Patents

Literature

3935results about How to "Improve appearance quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

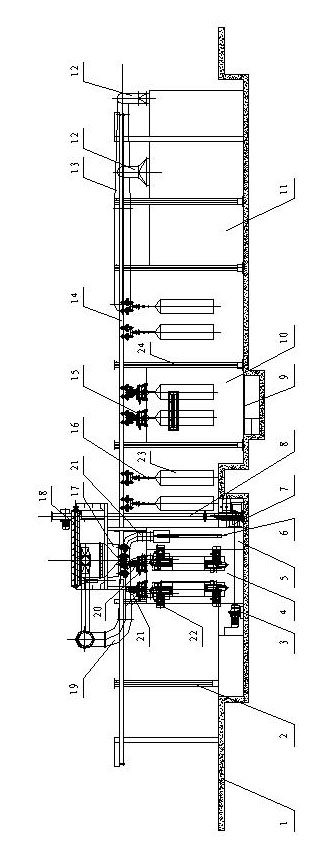

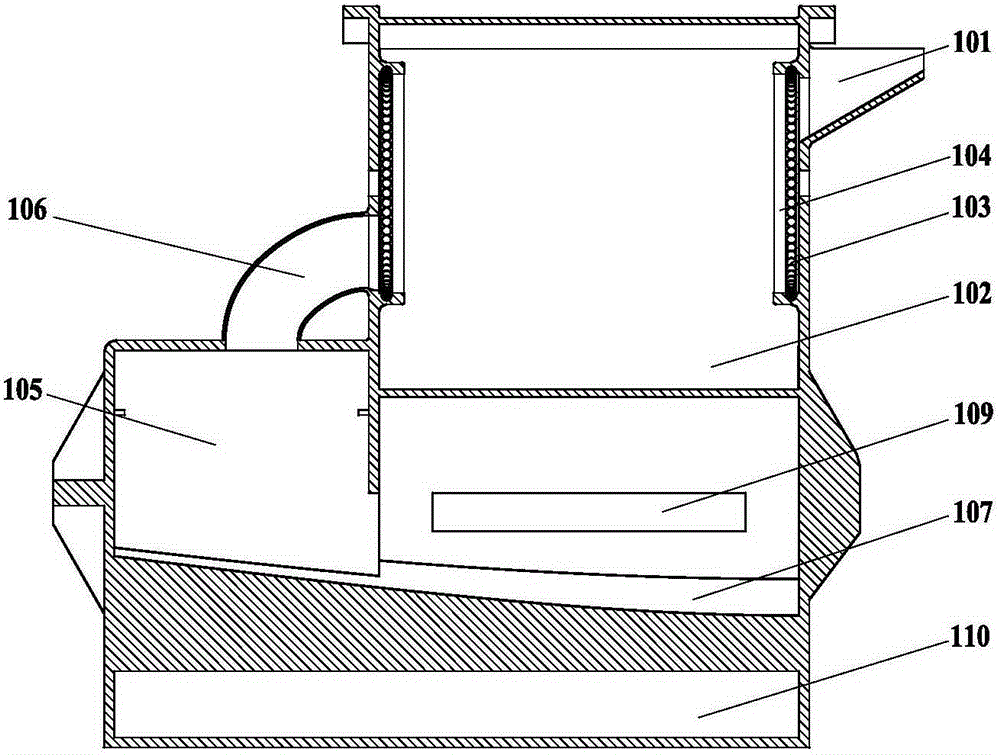

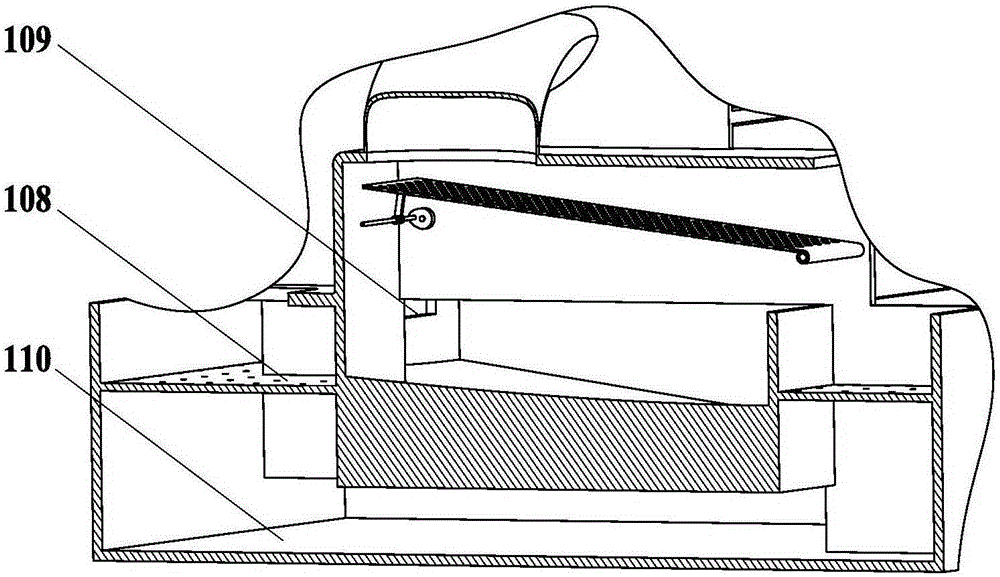

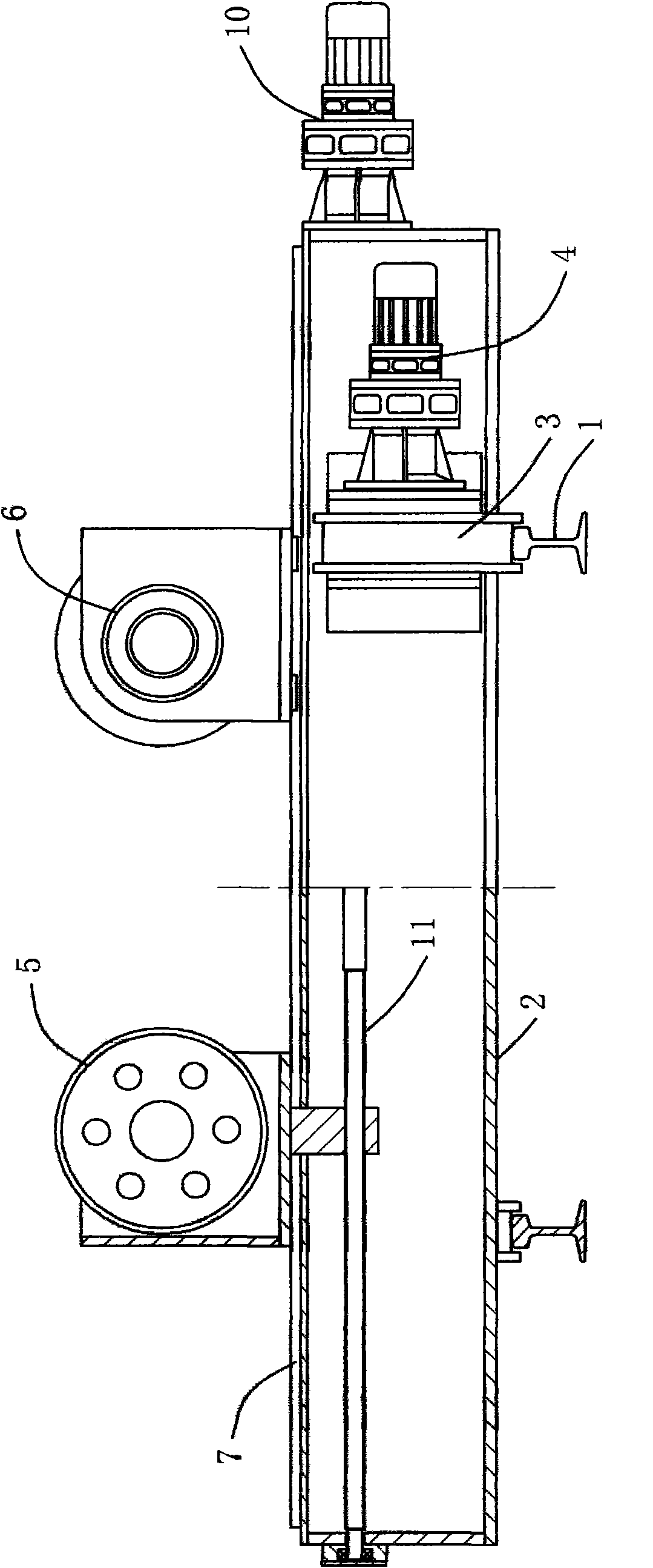

Hydraulic cylinder surface shot blasting, paint spraying and drying system and shot blasting, paint spraying and drying process thereof

InactiveCN101972726AIncrease productivityImprove cleanlinessSpraying apparatusPretreated surfacesHydraulic cylinderLacquer

The invention relates to a hydraulic cylinder surface shot blasting, paint spraying and drying system and a shot blasting, paint spraying and drying process thereof, and the hydraulic cylinder surface shot blasting, paint spraying and drying system consists of a hanging chain conveying system, a shot blasting working position, a paint spraying working position, a drying working position, an overhauling working position, an unloading working position, a loading working position, a paint mixing room, an air compressor and an operating room. The shot blasting, paint spraying and drying process comprises the following process steps: loading of a piece, shot blasting, derusting and cleaning (10-15min), automatic paint spraying (3-5min), paint refinishing, leveling (5min), drying at 60-80 DEG C (30min), natural cooling and unloading of the piece. The hydraulic cylinder surface shot blasting, paint spraying and drying system has the advantages of high degree of mechanical and electrical automation, small occupied area, good safety performance, and high production efficiency, is not affected by weather and can ensure the cleanliness, the temperature, the illumination and the safety and sanitation standard required by the paint spraying environment; and the shot blasting, paint spraying and drying process is simple, safe, time-saving, environment-friendly and high in working efficiency and can obtain the good appearance quality of a paint film.

Owner:中煤邯郸煤矿机械有限责任公司

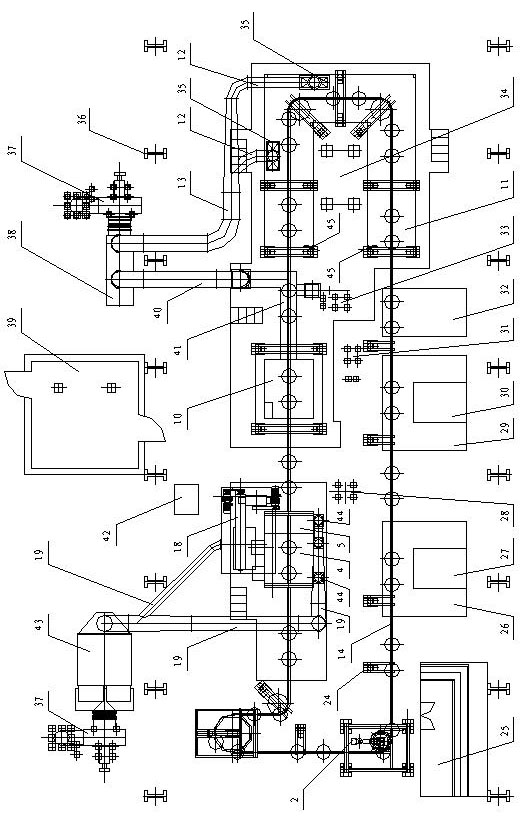

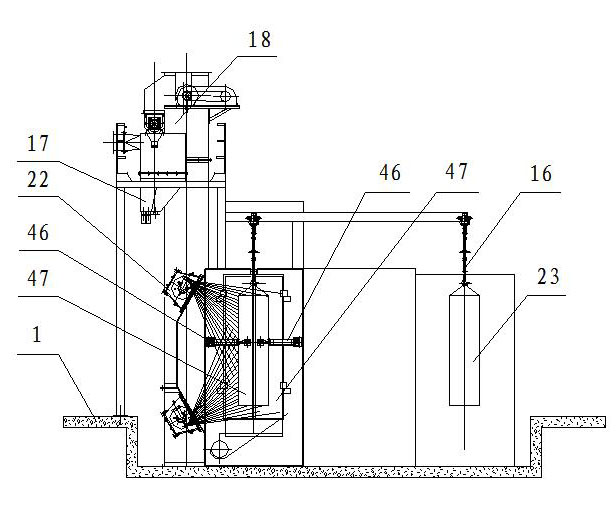

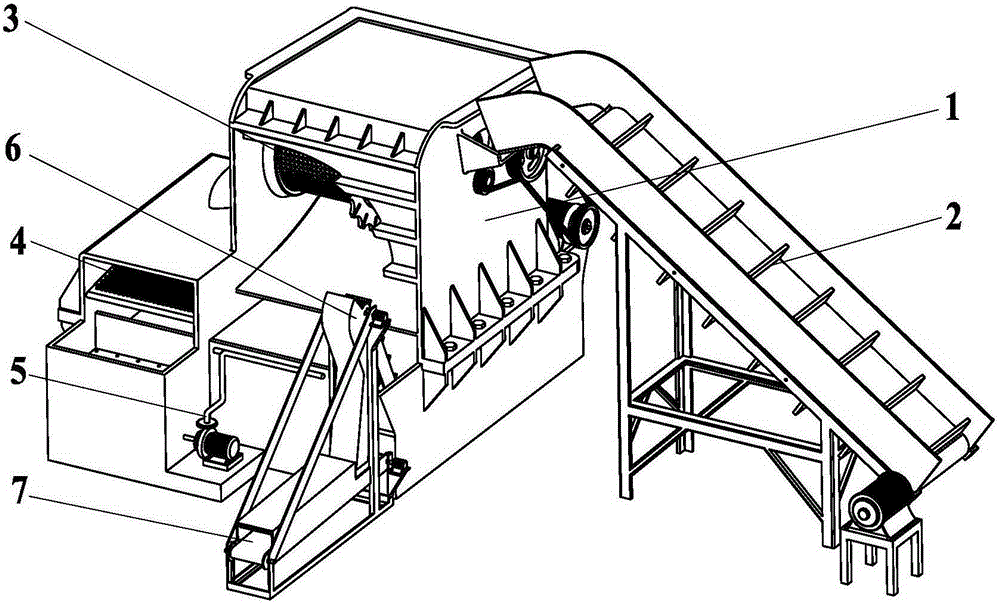

Three-time separating seed extractor for seed melons

The invention relates to the field of agricultural product processing, particularly a three-time separating seed extractor for seed melons. The seed extractor comprises a machine body, a whole seed melon transfer device, a roller separating device, a vibrating separation device, a washing device, a fishing device and a transferring and drying device, wherein the whole seed melon transfer device is positioned on the right side of the machine body for transferring the whole melon to the machine body; the roller separating device is mounted on the right side in the machine body for primarily separating the seed melon; the vibrating separating device is mounted on the left side of the roller separating device for secondarily separating the seed melon; the washing device is mounted at the front end of the machine body for separating the seed melon for the third time; the fishing device is positioned on the right side of the washing device for fishing out separated seeds; and the transferring and drying device is positioned below the front end of the fishing device for drying and transferring the seeds. The seed extractor provided by the invention can be used for separating seeds from melon pulp and melon peel for seed melons, soaking the seeds by melon juice and drying the seeds.

