Patents

Literature

548 results about "Pad printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

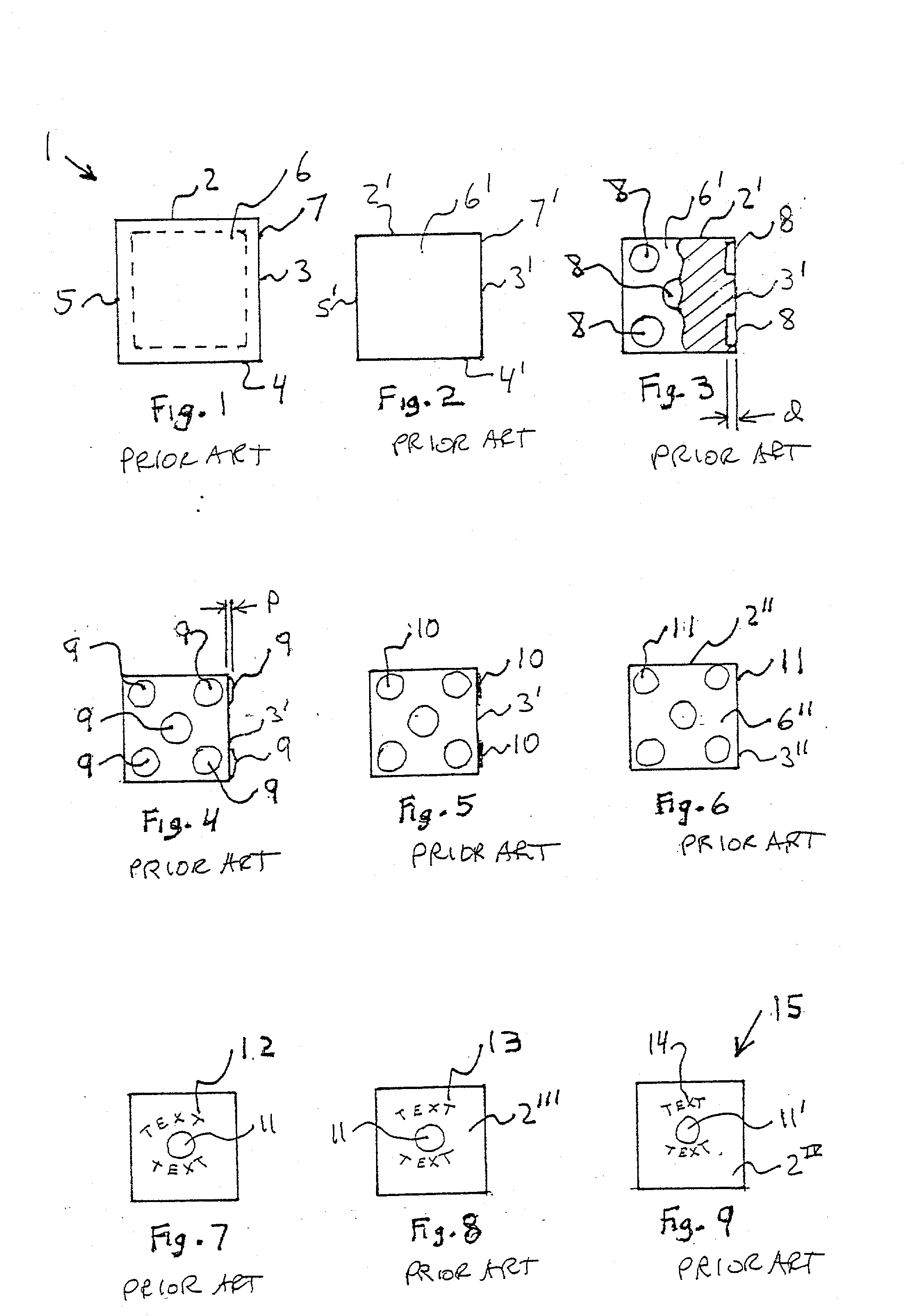

Pad printing (also called tampography) is a printing process that can transfer a 2-D image onto a 3-D object. This is accomplished using an indirect offset (gravure) printing process that involves an image being transferred from the cliché via a silicone pad onto a substrate. Pad printing is used for printing on otherwise difficult to print on products in many industries including medical, automotive, promotional, apparel, and electronic objects, as well as appliances, sports equipment and toys. It can also be used to deposit functional materials such as conductive inks, adhesives, dyes and lubricants.

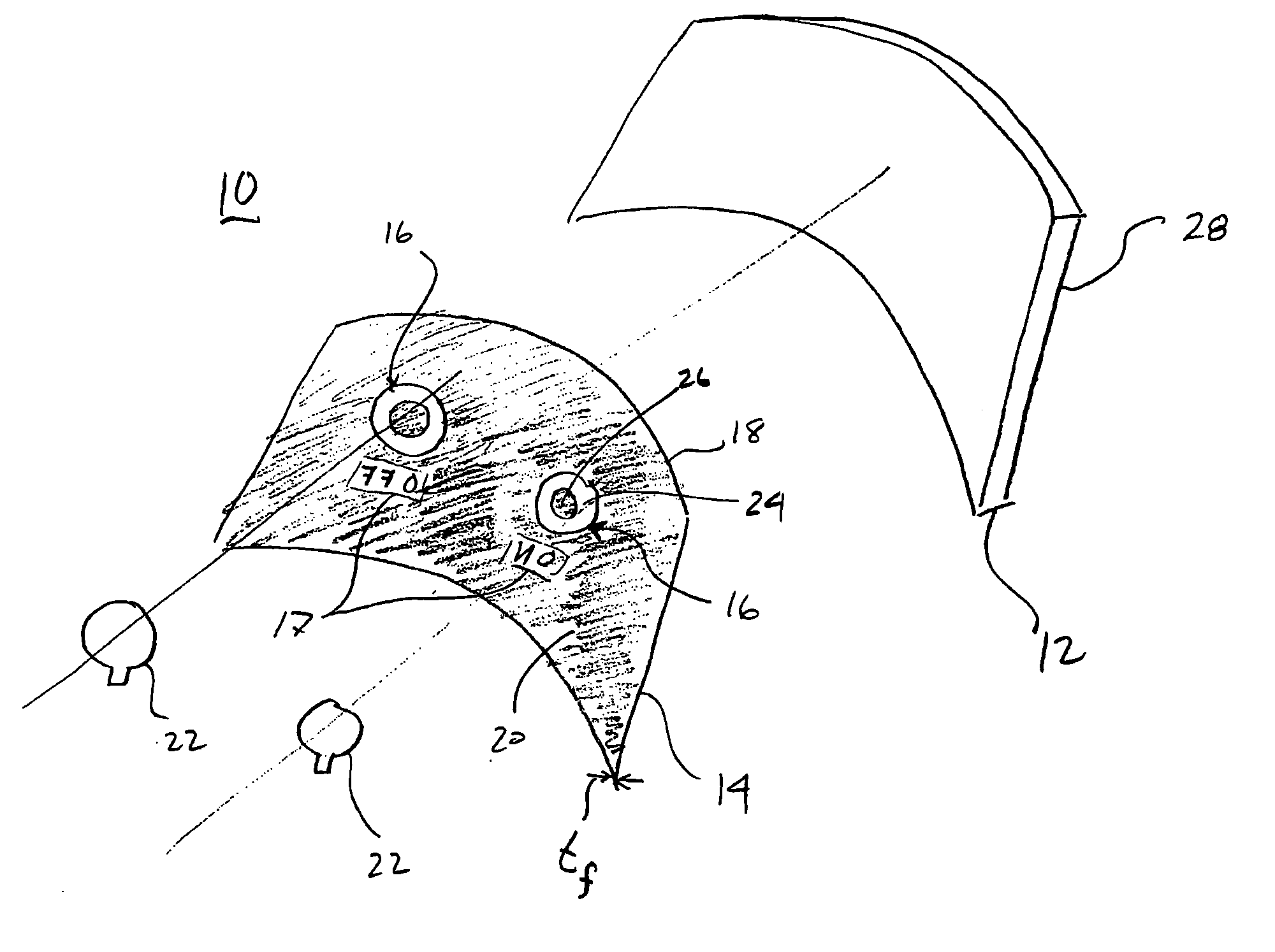

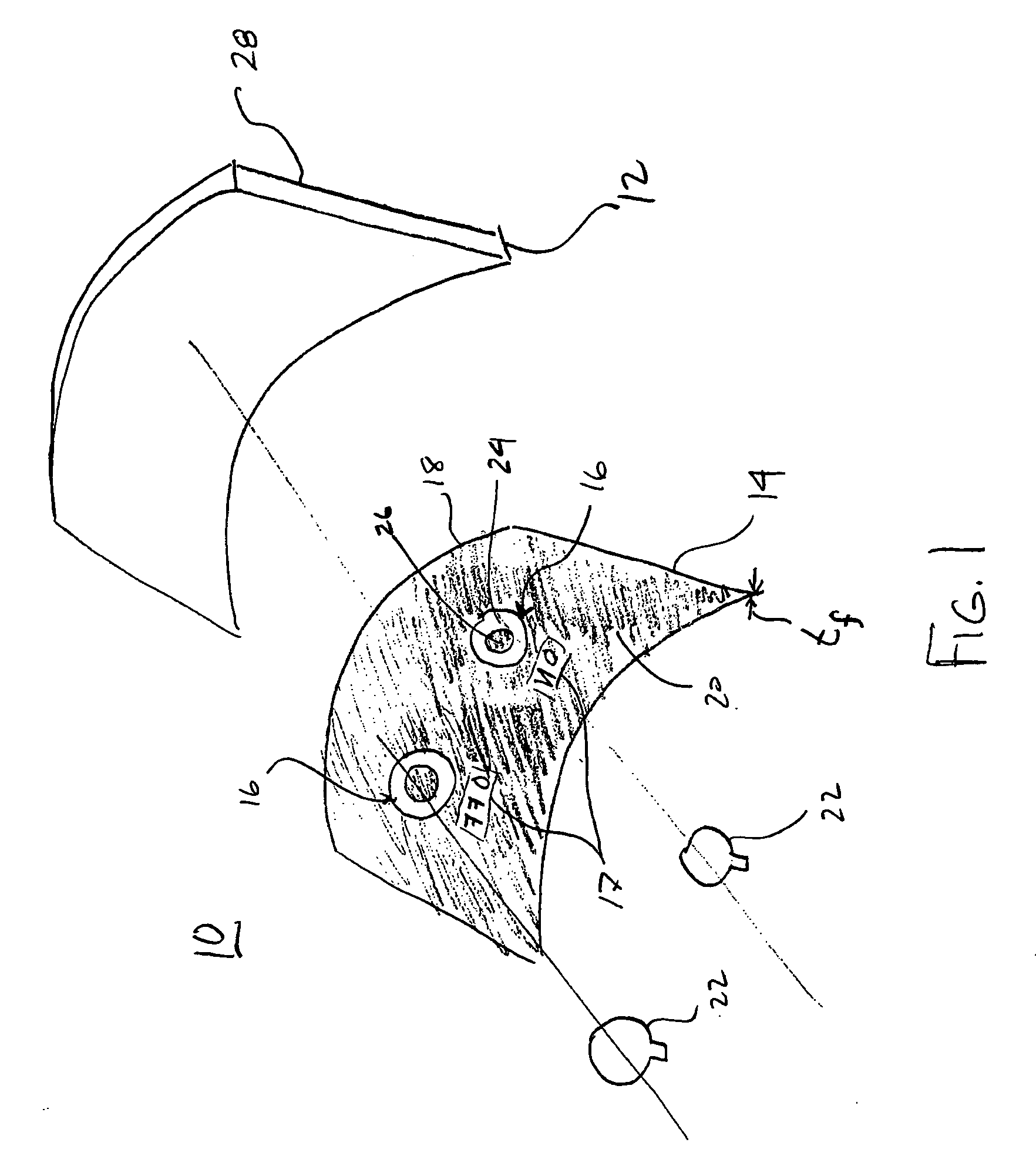

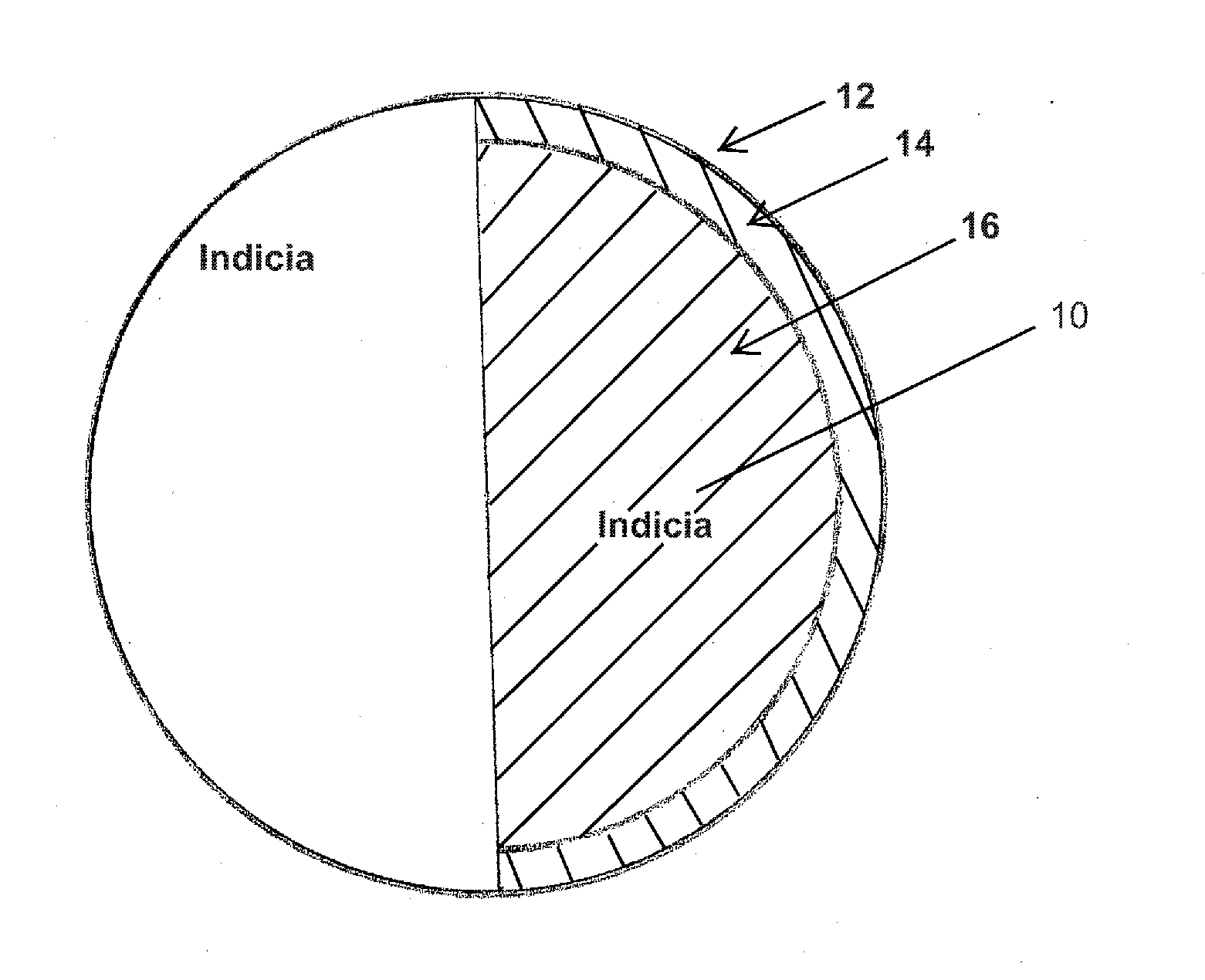

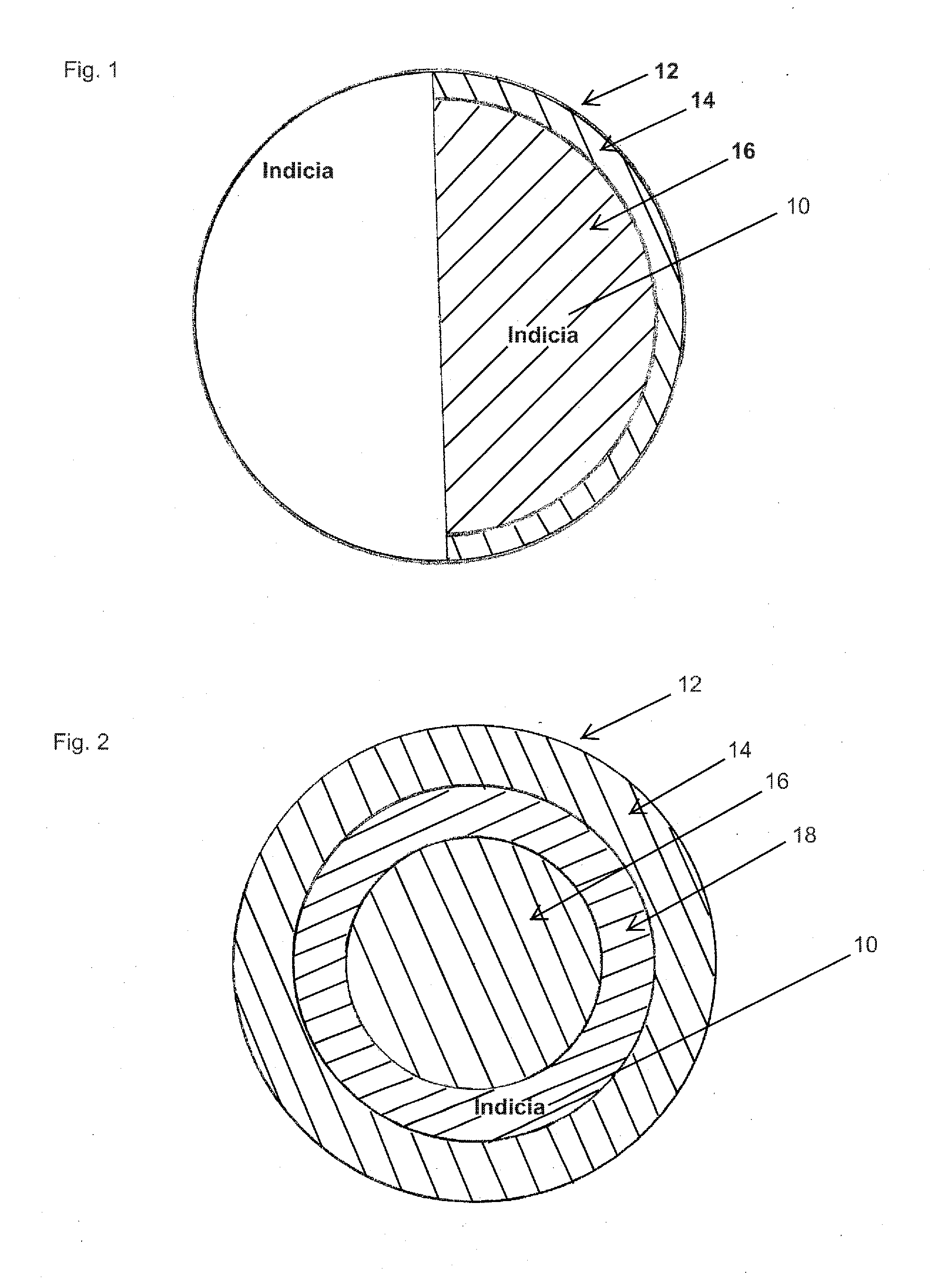

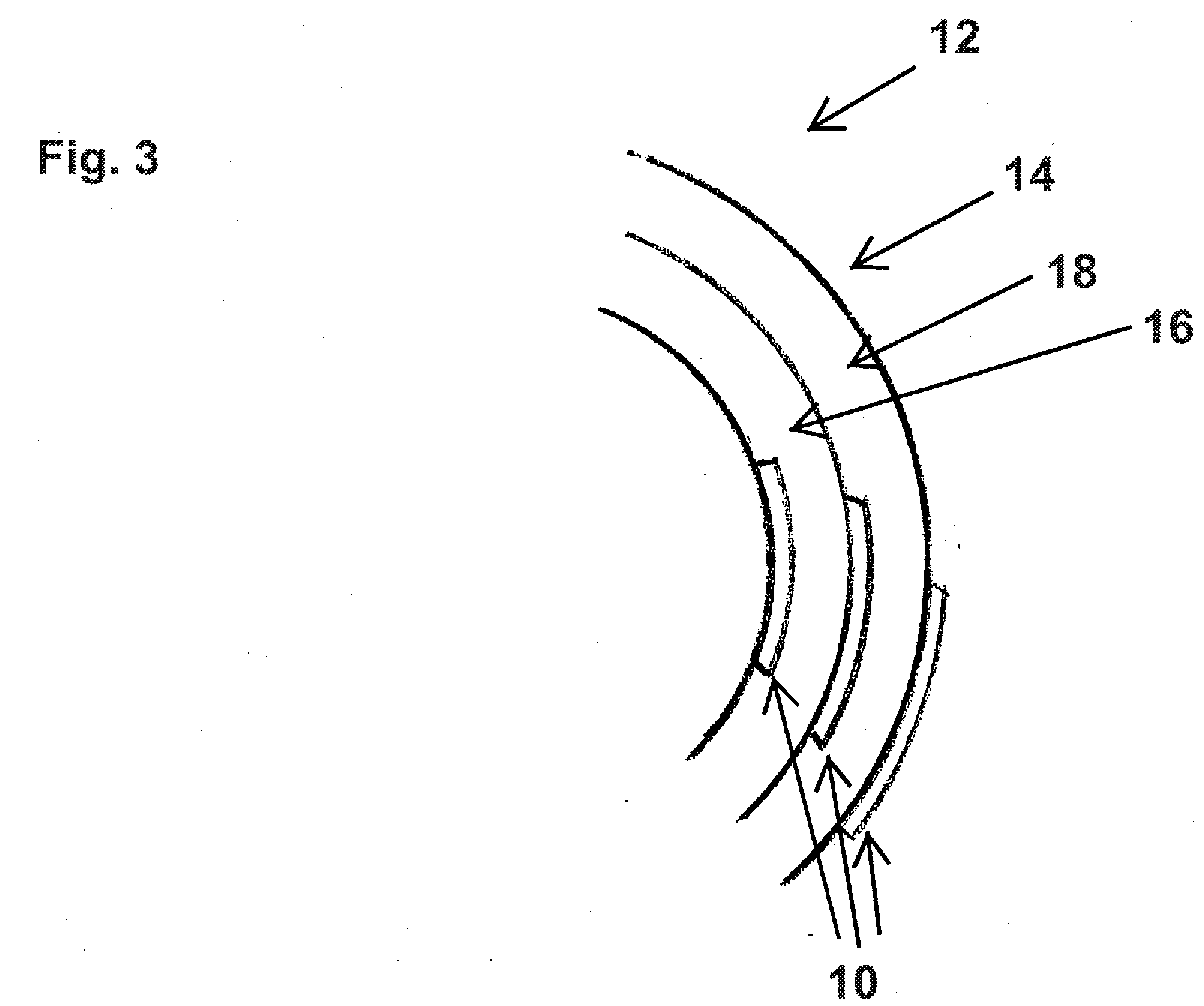

Contoured capacitive touch control panel

A method of manufacturing a contoured capacitive touch screen control panel includes printing control indicia on at least one of a front surface and a back surface of a flexible film. The method also includes printing conductive ink pads on a back surface of the film with each pad being aligned with respective printed control indicia. The method also includes disposing the printed film in an injection mold with the conductive pads printed on the back surface of the flexible film being in contact with a back surface of the mold so that a space remains between the front surface of the flexible film and a front surface of the mold. The method then includes flowing a molten plastic into the space in engagement with the front surface of the film to form a control panel with the printed indicia being visible through the control panel from a face of the control panel opposite from the film molded in situ.

