Patents

Literature

6933results about How to "No emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light curing offset printing ink and preparation method thereof

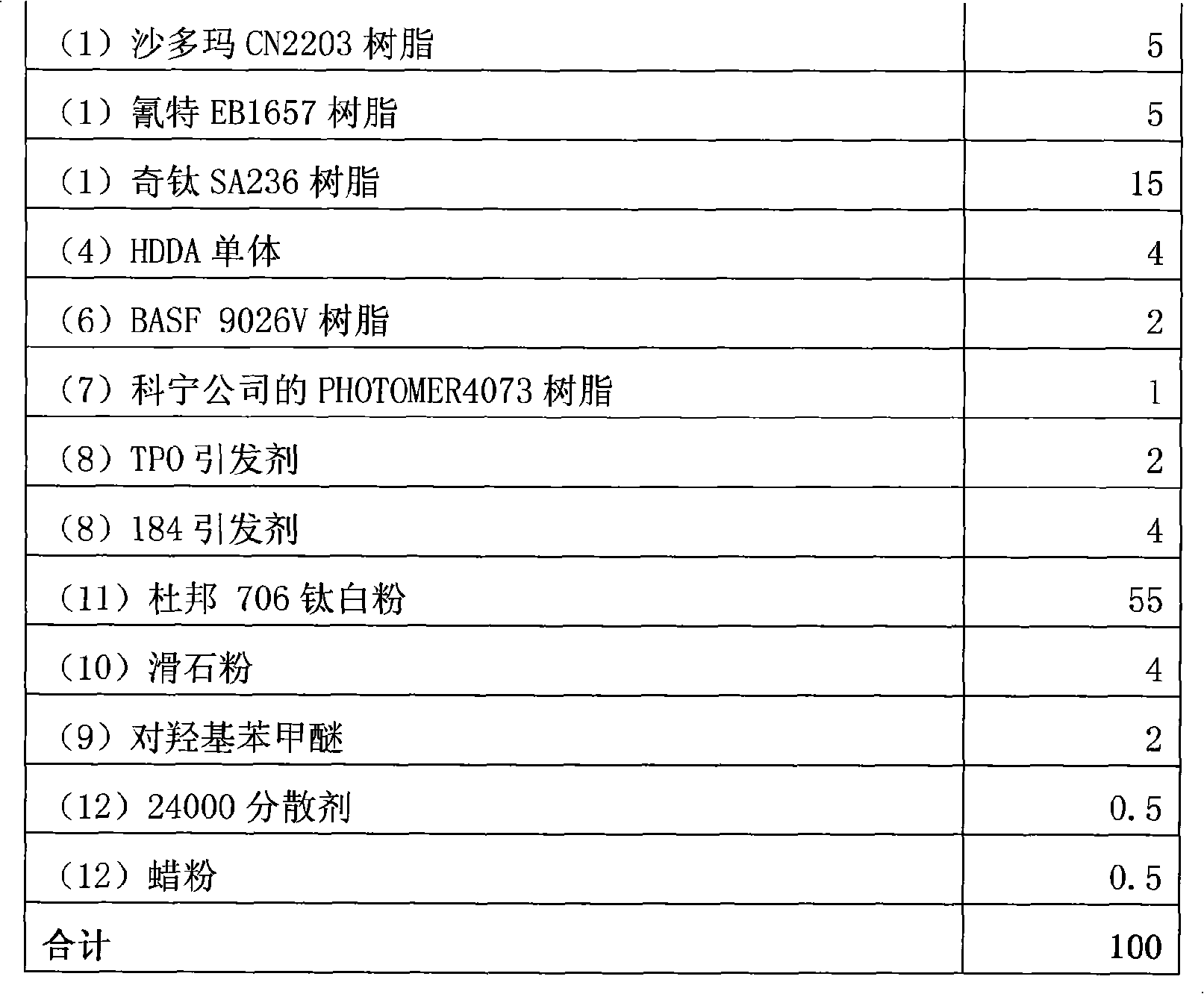

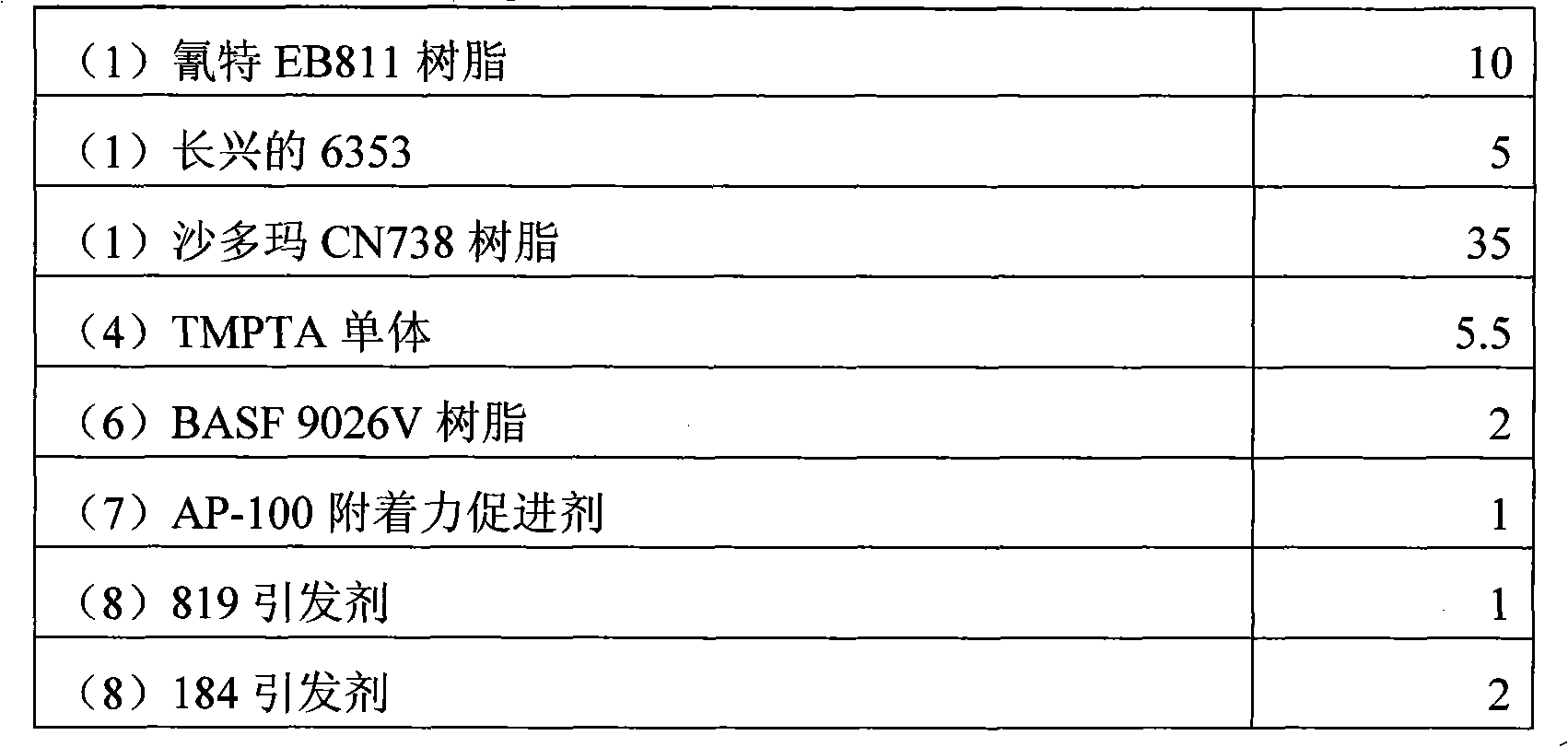

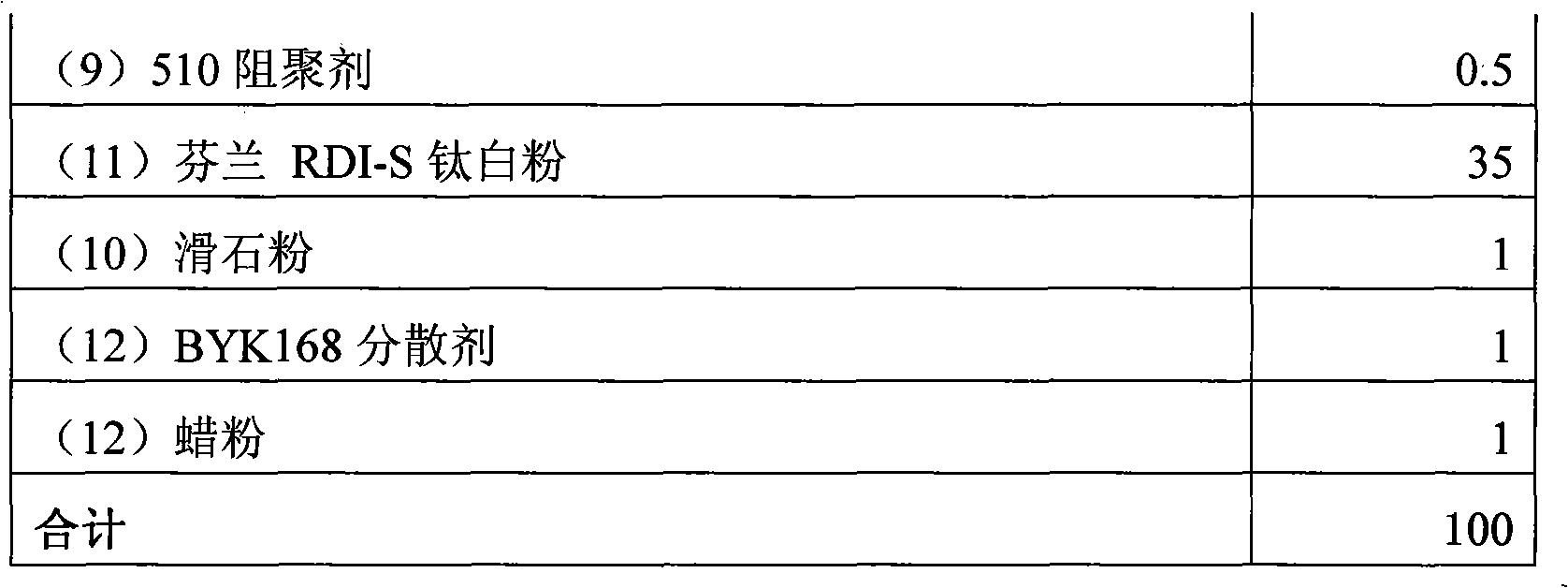

The invention relates to an ultraviolet light curing offset printing ink and a preparation method thereof. The ultraviolet light curing offset printing ink is made of 25.0-50.0% of polyfunctional polyester acrylic resin or polyfunctional chlorinated polyester acrylate, 0.0-15.0% of epoxy acrylate oligopolymer, 0.0-20.0% of polyfunctional urethane acrylate, 0.0-15.0% of difunctional or polyfunctional acrylic monomer, 0.0-20.0% of grinding-type resin, 2.0-10.0% of polyether acrylate modified by nano silicon dioxide, 0.0-5.0% of adhesion promoter, 3.0-5.0% of photoinitiator, 0.1-2.0% of polymerization inhibitor, 0.0-10.0% of filler, 16.0-55.0% of paint or dye and 0.2-5.0% of accessory ingredient. The prepared offset printing ink has high transparency as well as good adhesive attraction and flexility, and can be widely applied to packages printing industry and the printing of various transfer paper.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