Owner:威海高新园区运营管理有限公司

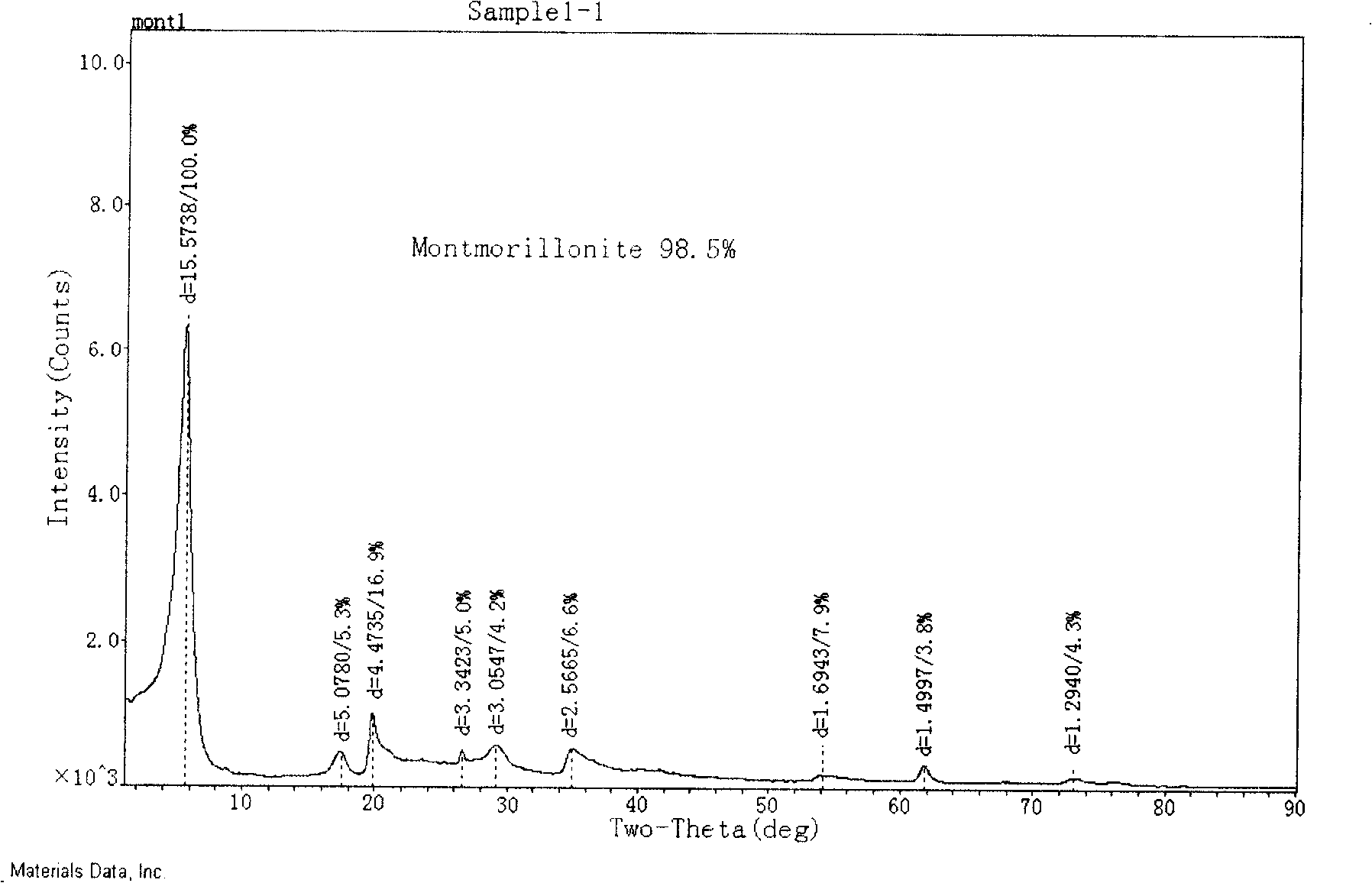

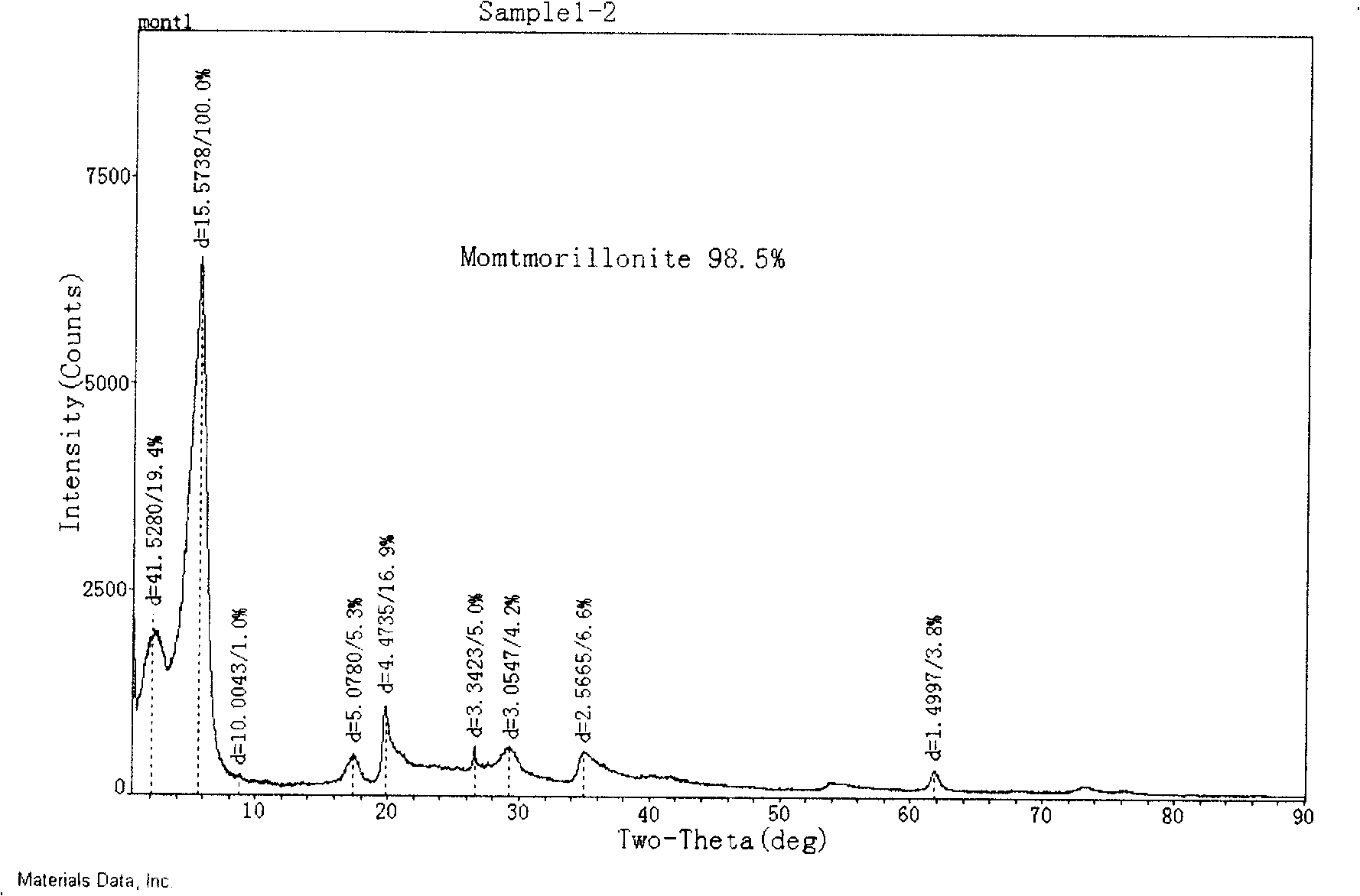

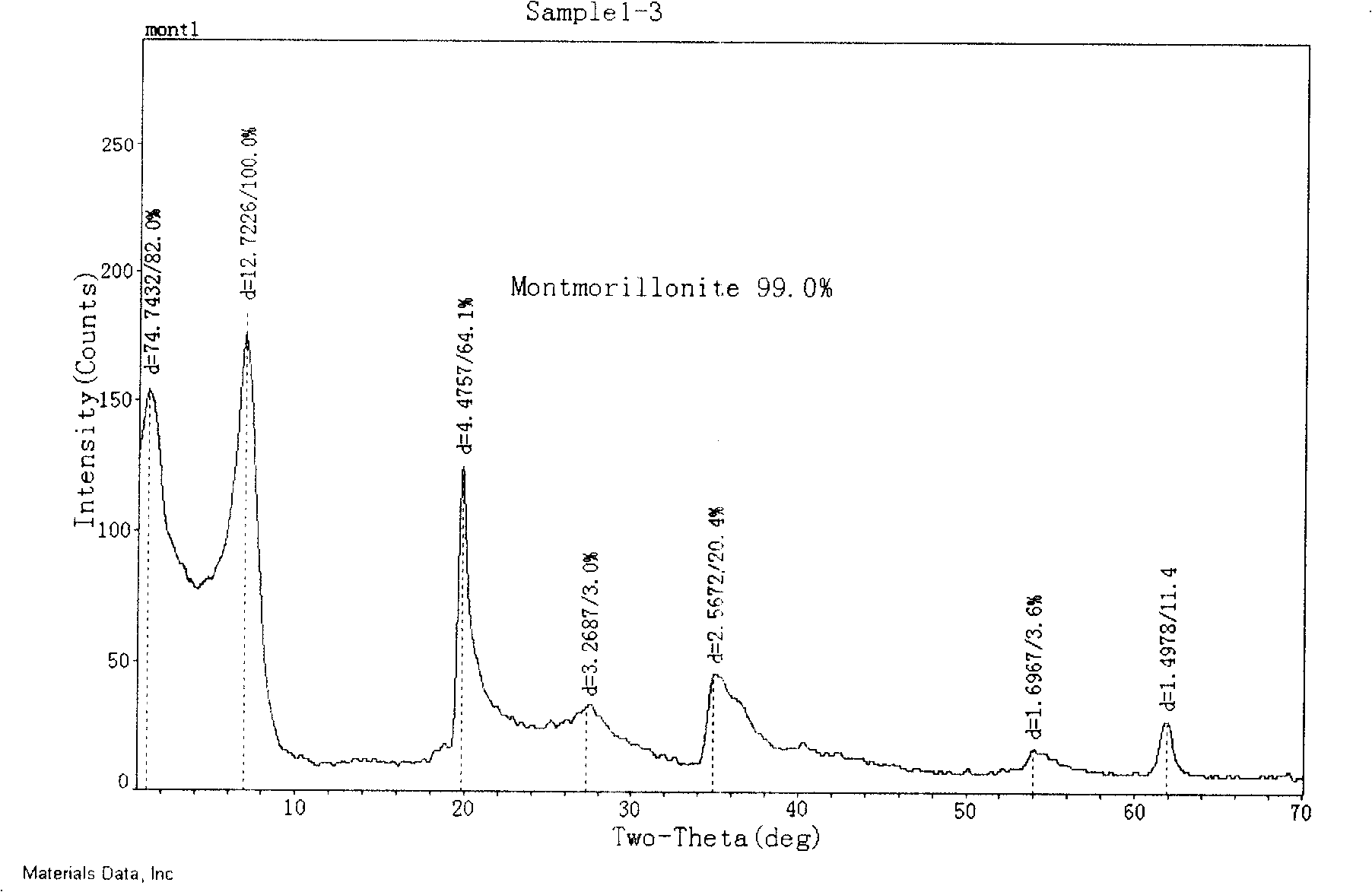

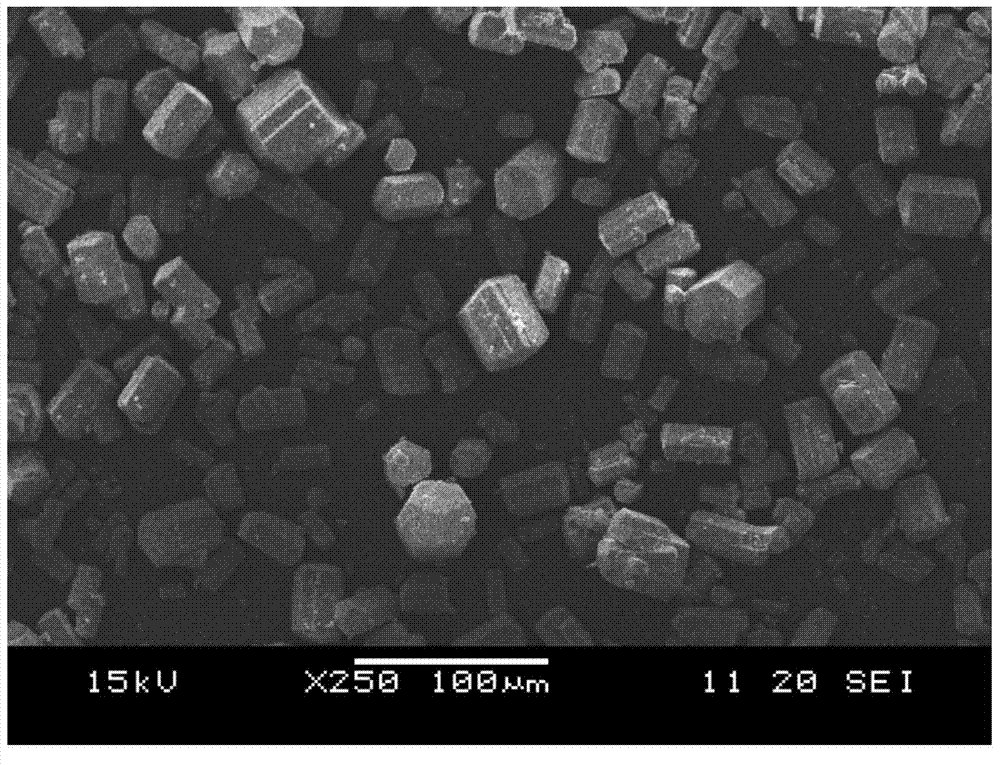

Modified smectite and method for producing the same and its application

ActiveCN101272986ANot easy to raise dustReduce moisture contentCosmetic preparationsOther chemical processesChemical compositionMontmorillonite

Disclosed is an inorganic medicine, particularly modified montmorillonite, method for preparing the same and use thereof. The said modified montmorillonite means that dioctahedron of natural montmorillonite is not destroyed and basic chemical composition for the same is not changed, and the microstructure stacked from dioctahedron layer is changed to decrease the thickness of stacking layer and to expose and increase the end face charge and the interlayer charge of montmorillonite, thereby resulting in its lower degree of C axis order. The present medical use of montmorillonite is thus significantly strengthened, particularly the reversal treatment effect on chronic atrophic gastritis. Also disclosed are a medicine composition containing modified montmorillonite and the reversal treatment effect of natural montmorillonite on chronic atrophic gastritis.

Owner:ZHEJIANG HAILISHENG PHARM CO LTD

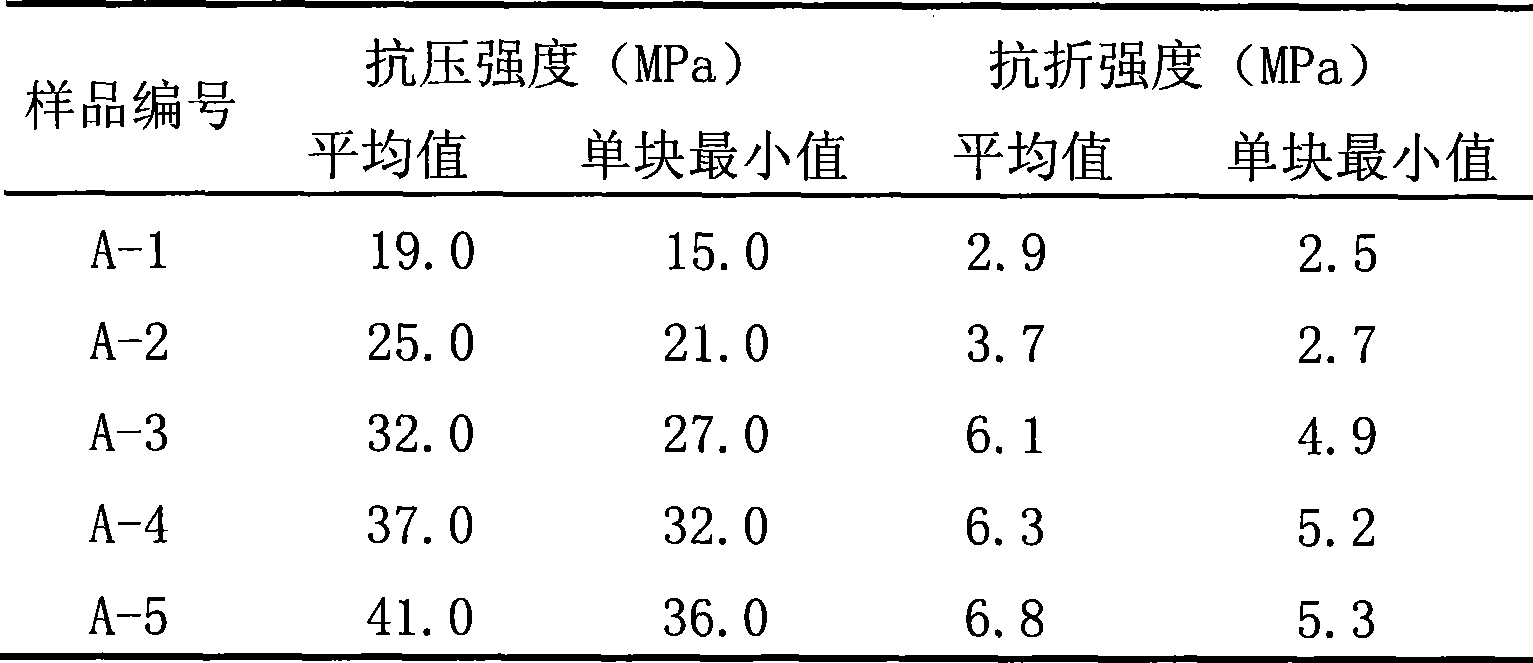

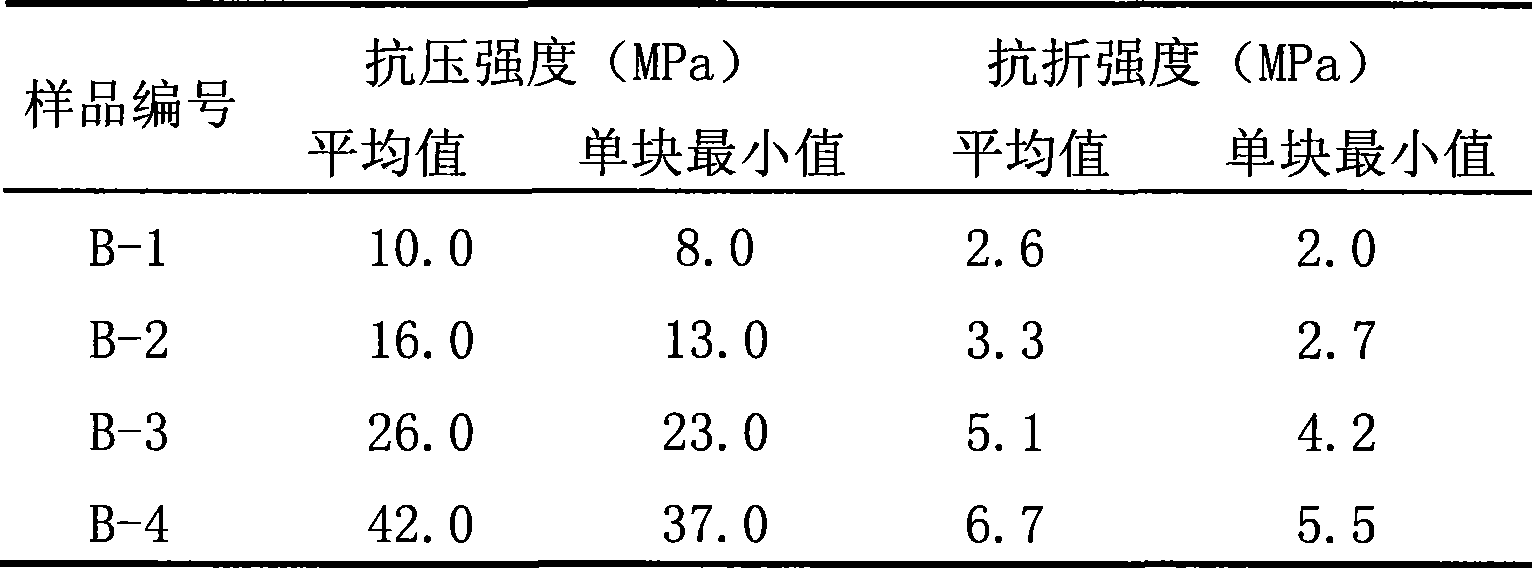

Gypsum material for 3D printing and preparation method thereof

ActiveCN104744000AHigh mechanical strengthGood dispersionAdditive manufacturing apparatusFilling materials3d printer

The invention discloses a gypsum material for 3D printing. The gypsum material is that a gypsum product is printed and formed through 1 part by mass of powder and 0.25 to 1 part by mass of liquid-phase material by a 3D printer, wherein the powder is prepared from the following raw materials in parts by mass: 90 to 98 parts of hemihydrate gypsum, 1 to 10 parts of filling material, and 0 to 2 parts of fibers; the liquid-phase material is prepared from the following raw materials in parts by mass: 80 to 90 parts of water, 5 to 15 parts of flexible adhering material, and 1 to 5 parts of coagulating material. The invention further discloses a preparation method of the gypsum material for 3D printing; the gypsum material is prepared by mixing and uniformly agitating all raw materials. The gypsum material for 3D printing and the preparation method have the advantage that the problems of small strength, poor fluidity, large fineness and poor flexibility in the prior art can be solved.

Owner:NANJING UNIV OF TECH

Method for producing tobacco sheets by paper making method

ActiveCN101695407AIncrease the content of reaction intermediatesPromotes Maillard reactionTobacco preparationMaillard reactionPhosphate

The invention relates to a method for producing tobacco sheets by a paper making method, which is characterized by using acidic proteinase, pectase and amylase to carry out biological degradation on sheet materials, improving the content of Maillard reactants in a tobacco extraction liquid, utilizing Maillard reaction catalysts, namely phosphate, phosphate, dibasic alkaliine, dihydric phosphate, propanediol and the like, and regulating and controlling the condition of reaction medium, on-line promoting the Maillard reaction in a tobacco aqueous solution, and improving the content of Maillard reaction intermediates and products in concentrated solution. The method for producing the tobacco sheets by the paper making method can reduce acrimony and offensive taste of the sheets, coordinate smell, improve after taste and improve comfort level of sheet suction.

