Patents

Literature

206results about How to "Low molding shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

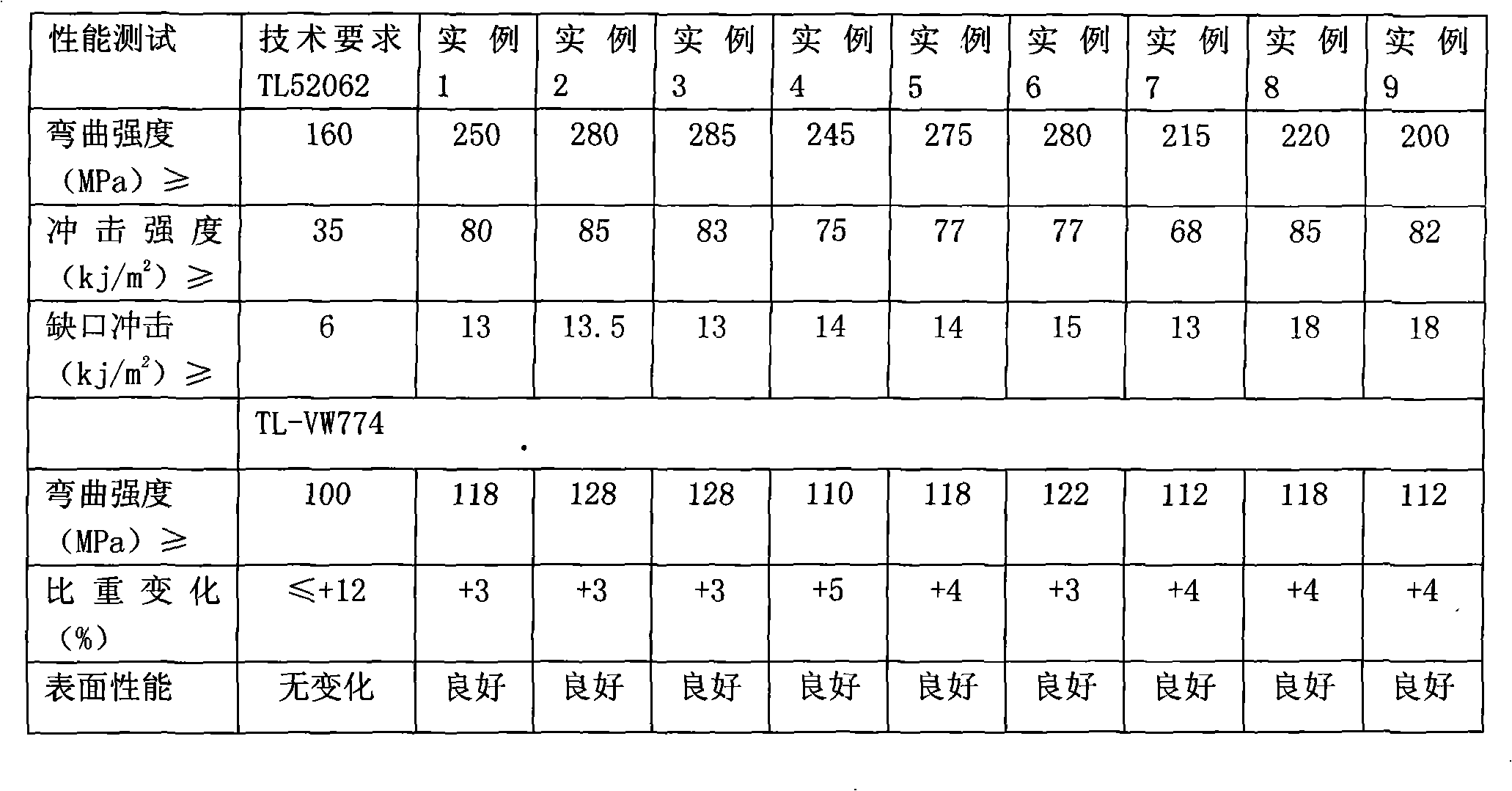

Alcoholysis resistance nylon composite material and preparation method thereof

The invention provides an alcoholysis resistance nylon composite material and a preparation method thereof; the composite material is applicable to the cooling water chamber of vehicles and comprises nylon, short glass fiber, glass fiber emergence resistance regulating additive, nucleating agent, colorant, heat stabilizer and alcoholysis resistance additive. The physical property of the nylon composite material provided by the invention can meet or exceed the TL52062 technical requirement and the alcoholysis resistance chemical property can meet the TL-VW774 technical requirement so that the surface of the product does not change and crack after being placing in 100% of glycol solution for 48h at 135 DEG C and the product has high shock resistance and dimension stability, thus ensuring that the stress cracking does not appear on joints.

Owner:辰东意普万新材料(广东)有限公司

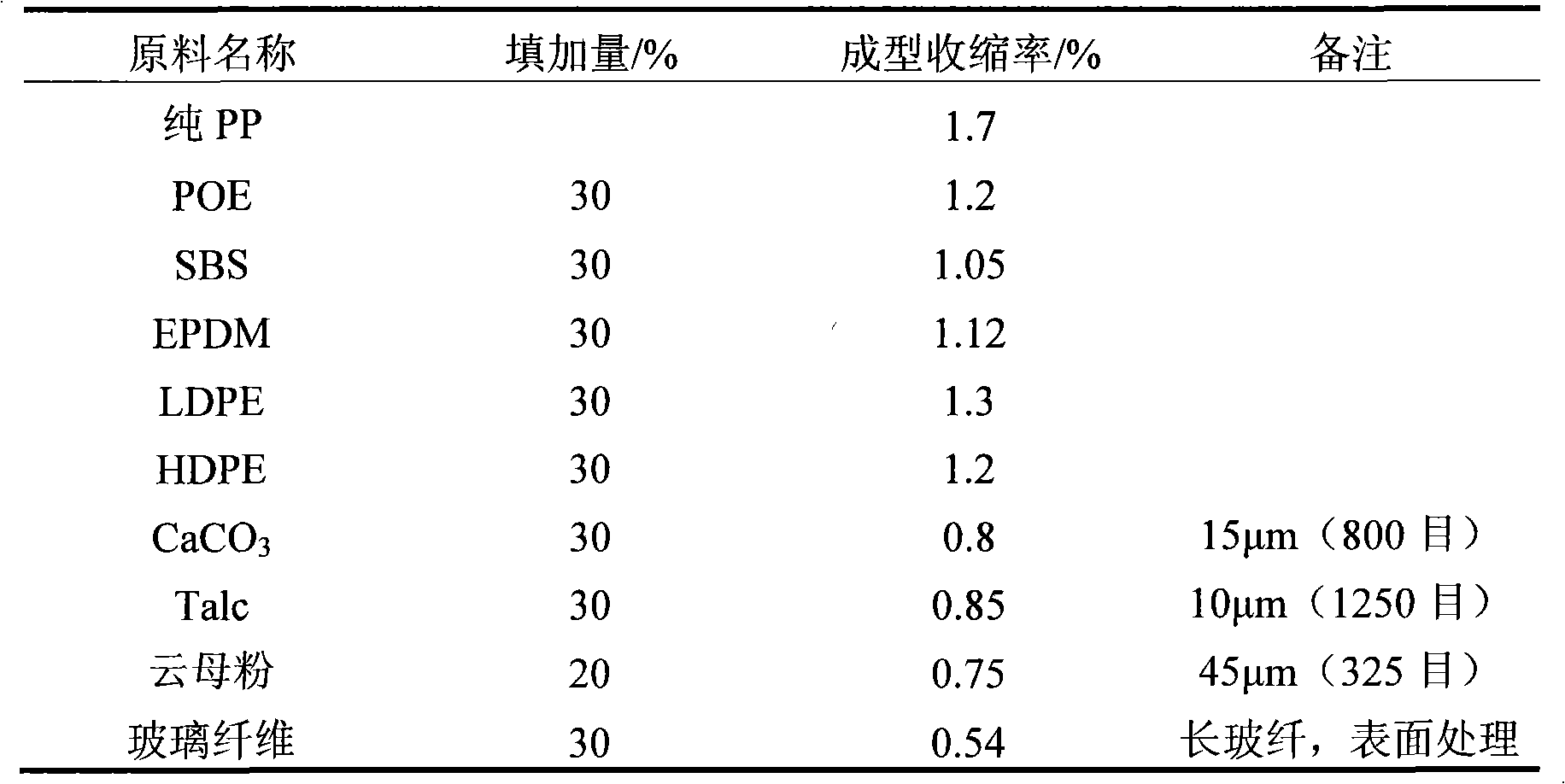

Mineral filled low-shrinkage modified polypropylene composite material and preparation method thereof

The invention relates to a mineral filled low-shrinkage modified polypropylene composite material which belongs to the field of modified polypropylene composite materials and comprises the following ingredients in parts by weight: 40 to 85 polypropylene, 5 to 30 polyethylene, 5 to 20 elastic bodies, 5 to 30 mineral filler, 0.1 to 3 compatilizers and 0.1 to 3 accessory ingredients. The mineral filled low-shrinkage modified polypropylene composite material prepared by the invention has good mechanical property, ensures good apparent performance of the composite material and has lower shrinkage. In addition, the method is simple and feasible and can be popularized and applied in a large scale.

