Patents

Literature

67results about How to "Avoid deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lateral shooting angle detecting method, inclined shooting angle detecting method and mobile phone

ActiveCN102353351AAvoid deviationGood shooting effectAngle measurementIncline measurementLateral deflectionDeflection angle

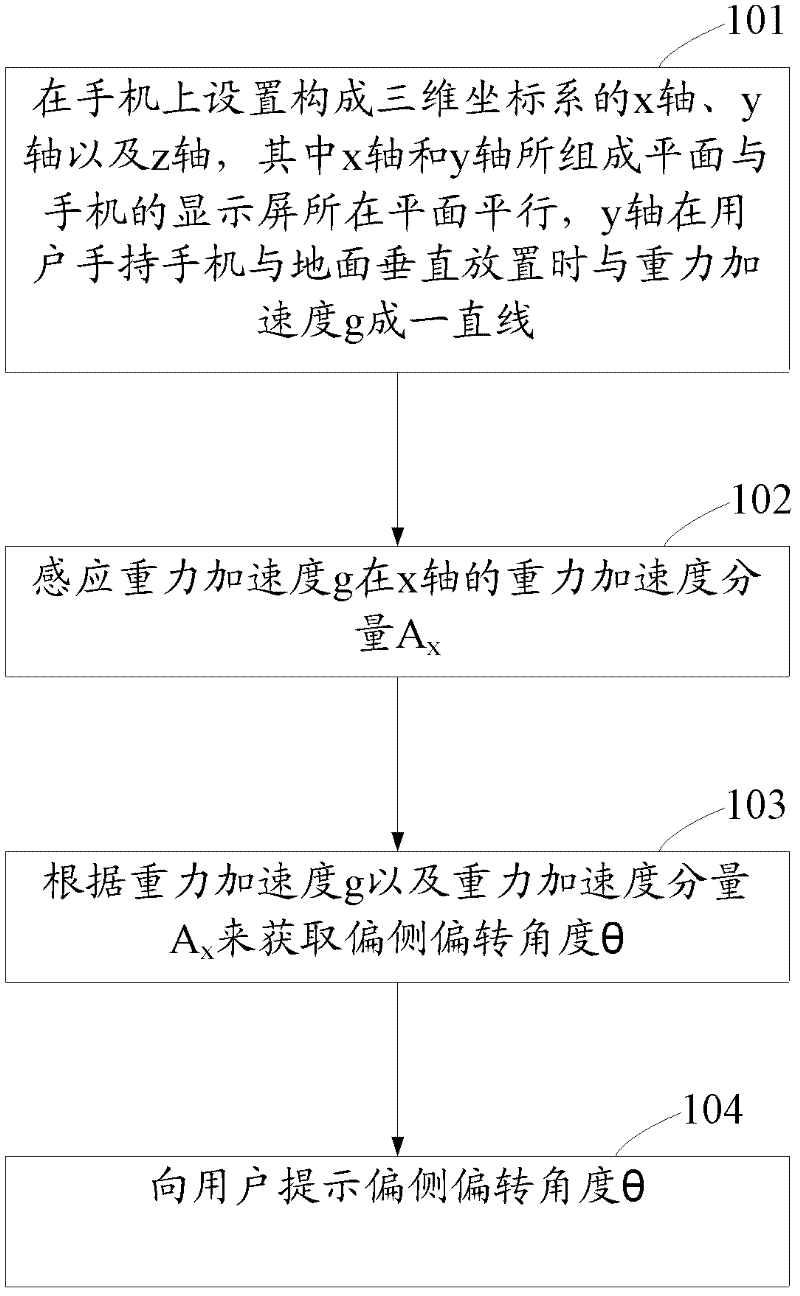

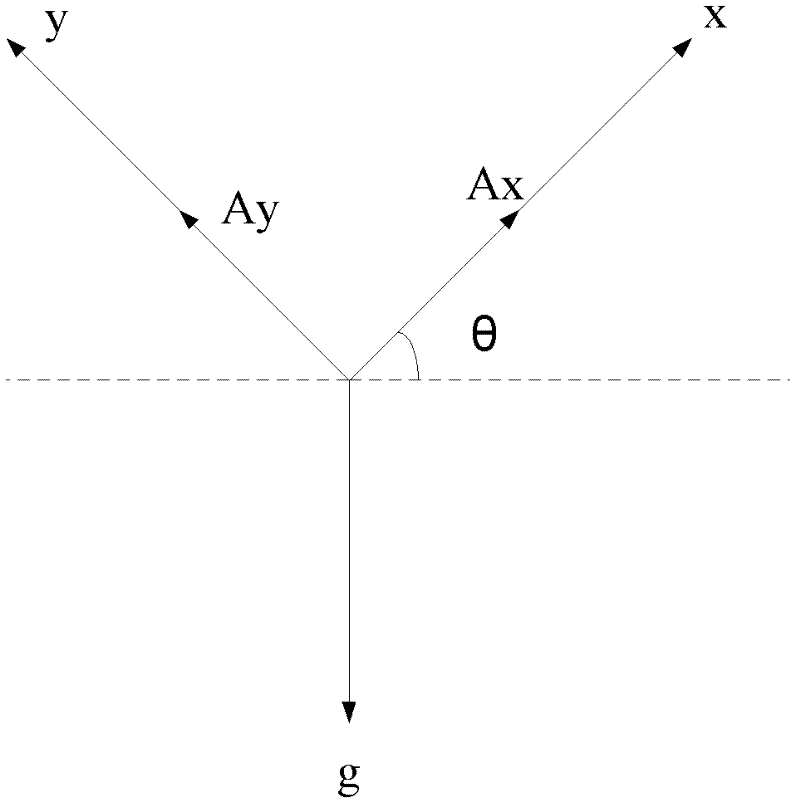

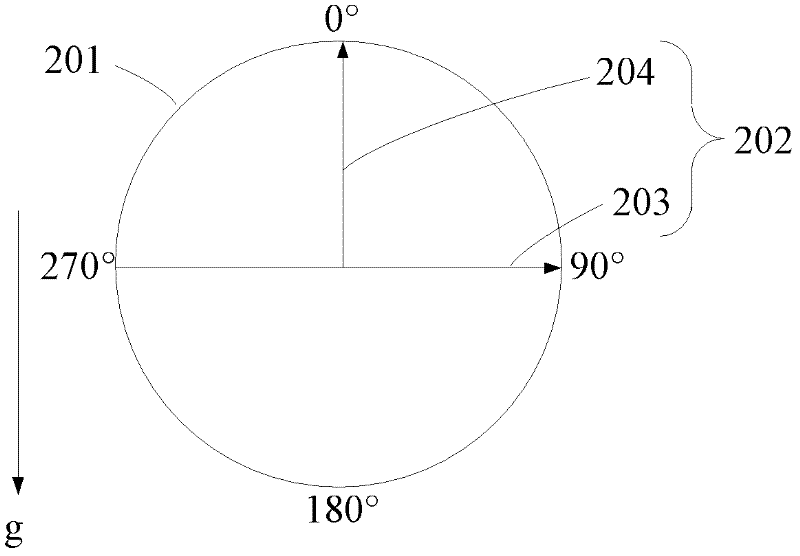

The invention discloses a lateral shooting angle detecting method, which is used for detecting the lateral shooting angle of a mobile phone. The method comprises the following steps of: setting an x axis, a y axis and a z axis which form a three-dimensional coordinate system on the mobile phone, wherein a plane formed by the x axis and the y axis is parallel to a plane on which a display screen of the mobile phone is positioned, and the y axis and gravity acceleration g are on the same straight line when the mobile phone held by a user is placed vertical to the ground; sensing gravity acceleration component Ax of the gravity acceleration g on the x axis; acquiring a lateral deflection angle theta according to the gravity acceleration g and the gravity acceleration component Ax; and prompting the deflection angle theta to the user. The invention further discloses an inclined shooting angle detecting method and the mobile phone. In the lateral shooting angle detecting method, the inclined shooting angle detecting method and the mobile phone, the shooting angle is prevented from generating deviations by detecting the lateral deflection angel of the mobile phone and prompting the user to adjust the angle, so that a better shooting effect is achieved, and user experience is increased.

Owner:临沂高新人才教育发展集团有限公司

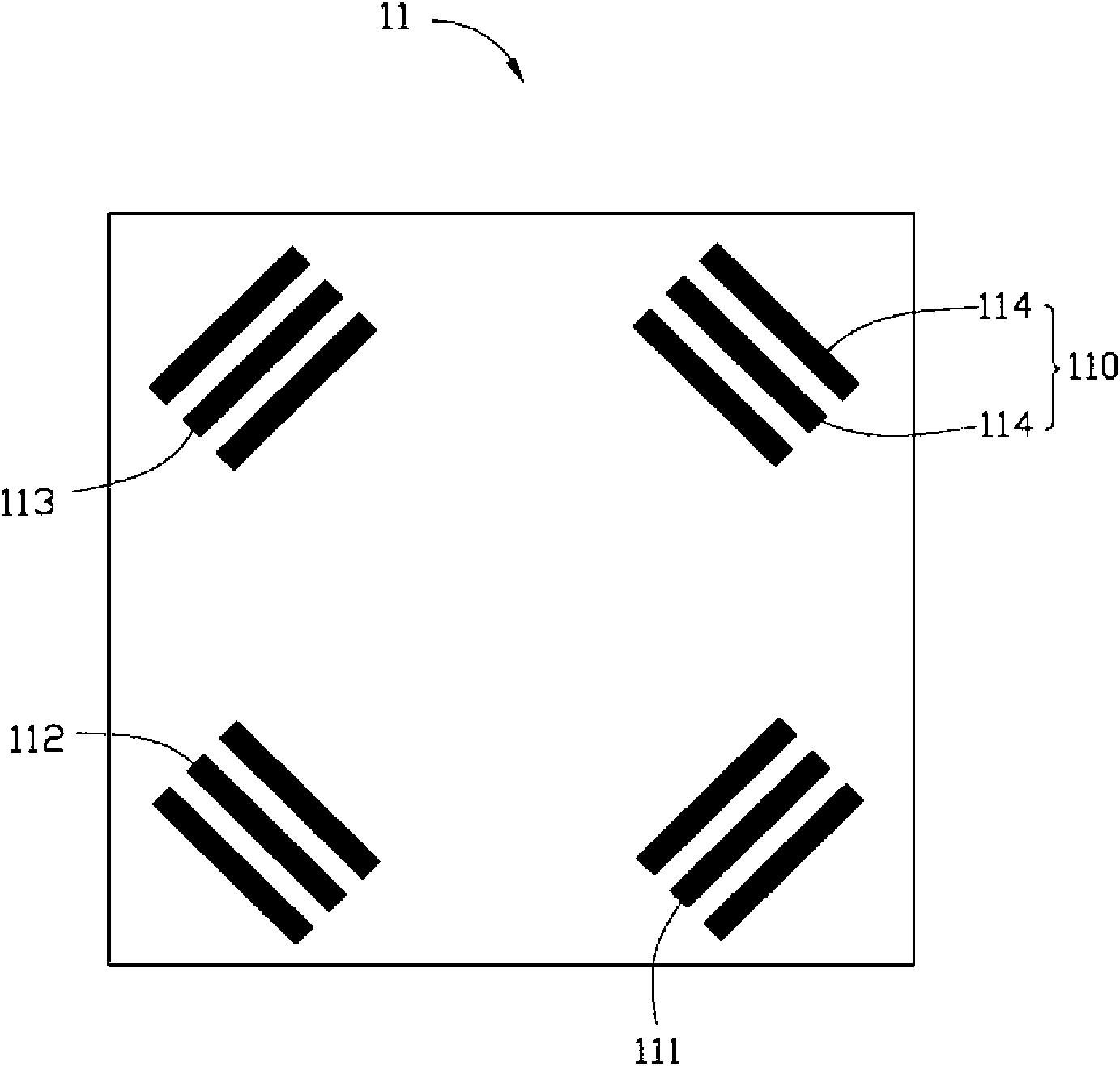

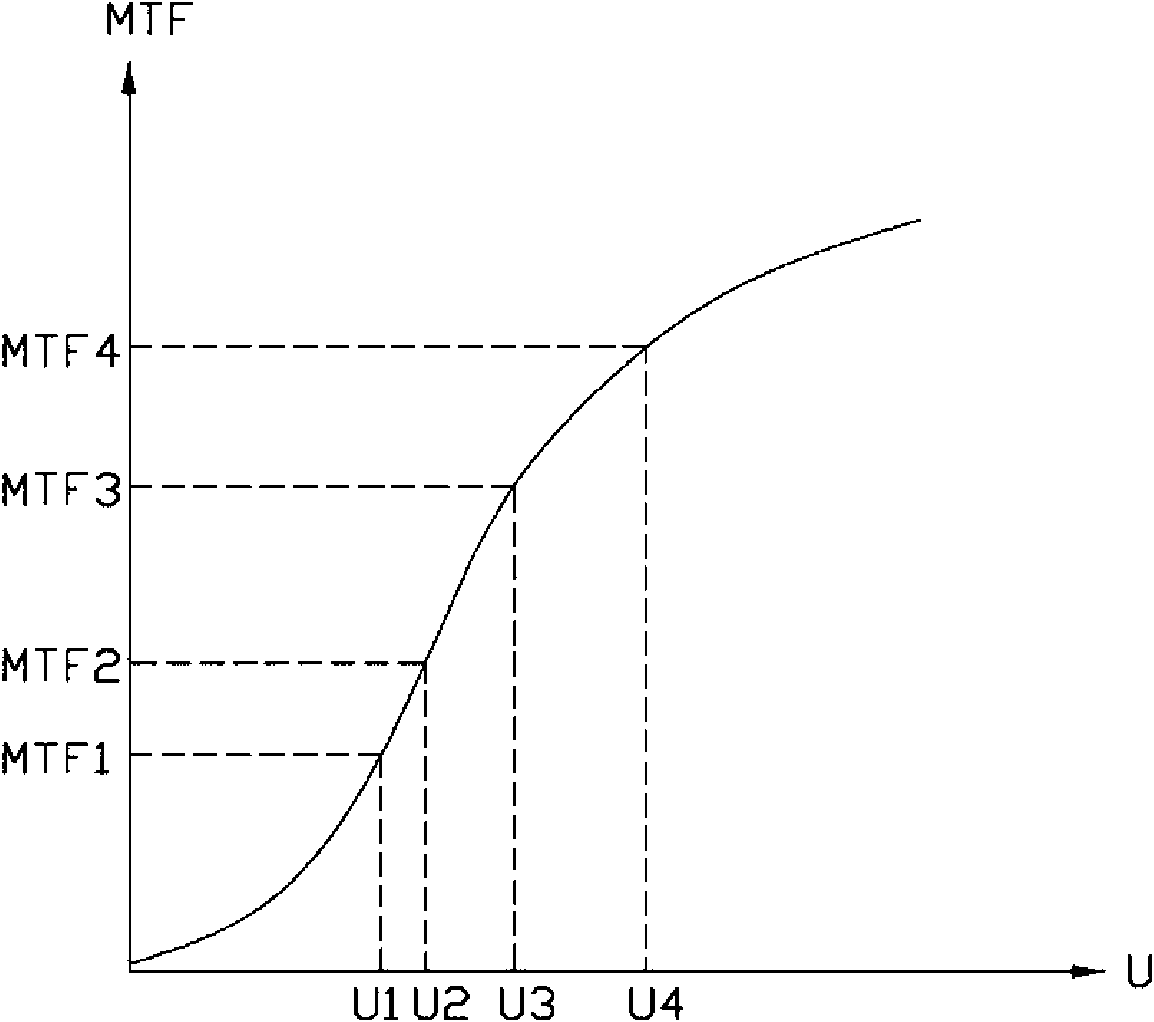

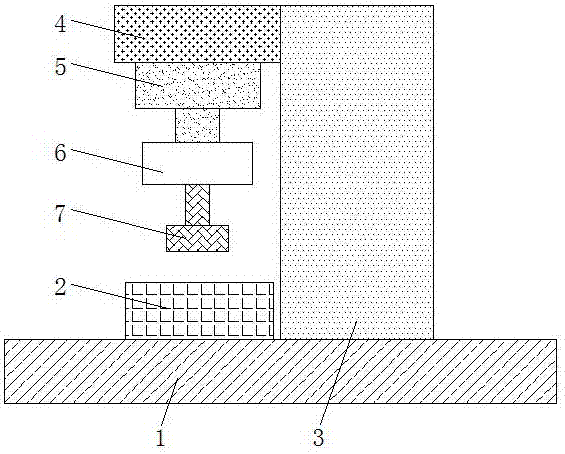

Method for measuring modulation transfer function value of measurement lens

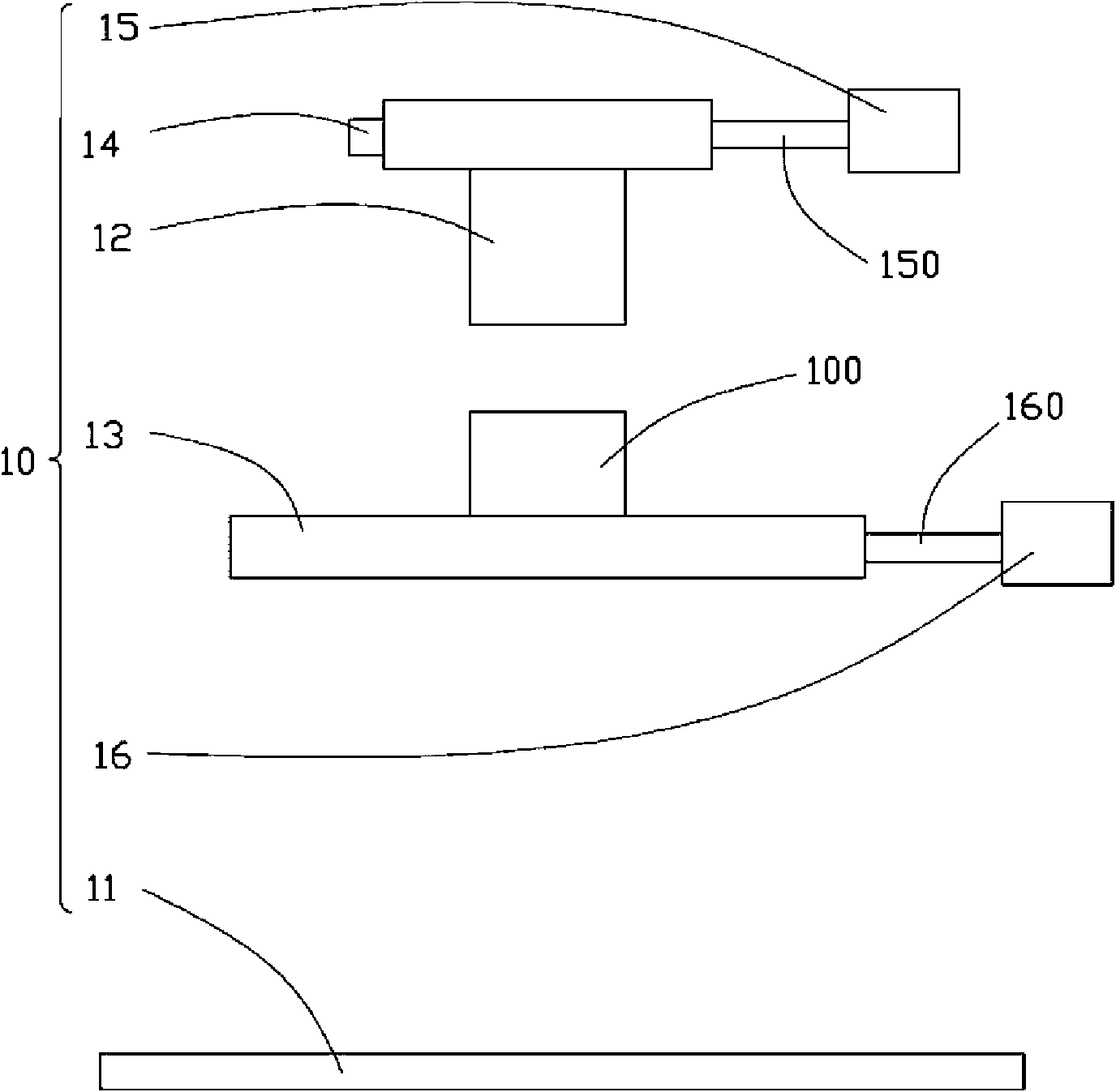

The invention discloses a method for measuring the modulation transfer function value of a measurement lens, which comprises: acquiring continuous modulation transfer function value for the lens to be tested to image a plurality of test patterns at a continuous image distance by using a mobile image sensor, and acquiring the continuous relationship curve of the object distance of the lens to be tested and the modulation transfer function value according to a Gauss formula; rotating the lens to be tested around the optical axis of the lens at the same angle for many times to a plurality of test positions to image the test patterns corresponding to the positions respectively, and acquiring the modulation transfer function values of the images; obtaining a plurality of object distance values corresponding to the modulation transfer function values obtained at the plurality of test positions from the continuous relationship curve, and adjusting a bearing table according to the plurality of object distances to make the distances between the bearing table and a test plate at the positions of the plurality of test patterns equal; and moving the bearing table along the optical axis of the lens to be tested and relative to the test plate for testing the accurate modulation transfer function value of the lens to be tested.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

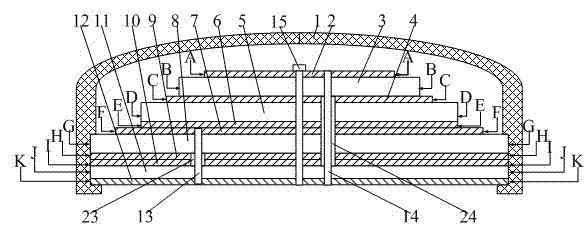

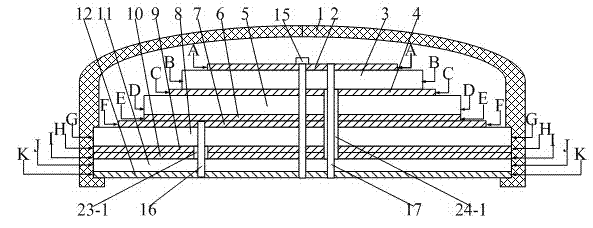

Tri-band wide wave beam circular polarization microstrip antenna

ActiveCN102570017AReduce working frequency point deviationAvoid deviationSimultaneous aerial operationsRadiating elements structural formsPhysicsPhase shifted

The invention realizes a tri-band wide wave beam circular polarization microstrip antenna, which comprises an antenna cover, wherein a feed network layer, a first medium layer, a first metal layer, a second metal layer, a second medium layer, a third metal layer, a fourth metal layer, a third medium layer, a fifth metal layer, a fourth medium layer and a sixth metal layer are sequentially stackedin the antenna cover from bottom to top and penetrated and fixed by short-circuit screws; the third metal layer is connected with the fourth metal layer; a first metallization through hole and a second metallization through hole are formed in the second medium layer and connected to the third metal layer; a Wilkinson 90-degree phase shift power divider and a four-branch 90-degree phase shift power divider are arranged on the feed network layer; a first feed needle and a second feed needle are arranged between the third metal layer and the feed network layer; and a third feed needle and a fourth feed needle are arranged between the sixth metal layer and the feed network layer.

