Patents

Literature

1623results about "Office printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

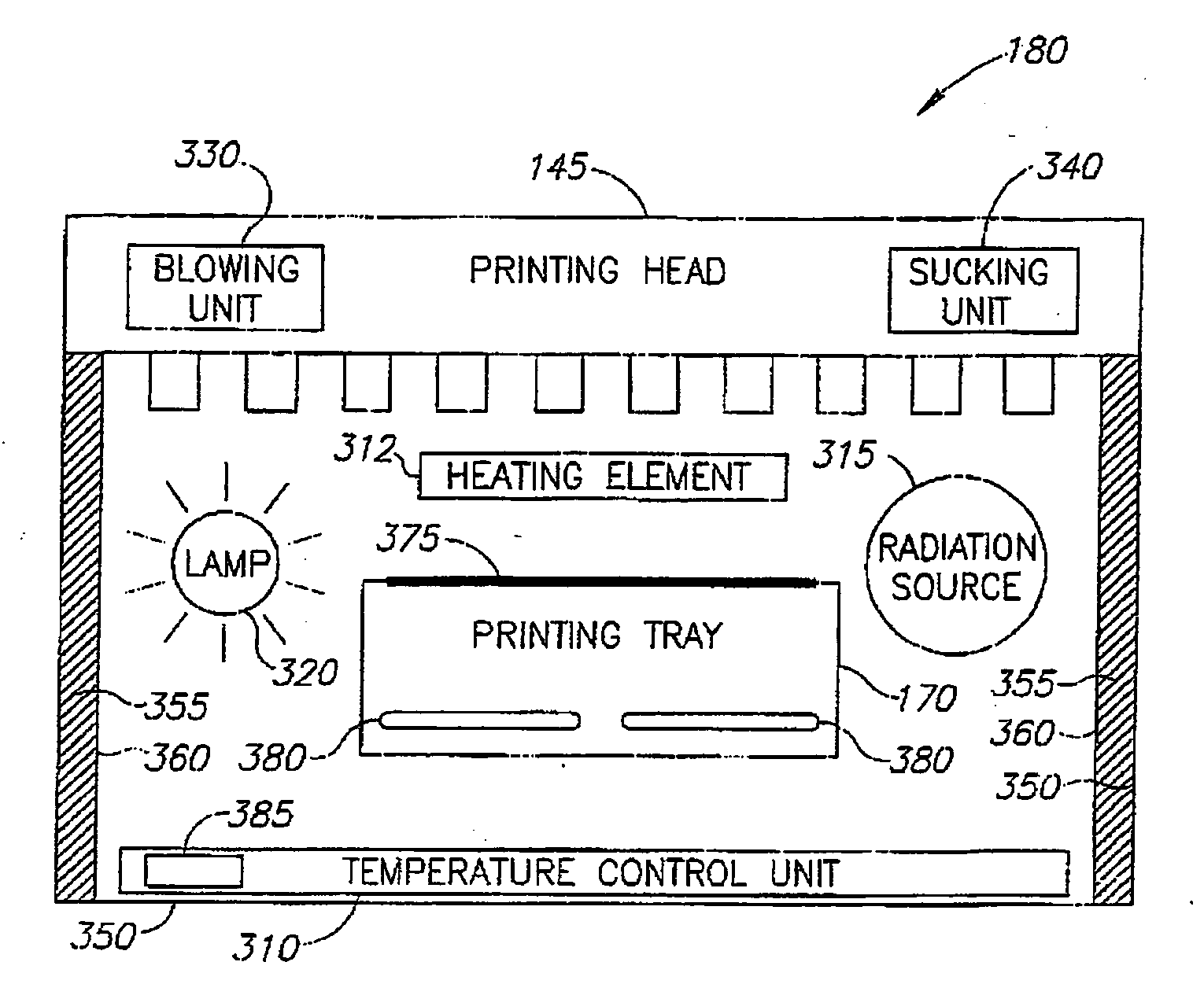

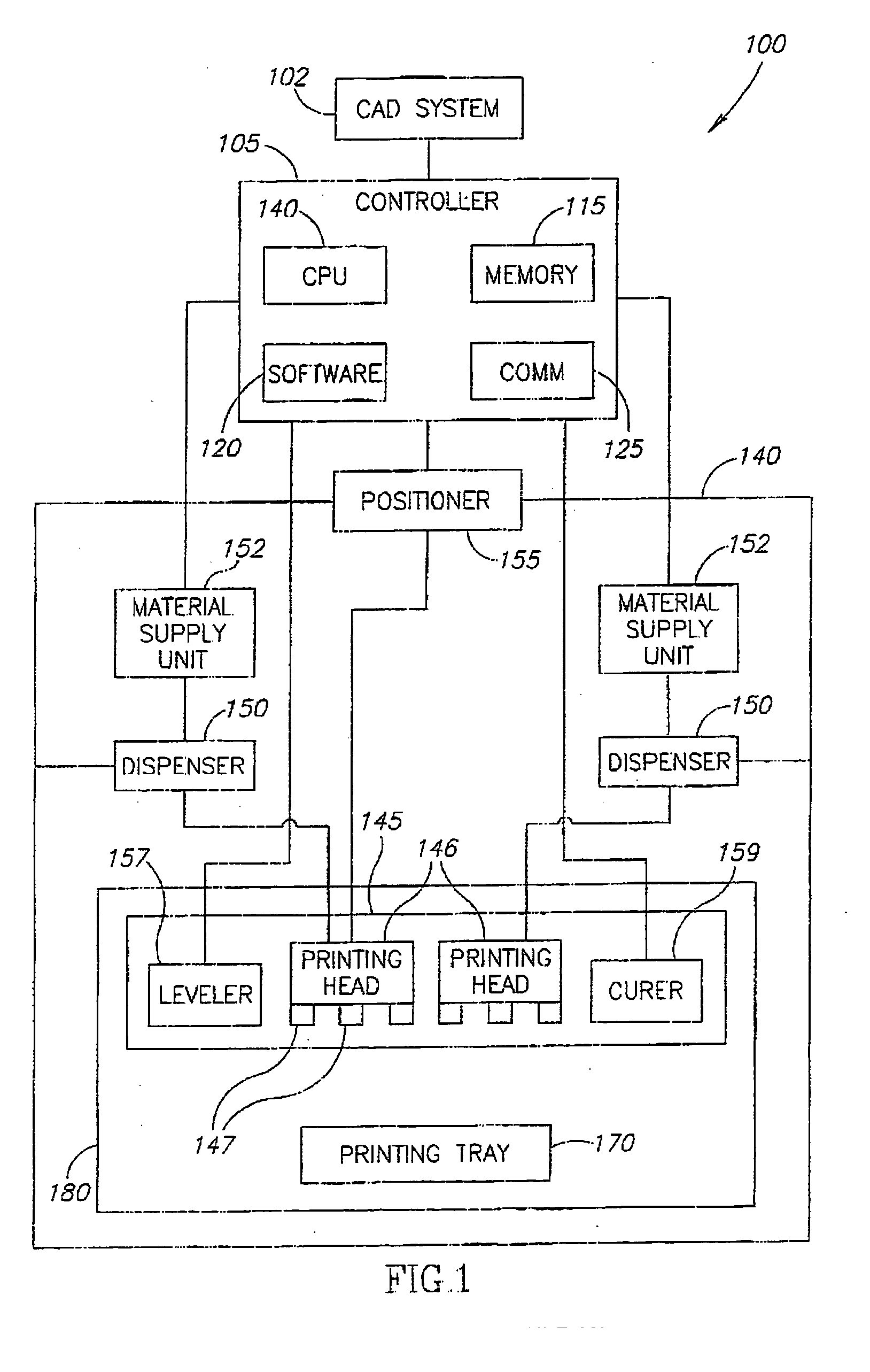

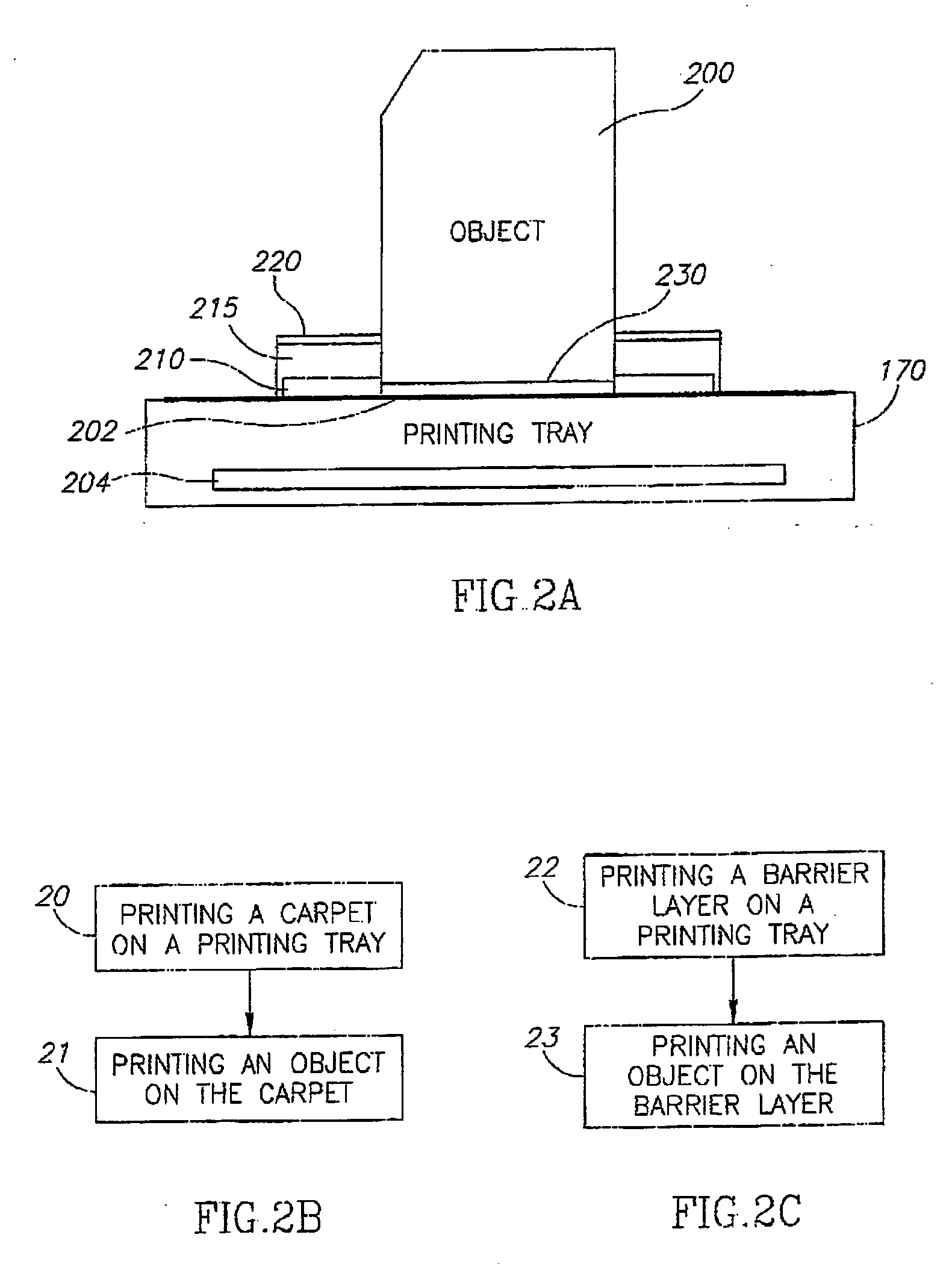

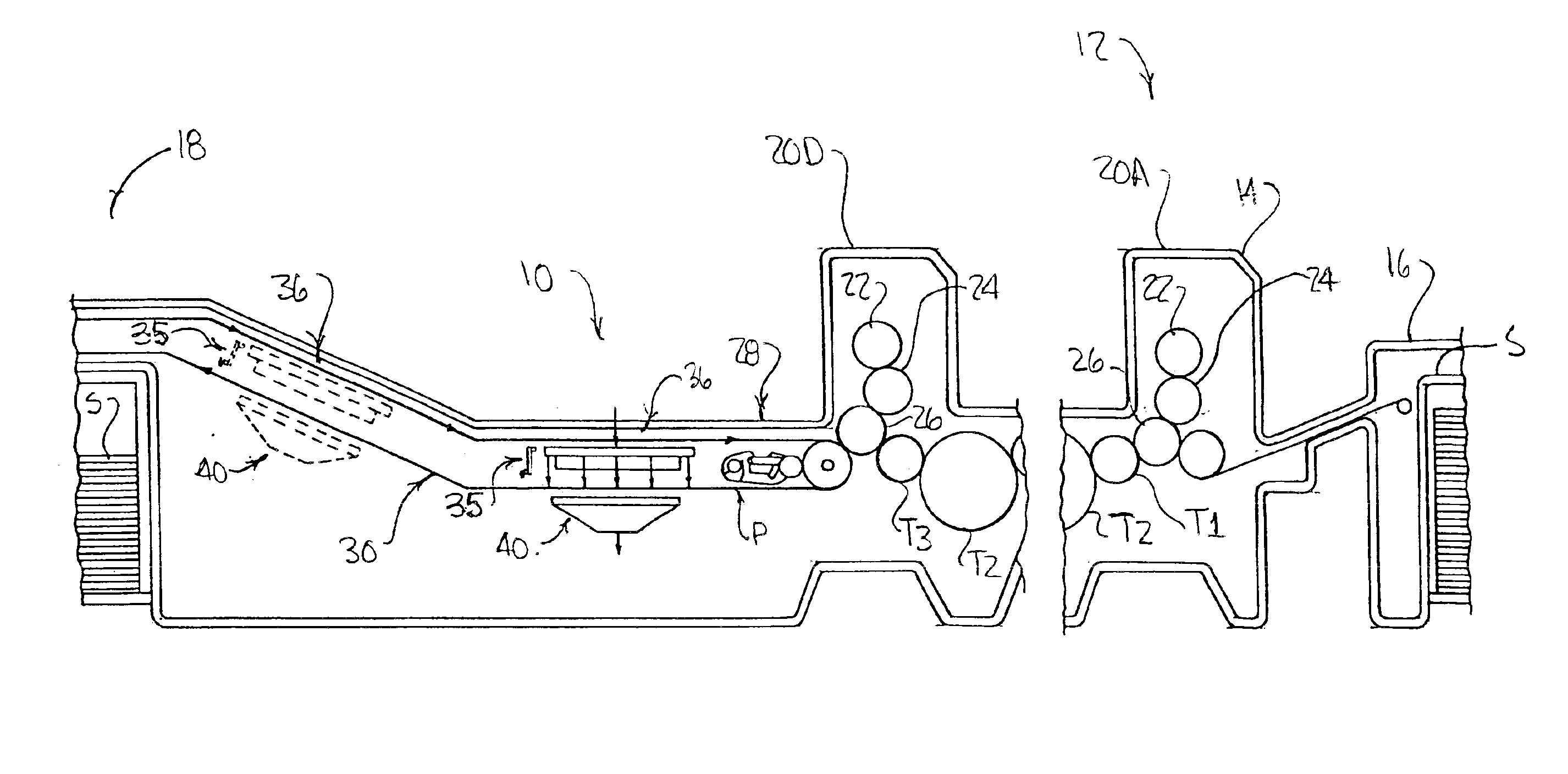

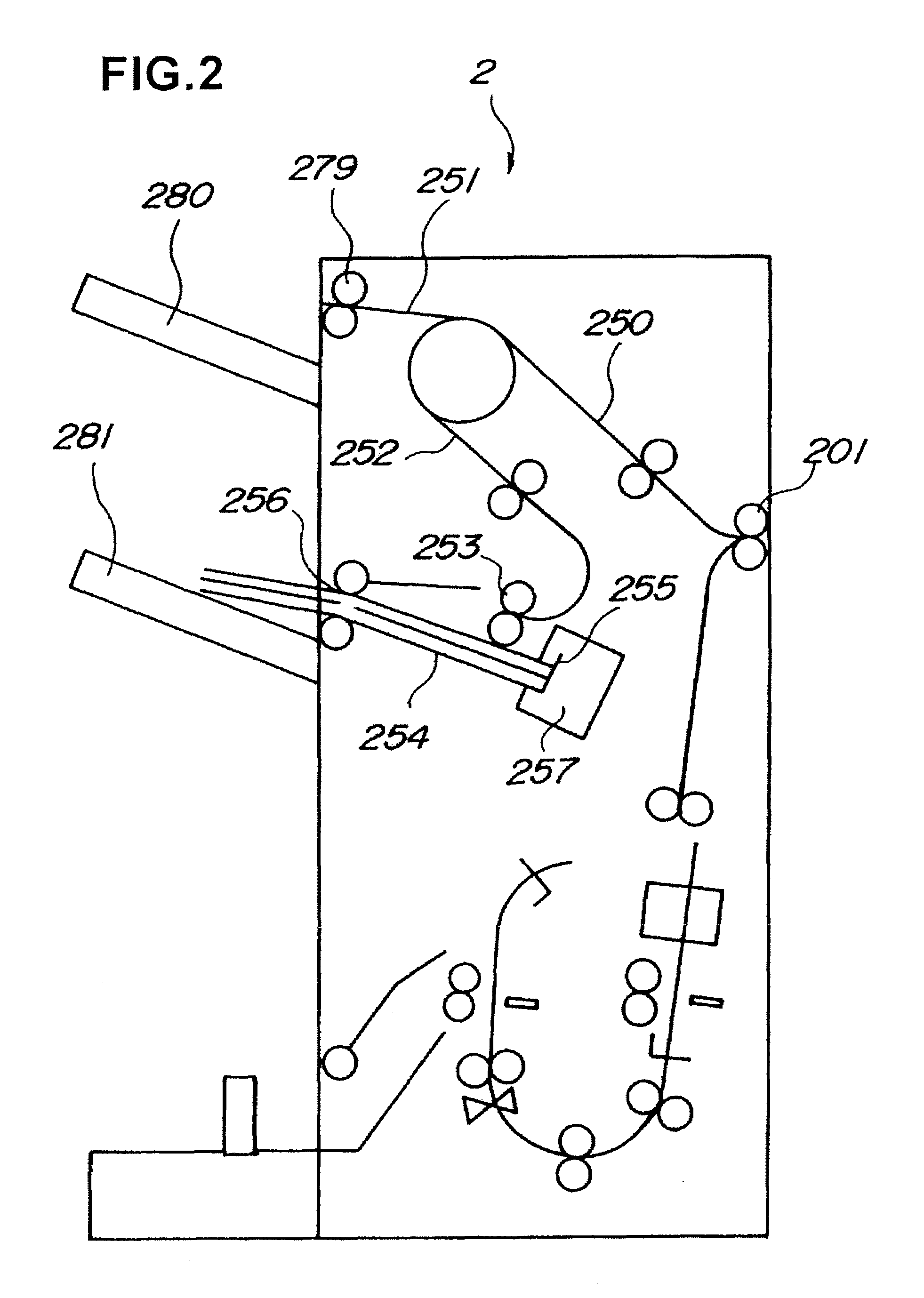

Process of and apparratus for three-dimensional printing

InactiveUS20060054039A1Low adhesion characteristicAvoid mechanical deformationManufacturing platforms/substratesPattern printingTemperature controlEngineering

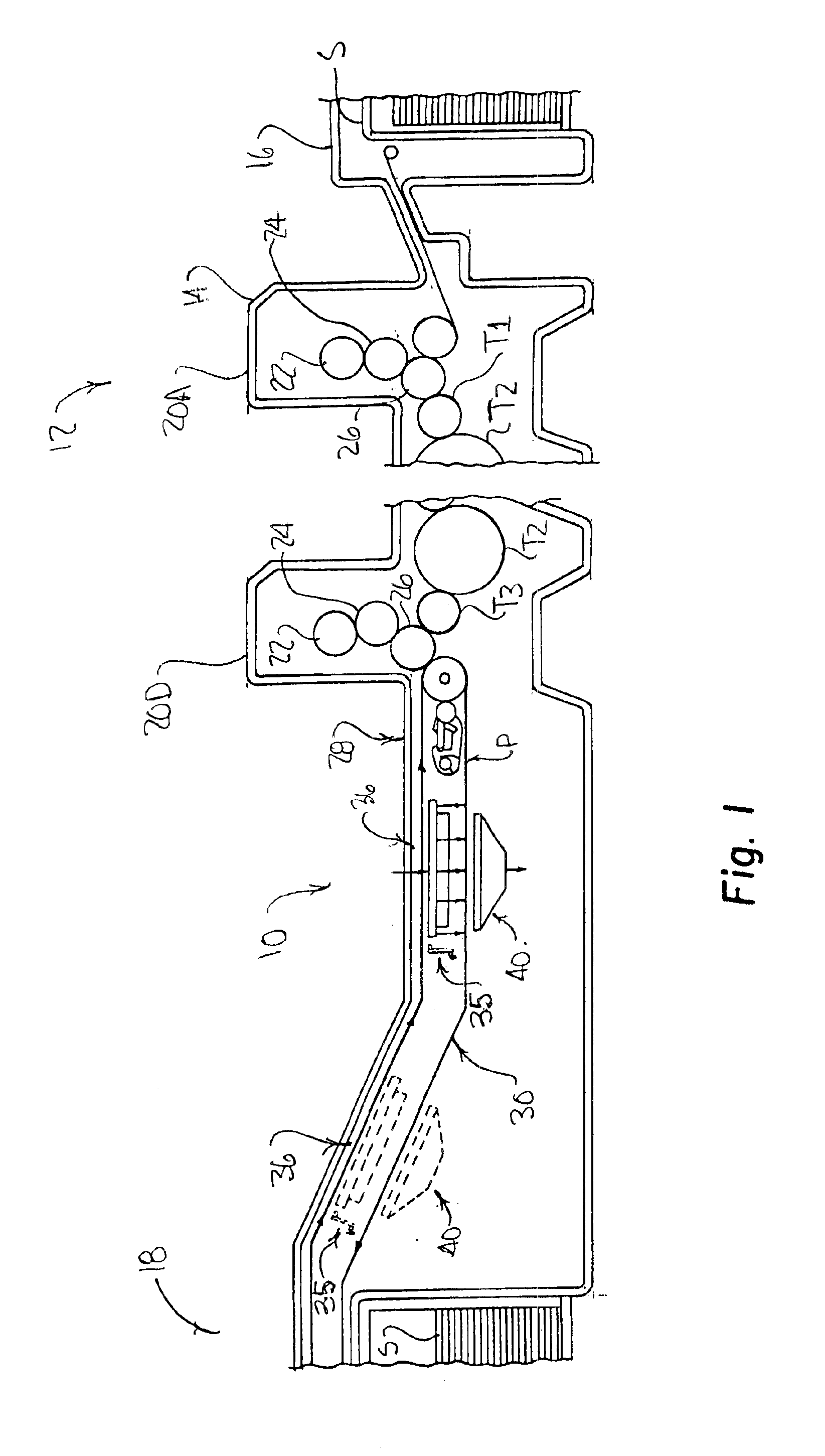

A process of, and apparatus for, three-dimensional printing of an object (200) from modeling material (220) including a printing tray (170) having a surface coating (202), a carpet (210), a support material (215), a support pedestal (210), a barrier layer (230) and a temperature control unit (204).