Owner:SUZHOU SUNWAY POLYMER

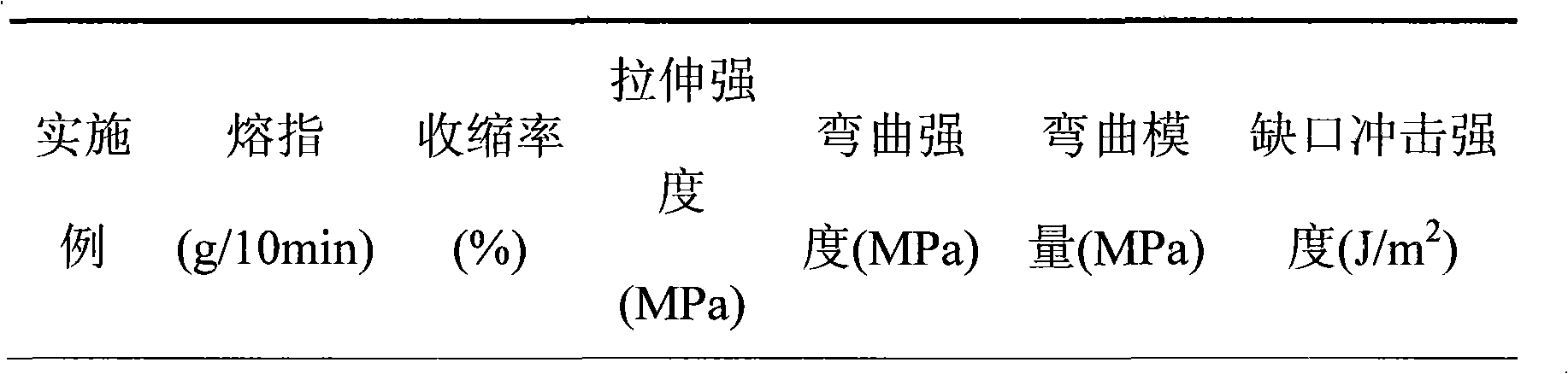

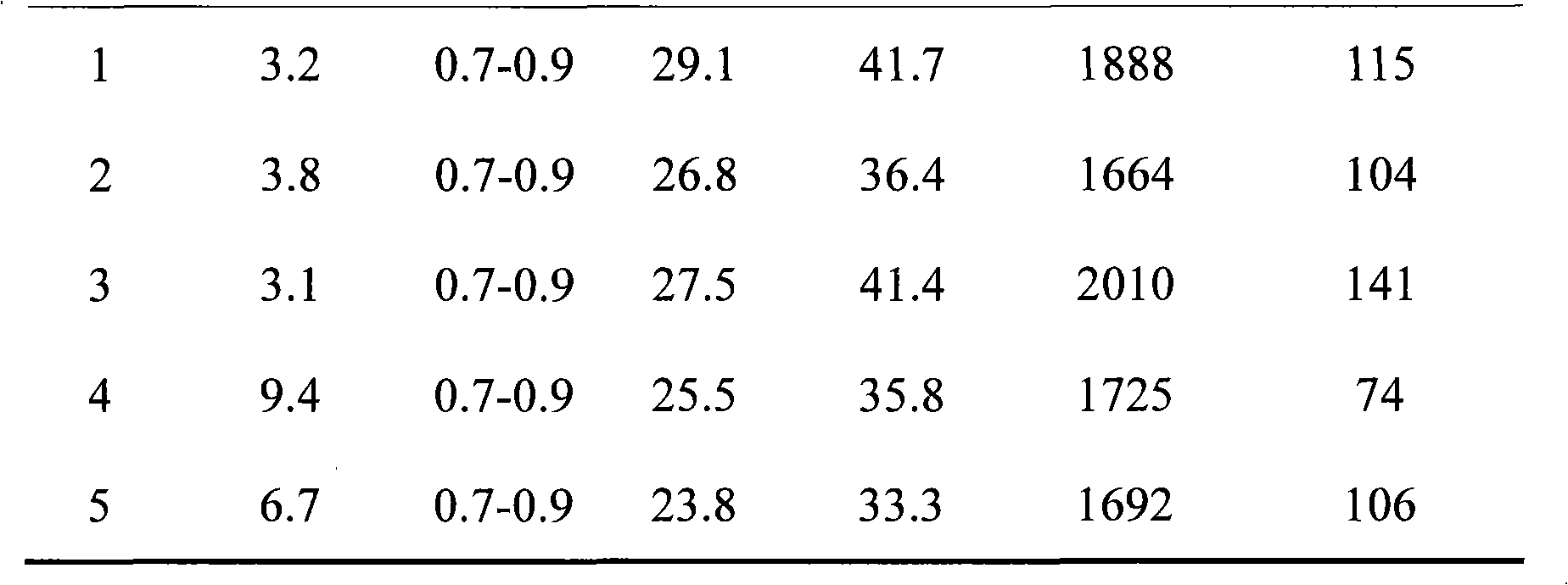

Low-shrinkage sprayable PP/PS blend alloy and preparation method thereof

The invention discloses a low-shrinkage sprayable PP / PS blend alloy and a preparation method thereof. The low-shrinkage sprayable PP / PS blend alloy is prepared from the following components in percentage by weight: 30 to 45 percent of polypropylene resin, 25 to 30 percent of styrene resin, 6 to 12 percent of graft compatilizer, 4 to 8 percent of toughening agent, 15 to 20 percent of functional filler, 0.2 to 0.5 percent of antioxidant, and 0.2 to 1 percent of lubricant. The forming shrinkage of the low-shrinkage sprayable PP / PS blend alloy is as low as 0.7 to 0.9 percent and is closed to the level of ABS, and the low-shrinkage sprayable PP / PS blend alloy can directly replace the ABS under the condition of no die repair and does not influence the appearance of an injection molding product.

Owner:KINGFA SCI & TECH CO LTD +1

Glass fiber reinforced flame retardant polypropylene material for household appliance products and preparation method thereof

The present invention relates to a glass fiber reinforced flame retardant polypropylene material for household appliance products, and belongs to the field of modified polypropylene plastic. The material comprises the following raw materials, by weight: a high-impact-resistance copolymer polypropylene resin, a bromine-based flame retardant agent, antimony trioxide, a flame retardant synergist, alkali-free continuous long glass fibers, a compatibility agent, a toughening agent, a lubricant, a UV absorber and an antioxidant. The present invention provides the glass fiber reinforced flame retardant polypropylene material with higher tensile strength, bending modulus and hardness as well as high impact-resistance, low molding shrinkage, aging resistance and the like. The glass fiber reinforced flame retardant polypropylene material has a high heat deformation temperature, good oxidation resistance at high temperature, and the flame retardant performance up to the level of UL94 V-2, and passes the glow wire test of GWIT: 700 / 3.0. The glass fiber reinforced flame retardant polypropylene material has a low cost and a light weight, and can be used instead of metal or plastic material to produce the household appliance products which need flame retardation and high temperature resistance.

Owner:GUANGDONG JUSHI CHEM CO LTD

Polyamide composition with high dimensional stability and preparation method thereof

InactiveCN101857723AReduce the degree of orderLow water absorptionHeat deflection temperaturePolyamide

The invention relates to a polyamide composition with high dimensional stability and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 60 to 90 of fatty polyamide composition, 2 to 10 of compatilizer, 1 to 10 of inorganic metal compound, 0 to 5 of polysiloxane with low molecular weight and 0 to 2 of auxiliary agent. The preparation method comprises the following steps of: premixing the raw materials in a high-speed mixer for 10 to 30min, controlling the temperature to be 40 to 60 DEG C, then adding premix into a double-screw extruder, conveying, melting, shearing, extruding, cooling and granulating so as to prepare a polyamide composition product with high dimensional stability. Compared with the prior art, the invention shows excellent dimensional stability and heat distortion temperature with high retention rate, is suitable for occasions with higher requirement to the dimensional stability, such as the panel of the air conditioner of an automobile, an instrument panel, a camera bracket, a sports apparatus and the like, and can be directly processed by injection molding or other forming methods.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Long glassfiber reinforced nylon composite material and preparation method thereof

The invention belongs to the technical field of high-molecular composite materials, and relates to a long glassfiber reinforced nylon composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 100 parts of nylon, 2 to 10 parts of compatilizer, 0.1 to 0.5 part of antioxidant, 0.2 to 1.0 part of lubricant and 10 to 40 parts of glassfibers. Compared with the short glassfiber reinforcement mode, according to the composite material provided by the invention, abrasions among short glassfibers, a screw rod and a feed cylinder are decreased during a double-screw extruding process, namely, the minimum fiber retained in an injection-molding product is large in length, so that the glassfiber reinforced nylon composite material with excellent performance is prepared. Thus, the applications of the glassfiber reinforced nylon composite material in the fields of automobiles, electric appliances, machinery, military industry and the like are enlarged.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Foaming composition for water tank of solar water heater

InactiveCN102516494APrevent severe shrinkageNo significant deformationSodium bicarbonateFoaming agent

The invention discloses a foaming composition for a water tank of a solar water heater, which is characterized by comprising the following main raw materials: a polyether foaming agent, sodium bicarbonate, chitosan and hollow glass beads. The improved polyether rigid foam composition can be used for reducing the phenomena that after being sprayed from a glossy jar and formed, a polyurethane material has high contractibility, the heat preservation effect of the water tank of the solar water heater is influenced and the water tank is deformed, bulged and barred, or even cracked.

Owner:杜立立

Compoisite material of polypropylene resin for case of household office electrical equipment and injection products thereof

The invention discloses a polypropylene resin composite, containing polypropylene resin 30-90 wt%, microball 5-70wt%, inorganic micron or nano particles 0-50 wt% and microfiber 0-50 wt%. The composite not only maintains original excellent properties of polypropylene but also has good molding property, balanced rigidity / flexibility, excellent surface quality of components made by injection molding, high surface hardness, property of uneasily scratching, and excellent molding processing property and lower molding shrinkage, able to make direct injection molding in original HIPS and ABS modules, thus replacing HIPS and ABS. It can be used in preparing the outer casing of home appliances and the cases office appliances, especially the front / back cases of TV sets, the outer casing of the remote controllers, etc as well as the cases of duplicating maclines, monitors, etc.