Owner:CHINA TOBACCO ANHUI IND CO LTD

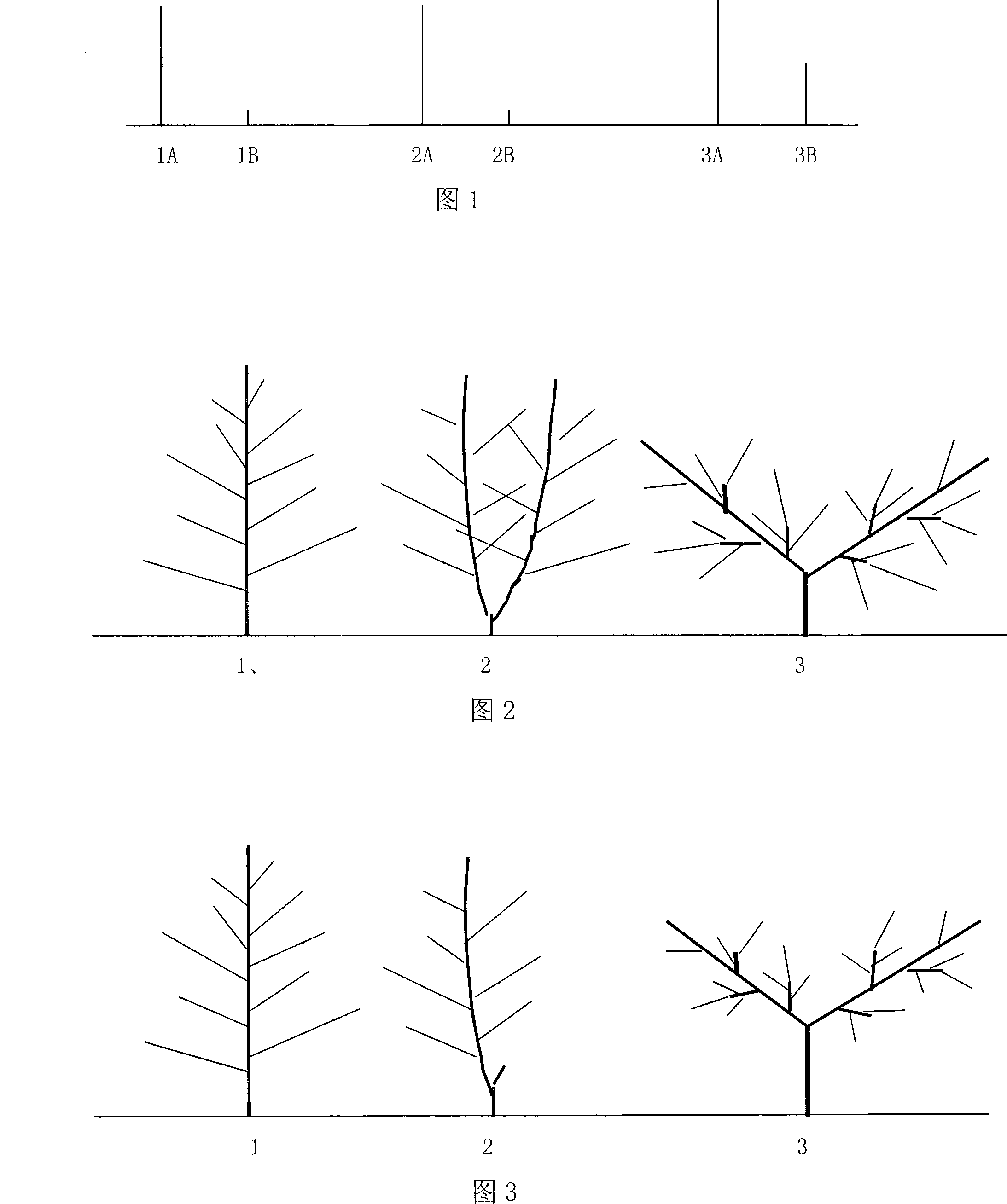

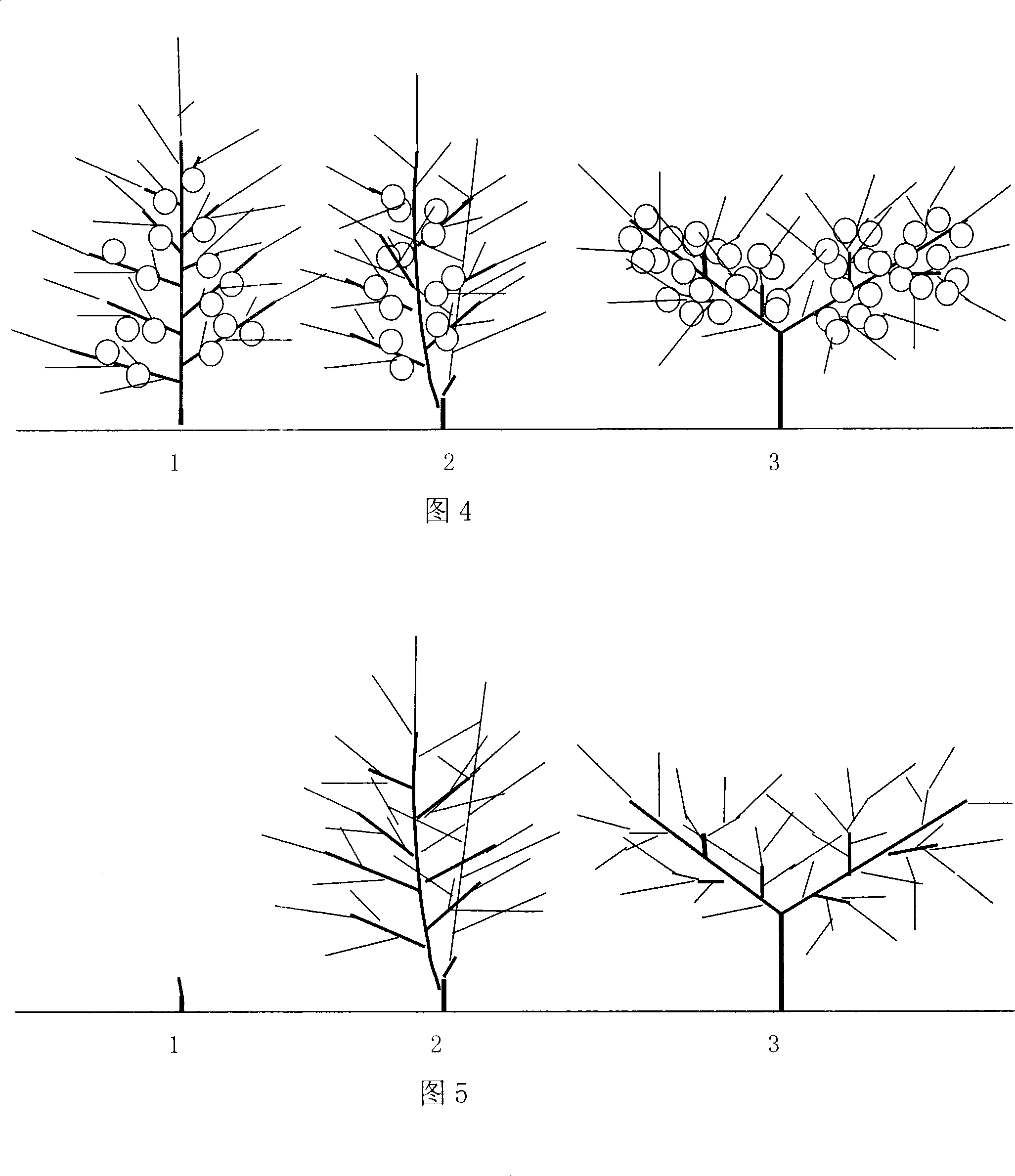

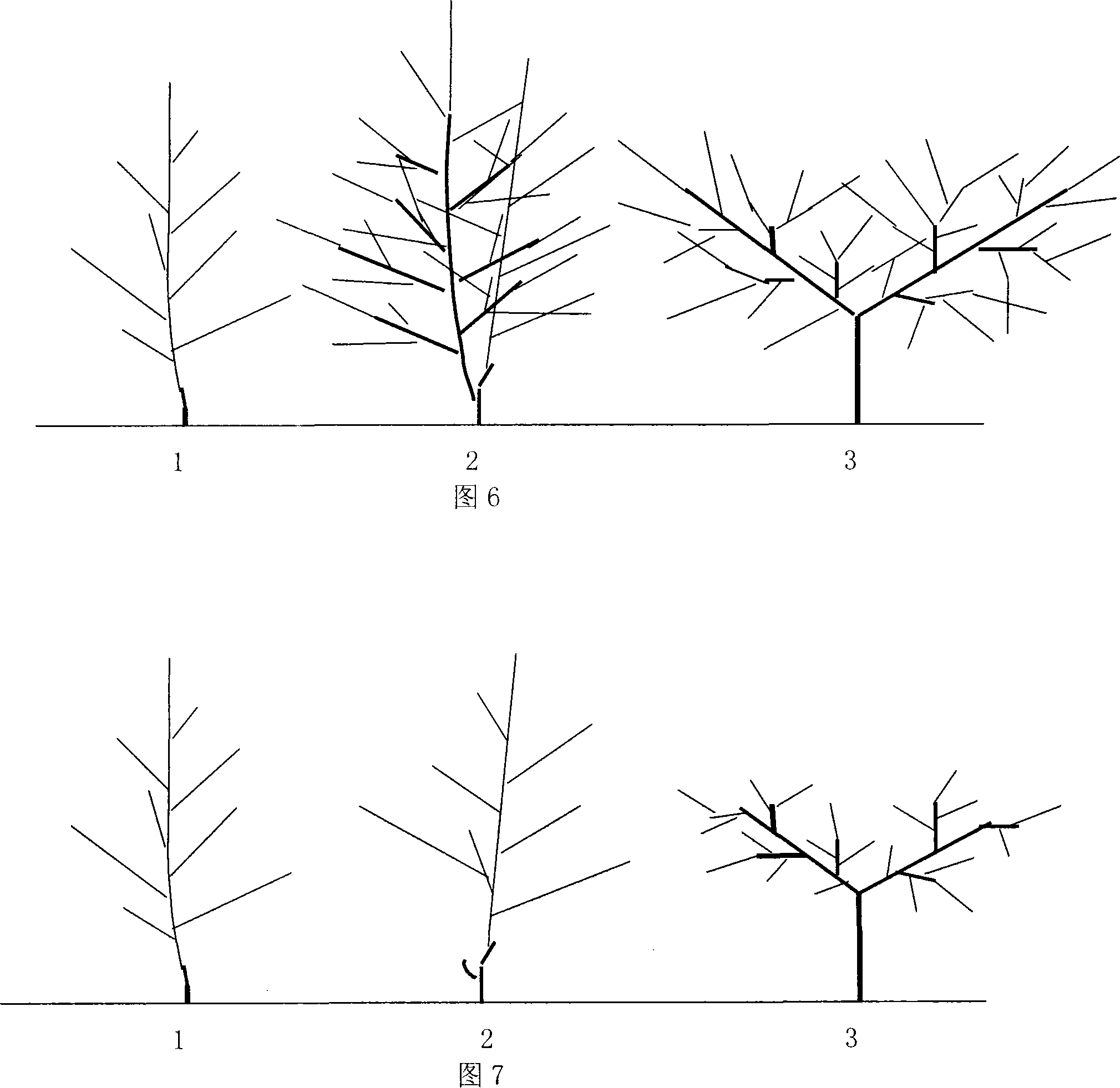

A peach shape for high-density planting and tree body controlling means

InactiveCN101156540ASmall footprintUncontrollable sizeCultivating equipmentsHorticultureHigh densityPeach orchard

The invention discloses a peach tree shape applicable for high-density planting. The peach tree shape of the invention is Y-shaped, and consists of a trunk and two large branch groups. Two large fruit branch groups can be produced on the upside of the trunk, and are arrayed oppositely in a line, and respectively extend into the two side rows; the extension direction is perpendicular to the row direction, as well as has a 45-55 degrees angle with the vertical direction. Fruit branches and small sized fruit branch groups are produced on the large fruit branch groups. The peach tree shape of the invention is applicable for high density planting, the structure of the tree is simple, the pruning is simple, the forming is quick, and the cost is low. The method of the invention is easy to be learned, the operation is simple. Standard management can be conducted for the invention to ensure that the peach orchard realize early rich and high-quality yield, high yield and stable yield.

Owner:CHINA AGRI UNIV

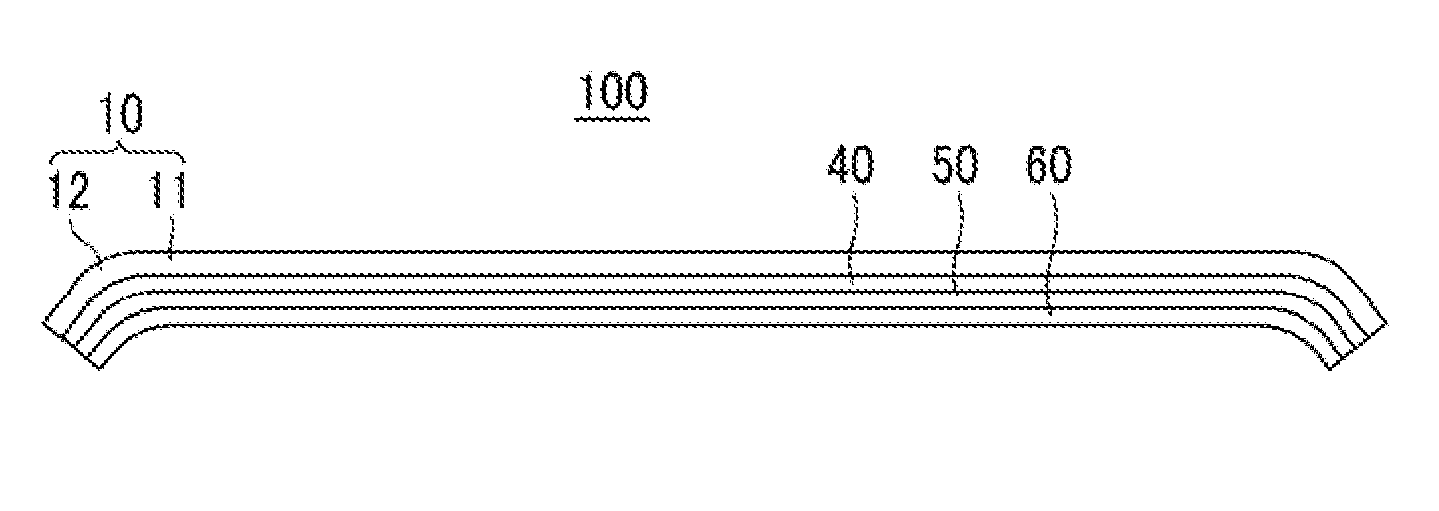

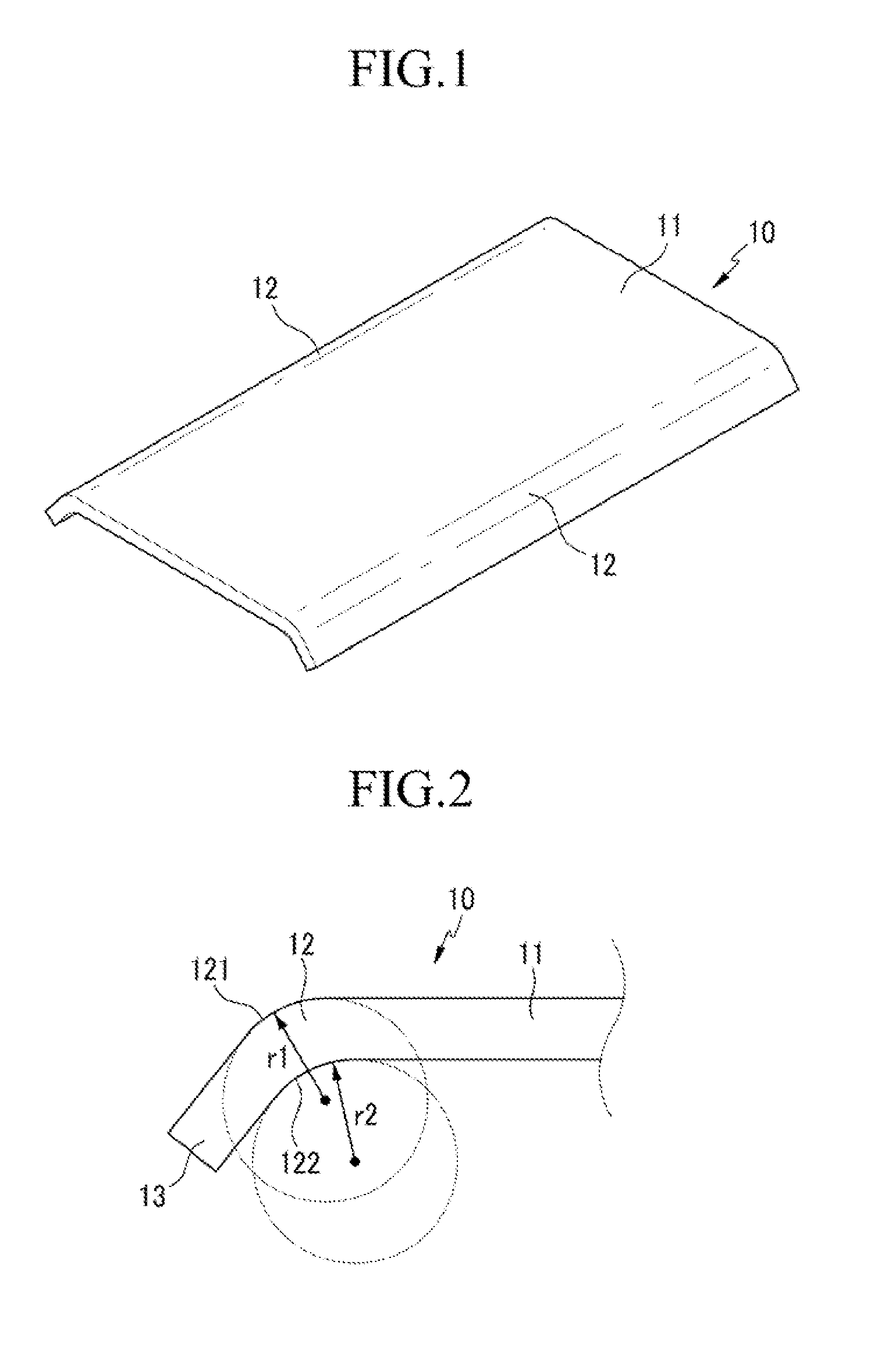

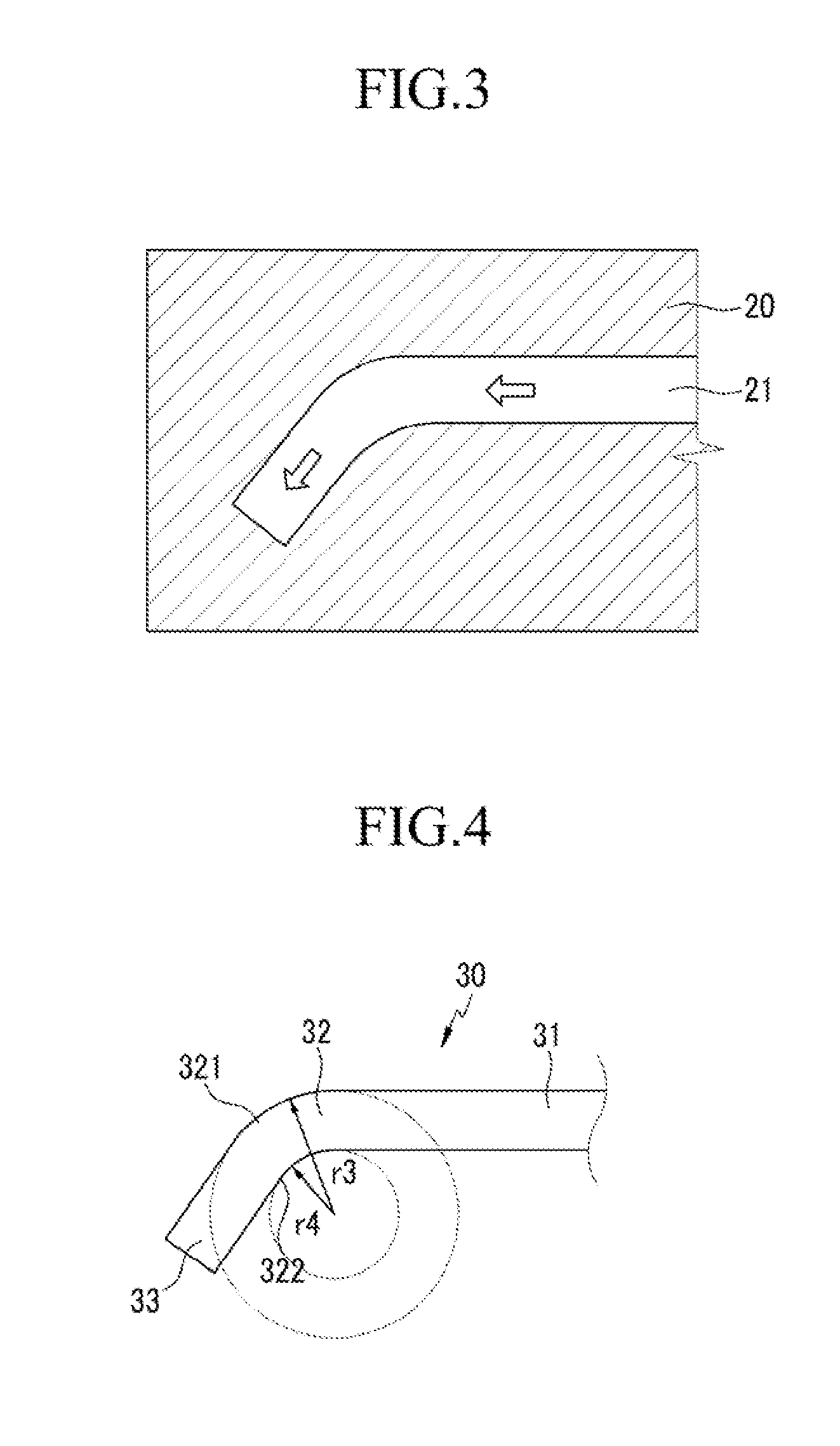

Cover window and display device with cover window

ActiveUS20140233194A1Improve liquidityImprove appearance qualityCircuit bendability/stretchabilityDigital data processing detailsVisibilityDisplay device

In a display device, a cover window is capable of increasing transparency of a curved part to improve visibility of a screen and appearance quality of a product. The cover window for the display device includes at least one curved part. In addition, the curved part includes an outer surface formed in an arc having a curvature radius of r1 and an inner surface formed in an arc having a curvature radius of r2, where r1≦r2≦2r1.

Owner:SAMSUNG DISPLAY CO LTD

Former hot blast and latter vacuum microwave combining drying process of producing crisp fruit and vegetable grains

InactiveCN1672531AReduce drying loadReduced moisture removal requirementsFruits/vegetable preservation by dehydrationWater contentFood processing

The present invention is former hot blast and latter vacuum microwave combining drying process of producing fruit and vegetable grains, and belongs to the field of fruit and vegetable food processing technology. The drying process includes the steps of: washing fruit and vegetable material, dicing, scalding to killing enzyme, cooling in flow water, draining, optional fast freezing and defrosting, soaking with seasoning, draining, pre-dewatering with hot blast to obtain semi-finished product with water content of 40-60 %, and final vacuum microwave drying to obtain product with water content of 2-5 %. The said process has the nutritious components and color well maintained, crisp product, short production period, low cost, high product quality and other features.

Owner:JIANGNAN UNIV

Application of hyperbranched polyester to plastic processing

The invention discloses an application of hyperbranched polyester to plastic processing, and belongs to the technical field of plastic processing assistants. The application of the hyperbranched polyester to plastic processing includes the steps that by mass, 0.1% to 5% of the hydroxyl-terminated hyperbranched polyester is added into plastic; the mixture is mixed to be even, extruded, prilled and dried, and a modified plastic product is obtained. According to the application, the plastic such as PPC and the hyperbranched polyester are melted and blended, and the plastic such PPC is modified through a double-screw extruder; after the hyperbranched polyester is added into a base material of the plastic such as PPC, the effective melt viscosity of the plastic such as PPC can be remarkably reduced; in other words, processing temperature and thermal degradation are reduced; in addition, melting fluidity improved in this way can also be achieved through the small adding amount,, and extruding film forming can be more easily achieved; the tensile strength of the modified plastic such as PPC is up to 30 MPa, and the strength can be higher than the strength of thin-film-level LLDPE and the strength of thin-film-level PVC.

Owner:WEIHAI CY DENDRIMER TECH

Super fine crystal microalloyed medium carbon steel coil and its producing method

InactiveCN1858284AImprove appearance qualityImprove quality and efficiencyFurnace typesMetal rolling arrangementsMetallic materialsHeating furnace

The present invention relates to metal material, and especially cold forging steel coil for fastener and its production process. The superfine crystal microalloyed medium carbon steel coil has the alloy elements including: C 0.10-0.25 wt%, Si not more than 0.08 wt%, Mn 0.80-1.70 wt%, P not more than 0.035 wt%, S not more than 0.035 wt%, V, Nb, Ti and Al trace quantity, and Fe for the rest. Its production process includes the following steps: smelting in a converter, external refining, casting blank; heating to 1100 deg.c in a heating furnace; rolling at 750-830 deg.c, finish rolling in a TMCP process and rolling in a two phase region and great deformation quantity; controlled cooling and spinning; cooling and bundling at temperature lower than 500 deg.c. The cold forging steel coil is used in producing fastener directly in a cold header, has simple technological process, low cost, less pollution and raised production efficiency.