Owner:OBJET GEOMETRIES

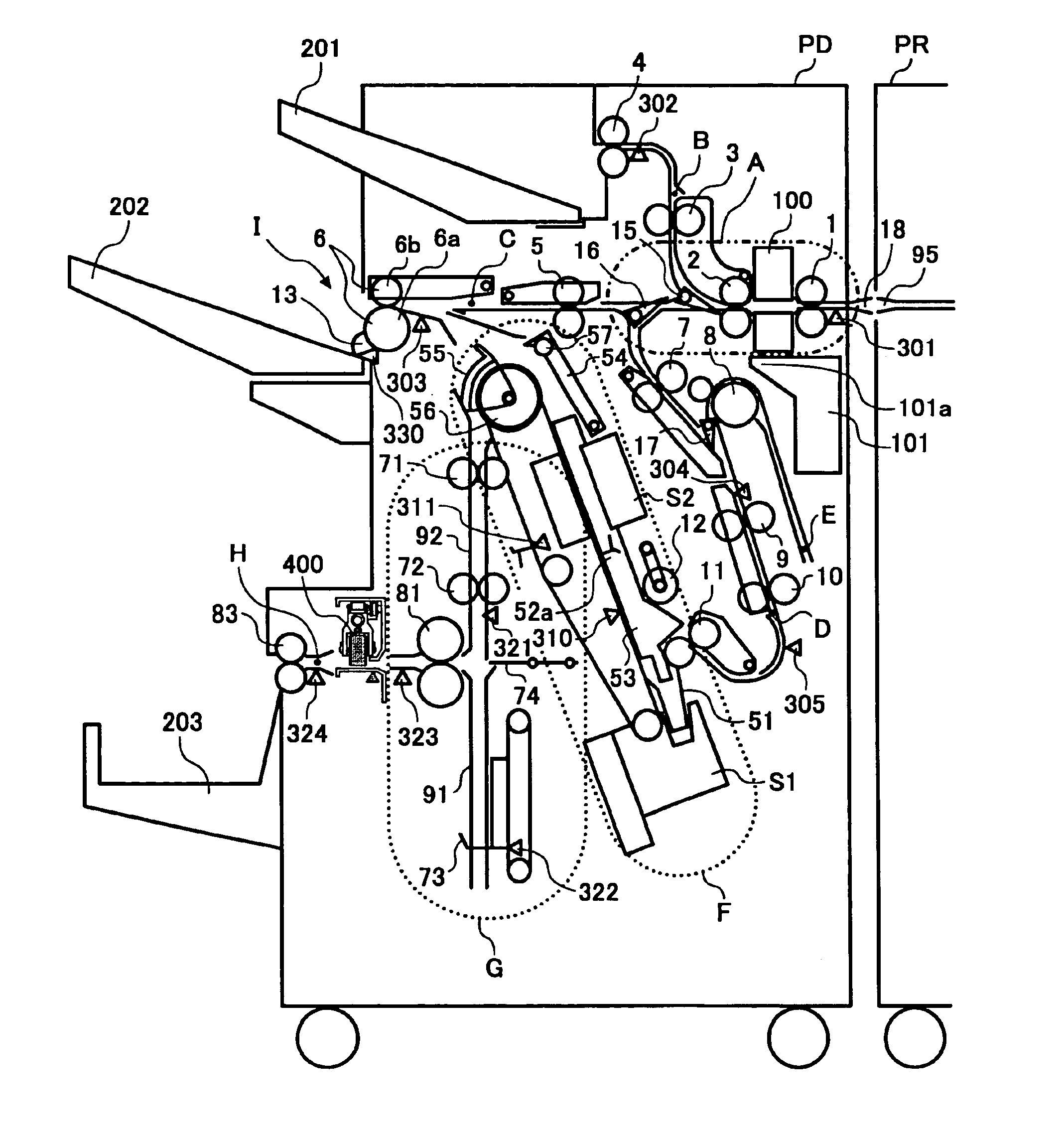

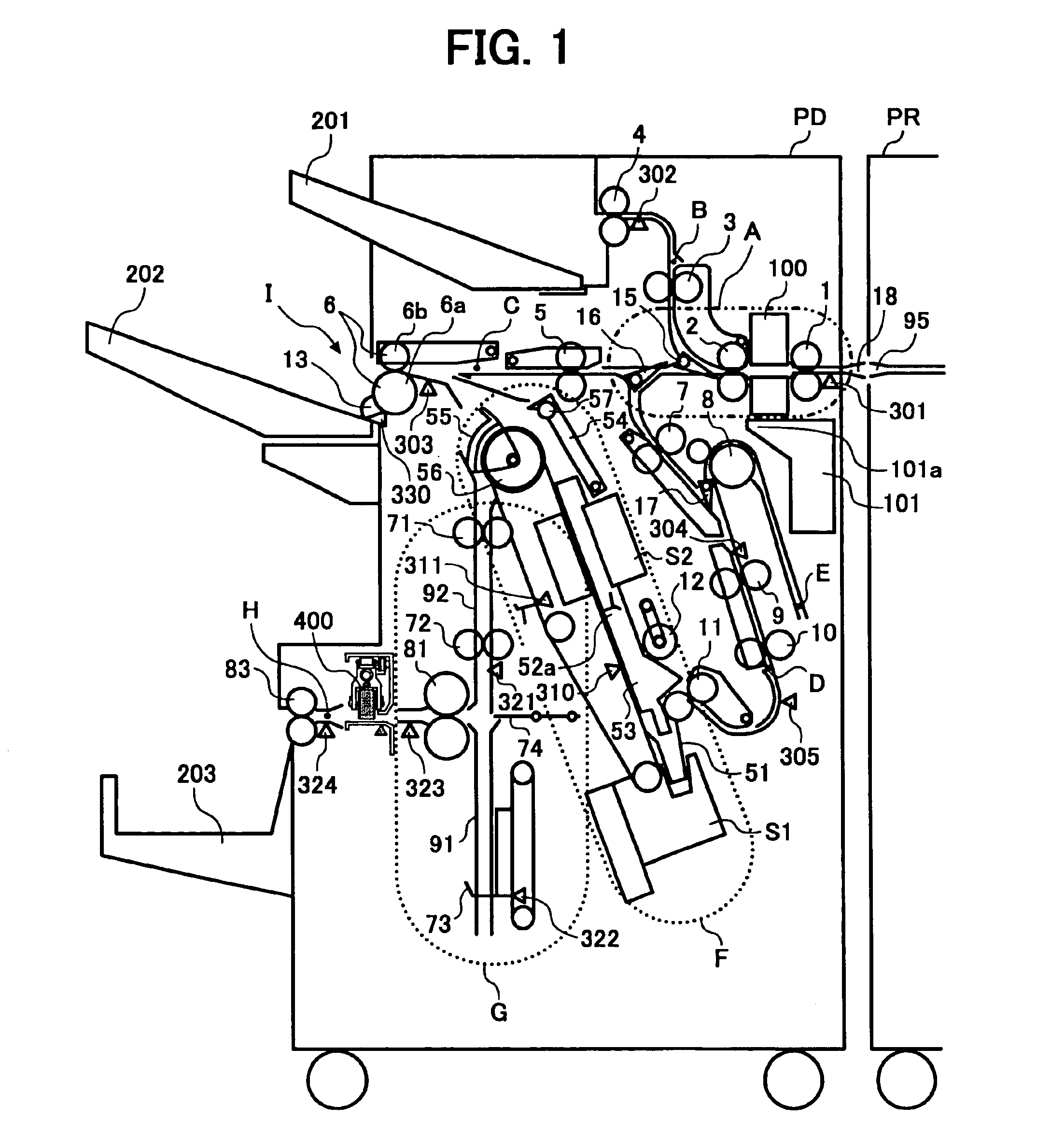

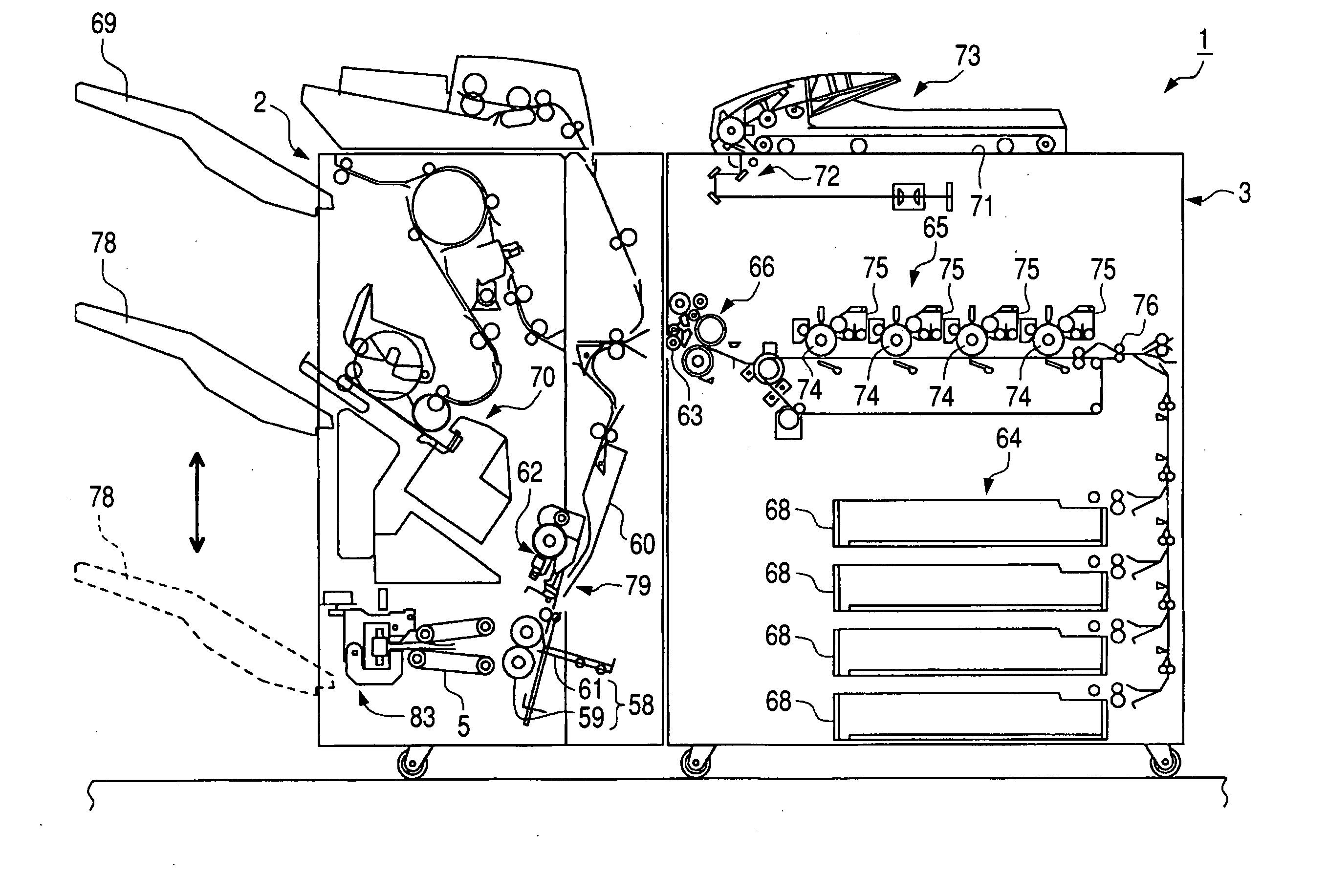

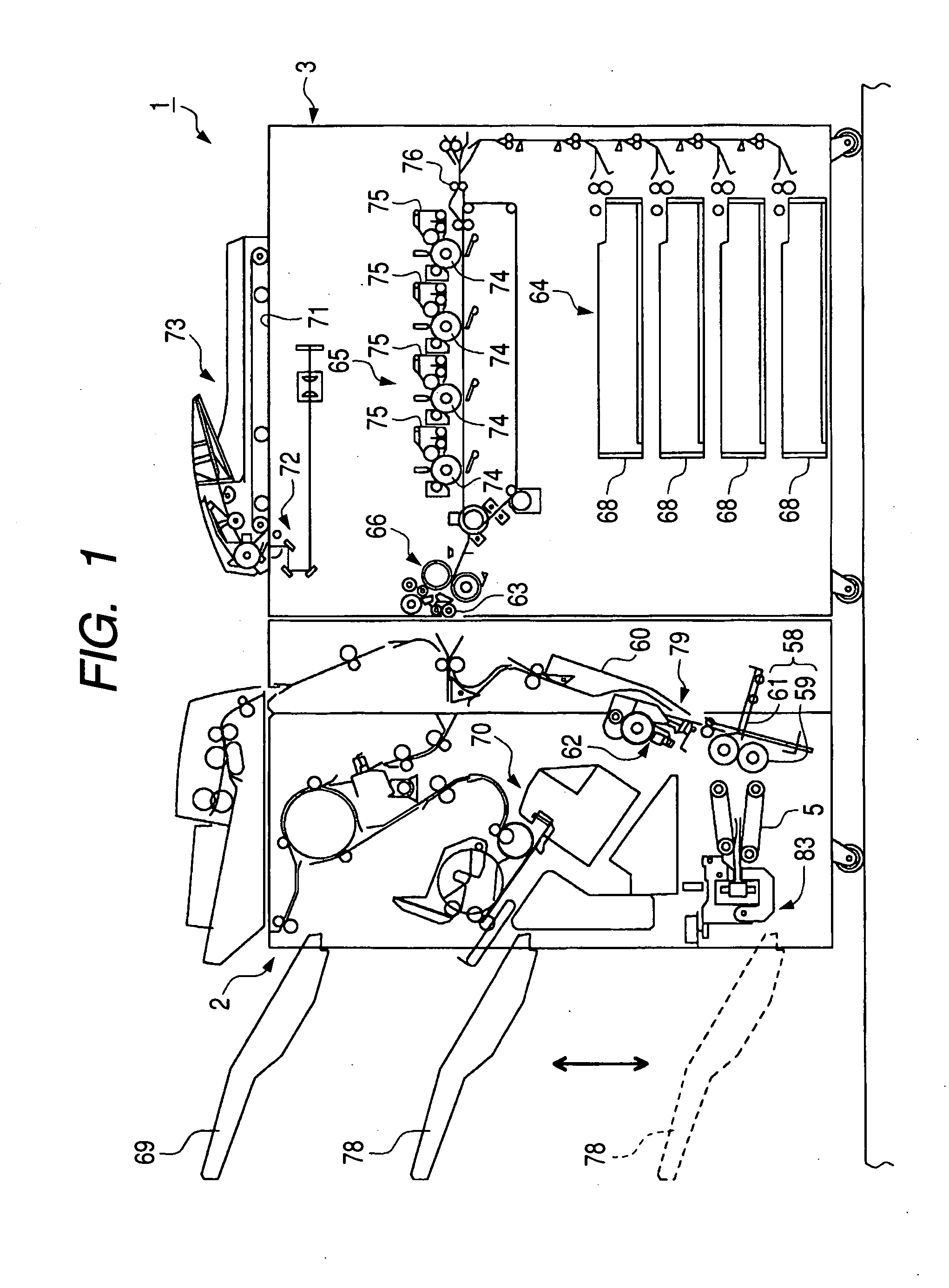

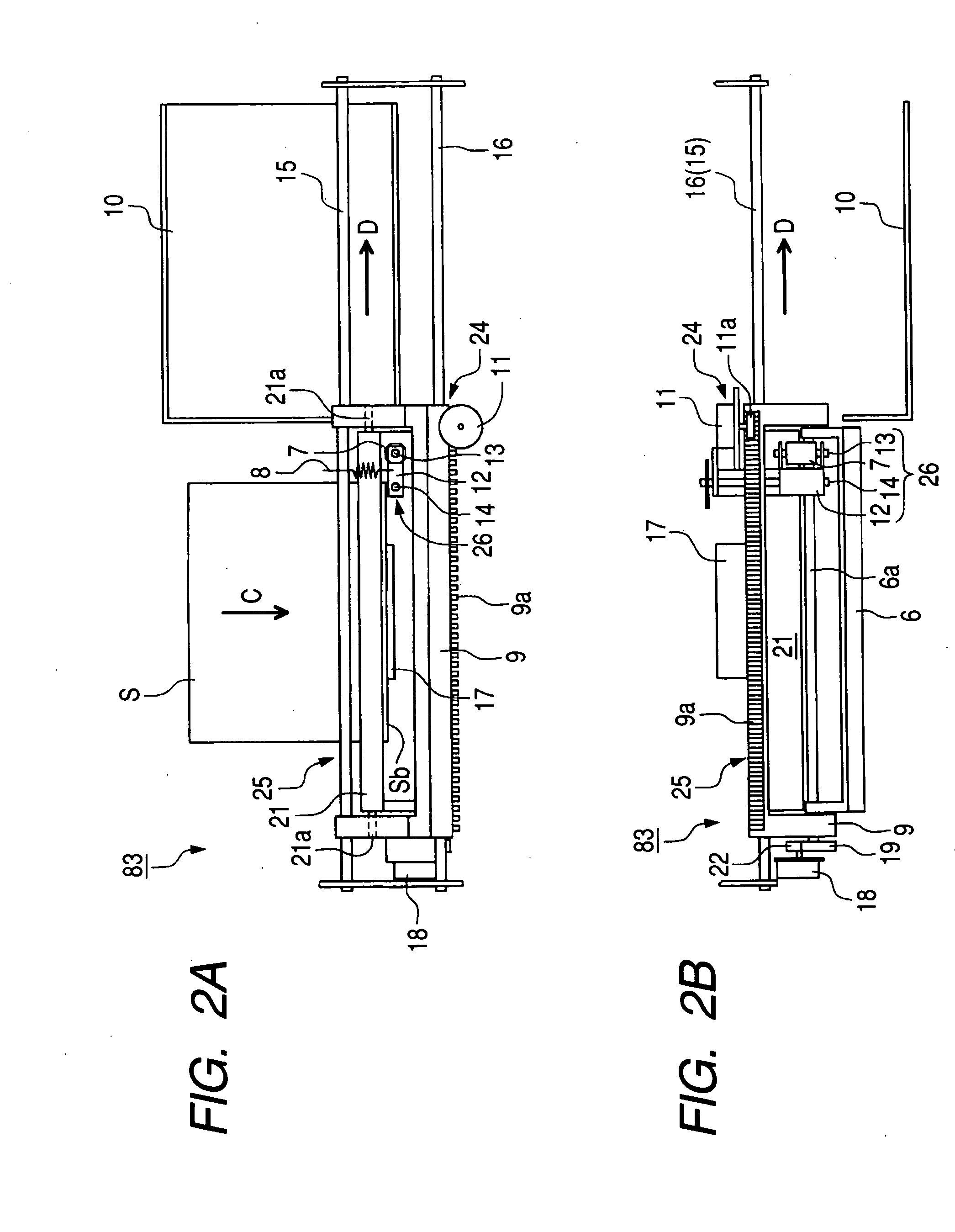

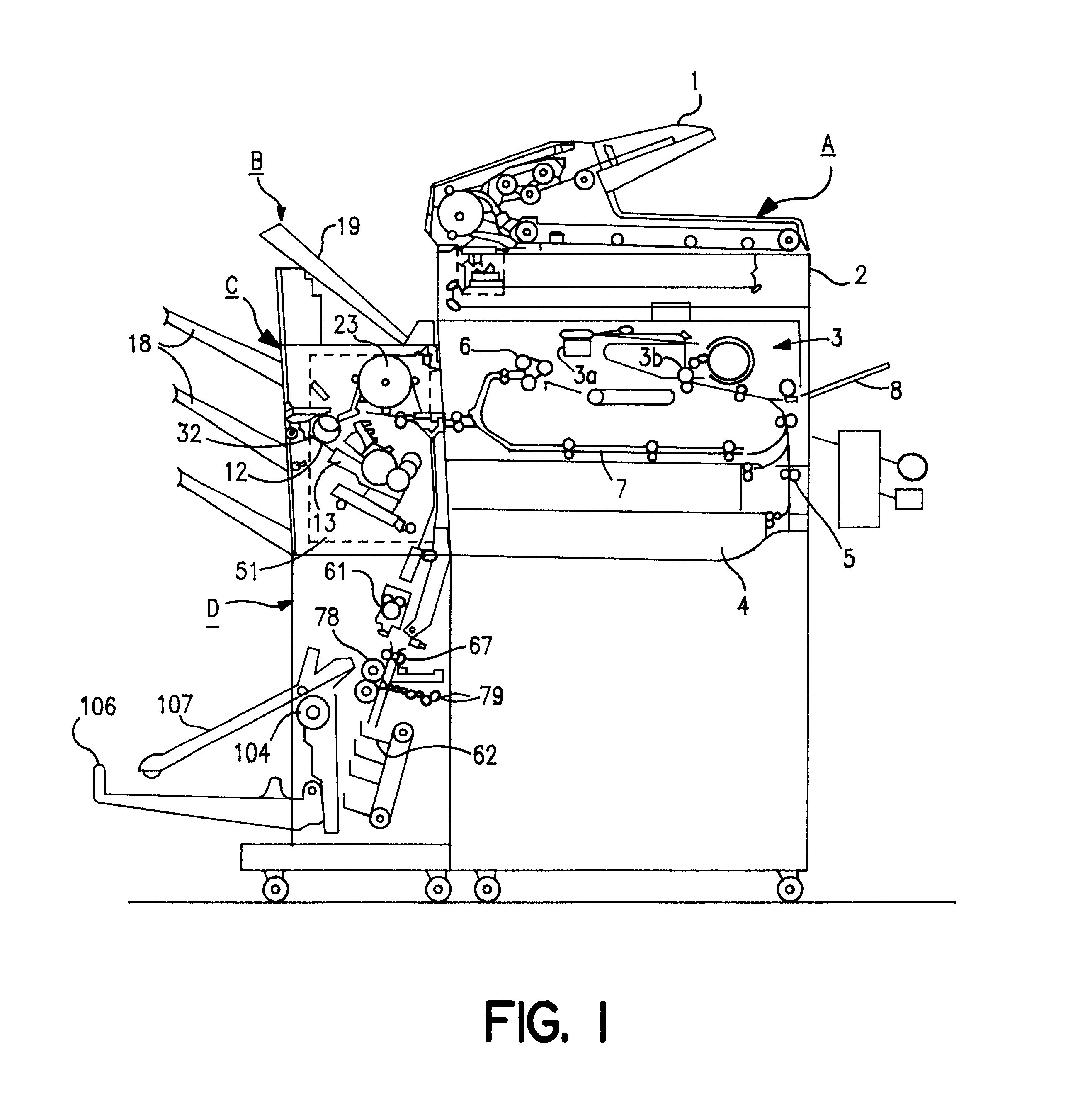

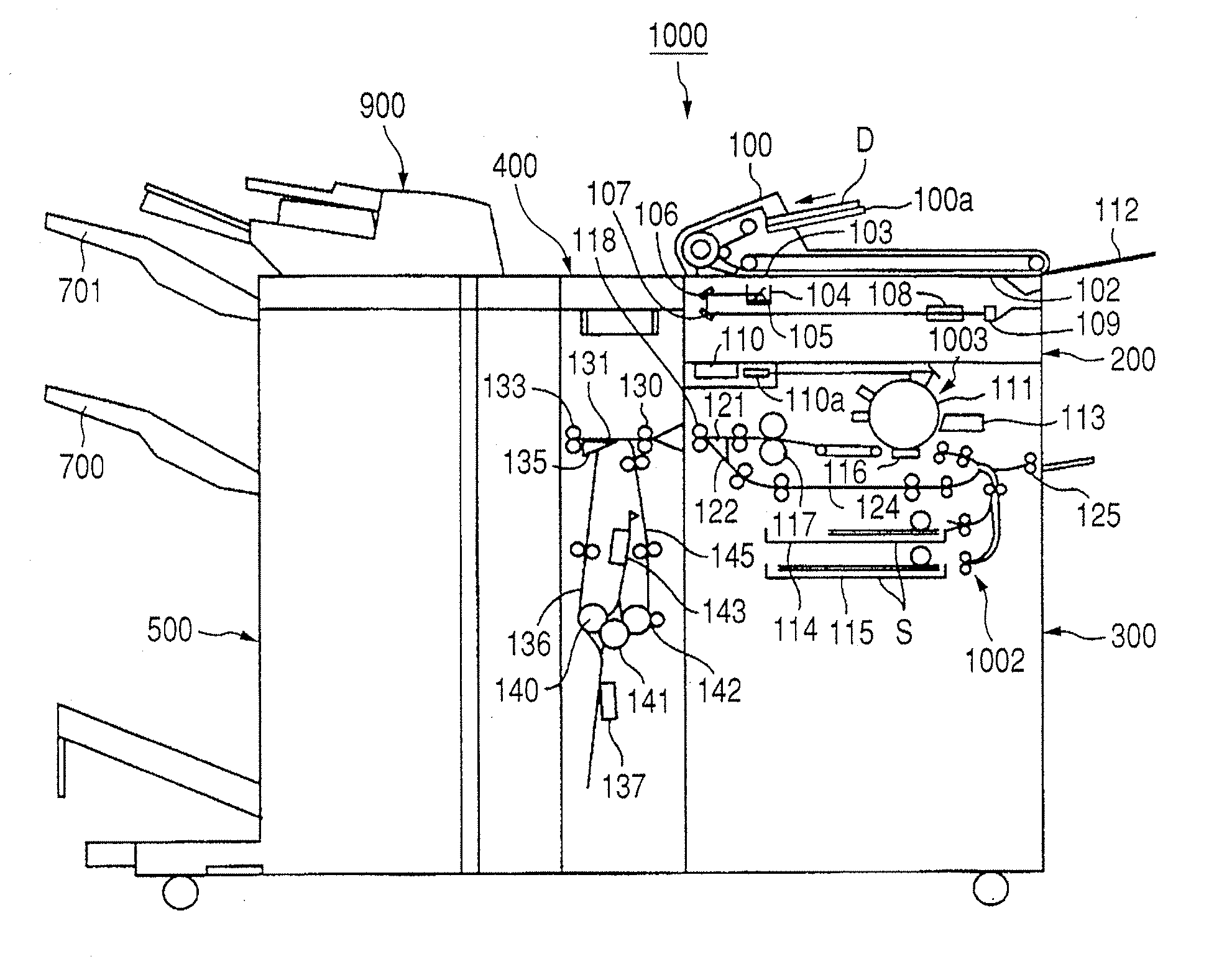

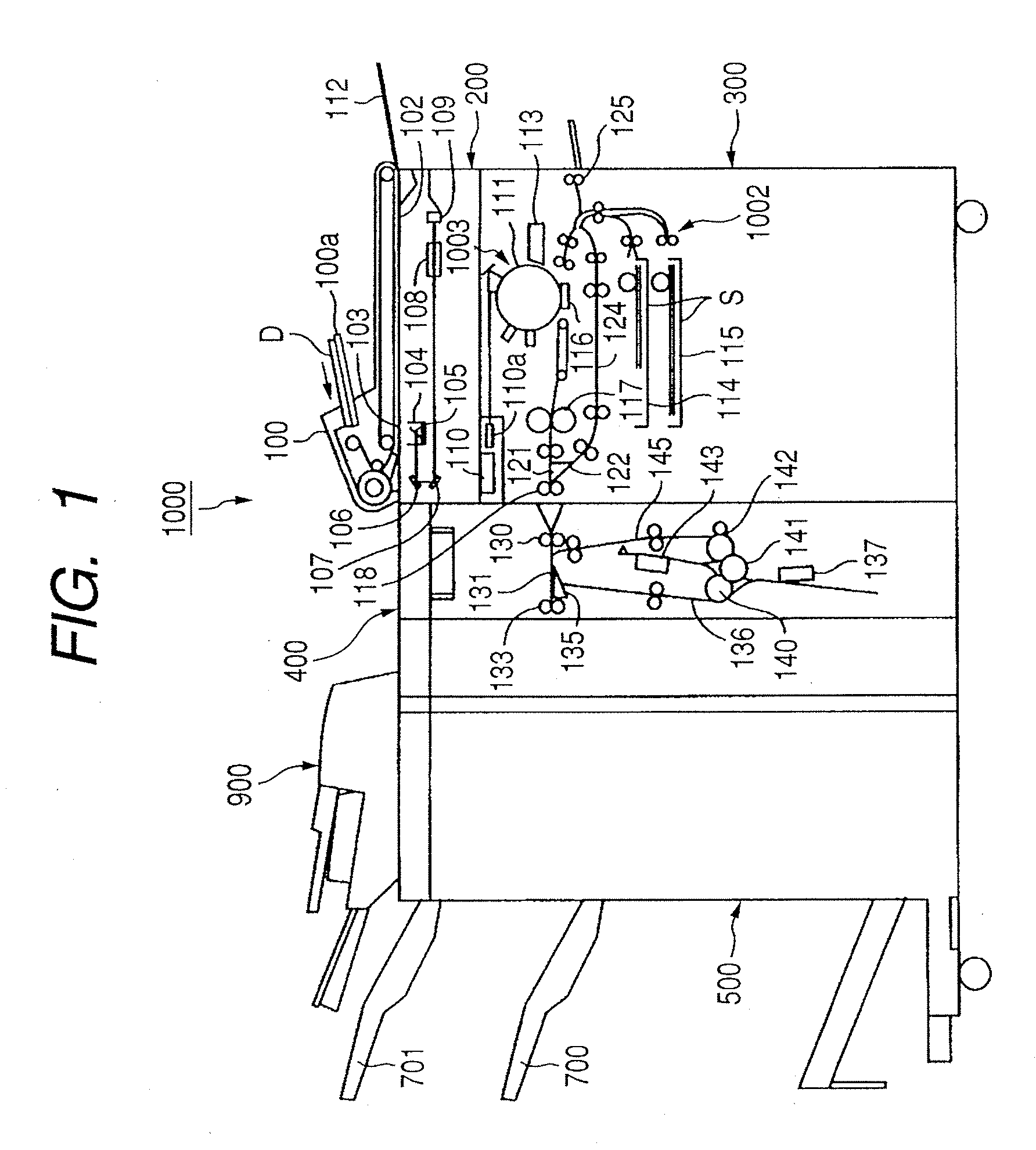

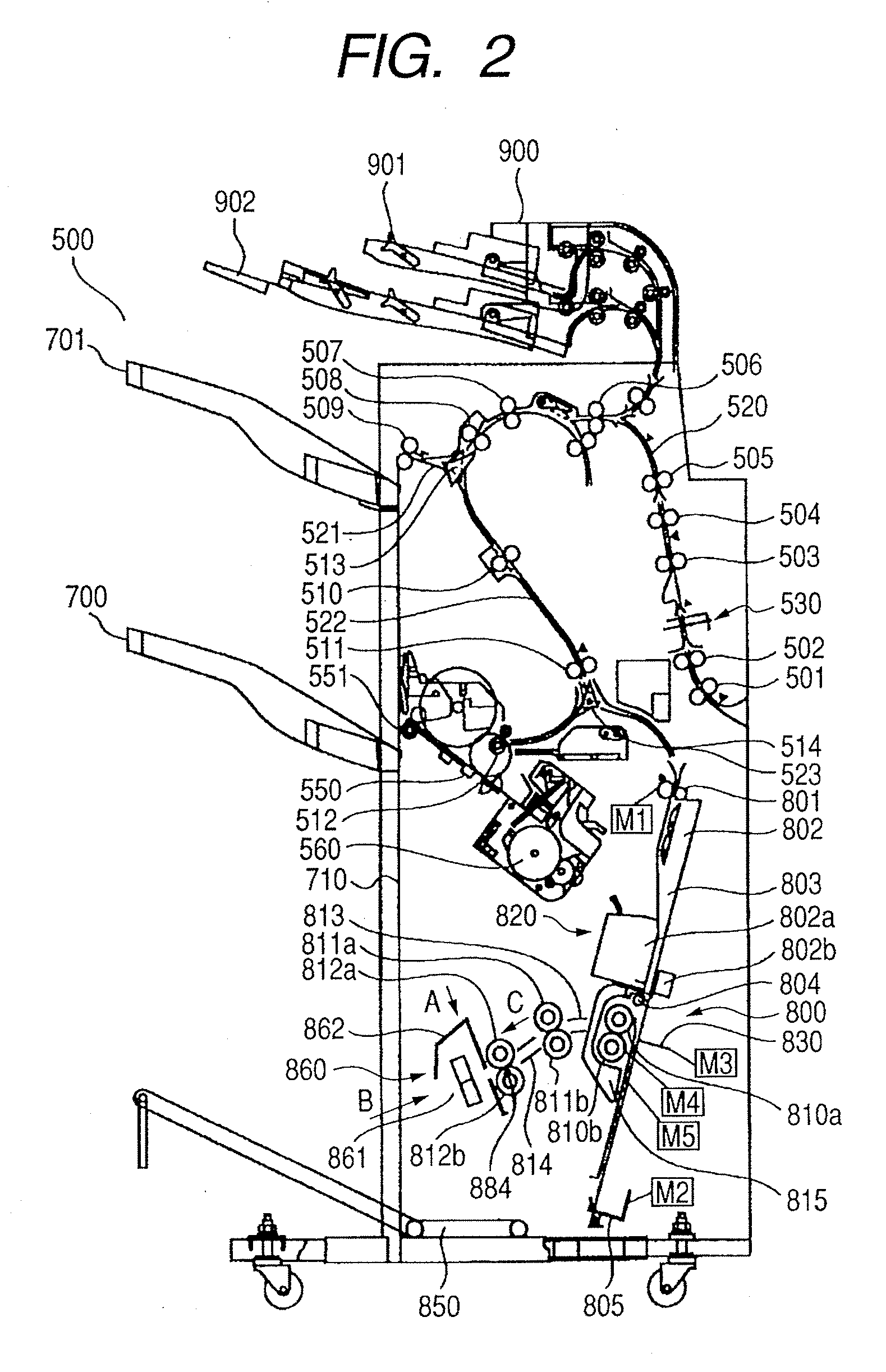

Sheet finisher and image forming system using the same

InactiveUS6905118B2Neatly foldedReduce frictionMechanical working/deformationFolding thin materialsImage formationEngineering

A sheet finisher of the present invention is included in an image forming system and folds a stack of sheets sequentially transferred from an image forming apparatus thereto. The sheet finisher includes a fold roller pair for holding the stack of sheets being conveyed via a nip thereof. A reinforce roller reinforces the fold of the folded sheet stack in cooperation with a guide plate. A drive mechanism causes the reinforce roller to move in a direction perpendicular to a direction of sheet conveyance. A shock absorbing member is located at a position where the reinforce roller and guide plate contact each other.

Owner:RICOH KK

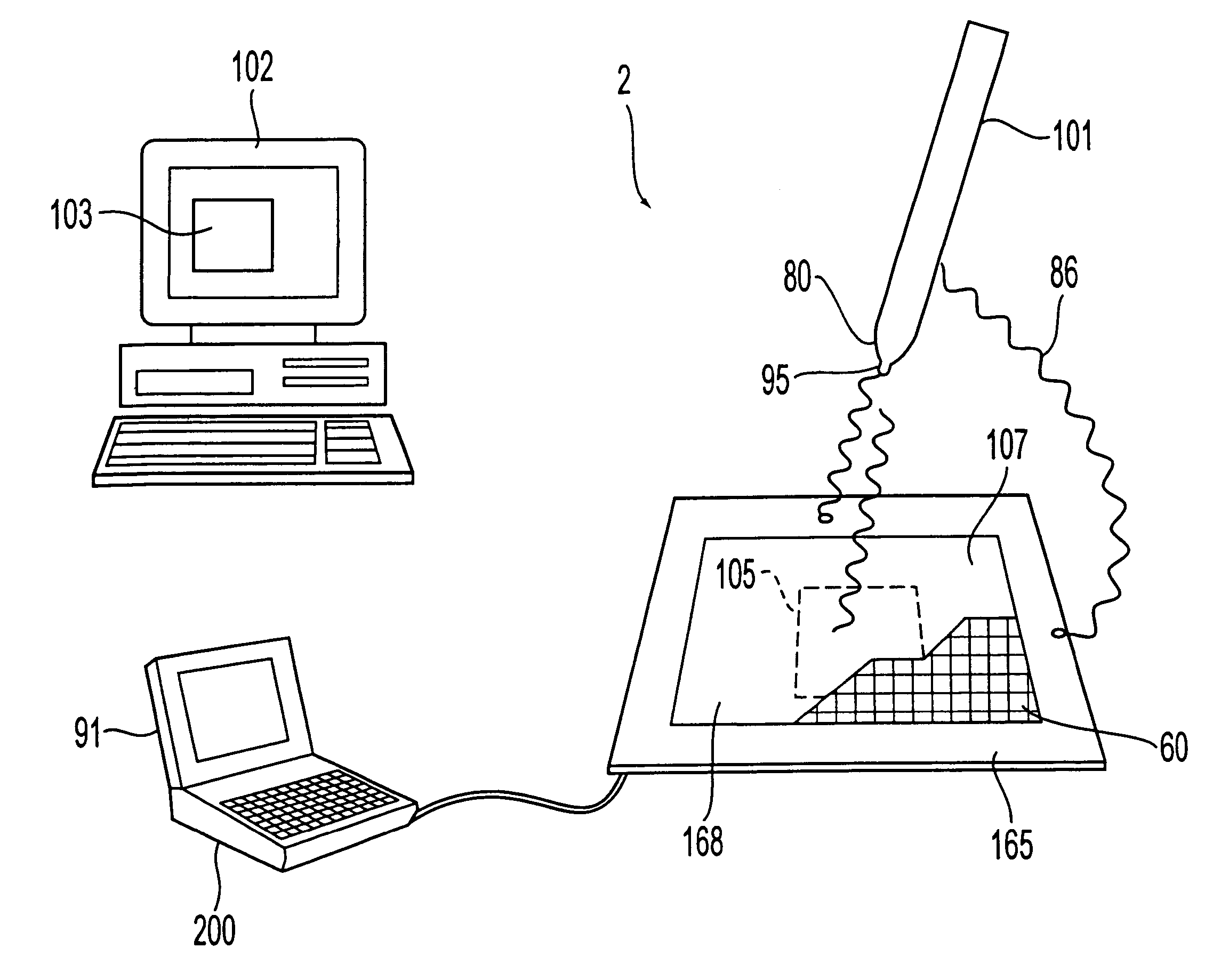

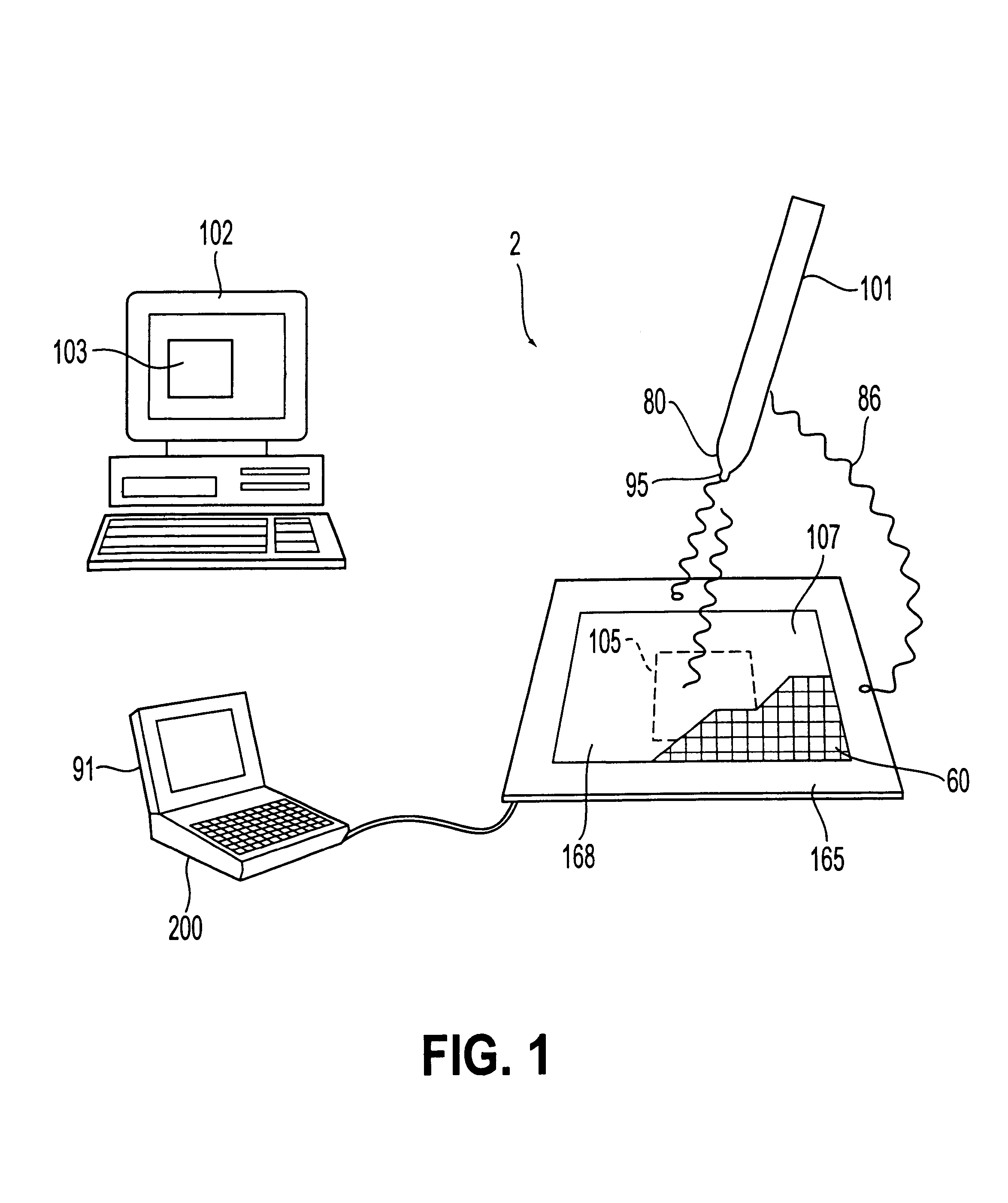

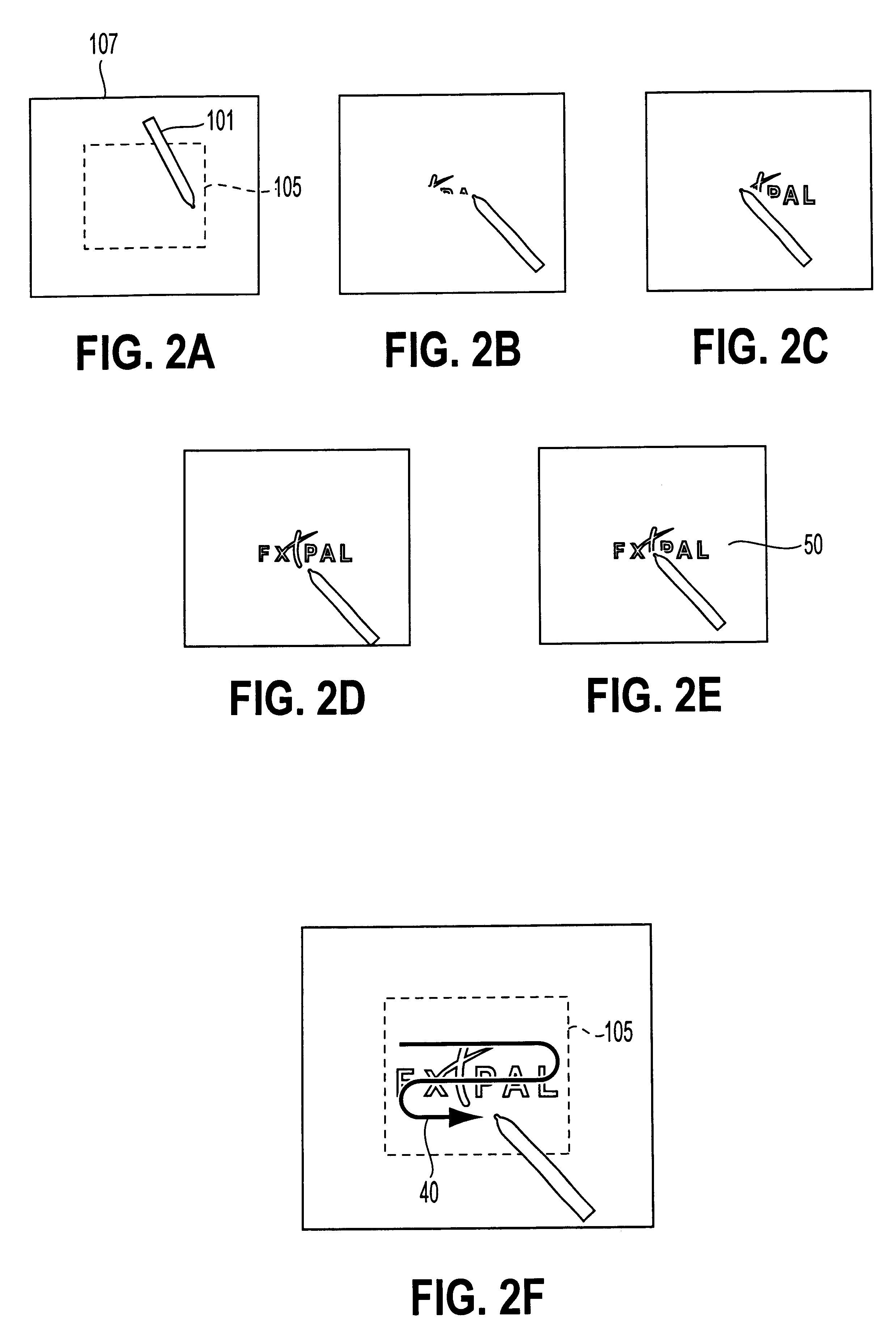

Method and system for position-aware freeform printing within a position-sensed area

