Patents

Literature

417 results about "Cornice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In architecture, a cornice (from the Italian cornice meaning "ledge") is generally any horizontal decorative molding that crowns a building or furniture element – the cornice over a door or window, for instance, or the cornice around the top edge of a pedestal or along the top of an interior wall. A simple cornice may be formed just with a crown.

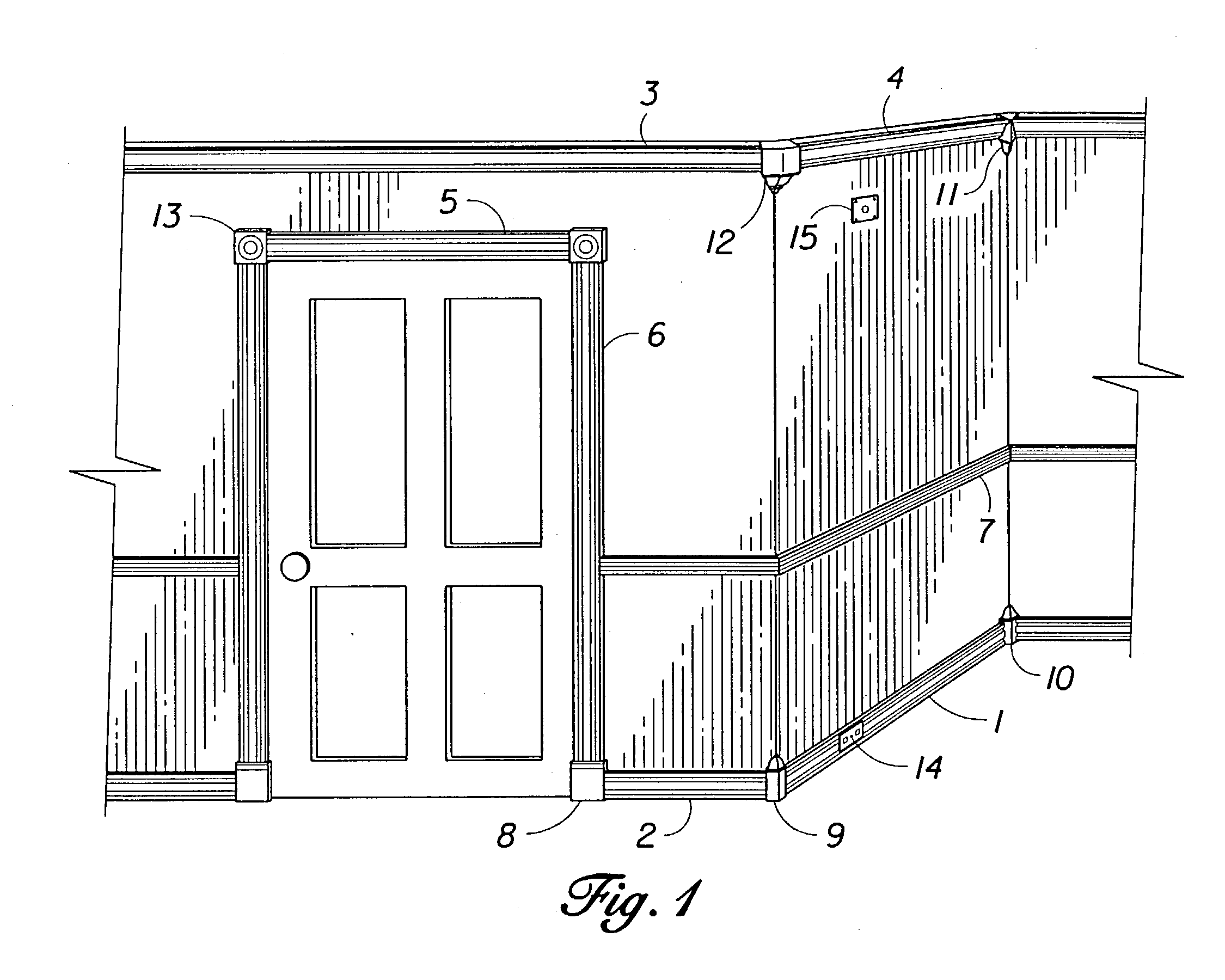

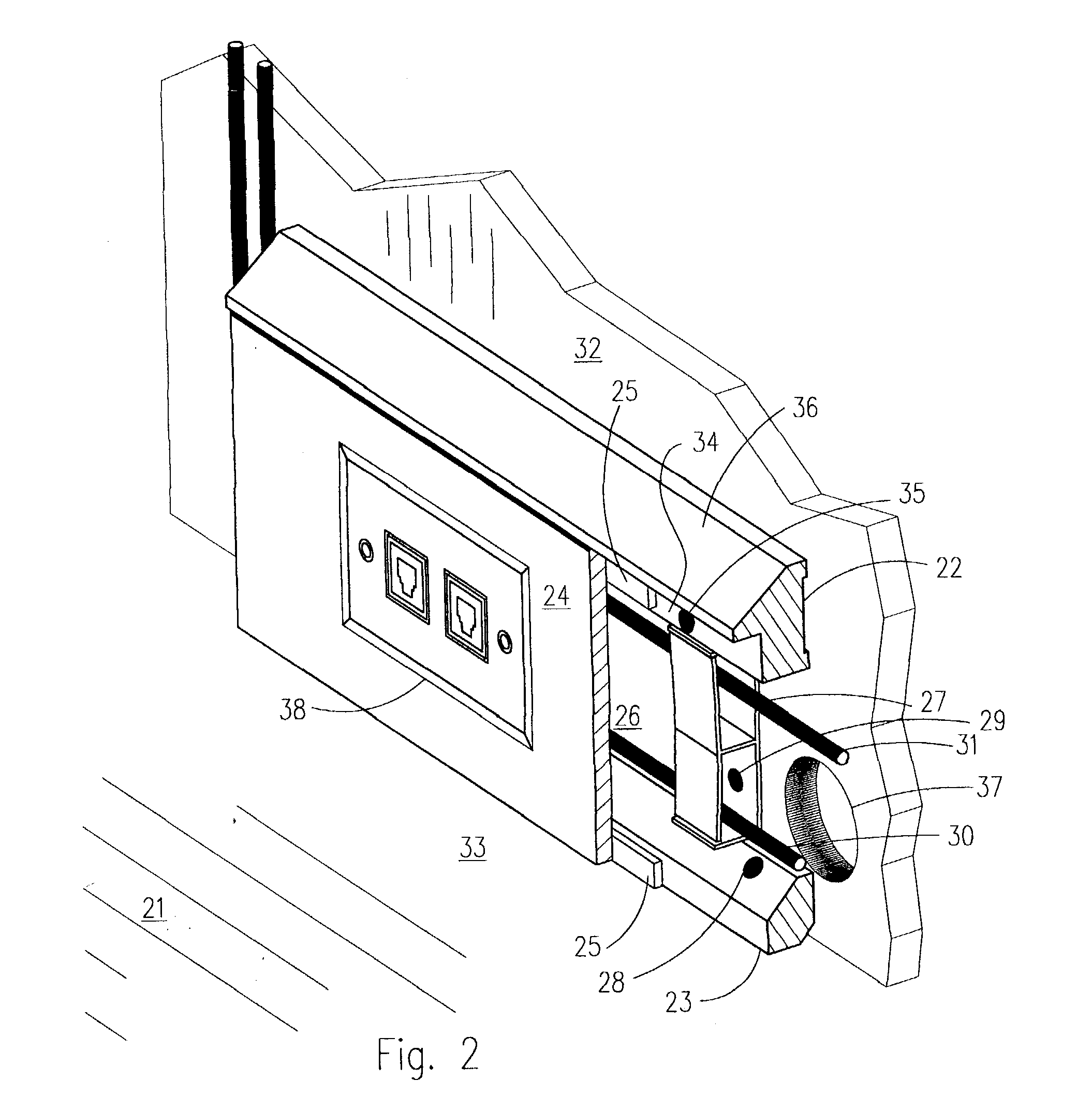

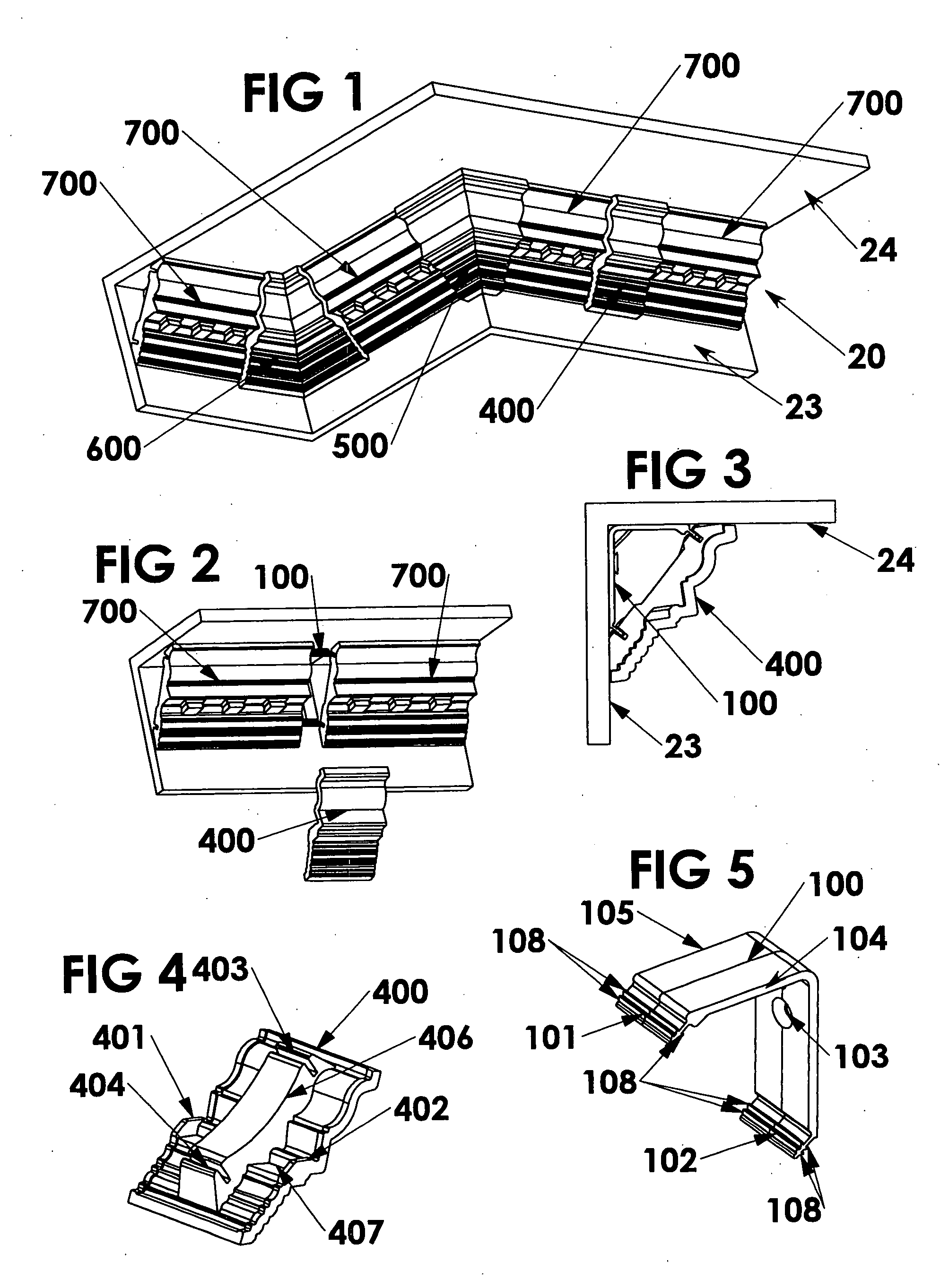

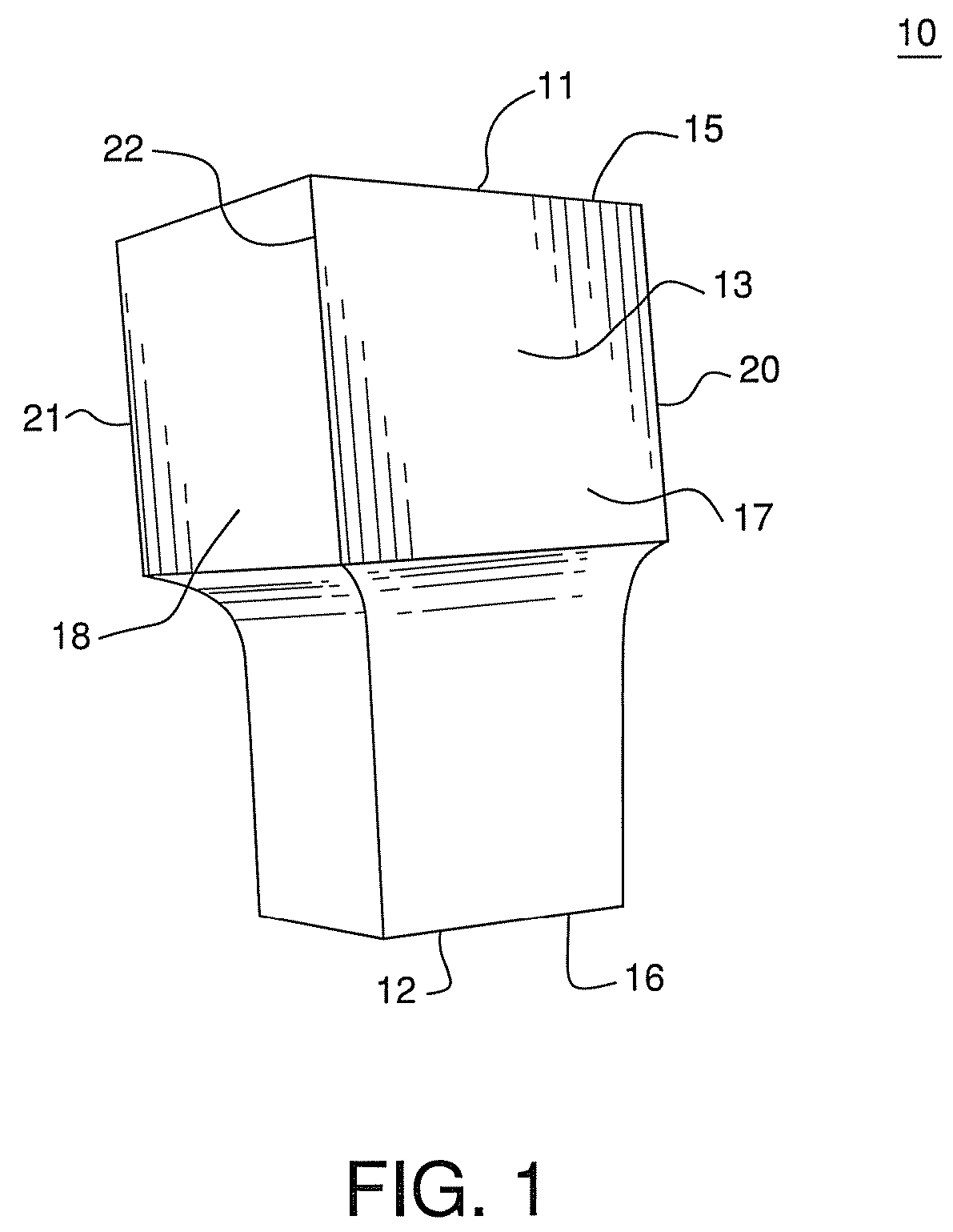

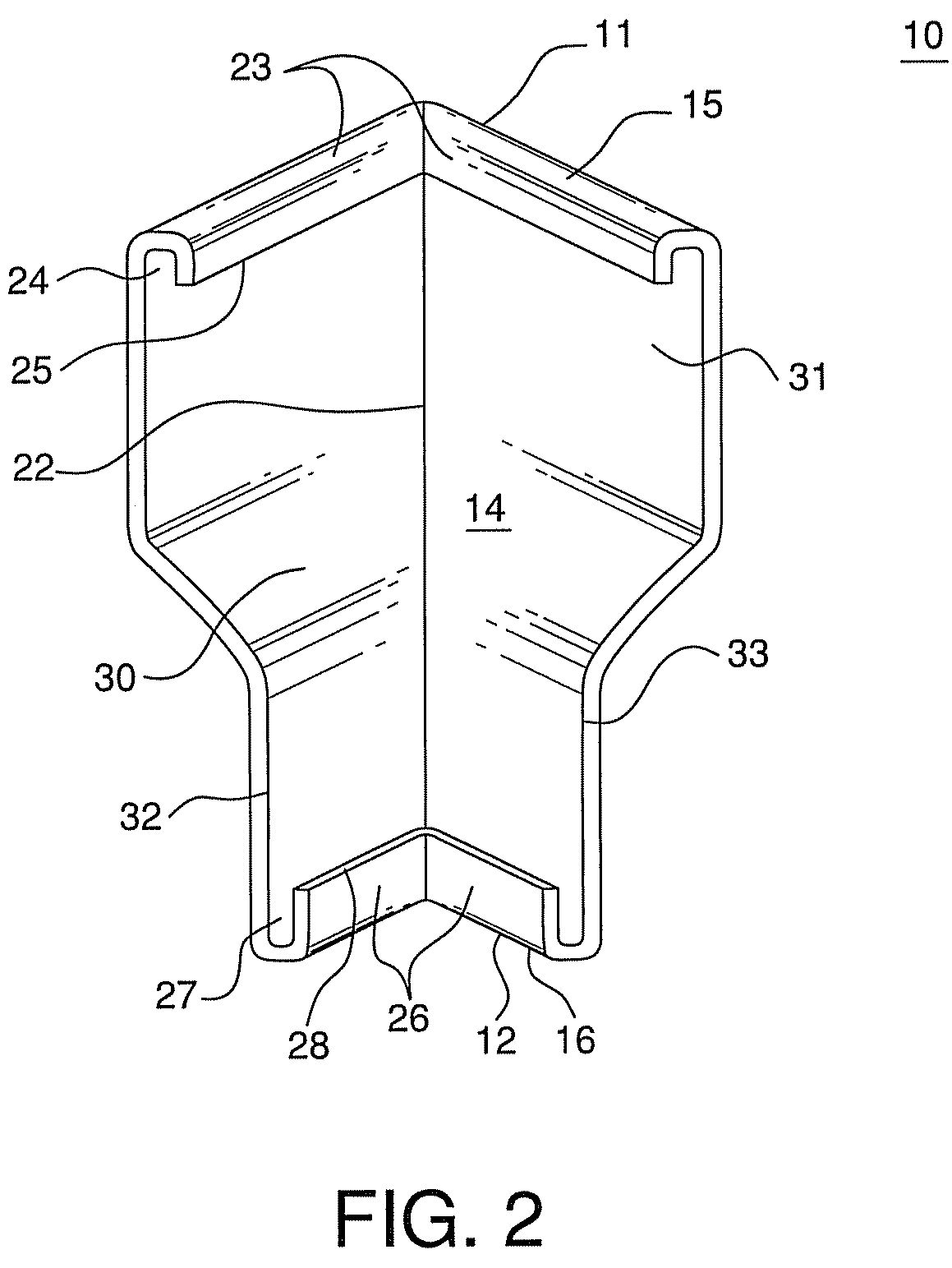

Architectural moldings for protecting, concealing and accessing indoor wiring and cables

A system of architectural moldings that, when installed, form a passage for electrical wiring, coaxial cables, fiber optic cables, and associated devices used in the transmission of low-voltage power, communication, and control signals. The architectural moldings may also be used to cover and improve the aesthetic appeal of pre-existing wiring raceways and conduits. The system as a whole may be installed during construction of new a home or building or when retrofitting an existing structure. The moldings can be removably mounted on the interior surfaces of residential and commercial structures in a manner that allows for easy removal and replacement of some or all of the molding without disturbing the enclosed wiring and cables or harming finished surfaces. The moldings may be made of wood, polyurethane, fiberboard, or any material that is suitable to manufacture pieces that resemble baseboards, cornice moldings, chair rails, casings, or other interior millwork for homes or commercial structures. The system of moldings greatly facilitates any upgrades or modifications to the number, type, or placement of wiring, cables, outlets, jacks, or associated devices.