Owner:MAANSHAN IRON & STEEL CO LTD

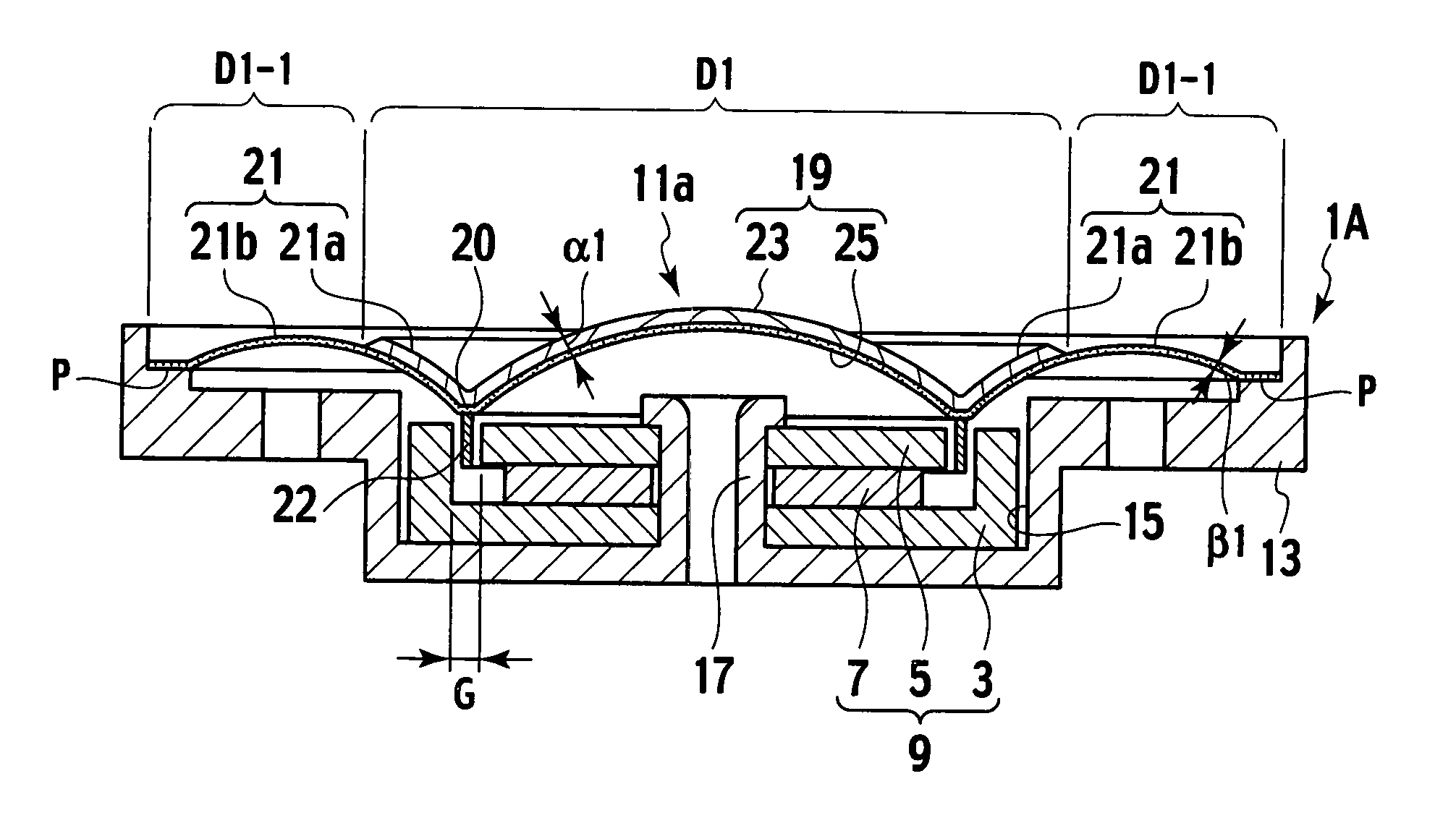

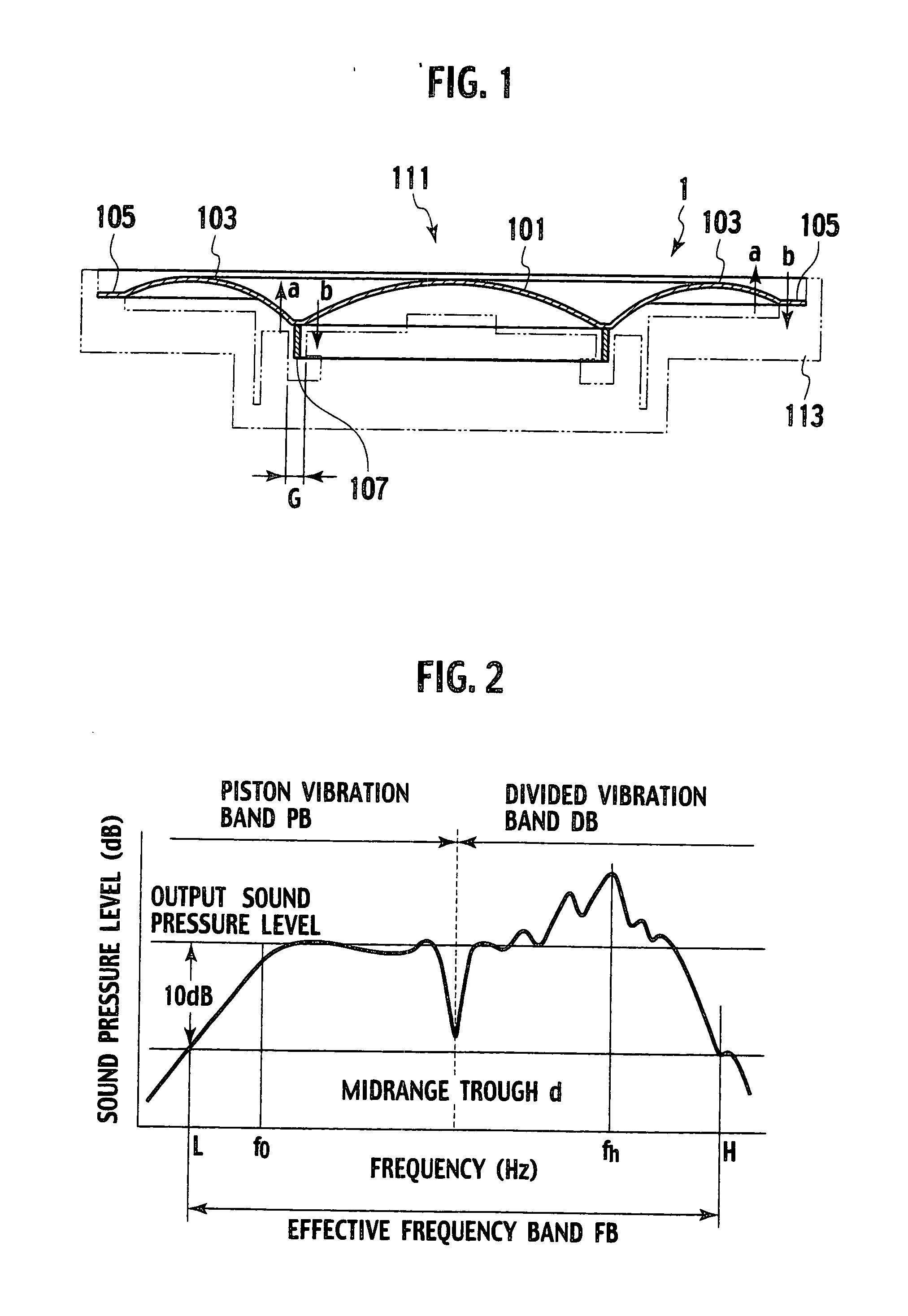

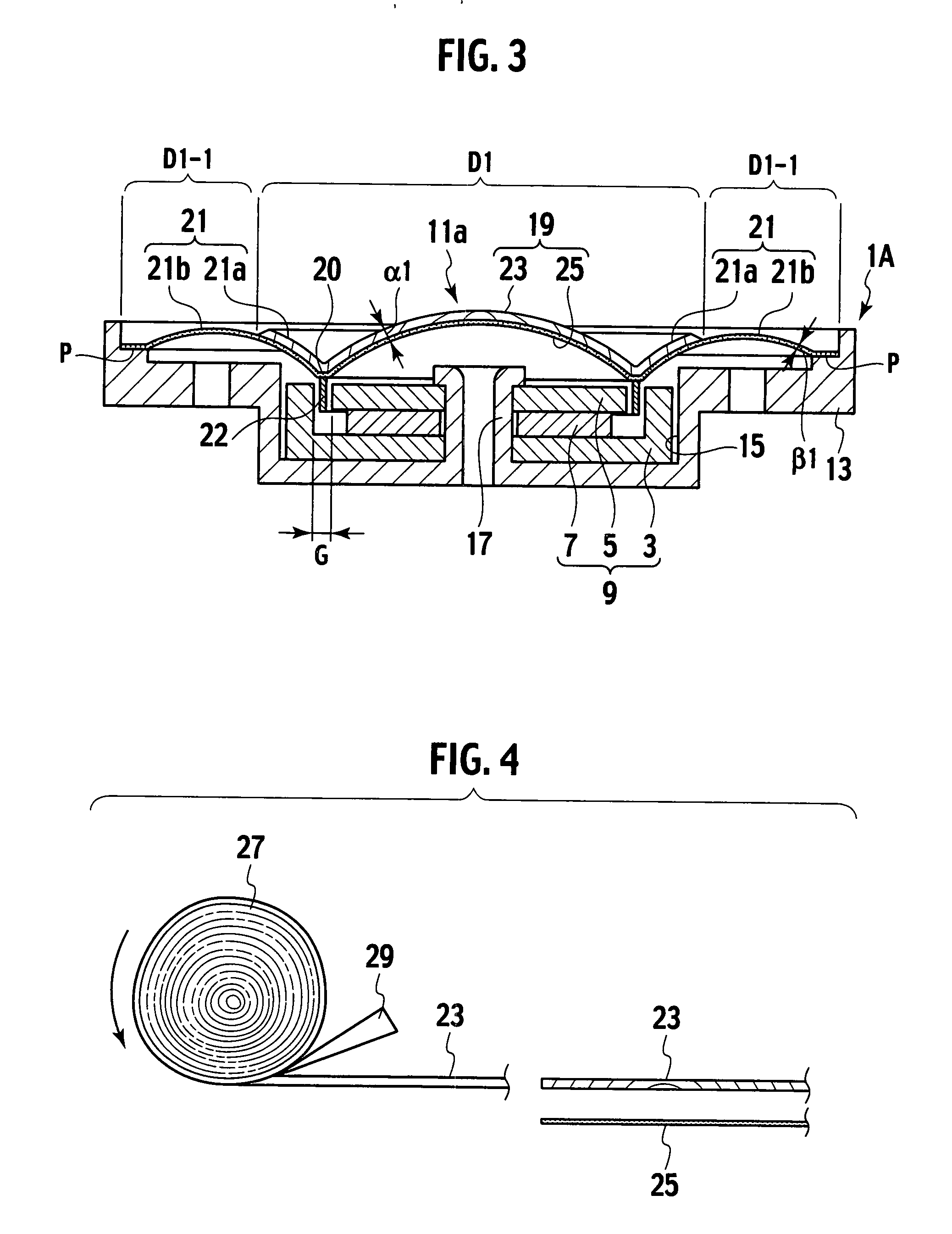

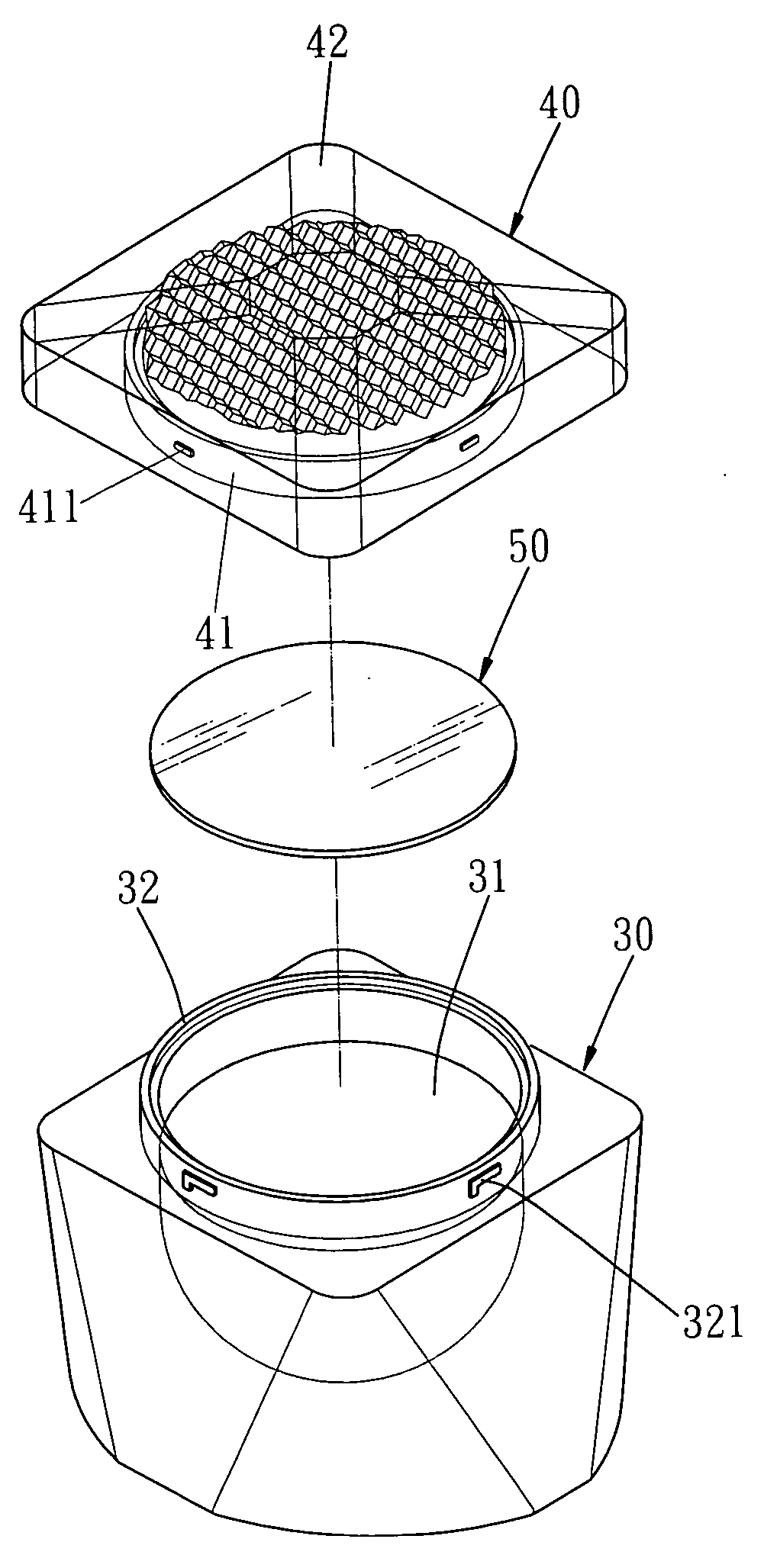

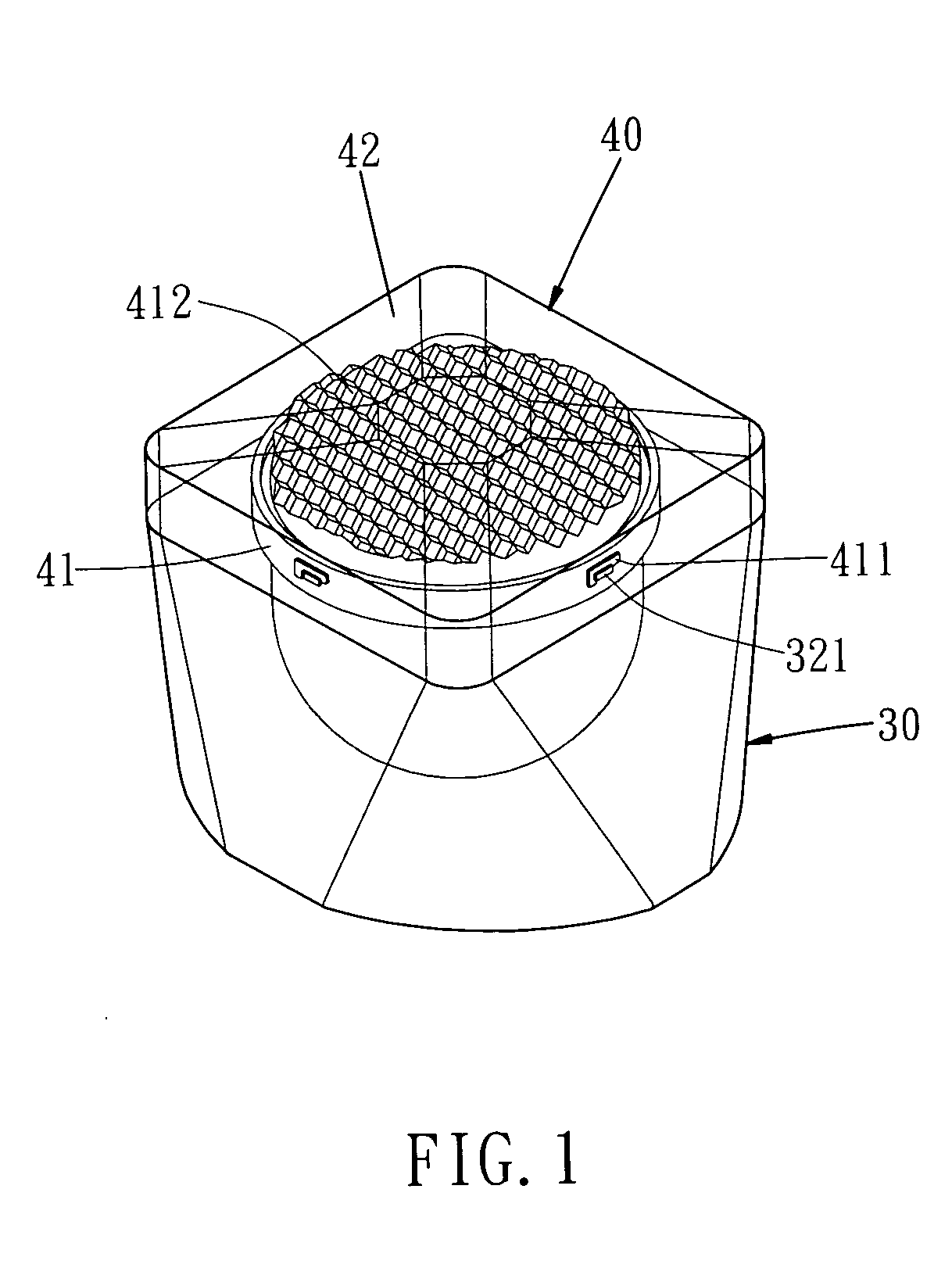

Electroacoustic transducer and diaphragm

InactiveUS20080053745A1Large shapeImprove appearance qualityHeadphones for stereophonic communicationEarpiece/earphone attachmentsEngineeringTransducer

An electroacoustic transducer includes a magnetic circuit; a frame enclosing the magnetic circuit; and a diaphragm including a center vibrating portion and an outer circumferential vibrating portion, the diaphragm comprising: a first plate thickness area including an entirety of the center vibrating portion, having a double-layer structure of a wood sheet and a reinforcement sheet; and a second plate thickness area including the edge portion of the outer circumferential vibrating portion, having a plate thickness thinner than a thickness of the first plate thickness area, and having a single-layer structure of the reinforcement sheet.

Owner:VICTOR CO OF JAPAN LTD

Wood-plastic composite material and preparation method thereof

The invention relates to the technical field of polymer processing, in particular to a wood plastic composite material and a preparation method thereof. The invention discloses the wood plastic composite material which is prepared from the following raw materials in weight percentage: 30 to 60 percent of wood fibre, 30 to 60 percent of waste plastics, 1 to 4 percent of stearic acid, 1 to 4 percent of industrial white oil, 1 to 3 percent of a coupling agent and 4 to 6 percent of a lubricant. The invention also discloses the method for preparing the wood plastic composite material and wood plastic products which are prepared from the wood plastic composite material. The wood plastic products produced by using the wood plastic composite material as a raw material are superior to similar products in the appearance quality and the physiochemical performance.

Owner:SHANGHAI BESTON PLASTICS

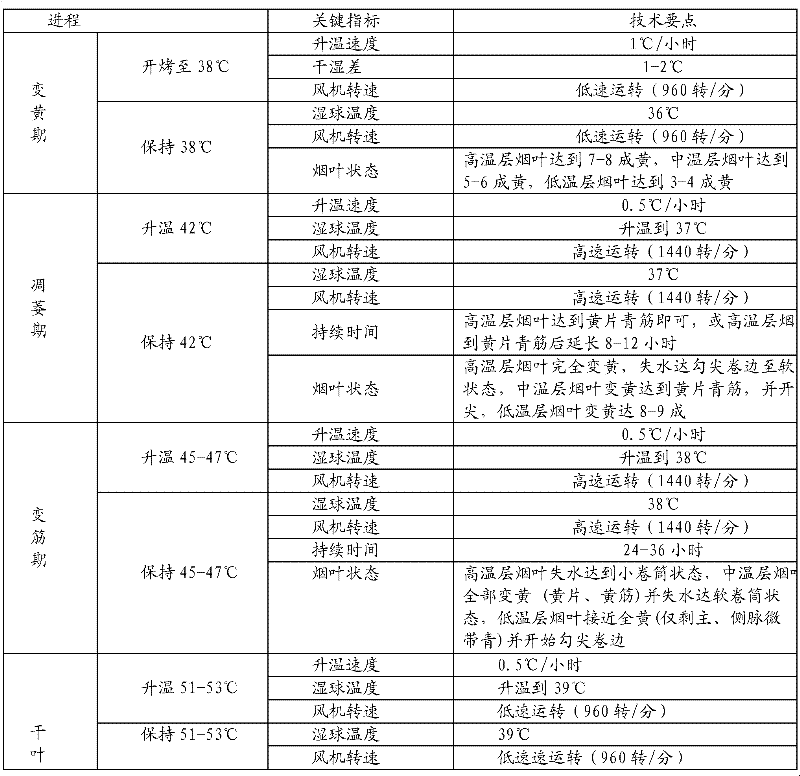

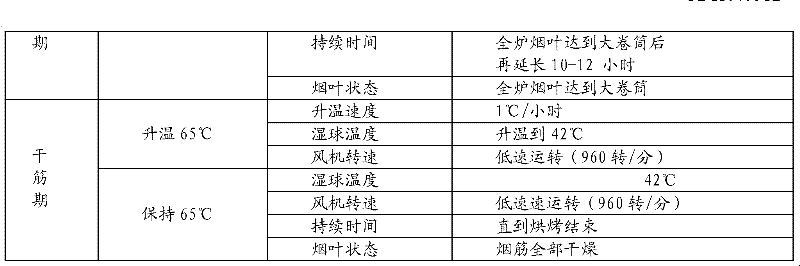

Tobacco flue-curing method for bulk curing barn

The invention relates to the technical field of flue-cured tobacco modulation, in particular to a tobacco flue-curing method for a bulk curing barn. The flue-curing process of the tobacco flue-curing method includes a yellowing period, a withering period, a stem yellowing period, a tobacco leaf drying period and a stem drying period according to factors such as dry-bulb temperature, wet-bulb temperature, drying time, heating rate, variable speed ventilation and tobacco leaf change targets, a color fixing period in the traditional tobacco flue-curing method is prolonged at a fixed point and steady temperature under the condition of hot air circulation, and sufficient decomposition and transformation of amylum, protein and other macromolecular substances in tobacco leaves and forming of aromatic matters are promoted. The tobacco flue-curing method for the bulk curing barn is easy to operate, safe and secure, can keep tobacco leaf yellow to be stable, leaf shrinking degree to be good, oil content to be increased and tobacco leaf aromatic amount to be increased greatly, further can reduce or avoid tobacco leaf roasting damage of green smoke roasting, ash smoke hanging, black bad smoke, lousy smoke roasting and the like, and can obtain high-quality tobacco leaves through roasting.

