Patents

Literature

194results about How to "Good low temperature characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium electrolytic capacitor and electrolyte

InactiveCN1707710ANon-flammableImprove reliabilityCapacitor electrolytes/absorbentsCapacitor housing/encapsulationElectrolysisSolvent

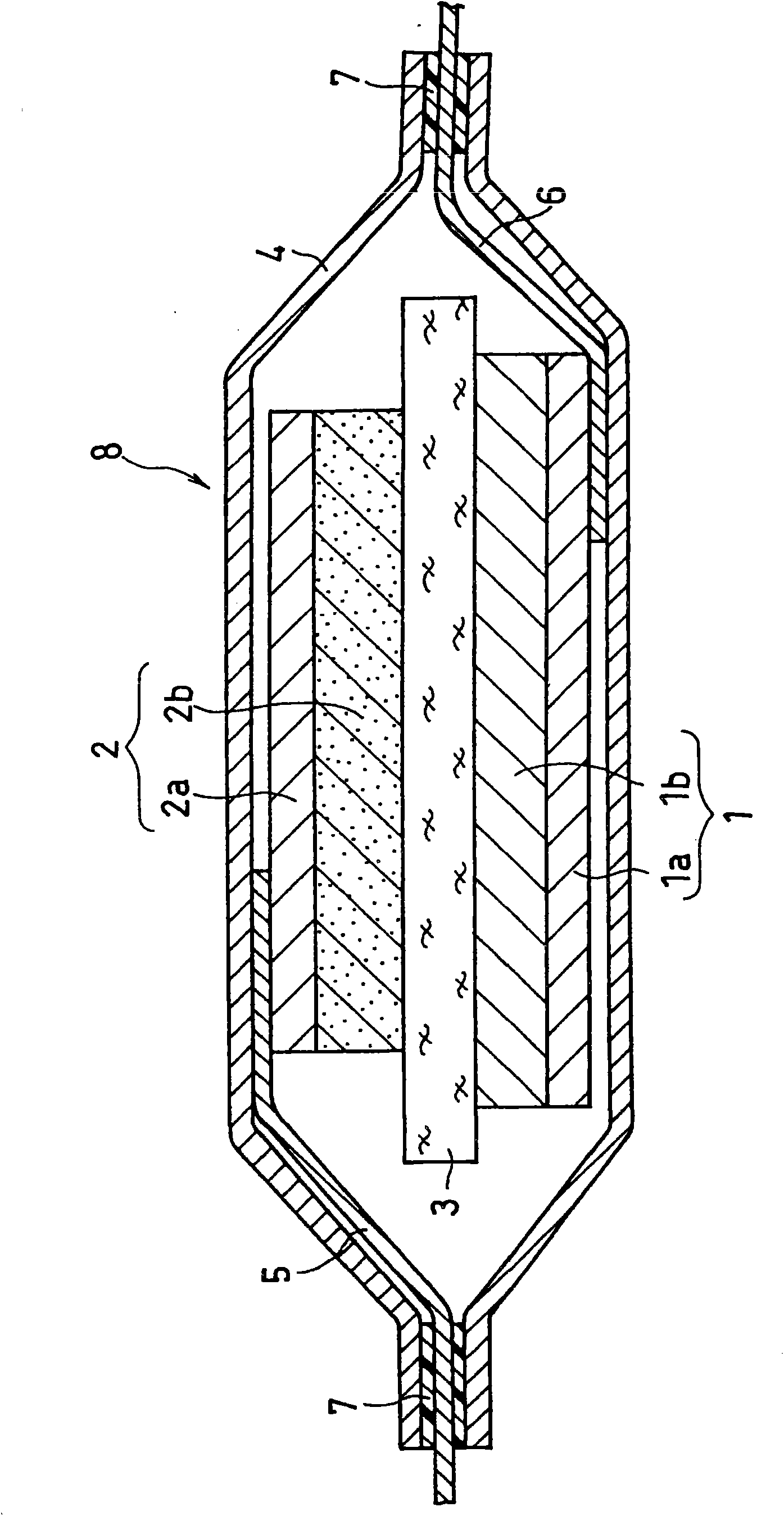

The aluminum electrolytic capacitor consists of anode aluminum foil, electrolyte paper, cathode aluminum foil, and is produced through winding the electrolyte paper into roll core, soaking the roll core inside electrolyte solution, setting the roll core inside aluminum casing and sealing. The present invention features the electrolyte solution comprising main electrolyte 10-30 wt%, solvent 65-89.95 wt%, and additive 0.05-5 wt%; the main electrolyte of ammonium salt compound and with water content of 15-95 %; the organic solvent of alcohol or ether; and the additive of waterproof compound. The electrolyte paper is made of Manila hemp and soaked with the electrolyte solution. The mouth of the aluminum casing is sealed with rubber ring of rubber mixture. The aluminum electrolytic capacitor has electrolyte solution well adsorbed onto the anode aluminum foil and the cathode aluminum foil, no corrosion to leads, high sealing performance and other advantages.

Owner:WUXI WANYU ELECTRONICS

Negative electrode of lithium ion battery and preparation method thereof

InactiveCN103985841AImprove convenienceImprove adhesionCell electrodesSecondary cellsAdhesivePhysical chemistry

The invention belongs to the field of materials of lithium ion batteries, and particularly relates to a negative electrode of the lithium ion battery and a preparation method thereof. The negative electrode of the lithium ion battery comprises a current collector and negative electrode paste for coating the current collector, wherein the negative electrode paste comprises the following dry ingredients by weight percent: 92-99% of active material and 1-8% of an adhesive; the active material is graphite or graphite alloy; the adhesive is waterborne multi-component copolymerization emulsion. The waterborne multi-component copolymerization emulsion is used for replacing conventional butadiene styrene rubber and serves as the adhesive for the lithium ion battery, so that the more excellent adhesive performance is realized in comparison with the adhesive performance of a conventional adhesive, and meanwhile, the prepared battery has prominently excellent performances such as good low temperature characteristics, low circulation expansion rate, good long cycling performance and relatively excellent processing characteristics; the negative electrode prepared by using the method has relatively small impedance and relatively good dynamic performance and is capable of effectively solving the problem of risk of separation of lithium in the lithium ion battery at low temperature; the prepared battery has the characteristics of safety, reliability and long cycle life.

Owner:MCNAIR TECH +1

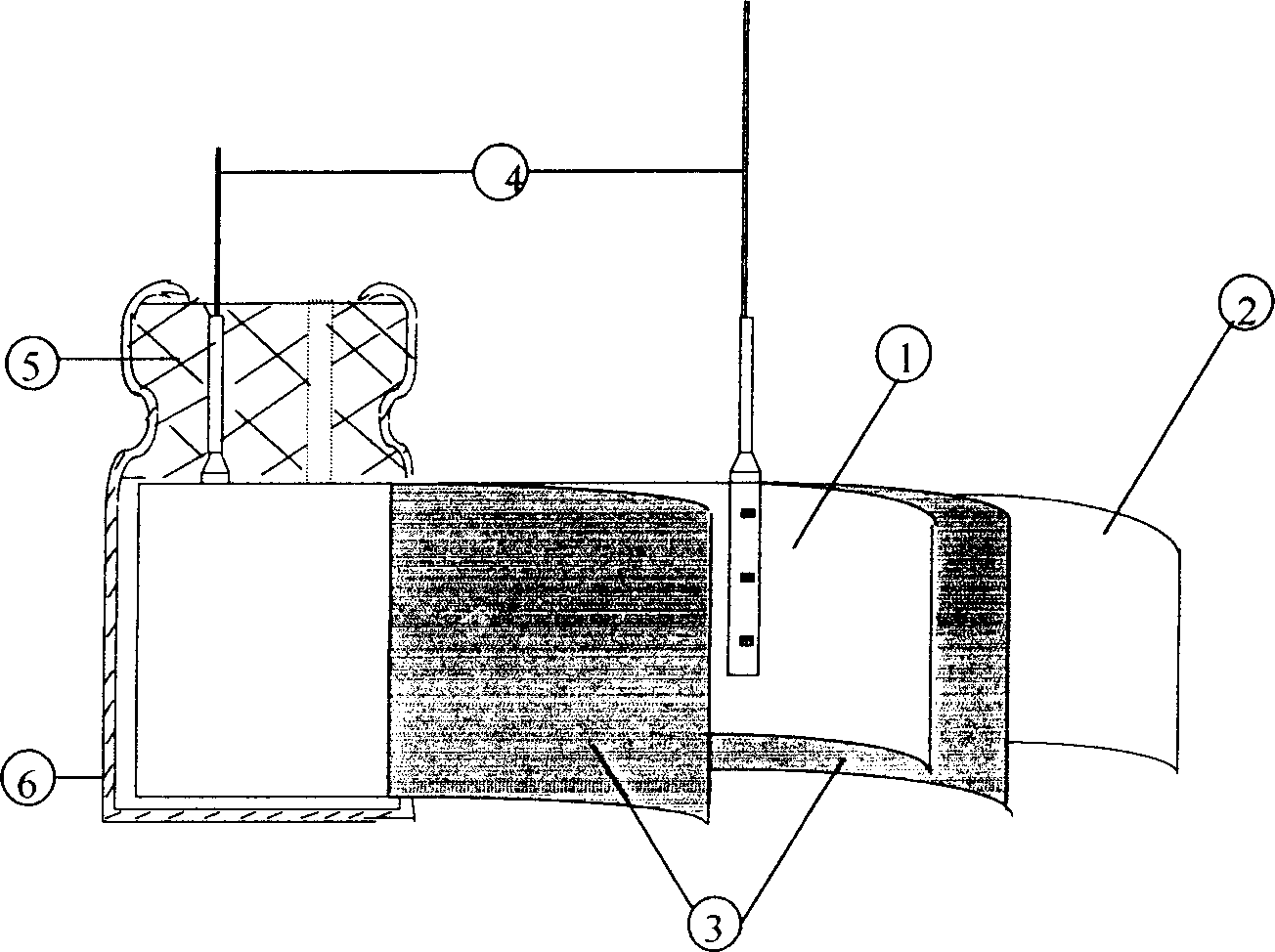

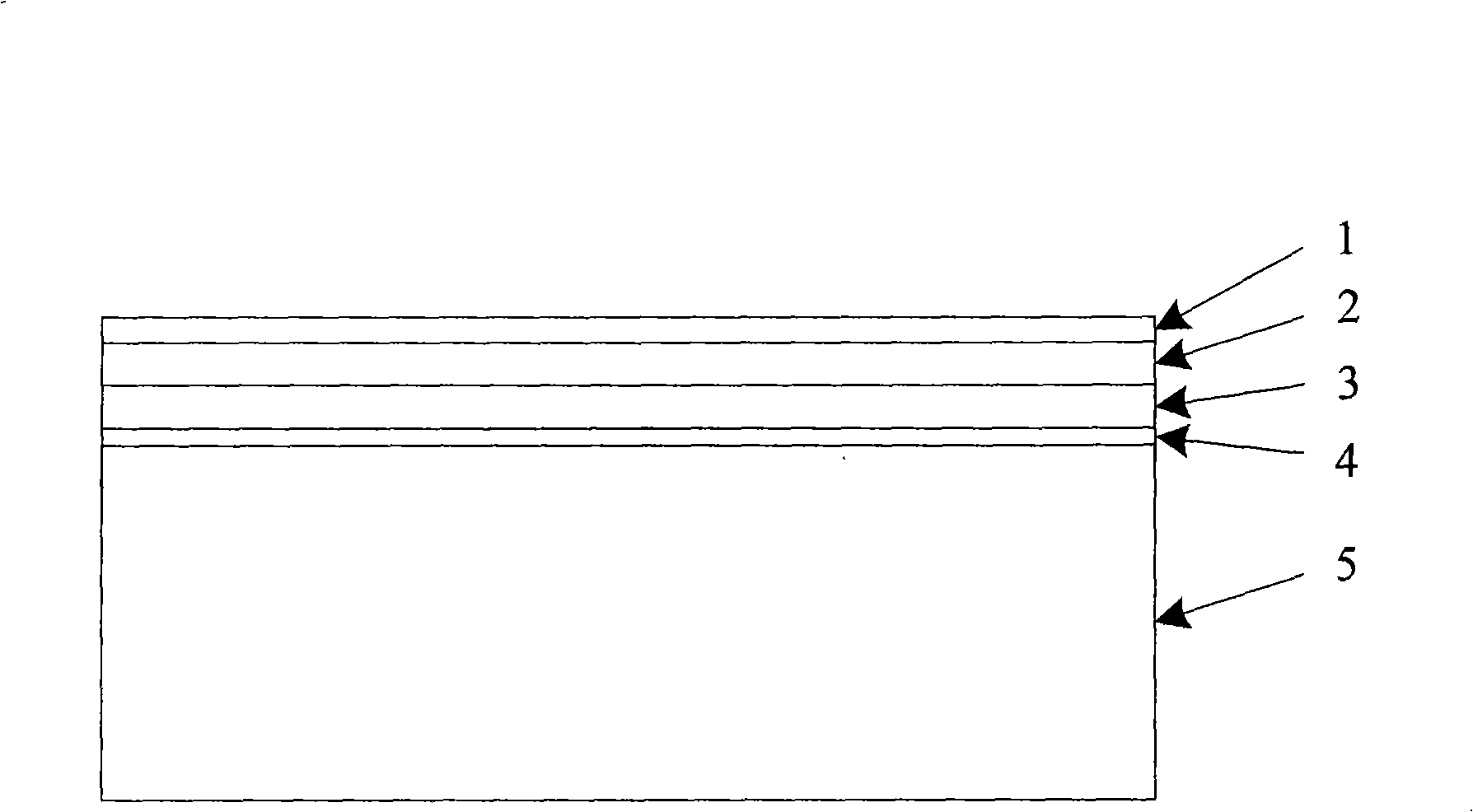

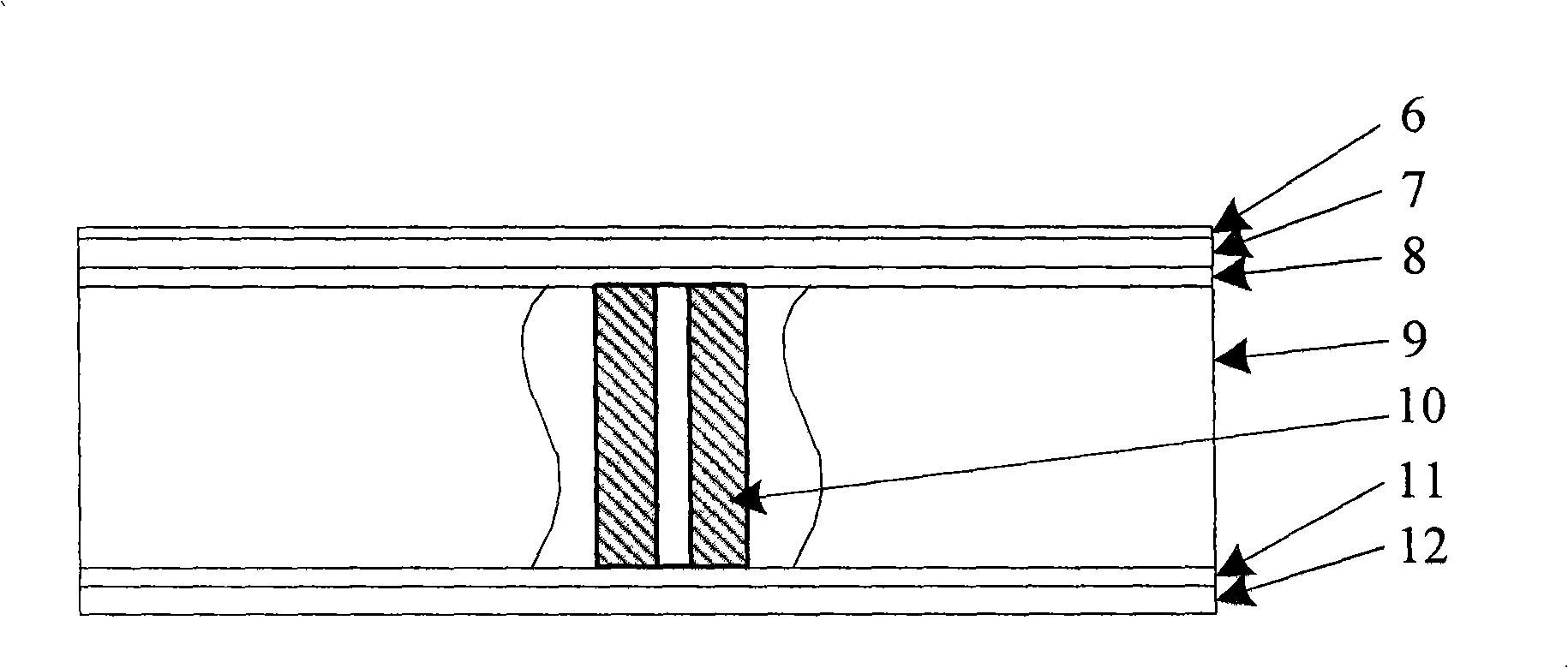

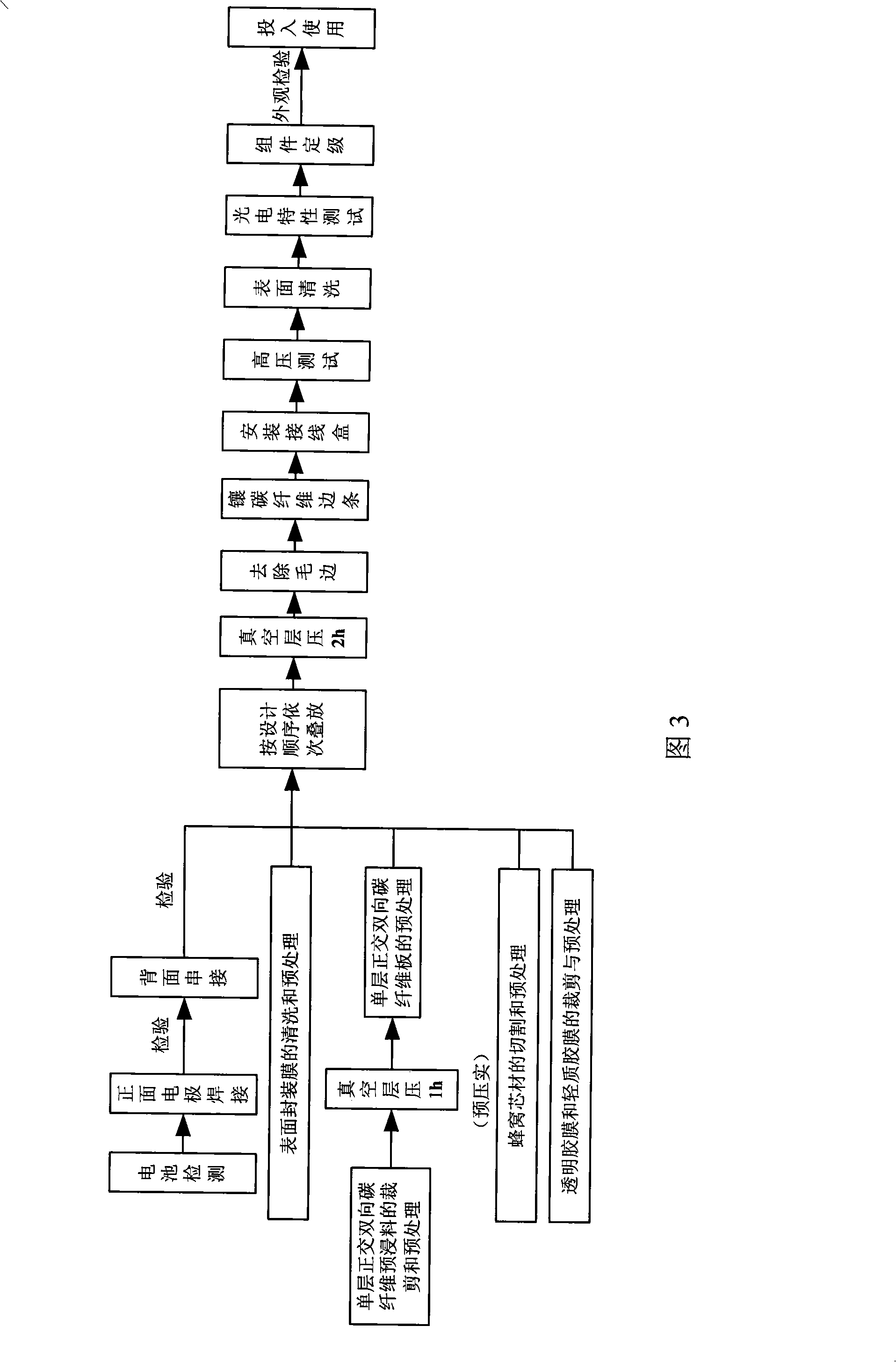

Solar cell module and preparation method thereof

ActiveCN101320760AEfficient outputTo achieve the purpose of lightweightFinal product manufacturePhotovoltaic energy generationFiberStrake

The invention provides a solar module which is composed of a surface sealing film, a transparent adhesive film, a solar cell, a lightweight adhesive film A and an isolated substrate which are stacked from the top to the bottom in order; and the isolated substrate is composed of an isolated film, a carbon-fiber sheet, a lightweight adhesive film B, a honeycomb core, a lightweight adhesive film C and the carbon-fiber sheet which are stacked from the top to the bottom in order, wherein the honeycomb core inside also needs to be appropriately added embedded parts according to concrete operating requirements. The technical scheme of a preparation method of the solar module comprises following steps: (1) making use of an oven to match with a vacuum air pump to process a pre-compacting treatment for a carbon-fiber prepreg; (2) meanwhile, processing a welding sequence of the solar cell; (3) processing a cutting sequence; (4) processing a laminating technology treatment; (5) processing post treatment procedures which in order are: removing raw edges, embedding strakes, arranging a junction box, measuring high voltage, cleaning the surface, measuring photo-electrical output characteristics, classifying components, and examining the appearance. The solar module has the advantages of lightweight, high efficiency and good low-temperature characteristics, and being very suitable to being applied in the stratosphere.

