Patents

Literature

78results about How to "Life Prediction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

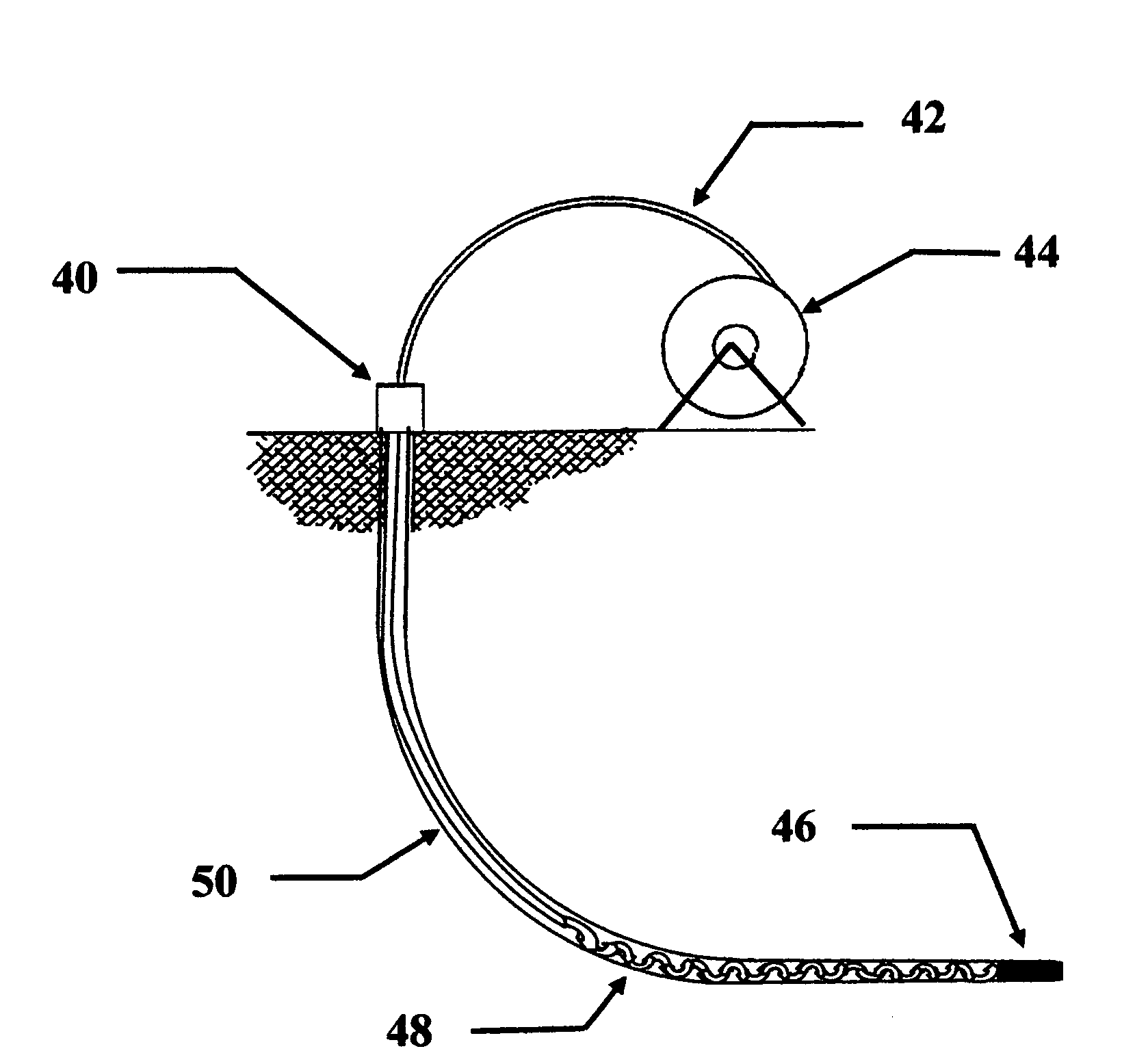

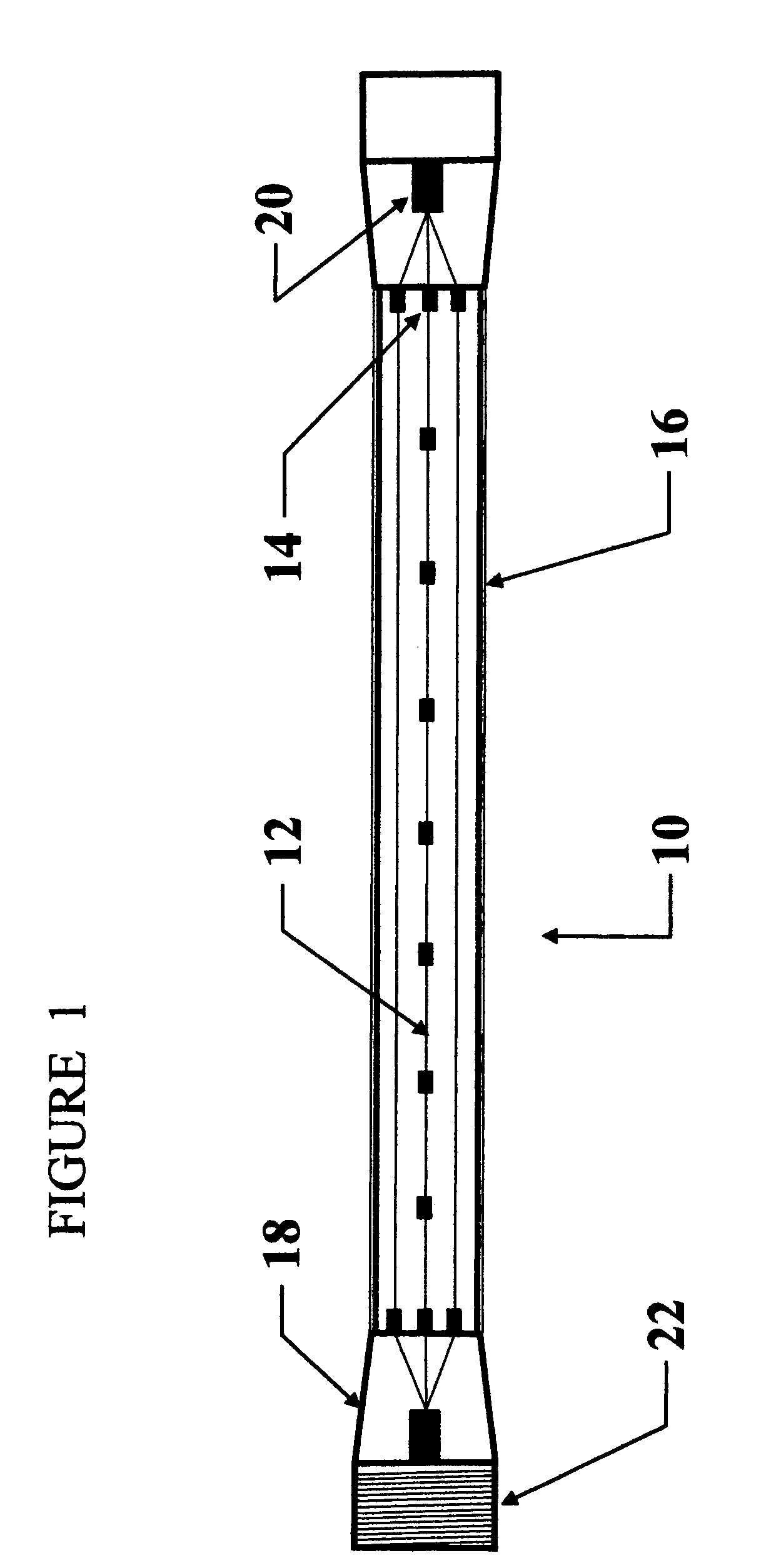

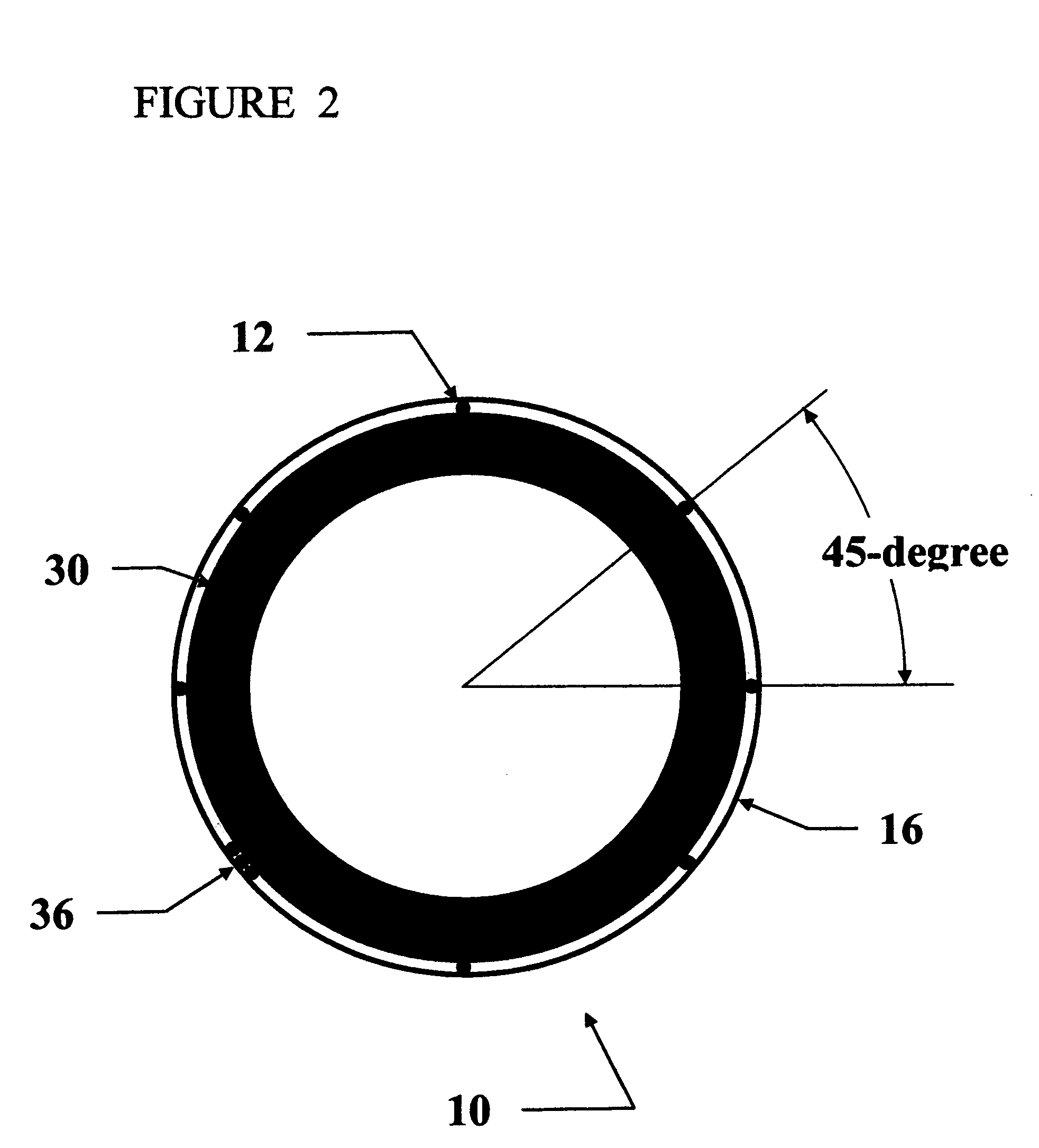

Dynamic performance monitoring of long slender structures using optical fiber strain sensors

A method is described using optical fiber technology to measure the vibration characteristics of long slender structures subjected to dynamic disturbances imposed by water or wind generated loads. The method is based on making bending strain measurements at selected locations along the length of long slender structures such as marine risers or large ropes using fiber optics technology including Optical Time Domain Reflectometry and Bragg diffraction gratings. Engineering interpretation of information obtained from bending strains determines the vibration characteristics including frequency, amplitude, and wave length. Maximum bending strain measurements assess pending structural damage. One application is measurement of vortex induced vibrations (VIV) response of marine risers. The fiber optics based method is also applicable to the measurement of the bending characteristics of spoolable pipe using plastic optical fibers which can be interpreted to assess the pipe structural integrity and to prevent lock-up during deployment into a small diameter annulus.

Owner:WILLIAMS JERRY GENE

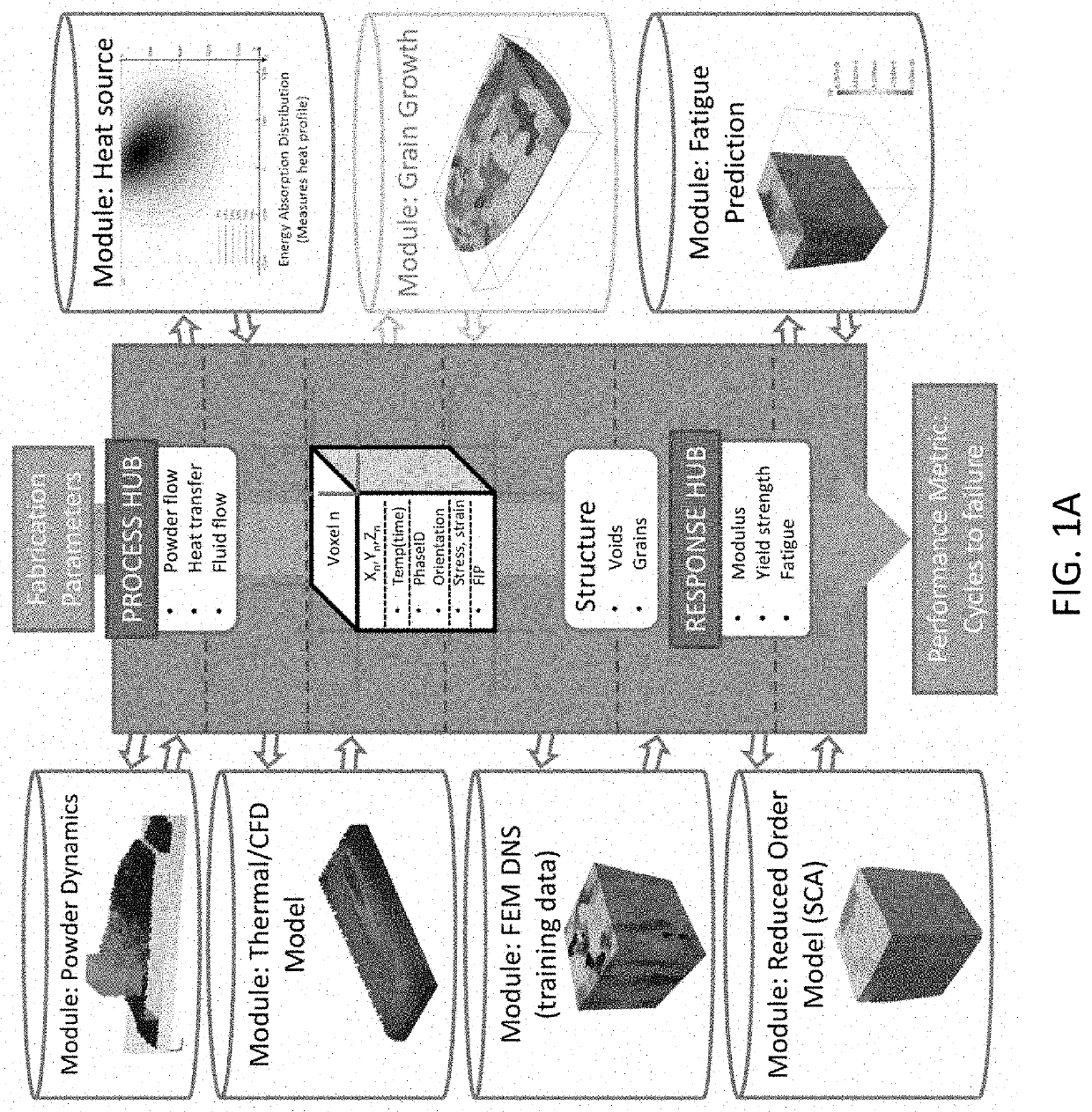

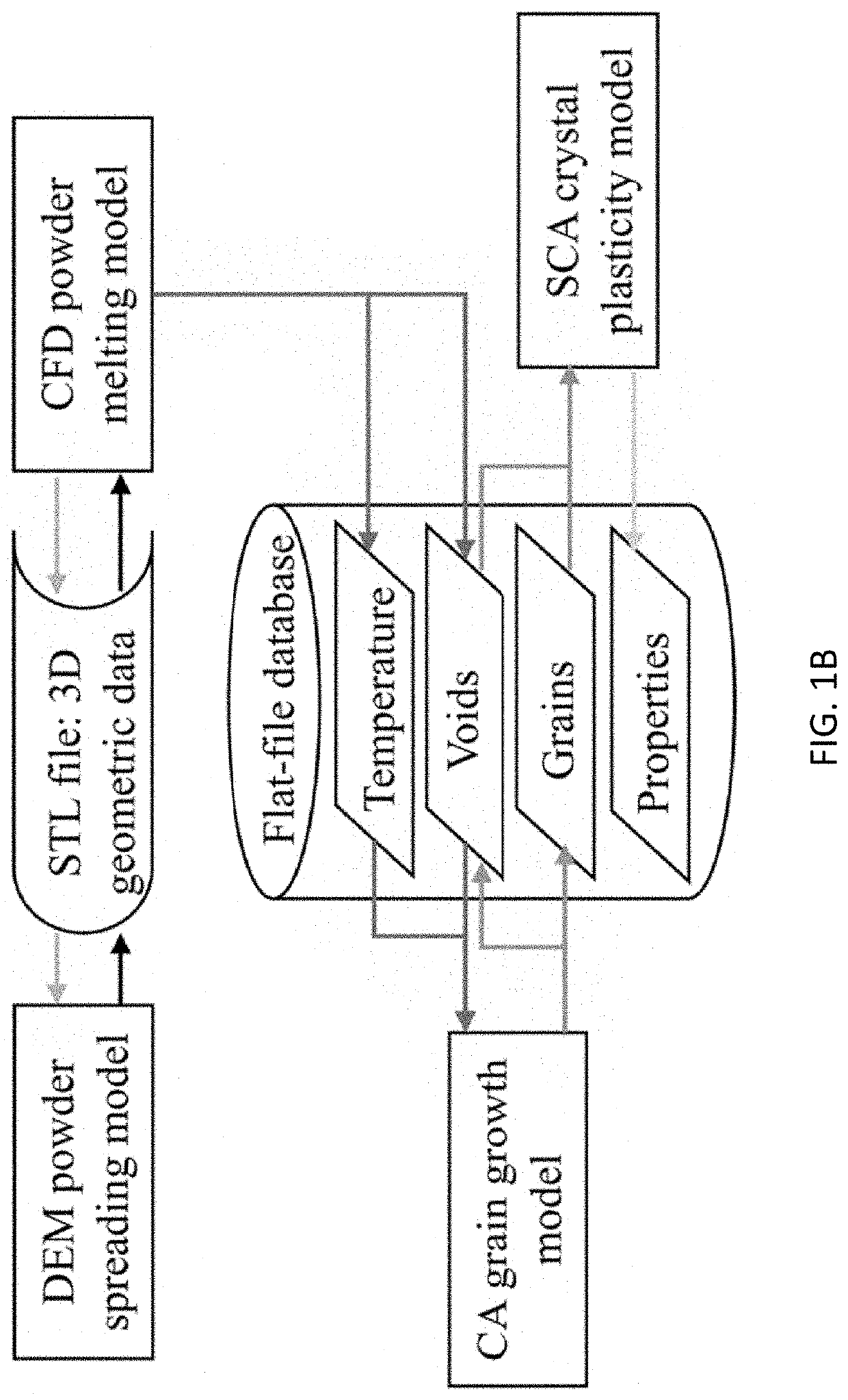

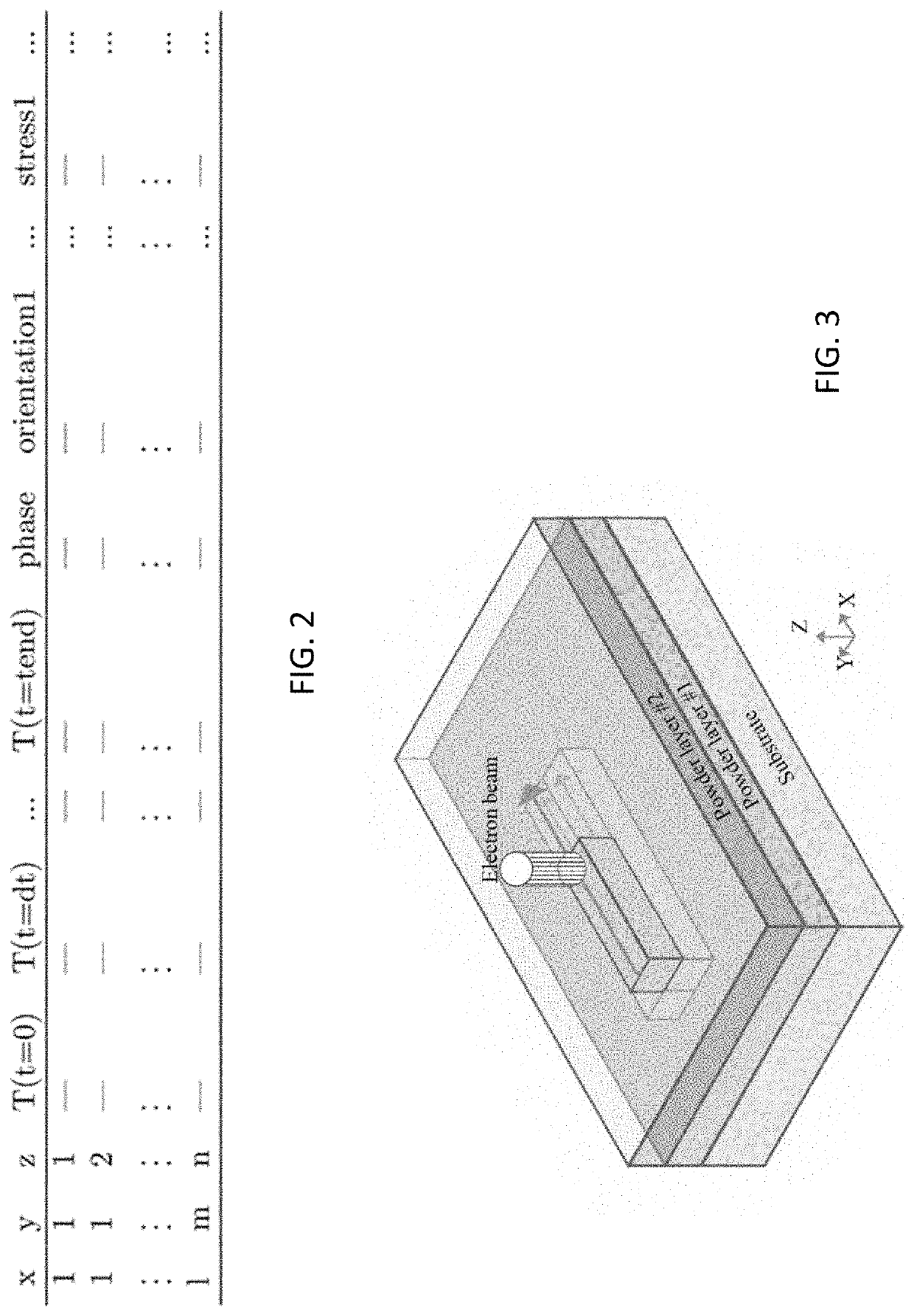

Integrated process-structure-property modeling frameworks and methods for design optimization and/or performance prediction of material systems and applications of same

PendingUS20200089826A1Life predictionHigh cycle fatigueAdditive manufacturing apparatusDesign optimisation/simulationPhysicsPowder bed

Integrated process-structure-property modeling framework and method for design optimization and / or performance prediction of a material system are provided. The Integrated process-structure-property modeling framework includes a powder spreading model using a discrete element method to generate a powder bed; a thermal-fluid flow model of the powder melting process to predict voids and temperature profile; a cellular automaton model to simulate grain growth based on the temperature profile; and a reduced-order micromechanics model to predict mechanical properties and fatigue resistance of resultant structures by resolving the voids and grains.

Owner:NORTHWESTERN UNIV

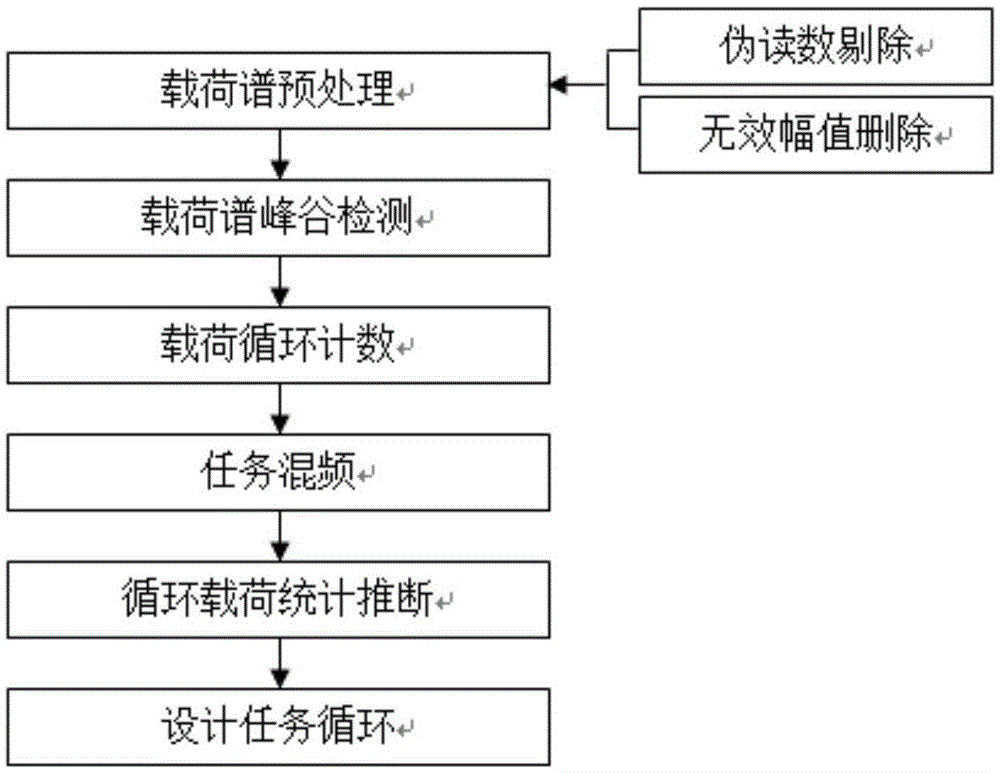

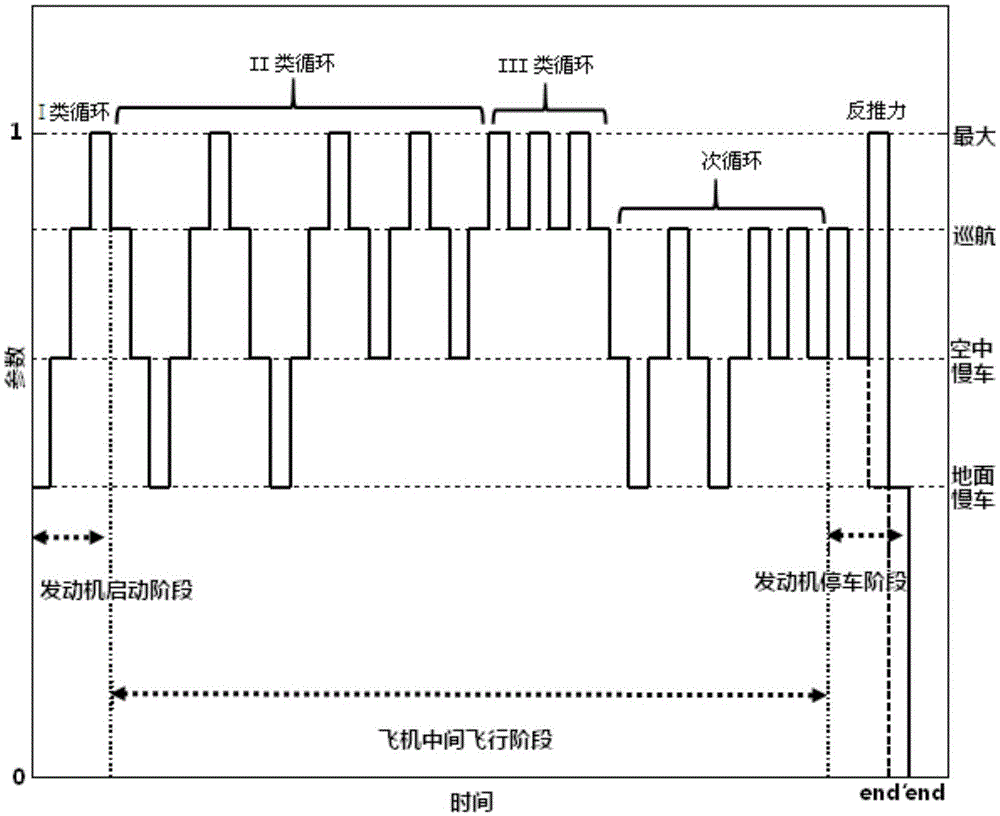

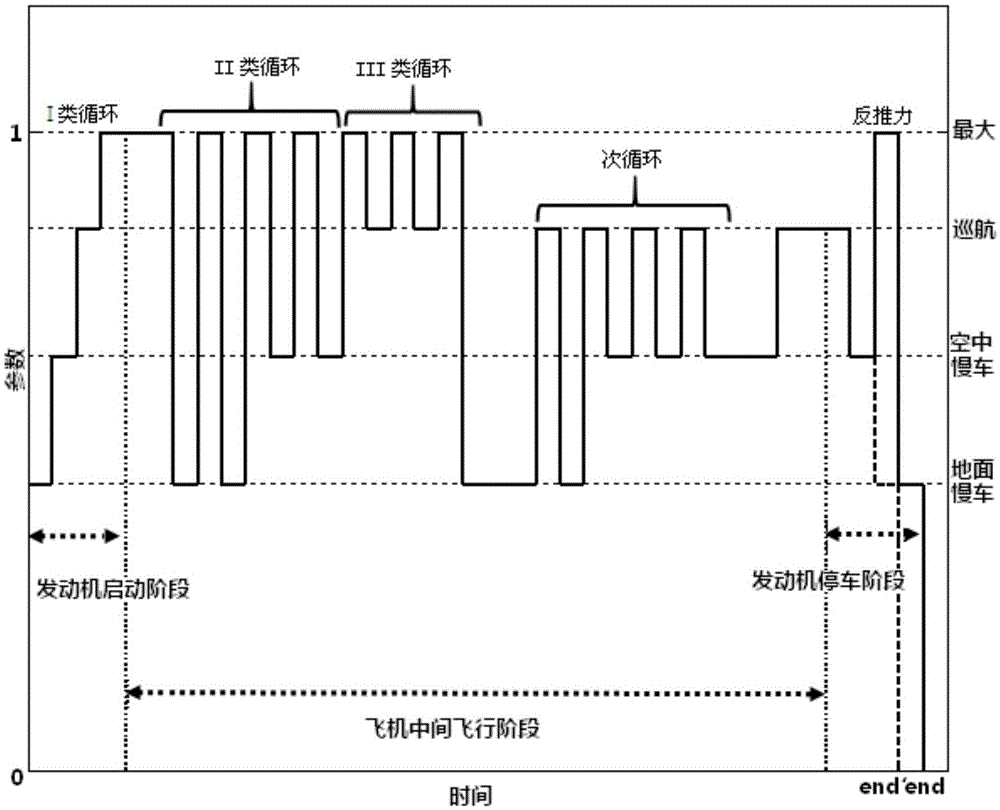

Compilation method for general standard test load spectrum of aero-engine

ActiveCN105574247ASimplify the compilation processLife PredictionGeometric CADEngine testingAviationCompilation error

The invention discloses a compilation method for a general standard test load spectrum of an aero-engine. The method comprises the following main steps: (1) standardizing a mission profile load parameter; (2) generating a mission profile load parameter sequence; (3) generating a load parameter standard test spectrum of a single mission profile of the aero-engine; and (4) compiling the general standard test load spectrum of the aero-engine by frequency mixing of flight missions. The test load spectrum of the aero-engine, compiled with the method, can serve as a main part life test load of the aero-engine; and based on an original aero-engine load spectrum compilation technology, load requirements of an aircraft in all periods and test conditions during actual flight are comprehensively considered. The test load spectrum of the aero-engine, compiled based on the general standard test load spectrum of the aero-engine, can not only really reflect the change of the load parameter of the aero-engine along with the flight time but also simplify a test load spectrum compilation process and improve the working efficiency.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

