Patents

Literature

2103results about "Capacitor electrolytes/absorbents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

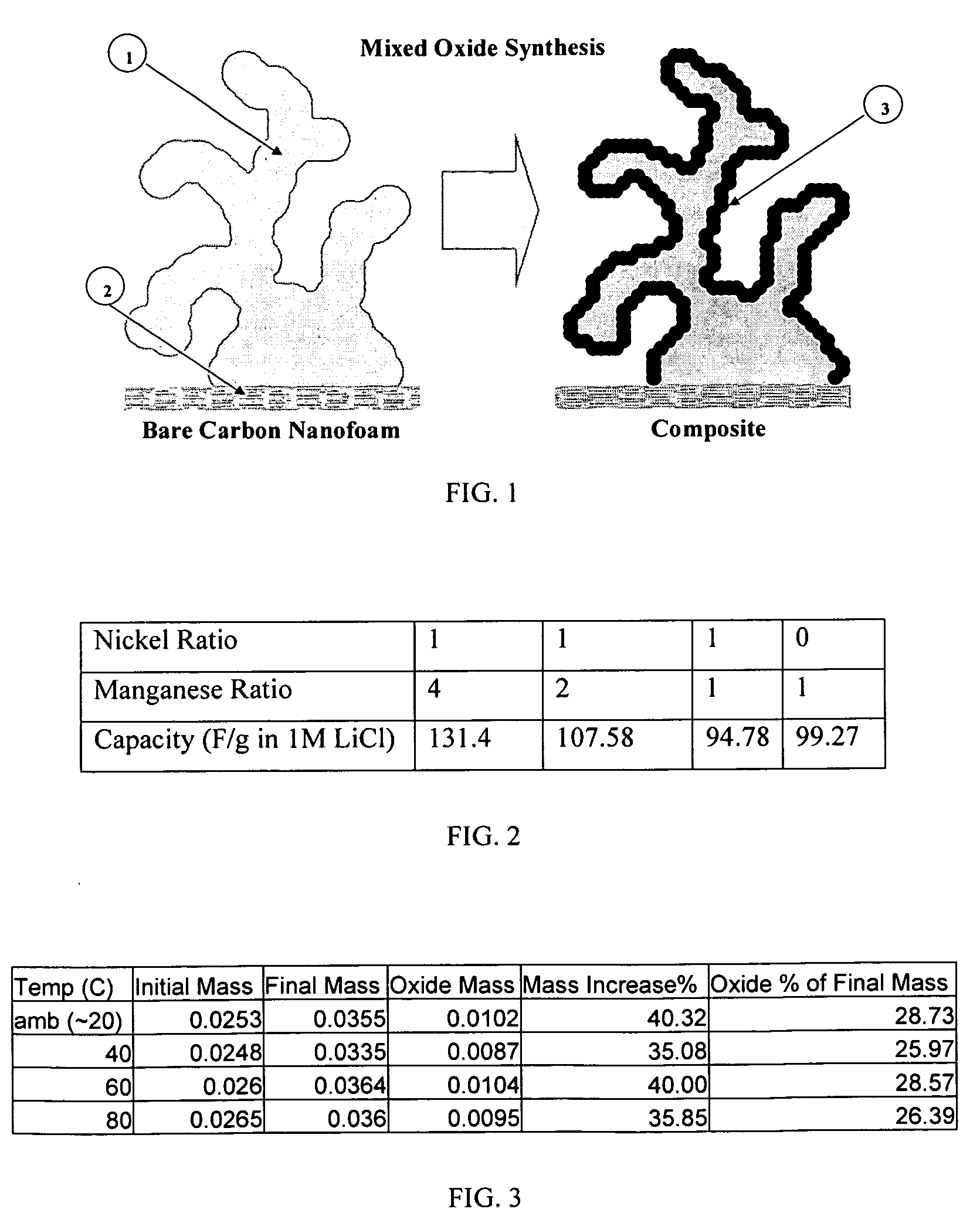

Electrolytic capacitors with a polymeric outer layer

ActiveUS6987663B2Reduce leakage currentLow ESRHybrid capacitor electrolytesSolid electrolytic capacitorsPolymer scienceElectrolysis

