Colorless and transparent light-cured 3D printing material

A 3D printing and photocuring technology, applied in the field of photocuring 3D printing materials and their preparation, can solve problems such as less research, and achieve the effects of good transparency, low molding shrinkage, and elasticity in transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

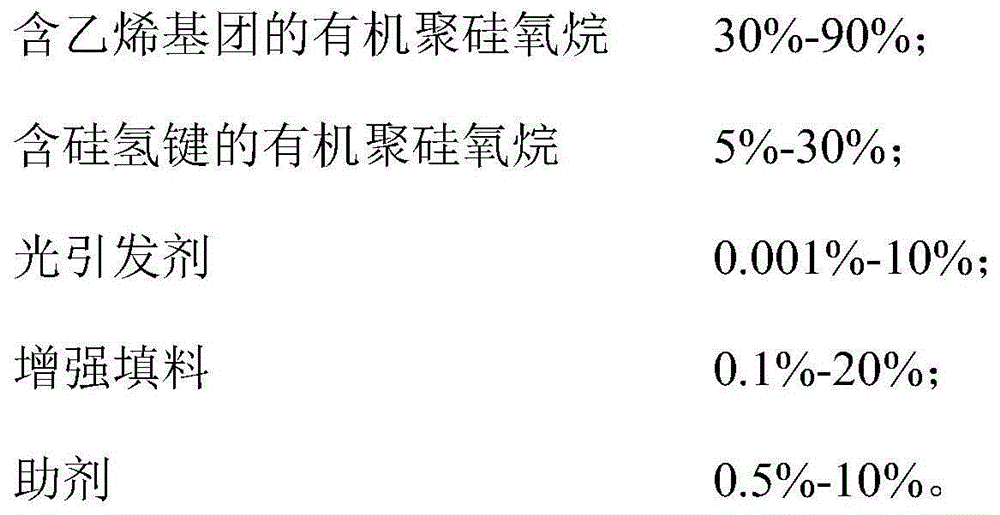

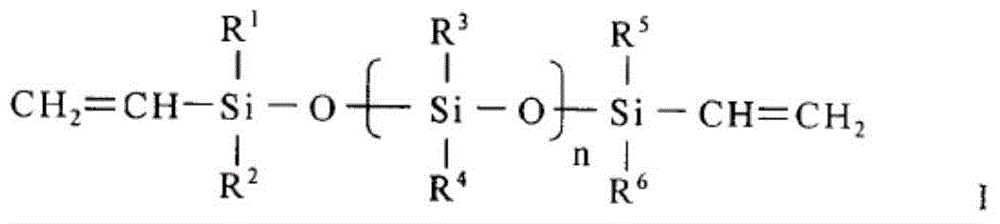

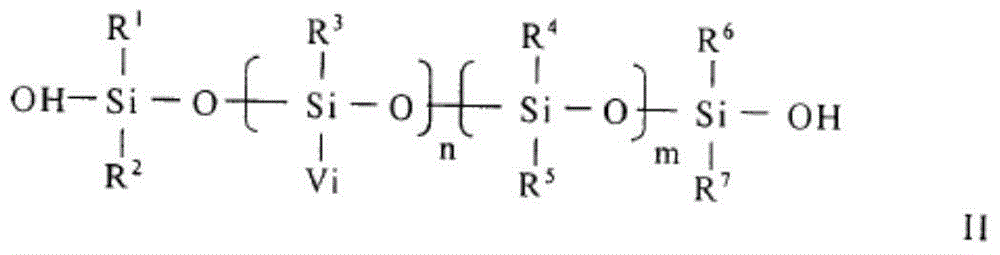

Method used

Image

Examples

Embodiment 1

[0037]

[0038] Preparation Process:

[0039] (1) Mix 70g of dimethylvinylsiloxy-terminated dimethylpolysiloxane, 12g of trimethylsiloxy-terminated methylhydrogenpolysiloxane, 7g of fumed silica, and 8g of inhibitor Mix and stir well.

[0040] (2) Add 3 g of alcohol solution of chloroplatinic acid to the mixture obtained in (1), stir and mix evenly to obtain a colorless and transparent photocurable 3D printing material.

[0041] The light-curing 3D printing material was applied to a light-curing 3D printer in the container, and the printing test was performed at 25°C. The curing rate was fast, and the molded parts had general transparency and high strength.

Embodiment 2

[0043] Dimethylvinylsiloxy-terminated copolymer of dimethylsiloxane and methylphenylsiloxane

[0044]

[0045] Preparation Process:

[0046] (1) Mix 65g of dimethylvinylsiloxy-terminated dimethylsiloxane and methylphenylsiloxane copolymer, 20g of trimethylsiloxy-terminated dimethylsiloxane and methyl The copolymer of hydrogen siloxane, 10g of vinyl-containing MQ resin, and 4g of defoamer were mixed and stirred evenly.

[0047] (2) Add 1 g of the complex of chloroplatinic acid and diethyl phthalate to the mixture obtained in (1), stir and mix evenly to obtain a colorless and transparent photocurable 3D printing material.

[0048] The light-curing 3D printing material was applied to a light-curing 3D printer in a container, and the printing test was performed at 25°C. The curing rate was fast, and the molded parts had good transparency and high strength.

Embodiment 3

[0050]

[0051] Preparation Process:

[0052] (1) Mix 40g of dimethylvinylsiloxy-terminated dimethylpolysiloxane, 30g of trimethylsiloxy-terminated methylhydrogenpolysiloxane, 20g of fumed silica, and 9.999g of inhibitor The agent is mixed and stirred evenly.

[0053] (2) Add 0.001 g of an alcohol solution of chloroplatinic acid to the mixture obtained in (1), stir and mix evenly to obtain a colorless and transparent photocurable 3D printing material.

[0054] The light-curing 3D printing material was applied to a light-curing 3D printer in a container, and the printing test was performed at 25°C. The curing rate was slow, and the molded parts had general transparency and low strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com