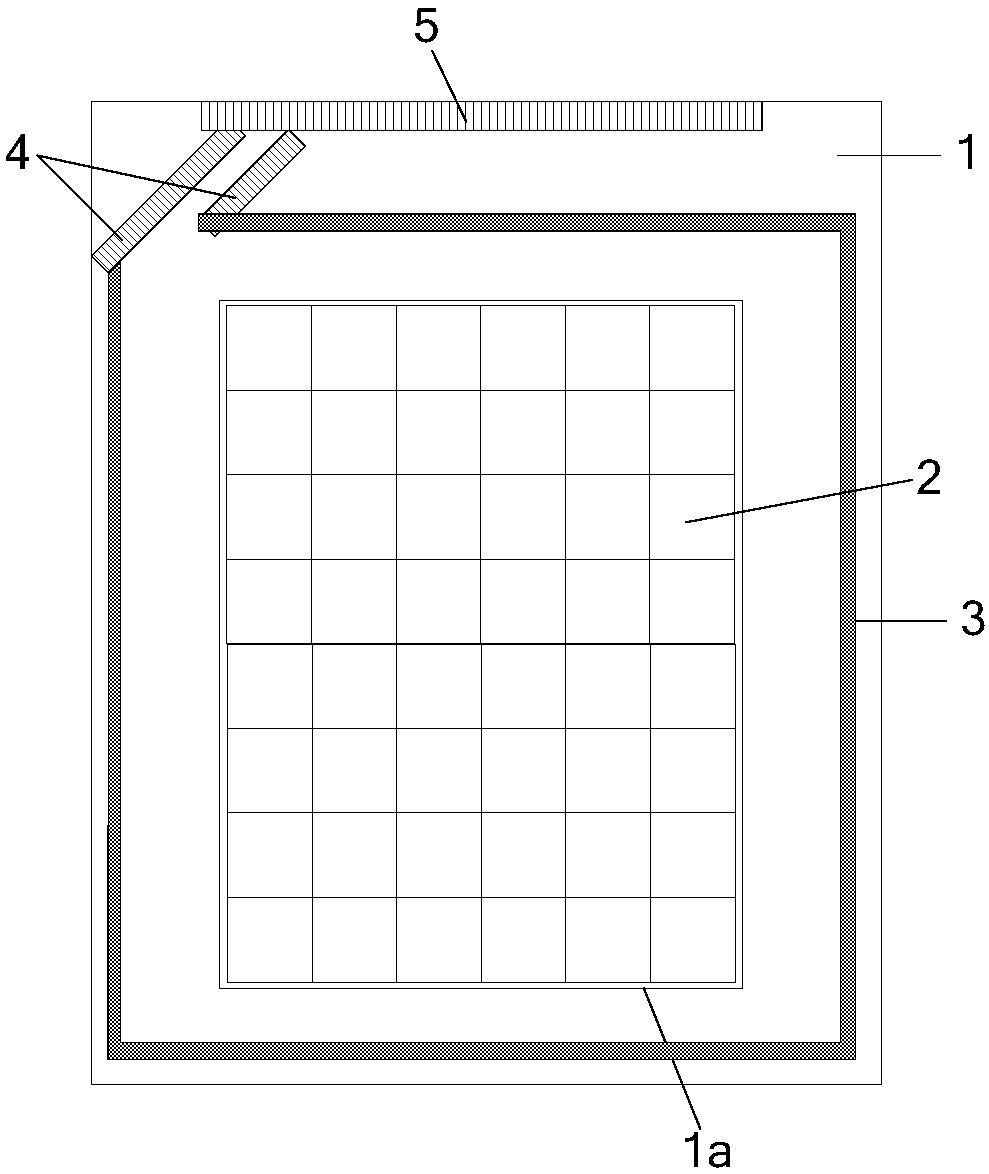

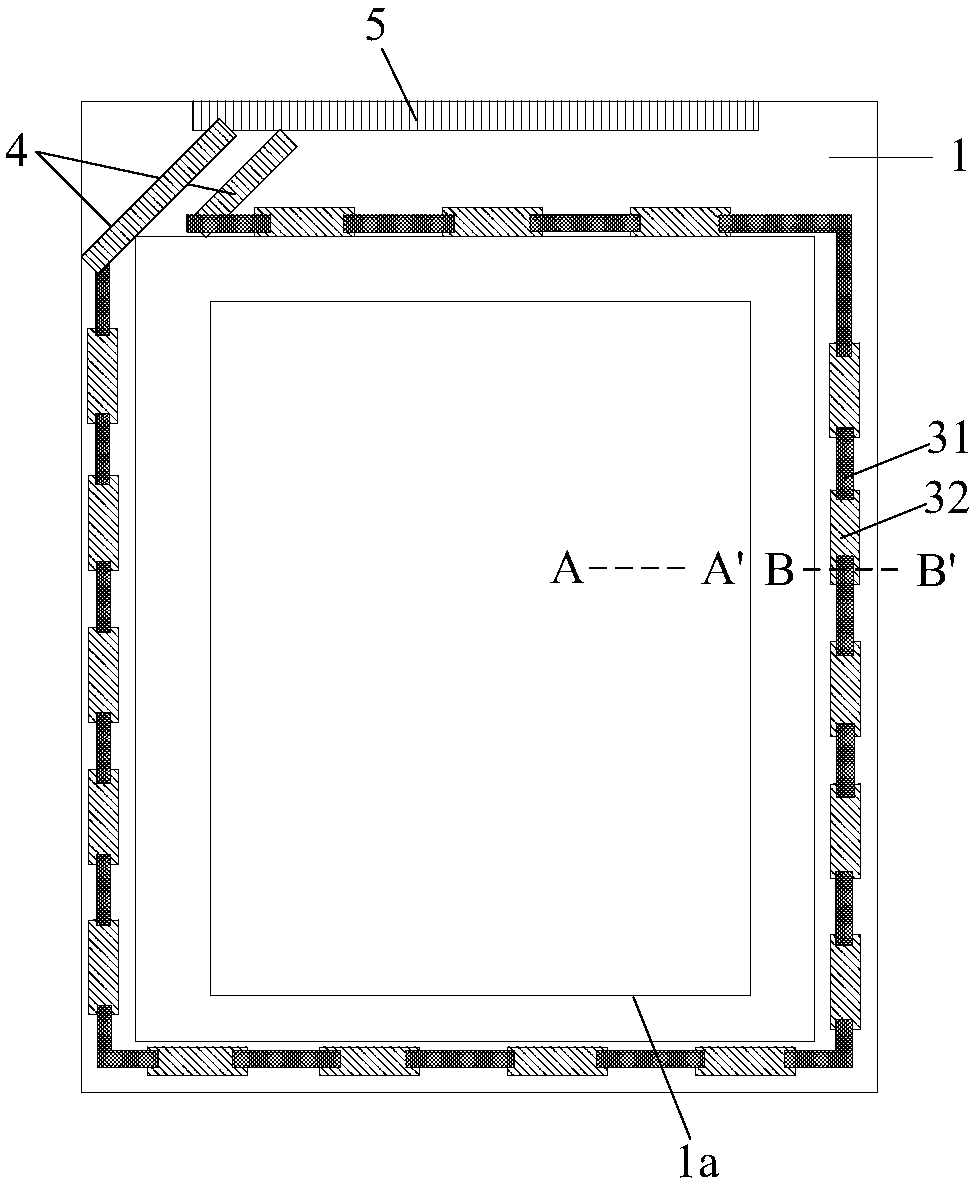

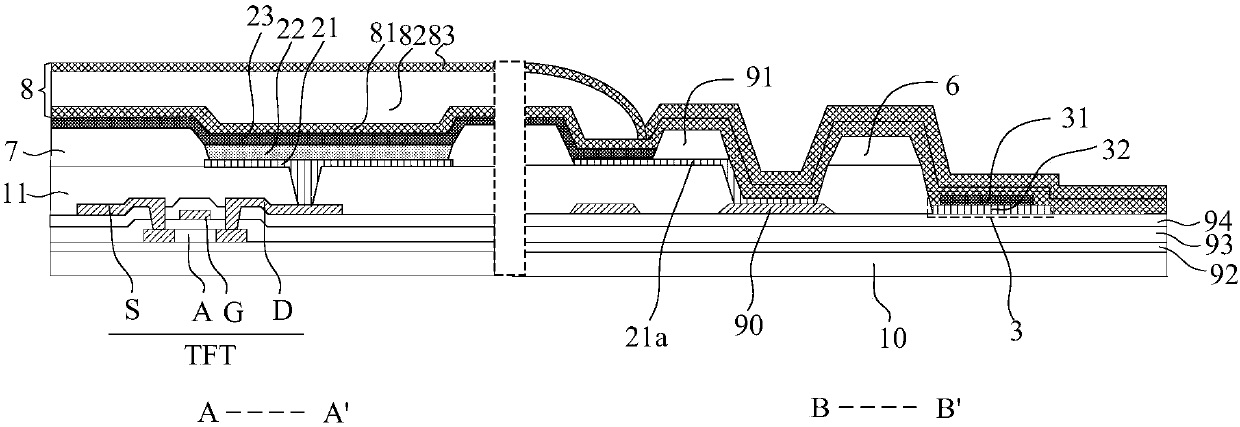

Display panel and preparing method thereof

ActiveCN107742635AAvoid erosionExtended service lifeSemiconductor/solid-state device testing/measurementSolid-state devicesCorrosionSurface plate

The invention provides a display panel and a preparing method thereof, and relates to the technical field of displaying. Whether encapsulation of the display panel is invalid or not can be monitored through change of the resistance value of a monitoring electrode located outside a display area to further monitor the water-and-oxygen corrosion degree and the service life of OLED units at the edge of the display area in the display panel. The display panel comprises a substrate, and the substrate is divided into the display area; the display panel further comprises multiple OLED units, the monitoring electrode and a thin film encapsulation layer, wherein the multiple OLED units are arranged in the display area, the monitoring electrode is arranged on the substrate and is located outside thedisplay area, and the resistance value is changed after the monitoring electrode reacts with water and / or oxygen; the thin film encapsulation layer at least covers the inside of the display area and the monitoring electrode.

Owner:BOE TECH GRP CO LTD

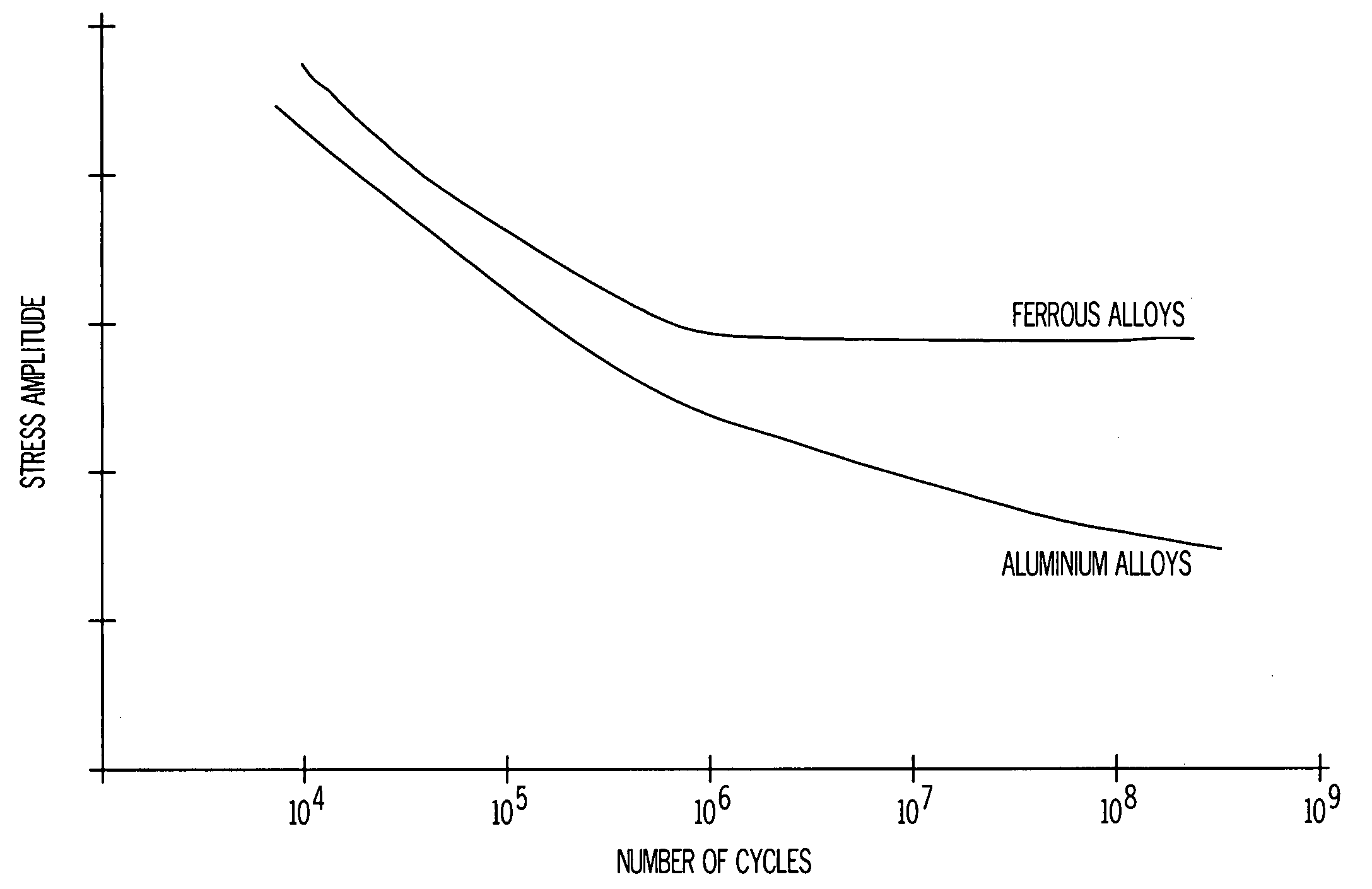

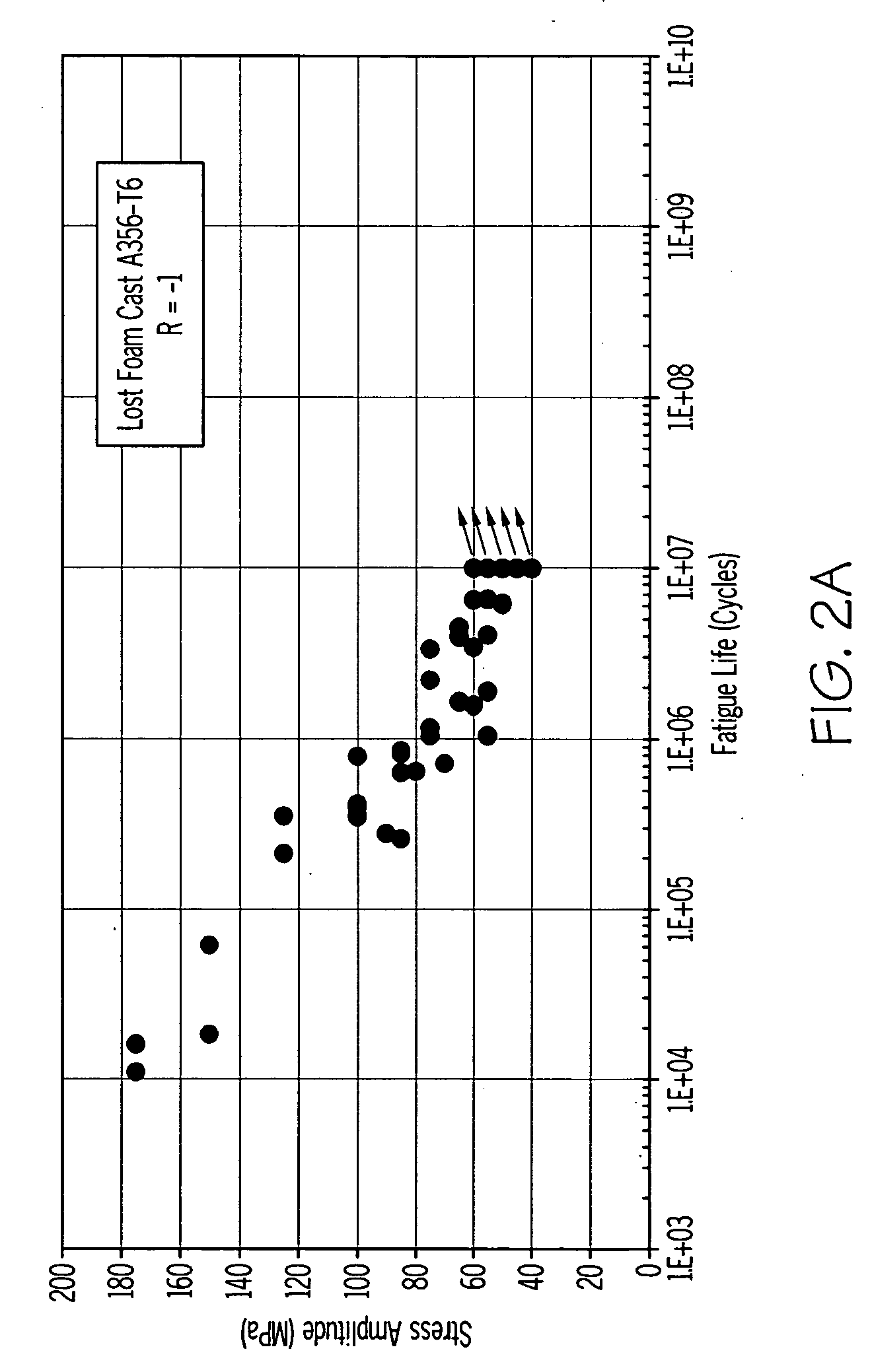

Methods and systems for predicting very high cycle fatigue properties in metal alloys

ActiveUS20100030537A1Life predictionDesign optimisation/simulationAnalogue computers for heat flowCrazingMicrostructure

A system and method for predicting fatigue life in metal alloys for very high cycle fatigue applications. The system and method are especially useful for cast metal alloys, such as cast aluminum alloys, where a fatigue endurance limit is either non-existent or hard to discern. Fatigue properties, such as fatigue strength in the very high cycle fatigue region, are based on a modified random fatigue limit model, where the very high cycle fatigue strength and infinite life fatigue strength are refined to take into consideration the sizes of the discontinuities and microstructure constituents since the fatigue life scatter depends upon the presence of discontinuities and microstructure constituents. The sizes of the discontinuities and microstructure constituents that can initiate fatigue cracks can be determined with extreme value statistics, then input to the modified random fatigue limit model.

Owner:GM GLOBAL TECH OPERATIONS LLC

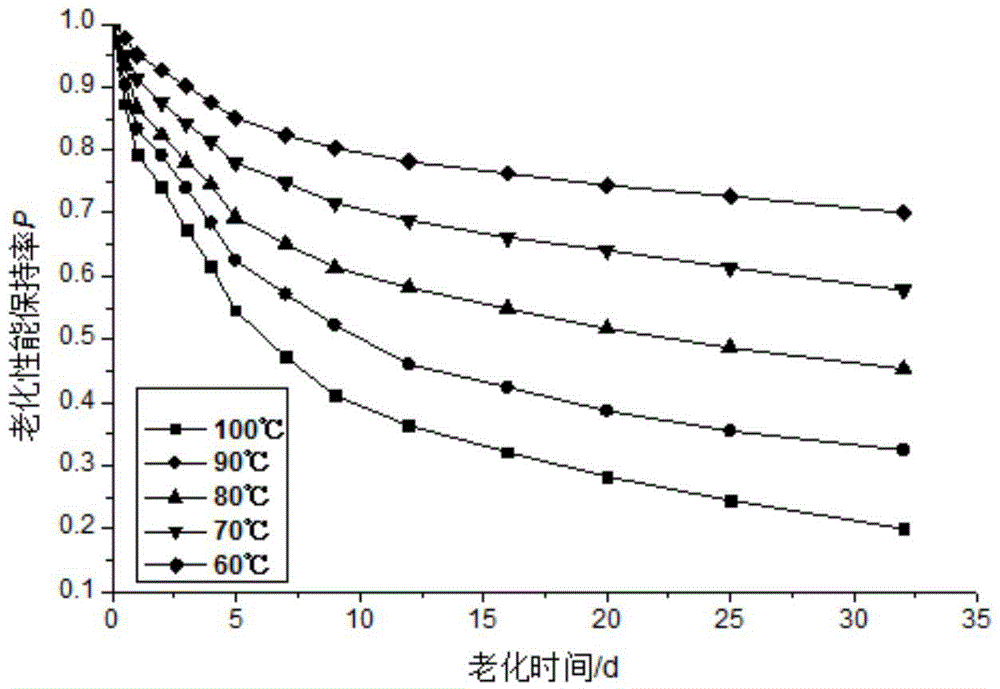

Method for predicting service life of rubber shock absorber

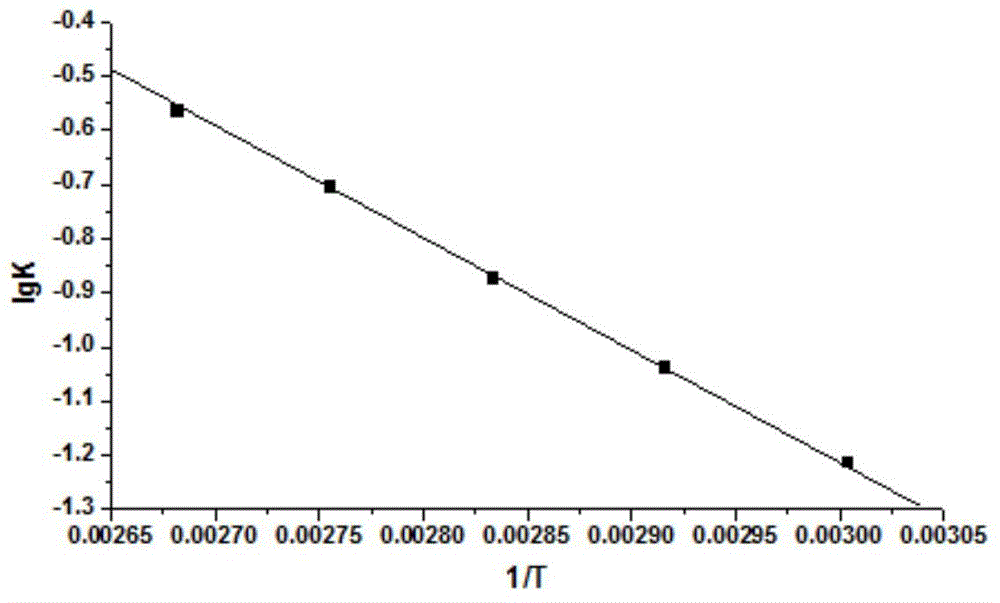

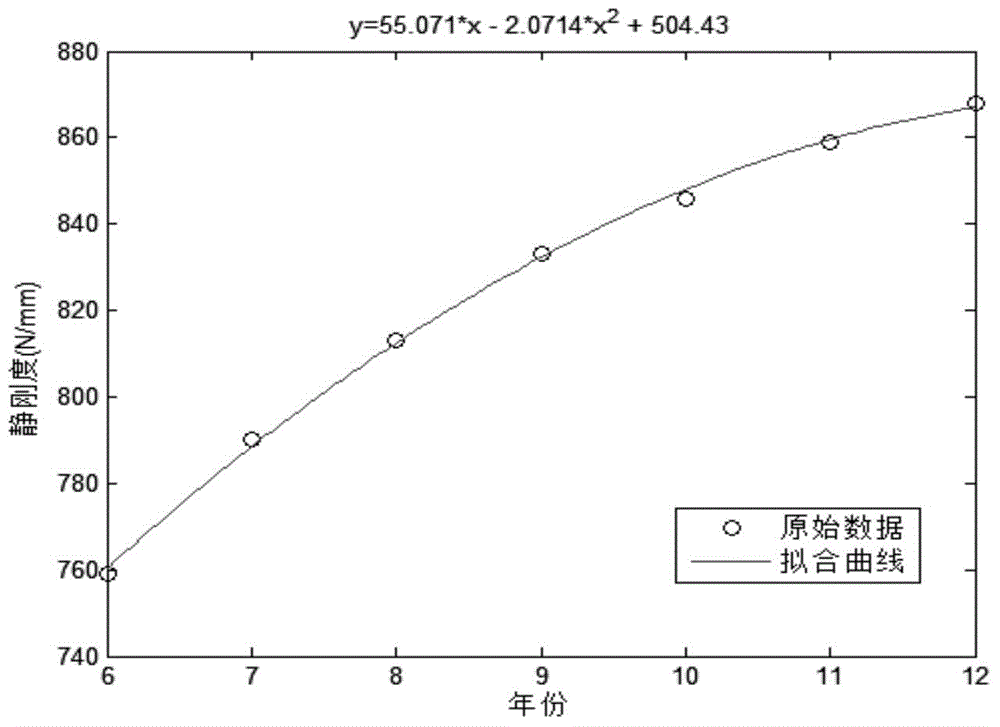

InactiveCN104697920ALife PredictionLifespan reflectionWeather/light/corrosion resistanceStrength propertiesEngineeringAge factor

The invention discloses a method for predicting a service life of a rubber shock absorber; the method comprises the steps: combining aging factors, influencing the use of the rubber shock absorber, and fatigue factors; firstly, establishing an aging service life prediction mathematic model of the rubber shock absorber in use of a hot air accelerated aging test; secondly, establishing a model relationship between static rigidity of a new absorber and fatigue times by means of the aging service life prediction model and the existing performance parameter of an old absorber; further, establishing a relation model between the static rigidity and the time and obtaining a service life prediction model of the rubber shock absorber, thereby realizing prediction of the service life of the rubber shock absorber. The aging factors and the fatigue factors are combined well to predict the service life of the rubber shock absorber, and the prediction precision is high.

