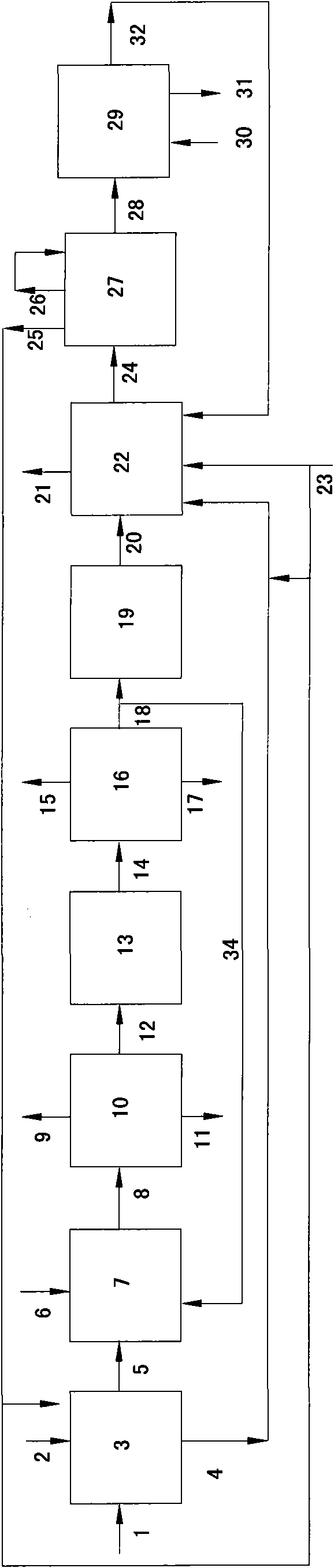

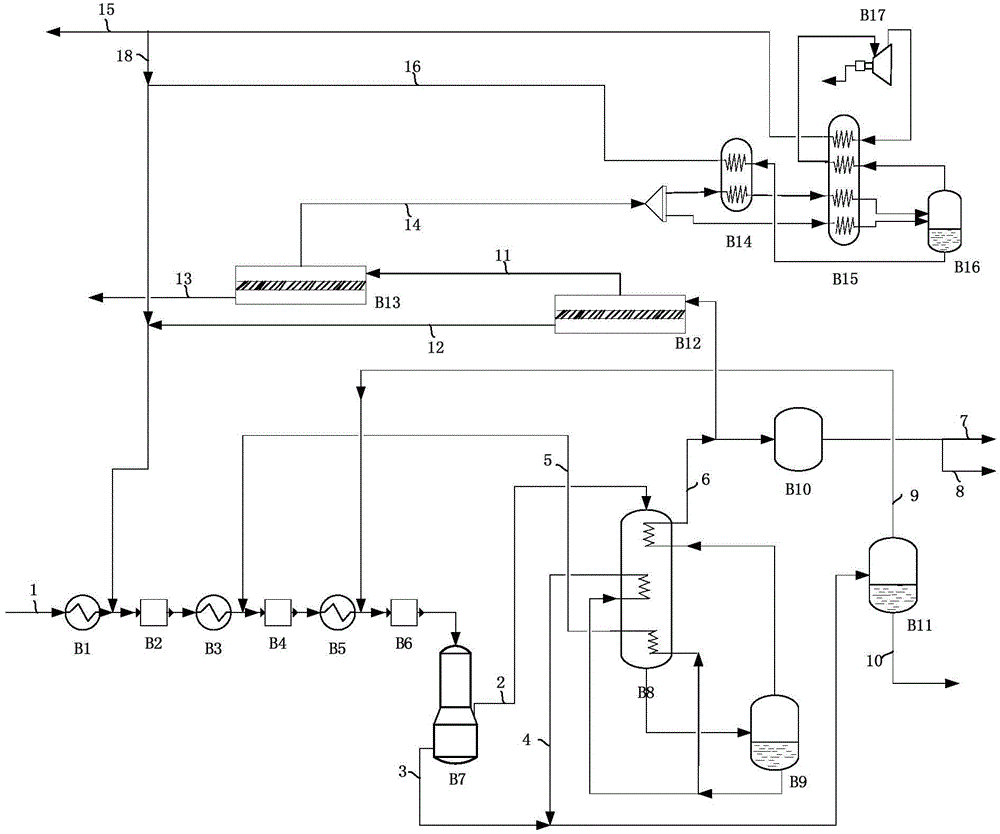

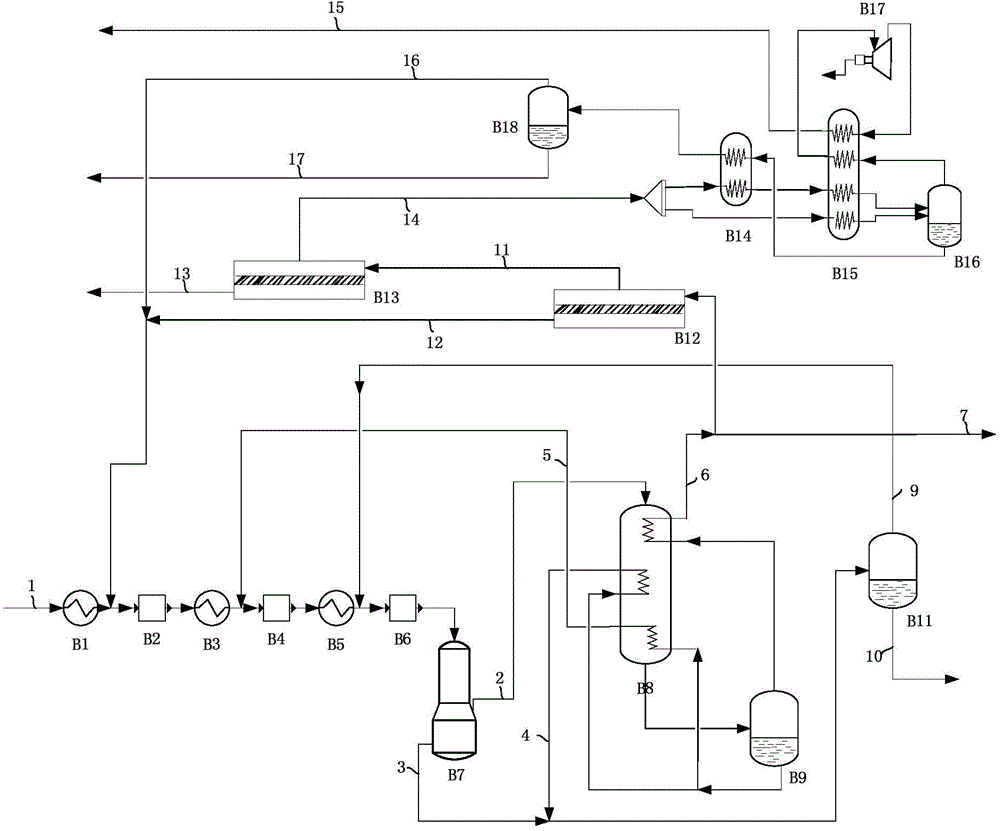

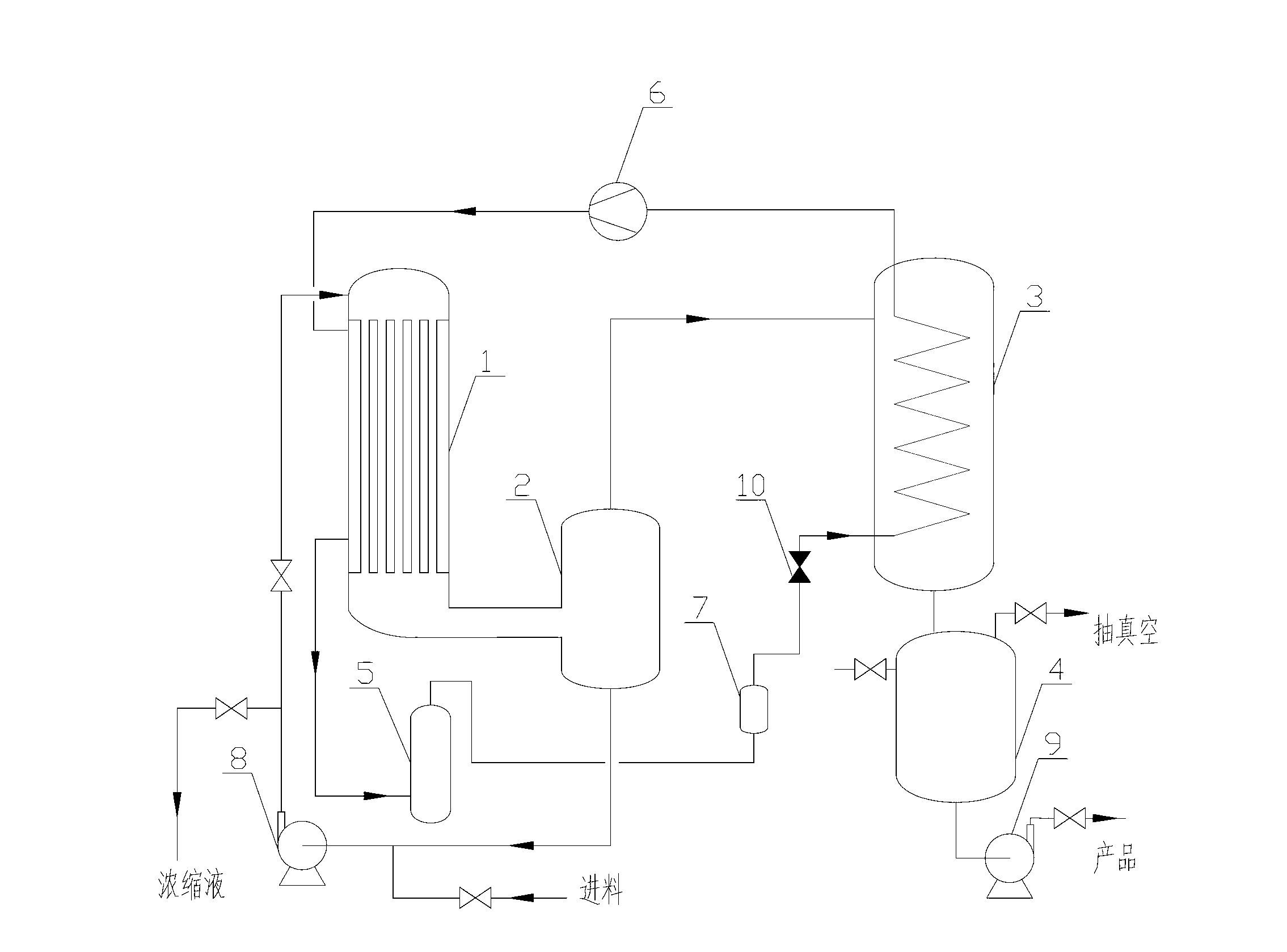

Method for recovering exhaust gas according to polyolefin gas phase method

ActiveCN104923029AHigh recovery rateHigh purityNitrogen purification/separationSolidificationRecovery methodPolyolefin

The invention relates to a method for recovering exhaust gas according to the polyolefin gas phase method. The method for recovering the exhaust gas comprises the following steps: 1) compression, condensation and separation steps are carried out; 2) after the compression, condensation and separation steps, gas enters a heat exchanger to be subjected to cryogenic separation; 3) compressed and condensed liquid and liquid subjected to cryogenic separation are subjected to gas-liquid separation through a separation tank, and after the flash evaporation, light component gas flows to a compressor to be recycled; 4) after cryogenic separation, part of uncondensed gas enters a membrane separation device to enable hydrocarbons to be further recovered; 5) after membrane separation, hydrocarbon-rich phase gas returns back to the compressor to be recycled, hydrogen-deficient phase gas flows to an unpowered expansion refrigeration device to enable hydrocarbons to be recovered, and obtained high-purity nitrogen is used as supplementation gas for sweeping gas of a product receiving bin or a degassing bin. According to the method for recovering the exhaust gas, unreacted monomers can be effectively recovered, the gas emission can be reduced, the total utilization of the monomers can be increased, the gas consumption amount of the sweeping gas can be reduced, the cost can be reduced, the power of the compressor can be reduced, and the energy consumption of the heat exchanger can be reduced.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD

Gas turbine combustor, gas turbine, and jet engine

InactiveUS6973790B2Avoid resonanceReduce oscillationBurnersContinuous combustion chamberJet engineCombustor

For the purpose of reduced NOx gas emission, a gas turbine engine comprises a cylinder having a combustion region inside of the cylinder; a resonator having a cavity and provided around the surface of the cylinder and sound absorption holes formed on the cylinder and having opening ends on the cylinder.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

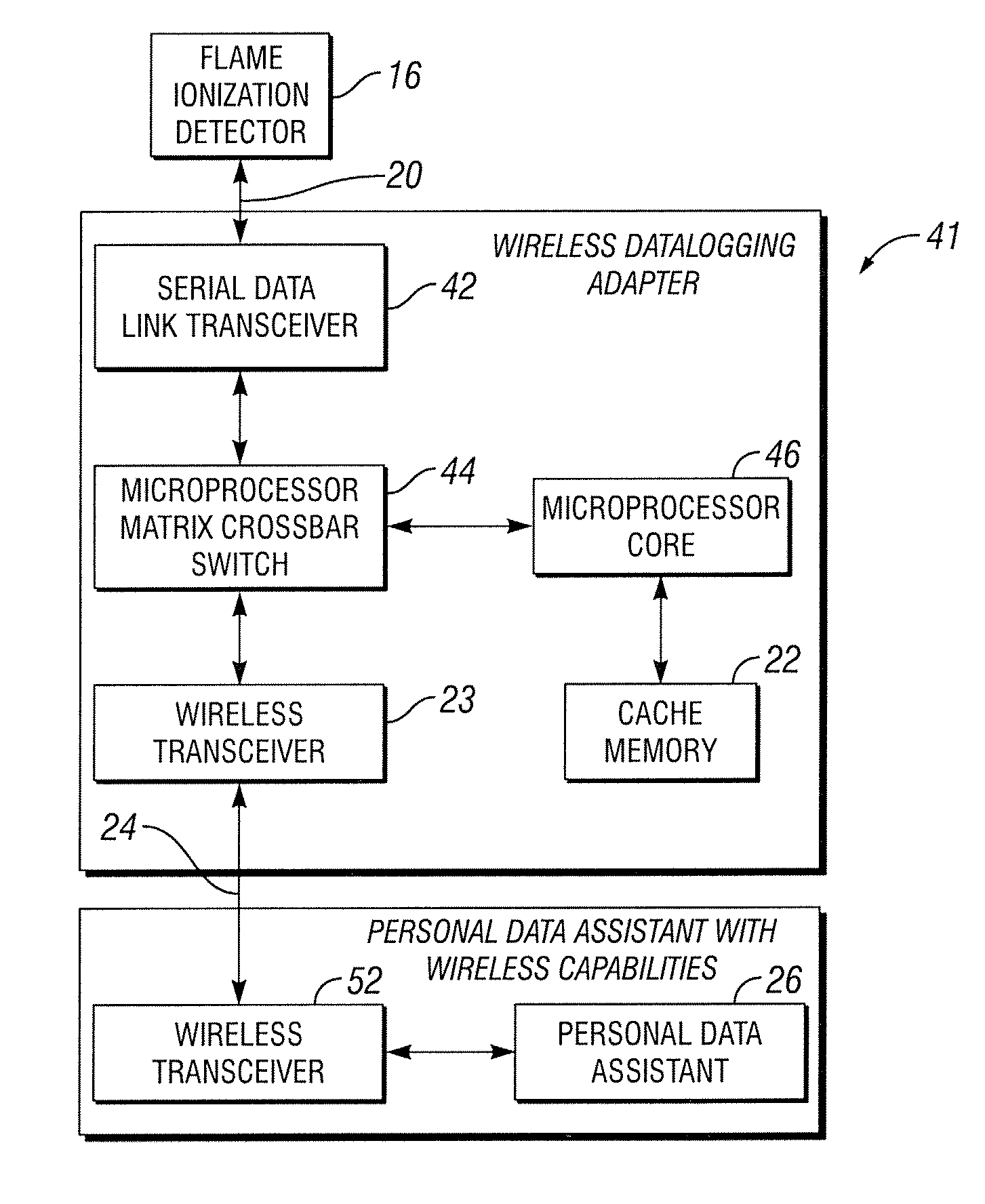

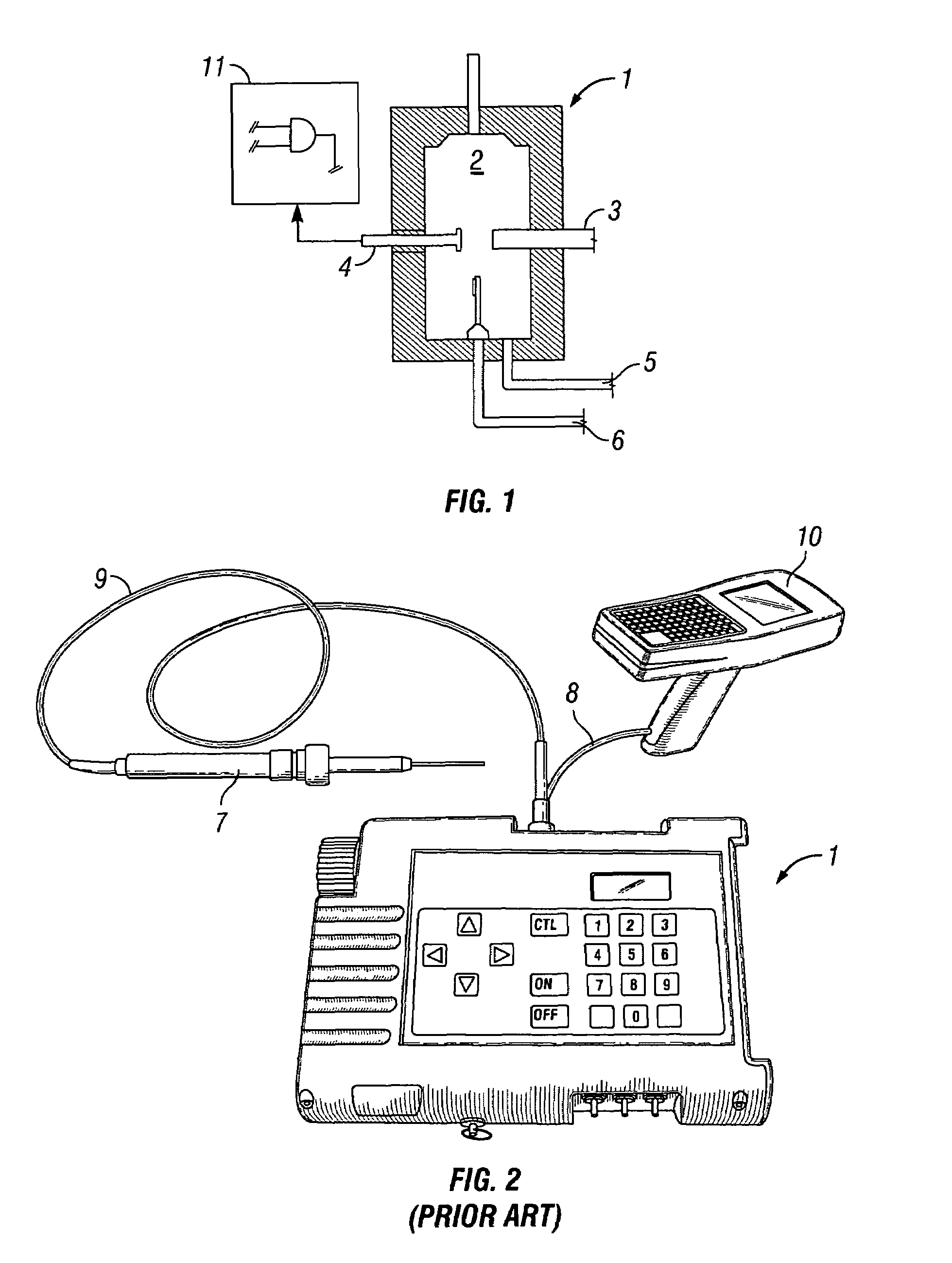

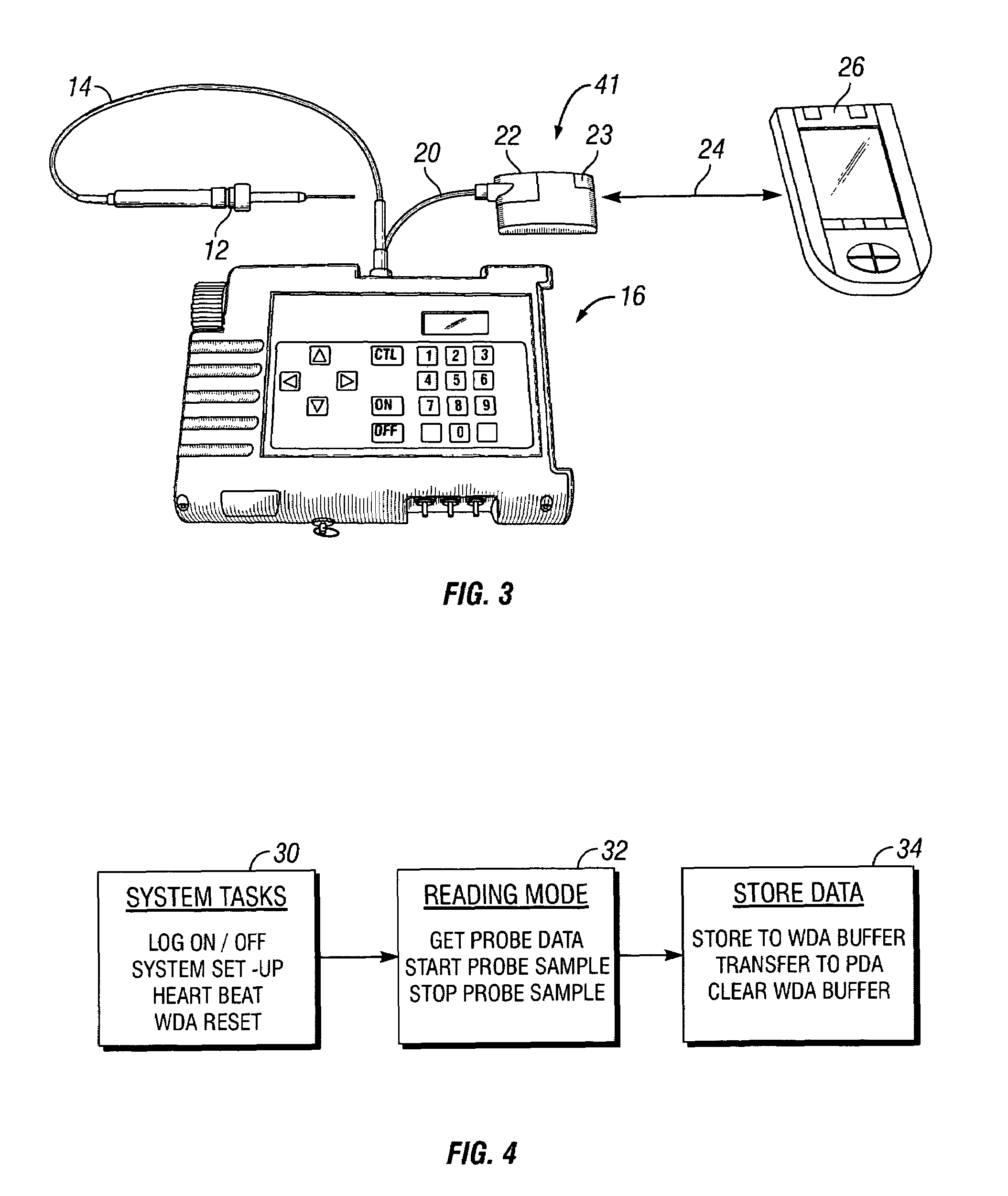

Apparatus and method for storing and transporting data related to vapor emissions and measurements thereof