Owner:BEIHANG UNIV

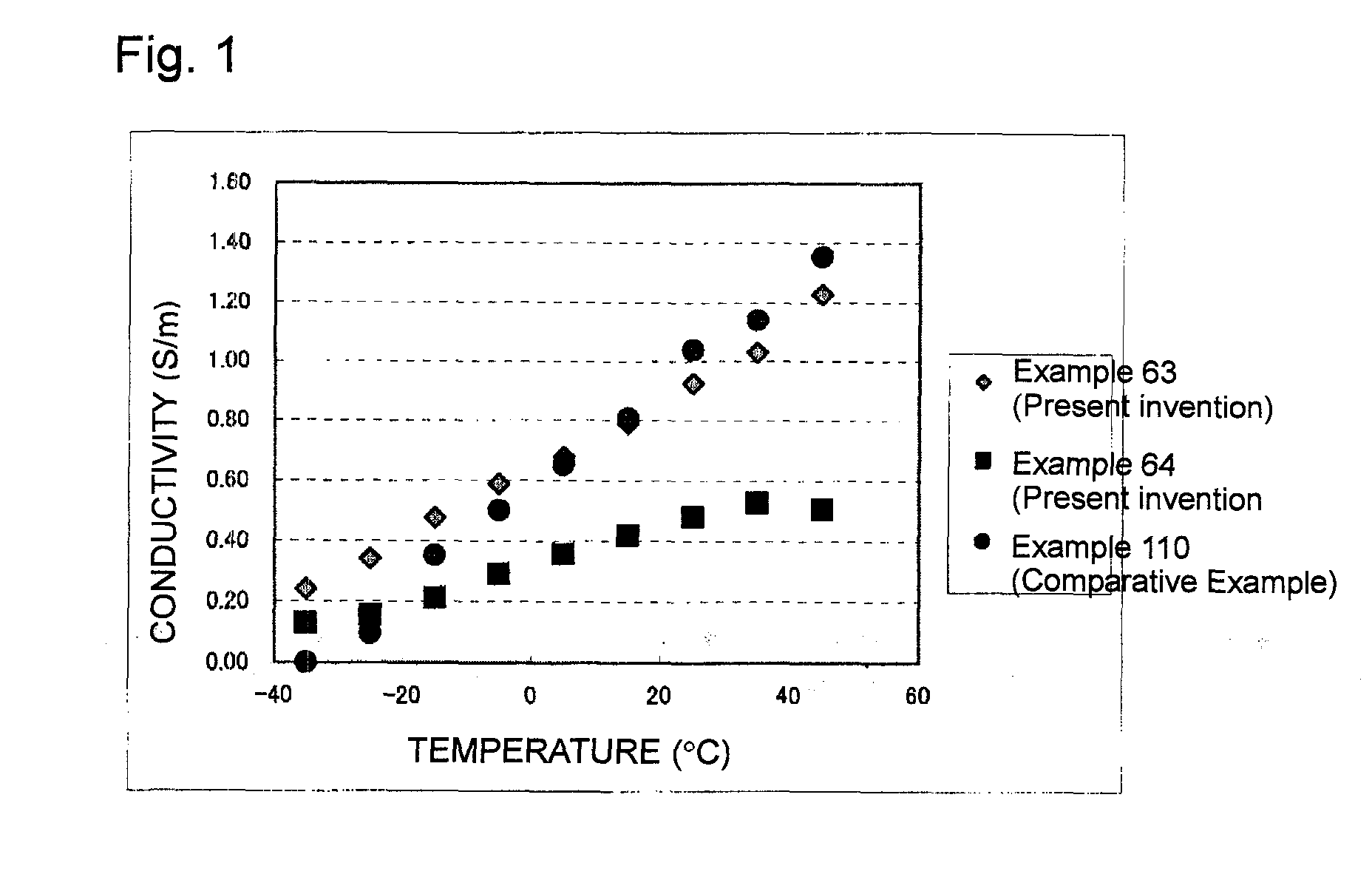

Nonaqueous electrolyte for secondary cell, and secondary cell

InactiveUS20110020700A1Reduce erosionGood low temperature characteristicsLi-accumulatorsVehicular energy storageMetallic lithiumElectrolytic agent

Provided are a nonaqueous electrolyte for a secondary cell, and a secondary cell, which are free from erosion of electrodes or generation of carbon dioxide gas and which have a long-term nonflammability, an excellent low-temperature characteristic and a practically sufficient conductivity.A nonaqueous electrolyte for a secondary cell, which comprises a lithium salt, a specific hydrofluoroether and a specific glyme type solvent. A secondary cell comprising such a nonaqueous electrolyte for a secondary cell, a negative electrode made of a material capable of storing or discharging lithium ions electrochemically, or metal lithium or a lithium alloy, and a positive electrode made of a material capable of storing or discharging lithium ions electrochemically.

Owner:ASAHI GLASS CO LTD

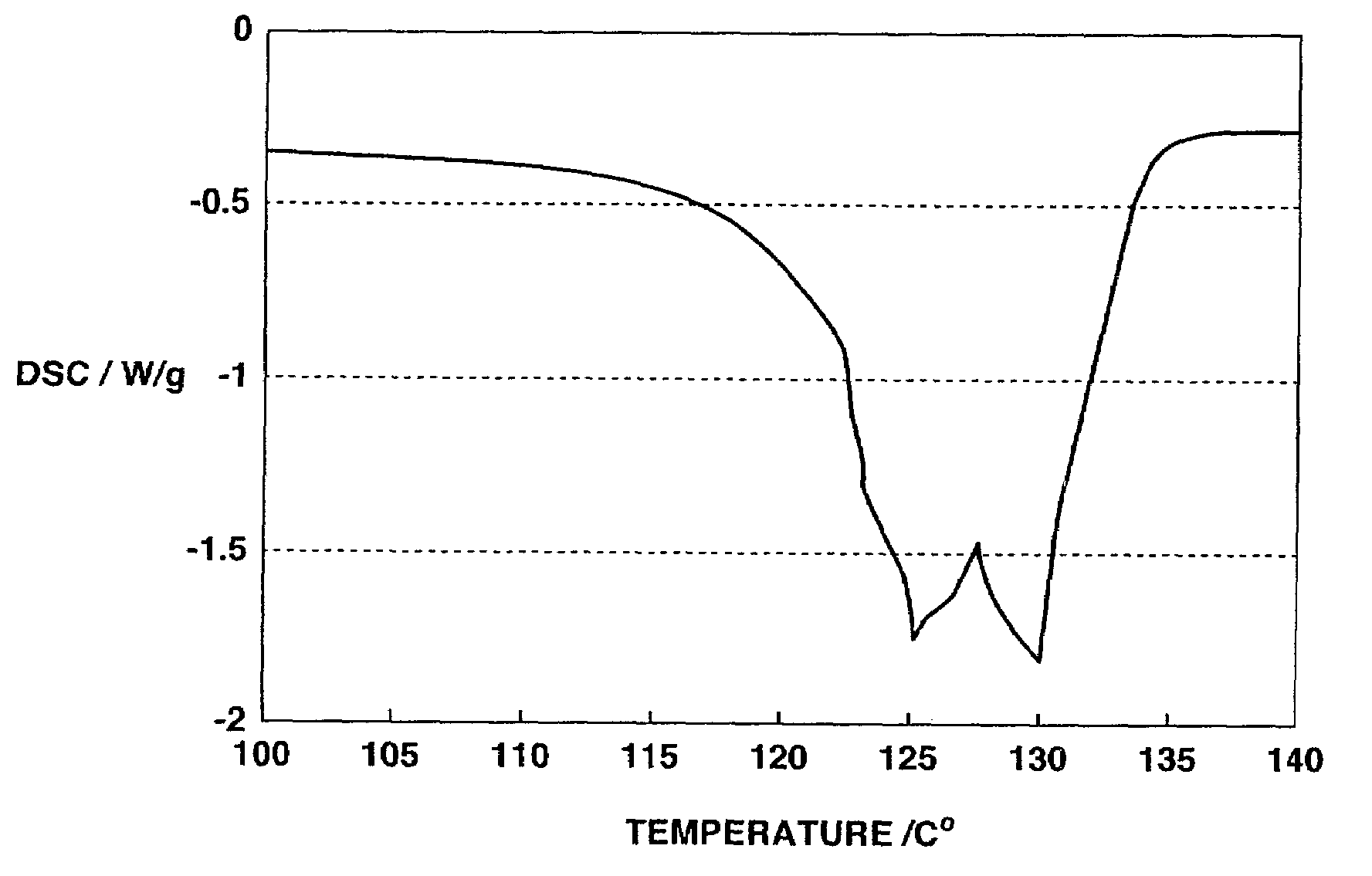

Non-aqueous electrolyte secondary cell

InactiveUS7138207B2Good low temperatureImprove securityCell component detailsSecondary cells servicing/maintenancePorosityMaterials science

A non-aqueous electrolyte secondary cell which achieves satisfactory low temperature characteristics and high safety against overcharging in combination. The cell includes a lithium-containing cathode, an anode capable of doping and undoping lithium, a non-aqueous electrolyte and a separator. The separator is made up by a plurality of layers of a porous material or materials presenting micro-sized pores. The layers of the porous material or materials is formed of micro-porous separator materials representing different combinations of the porosity, melting point or material / compositions.

Owner:MURATA MFG CO LTD

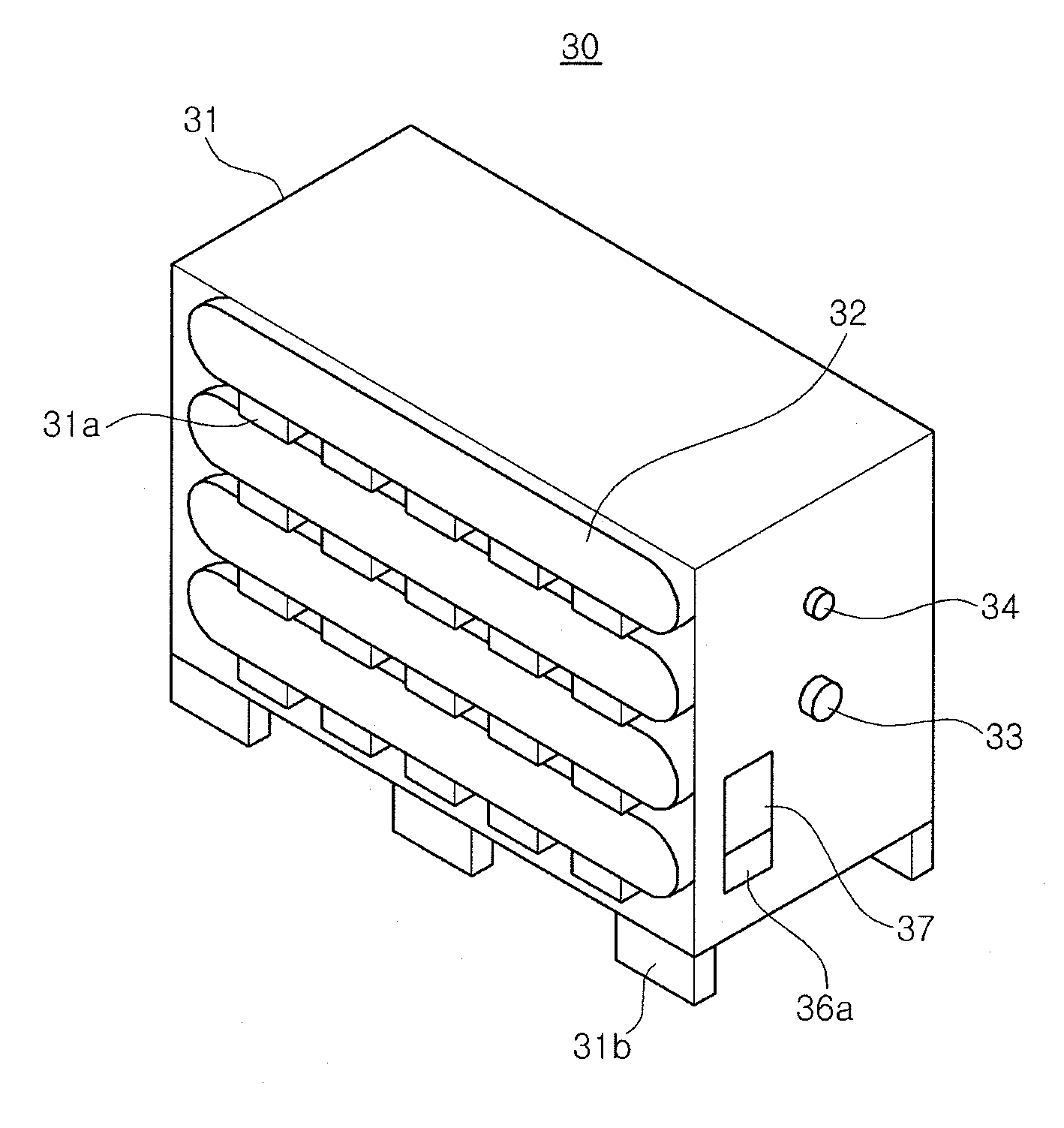

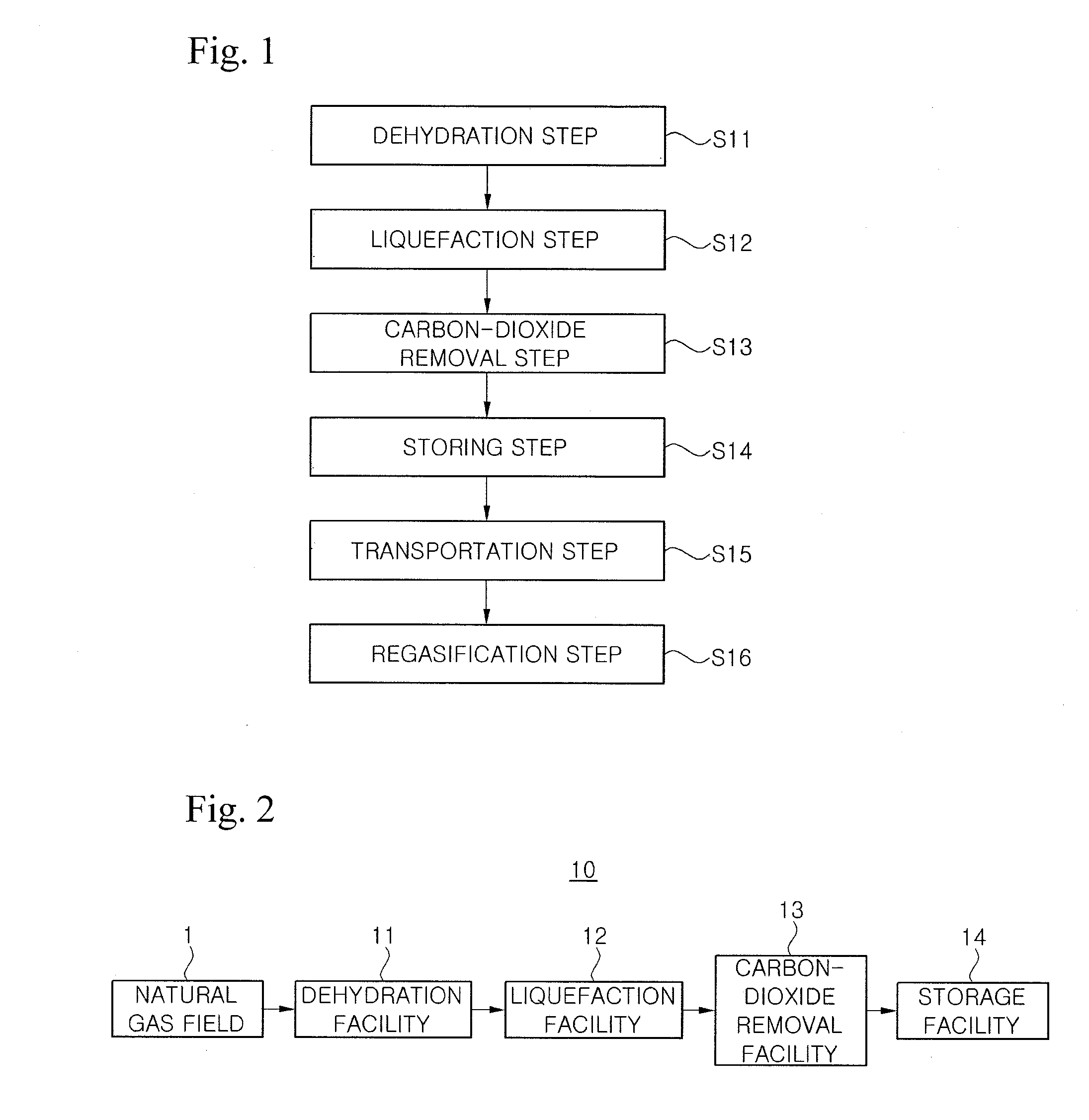

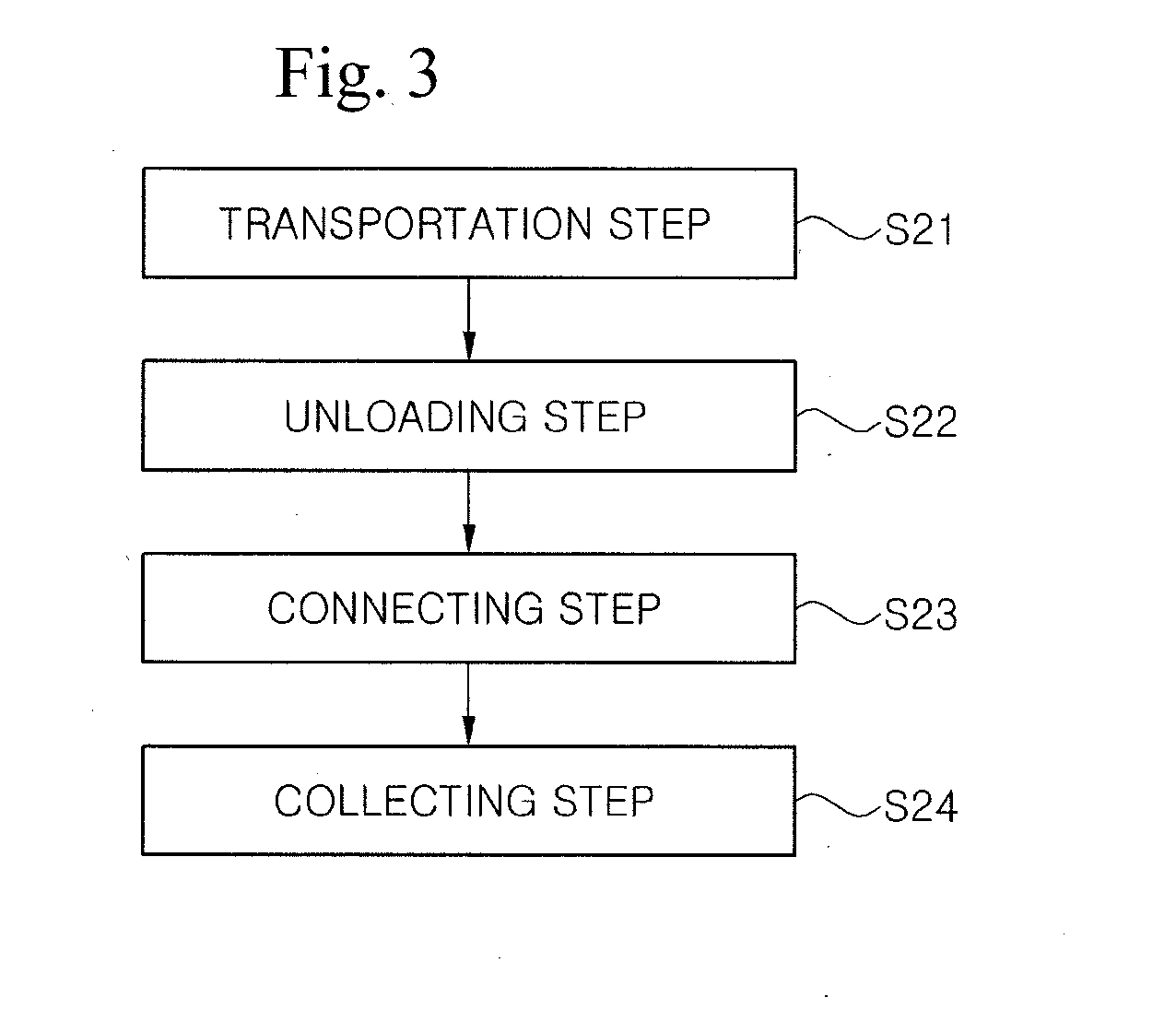

Liquefied natural gas storage container and method for manufacturing the same

ActiveUS20140069931A1Efficient storageReduce manufacturing costSolidificationLiquefactionLiquefied natural gasEngineering

Provided are an LNG storage container with an inner shell, which is capable of efficiently storing LNG or pressurized LNG (PLNG) pressurized at a predetermined pressure and supplying the LNG or PLNG to a consumption place, and capable of reducing manufacturing costs by minimizing the use of a metal having excellent low temperature characteristic, and a method for manufacturing the same. The LNG storage container includes: an inner shell configured to store LNG inside; an outer shell configured to enclose the outside of the inner shell such that a space is formed between the inner shell and the outer shell; a support installed in the space between the inner shell and the outer shell to support the inner shell and the outer shell; and a heat insulation layer part installed in the space between the inner shell and the outer shell and configured to reduce a heat transfer.