Owner:四川省烟草公司宜宾市公司

Half-dry rice noodle and preparation method thereof

ActiveCN105410624AMuscular strengthGood elasticityFood ingredient as mouthfeel improving agentLoss ratePowder mixture

The invention discloses a half-dry rice noodle and a preparation method thereof. The half-dry rice noodle comprises the following raw materials: rice, a starch mixture, a fresh fruit and vegetable paste mixture and a fruit and vegetable powder mixture and is prepared by the following steps of fermentation and preprocessing of the rice, mixing of all raw materials, twin-screw extrusion forming, aging, re-steaming, washing and cutting oof noodles, measuring and packing, post-sterilization, cooling and the like. The half-dry rice noodle prepared by the invention has the advantages of smooth and bright appearance, strong gluten power, good elasticity, natural flavor, long shelf time, clear finished product soup and the like, the breaking rate is controlled to be lower than 2%, and the loss rate of cooking is controlled to be lower than 4%. According to the half-dry rice noodle and the preparation method thereof, the problem of the existing rice noodle of single nutrition is solved; the ingredients rich in protein and vitamins are added in the formula, so that the product has comprehensive nutrients; in addition, any preservative, brightening agent and thickening agent are not added in the product, so that the product prepared by the preparation method has excellent taste and is nutrient and healthy.

Owner:GAEA GEM RICE

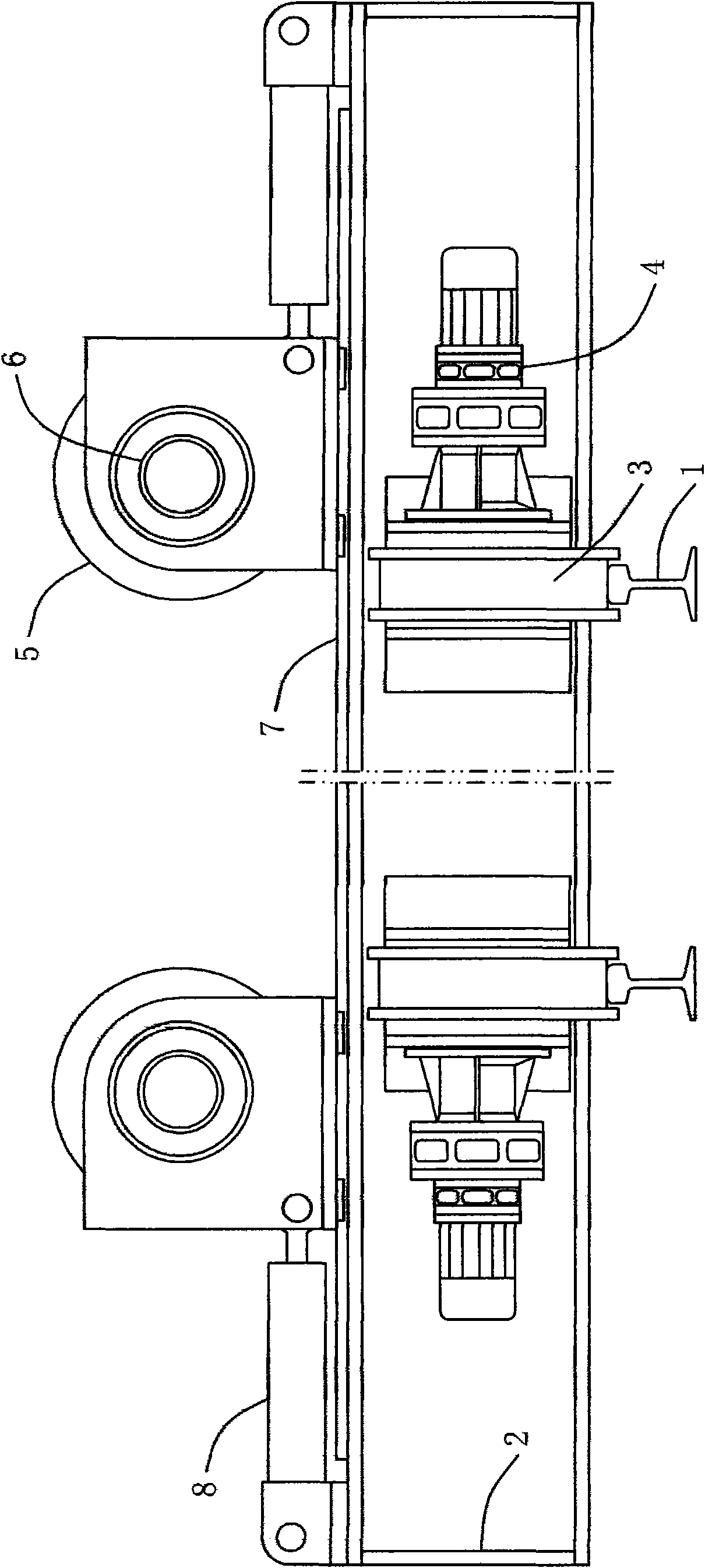

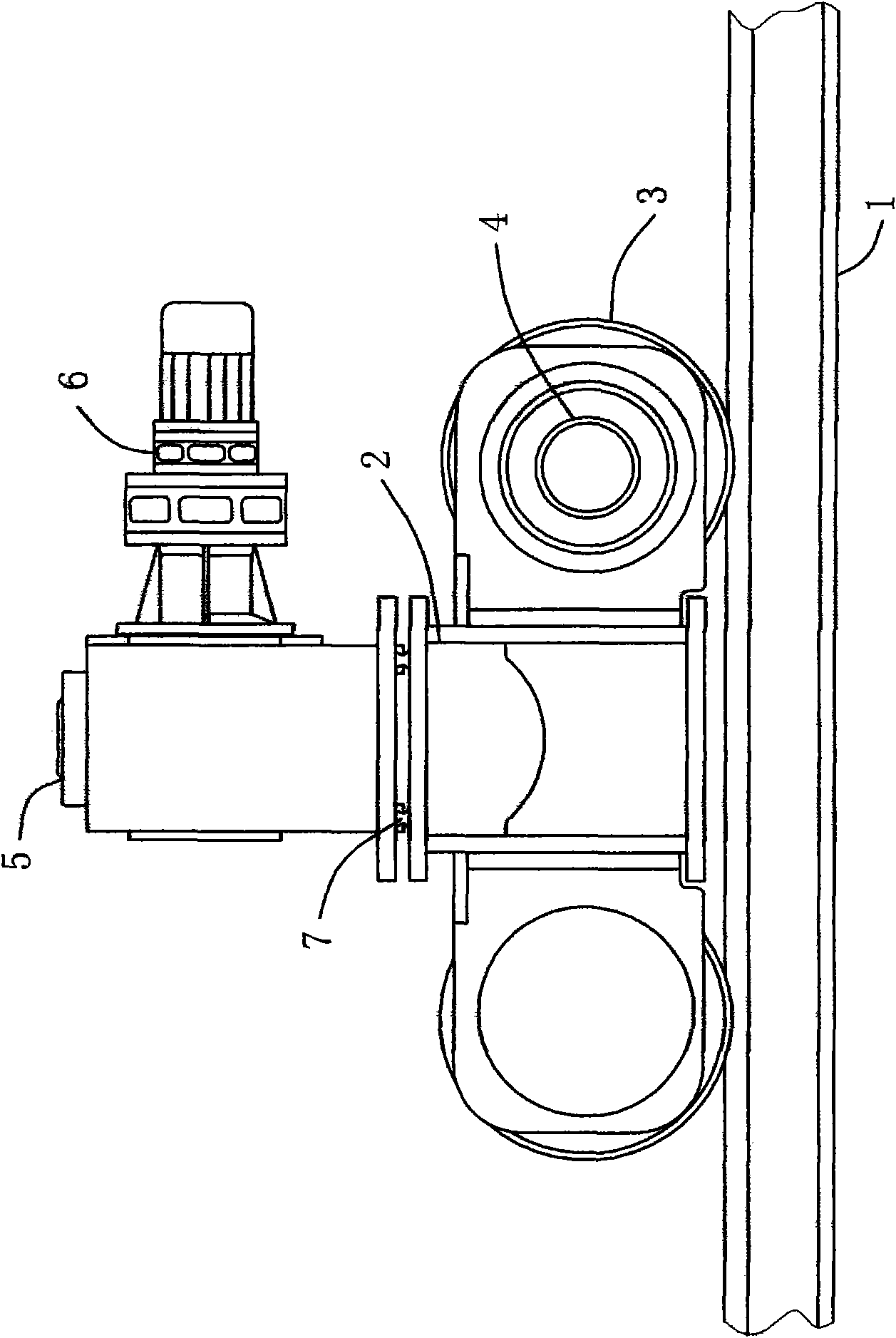

Shell ring assembly device for assembly of tower body of wind power generation iron tower

InactiveCN101885129AIncrease productivityEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTower

The invention discloses a shell ring assembly device for the assembly of a tower body of a wind power generation iron tower, which belongs to the technical field of wind power generation iron tower machining equipment. The shell ring assembly device comprises at least two groups of assembly units which are arranged on horizontal rails in a sliding way, and two rotating wheels for bearing shell rings, wherein each assembly unit comprises a roller frame arranged on the horizontal rails; the roller frame is provided with a roller matched with the corresponding horizontal rails; the upper end face of the roller frame is provided with a sliding rail which is vertical to the extension direction of the horizontal rails; and the two rotating wheels are oppositely arranged on the corresponding sliding rails in the sliding way. The shell ring assembly device solves the technical problems, in the assembly of the tower body of the wind power generation iron tower, that the coaxiality of a plurality of groups of shell rings is difficult to regulate, that the labor intensity of operators is high and that the working efficiency is low, has a rational structure and is widely applied to the machining process of the wind power generation iron tower.

Owner:WEIFANG WUZHOU WIND POWER EQUIP

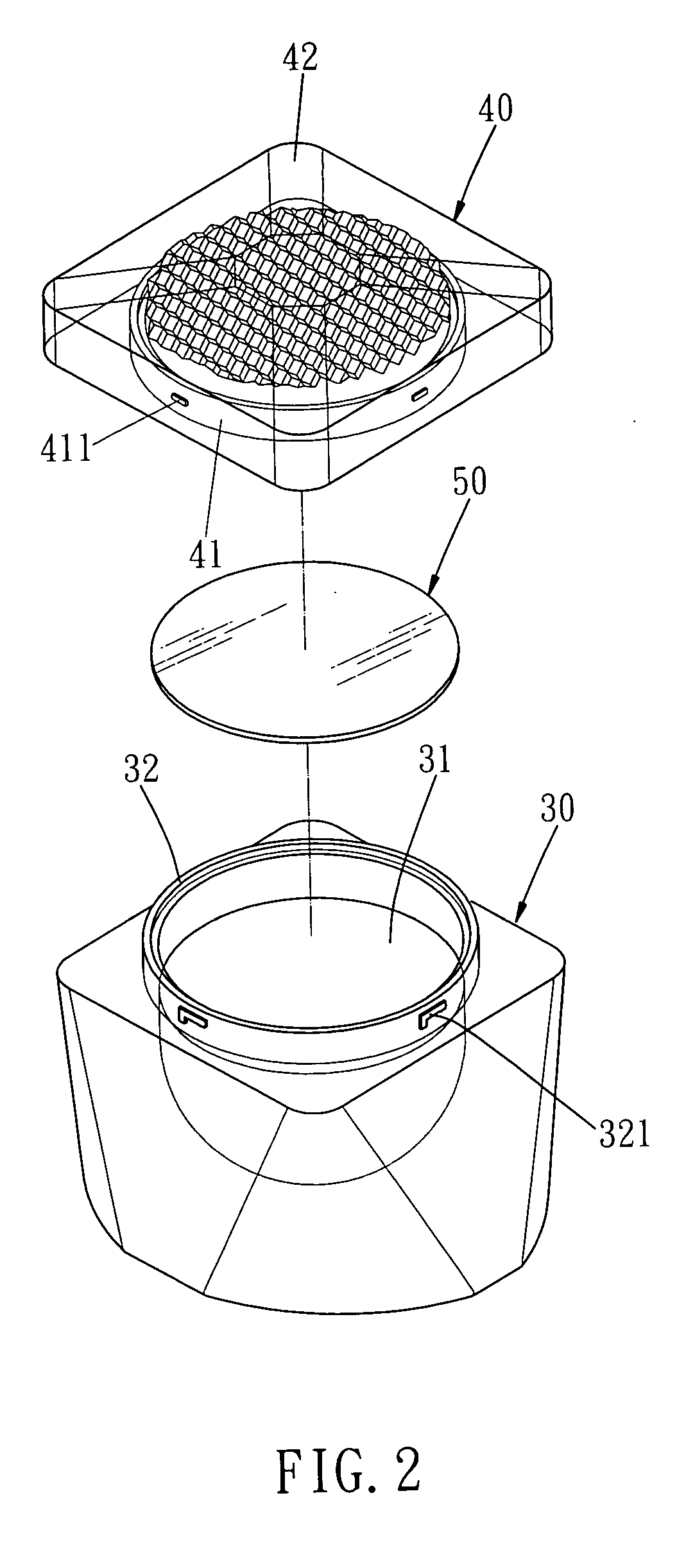

Cosmetics container having outstanding appearance

InactiveUS20050011895A1Outstanding appearanceImprove appearance qualityCapsClosure capsCosmetic appearanceColored light

A cosmetics container includes a main body, a top cover, and a colored plate. Thus, the reflective face of the top cover co-operates with the colored plate to produce a colorful optical reflective effect, and the refractive face of the top cover produces a refractive effect, thereby enhancing the aesthetic quality of the cosmetics container so that the cosmetics container has an outstanding appearance.

Owner:LIN YI HUNG

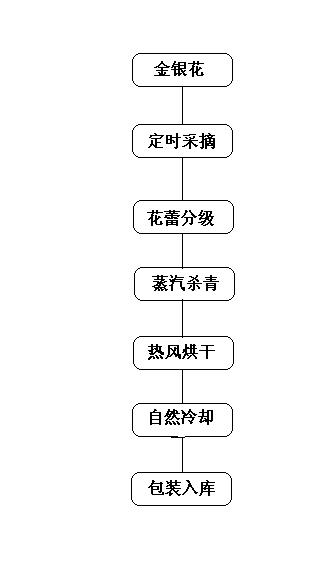

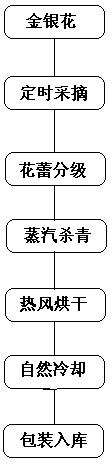

Processing method of honeysuckle tea

InactiveCN102356794ARapid inhibitory activityAvoid decompositionTea substituesCold airChlorogenic acid

A processing method of honeysuckle tea has a technical scheme that the method comprises the following steps of picking at regular time, bud grading, enzyme deactivation by steam, hot air drying, natural cooling, packaging and warehousing; the beneficial effect is that: honeysuckle buds are picked at 8:30-11:00 in the morning everyday, which can ensure that fresh flowers contain the most beneficial components and dew is prevented; grading of the buds can ensure uniform processing; enzyme deactivation by steam can rapidly inhibit the activity of polyphenol oxidase, and effectively prevent the decomposition of honeysuckle chlorogenic acid; direct hot air drying is performed after enzyme deactivation without cooling or cold air dehumidification, which can rapidly remove residual water contained in fresh flowers, destroys the activity of polyphenol oxidase, and allows the honeysuckle tea to be maintained to be undeteriorated for a long time; the honeysuckle tea processed by the method has a jade green color, and a lifelike shape; nutrient components can be maintained to be less lost; the infused tea has a bright and clear soup color, and a complete flower shape; the invention can greatly increase the drinking value and appearance quality of honeysuckle tea.

Owner:重庆市秀山红星中药材开发有限公司

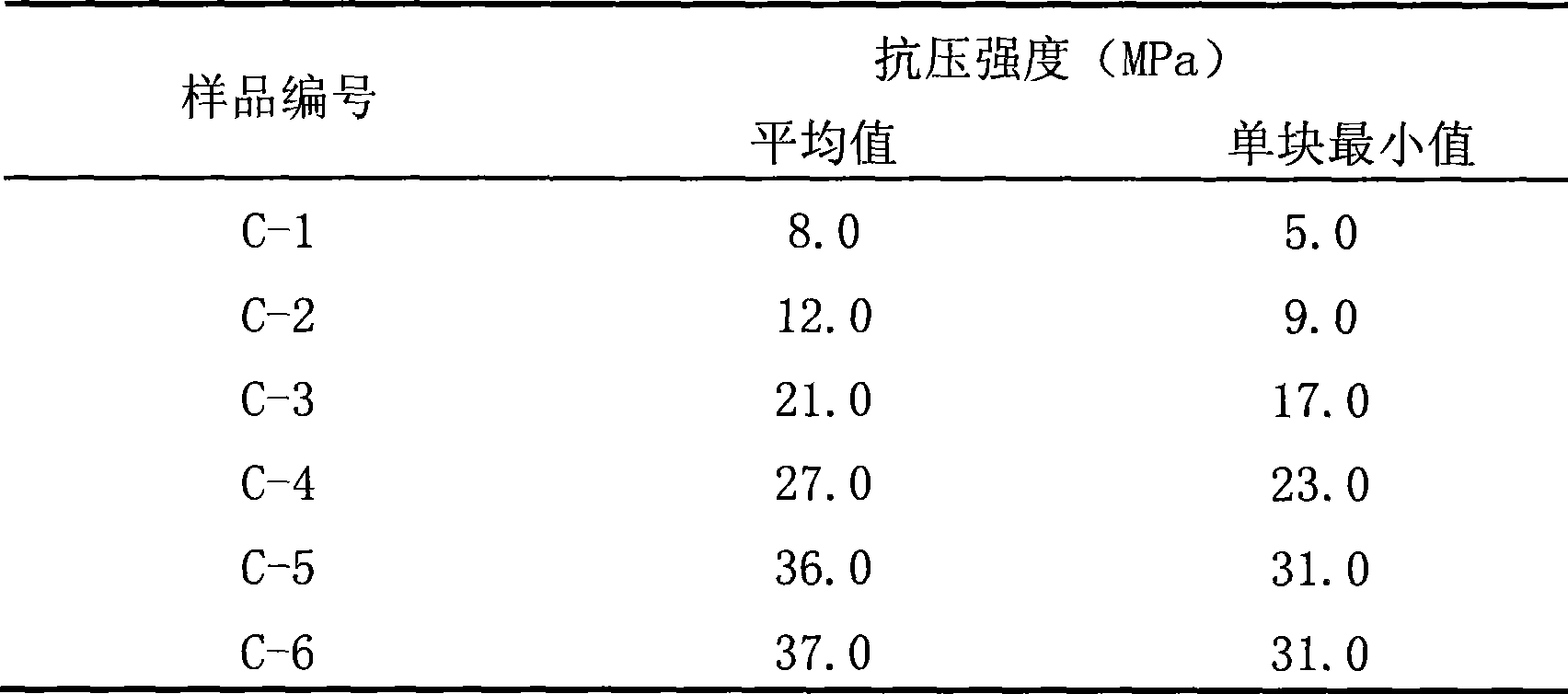

Building material based on interaction of alkali and CO2

ActiveCN101381217AWiden the range of process parametersReduce carbonization depth requirementsSolid waste managementSlagCarbonization

The invention discloses a building material product based on the synergic action between alkali and CO2 and a method for preparing the same, which belongs to the field of silicate building material and product thereof. In the building material product, the fly ash the fineness of which is controlled in the range of between 400 and 600m<2> / Kg and the slag form a mixed powder material, and an aggregate and water glass are added into the mixed powder material for forming so as to obtain a blank, and the blank is subjected to natural curing and carbonization to obtain the building material product. In the invention, the industrial waste slag is used as raw materials, the high-performance silicate product is prepared under the conditions of low alkali and not doping lime and cement clinker, so that the strength level is high, no scumming phenomenon occurs on the surface of the product, the release quantities of various toxic and harmful ions are far below the threshold value; moreover, the building material product has the advantages of good durability, strong freezeproof and weather resistance capabilities, and is suitable to be the building wall material. The invention has active effect on utilizing waste slag resources, saving energy and reducing emission.

