Patents

Literature

237 results about "Hydrofluoroether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Hydrofluoroether (HFE) is a complex organic solvent. As a non-ozone-depleting chemical, it was developed originally as a replacement for CFCs, HFCs, HCFCs, and PFCs HFE does not occur naturally. It is colorless, odorless, tasteless, low toxicity, low viscosity, and liquid at room temperature. It is visually indistinguishable from water at room temperature. The vapor-point of HFE varies by chemistry from 50C to nearly 100C.

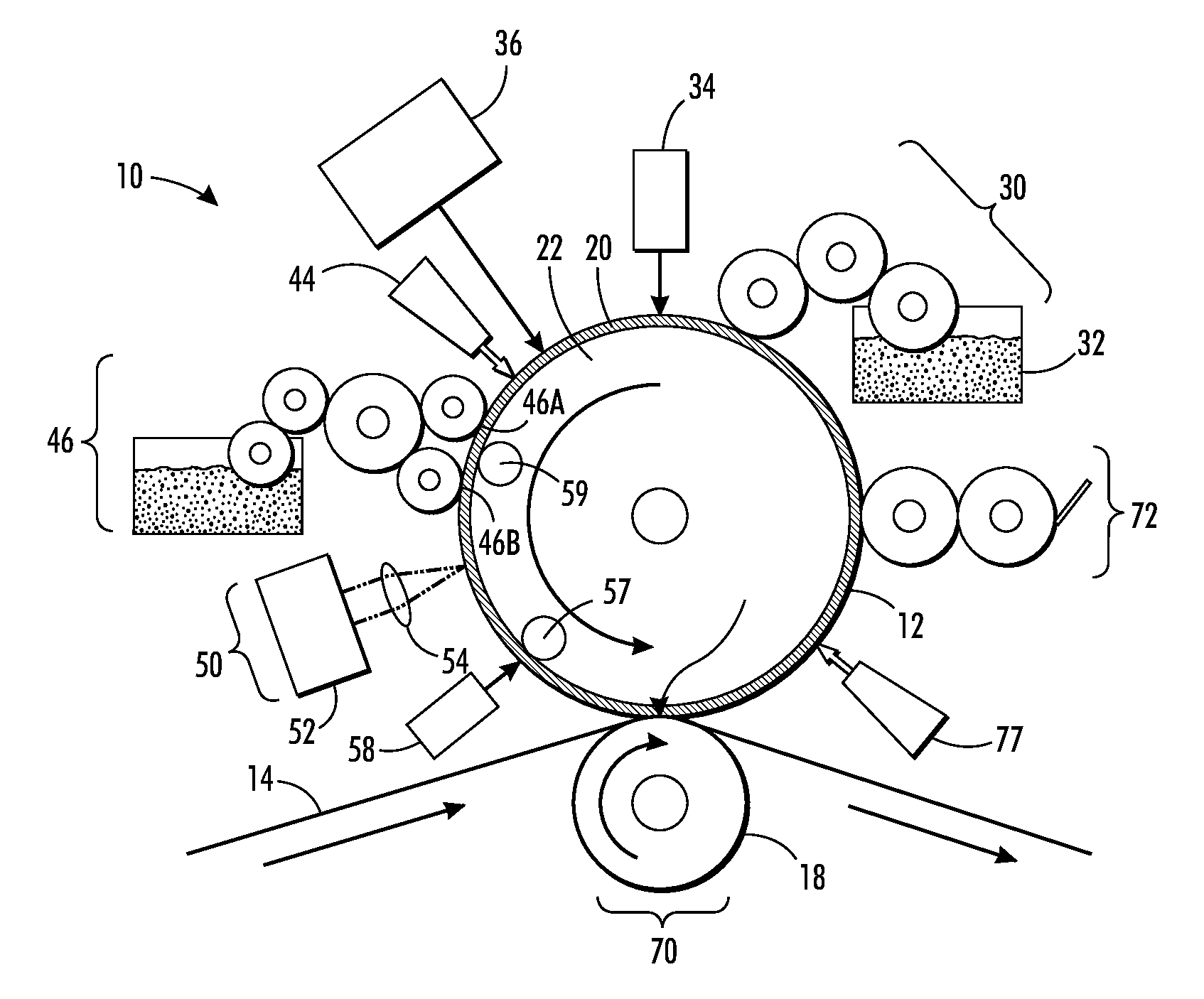

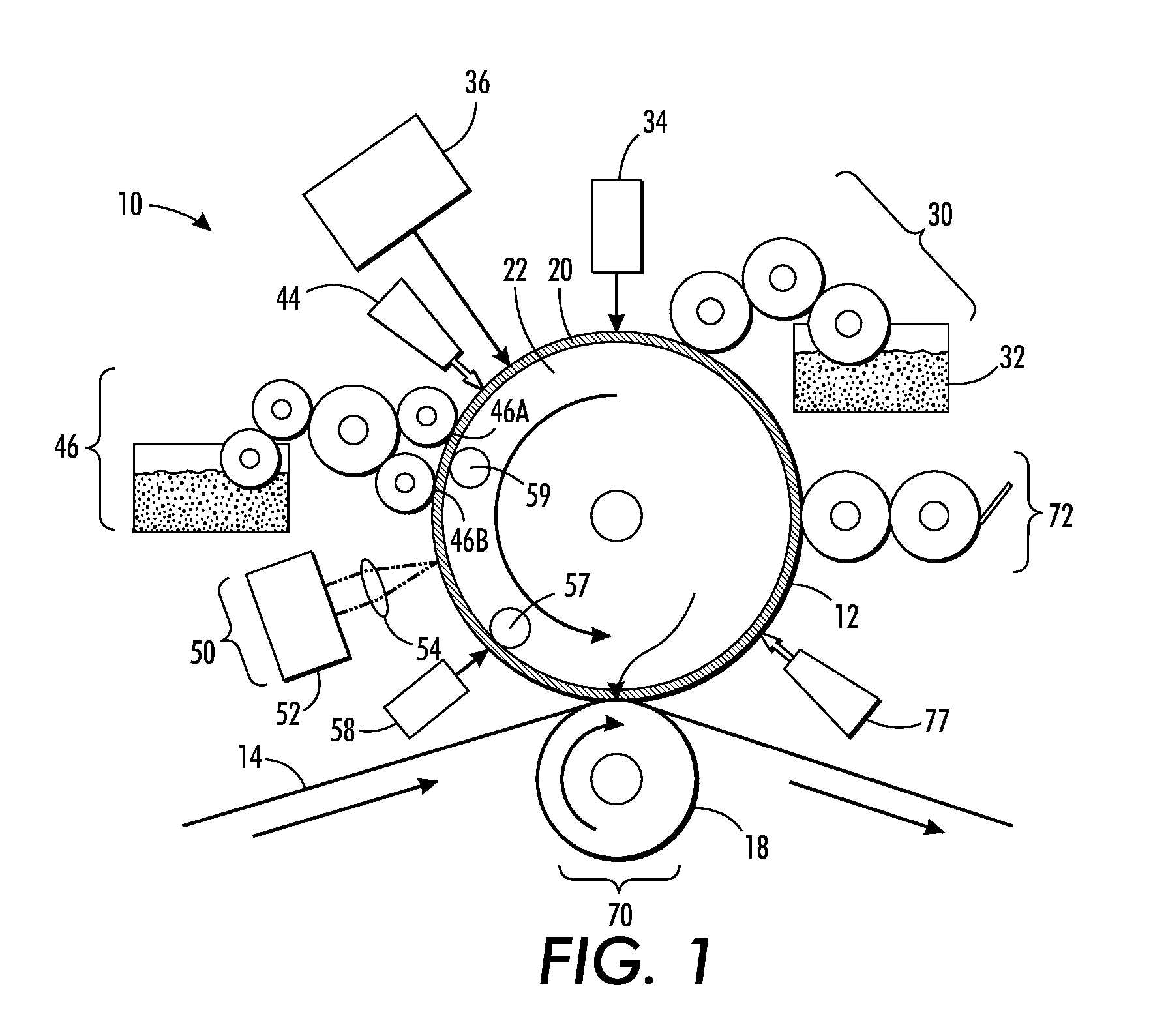

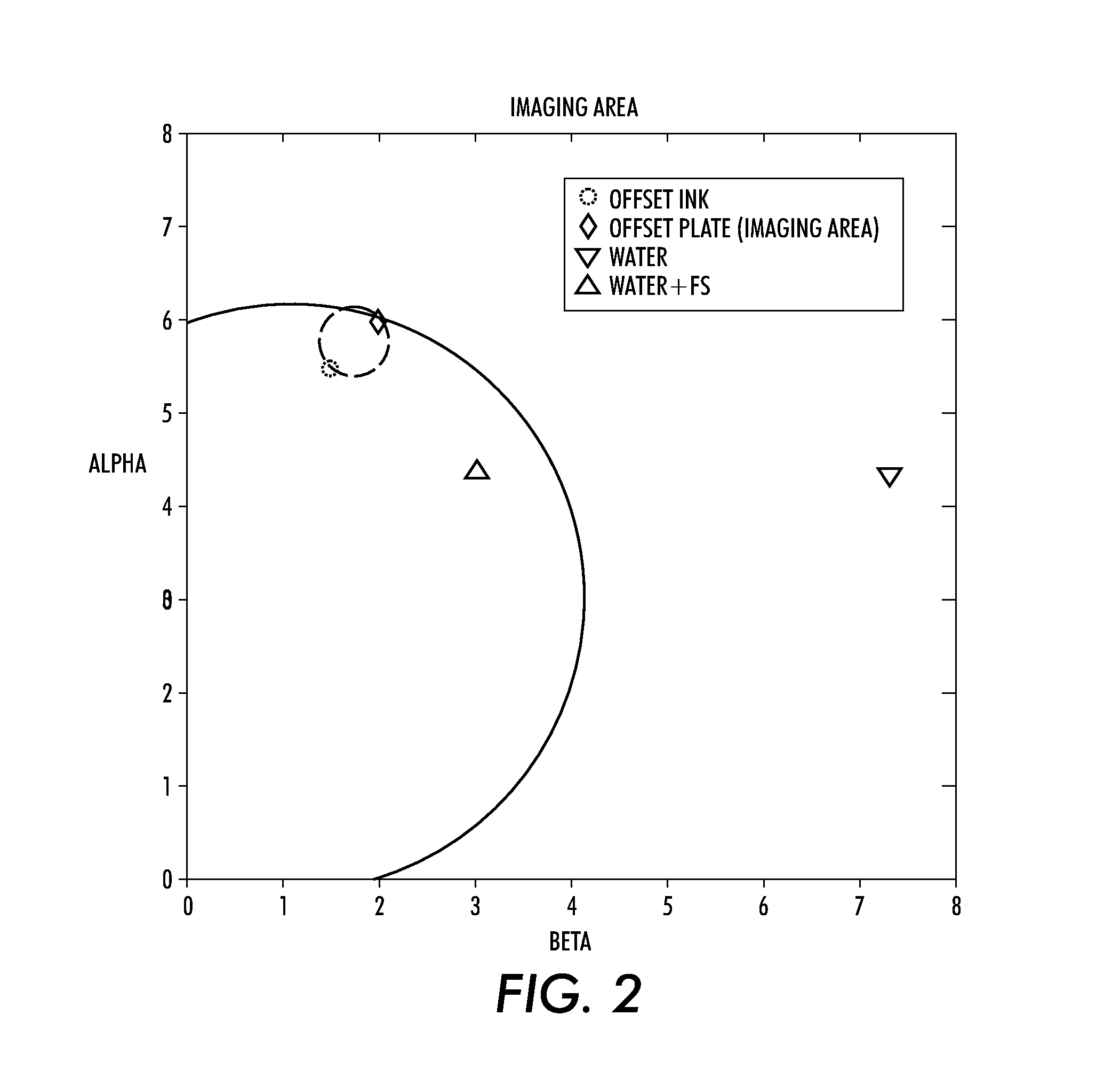

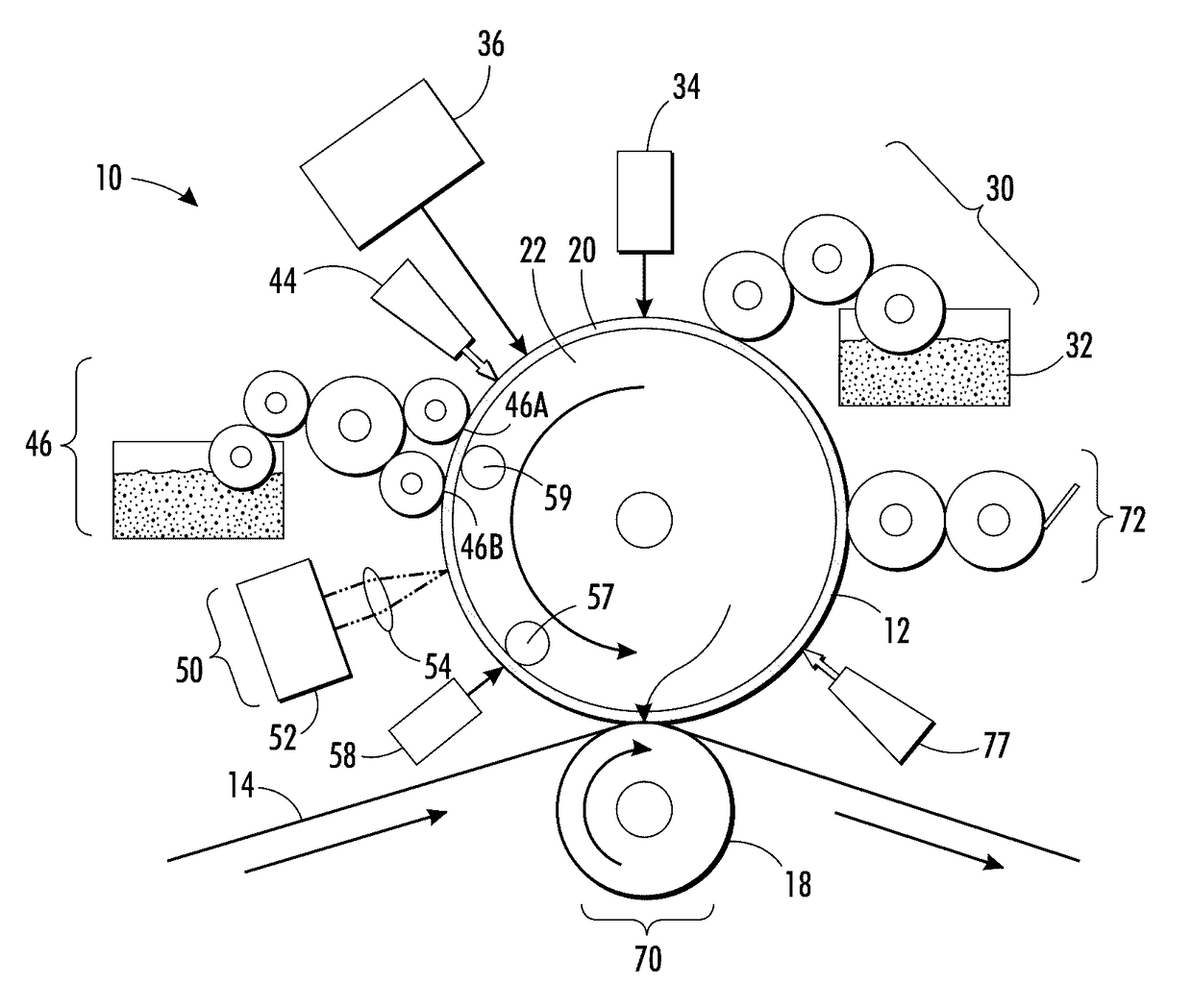

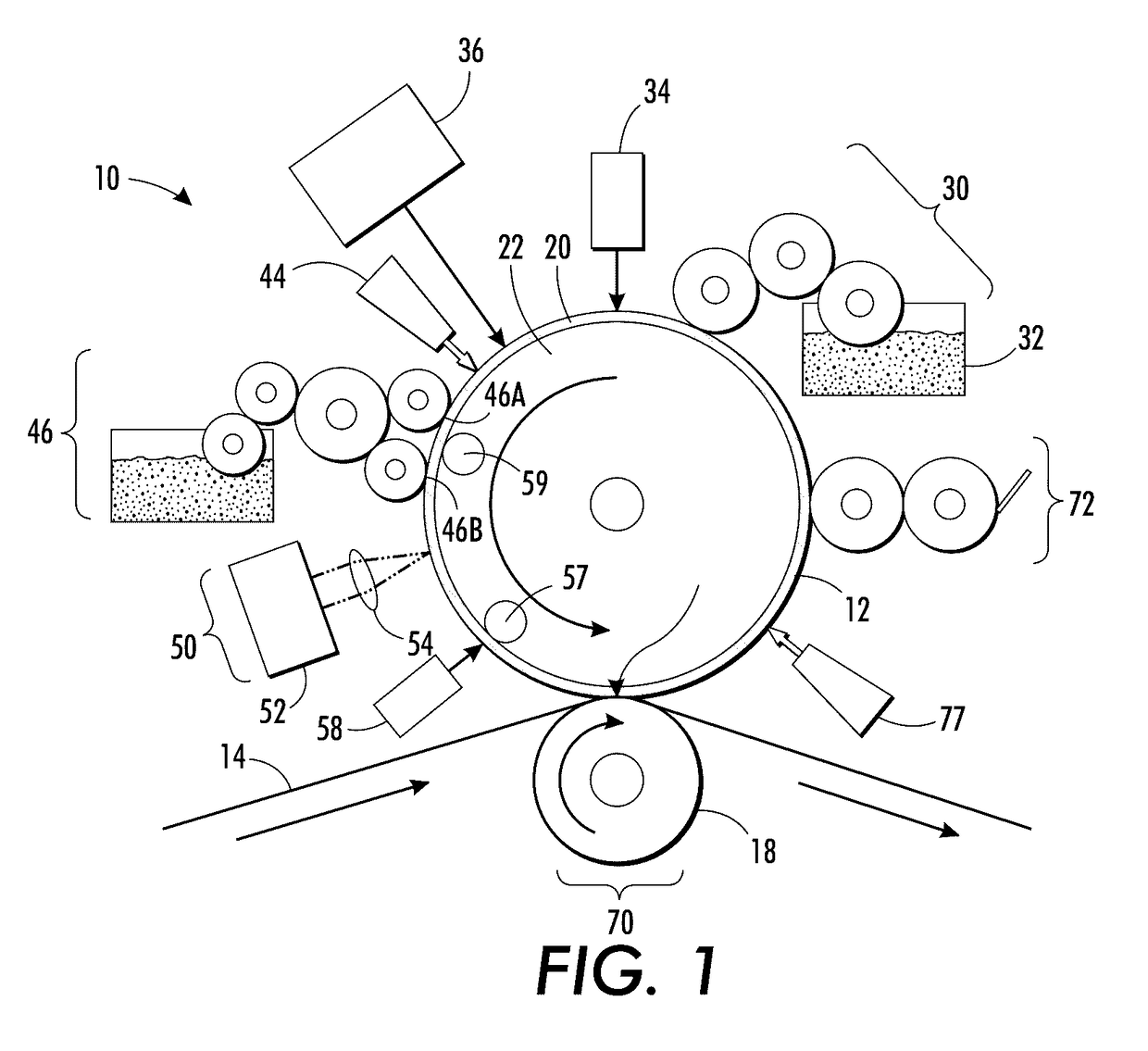

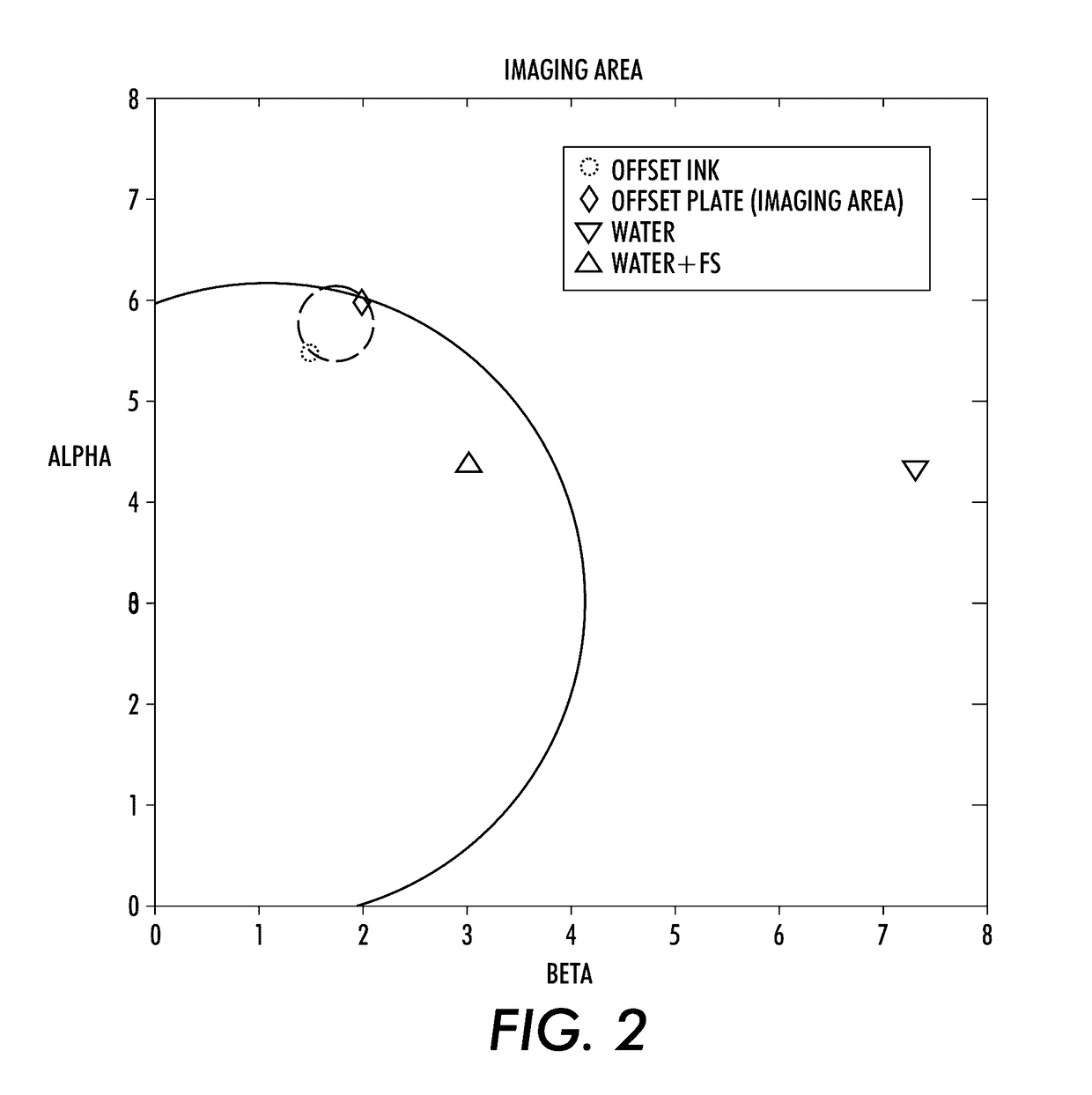

Dampening fluid for digital lithographic printing

ActiveUS20130104756A1Less residueSilicon organic compoundsPlaten pressesElectrical polarityVaporization

Different solvents for a dampening fluid are disclosed. The solvent is a volatile hydrofluoroether liquid or a volatile silicone liquid. Such liquids have a lower heat of vaporization, a lower surface tension, and better kinematic viscosity compared to water, which is the conventional solvent used in dampening fluids. The dampening fluids, which are relatively nonpolar, can be used in a combination with polar inks to form a new type of digital lithographic printing system.