Owner:QINGDAO UNIV OF SCI & TECH

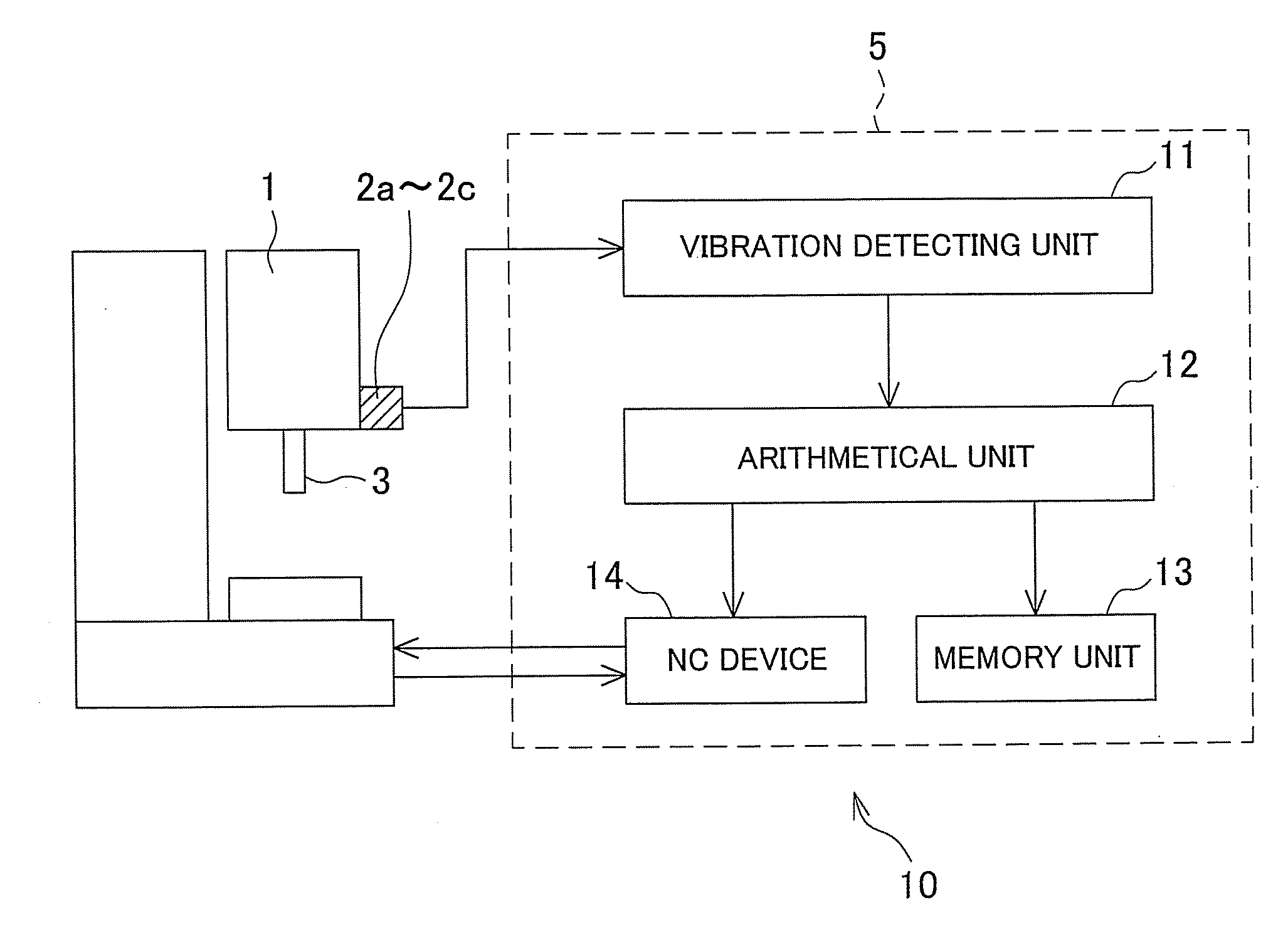

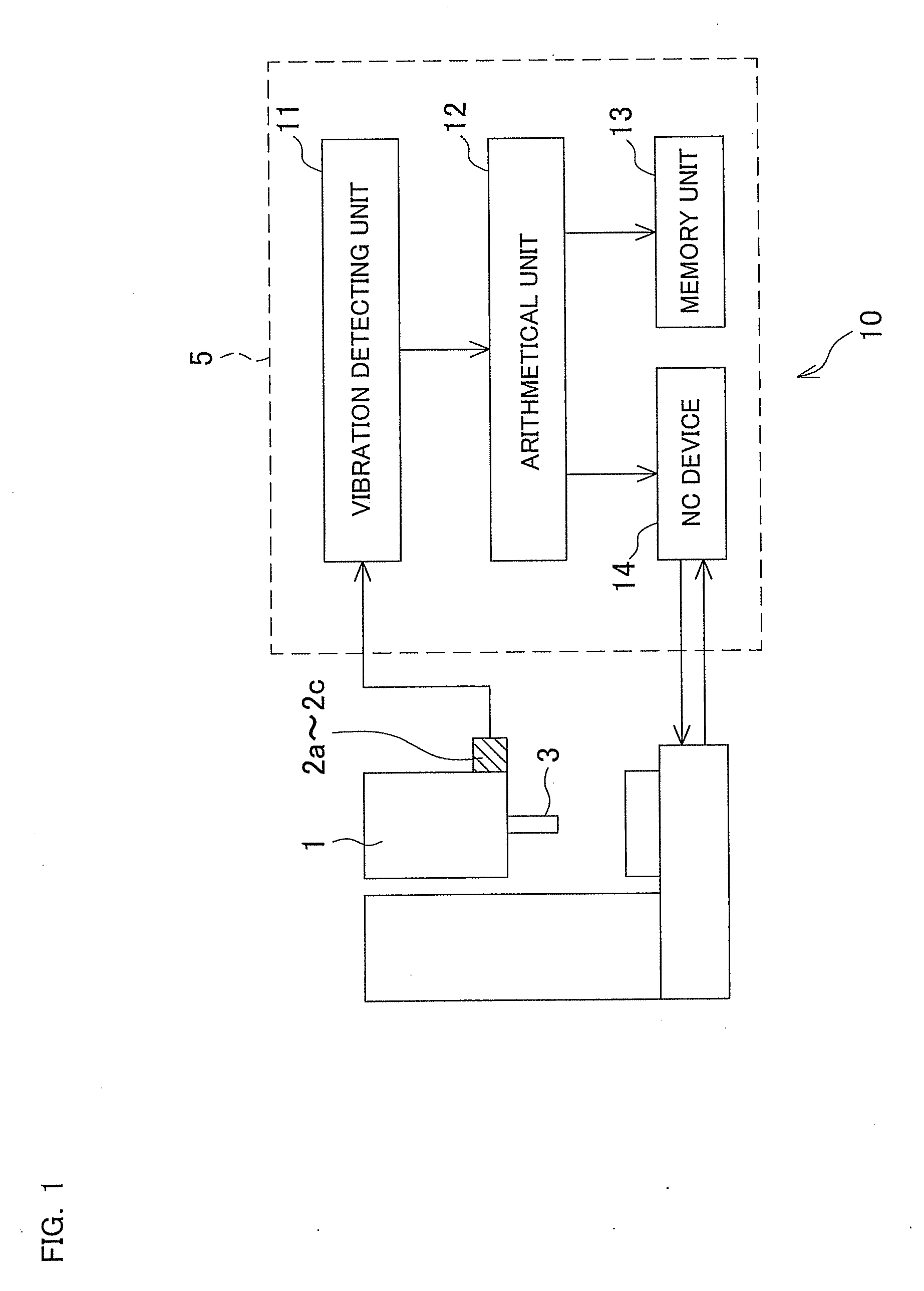

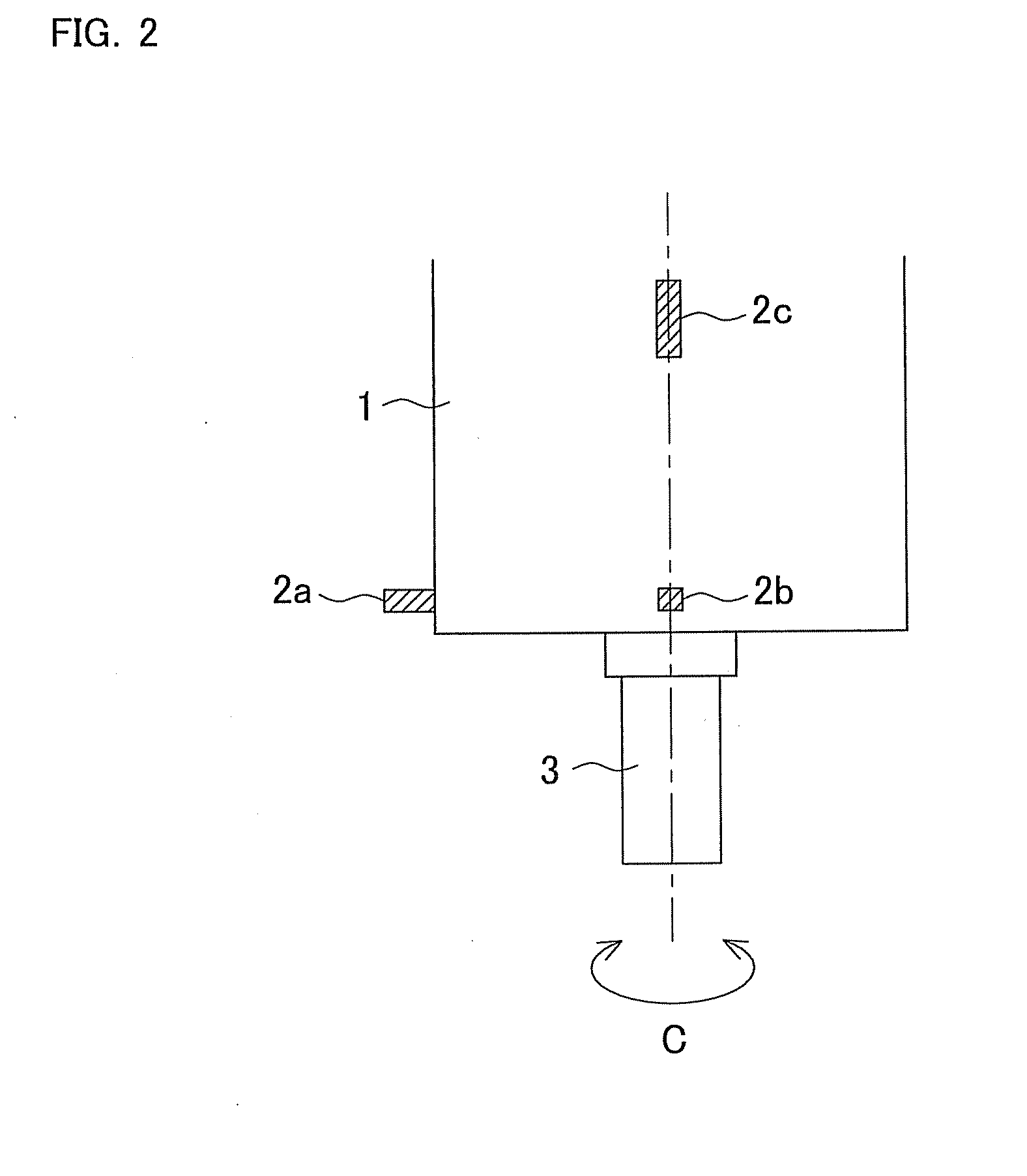

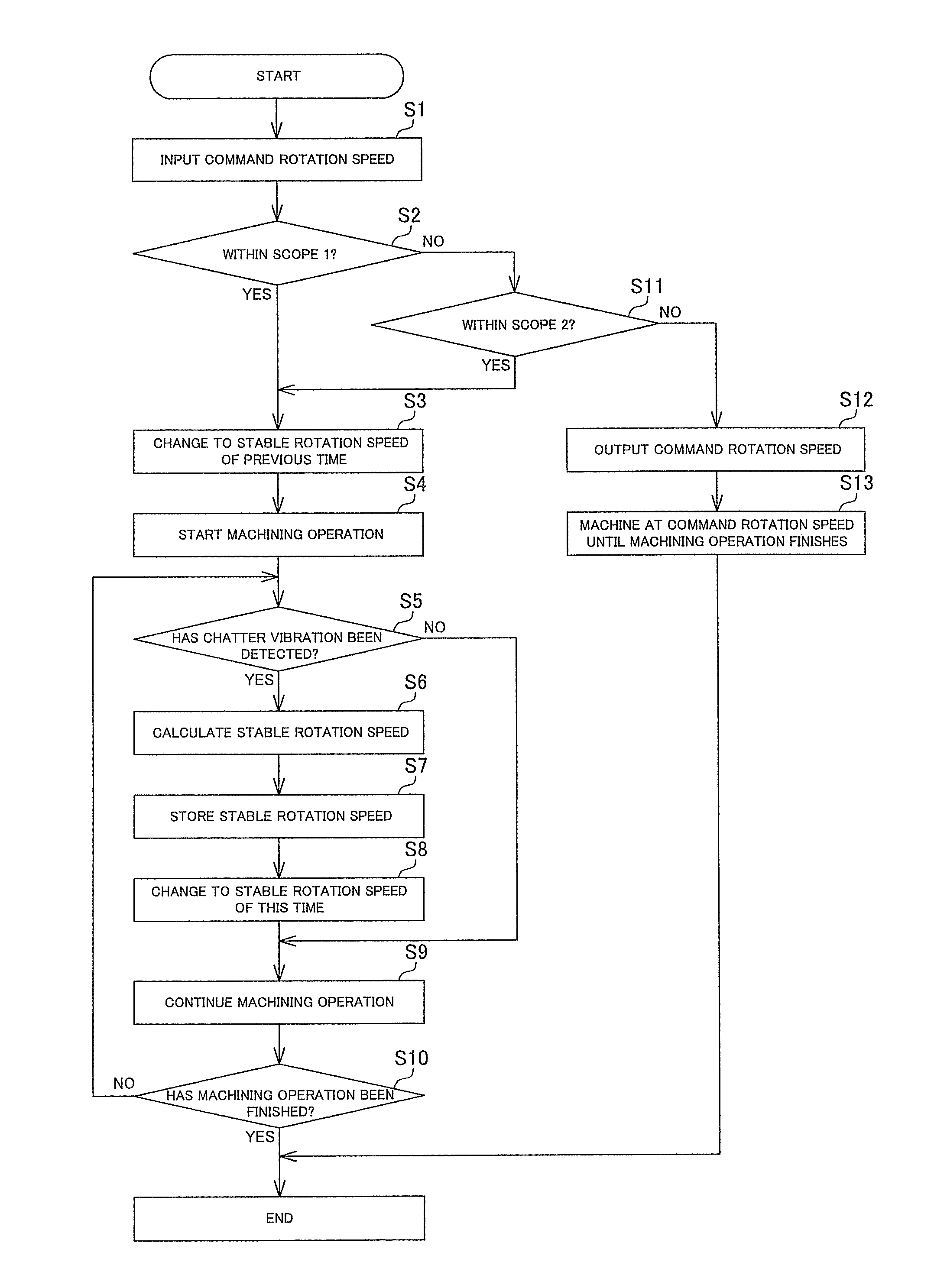

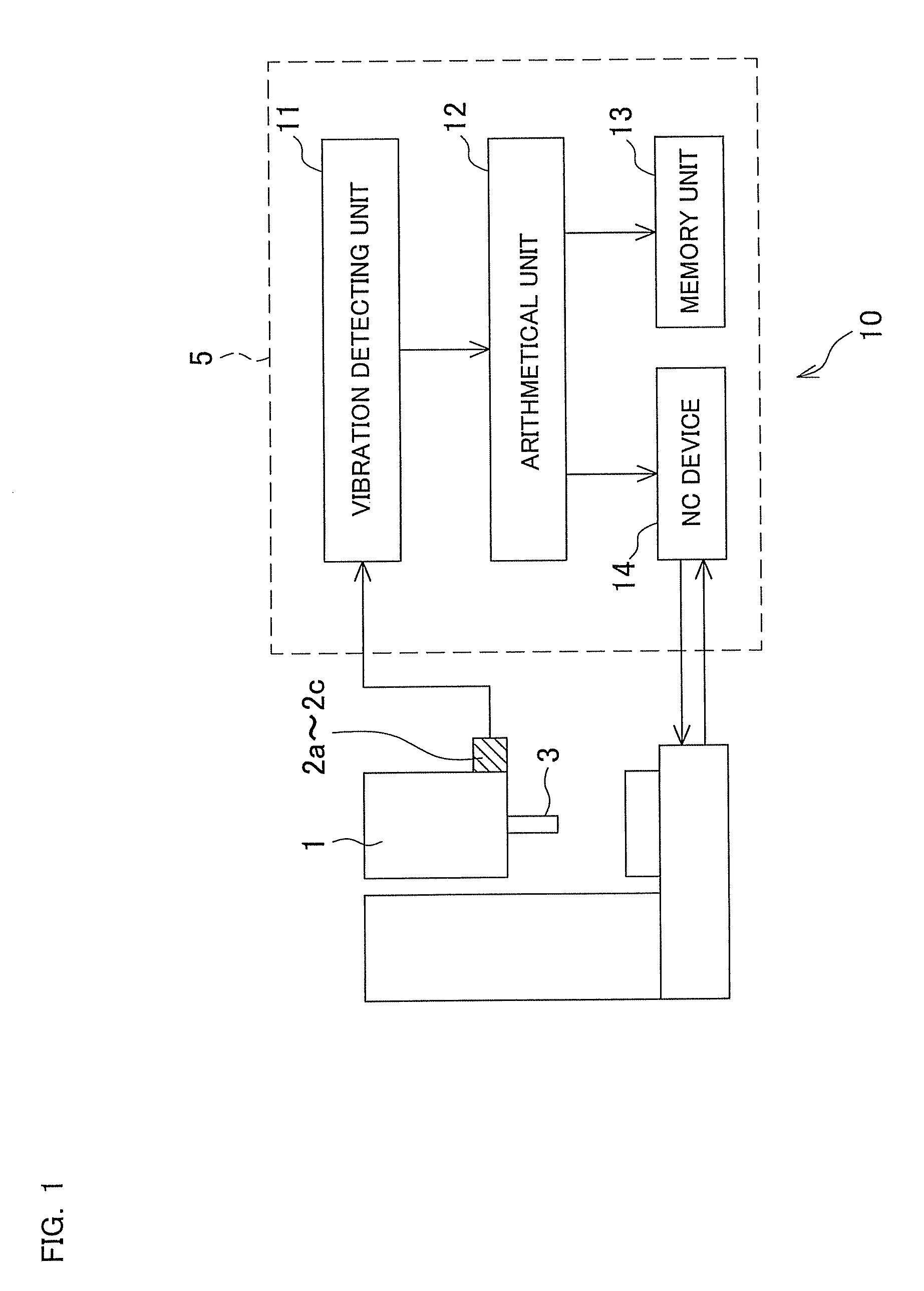

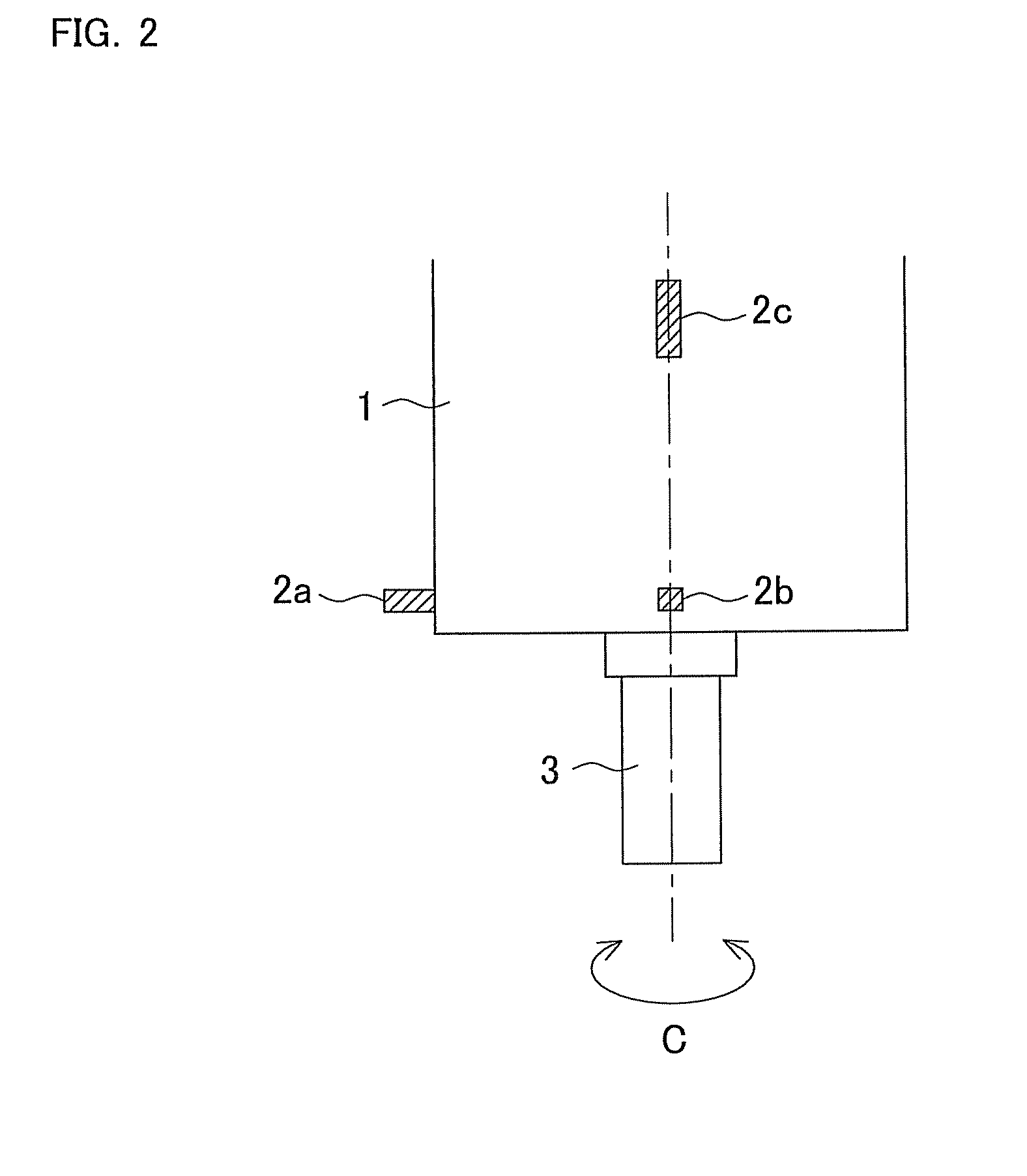

Vibration suppressing device

InactiveUS20120065766A1Machine efficiency and machine surface accuracy be improveHighly accurateProgramme controlComputer controlEngineeringControl theory

A vibration suppressing device includes a memory unit storing a stable rotation speed calculated by an arithmetical unit in association with a rotation speed range that includes the stable rotation speed, in which, when a command rotation speed that is a rotation speed of a rotary shaft is inputted in starting machining operation by rotation of the rotary shaft and, the arithmetical unit determines whether the command rotation speed is included in the rotation speed range or not, reads out the stable rotation speed when the command rotation speed is included in the rotation speed range and outputs the stable rotation speed to an NC device instead of the command rotation speed, and starts the machining operation at the stable rotation speed.

Owner:OKUMA CORP

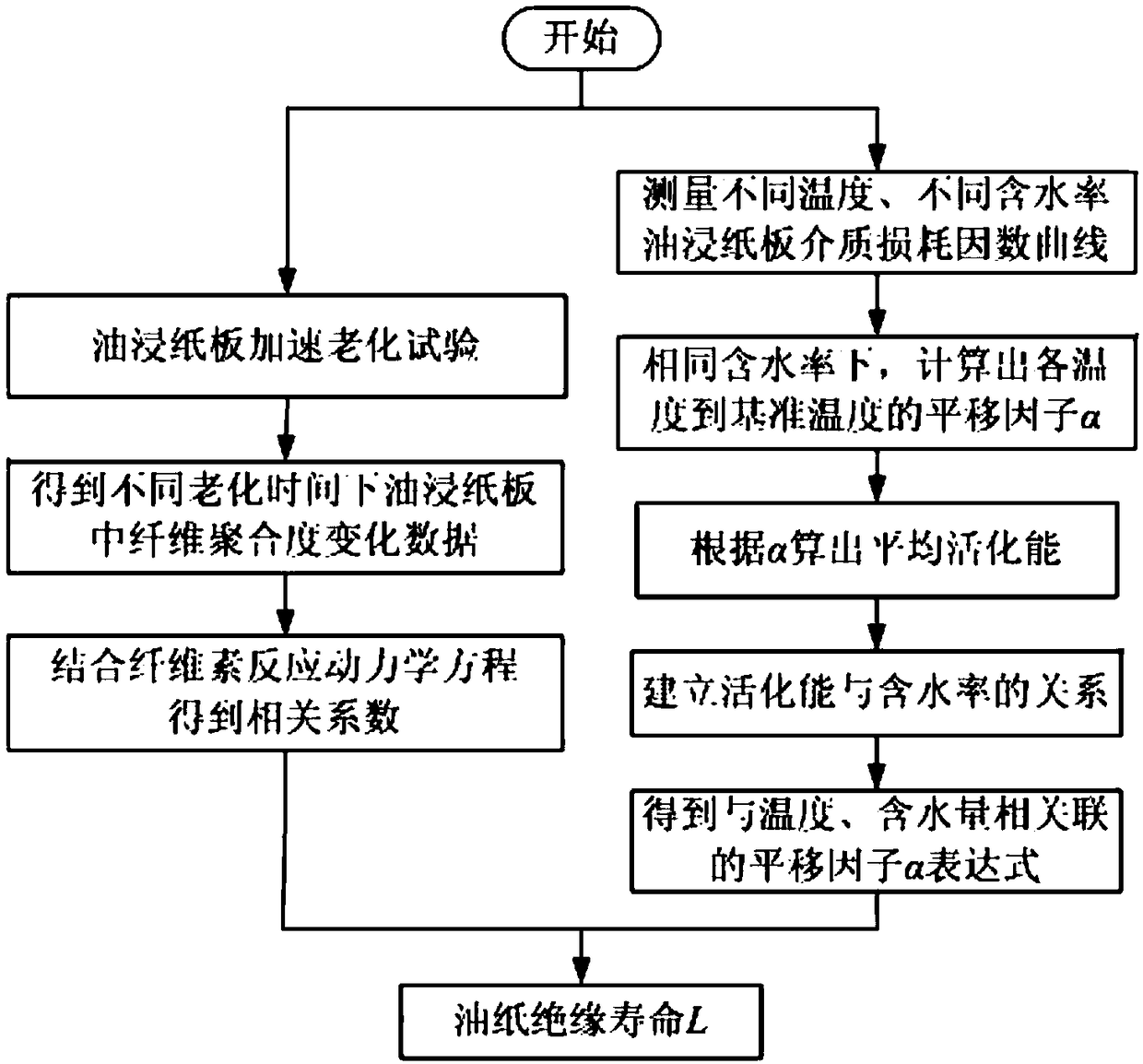

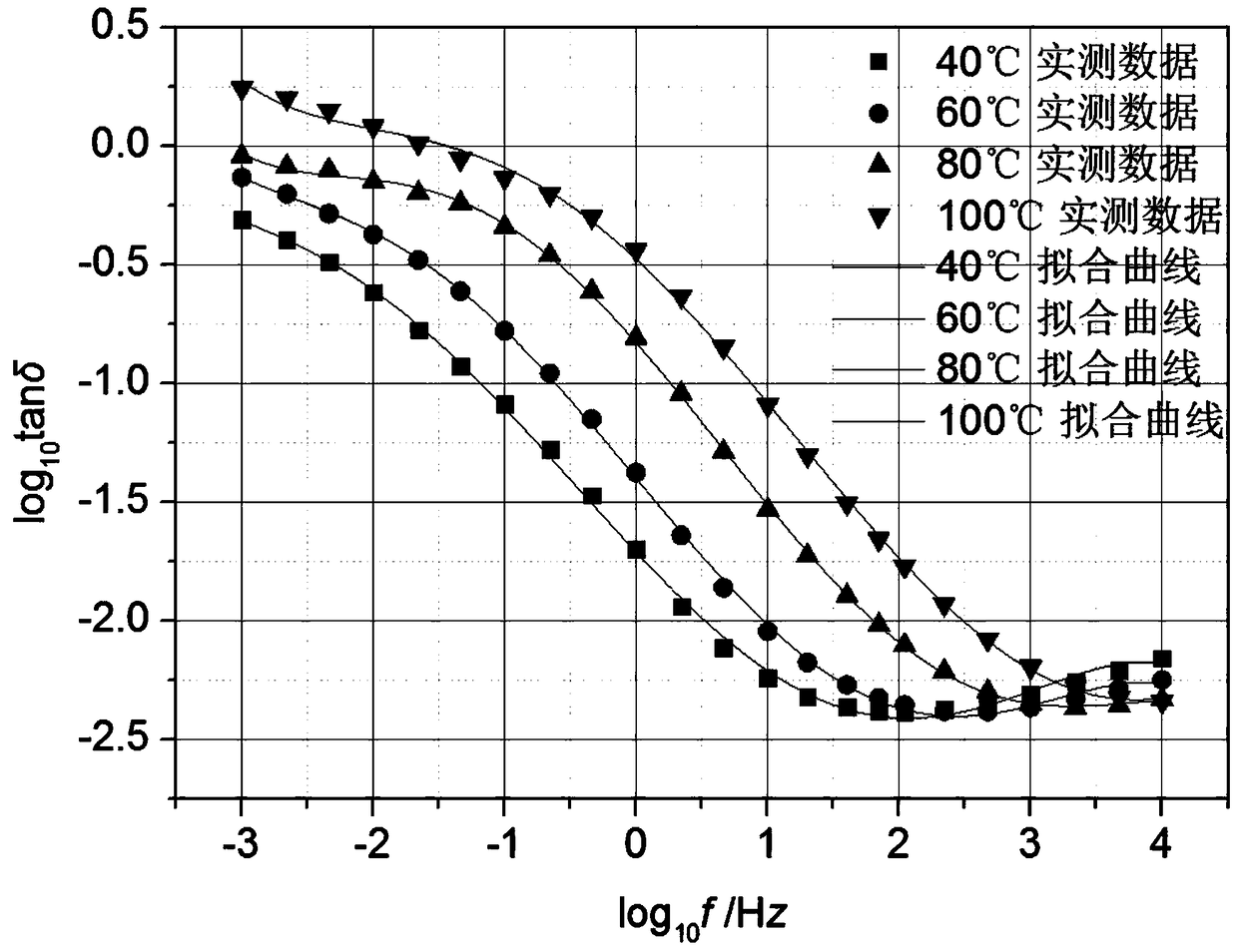

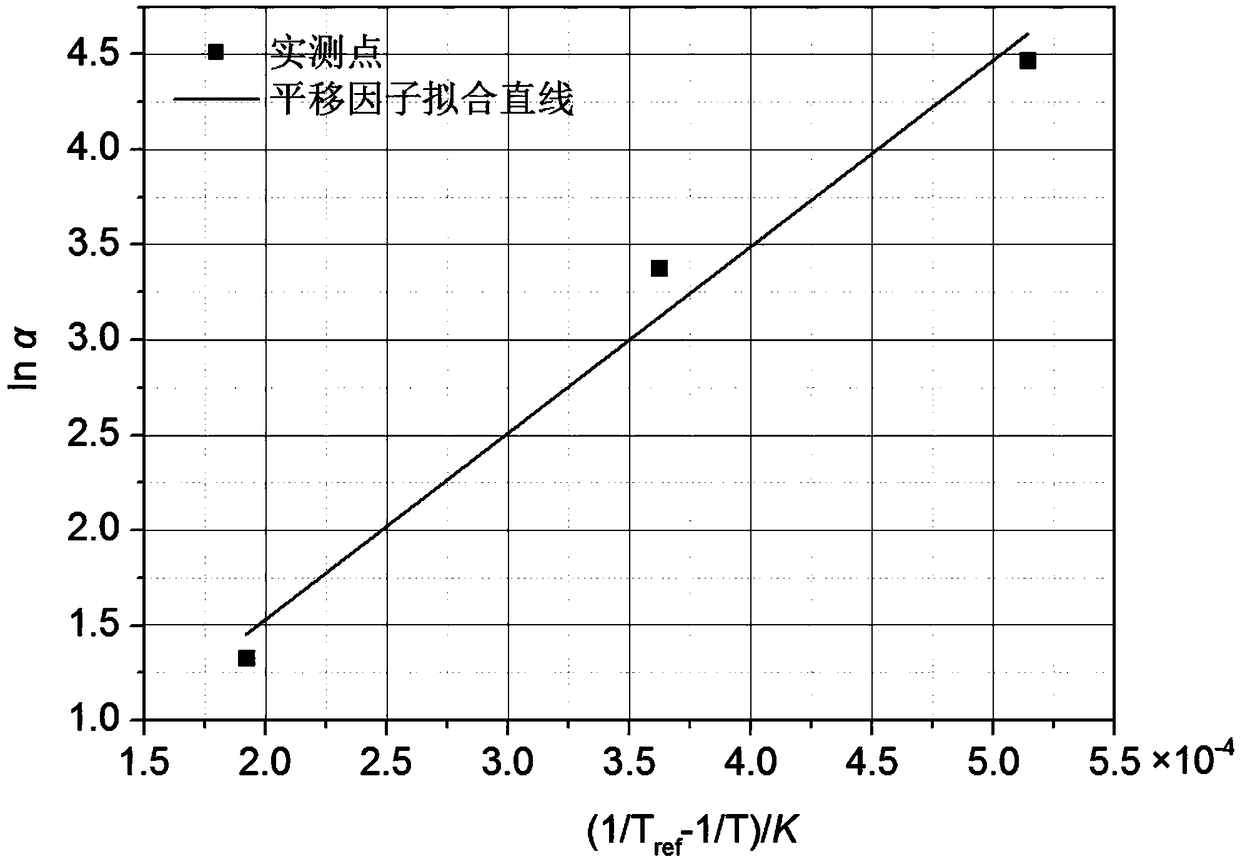

Method for evaluating service life of oil-paper insulation inside high-voltage current transformer

The invention relates to a method for evaluating the service life of oil-paper insulation inside a high-voltage current transformer. The invention provides the effective numerical calculation method for evaluating the service life of the oil-paper insulation inside the high-voltage current transformer, and the method comprises the steps: carrying out the translation reduction through the oil-paperinsulation dielectric loss factor curves tested at different temperature values to obtain a temperature translation factor; obtaining a corresponding moisture content oil-immersed paper board activation energy according to the calculated temperature translation factor; repeatedly performing the calculation process of the oil-immersed paper board activation energy, and building the relation between the oil-immersed paper board activation energy and the moisture content; and accurately evaluating the aging state of the oil-paper insulation inside the high-voltage current transformer through combining a reaction kinetic model of cellulose aging in the oil-paper insulation. The method achieves the prediction of the service life of oil paper with different test temperatures and moisture contents.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +2

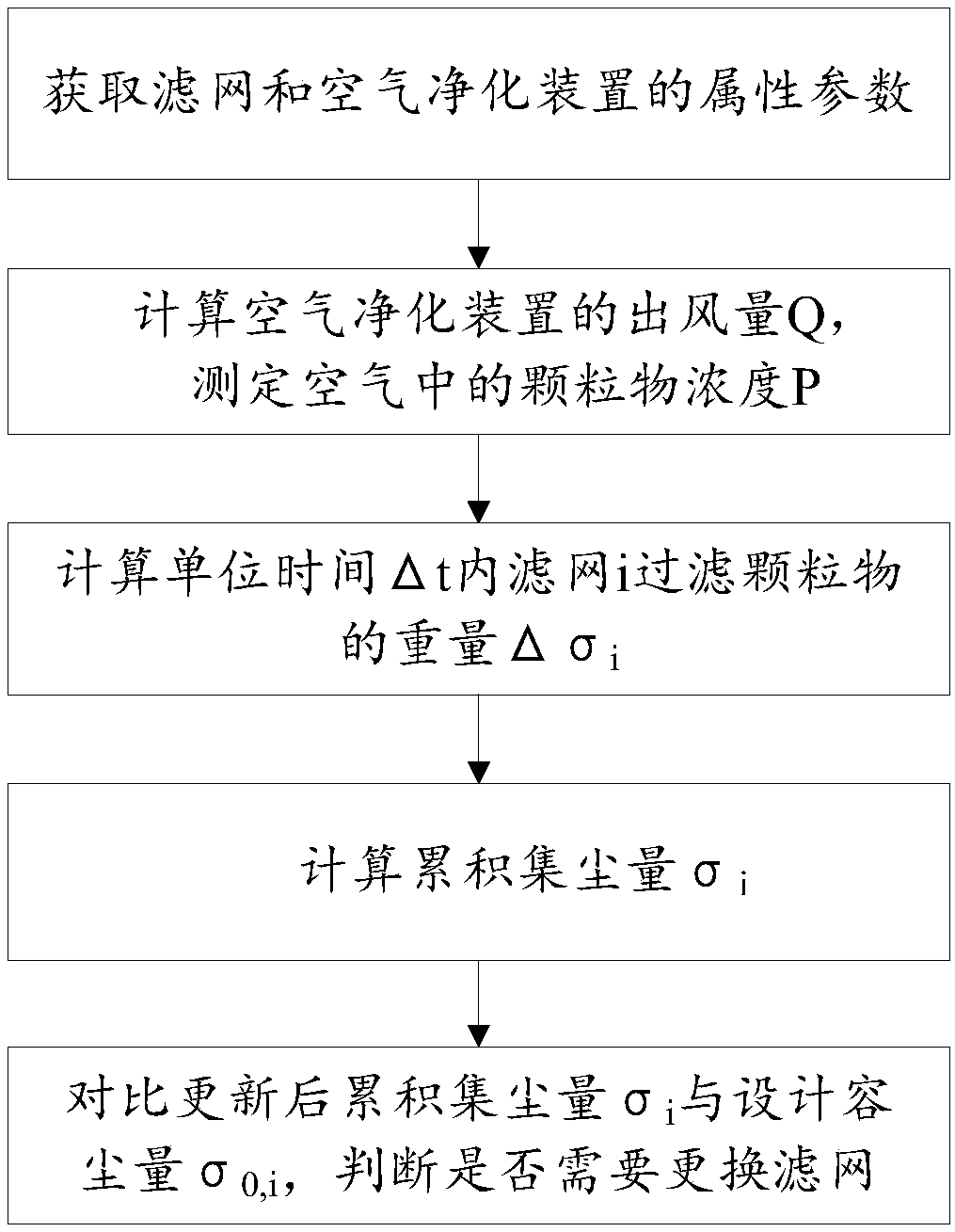

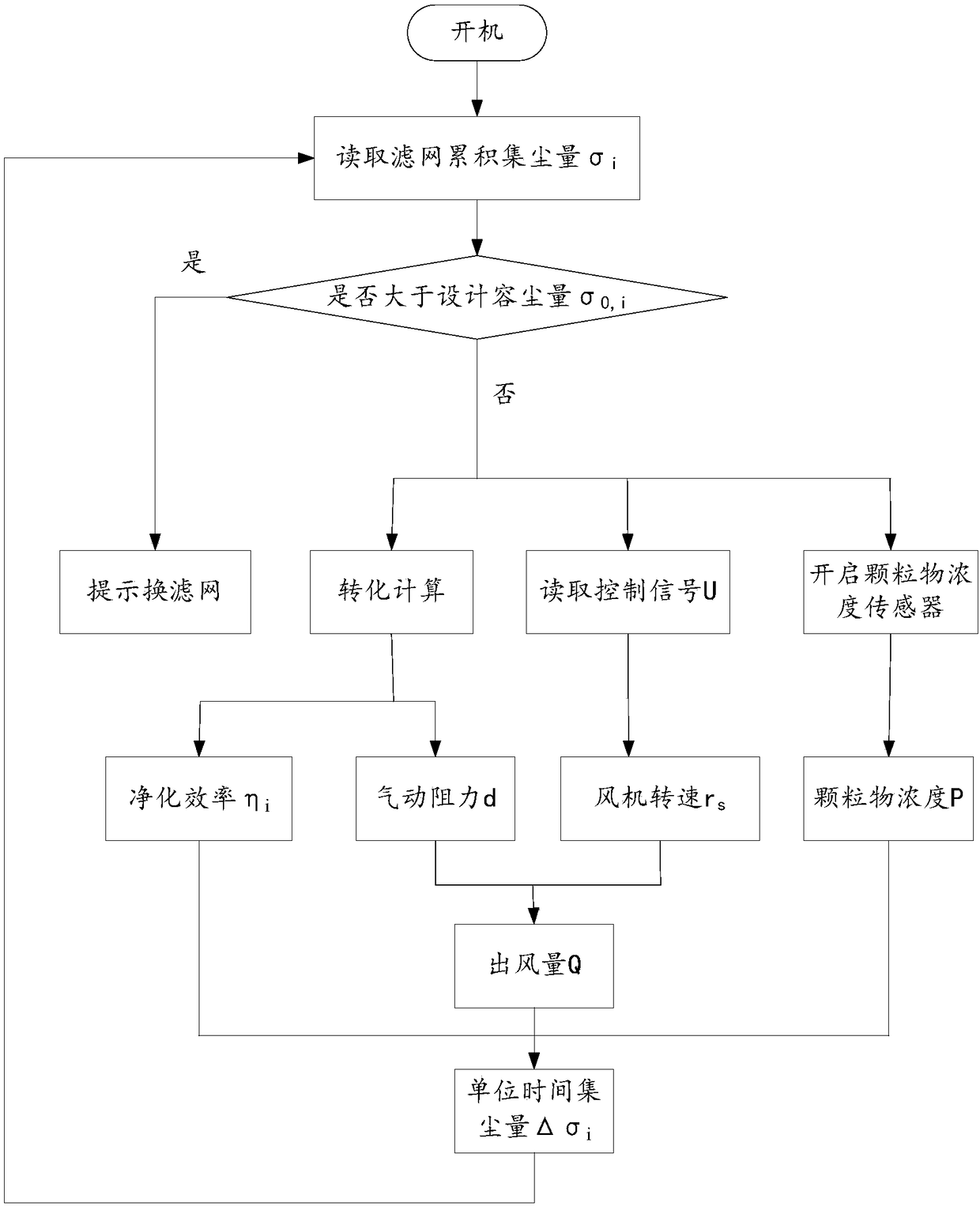

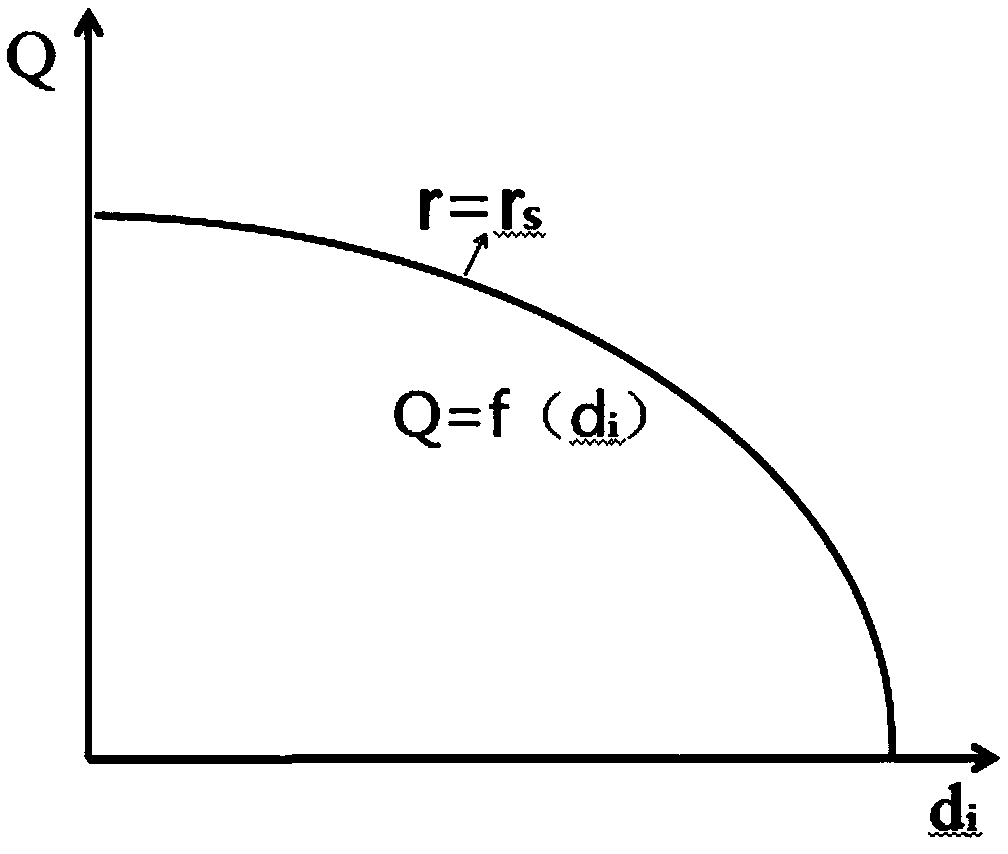

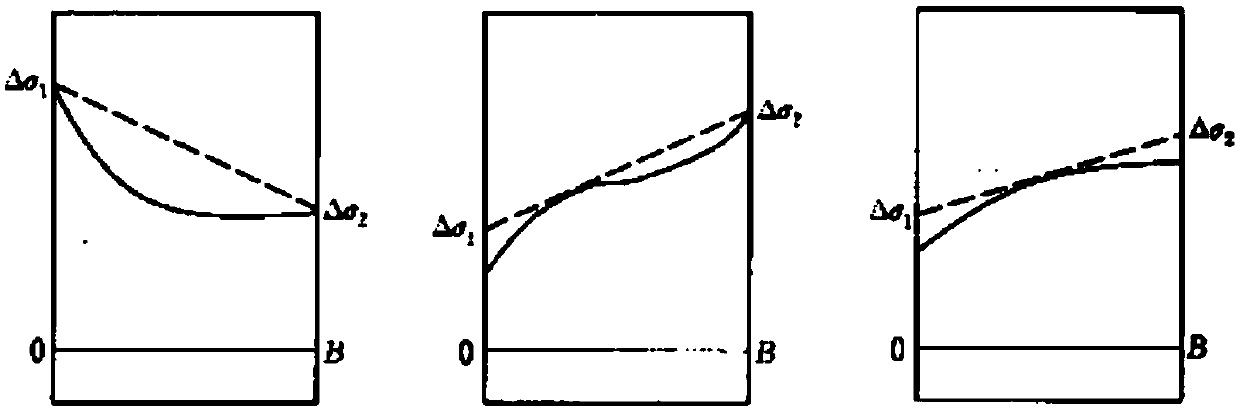

Filtering screen service life forecasting method based on dust holding capacity and air purification device

PendingCN108211556ALife predictionTimely replacementDispersed particle filtrationPermeability/surface area analysisParticulatesFresh air

The invention relates to a filtering screen service life forecasting method based on the dust holding capacity. The method comprises the following steps of (1) obtaining an attribute parameter of a filter screen or an air purification device; (2) calculating the air-out quantity Q of the air purification device; (3) determining the concentration P of particulate matters in the air; (4) calculatingthe weight delta sigma[i] of the particulate matters filtered by the filtering screen in a unit time delta[t] according to a calculation formula that deltasigm[i] equals to PQ[Eta][i]delta[t]. (5) calculating the accumulated dust collecting quantity sigma[i]: accumulating the weight delta sigma[i]of the particulate matters filtered by the filtering screen in a unit time delta[t] onto the originalaccumulated dust collection quantity to obtain the updated accumulated dust collection quantity sigma[i]; (6) comparing the updated accumulated dust collecting quantity and the designed dust accommodating quantity sigma [0,i]; judging whether the filtering screen needs to be replaced or not. The filtering screen service life forecasting method based on the dust holding capacity can be used for more accurately predicting the filtering screen service life so as to remind people of timely replacing the filtering screen of an air purifier or a fresh air system.

