Patents

Literature

220 results about "Climbing formwork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Climbing formwork is a special type formwork for vertical concrete structures that rises with the building process. While relatively complicated and costly, it can be an effective solution for buildings that are either very repetitive in form (such as towers or skyscrapers) or that require a seamless wall structure (using gliding formwork, a special type of climbing formwork).

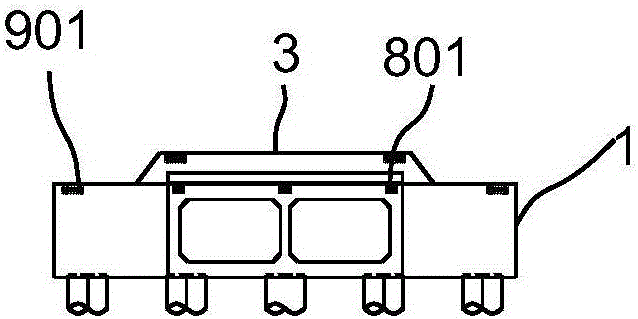

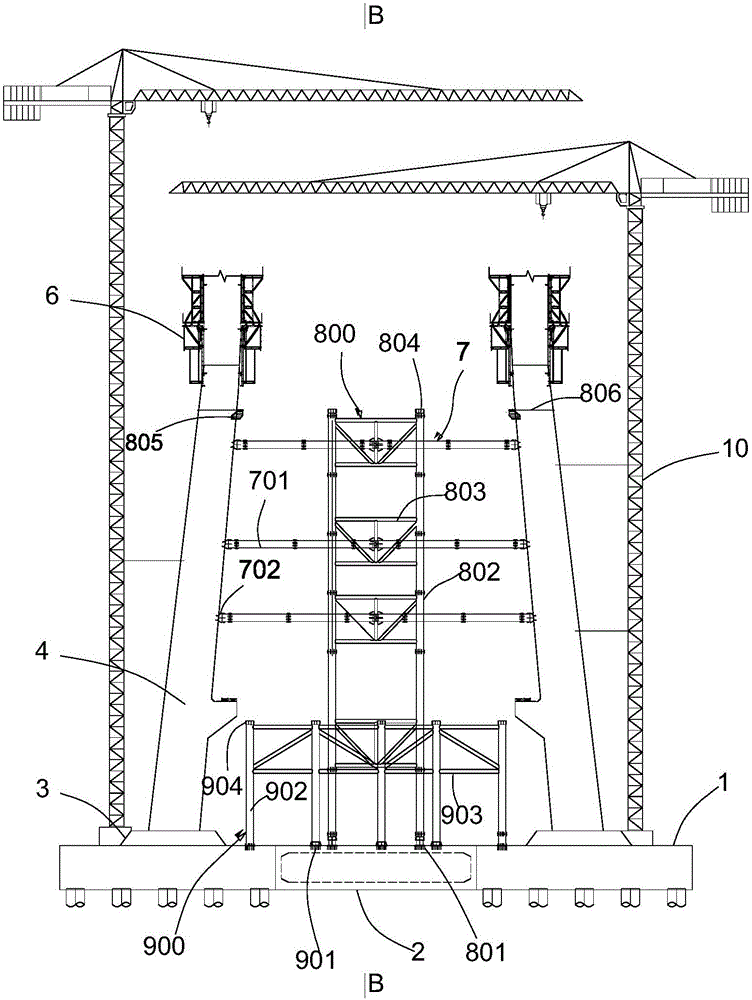

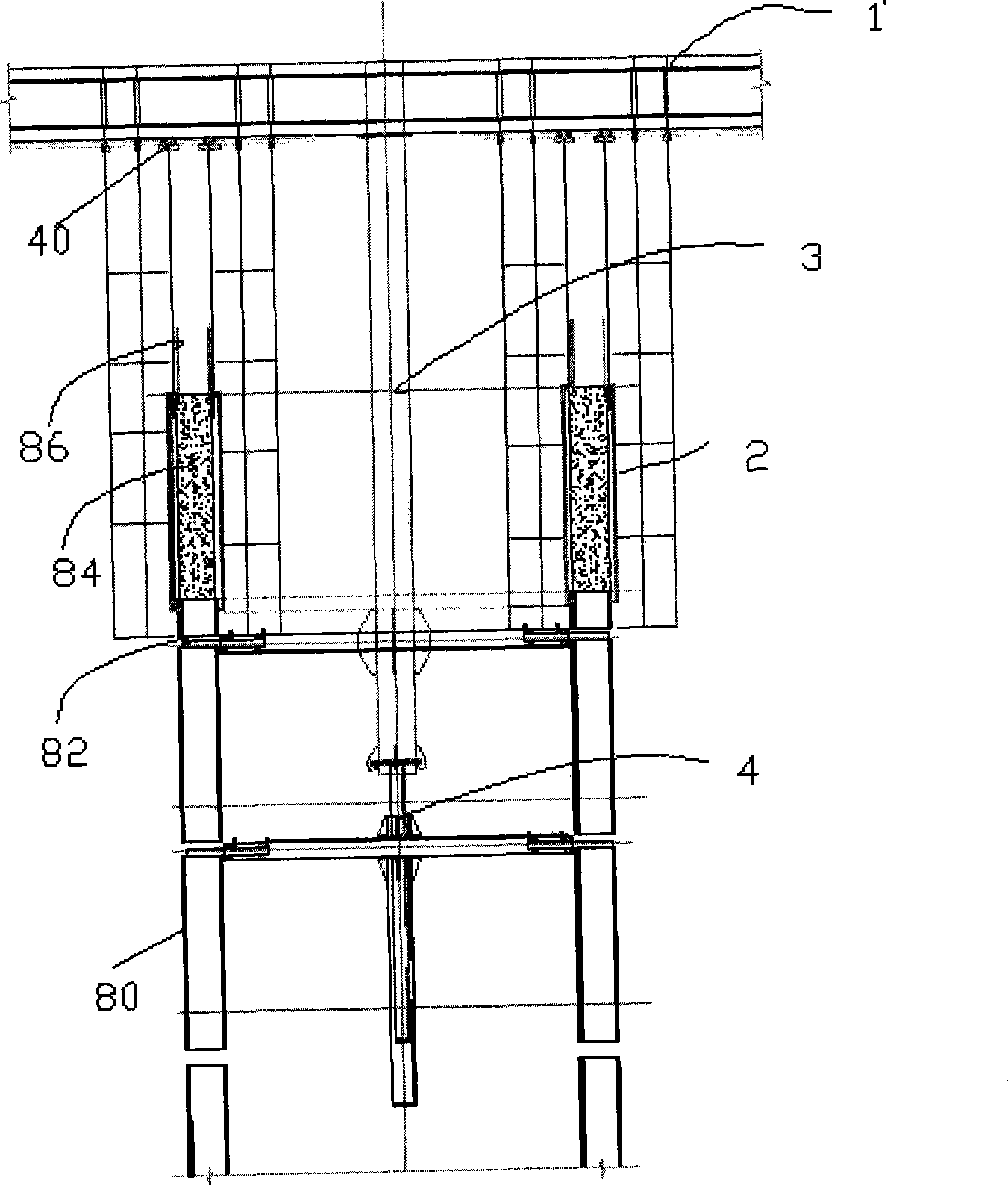

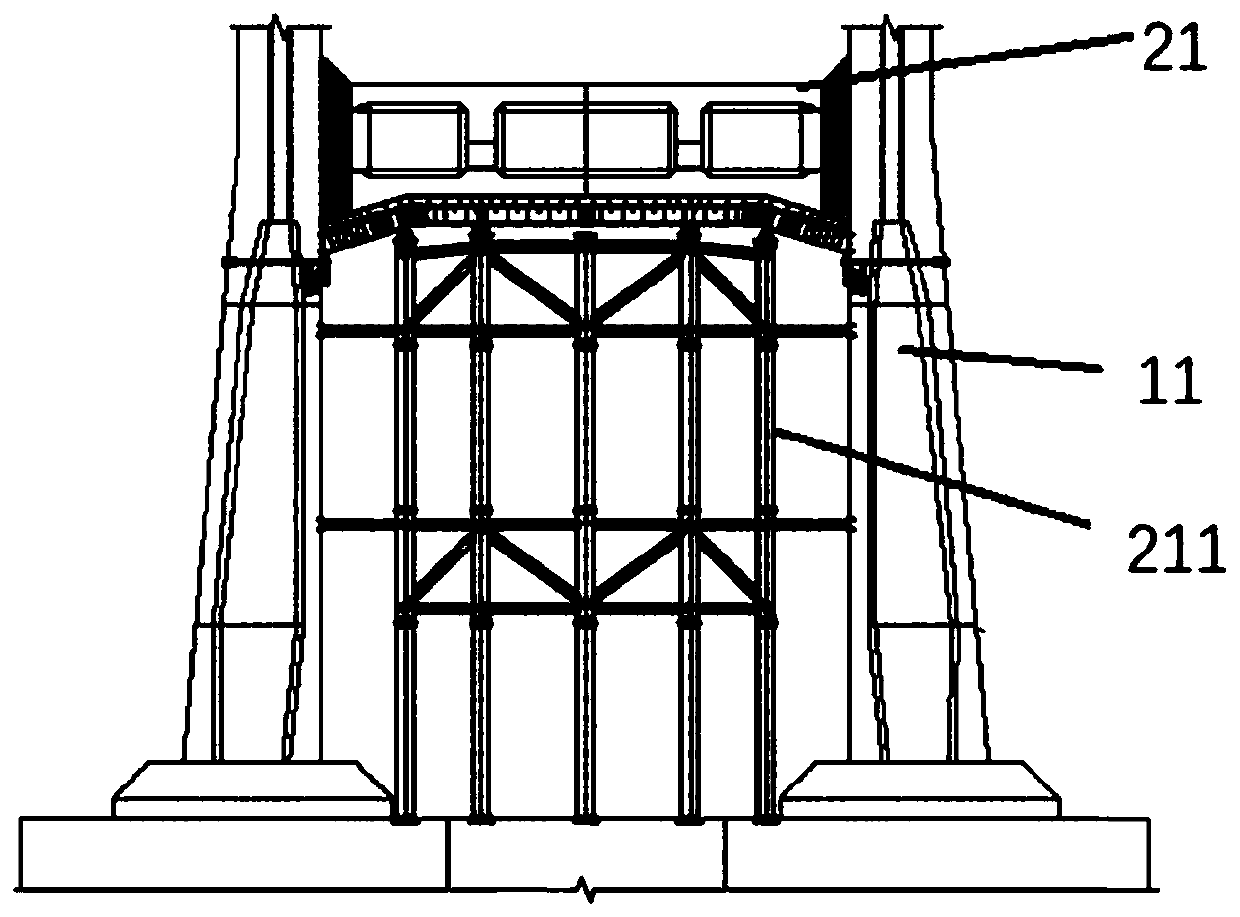

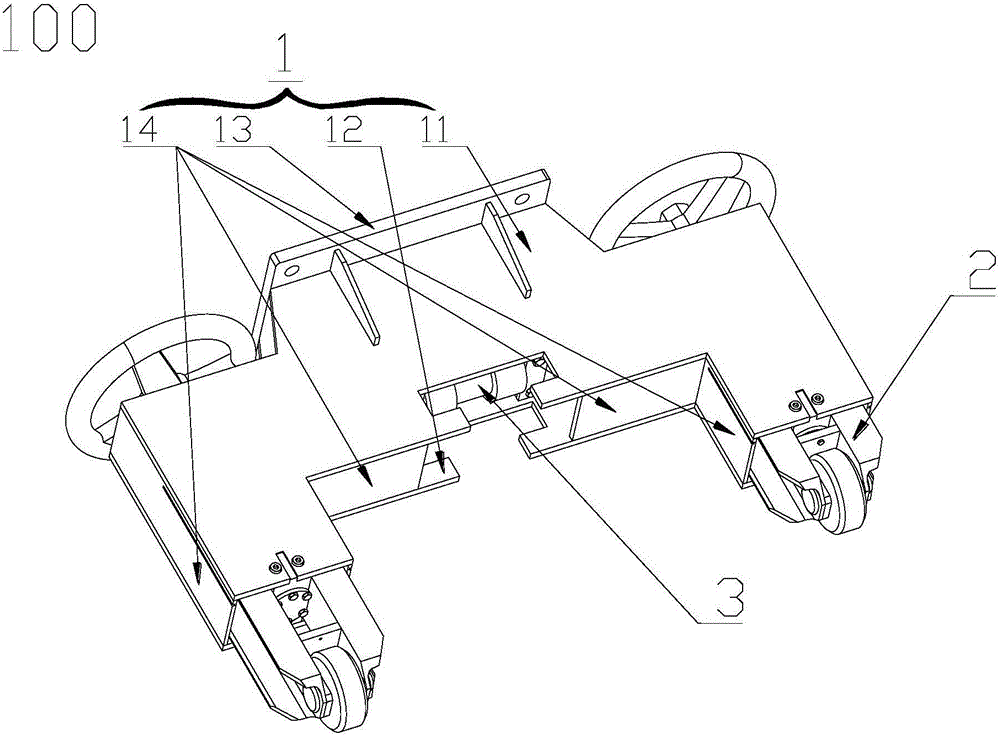

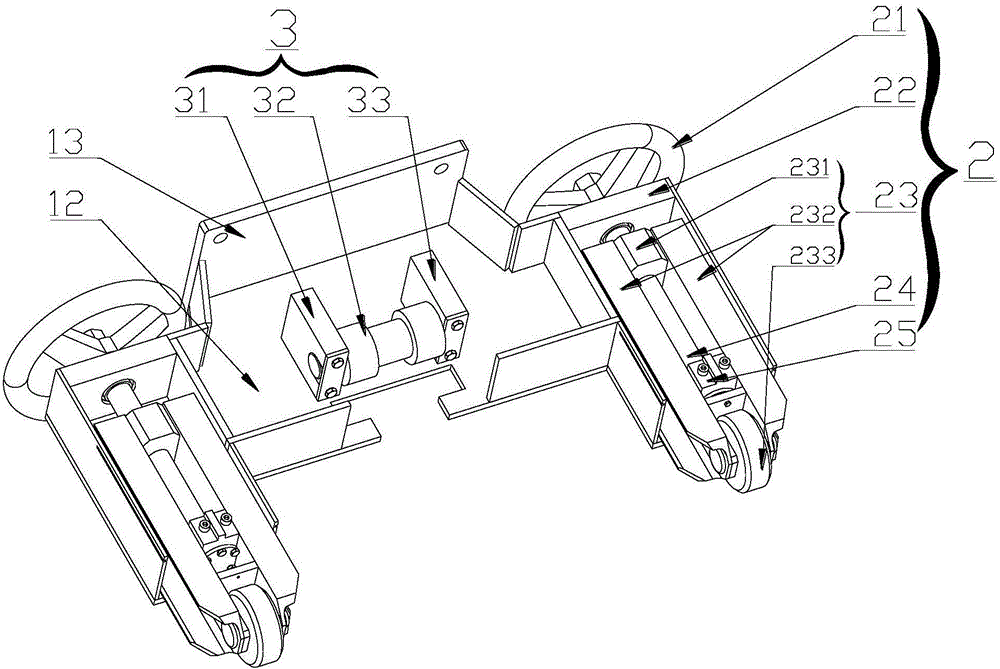

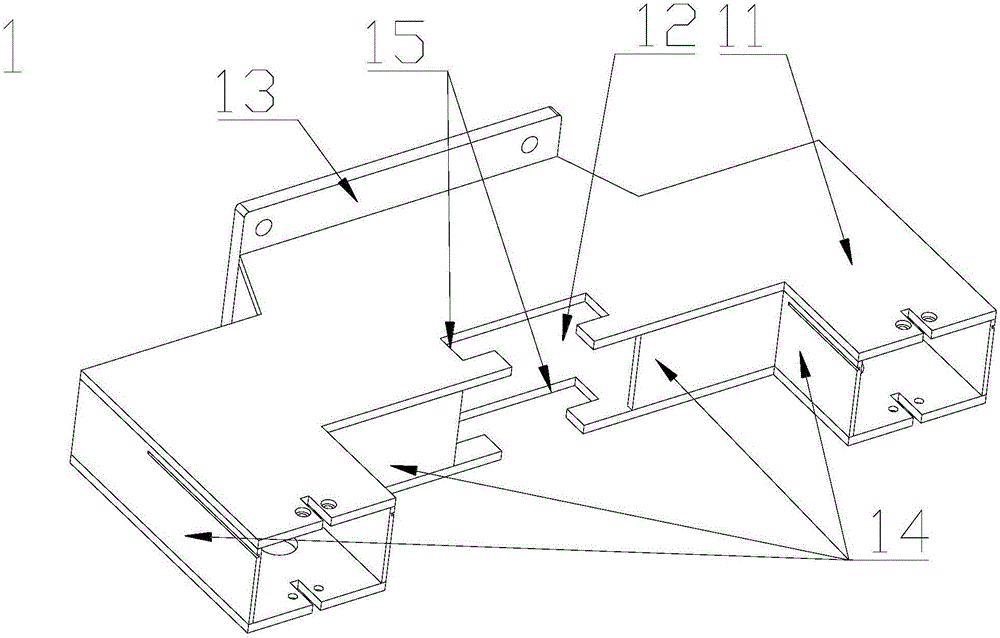

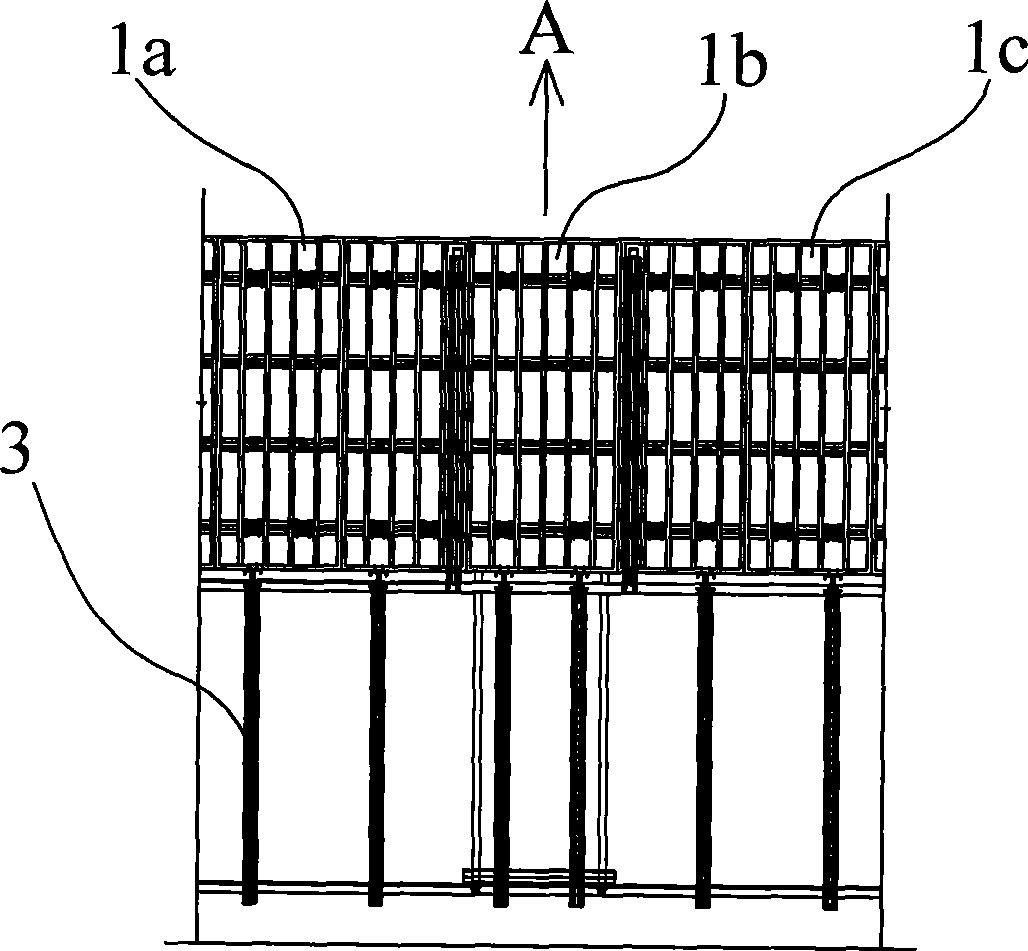

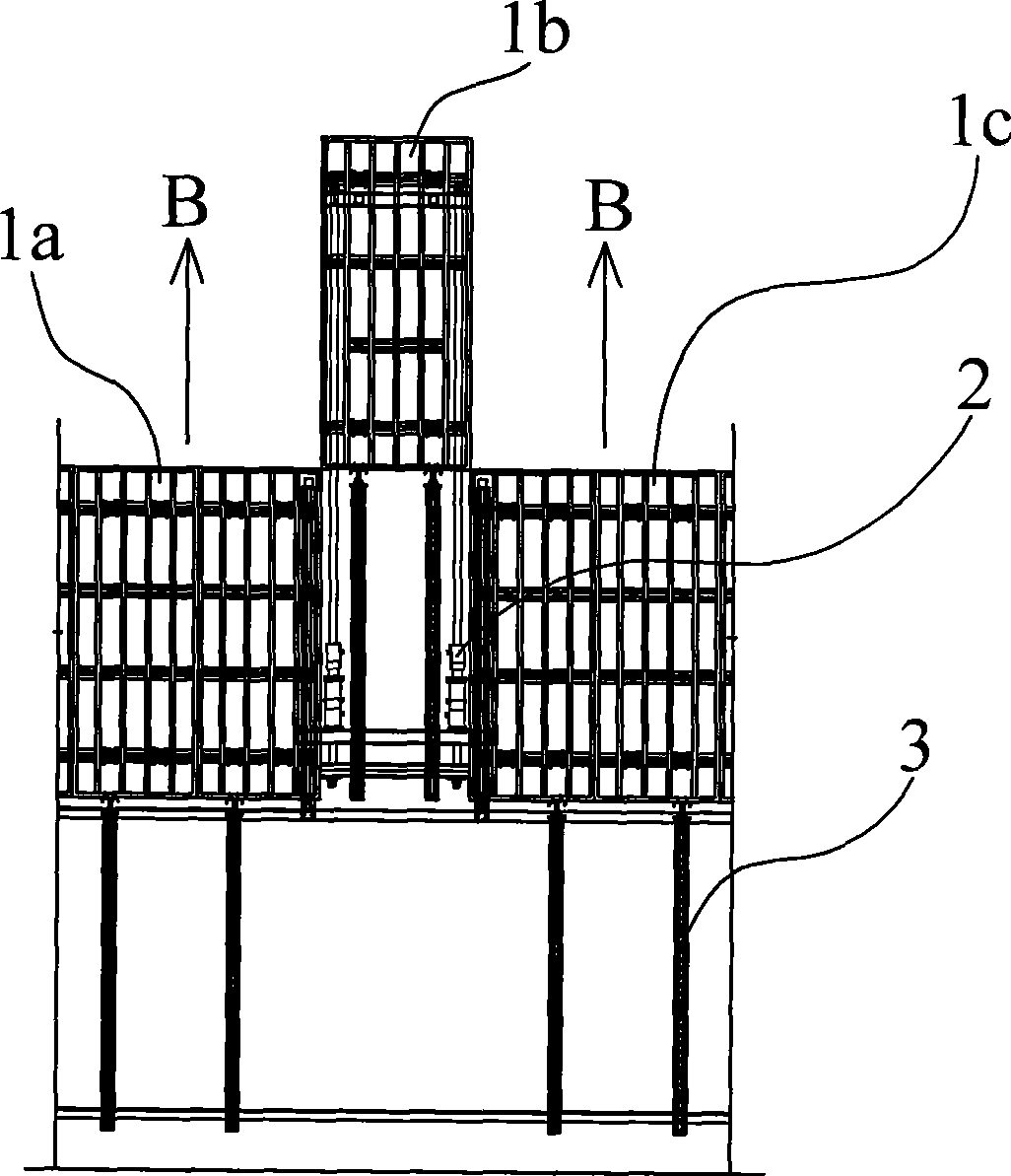

Integrated formwork system for construction of super high-rise building

InactiveUS20200002958A1Improve carrying capacityLight weightForms/shuttering/falseworksBuilding material handlingArchitectural engineeringStructural safety