Owner:UNIPLAS ENTERPRISES PTE

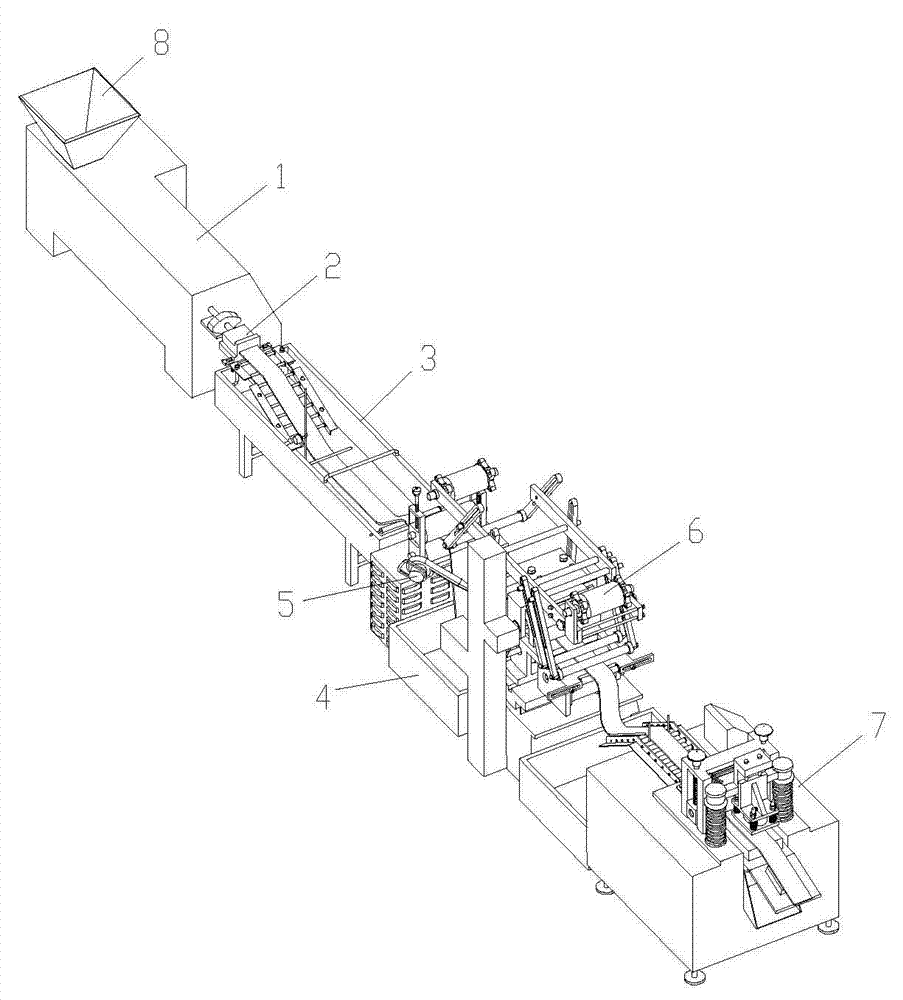

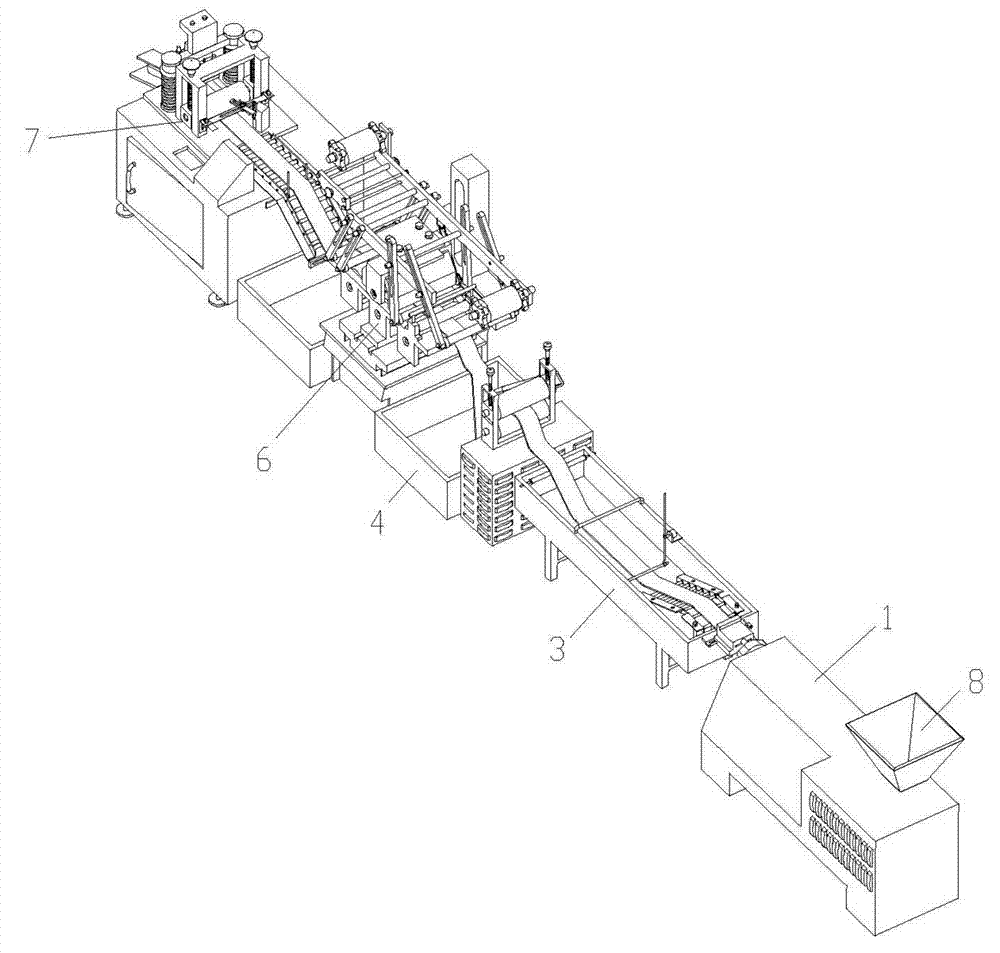

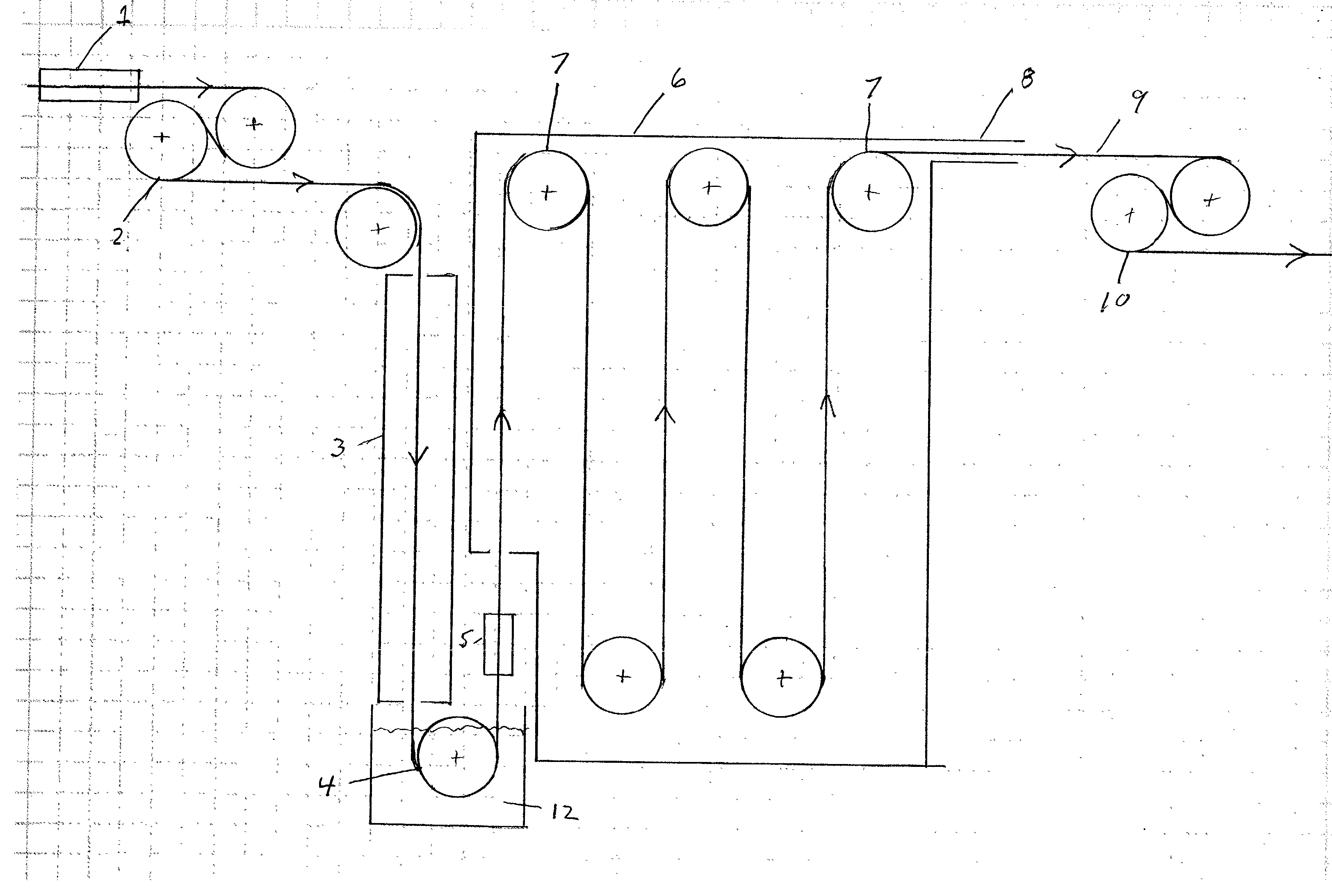

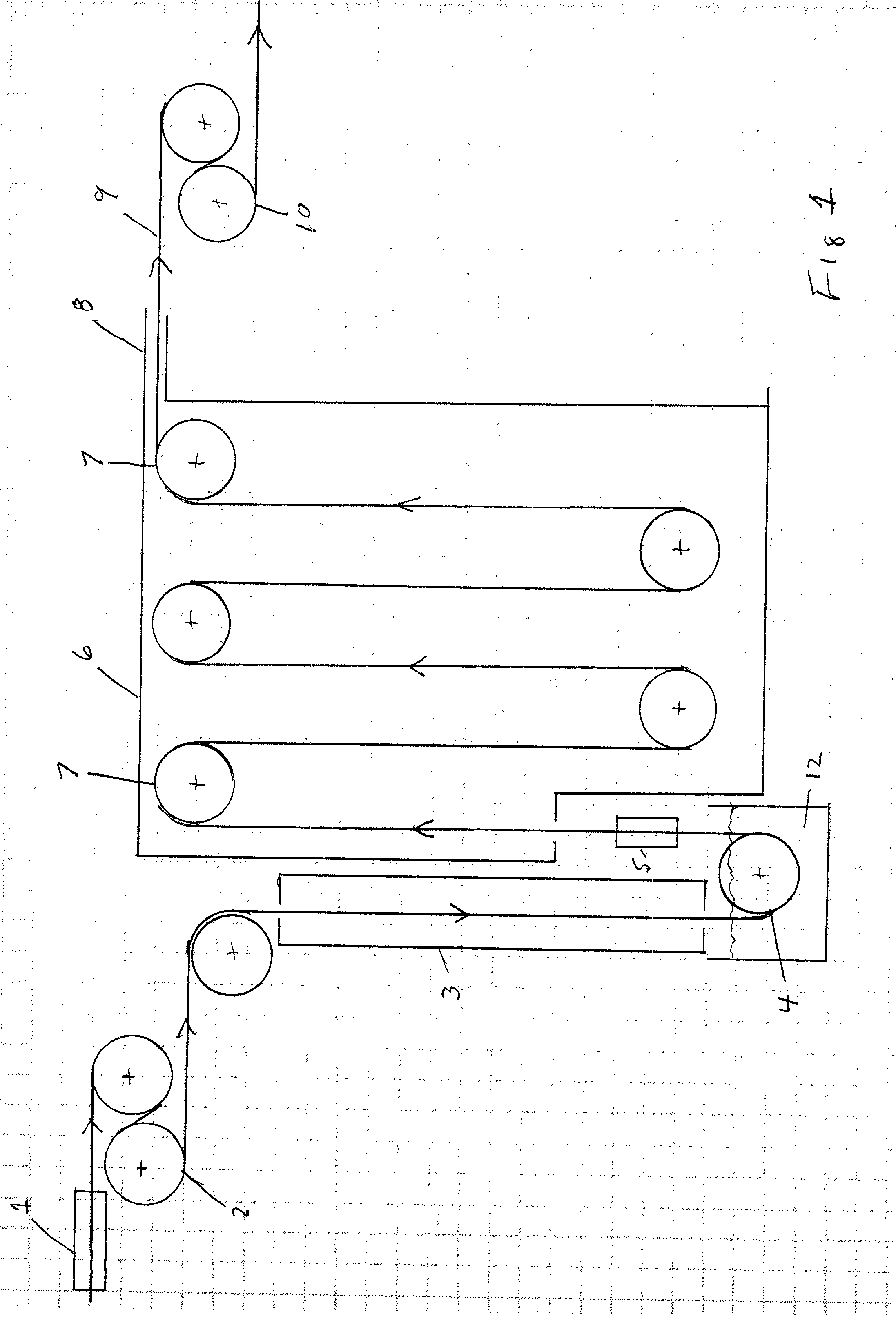

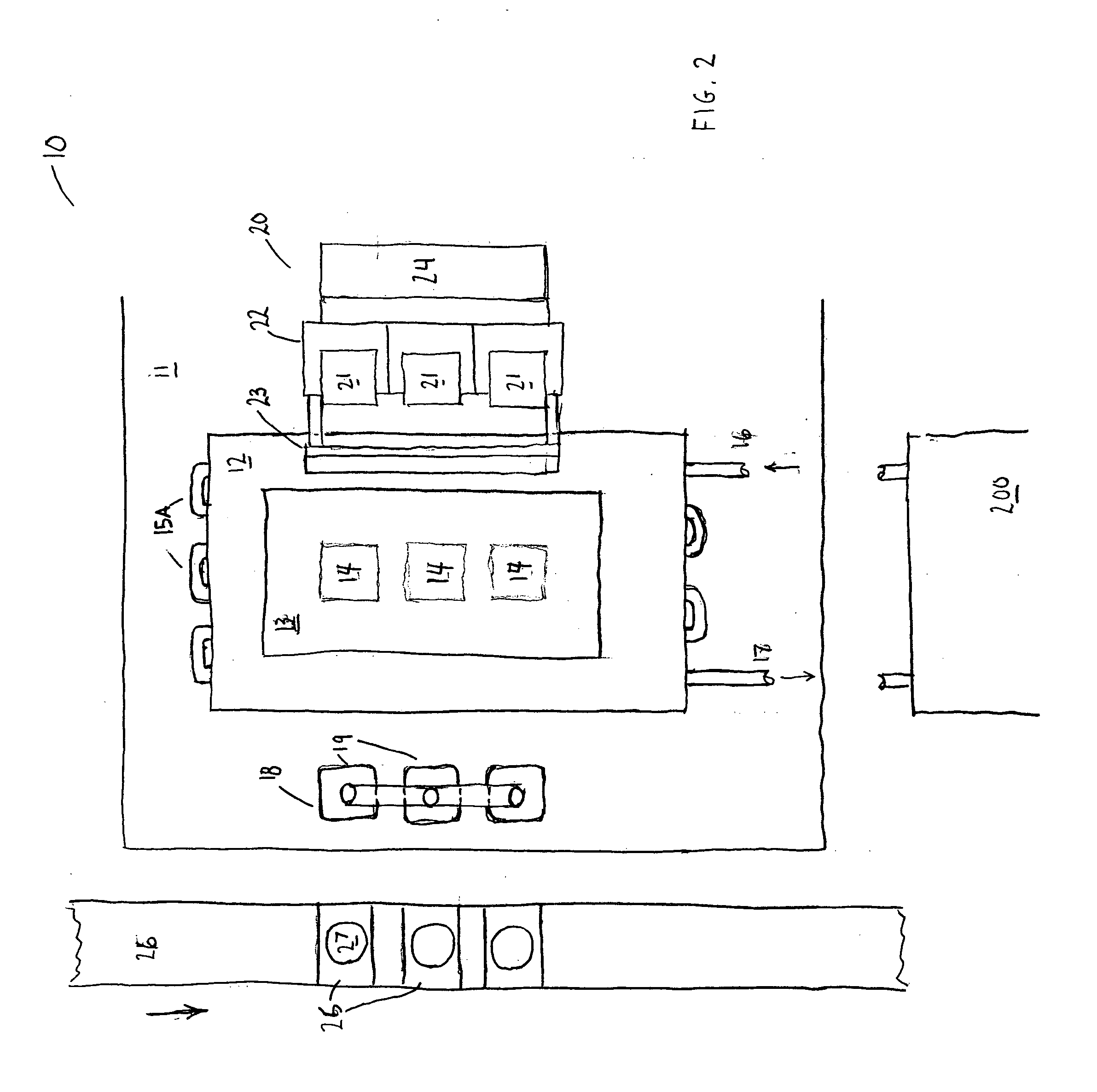

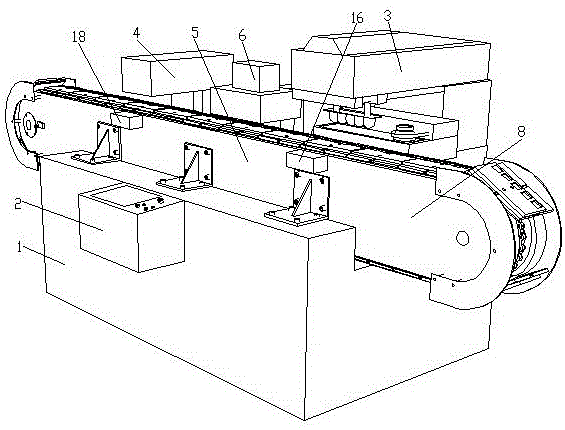

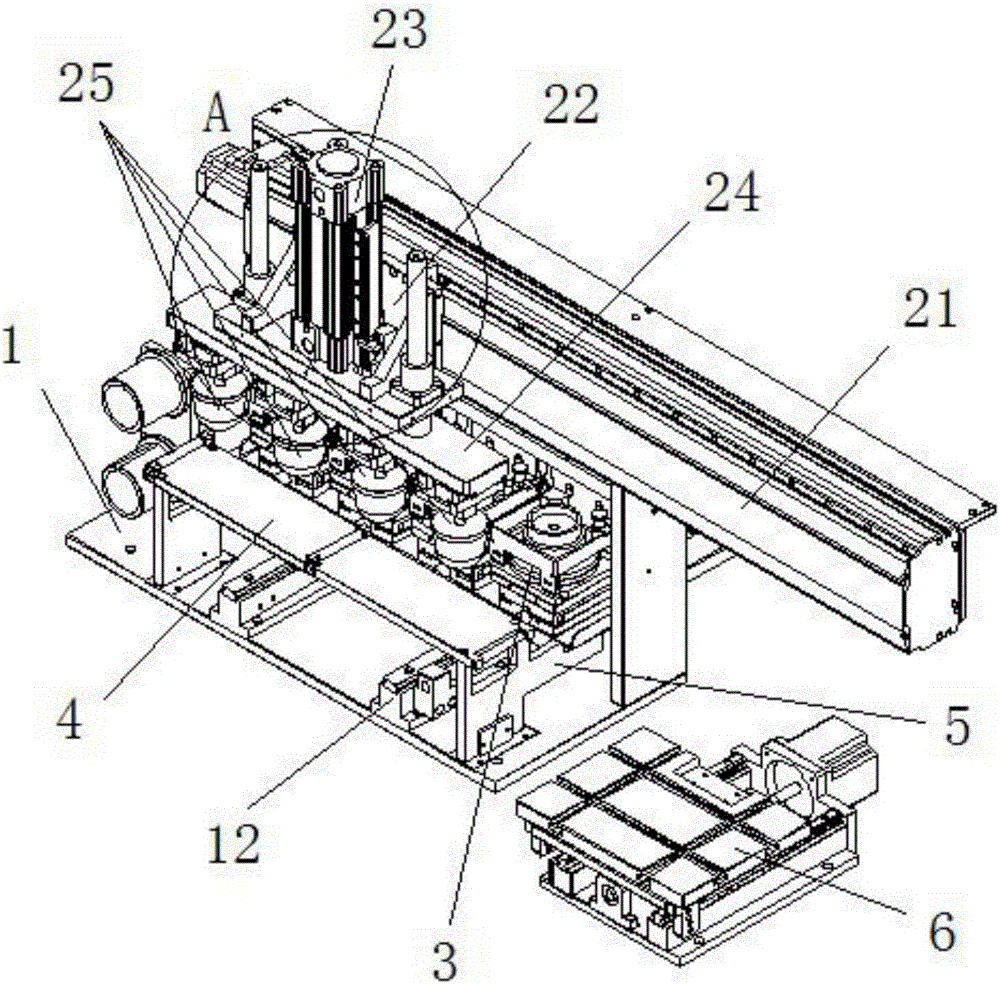

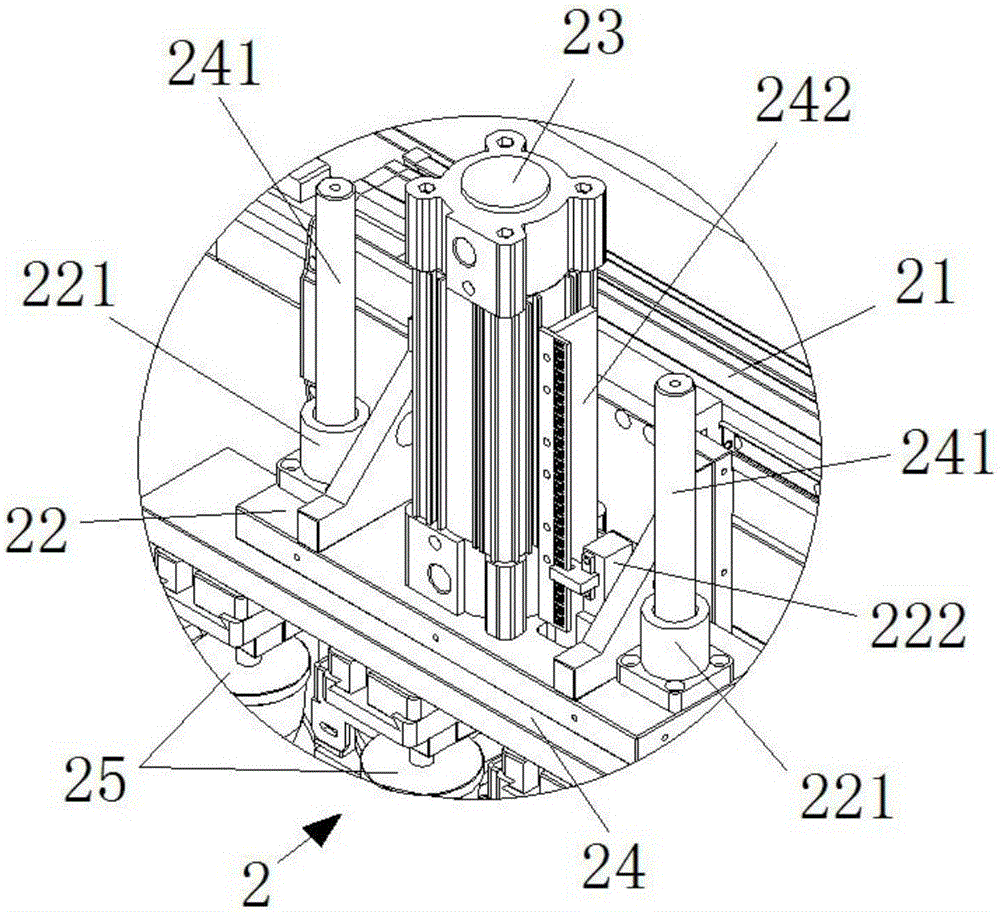

Rubber pad-printing production line

ActiveCN103587123AProduction Process AutomationEarly printingMetal working apparatusPad printingProduction line

A rubber pad-printing production line comprises a rubber extruder, the feed inlet of the rubber extruder is provided with a hopper, and the rubber extruder is successively connected with a forming die, a cooling tank, a water-washing tank, a blower, a hot-pressing pad printing mechanism and a cutting mechanism. According to the rubber pad-printing production line, the processes of manufacturing, forming, pad-printing, cutting and the like are combined into the production line, so that needed rubber are continuously rapidly manufactured, is subjected to rapid cooling by the cooling tank, and is subjected to cleaning, blow-drying, beforehand printing, mechanized automatic pad printing and cutting, and the various processes are linked up reasonably, and thus the production efficiency on rubber is improved and rubber production is automatically achieved.

Owner:ZHEJIANG QINGYUAN OUDI IND

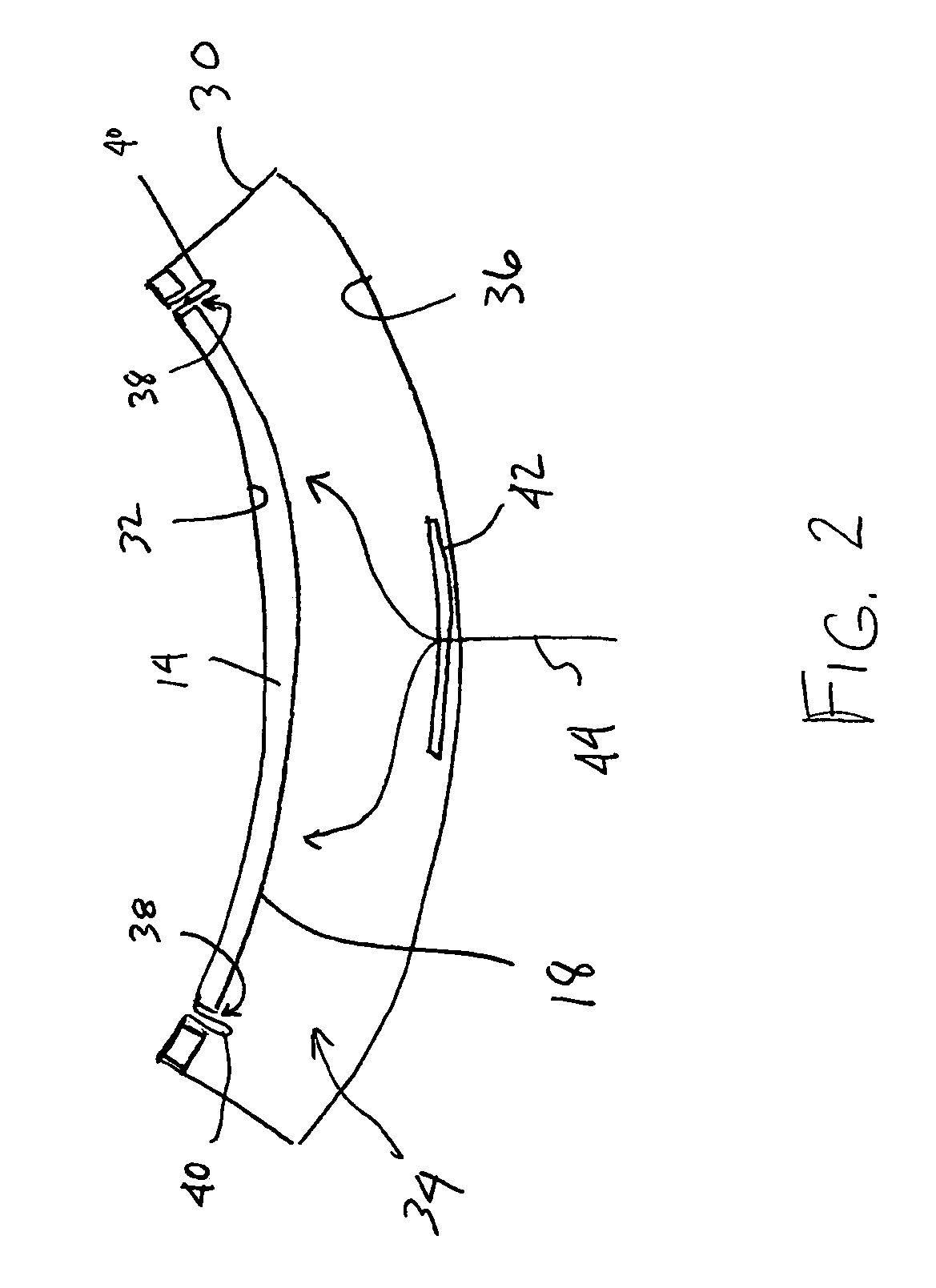

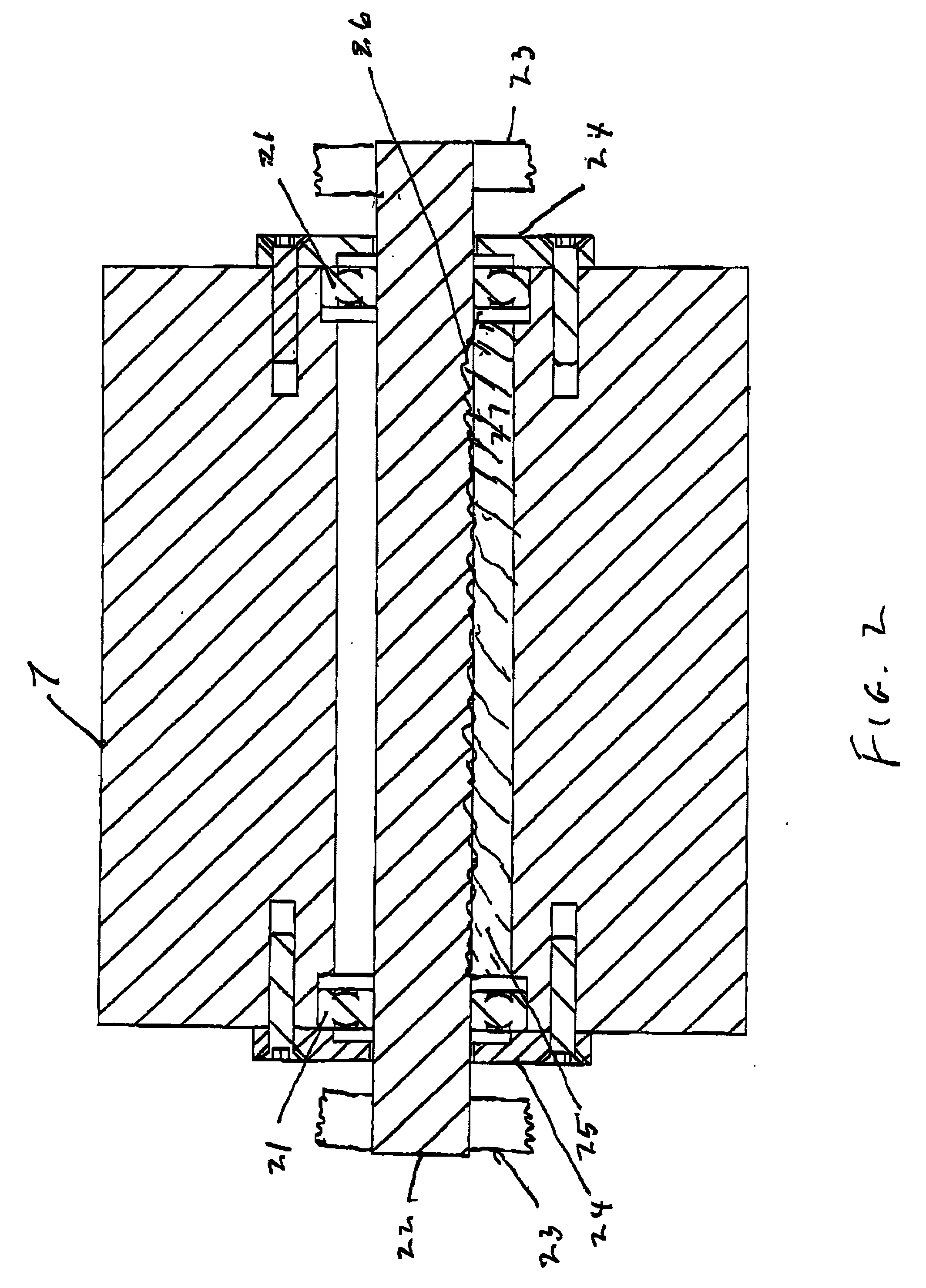

Method and apparatus for bainite blades

InactiveUS20020100522A1Maximize propertyMaximize straightnessRotary intaglio printing pressFurnace typesPad printingFerritic matrix

The present invention includes bainitic steel doctor blades, bainitic steel coating blades, bainitic steel creping blades and bainitic steel rule die knives used in gravure printing, flexographic printing, paper making, die cutting of materials including paper, plastic, foam, leather, etc. Other uses include printing processes such as pad printing and electrostatic printing. The invention also includes an improved method for producing bainitic steel strip. The present invention is accomplished by using bainitic steel components that exhibit superior straightness and wear properties and are bendable around small radii. The process of the present invention comprises the steps of annealing a carbon steel resulting in a microstructure of the steel having a dispersion of carbides in a ferritic matrix; cold rolling the annealed steel; cleaning the cold rolled steel to remove oil and dirt; bridle braking the cleaned steel to increase strip tension; austenitizing the steel; submersing the austenitized steel into a quenchant; removing excess quenchant; and isothermally transforming the austenitized steel into bainite. The present process of the invention also includes the use of turn rolls that are housed in an assembly containing salt and / or tin.

Owner:BENTON GRAPHICS

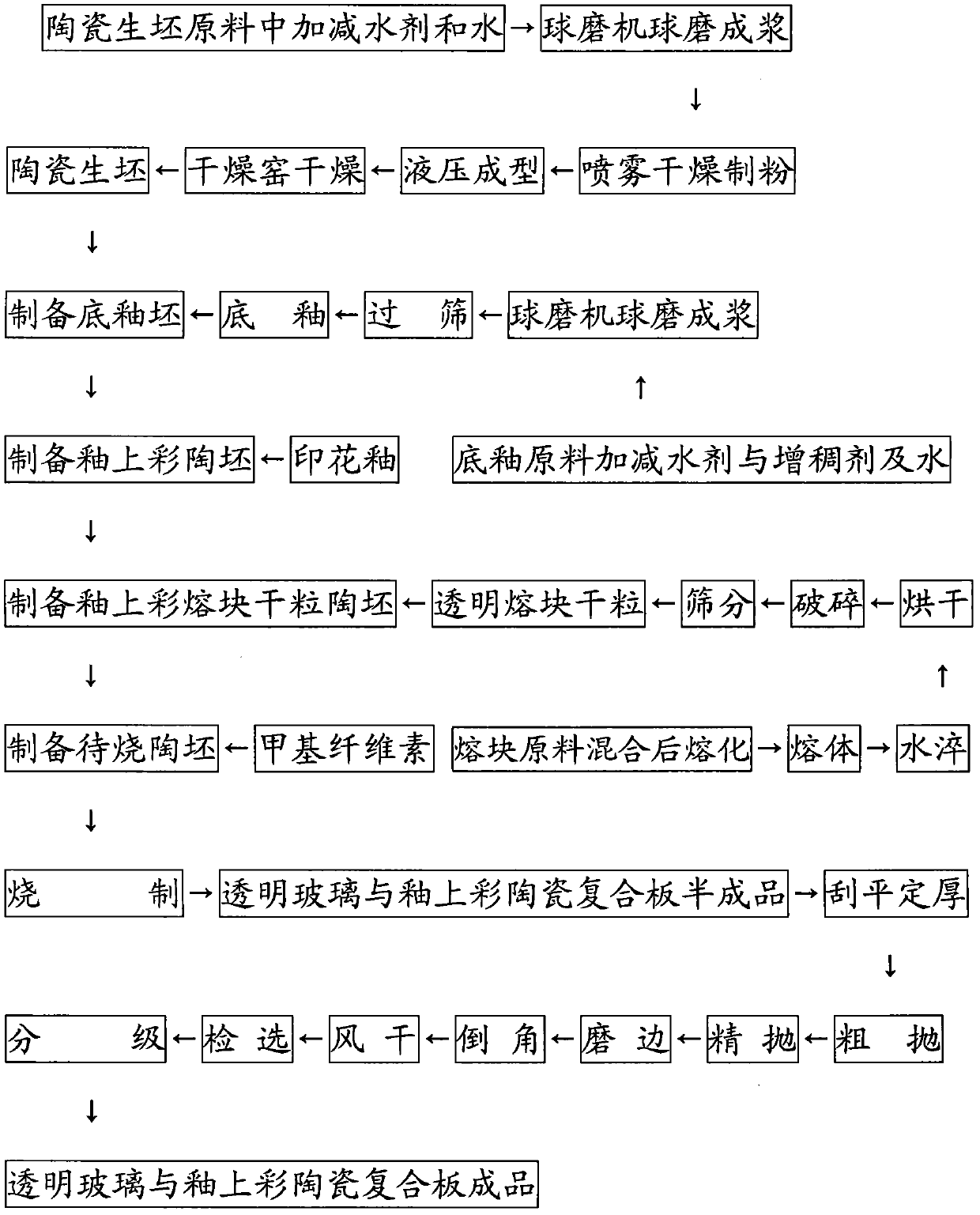

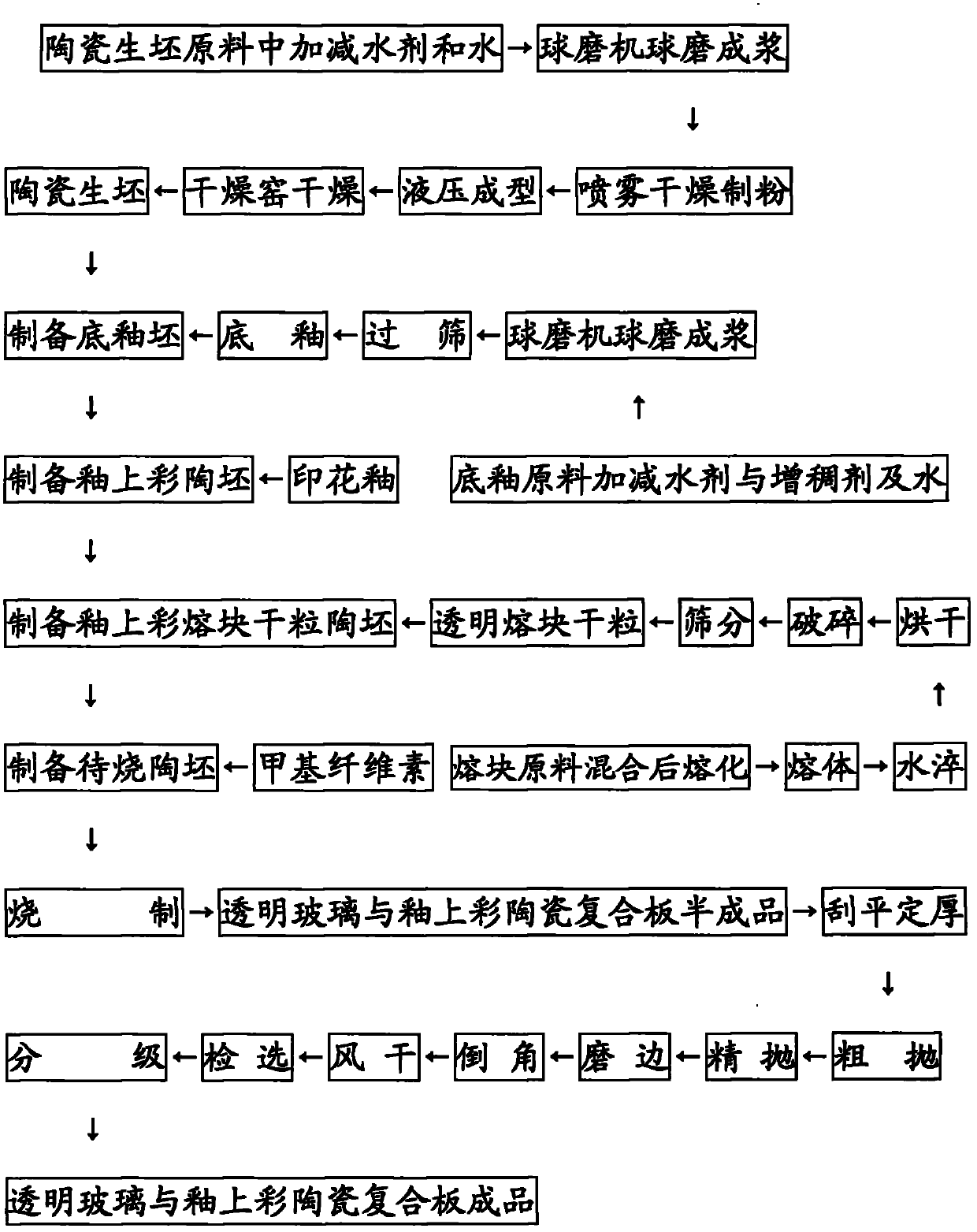

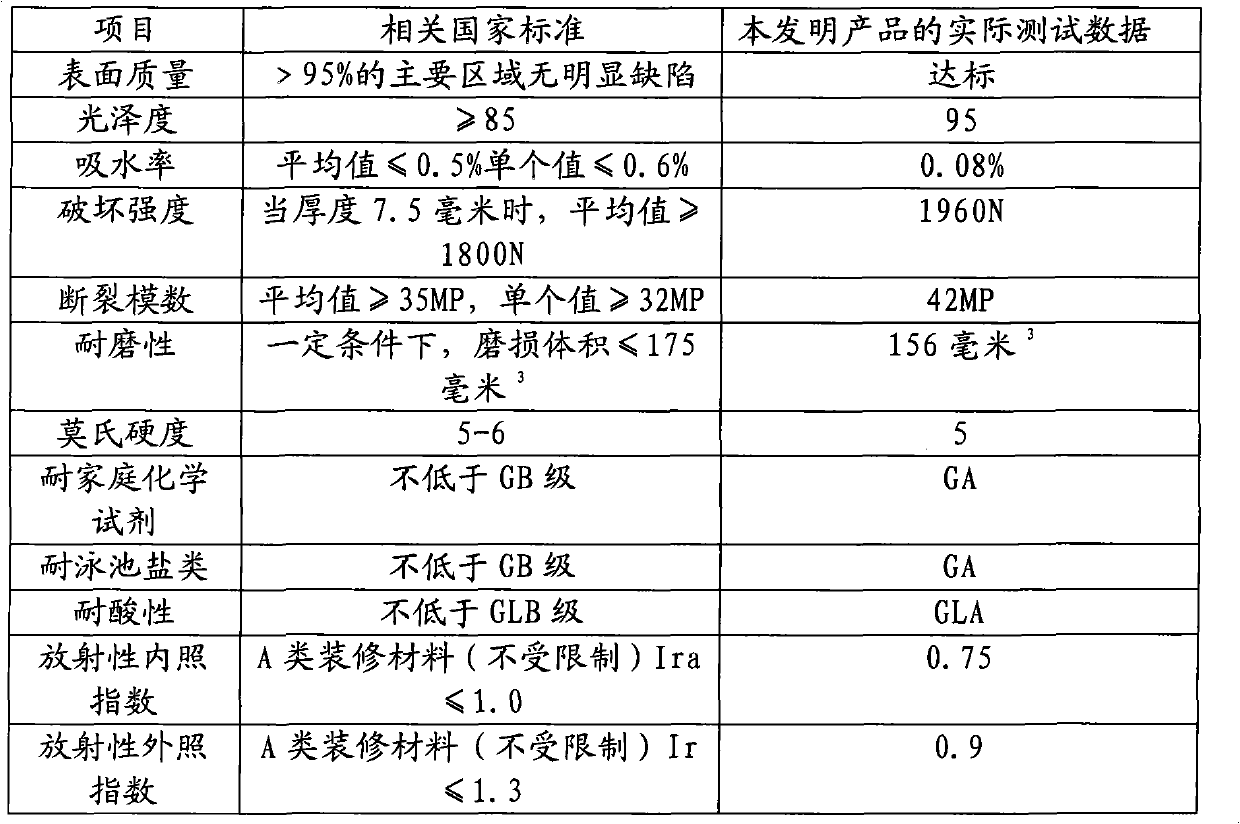

Method for producing transparent glass and overglazed color ceramic sandwich by single firing

A method for producing transparent glass and overglazed color ceramic sandwich by single firing in the invention relates to the technical field of building materials. By the adoption of ''a key single firing technology with material selection within the range of predetermined product components'', the method provided by the invention comprises the following steps of: applying ground-coat enamel on a ceramic green compact to prepare an enamel green body, printing gelatine-pad printed fancy glaze to prepare an overglazed color ceramic green body, applying transparent frit dry granules on the overglazed color ceramic green body to prepare overglazed color frit dry granular ceramic green body, spraying methyl cellulose for fixation to prepare a greenware to be sintered, sintering the greenware to be sintered to form a semi-finished product, followed by strickling for thickness determination, rough casting, fine casting, edging, chamfering, air drying, picking and grading to prepare the transparent glass and overglazed color ceramic sandwich finished product. The method is used for the production of transparent glass and overglazed color ceramic sandwiches and is the single firing technology with material selection within the range of predetermined product components.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

