Patents

Literature

60 results about "Degradation index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for memory management

InactiveUS20040139282A1Memory loss protectionMemory adressing/allocation/relocationData accessAccess frequency

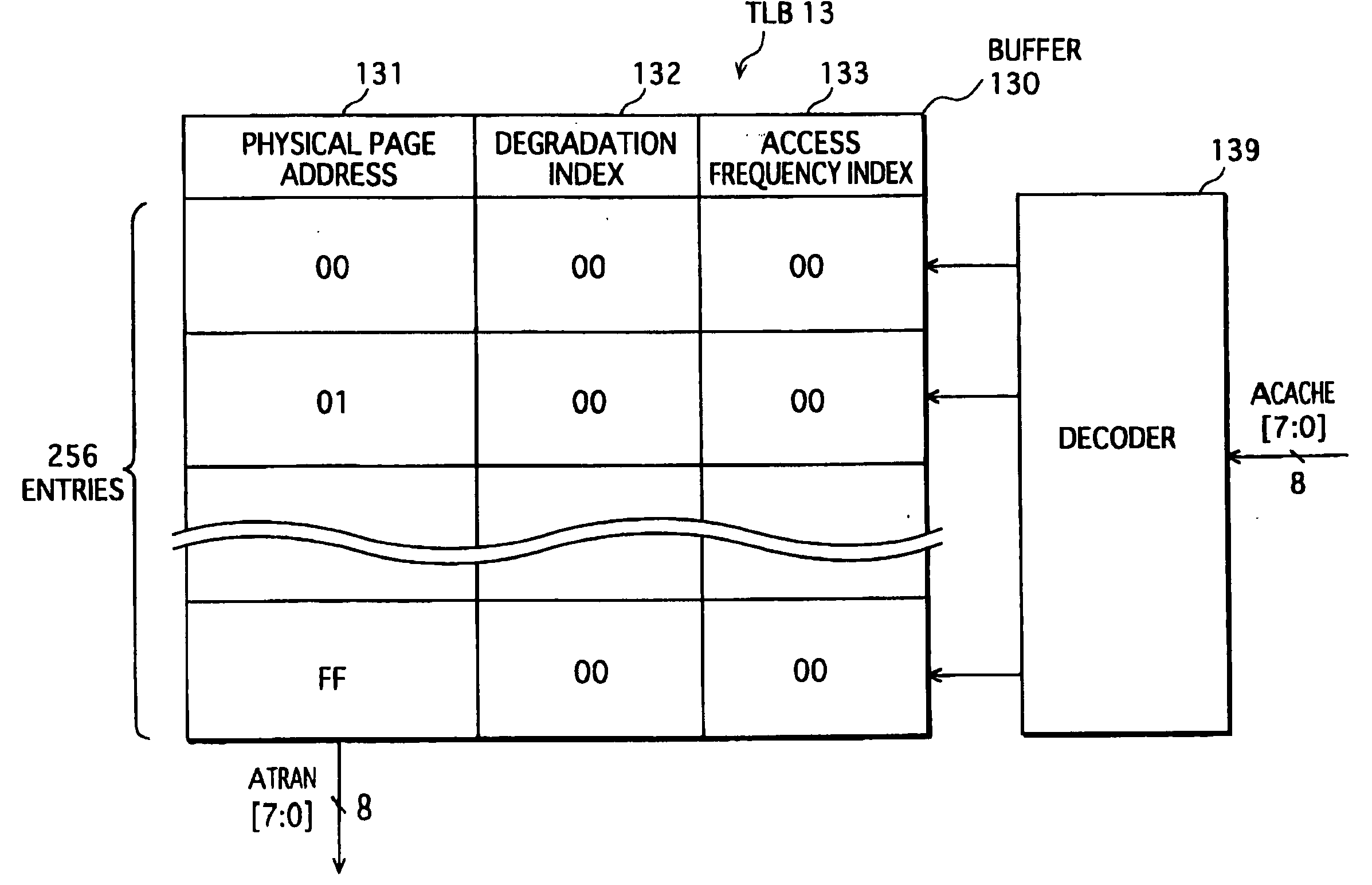

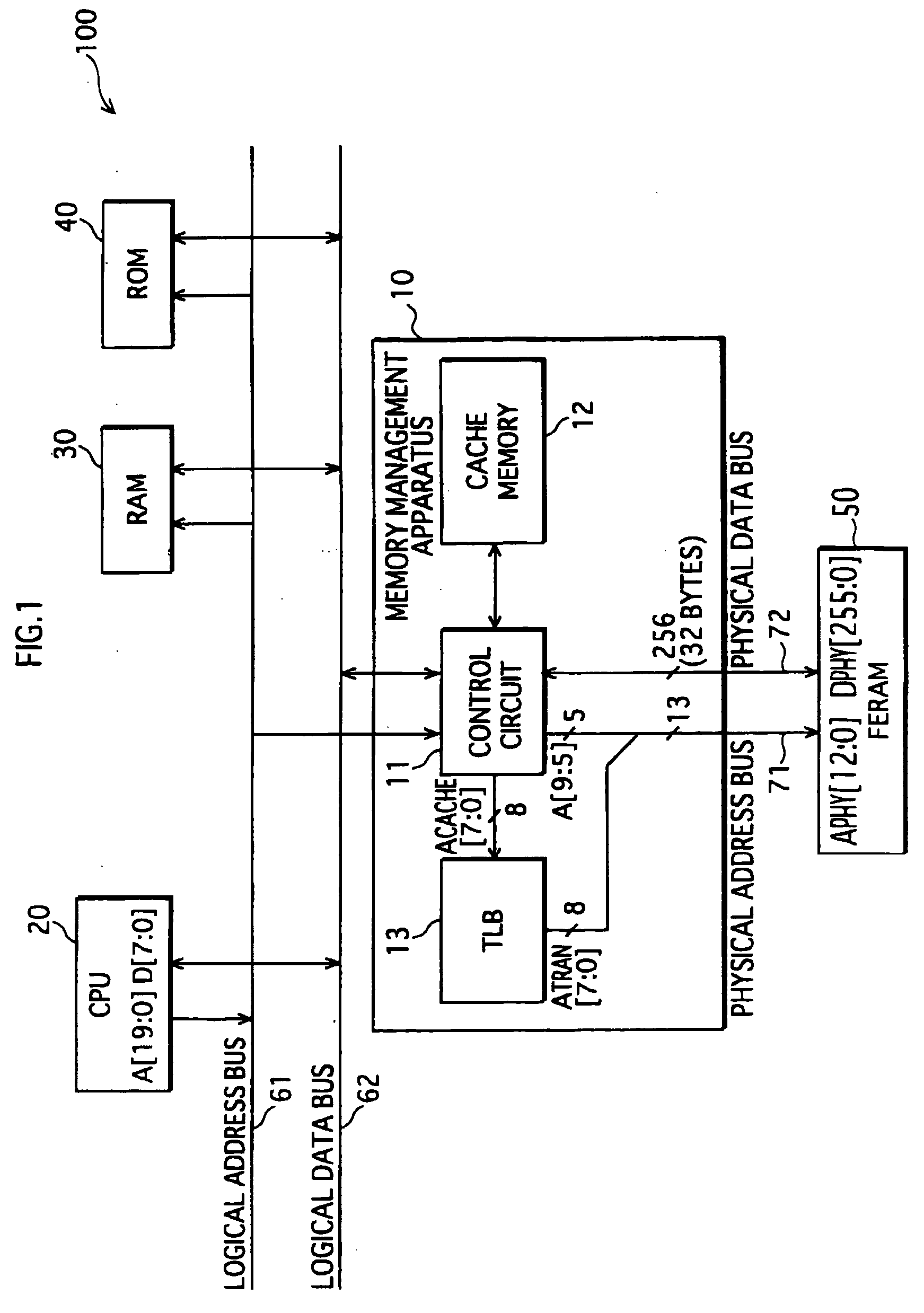

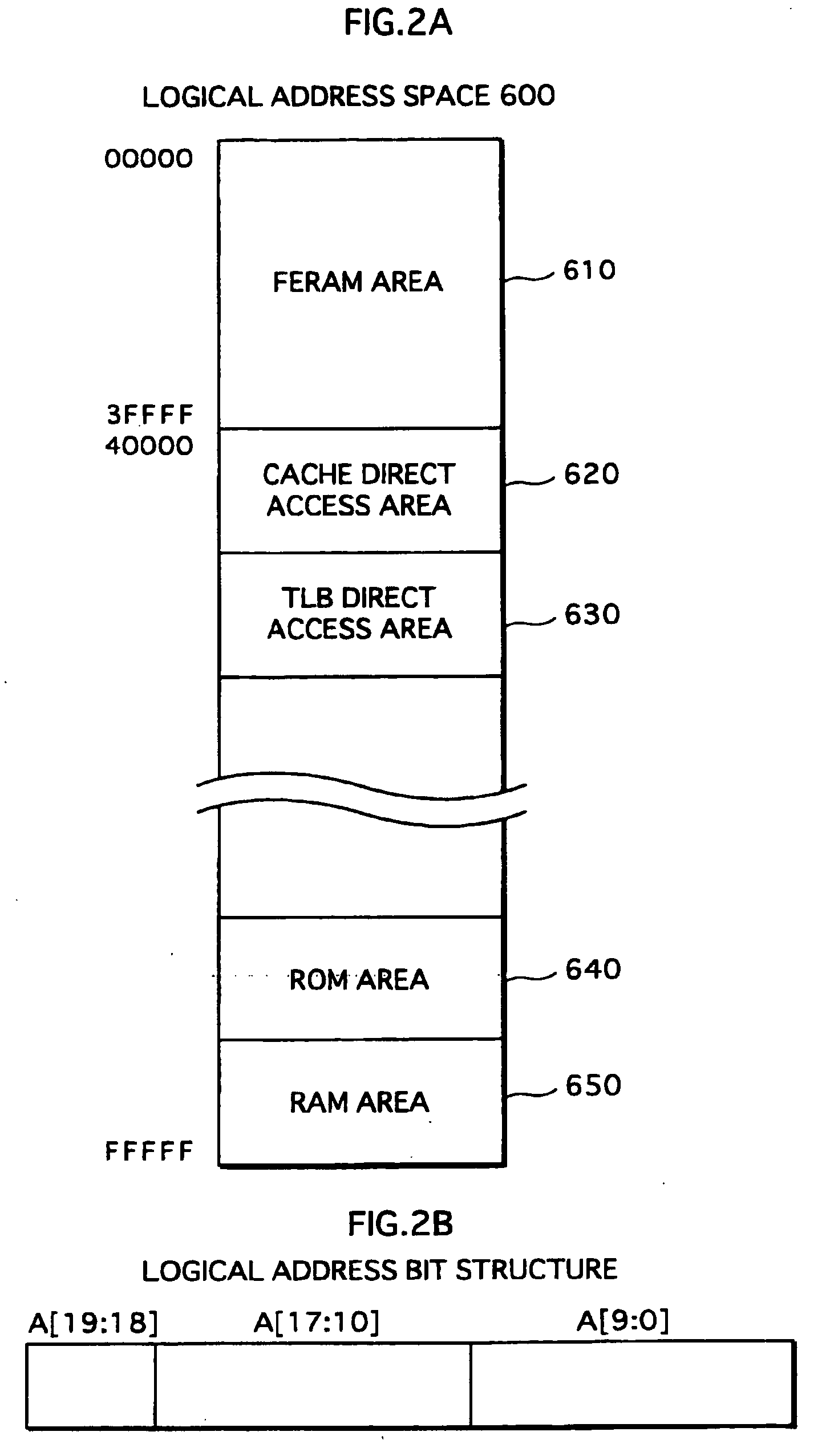

A TLB provided in a memory management apparatus stores an entry for each logical page, and each entry holds an address of a physical page mapped to a corresponding logical page, an index showing the degradation degree of the physical page, and an index showing the access frequency to the logical page. The memory management apparatus accesses a physical page mapped to a desired logical page according to the data stored in the TLB, periodically exchanges the contents between a first physical page mapped to a specific logical page having a largest access frequency index and a second physical page having a smallest degradation index, and then maps the specific logical page to the second physical page. Through the physical page exchange and corresponding mapping process, accesses to each physical page are distributed, so that degradation in storage function is substantially equalized.

Owner:SOCIONEXT INC

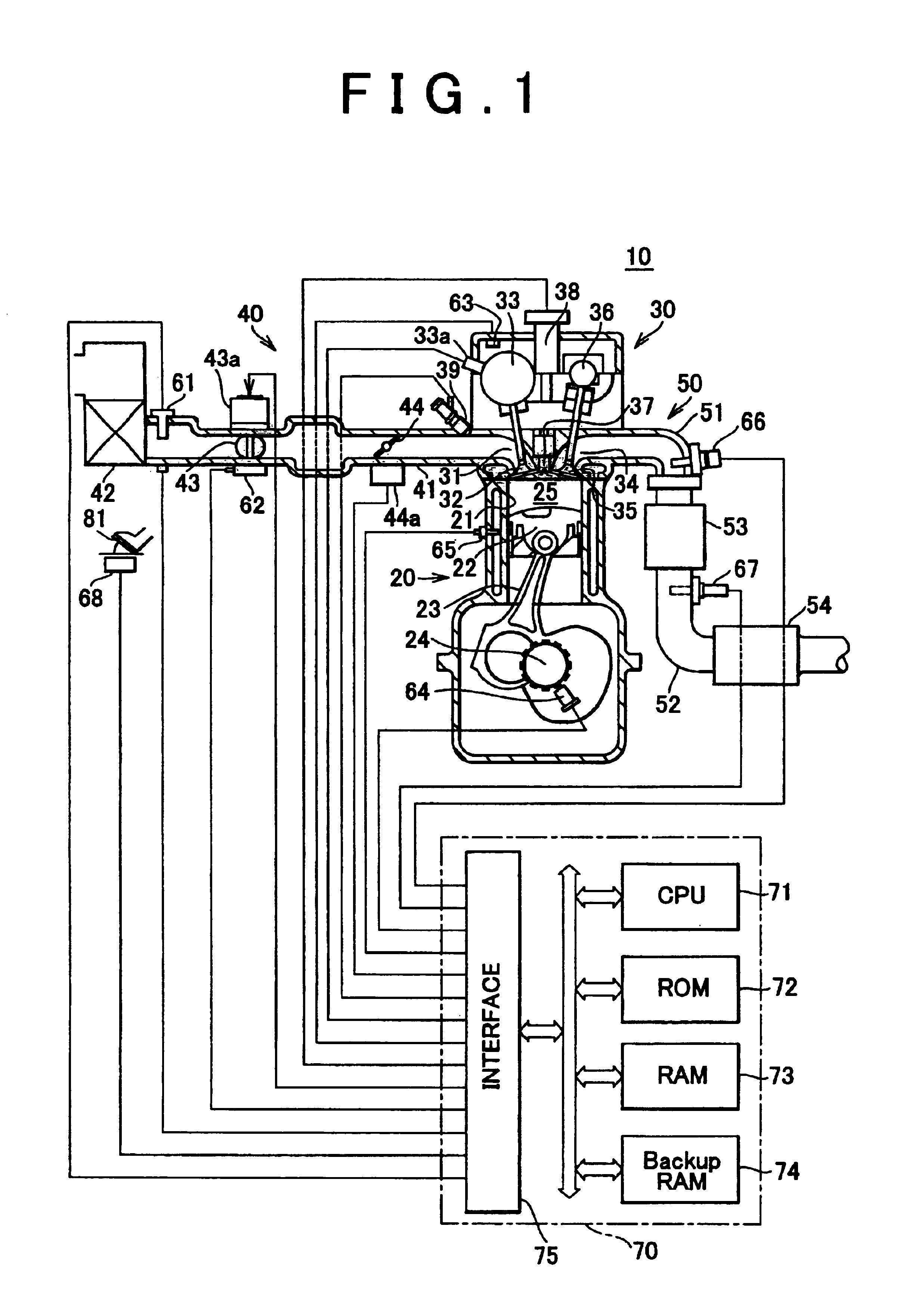

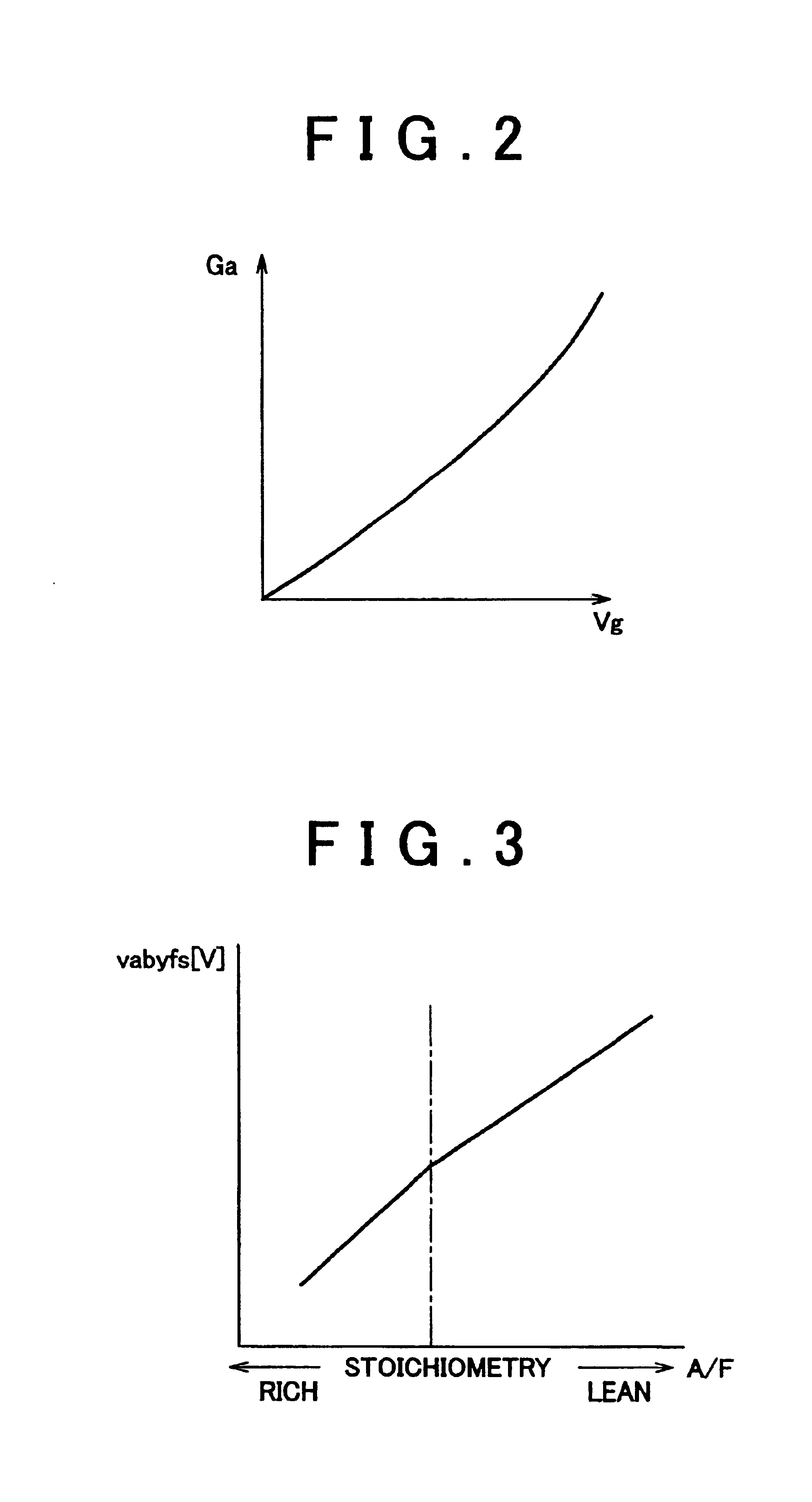

Catalyst degradation determining apparatus and method

InactiveUS6877311B2Easily determine whether correction is appropriateHigh frequencyElectrical controlInternal combustion piston enginesCatalyst degradationEngineering

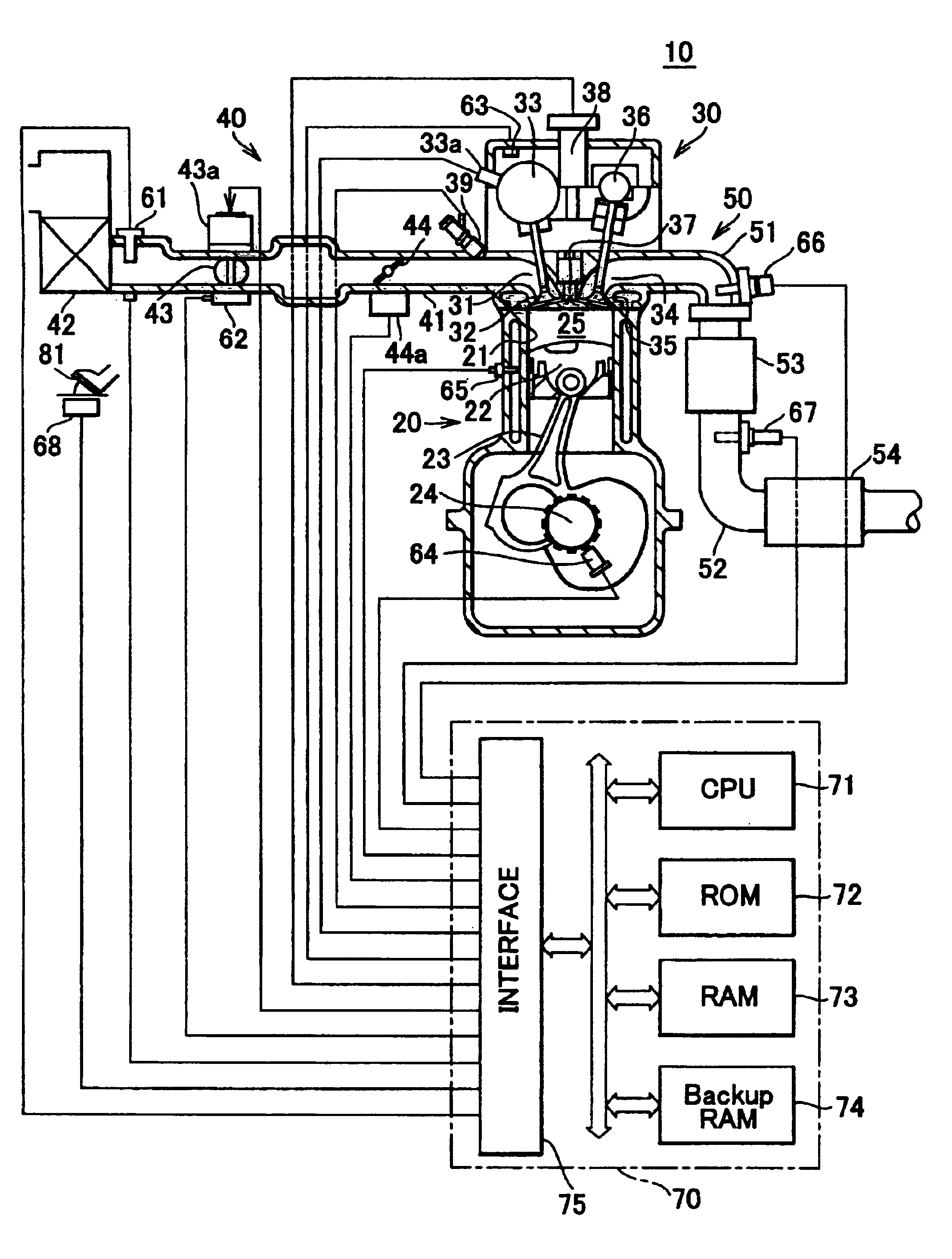

A catalyst degradation determining apparatus determines whether a catalyst provided in an exhaust passage of an internal combustion engine has degraded. The apparatus includes a controller. The controller acquires a degradation index value that changes in accordance with a degree of degradation of the catalyst. The controller corrects the degradation index value acquired, based on a factor that affects the degradation index value, so that the degradation index value becomes equal to a post-normalization index value that is a degradation index value acquired when the factor is a predetermined value. The controller also determines whether the catalyst has degraded, based on a result of comparison regarding whether the post-normalization index value is greater than a catalyst degradation criterion value.

Owner:TOYOTA JIDOSHA KK

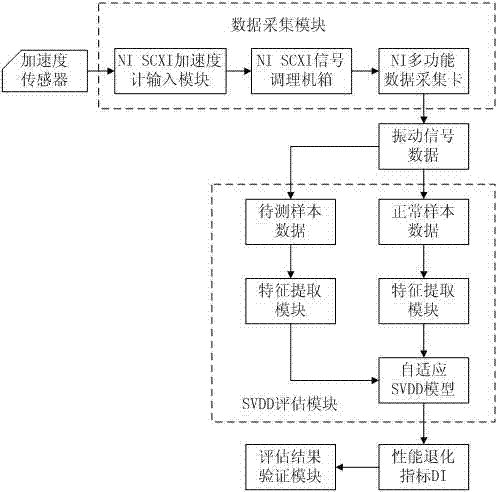

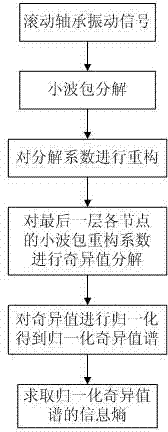

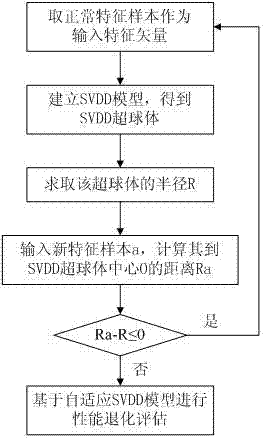

Rolling bearing performance degradation evaluation device and method

InactiveCN104729853AImprove accuracyEnsure correctnessMachine bearings testingVibration testingData acquisitionEngineering

The invention provides a rolling bearing performance degradation evaluation device and method. The device comprises an acceleration sensor, a data acquisition module, a feature extraction module, an SVDD evaluation module and a verification module. According to the method, the acceleration sensor is made to be used for acquiring vibration signals of a bearing to be measured and converting the vibration signals to simulation signals; the data acquisition module is made to be used for conducting amplifying, smoothing and other processing on the simulation signals, converting the simulation signals into digital signals and then transmitting the digital signals to a computer; the feature extraction module is used for extracting wavelet packet singular spectrum entropies of the vibration signals to serve as input feature vectors so as to be used for the SVDD evaluation module; The SVDD evaluation module is used for establishing a self-adaption SVDD model and evaluates the performance degradation process of the rolling bearing through the self-adaption SVDD module to obtain a performance degradation index DI; the verification module verifies the correctness of the evaluation result through an Hilbert envelope demodulation method based on EMD. The rolling bearing performance degradation evaluation device and method are applied to performance degradation evaluation of the rolling bearing in the whole life cycle.