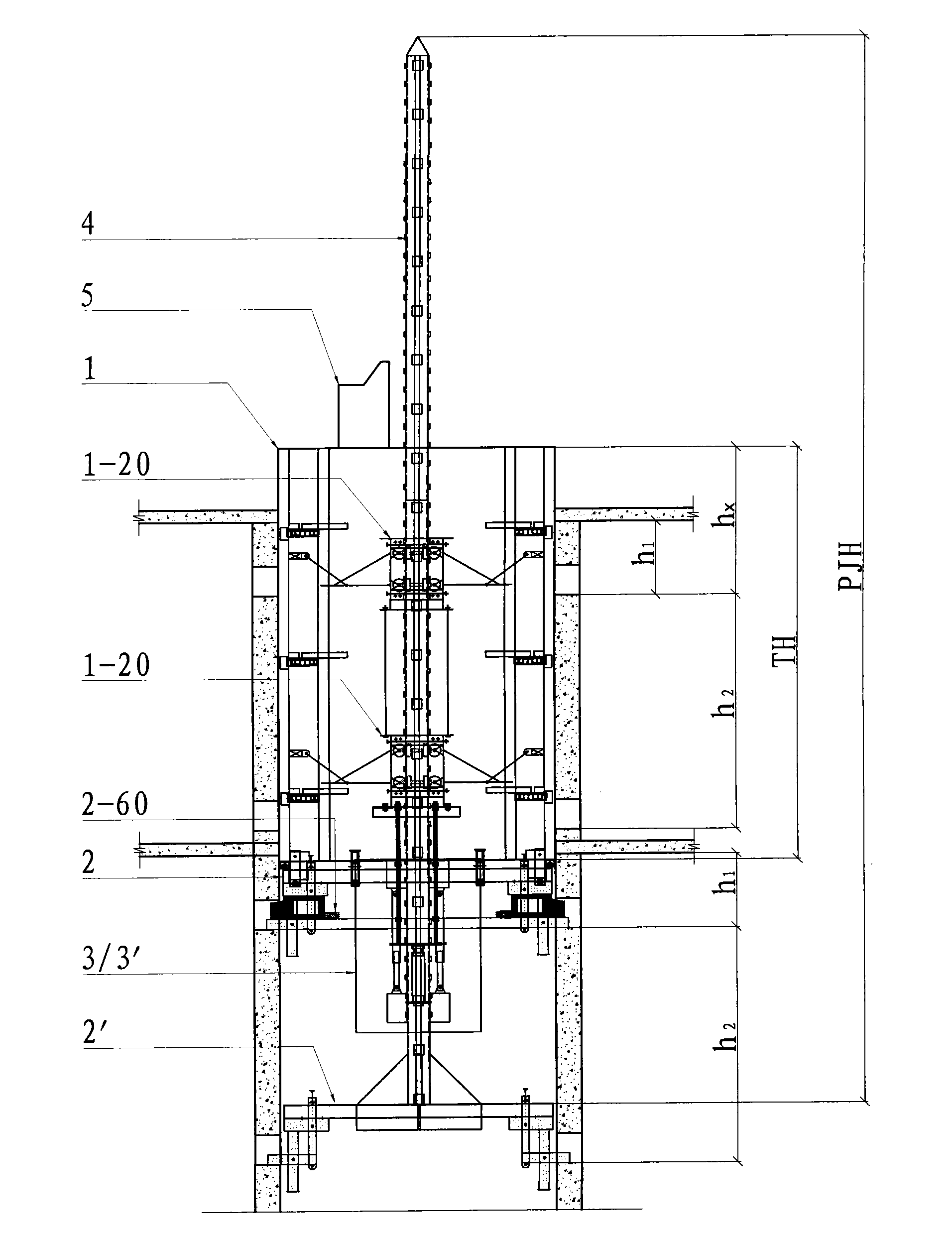

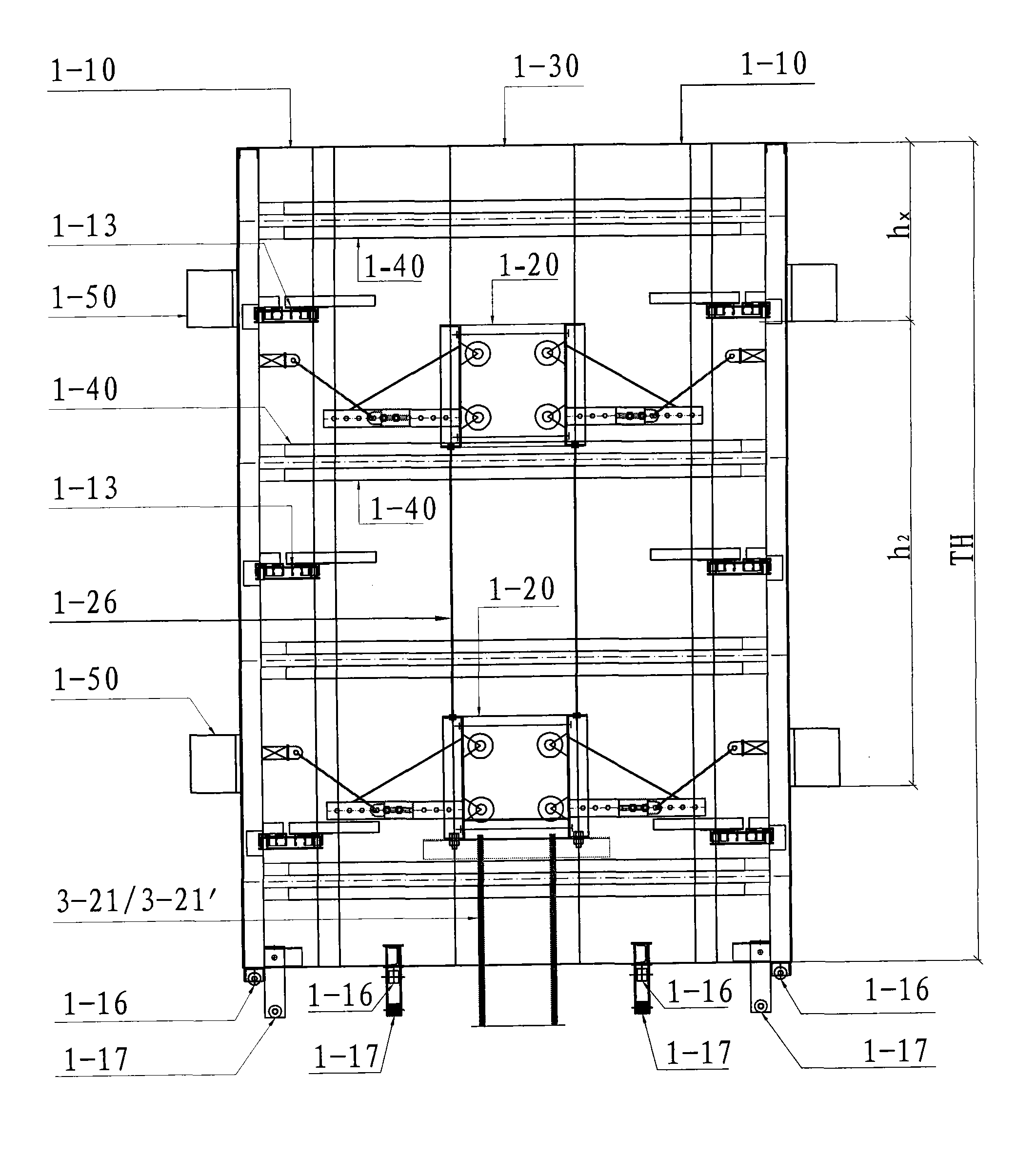

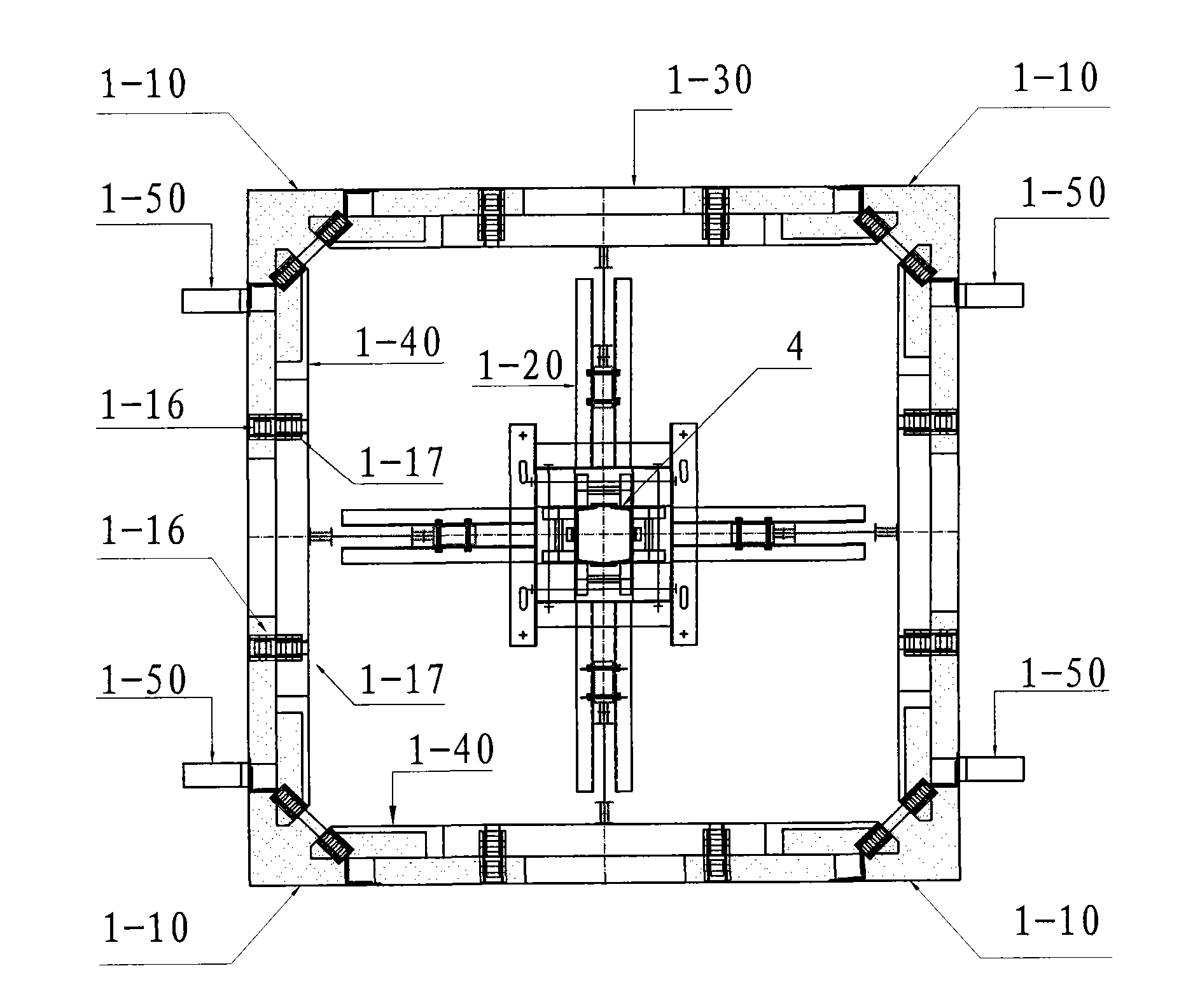

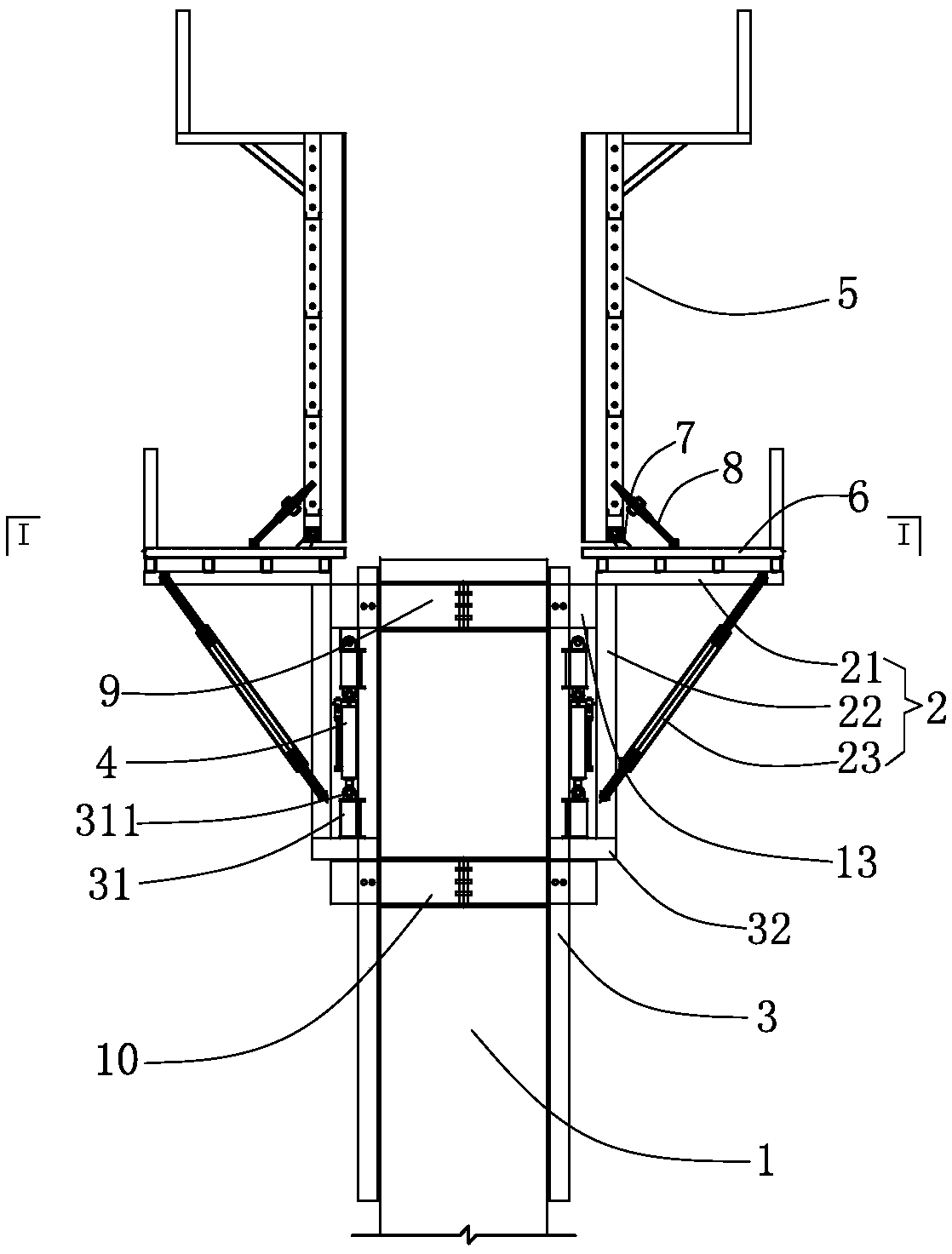

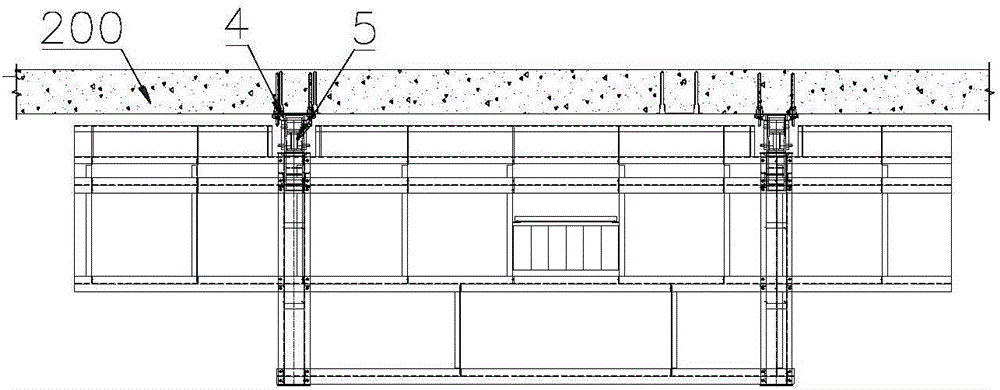

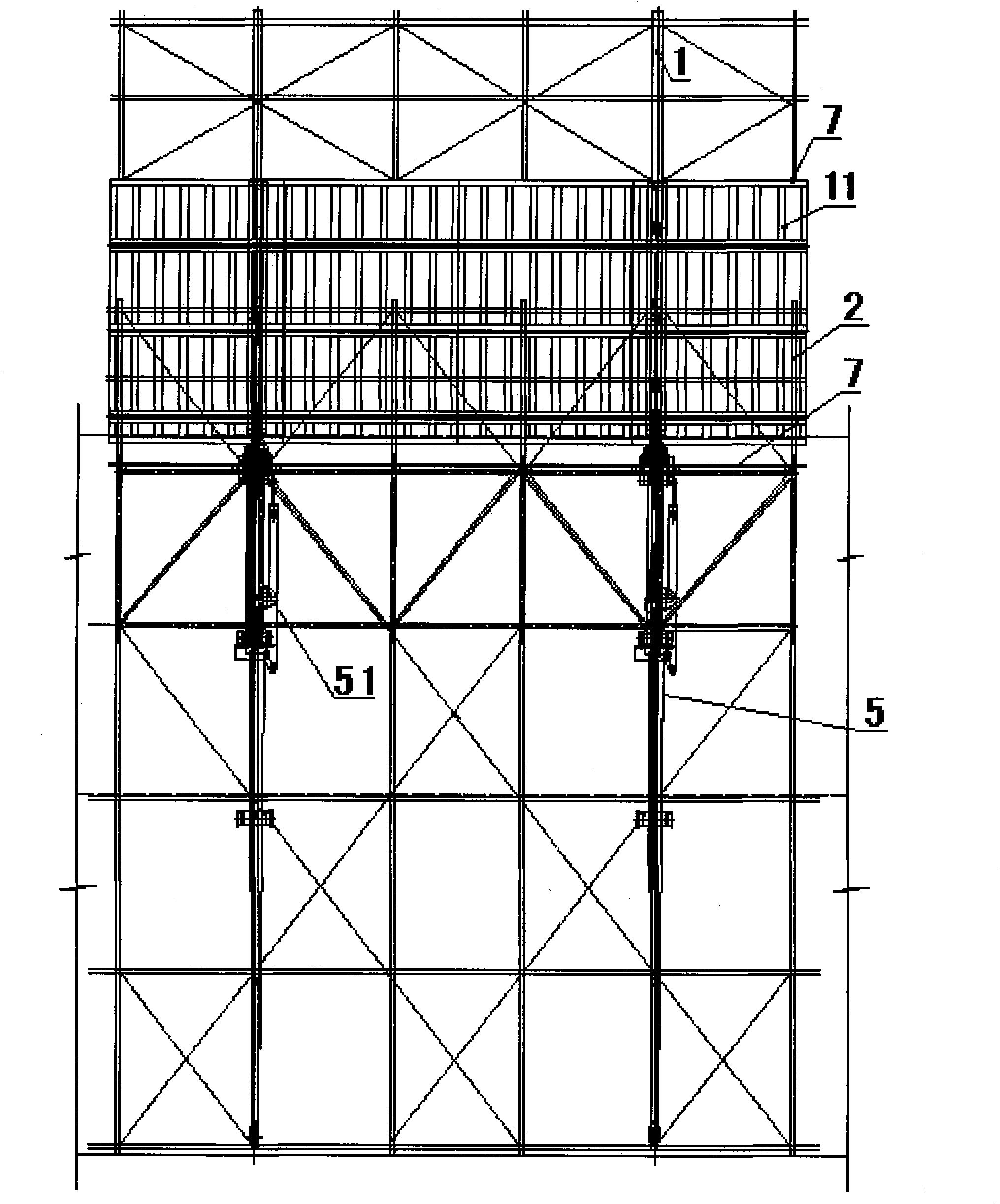

An integrated formwork system for construction of a super high-rise building, comprising a climbing system in a stereoscopic structure formed by a successive enclosure of a plurality of climbing formwork units, a jacking system formed by a plurality of jacking units arranged side by side being disposed in the stereoscopic structure, and a working space formed between the climbing system and the jacking system, wherein the climbing formwork units located at a same side wall of the stereoscopic structure all correspond to the jacking units adjacent to the side wall and are capable of moving synchronously or separately, the jacking units are provided thereon with a vertical adjusting device and a horizontal adjusting device, and a plurality of groups of tensioning devices are disposed in each of the jacking units. Such formwork has light deadweight, a low gravity center, good structural safety, a broad construction work plane.

Owner:SICHUAN HUASHI GRP CO LTD +1

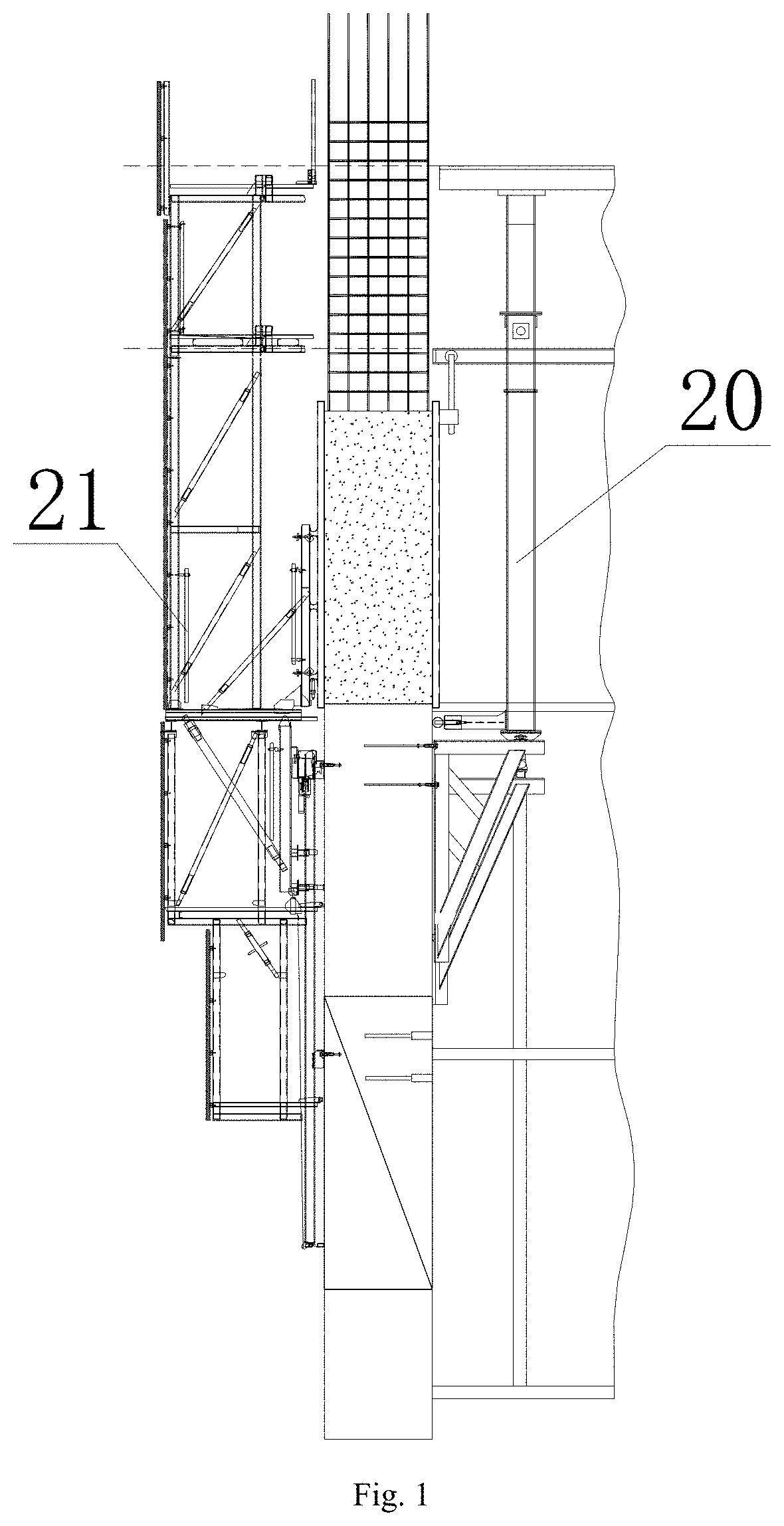

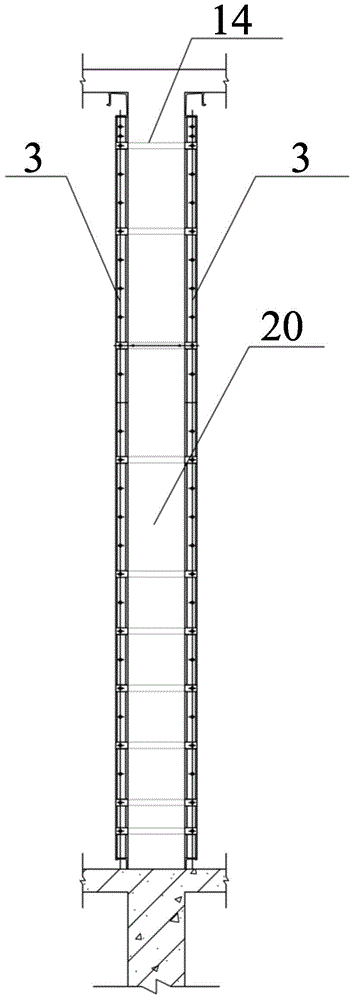

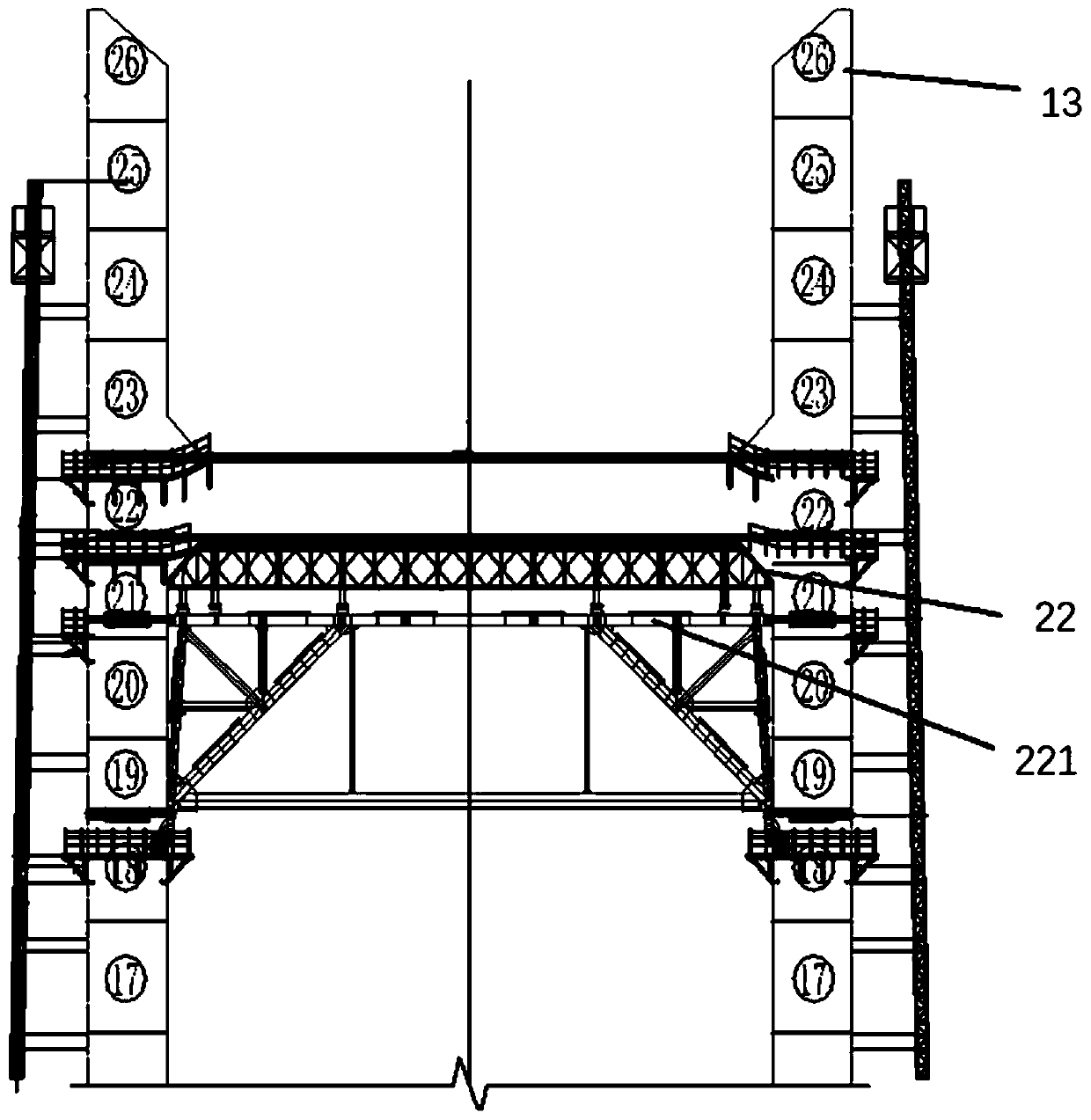

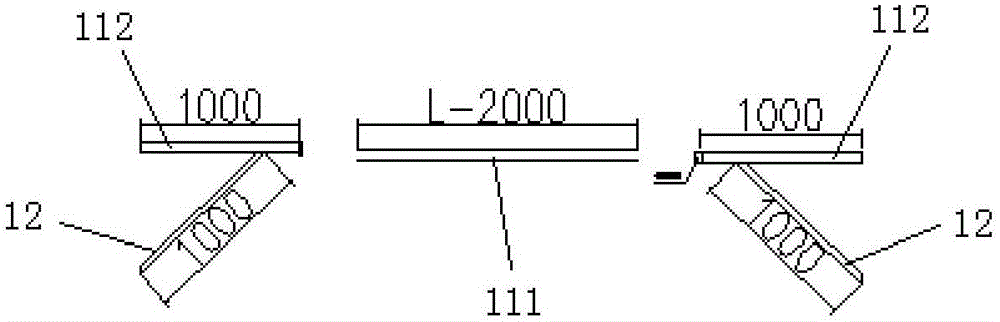

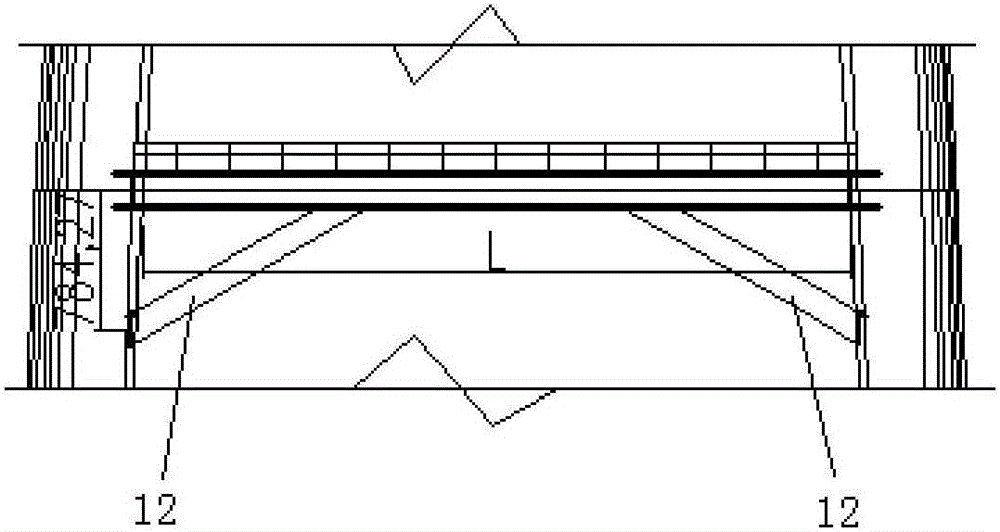

Method for constructing core tube wall through self-climbing formwork and adopted self-climbing formwork

InactiveCN104131703AGood climbing stabilitySmooth connectionForms/shuttering/falseworksBuilding material handlingTube (structure)Architectural engineering

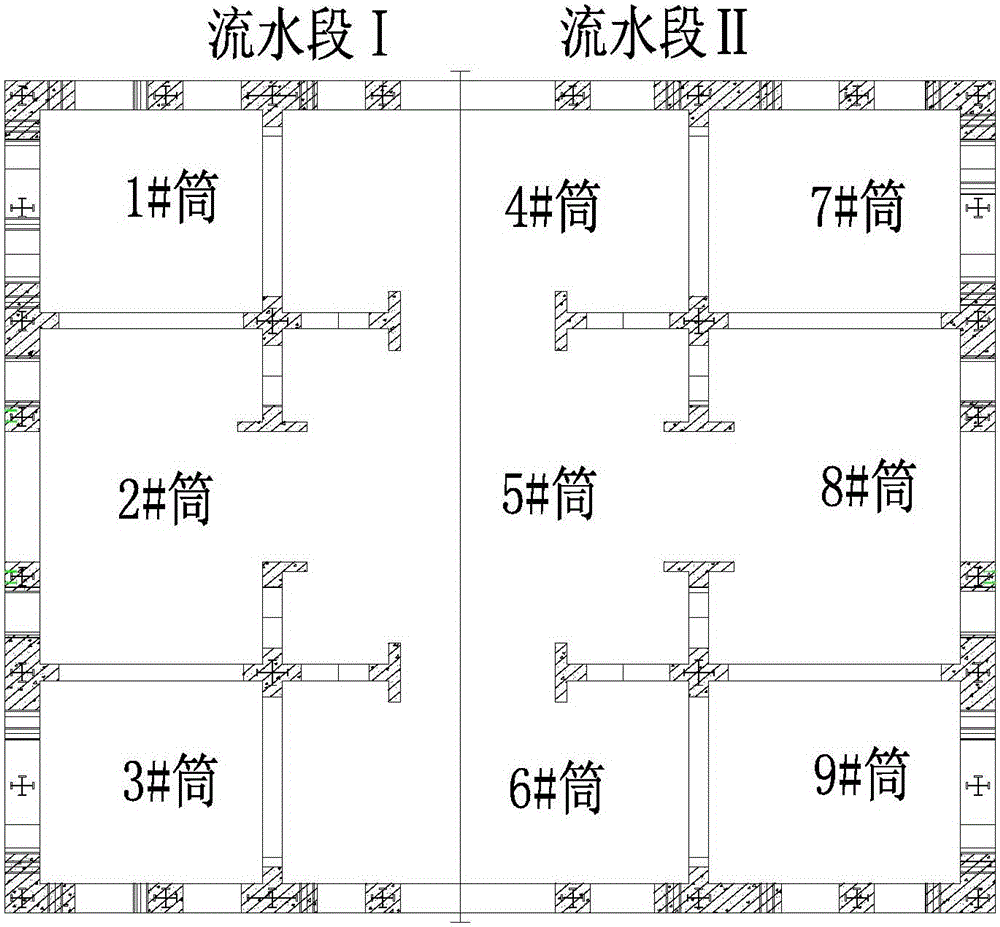

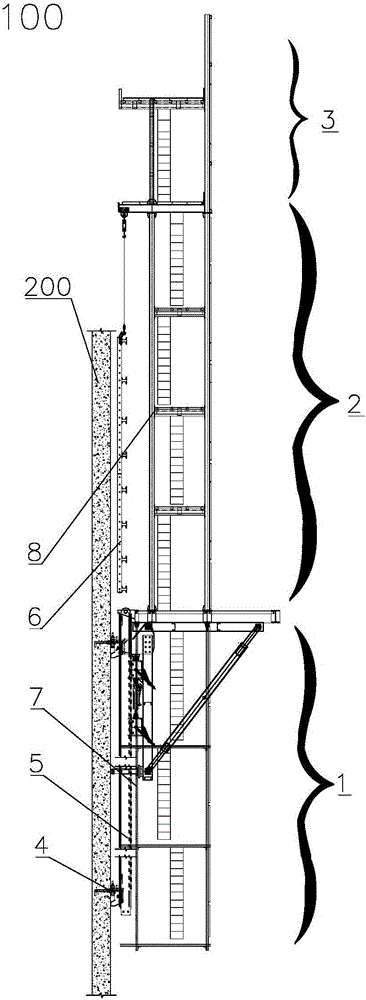

The invention discloses a method for constructing a core tube wall through a self-climbing formwork and the adopted self-climbing formwork. The method comprises the steps that the core tube wall is constructed from bottom to top layer by layer; when a first-layer wall body is constructed, a first pre-buried component is pre-buried, and pouring of the first-layer wall body is completed; after construction of the first-layer wall body is completed, a second-layer wall body is constructed, and a second pre-buried component is pre-buried in the second-layer wall body; each pre-buried component is provided with a wall attachment device, after pouring of the second-layer wall body is completed, a guide rail is arranged between the first wall attachment device and the second wall attachment device, a self-climbing device on the formwork is connected with the guide rail, alternate mutual climbing of the formwork and the guide rail is achieved through the self-climbing device, a form board is arranged on the formwork, and the construction of the core tube wall is completed layer by layer through the form board. The method is suitable for core tube construction of a super high-rise building of a frame core tube structure of 200 m to 400 m, a wide platform is provided for operating personnel for construction, safety is guaranteed well, construction efficiency is greatly improved, and construction cost is lowered.

Owner:CHINA CONSTR FOURTH ENG DIV

Bowstring truss type fully-enclosed hydraulic climbing formwork system and application method for same

InactiveCN103061500AOffset up and down wind loadsAchieve self-balancingForms/shuttering/falseworksBowstringHigh rise

The invention provides a bowstring truss type fully-enclosed hydraulic climbing framework system and an application method for the same. A truss type load-bearing frame, namely a space truss type main platform, and a bowstring truss are arranged inside an operation platform frame, the truss type load-bearing frame is used as a main platform structure, the structural stiffness is obviously improved, the bowstring truss type fully-enclosed hydraulic climbing formwork system can resist a huge wind load without structural damage under the fully-enclosed containment condition, and accordingly construction requirements of super high-rise buildings are met. A space truss is used as a main platform of the climbing framework system, the bowstring truss is added to the outer side of the truss type load-bearing frame, so that the height of a cantilever section of the operation platform frame is effectively reduced, upper and lower wind loads of the operation platform frame can be offset, the operation platform frame can be self-balanced, and the technical problem that an operation platform system is difficult to bear wind loads during fully-enclosed construction for a high-rise building is solved.