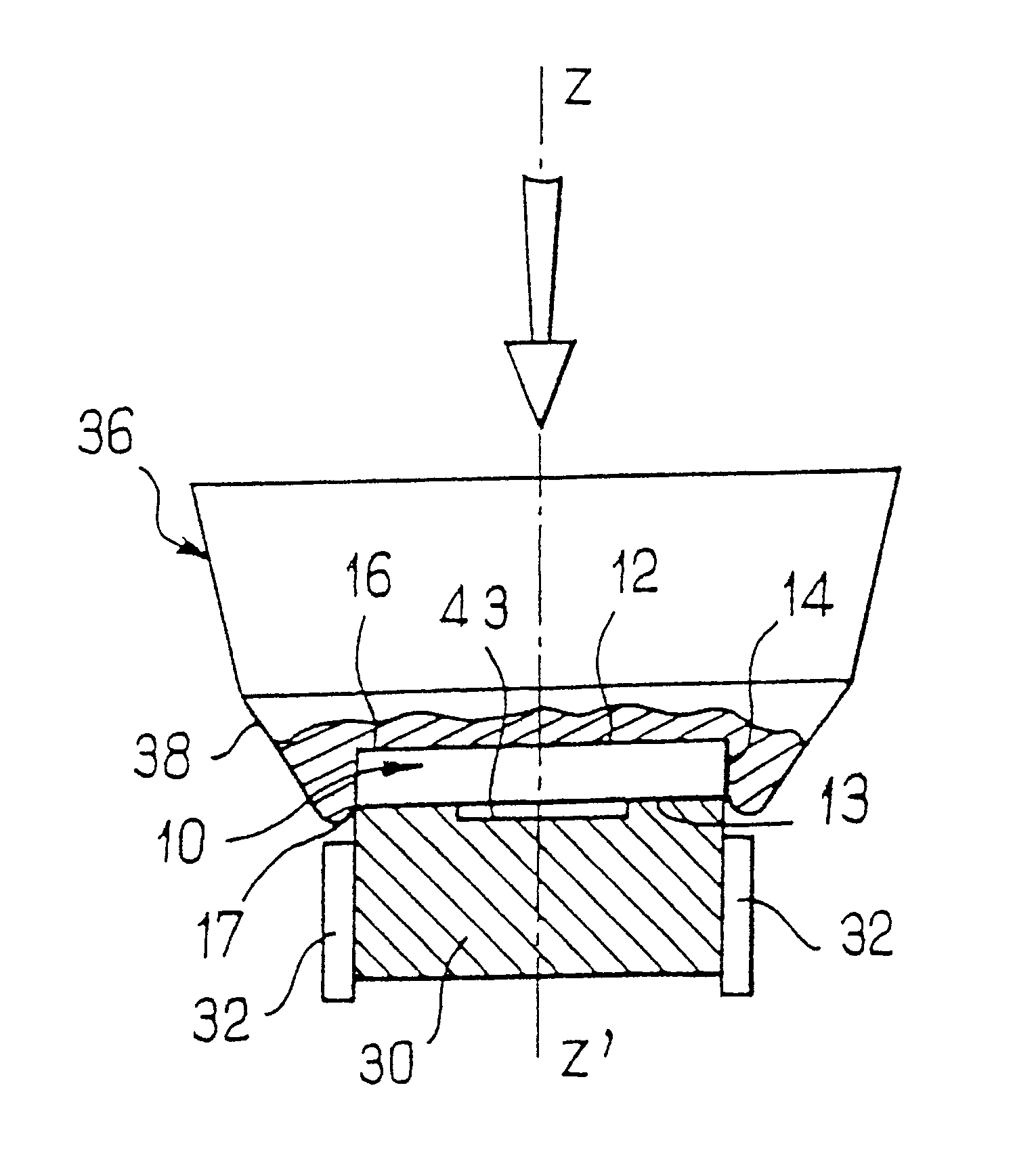

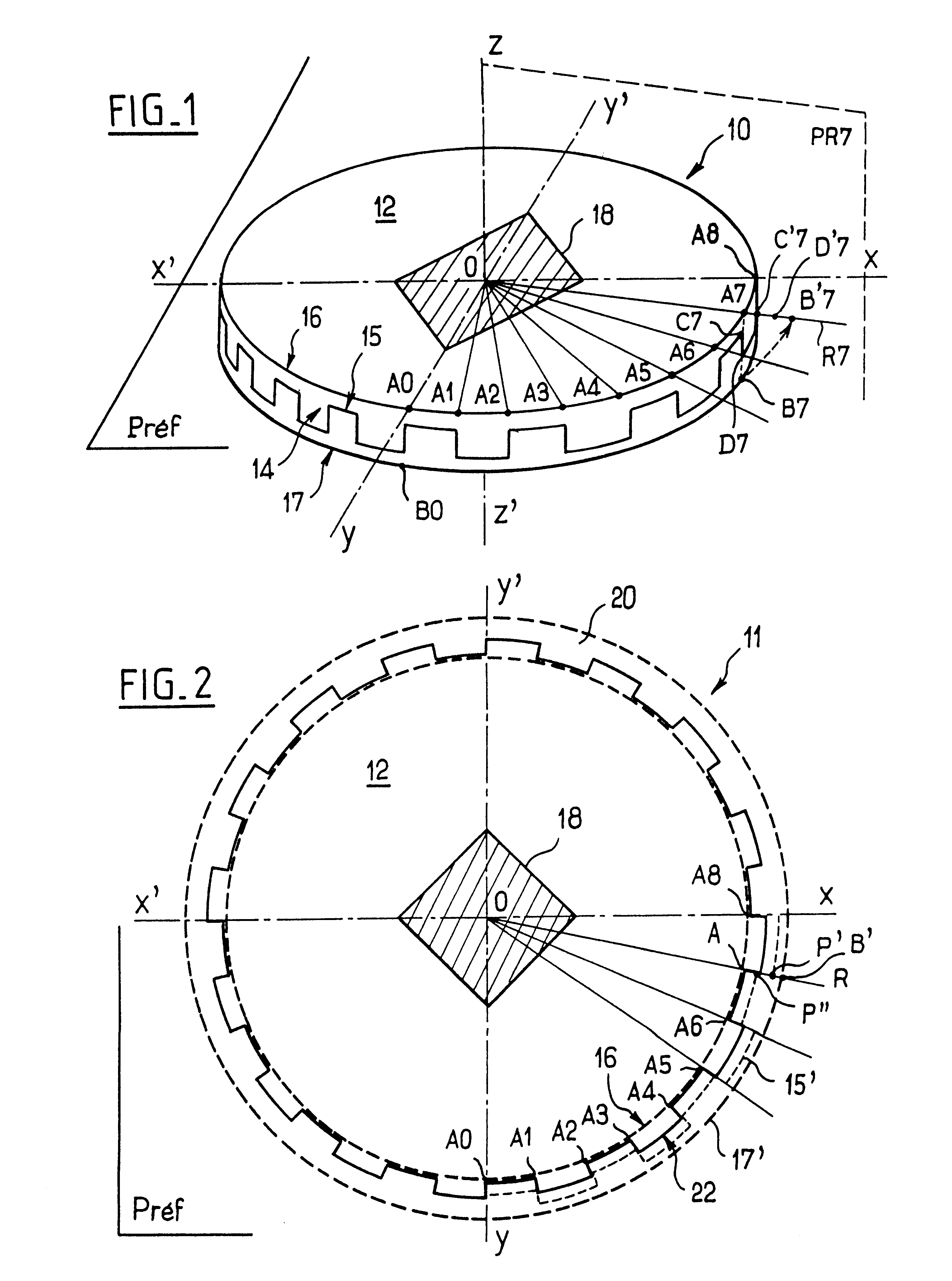

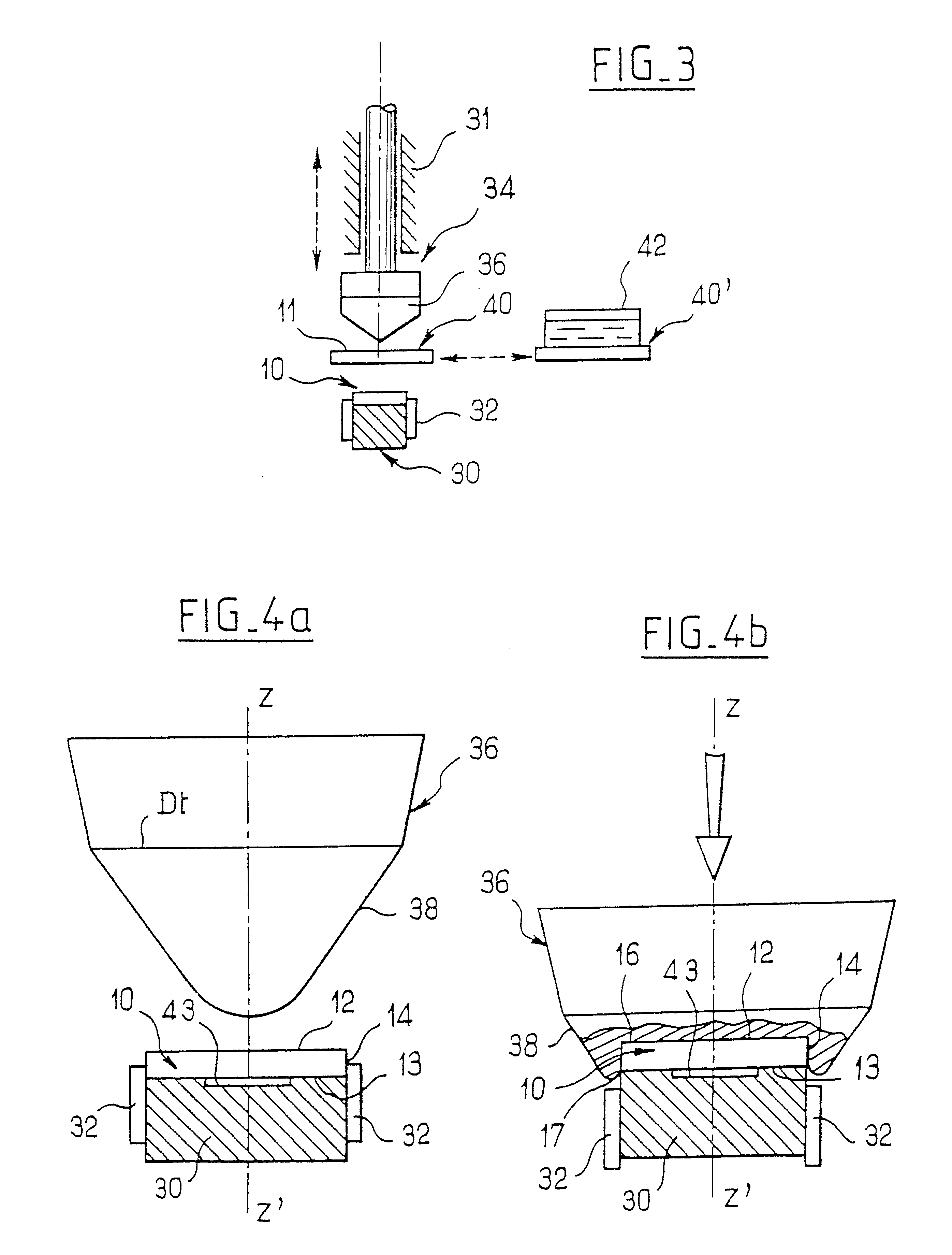

Method for marking a gaming disk by pad printing

A method for marking a side of a straight-sided chip with a decoration by pad printing. The method comprises providing an ink plate with an image defined by radially deformed representation of the decoration of the straight side of the chip in a ring-shaped zone, moving a pad coaxially into contact with the ink plate such that the image transfers to the pad, and moving the pad coaxially into contact with the chip such that the image transfers to the side of the chip.

Owner:GAMING PARTNERS INTERNATIONAL CORPORATION +1

Pattern adhesive seal products and method of production

The present invention is drawn to a method of making a sealing product, by a) selecting an a sealing material of an optimum film, mat or multi-well plate surface material for a specific sealing application; b) treating the sealing material; and c) directly coating the sealing material with an adhesive in a pattern format using Gravure, screen, rotary screen, flexographic, pad printing or dry transfer techniques. The present invention is further drawn to a sealing product made using the aforementioned method.

Owner:RAZAVI ALI

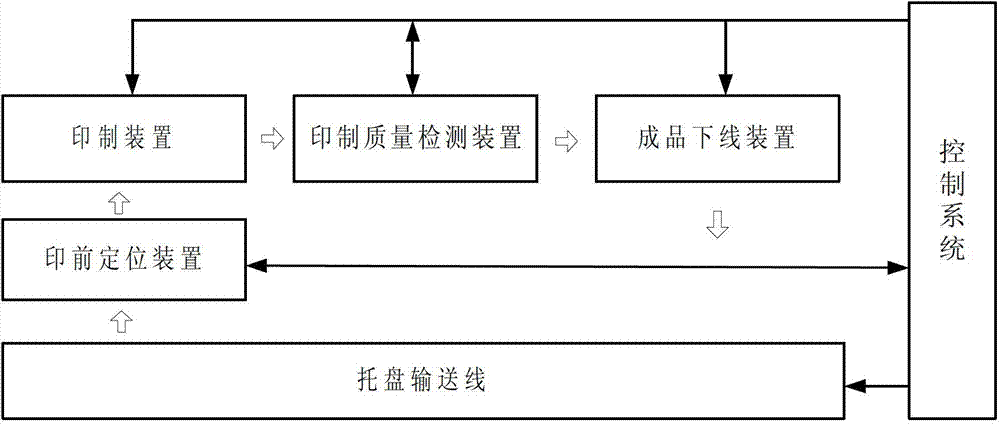

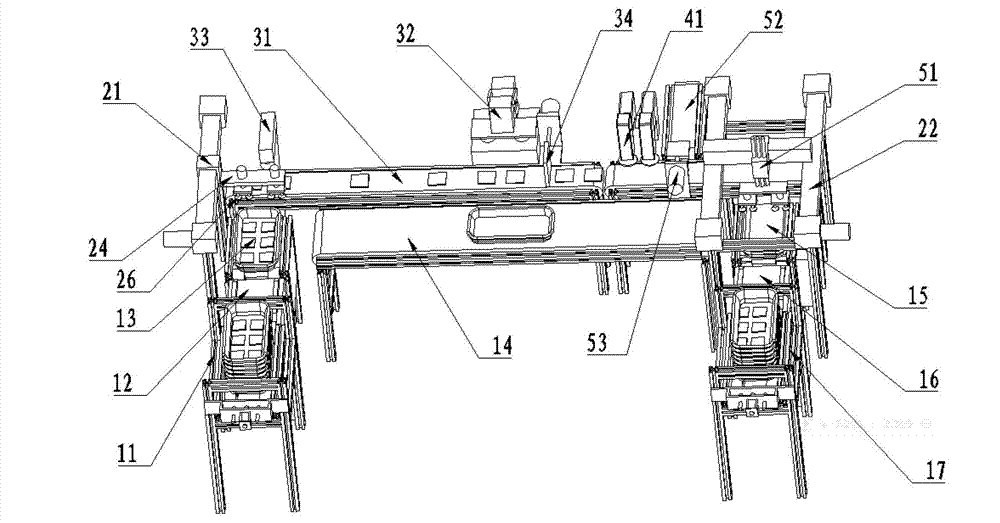

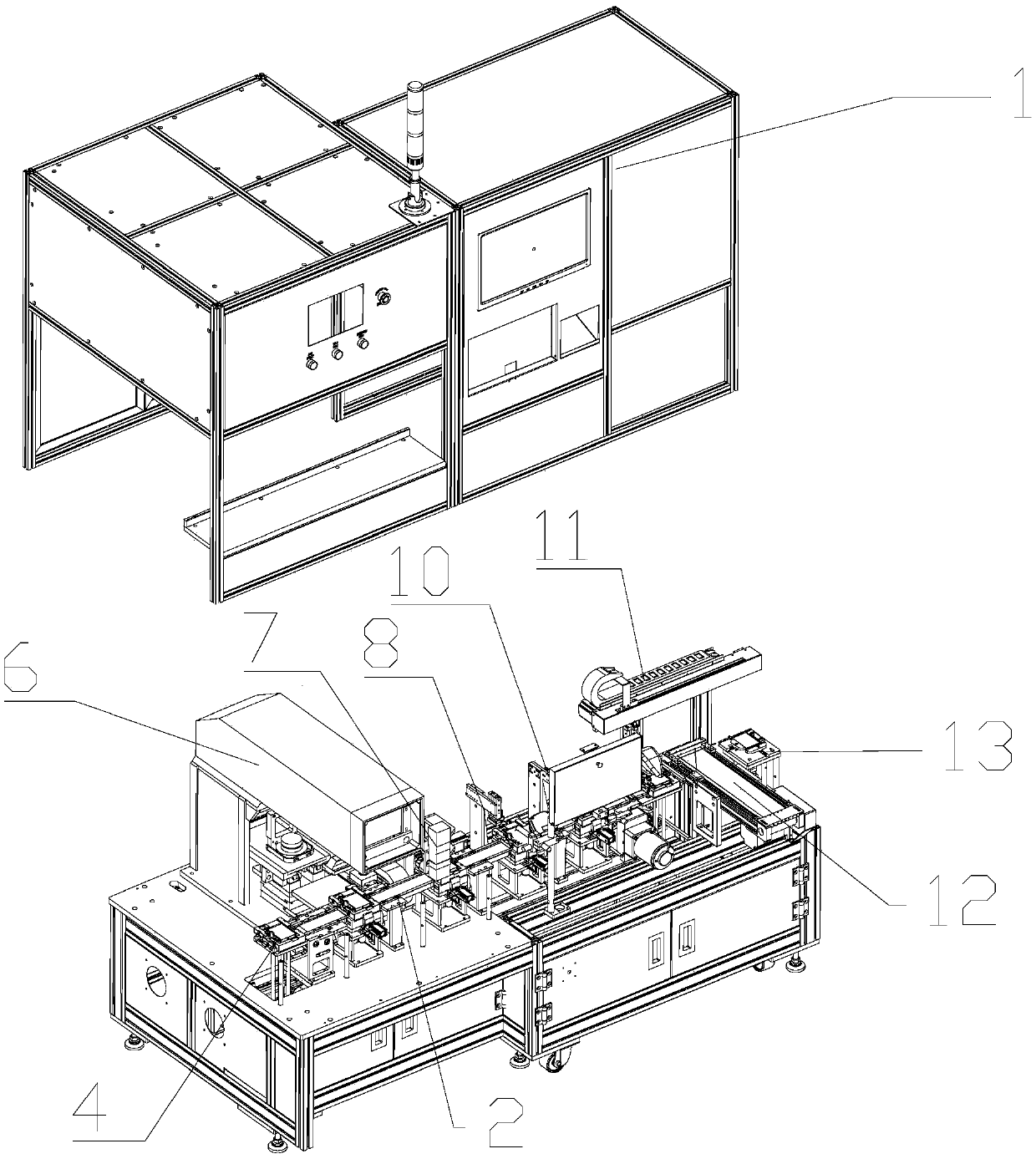

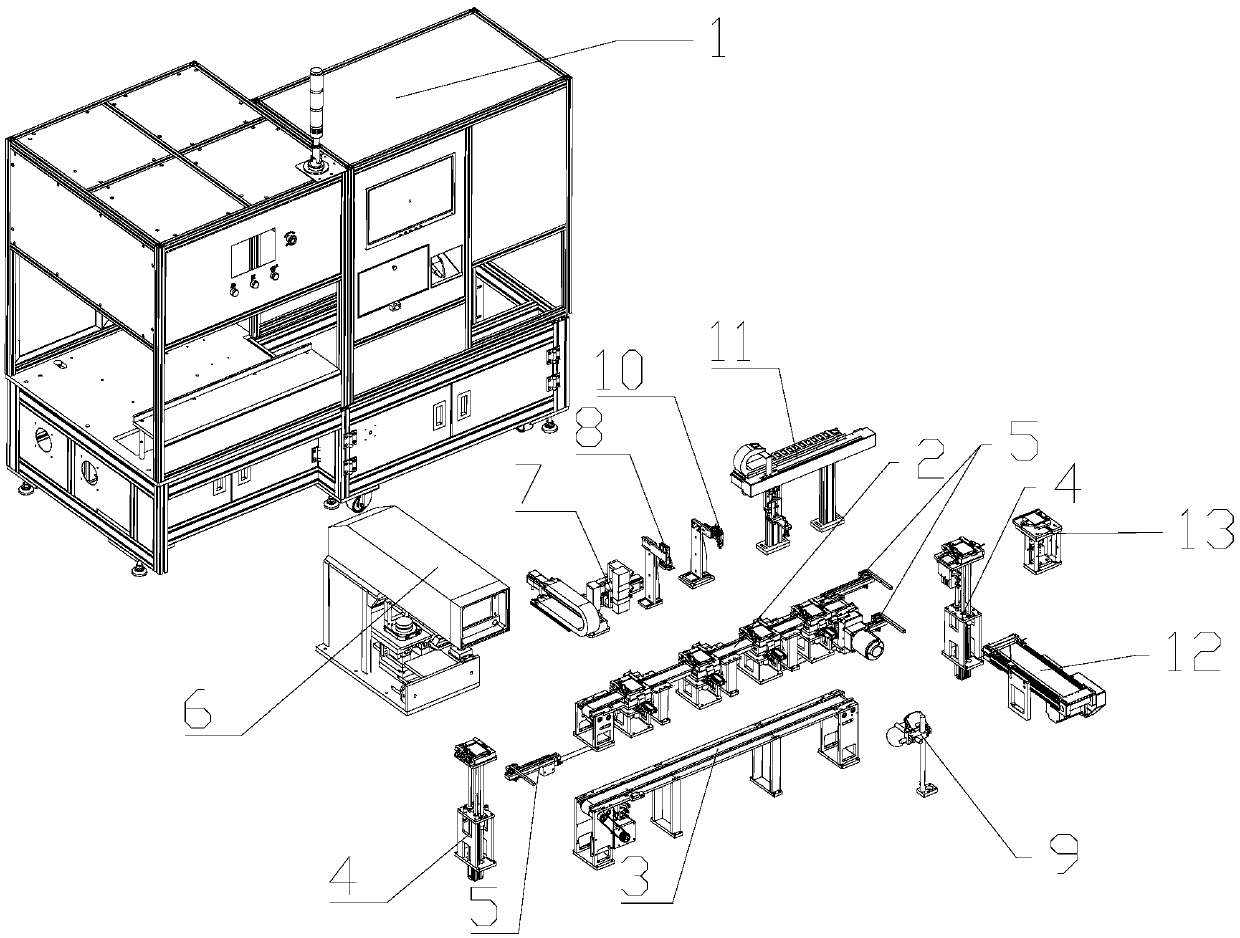

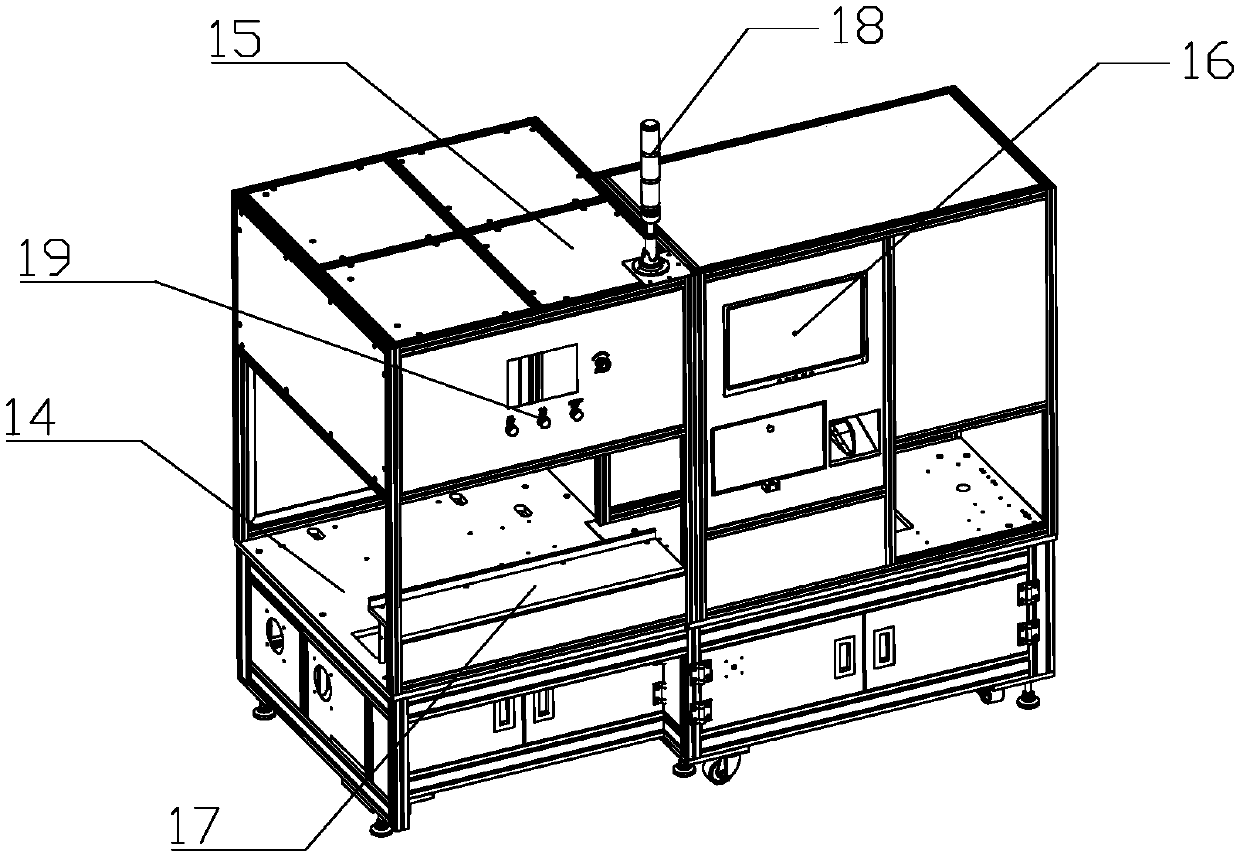

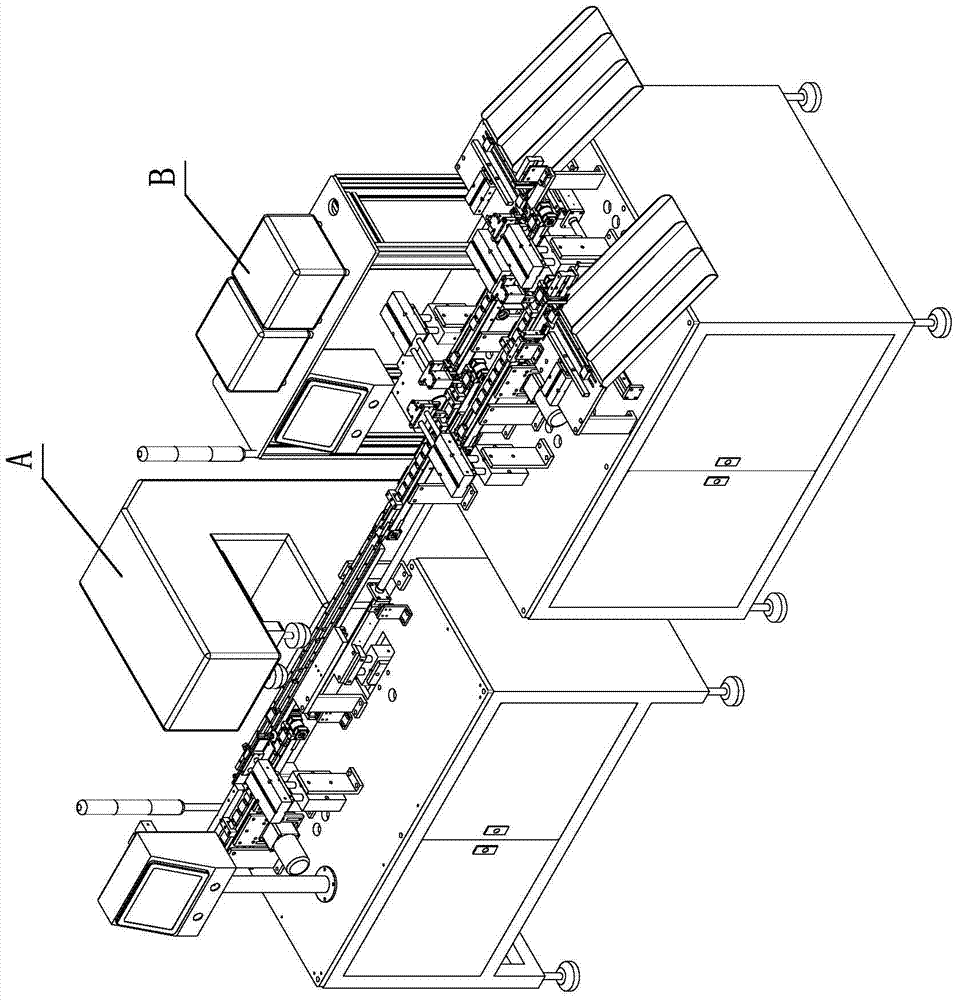

Automatic printing production line of panel trademarks

InactiveCN102922870AReduce labor costsIncrease productivityTransfer printingPrinting press partsPad printingProduction line

The invention provides an automatic printing production line of panel trademarks. The automatic printing production line comprises a tray conveying line, a pre-print positioning device, a printing device, a printing quality detection device, a finished product discharging device and a control system, wherein the tray conveying line, the pre-print positioning device, the printing device, the printing quality detection device and the finished product discharging device are electrically connected with the control system. According to the automatic printing production line of panel trademarks, the product to be printed is grabbed from a tray on the tray conveying line by a first mechanical arm and is placed onto a printing conveyor line after adjusting the direction, the printing quality is detected after a pad printing machine finishes printing, and a first air cylinder directly pushes unqualified products onto an unqualified product conveying line and grabs qualified products into the tray of a blanking turning machine. The above process is automatically finished by the control system, so that the labor cost is greatly saved, the production efficiency is increased, and the printing quality can be ensured simultaneously.

Owner:衡宝(上海)电气有限公司

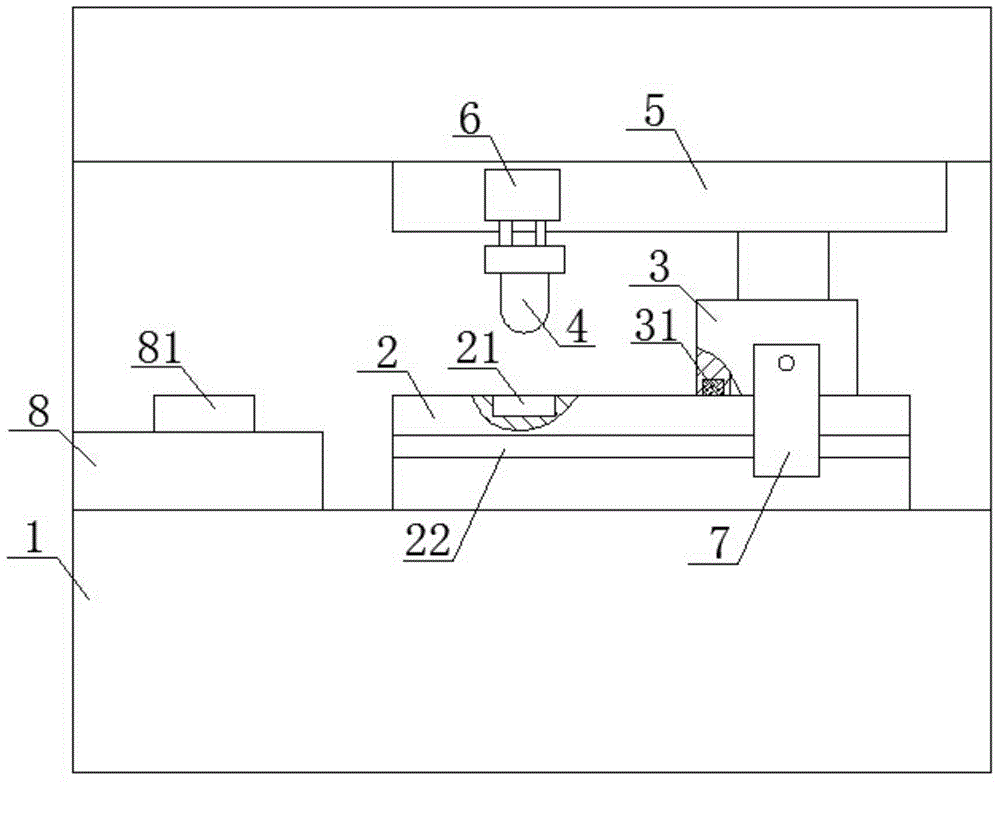

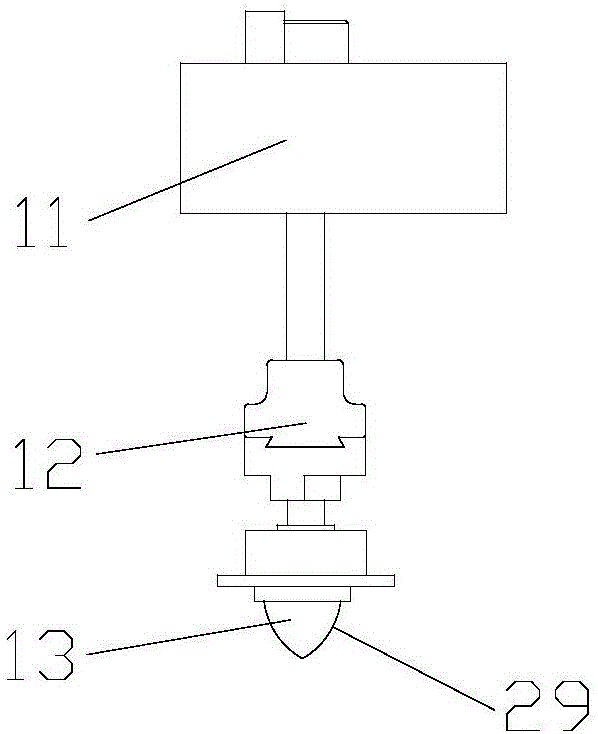

Oil cup type pad printing machine

InactiveCN104553276ASimple structurePad printing has a tight cycleRotary pressesPad printingSheet steel

The invention provides an oil cup type pad printing machine which is aimed at solving the problems of the existing oil cup type pad printing machines that the complicity of control is high, and the whole pad printing work is long in time and low in work efficiency. The oil cup type pad printing machine comprises a machine frame, a pad printing steel plate with a sunk pattern, an oil cup and a pad printing glue head, wherein a sliding block which can slide along the horizontal direction is arranged on the machine frame, the upper end of the oil cup is connected onto the sliding block, the lower end of the oil cup is press-fit on the upper surface of the pad printing steel plate, a guiding groove is formed in the side face of the pad printing steel plate, a guiding block which can slide along the guiding groove is matched with the guiding groove, and the upper end of the guiding block extends upwards and is connected onto the side face of the oil cup; an air cylinder is arranged on the sliding block, the pad printing glue head is connected to the lower end of the air cylinder, and the horizontal distance between the pad printing glue head and the oil cup is equal to the distance between a position, for fixing a printed workpiece, on a printed workpiece fixing table and the sunk pattern. The oil cup type pad printing machine has the beneficial effects that the structure is simple, the rhythm of pad printing work is compact, time is saved, control is facilitated, and the work efficiency is high.

