Patents

Literature

842results about "Addressographs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

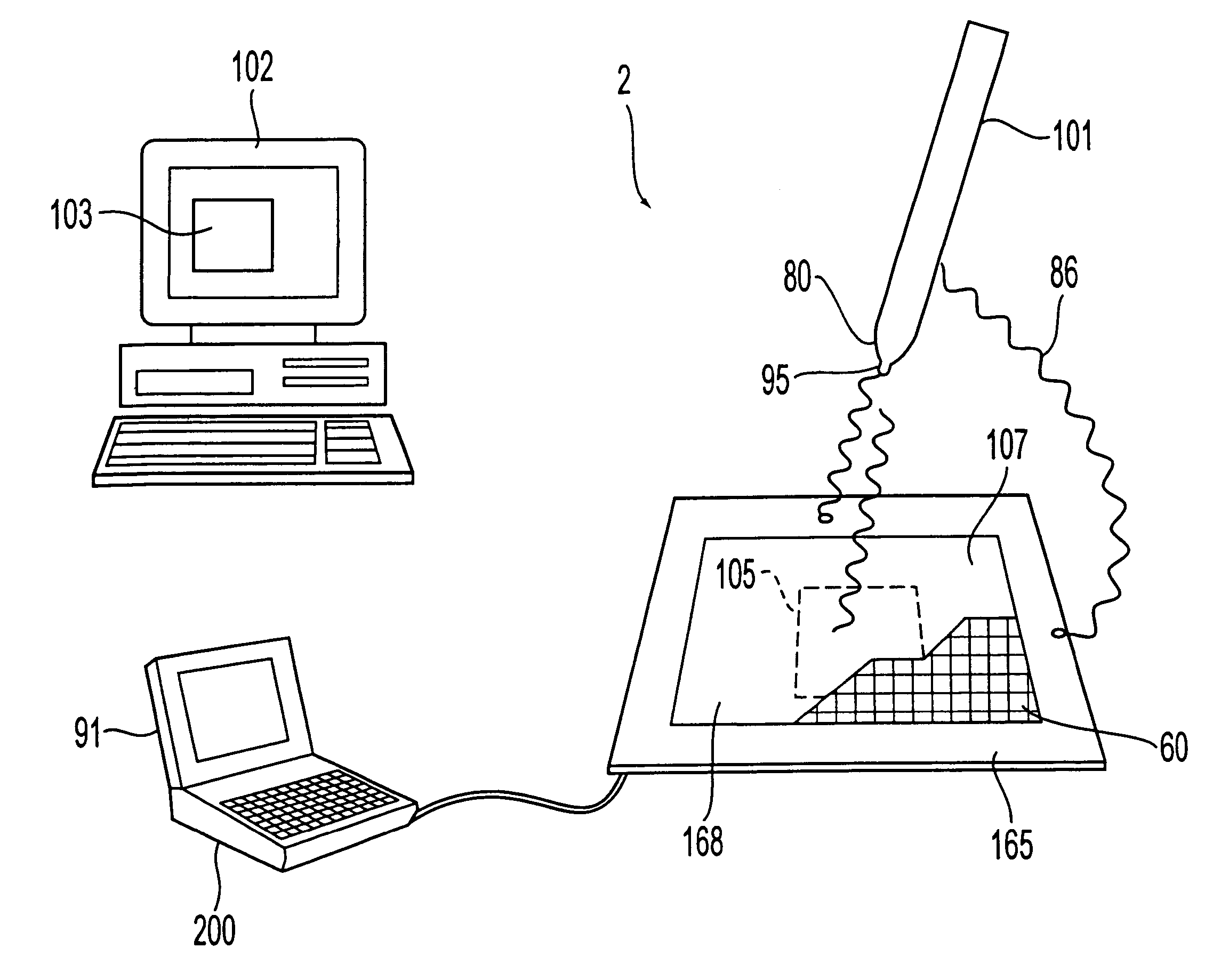

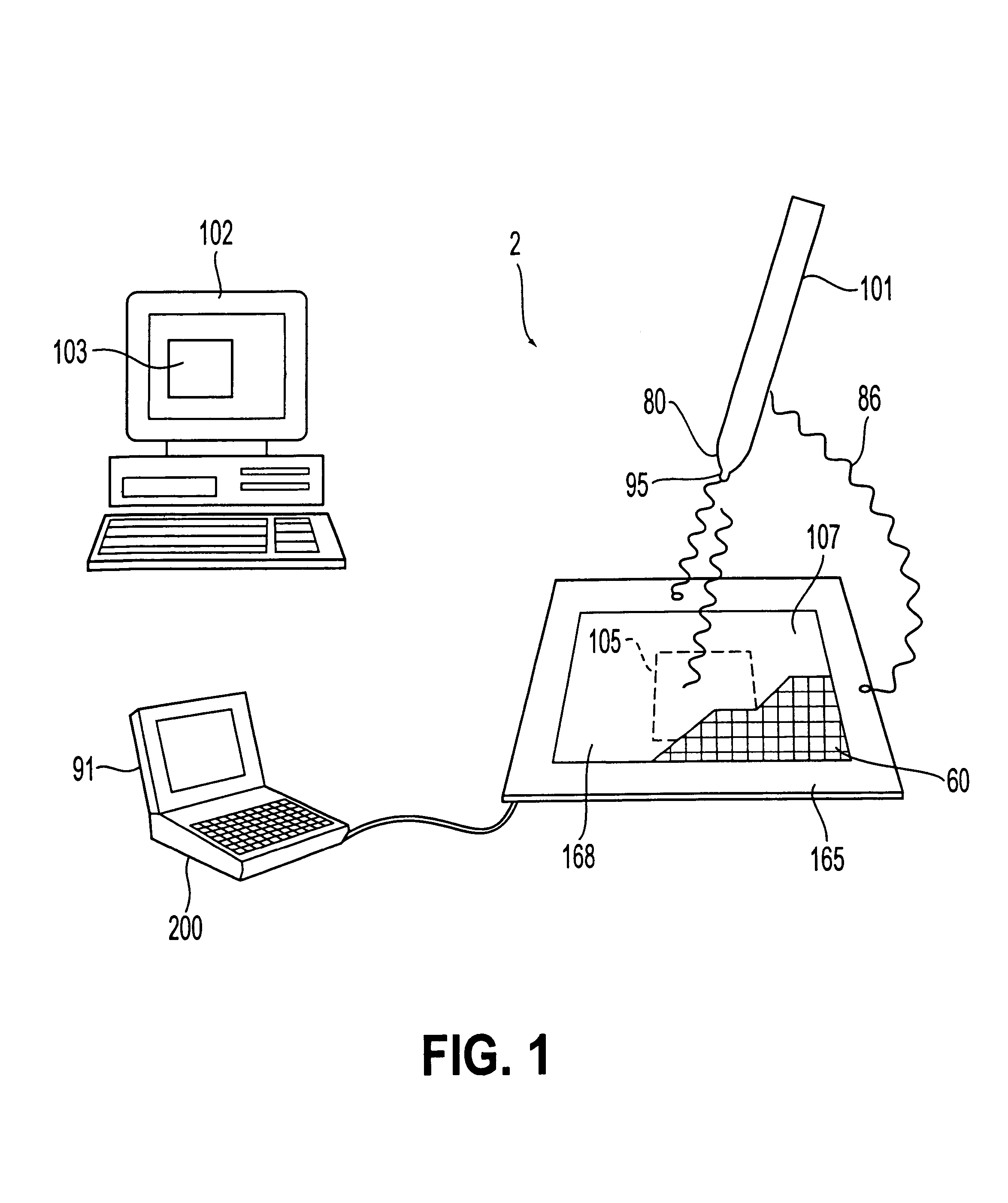

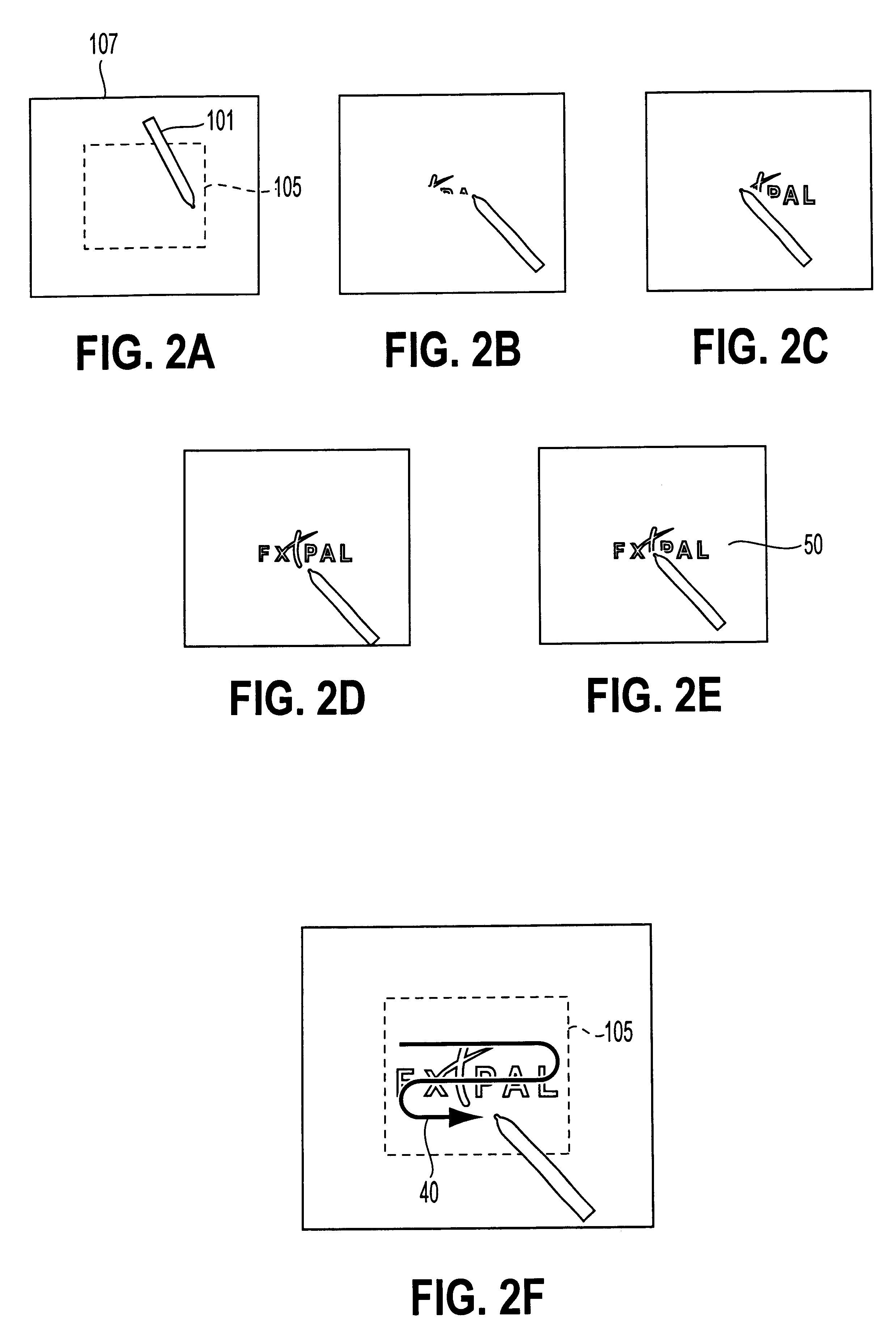

Method and system for position-aware freeform printing within a position-sensed area

Owner:FUJIFILM BUSINESS INNOVATION CORP

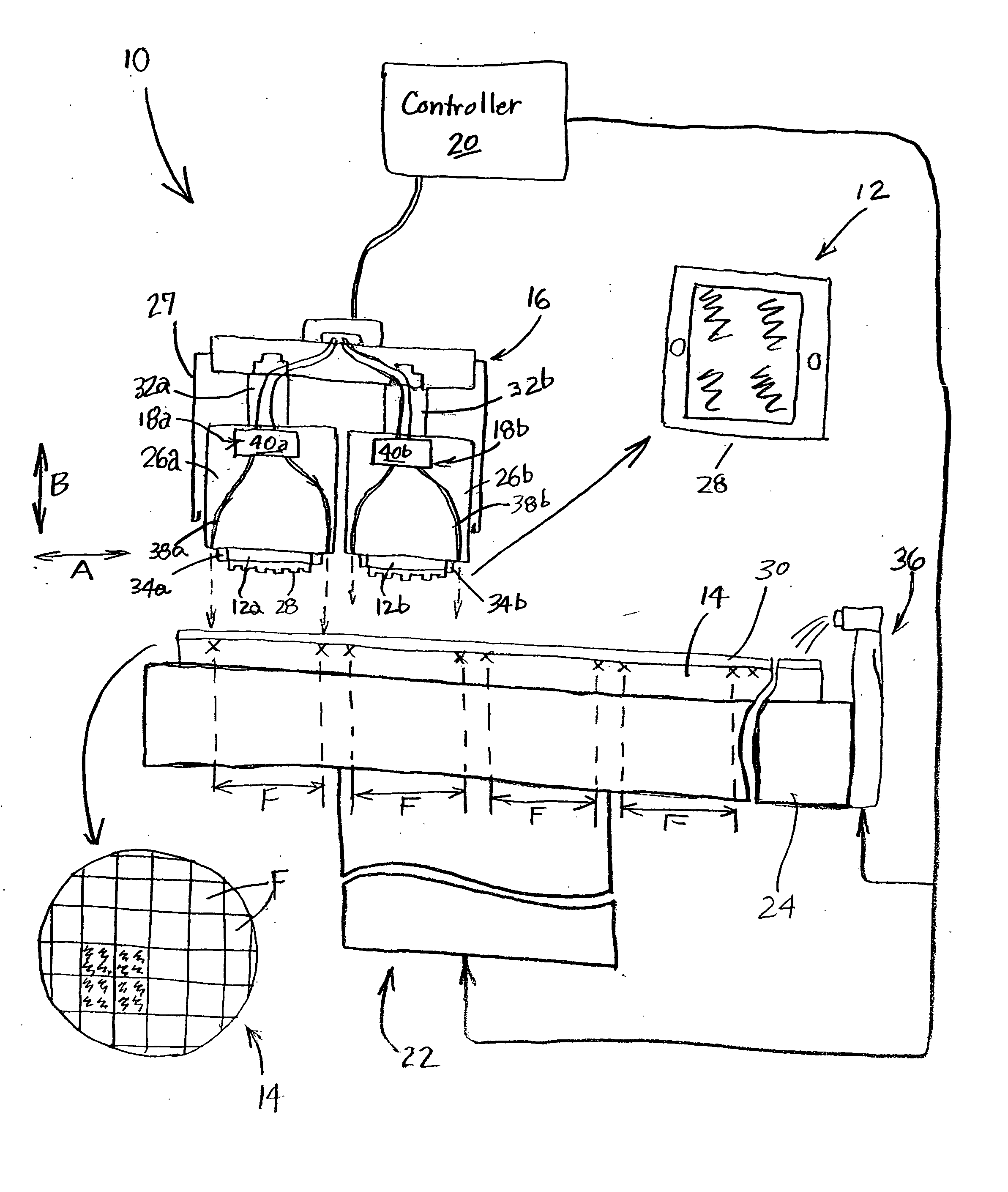

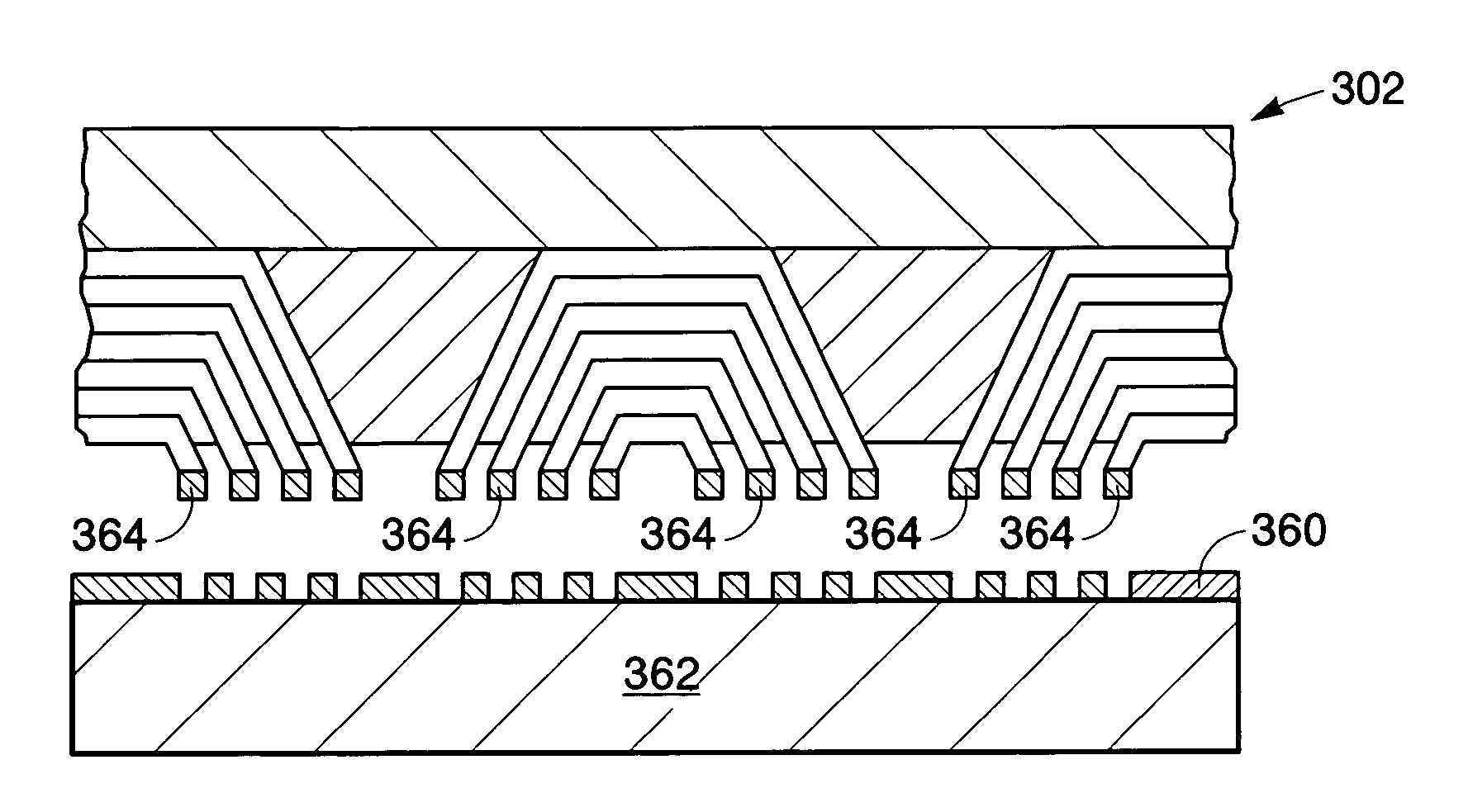

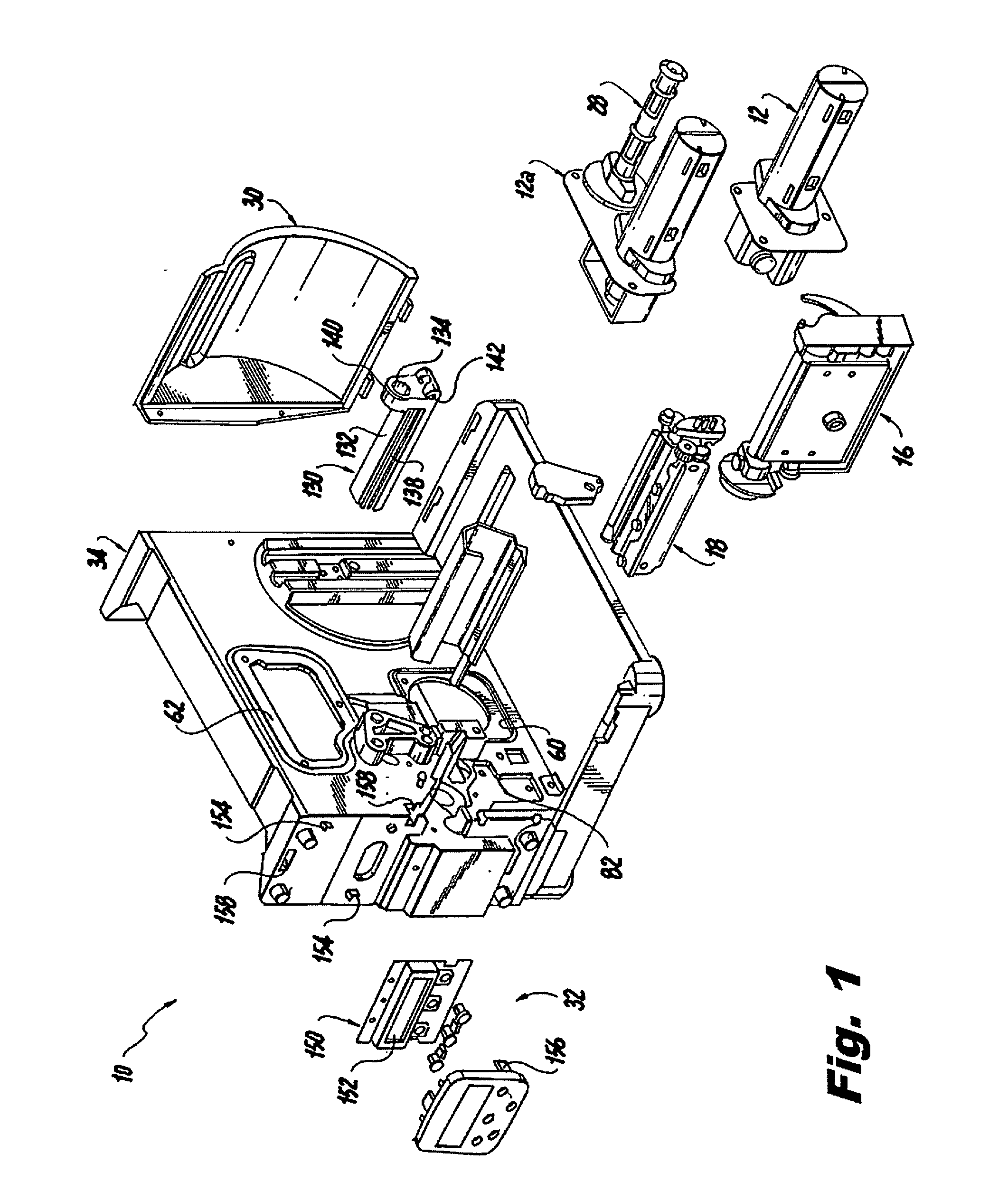

Method for rapid printing of near-field and imprint lithographic features

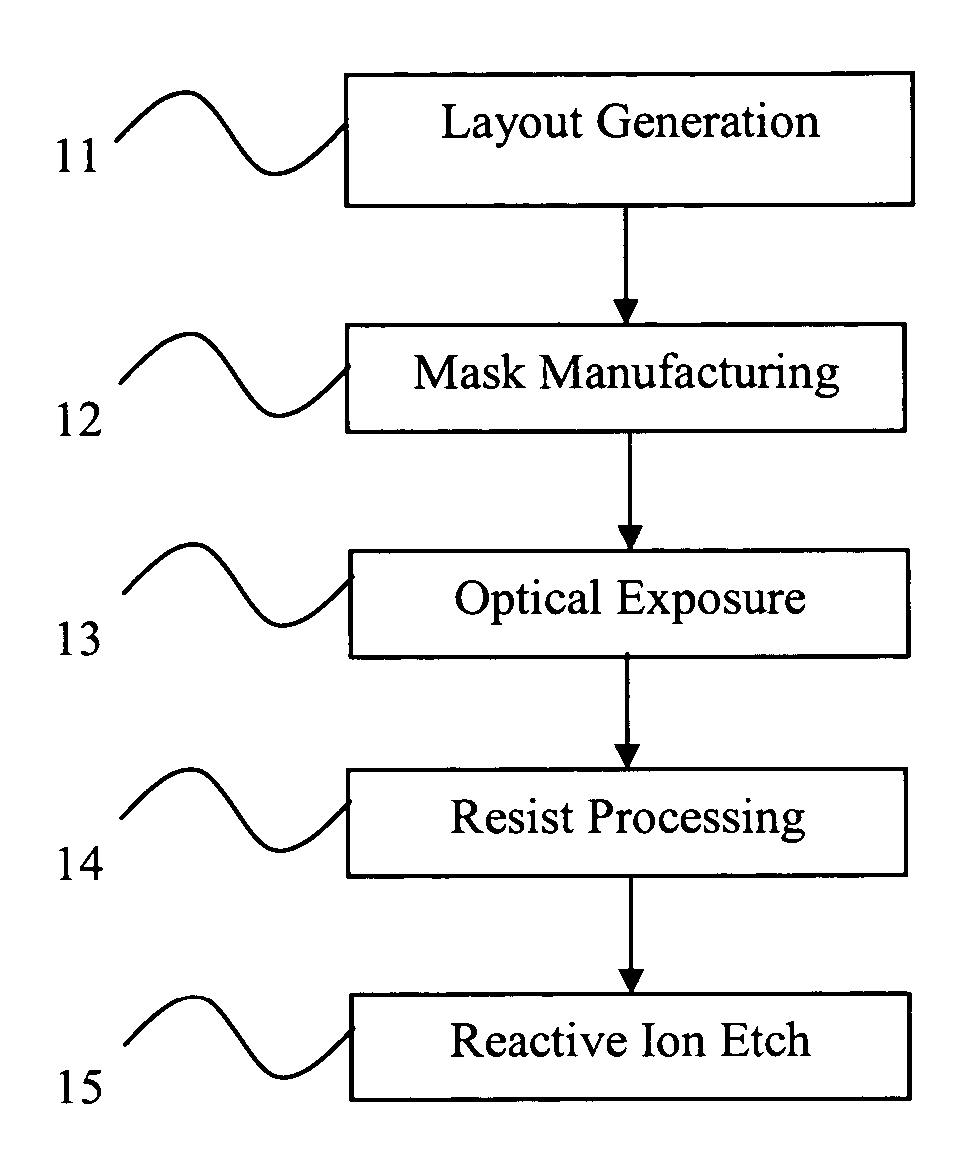

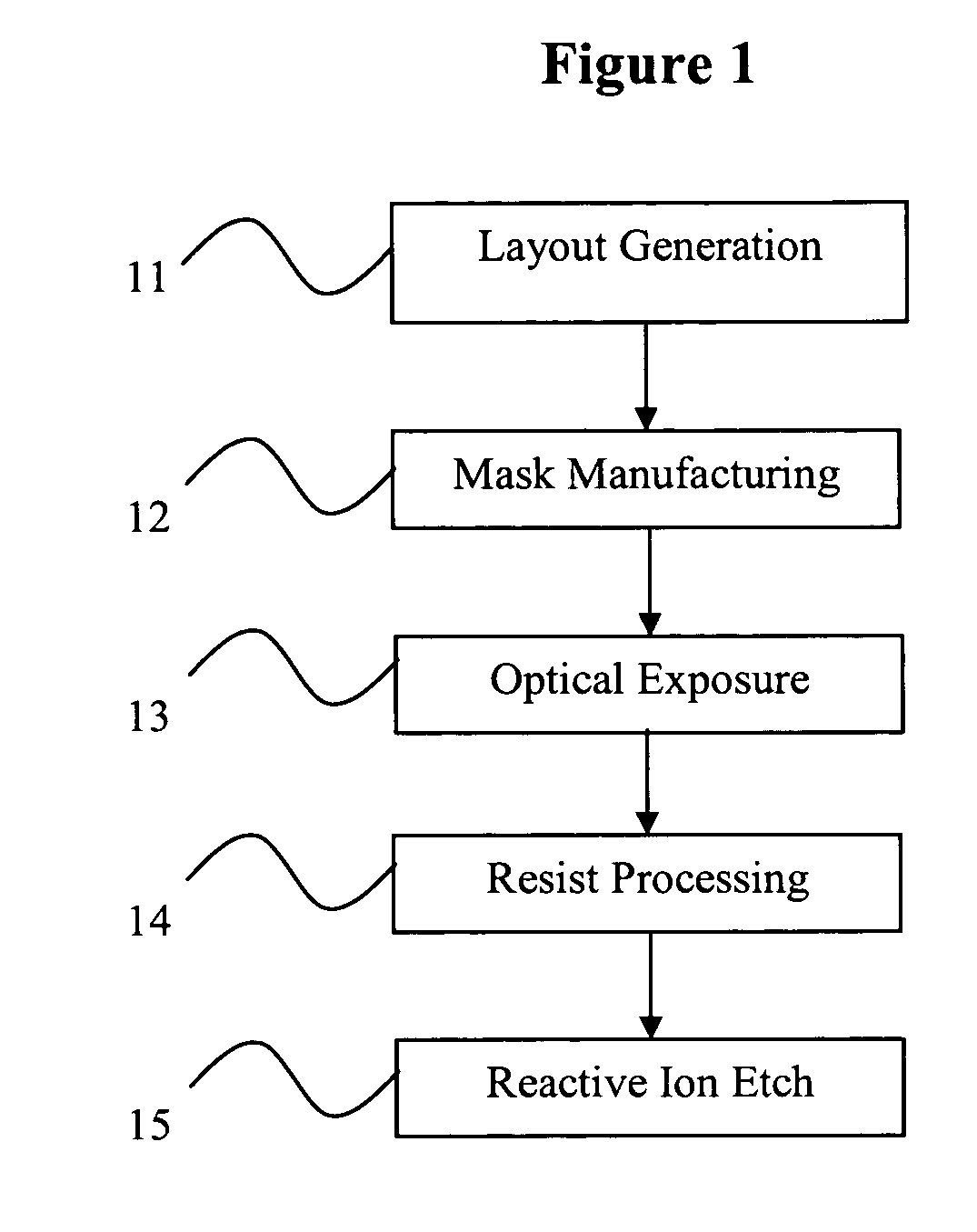

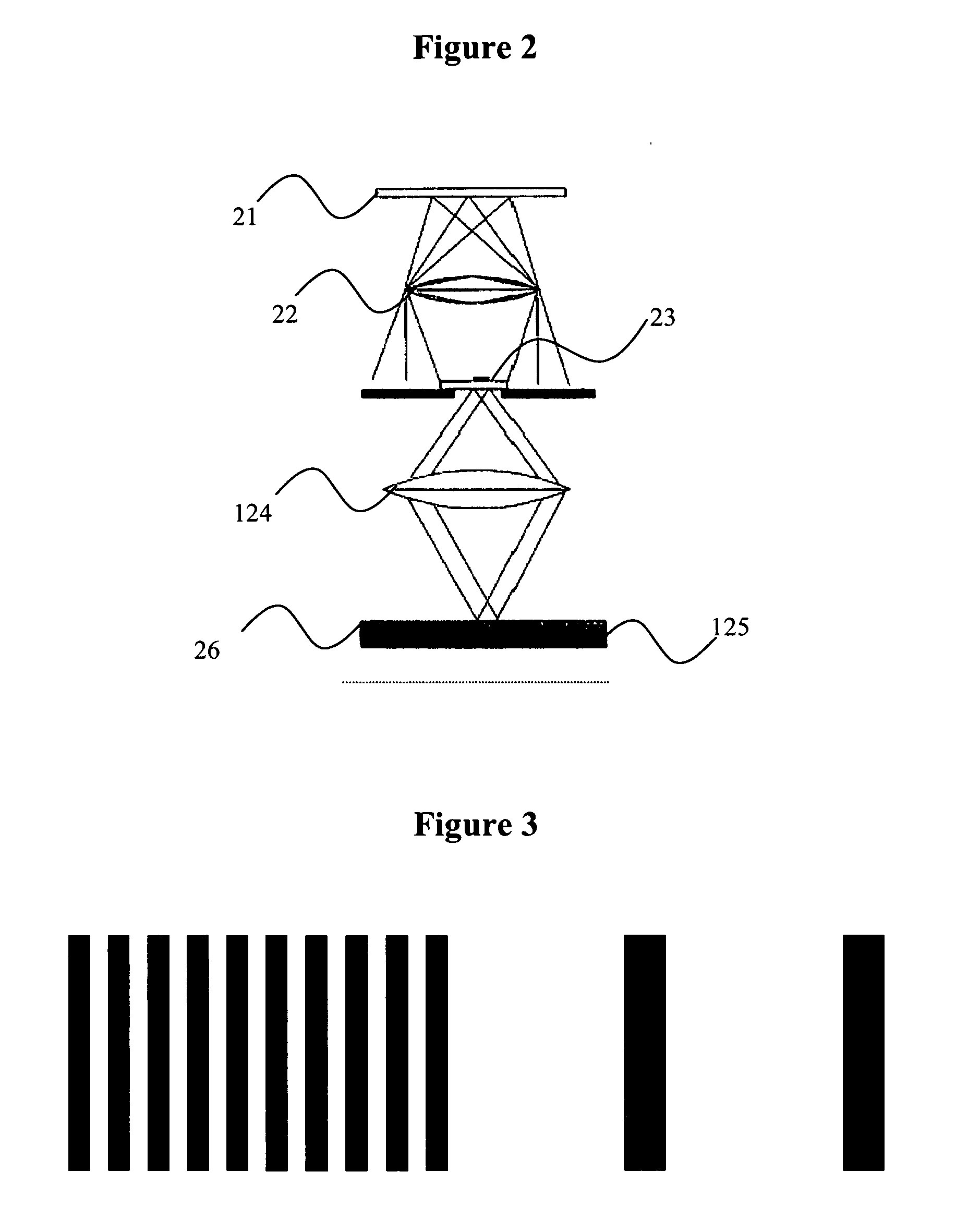

InactiveUS20070200276A1Improve throughputReduce processing timeNanoinformaticsConfectioneryEngineeringSoftware

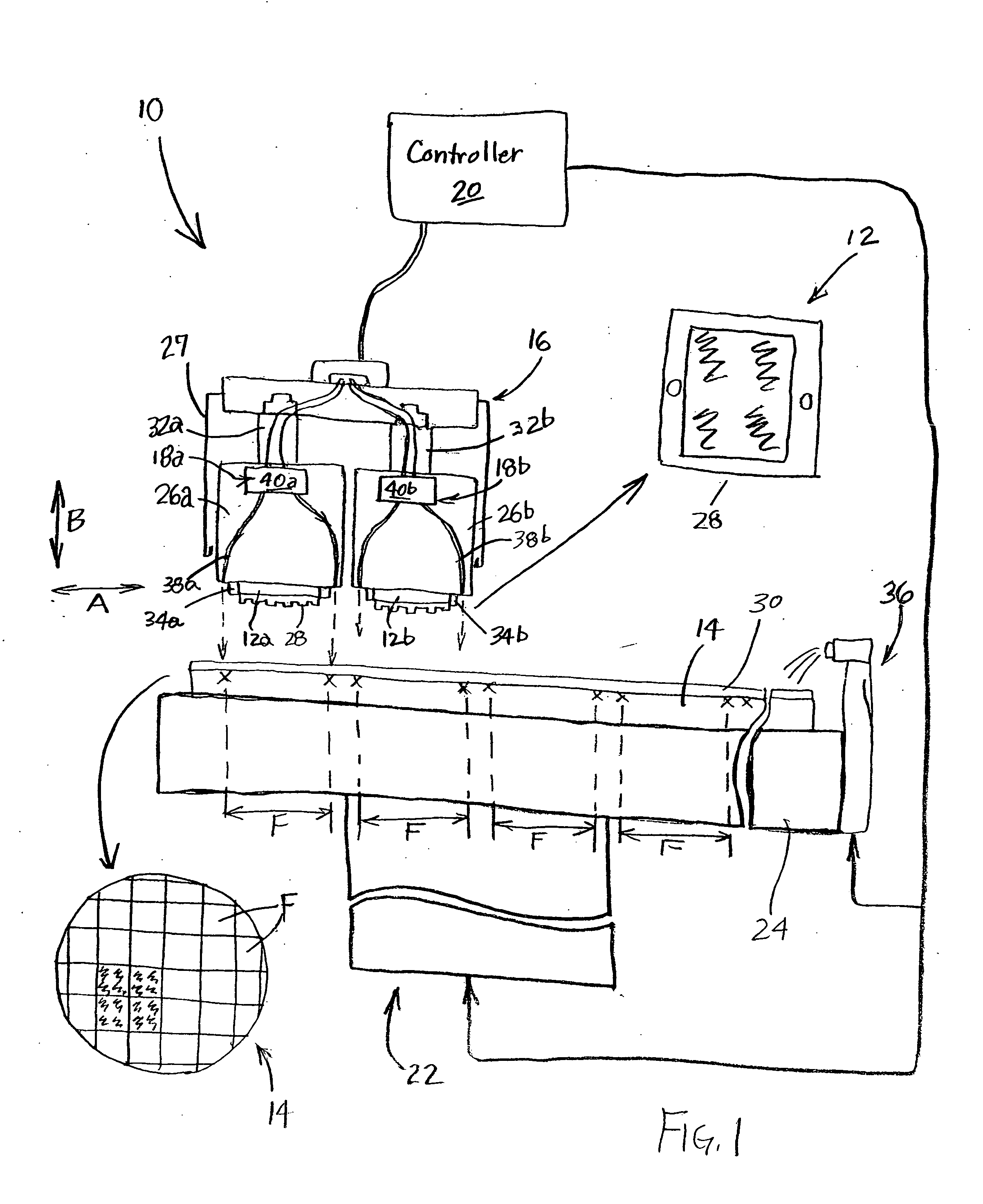

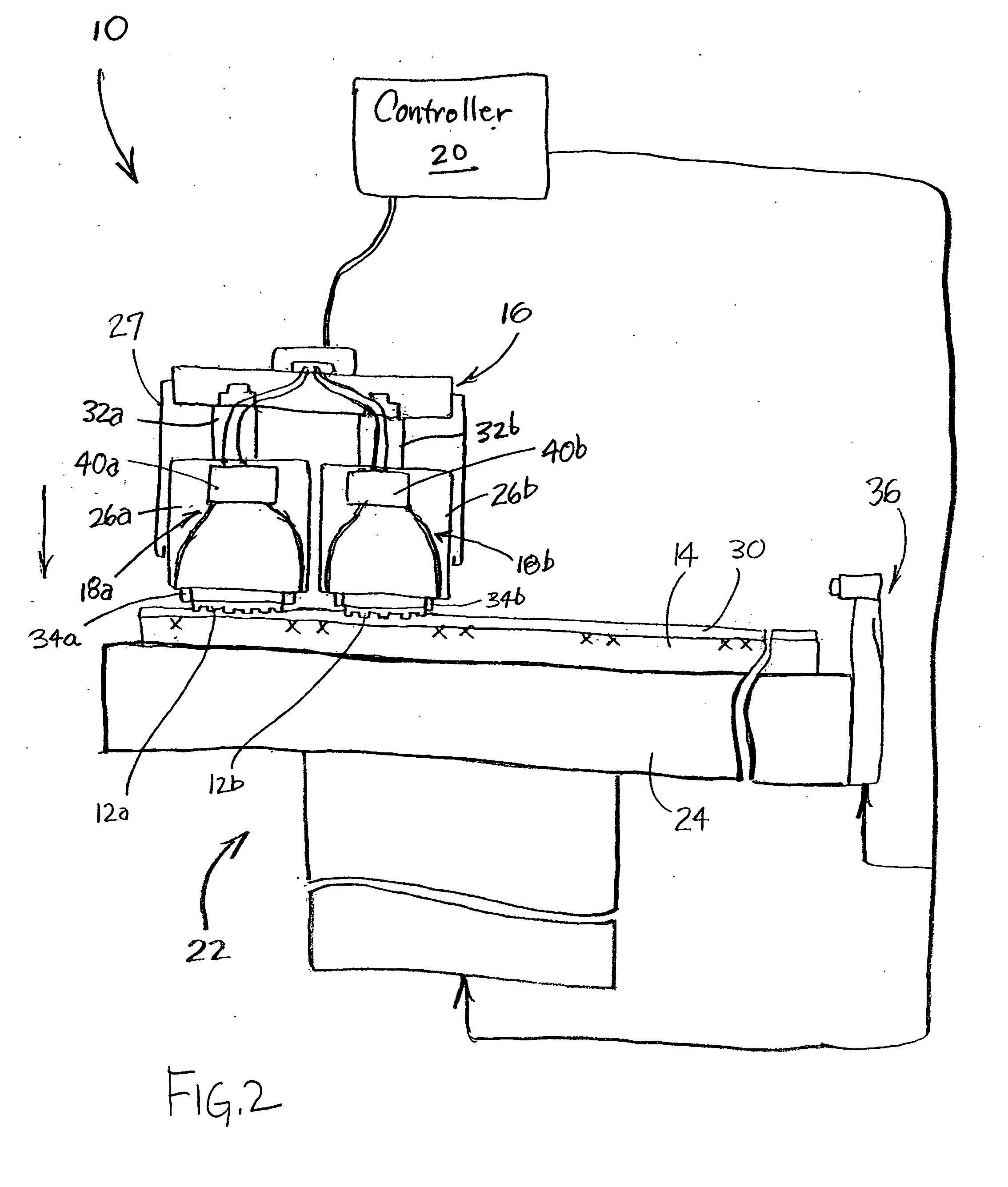

An apparatus, systems, and methods to print multiple fields on a substrate in parallel are provided. The apparatus incorporates a lithographic apparatus composed of two or more lithographic heads coupled to a common housing as a unit, with each head configured to hold a patterned template. Software can be utilized to keep track of what is printed at any given step, and conventional servometers can be used to reposition the head unit and templates in multiple steps to print the remainder of a wafer.