Owner:SHANGHAI CONSTRUCTION GROUP

Whole process optimization method for hydraulic climbing formwork scaffold construction of super high-rise building

InactiveCN108319755AEfficientIntegrityGeometric CADDesign optimisation/simulationStructure analysisHigh rise

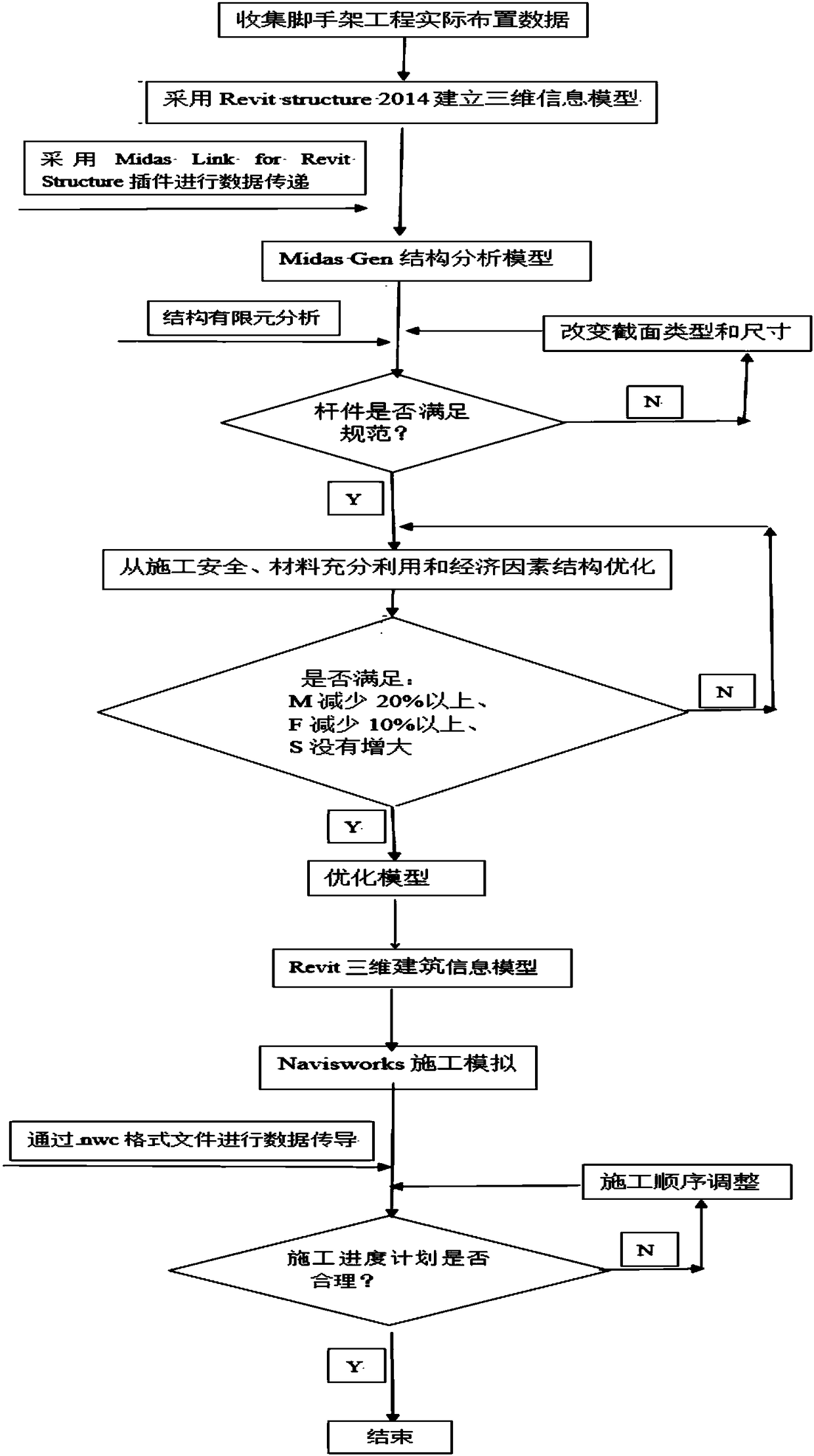

The invention discloses a whole process optimization method for hydraulic climbing formwork scaffold construction of a super high-rise building, relates to a scaffold whole process optimization method, and solves the technical problem of incapability of prejudging the rationality and safety of an existing hydraulic climbing formwork scaffold erection scheme of the super high-rise building. According to the method, a scaffold system is subjected to structure optimization and construction simulation by utilizing core modeling software Revit structure 2014, finite element structure analysis software Midas Gen and construction simulation software Autodesk Navisworks of a BIM platform; design and management enter a 3D visual design stage; and proactive management of safety calculation and construction processes is realized. The method can be used in the field of building structure design and construction management.