Owner:长兴艾飞特科技股份有限公司

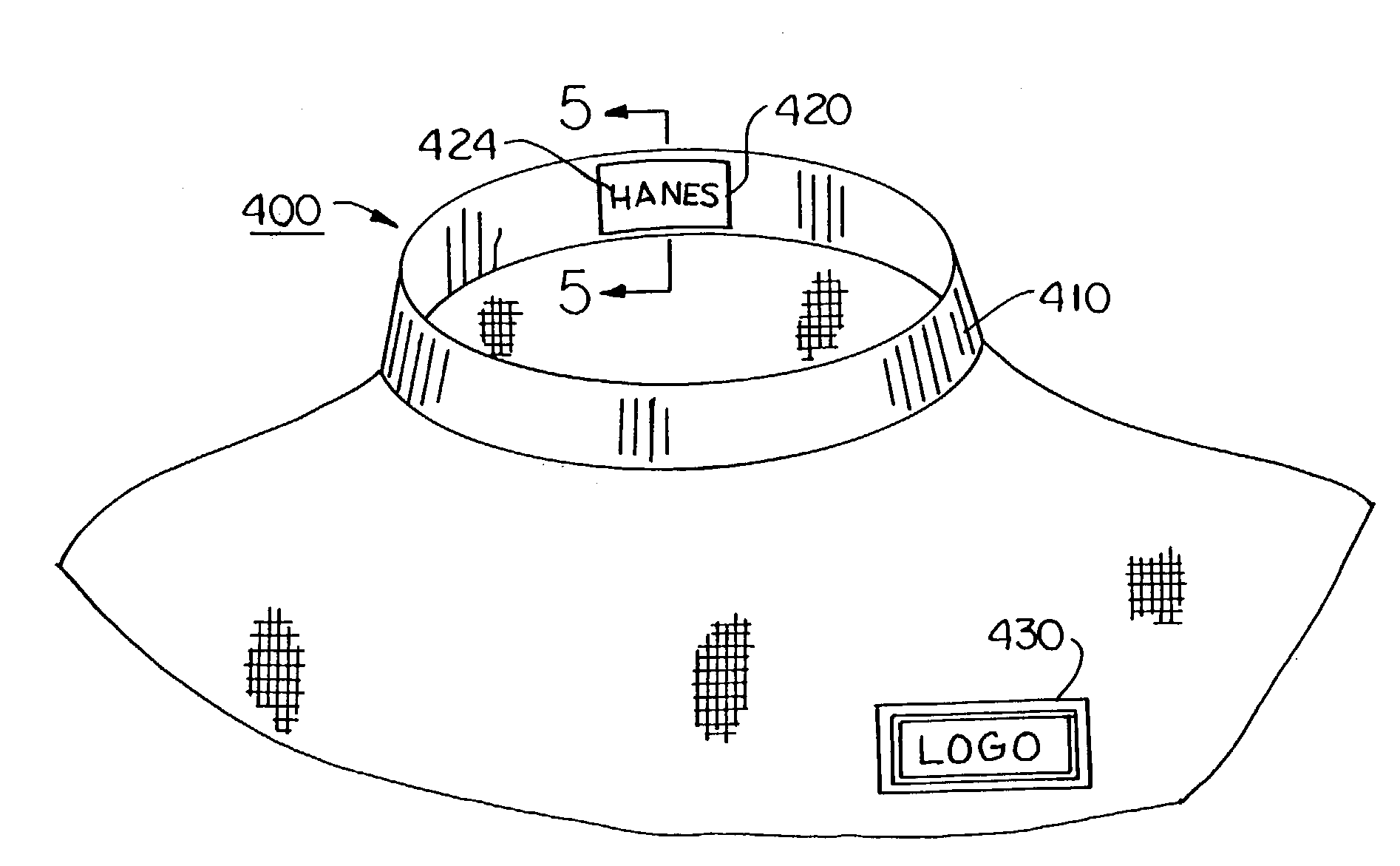

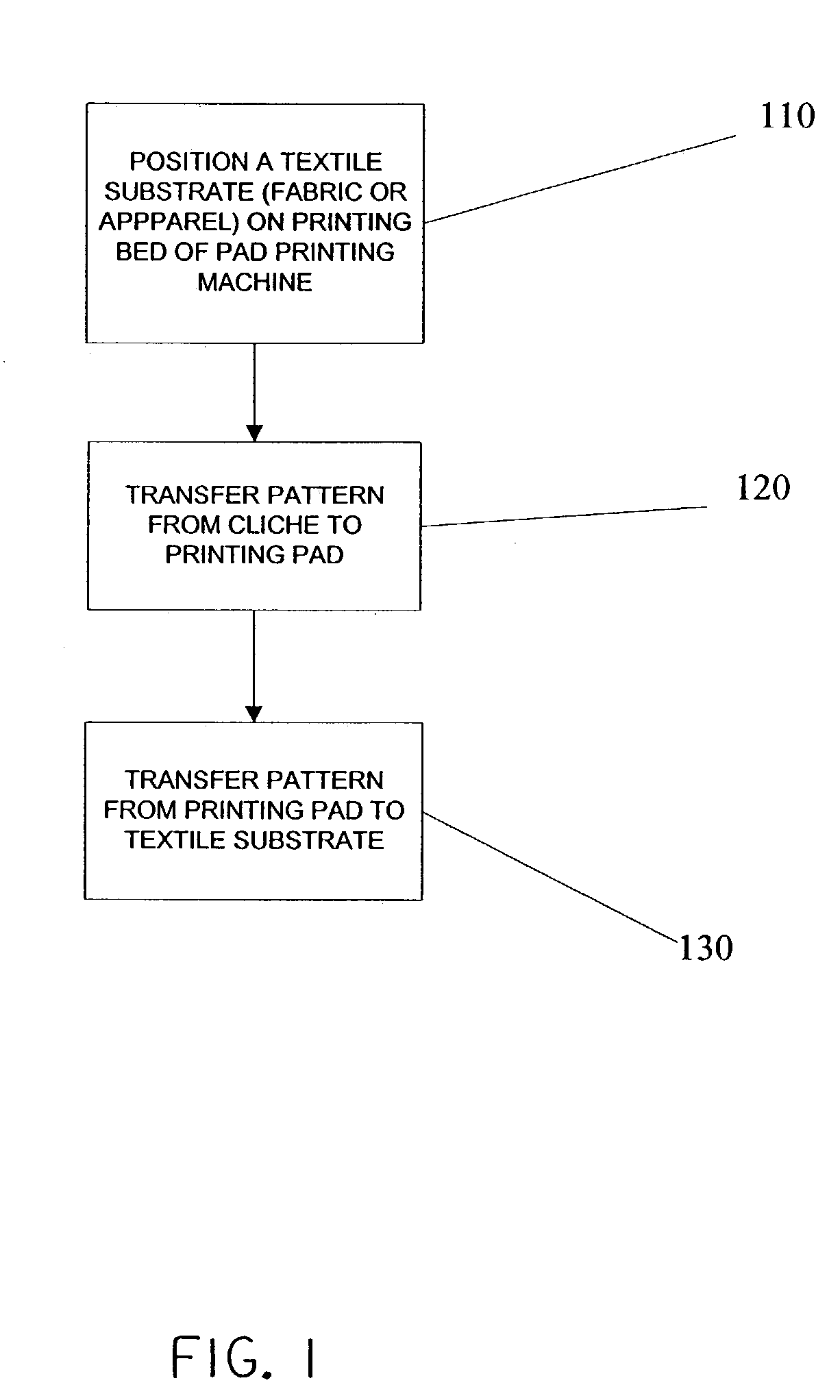

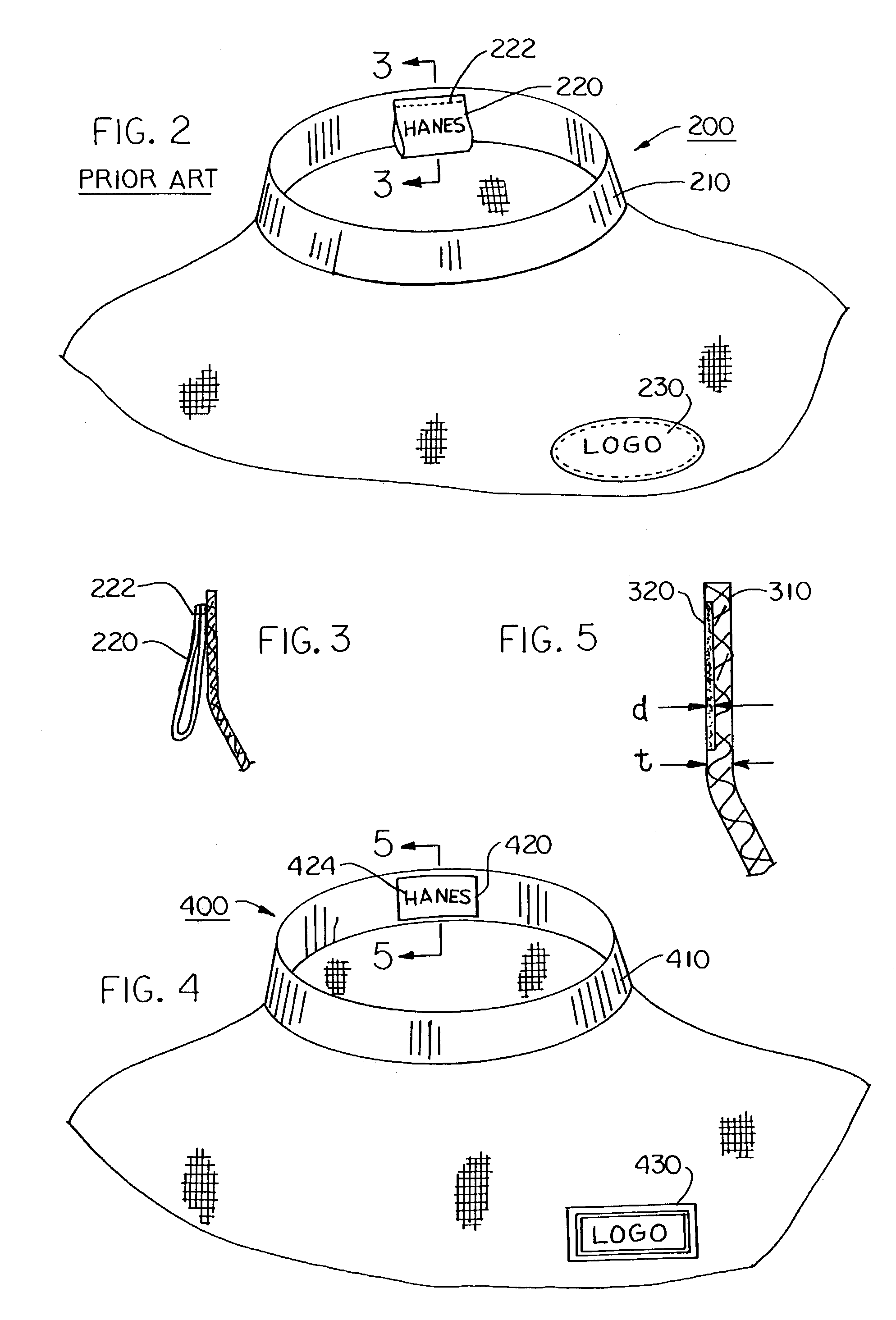

Pad printing on textile substrates

Owner:HBI BRANDED APPAREL ENTERPRISES

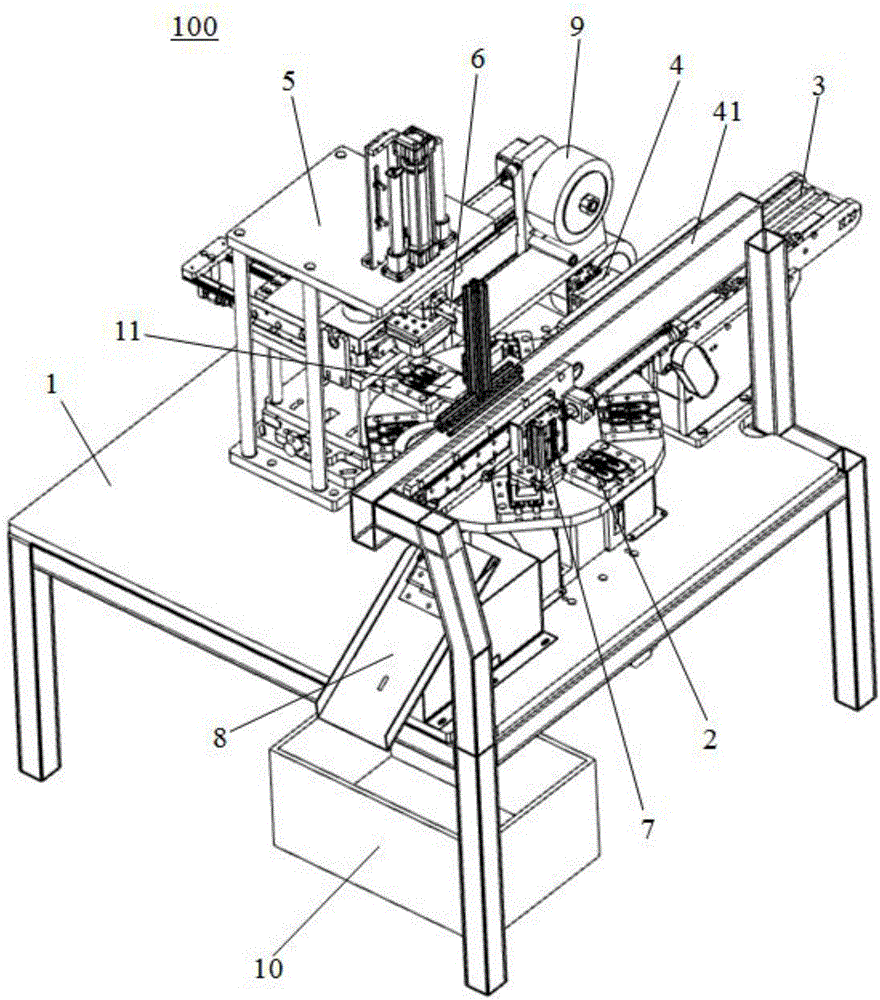

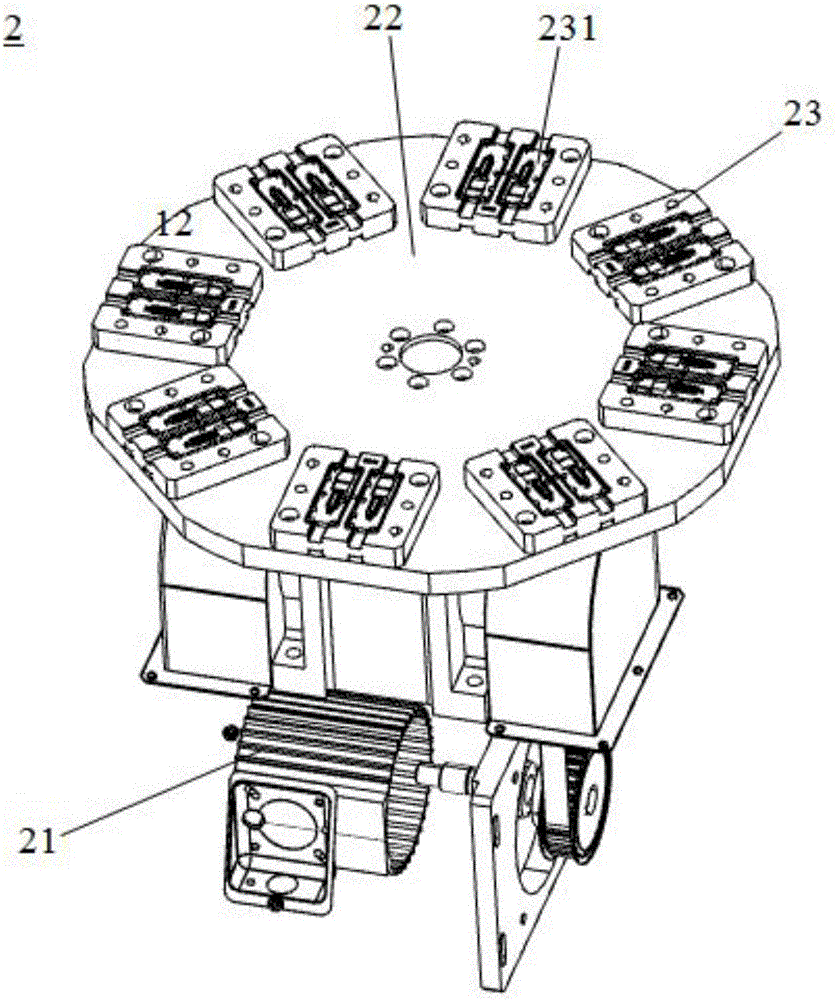

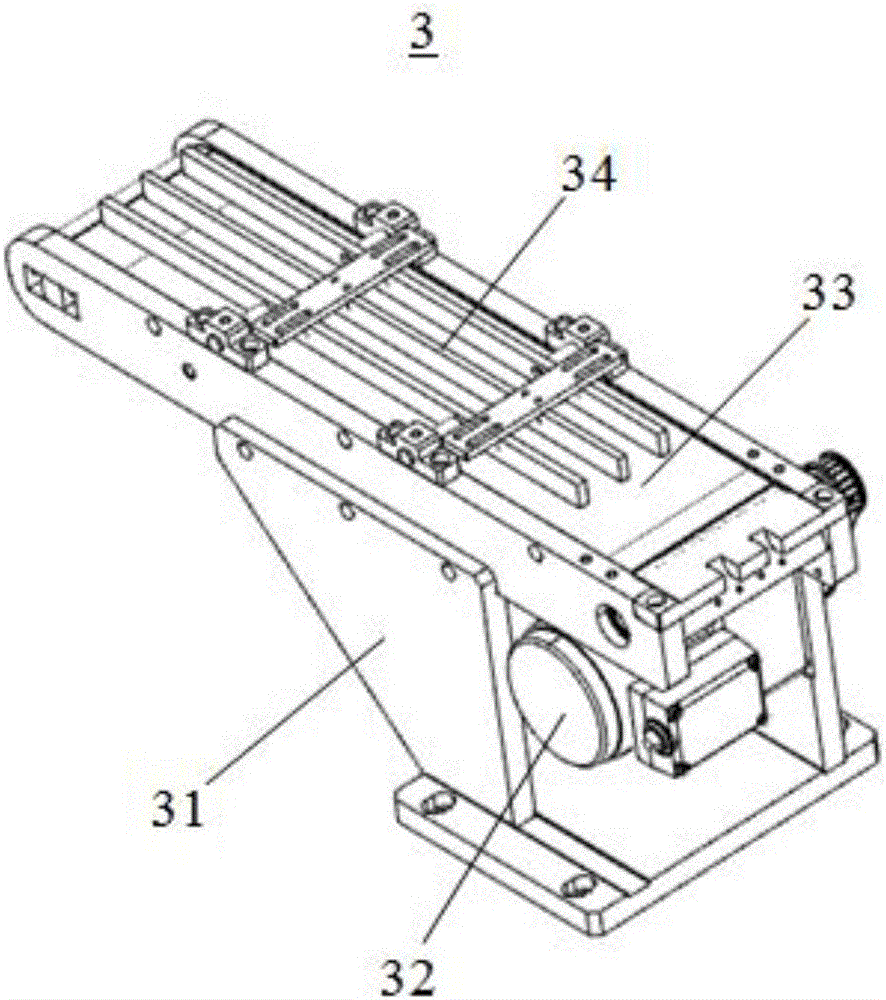

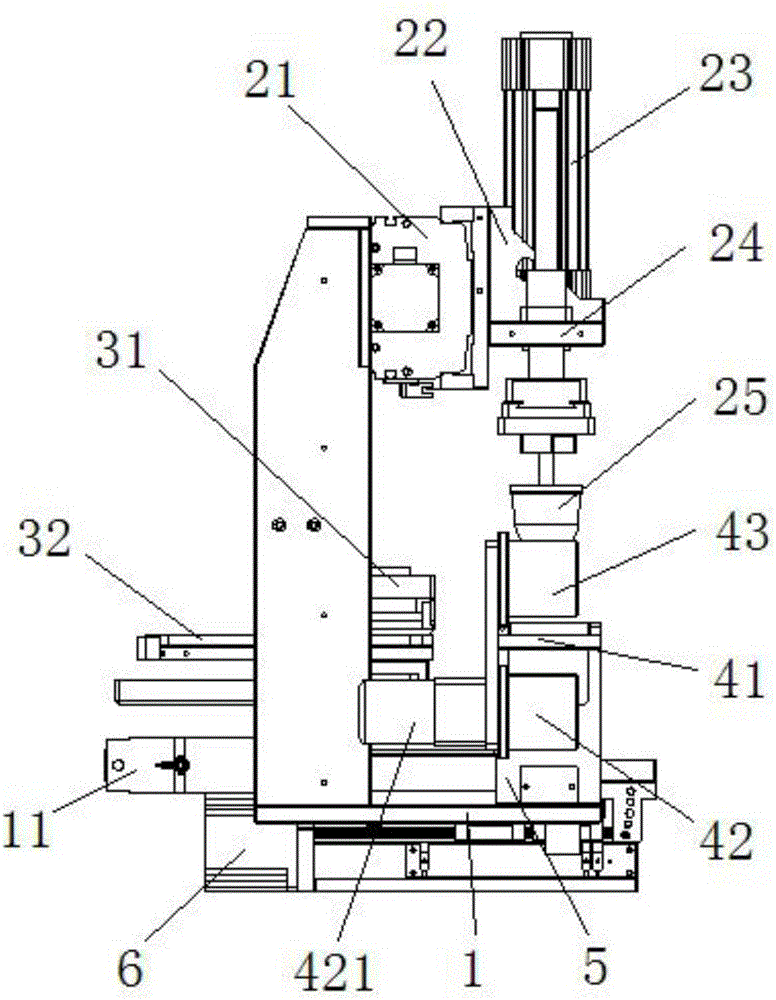

Rotating type multi-station pad printing machine

InactiveCN106113923ARealize automatic feeding processIncrease productivityRotary pressesPad printingButt joint

Owner:KUNSHAN YITIAN AUTOMATION

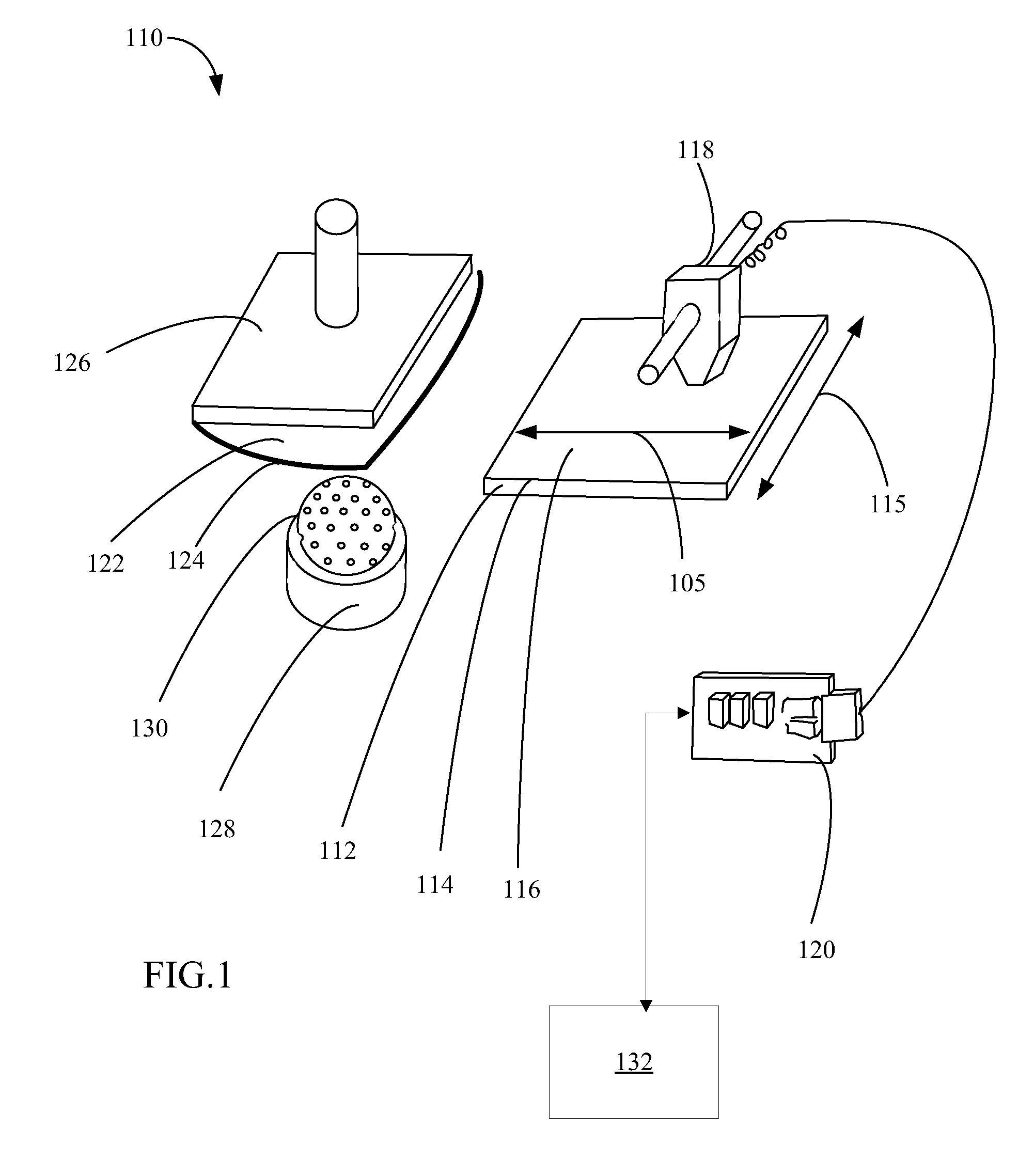

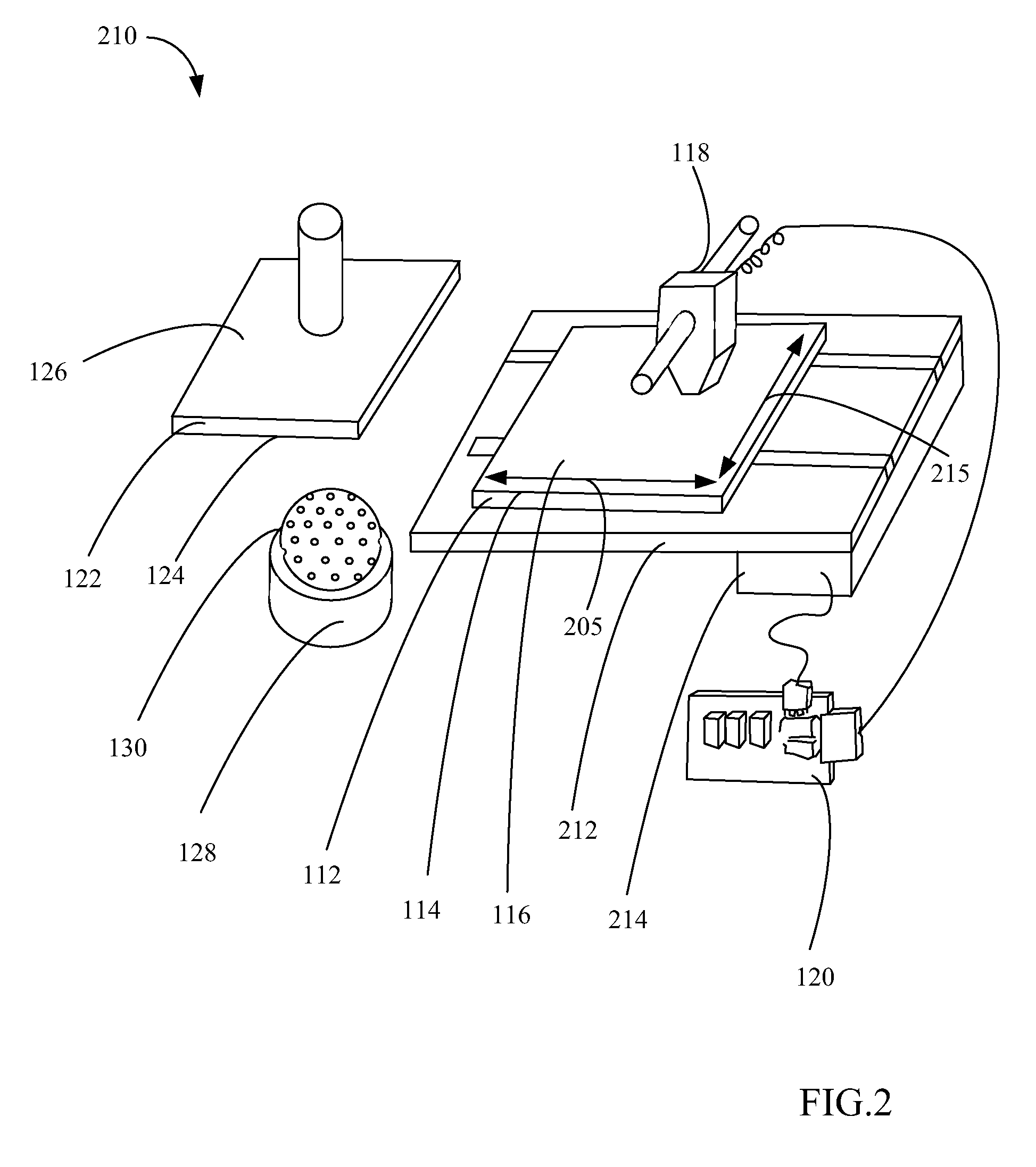

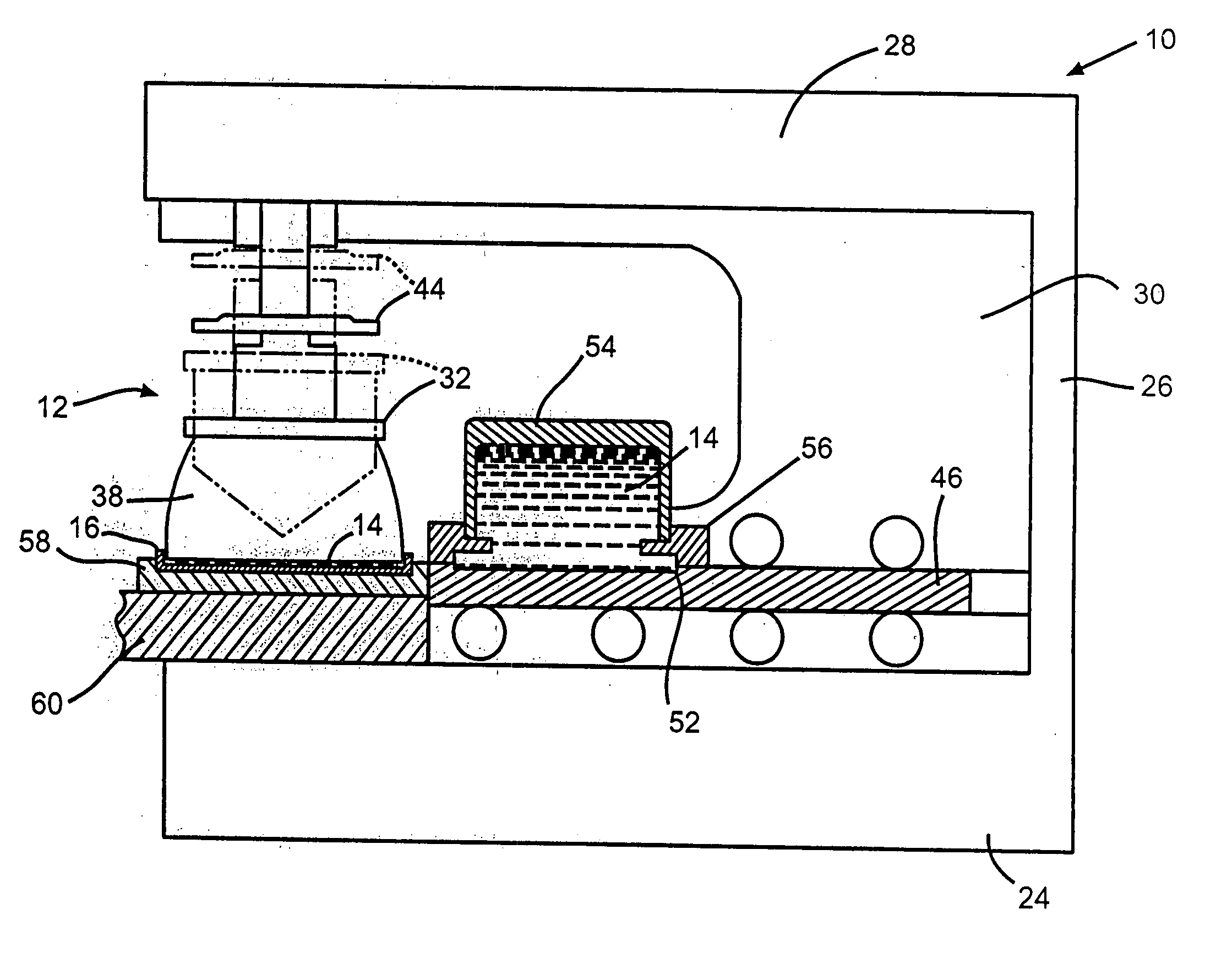

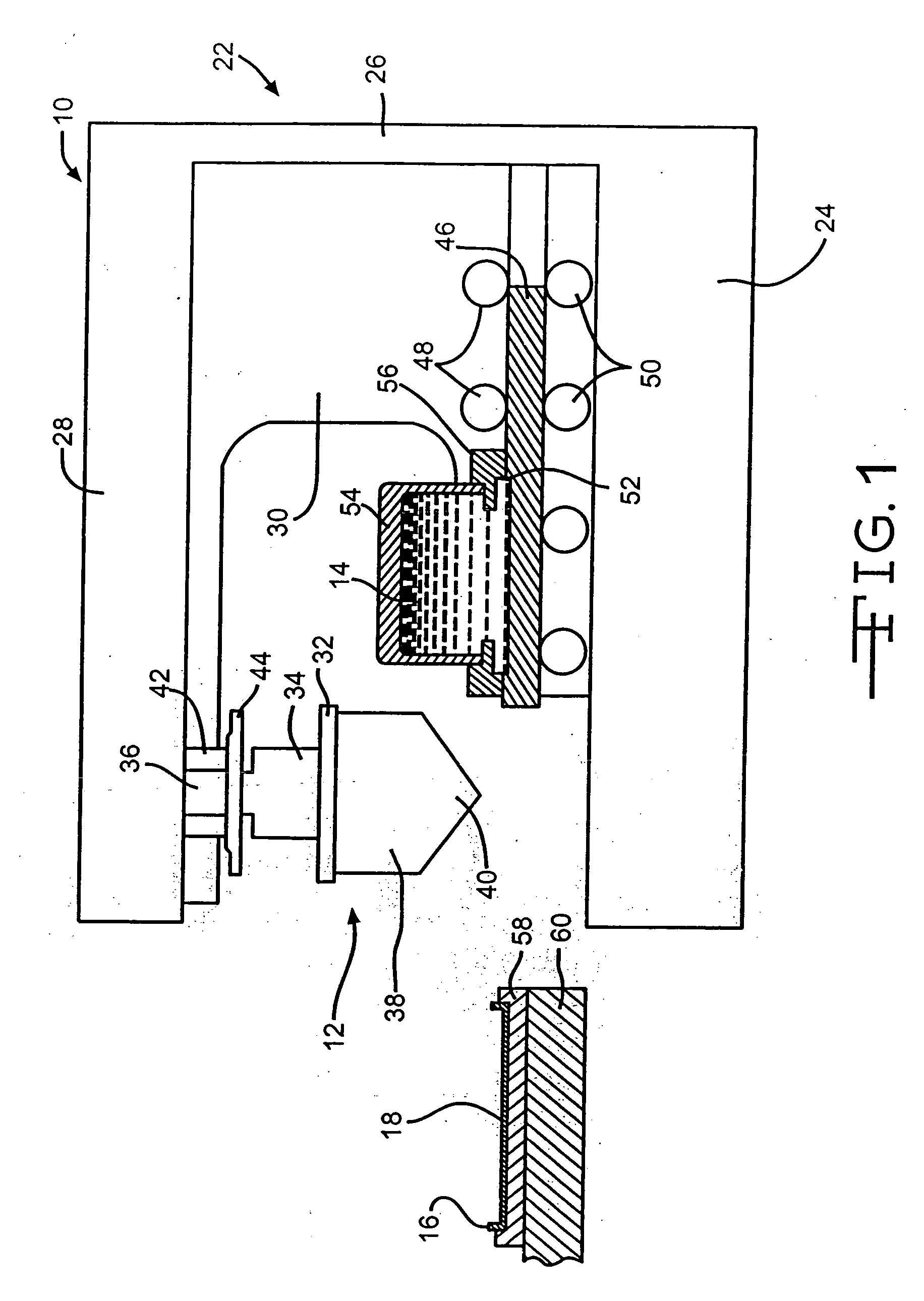

Inkjet pad printer

A pad printing system has an ink jet printing mechanism, a cliché device including an imaging surface, a pad assembly including a deformable pad, and an ink jet printing controller. The ink jet printing controller controls positioning of the ink jet printing mechanism to deposit a ink jet deposited image on the imaging surface. A method of printing an image on a workpiece surface includes forming an ink jet deposited image on an imaging surface of a cliché device, transferring the ink jet deposited image from the imaging surface to a deformable pad, and transferring the ink jet deposited image from the deformable pad to the workpiece surface.