Owner:SEAMANS JAMES D

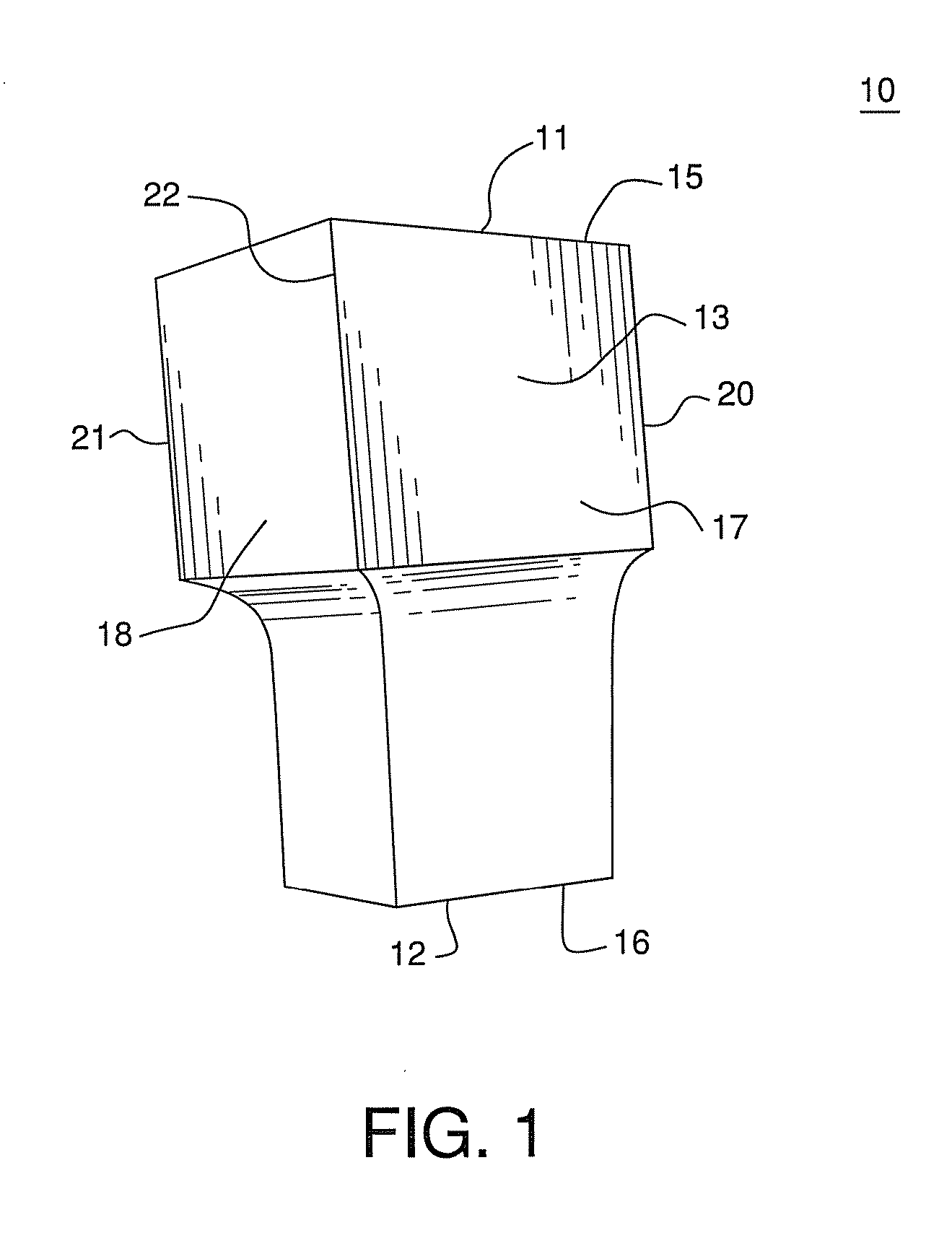

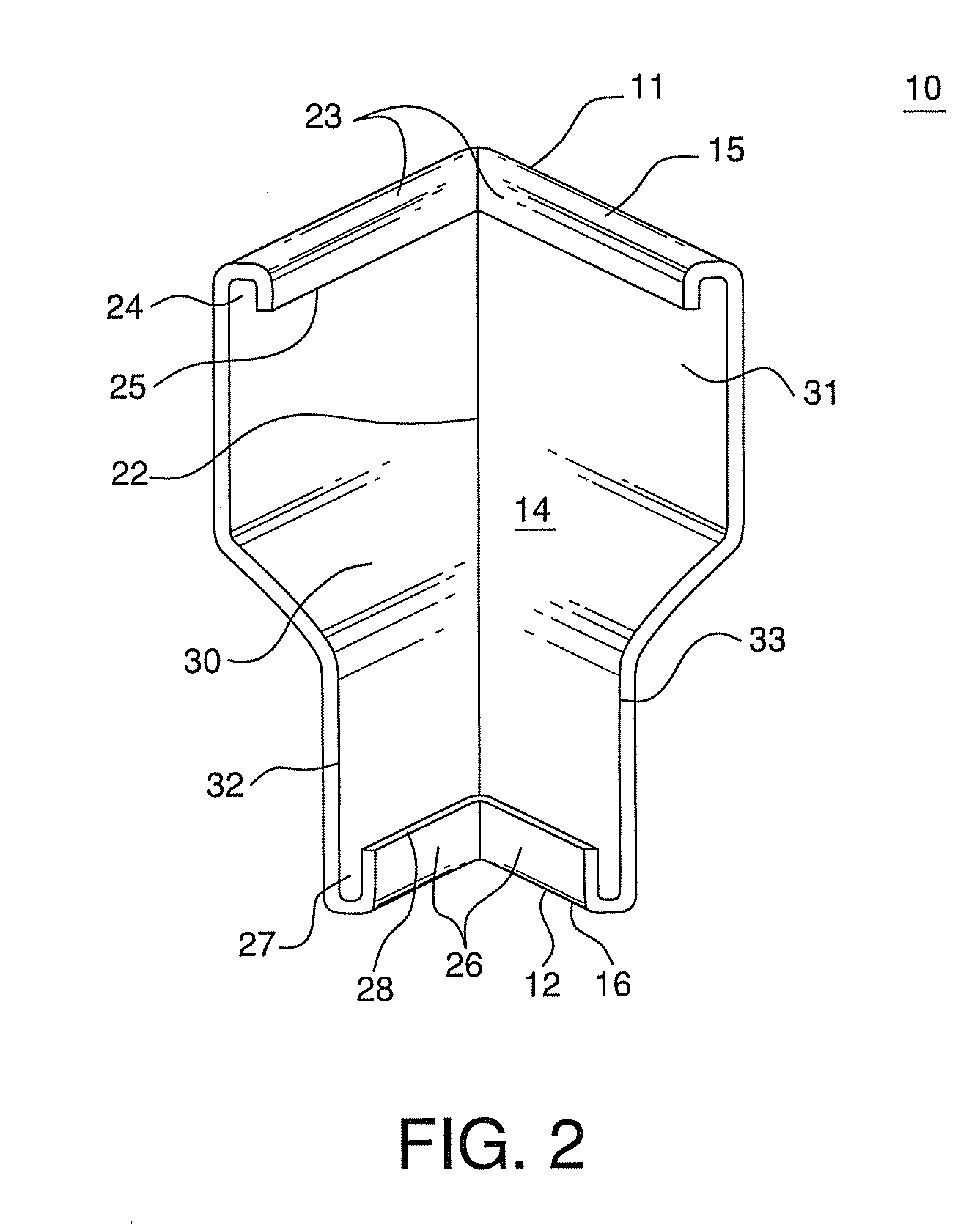

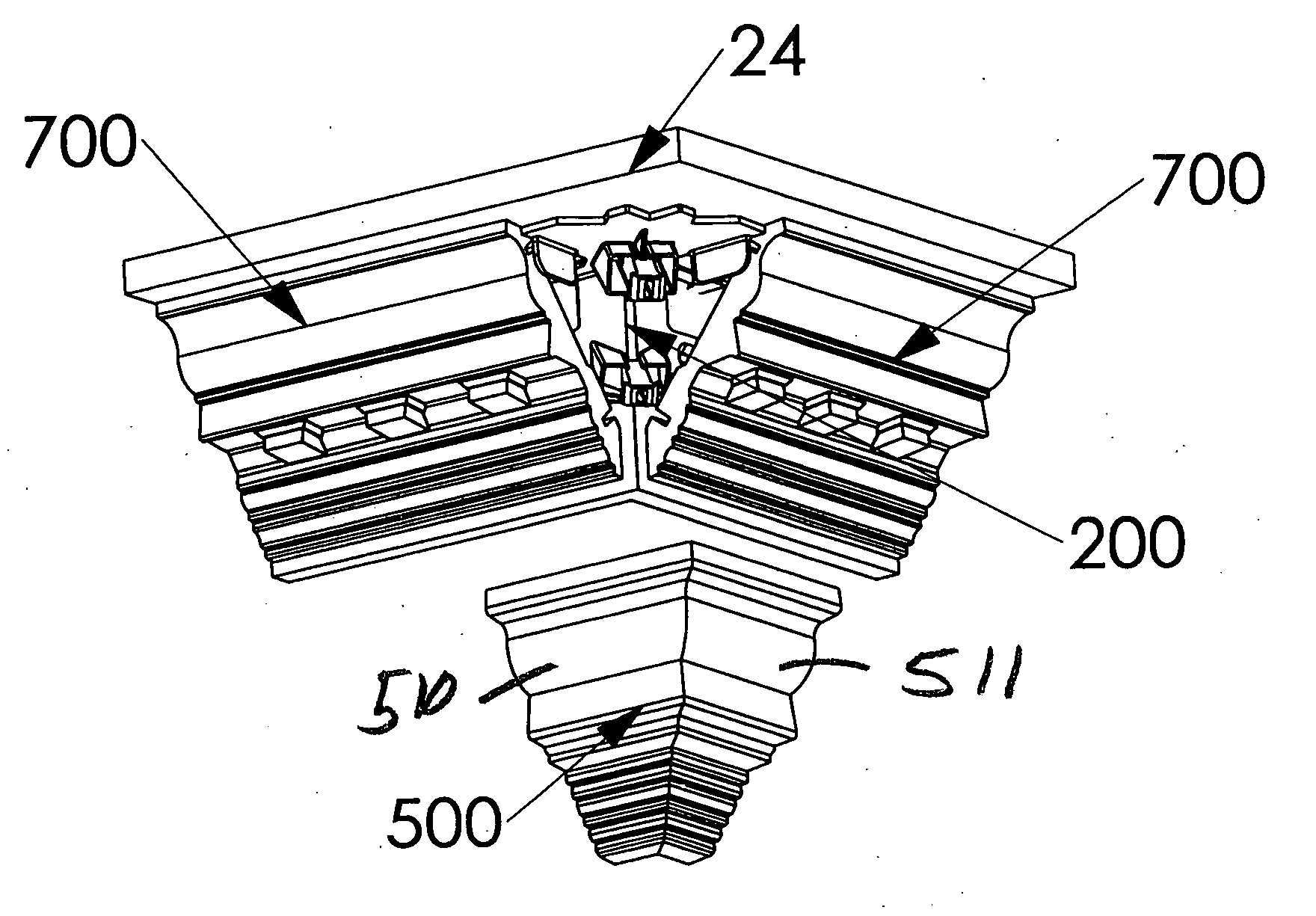

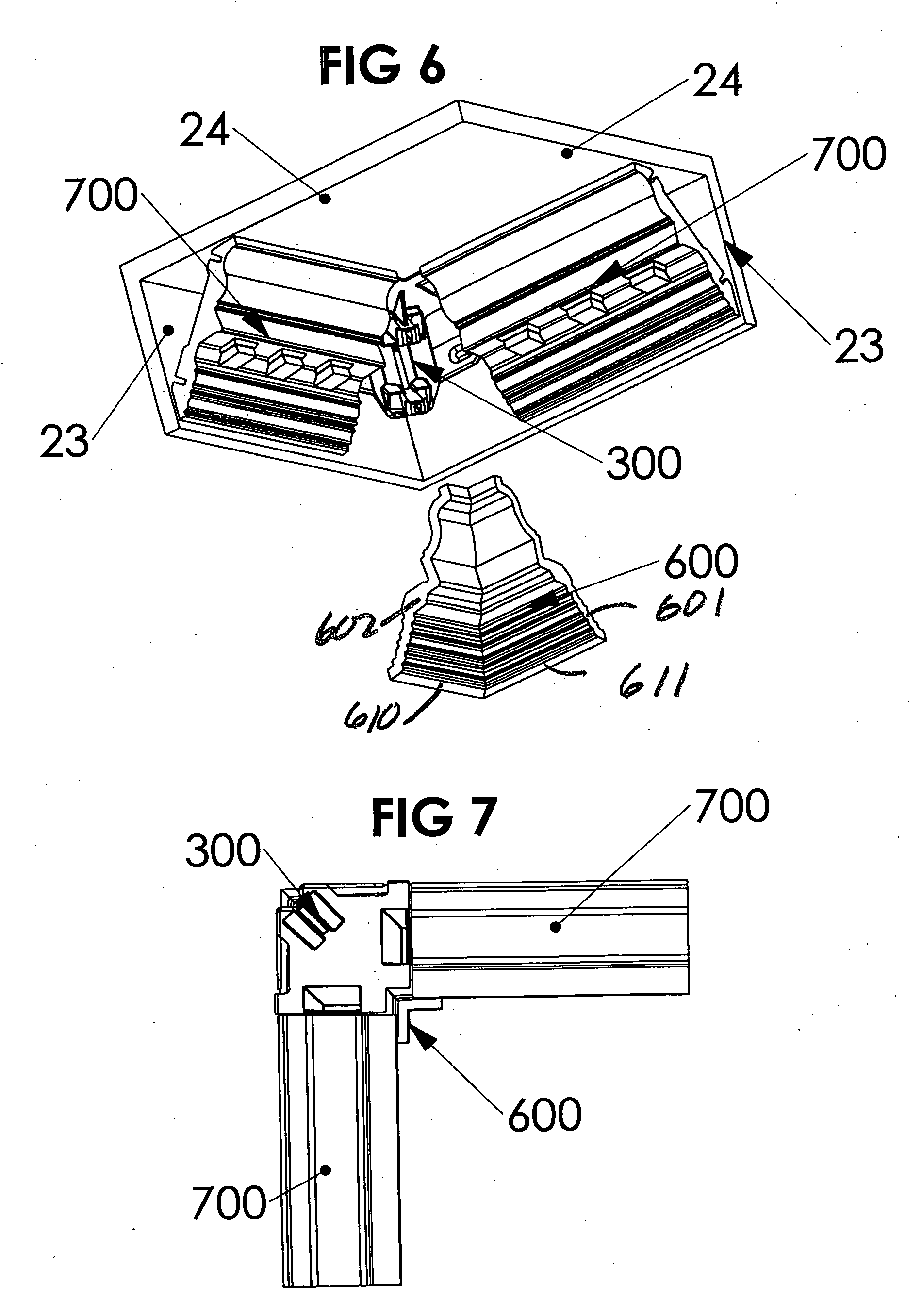

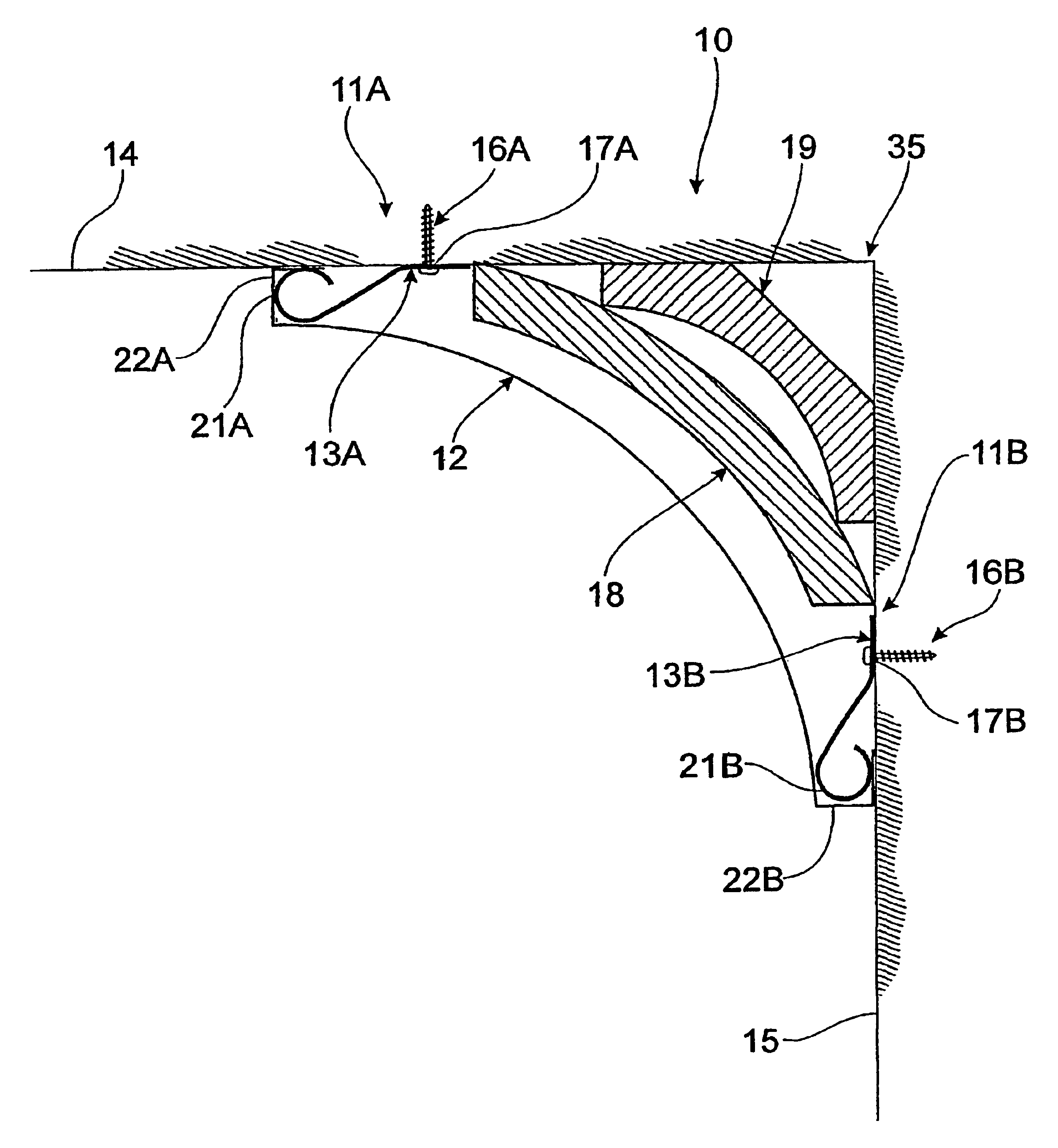

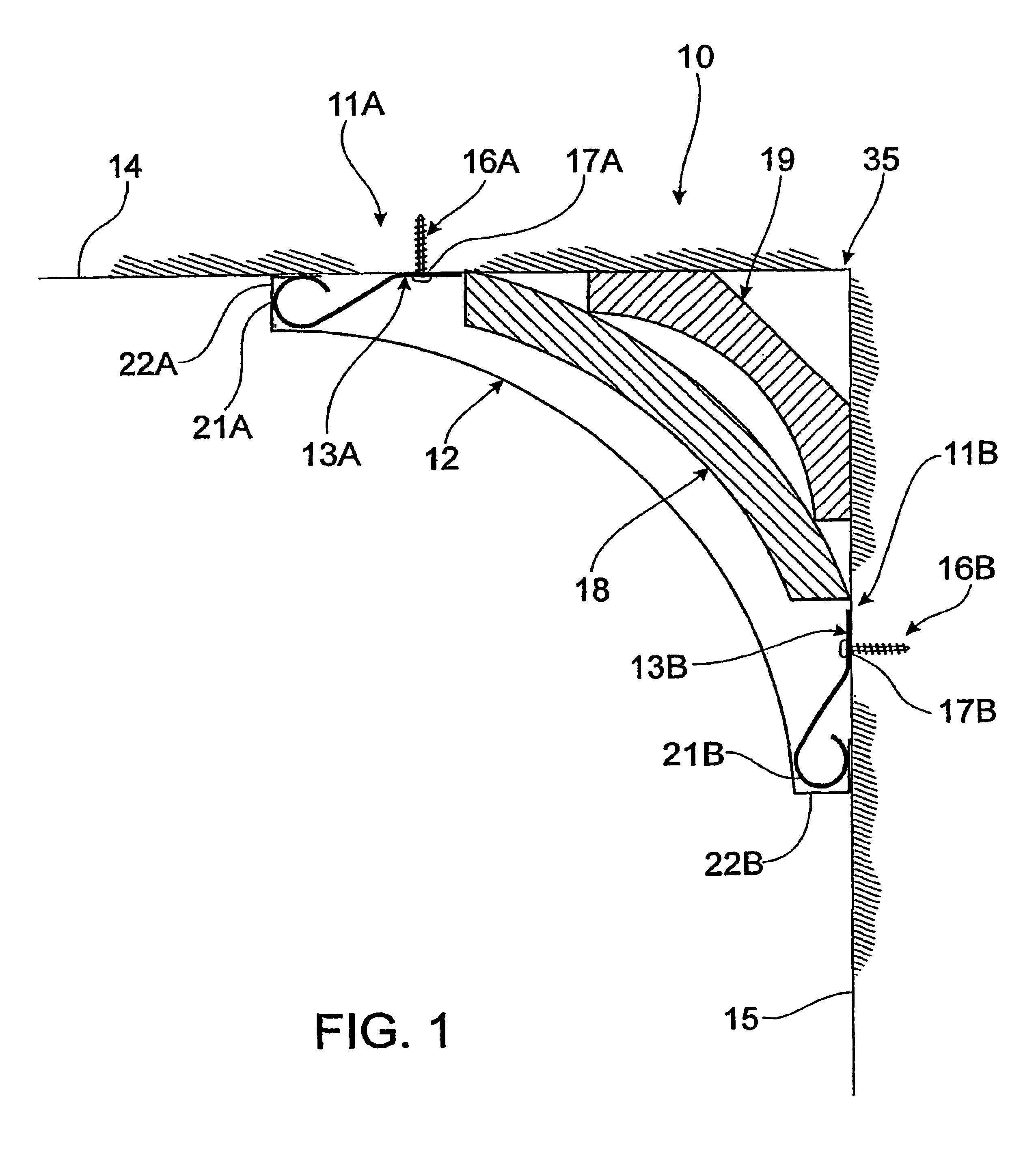

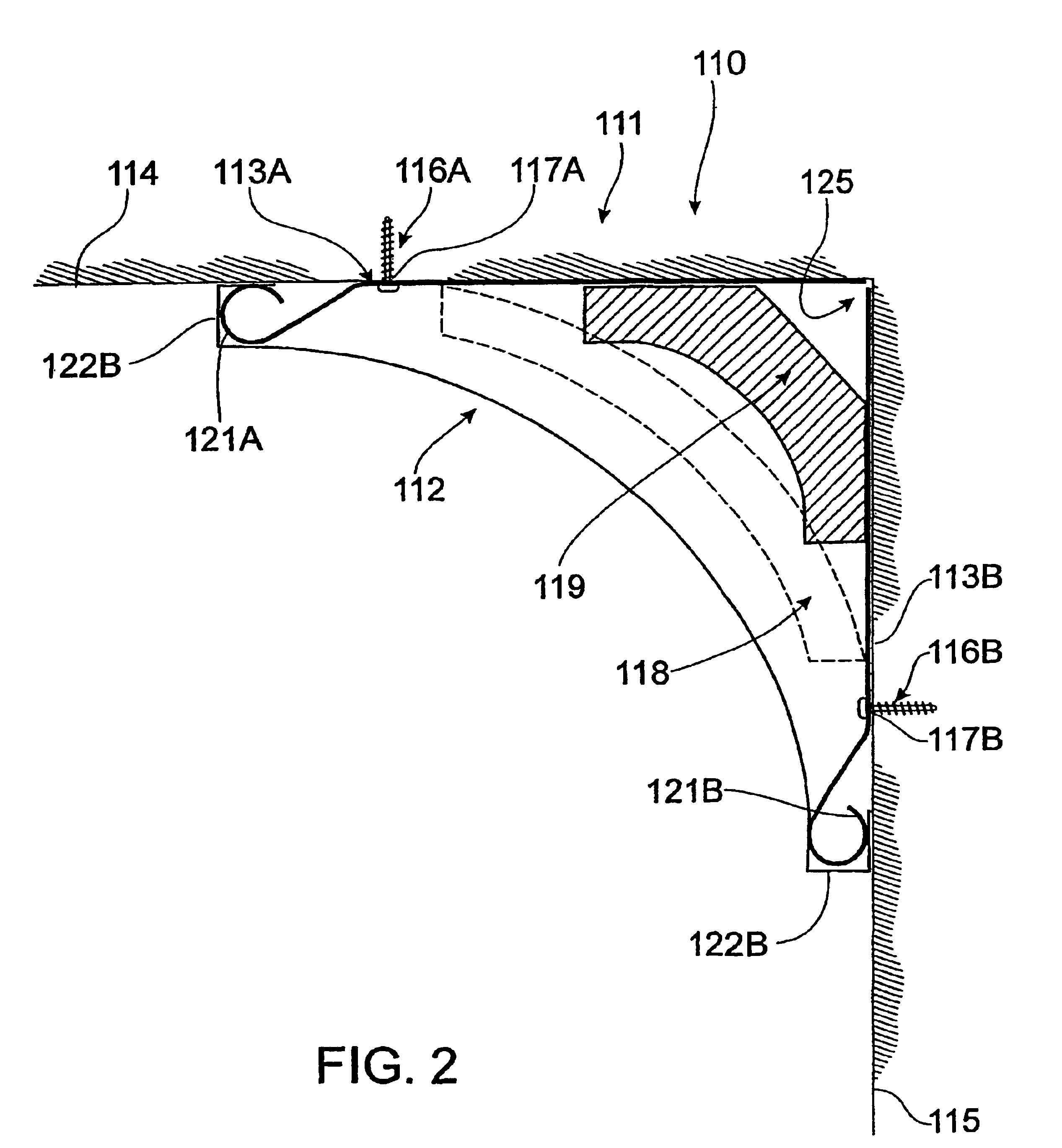

Cornice Corner Cap and Methods Related Thereto

A cornice molding cap is provided as an accessory to cover or eliminate gaps created where cornice molding meets at a corner of a building. The cap covers gaps where cornice molding meets at a corner structure formed by two walls. The cap is particularly useful in exterior siding installations at corners not employing corner posts having receiver pockets for cladding material end edges. A method of finishing a corner molding installation is described, as is a system for finishing such installation, and an assembly including a unitary cornice molding corner cap.

Owner:CERTAINTEED CORP

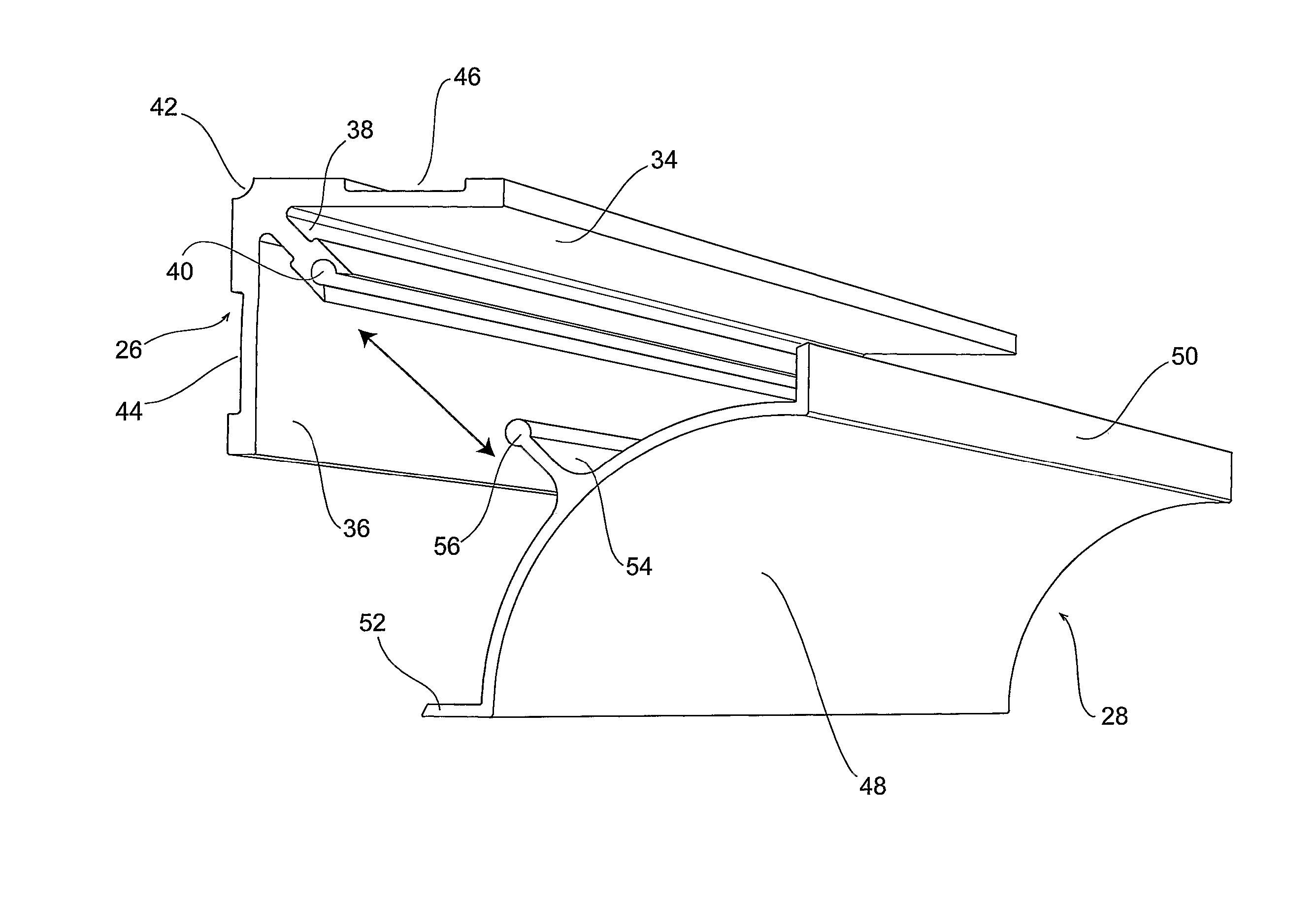

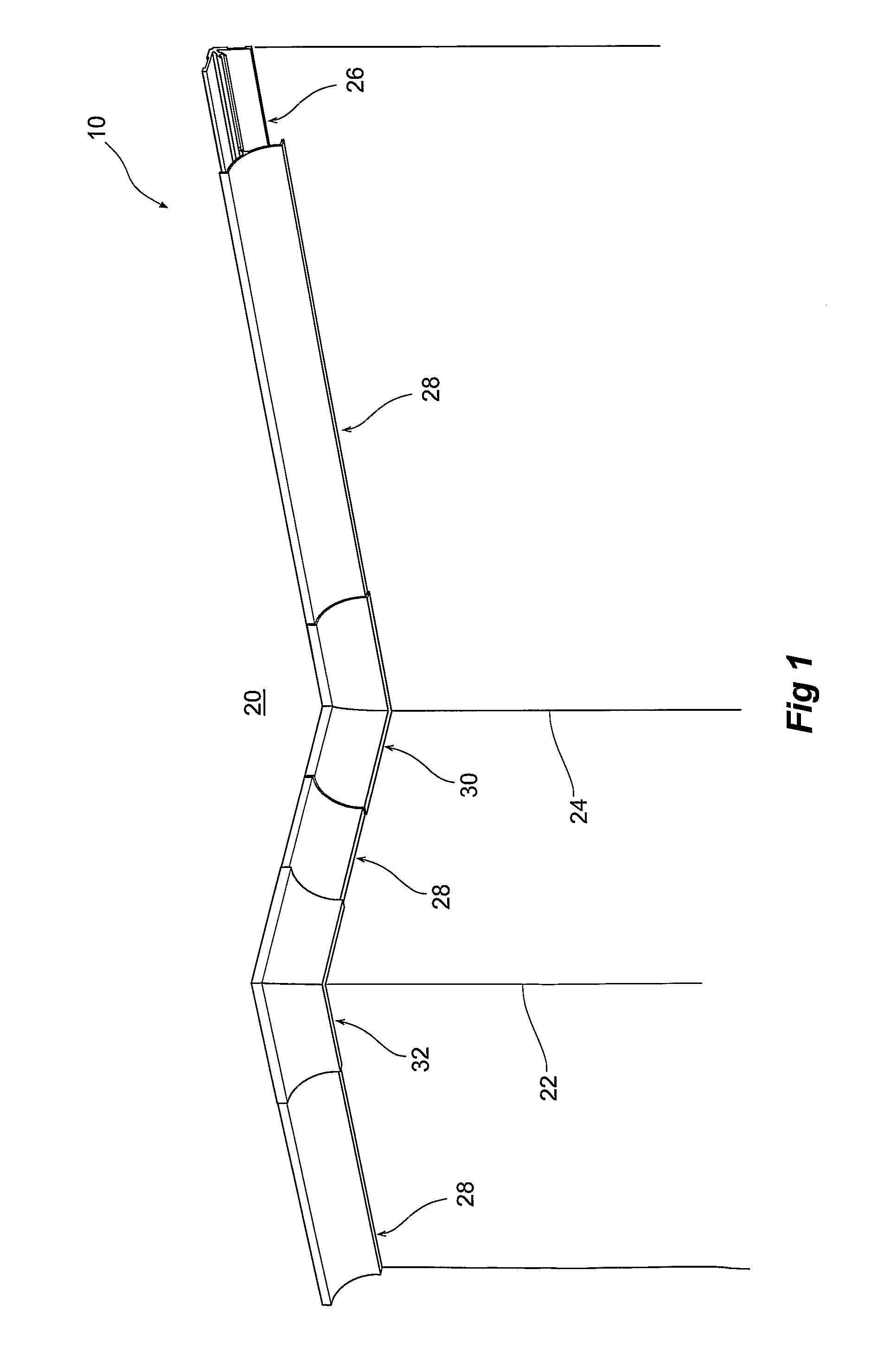

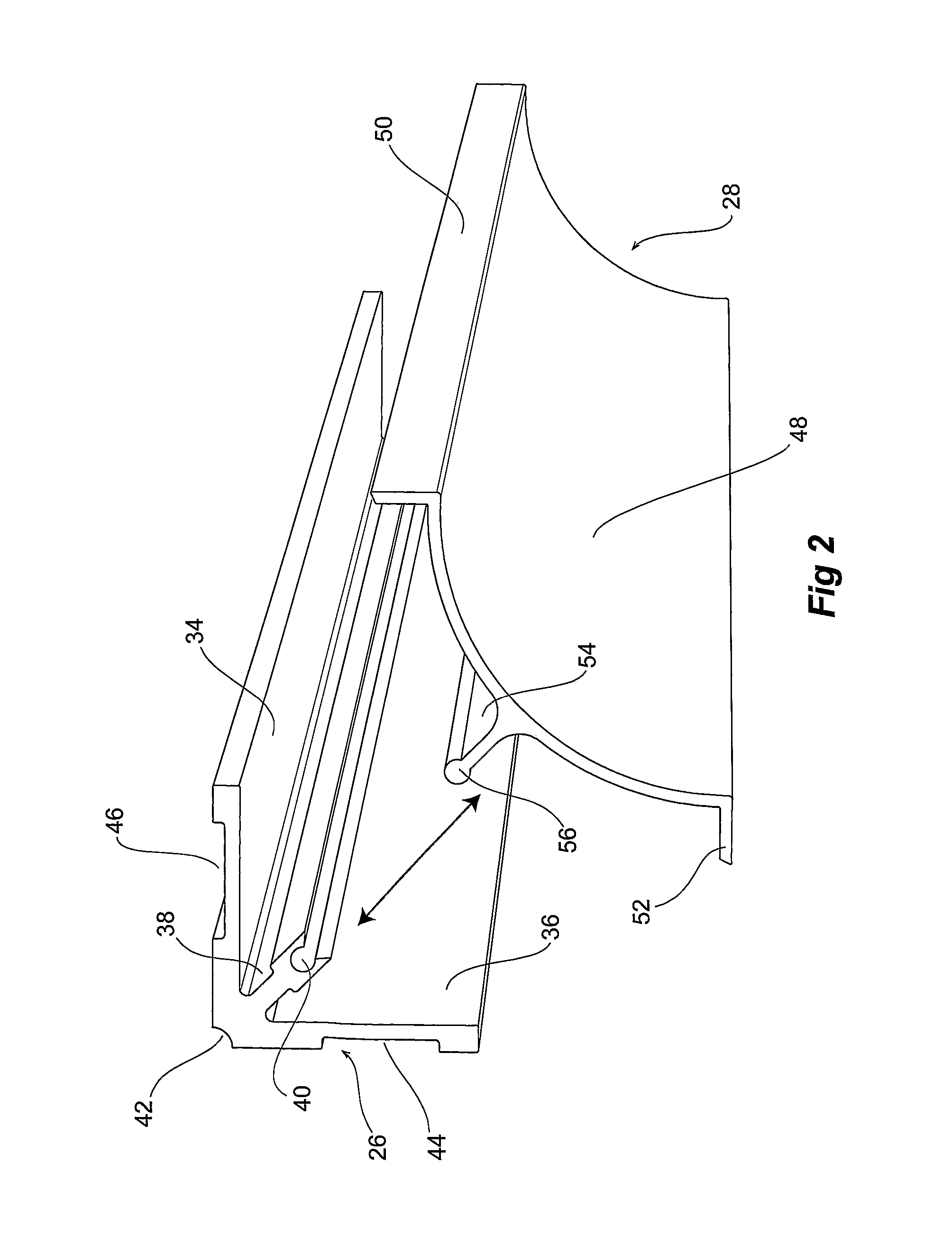

Cornice/Skirting Mounting System

The present invention relates to a cornice / skirting mounting system and, in particular, to a 2-part system involving an anchor member (26) and an outer fascia member (28) which is removably attachable to the anchor member (26). The cornice / skirting mounting system of the present invention thus provides a complete system for fitting out a home with wall-wall, wall-ceiling, and wall-floor lining, with benefits prior to installation, and post-installation.