ActiveUS7369945B2Data augmentationImprove reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectric signal transmission systemsThermodynamicsWireless data

Owner:TMX2

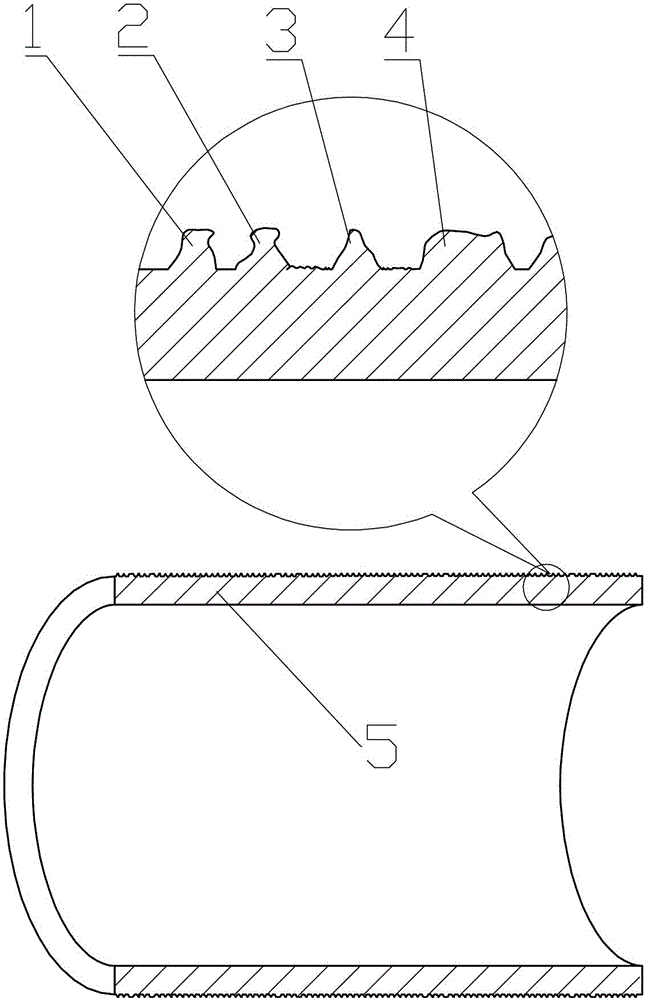

Light-weight engine cylinder sleeve of passenger vehicle and production method of light-weight engine cylinder sleeve

ActiveCN104595050AImprove wear resistanceImprove the anti-friction performance and prolong the service life of the cylinder linerCylinder headsFoundry mouldsCombustion chamberBlack spot

The invention belongs to a light-weight engine cylinder sleeve of a passenger vehicle and a production method of the light-weight engine cylinder sleeve. Black spots are distributed on the outer circular surface of the cylinder sleeve, wherein the shapes of the black spots comprise a dumbbell shape, a positive frustum shape, a worm shape and an olecranon shape; the black spots in the four shapes are randomly distributed on the outer circular surface of the cylinder sleeve; the black spots are 0.25-1.1mm in height. The black points of the cylinder sleeve are only 0.25-1.1mm; the blank cooling speed in the centrifugal casting process of the cylinder sleeve is obviously reduced, thereby obviously improving a metallographic structure, improving the friction resistance of the cylinder sleeve and prolonging the service life of the cylinder sleeve; meanwhile, the black spots are small in height fluctuation, so that the roundness fluctuation in the process of casting an aluminum cylinder body is remarkable reduced; the possibility that engine oil sneaks into a combustion chamber is reduced; the tail gas emission of the combustion chamber is reduced; by the low-height black spots and the excellent metallographic structure, the wall thickness of the cylinder sleeve is reduced by 1mm; the cylinder center distance of the engine cylinder sleeve is reduced by over 2mm.

Owner:ZYNP GRP +1

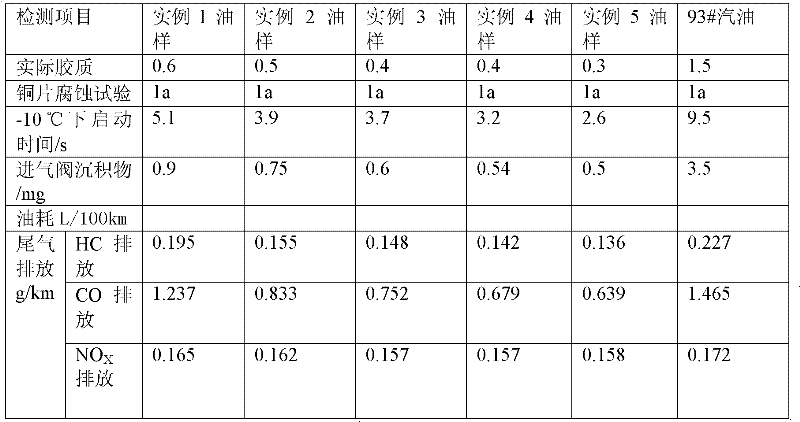

Gasoline compound additive

ActiveCN102643691AImprove detergencyImprove antioxidant capacityLiquid carbonaceous fuelsFuel additivesEngineeringFuel oil

The invention provides a multifunctional gasoline compound additive which is capable of reducing fuel consumption and decreasing the pollution caused by tail gas emission. The additive comprises a gasoline cleaning agent, a combustion improver, a low temperature start improving agent, an antiknock agent, an anti-oxidizing and anti-gum agent and a metal corrosion inhibitor. By adopting the gasoline compound additive, the cleanness, oxidation resistance and anti-corrosion performance of gasoline can be improved; and meanwhile, the combustion performance of fuel oil can be improved, the fuel consumption is reduced, and the automobile tail gas pollutants can be reduced.