Owner:ILLINOIS TOOL WORKS INC

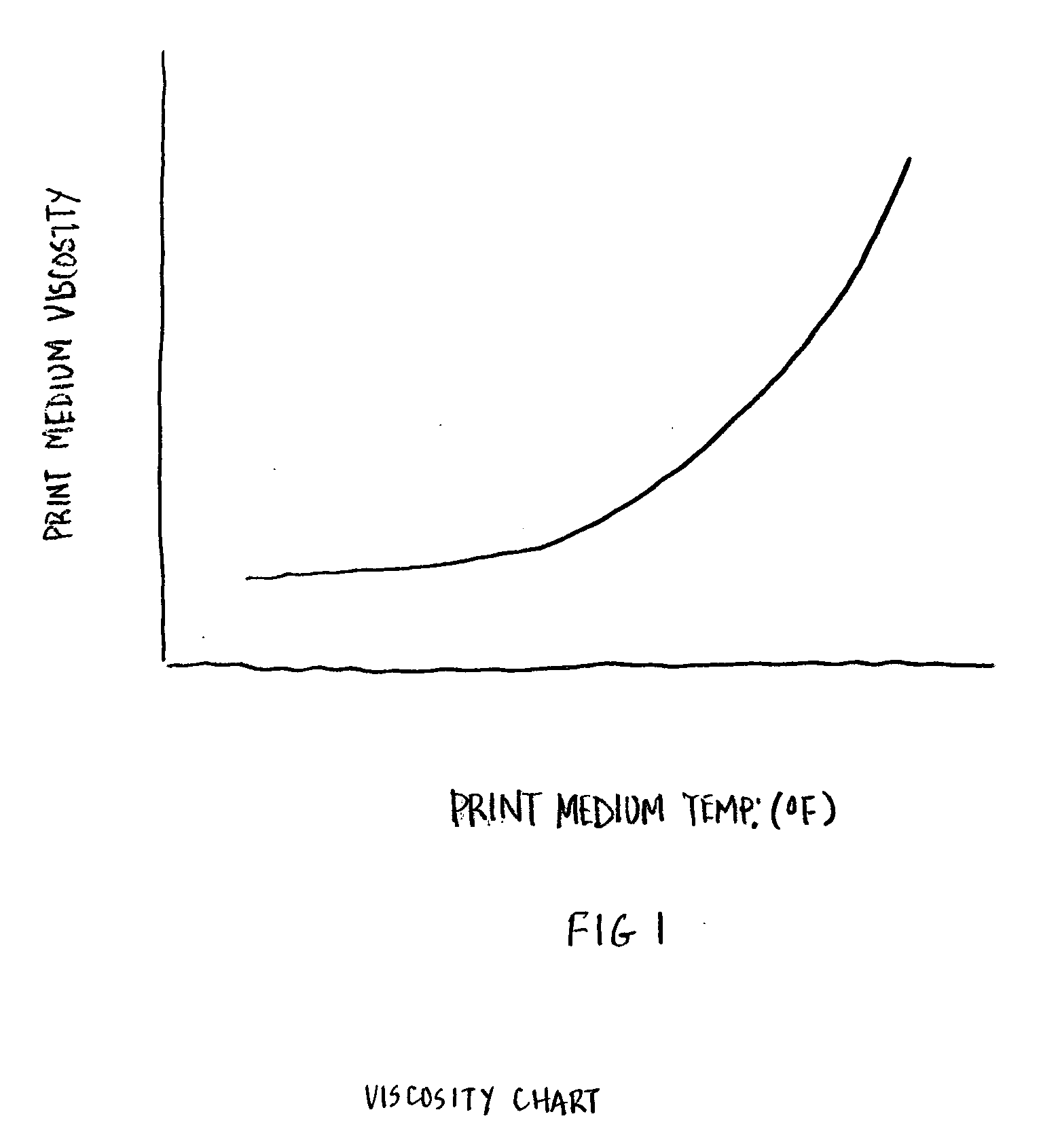

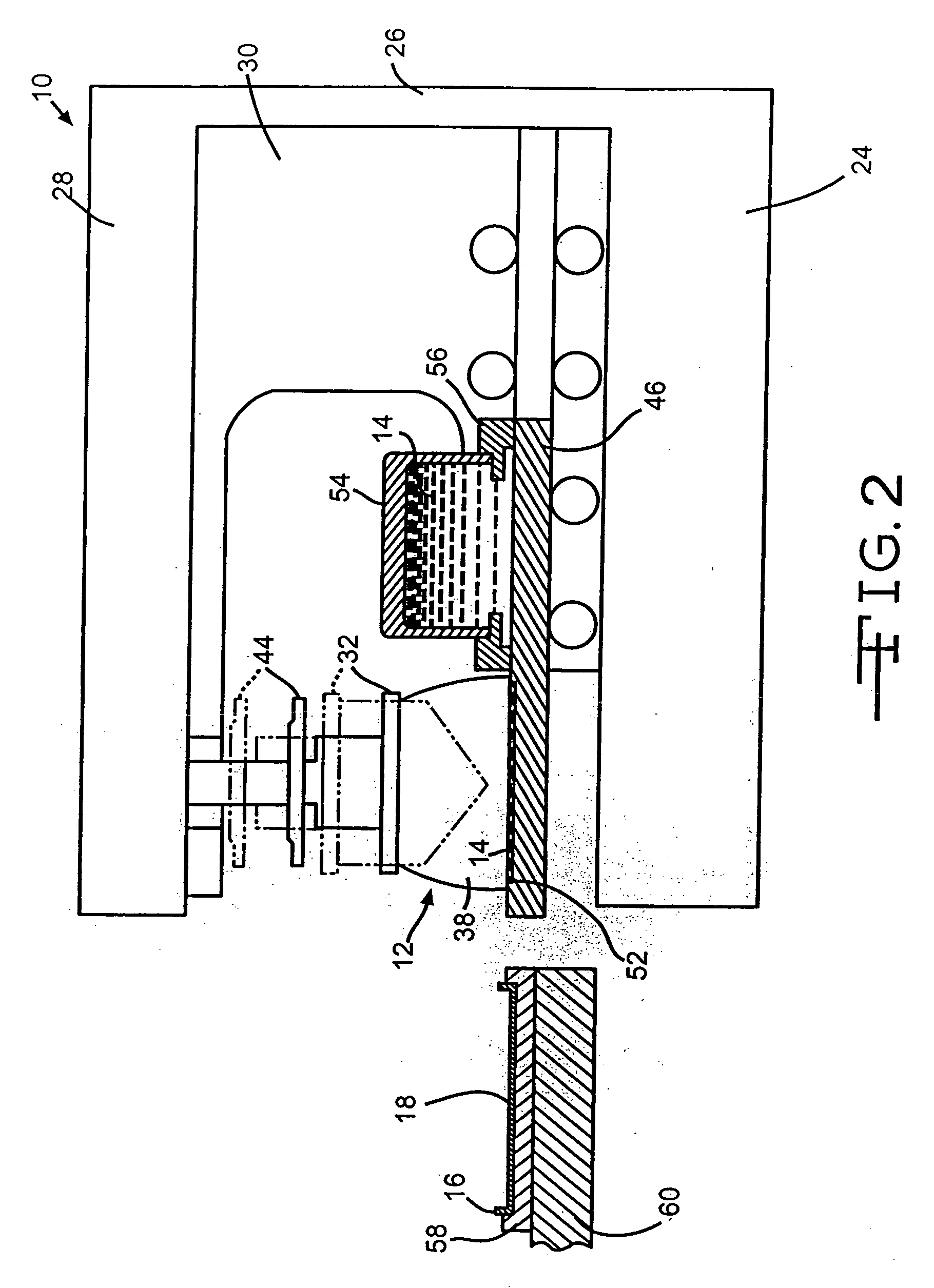

Apparatus and method for controlling ink or paint temperature in a printing device

InactiveUS20050183604A1Reduce the temperatureReduce solvent evaporationPlaten pressesRotary intaglio printing pressTemperature controlPad printing

Apparatus and methods of controlling the temperature of printing ink or paint in a pad printing apparatus are described. The apparatus comprise temperature control elements that are connected to a chiller unit. Temperature sensors on a support plate or ink cup, or both monitor the temperature of the ink cup and / or ink. As the temperature of the ink in an ink cup rises due to ambient air temperature in the working environment, a chill medium is applied to the support plate, ink cup, ink or any combination thereof to cool the temperature of the ink thereby reducing evaporation of solvents in the ink to maintain a relatively constant ink viscosity.

Owner:TAYLOR MADE GOLF

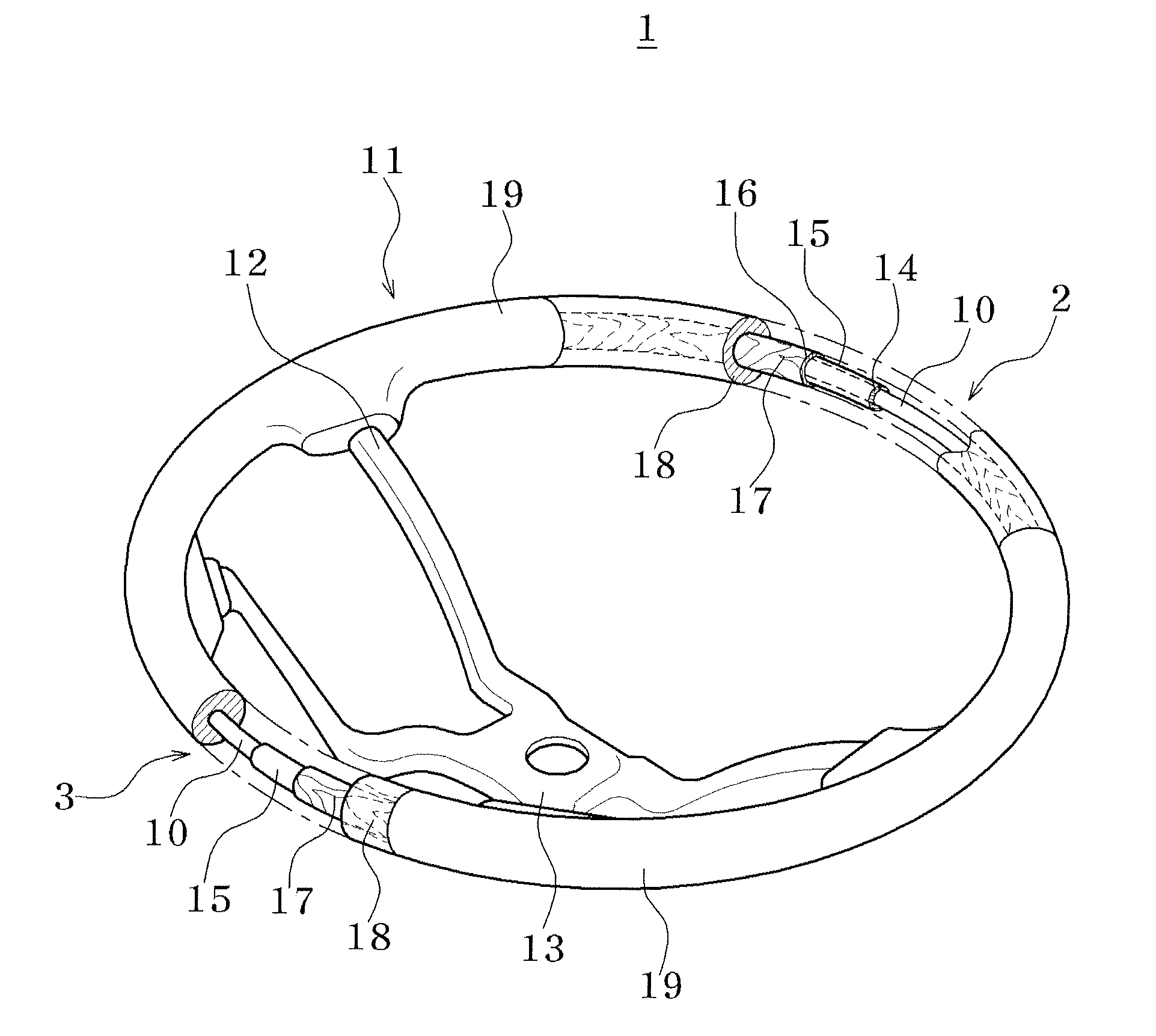

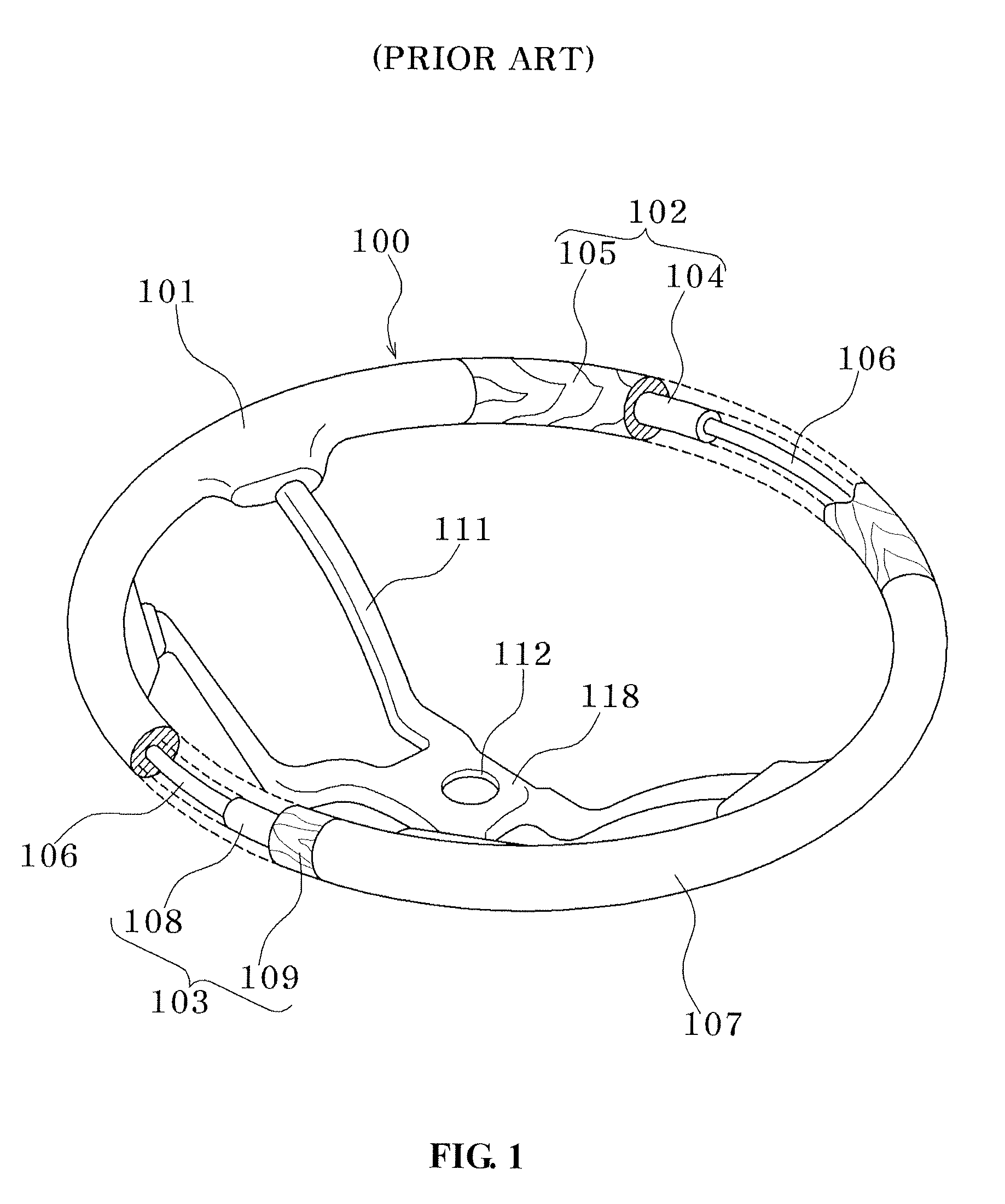

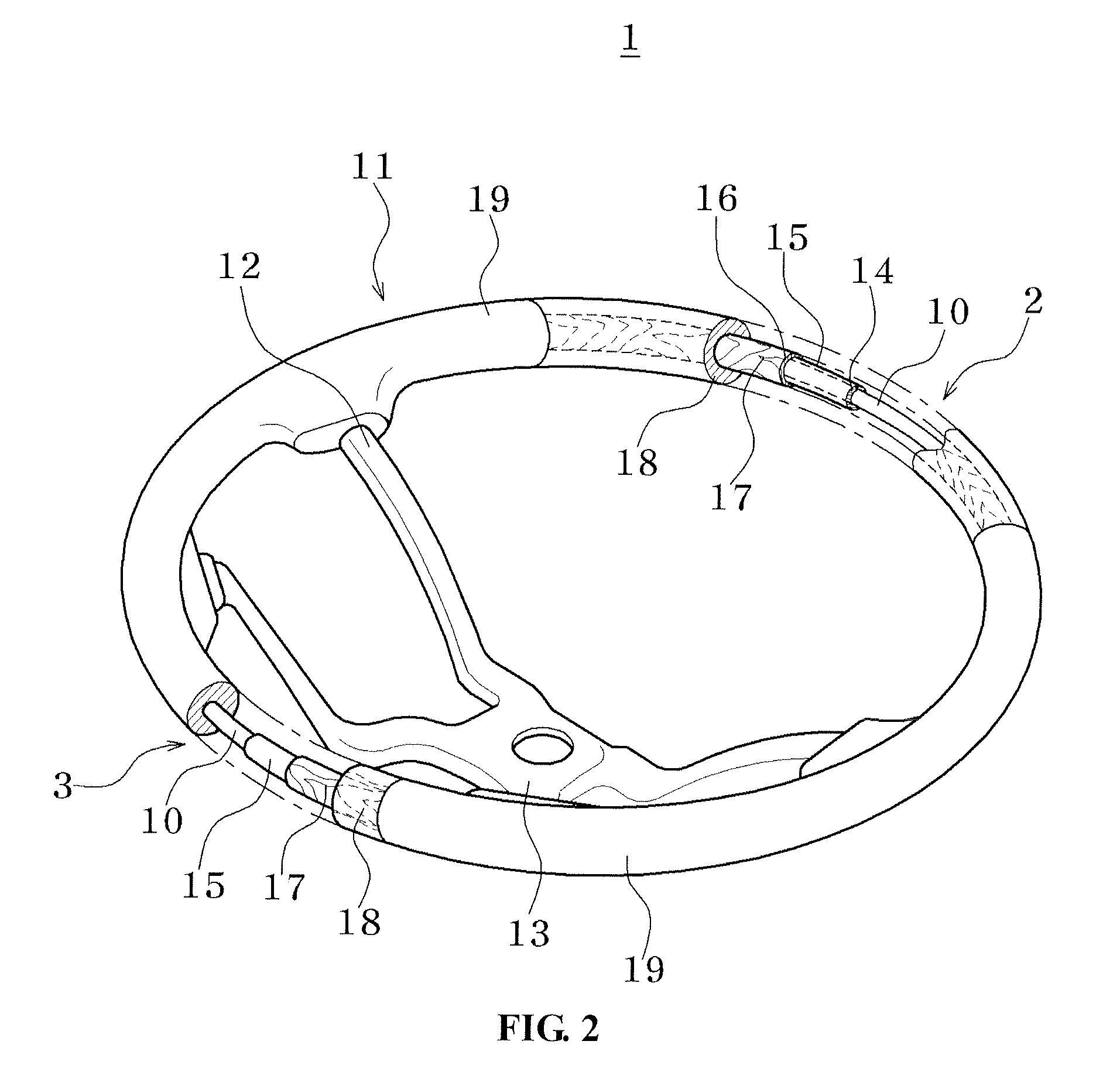

Steering wheel for automobile and method of fabricating the same

InactiveUS20100288073A1Luxurious and pleasant appearanceAvoid it happening againControlling membersMechanical apparatusPad printingSteering wheel

The present disclosure relates to a steering wheel for automobiles and a method of fabricating the same. The steering wheel is formed in multiple layers having a thickness difference of 2˜3 mm by multi-stage injection molding and has a pattern or picture between the layers to provide a luxurious and pleasant appearance. In the method, after being preheated in a dryer to remove moisture, a metal frame is subjected to primary to tertiary injection molding in a mold to form the multiple layers. Here, drying is performed to remove moisture from the surface of injection-molded parts to prevent deterioration in adherence and quality during the process. Here, the pattern or figure is inserted between the layers by pad printing or a combination of pad printing and vacuum deposition. The multi-stage injection molding allows various colors, patterns, and figures to be printed on injection-molded parts excluding the uppermost layer.

Owner:MIRAETEC

Pad printing method for making colored contact lenses

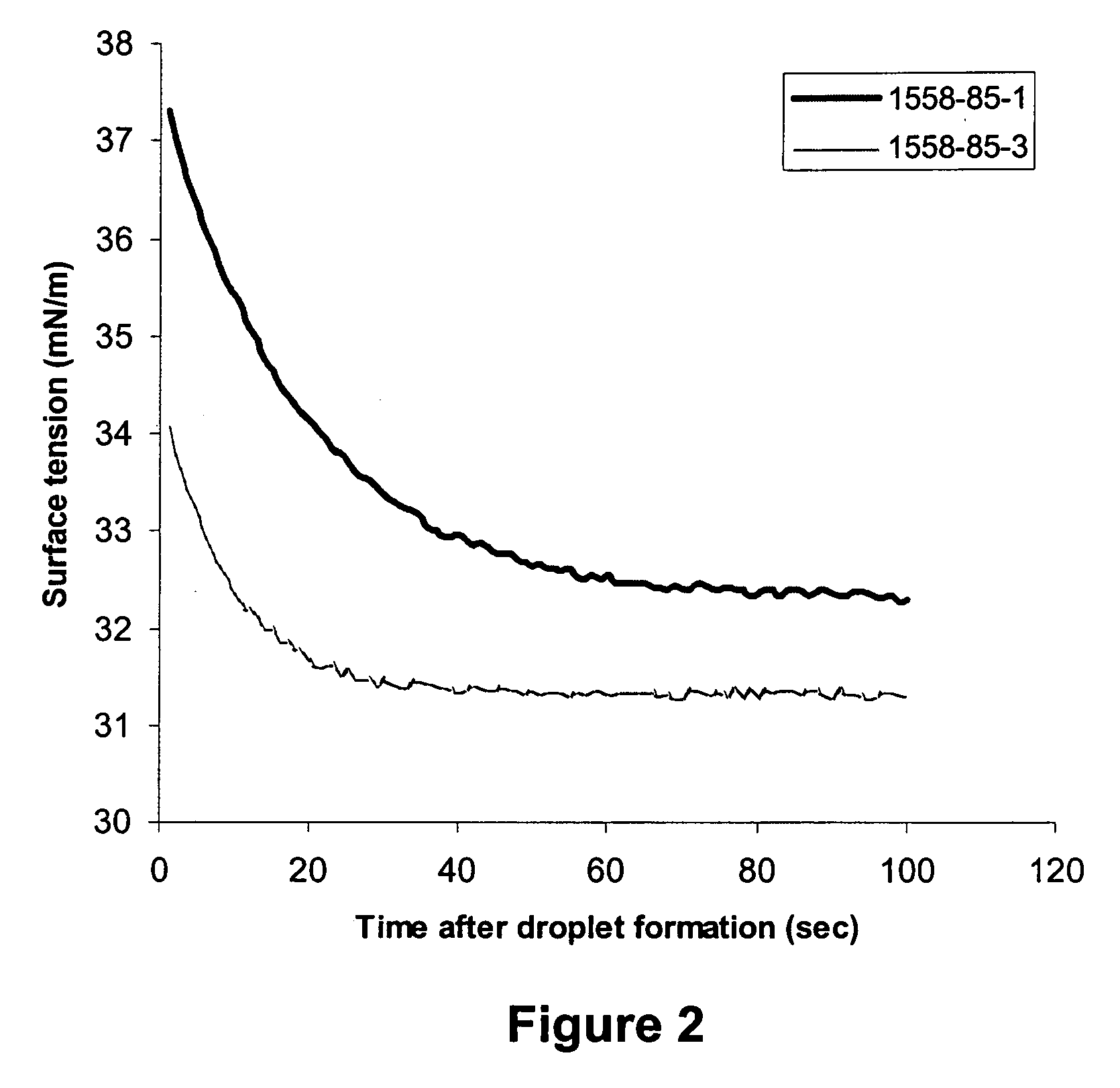

The invention provides a method for producing colored contact lenses with relatively high quality color images. The method of the invention comprises the steps of: (a) obtaining a water based ink having a viscosity of greater than about 100 centipoise (cps) and comprising at least one colorant, a water-soluble binder polymer having ethylenically unsaturated groups, an initiator, and a surfactant, wherein the surfactant is present in an amount sufficient to provide the ink a dynamic surface tension of less than about 40 dyne / cm at surface age of about 1 second, and wherein the initiator is present in an amount sufficient to allow the ink to be cured with an energy exposure which is comparable with an energy exposure required for curing the lens-forming material; (b) applying the ink, by using pad transfer printing technique, to at least a portion of at least one of molding surfaces of a lens mold to form a colored coat; (c) actinically curing the ink printed on the mold to form a colored film, wherein the printed ink is cured to an extent so that no noticeable color smearing is observed by examination with naked eyes; (d) dispensing a lens-forming material into the lens-forming cavity of the mold; and (e) actinically or thermally curing the lens-forming material within the lens-forming cavity to form the contact lens, whereby the colored film detaches from the molding surface and becomes integral with the body of the contact lens, wherein the colored film becomes part of one of the anterior and posterior surface of the colored contact lens and has a good adhesion to the lens.

Owner:NOVARTIS AG

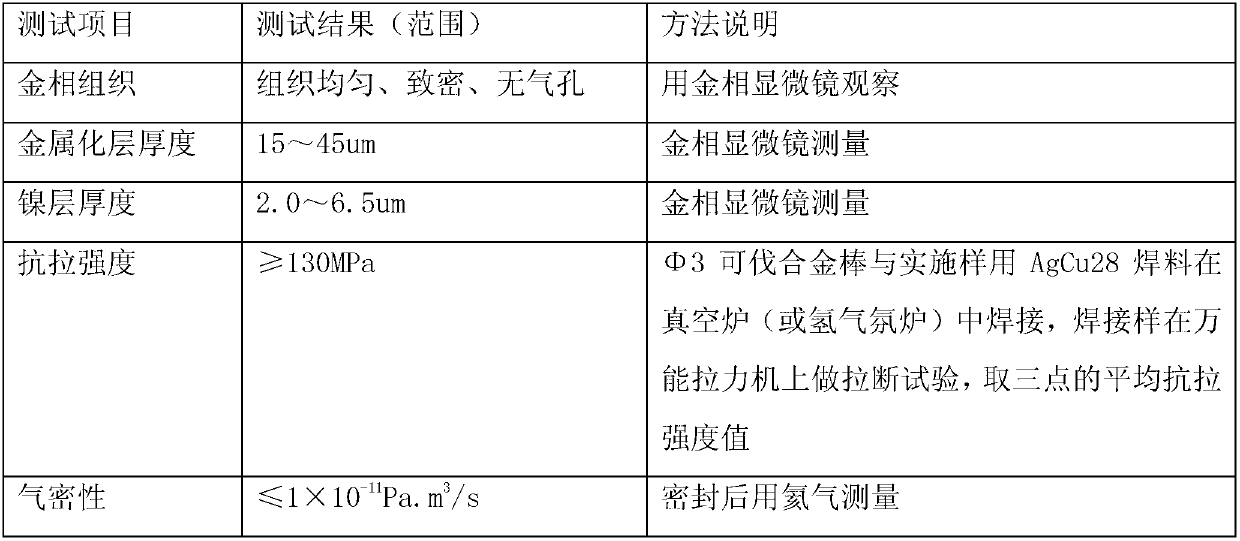

Metallized surface of zirconia ceramic and preparation method

Owner:ZHEJIANG YATONG METAL CERAMICS

Method of printing golf balls with radiation curable ink

The present invention relates to a method printing indicia that includes dynamically controlling viscosity within a sealed cup assembly that is used in pad printing radiation curable inks on game balls. The present invention further relates to a method of removing radiation ink from an uncured inked golf ball surface.

Owner:ACUSHNET CO

System and method of marking articles coated with a laser-sensitive material

InactiveUS20160074865A1Low costReduce usageEnvelopes/bags making machineryLayered productsPad printingUnique identifier

A method for uniquely identifying tubes may include programming a motion of a laser relative to a tube pad printed with a mixture of ink and a laser sensitive material and exposing the laser-sensitive material to the laser to colorimetrically transform the material and reveal a unique identifier. A method of coating tubes includes plasma or flame treating the tube and mixing a laser-sensitive material with ink to form a mixture to pad print onto the tube. A system for identifying tubes coated with laser-sensitive material includes a laser mounted in translational relationship to a stage, a camera positioned to capture an image of a tube on a stage, a processor that receives the image and translates the laser relative to the stage in order to position the laser for marking the tube, and a laser controller to move the laser in order to mark the tube.