Owner:上海金发科技股份有限公司 +1

Calcium carbonate filler master batch for polypropylene and polyethylene and preparation process thereof

The invention relates to the field of high polymer processing assistants and particularly relates to a calcium carbonate filler master batch for polypropylene and polyethylene and a preparation process thereof. The calcium carbonate filler master batch is prepared from the following ingredients in parts by weight: 60-80 parts of function-modified calcium carbonate whisker, 10-20 parts of carrier resin, 0.5-3 parts of coupling agent and 1-3 parts of lubricant, and is prepared through the steps of keeping all the ingredients at the temperature of 170-210 DEG C for 10-20 min and carrying out extrusion and granulation. The calcium carbonate filler master batch has the advantages that the cost is relatively lower, inorganic particles are uniformly dispersed in a high-polymer matrix, the combination between the inorganic particles and the high-polymer matrix is better, the calcium carbonate filler master batch has bacterium resisting and inhibiting properties, and mechanical properties, such as tensile strength, notched impact strength, wear resistance and the like, are improved.

Owner:JIANDE XINYU PLASTIC MATERIAL

Preparation method of single-component water-based polyurethane adhesive for use in flexible package compounding

ActiveCN103881640AImprove performanceEasy to useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterEpoxy

The invention discloses a preparation method of a single-component water-based polyurethane adhesive for use in flexible package compounding. The method comprises the following steps: reacting polyisocyanate with polyester polyol and polyether polyol, adding a chain extender, and continually reacting to obtain a polyurethane prepolymer; continually reacting epoxy resin with a modifier of a silane coupling agent to obtain a modified polyurethane prepolymer; cooling the modified prepolymer, neutralizing and salifying, and adding water for high-speed dispersion to obtain the single-component water-based polyurethane adhesive for use in flexible package compounding. The method is simple in preparation process, and the obtained single-component water-based polyurethane adhesive is convenient to use.

Owner:SHANDONG HUACHENG HIGH TECH ADHESIVE

Resin-based composite material with controllable linear expansion coefficient and preparation method thereof

ActiveCN102337014ASmall coefficient of linear expansionEasy to produceCompression moldingFilling materials

The invention provides a resin-based composite material with a controllable linear expansion coefficient and a preparation method thereof. The composite material is characterized by mainly comprising the following components in parts by weight: 10 parts of unsaturated polyester resin, 2-30 parts of filling material, 2-20 parts of fiber, 1-5 parts of low shrinking agent, 0.6-2 parts of mould release agent and 0.2-1 parts of initiator, wherein the filling material and fiber are materials with negative expansion coefficients or low expansion coefficients. The preparation method comprises the following steps: evenly mixing 1-5 parts of low shrinking agent, 0.6-2 parts of mould release agent and 0.2-1.5 parts of initiator with 10 parts of unsaturated polyester resin; then adding 2-30 parts of filling material and 2-20 parts of fiber for evenly mixing again; and finally, carrying out compression molding at the temperature of 140-160 DEG C. The linear expansion coefficient of the material provided by the invention is adjustable within a range of (8-30)*10<-6> / DEG C, and the material provided by the invention has isotropy.

Owner:SHENZHEN XINTIAN TECH

In-situ compatibilization polyolefin/polystyrene alloy and preparation method and application thereof

The invention discloses an in-situ compatibilization PO / PS (polyolefin / polystyrene) alloy and a preparation method and application thereof. The alloy is prepared by 45-65% of polyolefin, 10-30% of polystyrene, 2-5% of compatibilization initiation mother liquor and 20-25% of processing agent, and the compatibilization initiation mother liquor is obtained by dissolving crosslinking agent and crosslinking agent auxiliaries to oily carrier., wherein the crosslinking agent is at least one of 2, 5-dimethyl-2, 5-di (tertiary butyl peroxide) hexine, 2, 5-dimethyl-2, 5-di (tertiary butyl peroxide) hexane or dicumyl peroxide, and the crosslinking agent auxiliaries is at least one of liquid polybutadiene, prussic acid ester type substances, isocyanate substances or acrylate substances. Compared withthe dynamic sulfuration in-situ compatibilization method and the common compatibilization method, the preparation of the in-situ compatibilization PO / PS alloy is capable of effectively reducing production cost of the PO / PS alloy, the PO / PS alloy prepared has lower molding shrinkage rate, higher modulus and excellent overall performance and can be used as substitutes for acrylonitrile butadiene styrene partially.

Owner:KINGFA SCI & TECH CO LTD +2

Heat resistant polyamide composite and applications thereof

ActiveCN102372921AImprove reflectivityImprove initial whitenessSemiconductor devicesFiberGlass fiber

The invention discloses a heat resistant polyamide composite and applications thereof. The composite comprises the following components by weight percent: 40%-90% of heat resistant polyamide resin, 5%-35% of mineral fiber A, 0-35% of mineral filler B, 0.1%-1% of light stabilizer, 0.1%-1% of flow modifier and 0.1%-1% of antioxidant. The heat resistant polyamide resin of which concentration ratio of amino end groups to carboxyl end groups is 0.1-0.8, as well as the irregular glass fiber of which thickness-breadth ratio is 2-6, the mineral filler B and the flow modifier, is selected to prepare the heat resistant polyamide composite; and the composite has high original brightness and reflectivity, excellent heat resistance, good formability and good dimensional stability and can be used to prepare the reflection supports of light sources such as the backlights, vehicle headlights, instrument panels and illuminating implements of liquid crystal displays such as portable phones, computers, televisions and the like.