Owner:XEROX CORP

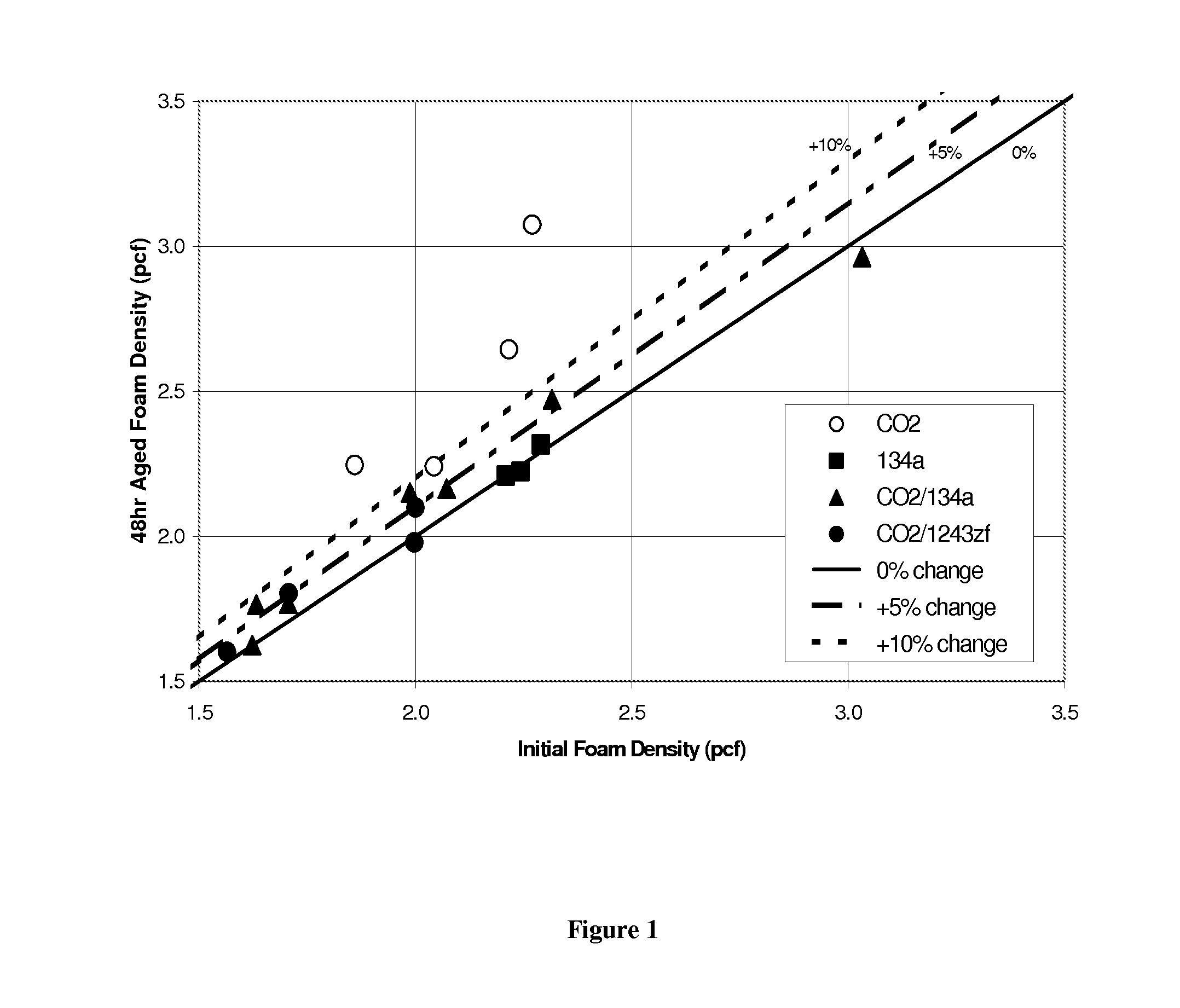

Biodegradable foams with improved dimensional stability

InactiveUS20120225961A1Good dimensional stabilityLow densityOther chemical processesTransportation and packagingHydrofluoroetherLow density

The invention provides a blowing agent composition and method of making the same comprising mixing carbon dioxide and a co-blowing agent or a blowing agent selected from the group consisting of hydrofluorocarbons, hydrochlorofluorocarbons, hydrofluoroethers, hydrofluoroolefms, hydrochlorofluoroolefms, hydrobromofluoroolefms, hydrofluoroketones, hydrochloroolefins, fluoroiodocarbons, alkyl esters, water, and mixtures thereof. Also provided is a method of making a low density foam using the blowing agent composition, and a biodegradable or biorenewable foam formed from a foamable biodegradable or biorenewable resin composition and the blowing agent composition.

Owner:ARKEMA INC

Isopropyl chloride with hydrofluorocarbon or hydrofluoroether as foam blowing agents

InactiveUS6646020B2Combustibility is reduced and eliminatedReduce flammabilityHeat-exchange elementsLiquid soapsPolyisocyanurateHydrofluoroether

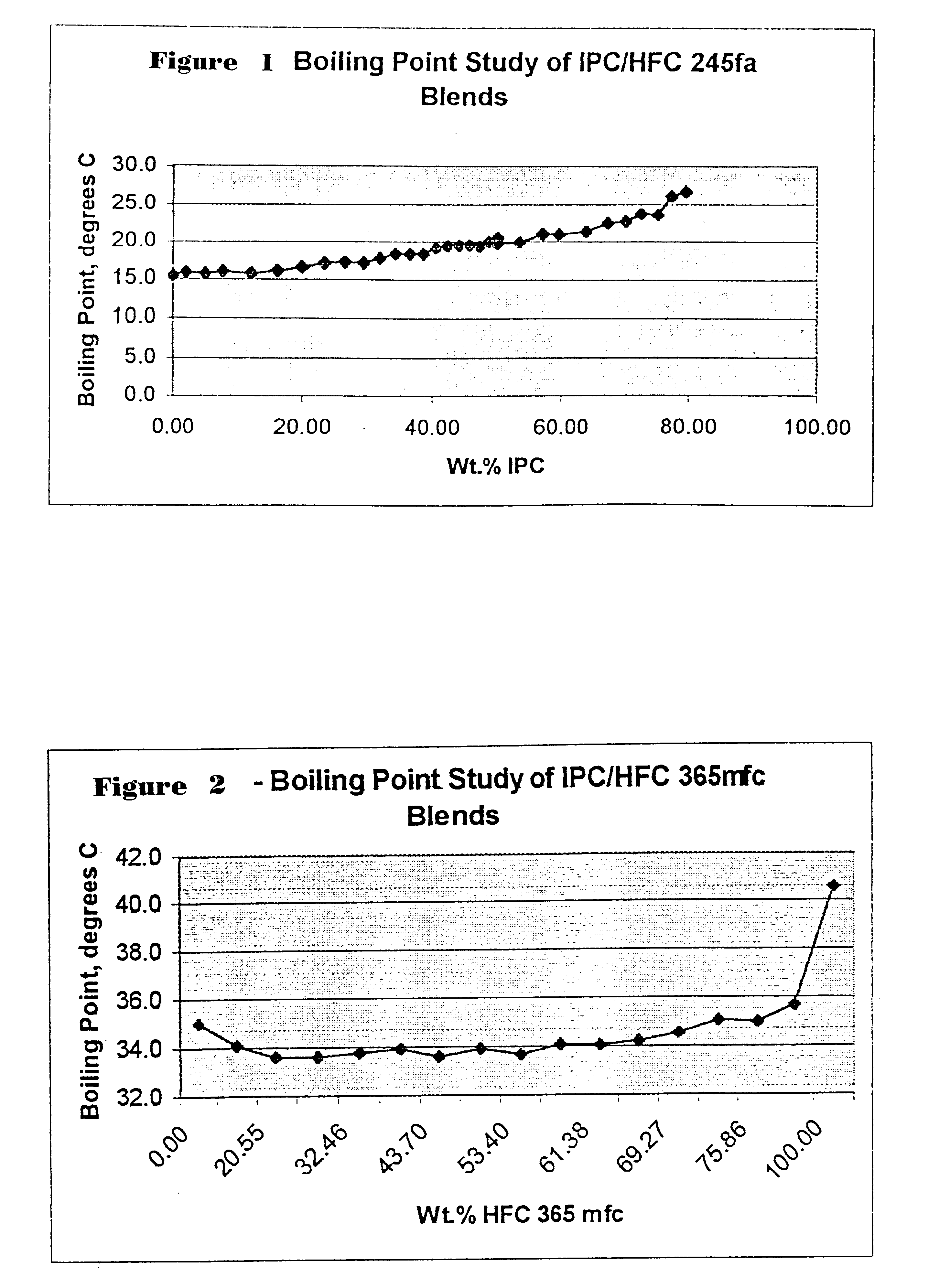

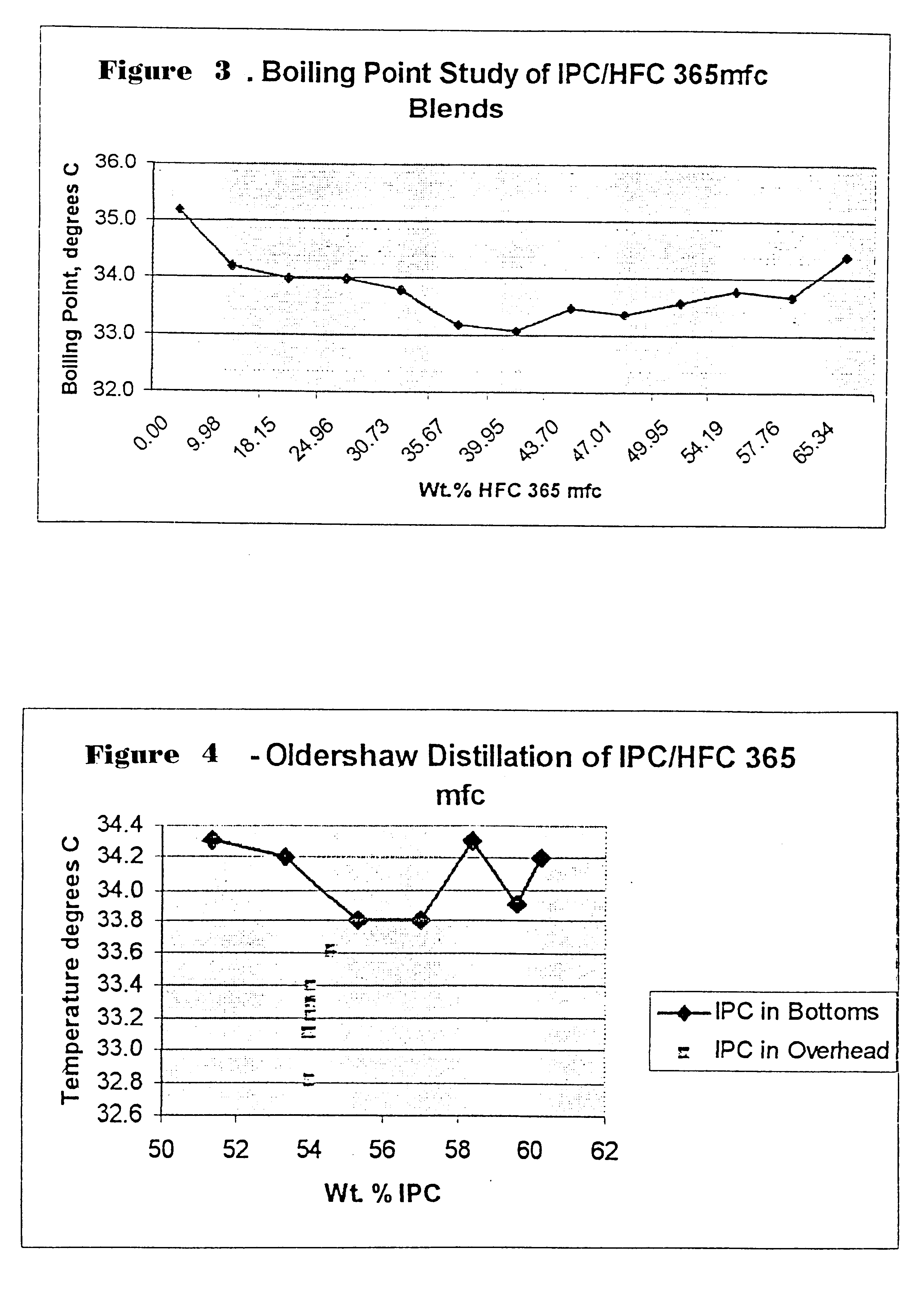

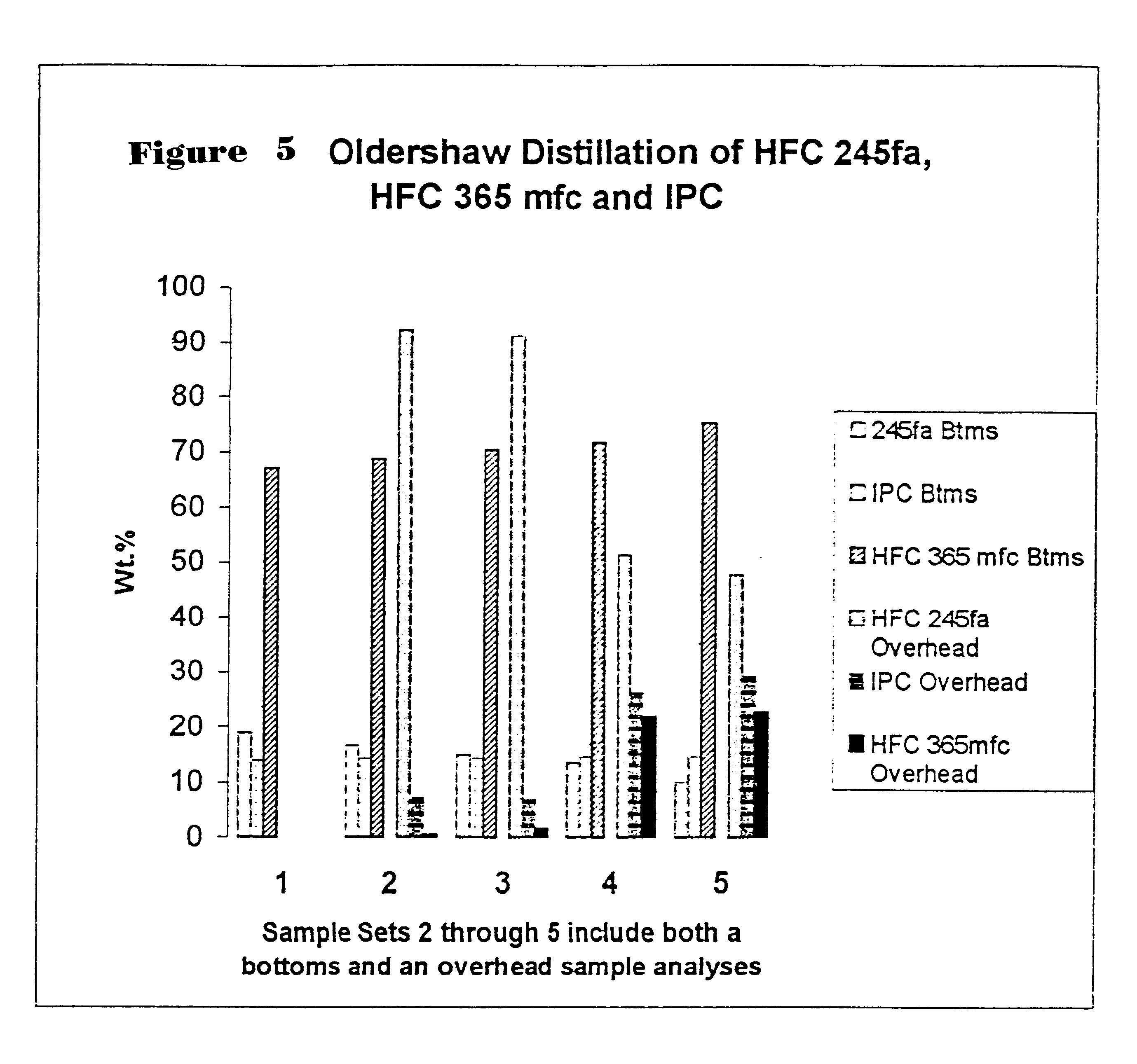

A composition useful as a blowing agent having no flash point or reduced combustibility comprising 2-chloropropane and a gas selected from the group consisting of a fluorohydrocarbon, perfluorocarbons, fluoroethers, hydrofluoropolyethers and mixtures thereof is disclosed. A polyisocyanurate foam or a polyurethane modified polyisocyanurate foam having a mainly closed cell structure and also a method for preparing this foam, the latter comprising closed cells wherein a foam blowing agent consisting of a mixture of 2-chloropropane and one or more HFC compounds including pentafluoropropane, pentafluorobutane, heptafluoropropane, hexafluoropropane or pentafluoroethane are disclosed. Pentanes can be added if desired. Azeotropic mixtures in which 2-chloropropane is an ingredient are disclosed.