Owner:MICRON TECH INC

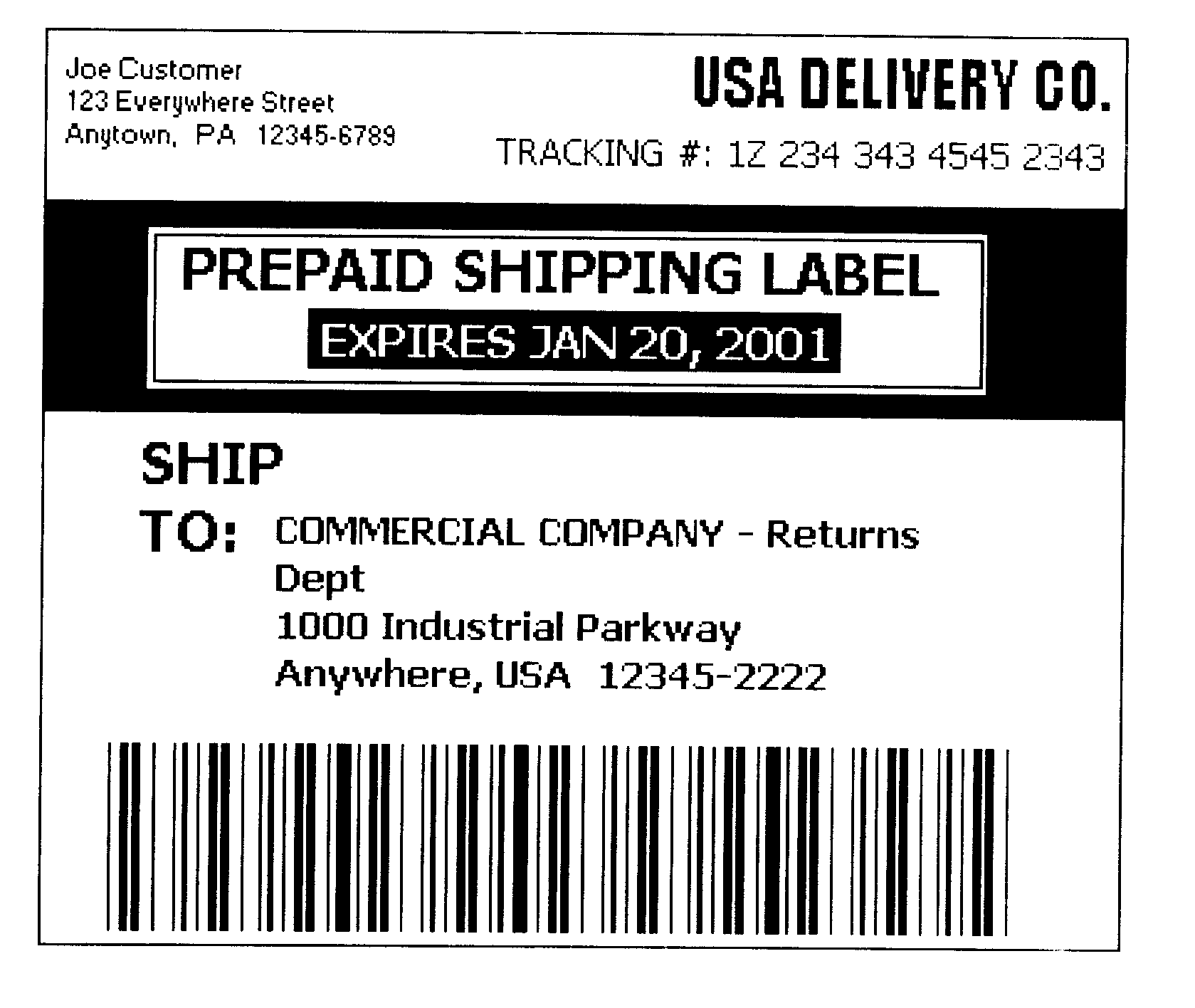

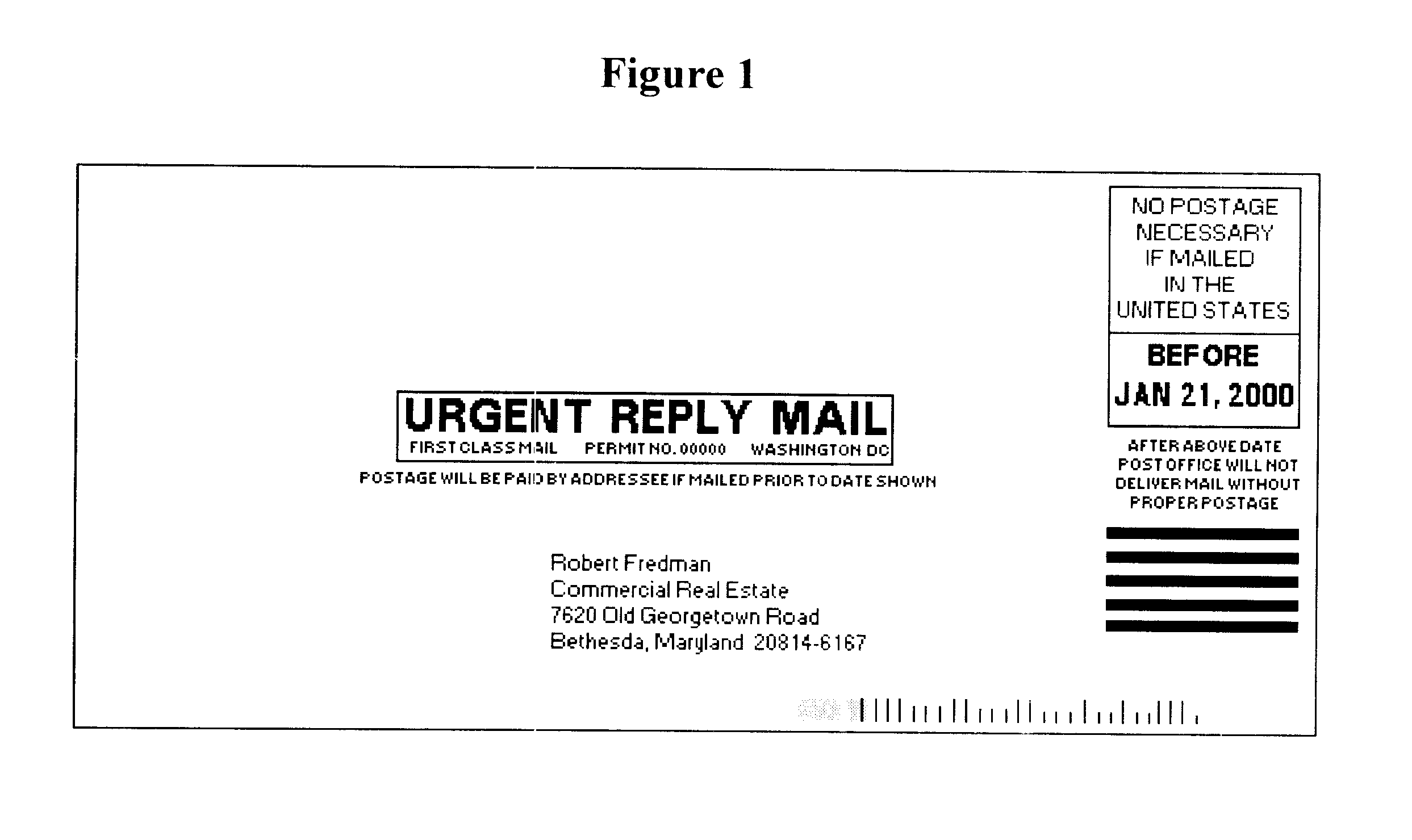

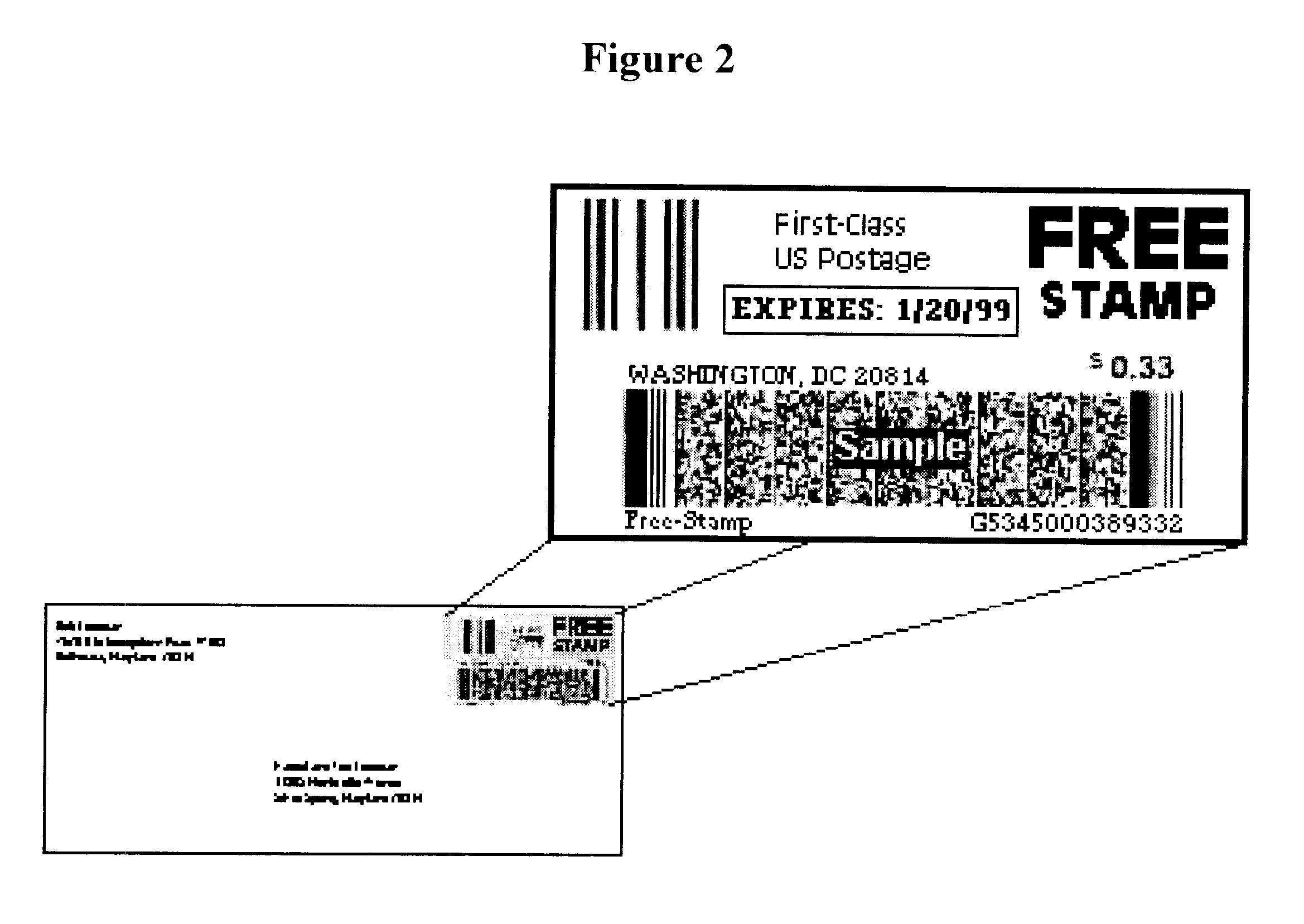

Time controlled pre-paid delivery

A method for generating, providing, and utilizing time controlled date sensitive pre-paid postage on an item to be delivered, including a desired delivery amount and personalized postage mark, with the intention of causing action prior to a chosen date. An Issuer would send prepaid postage to a Recipient with a chosen effective date and a chosen expiration date. Said effective date and expiration date would allow Issuer to encourage Recipients to initiate action within a predetermined time window. After effective expiration date, postage would expire requiring new postage / delivery fees to be added to the item for it to be mailed / delivered.

Owner:FREDMAN ROBERT ALAN

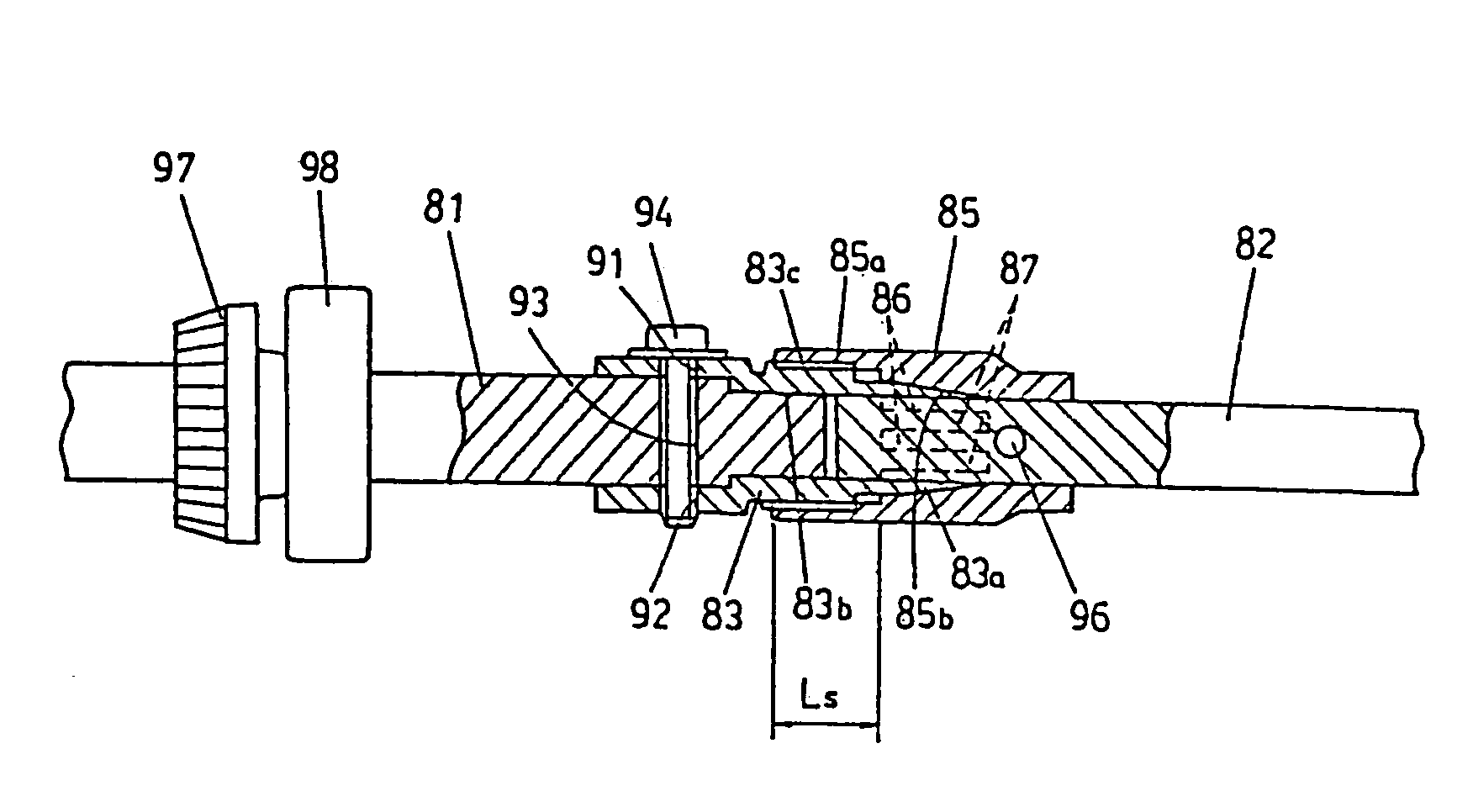

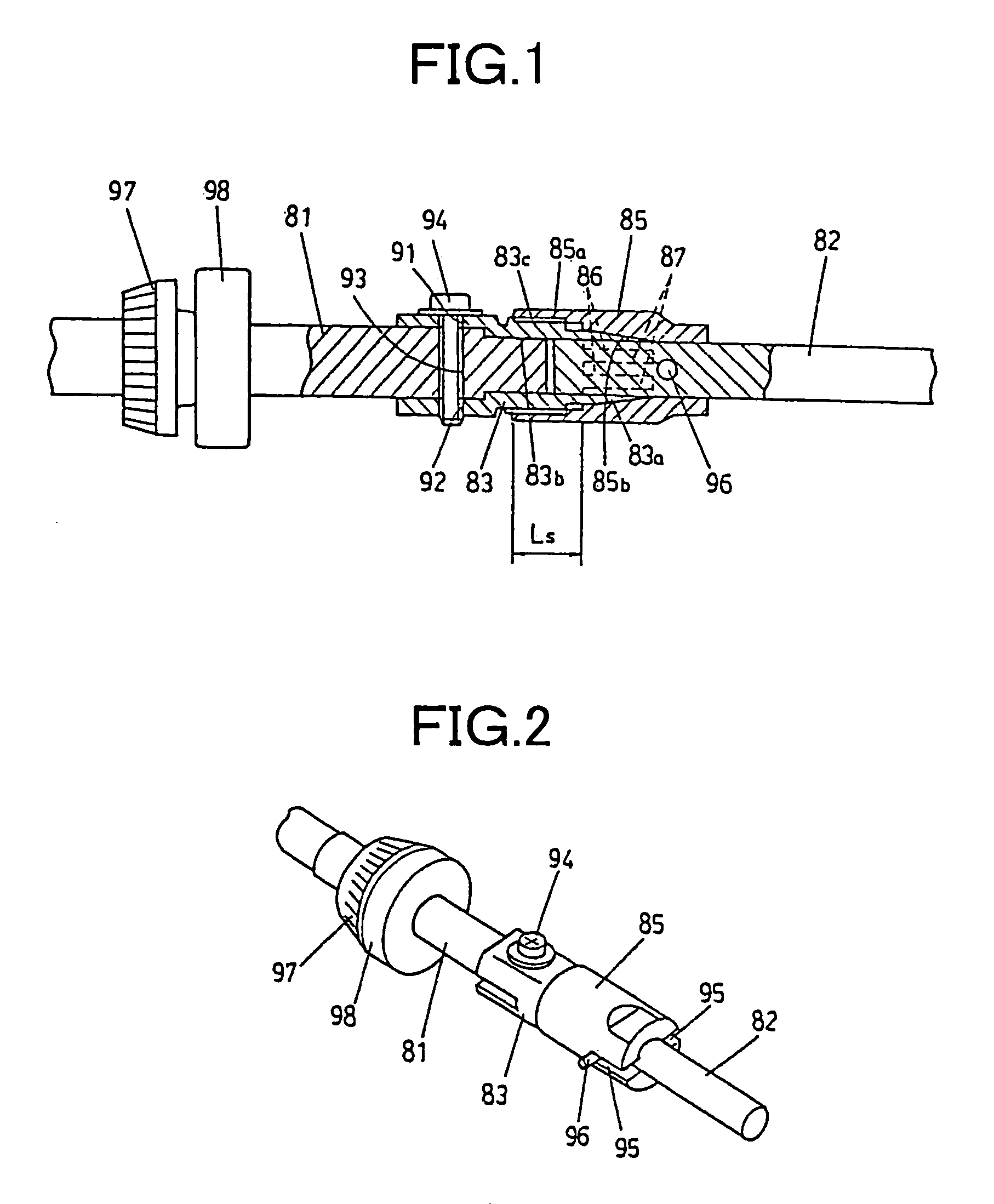

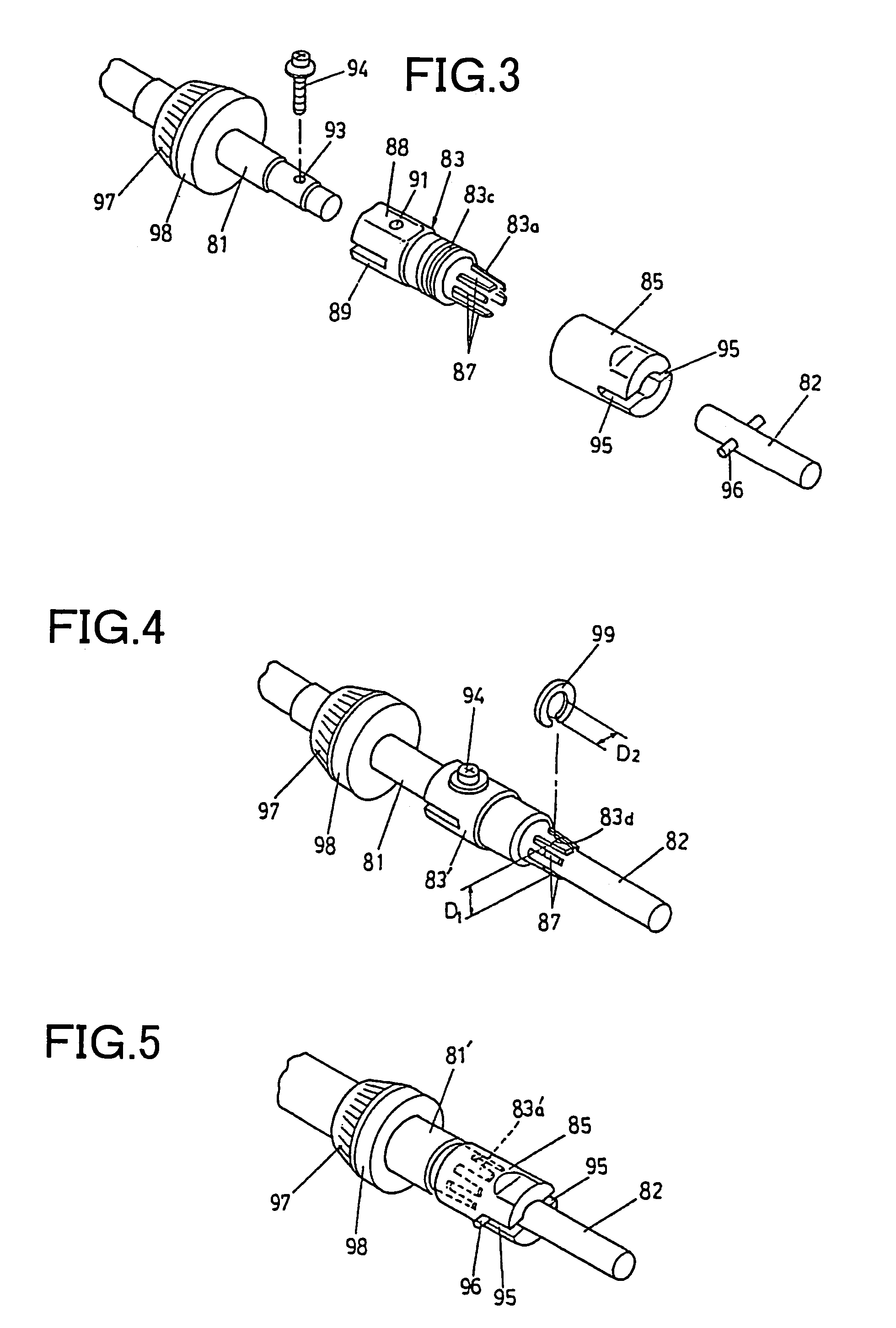

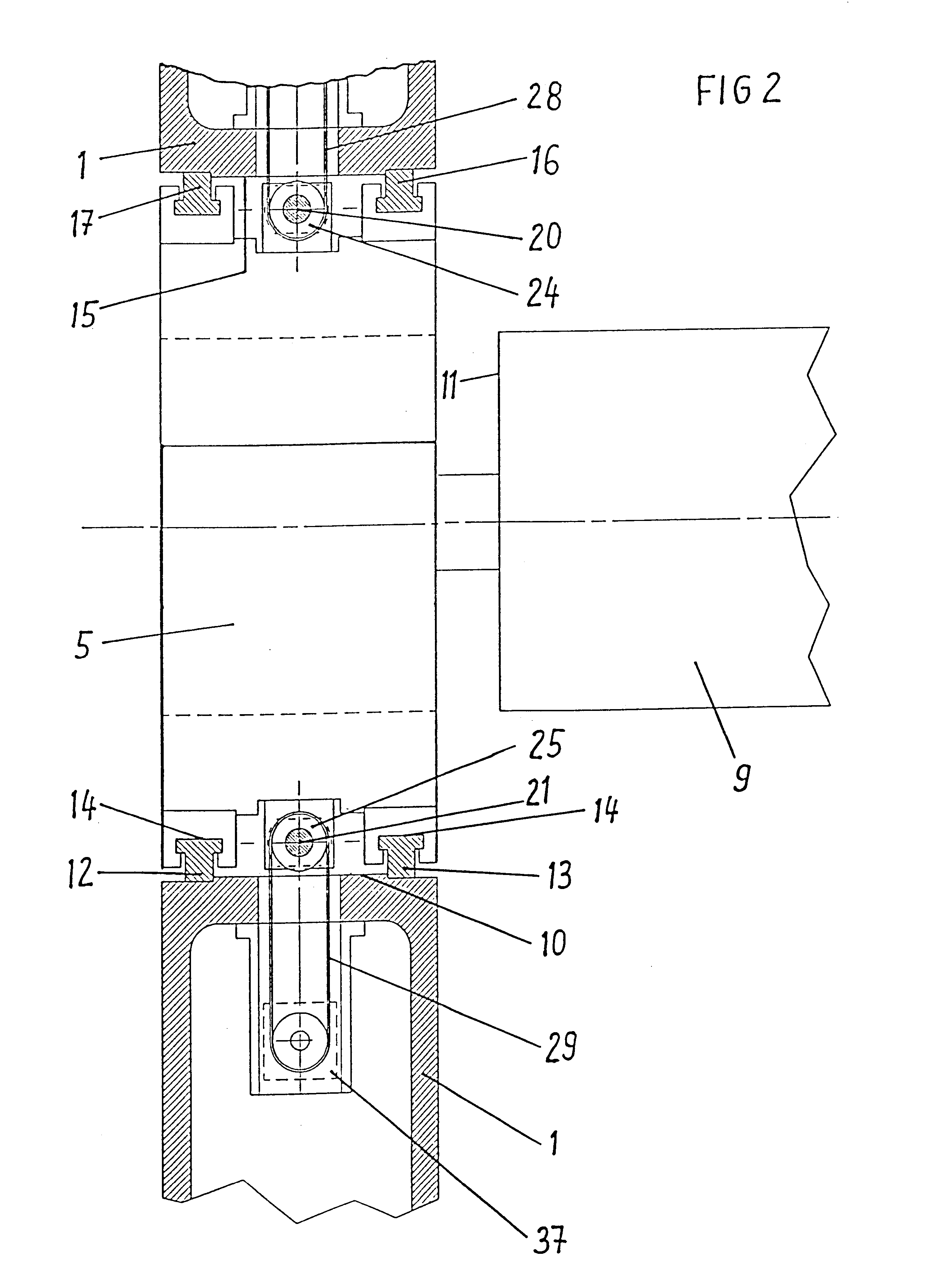

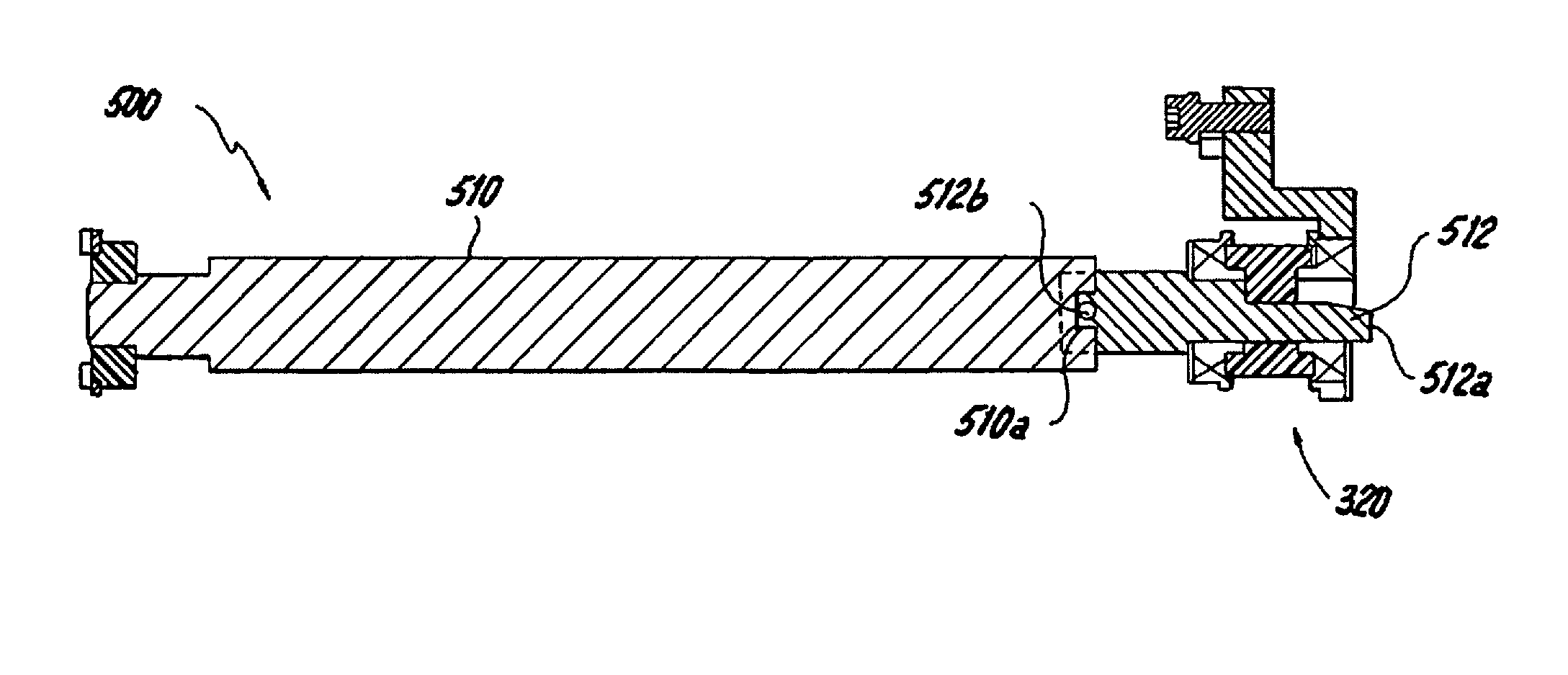

Device for and method of coupling shafts, image formation apparatus, process cartridge, and belt unit

A shaft coupling device for coupling a first shaft and a second shaft together includes a grip unit to be attached to the first shaft and including a grip portion configured to grip the second shaft, the grip portion having an end with notches of a length being parallel with an axial direction of the first shaft. The shaft coupling device also includes a grip force acting unit to be attached to the second shaft and configured to cause a grip force for gripping the second shaft to act on the grip portion by moving the grip portion in a radial direction of the second shaft.

Owner:RICOH KK

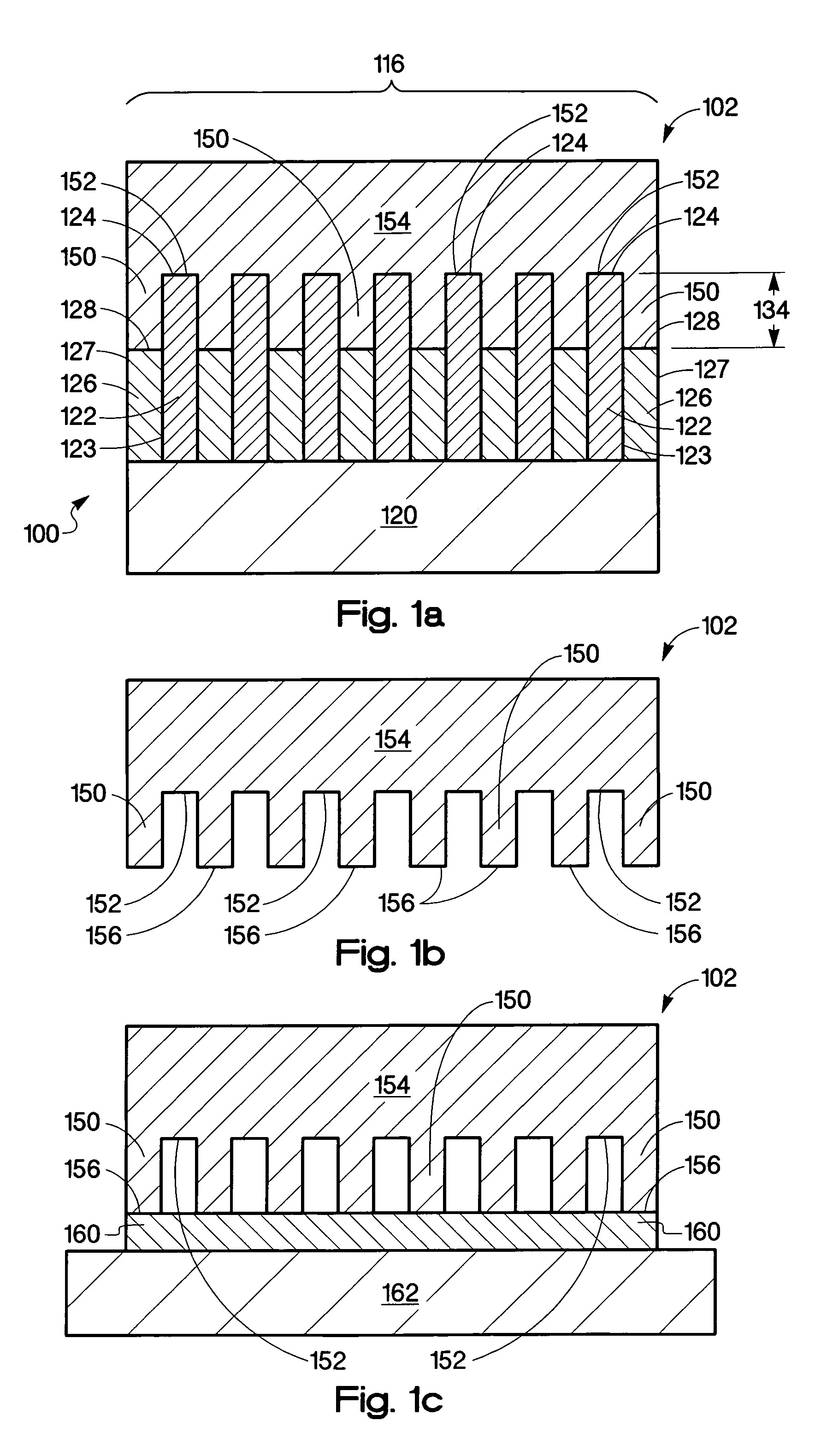

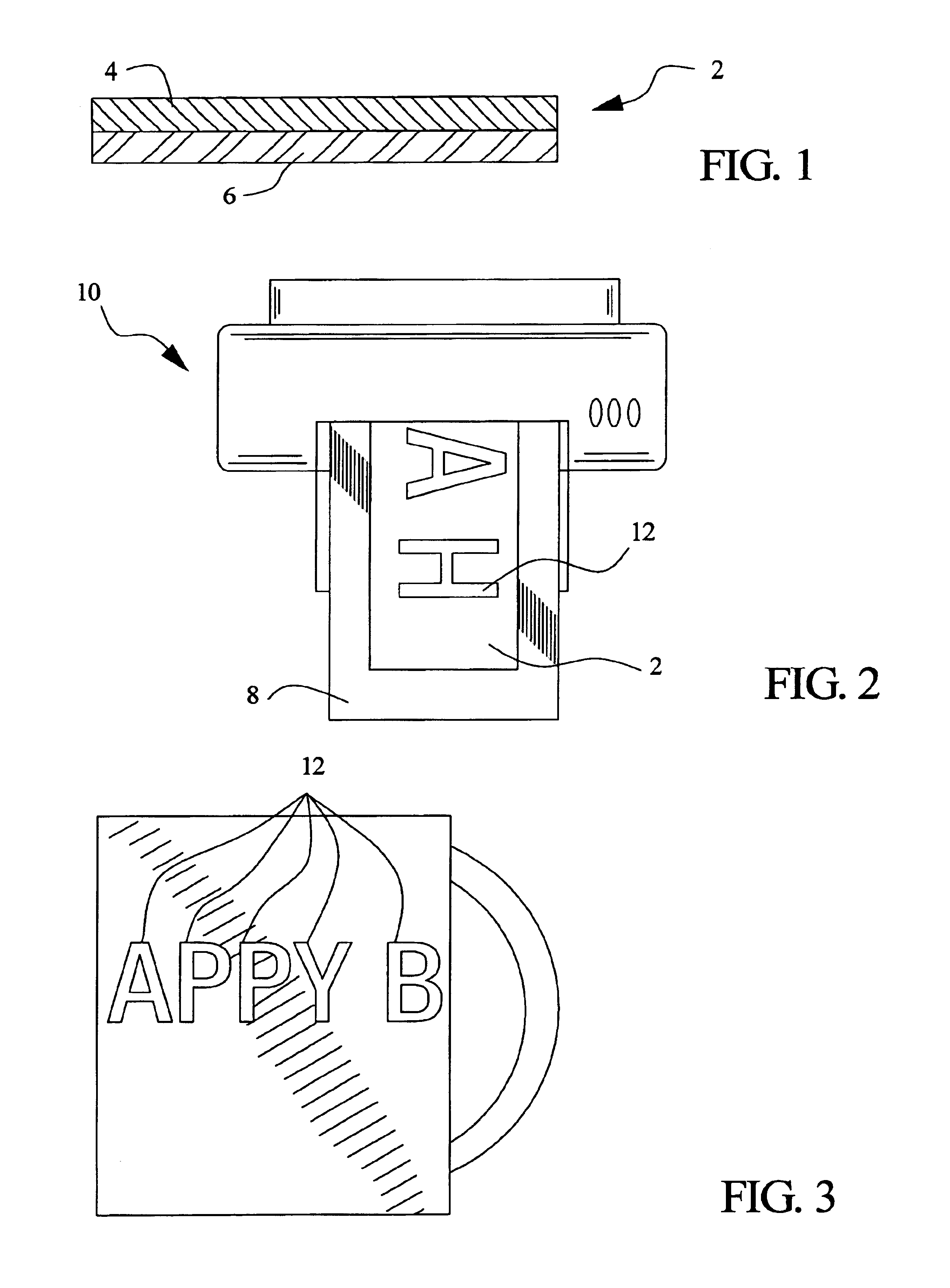

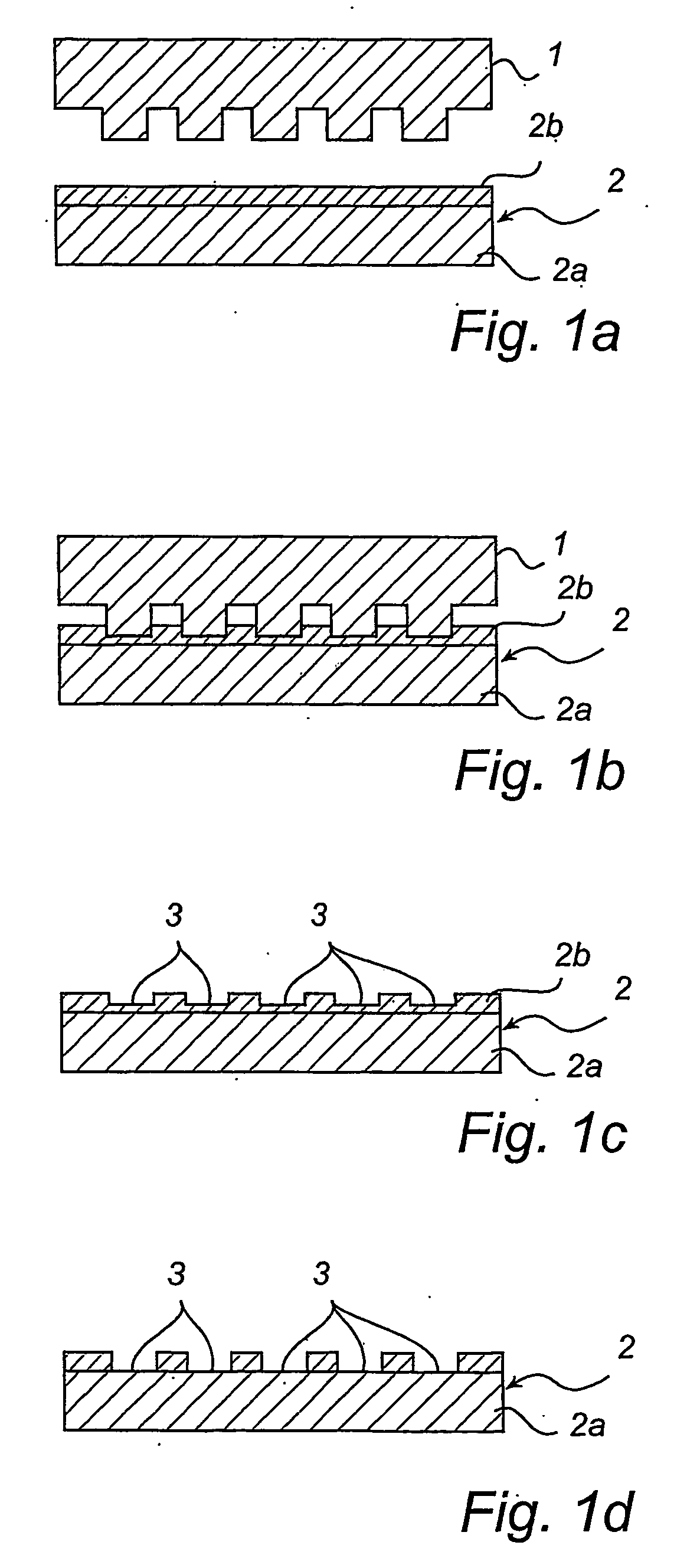

Method of utilizing a contact printing stamp

ActiveUS7374968B2AddressographsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A method of using a contact printing stamp, including forming a transfer material on a plurality of stamping surfaces. The plurality of stamping surfaces are disposed on a plurality of stamp protrusions adapted from the forming of a stamp material in a plurality of recessed regions formed in an exposed end-region of a multilayer thin film structure.