Owner:加丁(天津)科技有限公司

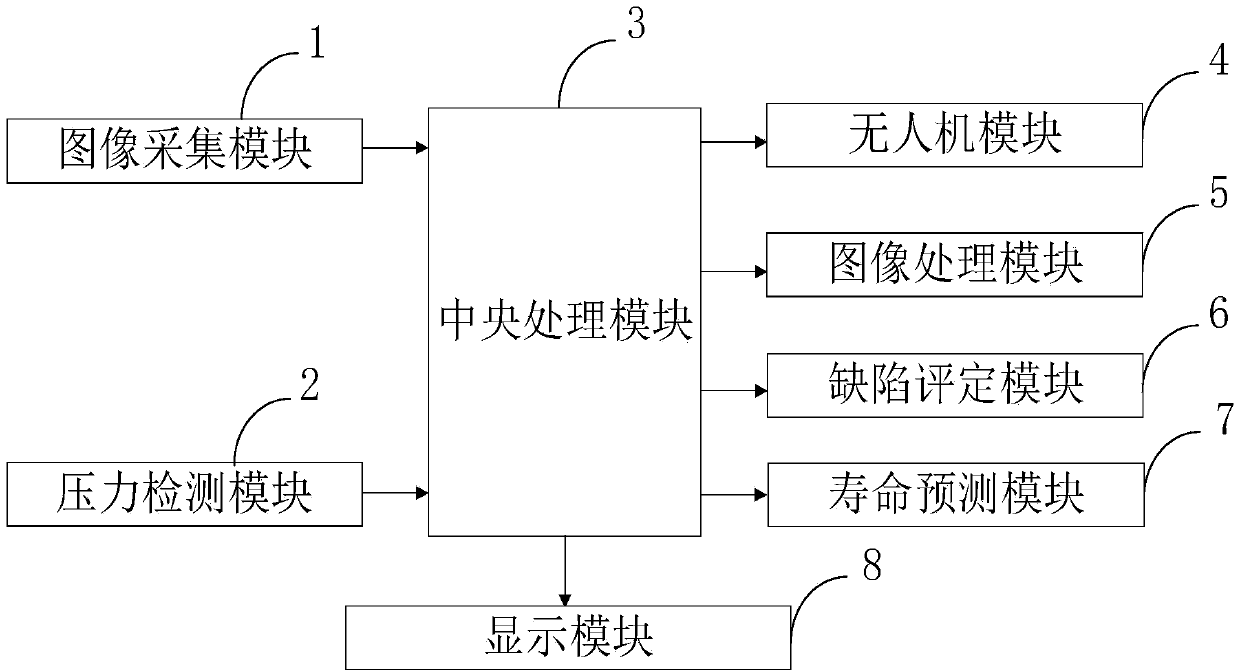

Evaluation and detection system for apparent defects of civil engineering structure

InactiveCN108956638ALife PredictionThe assessment result is accurateOptically investigating flaws/contaminationElasticity measurementAttenuation coefficientImaging processing

The invention belongs to the technical field of civil engineering, and discloses an evaluation and detection system for the apparent defects of a civil engineering structure. The system comprises an image acquisition module, a pressure detection module, a central processing module, a drone module, an image processing module, a defect evaluation module, a life prediction module and a display module. The image acquisition module and the drone module can collect image data of each corner of the engineering structure through a drone in order to obtain complete image data, so an evaluation result is accurate; the life prediction module can judge the possible control section of the structure, calculate the stiffness attenuation coefficient under the influences of load, shrinkage and creep and predict the remaining service life of the structure after the structure is loaded according to numerical analysis or mechanics knowledge; the remaining life prediction result is continuously updated bycombining actual measurement information; and the life of the structure can be accurately predicted.

Owner:HUNAN UNIV OF ARTS & SCI

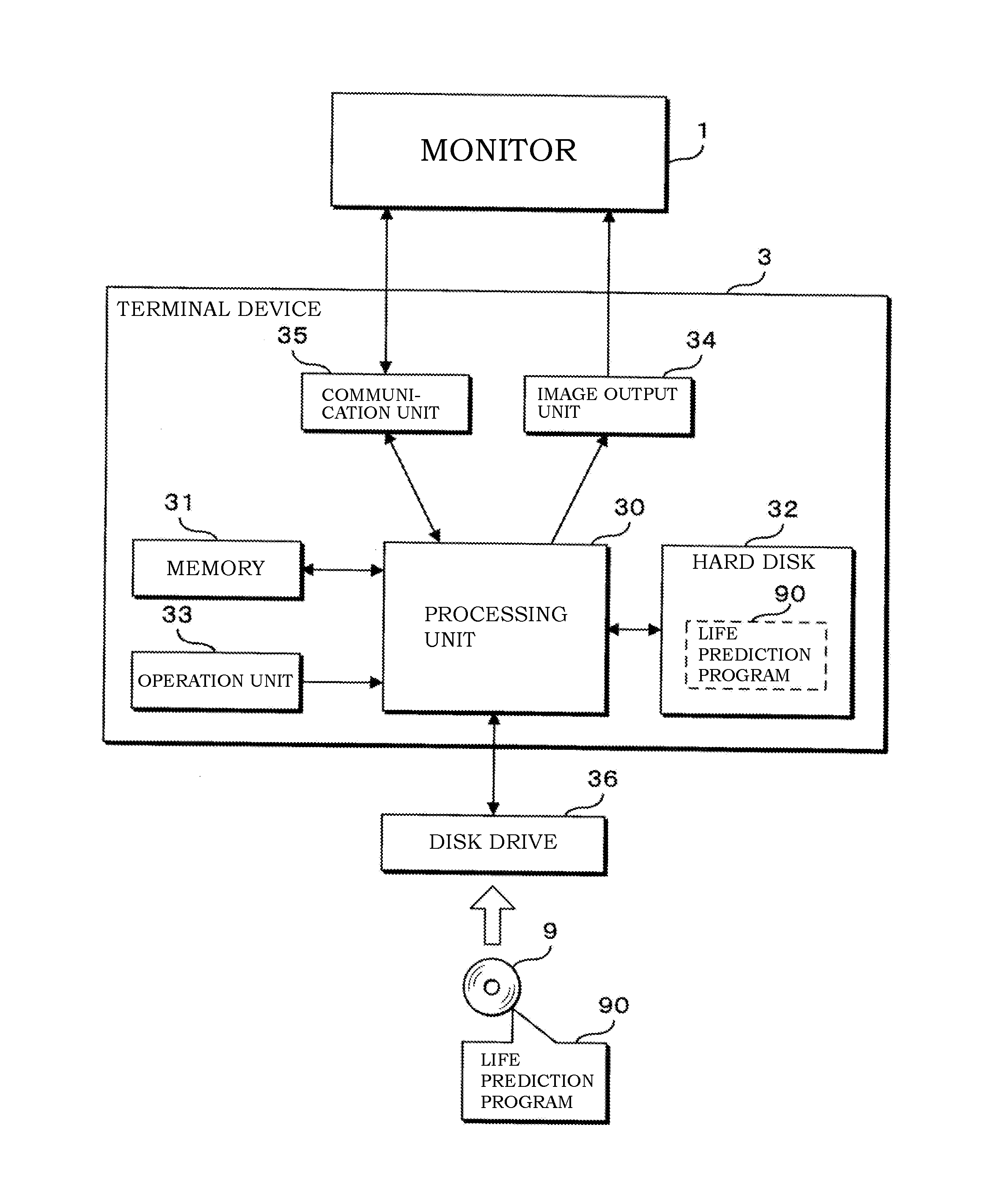

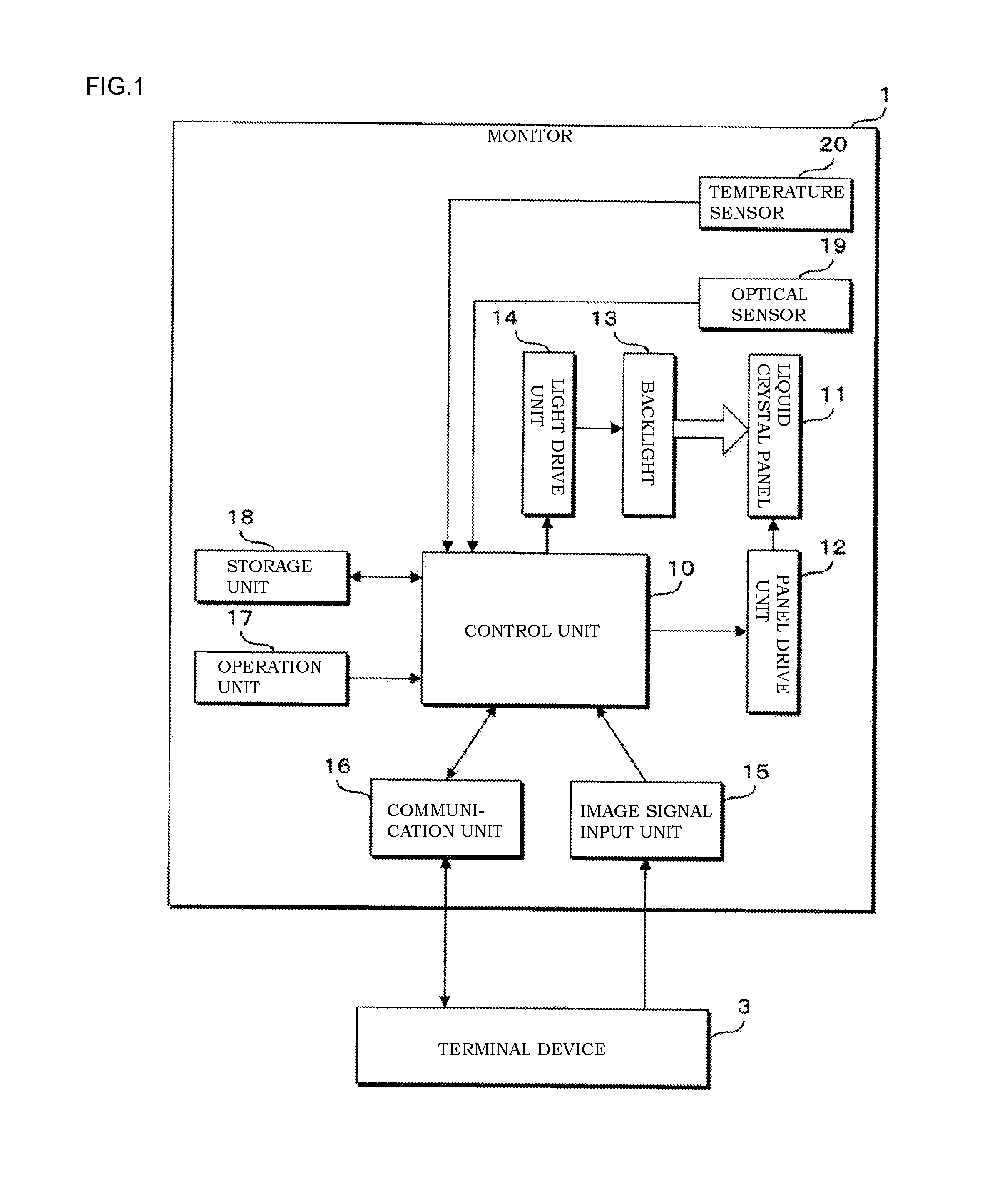

Life prediction method, computer readable media including life prediction program, and life prediction device

ActiveUS20170032745A1Accurate lifeLife predictionStatic indicating devicesEngineeringOptical transducers

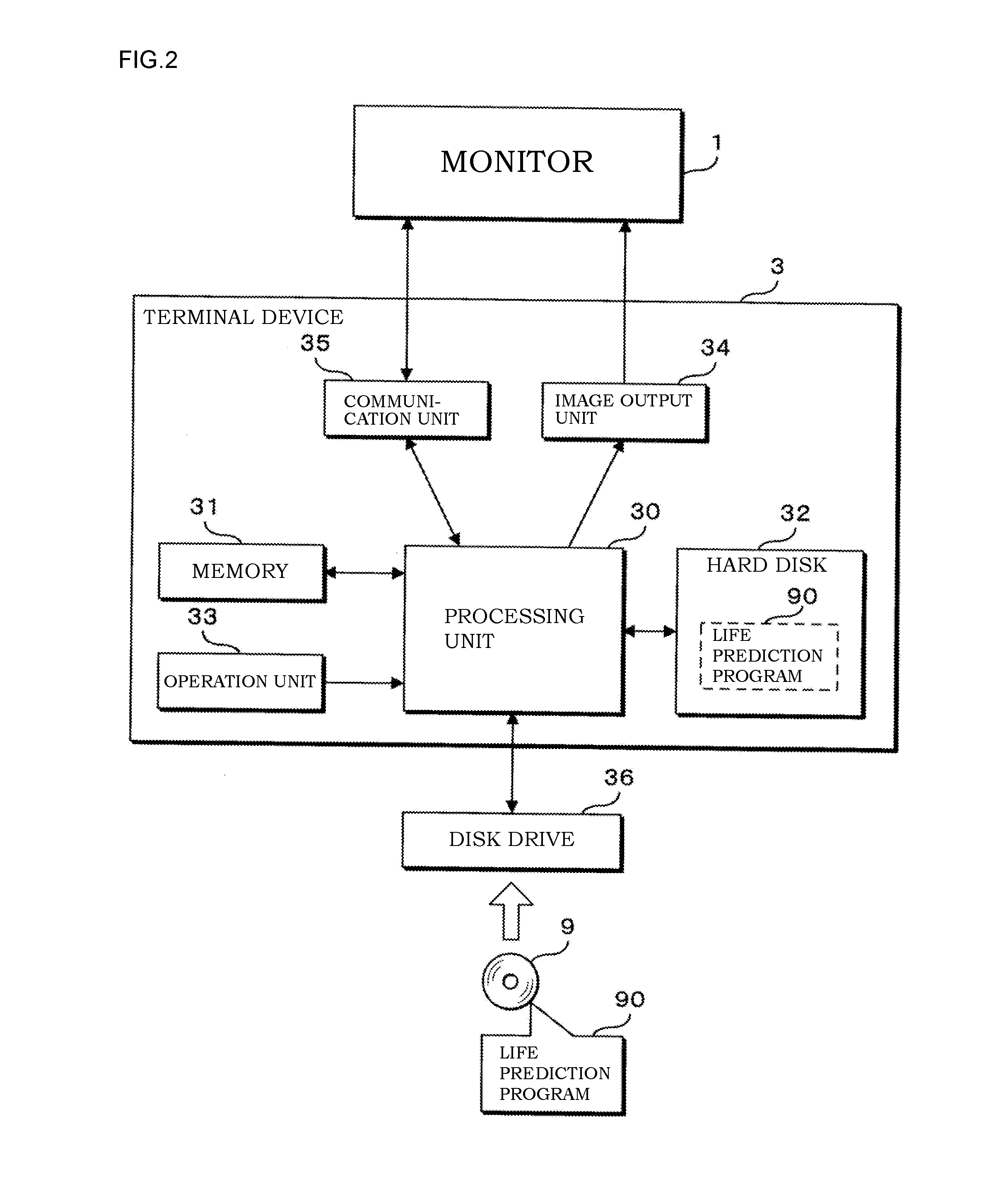

A life prediction method and device that can predict the life of a display device considering the differences between temperatures at measurements of the luminance of the display device. A monitor measures the luminance of the display screen using an optical sensor and measures the temperature around the display screen using a temperature sensor. A terminal device stores the measured luminances and temperatures in such a manner that the luminance and temperature are associated with each other. On the basis of the measured luminances and temperatures obtained by repeated measurements, the terminal device predicts the trend of changes in the luminance assuming that the temperatures at the measurements have been approximately constant, and predicts the life of the monitor on the basis of the predicted change trend.

Owner:EIZO

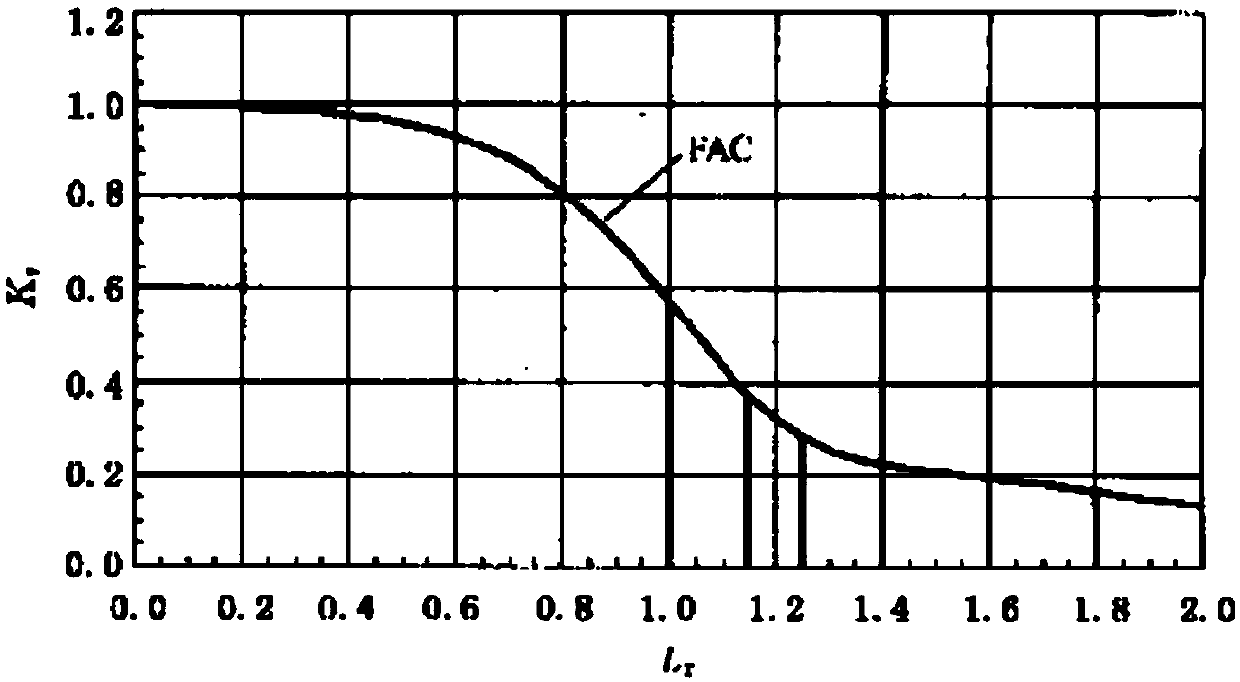

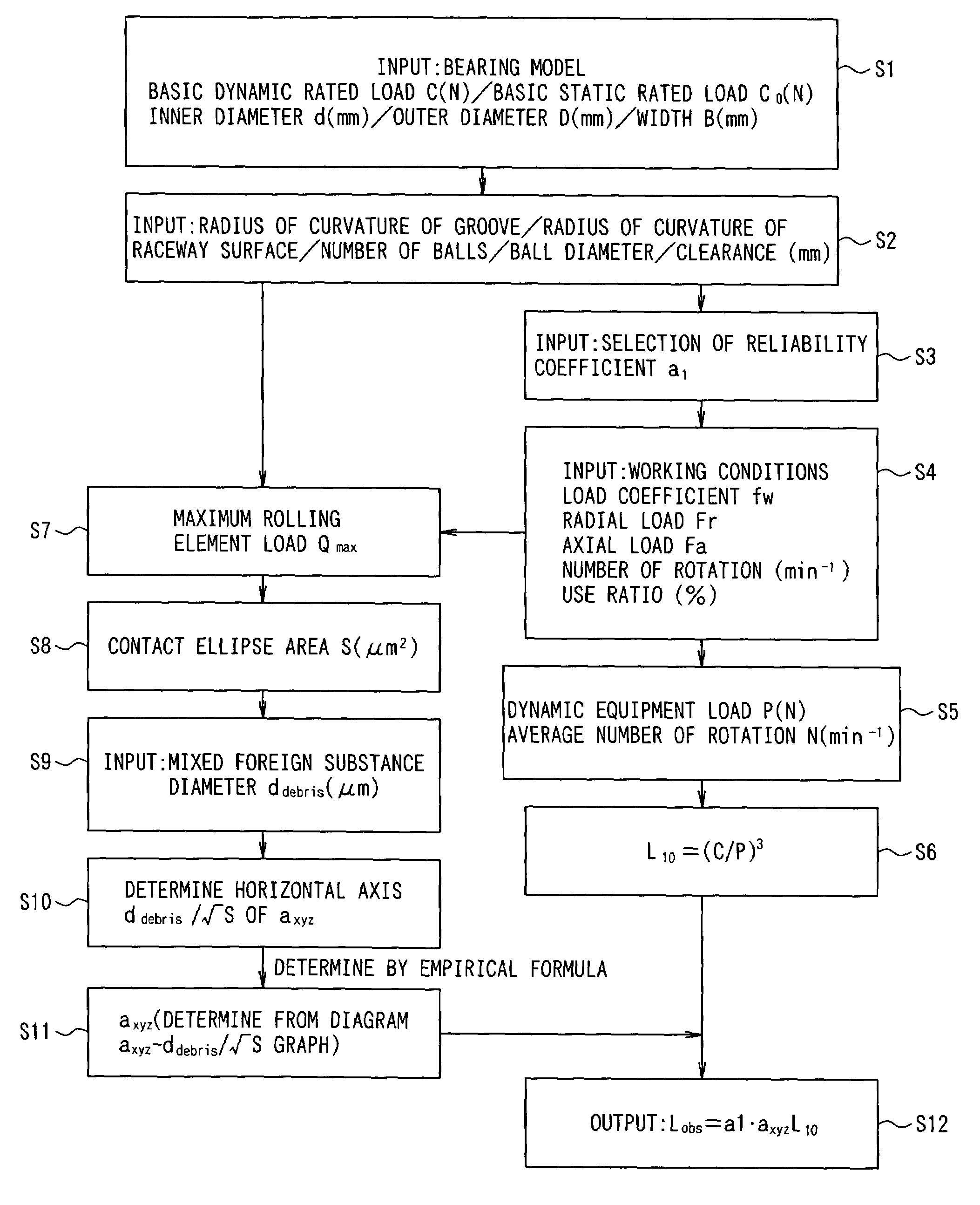

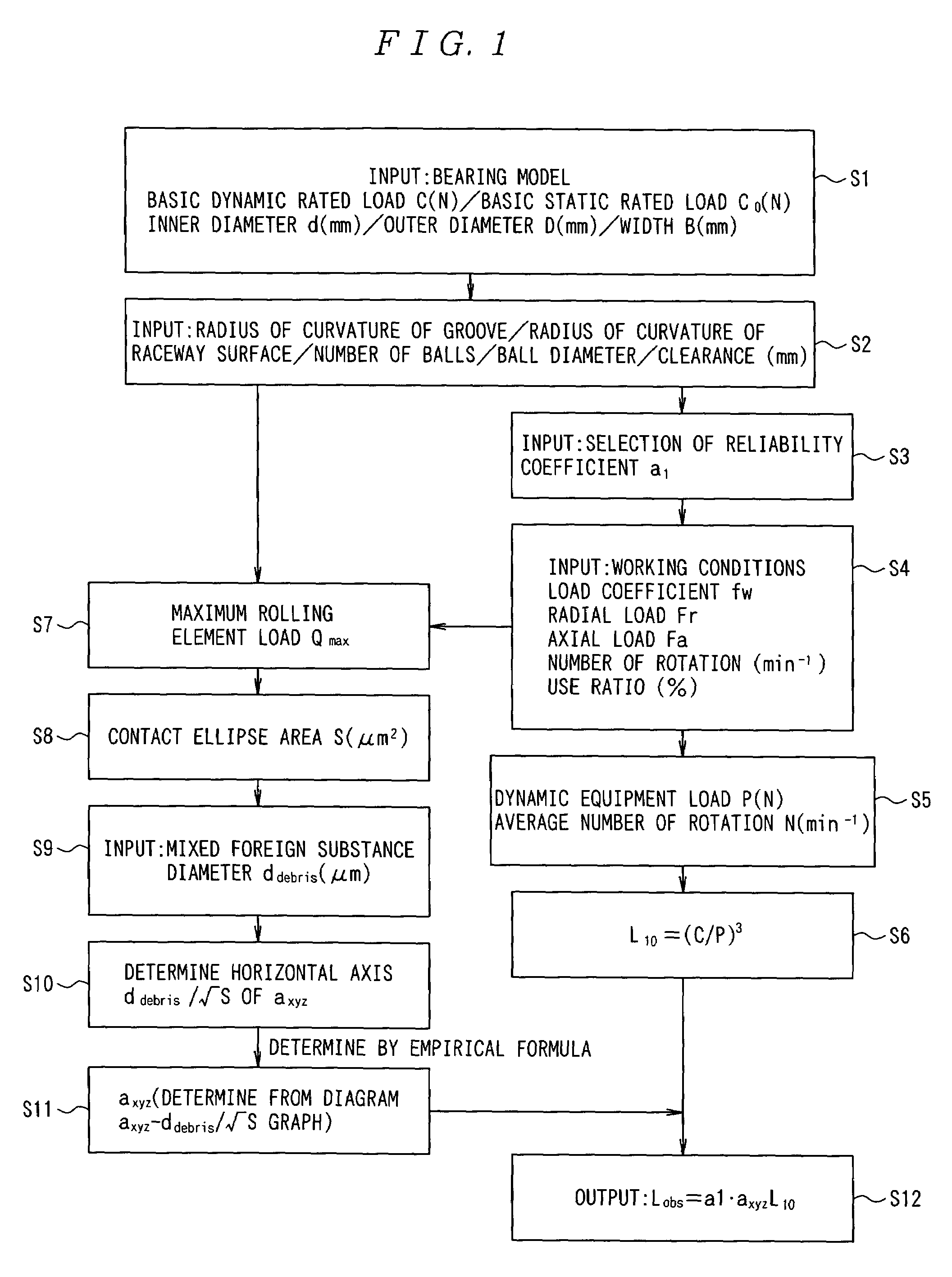

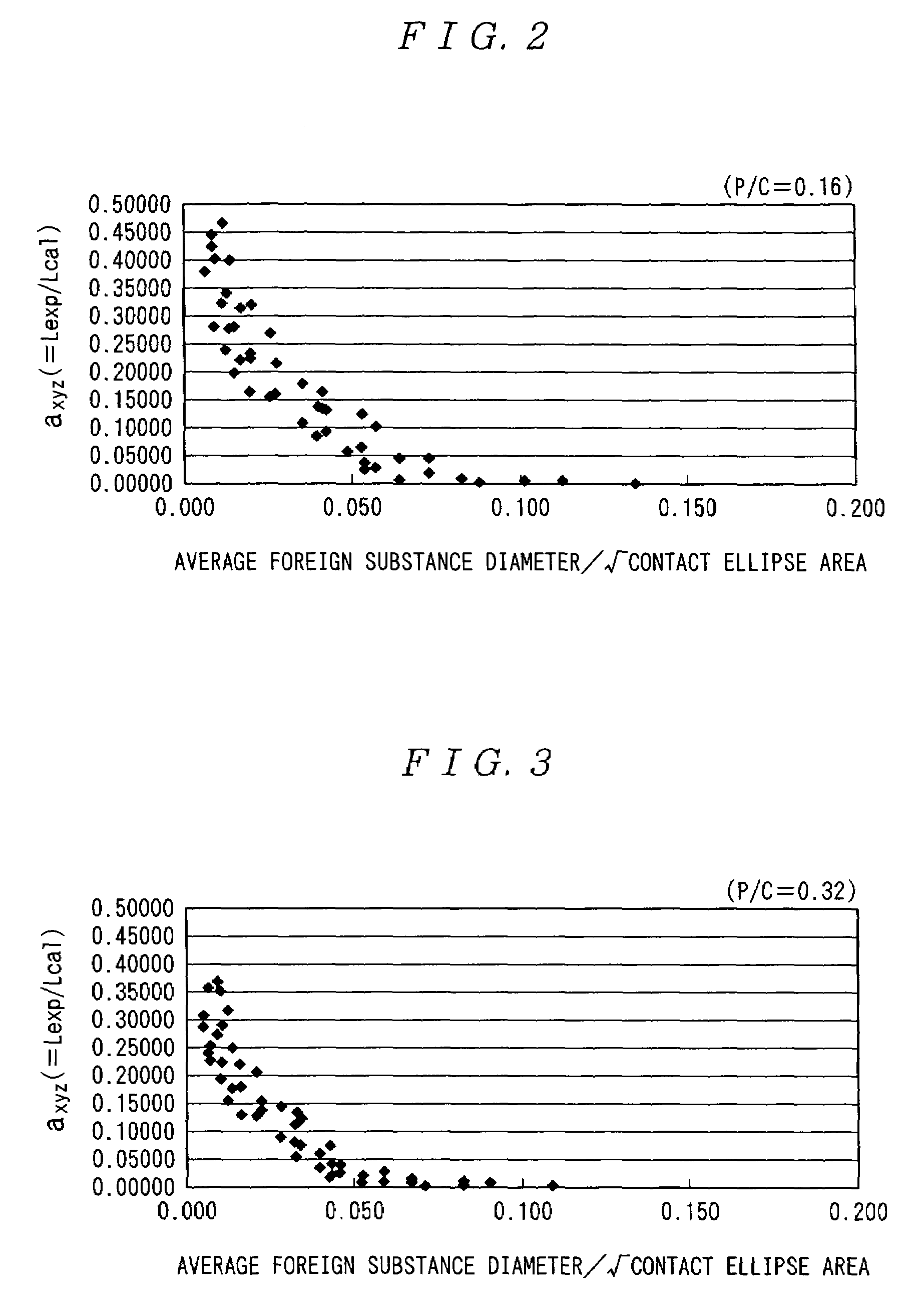

Life predicting method for rolling bearing, life predicting device, rolling bearing selecting device using life predicting device, program and environment coefficient determining method

InactiveUS7305330B2Improve accuracyLife predictionRolling contact bearingsComputation using non-denominational number representationEllipseEngineering

To predict a correction rated life at high accuracy. A life predicting device executes step S1, step S2, step S4 for inputting specification information including a basic dynamic rated load C and basic static rated load C0, step 5 for computing a dynamic equivalent load P based on the specification information. step S3 for setting a reliability factor a1, step S7 and step S8 for determining a contact ellipse area S, step S9 for inputting a foreign substance purchasing diameter ddebris (“debris” means “foreign substance”), step 10 for determining a standardized foreign substance diameter (ddebris / √ S), step S11 for setting a life correction coefficient axyz based on the standardized foreign substance diameter, and step S6 and step S12 for calculating a correction rated life Lnm based on the reliability coefficient, the life correction coefficient, the basic dynamic rated load and the dynamic equivalent load and the like.