Owner:JACKSON ANDREW

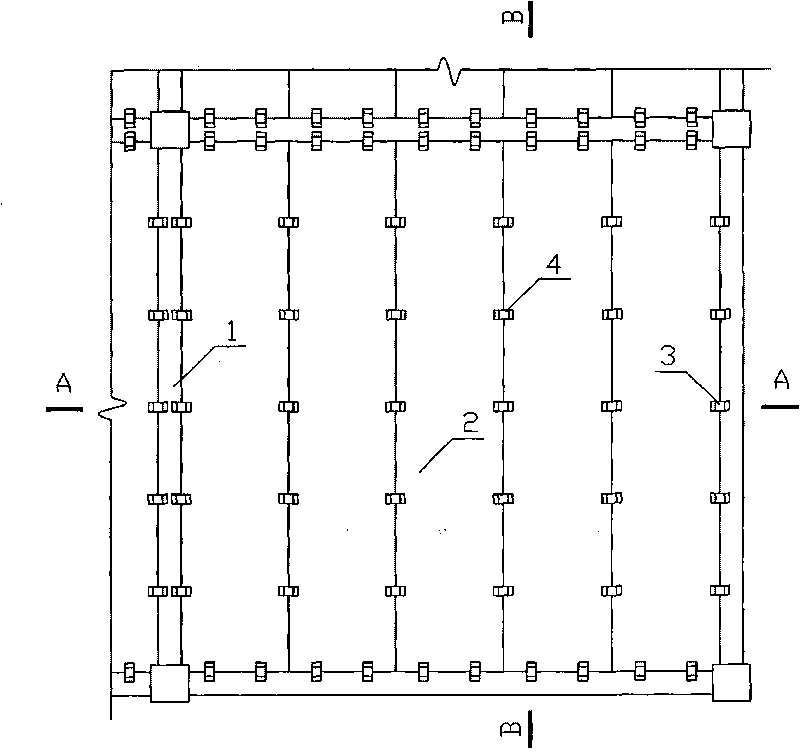

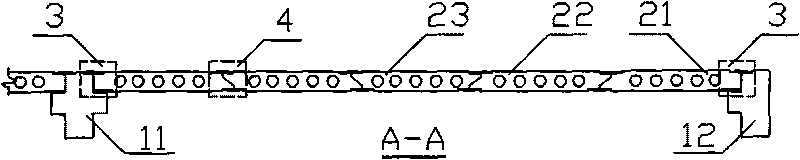

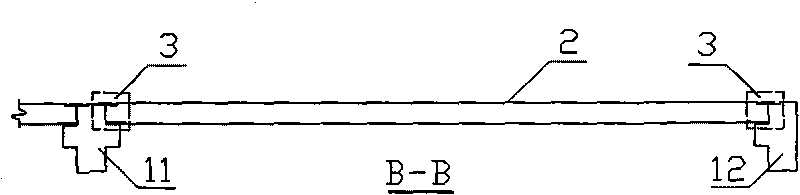

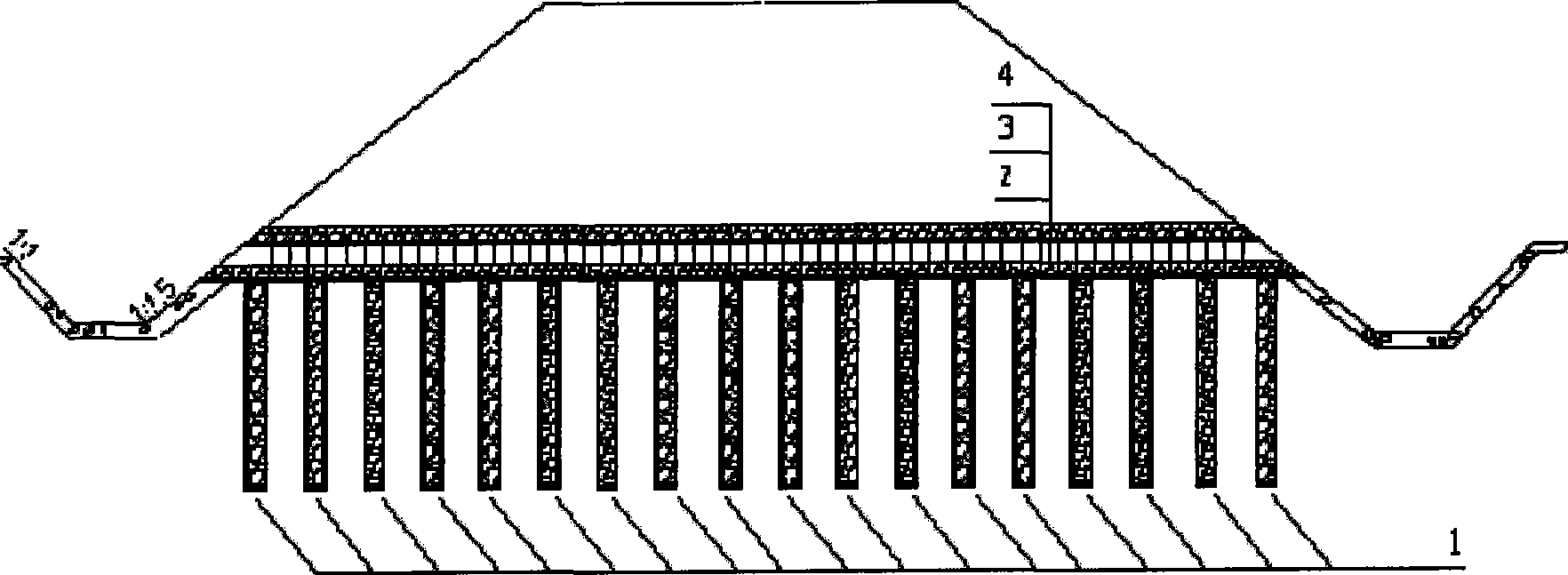

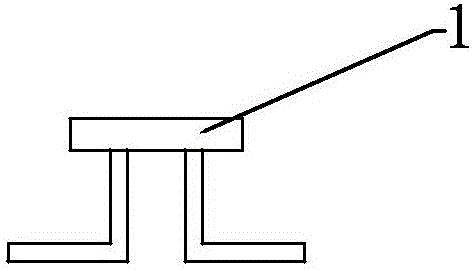

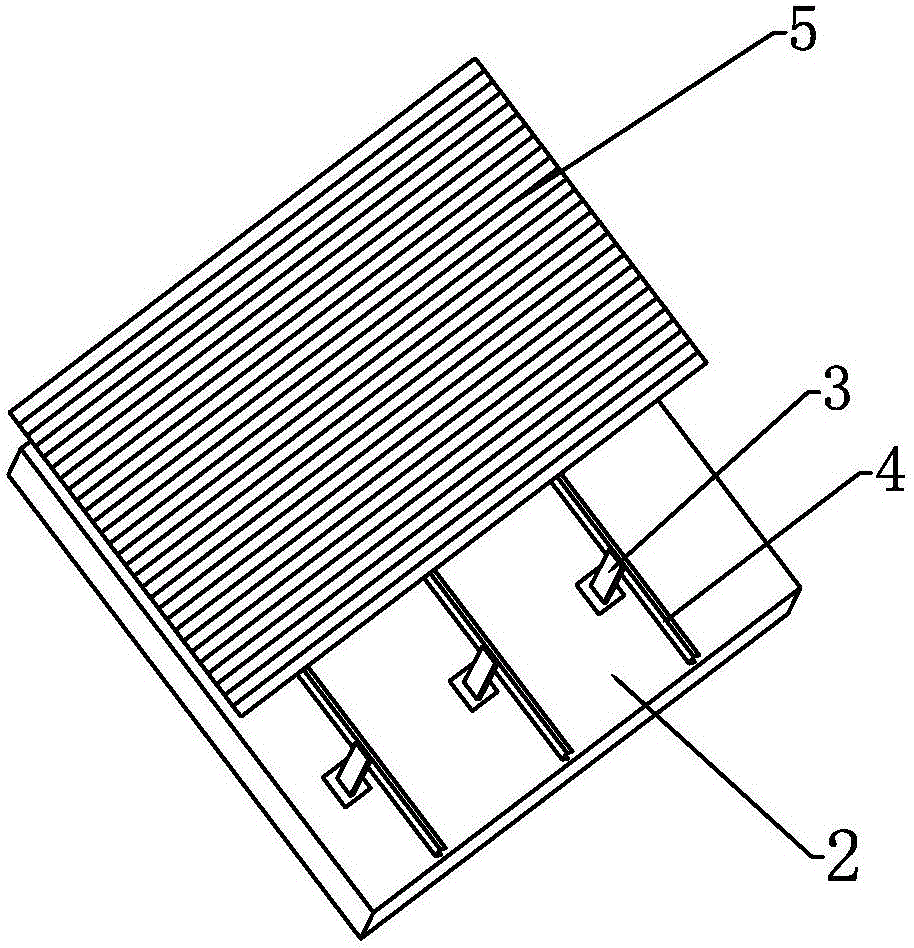

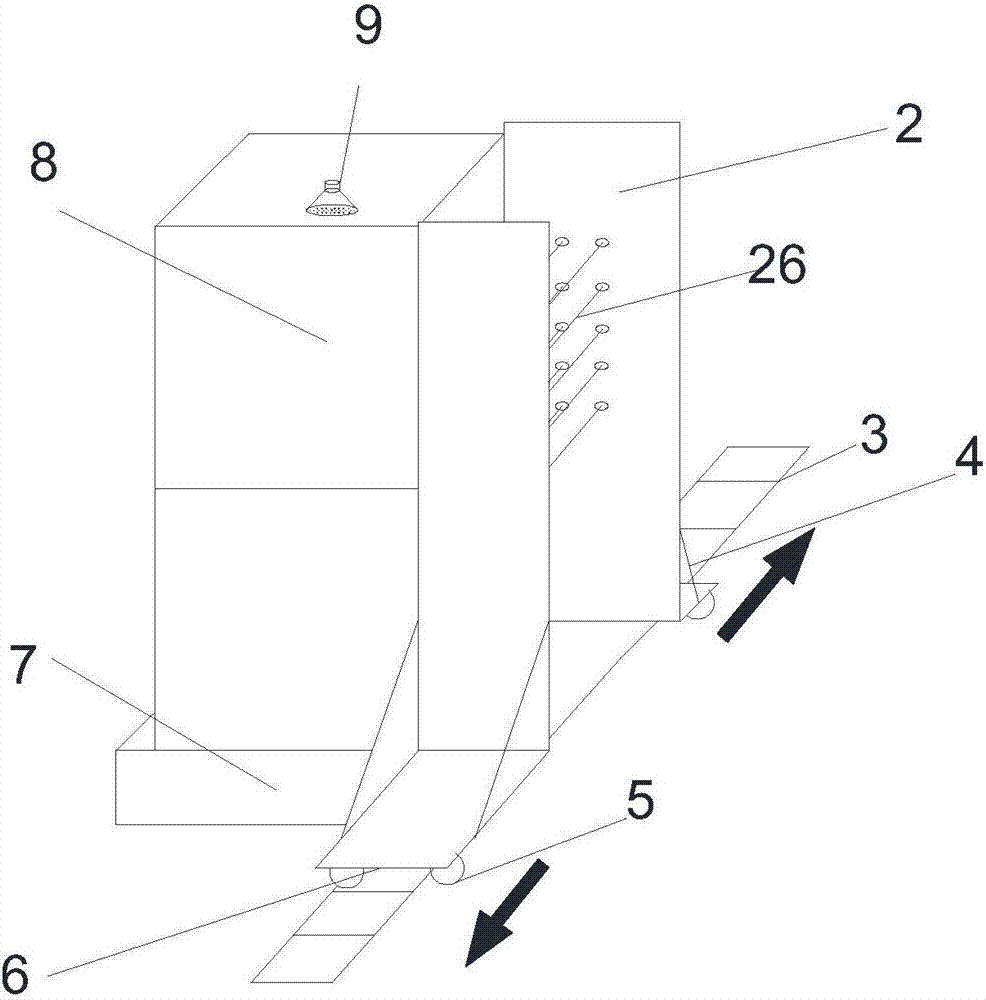

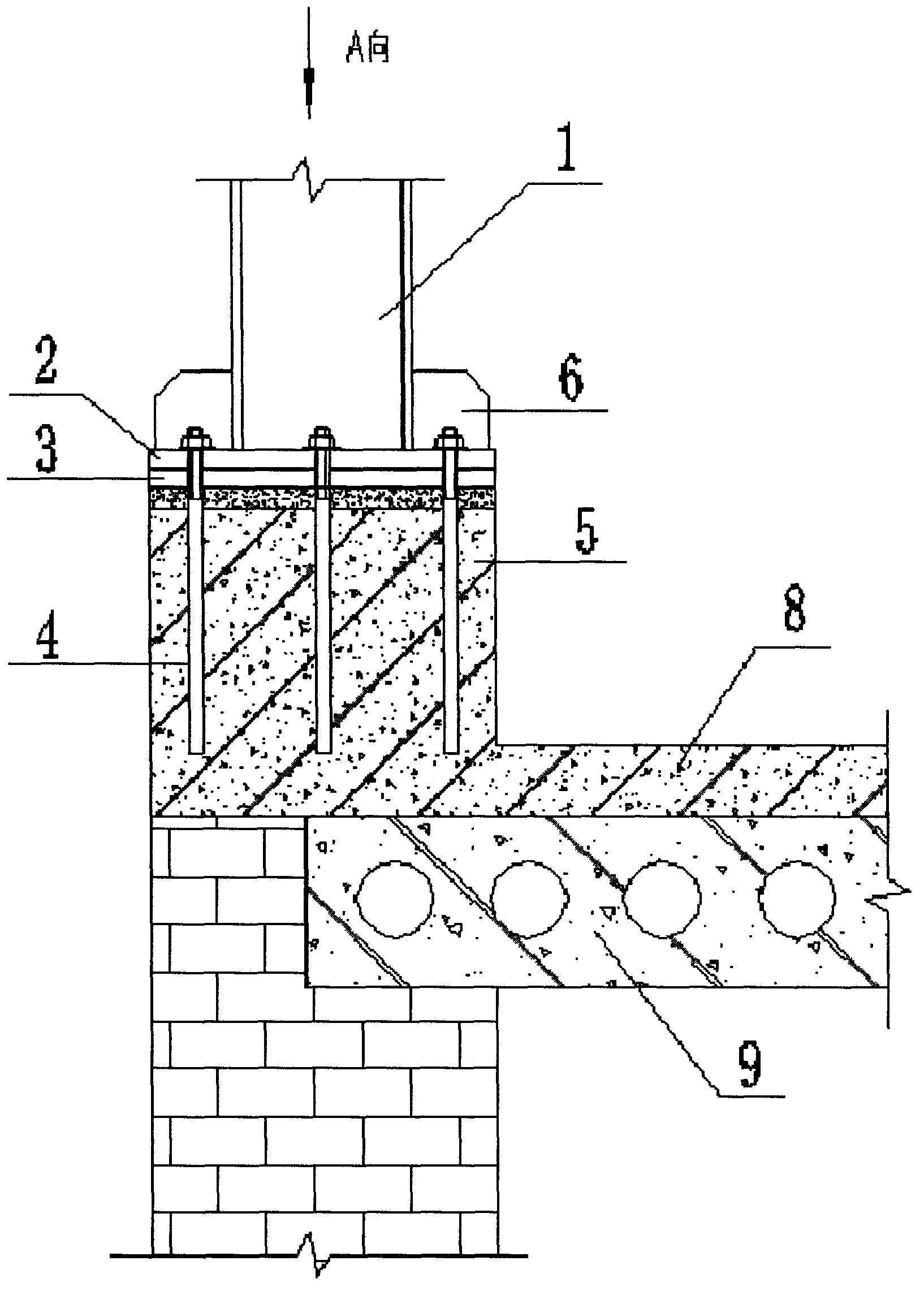

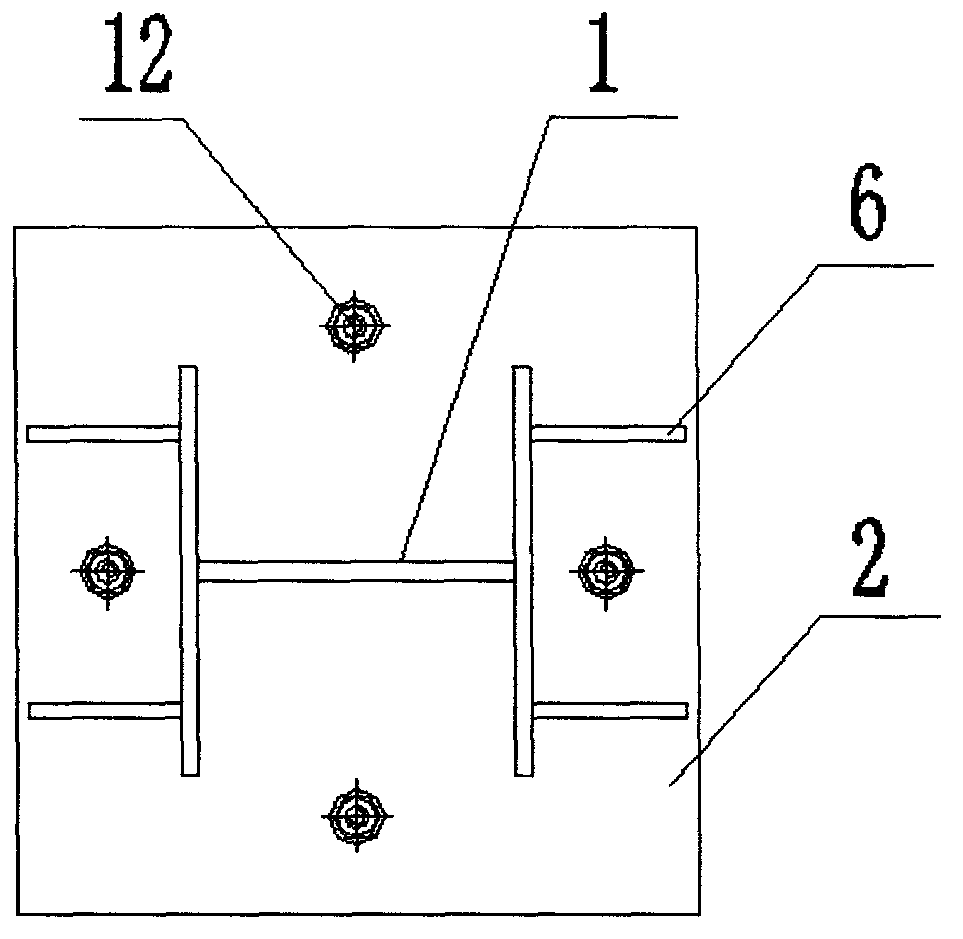

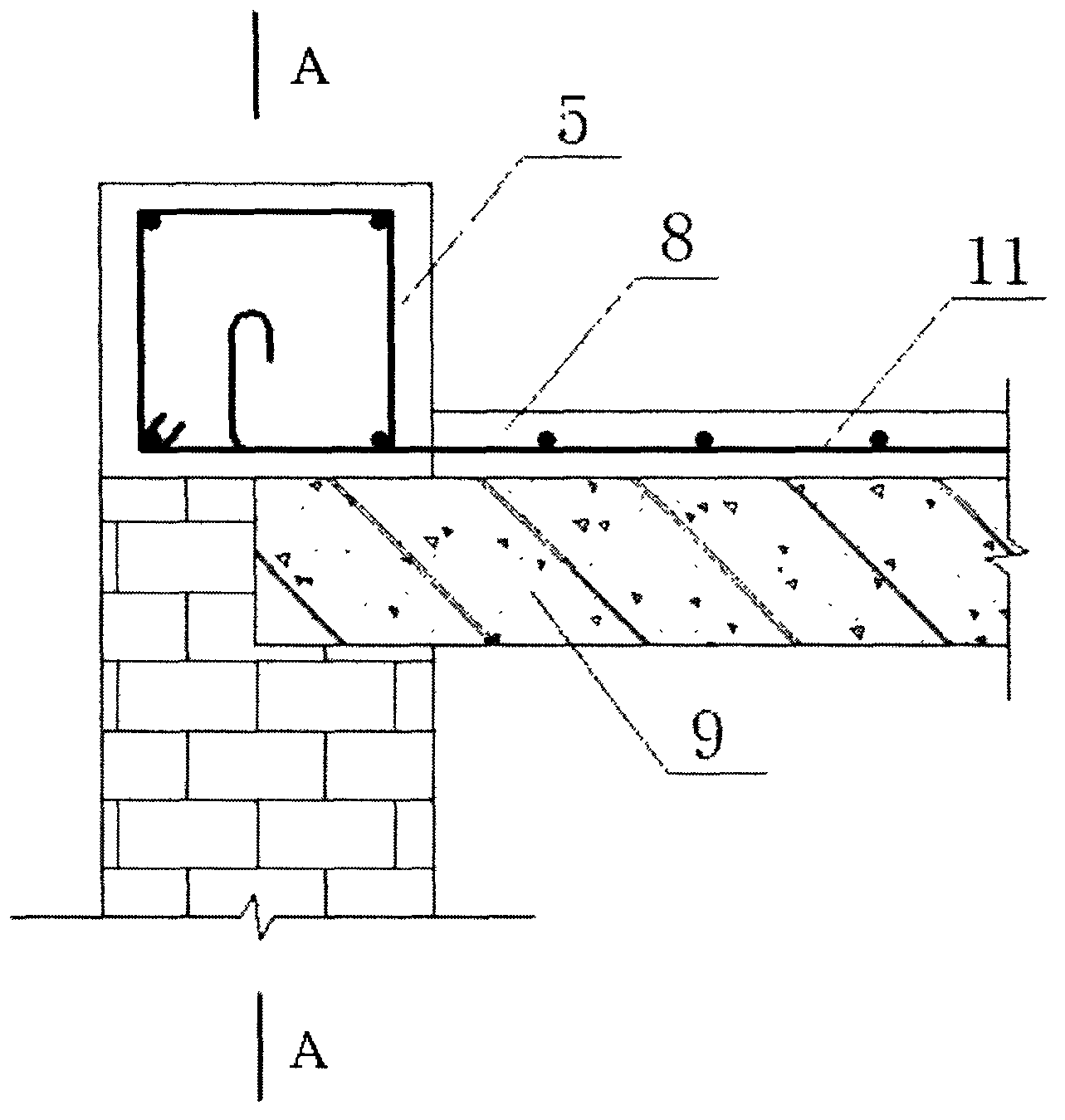

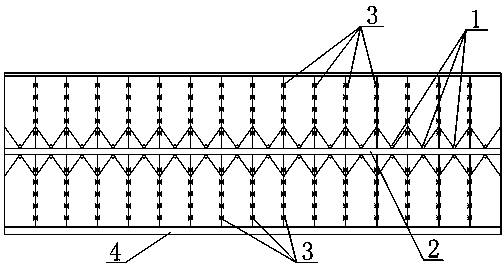

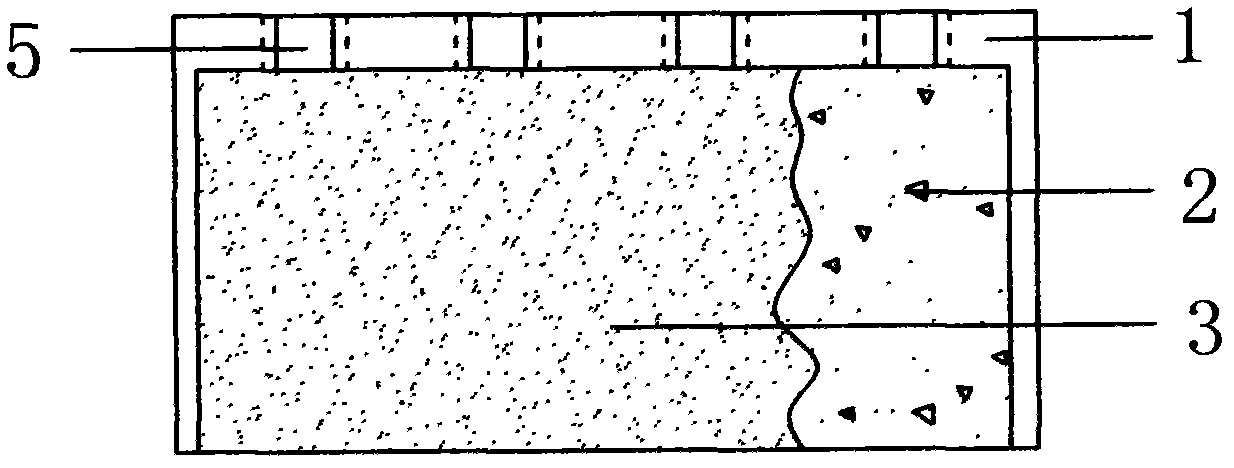

Totally-prefabricated assembling type reinforced concrete floor system

The invention discloses a totally-prefabricated assembling type reinforced concrete floor system which consists of girders, prefabricated slabs, girder-slab connecting pieces, and slab-slab connecting pieces. The invention is characterized in that: the prefabricated girders are cornice girders, and the prefabricated slabs are matchboards; the prefabricated slabs are fixedly connected by the girder-slab connecting pieces after being arranged on the prefabricated girders; and the prefabricated slabs are fixedly connected by the slab-slab connecting pieces after being lap-jointed with each other. The prefabricated slabs can be prefabricated prestressed concrete cored slabs, superimposed slabs or other flat slabs. The invention realizes the bidirectional force bearing performance of the unidirectional prefabricated slabs and the four-edge fixed-end limiting form of the floor system, and can effectively meet the requirement for large span and heavy load; moreover, belonging to a totally-assembled system, the invention has the characteristics of less field operation, high construction speed, good earthquake resisting performance, and obvious effects of energy saving and environmental protection.

Owner:SOUTHEAST UNIV

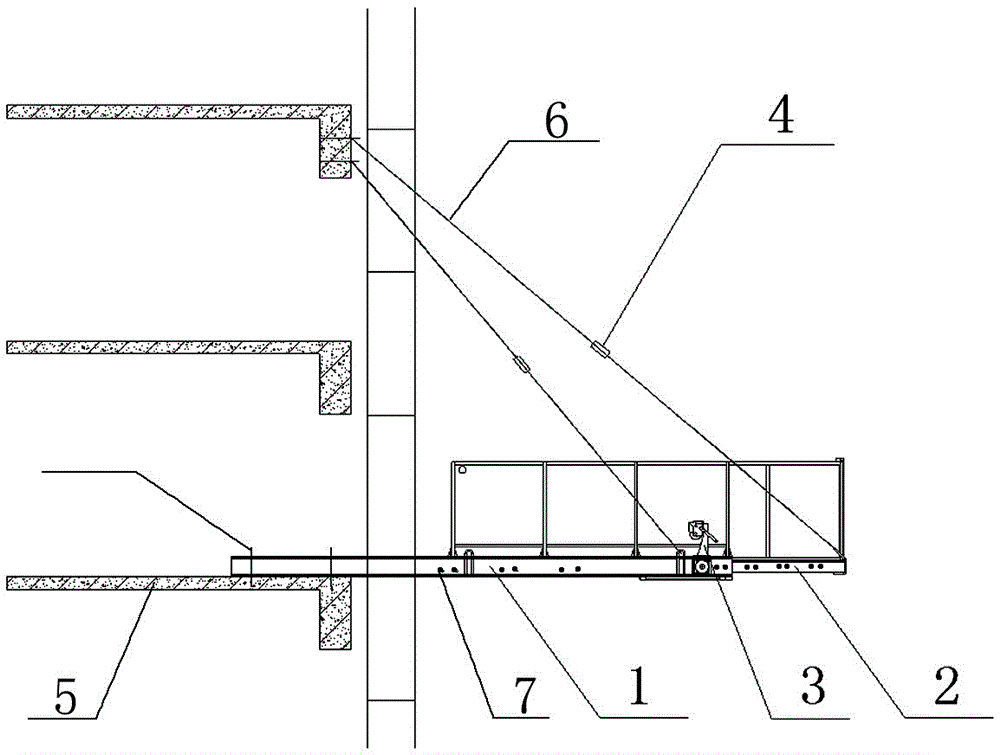

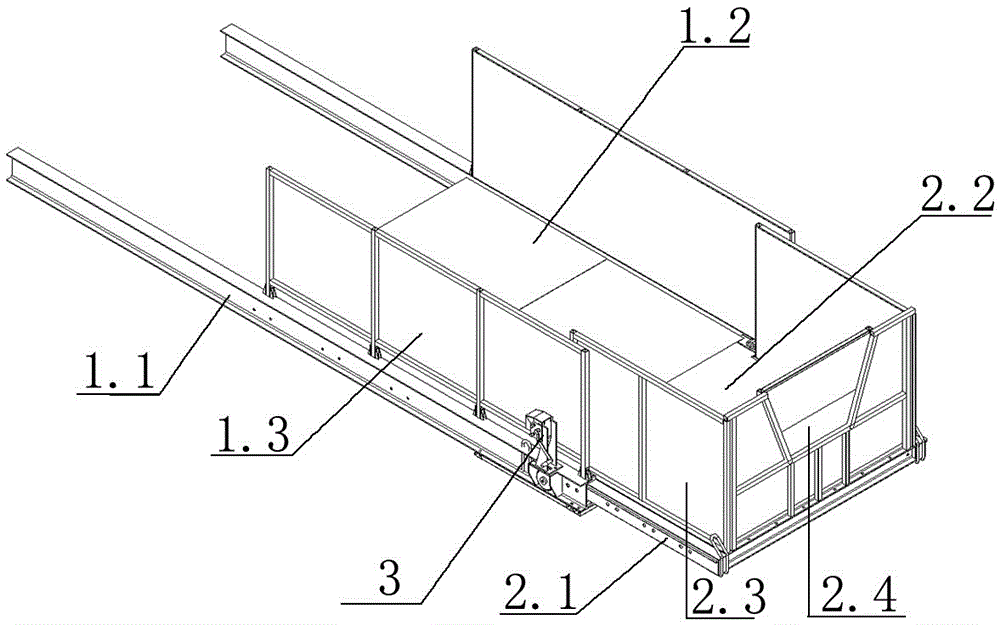

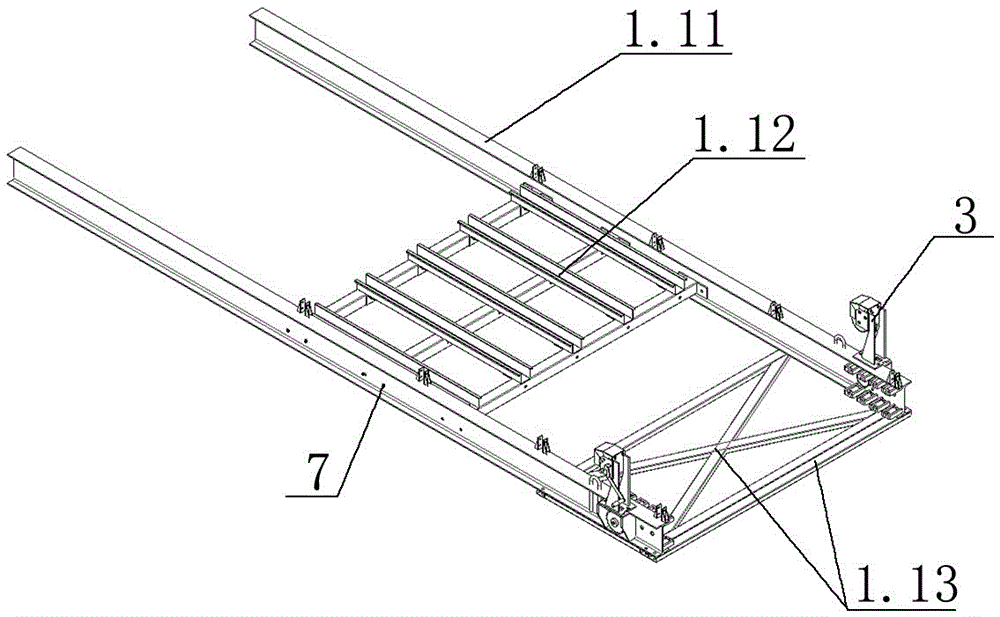

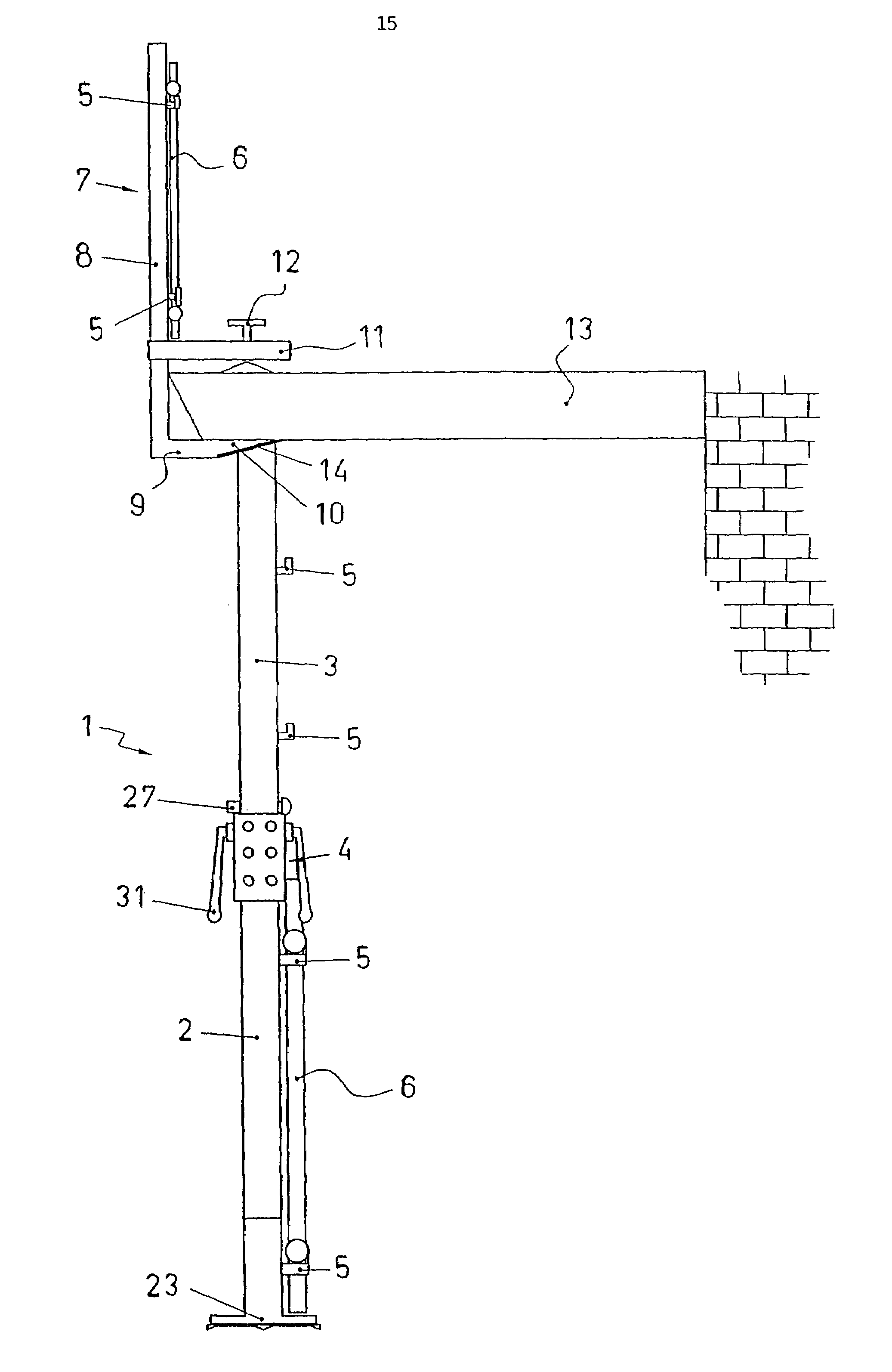

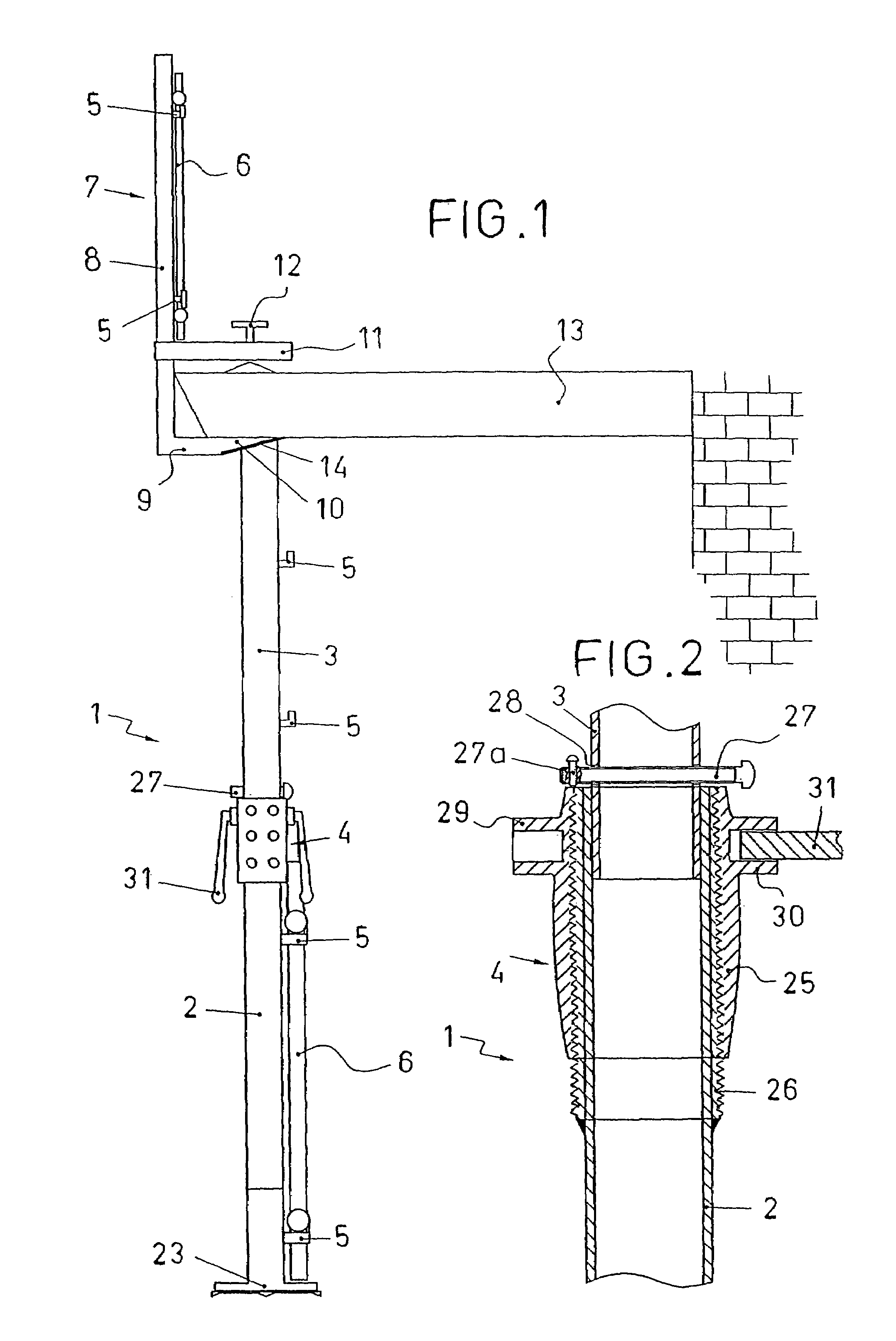

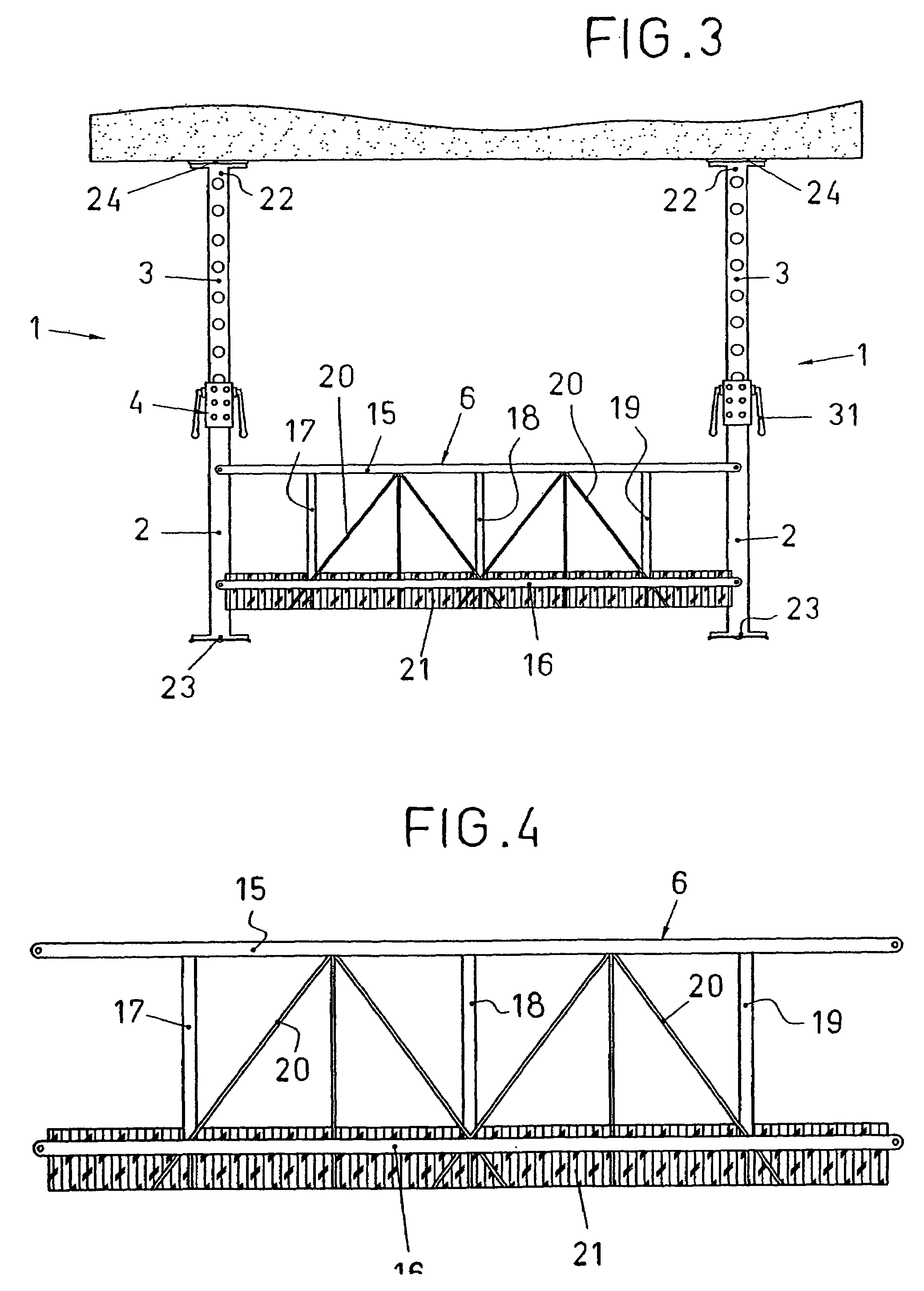

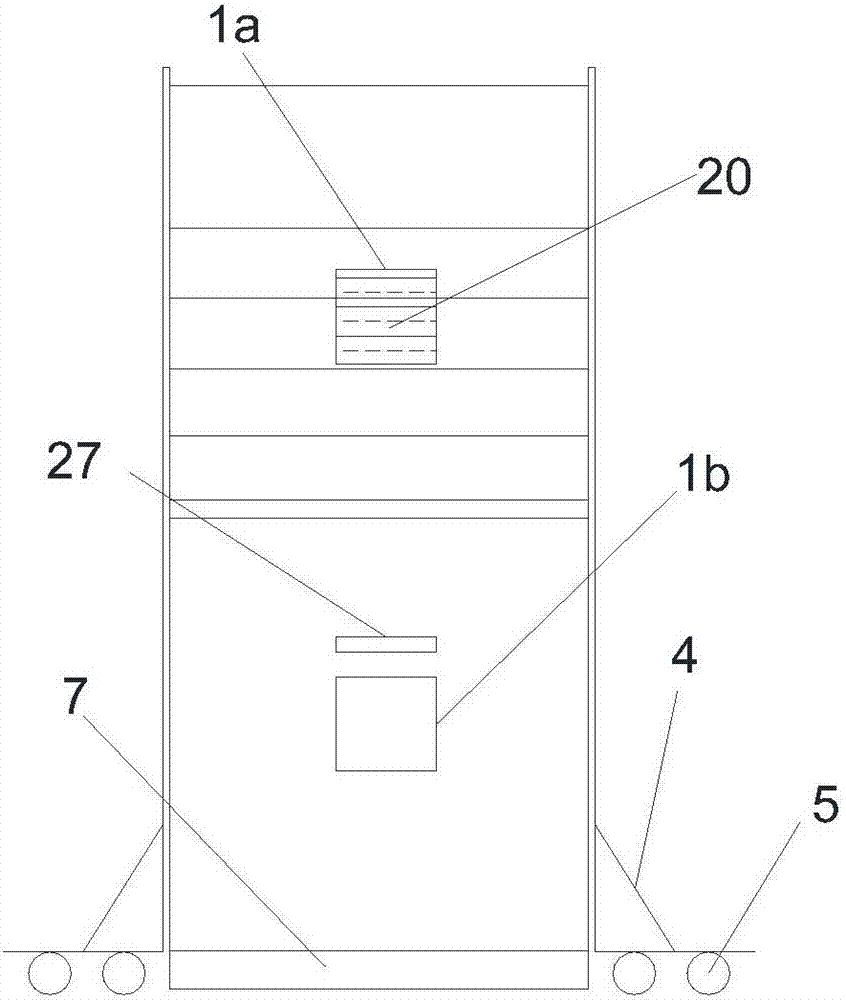

Assembling type telescopic early-warning discharging platform and assembling construction method thereof

