Integrated and comprehensive soil in-place position-changing combined remedying equipment

A combined restoration and equipment technology, applied in the field of soil restoration, achieves the effects of high restoration efficiency, strong continuity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

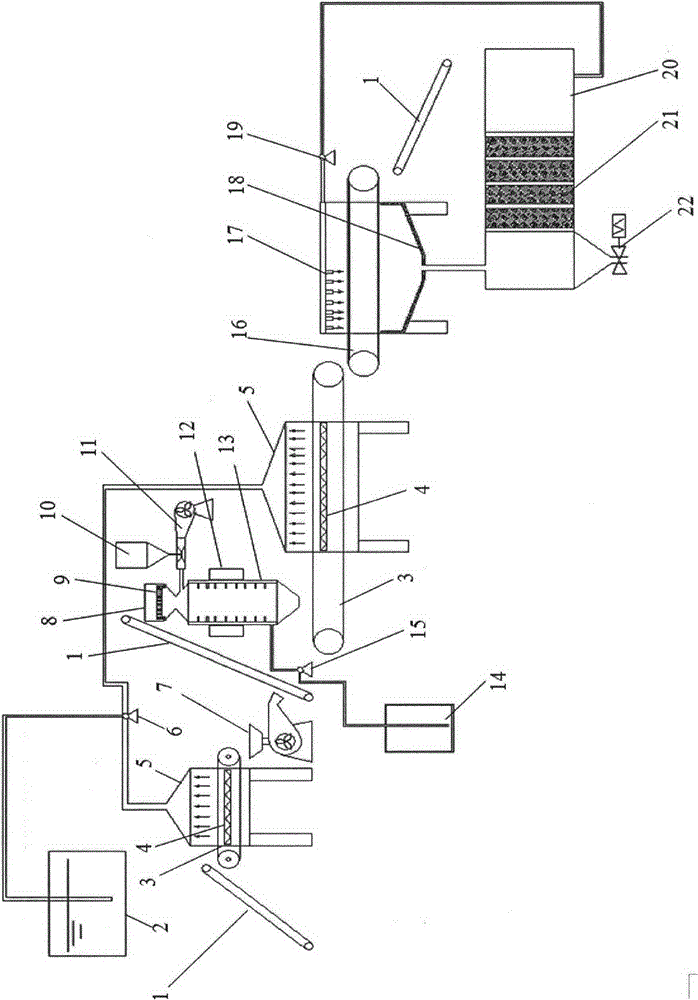

[0027] Such as figure 1 As shown, the integrated and comprehensive soil in situ joint restoration equipment can realize three restoration functions: heat treatment, chemical oxidation / reduction, and chemical leaching, including loading / unloading machine (1), heating and drying tunnel (5), conveying Belt (3), vacuum pump (6), pulverizer (7), mixer (8), solid drug dosing tank (10), Venturi delivery pump (11), ultrasonic nebulizer (12), peristaltic pump ( 15), liquid medicine storage tank (14), rinser (17), activated carbon adsorption purification tank (20), electromagnetic mud discharge valve (22) and absorption filter module (2). Among them, there are 3 sets of loading / unloading machines (1) and conveyor belts (3); 2 sets of heating and drying tunnels (5). The track (16) of the conveyor belt (3) is made of dense corrosion-resistant metal mesh, which can withstand high temperature and high humidity, and is air-permeable and water-permeable; the heating and drying tunnel (5), ex...

Embodiment 2

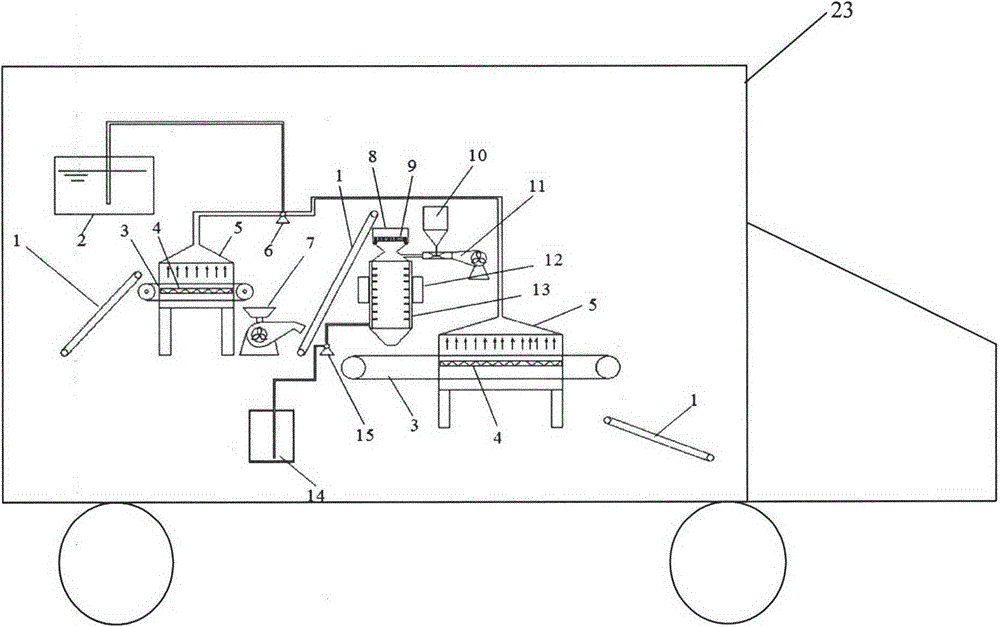

[0030] Such as figure 2 As shown, the integrated and comprehensive soil in situ joint repair equipment can realize two repair functions of heat treatment and chemical oxidation / reduction, including loading / unloading machine (1), heating and drying tunnel (5), conveyor belt (3) , vacuum pump (6), pulverizer (7), mixer (8), solid drug dosing tank (10), Venturi delivery pump (11), ultrasonic nebulizer (12), peristaltic pump (15), liquid Medicament storage tank (14), absorption filter module (2). Among them, there are 3 sets of loading / unloading machines (1), 2 sets of conveyor belts (3) and 2 sets of heating and drying tunnels (5). The whole set of restoration equipment is installed on the trailer (23) for easy movement. Among them, the track material of the conveyor belt (3) is made of dense corrosion-resistant metal mesh, which can withstand high temperature and high humidity, and is breathable and water-permeable; the heating and drying tunnel (5), except the part where the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com