Owner:OCCIDENTAL CHEM CORP

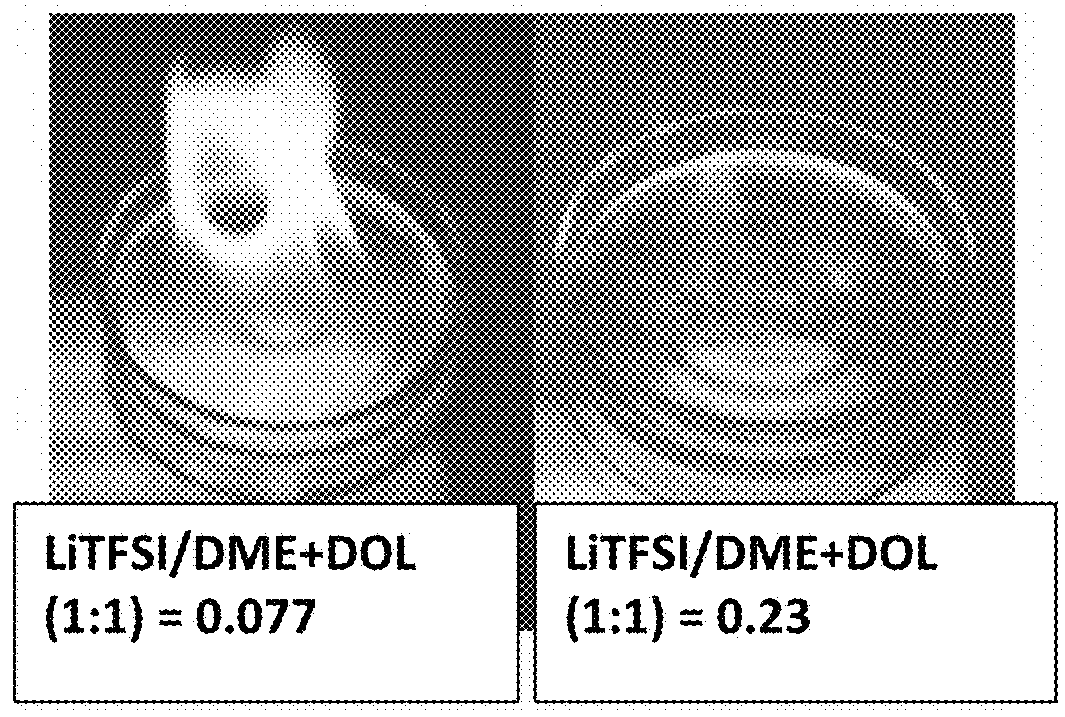

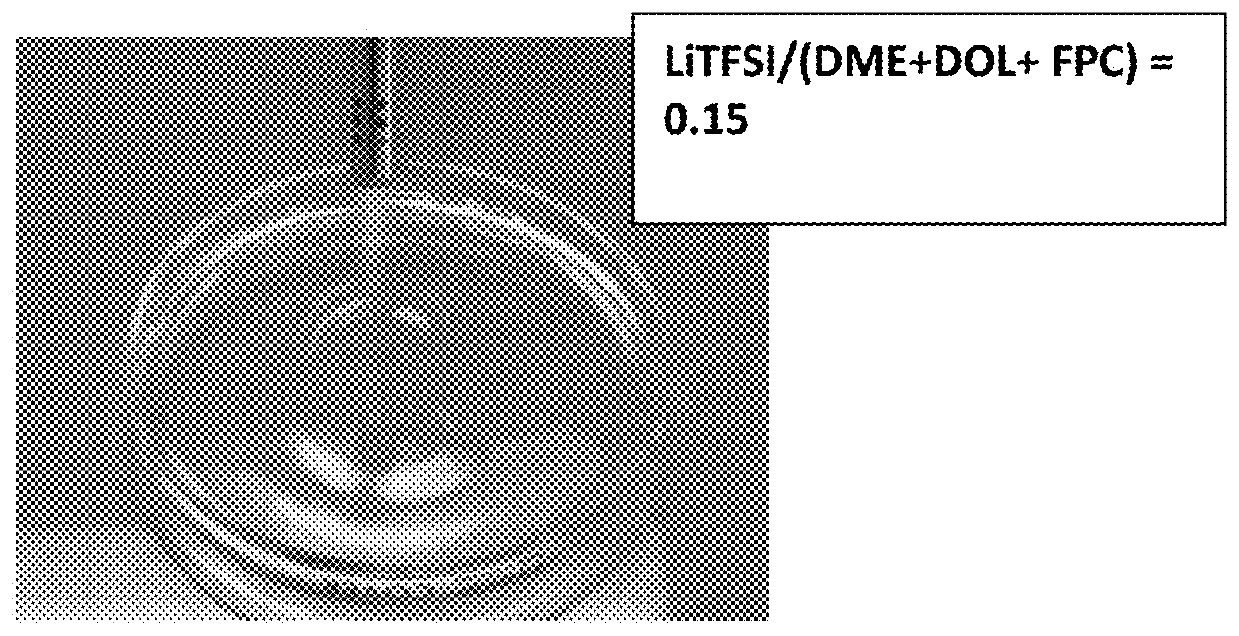

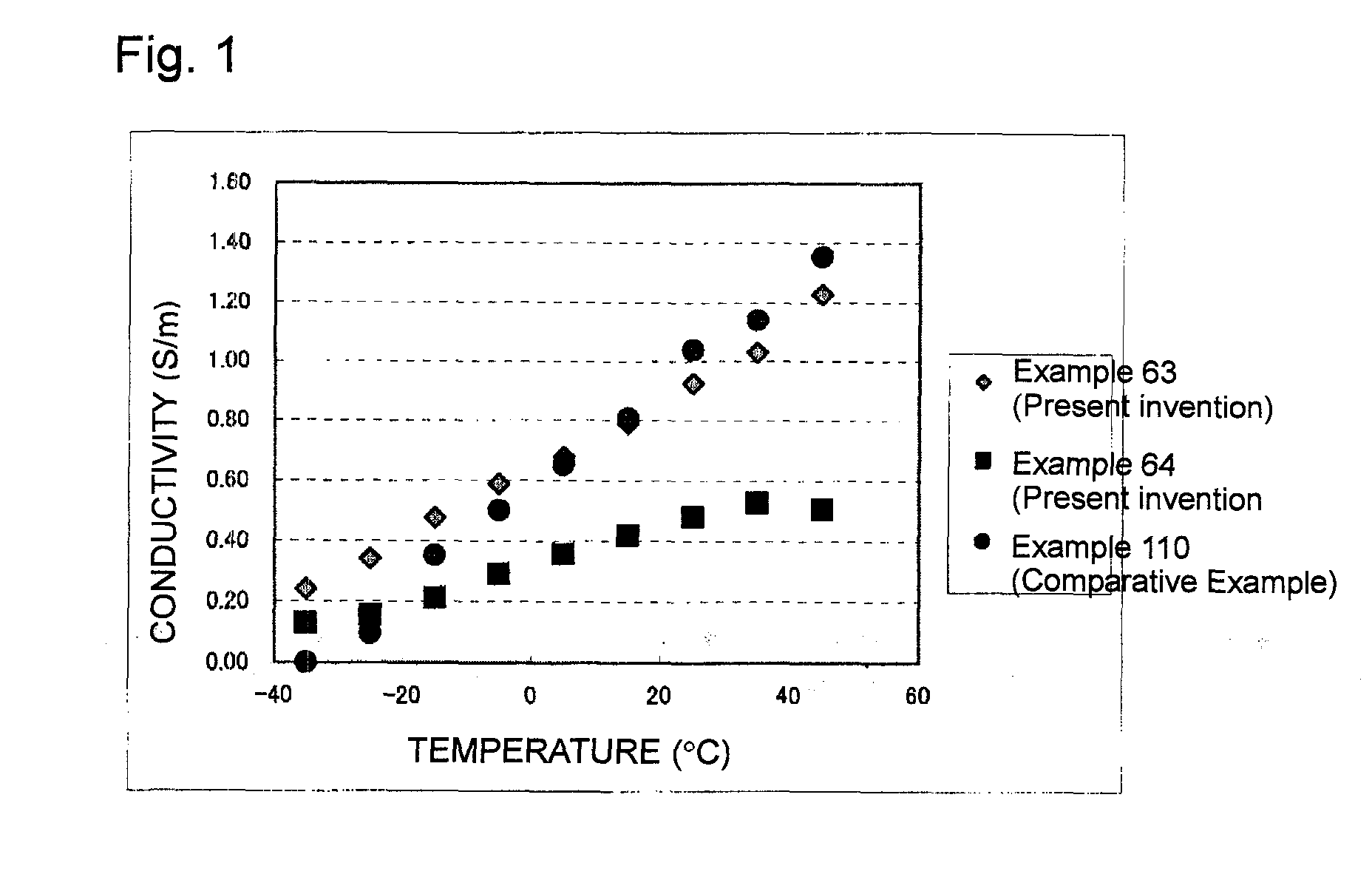

Non-flammable Quasi-Solid Electrolyte and Lithium Secondary Batteries Containing Same

PendingUS20180277913A1Reduce electrical conductivityLow ionic conductivityFuel and secondary cellsCell electrodesSolid state electrolyteCelsius Degree

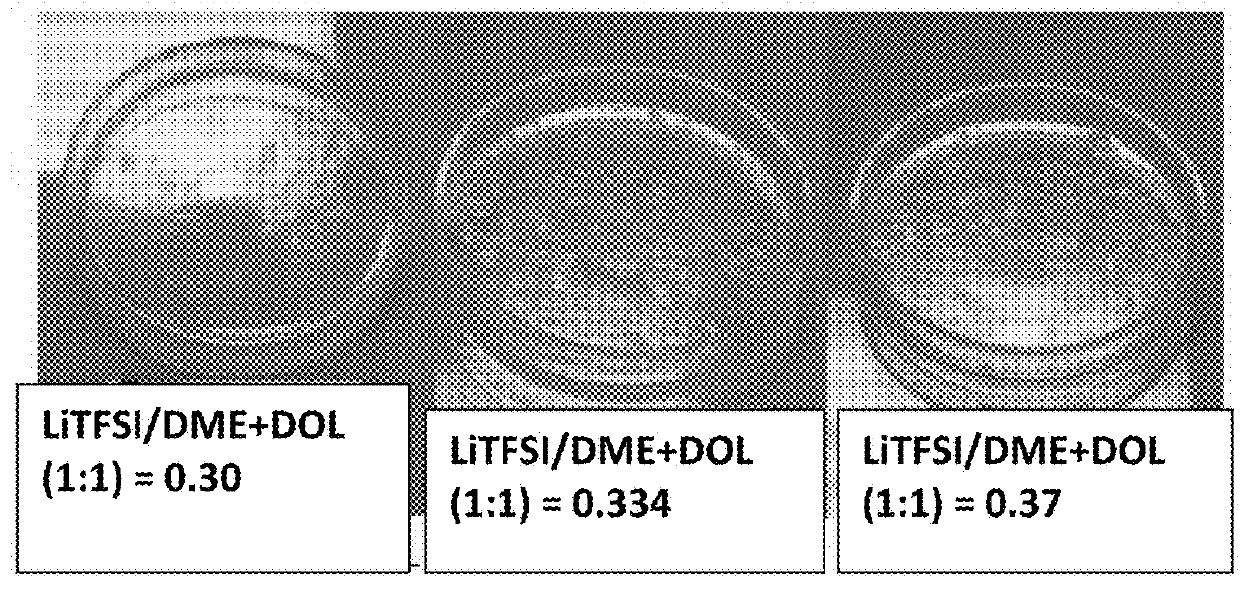

A rechargeable lithium cell comprising a cathode, an anode, a non-flammable quasi-solid electrolyte containing a lithium salt dissolved in a mixture of a liquid solvent and a liquid additive having a salt concentration from 1.5 M to 5.0 M so that said electrolyte exhibits a vapor pressure less than 0.01 kPa, a vapor pressure less than 60% of the vapor pressure of the liquid solvent alone, a flash point at least 20 degrees Celsius higher than the flash point of the liquid solvent alone, a flash point higher than 150° C., or no flash point, wherein the liquid additive is selected from Hydrofluoro ether (HFE), Trifluoro propylene carbonate (FPC), Methyl nonafluorobutyl ether (MFE), Fluoroethylene carbonate (FEC), Tris(trimethylsilyl)phosphite (TTSPi), Triallyl phosphate (TAP), Ethylene sulfate (DTD), 1,3-propane sultone (PS), Propene sultone (PES), Diethyl carbonate (DEC), Alkylsiloxane (Si—O), Alkylsilane (Si—C), liquid oligomeric silaxane (—Si—O—Si—), Tetraethylene glycol dimethylether (TEGDME), or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

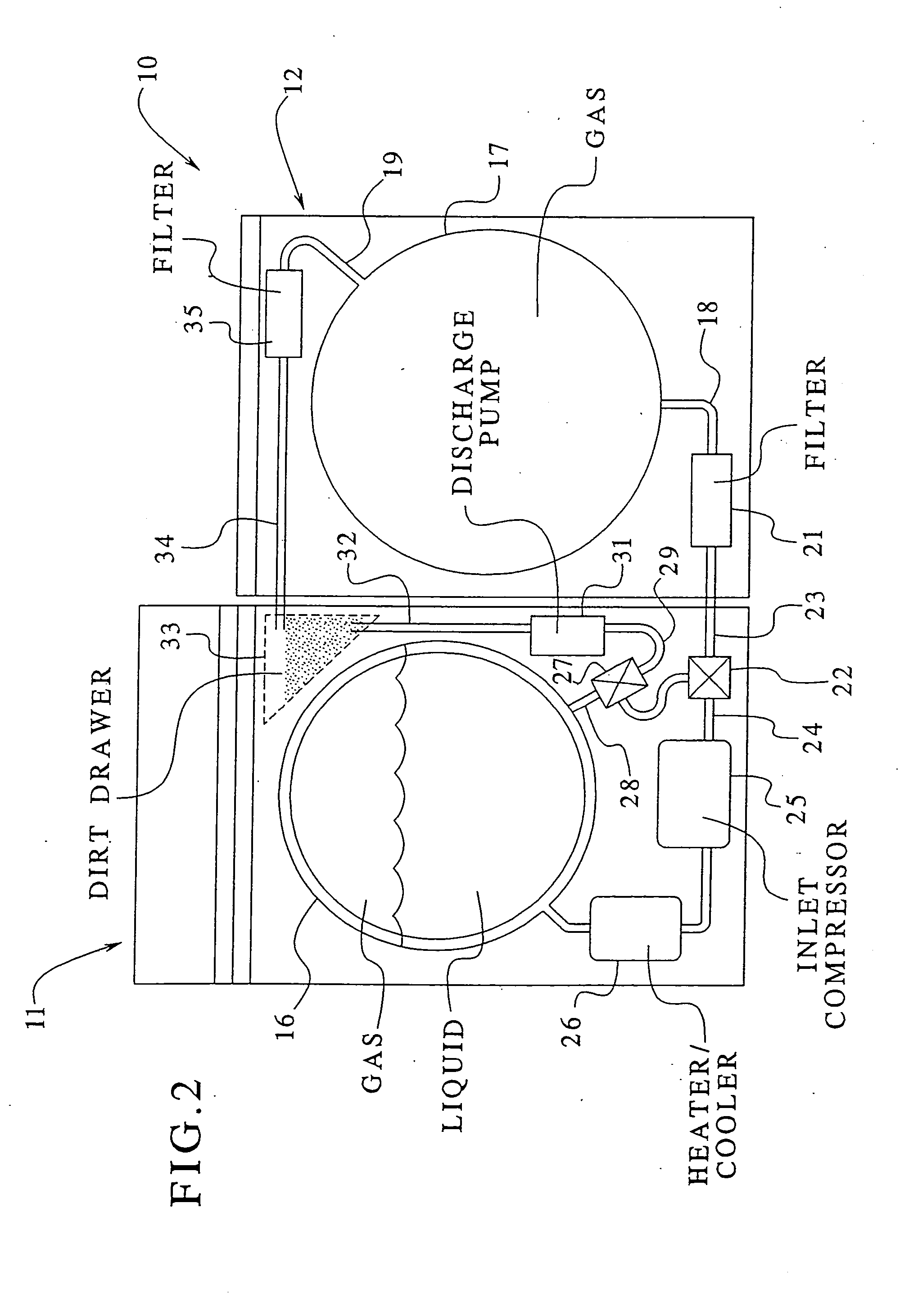

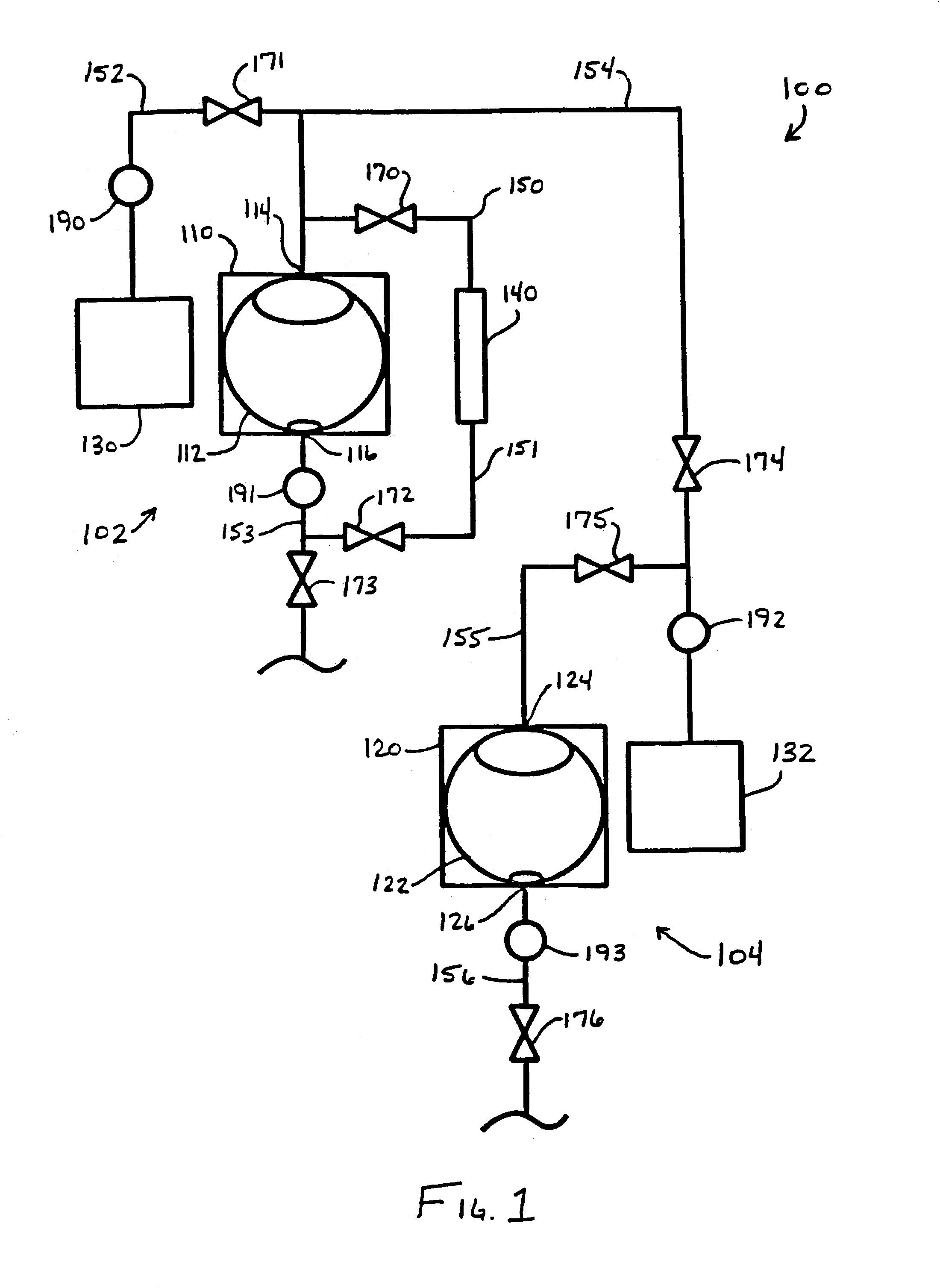

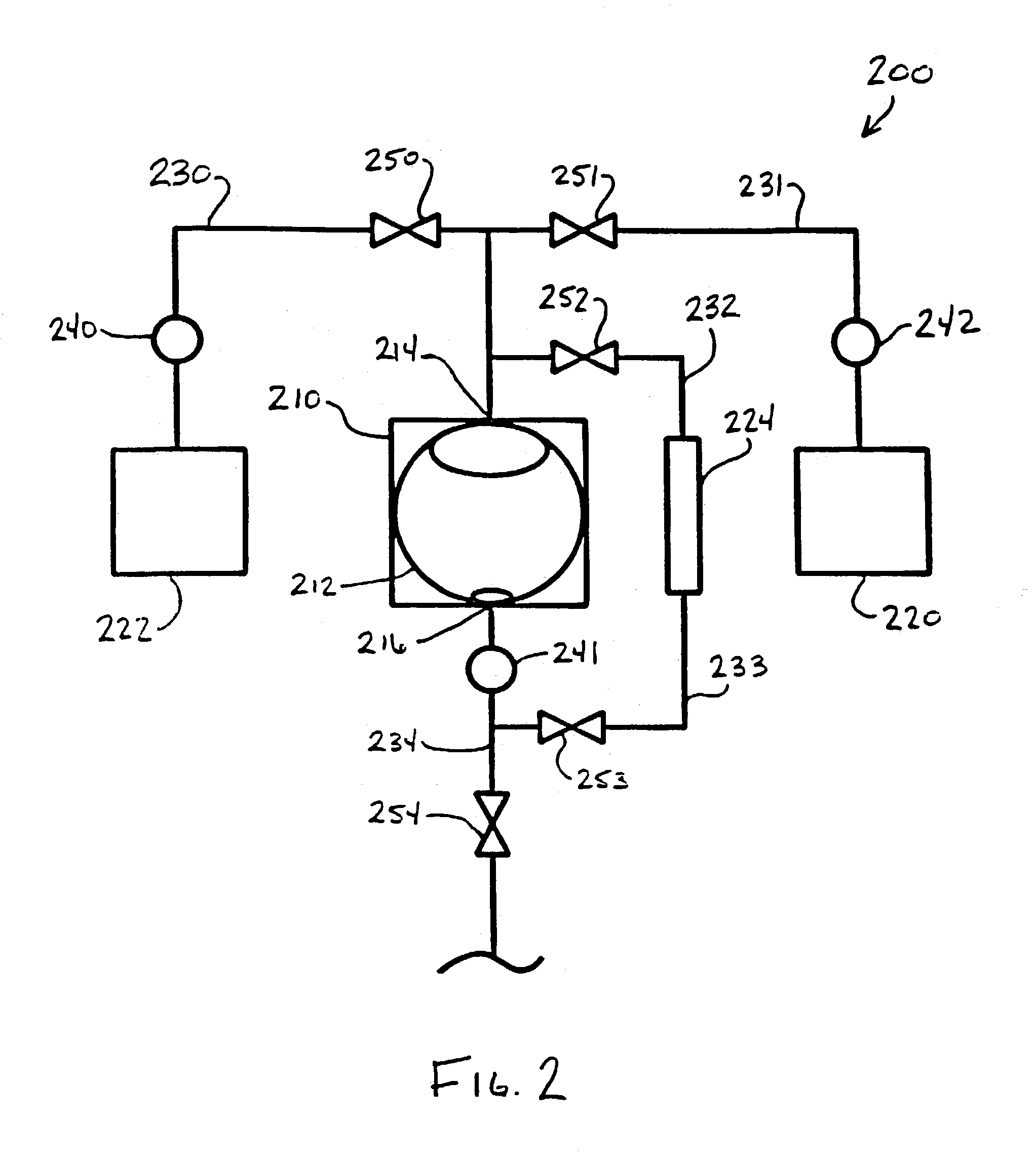

Non-aqueous washing apparatus and method

InactiveUS20050043196A1Low costSave energyOrganic detergent compounding agentsDry-cleaning apparatusWorking fluidMechanical energy

Methods for washing fabric loads without water or using water only as a co-solvent are disclosed. One method of non-aqueous clothes washing includes the steps of disposing clothing in a wash container, delivering a wash liquor to the fabric load, the wash liquor comprising a substantially non-reactive, non-aqueous, non-oleophilic, apolar working fluid and at least one washing additive, applying mechanical energy to the clothing and wash liquor for a sufficient amount of time to provide fabric cleaning and, thereafter, substantially removing the wash liquor from the fabric load. The working fluid may be selected from the group consisting of perfluorocarbons, hydrofluoroethers, fluorinated hydrocarbons and fluoroinerts.

Owner:WRIGHT TREMITCHELL L +2

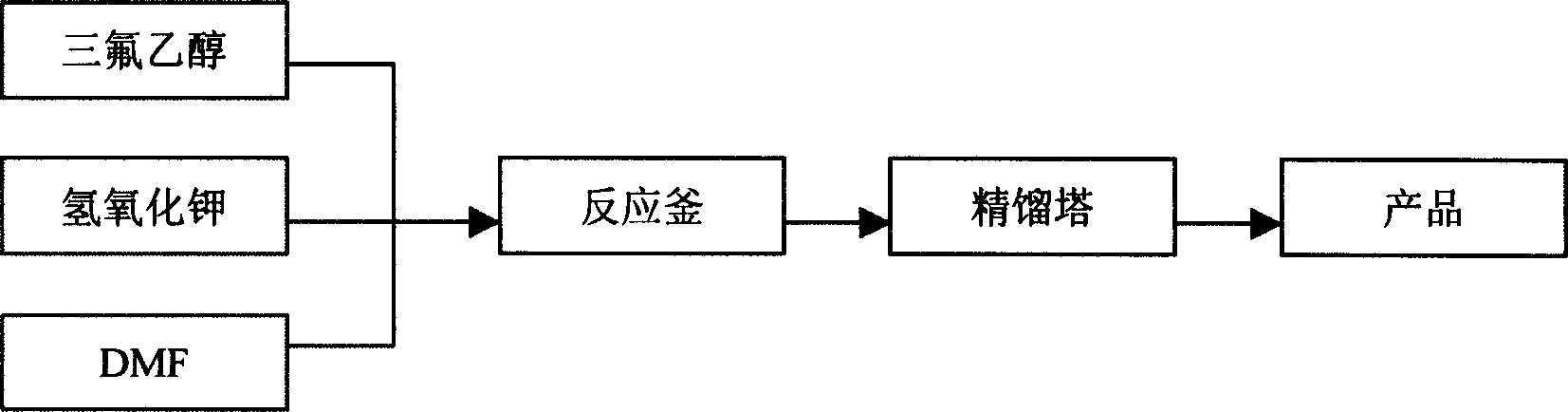

New hydrofluoro ether and its preparation method

InactiveCN1651378AHigh yieldEasy to separate and purifyEther preparationFoaming agentOrganic solvent

A process for preparing hydrofluoroether features the reaction between one of trifluoroethene, tetrafluoroethene, hexafluoro propene, etc and one of trifluoroethanol, trifluoropropanol, metanol, etc in organic solvent (DMF or DMSO). Its advantages are high output rate and easy purifying and separating.