InactiveCN106382014AAdjust the overhangSolve problems such as poor operationBuilding material handlingEarly warning systemFloor slab

The invention relates to an assembling type telescopic early-warning discharging platform and an assembling construction method thereof. The platform comprises a fixing part, a telescopic part, a transmission mechanism and an early-warning system, wherein the inner side of the fixing part is anchored to a structural floor slab, and the outer side of the fixing part is movably connected with the telescopic part through the transmission mechanism. The fixing part and the telescopic part are two intelligent wholes, are of a drawer type design, can stretch out and shrink in by virtue of rolling wheels and the transmission mechanism, so as to regulate the stretch-out length of the discharging platform; the discharging platform can easily shrink in or stretch out by virtue of the transmission mechanism, so that the stretch-out length of the discharging platform can be flexibly regulated, and the problem that a tower crane is difficult to operate when site operation conditions are limited, particularly a cornice is formed in an upper part structure is solved; the fixing part and the telescopic part are respectively of an assembling design, and components are connected through bolts, so that the platform is convenient to detach and transport; and by arranging the early-warning system, the tensile force on a steel wire rope is monitored in real time by virtue of a tension sensor, and sound-light alarm is given when the load exceeds a design limiting value, so that the accident is prevented.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

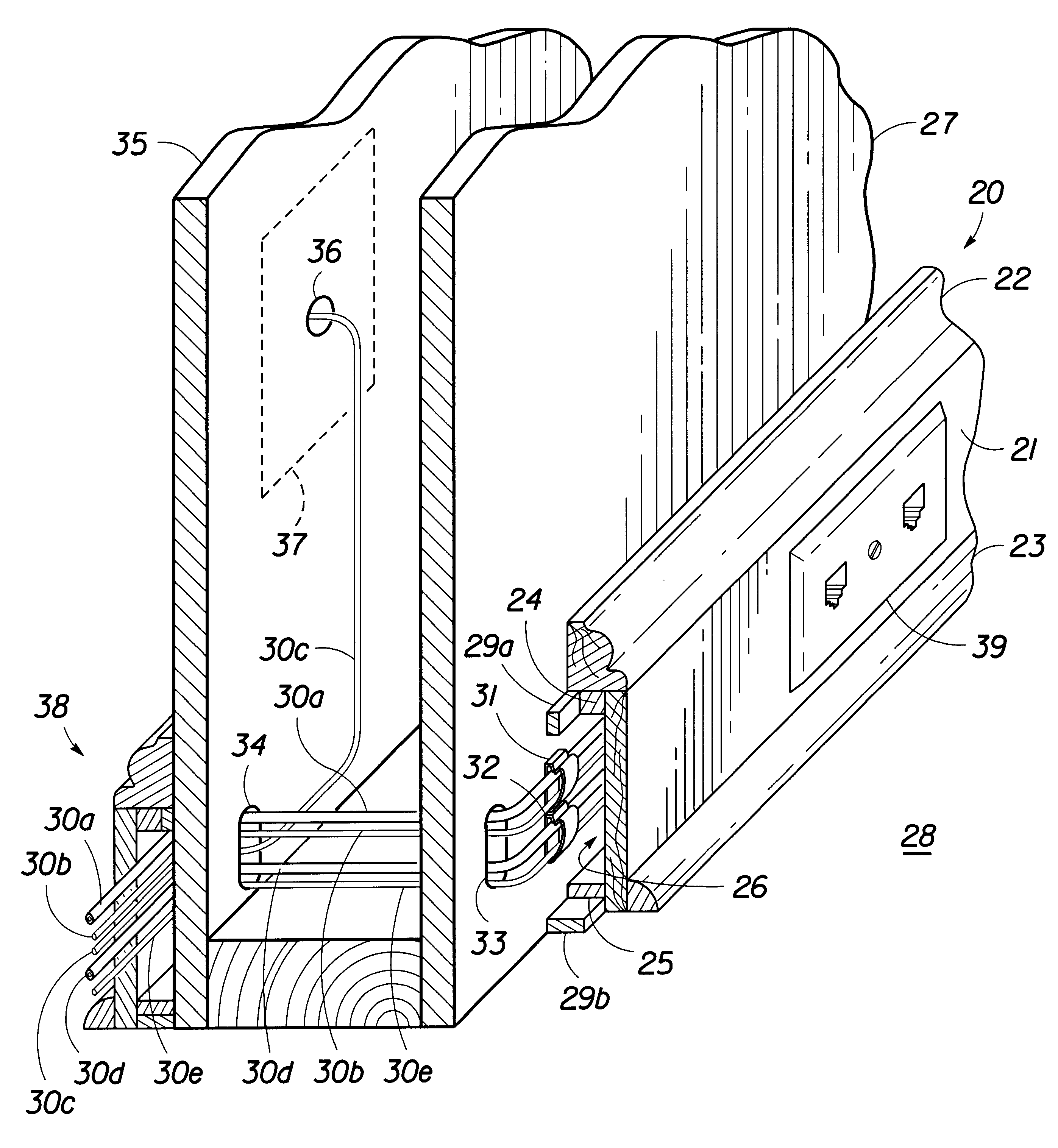

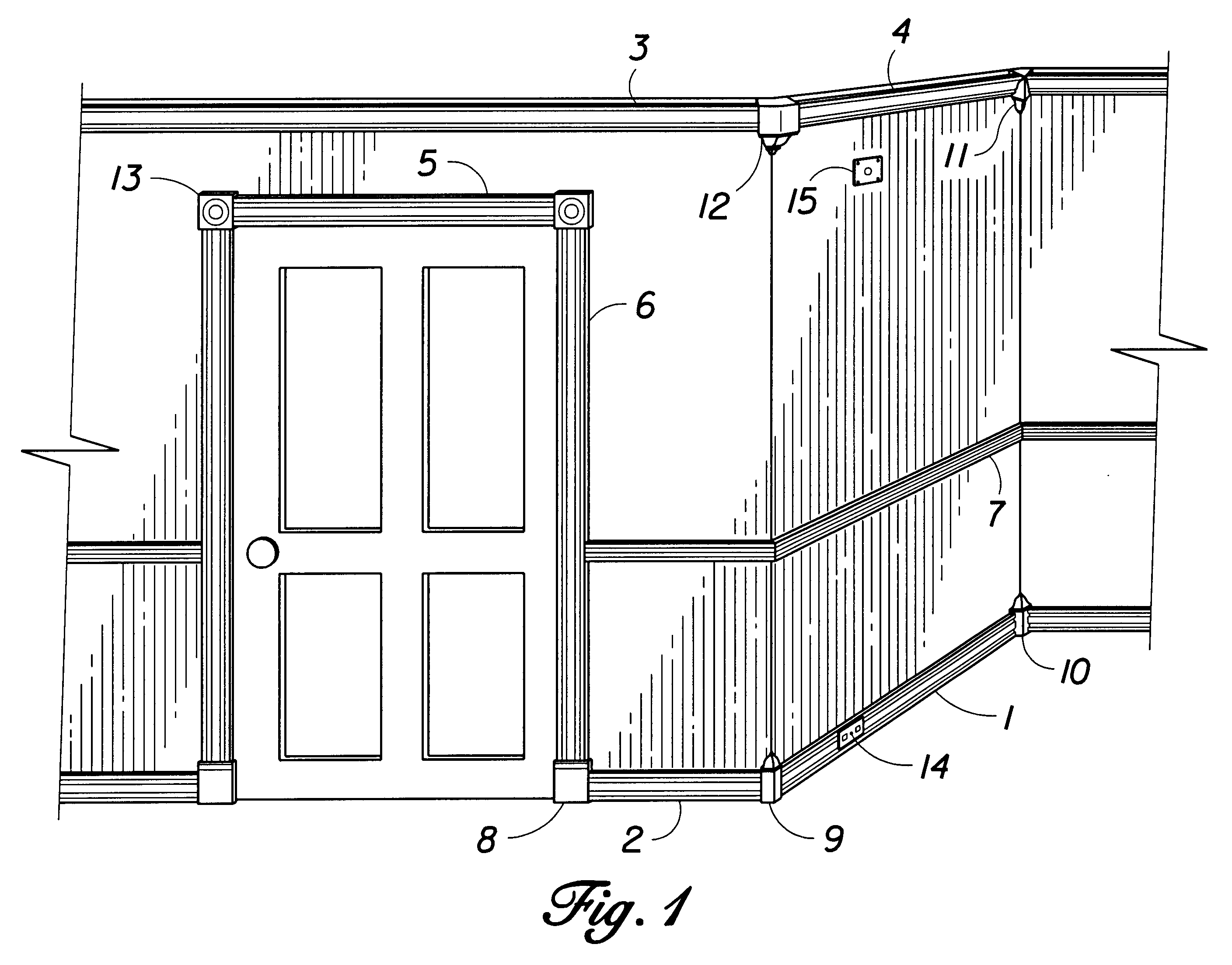

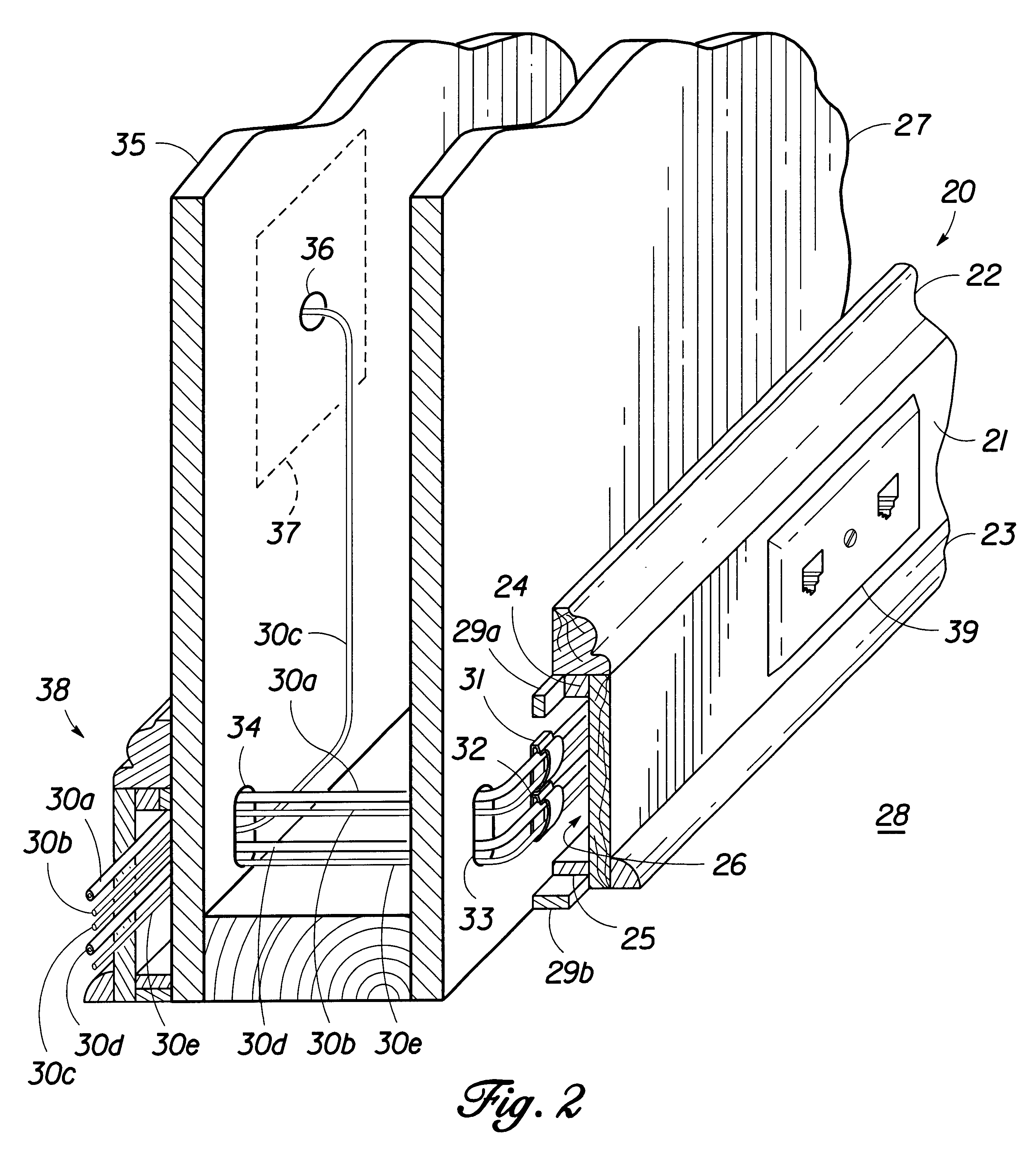

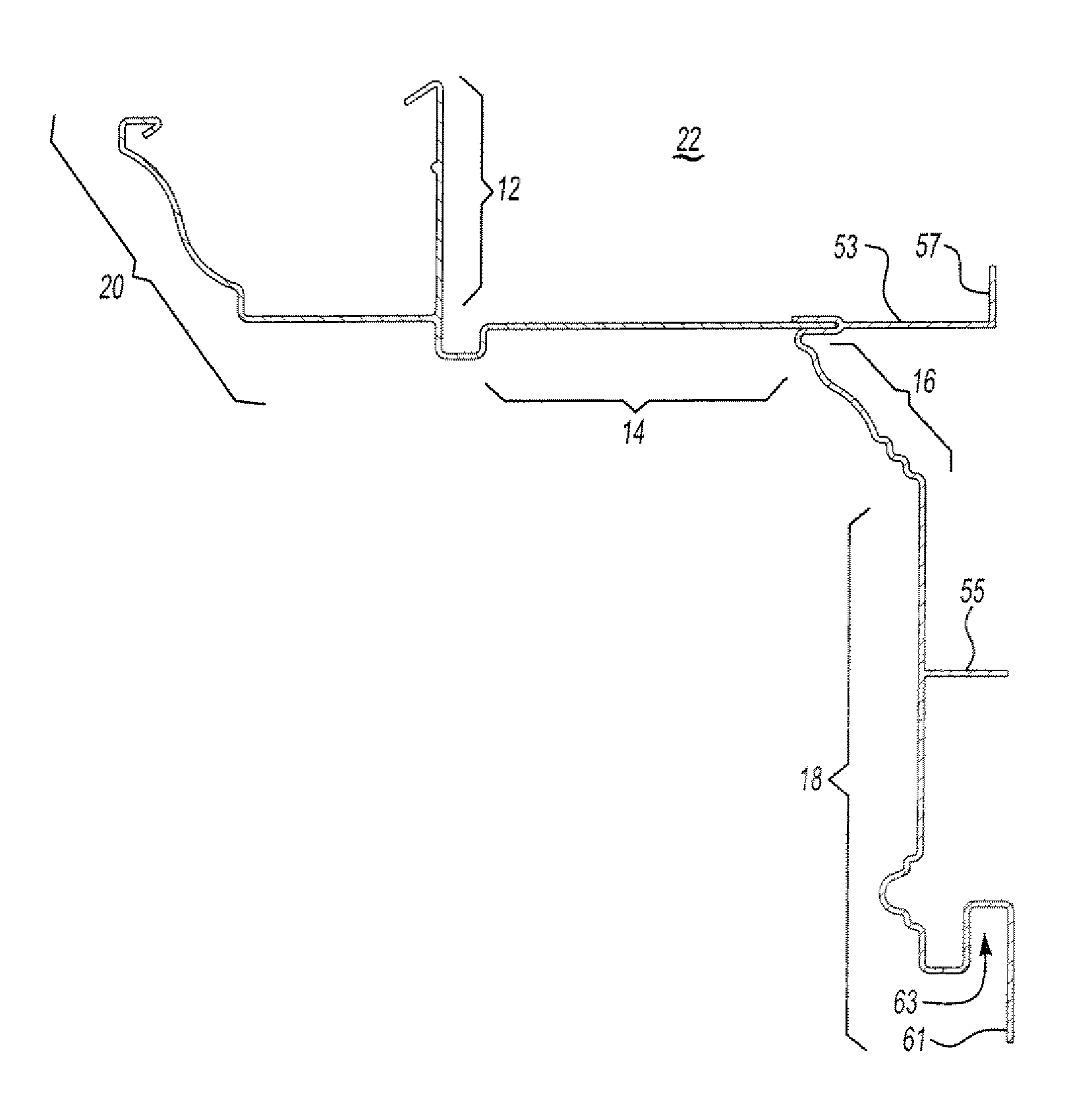

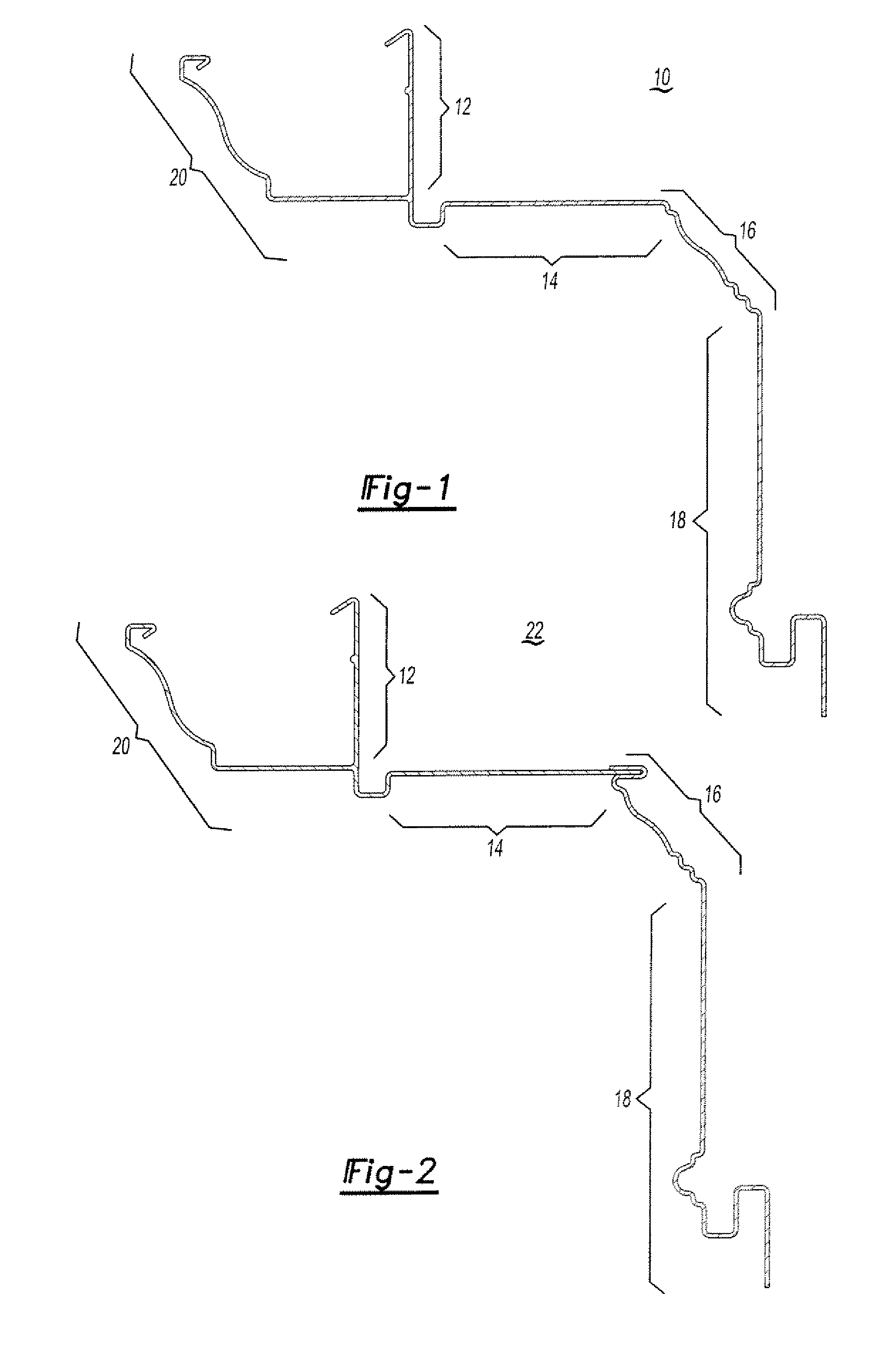

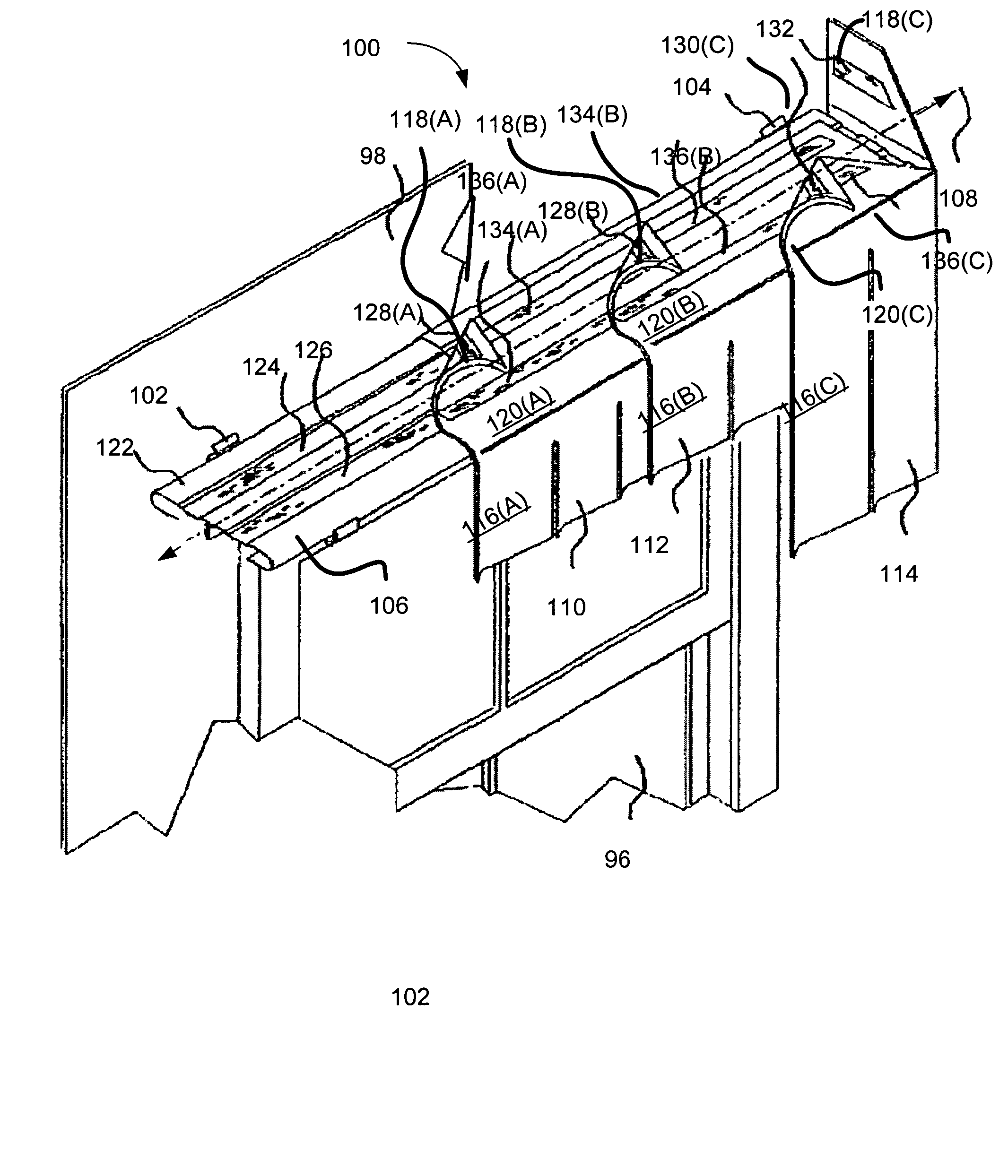

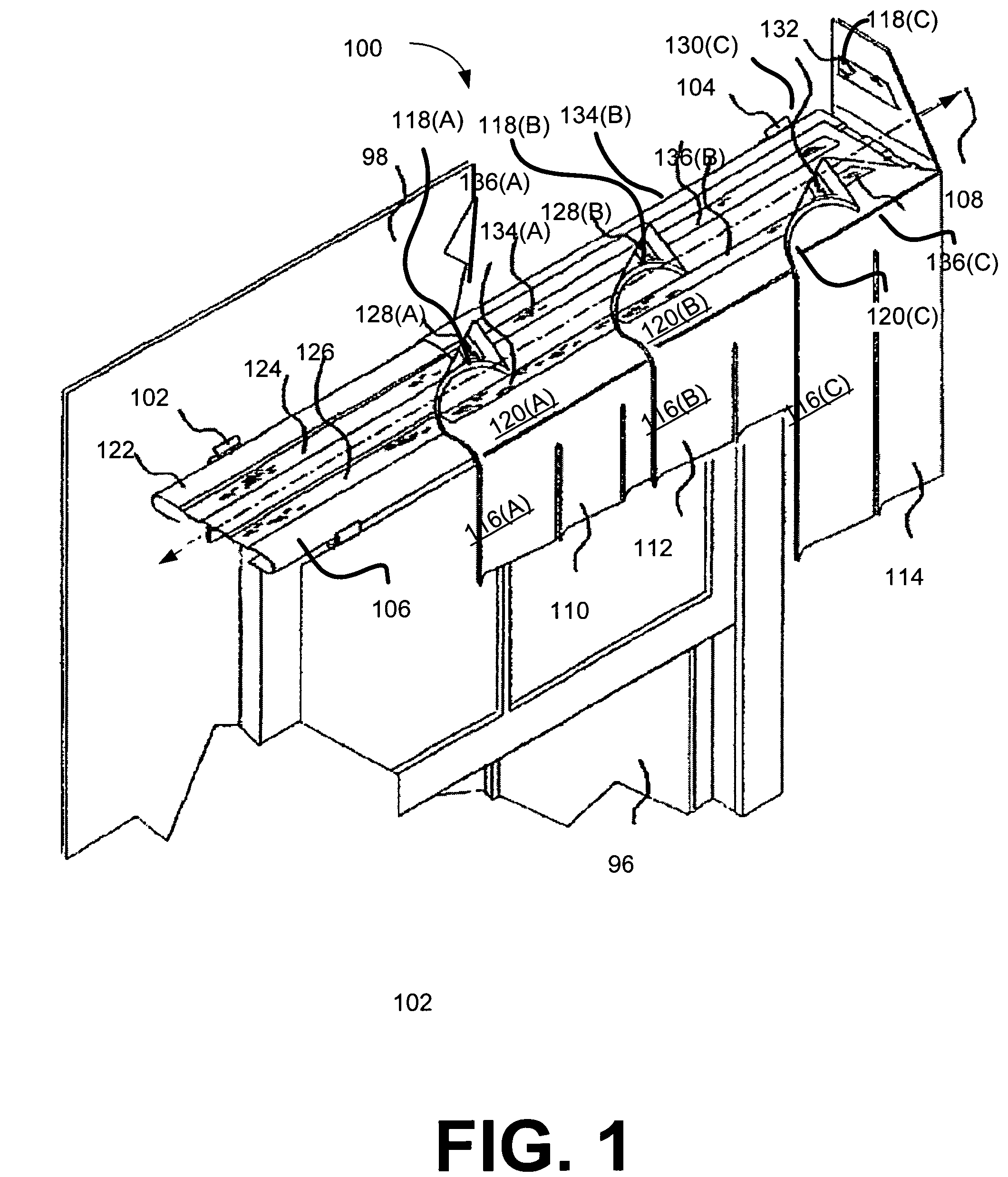

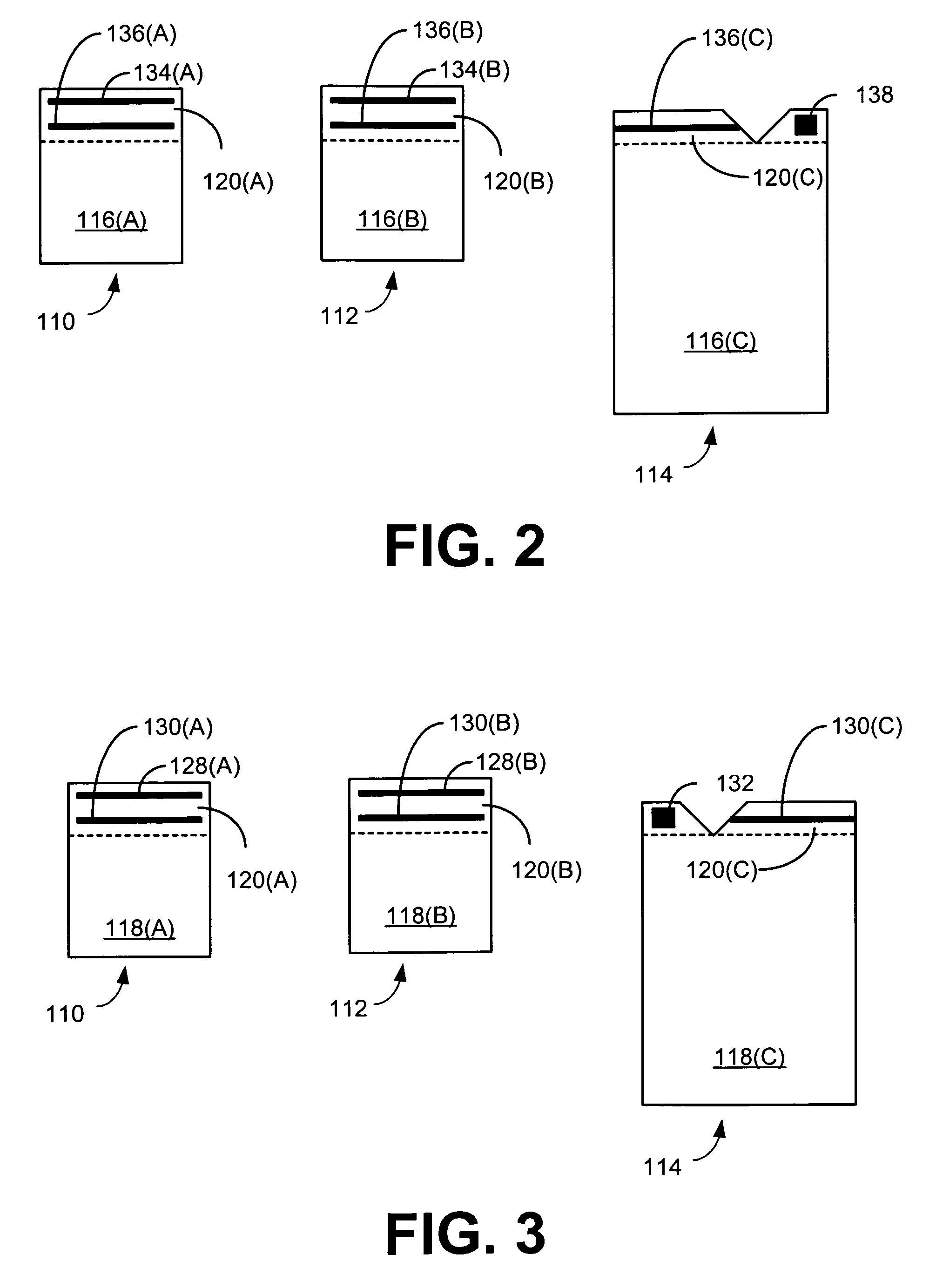

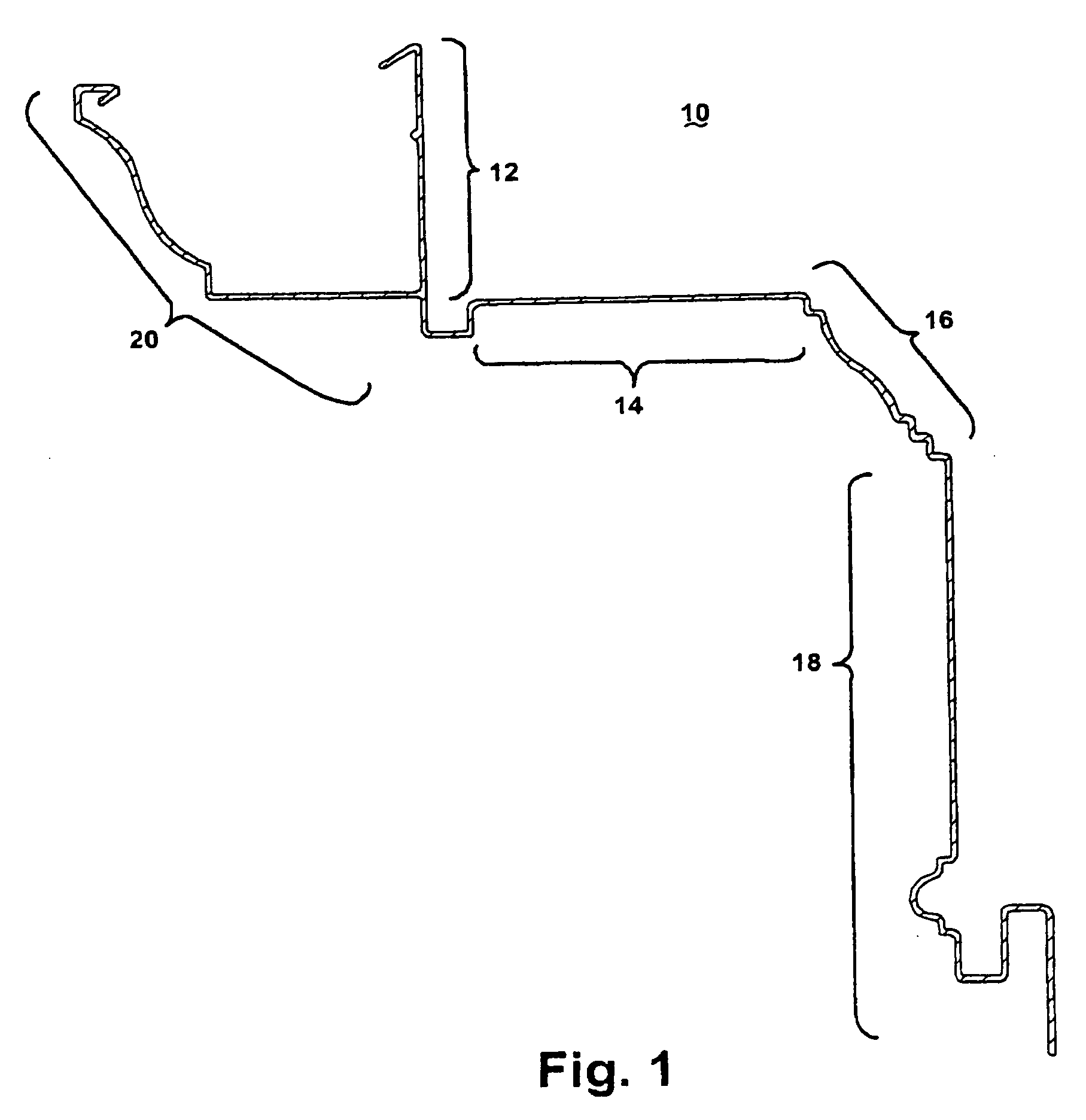

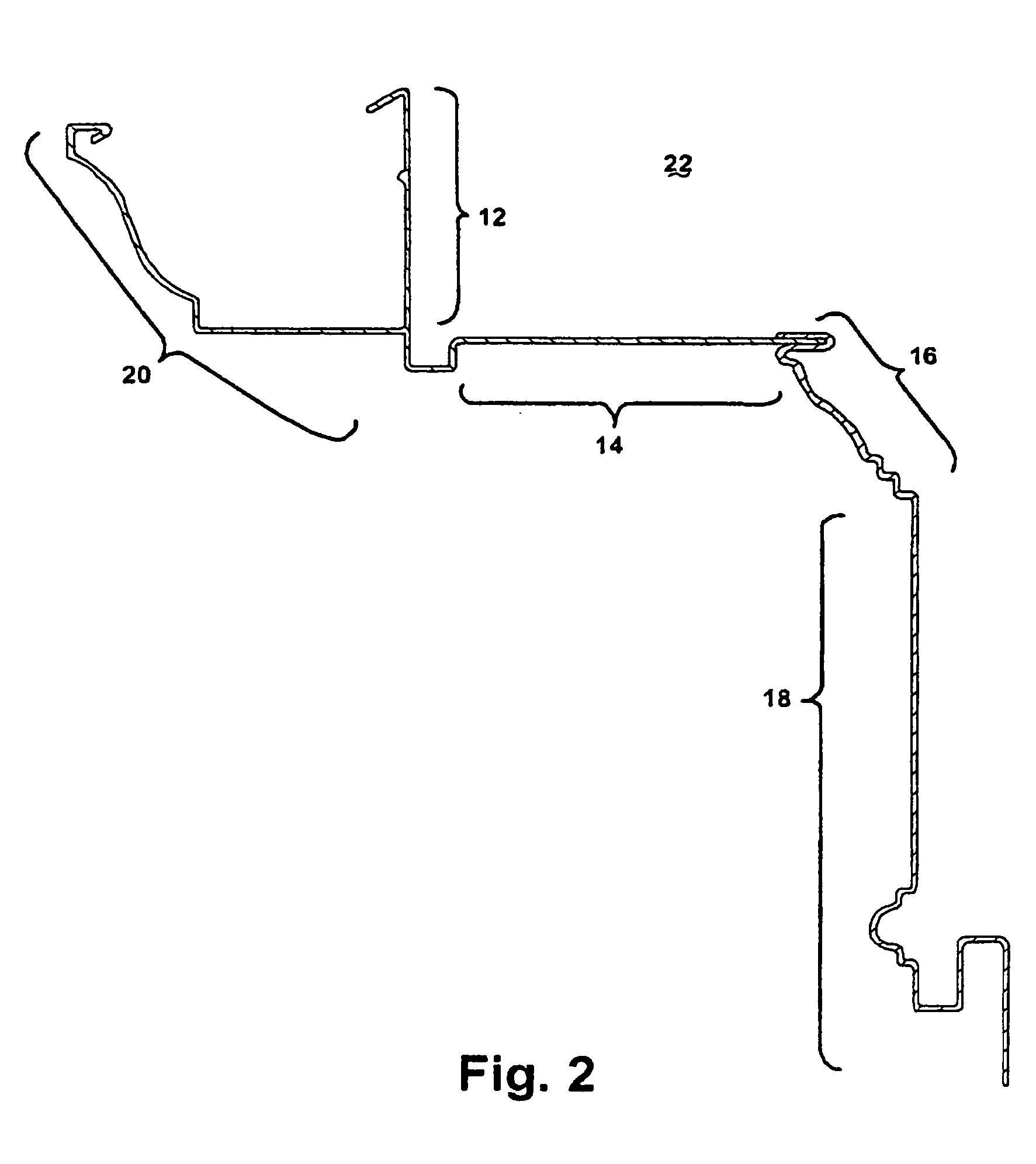

Architectural moldings for protecting, concealing and accessing indoor wiring and cables

InactiveUS20030106702A1Increased durabilityMinimizing penetrationCoupling device connectionsBuilding componentsFiberLow voltage

A system of architectural moldings that form a passage for electrical wiring (30), coaxial cables, fiber optic cables, and associated devices used in transmitting low-voltage power, communication, and control signals. The architectural moldings may also be used to cover pre-existing wiring raceways and conduits. The system may be installed when constructing a building or when retrofitting an existing structure. The moldings can be removably mounted on the interior surfaces of residential and