Owner:SAMSUNG ELECTRONICS CO LTD

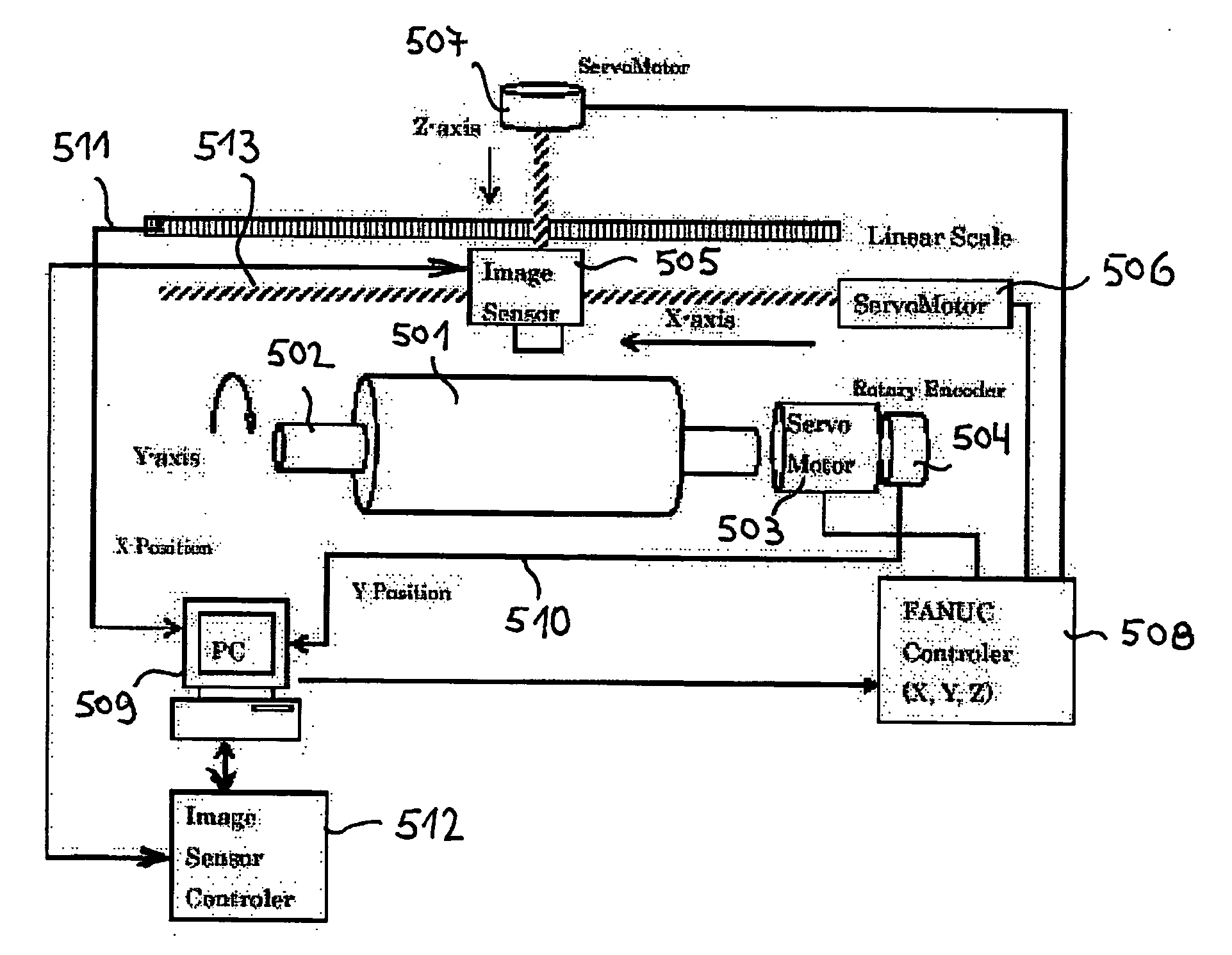

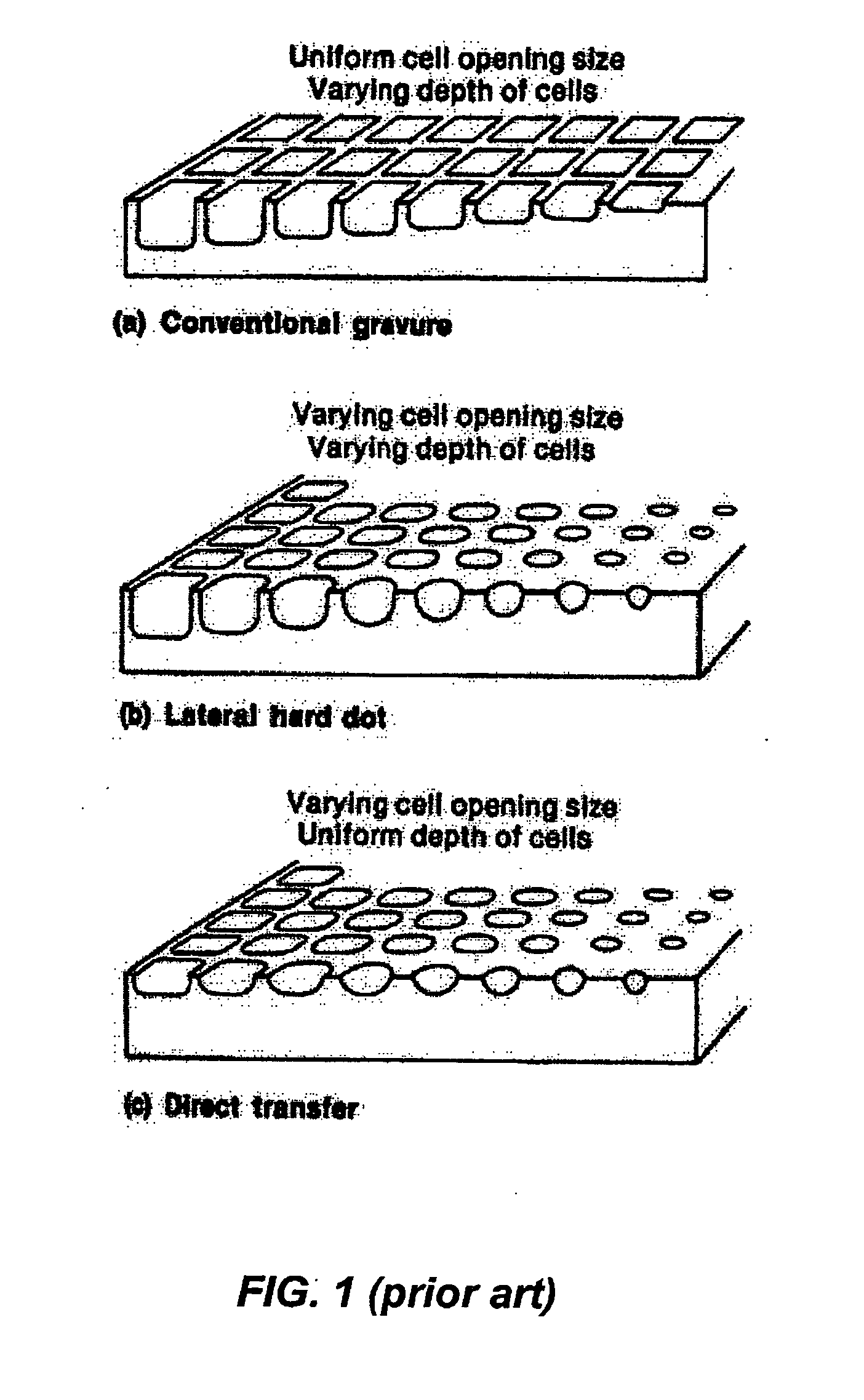

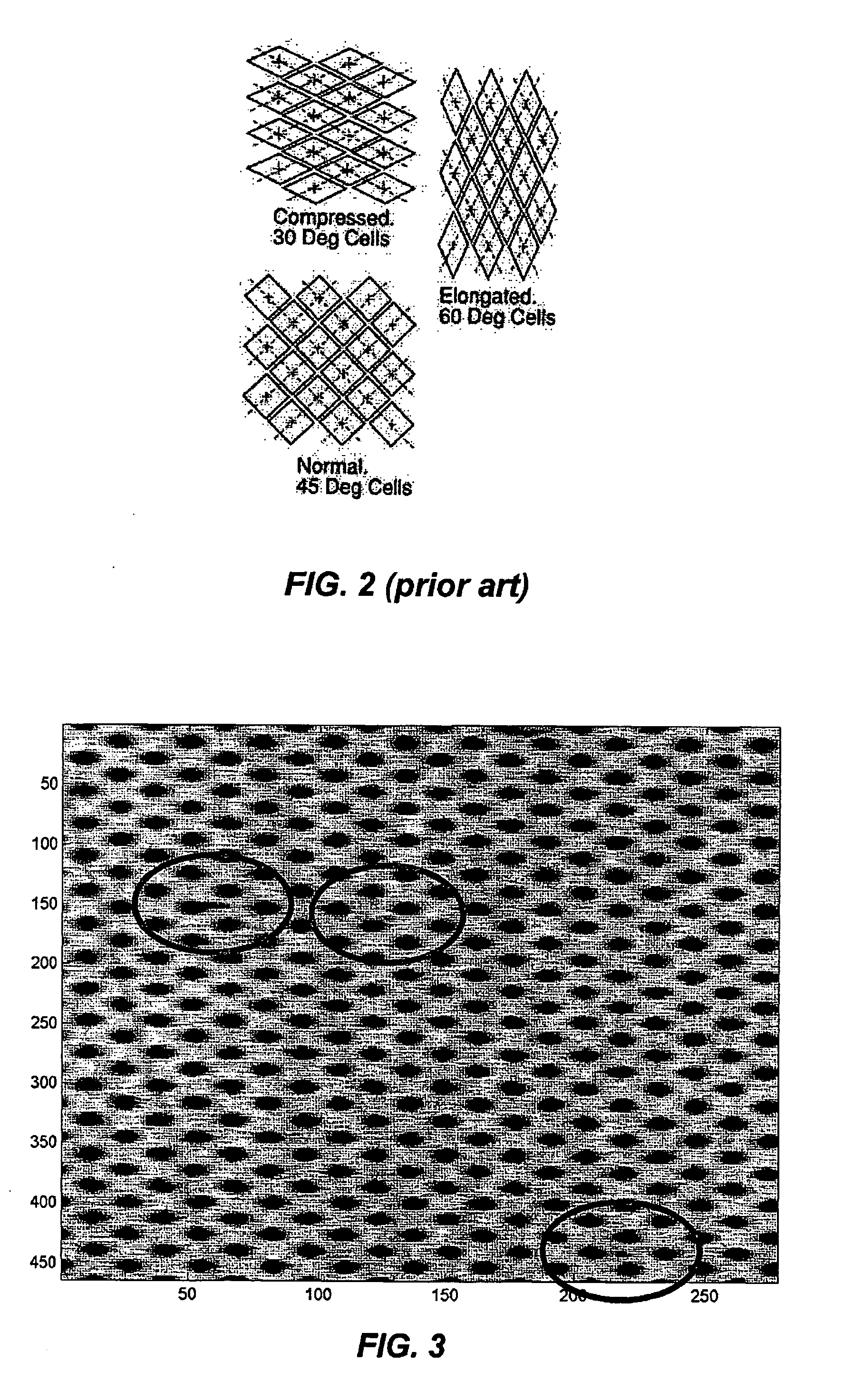

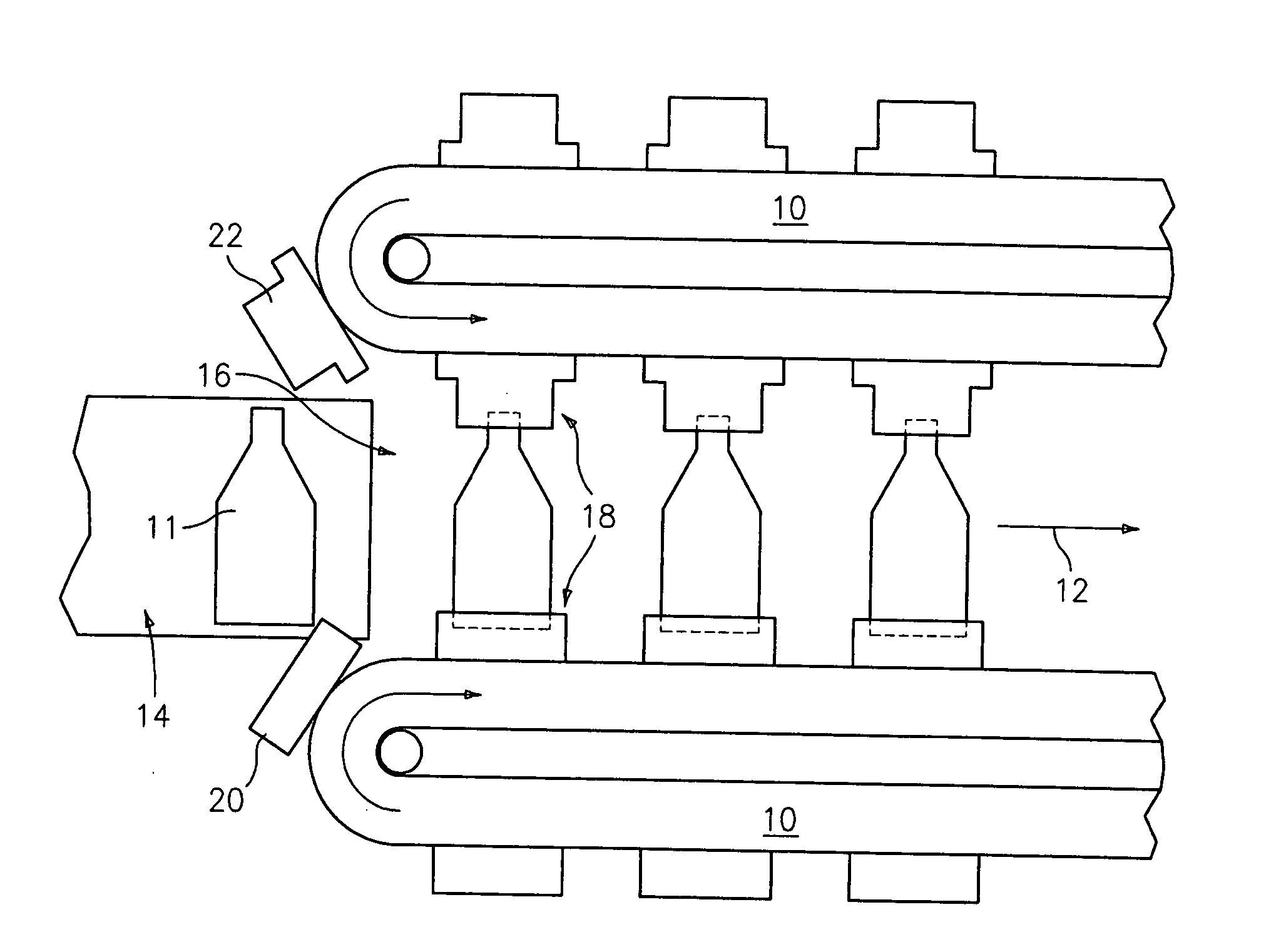

Method and system for detecting defects during the fabrication of a printing cylinder

The invention relates generally to the field of printing. More specifically, the invention relates to a method and system for automatically detecting defects in a printing cylinder during its fabrication process. The invention further relates to a process for fabricating a printing cylinder.

Owner:ELBIT VISION SYST

Printing plastic containers with digital images

A method for printing digital images on plastic containers having curved surfaces, including providing a series of hollow plastic containers, moving the containers along a track past first and second digital printing locations, and printing first and second digital images on the curved container surfaces while maintaining the container being printed under internal pressure and while firmly holding the container being printed at spaced locations thereon.

Owner:PLASTIPAK PACKAGING

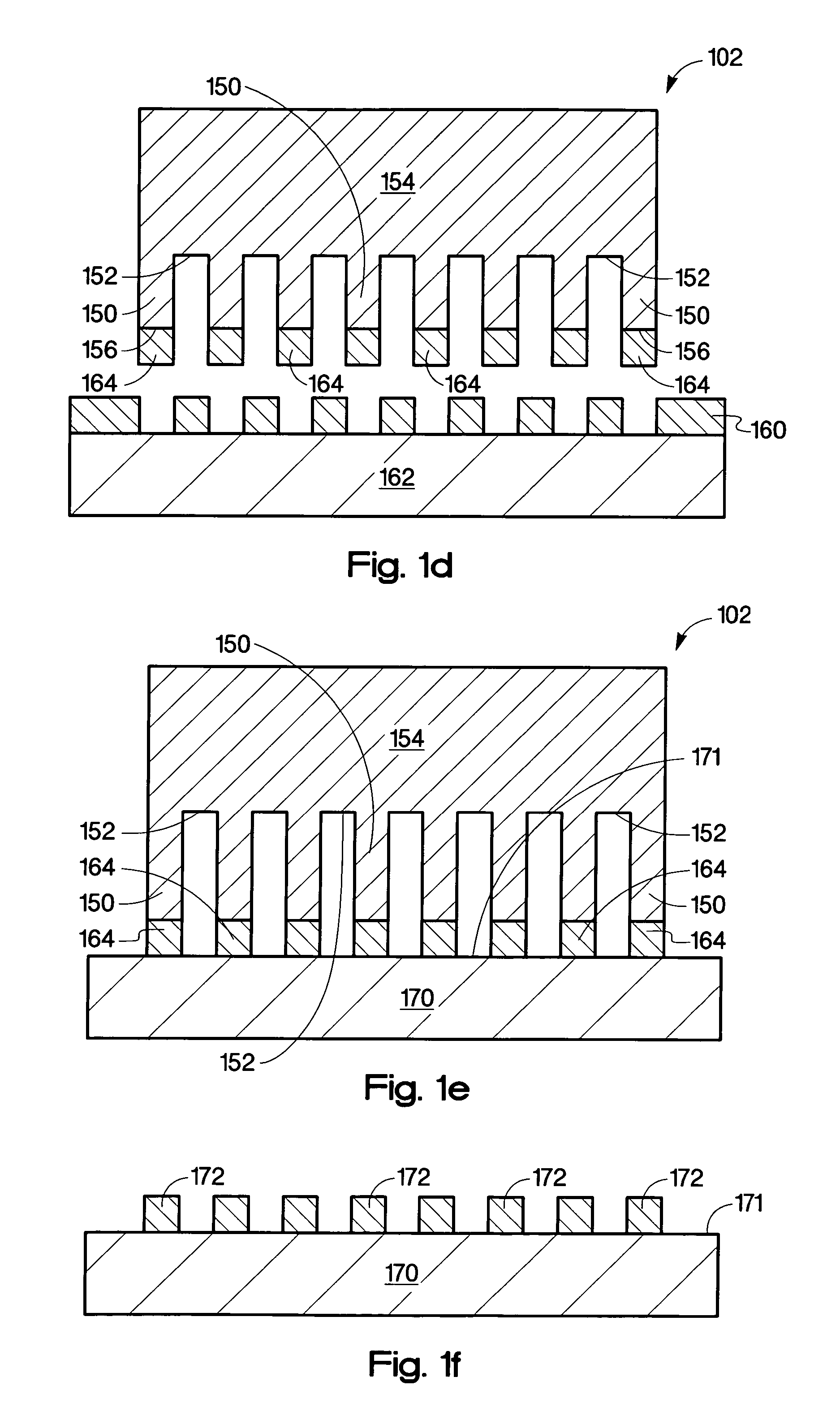

Stamp having an antisticking layer and a method of forming of repairing such a stamp

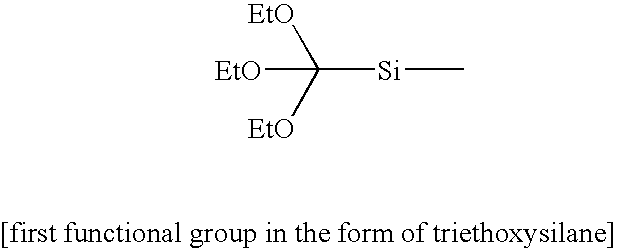

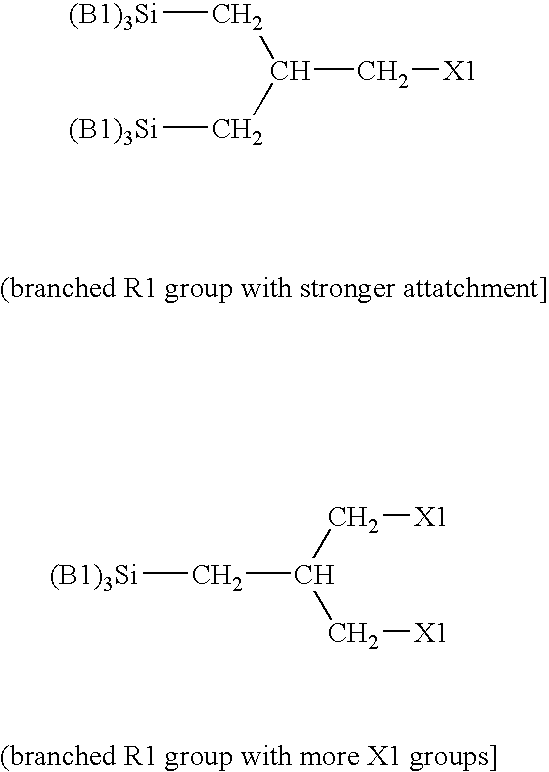

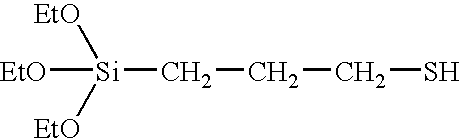

InactiveUS20050039618A1Good effectStable antisticking layerNanoinformaticsPhotomechanical apparatusCouplingNanoscopic scale

A stamp for use in transferring a pattern in nano-scale has a monomolecular antisticking layer. The anti-sticking layer comprises molecular chains, which are covalently bound to the surface of the stamp and which each comprise at least one fluorine-containing group. Each molecular chain contains a group Q, which comprises a bond which is weaker than the other bonds in the molecular chain as well as the covalent bond that binds the molecular chain to the surface of the stamp. Splitting of said bond in the group Q creates a group Q1, which is attached to the part of the molecular chain being left on the surface of the stamp and which is capable of reacting with a fluorine-containing compound to restore the antisticking layer. In a method of manufacturing a stamp for use in transferring a pattern in nanoscale, the stamp is provided with the above-mentioned molecular chain. In a method of repairing a damaged antisticking layer of the above-mentioned stamp, the stamp is treated with a repairing reagent, which has a coupling end, which is capable of reacting with the group Q1, and a fluorine-containing group located at the other end of the repairing reagent.

Owner:OBDUCAT AB SE

Calibration on wafer sweet spots

A method for generating an OPC model is provided which takes into consideration across-wafer variations which occur during the process of manufacturing semiconductor chips. More particularly, a method for generating an OPC model is provided which takes into consideration across-wafer variations which occur during the process of manufacturing semiconductor chips based on the parameters of test patterns measured at the “wafer sweet spots” so as to arrive at an accurate model.

Owner:CADENCE DESIGN SYST INC

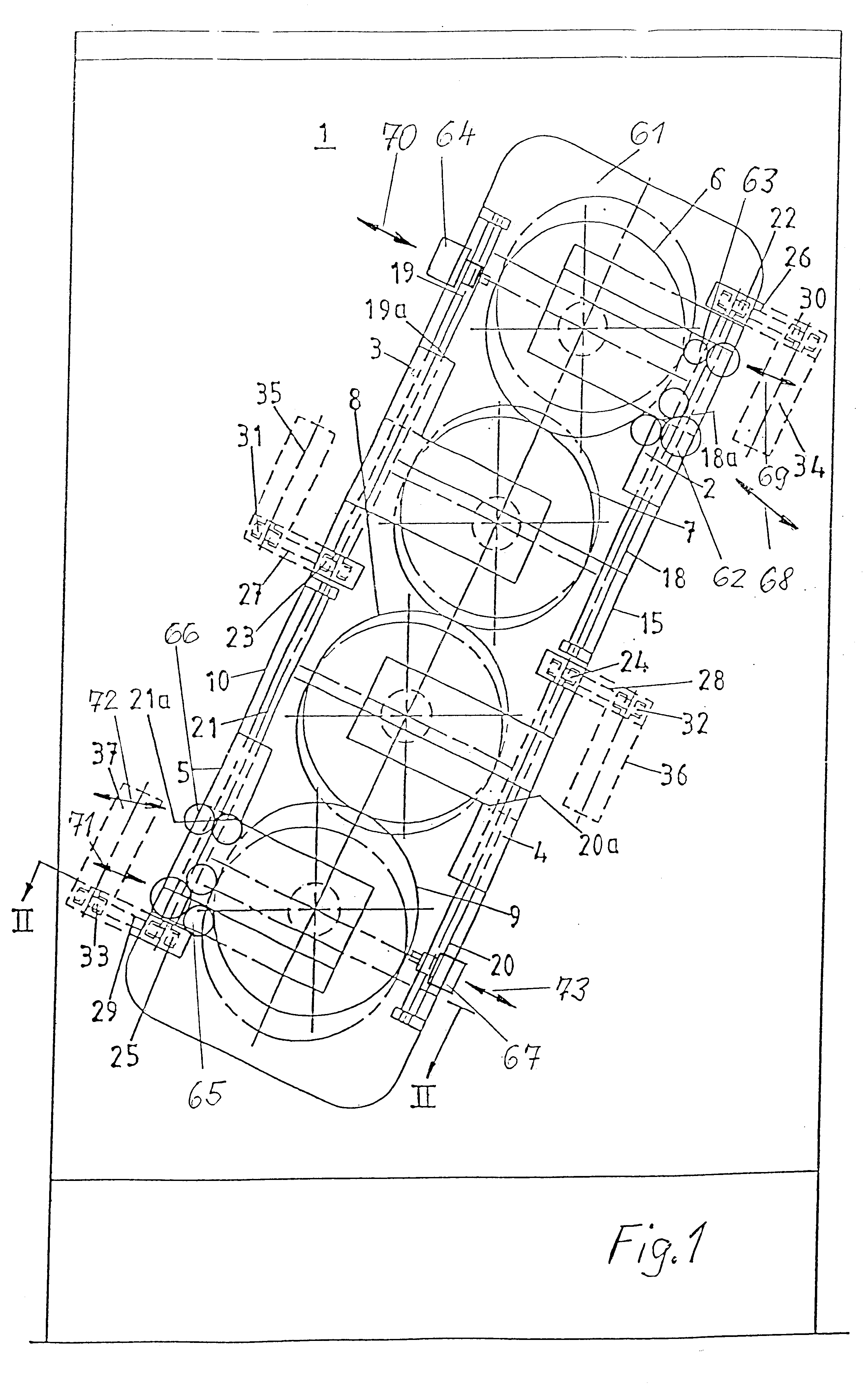

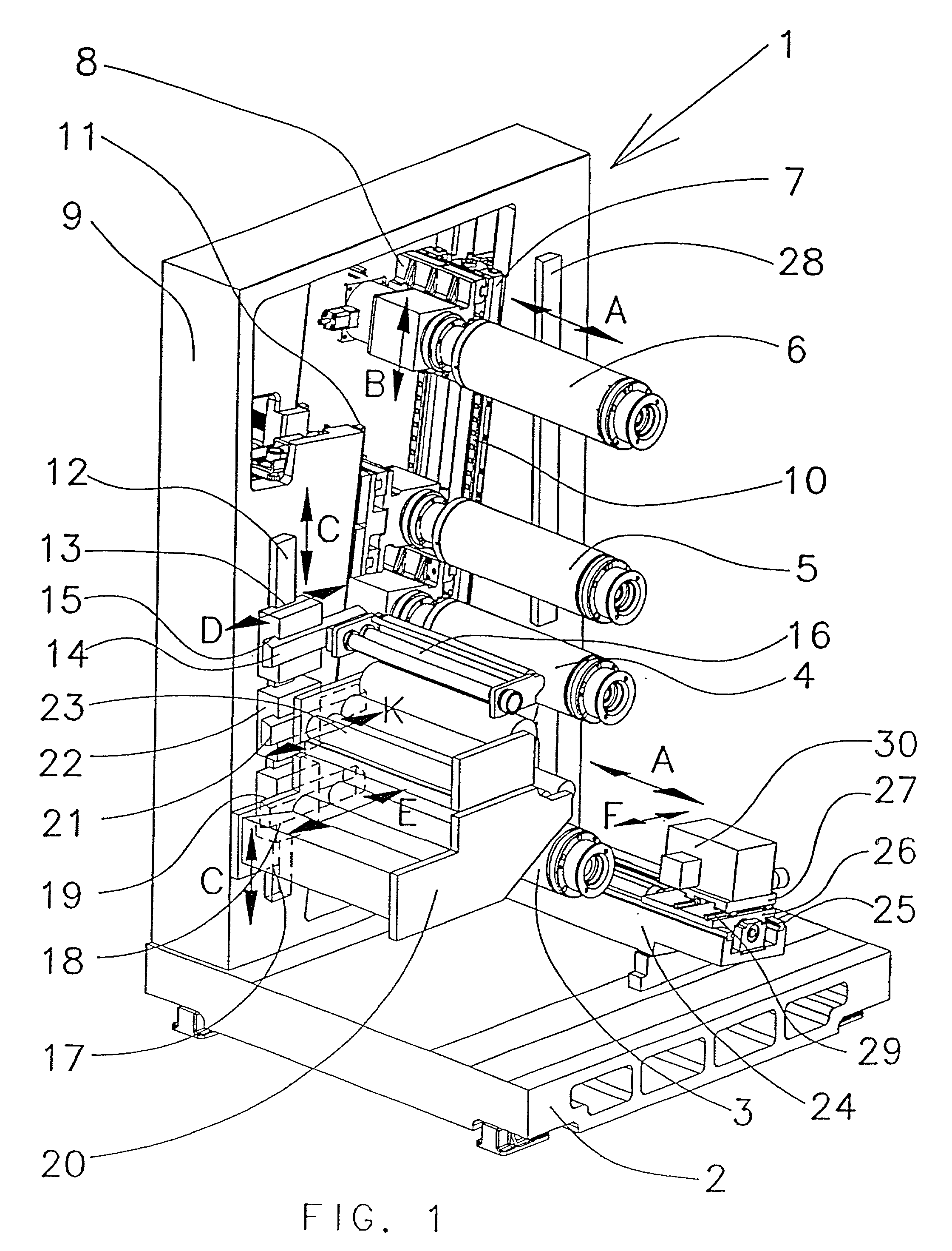

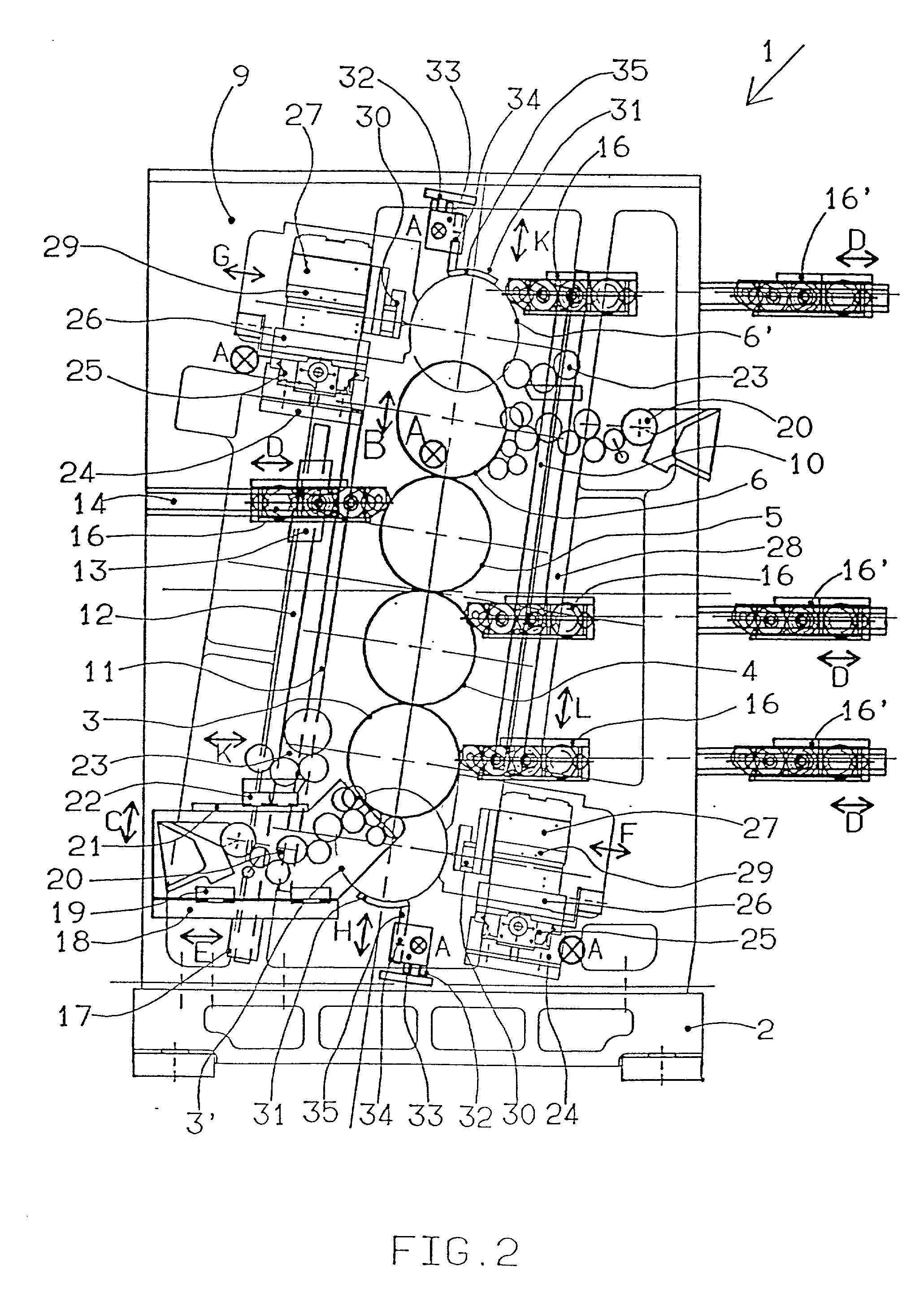

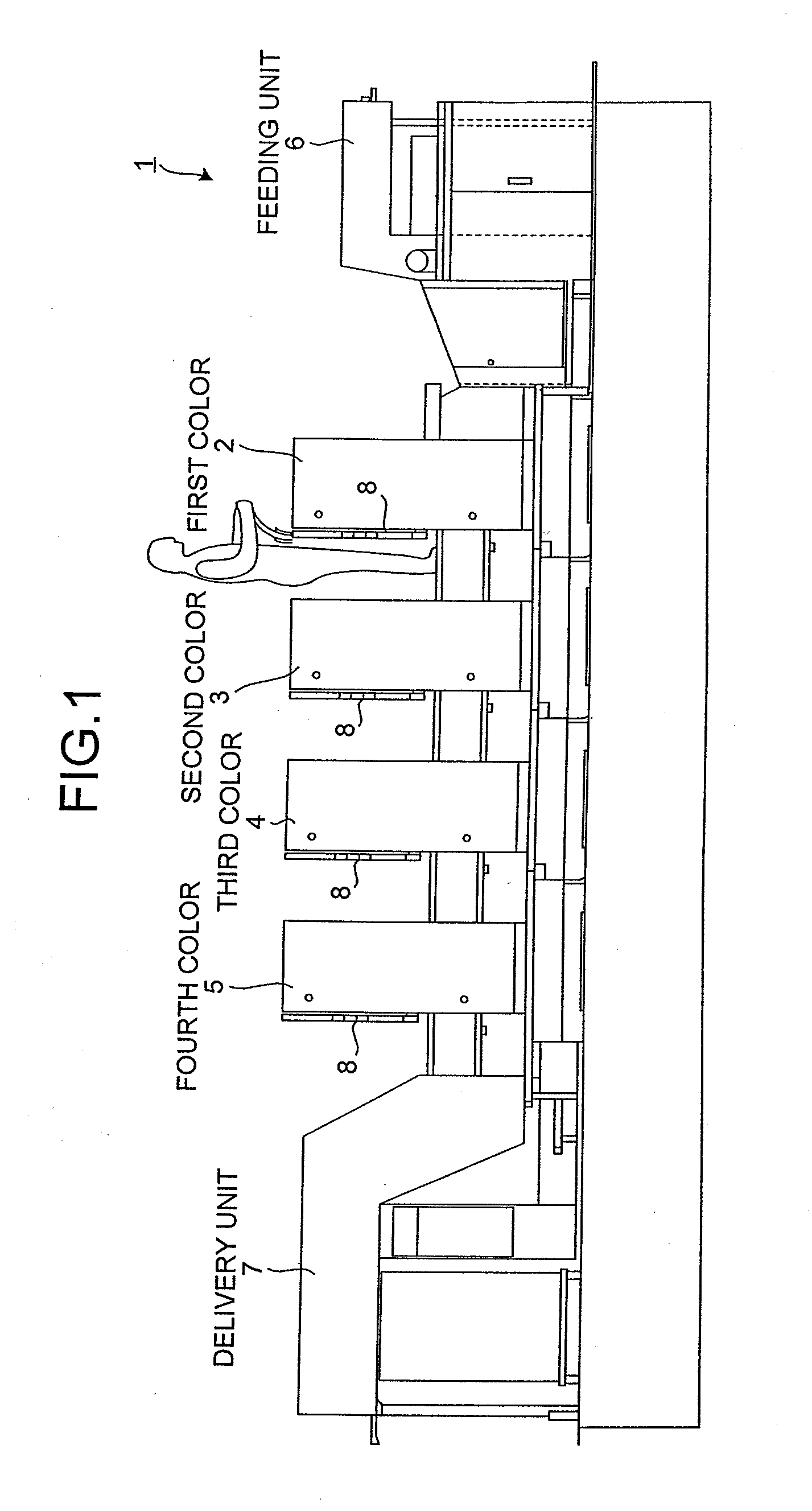

Printing unit

A printing unit for a web-fed rotary printing machine is provided having at least one carrying wall, a plurality of cylinders mounted on the carrying wall, a drive motor corresponding to each cylinder and a slide corresponding to each cylinder. Each slide carries its corresponding cylinder and receives the corresponding drive motor. A drive means is provided for driving the slides and a plurality of guide elements are mounted on the carrying wall and arranged laterally next to the adjacent end faces of the cylinders for guiding the slides along the wall. The guide elements are arranged opposite and parallel to one another on the carrying wall. Optionally, the carrying wall includes panels defining an orifice to allow cylinders, journals and sleeves of the printing machine of varying sizes to be changed readily.