Owner:CLUSTER LNG CO LTD

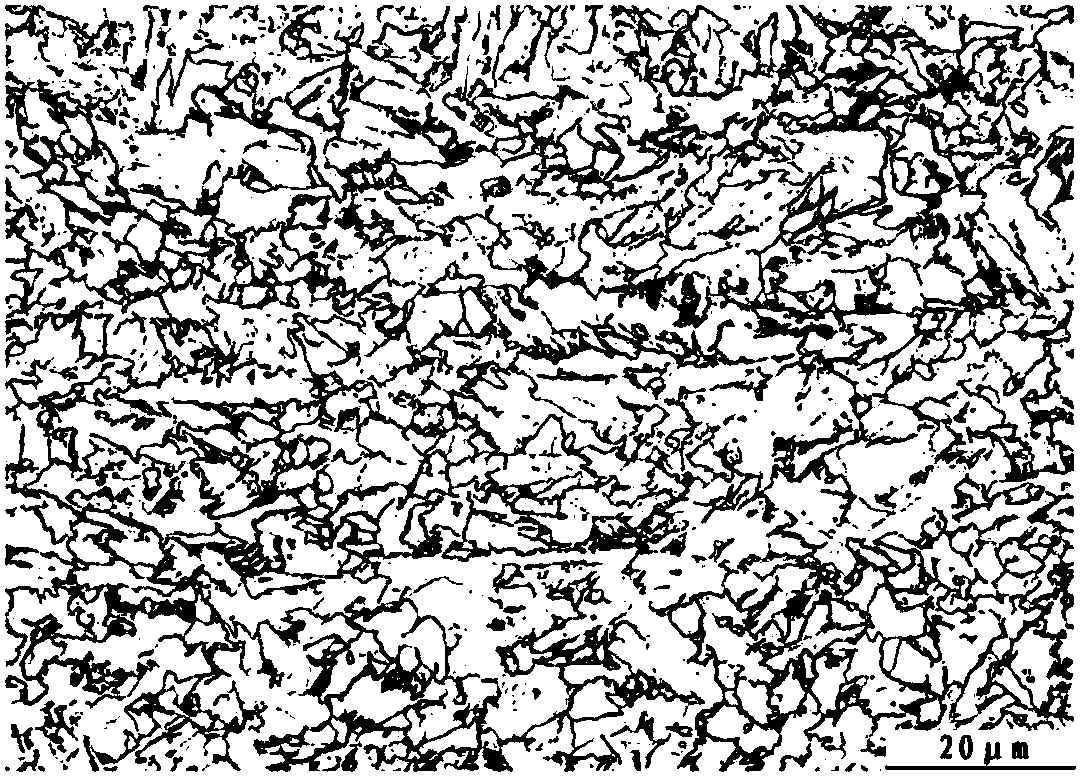

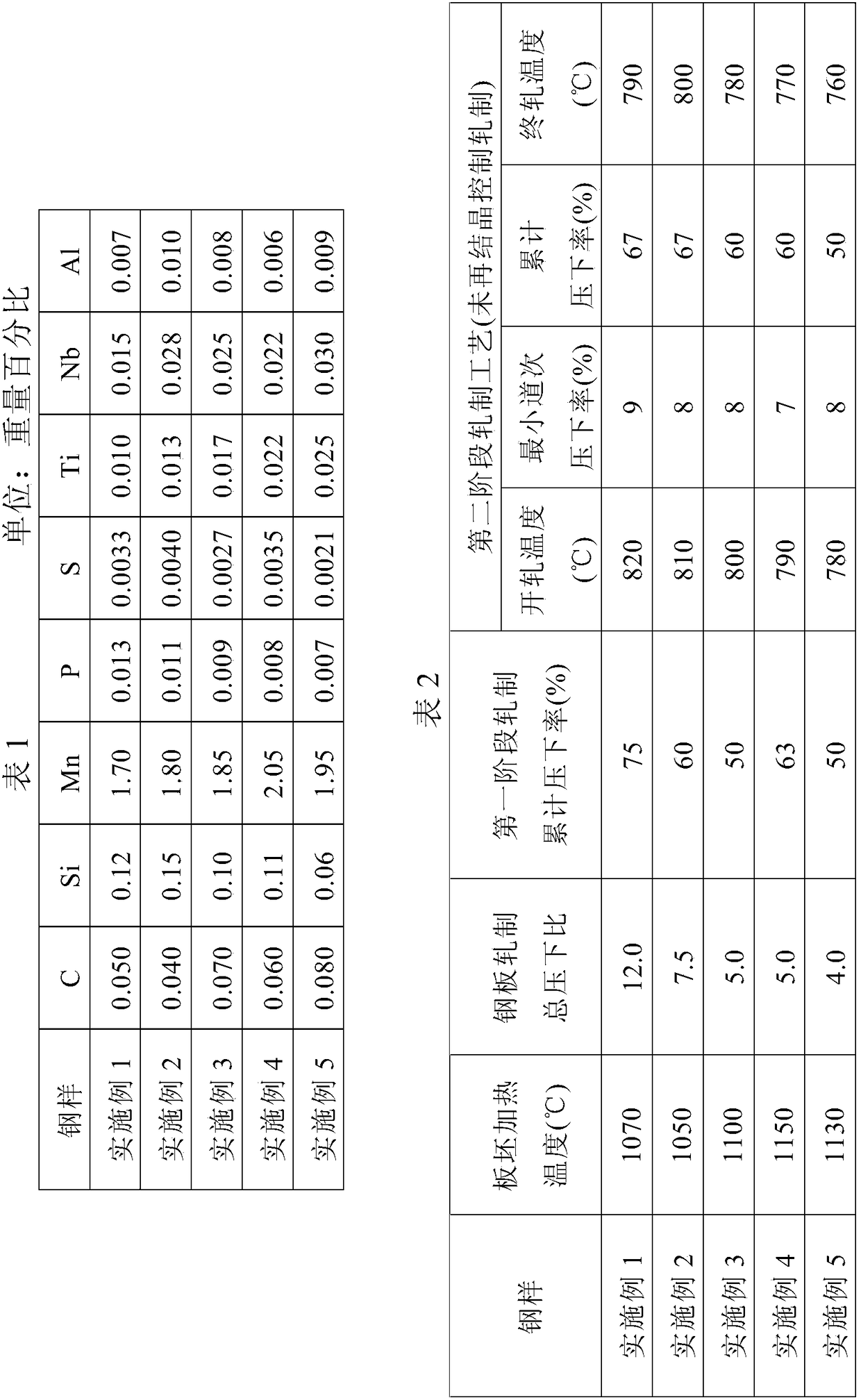

460MPa crack arresting steel plate with low cost and large heat input welding and manufacturing method thereof

The invention discloses a 460MPa crack arresting steel plate with low cost and large heat input welding and a manufacturing method thereof. The 460MPa crack arresting steel plate is prepared from thefollowing components in percentage by weight: 0.040% to 0.080% of C, less than or equal to 0.15% of Si, 1.70% to 2.05% of Mn, less than or equal to 0.013% of P, less than or equal to 0.0040% of S, 0.015% to 0.030% of Nb, 0.010% to 0.025% of Ti, less than or equal to 0. 010% of Al, and the balance of Fe and inevitable impurities. According to the invention, ultra-low carbon C, ultra-low Si, high Mn-Nb combined low alloy steel is taken as the basis, the (%Al) is less than or equal to 0.010%, micro Ti treatment is carried out, DI*T cold opening*Vc) / T stop cooling is more than or equal to 11.5 andless than or equal to 26.5, (%Mn)*Ceq is more than or equal to 0.55 and less than or equal to 0.85, TMCP process is optimized, the yield strength of the steel plate is more than or equal to 460MPa, the tensile strength is more than or equal to 550MPa, Charpy impact energy (Single value) at -40 DEG C is more than or equal to 100J, Kca at -10 DEG C) is more than or equal to 6,500N / mm<1.5>, and large heat input welding and ultra-low cost manufacturing can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

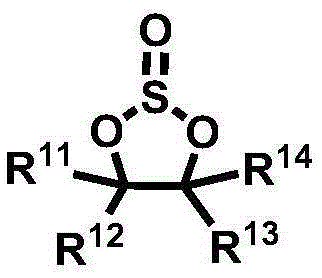

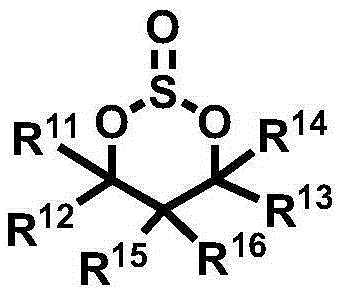

Additive for electrolytic solution, non-aqueous elecrolytic solution using said additive and secondary cell

InactiveCN1474476AImprove life characteristicsHigh flash pointSecondary cellsDecompositionPhysical chemistry

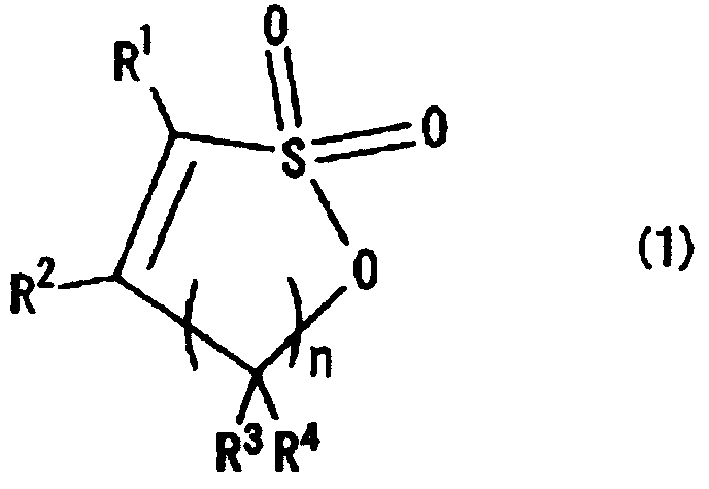

The purpose of this invention is to provide an electrolyte capable of suppressing decomposition of a solvent on he negative pole, suppressing energy reduction, gas and load charcteristic going worse to provide a nonaqueous electrolyte providing excellent load property and low temperature property to the battery, and provide a secondary battery containing the electrolyte and additives for it characterizing in containing unsaturated sultone nonaqueous electrolyte and secondary battery using this electrolyte and its additives composed of same compositions.

Owner:MITSUI CHEM INC

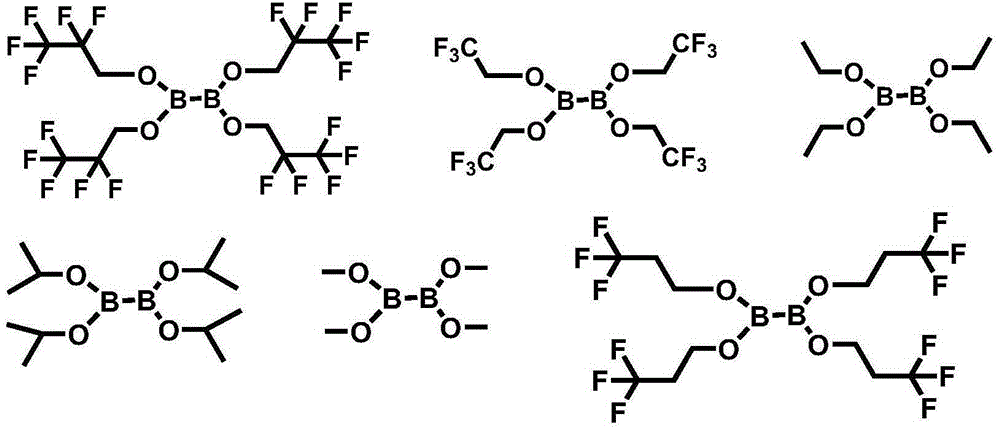

Electrolytic Solution

InactiveUS20090291364A1Good low temperatureSolve the lack of withstand voltageHybrid capacitor electrolytesElectrolytic capacitorsHalogenHydrocarbon solvents

There is provided an electrolytic solution comprising a chain carbonate (I) represented by the formula (I):wherein Rf is a fluorine-containing ether group (Ia) having, at its end, a moiety represented by the formula: HCFX (X is H or F); R is an alkyl group in which hydrogen atom may be substituted with halogen atom and hetero atom may be contained in its chain, and an electrolyte salt (II), and the electrolytic solution is excellent in flame retardance, low temperature characteristics, withstand voltage and compatibility with a hydrocarbon solvent and is high in solubility of an electrolyte salt.

Owner:DAIKIN IND LTD

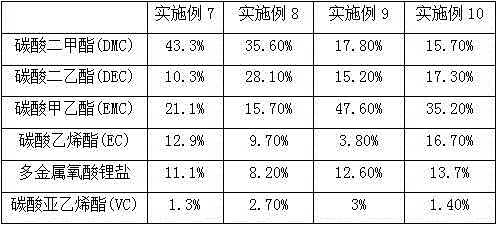

Low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries

InactiveCN102983362AIncrease migration rateGood low temperature characteristicsSecondary cellsElectrolytic agentPhosphomolybdic acid

The invention relates to a low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries, belonging to the technical field of low-temperature electrolytes for lithium batteries. The electrolyte comprises dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, ethylene carbonate, a film-forming additive and lithium polyoxometallate, wherein the lithium polyoxometallate refers to lithium phosphomolybdate Li3PMo12O40, lithium phosphotungstate Li3PW12O40, lithium silicotungstate Li4SiW12O40 or lithium silicomolybdenate Li4SiMo12O40. For solving the problems that in the prior art, the lithium ion transport of an electrolyte is blocked, slow in speed and low in efficiency and the electrolyte is poor in low-temperature performance, the invention provides a novel fluoride-free low-temperature electrolyte for LiFePO4 lithium-ion batteries; and by taking the non-fluoride lithium polyoxometallate with a three-dimensional skeleton structure as an electrolytic lithium salt and selectively adopting a low-viscosity carbonate solvent, through optimized proportioning, the migration rate of lithium ions is increased, and the low temperature properties of LiFePO4 batteries can be significantly improved.

Owner:中国东方电气集团有限公司

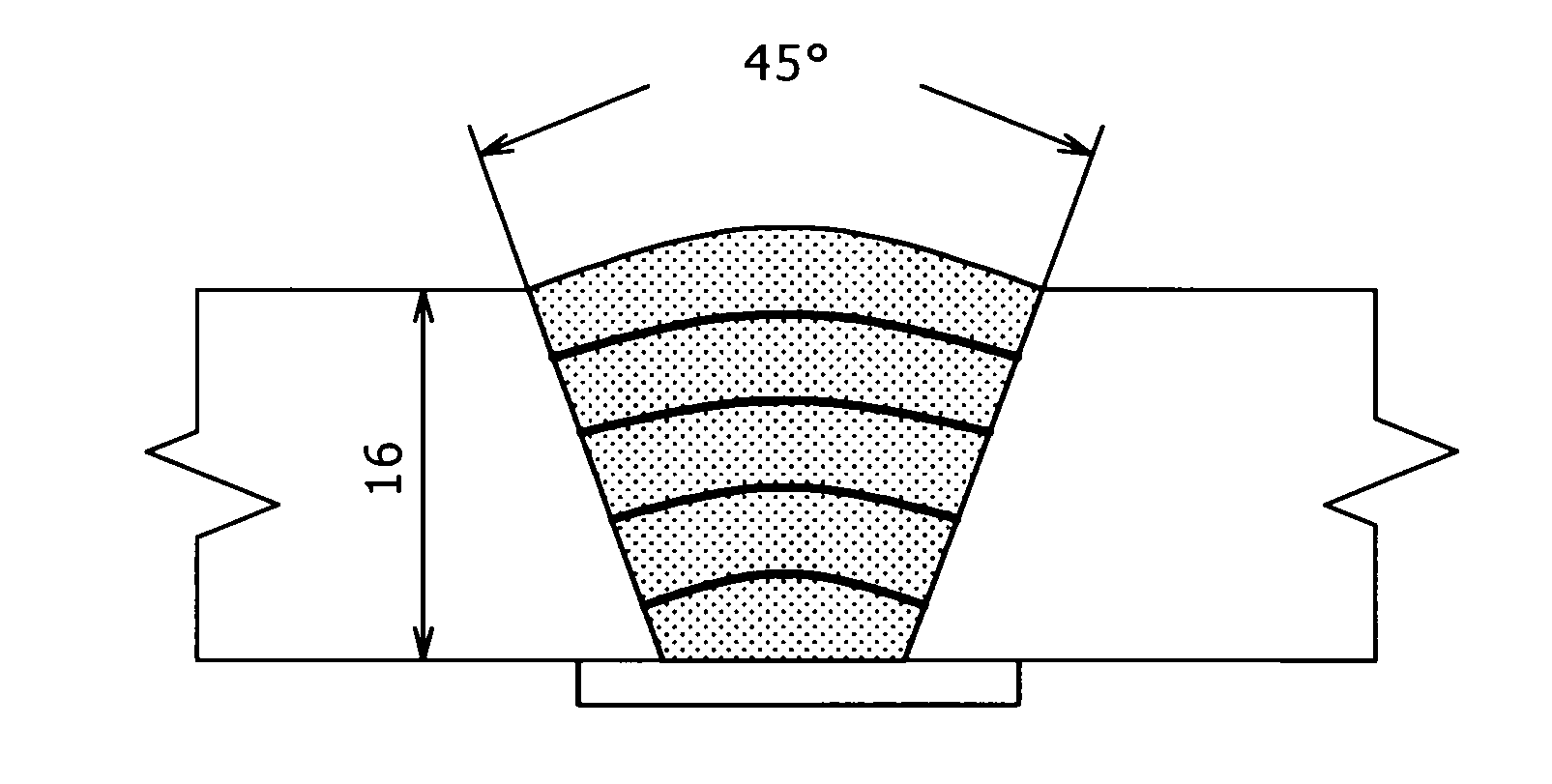

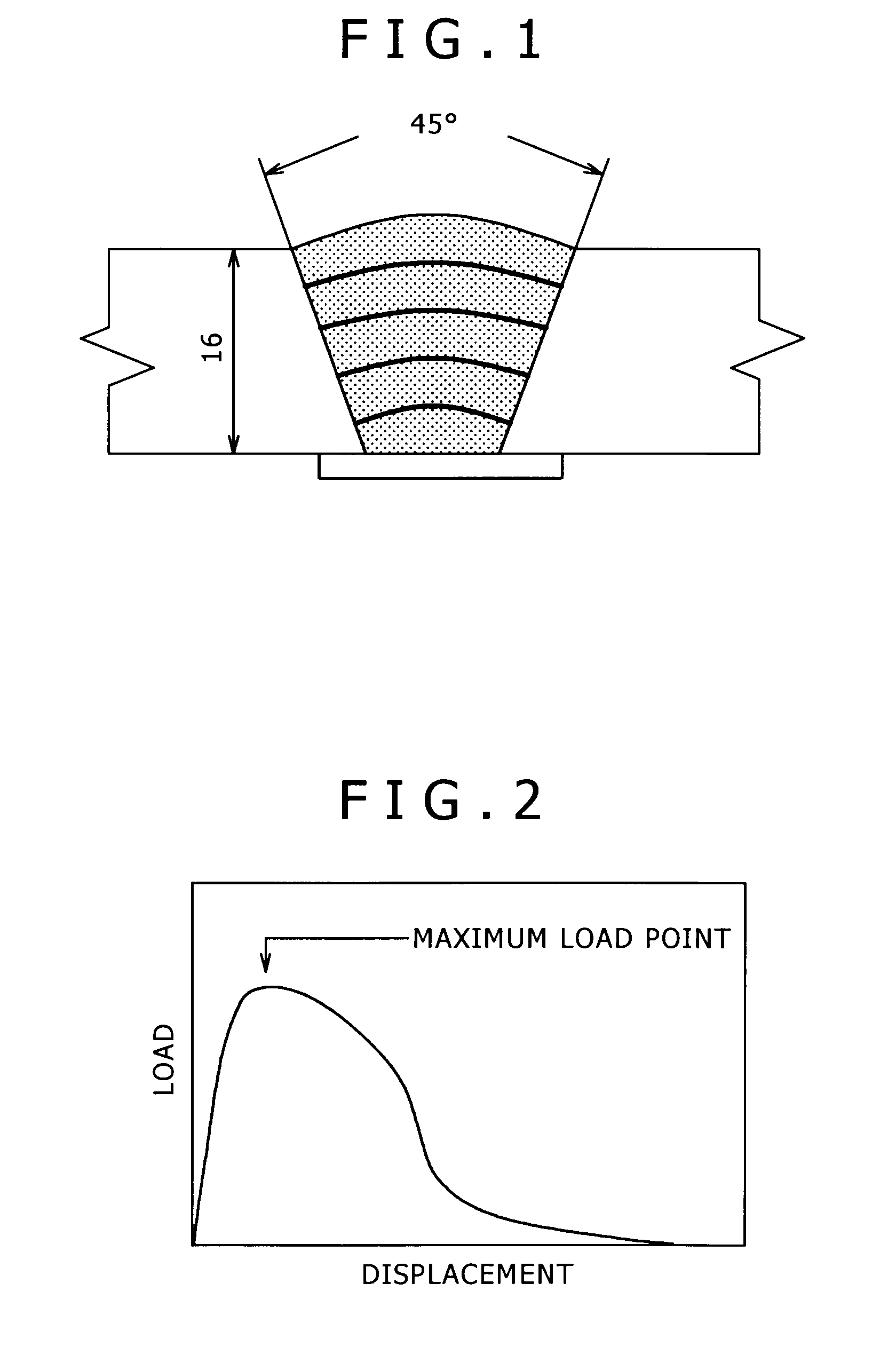

Welding solid wire

ActiveUS20100206130A1Sufficient low-temperature toughnessHigh absorption energyElectric discharge heatingWelding/cutting media/materialsManganeseOxygen

It is an object of the present invention to provide a similar composition metal type welding solid wire capable of forming a welded joint having excellent cryogenic characteristics, such as ensuring a low-temperature toughness equivalent to that of the cryogenic base metal, and in addition, further having a high crack initiation resistance, and a weld metal thereof. The welding solid wire of the present invention is an iron base welding solid wire including carbon: 0.10 mass % or less (not inclusive of 0%), silicon: 0.15 mass % or less (not inclusive of 0%), nickel: 8.0 to 15.0 mass %, manganese: 0.10 to 0.80 mass %, and Al: 0.1 mass % or less (not inclusive of 0%), and oxygen in an amount of 150 ppm or less (inclusive of 0), characterized by including: a REM: 0.005 to 0.040 mass %, or chromium: 4.0 mass % or less (not inclusive of 0%).