Owner:SUZHOU TIANYE MECHANICAL IND

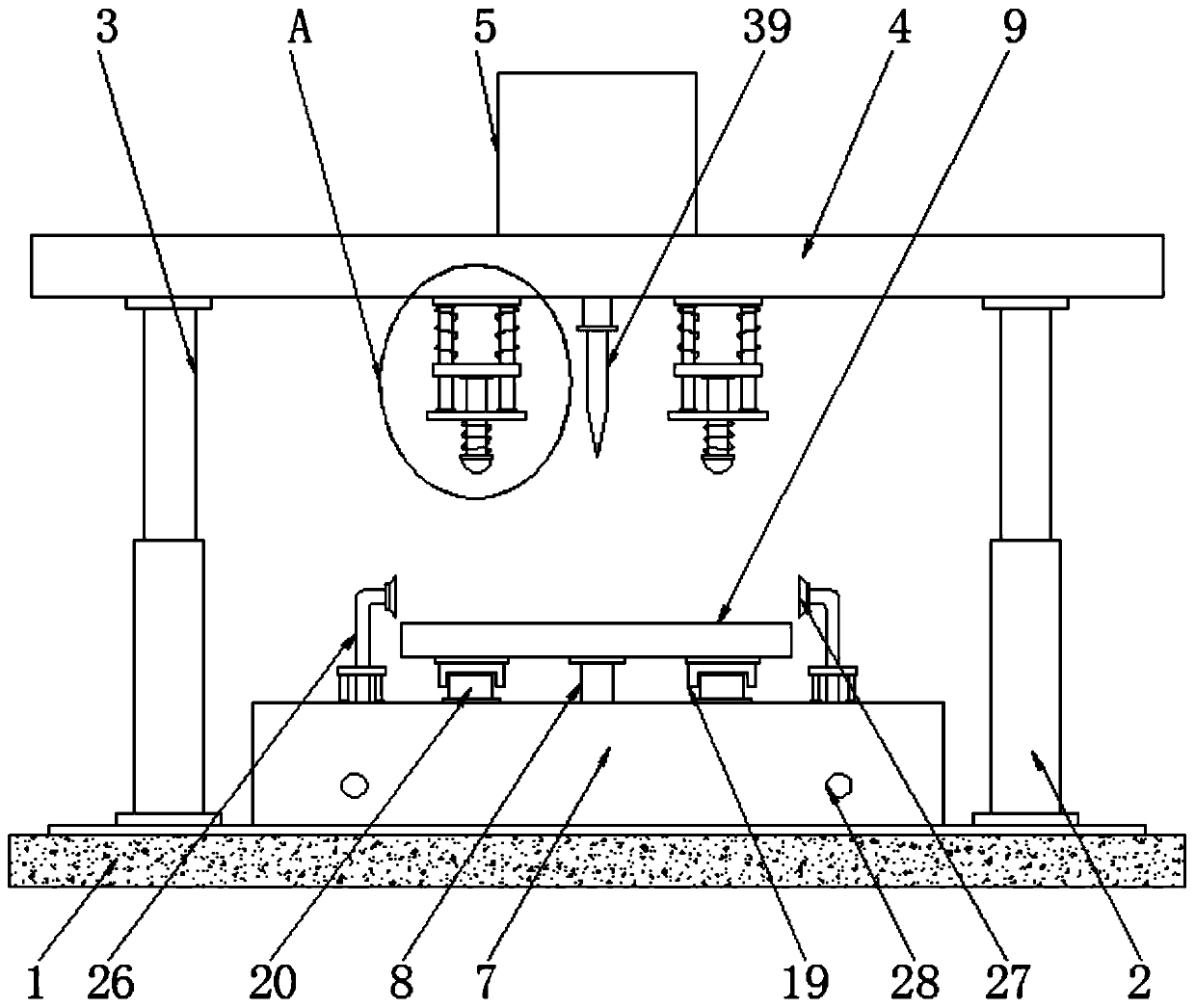

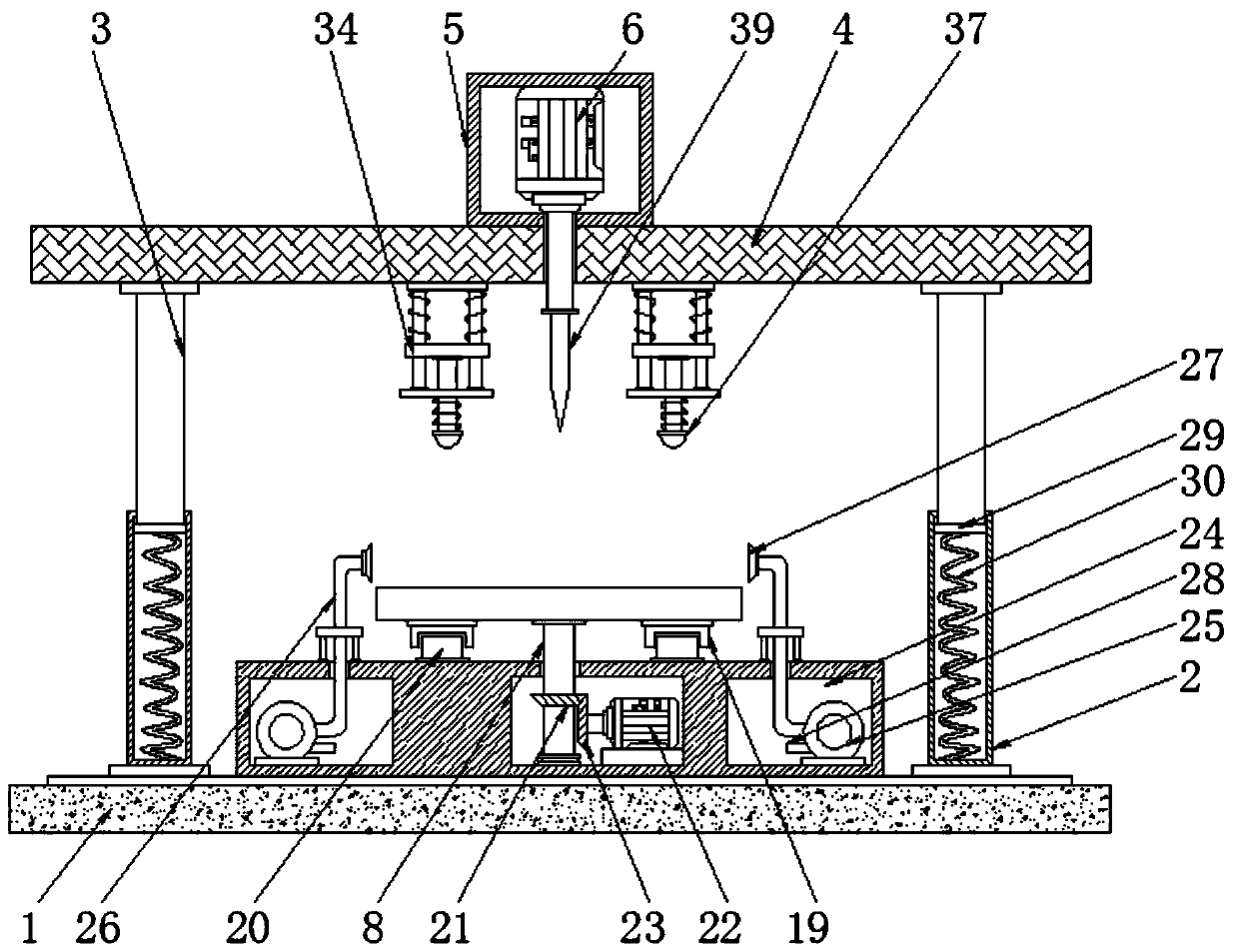

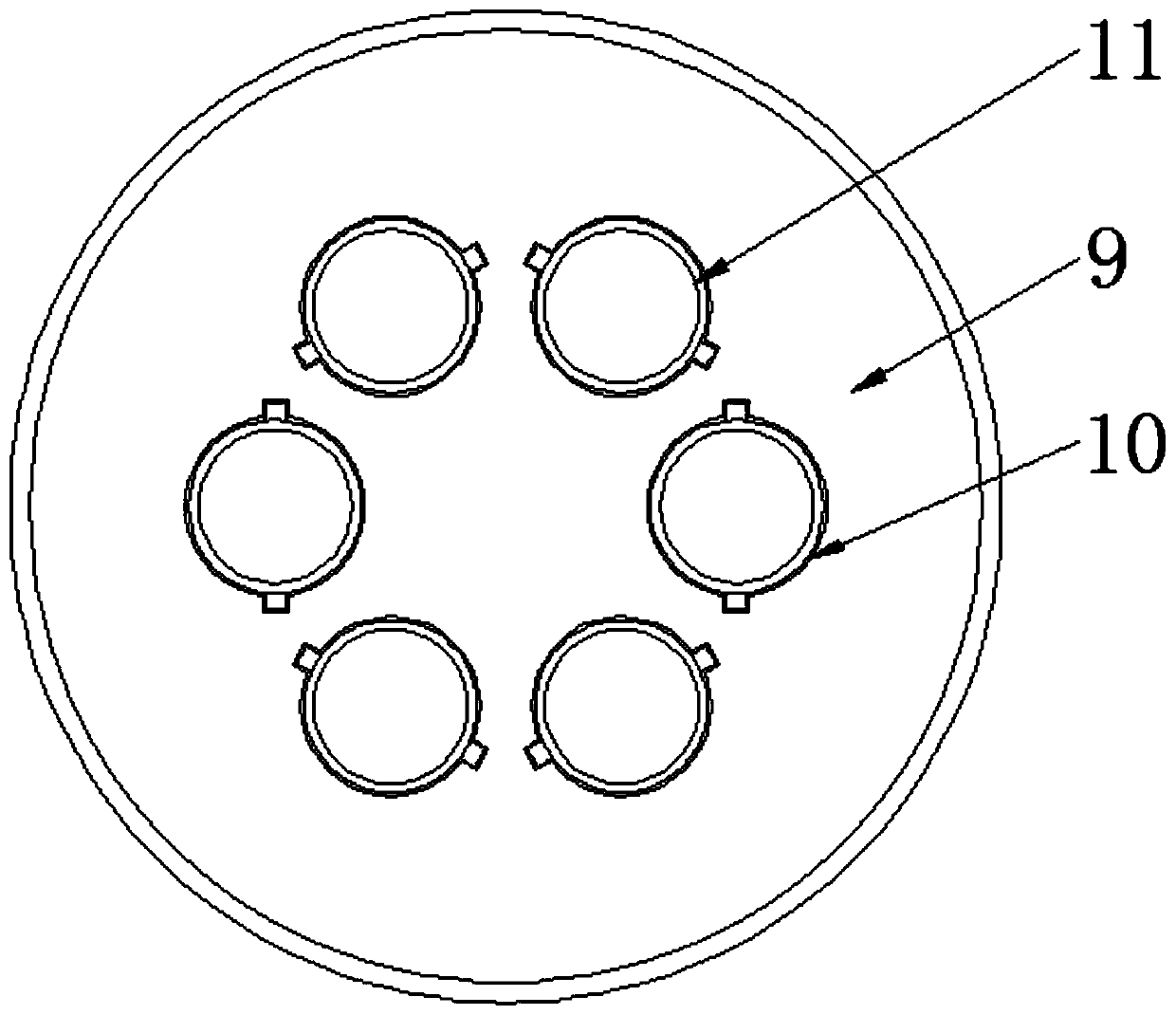

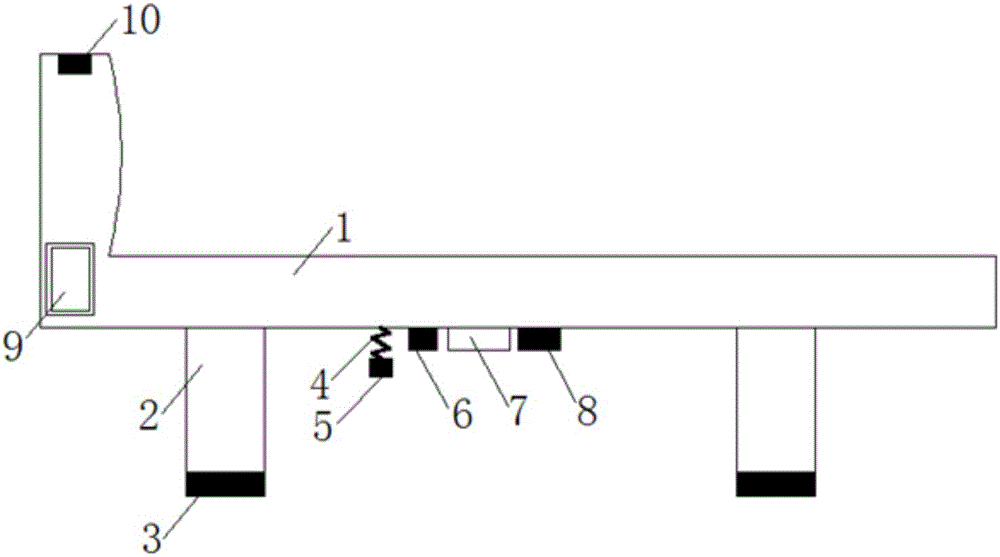

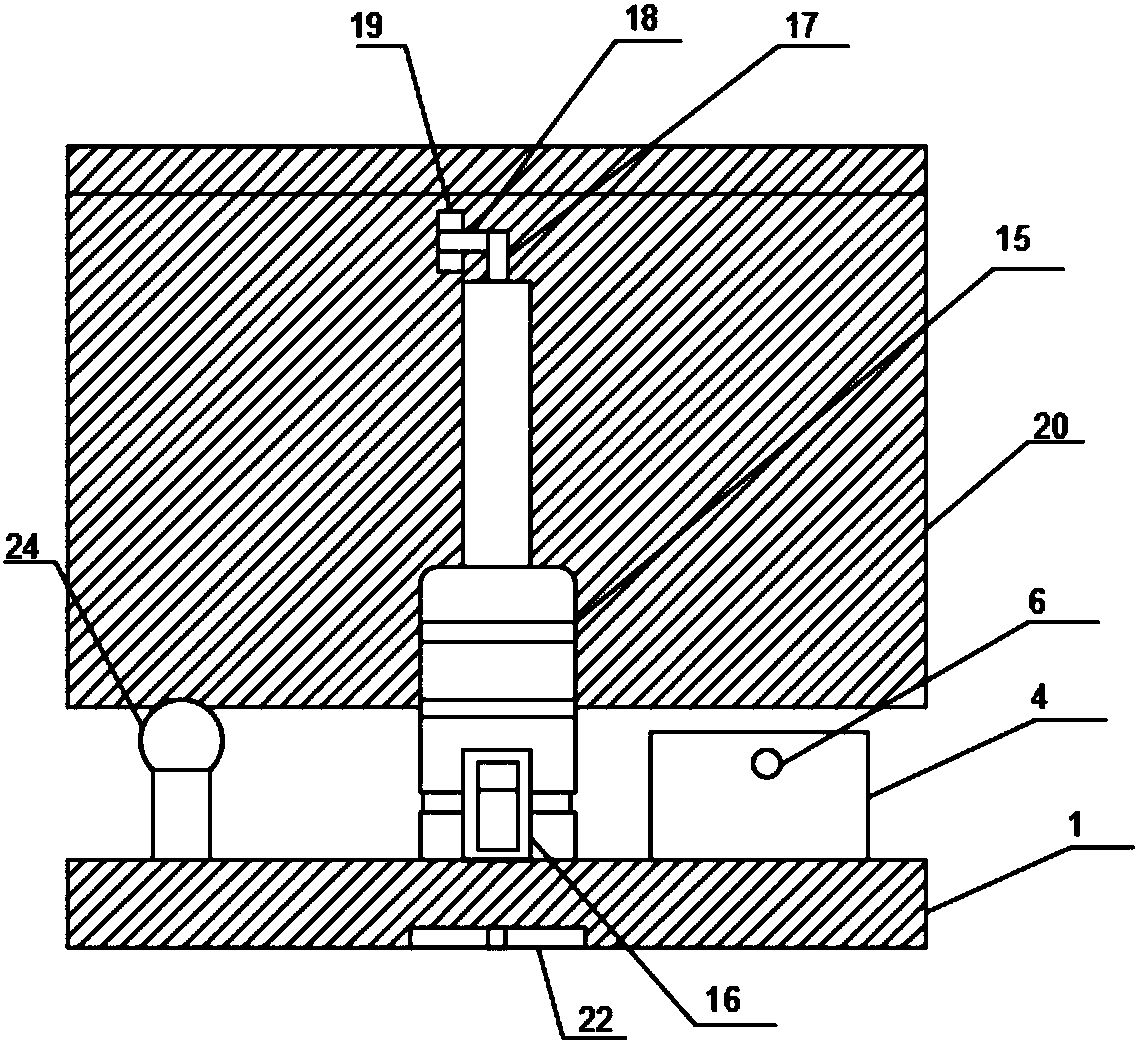

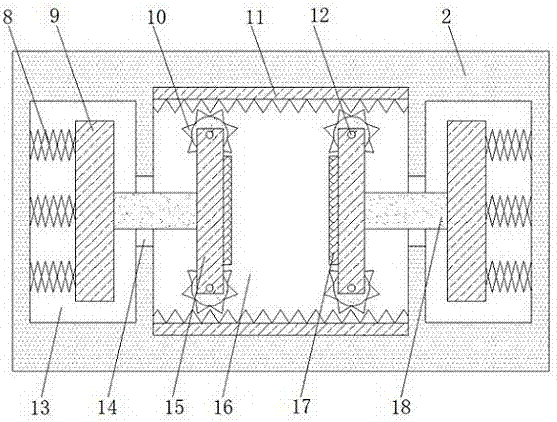

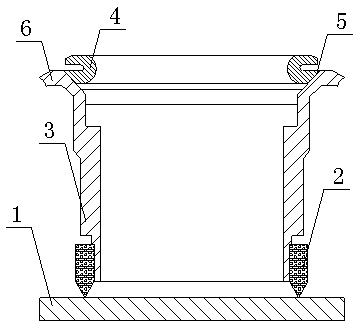

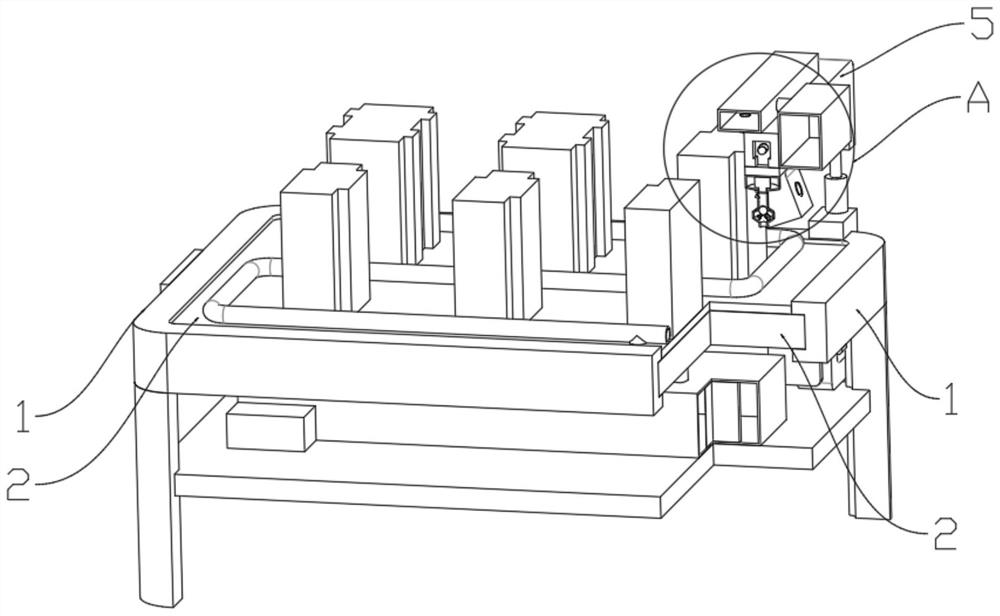

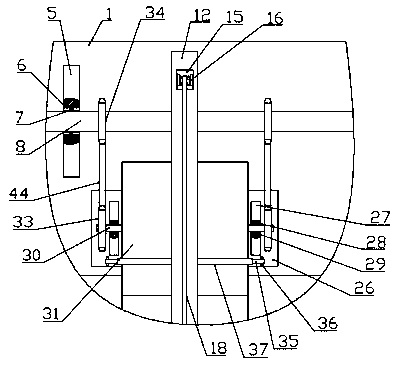

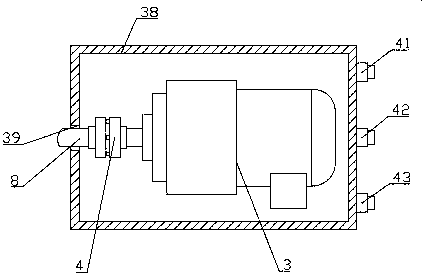

Drilling machine for mechanical part machining

InactiveCN110202176AAvoid deviationShorten the timeMetal working apparatusPositioning apparatusElectric machineryDrill hole

The invention discloses a drilling machine for mechanical part machining. The drilling machine for mechanical part machining comprises a bottom plate; the two sides of the top of the bottom plate arefixedly connected with a shell; the top of the shell is movably connected with a vertical rod; the top end of the vertical rod is fixedly connected with a top plate; the top of the top plate is fixedly connected with a protective box; the top of the inner wall of the protective cover is fixedly connected with a first motor; the output end of the first motor runs through the protective box and thetop plate and extends to the bottom of the top plate; and the output end of the first motor extends to one end of the bottom of the top plate and is fixedly connected with a drill bit. The invention relates to the technical field of mechanical part machining. According to the drilling machine for mechanical part machining, the top of the top plate is fixedly connected with the protective box and six mechanical parts can be operated at one time, so that the part changing time is reduced and the whole operation efficiency is improved; and the supporting rod extends to one end of the top of the box body and is fixedly connected with an operating plate, so that parts can be changed and fixedly conveniently and the drilling efficiency is improved.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