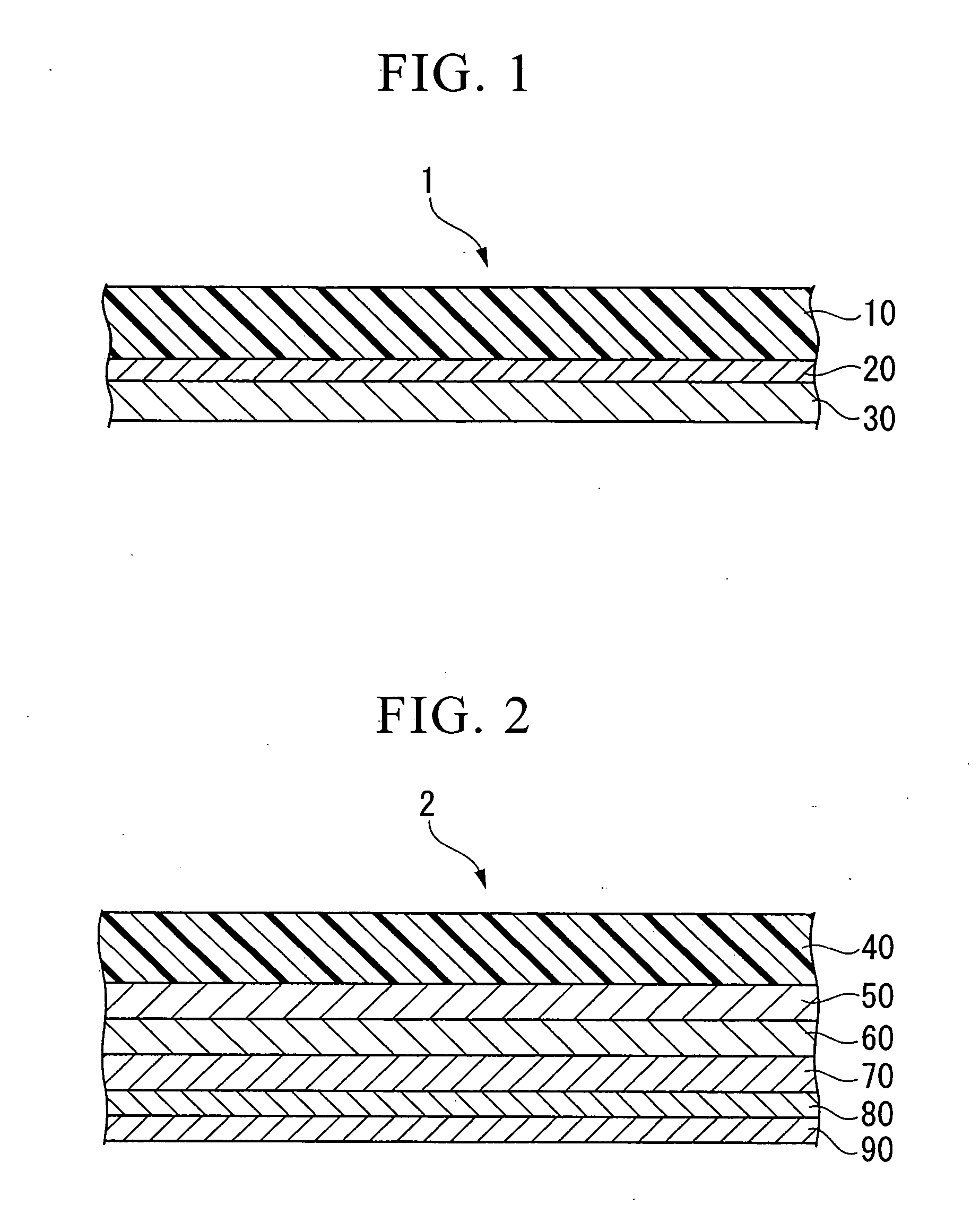

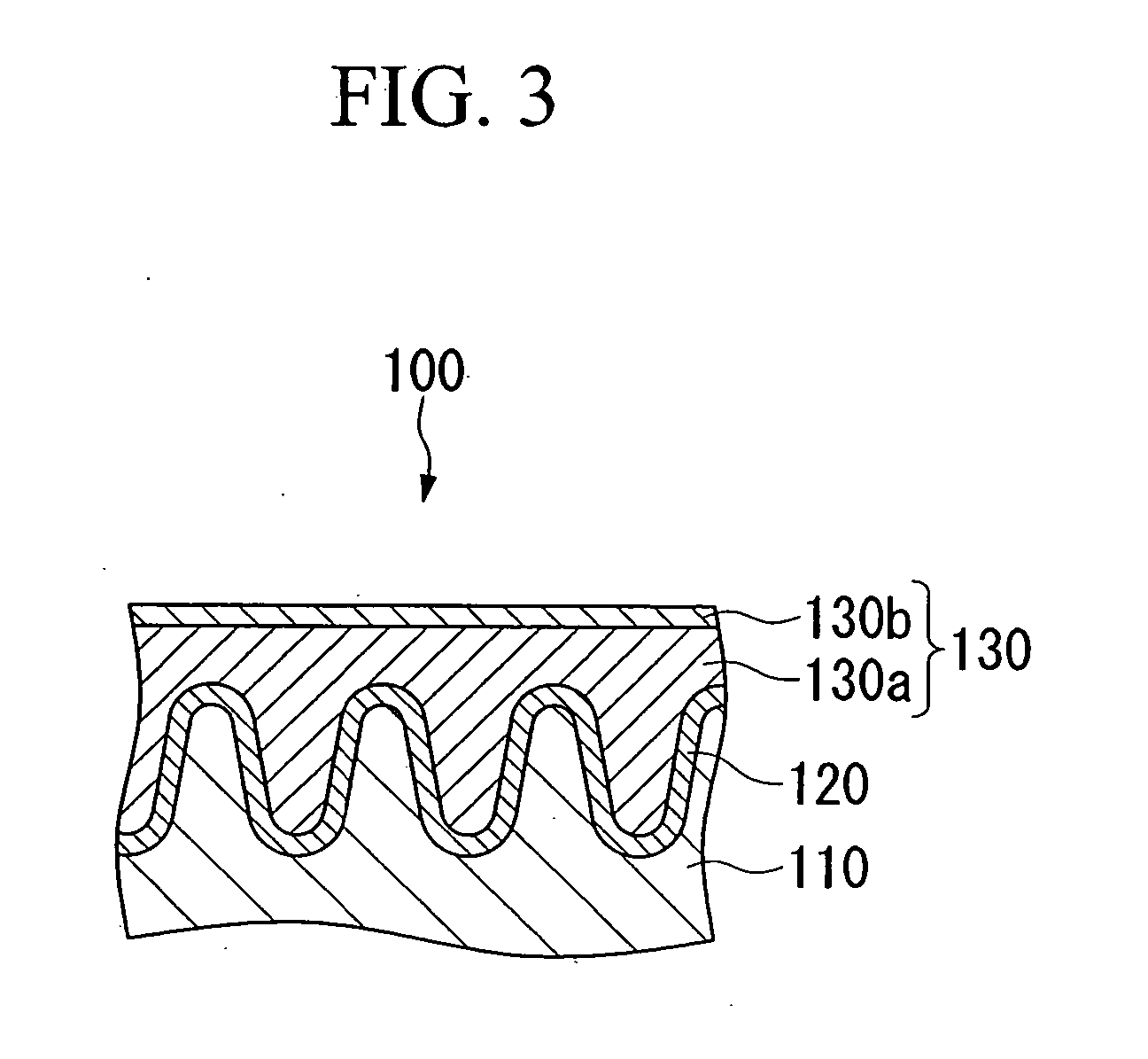

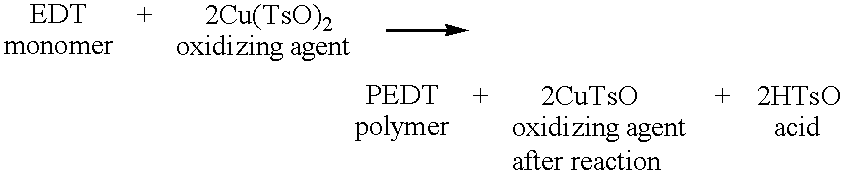

Electrolytic capacitors having low equivalent series resistance and low leakage current are described. The electrolytic capacitors include a solid electrolyte layer of a conductive material in particular a conductive polymer, and an outer layer that includes binders, polymeric anions and conductive polymers (e.g., polythiophenes). Also described is a method of preparing electrolytic capacitors that involves forming the conductive polymer of the solid electrolyte layer in situ by means of chemical oxidative polymerization or electrochemical polymerization. Electronic circuits that include the electrolytic capacitors are also described.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Solid electrolytic capacitor containing a conductive polymer

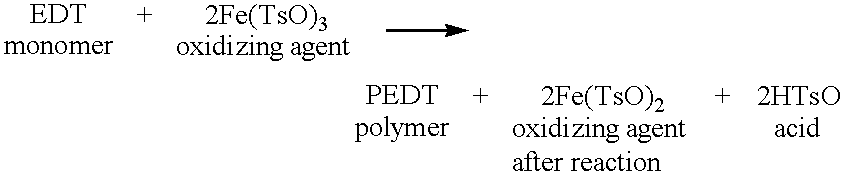

ActiveUS7515396B2Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

Composition containing carbon nanotubes having coating thereof and process for producing them

ActiveUS20060052509A1Not impair characteristicImprove conductivityMaterial nanotechnologySynthetic resin layered productsColloidal silicaConductive polymer

The object of the present invention is to provide a carbon nanotube composition that does not impair the characteristics of the carbon nanotubes itself, allows the carbon nanotubes to be dispersed or solubilized in a solvent, does not cause separation or aggregation of the carbon nanotubes even during long-term storage, has superior electrical conductivity, film formability and moldability, can be easily coated or covered onto a base material, and the resulting coated film has superior moisture resistance, weather resistance and hardness; a composite having a coated film composed thereof; and, their production methods. In order to achieve this object, the present invention provides a carbon nanotube composition that contains a conducting polymer (a) or heterocyclic compound trimer (i), a solvent (b) and carbon nanotubes (c), and may additionally contain a high molecular weight compound (d), a basic compound (e), a surfactant (f), a silane coupling agent (g) and colloidal silica (h) as necessary; a composite having a coated film composed of the composition; and, their production methods.