Owner:大连振邦氟涂料股份有限公司

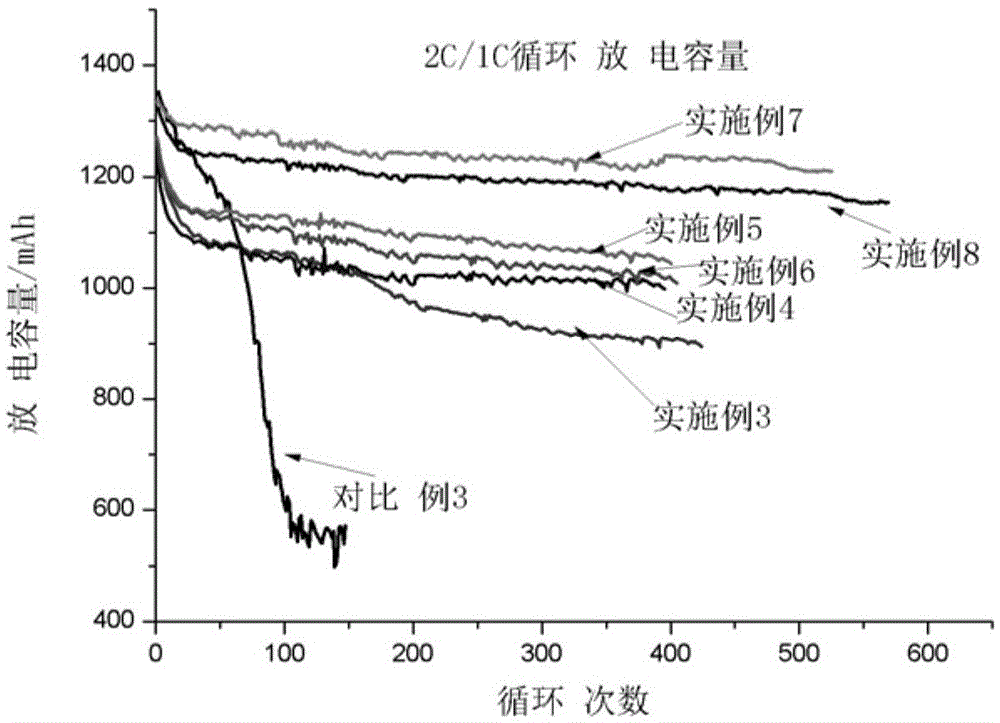

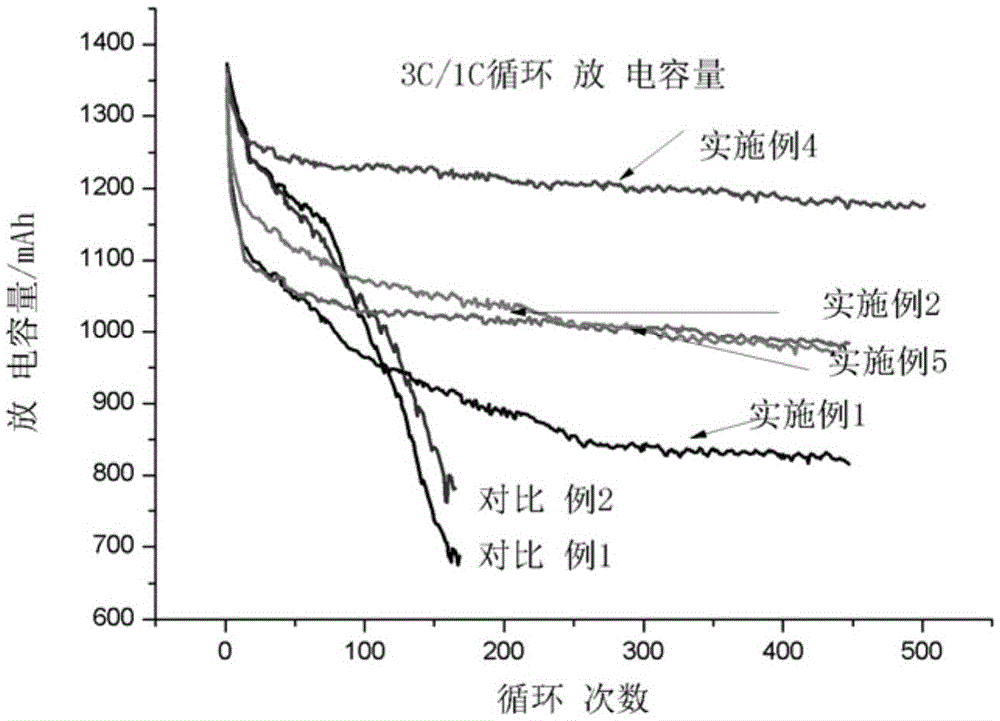

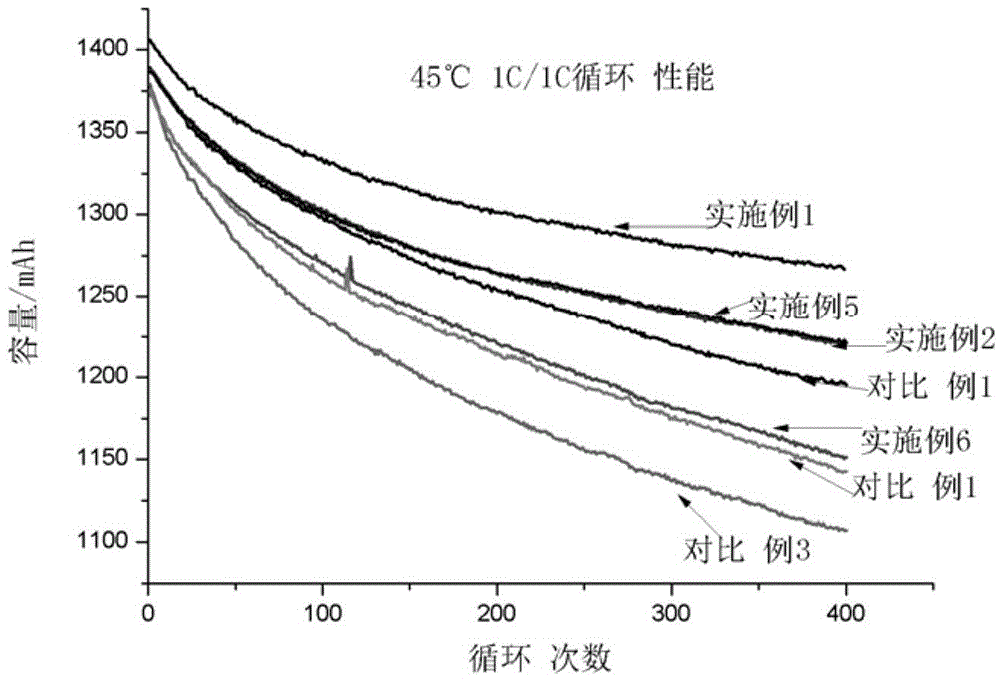

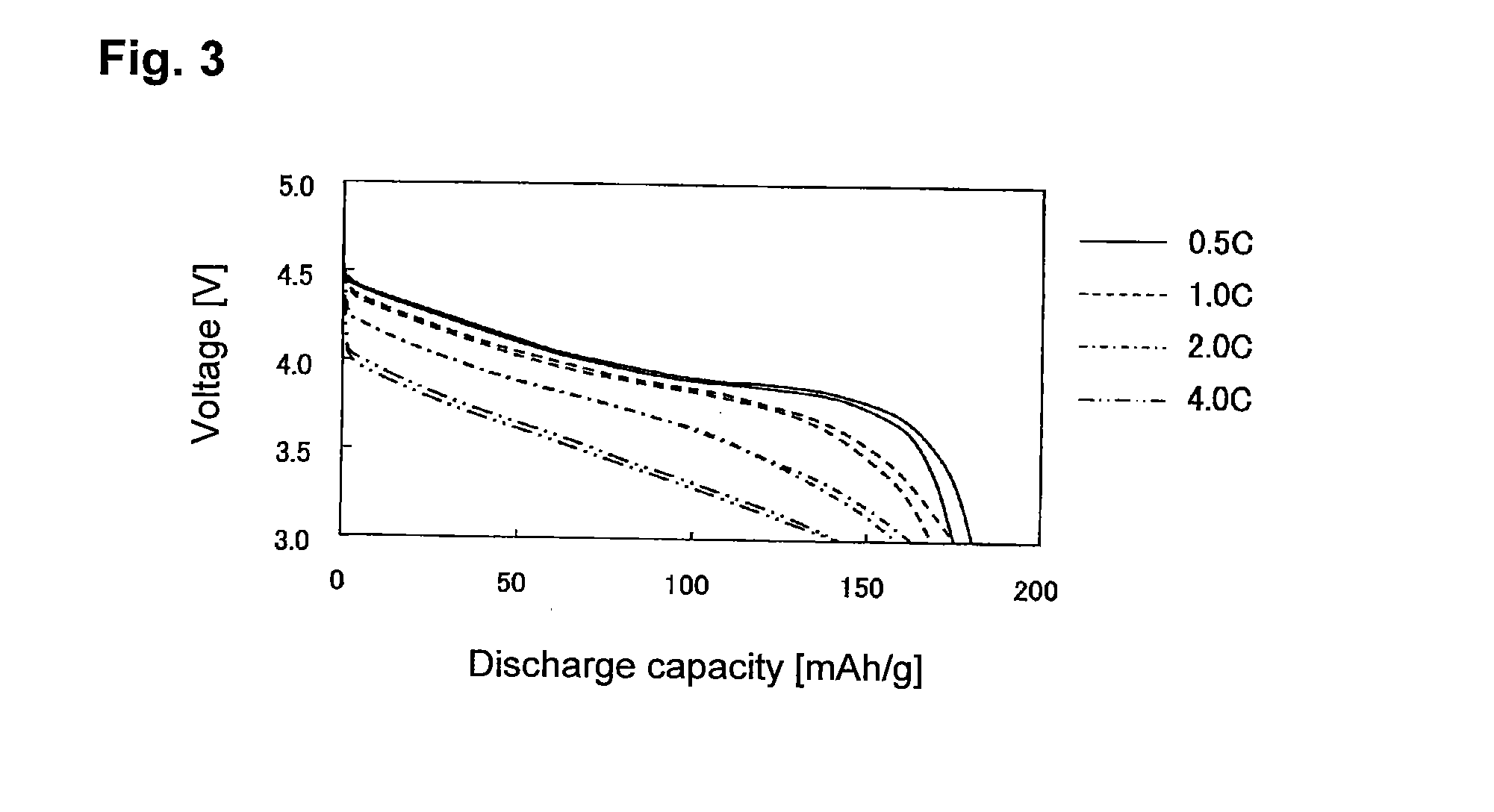

Electrolyte of rapid-charging lithium ion battery

InactiveCN105552439AImprove dynamic performanceGood film formingSecondary cellsElectrolytesOrganic solventBoiling point

The invention relates to technical field of a lithium ion battery, in particular to an electrolyte of a rapid-charging lithium ion battery. The electrolyte comprises a solvent, a lithium salt and an additive, wherein the solvent contains more than two mixtures of linear carbonic ester with a low boiling point, linear carboxylic ester, fluorobenzene and hydrofluoroether, and the additive comprises a first additive for negative electrode film forming, a second additive for improving the cycle performance of the battery and a third additive for improving the high-temperature performance of the battery. Compared with the prior art, the organic solvent and the three additives are used in a combination way to generate a synergistic effect, the rapid charging demand of a high-potential, high-compaction-density and more than 2C rapid-charging system battery with a voltage of 4.35V and negative electrode compaction density of over 1.6g / cm<3> can be met, and meanwhile, the electrolyte has favorable cycle performance and high- and low-temperature performance.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Dampening fluid for digital lithographic printing

Owner:XEROX CORP

Method for preserving organs or limbs using a composition containing a siloxane and a semifluorinated alkane and/or hydrofluoroether

Owner:NOVALIQ GMBH

Emulsifier free aqueous emulsion polumerization process for making fluoropolymers

Emulsifier free fluoropolymer manufacturing method in which (a) a chain transfer agent, or a mixture of chain transfer agents are used wherein the chain transfer agents do not yield more than 0.4 weight % relative to the monomer feed of water soluble fluorinated compounds, or (b) a chain transfer agent or a mixture of chain transfer agents selected from alkanes, dialkyl ethers, hydrofluoroethers and / or hydrofluorocarbons.

Owner:3M INNOVATIVE PROPERTIES CO

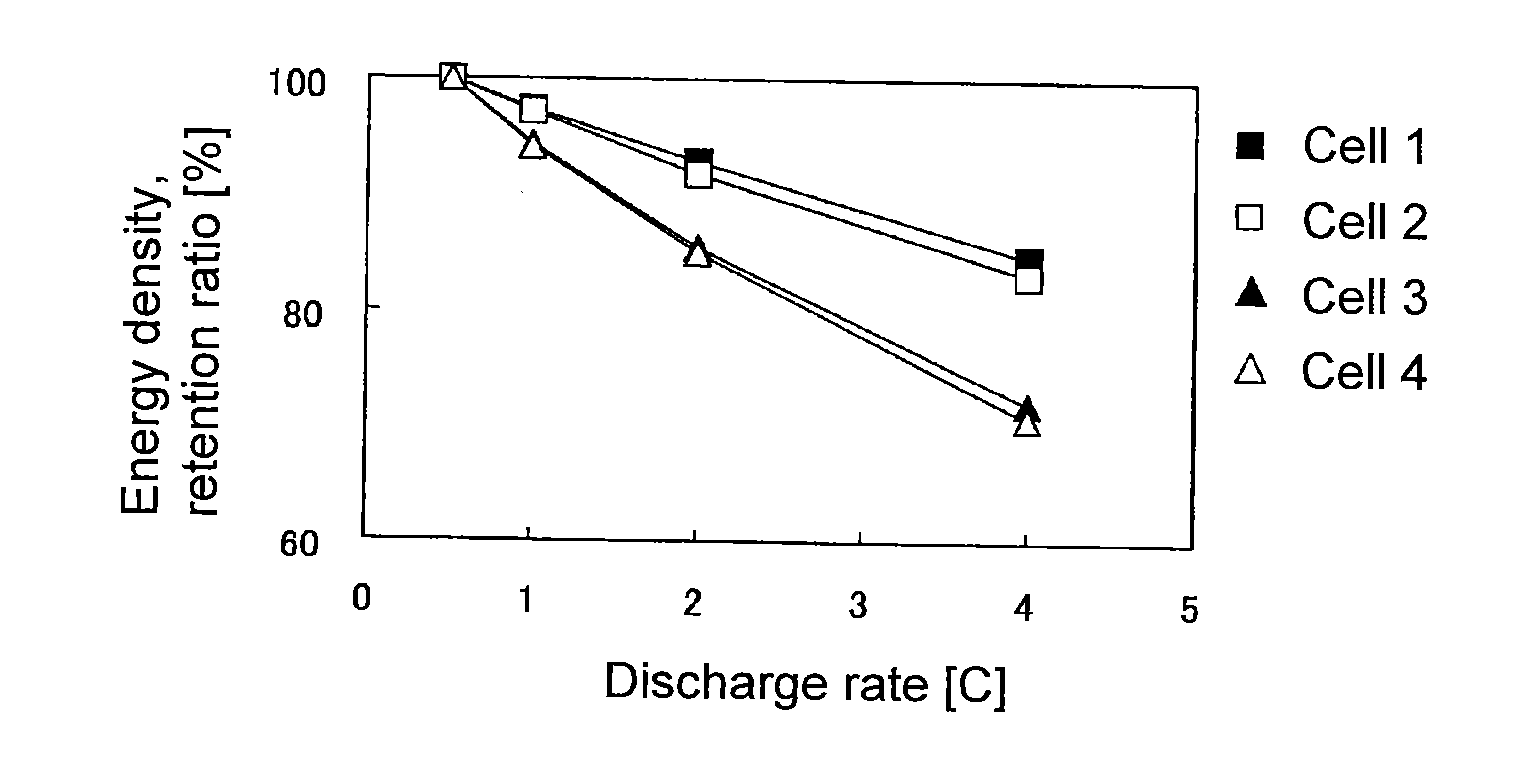

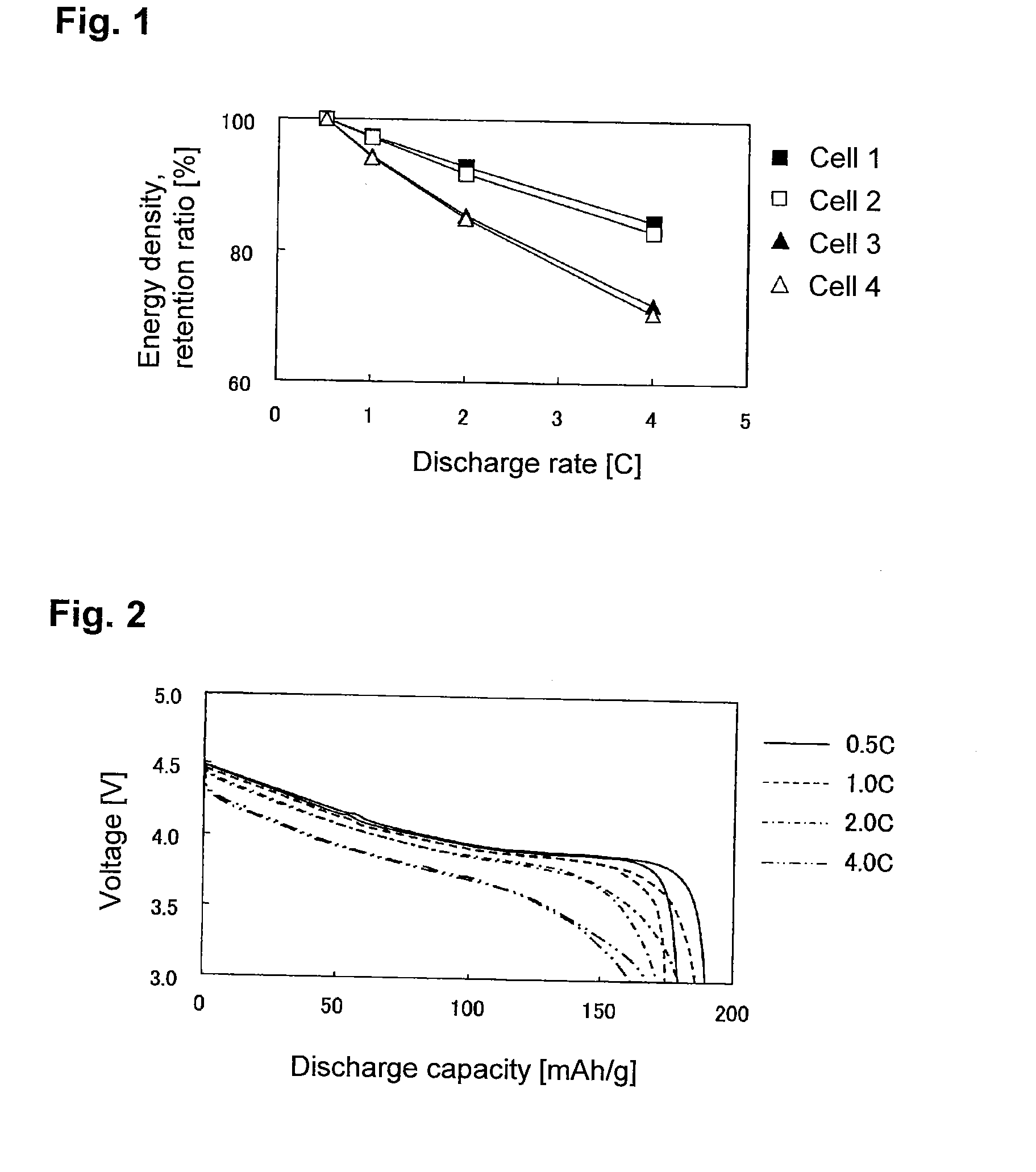

Nonaqueous electrolyte for secondary cell, and secondary cell

InactiveUS20110020700A1Reduce erosionGood low temperature characteristicsLi-accumulatorsVehicular energy storageMetallic lithiumElectrolytic agent

Provided are a nonaqueous electrolyte for a secondary cell, and a secondary cell, which are free from erosion of electrodes or generation of carbon dioxide gas and which have a long-term nonflammability, an excellent low-temperature characteristic and a practically sufficient conductivity.A nonaqueous electrolyte for a secondary cell, which comprises a lithium salt, a specific hydrofluoroether and a specific glyme type solvent. A secondary cell comprising such a nonaqueous electrolyte for a secondary cell, a negative electrode made of a material capable of storing or discharging lithium ions electrochemically, or metal lithium or a lithium alloy, and a positive electrode made of a material capable of storing or discharging lithium ions electrochemically.

Owner:ASAHI GLASS CO LTD

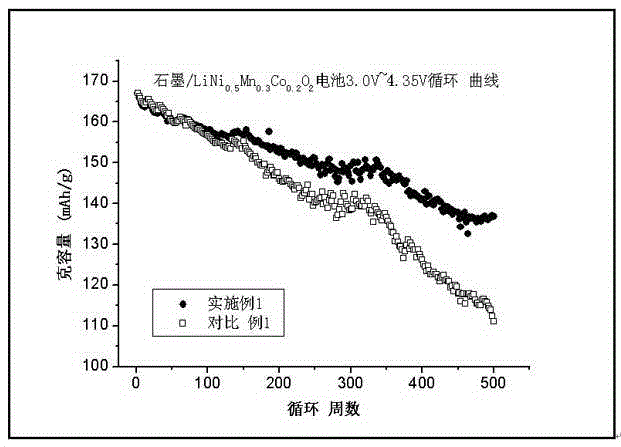

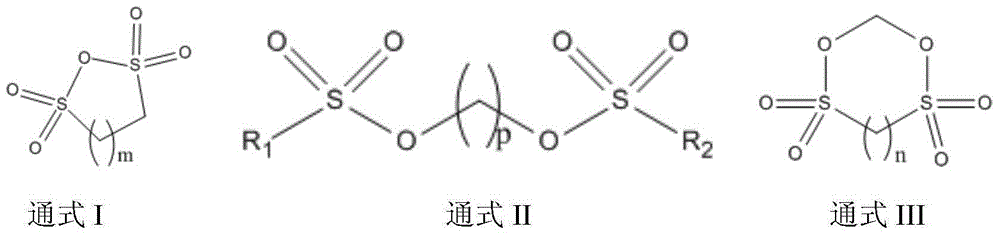

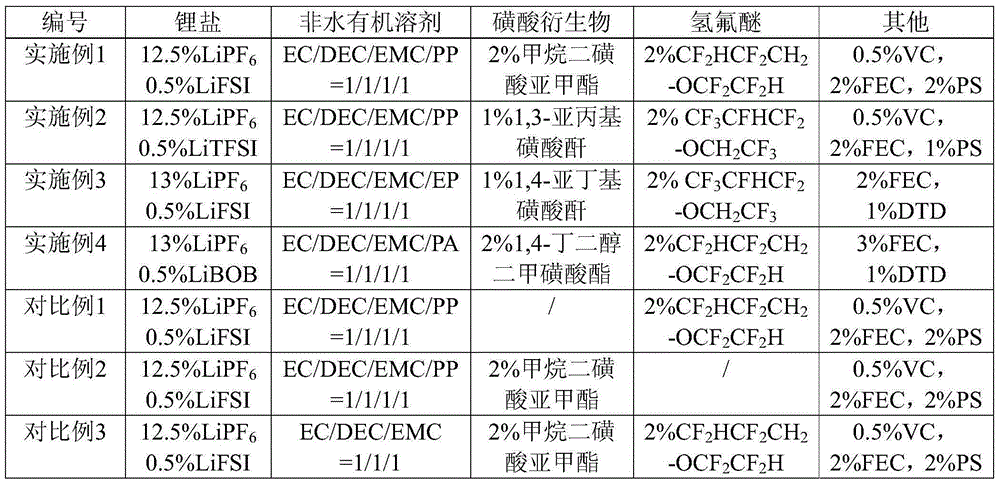

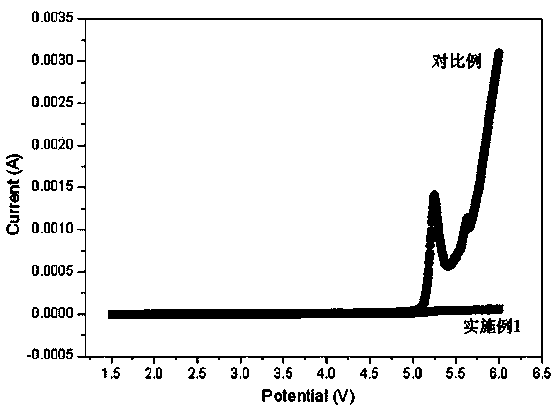

High-voltage lithium-ion battery electrolyte and lithium-ion battery using high-voltage lithium-ion battery electrolyte

InactiveCN105186032AImprove conductivityImprove wettabilitySecondary cellsHigh temperature storageOrganic solvent

The invention discloses high-voltage lithium-ion battery electrolyte and a lithium-ion battery using the high-voltage lithium-ion battery electrolyte. The lithium-ion battery electrolyte is prepared from a nonaqueous organic solvent, a lithium salt and an additive, and is characterized in that the nonaqueous organic solvent comprises a carbonic ester solvent and a carboxylic ester solvent which accounts for 5 to 50 percent of the mass of the electrolyte; the additive comprises a hydrofluoroether compound and at least one of sulfonic acid derivative from a cyclic disulfonic anhydrid, chain disulfonate, and cyclic disulfonate shown in a general formula I, a general formula II and a general formula III. The electrolyte is prepared by taking carboxylic ester of low viscosity and good wettability as one of the main solvents, and taking the sulfonic acid derivative of good film-forming property and the hydrofluoroether of good oxidative resistance as the functional additives, thus the formed lithium-ion battery electrolyte has the multiple advantages such as good electrode / electrolyte interface compatibility, strong oxidative resistance, high electric conductivity and wide liquid path range. The lithium-ion battery prepared by using the lithium-ion battery electrolyte is high in specific energy, less in gas yield of high-temperature storage, and long in cycle life.