commercial structures in a manner that allows for easy removal and replacement of some or all of the moldings without disturbing the enclosed wiring and cables or harming finished surfaces. The moldings may be made of wood, polyurethane, fiberboard, or any material suitable for manufacturing pieces that resemble baseboards, cornice moldings, chair rails, casings, or other interior millwork. The system of moldings facilitates upgrades or modifications to the number, type, or placement of wiring, cables, outlets, jacks, or associated devices.

Owner:SEAMANS JAMES D +2

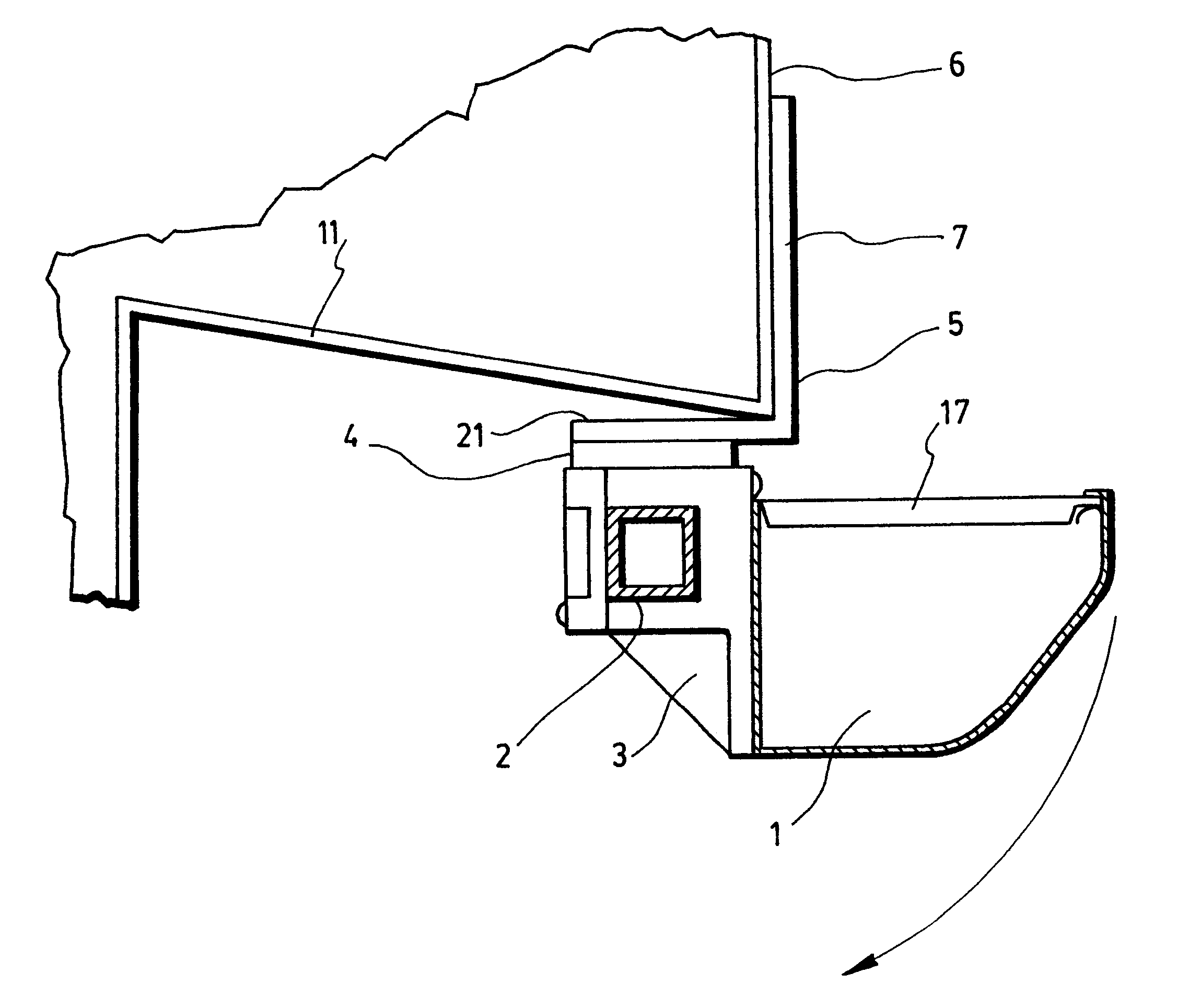

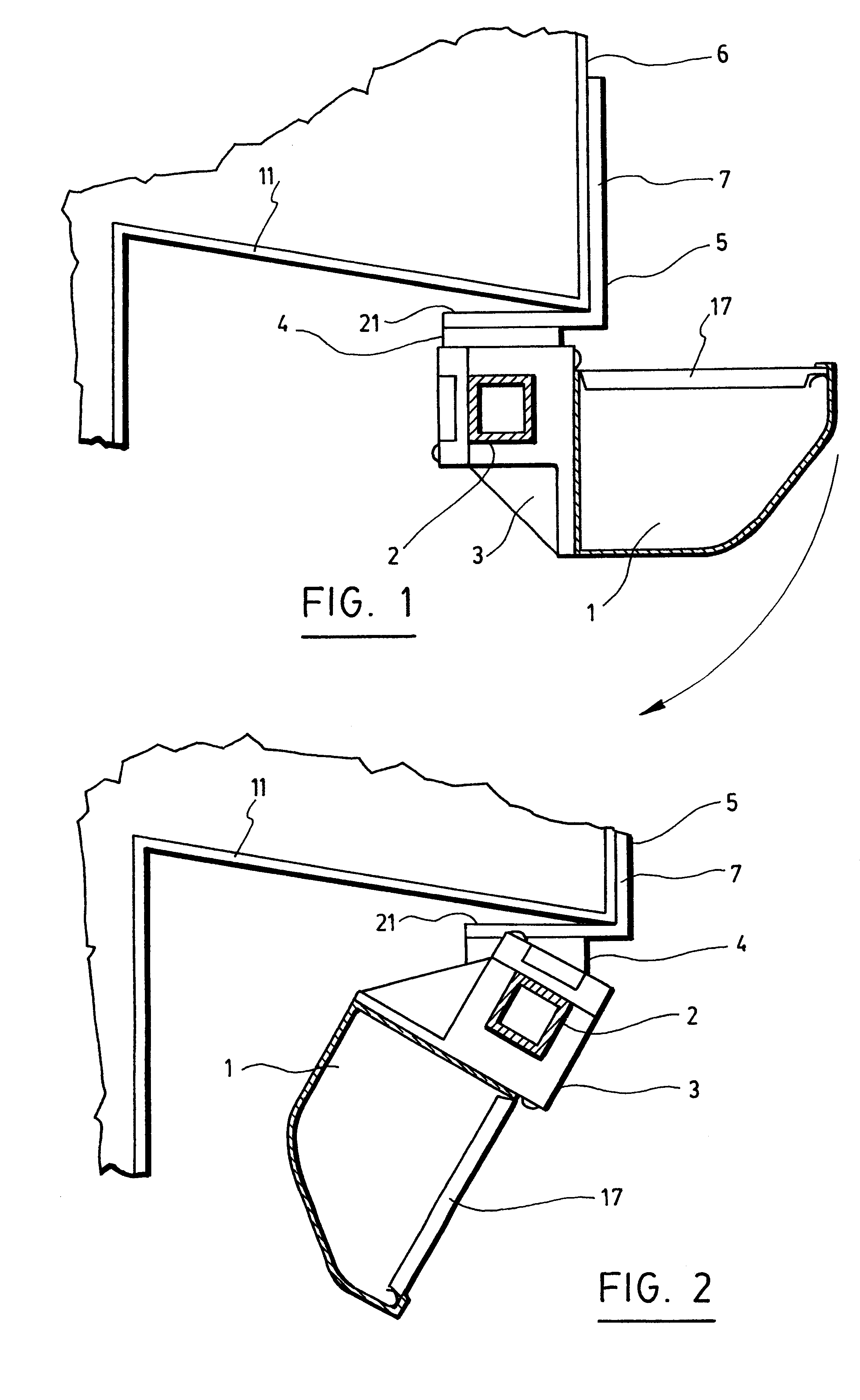

Pivotable gutter assembly and kit therefor

InactiveUS6233876B1Easy to cleanEase of evacuationRoof drainageStands/trestlesMotor driveRemote control

A pivoting gutter assembly is disclosed, in which the gutter can be, during summer months, put into the horizontal collecting position to receive rainwater from the roof and to direct it to a down-spout. For the winter months and or maintenance, the gutters are swung-out to downwards vertical position below the roof cornice thus being protected from damage. The gutter system includes hangers attached to the roof, the hangers each having a bearing. A shaft is inserted into the bearing and the gutter is fixed to the shaft. The system provides for special hangers assuring the correct pitch of the gutters. Also, it contains a down-spout for location above a fixed downward collector for rainwater, thus permitting the gutters to be pivoted from horizontal to vertical position without the need to disconnect the down-spout. A wormgear and wormdrive are attached to the end of shaft, outside the house fascia; this drive permits to operate the gutter's position from the ground level by an extended bar and manually driven crank or by using electric motor's drive attached to worm and remote control, eliminating the need of a ladder to reach downward position particularly important for the gutters installed on the roof high above the ground such as high rise buildings.

Owner:OBIDNIAK LOUIS

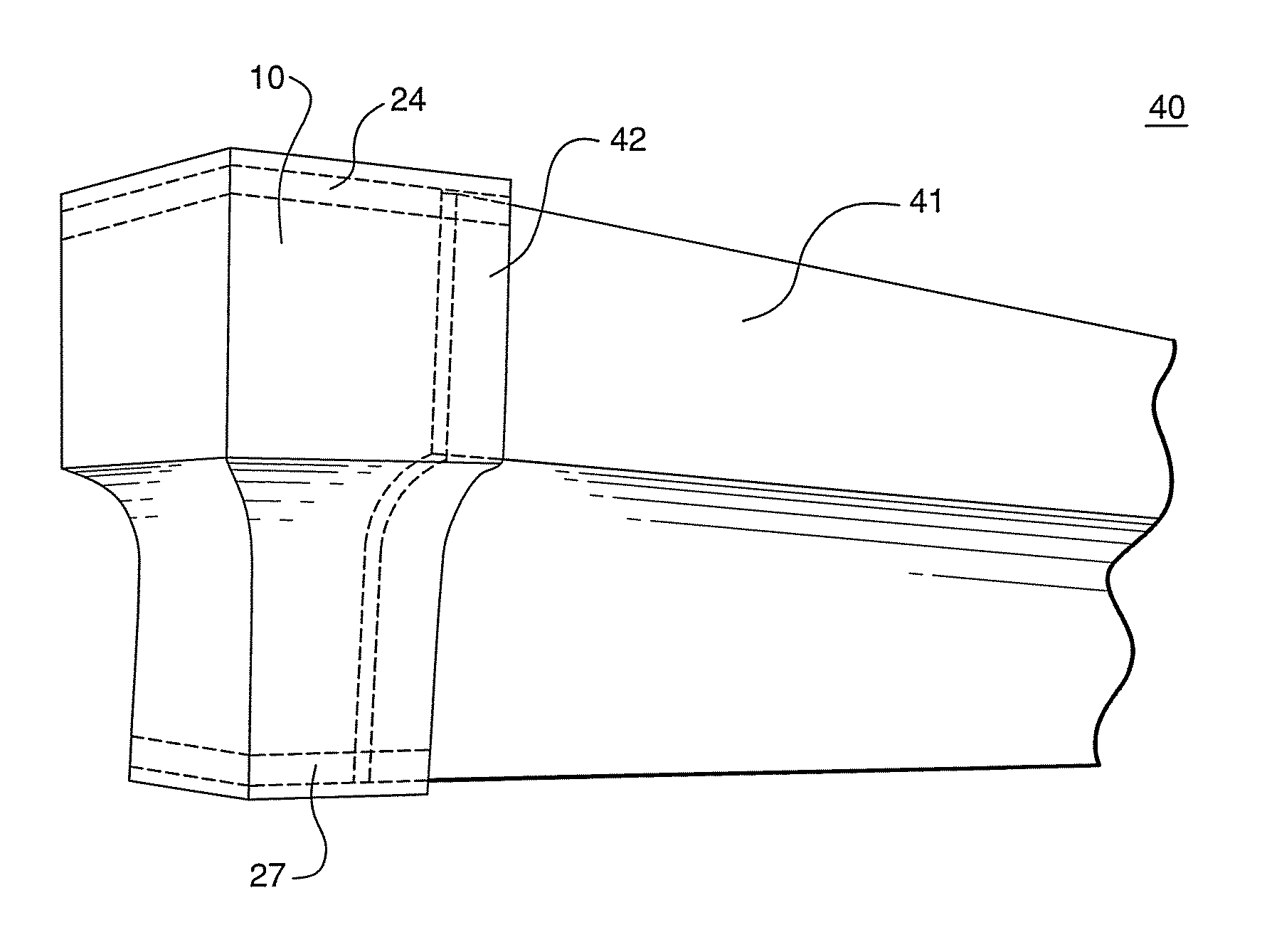

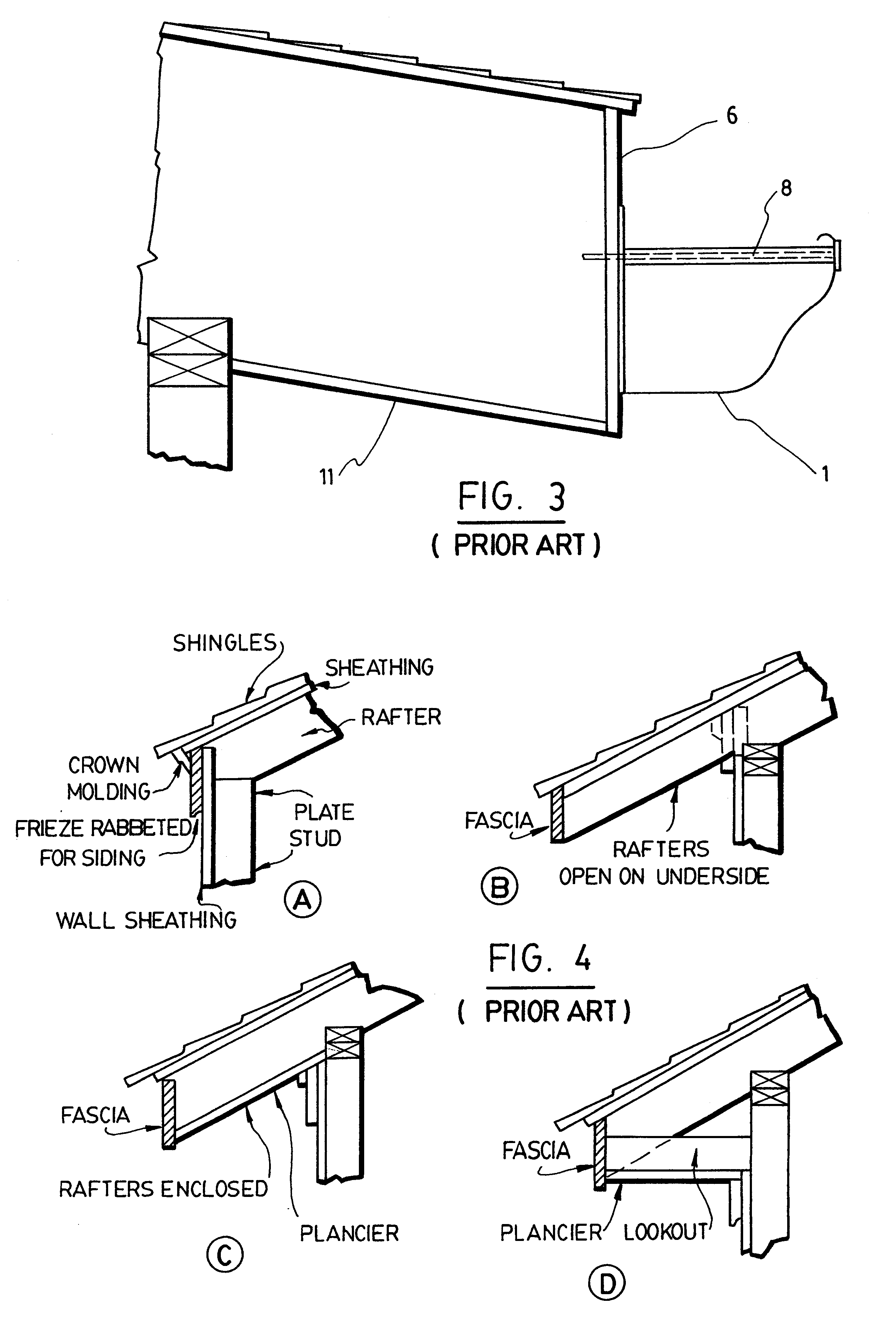

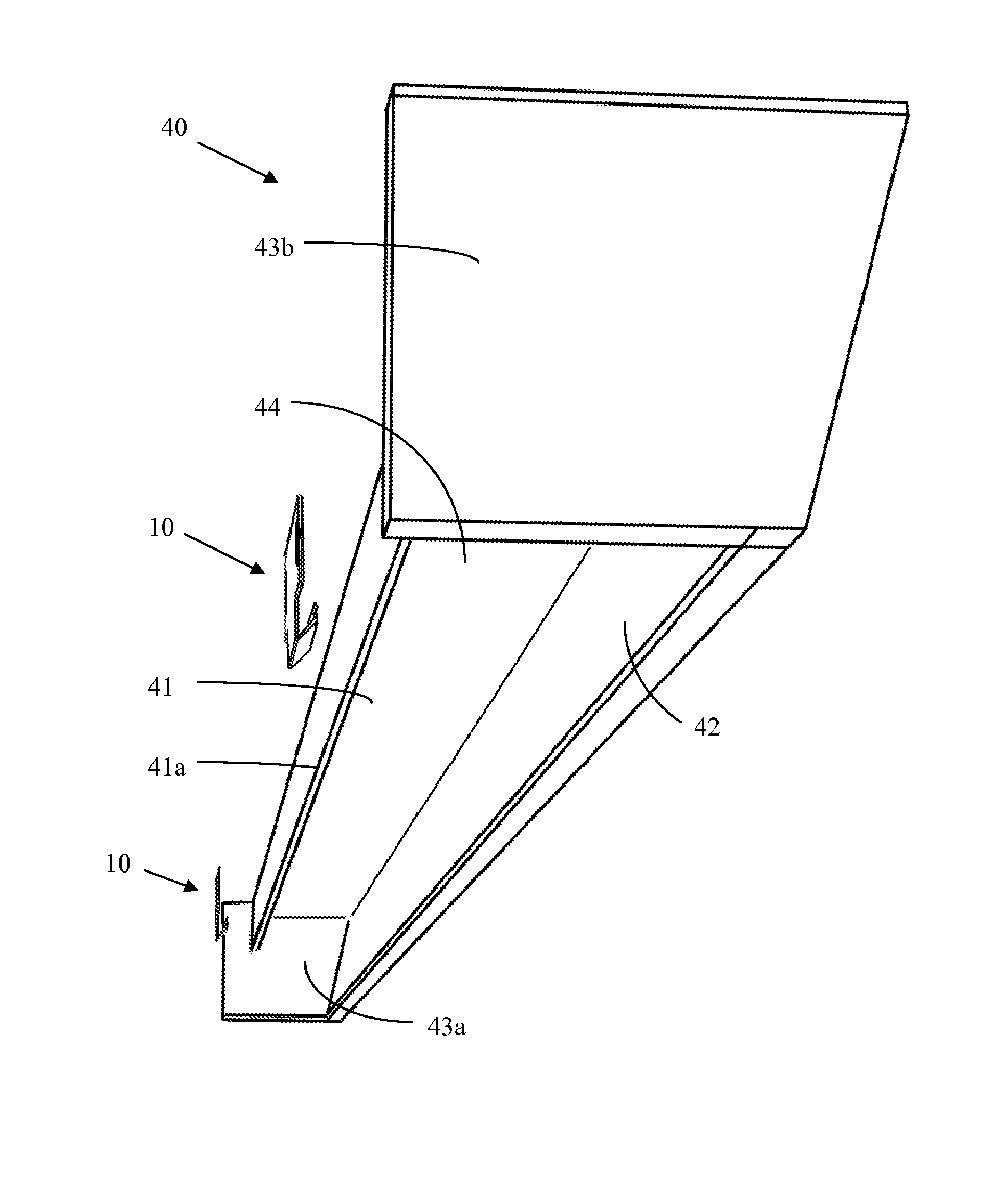

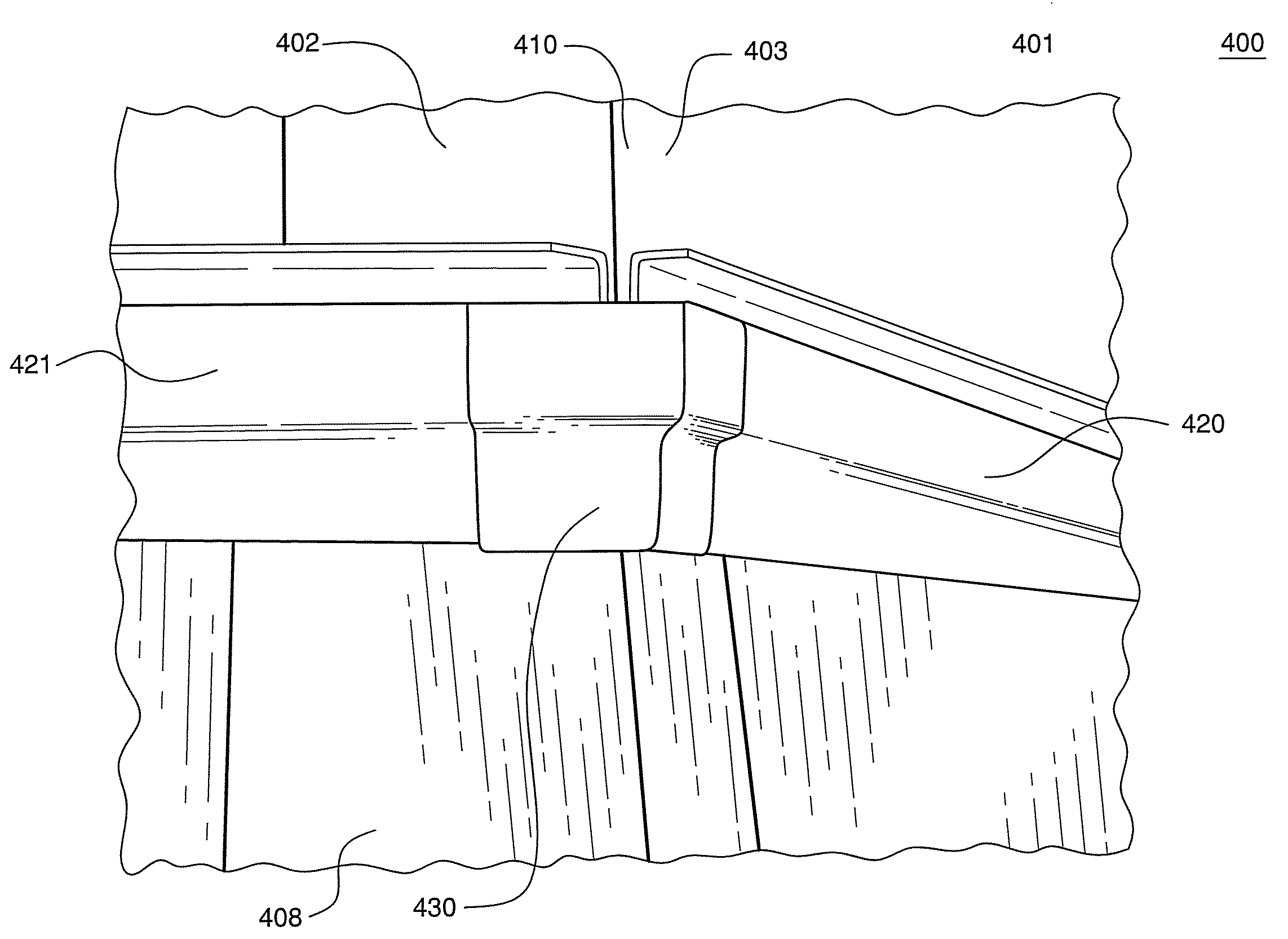

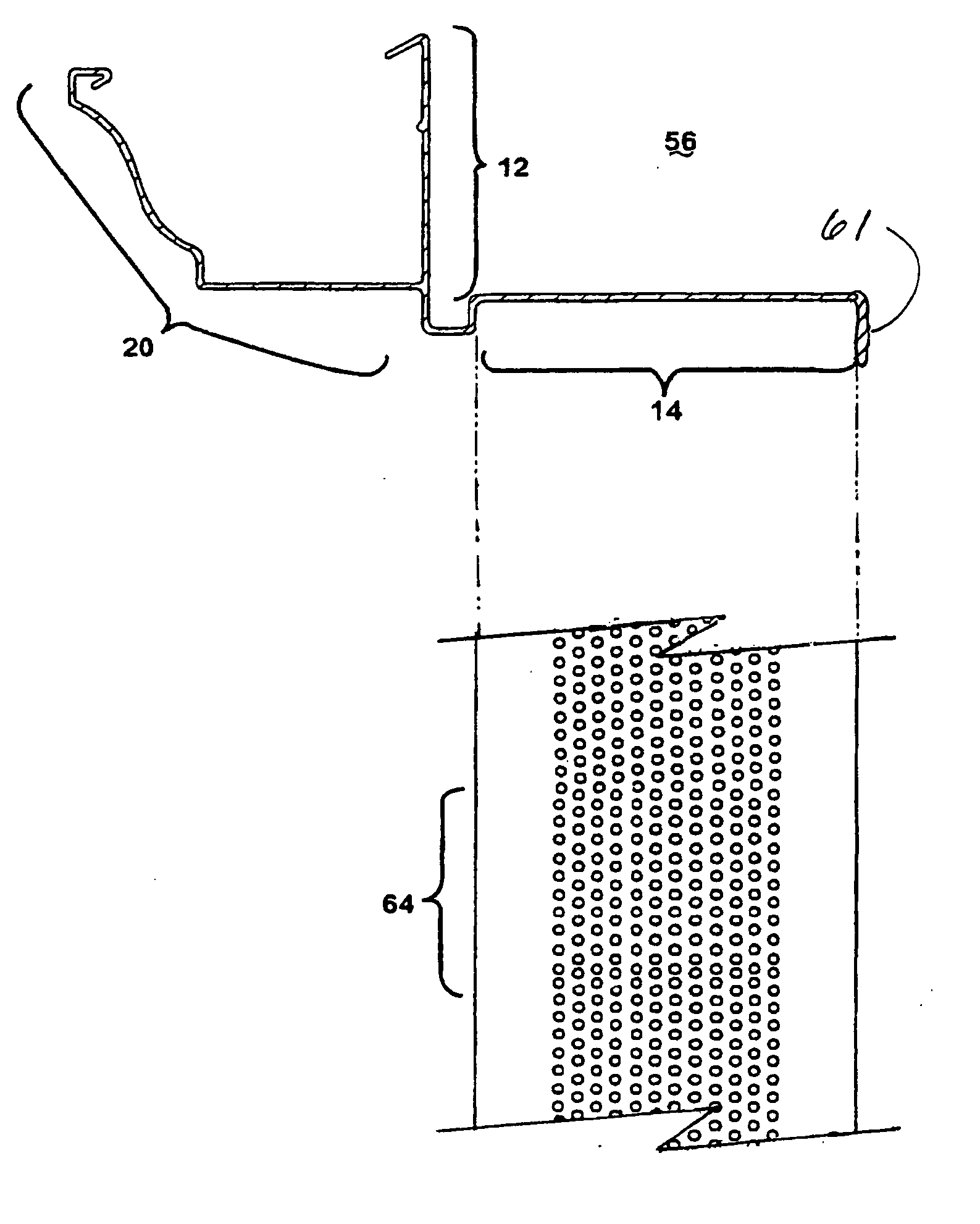

Pultruded trim members

InactiveUS7318282B2Simple methodBuilding roofsRoof covering using slabs/sheetsCorniceImproved method

The present invention is an improved method of making cornice assemblies and other trim members utilizing the process of pultrusion. The cornice assemblies and the other trim members made by the method of the present invention exhibit superior strength to weight ratios, low expansion and contraction due to changes in temperature and humidity, as well being less labor intensive to install.