Owner:MANROLANAD AG

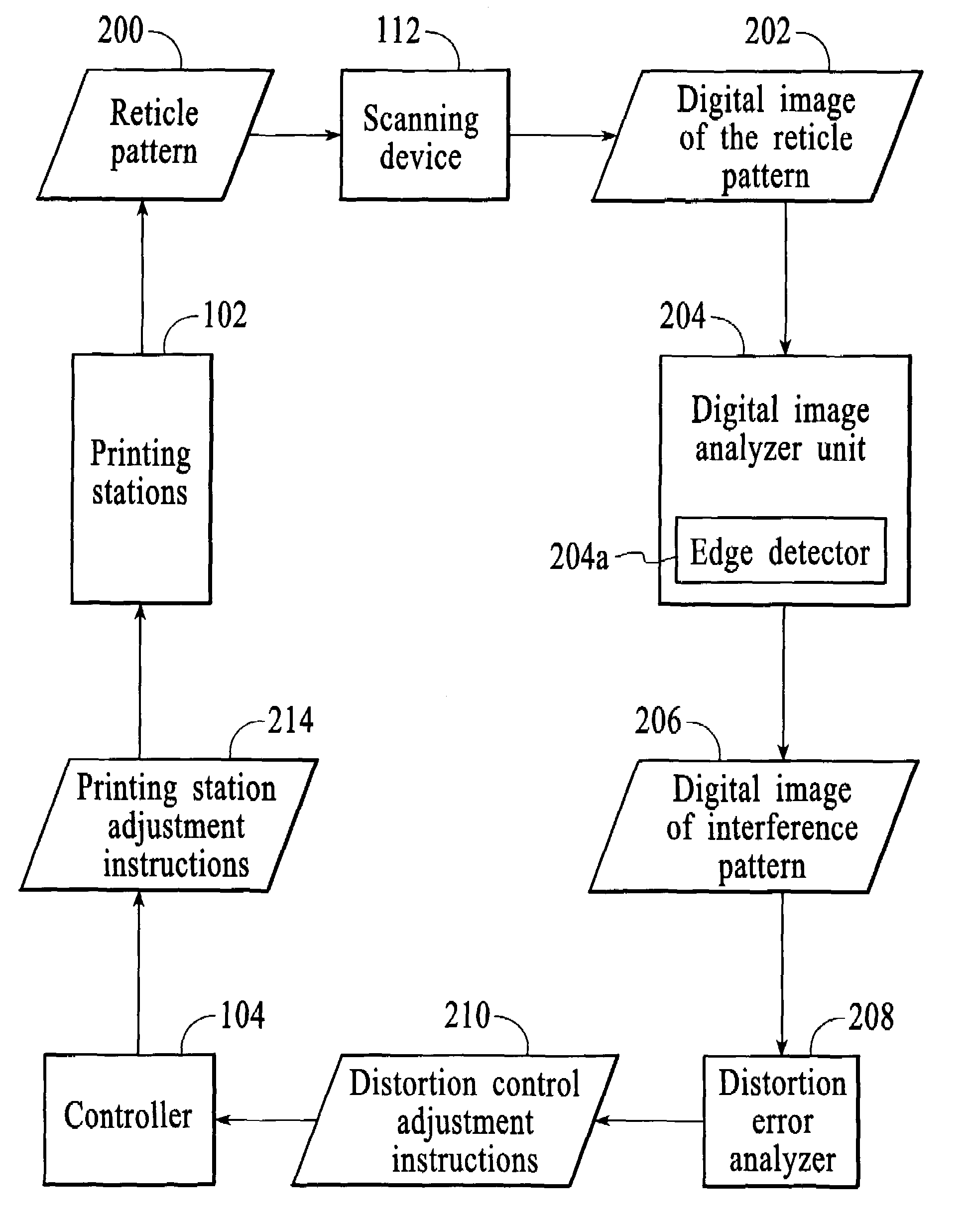

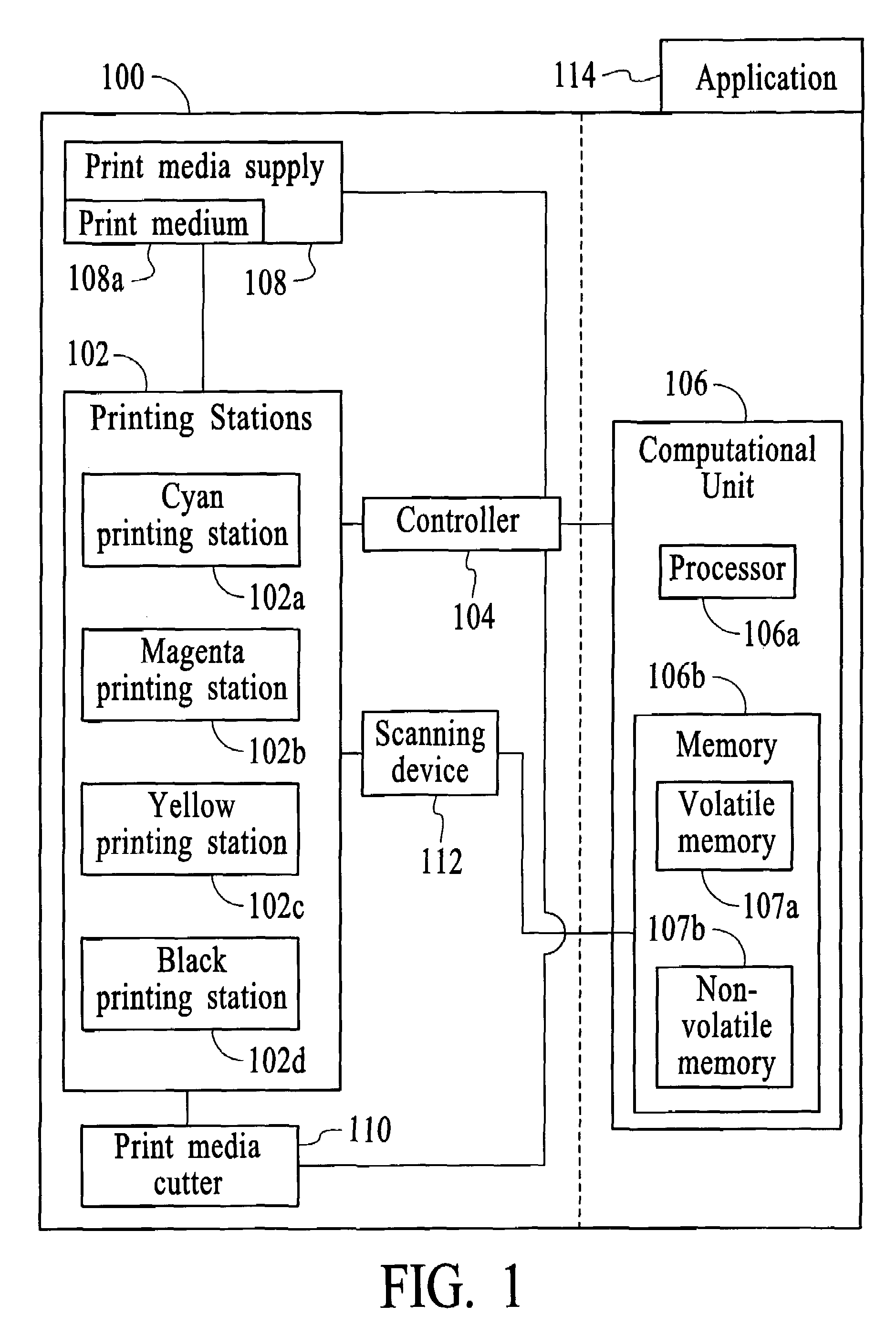

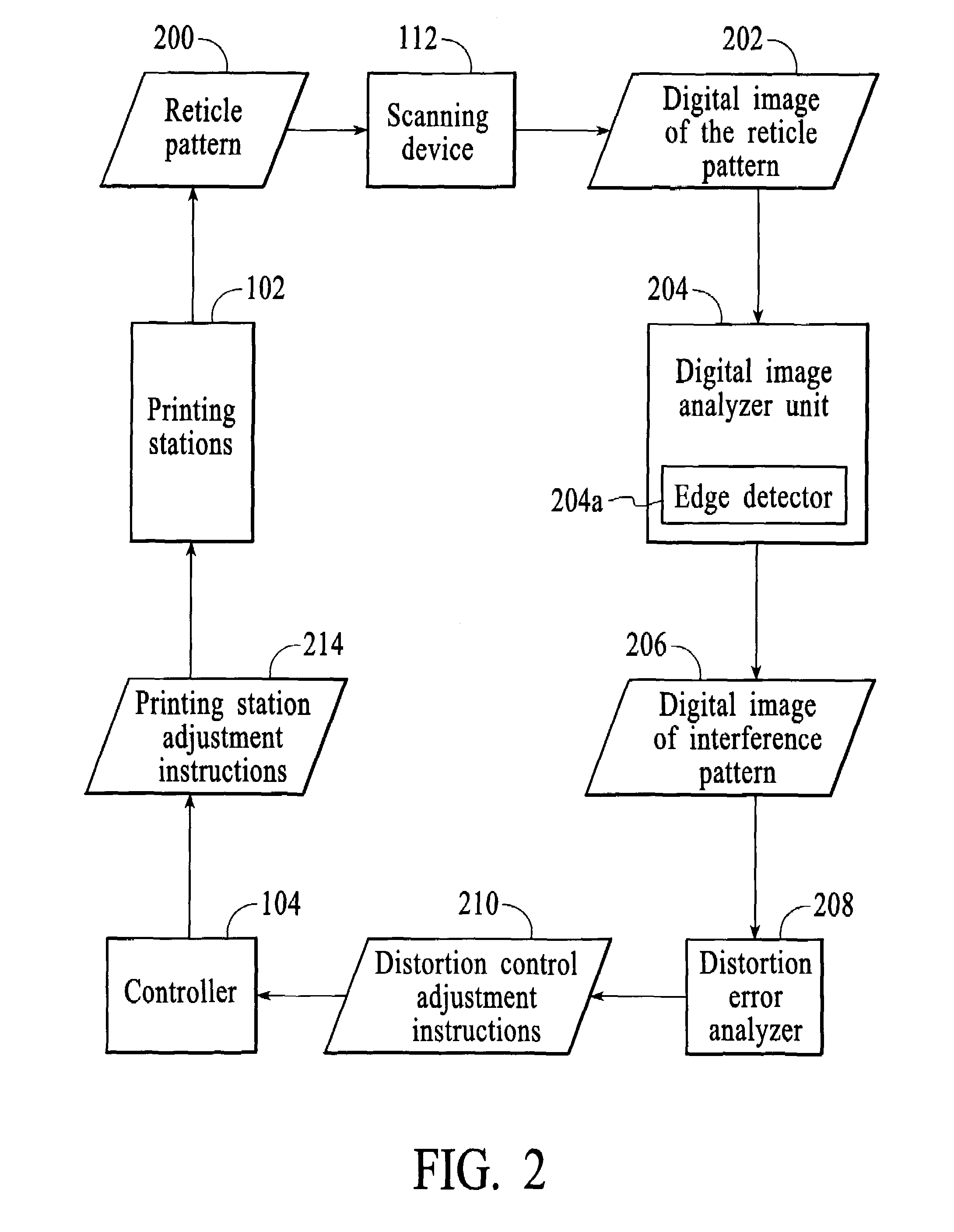

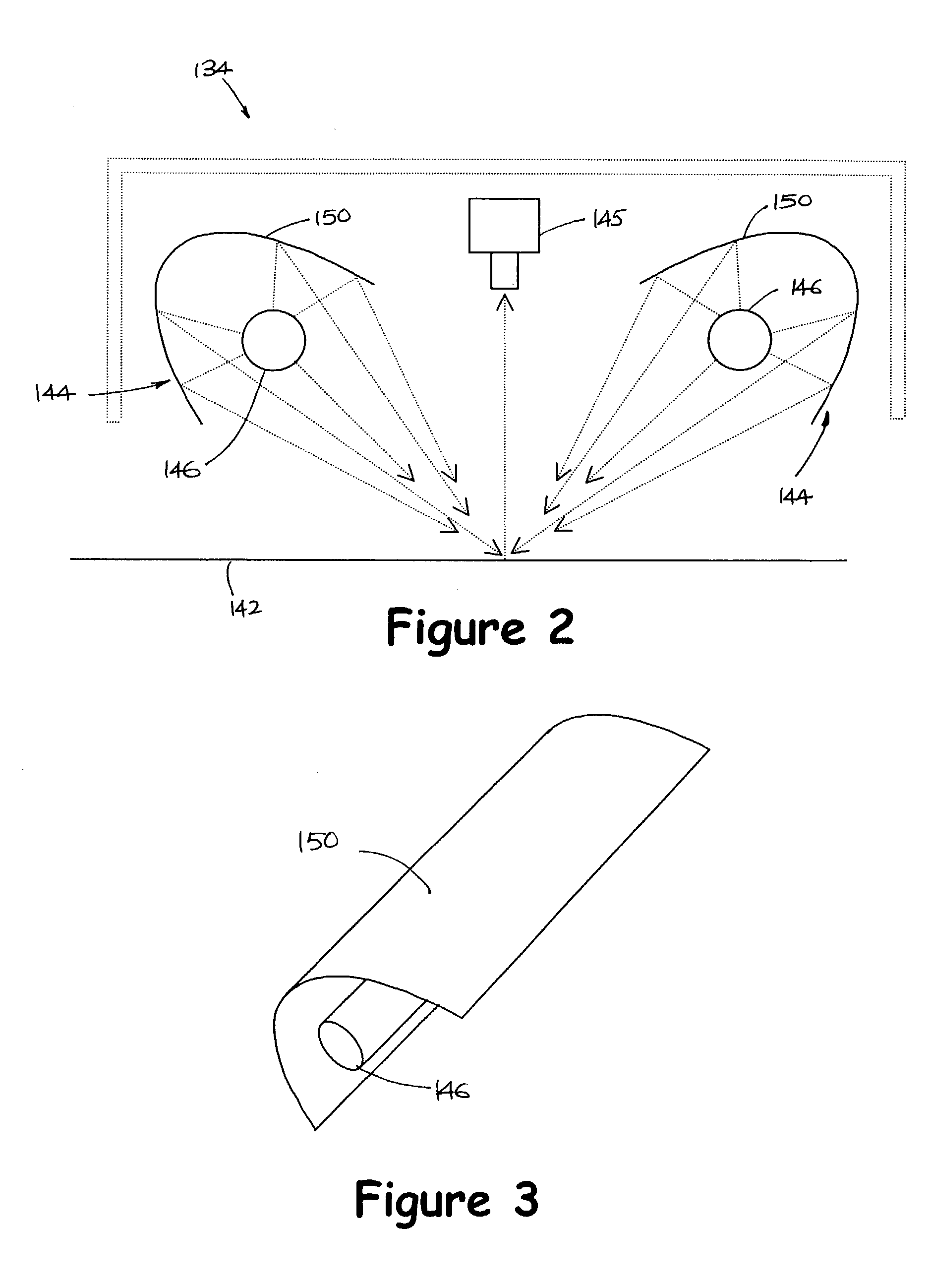

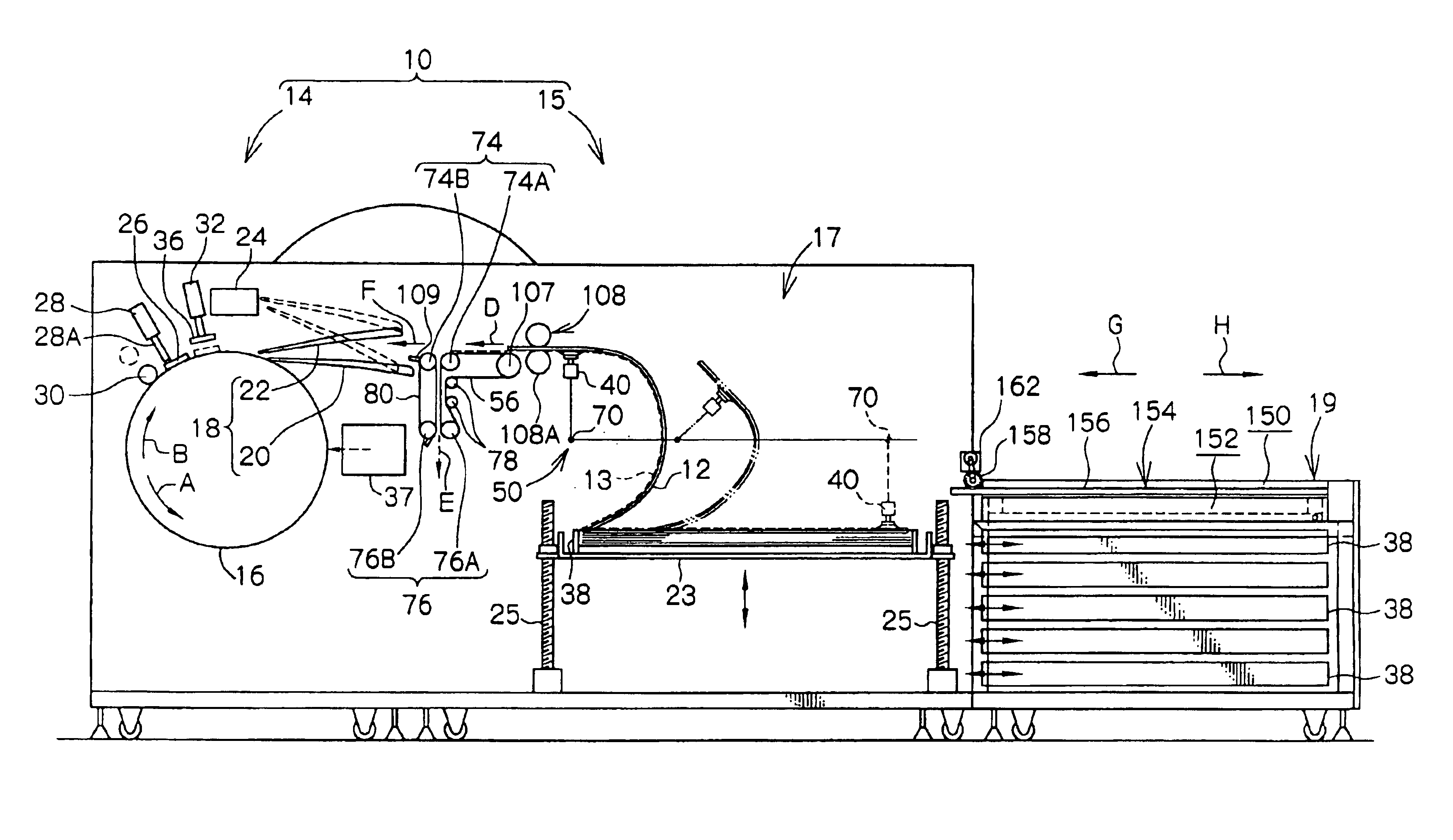

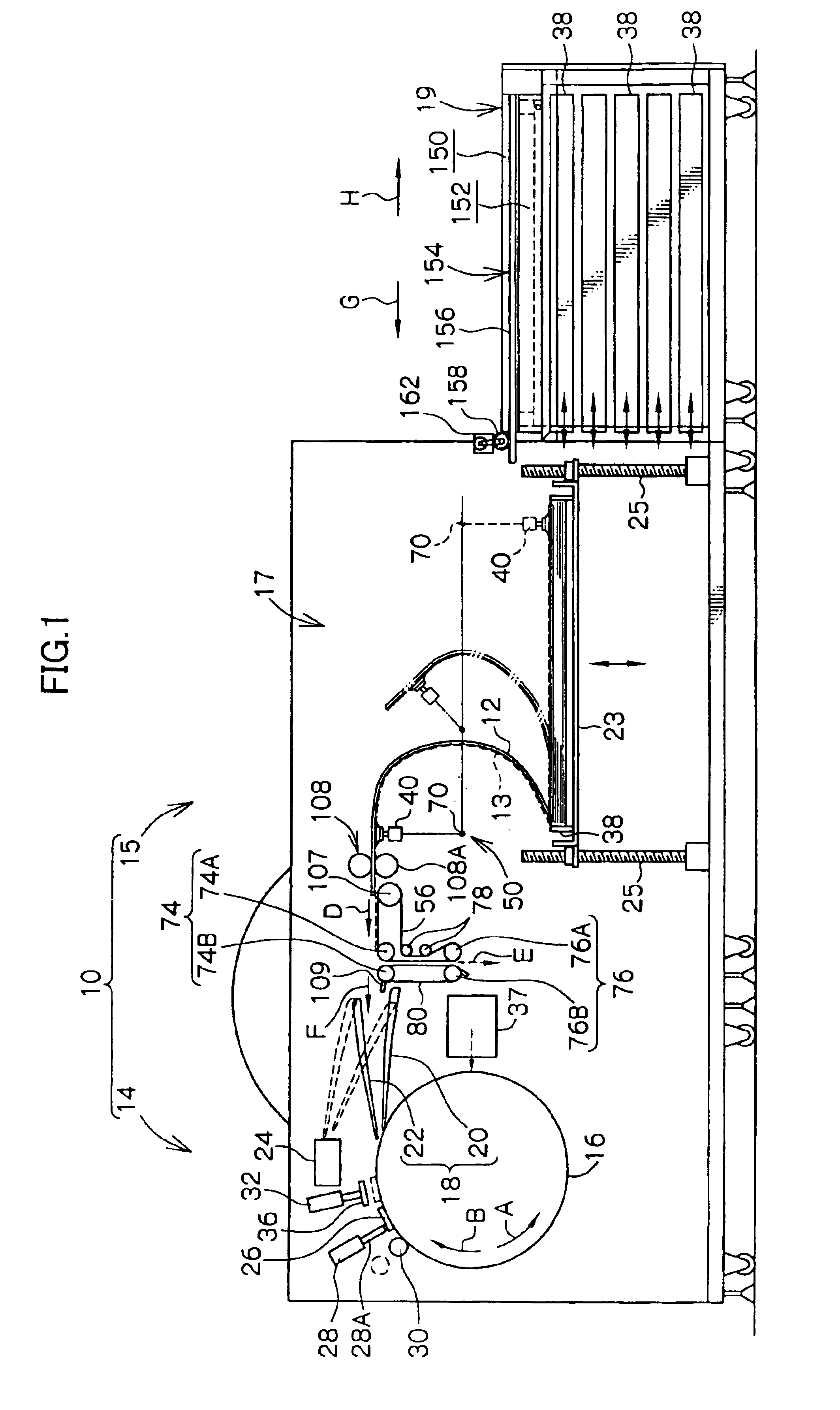

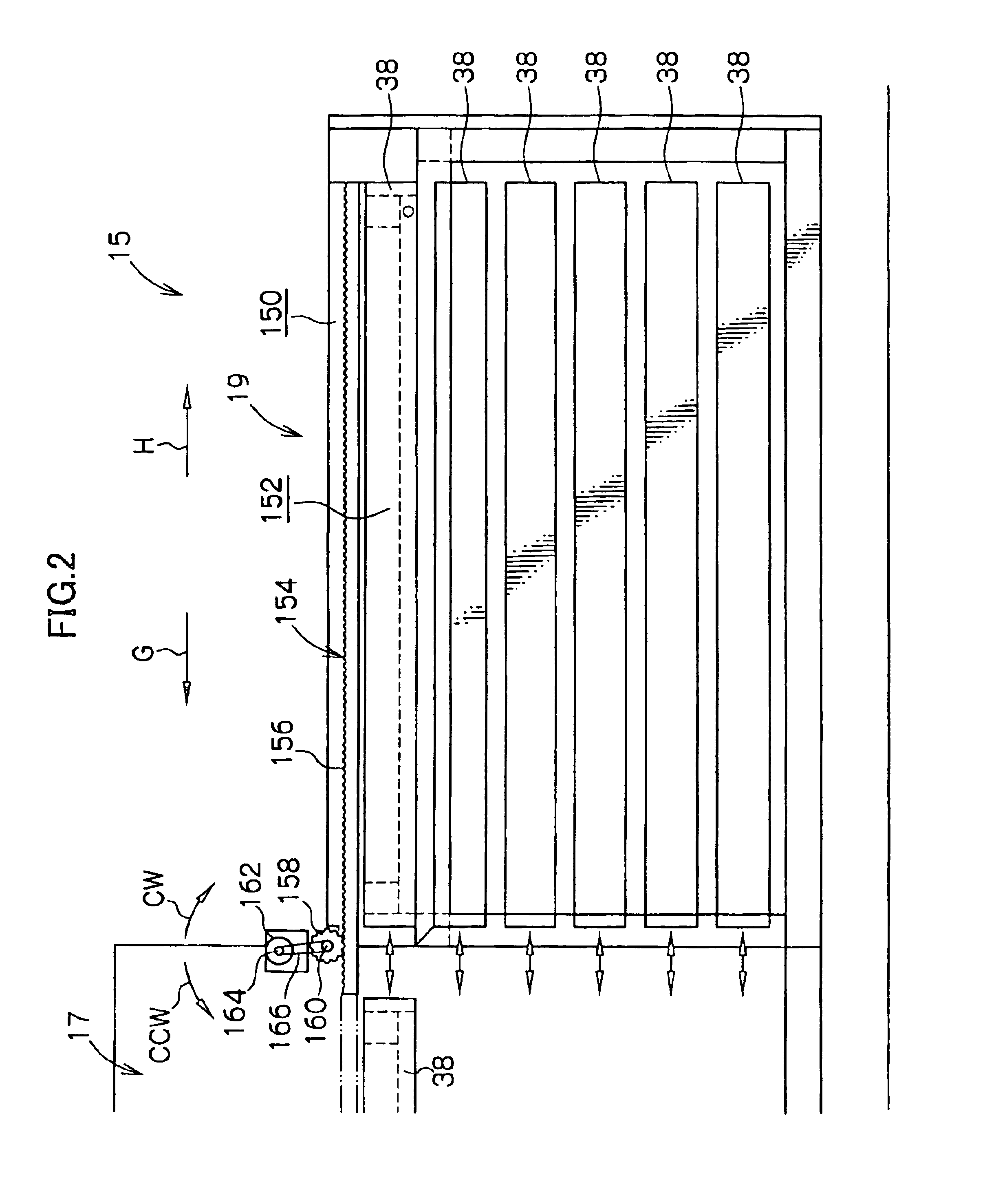

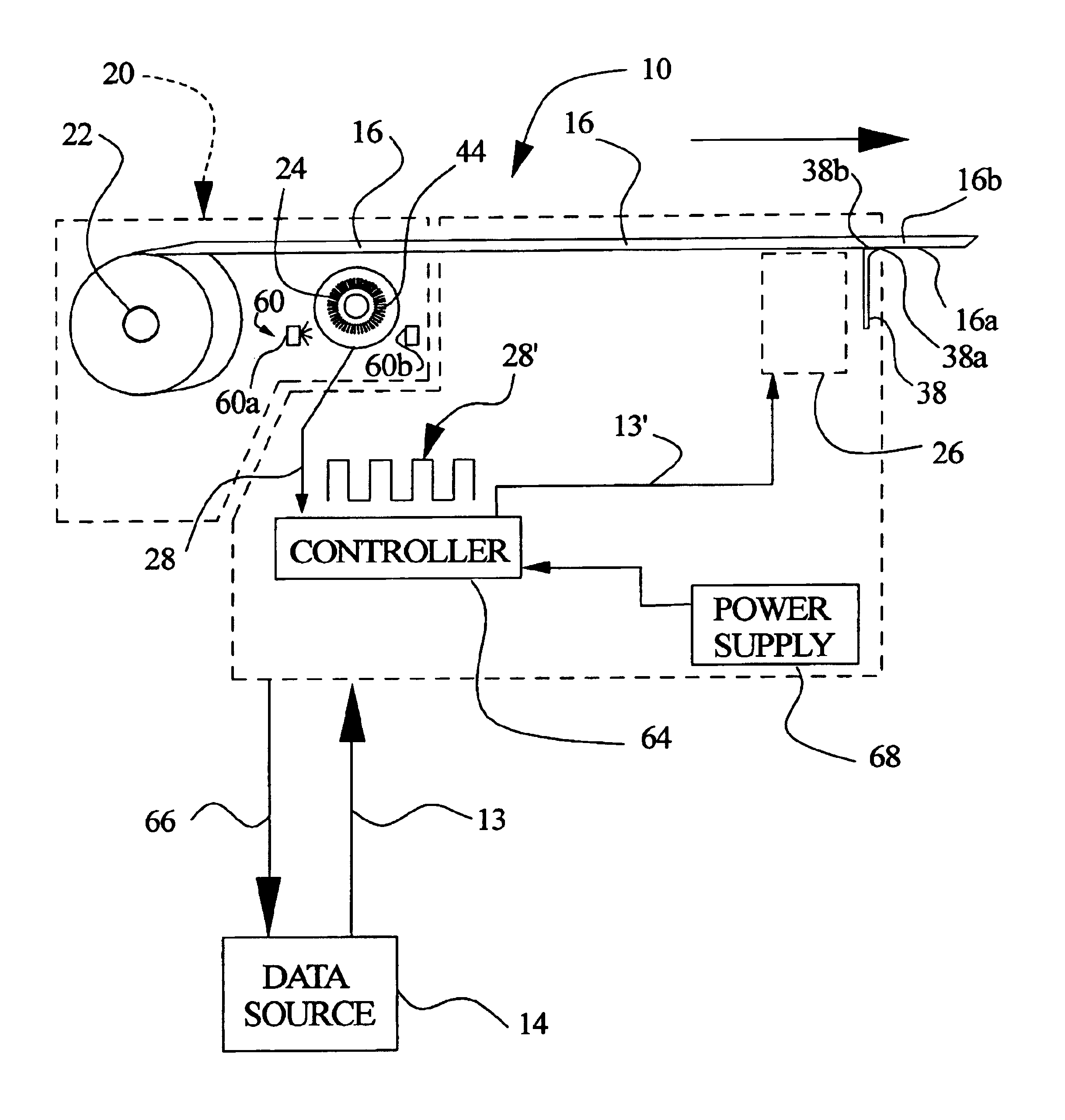

Method and system for minimizing the appearance of image distortion in a high speed inkjet paper printing system

ActiveUS6966712B2True colorPrecise registrationAddressographsPlaten pressesColor printingEngineering

A method and system for a printing device is disclosed. The method and system comprise printing a test pattern on a print medium and generating a digital image of the printed test pattern by an imaging device. The method and system include analyzing an interference pattern to measure for distortion of the print medium and calibrating the printing device based upon the measured distortion.In a preferred embodiment, the present invention utilizes the reticle patterns, which are printed in the margins of the paper, which are measured real-time during printing. The interference or Moiré patterns created by superimposed reticles may be used to measure image distortion, process direction misalignment, and misregistration caused by web distortion. The advantage of this invention is that image distortion compensation, RIP (Raster Image Processor) parameters, timing, or other printer characteristics may be adjusted on-the-fly in a closed feedback system, for high-speed textile or paper color printing, utilizing on-the-fly distortion or stretch measurement for accurate color and / or duplex images registration. In a duplex printer, automatic images alignment front-to-back is obtained by combining optically or logically the two images for the evaluation of interference patterns and amount of distortion in the process and scan direction.