Owner:EAST CHINA JIAOTONG UNIVERSITY

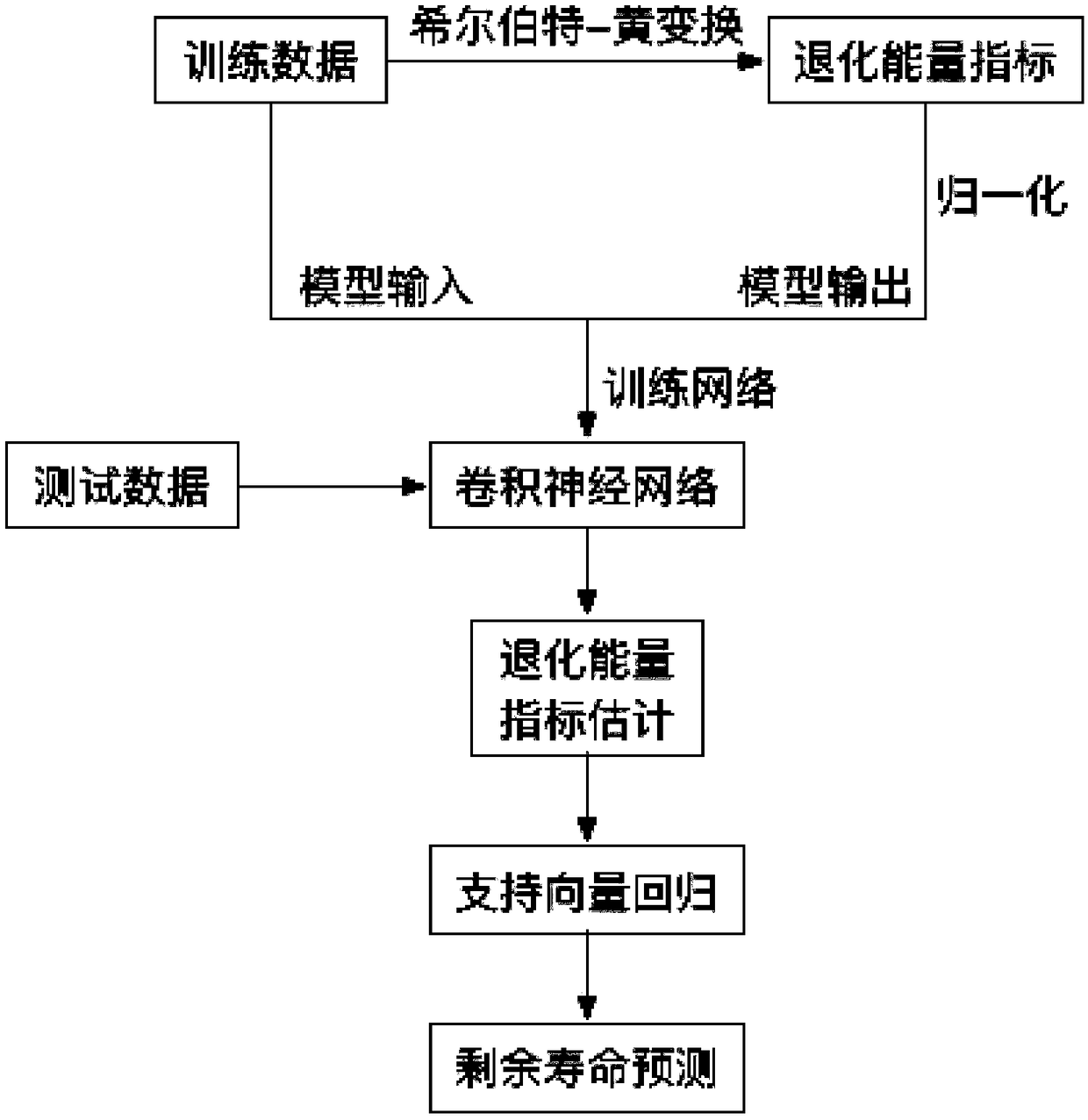

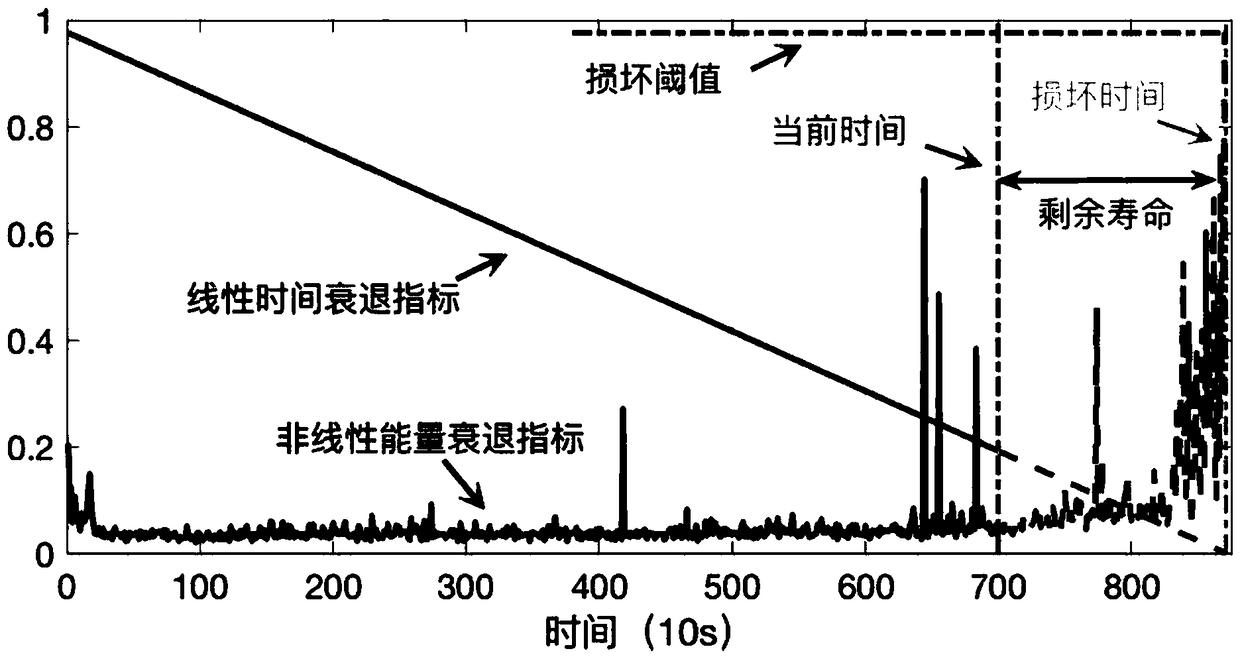

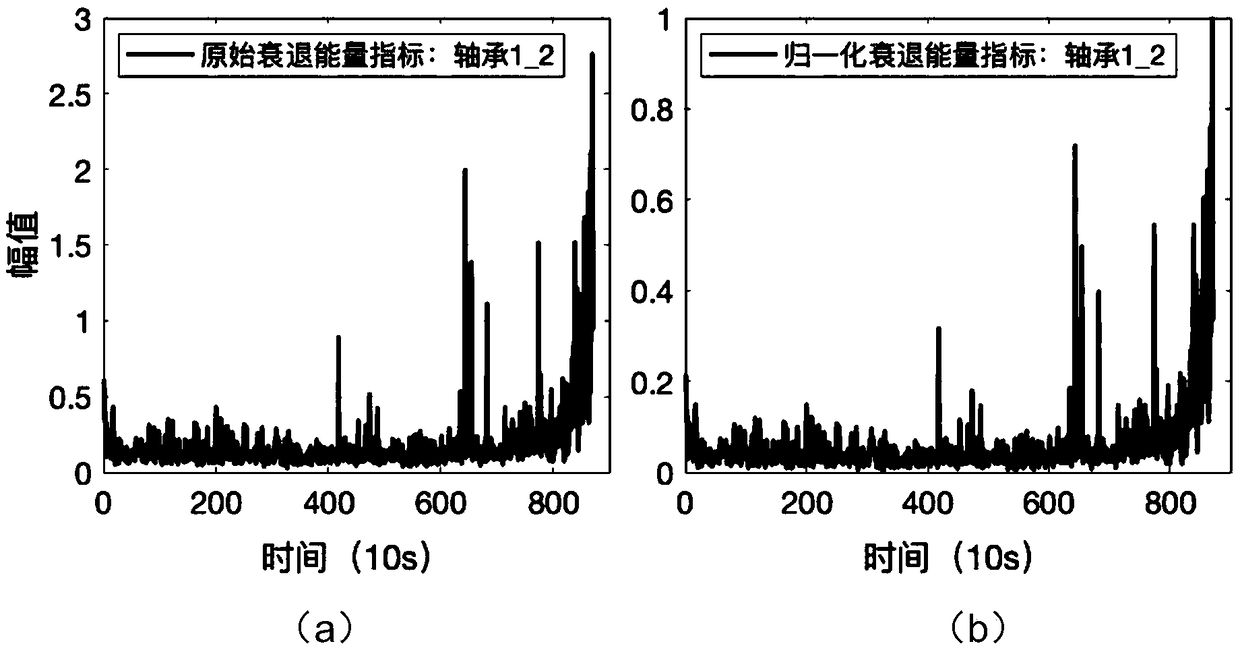

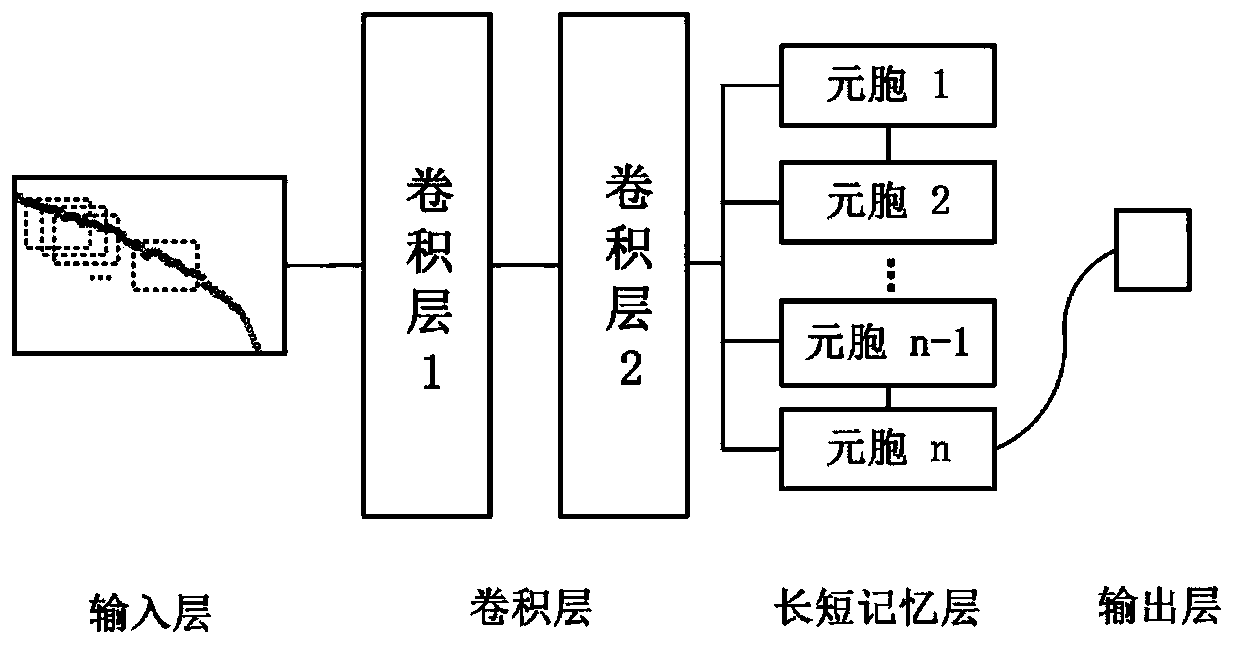

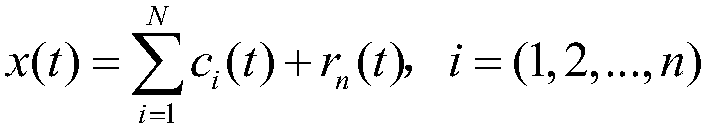

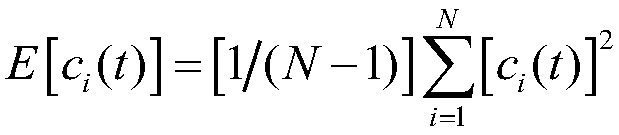

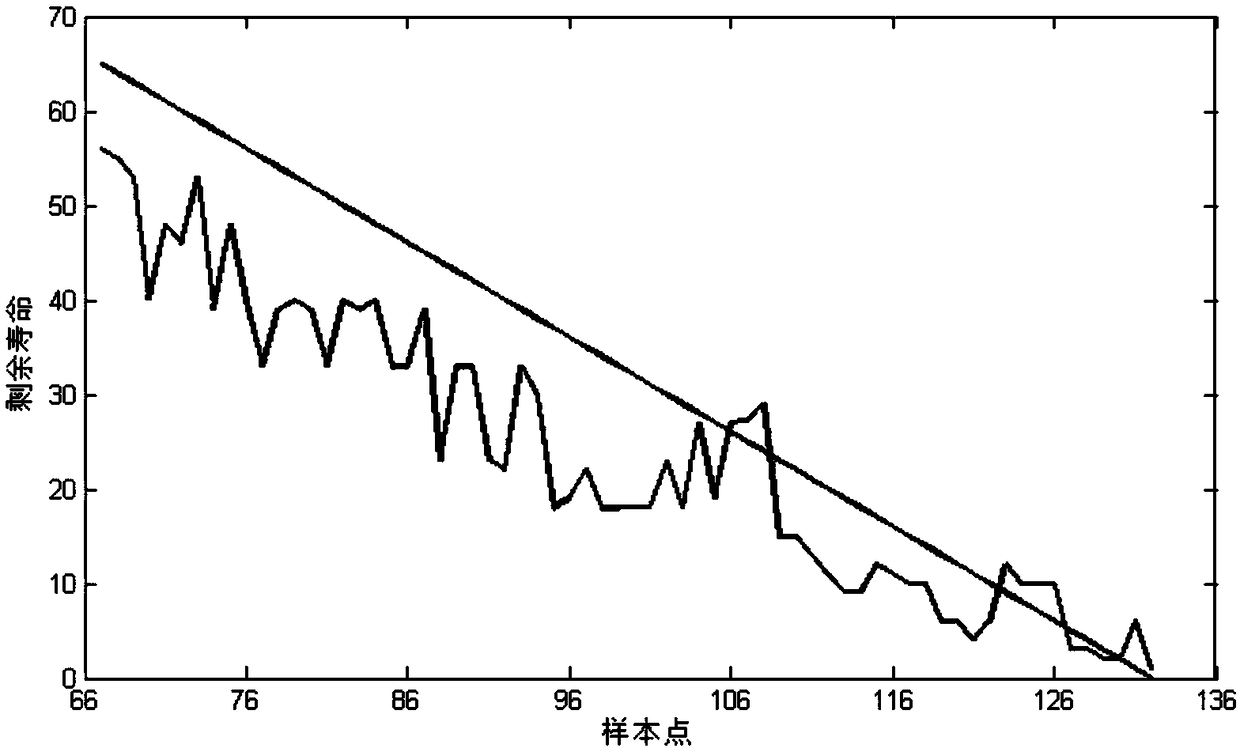

A method and system for on-line predict residual life of rolling bear

ActiveCN109460618AAccurate predictionStrong generalizationGeometric CADMachine bearings testingFeature extractionState model

The invention discloses an on-line prediction method for residual life of rolling bearing, As that roll bearing move from a healthy state to a damaged state, The original signal samples and corresponding degeneration energy indexes are extracted from the running process of the bearing, and the original signal samples are used as the input of the five-layer convolution neural network model, and thedegeneration energy indexes are used as the output of the convolution neural network model, and the degeneration energy state model is obtained by training. Real-time acquisition of the original running signals of the rolling bearings to be tested; The original running signal of the rolling bearing to be tested is input into the degradation energy state model, and the degradation energy index isestimated. Then the estimated energy degradation index is used to predict the residual life of the rolling bearings to be tested. The prediction process of the invention only needs to collect the original operation signal of the bearing, and does not need to extract and screen the features, thus overcoming the technical problems that the prior art adopts the methods of feature extraction, featurescreening and regression prediction, which have the characteristics extraction difficulty and the precision is limited.

Owner:HUAZHONG UNIV OF SCI & TECH

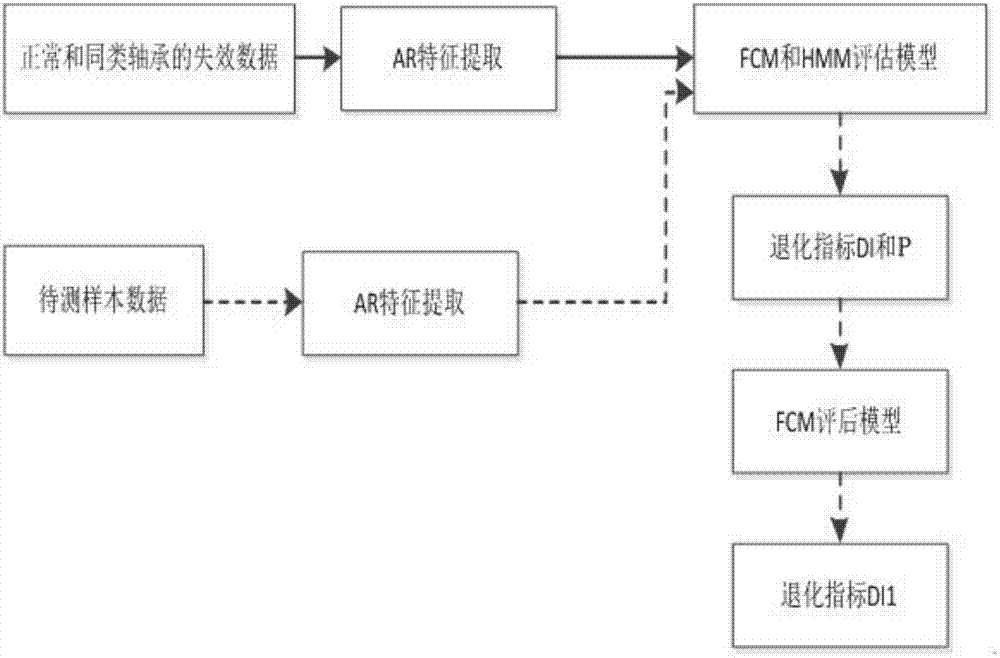

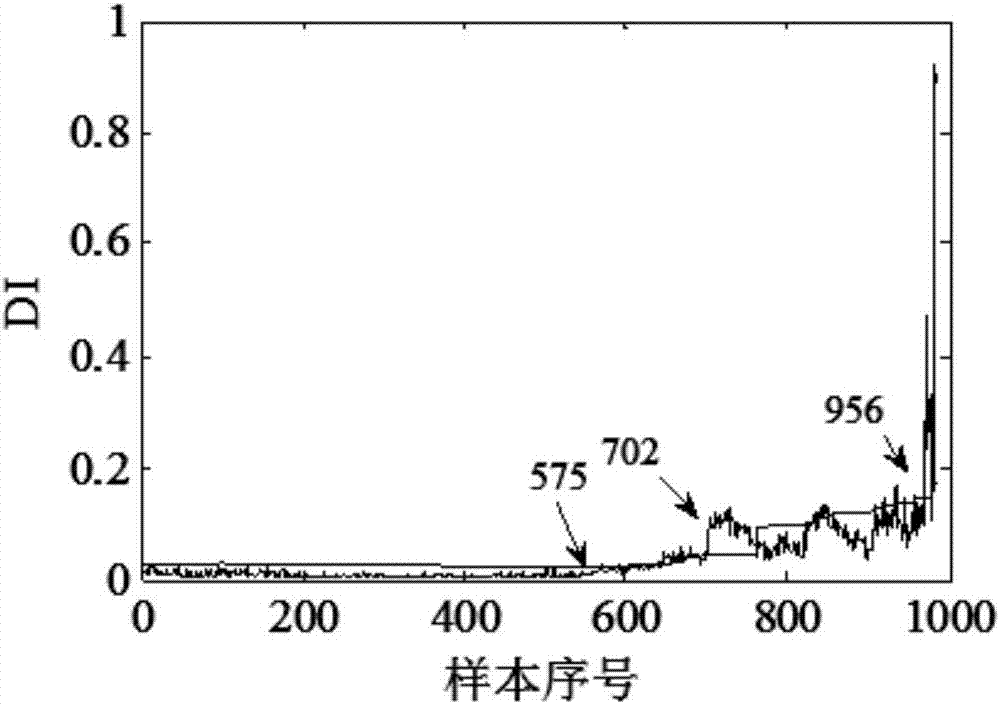

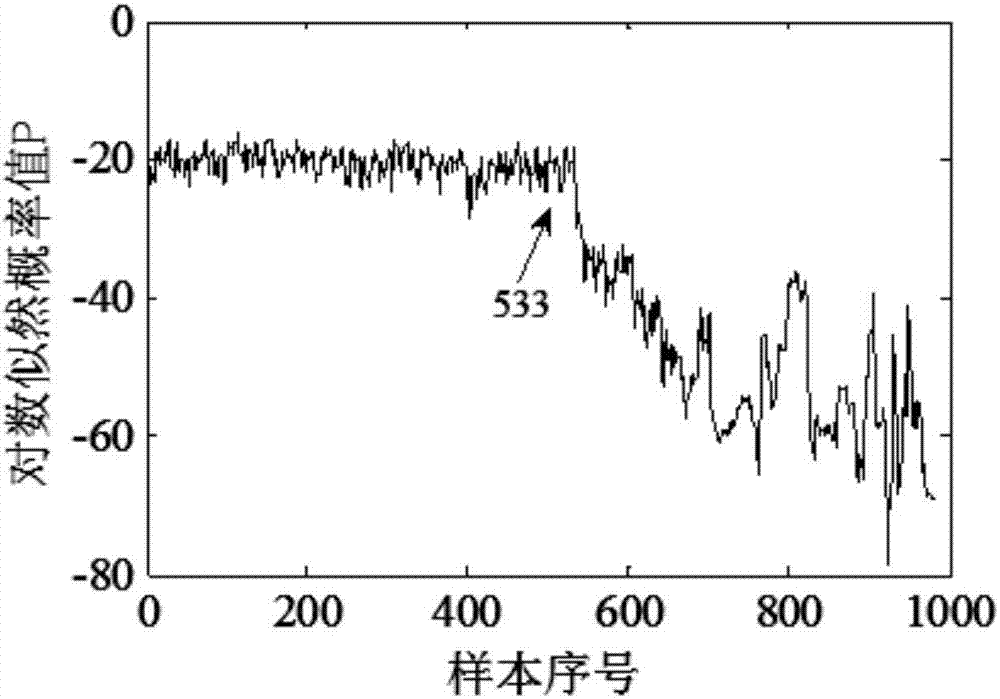

Performance degradation evaluation method based on FCM-HMM rolling bearing

ActiveCN106885697AReal-time monitoring of initial faultsReal-time monitoring of failure timeMachine bearings testingEngineeringModel Number

The invention discloses a performance degradation evaluation method based on an FCM-HMM rolling bearing. The method comprises the steps that an autoregressive model (AR) is used to extract the characteristic of the vibration signal of an early fault-free rolling bearing and the failure characteristic of a failure rolling bearing of the same type and position (bearing of the same kind in short for the sake of description); a fuzzy C-mean value (FCM) performance degradation evaluation model is established through an early fault-free sample and a failure sample; an HMM model is established through the fault-free sample; in view of the advantages of FCM and HMM, degradation indexes acquired through FCM and HMM is input into the FCM performance degradation model as input characteristics, so as to acquire normal and failure clustering centers; and an early fault threshold is set at the same time. Experimental analysis shows that the evaluation indexes acquired through the performance degradation method provided by the invention can monitor the performance degradation trend of the rolling bearing in real time, and early faults can be detected in time.

Owner:EAST CHINA JIAOTONG UNIVERSITY

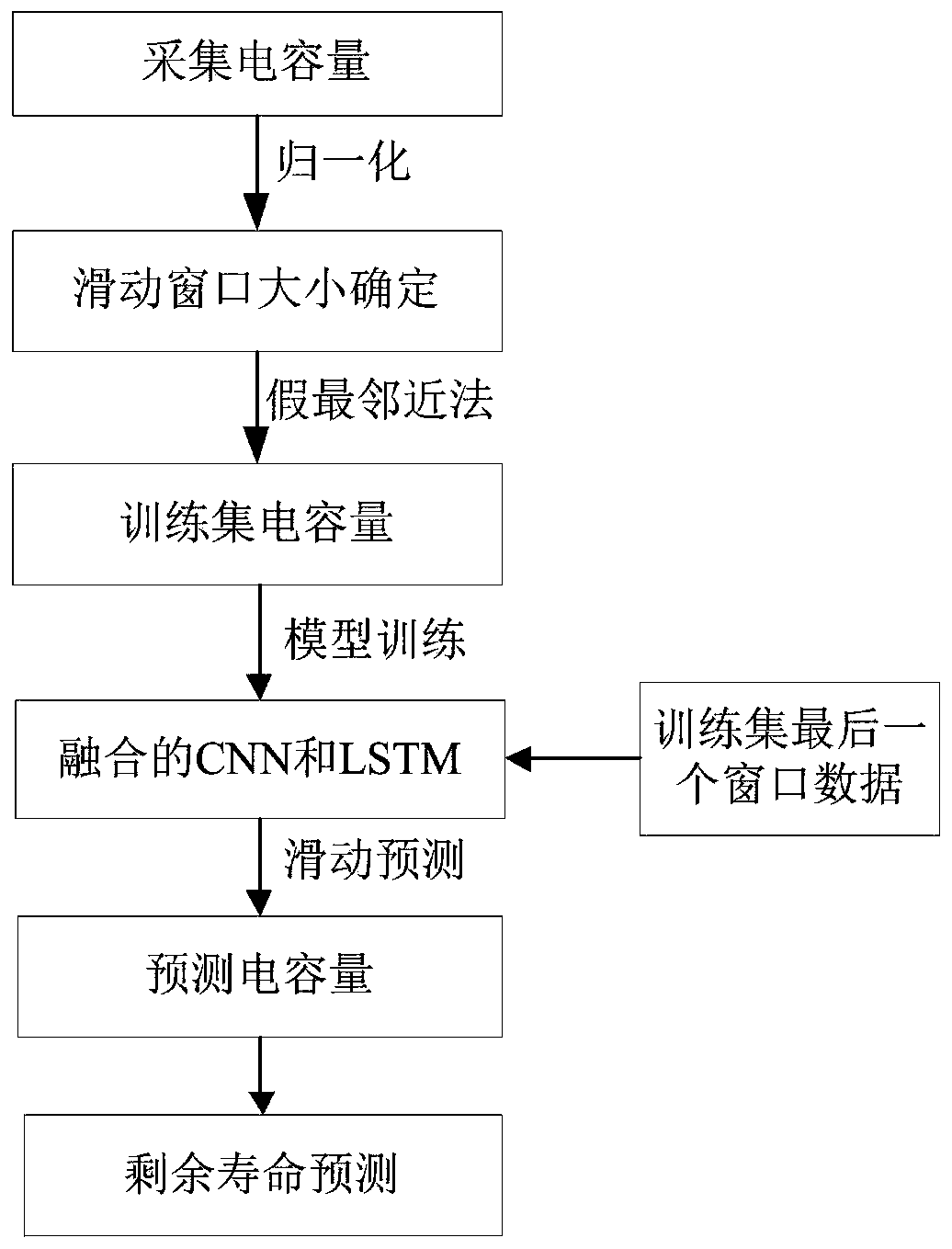

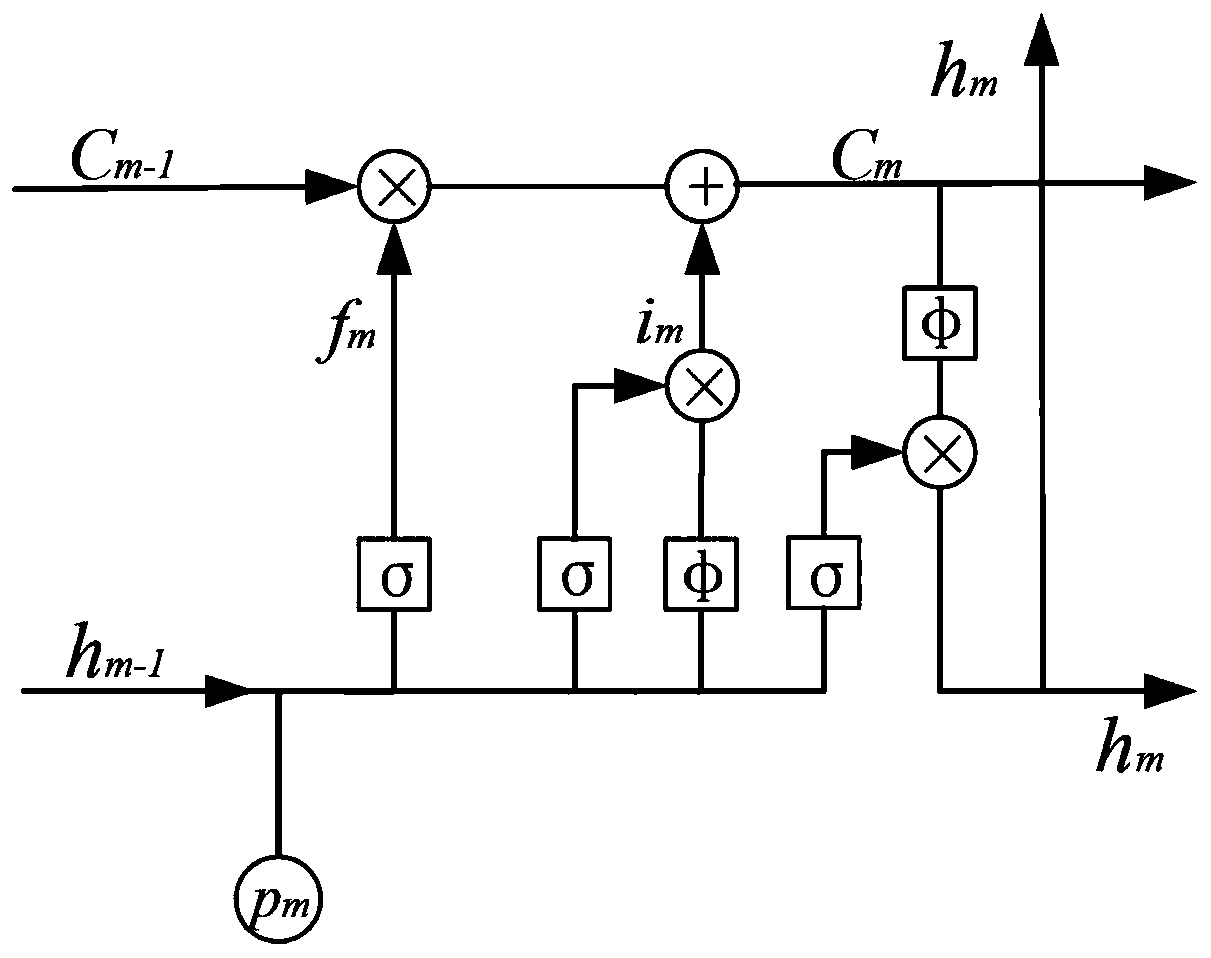

Lithium battery remaining life prediction method

InactiveCN110188920AEasy to handleEfficient extractionElectrical testingForecastingCapacitanceData set