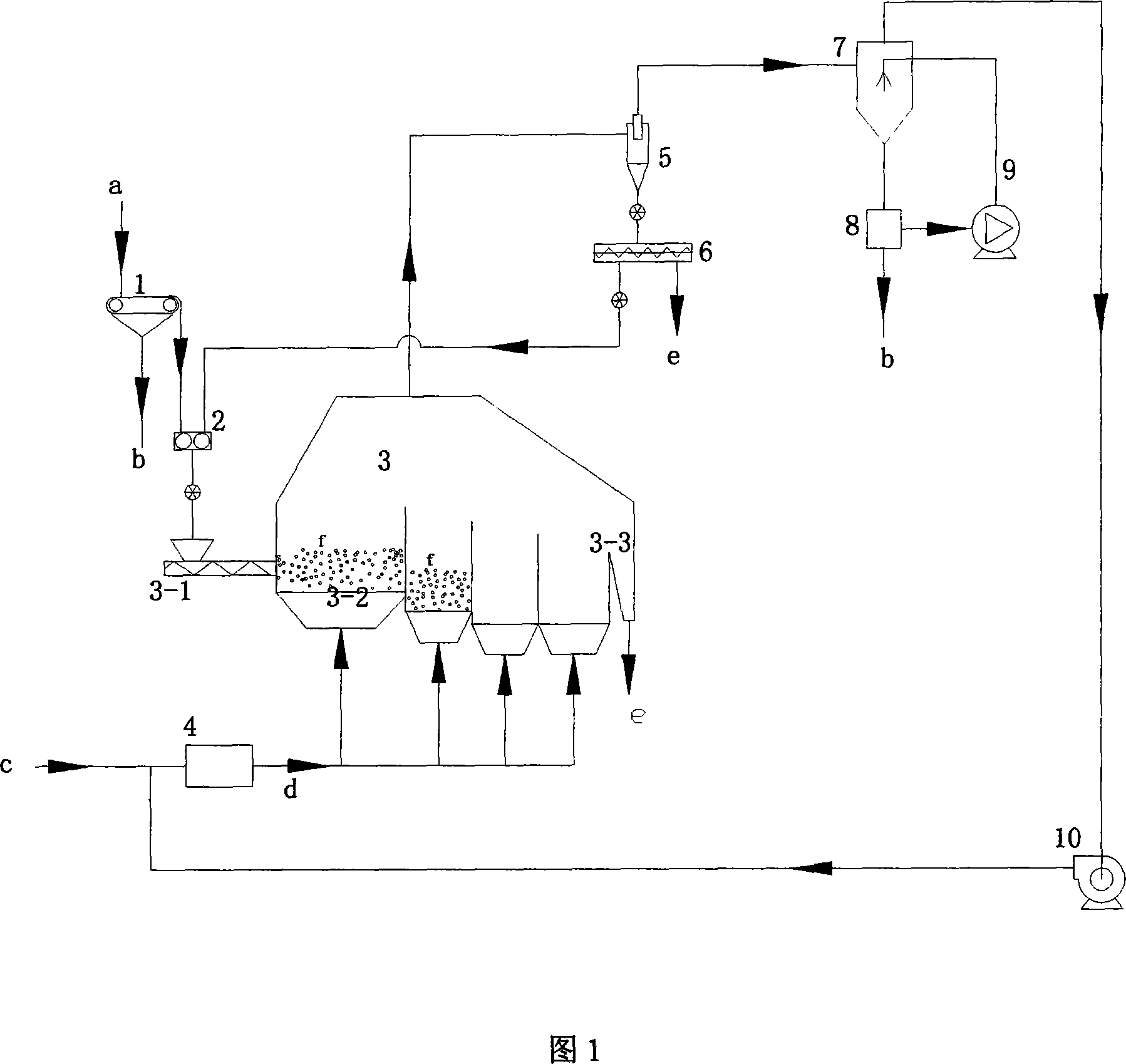

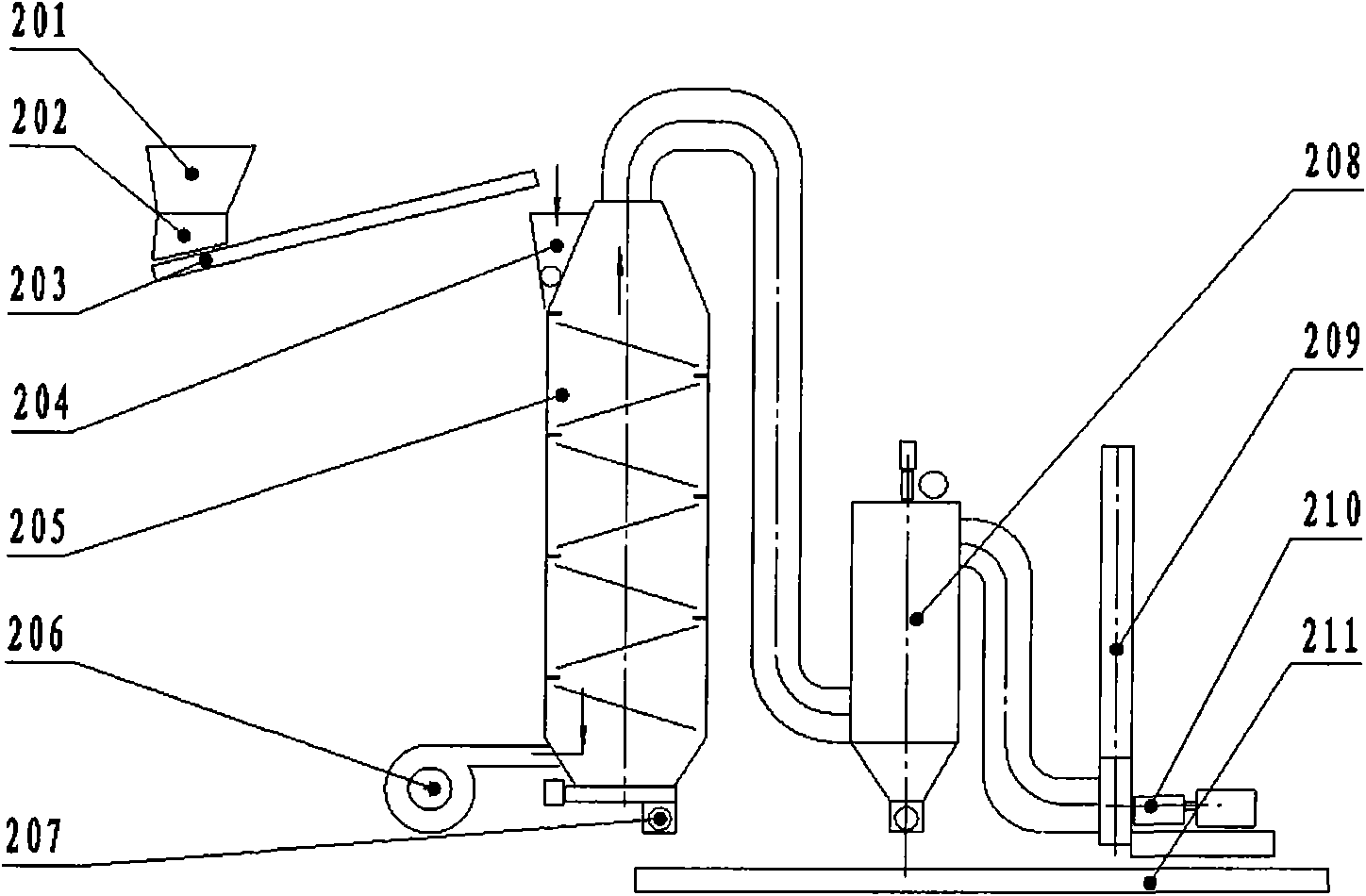

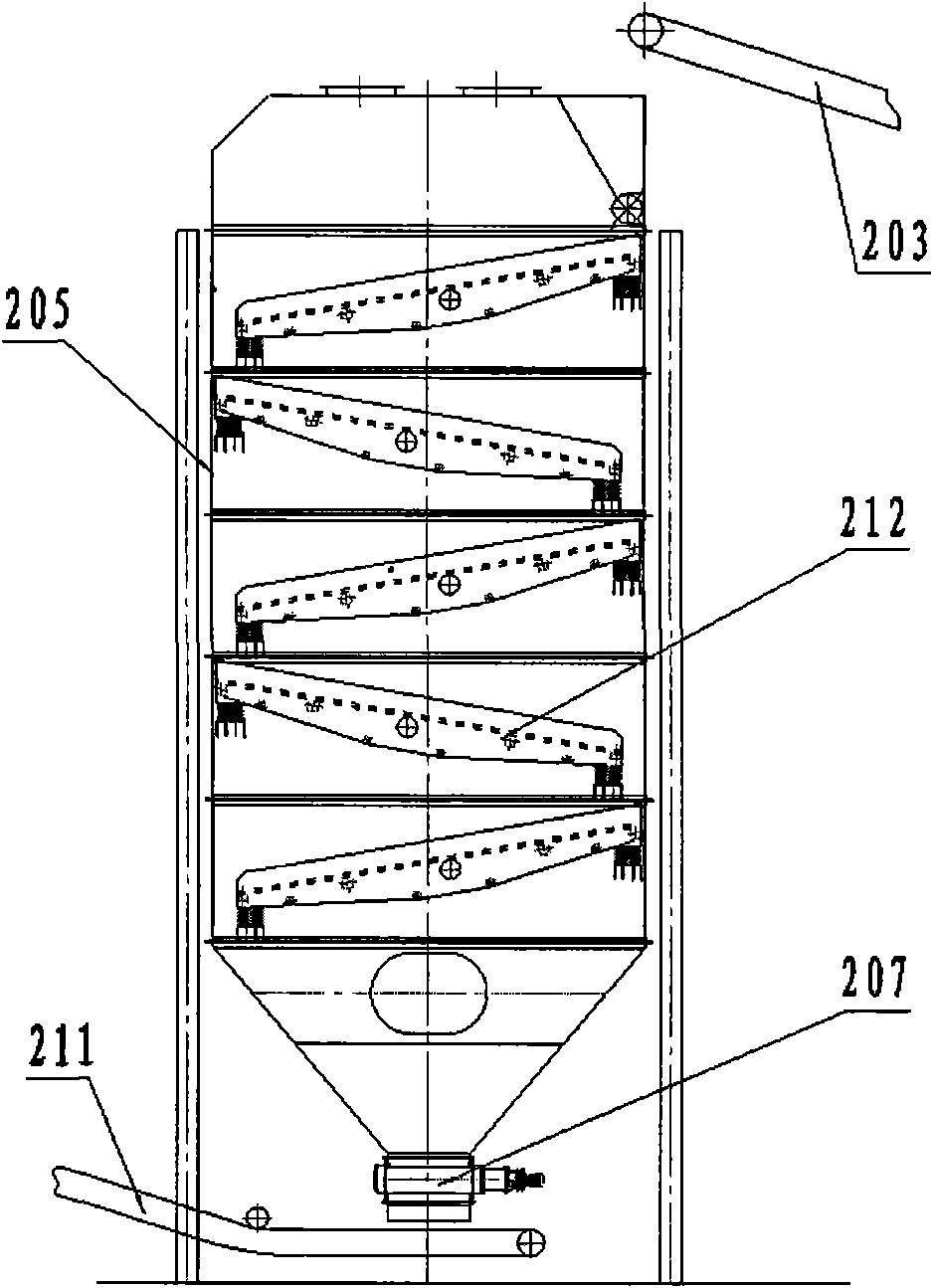

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

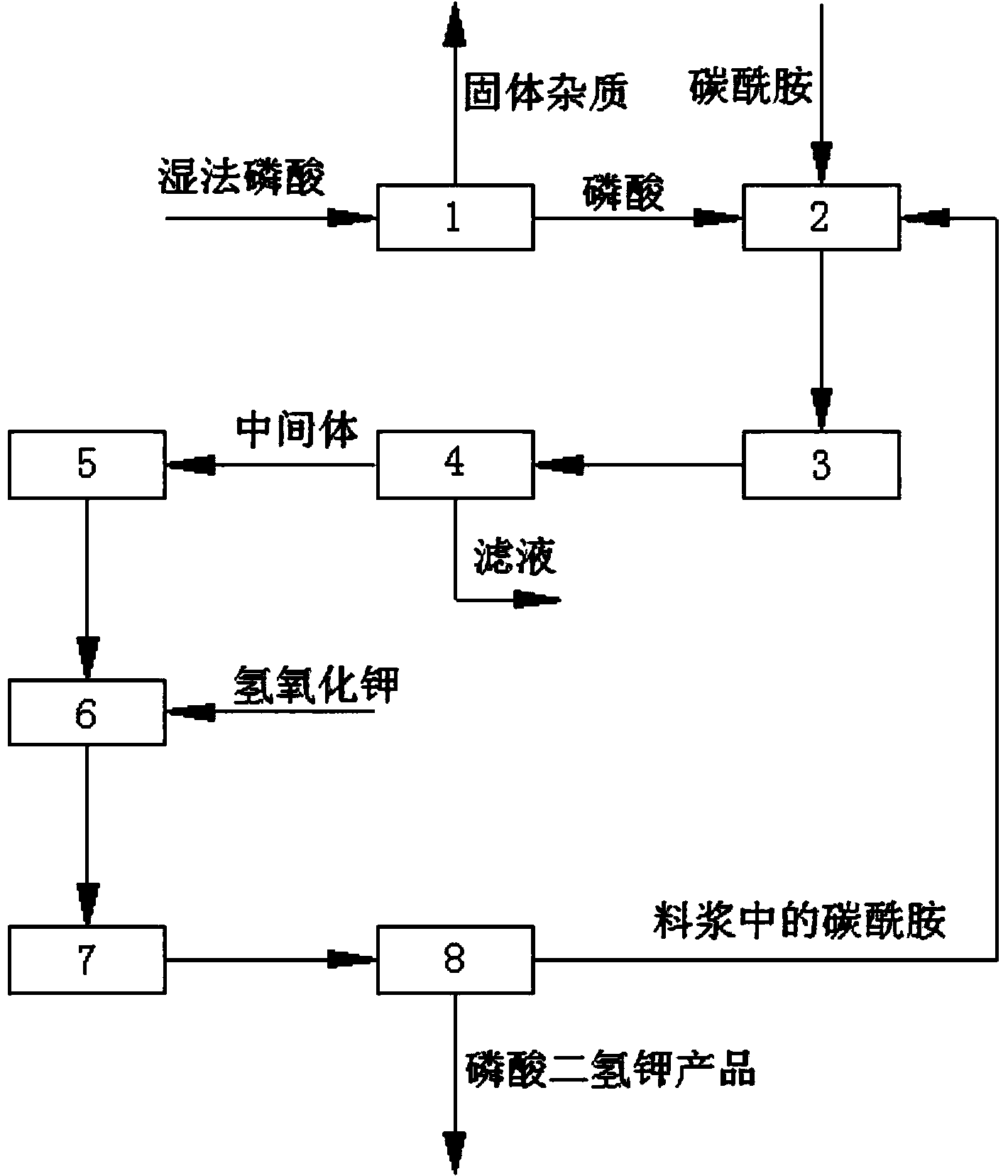

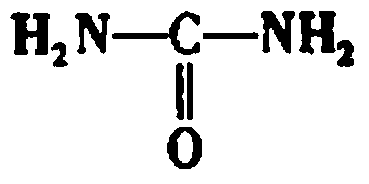

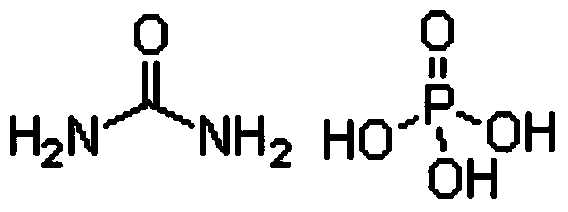

Method for preparing monopotassium phosphate by using wet-process phosphoric acid

InactiveCN103803518AReduce manufacturing costNo pollution in the processPhosphorus compoundsFertilizer mixturesEnvironmental resistanceHigh energy

The invention discloses a method for preparing monopotassium phosphate by using wet-process phosphoric acid. The method comprises the following steps: reacting carbonyl diamide and wet-process phosphoric acid to obtain an intermediate; reacting the intermediate and potassium hydroxide to prepare a monopotassium phosphate product. The method has the advantages of short process route, low energy consumption, stable product quality, low production cost, convenience in operation and safety in production. A side product, namely, slurry can be recycled completely, an entire production process is environment-friendly, clean and free from pollution, and no waste gas, waste water or waste residues are discharged. A response is made to the policy calling of energy saving, emission reduction and clean production, the problems of complex process, instable product quality, high energy consumption and environmental pollution existing in the prior art are solved, and the purity of the obtained monopotassium phosphate product is more than or equal to 98 percent.

Owner:GUIYANG KAILIN FERTILIZER CO LTD +1

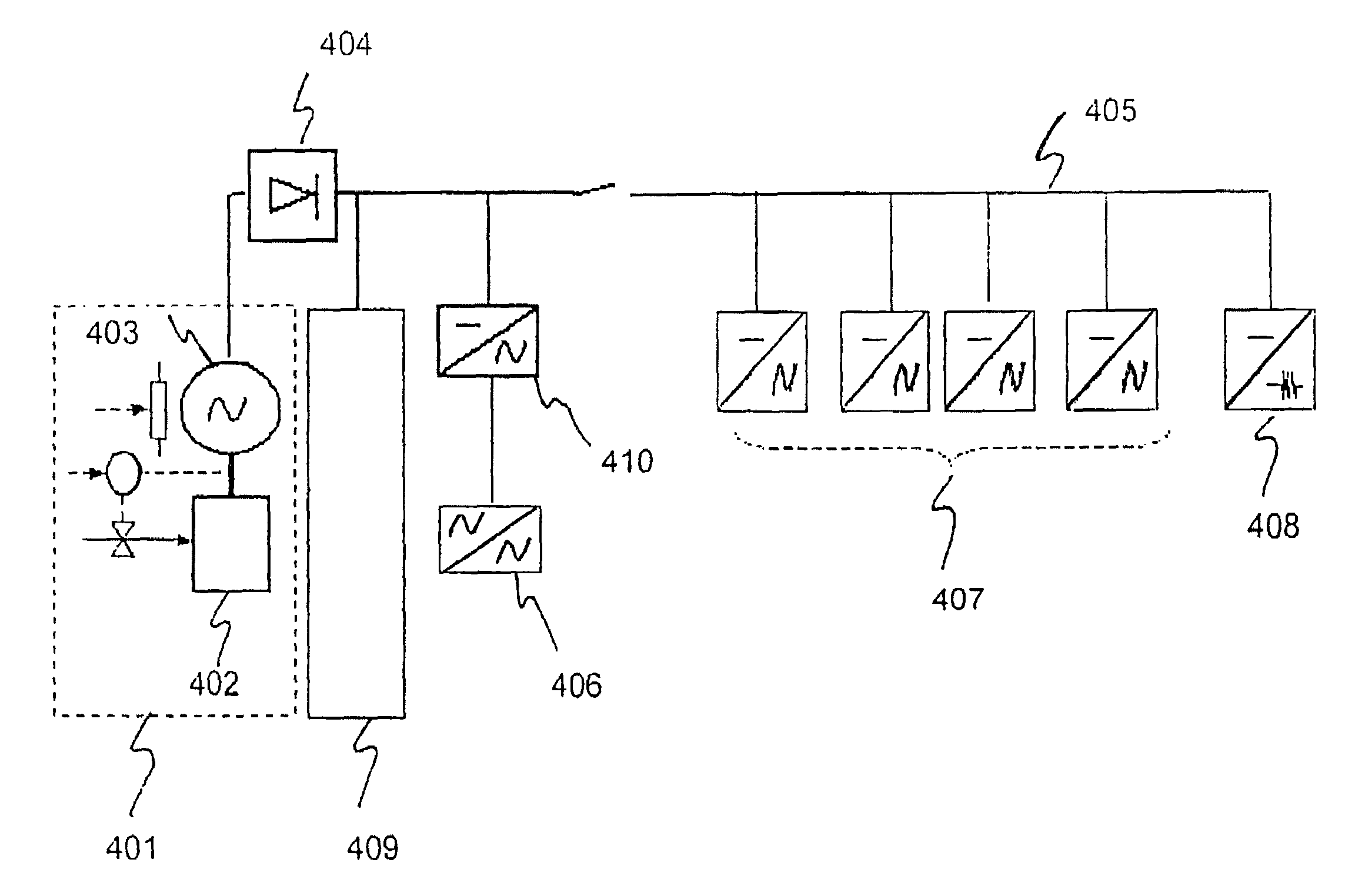

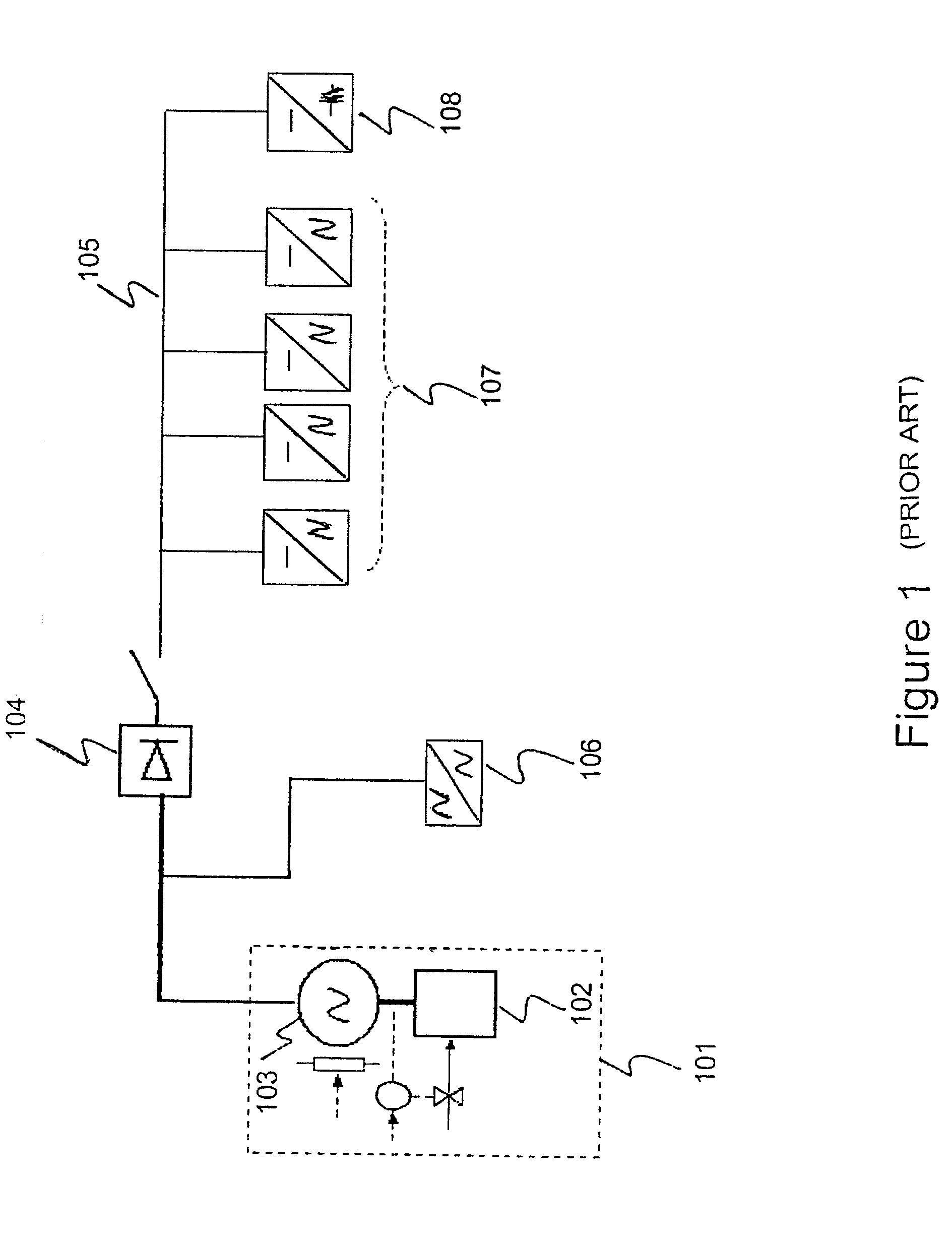

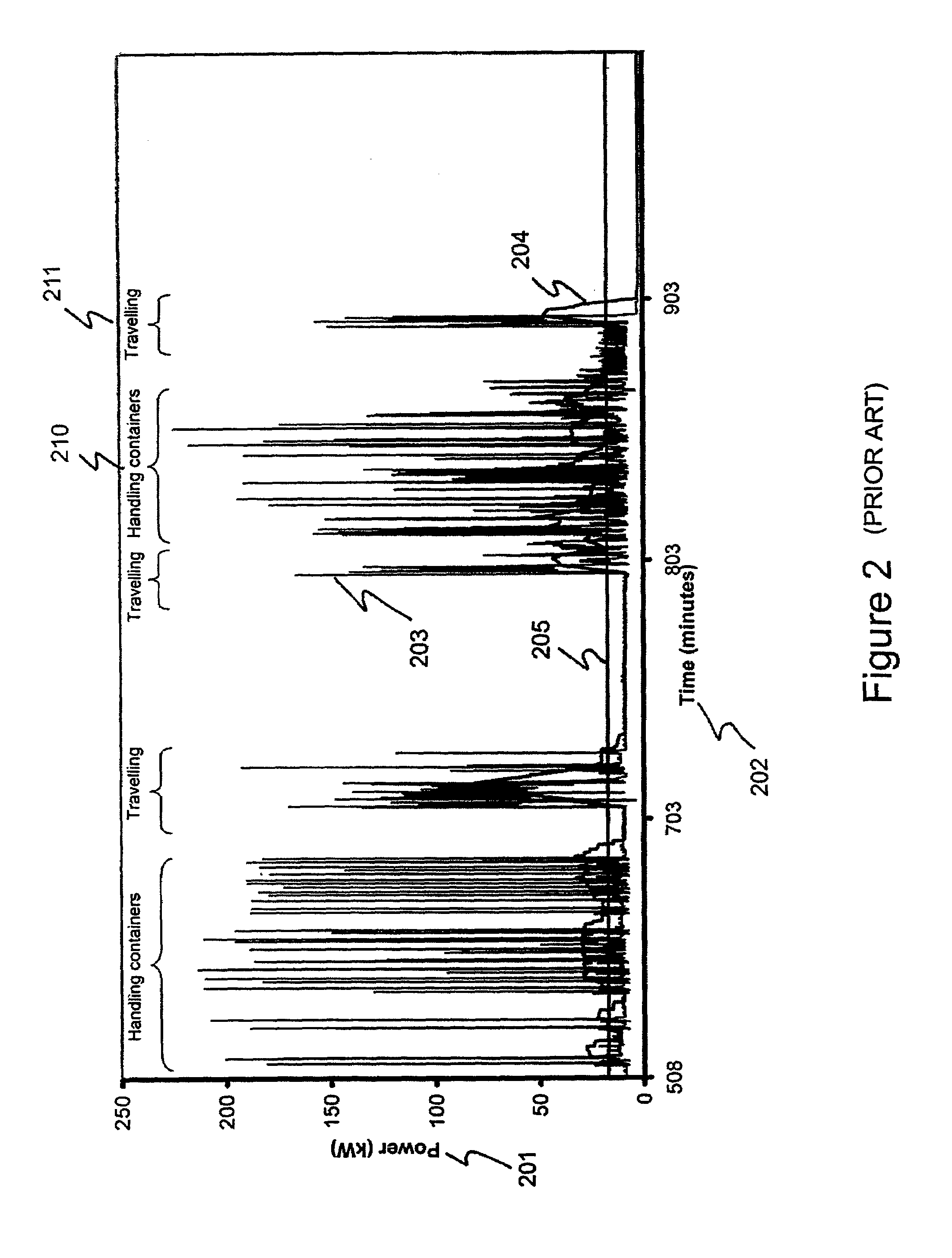

Load-lifting apparatus and method of storing energy for the same

ActiveUS7554278B2Small sizeAlleviate power rating requirementDc motor stoppersDynamo-electric converter controlRegenerative brakeContainer crane

A load-lifting apparatus has one or more prime power sources, one or more energy storage systems and regenerative braking. Regenerative energy is recovered when the load-lifting apparatus lowers its load. The elements of the prime power sources, energy storage devices and electrical components may be distributed to provide stability for the load-lifting apparatus. The general power architecture and energy recovery method can be applied to cranes, rubber-tired gantry cranes, overhead cranes, mobile cranes, ship-to-shore cranes, container cranes, rail-mounted gantry cranes, straddle carrier cranes and elevators. In such an architecture, the energy storage system helps alleviate the power rating requirement of the prime power source with respect to the peak power requirement for lifting a load.

Owner:MI JACK CANADA

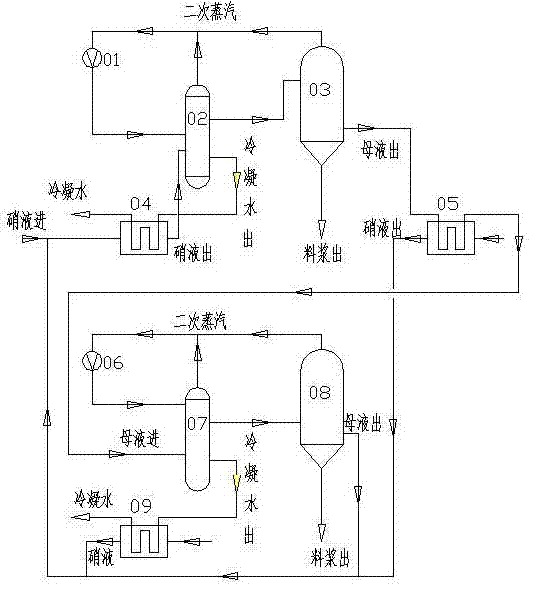

Application of MVR (mechanical vapor recompression) crystallizing evaporator in sodium sulfate and sodium chloride separation technology

InactiveCN103172088AImprove thermal efficiencyReduce energy consumptionAlkali metal sulfite/sulfate purificationAlkali metal chloridesPhysical chemistryExhaust fumes

The invention discloses an industrial application of an MVR (mechanical vapor recompression) crystallizing evaporator technology in the production of sodium sulfate and sodium chloride in Huaian, Jiangsu, and relates to an improvement of a salt and sodium sulfate coproduction evaporation technology, belonging to the technical field of chemical three-waste treatment and utilization, and in particular to an application of an MVR crystallizing evaporator in a sodium sulfate and sodium chloride separation technology. The application is mainly technically characterized in that sodium sulfate liquid is concentrated by the MVR crystallizing evaporator, the sodium sulfate is produced at high temperature, and the sodium chloride is produced at low temperature. According to the invention, the mechanical re-compressed vapor is evaporated, concentrated and crystallized at 90-100 DEG C to obtain sodium sulfate, and the re-compressed vapor at a low temperature of 55 DEG C is concentrated and crystallized to obtain sodium chloride. According to the invention, the application of the MVR technology to the concentration of sodium sulfate liquid is realized, the sodium sulfate is produced at high temperature, and sodium chloride is produced at low temperature. The application disclosed by the invention is an environmental protection project which saves energy, reduces emission and avoids waste gas, waste water and waste residue.

