Micro-electromechanical device service life prediction method based on single acceleration factor

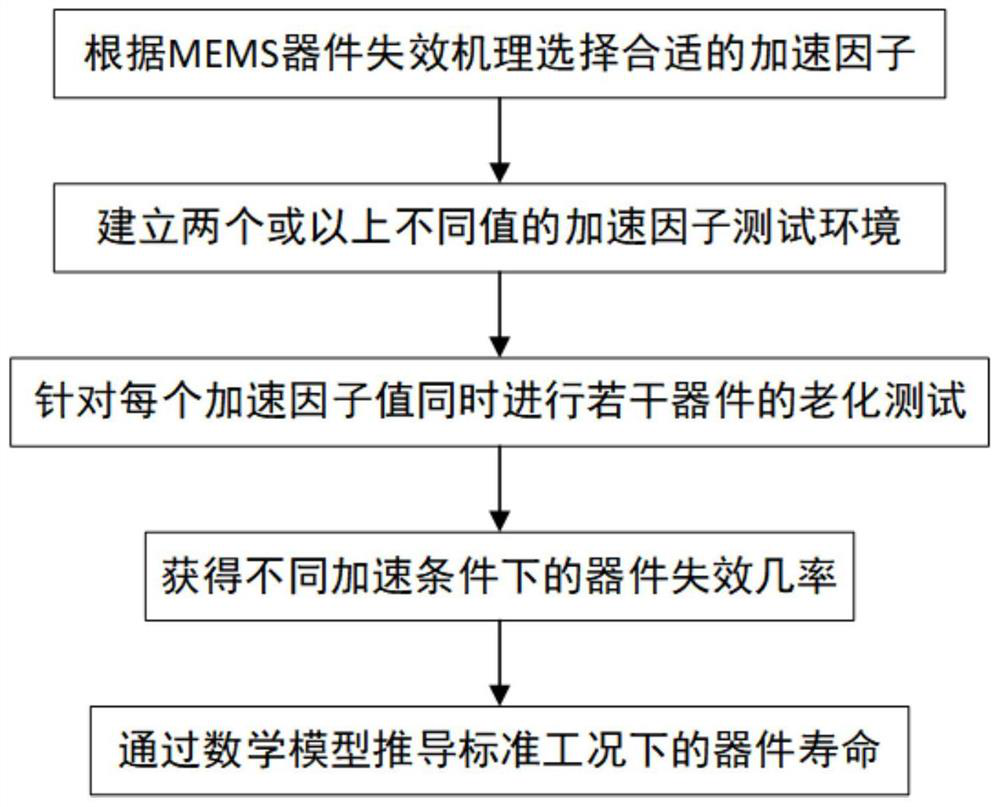

A technology for acceleration factor and life prediction, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc. It can solve the problems of insufficient accelerated life testing methods for MEMS devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

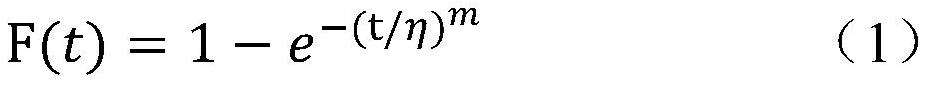

[0070] Embodiment 1 temperature stress (constant stress)

[0071] Step 1, record the initial temperature value of the electromagnetic MEMS micromirror environment;

[0072] This test selects the electromagnetic MEMS micromirror as the test object. The torsion beam of the micromirror is the key part of the whole product; there are many factors that affect the failure of the torsion silicon beam, such as the amplitude of cyclic stress, temperature and other environmental factors.

[0073] In order to calculate the corresponding parameters to obtain the acceleration coefficient under different temperature stresses, design at least two groups of temperature stress tests a and b. The test first measures the initial temperature value of the MEMS device in the test box, and places 20 pieces of MEMS micromirrors in an oven for heating. The heating temperatures of the oven are 80°C and 120°C respectively. The capacitance value and resistance value of the circuit, as well as the reson...

Embodiment 2

[0084] Step 1, select the appropriate cyclic stress according to the test object;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com