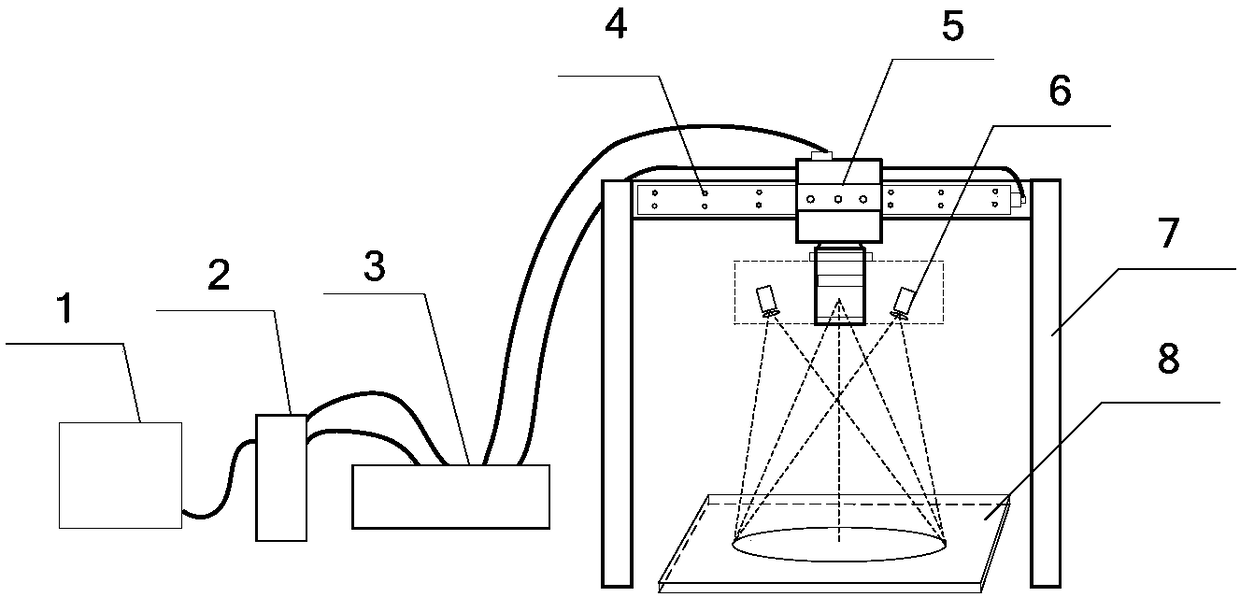

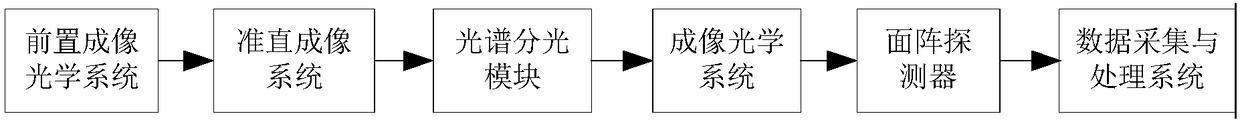

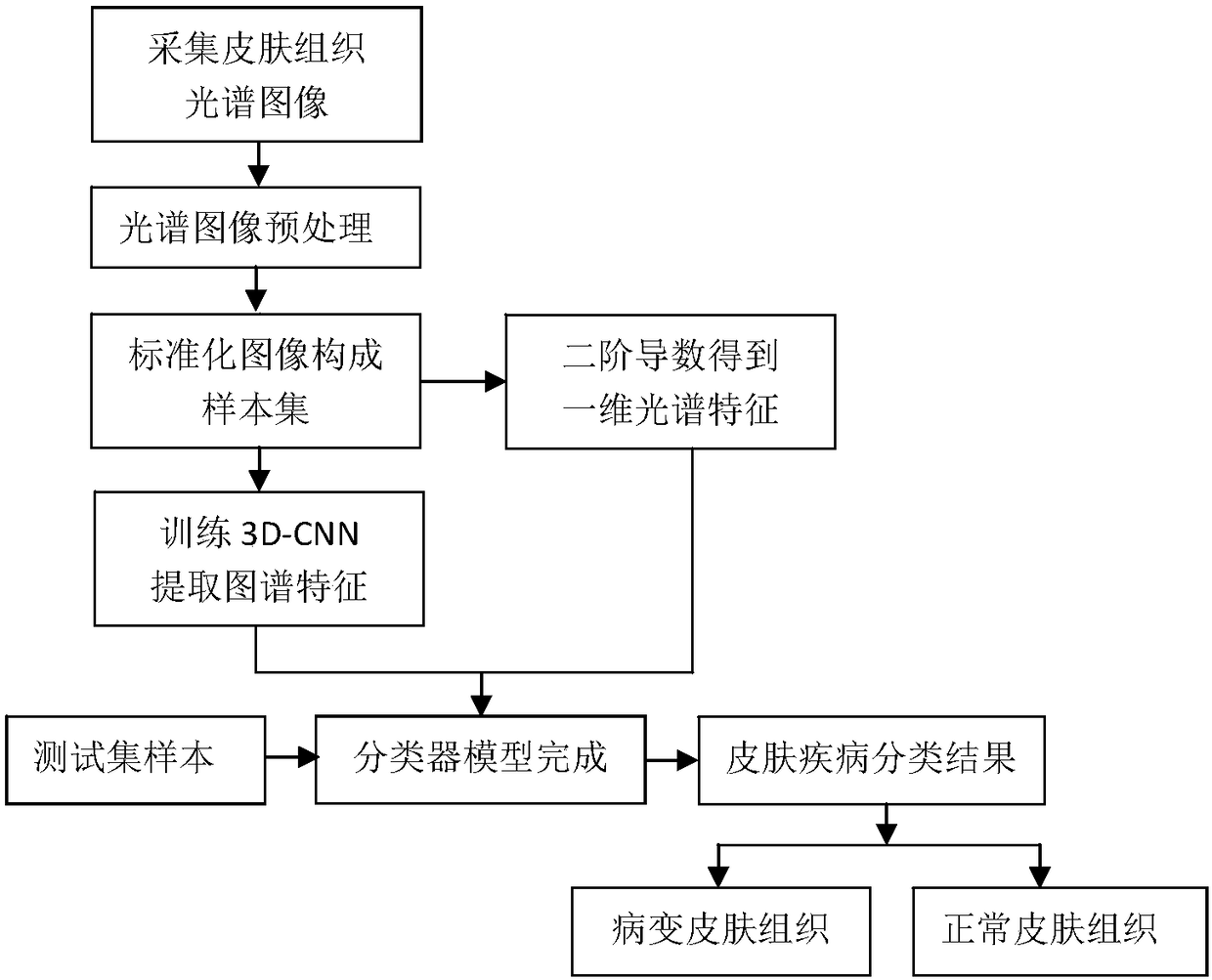

Spectrum detection system for skin disease diagnosis and establishment method for classifier model

InactiveCN108272437AAvoid deviationQuick online diagnosisDiagnostics using spectroscopySensorsDiseaseData processing

The invention provides a non-traumatic spectrum detection system which is used for skin disease diagnosis and can achieve online quick diagnosis and an establishment method for a classifier model. Theproblems of existing skin disease diagnosis technologies are solved. One-dimensional spectrum information and two-dimensional spatial image information of diagnosed skin tissue can be acquired, the acquired spectrum information is used for quickly identifying and classifying the lesion tissue, the image information is used for accurately positioning the lesion tissue, and a novel technical approach is provided for diagnosis of skin diseases, particularly skin melanomas. According to the system and method, the fact is considered that the normal tissue and the lesion tissue have high differenceon spectrum information, an image of a skin lesion area is collected, lesion identification is conducted based on tissue spectrum characteristics, imaging data is subjected to data processing so thatan identification result can be obtained, the lesion tissue and lesion parts can be quickly positioned, and meanwhile deviation caused by manual identification is avoided.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

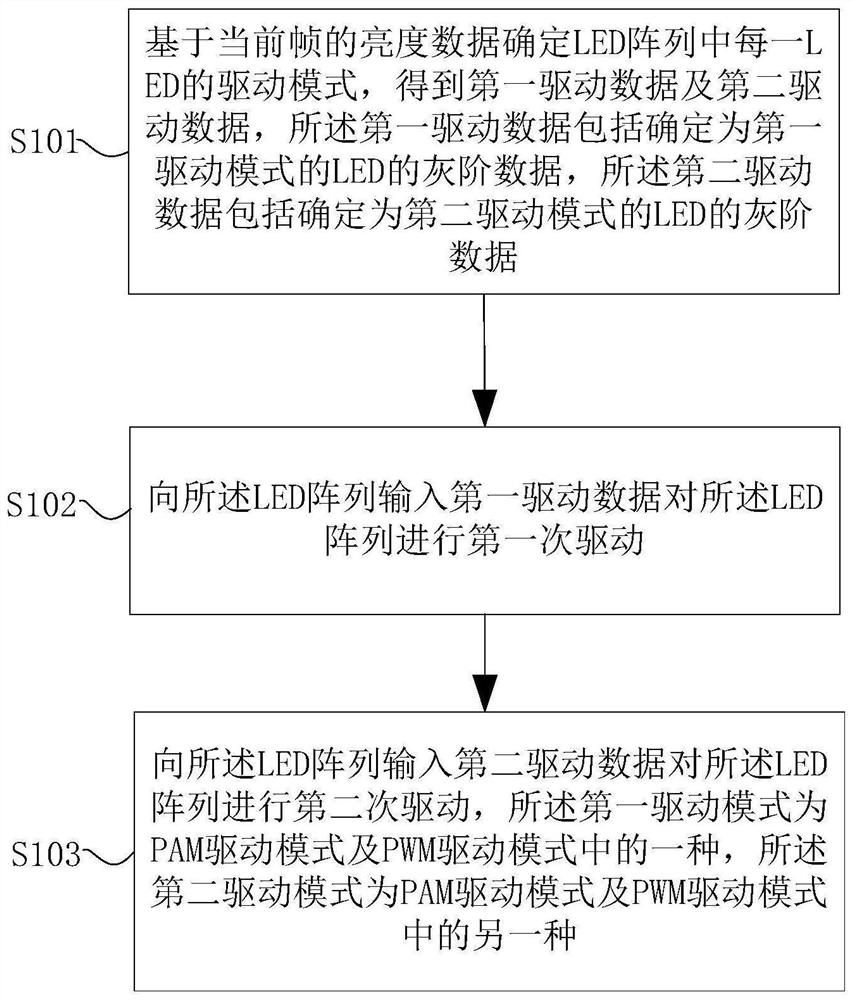

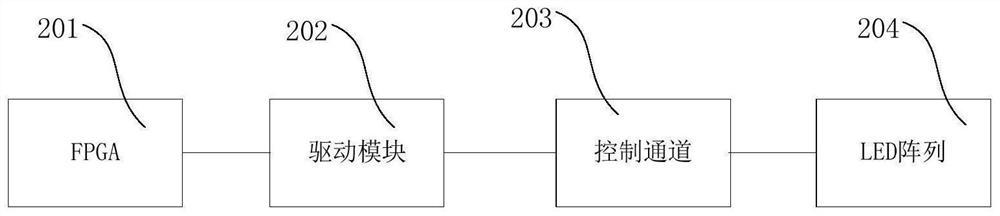

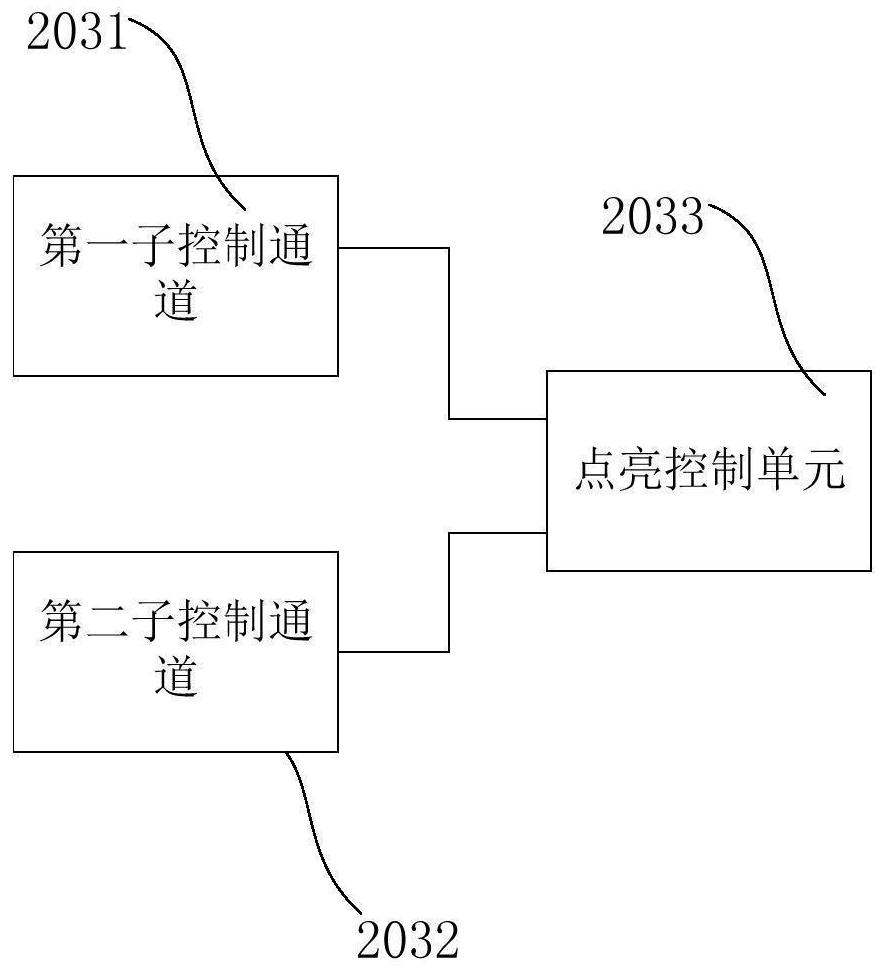

LED display drive control method and device

InactiveCN113066423AAvoid current fluctuationsAvoid deviationStatic indicating devicesEngineeringDriving mode

The invention is suitable for the technical field of display screen driving, and provides an LED display driving control method and device, and the control method comprises the steps: determining a driving mode of each LED in an LED array based on the brightness data of a current frame, and obtaining first driving data and second driving data; inputting the first driving data into the LED array to drive the LED array for the first time; and inputting the second driving data into the LED array to drive the LED array for the second time, wherein the first driving mode and the second driving mode each correspond to one of a PAM driving mode and a PWM driving mode. According to the technical scheme of the invention, PAM and PWM joint driving is achieved, reliable display of the LED array can be realized when the LED array is in a high gray scale or a low gray scale, and the gray scale uniformity of the LED array can be effectively improved, so that accurate gray scale control can be realized, and the display effect of the LED array is improved.

Owner:TCL CORPORATION

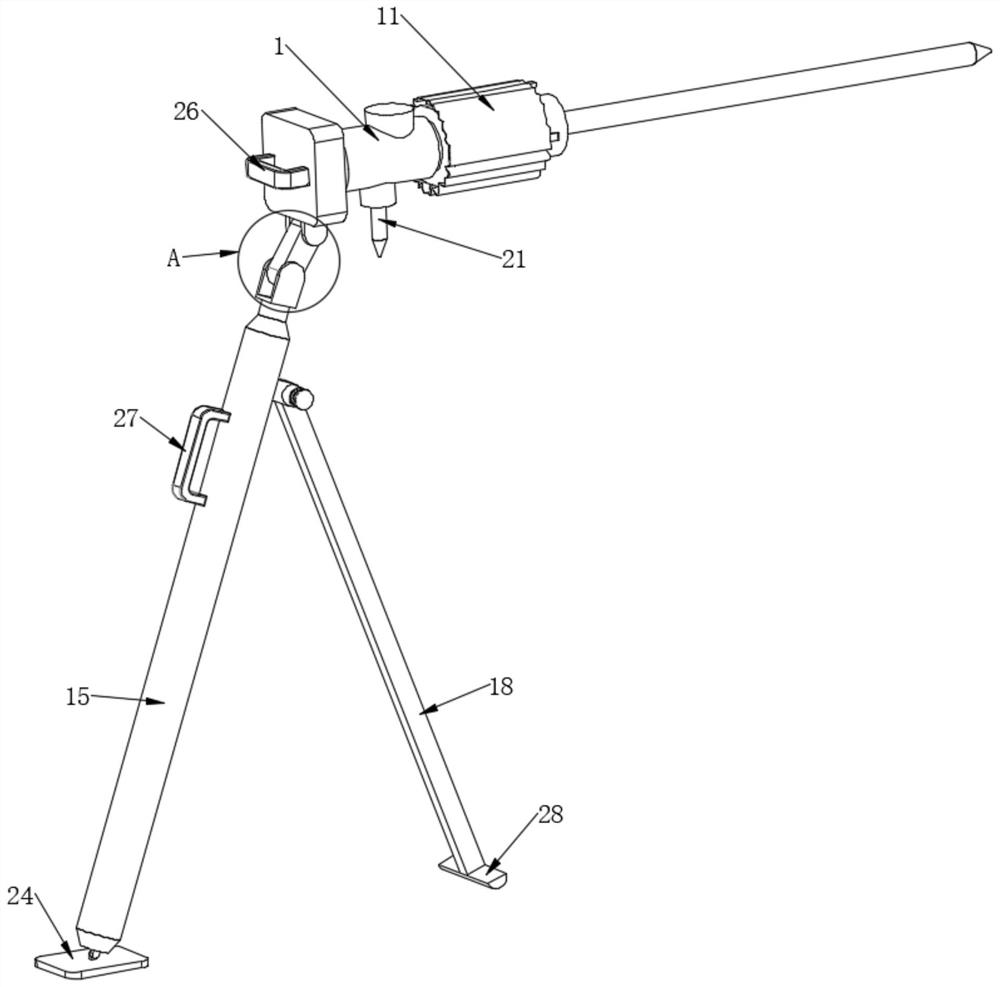

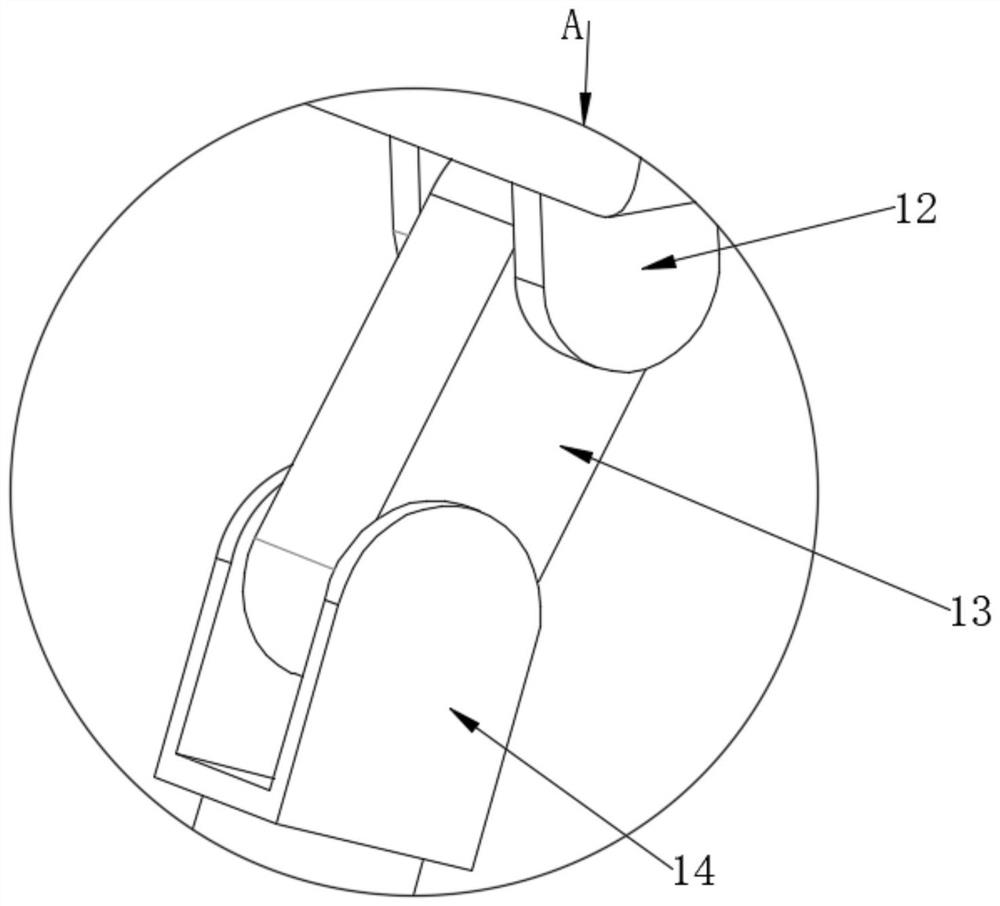

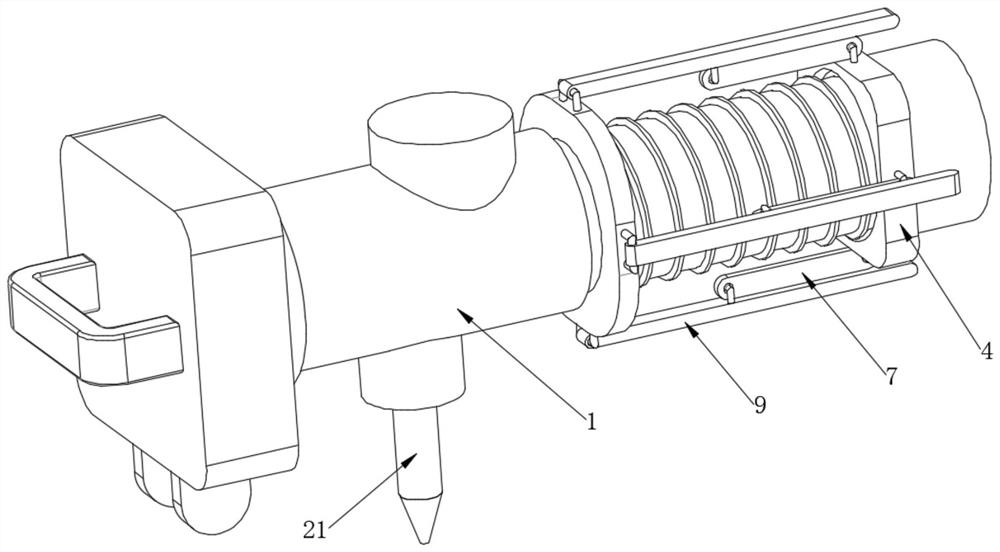

Supporting leg type full-hydraulic rock drill

InactiveCN112343517AAvoid deviationEasy to moveEarth drilling toolsConstructionsGeotechnical engineeringDrill

The invention relates to the technical field of rock drills, and discloses a supporting leg type full-hydraulic rock drill. The rock drill comprises a full-hydraulic rock drill body and an air cylinder, wherein one side of the full-hydraulic rock drill body is fixedly sleeved with a threaded barrel, one side of the threaded barrel is movably sleeved with a sleeve, the other side of the threaded barrel is fixedly sleeved with a side plate, and one side of the sleeve is movably sleeved with a moving plate. According to the supporting leg type full-hydraulic rock drill, the sleeve and the threaded barrel are connected through thread engagement, and the sleeve and the moving plate are movably connected, so that the moving plate can be conveniently driven to move on the outer side of the threaded barrel when the sleeve is rotated, therefore a connecting plate is driven to rotate along the outer side of a first guide rod to support a supporting plate towards the outer side of the threaded barrel, and oil paper cloth is stretched, so that a worker can be protected when the leg type full-hydraulic rock drill is used, and flying chips are prevented from splashing to the body of the worker and hurting the worker.

