Aluminium electrolytic capacitor and electrolyte

A technology of aluminum electrolytic capacitors and aluminum electrolytic capacitors, applied in the direction of electrolytic capacitors, capacitor electrolytes/absorbents, capacitors, etc., can solve the problems of high-frequency impedance reduction of aluminum electrolytic capacitors, electrolyte leakage from capacitors, and corrosion of cathode wires. Achieve good low-temperature characteristics, non-combustibility, and good opening and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

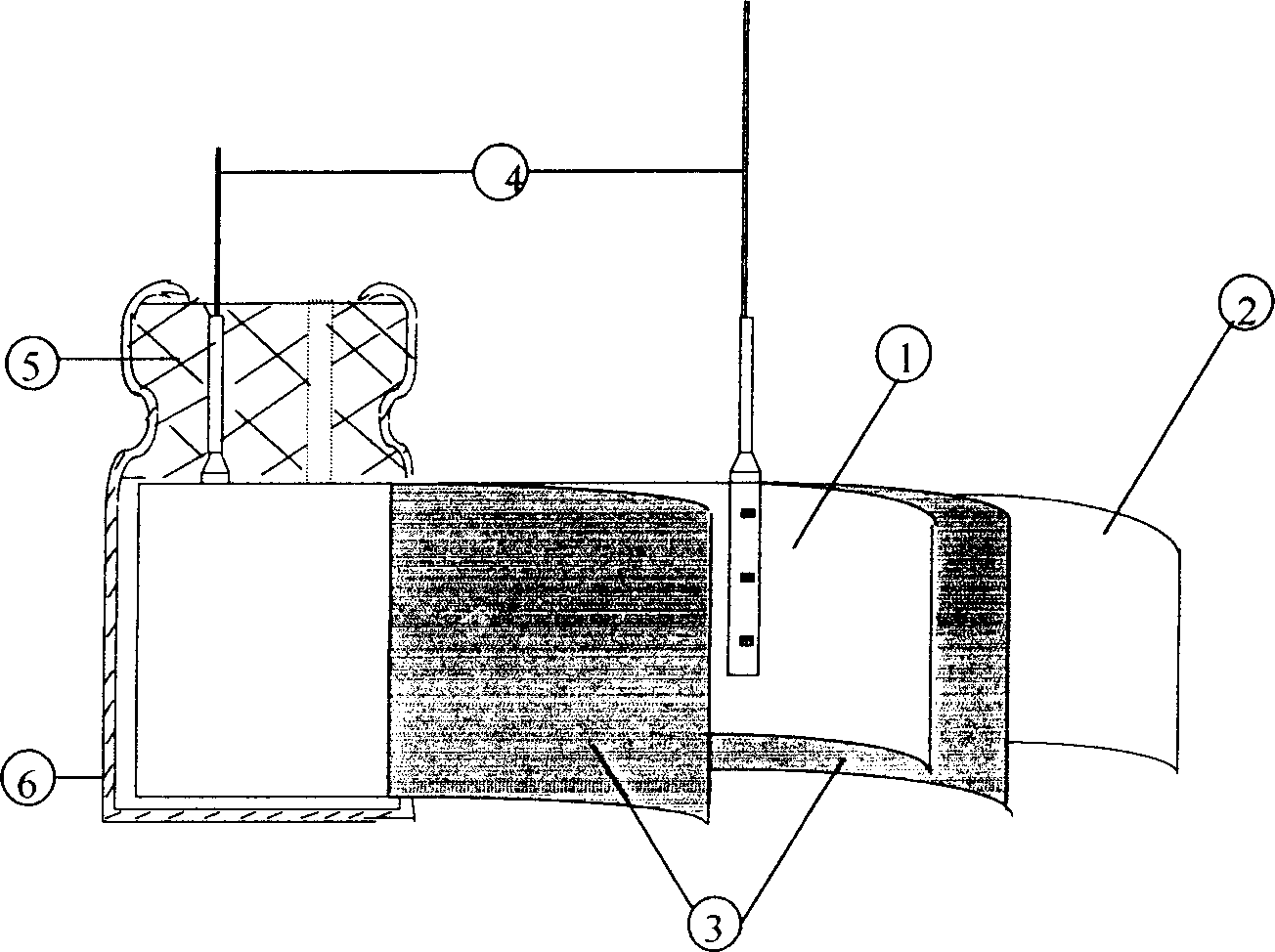

Image

Examples

Embodiment Construction

[0021] The electrolyte solution of the present invention is improved according to the defects produced in the prior art. In order to solve the above-mentioned technical problems, an effective method is to use an electrolytic solution with a small amount of basic compound generation and a resistivity (ρ30 ℃)<50Ω·cm at 30 ℃. The electrolytic solution of the present invention is based on alcohols or ether compounds and The technical effect of the present invention can be achieved by using water as a solvent and using an ammonium salt compound as the electrolyte solution of the main electrolyte. The aluminum electrolytic capacitor electrolyte of the present invention is composed of the following components by weight: main electrolyte: 10%-30%, solvent: 65%-89.95%, additives: 0.05%-5%. The main electrolyte uses ammonium salt compounds, such as ammonium formate, ammonium acetate, ammonium malonate, ammonium succinate, ammonium glutarate, ammonium adipate, ammonium azelate, ammonium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com