Owner:GUANGZHOU TINCI MATERIALS TECH

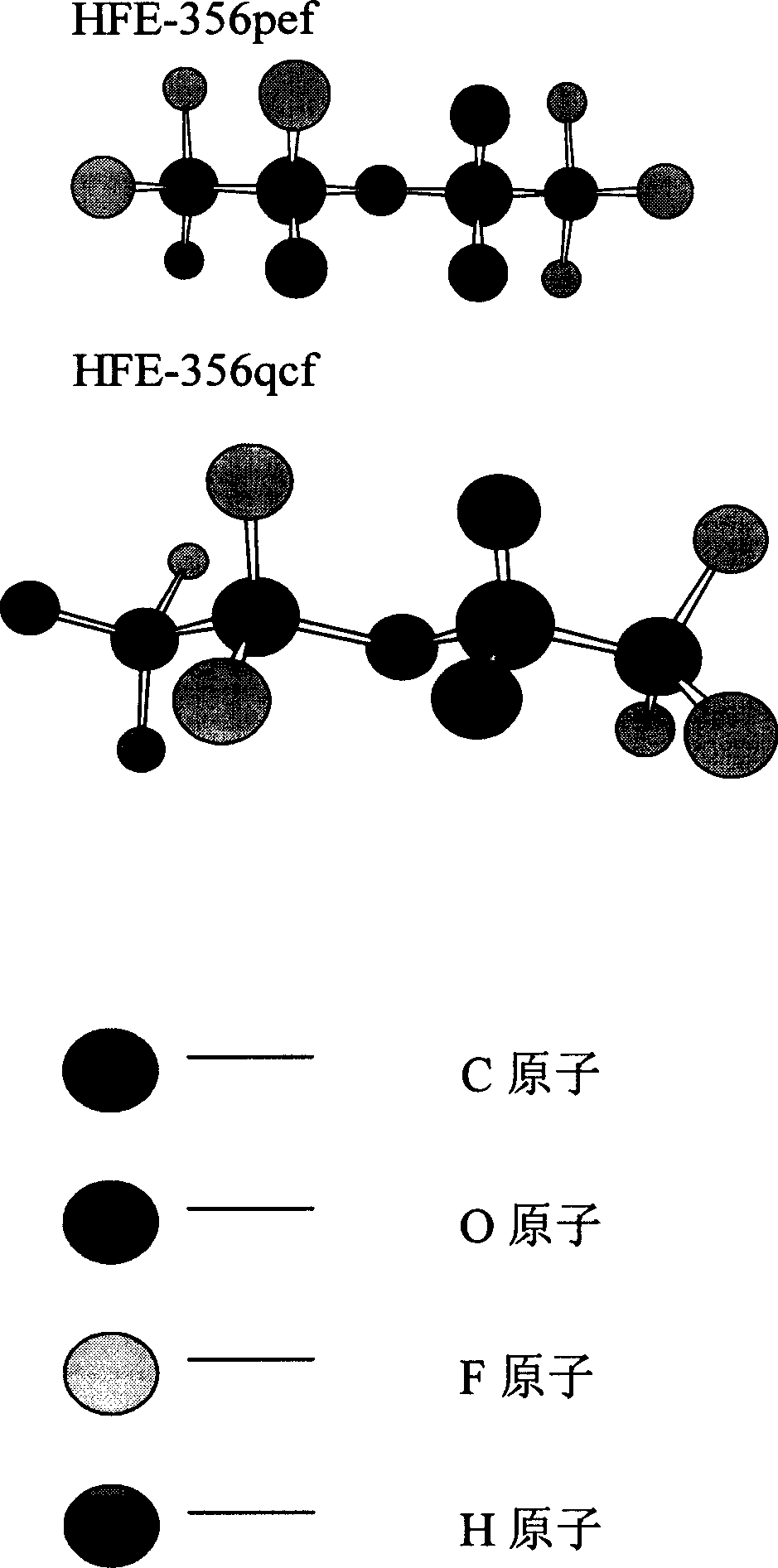

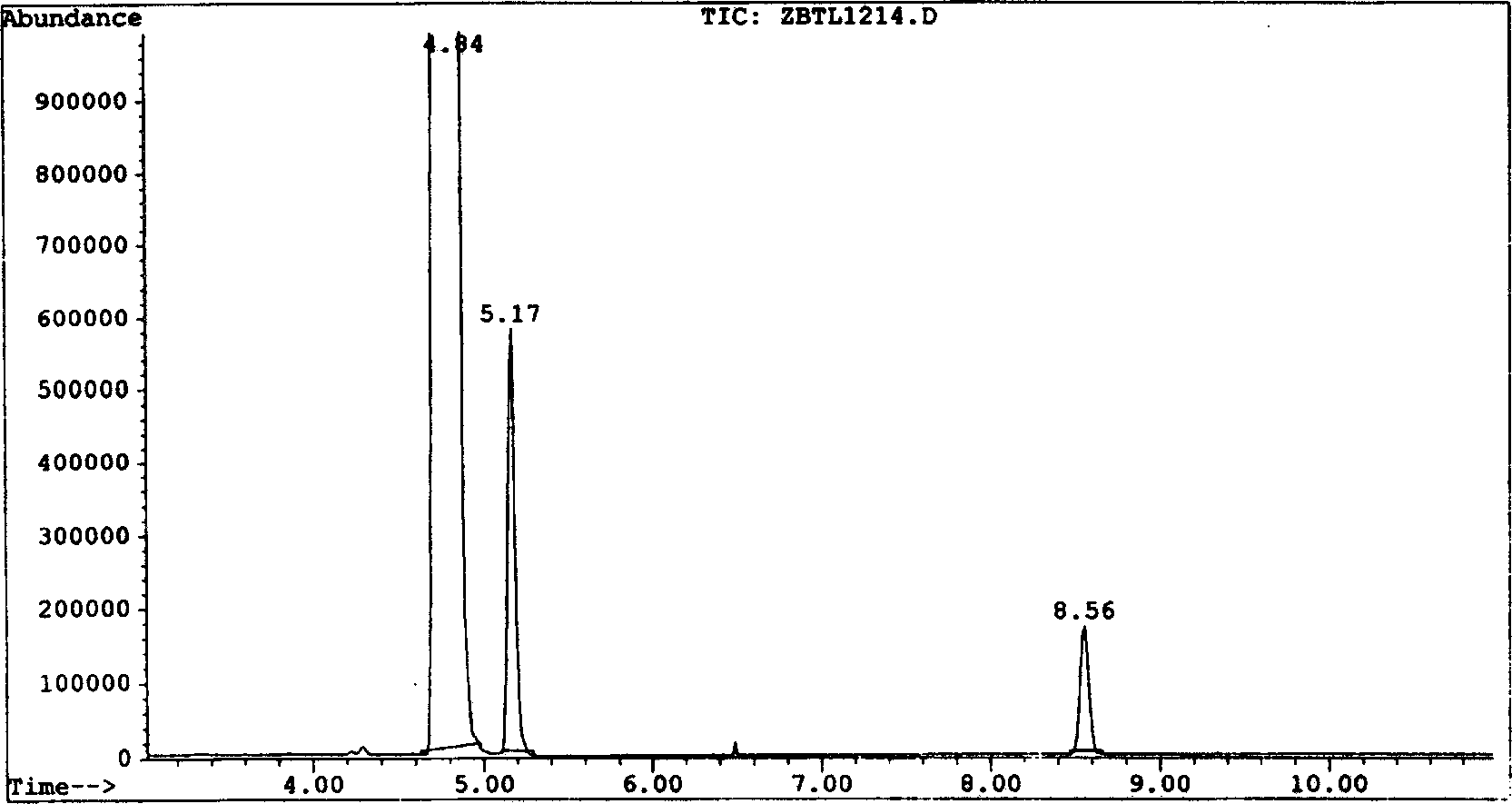

Preparation method of hydrofluoroether

ActiveCN103254041AMild reaction conditionsEasy to operateEther preparation by compound additionHydrofluoroetherReactions stress

The invention discloses a preparation method of hydrofluoroether. The preparation method comprises the following steps of: mixing a solvent, a catalyst, olefin and alcohol to have reaction, wherein the mole ratio of the solvent to the alcohol is (1-6):1, the mole ratio of the catalyst to the alcohol is (0.01-0.15):1, the mass ratio of the olefin to the alcohol is (0.5-5):1, the reaction temperature is 20-60 DEG C, the reaction pressure is 0.05-0.6MPa, and the reaction time is 0.5-3 hours; and rectifying after the reaction is accomplished, so as to obtain a hydrofluoroether product. The preparation method has the advantages that the reaction condition is gentle, the operation is simple, products are easy to separate, and less wastewater, waste gas and waste residue are discharged.

Owner:JUHUA GROUP TECH CENT

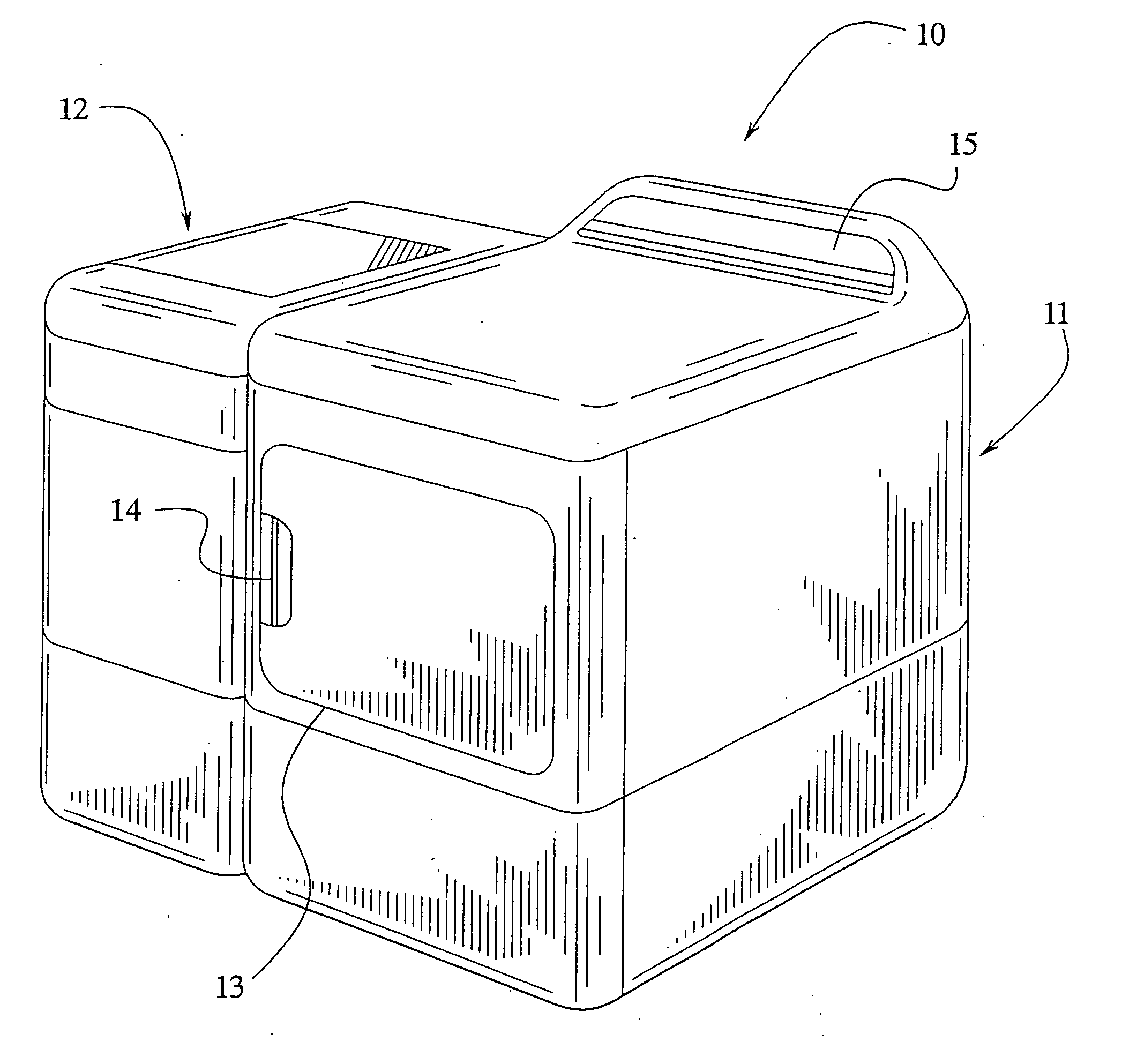

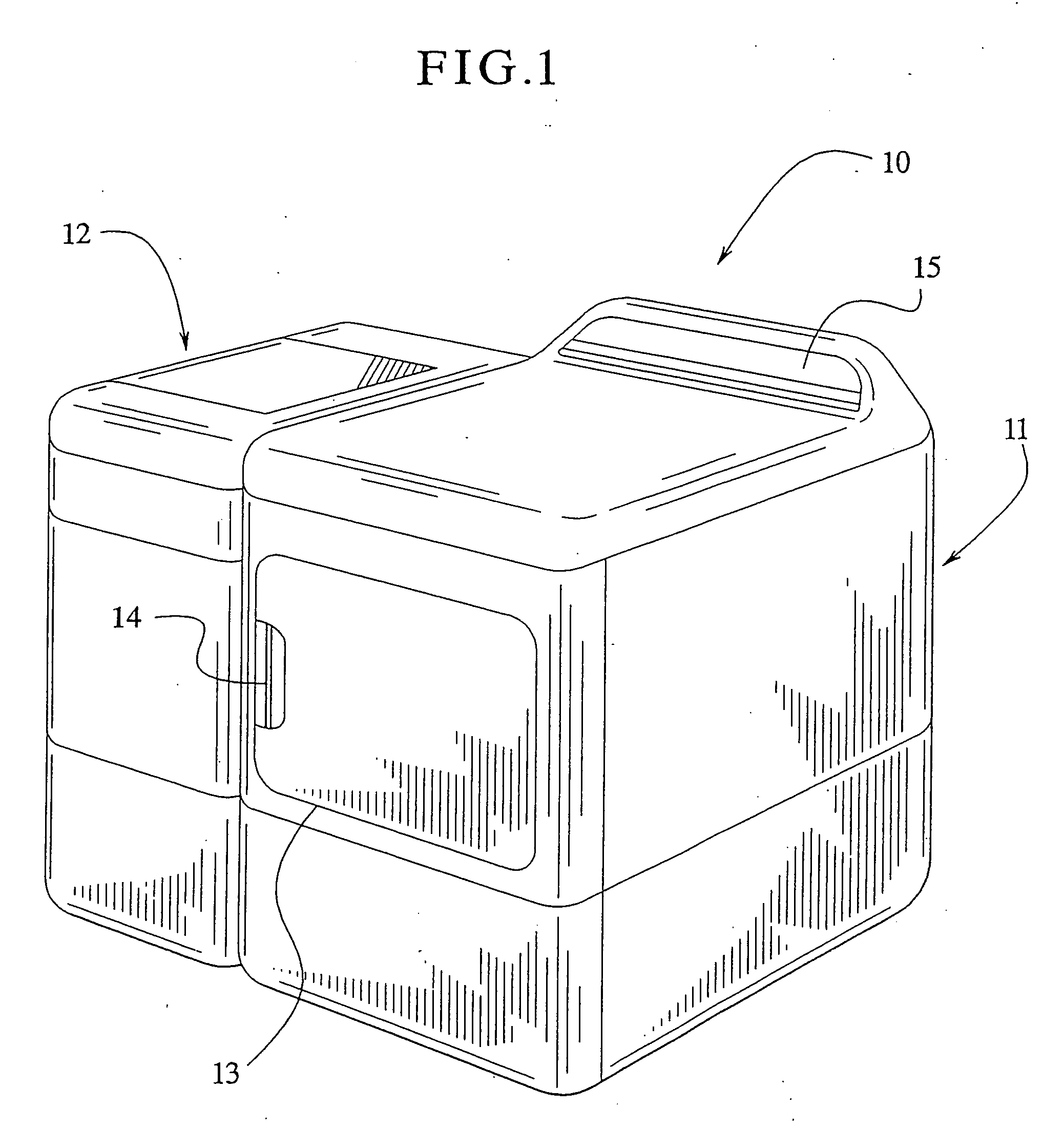

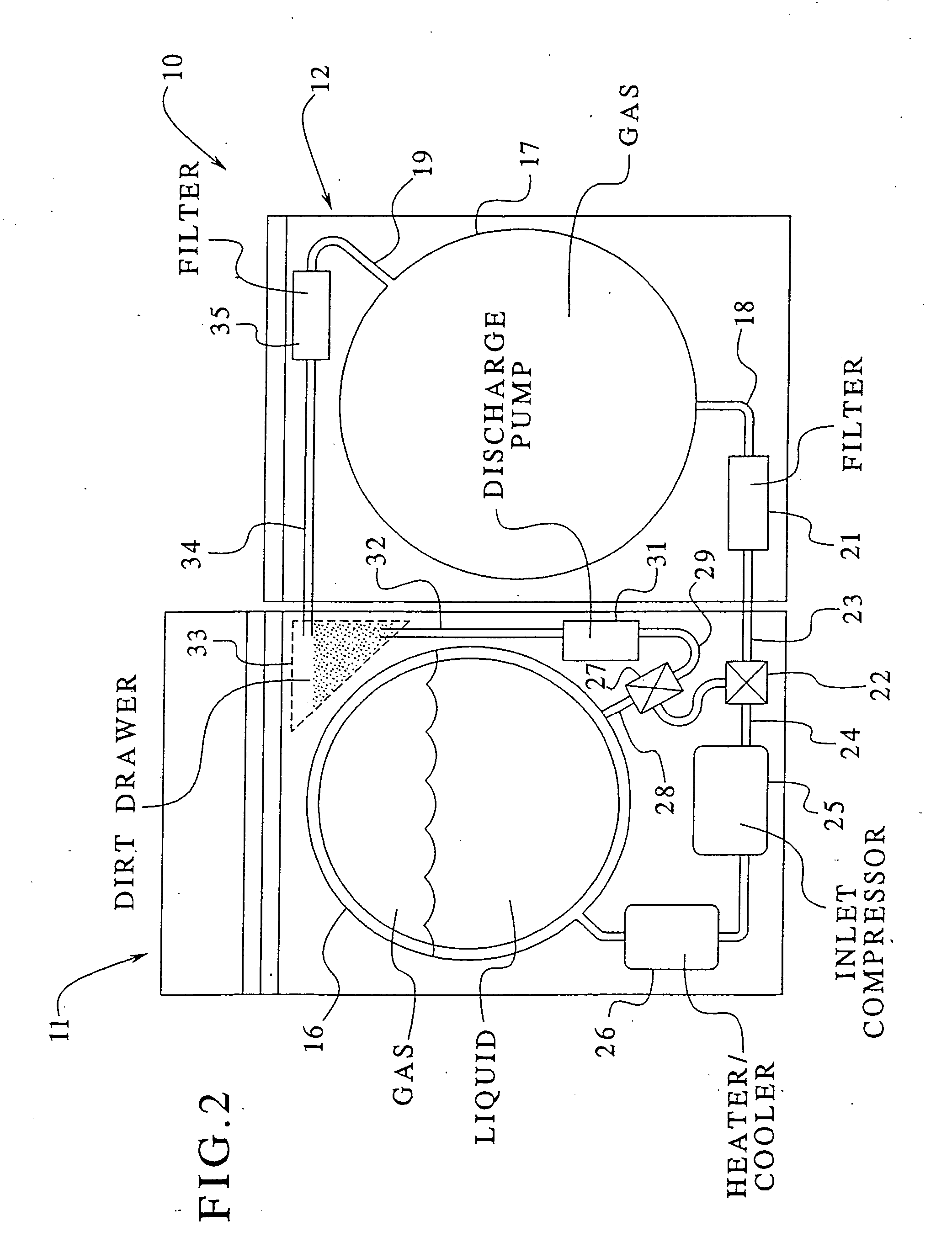

Non-aqueous washing apparatus and method

InactiveUS20050071928A1Low costSave energyDry-cleaning apparatusDetergent mixture composition preparationWorking fluidMechanical energy

Methods for washing fabric loads without water or using water only as a co-solvent are disclosed. One method of non-aqueous clothes washing includes the steps of disposing clothing in a wash container, delivering a wash liquor to the fabric load, the wash liquor comprising a substantially non-reactive, non-aqueous, non-oleophilic, apolar working fluid and at least one washing additive, applying mechanical energy to the clothing and wash liquor for a sufficient amount of time to provide fabric cleaning and, thereafter, substantially removing the wash liquor from the fabric load. The working fluid may be selected from the group consisting of perfluorocarbons, hydrofluoroethers, fluorinated hydrocarbons and fluoroinerts.