Owner:NAFINE CHEMICAL INDUSTRY GROUP CO LTD

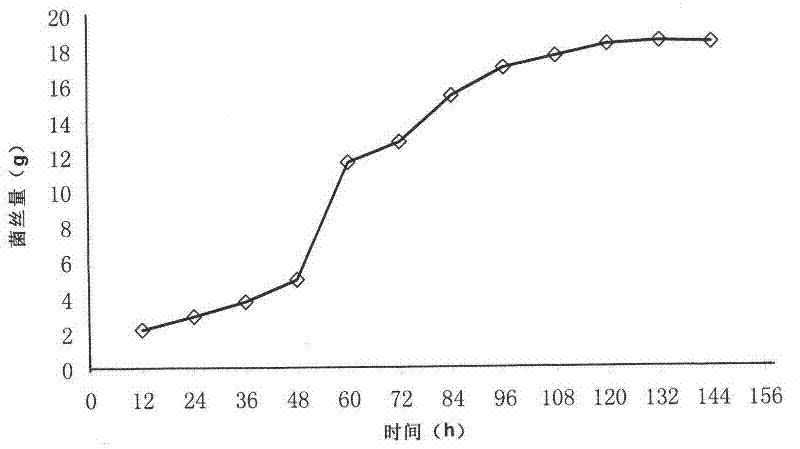

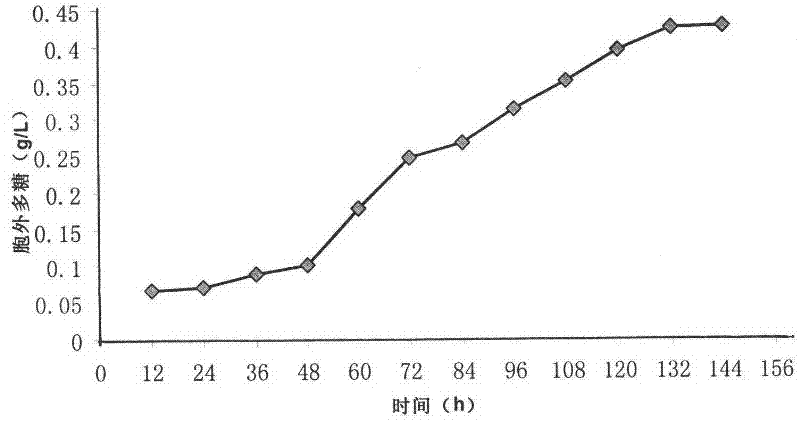

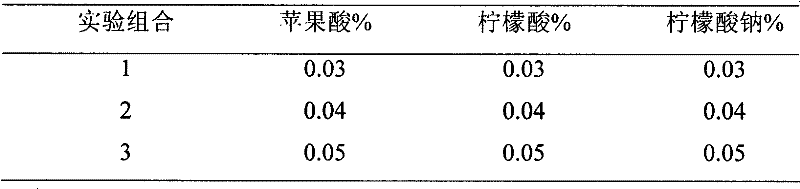

Preparation method for edible fungus nutritional health-care functional drink

ActiveCN102389139AImprove immunityEnhance anti-tumor abilityFood preparationHorticultureNutrientSubmerged fermentation

The invention discloses a preparation method for edible fungus nutritional health-care functional drink. The method comprises the following steps of: performing deep fermentation cultivation on special edible fungus strains in a fermentation tank to obtain fermentation liquor and mycelium; directly crushing the fermentation liquor and mycelium mechanically and performing homogenate without performing hot-water lixiviating or enzymolysis treatment to obtain drink raw stock; and blending the raw stock and purified water in a certain ratio, and adding an appropriate amount of flavoring agent, stabilizing agent and the like, and sterilizing and packaging to obtain a finished product. The editable fungus drink which is prepared by the method contains the nutrient substances such as crude fiber, crude protein, crude fat, vitamin, and amino acid and trace elements which are essential in a human body and the like, and simultaneously contains edible fungus polysaccharide, terpenoids, total phenol, alkaloid, flavonoid and other physiological activator and has the health-care function of improving immunity of a human body, and resisting tumors, oxidation and aging and the like. The drink hasoriginal taste, sour and sweet taste, milk taste, fruit taste and the like according to the requirements of different crowds.

Owner:承德森源绿色食品有限公司

Deep desulfurization method for liquefied petroleum gas

The liquefied petroleum gas deep desulfurizing process includes the following steps: mixing alcohol amine treated liquefied petroleum gas with desulfurizer aqua, feeding the mixture into a reactor with carbonyl sulfide hydrolyzing catalyst for hydrolyzing carbonyl sulfide into hydrogen sulfide and CO2 and eliminating hydrogen sulfide, regenerating the used desulfurizer, water washing the liquefied petroleum gas to eliminate residual desulfurizer with water containing dissolved oxygen or hydrogen peroxide in a water washing tower with hydrogen peroxide decomposing catalyst in the stuffing layer, eliminating mercaptan from the liquefied petroleum gas through oxidizing mercaptan into disulfide in a mercaptan eliminating reactor with catalyst, and final rectifying in a rectifying tower to eliminate disulfide. The process is simple and practical, and can lower the total sulfide content in liquefied petroleum gas to below 5 ppm.

Owner:北京石大世通科技发展有限公司

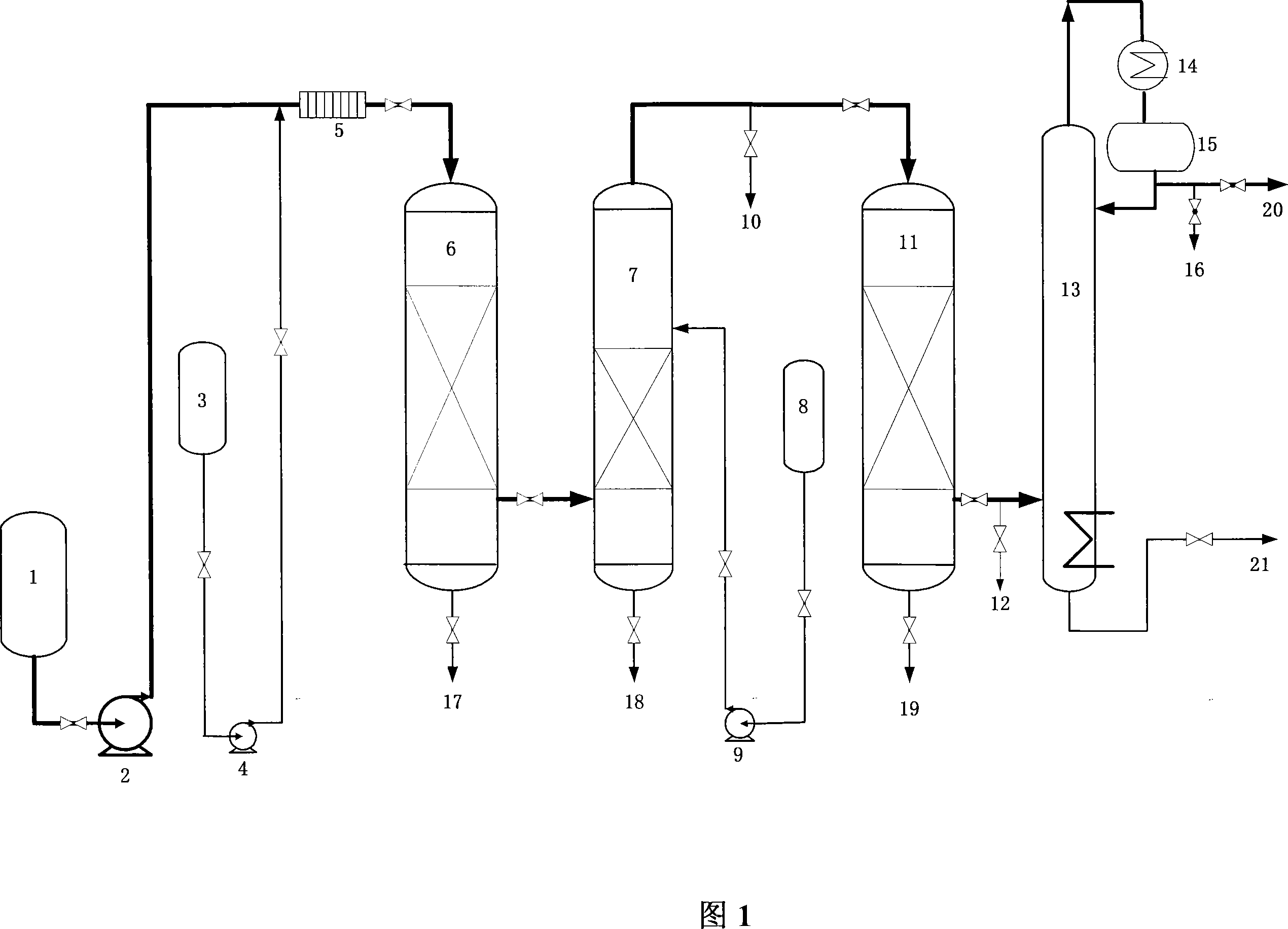

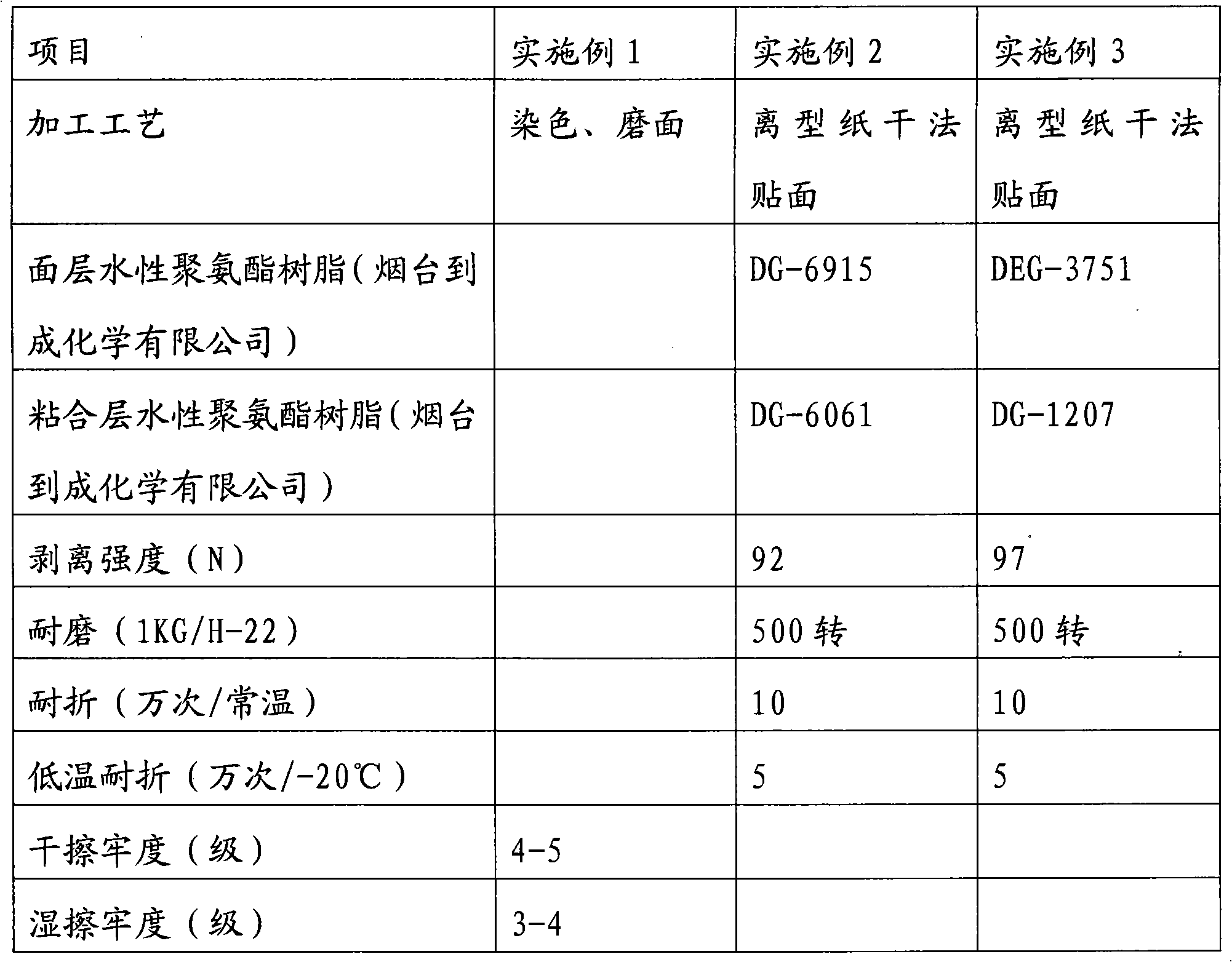

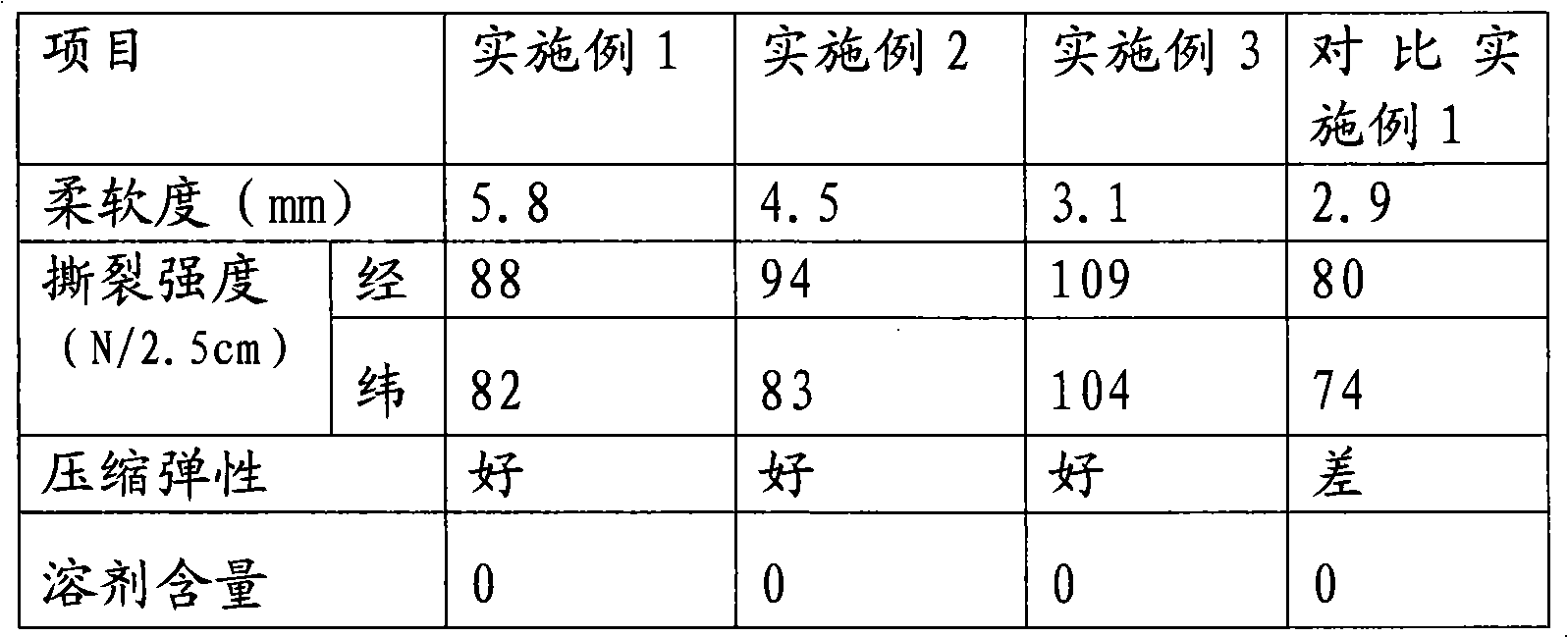

Aqueous polyurethane superfine fiber synthetic leather and preparation method thereof

The invention relates to aqueous polyurethane superfine fiber synthetic leather and a preparation method thereof. The preparation method comprises the following steps of: firstly, adding the following components according to parts by weight, i.e. 2-5 parts of foaming agents, 50-200 parts of water, 2-3 parts of foam stabilizers and 0-3 parts of waterborne colorants, into 100 parts of aqueous anionic polyurethane dipping sizing agents, and stirring the components and the sizing agents uniformly at high speed by using a blender so as to prepare a sizing agent; secondly, dipping non-woven fabricsin the sizing agent, scrapping the surface of the fabrics and keeping partial cells; thirdly, solidifying aqueous polyurethane on the dipped non-woven fabrics through aqueous coagulating liquid so asto form cells; fourthly, carrying out water scrubbing after aqueous polyurethane resin is completely solidified, and drying the aqueous polyurethane resin by an infrared drying oven so as to obtain base cloth; fifthly, treating the dried base cloth through an alkali reducing process; sixthly, treating the base cloth treated through the alkali reducing process through an postprocessing process; and seventhly, preparing the obtained base cloth into the synthetic leather. The aqueous polyurethane superfine fiber synthetic leather is prepared by the method.