Owner:KINGFA SCI & TECH CO LTD +1

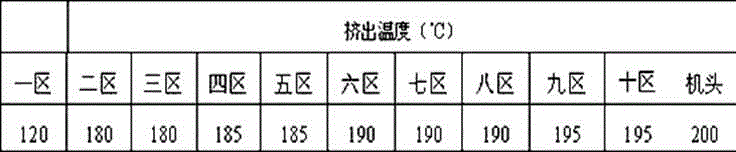

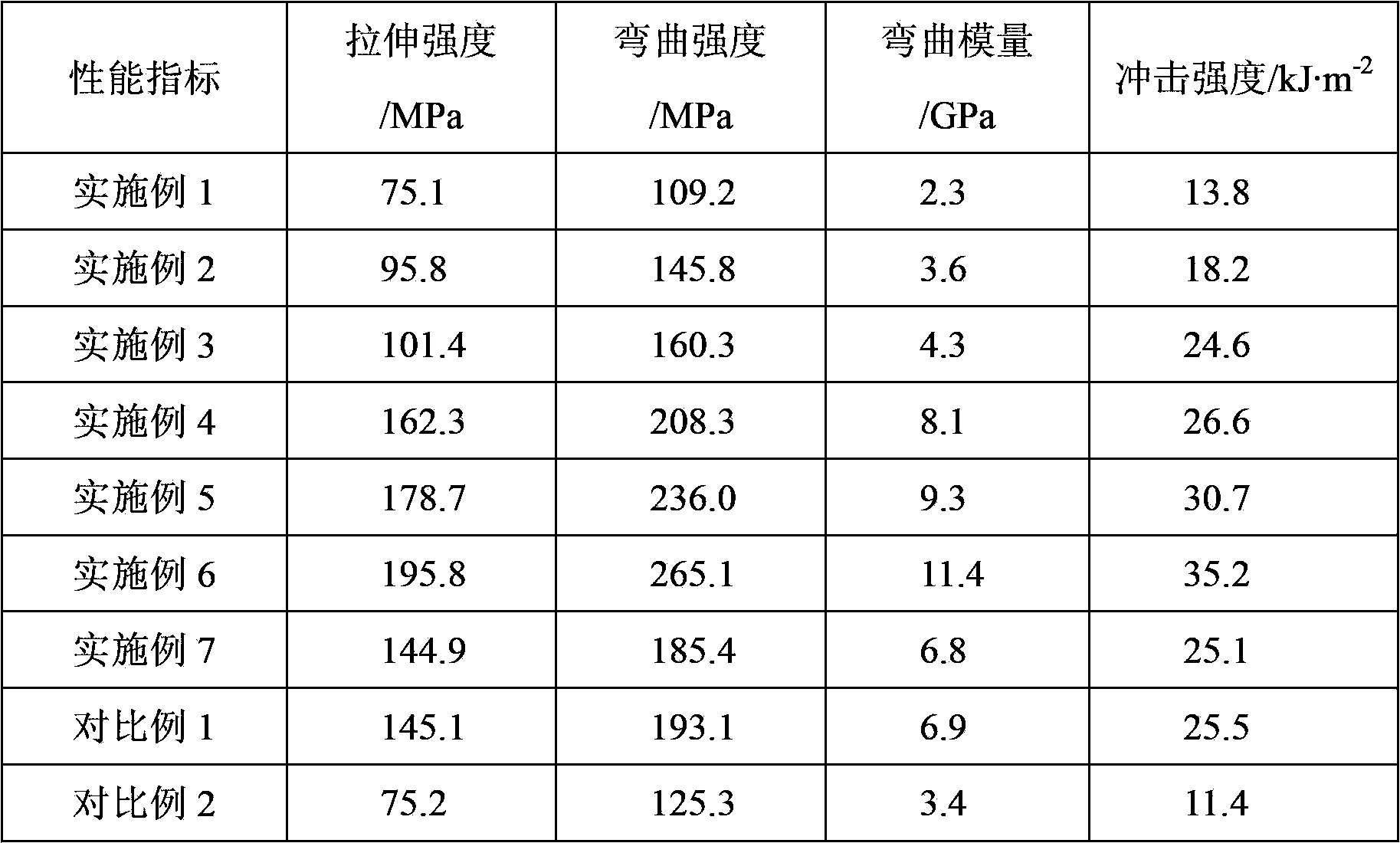

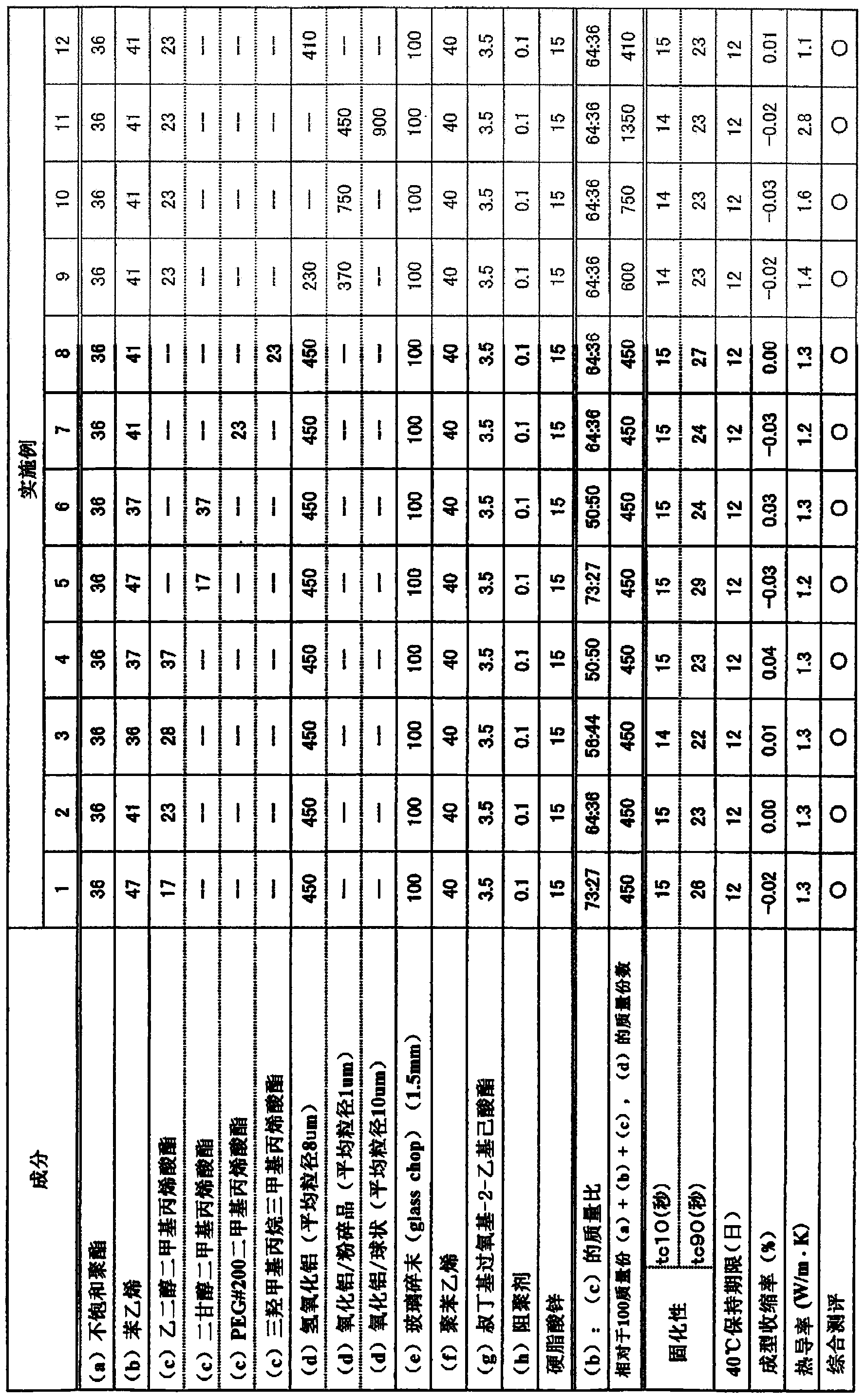

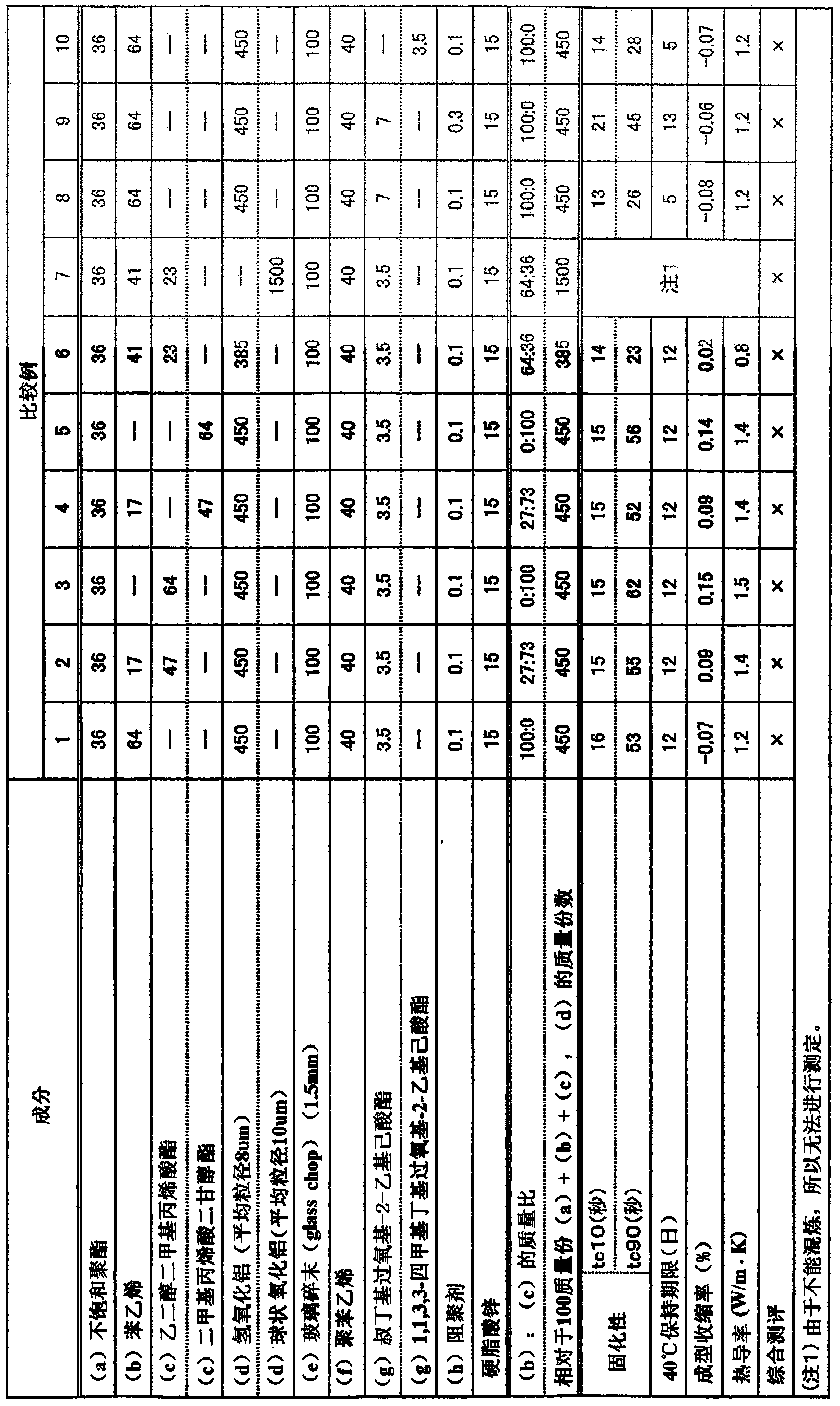

Unsaturated polyester resin composition and encapsulated motor

ActiveCN103987747ALow molding shrinkageHigh thermal conductivityWindings insulation materialSemiconductor/solid-state device detailsGlass fiberShrinkage rate

The present invention is an unsaturated polyester resin composition that contains (a) an unsaturated polyester, (b) a monomer that has one polymerizable carbon-carbon double bond, (c) a monomer that has two or more (meth)acrylate groups, (d) a high-thermal-conductivity filler, (e) glass fibers, (f) a shrinkage-reducing agent, (g) a hardener, and (h) a polymerization inhibitor. This unsaturated polyester resin composition is characterized in that: the mass ratio between component (b) and component (c) is between 50:50 and 75:25, inclusive; and the composition contains 400 to 1400 parts of component (d) per 100 total parts of components (a), (b), and (c) by mass. This unsaturated polyester resin composition exhibits a low molding shrinkage rate and a high thermal conductivity when cured, and despite being easy to cure, exhibits good storage stability.