The invention discloses a lithium battery residual life prediction method, which comprises the following steps: acquiring the capacities of a plurality of charge-discharge cycles of a lithium battery,and normalizing the capacities; performing window division on the normalized capacitances to obtain a training data set; inputting the training data set into a degradation state model comprising a convolutional neural network and a long and short memory recurrent neural network for training; inputting the last window data of the training data set into a trained degradation state model for slidingprediction until the predicted capacitance reaches a capacity degradation threshold point; and predicting the remaining life of the to-be-tested lithium battery according to the sliding cycle numbercorresponding to the predicted capacity value. According to the method, the feature extraction capability of the convolutional neural network and the time sequence prediction capability of the long and short memory recurrent neural network are fused, the degradation features of the lithium battery are effectively extracted and predicted, and the prediction precision is improved. And the window size of the degradation index is automatically determined by using the false nearest neighbor method, so that the calculation efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Fluorine-containing magnesium oxide pellet ore

The invention relates to a fluorine-containing magnesium oxide pellet ore which comprises the following raw materials: an iron material, bentonite and caustic calcined dolomite. The iron material is the mixed iron ore concentrate of Baotou steel Baiyun'ebo iron ore concentrate and common iron ore concentrate; the proportion of the Baiyun'ebo iron ore concentrate in the iron material is larger than 0 and not larger than 60wt percent, the bentonite accounts for 1.0-1.2wt percent relative to the raw materials, and the caustic calcined dolomite accounts for 3-4wt percent relative to the raw materials, wherein in the caustic calcined dolomite, CaO content is larger than 40wt percent, MgO content is not smaller than 28wt percent, SiO2 content is smaller than 8.0wt percent, and the proportion of granularity of 200 meshes is not smaller than 80wt percent; and MgO / SiO2 content in the fluorine-containing magnesium oxide pellet ore is not larger than 0.5. The invention fully utilizes Baotou steel Baiyun'ebo iron ore resources and can reduce the dosage of the bentonite and improve the reducibility and dropping temperature of the pellet ore by adjusting the pellet ore alkalinity and magnesium oxide content through adopting the dolomite; compared with acid pellet ore, the magnesium oxide pellet ore improves the reducibility and a low-temperature reduction degradation index, reduces the expansion ratio, and can meet the production requirement of a large blast furnace though with slightly reduced compressive strength of the pellet ore.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

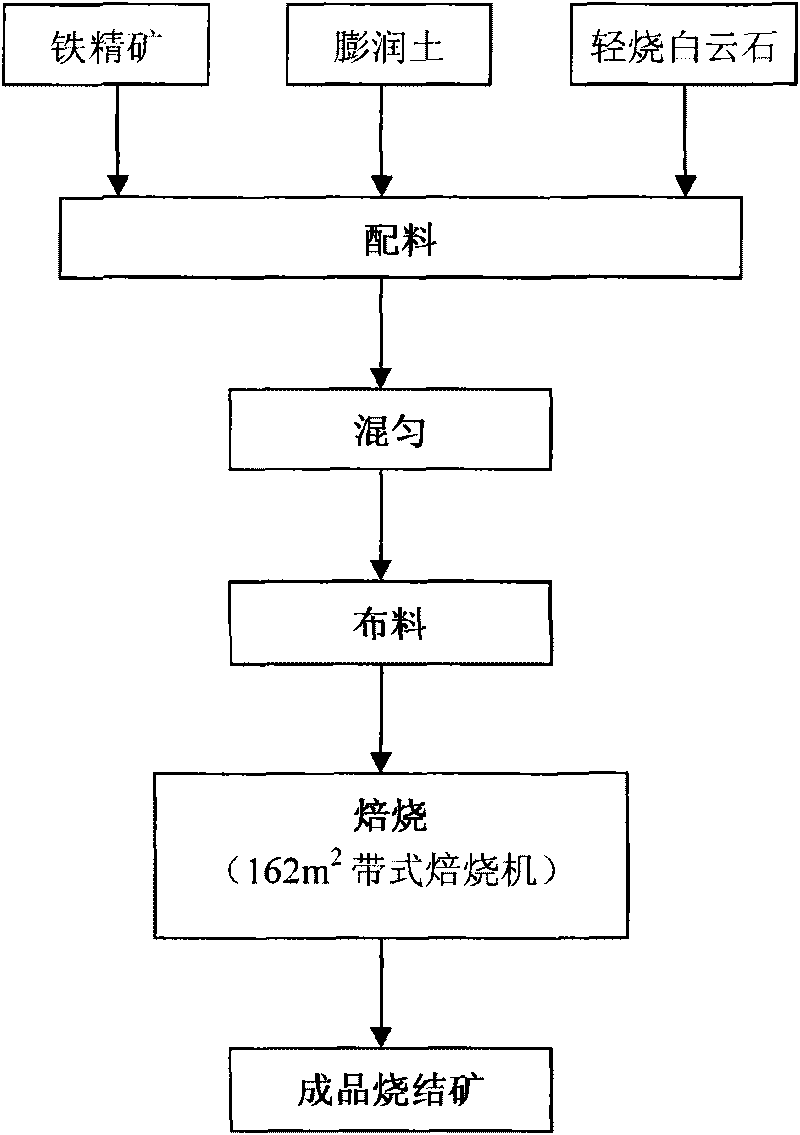

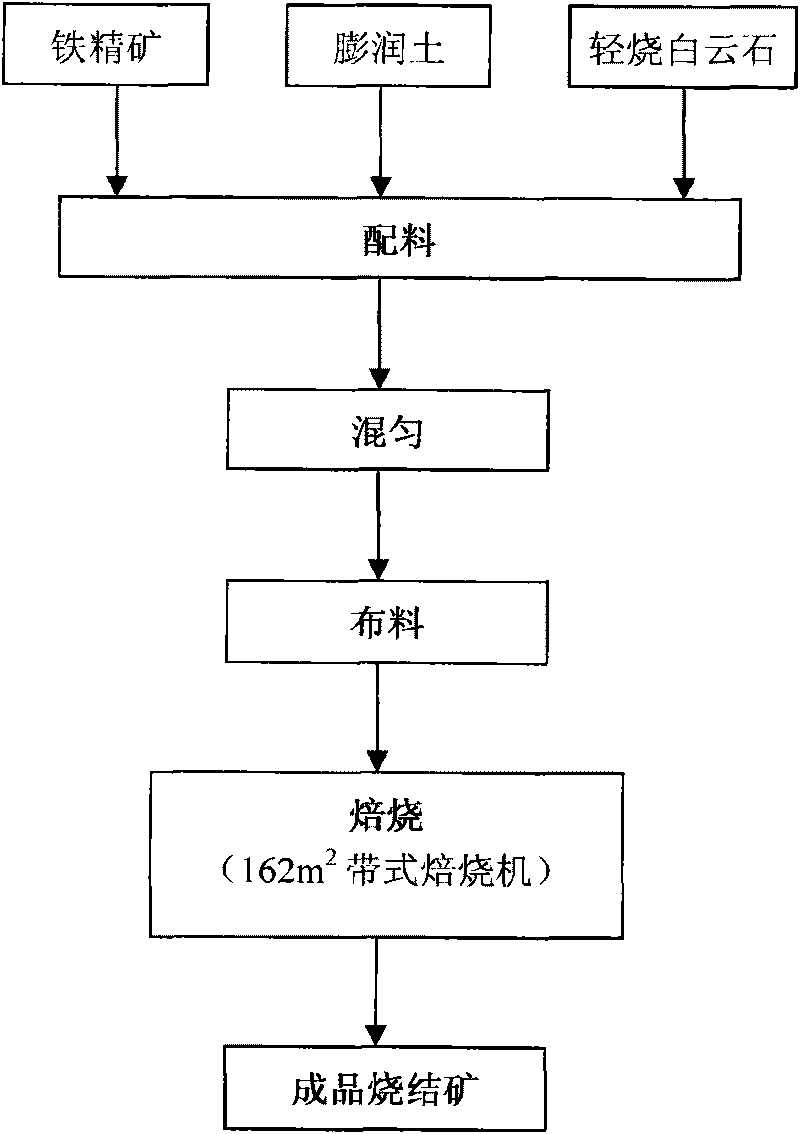

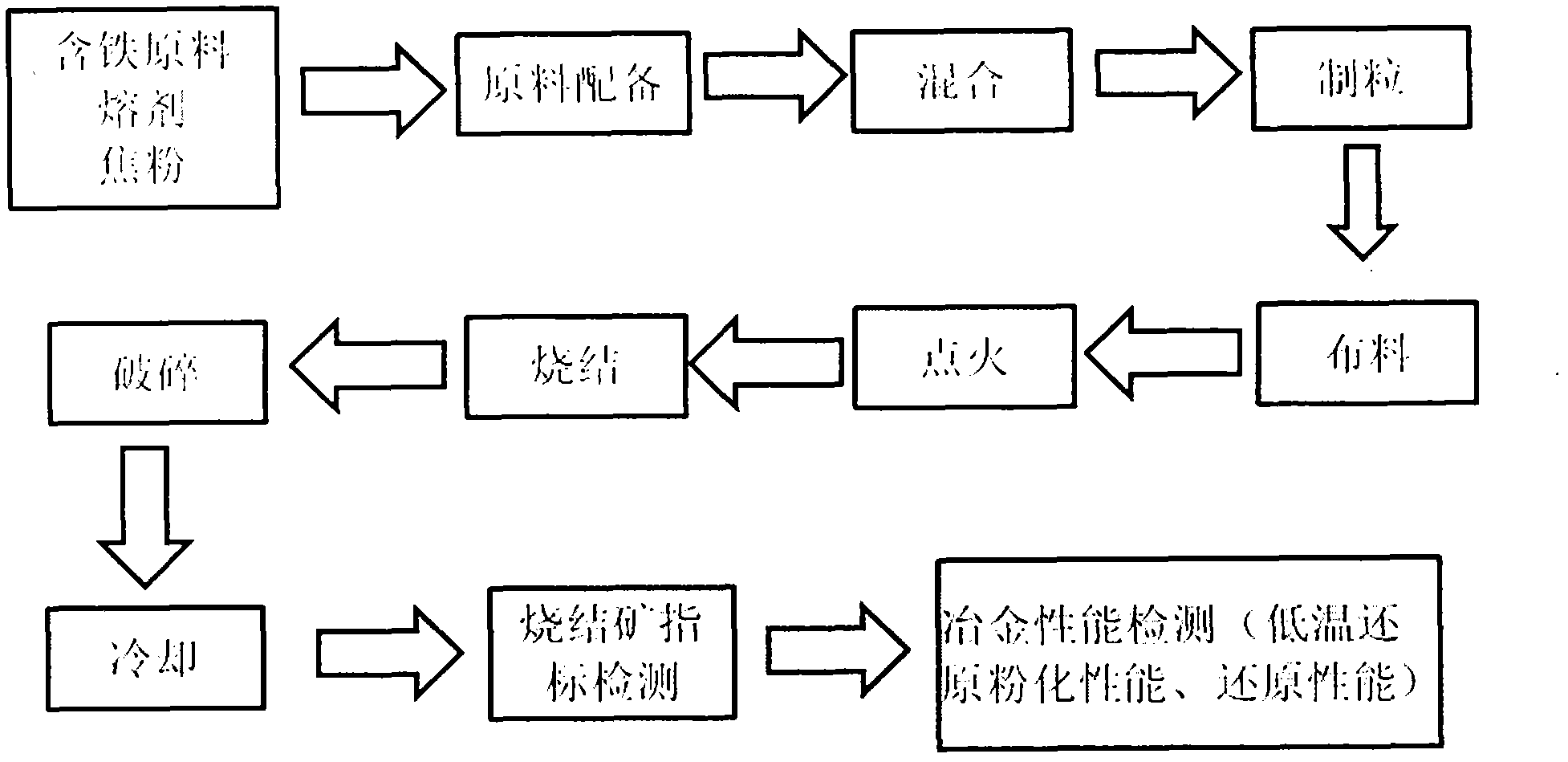

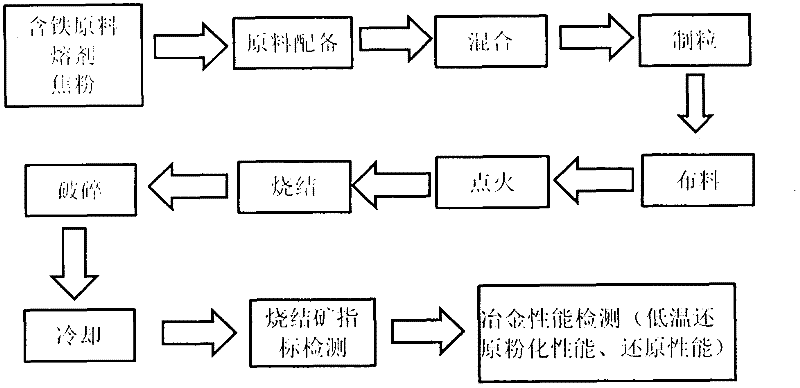

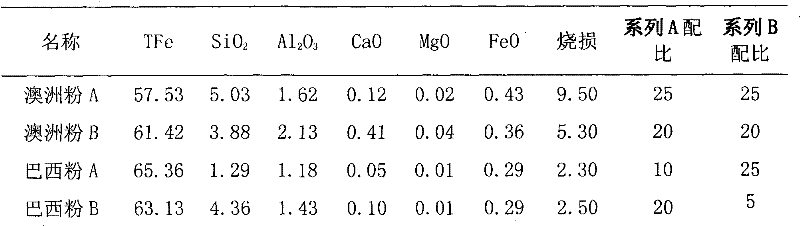

Method for preparing low-SiO2 high-performance sinter ore

The invention discloses a method for preparing a low-SiO2 high-performance sinter ore, and belongs to the technical field of sintering of iron ore powder. The method comprises the following steps of: proportioning; mixing; granulating; dispensing; igniting; sintering; crushing; cooling; detecting indexes of the sinter ore; detecting a reduction property; and detecting low-temperature reduction degradation performance. The sinter core comprises the following raw materials in percentage by weight: 75 to 85 percent of iron-containing raw material, 3.5 to 4.5 percent of quick lime, 3.5 to 5.0 percent of dolomite, 2.0 to 3.5 percent of limestone and 5.0 to 6.0 percent of coke powder; and alkalinity CaO / SiO2 of the sinter core is equal to 1.8 to 2.0, TFe content is between 55 and 60 percent, SiO2 content is between 4.2 and 4.5 percent, MgO content is between 1.9 and 2.3 percent, and FeO content is between 8 and 10 percent, wherein the FeO content in the sinter core is realized by a method for increasing the proportion of the coke powder, and the proportion of the coke powder is increased from 3.0-4.0 percent to 5.0-6.0 percent; and finally, a drum index of the sinter core is increased from 82 percent to 83.6 percent, a low-temperature reduction degradation index RDI+3.15 is increased from 39 percent to 51 percent, and a reduction index is increased from 79 percent to 85 percent under conditions of low SiO2 and high FeO.

Owner:SHOUGANG CORPORATION

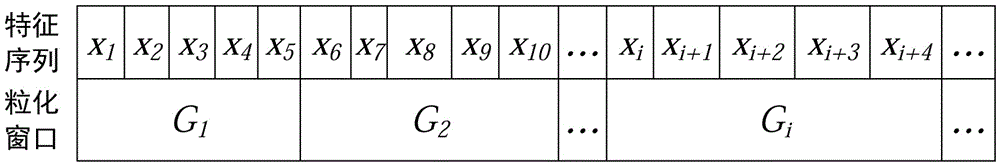

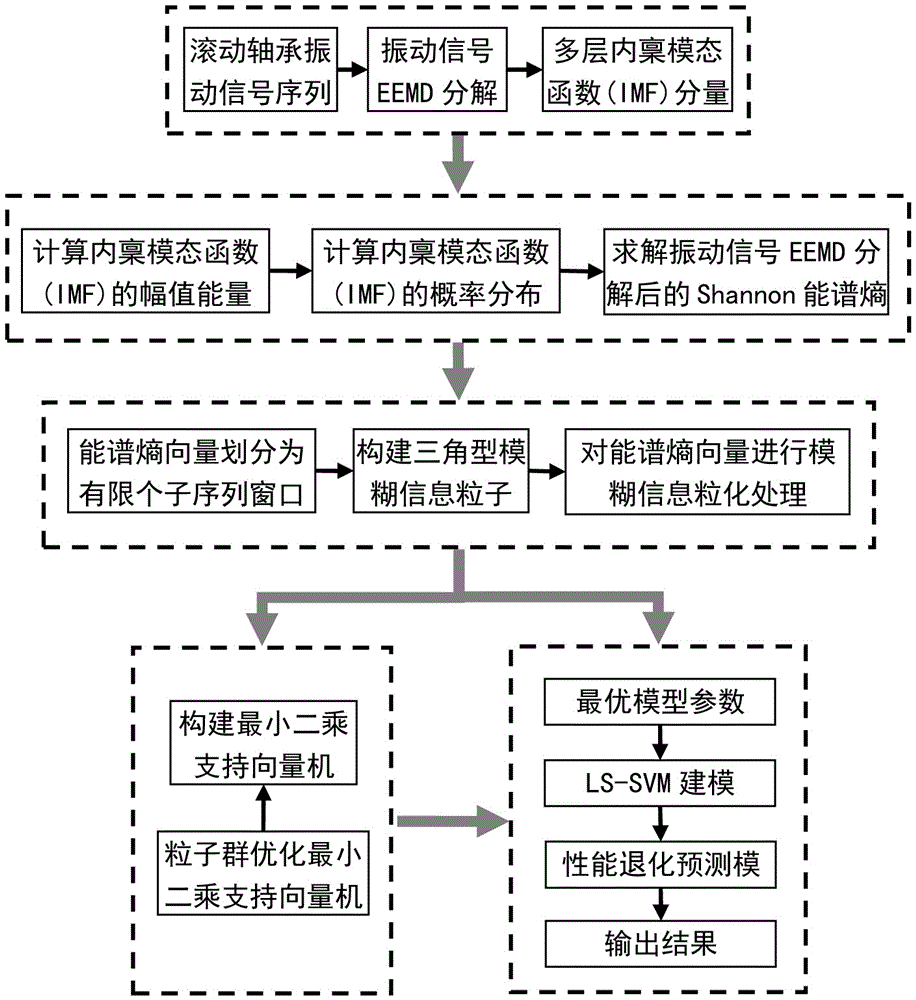

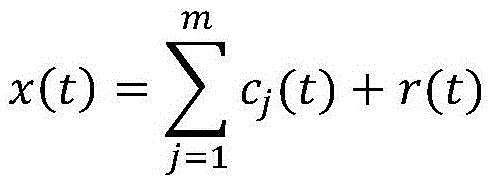

Fuzzy granulation prediction method of performance degradation of rolling bearing on the basis of information entropy

InactiveCN105590023AReflect performance degradation trendImproved information differentiationInformaticsSpecial data processing applicationsFuzzy granulationPredictive methods

The invention discloses a fuzzy granulation prediction method which specially aims at the performance degradation tendency of a rolling bearing. The method comprises the following steps: firstly, decomposing the vibration signal sequence of the rolling bearing by EEMD (Ensemble Empirical Mode Decomposition), and extracting the performance degradation index sequence of the vibration signal of the rolling bearing by a Shannon entropy theory; then, utilizing a fuzzy information granulation theory to carry out fuzzy information granulation on the performance degradation index sequence; and finally, inputting granulated granular information into an LS-SVM (Least Squares Support Vector Machine) to carry out regression prediction. The fuzzy granulation prediction method gives full play to the advantages of the EEMD on the aspect of the performance degradation gradual change information extraction of the rolling bearing, the advantages of information entropy on the aspect of information mining, the advantages of the LS-SVM on the aspect of regression prediction and the like, can predict the performance degradation tendency of the rolling bearing in a service cycle and also can effectively predict the performance change fluctuation range of the rolling bearing in one service time period.

Owner:CHINA THREE GORGES UNIV

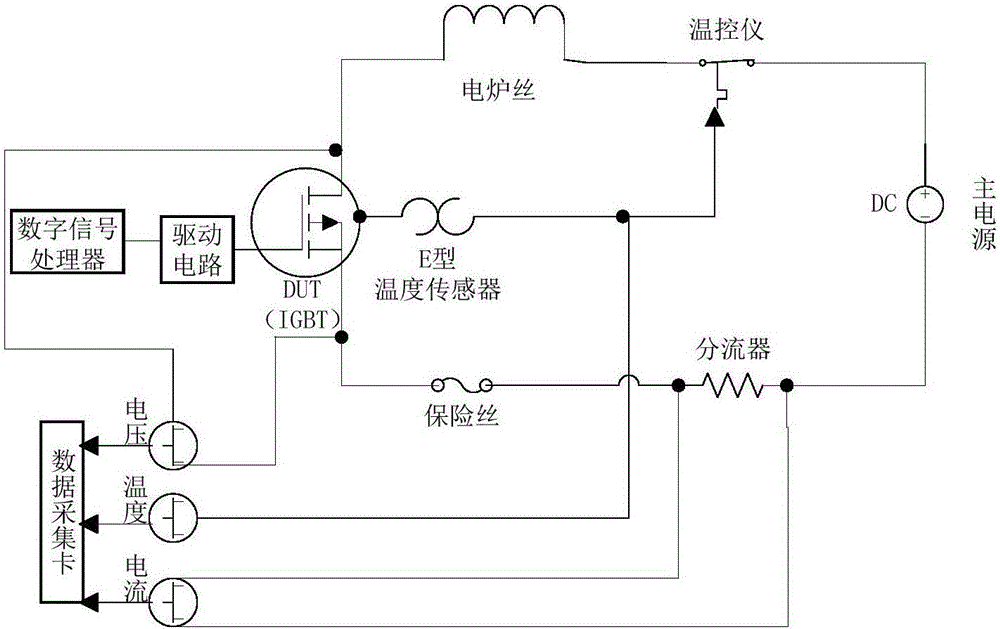

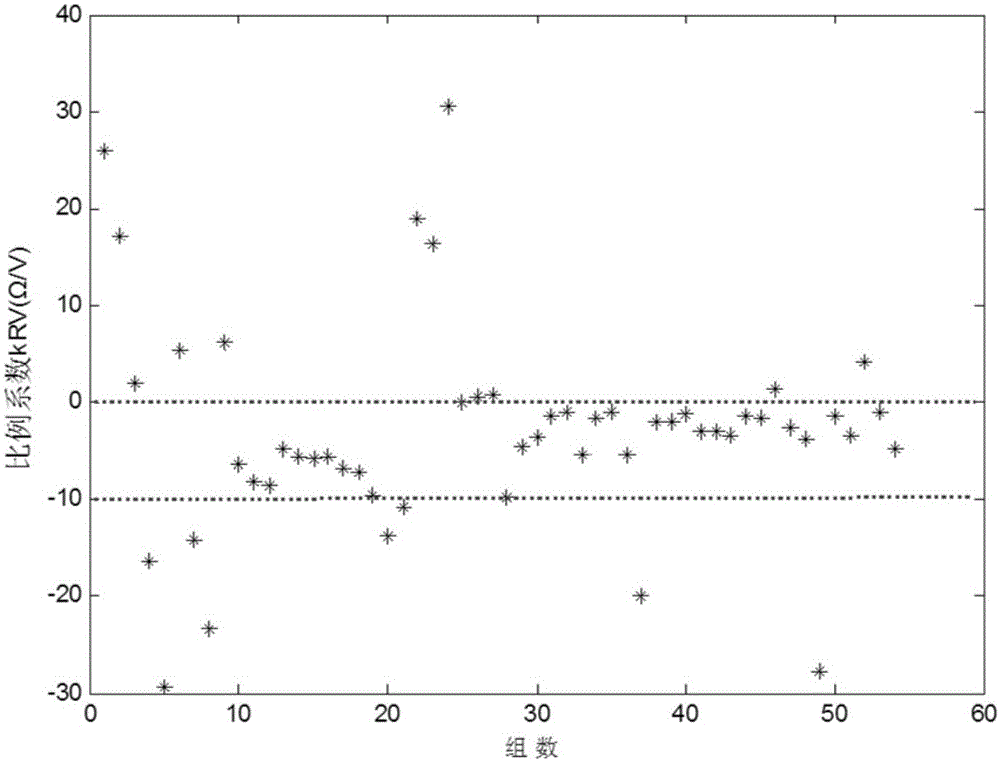

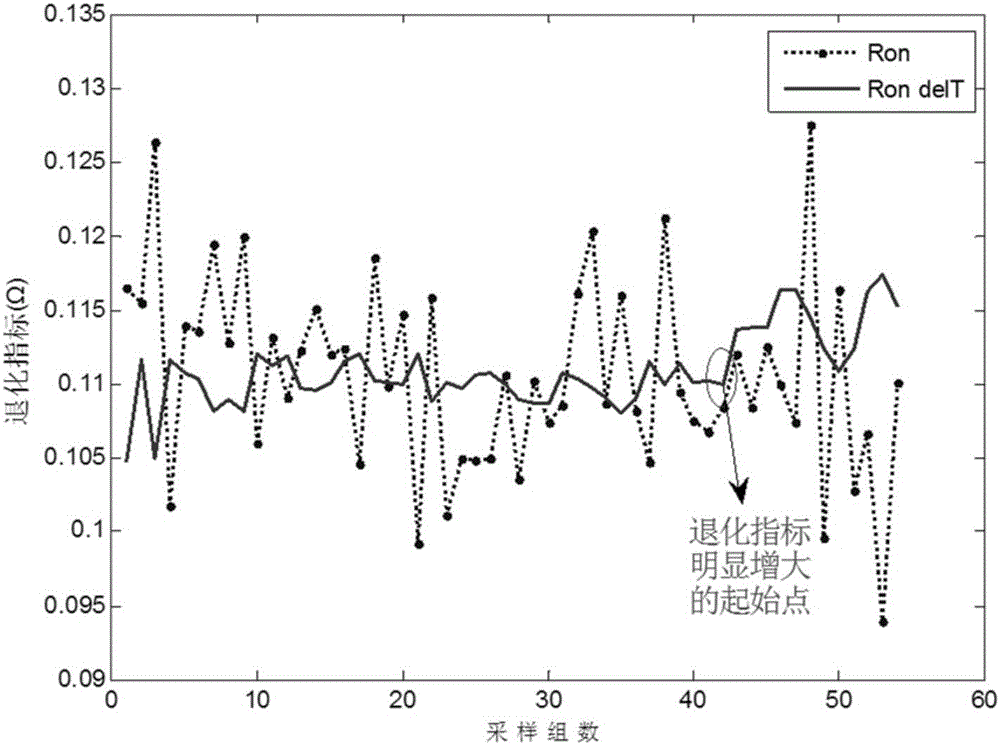

Online monitoring method for degradation of insulated gate bipolar transistor

ActiveCN106124957AAddress reliabilityEasy to operateBipolar transistor testingVoltage dropJunction temperature

The invention discloses an online monitoring method for degradation of an insulated gate bipolar transistor (IGBT). The online monitoring method can be used for monitoring the degradation degree of the IGBT in actual operating process, so as to send out early warning before the IGBT fails. The online monitoring method comprises the steps of: under the condition that the IGBT does not degrade, conducting a temperature experiment on an IGBT to be monitored, measuring junction temperature indexes (invariant voltage drop) representing IGBT junction temperature levels at different junction temperatures of the IGBT to be monitored and degradation indexes (conductive resistance) representing IGBT degradation degrees, and calculating a proportionality coefficient of degradation index variable quantity and junction temperature index variable quantity under the same junction temperature variation; and under the condition that the IGBT degrades, measuring a junction temperature index and a degradation index online, carrying out optimization of removing junction temperature influence on the degradation index by combining with the proportionality coefficient obtained through the temperature experiment under the normal condition, and monitoring the degradation degree of the IGBT to be monitored according to the optimized degradation index.