Owner:CALIFORNIA ADVANCED LABELING

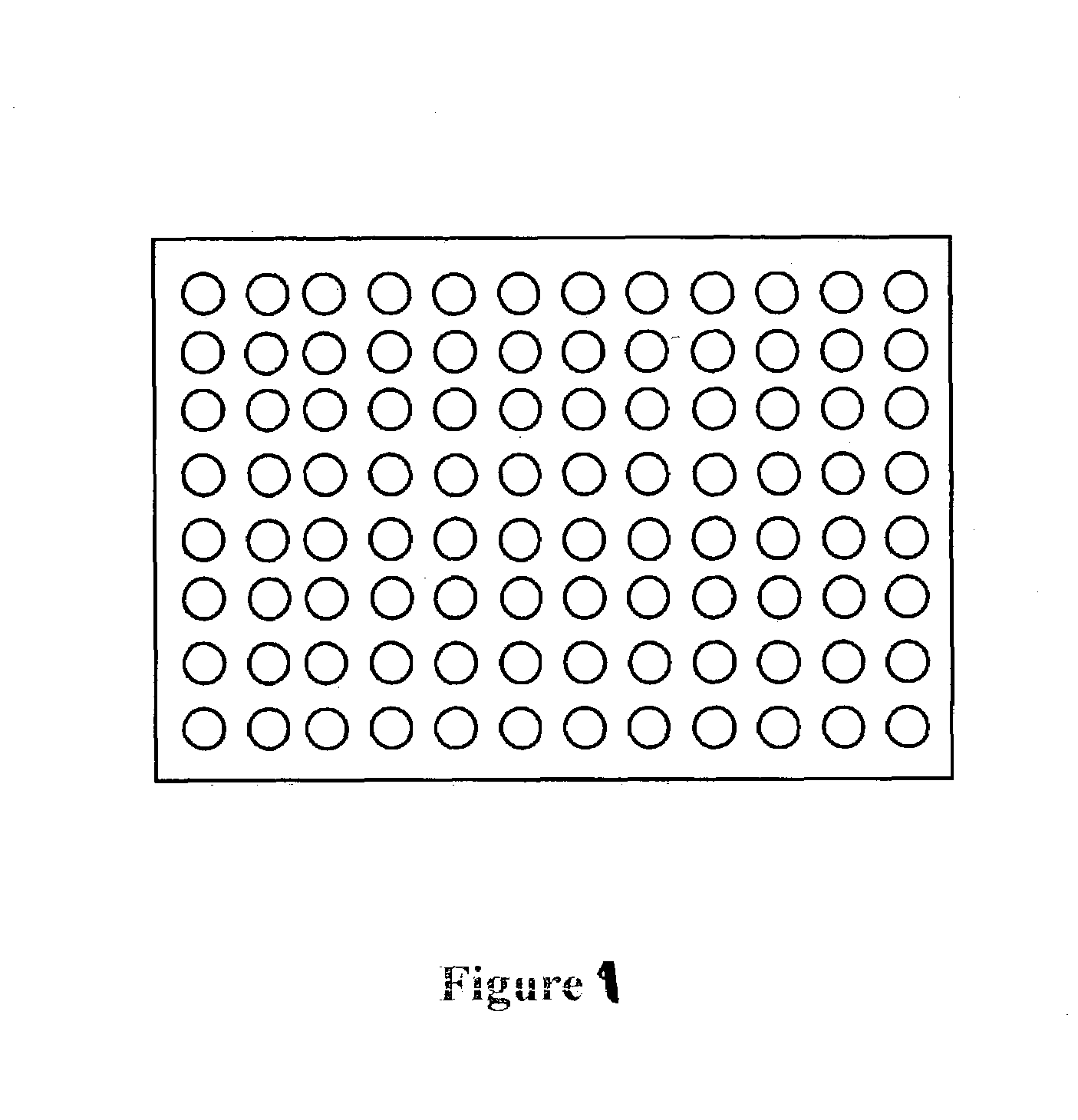

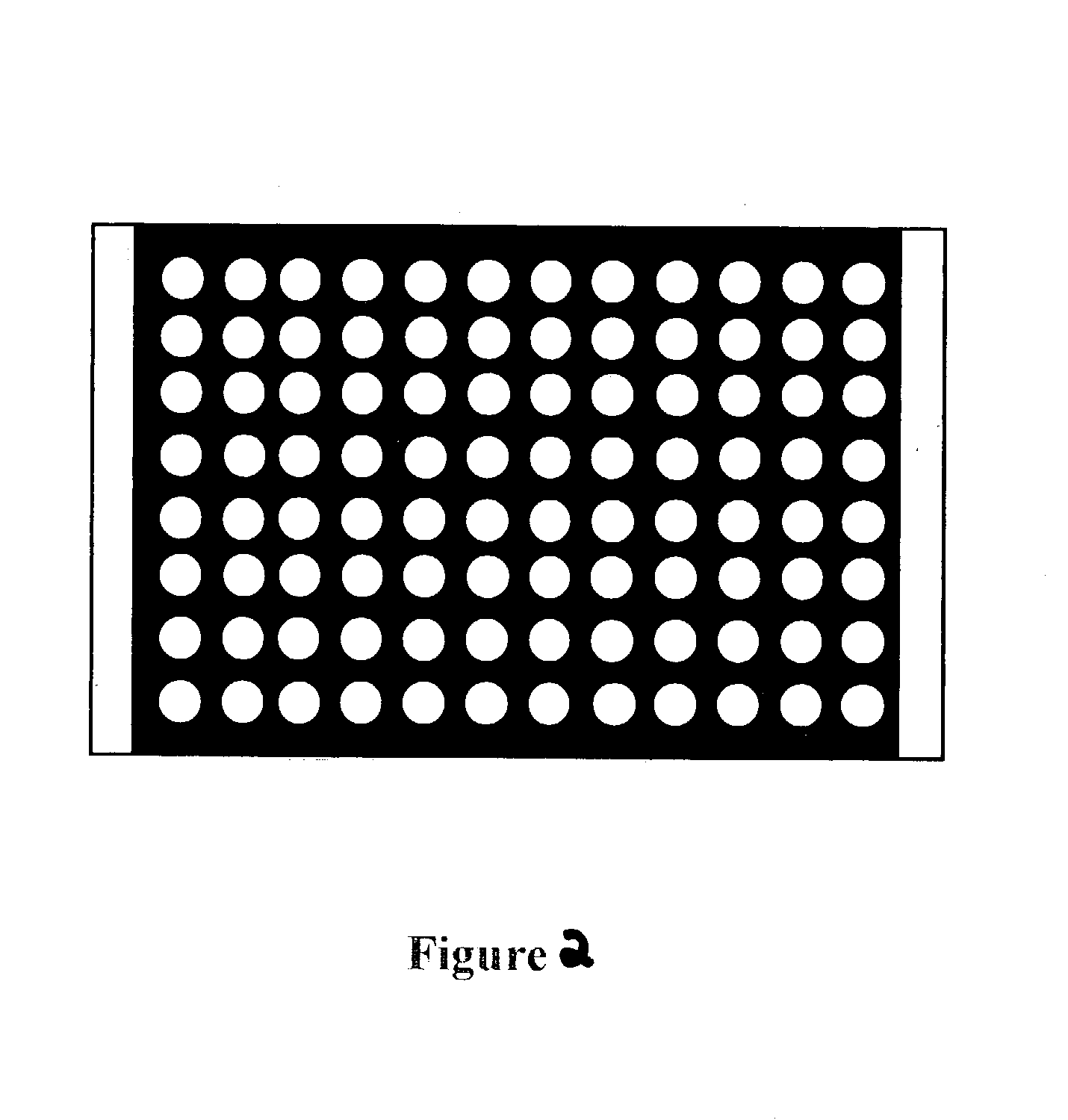

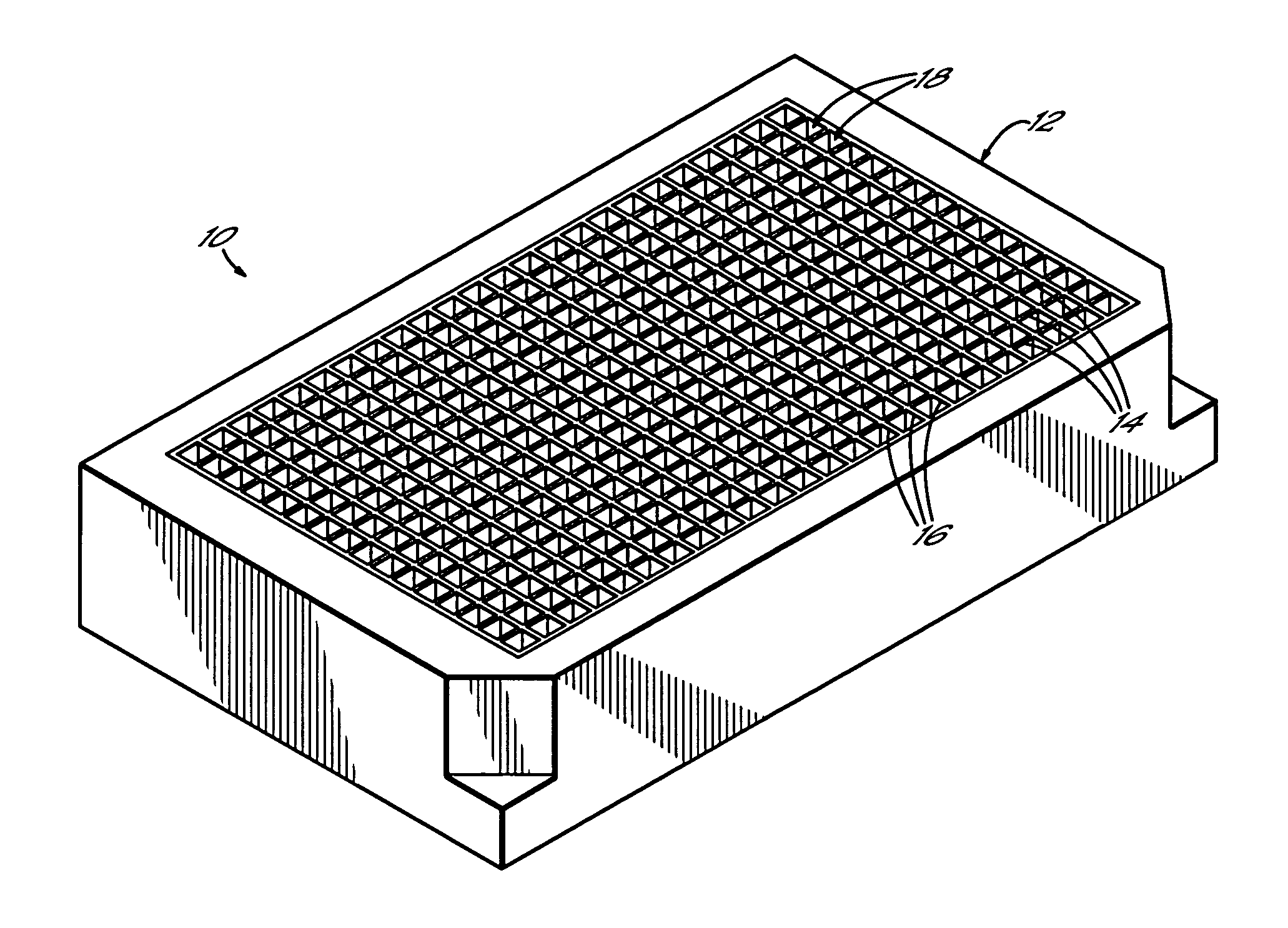

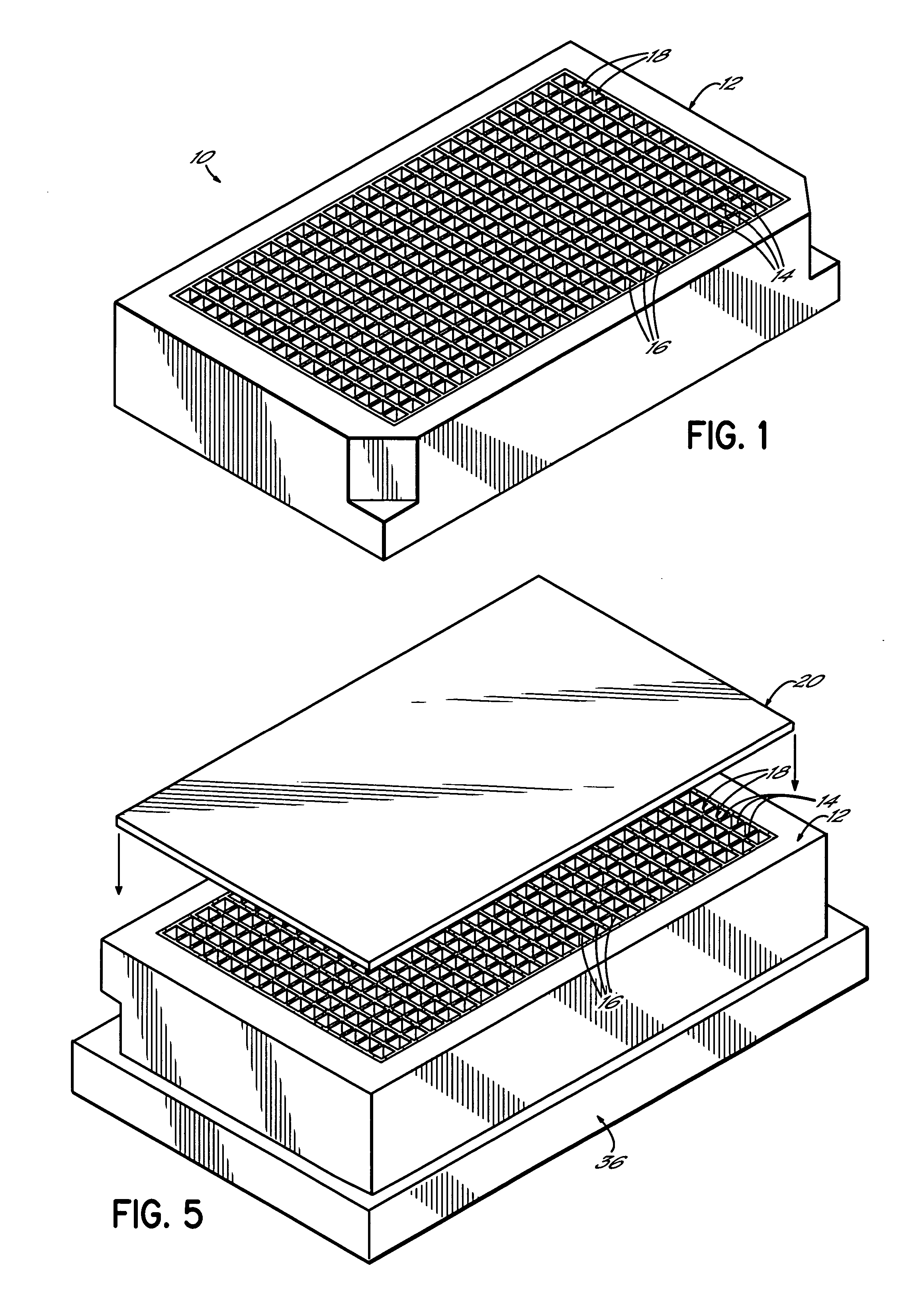

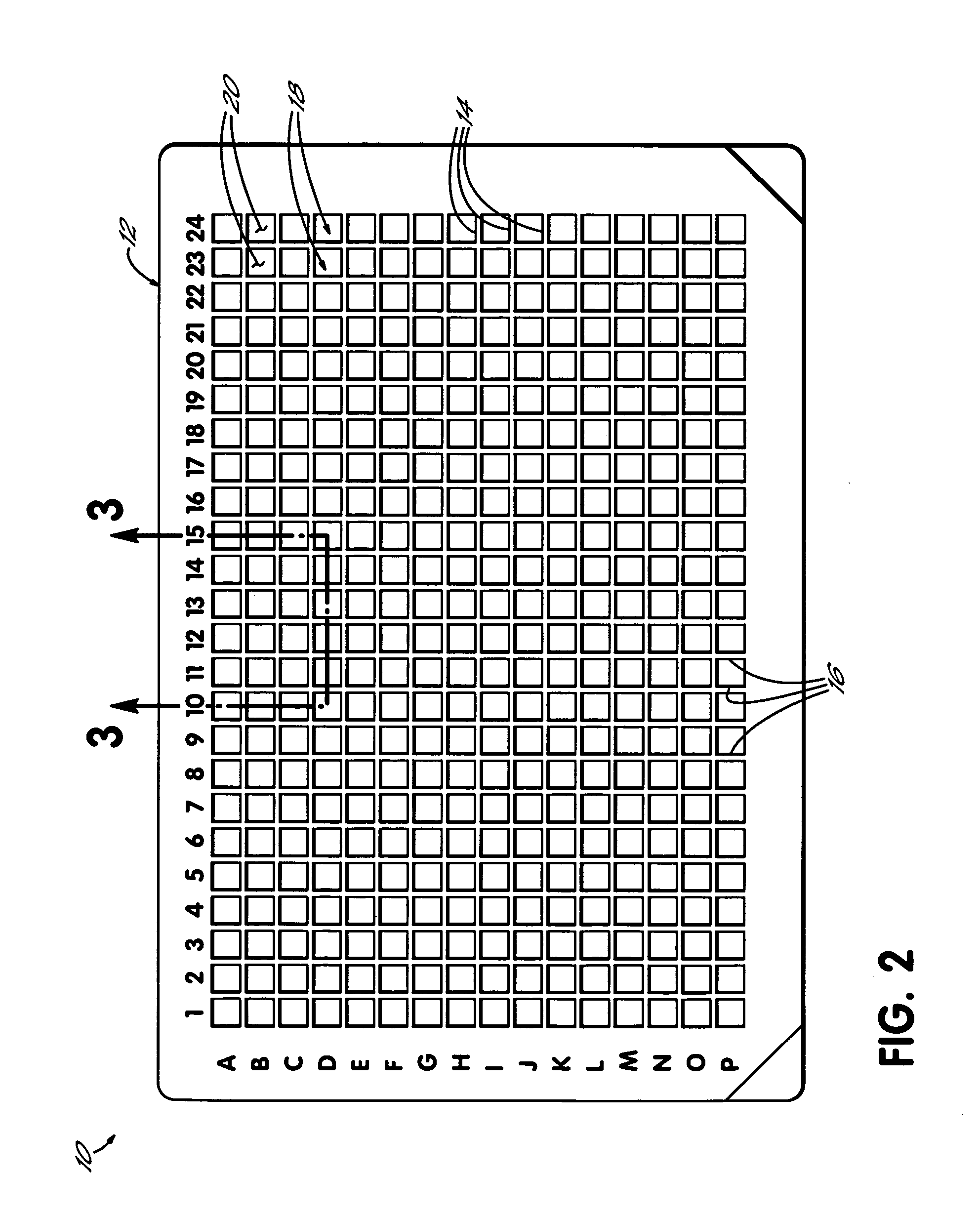

Methods of making a multi-well test plate having an adhesively secured transparent bottom panel

Methods of making a multi-well test plate including an upper frame portion and a transparent panel secured to a lower side of the upper frame portion with adhesive. The upper frame portion includes a plurality of walls defining adjacent wells for receiving assay samples. The adhesive may be applied to either the transparent panel or the upper frame portion by various techniques including, but not limited to, transfer printing, robotic dispensing, silk screening, flexographic printing, and pad printing.

Owner:NALGE NUNC INTERNATIONAL

Use of pad printing in the manufacture of capacitors

ActiveUS20050041374A1Increase productionImprove adhesionRotary intaglio printing pressHybrid capacitor electrodesPad printingCarbide coating

Deposition of a metal-containing reagent solution or suspension onto a conductive substrate by various pad-printing techniques is described. This results in a pseudocapacitive oxide coating, nitride coating, carbon nitride coating, or carbide coating having an acceptable surface area for incorporation into an electrolytic capacitor, such a s one have a tantalum anode.

Owner:WILSON GREATBATCH LTD

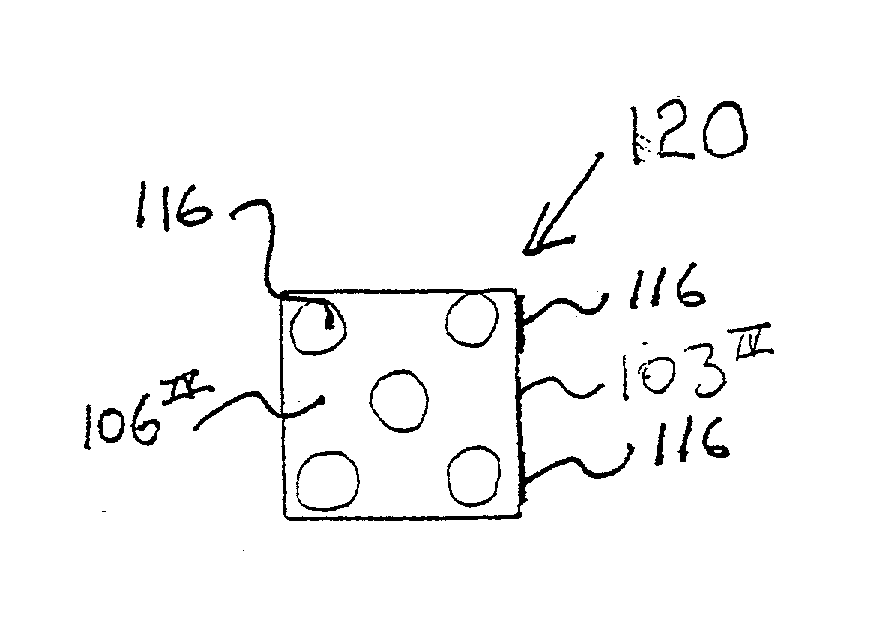

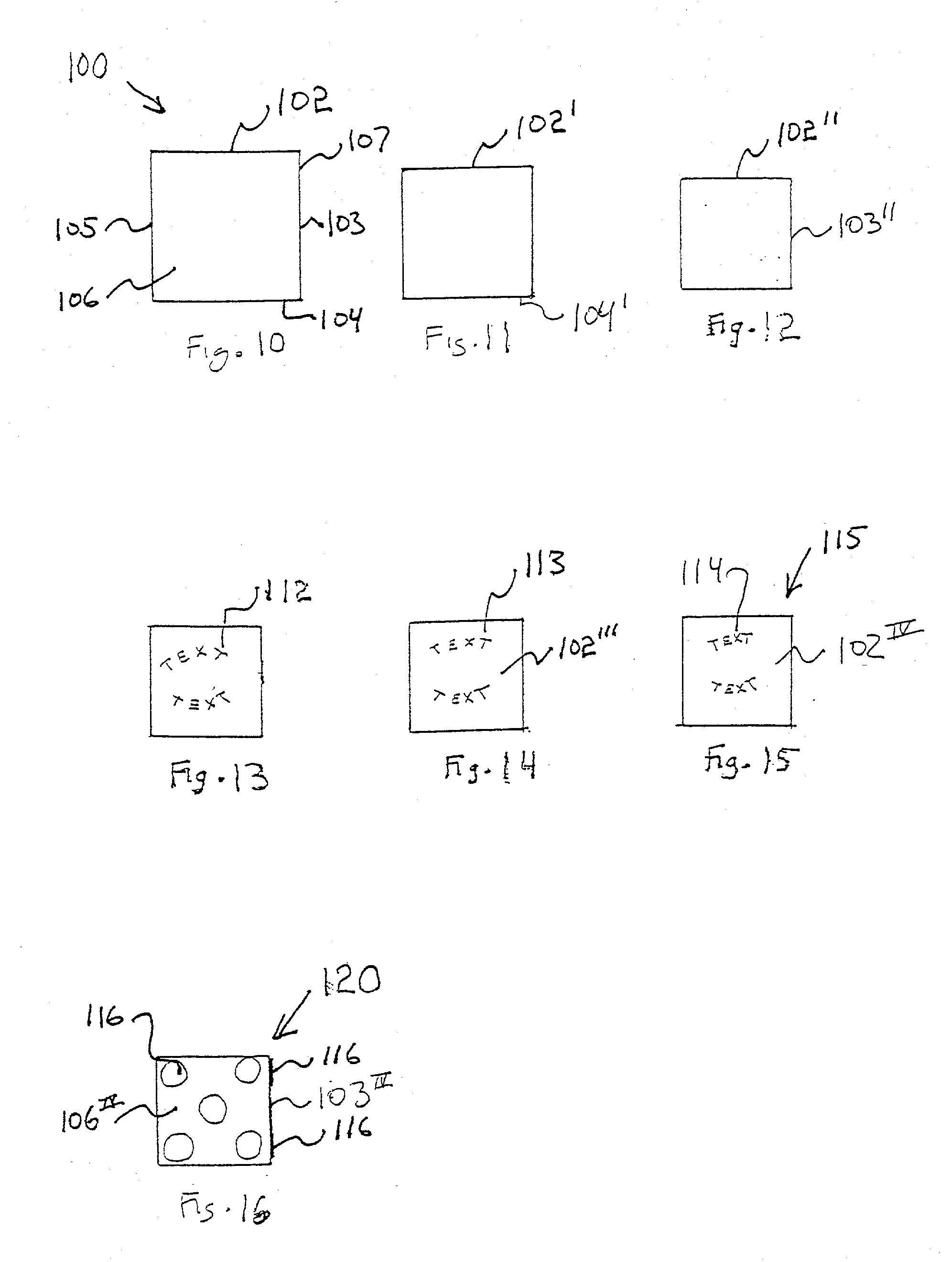

Method of manufacturing gaming dice and die made thereby

Method of manufacturing a gaming die or dice and die or dice made thereby. The method includes pad printing at least one of spots and text on at least one surface of the die or dice.

Owner:GAMING PARTNERS INTERNATIONAL CORPORATION

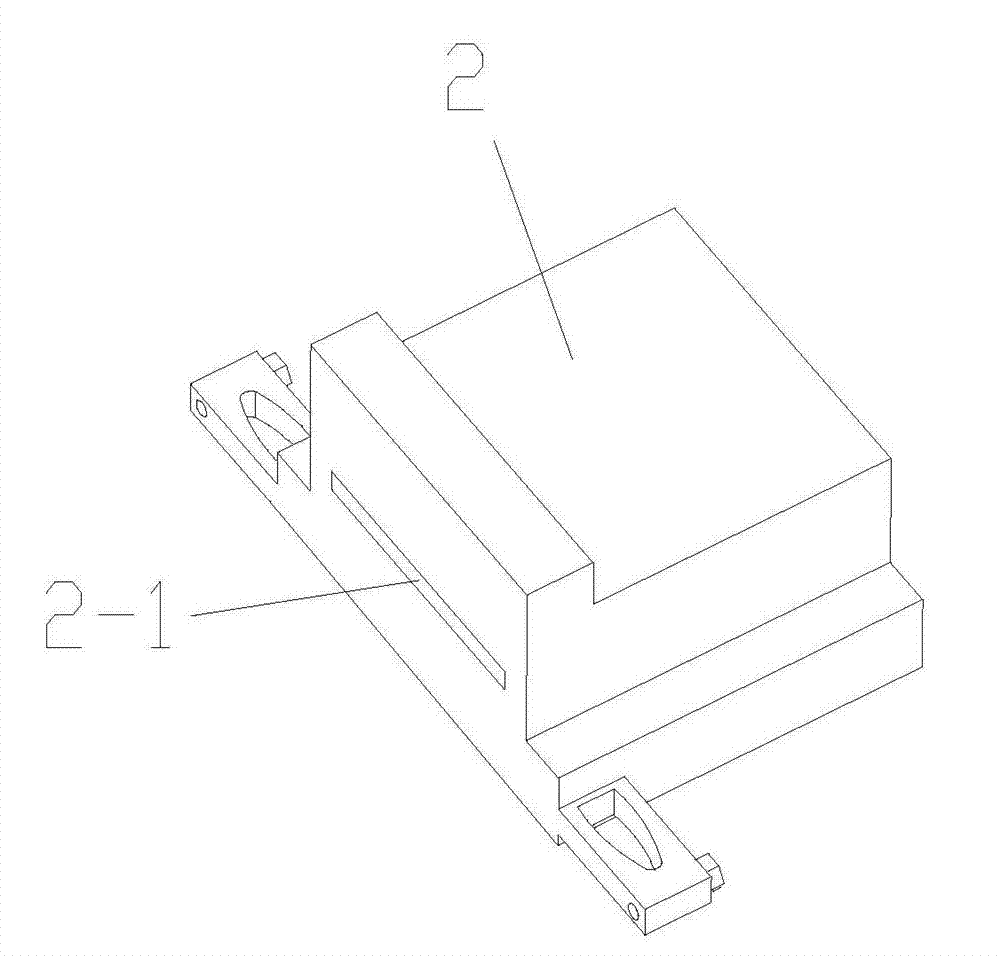

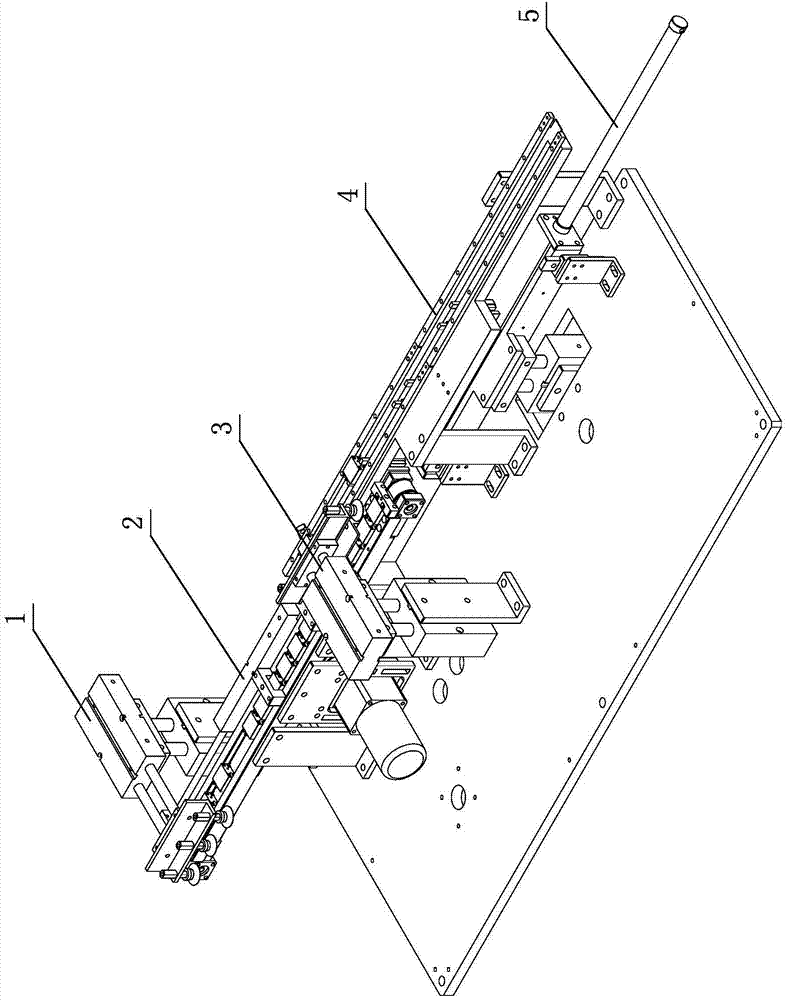

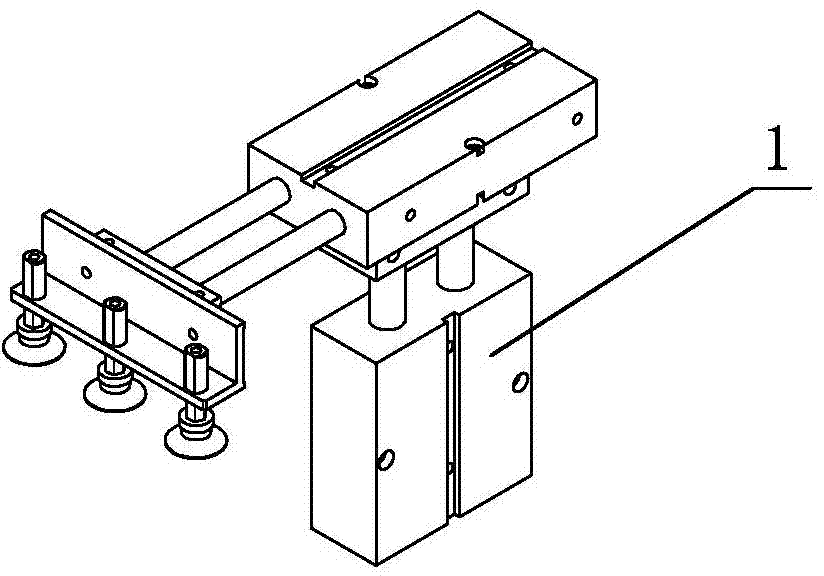

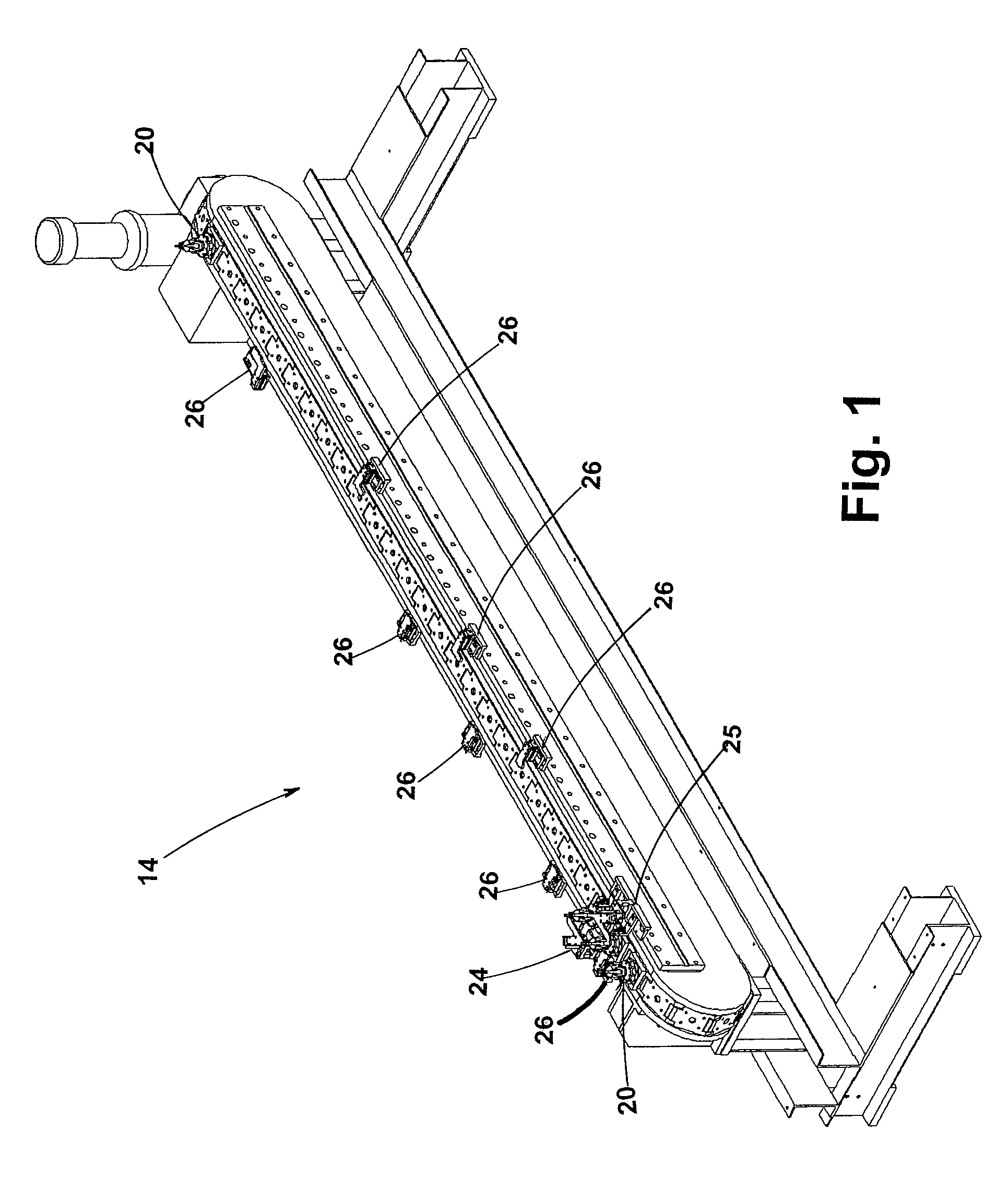

Conveying device of lithium battery carrier

InactiveCN108674915AMeet strict process requirementsIncrease productivityMechanical conveyorsPad printingElectrical battery

The invention relates to the field of lithium battery production, in particular to a conveying device of a lithium battery carrier. The conveying device of the lithium battery carrier comprises a carrier, a conveying belt mechanism and a carrier positioning mechanism, wherein the carrier is used to place a battery a to be processed. Two through grooves are formed in the bottom of the carrier and two conveying guide rails are arranged on the conveying belt mechanism. The through grooves are formed in the conveying guide rails. The carrier can be moved from left to right by the conveying belt mechanism to switch stations, the carrier is positioned in the carrier positioning mechanism by the detection of the carrier positioning mechanism, and batteries at corresponding stations of batteries are operated correspondingly. The conveying device of the lithium battery carrier is applied to achieve the circulation of the battery carrier, and battery pad printing, battery code-spurting, code-scanning detection, and the automatic sorting of good products and defective products can be completed at a time. The conveying device of the lithium battery carrier adopts original mechanism layout, notonly is finished batteries meeting strict process requirements guaranteed, but also production efficiency and operational reliability are enhanced, and production cost is reduced.

Owner:柯文生

Method of pad printing in the manufacture of capacitors

InactiveUS20060154416A1Increase productionImprove adhesionElectrode thermal treatmentHybrid capacitor electrodesPad printingCarbide coating

Deposition of a metal-containing reagent solution or suspension or a carbon nanotube-containing suspension onto a conductive substrate by various pad-printing techniques is described. In the case of a metal-containing solution or suspension, a pseudocapacitive oxide coating, nitride coating, carbon nitride coating, carbide coating, or carbon nanotube coating results. In any event, the active coating has acceptable surface area for incorporation into an electrolytic capacitor, such as one having a tantalum anode.

Owner:WILSON GREATBATCH LTD

Device used for producing relay

ActiveCN103943411AMeet lean production requirementsShorten the timeScreen printersRelaysCombined testPad printing

A device used for producing a relay comprises a device body, wherein a silk-screen system used for relay printing and a comprehensive test system used for testing performance of the relay are integrally arranged on the device body. The silk-screen system comprises a silk-screen feeding mechanism and a pad printing machine. The comprehensive test system comprises a test feeding mechanism and a computer comprehensive tester. The silk-screen feeding mechanism and the test feeding mechanism are connected end to end. The relay silk-screen and comprehensive test integrated automatic production mode is adopted, parts are assembled into the relay, printing is then conducted, the comprehensive test is directly conducted after printing is completed, and therefore assembling, printing and testing integrated streamlined work can be achieved for relay production, time for moving a shell of the relay to a silk-screen workshop to be operated and material circulation time are saved, the requirement for lean production of the relay can be met, and the device can be widely applied to production, popularization and use for part assembly in the hardware industry and the electronic industry, and has wide market prospects.

Owner:GUANGDONG GALANZ GRP CO LTD

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Noncontact printing on subsurface layers of translucent cover golf balls

The present invention relates to a noncontact printing method for applying indicia, such as insignia or stripes, on at least one subsurface layer of a transparent or translucent cover golf ball, e.g. the core, or one or more intermediate layers. The indicia may be visible in ambient light or are only visible when exposed to specific non-ambient light wavelengths, e.g. ultraviolet wavelengths. Advantageously, this method of noncontact printing on subsurface golf ball layers substantially improves the durability of indicia because such indicia are protected from direct abrasion and club impacts by the cover. Moreover, unlike pad printing, noncontact printing forms indicia that are not susceptible to ink degradation because the indicia are solid markings created by very small discrete dots. In one embodiment, both the cover and the intermediate layer(s) may be transparent or translucent and thusly decorated to achieve previously unattainable image depth effects.

Owner:ACUSHNET CO

Multi-color and multi-position pad printing machine

The invention belongs to the technical field of pad printing and discloses a multi-color and multi-position pad printing machine. The multi-color and multi-position pad printing machine comprises a base, a pad printing assembly arranged on the base in a straddling manner, a plurality of ink feeding assemblies located below the pad printing assembly, a cleaning assembly located in front of the ink feeding assemblies and a material supporting assembly located beside the ink feeding assemblies; the pad printing assembly comprises a horizontally-arranged servo module which is provided with an X movement module capable of moving in the X direction; the X movement module is provided with a first cylinder which drives an adhesive head assembly to move up and down in the Z direction; the adhesive head assembly is provided with pad printing adhesive heads side by side in the X direction, and the number of the pad printing adhesive heads corresponds to that of the ink feeding assemblies; and the material supporting assembly comprises a base, a carrying table located above the base and a third cylinder fixed to the base and driving the carrying table to move in the X direction. The multi-color and multi-position pad printing machine can print colorful patterns formed by combining different color blocks on products, cost is saved compared with a common multi-color pad printing machine, and besides, debugging is easy and fast.

Owner:YINGTUO ELECTRONICS APP KUSN

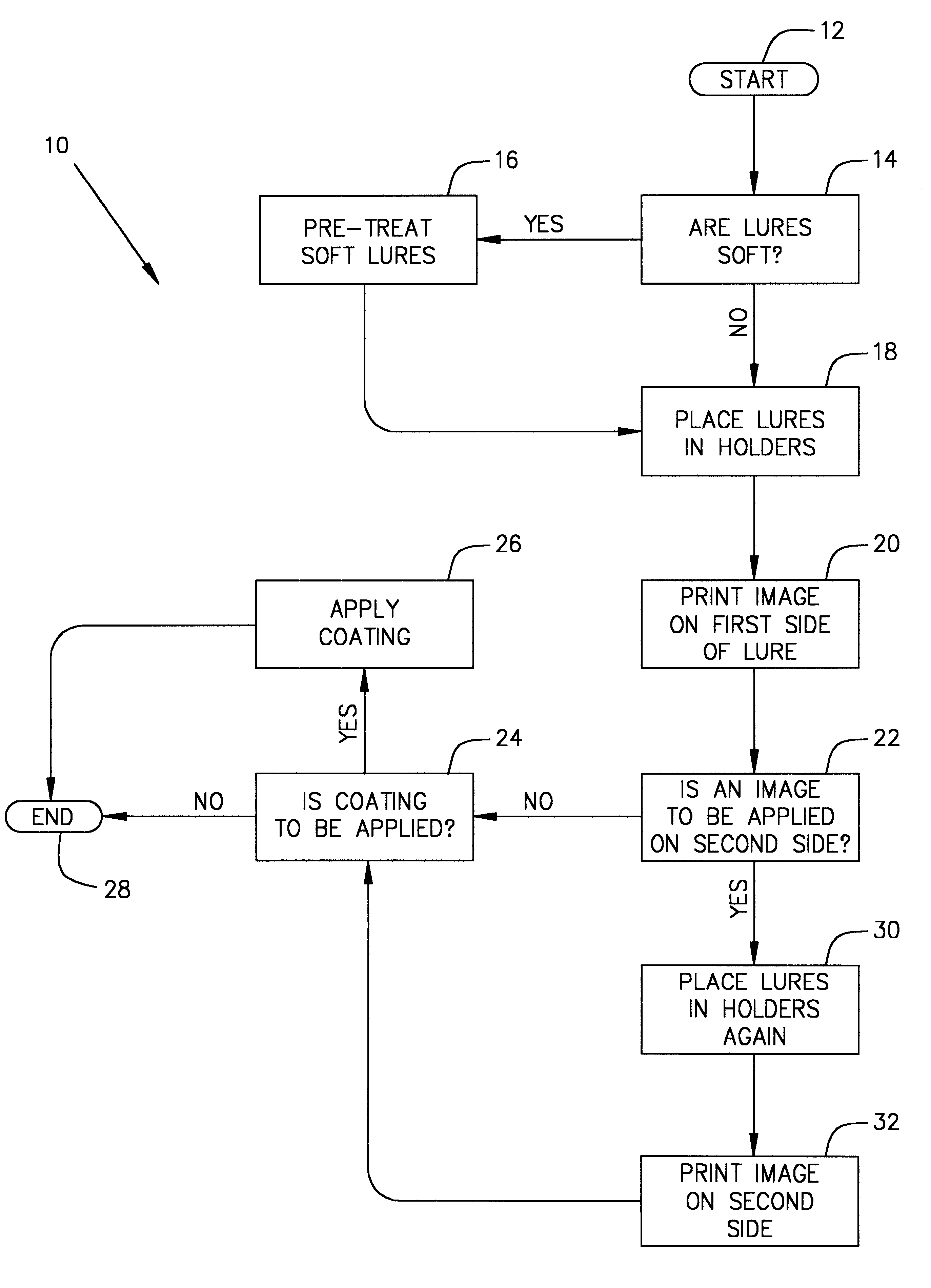

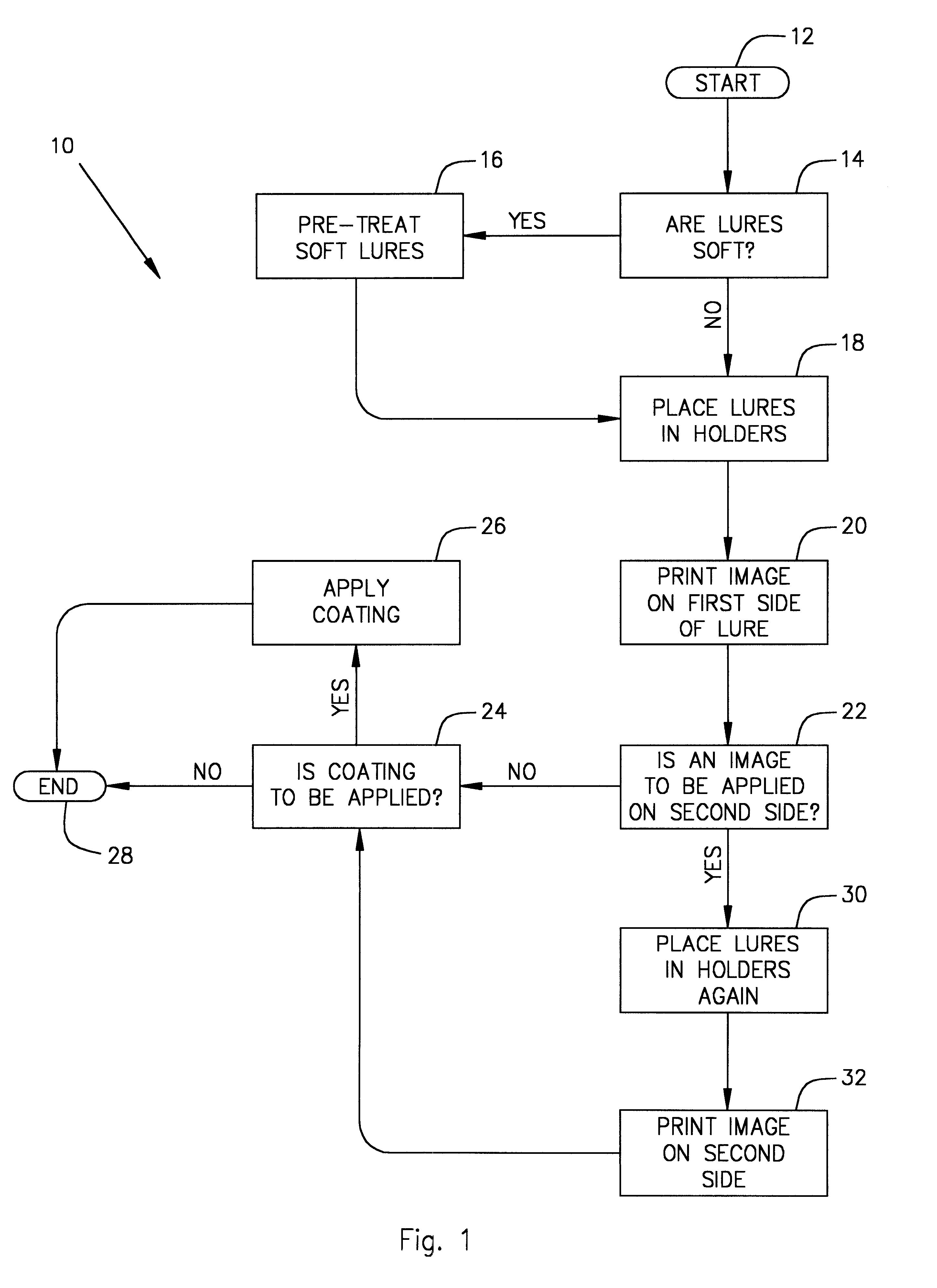

Process for applying 4 color image to a fishing lure

A process for printing a 4 color image directly onto a fishing lure. The process involves preparing the fishing lure to receive the ink if the fishing lure is soft bait, printing a 4 color image on one side of the fishing lure employing a 4 color pad printing machine, and optionally, turning the lure over and printing another 4 color image onto the other side of the lure with the 4 color pad printing machine. A clear topcoat may optionally be applied to the lure.