Owner:KOBE STEEL LTD

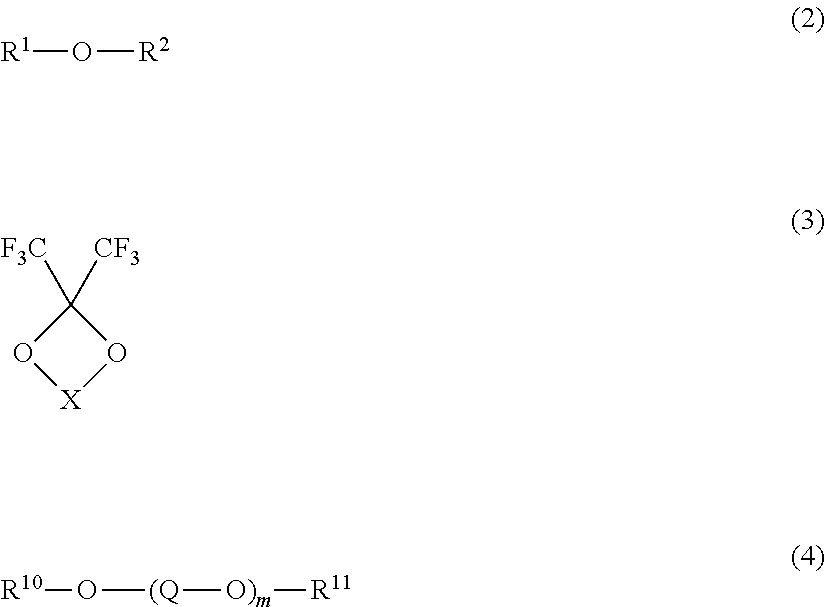

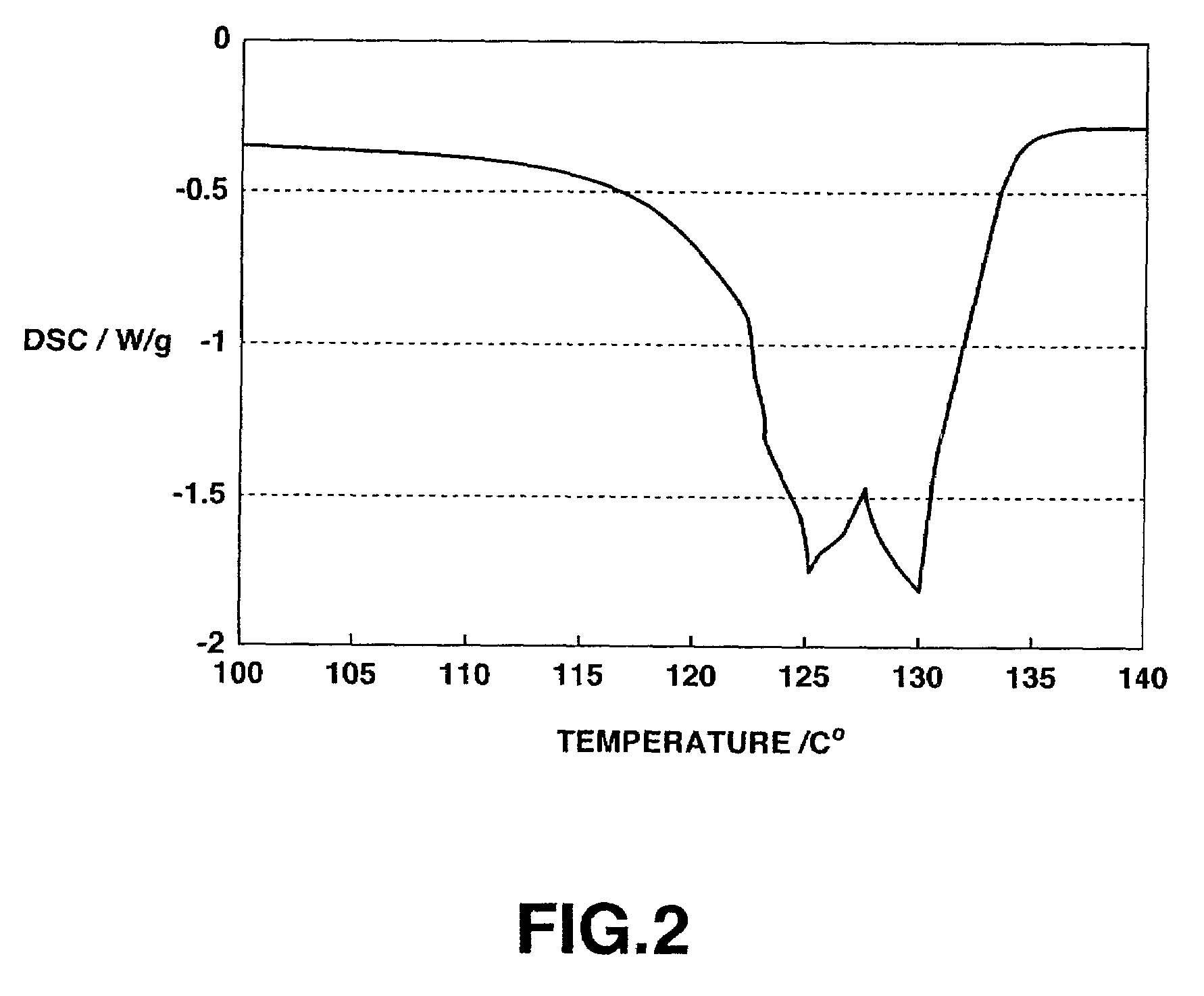

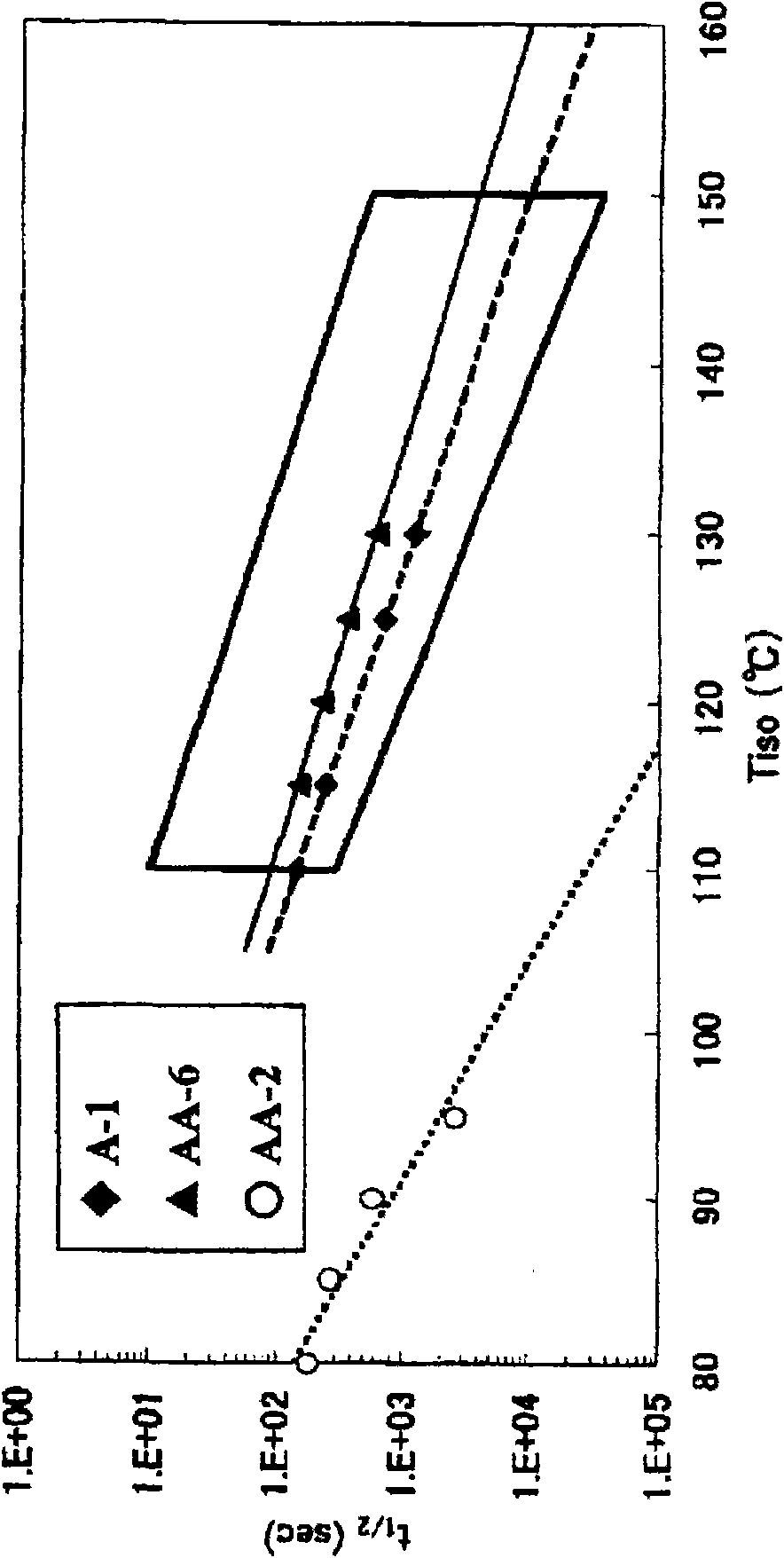

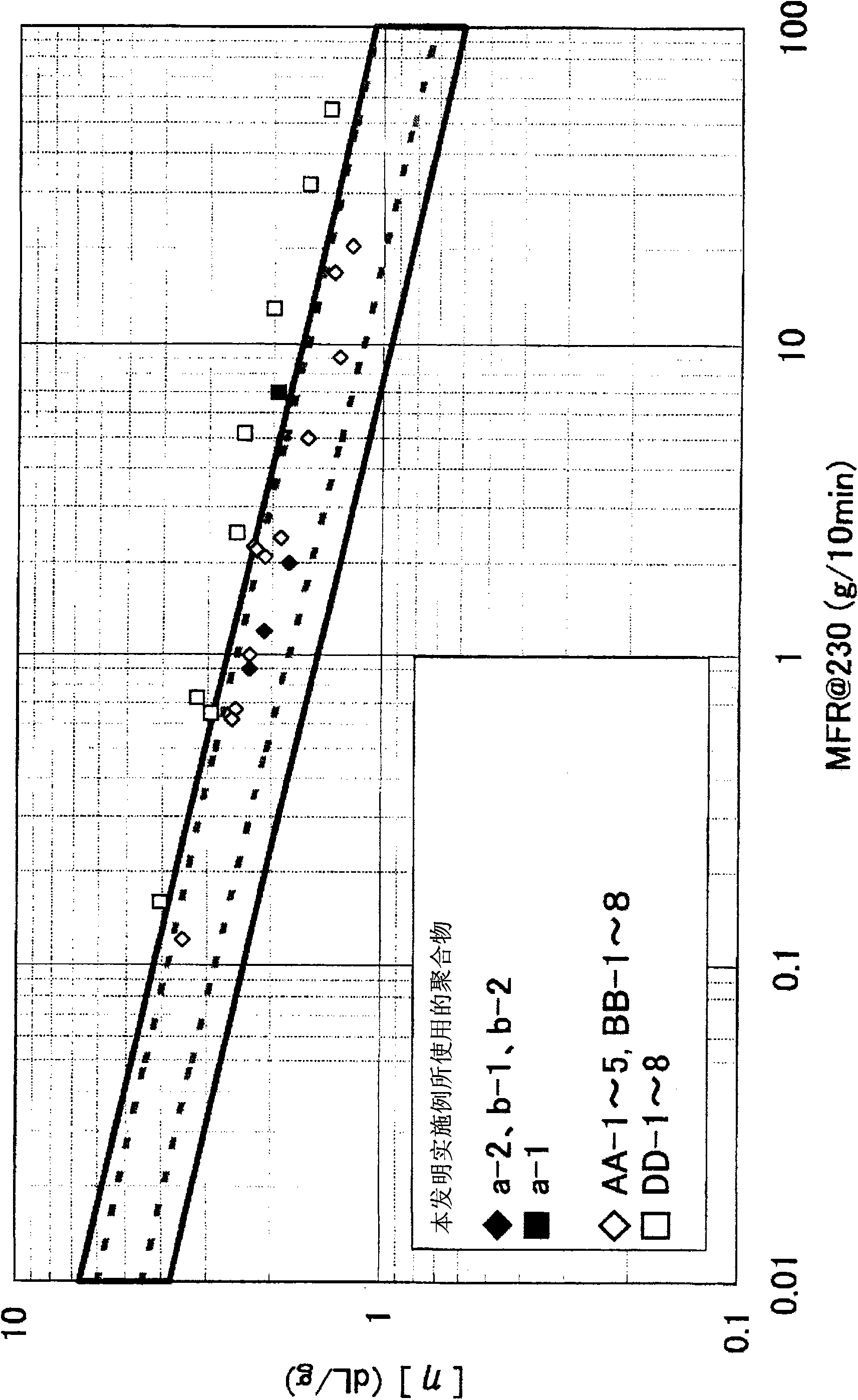

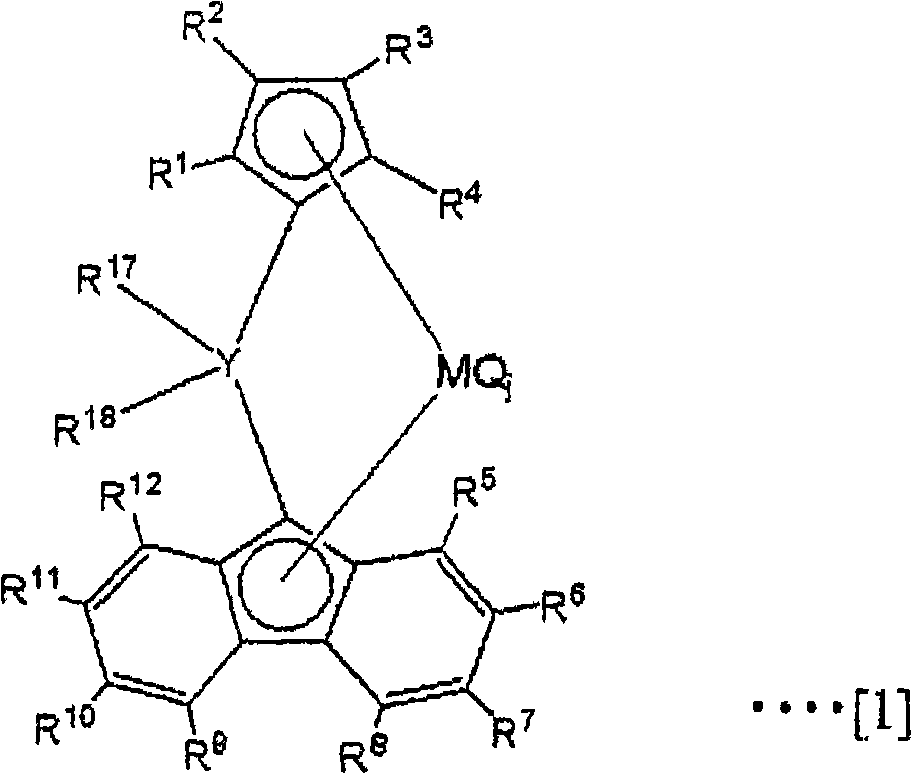

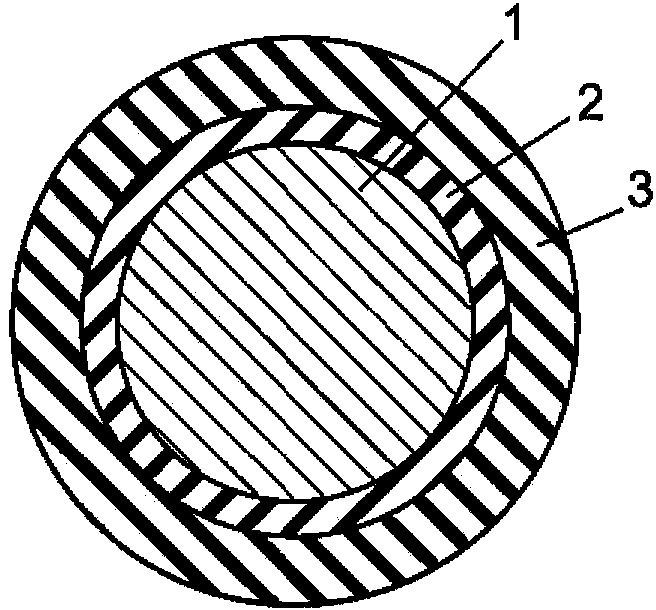

Propylene resin composition, method for producing propylene resin composition, propylene polymer composition, molded body made of the propylene resin composition, and electric wire

ActiveCN101595176AGood flexibilityHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesElastomerPropylene Polymers

Disclosed is a propylene resin composition characterized by containing 0-80% by weight of a propylene polymer (A) having a melting point not less than 100 DEG C as measured by a differential scanning calorimeter, 5-85% by weight of a specific soft propylene copolymer (B), 0-40% by weight in total of one or more elastomers (C) selected from ethylene elastomers (C1) and styrene elastomers (C2), and 15-80% by weight of an inorganic filler (D). (In this connection, the total of the components (A), (B), (C) and (D) is 100% by weight.) This propylene resin composition contains an inorganic filler at a high ratio, and has excellent elongation at break, low temperature characteristics, whitening resistance, scratch resistance, wear resistance, stress absorption and flame retardance in addition to good flexibility.

Owner:MITSUI CHEM INC

Novel environmental protection TPU advertising cloth

InactiveCN107489040ARealize comprehensive utilizationEasy to cleanTextiles and paperPolyesterUltraviolet

The invention discloses a novel environmental protection TPU advertising cloth, which comprises a base cloth and TPU films at two sides of the base cloth. The TPU film comprises the following components in parts by weight: 50-65% of thermoplastic polyurethane, 5-10% of aliphatic diisocyanate, 10-20% of carboxymethylcellulose sodium, 5-10% of anatase-type nano titanium dioxide, 3-8% of a modified ultraviolet ray absorber, 2-5% of a butyl reclaimed rubber, 1-4% of paraffin oil, 0.5-1.2% of a flatting agent, and the balance of an environment-friendly solvent. The employed TPU material has the advantages of no odour, easy processing, and low cost, and is 100 percent recyclable, can substitute PVC, and can effectively improve the yellowing problem of the advertising cloth due to long-term irradiation; the employed modified ultraviolet ray absorber makes the ultraviolet ray transmittance being 5%, the used butyl reclaimed rubber has the efficacy for preventing shock and reducing noise, and is obtained by processing and refining the waste and old butyl rubber, the waste is used, and the used butyl reclaimed rubber has the advantages of economic performance and environmental protection; the polyester filament gridding cloth and a TPU film solution enable on-line applying through a lamination machine, and no glue is added.

Owner:安徽嘉明新材料科技有限公司

Polymer electrolyte

InactiveUS7105254B2Improve discharge characteristicsGrowth inhibitionOrganic electrolyte cellsSolid electrolyte cellsPolymer electrolytesLithium

A polymer electrolyte providing lithium secondary batteries in which growth of lithium dendrites is suppressed and batteries exhibiting excellent discharge characteristics in low to high temperature, comprising a polymer gel holding a nonaqueous solvent containing an electrolyte, wherein the polymer gel comprises (I) a unit derived from at least one monomer having one copolymerizable vinyl group and (II) a unit derived from at least one compound selected from the group consisting of (II-a) a compound having two acryloyl groups and a (poly)oxyethylene group, (II-b) a compound having one acryloyl group and a (poly)oxyethylene group, and (II-c) a glycidyl ether compound, particularly the polymer gel comprises monomer (I), compound (II-a), and a copolymerizable plasticizing compound.