Owner:黄建秋

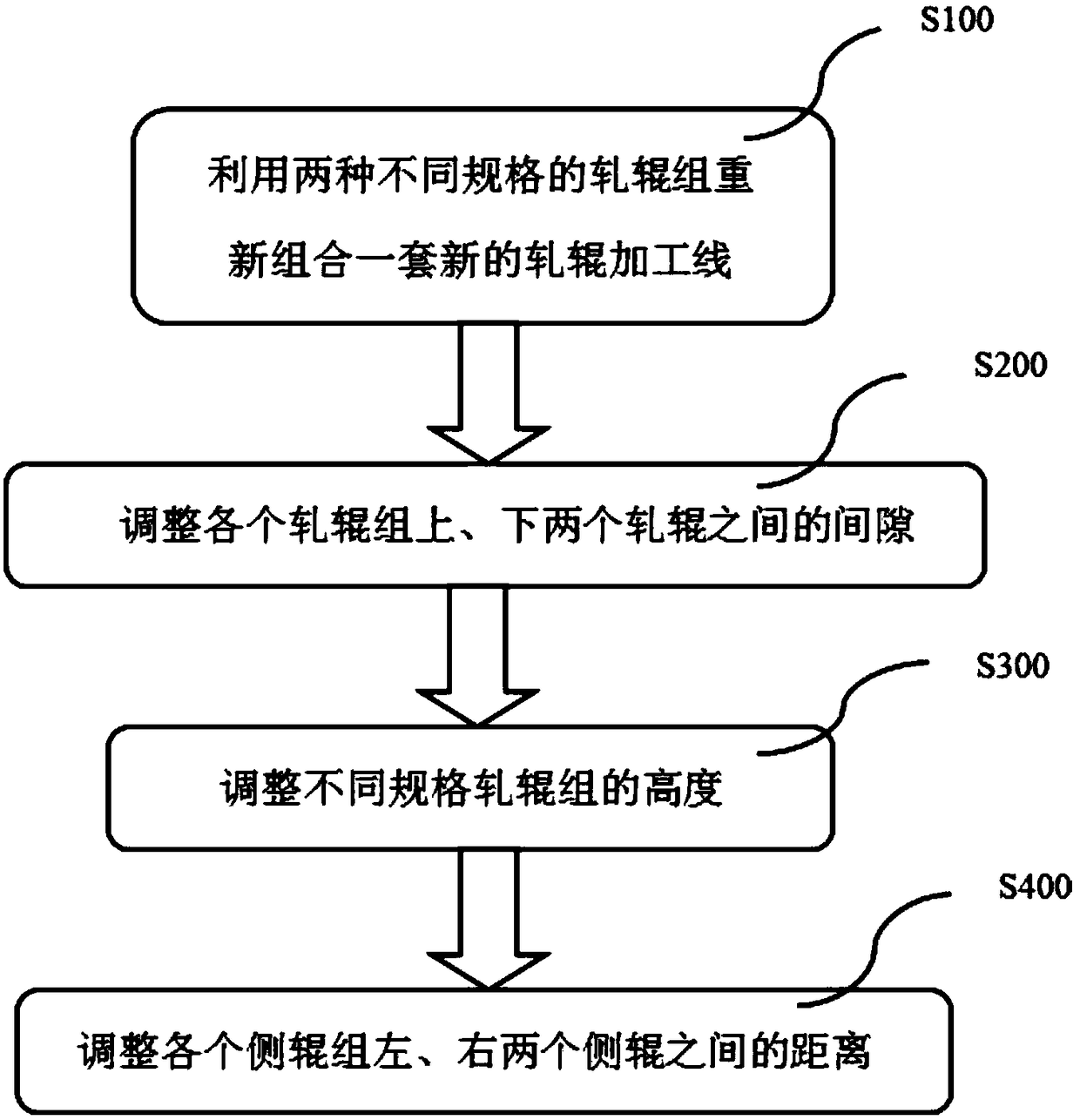

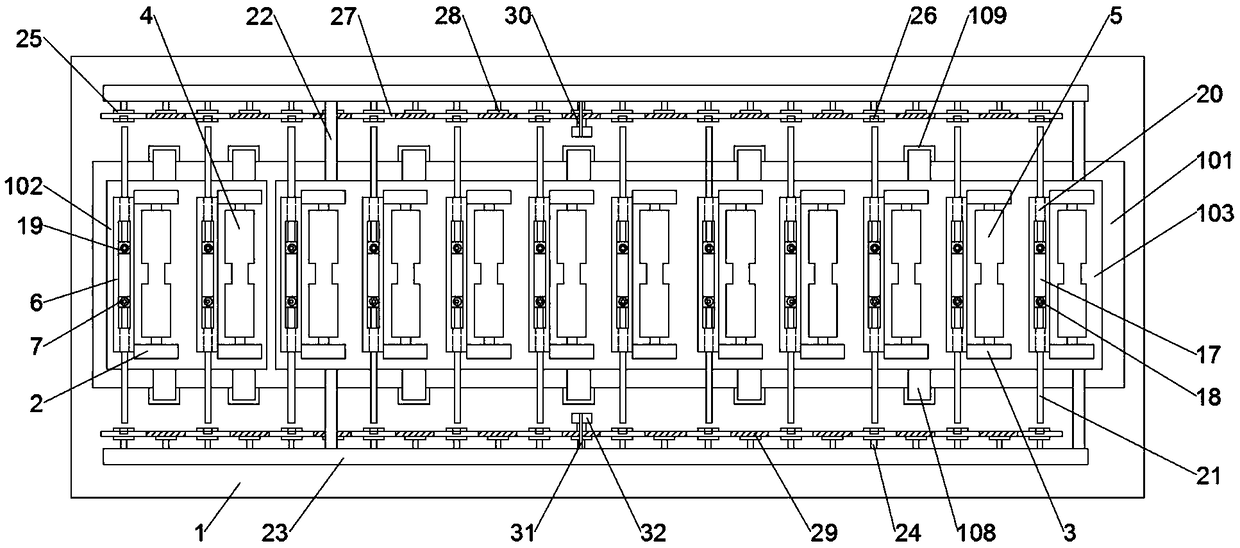

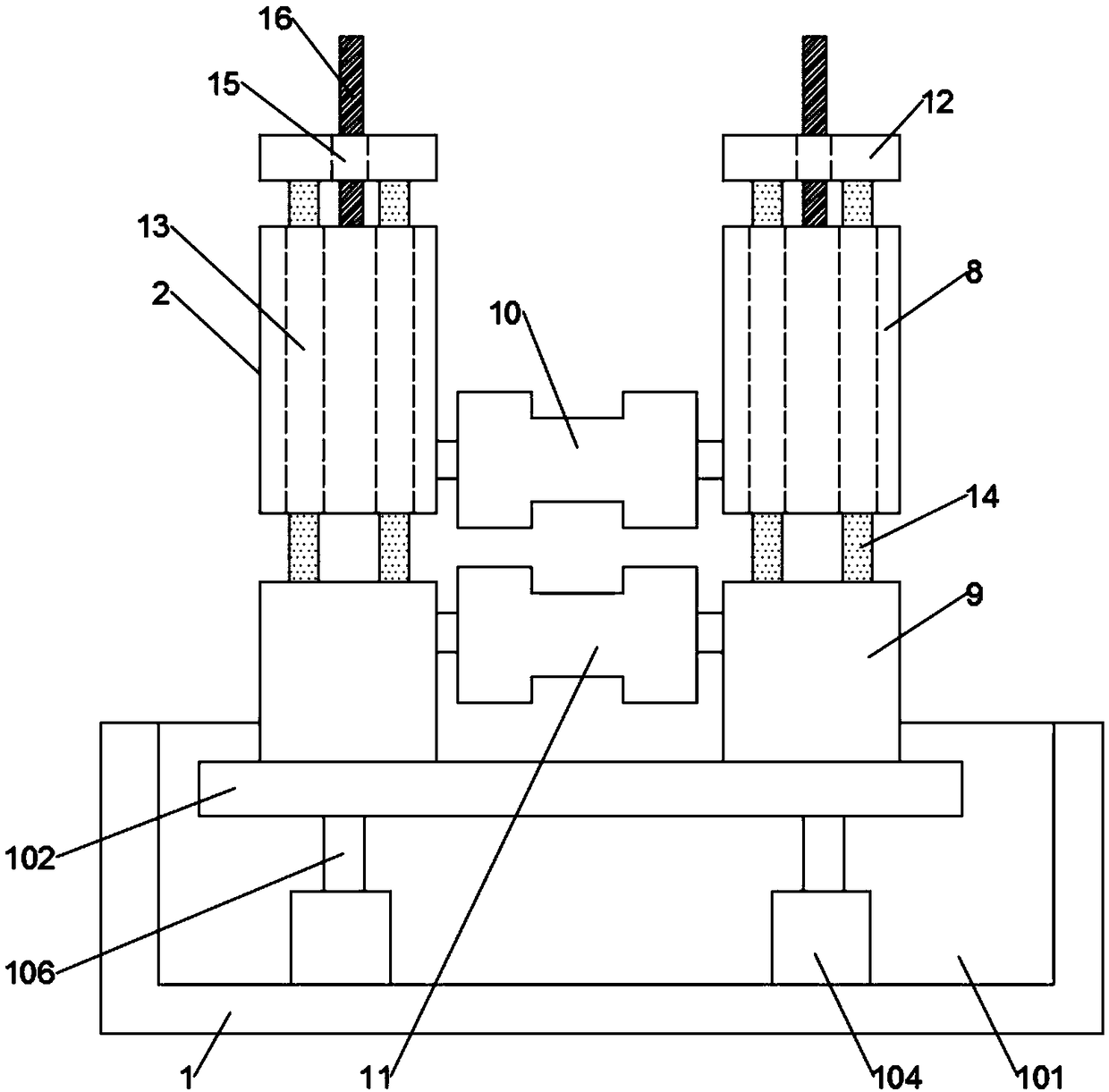

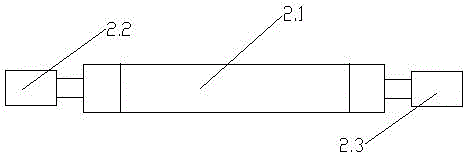

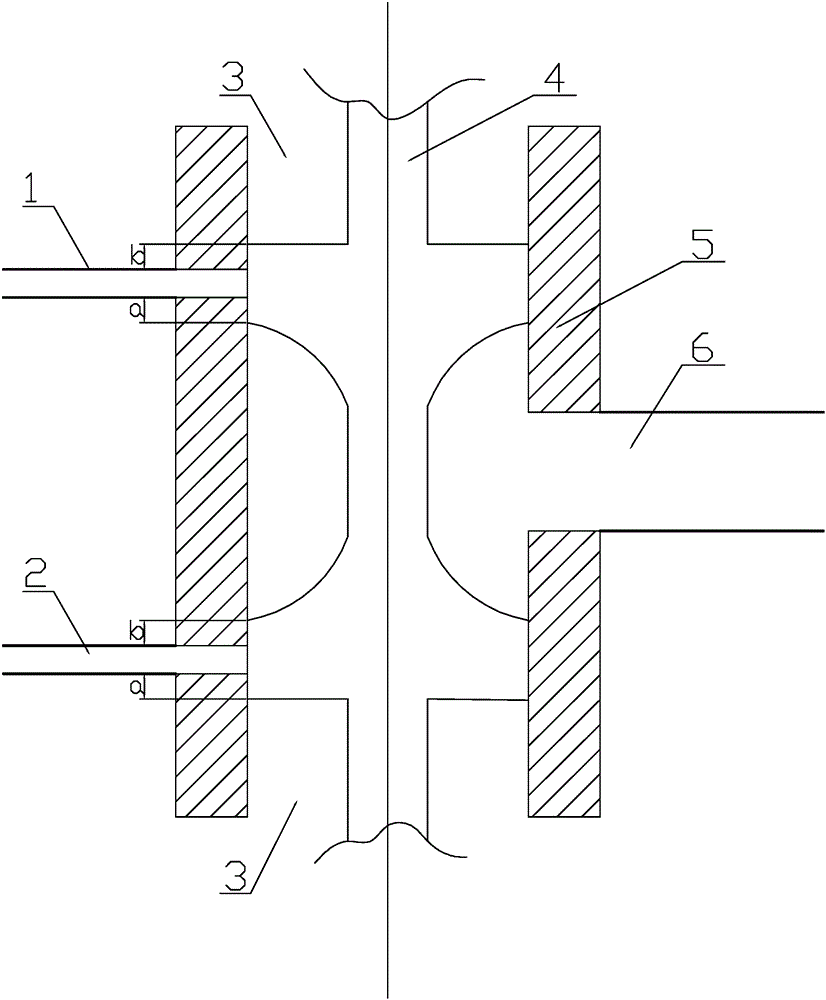

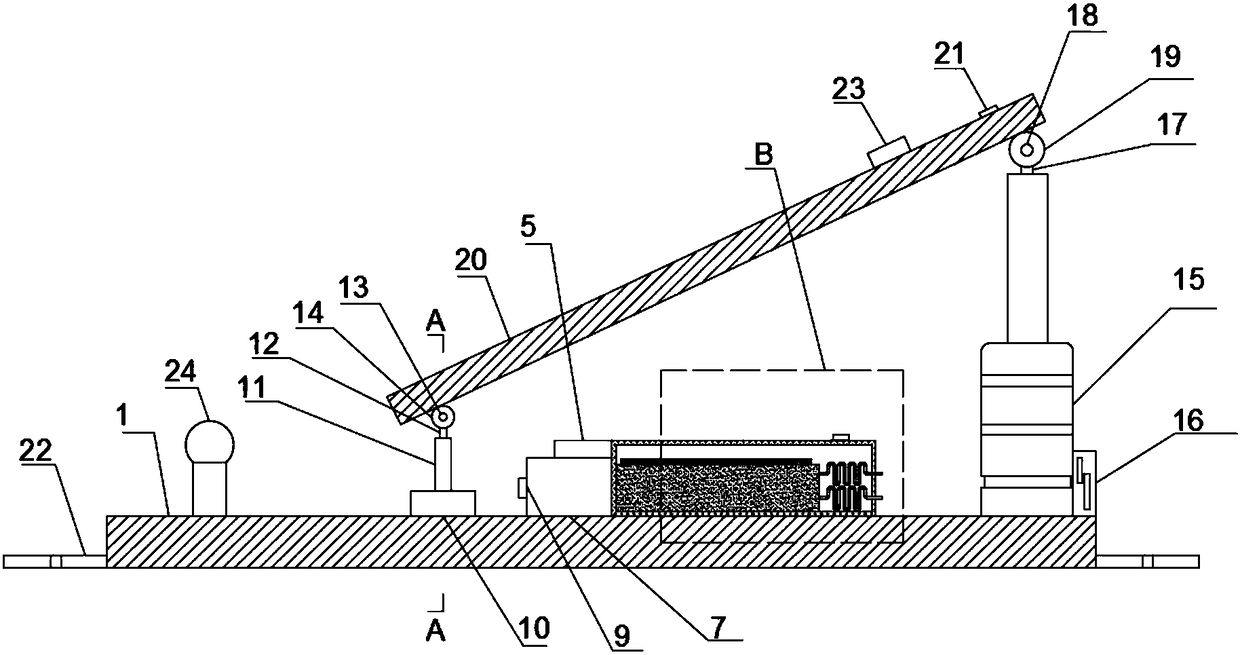

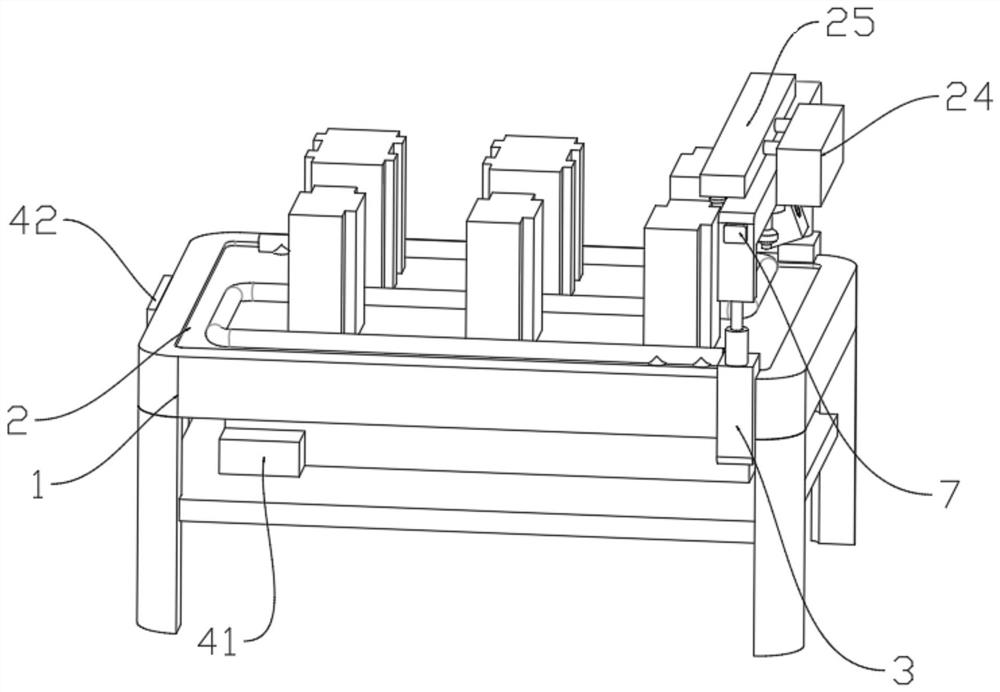

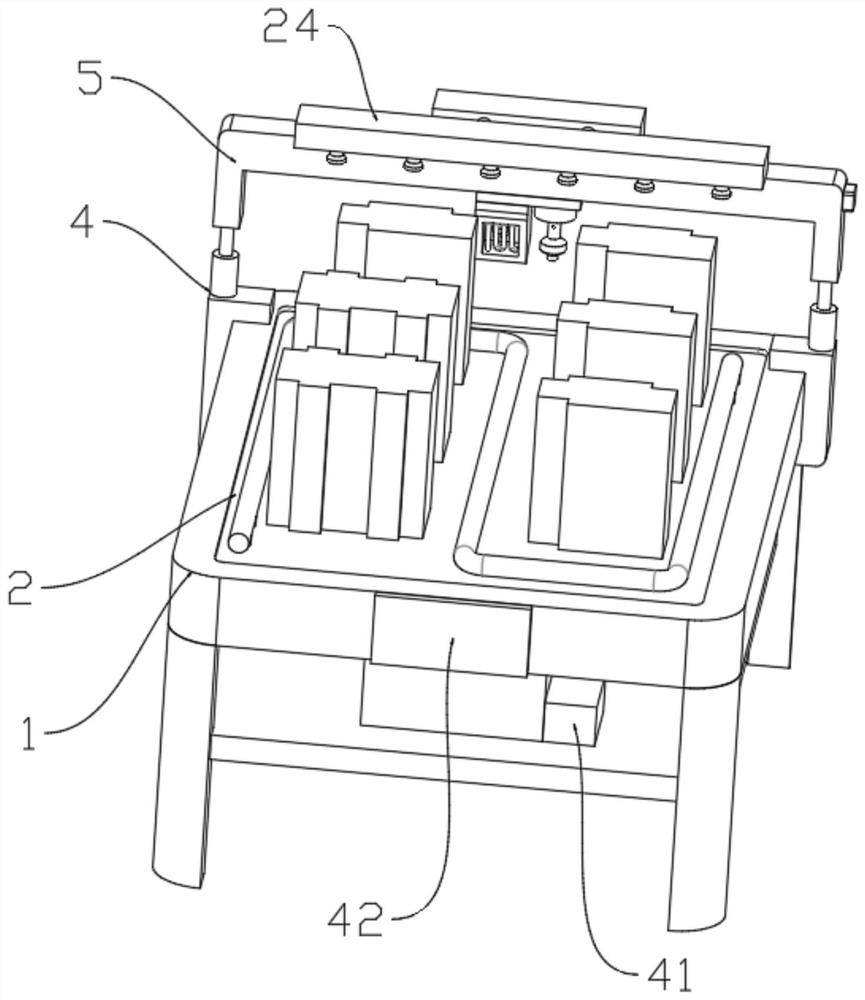

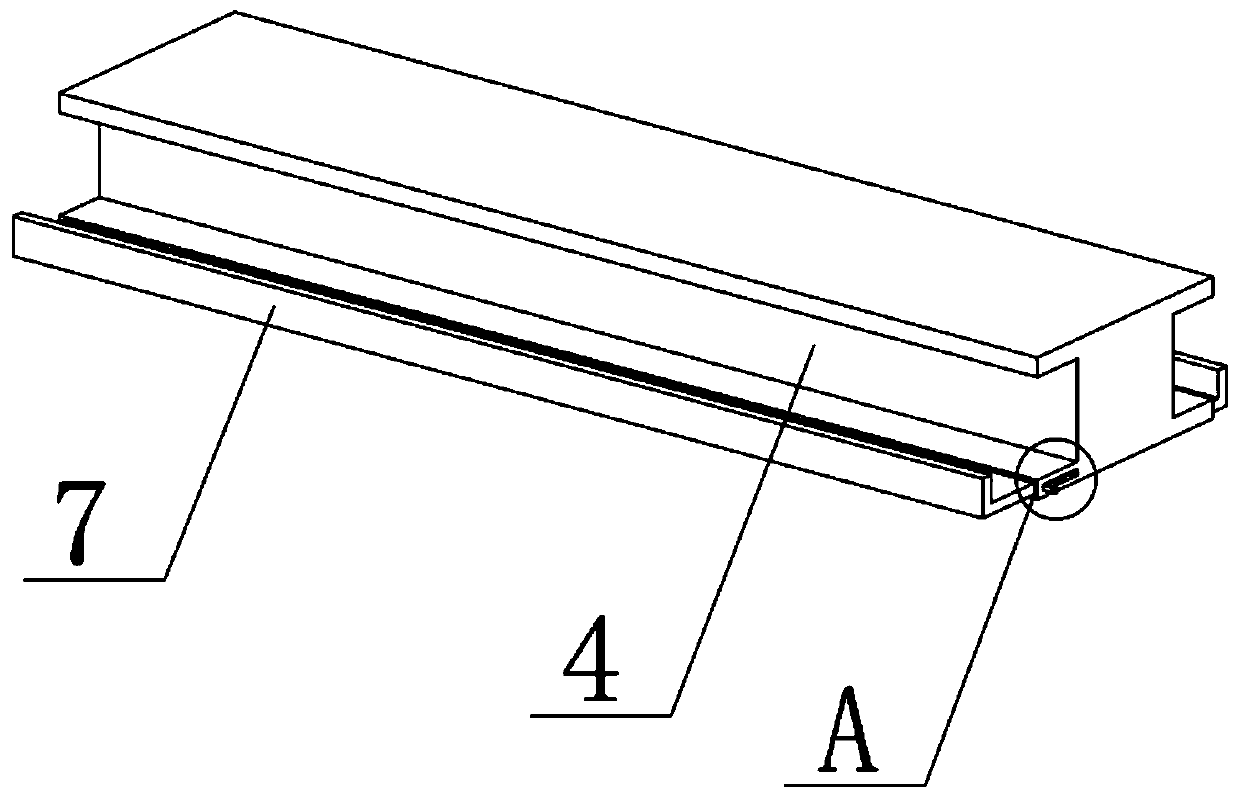

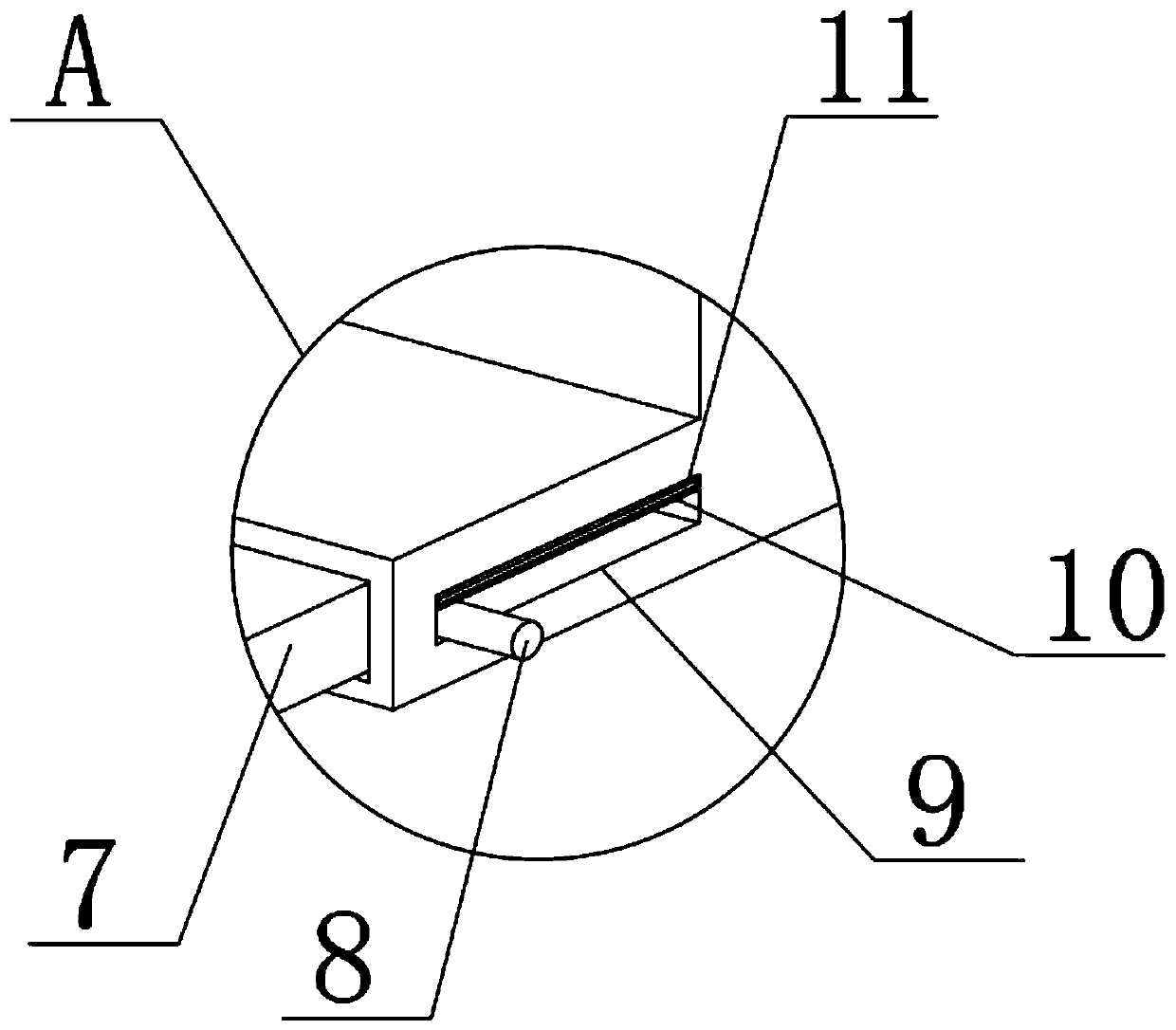

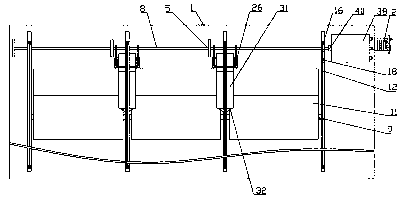

Method and device for quickly changing heights of rolls for wall keel production

ActiveCN109127736AReduced commissioning timeAvoid deviationMetal rolling stand detailsMetal rolling arrangementsMechanical engineeringKeel

The invention discloses a method and device for quickly changing the heights of rolls for wall keel production. The method comprises the following steps that S100, a new set of roll processing lines is recombined through two roll sets of different specifications; S200, the interval between an upper roll and a lower roll of each roll set is adjusted; S300, the heights of the roll sets of differentspecifications are adjusted; and S400, the distance between a left side roll and a right side roll of each side roll set is adjusted. Through the method, the heights of the rolls can be adjusted without replacing the whole set of rolls, the debugging time can be shortened, meanwhile, the width of each set of side rolls can be quickly adjusted, deviation can be avoided, in addition, the final stepof pressing or increasing the height of products can be omitted, and the production efficiency is improved advantageously.