Owner:FUJIFILM BUSINESS INNOVATION CORP

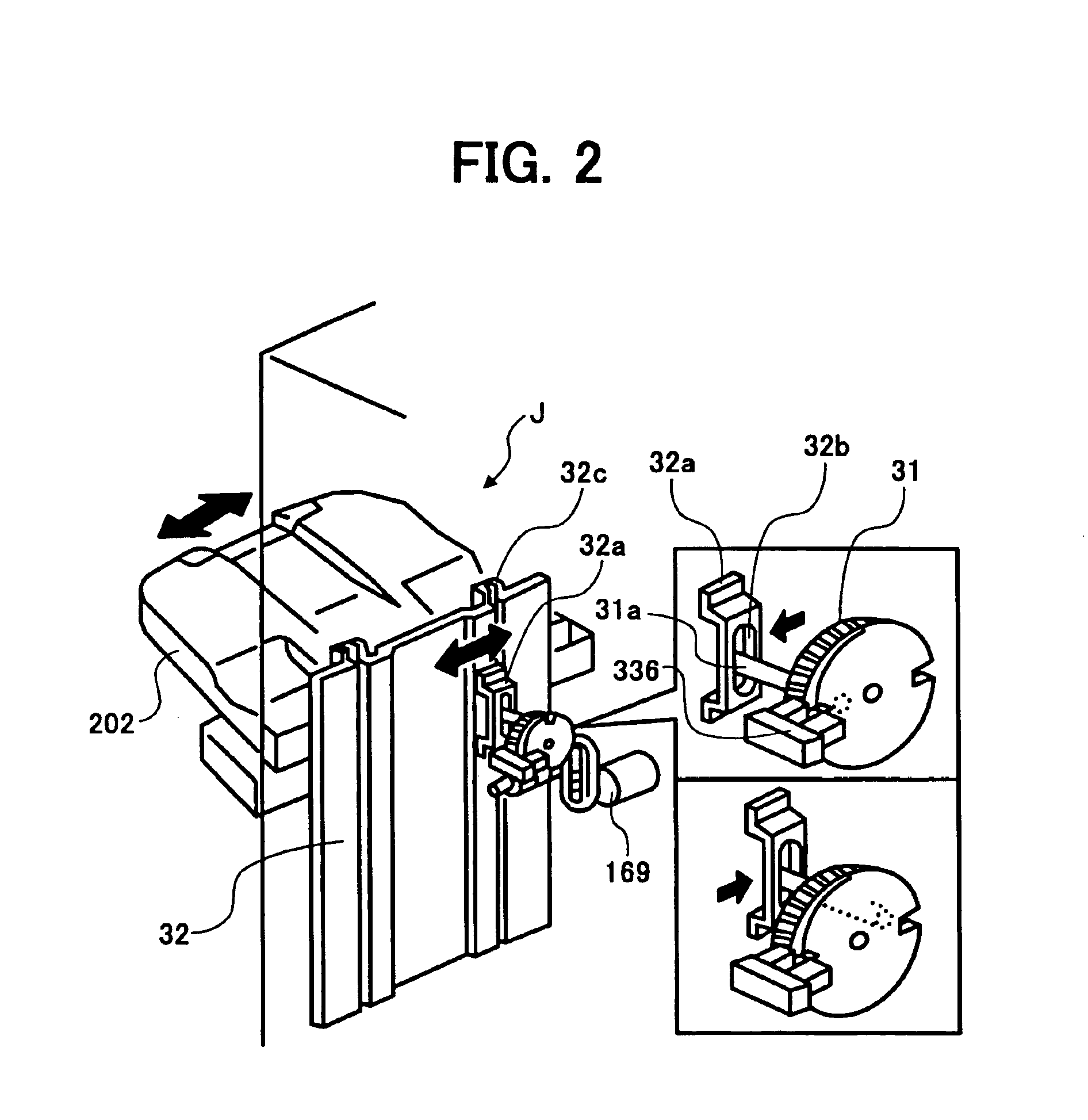

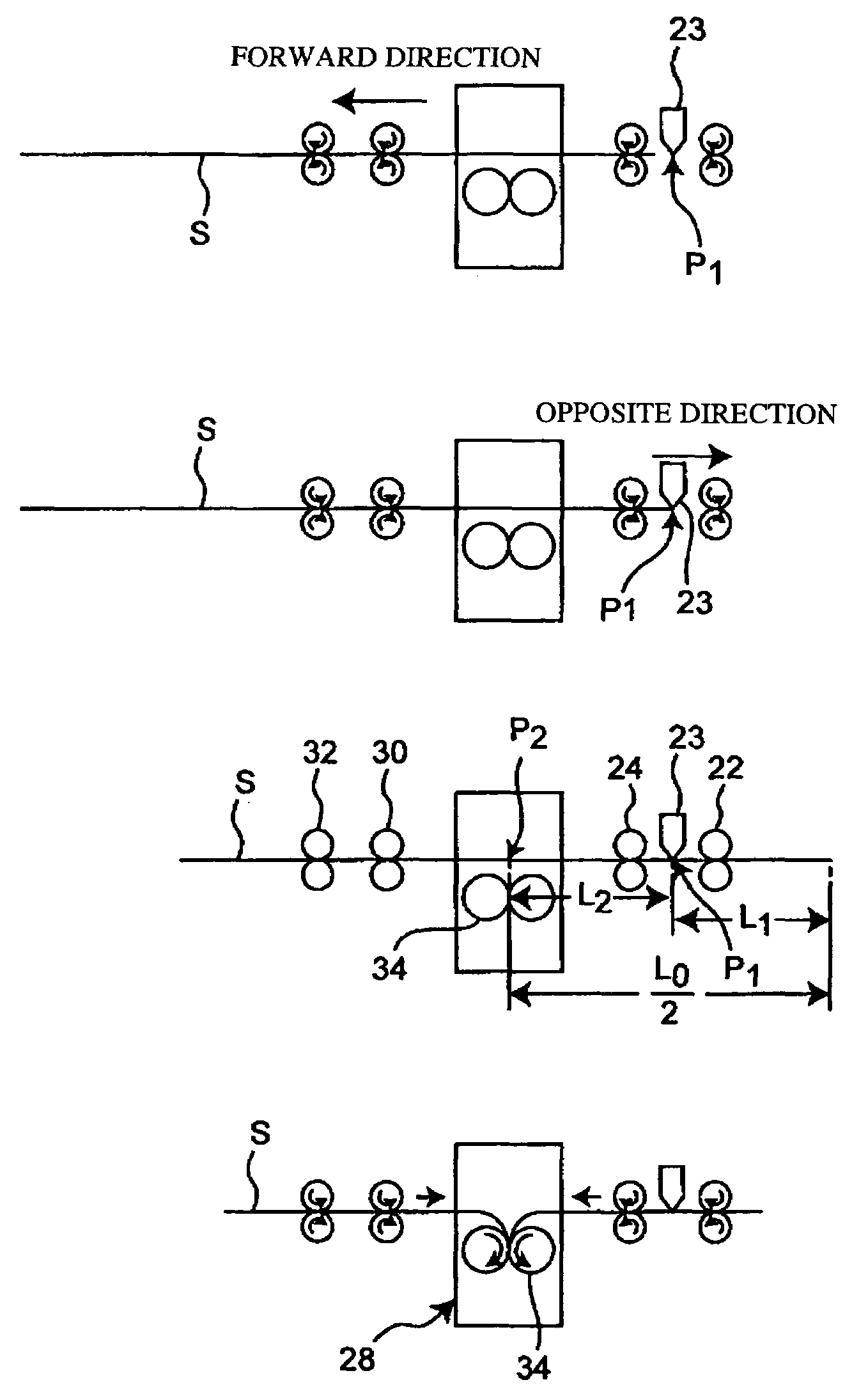

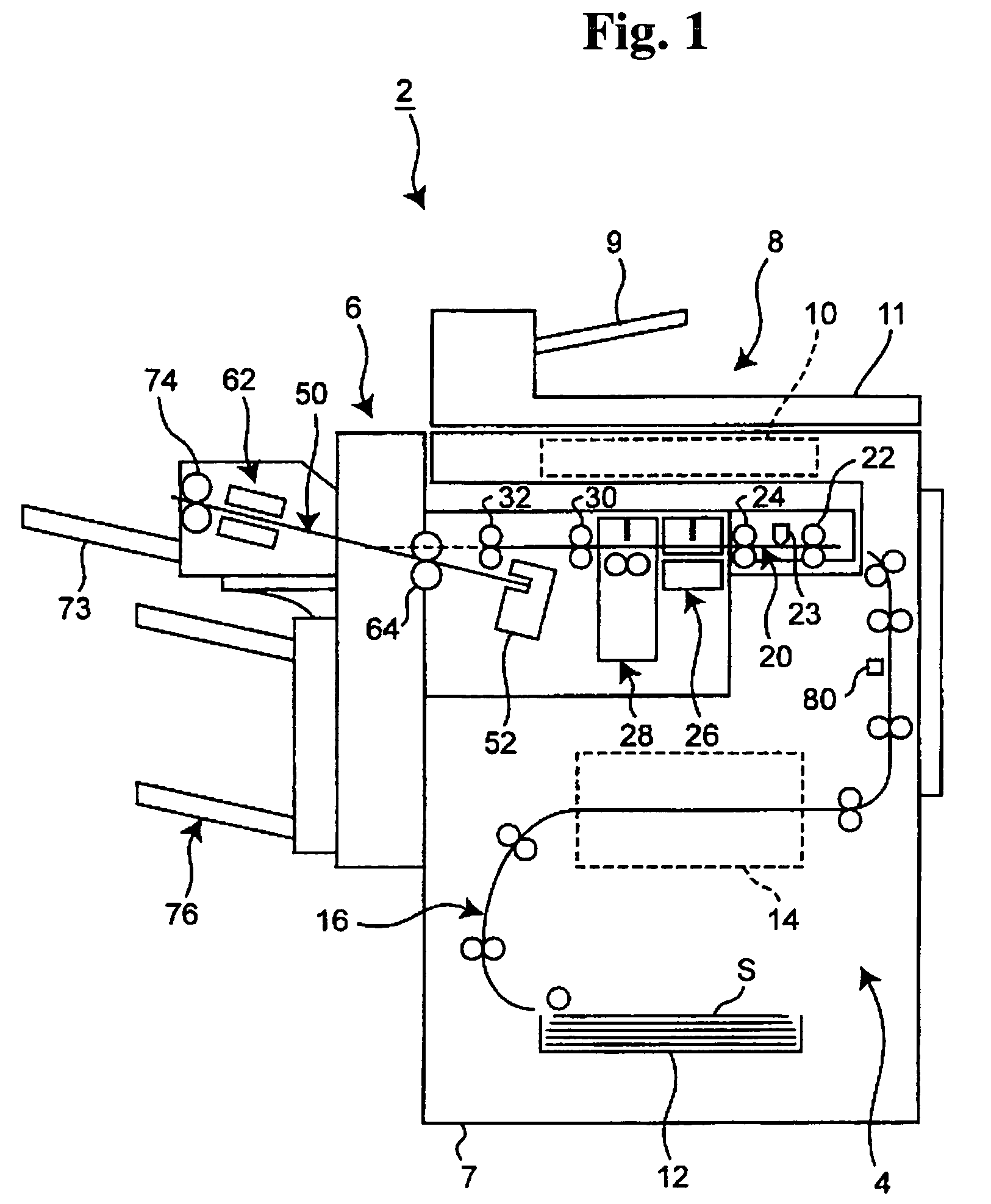

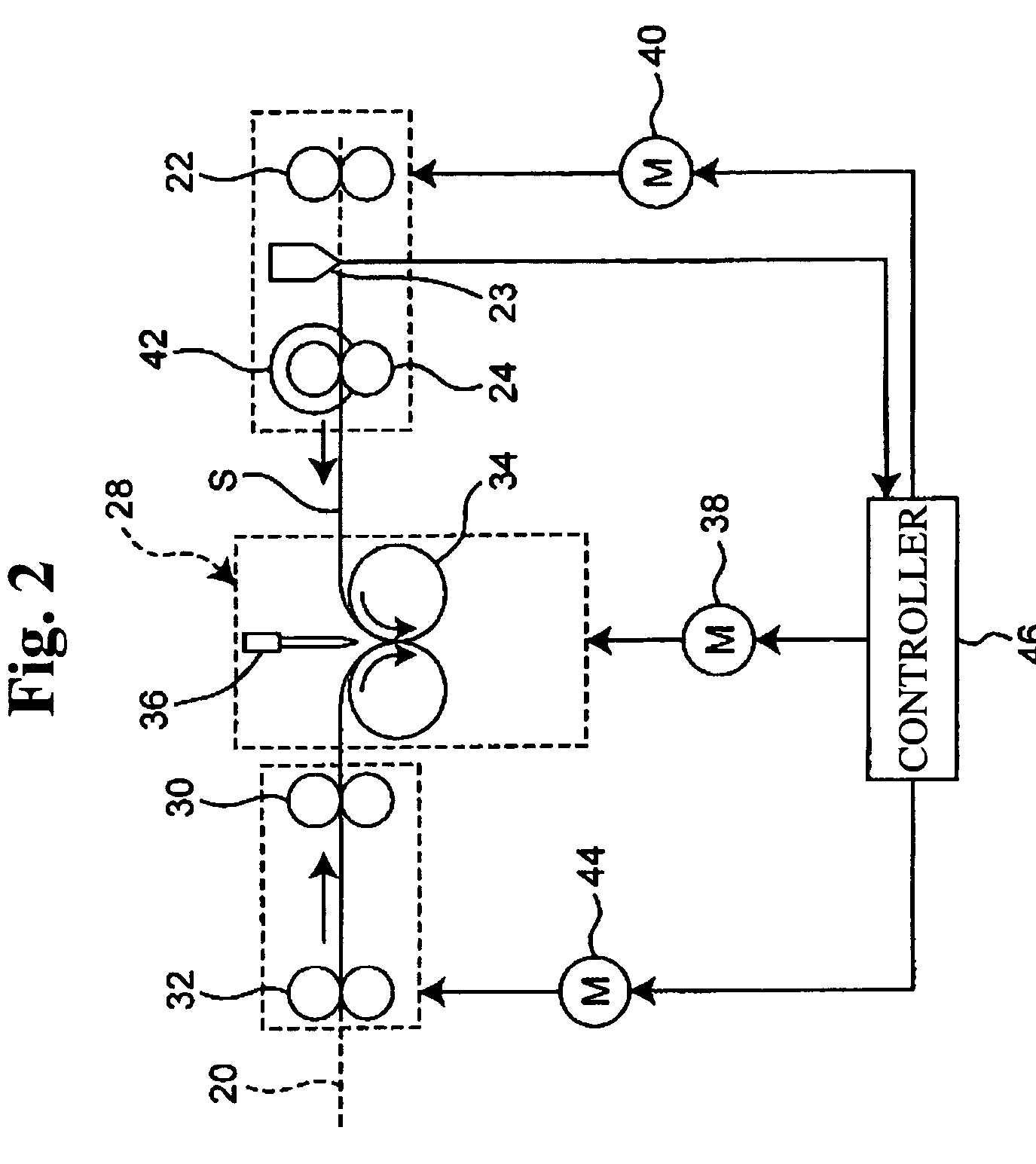

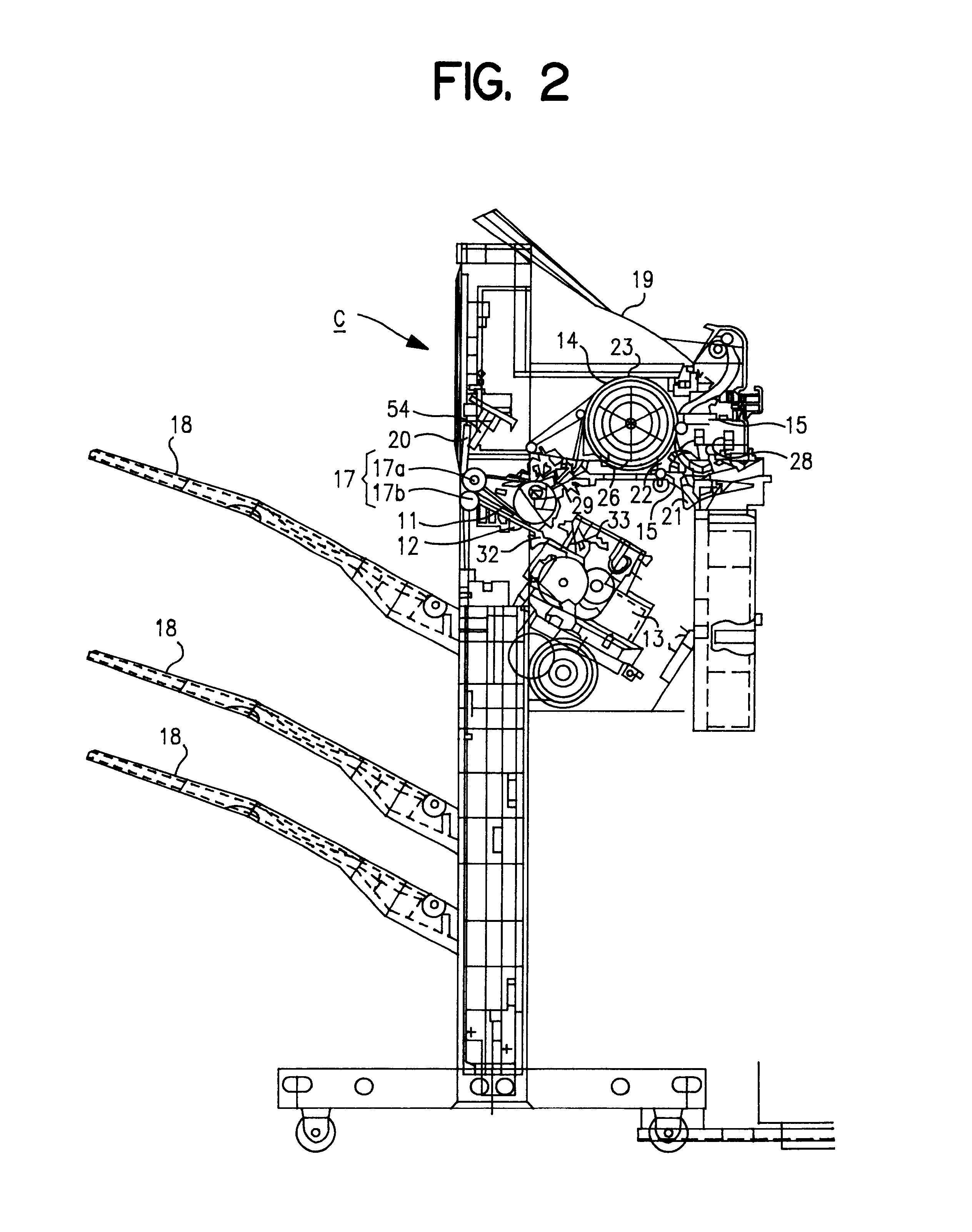

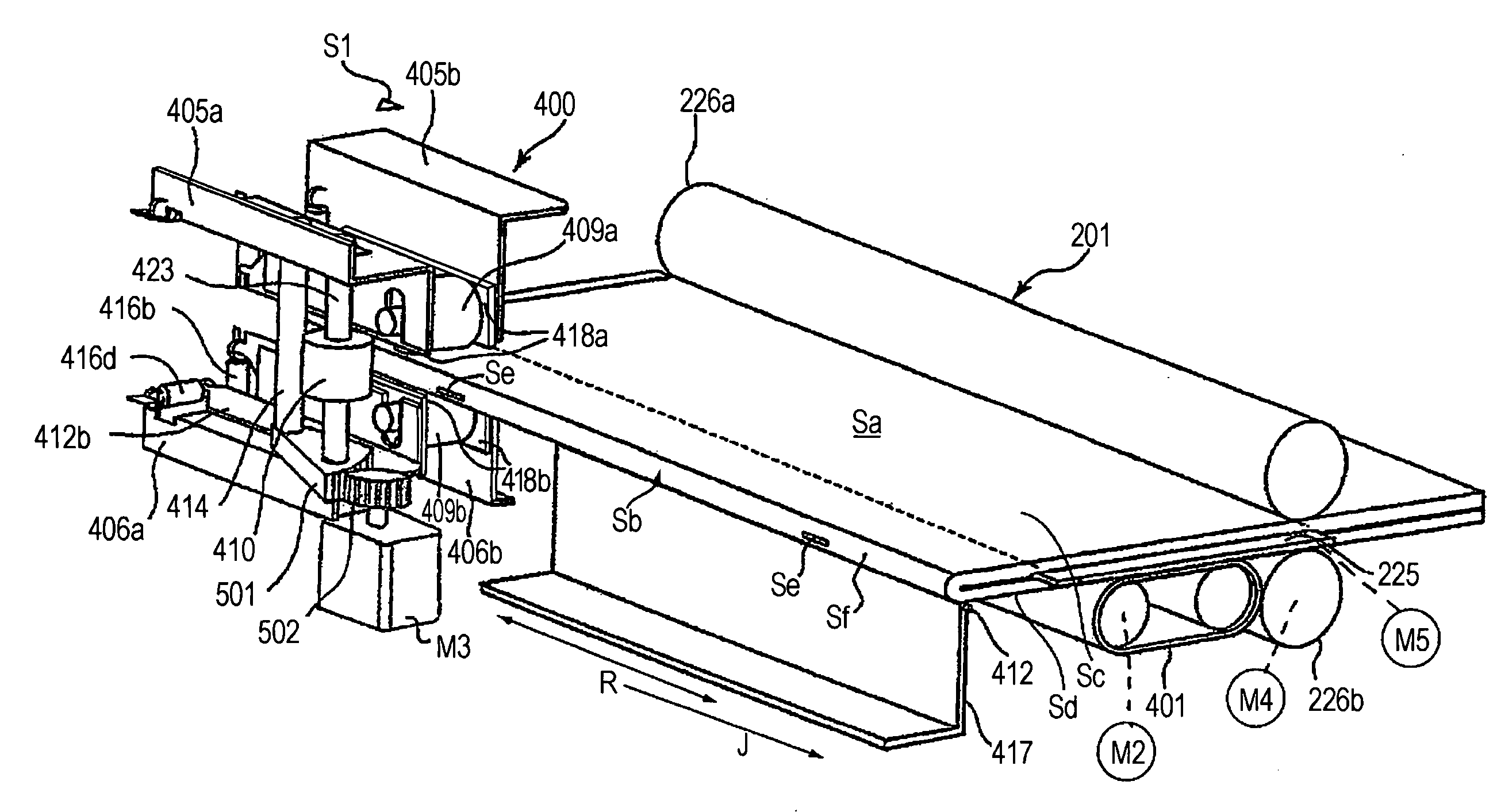

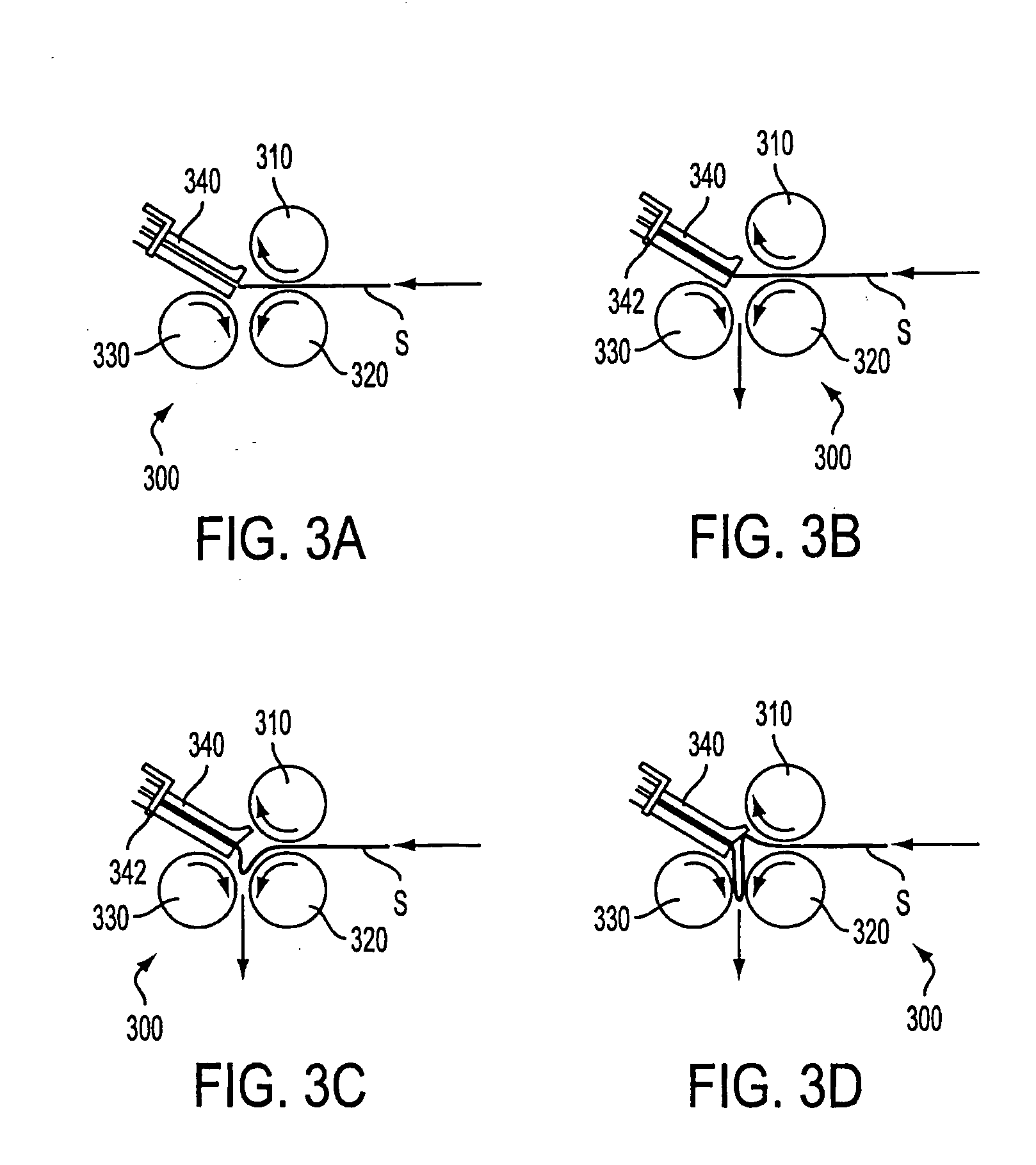

Sheet measurer and folder

ActiveUS7077393B2Accurate sheet processingSmall sizeMechanical working/deformationFolding thin materialsMechanical engineeringEngineering

A finisher that is capable of accurate sheet processing but is small in size, the finisher controlling a feeder and a sheet folding unit and executing 1) an operation in which the sheet is conveyed in the first direction, and after a downstream edge thereof relative to the first direction is detected by the detector during conveyance, the sheet is conveyed in the second direction, 2) an operation in which after such sheet edge is detected by the detector during conveyance in the second direction, the conveyance of the sheet in the second direction is continued for a prescribed amount based on a sheet length along a direction of conveyance, whereupon the sheet is stopped, and 3) an operation in which after the sheet is stopped, the sheet folding unit is operated to create a fold line at a prescribed position in the sheet.

Owner:KONICA MINOLTA BUSINESS TECH INC

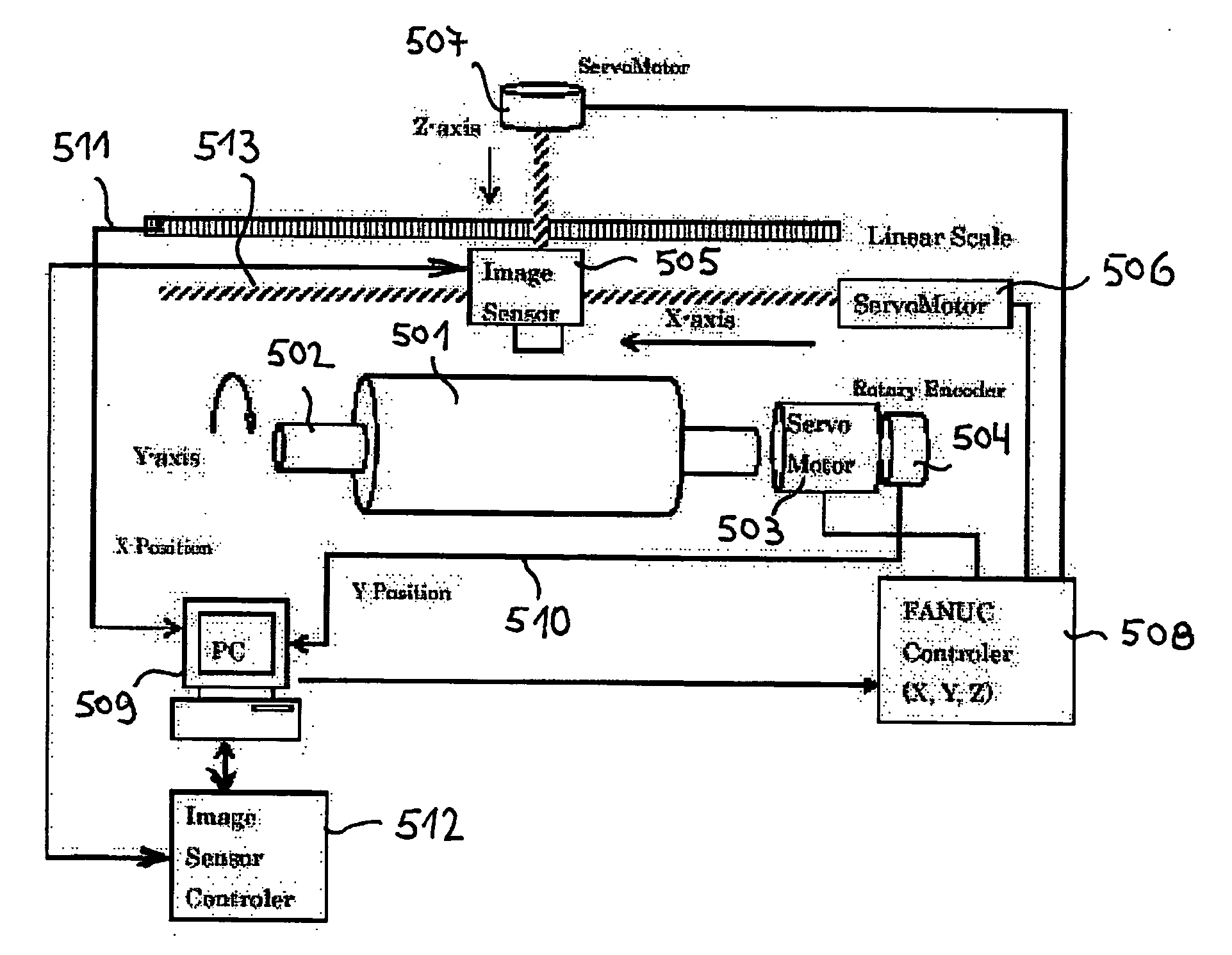

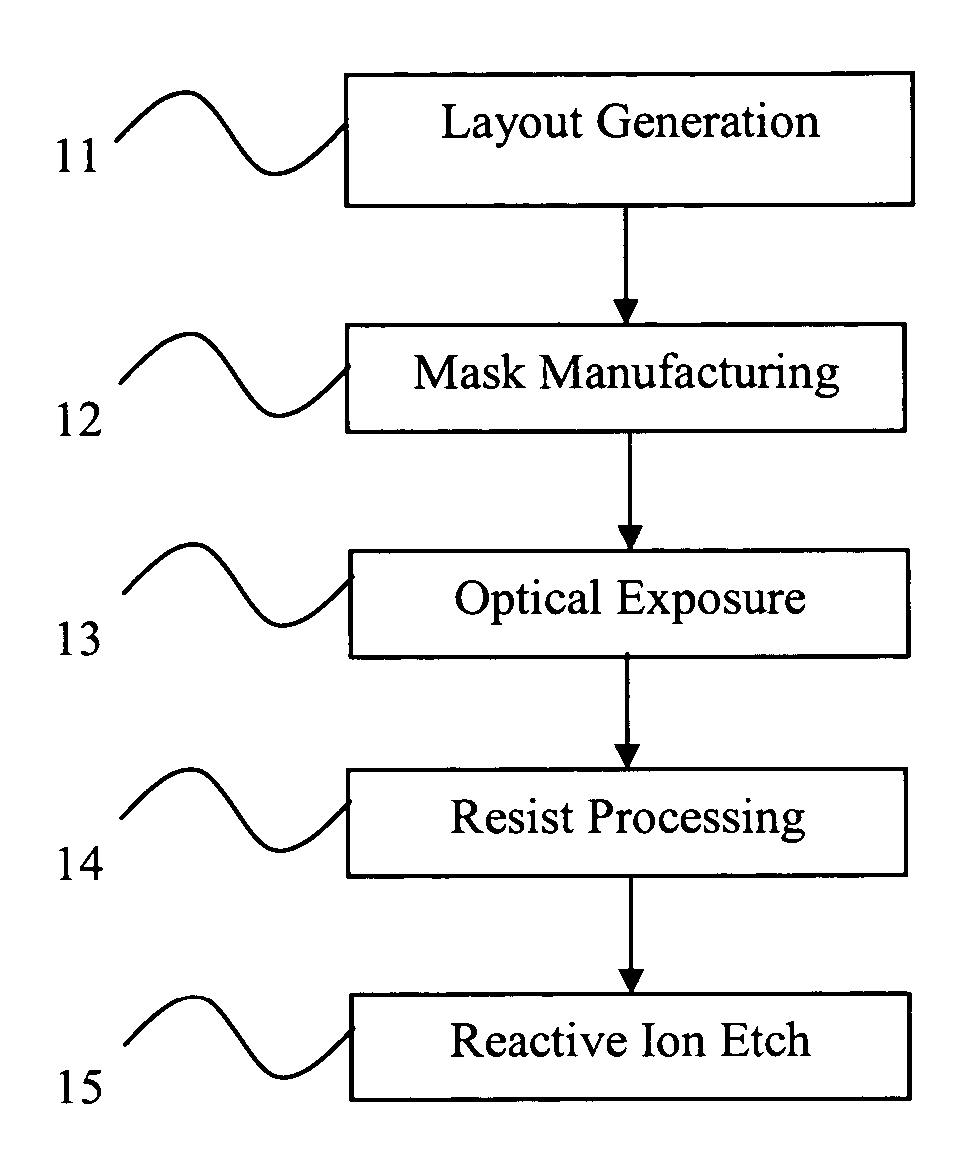

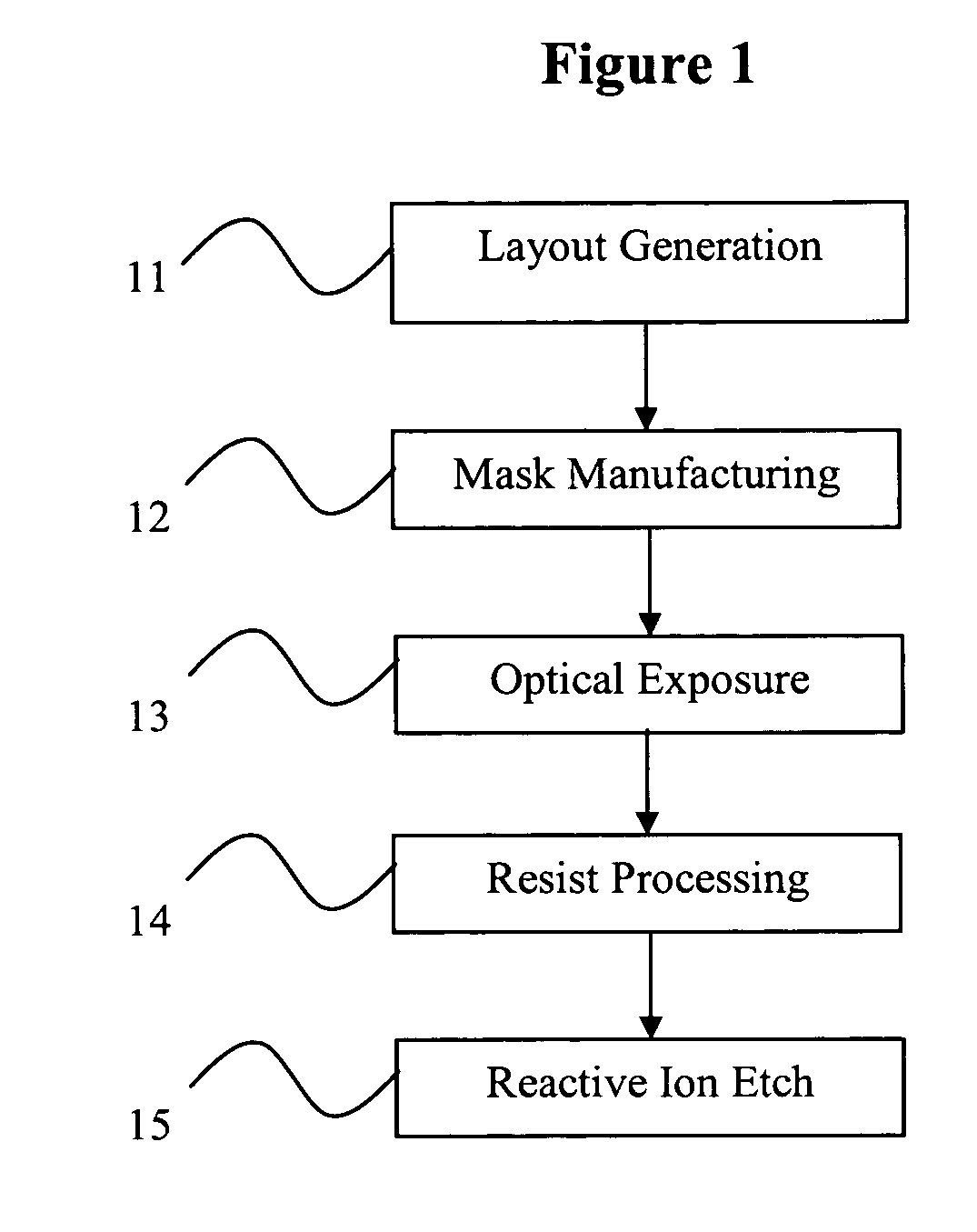

Method and system for detecting defects during the fabrication of a printing cylinder

The invention relates generally to the field of printing. More specifically, the invention relates to a method and system for automatically detecting defects in a printing cylinder during its fabrication process. The invention further relates to a process for fabricating a printing cylinder.

Owner:ELBIT VISION SYST

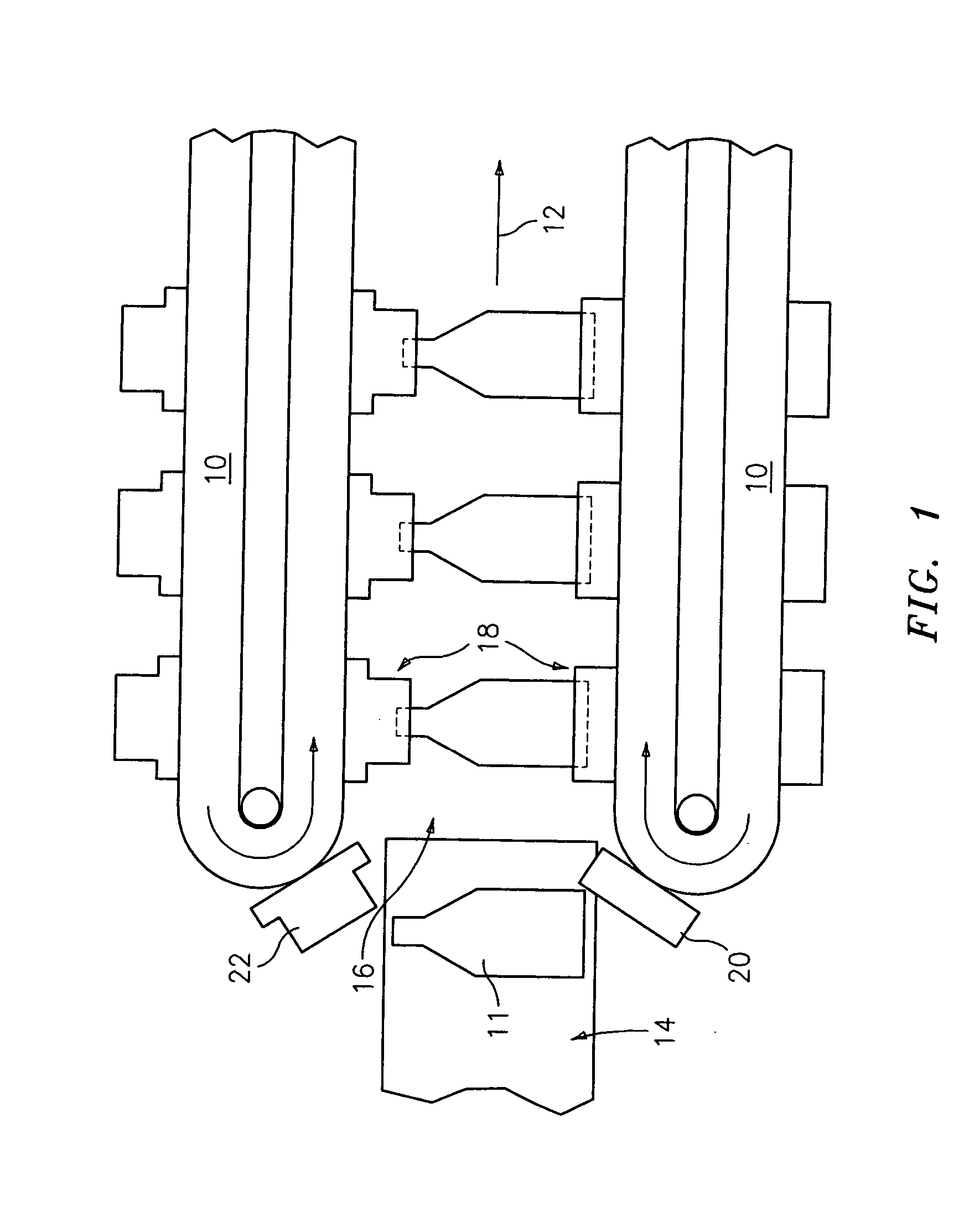

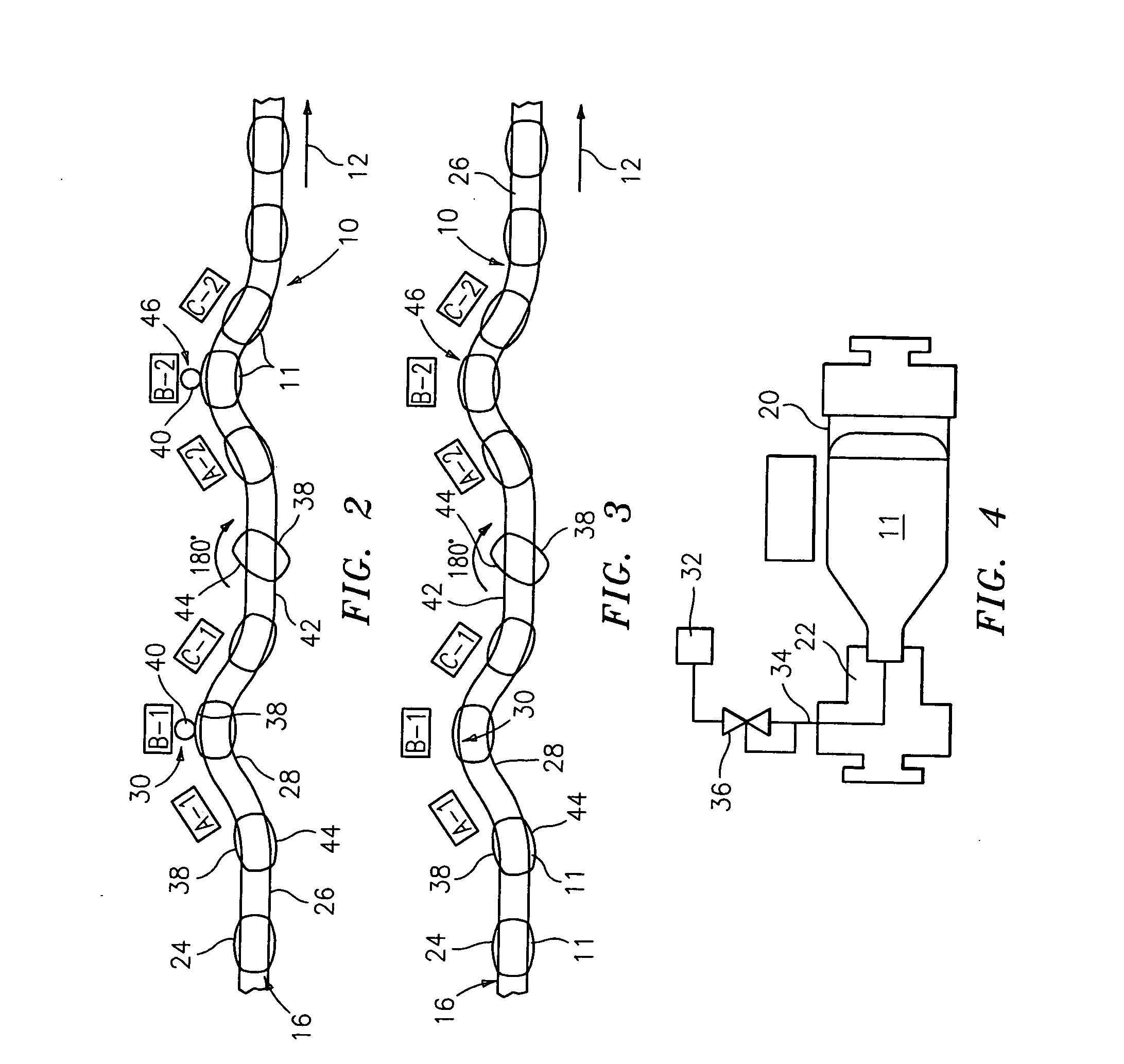

Printing plastic containers with digital images

A method for printing digital images on plastic containers having curved surfaces, including providing a series of hollow plastic containers, moving the containers along a track past first and second digital printing locations, and printing first and second digital images on the curved container surfaces while maintaining the container being printed under internal pressure and while firmly holding the container being printed at spaced locations thereon.

Owner:PLASTIPAK PACKAGING

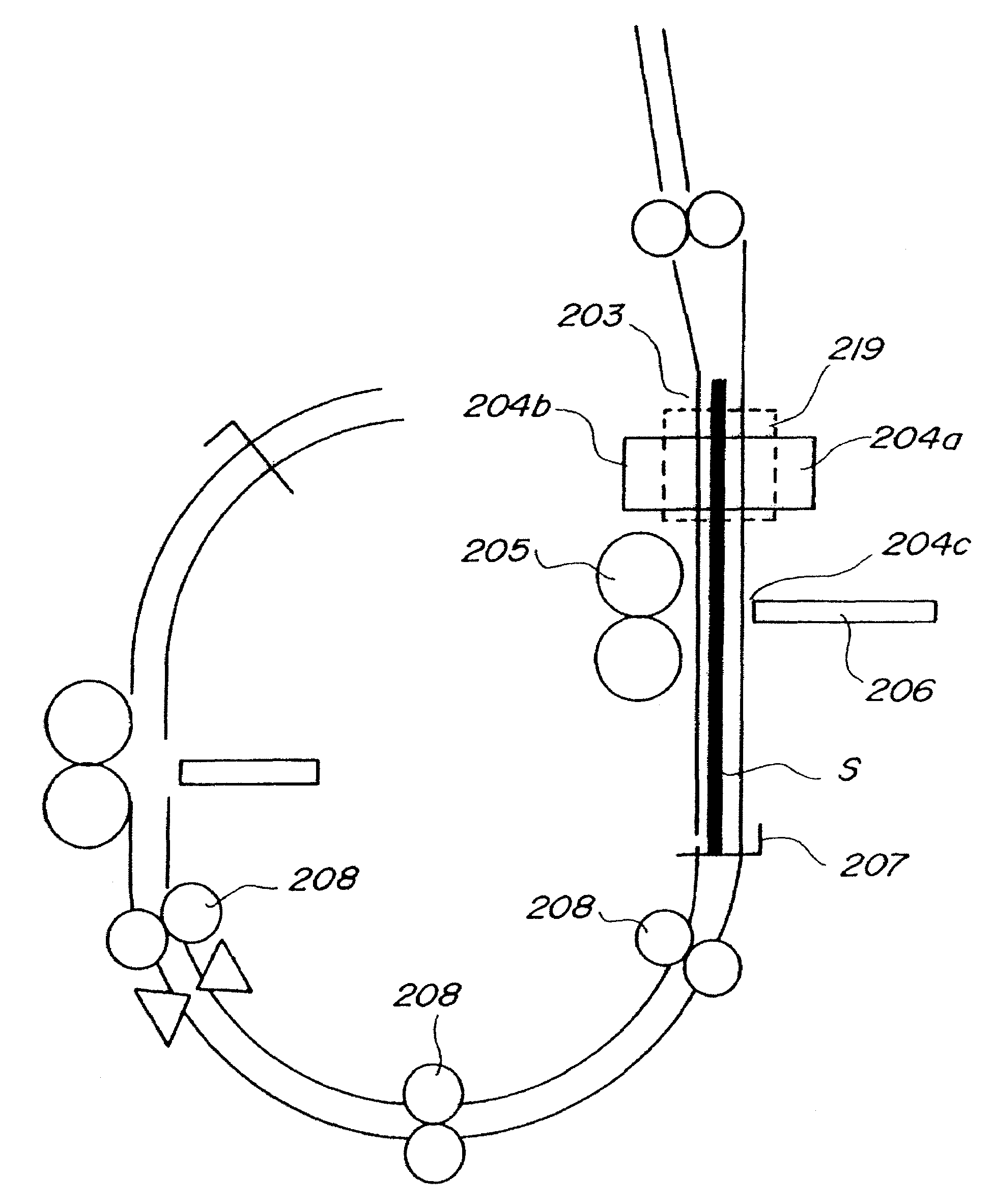

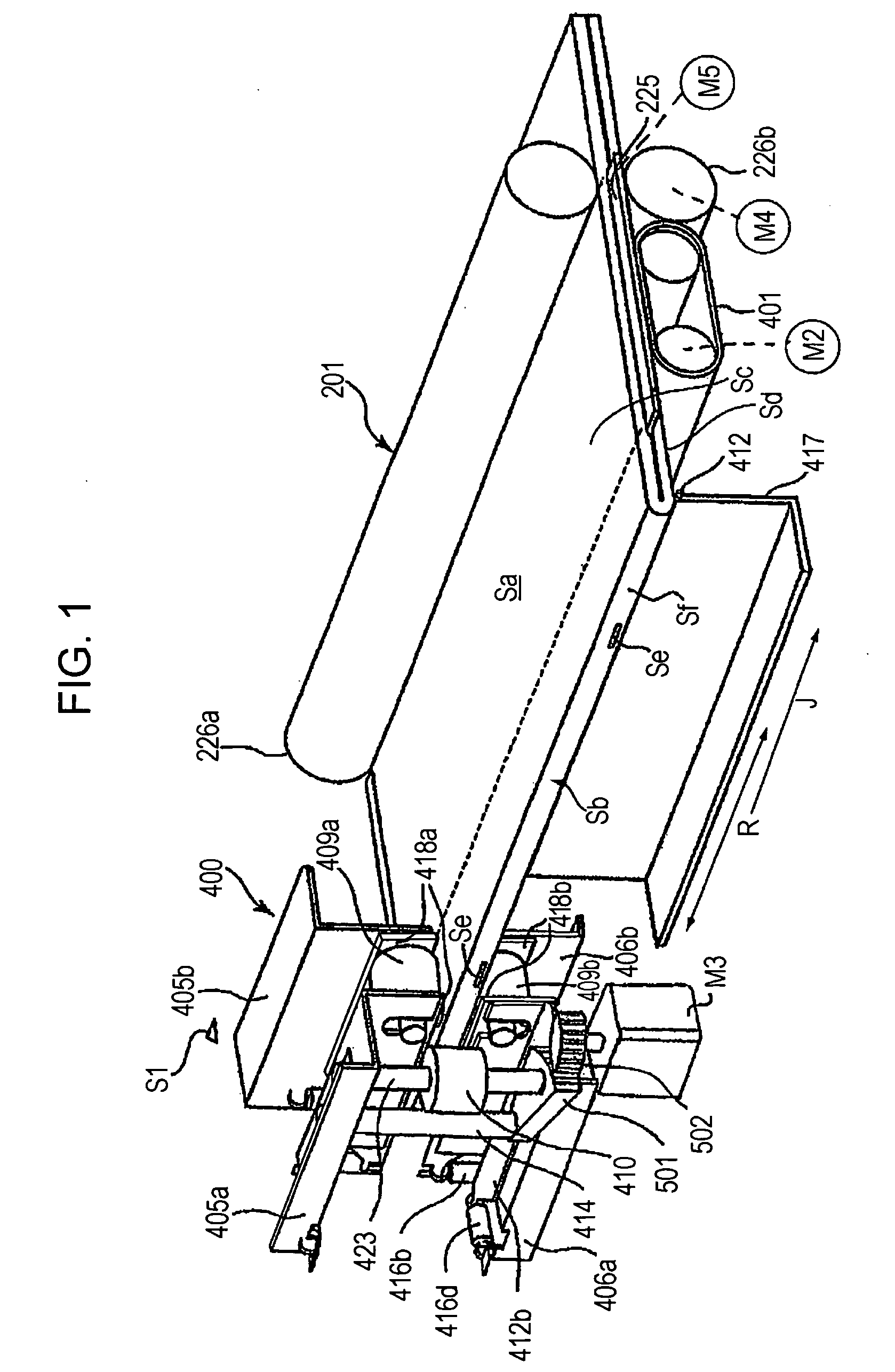

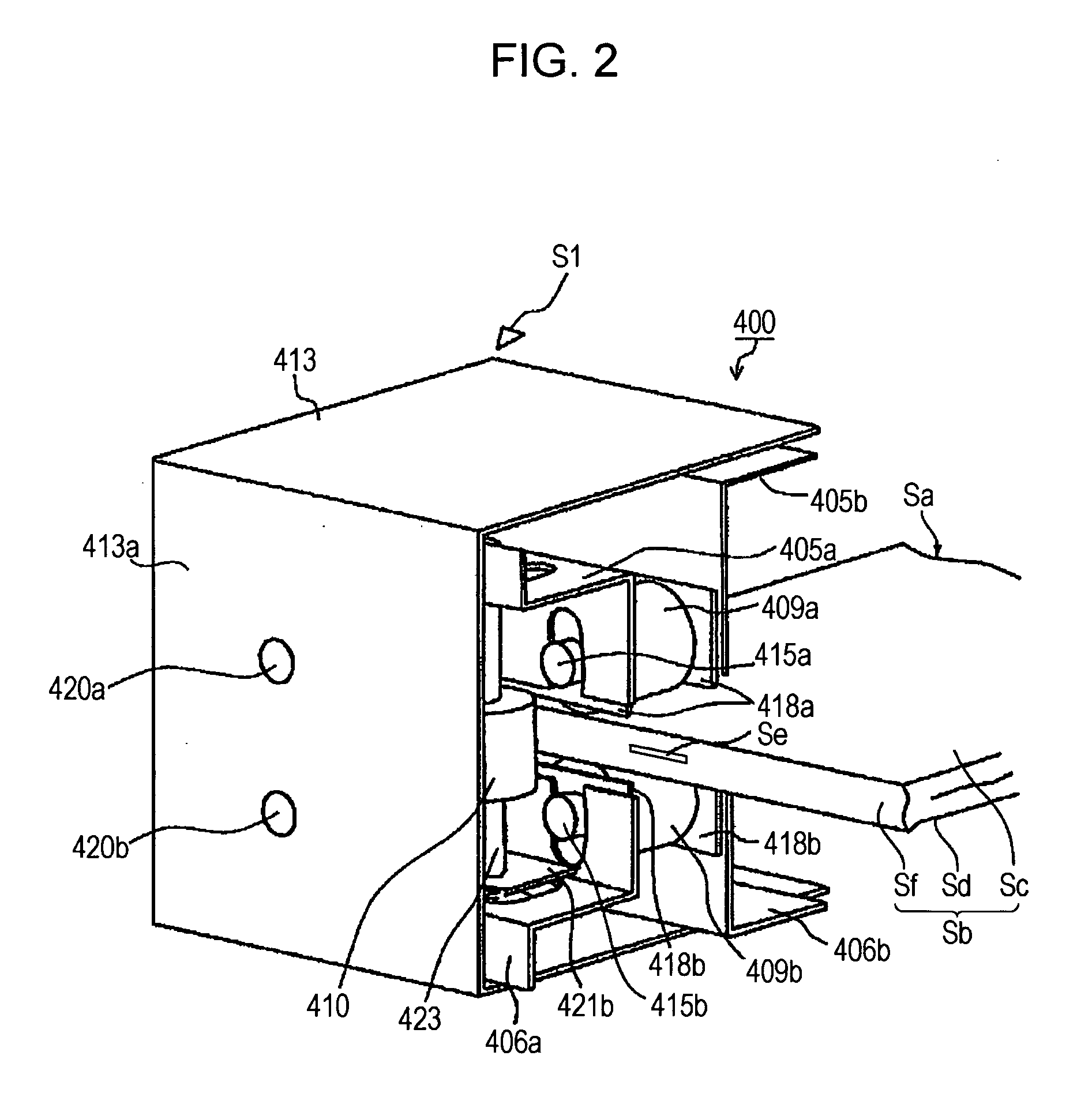

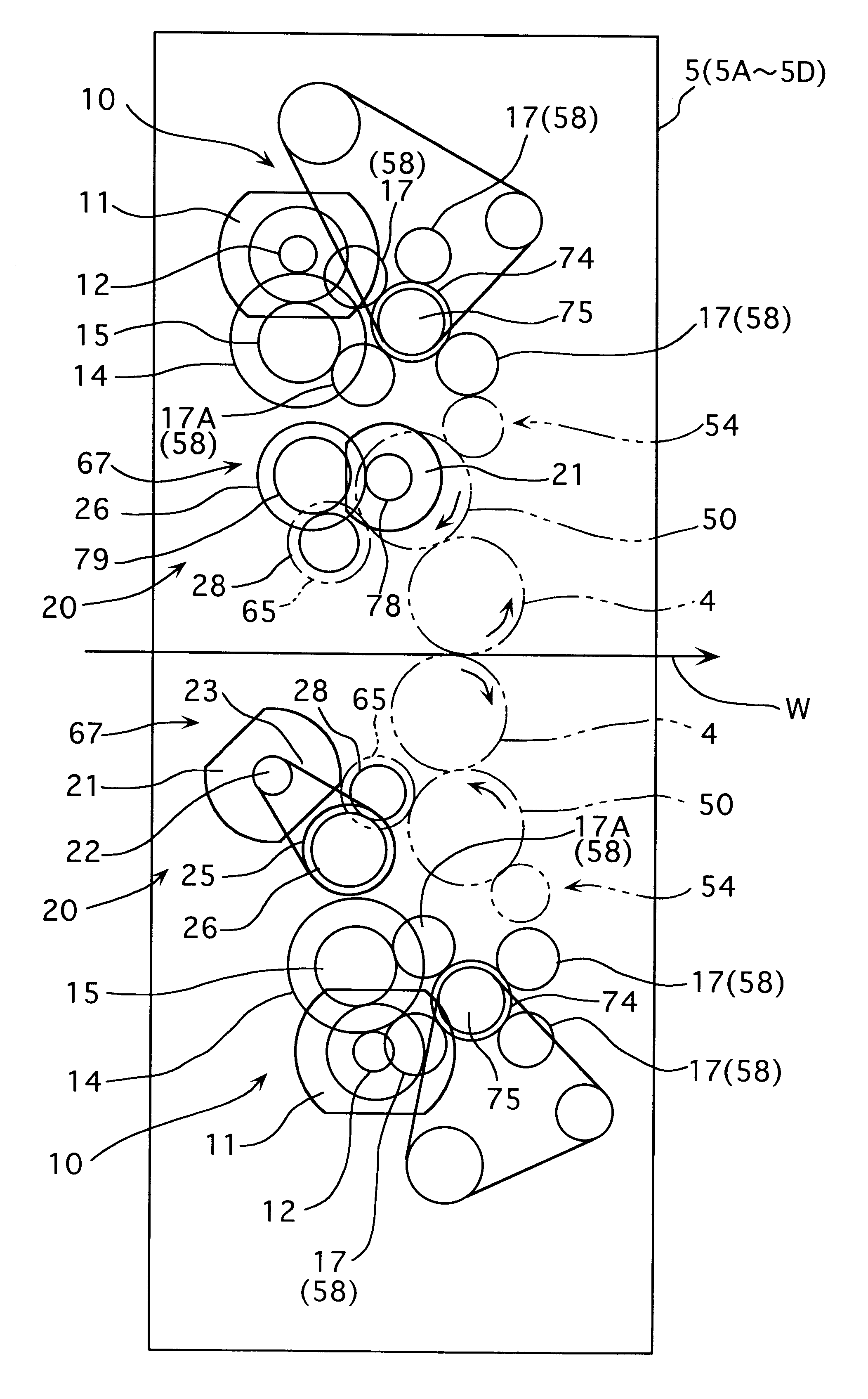

Spine folded portion flattening apparatus, sheet treating apparatus and image forming apparatus