Owner:PN II

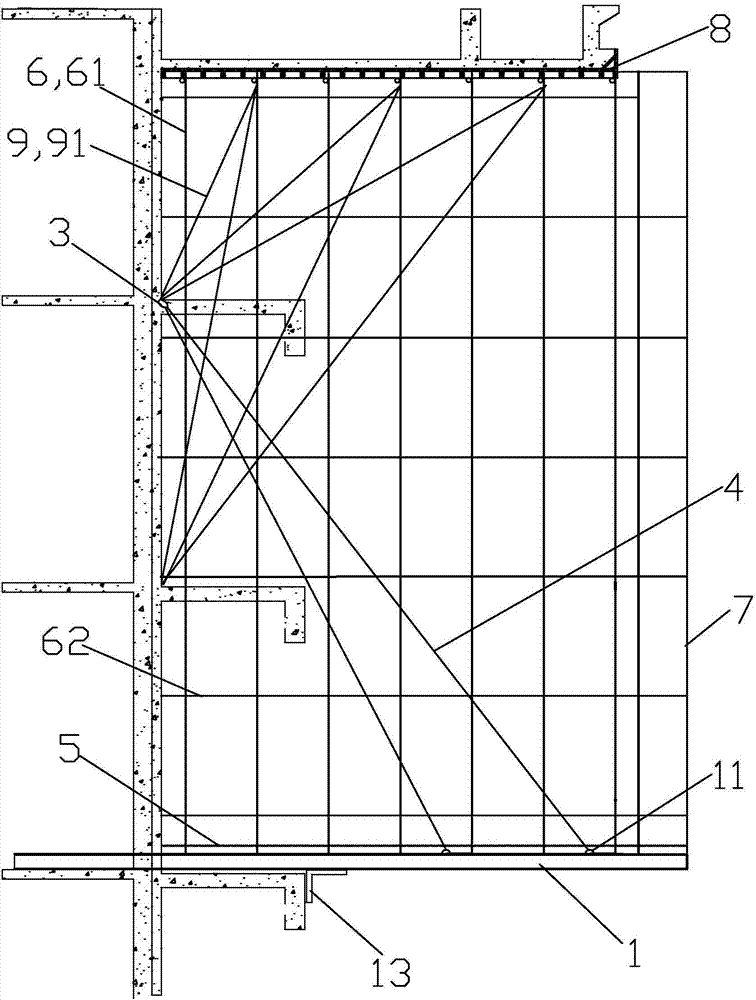

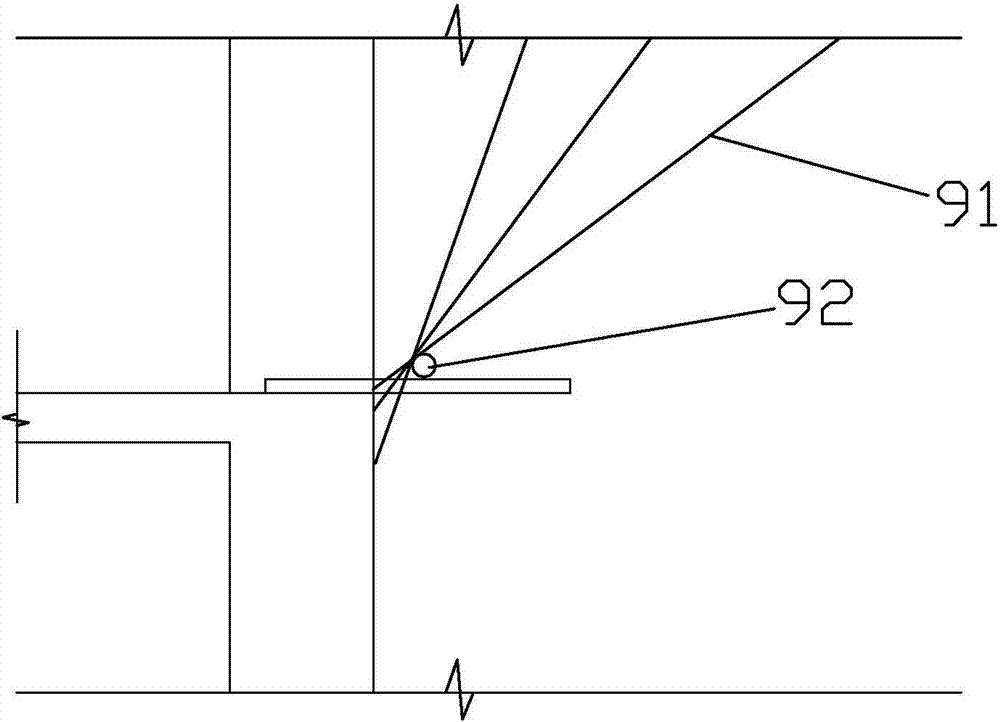

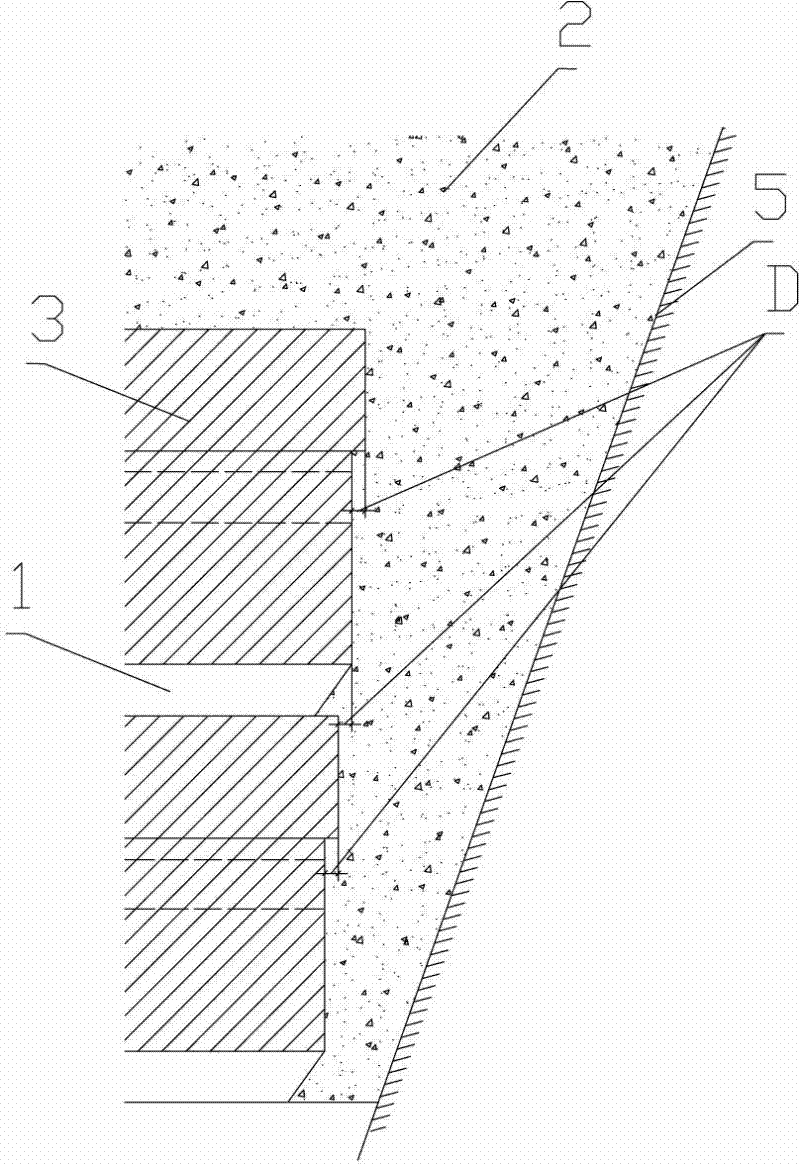

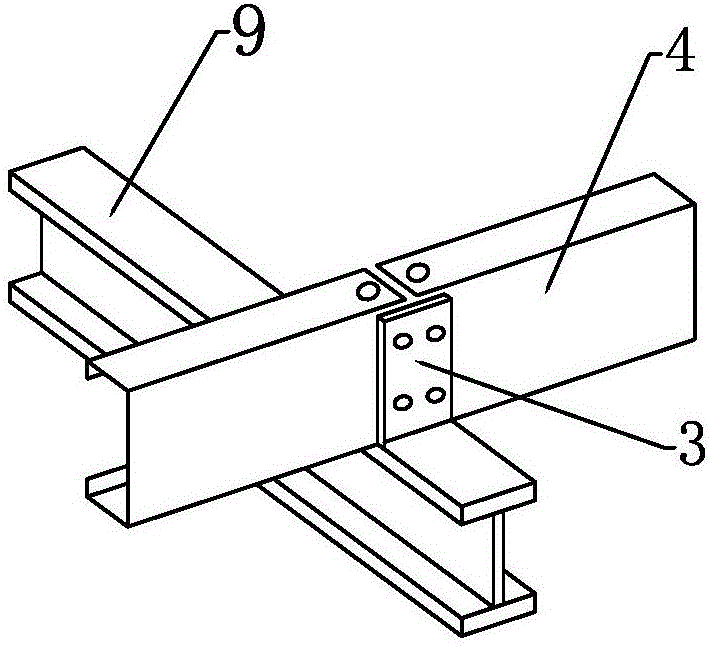

High-altitude long-span overhung cornice formwork supporting system and constructing method thereof

ActiveCN103669845ASimple construction methodSimple construction processForms/shuttering/falseworksBuilding material handlingFalseworkSupporting system

The invention provides a high-altitude long-span overhung cornice formwork supporting system. The system comprises an overhung I-shaped steel beam, an overhung I-shaped steel beam fixing hoop, an anchoring ring, a steel wire rope inhaul cable, an operating platform, an overhung structure load-bearing frame, an outer protecting scaffold, a cornice supporting formwork and a secondary unloading assembly, wherein a pull ring, a vertical rod inserting-connection positioning part and steel angles are arranged on the overhung I-shaped steel beam, one end E of the overhung I-shaped steel beam is fixed to an architectural structure plane through the overhung I-shaped steel beam fixing hoop, the other end of the overhung I-shaped steel beam is tensioned with the steel wire rope inhaul cable, the secondary unloading assembly comprises an inclined-supporting steel tube and a pre-buried supporting point steel tube, and the secondary unloading assembly is used for performing secondary unloading on a cornice supporting formwork system. A constructing method of the high-altitude long-span overhung cornice formwork supporting system includes the steps of manufacturing the overhung I-shaped steel beam, arranging the pre-buried part, installing the overhung I-shaped steel beam, setting up the operating platform, the overhung structure load-bearing frame, the outer protecting scaffold and the cornice supporting formwork, installing the inclined-supporting steel tube and the like. The high-altitude long-span overhung cornice formwork supporting system is easy to construct and operate and convenient to detach, the construction period is shortened, and cost is saved.

Owner:CHANGZHOU NO 1 CONSTR GRP

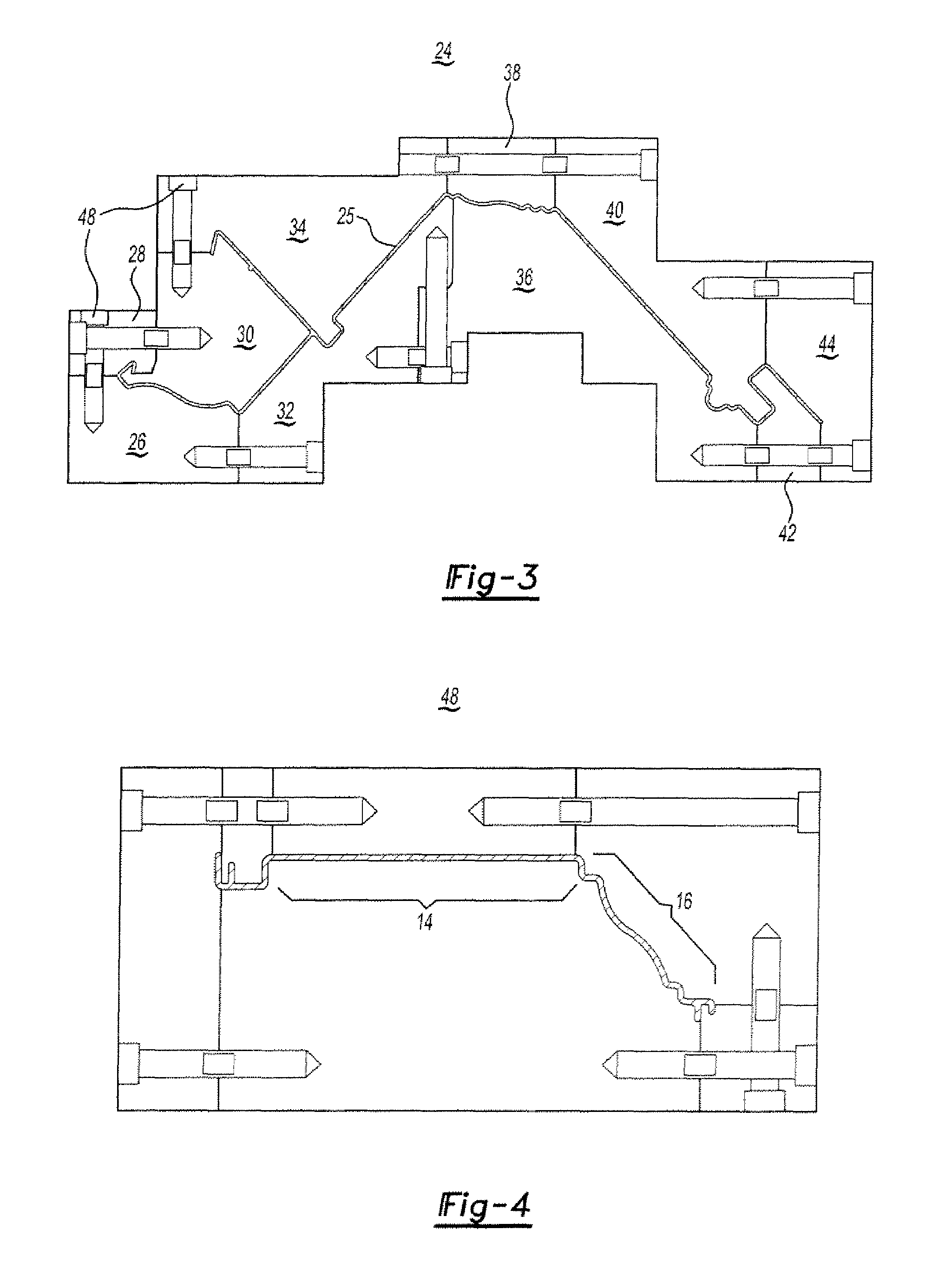

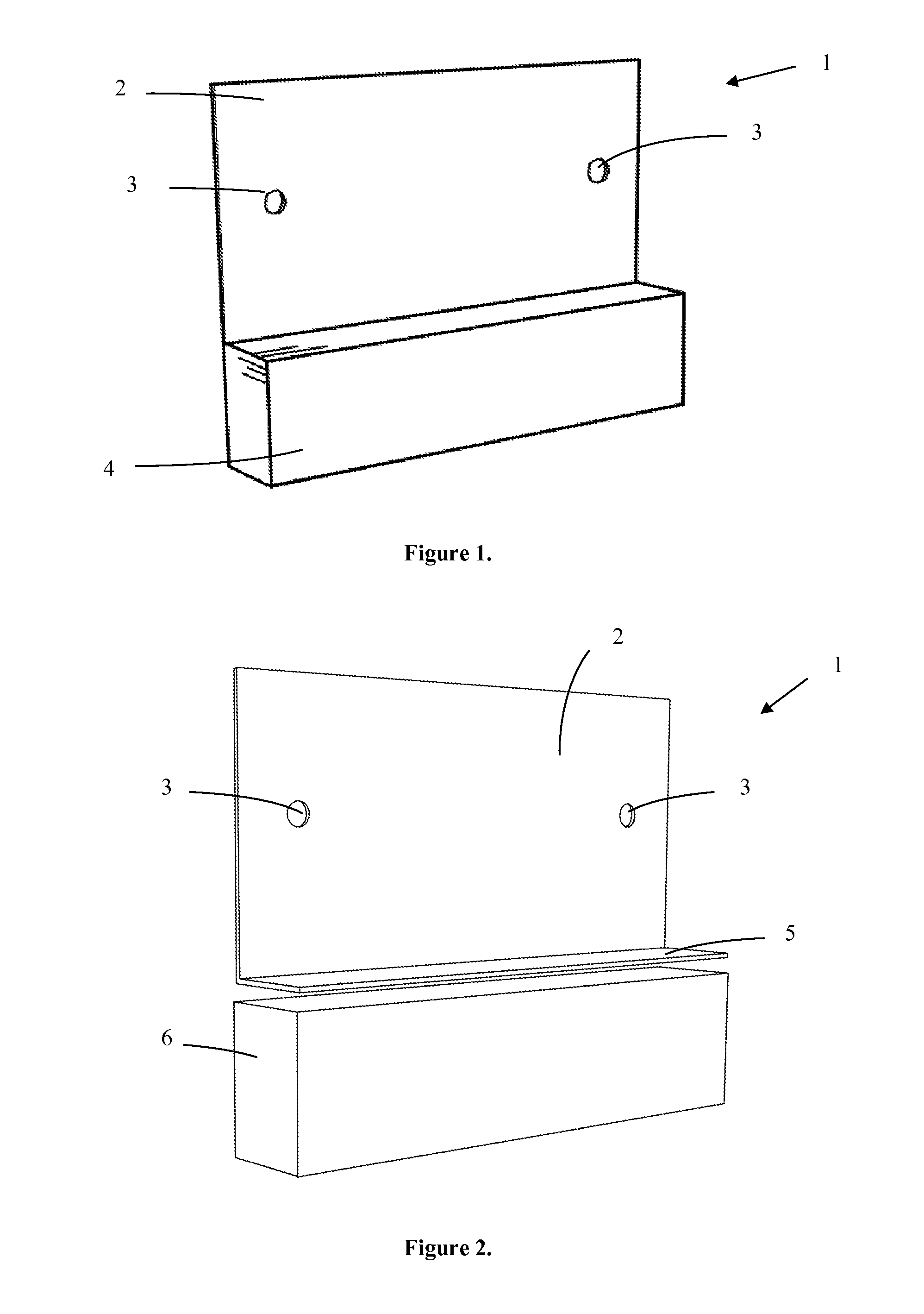

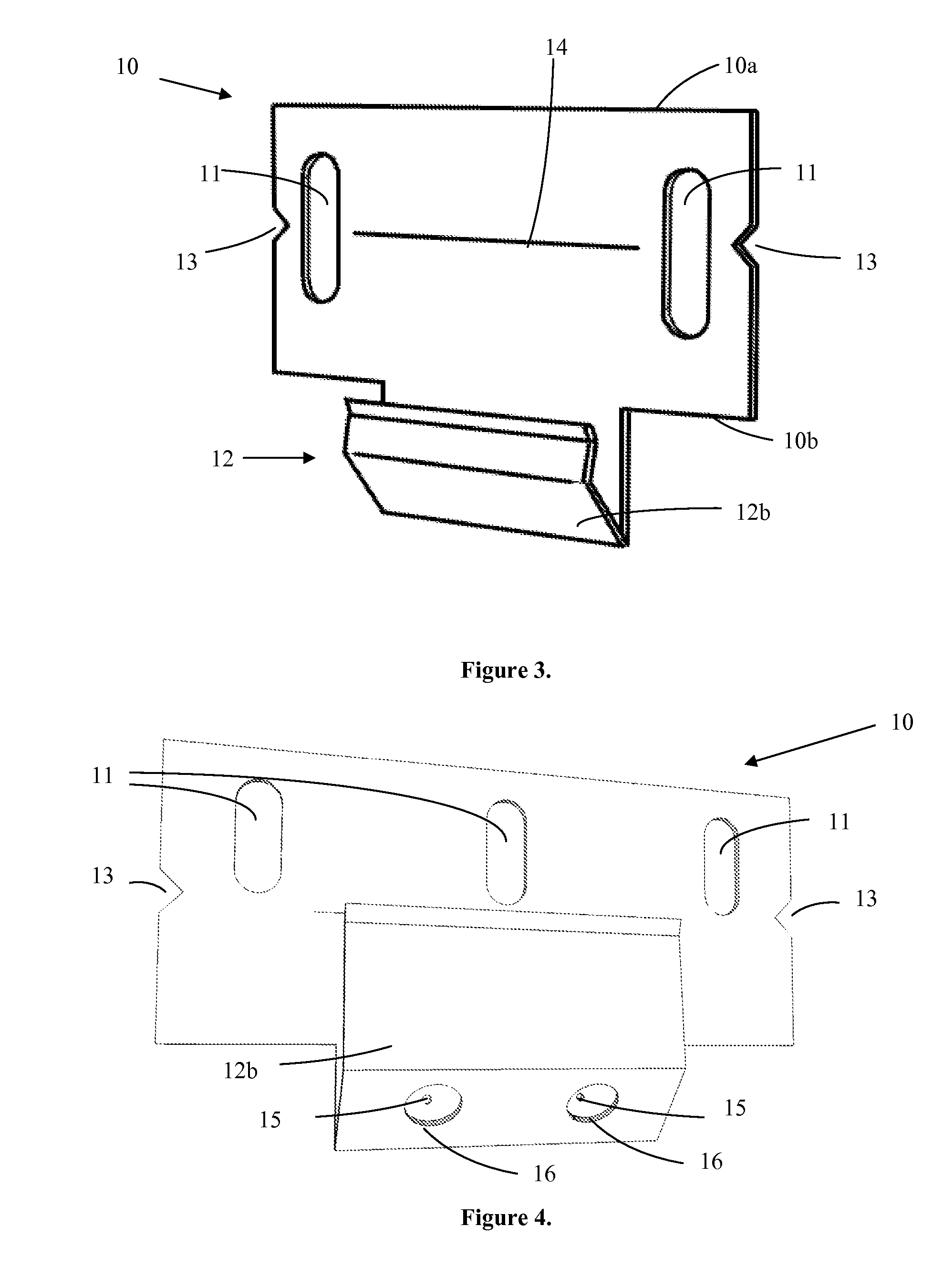

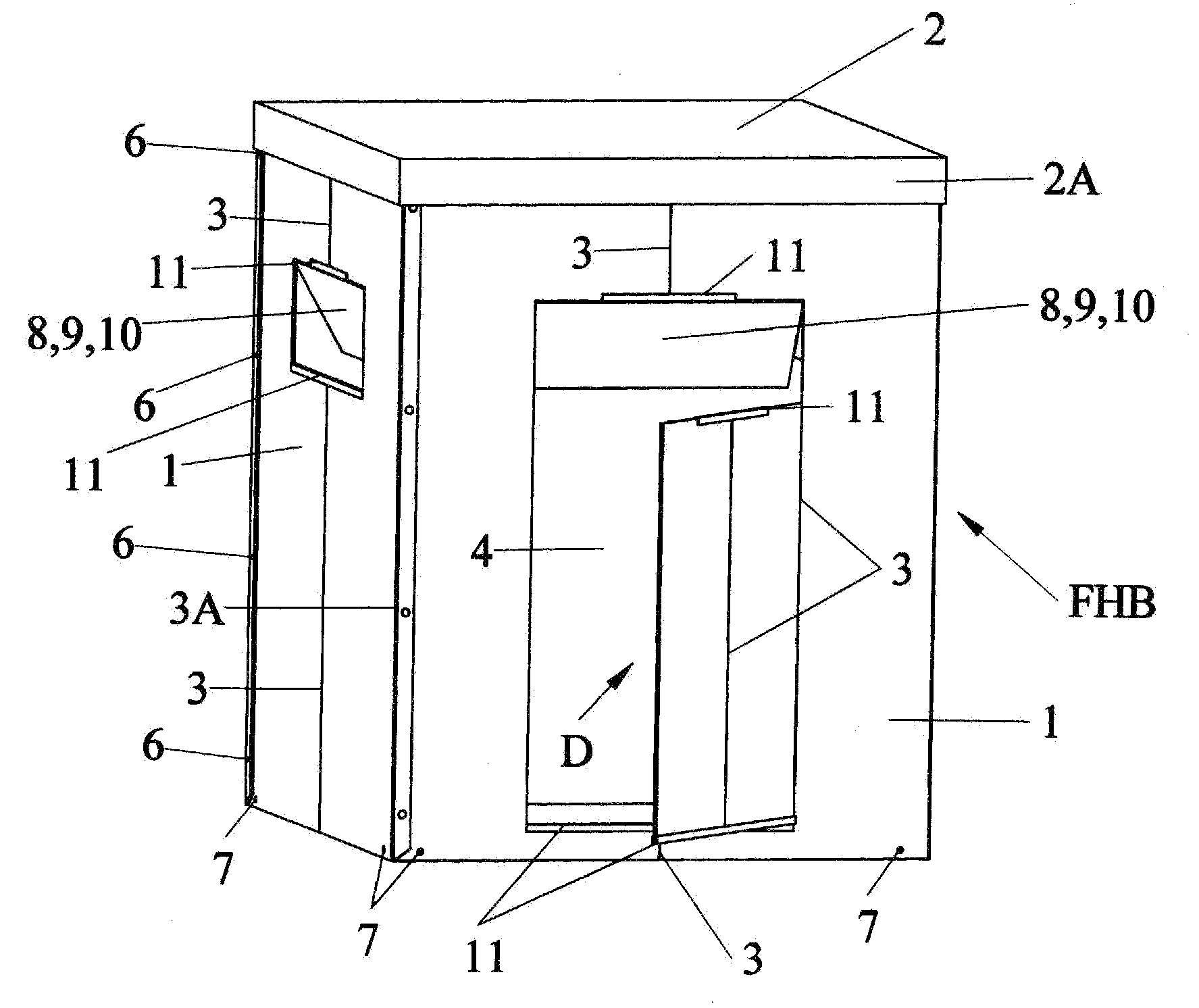

Bracket and spine mounted cornice and method of use

A bracket designed to reduce mounting system failures was designed, having a mounting surface and an angled clip on the lower edge of the mounting surface providing backward pressure for any hardware mounted onto the bracket. The sides of the mounting surface may include cut-outs for aligning multiple brackets. An optional screw-mounting system comprising corresponding holes in the clip, or a tab-mounting system, provide for connecting accessories to the bracket. A cornice centered around a spine element mounted to the bracket. The cornice has a front face and returns attached to either side of the front face, forming the structure. The spine is designed to fit into a plurality of brackets bent to provide backward pressure on the cornice, pulling it toward a mounting surface. The cornice is mounted by fixing the brackets onto a mounting surface and placing the spine of the cornice onto the brackets.

Owner:CORNICESMITH

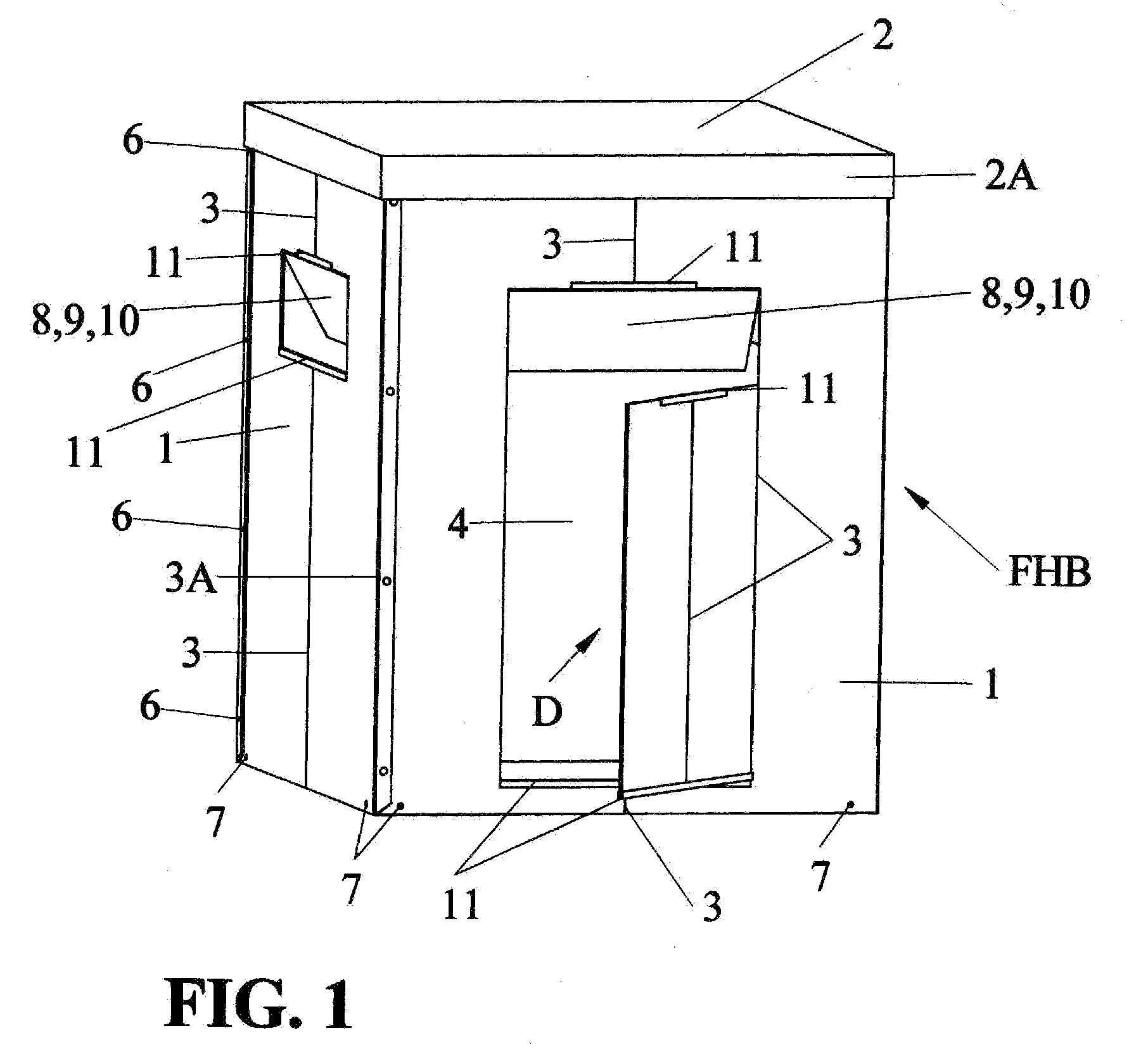

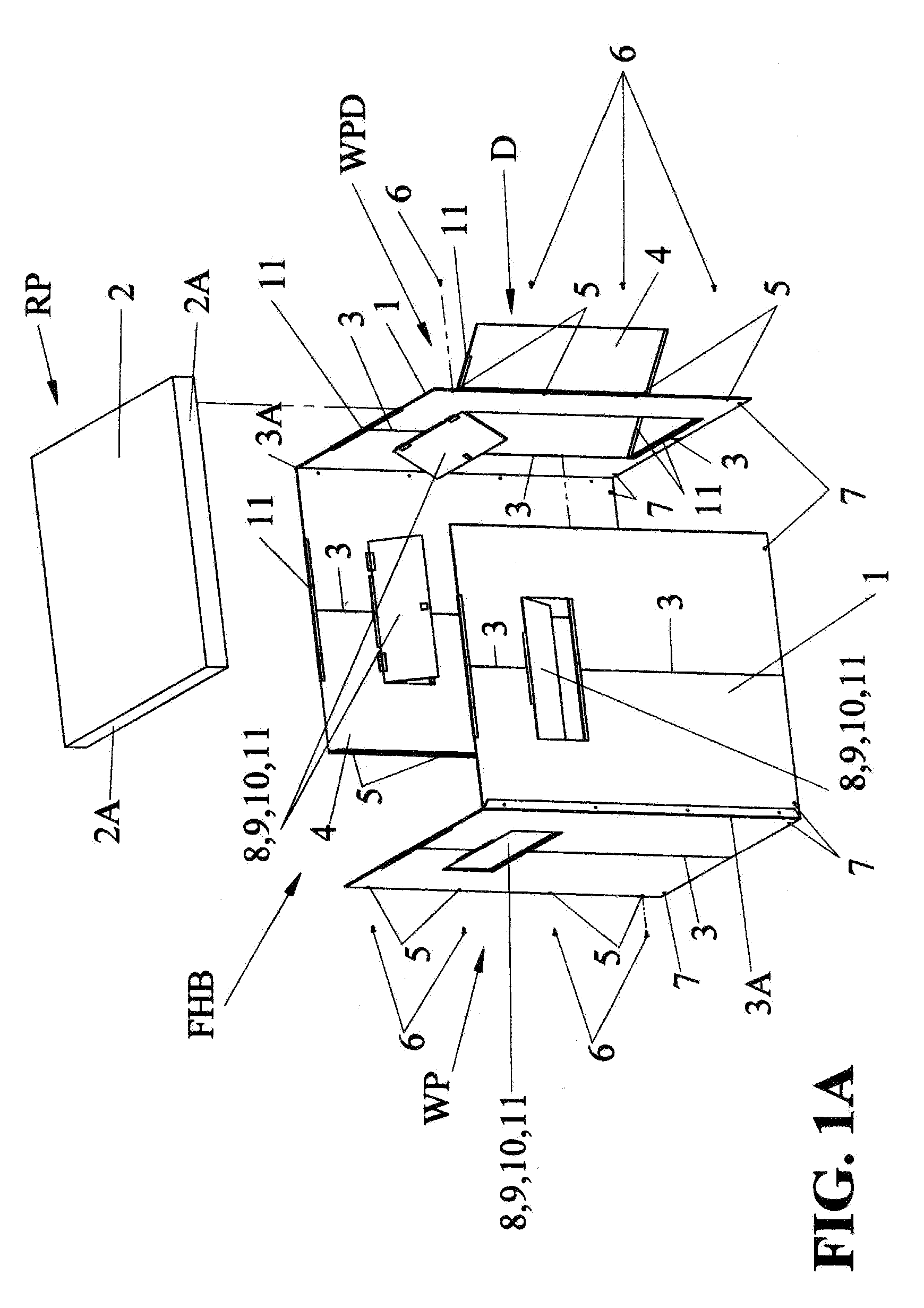

Frameless portable hunting blind/ice fishing hut that absorbs sounds and scent with carry/storage case

InactiveUS20070033854A1Small movementRule out the possibilityAnimal huntingTents/canopiesSlide windowWindow shutter

The invention is a frameless portable hunting blind / ice fishing hut that absorbs sounds, and scent with carry / storage case. The hunting blind / ice fishing hut, is a enclosed room-like structure with or without a tree break-up pattern on the exterior and having at least two wall panels forming at least four walls with at least one horizontal lift-up and or sliding window in each wall that open and close, a door that opens outward, an interior and a roof panel with outer fitting cornice is supported and anchored on ground surface or ice surface. The hunting blind is able to conceal at least one hunters / occupants within its structure, absorbs sounds, and scent from within eliminating the possibility of detection by animal's keen sense of sight, hearing and smell while keeping the occupants out of the harsh weather. The hunting blind / ice fishing hut allows said hunters / occupants ease of transport from location to location within minutes by a hand carried carrying / storage case, ease of assembly

Owner:RIDGE GLENN FIELDING

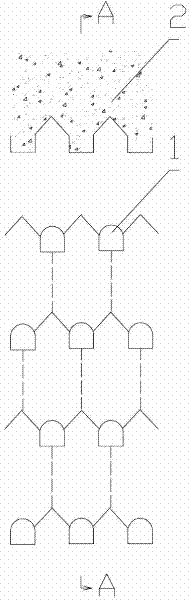

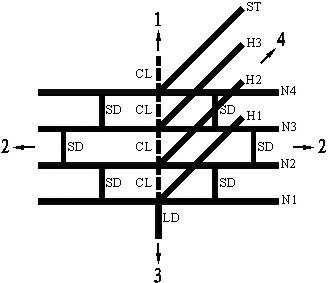

Bidirectional reinforcing and water drainage reinforcing means for highway soft soil foundation

The invention discloses a soft soil foundation two-way reinforcement and drainage reinforcement method for highways. The invention comprises the steps as follows: (1) the site is leveled and the pile positions are set out; (2) the construction is carried out by vibroflotation, hammering method, or vibrating tube sinking method to form a gravel pile; (3) the top of the pile is paved with Geocell coarse sand or gravel hardcore, the main composition body thereof is a Geocell layer with drain holes on the wall, the Geocell is filled with compact coarse sand or gravels, and the upper part and the lower part of the Geocell are respectively paved with drainage layers. By adopting the Geocell coarse sand or gravel hardcore and gravel pile two-way reinforcement and drainage structure, the method can realize a composite action of reinforcement, compaction, replacement and drainage on the soft foundation, effectively improve the strength and stability of the roadbed, reduce the differential settlement of the foundation and satisfy the requirement of traffic load increase on the bearing capacity and deformation of the roadbed.