Owner:RESONAC CORP

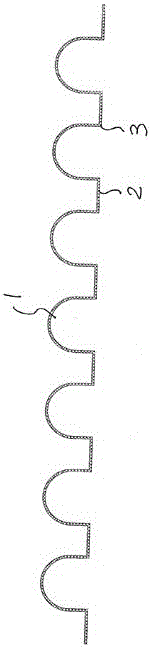

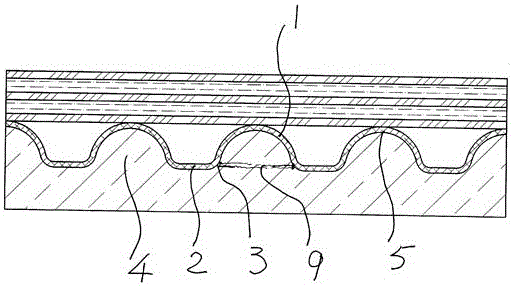

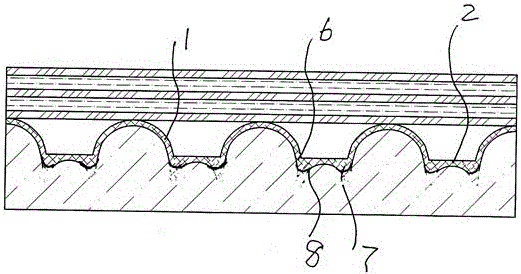

Waterproof board, draining board or waterproof and draining board and production method thereof

ActiveCN106046521AImprove connection strengthGood weather resistanceUnderground chambersDrainageStress concentrationLinear low-density polyethylene

The invention belongs to the technical field of waterproof materials for buildings and discloses a waterproof board, a draining board or a waterproof and draining board used between a primary tunnel support and a secondary lining. According to the technical scheme, the waterproof board, the draining board or the waterproof and draining board comprises a plurality of convex shells and plastic base plates connected between adjacent convex shells, and the convex shells and the plastic base plates are integrated. The waterproof board, the draining board or the waterproof and draining board is characterized in that each convex shell is semispherical, and the joint of each base plate and the corresponding convex shell is arc-shaped or of a chamfer structure; the base plates and the semispherical convex shells are made of linear low-density polyethylene, polyethylene, high-density polyethylene, toughening agent, antioxidant and metal deactivator. By the waterproof board, the draining board or the waterproof and draining board with improved mechanical performance, the problems that stress concentration occurs at the joints of the convex shells and the plastic base plates and concrete arranged in the convex shells is uncompacted are solved, and the problem that consideration cannot be given to both the extension property and the pressure resistance of the draining board is solved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

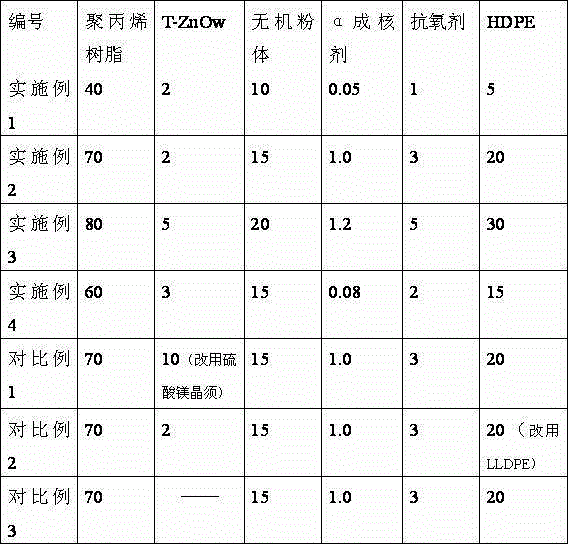

Low-shrinkage modified polypropylene material

The invention discloses a low-shrinkage modified polypropylene material. The material is prepared from the following raw materials in parts by weight: 40-80 parts of polypropylene resin, 2-5 parts of tetrapod-shaped ZnO whisker, 10-20 parts of inorganic powder, 0.05-1.2 parts of an alpha-nucleating agent, 1-5 parts of an anti-oxidant, and 5-30 parts of high density polyethylene; the polypropylene resin is co-polypropylene K9026, and in a test condition of 230 DEG C x 2.16kg, the melt flow rate of the co-polypropylene K9026 is 30g / 10min. Synergism of the whisker, the high density polyethylene and the inorganic powder is used, especially the tetrapod-shaped ZnO whisker is added, so that the moulding shrinkage of the polypropylene is substantially reduced, and the mechanical property of the material is substantially improved.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

A kind of high-strength nylon compound and preparation method thereof

The invention discloses a high-strength nylon composite, which consists of nylon 6 or nylon 66 with a mass percentage of 43.1% to 74.4%, alkali-free long glass fibers with a mass percentage of 20% to 50%, and magnesium with a mass percentage of 5%. It consists of salt whiskers, 0.2% to 1% by mass of nylon chain extender, 0.1% to 0.3% by mass of antioxidant and 0.3% to 0.6% by mass of lubricant. The high-strength nylon compound of the present invention adds formulation materials: magnesium salt whisker, nylon chain extender, antioxidant and lubricant on the basis of main material being nylon 6 or nylon 66, alkali-free long glass fiber, can have greatly Increases the physical and mechanical properties of nylon compounds. The advantages of the high-strength nylon compound of the present invention are: doubled mechanical properties, significantly improved heat resistance, reduced molding shrinkage, reduced water absorption, significantly improved creep resistance and fatigue resistance.

Owner:广东奇德新材料股份有限公司

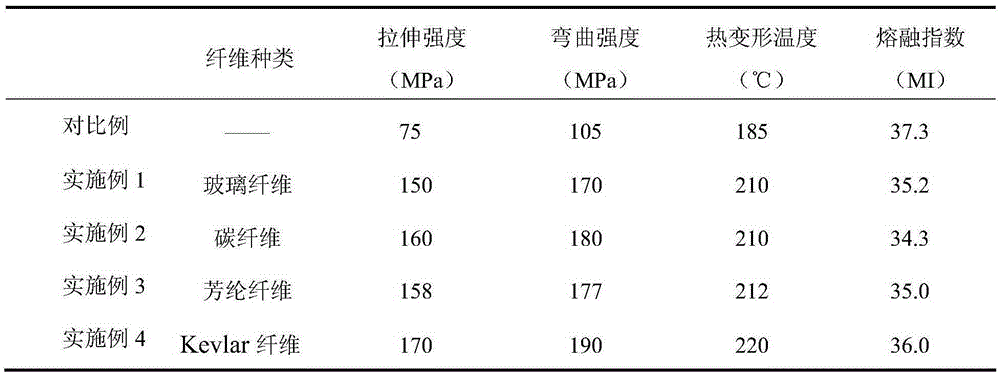

Preparation method of high-performance modified polysulfone resin

The invention discloses a preparation method of high-performance modified polysulfone resin. Monomers such as bisphenol A, 4,4'-dichlorodiphenyl sulfone and chain extender are used for preparing polysulfone resin, and then modification is conducted on the polysulfone resin through fibers, wherein when modification is conducted, a mixture comprises the components of 50%-90% of the polysulfone resin, 10%-50% of the fibers and 0.1%-5% of auxiliaries. According to the prepared high-performance modified polysulfone resin, the heat resistance is good, mechanical properties such as the stretching strength, the tensile strength, the tensile strength and the impact toughness can all be greatly improved after modification, and other excellent properties are kept constant.

Owner:JIANGMEN YOUJU NEW MATERIALS

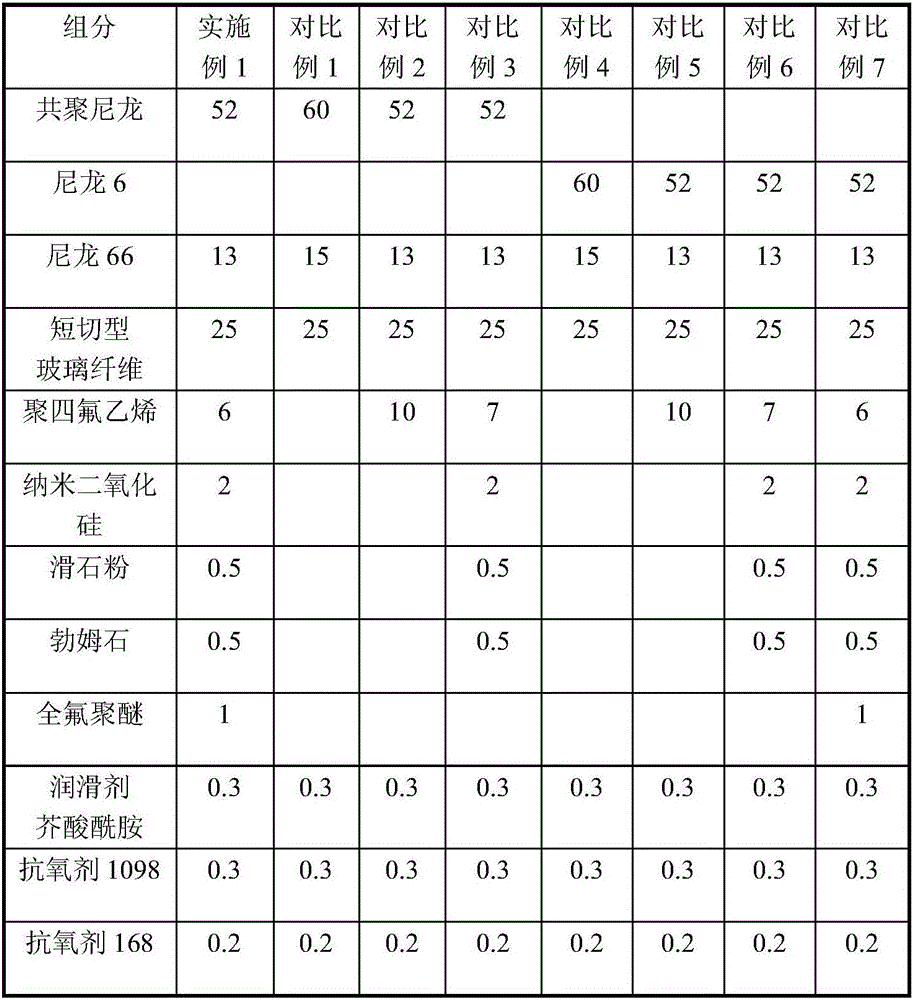

Wear-resistant high-impact-resistance nylon composite material, and preparation method and application thereof