Owner:MITSUBISHI CHEM CORP

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS20070064376A1Lower equivalent series resistanceHigh nominal voltageSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisPhysical chemistry

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

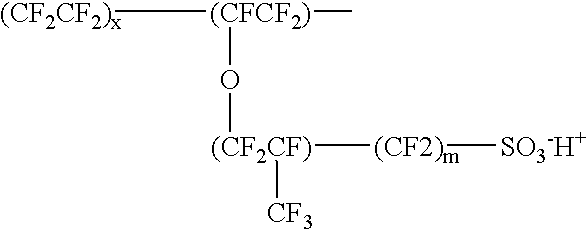

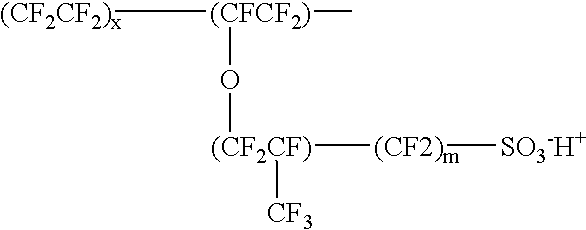

Proton-selective conducting membranes

InactiveUS20020127474A1Easy to operateSelective operationIon-exchanger regenerationSolid electrolyte cellsHydrophobic polymerProton

A membrane comprising: (a) a hydrophobic matrix polymer, and (b) a hydrophilic non-ionic polymer, wherein the hydrophobic polymer and the hydrophilic polymer are disposed so as to form a dense selectively proton-conducting membrane. The microstructure of such a membrane can be tailored to specific functionality requirements, such as proton conductivity vs. proton selectivity, and selectivity to particular species.