Owner:HEILONGJIANG UNIV +1

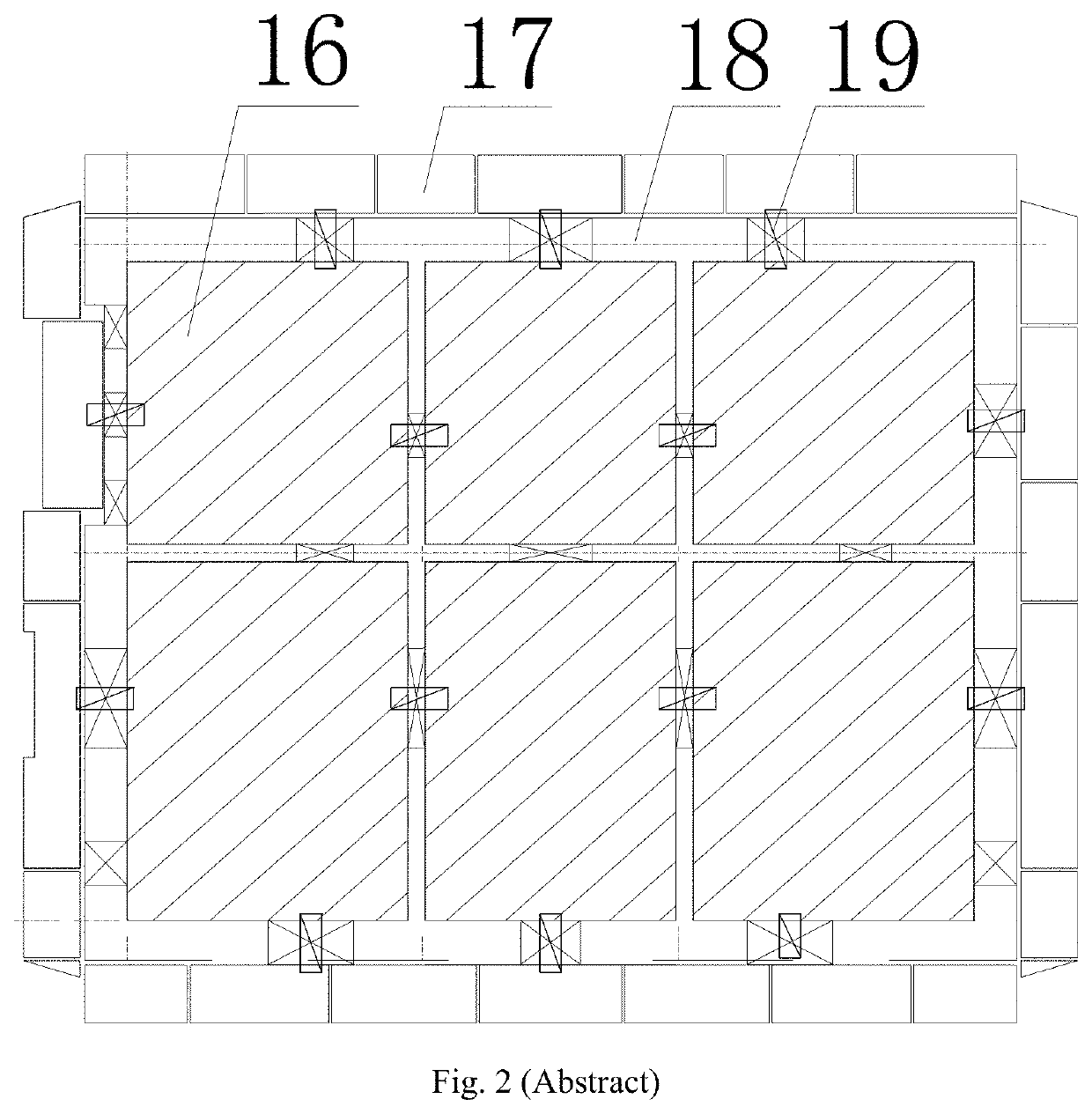

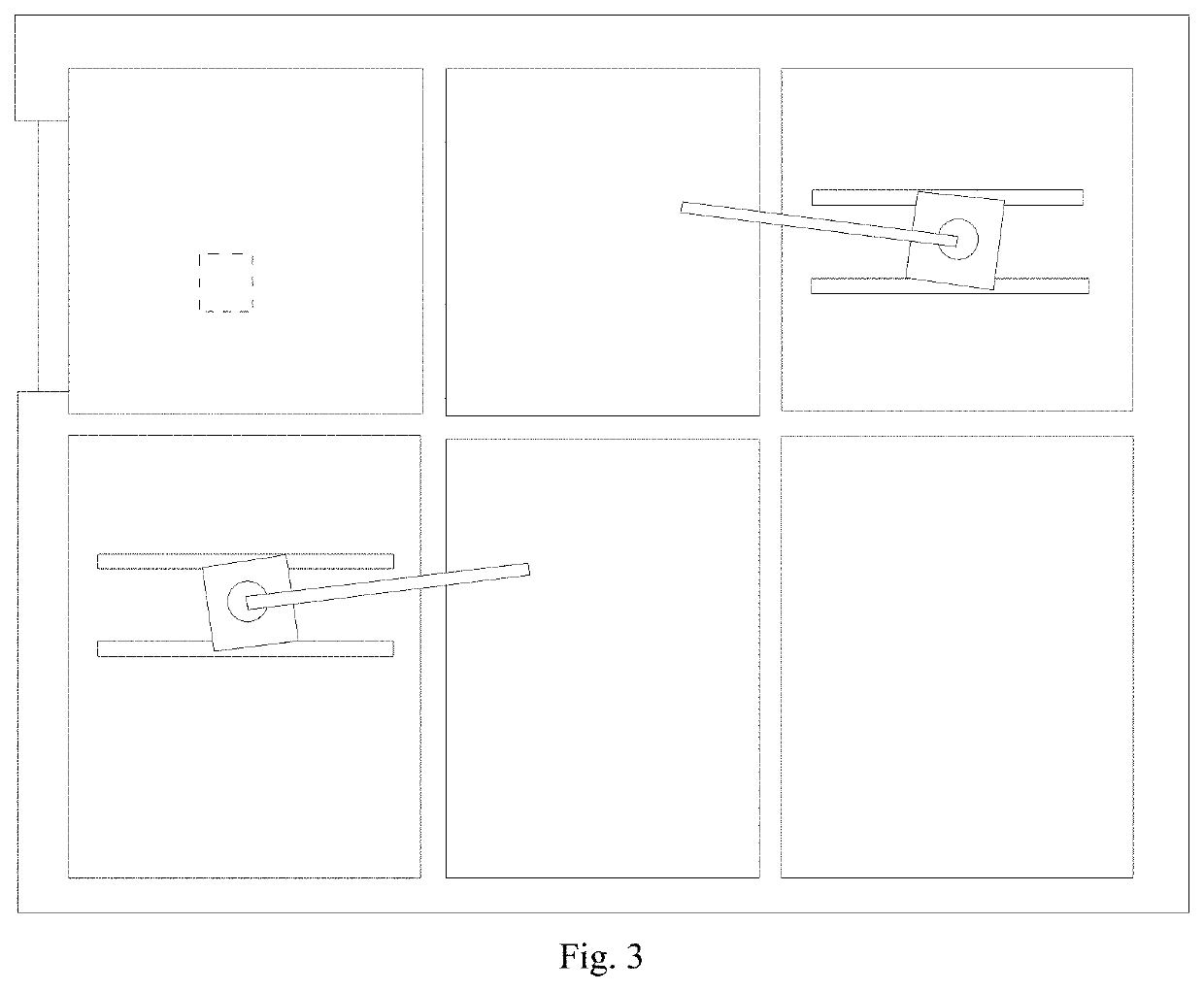

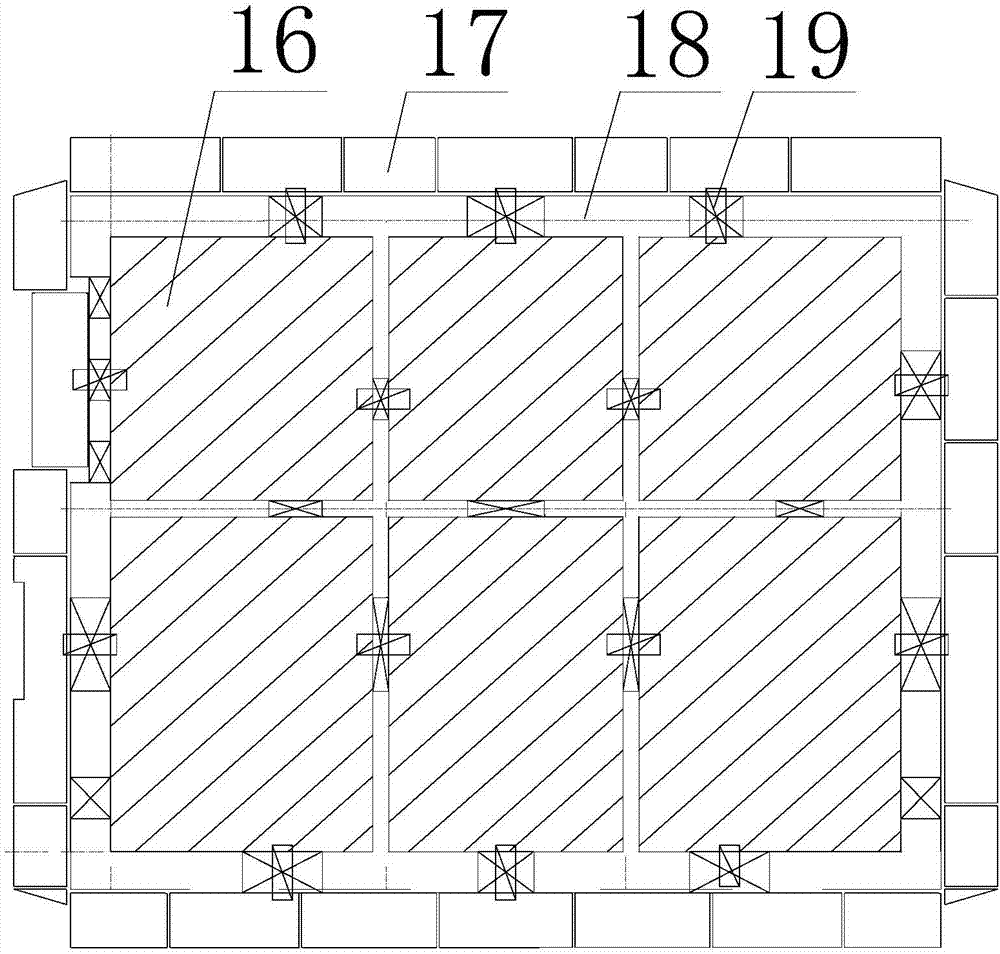

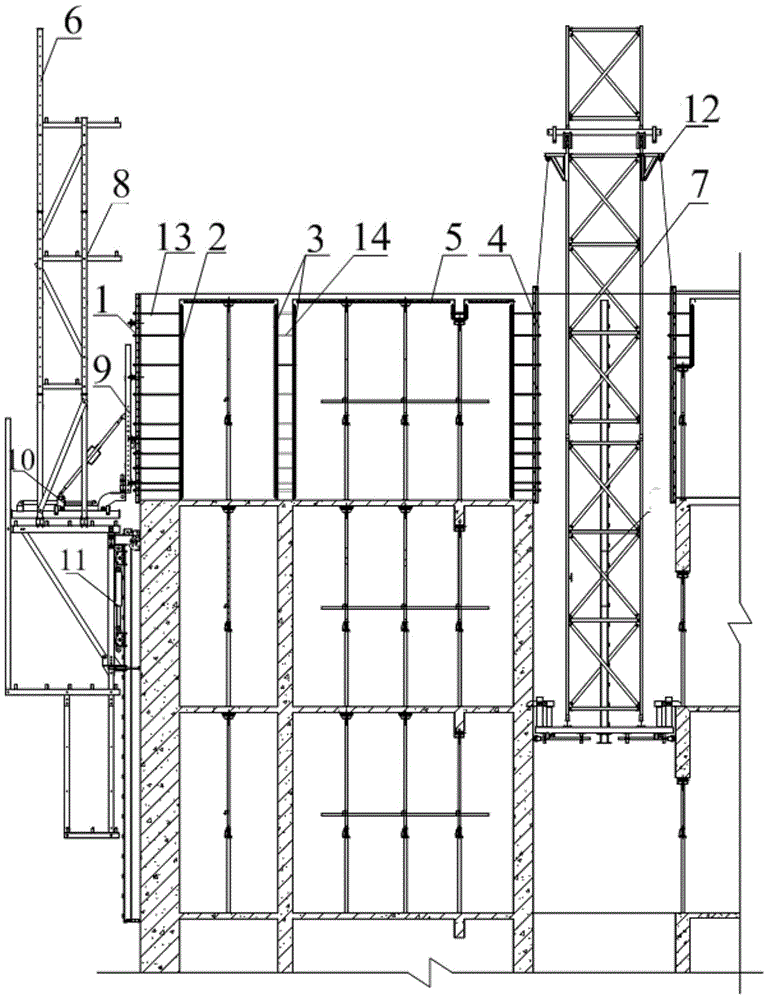

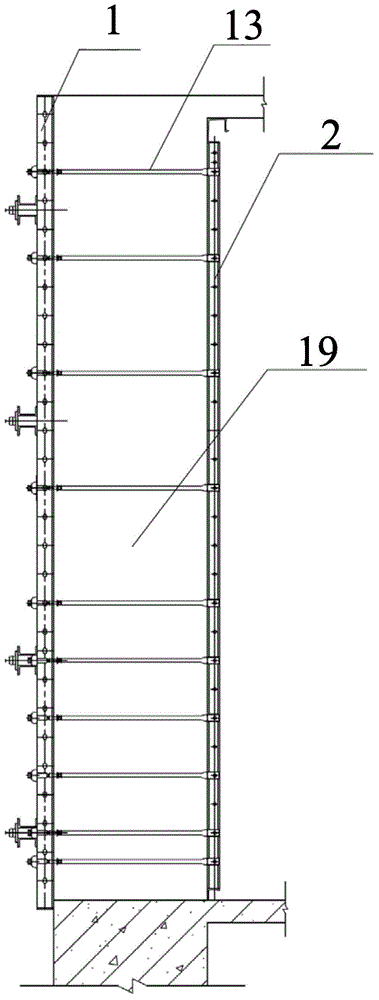

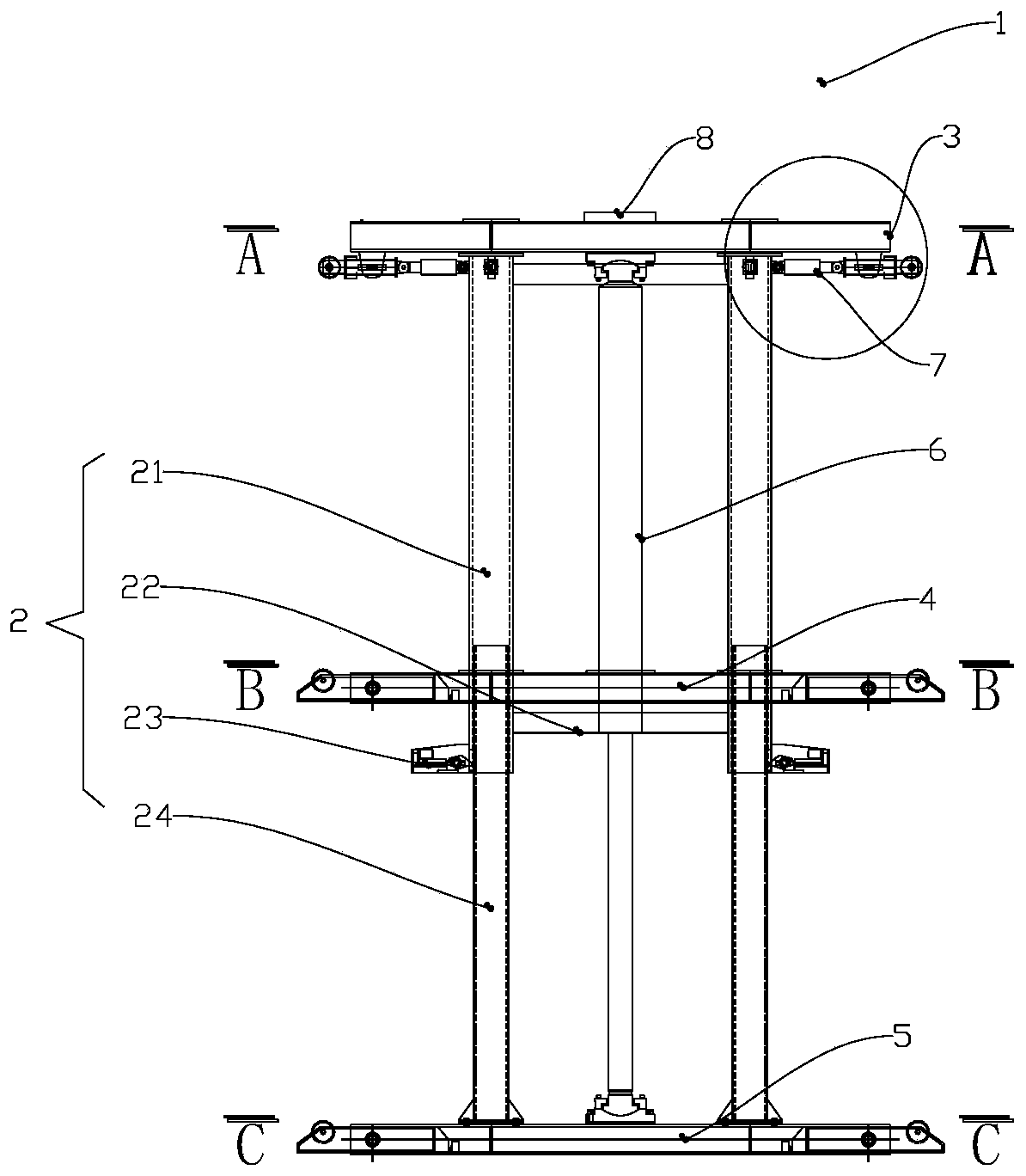

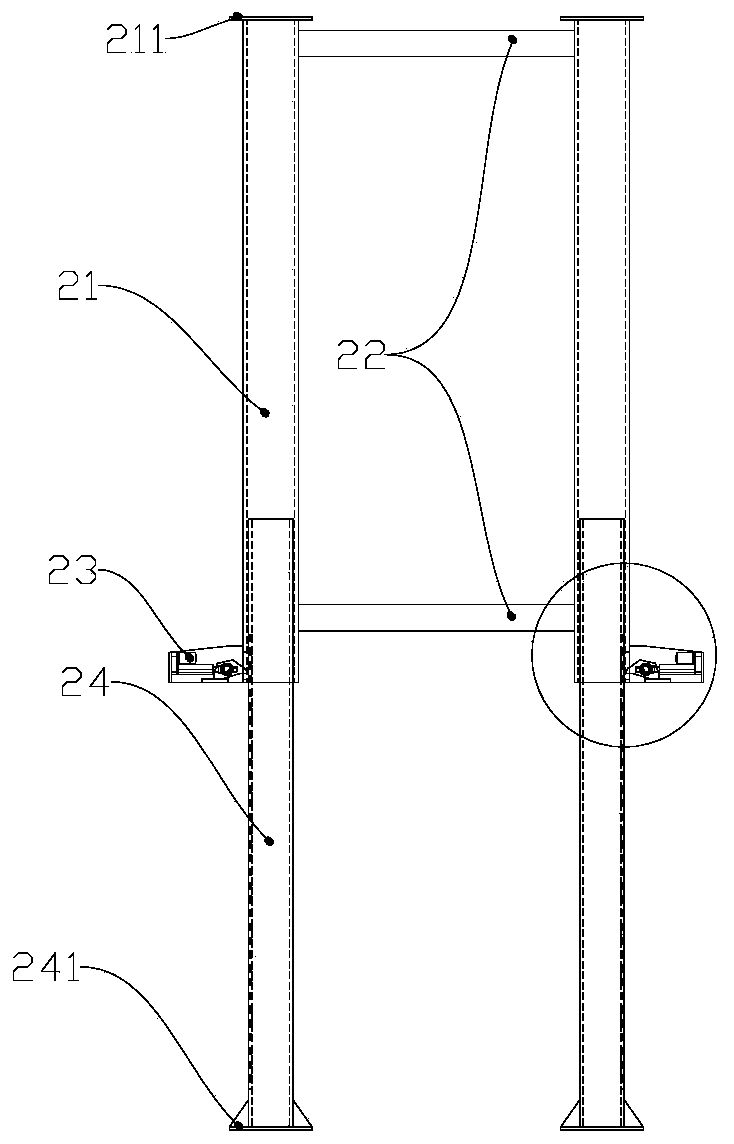

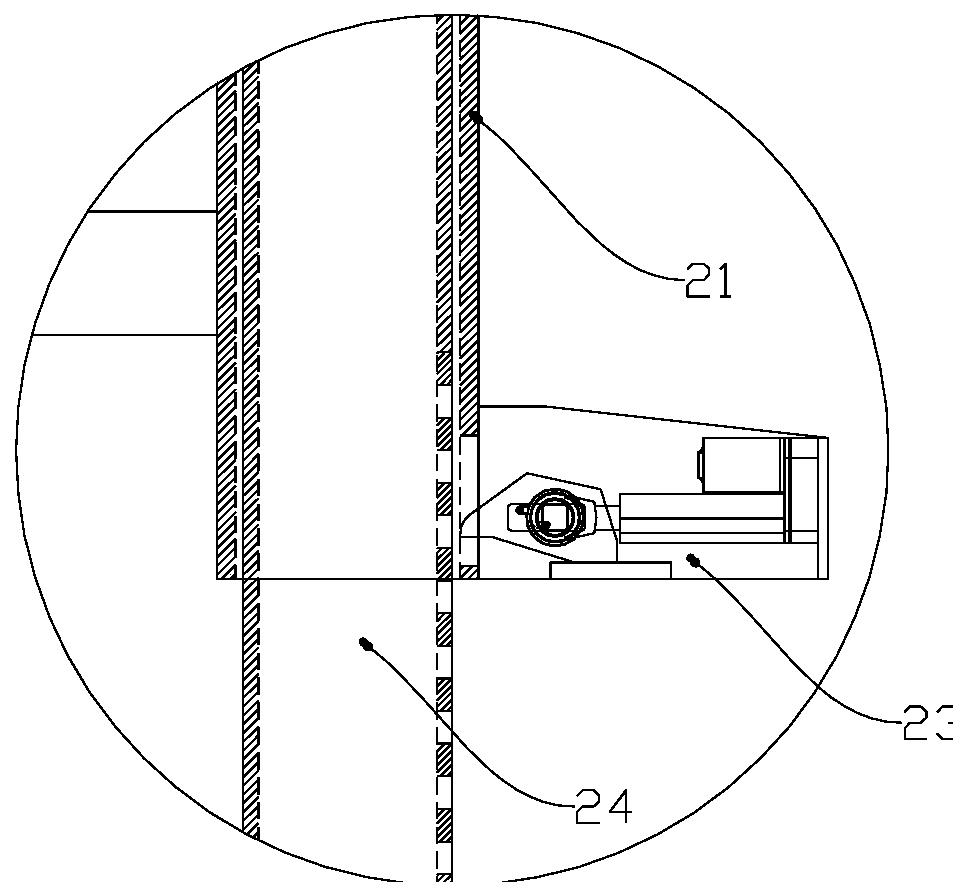

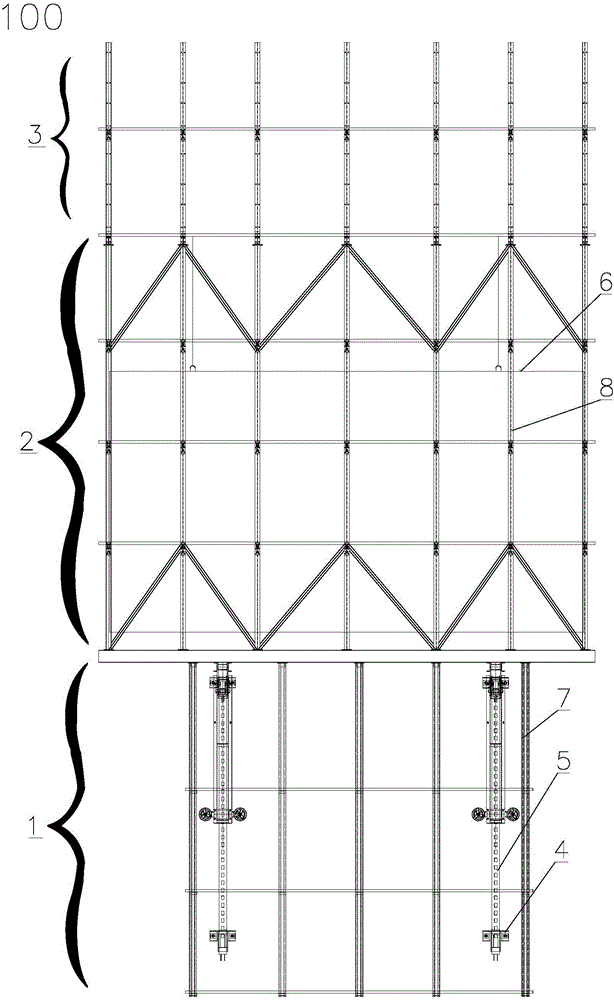

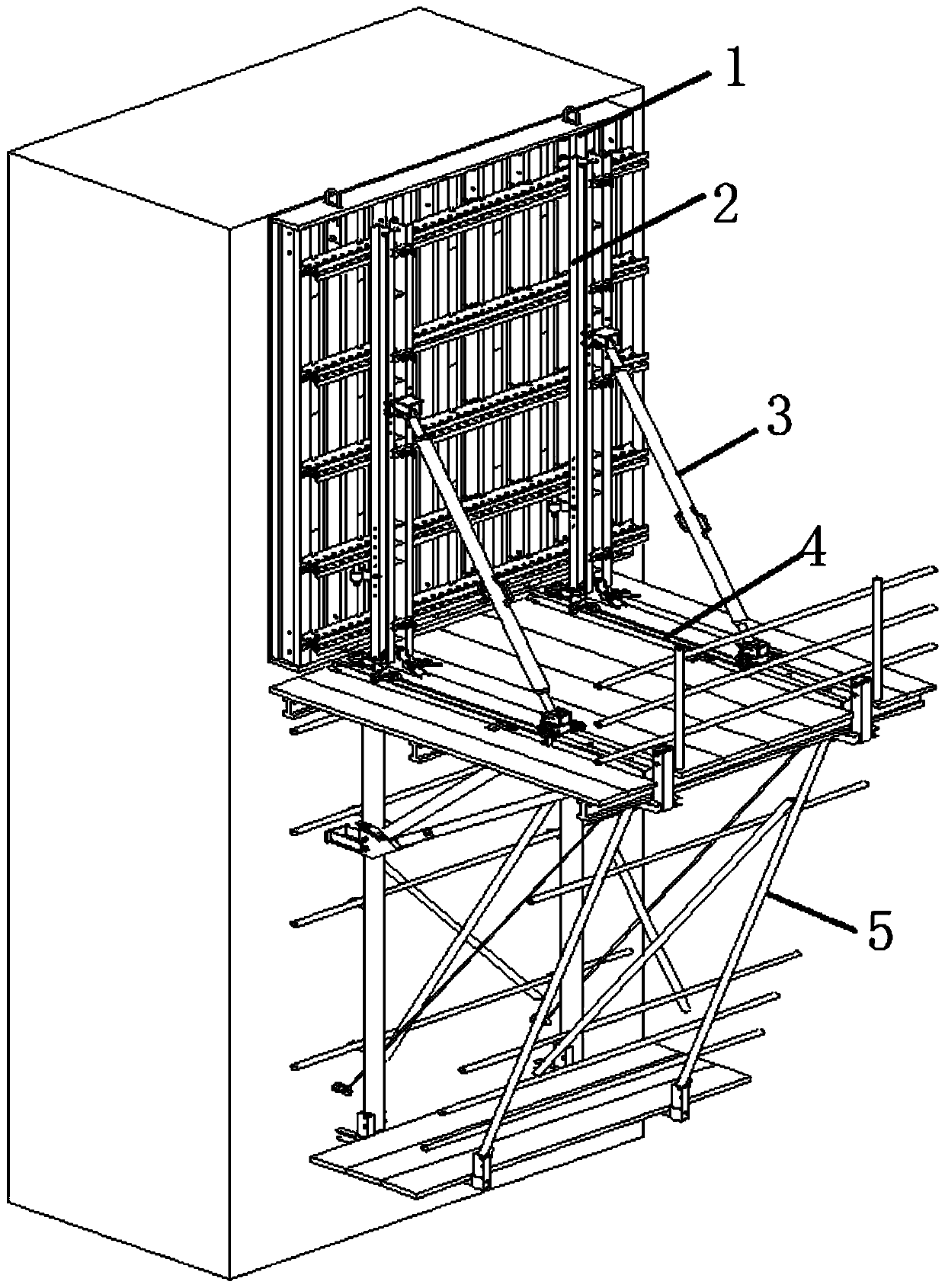

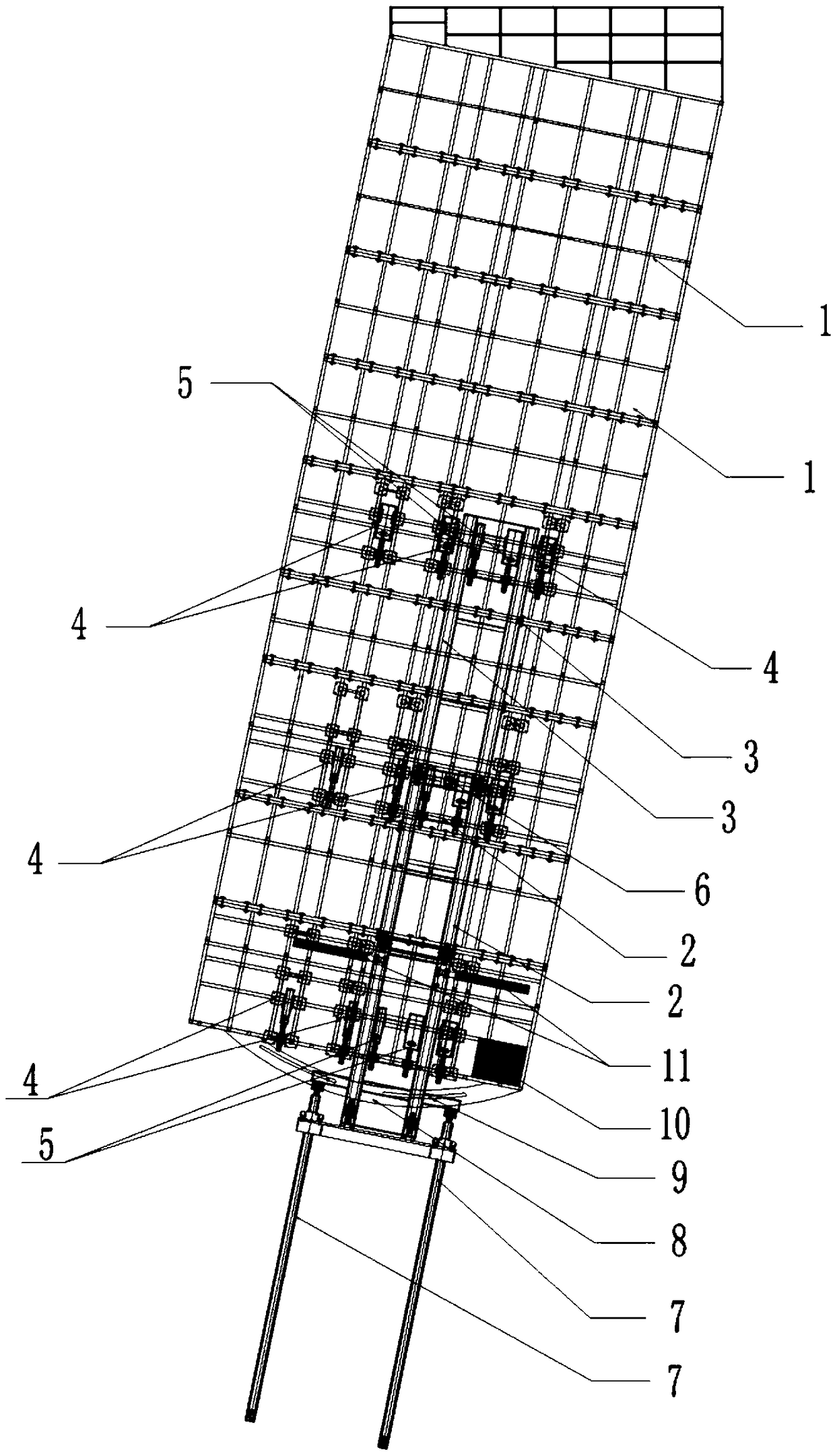

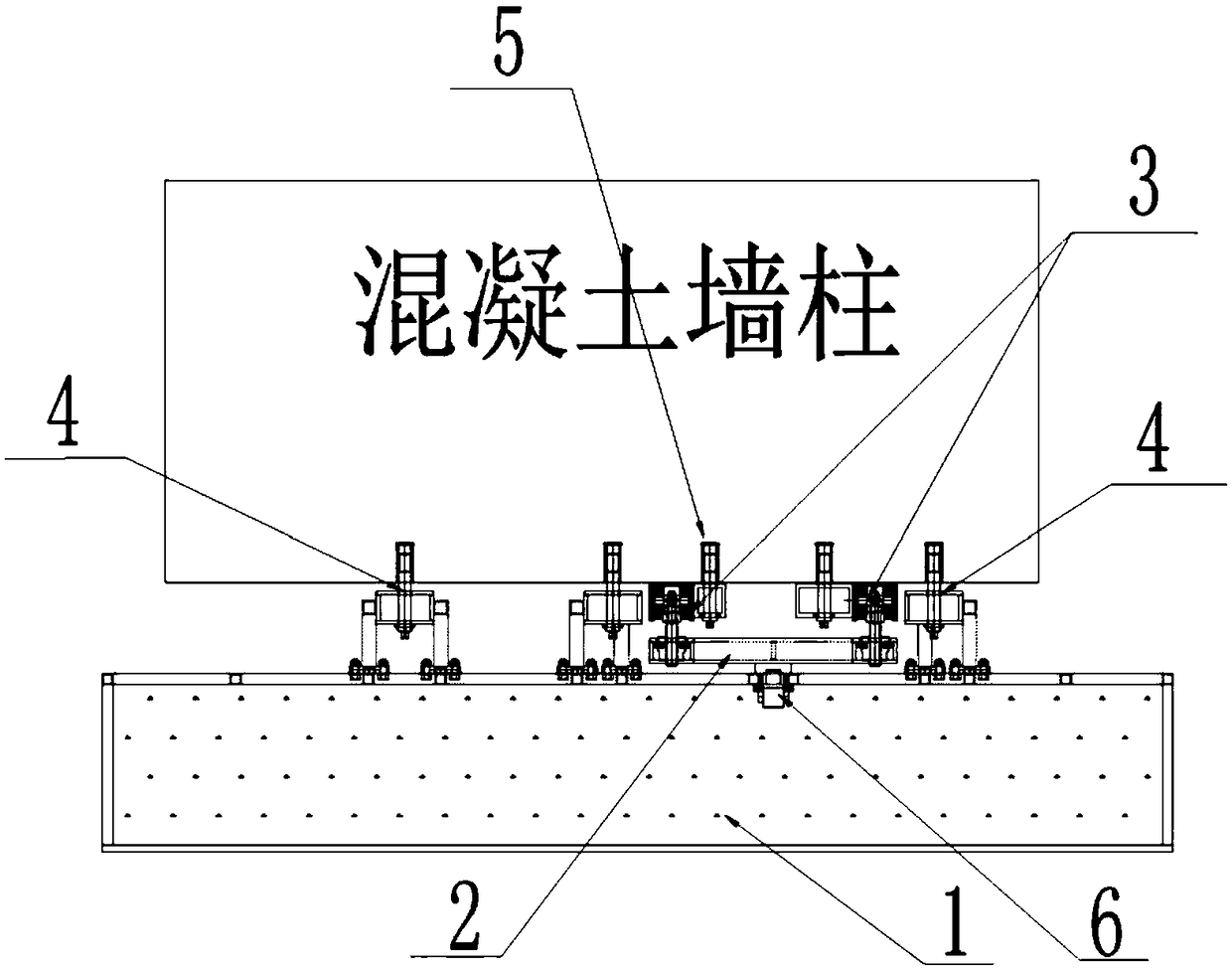

Comprehensive formwork system for super high-rise building construction

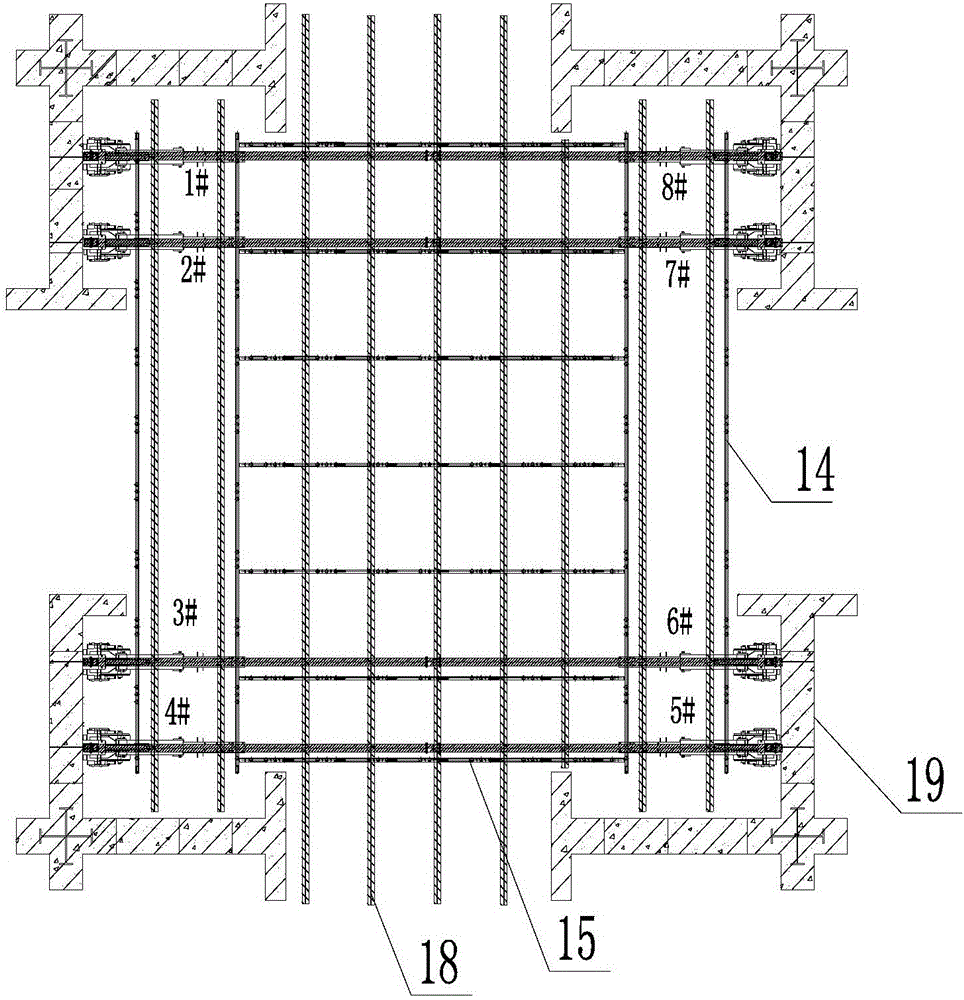

ActiveCN107190975AImprove bearing capacityImprove structural safetyForms/shuttering/falseworksBuilding material handlingRebarHigh rise

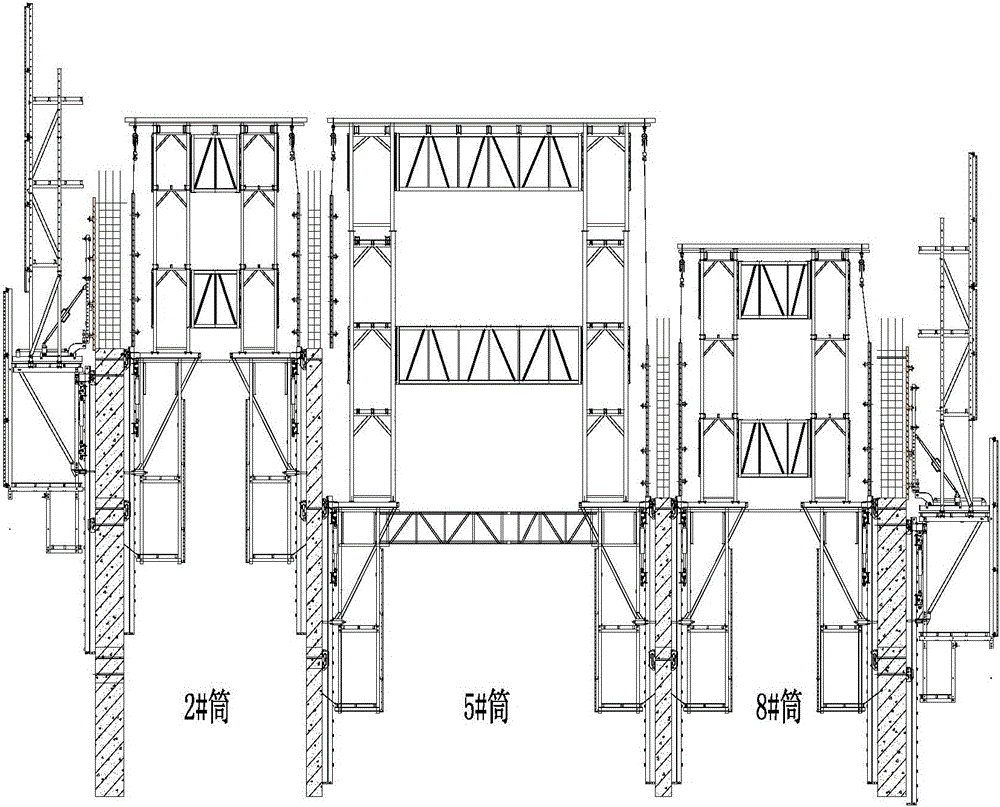

The invention discloses a comprehensive formwork system for super high-rise building construction. The comprehensive formwork system for super high-rise building construction comprises a climbing system of a stereoscopic structure, and the climbing system is formed by climbing formwork units in an enclosure mode. A jacking system composed of jacking units is arranged inside the stereoscopic structure. A space where steel structures and steel bars are installed and a concrete wall is poured is formed between the climbing system and the jacking system. The climbing system and the jacking system can move in the vertical direction. The climbing formwork units correspond to the jacking units close to the side wall separately and can move synchronously or separately with the jacking units. Each jacking unit is provided with a vertical adjusting device and a horizontal adjusting device which are used for positioning position junctions in the vertical direction and the horizontal direction correspondingly. Each jacking unit is internally provided with a plurality of sets of tensioning devices for improving structure stability. The formwork system is low in dead weight, low in center of gravity and good in structure safety, the construction operating surface is broad, the preparation time and lifting time for each climbing are the shortest, the working efficiency is the highest, and in standard floor construction of a super high-rise building, the formwork system can shorten the construction period by one day or over compared with other systems.

Owner:SICHUAN HUASHI GRP CO LTD +2

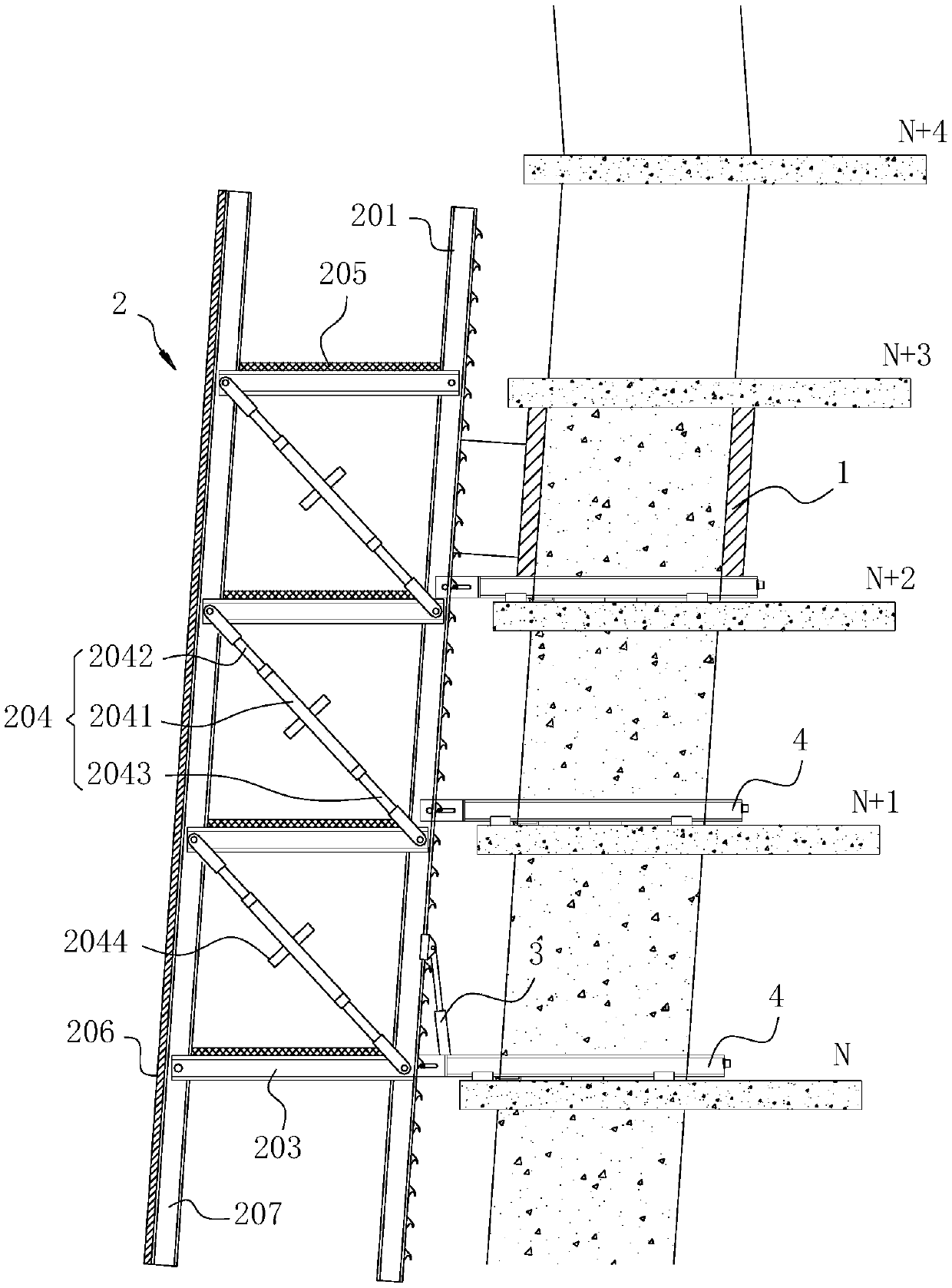

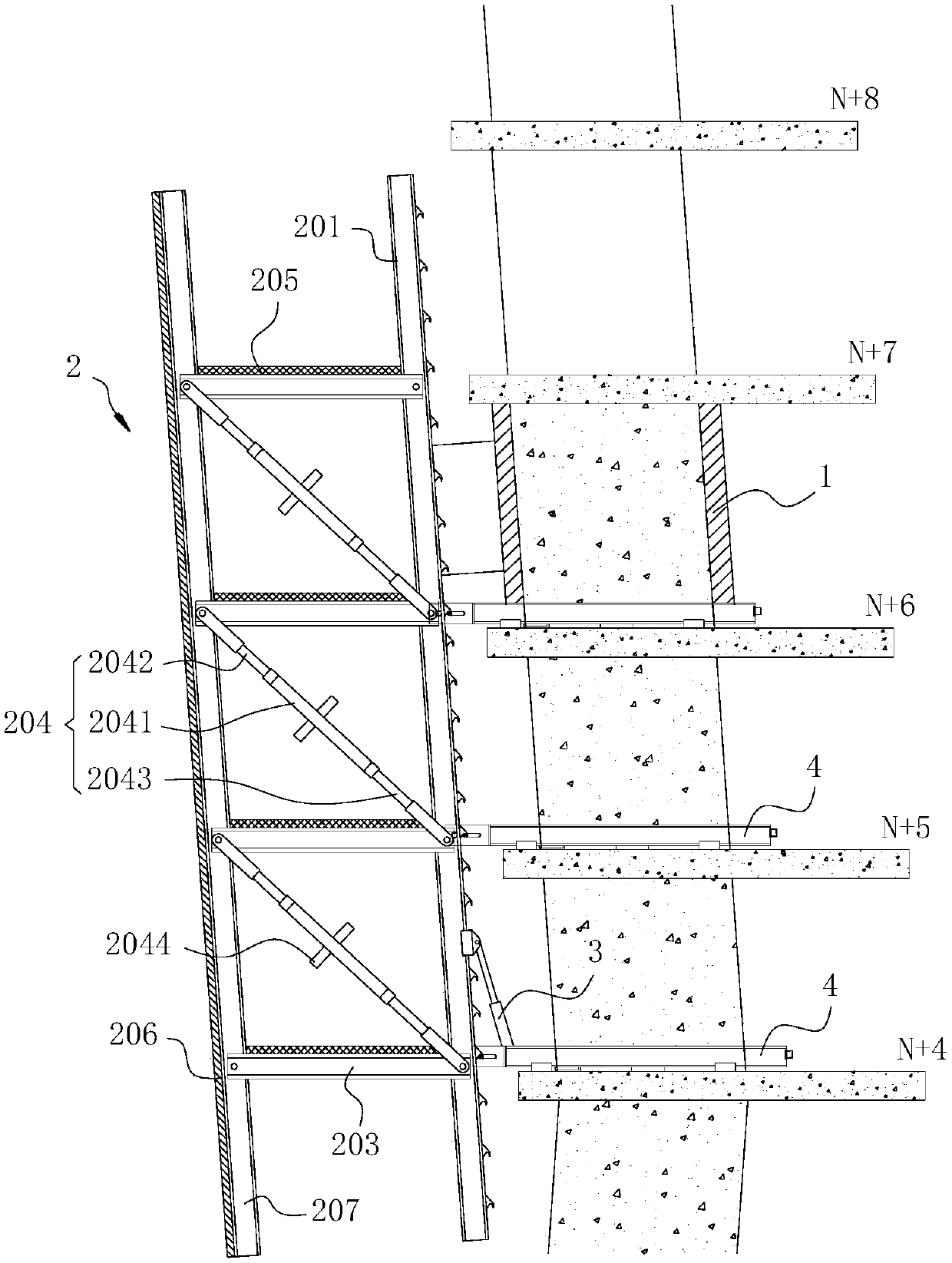

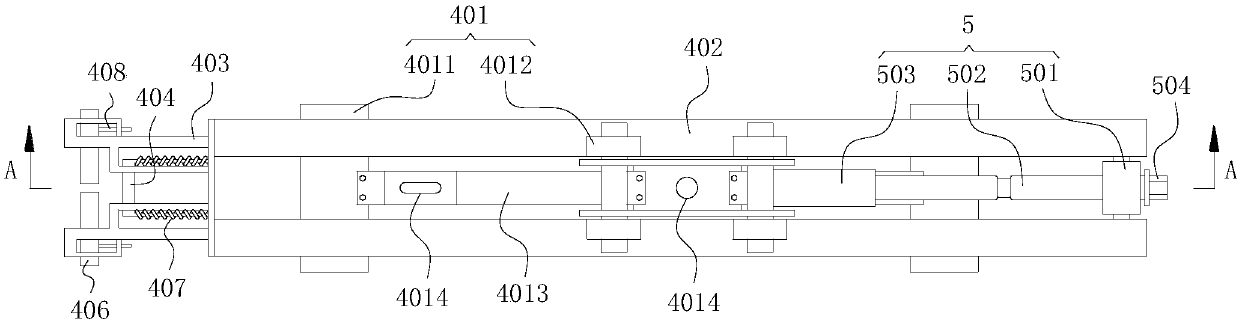

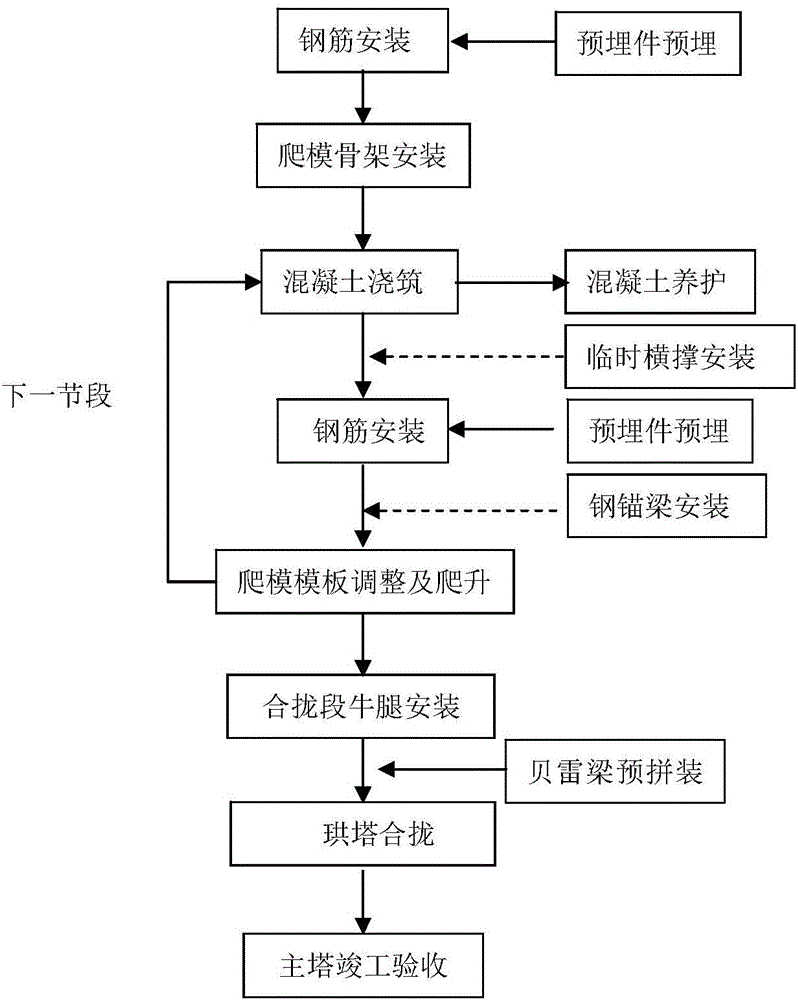

Construction method of cable-stayed bridge pylon

ActiveCN105839536ALow costEnsure construction does not interfere with each otherCable-stayed bridgeBridge structural detailsWork periodPre stress

The invention discloses a construction method of a cable-stayed bridge pylon. The construction method comprises specific steps as follows: step 1, cushion caps, a tie beam and pylon bases are constructed, main beam pier top segment support embedded parts are arranged on the cushion caps, the tie beam and the pylon bases, and upper cross beam support embedded parts are arranged on the tie beam; step 2, lower pylon columns and upper pylon columns are subjected to climbing formwork construction, an upper cross beam support, a main beam pier top segment support and cross bracings are synchronously mounted; step 3, after the bottom of a climbing formwork system is higher than the construction height of an upper cross beam, concrete pouring is performed for construction of the upper cross beam and a main beam pier top segment while the upper pylon columns are subjected to climbing formwork construction; step 4, after the strength of upper cross beam concrete meets design requirements and the upper cross beam is pre-stressed, the upper cross beam support and the cross bracings are detached from top to bottom, and after a main beam pier top segment stay cable is hung and tensioned, the main beam pier top segment support is detached. The construction method has the advantages of high construction speed, short work period, low cost and high safety coefficient.

Owner:THE 5TH ENG MBEC +1

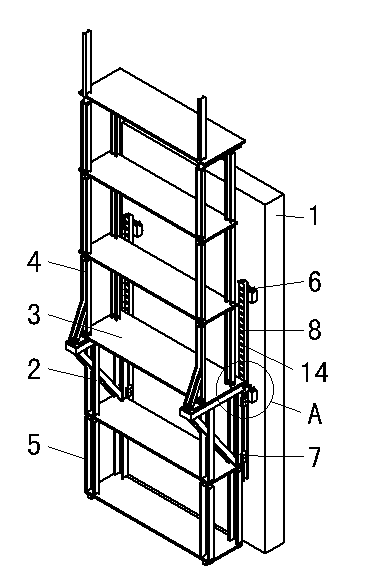

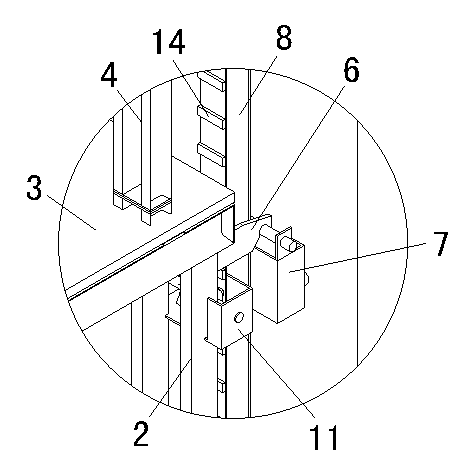

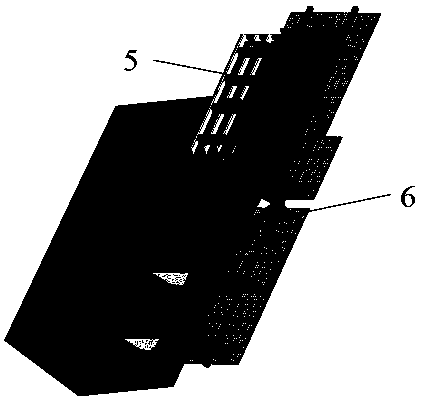

Outside-steel, inside-aluminum, outside-climbing and inside-crossing comprehensive formwork system

ActiveCN104314304ASmall sizeFirmly connectedForms/shuttering/falseworksBuilding constructionClimbing formwork

The invention provides an outside-steel, inside-aluminum, outside-climbing and inside-crossing comprehensive formwork system. The comprehensive formwork system comprises a formwork system, a lifting device and connecting devices; the formwork system comprises a core-tube exterior-wall outside steel formwork, a core-tube exterior-wall inside aluminum formwork, core-tube interior-wall aluminum formworks, an elevator shaft inside steel formwork and a floor and stair aluminum formwork; the lifting device comprises an outside climbing formwork and an elevator shaft formwork, the outside climbing formwork is used for enabling the core-tube exterior-wall outside steel formwork to climb upwards, the elevator shaft formwork is used for enabling the elevator shaft inside steel formwork to climb upwards, and the connecting devices are used for connection between the steel formworks and the aluminum formworks as well as between the aluminum formworks. By integral coordinated control, one-time concreting of the whole floor is realized, impression effect of concrete is improved, and construction efficiency is improved.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Combined type telescopic sleeve jacking device and method

ActiveCN111058618AImprove structural construction efficiencyImprove construction efficiencyForms/shuttering/falseworksBraced frameArchitectural engineering

The invention belongs to the technical field of construction engineering construction, and particularly relates to a combined type telescopic sleeve jacking device and method. The device solves a series of problems that in high-rise and super high-rise building concrete cylinder construction, a traditional climbing formwork system is complex in a power system, large in transmission mechanism number, poor in narrow cylinder space adaptability, low in combined construction flexibility and the like. The combined type telescopic sleeve jacking device comprises a plurality of jacking unit modules,a horizontal jacking frame, an upper supporting frame, a lower supporting side frame and a plurality of longitudinal connecting beams, wherein each unit jacking module comprises a jacking oil cylinderand a telescopic sleeve frame; the jacking oil cylinders are arranged at the center positions of the telescopic sleeve frames, and the upper ends of the jacking oil cylinders are connected with the horizontal jacking frame; and the jacking oil cylinders penetrate through gaps between the longitudinal connecting beams of the upper supporting frame, and the lower ends of the jacking oil cylinders are connected with the lower supporting frame. By providing a single-oil-cylinder jacking module device with a telescopic sleeve frame, formwork system jacking operation can be independently carried out, multi-module combined jacking can be carried out according to large-space cylinder construction needs, and large-load three-dimensional operation is achieved.