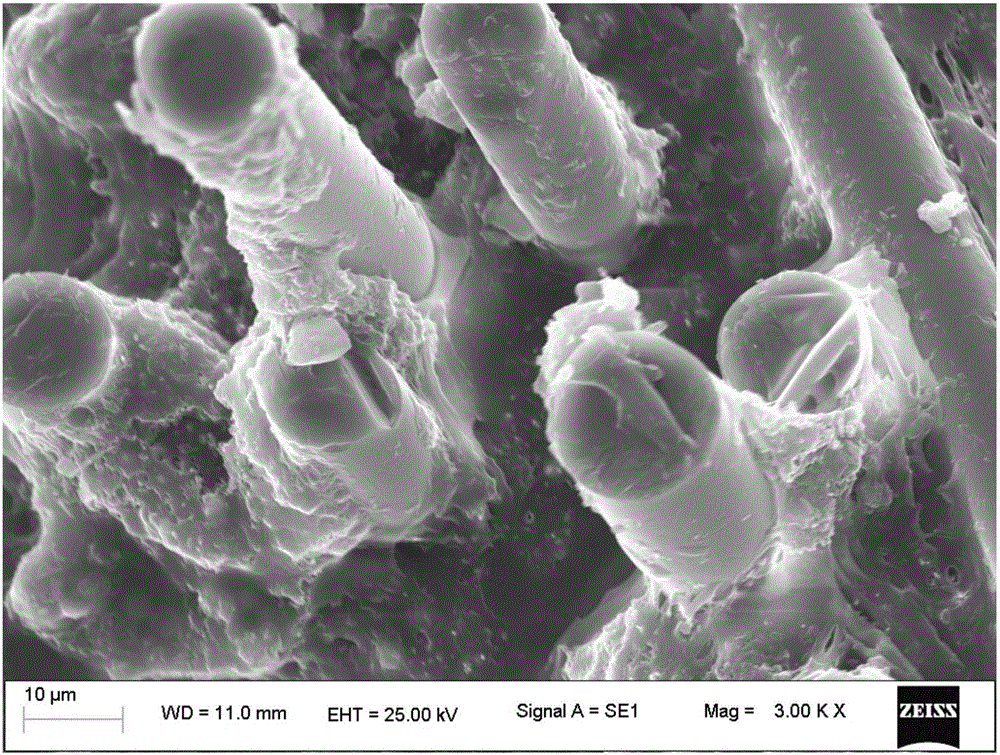

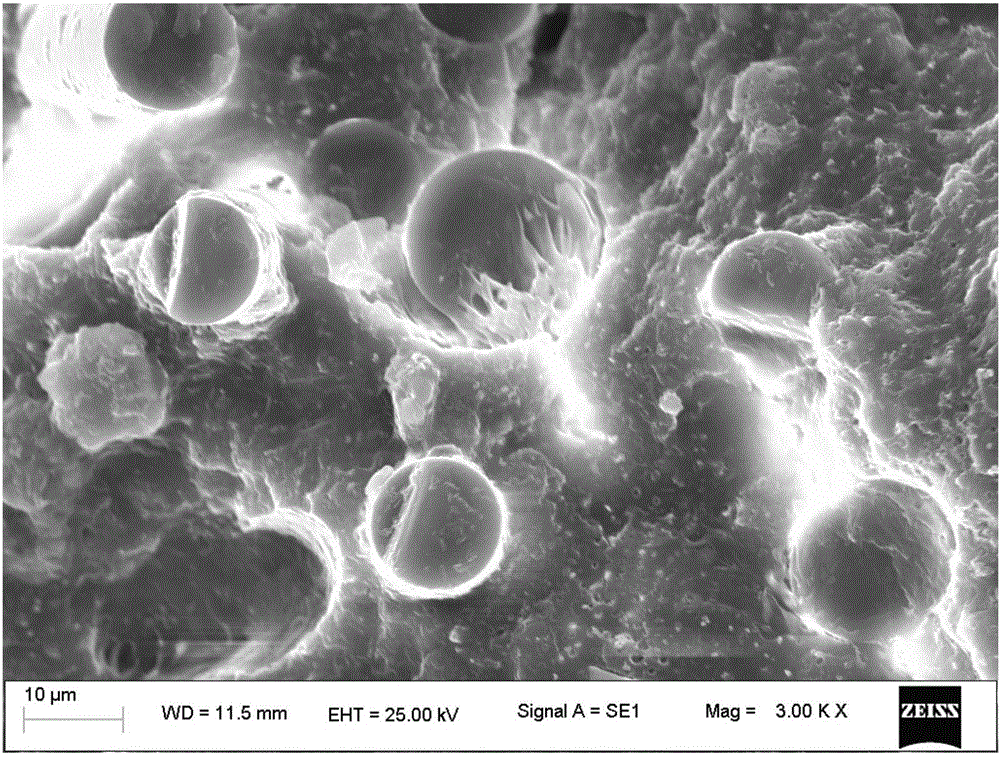

The invention relates to a wear-resistant high-impact-resistance nylon composite material which comprises the following components in parts by weight: 20-80 parts of nylon resin, 10-50 parts of fiber material, 10-40 parts of anti-wear agents, 0.1-2 parts of surface treating agent perfluoropolyether, 0.1-1.0 part of lubricant and 0.1-0.6 part of antioxidant. The preparation method comprises the following steps: uniformly mixing different types of anti-wear agents at medium speed; heating to 90-100 DEG C, adding the perfluoropolyether, and uniformly mixing at high speed; adding the nylon resin, lubricant and antioxidant, and continuing mixing uniformly; and carrying out melt blending extrusion, drawing, cooling, and granulation on the obtained mixture and fiber material through a double screw extruder, thereby obtaining the wear-resistant high-impact-resistance nylon composite material. The wear-resistant high-impact-resistance nylon composite material has the advantages of low friction factor, favorable wear resistance, high mechanical strength, favorable heat resistance, excellent toughness, excellent impact resistance, low mold shrinkage rate, favorable dimensional stability, favorable flowability and high processability.

Owner:株洲时代工程塑料实业有限公司

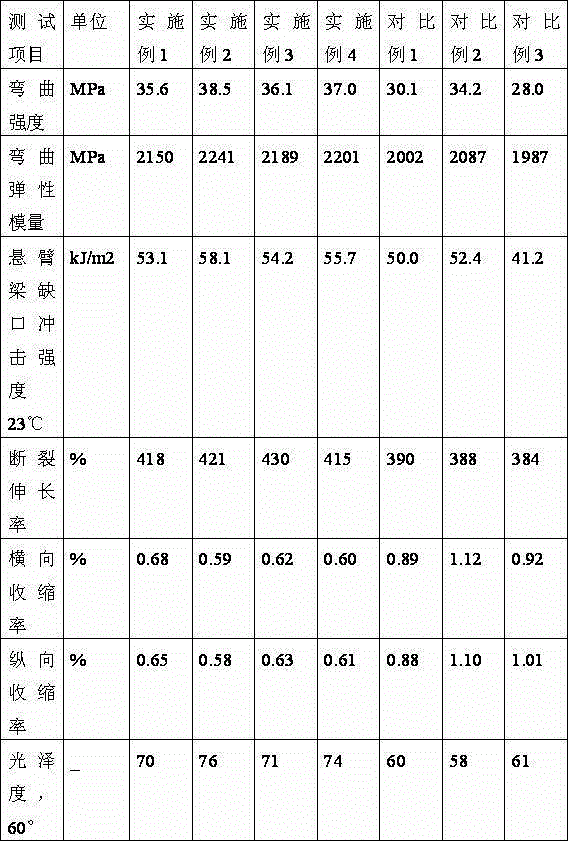

A high gloss polypropylene material

The invention provides a high-gloss polypropylene material which is characterized by being obtained by physical modification and comprising the following components: 100 parts of polypropylene, 20-35 parts of barium sulfate, 5-20 parts of POE (polyolefin elastomer), 0.1-0.4 part of nucleating agent, 0.1-0.2 part of antioxidant 1010, 0.1-0.2 part of antioxidant 168 and 0.1-0.3 part of lubricant. The modified PP aggregates have low forming shrinkage, high gloss and high toughness and have the advantage of elegant and attractive appearance of acrylonitrile butadiene styrene. Meanwhile, the cost is greatly reduced.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