Owner:HUADA CHEM GRP CO LTD

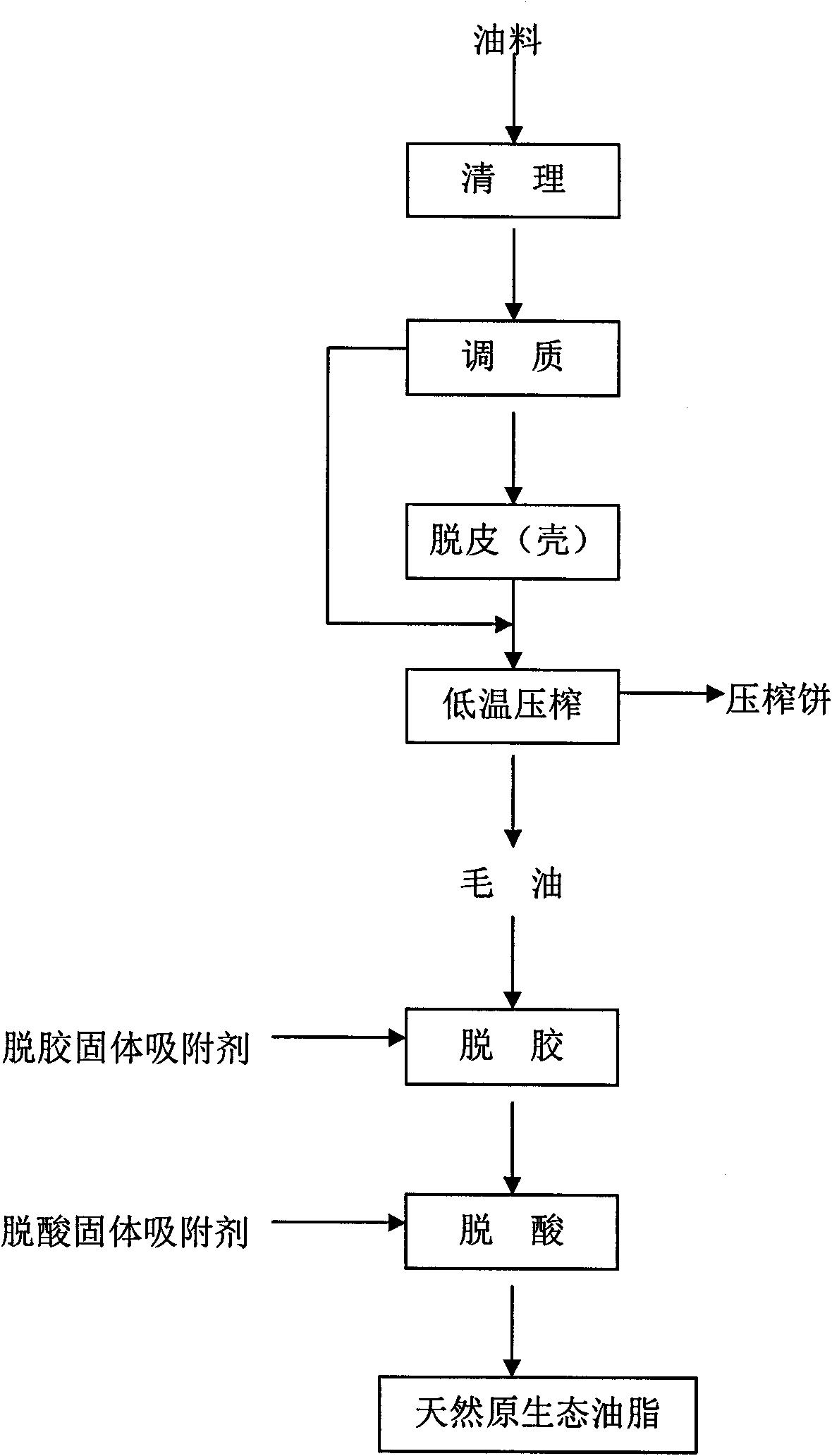

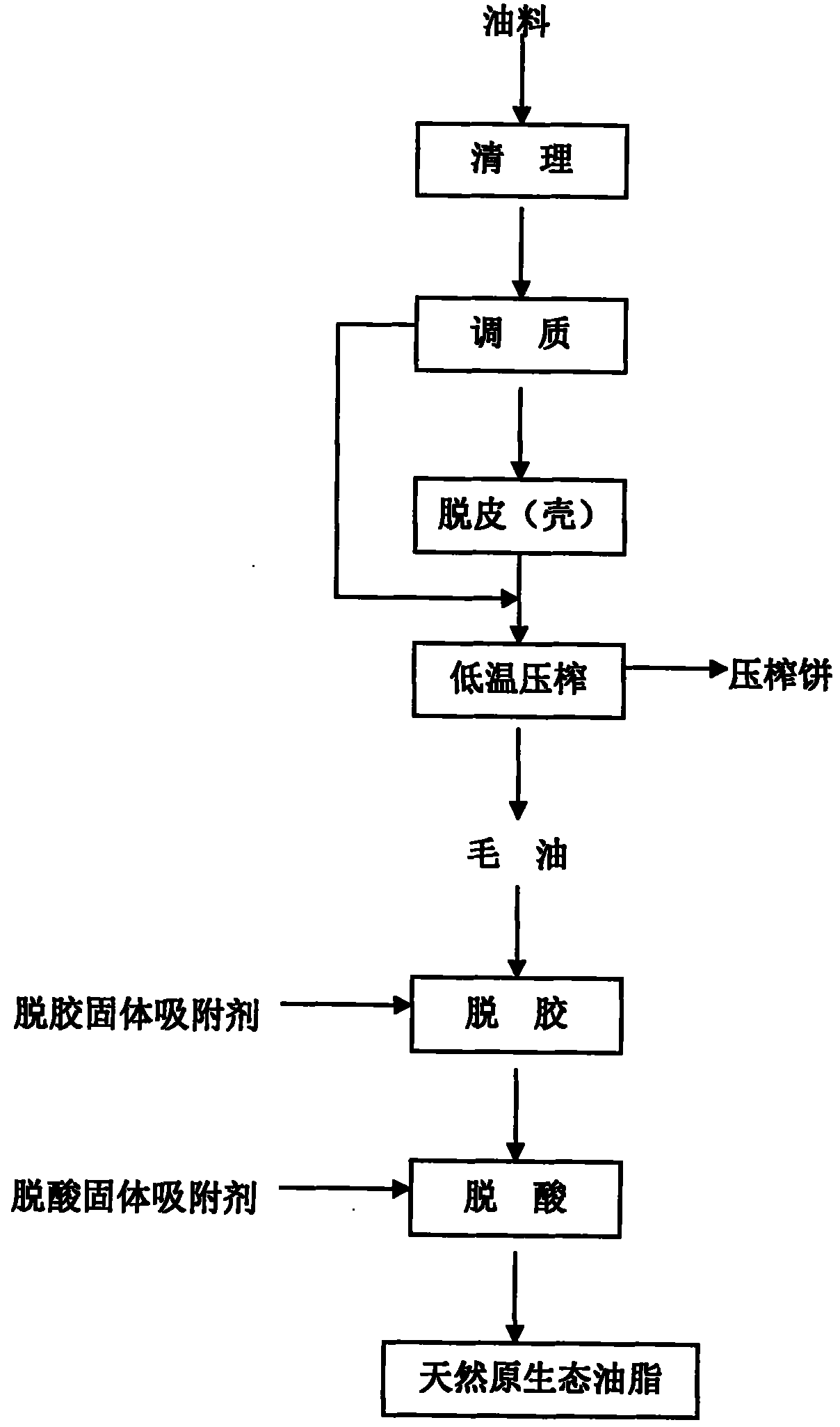

Method for preparing oil at low temperature

InactiveCN101880596ASuitable for industrial productionKeep the flavorFatty-oils/fats refiningFatty-oils/fats productionOil and greaseMoisture

The invention relates to a method for preparing oil at low temperature, which is characterized by comprising the following steps of: 1) clearing: removing impurities of an oil material; 2) conditioning: adjusting the temperature and moisture of the oil material, wherein the temperature of the oil material after the conditioning is 5 to 65DEG C, and the moisture mass of the oil material is adjusted to 4-16 percent; 3) pressing at low temperature: pressing the conditioned oil material, wherein the pressing temperature of the oil material is -10 to 65DEG C, and the moisture mass of the pressed oil material is 4 to 16 percent, and obtaining crude oil; 4) degumming: keeping the temperature of the crude oil between 5 and 65DEG C, adding a degumming solid adsorbent accounting for 0.1 to 5 mass percent of the crude oil, and controlling the degumming time to between 0.1 and 2 hours; and 5) removing acid: keeping the temperature of the degummed crude oil to between 5 and 65DEG C, adding an acid removing solid adsorbent accounting for 0.1 to 2 mass percent of the degummed crude oil, and controlling the acid removing time to between 0.1 and 3 hours to obtain the oil. The method is suitable for industrial production.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

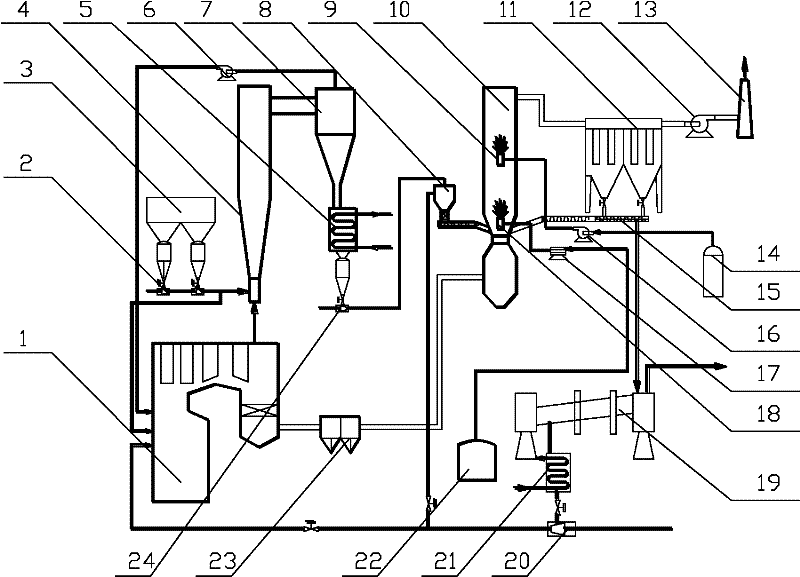

Device and method for suppressing refuse end gas injurant using pyrolysis and aerification technology

InactiveCN1769397ANo emissionsPrevent gasificationThermal non-catalytic crackingSolid waste disposalThermal dissociationVaporization

Owner:TIANJIN UNIV

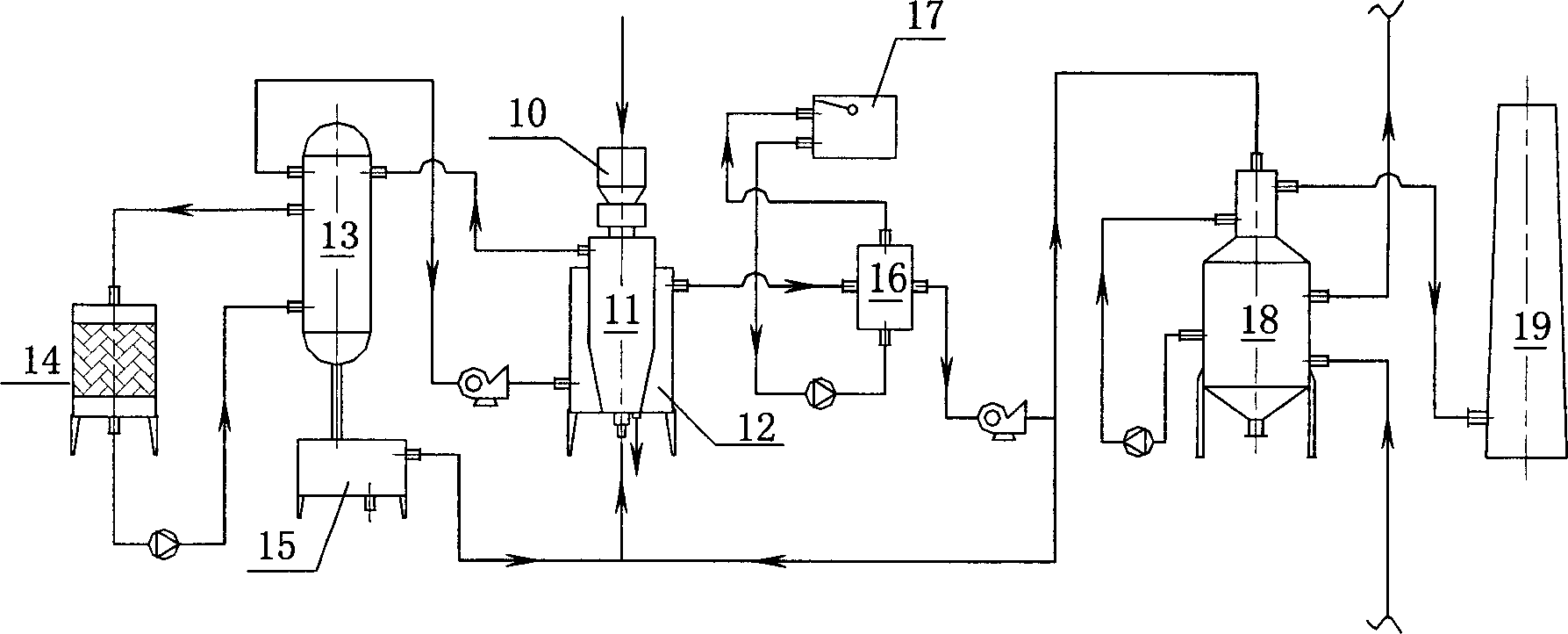

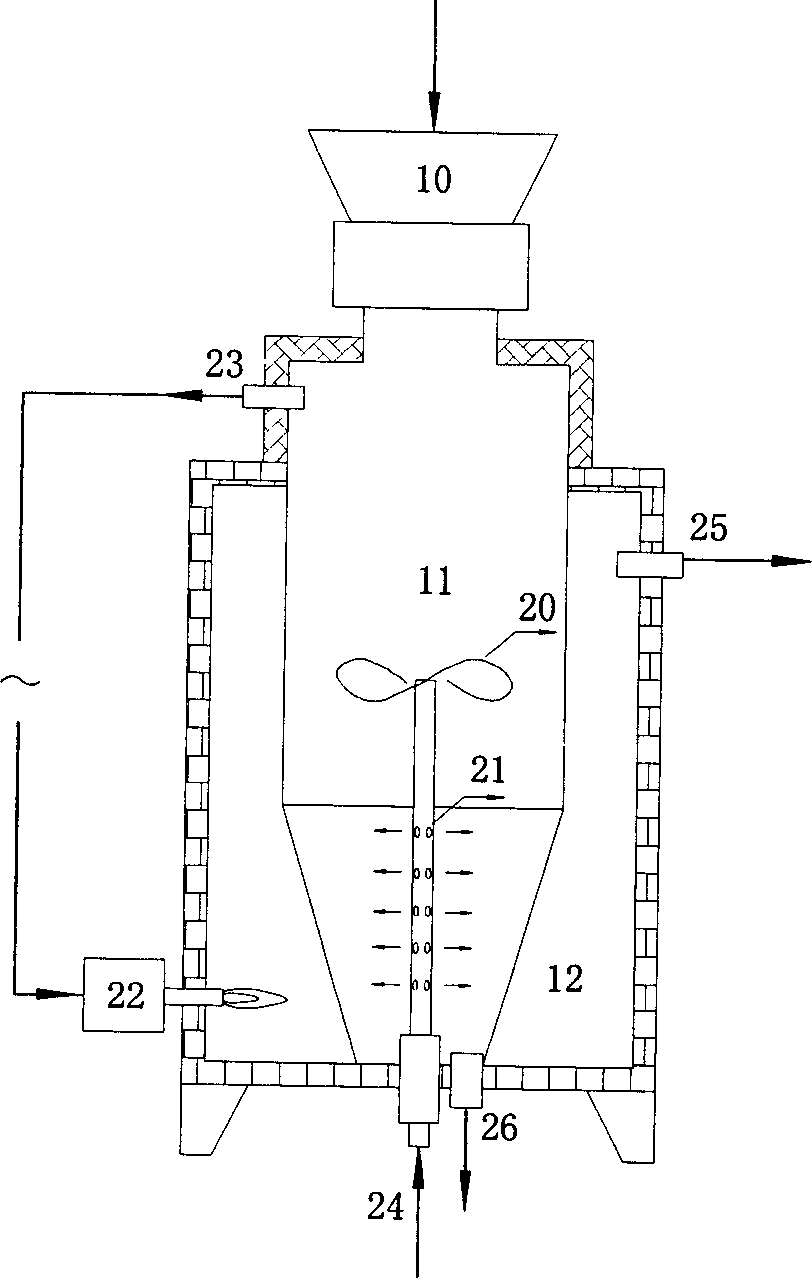

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

Solid fermentation method for cordyceps sinensis

ActiveCN101695257AImprove liquidityNo emissionsFood preservationFood preparationBiotechnologyHirsutella sp.

The invention discloses a solid fermentation method for cordyceps sinensis. The method adopts fermented liquor the seed lot of which is Hirsutella sinensis Liu, Guo, Yu et Zeng as a liquid strain to enable cordyceps sinensis to be fermented and produced on a solid culture medium taking grains as the matrix by pouring or blending inoculation. The method combines the advantages of both liquid fermentation and solid fermentation. The method has the advantages of short strain cultivating time, high activity and good flowability and many development points and has the characteristics of small investment of production equipment, low energy consumption, no waste liquor discharge, easy storage of products and the like. The final product of the invention is the grain being rich in cordyceps sinensis and can be directly used as raw material of health-care food.

Owner:SHANGHAI ZHICAO BIOTECH

Preparation method of novel diatom mud environment-friendly interior wall coatings

The invention relates to a preparation method of diatom mud environment-friendly interior wall coatings. The preparation method comprises the following steps of: firstly preparing the following materials in parts by weight: 20 of diatomite (325 meshes), 8 of adhesive powder, 0.6 of methyl cellulose, 7 of talc powder (700 to 900 meshes), 15 of calcium carbonate powder (400 to 600 meshes), 10of quartz sand (20 to 90 meshes), 10 of kaolin (750 to 850 meshes), 2 of attapulgite powder (550 to 750 meshes), 2 of titanium dioxide powder, 10 of ash calcium powder (550 to 650 meshes), 14.7 of r heavy calcium carbonate (1200 to 1300 meshes), 0.4 of wood fibers and 0.3 of staple fibers; loading the above materials into a horizontal high-speed dispersion machine according to the given ratio; and dispersing uniformly. The preparation method provided by the invention can produce novel interior wall coatings which are free of VOC (volatile organic compounds), temperature-resistant, fire-proof and wear-resistant and have stable performances, and a long useful service life.

Owner:HUNAN LANTIDEN ENVIRONMENTAL BUILDING MATERIAL LTD

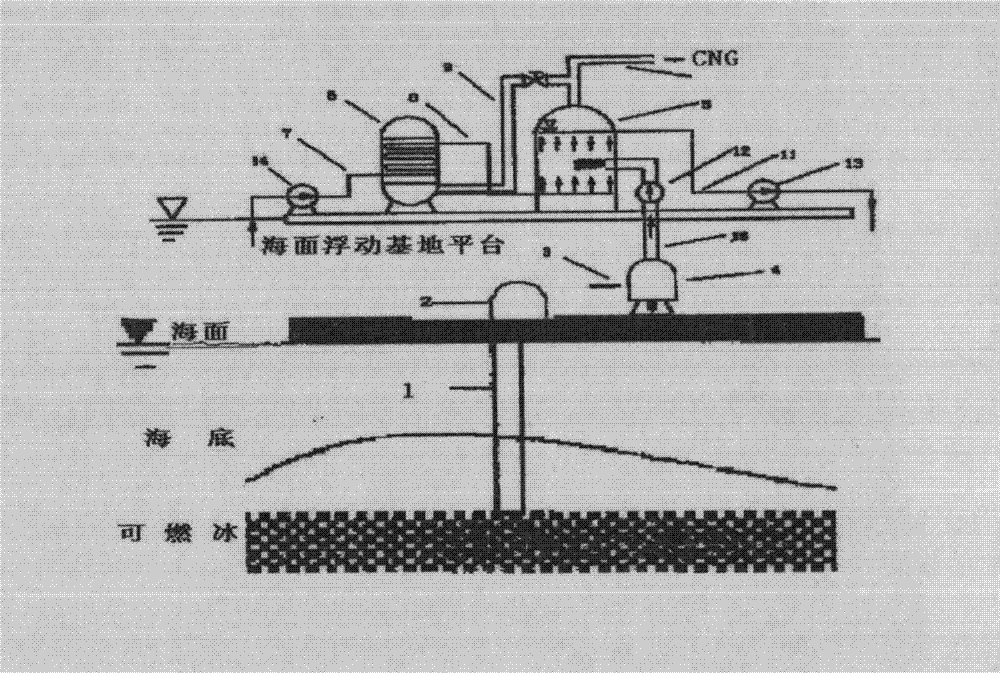

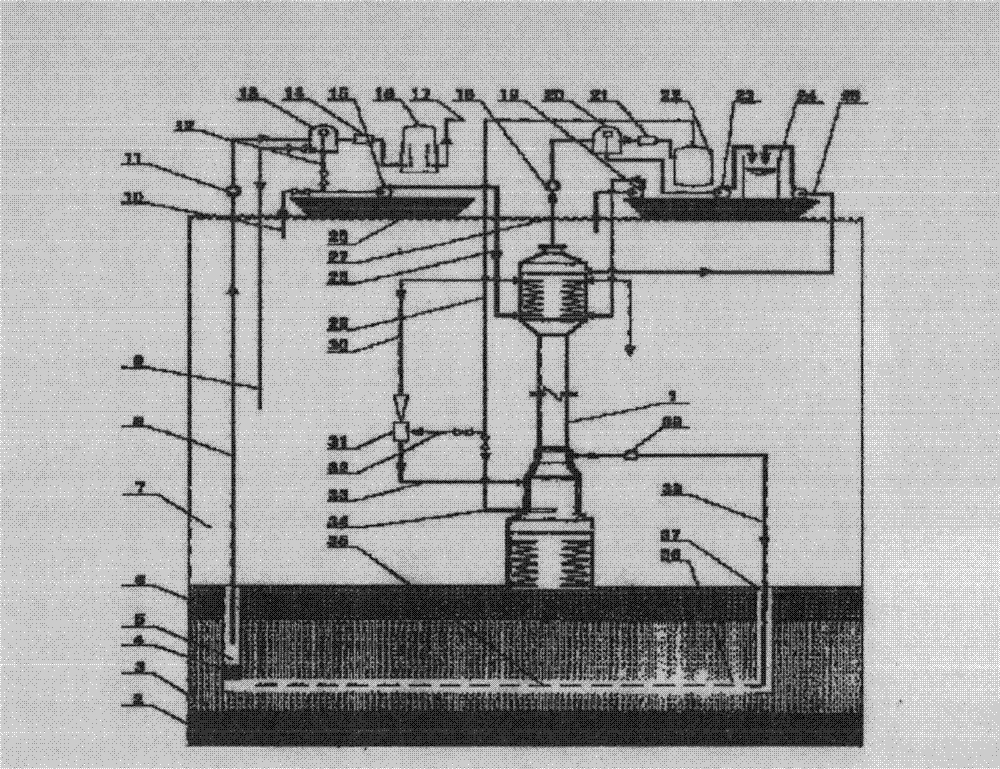

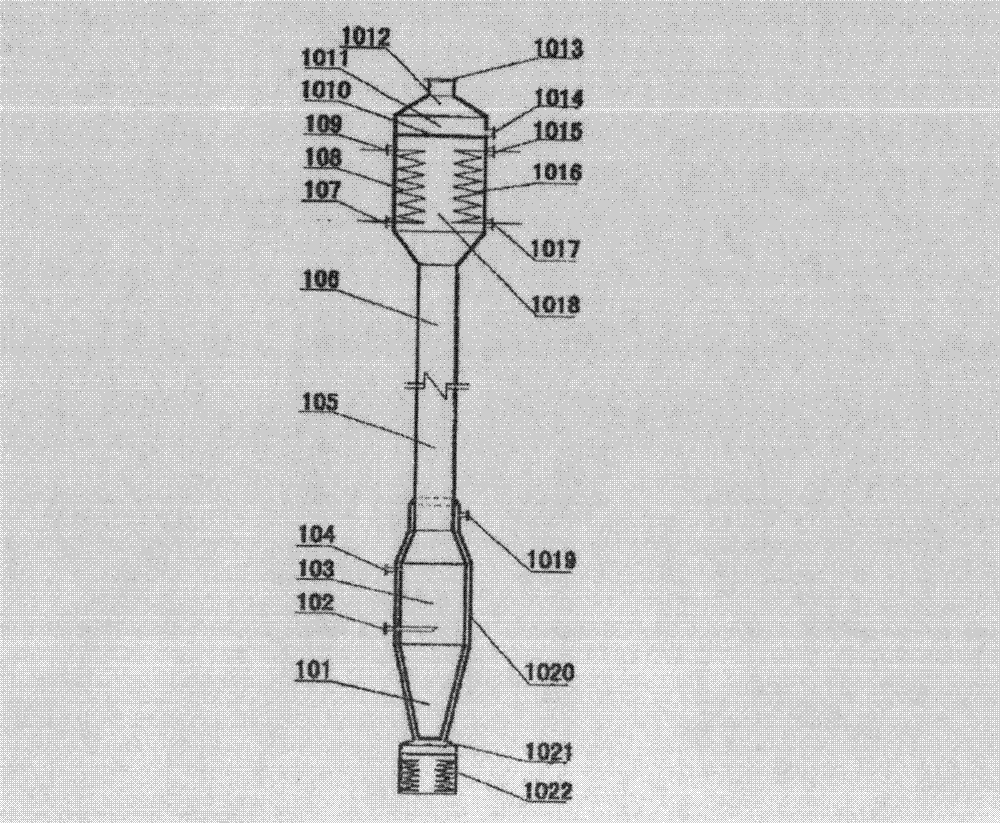

Ocean combustible ice mining device and method

The invention discloses an ocean combustible ice mining method and a mining device adopted by the same. According to the ocean combustible ice mining method, a device for mining combustible ice through heating concentrated saline water is adopted, and heat for heating a combustible ice storage layer is provided by heating the concentrated saline water. The ocean combustible ice mining method is energy-saving and environment-friendly, remarkable in economic benefit, is free from emission and pollution in a mining process, energy-saving and consumption-reducing; and the ocean combustible ice mining device is relatively sample in structure, convenient to use, lower in production cost and convenient for popularization.