Owner:SHANGHAI CONSTRUCTION GROUP

Tool type building shaft/elevator shaft climbing formwork

InactiveCN102277958AOvercome the defect of uneven forceOvercome transportForms/shuttering/falseworksOperation modeEngineering

Owner:马永乐

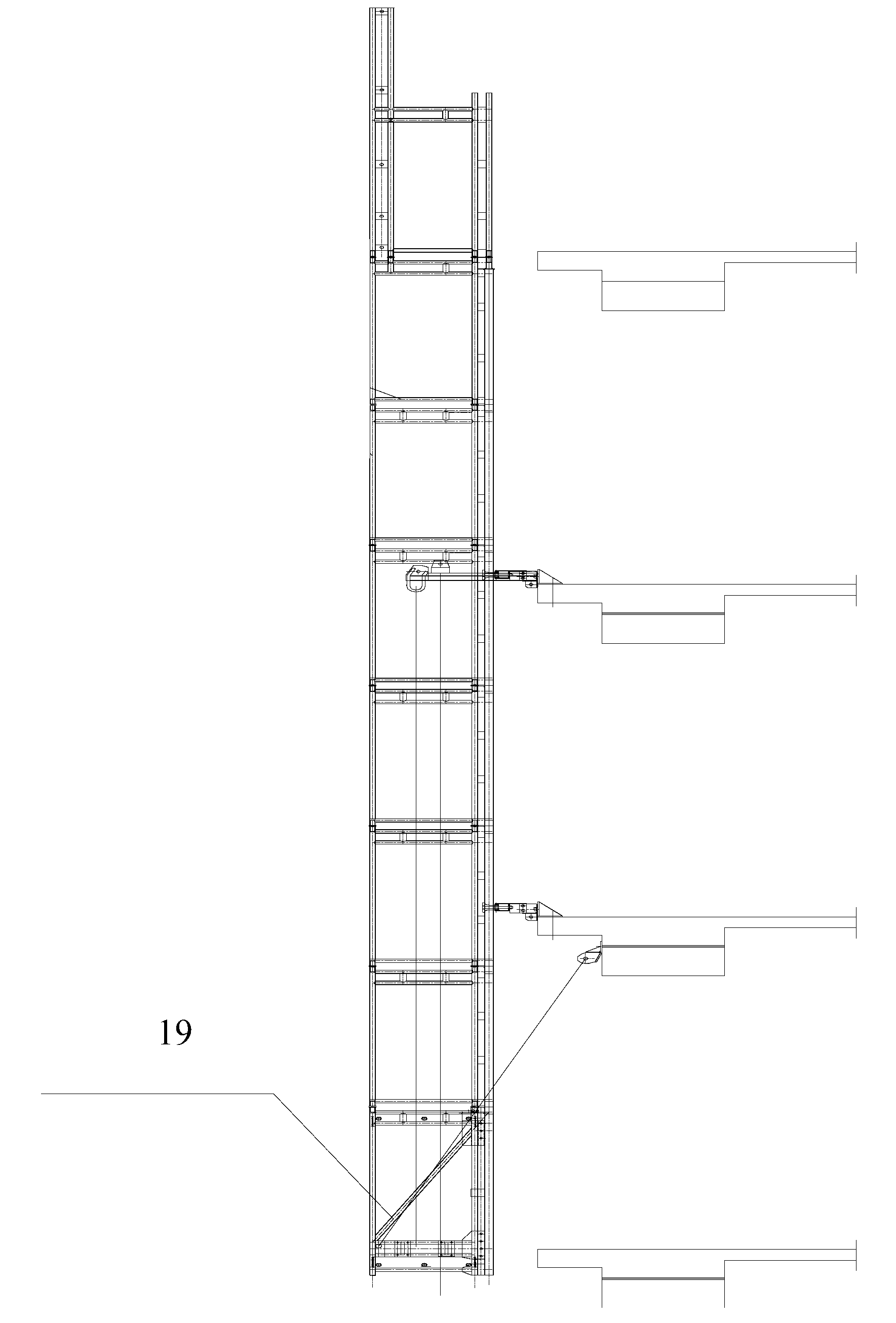

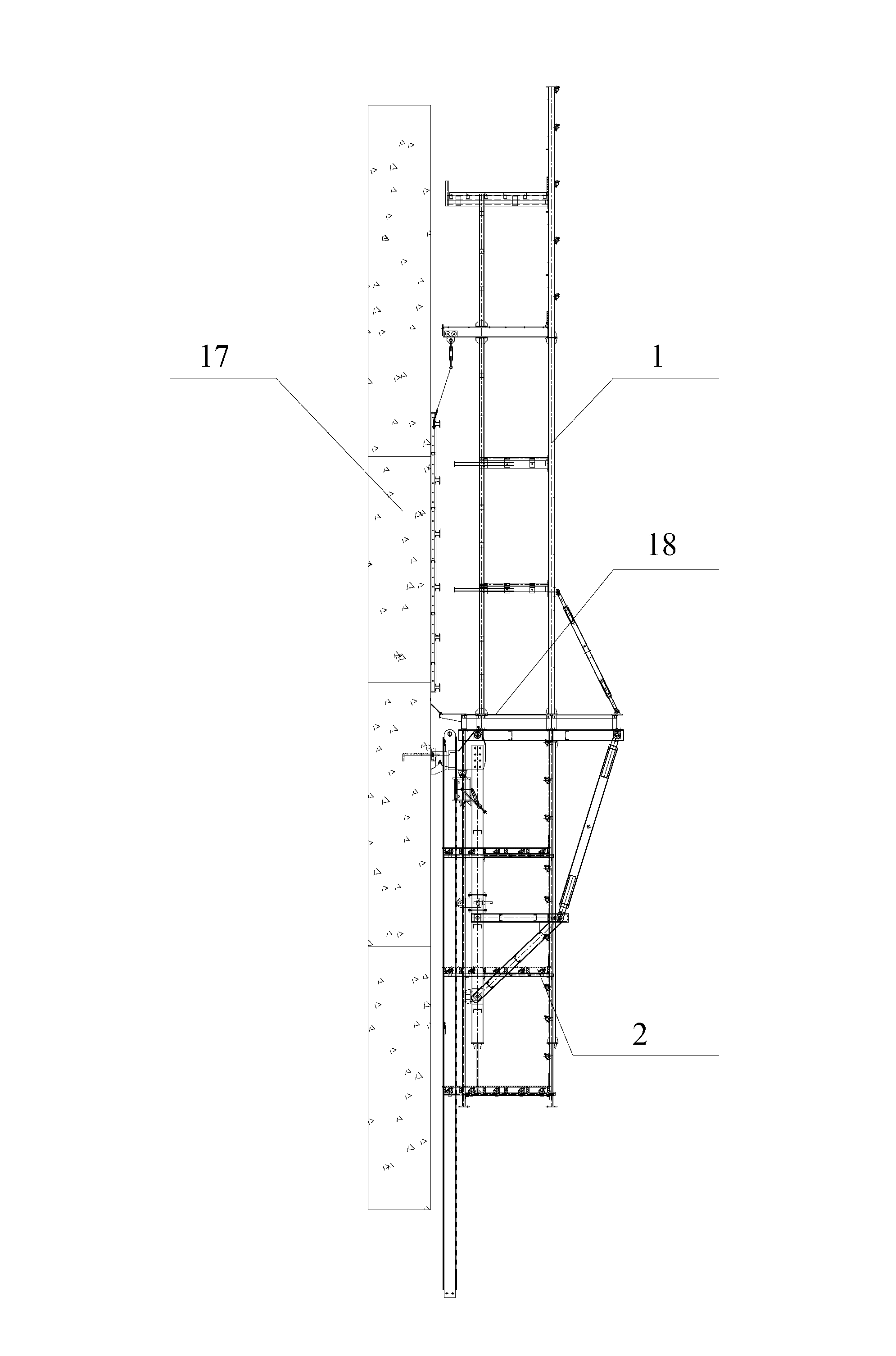

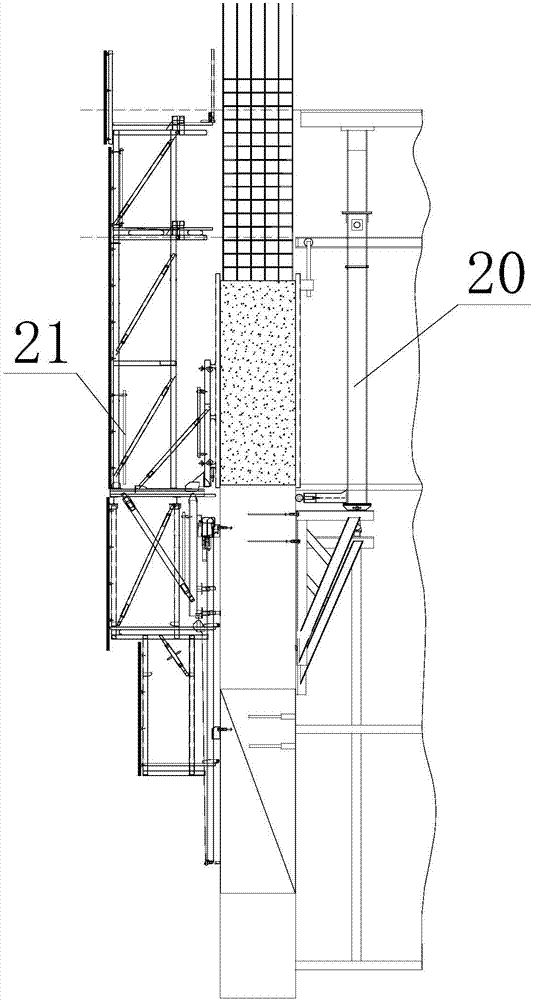

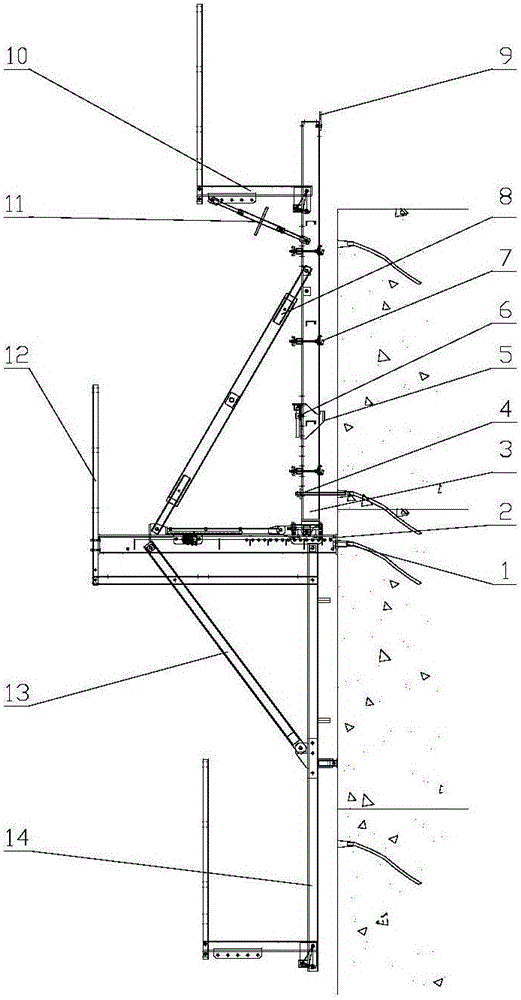

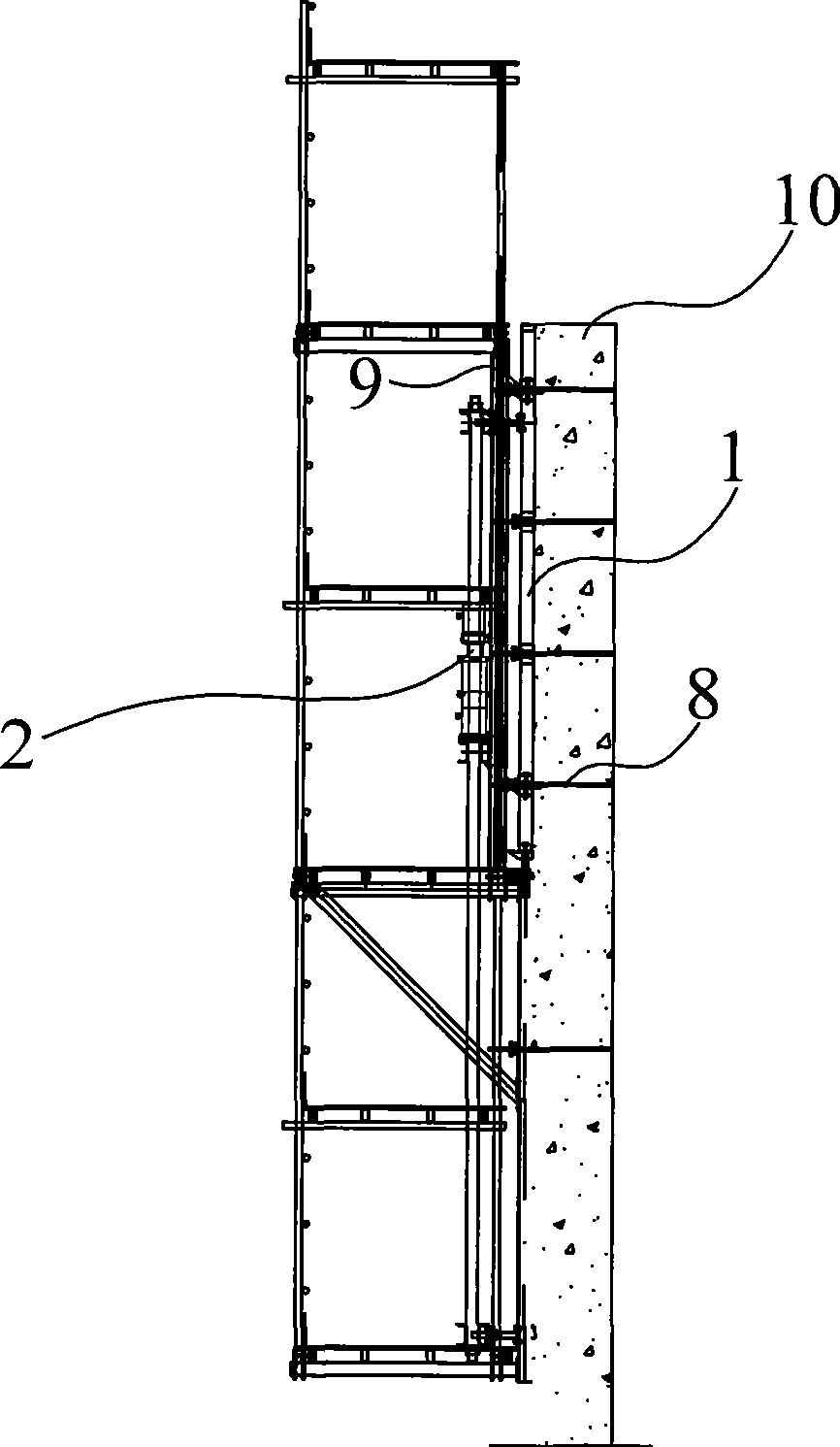

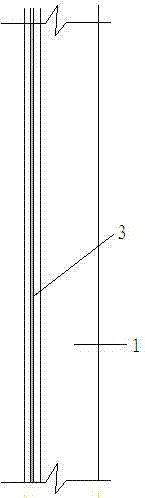

Single-side self-climbing cantilever formwork and construction method thereof

ActiveCN105971271AFlexible completion of project constructionSafely complete project constructionForms/shuttering/falseworksFoundation engineeringEngineeringCantilever

The invention discloses a single-side self-climbing cantilever formwork. The single-side self-climbing cantilever formwork comprises a self-climbing formwork body and a single-side cantilever formwork body. The single-side cantilever formwork body is installed on the self-climbing formwork body, and the self-climbing formwork body drives the formwork body to complete self-climbing. During engineering construction of the single-side self-climbing cantilever formwork, the construction ways and techniques such as an ordinary formwork and a scaffold group, a single-side cantilever formwork, a top formwork and a self-climbing formwork can be effectively replaced; although dam construction can be completed through the formworks in the ways, the effect that construction of towering or extremely-deep single-side concrete projects such as dams, ventilating shafts, slopes, underground factories and hydropower station diversion channels is completed effectively in time-saving and labor-saving modes cannot be achieved due to the fact that technique limitation exists and pertinence of specific projects is not available, installation is difficult, and technical defects exist during construction.

Owner:北京卓良模板有限公司

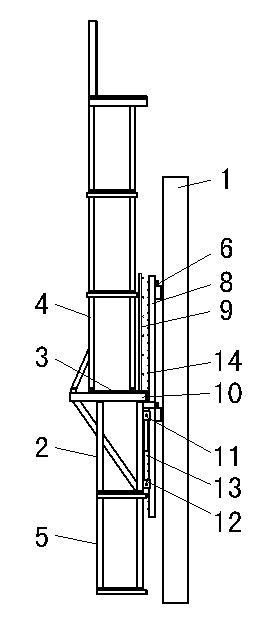

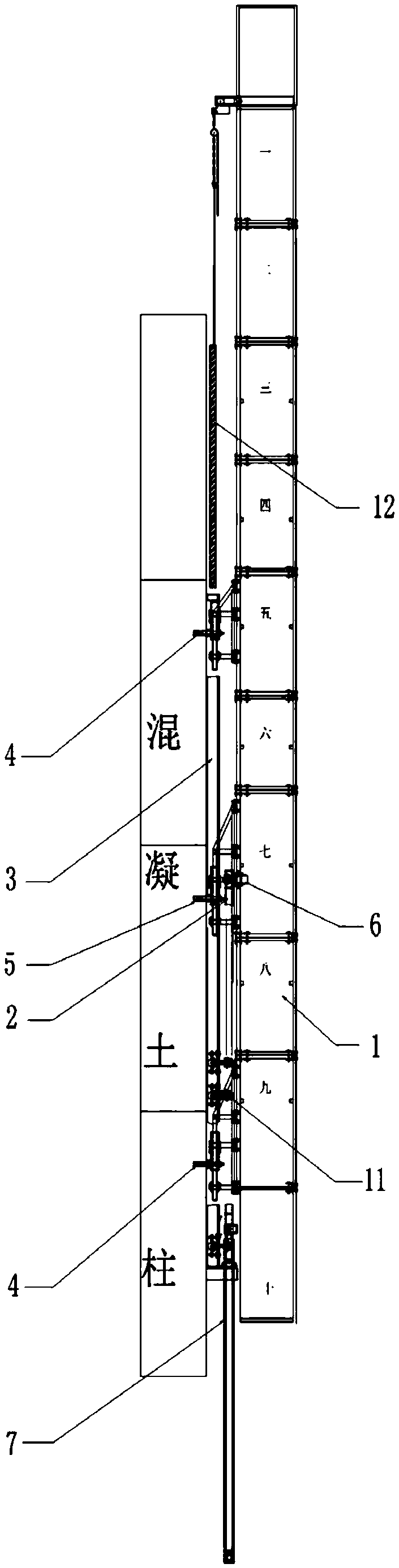

Truss type hydraulic entire steel platform climbing formwork

InactiveCN105781101AEasy to assembleSolve difficultyForms/shuttering/falseworksHydraulic cylinderStructural engineering

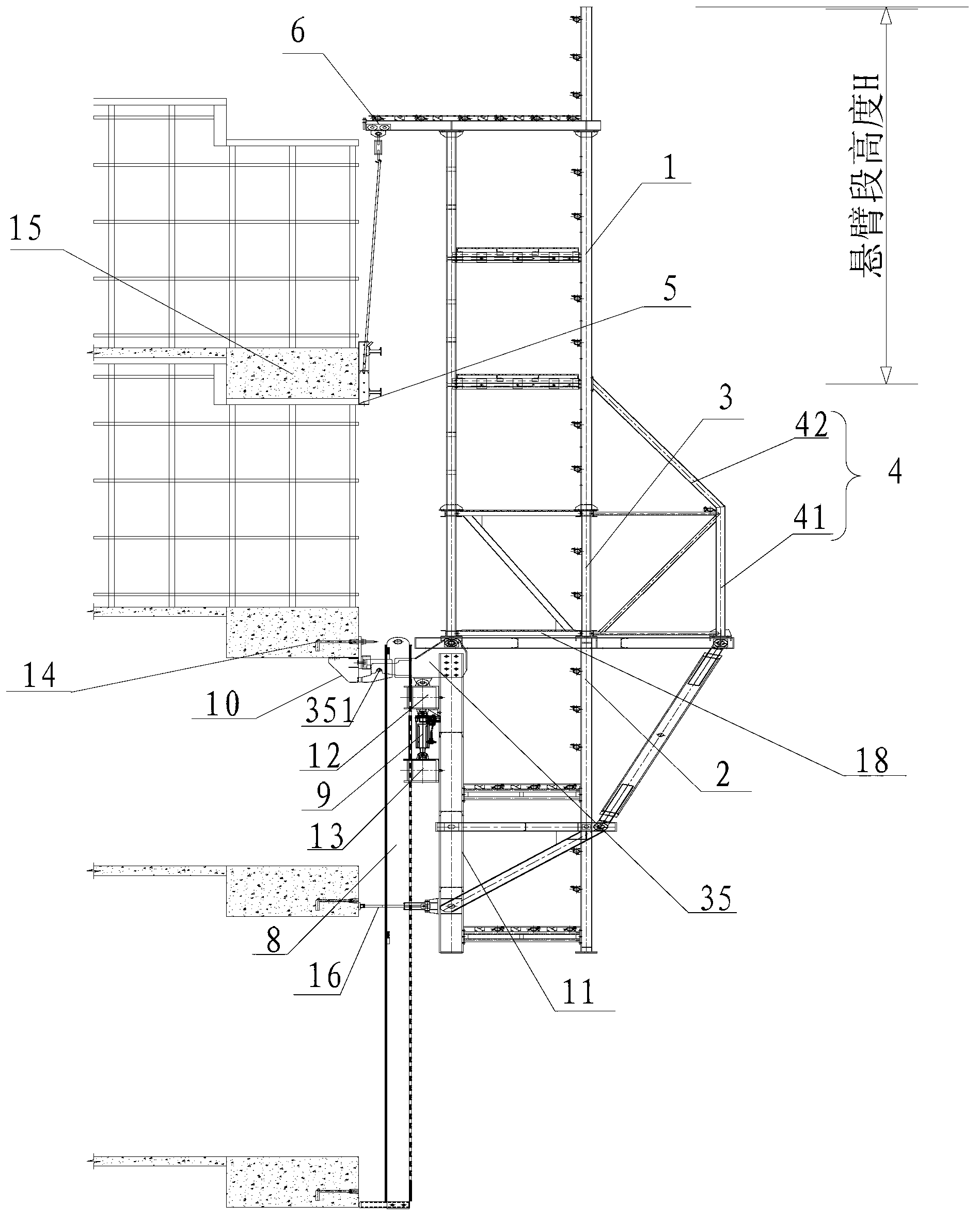

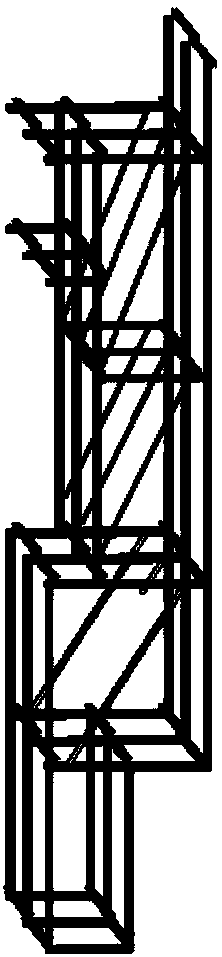

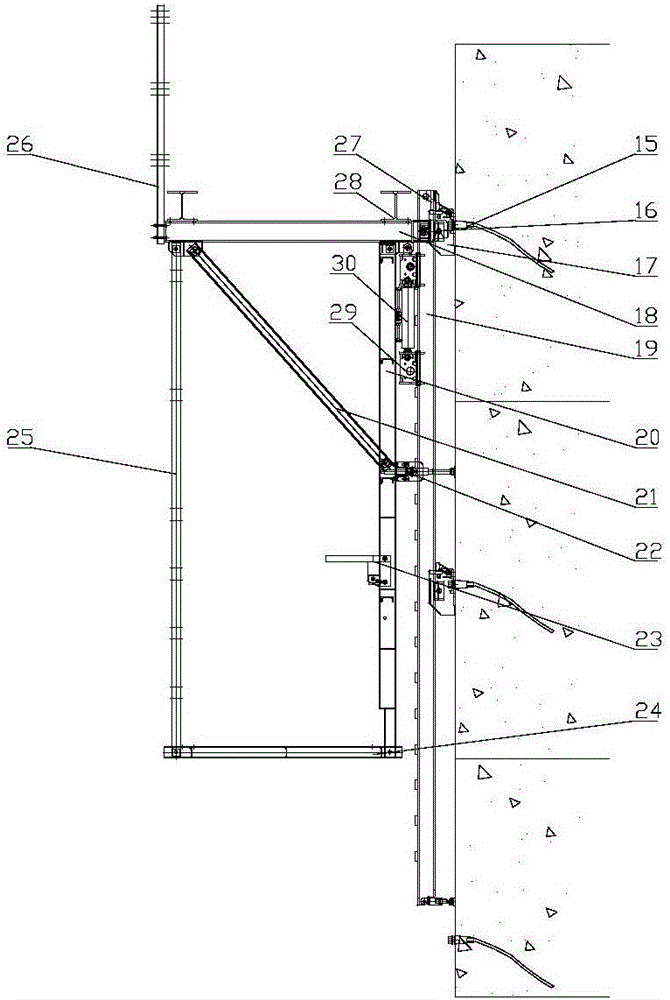

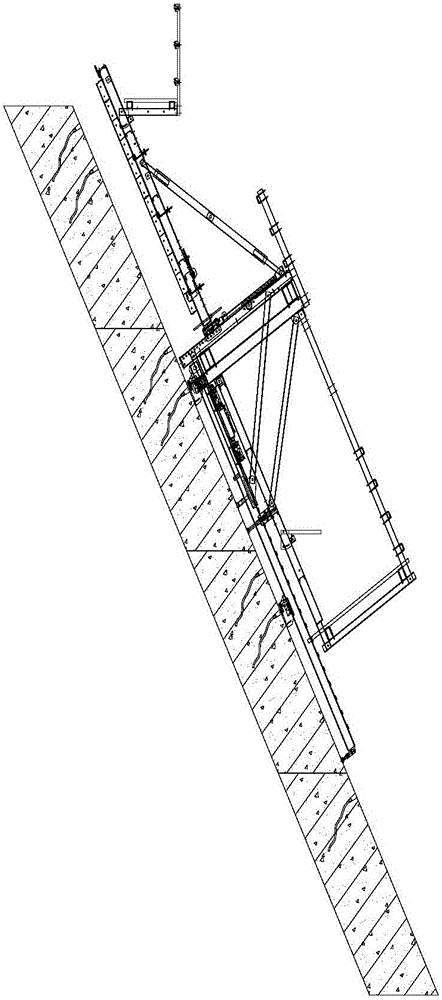

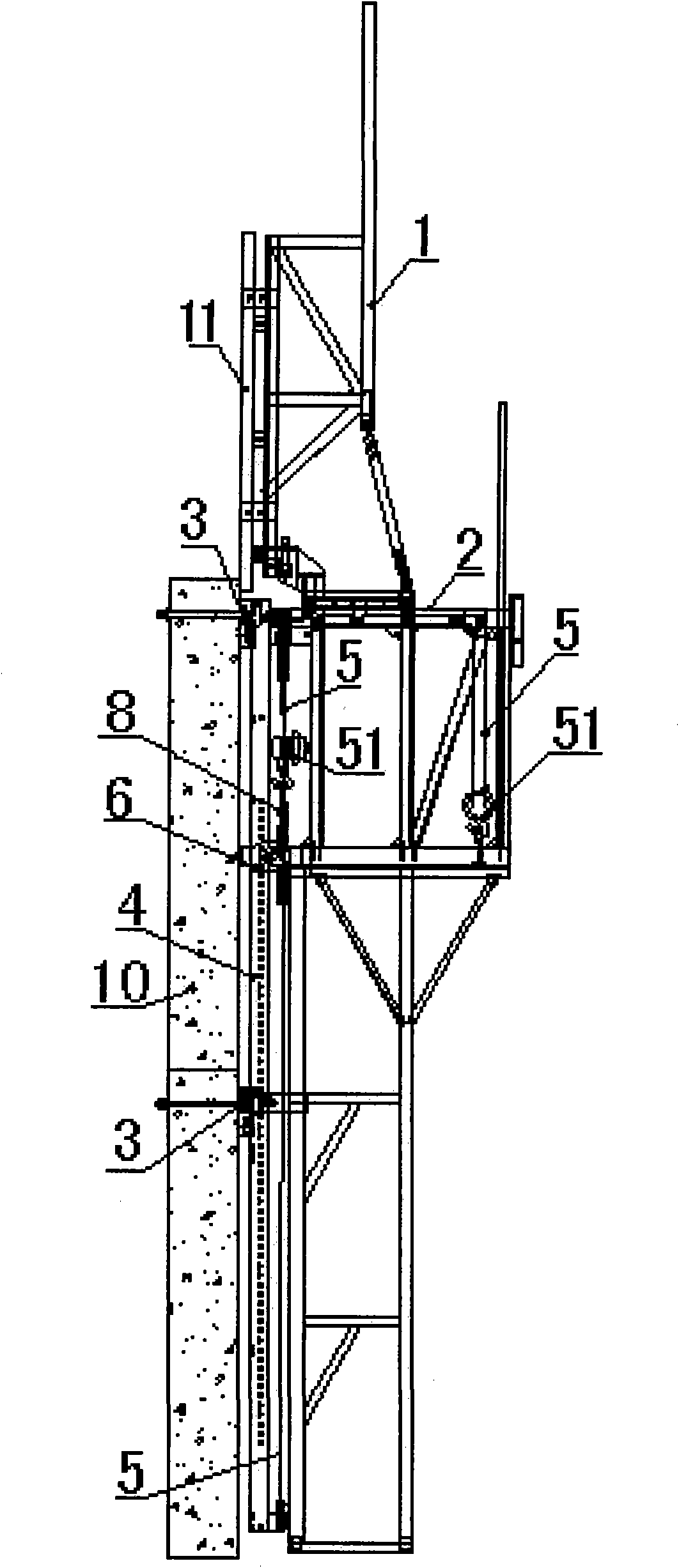

The invention relates to the technical field of building equipment, and discloses a truss type hydraulic entire steel platform climbing formwork, which comprises a vertical main frame, a wall-attaching device, a track, anti-dropping climbers, a horizontal formwork-pushing mechanism and a formwork; the wall-attaching device is connected with a preburied wall part, and the vertical main frame is hung on the wall-attaching device, and is detachably connected with the wall-attaching device through an unloading pin and a safety pin; the track is connected with the vertical main frame, and is detachably connected with the wall-attaching device, and the vertical main frame can slide up and down along the track; the anti-dropping climbers are fixed on the vertical main frame, and the anti-dropping climbers are driven by a climbing hydraulic cylinder to drive the entire vertical main frame to climb; the direction of an operating handle can be changed to drive the vertical main frame and the track to climb alternately; the horizontal formwork-pushing mechanism is fixed on a cross beam of the vertical main frame, and the formwork is fixed at the front end of the horizontal formwork-pushing mechanism. The invention adopts an integrated design, all the components can be produced in the factory, the equipment degree is high, climbing and all formwork dismounting and mounting operations adopt hydraulic power, the truss type hydraulic entire steel platform climbing formwork is easy to operate, and action is visual.