Owner:RICOH KK

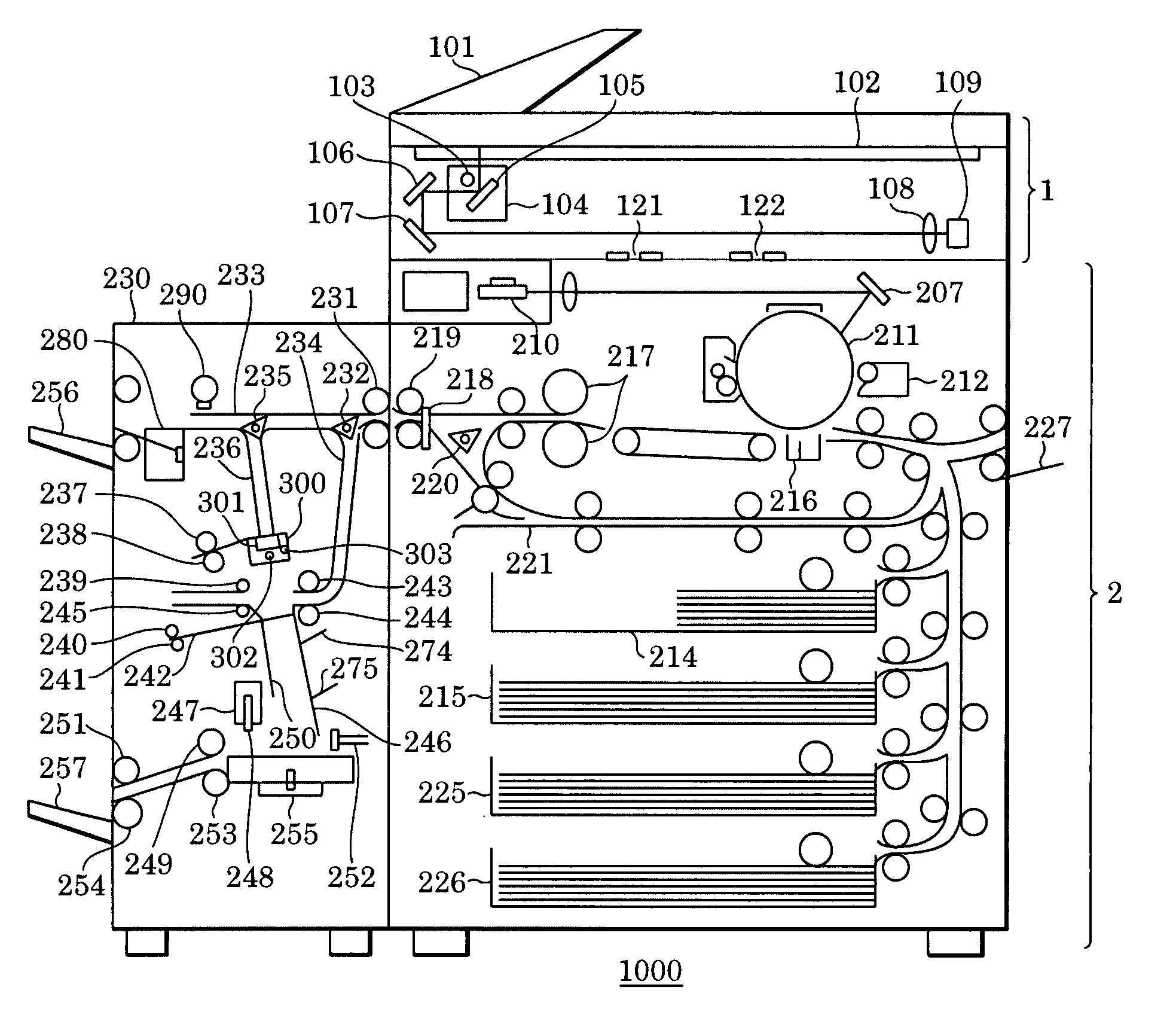

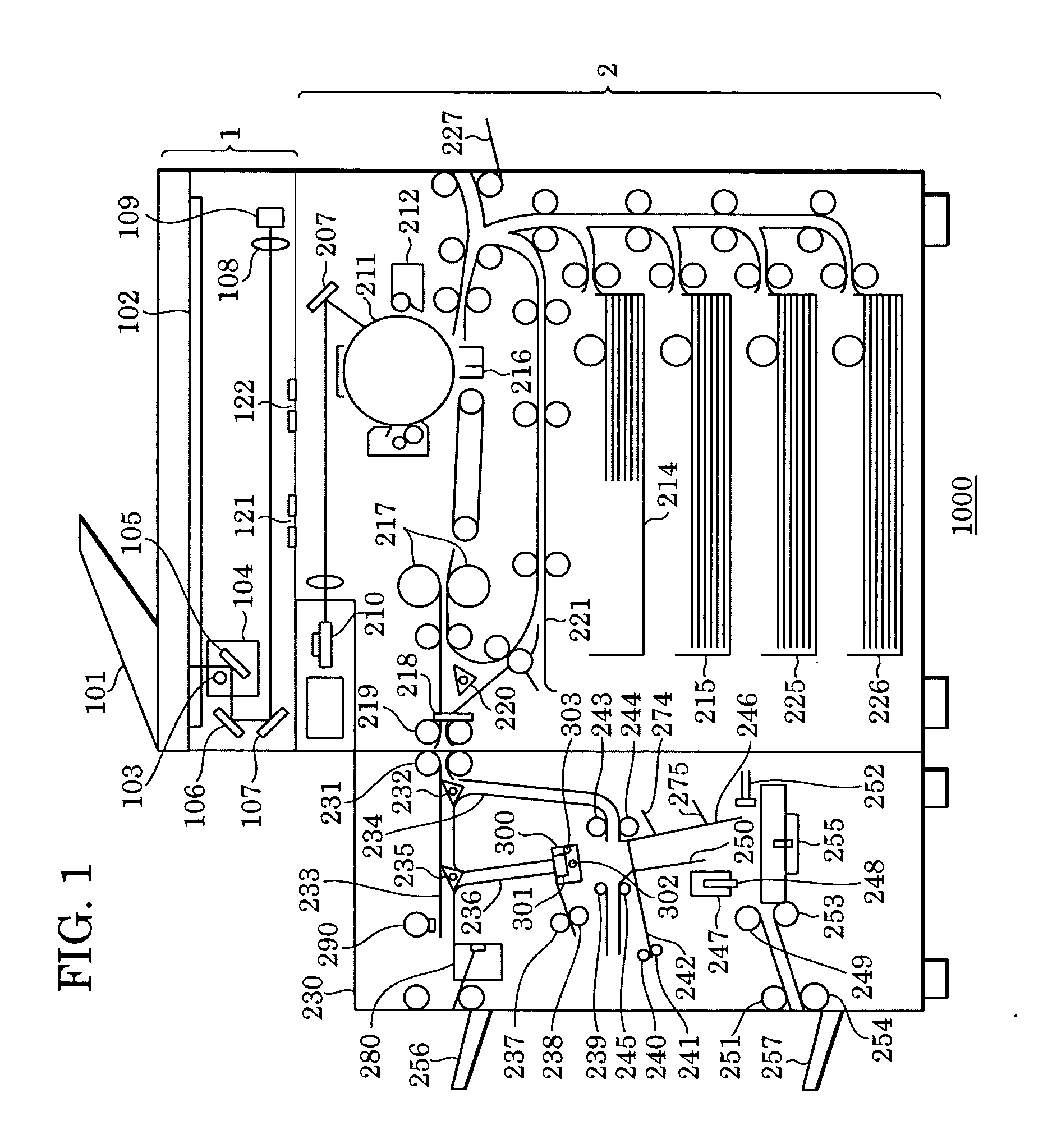

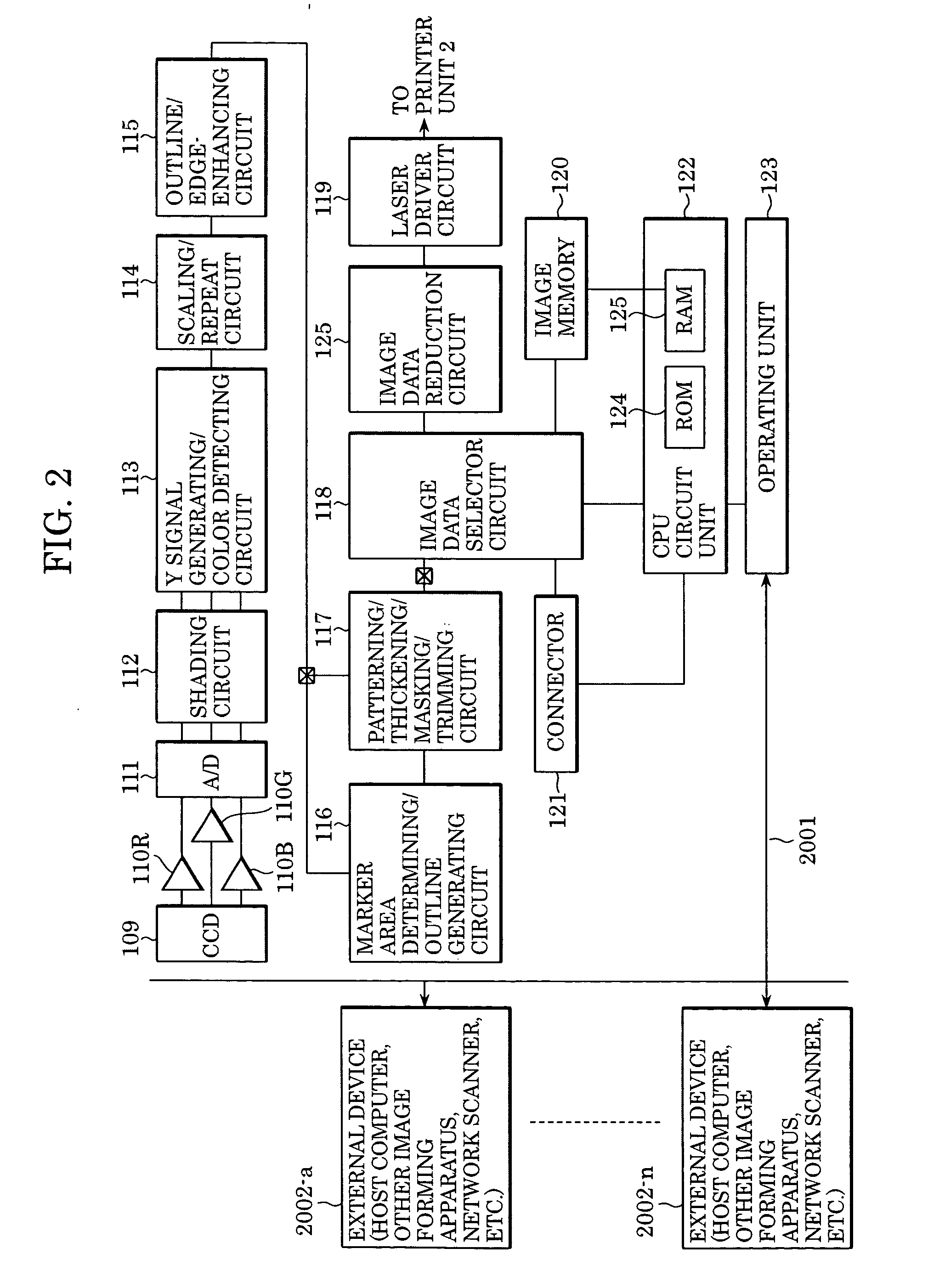

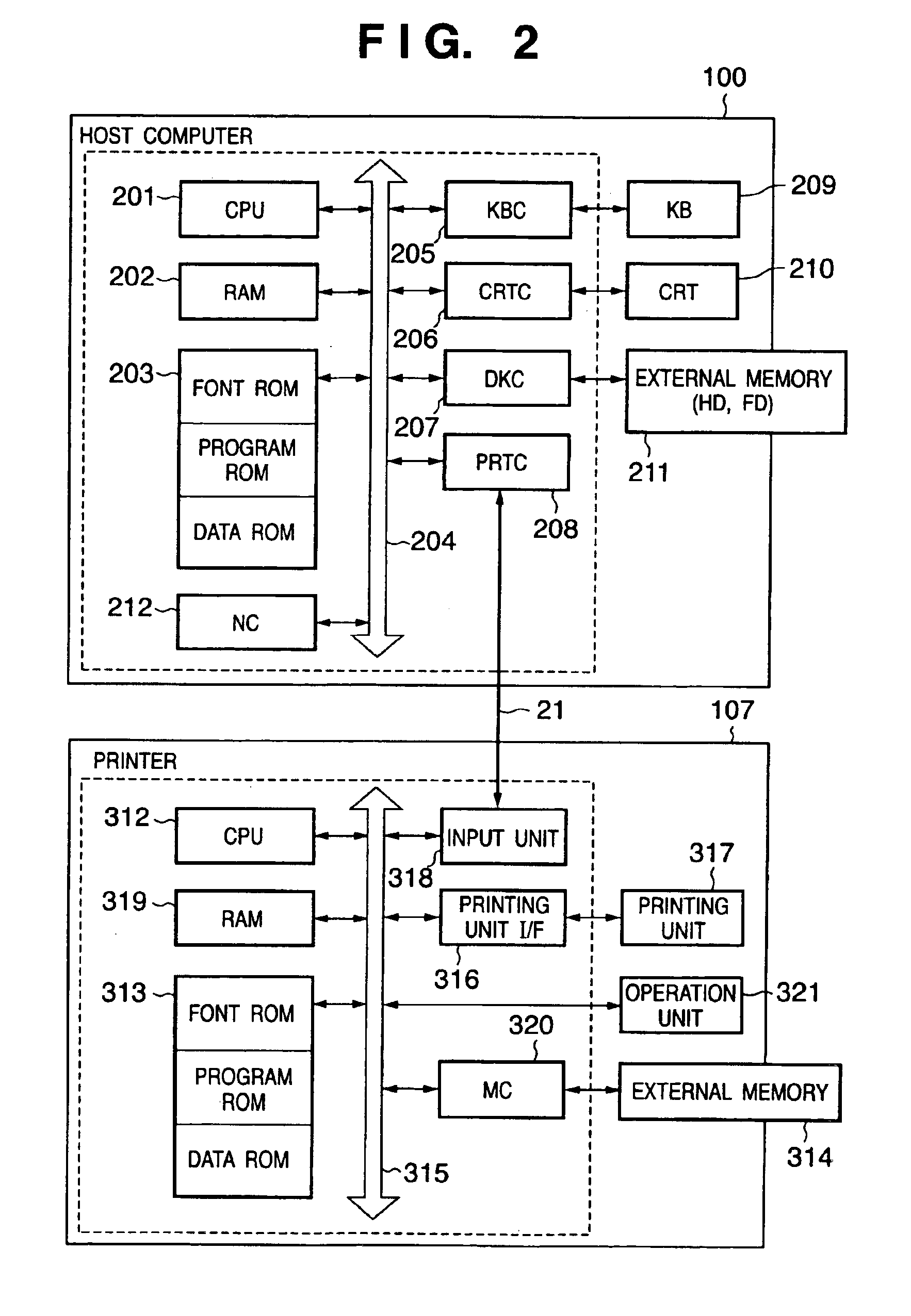

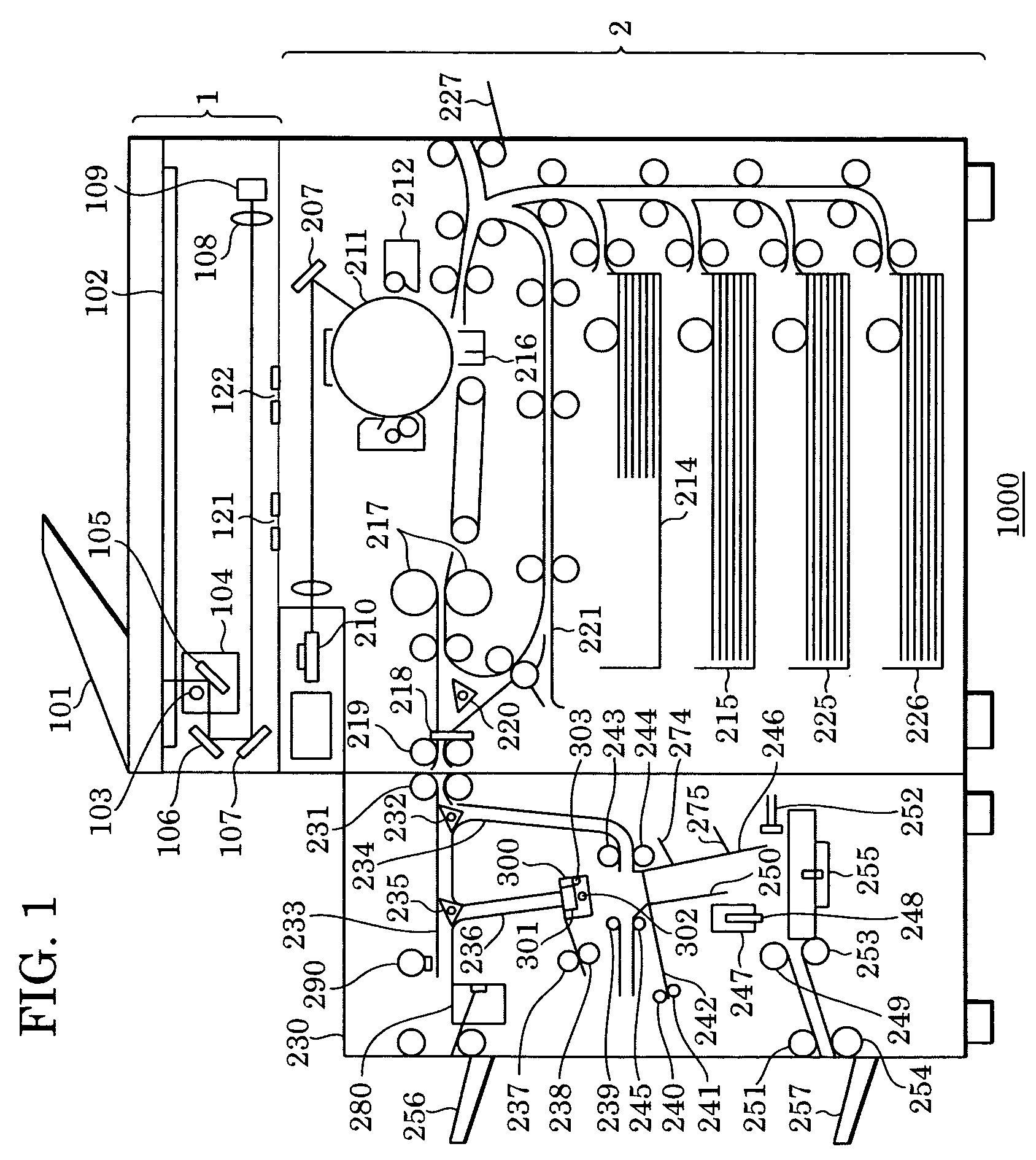

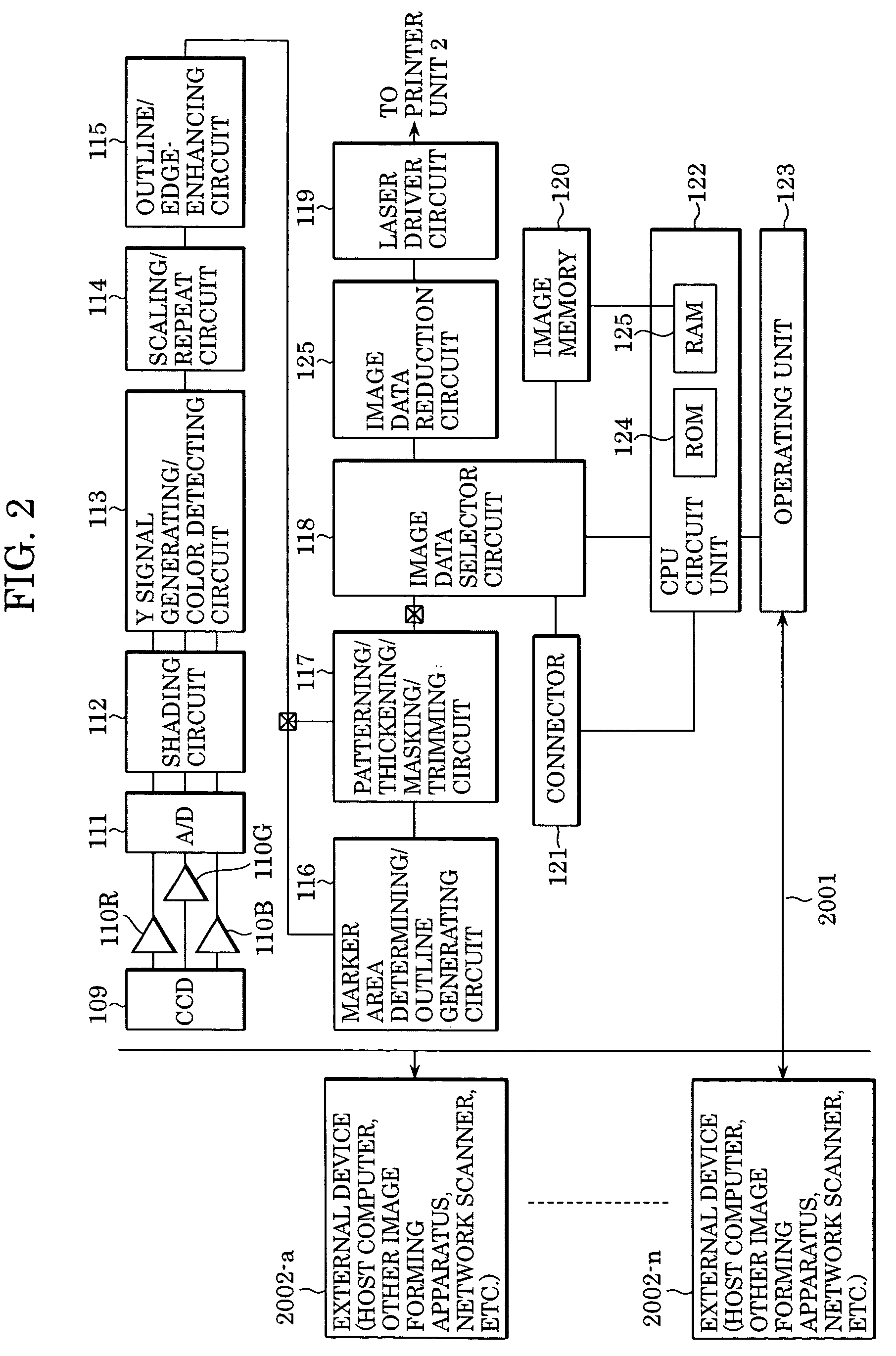

Image forming system, control method, recording medium, and program

ActiveUS20050232656A1Avoid problemsAddress usabilityAddressographsOther printing matterImage formationEngineering

An image forming system has an image forming apparatus which has a printing unit which can perform a printing process of data of a storage unit which can store data of a plurality of jobs and which has a conveying unit which can convey a sheet from the print unit to a sheet processing device which can perform sheet processing, including at least a gluing process, for sheets from the printing unit, the system comprising: a controller adapted to permit a predetermined process related to the gluing process when the job to be processed is a job which meets a predetermined condition, and to inhibit the predetermined process related to the gluing process when the job to be processed is not a job which meets the predetermined condition, thereby overcoming obstacles to realization of an image forming system capable of a gluing process.

Owner:CANON KK

Image data-oriented printing machine and method of operating the same

InactiveUS6230622B1Reduce materialReduce rejectionAddressographsPlaten pressesBasic knowledgePulp and paper industry

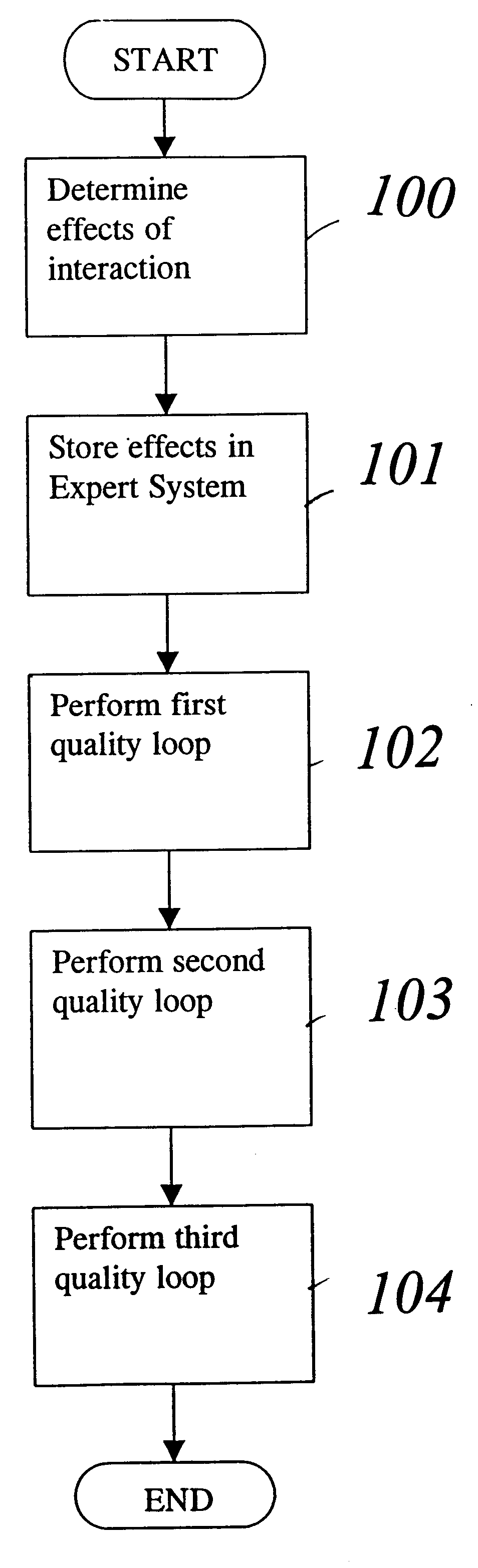

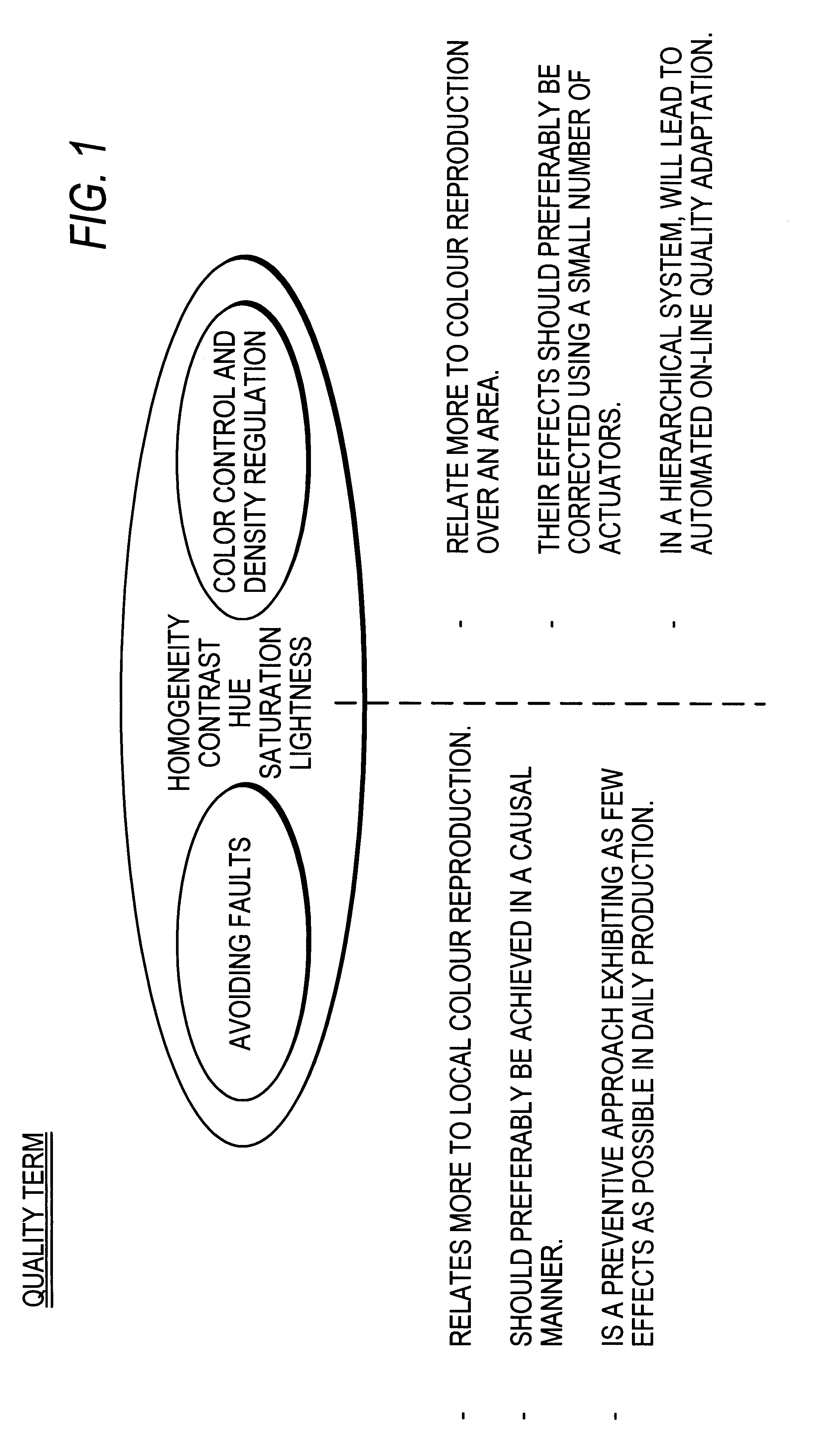

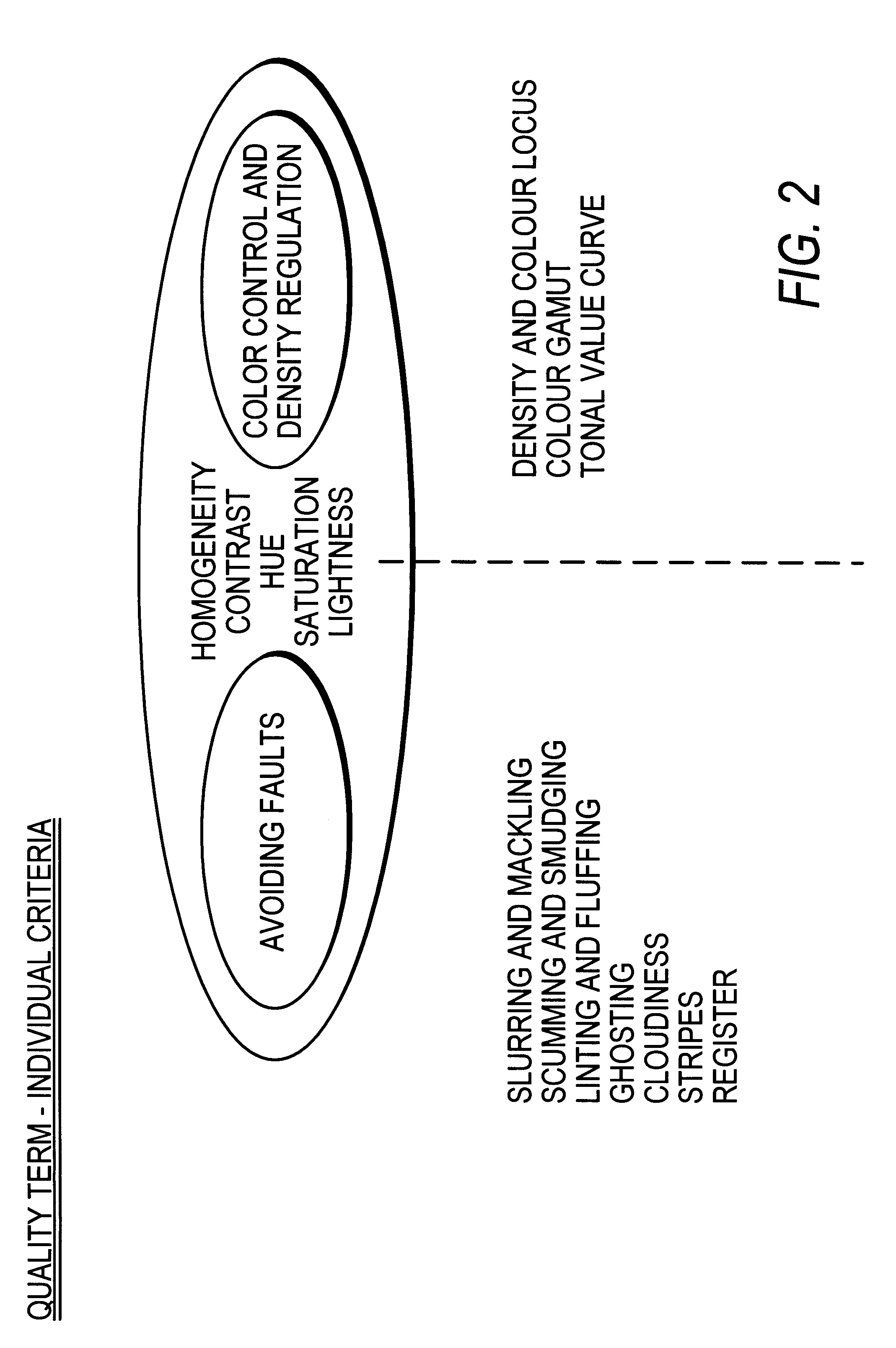

A method of operating a printing machine and a printing machine apparatus in which basic knowledge about the interaction between operating media in the printing machine is obtained through printing trials or during production. This knowledge is stored in an expert system and made available for the printing operation or else for the production of the printing plate. The expert system is preferably a self-teaching system. For color reproduction, basic calibrations are carried out in a first quality step, in a second step, the imaging operation is adapted to the areas and half tones to be imaged, and ink-density regulation is carried out in a third step.

Owner:MANROLANAD AG

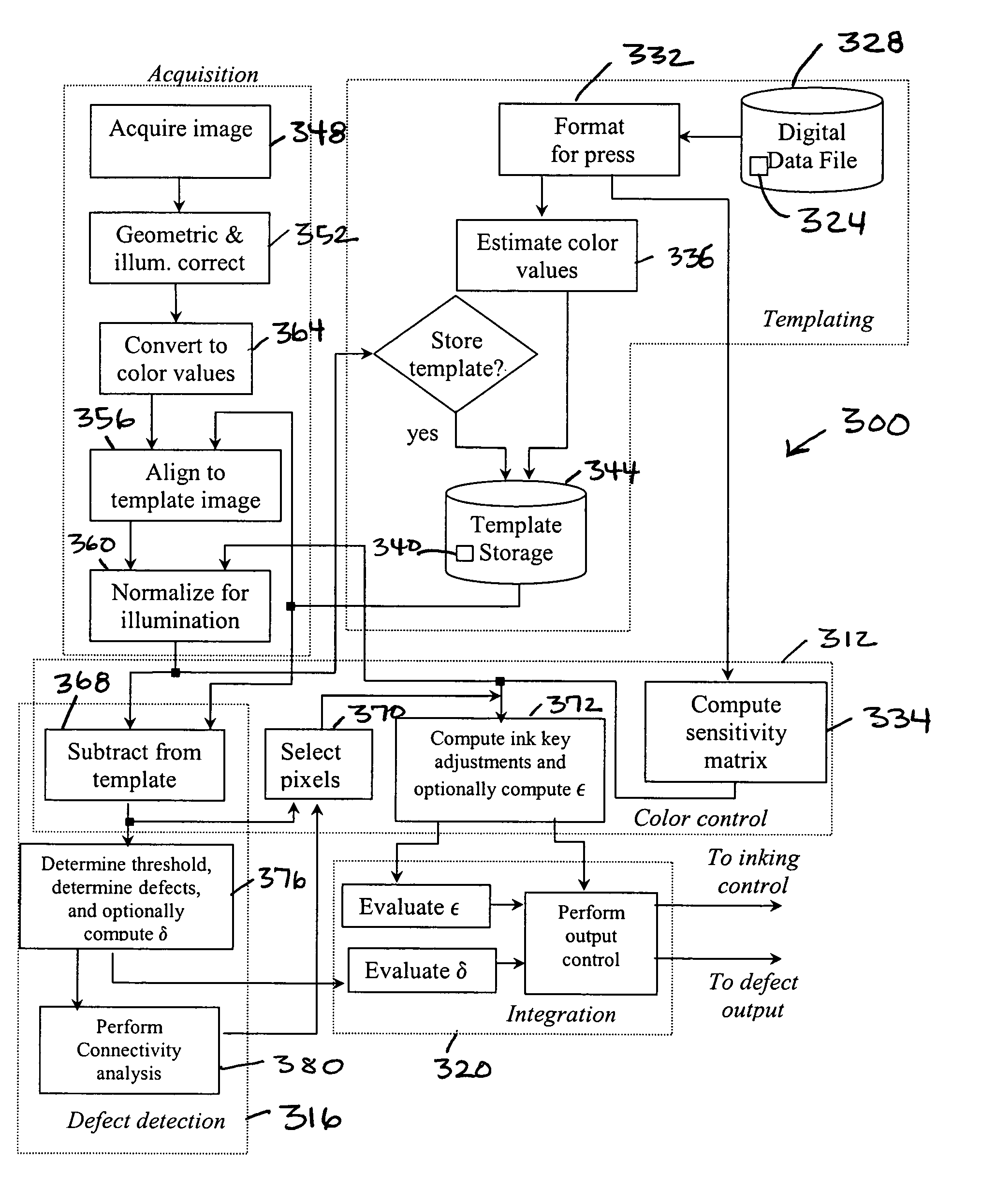

Coordinating the functioning of a color control system and a defect detection system for a printing press

A method of coordinating the utilization of a color control system and a defect detection system on a printing press includes acquiring image data and processing the data by a comparison to template image data and the generation of color error data and print defect data. The method further includes the steps of selectively enabling and disabling the color control system and selectively enabling and disabling the defect detection system based upon the color error data and the print defect data.

Owner:BALDWIN AMERICAS CORP

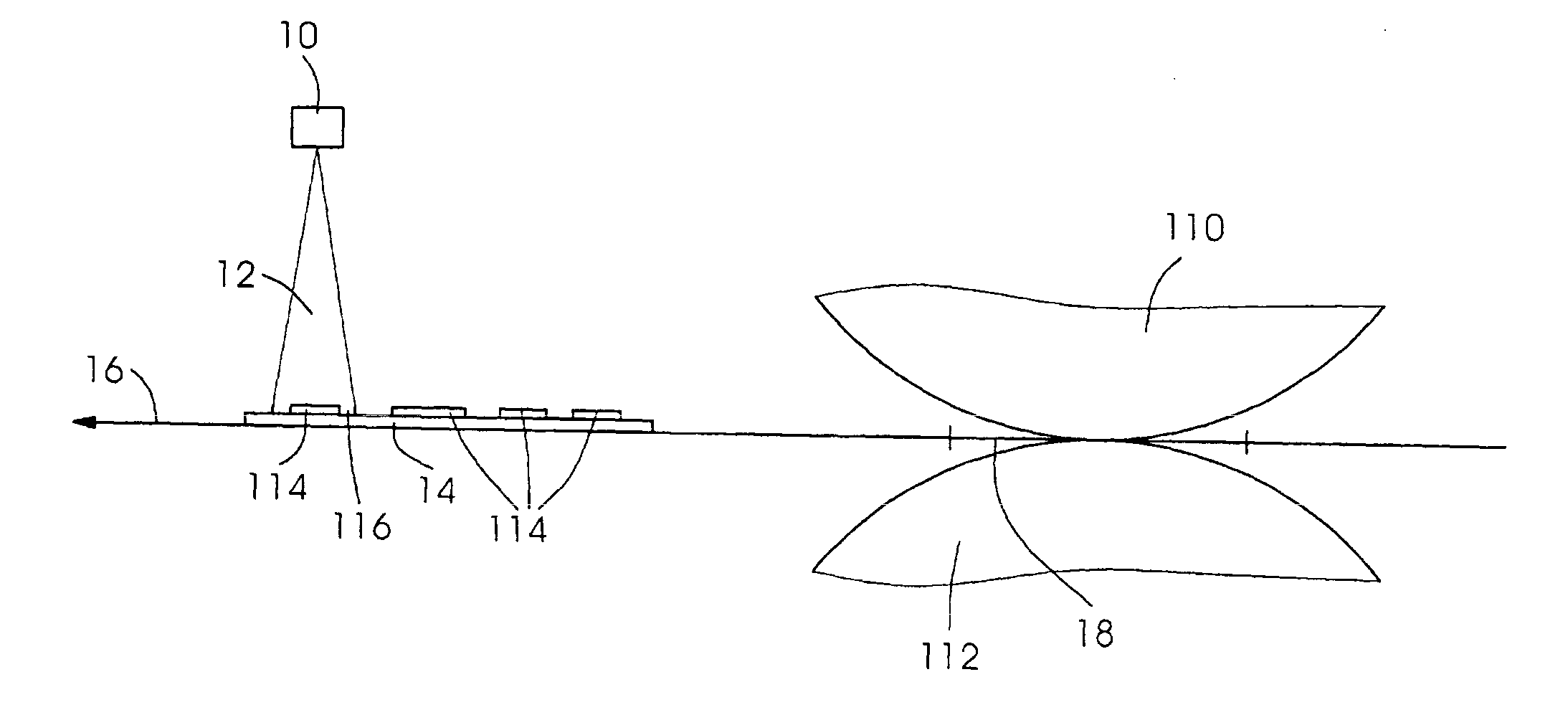

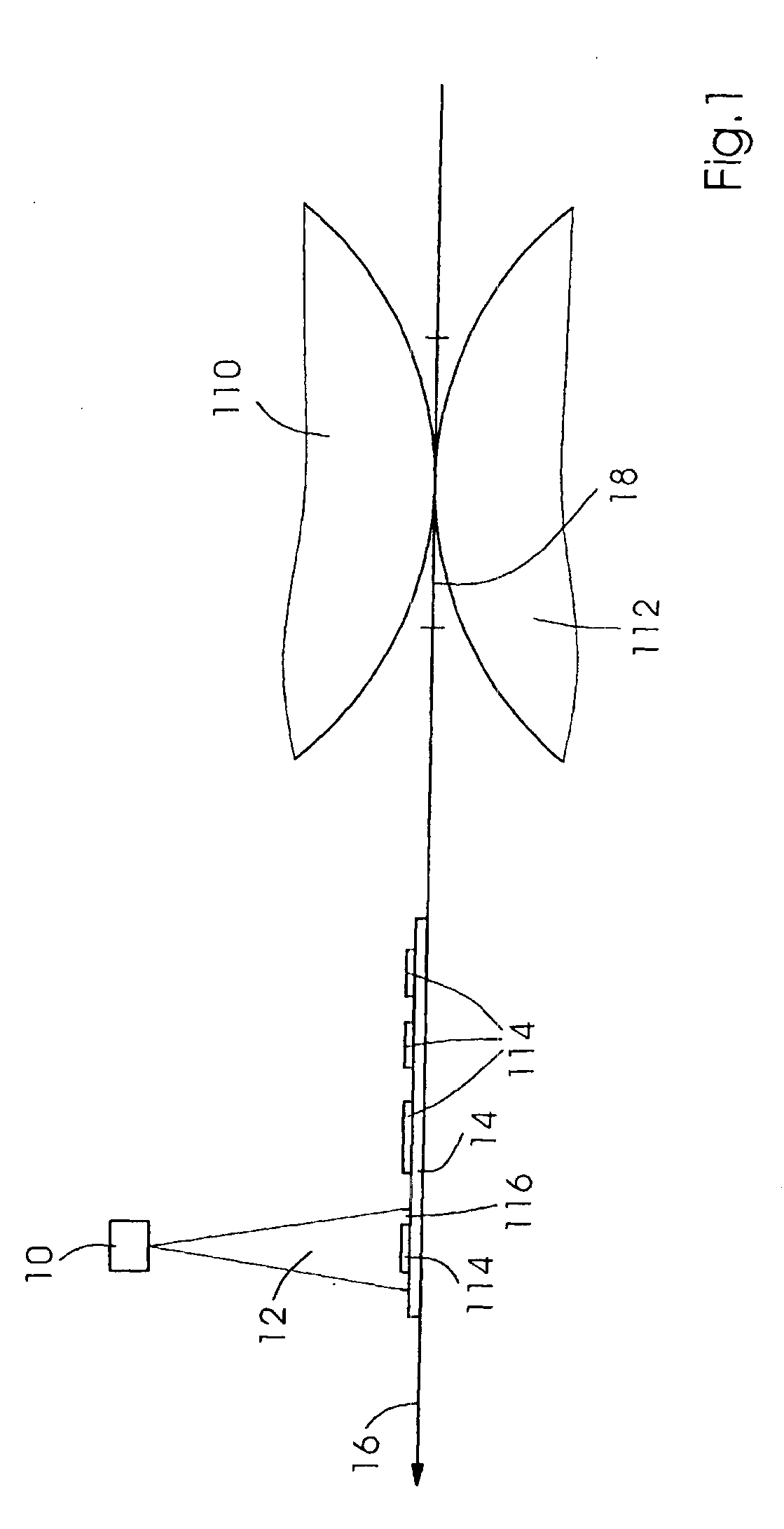

Device and method for supplying radiant energy onto a printing substrate in a planographic printing press

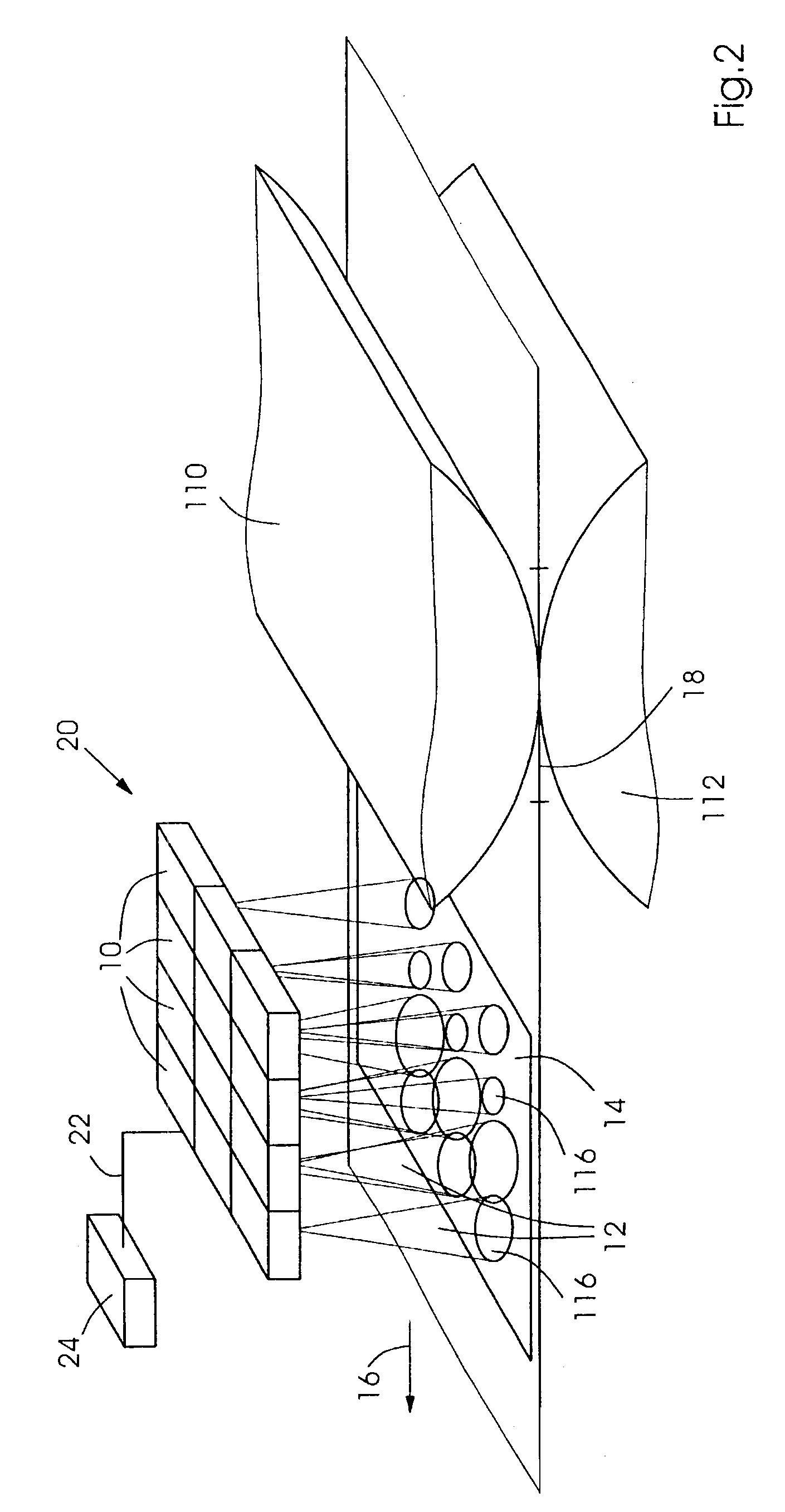

InactiveUS6857368B2Shorten drying timeAssisting or accelerating the drying of printing inkAddressographsPlaten pressesResonancePrinting ink

A device for supplying radiant energy of a wavelength in the near infrared onto a printing substrate (14) in a planographic printing press, including at least one radiant energy source (10) whose light (12) impinges on the printing substrate (14) on the path (16) of the printing substrate (14) through the printing press at a position (116) downstream of at least one printing nip (18) in a printing unit is described which has the feature that the radiant energy source (10) emits light (12) only in a narrow band, the wavelength of the light being non-resonant to absorption wavelengths of water and preferably being between 700.00 nm and 2500.00 run. Also disclosed is a method for supplying radiant energy. By supplying energy in this frequency range while avoiding absorption resonances of water, an unwanted drying or unnecessary heating of the printing substrate are advantageously reduced while providing energy to the printing ink for its particular drying process. The input of the radiant energy into the printing ink is assisted by an infrared-absorbing agent which is added to the printing ink.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Method and apparatus for equalizing pressure between rollers in a printing press