Owner:NOBORU OYAMA

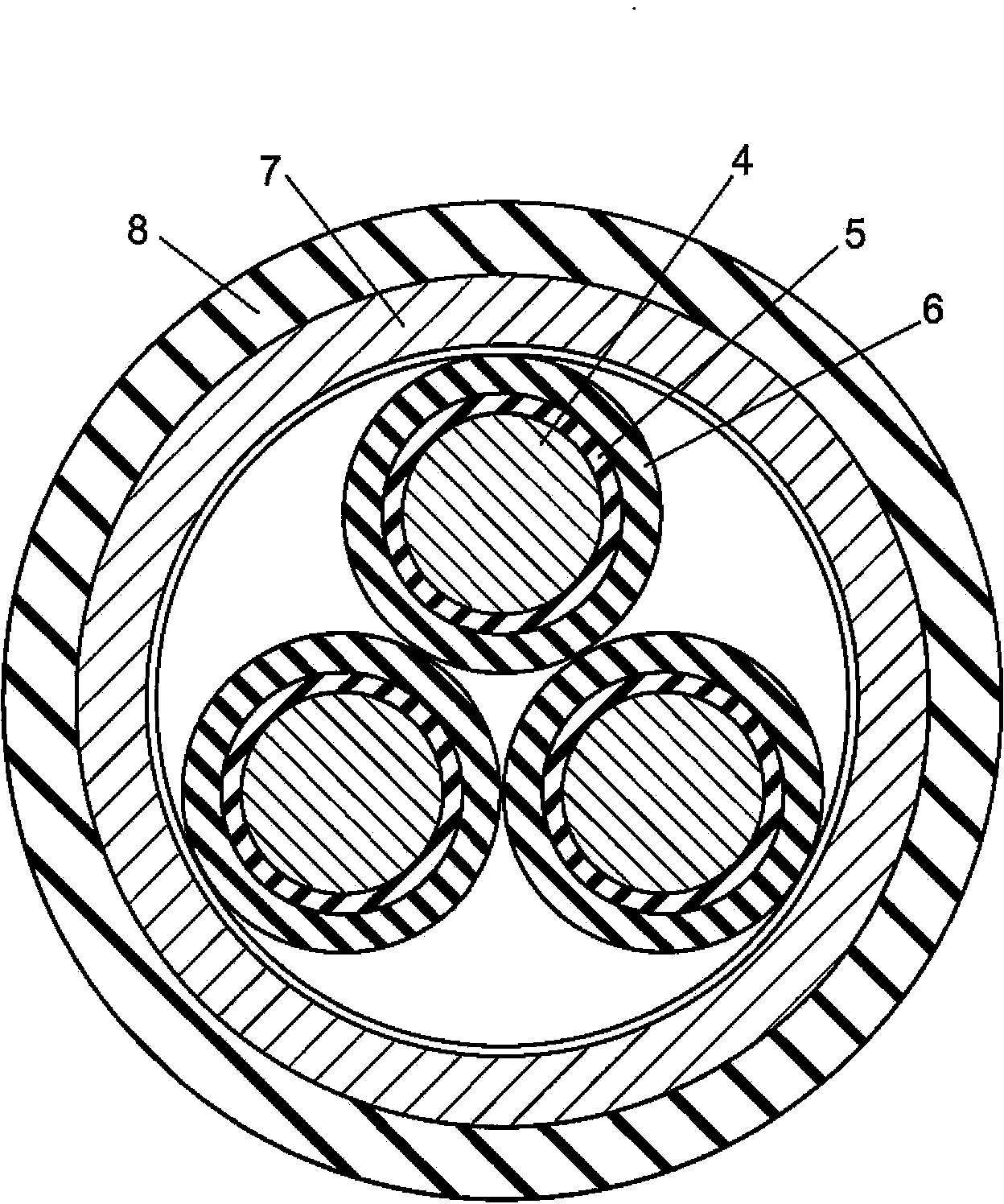

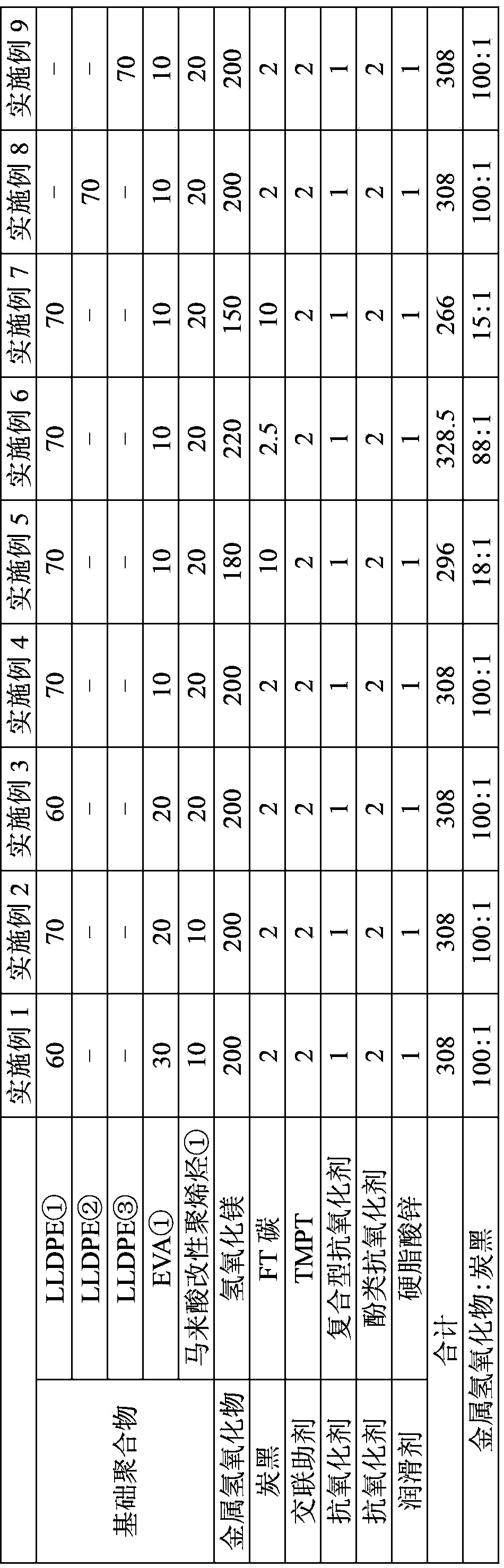

Halogen-free flame-retardant polymer composition, insulated electric wire, and cable

ActiveCN103571027AFlame retardantGood low temperature characteristicsPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyolefin

A halogen free flame-retardant polymer composition includes flame retardancy and excellent oil resistance / fuel resistance, low-temperature characteristics, and injury resistance, and an insulated electric wire and a cable include the composition. The halogen-free flame-retardant polymer composition includes a base polymer including 60 to 70% by mass of LLDPE, 10% by mass or more of EVA having a melt flow rate (MFR) of 100 or more, and 10 to 20% by mass of maleic acid-modified polyolefin, a metal hydroxide added at a ratio of 150 to 220 parts by mass relative to 100 parts by mass of the base polymer, and carbon black. The addition ratio (metal hydroxide / carbon black) between the metal hydroxide and the carbon black is 15:1 to 100:1.

Owner:HITACHI METALS LTD

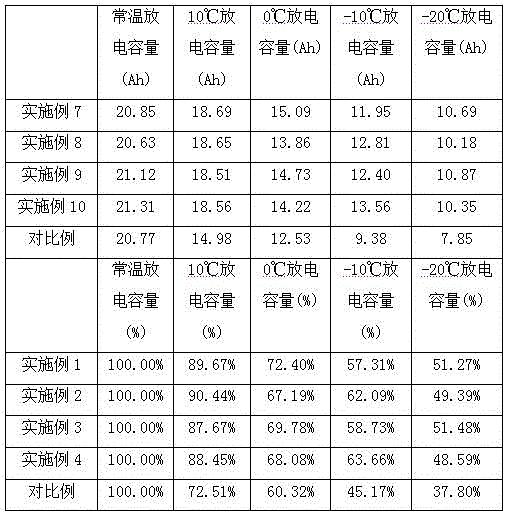

Electrolyte for lithium secondary battery and lithium secondary battery containing the same

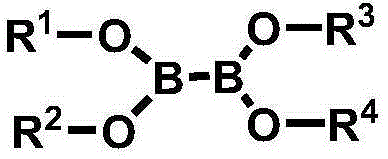

ActiveCN105428714AImprove swelling (swelling) phenomenonExcellent high temperature storage characteristicsGroup 3/13 element organic compoundsElectrolytesArylHalogen

Provided are an electrolyte for a lithium secondary battery, and a lithium secondary battery containing the same, wherein the electrolyte for a secondary battery has significantly excellent high-temperature stability, low-temperature discharge capacity, and life cycle characteristics. The electrolyte for the lithium secondary battery comprises a lithium salt; a non-aqueous organic solvent; and a boron derivative represented by the following chemical formula 1. In the chemical formula 1, R1 to R4 are each independently (C1-C10)alkyl, (C6-C12)aryl or (C6-C12)ar(C1-C10)alkyl, and alkyl, aryl, and aralkyl of R1 and R2 may be further substituted with at least one substituent selected from the group consisting of cyano, hydroxyl, halogen, (C1-C10)alkyl and (C6-C12)aryl.

Owner:SK ON CO LTD

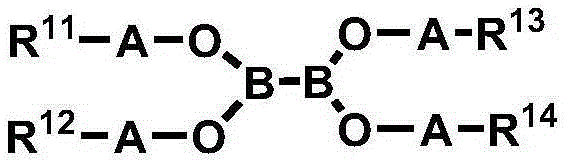

Electrolyte for Lithium Secondary Battery and Lithium Secondary Battery Containing the Same

InactiveCN105428713AImprovement of swellingExcellent high temperature storage characteristicsElectrolytesLi-accumulatorsLithiumEngineering

Provided are an electrolyte for a lithium secondary battery and a lithium secondary battery containing the same. The lithium secondary battery using the electrolyte for a lithium secondary battery according to the present invention has excellent high-temperature stability, high-temperature capacity recovery rate, low-temperature discharge capacity, and life cycle characteristics.

Owner:SK INNOVATION CO LTD

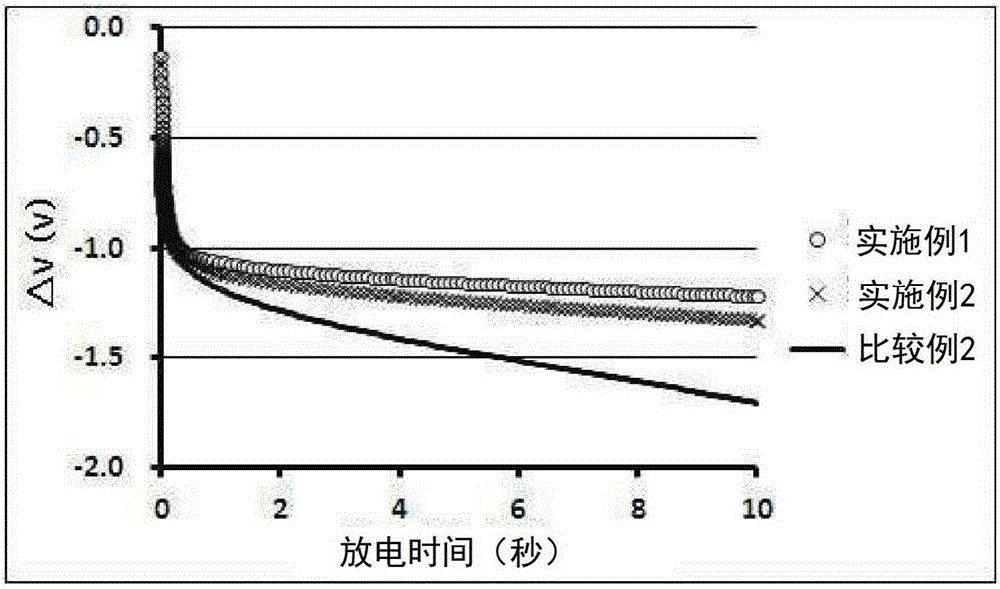

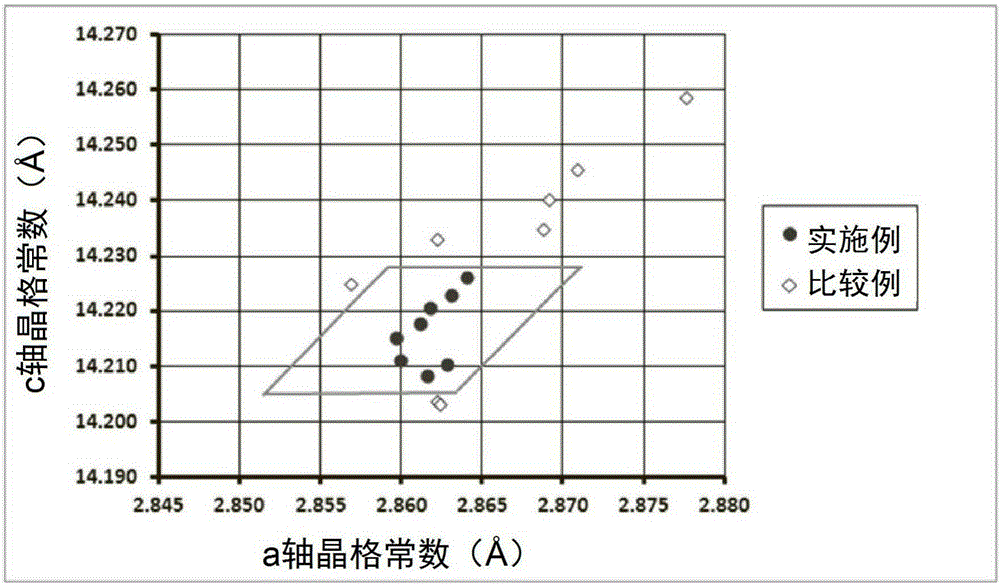

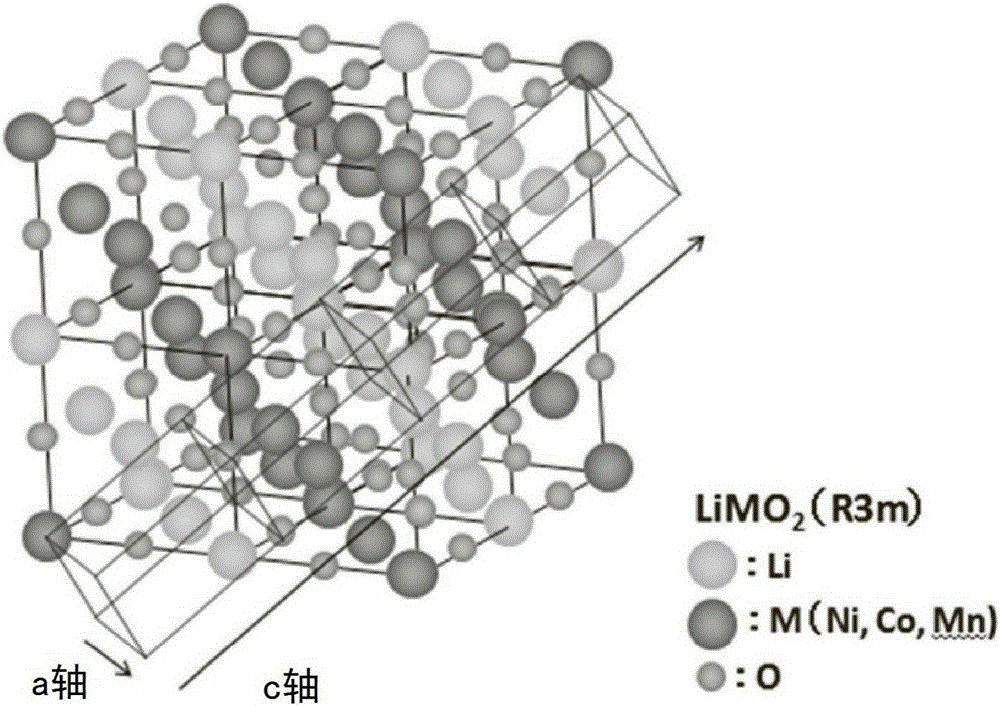

Lithium-containing composite oxide and process for its production

ActiveCN105226266AGood low temperature characteristicsPositive electrodesLi-accumulatorsCrystal structureLattice constant

To provide a lithium-containing composite oxide in which lithium ions highly diffuse in the primary particles, and which is excellent in the output characteristics at low temperature, and a process for its production. A lithium-containing composite oxide essentially containing Li, Ni, Co and Mn, which has a crystal structure with space group R-3m, with a c-axis lattice constant being from 14.208 to 14.228 not A, and with an a-axis lattice constant and the c-axis lattice constant satisfying the relation of 3a+5.615<=c<=3a+5.655, and of which the integrated intensity ratio (I003 / I104) of the (003) peak to the (104) peak in an XRD pattern is from 1.21 to 1.39.

Owner:SUMITOMO CHEM CO LTD

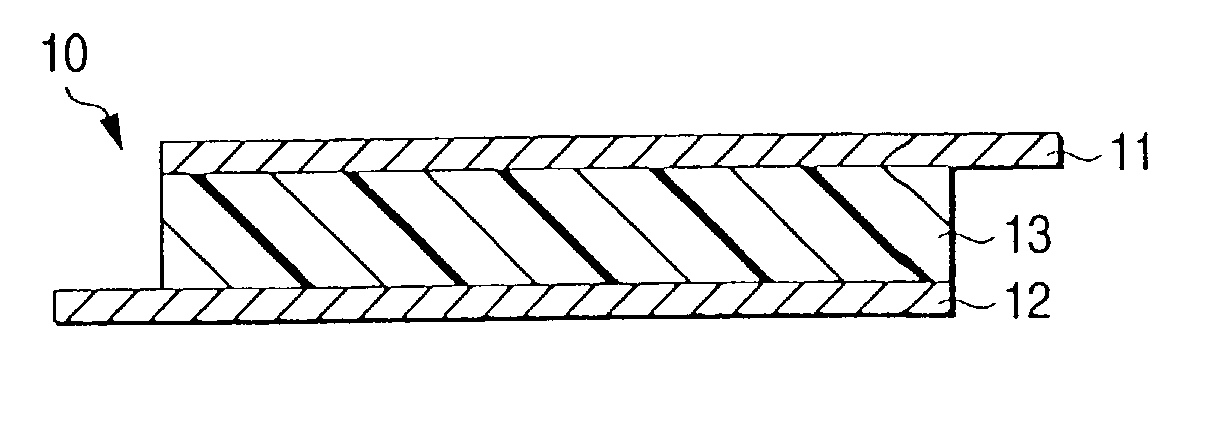

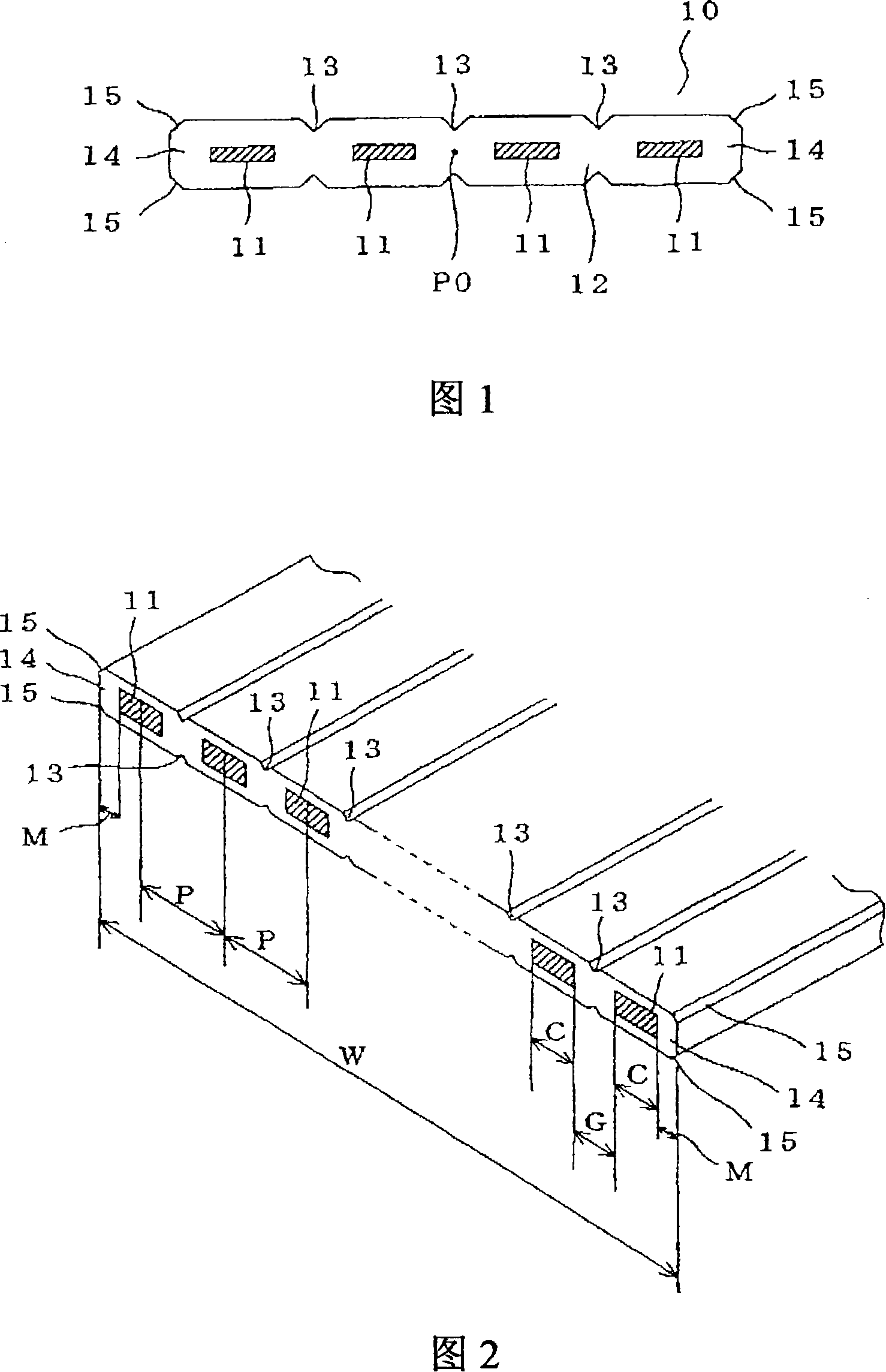

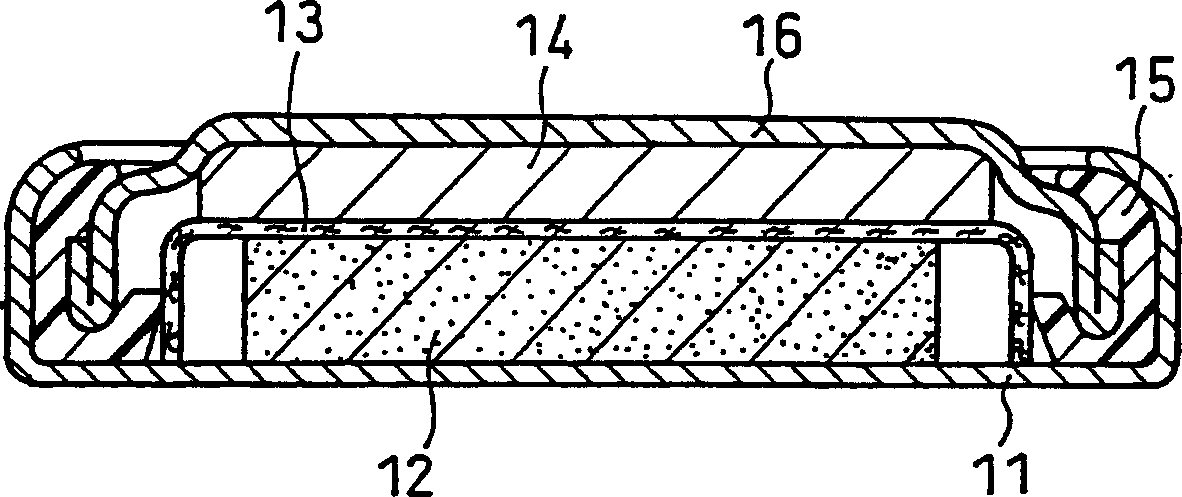

Flexible flat cable

InactiveCN101174491AImprove flame retardant performanceImprove flexibilityPlastic/resin/waxes insulatorsFlat/ribbon cablesElectrical conductorHeat resistance

A flexible flat cable is provided to facilitate division or branching into a plurality flexible flat cables with a predetermined number of straight angle conductors by including cutting grooves on both surfaces of an insulating coating along a longitudinal direction. A flexible flat cable(10) is formed by insulating coating of a plurality of straight angle conductors(11) arranged in parallel with an insulating coating material(12) at once. The insulating coating material is composed of a flame-retardance resin composition including a resin component 100 parts by weight and a metal hydroxide 40~250 parts by weight. The resin component includes a thermoplastic polyurethane elastomer with a JIS hardness of below A97 measured according to JIS K 7311 and an ethylene acetic vinyl copolymer with an acetic vinyl unit 50~90 wt% at a ratio of 40:60 to 90:10.