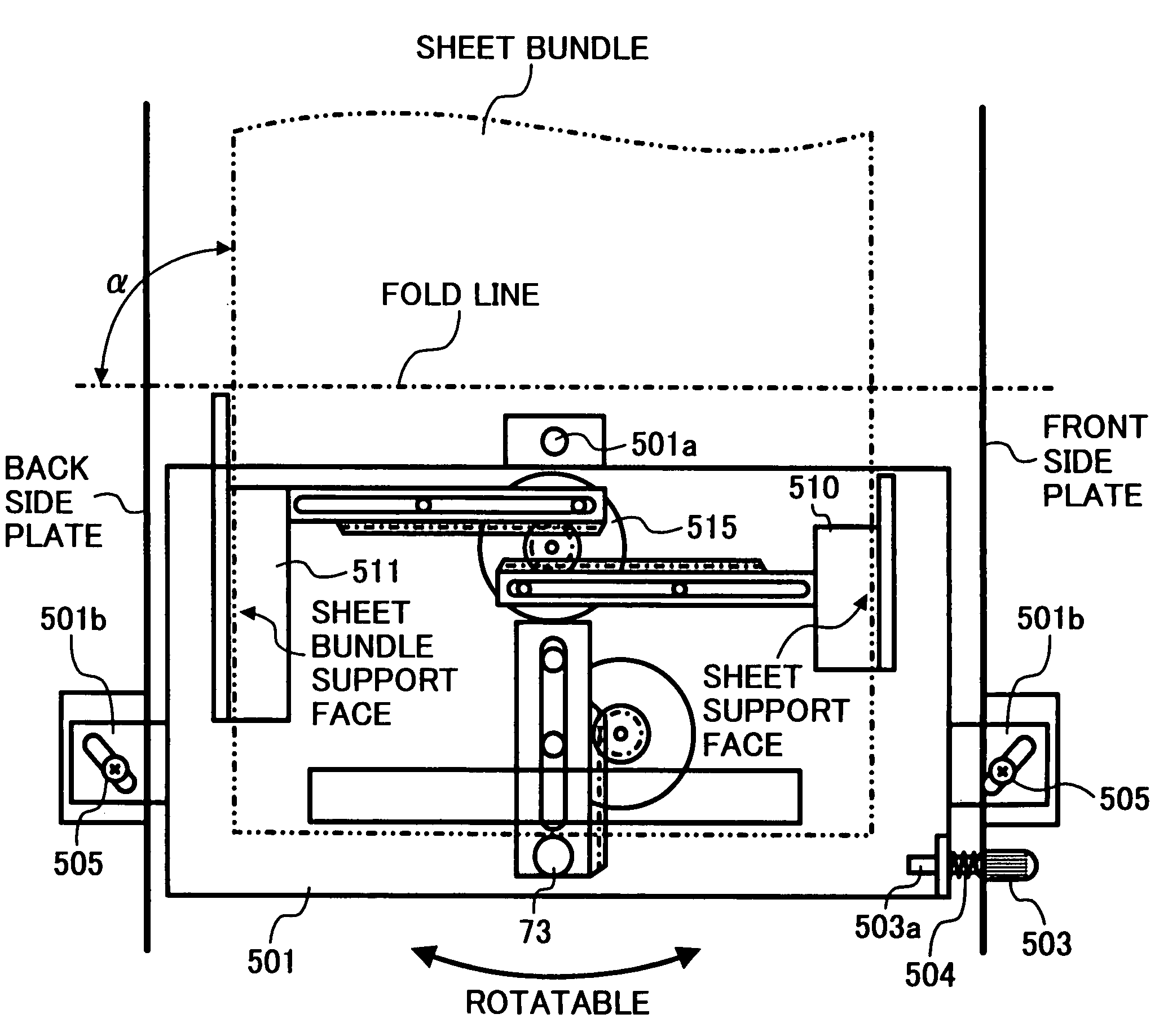

ActiveUS20050179190A1Enhancing spine folded portion flattening process efficiencyImprove efficiencyToysBook making processesEngineeringSheet material

Owner:CANON KK

Calibration on wafer sweet spots

A method for generating an OPC model is provided which takes into consideration across-wafer variations which occur during the process of manufacturing semiconductor chips. More particularly, a method for generating an OPC model is provided which takes into consideration across-wafer variations which occur during the process of manufacturing semiconductor chips based on the parameters of test patterns measured at the “wafer sweet spots” so as to arrive at an accurate model.

Owner:CADENCE DESIGN SYST INC

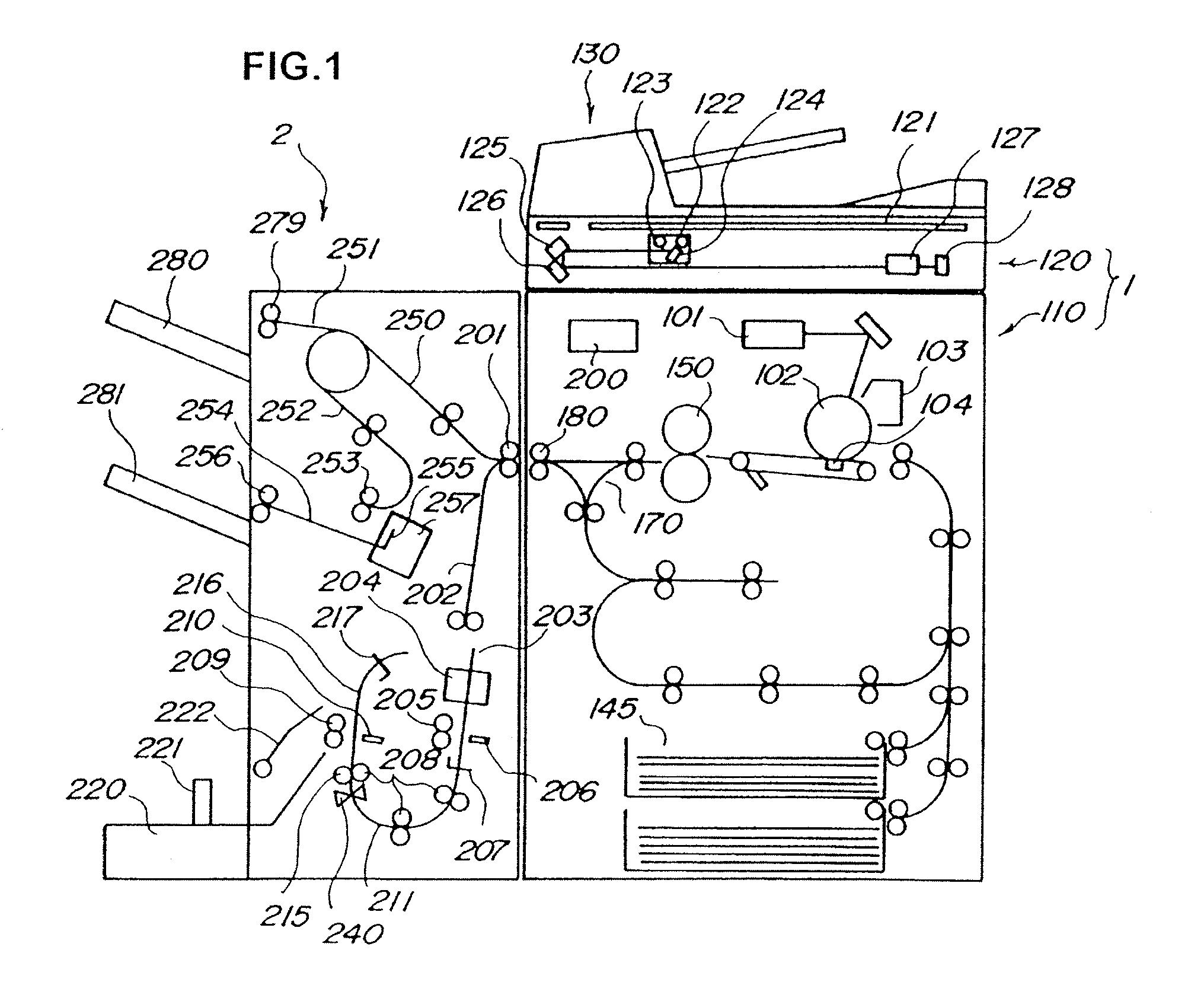

Sheet processor and image-forming apparatus

InactiveUS7431274B2Good lookingUniform forceFolding thin materialsElectrographic process apparatusSheet materialImage formation

Owner:CANON KK

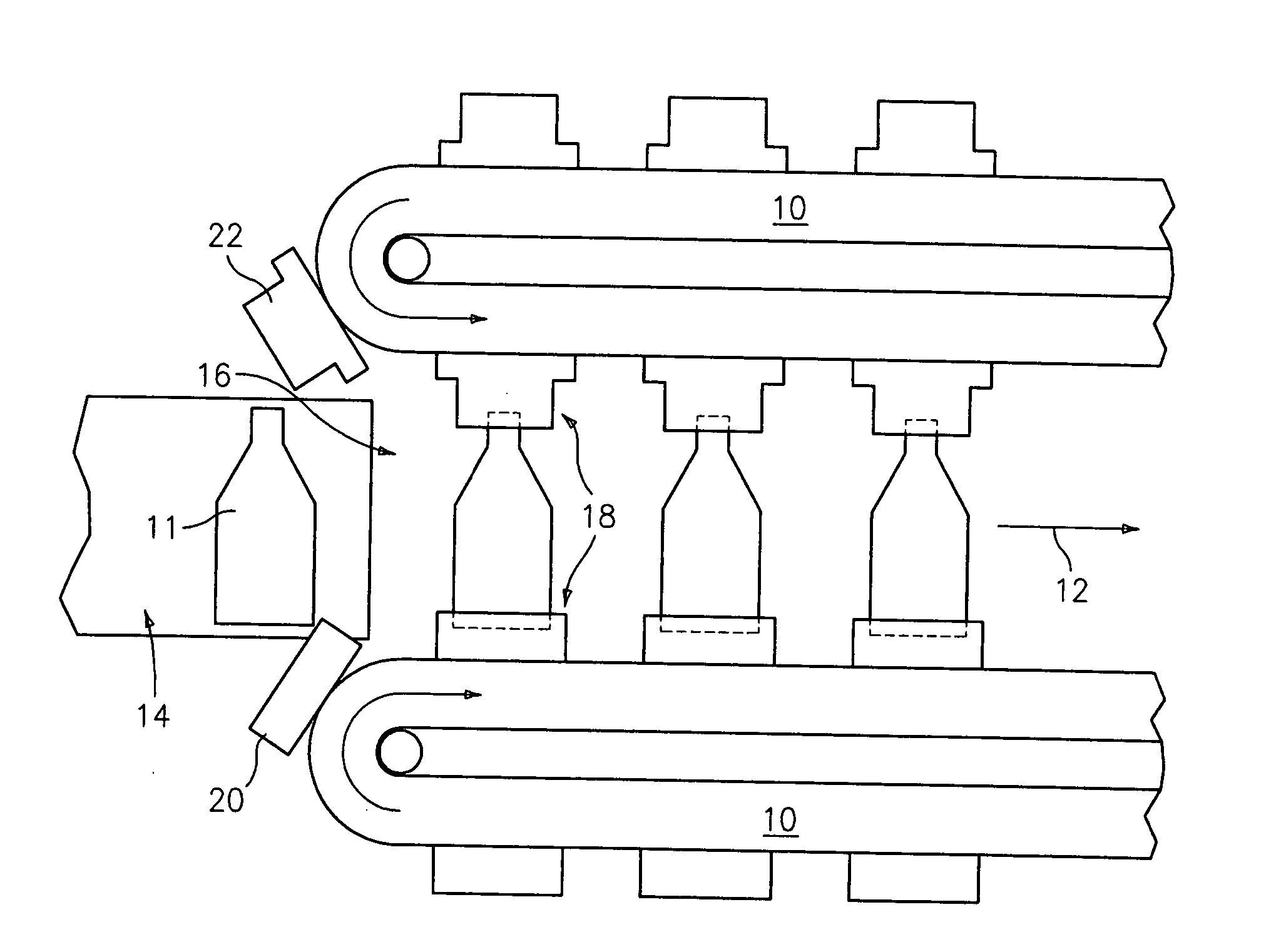

Power saving automatic zoned dryer apparatus and method

InactiveUS6877247B1Eliminates and greatly reduces needImprove paper qualityDrying solid materials with heatDrying gas arrangementsAuto regulationEngineering

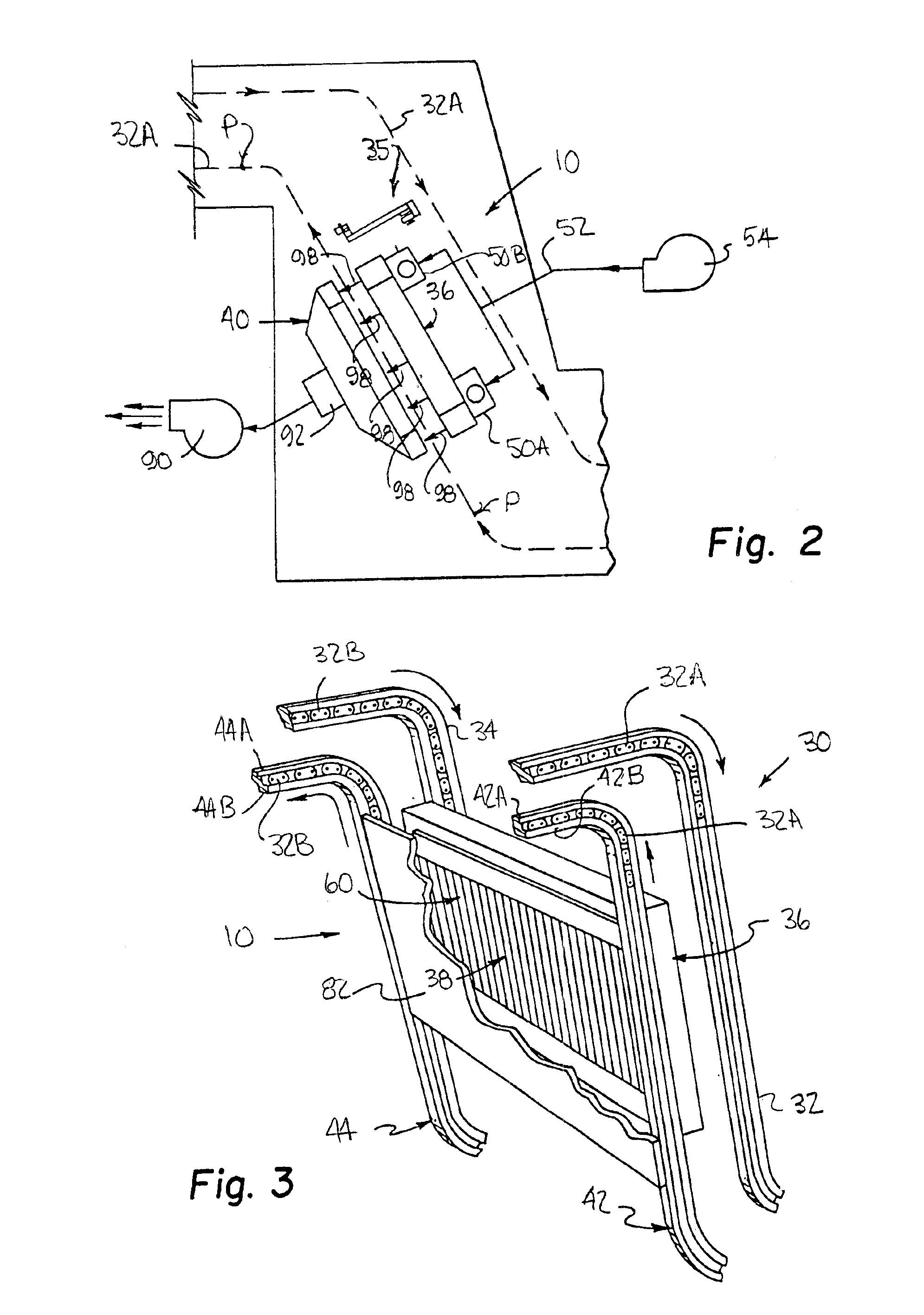

A computer controlled power saving automatic zoned dryer for a printing press has a dryer head facing the substrate travel path, having a multiplicity of IR lamps connected individually or in groups to form a plurality of heating zones running longitudinally and each extending laterally side by side across the substrate travel path. The radiant heat output of each heating zone is controlled separately by means of a control unit connected to a power supply. The control unit individually regulates output of the heating zones. Unneeded zones are turned off to reduce cost of power and conserve energy. A plurality of heat sensors spaced laterally across the substrate path measure the surface temperature of substrate heated areas corresponding to the heating zones being operated and maintain an automatic set point temperature. The temperature of each individual heated area can be regulated automatically by adjusting the output of its heating zone whereby printed substrates having a more even temperature profile are delivered. In an alternate manual mode any zone can be set independently to operate at any percentage of full available power from zero to 100%. Separate high velocity air scrubbers and additional air extraction are used to enhance the total drying effect of the zoned dryer assembly.

Owner:PRINTING RES

Sheet processor and image-forming apparatus

InactiveUS20050189689A1Good lookingUniform forceFolding thin materialsElectrographic process apparatusEngineeringMechanical engineering