Owner:ZHEJIANG UNIV +1

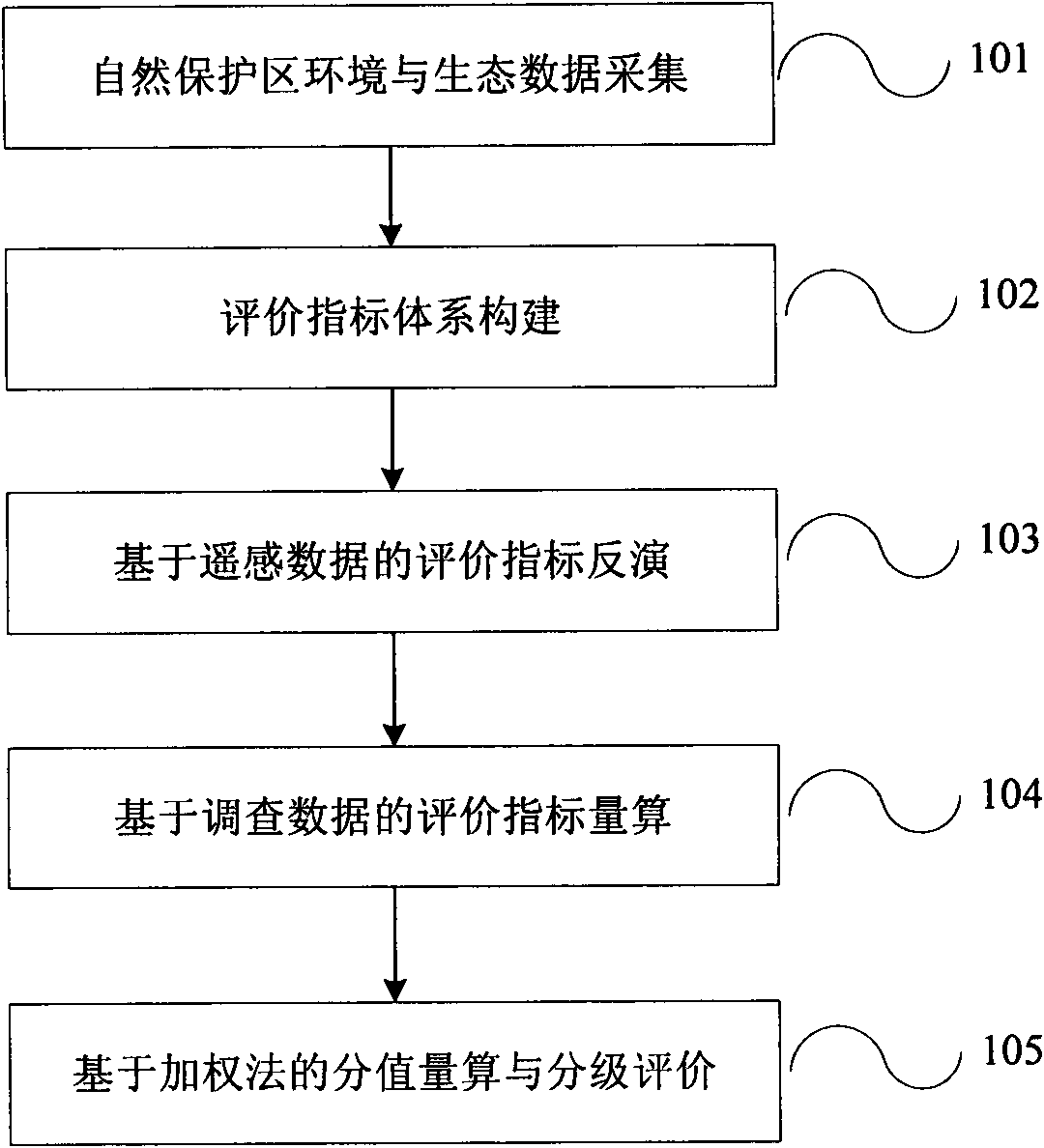

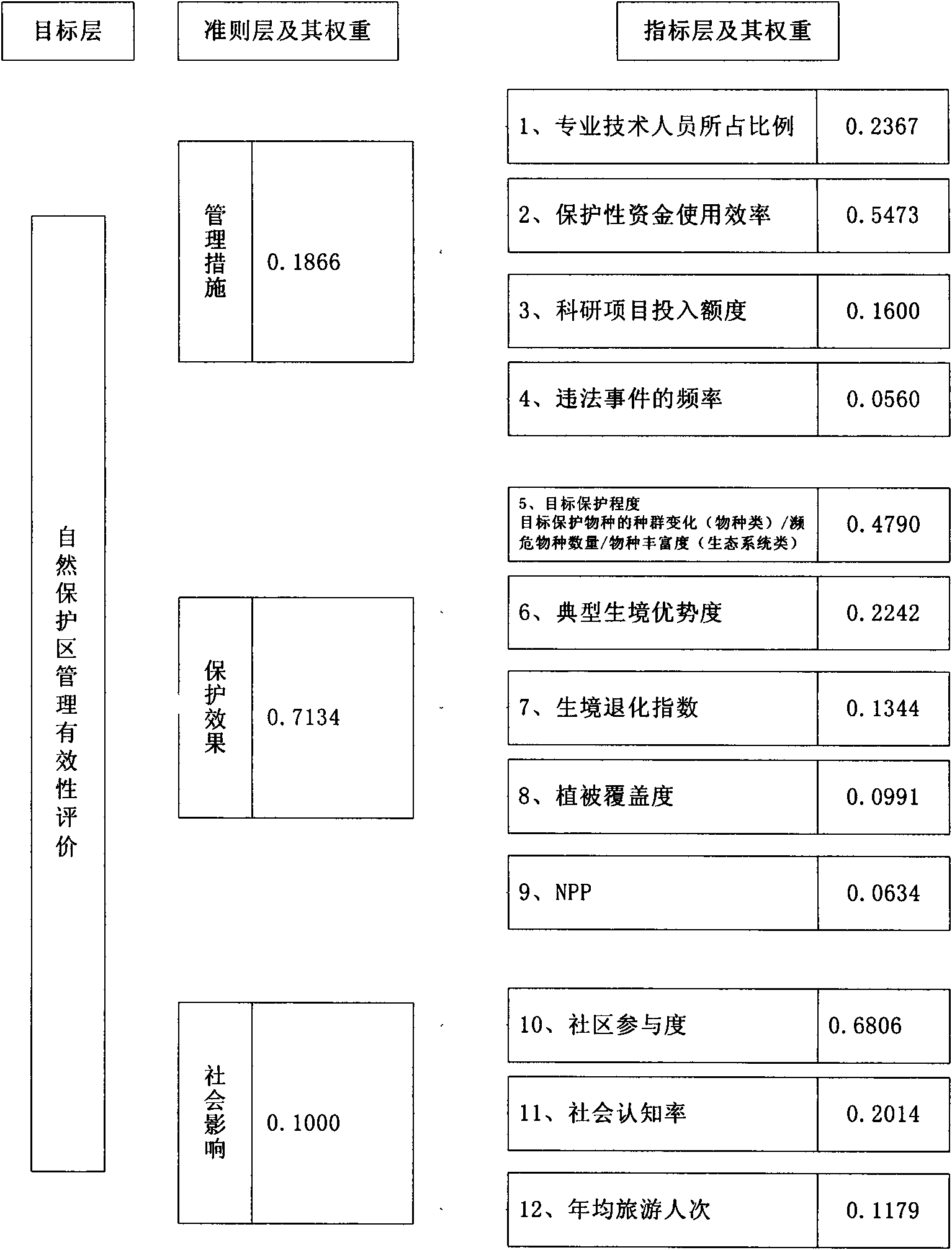

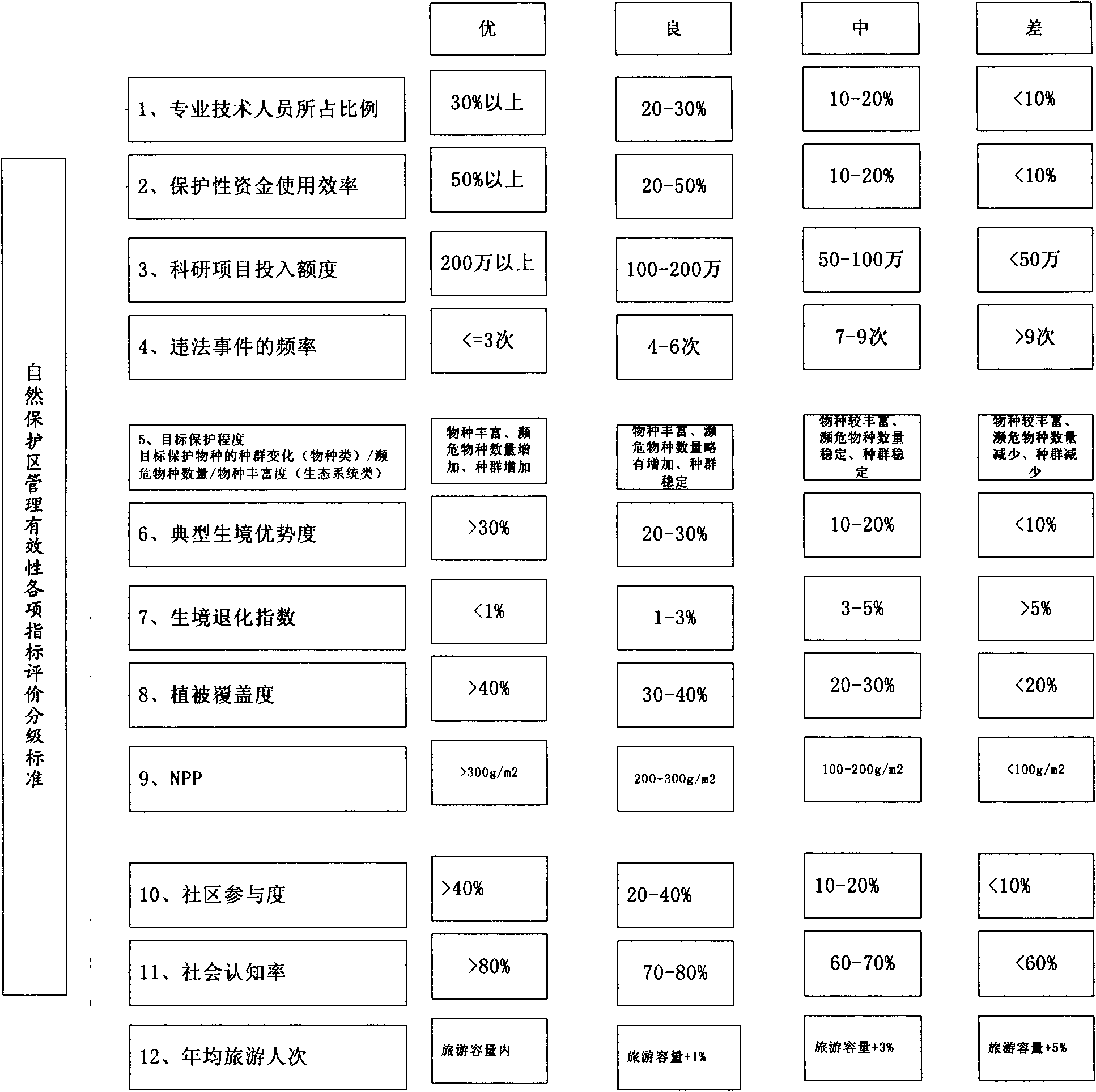

Natural preservation area management effectiveness quantitative evaluation method and system

InactiveCN102136103ARealization of Quantitative Evaluation of EffectivenessInstrumentsIndex systemDegradation index

The invention discloses a method and a system for quantitatively evaluating natural preservation area management effectiveness. The method comprises the following steps: obtaining environmental and ecological data of a natural preservation area by measures such as a remote sensing satellite and field survey and the like, determining a natural preservation area management effectiveness quantitative evaluation indexes system by utilizing an analytic hierarchy process and an expert scoring method, determining index intension and a quantitative measuring method of the index intension so as to be convenient for quantitative evaluation of the future preservation area; conducting inversion to index values of NPP (net primary productivity), vegetation coverage, a typical habitat dominance and habitat degradation indexes and the like by utilizing the remote sensing data; measuring management measures and social impact rule layer correlation indexes by utilizing ground investigation data; determining all index permissions by utilizing the analytic hierarchy process, and conducting weighting summation to measure all natural preservation area evaluation values; and determining an evaluation criterion, and conducting evaluation grading to the natural preservation area based on the standard. In the invention, the natural preservation area evaluation quantitative performance and representativeness are realized, so as to be beneficial to realization of on-line evaluation to the natural preservation area subsequently according to the category of the natural preservation areas.