Owner:NSK LTD

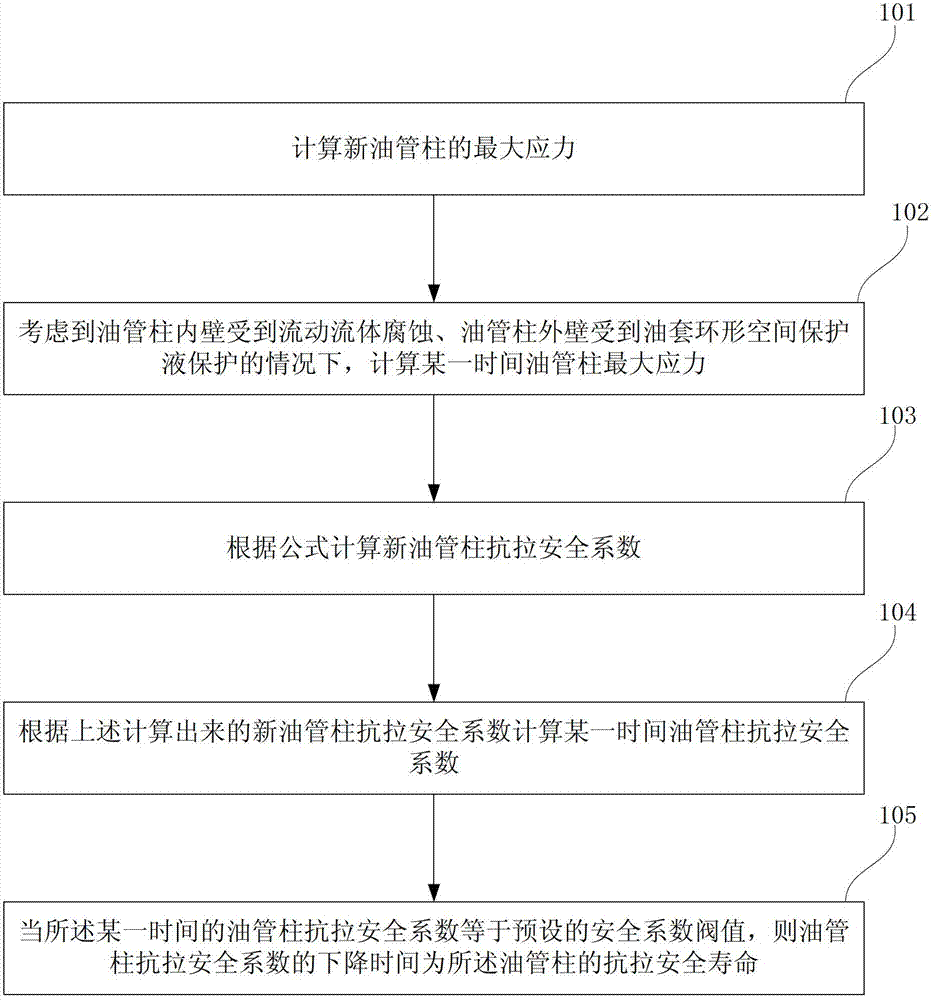

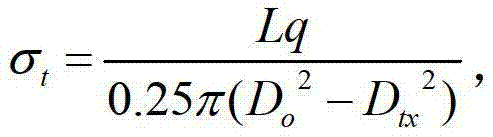

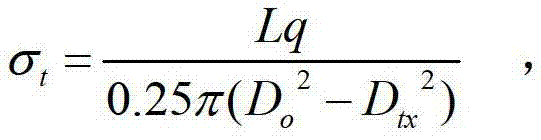

Tubing string service life prediction method

ActiveCN103206205ALife PredictionLife prediction of tubing string life is more accurate and reasonableConstructionsComputer scienceOil exploration

The invention relates to the technical field of oil exploration, in particular to a tubing string service life prediction method. The tubing string service life prediction method comprises the steps of calculating maximum stress of a new tubing string; calculating maximum stress of the tubing string at some time; calculating a tensile safety coefficient of the new tubing string; calculating a tensile safety coefficient of the tubing string at some time according to the calculated tensile safety coefficient of the new tubing string; and enabling fall time of the tensile safety coefficient of the tubing string to be tensile safety service life when the tensile safety coefficient of the tubing string at some time is equal to a preset safety coefficient threshold.

Owner:PETROCHINA CO LTD

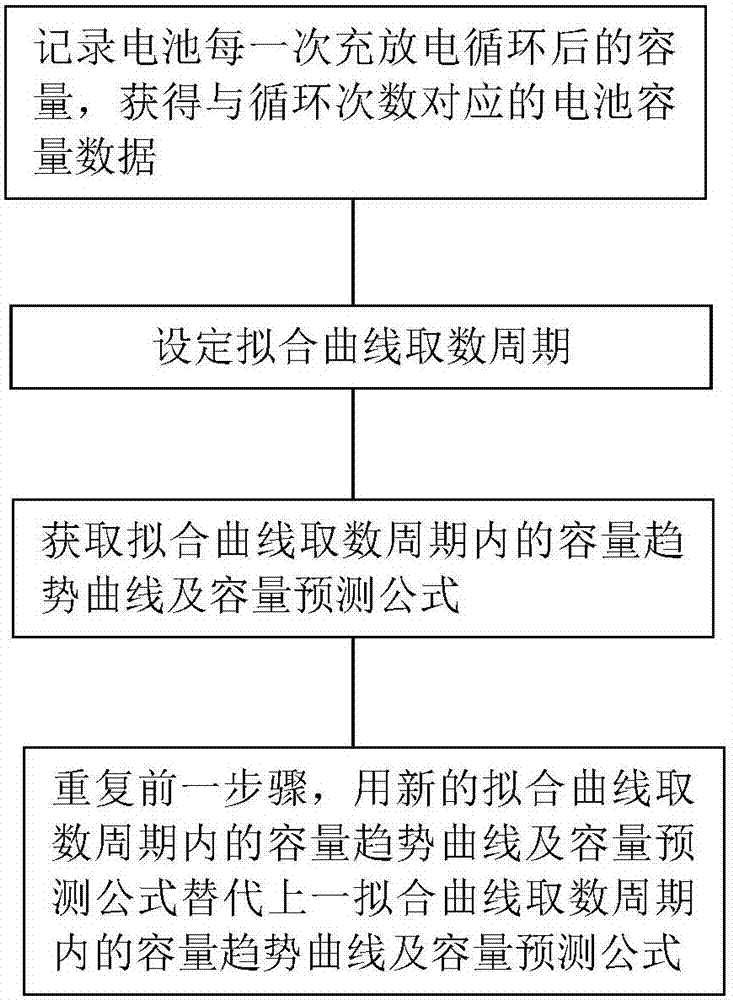

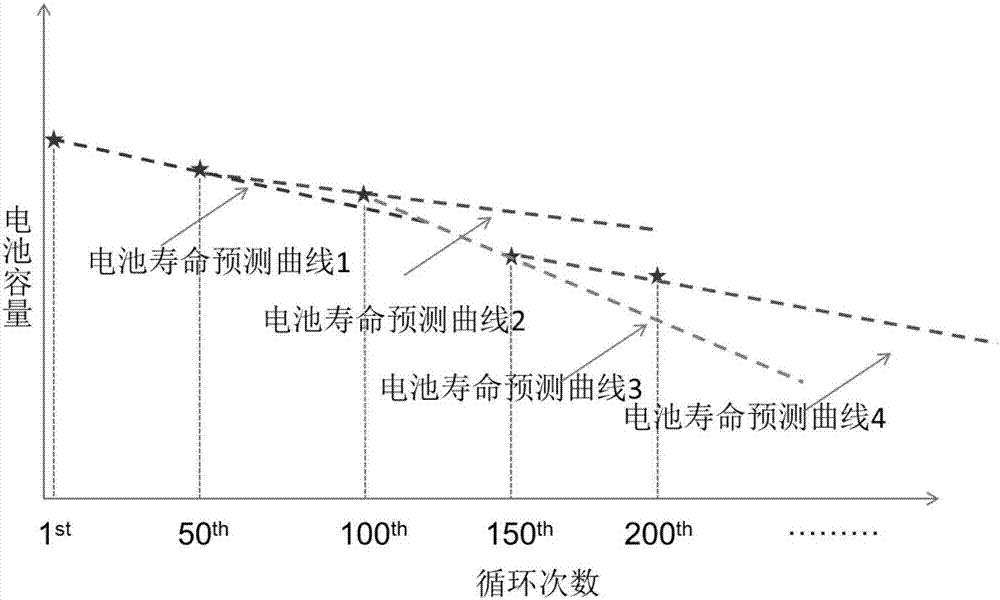

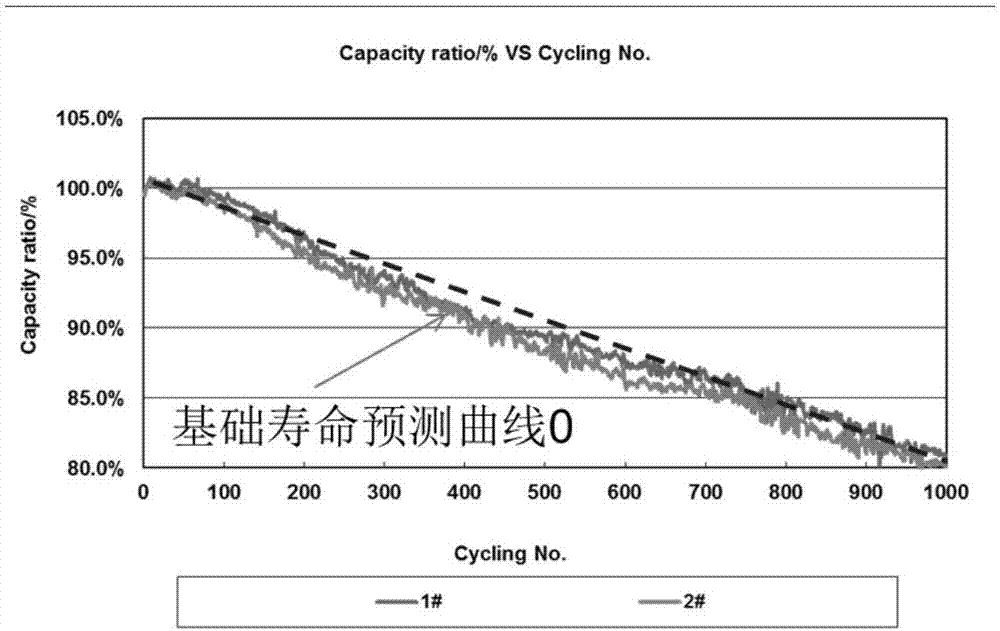

Service life prediction method of secondary cell and power supply management method

A service life prediction method of a secondary cell and a power supply management method are disclosed. The service life prediction method comprises the following steps of recording a capacity after each charge and discharge cycle during usage of the cell and acquiring cell capacity data corresponding to a cycle frequency; setting a fitting curve fetch period; acquiring a corresponding capacity trend curve and a capacity prediction formula in the fitting curve fetch period; and when the cycle frequency reaches the fitting curve fetch period, repeating a step3, and using the capacity trend curve and the capacity prediction formula acquired by a next fitting curve fetch period to replace the capacity trend curve and the capacity prediction formula acquired by a previous fitting curve fetch period. In the invention, according to an actual usage condition, prediction is performed, and a service life prediction curve can be continuously corrected and the capacity prediction formula can be updated so that the curve and the formula approach to the actual usage condition as close as possible and a cell service life is accurately predicted. By using the power supply management method based on the prediction method, according to the actual usage condition of the cell, correction and strategy adjusting are performed on a usage preference of the cell, and a cycle life of the cell is prolonged.

Owner:ZHUHAI COSMX BATTERY CO LTD

Vibration suppressing device

InactiveUS8700201B2Possibility of generating “ chatter vibration ”Improve accuracyProgramme controlFlow propertiesRotation velocityControl theory

A vibration suppressing device includes a memory unit storing a stable rotation speed calculated by an arithmetical unit in association with a rotation speed range that includes the stable rotation speed, in which, when a command rotation speed that is a rotation speed of a rotary shaft is inputted in starting machining operation by rotation of the rotary shaft and, the arithmetical unit determines whether the command rotation speed is included in the rotation speed range or not, reads out the stable rotation speed when the command rotation speed is included in the rotation speed range and outputs the stable rotation speed to an NC device instead of the command rotation speed, and starts the machining operation at the stable rotation speed.

Owner:OKUMA CORP

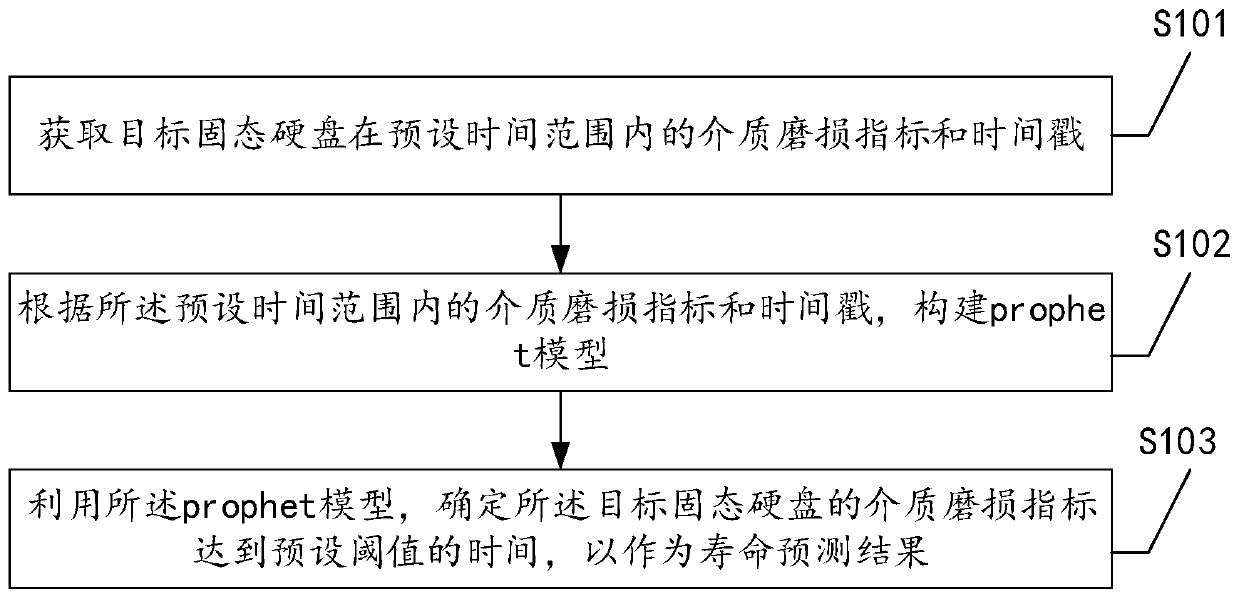

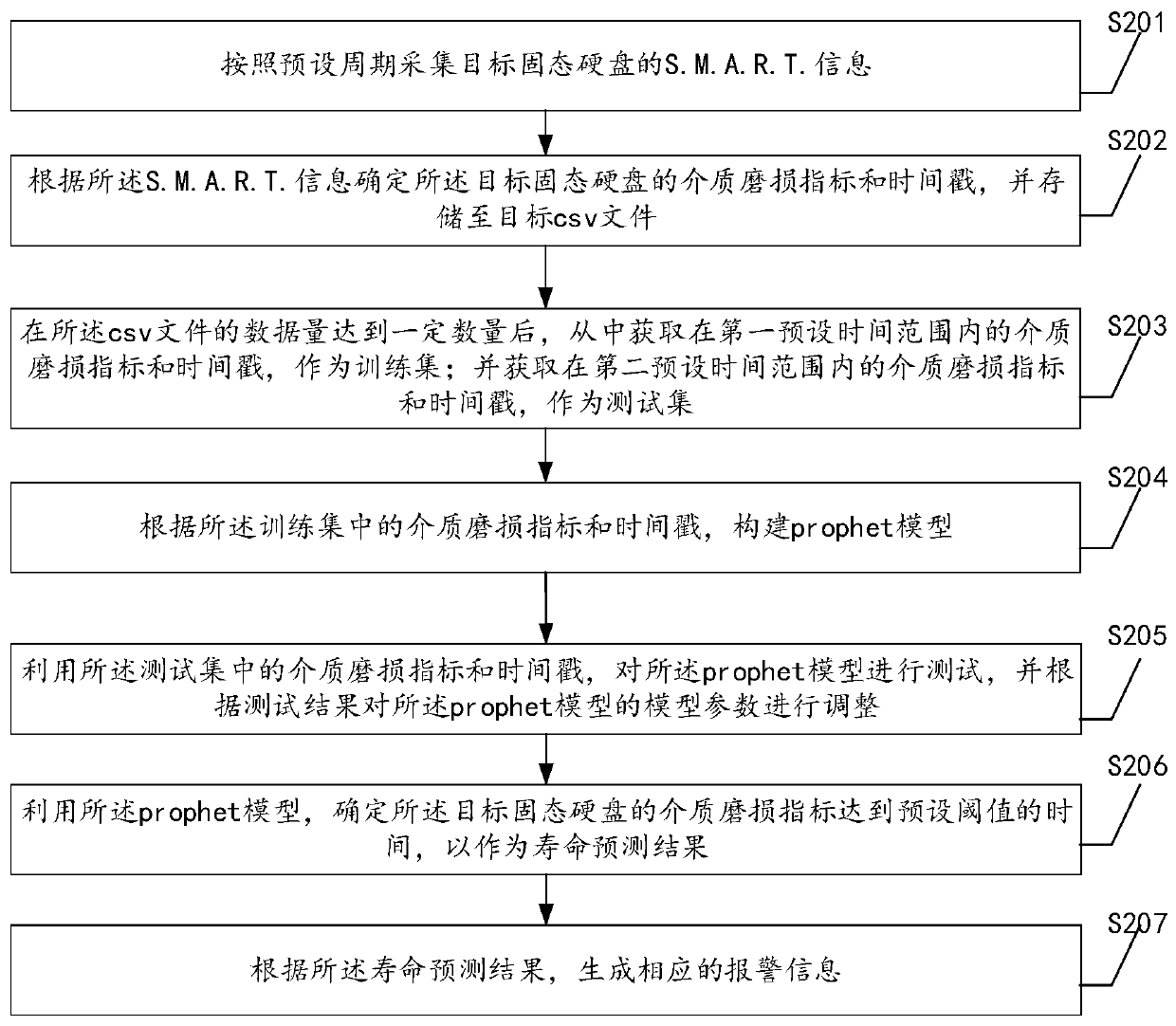

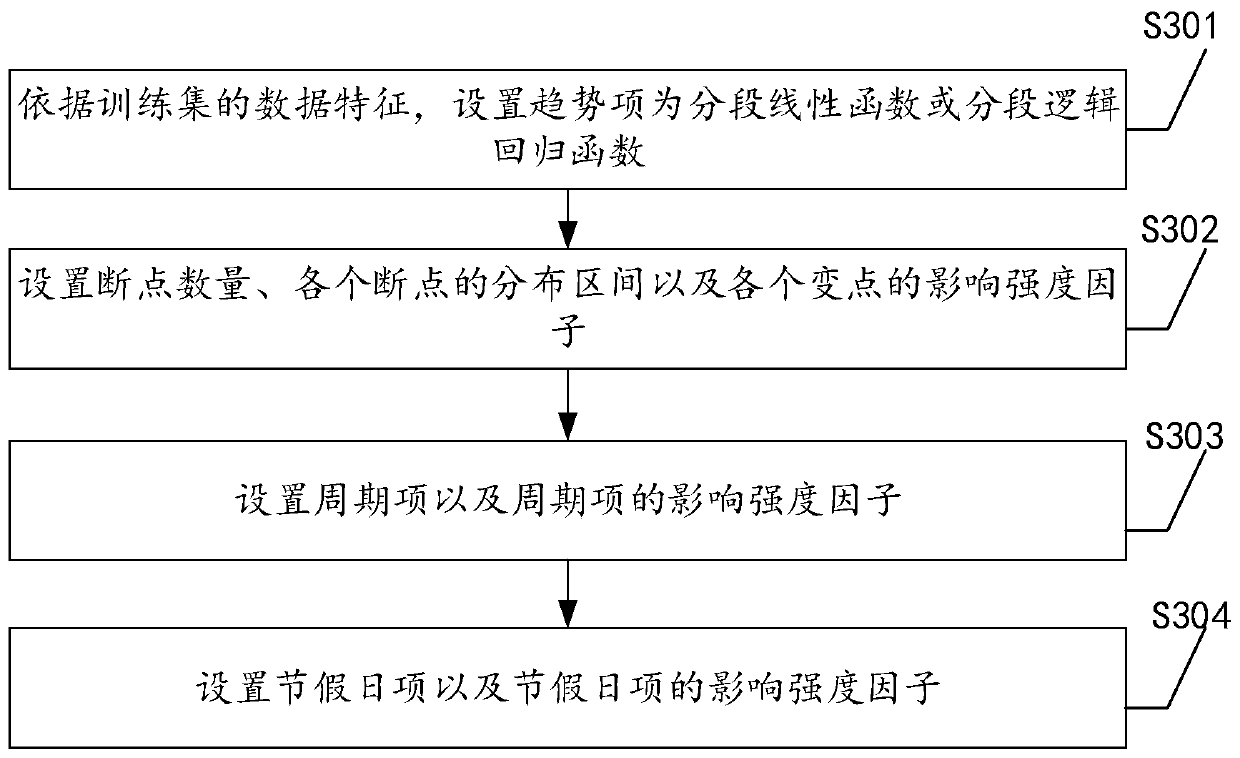

Method, device and apparatus for predicting service life of solid state disk

InactiveCN110413430ALife PredictionAccurately Predict LifespanReliability/availability analysisComplex mathematical operationsTime rangeTimestamp

The invention discloses a solid state disk life prediction method, device and apparatus and a readable storage medium. According to the scheme, a medium abrasion index and a timestamp of a solid statedisk within the preset time range are obtained by utilizing physical characteristics that programming and erasing cycle index of the solid state disk is fixed. A prophet model is constructed based on the medium abrasion index and the timestamp so as to predict the service life of the solid state disk. The prophet model can detect the trend change, periodic change and holiday change of the wear degree of the solid state disk. Compared with a simple linear formula, scene adaptability is stronger, so that service life of the solid state disk can be accurately predicted, a user is assisted to know the service condition of the solid state disk, loss caused by damage of the solid state disk is avoided, and safety of data in the solid state disk is remarkably improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

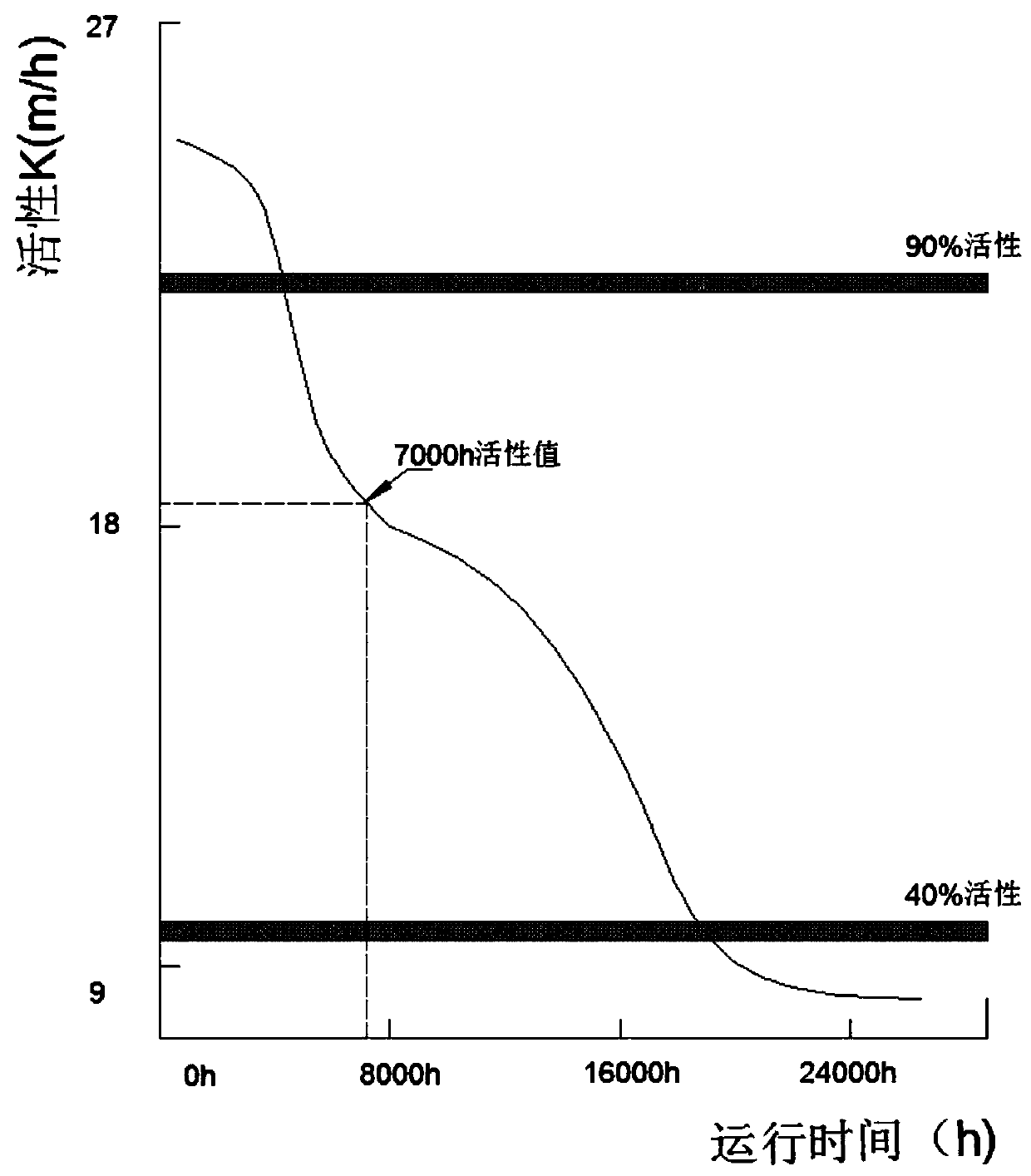

Method for predicting life of SCR denitration catalyst in power plant

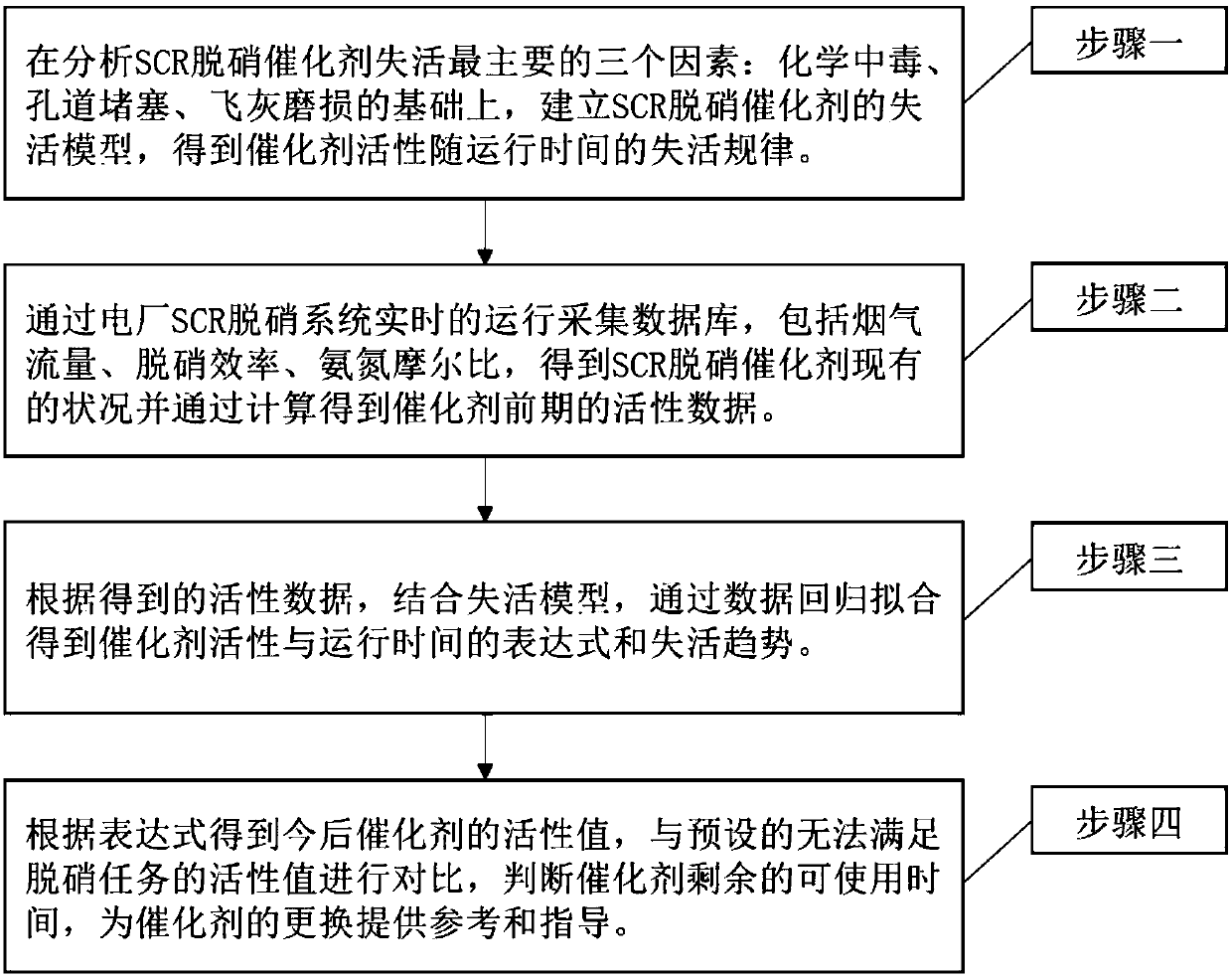

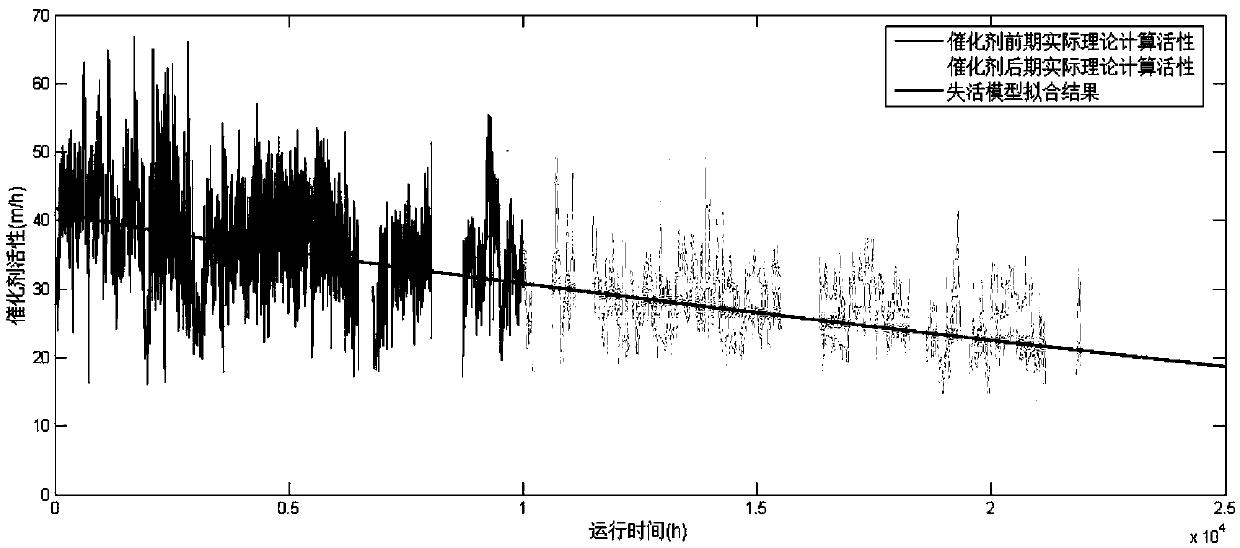

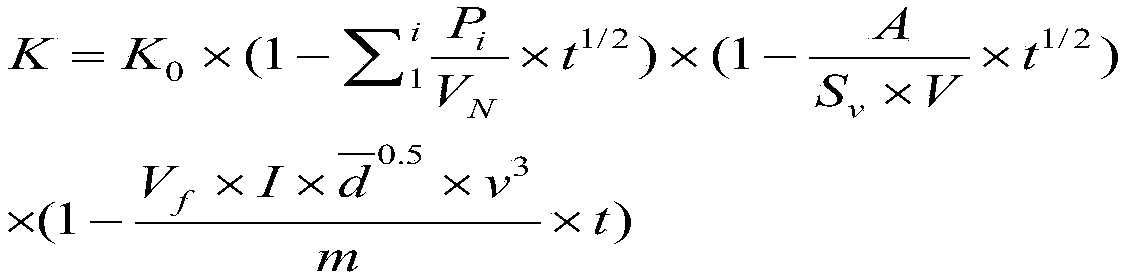

InactiveCN107679359ALife PredictionJudgment of lifeChemical property predictionDesign optimisation/simulationChemical poisoningRunning time