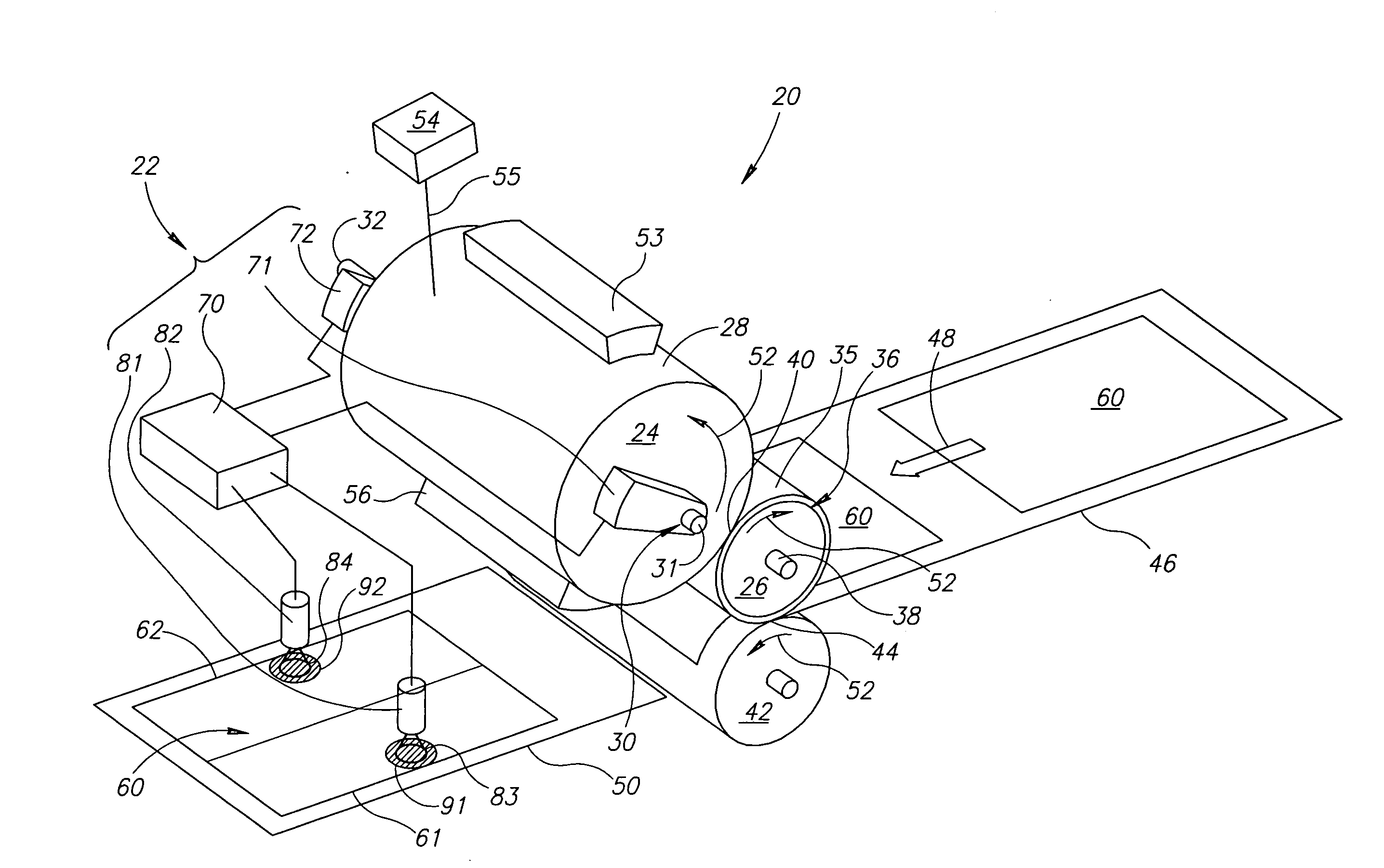

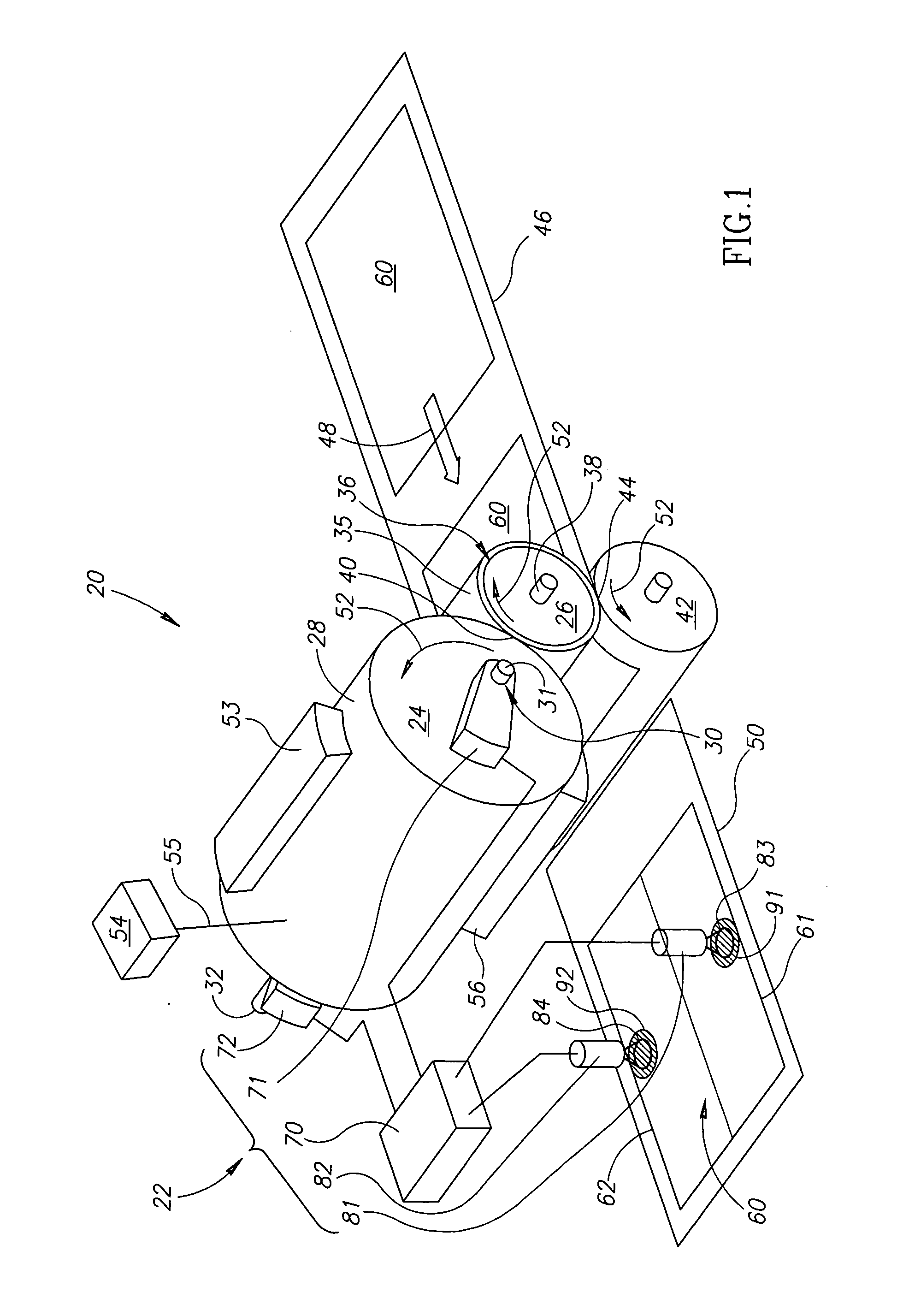

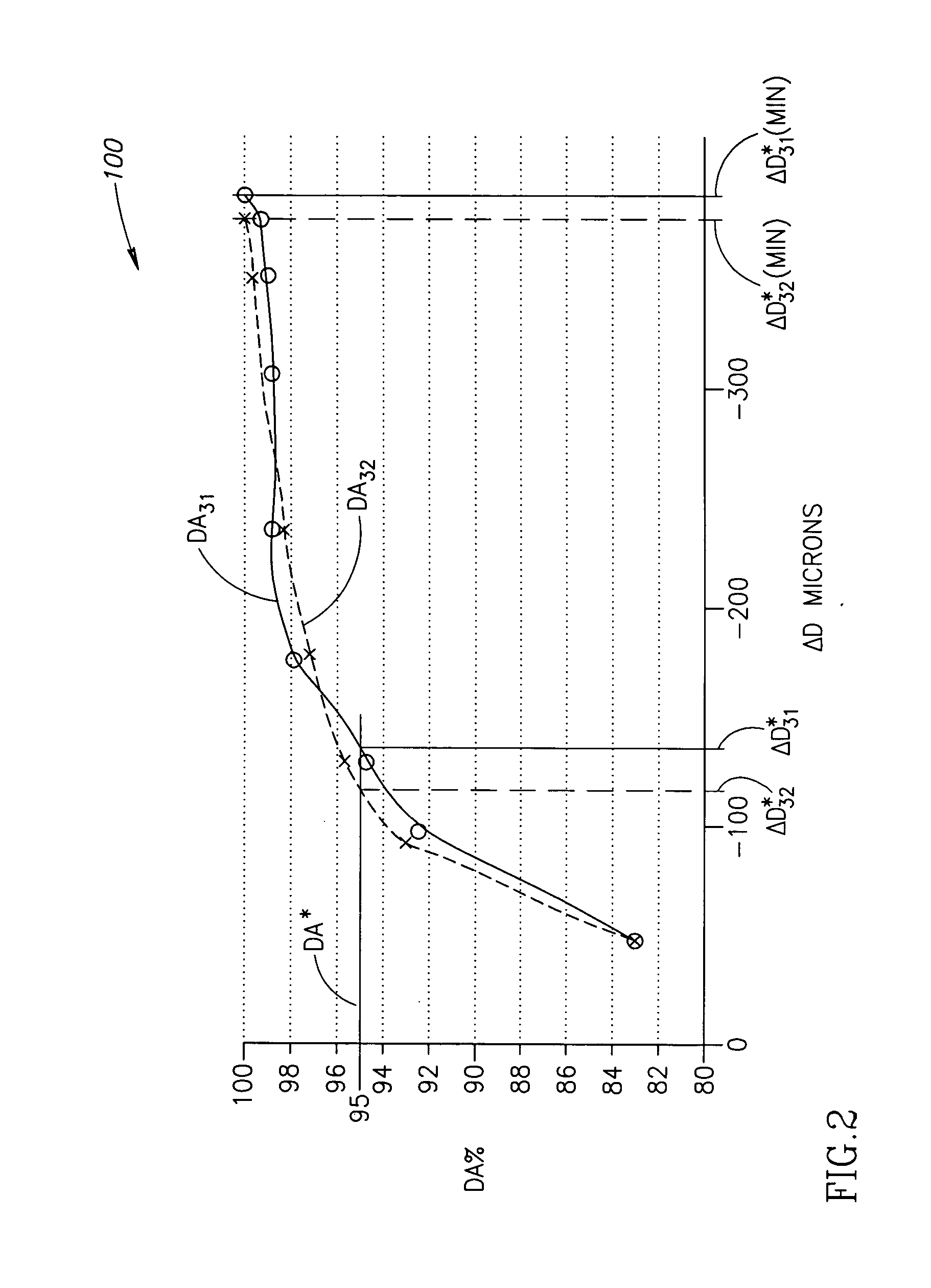

Apparatus for equalizing pressure along a nip between a photosensitive imaging cylinder (PIC) and an intermediate transfer member (ITM) in a printing press comprising: first and second optical sensors having first and second fields of view respectively that view different first and second regions of a substrate printed by the printer and generate signals responsive to the optical densities of first and second test patterns printed by the printer on the first and second regions of the substrate; at least one motor operable to control pressure between the rollers; and a controller that receives the signals and controls the at least one motor responsive to the signals to equalize the pressure along the nip.

Owner:HEWLETT PACKARD INDIGO BV

Printing plate removing/supplying device

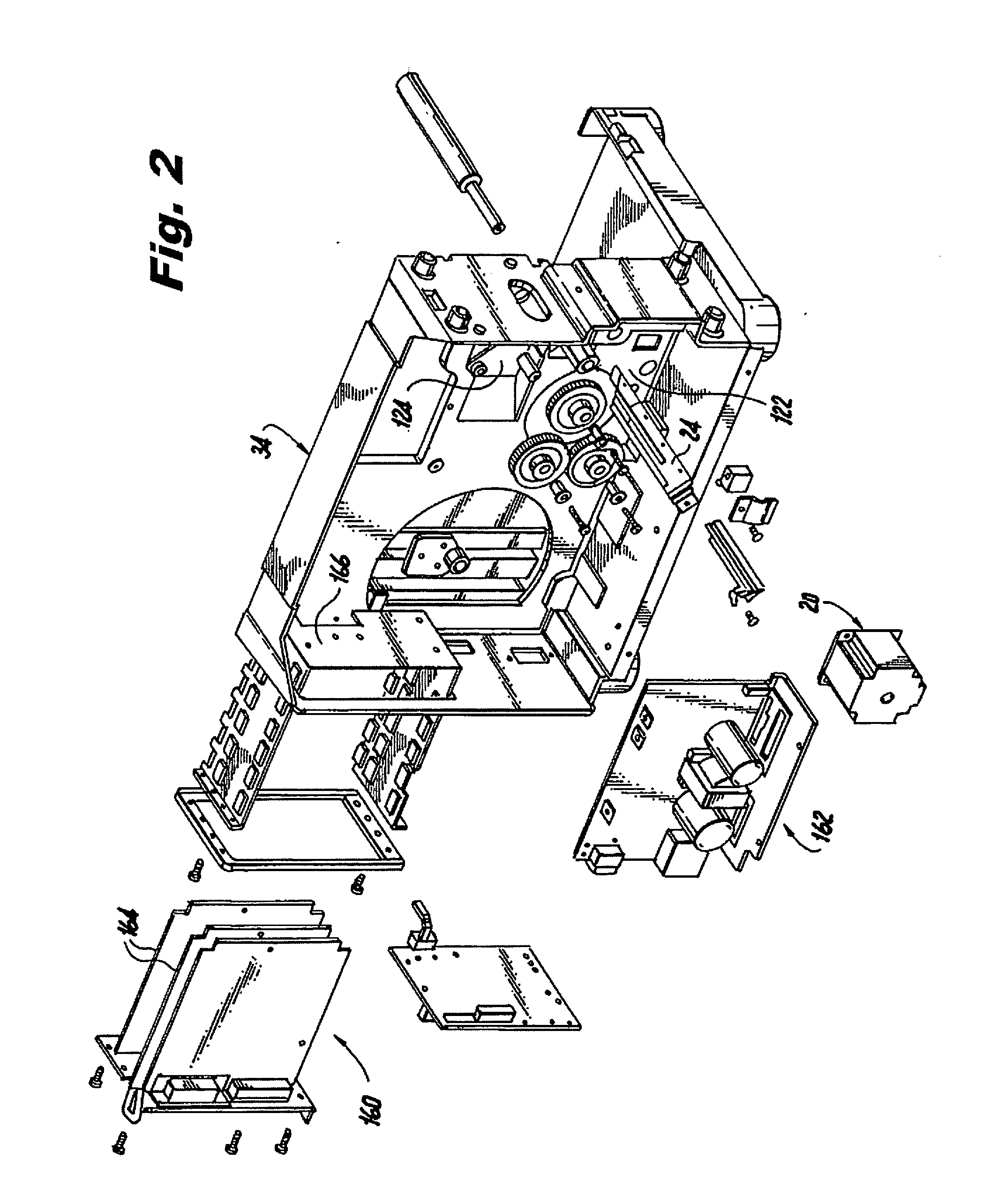

InactiveUS6904844B2Less space neededLow costAddressographsPhotomechanical exposure apparatusMagnetic tapeSpur gear

In a removing / conveying portion of a printing plate removing / supplying device, when one cassette among a plurality of cassettes is empty, the empty cassette is placed on a raising / lowering stand and moved to a loading space. Due to a spur gear being rotated clockwise by a motor, a sliding cover, with which the spur gear is engaging, is moved toward a removing portion such that an opening of a cassette stocker portion is opened. In this way, it is possible to refill and load printing plates from a top side of the cassette stocker portion into the empty cassette positioned at the loading space.

Owner:FUJIFILM HLDG CORP +1

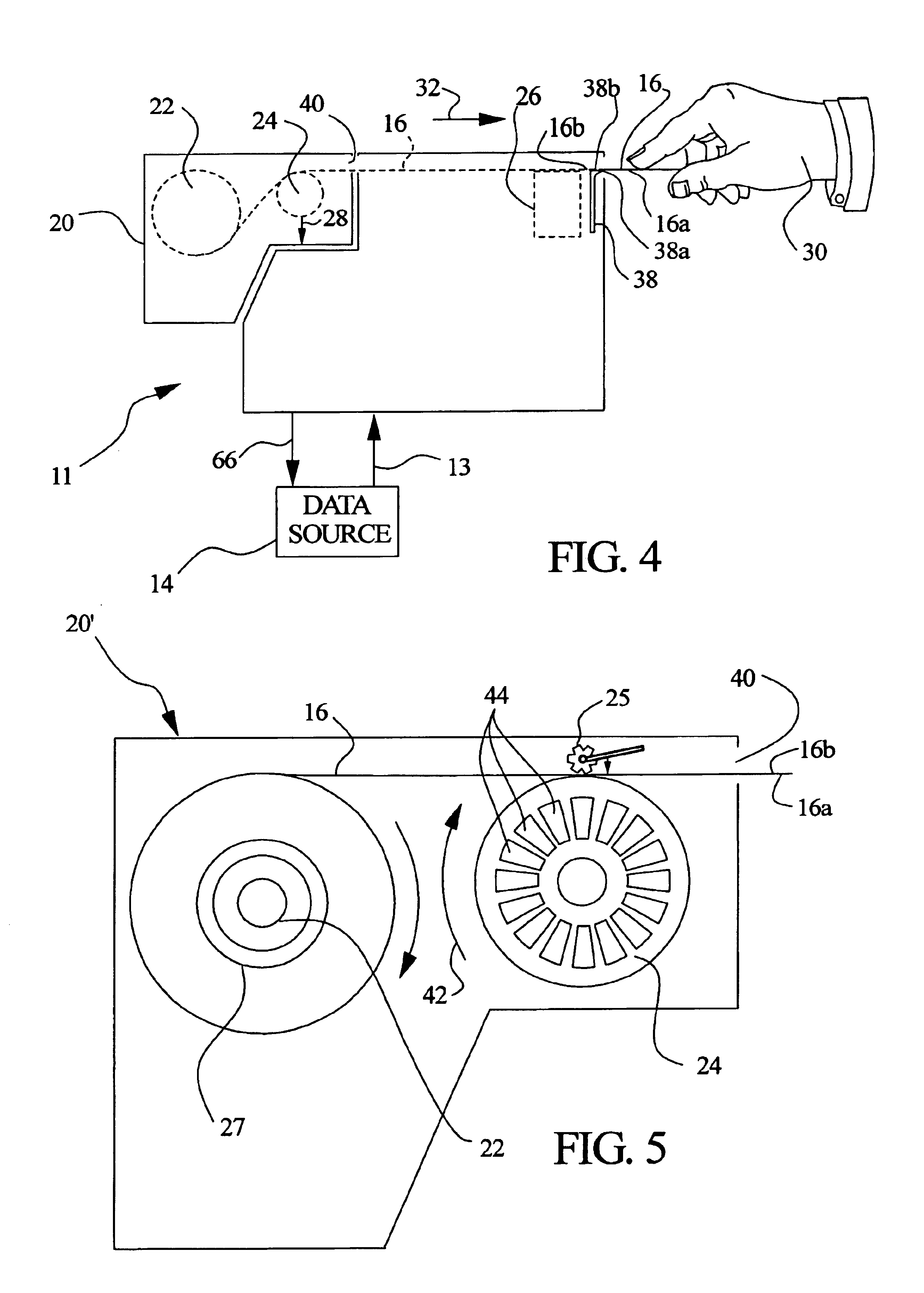

Label-making inkjet printer

A label making inkjet printer applies print imaging directly to the adhesive side of a media provided in sheet-form and in reel-form. Because inkjet printing is a non-contact printing method, print imaging may be applied to the adhesive side of the media According to one embodiment, a user manually pulls tape-form media through the printer while encoding signals detect linear movement of the media and provide basis for synchronizing operation of an inkjet print head. According to another embodiment, a motorized media transport carries tape-form media on a pair of media transport belts past an inkjet print head. The resulting adhesive label when applied to a contact surface substantially disappears due to its transparent nature leaving visible only print imaging applied thereto and captured between the protective tape media and contact surface therebelow.

Owner:HEWLETT PACKARD DEV CO LP

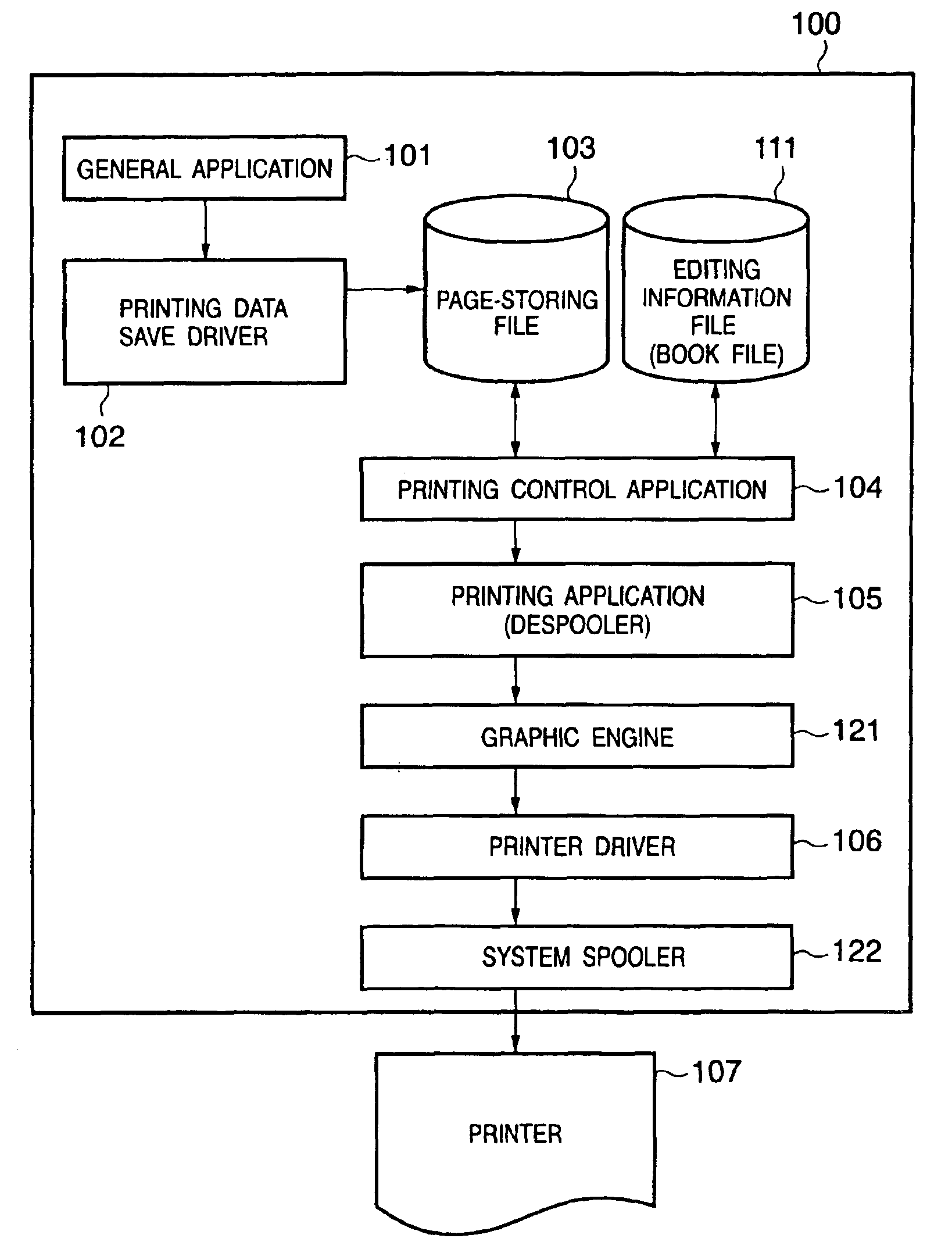

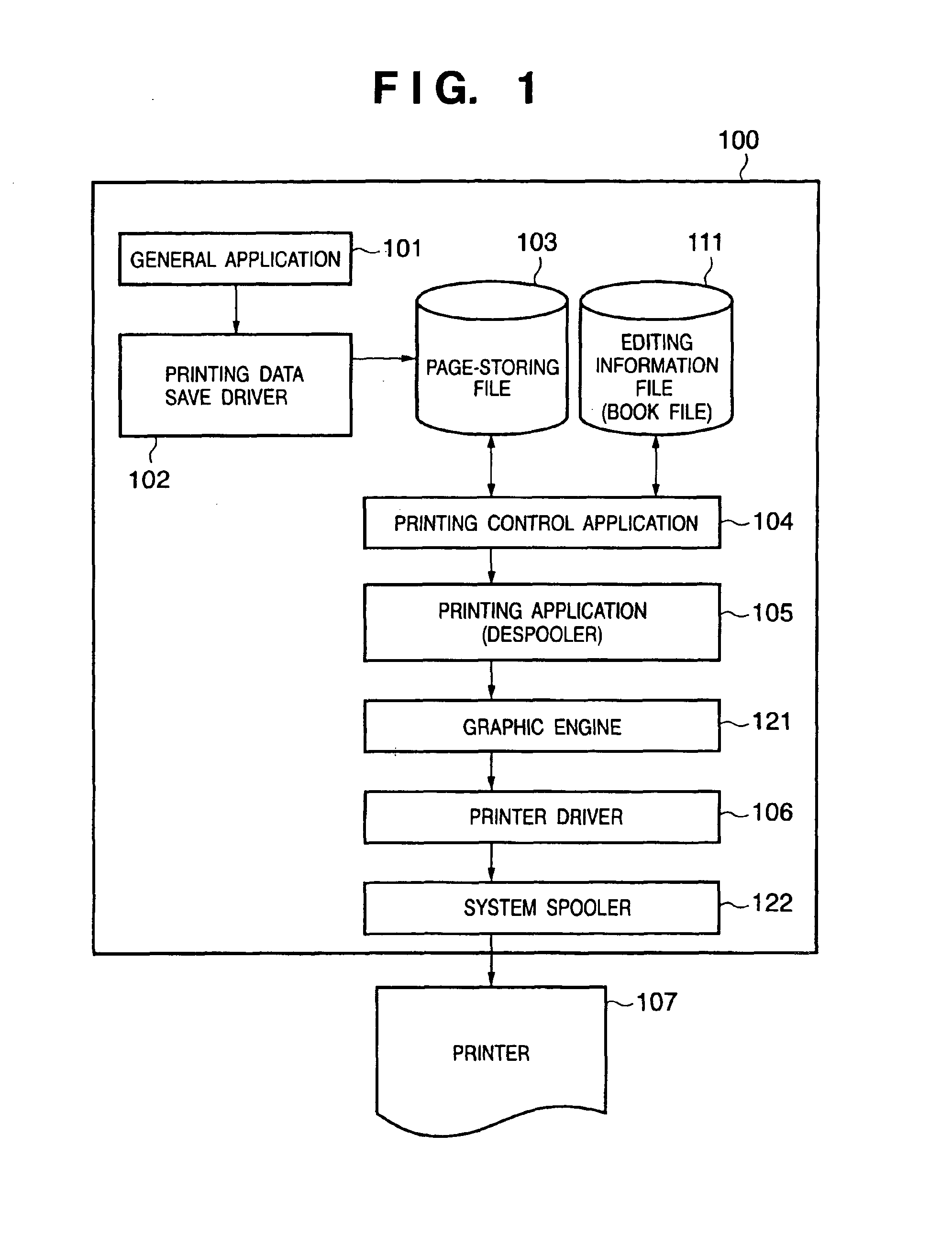

Printing control method and apparatus

ActiveUS6883981B2Efficient executionSpeed and maintenance costDigitally marking record carriersPlaten pressesLayered structureComputer program

This invention relates to a printing control method and apparatus, a computer program product, and the like in which printing data is held in a hierarchical structure and a printing job is issued to a printer to cause the printer to print. In the printing control method according to the present invention, different setting values can be set in the lower and upper layers of the hierarchical structure as printing setting data containing double-sided printing or single-sided printing setting. When a setting value different from that of the upper layer is set in the lower layer of the hierarchical structure, the printer is instructed on a setting in the lower layer for each printing data to which the setting value is applied.