Owner:韩中枢

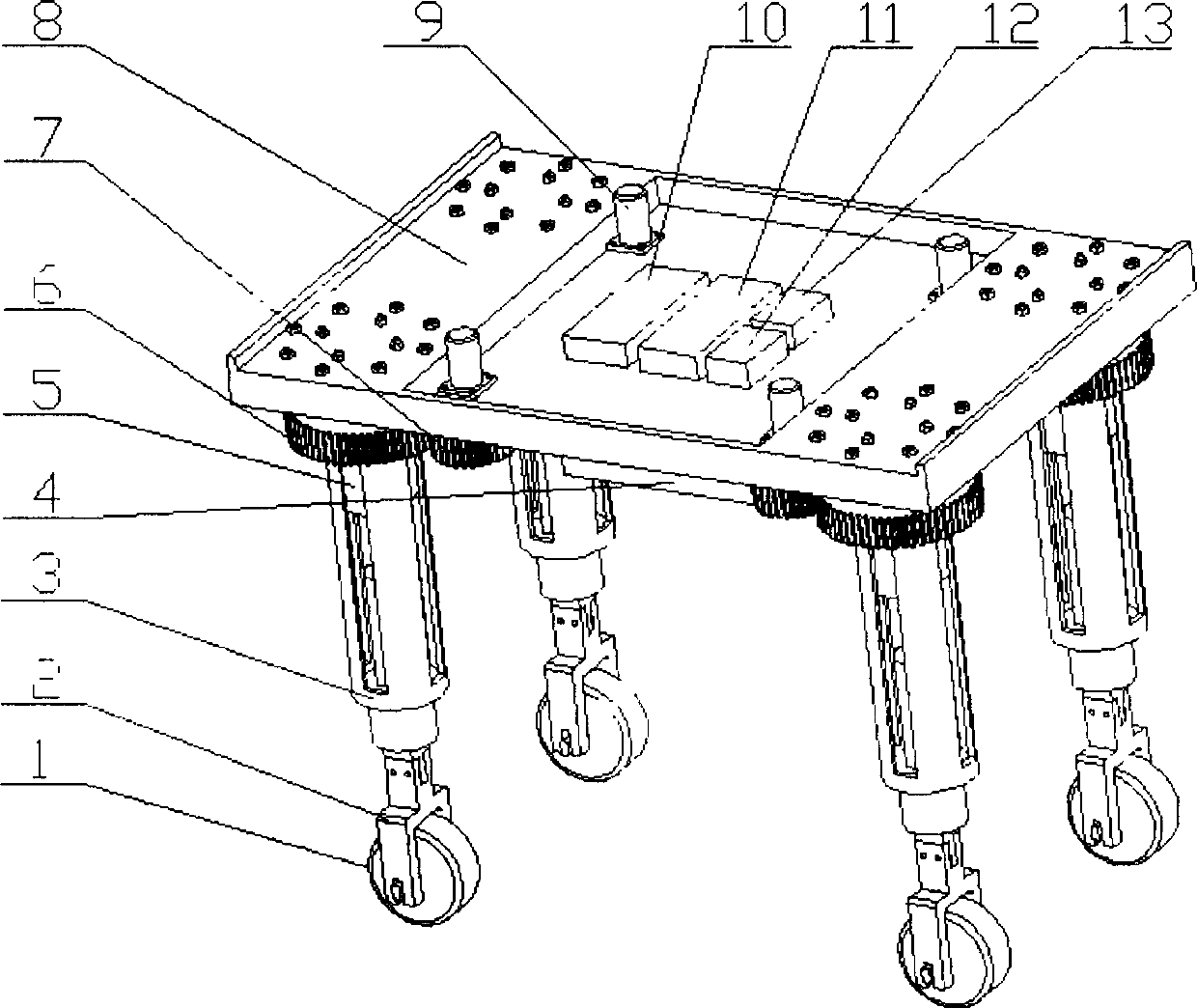

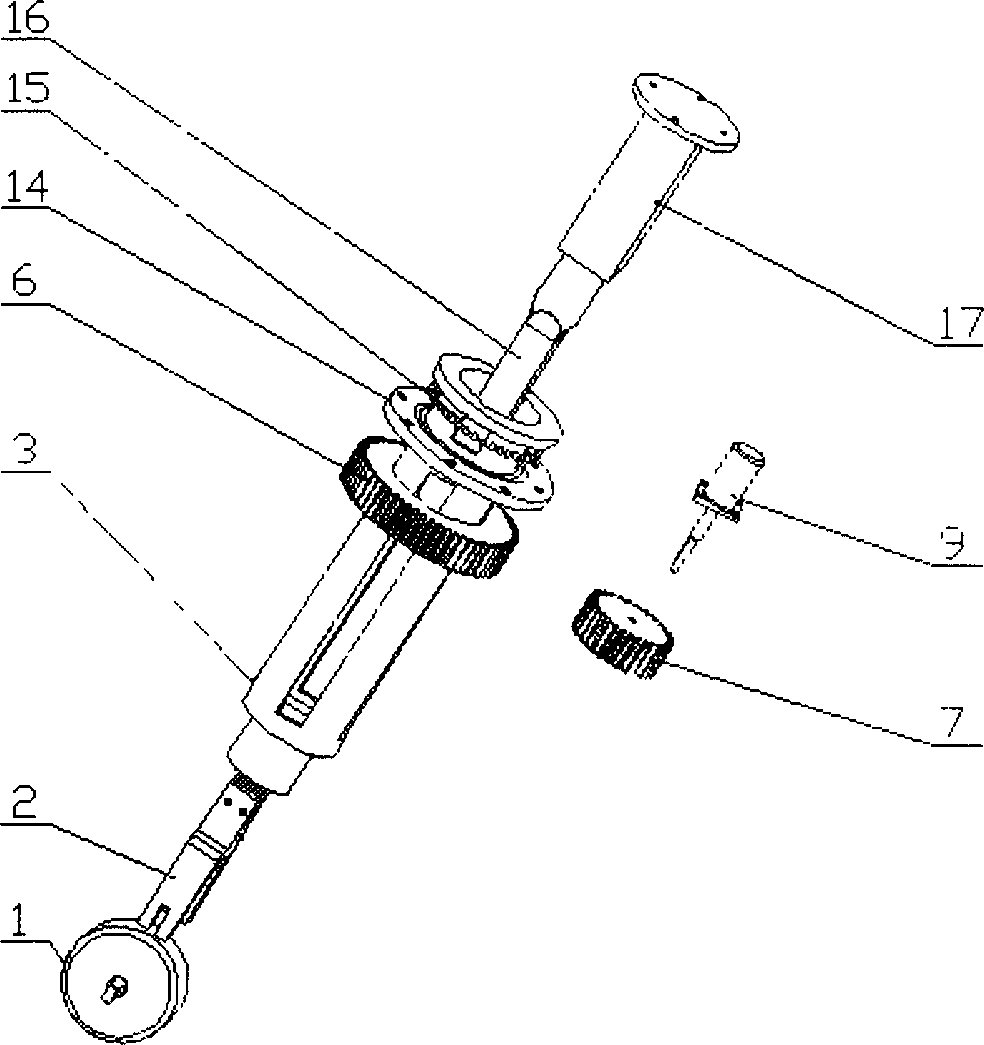

Omni-directional steering and lifting agricultural remote control mobile robot platform

InactiveCN103010289ARealize remote operationSimple structureElectrical steeringResilient suspensionsTerrainRemote control

The invention relates to an omni-directional steering and lifting agricultural remote control mobile robot platform. The platform comprises an omni-directional steering mechanism, a hydraulic lifting system, a frame bench, vehicular electronic equipment and a traveling mechanism, the omni-directional steering mechanism is driven by a servo motor and transfers power to a steering sleeve through a pinion and a gearwheel, and then the power is transferred to wheel supports and hub motor-type wheels so that omni-directional steering is achieved, and the hydraulic lifting system is capable of lifting the platform under the action of hydraulic driving. The omni-directional steering and lifting agricultural remote control mobile robot platform has the advantages that by means of motor driving and hydraulic lifting which are performed independently, the platform can achieve 360-degree in-situ rotation while adjust the height of a vehicle body so as to adapt to crops of different heights and terrain environments; the platform is small in steering resisting moment during rotation and is easy and flexible to steer; and by the aid of the hub motor wheels, motors and the wheels are integrated, and the platform is structurally simplified.