Owner:山东京博众诚清洁能源有限公司

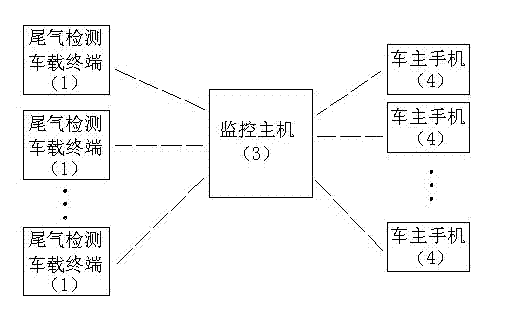

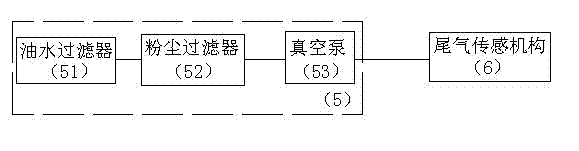

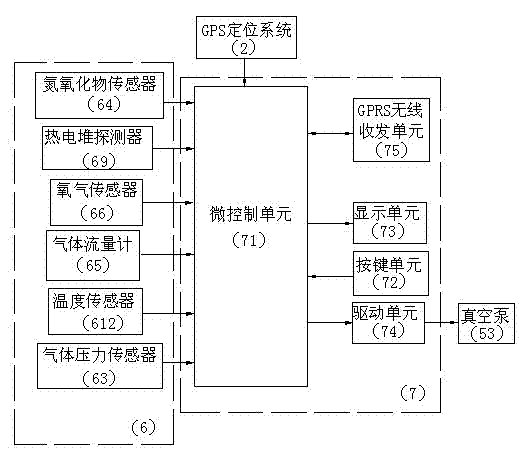

System and method for remotely monitoring automobile tail gas

InactiveCN102778537AQuality improvementGood shock protectionMaterial analysisElectricityGps positioning system

The invention relates to a system and a method for remotely monitoring automobile tail gas. The system comprises a monitoring main machine, an automobile owner mobile phone, a tail gas detection vehicle-mounted terminal and a global position system (GPS), wherein the tail gas detection vehicle-mounted terminal and the GPS are installed on an automobile. The tail gas detection vehicle-mounted terminal comprises a tail gas sampling mechanism, a tail gas sensing mechanism and tail gas analyzing mechanisms, wherein a gas inlet of the tail gas sampling mechanism is connected with an exhaust pipe, a gas outlet of the tail gas sampling mechanism is connected with an automobile silencer, the tail gas sensing mechanism and the GPS are electrically connected with each tail gas analyzing mechanism, the tail gas analyzing mechanisms are connected with the monitoring machine through a wireless network, and the monitoring main machine is connected with the automobile owner mobile phone through the wireless network. The tail gas detection vehicle-mounted terminal sends tail gas detection data and automobile position data to the far-end monitoring main machine which screens out the automobile exceeding emission level of tail gas and frequently running in urban areas and sends warning and rectification information to the automobile owner mobile phone of the automobile exceeding emission level of tail gas. By means of the system and the method for remotely monitoring the automobile tail gas, real-time monitoring and warning on the automobile tail gas are performed, control to automobile tail gas emission is strengthened, and air quality is ensured to be improved.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

Heat pump type low-temperature evaporating device and method

InactiveCN102698451AEvaporator accessoriesMultiple-effect evaporationSteam condensationChemical separation

The invention relates to a heat pump type low-temperature evaporating device and method, belonging to the technical fields of chemical separation, energy conservation and emission reduction. The method is characterized in that a solvent is evaporated and condensed in the heating circulation process of a heat-carrying medium, so that the aim that a thermosensitive material liquid is evaporated and concentrated or an organic solvent is recovered at the low temperature can be achieved; the heat pump type low-temperature evaporating device mainly comprises a material liquid evaporator, a gas-liquid separator, a secondary steam condenser, a condensate tank, a heat medium storage tank, a heat medium steam compressor, a filter, a material liquid pump, a condensate pump, a throttling device and a pipeline valve, wherein a single-effect or multi-effect falling-film evaporator is used as the material liquid evaporator. The material liquid evaporating temperature is controlled to be within the range of 25-60 DEG C by adjusting the system vacuum degree; and the system heating capacity is controlled to be matched with the evaporation capacity by adjusting the input power of the compressor at the variable frequency. The heat pump type low-temperature evaporating device and method have the beneficial effects and advantages that the gas emission is reduced, so that the environment is protected, and the energy is saved; and furthermore, the active ingredients of the material liquid can be maintained by low-temperature evaporation, equipment is seldom corroded, and a pipeline is not easily blocked, so that the equipment cost is lowered.