Owner:北京星河人施工技术有限责任公司

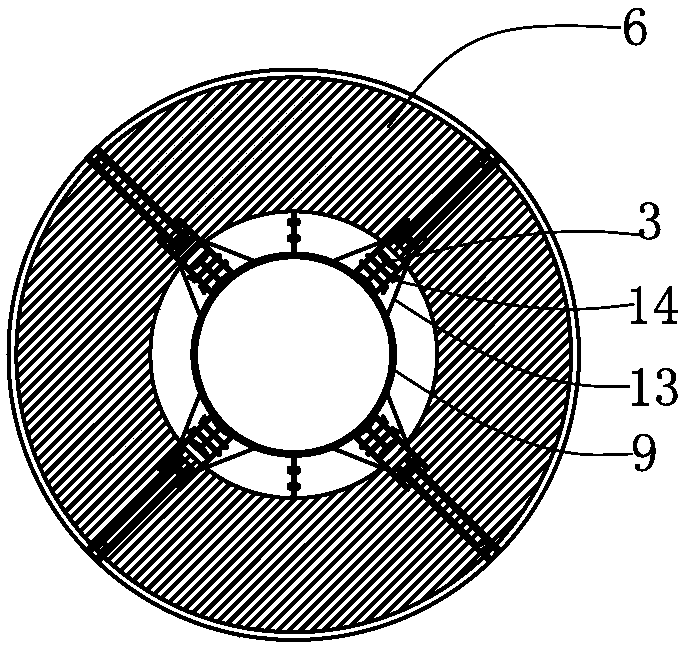

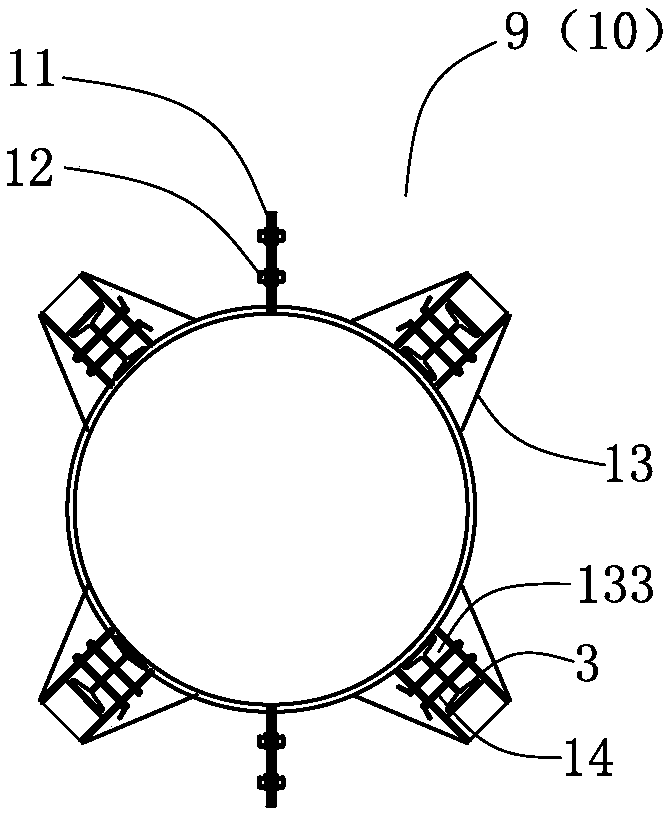

Hoop-type hydraulic climbing formwork system and a construction method used for the construction of a cylindrical pier

PendingCN109267494AGuaranteed appearanceFlexible control of climbing heightBridge erection/assemblyPre embeddingClimbing formwork

The invention provides a hoop-type hydraulic climbing formwork system and a construction method for the construction of a cylindrical pier, in view of the damage to the exterior of the pier caused bythe pre-embedding of the climbing cone in the concrete of the pier body during the construction of the existing column pier climbing formwork, and the climbing precision is difficult to be controlled.The upper and lower hug hoops are installed on the cylindrical pier, and the hug hoop is used as the support structure of the climbing form instead of the climbing cone, and the climbing cone is notembedded in the pier body when pouring, so that the appearance of the pier column can be effectively ensured, the climbing height of the formwork can be flexibly controlled, and the construction quality can be improved. The invention has the advantages of simple working procedure, fast construction speed and high construction safety.

Owner:ROAD & BRIDGE INT

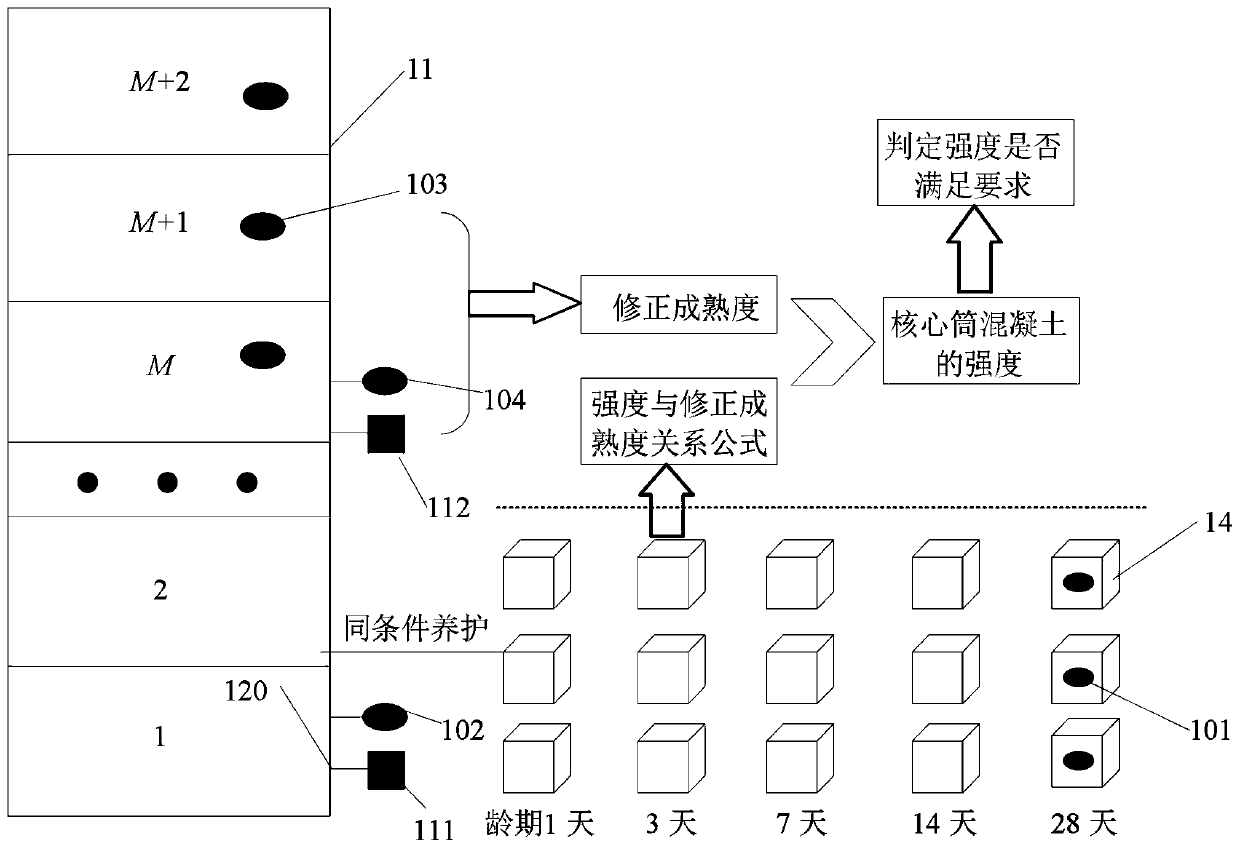

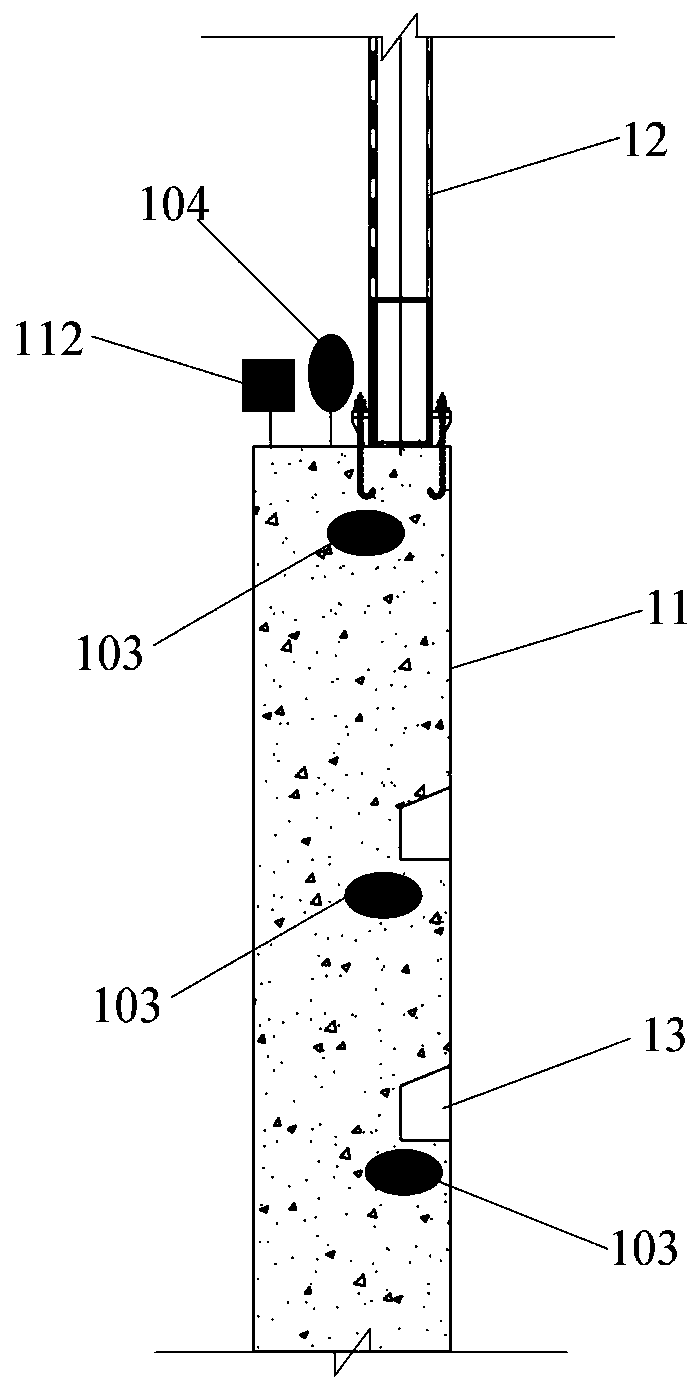

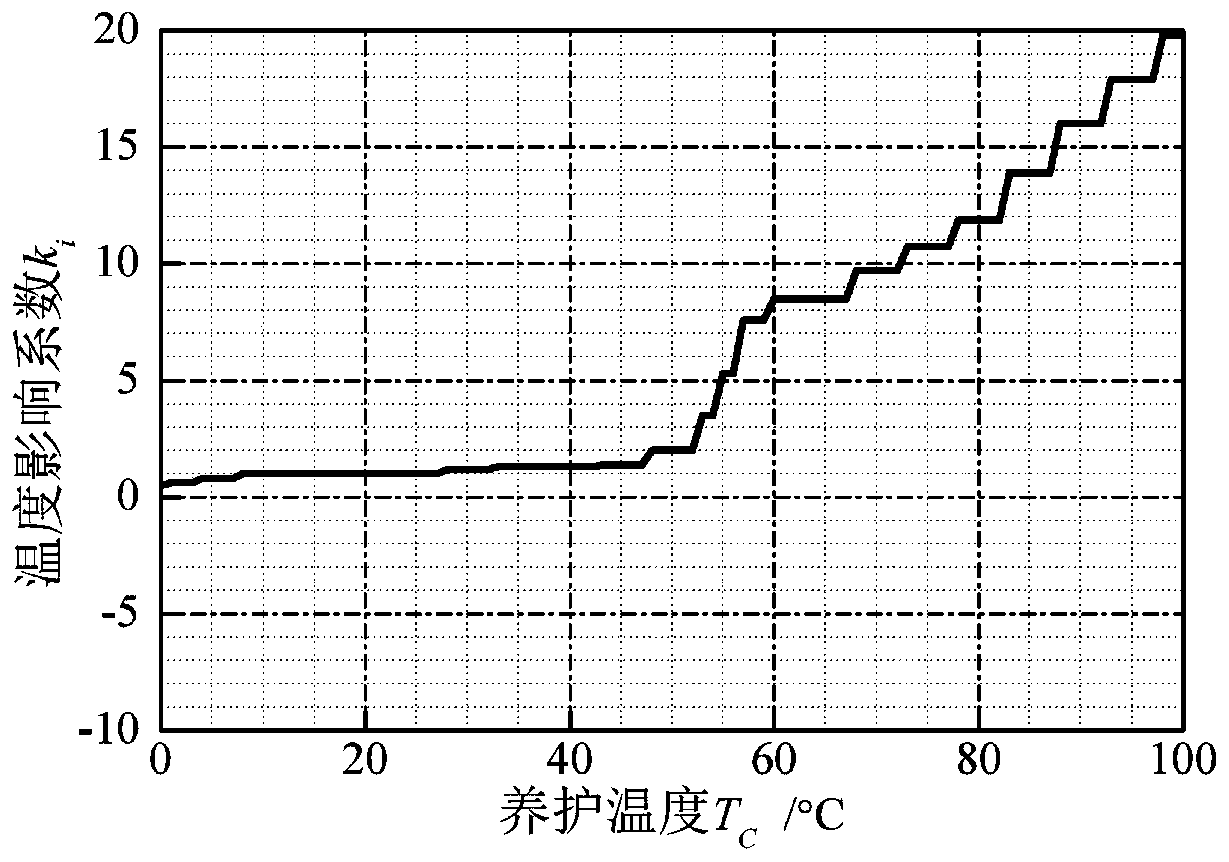

Method for monitoring strength of climbing formwork device attached to concrete structure in real time

The invention provides a method for monitoring the strength of a climbing formwork device attached to a concrete structure in real time. Modified maturity of the concrete is obtained by monitoring thetemperature of a concrete test block, the environment maintenance temperature and the environment maintenance humidity and the like and by measuring and determining the volume ratio; the compressivestrength of the concrete test block is determined by an experiment, and according to the modified maturity corresponding to the compressive strength, several groups of associated data are establishedbetween the concrete strength and the modified maturity to further fit a relation function of the concrete strength and the modified maturity; subsequently, data including the temperature of the concrete of a super high layer core tube, the concrete temperature, the humidity and so on are monitored, the strength of the super high layer core tube is calculated, and whether the strength satisfies the climbing strength of the climbing formwork device or not is judged so as to provide a reliable basis for climbing of the climbing formwork device of the super high layer core tube. The method considers factors including the environment maintenance temperature, the maintenance humidity and the size effect and so on, thus the method is highly reliable and is able to realize real-time monitoring and evaluation for concrete strength.

Owner:SHANGHAI CONSTRUCTION GROUP

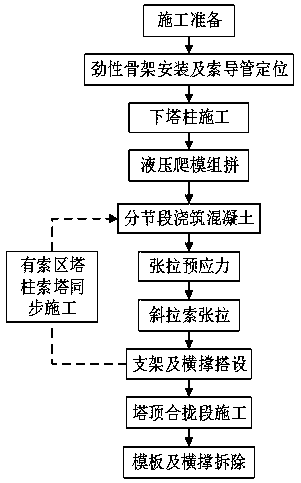

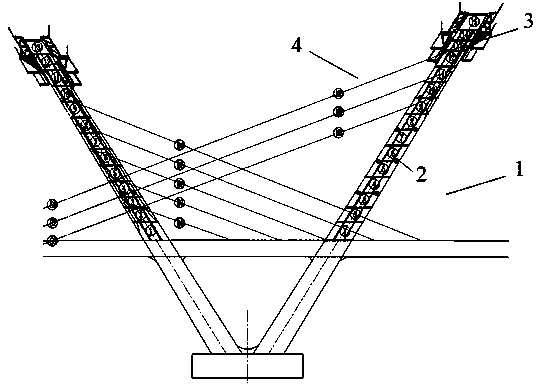

Construction method of bidirectional inclined v-shaped bridge tower of cable-stayed bridge without backstays

ActiveCN110331668ASimplify the construction processImprove construction qualityCable-stayed bridgeBridge erection/assemblyCable stayedPre stress

The invention discloses a construction method of a bidirectional inclined v-shaped bridge tower of a cable-stayed bridge without backstays. The construction method is characterized in that: the methodcomprises the following steps of: construction preparation, installation of a stiff framework, positioning of a cable guide pipe, construction of a lower tower column, assembly of a hydraulic climbing formwork, synchronous construction of a tower column and a cable tower in a cable area, construction of a closure section at the top of the tower and removal of a formwork and a cross brace, whereinthe synchronous construction step of the tower column and the cable tower in the cable area comprises four steps of: segmental concrete pouring, tensioning prestress, erection of a support and a cross brace and tensioning of a stay cable.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP 1ST ENG

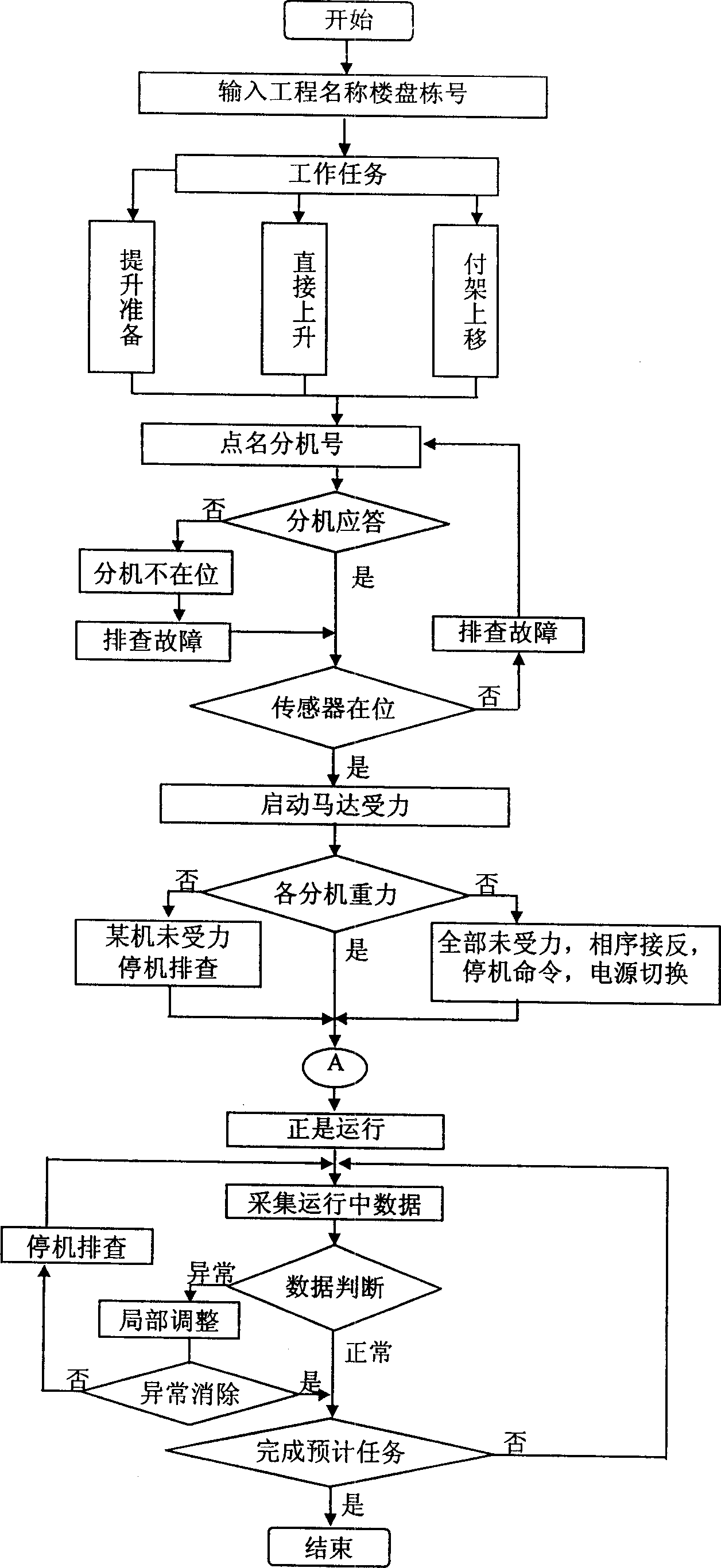

Jacking template control system and method for construction

The invention provides a control system and a method of a climbing formwork for construction, which comprises the steps as follows: A. a master cylinder jacks an upper support cross beam up to a certain height so that cantilevers at both ends of the cross beam are in the unstrained state; B. a small cylinder of the upper support cross beam drives the cantilevers to retract; C. the master cylinder extends and drives a support pillar to go up a certain distance; D. the small cylinder of the upper support cross beam drives the cantilevers to extend; E. the master cylinder retracts, which drives the cantilevers at both ends of the upper support cross beam to fall steadily and the lower support cross beam goes up so that the cantilevers at both ends of the lower support cross beam are unstrained. F. the small cylinder of the lower support cross beam drives the cantilevers to retract; G. the master cylinder drives the lower support cross beam to go up, H. the small cylinder of the lower support cross beam drives the cantilevers to extend, I. the master cylinder retracts so that both the upper support cross beam and the lower support cross beam are strained. The invention also provides a control system of a climbing formwork for construction. The control system is used for construction, which synchronously controls the whole process of climbing by hydraulic power and control system.

Owner:CHINA CONSTR FOURTH ENG DIV +2

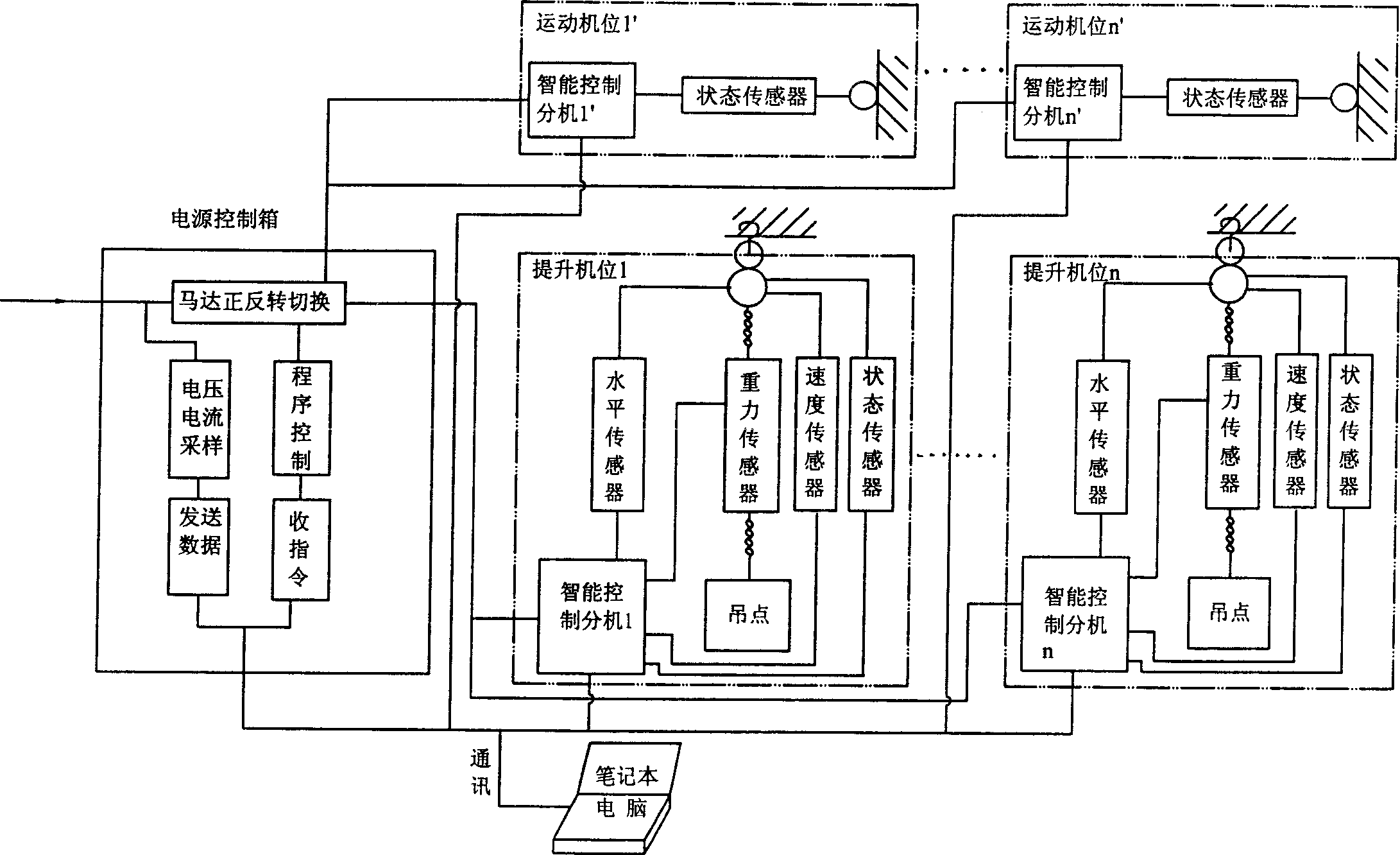

Climb formwork platform control system and its control method

InactiveCN1877470AImprove operational safetyAvoid overload damageComputer controlForms/shuttering/falseworksControl systemControl engineering

The invention discloses a system and a method for controlling a climb form platform. The climb form platform control system comprises a central processing machine, an intelligent sub control machine and sensors. The sensor is installed on each elevator site of the climb form platform and is connected with the intelligent sub control machine of the elevator site; the intelligent sub control machine is connected separately with the elevator device on the corresponding elevator site and the central processing machine. The inventive control method comprises performing promotion of the climb form platform and operation intelligent control via the climb form platform control system, preventing the damage of elevator overload on the elevator site and improving the safety and mechanism automatic level of promoting the climb form platform.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

Bridge high-tower construction method and construction equipment thereof

InactiveCN110042756AImprove working environmentReduce on-site installation timeBridge erection/assemblyBridge materialsRebarTower

The invention provides a bridge high-tower construction method, and belongs to the technical field of road and bridge construction. The bridge high-tower construction method comprises the steps that an initial segment of a tower column and a second section of the tower column and a third section of the tower column are constructed, then a climbing formwork body is installed on the tower column, alower tower column and a middle tower column are constructed, a fourth section of the tower column and above parts adopt climbing formwork construction, and the outer side of the climbing formwork body is totally sealed. The fourth section of the tower column and above parts adopt climbing formwork construction, punched steel meshes are used for totally sealing the outer side of the climbing formwork body, the sealed environment enables the internal operation environment of a climbing formwork to be significantly improved, and normal operation such as tower column reinforced steel bar bindingand concrete pouring in strong-wind weather is ensured. The invention further provides construction equipment used for the bridge high-tower construction method.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

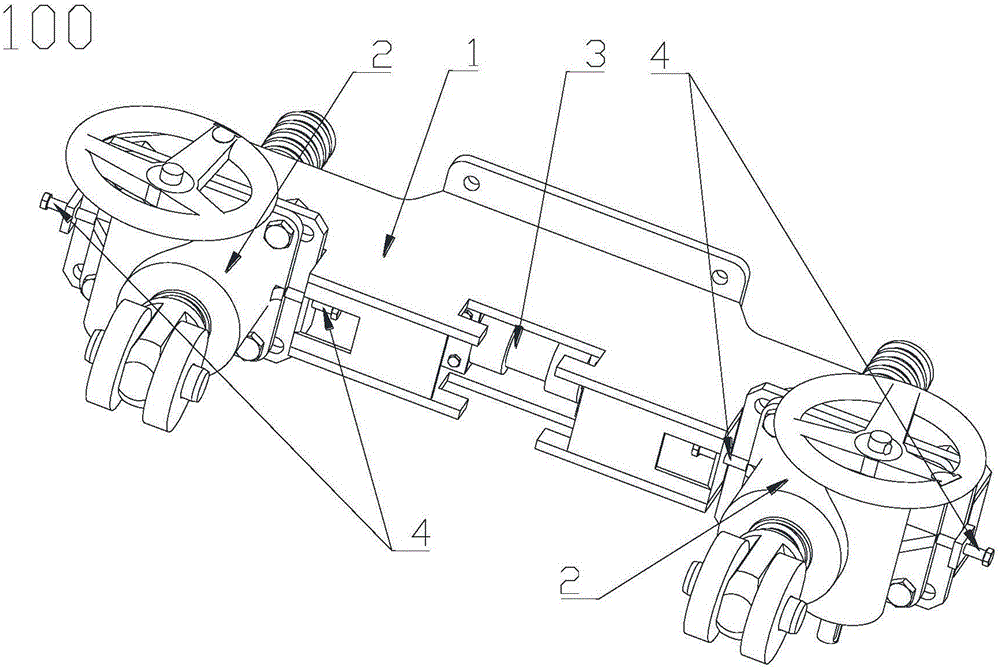

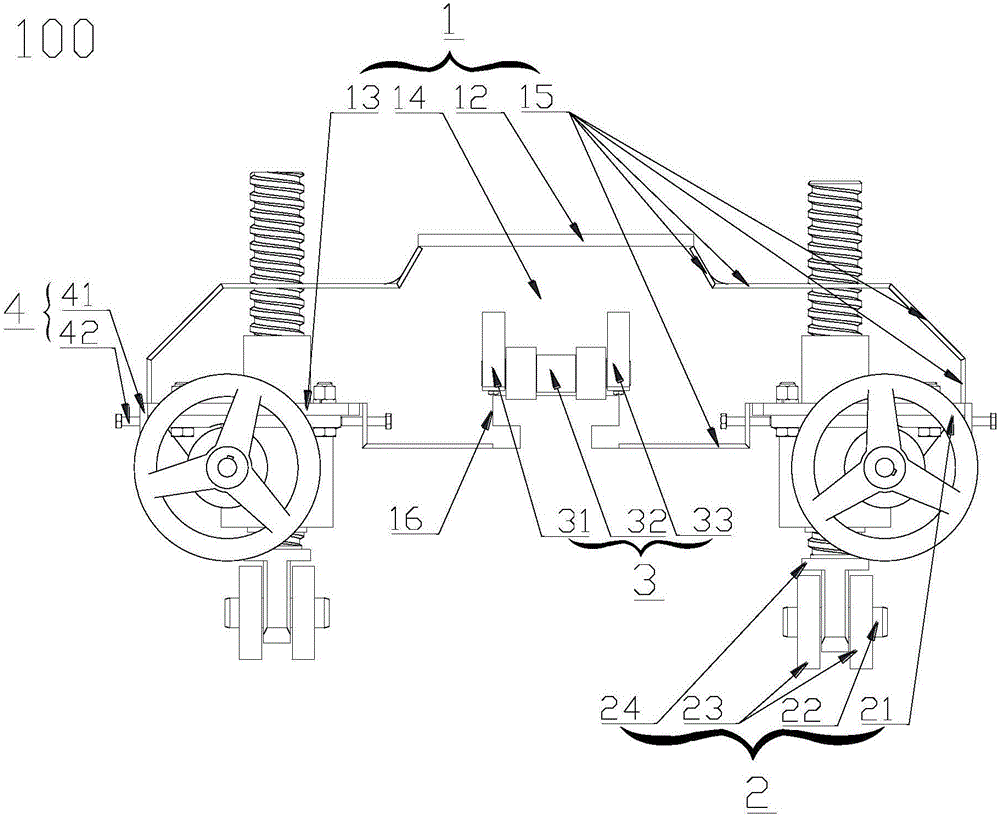

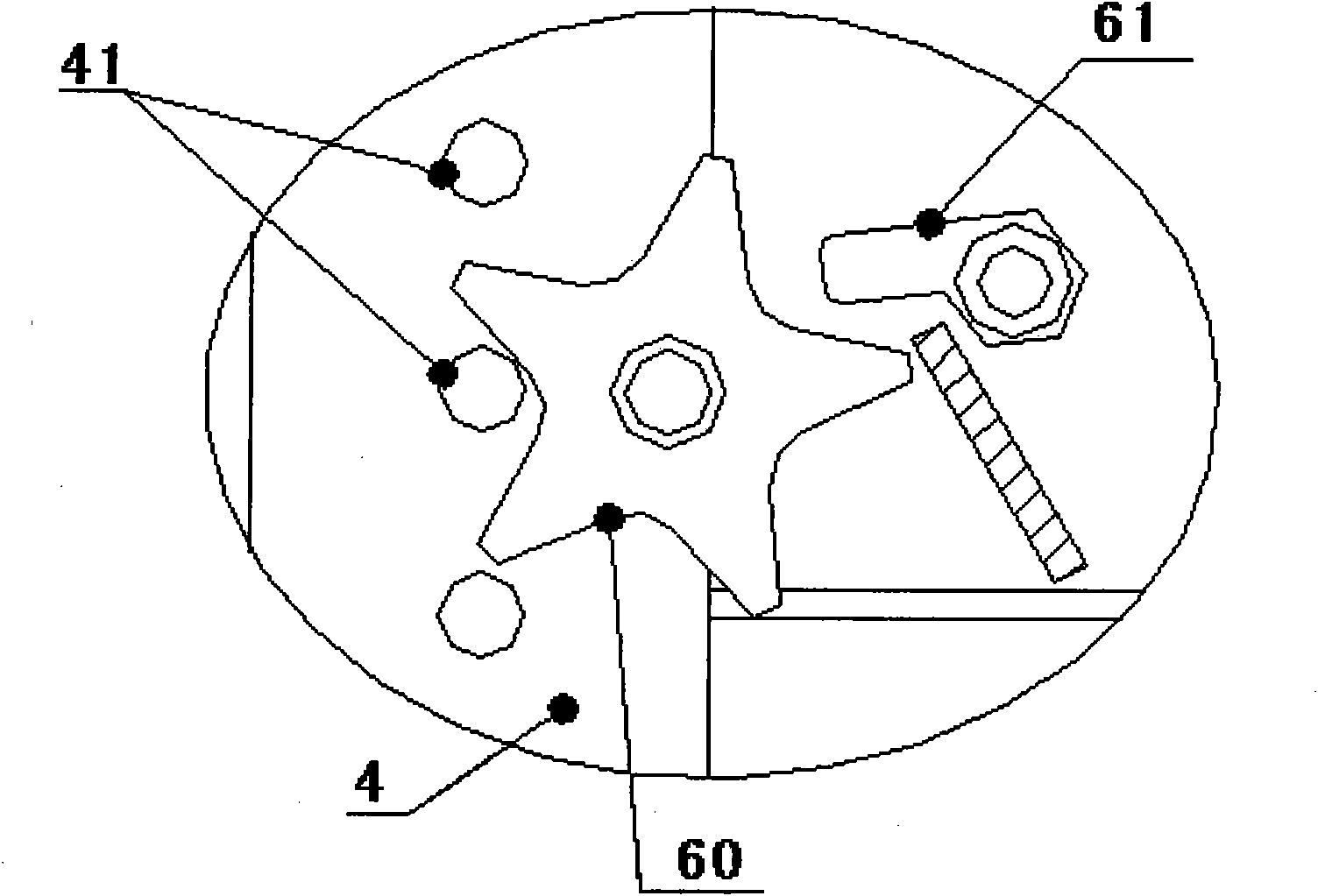

Turbine screw type continuous-adjustment supporting device for hydraulic climbing formwork system

ActiveCN106049857AImprove work efficiencyReduce labor intensityForms/shuttering/falseworksJackscrewEngineering

The invention provides a turbine screw type continuous-adjustment supporting device for a hydraulic climbing formwork system and belongs to the field of building construction. By the adoption of the turbine screw type continuous-adjustment supporting device for the hydraulic climbing formwork system, the problems that according to an existing lower supporting device, during climbing of a frame body of the hydraulic climbing formwork system, a temporary auxiliary jack needs to be arranged repeatedly, and resetting is needed are solved. A lifting screw is driven to move linearly along the axis of the lifting screw through two rotating mechanisms, namely a worm gear and a thread pair, of a turbine screw lifting machine by rotating a hand wheel, so that the purpose of support adjustment is achieved; wheels are installed at one ends of supporting legs, so that the effect that the wheels abut against a wall all the time in the climbing process is ensured, and the safety of a climbing frame body is guaranteed; and an interval adjustment mechanism can be used for adjusting the distance between two turbine screw lifting machines so that the supporting device can bypass small obstacles on a climbing advancing path. By the adoption of the technical scheme, potential safety hazards and various resource waste caused by repeated arrangement of the temporary auxiliary jack are avoided, and the requirements for zero risk, high efficiency and low cost of modern building construction are better met.