The invention relates to a method for predicting the life of an SCR denitration catalyst in a power plant. The method comprises the following steps: step 1, on the basis of analyzing the three most important factors in deactivation of the SCR denitration catalyst, establishing a deactivation model of the SCR denitration catalyst, wherein the three factors include chemical poisoning, porous channelblockage and fly ash abrasion; step 2, calculating an activity value and an activity decreasing trend in an operation process of the SCR denitration catalyst; step 3, according to acquired activity data, combining the deactivation model to obtain a relational expression between the catalyst activity and the operation time through a previous actual data regression fitting deactivation model; and step 4, acquiring the activity value of the catalyst in the future according to the expression, and comparing the activity value with preset activity values that cannot meet denitration tasks to judgethe remaining available time of the catalyst. According to the method disclosed by the invention, the activity values of the SCR denitration catalyst at different times can be accurately predicted byusing operation data acquired on site in combination with the deactivation model, and the life of the catalyst can be judged.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

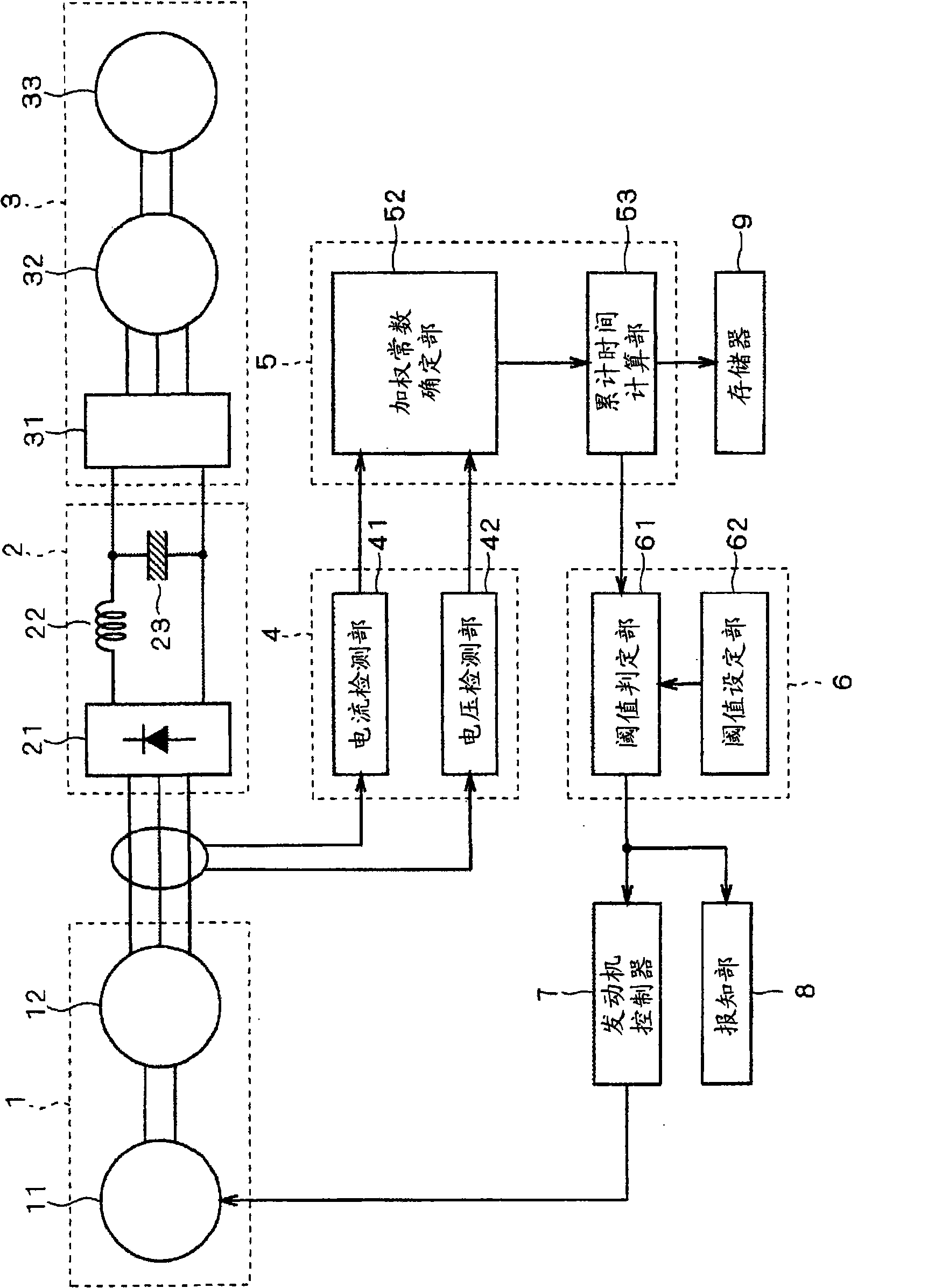

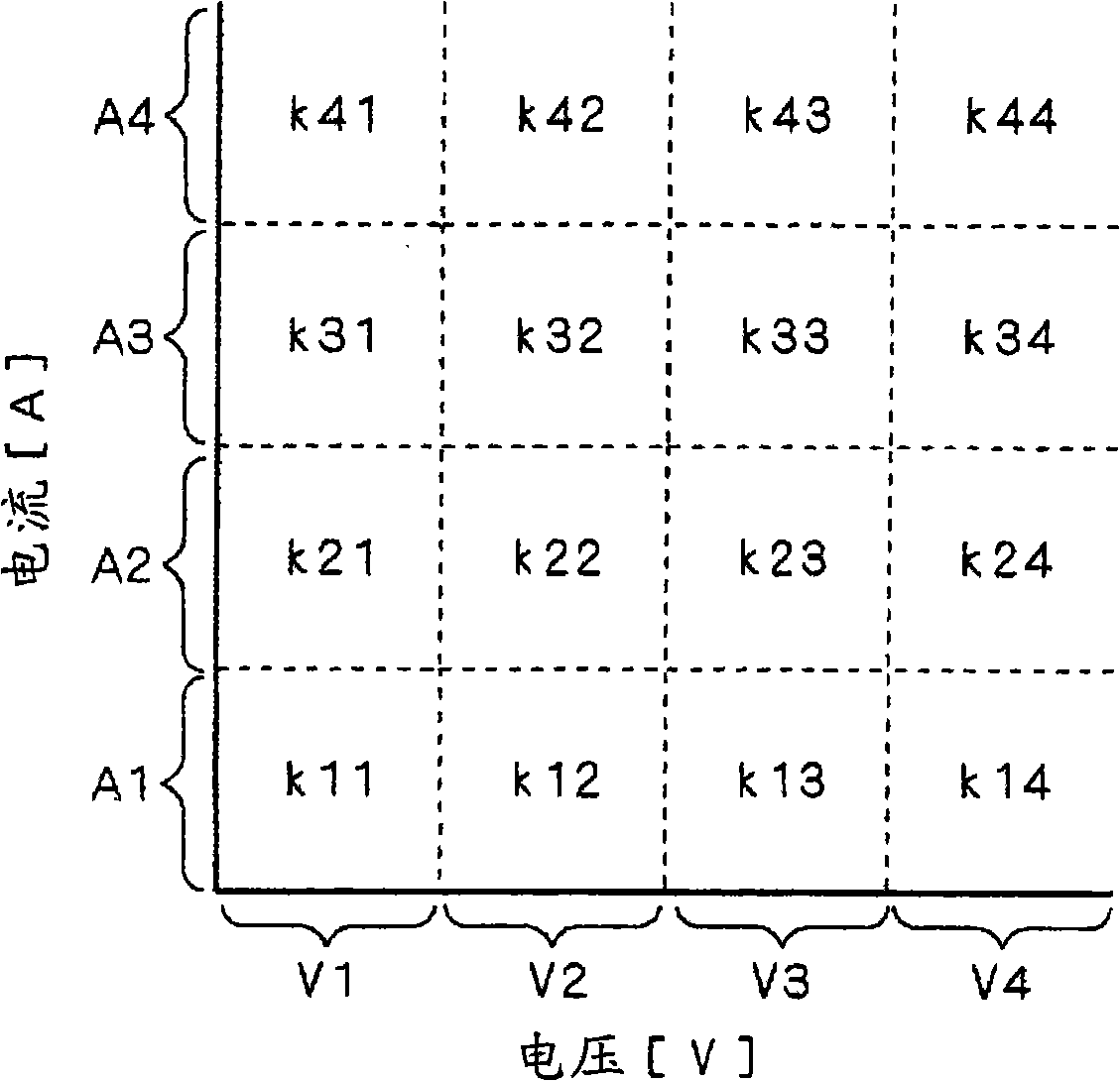

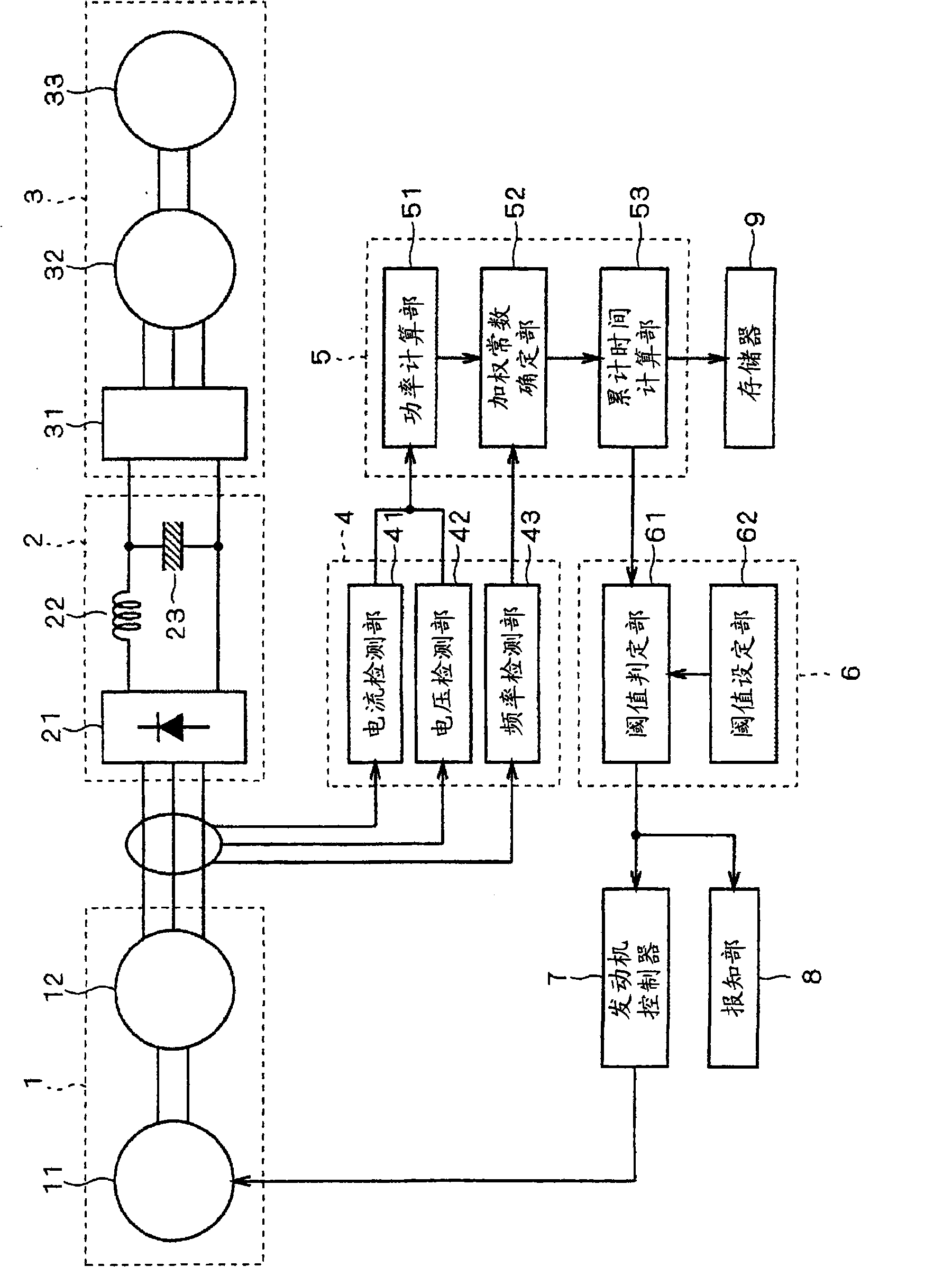

Engine life predication apparatus and refrigerator

InactiveCN101542261ALow costImprove reliabilityEngine testingDomestic refrigeratorsEngineeringRefrigerated temperature

An engine life prediction apparatus produced at a low cost and having a high reliability is provided. A current detecting section (41) and a voltage detecting section (42) detect the value of a current and the value of a voltage which are outputted by an engine generator (1), respectively. An arithmetic section (5) determines a weight constant from the current value and the voltage value, assigns the weight to the operating time of an engine (11) by using the weight constant, and integrates the weighted operating time to calculate the integrated time. A judgment section (6) compares the integrated time with a reference time and, when judging that the integrated time exceeds the reference time, notifies it to a report section (8). The report section (8) having received the notification reports it to the outside. The current detecting section (41) and the voltage detecting section (42) can be configured by an electrical circuit. Thus, the engine life can be predicted at the low cost and with the high reliability.

Owner:DAIKIN IND LTD

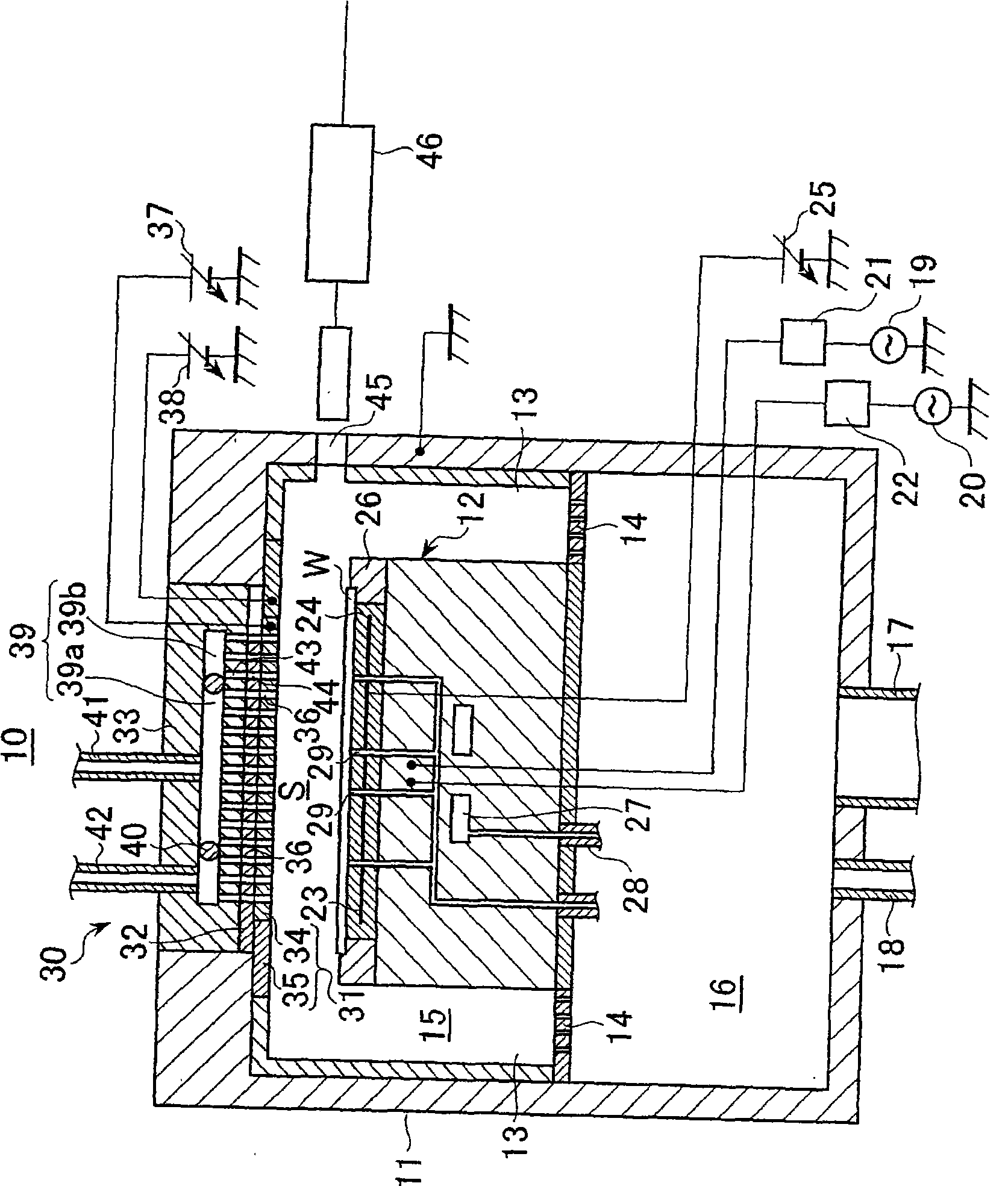

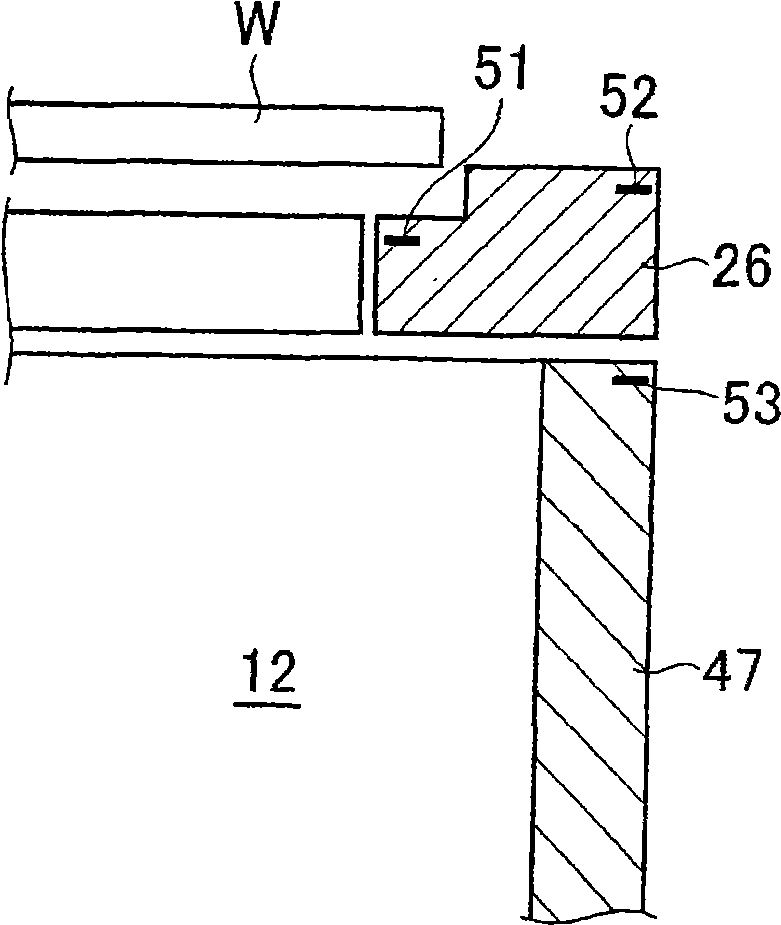

Plasma processing apparatus, chamber internal part, and method of detecting longevity of chamber internal part

InactiveCN101546705ALife testingAvoid wastingElectric discharge tubesAnalysis by electrical excitationEngineeringProduct gas

The present invention provides a plasma processing apparatus that can accurately detect the longevity of a chamber internal part to eliminate the waste of the replacement of the chamber internal part that has not reached its end of longevity and prevent the occurrence of troubles caused by continuously using the chamber internal part that has reached its end of longevity. The focus ring 26 and the like chamber internal parts for plasma processing apparatus, use the substrate processing apparatus 10 of the chamber internal part to perform RIE (reactive ion etching) processing to the wafer W, wherein, the longevity detecting elemental layers 51 and 52 are comprised of elements different from the constituted material, for example, scandium (Sc), for monitoring the luminous spectrum of the processing gas by using the plasma irradiance light splitter 46, the longevity of the focus ring 26 and the like chamber internal parts are detected by detected the light spectrum caused by the longevity detecting elemental layers 51 and 52.

Owner:TOKYO ELECTRON LTD

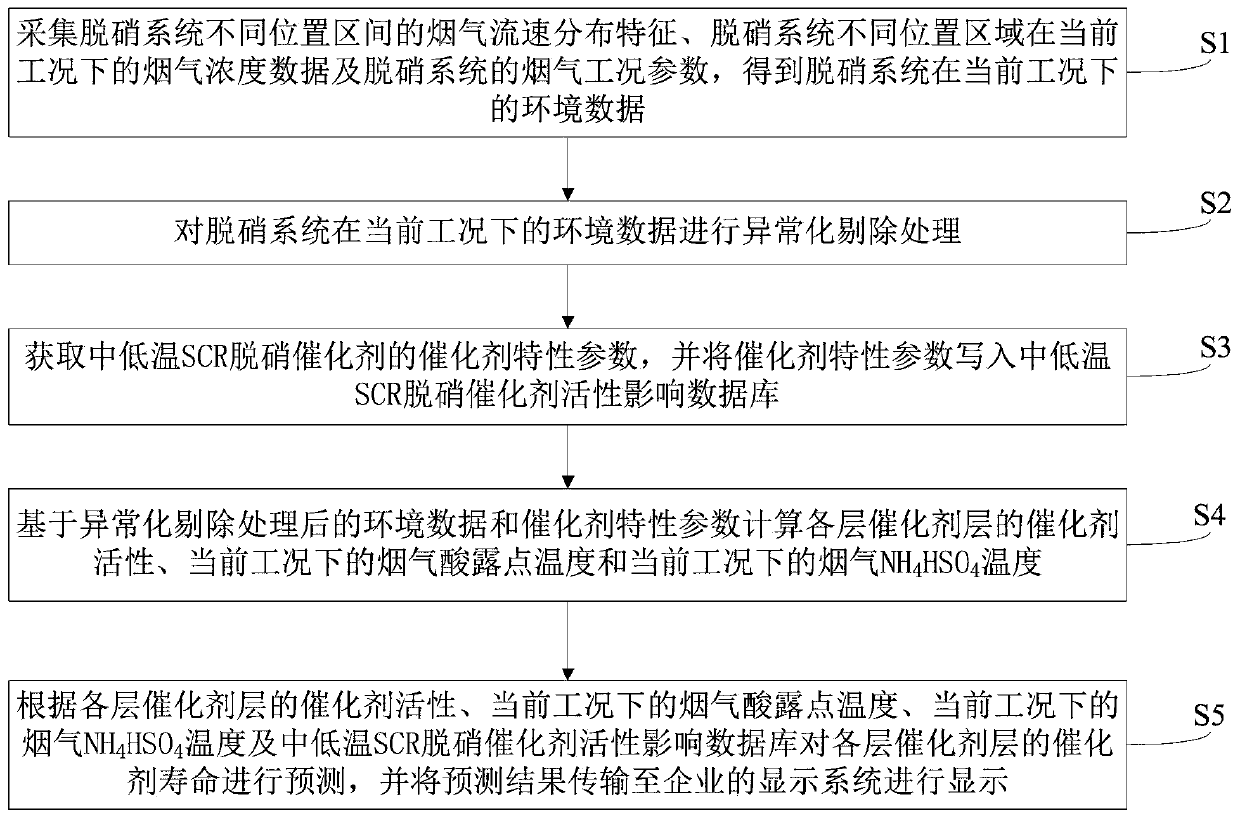

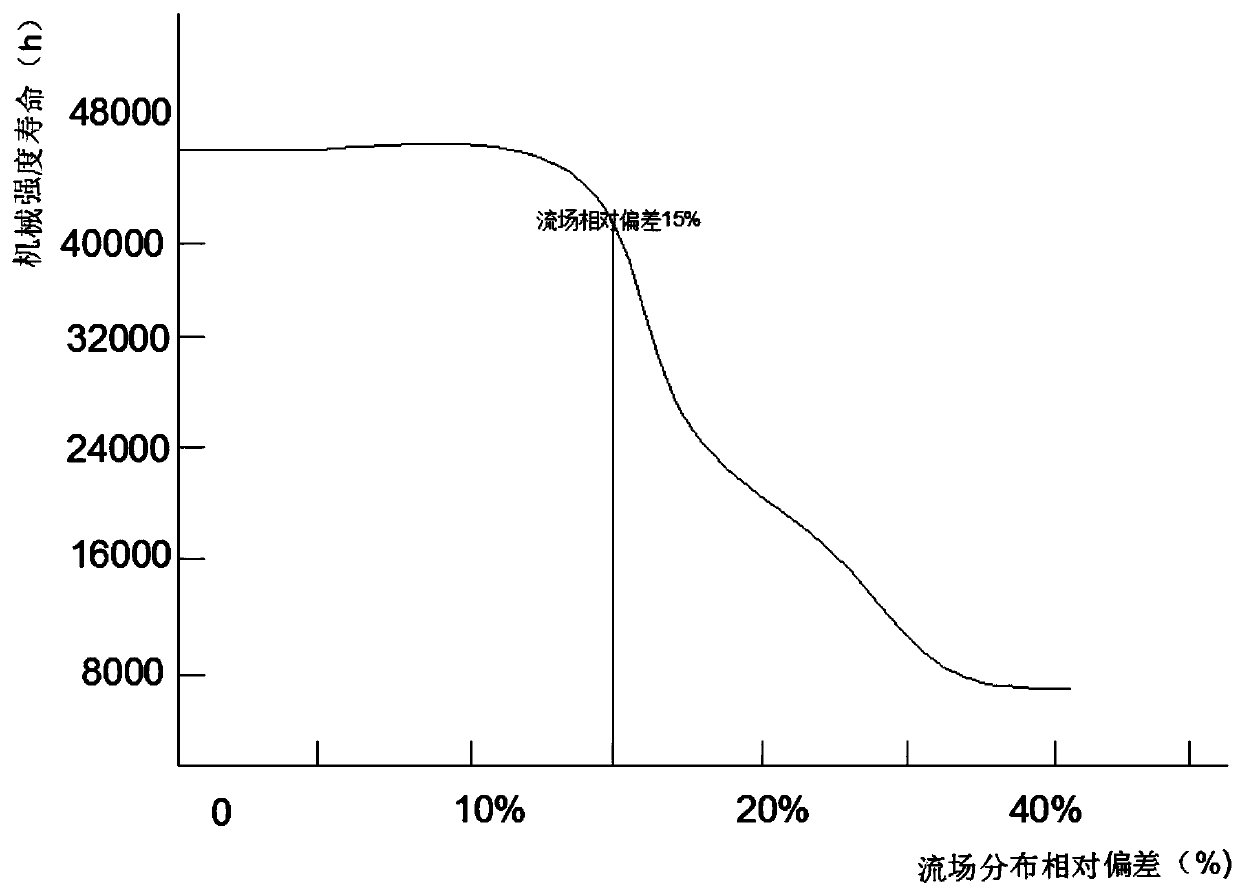

Method and system for predicting service life of medium-low-temperature SCR denitration catalyst

ActiveCN110580936ALife PredictionEfficient assessment of catalytic activity deactivationChemical property predictionMeasurement devicesFlue gasProcess engineering

The invention provides a method and a system for predicting the service life of a medium-low temperature SCR denitration catalyst, which belong to the field of atmospheric pollutant denitration management and aim to solve the problems that the conventional method cannot perform online prediction, has certain limitation and is not suitable for the medium-low temperature SCR denitration catalyst. The method comprises the following steps of: acquiring environmental data of the denitration system under the current working condition, performing abnormal elimination processing on the environmental data of the denitration system under the current working condition, obtaining catalyst characteristic parameters of the medium-low temperature SCR denitration catalyst and writing the catalyst characteristic parameters into a medium-low temperature SCR denitration catalyst activity influence database, calculating the catalyst activity of each catalyst layer, the flue gas acid dew point temperatureunder the current working condition and the flue gas NH4HSO4 dew point temperature under the current working condition on the basis of the environmental data and the catalyst characteristic parametersafter abnormal elimination processing, and predicting the catalyst life of each catalyst layer according to the calculation result and the medium-low temperature SCR denitration catalyst activity influence database, and transmitting the prediction result to a display system of an enterprise for display.

Owner:SHANXI PULI ENVIRONMENT ENG CO LTD

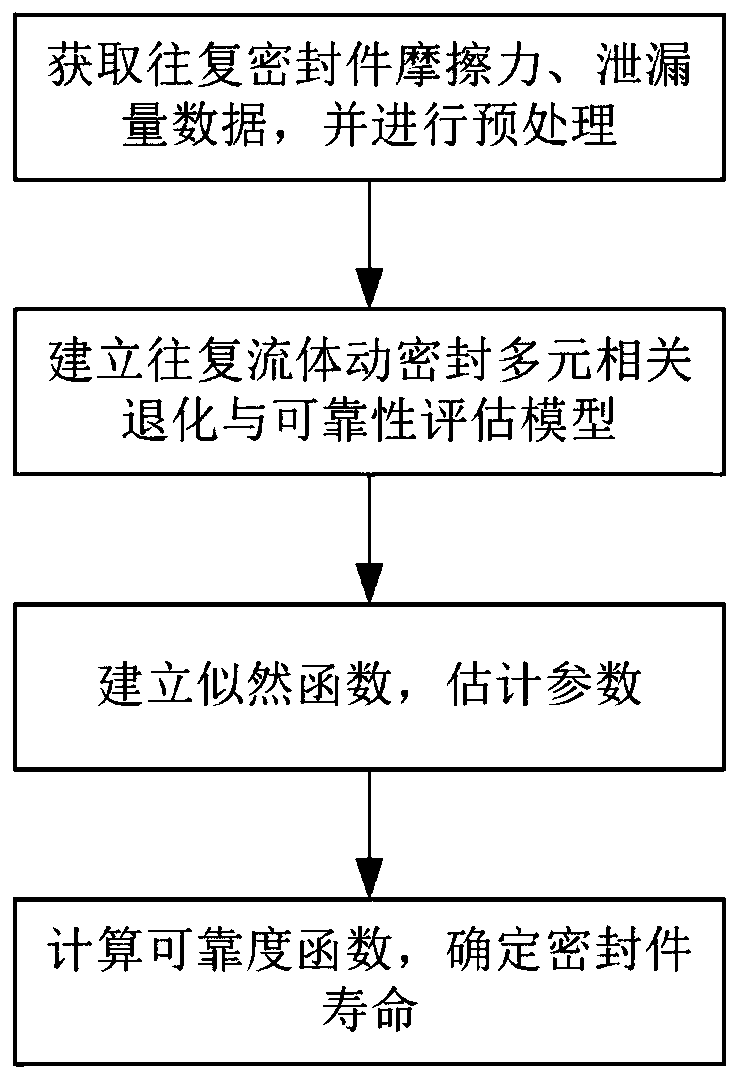

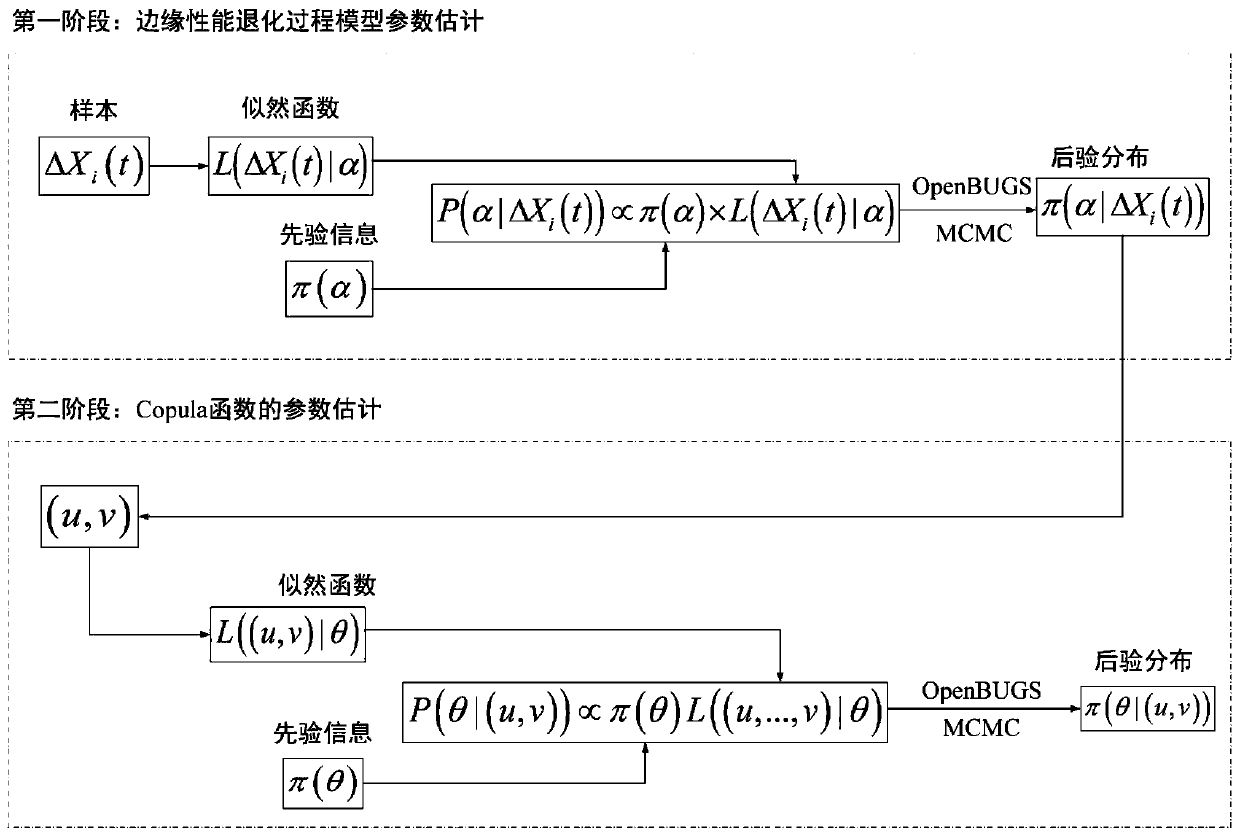

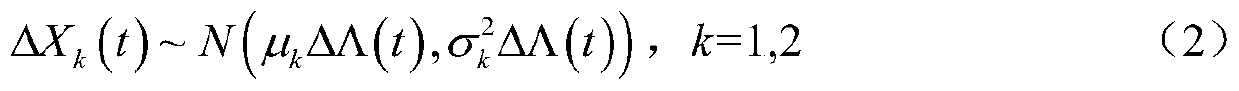

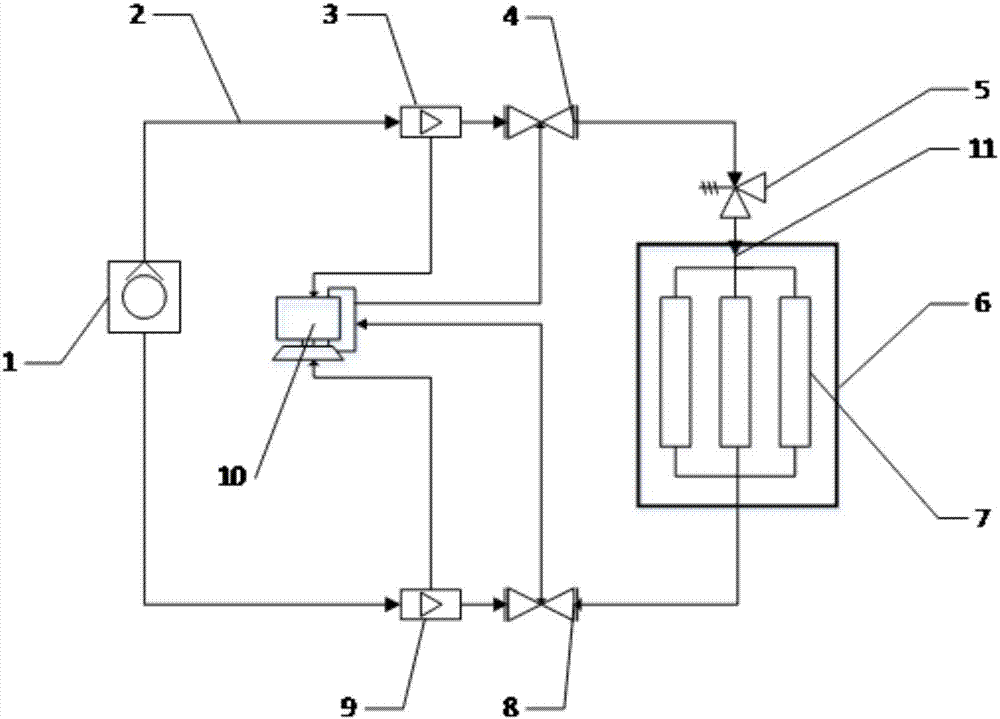

A reciprocating fluid dynamic seal life prediction method based on multivariate correlation degradation modeling

InactiveCN109948295ALife PredictionIncrease flexibilityForecastingSpecial data processing applicationsMachine partsEngineering

The invention provides a reciprocating fluid dynamic seal service life prediction method based on multivariate correlation degradation modeling, and belongs to the field of reciprocating seal reliability evaluation and service life prediction of motion machine parts. The method comprises the steps that 1, degradation amount data of friction force and leakage amount are collected; Step 2, accordingto the distribution function of the Frank Copula, establishing a joint distribution function of the friction force degradation increment and the leakage rate degradation increment; Step 3, establishing a reciprocating seal multivariate correlation degradation model; 4, establishing a log-likelihood function of the multivariate random correlation degradation process model, and obtaining an estimation result of a parameter sum through degradation data; and 5, calculating the reliability of the reciprocating sealing element by adopting a Monte Carlo method in combination with the multivariate related degradation model, and obtaining the service life of the reciprocating sealing element. The coupling relation between the two performance degradation indexes of the friction force and the leakage rate is comprehensively considered, the sealing element degradation process model is built based on the degradation data, the calculation process is simple and convenient, flexibility is high, and engineering practice is approached.