Owner:CANON KK

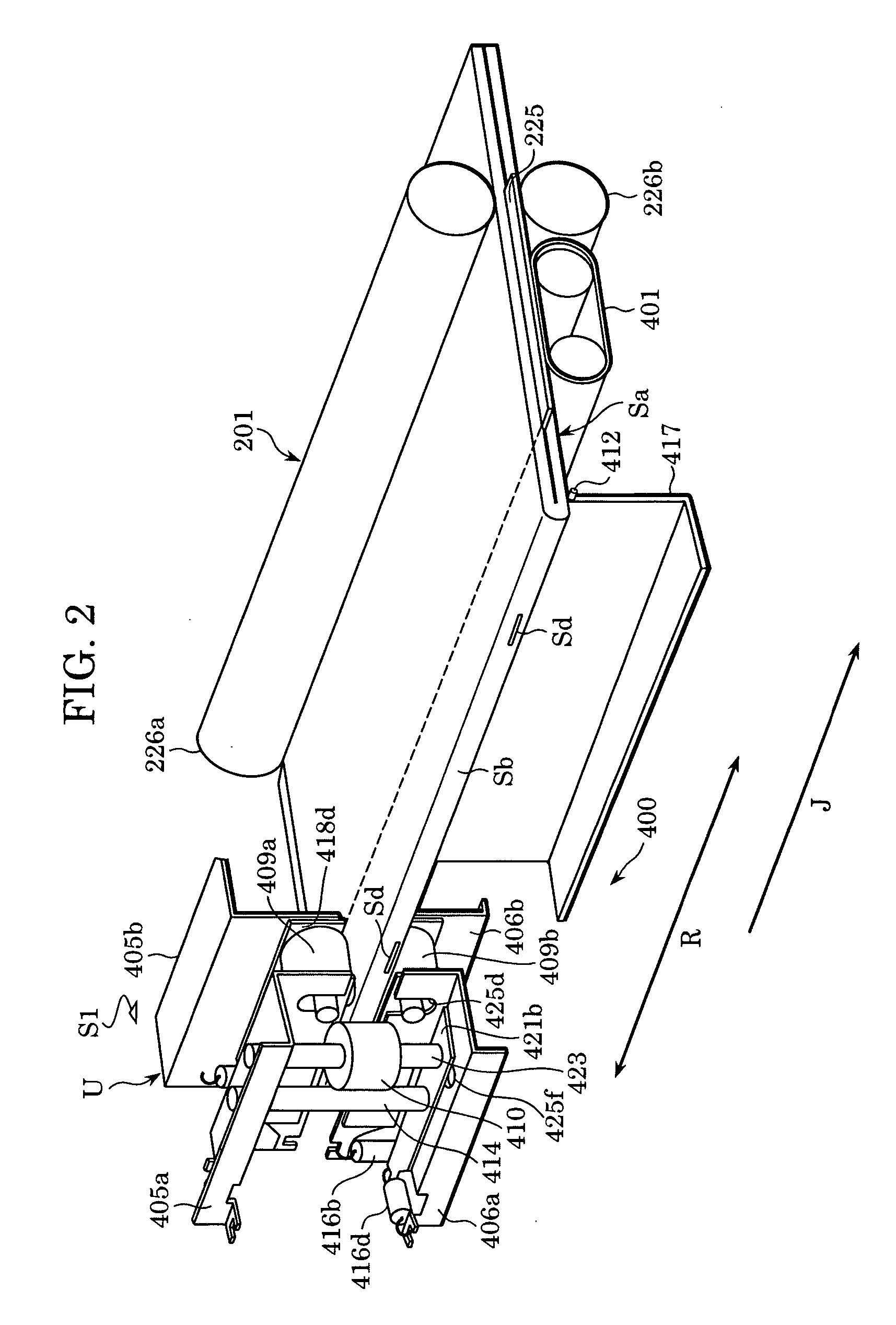

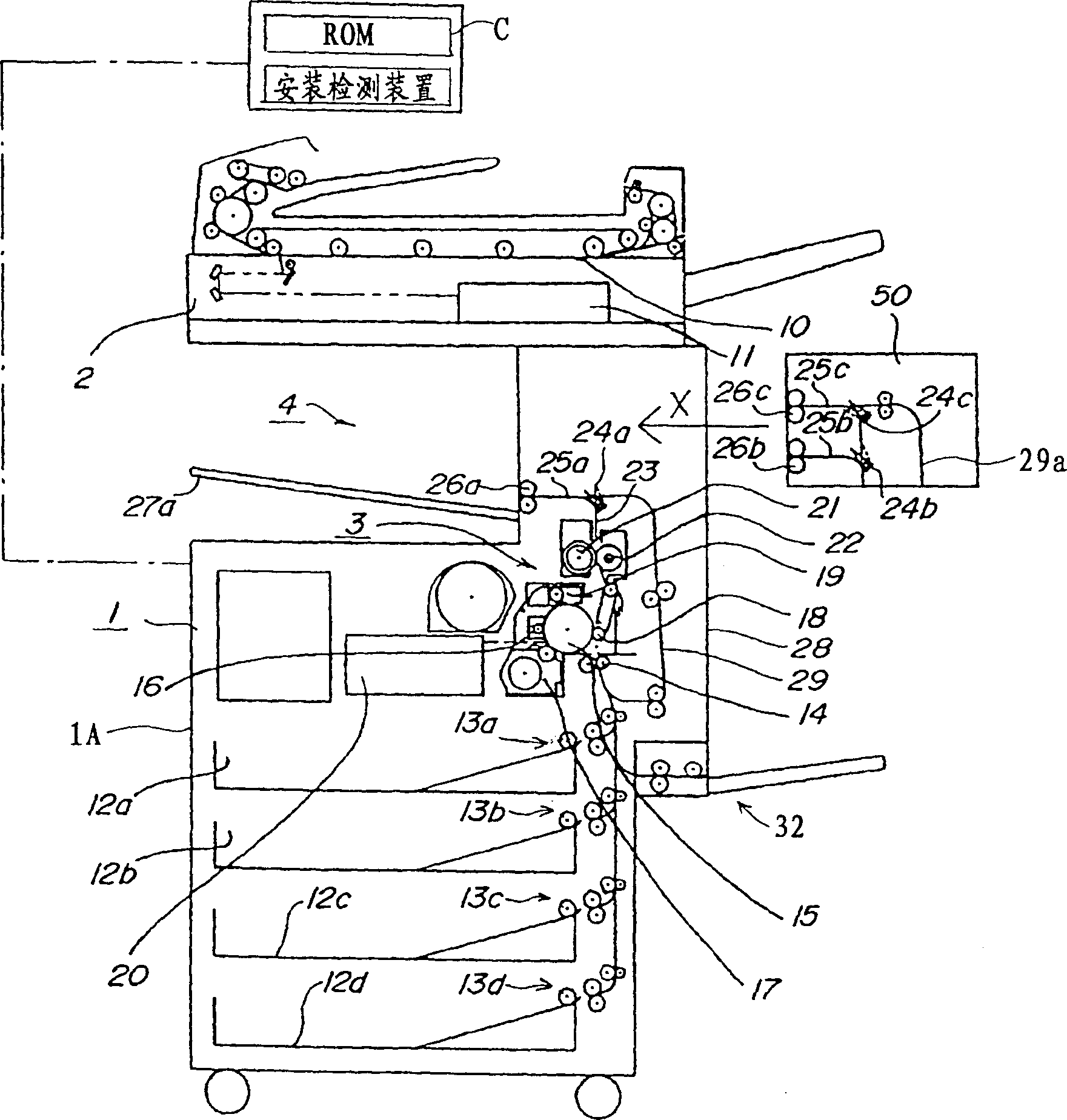

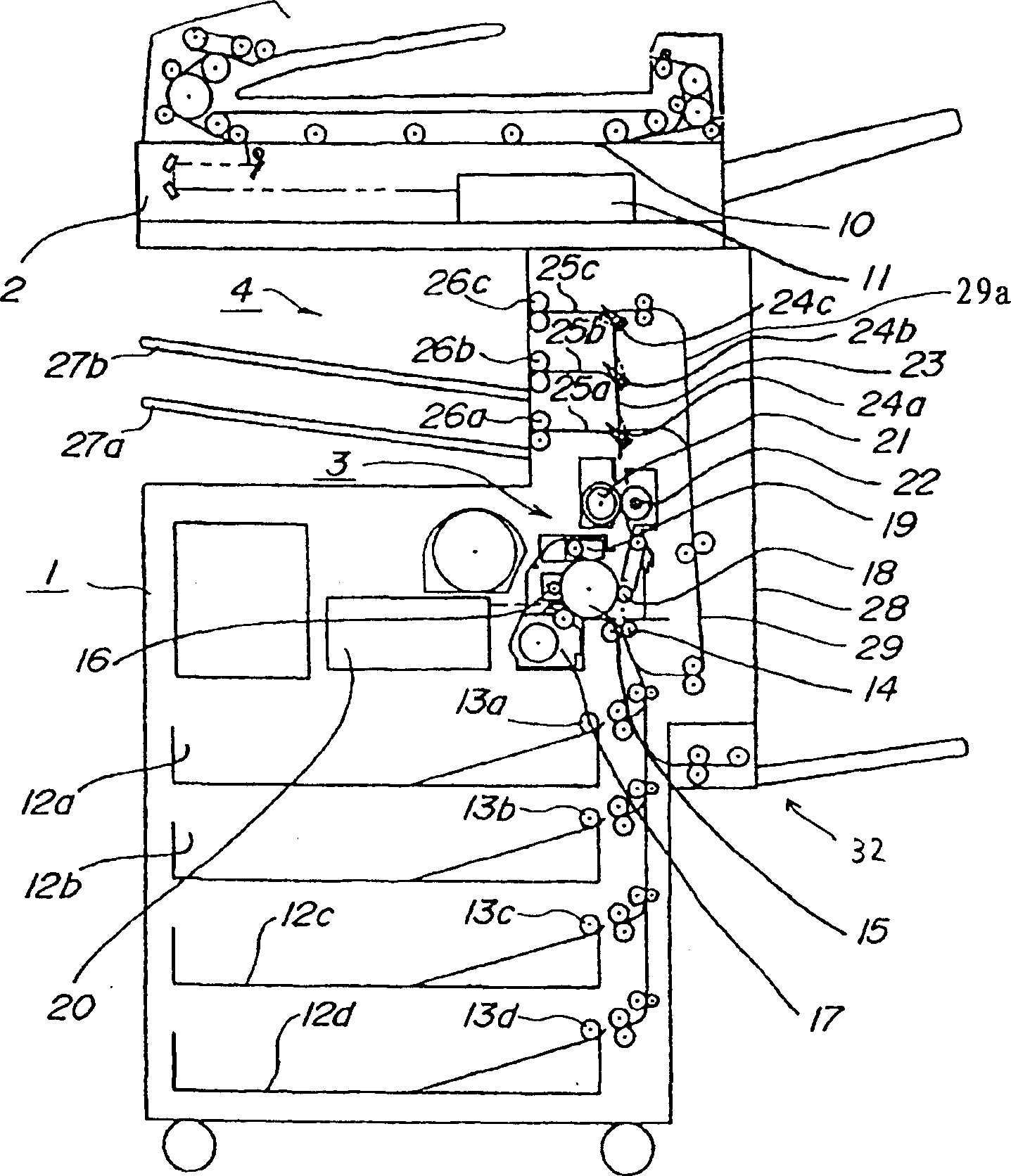

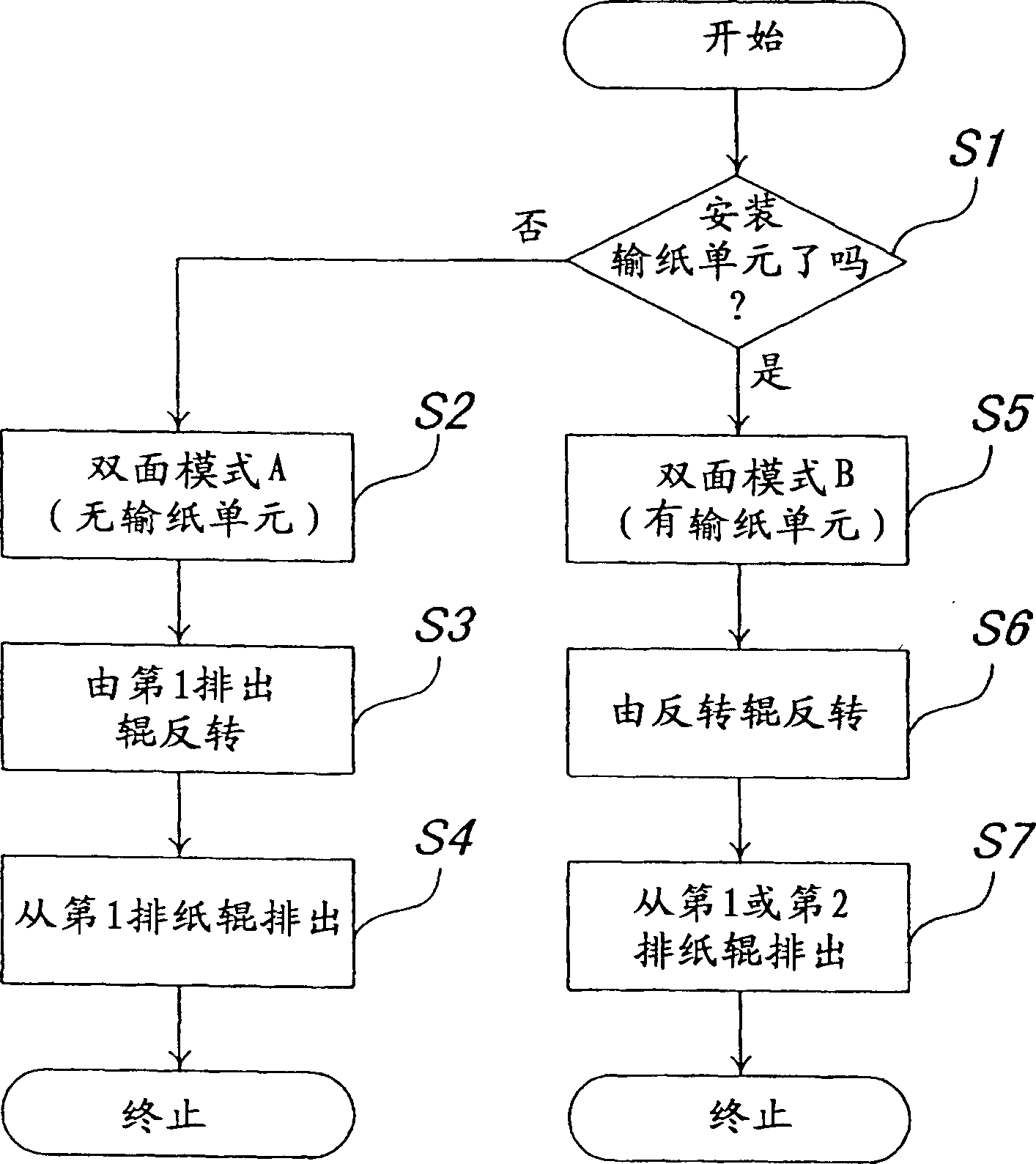

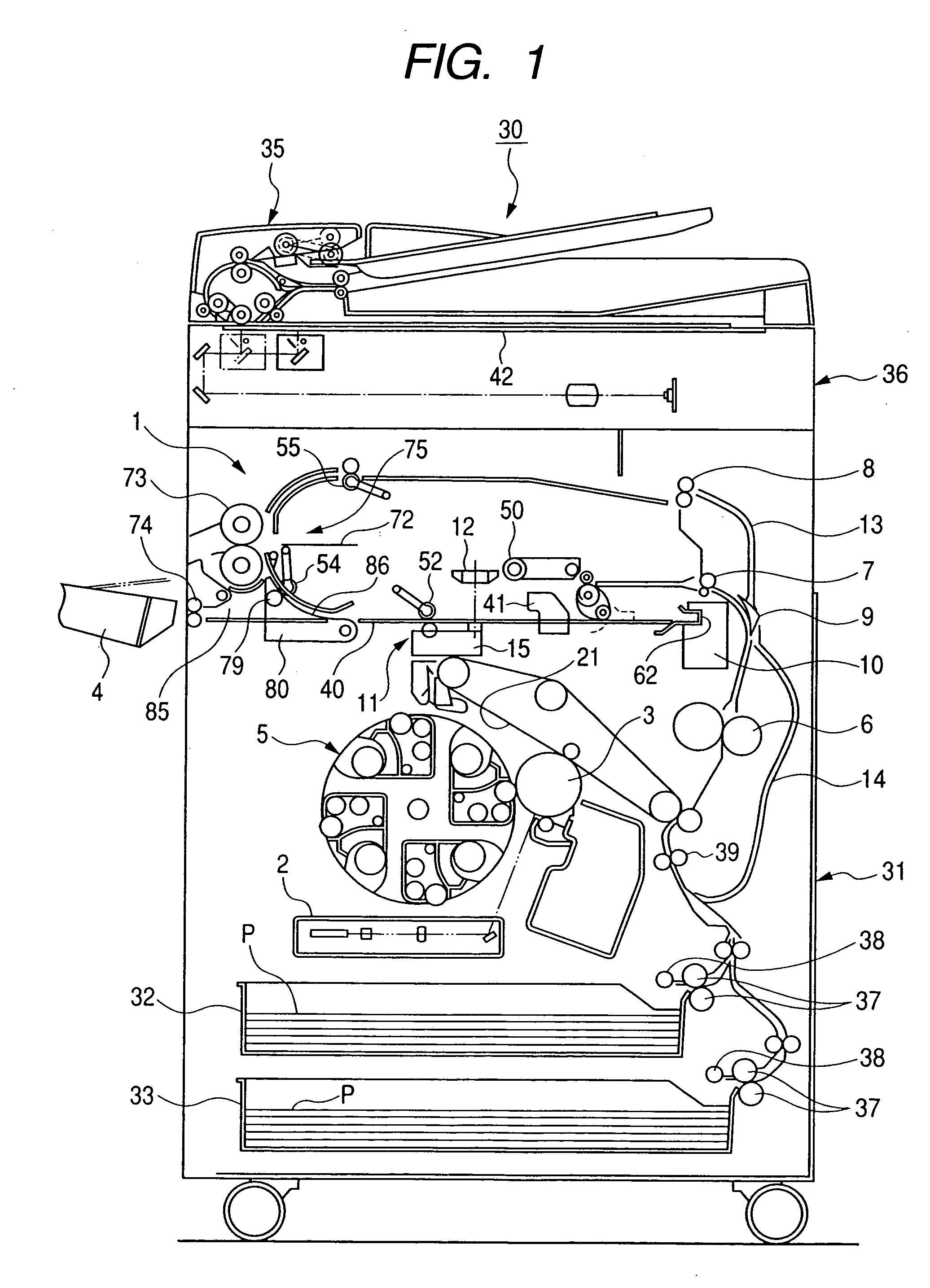

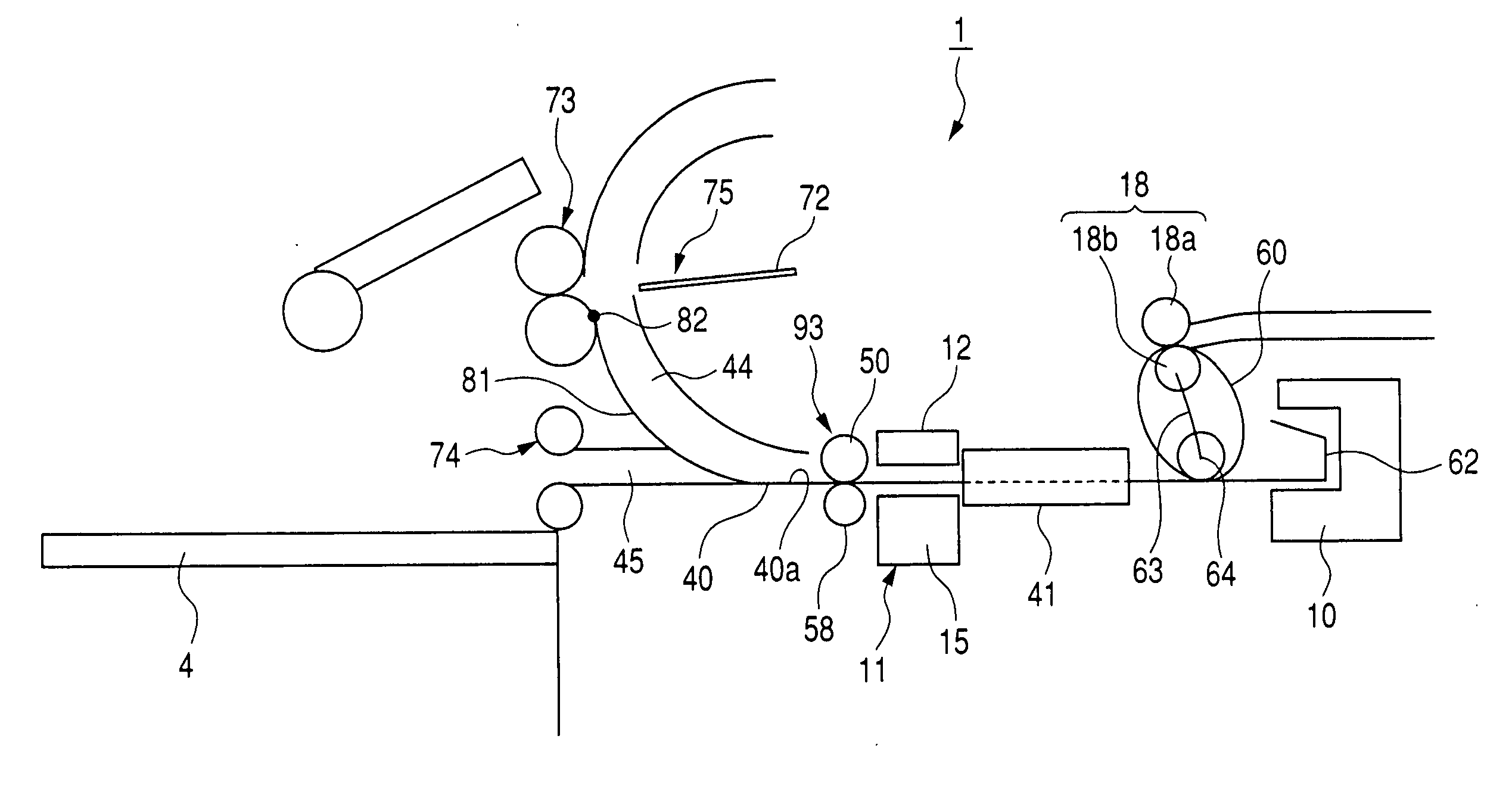

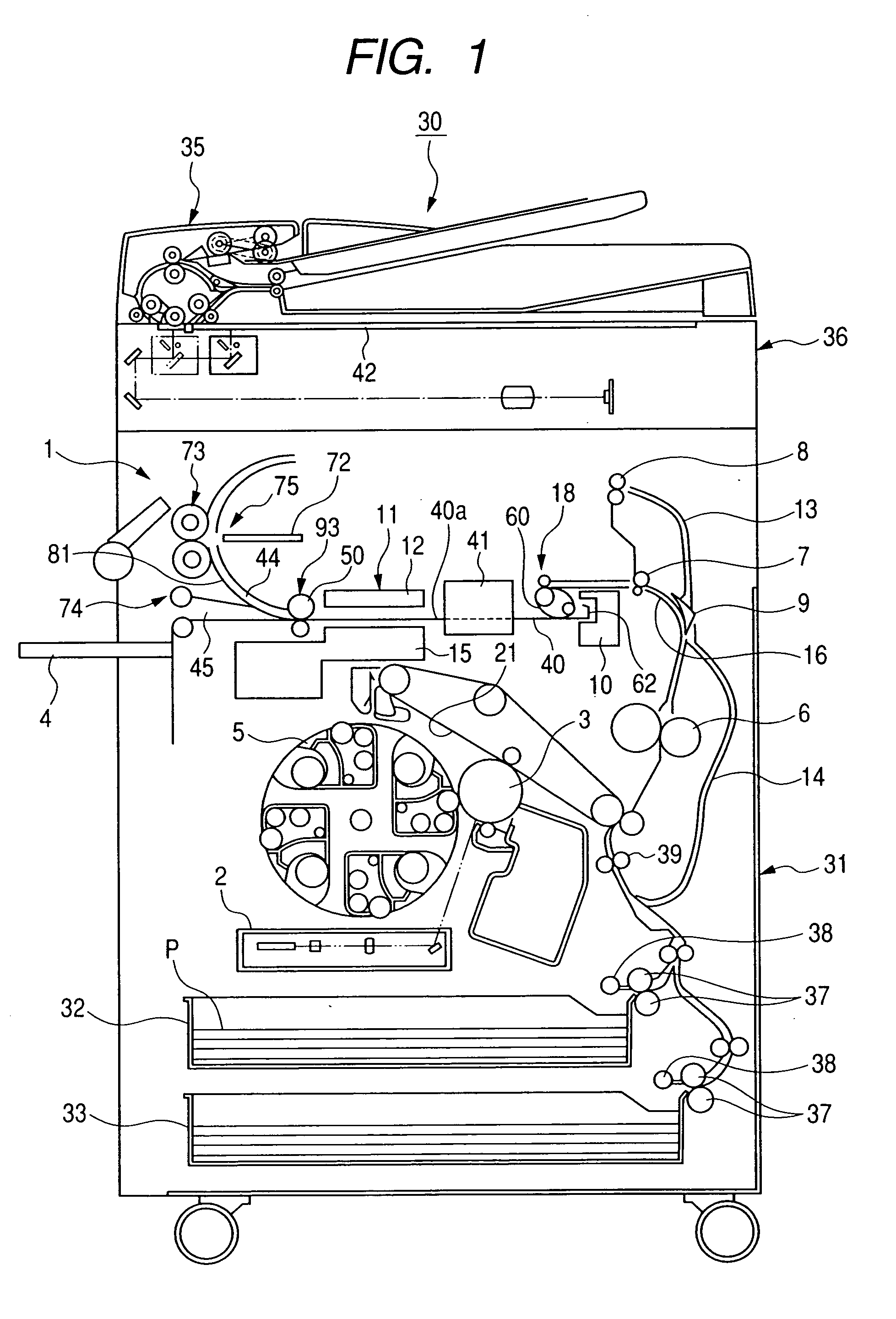

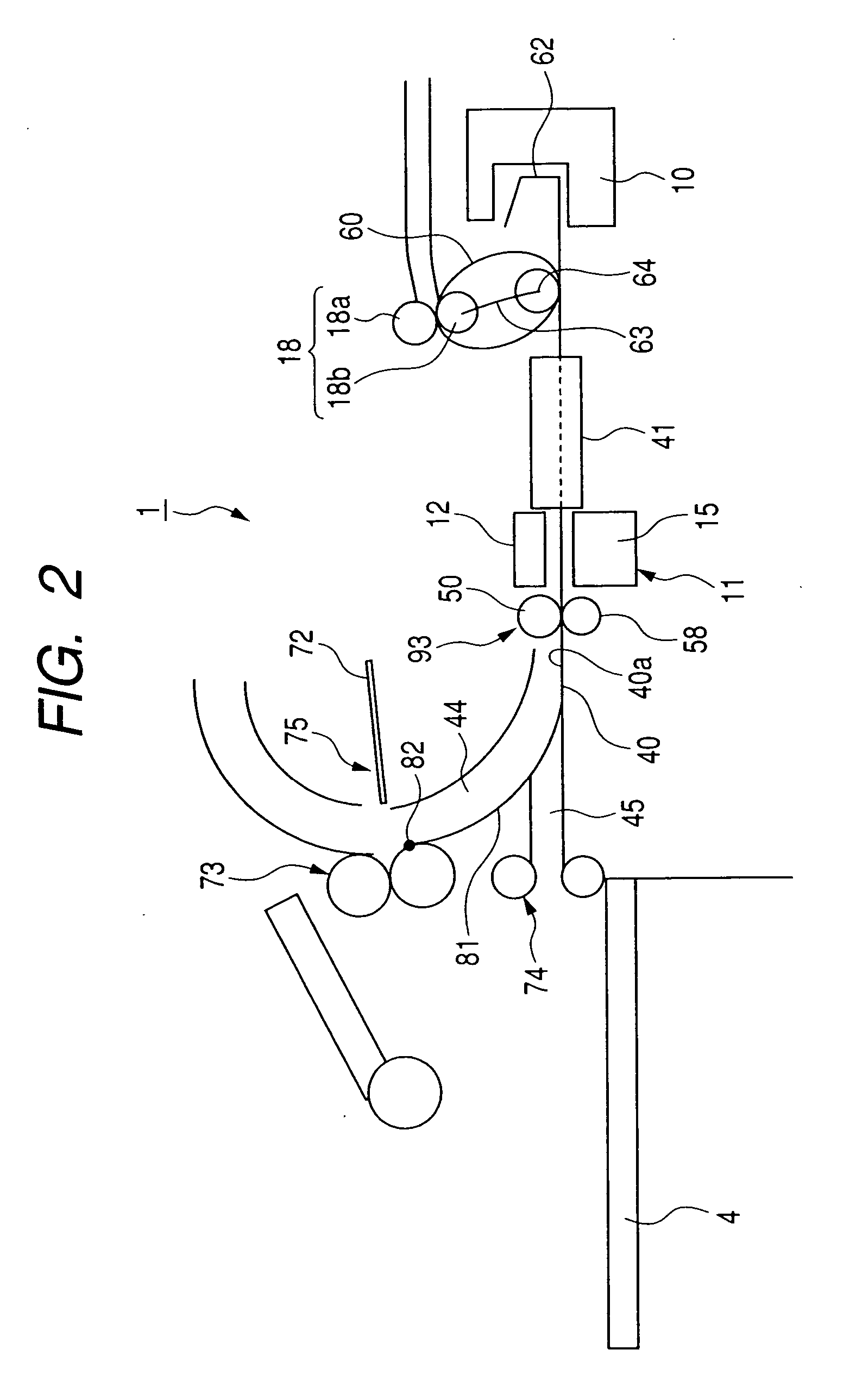

Paper sheet transfer appts. and image forming appts.

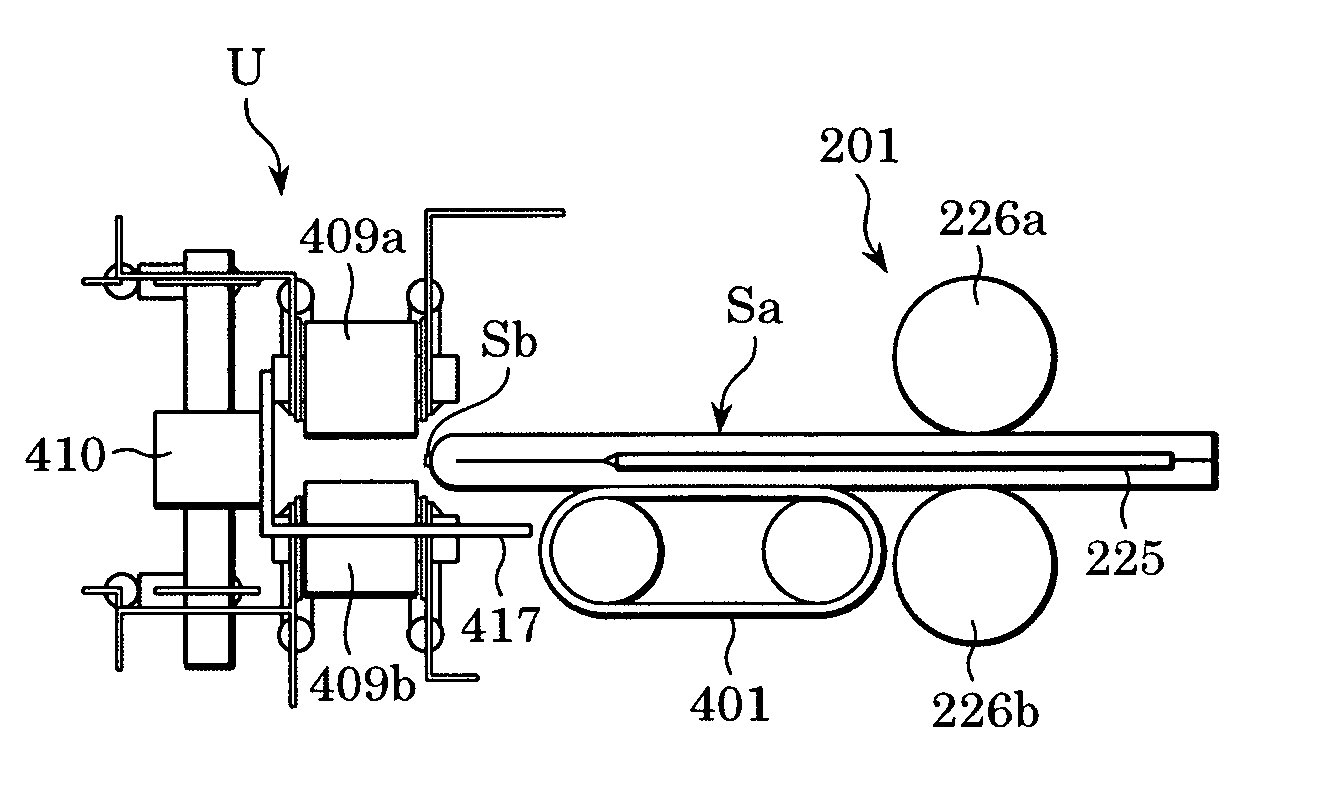

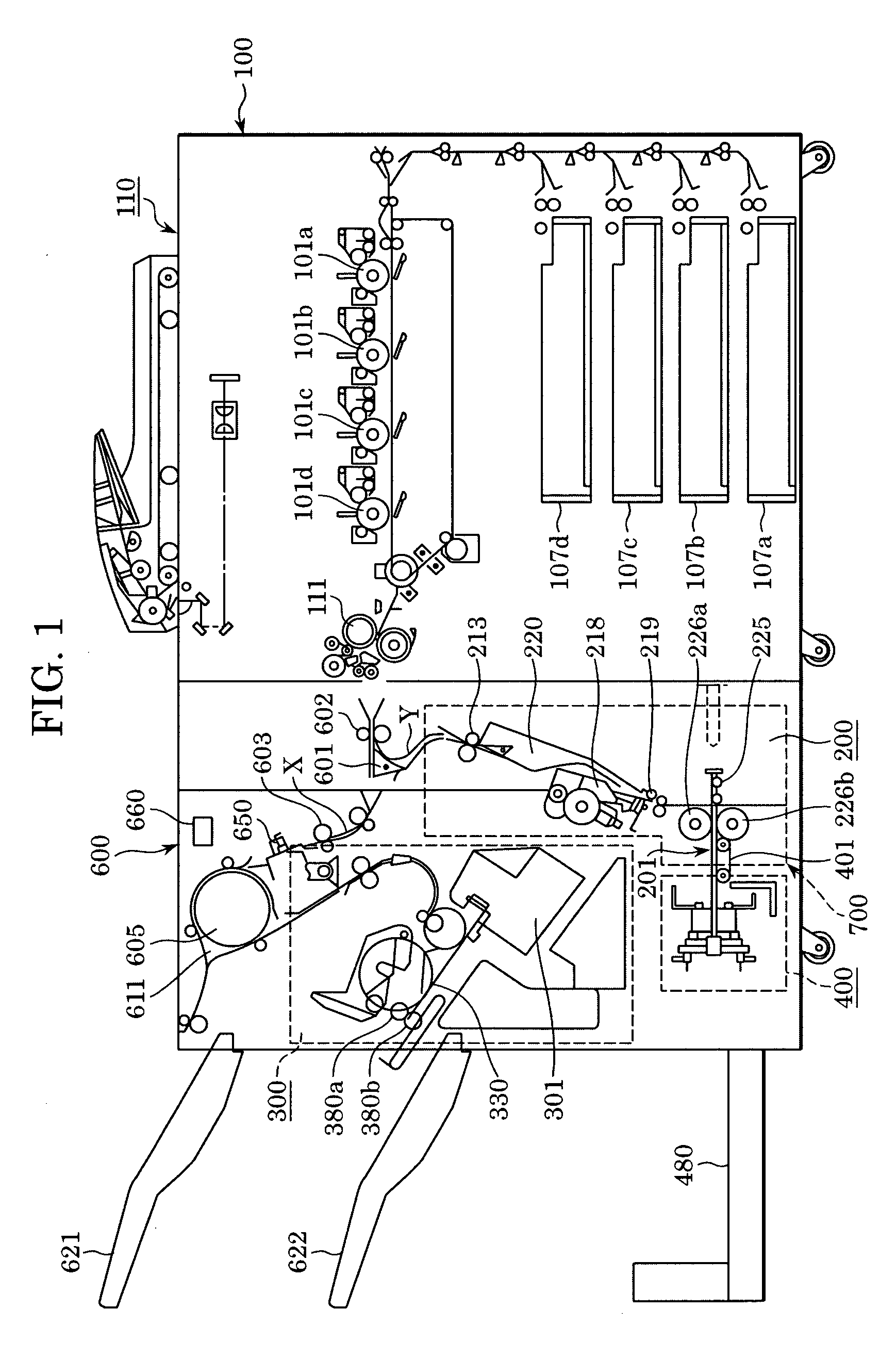

A sheet conveying apparatus and an image forming apparatus of the present invention enable a user himself or herself to select a plurality of double-sided recording modes by use of one common image forming apparatus. Each of the sheet conveying apparatus and the image forming apparatus includes a first reversing member, provided in an apparatus main body, for reversing a sheet on which an image is recorded by an image forming unit, a conveying unit including a second reversing member for reversing the sheet on which the image is recorded by the image forming unit, and so provided as detachably attachable to the apparatus main body, and a double-sided conveying portion for conveying the reversed sheet again to the image forming unit in order to perform double-sided recording.

Owner:CANON KK

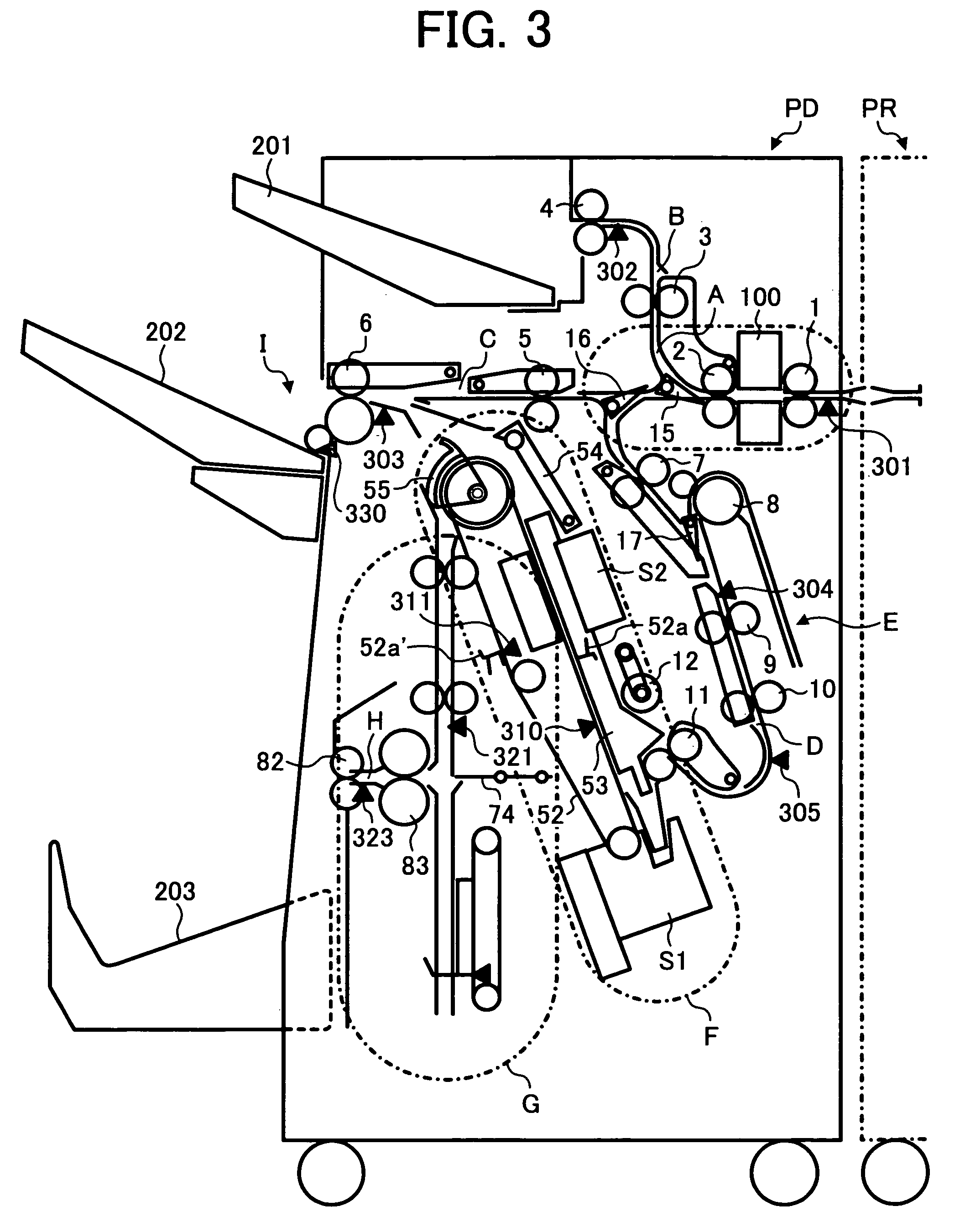

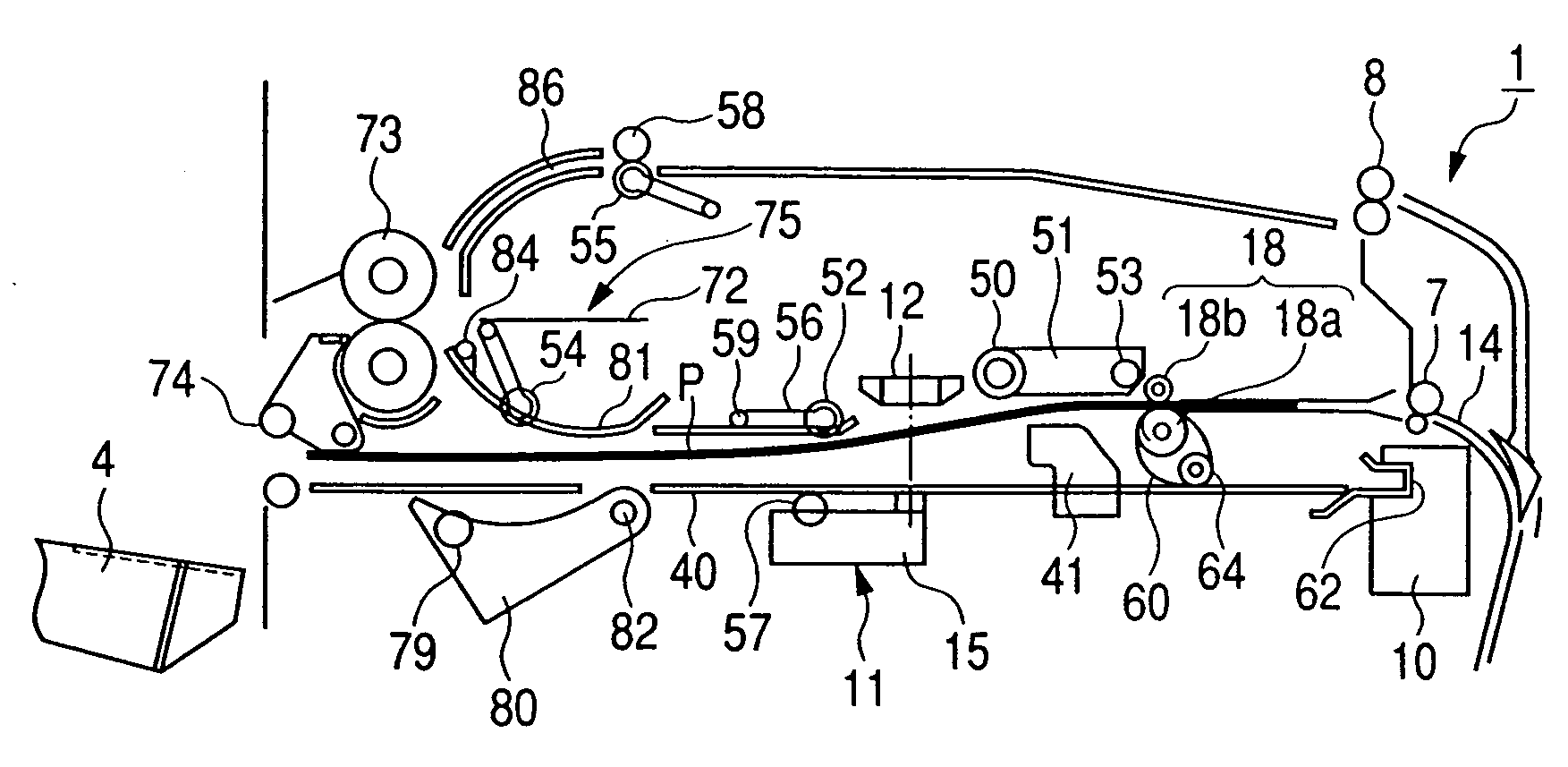

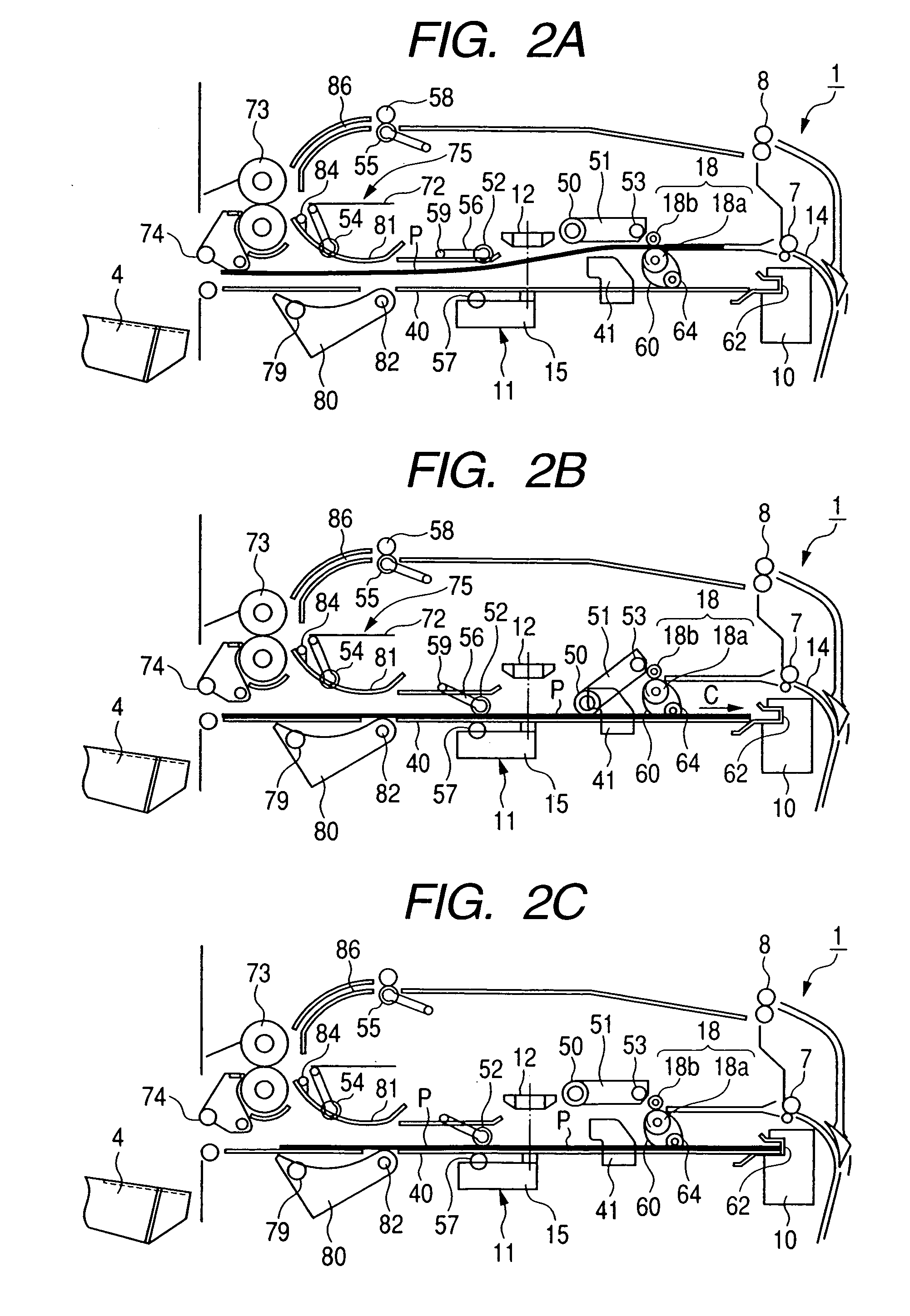

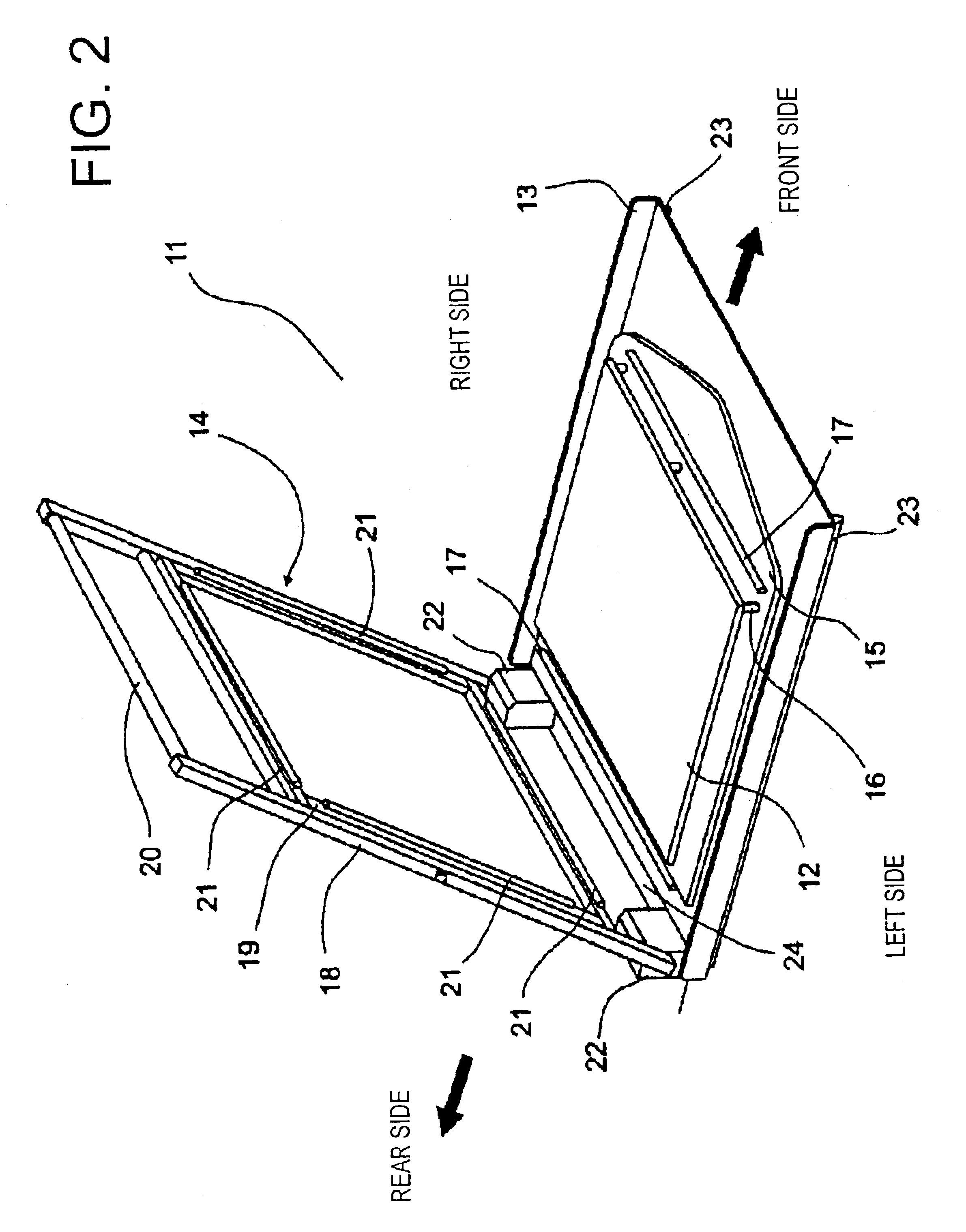

Sheet folding apparatus, sheet processing apparatus and image forming apparatus

ActiveUS7416177B2Preventing the misalignment of the end edgeAvoid displacementFunction indicatorsFolding thin materialsImage formationEngineering

A sheet processing apparatus for an image forming apparatus is configured so as to be capable of preventing the misalignment of the end edge of sheets to be scooped and transported from an intermediate tray, and reliably preventing the so-called displacement of end edges in the post-processing steps of sheets as a recording medium with an image formed thereon, and thereby preventing the inferior appearance during binding. A sheet folding apparatus enables a user to easily adjust the misalignment of the fold line of sheets that occurs during actual use, in the middle folding processing steps of sheets as a recording medium with an image formed thereon.

Owner:RICOH KK

Stack of fan folded material and combinations thereof

InactiveUS6905748B2Easily accommodate reach-in retrievalOptimize allocationStampsWrappersEngineeringSheet material

Owner:KIMBERLY-CLARK WORLDWIDE INC

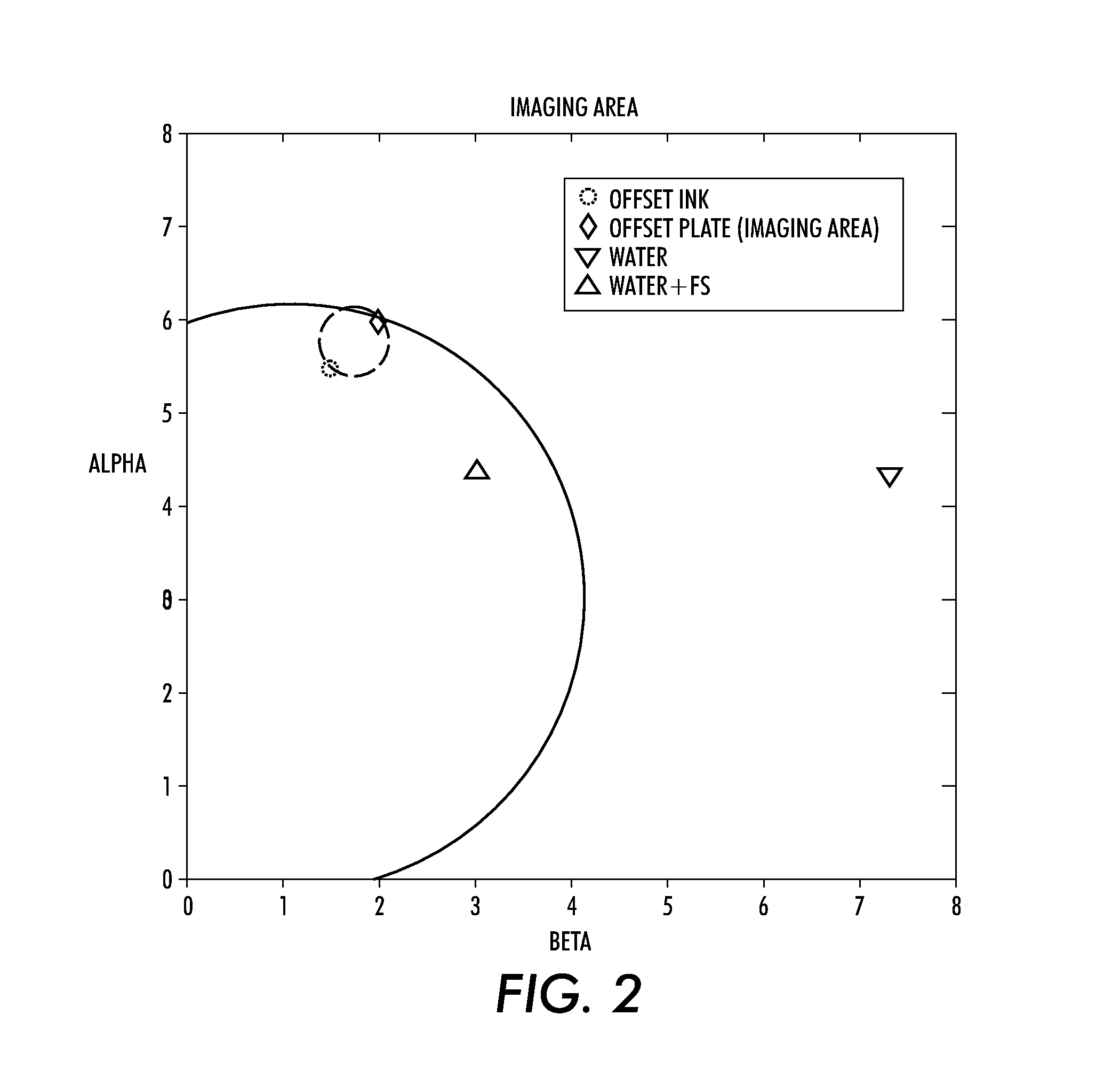

Dampening fluid for digital lithographic printing

ActiveUS20130104756A1Less residueSilicon organic compoundsPlaten pressesElectrical polarityVaporization

Different solvents for a dampening fluid are disclosed. The solvent is a volatile hydrofluoroether liquid or a volatile silicone liquid. Such liquids have a lower heat of vaporization, a lower surface tension, and better kinematic viscosity compared to water, which is the conventional solvent used in dampening fluids. The dampening fluids, which are relatively nonpolar, can be used in a combination with polar inks to form a new type of digital lithographic printing system.