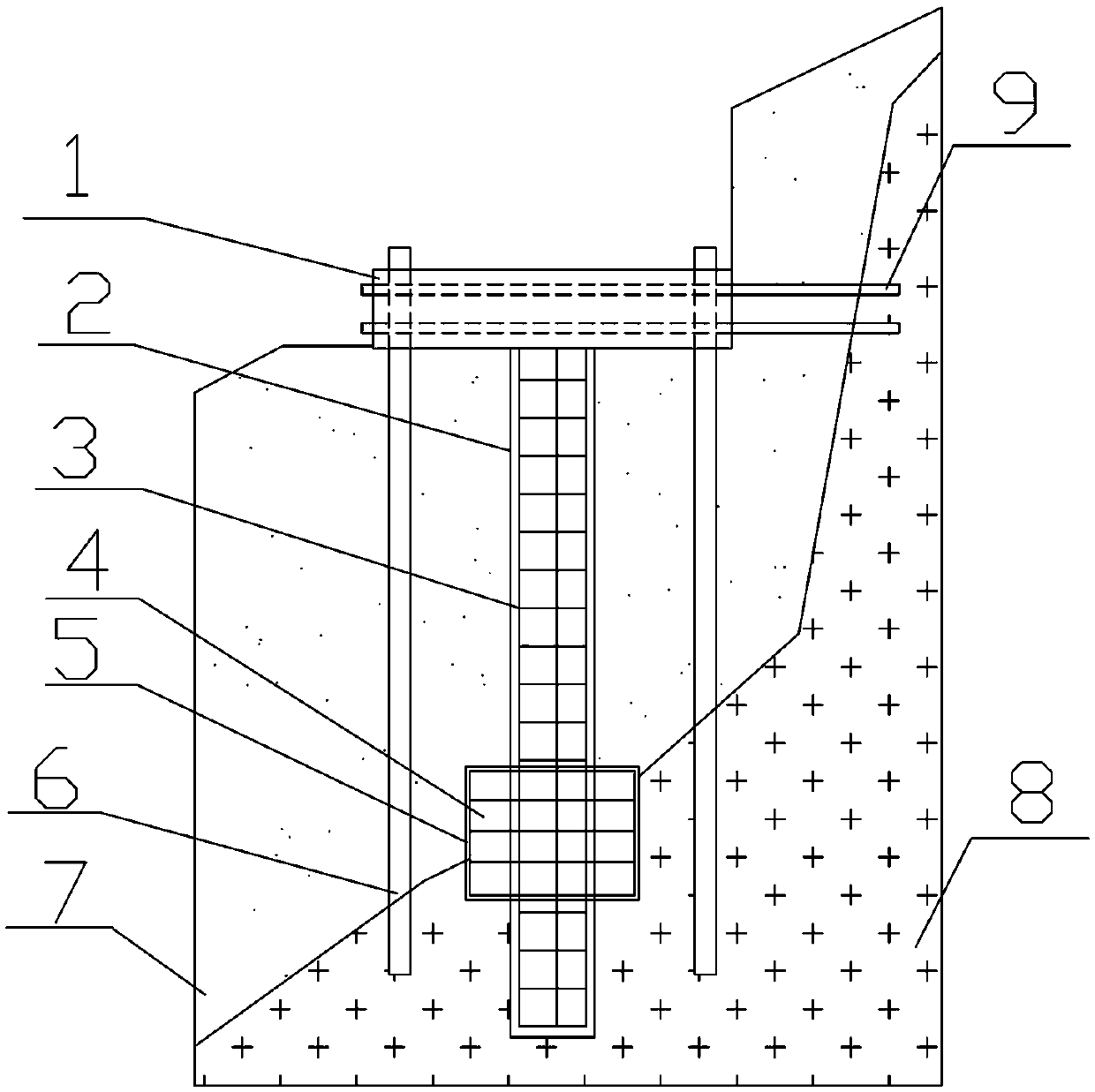

Construction method of bridge pile foundation in mountainous area

ActiveCN105507340AHigh strengthReduce the problem of crack growthFoundation engineeringSoil horizonGrout

The invention discloses a construction method of a bridge pile foundation in a mountainous area. The construction method comprises the following steps: (1) staking out in survey, namely locating position of the pile foundation; (2) digging a hole, namely enlarging hole on the bottom rock of a pile hole after digging the pile hole to form an enlarge hole cavity; (3) placing a steel reinforcement cage and an enlarged steel reinforcement cage, namely placing a main steel reinforcement cage in the pile hole and placing the enlarged steel reinforcement cage in the enlarged hole cavity; (4) pouring concrete, namely pouring concrete into the pile hole by adopting a guide pipe method and manufacturing a bearing platform; and (5) arranging anchor cables, namely drilling around the pile foundation, mounting a vertical anchor cable and a horizontal anchor cable, grouting by adopting a hole bottom grout returning method, and punching the vertical anchor cable and the horizontal anchor cable into the rock by passing through the soil layer. The construction method is simple; the pile foundation bearing capability is strong.

Owner:NANYANG INST OF TECH

Multi-injection molding process one-time molding method for high-toughness home appliance panel

The invention discloses a multi-injection molding process one-time molding method for a high-toughness home appliance panel. The multi-injection molding process one-time molding method is characterized by comprising the following steps of preparing materials for injection molding; inputting relative parameters of the four-stage injection molding process on a control panel of an injection molding machine; pushing a manual / automatic change-over switch on an electric control cabinet to the automatic position; inputting location parameters and pressure holding parameters of a screw rod on a touchinput screen when completion of filling meeting process switching conditions; closing a safety door of the injection molding machine, pressing an on / off switch in an on position to start the injectionmolding machine; and opening a mold and taking out workpieces after completion of injection molding. According to the multi-injection molding process one-time molding method, the injection molding machine is controlled by a PLC to conduct regulation to adopt different injection molding processes at different injection molding stages according to data stored from the control panel of the injectionmolding machine. Meanwhile, compared with a bonded panel, the panel manufactured through multi-injection molding one-time molding has the good integrity and toughness and is not likely to get bent and fall off.

Owner:太仓意欣智能科技有限公司

Graphene phenolic resin composite material and application thereof

The invention relates to the technical field of phenolic resin composite materials, in particular to a graphene phenolic resin composite material. Oxidized graphene, hydrazine hydrate, a surfactant and a formaldehyde solution are added into a reactor, stirred and heated up to 80-100 DEG C for reaction; the obtained liquid reactant is cooled down to 60-80 DEG C, then an acid catalyst and phenol are added, the temperature is increased to 85-100 DEG C for reaction, and then heating dehydration is performed. The graphene phenolic resin composite material can be applied to bakelite powder. As the proper surfactant is adopted, the problem of dispersion of graphene in resin is solved, and uniformly mixed graphene modified phenolic resin is obtained; the oxidized graphene which is not reduced can further react with phenolic resin to obtain graphene modified phenolic resin of an inorganic complexing structure; the bakelite powder prepared by resin has relatively high impact resistance and low forming shrinkage ratio.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Reinforcing toughening high-temperature-resistant nylon composite material and preparation method thereof

The invention belongs to the technical field of engineering plastics, and relates to a nylon composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 40-60 parts of a high-temperature-resistant nylon resin, 5-30 parts of ultra-fine barium sulfate, 20-40 parts of a filling reinforcing agent, 0.2-0.5 part of a compatilizer, 0.3-1.0 part of a lubricant, and 0.2-0.5 part of an antioxidant. Compared with the prior art, the high-temperature-resistant nylon is used as a matrix resin, glass fiber is used as the reinforcing agent, the ultra-fine barium sulfate is filled to be used as a toughening agent, in the premise of not reducing the thermal deformation temperature of the composite material, the strength and the toughness of the composite material are improved, and besides, the composite material has the advantages of low mold shrinkage rate, good processing performance, easy flowing, rapid molding, and relatively good apparent quality; the ratio of the expensive high-temperature-resistant nylon resin in the composite material is reduced, and thus the production cost of the composite material is reduced; and the preparation method has simple process.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparation method of rigid polyurethane foam heat insulation and energy saving material

The invention provides a preparation method of a rigid polyurethane foam heat insulation and energy saving material. The preparation method comprises the following steps of S1, preparing a black material and a white material with the weight ratio being (1.1-1.2) to 1, wherein the black material is isocyanate, and the white material is prepared by mixing the following raw materials in parts by weight: 70-95 parts of polyether polyol, 15-25 parts of deionized water, 6-9 parts of expanded vermiculite, 3-6 parts of acrylic resin, 2-3 parts of organosilicon oil foam stabilizer, 3-6 parts of rock wool fiber, 2-6 parts of bagasse fiber, 5-9 parts of nanometer calcium carbonate, 0.1-0.3 part of N,N-dimethyl cyclohexyl amine and 4-6 parts of modified tin catalyst; and S2, uniformly mixing the whitematerial in advance, then mixing the black material and the white material, foaming a mixture with a high-pressure foaming machine, injecting a foamed product into a die, and performing formation toobtain the rigid polyurethane foam heat insulation and energy saving material. The preparation method can reduce use of a chemical solvent and improves the heat insulation performance of a whole polyurethane material at the same time.

Owner:GUANGXI JISHUN ENERGY TECH

High-strength halogen-free epoxy molding compound, and preparation method thereof

ActiveCN102321340AExcellent high and low temperature impact resistanceHigh mechanical strengthPolymer scienceFirming agent

The invention discloses a high-strength halogen-free epoxy molding compound, and a preparation method thereof. The molding compound comprises raw materials of: 100 parts of modified epoxy resin, 0 to 100 parts of epoxy resin, 20 to 100 parts of a curing agent, 140 to 250 parts of a strengthening material, 100 to 250 parts of a filling material, 100 to 250 parts of a fire retardant and CTI modifier, and 10 to 50 parts of an auxiliary agent. The preparation method comprises steps that: the materials are well mixed, crushed, mixed, fused and mixed, cooled and crushed, and packaged. The preparation method of the modified epoxy resin comprises steps that: 100 parts of epoxy resin and 5 to 20 parts of liquid rubber are mixed for 4 to 6 hours under a temperature of 100 DEG C to 130 DEG C, the product is cooled, and the product is crushed to a size below 20 meshes. The invention is advantages in that: with the high-strength halogen-free epoxy molding compound prepared by the invention, the produced product has high mechanical strength, small molding shrinkage, good high / low temperature impact resistance, excellent electrical property under bad surroundings, and environment friendliness.

Owner:WUXI CHUANGDA ELECTRONICS

Polypropylene complex and preparation method thereof

The invention discloses a polypropylene complex. The polypropylene complex comprises, by mass, 59.15-69.4% of polypropylene (PP), 20-25% of talcum (Talc), 10-15% of rubber, 0.05-0.1% of a main antioxidant, 0.10-0.15% of a secondary antioxidant, 0.15-0.2% of a light stabilizer, 0.15-0.2% of polyethylene wax and 0.15-0.2% of a dispersing agent. The present invention further relates to a preparation method for the polypropylene complex. The forming shrinkage of the polypropylene complex is decreased, and the mechanical properties of the polypropylene complex are significantly increased, such that the PP can be effectively prevented from degradation aging during the processing and using process.