Owner:BEIHANG UNIV

Ageing test device for PE pipes under fluctuating pressure and lifetime prediction method

PendingCN107367432AApplicable to the actual situationIn line with actual working conditionsMaterial strength using repeated/pulsating forcesEngineeringElectric control

The invention relates to an ageing test device for PE pipes under fluctuating pressure. A pressure supply device provides gas load of a whole pipe, air pressure in the pipe is adjusted by combined action of a pressure sensor, an electric control valve and a central controller, a pressure injecting and relief process is repeated to form fatigue circulating load, a test pipe section is aged by an ageing device, by the device, research on existing single-factor ageing is changed, various environmental stresses are combined together, and therefore, a laboratory environment which simulates actual working conditions of an urban natural gas pipe is formed. The invention further relates to a lifetime prediction method for the PE pipes under fluctuating pressure. An aged pipe sample is taken out after a specific period, test on mechanical properties and physical and chemical properties is carried out to obtain related data, and change of ageing properties of optional environment temperatures and optional pipes is measured. Compared with an existing method, the lifetime prediction method has the advantages of simplicity, high efficiency and low cost.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

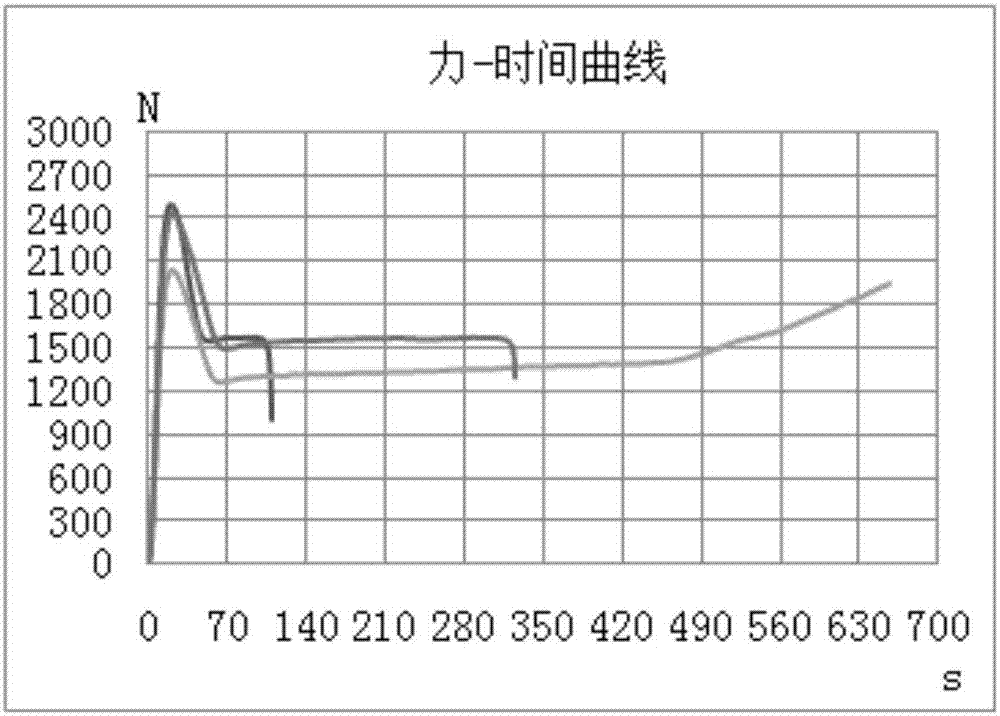

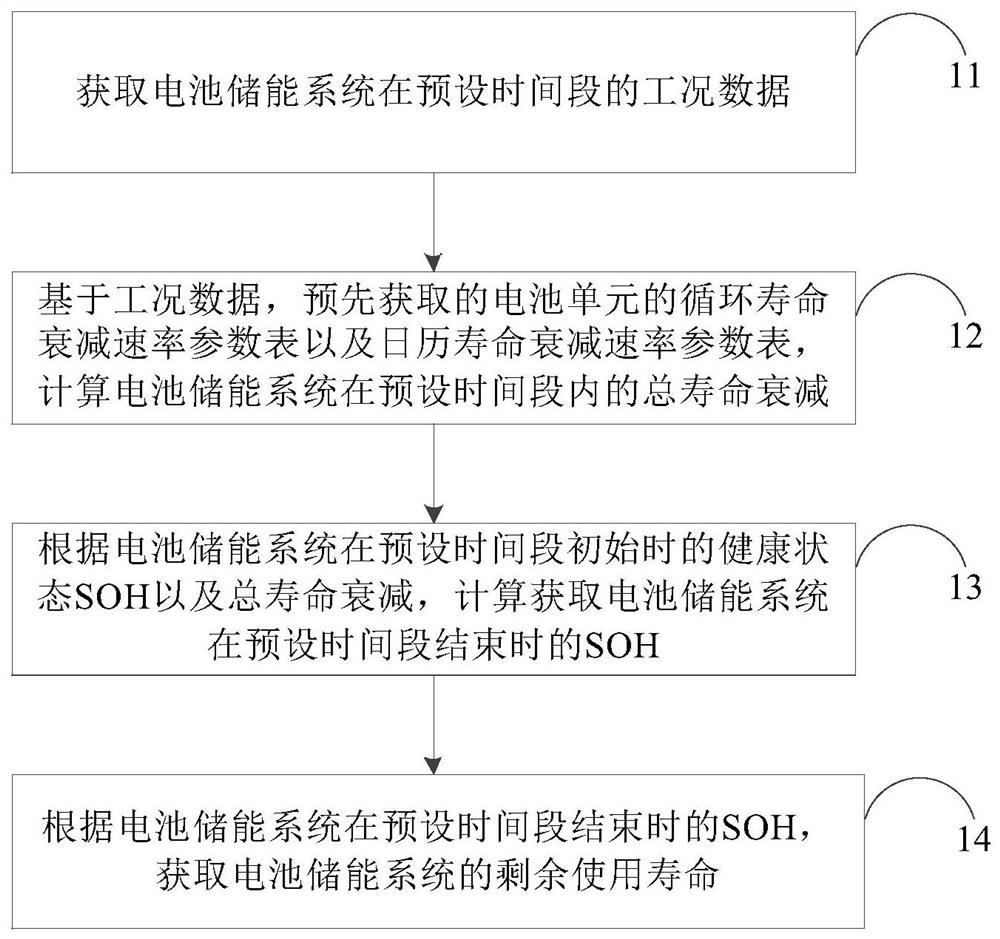

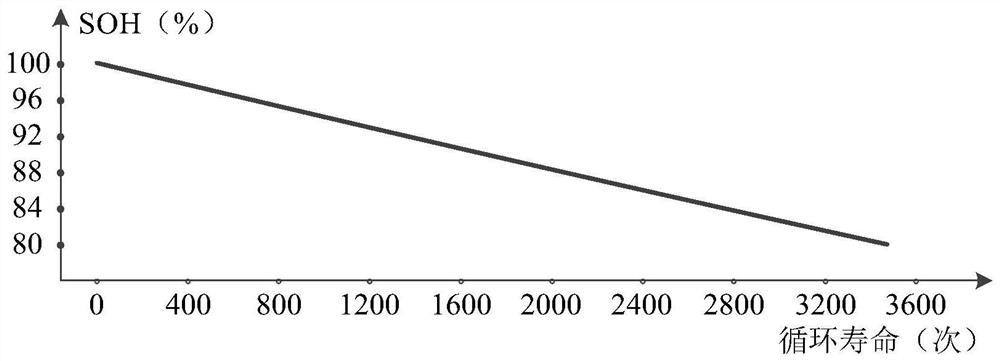

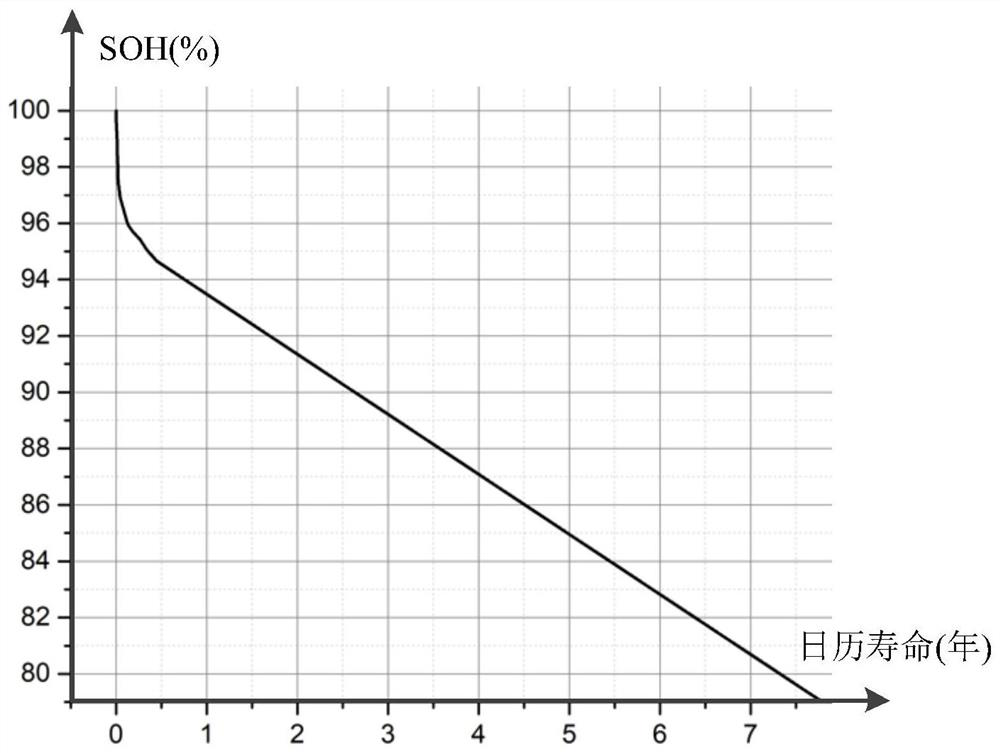

Method and device for predicting service life of battery energy storage system and equipment

The invention provides a method and device for predicting the service life of a battery energy storage system and equipment . The method comprises the following steps: acquiring working condition dataof the battery energy storage system comprising a plurality of battery units in a preset time period, and calculating the total life attenuation of the battery energy storage system in the preset time period based on the working condition data, a pre-acquired cycle life attenuation rate parameter table of the battery units and a calendar life attenuation rate parameter table, and then according to the SOH of the battery energy storage system at the beginning of the preset time period and the total life attenuation, calculating the SOH of the battery energy storage system at the end of the preset time period, and finally according to the SOH of the battery energy storage system at the end of the preset time period, acquiring the remaining service life of the battery energy storage system.According to the method, the SOH at the end of the preset time period is determined through the total life attenuation in the preset time period and the SOH at the beginning of the preset time period,so that the life of the battery energy storage system can be predicted more accurately.

Owner:BEIJING HYPERSTRONG TECH

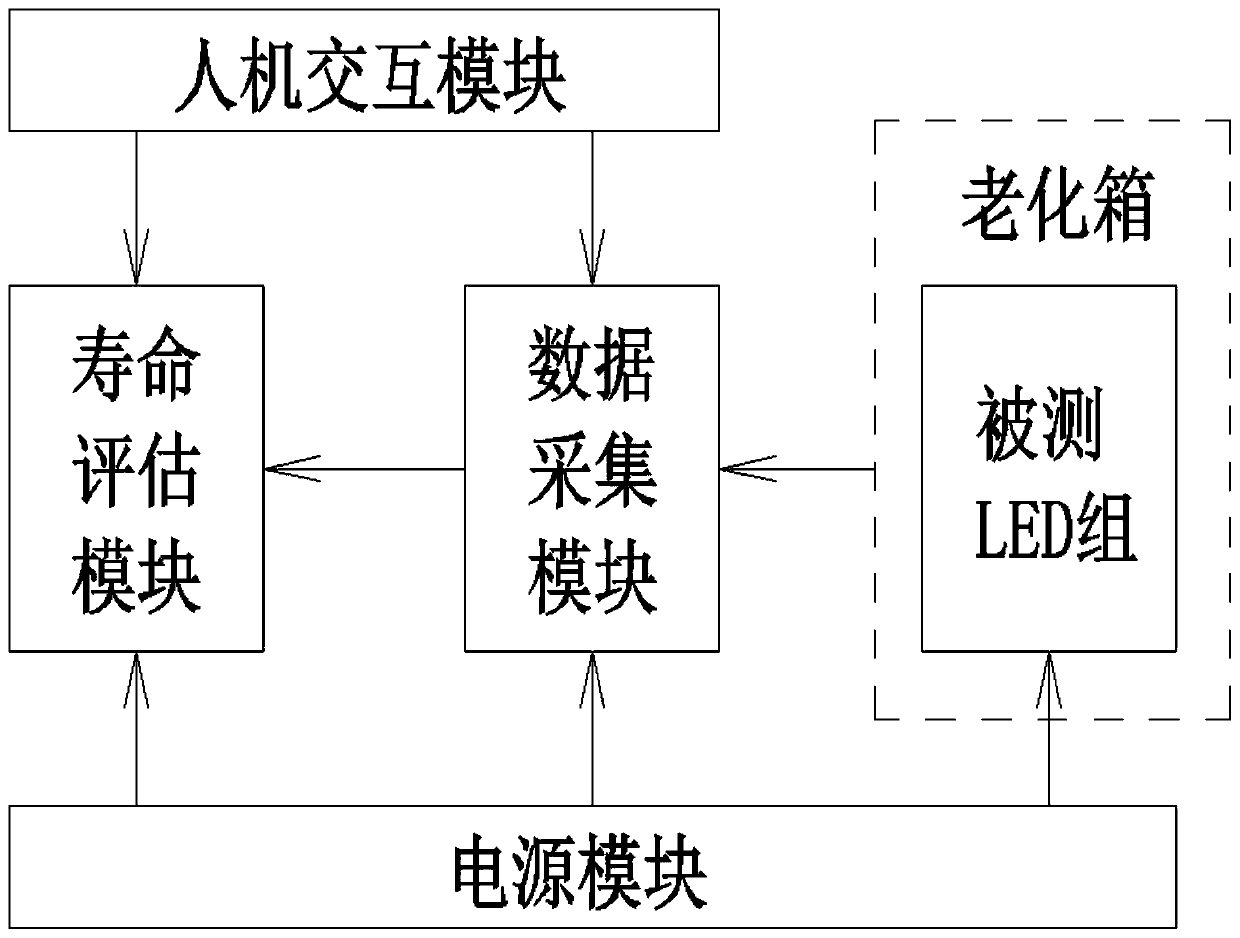

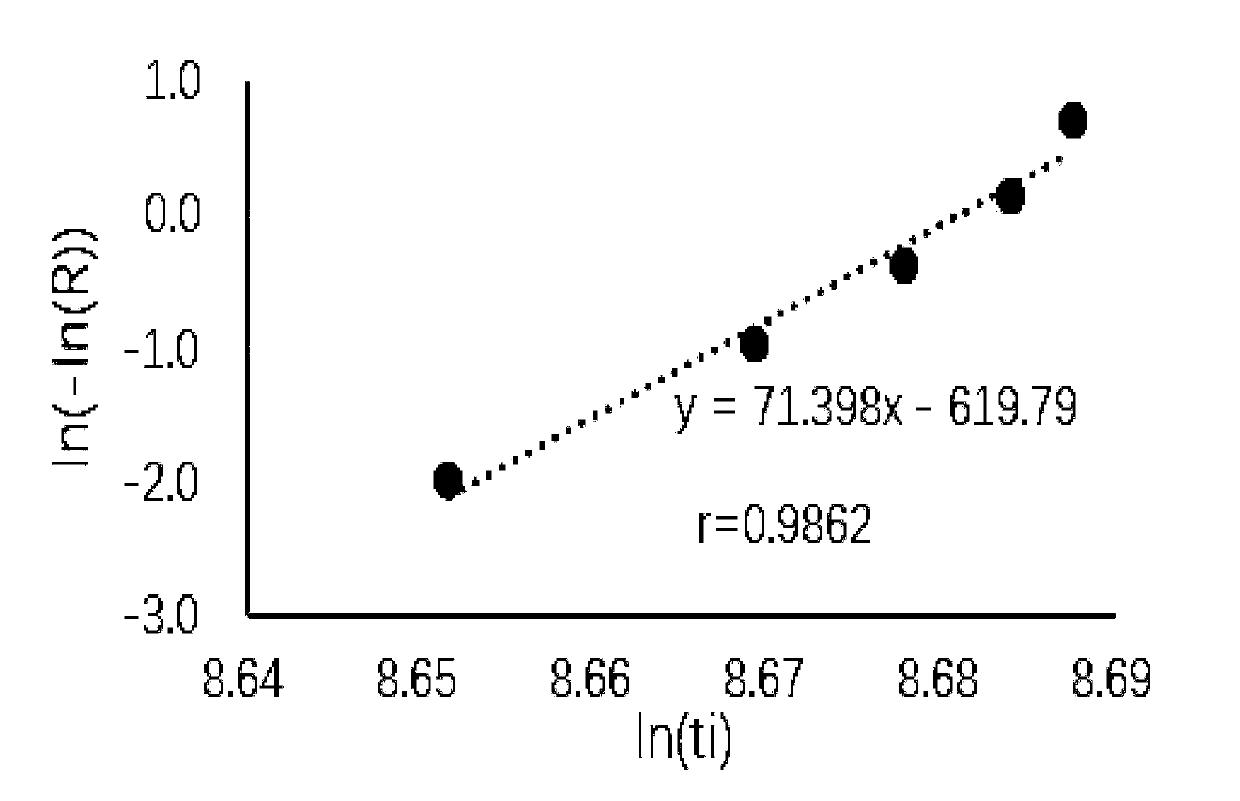

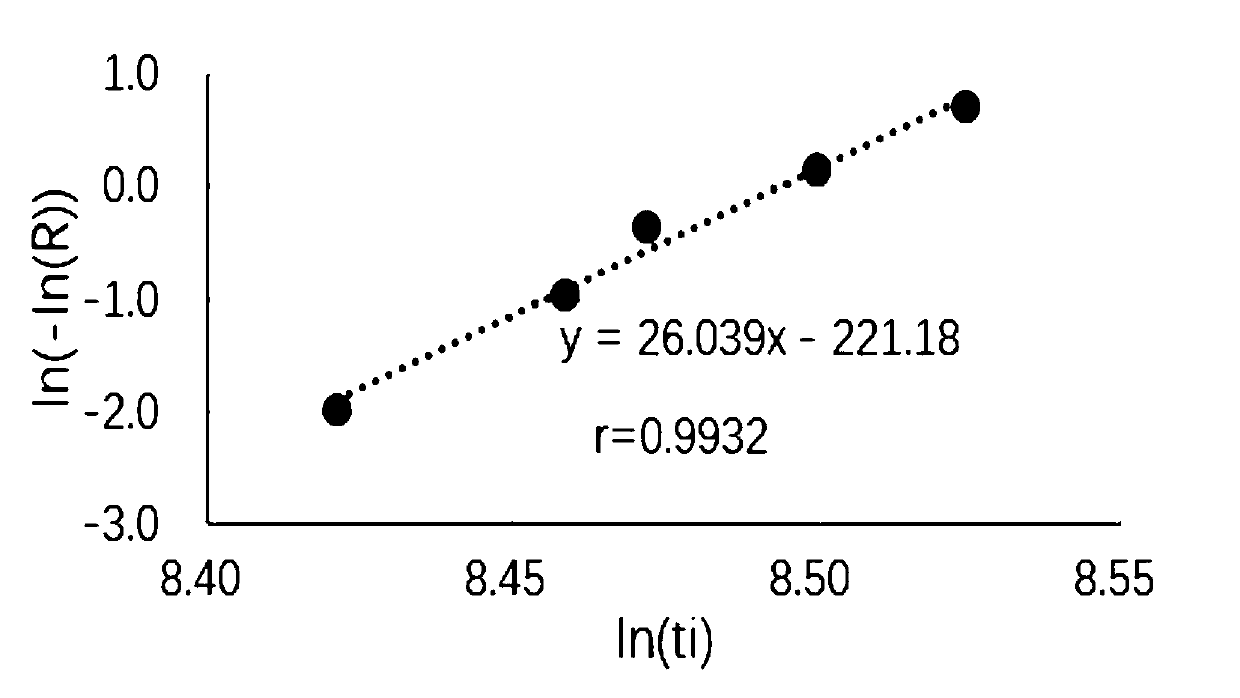

Automatic LED aging state detection and service life evaluation system and method thereof

InactiveCN109900997ALife predictionElectrical testingOptical apparatus testingAccelerated agingData acquisition

The invention relates to an automatic LED aging state detection and service life evaluation system and a method thereof, thereby carrying out characteristic parameter collection of LED samples and carrying out service life testing and service life evaluation of LED samples. The system comprises a power supply module, an aging box, a data acquisition Module, a human-computer interaction module, anda service life evaluation module. Besides, according to the automatic LED aging state detection and service life evaluation method, an LED sample is placed in the aging box to carry out accelerated aging testing; service life test parameters of the LED sample are transmitted to the service life evaluation module; the service life evaluation module calculates average testing time of the LED samplewith the service life testing under the accelerated stress by using a probability statistics method; the service life evaluation module establishes a service life prediction model of multiple LED samples and carries out parameter estimation on the service life prediction model based on test results; and the service life evaluation module calculates the residual service lives of the type of LED samples in the batch under the actual using condition to obtain the service life of the tested LED under actual use conditions.

Owner:SUZHOU UNIV OF SCI & TECH

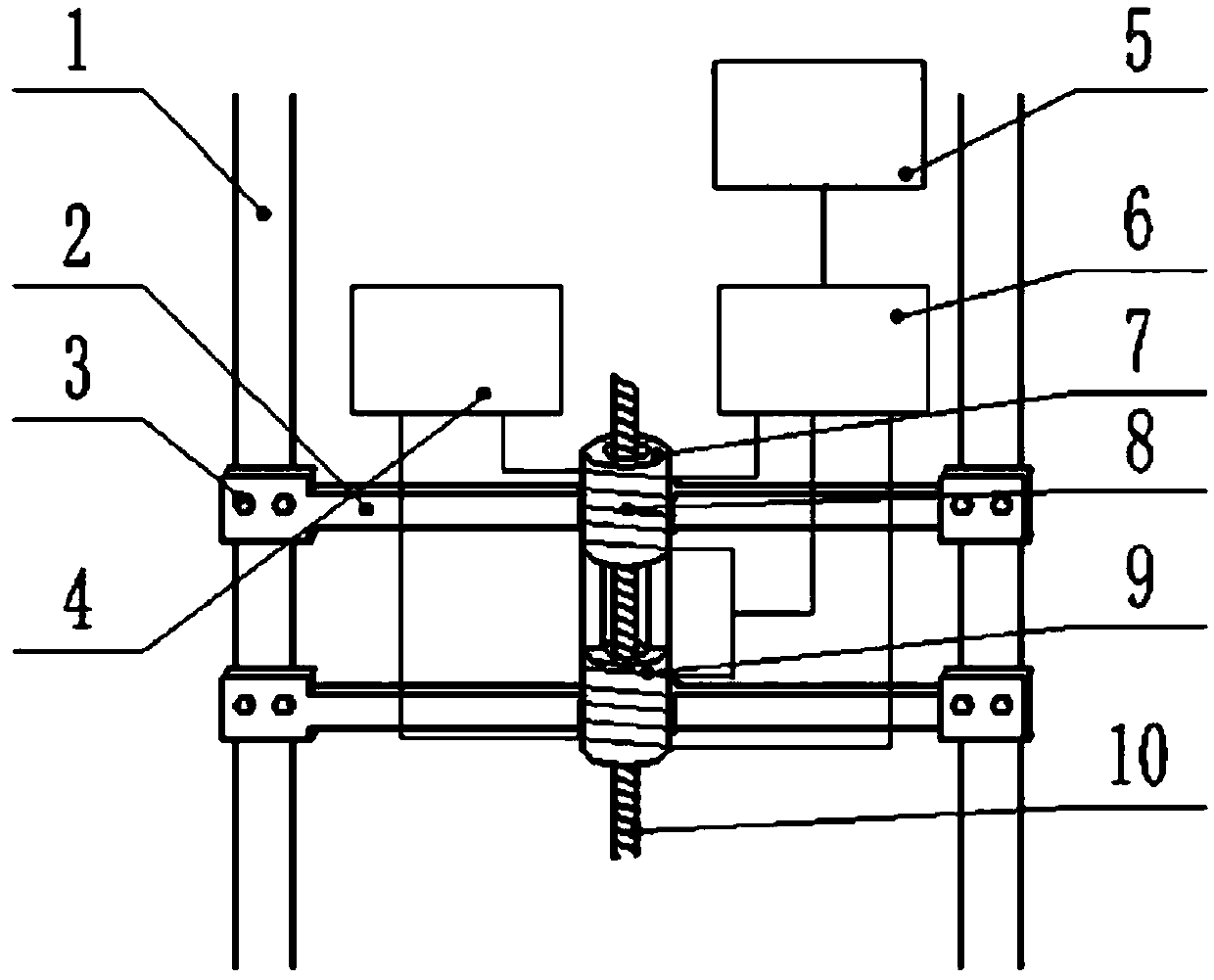

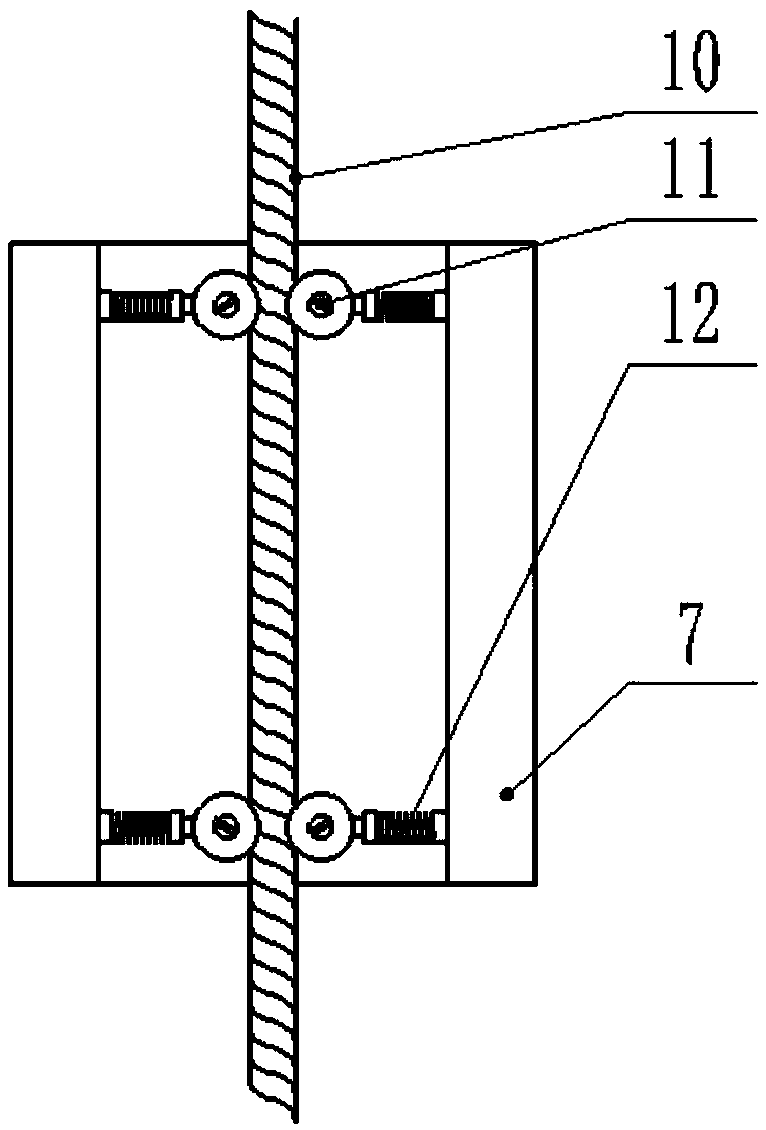

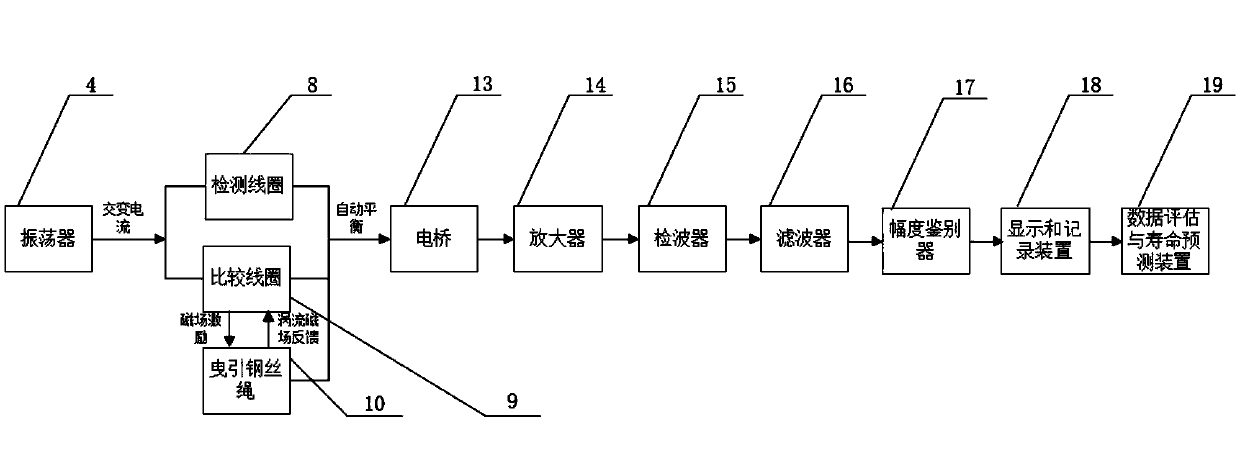

Online prediction system and method for remaining service life of elevator traction steel wire rope

The invention discloses an online prediction system and method for the remaining service life of an elevator traction steel wire rope. The system comprises a detection module, a signal conditioning module, and an analysis and evaluation module. The detection module includes an oscillator and a detecting device and is used for monitoring an elevator traction steel wire rope in running in real timeby means of eddy current detection. The signal conditioning module connected with the detection module is used for converting monitored data into a detection signal. The analysis and evaluation moduleconnected with the signal conditioning module is used for comparing the collected detection signal with information, stored in a database in advance, of different wearing degrees and service lives ofelevator traction steel wire ropes and thus predicting the service life of the detected elevator traction steel wire rope. With the eddy current detection method, whether the elevator traction steelwire rope in running has a defect is monitored in real time and the residual service life of the tested steel wire rope is predicted based on signal comparison, thereby providing effective informationfor in-time repairing and replacement of the elevator traction steel wire rope. Therefore, the online prediction system and method for the remaining service life of an elevator traction steel wire rope have the important significance in safety elevator running.