Owner:TIANJIN AGRICULTURE COLLEGE

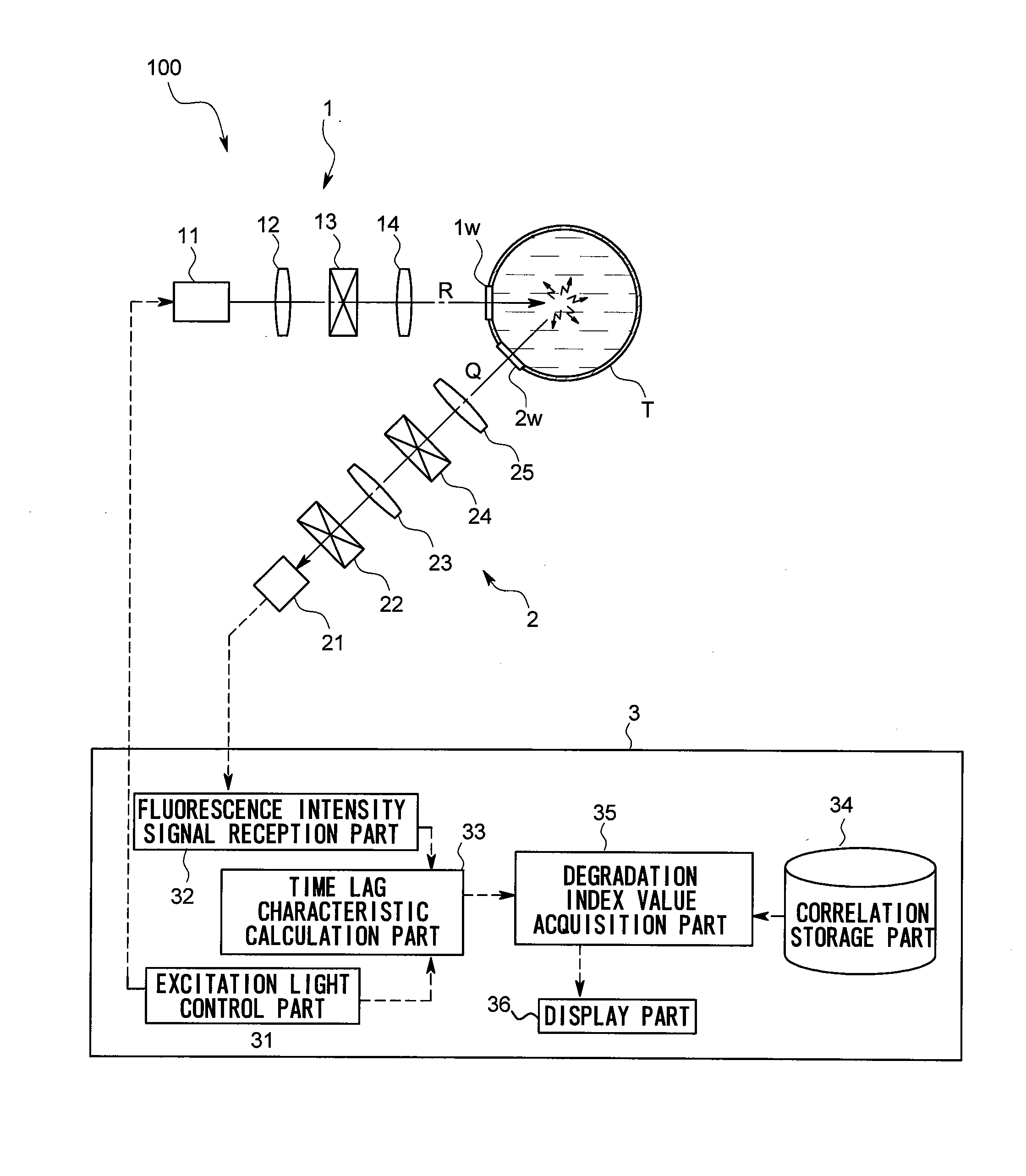

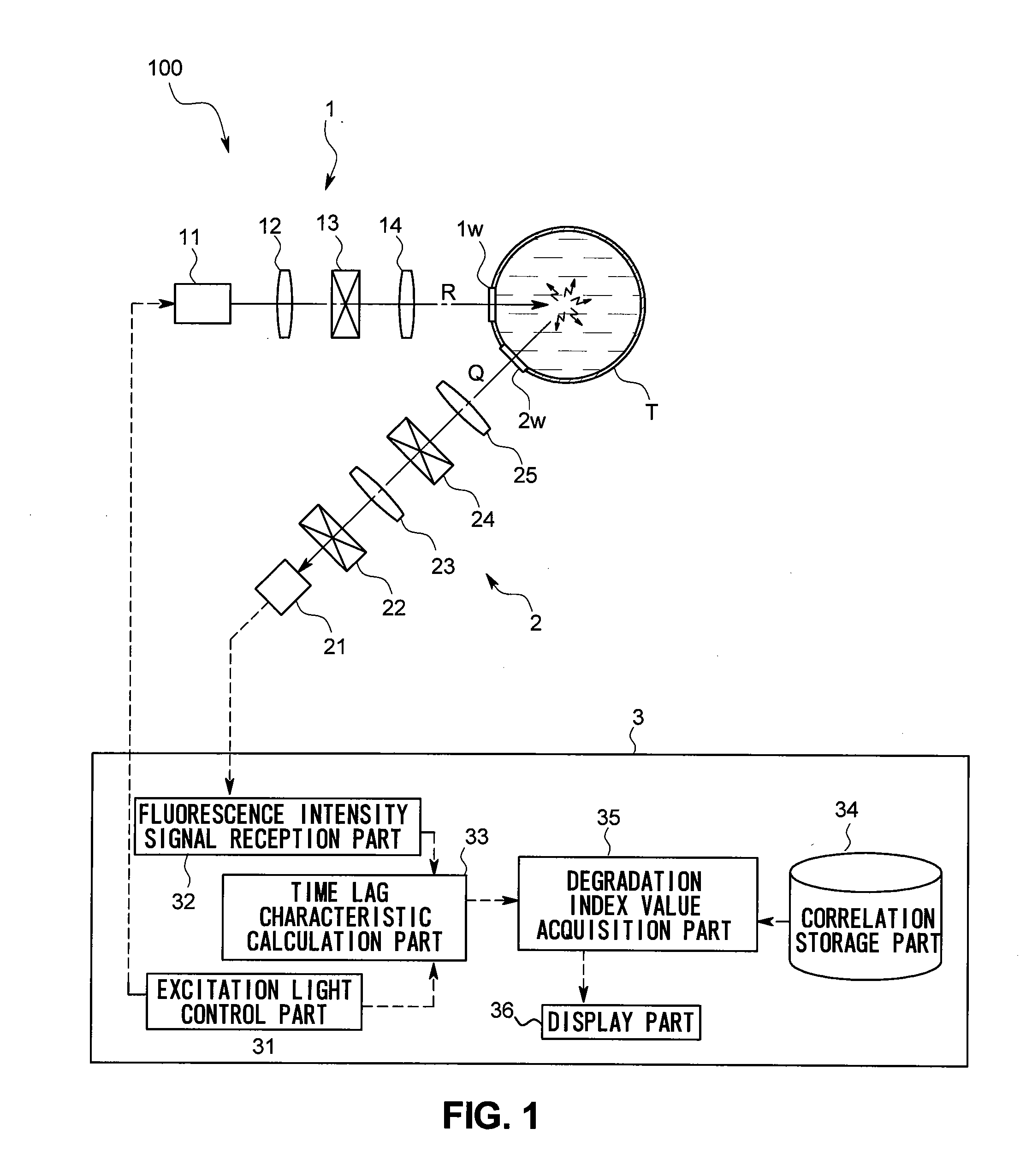

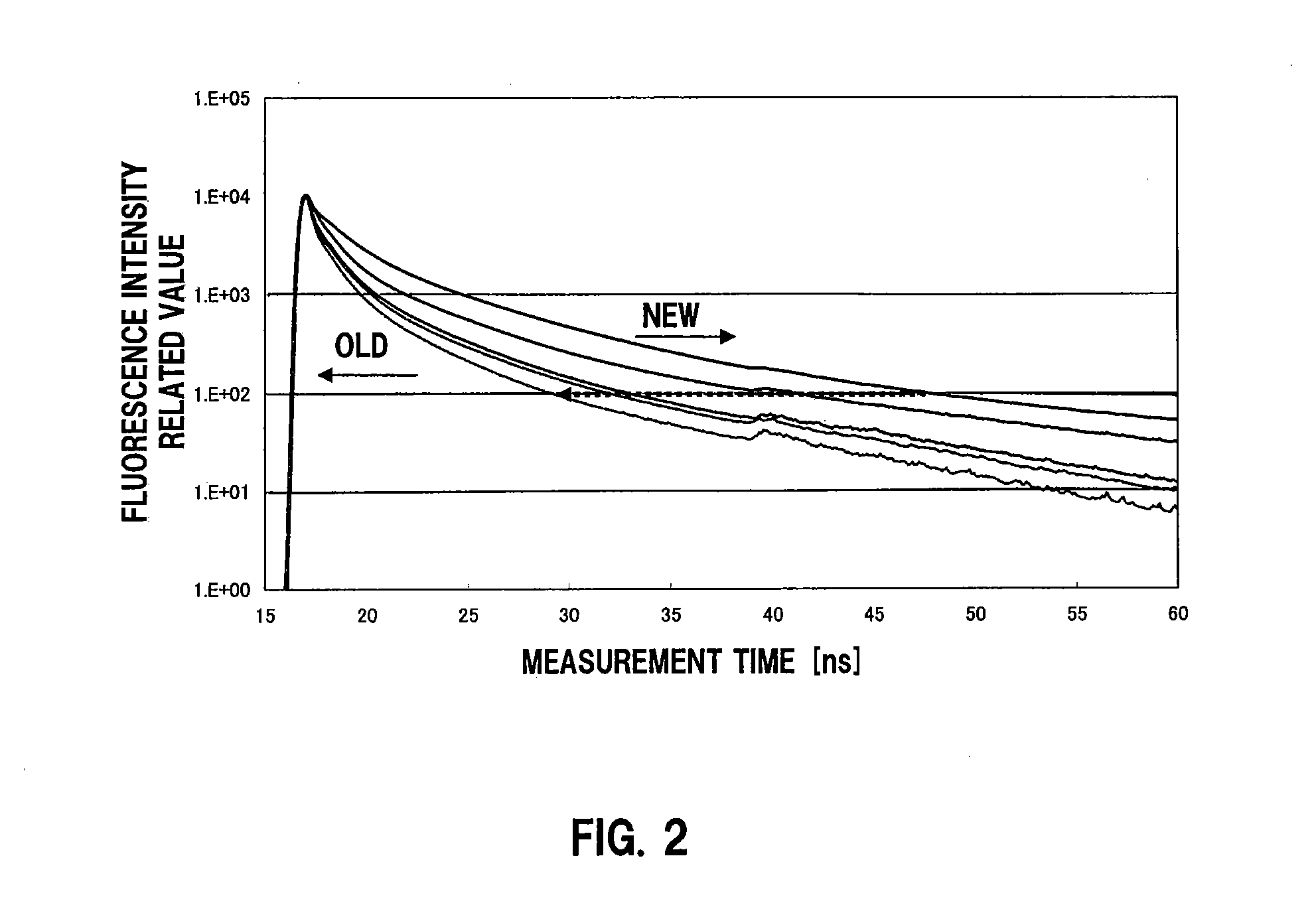

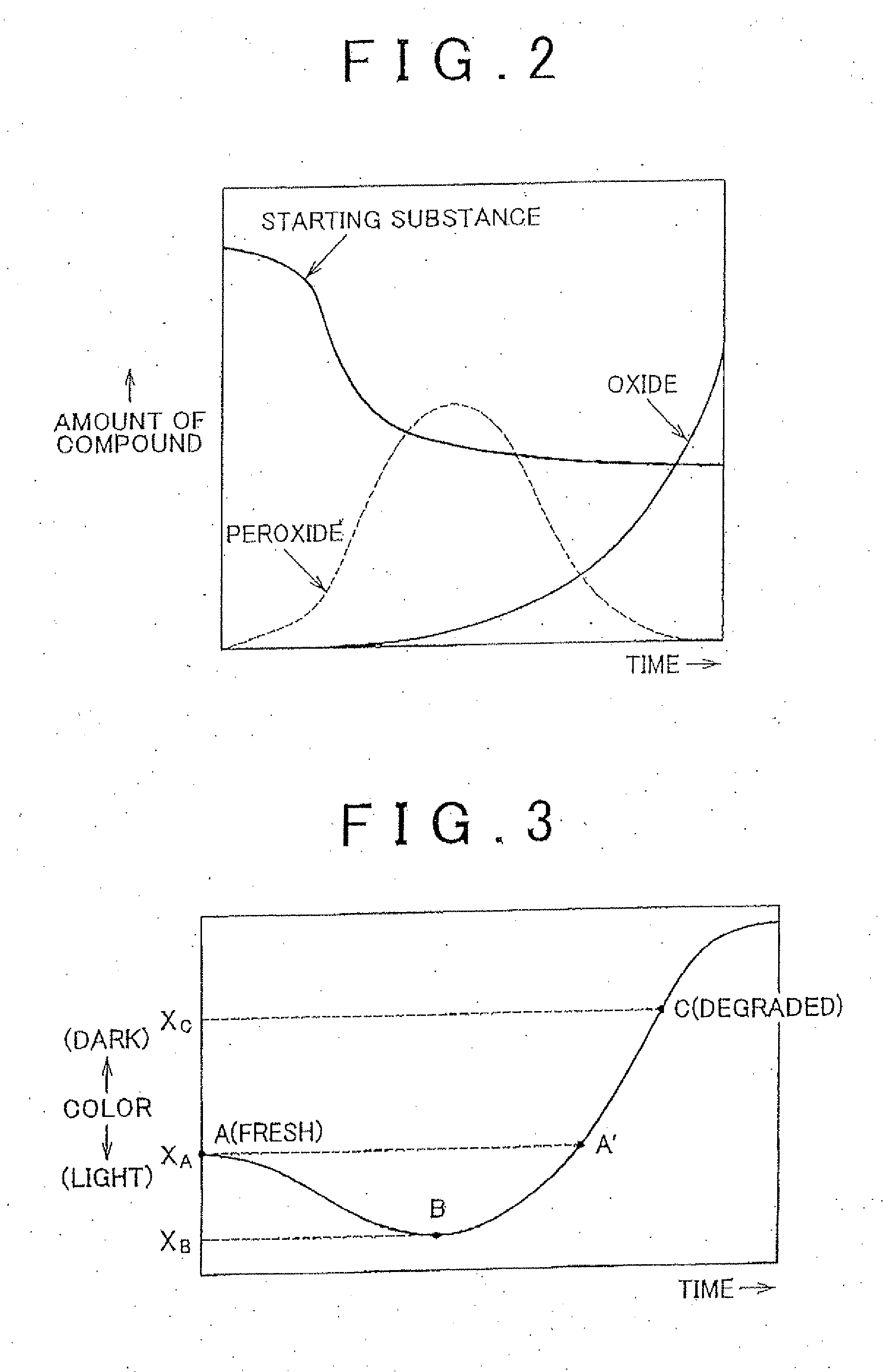

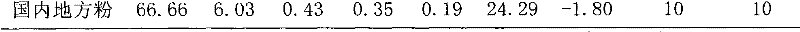

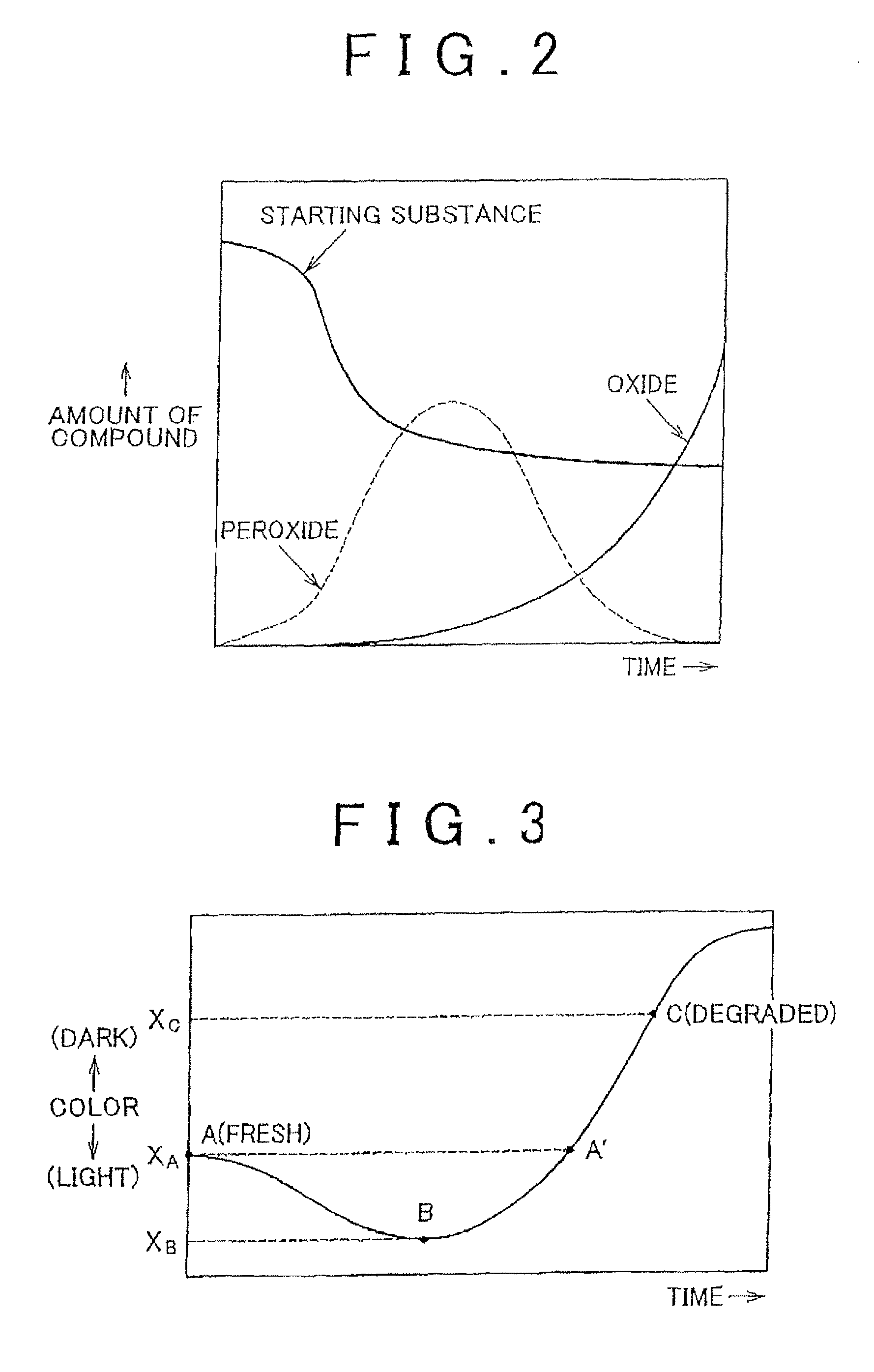

Refined oil degradation level measuring instrument and refined oil degradation level measuring method

InactiveUS20110155925A1Easy to operateUnnecessary wastePhotometryLuminescent dosimetersLight irradiationTime lag

In situ monitoring of a degradation level of refined oil during use is provided. An excitation light irradiation part varies intensity of excitation light to irradiate the excitation light onto the refined oil with a resulting fluorescence. A fluorescence intensity detection part detects the intensity of fluorescence generated by the irradiation of the excitation light, and a time lag characteristic calculation part calculates a time lag characteristic of a fluorescence intensity variation with respect to the intensity variation of the excitation light. A degradation index value acquisition part provides to a predetermined correlation between a degradation index value indicating a degradation level of the refined oil and the time lag characteristic is used to acquire a degradation index value from a time lag characteristic calculated in the time lag characteristic calculation part t determine the current degradation status of the oil.

Owner:HORIBA LTD

Sintered ore pulverization inhibitor and adding method thereof

The invention provides sintered ore pulverization inhibitor and an adding method thereof. The sintered ore pulverization inhibitor comprises the following chemical components by weight percentage: 65-85% of MgCl2, 3-7% of CaCl2, 5-15% of H3BO2 and 5-15% of CaO B2O3 4H2O. The adding method comprises the following steps that: pulverization inhibitor which is prepared and uniformly mixed is stored in a liquid storage pool; at a first spraying point, a 4.5kw pump and a spray tube are adopted for spraying sintered ores in a circular cooler; at a second spraying point, a 4.5kw pump and a spray nozzle are adopted for spraying a finished sintered ore belt; and at a third spraying point, a 7.5kw pump and an atomizing spray gun are adopted for spraying a finished product belt. After the pulverization inhibitor is sprayed to the finished sintered ores, the low-temperature reduction degradation index of the sintered ores is reduced, the breathability of a blast furnace is improved, the comprehensive coke ratio is reduced, and the yield of ferrum is improved; the content of chlorine is reduced, so the corrosion on a bag-type dust collector of the blast furnace is relieved; and simultaneously, the generation amount of TCDD (tetrachlorodibenzo-p-dioxin) is reduced, so the environmental pollution is avoided.

Owner:ANGANG STEEL CO LTD

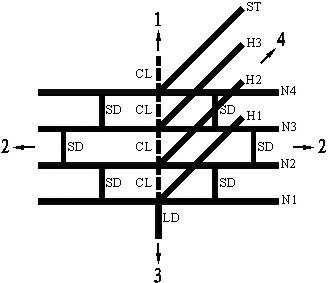

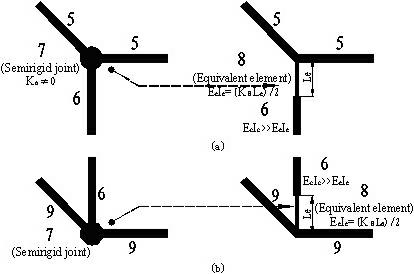

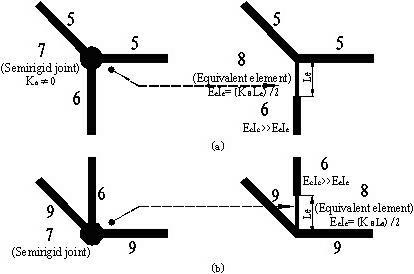

Finite element modeling method for integral structure of timber construction of ancient building

InactiveCN102323968ASimply and effectively reflect the force characteristicsSpecial data processing applicationsEngineeringElement modeling

The invention discloses a finite element modeling method for an integral structure of a timber construction of an ancient building. The method is characterized by comprising the following steps of: (1) simulating bearing components, such as a beam column and the like, by a beam unit; (2) simulating a cornice through a beam-short column unit; (3) simulating semi-rigid characteristics of the beam column and a column bottom joint through an equivalent (beam) unit; (4) reflecting structure deformation by moving a column frame joint position; (5) selecting wood property of aged material as a model wood property parameter to represent degradation of the wood property; (6) describing degradation degree of mechanical performance of the column frame joint by setting a mechanical performance degradation index; (7) based on a modal parameter model modification theory, solving the degradation index of model joint mechanical performance through a genetic algorithm. The method has the advantage of being capable of forming an integral model capable of representing mechanical characteristics and damage of the ancient timber construction, and solving the defect that the model formed by the existing method cannot roundly reflect the characteristics such as a force transmission path of the cornice, the semi-rigid characteristics of the column frame joint, the degradation of the mechanical performance, and the like. The method provided by the invention needs to be realized with the graphics software AutoCAD, the programming software Fortran and the element finite software (such as ANSYS and ABAQUS and the like).