Owner:SUMITOMO ELECTRIC IND LTD

Negative electrode for non-aqueous electrolyte secondary battery, producing method therefor, and non-aqueous electrolyte secondary battery

ActiveCN1901260AIncrease energy densityGood low temperature characteristicsSecondary cellsActive material electrodesALLYL SUCROSEConductive materials

A negative electrode for a non-aqueous electrolyte secondary battery in the present invention includes an active material including Si, a conductive material, and a binder. The binder is polyimide and polyacrylic acid, and the conductive material is a carbon material.

Owner:PANASONIC CORP

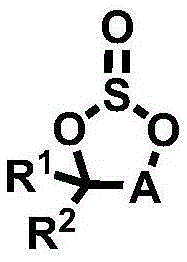

Nonaqueous electrolyte, and nonaqueous electrolyte secondary battery using same

InactiveCN102027624AImprove featuresImprove charge and discharge cycle characteristicsCell electrodesFinal product manufacturePropylene carbonateSolvent

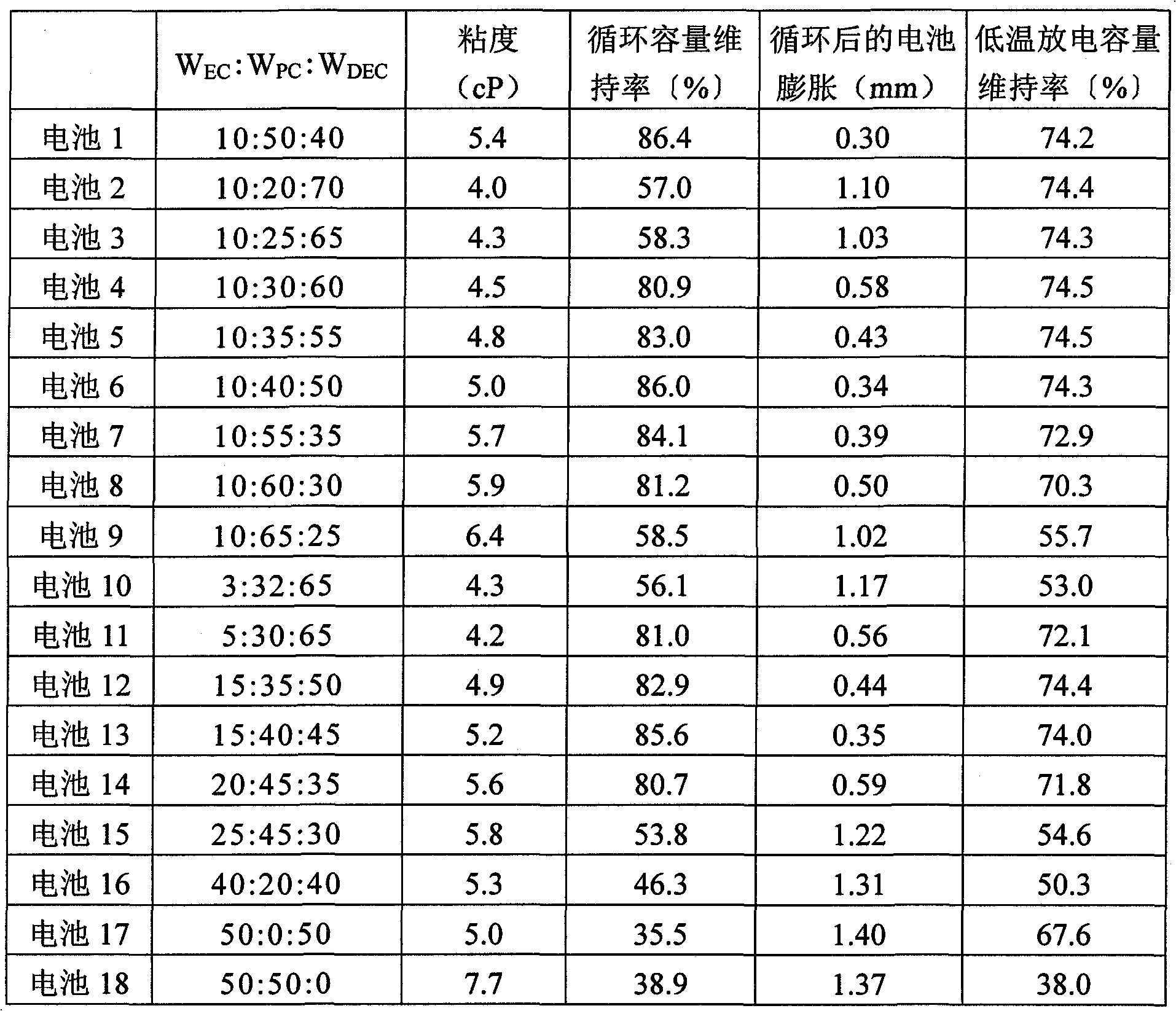

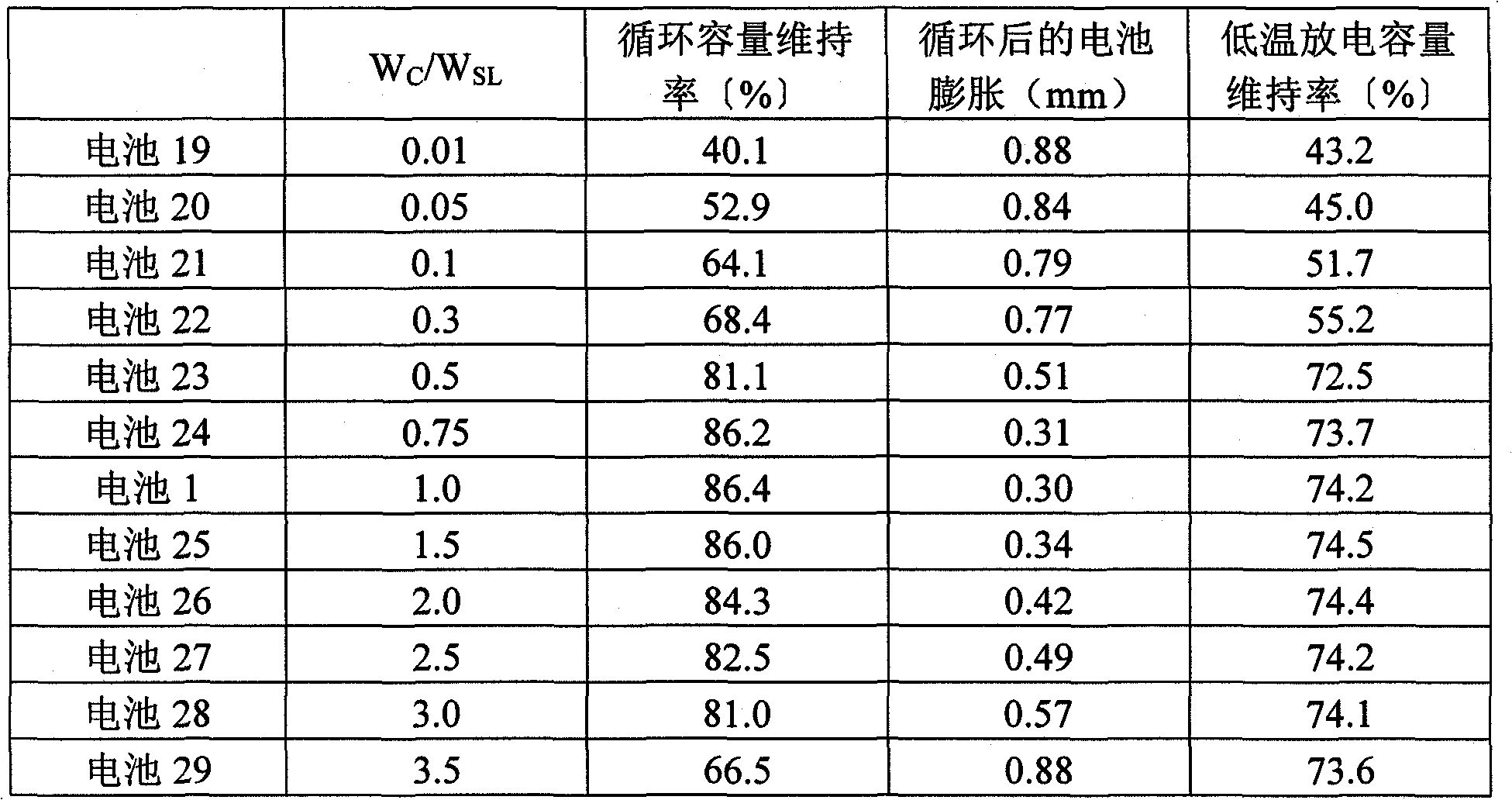

Disclosed is a nonaqueous electrolyte which is capable of satisfactorily suppressing gas generation in a nonaqueous electrolyte secondary battery when the battery is stored in a high temperature environment or during the charge / discharge cycles. The nonaqueous electrolyte contains a nonaqueous solvent and a solute dissolved in the nonaqueous solvent. The nonaqueous solvent contains ethylene carbonate, propylene carbonate, diethyl carbonate and an additive. The additive contains a sartone compound and a cyclic carbonate having a C=C unsaturated bond. The weight ratio of the propylene carbonate (WPC) in the total of the ethylene carbonate, propylene carbonate and diethyl carbonate is 30-60% by weight. The ratio of the weight ratio of the propylene carbonate (WPC) to the weight ratio of the ethylene carbonate (WEC) in the total of the ethylene carbonate, propylene carbonate and diethyl carbonate, namely WPC / WEC satisfies the following relation: 2.25 <= WPC / WEC <= 6. The weight ratio of the cyclic carbonate having a C=C unsaturated bond (WC) to the weight ratio of the sartone compound (WSL), namely WC / WSL satisfies the following relation: 0.5 <= WC / WSL <= 3.

Owner:PANASONIC CORP

Battery and cathode composition thereof

ActiveCN101777650AReduce dosageReduce rateLead-acid accumulatorsLead-acid accumulator electrodesFiberSodium lignosulfonate

The invention discloses a battery and a cathode composition thereof. The composition comprises the following components in percentage by weight: 80.8-82.6 percent of lead powder, 0.13-0.17 percent of carbon black, 0.06-0.1 percent of sodium lignosulfonate, 0.39-0.43 percent of humic acid, 0.1-0.13 percent of oxygen resistant agent, 0.32-0.5 percent of barium sulfate, 0.03-0.05 percent of short fiber, 7.1-8.0 percent of sulfuric acid and 8.9-9.9 percent of pure water. In the invention, the battery has high over-charge and over-discharge resistance and prolonged service life, and reserves simultaneously the advantages of high capacity, good large-current discharge performance, good low-temperature characteristic, and the like.

Owner:GUANGZHOU KAIJIE POWER SUPPLY INDAL

Electrolyte for non-aqueous electrolyte battery, and non-aqueous electrolyte battery using same

ActiveCN104380517AInitial feature improvementReduce free acid concentrationLi-accumulatorsVehicular energy storagePhosphatePhysical chemistry

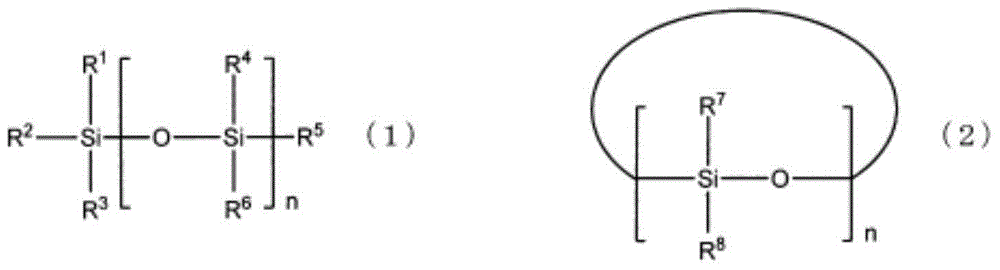

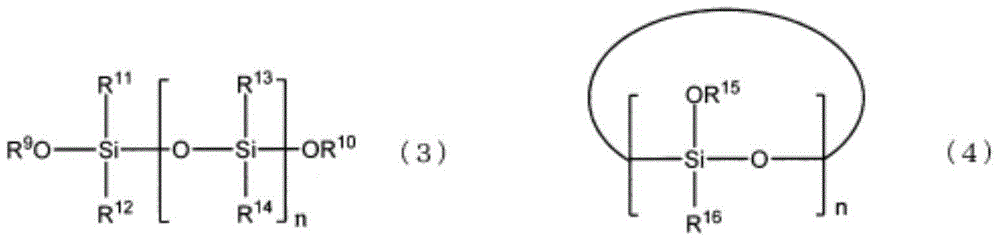

Provided is an electrolyte for a non-aqueous electrolyte battery comprising at least one compound selected from the group consisting of lithium difluoro(bis(oxalato))phosphate, lithium tetrafluoro(oxalato)phosphate, and lithium difluoro(oxalato)borate as a first compound, and at least one of the siloxane compounds represented by formulas (1) and (2) as a second compound. The electrolyte exhibits improved initial characteristics and superior storage stability and low-temperature characteristics, and yields a battery that demonstrates excellent, well-balanced overall performance.

Owner:CENT GLASS CO LTD

Lubricating oil additive, preparation method thereof and lubricating oil containing same

InactiveCN102199469AGood viscosity increasing effectHigh viscosity indexLubricant compositionViscosity indexCarbon atom

The invention relates to a lubricating oil additive, a preparation method thereof and lubricating oil containing the same. The lubricating oil additive has an acrylic acid series segmented copolymer structure and also has a general formula comprising at least one of (A-B)a, (A-B)b-A or (B-A)c-B, wherein A stands for a copolymer block consisting of (methyl) acrylic acid alkyl ester with alkyl with 1-3 carbon atoms; and B stands for a copolymer block consisting of (methyl) acrylic acid alkyl ester with alkyl with 4-30 carbon atoms, and the mass ratio of A to B is 1 / 99-40 / 60. Compared with the traditional acrylic acid series lubricating oil additive, the lubricating oil additive provided by the invention has good tackifying effect and can ensure that the viscosity index of the lubricating oil can be greatly improved with less addition amount, the low-temperature characteristics, the flowing characteristics and the shearing stability can be improved, the service life of the lubricating oil can be prolonged, energy resources can be saved, and the load on global environment is reduced.

Owner:巴鲁德(天津)润滑科技有限公司

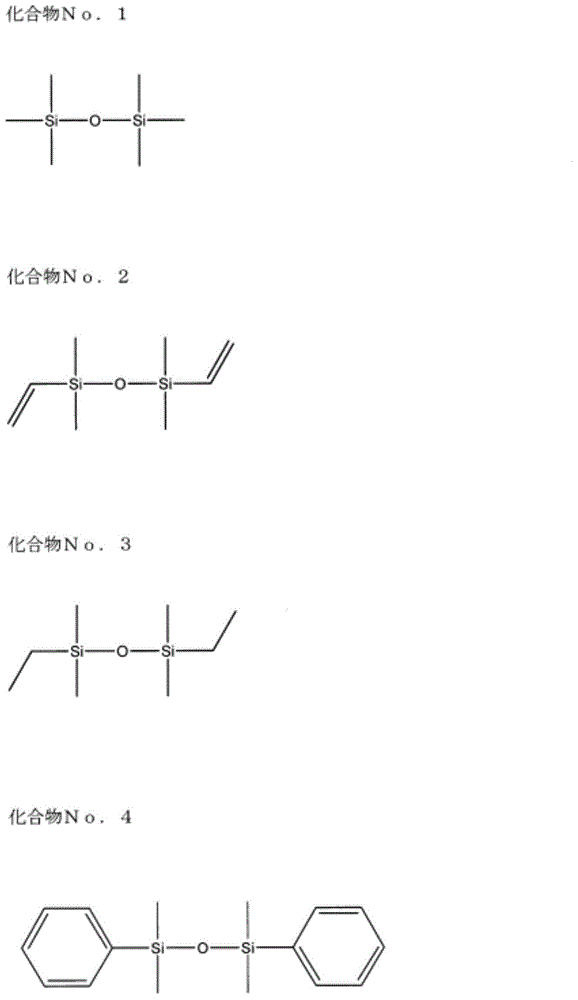

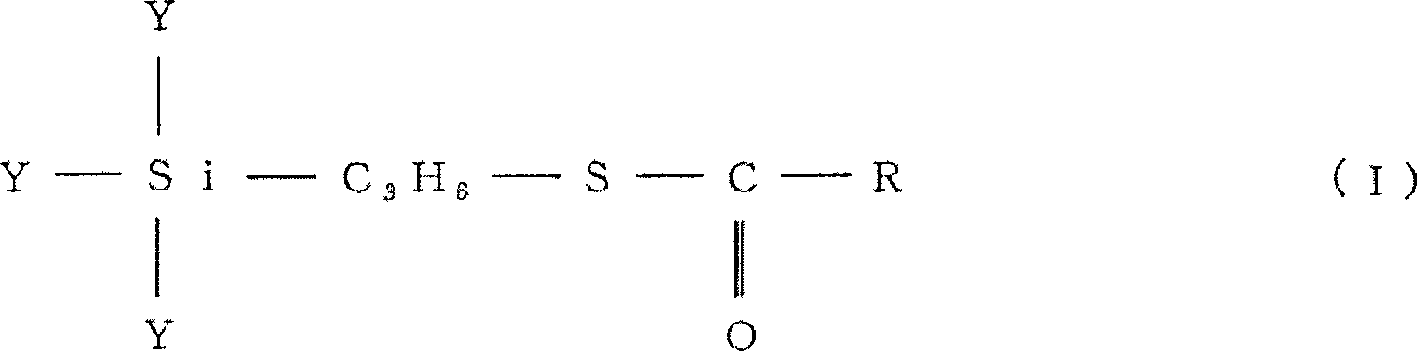

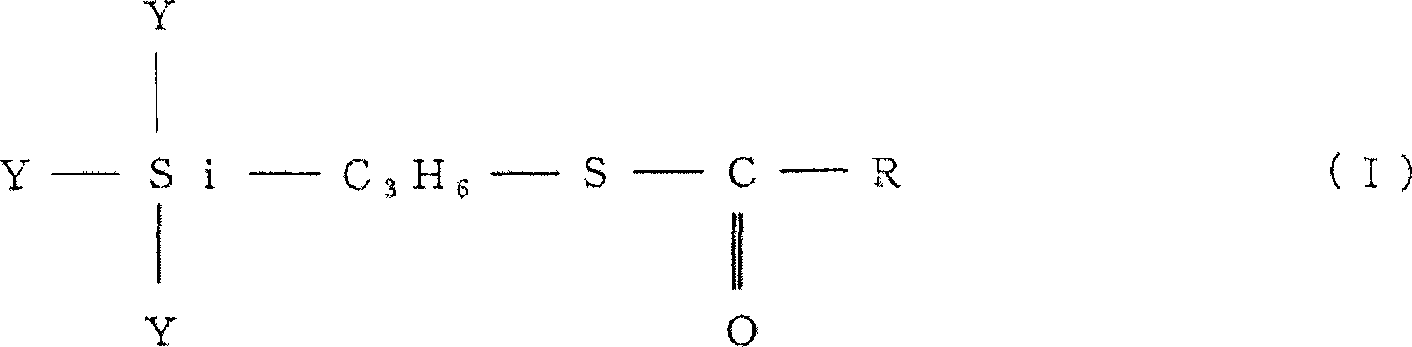

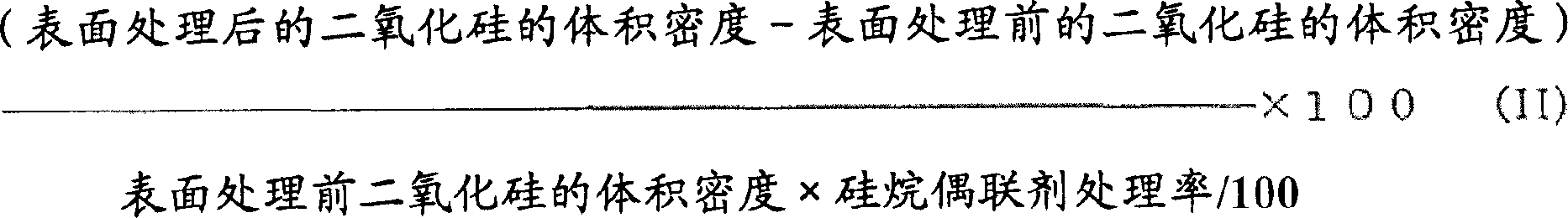

Silica treated with silane coupling agent and rubber composition containing same

InactiveCN1882504ASolve the real problemEasy to processSilicaPigment treatment with organosilicon compoundsArylSilicon dioxide

Disclosed is a surface-treated silica whose surface is treated in advance with at least one silane coupling agent X represented by the following formula (I): (wherein Y independently represents a methoxy, ethoxy, propoxy, isopropoxy, butoxy, isobutoxy or acetoxy group; R represents a C1-C18 hydrocarbon group selected from a straight chain, cyclic or branched alkyl groups, alkenyl groups, aryl groups and aralkyl groups). Also disclosed is a rubber composition comprising such a surface-treated silica and 100 parts by weight of a rubber component containing at least one diene rubber.