Owner:镇江北新建材有限公司 +1

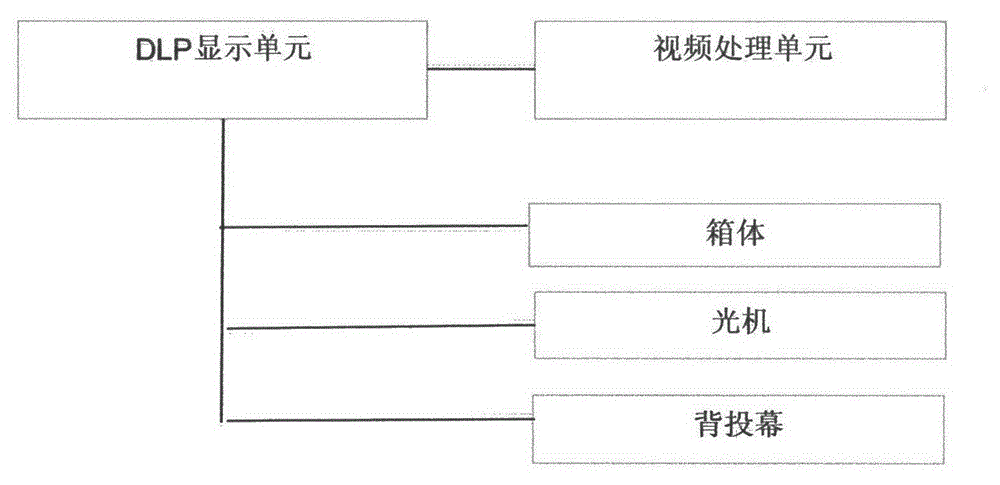

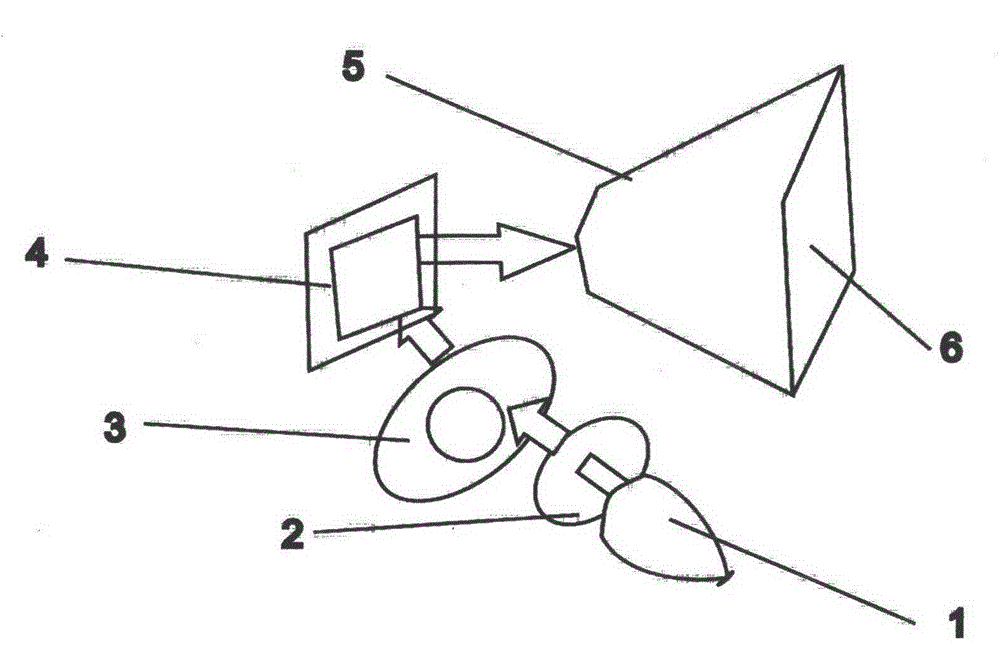

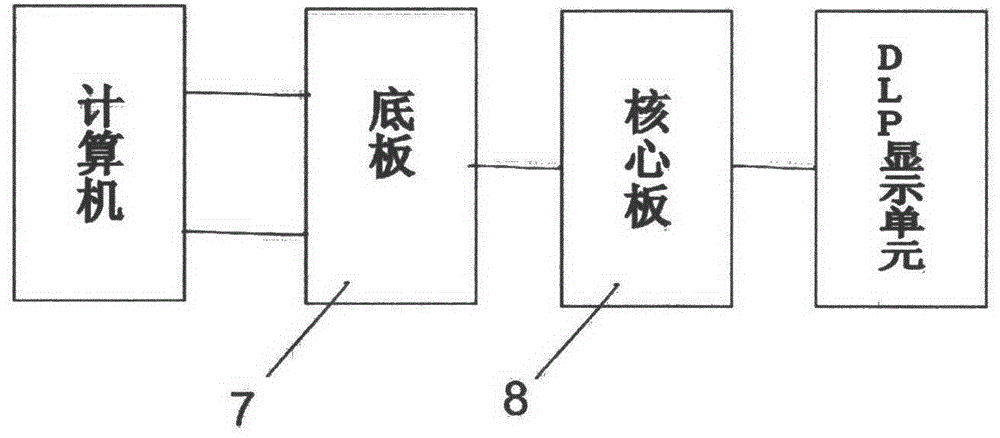

Optical projection system

InactiveCN105319809AGood for mass productionAvoid deviationProjectorsPicture reproducers using projection devicesCamera lensProjection system

The present invention relates to an optical projection system which comprises DLP display units and a video processing unit. Each of the DLP display units comprises a box body, an optical machine and a rear projection screen. The optical machine comprises a lens. The light which goes through the optical machine is projected to the rear projection screen through a lens. The video processing unit comprises a bottom plate and a core plate. The bottom plate comprises a video access end and a connection device. The video access end receives a video image signal. The core plate comprises a signal interface and a memory. The connection device is connected to the bottom plate and the core plate respectively. The signal interface is connected to the optical machine. The memory is used for storing a correction parameter after a video image is corrected. Through storing the parameter of the geometrically adjusted video image into the core plate, the six-axis adjustment of each of the DLP display units in the production process is not needed, and the large-scale production is facilitated. At the same time, the bias generated in the condition that a later six-axis is influenced by gravity and external force is avoided.

Owner:马国光

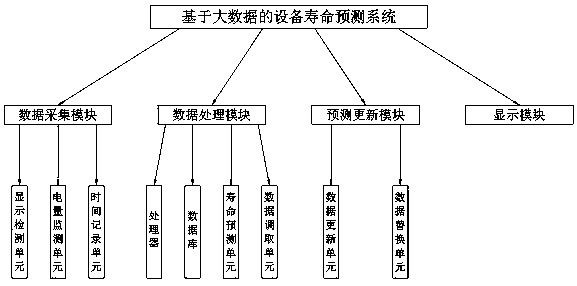

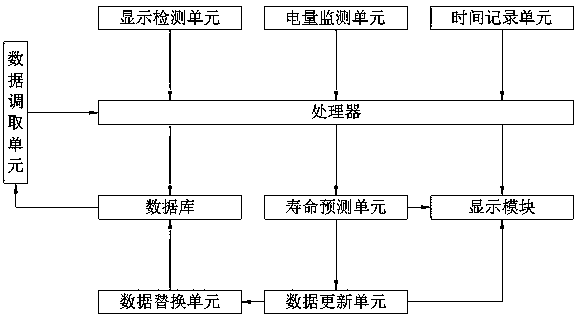

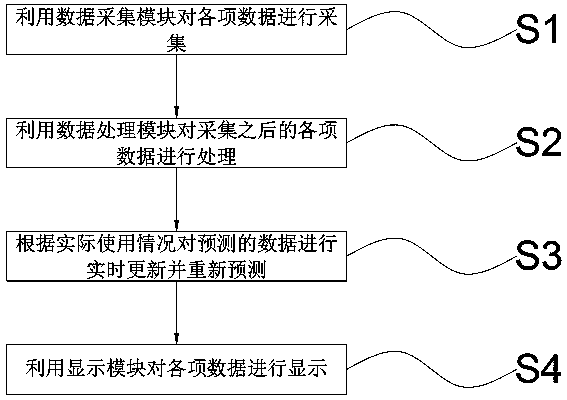

Equipment life prediction system and method based on big data

The invention belongs to the technical field of big data. The invention specifically discloses an equipment life prediction system and method based on big data. The service life prediction system comprises a data collection module and a data processing module, a prediction updating module and a display module, the data collection module is electrically connected with the data processing module; and the data processing module is electrically connected with the prediction updating module and the display module. Safe and convenient use, a data replacement unit and a data updating unit are arranged. Therefore, the static power consumption rate and the dynamic power consumption rate of the communication equipment battery in the actual use process can be used for calculating the original predicted static power consumption rate and dynamic power consumption rate at the time point; according to the method, the data can be updated, large deviation of the prediction result caused by complete prediction is avoided, the prediction data is replaced with the actual use data, prediction can better fit the actual use condition, and the prediction result can gradually become accurate.

Owner:广东招才通信息科技有限公司

Basketball shooting training system

ActiveCN109731316AAvoid deviationImprove accuracySport apparatusMuscle memoryCentral processing unit

The invention relates to a basketball shooting training system. The basketball shooting training system comprises a gesture sensor, a myoelectric sensor and a central processor, wherein the central processor is used for processing a gesture signal and carrying out comparison on the gesture signal and a standard basketball shooting gesture in a standard gesture database so as to generate at least one basketball shooting gesture; and the central processor is used for retrieving a muscle memory set mutually matched with the basketball shooting gesture from the standard gesture database, processing a myoelectric signal corresponding to the basketball shooting gesture, extracting a muscle feature set, carrying out comparison on the muscle feature set and the muscle memory set and transferring deviation to a prompt module when the deviation exists between the muscle feature set and the muscle memory set, so that an athlete can at least read the corresponding relation between the basketball shooting gesture and the muscle feature set from the prompt module and the deviation relation between the muscle feature set and the muscle memory set after finishing one time of or one group of training operations.

Owner:张皓翔

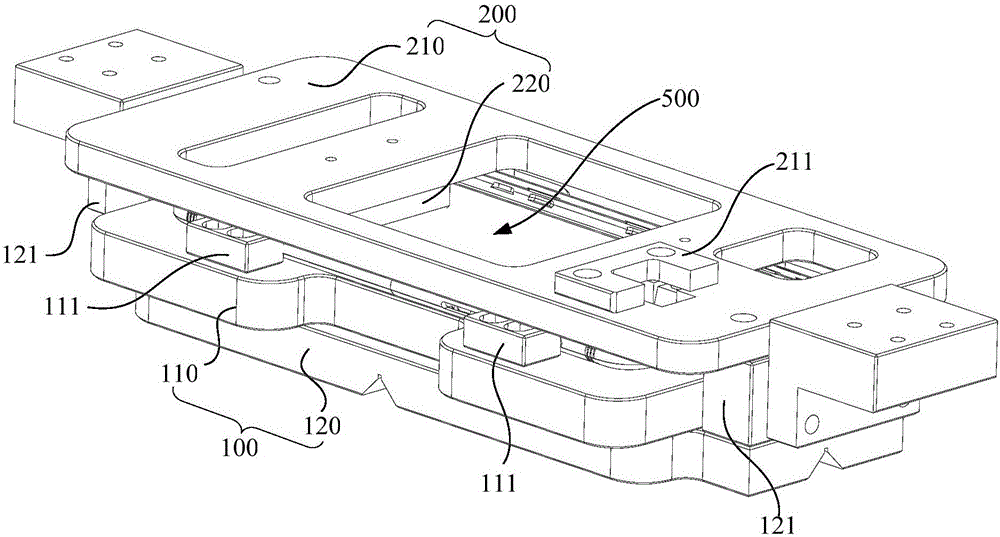

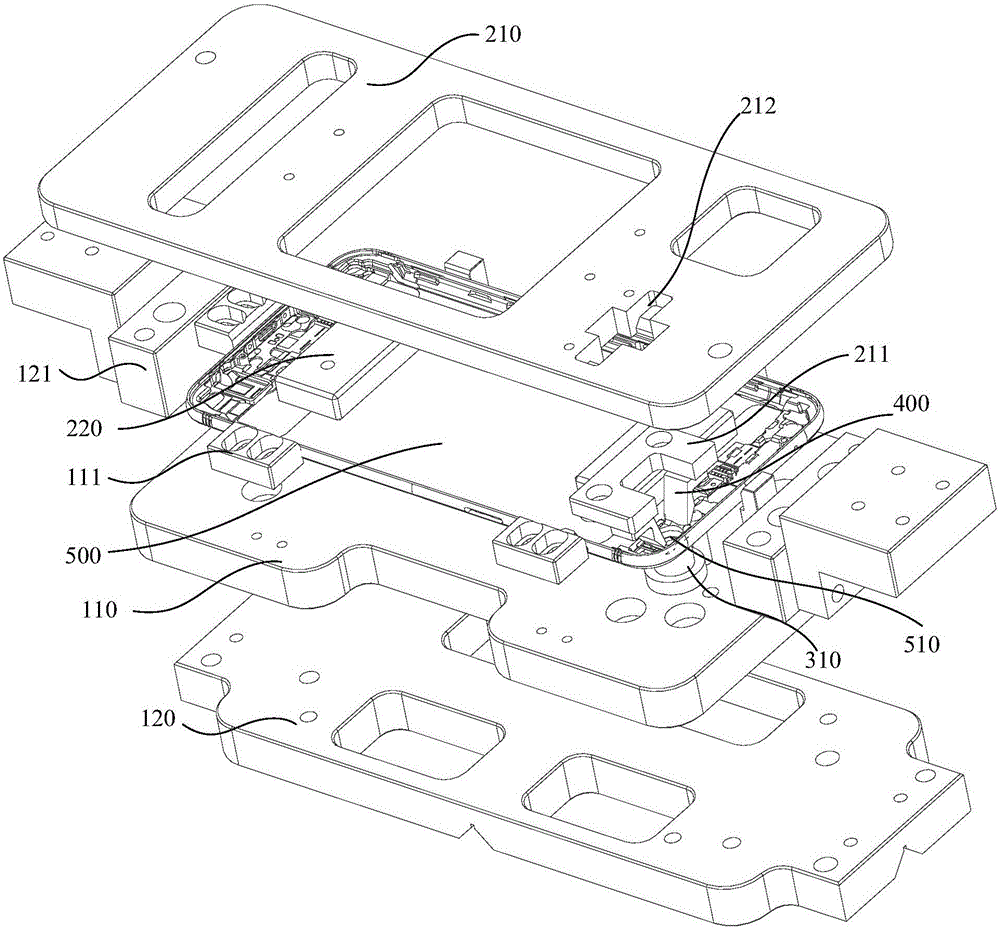

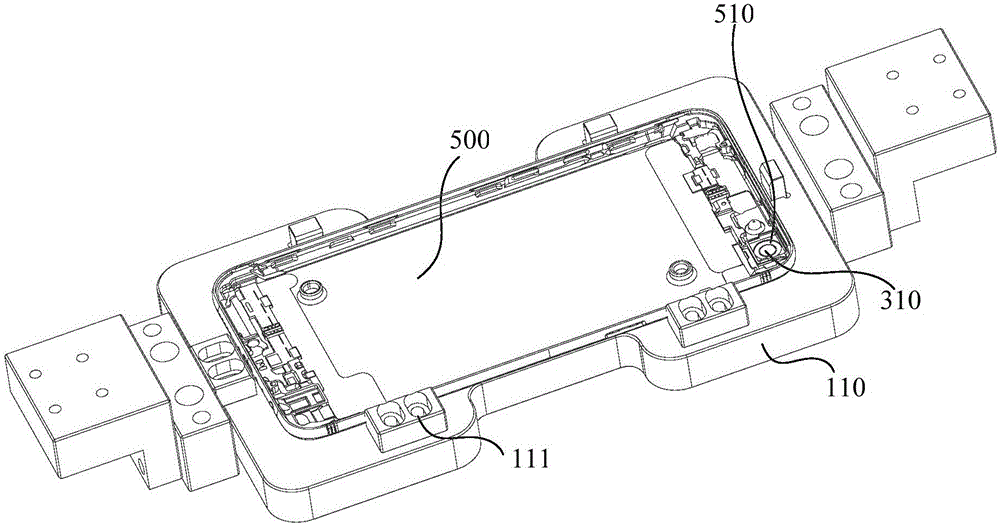

Laser spot welding clamp

ActiveCN106735959AHigh positioning accuracyNot easy to shakeLaser beam welding apparatusEngineeringSpot welding

The invention relates to a laser spot welding clamp. The laser spot welding clamp comprises a first clamping mechanism, a second clamping mechanism and a Y-axis positioning mechanism, wherein the first clamping mechanism is provided with X-axis positioning blocks for positioning a workpiece, the second clamping mechanism comprises a second clamping plate connected to the first clamping mechanism and an abutting-pressing part connected to the second clamping plate and used for abutting against the workpiece, and the Y-axis positioning mechanism comprises a positioning column which is arranged on the first clamping mechanism and penetrates through a round hole and an elastic part arranged between the positioning column and the first clamping mechanism. According to the laser spot welding clamp, because only one positioning column is required to be arranged in the round hole of the workpiece in a penetrating mode to realize the positioning of the workpiece in the Y-axis direction, the structure of the clamp is simplified, the positioning precision of the workpiece is improved, the phenomena of false welding, unwelding and deviation in the welding process of an auxiliary material are avoided, and the welding quality of the product is guaranteed; and meanwhile, the clamping capability of the whole clamp is guaranteed, the workpiece is not prone to shake in the spot welding process, and the positioning stability of the workpiece is ensured.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD +1

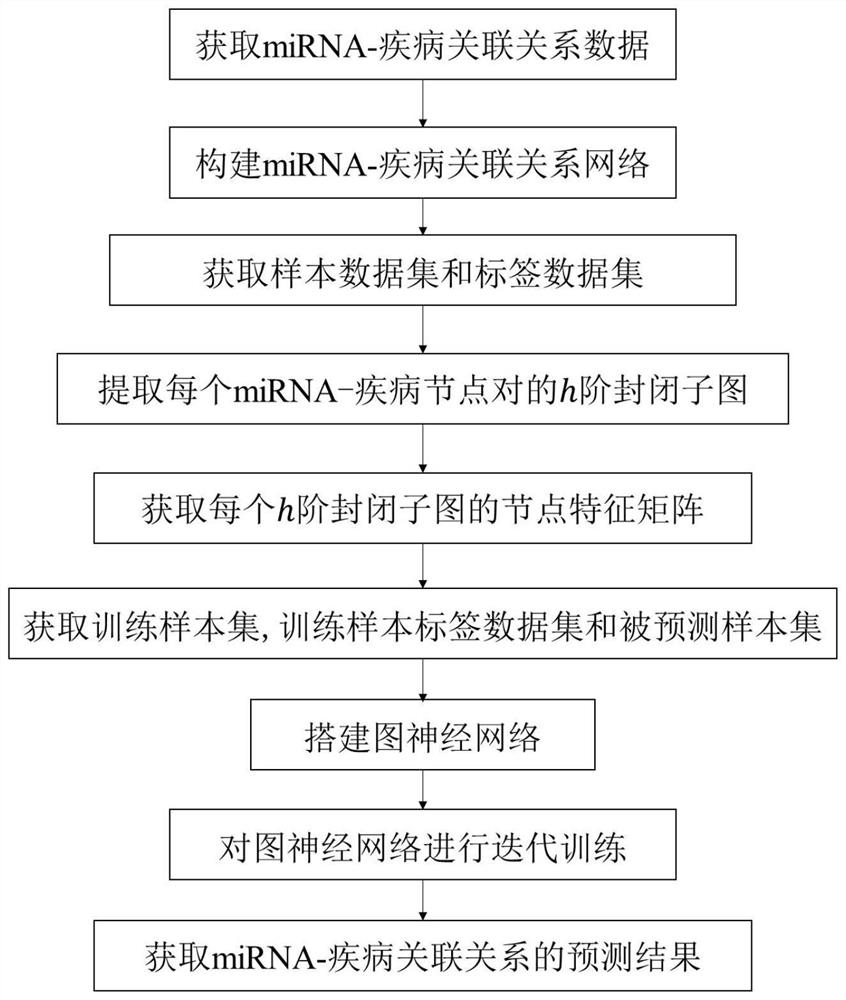

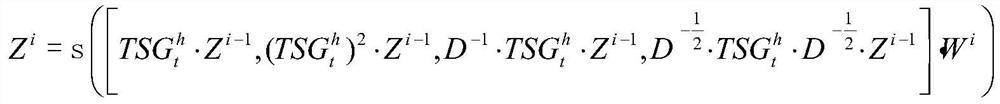

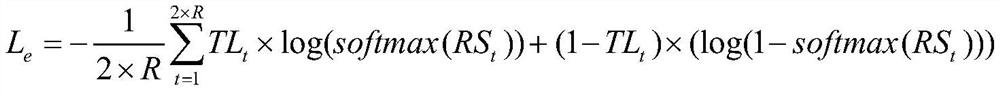

Method for predicting miRNA-disease association relationship based on graph neural network

ActiveCN113409892AImprove forecast accuracyAvoid deviationBiostatisticsNeural architecturesMachine learningGraph based

The invention provides a method for predicting a miRNA-disease association relationship based on a graph neural network. The method comprises the following implementation steps: acquiring miRNA-disease association data; constructing a miRNA-disease association network; acquiring a sample data set and a label data set; extracting an h-order closed subgraph of each miRNA-disease node pair; acquiring a node feature matrix of each h-order closed sub-graph; obtaining a training sample set, a training sample label data set and a predicted sample set; building a graph neural network; performing iterative training on the graph neural network; and obtaining a miRNA-disease associated prediction result. According to the method, the graph structure feature information is learned from the miRNA-disease association network by using the graph neural network, so that the problem of low prediction accuracy in the prior art is solved, the miRNA-disease association prediction accuracy is improved under the condition of not using similarity data, and the method can be used for predicting potential miRNA-disease association.