Owner:XEROX CORP

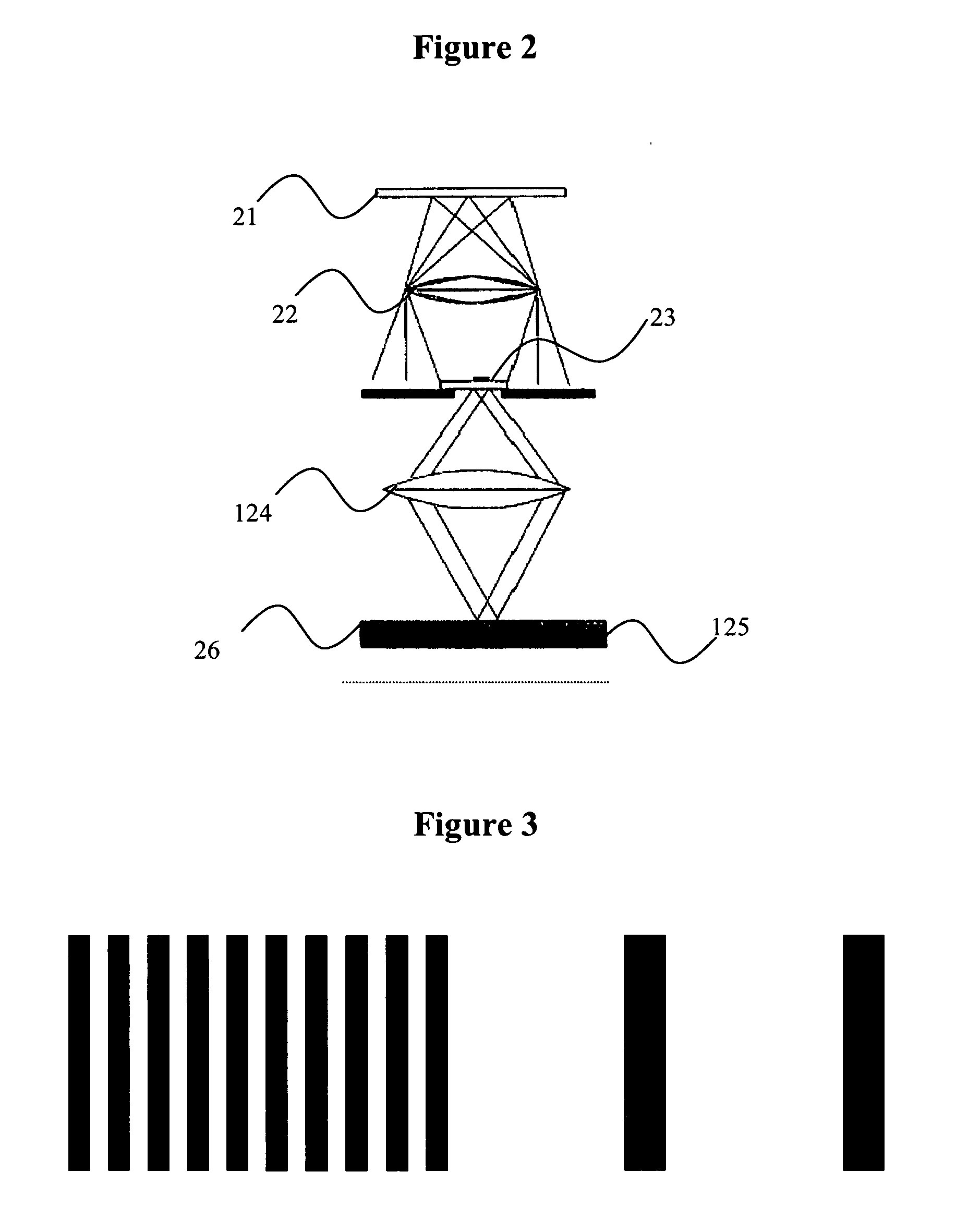

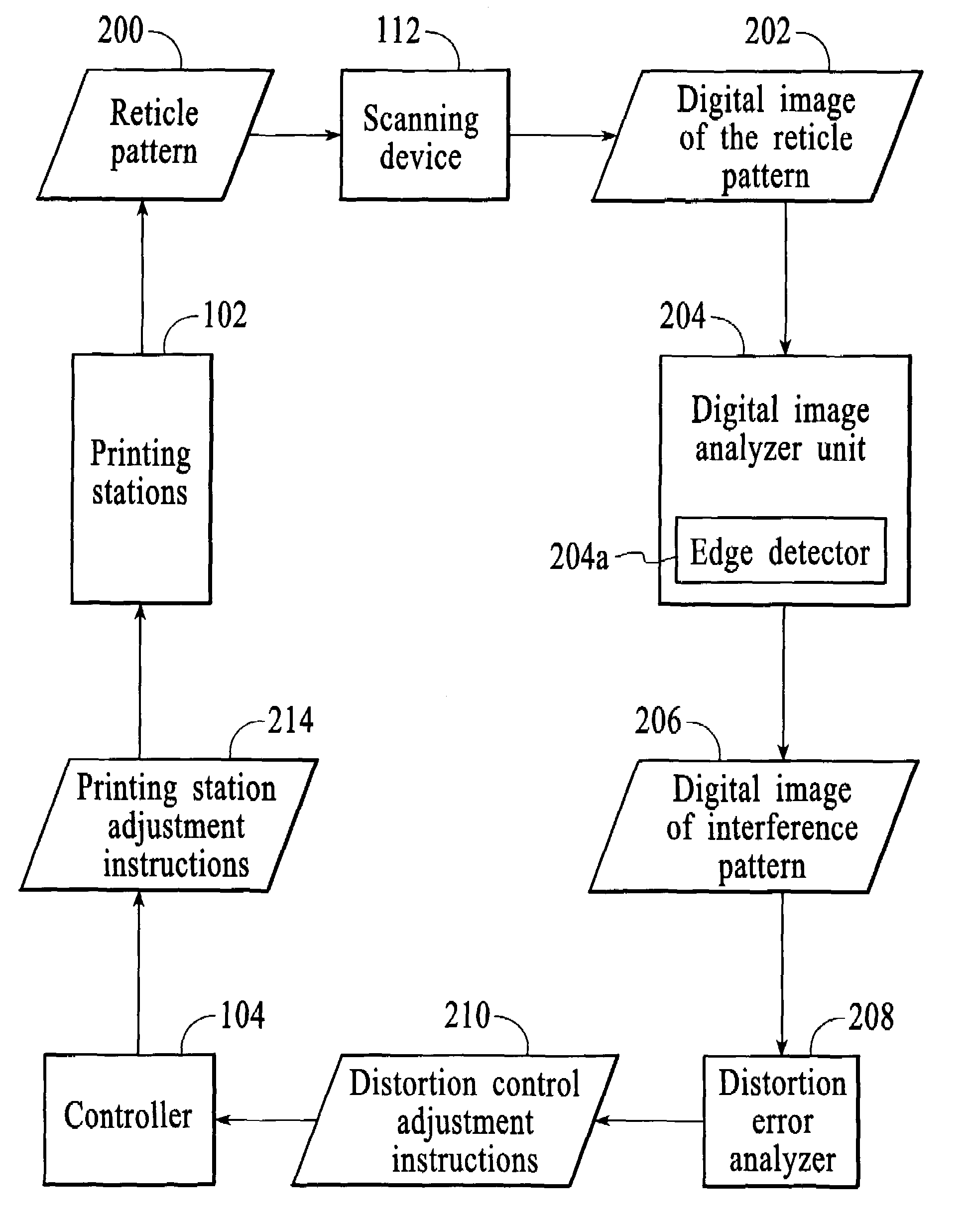

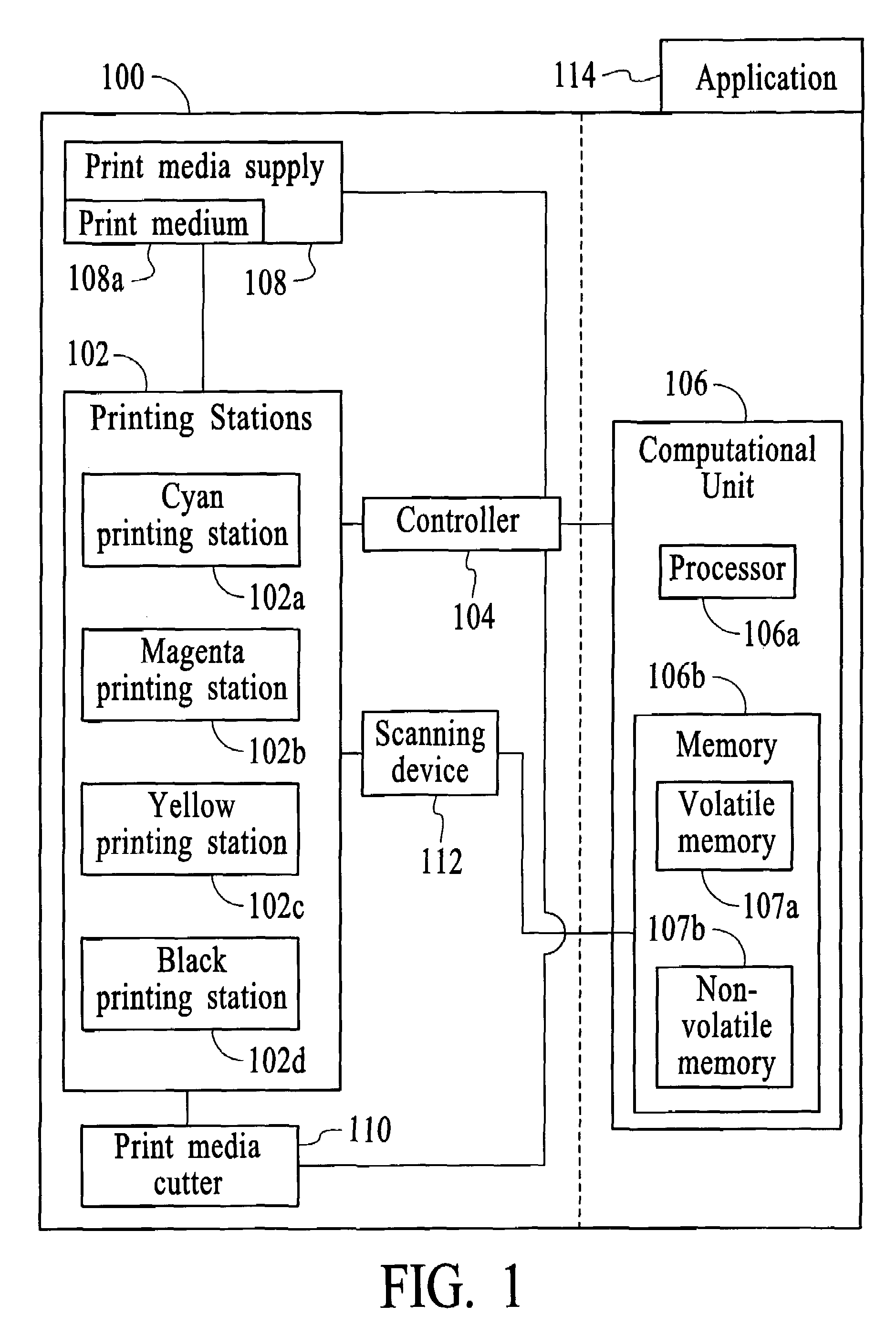

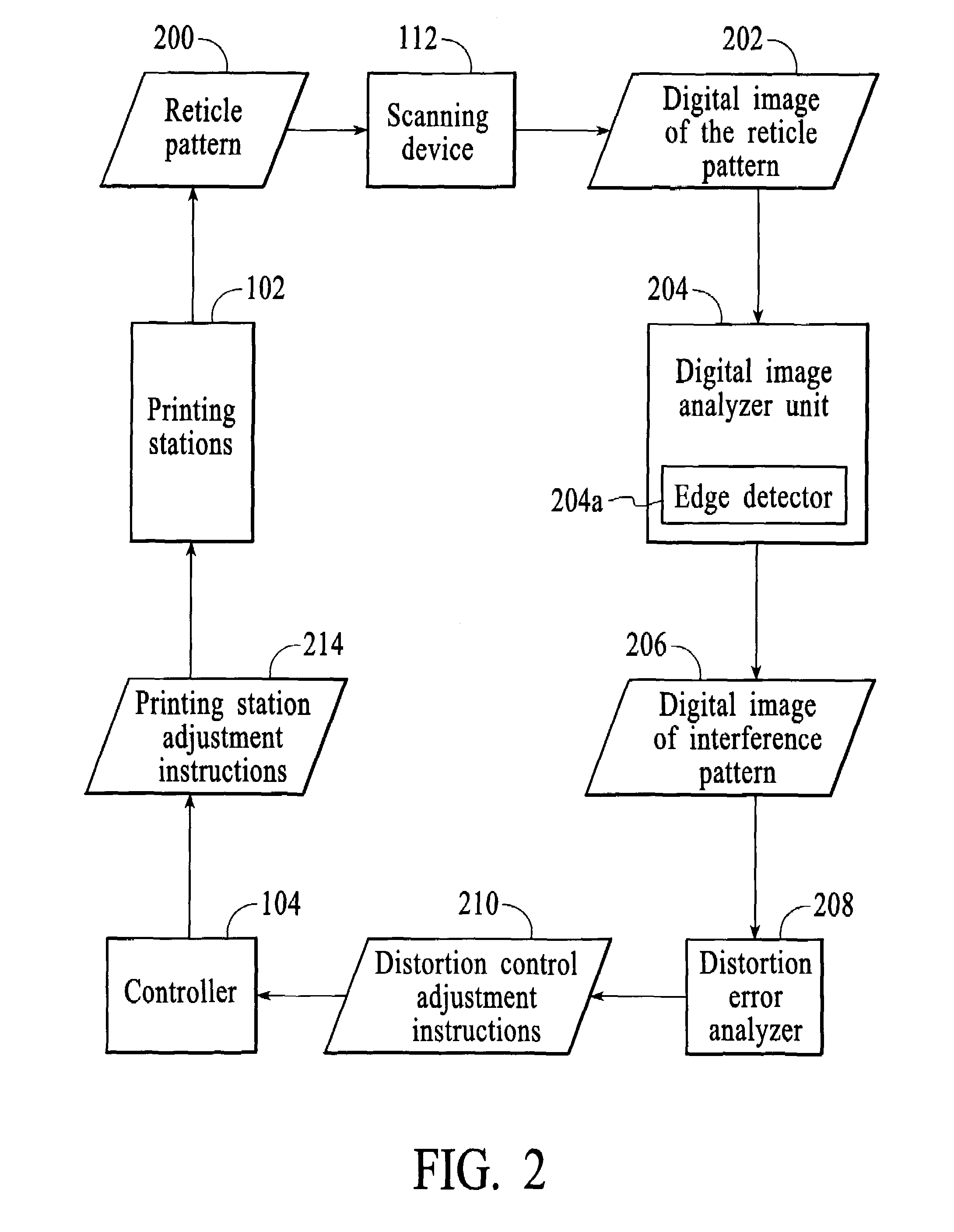

Method and system for minimizing the appearance of image distortion in a high speed inkjet paper printing system

ActiveUS6966712B2True colorPrecise registrationAddressographsPlaten pressesColor printingEngineering

A method and system for a printing device is disclosed. The method and system comprise printing a test pattern on a print medium and generating a digital image of the printed test pattern by an imaging device. The method and system include analyzing an interference pattern to measure for distortion of the print medium and calibrating the printing device based upon the measured distortion.In a preferred embodiment, the present invention utilizes the reticle patterns, which are printed in the margins of the paper, which are measured real-time during printing. The interference or Moiré patterns created by superimposed reticles may be used to measure image distortion, process direction misalignment, and misregistration caused by web distortion. The advantage of this invention is that image distortion compensation, RIP (Raster Image Processor) parameters, timing, or other printer characteristics may be adjusted on-the-fly in a closed feedback system, for high-speed textile or paper color printing, utilizing on-the-fly distortion or stretch measurement for accurate color and / or duplex images registration. In a duplex printer, automatic images alignment front-to-back is obtained by combining optically or logically the two images for the evaluation of interference patterns and amount of distortion in the process and scan direction.

Owner:RICOH KK

Sheet processing apparatus and image forming apparatus provided with the same

InactiveUS20060017209A1Reduced form requirementsConvey evenlyFolding thin materialsElectrographic process apparatusMechanical engineeringWrinkle

Owner:CANON KK

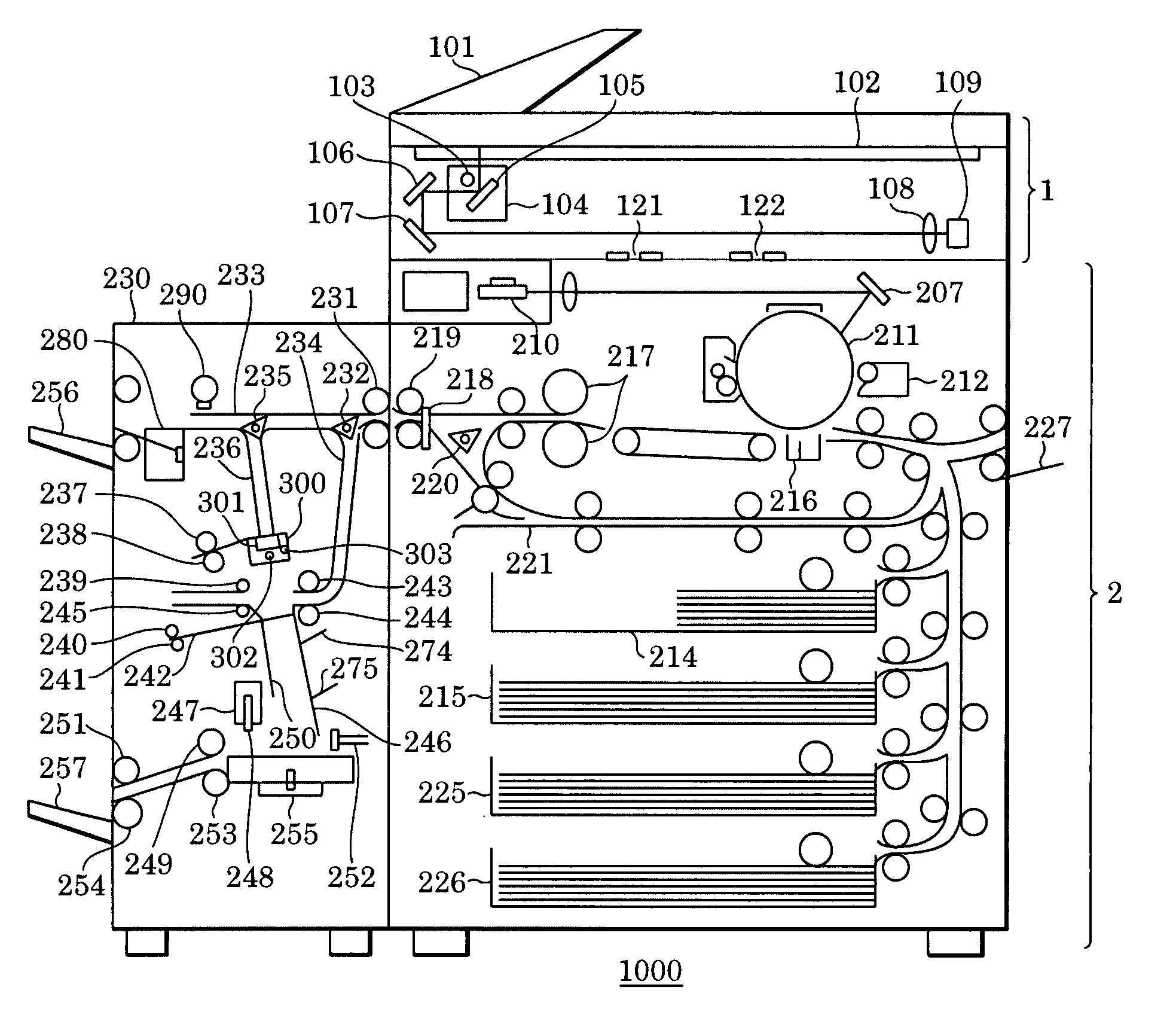

Image forming system, control method, recording medium, and program

ActiveUS20050232656A1Avoid problemsAddress usabilityAddressographsOther printing matterImage formationEngineering

An image forming system has an image forming apparatus which has a printing unit which can perform a printing process of data of a storage unit which can store data of a plurality of jobs and which has a conveying unit which can convey a sheet from the print unit to a sheet processing device which can perform sheet processing, including at least a gluing process, for sheets from the printing unit, the system comprising: a controller adapted to permit a predetermined process related to the gluing process when the job to be processed is a job which meets a predetermined condition, and to inhibit the predetermined process related to the gluing process when the job to be processed is not a job which meets the predetermined condition, thereby overcoming obstacles to realization of an image forming system capable of a gluing process.

Owner:CANON KK

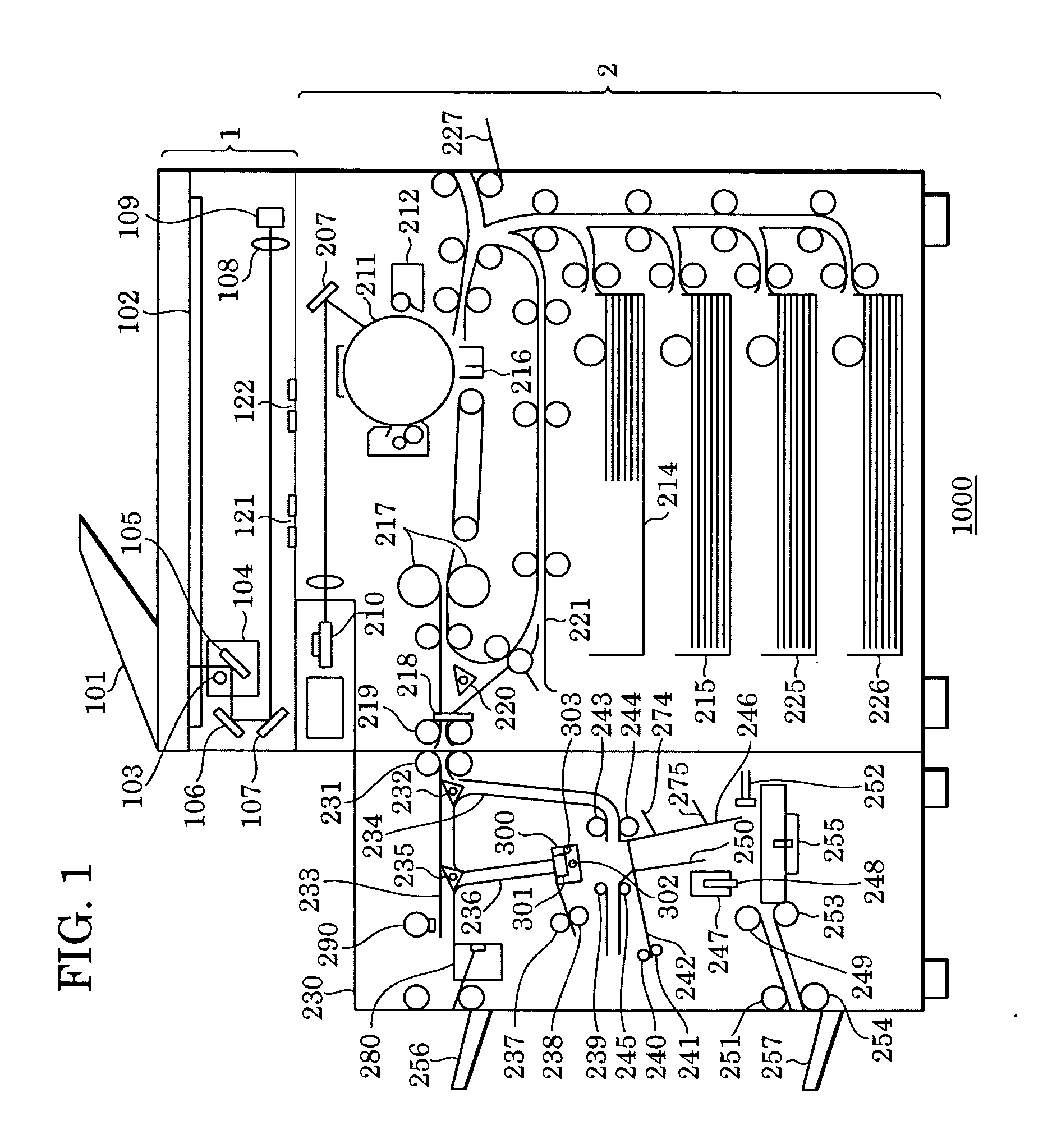

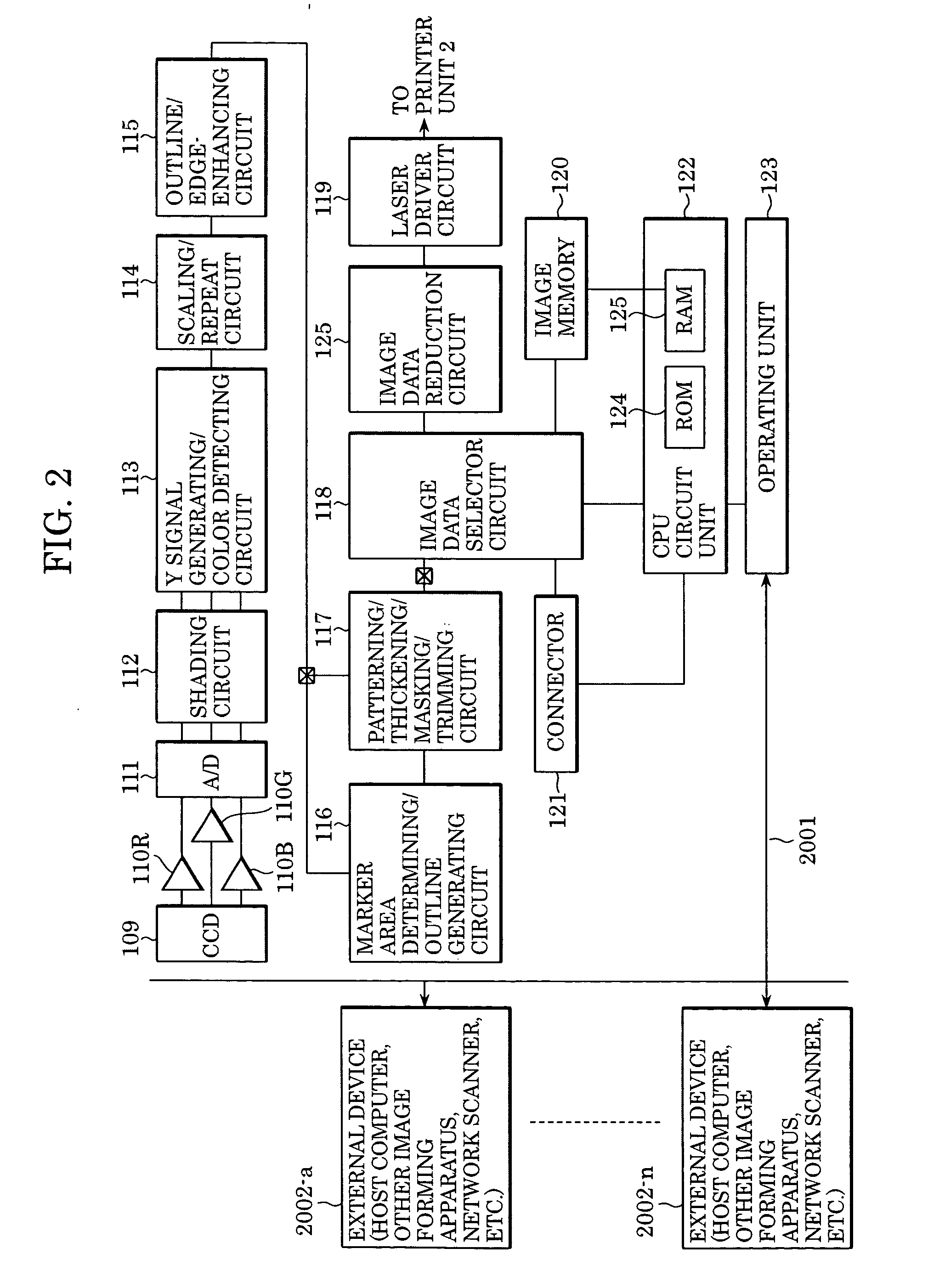

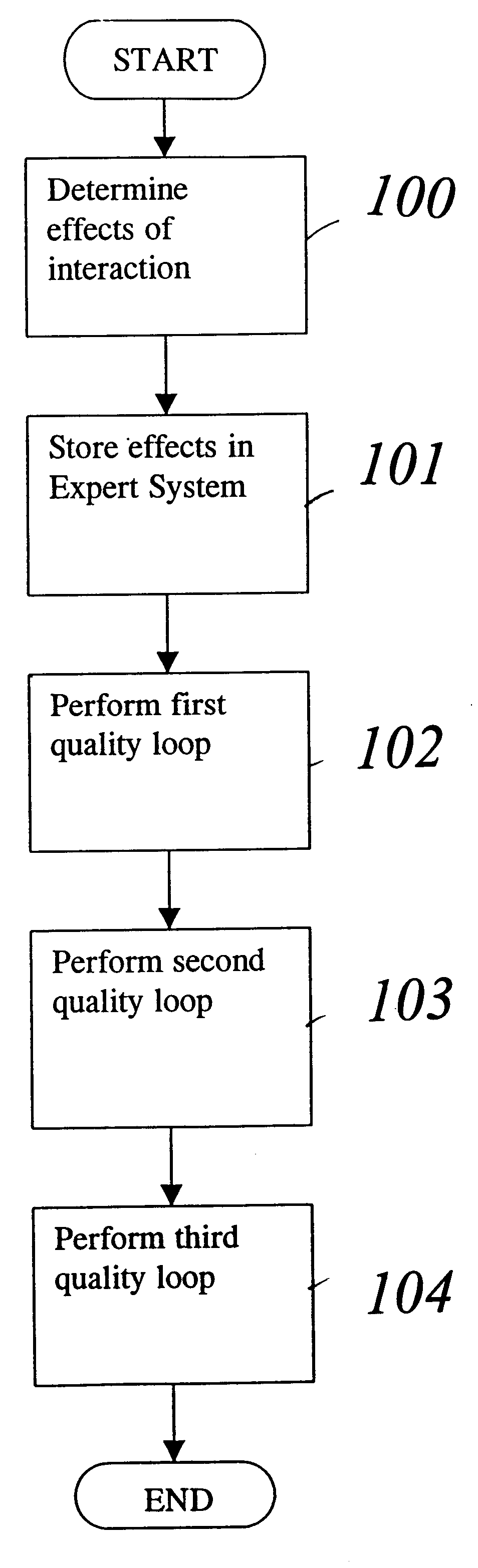

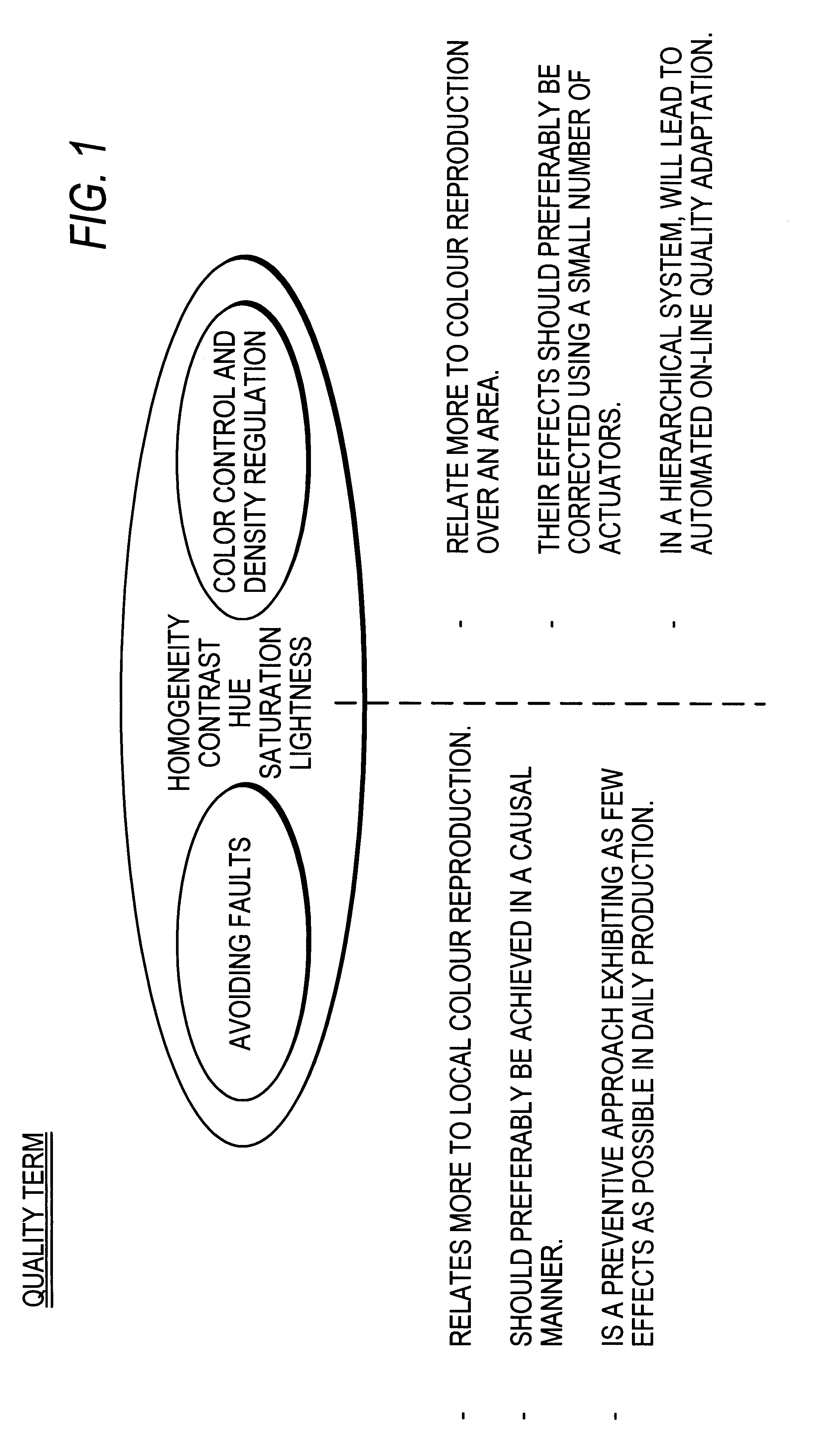

Image data-oriented printing machine and method of operating the same

InactiveUS6230622B1Reduce materialReduce rejectionAddressographsPlaten pressesBasic knowledgePulp and paper industry

A method of operating a printing machine and a printing machine apparatus in which basic knowledge about the interaction between operating media in the printing machine is obtained through printing trials or during production. This knowledge is stored in an expert system and made available for the printing operation or else for the production of the printing plate. The expert system is preferably a self-teaching system. For color reproduction, basic calibrations are carried out in a first quality step, in a second step, the imaging operation is adapted to the areas and half tones to be imaged, and ink-density regulation is carried out in a third step.

Owner:MANROLANAD AG

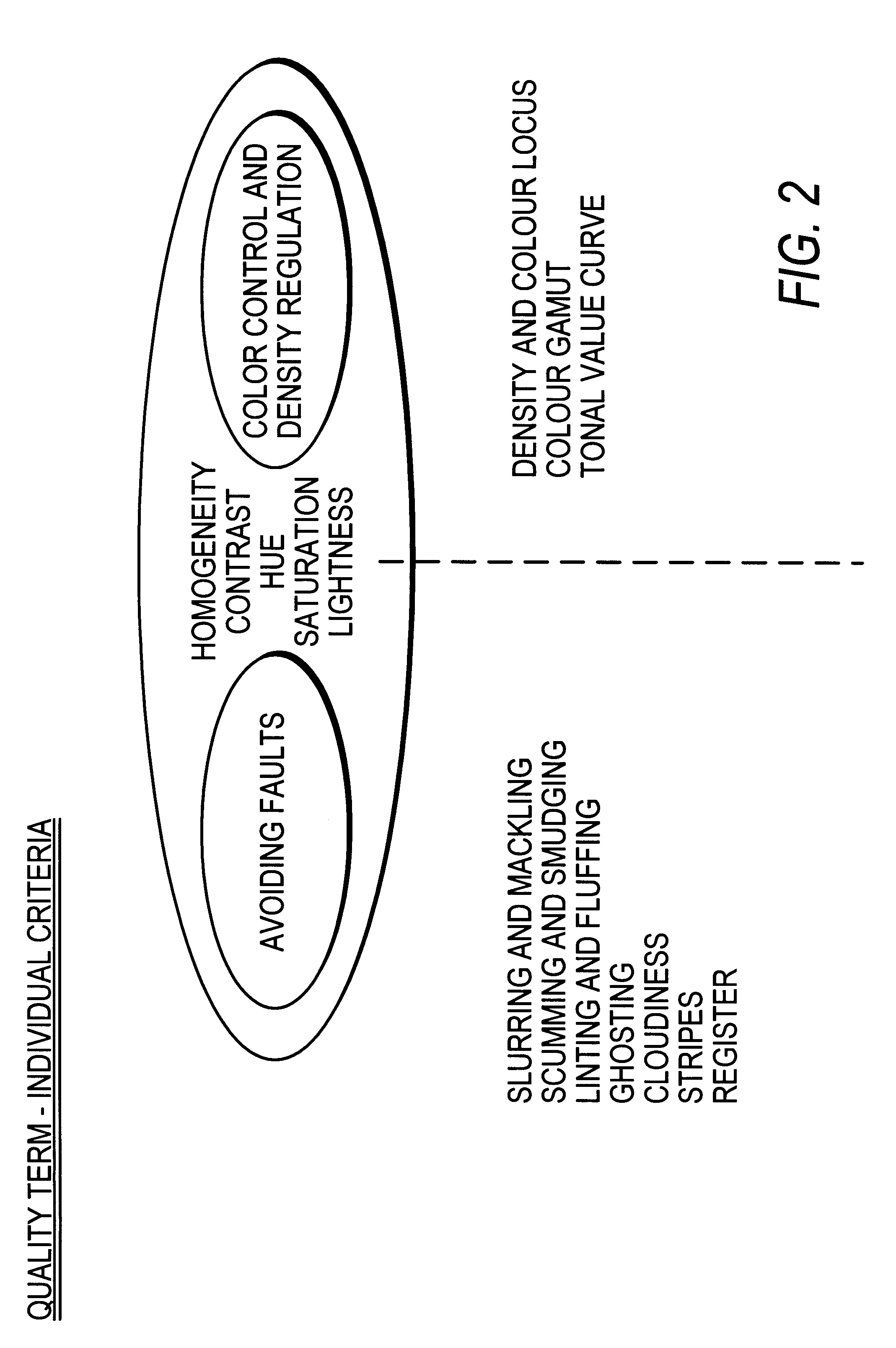

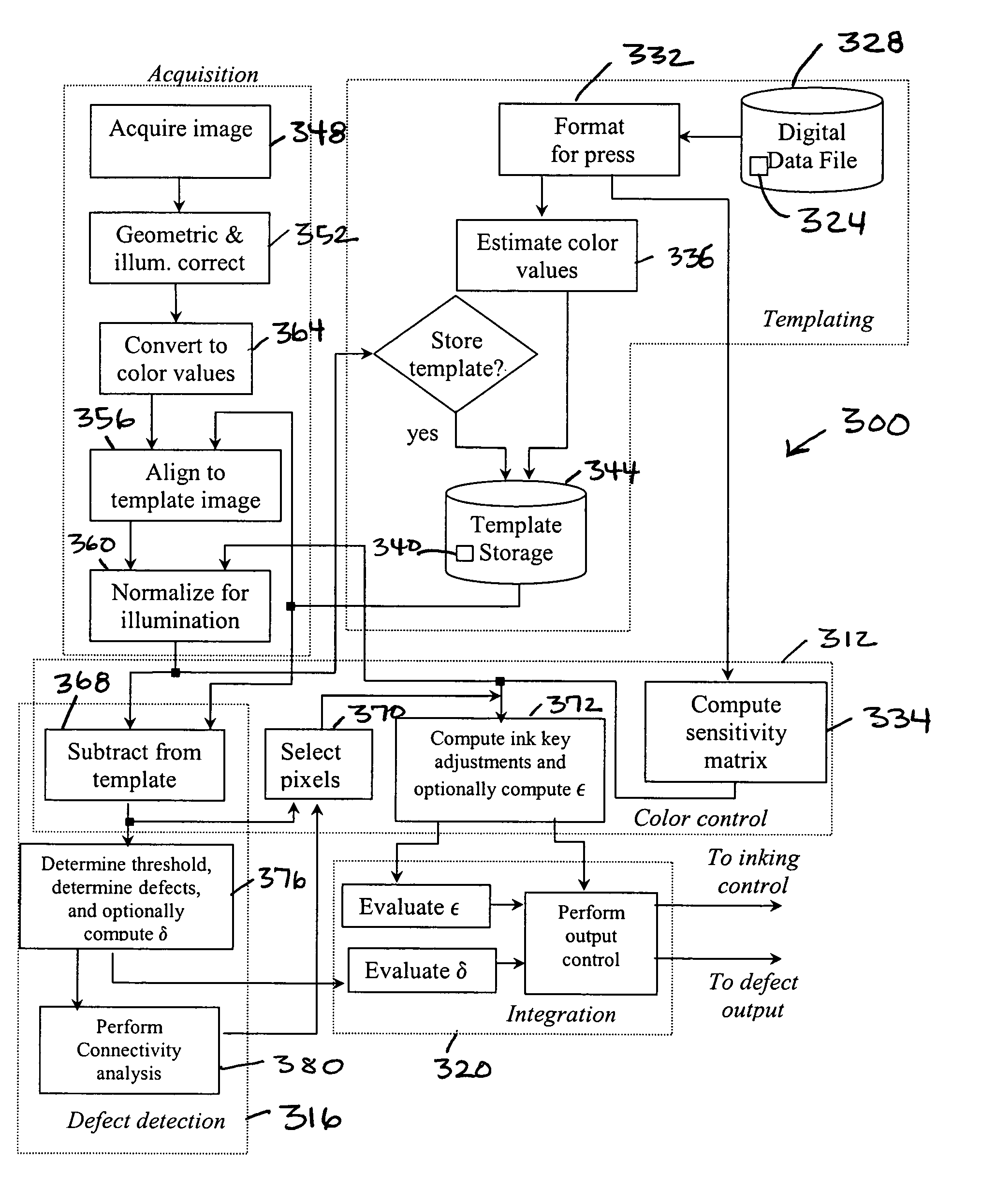

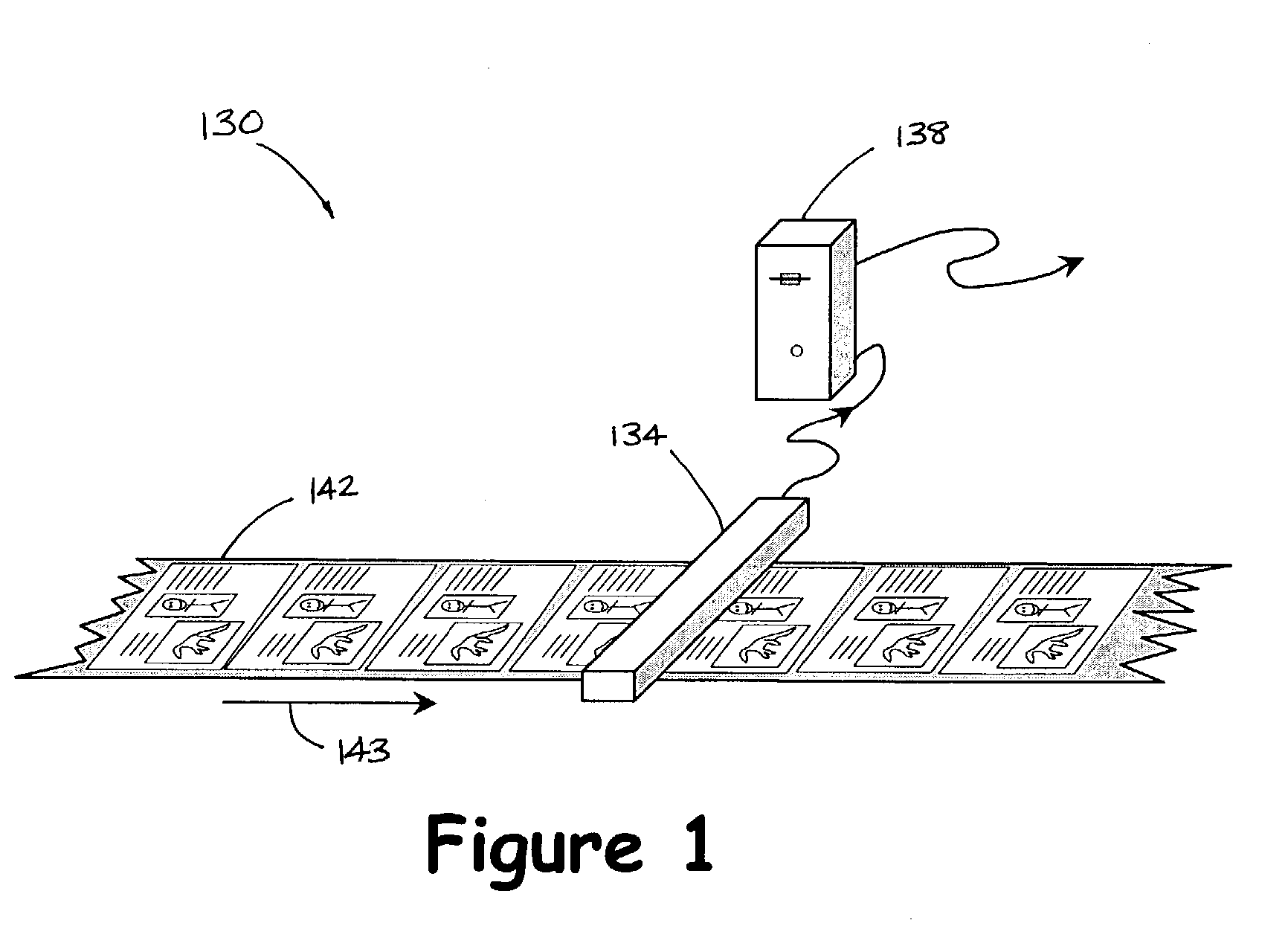

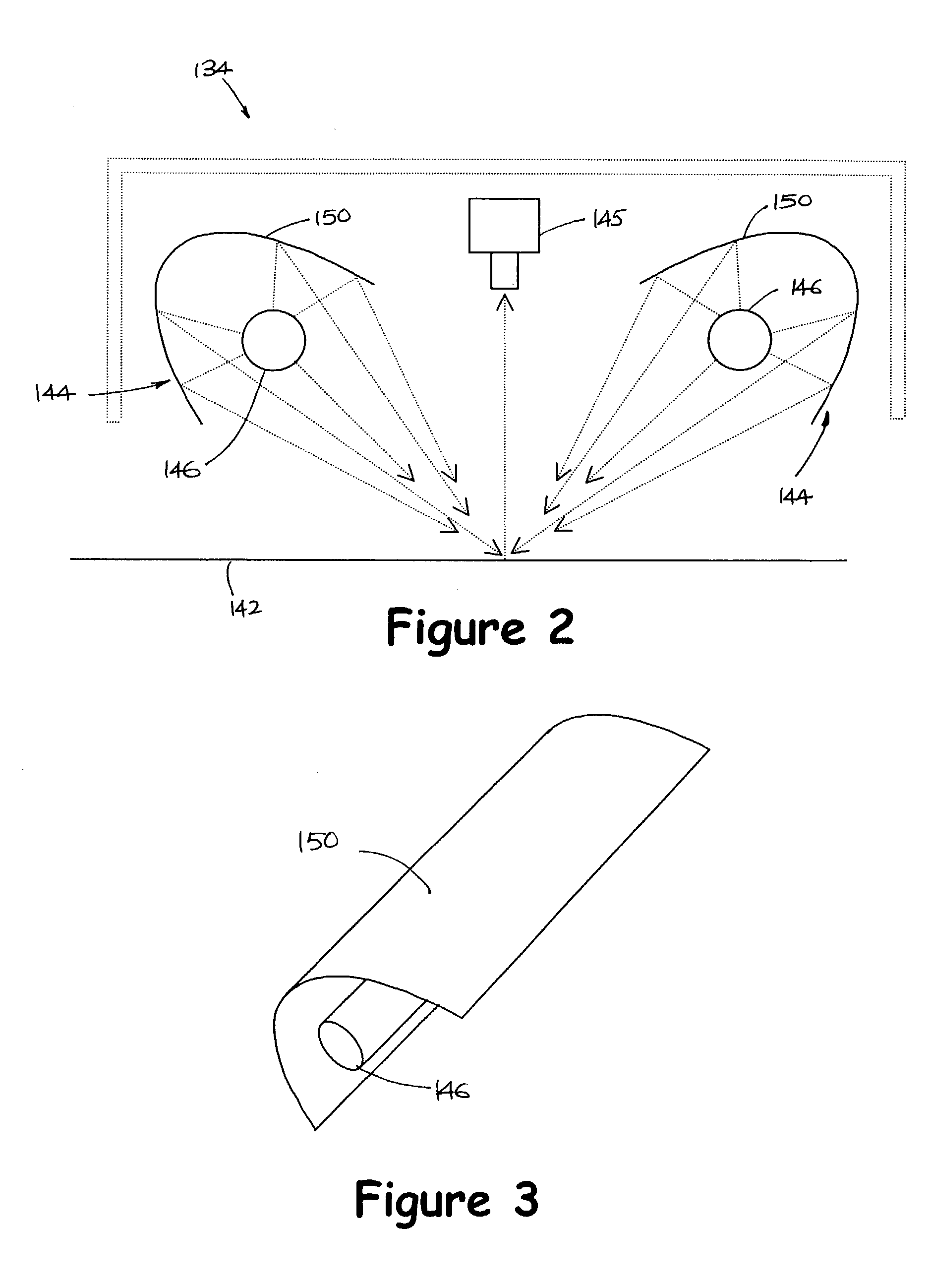

Coordinating the functioning of a color control system and a defect detection system for a printing press

A method of coordinating the utilization of a color control system and a defect detection system on a printing press includes acquiring image data and processing the data by a comparison to template image data and the generation of color error data and print defect data. The method further includes the steps of selectively enabling and disabling the color control system and selectively enabling and disabling the defect detection system based upon the color error data and the print defect data.