Owner:BEIJING ZHONGYANYI ENG TECH DEV CENT

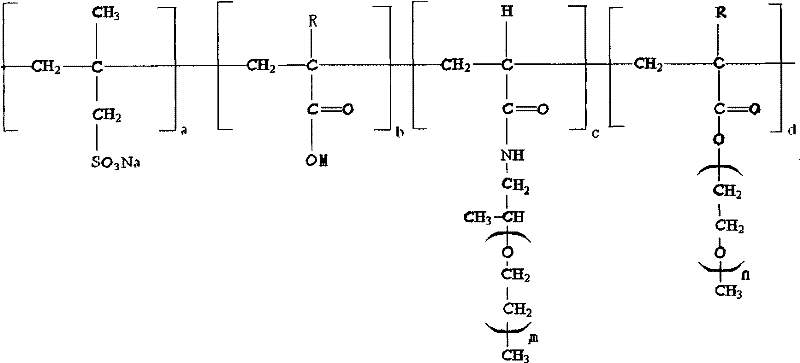

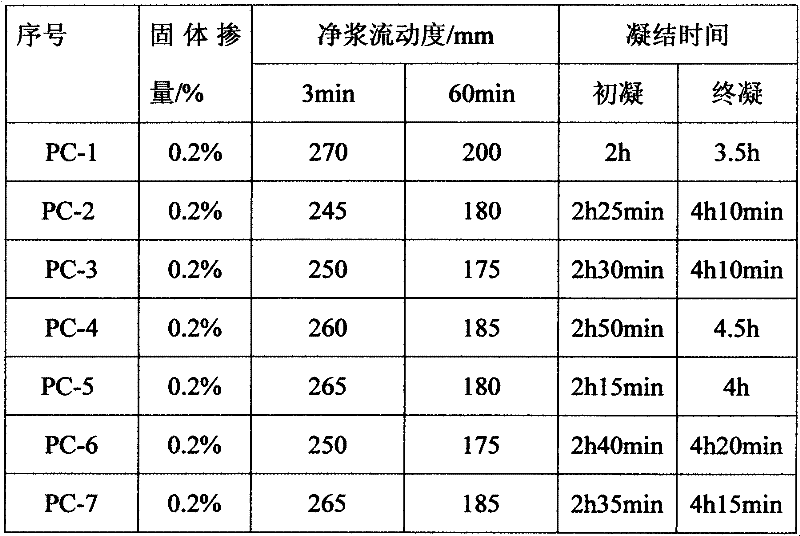

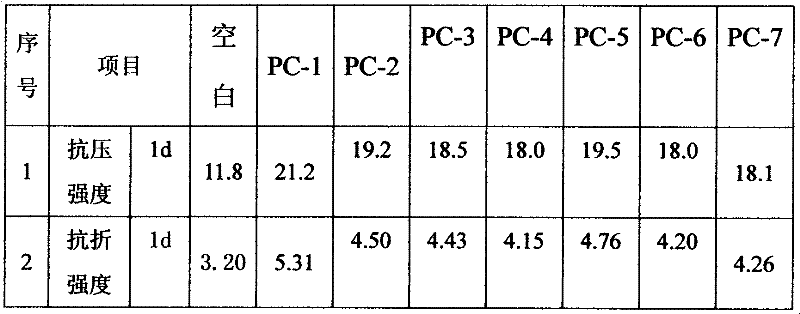

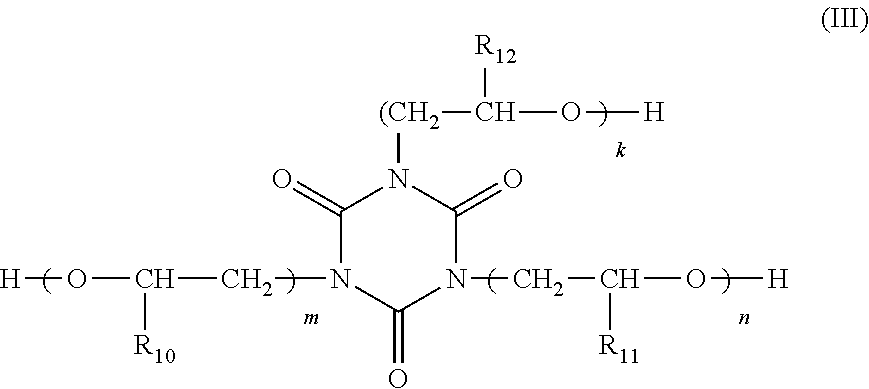

Early-strength polycarboxylic acid water reducing agent

The invention relates to an early-strength polycarboxylic acid water reducing agent and a preparation method thereof. The early-strength polycarboxylic acid water reducing agent is in a liquid state, and the solid content is 40%. The preparation method comprises the following steps: polymerizing modified polyoxyethylene ether or polyoxypropylene ether, (methyl)acrylic acid or itaconic acid, acrylamide, sodium methyl propenyl sulfonate and other monomers under the actions of a molecular weight chain initiator and a chain transfer agent; and neutralizing to obtain the water reducing agent containing carboxy, amino, sulfonic and polyethenoxy side chains. The early-strength polycarboxylic acid water reducing agent provided by the invention has the advantages of low alkali content and high water reducing rate; and when the early-strength polycarboxylic acid water reducing agent, which accounts for 0.6-1.4 wt of the cementing material, is added to the cementing material, the concrete is labor-saving for operation, and the cement mixture has high flowability and good workability. The early-strength polycarboxylic acid water reducing agent can effectively shorten the setting time and enhance the early strength. The invention has the advantages of simple production technique, easily controlled reaction conditions and no environmental pollution.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

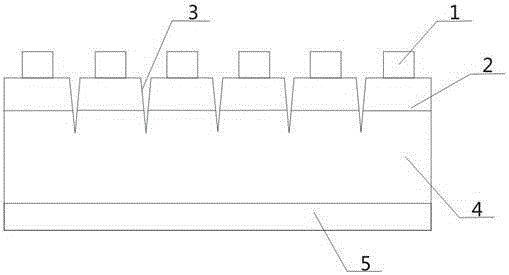

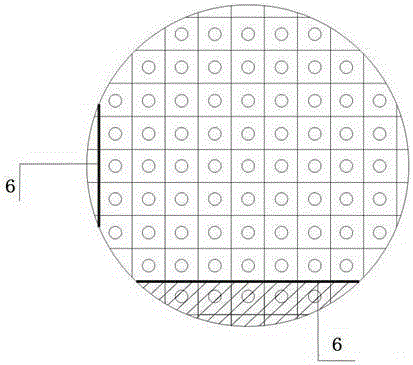

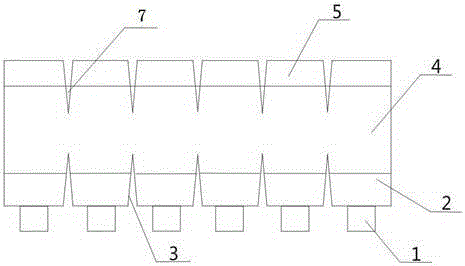

GaAs-based LED chip cutting method

ActiveCN105226143AGuaranteed FusionImprove appearance qualitySemiconductor/solid-state device manufacturingFine working devicesSurface stressSurface mounting

The invention discloses a GaAs-based LED chip cutting method. The method comprises the following steps: (1) semi-cutting is carried out on a P surface, criss-cross cutting grooves are formed, and chip P surface electrodes are separated at equal intervals; (2) the chip P electrodes face a white film downwardly, N electrodes face upwardly and are attached to the white film; (3) chip N surface scribing is carried out along the cutting grooves formed by P surface semi-cutting, and chip N surface stress is relieved; (4) film inverting is carried out on the scribed chip, and the chip is transferred to a blue film from the white film; and (5) on the chip N surface, a bonding tool of a chip breaking machine is used for chip breaking along scratches, and the chip is processed into independent crystal grains. The improved surface mount method is used, a cutting method which combines advantages of a chip sawing machine and a laser chip scribing machine is adopted, the chip P surface stress and the N surface stress are relieved maximally, deformation stress effects caused by film laminating can be reduced and edge collapse and pipe core breaking phenomena after the chip is cut are reduced, and the appearance quality after the chip is cut is improved.

Owner:SHANDONG INSPUR HUAGUANG OPTOELECTRONICS

Mineral filled low-shrinkage modified polypropylene composite material and preparation method thereof

The invention relates to a mineral filled low-shrinkage modified polypropylene composite material which belongs to the field of modified polypropylene composite materials and comprises the following ingredients in parts by weight: 40 to 85 polypropylene, 5 to 30 polyethylene, 5 to 20 elastic bodies, 5 to 30 mineral filler, 0.1 to 3 compatilizers and 0.1 to 3 accessory ingredients. The mineral filled low-shrinkage modified polypropylene composite material prepared by the invention has good mechanical property, ensures good apparent performance of the composite material and has lower shrinkage. In addition, the method is simple and feasible and can be popularized and applied in a large scale.

Owner:SUZHOU SUNWAY POLYMER

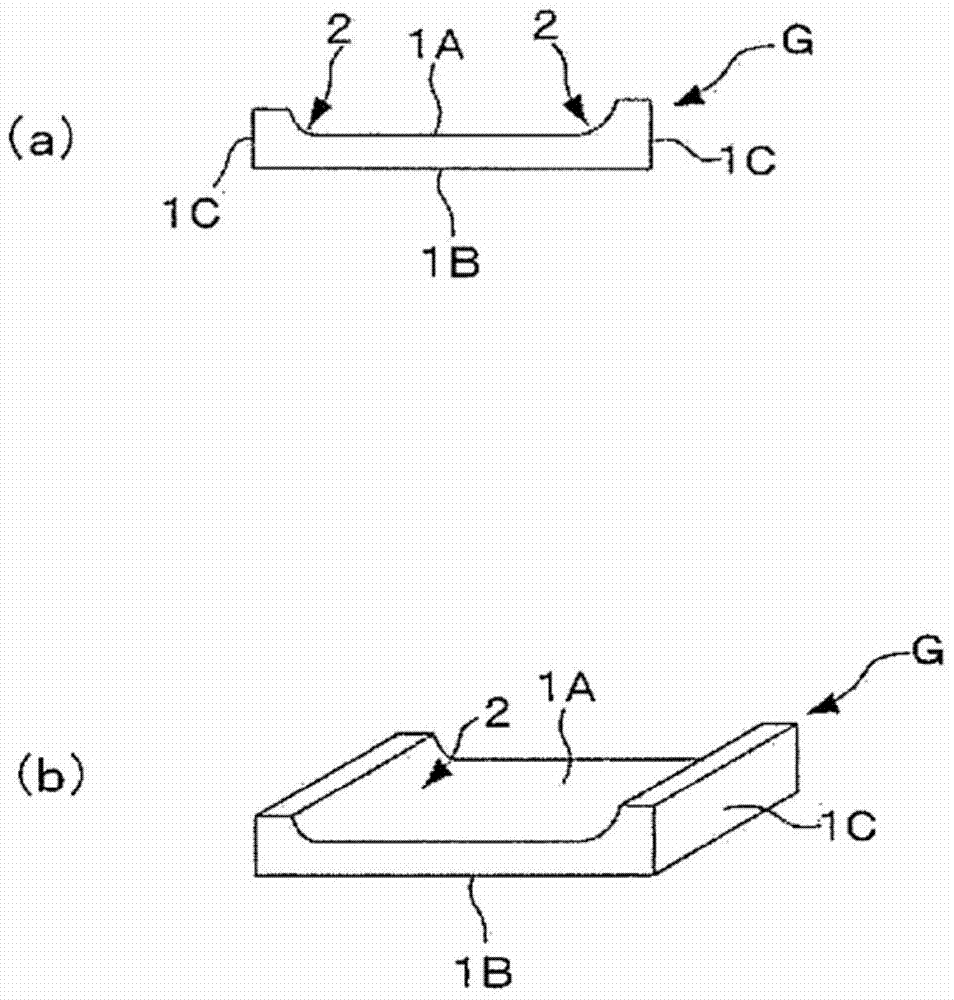

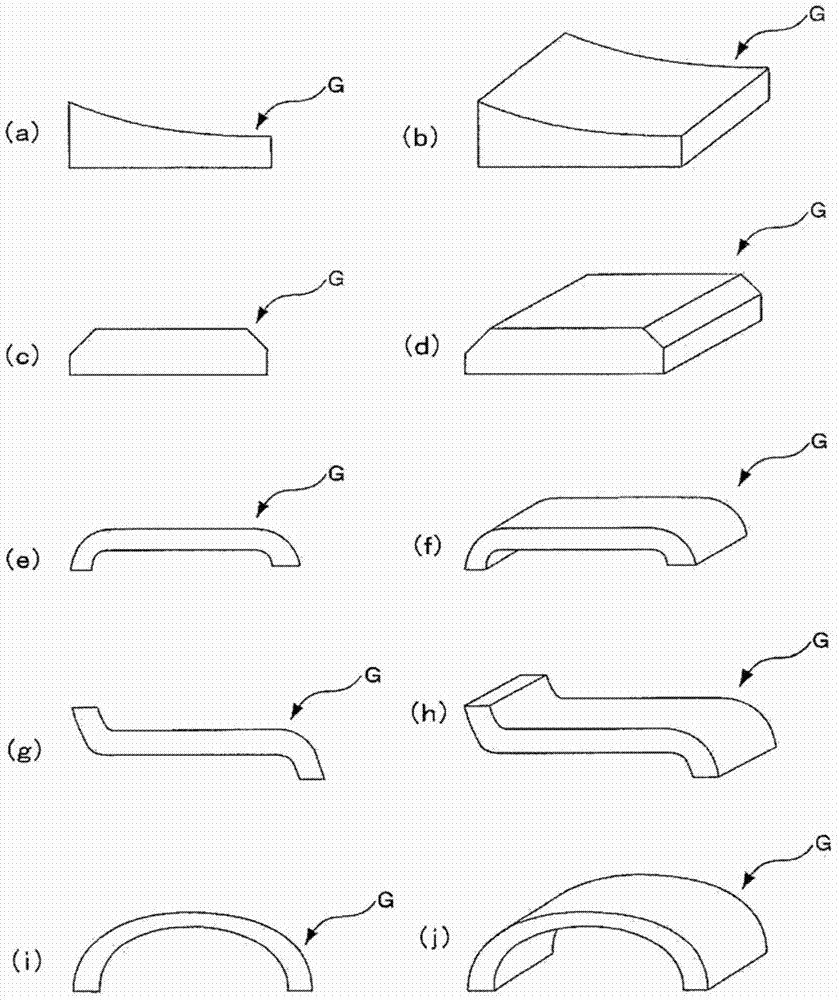

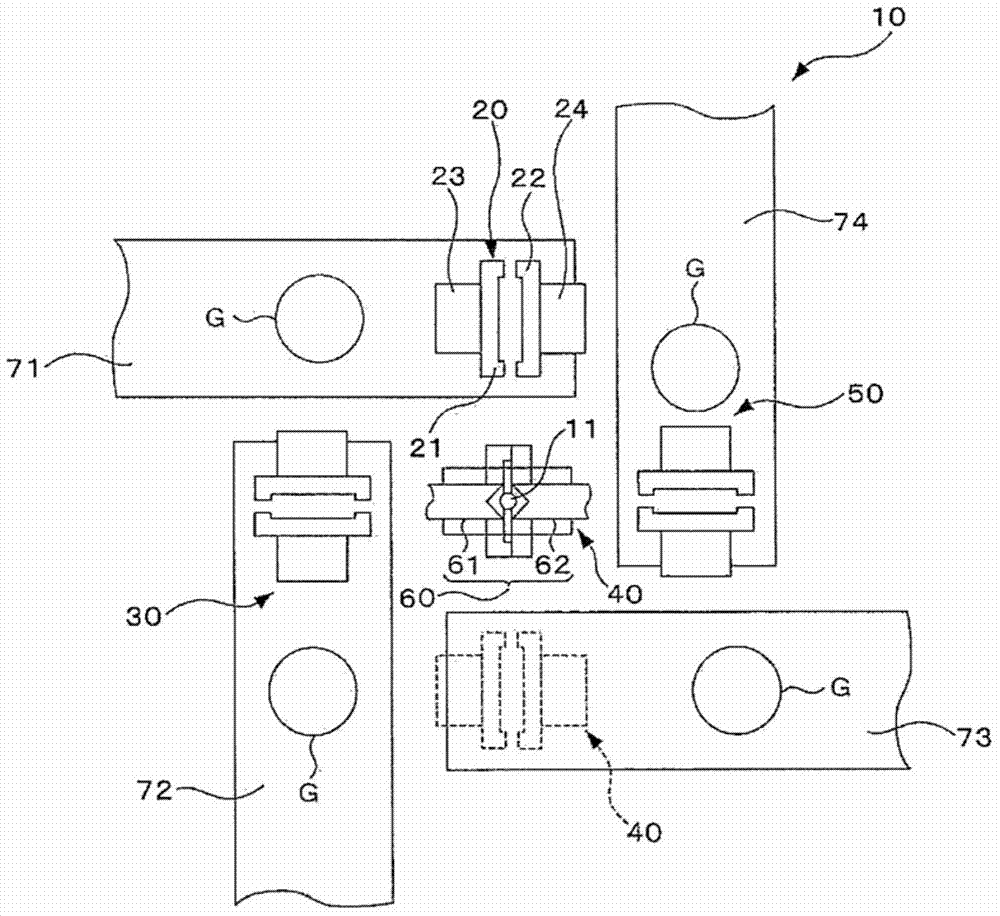

Electronic device cover glass blank, method for manufacturing same, electronic device cover glass, and method for manufacturing same

InactiveCN103946166AIncrease freedomImprove appearance qualityGlass pressing apparatusGlass press-moulding apparatusEngineeringCover glass

An electronic device cover glass blank (G) to be used as a substrate of an electronic device cover glass includes a pair of main surfaces (1A, 1B), and end surfaces that adjoin the pair of main surfaces (1A, 1B). The main surfaces are shaped so as to be asymmetric to each other in the thickness direction. The main surfaces (1A, 1B) are press-molded surfaces formed by direct pressing. A method for manufacturing the cover glass blank includes a molding step in which a pair of dies is used for press molding a mass of molten glass supplied from a molten glass supplying unit. The pressing surface of at least one of the pair of dies has a shape for forming the main surfaces and an interposed surface.

Owner:HOYA CORP

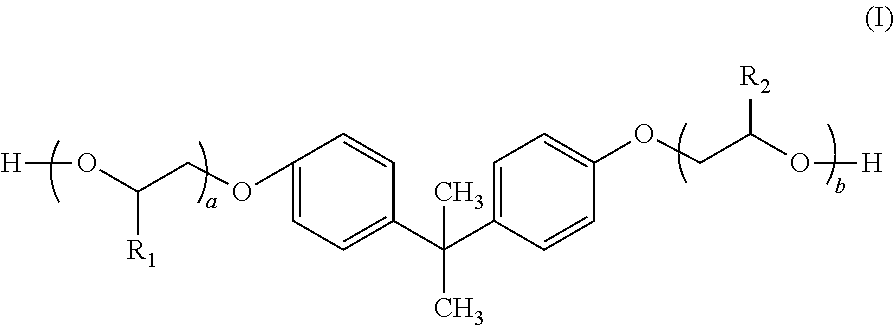

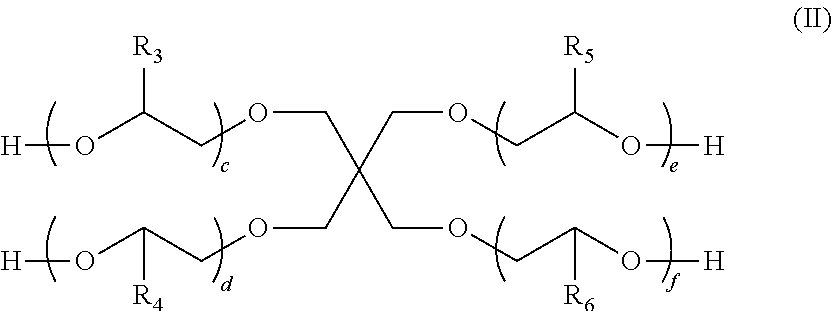

Kind of biodegradable polyester and its preparation method

ActiveUS20110190468A1Change softnessIncrease the rate of crystallizationAbsorbent padsBandagesHeat resistanceCrystallization temperature

The present invention relates to a kind of biodegradable polyester and its preparation method, which belongs to the field of biodegradable co-polyester product technology. The number-average molecular weight of the biodegradable polyester material under this invention is 6000-135000 g / mol, the molecular weight distribution is 1.2-6.5, and the range of crystallization temperature is 15° C.-105° C., which could overcome the disadvantages of existing technical products and can be processed into membrane materials, sheet materials and foam materials. During processing, the picking property will be dramatically changed with the appearance quality improved; after heat resistance is improved, this new type of polyester material could also be applied to the processing course with long cycles, for example, the injection processing course, and the biodegradable aliphatic / aromatic polyester materials provided by this invention has excellent mechanical properties.

Owner:KINGFA SCI & TECH CO LTD +1

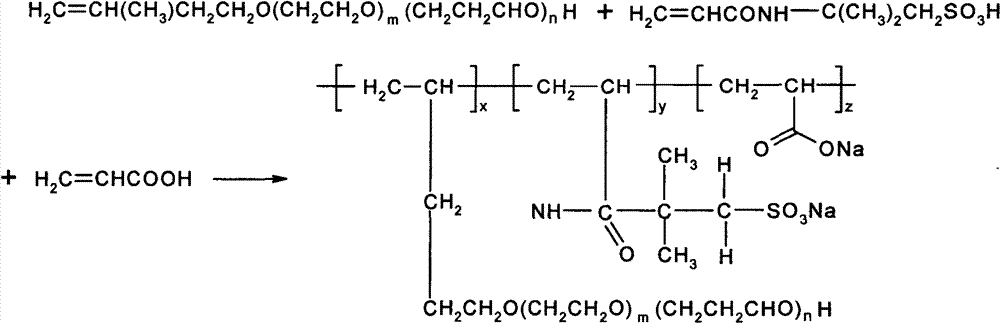

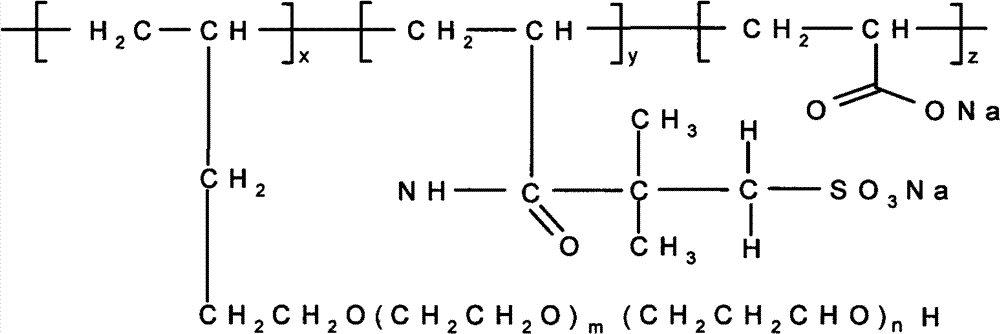

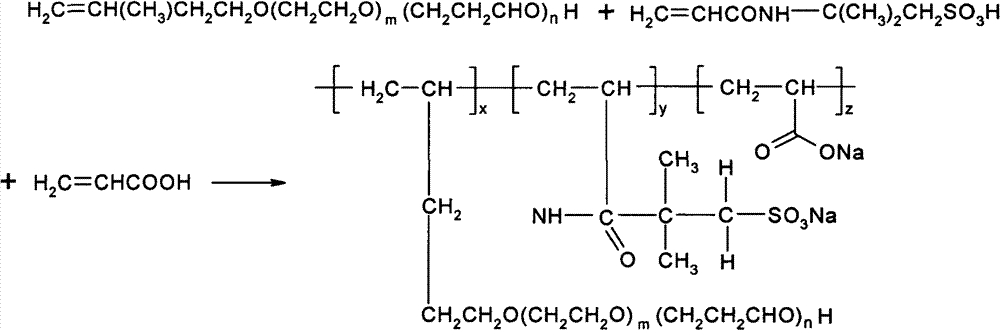

Synthesis method of polycarboxylic efficient concrete water reducer for high-performance prefabricated parts

The invention relates to polycarboxylic efficient concrete water reducer for high-performance prefabricated parts and a synthesis method thereof. The polycarboxylic efficient concrete water reducer in a comb structure is characterized by being formed by using TPEG 2400 (methyl alkenyl polyoxyethylene ether), unsaturated crylic acid and activated monomer AMPS (2-acrylamide 2- methylpro panesulfonic acid), and using a redox system (hydrogen peroxide-VC (ascorbic acid)) for one-step mid-temperature aqueous free radical polymerization. The polycarboxylic efficient concrete water reducer is provided with active groups such as ether bonds, carboxylic acid groups, sulfonic acid groups, polyoxyethylene alkyl ethers and amide groups on long main chains and side chains. The product with 40% solid content has the effects of high water reducing rate, high early strength, low gas content, low chlorine, low alkali and no rusting to reinforcement steel bars. The product is prepared into the product with 20% solid content for use. After 1.0-1.2% of cementing material is added, the product has fine wrapping performance and water retentivity when slump is 30-50mm. The product can be used for concrete for high-performance prefabricated parts, such as C80 high-strength tubular piles and C60 prefabricated beams.

