Automatic hydraulic climbing shuttering

A climbing formwork and hydraulic technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems that the climbing frame can only climb the guide rail, the structure of the climbing device is complex, and the formwork cannot be climbed, etc. Achieve the effect of good appearance quality, less formwork consumption and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

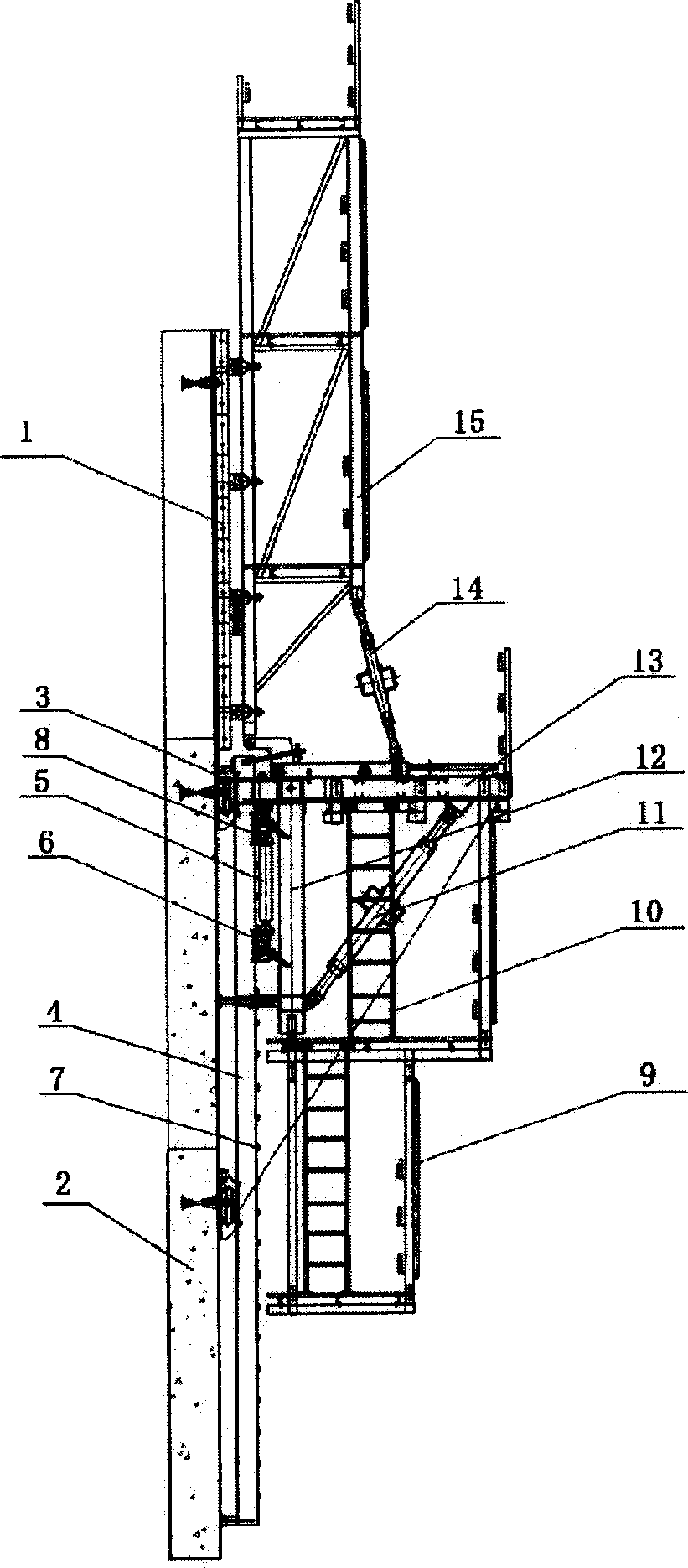

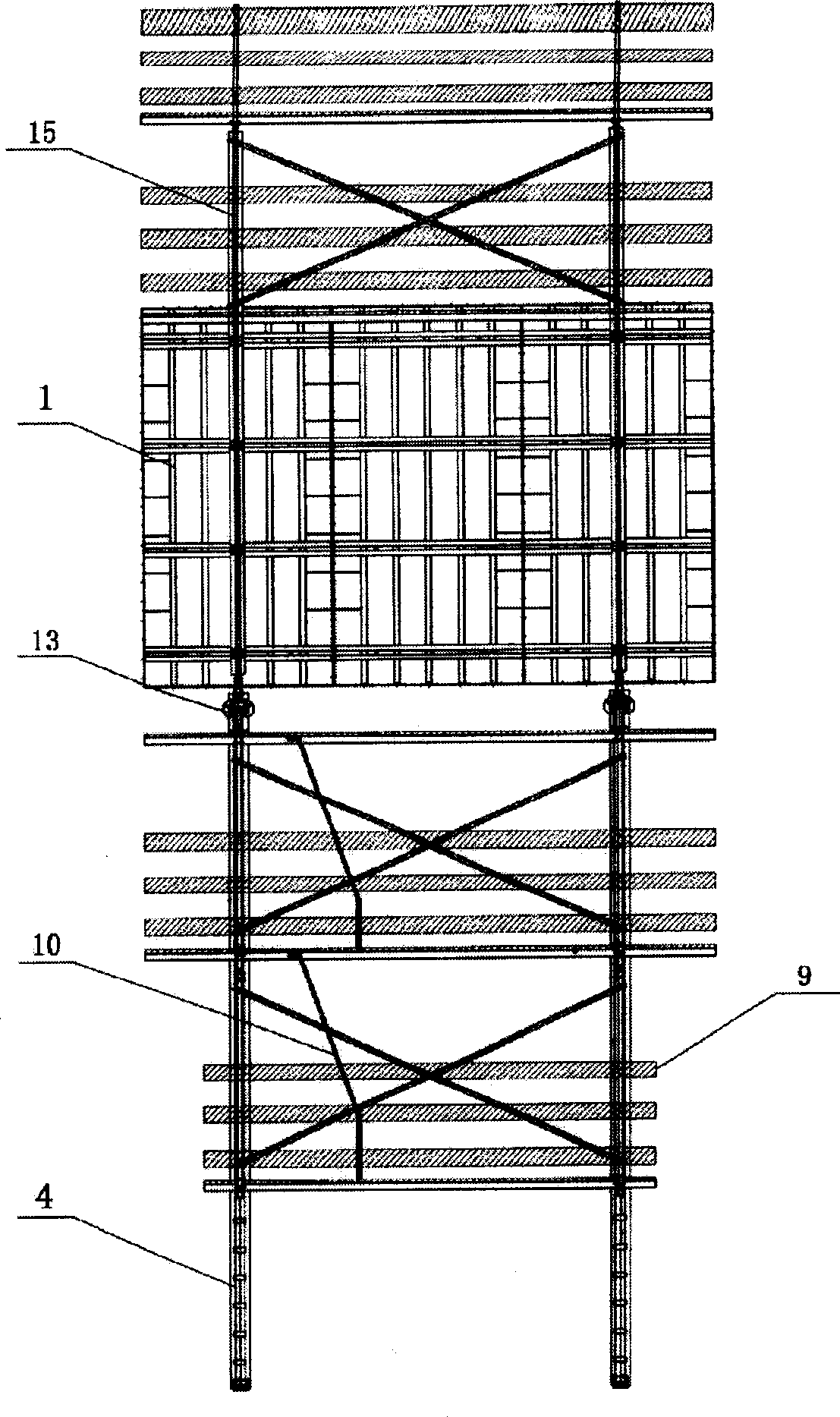

[0023] Examples see figure 1 , figure 2 , this automatic hydraulic climbing formwork includes a guide rail 4 attached to the wall, a moving beam 13 connected to the guide rail, a formwork system connected above the moving beam, a hydraulic lifting system and an operating platform connected below the moving beam, and the guide rail 4 is composed of The wall attachment device 3 is connected with the body of wall 2, and stepping blocks 7 are evenly distributed on the guide rail. The above formwork system includes a formwork support 15 , a formwork 1 connected to the formwork support 15 , and an adjustment support 14 connected to the moving beam 13 . Above-mentioned operation platform comprises main upright support 12, adjustment diagonal support 11, climbing ladder 10, and lower working platform 9 is also connected below this operation platform.