Owner:SHANGHAI CONSTRUCTION GROUP

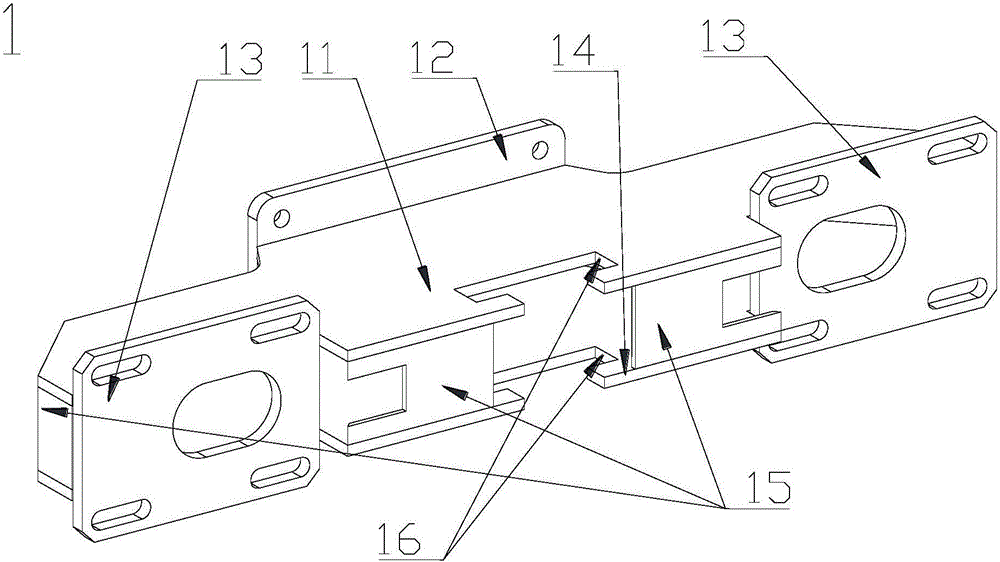

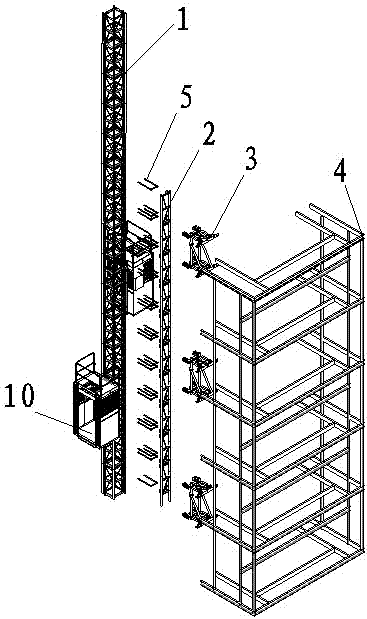

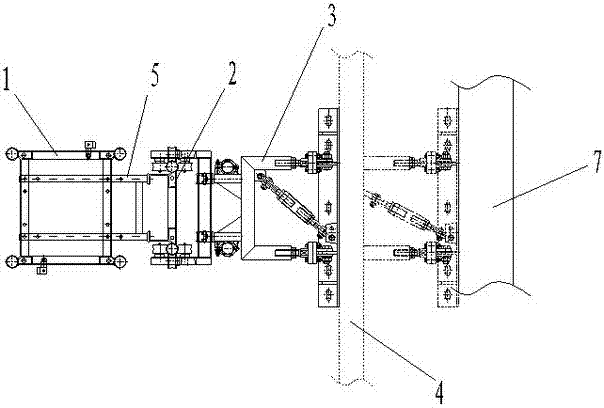

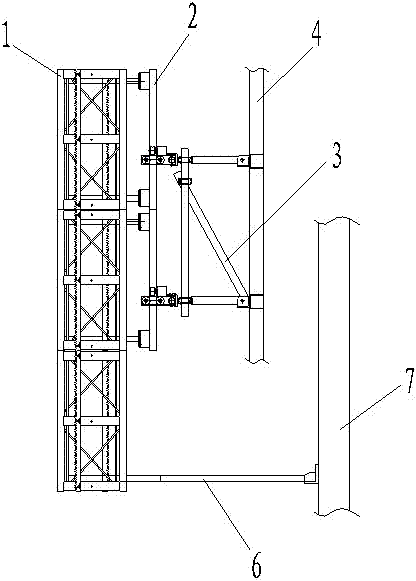

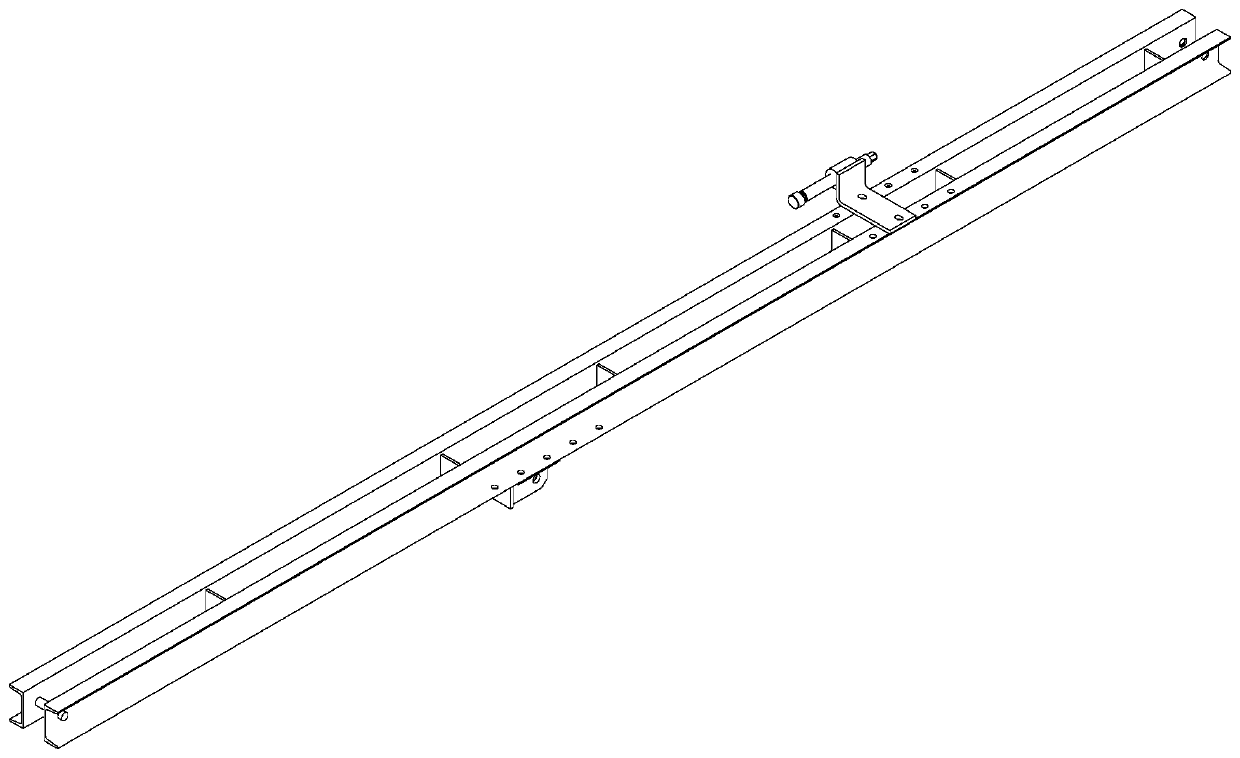

Connecting structure of construction hoist and building climbing formwork frame

The invention provides a connecting structure of a construction hoist and a building climbing formwork frame. The structure is composed of a main guide rail frame, an auxiliary guide rail frame, connecting arms, a fixed attachment frame, rolling attachment frames and the like. One side of the auxiliary guide rail frame is connected with the main guide rail frame through the connecting arms, the other side of the auxiliary guide rail frame is connected with the rolling attachment frames, the rolling attachment frames are fixedly connected with the building climbing formwork frame, one end of the fixed attachment frame is connected with the main guide rail frame, the other end of the fixed attachment frame is connected with a building wall, the auxiliary guide rail frame is composed of sheet standard joints, the height of the auxiliary guide rail frame is fixed, the number of sets of the rolling attachment frames is one or three, and idler wheels are arranged on the rolling attachment frames. According to the connecting structure of the construction hoist and the building climbing formwork frame, the construction hoist can move upwards to work on the top of the climbing formwork frame in a building in which the climbing formwork frame is used, and personal or materials can be sent to required floors.

Owner:GUANGZHOU JING LONG ENG MACHINERY

Hand wheel type online continuous adjustment lower supporting device used for hydraulic climbing formwork system

ActiveCN106121216AImprove work efficiencyReduce labor intensityForms/shuttering/falseworksJackscrewEngineering

The invention provides a hand wheel type online continuous adjustment lower supporting device used for a hydraulic climbing formwork system and belongs to the field of building construction. The hand wheel type online continuous adjustment lower supporting device is used for solving the problems that in the climbing process of a framework body of the hydraulic climbing formwork system, a temporary auxiliary jack needs to be repeatedly arranged for an existing lower supporting device, and repeated arrangement is conducted. Hand wheels are rotated to drive lead screws to rotate, thread pairs composed of square nuts and the lead screws are used for driving supporting legs to move linearly along the axes of the lead screws, and therefore the continuous adjustment purpose of the supporting legs is achieved. A wheel is installed at one end of each supporting leg, and it can be guaranteed that in the climbing process, the wheels jack a wall face all the time, and the safety of the formwork body climbing process is guaranteed. By the adoption of the provided lower supporting device capable of being continuously adjusted on line for the hydraulic climbing formwork system, potential safety hazards caused by repeated arrangement of the temporary auxiliary jack and waste of time and resources are avoided, and the requirements for low risks, high efficiency and low cost of modern building construction are better met.

Owner:SHANGHAI CONSTRUCTION GROUP

Full-automatic hydraulic climbing formwork system and using method thereof

ActiveCN106049856ABeneficial technical effectImprove climbing efficiencyForms/shuttering/falseworksControl systemPower control system

The invention provides a full-automatic hydraulic climbing formwork system and a using method thereof and belongs to the field of building construction. An operator can achieve free switching of two states of an up-down automatic reversing anti-falling device by operating a hydraulic power control system, switching between the guide rail climbing state and the frame body climbing state is conducted automatically, and manual rotation of the reversing anti-falling device by workers is avoided; and after the full-automatic hydraulic climbing formwork system is installed for the first time, a lower movable supporting leg is adjusted by the operator to abut against the surface of core cylinder concrete, the lower movable supporting leg can roll upwards along with the climbing of a whole frame body so as to support the whole frame body, and the preparation work of arranging a temporary support repeatedly every time before climbing is conducted is avoided. By the adoption of the full-automatic hydraulic climbing formwork system and the using method thereof, the construction efficiency can be improved, and meanwhile, the probability of occurrence of safety accidents of high-altitude falling and the like can be lowered.

Owner:SHANGHAI CONSTRUCTION GROUP

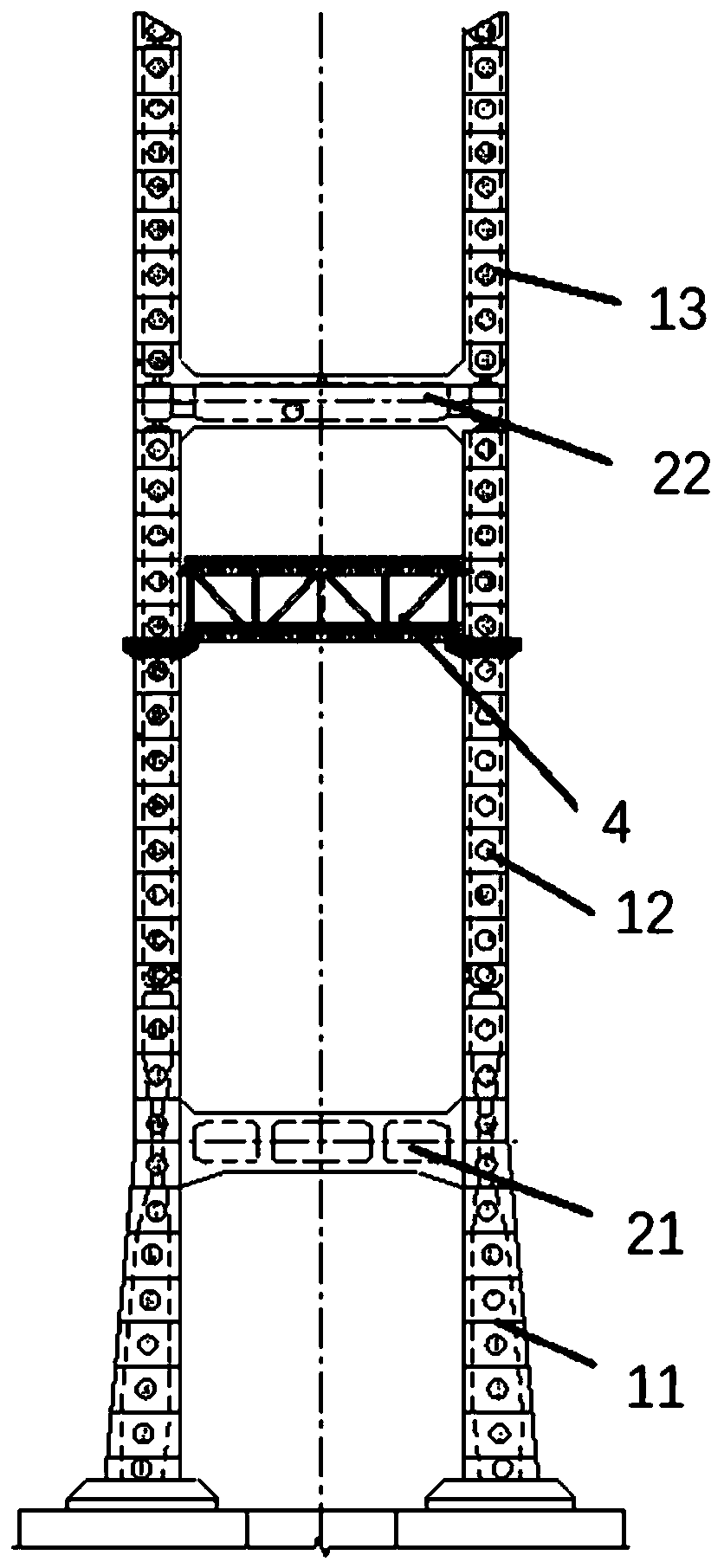

Electric climbing formwork system

ActiveCN101979800ARealize alternate load-bearing and mutual climbingRealize the function of anti-fallBuilding support scaffoldsControl systemEngineering

The invention relates to an electric climbing formwork system, which is used for the construction of cast-in-place concrete walls. The electric climbing formwork system comprises a formwork system, a branch formwork support body, an outrigger, and parts such as a working platform, climbing equipment, a wall-attached support, a guide rail, an anti-dropping device, a control system and the like, wherein the guide rail is in longitudinal sliding connection with the wall-attached support and the outrigger respectively; the branch formwork support body and the outrigger are in transverse sliding connection; the climbing of the formwork system and the working platform is realized through alternative rising and bearing in place of the guide rail and the outrigger; mold opening and mold closing of the formwork system are realized through the sliding of the branch formwork support body and the outrigger; the climbing equipment consists of a chain and an electric block; the chain encircles the upper end and the lower end of the guide rail and the outrigger by a pulley block; and the electric block rotates positively and reversely to drive the outrigger and the guide rail to rise alternatively and bear in place so as to realize the climbing of the formwork system and the working platform. The invention has the advantages that: the electric climbing formwork system is convenient to use, is easy to assemble and disassemble and has high safety performance.

Owner:北京韬盛科技发展有限公司

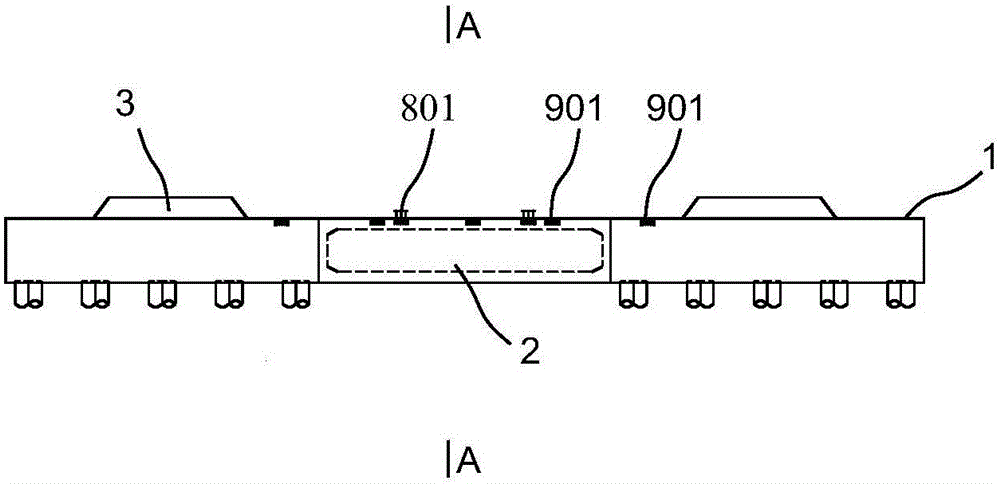

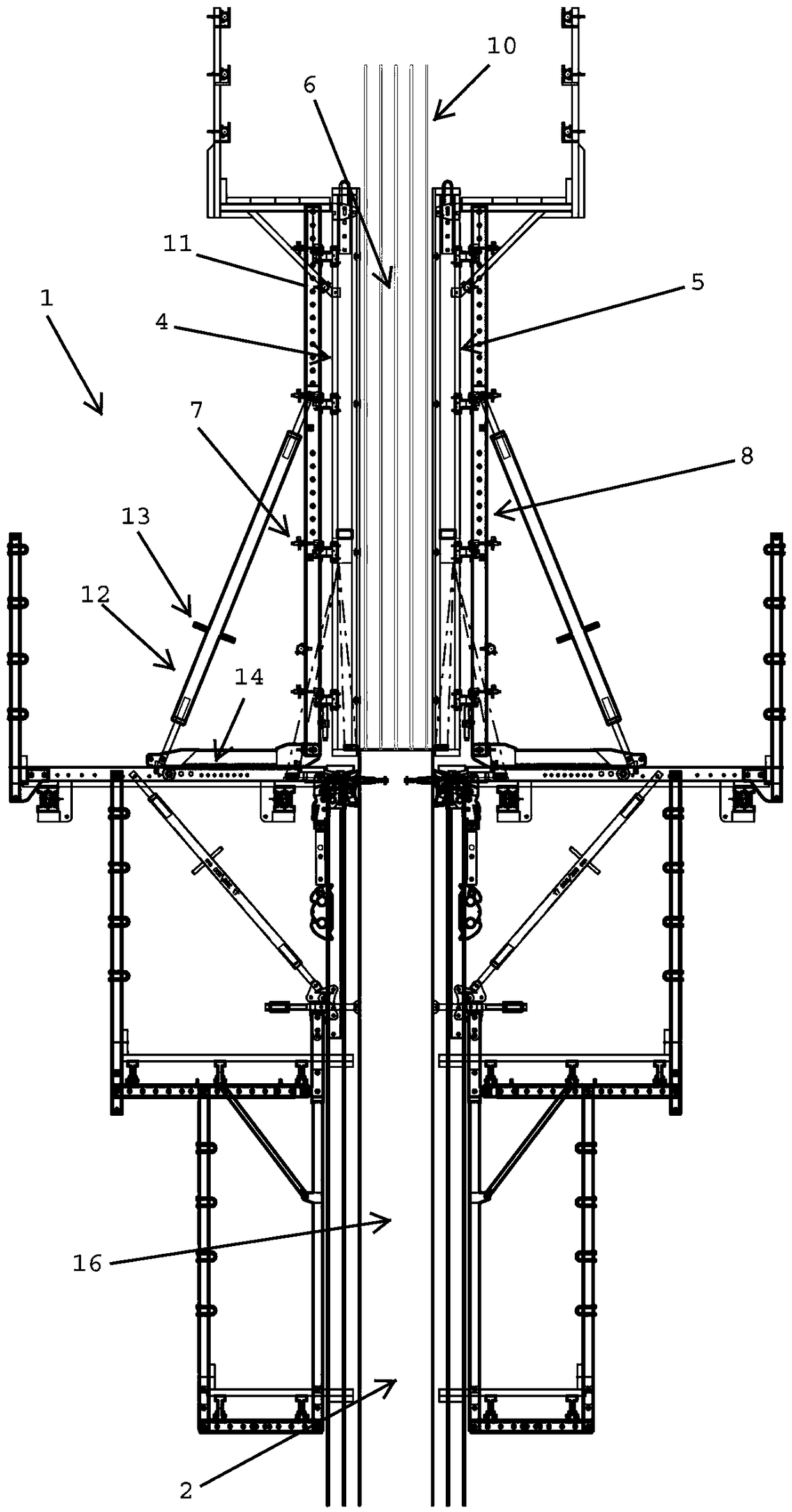

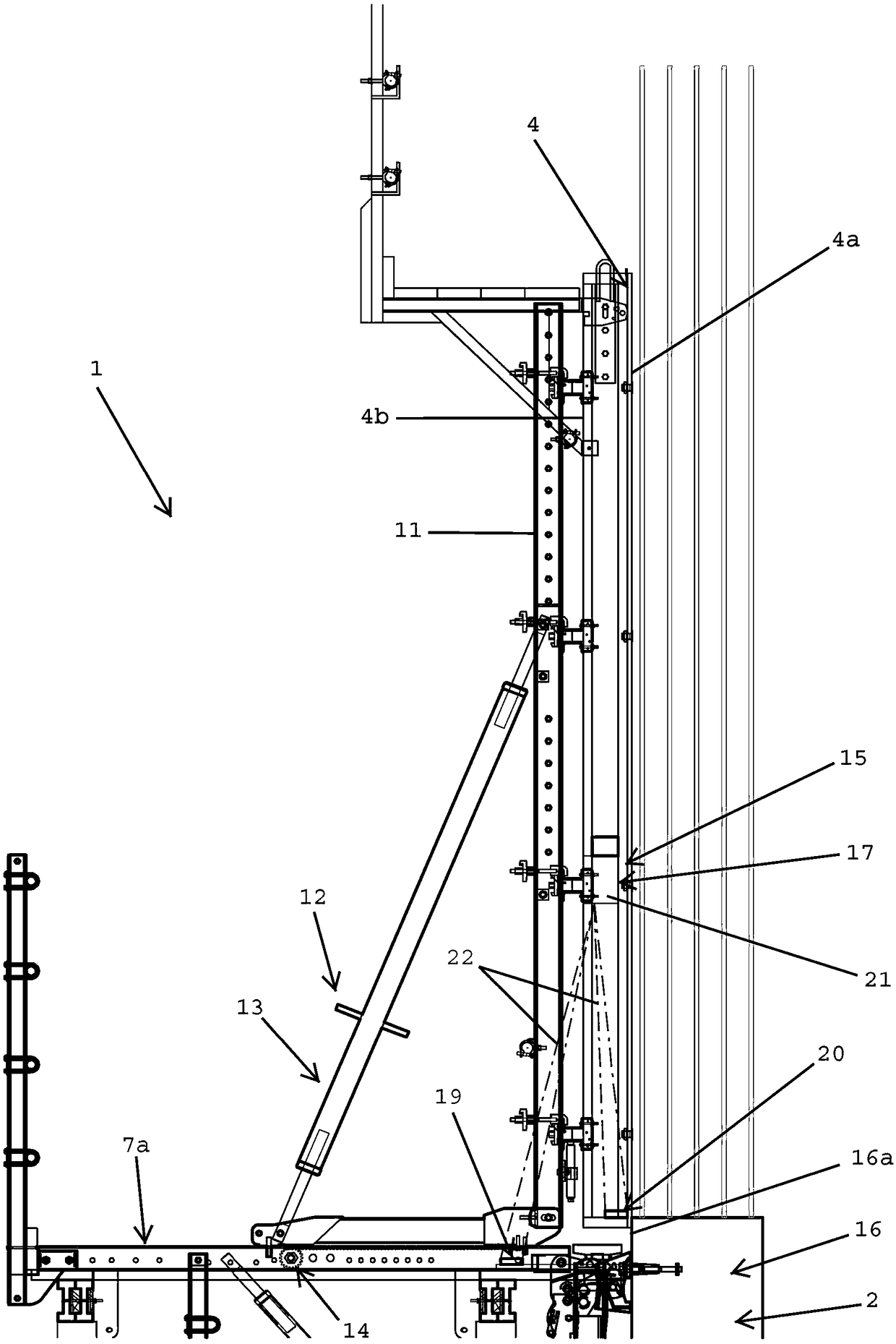

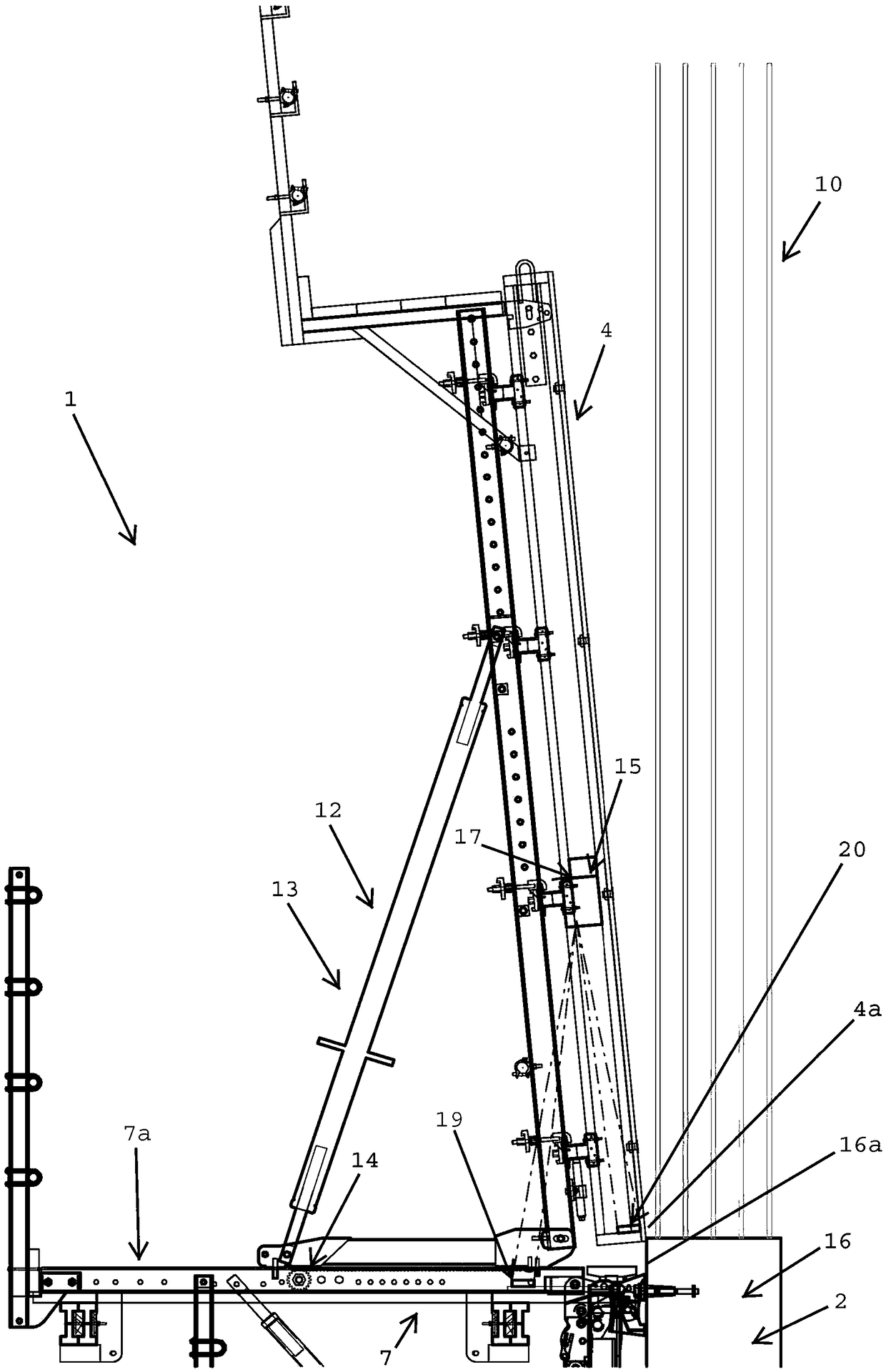

Climbing formwork and method for erection of a concrete structure

ActiveCN109154159AHigh measurement accuracyReduce measurement impactAngle measurementSurveying instrumentsEngineeringCasting

A climbing formwork (1) and a method for erection of a concrete structure by successively casting a plurality of casting segments (16), the climbing formwork comprising - at least a first form element(4) for delimiting a cavity (6) to receive concrete for forming an uppermost casting segment, the first form element (4) having an upper end and a lower end, - a first support structure (7) to support the first form element (4), - a first tilt sensor (15) for measuring a tilt of the first form element (4), - a first measuring unit (17) for measuring a horizontal distance between the lower end ofthe outer surface (4a) of the first form element (4) and the upper end of the outer surface (16a) of the previous casting segment (16), - a processing unit (18) communicating with the first tilt sensor (15) and the first measuring unit (17), the processing unit (18) being arranged for calculating a target tilt of the first form element (4) using the measurement of the horizontal distance between the lower end of the outer surface (4a) of the first form element (4) and the upper end of the outer surface (16a) of the previous casting segment (16), the processing unit (18) further being arrangedfor determining a deviation between the actual tilt and the target tilt of the first form element (4).

