Method for predicting life of SCR denitration catalyst in power plant

A denitrification catalyst and catalyst technology, applied in chemical property prediction, electrical digital data processing, design optimization/simulation, etc., can solve the problems of lack of scientificity and accuracy, unable to reflect the nature of physical and chemical changes in catalyst deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0068] The actual process of the present invention will be described in detail below through specific implementation.

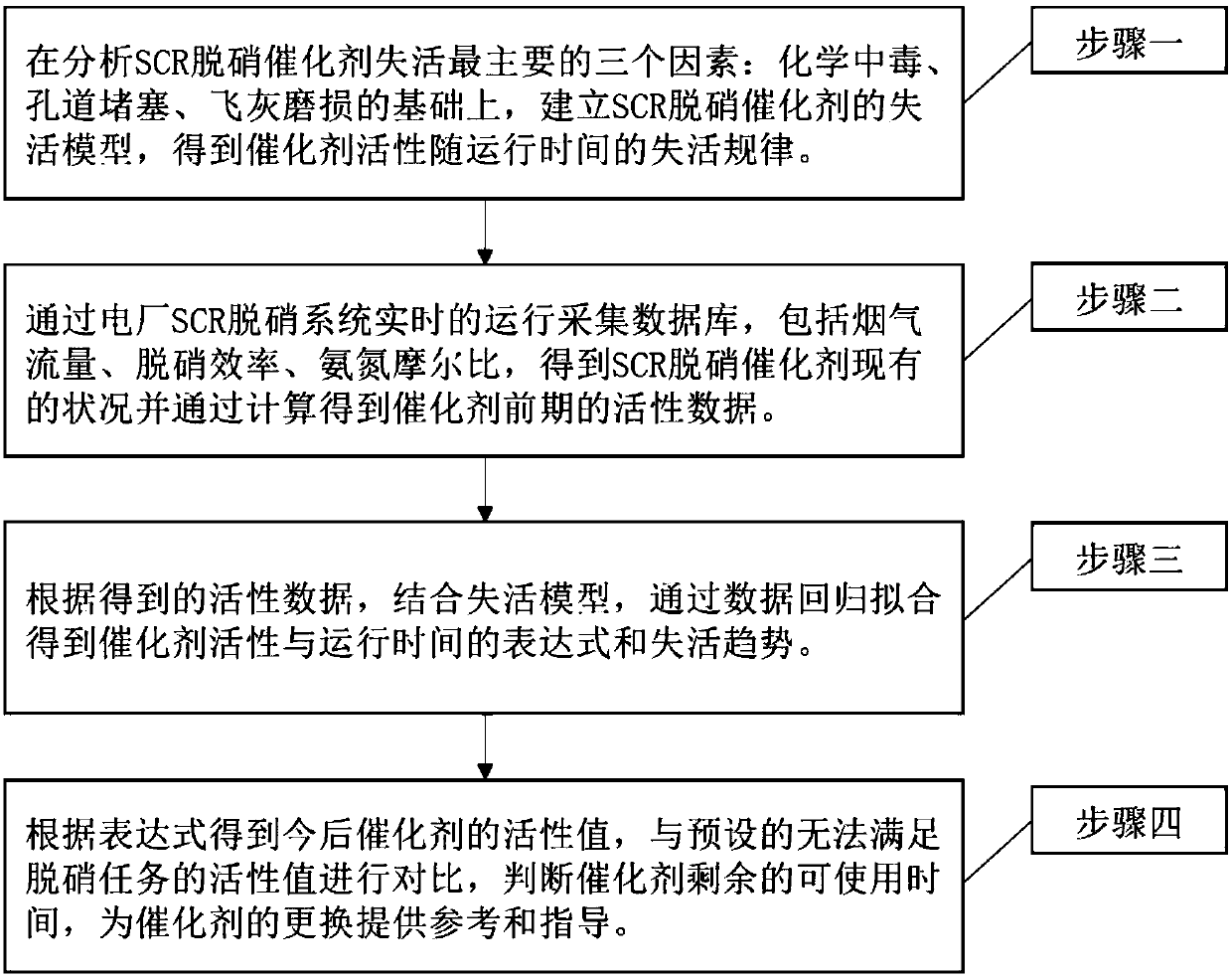

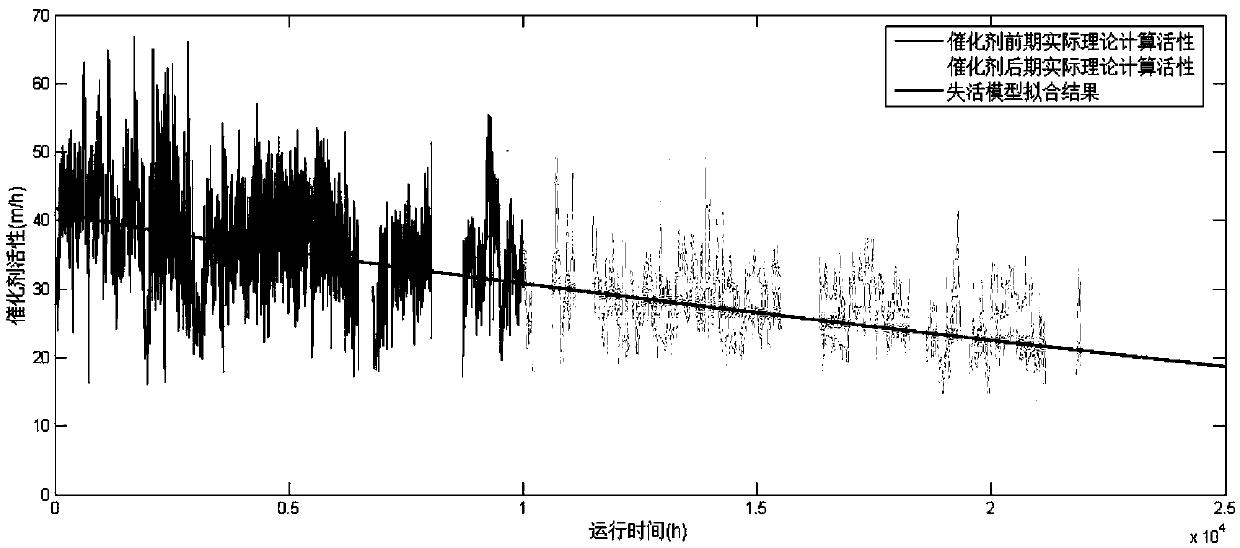