Owner:WHIRLPOOL CORP

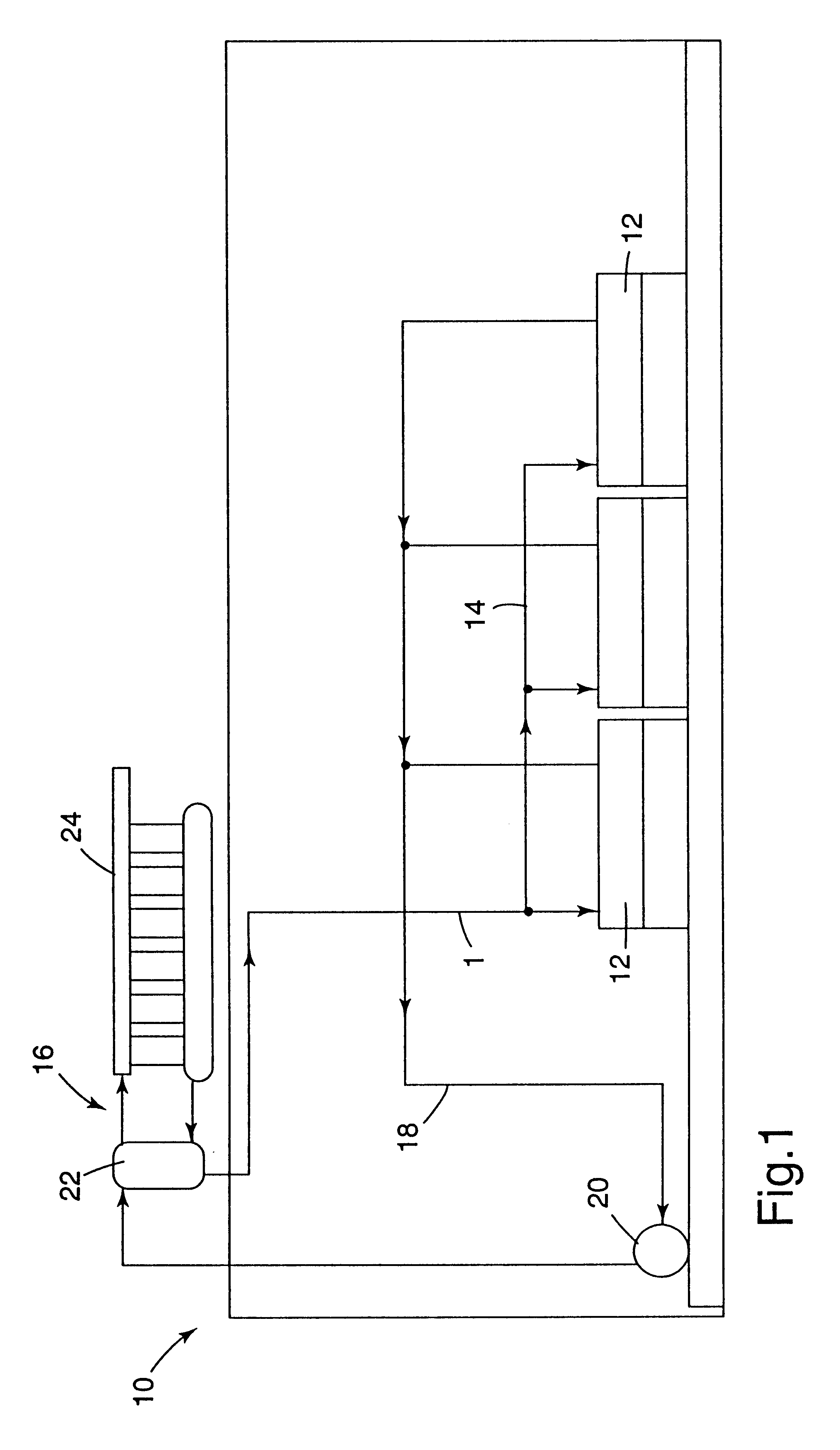

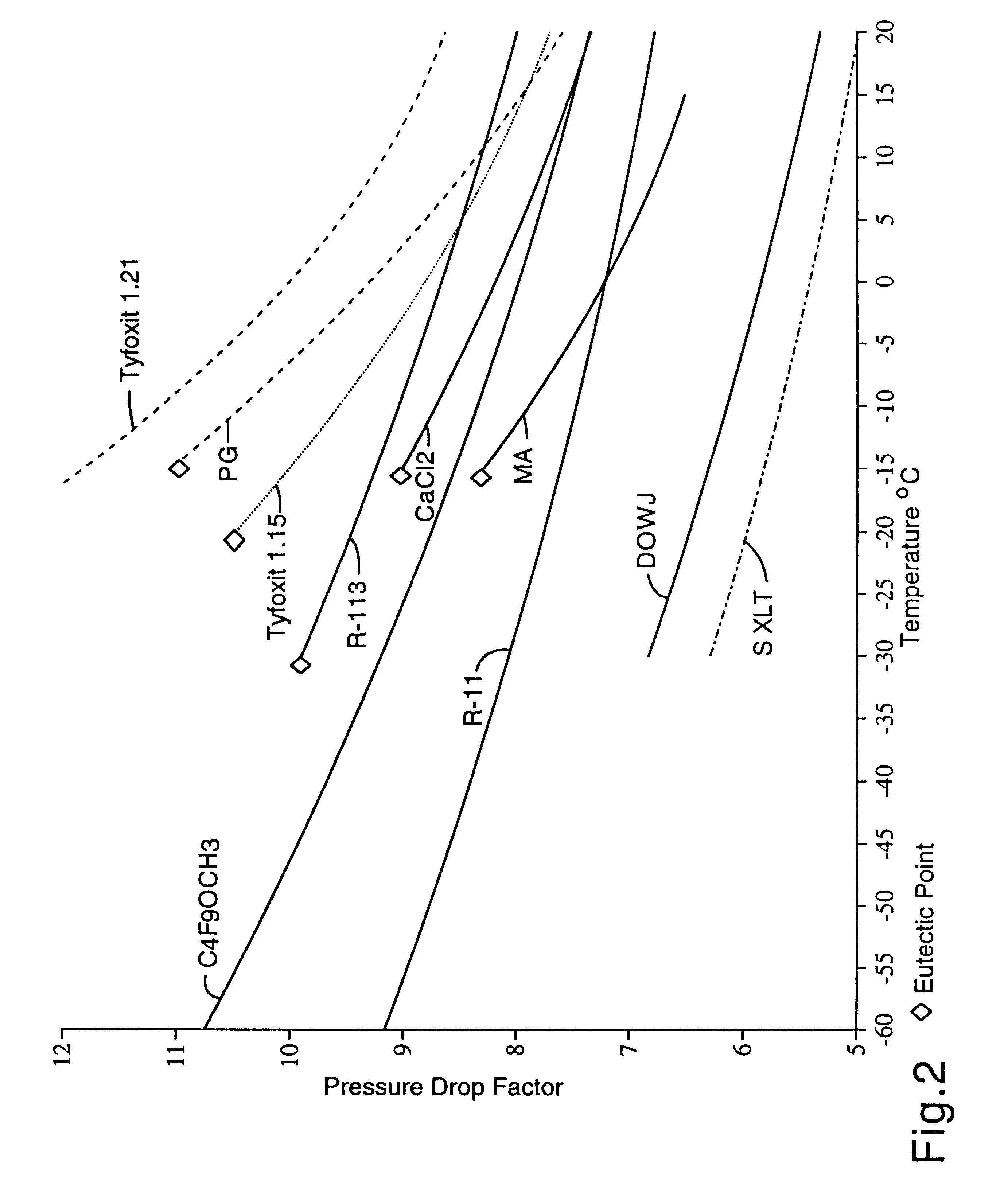

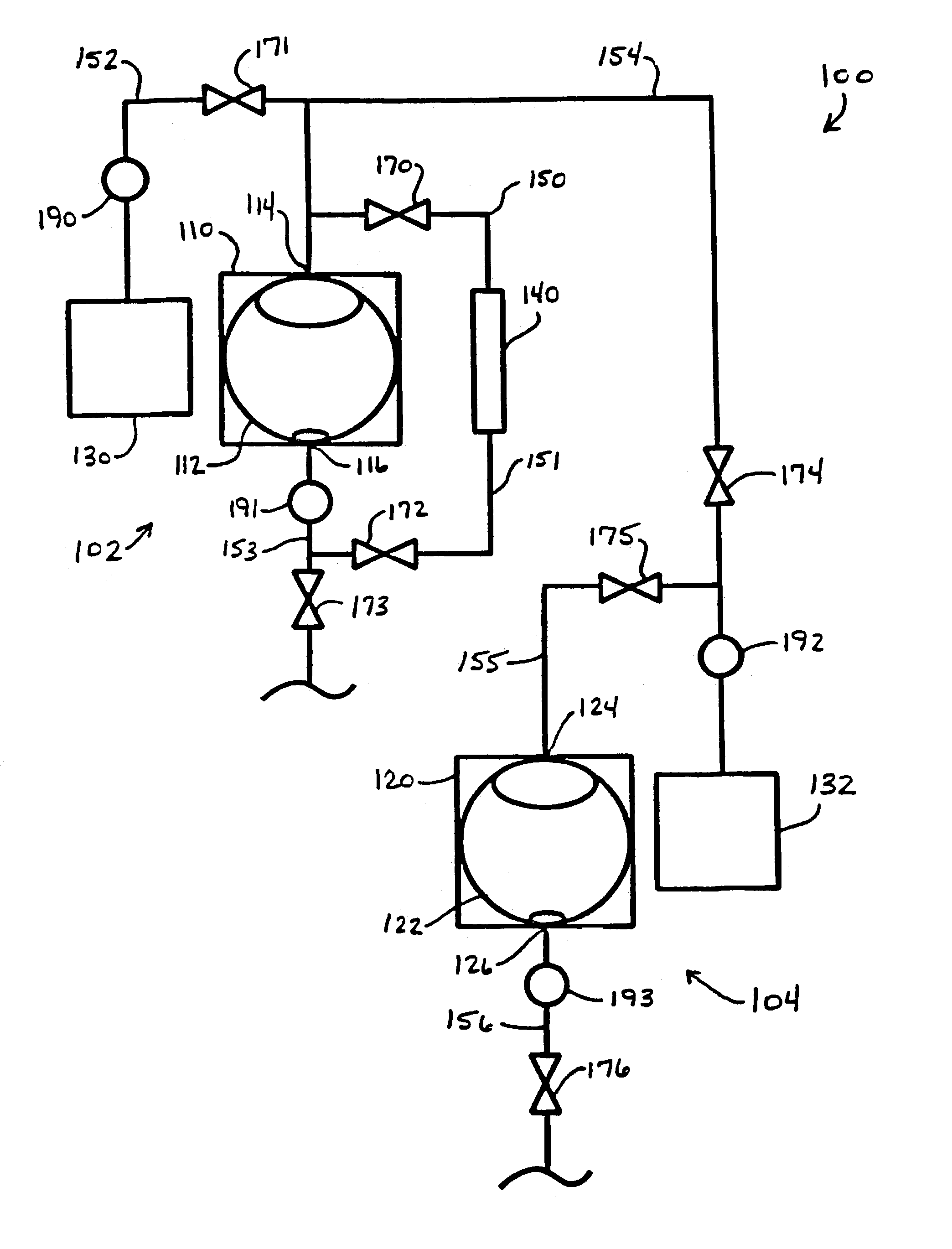

Hydrofluoroethers as low temperature refrigerants

InactiveUSRE37119E1Low and somewhat linear Temperature Difference FactorImprove heat transfer performanceCompression machinesHeat-exchange elementsEngineeringHydrofluoroether

A method and apparatus are provided for using certain hydrofluoroethers (HFEs) as low temperature heat transfer media in secondary loop refrigeration systems. These materials exhibit a low, somewhat linear Temperature Difference Factor over the temperature range of -15° C. to -65° C., making them ideal for use as low temperature heat transfer media. The HFEs of the present invention are nonflammable, nontoxic, environmentally benign, and have a high heat transfer capacity and low viscosity over the required operating temperatures. Furthermore, since these materials have high boiling points and low freezing points, they are not prone to phase changes over the required operating temperatures, and do not require pressurized systems.

Owner:3M INNOVATIVE PROPERTIES CO

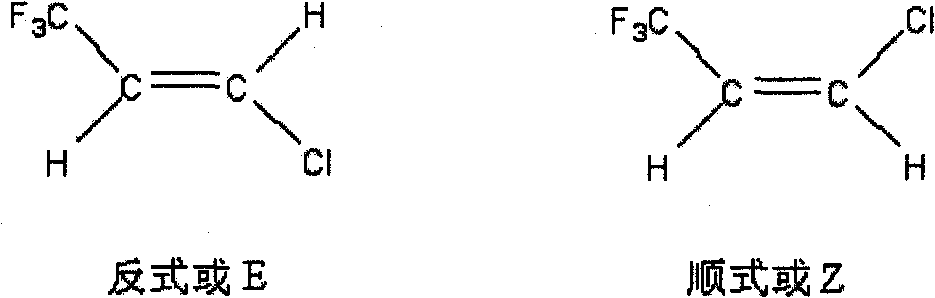

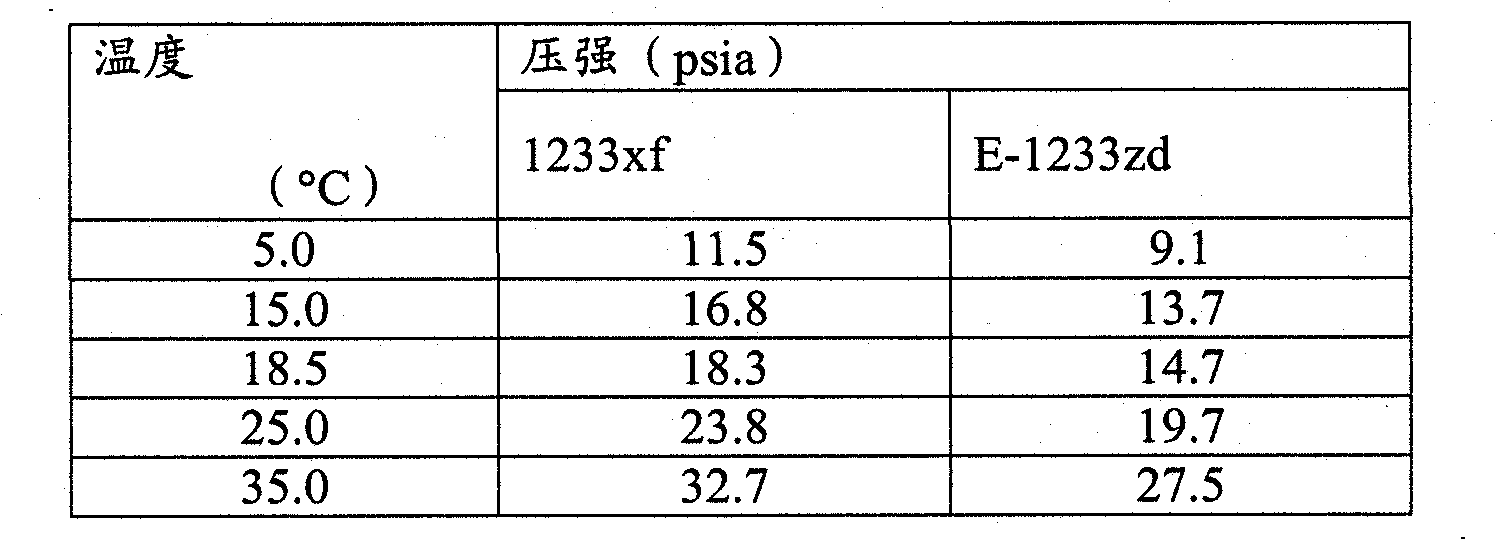

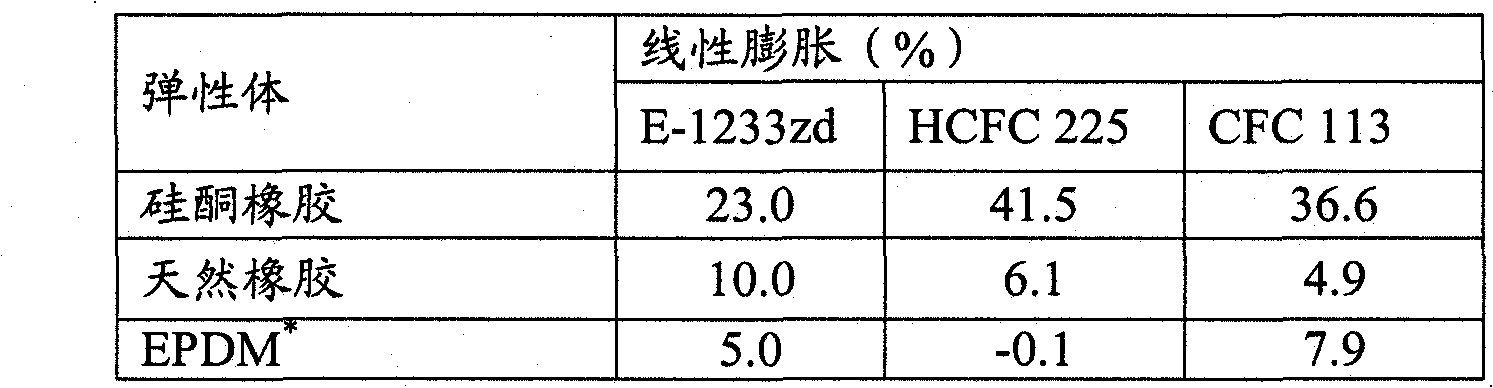

Compositions of hydrochlorofluoroolefins

The present invention relates to solvent / cleaner and heat transfer fluid compositions comprising at least one hydrochlorofluoroolefin (HCFO), 1-chloro-3, 3,3-trifluoropropene (HCFO-1233zd), particularly the trans- isomer. The HCFO of the present invention can be used in combination with co-agents including, hydrofluorocarbons (HFCs), hydrofluoroolefins (HFOs), hydrocarbons, ethers including hydrofluoroethers (HFEs), esters, ketones, alcohols, 1,2-transdichloroethylene and mixtures thereof.

Owner:ARKEMA FRANCE SA

Process for preparing hydrofluoroethers

InactiveUS6023002AFurther reactionAchieve efficiencyOrganic compound preparationEther preparation by compound additionEtherHydrofluoroether