Owner:CANON KK

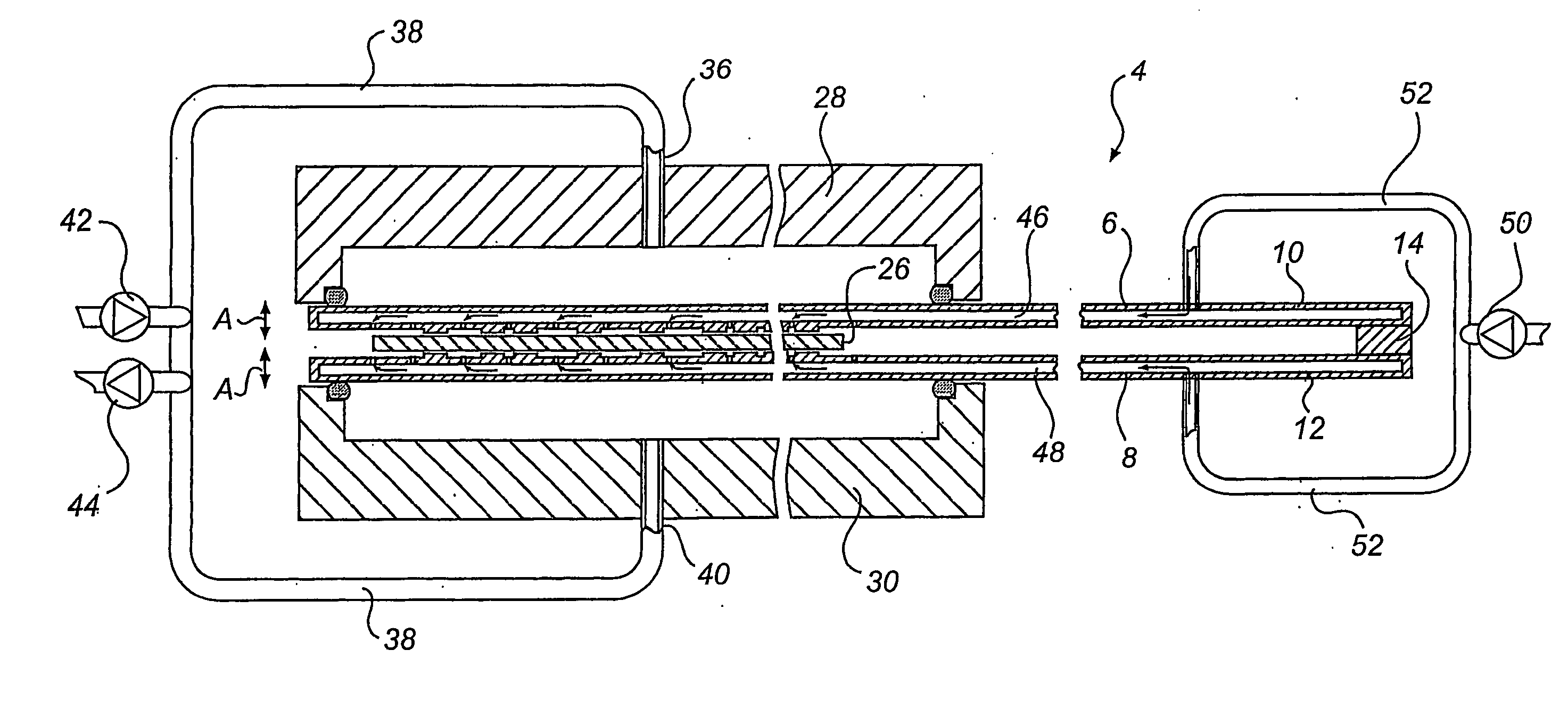

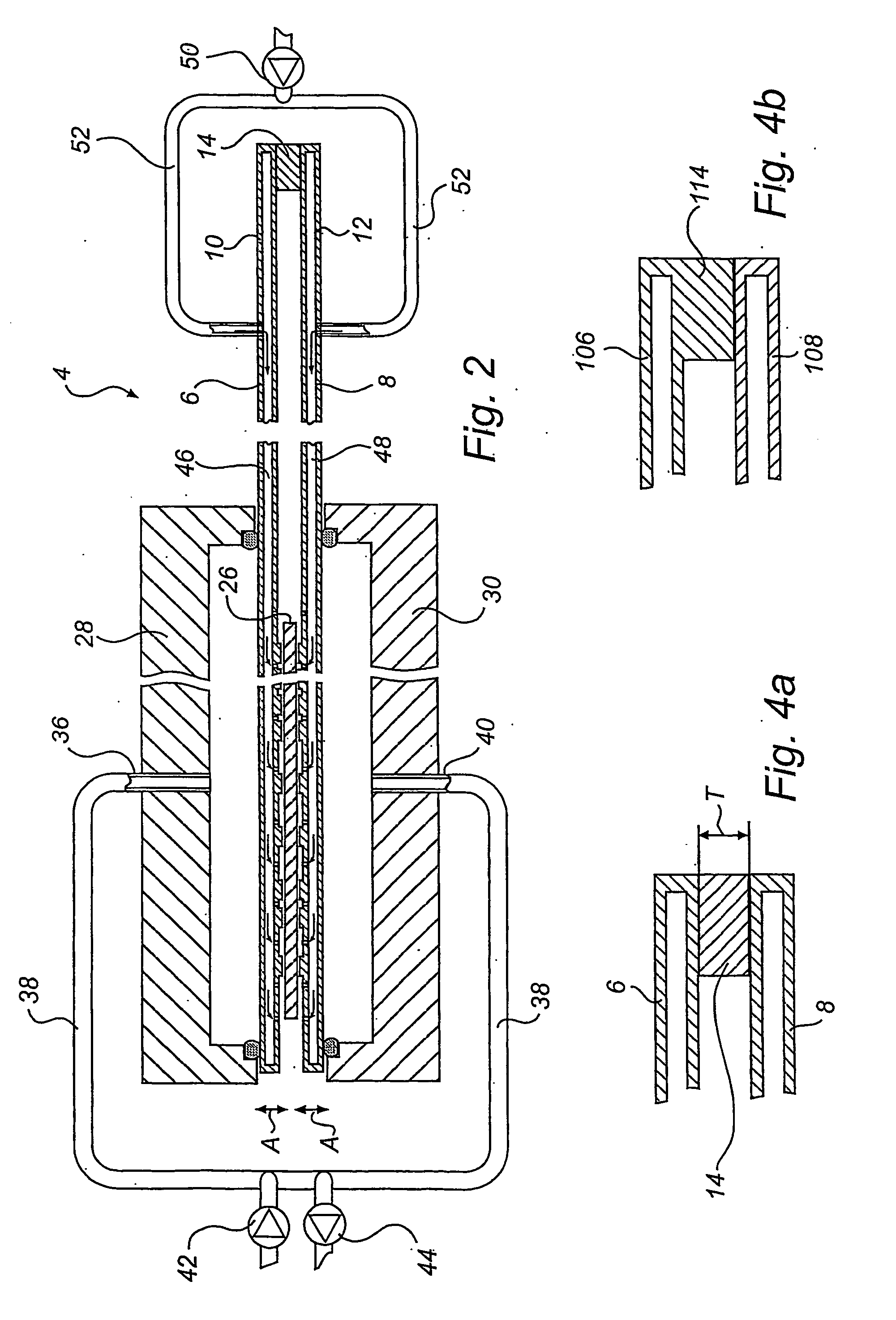

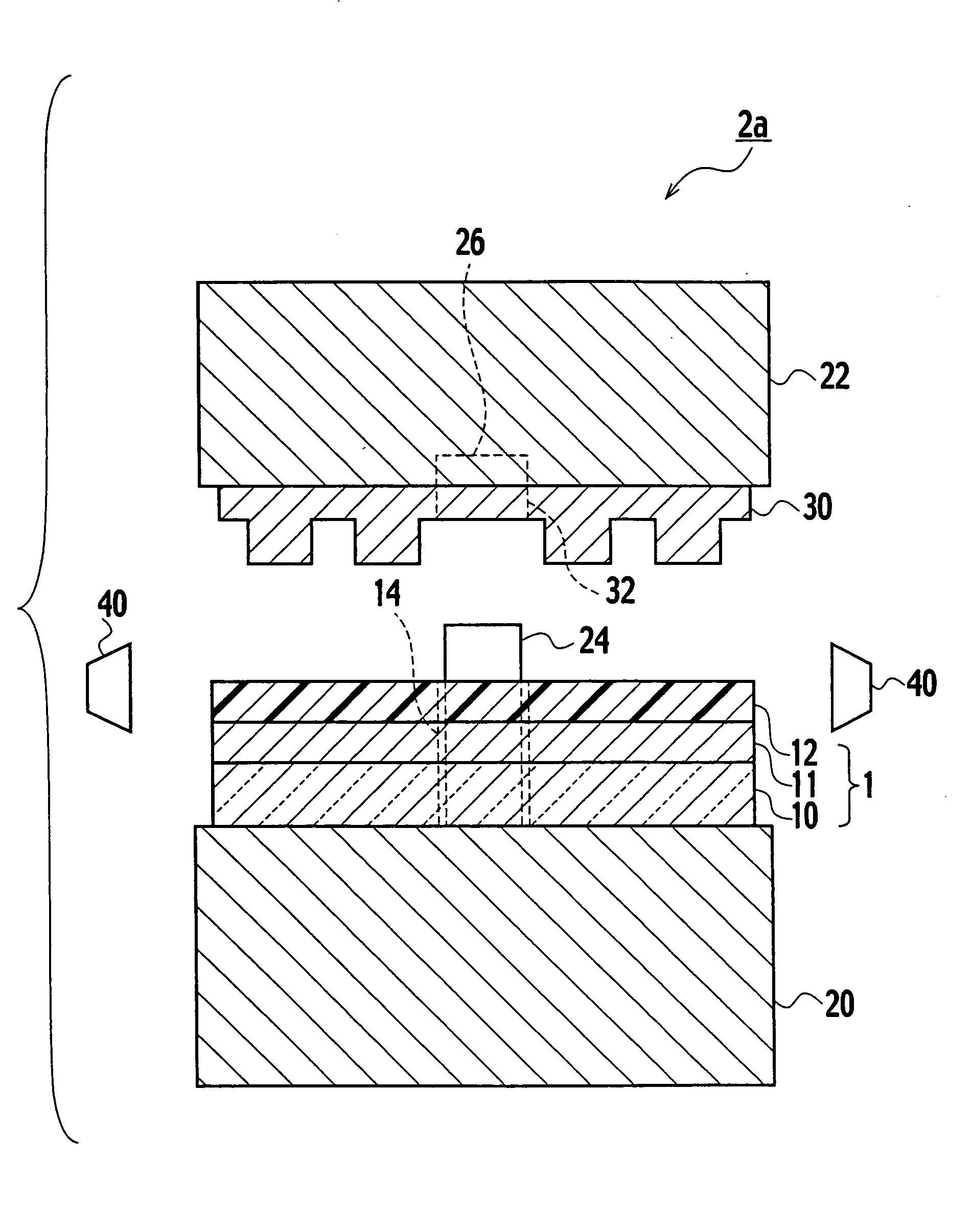

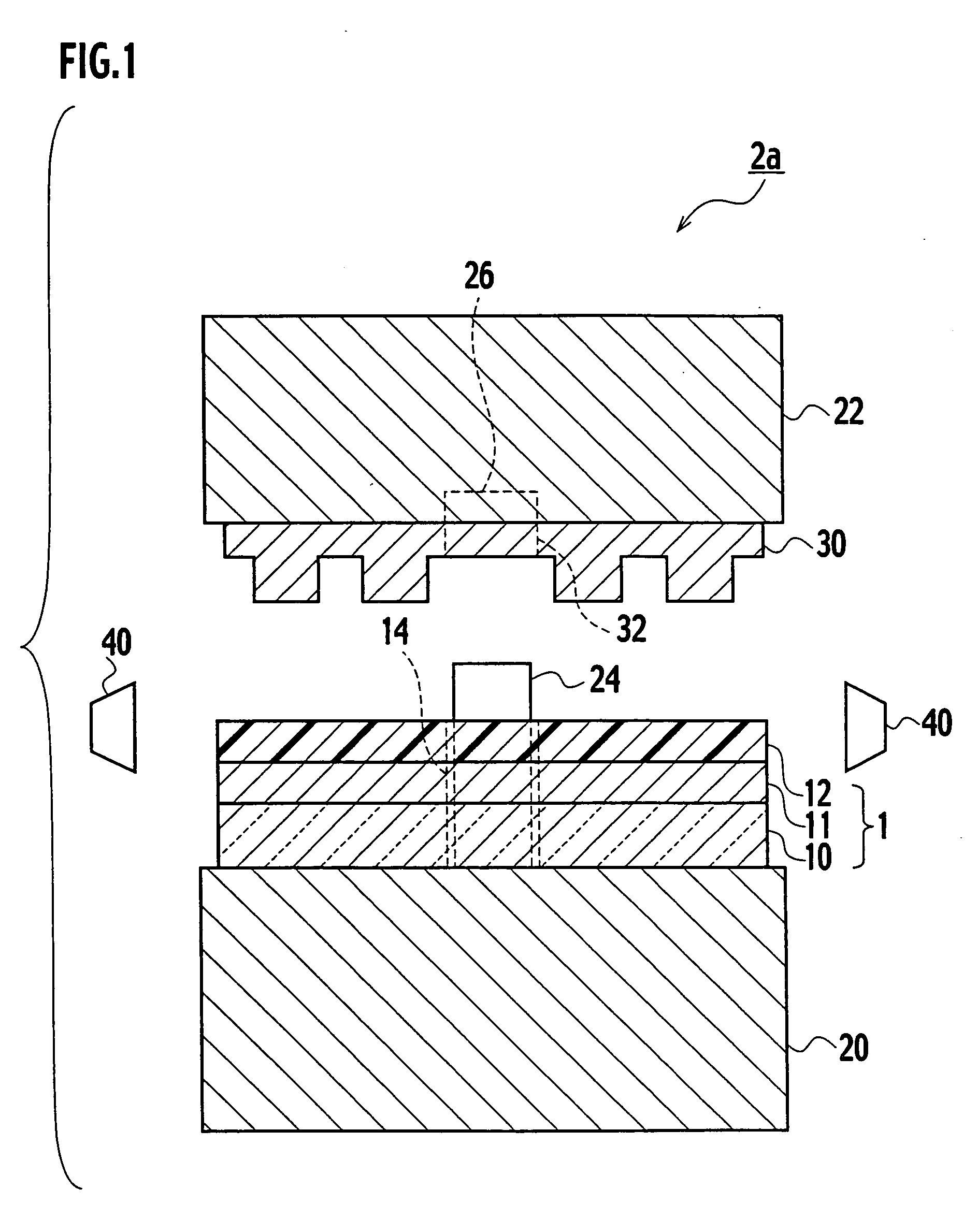

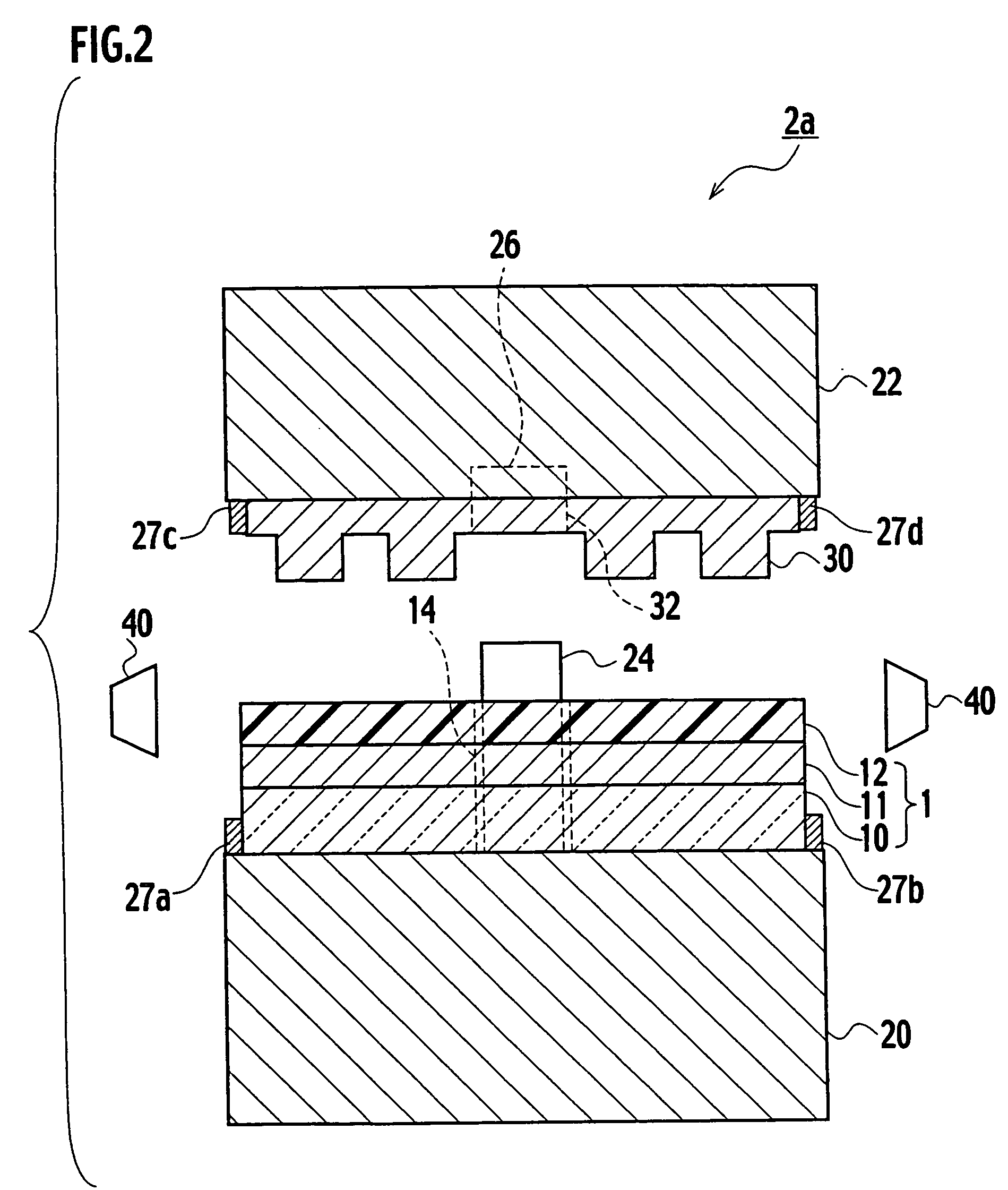

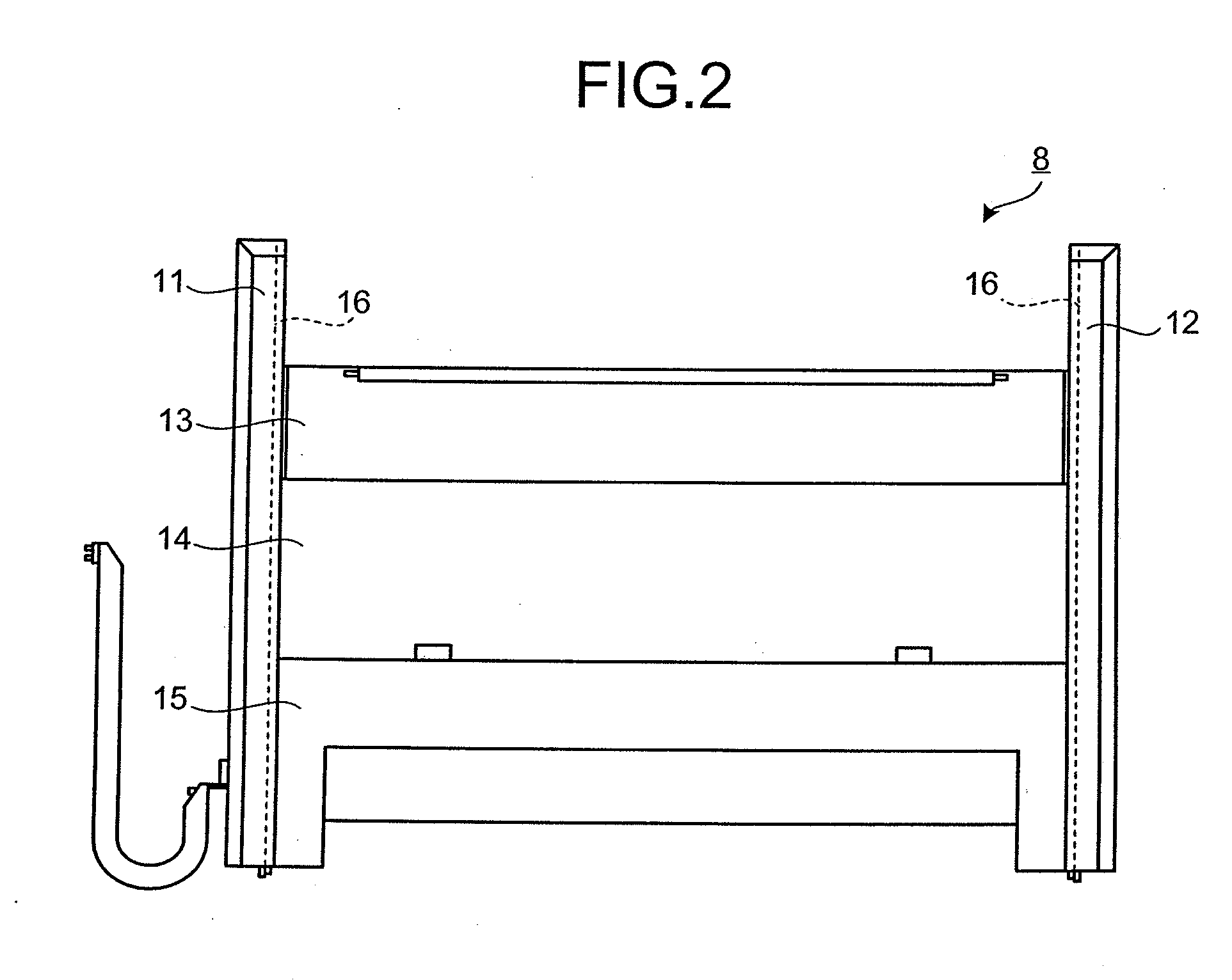

Device and method for transferring a pattern to a substrate

InactiveUS20050172848A1Efficiently patternAddressographsDecorative surface effectsEngineeringNanostructure

A device (4) for transferring patterns, especially micro- or nanostructures, to at least two faces of a substrate (26) comprises a first stamping plate (6) having a patterned area provided thereon for forming a first pattern on a first face of said substrate (26), a second stamping plate (8) having a patterned area provided thereon for forming a second pattern on a second face of said substrate (26), and a contacting means (28, 30) for contacting the respective patterned areas of the two stamping plates (6, 8) with the respective faces of said substrate (26). The first and the second stamping plates (6, 8) are aligned with each other and are secured to each other at respective holding areas (10, 12) of the stamping plates (6, 8) located at a distance from the patterned areas.

Owner:OBDUCAT AB SE

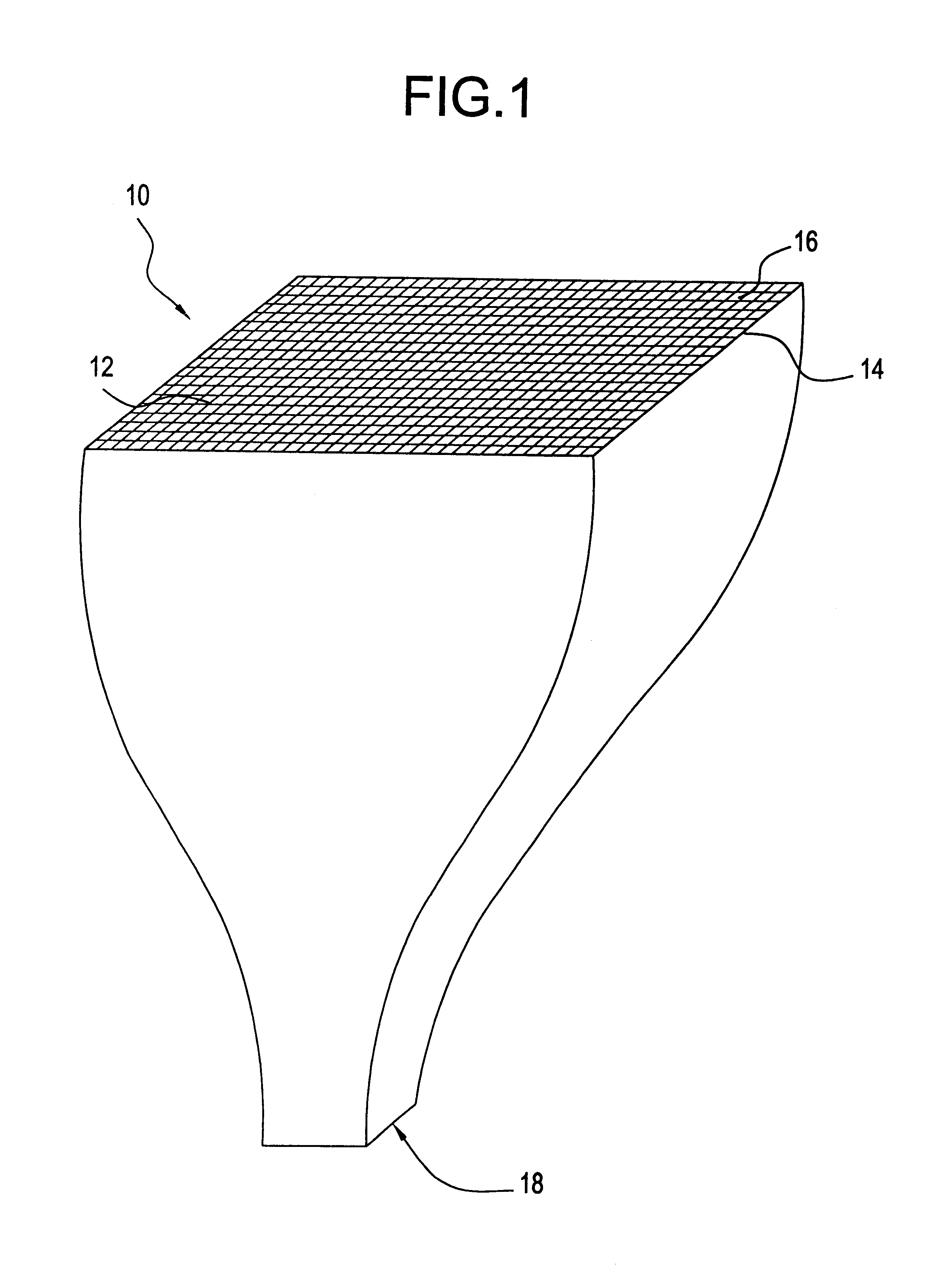

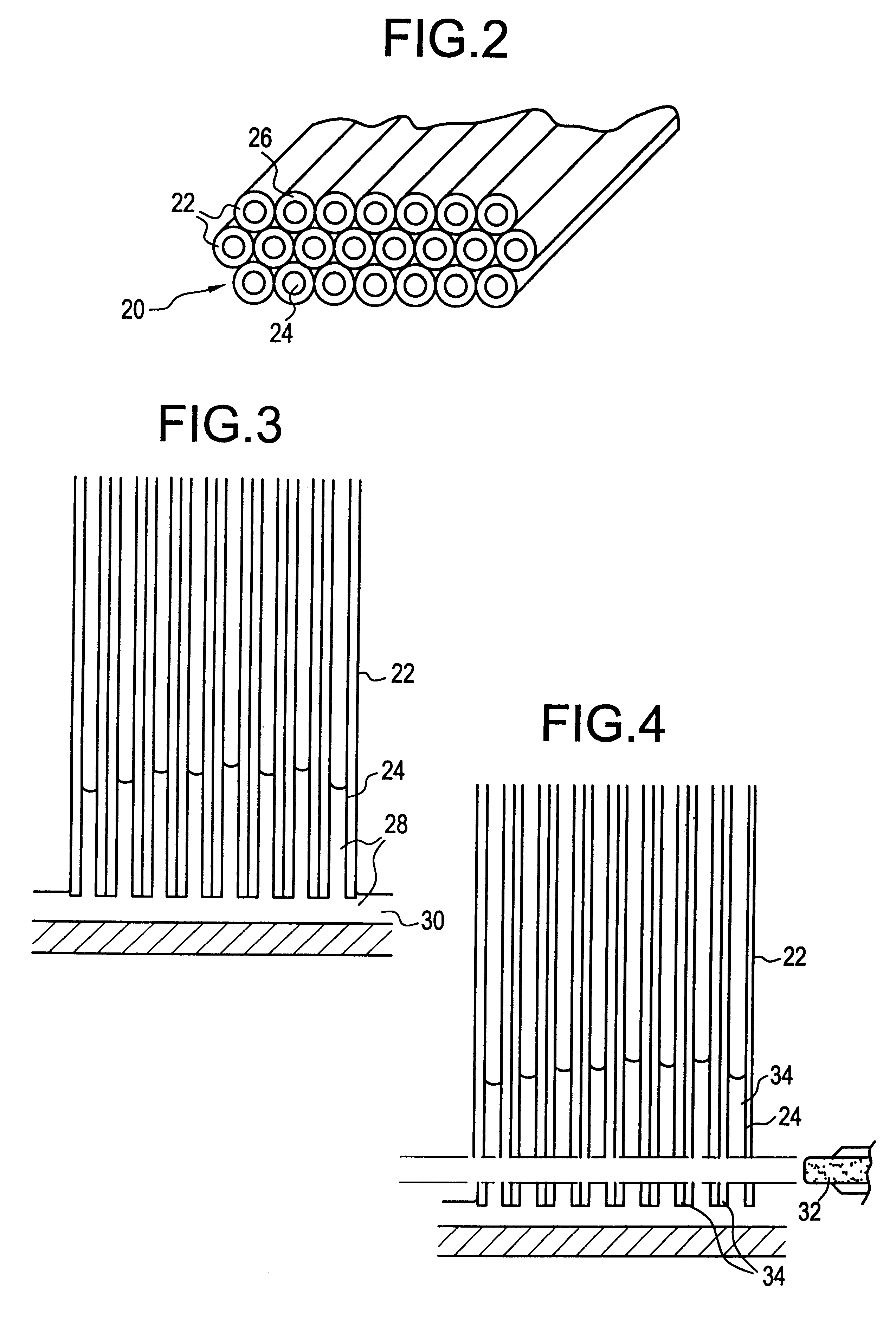

Redrawn capillary imaging reservoir

InactiveUS6762061B1ConstantWell formedSequential/parallel process reactionsTypewritersHigh densityCapillary pressure

Methods and apparatus for depositing a high density biological or chemical array onto a solid support. Specifically, the apparatus is made up of a plurality of open ended channels collectively forming a matrix. The matrix has been redrawn and cut such that the pitch of the channels on the loading end is larger than the pitch of the channels on the liquid delivery end. The upper portion of each channel serves as a reservoir, while the opposing end, which has been formed by the redrawing process, is diametrically sized such that liquid in the reservoir is retained by capillary pressure at the delivery end. At any point along the height of the capillary reservoir device, all cross-sectional dimensions and areas are uniformly reduced. In other words, the on-center orientation of any two channels, also referred to as the pitch between 2 channels, measured as a function of the diameter of any cross section, is constant throughout the structure. The liquid within the channels is either printed directly from the tool onto a substrate or transferred to a substrate by a typographical pin plate. In another embodiment, the device may be used in transferring sample between multiwell plates of different well density.

Owner:CORNING INC

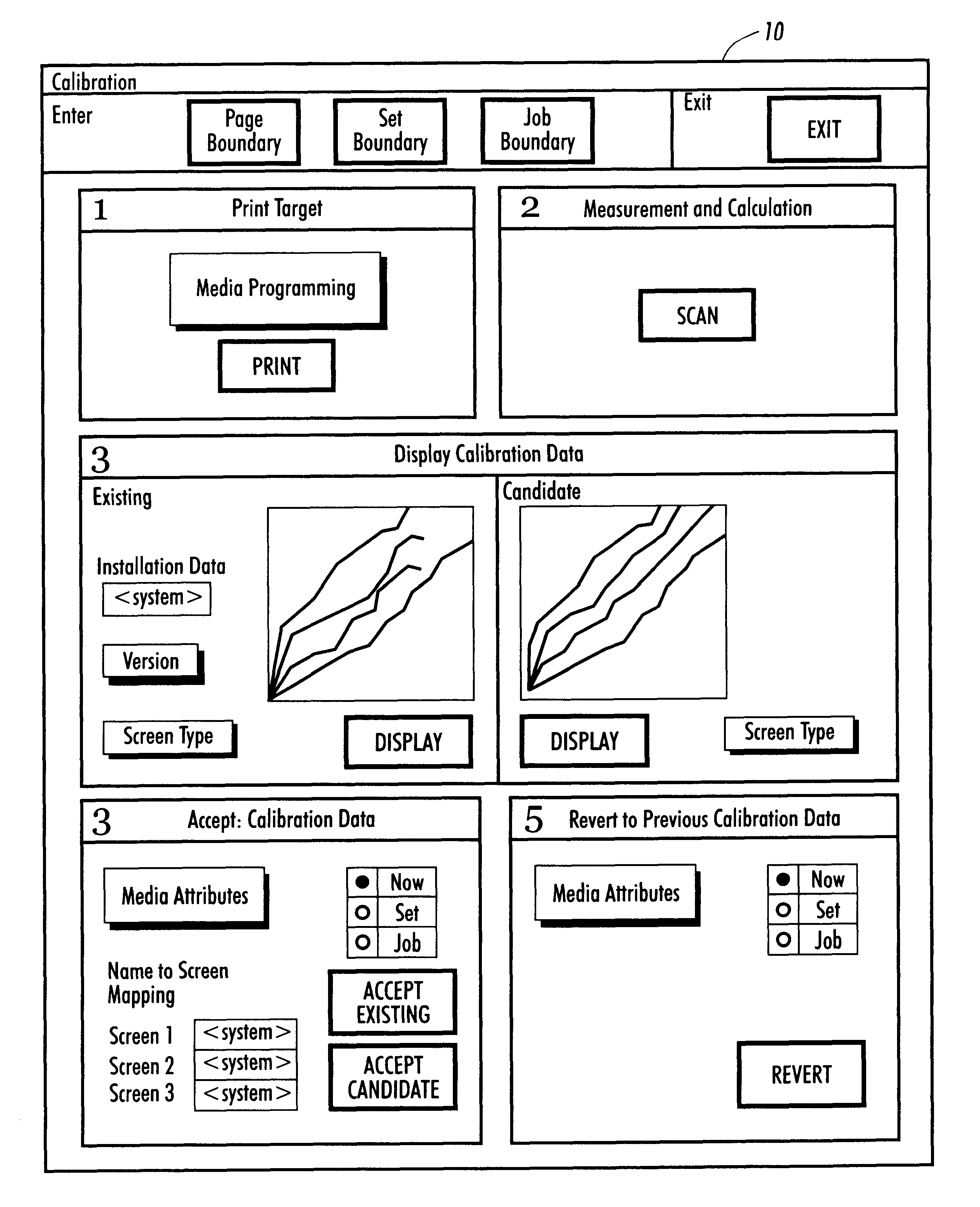

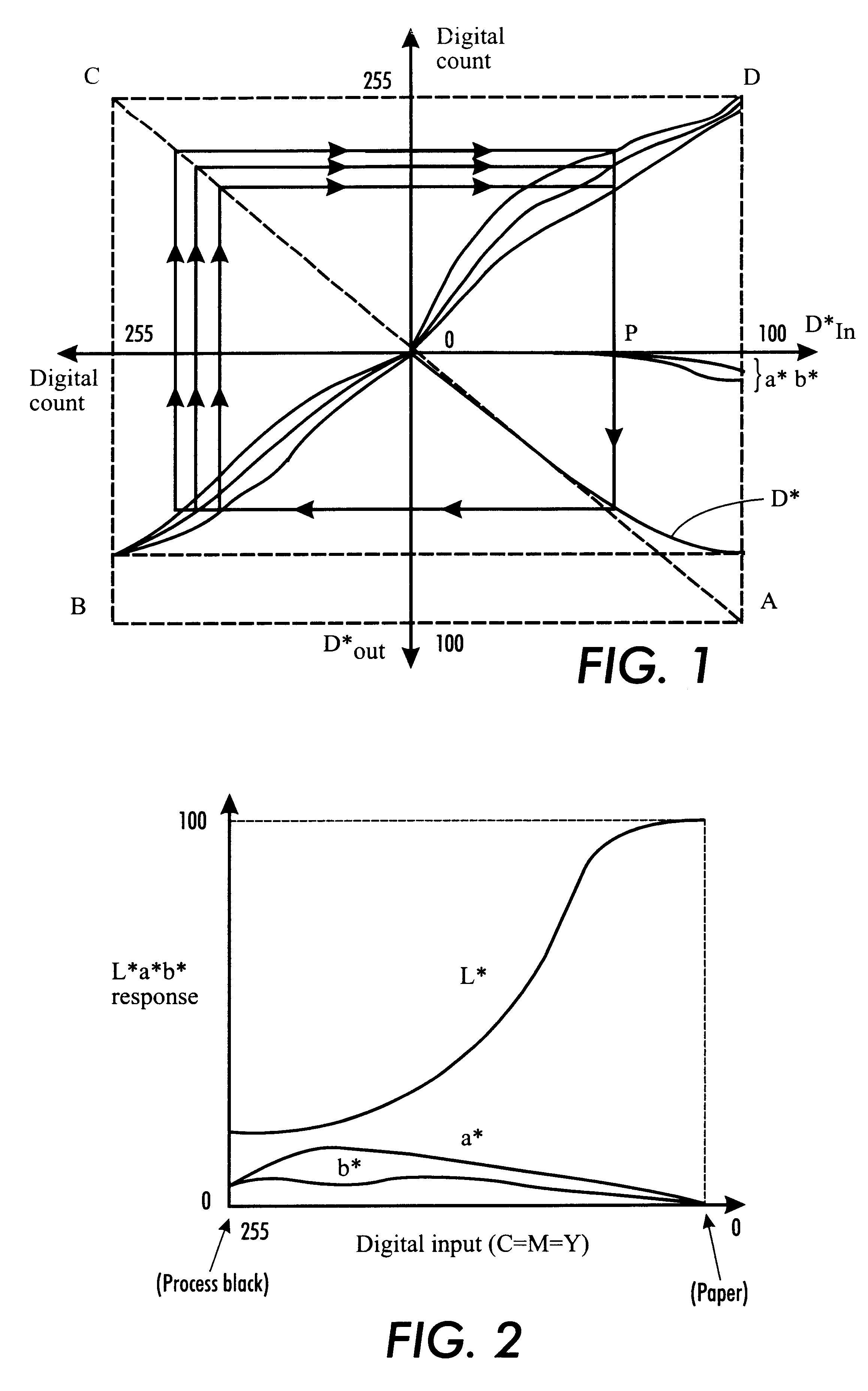

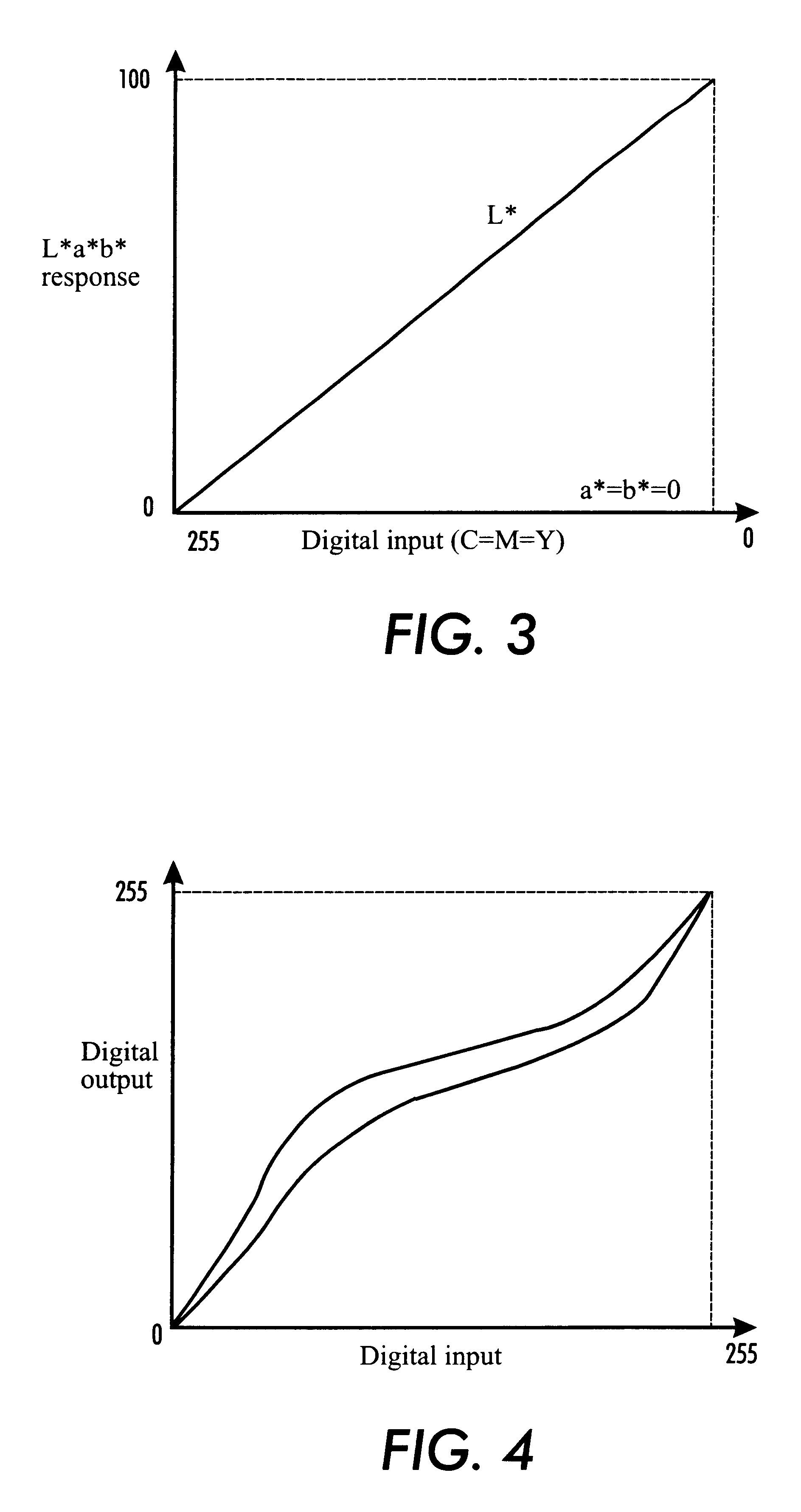

Method and system of individualizing tone-reproduction curves calibration and applying thereof

A method and system updates individualized calibrated tone-reproduction curves. A plurality of predetermined stored calibrated tone-reproduction curves are used, each predetermined stored calibrated tone-reproduction curve corresponding to a distinct media type and halftone type combination along with a plurality of predetermined relationships between each stored calibrated tone-reproduction curve and a reference media type and reference halftone type combination. A new tone-reproduction curve corresponding to a reference media type and reference halftone type combination calibration operation is generated, and each predetermined stored calibrated tone-reproduction curves based on the newly generated tone-reproduction curve corresponding to the reference media type and reference halftone type combination and the plurality of predetermined relationships between each stored calibrated tone-reproduction curve and the reference media type and reference halftone type combination is updated. The TRCs can be applied upon a page basis. Moreover, generated TRCs can be mapped to existing TRCs to save memory.

Owner:XEROX CORP

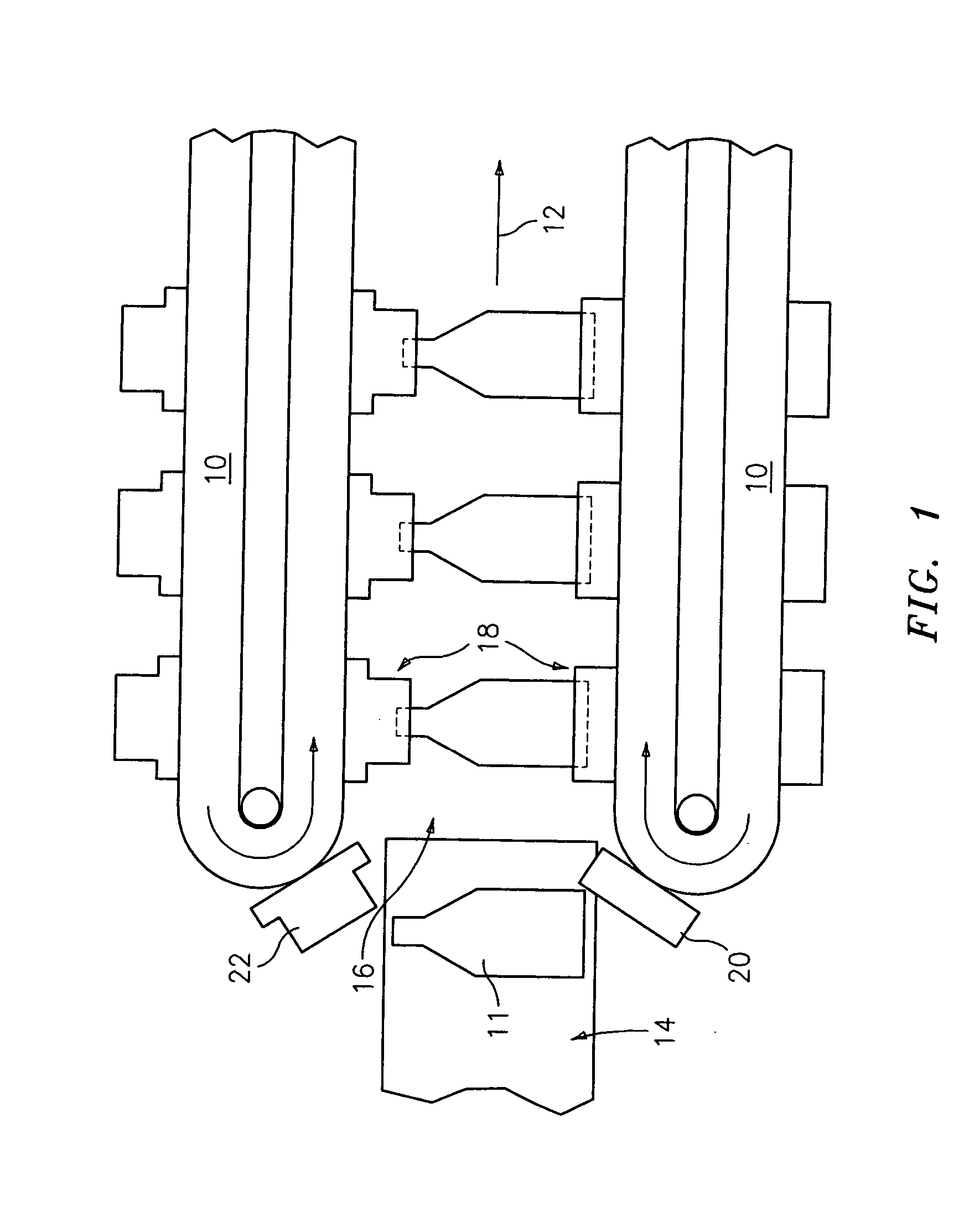

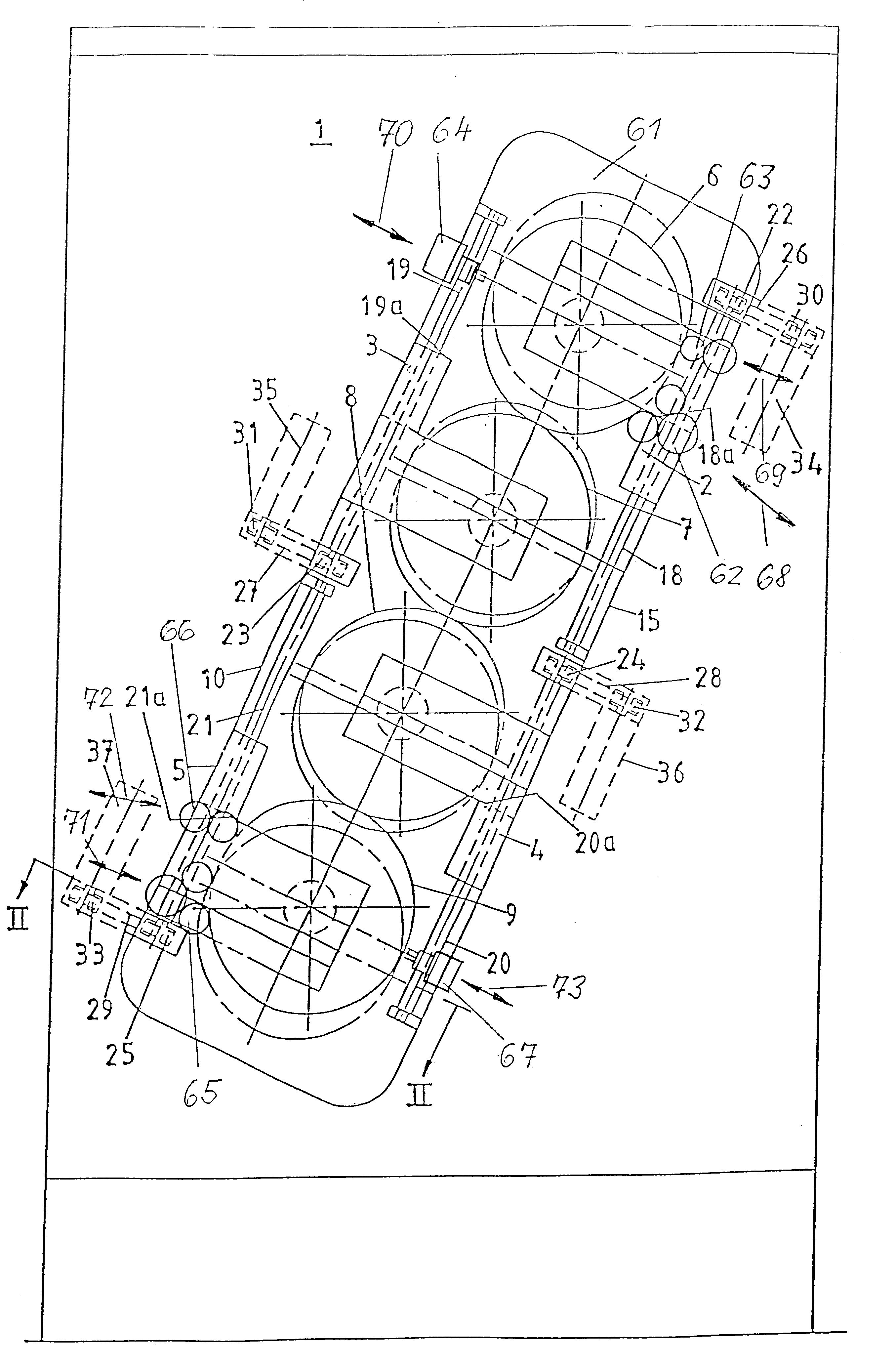

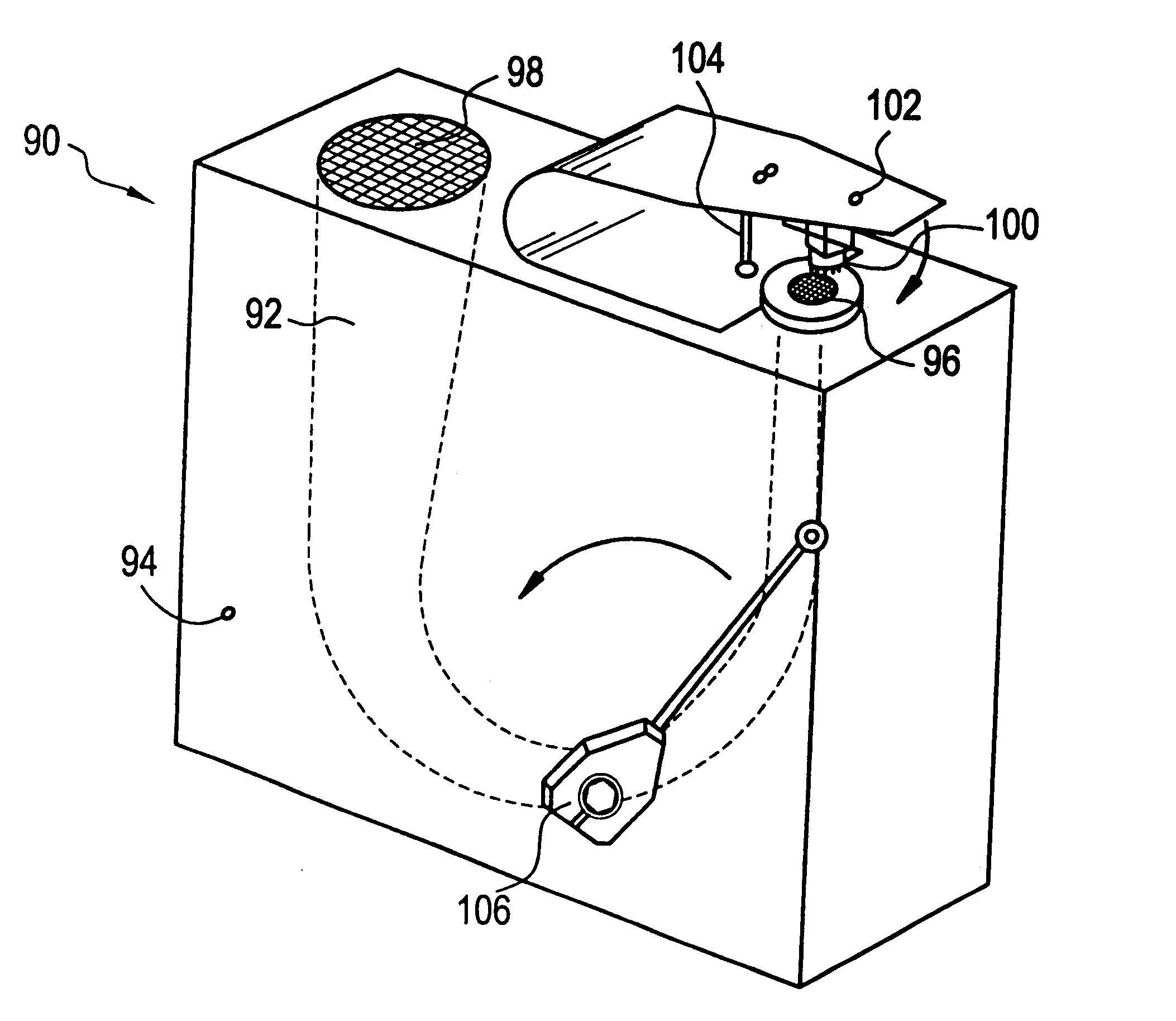

Printing unit for a rotary printing machine with cross slide

InactiveUS20010035104A1Long constructionEfficient introductionCylinder pressesAddressographsEngineeringPrinting press

Rotary printing machine with forme and impression cylinders for variable-format or variable-circumference printing and with service apparatus which are capable of being moved radially in relation to the printing-unit cylinders for throw-on or throw-off movements and in the axial direction of the cylinders or in the side-wall plane. The service apparatus and the printing-unit cylinders are arranged on cross slides which can each be moved in two directions relative to the printing-unit side wall.