Owner:XIDIAN UNIV

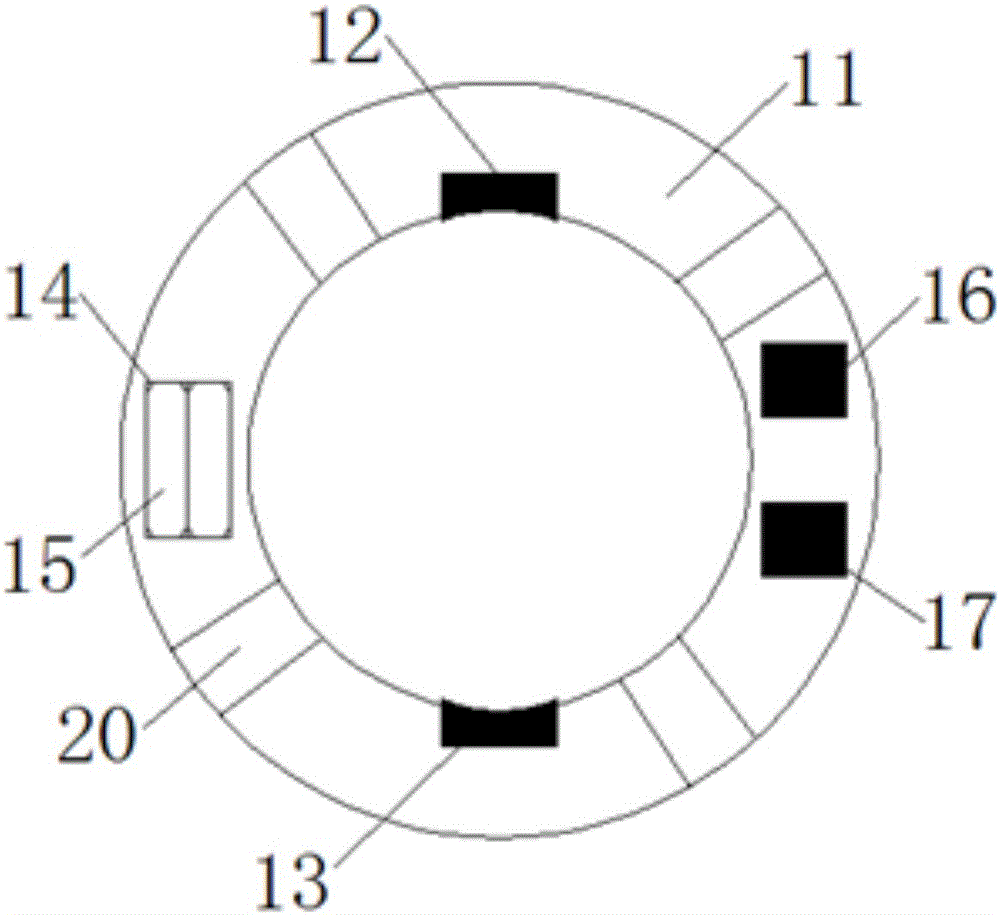

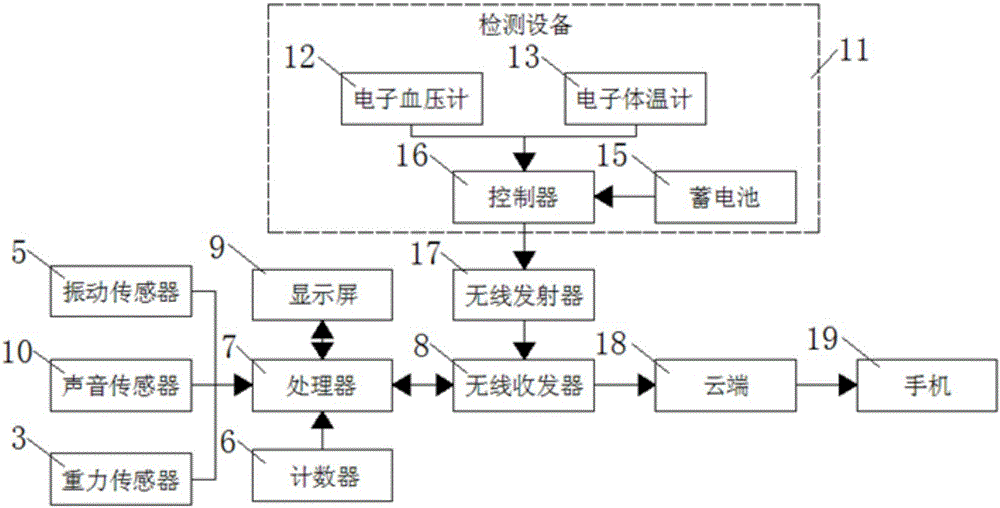

Remote health monitoring system design

InactiveCN106691412AAvoid deviationComprehensive monitoringDiagnostic recording/measuringSensorsTesting equipmentTransceiver

The invention discloses a remote health monitoring system design. An electronic sphygmomanometer and an electronic thermometer are electrically connected to a controller, the controller is electrically connected to a wireless transmitter, the battery is electrically connected to the controller, the wireless transmitter is wirelessly connected with a wireless transceiver, and the wireless transceiver is wirelessly connected with a cloud. The sleep quality of a user can be judged according to the sleep time of the user, the frequency of getting up at the night can be informed by the combined data of the nighttime gravity sensor and the counter, which can also reflex the physical condition of the user to a certain degree; the snoring situation of the user can be learned from the data of gravity sensor, vibration sensor and sound sensor; the user's pulse and body temperature are monitored in real-time through the electronic sphygmomanometer and electronic thermometer on the test device. The overall data are sent through the wireless transceiver to the cloud, so that real-time monitoring, more comprehensive monitoring are achieved, and physical and mental health of the user is more facilitated.

Owner:广州市晶品云科技有限公司

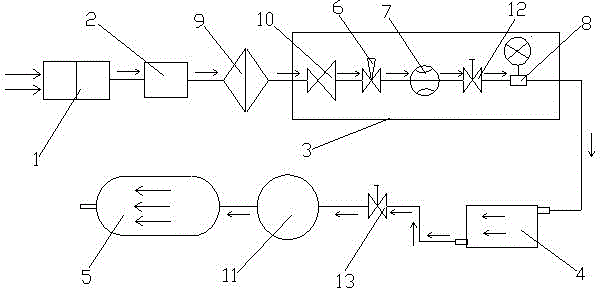

SF6 gas decomposition product analysis device based on Fourier transform

InactiveCN104865217APrecise controlAvoid deviationMaterial analysis by optical meansDecompositionEngineering

The invention discloses an SF6 gas decomposition product analysis device based on Fourier transform. The SF6 gas decomposition product analysis device comprises a primary filter, a sampling pipe, a flow regulating mechanism, an FTIR analysis meter and a waste gas collecting mechanism which are communicated in sequence, wherein the flow regulating mechanism comprises a flow regulating valve, a flow meter and a pressure gage which are connected in sequence, and the inlet of the flow regulating valve is communicated with the outlet of the sampling pipe, while the pressure gage is connected with the FTIR analysis meter; the sampling pipe comprises a sampling pipe body, and a first self-sealing joint and a second self-sealing joint are arranged at the inlet and the outlet of the sampling pipe body respectively, while the first self-sealing joint and the second self-sealing joint are communicated with the primary filter and the flow regulating valve respectively. The SF6 gas decomposition product analysis device provided by the invention can combine gas sampling and gas detection into one body, secondary pollution can be avoided, and the device also has the advantages of being high in detection precision and small in required gas amount and being capable of accurately controlling gas amount.

Owner:JILIN ELECTRIC POWER RES INST +1

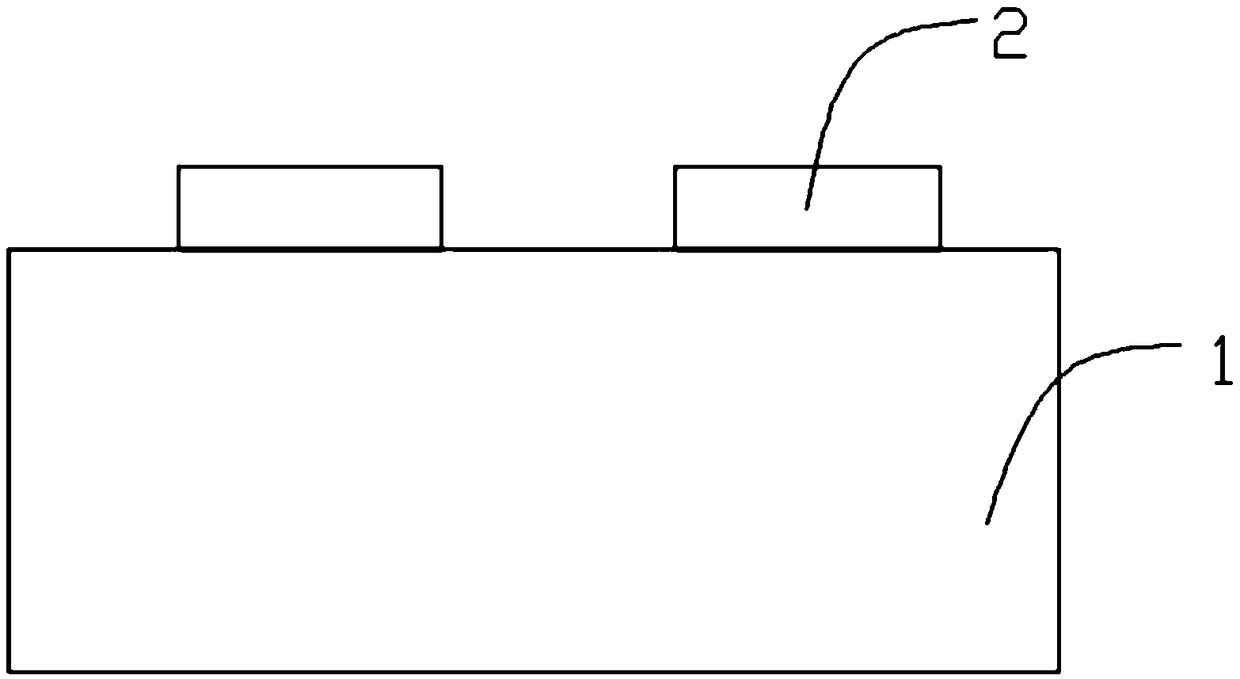

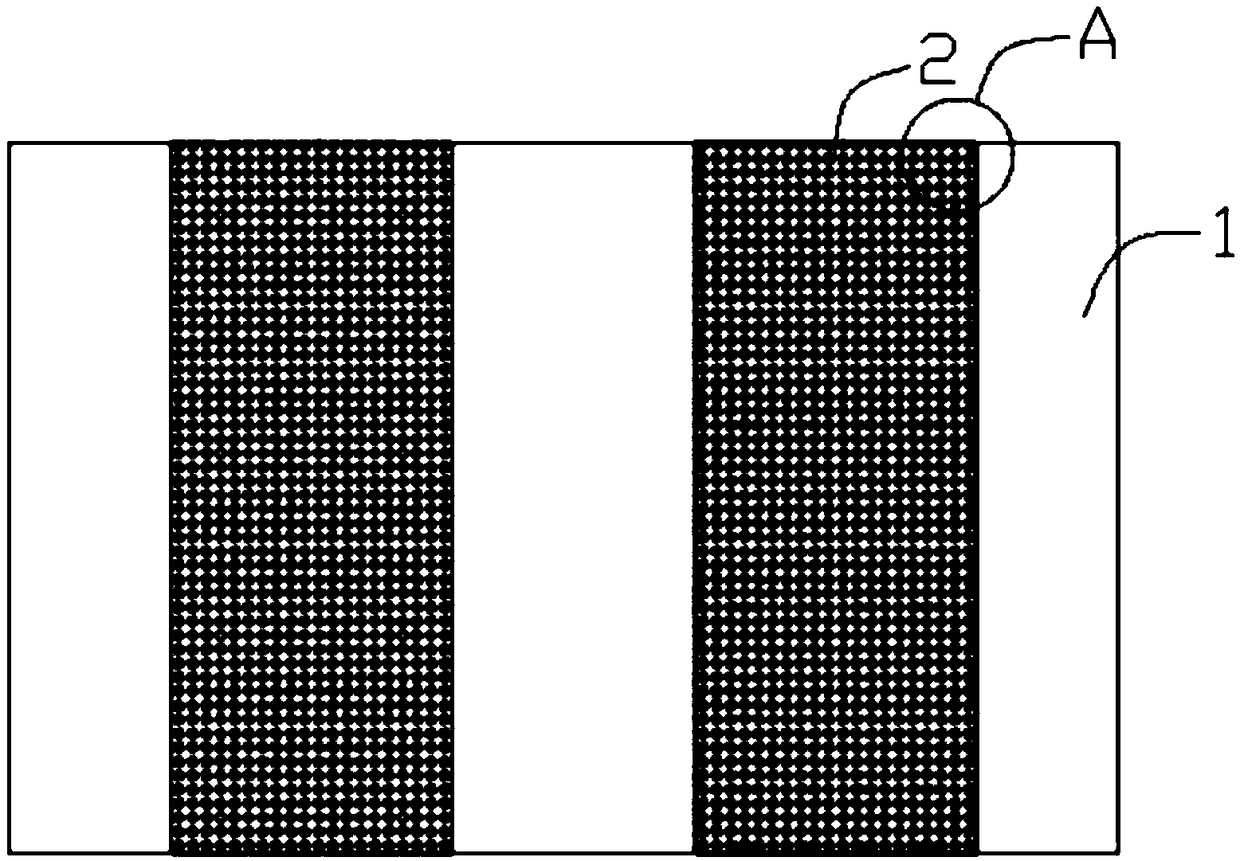

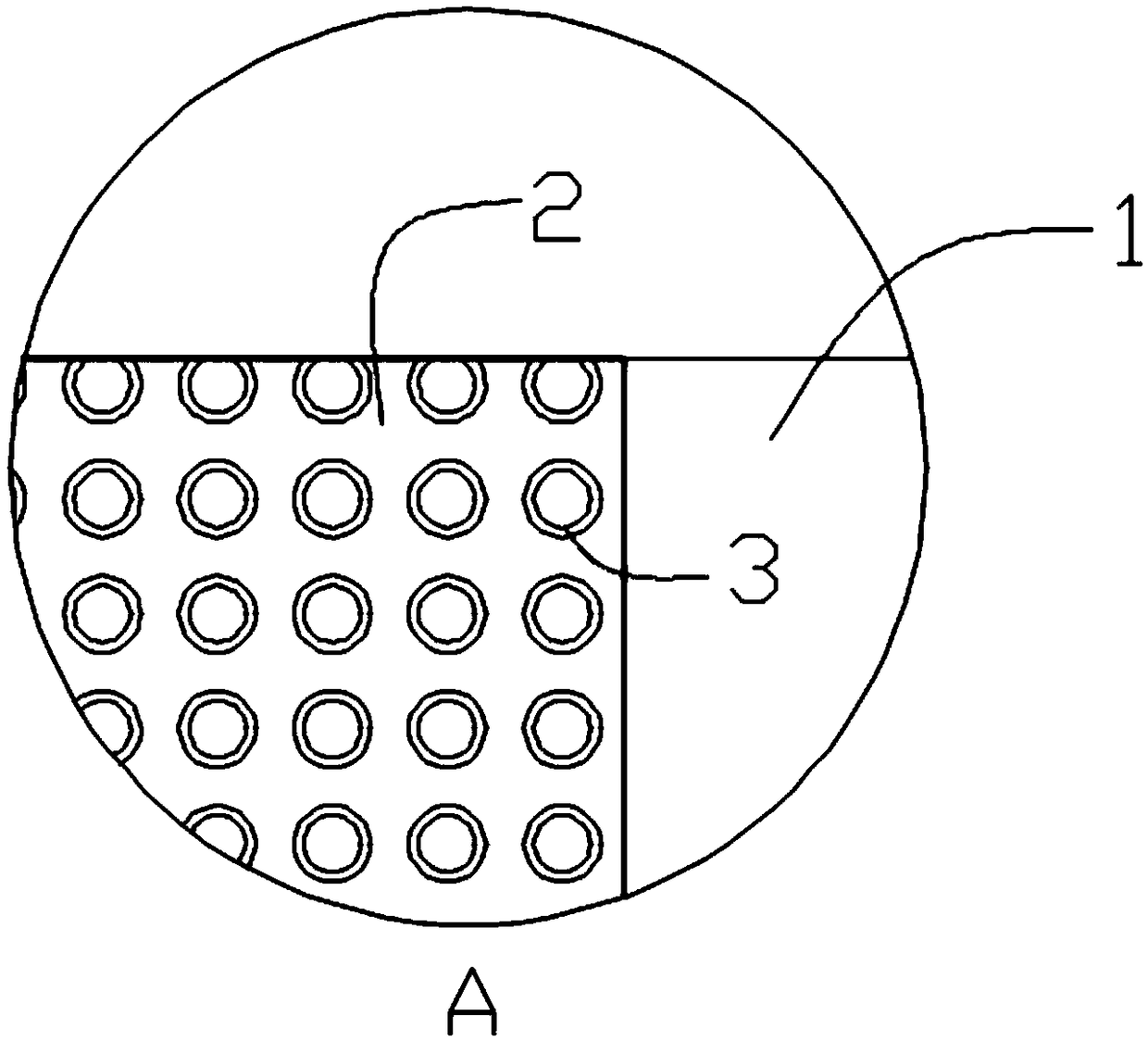

Mask plate and making method thereof

PendingCN109491191AAvoid deviationHigh precisionOriginals for photomechanical treatmentLight diffractionOptical transmittance

The invention discloses a mask plate and a making method thereof. The mask plate comprises a substrate and a light stopping layer; the light stopping layer is laid on the substrate; and a plurality oflight-transmitting through holes are arranged on the light stopping layer, the light-transmitting through holes penetrate through the light stopping layer in a direction which is perpendicular to thelight stopping layer, and the aperture a of each light-transmitting through hole is greater than or equal to 0.8 mu m and less than or equal to 4 mu m. The aperture of each light-transmitting throughhole is smaller than the minimum resolution of an aligned exposure system, during explosion, light which penetrates through the through holes does not illuminate to the raw material of the product ina direct illuminating mode, but exists in a photosensitive material of the surface of the raw material of the product in a light diffraction radiation energy mode, therefore, an effect of changing the optical transmittance of the light stopping layer is achieved, the transmittance of the light stopping layer can be an optional value between 0 (light proofing) to 100% (light transmission), and thus, the different portions of the light stopping layer can have different optical transmittance.

Owner:深圳市龙图光电有限公司

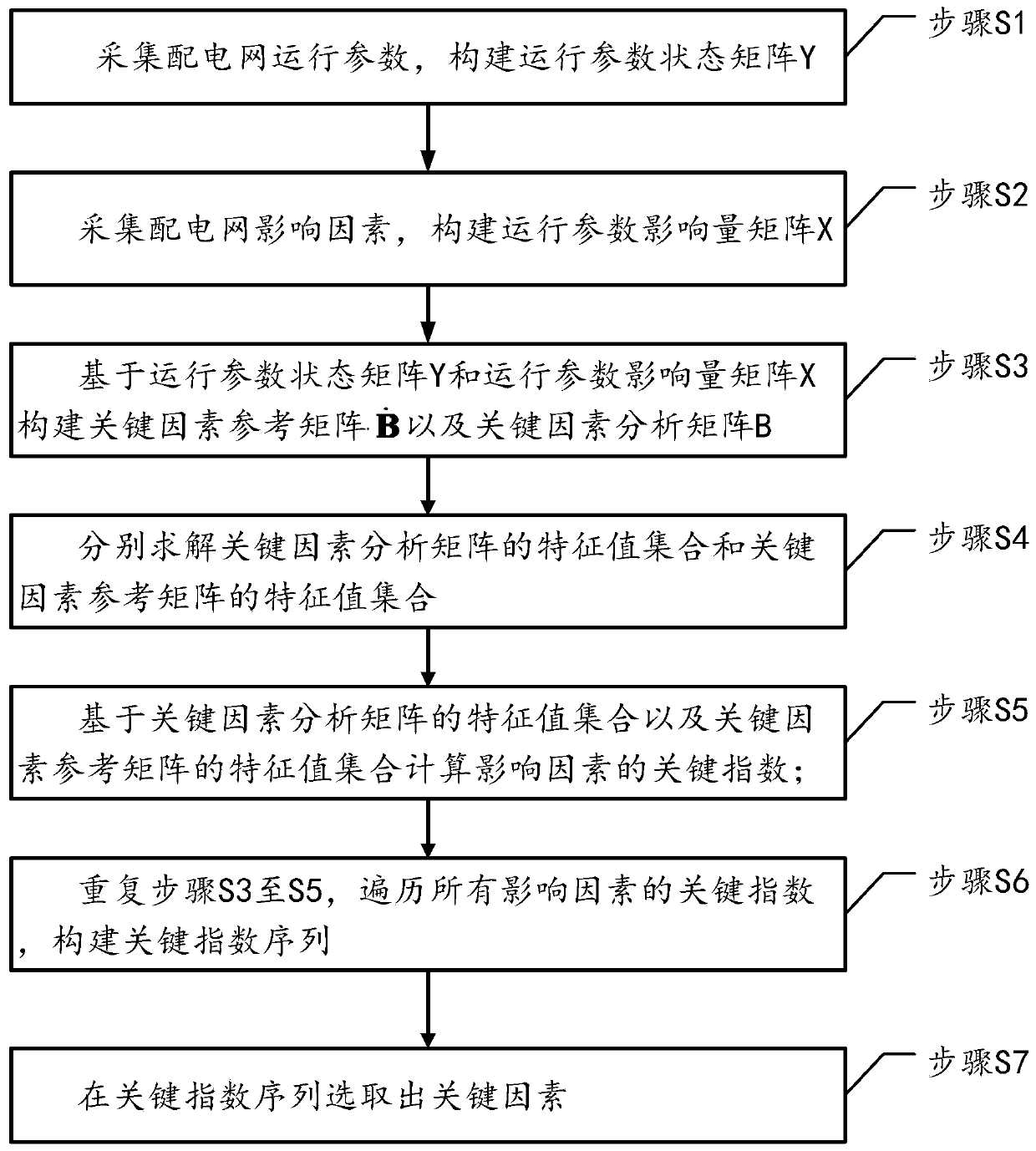

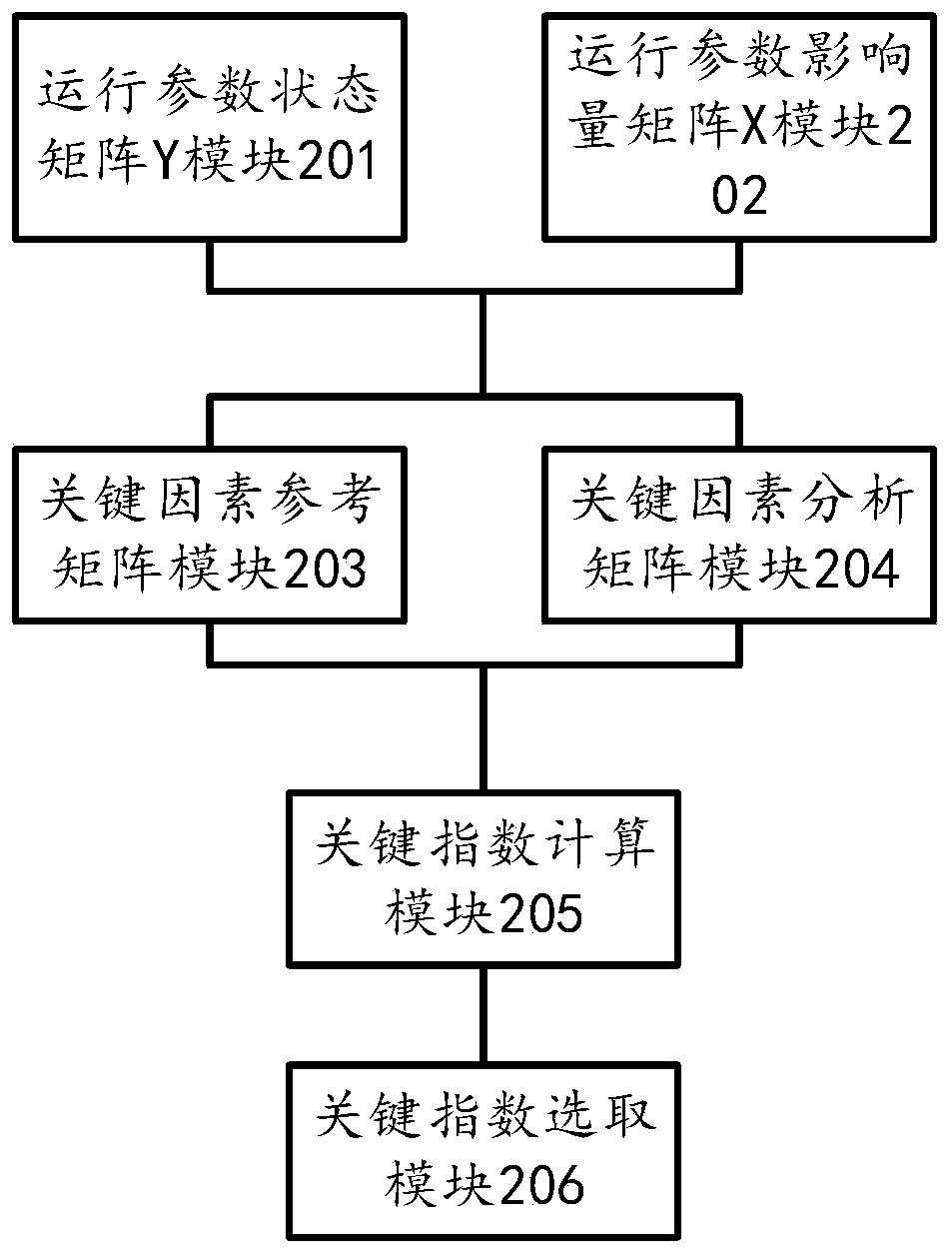

Power distribution network operation parameter key factor analysis method, system and device

ActiveCN111260255AAvoid limitationsAvoid deviationResourcesInformation technology support systemEngineeringDistribution grid

The invention discloses a power distribution network operation parameter key factor analysis method, system and device. The method comprises the steps of: constructing an operation parameter state matrix Y and an operation parameter influence quantity matrix X; constructing a key factor reference matrix and a key factor analysis matrix B; and respectively solving the characteristic value set [lambda] (B) of the key factor analysis matrix and the characteristic value set of the key factor reference matrix to calculate key indexes of all influence factors, constructing a key index sequence and selecting key factors. According to the embodiment of the invention, a key factor reference matrix and a key factor analysis matrix B are constructed through an operation parameter state matrix Y and an operation parameter influence quantity matrix X; according to the embodiment of the invention, the correlation between multiple factors and the operation parameters is analyzed based on the drivingof the operation parameters and the influence factor data, the limitation of a model analysis method is avoided, the correlation between the variable data and the target data can be accurately and quantitatively analyzed in a massive data environment, and the problem of deviation of correlation analysis is avoided.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Governor main distribution electric neutral position and proportional valve neutral position adjusting method

InactiveCN106121903AGet rid of dependenceAvoid deviationHydro energy generationMachines/enginesServomotorHydropower

The invention relates to a governor main distribution electric neutral position and proportional valve neutral position adjusting method. The method comprises the steps of: (1) main distribution neutral position adjustment; (2) primary adjustment of a main distribution neutral position sensor zero position; (3) zero point and full point adjustment of a guide blade main connecting sensor; and (4) fine adjustment of a main distribution neutral position sensor and a proportional valve neutral position. The method is suitable for a hydropower unit using a proportional valve (or such redundant configurations as the proportional valve and a stepper motor), the main distribution and a servomotor as actuation structure forms, and aims to solve the frequent action problem of the governor main distribution and a guide blade.