Owner:BALDWIN AMERICAS CORP

Sheet processing apparatus and image forming apparatus equipped with the same

InactiveUS20060017218A1Improved alignment propertyEasy alignmentFolding thin materialsPile receiversEngineeringTrailing edge

The sheet processing apparatus is equipped with a process tray on which sheets conveyed are stacked, a return belt which moves the sheets stacked on the process tray, a trailing edge stopper which receives an end portion of the sheets moved by the return belt, and a conveyance assist roller which comes into contact with the sheets on the upstream side of the return belt with respect to the sheet moving direction and imparts a load to the movement of the sheets. The return belt moves the sheets to which a load has been imparted by the conveyance assist roller and causes them to be abutted on the trailing edge stopper.

Owner:CANON KK

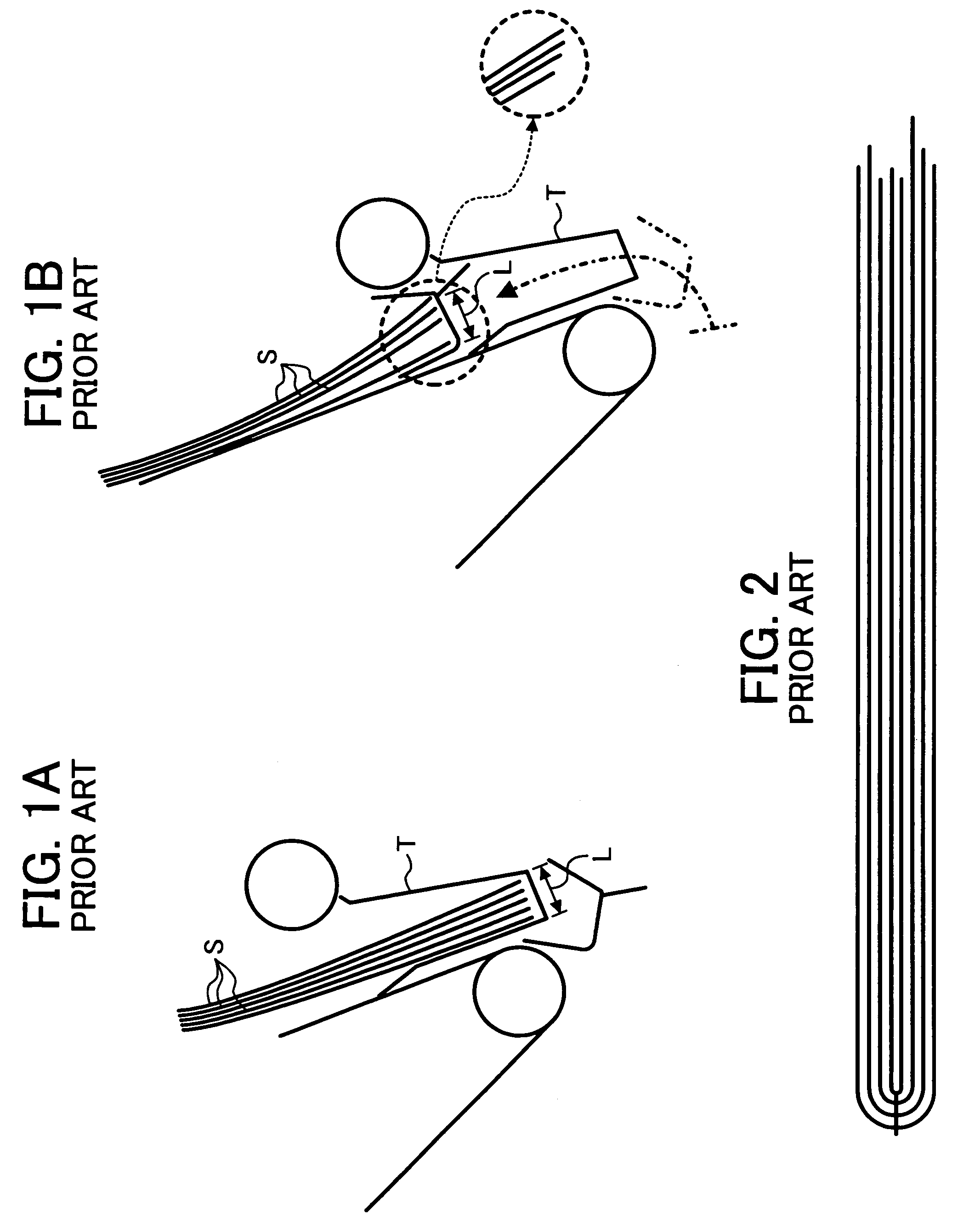

Sheet processing apparatus and image forming apparatus

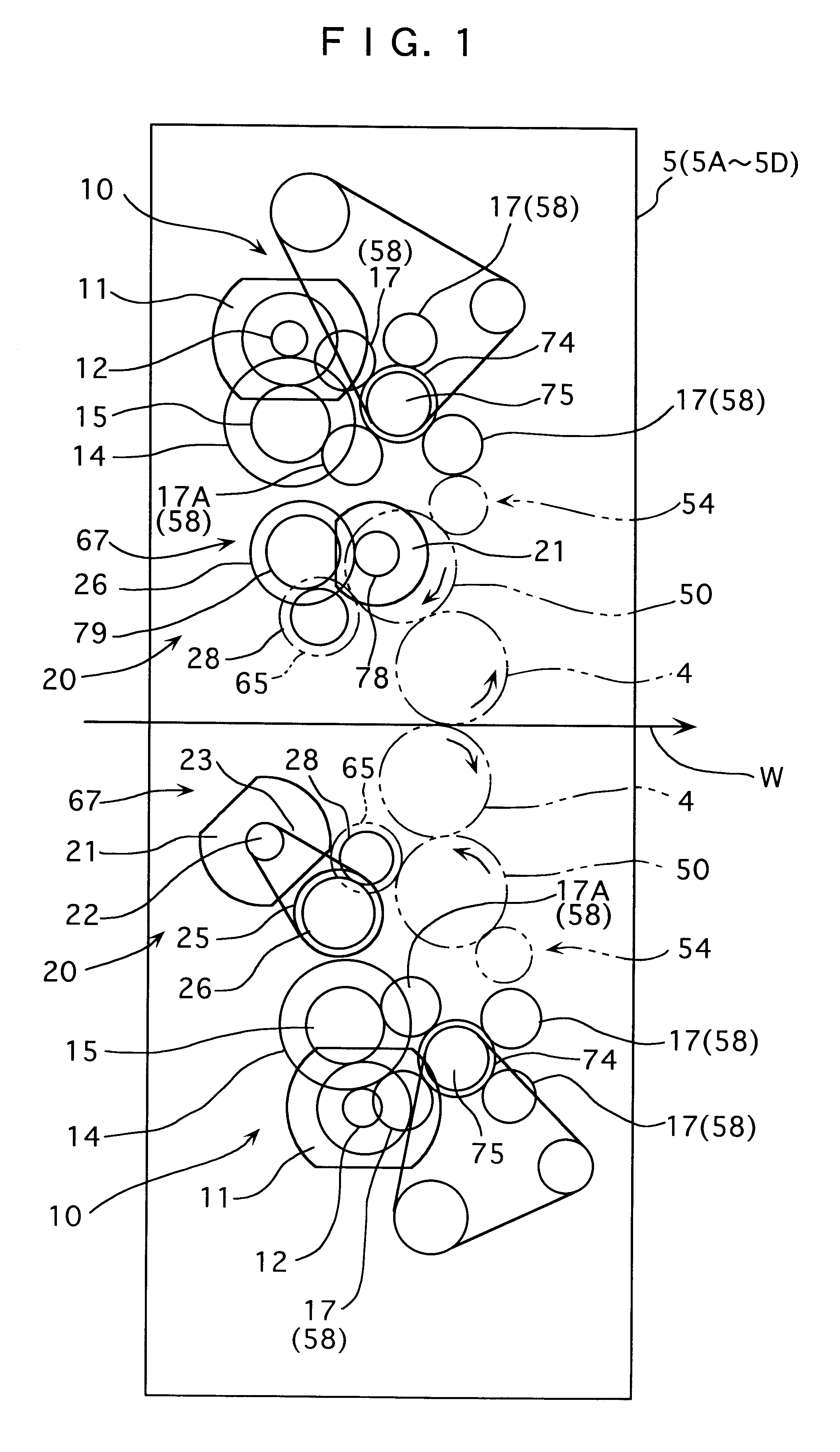

This invention relates to a sheet processing apparatus for stapling multiple sheets with a stapling means and delivering the sheets in folio, comprising two rollers for folding the sheets in folio and projecting means for projecting between the two rollers to fold the sheets in sandwiching the sheets between the two rollers. One roller of the two rollers, at least, is made movable, and a cam member is further provided capable of correcting a projecting position by the projecting means according to traveling of the roller.

Owner:CANON KK

Sheet processing apparatus and image forming apparatus provided therewith and sheet processing method

InactiveUS7597311B2Improve productivityEfficient deliveryFolding thin materialsRotary pressesEngineeringSheet material

A sheet bundle stored in a sheet storage portion is pushed from a predetermined folded position with a first pushing plate, and the sheet bundle is normally conveyed along with the first pushing plate and plunged into a nip between first folding rollers to make a fold. The first folding rollers are reversely rotated while the first pushing plate is retreated, and the sheet bundle with the fold is reversely conveyed and returned to the sheet storage portion. Then, a second pushing plate pushes the sheet bundle, conveyed through a U-shape conveyance path, from a backside of the fold to reversely fold the sheet bundle, and the sheet bundle is completely folded. Therefore, the sheet bundle having good appearance can be realized in good bundle folding processing.

Owner:CANON KK

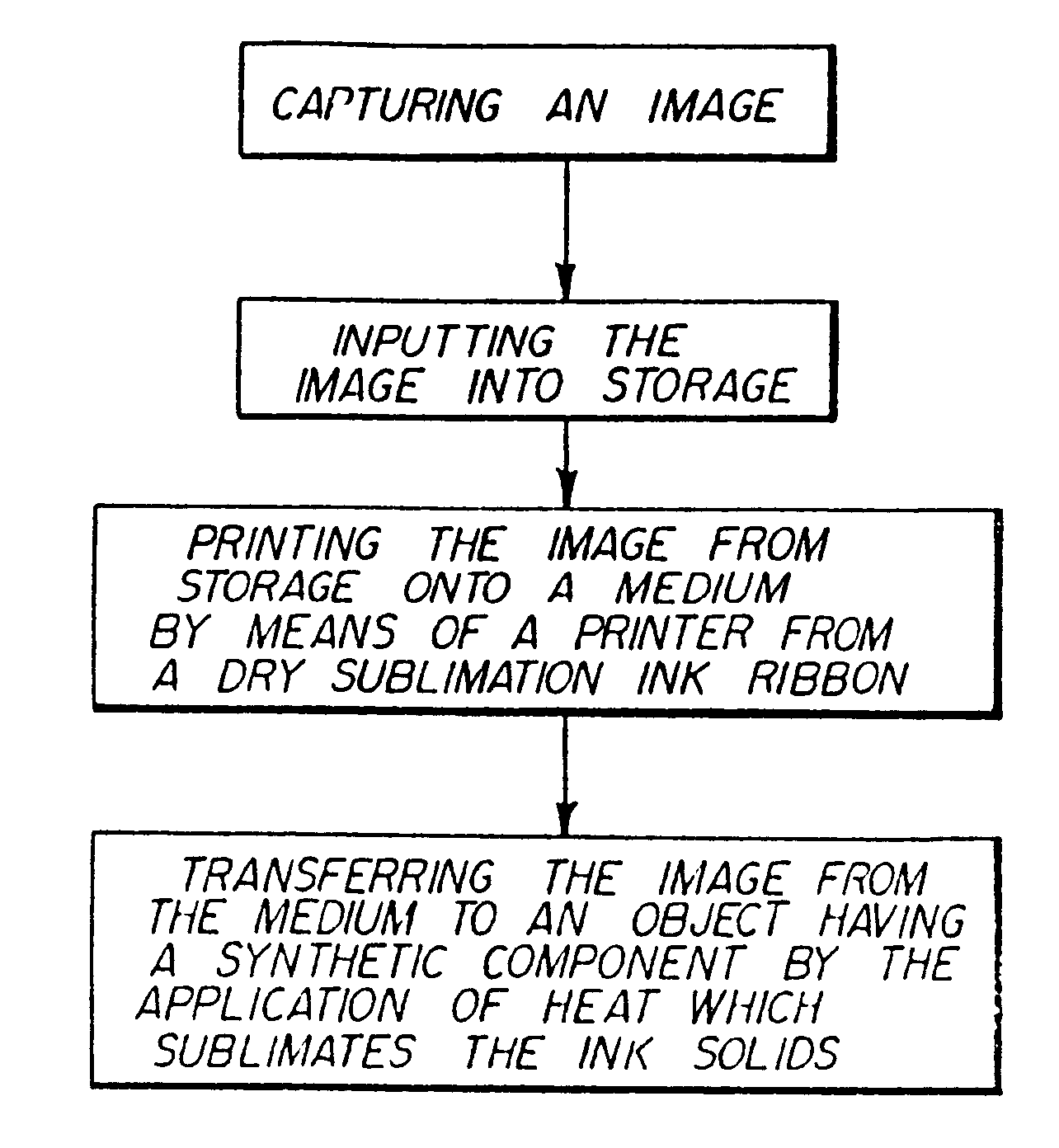

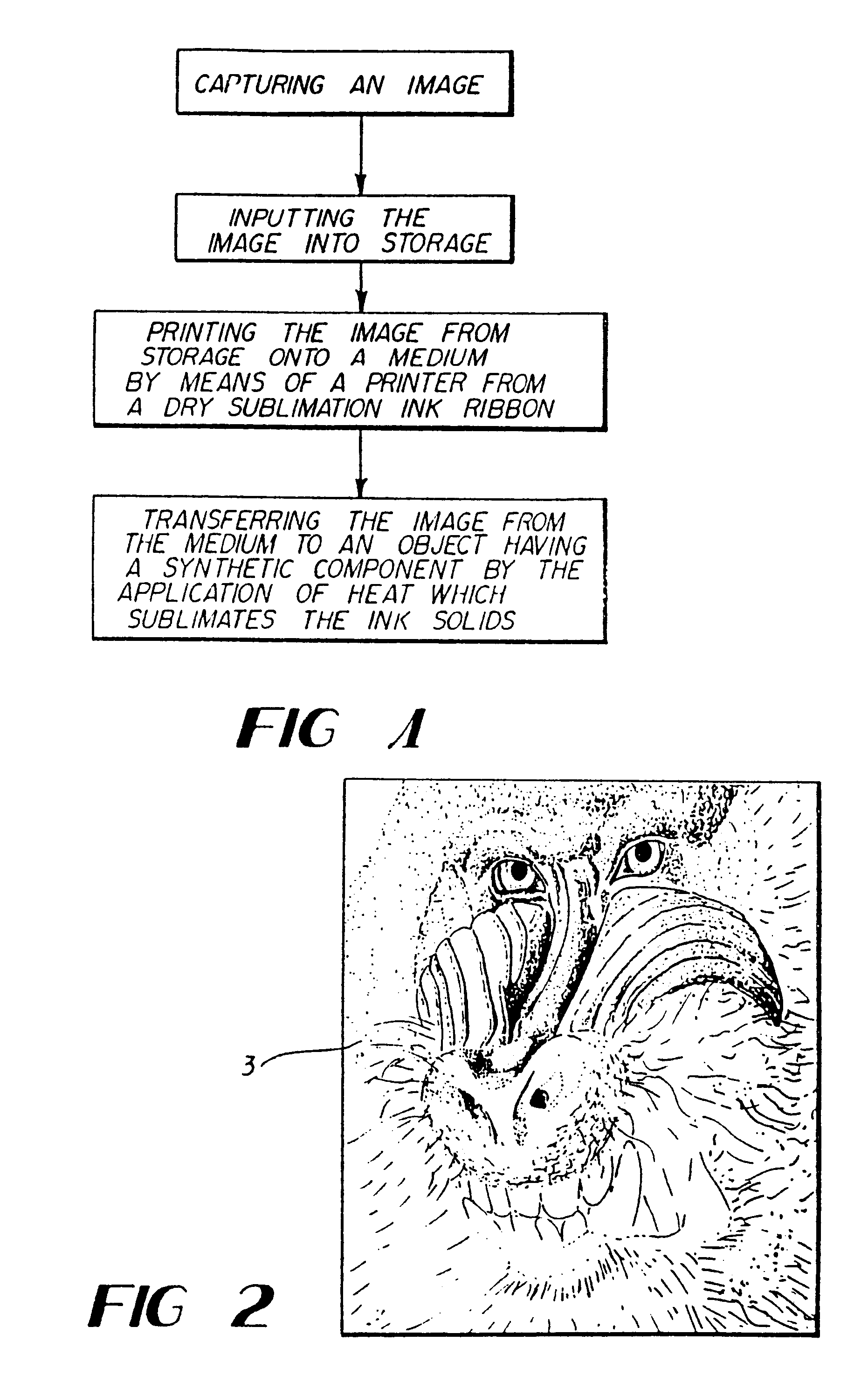

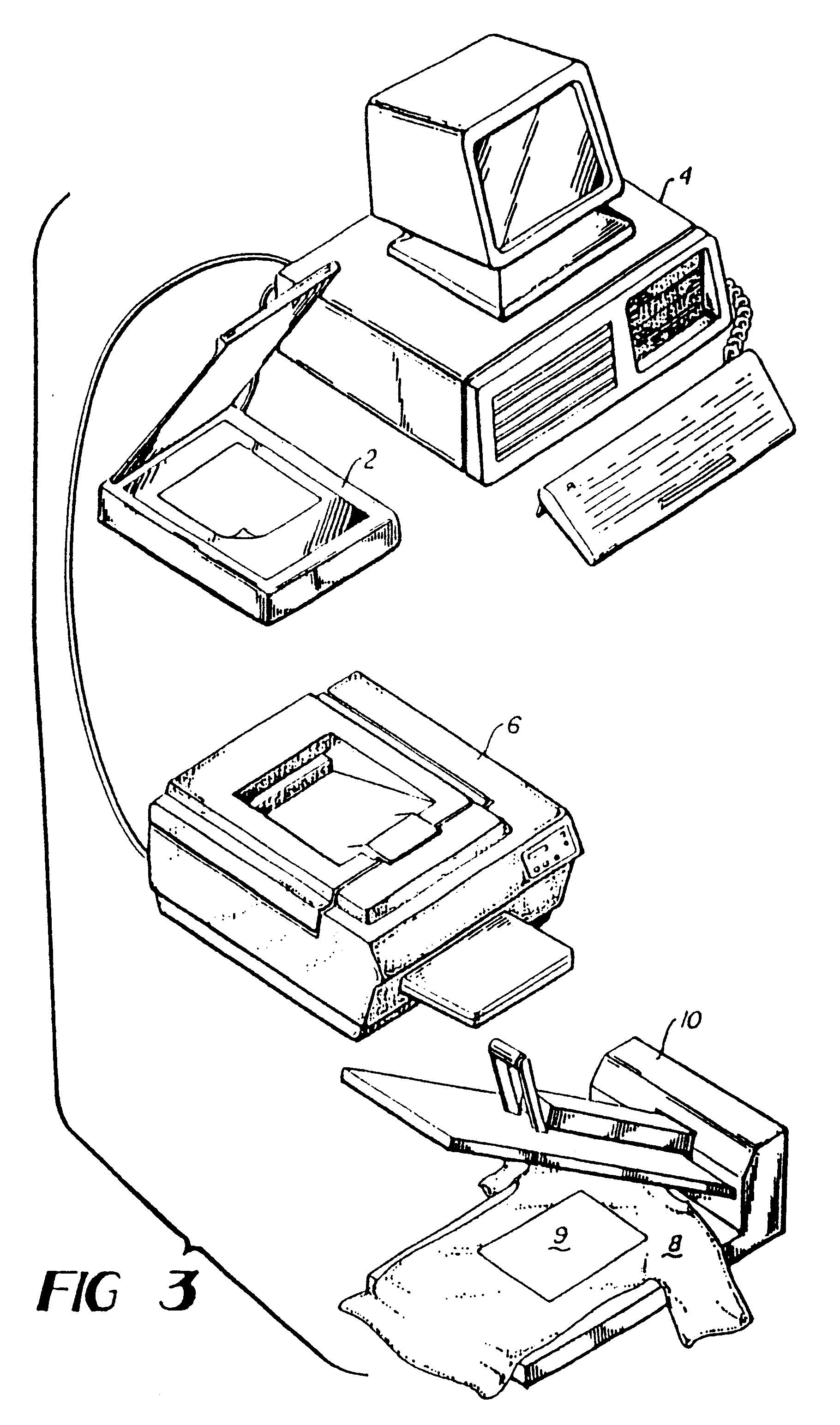

Permanent heat activated ink jet printing process

InactiveUS6450098B1Improve bindingFacilitate and withstand temperatureTransfer printingMeasurement apparatus componentsEngineeringComputer drive

Owner:SAWGRASS SYST INC

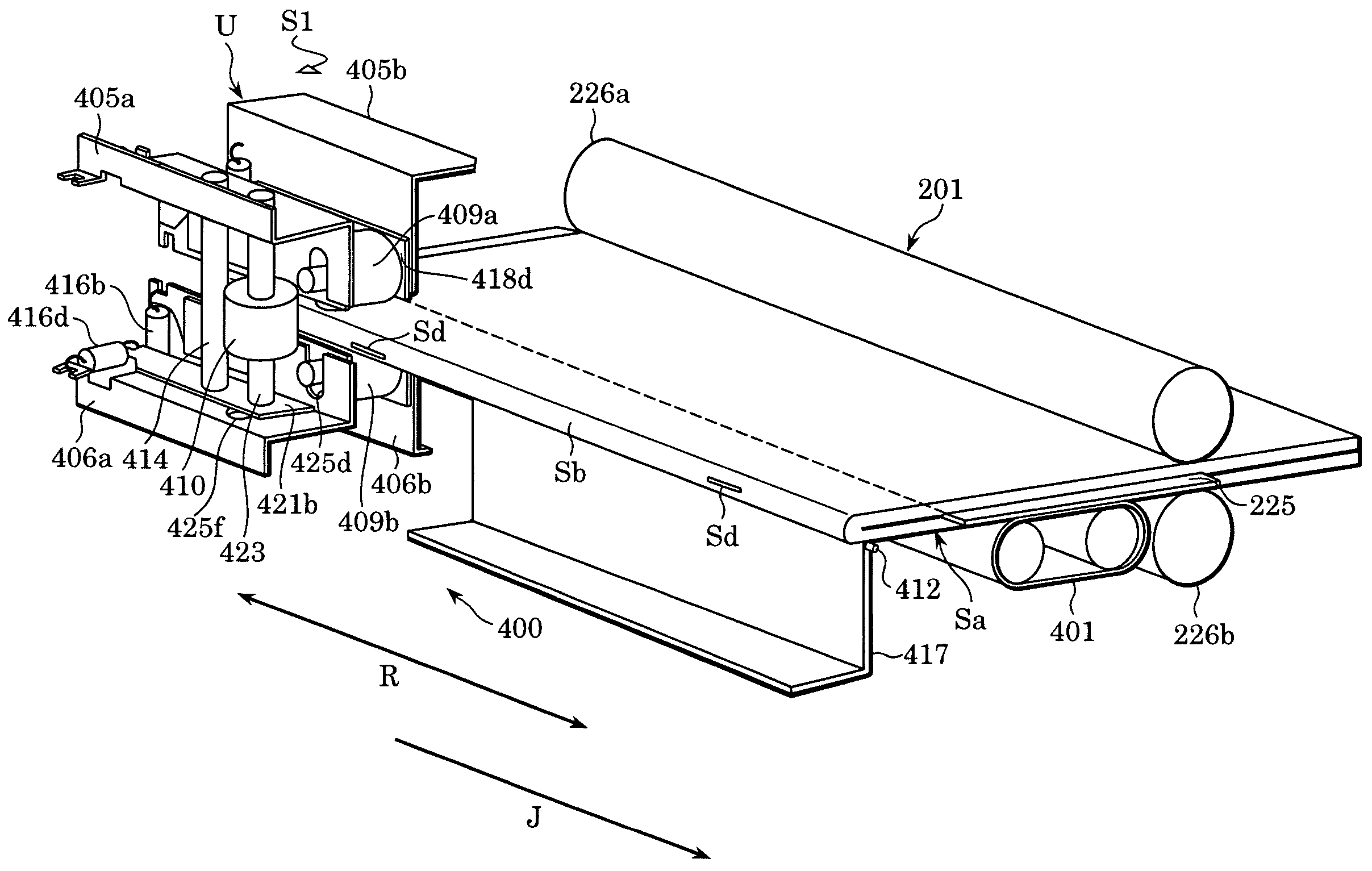

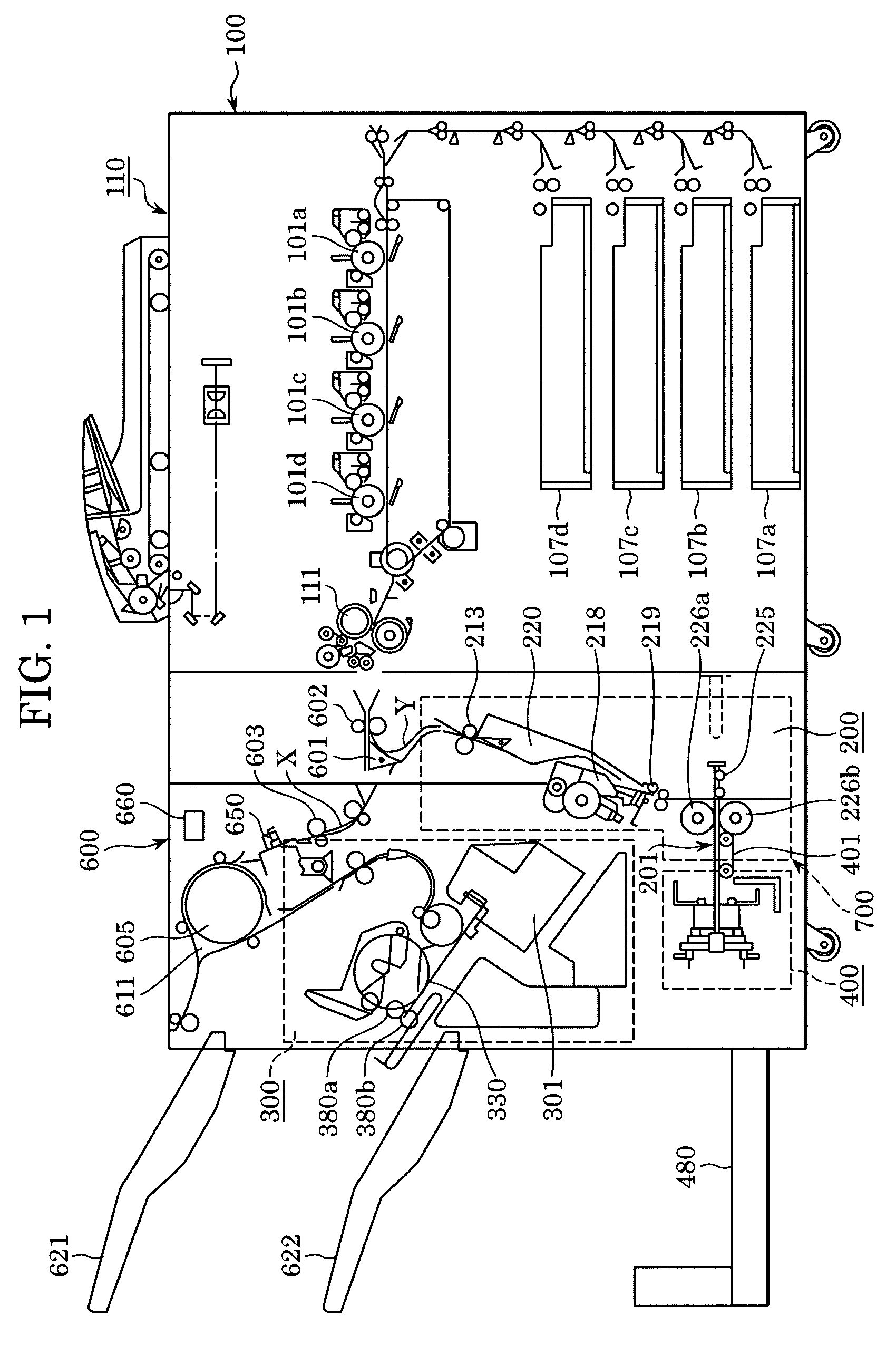

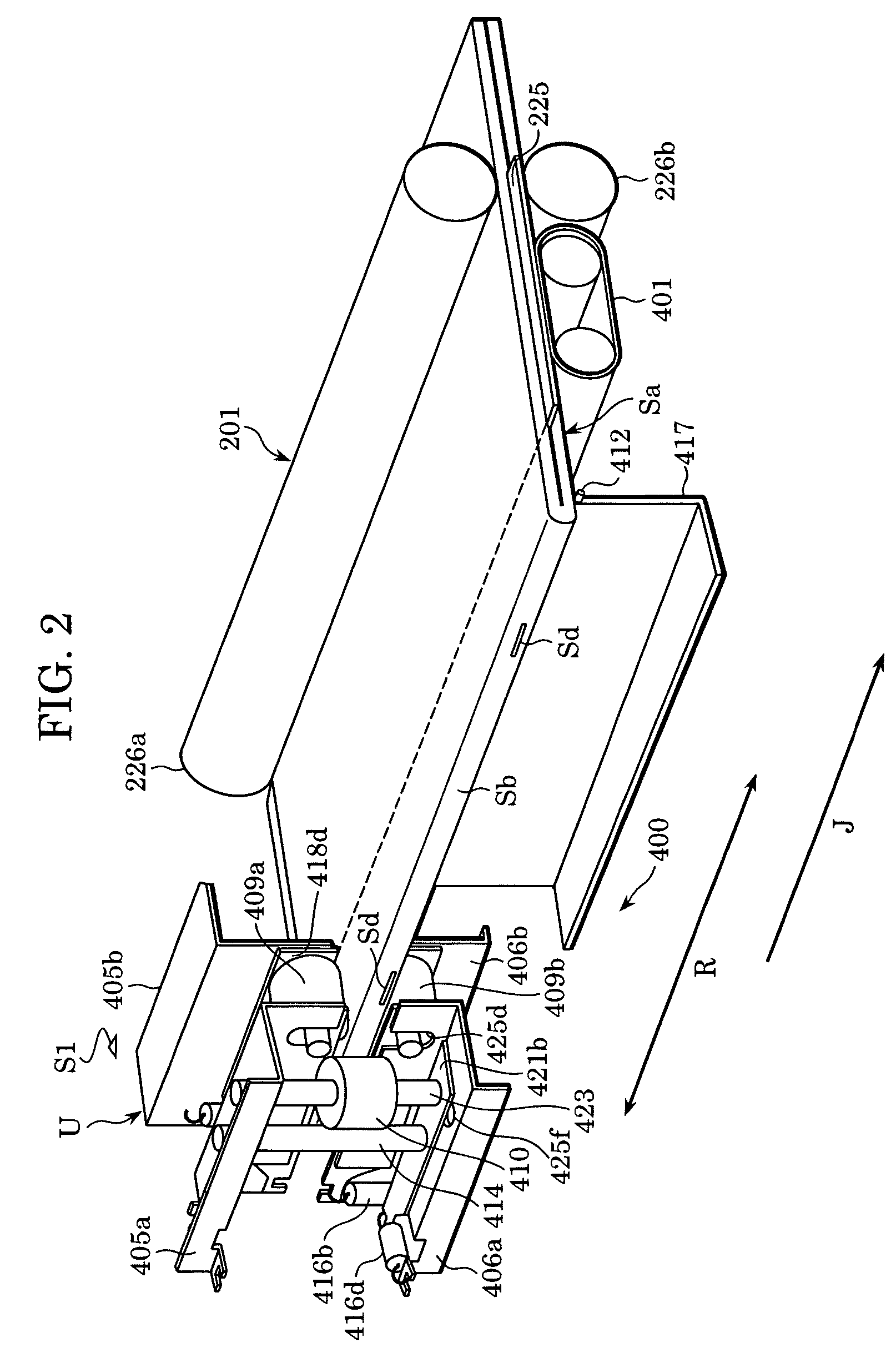

Sheet processing apparatus and image forming apparatus

ActiveUS20070060459A1Simple structureReduce manufacturing costMechanical working/deformationFolding thin materialsEngineeringSheet material

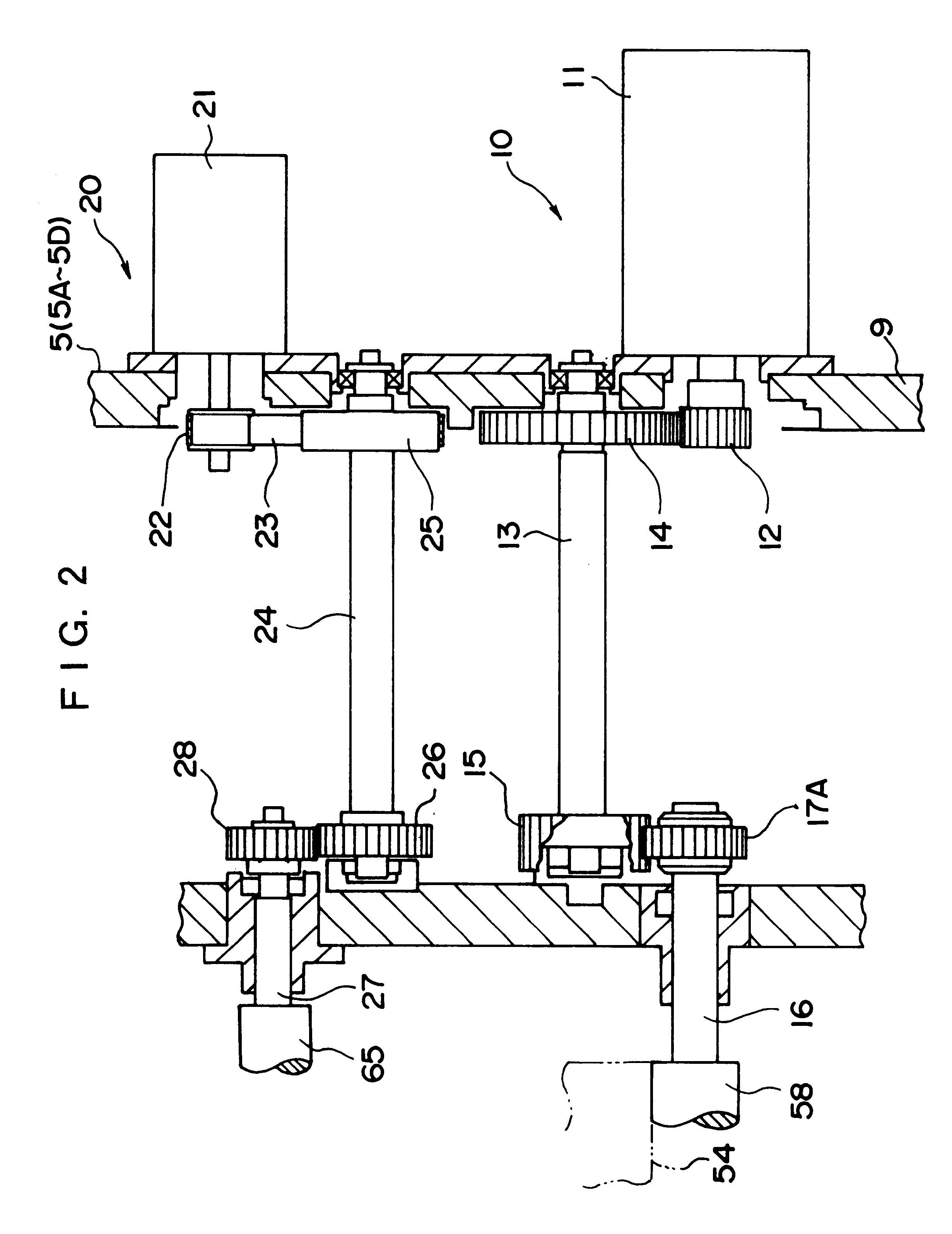

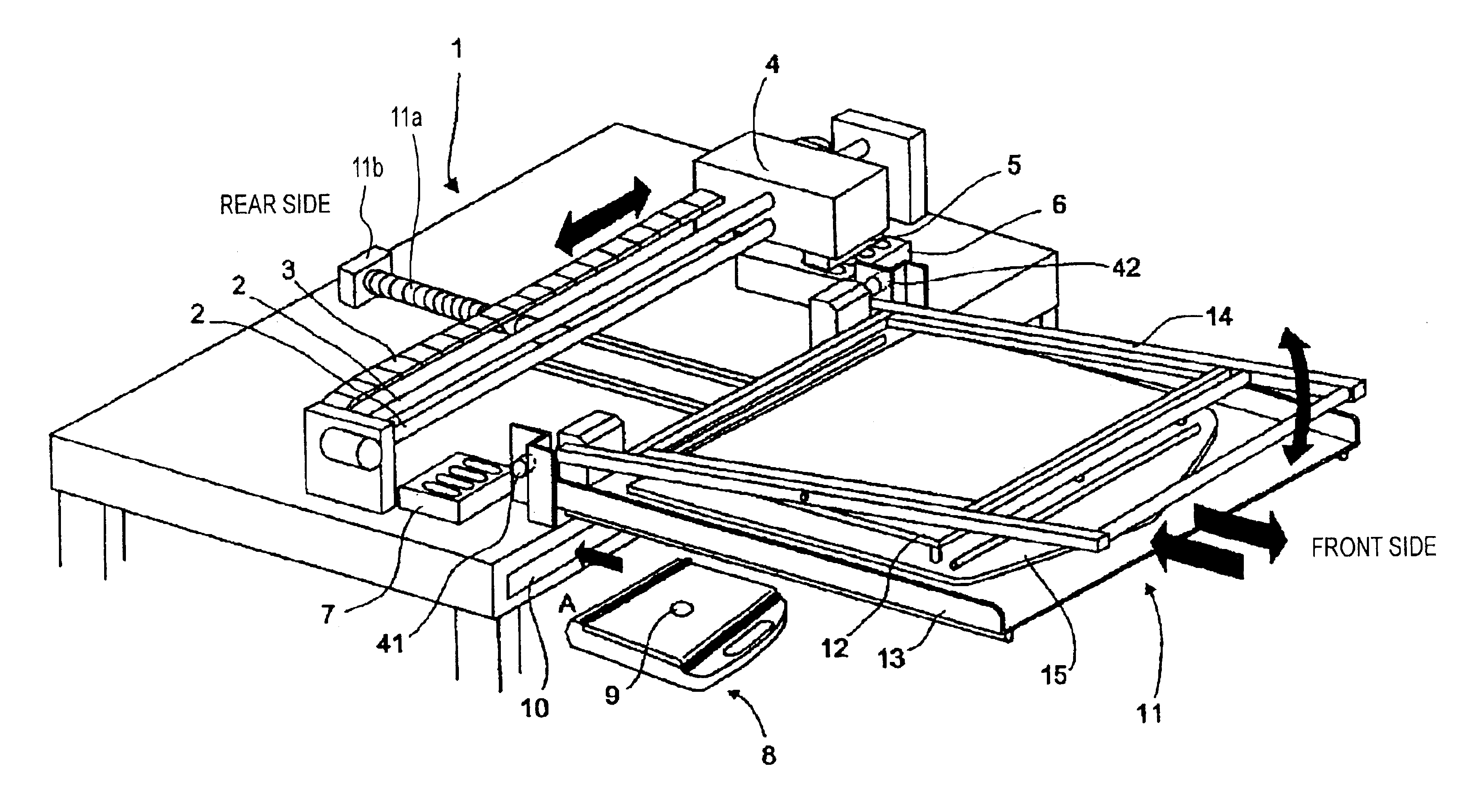

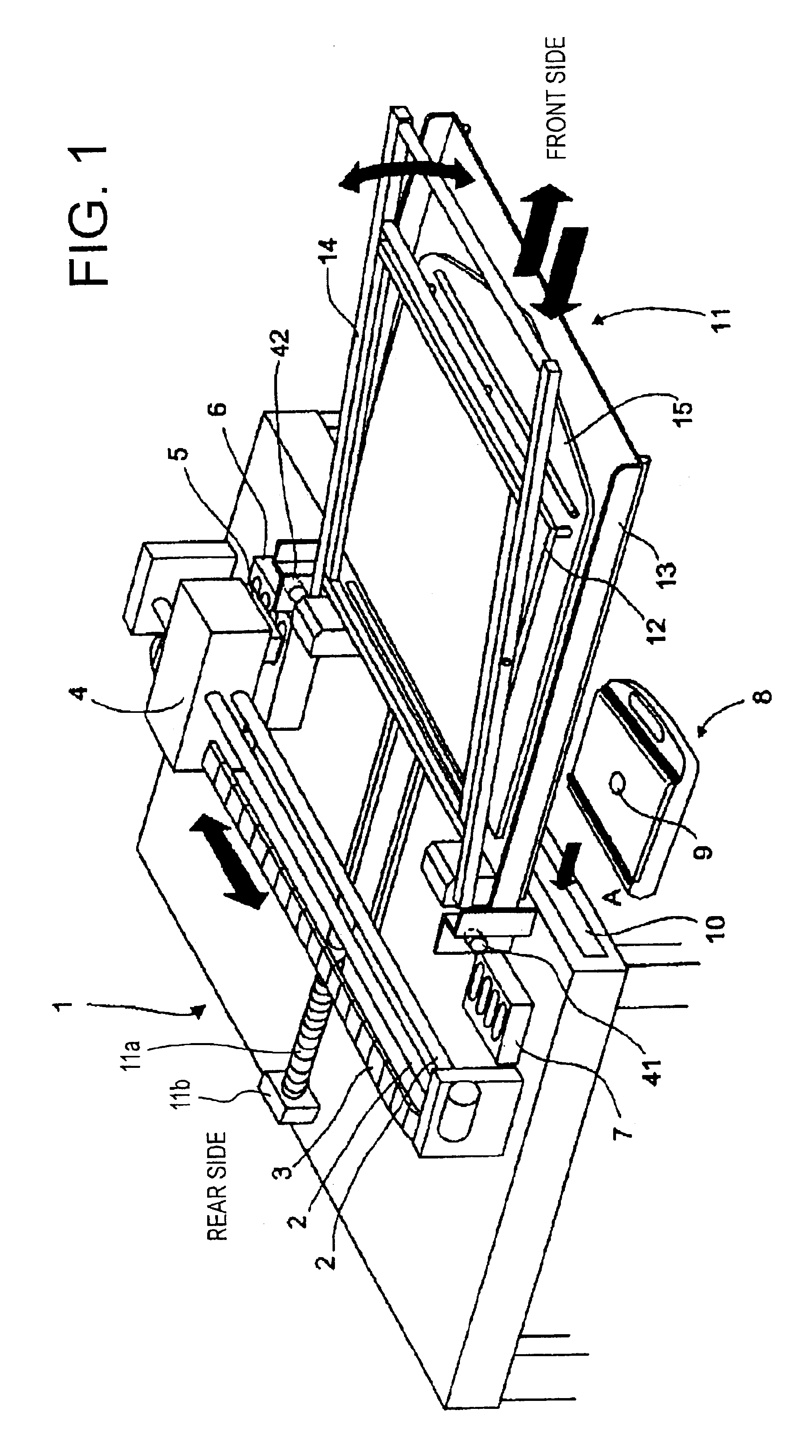

Provided is a sheet processing apparatus including: a pressing rotation member rotating while pressing a folded sheet bundle; a hold member movable along a fold line of the folded sheet bundle, for holding the pressing rotation member; a common drive source; and a drive transfer member for transferring a drive from the common drive source to the pressing rotation member and the hold member.