Owner:陈志勇

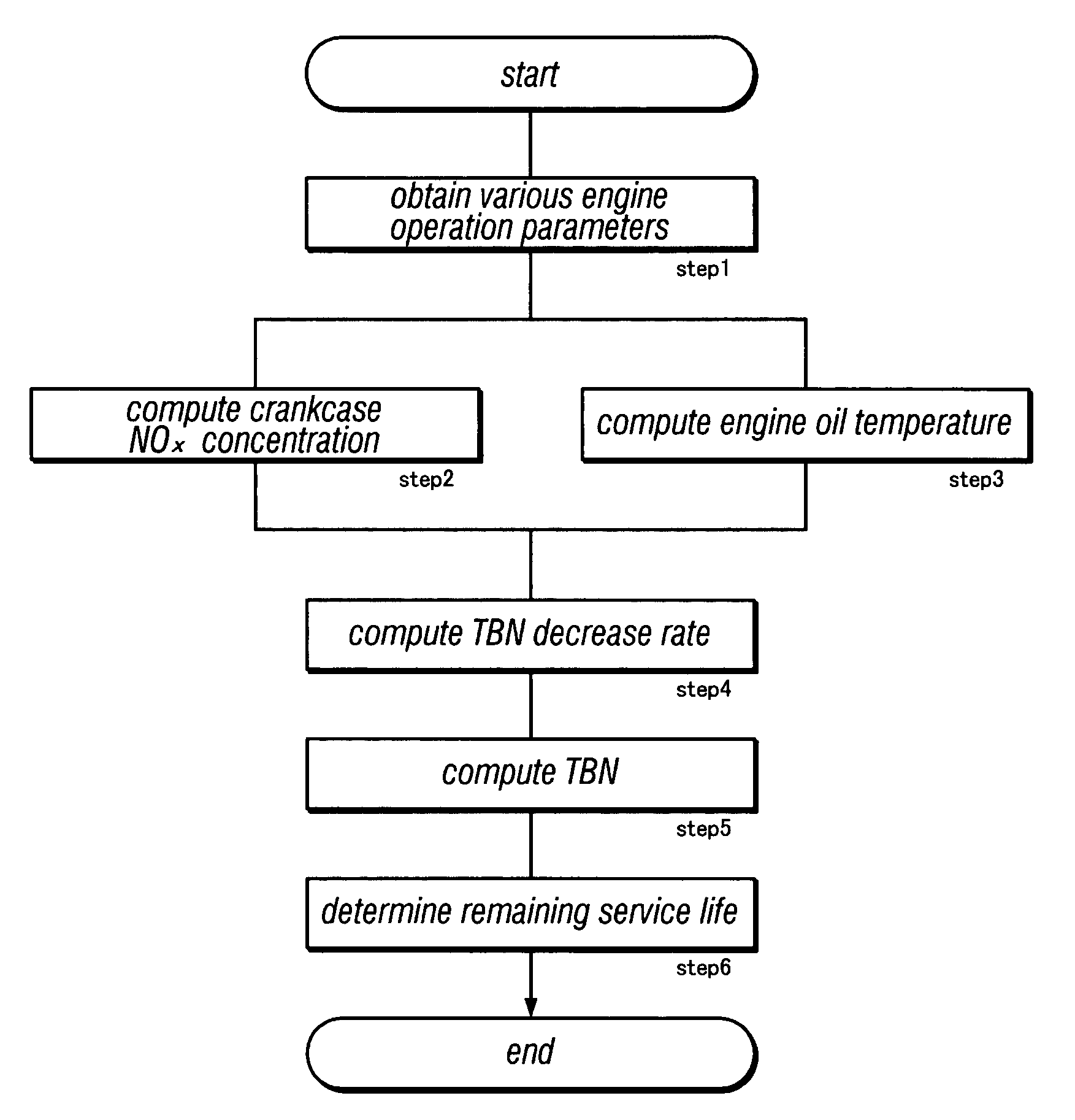

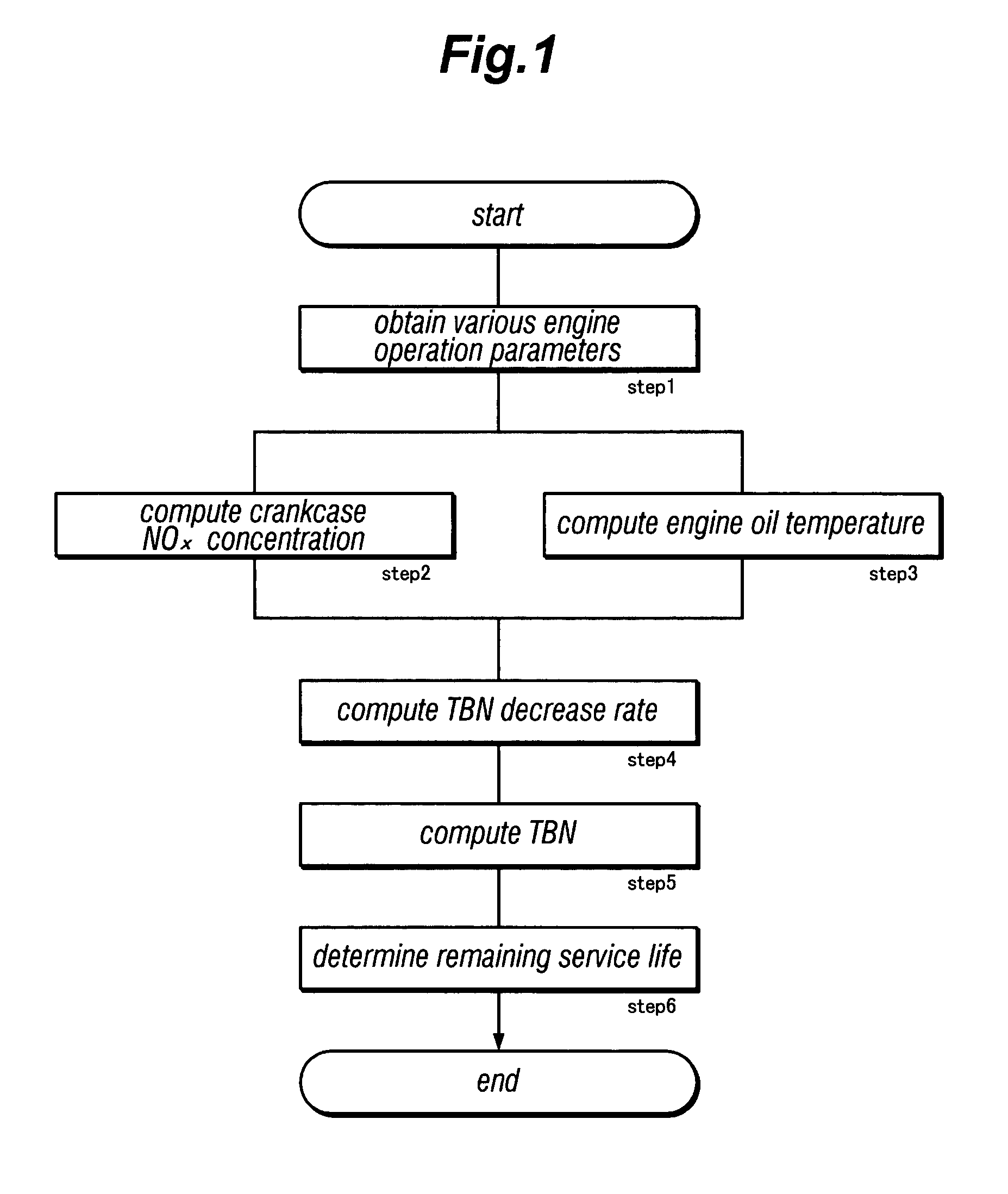

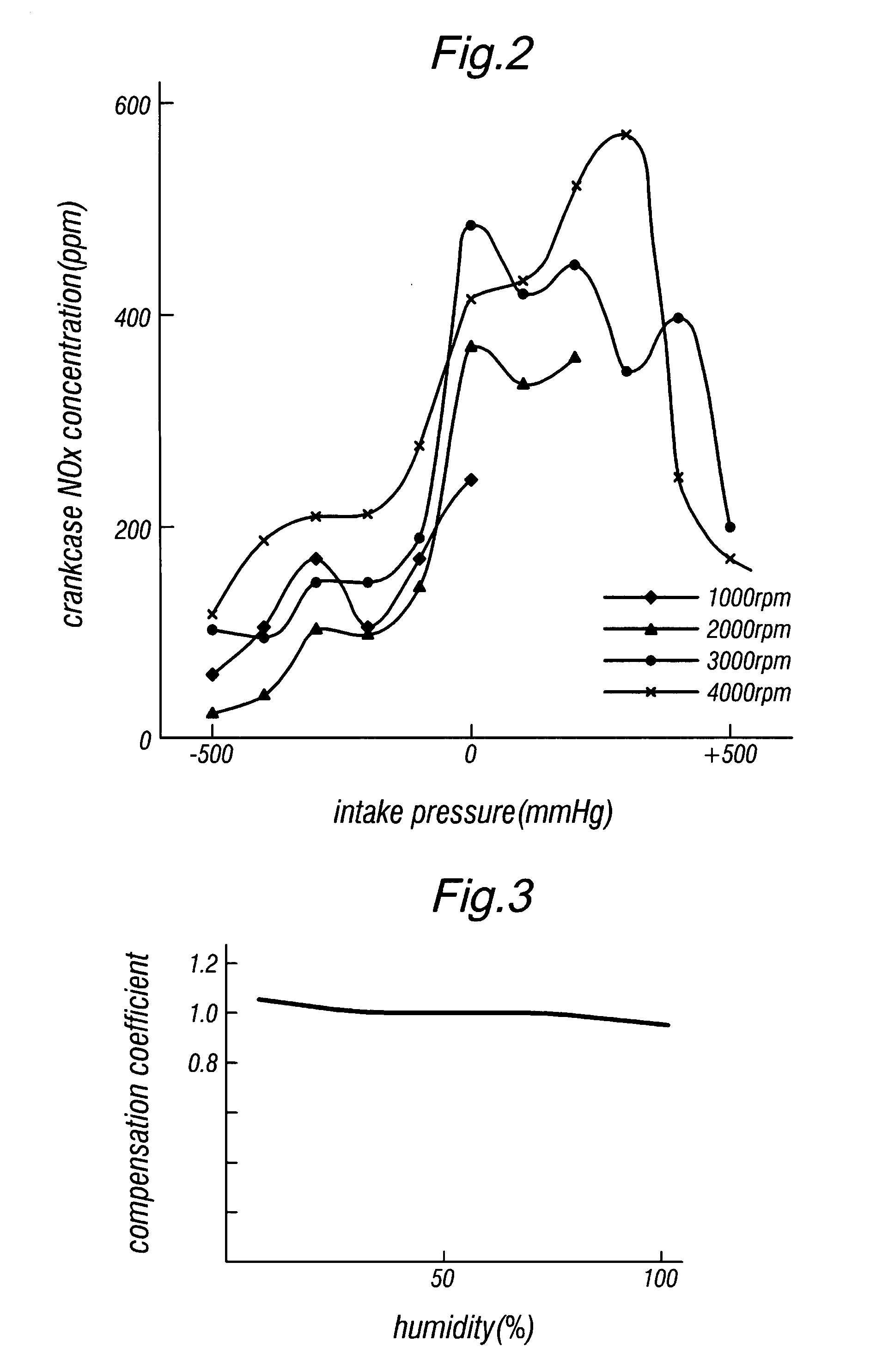

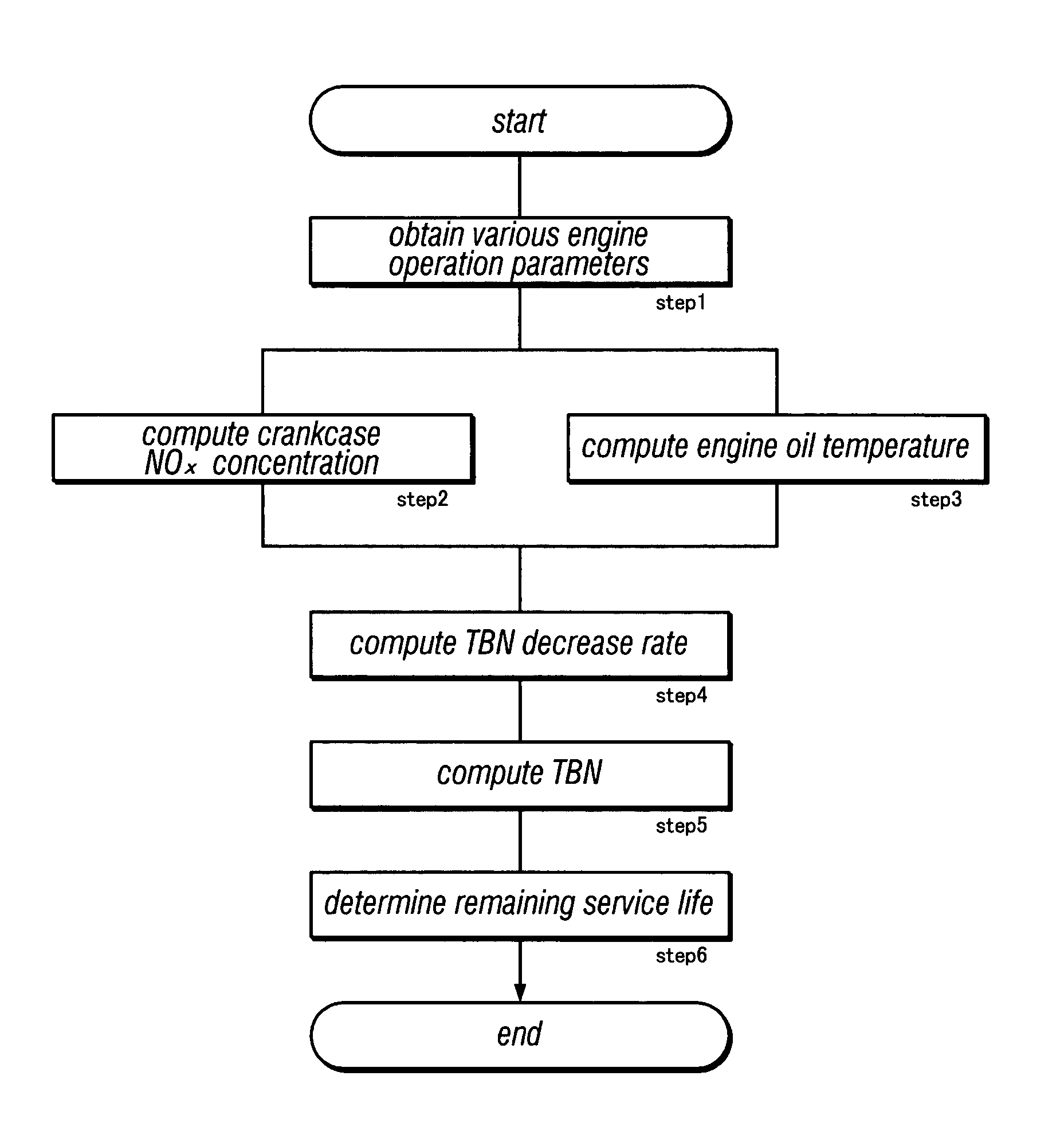

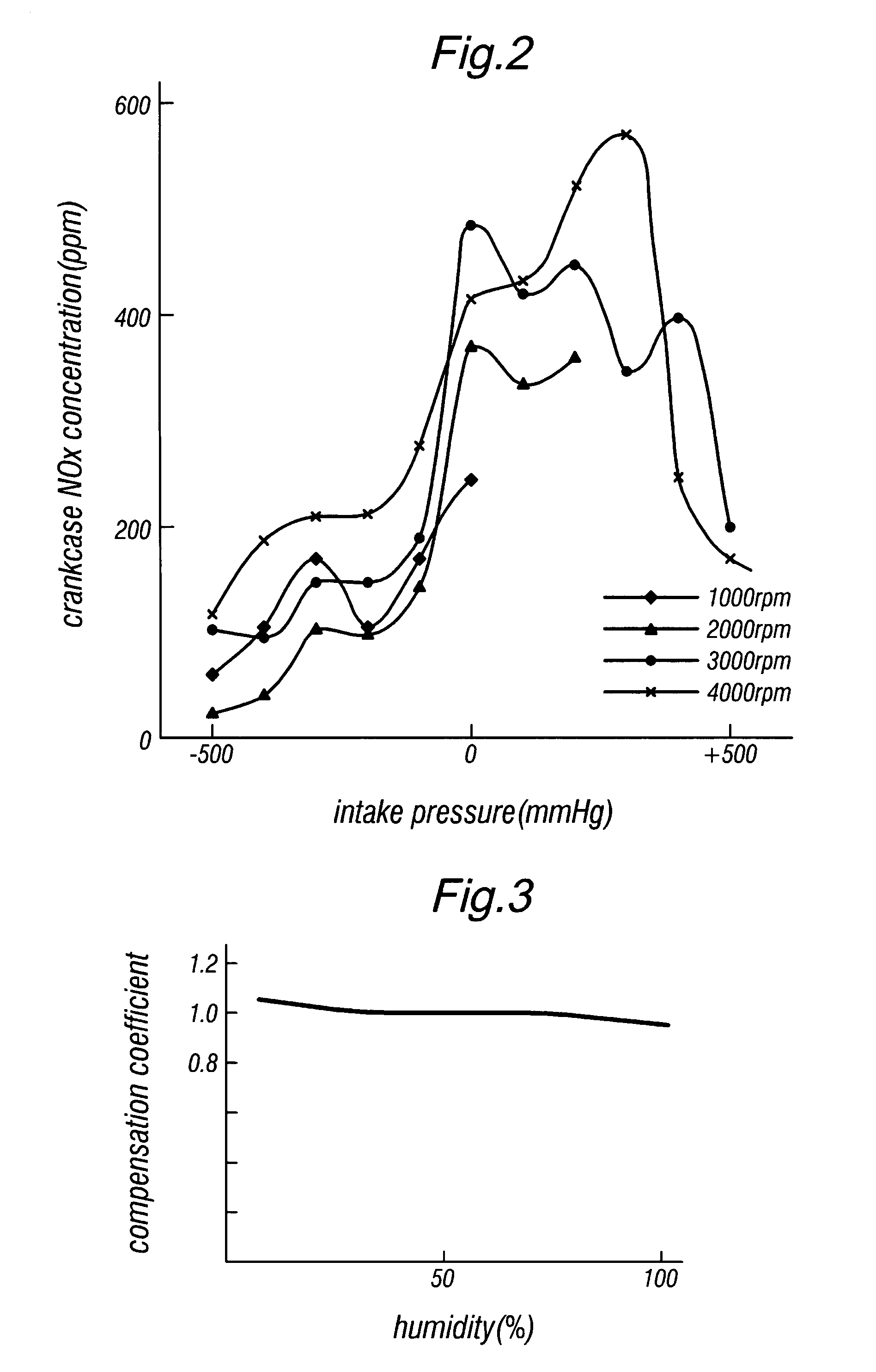

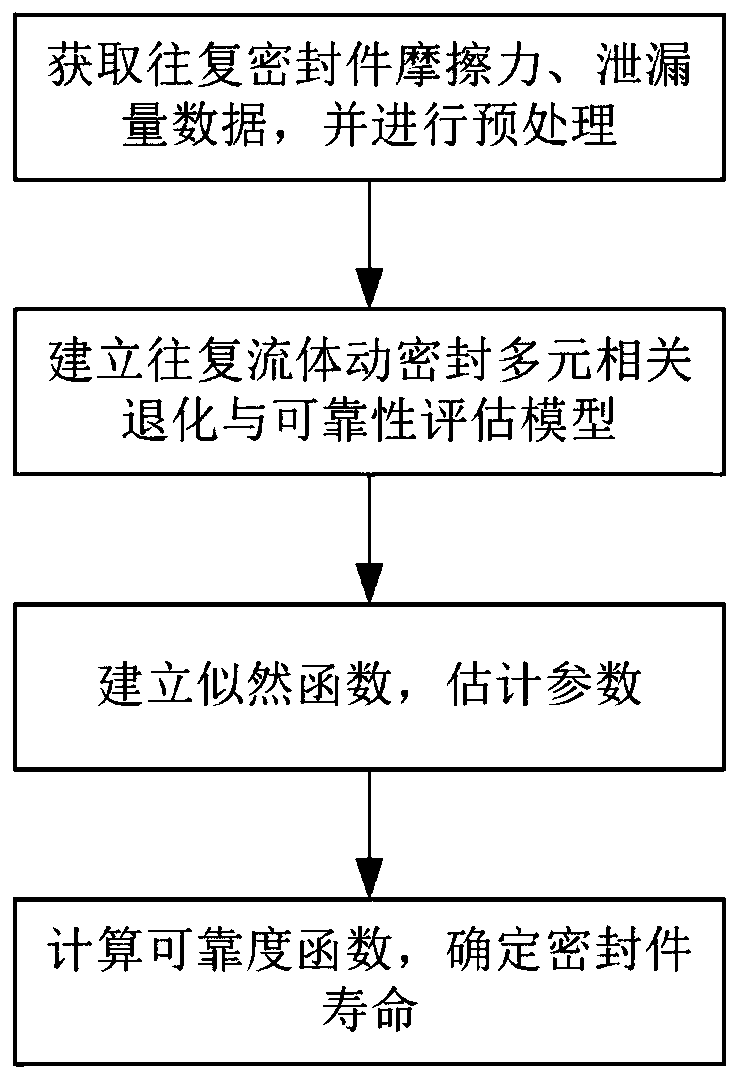

Method for detecting a condition of engine oil

ActiveUS20080027661A1Accurately determineImprove accuracyEngine testingFlow propertiesTotal Base NumberCrankcase

Provided is a method for detecting a condition of engine oil that allows the progress of degradation of engine oil to be more accurately determined without incurring any significant cost. In a method for detecting a state of engine oil by defining a degradation index that changes with a progress in degradation of the engine oil that lubricates an internal combustion engine and determining a progress of the degradation of the engine oil according to the degradation index, a value related to a concentration of blow-by gas that flows into a crankcase of the engine is computed, and the degradation index is computed according to the computed value related to a concentration of blow-by gas that flows into a crankcase of the engine. The degradation index may consist of a total base number of the engine oil, and the concentration of blow-by gas that flows into a crankcase of the engine may consist of a NOx concentration.

Owner:HONDA MOTOR CO LTD

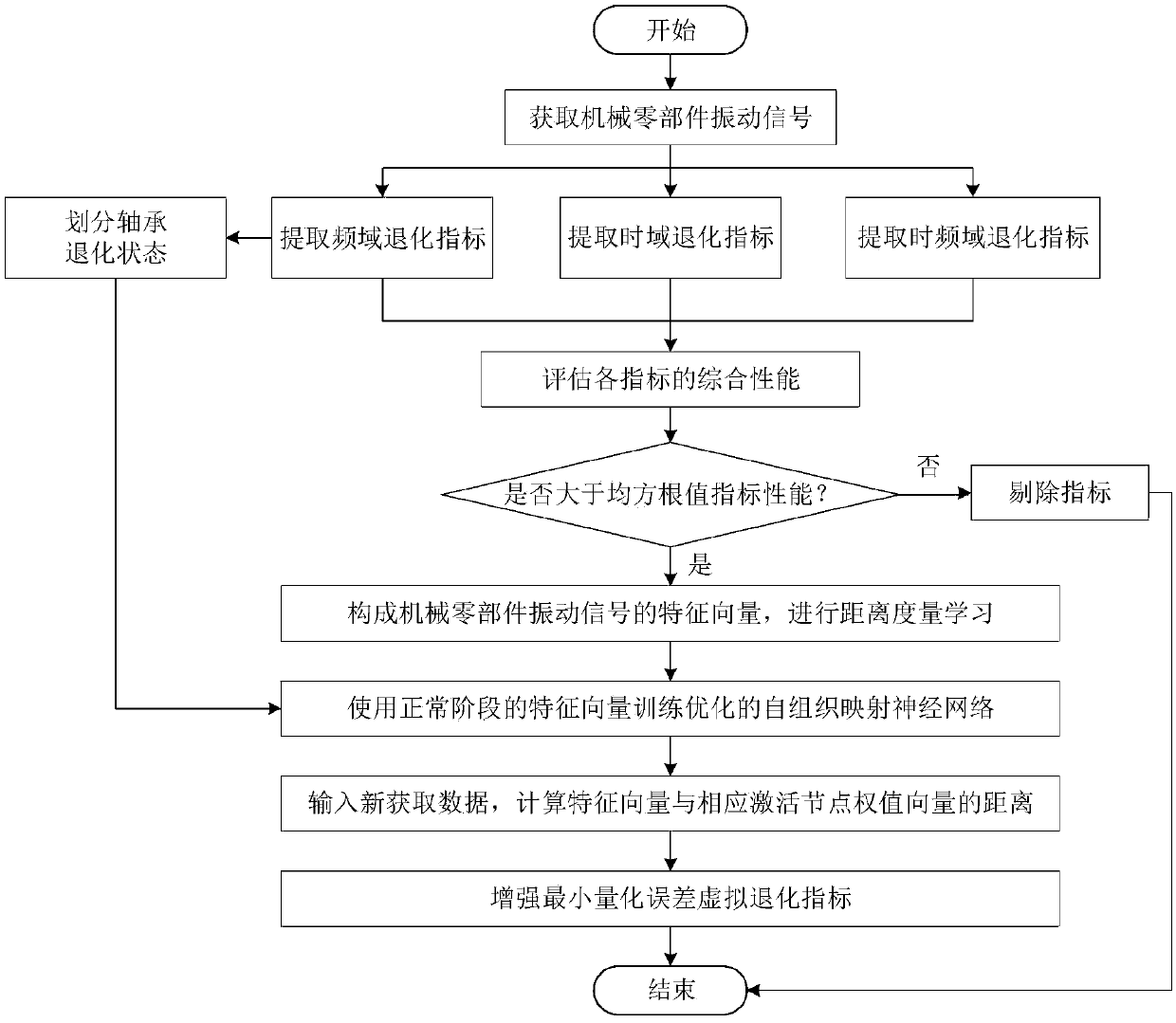

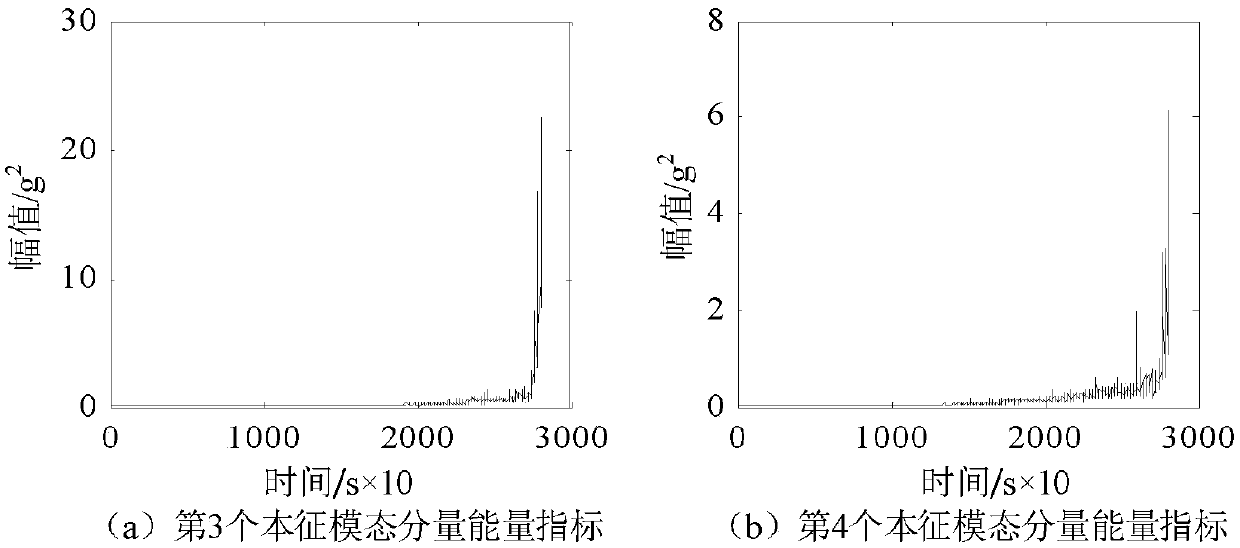

Mechanical critical component virtual degradation index construction method based on distance metric learning

ActiveCN108760266AImprove accuracyEnhanced minimum quantization errorMachine part testingNeural learning methodsNODALFrequency spectrum

The invention provides a mechanical critical component virtual degradation index construction method based on distance metric learning. First, time domain, frequency domain and time-frequency domain characteristics of a vibration signal of a mechanical critical component are extracted, dividing a degradation state of the mechanical critical component according to a frequency spectrum and a power spectrum, next, the relevance, monotonicity and predictability of each index are evaluated comprehensively, indices to which performance correspond is superior to root-mean-square values are selected to form feature vectors of the mechanical critical component are selected and distance metric learning is performed, then the feature vectors in a normal state are utilized to train an optimized self-organizing mapping neural network, inputting newly acquired vibration signal data, and calculating the distance between the eigenvectors and weight vectors of corresponding activation nodes, thereby establishing virtual degradation indices with enhanced minimum quantization error. The mechanical critical component virtual degradation index construction method based on distance metric learning synthesizes various physical degradation indices of multiple domains, can fully mine the degradation information of a critical component of mechanical equipment, and is beneficial to improving the accuracyof residual life prediction.

Owner:XI AN JIAOTONG UNIV

Degradation modeling and life prediction method considering effective impact

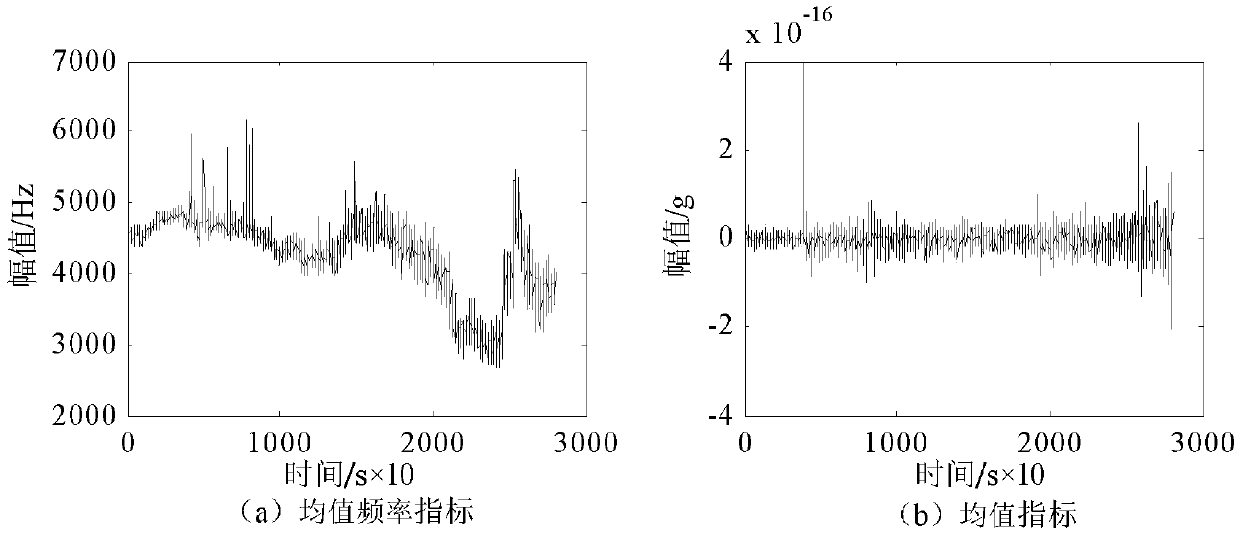

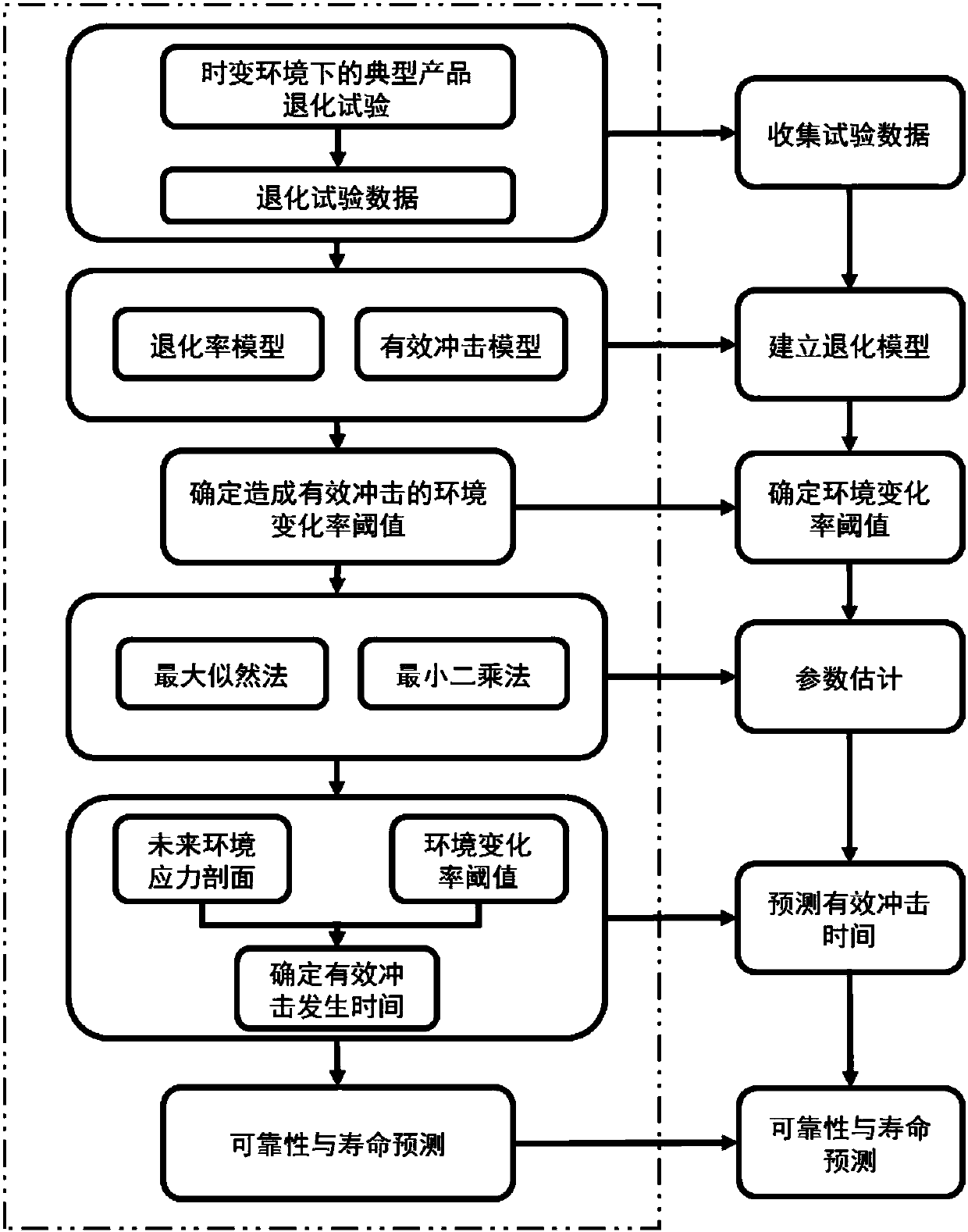

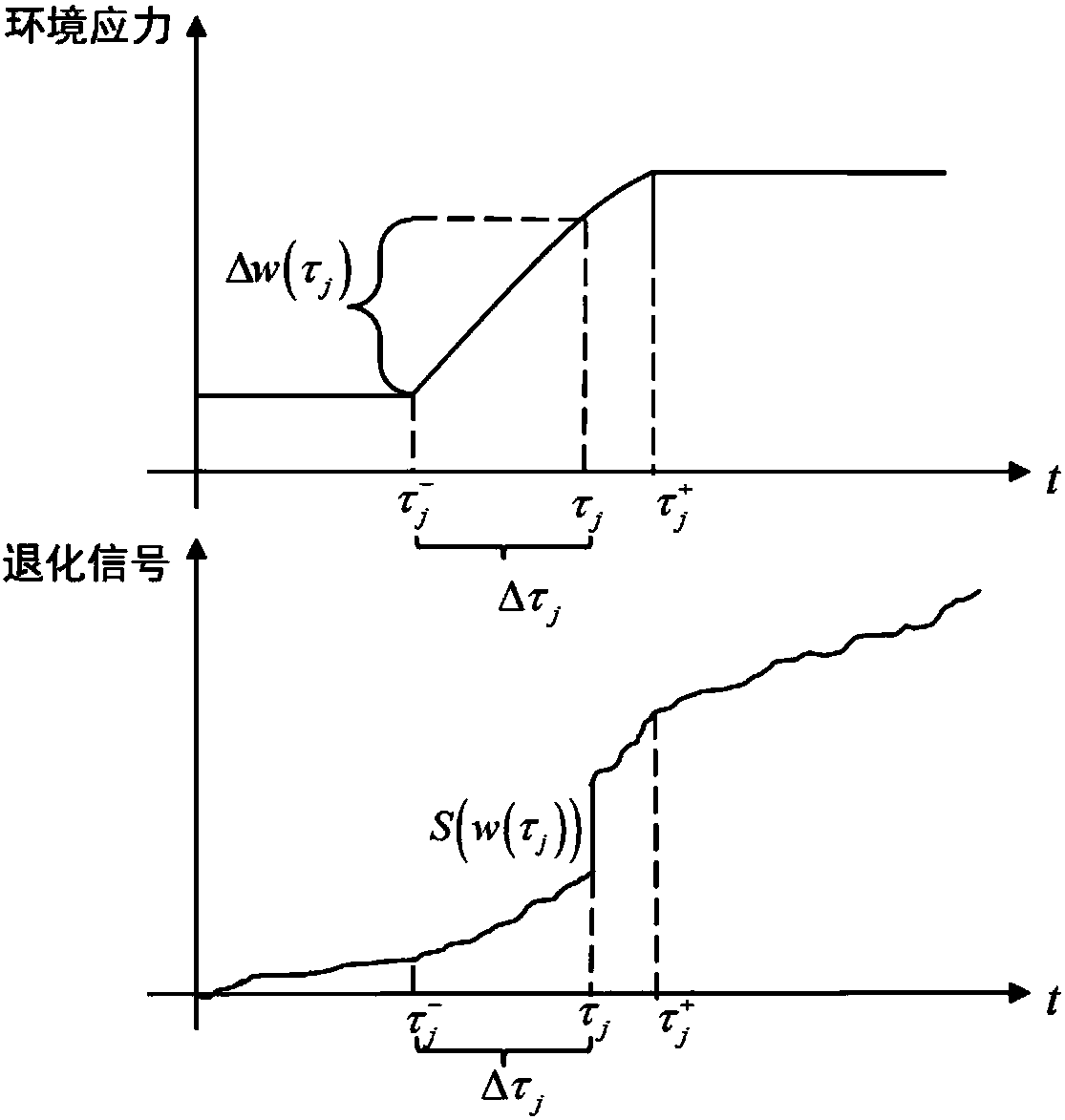

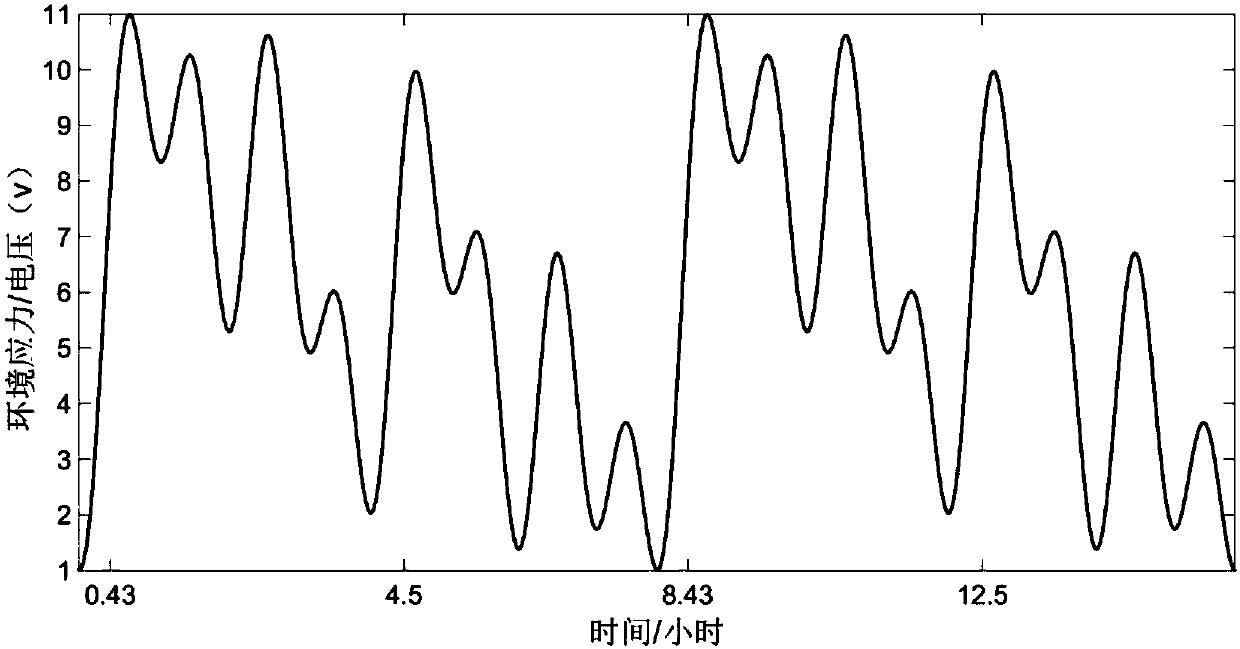

ActiveCN108959676AThe prediction method is in line with realityImprove forecast accuracyMathematical modelsDesign optimisation/simulationDeterioration rateSimulation

The invention provides a degradation modeling and life prediction method considering an effective impact. Firstly, test data are collected, and then a performance index degradation model is built; anenvironmental change rate threshold of a product subjected to the effective impact of an environment load is determined according to the test data, and unknown parameters in the model are estimated; and finally, the time of occurrence of the effective impact is determined and then life and reliability prediction is performed. The method comprises the following specific steps: step 1, collecting the test data; step 2, building the degradation model; step 3, determining the environmental change rate threshold; step 4, estimating parameters to be estimated; step 5, predicting the time of occurrence of the effective impact; and step 6, performing reliability prediction and verification. According to the method provided by the invention, the influence of changes of environment and load on product performance degradation is considered, namely, the performance degradation rate and the effective impact on a degradation index are considered at the same time, so that the prediction method can better meet the actual requirements and the prediction accuracy is improved.