Owner:CHINA YANGTZE POWER

Photovoltaic system

InactiveCN108388273AIncrease profitAvoid deviationControl without using feedbackPower storageEngineering

The invention discloses a photovoltaic system, which comprises a mounting bottom plate. The surface of the mounting bottom plate is provided with a sliding groove; a sliding block is arranged in the sliding groove; the top part of the mounting bottom plate is provided with a power storage box; the power storage box is internally provided with a photovoltaic cell; the power storage box is providedwith multiple cooling holes; the cooling holes are arranged in the top end of the power storage box; the top part of the photovoltaic cell is provided with a semiconductor refrigeration chip and the side wall is provided with a cooling copper pipe; and the semiconductor refrigeration chip is fit with the top part of the photovoltaic cell. As the angles of a solar panel change with changes of timeand angles of sunlight, the solar energy is received to the greatest extent for conversion and generation, and the utilization rate of the solar photovoltaic system is improved; and as the photovoltaic cell is constantly in a working environment with a relatively low temperature, the conversion efficiency of the photovoltaic cell is improved, the service life of the photovoltaic cell is prolonged,and the aging rate is slowed down.

Owner:广东南控电力有限公司

Automobile accessory polishing equipment for automobile manufacturing

InactiveCN108000340AAvoid deviationAvoid sliding or droppingGrinding carriagesPolishing machinesAutomotive engineering

The invention discloses automobile accessory polishing equipment for automobile manufacturing. The automobile accessory polishing equipment comprises a base; a supporting column is fixedly connected to the upper surface of the base; a fixed block is fixedly connected to the upper portion of the left side face of the supporting column; and an electric push rod is fixedly connected to the middle ofthe bottom face of the fixed block. According to the automobile accessory polishing equipment for automobile manufacturing, a polishing wheel is fixed over a groove, and thus the situation that the polishing wheel deviates from an automobile accessory needing to be polished, and thus polishing is uneven can be effectively avoided; and the groove and two symmetrical cavities are formed in the fixedblock, extruding plates, gears and racks are arranged in the groove, limiting plates and strong springs arranged at equal distances are arranged in the cavities, the automobile accessory needing to be polished can be extruded through elasticity of the strong springs, thus sliding or falling of the automobile accessory is effectively avoided, using is more convenient, and the polishing quality ofthe automobile accessory is improved accordingly.

Owner:郭斌

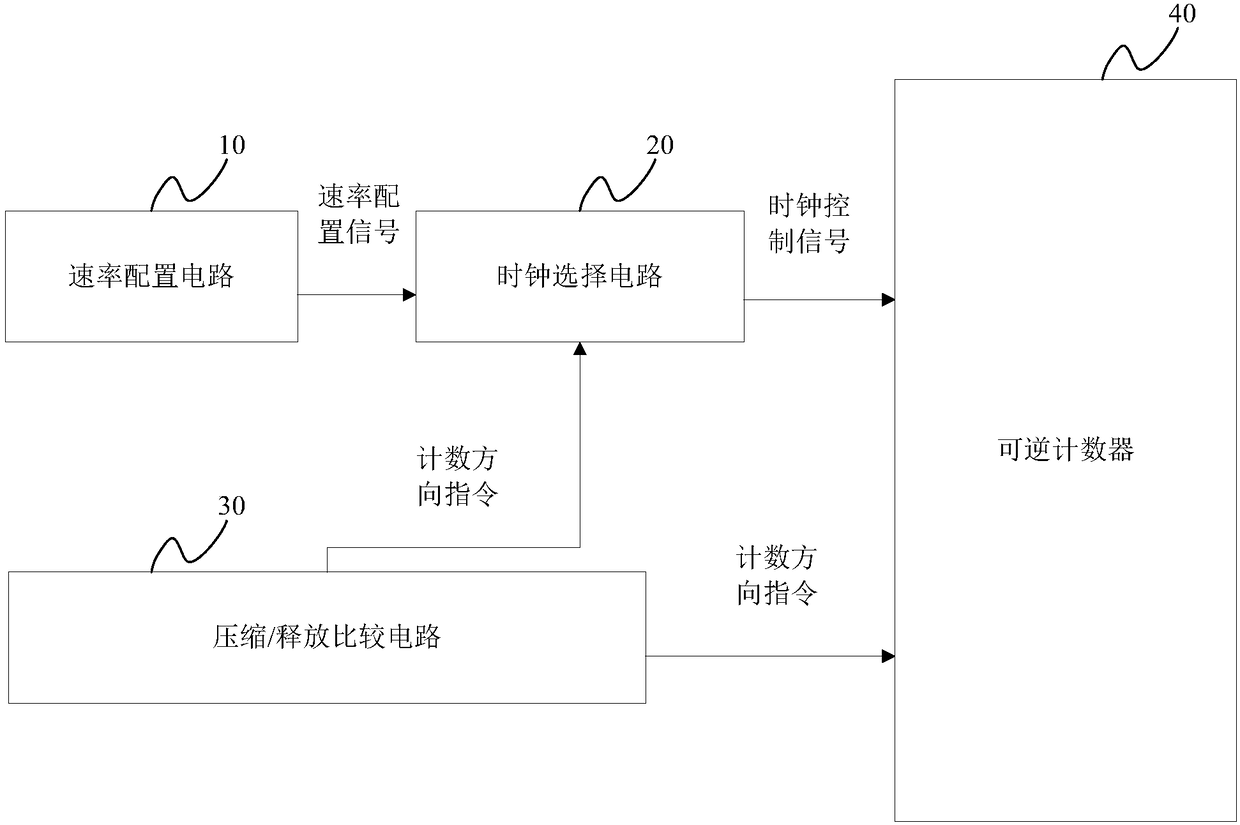

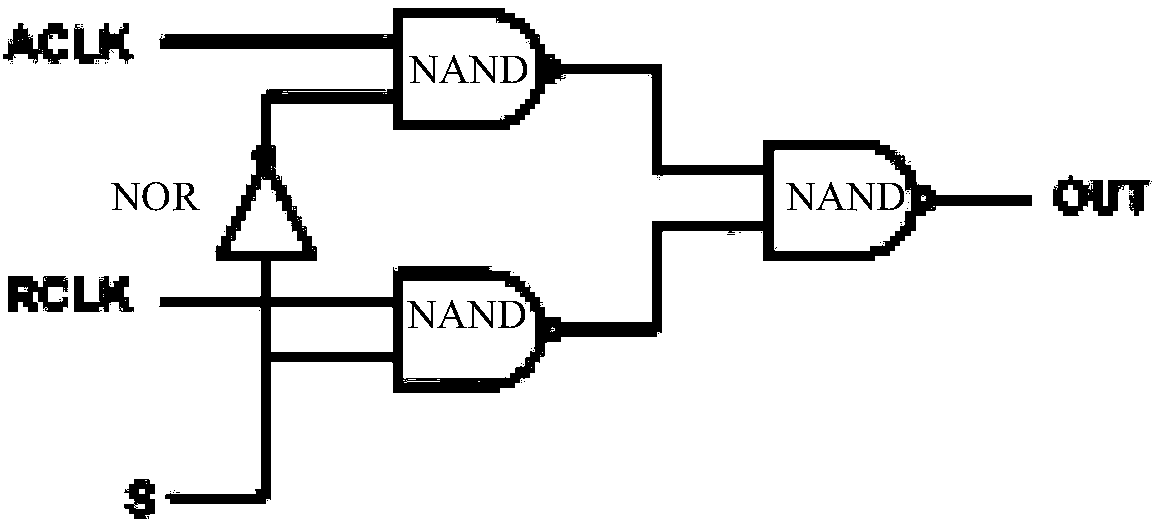

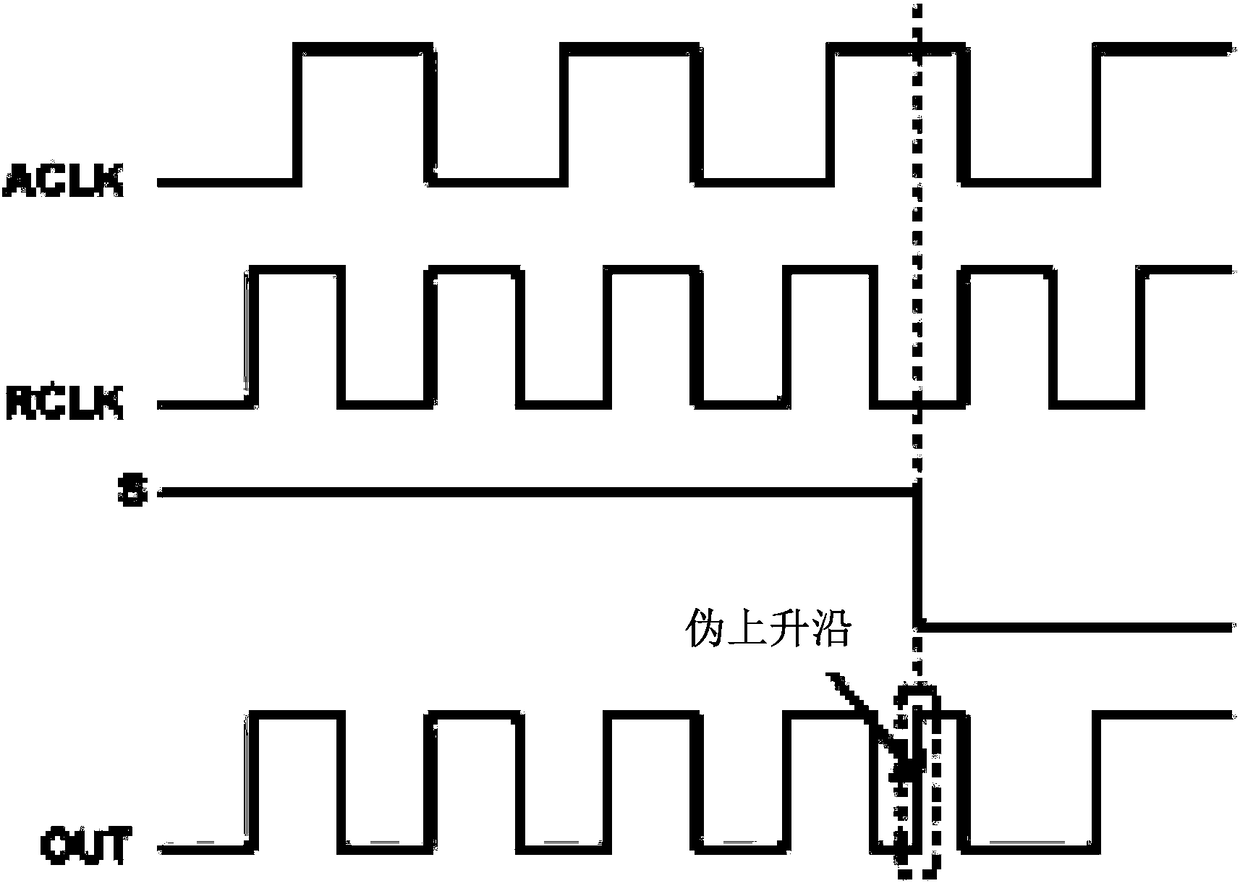

Automatic gain control circuit and signal processing system

The invention discloses an automatic gain control circuit and a signal processing system, wherein the clock module of the automatic gain control circuit provides only one working clock to a reversiblecounter; in comparison with the use of the multi-clock to realize the adjustment of the gain change rate, the automatic gain control circuit realizes the adjustment of the gain change rate by changing the number of the counting units participating in counting in the reversible counter, so that the problem that the error between an actual compression rate or an actual release rate and a preset compression rate or a release rate is large, which is caused by switching of the clock signals in the multi-clock system, is solved, and the problem that the output signal of the reversible counter causes deviation is avoided. Further, a clock signal with a higher frequency can be selected as a working clock in practical application so as to avoid the timing error occurring when the signal to be processed is closer to a set compression threshold value, so that the requirements of application scenes with high precision requirements can be met.

Owner:SHANGHAI AWINIC TECH CO LTD

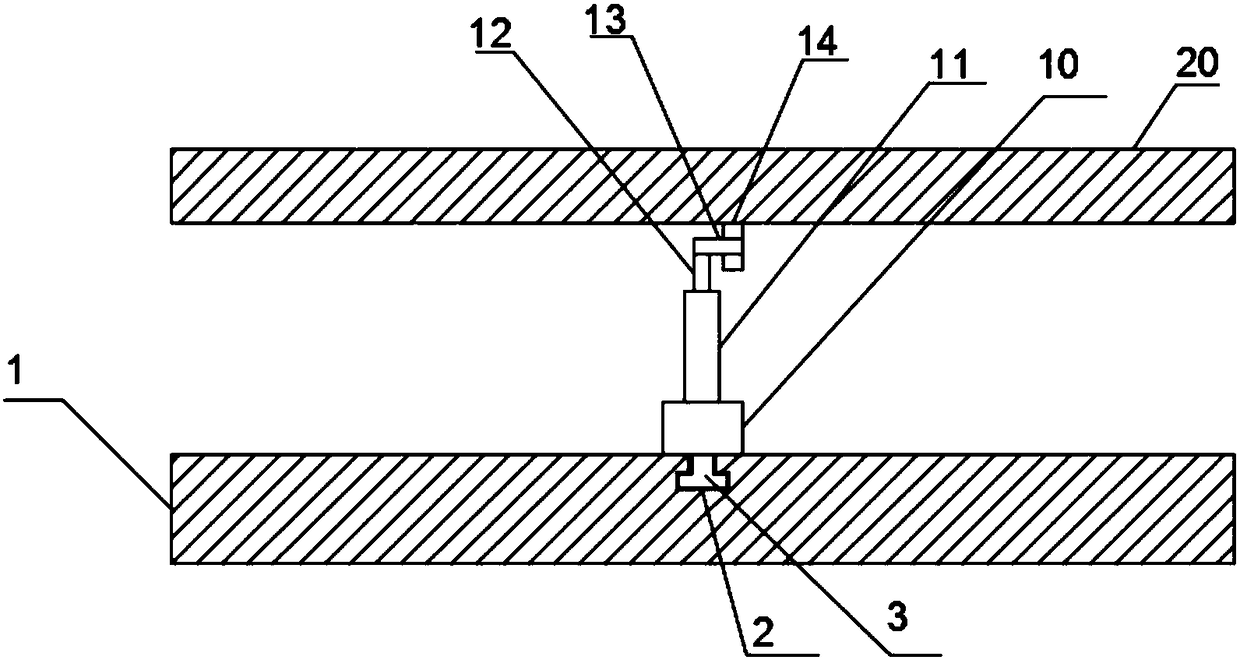

Overall expansion-joint device for fuel assembly skeleton

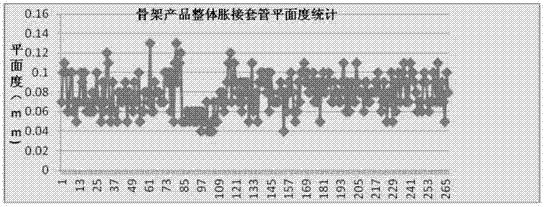

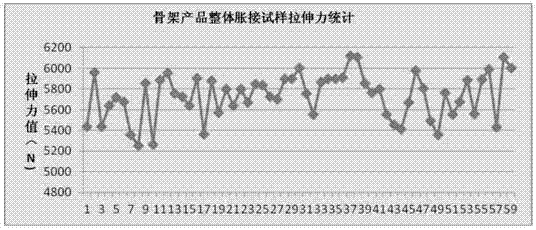

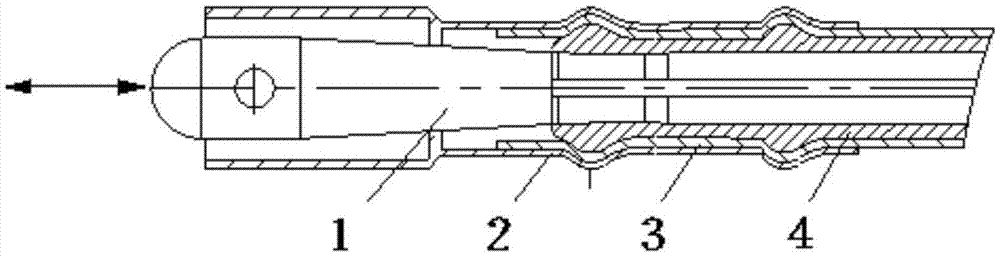

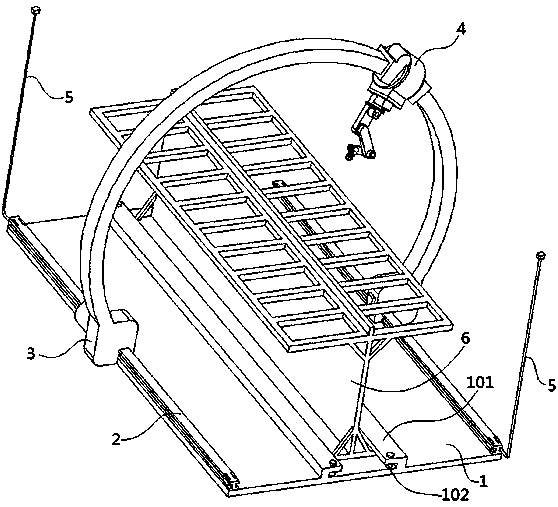

InactiveCN106925683AAvoid safety hazardsAvoid deviationMetal-working feeding devicesPositioning devicesExpansion jointIndustrial engineering

The invention belongs to an expansion-joint device, and specifically relates to an overall expansion-joint device for a fuel assembly skeleton. The overall expansion-joint device for the fuel assembly skeleton comprises an expansion-joint assembly, a lifting assembly, a support and a location assembly, wherein the support is located at the bottommost end and supports the whole expansion-joint device; the lifting assembly is arranged on the support and capable of lifting and driving the expansion-joint assembly and the location assembly to lift together; the location assembly is arranged at the foremost end of the lifting assembly and used for locating a position to be subjected to expansion joint; and the expansion-joint assembly is further arranged on the lifting assembly and comprises a plurality of expansion-joint pipes, and each expansion-joint pipe is capable of independently completing one-process expansion joint. The overall expansion-joint device for the fuel assembly skeleton has the following remarkable effects: 700 and more groups of overall expansion joint is carried out through applying a new process of overall expansion joint for a guide pipe and a sleeve pipe of the skeleton, the dimensions of an expansion-joint specimen and stretching inspections are both qualified, planeness inspections on the sleeve-pipe end of the skeleton product are all qualified (the planeness is required to be not greater than 0.15mm), and the value of an expansion-joint stretching force is high (the value is required to be greater than 4500N).

Owner:CNNC JIANZHONG NUCLEAR FUEL

Method for making portable hardometer verification test block

The invention discloses a method for making a portable hardometer verification test block. The method comprises the following steps: 1, selecting a die steel plate having a certain thickness, carryingout heat treatment on the die steel, and sampling the head of the die steel plate with the sampling position being 1 / 2 or 1 / 4 position of the steel plate in a width direction to obtain a sample; 2, cooling the sample, milling and processing the sample to obtain a required sample size, and smoothing the surface of the sample by using sand paper and polishing paper to obtain a hardometer verification test block; 3, measuring the hardness, which can be Brinell hardness or Rockwell hardness, of the same cross section of the produced hardometer verification test block by a desk hardometer, and recording the hardness values of four corners and the center; and 4, verifying an onsite portable hardometer by a standard test block, and determining the hardness values of the four corners and the center of the hardometer verification test block. The method ensures the accuracy of the portable hardometer to be used before use according to the characteristics of a hardometer test material, and the produced hardometer verification test block can save the cost.

Owner:NANJING IRON & STEEL CO LTD

High-freedom-degree mechanical arm structure used for machining

InactiveCN108481304AHigh degree of freedom of workAvoid deviationManipulatorIndustrial machineMachining

The invention discloses a high-freedom-degree mechanical arm structure used for machining, and relates to the technical field of industrial machines. The structure comprises a base, sliding rails arefixed to the two sides of one surface of the base, a moving support is in sliding connection to one surfaces of the sliding rails, one surface of the moving support is rotatably connected with a mechanical arm, a positioning device is arranged at one ends of the first sliding rails, a mounting frame is arranged on the first base, sliding bases are arranged on the two ends of the moving support, one surfaces of the sliding bases are in sliding connection with the sliding rails, one surfaces of the sliding bases are fixedly connected with a first drive device, wireless receiving devices are arranged on the opposite surfaces of the sliding bases, the mechanical arm comprises a mechanical arm base, the inner surface of the mechanical arm base is in sliding connection with the moving support, asecond drive device is arranged at the position of one surface of the mechanical arm base, and a fixed plate is fixedly connected to one surface of the mechanical arm base. Through the C structure ofthe moving support, rotatable moving of the mechanical arm base can be achieved, and the advantage of improving the mechanical arm work freedom degree can be achieved.