Owner:MANROLANAD AG

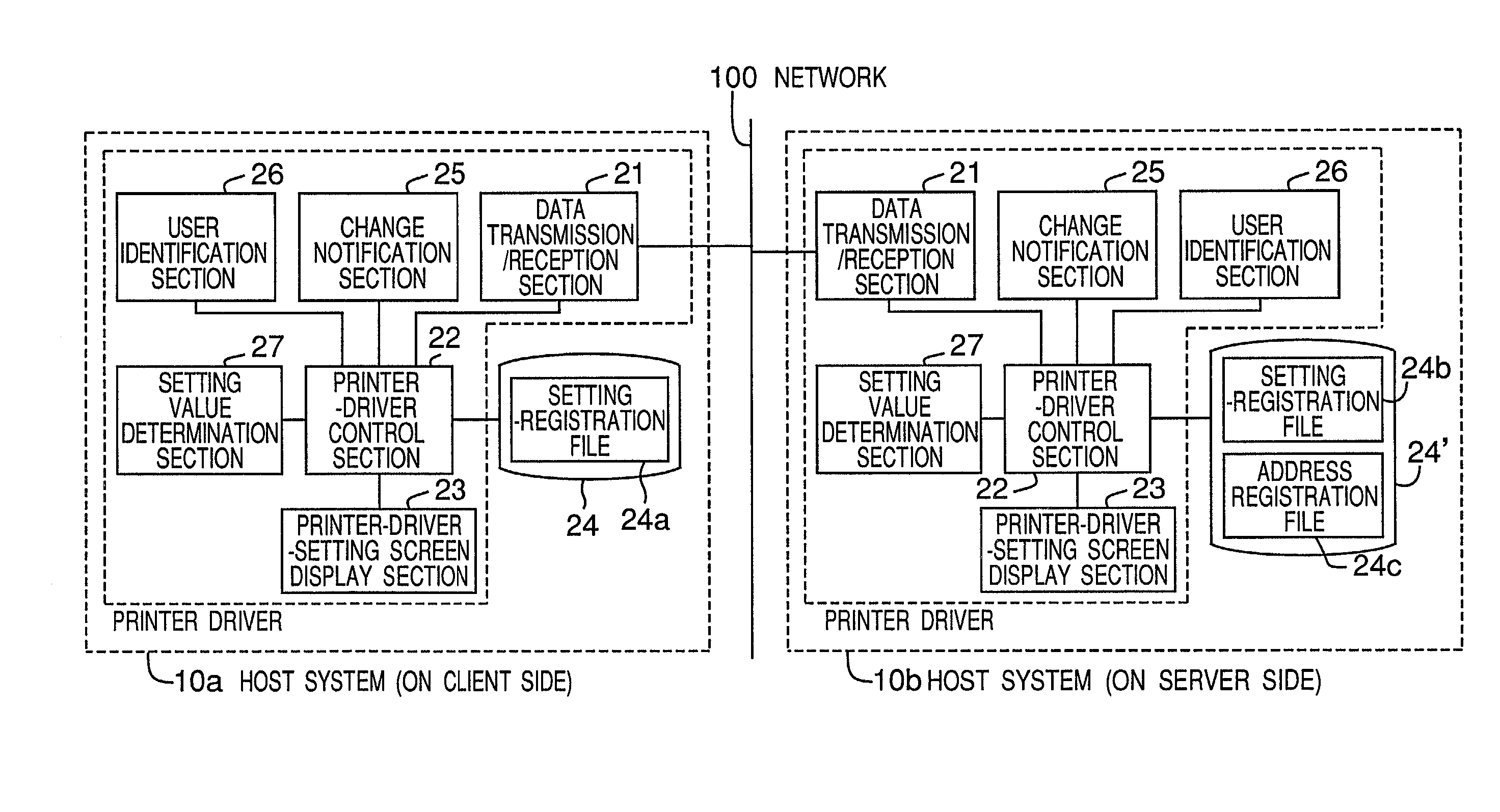

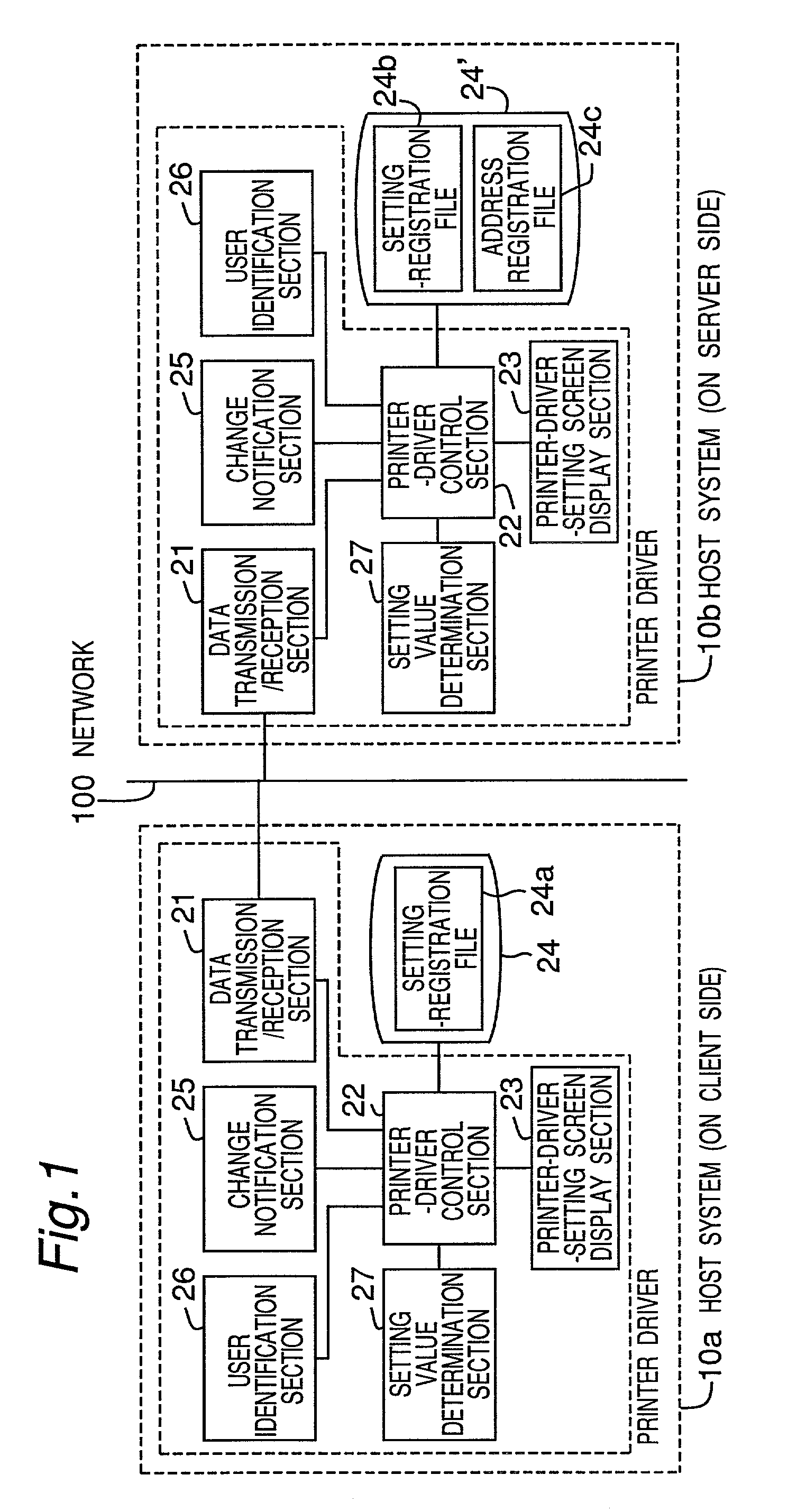

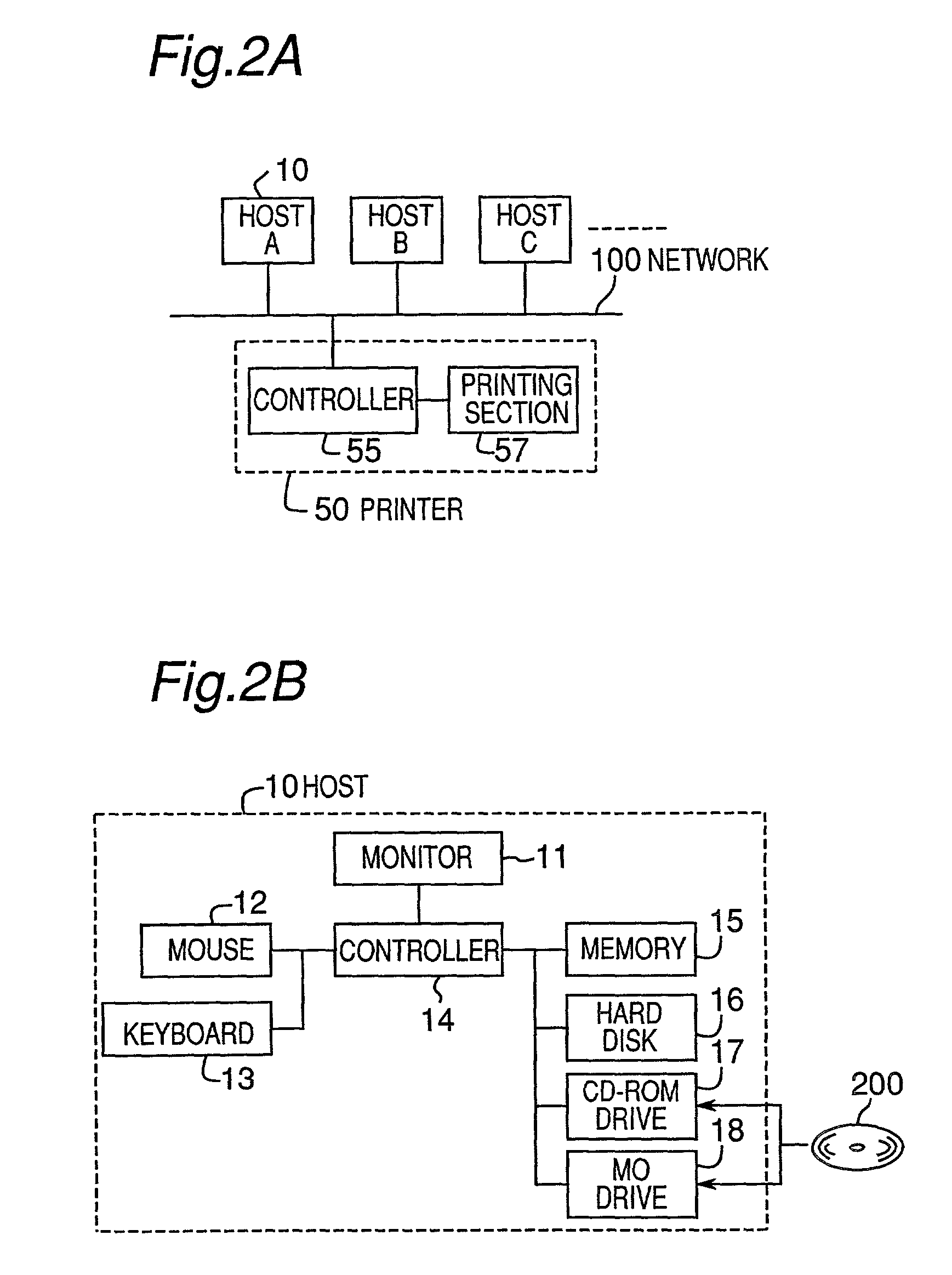

Data processing apparatus, print-setting method, and recording medium

In the data processing apparatus which performs a predetermined process over data to be printed on a printer according to the printer, and then transfers the data, groups of various printing setting values and registration names each identifying each group are mutually correlated and registered in setting-registration files for each user who uses the apparatus. When a printing request is received from one of the users, a setting window displays registration names indicating the groups of the setting values which are registered for each user and correspond to the user so that the user can select one of groups. One of the registration names displayed on the setting window is selected by the user. The apparatus performs the predetermined process for printing to the data to be printed in accordance with the various setting values included in the group corresponding to the selected registration name.

Owner:MINOLTA CO LTD

Platen roller assemblies for printer and methods of removal therefrom

A platen roller assembly for a printer includes a platen roller, a retaining clip, a plurality of bearings, and a pulley assembly. The platen roller defines a longitudinal axis. The retaining clip mounts to a support body of the printer and is positioned to retain the platen roller relative to the support body. The plurality of bearings are operably coupled to the platen roller. Each of the bearings permit rotational movement of the platen roller about the longitudinal axis thereof. The pulley assembly is mounted to the support body and is operably associated with one or more of the bearings. The pulley assembly includes a pulley and a belt. The belt is operably coupled to the pulley such that the platen roller rotates in response to rotational movement of the belt. The platen roller may be selectively coupled and uncoupled to / from the support body independent of the pulley assembly.

Owner:HAND HELD PRODS

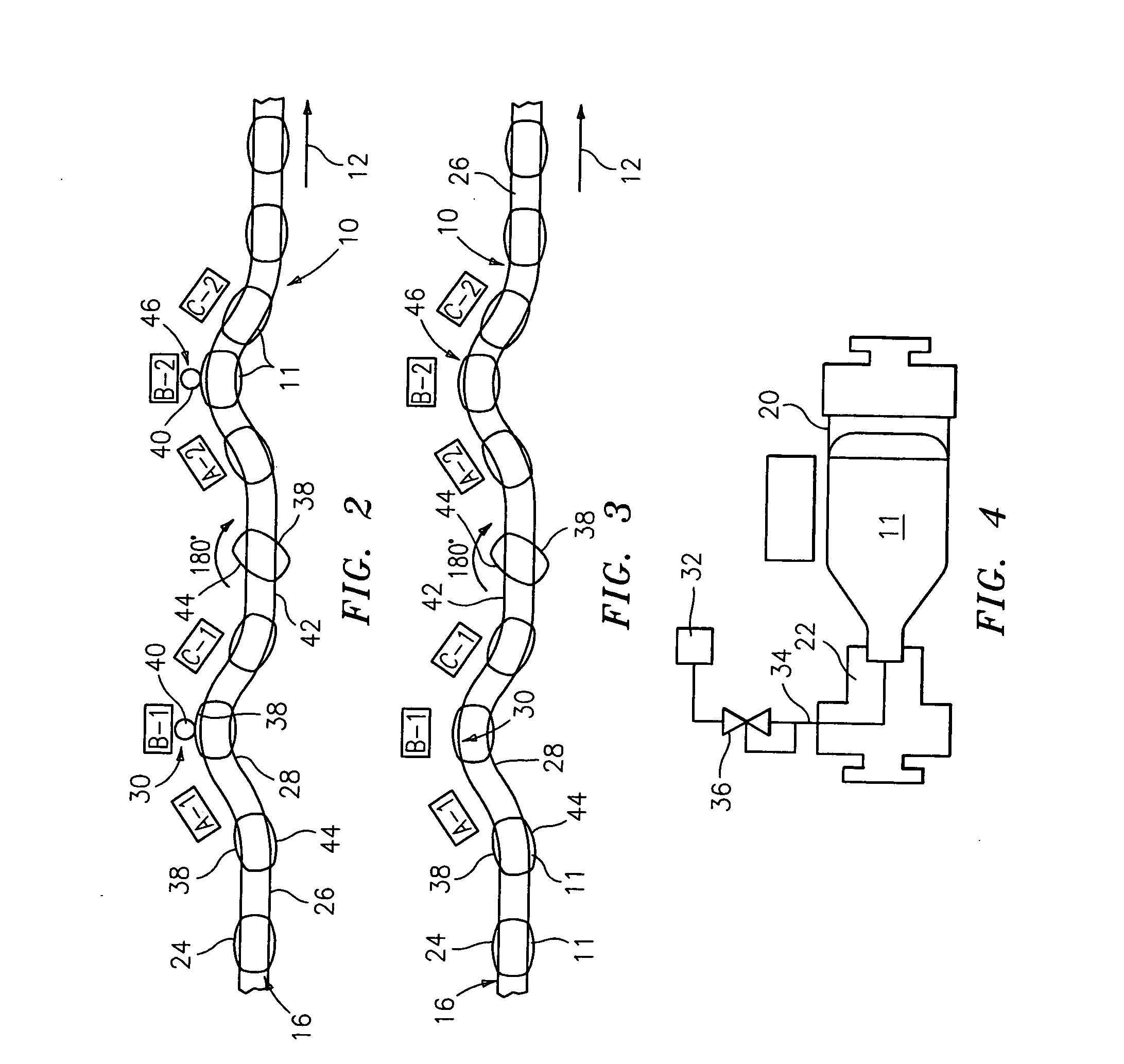

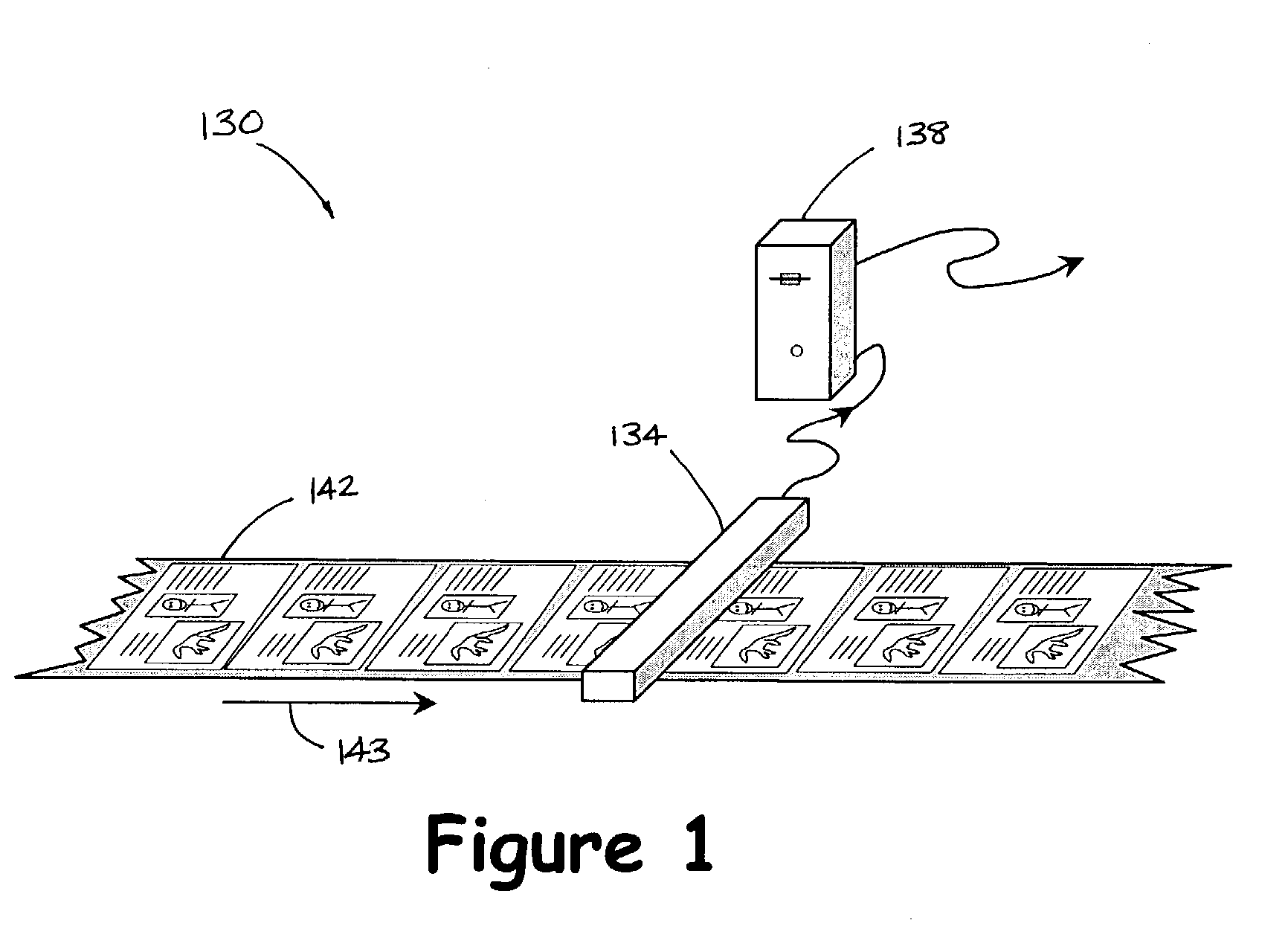

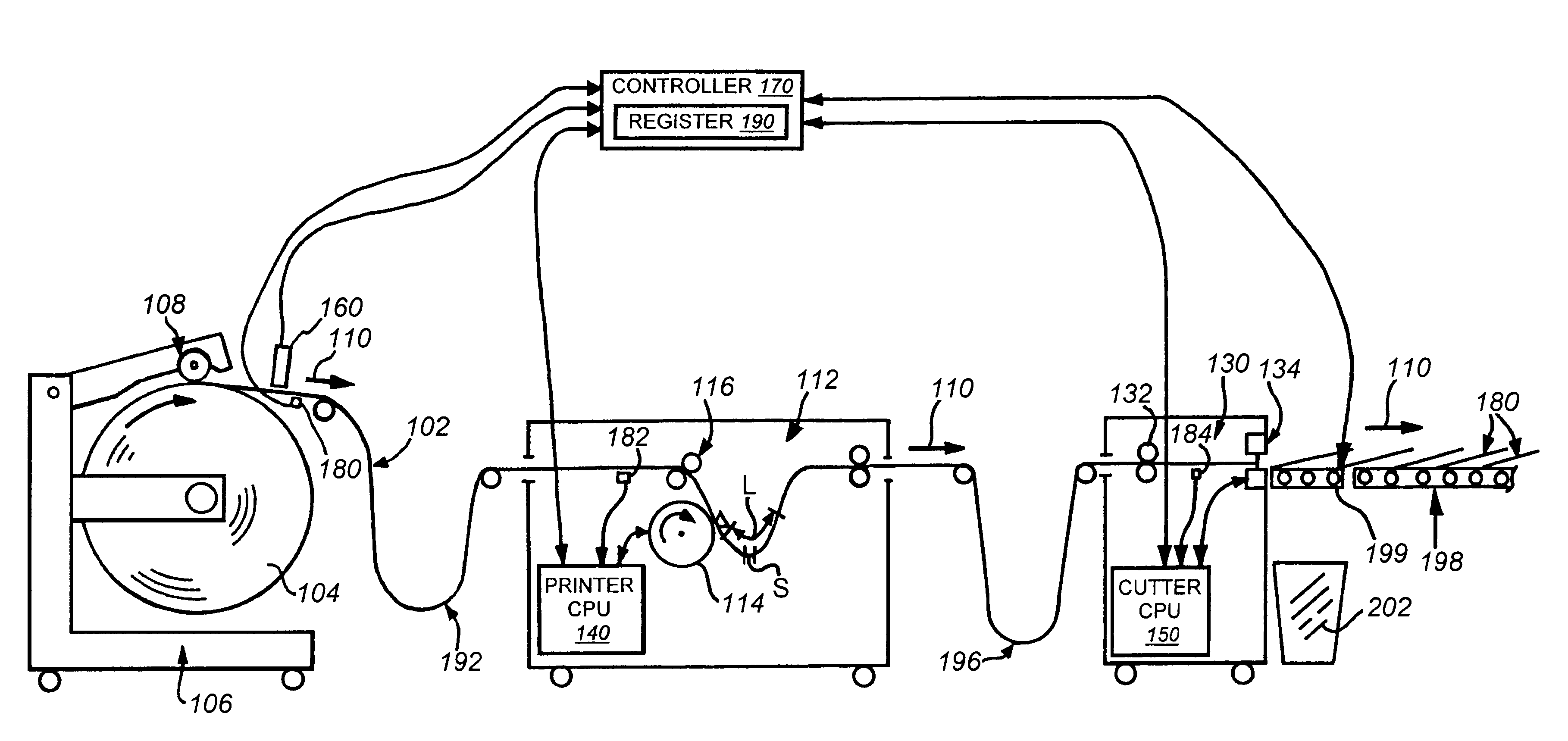

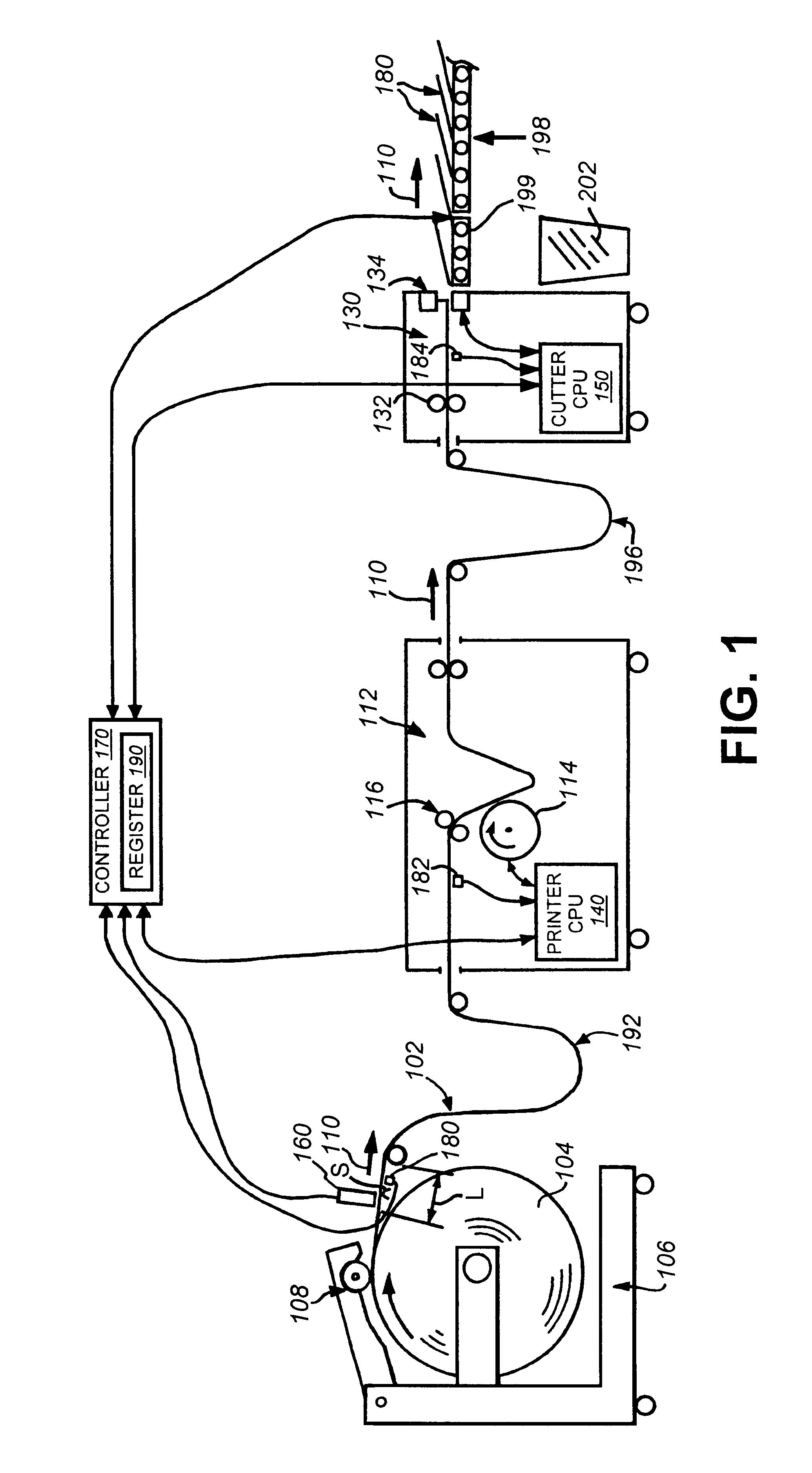

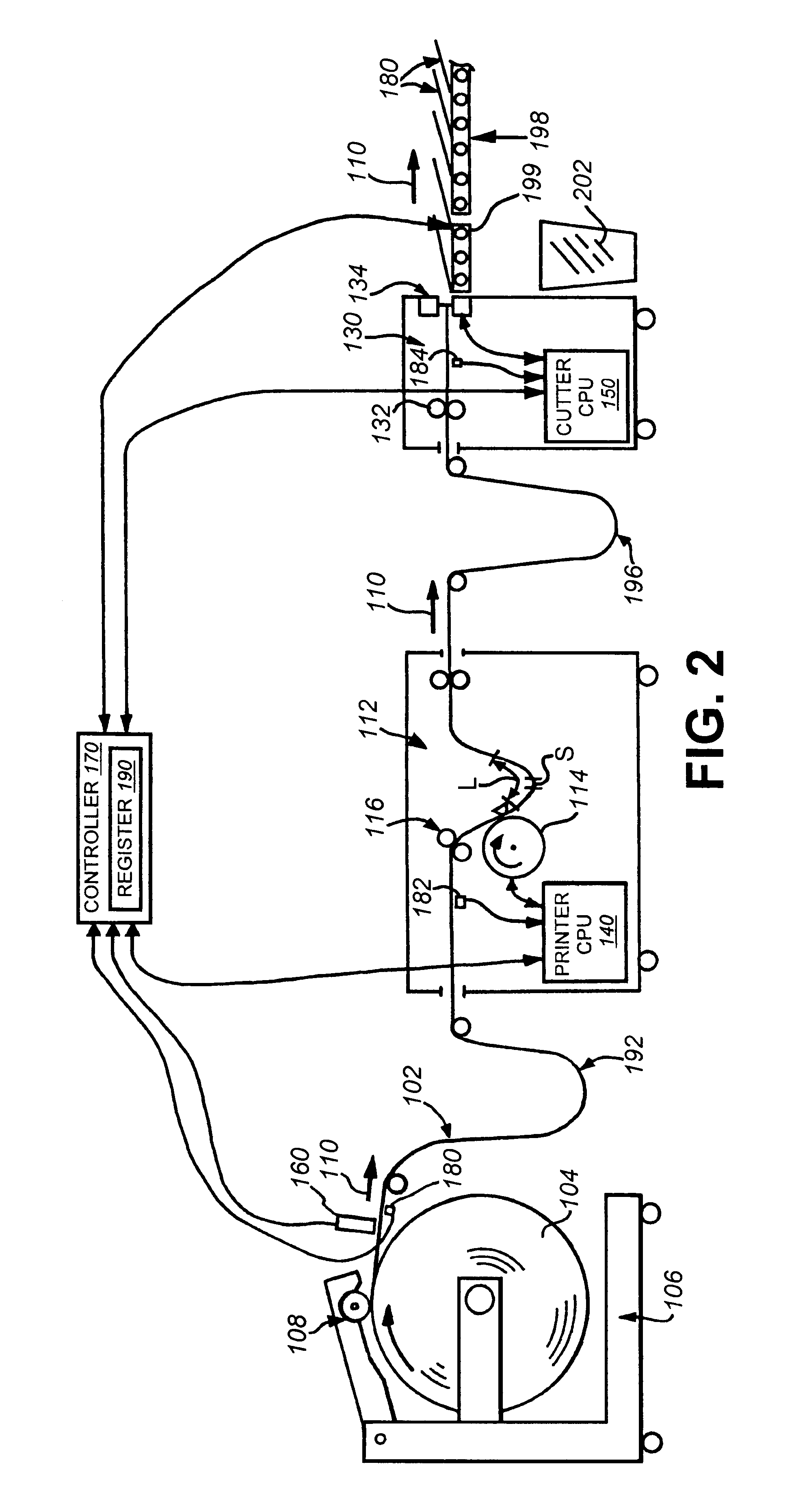

System and method for utilizing web from a roll having splices

A system and method for detecting and diverting sections of web having splices on a continuous web is provided. A splice detector is located adjacent a source of continuous web, typically a roll. The movement of the web from the roll is tracked, and the relative location of the splice within the web stream is noted by a controller. Downstream, a web utilization device is provided with a movement detector also connected to the controller. Movement of the splice-containing section through utilization device is tracked so that the splice-containing section is not processed by the utilization device, or is reprocessed on a non-splice-containing section. A cutter is also provided with a movement detector, also connected to the controller. Movement of the web from the utilization device to the cutter is tracked and the section containing the web is cut. A diversion mechanism can be used to remove the cut section of web containing the splice so that it does not appear in the final stream of finished cut sheets.

Owner:ROLL SYST

Imprint apparatus and method for imprinting

An imprint apparatus configured such that it can press a laminate structure in which a magnetic film and a resist film are sequentially laminated on a substrate. The imprint apparatus includes a first press plate configured to mount the laminate structure, a second press plate adapted for sandwiching the laminate structure, a stamper placed on a surface of the second press plate, and has projections and recesses configured to be transferred onto the resist film, and a light source configured to dispose on the same plane as the laminate structure, and is oriented so that the light source can shine the resist film.

Owner:KK TOSHIBA

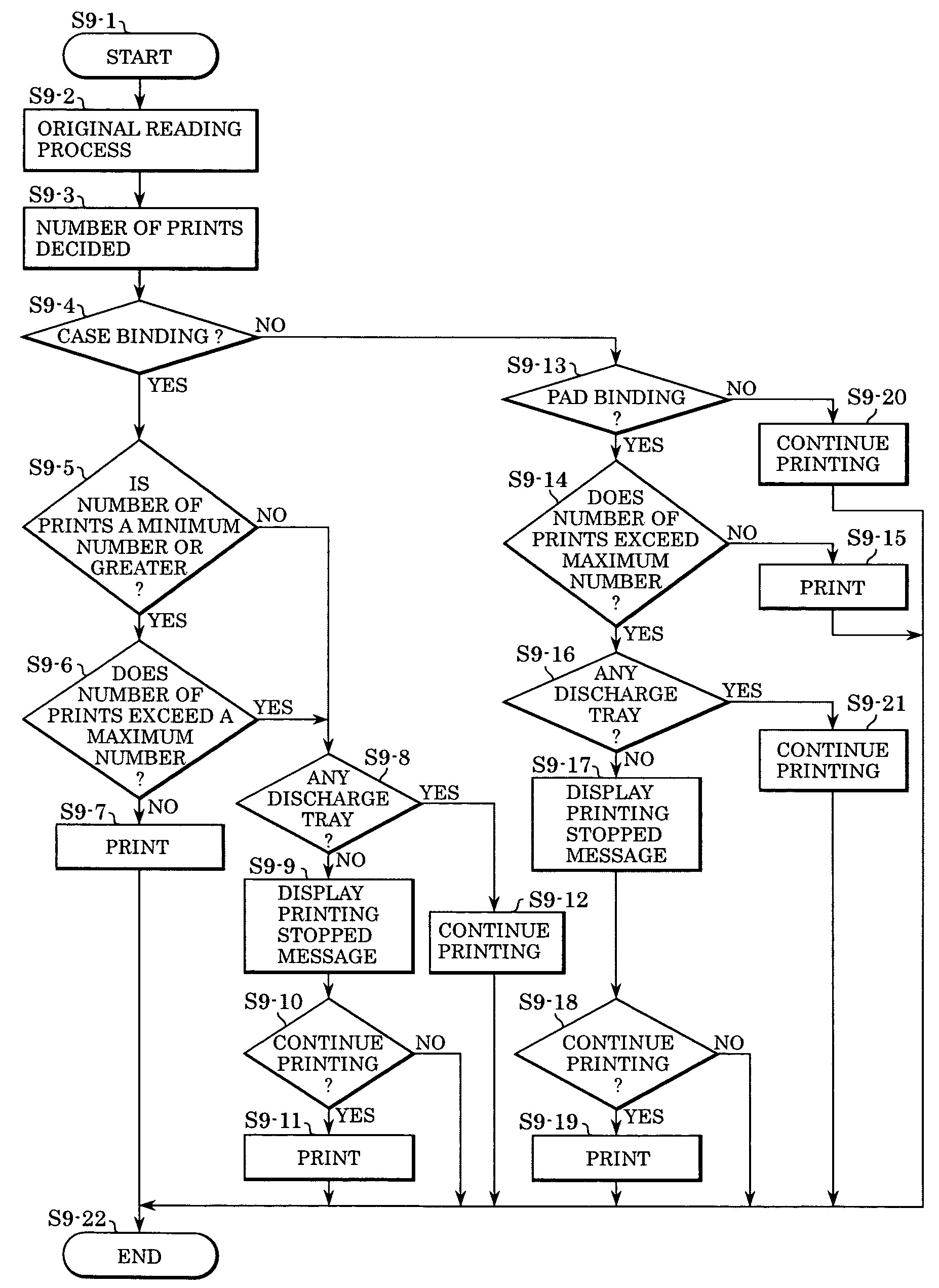

Image forming system, control method, recording medium, and program

ActiveUS7263328B2Avoid problemsAddress usabilityAddressographsOther printing matterImage formationIndustrial engineering

An image forming system has an image forming apparatus which has a printing unit which can perform a printing process of data of a storage unit which can store data of a plurality of jobs and which has a conveying unit which can convey a sheet from the print unit to a sheet processing device which can perform sheet processing, including at least a gluing process, for sheets from the printing unit, the system comprising: a controller adapted to permit a predetermined process related to the gluing process when the job to be processed is a job which meets a predetermined condition, and to inhibit the predetermined process related to the gluing process when the job to be processed is not a job which meets the predetermined condition, thereby overcoming obstacles to realization of an image forming system capable of a gluing process.

Owner:CANON KK

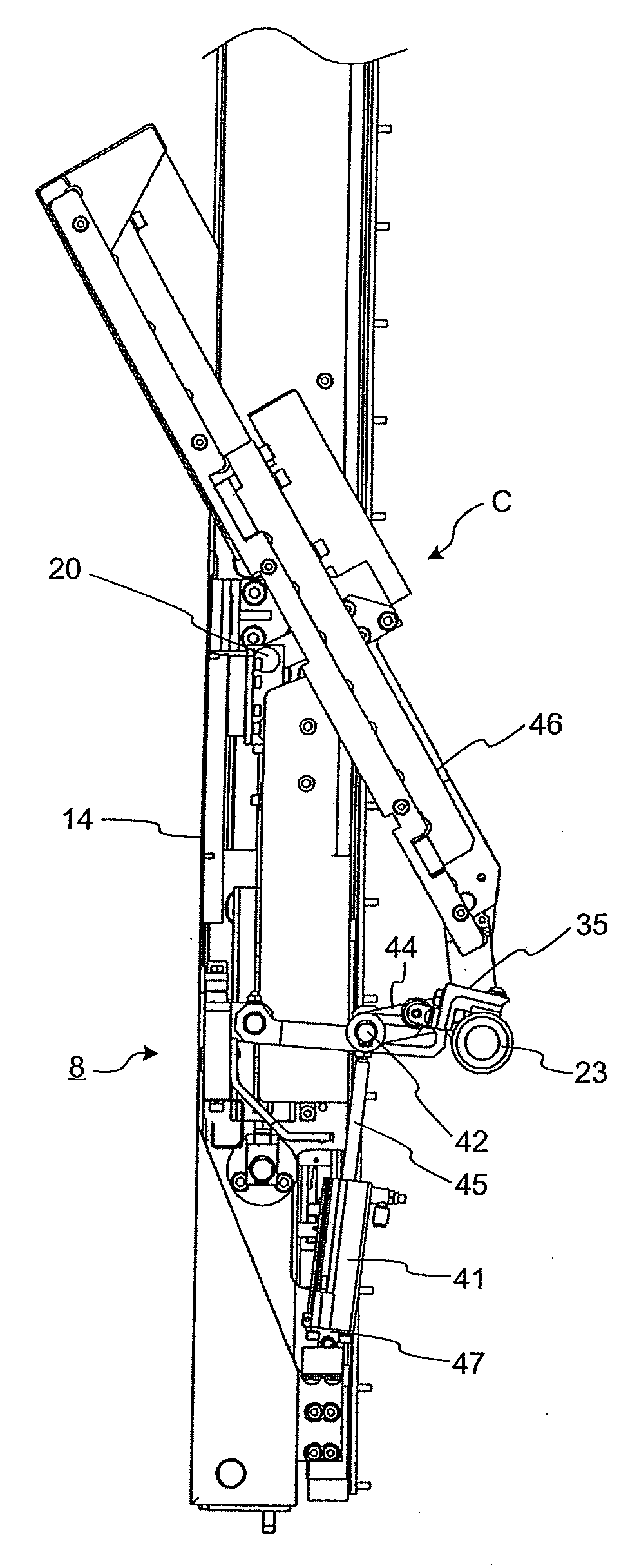

Plate replacing apparatus

A plate replacing apparatus includes a plate-winding support roller that presses a plate on a plate cylinder and a plate pressing unit that rotates around the plate-winding support roller and thereby pressing a trailing end of the plate in an edge portion of the plate pressing unit. The plate pressing unit presses the plate in a position in front of a lower tooth of a vice built in the plate cylinder.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com