Owner:3M INNOVATIVE PROPERTIES CO

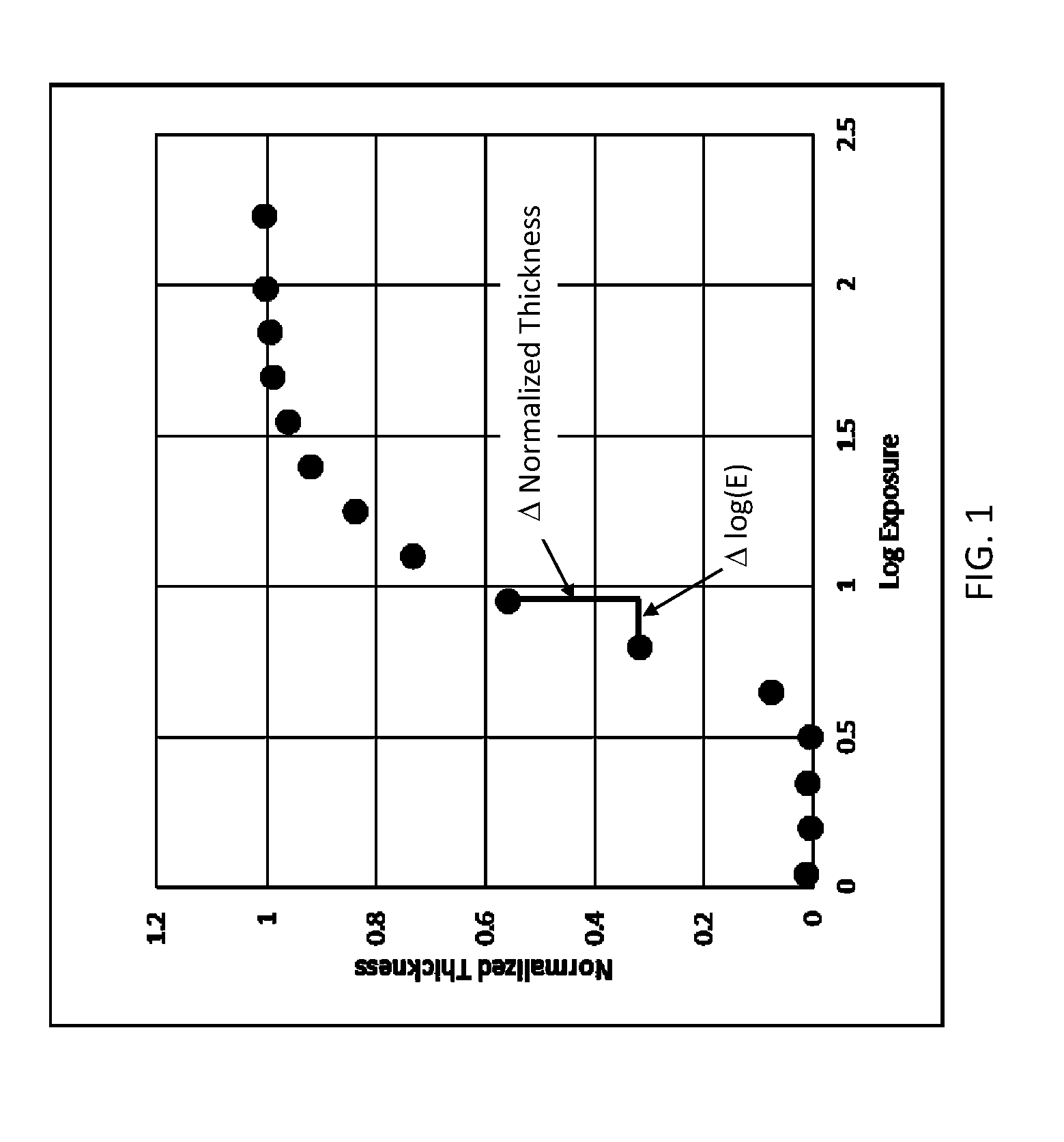

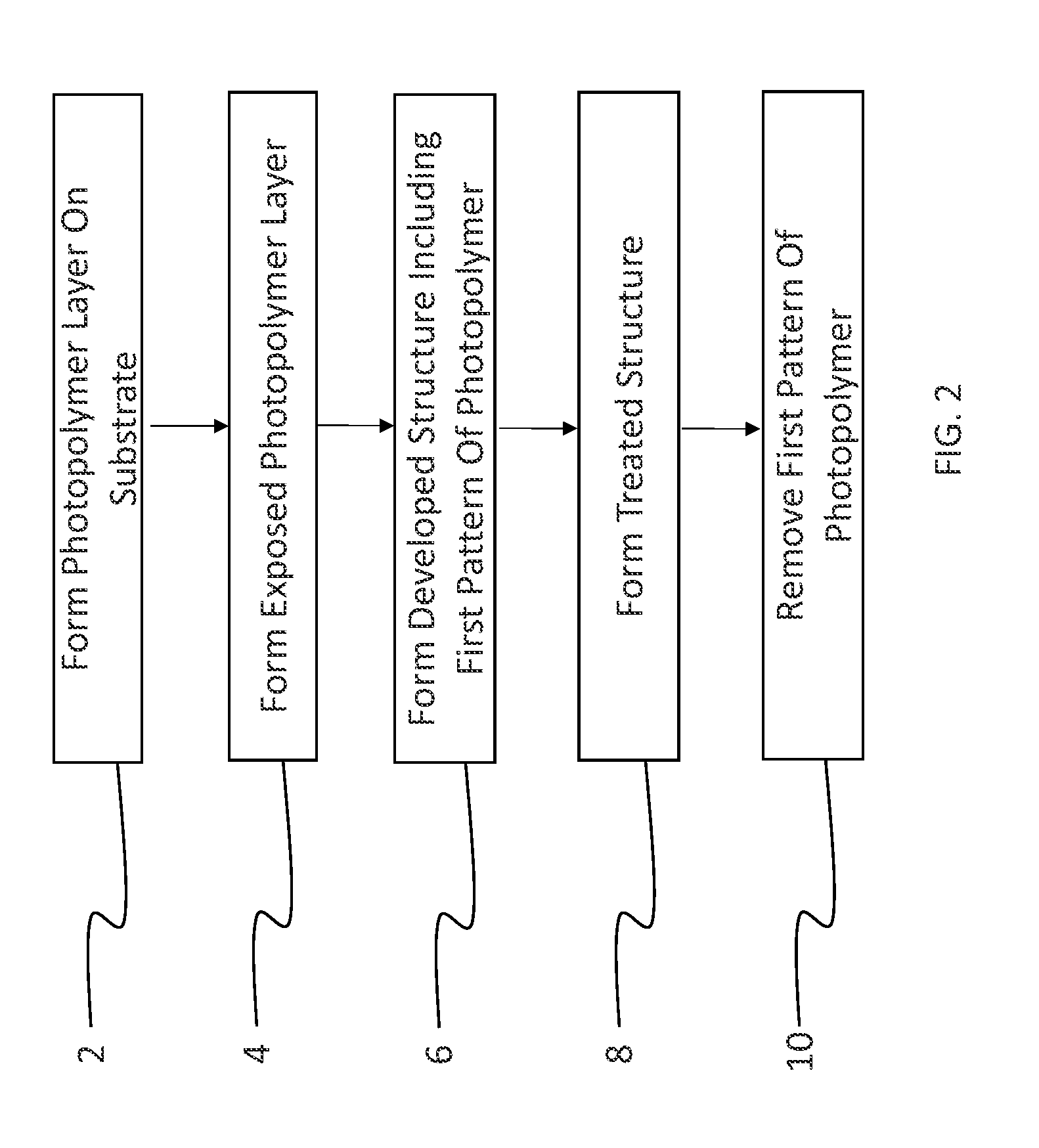

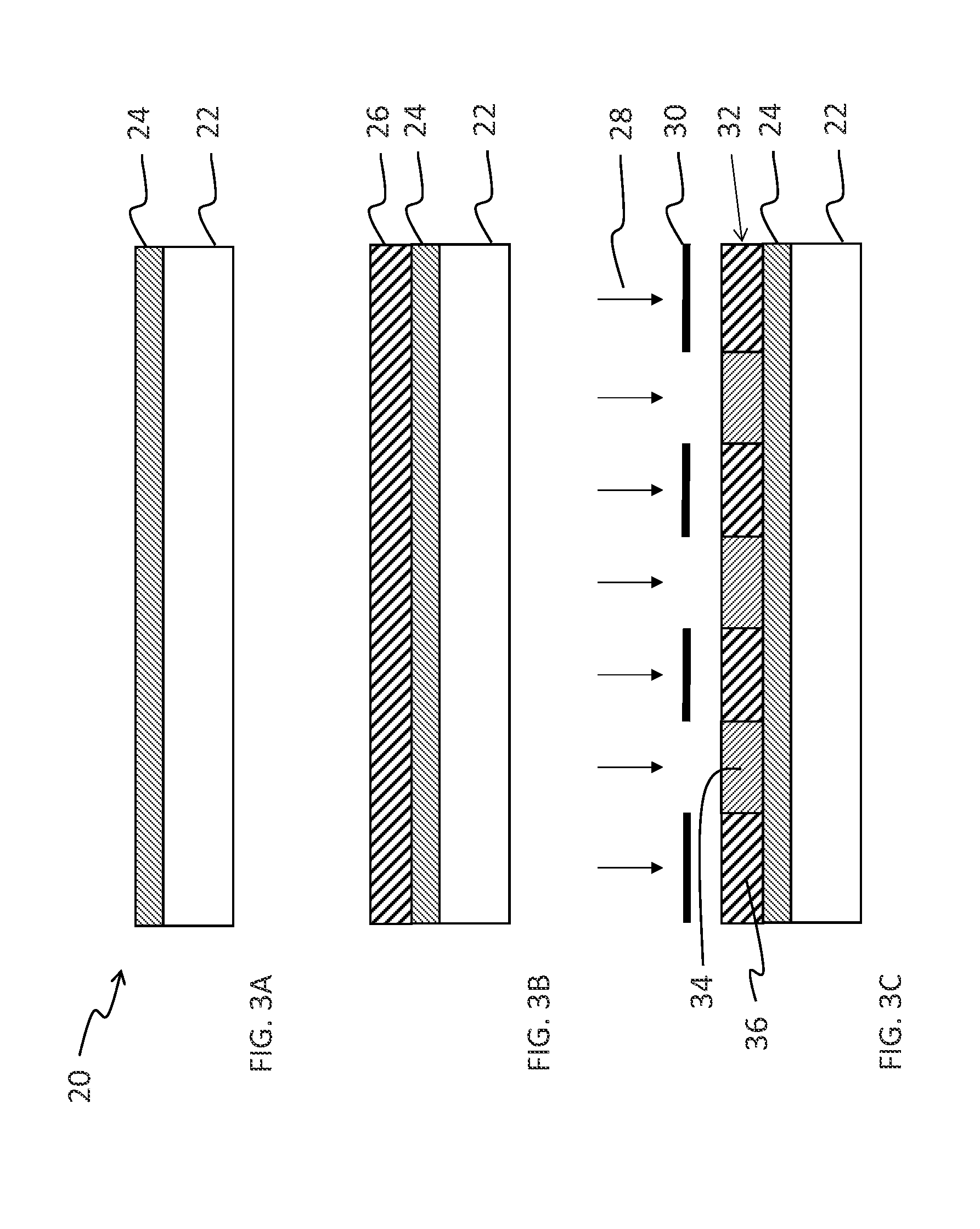

Method of patterning a device

ActiveUS20140248565A1Reduce manufacturing costSharp contrastPhotomechanical coating apparatusPhotomechanical exposure apparatusSolubilityPhotosensitive polymer

A photopolymer layer is formed on an organic device substrate and exposed to patterned radiation. The photopolymer layer includes a photopolymer comprising at least a first repeating unit having an acid-catalyzed, solubility-altering reactive group, wherein the total fluorine content of the photopolymer is less than 30% by weight. The pattern exposed photopolymer is contacted with a developing agent, such as a developing solution, to remove unexposed photopolymer, thereby forming a developed structure having a first pattern of exposed photopolymer covering the substrate and a complementary second pattern of uncovered substrate corresponding to the unexposed photopolymer. The developing agent comprises at least 50% by volume of a hydrofluoroether developing solvent.

Owner:ORTHOGONAL

Composition for engine cleaning

InactiveUS7033979B2Surface-active detergent compositionsDetergent mixture composition preparationHydrofluoroetherTurbine

A composition and method for cleaning gas turbine engines to remove fuel or lubricant residues. The composition can include a mixture of hydrofluorocarbon and hydrofluoroether. The method can include the step of directing a pressurized stream of the cleaning composition against one or more portions of the gas turbine engine to remove fuel and / or lubricant residues.

Owner:GENERAL ELECTRIC CO

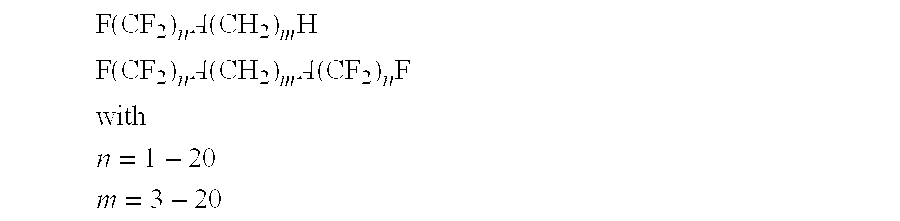

Cosmetics with hydrofluoroether (HFE)

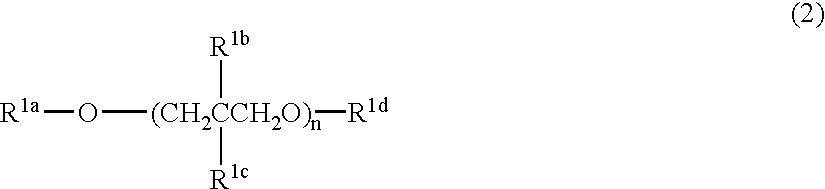

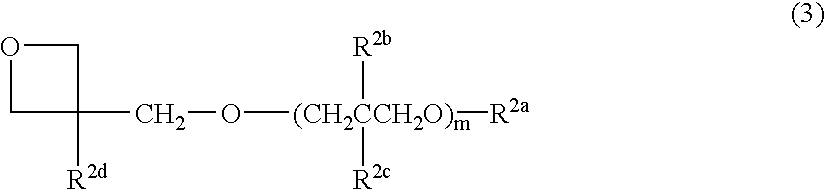

A cosmetic containing at least 1% by weight of hydrofluoroether having a viscosity of less than 5 mPa.s at 25° C., which is represented by the general formula (1):wherein n is a number of 1 to 12, m is a number of 0 to 25, l is a number of 0 to 11, m+l=2n+1, x is a number of 1 to 12, y is a number of 0 to 25, z is a number of 0 to 11, and y+z=2x+1, provided that m and y are not be simultaneously zero, and l and z are not be simultaneously zero, gives no environment disruption, is highly safe for the skin and improves the feeling in use.

Owner:DAIKIN IND LTD

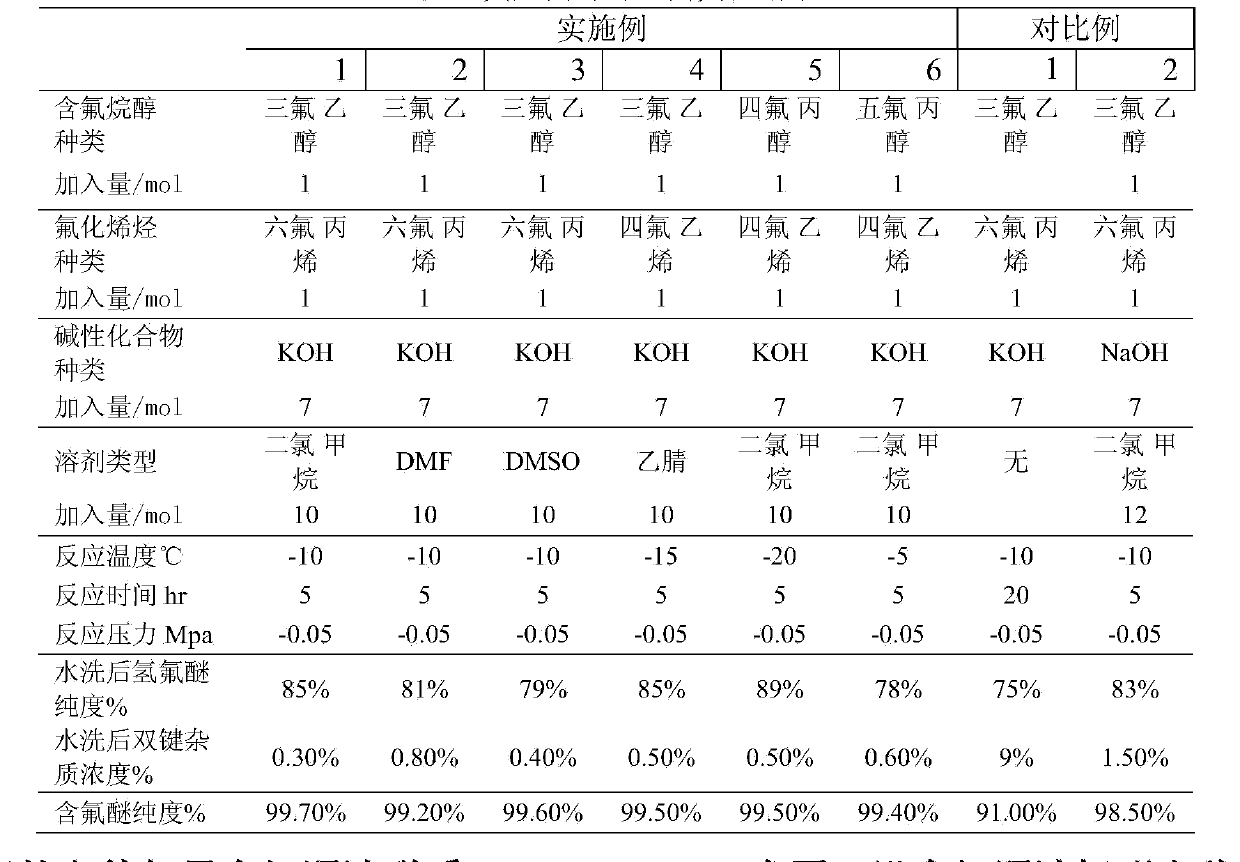

Preparation method of hydrofluoroether

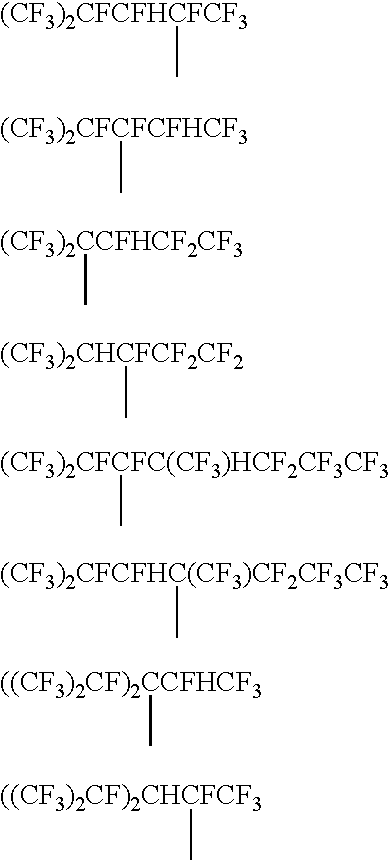

InactiveCN103739450AInhibitionEasy to purifyEther preparation by compound additionReaction temperatureDouble bond

The invention relates to a preparation method of hydrofluoroether. The preparation method comprises the following steps: (1), dissolving an alkali compound in fluorine-containing alkanol, adding a solvent, adding fluorinated olefin, and heating and stirring for reaction to obtain a mixed solution; (2), washing the mixed solution obtained in the step (1) by using water, standing for demixing, collecting an organic phase solution of a lower layer, and rectifying to obtain a hydrofluoroether product. According to the preparation method, the generation of double-bond impurities can be inhibited, and a reaction product from which a target product is easily purified can be obtained; the reaction temperature and the reaction pressure are relatively mild, the safety coefficient is high, and more satisfactory reaction speed can be obtained; the solvent is easily recycled, the cost is lowered, and a plurality of wastes are prevented from polluting the environment.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

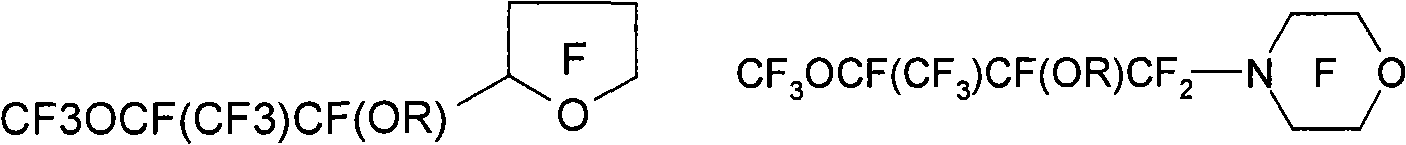

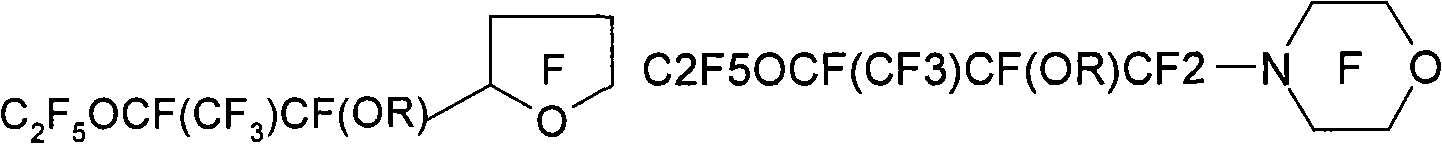

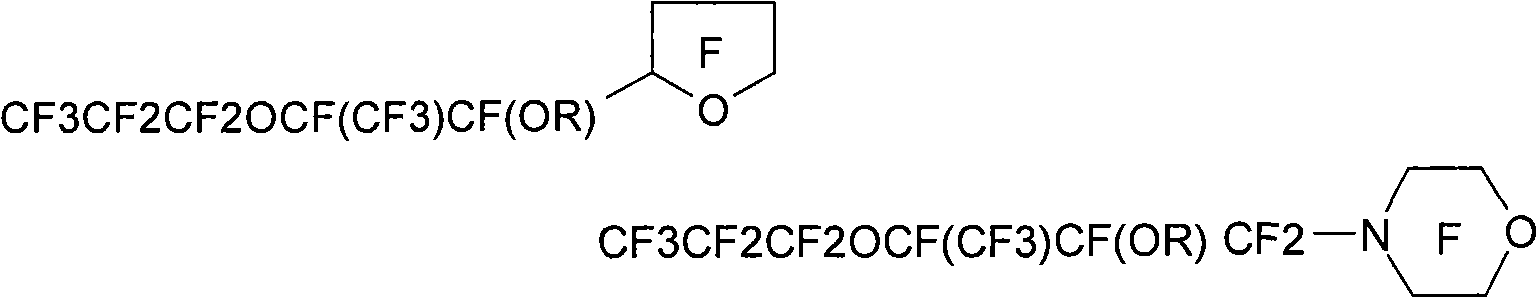

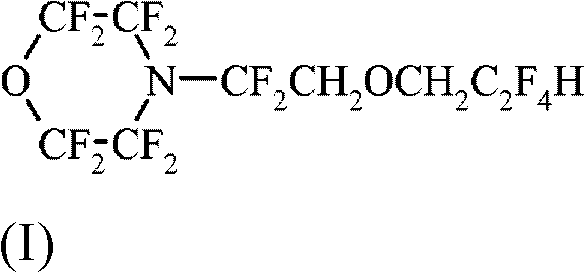

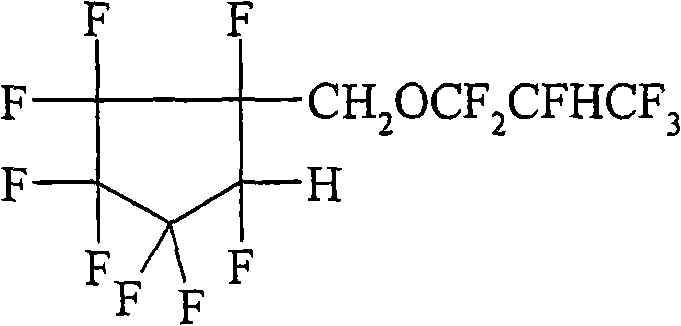

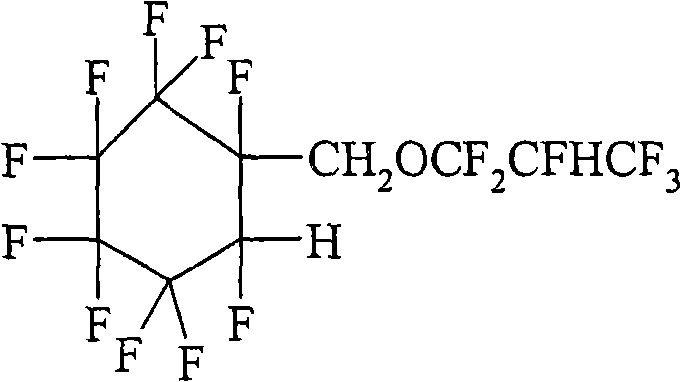

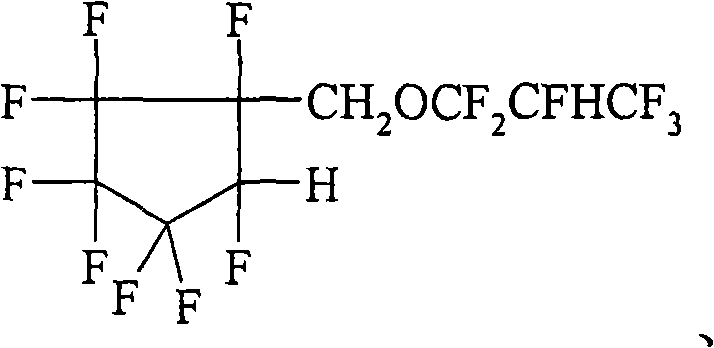

Hydrofluoroether compounds and processes for their preparation and use

A hydrofluoroether compound comprises two terminal, independently fluoroalkyl or perfluoroalkyl groups and an intervening oxytetrafluoroethylidene moiety (-OCF(CF3)-) bonded through its central carbon atom to an alkoxy- or fluoroalkoxy-substituted fluoromethylene moiety (-CF(OR)-), each of the terminal groups optionally comprising at least one catenated heteroatom.

Owner:3M INNOVATIVE PROPERTIES CO

Method for synchronously preparing hydrofluoroether and fluorine-containing olefine ether

InactiveCN105906489AShort processHigh yieldEther preparation by compound additionEther preparation by ester reactionsAlcoholDistillation

The invention discloses a method for synchronously preparing hydrofluoroether and fluorine-containing olefine ether. The method for synchronously preparing the hydrofluoroether and the fluorine-containing olefine ether comprises the following steps of making fluorine-containing olefine react with alcohol in a solvent in the presence of a catalyst, and controlling reaction pressure to be 0.2MPa to 1.5MPa through regulating the introduction amount of the fluorine-containing olefine in a reaction process, wherein the molar ratio of the alcohol to the solvent to the catalyst is 1: (0.5 to 3): (0.1 to 1.5), and a reaction temperature is 50 DEG C to 150 DEG C; when the molar ratio of the introduction amount of the fluorine-containing olefine to the alcohol is (1.0 to 1.2): 1, terminating a reaction, and carrying out distillation separation to obtain products of the hydrofluoroether and the fluorine-containing olefine ether respectively. The method for synchronously preparing the hydrofluoroether and the fluorine-containing olefine ether has the advantages of being simple in technique, high in operating flexibility, low in cost, green and environmentally-friendly.