Owner:SHANGHAI SHENLI BUILDING MATERIAL +2

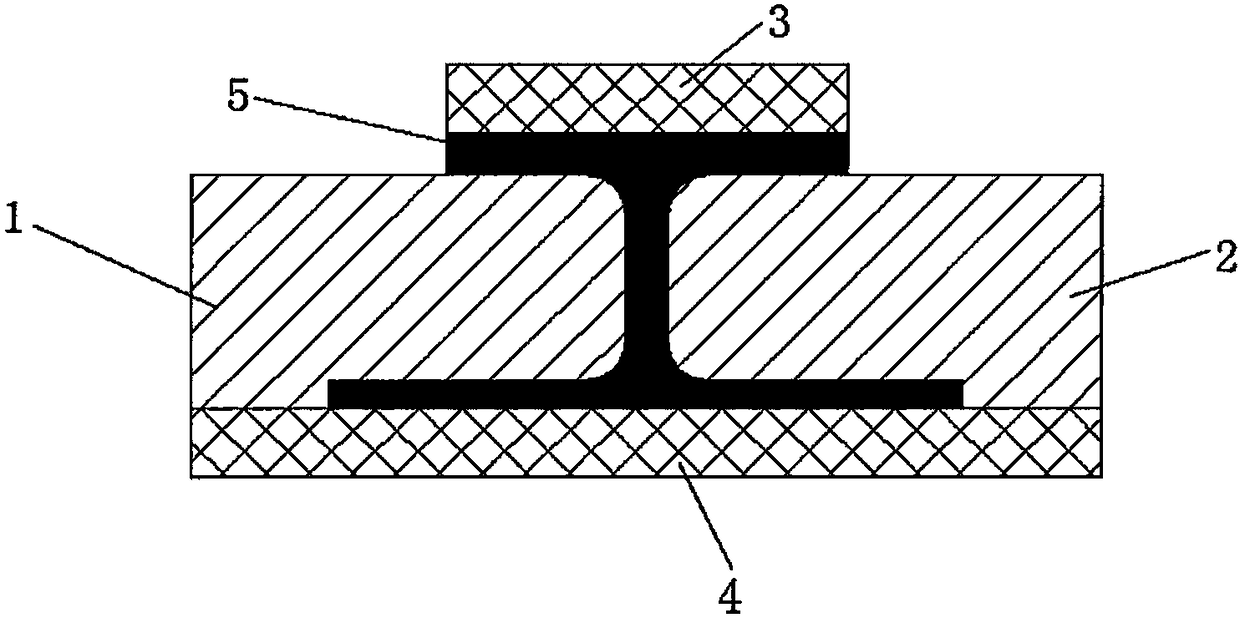

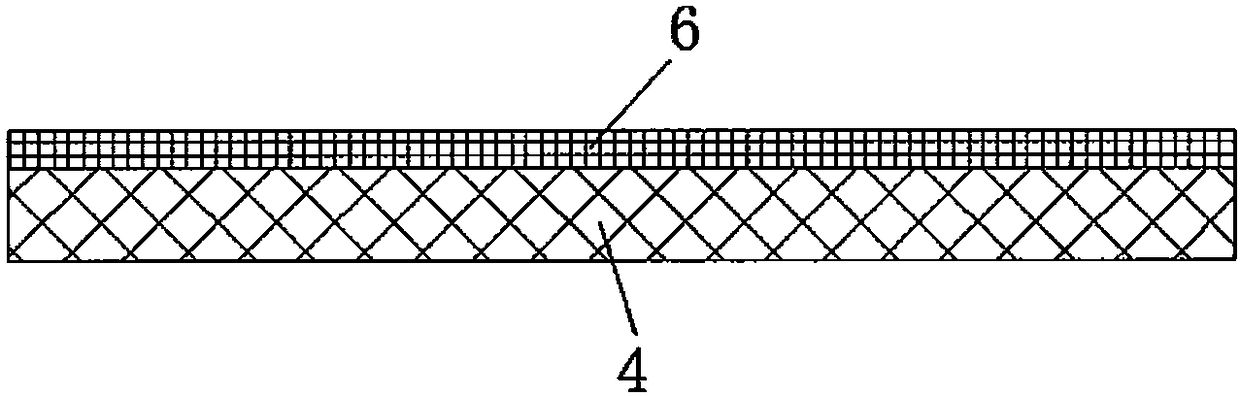

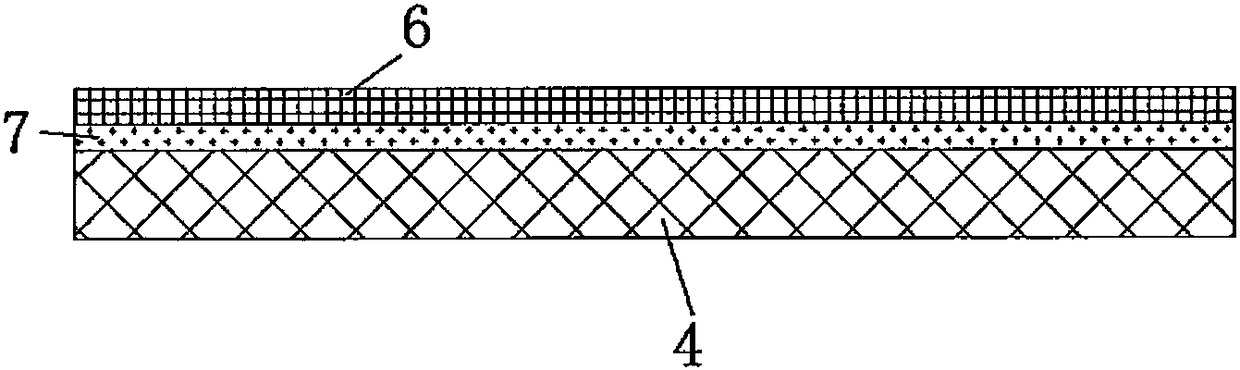

Composite material I-shaped stringer molding process

The invention provides a composite material I-shaped stringer molding process, which comprises: manufacturing a hard mold tool; manufacturing a soft mold process cover plate; manufacturing a lower edge strip soft mold; molding an I-shaped stringer core mold; molding an I-shaped stringer lower edge strip flat plate; molding an I-shaped stringer upper edge strip flat plate; molding a stringer wick strip; combining to obtain an I-shaped stringer tool; preparing a vacuum bag; curing; and demolding. According to the present invention, the part manufactured according to the process has good appearance quality, the generation of internal defects cannot be caused, the molding quality of the thin part can be improved, and the requirements on the manufacture precision and the matching precision of the molding tool are reduced so as to reduce the manufacturing cost of the part.

Owner:COMAC +1

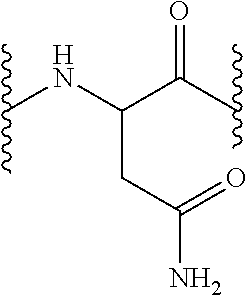

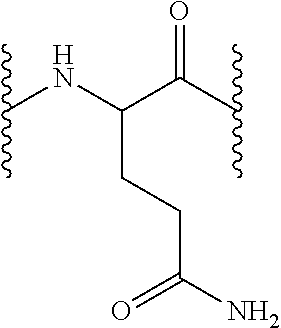

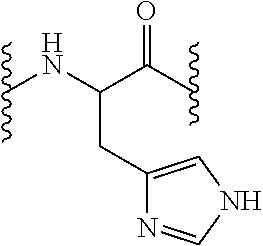

Compounds useful in the treatment and/or care of the skin, hair and/or mucous membranes and their cosmetic or pharmaceutical compositions

ActiveUS20150342852A1Prevent and delay and hinder appearance and developmentImprove appearance qualityCosmetic preparationsHair cosmeticsPhotoagingPharmaceutical medicine

Compounds of general formula (I): R1-Wn-Xm-AA1-AA2-AA3-AA4-AA5-AA6-Yp-Zq-R2; their stereoisomers, mixtures thereof and / or their cosmetically or pharmaceutically acceptable salts, cosmetic and / or pharmaceutical compositions which contain them and their use in medicine, and in processes of treatment and / or care of the skin, hair and / or mucous membranes, in particular in the aging and photoaging of the skin.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Neutral boron silicate glass used for medicinal mold-formed bottle and manufacturing method thereof

InactiveCN101186437AImprove performanceSmall coefficient of thermal expansionElectric furnaceGlass productionSilicate glassHeat stability

Neutral borosilicate glass used for moulding medicinal bottles is provided, which pertains to the technology filed of glass containing aluminum, boron, 40 percent to 90 percent (by weight) of silicon dioxide and provides neutral borosilicate glass meeting the standard of medical packaging container (material) YBB00292002, YBB00322002. The glass contains 8-12 percent of B2O3 with expansion coefficient of 4.0-5.0 multiplied by 10<-6> / K, as well as a series of excellent physical and chemical properties such as good heat stability, strong acid-resistance, alkali-resistance, water-resistance and erosion-resistance. The invention adopts cold furnace top and deep bed, recycles volatiles of boron during the course of melting, thus effectively reducing boron volatilization, preventing unfavorable phenomenon from taking place, for example, the combined material layer from incrustation and reversing, and obtaining comparatively good economic benefit and quality benefit.

Owner:SHANDONG PHARMA GLASS

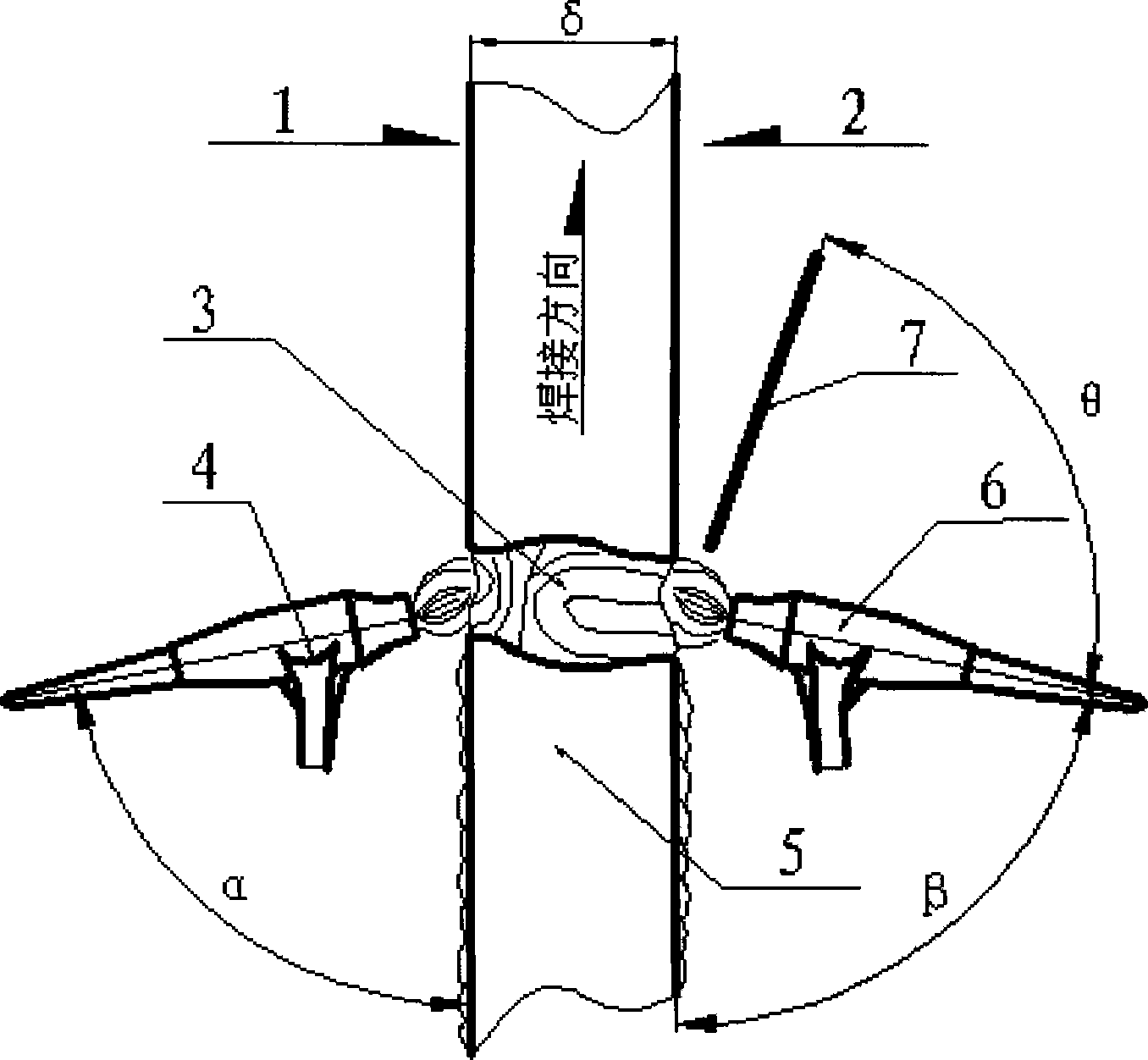

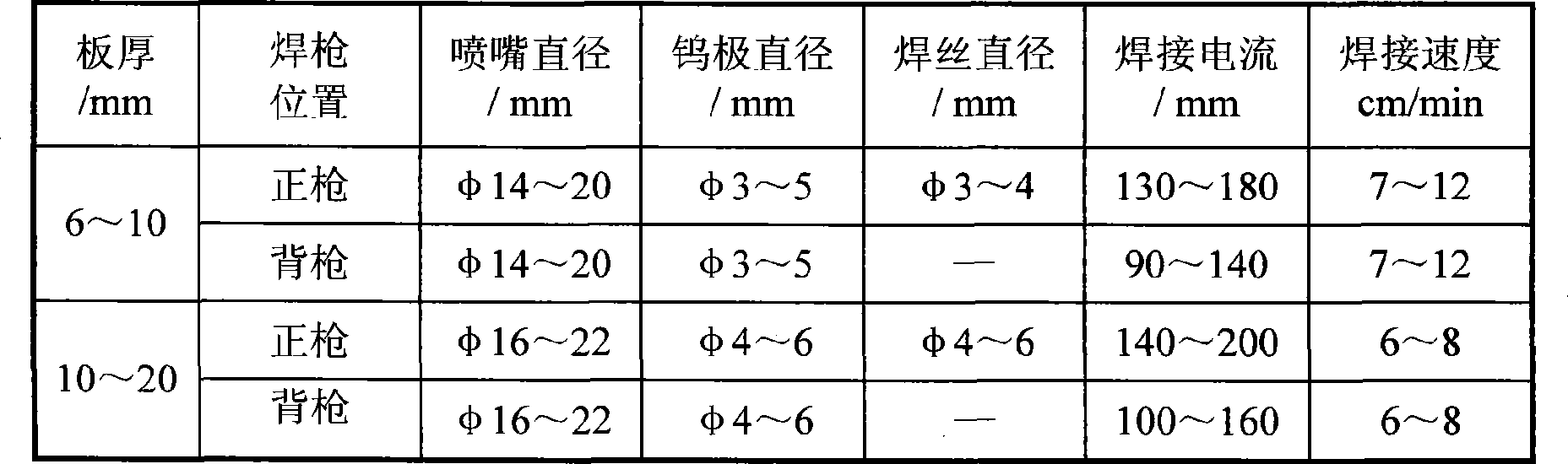

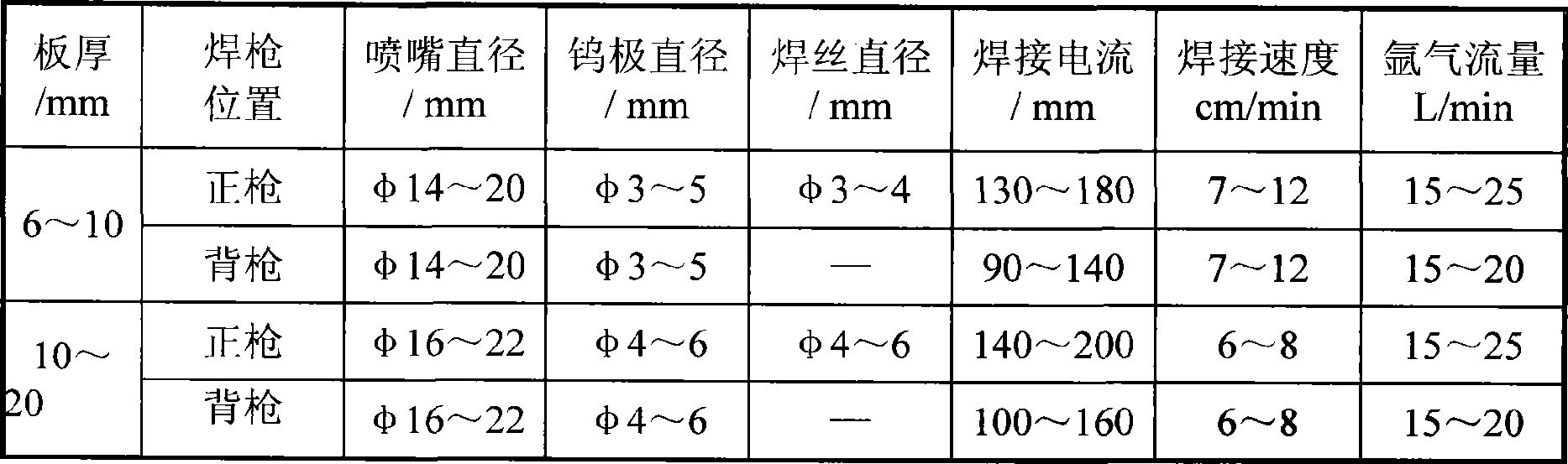

Aluminum and aluminum alloy handwork double-gun double-face TIG welding technique

InactiveCN101474709AFlexible approachAdaptableArc welding apparatusWelding/soldering/cutting articlesAluminium alloyWelding joint

The invention introduces a manual double-torch double-side TIG welding technology for welding aluminum and aluminium alloy. The welding process comprises the following steps: a vertical upward welding technique is adopted, two manual welding torches simultaneously and respectively initiate arc and weld at the front side and the reverse side of welding joints to be welded; two tungsten electrodes are basically aligned; the two welding torches move simultaneously and share a melting bath; the front side of welding lines are filled with welding sticks while the reverse side is not. Welding parameters such as the reverse side welding torch current and the like are less than the welding parameters of the front side welding torch; once weld penetration is achieved and both sides are shaped; argon shield is adopted in the process of welding; inclination angles Alpha and Beta are controlled within the range of 70-100 degrees, the included angle Theta between the welding sticks and the welding torches is maintained within the range of 80-110 degrees. According to the welding technology of the invention, irregular space curve welding lines of medium wall are welded, the applied technology is flexible and the adaptability is high, thus simplifying production procedures and process steps, greatly improving welding efficiency, avoiding possibility of causing interlayer defects due to multilayer welding and improving interior quality of welding lines and appearance quality thereof.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