Owner:E C R ELECTRO CHEM RES

Ceramic material and process for producing the same

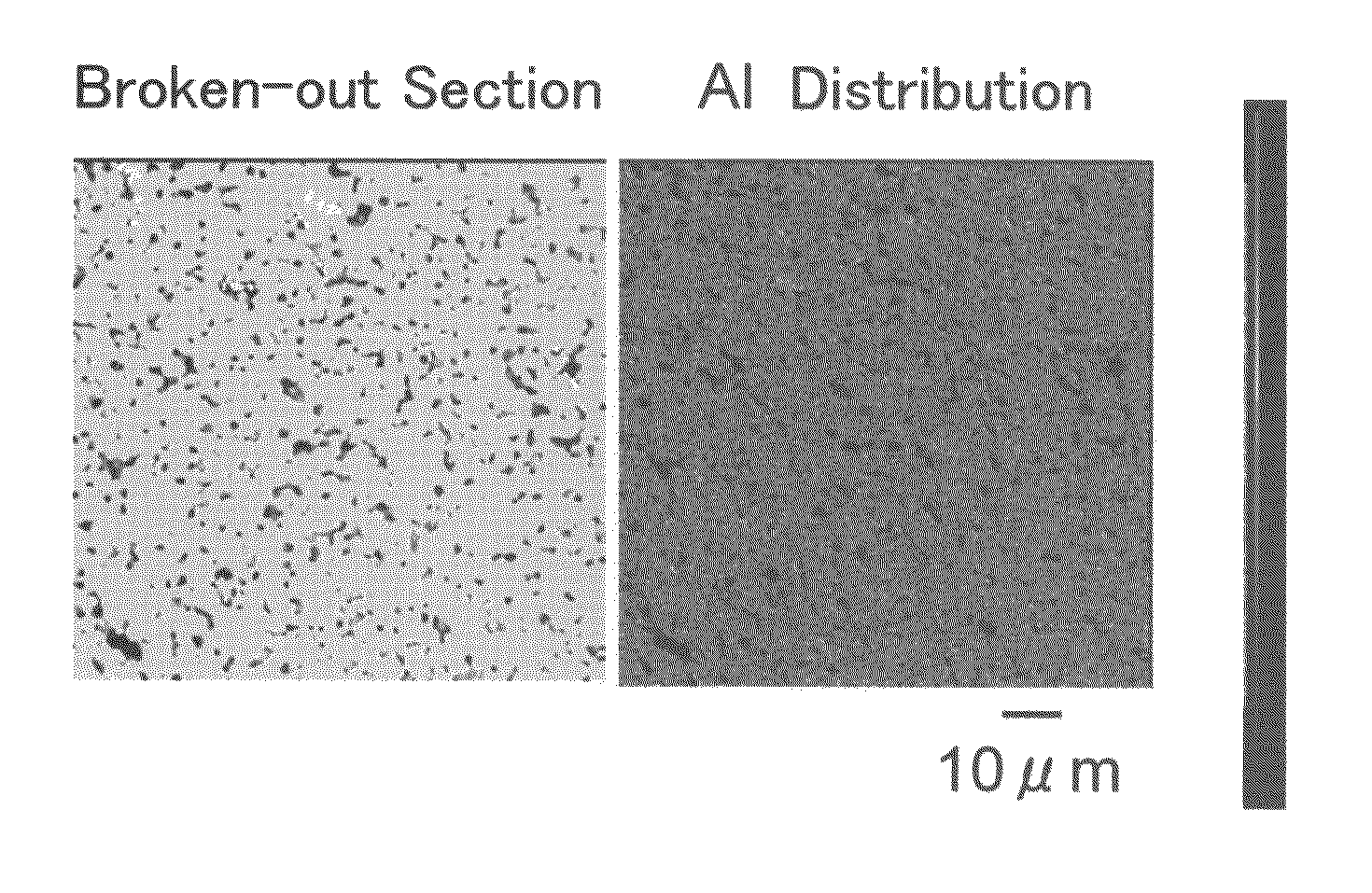

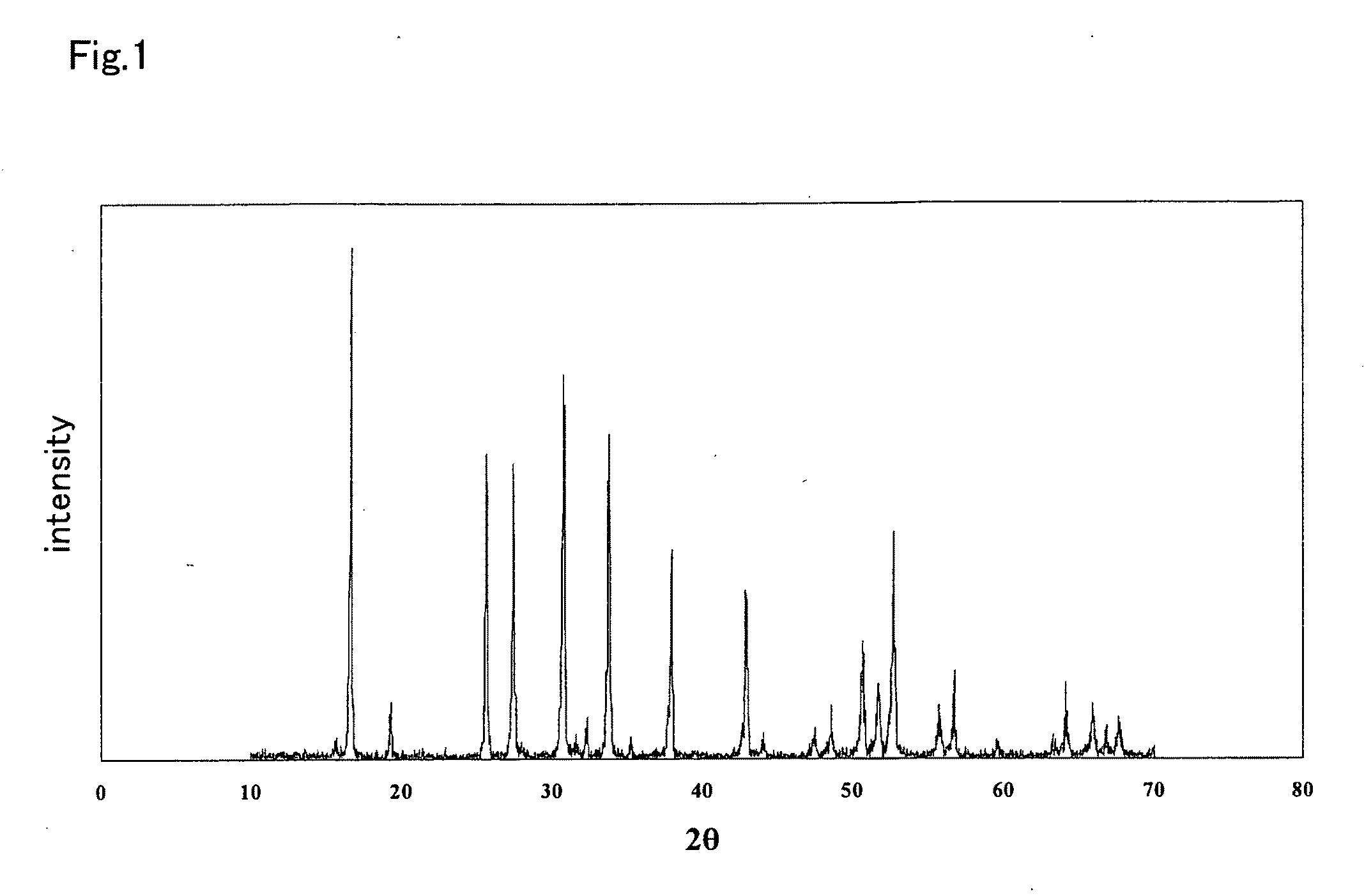

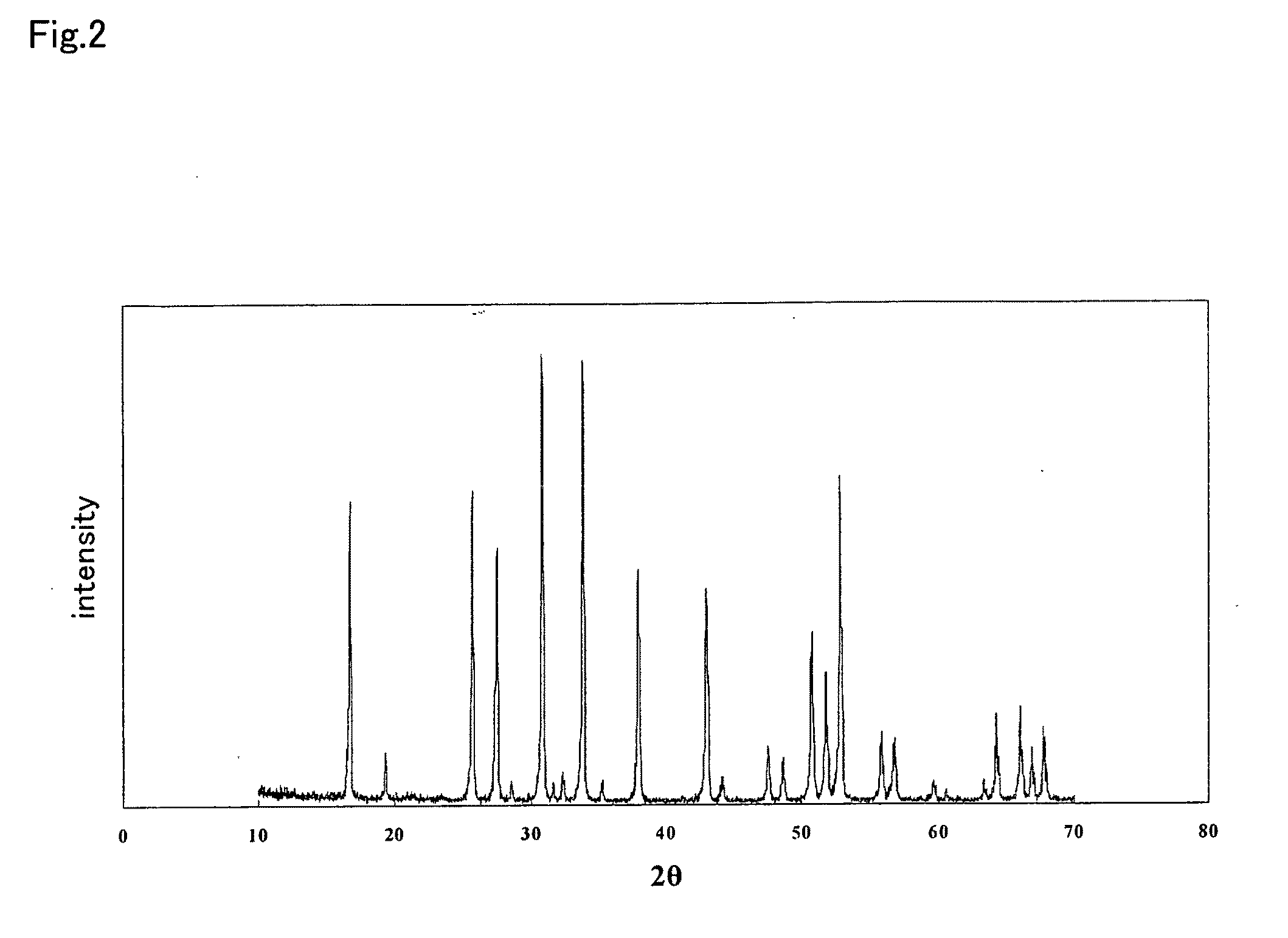

ActiveUS20100047696A1Compactness sufficientOvercome lack of conductivitySolid electrolyte cellsCapacitor electrolytes/absorbentsLithiumCrystal structure

A ceramic material that can exhibit sufficient compactness and lithium (Li) conductivity to enable the use thereof as a solid electrolyte material for a lithium secondary battery and the like is provided. The ceramic material contains aluminum (Al) and has a garnet-type crystal structure or a garnet-like crystal structure containing lithium (Li), lanthanum (La), zirconium (Zr) and oxygen (O).

