Method for forecasting engineering service life of glass fiber reinforced plastic sleeve

A glass fiber reinforced plastic casing, engineering life technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as complex fatigue life, and achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

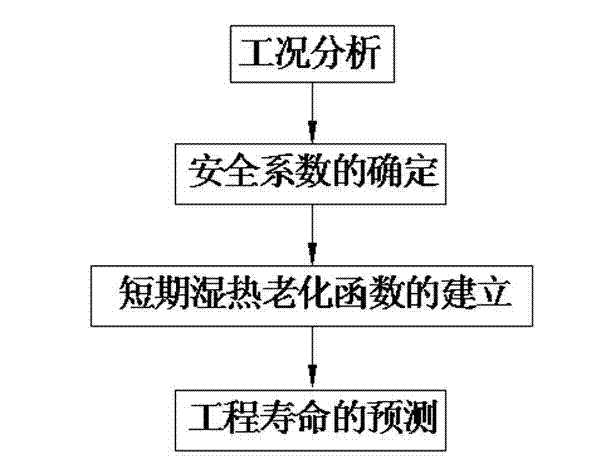

[0022] 1. Working condition analysis:

[0023] A motor uses FRP bushings, and the stress states of its various parts include tension-tension fatigue and tension-compression fatigue; the temperature and humidity environment where it is located is salt spray and high temperature of 80-85 °C.

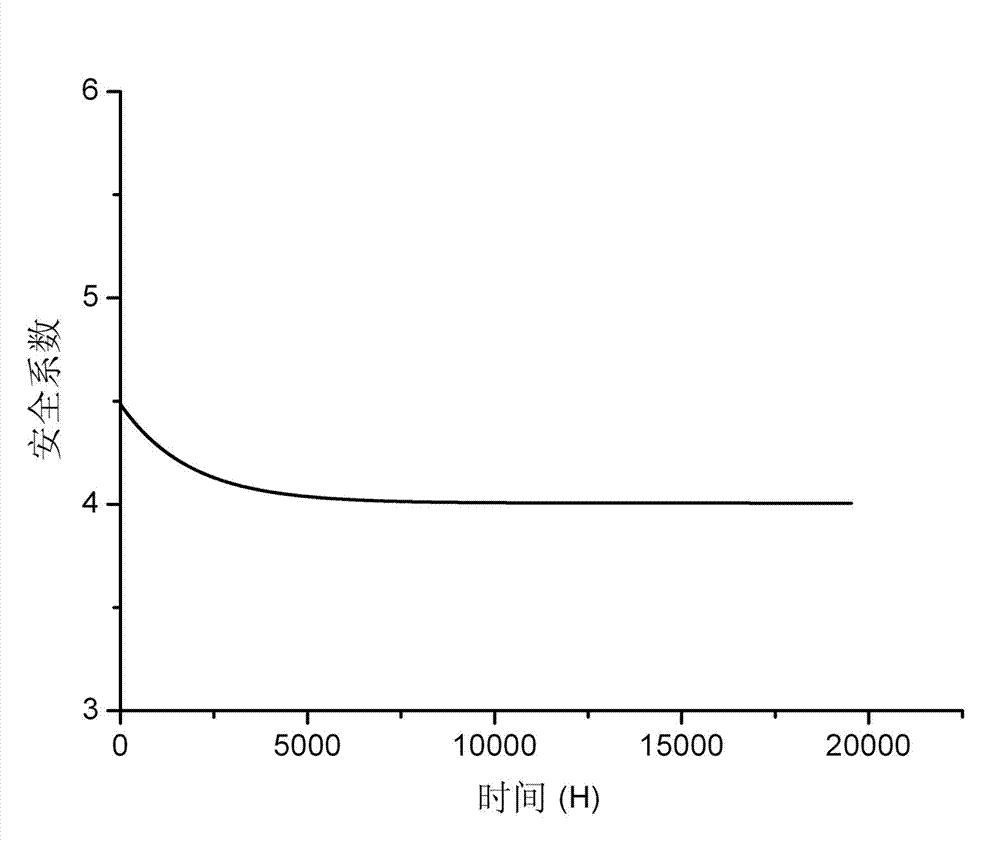

[0024] 2. Determination of safety factor:

[0025] 1) Mechanical performance test of FRP casing material

[0026] The test samples for tensile strength and bending strength of FRP casing are prepared according to the national standard "GB / T 1447-2005 Test Method for Tensile Properties of Fiber Reinforced Plastics" and "GB / T 1449-2005-T Test Method for Bending Properties of Fiber Reinforced Plastics", At least 10 of each.

[0027] The FRP casing is tested according to the national standard "GB / T 1447-2005 Test Method for Tensile Properties of Fiber Reinforced Plastics". Its tensile strength is 33.079MPa and elastic modulus is 10.786GPa.

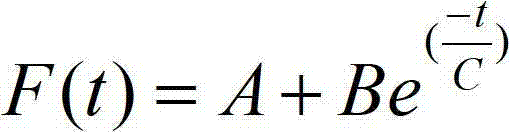

[0028] According to "GB / T 16779-1997 Fiber Reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com