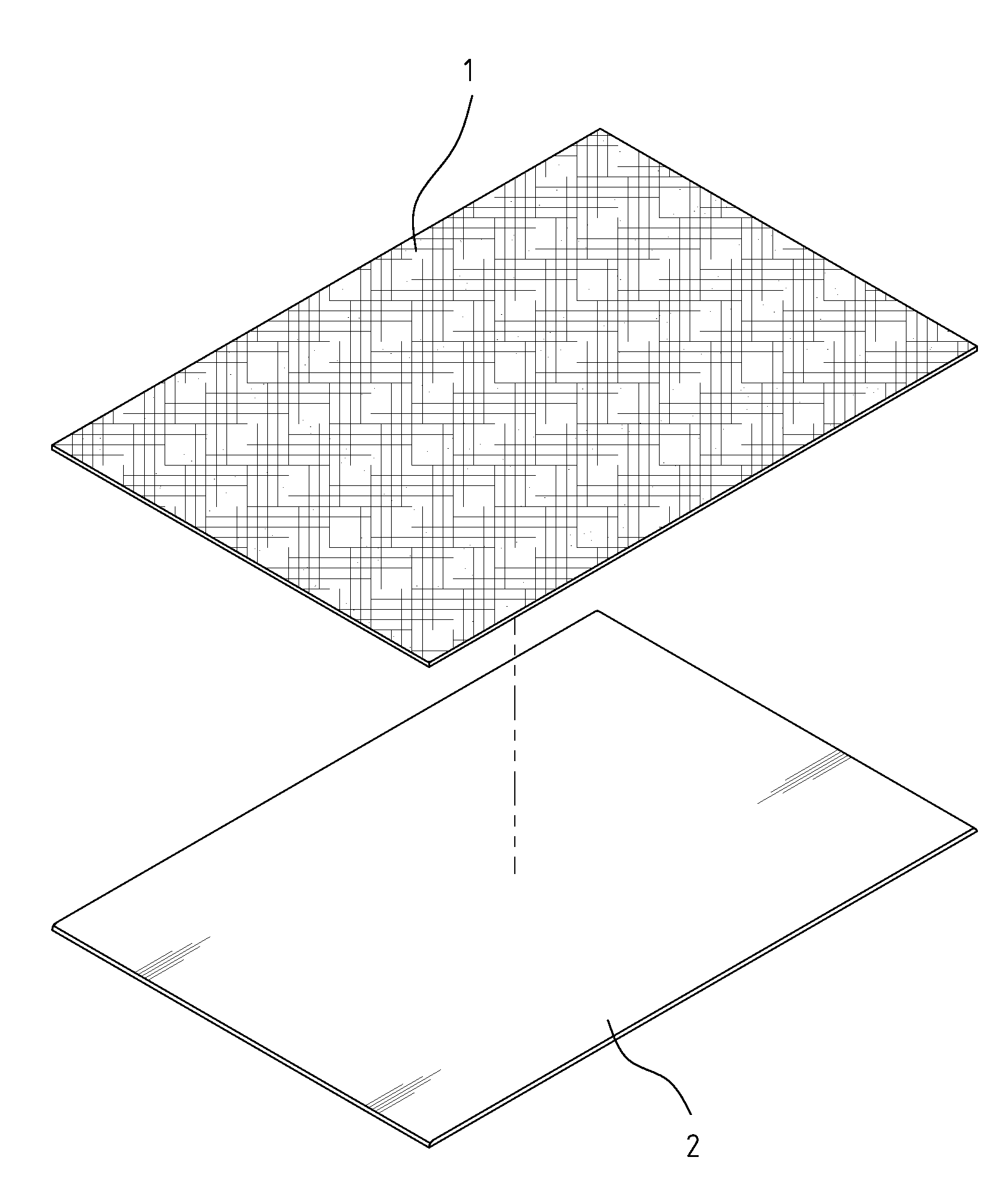

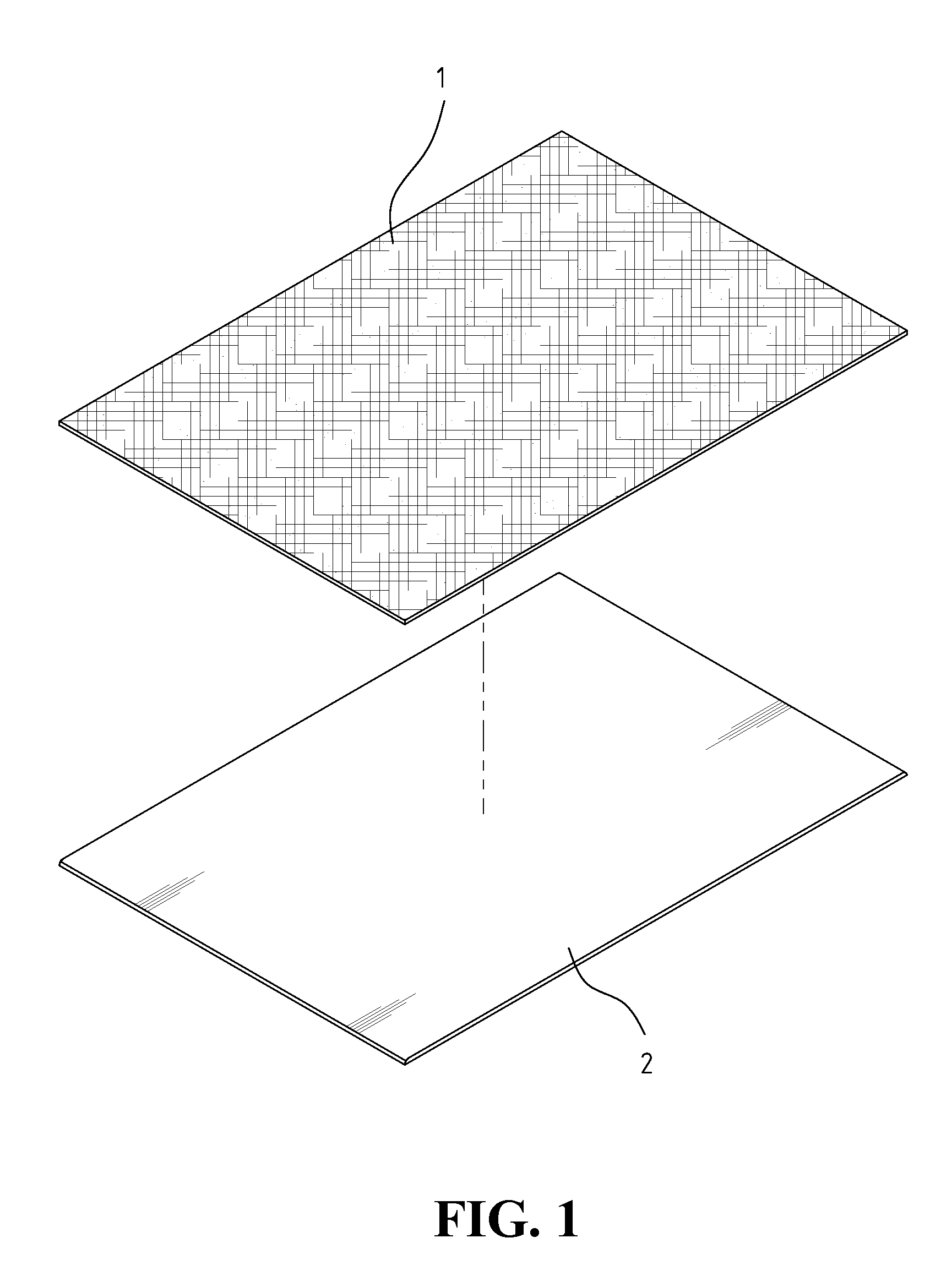

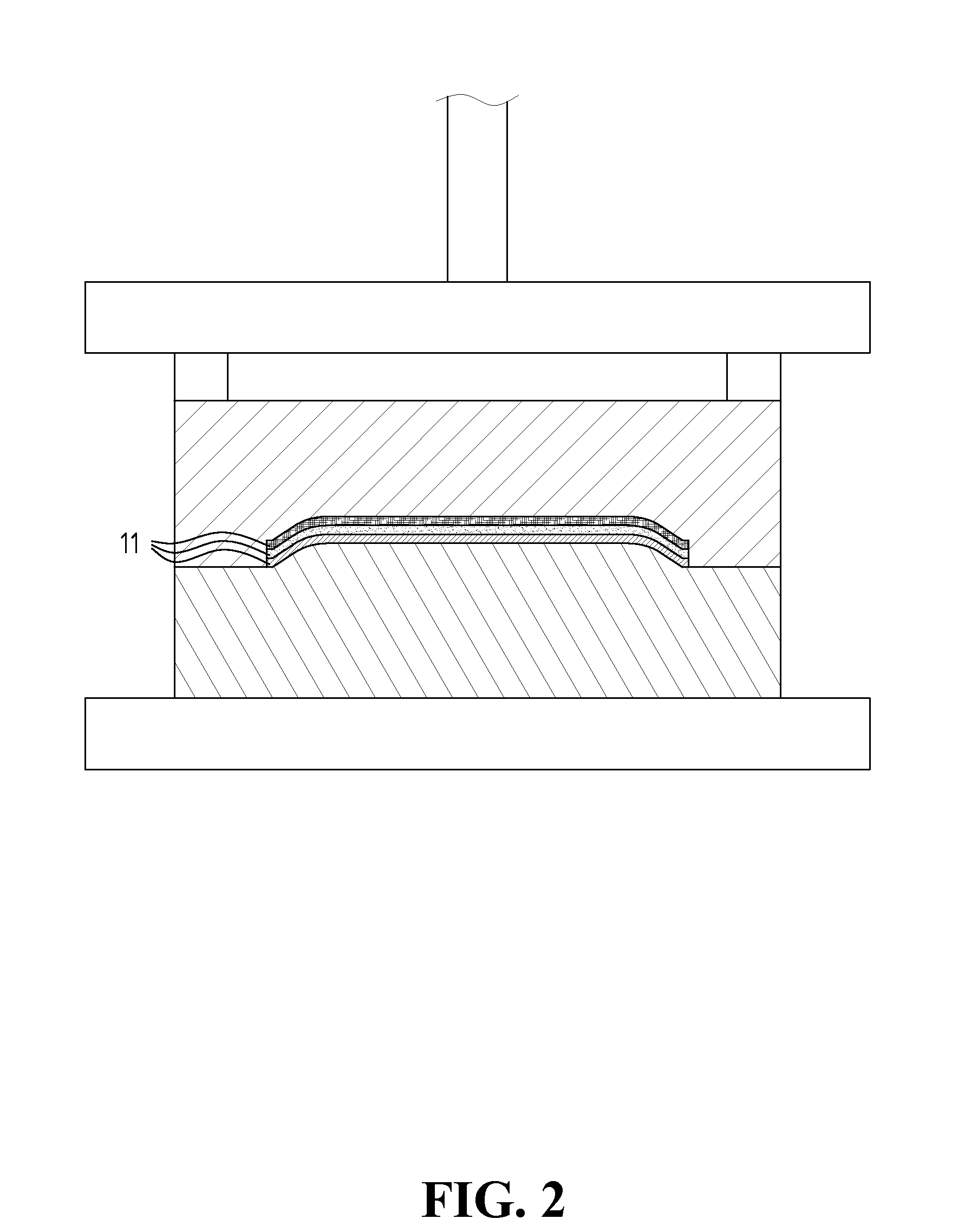

Composite Structure Of Composite Substrate And Plastic Material

InactiveUS20090136708A1Improve adhesionAvoid problemsSynthetic resin layered productsElectrical equipmentCompression moldingPlastic injection molding

A composite structure of a composite substrate and a plastic material is provided. The composite structure is fabricated by a method including the steps of: preparing a plurality of fiber layers weaved in different directions and laminating the fiber layers to configure a stack; soaking the stack in a resin, and drying the soaked stack to obtain a composite substrate; conducting a compression molding process to the composite substrate to achieve a predetermined shape; putting the compression molded composite substrate in a mold of a plastic injection molding machine; injecting a melting plastic material obtained from plastic particles melted by an extrusion machine into the mold, for combining with the composite substrate; and water cooling for hardening the combination, thus achieving a product of the composite structure.

Owner:HUANG CHUN YING +1

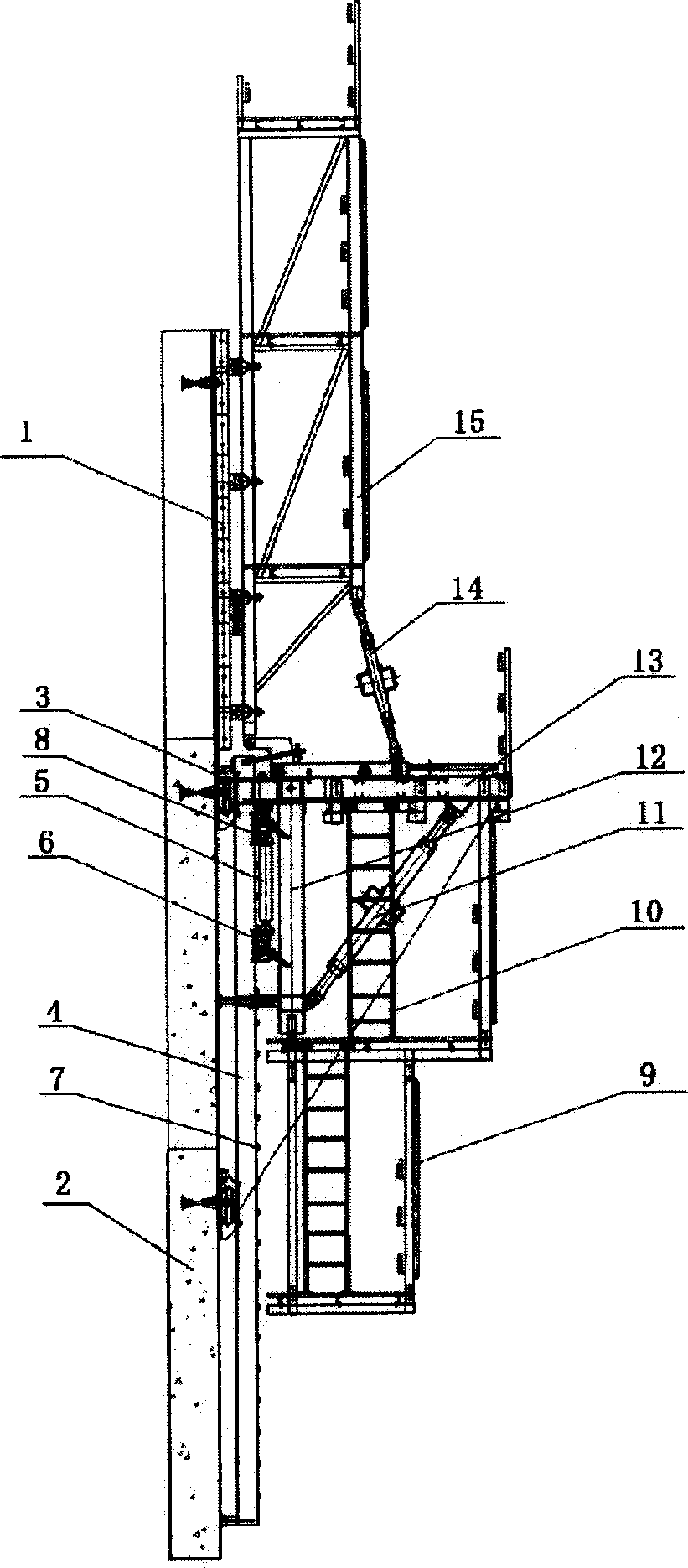

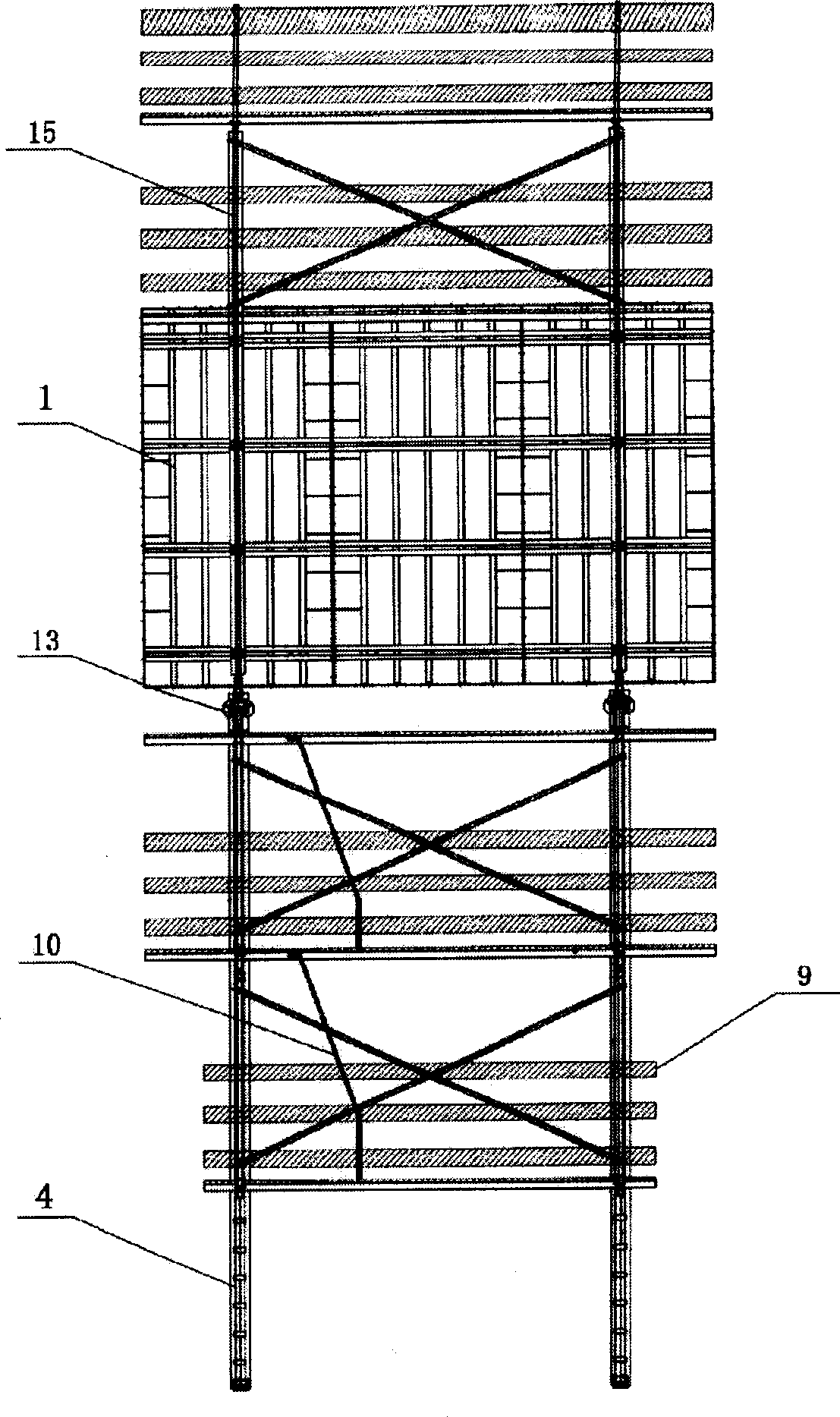

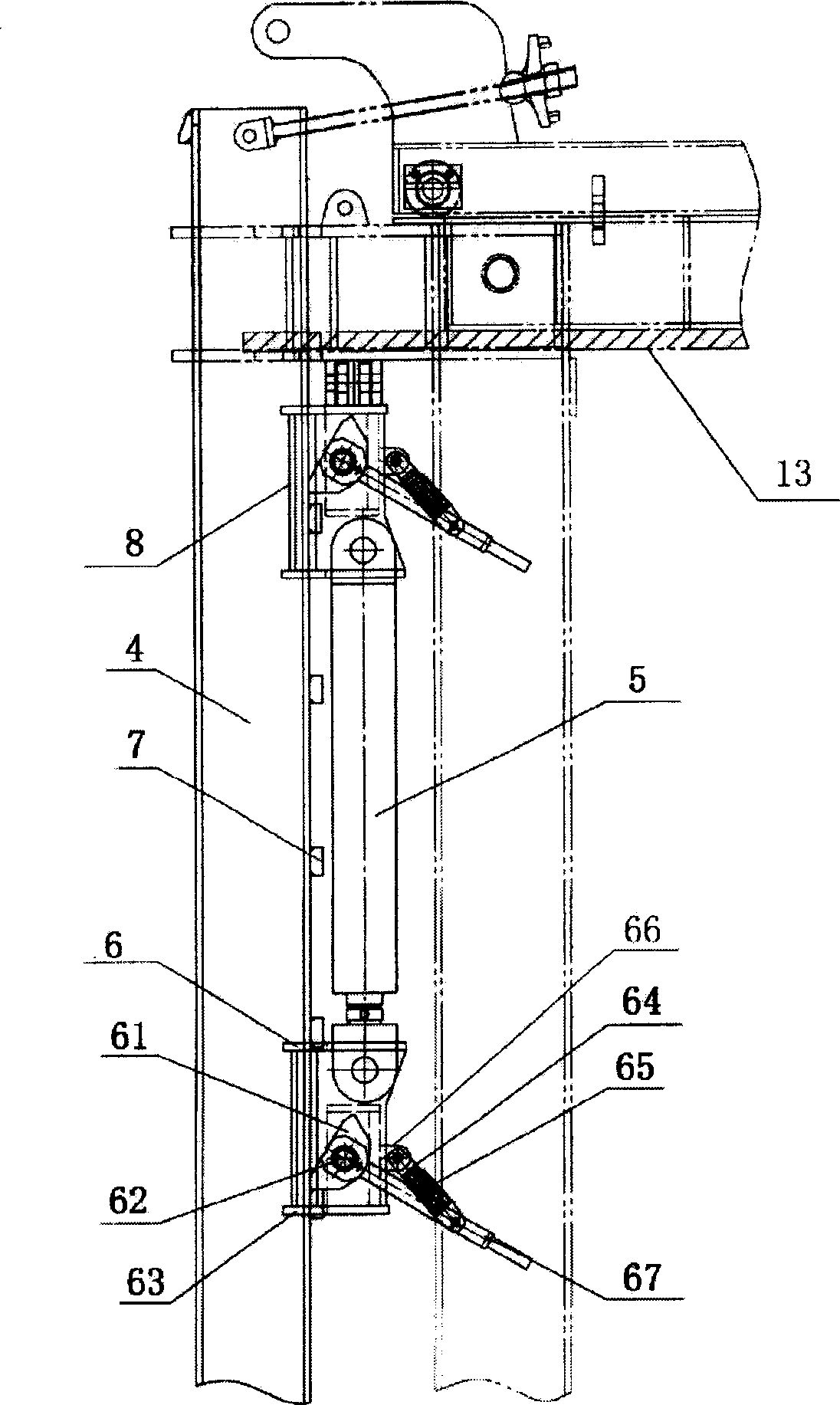

Automatic hydraulic climbing shuttering

A hydraulic template being able to be lifted up automatically is prepared as setting guide track on wall, connecting movable horizontal beam with guide track, setting template system above movable horizontal beam and connecting movable horizontal beam to hydraulic lifting system and operation platform.

Owner:杨秋利

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com