Owner:NGK INSULATORS LTD

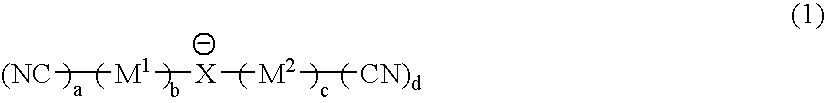

Material for electrolytic solutions and use thereof

InactiveUS20040002002A1Avoid corrosionImprove ionic conductivityHybrid capacitor electrolytesAlkaline accumulatorsOrganic linkingElectrical conductor

It is an object of the present invention to provide a material for electrolytic solutions suited for use as material in electrolytic solutions serving as ionic conductors in electrochemical devices, such as large-capacity cells or batteries. The present invention is related to a material for electrolytic solutions which comprises, as an essential constituent, an anion represented by the general formula (1): wherein X represents at least one element selected from among B, N, O, Al, Si, P, S, As and Se; M<1 >and M<2 >are the same or different and each represents an organic linking group; a is an integer of not less than 1, and b, c and d each independently is an integer of not less than 0.

Owner:NIPPON SHOKUBAI CO LTD

Conductive composition and conductive cross-linked product, capacitor and production method thereof, and antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium

ActiveUS20060047030A1Improve conductivityLower impedanceHybrid capacitor electrolytesHybrid capacitor electrodesCross-linkElectron donor

A conductive composition comprises a π conjugated conductive polymer, a dopant, and a nitrogen-containing aromatic cyclic compound. A capacitor comprises an anode composed of a porous material of valve metal, a dielectric layer formed by oxidizing the surface of the anode, and a cathode provided on the dielectric layer and having a solid electrolyte layer containing a π conjugated conductive polymer, which comprises an electron donor compound containing an electron donor element provided between the dielectric layer and the cathode. Another capacitor is based on the above-described capacitor, wherein the solid electrolyte layer further comprises a dopant and a nitrogen-containing aromatic cyclic compound. An antistatic coating material comprises a π conjugated conductive polymer, a solubilizing polymer containing an anion group and / or an electron attractive group, a nitrogen-containing aromatic cyclic compound, and a solvent. An antistatic coating is formed by applying the antistatic coating material.