Owner:天航长鹰(江苏)科技有限公司

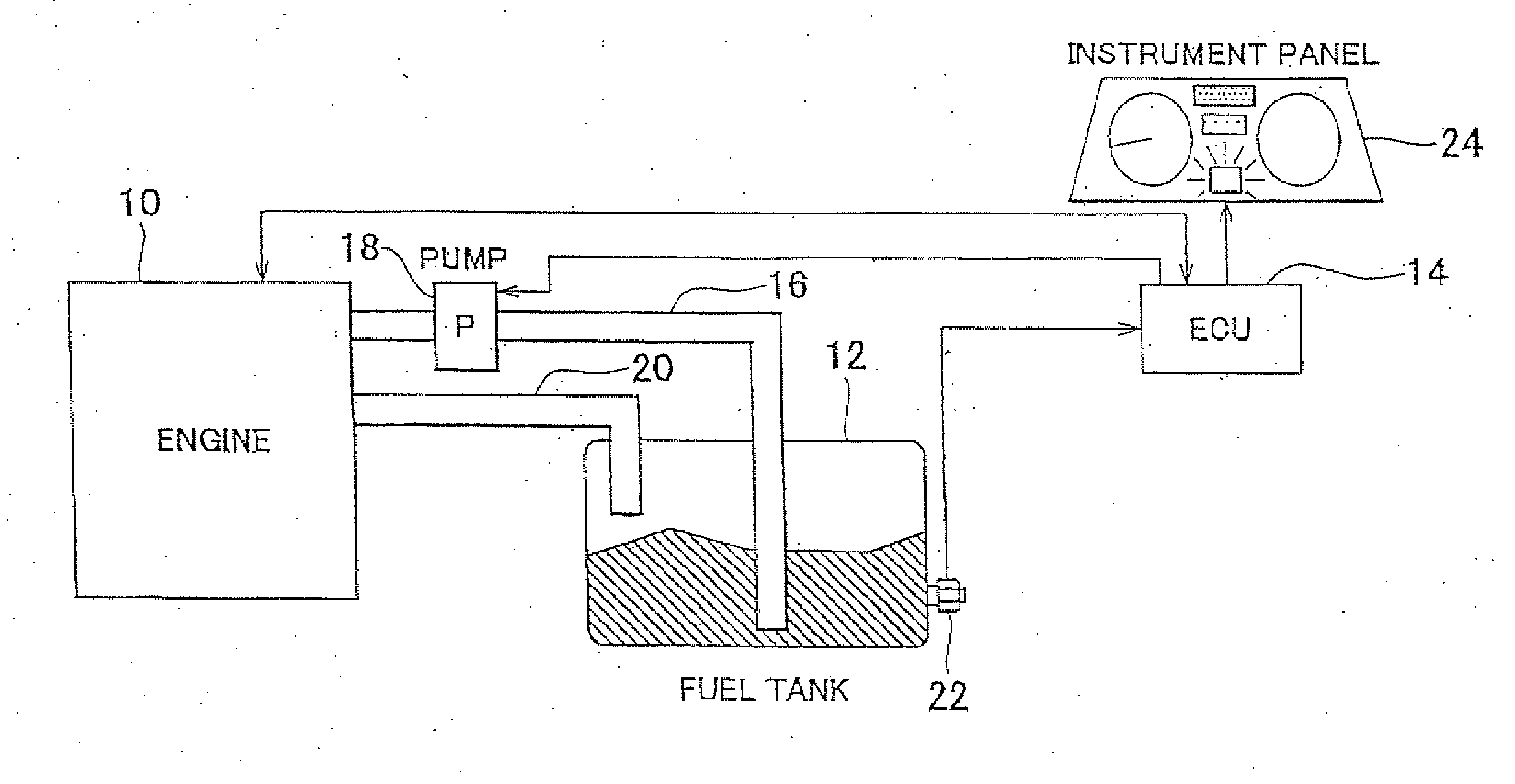

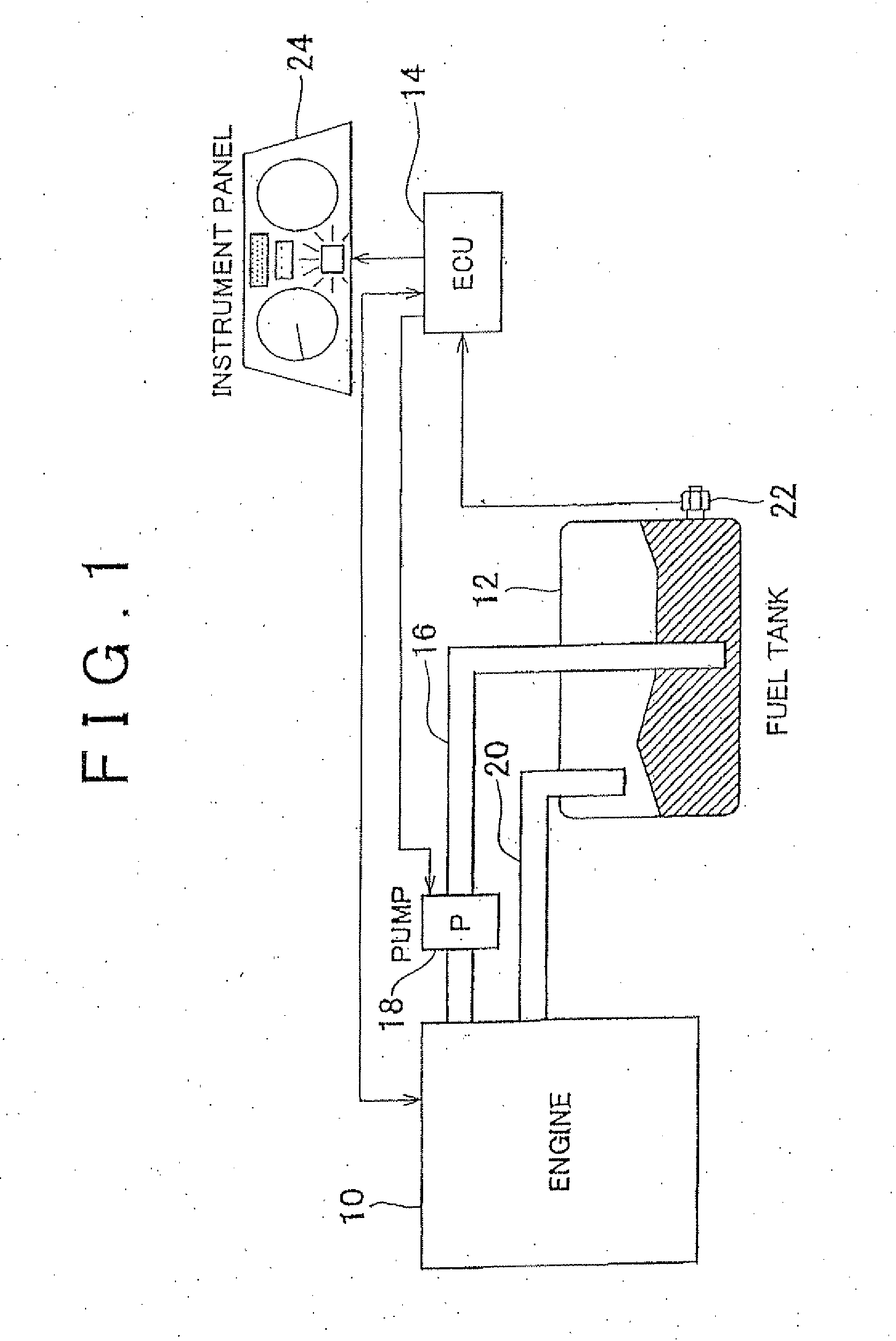

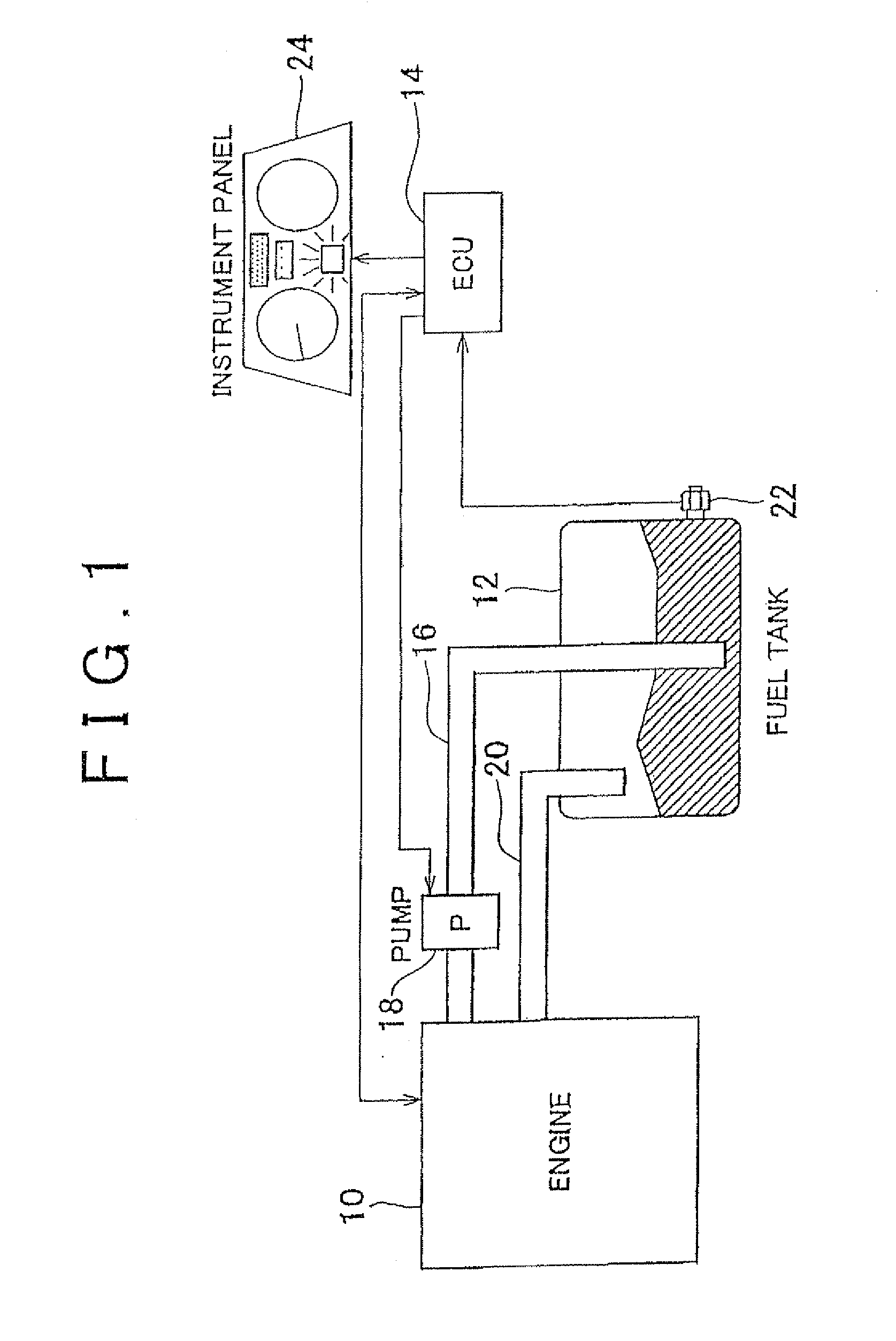

Device and method for detecting degradation of fuel for internal combustion engine

InactiveUS20100211289A1Accurate calculationImprove accuracyAnalogue computers for vehiclesElectrical controlFuel tankBiofuel

A transmittance sensor that detects the optical transmittance of biofuel is provided on a fuel tank that stores biofuel to be supplied to an internal combustion engine. An ECU periodically acquires the optical transmittance detected by the transmittance sensor, and calculates the amount of change from the previous value. In addition, the ECU calculates a degradation index value indicating the degree of degradation of the biofuel by accumulating the amount of change.

Owner:TOYOTA JIDOSHA KK

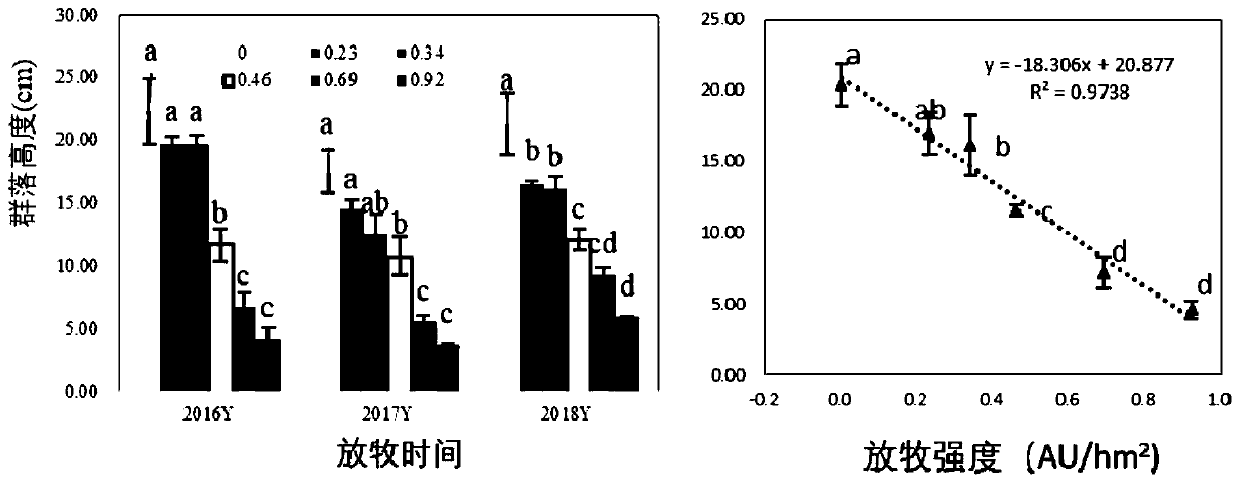

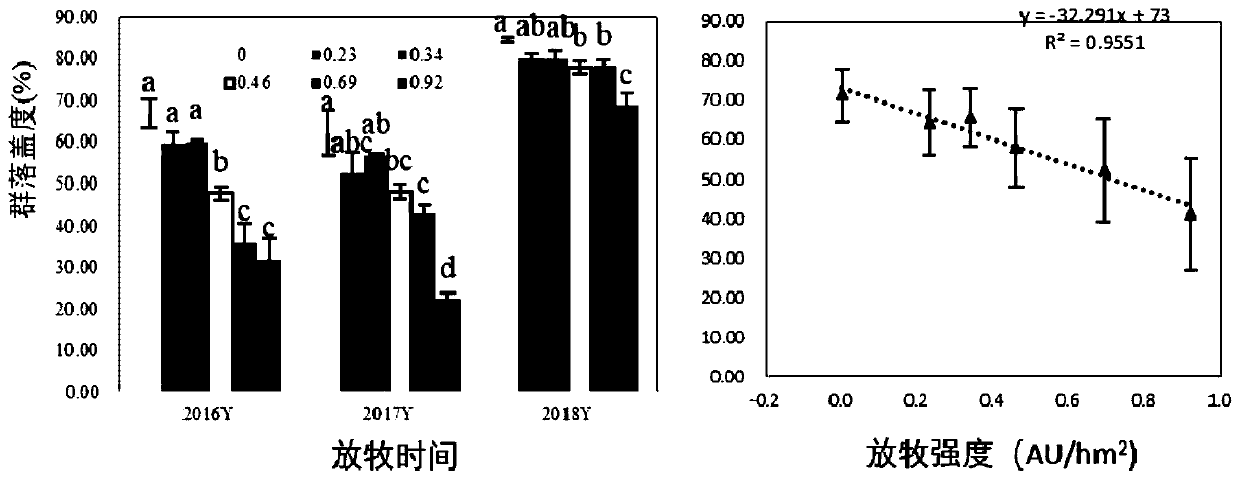

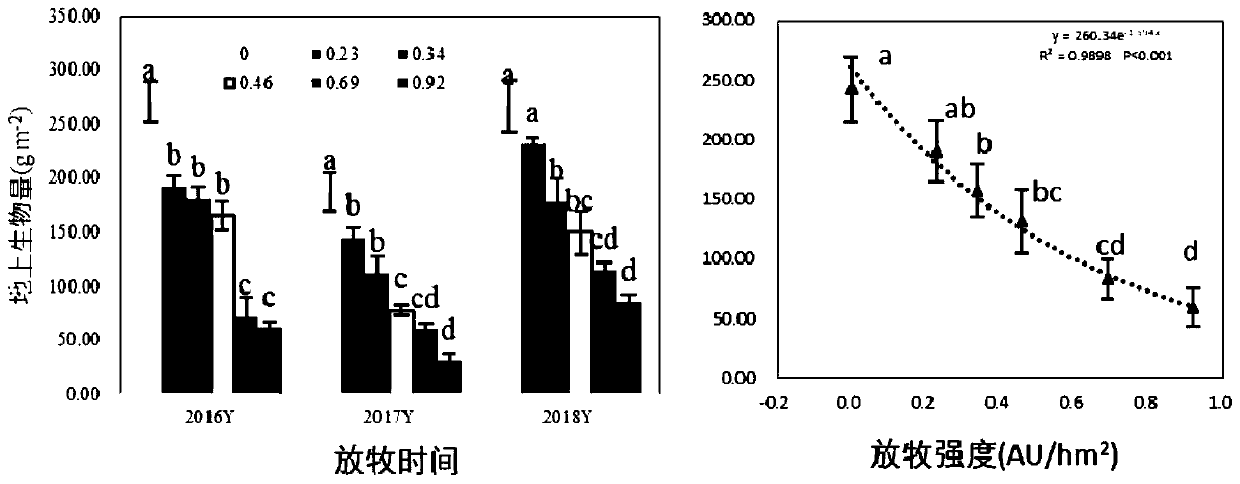

Model for evaluating different degradation degrees of meadow grassland and an establishing method and application thereof

ActiveCN109829650AIncrease production capacityImprove protectionCharacter and pattern recognitionFuzzy logic based systemsPrincipal component analysisOperability

The invention discloses a model for evaluating different degradation degrees of meadow grassland and an establishing method and application thereof. The method aims at natural grassland with differentdegradation degrees caused by different utilization degrees of meadow grassland. Through a field control experiment, a field ecology investigation method is adopted. the response mechanism of meadowgrassland degradation to human activities (controlling grazing) is studied;A principal component analysis is made, a matrix through typical correlation and fuzzy mathematics are establsihed; The an indication degree diagnosis method of a degradation evaluation system is established with different utilization degrees, grassland vegetation and soil index systems with different utilization modes anddifferent degradation degrees are screened, indication degrees of different degradation degrees is acquiredand a meadow grassland degradation quantitative evaluation index system indication degree diagnosis method with relatively high scientificity and operability is established. The method has practical significance in establishment of meadow degradation index system evaluation, objective judgment of the degradation condition of meadow and promotion of production and environmental protection of meadow animal husbandry.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

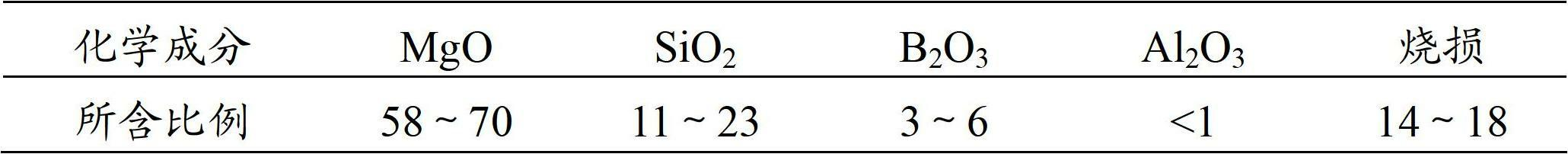

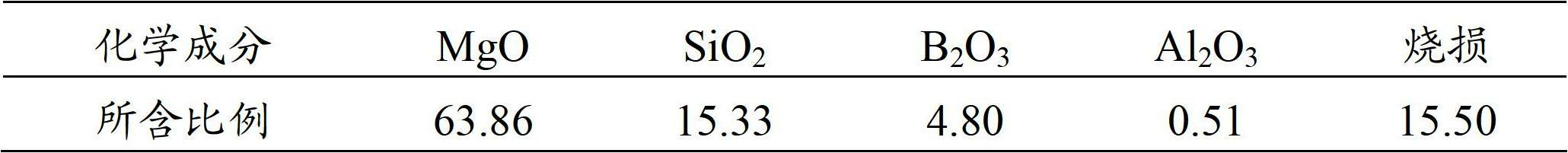

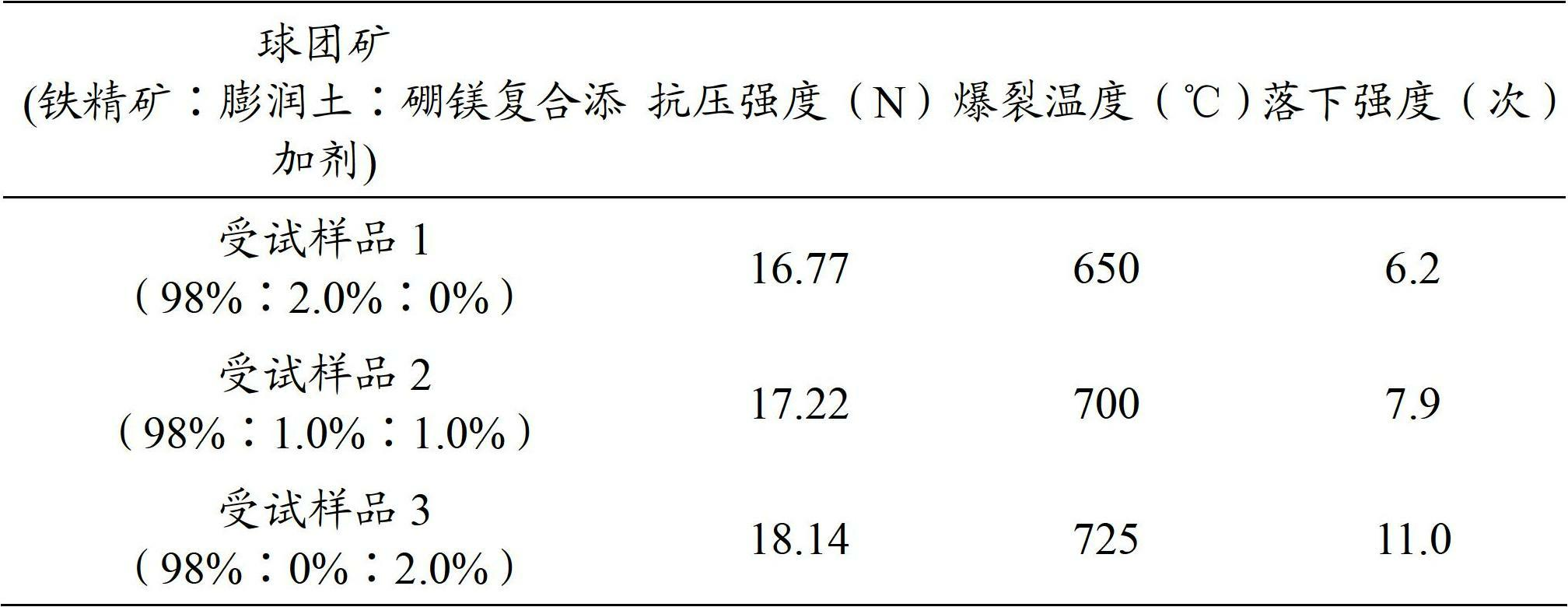

Preparation method for boron-magnesium composite additive for pellets and product

InactiveCN102676799AGuaranteed gradeReduction expansion rate improvementChemical compositionBoron containing

The invention discloses a preparation method for a boron-magnesium composite additive for preparing pellets and a product. The method is characterized by comprising the following steps: crushing and drying magnesium ore serving as a raw material; roasting at the temperature of between 750 and 900DEG C for 30 to 120 minutes, taking out of a furnace, cooling, and grinding to obtain magnesium ore powder; grinding a boron-containing material of which the B2O3 grade is 5to 15 percent to obtain boron powder, mixing the two kinds of powder in a ratio to obtain the boron-magnesium composite additive comprising the following chemical compositions in percentage by weight: more than or equal to 58 and less than or equal to 70 percent of MgO, more than or equal to 11 and less than or equal to 23 percent of SiO2, more than or equal to 3 and less than or equal to 6 percent of B2O3, less than 1 percent of Al2O3 and more than or equal to 14 and less than or equal to 18 percent of burning loss; and adding the composite additive in an amount which is 1 to 2 percent of pellet raw material into the pellet raw material for pelletizing, and roasting at the temperature of between 1,200 and 1,300DEG C for 20 to 60 minutes to obtain the pellets. By the additive, the metallurgical properties of the pellets, such as decrepitation temperature, compressive strength, drop strength, low temperature reduction degradation index, medium temperature reducibility and reduction swellability can be obviously improved.

Owner:NORTHEASTERN UNIV

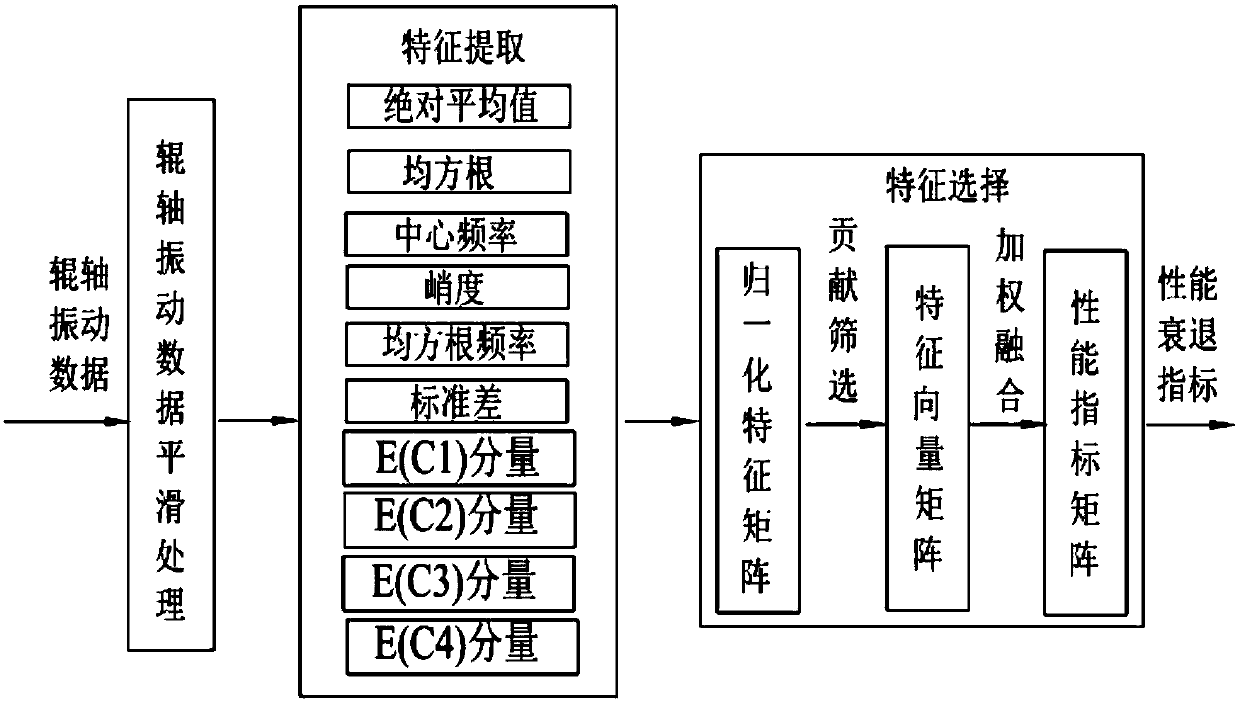

Method for calculating roll shaft performance index of flexible material processing device

InactiveCN108898050ASimple dataAccurate assessmentCharacter and pattern recognitionTime domainFeature extraction

A method for calculating a roll shaft performance index of a flexible material processing device comprises the following steps: a step 1: acquiring vibration data of a roll shaft through a three-axisacceleration sensor; a step 2: performing data feature extraction after the vibration data is subjected to sliding average noise reduction, wherein the data feature includes a time domain feature parameter, a frequency domain feature parameter, and a time-frequency domain feature parameter of the vibration data; and a step 3: inputting the data feature into a principal component analysis weightedfusion module, and obtaining a performance degradation index for a roll shaft after the data feature is subjected to dimension reduction. The features of the vibration data of the flexible material processing device mainly include time domain features, frequency domain features and time-frequency domain features. The time domain features, the frequency domain features and the time-frequency domainfeatures are used for calculation of the performance degradation index for the roll shaft, which can comprehensively and accurately evaluate the performance degradation of the roll shaft.