Owner:NORTHWEST A & F UNIV

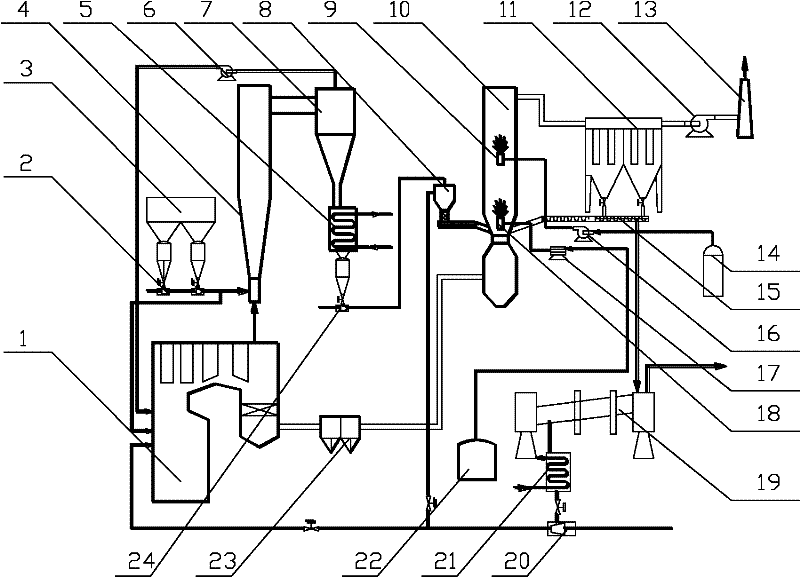

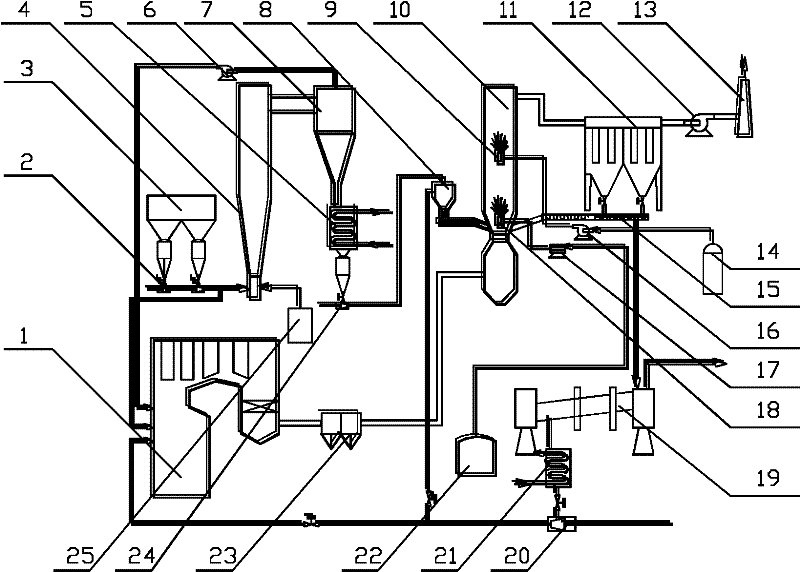

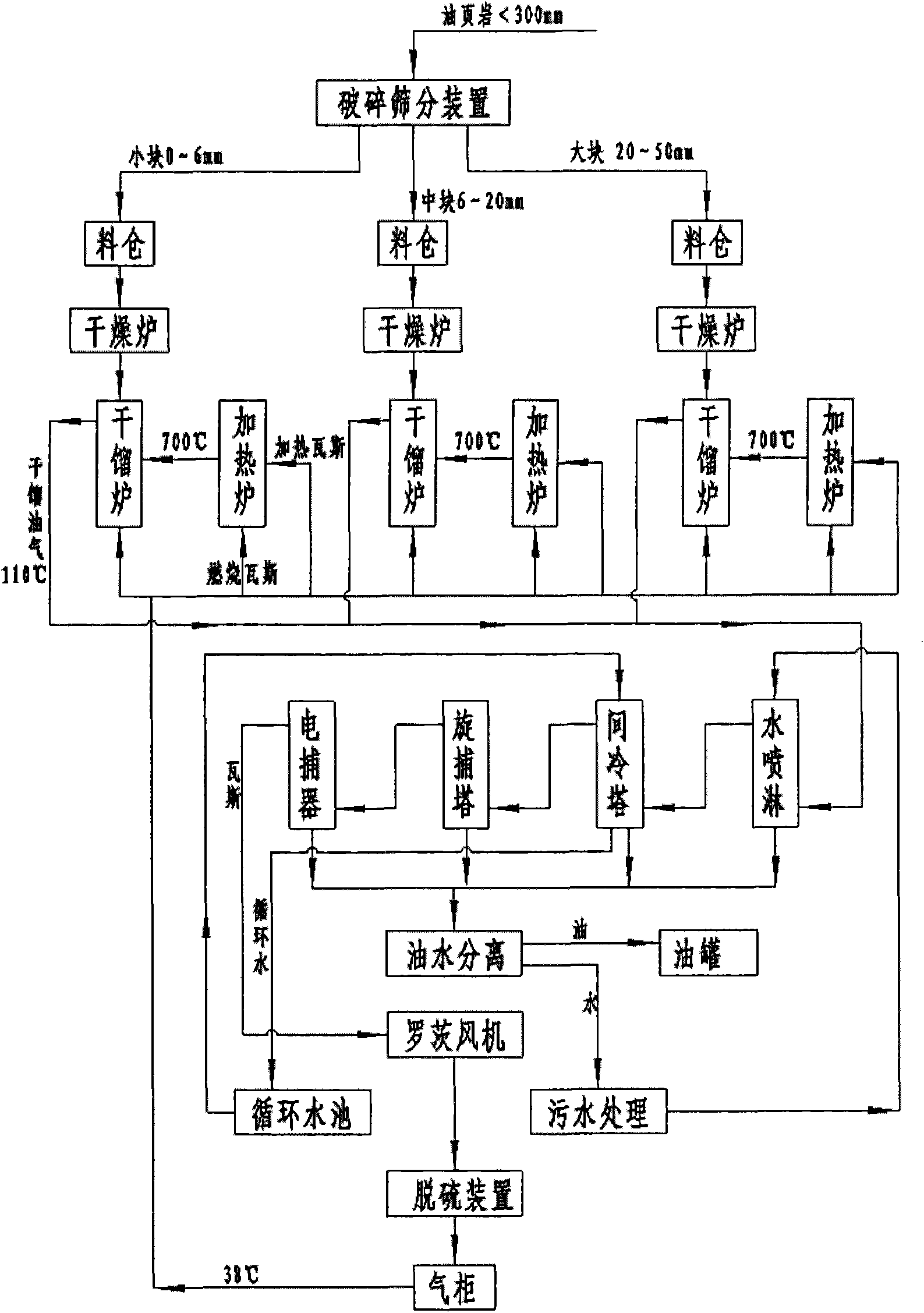

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

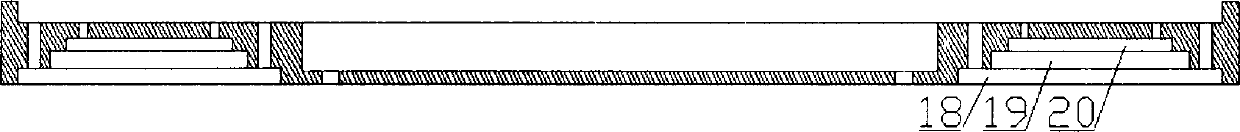

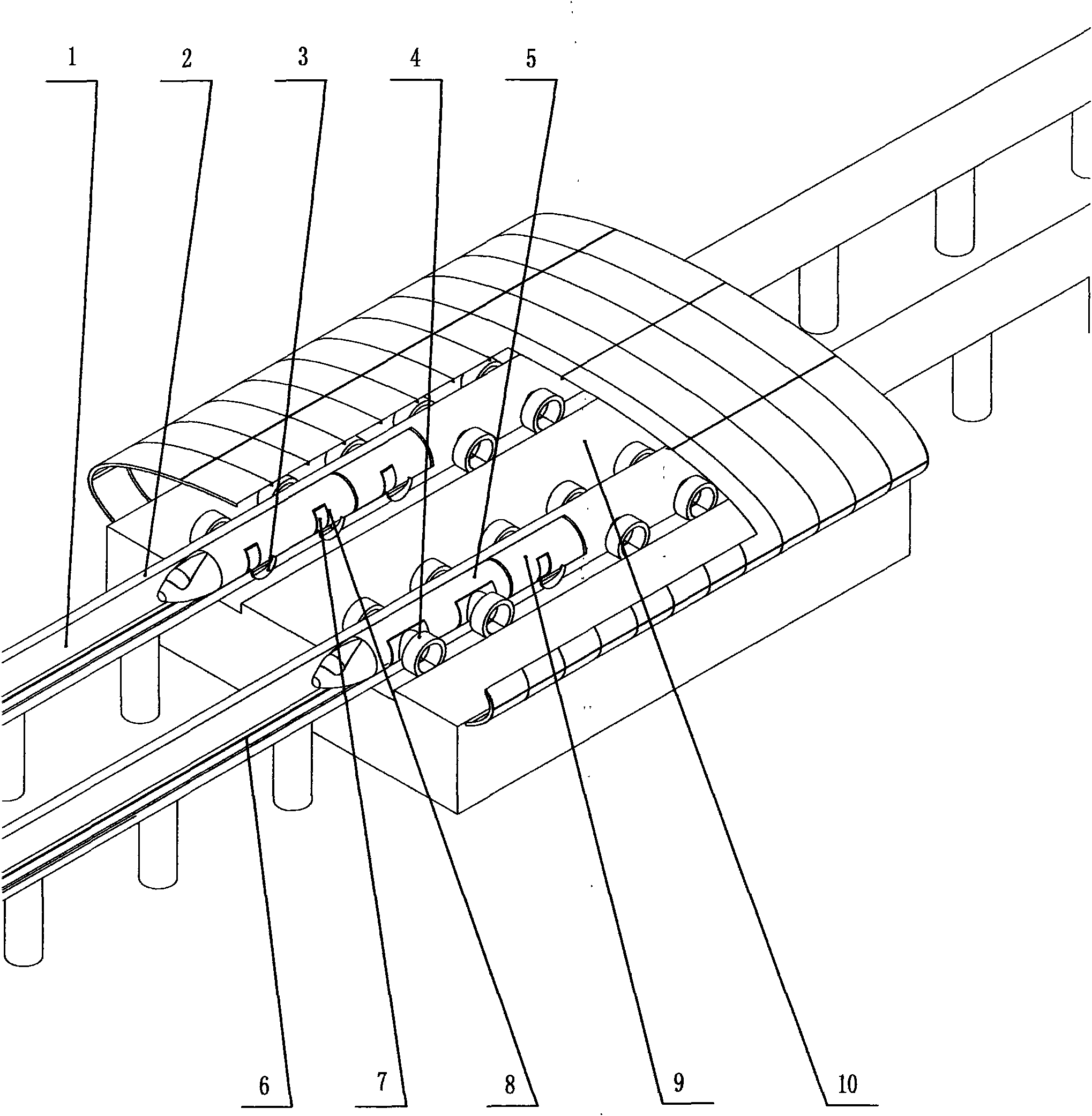

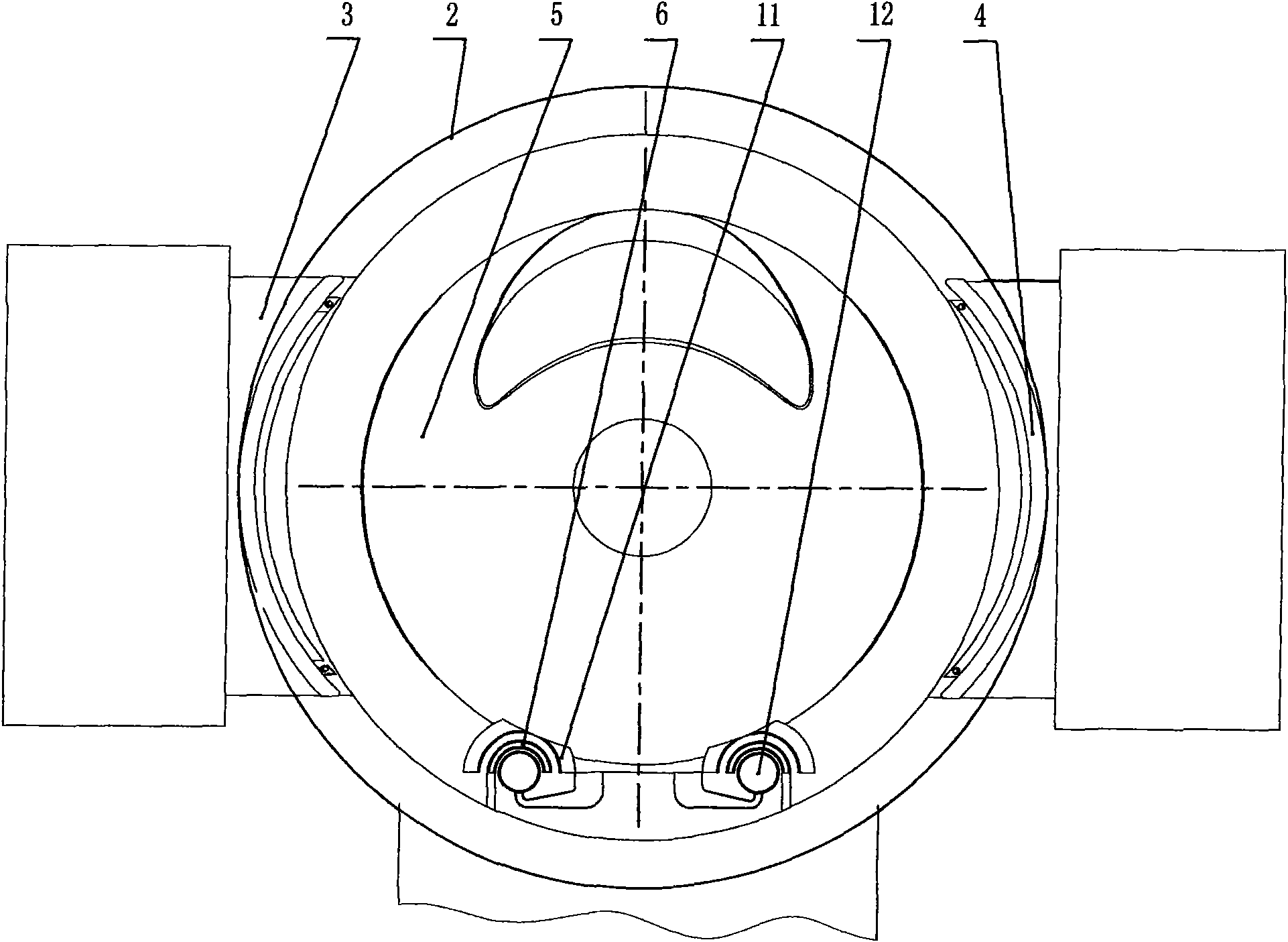

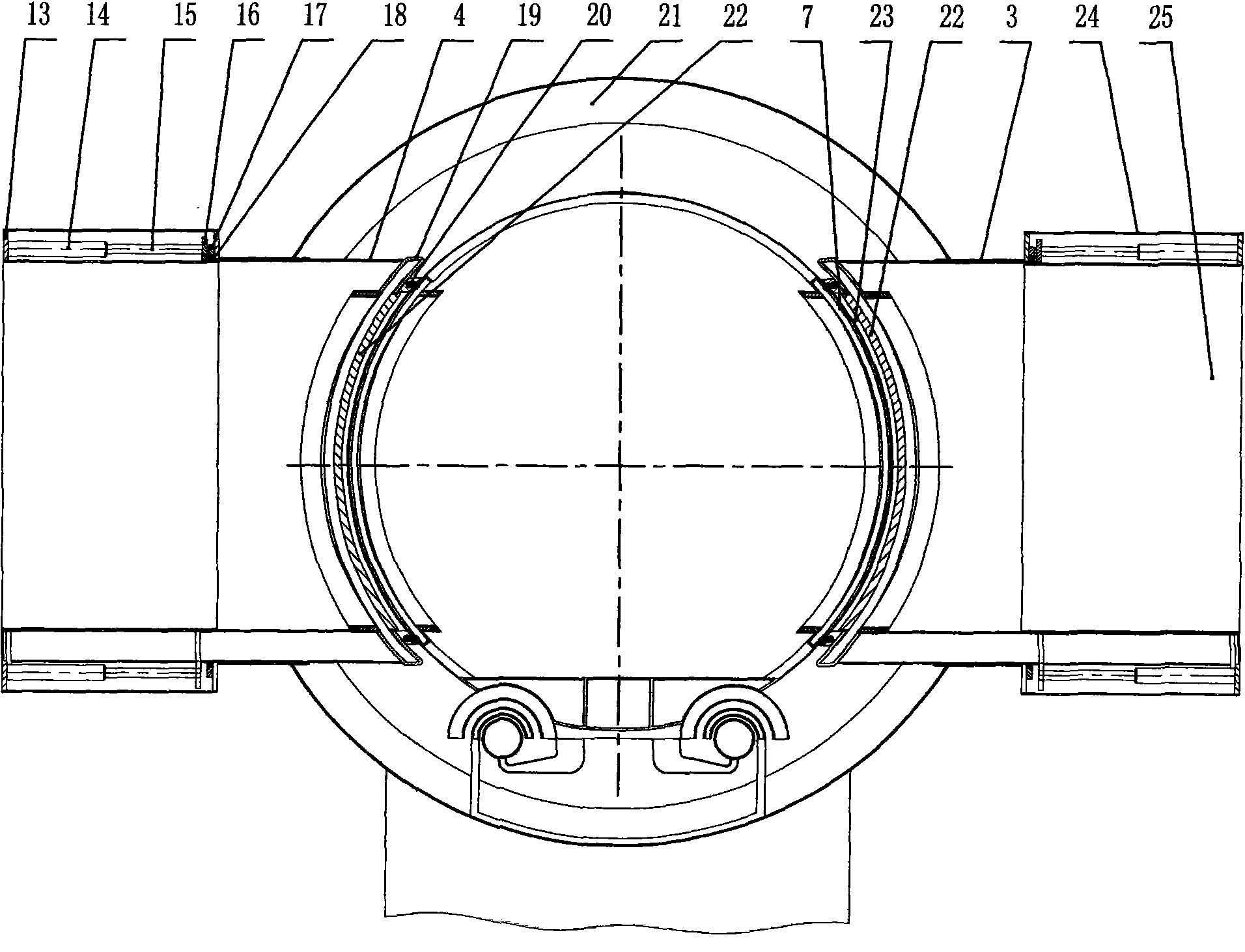

Vacuum pipeline docking technology and high-speed permanent maglev train system

InactiveCN101823488AGet off fastWill not affect high-speed passingRailway tunnelsRailway componentsEngineeringElectric power

The invention provides a vacuum pipeline docking technology and a high-speed permanent maglev train system. With the station-training docking technology, the door closing time of the maglev train inside the vacuum pipeline can be shortened for scores of seconds, so the rapid on-off can be realized. When a telescopic door and a separation cabin door are withdrawn to be close to the wall of the vacuum pipeline, the high-speed pass of the tray is free from being influenced. The telescopic door is locked by a permanent magnet suction disc, and the locking force is free from being controlled by the electric power, so the gas leakage and pressure relief caused by the invalid locking for sudden power down can be prevented. The energy can be remarkably saved, the energy can be saved by more than 97 percent compared with that of high-speed track train, and the energy can be saved by more than 99 percent compared with that of the airplane.

Owner:刘忠臣

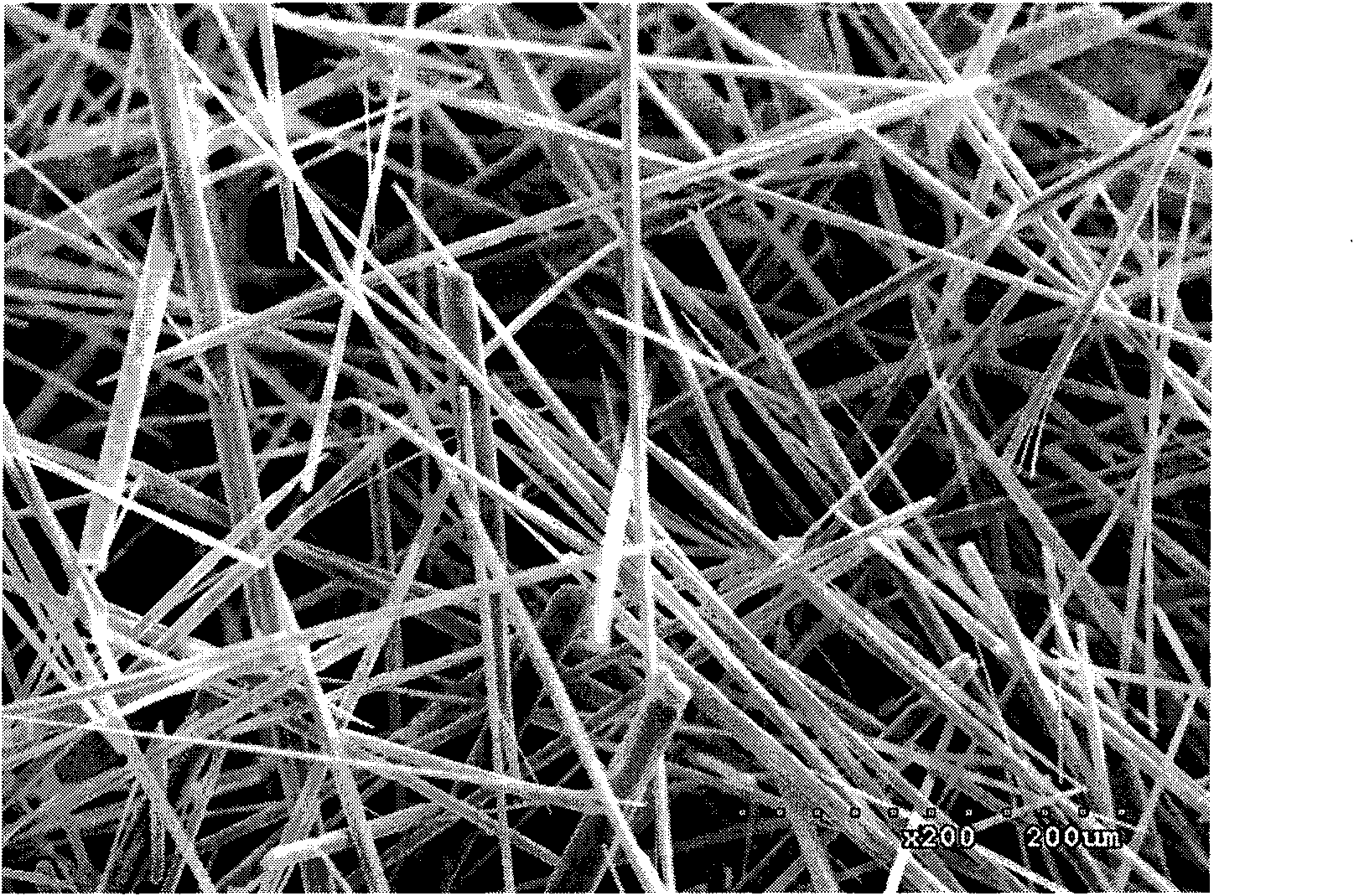

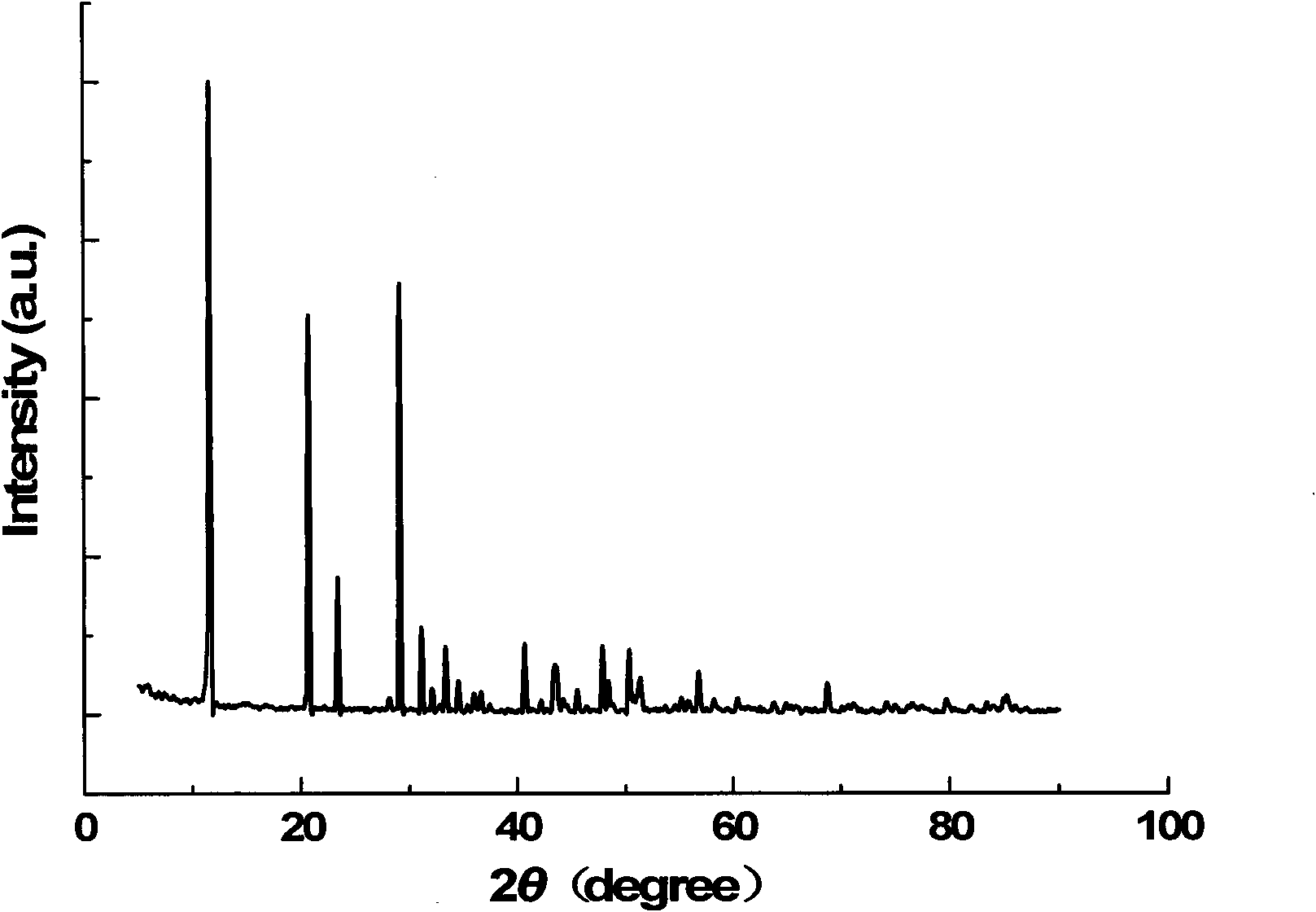

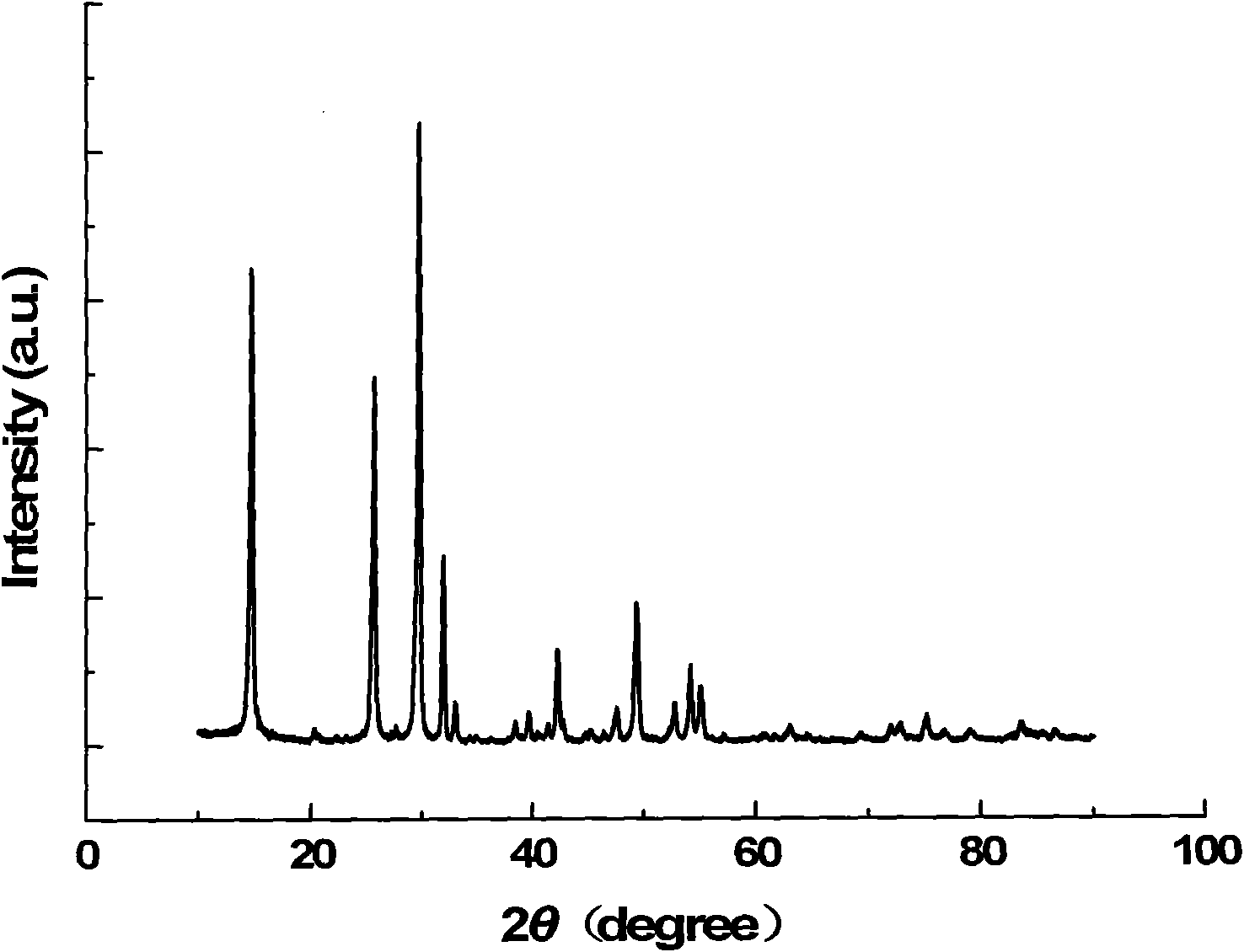

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Preparation method of essence microcapsules

InactiveCN102039108AGood chemical stabilityHigh mechanical strengthEssential-oils/perfumesMicroballoon preparationTextile fiberEthylic acid

The invention discloses a preparation method of essence microcapsules. The preparation method comprises the following steps: (1) dissolving chitosan in acetum; (2) adding emulsifier and essence into the chitosan acetum for high-speed emulsification and dispersion to obtain the chitosan essence emulsion; (3) adding the mixed solution of sodium alginate and sodium tripolyphosphate dropwise into the chitosan essence emulsion; (4) adjusting the pH value of the system to 5-7 with NaOH solution to obtain the condensed essence microcapsules; and (5) adding cross-linking agent into the condensed essence microcapsule system to perform chemical cross-linking process on the condensed essence microcapsules to obtain the essence microcapsules. For the essence microcapsules prepared according to the method disclosed by the invention, as chemical cross-linking process is implemented on the walls of the capsules, the density of the capsule walls and the resistance to the solution alkalinity / acidity are improved, and the application stability of the essence microcapsules is increased; moreover, with small size, the capsules can easily permeate into textile fiber, and the water-washing resistance of the textile fiber is greatly improved.