Owner:ILLUSION LURES

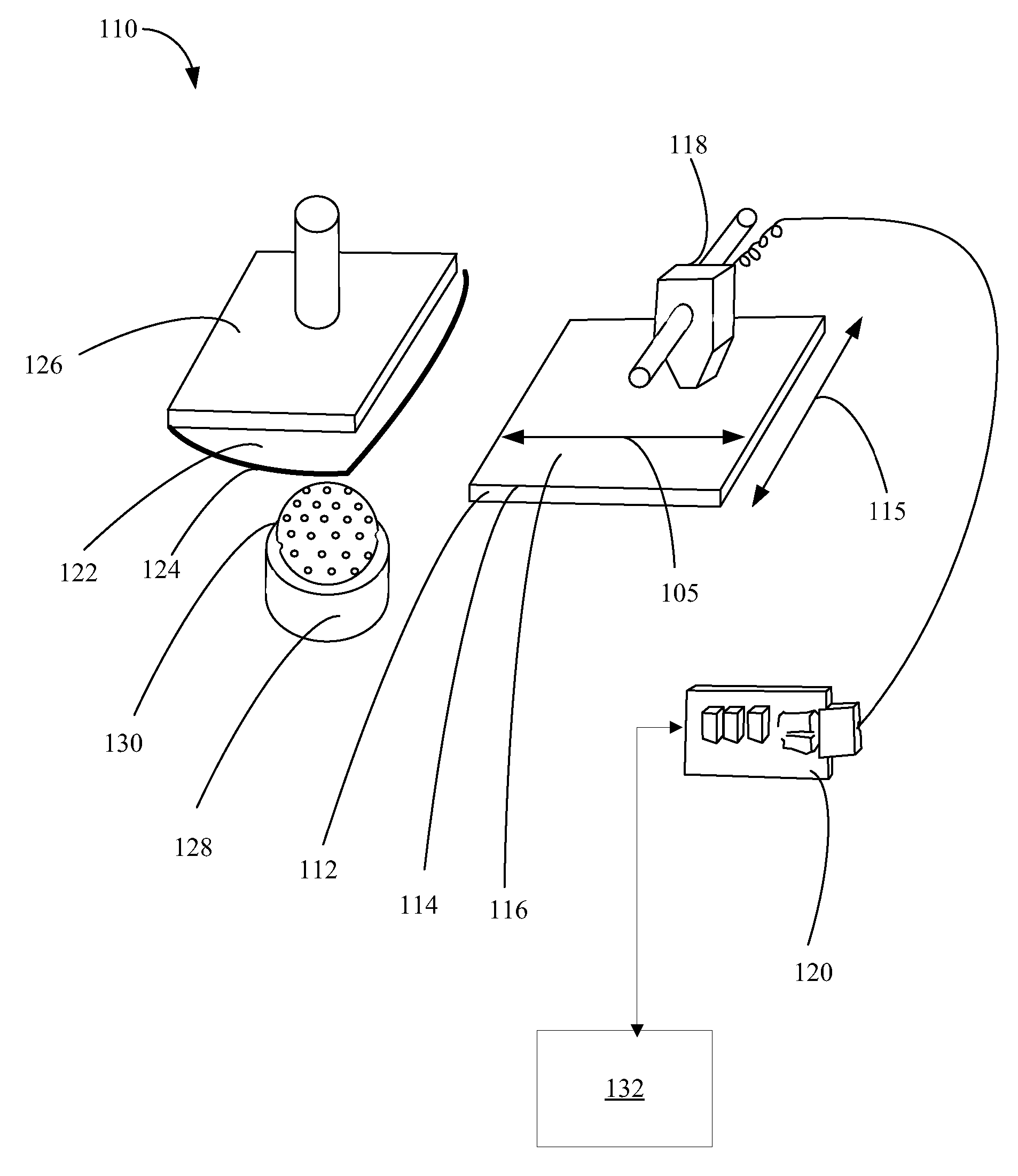

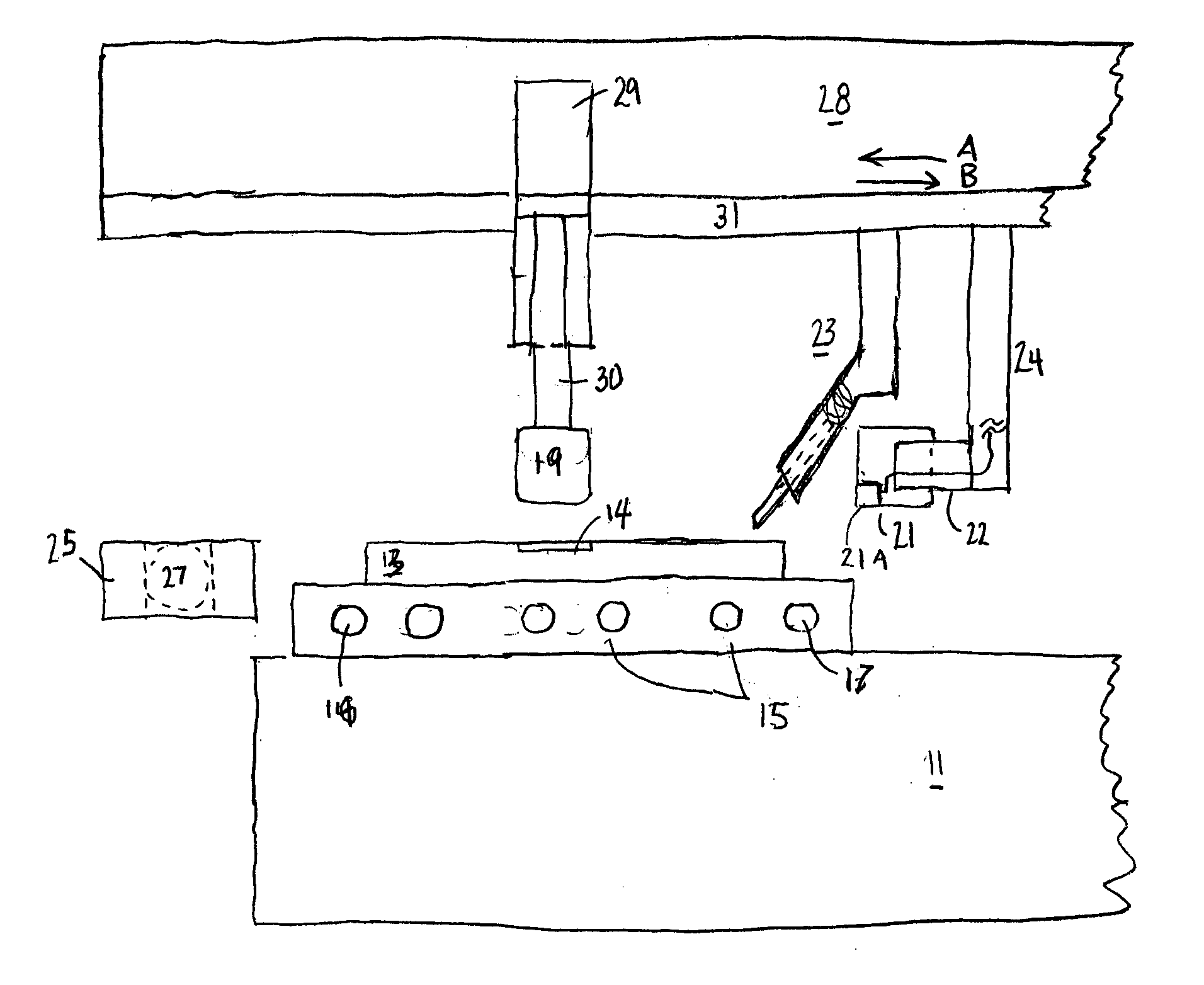

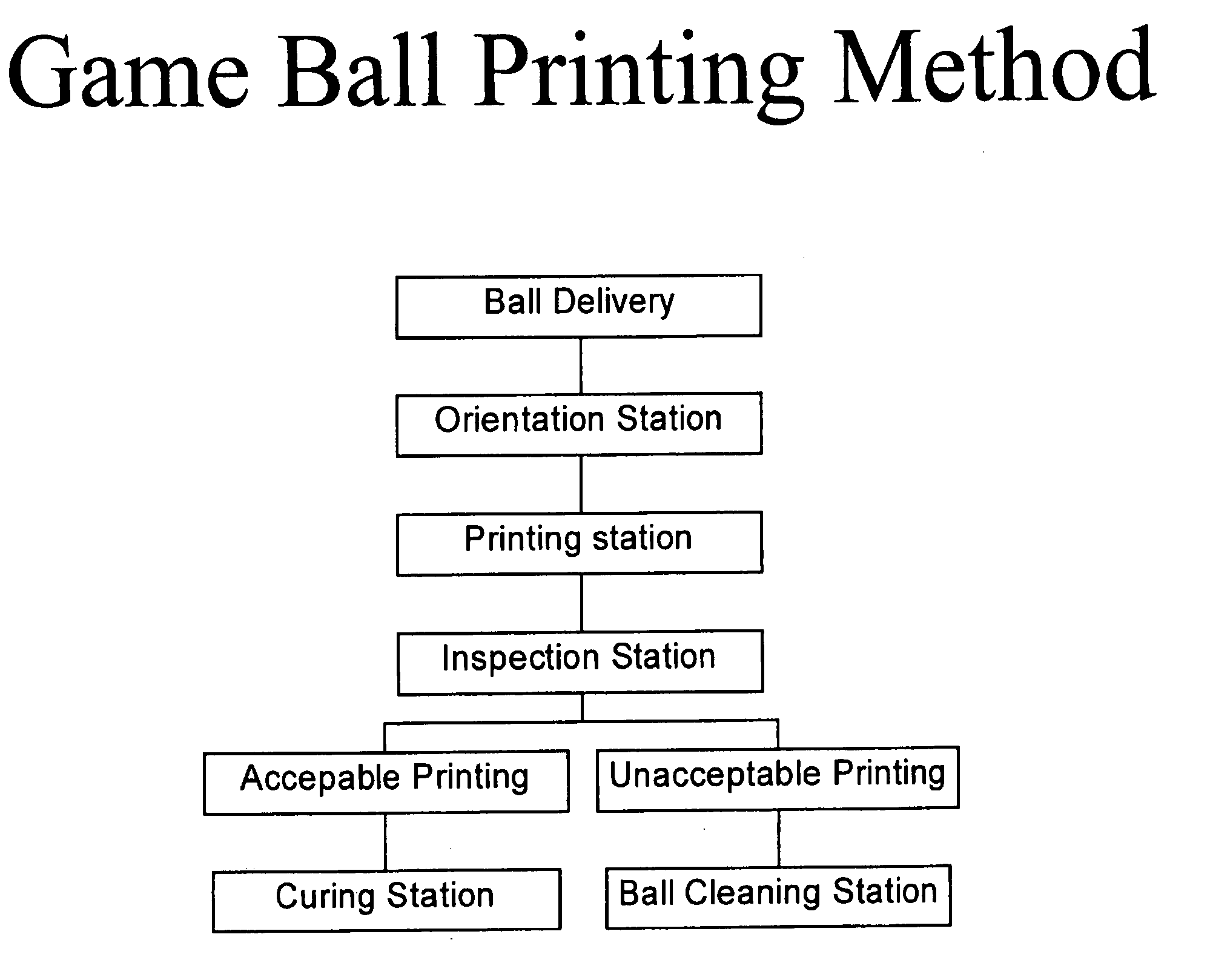

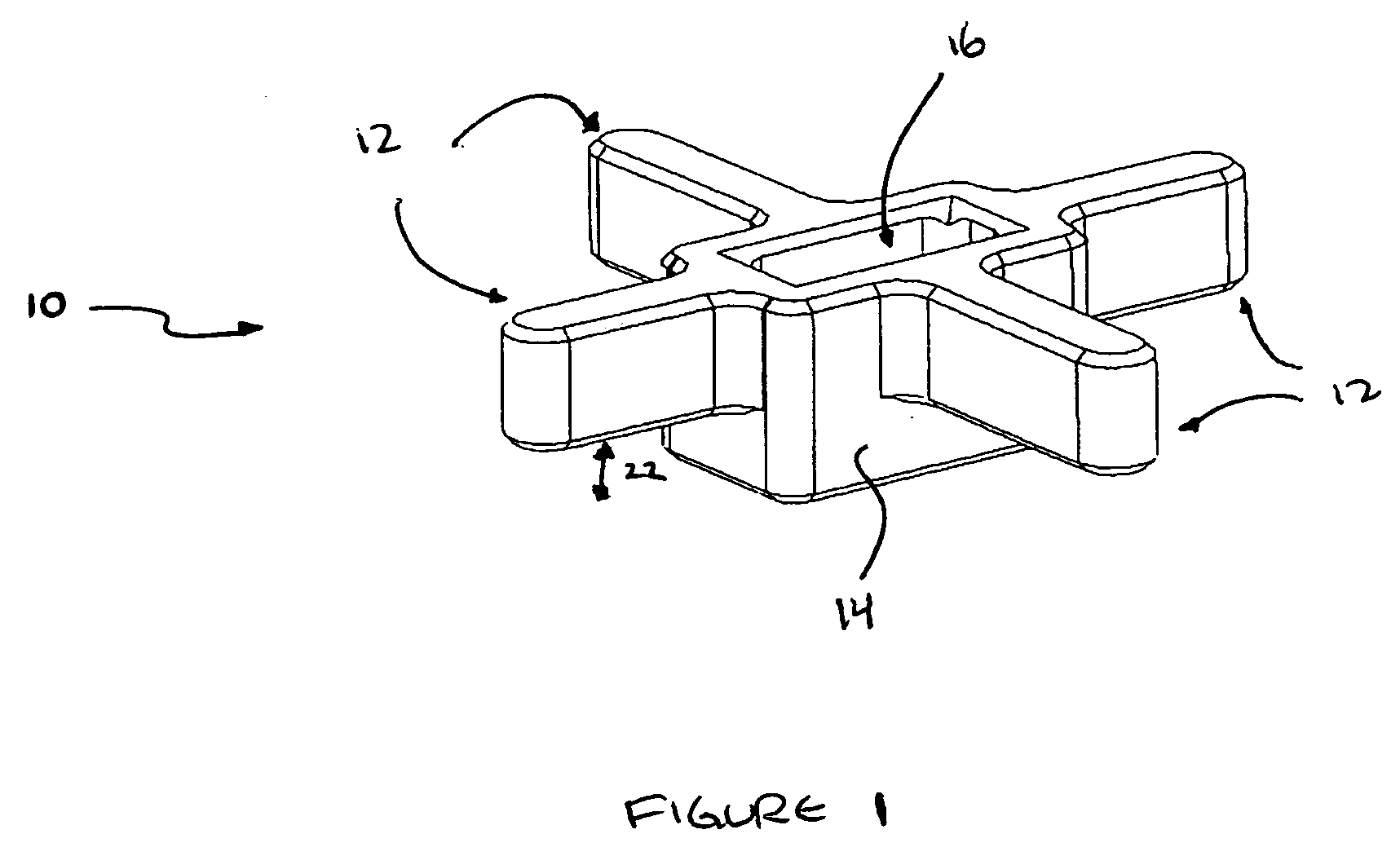

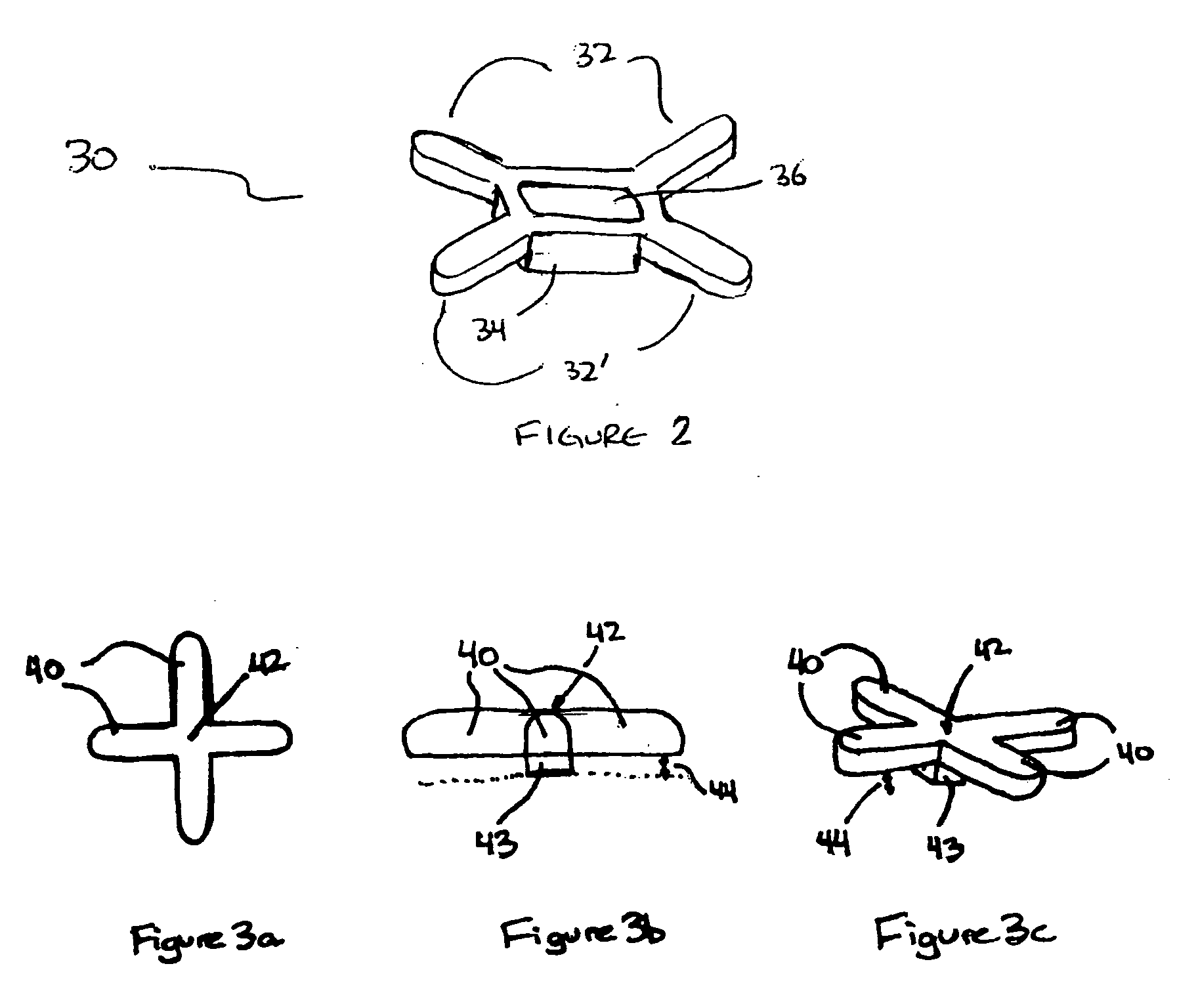

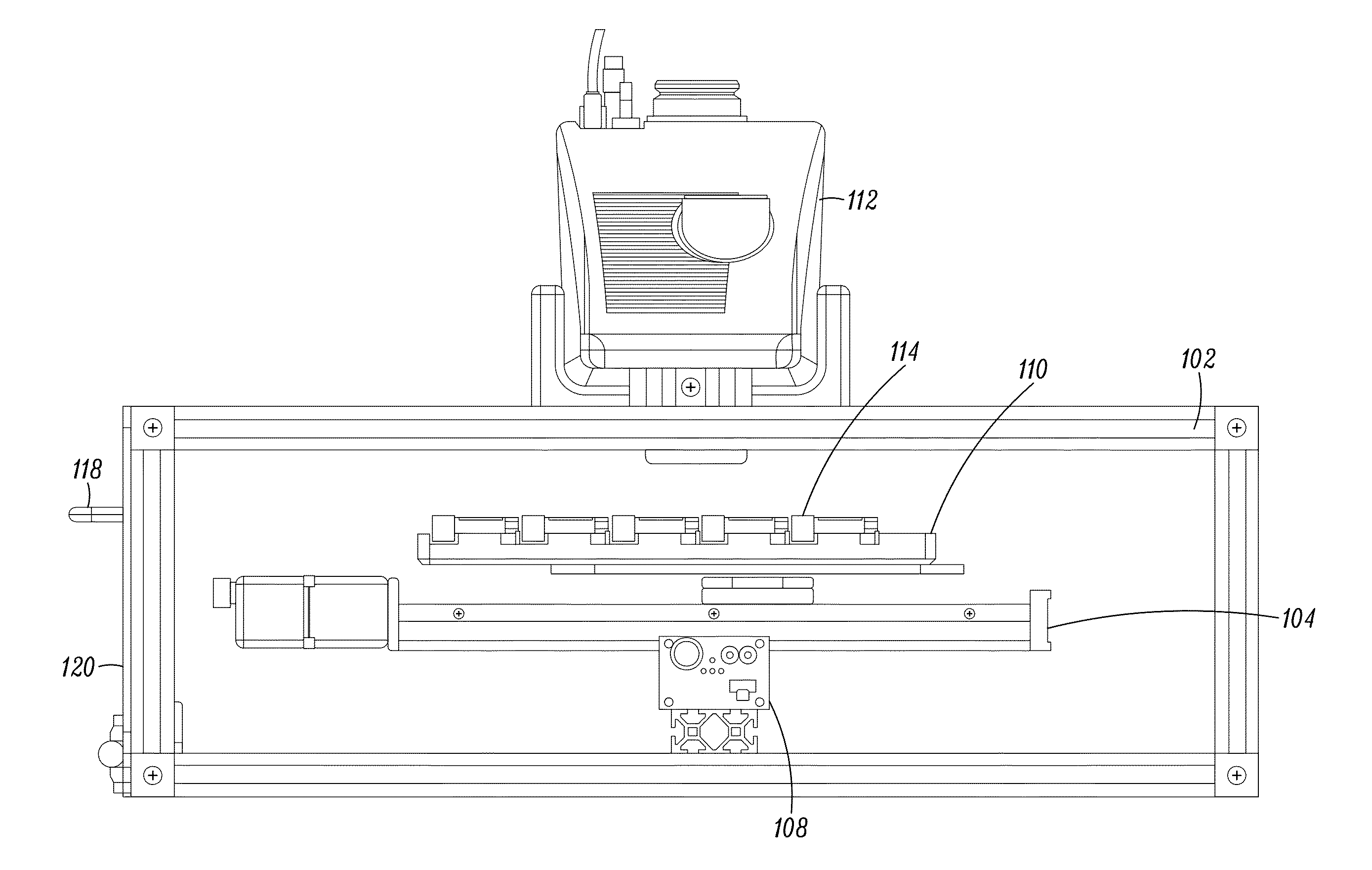

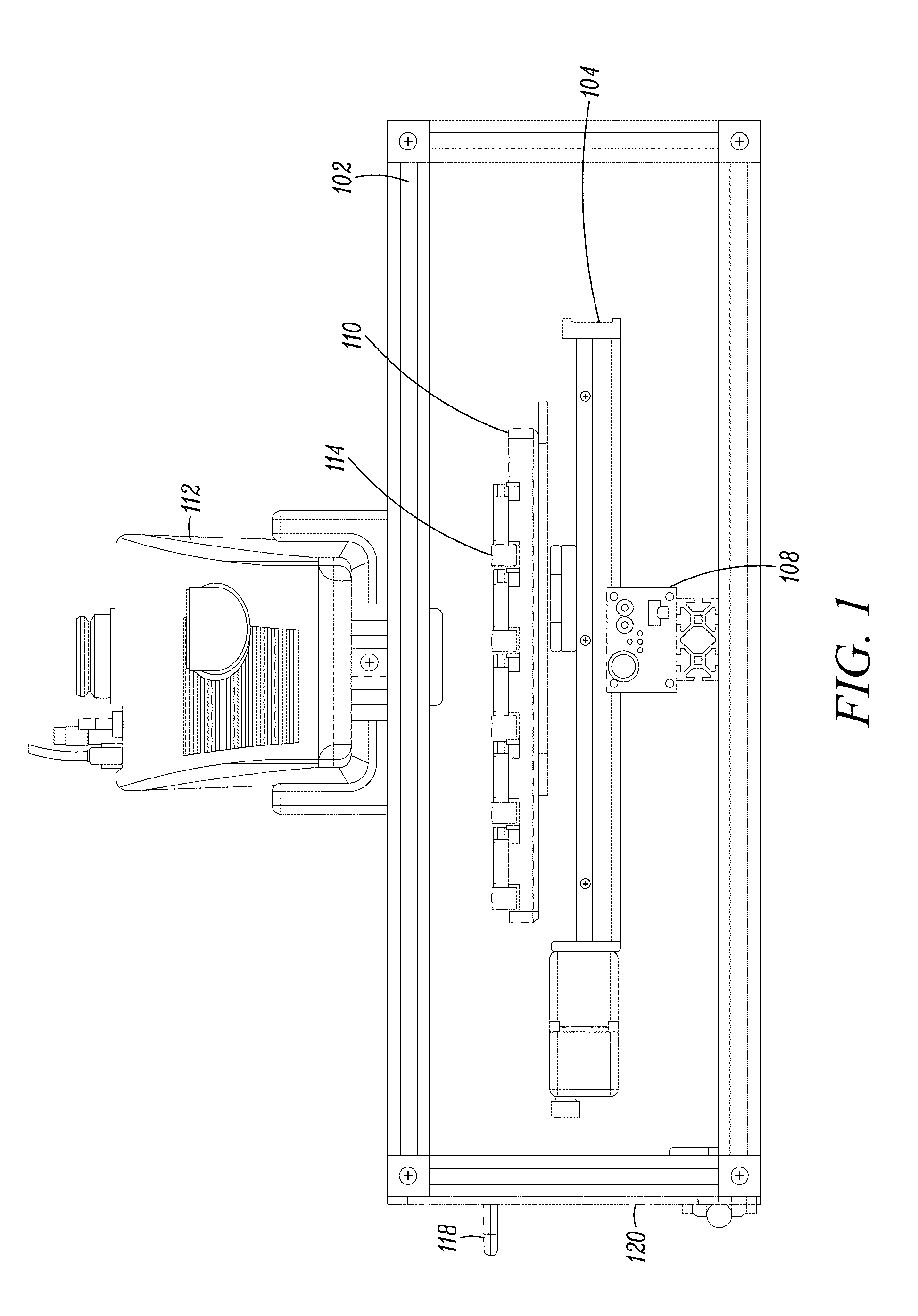

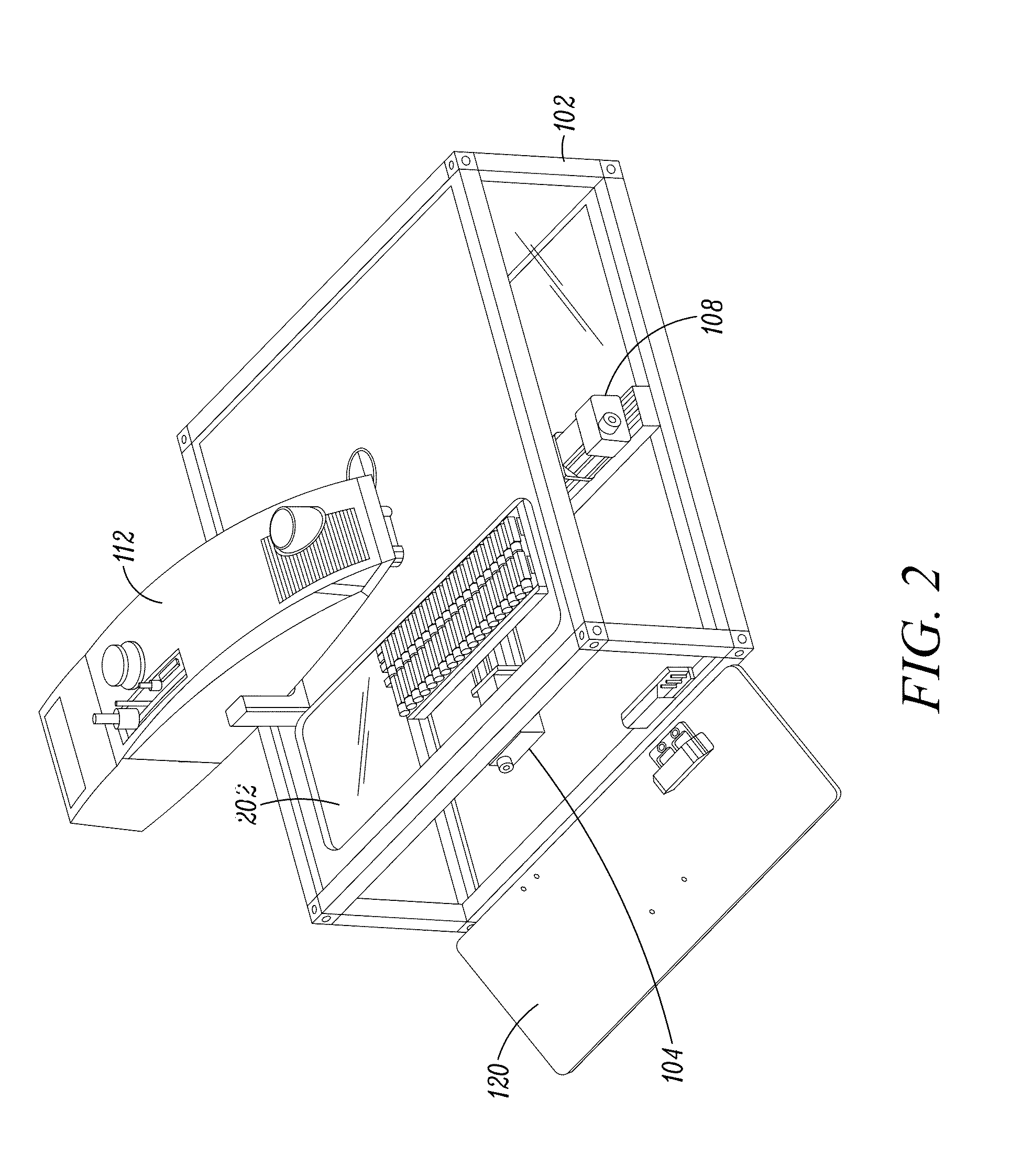

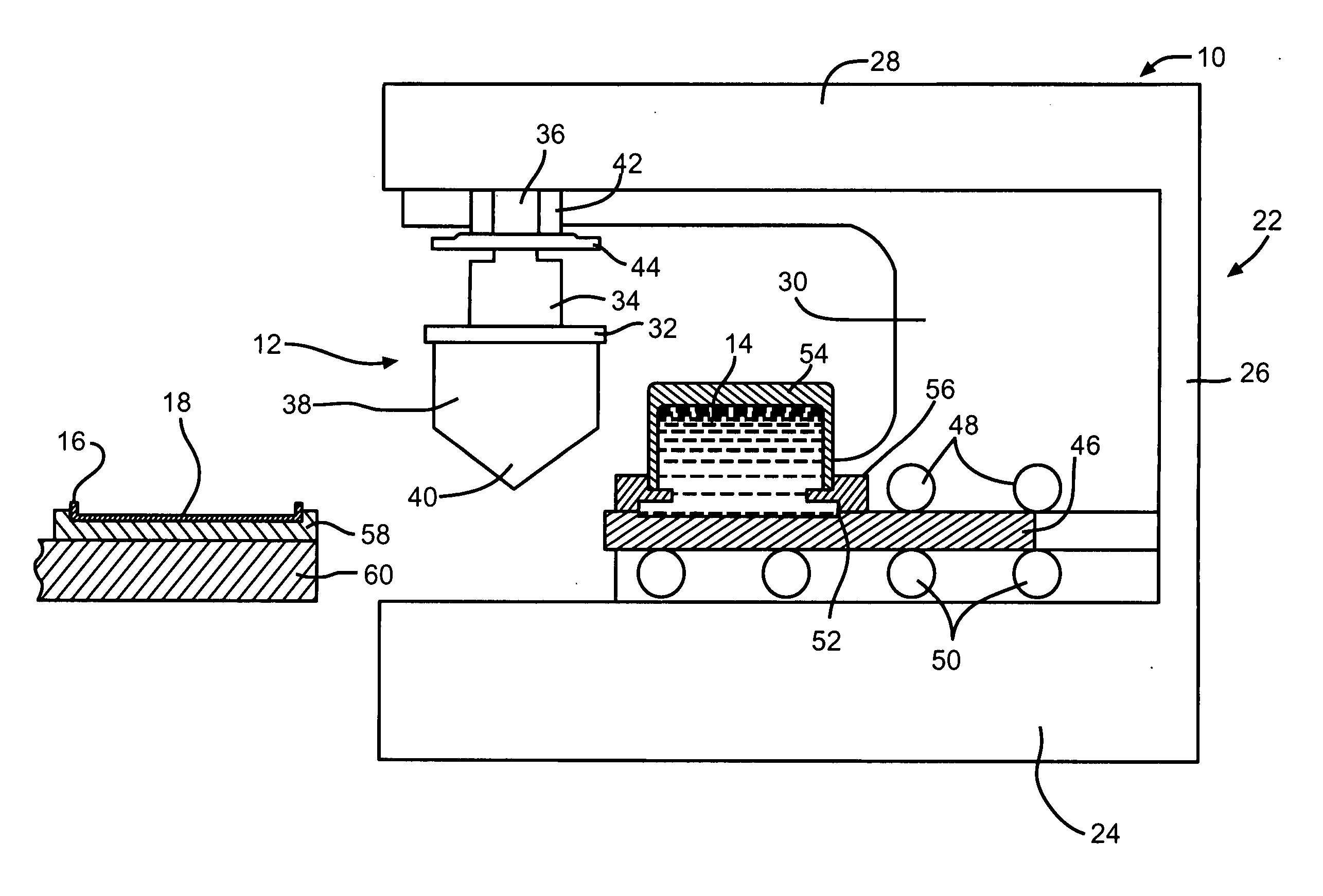

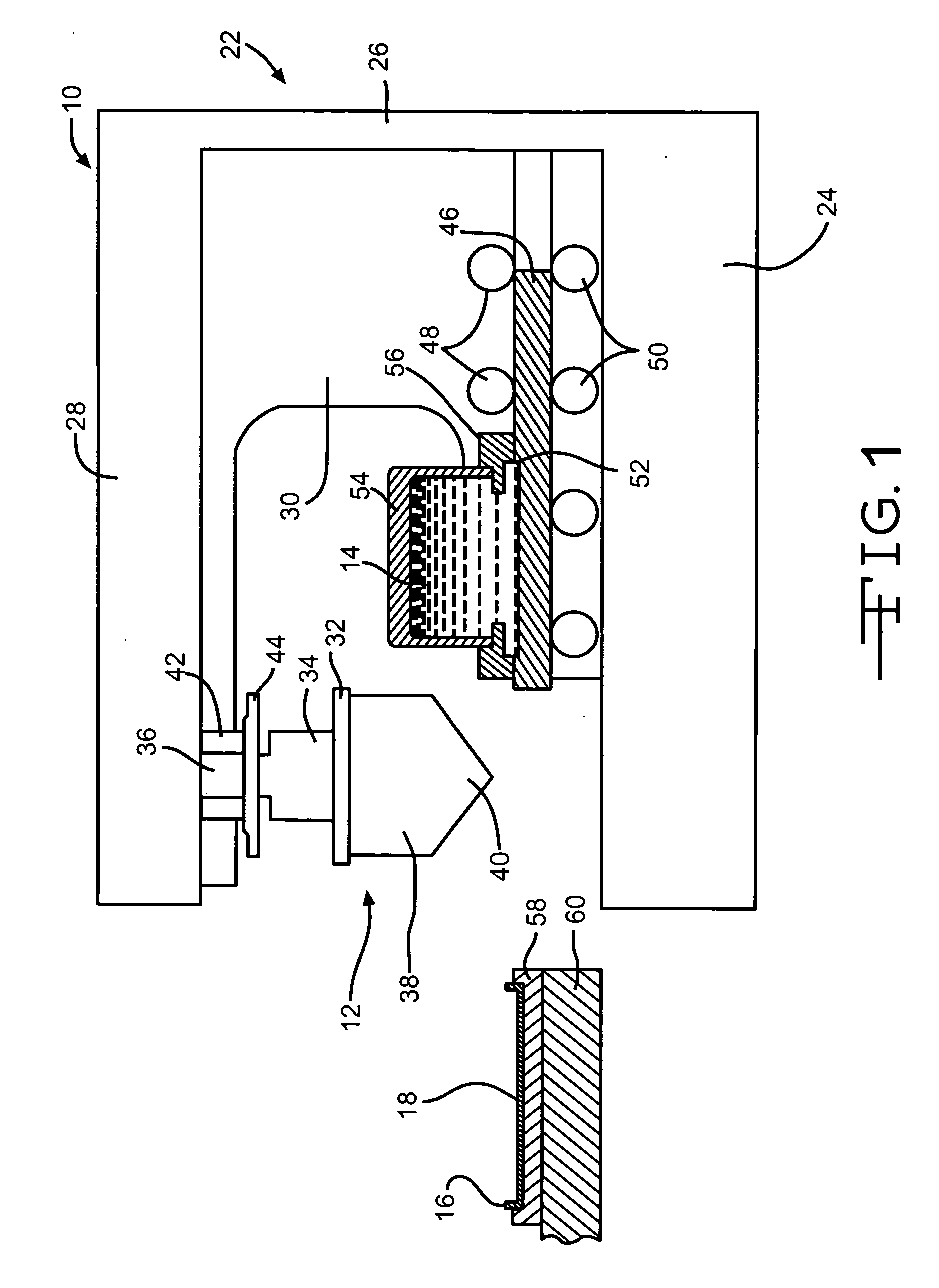

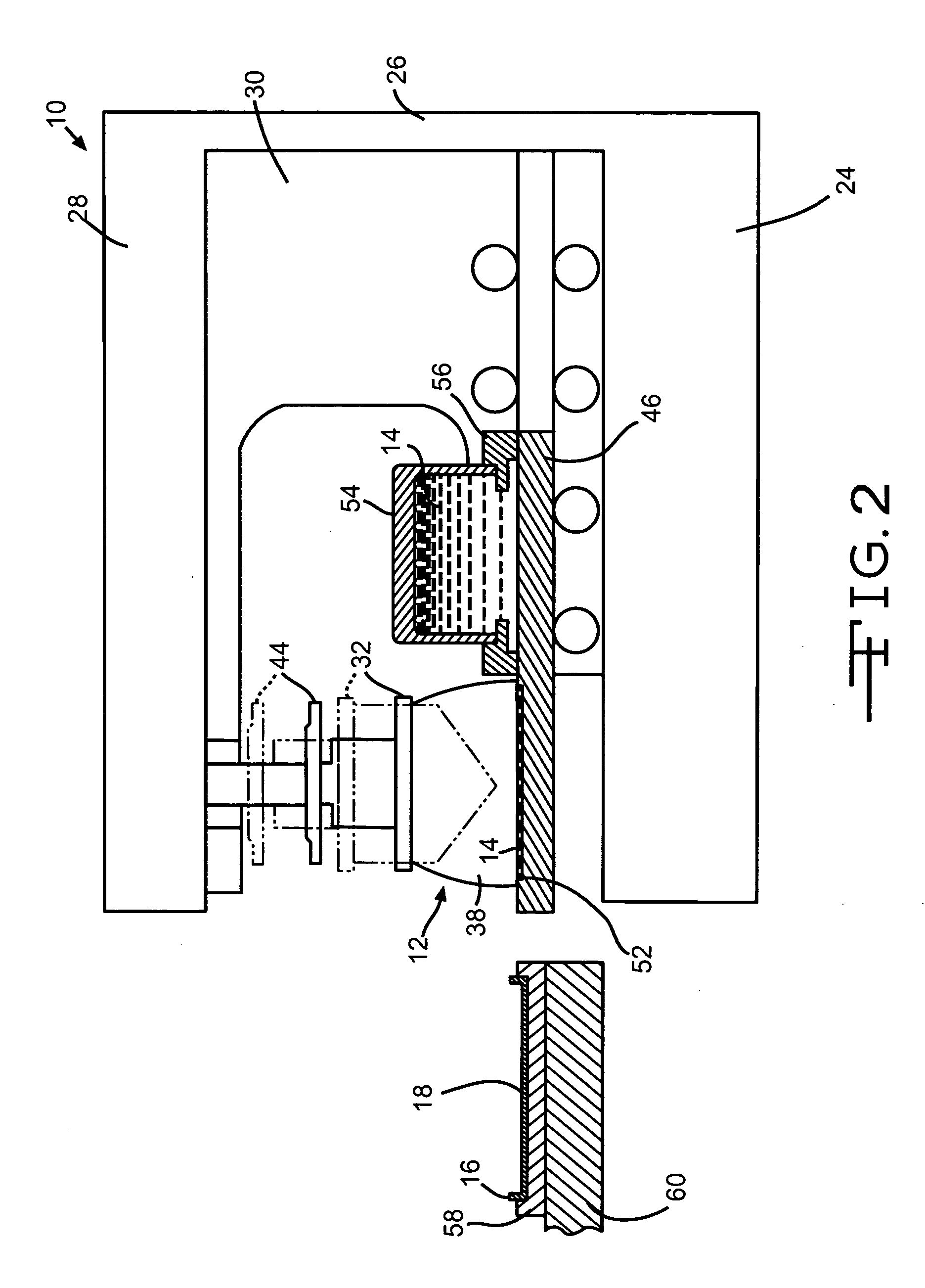

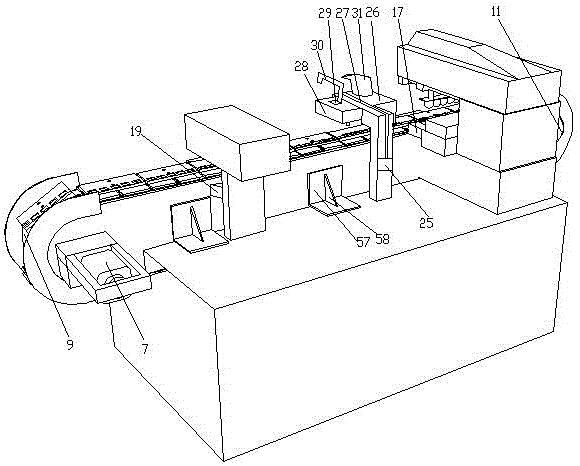

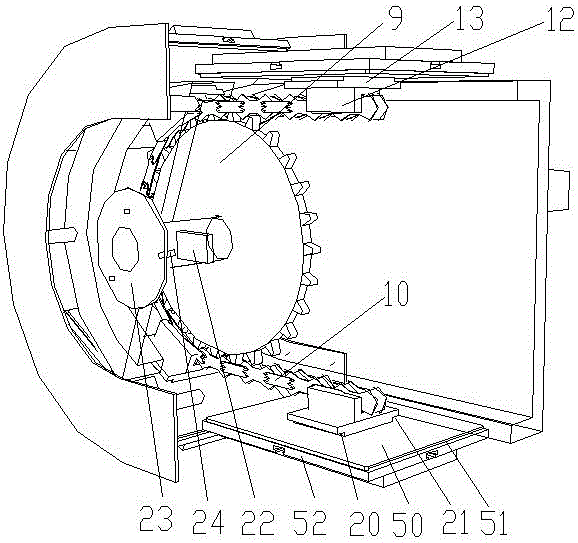

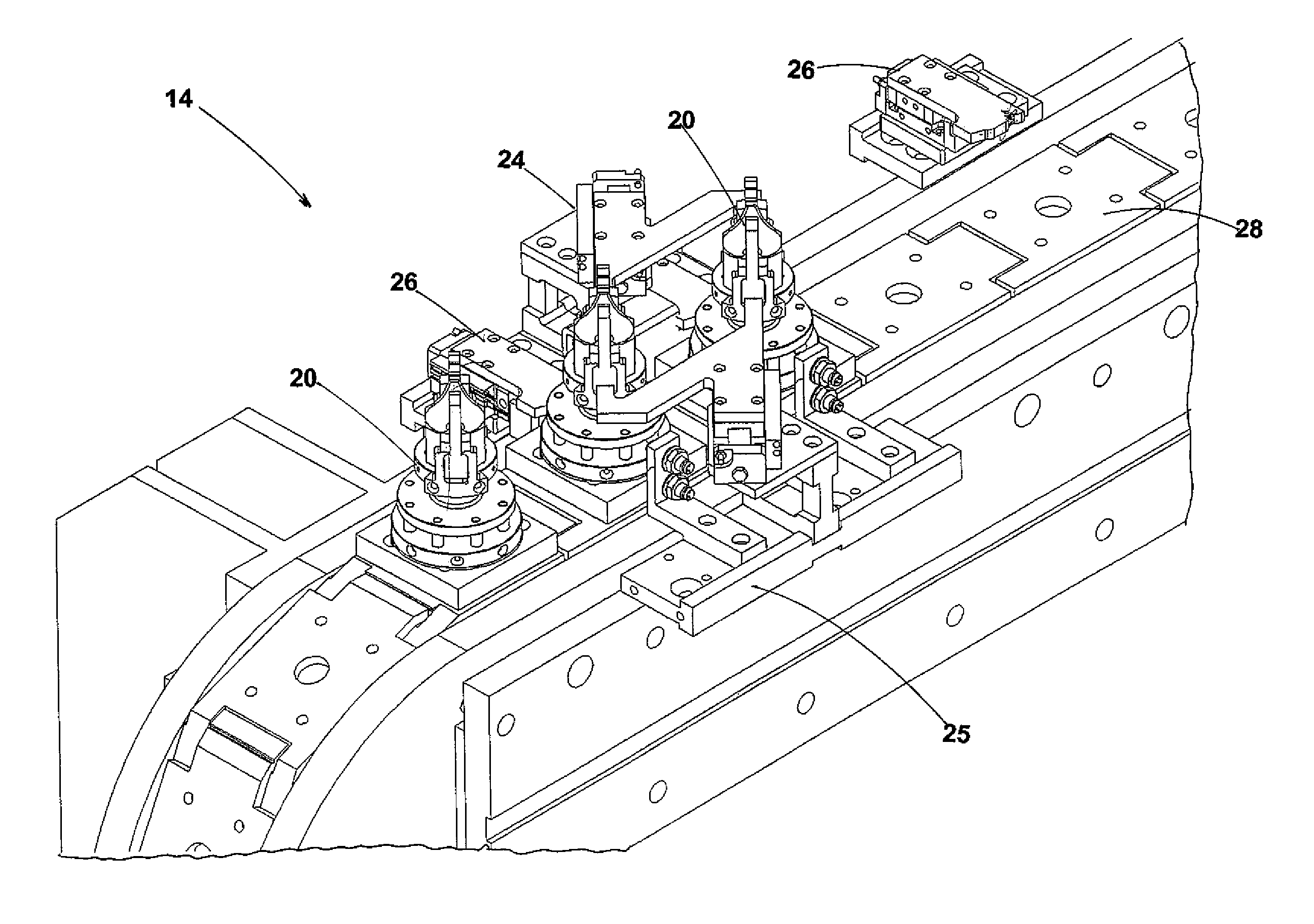

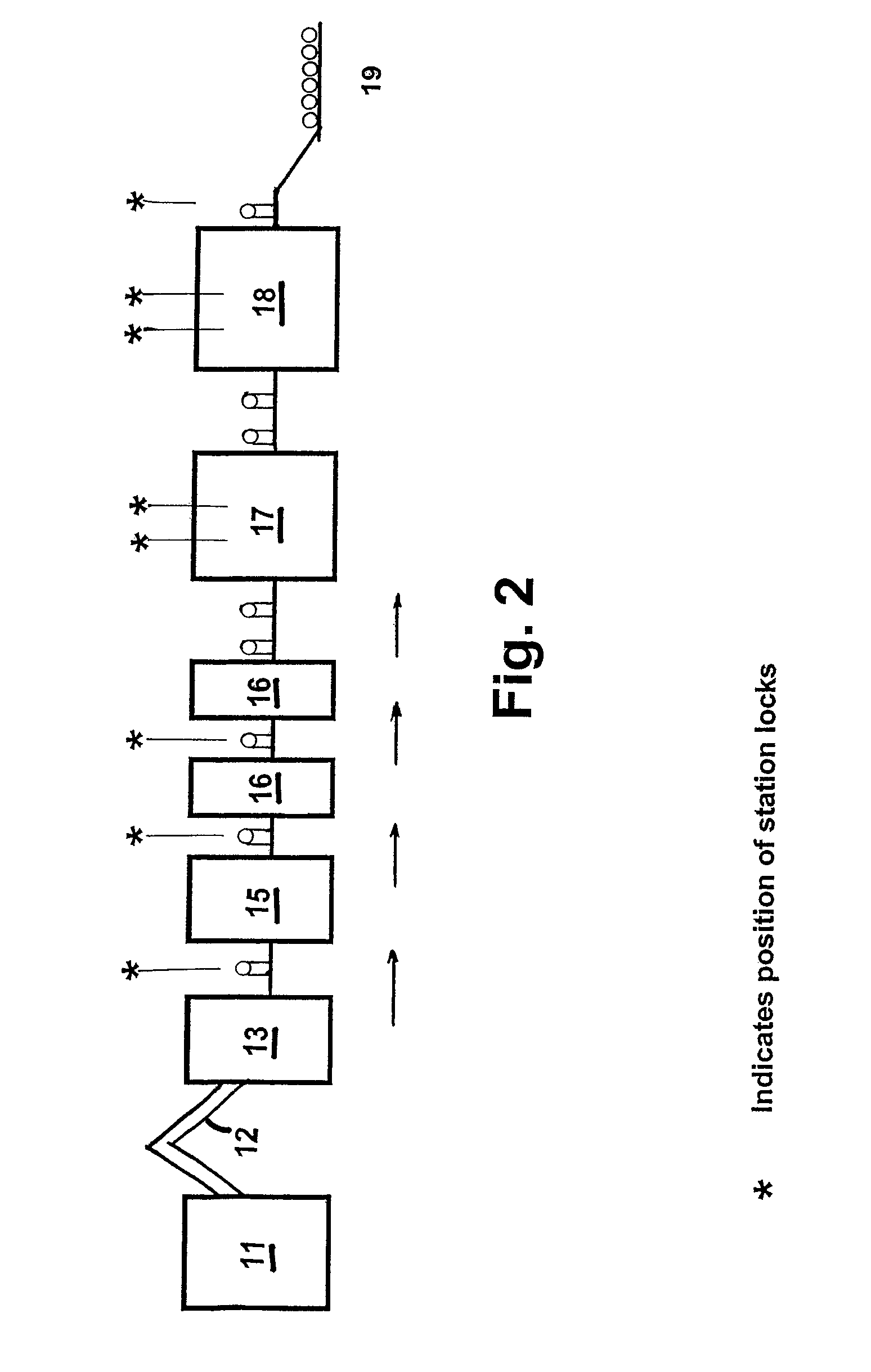

Method and apparatus for automatic indexing of a golf ball

ActiveUS7387070B1Reduce and eliminate wearReduce and eliminate and tearCylinder pressesPlaten pressesPad printingAutomatic indexing

A method and apparatus for applying printing of indicia and logo to golf balls held and indexed by magnetic indexing devices connected to a conveyor. The device includes a stationary base portion and a rotating cup portion which are magnetically coupled to each other. Each portion has recesses for housing magnets to create a magnetic field of attraction which firmly locks the two portions together. When rotation of the cup portion to the base portion is required, the rotation is substantially friction-free because of a thrust bearing ring set in the base portion. The cup portion is caused to rotate 45° or 90° upon being biasly urged by station locks located on the conveyor. The cup portion has an open bridge section wherein cam surfaces of the station locks can engage and cause the cup portion to rotate, which is necessary for each new procedure, whether it be inspection of the ball, pad printing of indicia and logo, or curing the printed ink with ultraviolet light.

Owner:ACUSHNET CO

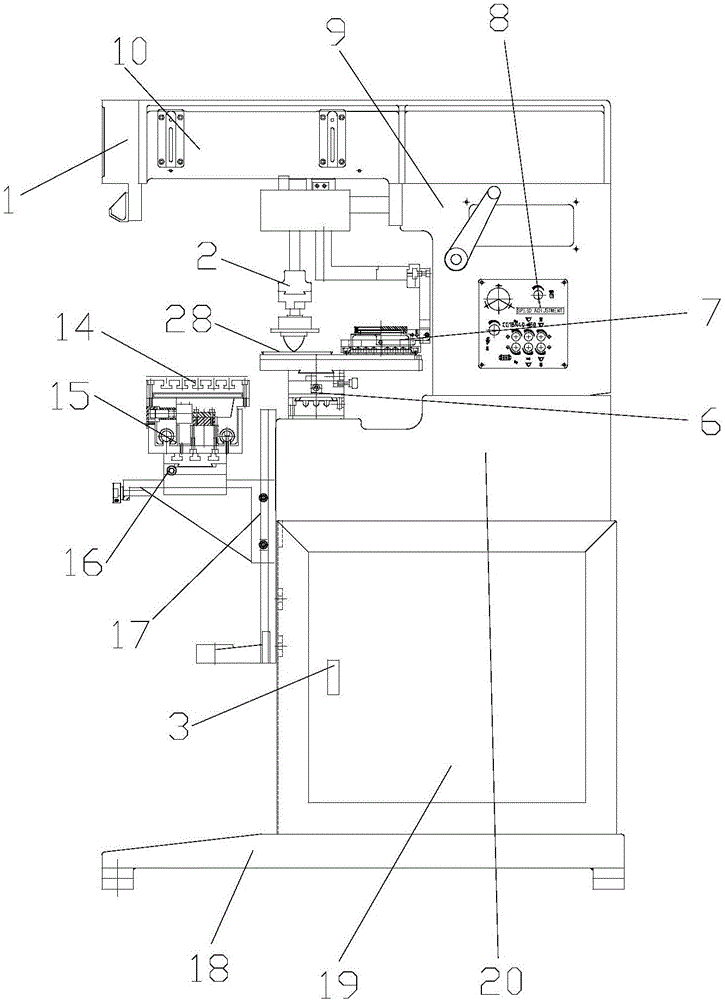

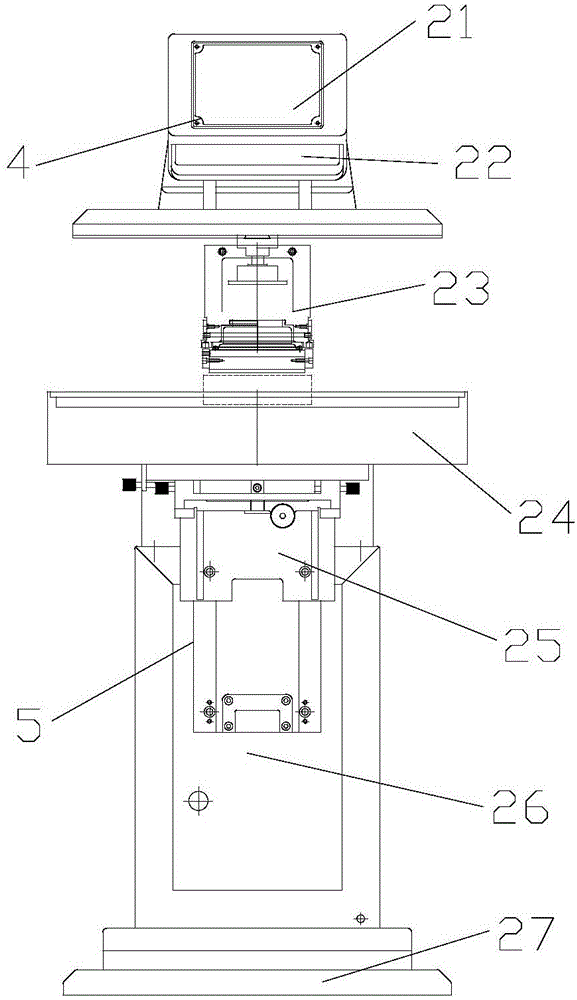

3D curved face cover plate glass window pad printing device and pad printing process thereof