Owner:SHIN-ETSU POLYMER CO LTD

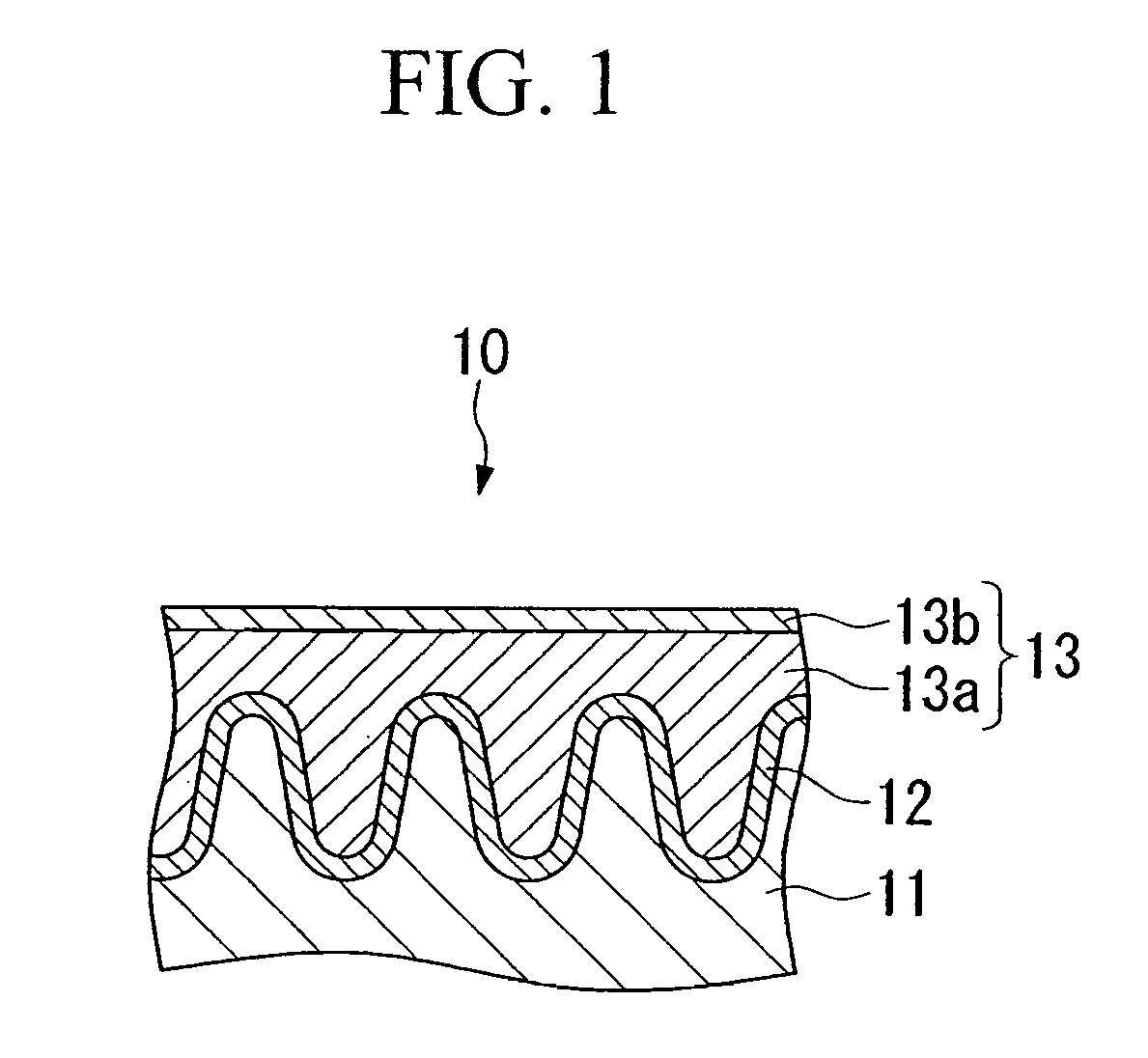

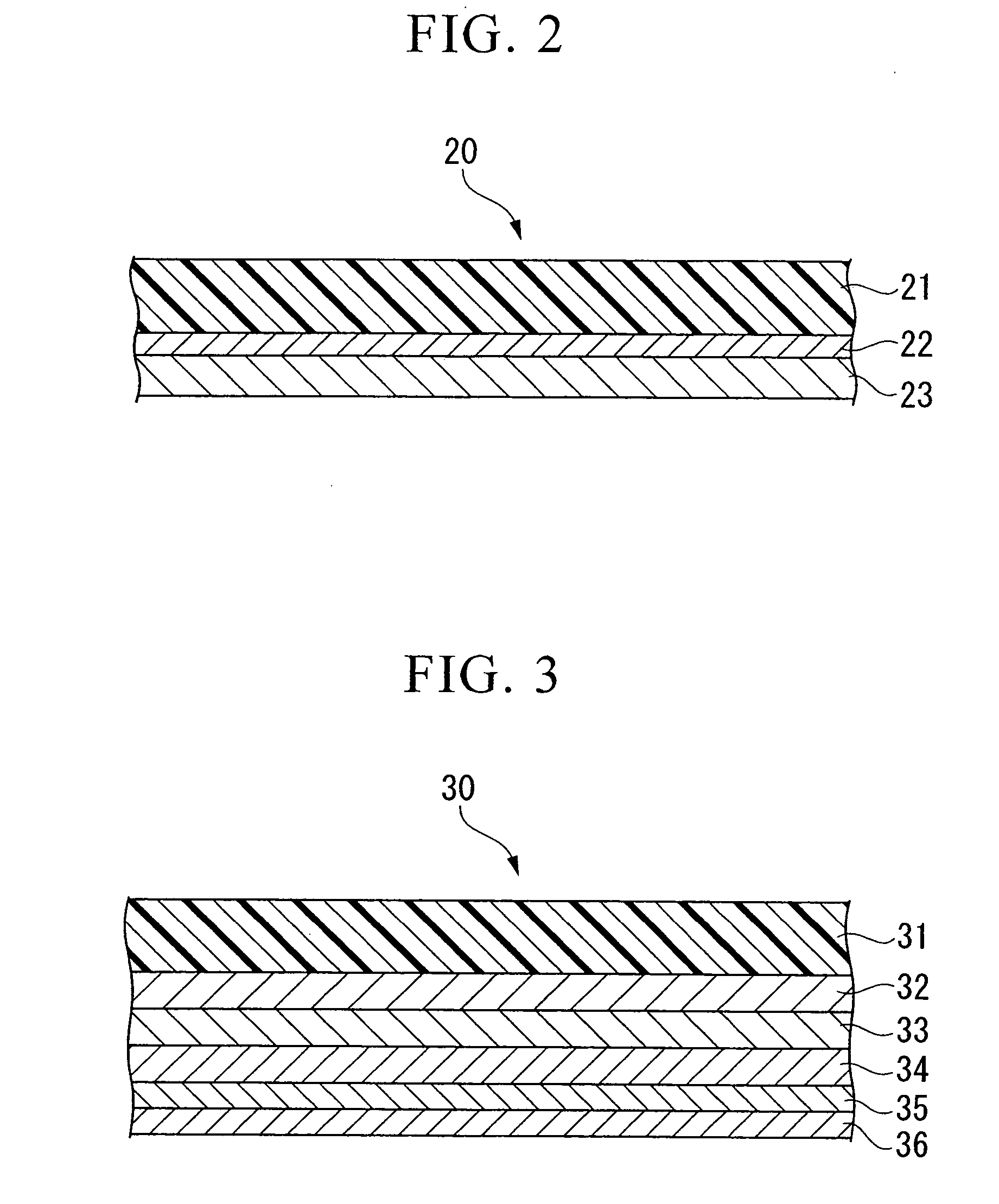

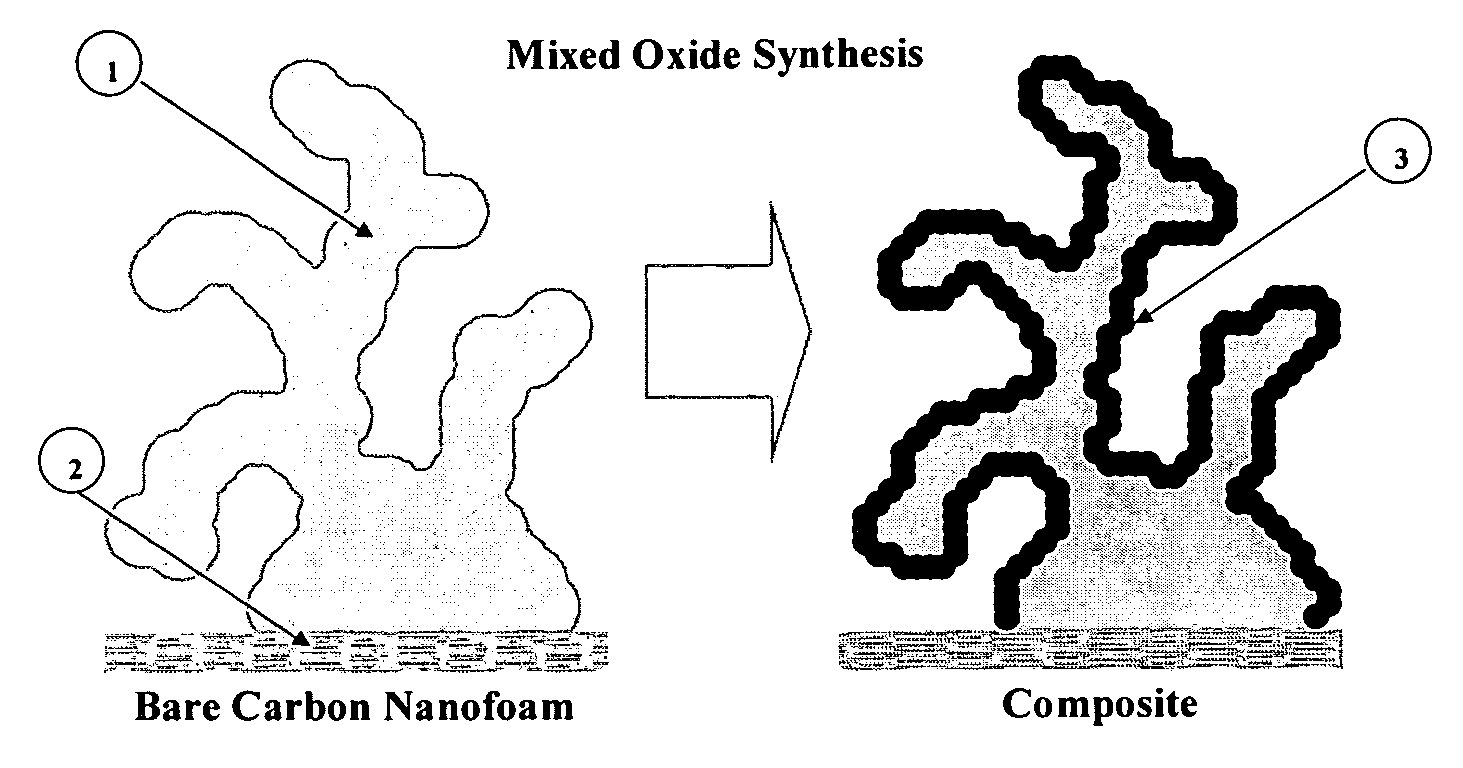

Composite electrode comprising a carbon structure coated with a thin film of mixed metal oxides for electrochemical energy storage