Owner:YOKOHAMA RUBBER CO LTD +1

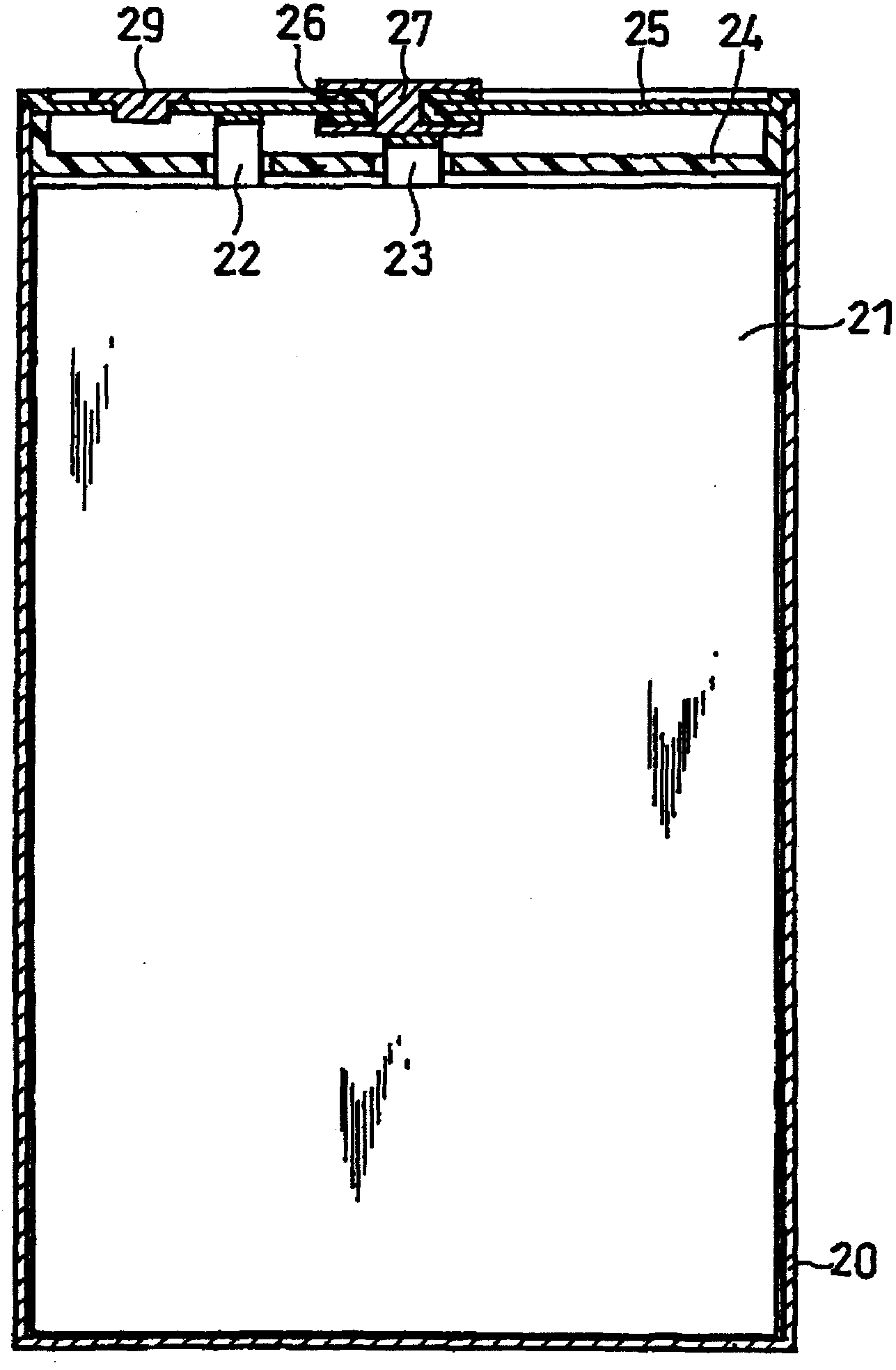

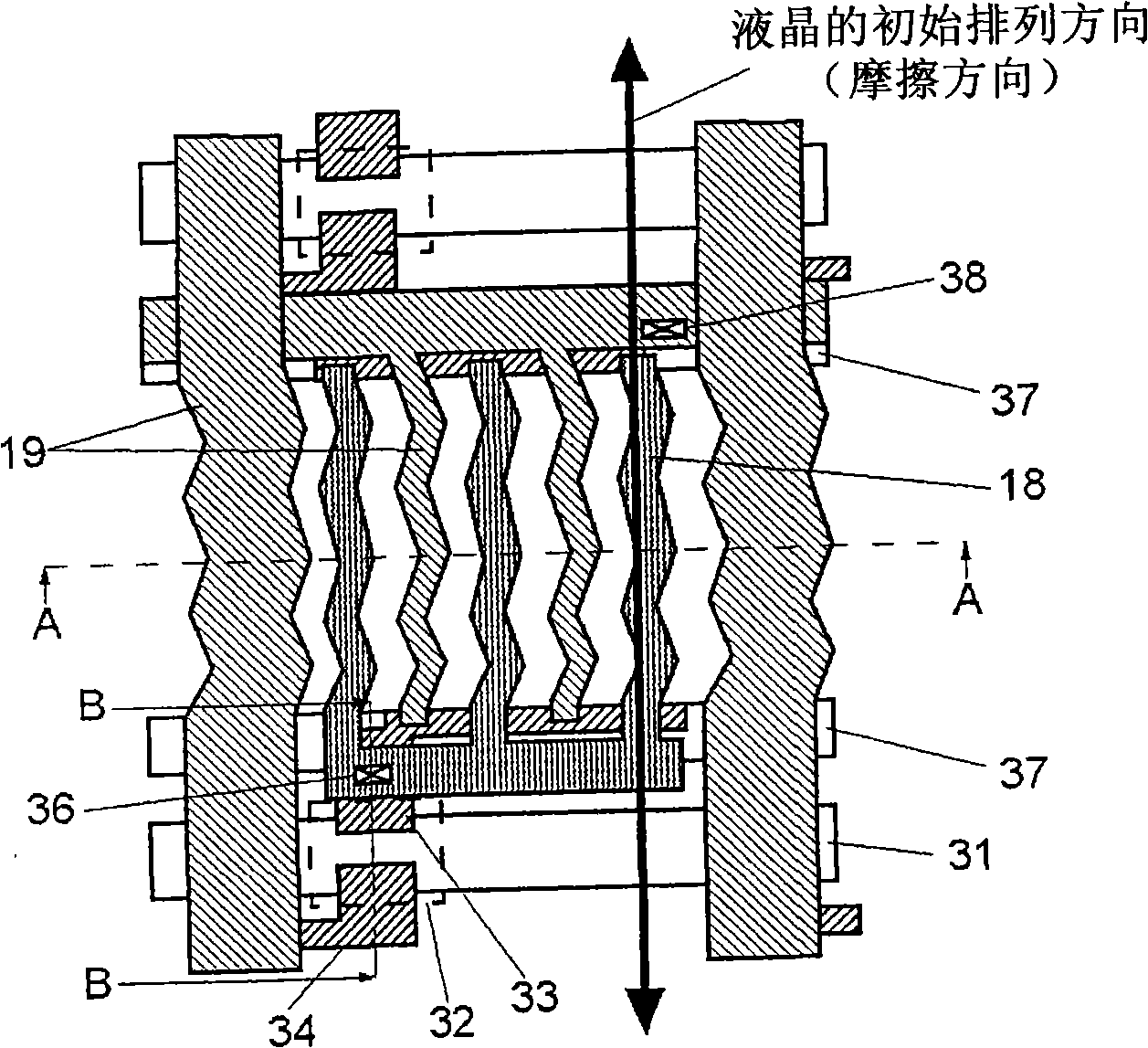

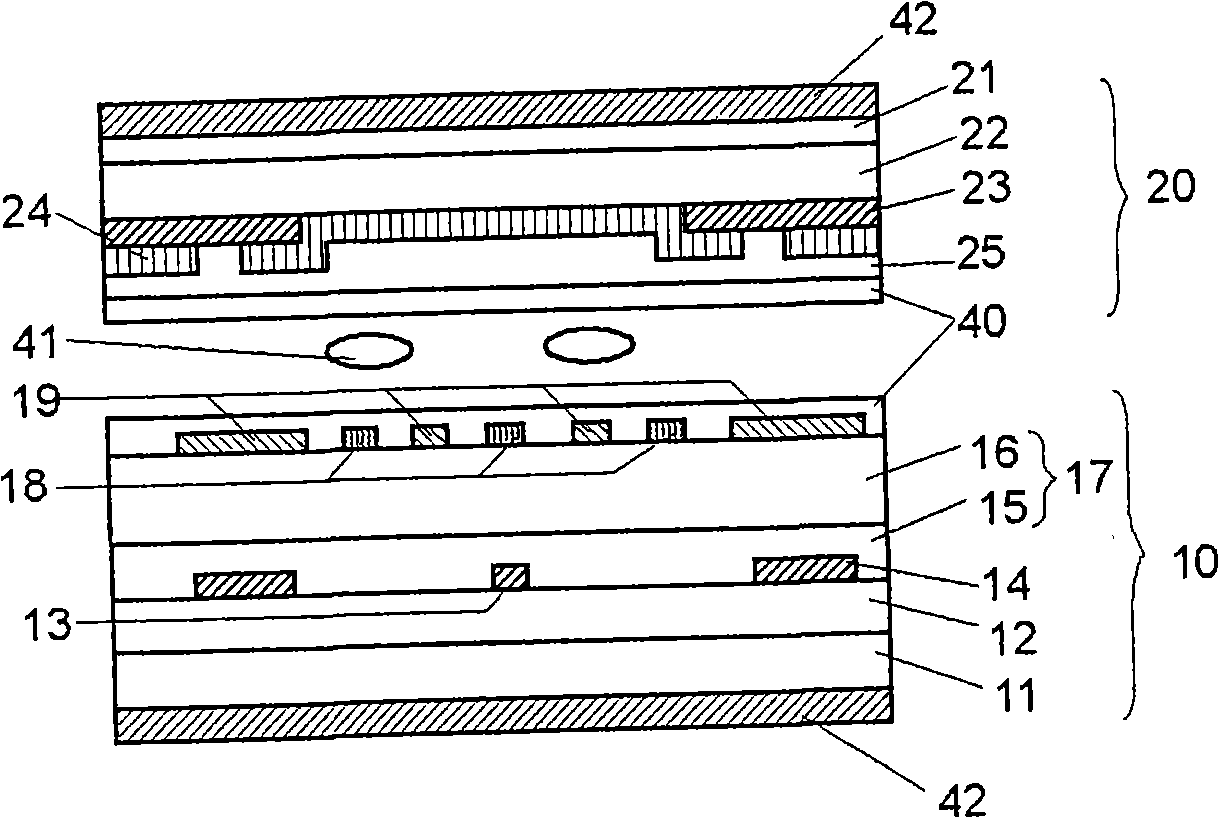

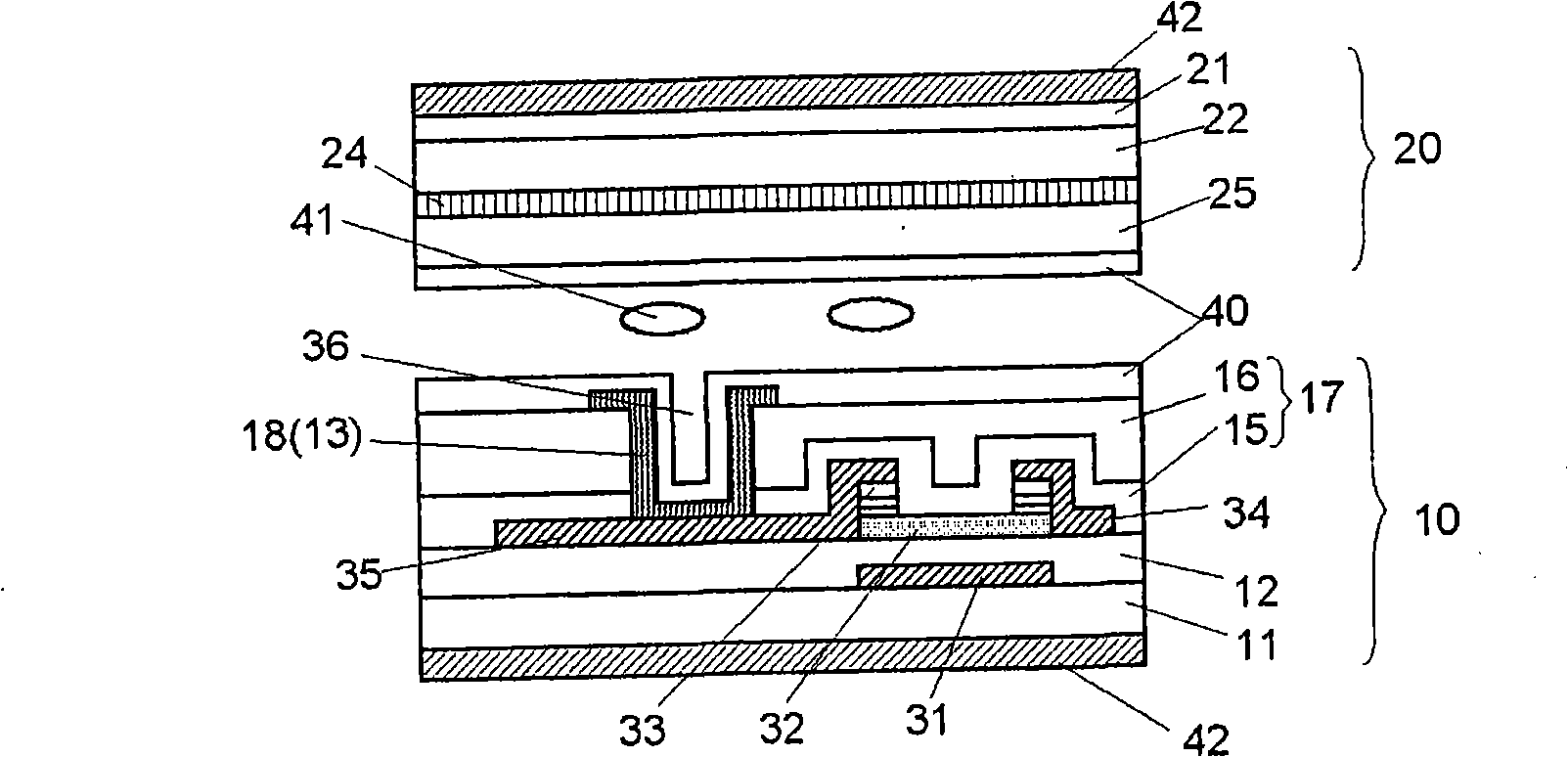

Liquid crystal display

InactiveCN101271213AAvoid formingExcellent residual image characteristicsLiquid crystal compositionsStatic indicating devicesDielectricLiquid-crystal display

The invention provides a liquid crystal display device (LCD), which is an active matrix addressing LCD, prepared by instillation and substrate assembly method, capable of preventing generation of falling trace and having excellent residual image characteristics. The dielectric constant is regulated by adding acid compounds (such as amphyl 412) into the liquid crystal compound so as to improve the residual image characteristic of pattern. The compound (such as alkoxyl compound 413) capable of forming hydrogen bond with acid compound is added to the liquid crystal compound in order to prevent hydrogen bond from being generated by acid compound and water 409 when the LG compound falls on the substrate, and thereby avoiding the generation of falling trace. In a successive mode, the content of phenolic compound is 0.00010N above; and the content of the alkoxyl compound is below 0.265 mol / l and 10 equivalent weight above with respect to the phenolic compound. In an interlaced mode, the content of the phenolic compound is 0.00100N above; and the content of the alkoxyl compound is 1.324 mol / l and 150 equivalent weight above with respect to the phenolic compound.

Owner:NEC LCD TECH CORP

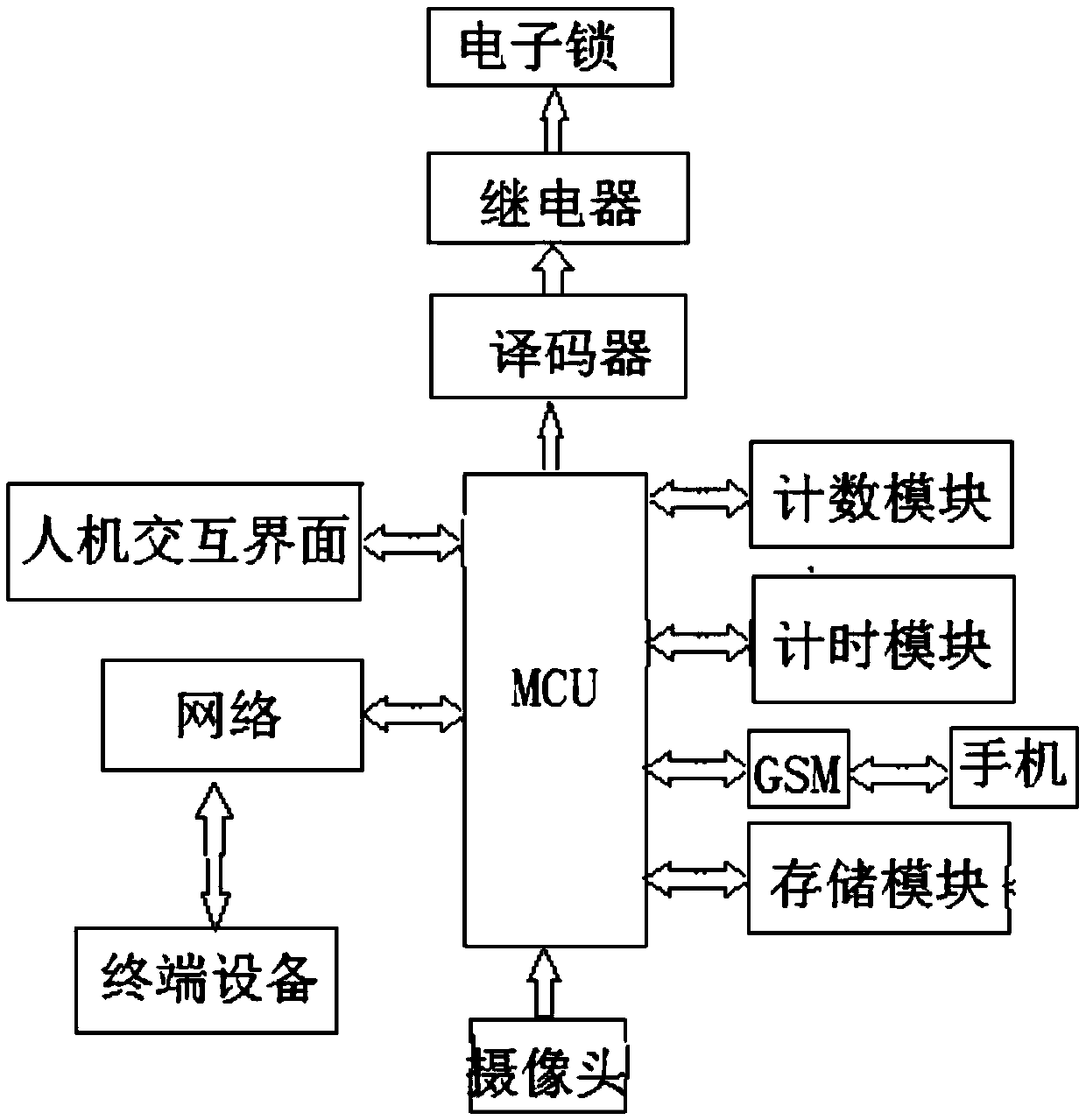

Multifunctional intelligent convenience cabinet

InactiveCN105513218AEasy to useAvoid occupyingTelephonic communicationApparatus for meter-controlled dispensingTime efficientTerminal equipment

A multifunctional intelligent convenience cabinet comprises a cabinet body with a plurality of cabinet doors; each cabinet door is provided with an electronic lock; the cabinet body is provided with a human-computer interaction interface and an MCU; the MCU, a decoder, a relay and the electronic locks are connected in sequence; the MCU is respectively connected with a camera, a GSM, a counting module, a timing module, a storage module and a network; the network is connected with a terminal device. The camera shoots a stored object and transmits to a user cellphone, after determining no problem, the user sends a message by the cellphone and opens the door of the cabinet body to store the object, the object stored into the cabinet body is in intact, and use by the user is facilitated; the counting module counts door opening times, and transmits to a manufacturer or an investor terminal, a use condition is convenient to know and count, and time and labor are saved; the timing module conveniently prompts an express which is not taken away after a set time by a short message.

Owner:TIANJIN ORION TECH CO LTD

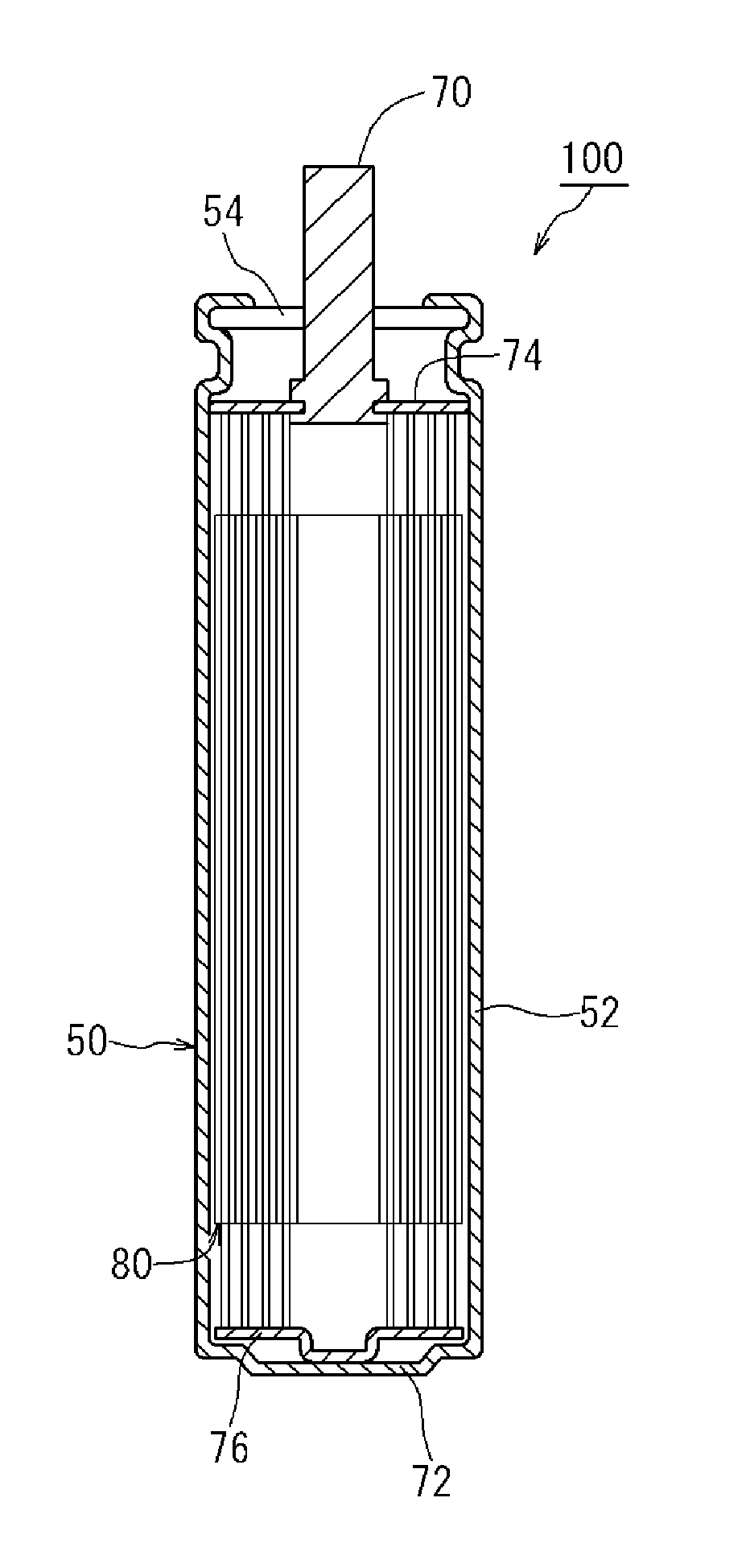

Electrode for electrochemical device and electrochemical device using the same

InactiveCN101682023AImprove featuresGood low temperature characteristicsHybrid capacitor electrodesElectrode carriers/collectorsLithiumElectrochemistry

Owner:PANASONIC CORP

Electrolyte of super battery

InactiveCN102738519ANo pollution in the processEfficient powerLead-acid accumulatorsElectrolytic agentSODIUM METAPHOSPHATE

The invention discloses an electrolyte of a super battery. The electrolyte comprises 35-50% of sulfuric acid, 1-10% of a silicate, 0.1-2% of sodium hexametaphosphate, 0.2-1% of nanometer carbon, 0.3-1.5% of cetyltrimethylammonium bromide, 0.1-1.5% of a sulfate, 0.02-0.4% of a polymeric stabilizing agent and 45-52% of water. The electrolyte of the invention allows the charging accept capability of the battery to be improved and the cycle life of the battery to be obviously improved. The electrolyte has the advantages of no generation of corrosive gases in the production process, realization of no pollution in the preparation process and the use process and no pollution of wastes, and fundamental solving of main disadvantages of electrolytes of traditional lead acid batteries.