Owner:CANON KK

Sheet-bundle spine treatment apparatus, sheet-bundle treatment apparatus, and image-forming apparatus

Owner:CANON KK

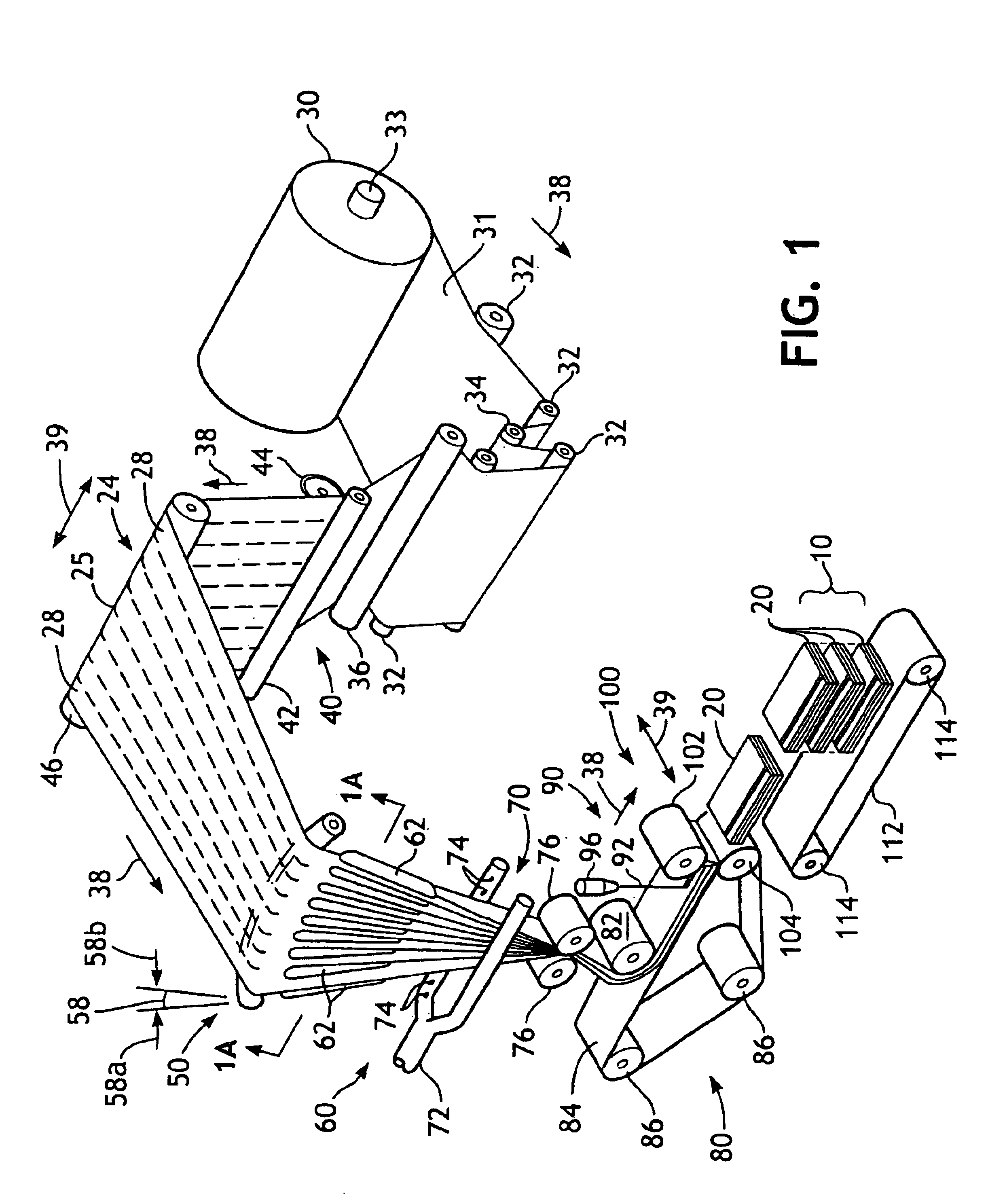

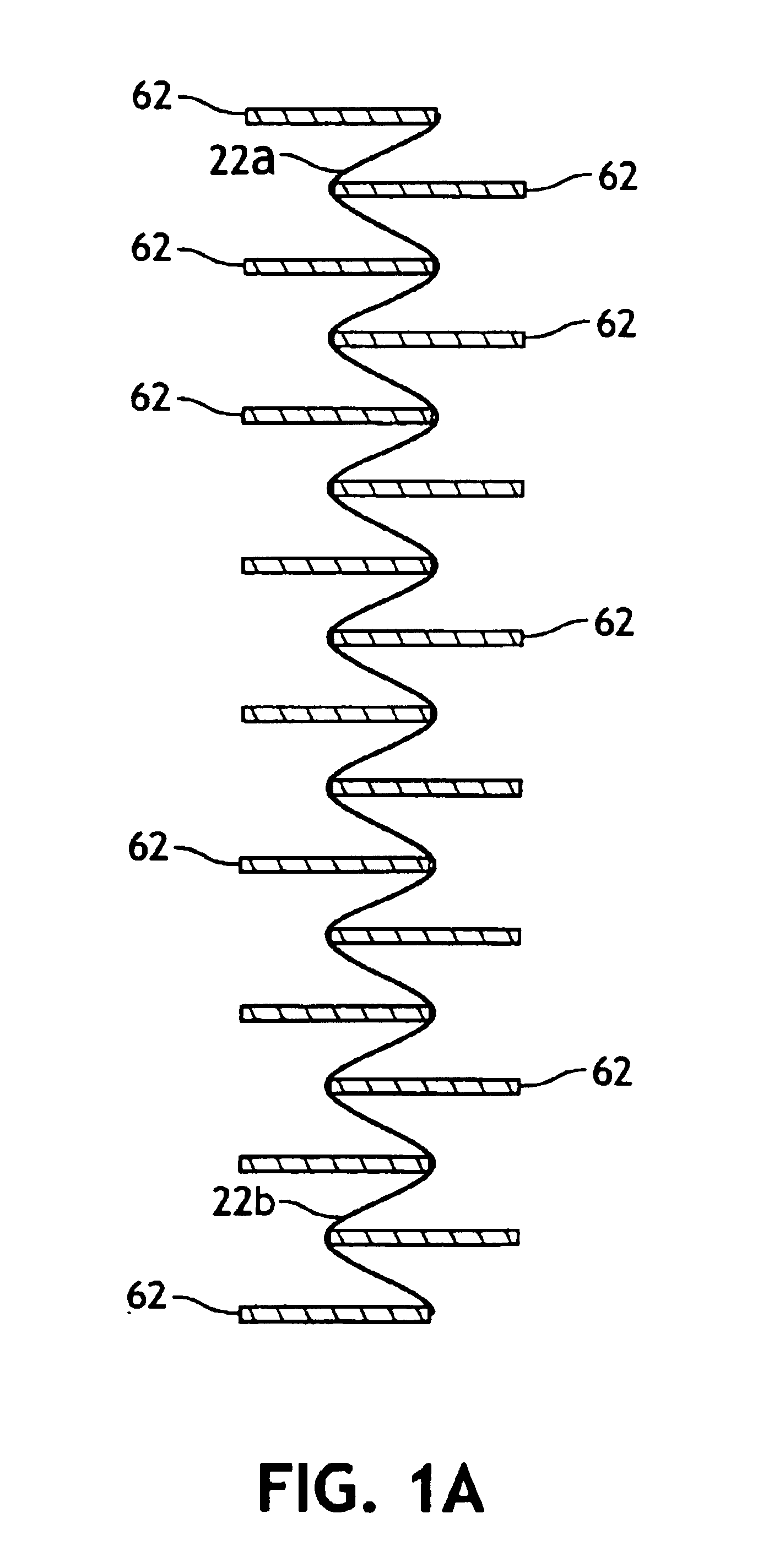

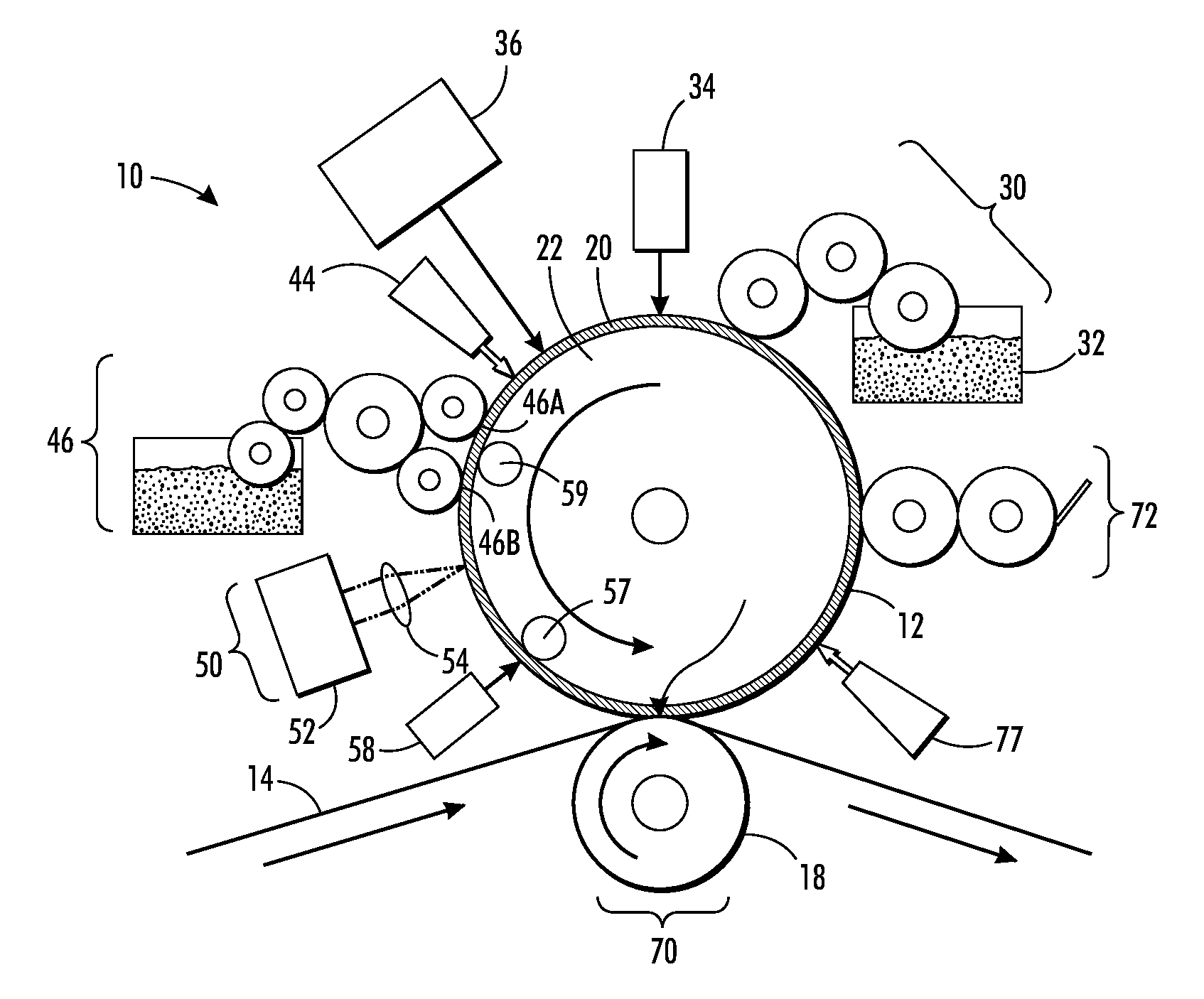

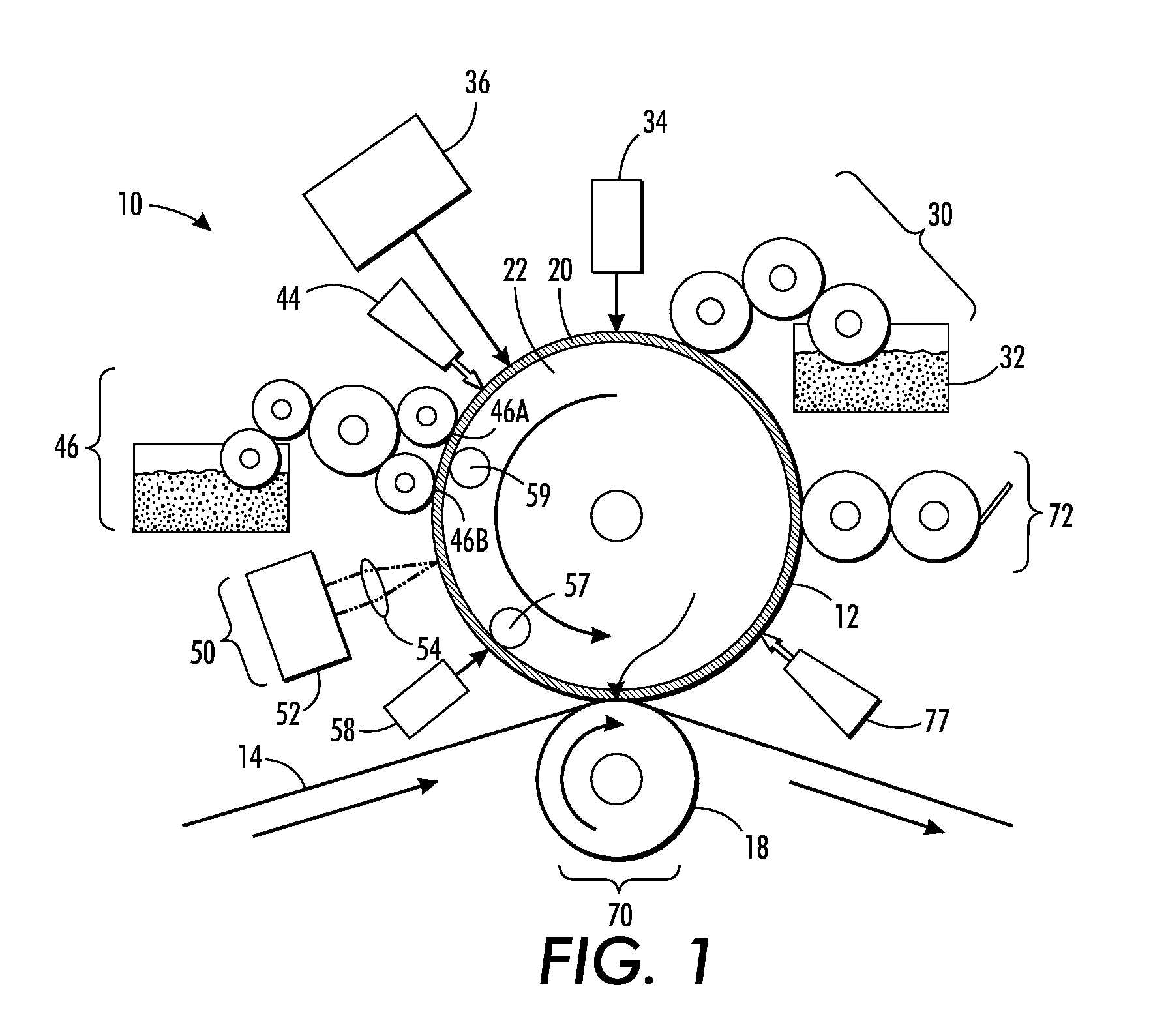

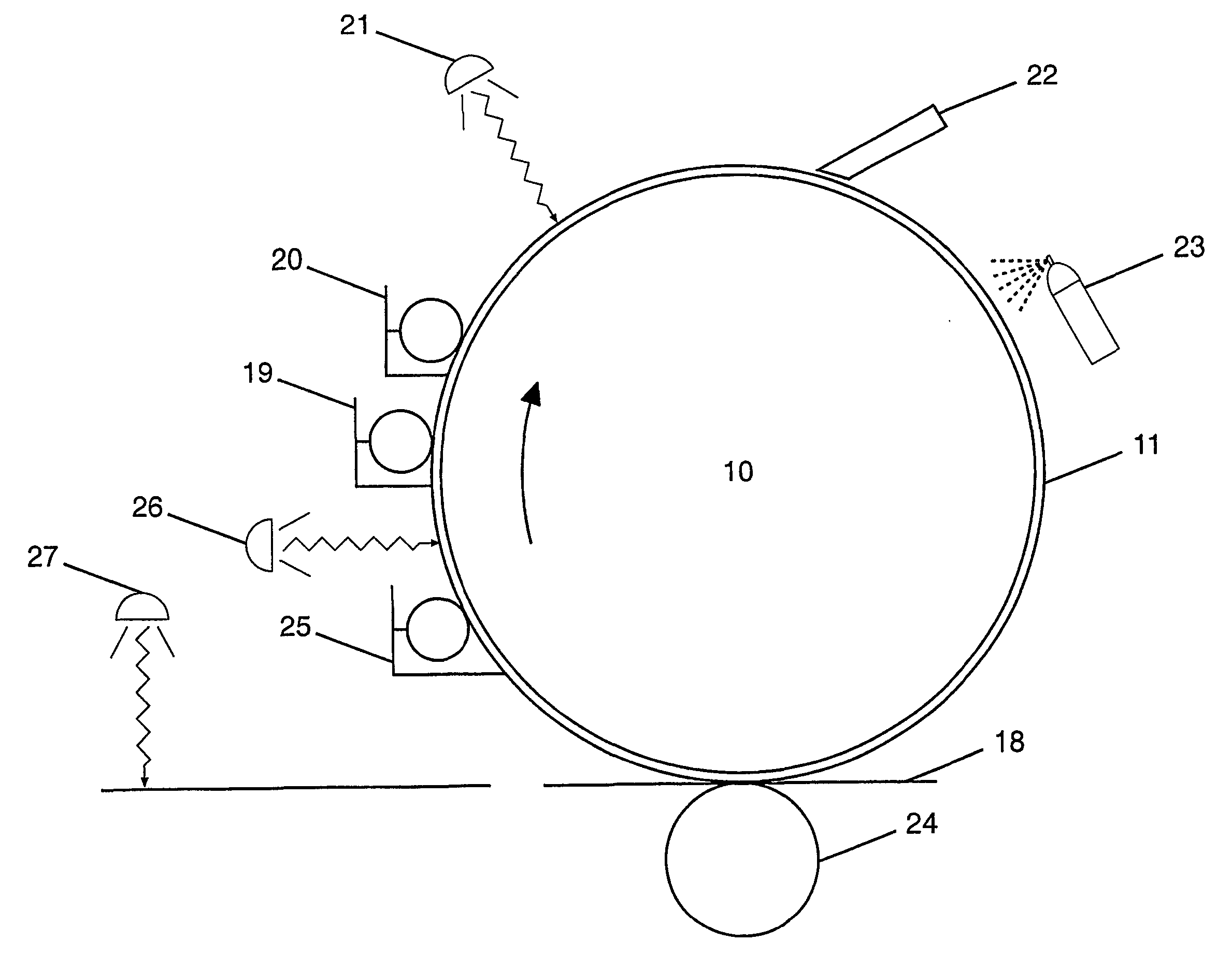

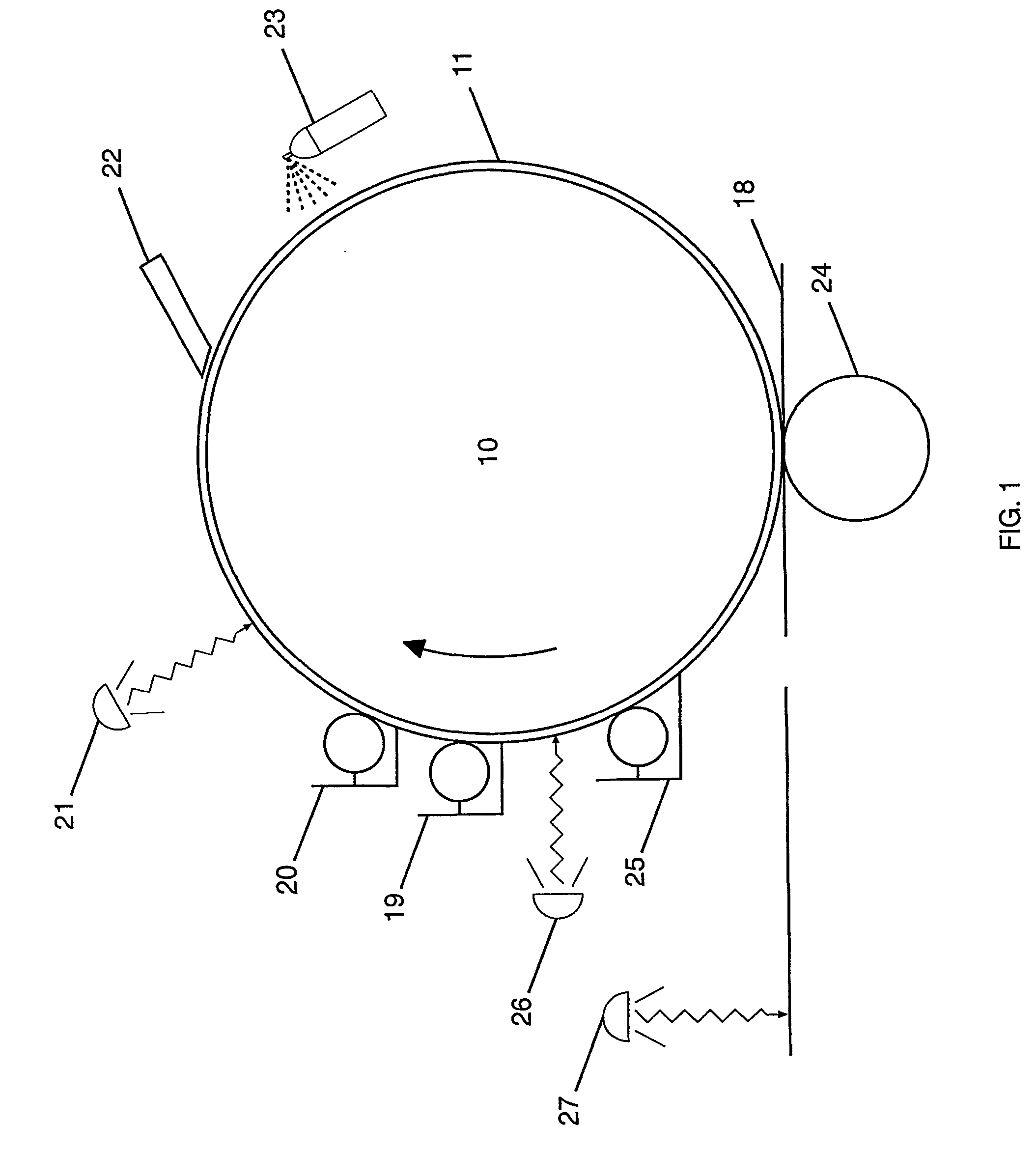

Method of printing variable information

The gel method of printing variable information of the present invention involves applying inks onto a substrate that is part of or attached to a cylinder of the printing machine. Imaging is by means of an energy source in the UV, visible or infrared regions, modulated to represent a digital image pattern that has been composed on a computer. The consequence of imaging is to gel the ink and increase its adhesion to the substrate of the printing cylinder. The non-gelled background ink with lower adhesion is then removed by a squeegee action and returned to an ink reservoir. The remaining image is transferred to an offset blanket or directly to print stock by pressure. The process does not use a master, but produces an image that is erased after printing with each cylinder rotation so that the next rotation producing the next print can have fresh information written upon it.

Owner:KODAK IL

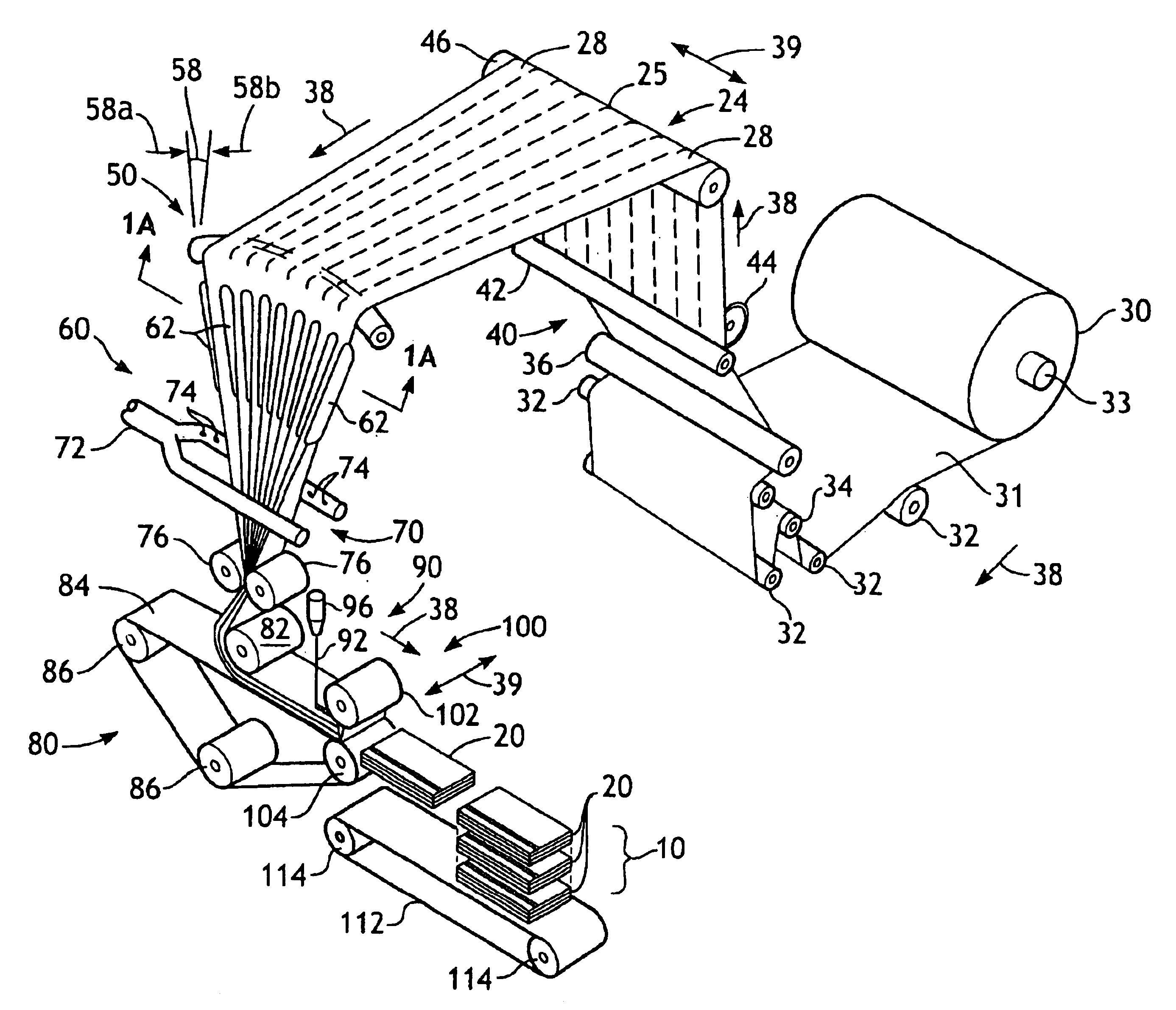

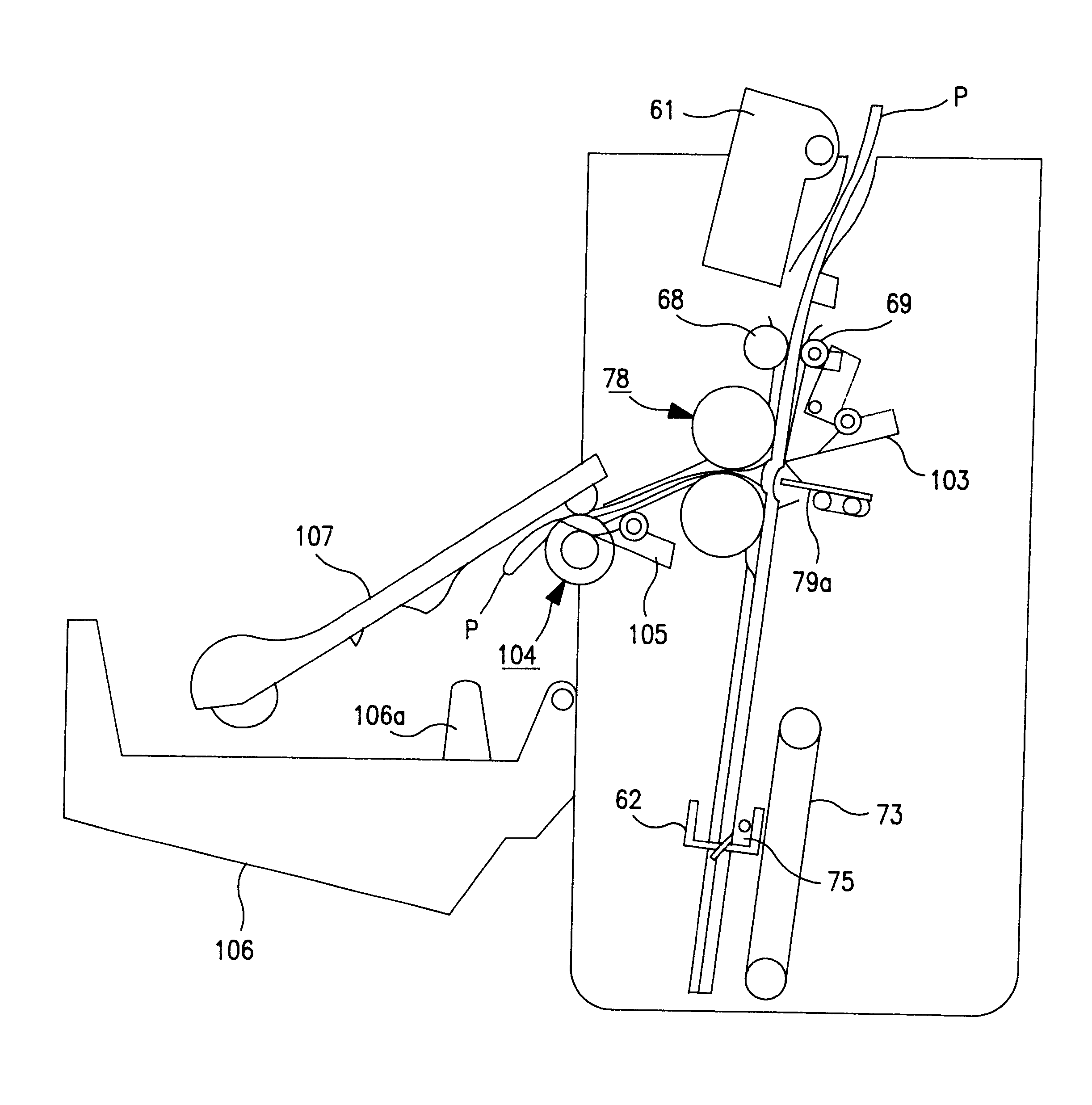

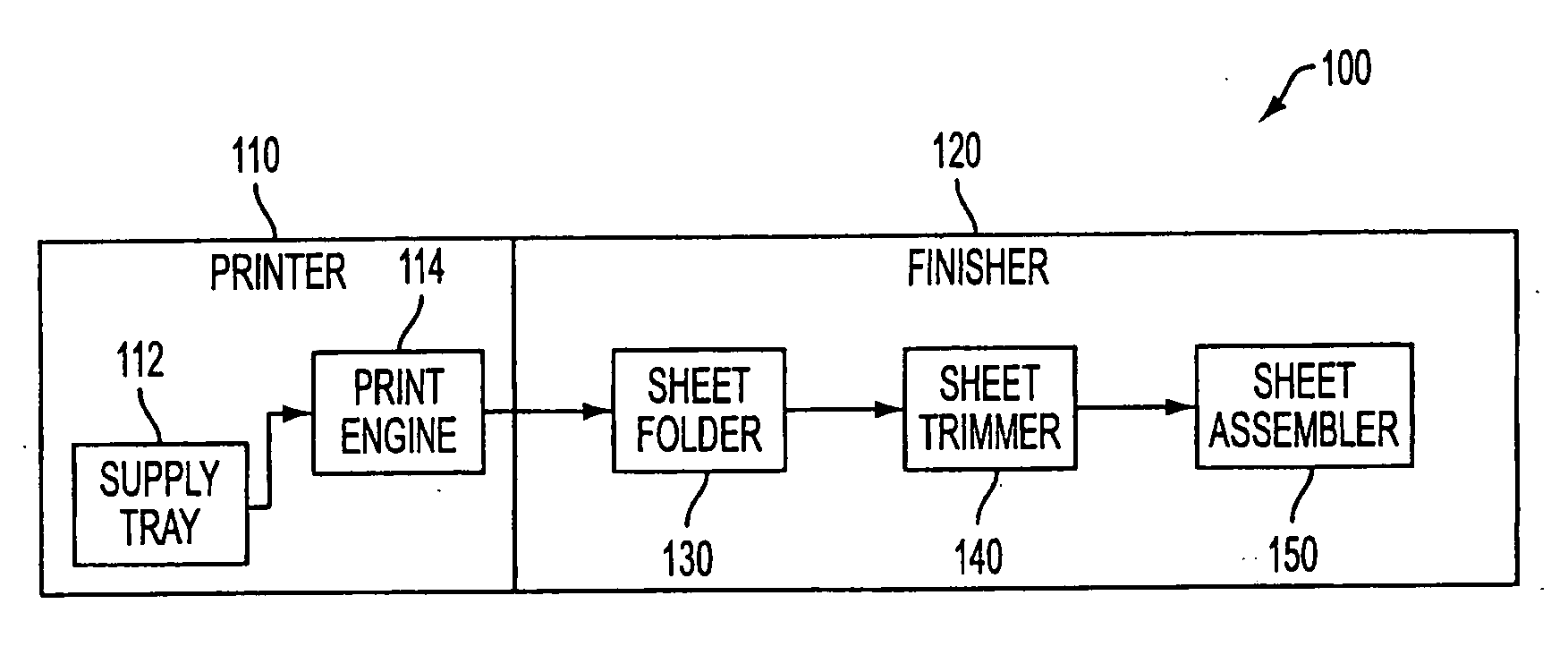

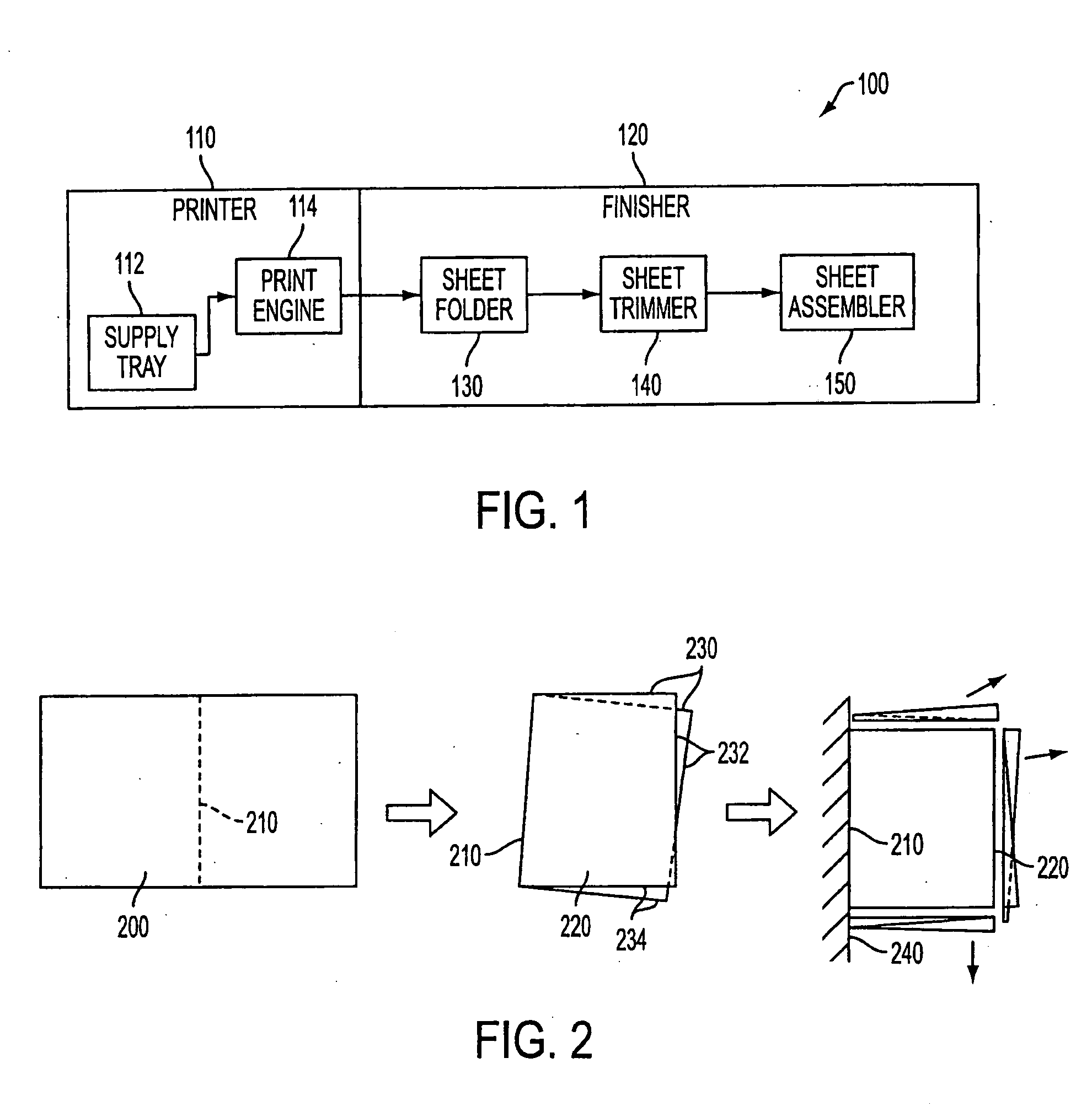

Sheet folding and trimming apparatus

A sheet folding and trimming apparatus for a booklet maker or bookbinder includes a folding apparatus and a sheetwise trimming apparatus configured to trim the folded sheet from the folding apparatus on three unfolded sides of the sheet in a sheetwise manner. The location of the sheet folder prior to the sheet trimmer allows the use of a relatively imprecise and inexpensive folding apparatus, such as a buckle folder, and adjusts for the imprecision of the fold by trimming the folded sheet.

Owner:HEWLETT PACKARD DEV CO LP

Rotary press

Owner:TOSHIBA MASCH CO LTD

Platen device for holding workpiece in ink-jet printer

InactiveUS6908190B2Easy to set upMinimize permeation of inkInking apparatusPlaten pressesMechanical engineeringInkjet printing

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com