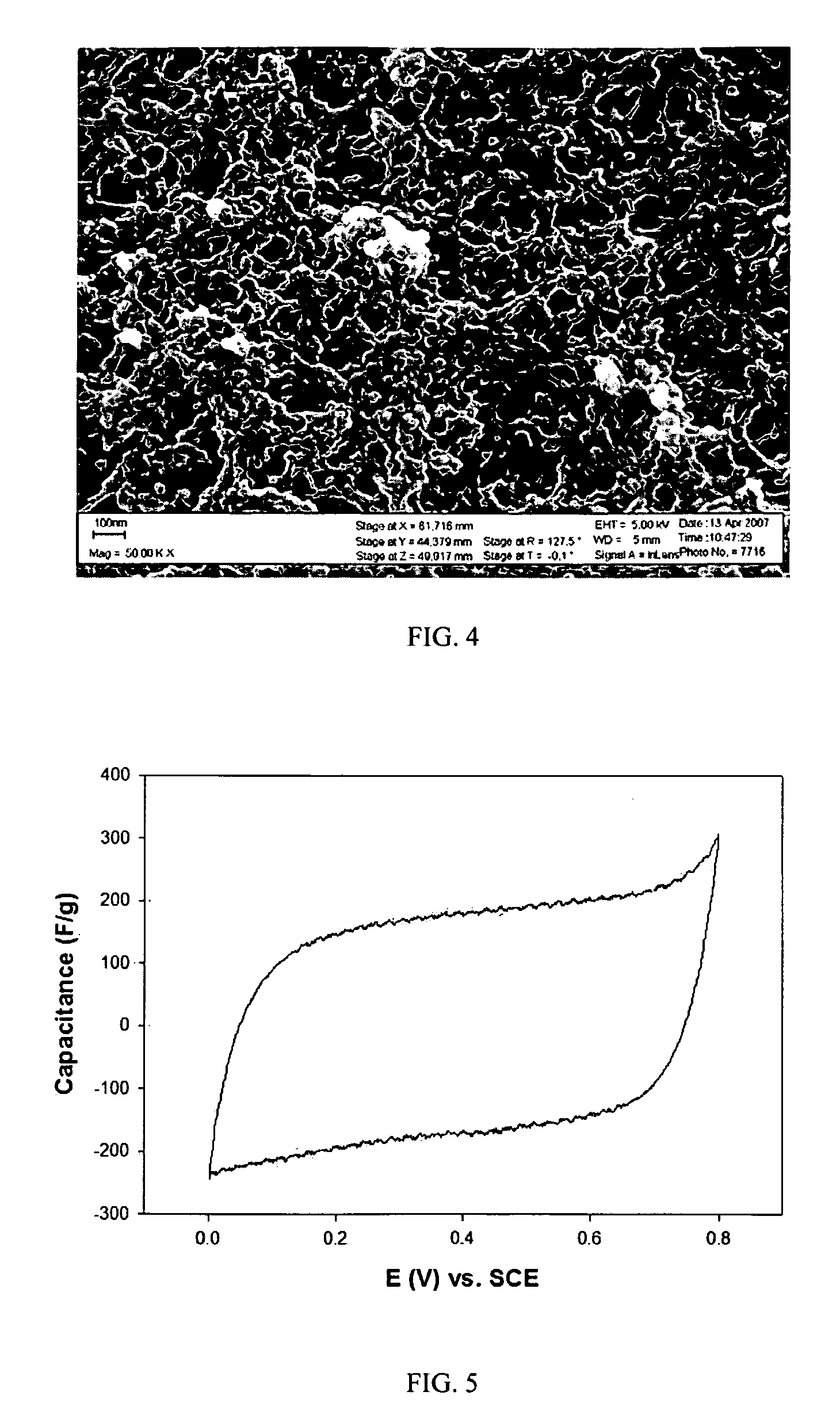

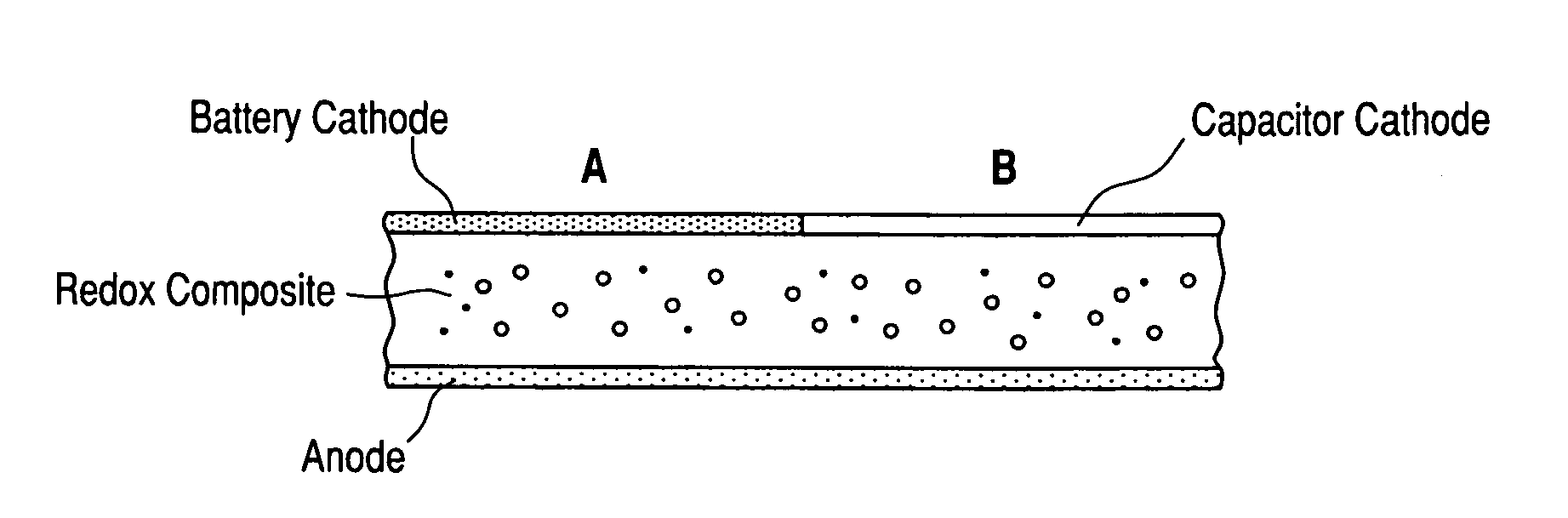

InactiveUS20090185327A1Increase capacityProlong lifeLiquid electrolytic capacitorsFinal product manufactureComposite electrodeMixed oxide

A composite electrode is created by forming a thin conformal coating of mixed metal oxides on a highly porous carbon structure. The highly porous carbon structure performs a role in the synthesis of the mixed oxide coating and in providing a three-dimensional, electronically conductive substrate supporting the thin coating of mixed metal oxides. The metal oxide mixture shall include two or more metal oxides. The composite electrode, a process for producing said composite electrode, an electrochemical capacitor and an electrochemical secondary (rechargeable) battery using said composite electrode are disclosed.

Owner:SEYMOUR FRASER WADE

Solid electrolytic capacitor containing a conductive polymer

ActiveUS20080232037A1Hybrid capacitor electrolytesSolid electrolytic capacitorsOligomerConductive polymer

A method for forming an electrolytic capacitor is disclosed. The method includes forming a conductive polymer coating by polymerizing a monomer in the presence of less than a stoichiometric amount of an oxidative polymerization catalyst. The present inventor has found that the use of less than the stoichiometric amount of the oxidative polymerization catalyst per mole of monomer can slow the polymerization of the monomer, creating oligomers that are shorter in length than if fully polymerized into a polymer. Without wishing to be bound by theory, it is believed that these shorter oligomers provide better penetration into the porous anode. Thus, the resulting conductive polymer layer can be more intimately positioned with respect to the anode. As a result, the formed capacitor can exhibit better performance.