Owner:广州市戴文高分子材料科技有限公司 +1

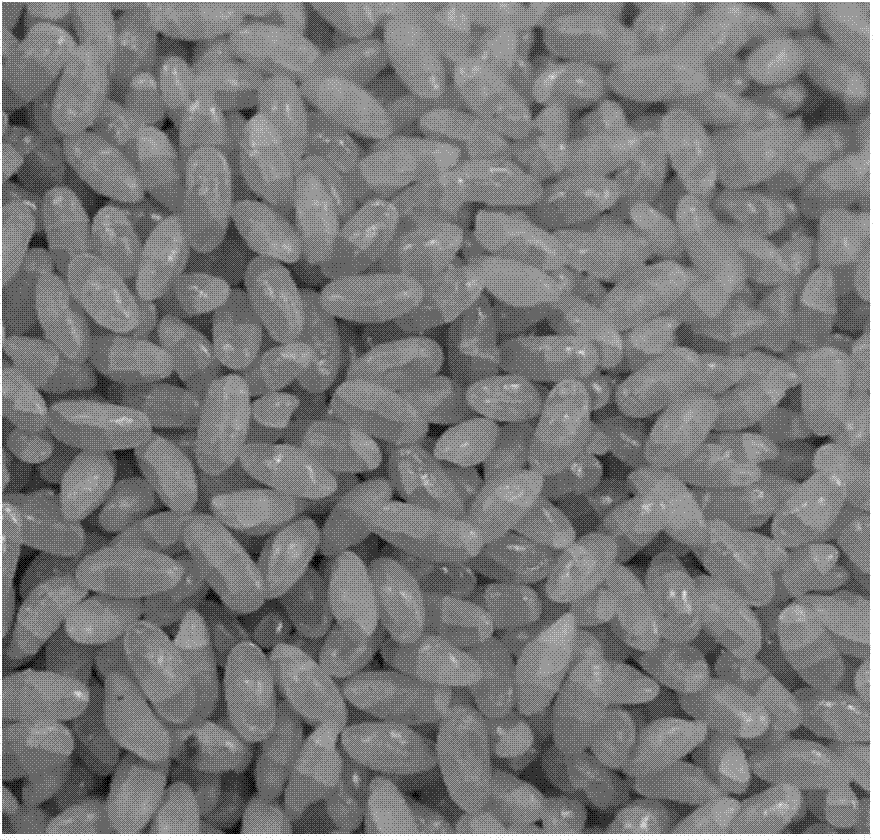

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

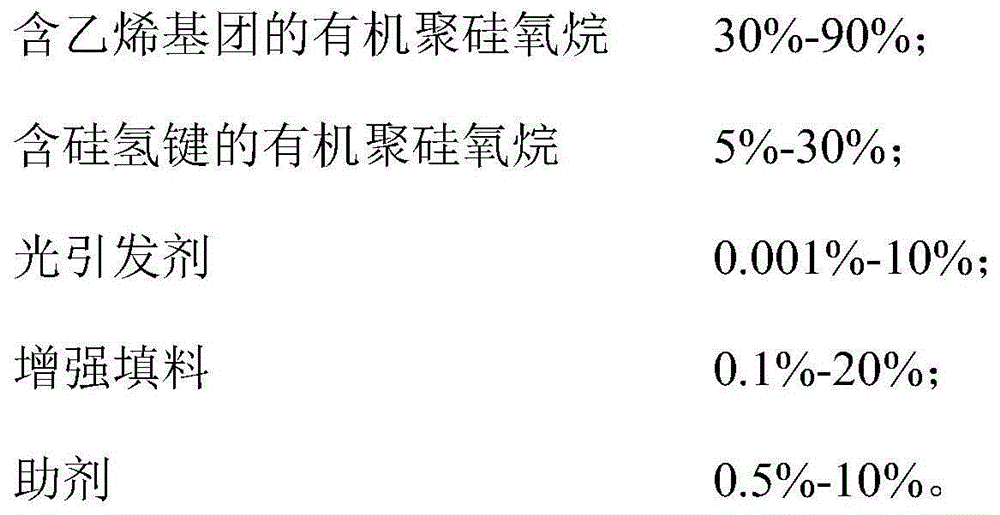

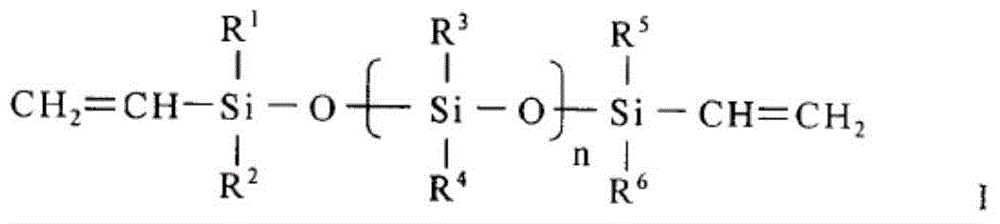

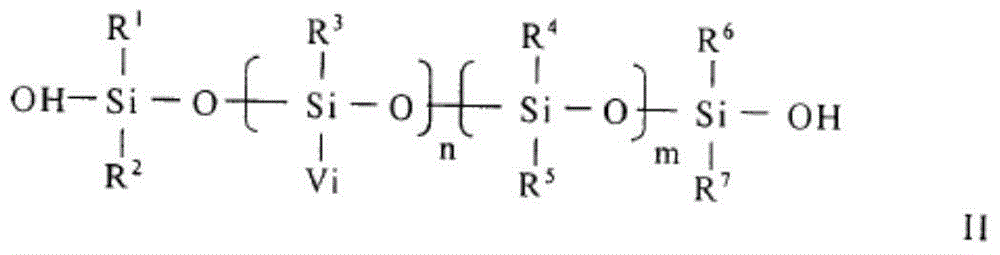

Colorless and transparent light-cured 3D printing material

The invention discloses a colorless and transparent light-cured 3D printing material and belongs to the technical field of cured materials. The printing material comprises organopolysiloxane containing a vinyl group, organopolysiloxane containing a silicon-hydrogen bond, a photoinitiator, reinforcing filler and an aid. A preparation method of the material comprises steps as follows: evenly mixing the organopolysiloxane containing the vinyl group, the organopolysiloxane containing the silicon-hydrogen bond, the reinforcing filler and the aid in percentage by mass; then adding the photoinitiator, and evenly mixing the mixture to obtain the colorless light-cured 3D printing material. The printing material has the benefits as follows: (1) the light-cured product is colorless, good in transparency and elastic; (2) the light-cured material is low in molding shrinkage, and the volume shrinkage is lower than 1.0%; (3) all components in a resin mixture participate in curing, no volatile solvent exists, and pollution is avoided; (4) the printing material is high in curing light source applicability, and the maximum curable light wavelength is 405 nm.

Owner:CHANGSHU RES INST OF DALIAN UNIV OF TECH CO LTD

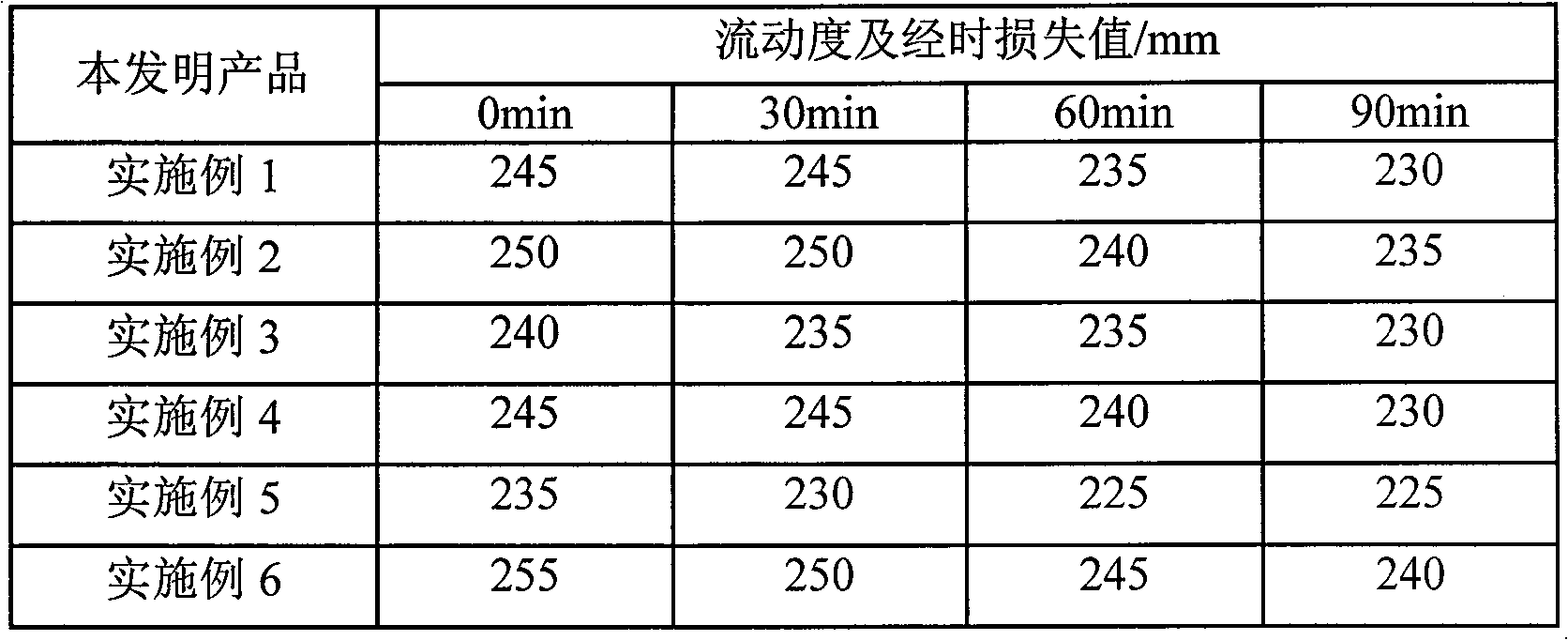

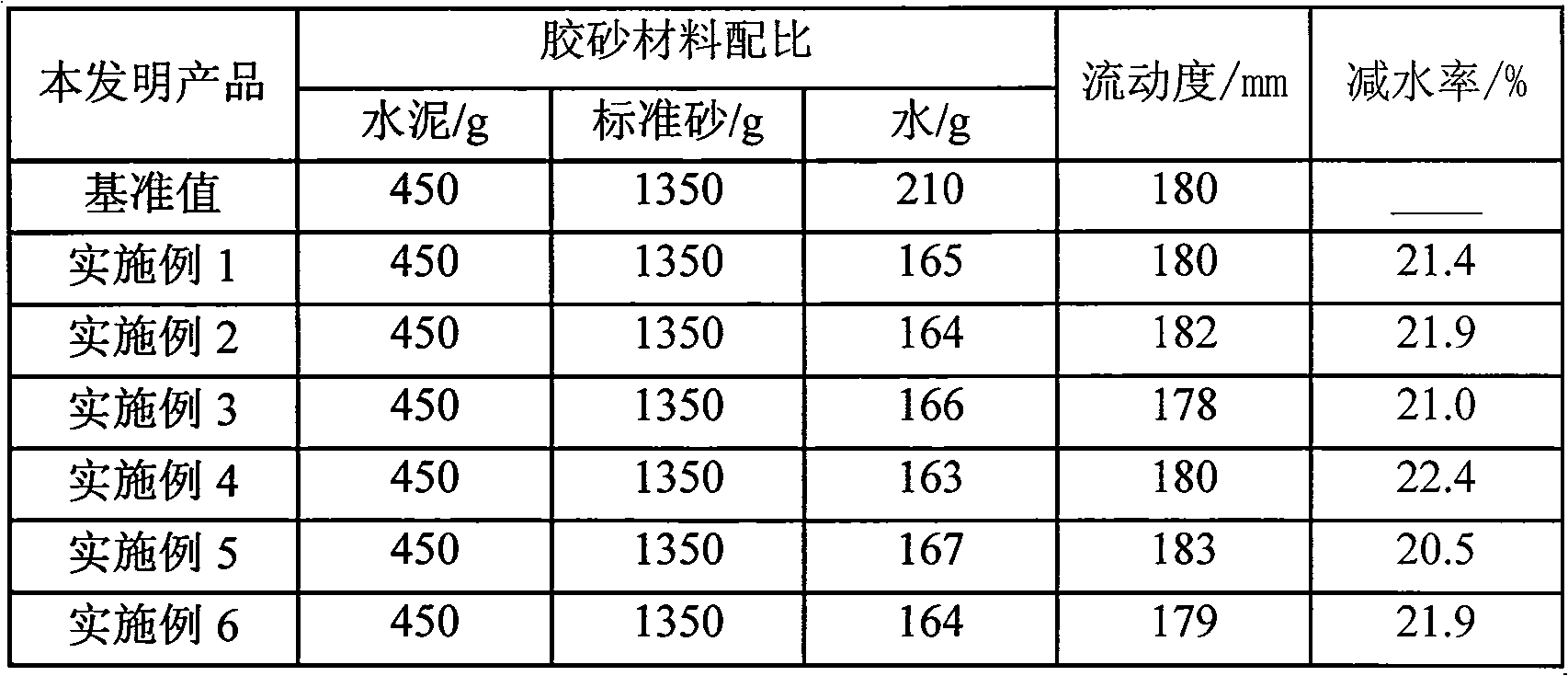

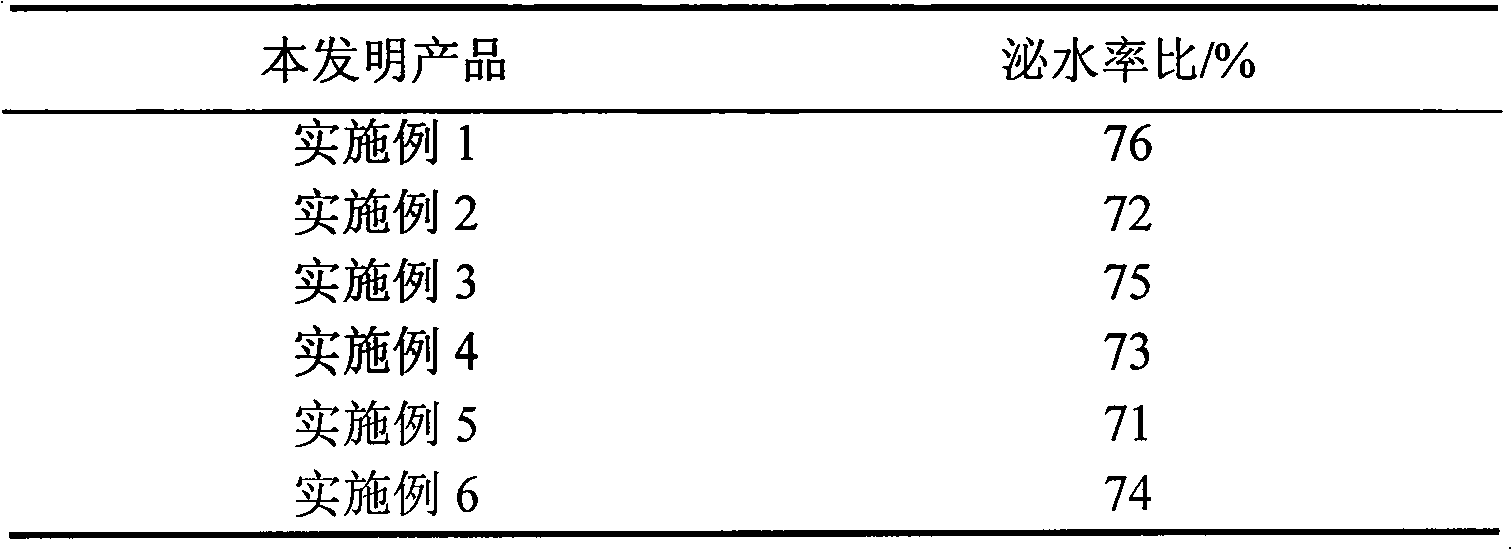

Modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate and preparation method thereof

The invention relates to a method for preparing a modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate, belonging to the field of concrete water-reducing agents. The invention adopts acetone and formaldehyde as condensation monomers and lignosulfonate as a modifying agent and carries out sulfonating and condensation reactions under an alkaline condition to produce anovel high-efficiency concrete water-reducing agent. The preparation method of the novel high-efficiency concrete water-reducing agent comprises the following steps: (1) adding a sulfonating agent, acetone and water to a reactor, increasing the temperature to 25-65 DEG C and reacting for 0.1-1.5 hours; (2) dipping part of formaldehyde solution for 0.25-2.5 hours, increasing the temperature to 70-95 DEG C and reacting for 1-6 hours; and (3) decreasing the temperature to below 60 DEG C, adding the lignosulfonate and the rest of the formaldehyde solution to the reactor, using an alkaline regulator to regulate a pH value of the system to be 8.0-14.0, increasing the temperature to 70-98 DEG C, reacting for 1-5 hours and decreasing the temperature before discharging. The modified aliphatic high-efficiency water-reducing agent is suitable for producing commercial concrete which has similar color as normal concrete and has smaller collapsed slump loss. By adjusting the process, such as proportioning raw materials, and the like and effectively utilizing the lignosulfonate, the invention not only decreases the product cost, but also lessens environmental pollutants and has favorable industrialized prospects.

Owner:NANJING FORESTRY UNIV

Method for preparing biodiesel by using supported solid acid combining cosolvent

InactiveCN101418225AReduced post-processingReaction is easy to controlMolecular sieve catalystsBiofuelsBiodieselAlcohol

The invention discloses a method for producing biodiesel in the presence of a supported solid acid catalyst and a solubilizing agent. The method is characterized in that: (1) a hydrophobic solid acid catalyst which is high in catalytic efficiency, recyclable, easily separable and simple in post treatment process is adopted; (2) a cosolvent is introduced during a reaction process to improve reaction conditions and reduce reaction temperature and pressure; (3) the cosolvent and lower alcohols used in the reaction can be recycled; and (4) equipment corrosion and environmental pollution are avoided and advantages of low requirements on equipment corrosion, short technical process, environmental-friendly production, low investment in equipment and low operation cost are achieved.