Owner:符立华 +1

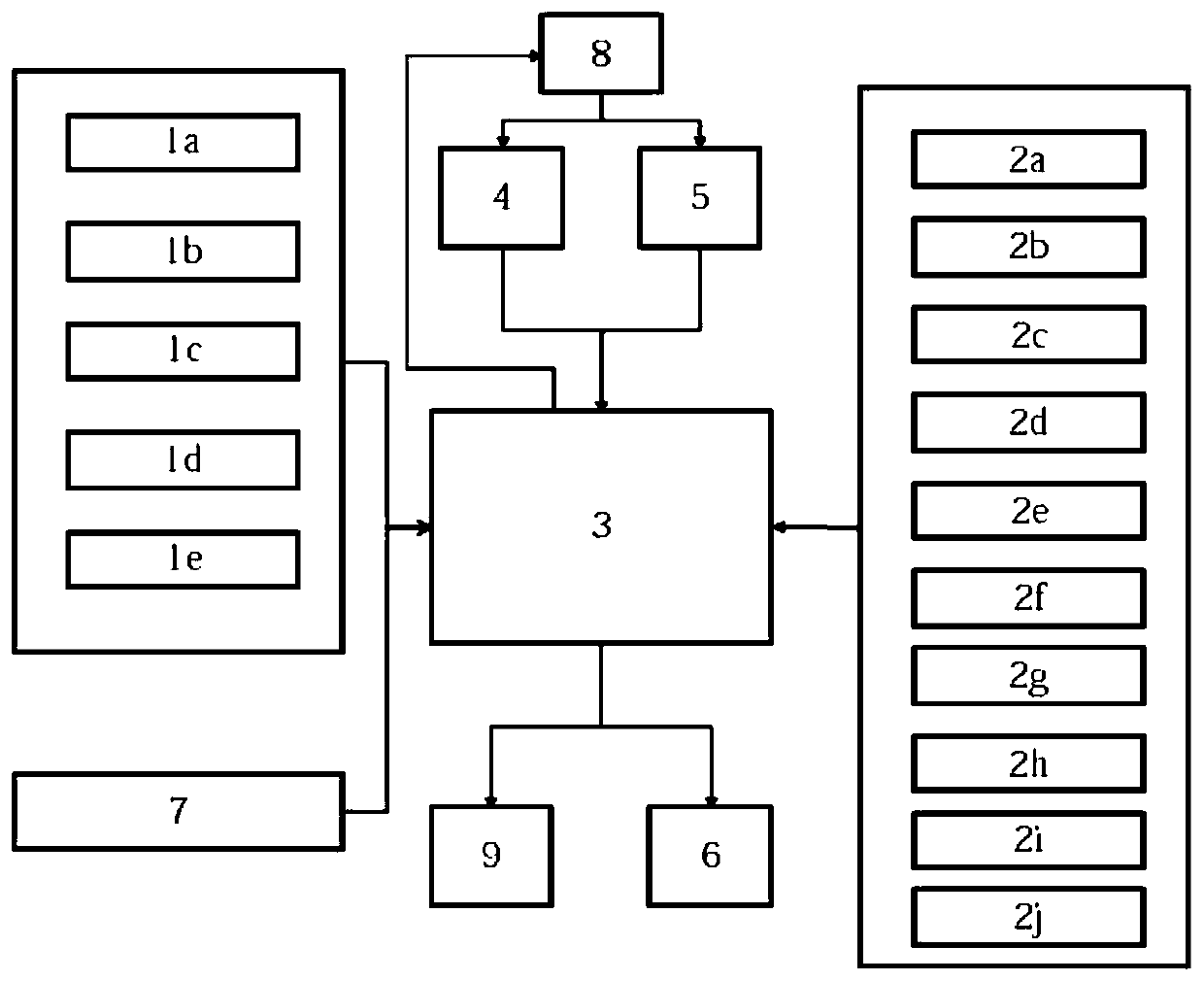

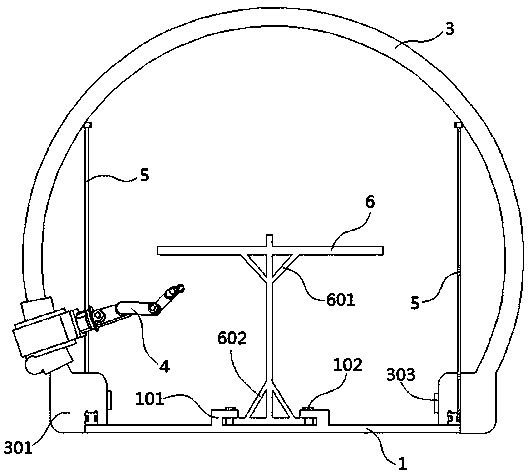

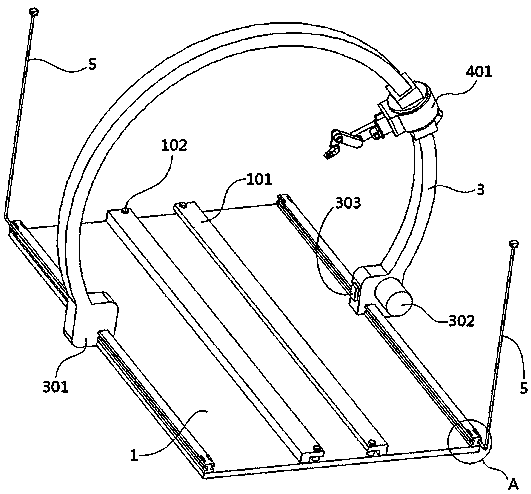

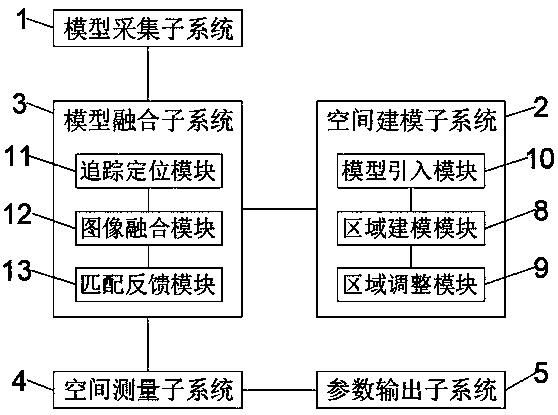

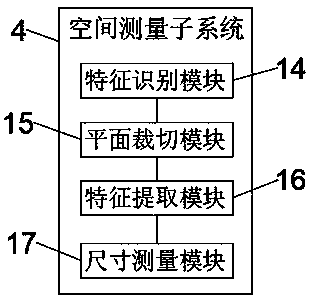

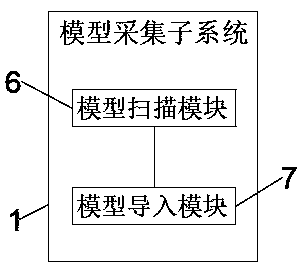

Automatic clothing size measurement system and method based on machine vision

InactiveCN109770463AAvoid deviationHigh precisionClothes making applicancesEngineeringSize measurement

The invention discloses an automatic clothing size measurement system based on machine vision. The system comprises a model acquisition subsystem, a spatial modeling subsystem, a model fusion subsystem, a spatial measurement subsystem and a parameter output subsystem, the output ends of the model acquisition subsystem and spatial modeling subsystem are connected with the model fusion subsystem, the model fusion subsystem is in feedback connection with the spatial modeling subsystem, the output end of the model fusion subsystem is connected with the spatial measurement subsystem, and the outputend of the spatial measurement subsystem is connected with the parameter output subsystem. Meanwhile, the invention also provides an automatic clothing size measurement method based on the machine vision. According to the system and the method, the design is reasonable, the characteristic parts of a 3D human body model are converted to a plane by introducing a reference comparison model, and measurement of the size information of the characteristic parts is carried out through software, so that deviation generated in a manual measurement process is avoided. The precision of clothing size measurement is improved, and automated measurement improves the efficiency of measuring clothing size.

Owner:江苏皓之睿数字科技有限公司

Sealed printing ink cup of pad printing machine

InactiveCN103240981ASimple structureAvoid deviationRotary pressesPrinting press partsSteel platesPrinting ink

The invention relates to a sealed printing ink cup of a pad printing machine, which comprises a steel plate, scrapers and a sealed oil cup, wherein a sealing ring is arranged on the sealed oil cup; a chamfering surface is arranged at a contact part between the sealed oil cup and the sealing ring; and a magnetic block is embedded into a peripheral wall of the sealed oil cup. The sealed printing ink cup is simple in structure; due to the chamfering surface arranged at the contact part between the sealing ring and the sealed oil cup, the sealing ring is guided to be in position, a deviation phenomenon is avoided, a sealing effect is enhanced, and the volatilization of an organic solvent in printing ink is prevented.

Owner:昆山欧莱特印刷机械工业有限公司

Assembled simulation sand table for real estate

ActiveCN113793547AAvoid deviationGuaranteed accuracyEducational modelsChemicalsElectric machineryIndustrial engineering

The invention discloses an assembled simulation sand table for real estate, and relates to the technical field of real estate. The sand table comprises a frame and a model body, a supporting plate is clamped in the frame, a lower supporting frame is installed on the frame, the lower supporting frame and the frame can slide relatively, a first electric telescopic rod is installed on the lower supporting frame, the lower supporting frame is connected with an upper supporting frame through the first electric telescopic rod, a transverse adjusting motor is installed on the lower supporting frame, and a gear is installed at one end of an output shaft of the transverse adjusting motor. According to the assembled simulation sand table for the real estate, the glue dripping position can be accurately positioned, deviation of the glue dripping position can be prevented, then the precision of the position of the model body and the precision of the sand table are guaranteed, meanwhile, a worker can be assisted in scraping liquid glue and moving away a bonding plate, the working intensity of workers can be reduced, and the working efficiency is improved.

Owner:王银花

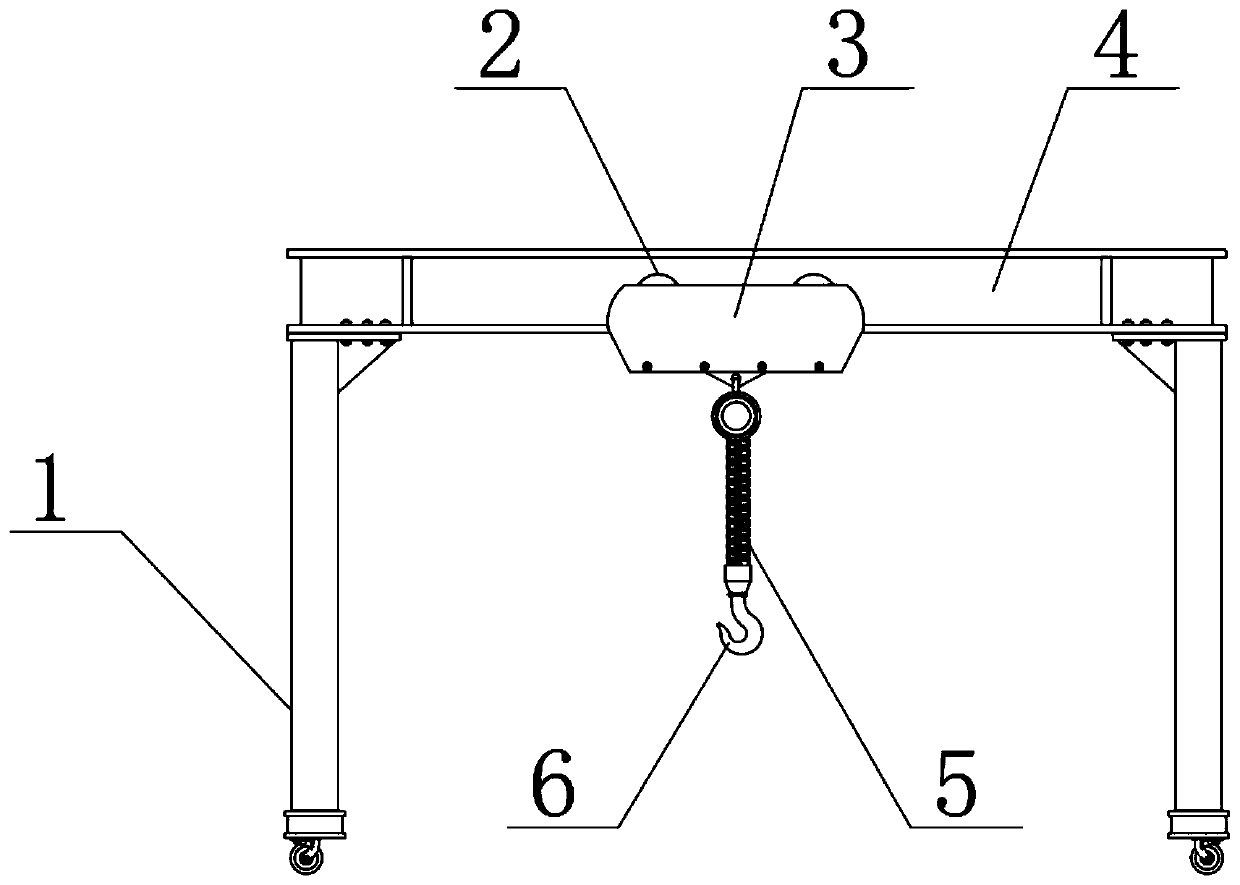

Lifting device for hot galvanizing production

InactiveCN110759249AAvoid deviationGuaranteed stabilityHot-dipping/immersion processesTrolley cranesStructural engineeringManufacturing engineering

Owner:鑫领域智能科技(邳州)有限公司

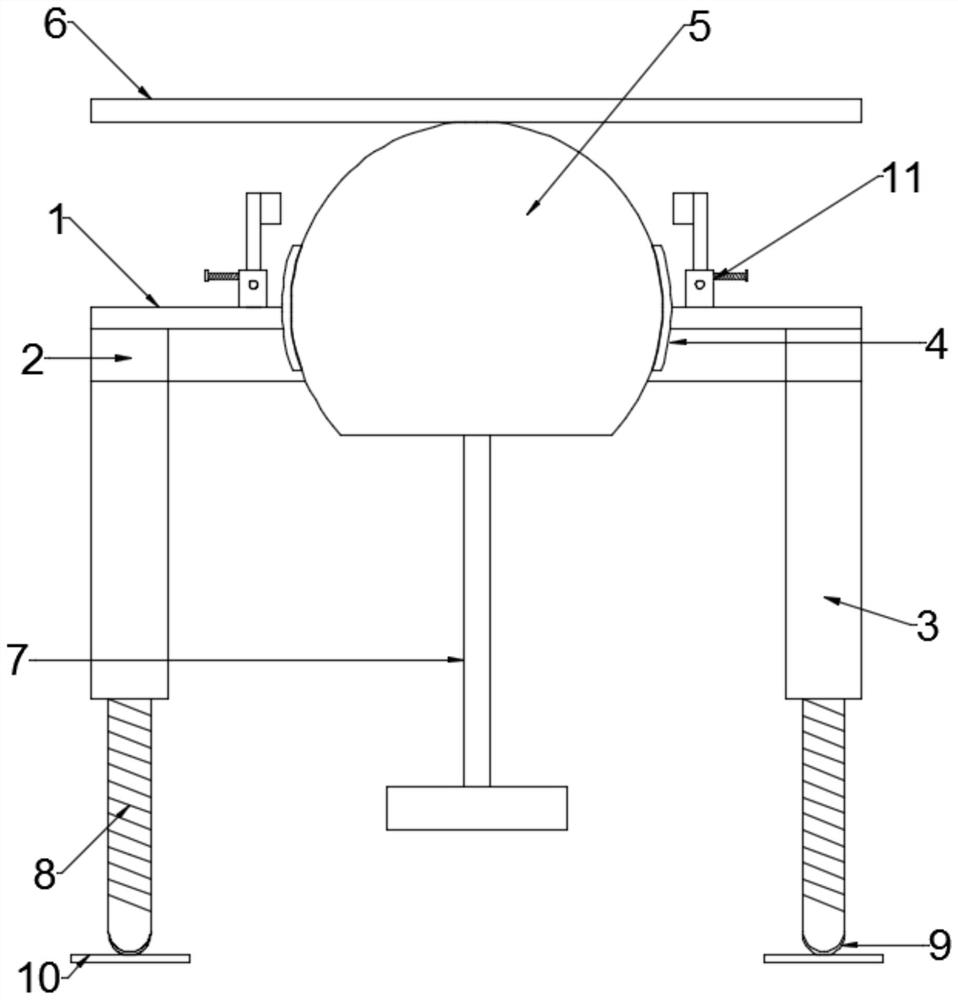

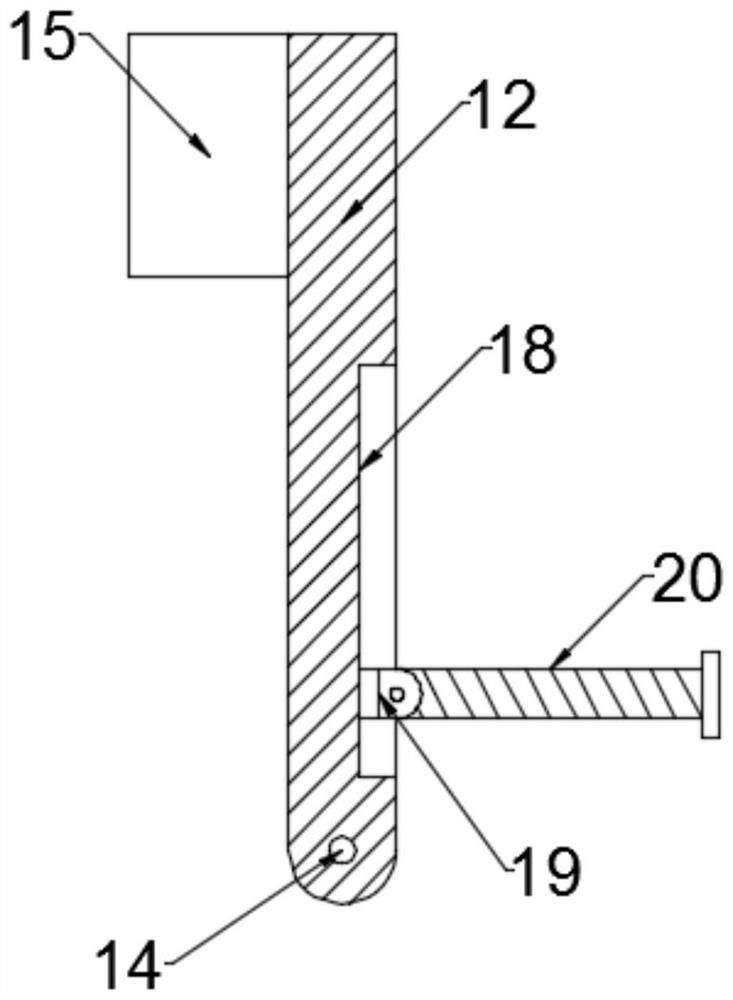

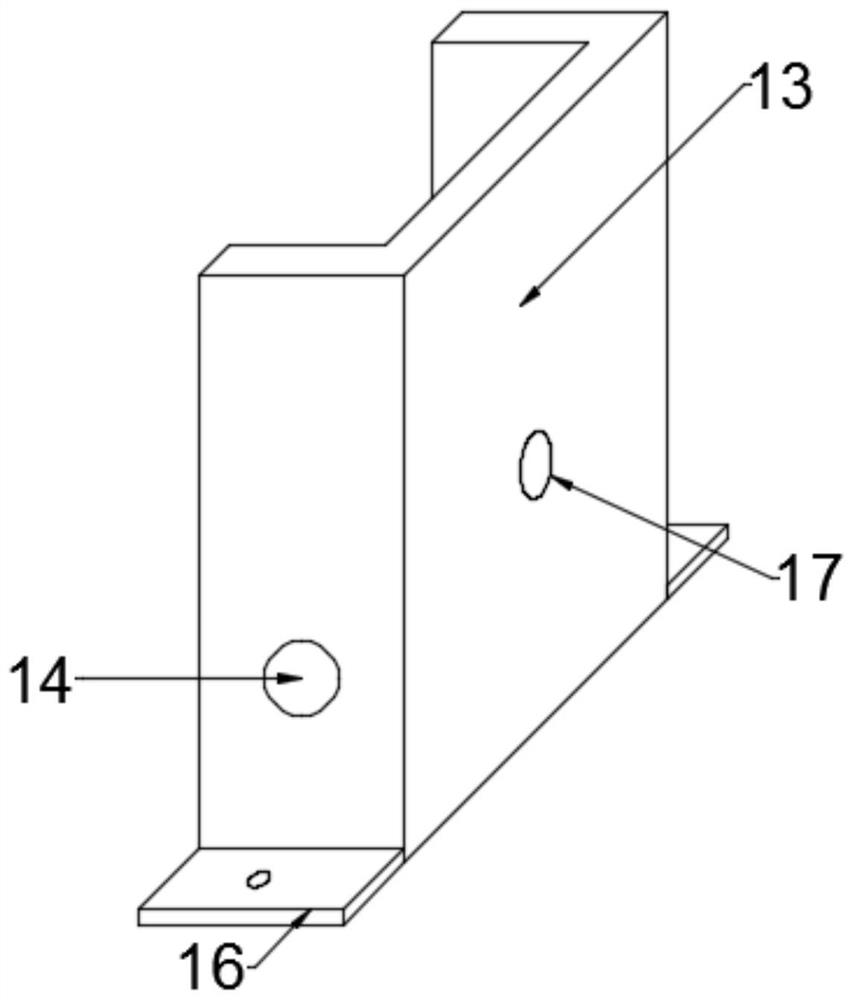

Engineering surveying instrument positioning device

PendingCN112146633AGuaranteed accuracyAvoid deviationSurveying instrumentsWork holdersPhysicsSurvey instrument

The invention discloses an engineering surveying instrument positioning device. The engineering surveying instrument positioning device comprises a bottom plate, a supporting cylinder and a placementplate, the lower end of the bottom plate is rotationally connected with the supporting cylinder through a bearing seat, an annular cavity is formed in the middle of the bottom plate in a penetrating mode, a ball seat is movably connected into the annular cavity in a matched mode, the upper end of the ball seat is horizontally and fixedly connected with the placement plate, the lower end of the ball seat is vertically and fixedly connected with a suspender, the tail end, away from the ball seat, of the suspender is fixedly connected with a balance weight lead block, a plurality of groups of limiting clamps used for movably pressing the ball seat tight are connected to a portion on the bottom plate and located on the periphery of the annular cavity. According to the engineering surveying instrument positioning device, the tail end of the suspender can be kept vertically downward through the balance weight lead block, meanwhile, the placement plate can be driven to be kept horizontal through the ball seat, and therefore a surveying instrument can be kept horizontal under any condition, the surveying accuracy is effectively guaranteed, and effective limitation can be carried out on theball seat through the limiting clamps, so that deviation caused by movement of the ball seat in the annular cavity during installation of the surveying instrument is avoided.

Owner:黑龙江省公路勘察设计院

Automatic curtain rolling device for agricultural greenhouses

ActiveCN111108981AAvoid deviationGood thermal effectClimate change adaptationGreenhouse cultivationElectric machineryAgricultural engineering

The invention discloses an automatic curtain rolling device for agricultural greenhouses, and relates to the technical field of agricultural equipment. Thus, the problems of the non-uniform paving oftwo ends during paving due to soft grass curtains when the grass curtains are paved on an agricultural greenhouse and the heat preservation of the agricultural greenhouse affected by large gaps can bemainly solved. The device mainly includes an agricultural greenhouse body; one side of the agricultural greenhouse body is provided with a limit mechanism, a rainproof mechanism, an indicating mechanism, a controller, an automatic curtain rolling mechanism and a gap covering mechanism. A gear motor drives a rotating shaft to rotate, and a curtain rolling shaft is stretched to move through a driving belt, so that the convenient paving and rolling of covering grass curtains can be realized; during the moving of the curtain rolling shaft, directional movement can be performed on the curtain rolling shaft through arc-shaped slide rails, so that the smoothing of the two sides of the covering grass curtains can be guaranteed; and supplementary grass curtains on a rotary shaft can be pulled to move and paved between the gaps of the covering grass curtains. The beneficial effects of the device are as follows: the paved grass curtains can be smoother; the paving can be more comprehensive; andbetter heat preservation effects can be achieved.

Owner:杭州稼禾秀实农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com