Owner:广东奇德新材料股份有限公司

Polybutylene terephthalate monofilament yarn

InactiveCN101041909AHigh strengthHigh impact strengthMelt spinning methodsMonocomponent polyesters artificial filamentFiberYarn

The invention relates to a polybutylene terephthalate filament fiber. For improving the flexibility of said fiber, the invention adds polybutylene terephthalate into ultra-fine chopped carbon strand, to spin at 250-300Deg. C to obtain needed filament fiber, with high strength, impact resistance, and low contraction percentage and deformation resistance. The invention can be used to produce face fabric filament.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

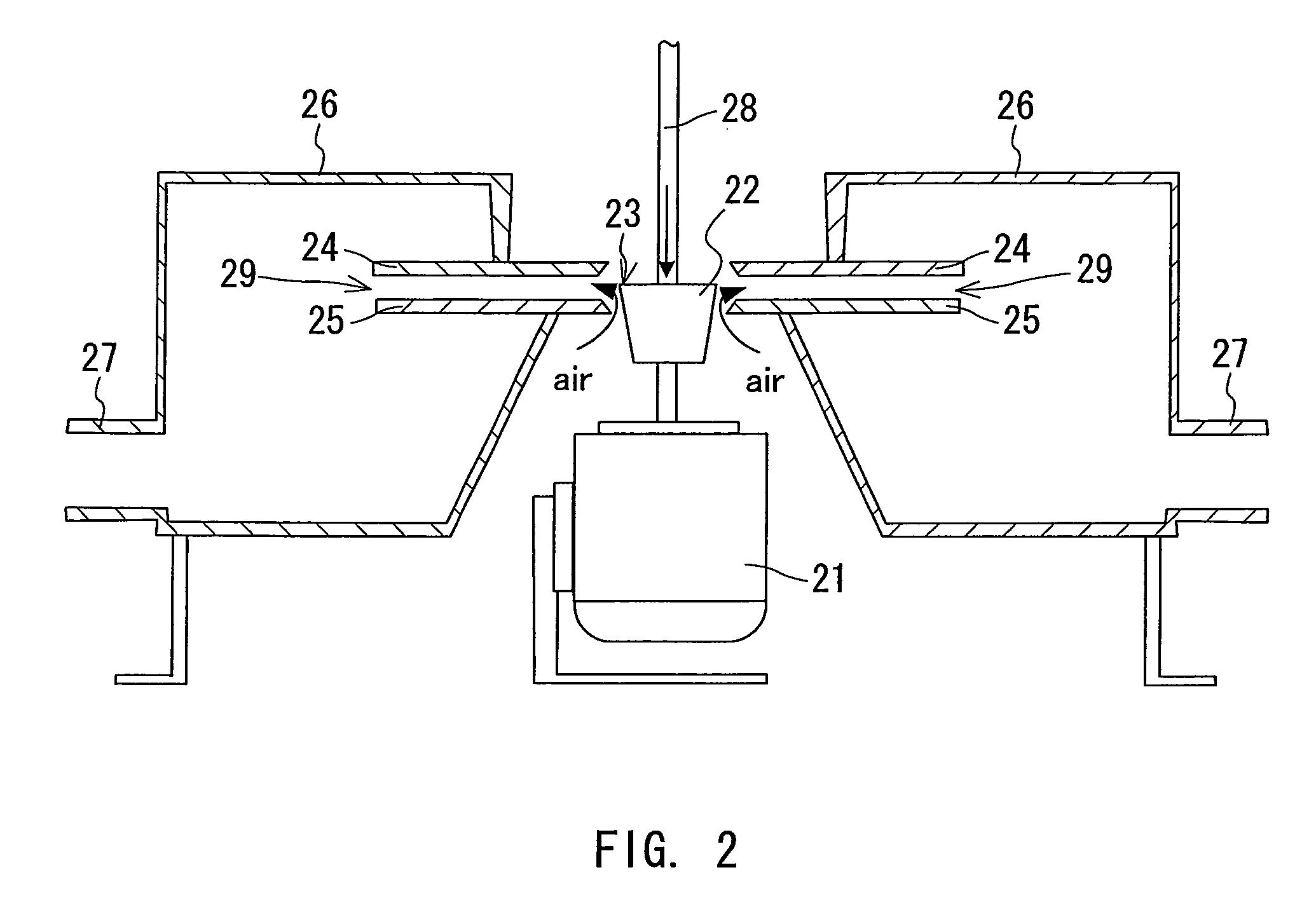

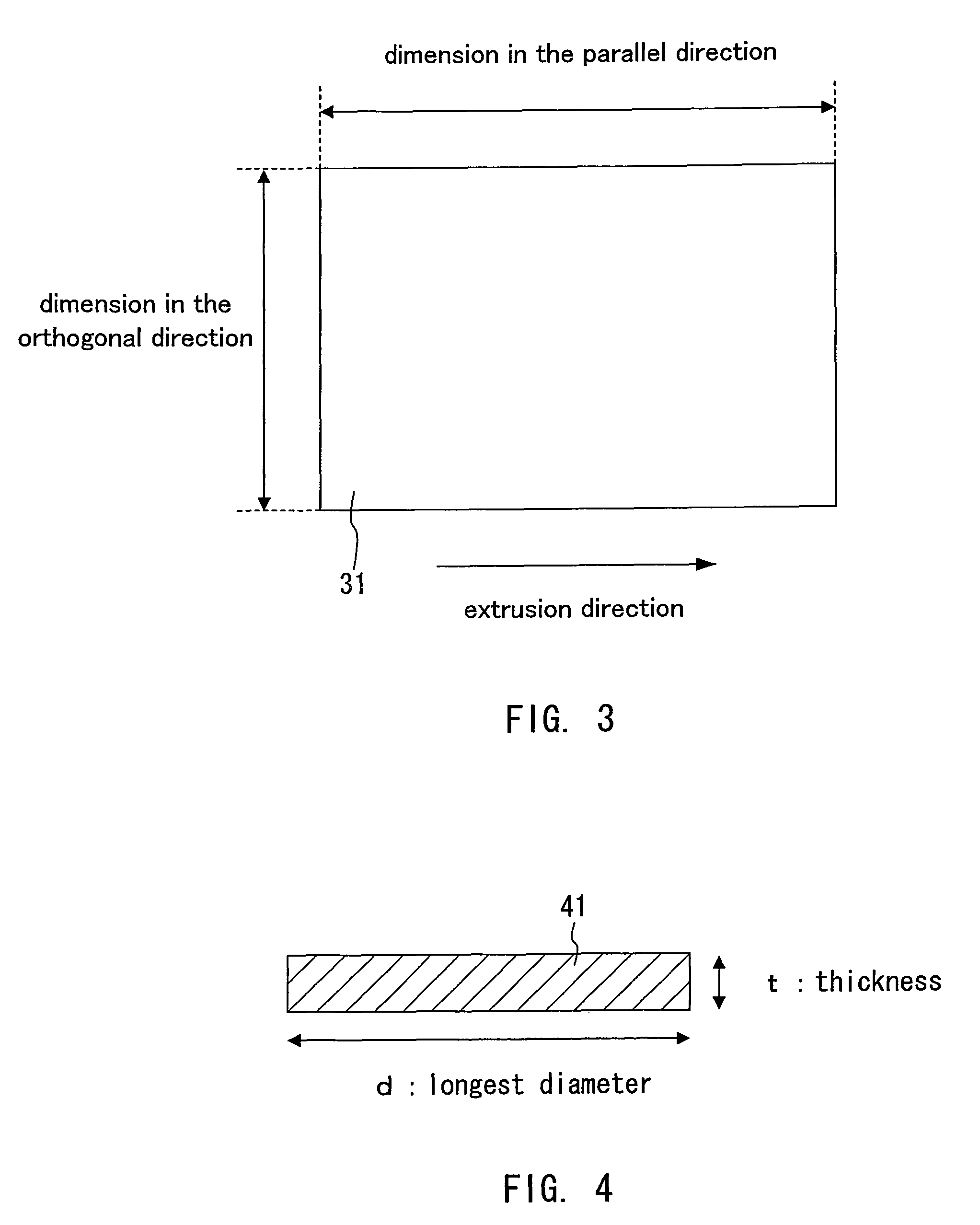

Glass flake filler, and resin composition including the same

ActiveUS8946340B2Improve acceleration performanceReducing a molding shrinkage of a resinGlass making apparatusSynthetic resin layered productsPolyresin

A glass flake filler of the present invention is composed of glass flakes. The average thickness of the glass flakes is at least 0.1 μm but less than 0.5 μm, and the glass flakes include glass flakes having a thickness of at least 0.01 μm but not more than 2.0 μm in an amount of at least 90% by mass. A resin composition of the present invention is a resin composition including a thermoplastic resin and a glass flake filler. This glass flake filler is composed of glass flakes, the average thickness of the glass flakes is at least 0.1 μm but less than 0.5 μm, and the glass flakes include glass flakes having a thickness of at least 0.01 μm but not more than 2.0 μm in an amount of at least 90% by mass.

Owner:NIPPON SHEET GLASS CO LTD

Super-tough nylon and preparation method thereof

The invention discloses super-tough nylon. The super-tough nylon is characterized by comprising the following components by weight: 55 to 75 percent of nylon 6, 5 to 15 percent of ultra-fine barium sulfate, 10 to 20 percent of POE-g-MAH, 0.1 to 0.3 percent of antioxidant 1010, 0.2 to 0.5 percent of antioxidant 168, and 0.3 to 0.7 percent of lubricant TAF. A method for preparing the super-tough nylon is characterized by comprising the following steps that the nylon 6 resin, the ultra-fine barium sulfate, the POE-g-MAH, the antioxidant 1010, the antioxidant 168 and the lubricant TAF are mixed well, put into a double-screw extruder, fully melted and compounded in the double-screw extruder, extruded through a nose, pulled into strips, cooled, palletized, dried and packaged. The invention aims to overcome the deficiencies of the prior art and provide the super-tough nylon with low mold shrinkage and good dimensional stability. Another aim of the invention is to provide a method for preparing the super-tough nylon.

Owner:广东顺威赛特工程塑料开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com