Owner:TIANNENG GRP JIANGSU TECH

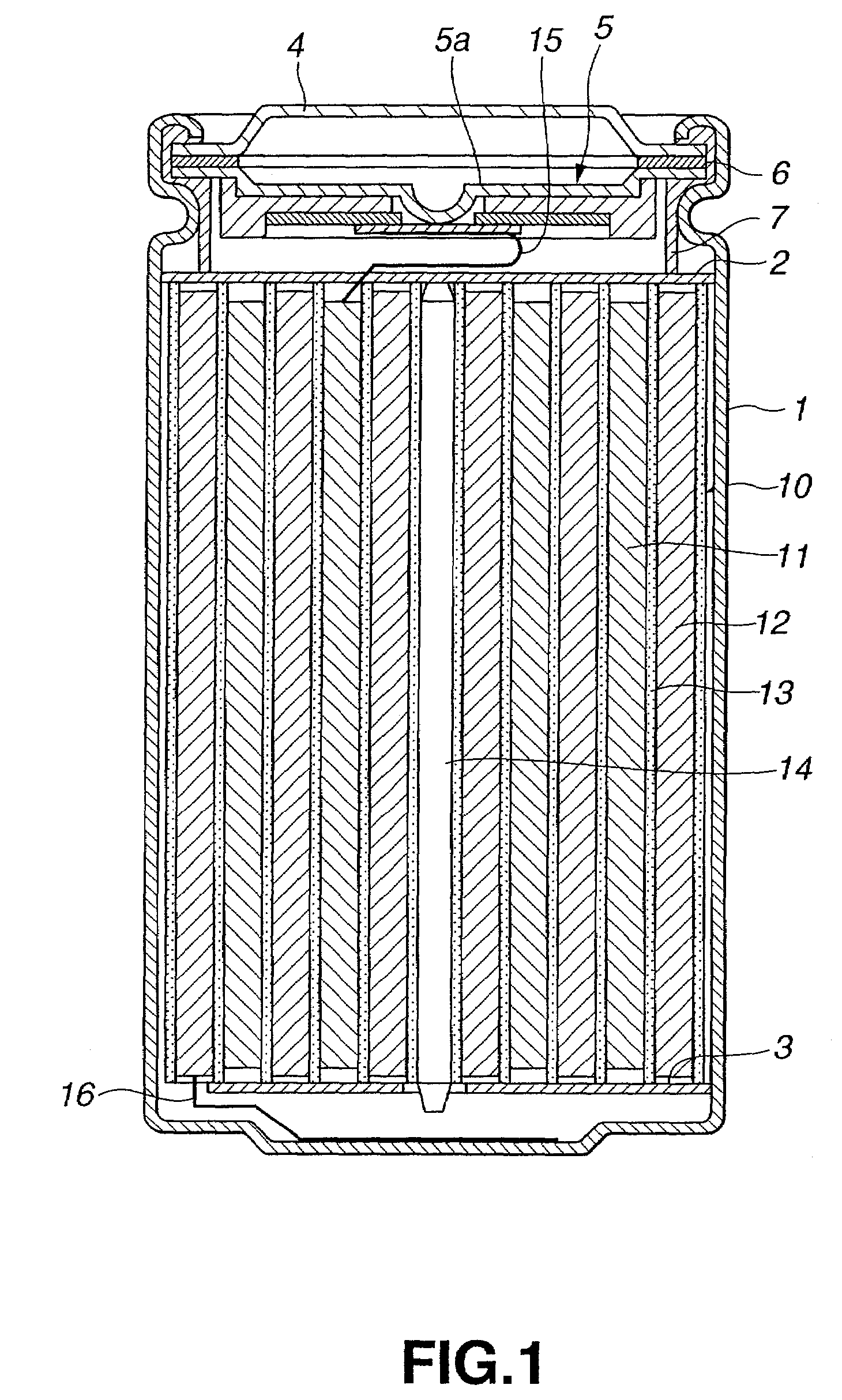

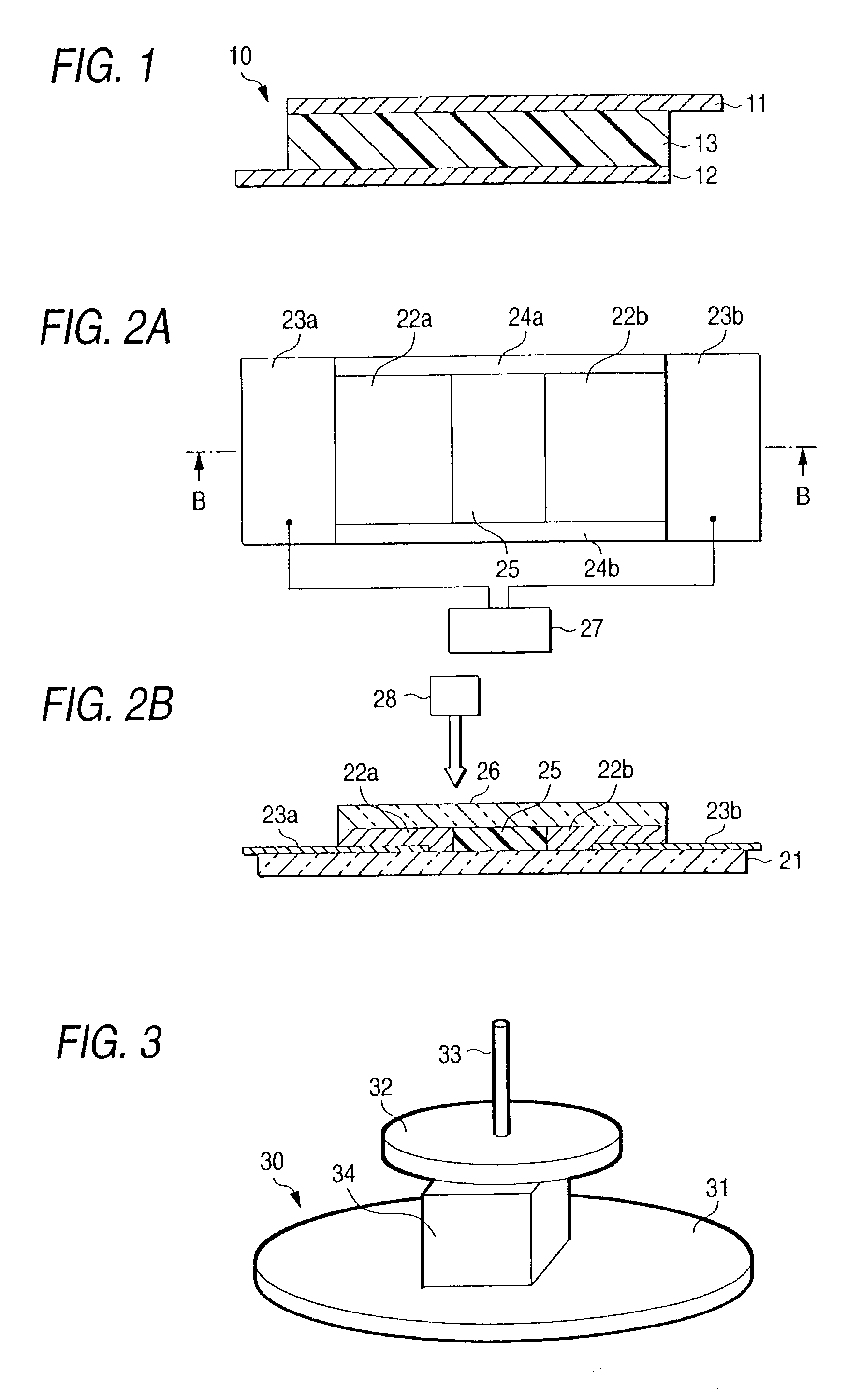

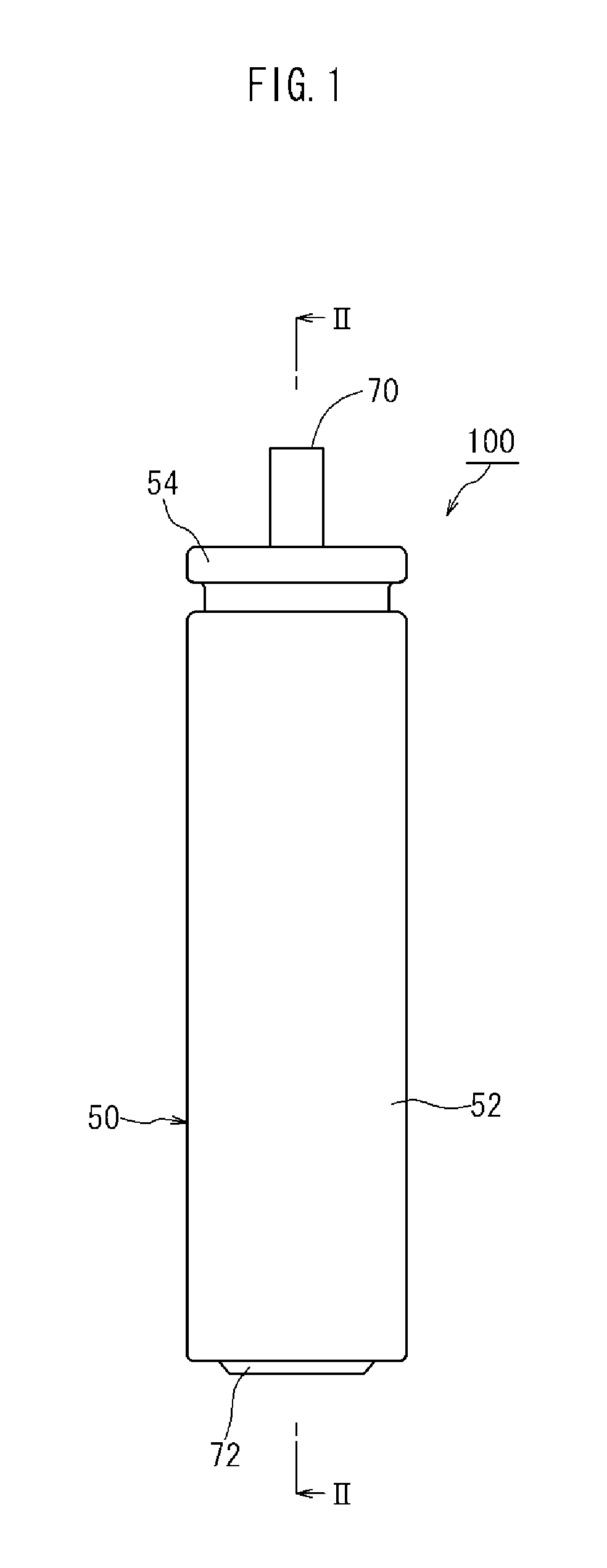

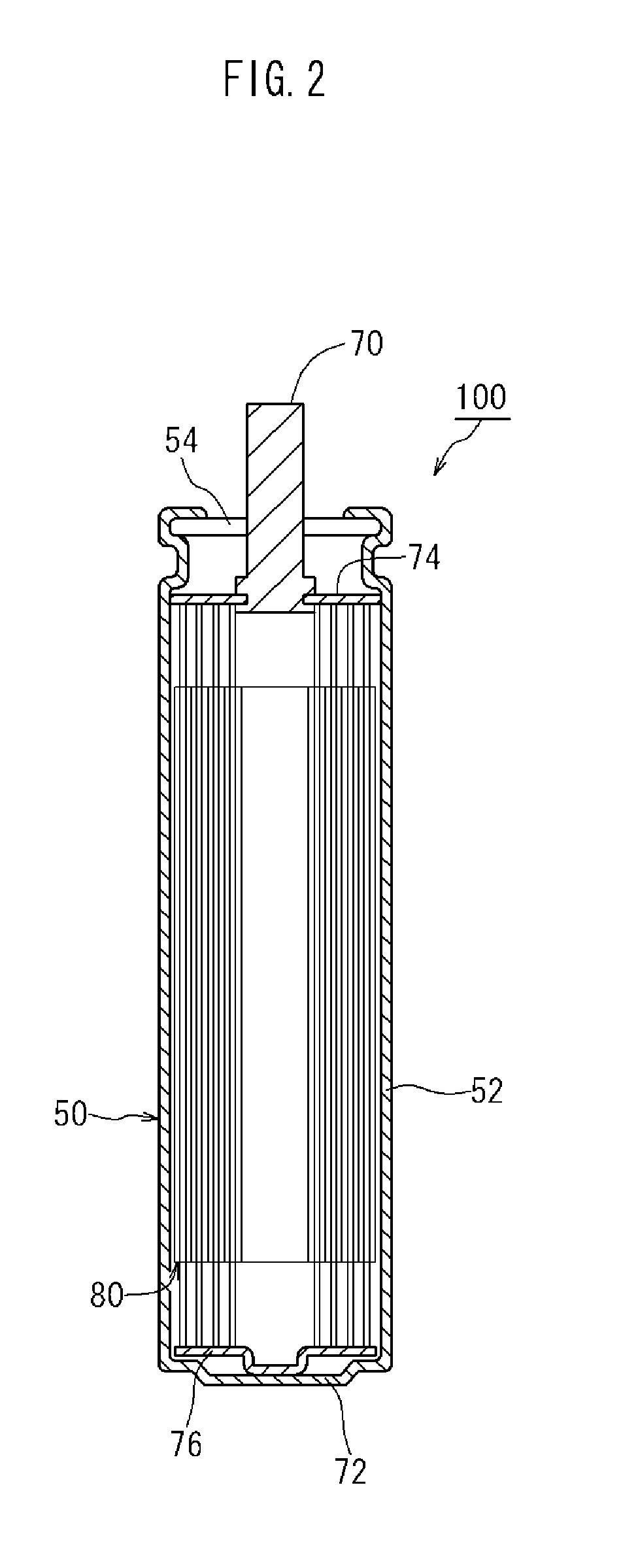

Lithium secondary battery

ActiveUS20120258343A1Improve adhesionReduce the amount requiredElectrode manufacturing processesFinal product manufactureEngineeringLithium-ion battery

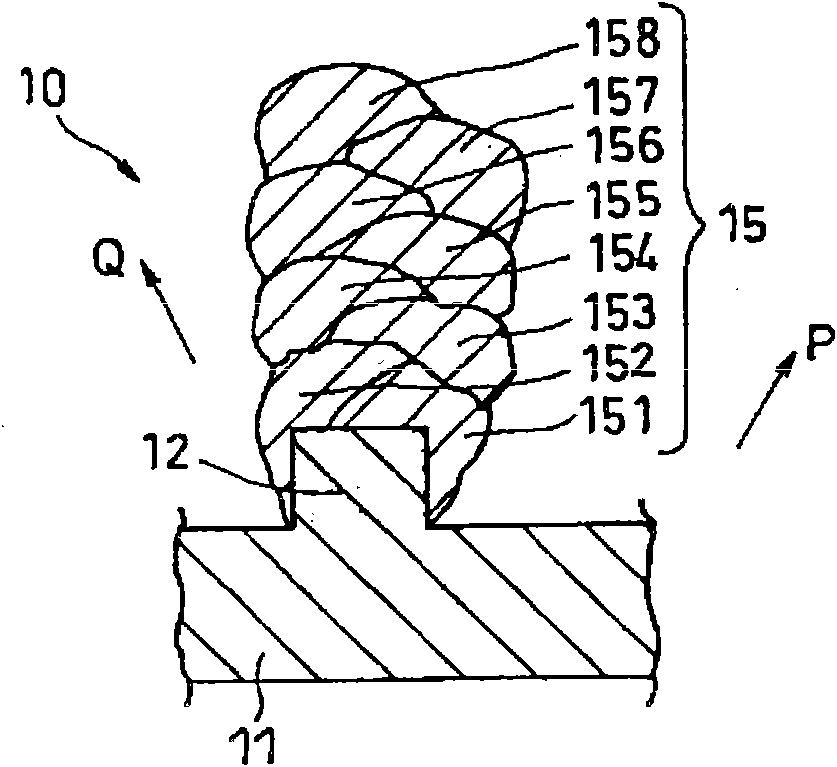

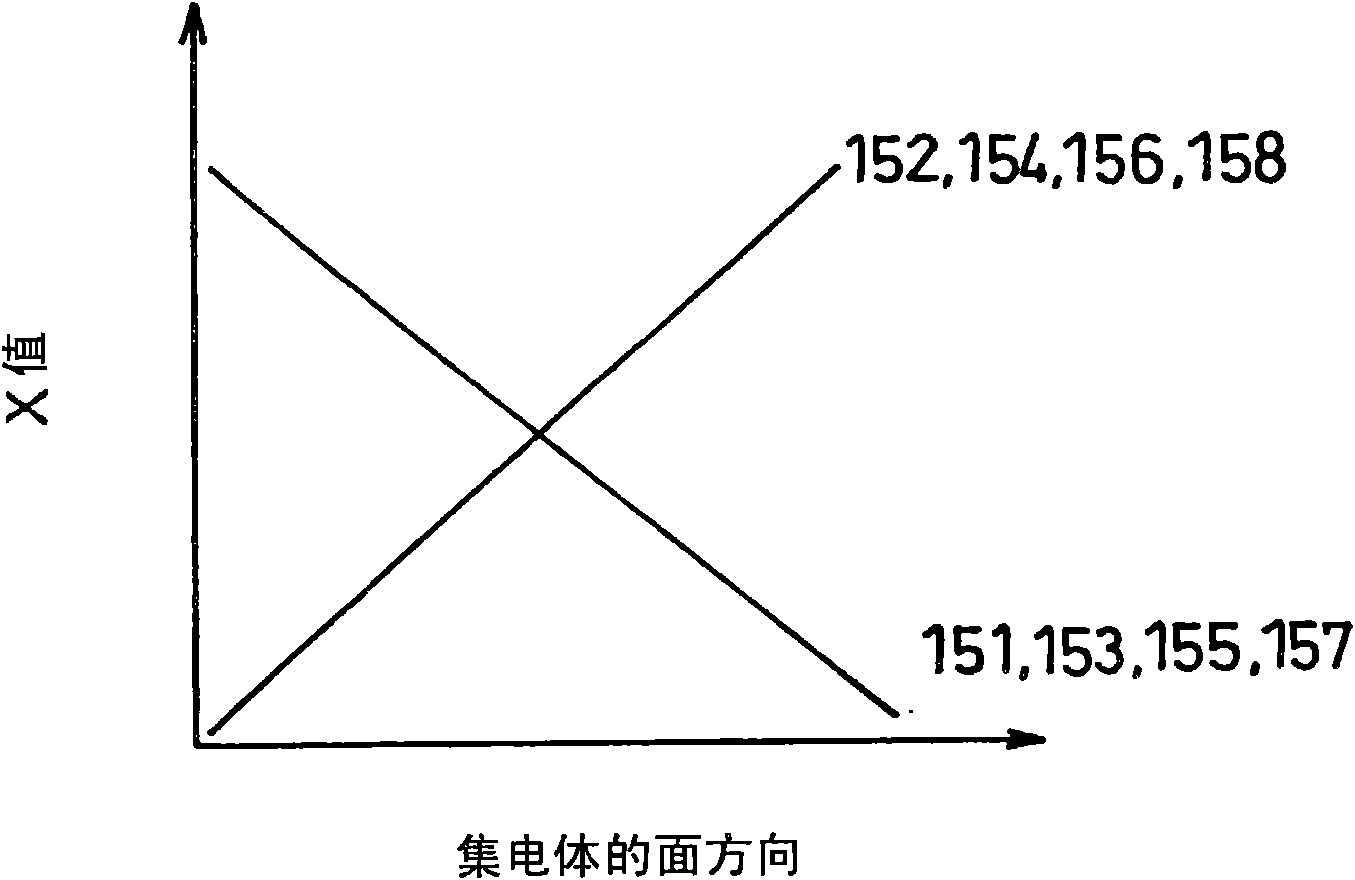

A lithium secondary battery obtained by the present invention has a negative electrode sheet 20 in which the theoretical capacities of the negative active material per unit area are equalized in a negative active material layer 24b on the outer circumference side and a negative active material layer 24a on the inner circumference side of a negative electrode collector 22, and at least one of the following conditions is met with respect to at least part of a bent section 85, which is bent toward the inside of a wound electrode body 80: (1) the percentage content of binder of the outer negative active material layer 24b is smaller than the percentage content of binder of the inner negative active material layer 24a; and (2) the density of the outer negative active material layer 24b is smaller than the density of the inner negative active material layer 24a.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com