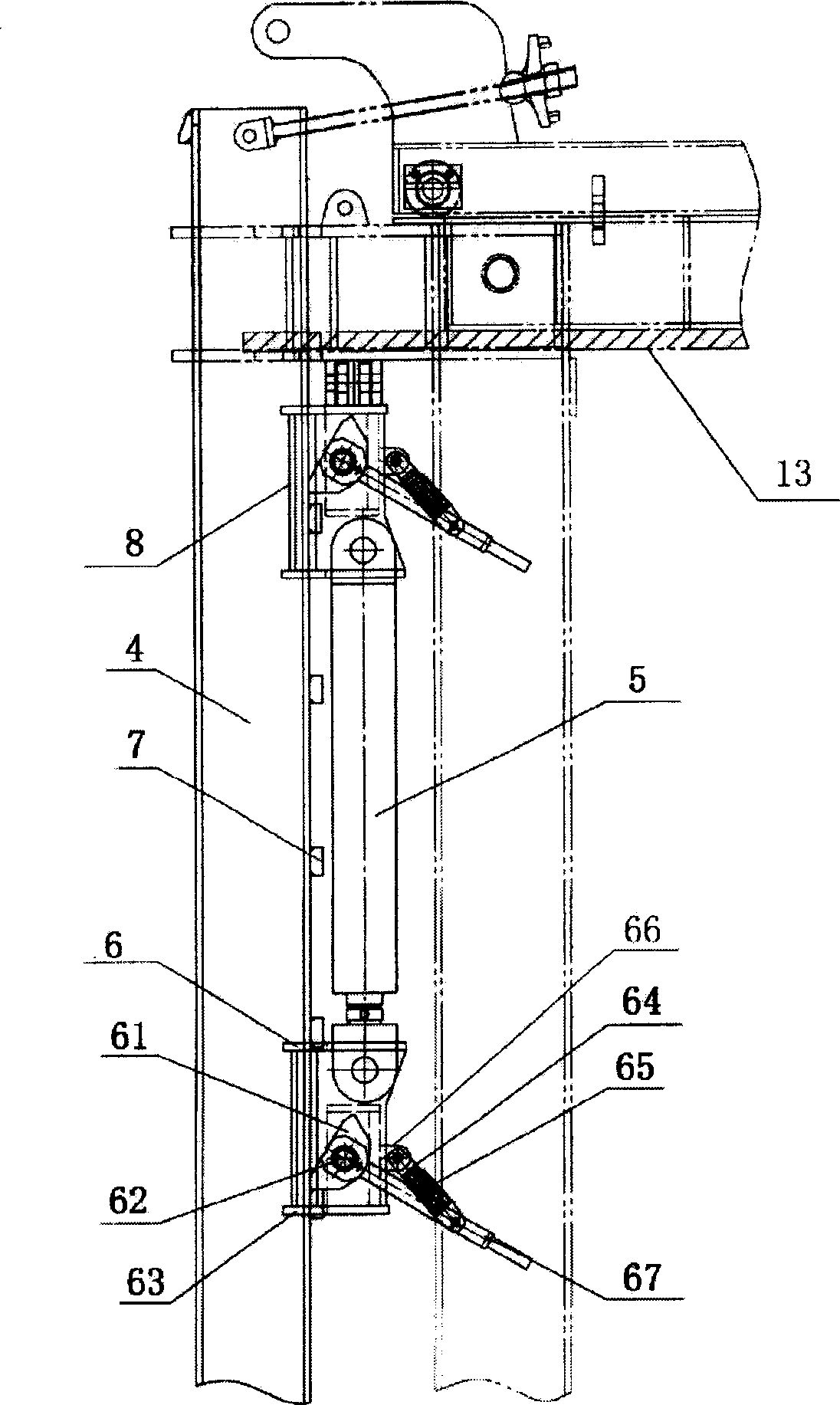

[0024] see Figure 3-8 , the upper and lower ends of the hydraulic cylinder 5 are respectively connected with the upper climbing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com