Owner:HUNAN UNIV

A stage caving mining method with overhanging eaves and bottomless pillars with artificial false roof of steel-concrete structure

Owner:ANSTEEL GRP MINING CO LTD

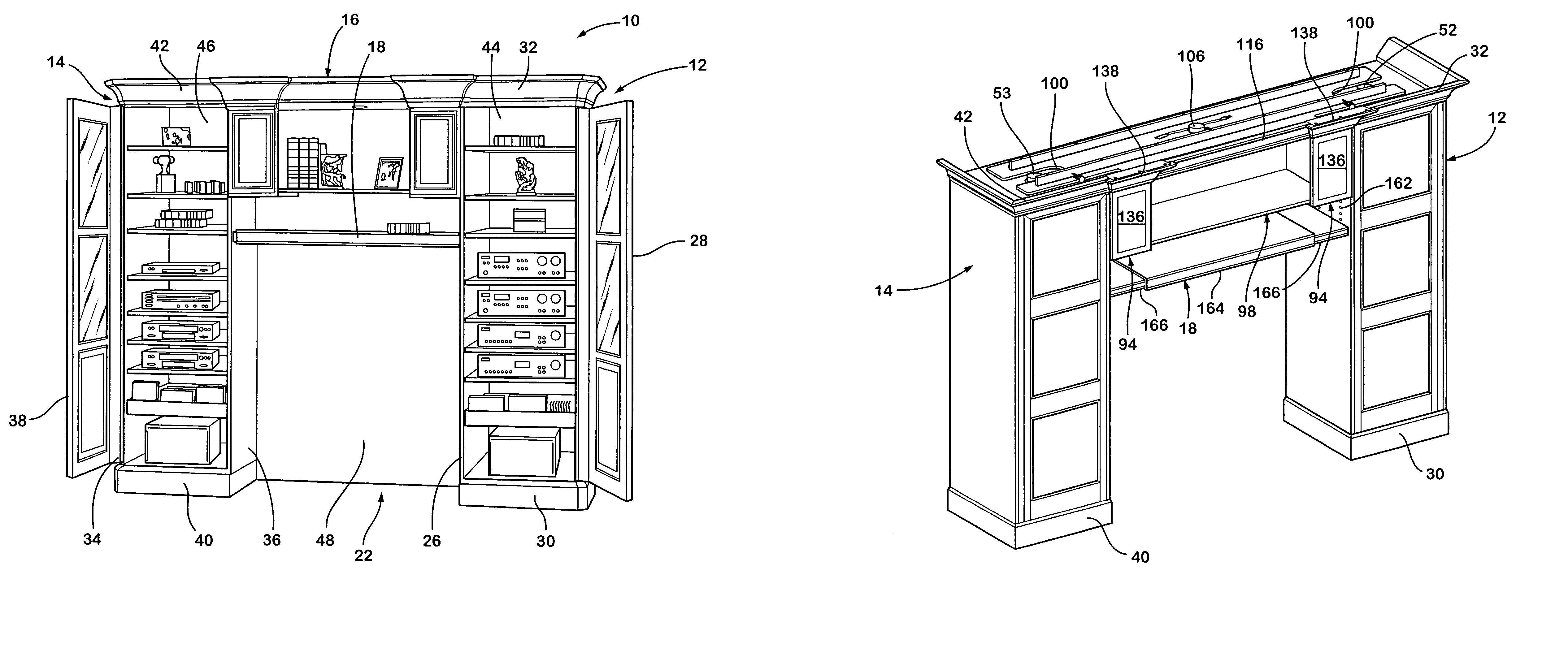

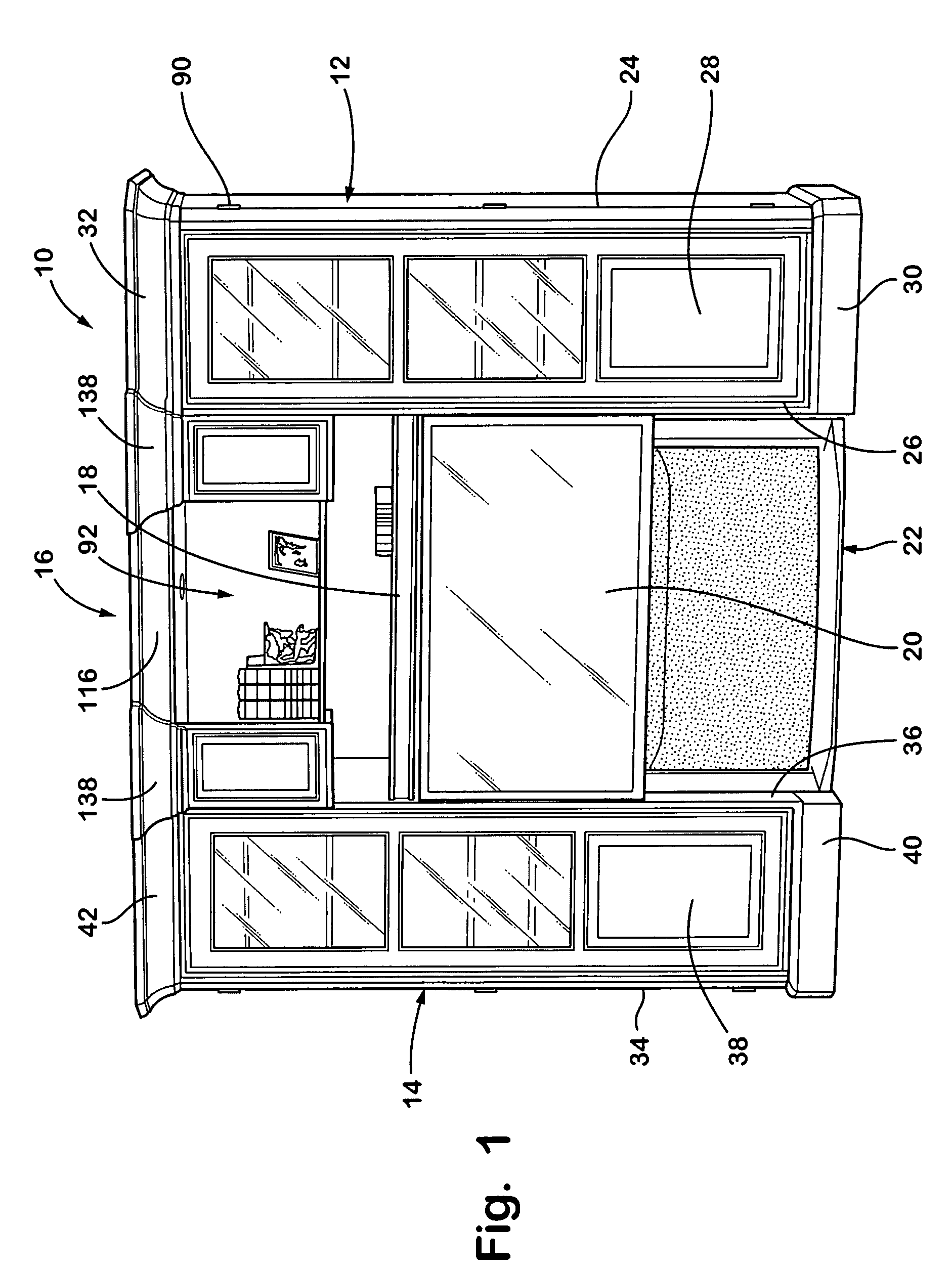

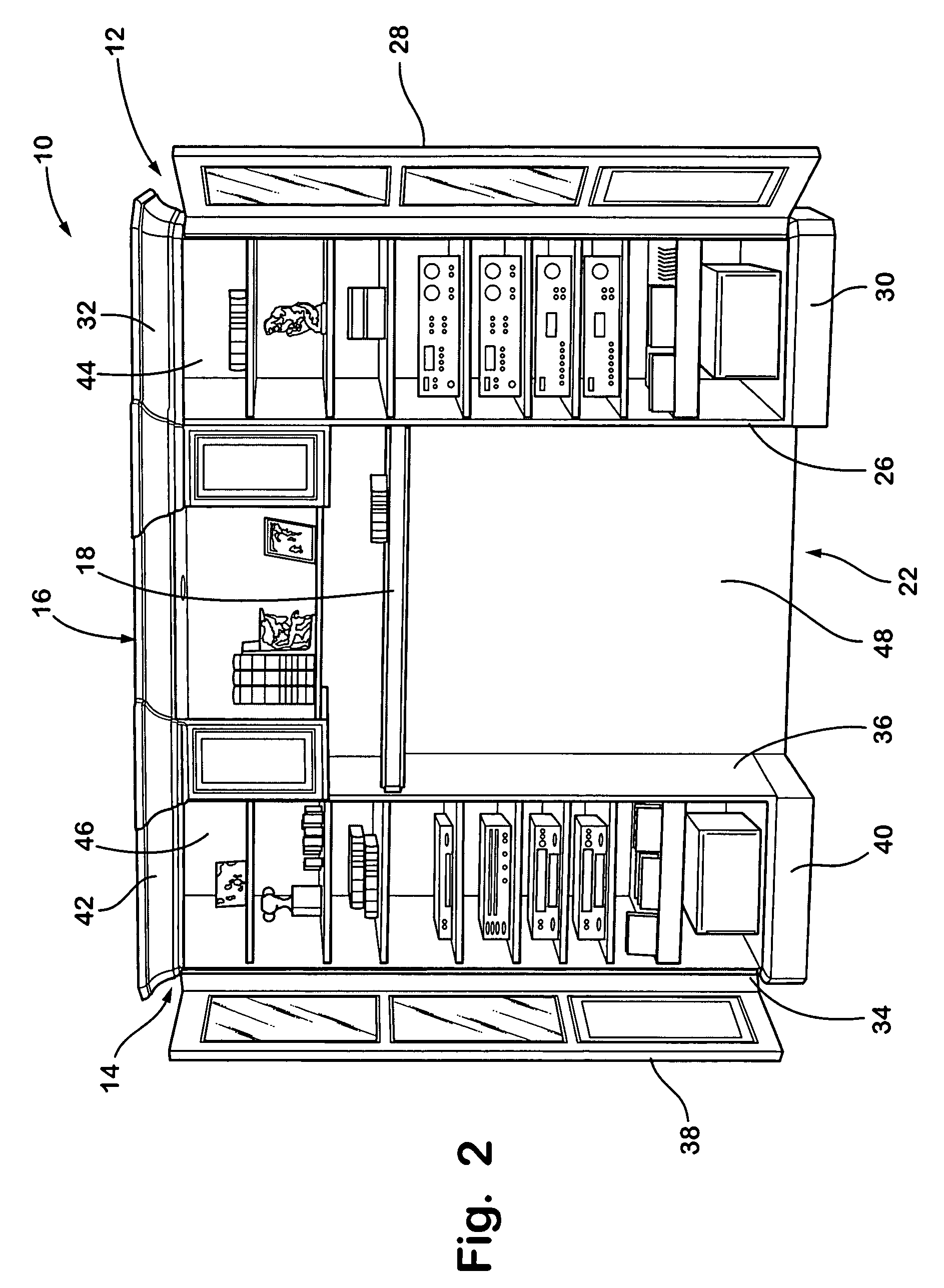

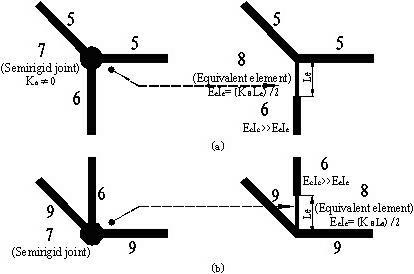

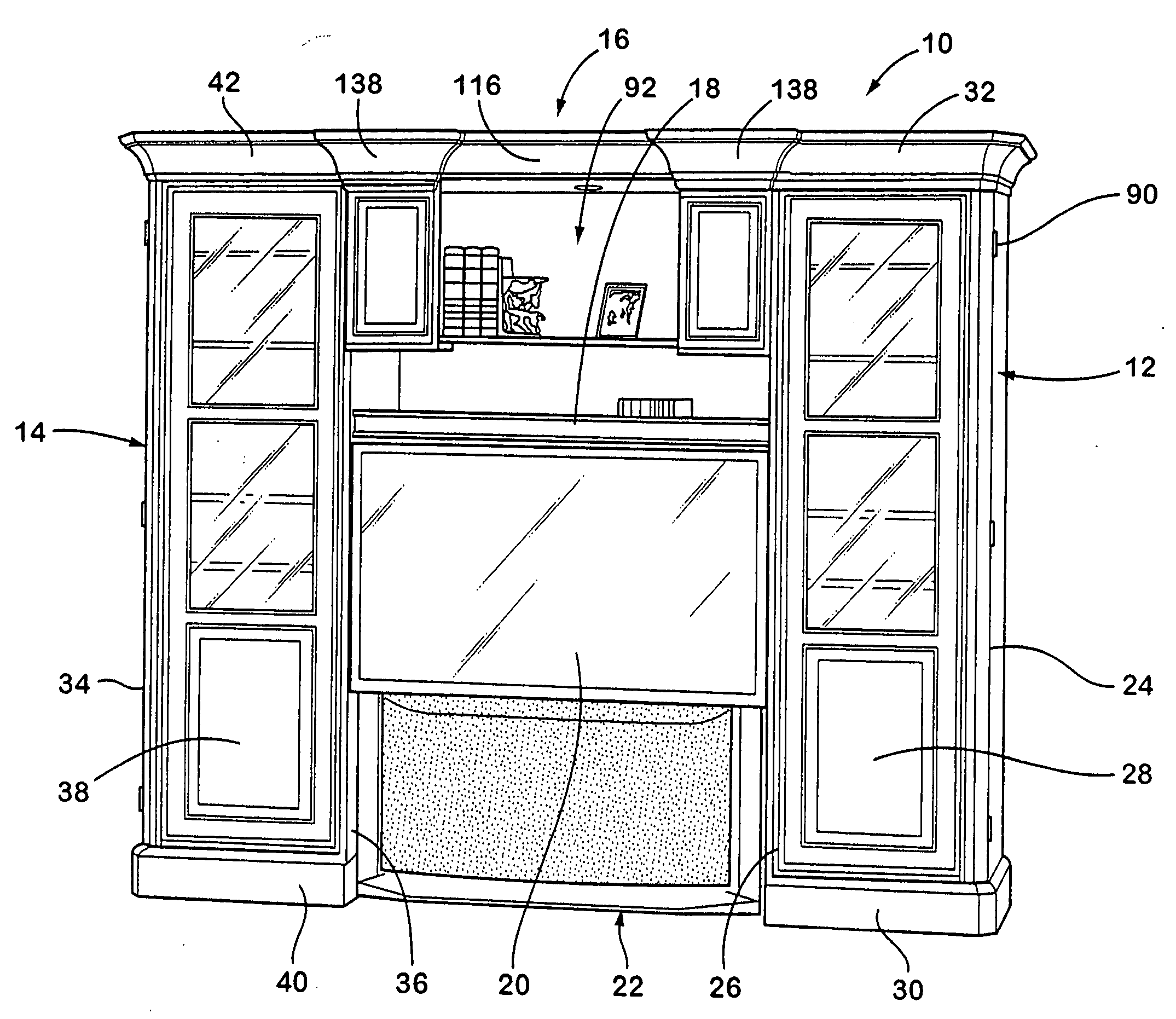

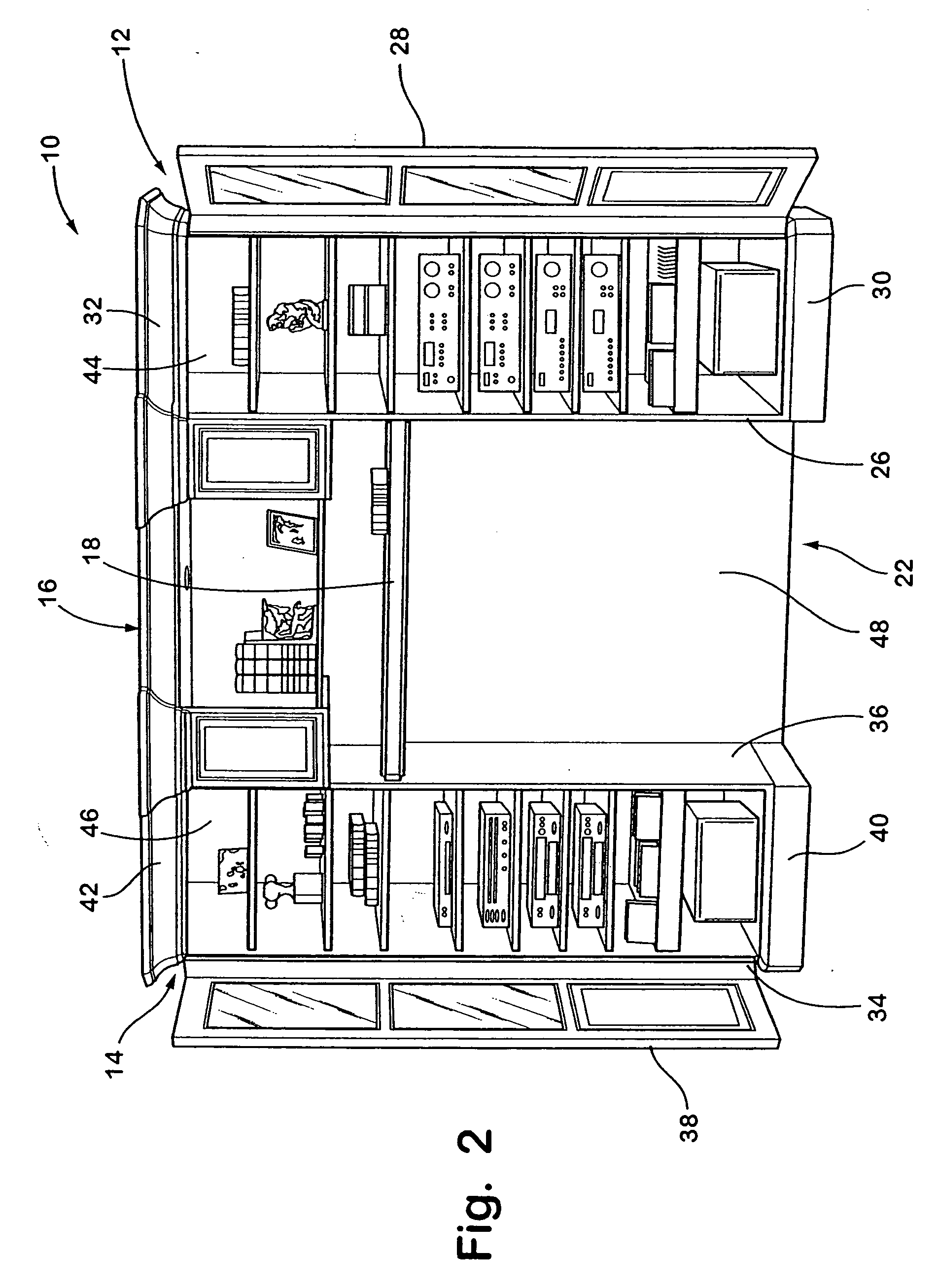

Expandable home entertainment cabinet

InactiveUS7040724B2Gap be minimalRestrict vertical deflection and saggingSuspended tablesWall tablesEngineeringCornice

An adjustable home entertainment cabinet for enclosing television sets of different sizes comprises a pair of movable tower cabinets and a bridge assembly that extends between the cabinets. A center section of the bridge rests on the tops of the cabinets. A bookshelf or shelf box is mounted on an underside of the center section. End sections movably mounted on the center section extend downwardly to cover gaps between the bookshelf and the inner sides of the tower cabinets. The center section includes a cornice molding that matches and is aligned with cornice molding on the tops of the tower cabinets. The end sections have a matching cornice molding that overlays and conceals the gap between the cornice moldings on the end sections and tower cabinets. Free standing television sets can rest on the floor. Table model sets and monitors can rest on free standing TV stands / storage cabinets of different widths that fit snugly between the tower cabinets. An adjustable media storage drawer has movable dividers with hook and loop fabric on lower edges that attach where desired to a loop fabric that covers the bottom of the drawer.

Owner:SLIGH FURNITURE

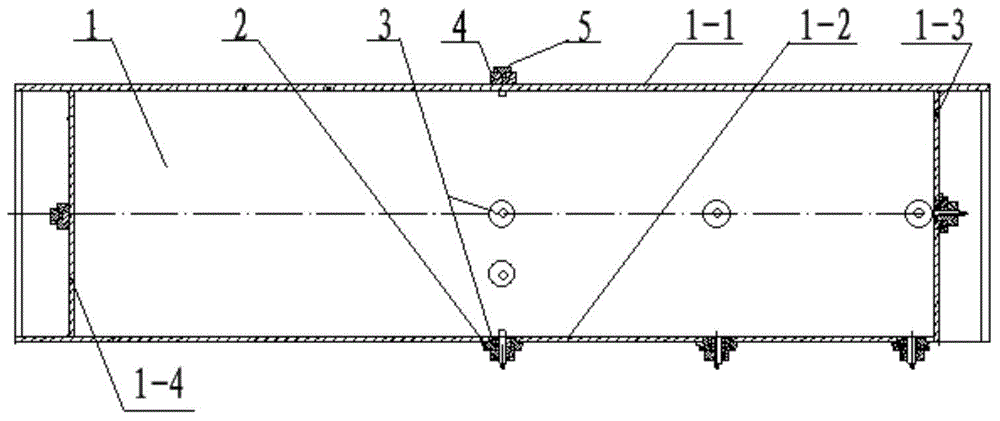

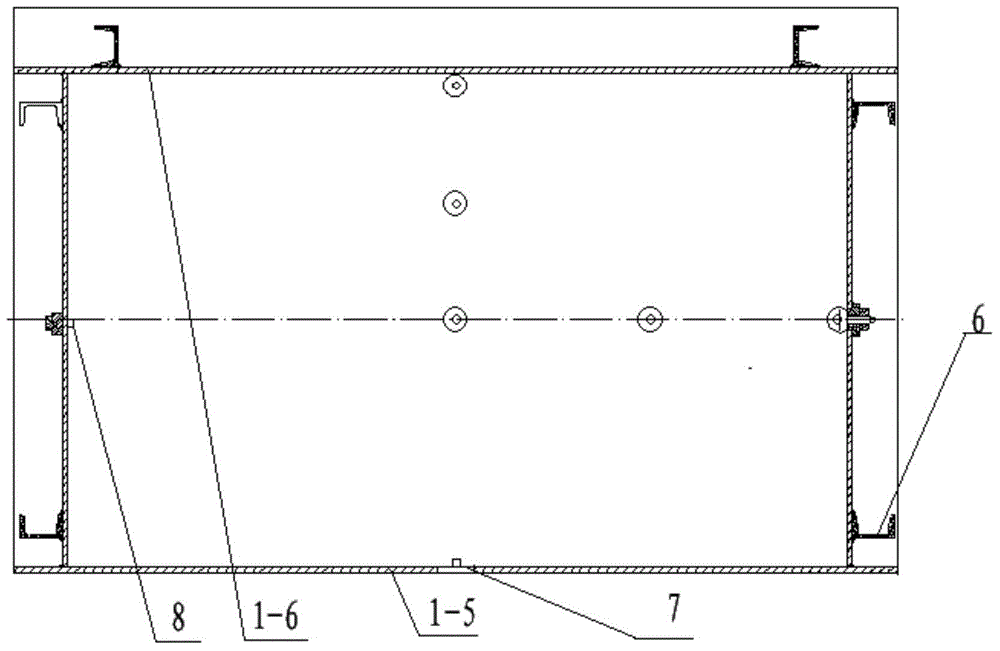

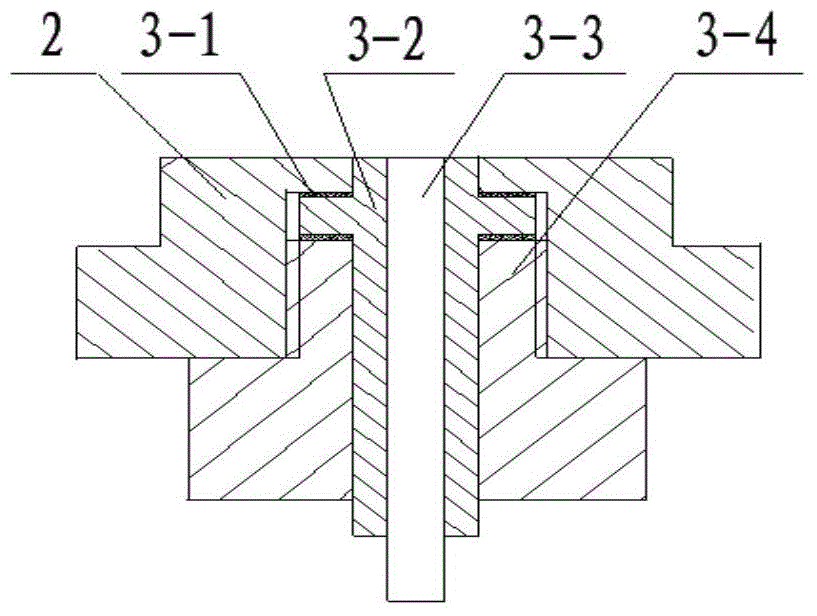

Shrink ratio equivalent test model for explosion effect in warship cabin

ActiveCN104568612AMeet the needs of damage effect assessmentReduce manufacturing costStrength propertiesVibration measurementAccelerometer

The invention discloses a shrink ratio equivalent test model for the explosion effect in a warship cabin. The shrink ratio equivalent test model comprises a cabin body, a pressure measurement mounting seat, a pressure measurement assembly, a vibration measurement mounting seat, an accelerometer, a support pillar, a powder charge hole and a locating block; the shrink ratio equivalent test model is mainly characterized in that the cabin body is an enclosed compartment provided with a cornice; the dimensions of all wall plates are determined according to the shrinkage scale of 1 to 4 with the prototype, and the thicknesses of the wall plates are determined according to the shrinkage scale of 1 to 4 and by the similarity criterion formed by material and the thickness of the wall plates; the restraint of an adjacent cabin for a compartment structure is simulated by the support pillar and the cornice of the compartment. The shrink ratio equivalent test model has the remarkable advantages the test model is the shrink ratio equivalent model for the warship cabin, so that the dimension is small, the manufacturing cost is low, and the destroy effect of the test model is basically equivalent to that of the actual ship; therefore, the shrink ratio equivalent test model is suitable for warship target damage effect test and evaluation research.

Owner:XIAN MODERN CHEM RES INST

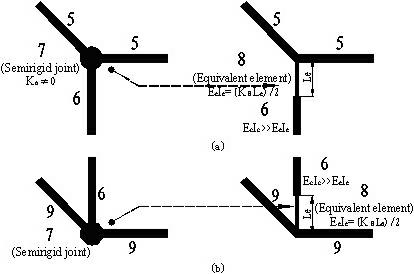

Finite element modeling method for integral structure of timber construction of ancient building

InactiveCN102323968ASimply and effectively reflect the force characteristicsSpecial data processing applicationsEngineeringElement modeling

The invention discloses a finite element modeling method for an integral structure of a timber construction of an ancient building. The method is characterized by comprising the following steps of: (1) simulating bearing components, such as a beam column and the like, by a beam unit; (2) simulating a cornice through a beam-short column unit; (3) simulating semi-rigid characteristics of the beam column and a column bottom joint through an equivalent (beam) unit; (4) reflecting structure deformation by moving a column frame joint position; (5) selecting wood property of aged material as a model wood property parameter to represent degradation of the wood property; (6) describing degradation degree of mechanical performance of the column frame joint by setting a mechanical performance degradation index; (7) based on a modal parameter model modification theory, solving the degradation index of model joint mechanical performance through a genetic algorithm. The method has the advantage of being capable of forming an integral model capable of representing mechanical characteristics and damage of the ancient timber construction, and solving the defect that the model formed by the existing method cannot roundly reflect the characteristics such as a force transmission path of the cornice, the semi-rigid characteristics of the column frame joint, the degradation of the mechanical performance, and the like. The method provided by the invention needs to be realized with the graphics software AutoCAD, the programming software Fortran and the element finite software (such as ANSYS and ABAQUS and the like).

Owner:陈志勇

Expandable home entertainment cabinet

InactiveUS20060273701A1Restrict vertical deflection and saggingImprove scalabilityVariable dimension cabinetsEngineeringCornice

An adjustable home entertainment cabinet for enclosing television sets of different sizes comprises a pair of movable tower cabinets and a bridge assembly that extends between the cabinets. A center section of the bridge rests on the tops of the cabinets. A bookshelf or shelf box is mounted on an underside of the center section. End sections movably mounted on the center section extend downwardly to cover gaps between the bookshelf and the inner sides of the tower cabinets. The center section includes a cornice molding that matches and is aligned with cornice molding on the tops of the tower cabinets. The end sections have a matching cornice molding that overlays and conceals the gap between the cornice moldings on the end sections and tower cabinets. Free standing television sets can rest on the floor. Table model sets and monitors can rest on free standing TV stands / storage cabinets of different widths that fit snugly between the tower cabinets. An adjustable media storage drawer has movable dividers with hook and loop fabric on lower edges that attach where desired to a loop fabric that covers the bottom of the drawer.

Owner:SLIGH FURNITURE

Construction process for aluminum sheet roof upright standing seam system

InactiveCN106284857AGuaranteed reliabilityNo thermal stressRoof covering using slabs/sheetsRoof toolsTemperature stressPurlin

The present invention belongs to the technical fields of building engineering design and construction, and particularly discloses a construction process for an aluminum sheet roof upright standing seam system. The construction process for an aluminum sheet roof upright standing seam system comprises the process steps of installing built-in fittings, pouring concrete, installing purlin supporting plates, installing purlins, installing steel bottom sheets, installing non-woven fabric, installing a supporting seat, carrying out construction of aluminum panels, installing side flashings, installing cornices and aluminum sheets, and the like. The construction process for an aluminum sheet roof upright standing seam system has the following advantages: the degrees of freedom of roof sheets in the sheet length direction is not limited by fixed seats, and therefore, when temperature changes, the roof sheets are able to freely slide to stretch out and draw back on the fixed seats with no temperature stress generated; thus, the temperature deformation problem which is difficult to overcome for other sheet types is effectively solved, and the reliability of various properties of the roof sheets is guaranteed.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Safety equipment for building sites

InactiveUS7273200B2Simple equipmentEasy to assembleFencingLifting devicesArchitectural engineeringCornice

The invention relates to a construction safety assembly. The inventive assembly comprises: safety posts with non-skid ends, which are provided with means for the rapid connection of a barrier; and, optionally, an upper jack-type safety element having a lower horizontal protrusion along an inclined plane, which is used to brace the cornice or projecting element of a building and which can also comprise the aforementioned barrier connection means. The adjustable-length barrier comprises a base which covers the lower part thereof. In this way, the invention provides a dual safety assembly of very simple construction, which can be used to guarantee the collective safety of labourers performing external and internal construction work and prevent accidents.