Owner:BEIJING UNIV OF CHEM TECH

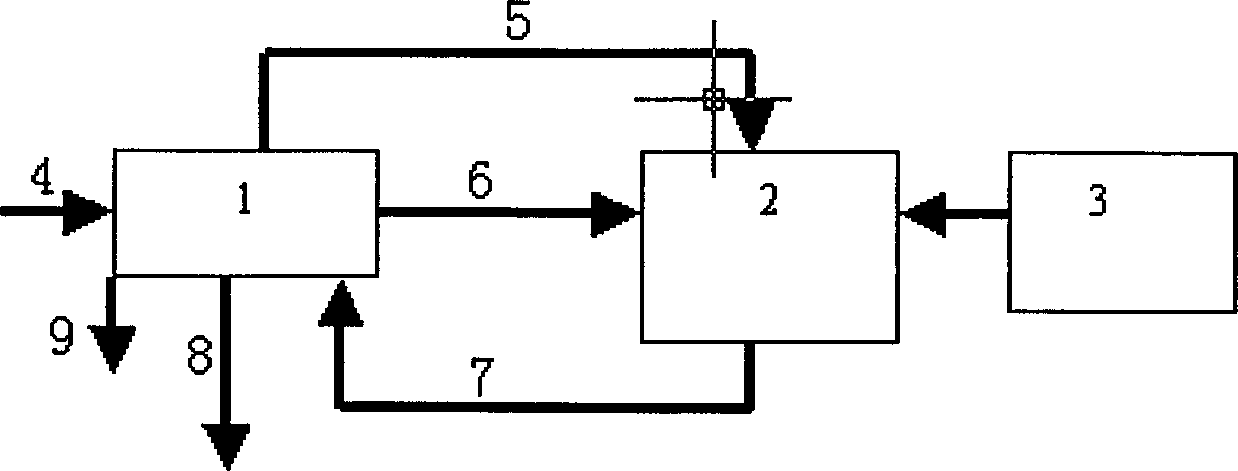

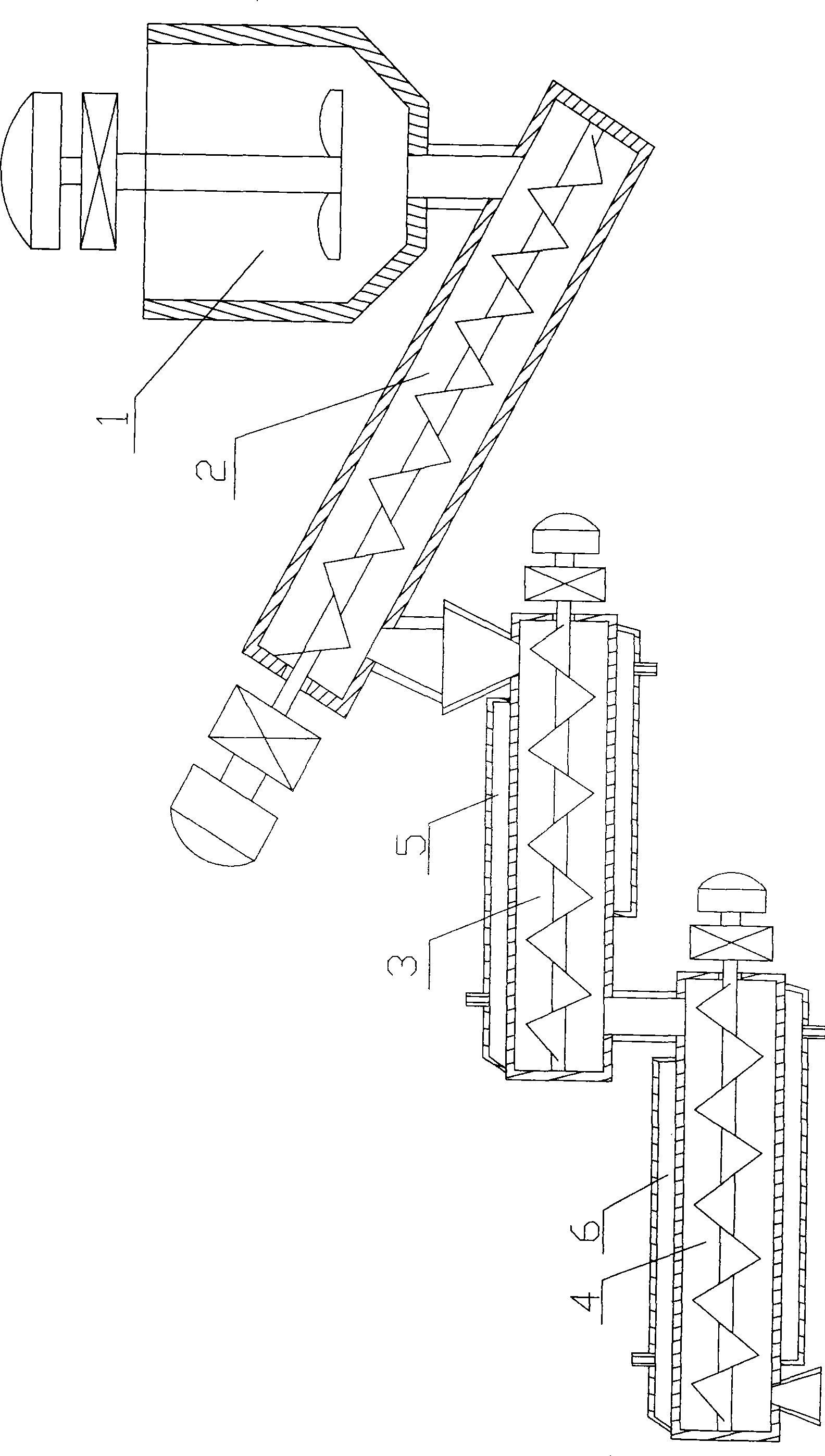

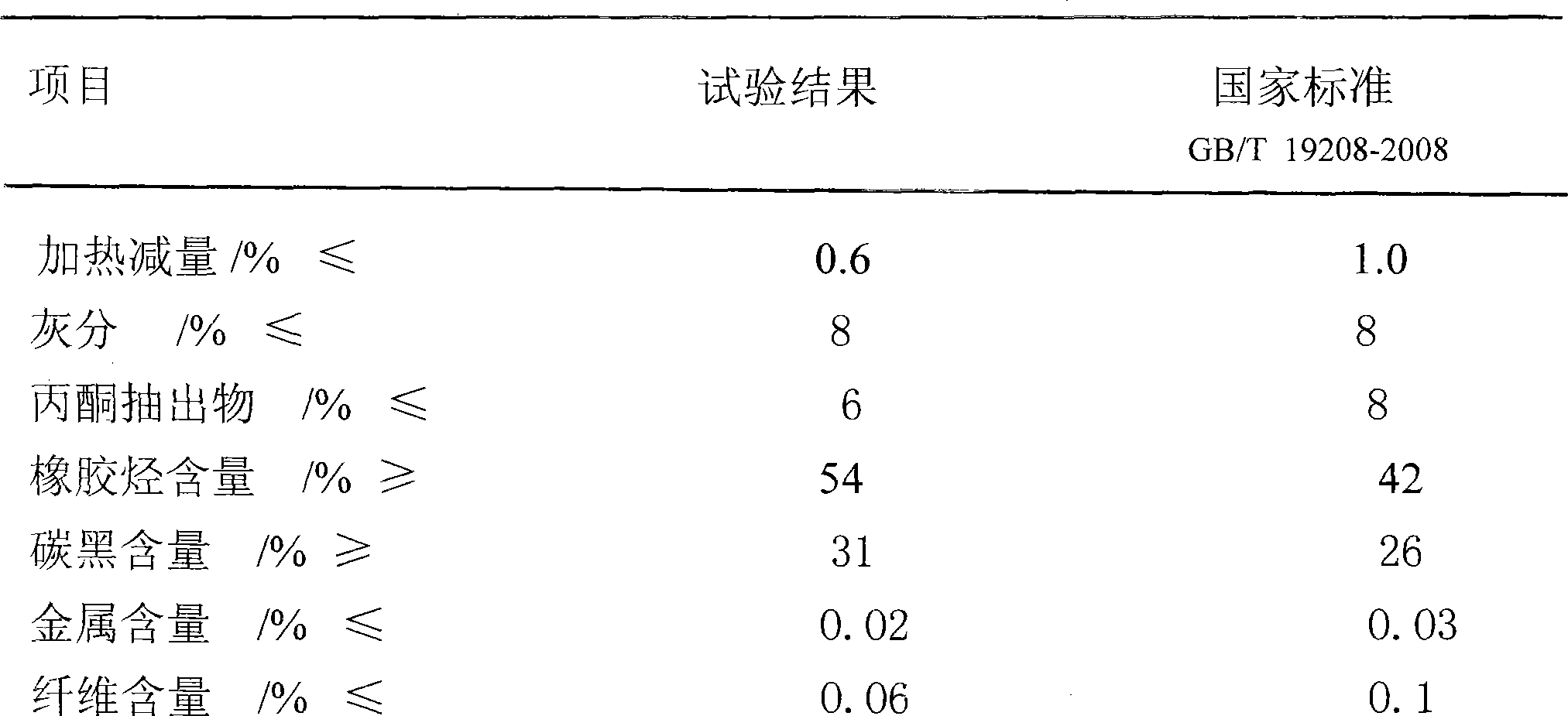

Automatic rubber powder plasticizing process and apparatus thereof

The invention relates to a technique of automatic rubber powder plasticization which carries out plasticization to the rubber powder in the recovery, processing and utilization of waste rubber. The waste rubber powder is smashed to 10 meshes to 40 meshes, added with an activator and a softer according to a weight ratio of 1:0.3-0.4 percent: 8-18 percent, evenly mixed, and heated to 180 DEG C to 320 DEG C with temperature preserved for 8min to 15min; then desulfurization and plasticizing are carried out, and plasticized rubber powder is obtained after being cooled. The invention also provides a device for plasticizing processing, which comprises a stirring device (1), a feeding device (2), a thermal reaction device (3) and a cooling device (4), which are all communicated with each other in sequence. The technique is simple, can realize automatic continuous production, has no pressure and no discharging of waste gas and no pollution, is safe and reliable, and has stable quality stable and easy control. The plasticized rubber powder processed can be directly used for the production of rubber products without dehydration, thereby saving energy, reducing consumption and having little investment and low cost. The device can realize automatic continuous production, and is simple in structure, easy and convenient in operation, easy to control and low in cost.

Owner:TAIAN JINSHAN RUBBER IND

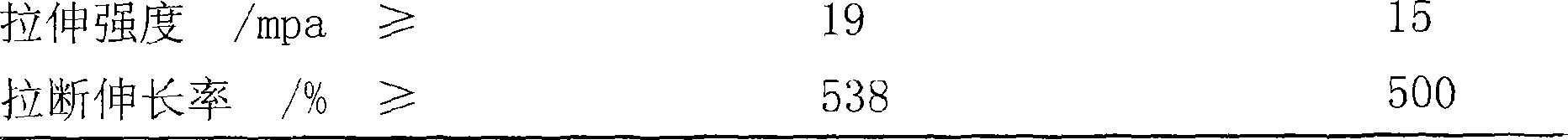

Ultraviolet light-heat dual-curing gloss oil, and preparation method and application thereof

ActiveCN102649895AIncreases aesthetics and resistanceLong storage timePolyurea/polyurethane coatingsEpoxy resin coatingsIsocyanateDefoaming Agents

The invention relates to ultraviolet light-heat dual-curing gloss oil for a transfer film, and a preparation method and application thereof. The ultraviolet light-heat dual-curing gloss oil comprises the following components by part by weight: 20 to 70 parts of resin composition, 10 to 50 parts of diluting monomer, 1 to 10 parts of photoinitiator, 0.01 to 5 parts of polymerization inhibitor, 1 to 10 parts of flatting agent, 1 to 10 parts of defoaming agent and 1 to 10 parts of base material wetting agent, wherein the resin composition is a composition of polyurethane acrylic ester resin containing isocyanate group and resin comprising hydroxyl group. The ultraviolet light-heat dual-curing gloss oil is applied to the transfer film industry, so that the problems of low glossiness of printing ink and low resistance and wear resistance of the surface ink layer are effectively solved, the delay curing characteristic of a gloss oil protective layer is improved, the protective layer gloss oil can be extended on the surface of a three-dimensional object completely to form a transfer pattern with good glossiness, the service life is prolonged, and the ultraviolet light-heat dual-curing gloss oil can be stored for 12 months under the conditions of normal temperature and dark place.

Owner:中国印刷科学技术研究所

Method for abstracting tea seed oil from camellia oleifera seed

InactiveCN101096612AReduce the number of operationsQuality controllableEnzymesFatty-oils/fats productionCamellia oleiferaSlurry

The invention discloses an extracting method of tea seed oil from tea seed, which comprises the following steps: adopting tea seed core as raw material; grinding to add water to stir into slurry; adding amylase or / and cellulose enzyme to enzymolyze; separating to obtain the product. The invention improves the oil-out rate more than traditional extracting method, which remains more non-oil nourishing element.

Owner:HUNAN AGRICULTURAL UNIV

Method for preparing biodiesel by lowering value of high acid palm oil

InactiveCN101230309AReduce energy consumptionLow acid valueFatty acid esterificationBiofuelsChemistryAcid value

The invention provides a method which uses palm oil to prepare biologic diesel oil and can lower the high acid value. The method uses solid super acids of SO>4<2- > / ZrO2, SO4< 2- > / TiO2, and SO4< 2- > / xZrO<2- yTiO2 as catalyst, and uses low-carbon alcohol as esterifying agent to pre-treat the high acid value palm oil, can effectively lower the acid value of the oil, and can ensure the acid vale of the obtained biologic diesel oil to easily meet the standard (less than 0.8mgKOH / g, ASTM). The catalyst used by the invention has high catalytic activity, and is reusable. The process flow is simple, the production cost is decreased, and the environmental pollution is reduced greatly.

Owner:SICHUAN UNIV

Bicomponent terminal mercapto polyurethane mildewproof sealant and preparation thereof

InactiveCN101434825AImprove mechanical propertiesLess irritatingOther chemical processesPolyureas/polyurethane adhesivesVulcanizationAntioxidant

The invention relates to a dual-component sulfhydryl-terminated polyurethane mildew-proof sealant and a preparation method thereof, wherein, the sealant consists of component A and component B, wherein, according to the parts by weight, the component A comprises 80-120 parts of sulfhydryl-terminated polyurethane liquid rubber, 20-200 parts of filling material, 10-100 parts of plasticizer, 0.5-10 parts of tackifier, 0.1-5 parts of mould inhibitor, 0-5 parts of vulcanization regulator, and 0-5 parts of antioxidant; the component B comprises 80-120 parts of vulcanizing agent, 20-150 parts of plasticizer, 20-200 parts of filling material, and 0-5 parts of vulcanization regulator; and the proportion of component A and component B is 10:0.5-2. The mildew-proof sealant has the tensile strength of 5.0MPa, breaking elongation rate of 1020 percent, the bonding strength with the concrete of 2.5MPa, and the mildew-proof level of being less than or equal to 1; the sealant can be used for the fields such as electrons, mechanicals, and the like, can meet the sealing and mildew-proof requirement under the conditions of long-term water immersion, damp-heat or other conditions where mildews are easy to breed, has no exhaust of three wastes and is friendly to environment.

Owner:HENAN YONGLI CHEM

Ageing-resistant heat-insulation tarpaulin and production method thereof

InactiveCN101792975AImprove waterproof performanceGood insulation performanceHeating/cooling textile fabricsTextile treatment by pouringFiberPre treatment

The invention discloses an ageing-resistant heat-insulation tarpaulin. The tarpaulin is composed of a polymer cloth base and an ageing-resistant heat-insulation coating which is coated on the polymer cloth base in a casting mode. After aging is quickened for 236 hours by simulating natural manual work, the tensile strength of the tarpaulin is improved by at least 10%, the elongation at break thereof is improved by at least 5% than the elongation at break before aging, the ultraviolet reflectivity thereof is more than or equal to 80%, and the infrared obstruction rate thereof is more than or equal to 85%. The invention also discloses a preparation method thereof, comprising the following step: pretreating a heat-insulation material by utilizing a surface treating agent; and premixing the heat-insulation material with accessory ingredients such as vinyl type polymer, antioxidant and the like, then putting the heat-insulation material and the accessory ingredients into a double-screw extrusion casting coating machine to be fused, plasticized and extruded out to be casted and coated on the polymer fiber cloth base, and carrying out cooling shaping and reeling by utilizing a cooling roll to obtain the ageing-resistant heat-insulation tarpaulin. The tarpaulin product obtained by the invention has favourable water proofness, heat-insulating property and ageing-resistant property, wide application range, no pollution in the production process, small energy consumption, low cost and easy popularization and application.

Owner:SICHUAN UNIV

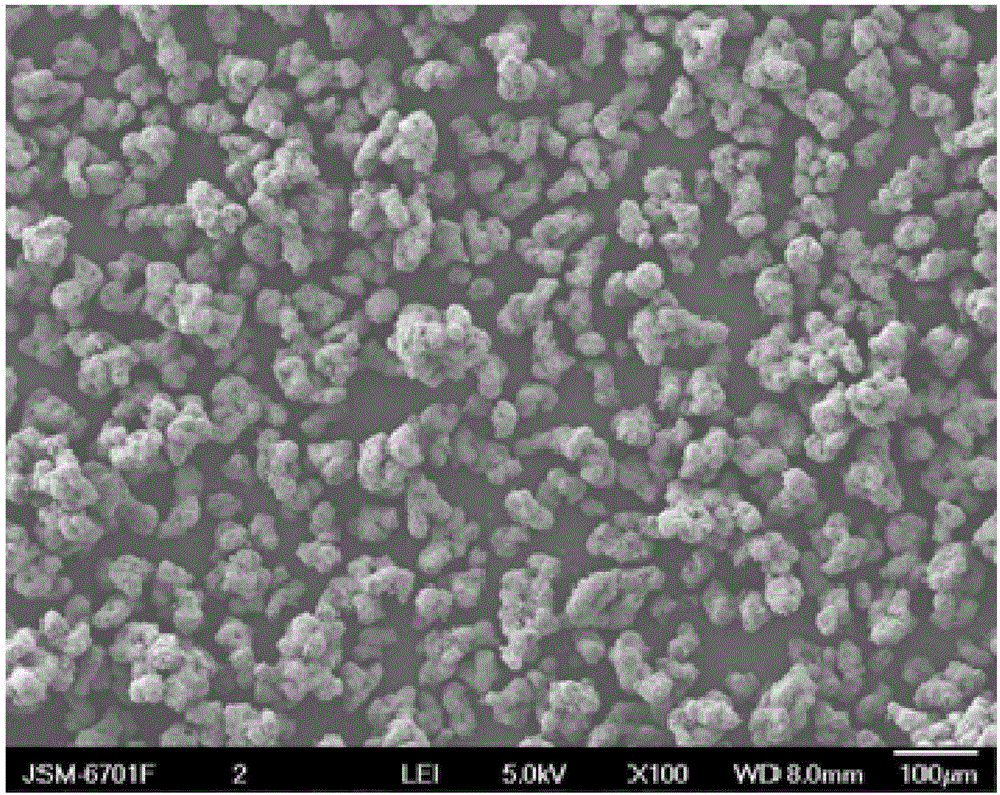

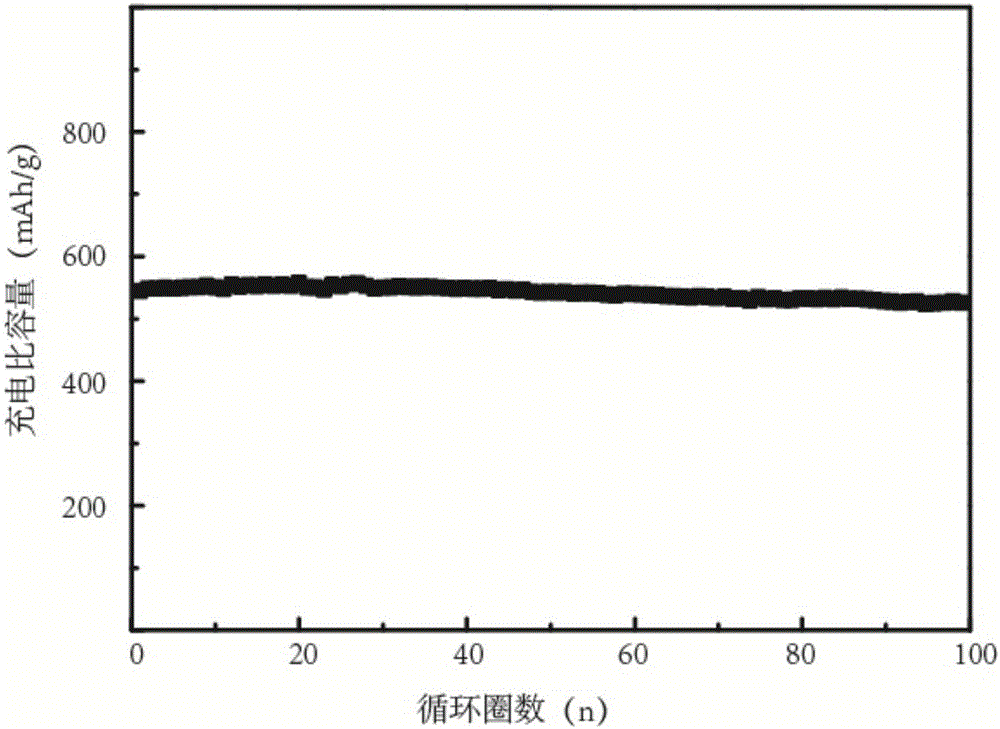

Graphene modified silicon monoxide and carbon composite microsphere, and preparation method and application thereof

ActiveCN106410158AAlleviate volume expansionActive connectionCell electrodesBatteriesCarbon compositesSilicon monoxide

The invention provides a graphene modified silicon monoxide and carbon composite microsphere prepared from graphene, asphalt and silicon monoxide, and a preparation method and an application thereof. Asphalt and silicon monoxide bulk are adopted as raw materials, so the cost is low; a high temperature and high pressure reaction is adopted to obtain a silicon monoxide and carbon composite material in a liquid phase, so the technology is simple; and a dispersant can be recycled, so no waste liquid is generated, and no toxic substances are discharged. The above obtained material has a small specific surface area, and is in favor of forming a stable SEI film; a graphene two-dimensional material has an obvious modification effect, effectively connects active substances, and alleviates volume expansion of an electrode, and good dispersion and reasonable cavity of silicon monoxide make the material have excellent cycle performances.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com