Owner:DOKA

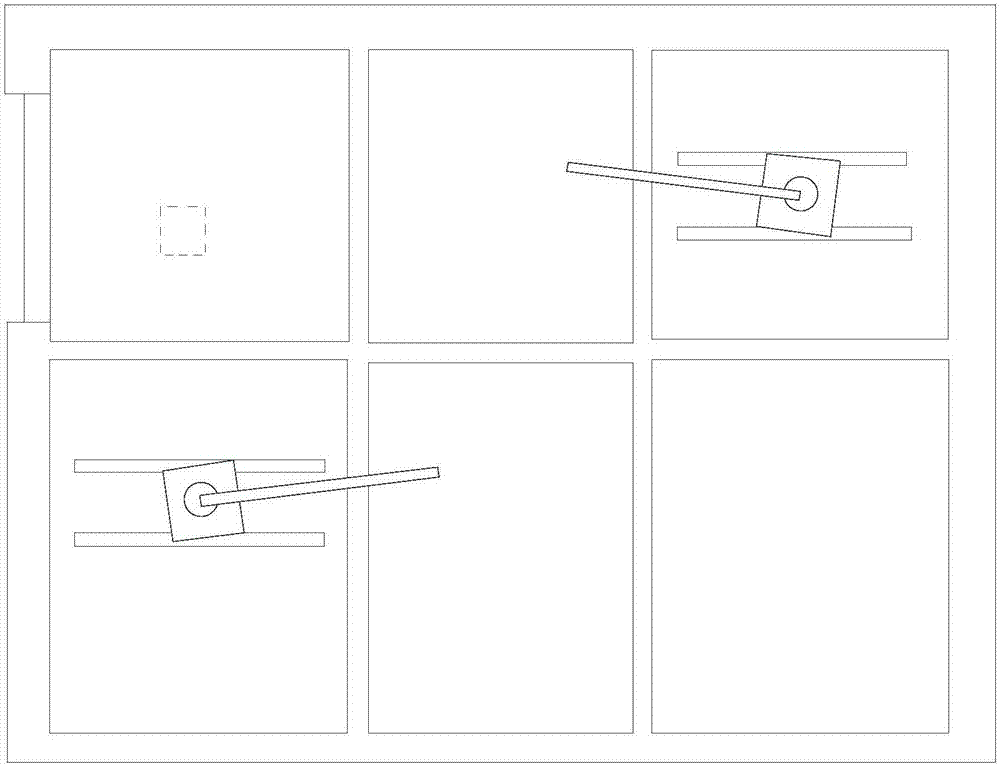

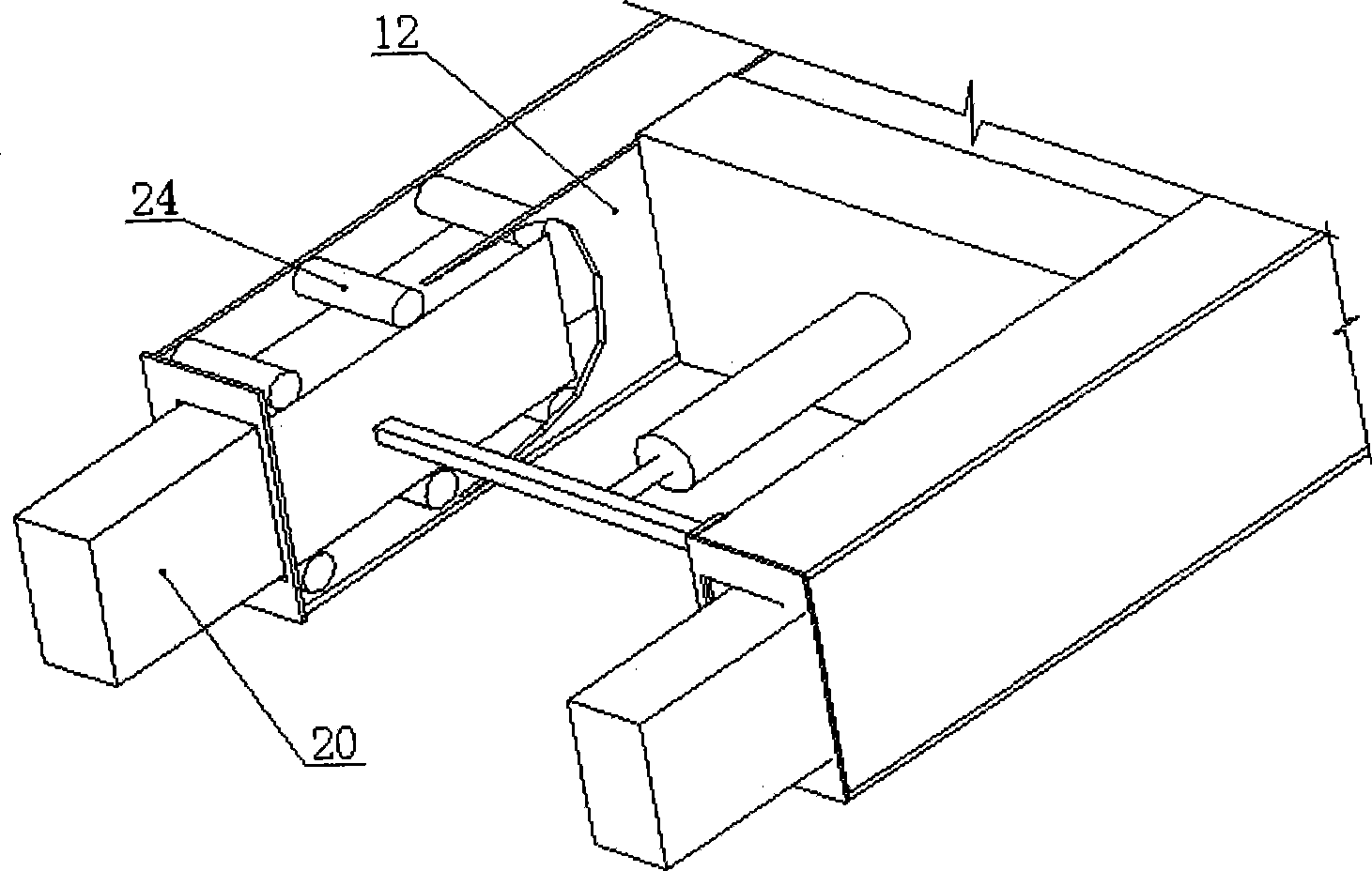

Template mutually lifting climbing apparatus and method

ActiveCN101457587ASimple structureImprove work efficiencyForms/shuttering/falseworksEngineeringPower equipment

The invention relates to a climbing formwork device with mutually-lifting formwork, comprising a formwork, a supporting body used for supporting the formwork and a power equipment which is used for driving the formwork to climb, wherein, the formwork is provided with a retractable cone-shaped supporting body which locates the formwork and bears dead load of the formwork, live construction load and wind load; the supporting body comprises a supporting rod which supports the formwork at one end of the formwork and tightens the formwork on a vertical backridge of the wall body by combining the supporting rod; during the process of operation, a lifting device provides the formwork with the power so that the formwork can climb; the supporting role supports the formwork at one end of the formwork so as to ensure that the formwork remains in a fixed position, cooperates with the vertical backridge to fix the formwork in a certain position and is positioned on and connected with the wall body by the retractable cone-shaped supporting body and a split bolt; is the formwork mutually serves as a motion orbit, namely, the non-climbing formwork serves as the motion orbit of the climbing formwork. The device has the advantages that the structure is simple and the corresponding operational platform is unnecessary to be too large during practical use, thus saving space, facilitating operation and having high working efficiency.

Owner:JIANGSU JIANGDU CONSTR GRP

Building cornice double-water-drip-line formwork and construction method thereof

InactiveCN103938857ASimple processEasy to masterForms/shuttering/falseworksBuilding material handlingArchitectural engineeringCornice

The invention relates to the field of architectural engineering construction, and particularly discloses a building cornice double-water-drip-line formwork and a construction method thereof. The building cornice double-water-drip-line formwork comprises a building outer cornice formwork body, and is characterized in that a groove is formed in the bottom formwork edge of the building outer cornice formwork body, and an aluminum alloy bar is arranged in the center of the groove. According to the building cornice double-water-drip-line formwork and the construction method thereof, working procedures are simple, the technology is easy to grasp, two small working procedures are added in the formwork assembling process, the occupied time is not large, and due to the fact that the formwork and a structural part are cast in situ through one-time forming, the phenomena of disengaging and cracking in a later period can be avoided.

Owner:SHANDONG ELECTRIC POWER TRANSMISSION & SUBSTATION ENG CO

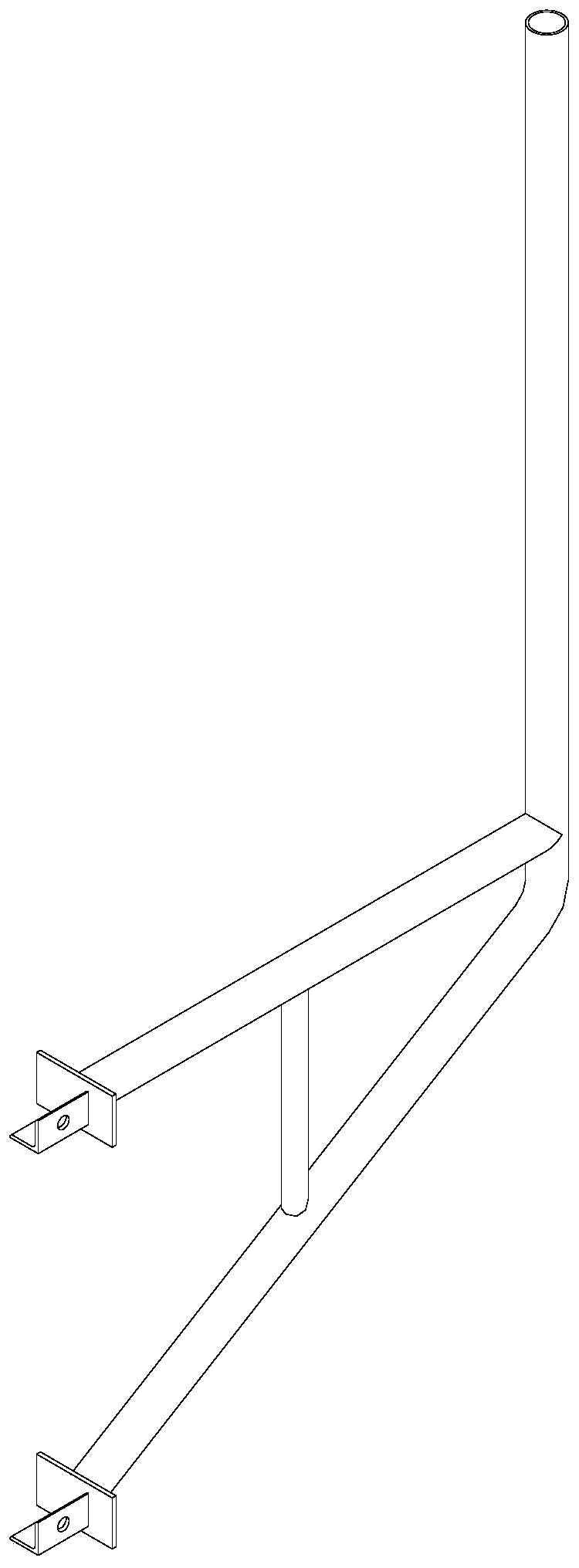

Cantilever formwork for concrete construction and construction method thereof

InactiveCN109989348AEasy constructionFast constructionBridge erection/assemblySurface finishFalsework

The invention discloses a cantilever formwork for concrete construction and a construction method thereof, and belongs to the technical field of bridge construction. The problems that construction iscomplicated, cost is high and concrete surface smoothness is low when the outer surfaces of all supporting columns of a bridge are constructed are solved. The cantilever formwork comprises a cantilever formwork support, an anchoring assembly and a planar formwork and is a single-sided wall body climbing formwork used for formwork construction of concrete linings and other structures of dams, piers, concrete retaining walls, tunnels and underground plants, the formwork is easy and rapid to construct and economical, the concrete surface is smooth, the support, the formwork and construction loadsare all borne by an embedded piece assembly, no scaffold needs to be additionally erected, and the formwork is suitable for aloft operation; by means of an anchoring device, the formwork is closely attached to a concrete wall surface, and mortar leakage and slab end faulting are prevented; an inclined strut is arranged on the cantilever support, and the perpendicularity of the formwork can be conveniently adjusted; all connectors are standard, universality is high, and a hanging platform is arranged at the lower portion of the formwork and can be used for assembling and disassembling embeddedpieces and processing the concrete surface.

Owner:中交中南工程局有限公司 +1

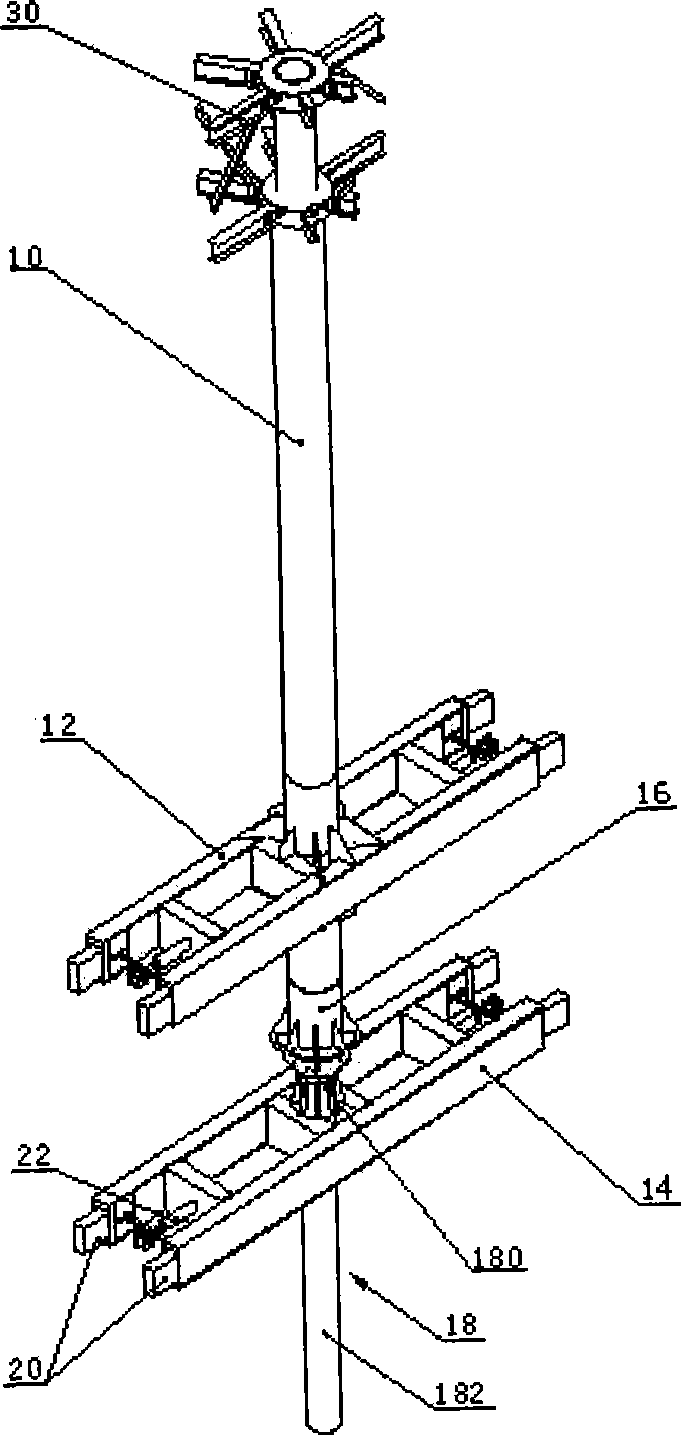

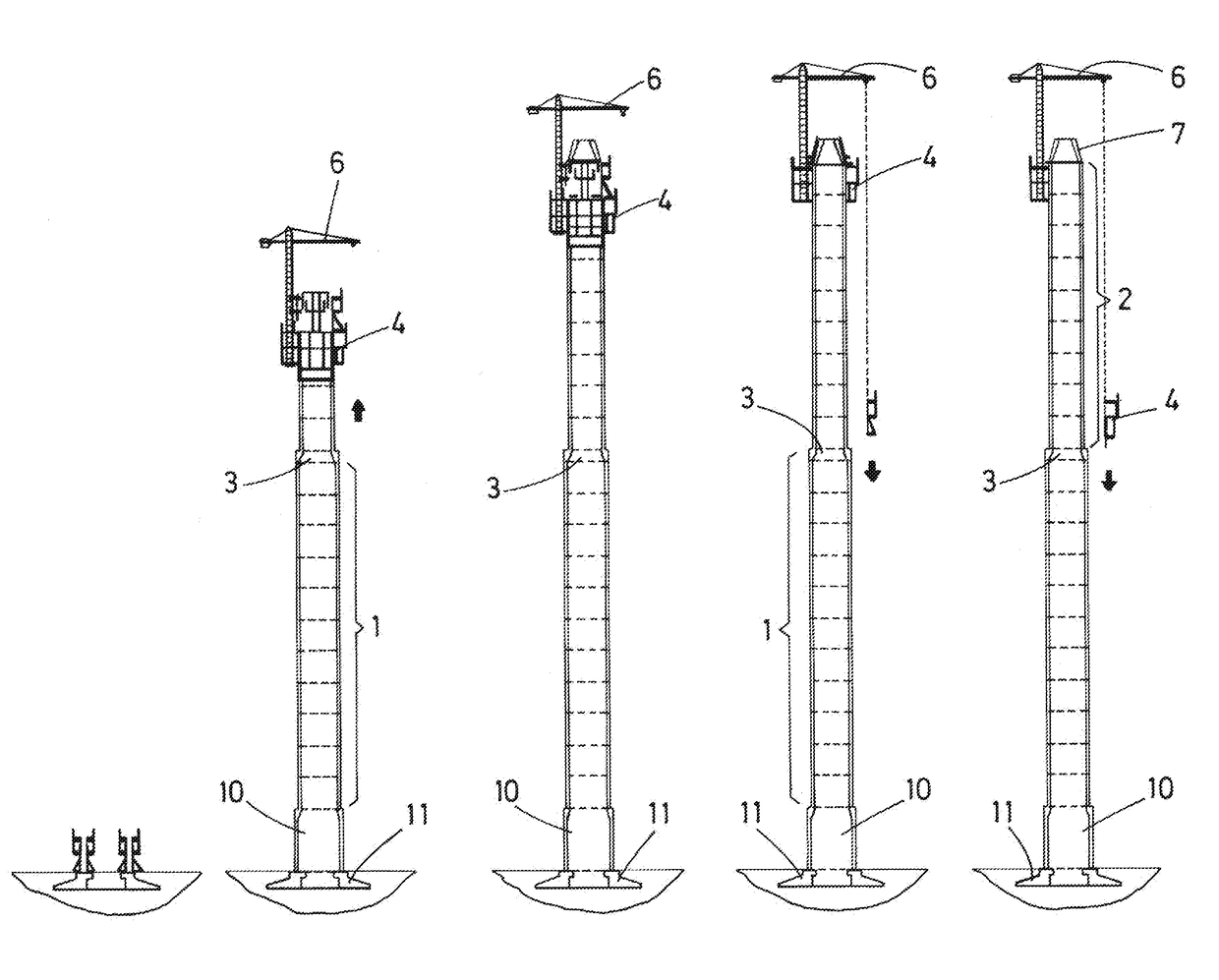

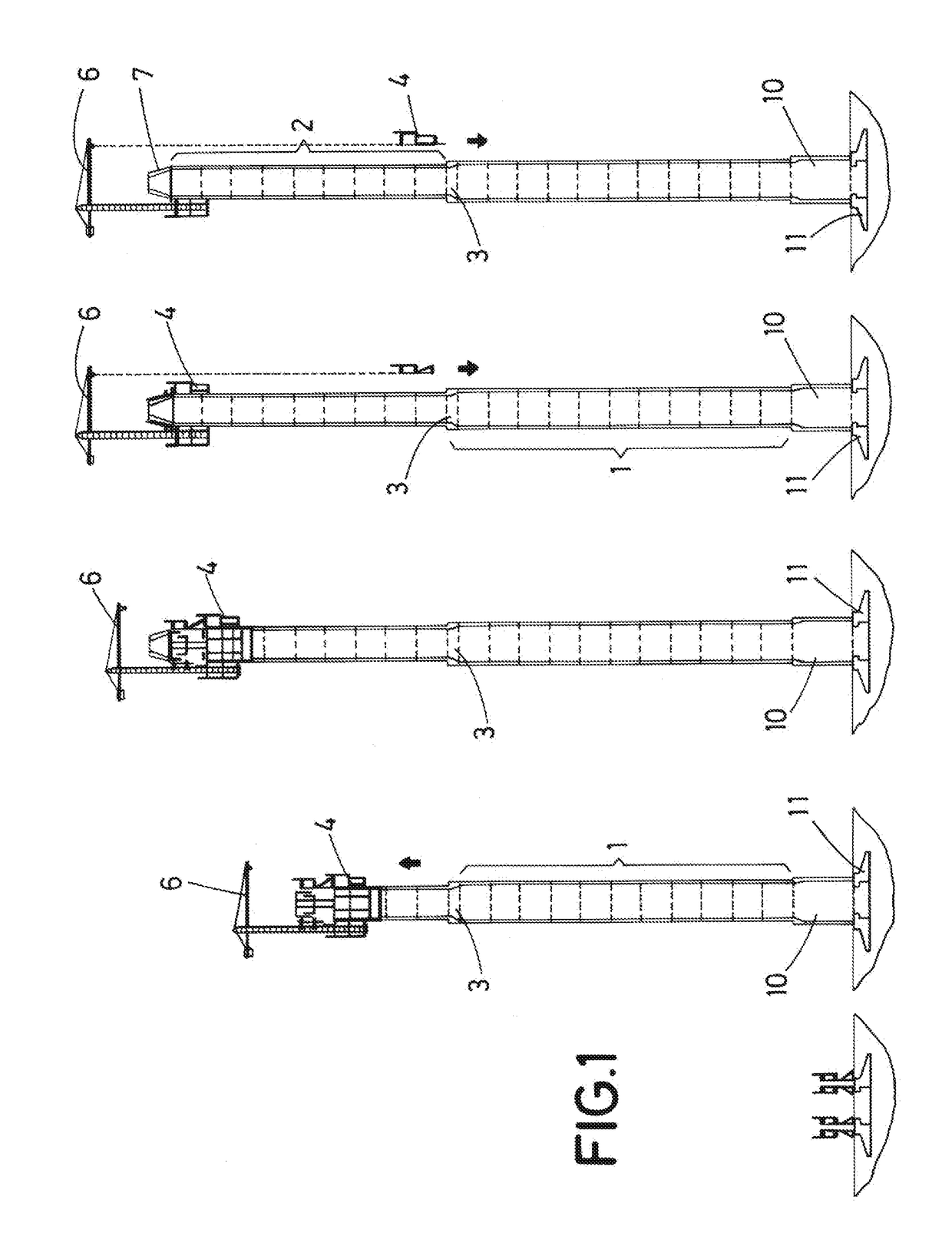

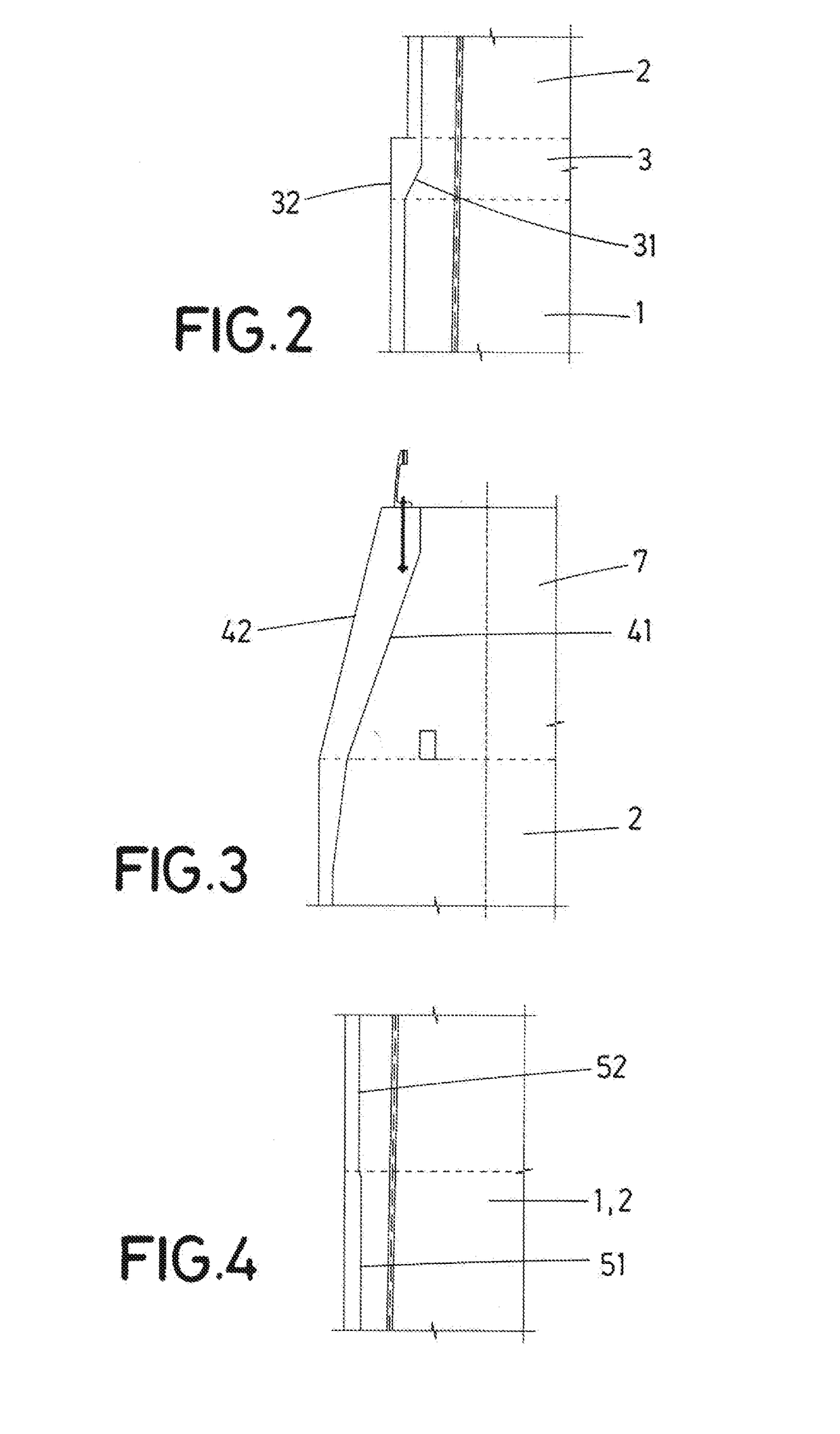

Concrete towers manufacturing method for wind turbines and concrete tower for wind turbine

The present invention relates to a manufacturing process in situ of concrete towers for wind turbines which enables executing a design of concrete tower manufactured in situ by means of climbing formwork, which reduces the execution time of the concrete tower, where the invention also relates to the associated concrete tower for wind turbine.

Owner:NORDEX ENERGY SPAIN SA

Self-angle-changing hydraulic-climbing formwork system

PendingCN108678365AReasonable structural designEasy to operateForms/shuttering/falseworksHydro energy generationFloor slabEngineering

The invention relates to the technical field of building construction and provides a self-angle-changing hydraulic-climbing formwork system. The self-angle-changing hydraulic-climbing formwork systemcomprises a climbing rack system and floor supports and is characterized in that each floor support comprises a mounting seat and a slide part in slide fit with the mounting seat, one end of the slidepart is fixedly connected with a hanging seat, and a displacement adjusting device is arranged between the mounting seat and the slide part; the climbing rack system comprises a vertically arranged climbing guide rail which is supported on the hanging seats of at least two floor supports. The self-angle-changing hydraulic-climbing formwork system has the advantages that by adjusting the displacement adjusting devices, the inclination angle of the climbing guide rail can be changed so as to change the inclination angle of a form board system mounted on the climbing rack system to allow the form board system to adapt to the inner inclination, outer inclination and inner and outer inclination turning change of an outer frame cylinder, operation can be performed without the assistance of a tower crane, and high construction efficiency is achieved.

Owner:华西工程科技(深圳)股份有限公司 +1

Construction method for curved surface arc-shaped concrete tower

InactiveCN106522104AEasy to adjustImprove precision controlBridge structural detailsBridge erection/assemblyCable stayedEngineering

The invention discloses a construction method for a curved surface arc-shaped concrete tower. The curved surface arc-shaped concrete tower comprises double limb tower columns and tower top closure sections. Through a hydraulic climbing formwork method, the double limb tower columns are constructed section by section and step by step along the tower column elevation. During construction of the double limb tower columns, one or more temporary cross struts are installed between the double limb tower columns, brackets are embedded in the upper end inner side walls of all the tower columns to serve as fulcrums, bailey beams are hoisted on the brackets to serve as support platforms of the tower top closure sections, and finally, through a scaffolding method, concrete layered pouring construction is conducted to complete tower closure. The construction method can be used for an extra large cable-stayed bridge double curved surface arc-shaped concrete tower, a curved surface adjustable template is matched with a hydraulic climbing formwork system for construction, operation is convenient, safety is high, the curved surface adjustable template is convenient to adjust, the tower column linetype and matching precision are controlled from the source, and precision control over main tower hoisting is convenient.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Angle-adjustable hydraulic inclined climbing framework

InactiveCN109184191AAchieve regulationSolve construction problemsForms/shuttering/falseworksEngineeringColumn structure

The invention discloses an angle-adjustable hydraulic inclined climbing framework, which comprises operating frames, guide rails, rotating frames and jacking devices, wherein the operating frames andthe guide rails are fixedly connected with a wall body through wall attachment devices; the rotating frames are erected in the operating frames and connected with the operating frames and the guide rails respectively, the rotating frames are arranged in the middle parts of the guide rails, rotating shafts are arranged at places where the rotating frames and the operating frames are connected, andthus, the rotating frames can perform rotary movement relative to the operating frames around the rotating shafts; and the base of the jacking device is connected with the guide rail, and the jackingpart of the jacking device is connected with the rotating shaft. Attachment to a large-angle inclined wall / column structure for climbing can be realized, the angle of the inclined climbing framework can be adjusted according to structure angle changes, the adjustment accuracy is low, the operating difficulty is large, construction of a wall / column structure with large-angle inclination and angle changes can be effectively solved, the application range of the climbing formwork is expanded, and the construction problem of an inclined stiff mega column is solved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com