Owner:GUANGDONG UNIV OF TECH

Multifunctional additive for pulverized coal injected into blast furnace and multifunctional additive addition method

InactiveCN103266190ALower ignition pointReduced responseSolid fuelsBlast furnace detailsReaction rateUltimate tensile strength

The invention provides a multifunctional additive for pulverized coal injected into a blast furnace and a multifunctional additive addition method and belongs to the field of blast furnace iron making. The multifunctional additive is a powdery compound mixture, the particle size of the multifunctional additive is required to be larger than 100 meshes, and the proportion of the multifunctional additive with the particle size of above 200 meshes is required to account for above 80%. The multifunctional additive has the characteristics of being capable of obviously improving the combustion characteristic of the pulverized coal, reducing the ignition point, increasing the precipitation yield of volatiles, the combustion speed and the combustion heat, passivating the reaction activity of coke, reinforcing the supporting effect of a skeleton and inhibiting the low-temperature reduction degradation of iron-containing furnace burden. After 1%-6% of multifunctional additive is added to the pulverized coal injected into the blast furnace, the ignition point of the injected pulverized coal can be obviously reduced by 14 DEG C, the yield of the volatiles is increased by 23.38%, the combustion ratio of the pulverized coal is increased by 11.9%, the average reaction rate of the pulverized coal is increased by 8.7%, the low-temperature reduction degradation index (RDI) of sinters at 500 DEG C is increased by 23.10%, the coke reactivity (CRI) of the pulverized coal is reduced by 11.23%, and the post-reaction strength (CSR) of the pulverized coal is increased by 10.57%.

Owner:UNIV OF SCI & TECH BEIJING

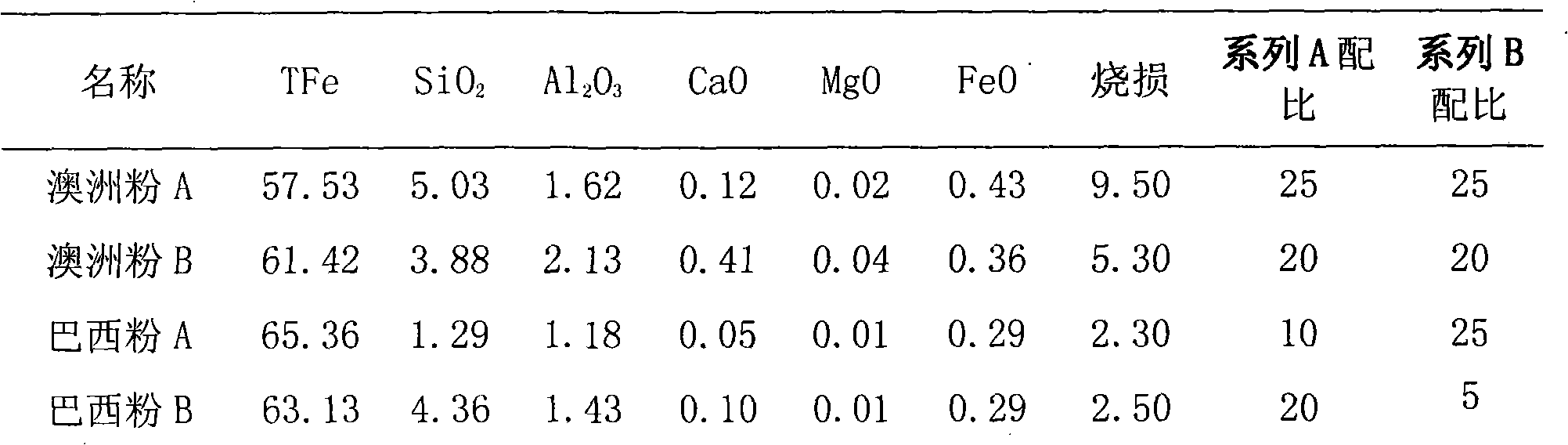

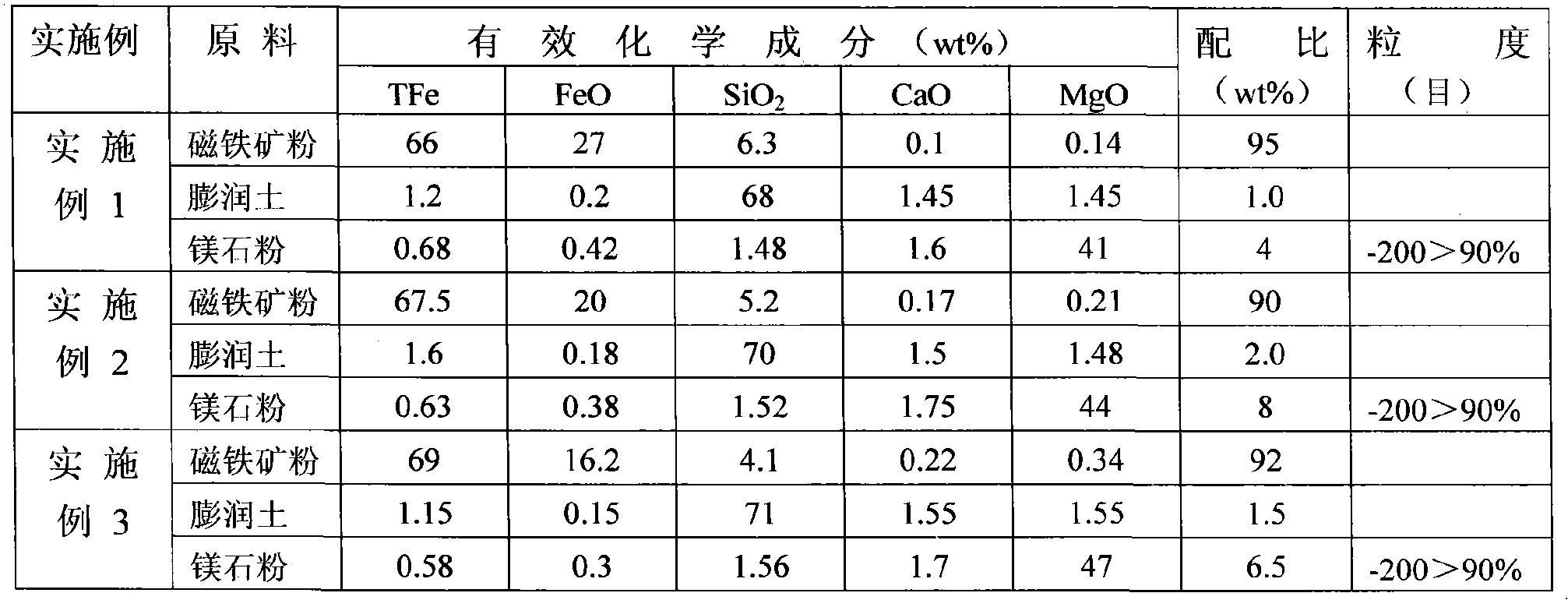

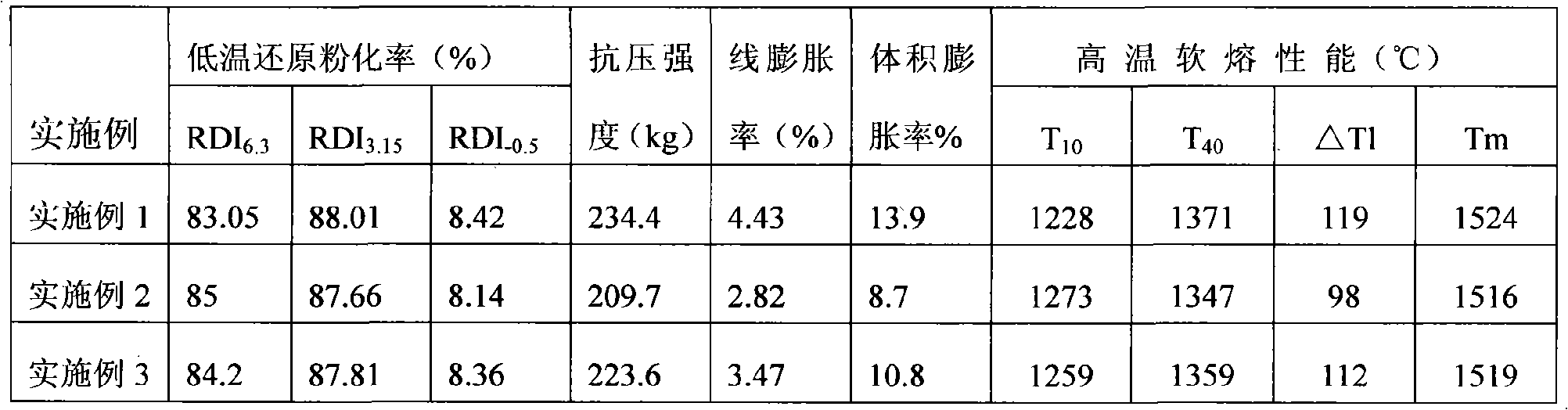

Acidic magnesia pellet and preparation method thereof

InactiveCN101550484AImprove low temperature reduction pulverization rate indexImprove smelting conditionsSodium BentoniteDegradation index

The invention relates to an acidic magnesia pellet and a preparation method thereof. 90-95 percent of magnetite powder, 1-2 percent of bentonite and 4-8 percent of magnesite powder with grain size of 200 meshes are blended with magnesite powder and bentonite in a batching room for dry mixing, and in the controlled pellet raw material, MgO / SiO2 is equal to 0.4-0.55; and meanwhile, the roasting temperature is kept between 1250 DEG C and 1300 DEG C, thus the acidic magnesia pellet can be produced. The low-temperature reduction degradation index of the pellet is improved under the conditions without increasing the equipment investment and changing the original process, and the low-temperature reduction expansion rate is reduced by 50 percent; the softening temperature of the pellet is raised by 120-150 DEG C, the high-temperature metallurgical property of the pellet is enhanced and the smelting conditions of the blast furnace are improved; and the invention is adequate in raw materials, simple in production process and convenient for operation and grasping and has the superiority and the value for the increase of the use proportion of the pellet and the broad popularization.

Owner:ANGANG STEEL CO LTD

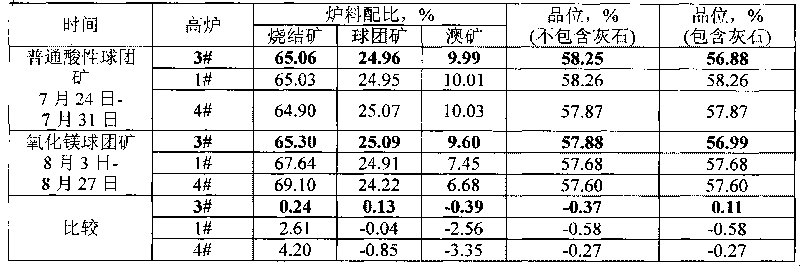

Ore blending method for improving heat-state intensity index of sintering ore

The invention provides an ore blending method for improving a heat-state intensity index of a sintering ore. The ore is prepared from the following raw materials in percentage by weight: 66-88 percent of hematite powder, 5-15 percent of magnet ore powder, 3-12 percent of ludwigite concentrate fines, and 4-7 percent of mixed material; the ludwigite concentrate fines comprise the main components in percentage by weight: 52-54 percent of TFe, 20-24 percent of FeO, 4-6 percent of SiO, 0.5-1.0 percent of CaO, 10-13 percent of MgO, 0.2-0.4 percent of Al2O3, 3-5 percent of B2O3, 0.3-0.5 percent of S, 3-5 percent of burning loss Ig and 1.0-1.5 percent of crystal water. According to the ore blending method, the heat-state intensity index of the sintering ore can be obviously improved, and low-temperature reduction degradation ratio of the sintering ore is reduced on the premise that the requirements of a blast furnace on the grade of the sintering ore and the alkalinity can be completely met. The low-temperature reduction degradation index RDI+3.15mm of the sintering ore reaches an average of 62.92 percent, and the low-temperature reduction degradation index RDI-0.5mm reaches 7.11 percent, so that the smooth operation of the production of the blast furnace can be guaranteed, the yield of the blast furnace is improved, and the coke ratio is reduced.

Owner:ANGANG STEEL CO LTD

Method for detecting a condition of engine oil

ActiveUS7826987B2Accurately determineImprove accuracyLubrication of auxillariesFlow propertiesTotal Base NumberCrankcase

Provided is a method for detecting a condition of engine oil that allows the progress of degradation of engine oil to be more accurately determined without incurring any significant cost. In a method for detecting a state of engine oil by defining a degradation index that changes with a progress in degradation of the engine oil that lubricates an internal combustion engine and determining a progress of the degradation of the engine oil according to the degradation index, a value related to a concentration of blow-by gas that flows into a crankcase of the engine is computed, and the degradation index is computed according to the computed value related to a concentration of blow-by gas that flows into a crankcase of the engine. The degradation index may consist of a total base number of the engine oil, and the concentration of blow-by gas that flows into a crankcase of the engine may consist of a NOx concentration.

Owner:HONDA MOTOR CO LTD

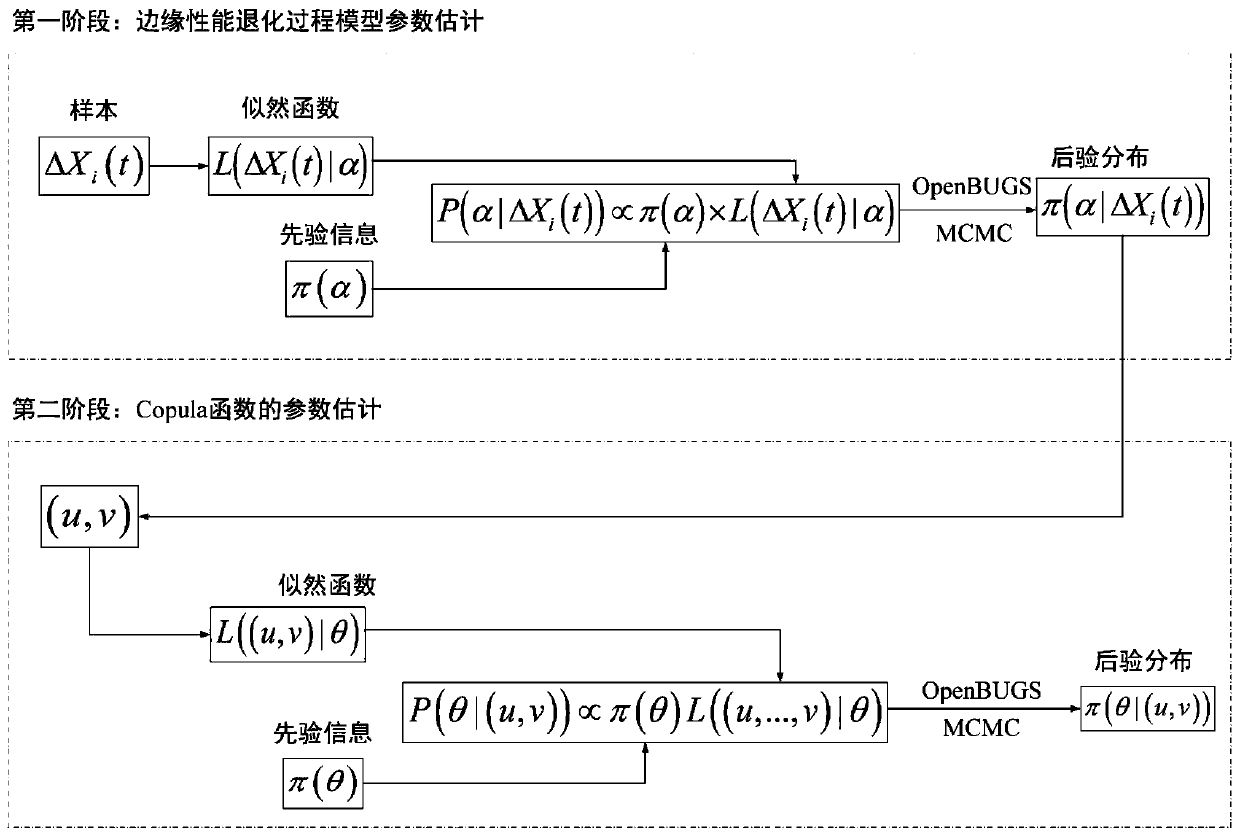

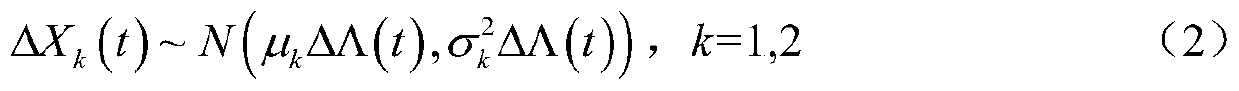

A reciprocating fluid dynamic seal life prediction method based on multivariate correlation degradation modeling

InactiveCN109948295ALife PredictionIncrease flexibilityForecastingSpecial data processing applicationsMachine partsEngineering

The invention provides a reciprocating fluid dynamic seal service life prediction method based on multivariate correlation degradation modeling, and belongs to the field of reciprocating seal reliability evaluation and service life prediction of motion machine parts. The method comprises the steps that 1, degradation amount data of friction force and leakage amount are collected; Step 2, accordingto the distribution function of the Frank Copula, establishing a joint distribution function of the friction force degradation increment and the leakage rate degradation increment; Step 3, establishing a reciprocating seal multivariate correlation degradation model; 4, establishing a log-likelihood function of the multivariate random correlation degradation process model, and obtaining an estimation result of a parameter sum through degradation data; and 5, calculating the reliability of the reciprocating sealing element by adopting a Monte Carlo method in combination with the multivariate related degradation model, and obtaining the service life of the reciprocating sealing element. The coupling relation between the two performance degradation indexes of the friction force and the leakage rate is comprehensively considered, the sealing element degradation process model is built based on the degradation data, the calculation process is simple and convenient, flexibility is high, and engineering practice is approached.

Owner:BEIHANG UNIV

Method for preparing low-SiO2 high-performance sinter ore

The invention discloses a method for preparing a low-SiO2 high-performance sinter ore, and belongs to the technical field of sintering of iron ore powder. The method comprises the following steps of: proportioning; mixing; granulating; dispensing; igniting; sintering; crushing; cooling; detecting indexes of the sinter ore; detecting a reduction property; and detecting low-temperature reduction degradation performance. The sinter core comprises the following raw materials in percentage by weight: 75 to 85 percent of iron-containing raw material, 3.5 to 4.5 percent of quick lime, 3.5 to 5.0 percent of dolomite, 2.0 to 3.5 percent of limestone and 5.0 to 6.0 percent of coke powder; and alkalinity CaO / SiO2 of the sinter core is equal to 1.8 to 2.0, TFe content is between 55 and 60 percent, SiO2 content is between 4.2 and 4.5 percent, MgO content is between 1.9 and 2.3 percent, and FeO content is between 8 and 10 percent, wherein the FeO content in the sinter core is realized by a method for increasing the proportion of the coke powder, and the proportion of the coke powder is increased from 3.0-4.0 percent to 5.0-6.0 percent; and finally, a drum index of the sinter core is increased from 82 percent to 83.6 percent, a low-temperature reduction degradation index RDI+3.15 is increased from 39 percent to 51 percent, and a reduction index is increased from 79 percent to 85 percent under conditions of low SiO2 and high FeO.

Owner:SHOUGANG CORPORATION

Device and method for detecting degradation of fuel for internal combustion engine

InactiveUS8347828B2Degree degradation can be determinedImprove accuracyAnalogue computers for vehiclesDigital data processing detailsFuel tankBiofuel

A transmittance sensor that detects the optical transmittance of biofuel is provided on a fuel tank that stores biofuel to be supplied to an internal combustion engine. An ECU periodically acquires the optical transmittance detected by the transmittance sensor, and calculates the amount of change from the previous value. In addition, the ECU calculates a degradation index value indicating the degree of degradation of the biofuel by accumulating the amount of change.

Owner:TOYOTA JIDOSHA KK

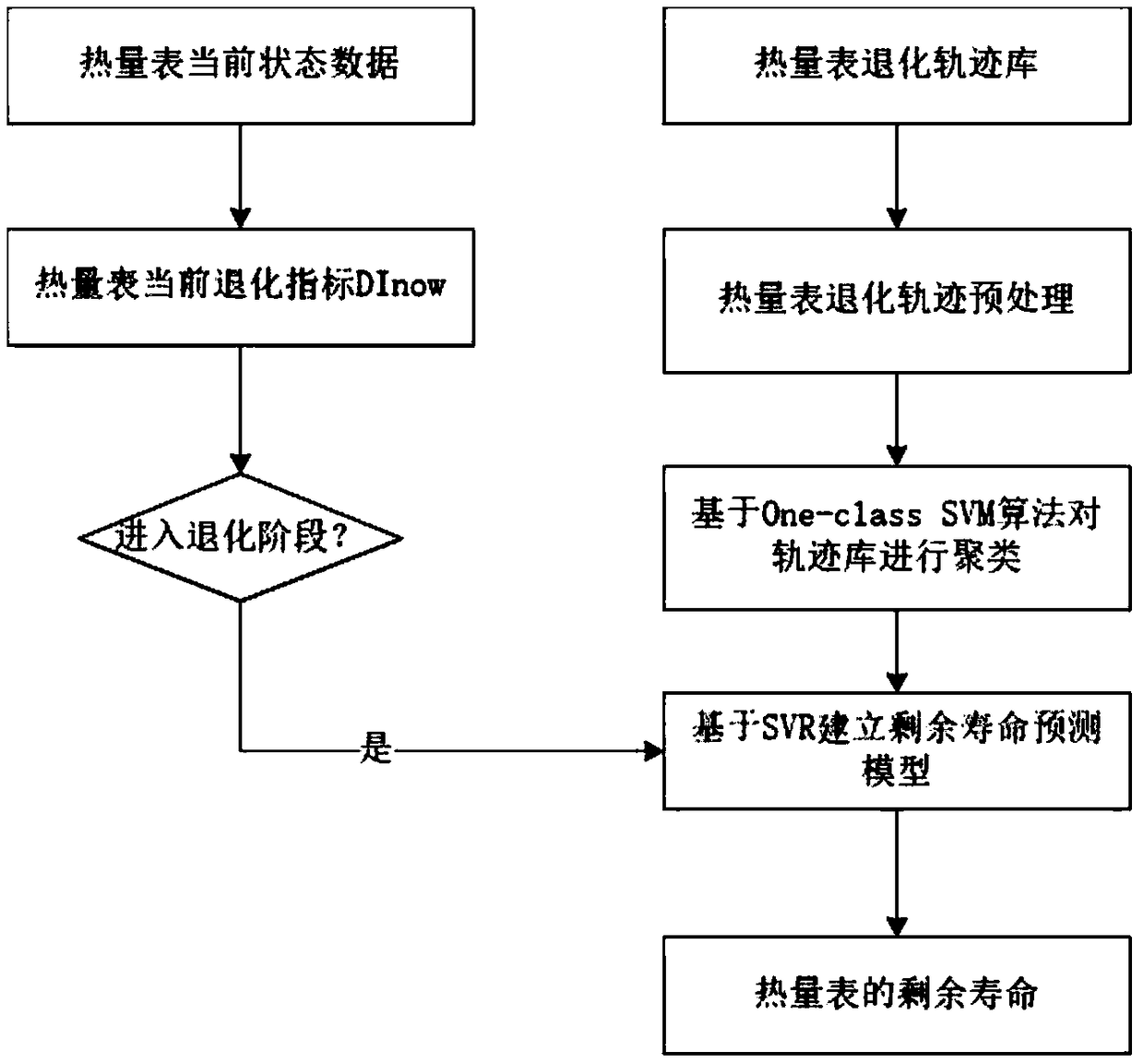

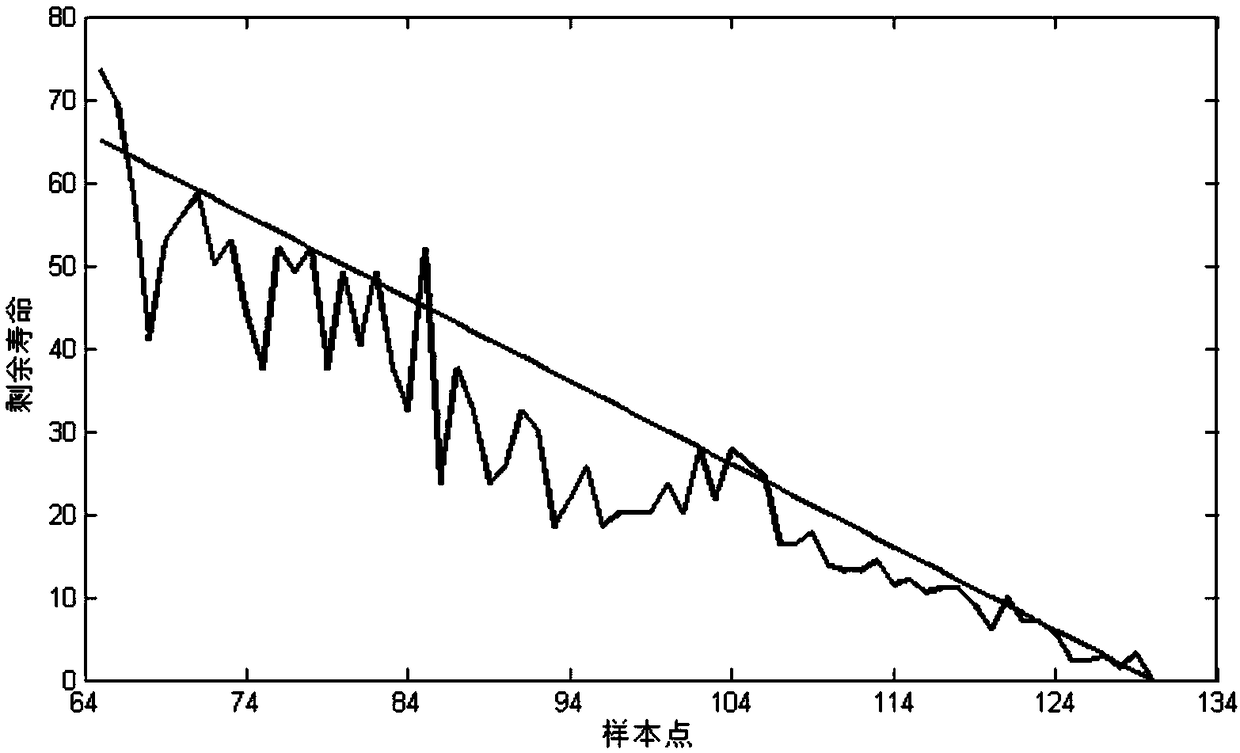

Method for predicting residual lives of heat meters based on multiple degradation sample data fusion

The invention discloses a method for predicting the residual lives of heat meters based on multiple degradation sample data fusion. The method comprises the steps that performance degradation data ofeach heat meter are obtained, a performance degradation index-residual life sequence set R of the N heat meters is established, and the performance degradation index-residual life sequence set R of the N heat meters is clustered by using a One-class SVM; and a regression model between degradation indexes and the residual lives are established by using the SVR, by utilizing the performance degradation data of the to-be-predicted heat meters at the current time and combining the regression model, the residual lives rul of the to-be-predicted heat meters at the current time are determined, and thus the residual lives of the heat meters are predicted. The analysis result of the method for predicting the residual lives of the heat meters is reliable, improving of the reliability of the heat meters can be promoted, and the reference means can be provided for quality verification of the heat meters in China.

Owner:XI AN JIAOTONG UNIV

Additive capable of inhibiting low-temperature reduction degradation of iron ore sinter and iron ore sinter

The invention discloses an additive capable of inhibiting low-temperature reduction degradation of iron ore sinter and the iron ore sinter. The additive is prepared from a barium compound (BaO), a manganese compound (MnO) and fatty alcohol polyoxyethylene ether by mixing, and specifically, the additive is prepared from 31%-60% by mass of BaO, 10%-20% by mass of MnO, 0.1%-2% by mass of fatty alcohol polyoxyethylene ether and the balance of impurities. After the additive with certain granularity is added to a sintering mixture in a certain ratio, the sinter is obtained by material distribution and sintering on a sintering machine, low-temperature reduction degradation of the sinter can be inhibited effectively, low-temperature reduction degradation index (RDI+3.15) of the sinter is optimized, quality of the sinter is improved, and a blast furnace operates smoothly.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com