Owner:JUHUA GROUP TECH CENT

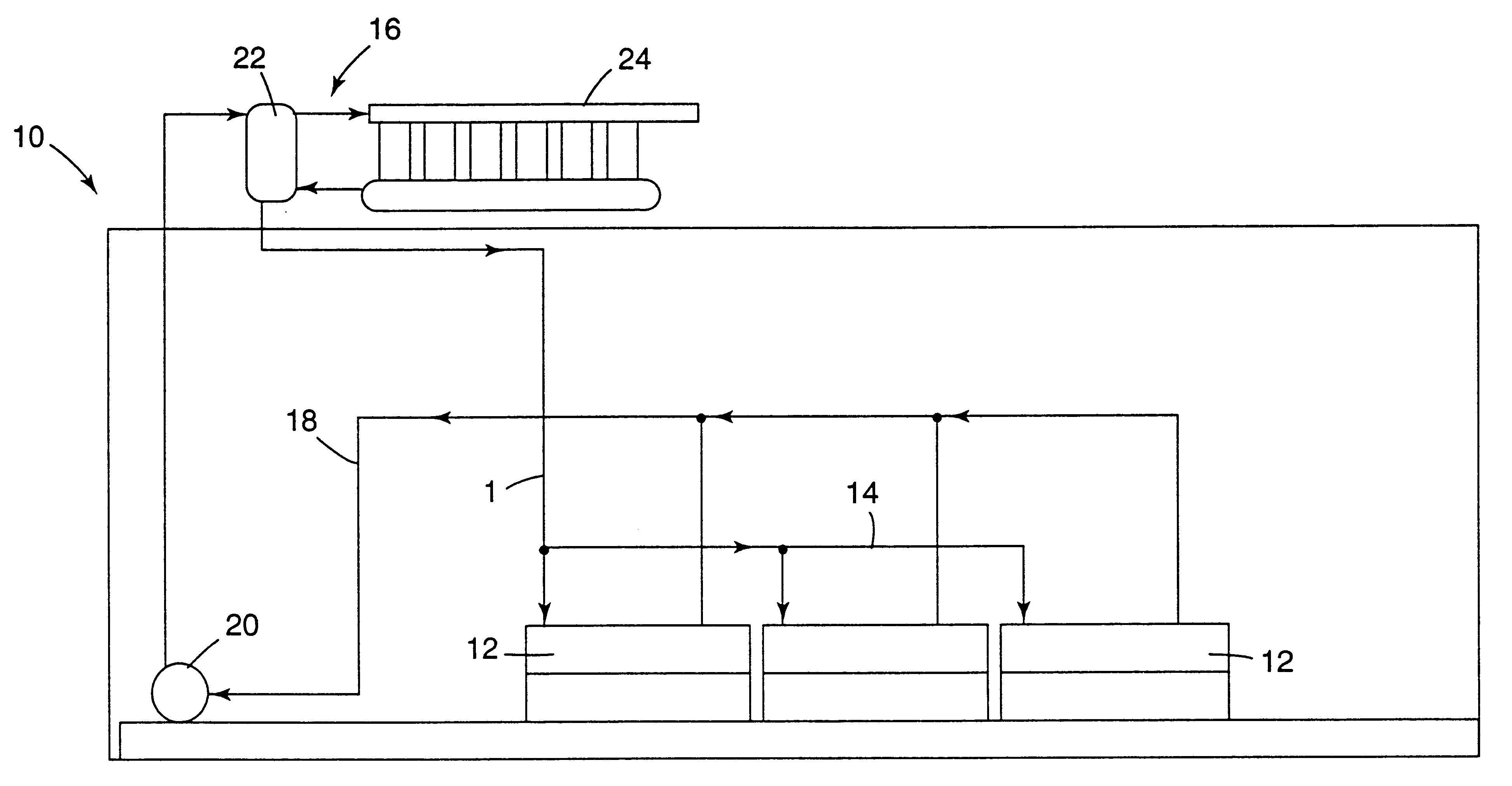

Cleaning system utilizing an organic cleaning solvent and a pressurized fluid solvent

InactiveUS7147670B2Increase vapor pressureLow boiling pointDry-cleaning apparatusDetergent mixture composition preparationSolubilityHalohydrocarbon

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably selected from terpenes, halohydrocarbons, certain glycol ethers, polyols, ethers, esters of glycol ethers, esters of fatty acids and other long chain carboxylic acids, fatty alcohols and other long-chain alcohols, short-chain alcohols, polar aprotic solvents, siloxanes, hydrofluoroethers, dibasic esters, and aliphatic hydrocarbons solvents or similar solvents or mixtures of such solvents and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:EMINENT TECHNOLOGY

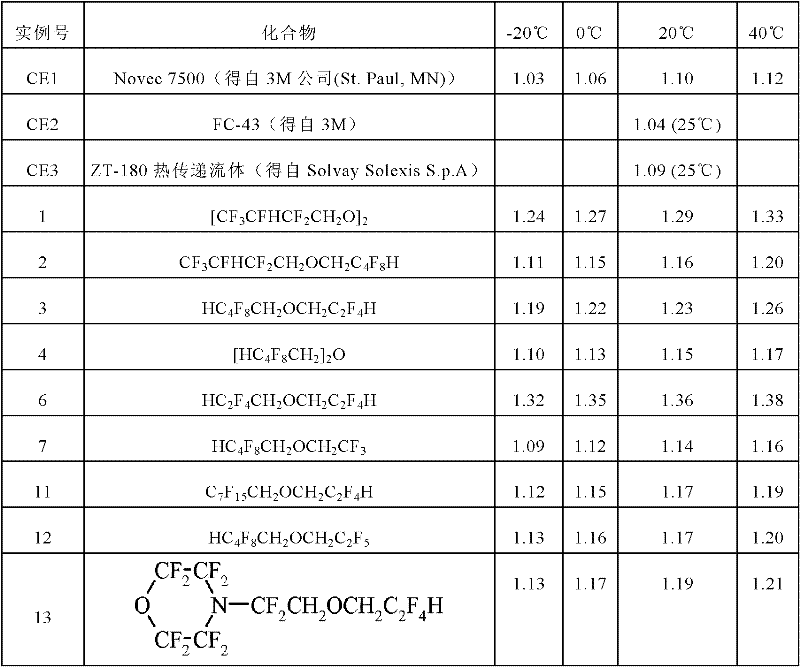

Methods of using hydrofluoroethers as heat transfer fluids

InactiveCN102597156AHigh dielectric strengthLow conductivityOrganic chemistryHeat-exchange elementsHydrogen atomHeteroatom

An apparatus is provided that includes a device and a mechanism for heat transfer. The mechanism includes a hydrofluoroether heat-transfer fluid wherein the heat transfer fluid is represented by the following structure: Y-Rf-CH2OCH2Rf-Y wherein Rf may be the same or different and is, independently, selected from the group consisting of perfluorinated alkylene groups which may be linear, cyclic, or branched having from 1 to 10 carbon atoms, partially fluorinated alkylene groups having from 1 to 10 carbon atoms, and derivatives thereof wherein one or more carbon atoms are replaced by catenated nitrogen or oxygen heteroatoms, wherein each Rf contains at most one hydrogen atom, wherein Y represents H, F, or an RfCH2OCH2- group, and wherein the total number of carbon atoms in the molecule is at least 6.; A method of transferring heat including the device and the provided heat-transfer fluid is also provided.

Owner:3M INNOVATIVE PROPERTIES CO

High voltage electrolyte for lithium ion batteries

ActiveCN104282939AImprove solubilityAvoid structural changesSecondary cellsSolubilityHydrofluoroether

The invention discloses a high voltage electrolyte for lithium ion batteries, the high voltage electrolyte is composed of an organic solvent, electrolyte lithium salt and a cathode film-forming additive, wherein the organic solvent is a mixed solvent of fluorinated ethylene carbonate, trifluorinated propylene carbonate and hydrofluoroether, the electrolyte lithium salt mixed is lithium salt of lithium hexafluorophosphate and lithium bis(oxalate)borate. The high voltage electrolyte effectively solves the problems that fluorinated solvents are high in viscosity and the electrolyte lithium salt is poor in solubility in fluorinated organic solvents, so that the fluorinated organic solvents can be directly used as the organic solvents in lithium ion battery electrolyte, the high voltage electrolyte has wide electrochemical window and good oxidation resistance and high voltage resistant characteristics, has high electric conductivity, can guarantee the high magnification and power characteristics of a power battery, is high in safety, and can greatly improve the safety performance of the power battery.

Owner:WANXIANG 123 CO LTD

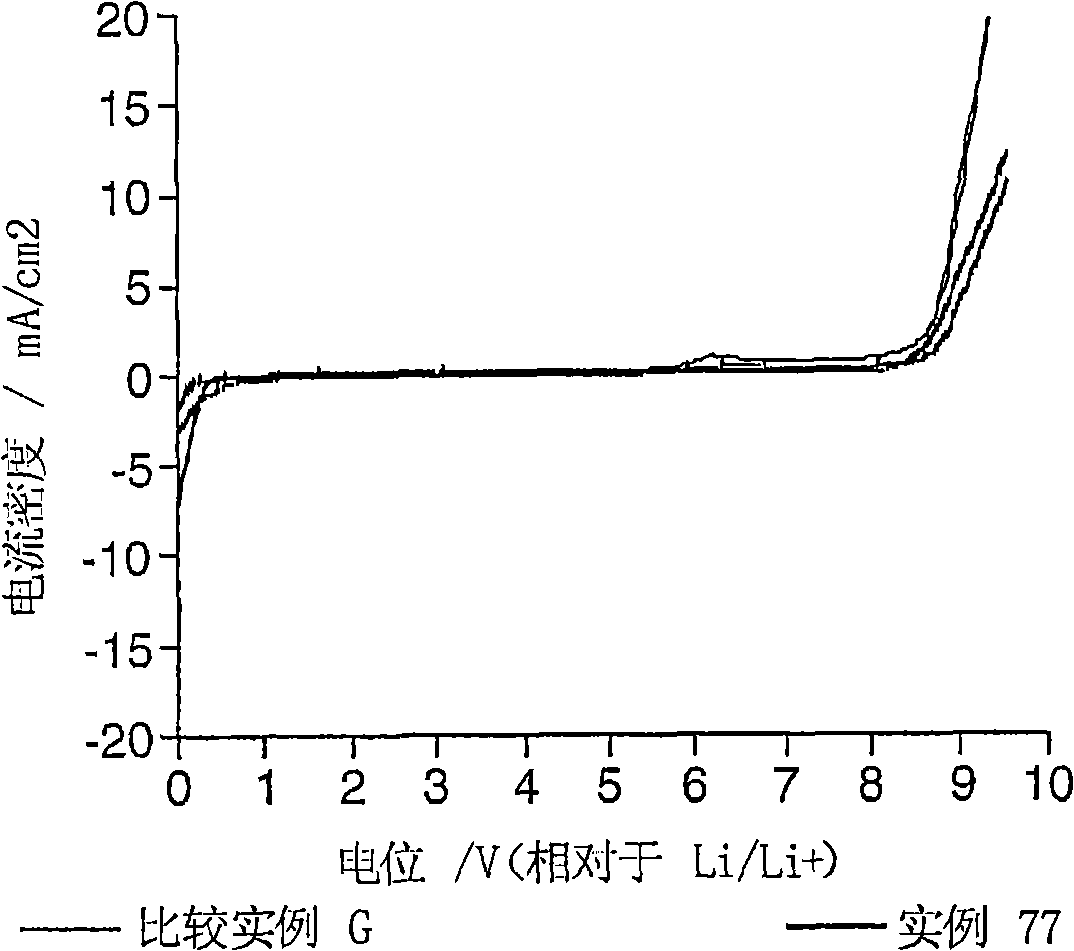

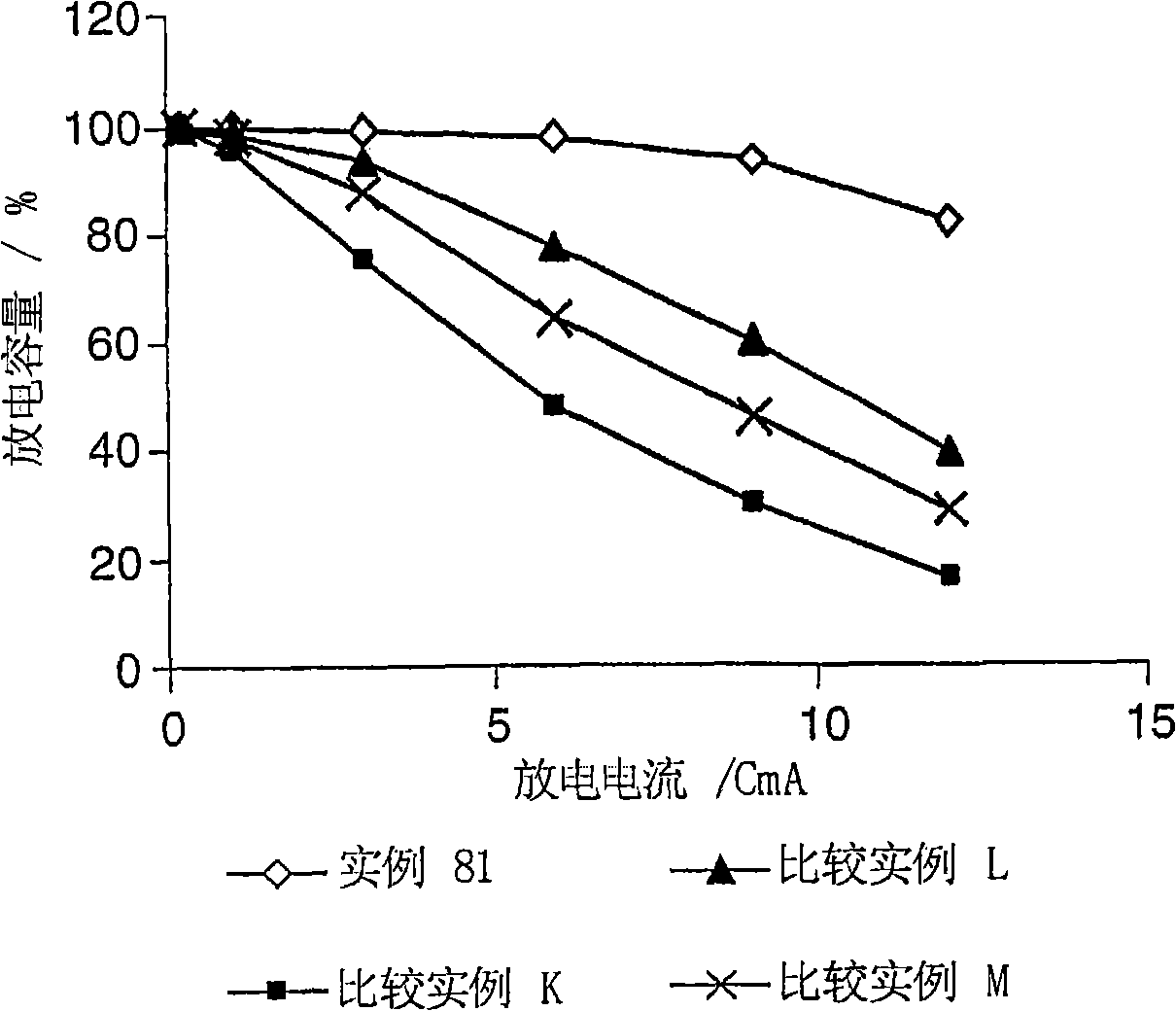

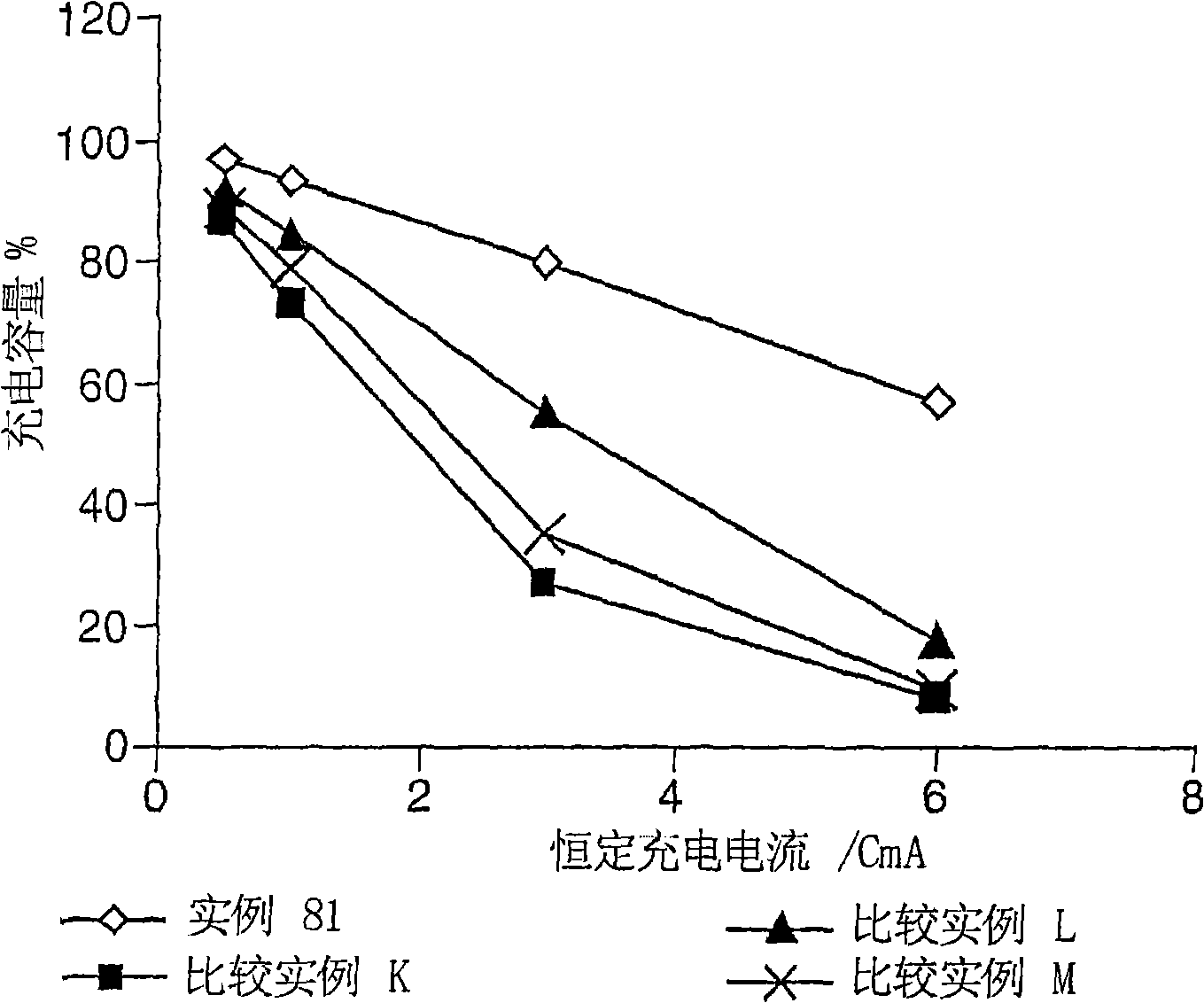

Non-aqueous electrolyte solution for secondary batteries, and secondary battery

InactiveUS20130108932A1Improve cycle performanceHigh rate charge/discharge propertiesOrganic electrolyte cellsSecondary cellsHigh rateElectrical battery

To provide a non-aqueous electrolyte solution for secondary batteries, which has a long term flame retardancy and which is excellent in cycle properties particularly under high voltage conditions and in high rate charge / discharge properties, and a secondary battery using such a non-aqueous electrolyte solution for secondary batteries. A non-aqueous electrolyte solution for secondary batteries, comprising a lithium salt and a solvent for dissolving the electrolyte salt, which comprises a specific hydrofluoroether, a specific ether compound and a specific carbonate compound, wherein the ratio (N0 / NLi) of the total number of moles (N0) of etheric oxygen atoms derived from the above ether compound to the total number of moles (NLi) of lithium atoms derived from the lithium salt, contained in the solvent for dissolving the electrolyte salt, is more than 1 and at most 6; and a secondary battery using such a non-aqueous electrolyte solution for secondary batteries.

Owner:ASAHI GLASS CO LTD

Hydrofluoroether compounds and processes for their preparation and use

InactiveCN101263103AImprove thermal stabilityMeeting ongoing needsOrganic chemistryHeat-exchange elementsHydrofluoroetherComponentOf

A hydrofluoroether compound comprises two terminal fluoroalkyl groups and an intervening substituted or unsubstituted oxymethylene group, each of the fluoroalkyl groups comprising only one hydrogen atom and, optionally, at least one catenated (that is, in-chain) heteroatom; with the proviso that the hydrogen atom is part of a monofluoromethylene moiety.

Owner:3M INNOVATIVE PROPERTIES CO

Electrolyte composition

InactiveCN101258637ASufficiently conductiveReduce fireFinal product manufactureActive material electrodesHydrogen atomHeteroatom

An electrolyte composition includes (a) a solvent composition including at least one hydrofluoroether compound, the hydrofluoroether compound including two terminal fluoroalkyl groups and an intervening substituted or unsubstituted oxymethylene group, each of the fluoroalkyl groups including only one hydrogen atom and, optionally, at least one catenated (that is, in-chain) heteroatom, with the proviso that, when the oxymethylene group is unsubstituted, at least one of the terminal fluoroalkyl groups is branched and / or includes at least one catenated heteroatom; and (b) at least one electrolyte salt.

Owner:3M INNOVATIVE PROPERTIES CO

Compositions based on 2,3,3,4,4,4-hexafluorobut-1-ene

InactiveUS20150096312A1Reduce environmental impactOvercomes drawbackCompression machines with non-reversible cycleHeat-exchange elementsFluorescenceBoiling point

A composition including 2,3,3,4,4,4-hexafluorobut-1-ene as a mixture with one or more hydrocarbon, hydrofluorocarbon, ether, hydrofluoroether or fluoroolefin compounds having a boiling point of less than or equal to 0° C. Also, the use of such a composition in heat transfer applications. Also, a heat transfer installation including a vapor compression circuit containing such a composition as heat-transfer fluid or containing a heat-transfer composition including such a composition, and also one or more additives chosen from lubricants, stabilizers, surfactants, tracers, fluorescers, odorous agents and solubilizers, and mixtures thereof.

Owner:ARKEMA FRANCE SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com