The invention discloses a 3D curved face cover plate glass window pad printing device and a pad printing process thereof. The 3D curved face cover plate glass window pad printing device structurally comprises a pad printing machine body, a pad printer, an equipment cabinet, a data control system and a workbench lifting seat frame. The pad printing machine body is connected with the equipment cabinet, the pad printer is movably connected with the pad printing machine body, the data control system is connected with the workbench lifting seat frame, the pad printing machine body comprises a steel sheet supporting base, an oil cup mechanism, a data plate, a machine body connection body and an end frame, and the steel sheet supporting base is connected with the oil cup mechanism. The 3D curved face cover plate glass window pad printing device and the pad printing process thereof have the advantages that the process is simple, a product meeting drawing requirements can be produced just through four processes, and the production rate is high.

Owner:深圳市久和丝印器材有限公司

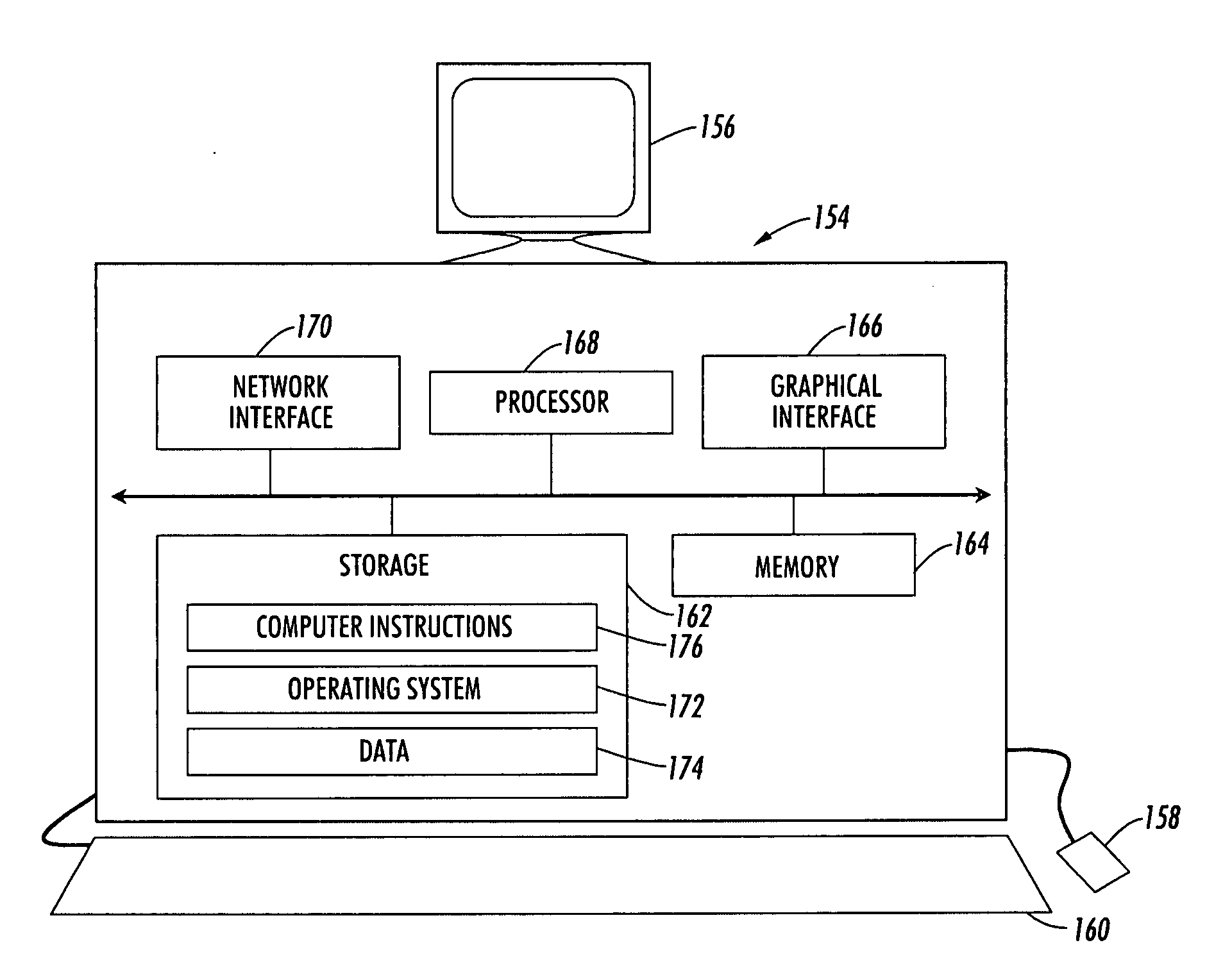

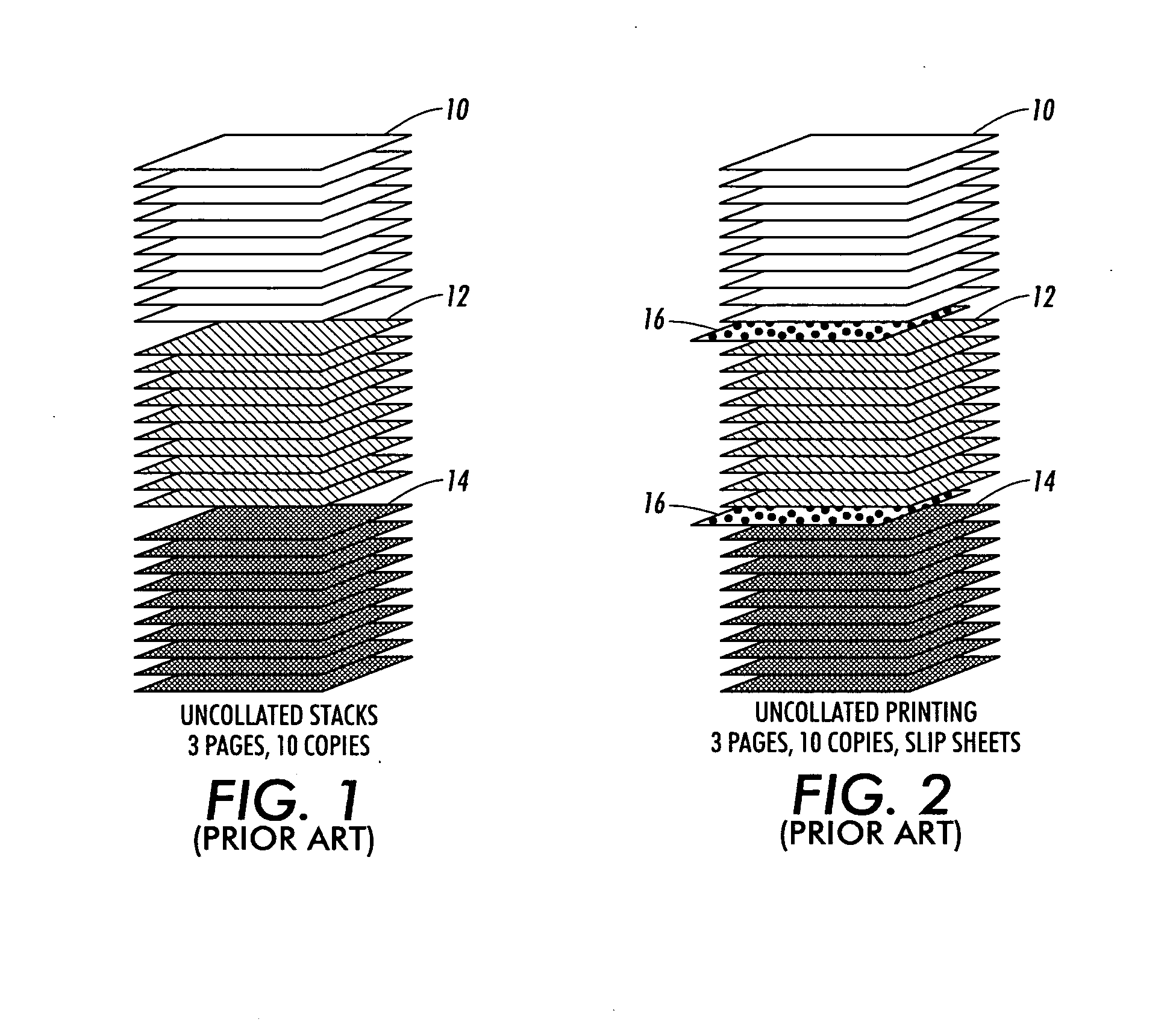

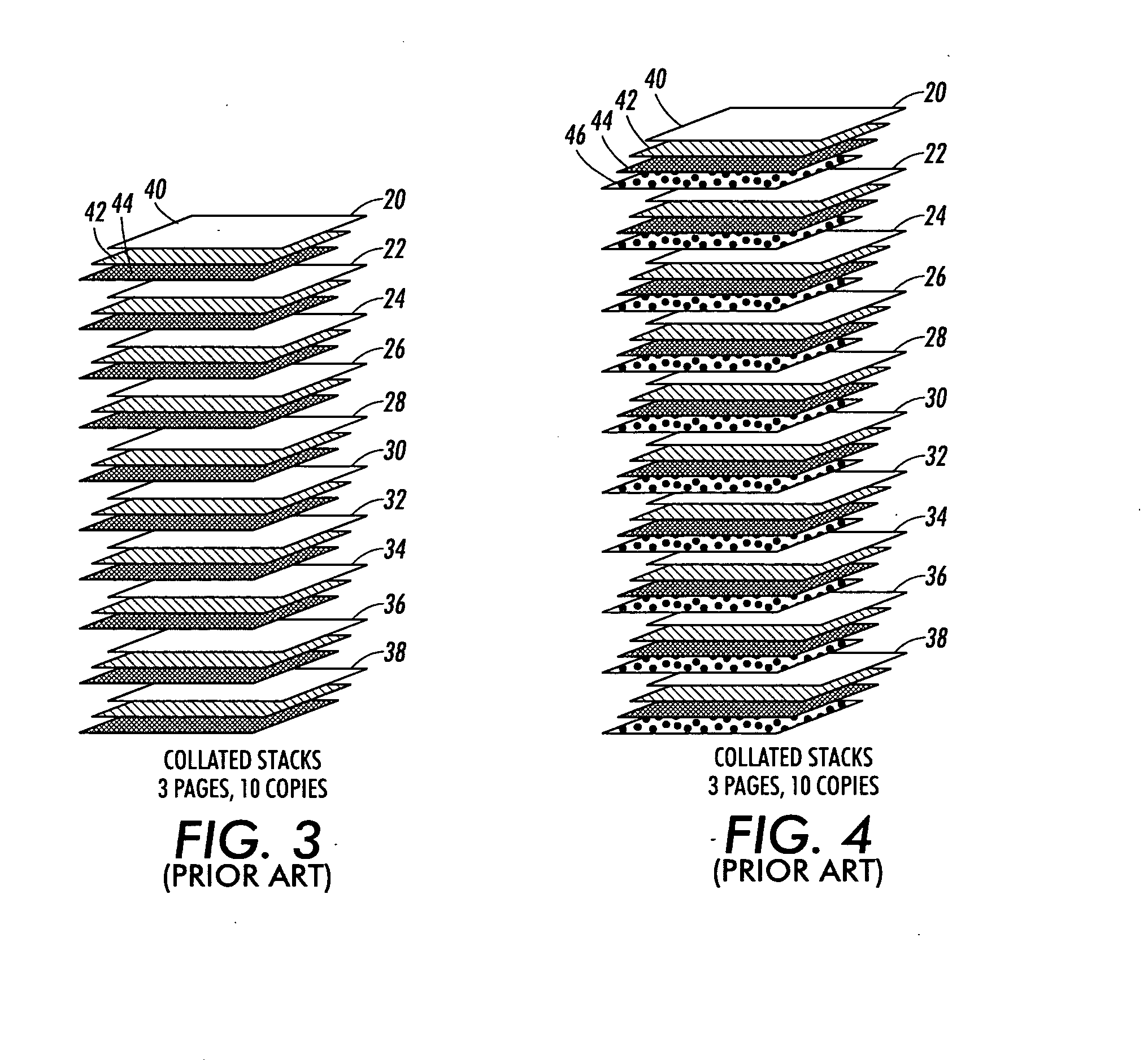

Enhanced job programming for pad printing

ActiveUS20080151285A1Digitally marking record carriersFunction indicatorsPad printingComputerized system

A system and method of job programming in a computer system for programming print jobs for pad printing. Parameters are programmed by a user for printing a pad, and the programming involves one or more of the following programming steps: programming a slip sheet parameter, programming insert sheet parameters, and for each first sheet insertion point, an insertion frequency, and programming cover sheet parameters. The slip sheet parameter includes at least a yes value or a no value. The insert sheet parameters include one or more first sheet insertion points and, for each first sheet insertion point programmed, an insertion frequency.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com