Owner:DALIAN UNIV OF TECH

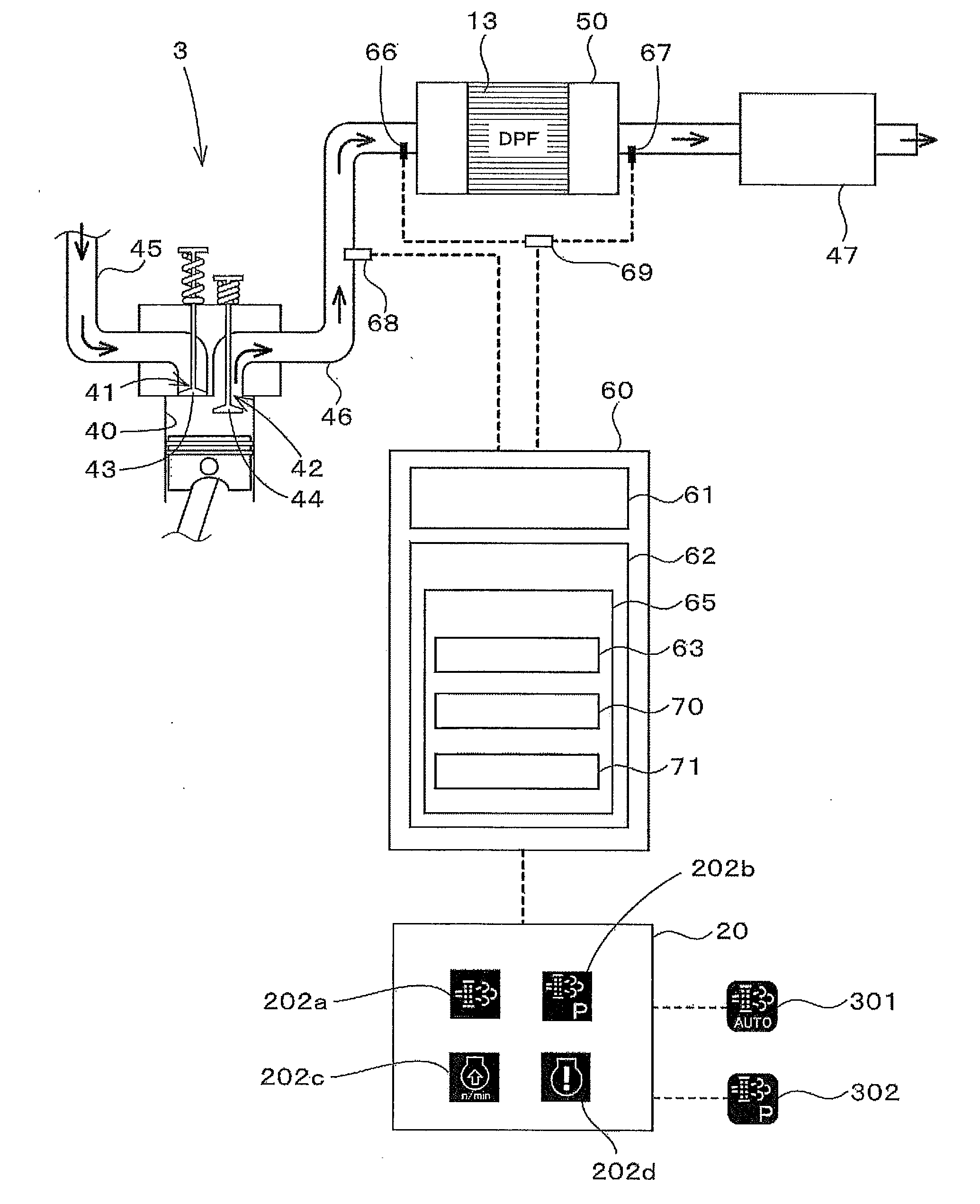

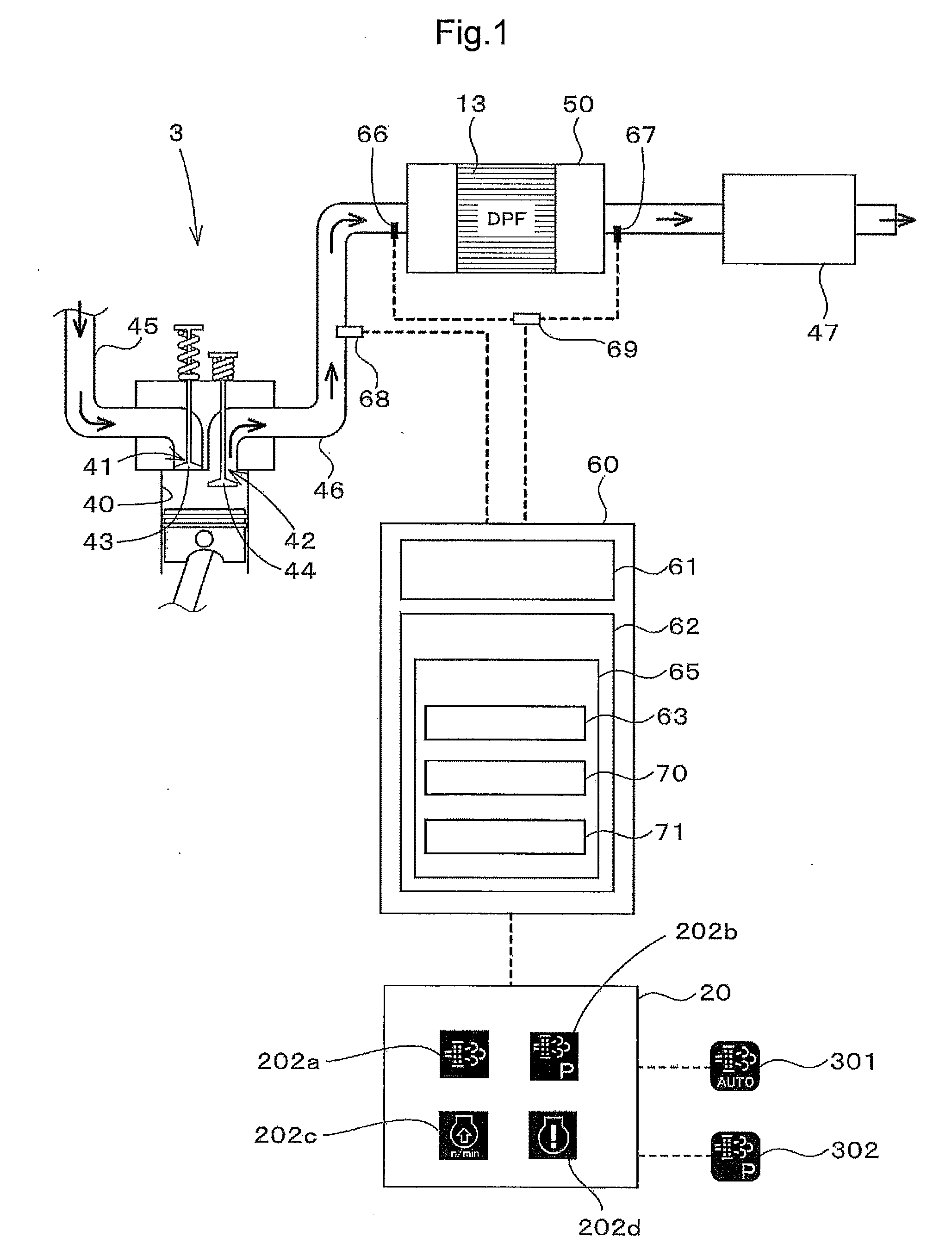

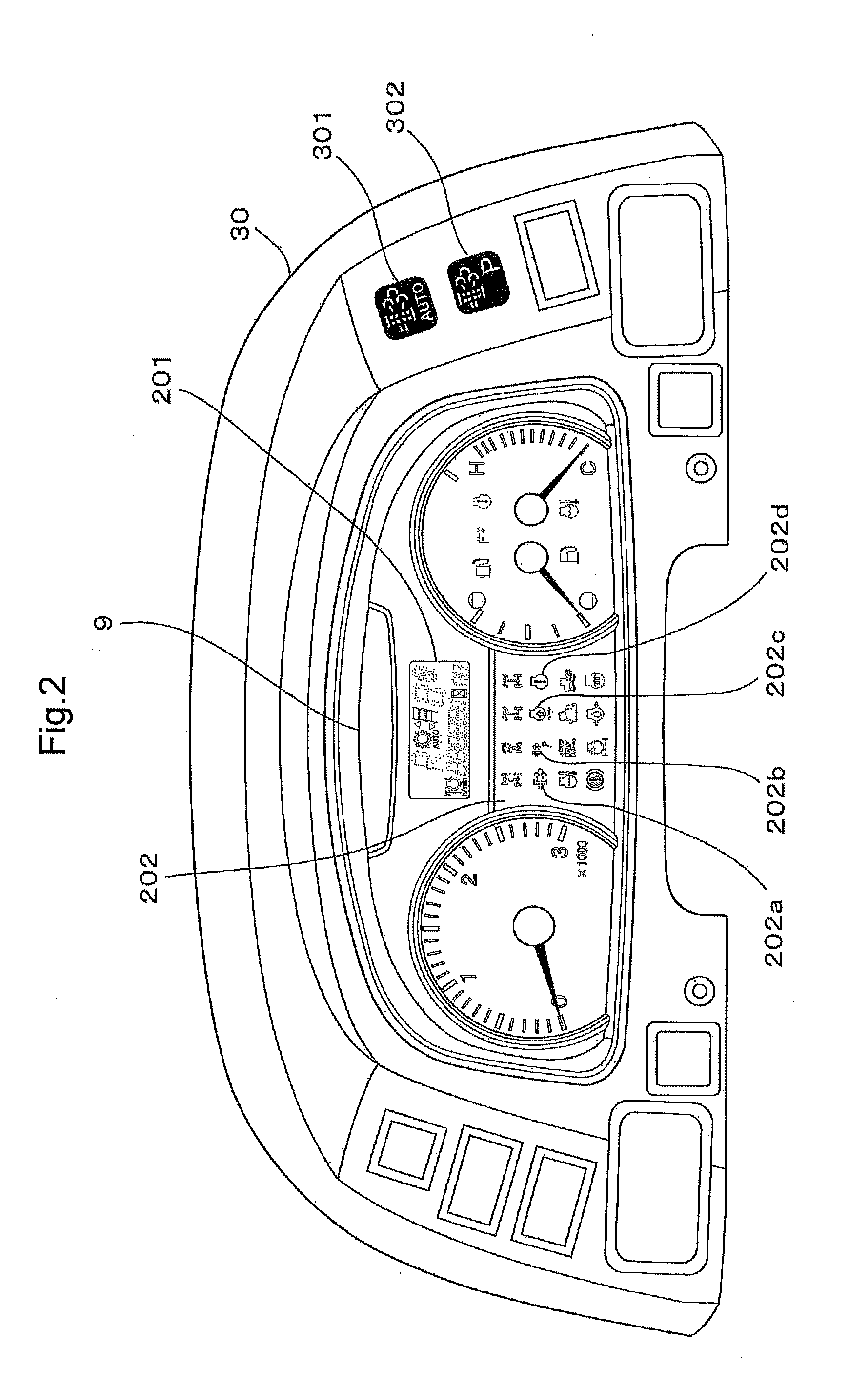

Work Machine

ActiveUS20130133315A1Increase temperatureSimple fashionElectrical controlInternal combustion piston enginesParticulatesProcess engineering

A work machine, comprising:a diesel engine;a gas emission cleaning device having a filter for trapping particulate matter included in gas emissions emitted from the diesel engine; andfilter regenerating means for performing automatic regeneration to automatically combust and eliminate particulate manner that has accumulated in the gas emission cleaning device, when the accumulated amount of the particulate matter has exceeded a predetermined value; wherein the filter regenerating means has automatic-regeneration-allowing means for allowing the automatic regeneration to be carried out by an external command; and, at startup, the automatic-regeneration-allowing means disallows carrying out automatic regeneration.

Owner:KUBOTA LTD

Preparation of waste paper-reinforced regenerative high-density polyethylene composite material

InactiveCN101302312AImprove the level of comprehensive utilizationHigh strengthFiberPollutant emissions

The invention provides a waste paper reinforced recycled high density polyethylene composite material, which is characterized by comprising the following raw materials by mass percentage: 5 to 15 percent of waste paper, 85 to 95 percent of recycled high density polyethylene, 0 to 4 percent of coupling agent and 0 to 10 percent of compatilizer. The waste paper is mixed with the recycled HDPE, the coupling agent and the compatilizer after fiber dispersion, and the mixture is sent into an open dual-roller mixing device for mixing and homogenizing, pressed by a section mold, and then cooled, demoulded and made into the waste paper reinforced recycled high density polyethylene composite material. The waste paper reinforced recycled high density polyethylene composite material not only can fully utilize the waste paper and waste plastics and change the waste into the valuable but also can greatly improve the comprehensive utilization level of waste resources and save a large number of resources, and simultaneously can reduce the environmental pollution caused by mismanagement of waste material resources. Moreover, the waste paper reinforced recycled high density polyethylene composite material has the advantages of simple technique, short flow, low investment, no pollutant emission, energy conservation and low consumption, low cost of the raw materials, good texture and high strength of the composite material obtained, and no harmful gas emission, and is a waste utilization project which is favorable for the country, the people and the enterprises.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com