Owner:FUNES GAVILAN TOMAS

Seam cover system for crown molding installations

InactiveUS20090064613A1Quickly and easily securedEasily secured in placeCovering/liningsNatural patternsAdhesiveCrown molding

By providing a plurality of support brackets which are quickly and easily mounted to any desired surface and are constructed for receiving and supportingly retaining elongated, lineal crown molding strips, inside and outside corner seam covers, and lineal seam covers, each of which are formed from a wide variety of decorative and visually distinctive appearances, a cornice or crown molding system is achieved which is capable of being quickly and easily installed in any desired location by any unskilled individual, without requiring the use of mitered corners, abutting junctures, nails, adhesives, and the like. By employing a combination of the components of the present invention, any desired location can be quickly and easily decorated with a completely installed molding system for enhancing the visual and aesthetic appeal of any room or building.

Owner:FOCAL POINT PRODS

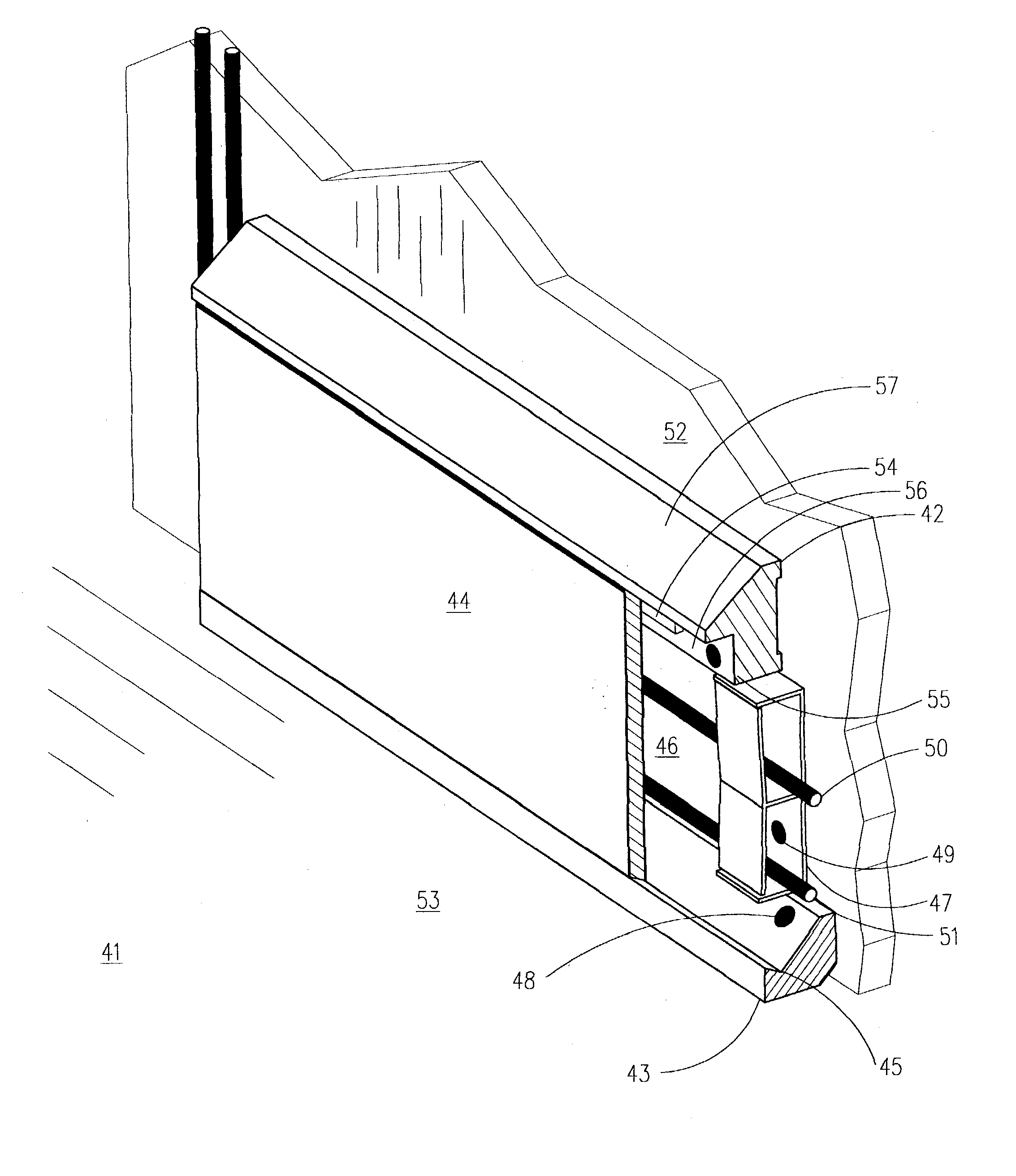

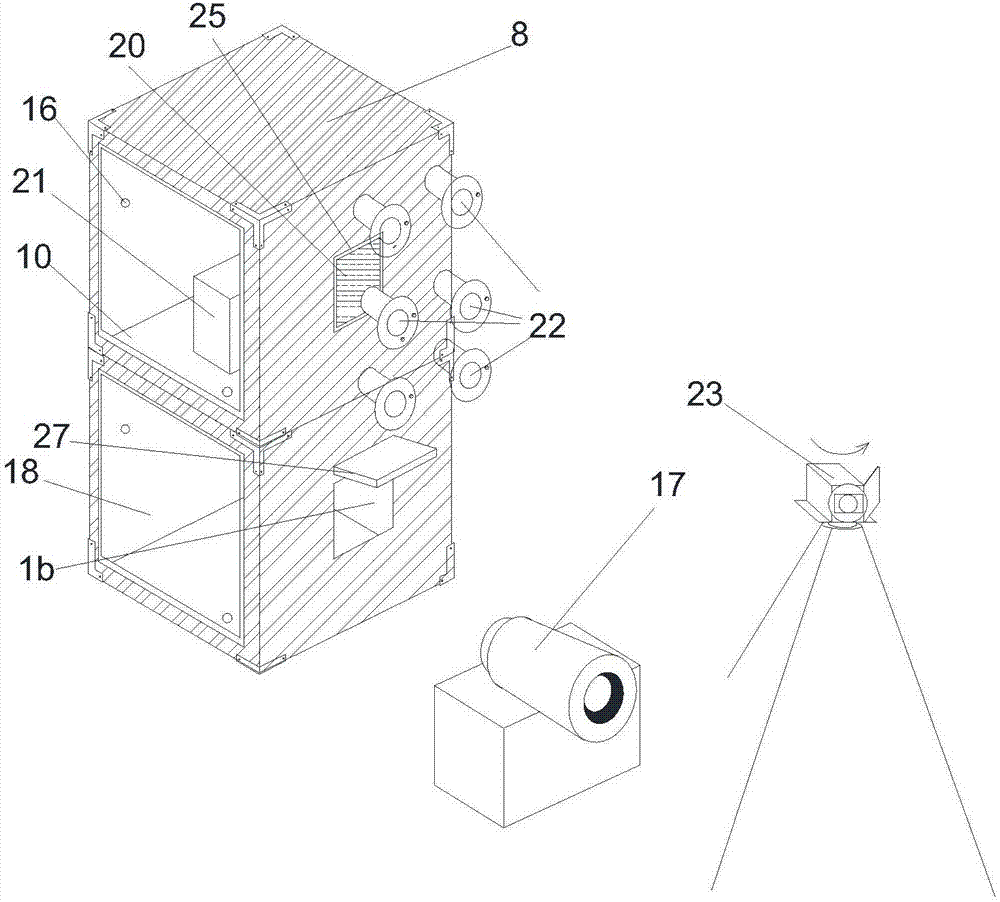

Building outer face fire simulation apparatus

ActiveCN106875822AEasy to operateImprove economyEducational modelsCombustion chamberMeasuring instrument

The invention discloses a building outer face fire simulation apparatus, characterized by comprising: a multi-layer combustion chamber, a simulated side wall, a moving platform, an armored thermocouple probe, a heat radiation flux measuring instrument, a thermocouple patch, a glass frame, sunlight-controlled film-coated glass, simulated combustibles, a water-cooled heat flow meter, an axial fan, a DV camera, and a telescopic fireproof cornice. The multi-layer combustion chamber is formed by the lamination of two combustion chambers. The simulated side wall is combined with the wall faces with windows to form a U shaped structure. The telescopic fireproof cornice is arranged at the upper part of the lower-layer combustion chamber's windows. The apparatus of the invention can be used in the research on the fire spreading condition of the outer wall face of a high rise building under the action of an environmental wind, the research on the development characteristics of the fire flames and the smoke plume under the restrictive condition of the side wall as well as the characteristic rule of a secondary fire generated from the fire overflow at the outer side of the building into the upper layer combustion chamber, so as to provide reference to fire prevention designs for similar buildings.

Owner:HEFEI UNIV OF TECH +1

Post welding mounting construction method of pseudo-classic architecture element

ActiveCN101417460AShorten the construction periodShorten the durationCeramic shaping apparatusBuilding material handlingControl lineCornice

The invention discloses a method for post-placing, welding, installing and constructing antique building components. The method comprises the following steps: firstly, the main structure is finished, and then the preset special-shaped antique components are welded on the main body structure sequentially, thus finishing the construction of the antique building cornice component. Before the main body is constructed, the components of Chinese peck, arch, rise, and the like, are preset, and then iron pieces are pre-buried. After the main body is constructed or the column strength reaches 75 percent, the components can be installed. When installing, controlling lines are reeled out on the column, the positions of the lines correspond to the components of Chinese peck, arch, rise, and the like, and then the frame body is set up. When installing every layer of the component system of Chinese peck, arch, rise, and the like, a suspension component is hung at the four corners of every layer, and then the lines are pulled through to adjust the positions of other components of the layer. Every component is installed after the levelness and verticality are examined to ensure no mistake. The method has simple processes and can reduce the cost and the construction difficulty, be easy to control the quality, improve the work efficiency and ensure the antique components to be firm and durable.

Owner:SHAANXI CONSTR ENG GRP NO 7 BUILDING ENG

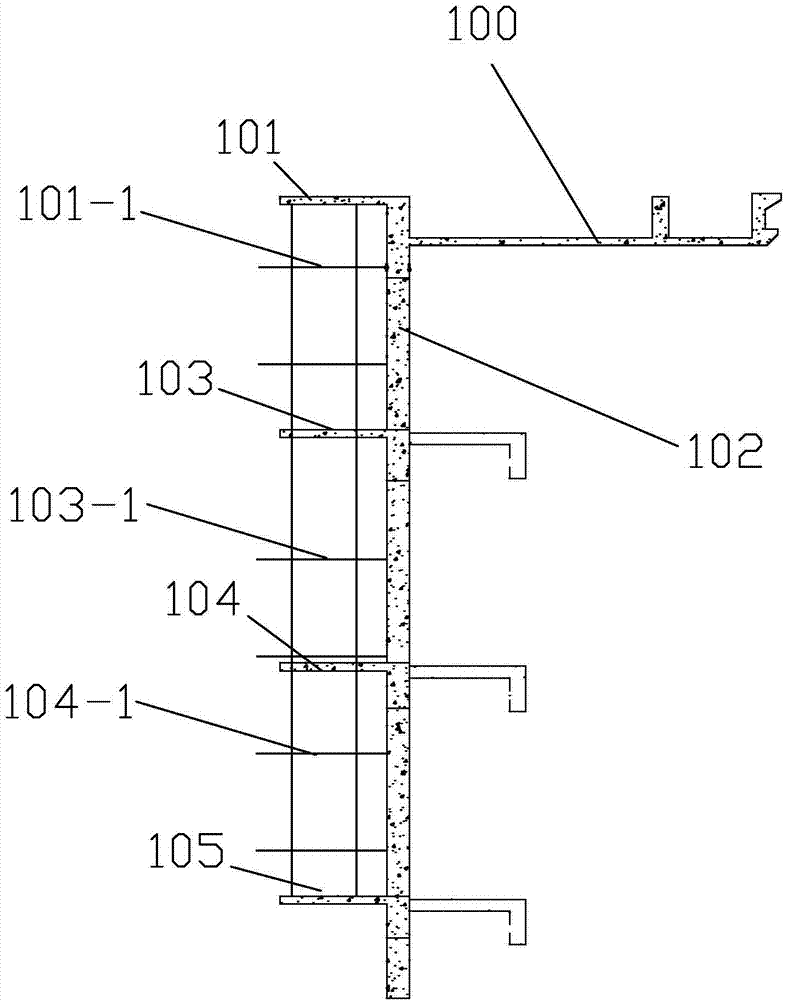

Existing masonry structure using light steel structure direct storey-adding technology and construction method of existing masonry structure

ActiveCN103225422AThe power transmission route is clearReasonable stiffness distributionBuilding repairsBuilding material handlingSocial benefitsLand resources

The invention relates to an existing masonry structure using light steel structure direct storey-adding technology and a construction method the existing masonry structure, and belongs to the field of seismic reinforcement of a structure. The construction method comprises the following steps: firstly, detaching a parapet wall, a cornice and a roof waterproofing layer of the original masonry structure before a storey is directly added onto the masonry structure; secondly, embedding steel bars into roof structural columns, and adding a ring beam, steel bars of a roof overlapped storey, and embedded screw rods in the newly-added ring beam; and thirdly, integrally pouring the steel bars embedded into the roof structural columns, steel bars of the newly-added ring beam, the steel bars of the roof overlapped storey, and the embedded screw rods to effectively joint a new structure and an old structure into a whole. When the concrete strength is higher than 70%, an upper light steel structure is installed. The existing masonry structure is restructured by directly adding a new storey through the light steel structure, the difficulty that people are short of houses at present can be relieved and a lot of land resources in China are saved, with significant economic and social benefits.

Owner:河源市客族装配式建筑有限公司

Ornament and bracket

A removably mountable ornament assembly as a temporary or permanent fitting to a wall and / or ceiling is provided. The ornament may be a cornice or skirting board, and a bracket is provided for releasably engaging and mounting the cornice or skirting board to a wall and / or ceiling. The arms of the bracket each terminate in mating portions that releasably engage respective complementary channels in the cornice. The ornament assembly provides an alternative to traditional plaster cornices and may be mounted to cover an existing cornice or moulding.

Owner:PICKUP LESLIE WILLIAM +1

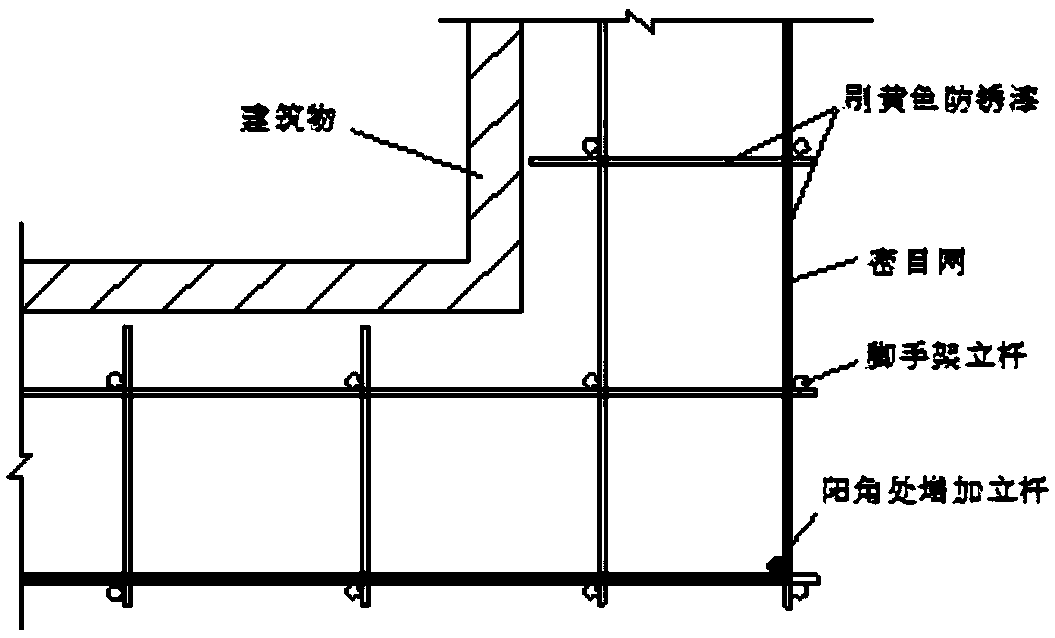

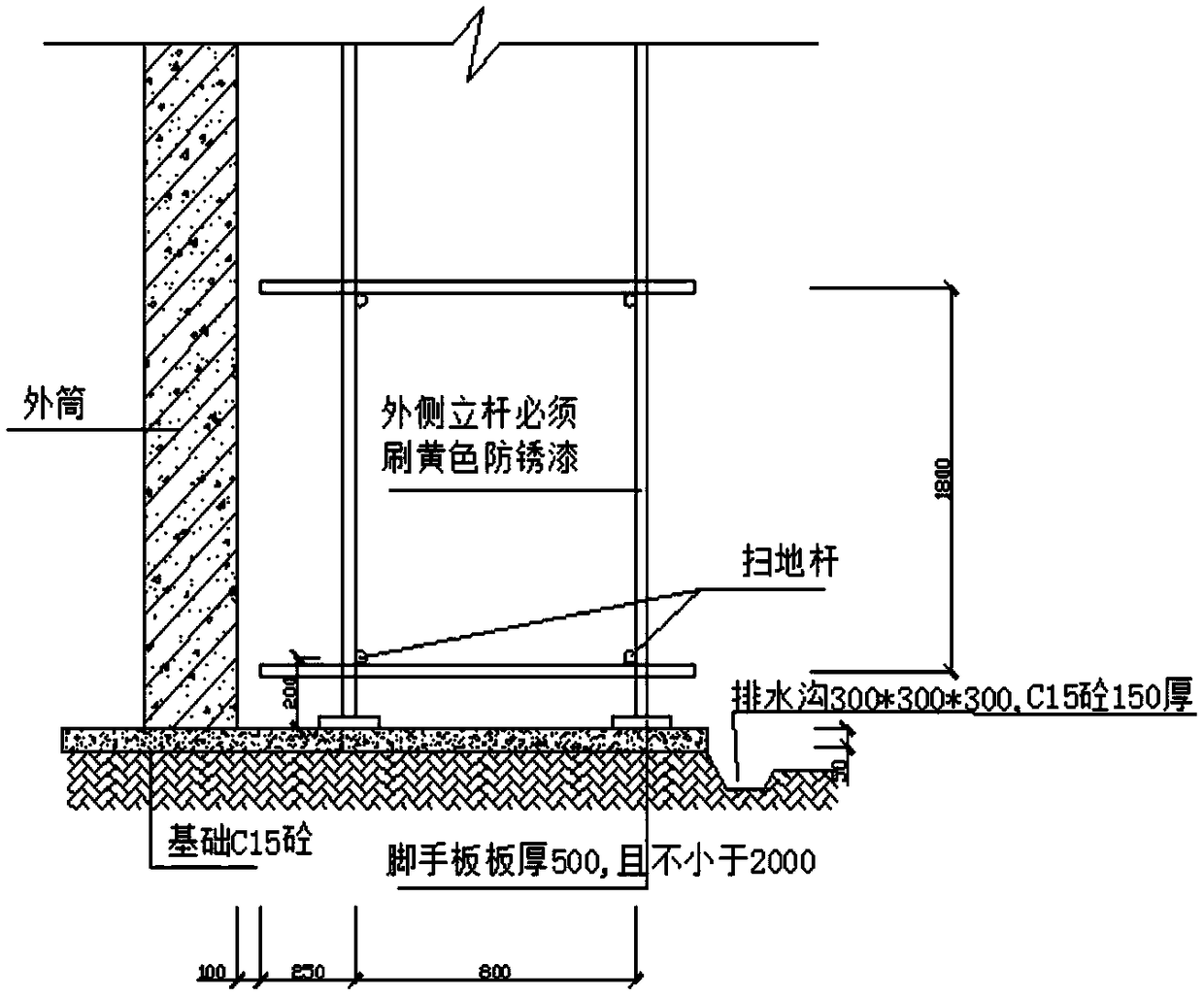

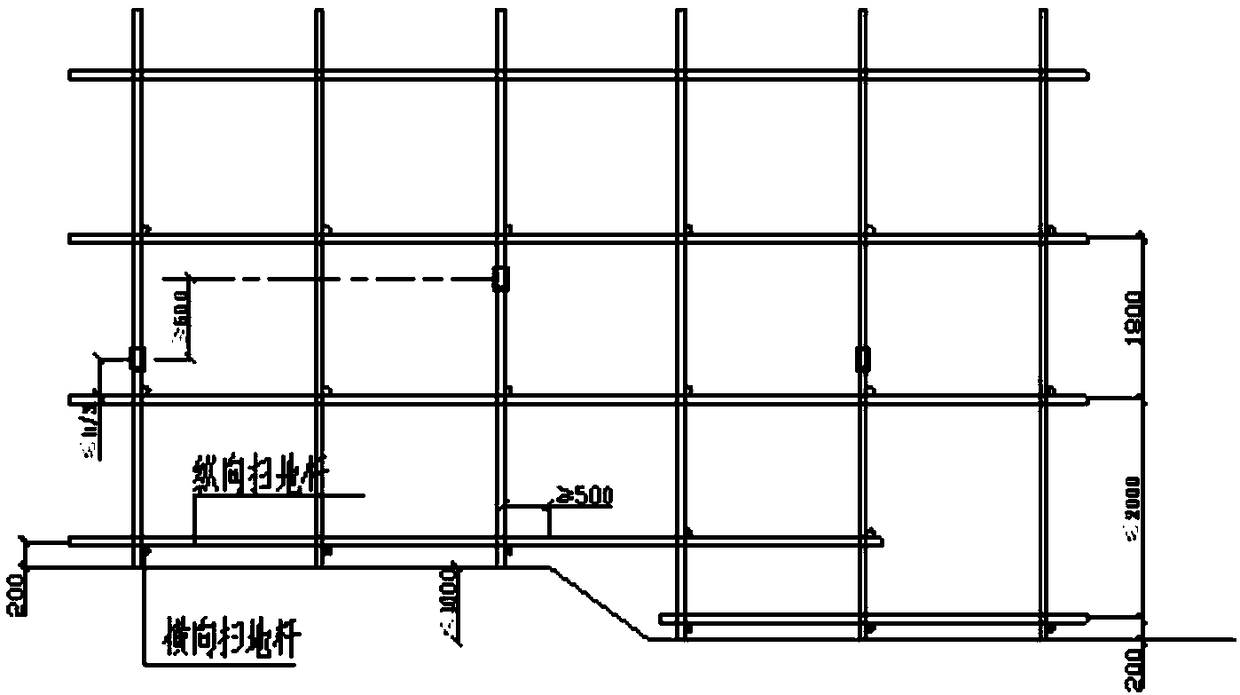

Building method of floor type scaffold

InactiveCN108708536AFast constructionImprove survival rateBuilding scaffoldsFalseworkArchitectural engineering

The invention relates to a building method of a floor type scaffold. The method includes: building a foundation and a base, building vertical rods, building longitudinal horizontal rods, building transverse horizontal rods, building diagonal bridging, building scaffold boards, building wall connectors and processing special parts. By the method, the scaffold construction technical problems, causedby the construction of special-shaped, polygonal and large-inclination-angle building scaffolds, of corners, cornices and other protruding parts are solved.

Owner:MCC NORTHEAST CONSTR SHENYANG ENGTECH CO LTD

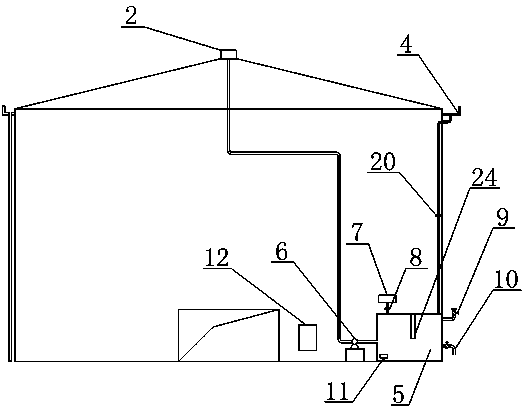

Light-weight steel structure roof green intelligent snow removing system

InactiveCN103953165AImprove solubilityReduce wasteRoof covering using slabs/sheetsRoof covering using tiles/slatesSnow meltingEngineering

The invention discloses a light-weight steel structure roof green intelligent snow removing system. In the snow removing process, when the snow load is about to reach or exceeds the limiting value of the structure design specification, the intelligent sensing early warning can be realized through a sensor, and in addition, a spraying snow removing system can be started to reach the goal of intelligent snow removal. The light-weight steel structure roof green intelligent snow removing system comprises a spraying pipe, a stress sensor and a first collecting groove, wherein the spraying pipe is arranged on a roof and is provided with a plurality of spraying heads, the stress sensor is arranged on a roof purline, the first collecting groove is formed in a cornice opening part at one side of the house roof and is used for collecting snow water, a water tank communicated with the first collecting groove and a water pump used for pumping liquid from the water tank into the spraying pipes are arranged in a house, a salt storage jar connected with the water tank is also arranged in the house, in addition, an electromagnetic valve is also arranged between the salt storage tank and the water tank, a water inlet pipe and a water outlet pipe are arranged on the water tank, a liquid concentration sensor and a heater are also arranged inside the water tank, and a central processing unit is also arranged in the house. The light-weight steel structure roof green intelligent snow removing system has the advantages that the roof snow load can be automatically subjected to snow melting unloading, and meanwhile, the snow water can be circularly utilized.

Owner:XIHUA UNIV

Cornice corner cap and methods related thereto

A cornice molding cap is provided as an accessory to cover or eliminate gaps created where cornice molding meets at a corner of a building. The cap covers gaps where cornice molding meets at a corner structure formed by two walls. The cap is particularly useful in exterior siding installations at corners not employing corner posts having receiver pockets for cladding material end edges. A method of finishing a corner molding installation is described, as is a system for finishing such installation, and an assembly including a unitary cornice molding corner cap.

Owner:CERTAINTEED CORP

Cornice fixture

Owner:HAFFAMIER KATHLEEN +1

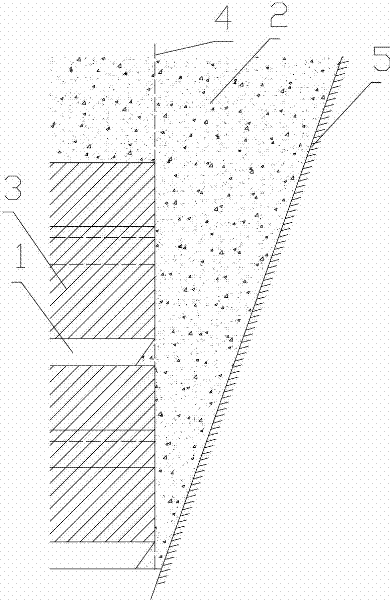

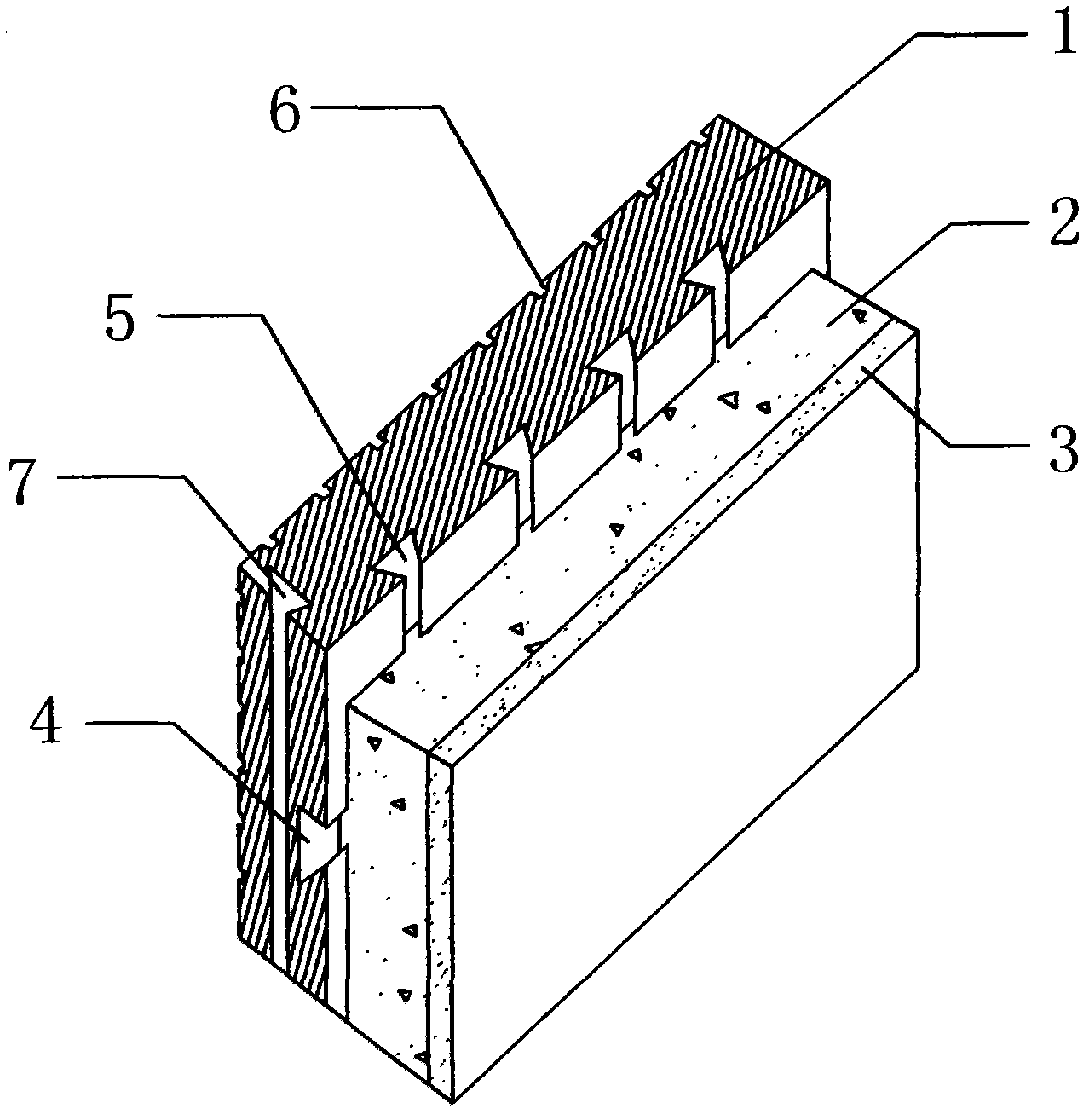

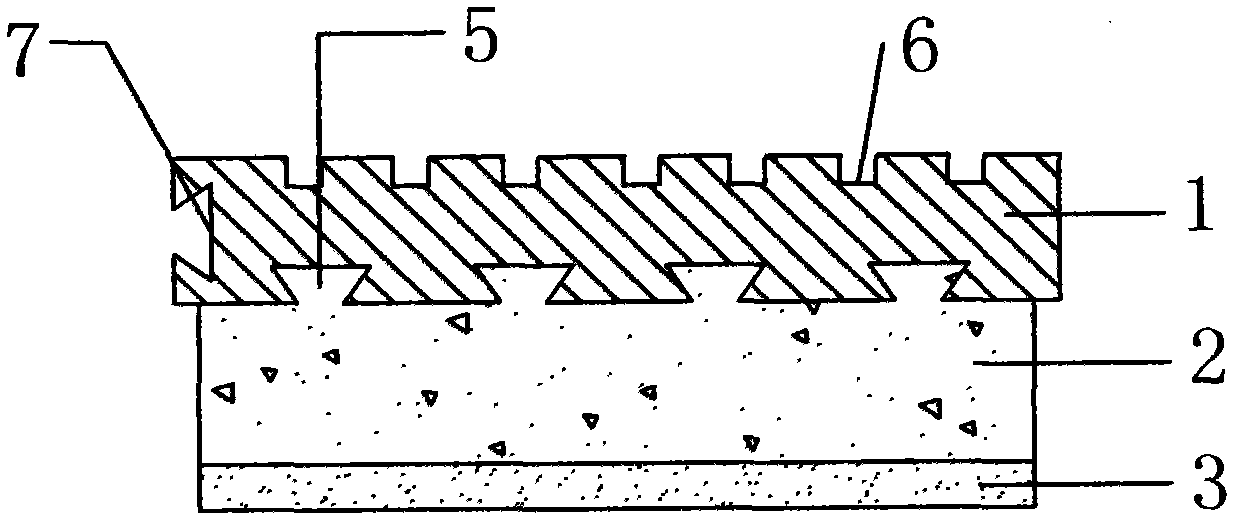

Decoration and heat insulation external building block structural system

The invention discloses a decoration and heat insulation external building block structural system, which is characterized by consisting of eight block types of decoration and heat insulation external building blocks, namely a main block, a half block, an external corner block, an internal corner long main block, an internal corner long half block, an internal corner main block, an internal corner half block and a cornice external block, wherein except the cornice external block, each of the other seven block types is formed by compositing a heat insulation board 1, a concrete protection layer 2 and a decoration surface layer 3; a plurality of vertical dovetail grooves 5 and one horizontal dovetail groove 4 are formed on one large face of the heat insulation board 1, and a sign-shaped groove 6 is formed on the other large face; each edge of the heat insulation board 1 is protruded from the concrete protection layer 2 about 5 millimeters in the horizontal direction and 10 millimeters in the vertical direction; a plurality of concrete protection layers 2 form a dust gap of which the width is about 10 millimeters; anti-cracking mortar is filled in the dust gap; and a plurality of heat insulation boards 1 are connected mutually so as to stop a cold bridge of the building blocks. The decoration and heat insulation external building block structural system has the characteristics that: a decoration effect and a heat insulation effect are integrated, and the heat insulation material and the building have the same service life.

Owner:金立虎

Pultruded trim members

The present invention is an improved method of making cornice assemblies and other trim members utilizing the process of pultrusion. The cornice assemblies and the other trim members made by the method of the present invention exhibit superior strength to weight ratios, low expansion and contraction due to changes in temperature and humidity, as well being less labor intensive to install.

Owner:PN II

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com