[0069] Such as figure 1 As shown, the specific steps of a method for predicting the life of a power plant SCR denitration catalyst are:

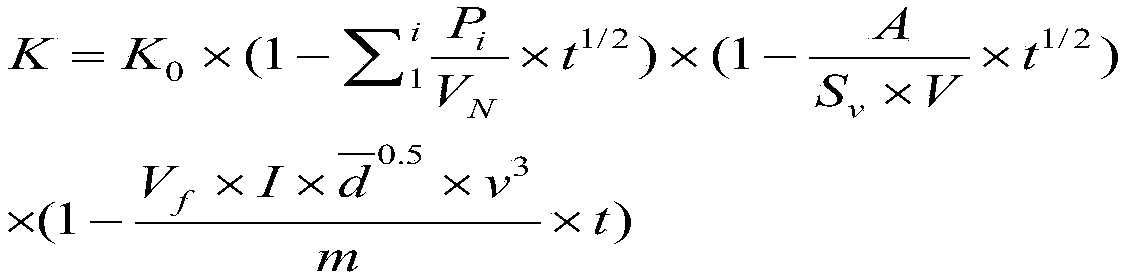

[0070] Step 1. Based on the analysis of the three most important factors for the deactivation of the SCR denitration catalyst: chemical poisoning, pore blockage, and fly ash wear, the deactivation model of the SCR denitration catalyst is established:

[0071] 1) Establishment of catalyst chemical deactivation function

[0072] One of the most important reasons for deactivation of SCR denitration catalysts in coal-fired power plants is chemical poisoning. As a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com