Owner:SHANDONG UNIV OF SCI & TECH

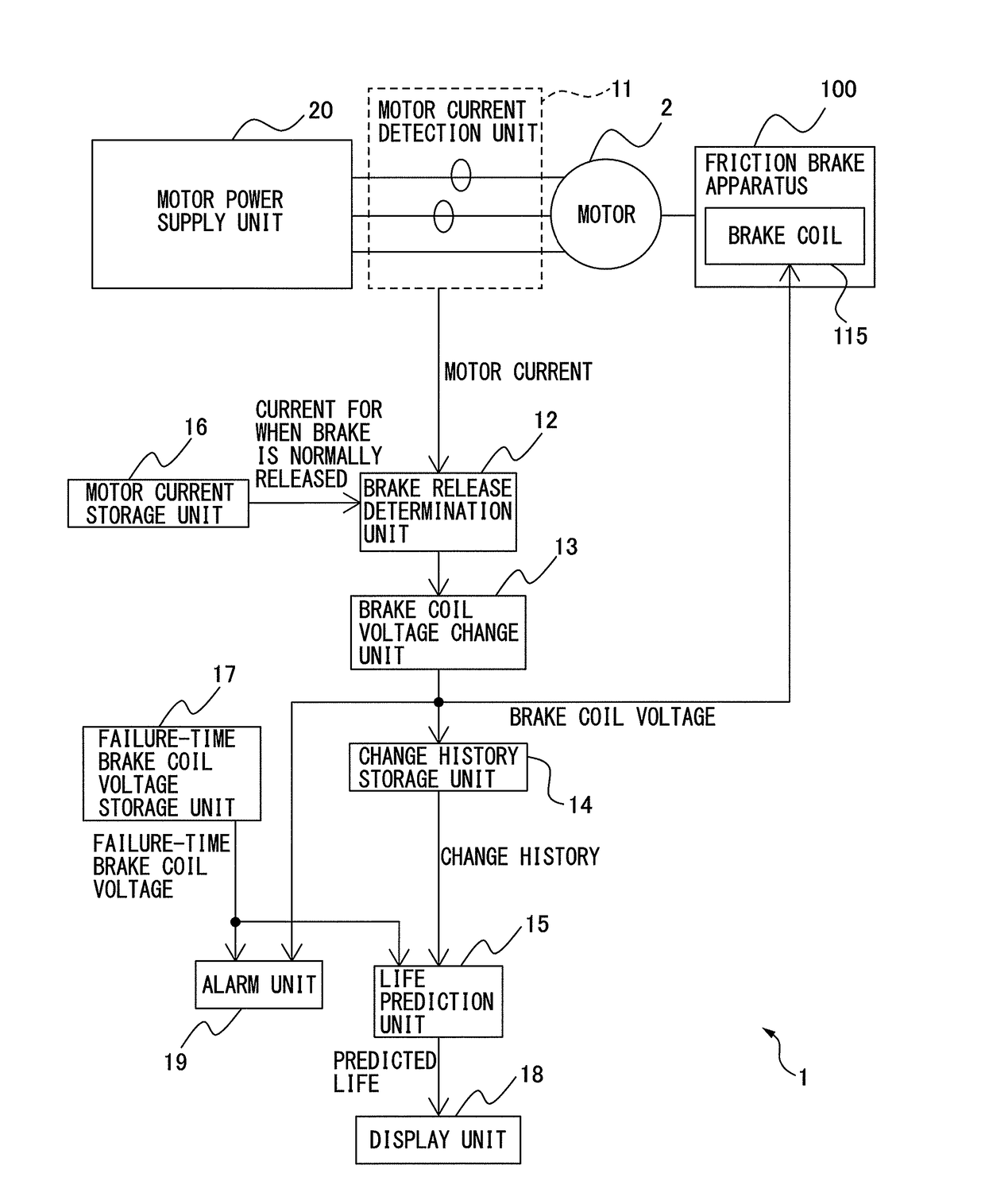

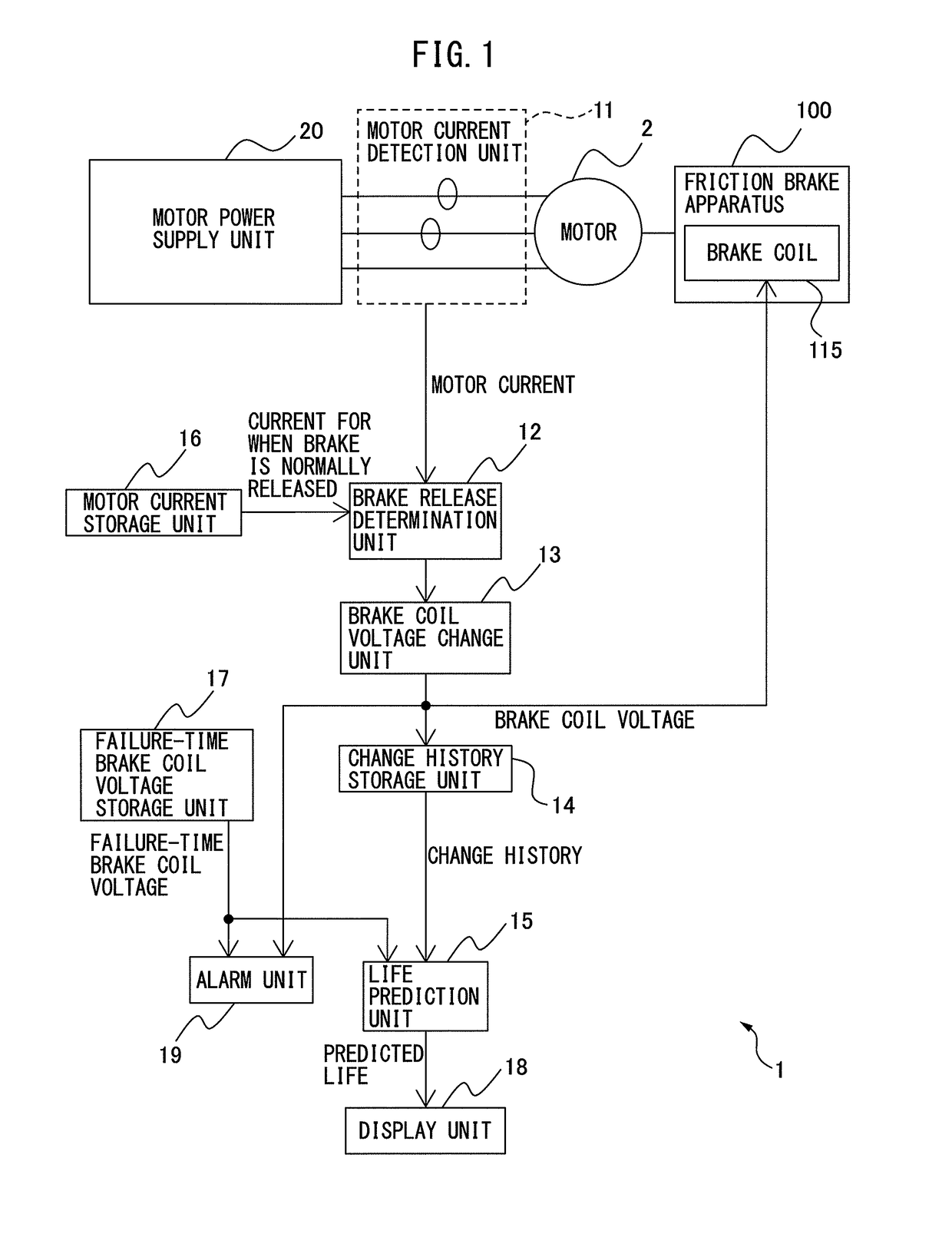

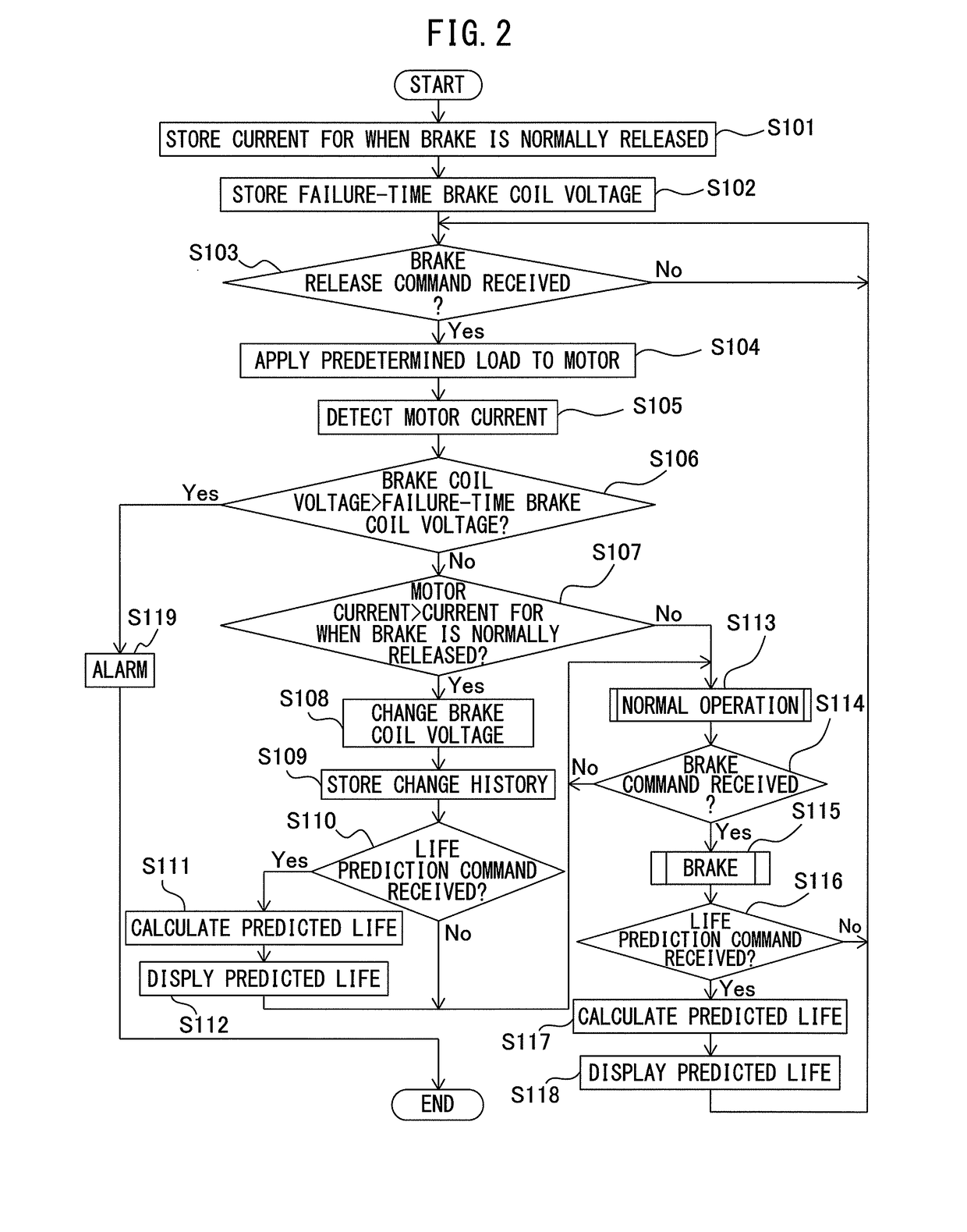

Motor drive apparatus equipped with life prediction function for motor brake

ActiveUS20170108071A1Reduce power consumptionLife predictionBraking componentsBrake typesMotor driveEngineering

A motor drive apparatus includes: a motor current detection unit; a brake release determination unit that determines that the brake is not released when the motor current detected when the motor is operated under a predetermined load by application of a voltage to a brake coil is larger than a current for when the brake is normally released; a brake coil voltage change unit that changes a voltage applied to the brake coil when it is determined that the brake is not released to a larger value; a change history storage unit that stores the voltage after being changed and change date and time; and a life prediction unit that calculates a predicted life of the brake apparatus based on the voltage after being changed and the change date and time and the previously stored failure-time brake coil voltage.

Owner:FANUC LTD

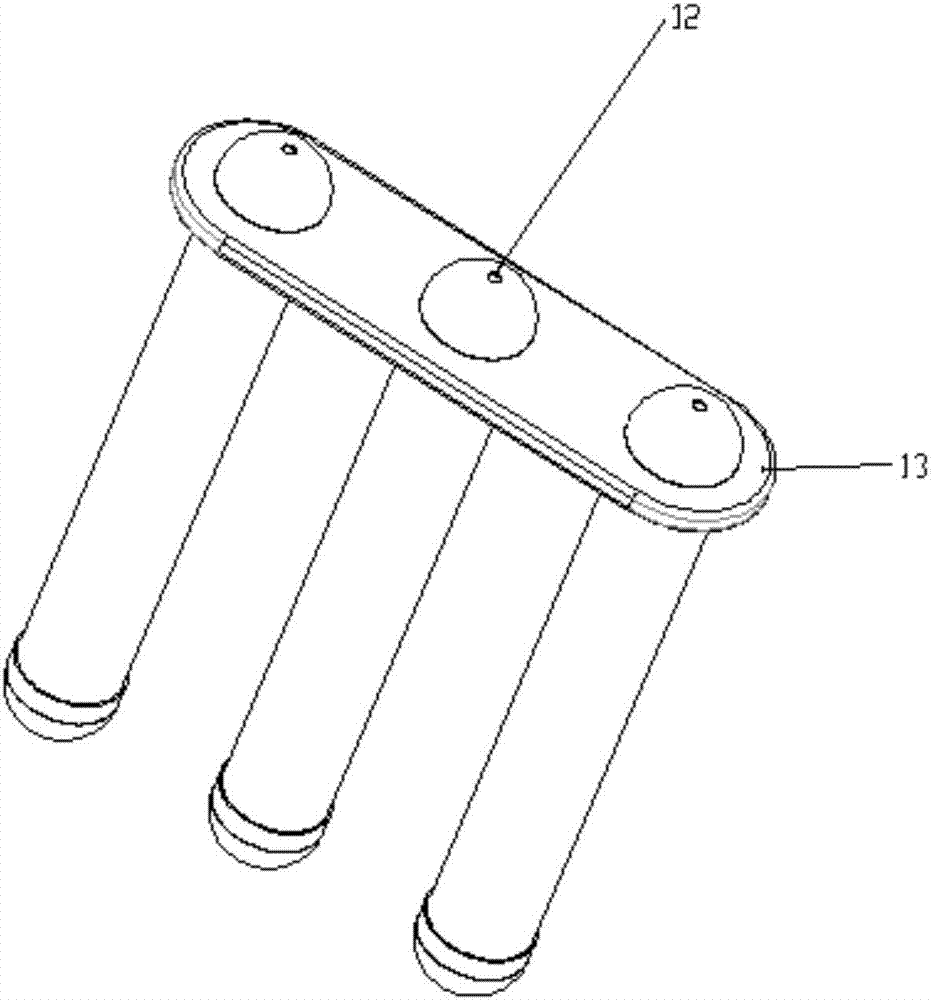

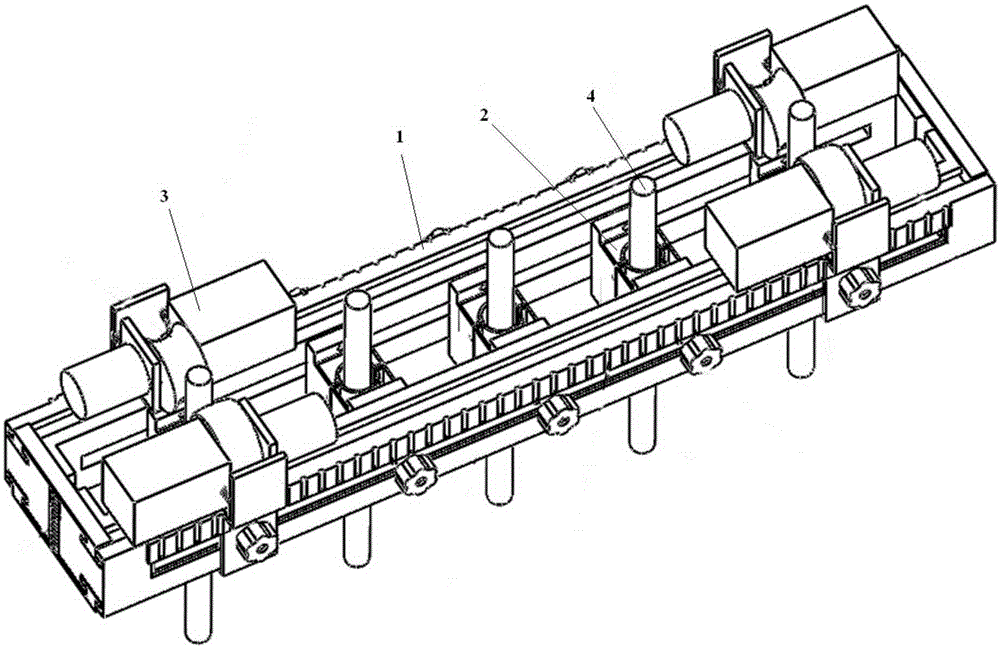

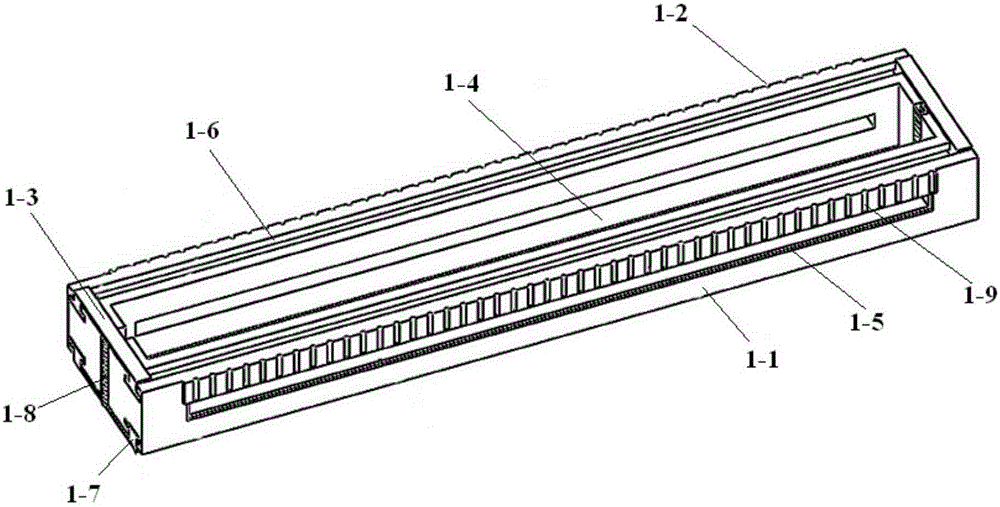

Device for detecting multiple steel wire ropes and application thereof

ActiveCN105181787ALife PredictionStrong comparabilityMaterial magnetic variablesStress concentrationMagnetic memory

The invention provides a device for detecting multiple steel wire ropes and application thereof. The device comprises a bracket main body, wherein a plurality of detection bases are installed inside the bracket main body, each steel wire rope to be detected correspondingly penetrates through the middle of one detection base, a pair of lifting mechanisms is installed on the bracket main body, and can ascend and descend along the steel wire rope to be detected, so that the movement detection of the whole device on the multiple steel wire ropes can be realized. The device is used for detecting the steel wire ropes through a metal magnetic memory detection method. The adjustable device can guarantee the same lifting heights, the multiple steel wire ropes can be detected at a time simultaneously, the reference performance between the detection results is strong, the abrasion of a sensor can be avoided, and meanwhile, the detection precision can be guaranteed. A three-dimensional magnetic memory detection sensor is installed on the bracket, and the multiple steel wire ropes are detected according to the metal magnetic memory detection principle, so that the detection of stress concentration in the early stage and the prediction of the service lives of the steel wire ropes can be realized.

Owner:西安建筑科大工程技术有限公司

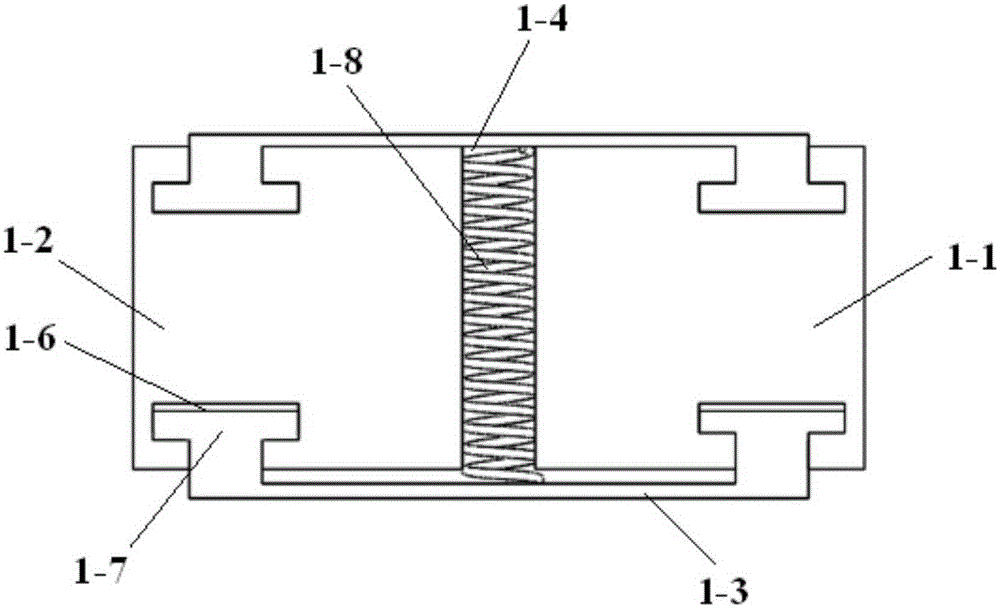

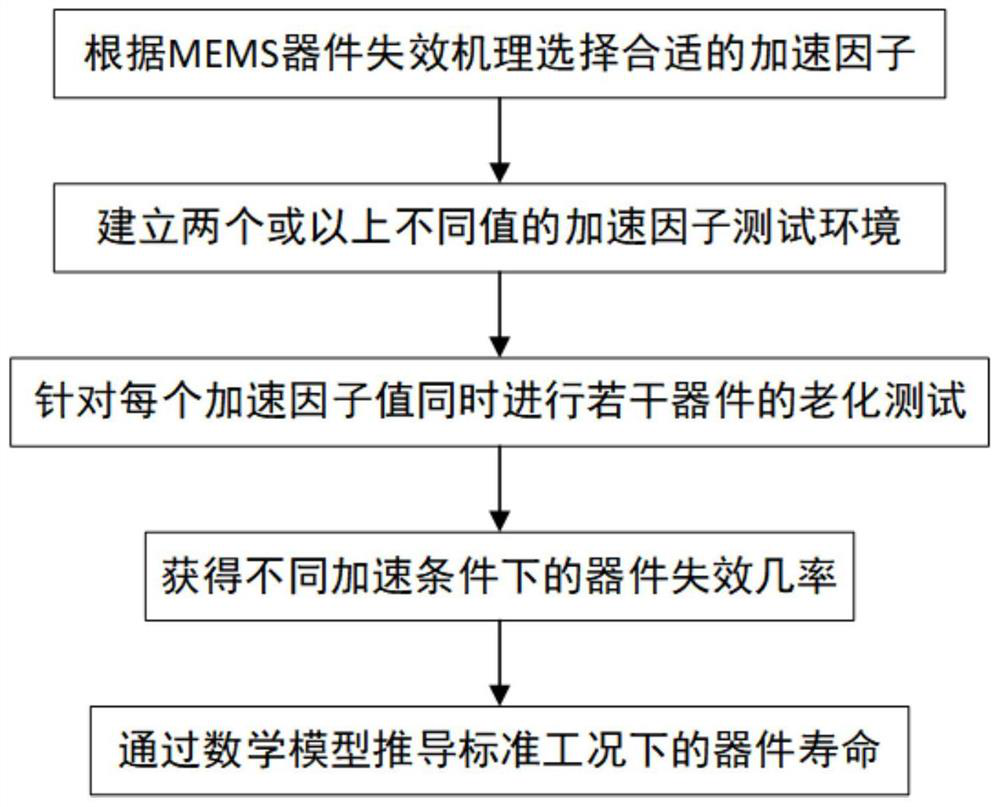

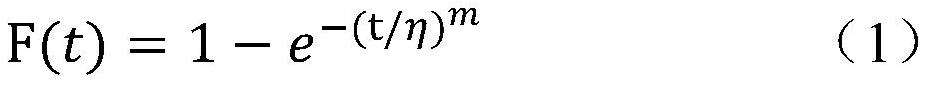

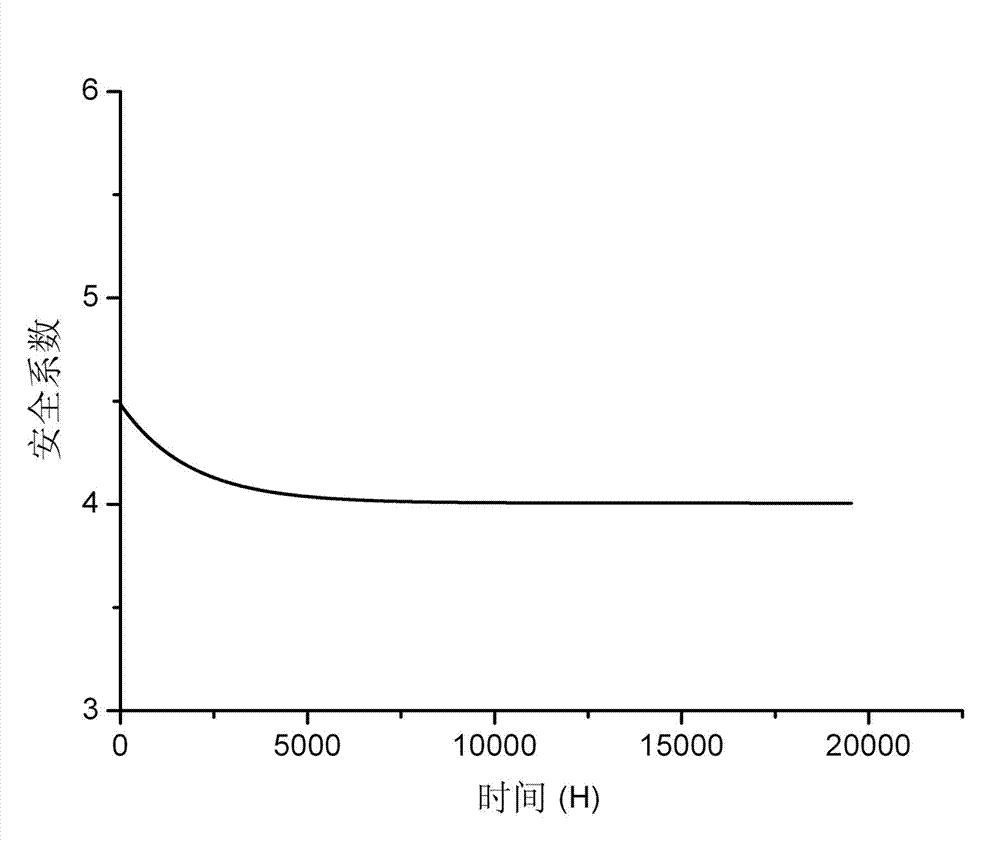

Micro-electromechanical device service life prediction method based on single acceleration factor

PendingCN113074930ALife PredictionMachine part testingWeather/light/corrosion resistanceAcceleration factorMathematical model

The invention discloses a micro-electromechanical device life prediction method based on a single acceleration factor, and the method needs to consider the influence of temperature stress and cyclic stress on the life of an MEMS device in an accelerated life test in order to accurately predict the life of the MEMS device under the single acceleration factor. According to the accelerated life test, stress (such as temperature stress, cyclic stress and the like) higher than the normal level is applied to a product in a short time in an accelerated environment with an abnormal stress level, and the service life of the MEMS device can be predicted according to test data obtained by an alternative test, and related parameters of the accelerated life test mathematical model are deduced in the temperature stress and cyclic stress environment, and the life of the MEMS device in the temperature stress and cyclic stress environment.

Owner:XI AN JIAOTONG UNIV

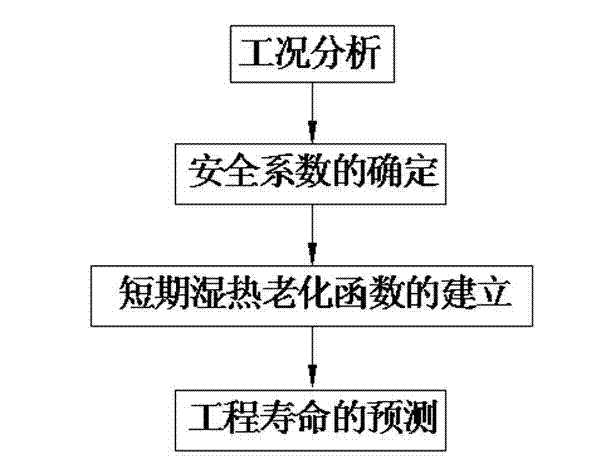

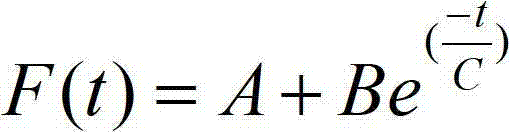

Method for forecasting engineering service life of glass fiber reinforced plastic sleeve

The invention discloses a method for forecasting the engineering service life of a glass fiber reinforced plastic sleeve, which comprises the following steps of: 1, analysis of the working conditions, i.e. analyzing the working conditions and determining the main strained condition and the hygrothermal aging condition of the glass fiber reinforced plastic sleeve; 2, determination of safety coefficients, i.e. measuring relative mechanical properties by utilizing a test sample, measuring the stress of the glass fiber reinforced plastic sleeve by the field test and further determining the working safety coefficients of the glass fiber reinforced plastic sleeve; 3, establishment of a short-period hygrothermal aging function, i.e. carrying out hygrothermal aging test on the test sample for 1,000 hours to establish the hygrothermal aging function; and 4, forecasting of the engineering service life, i.e. selecting the safety coefficient according to the minimum rule, carrying out integration on the safety coefficient and the hygrothermal aging function to establish a glass fiber reinforced plastic sleeve engineering service life estimation model, setting the residual safety coefficients as 2 and extrapolating to 100 thousand of hours according tot he estimation model. The method can be used for accurately forecasting the engineering service life of the glass fiber reinforced plastic sleeve. The method has the advantages of time saving, economy and simple method.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

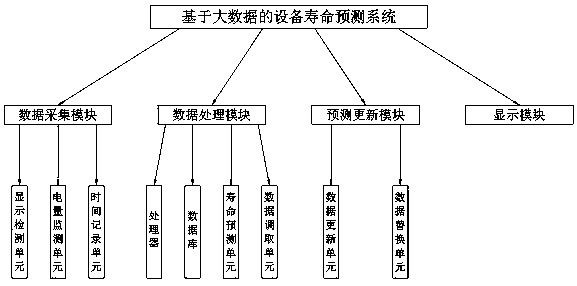

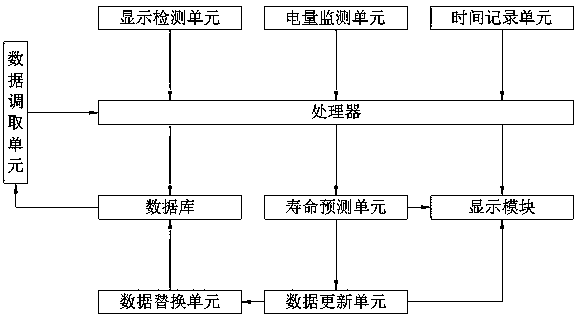

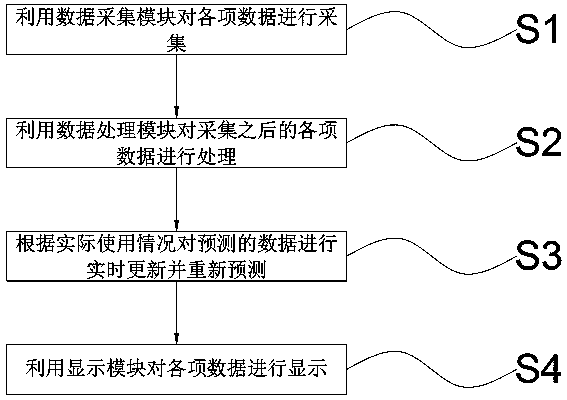

Equipment life prediction system and method based on big data

The invention belongs to the technical field of big data. The invention specifically discloses an equipment life prediction system and method based on big data. The service life prediction system comprises a data collection module and a data processing module, a prediction updating module and a display module, the data collection module is electrically connected with the data processing module; and the data processing module is electrically connected with the prediction updating module and the display module. Safe and convenient use, a data replacement unit and a data updating unit are arranged. Therefore, the static power consumption rate and the dynamic power consumption rate of the communication equipment battery in the actual use process can be used for calculating the original predicted static power consumption rate and dynamic power consumption rate at the time point; according to the method, the data can be updated, large deviation of the prediction result caused by complete prediction is avoided, the prediction data is replaced with the actual use data, prediction can better fit the actual use condition, and the prediction result can gradually become accurate.

Owner:广东招才通信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com