Owner:KYOCERA AVX COMPONENTS CORP

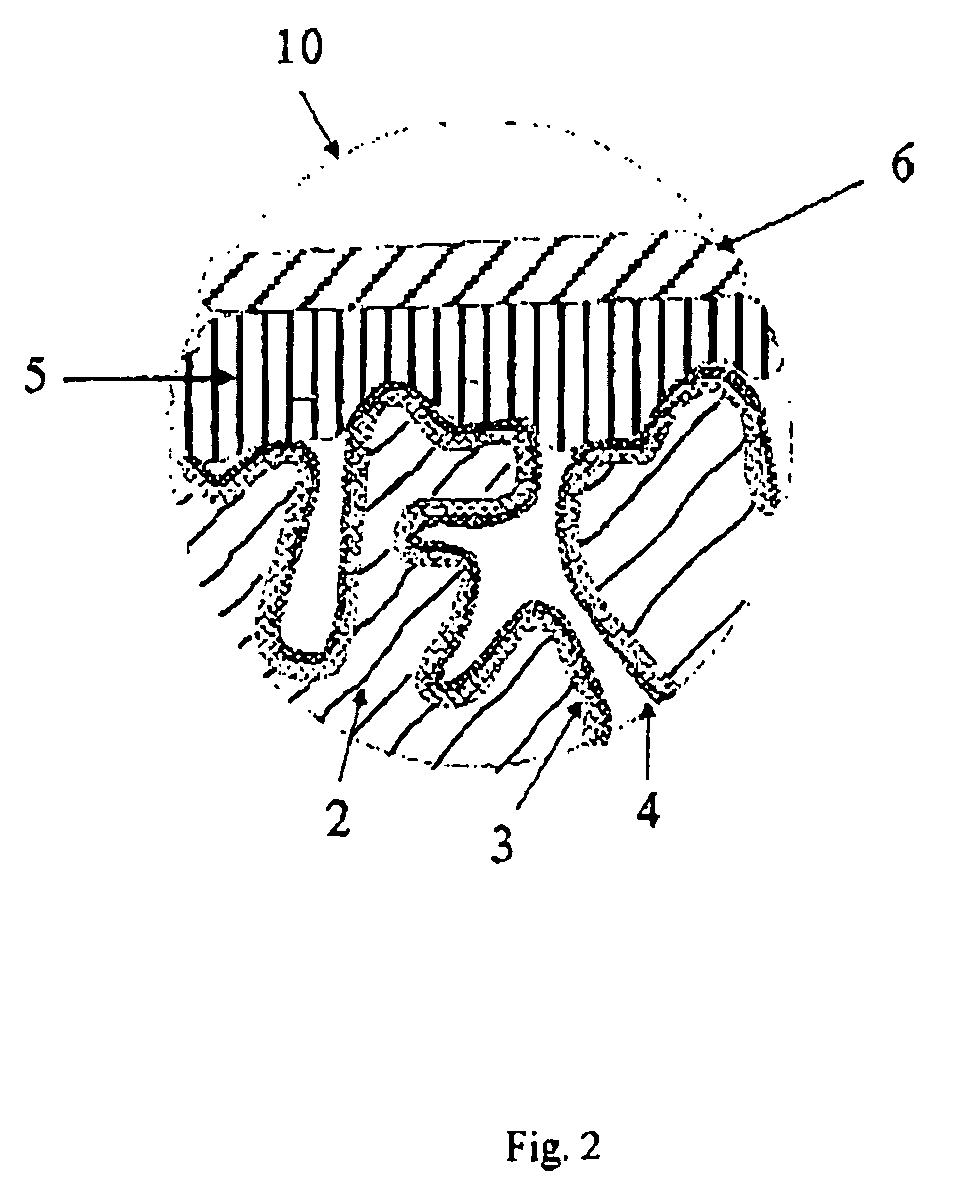

Composite ionic conducting electrolytes

InactiveUS20130026409A1High operating requirementsOptimize volumeFuel and primary cellsHybrid capacitor electrolytesComposite electrolyteConductive polymer

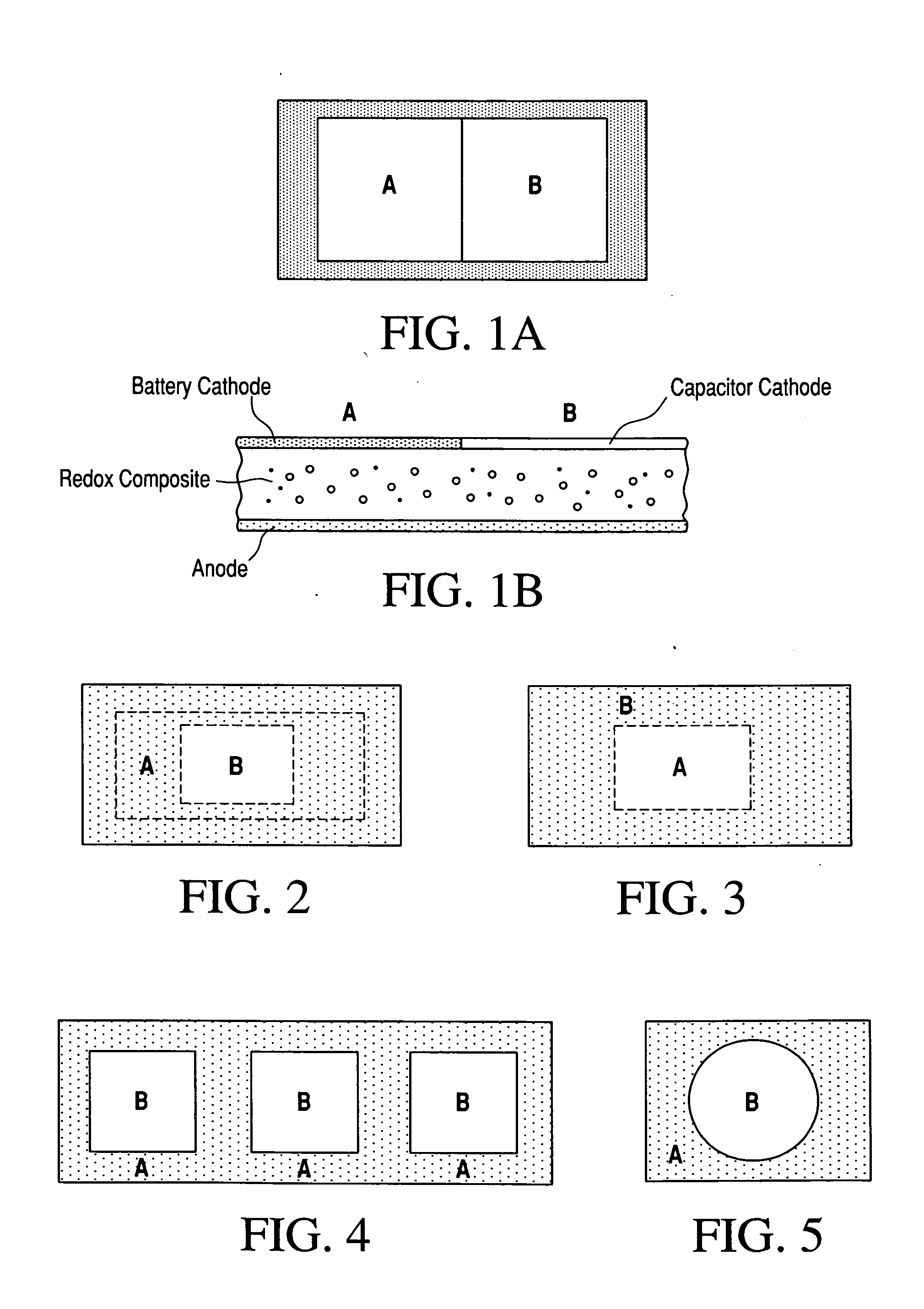

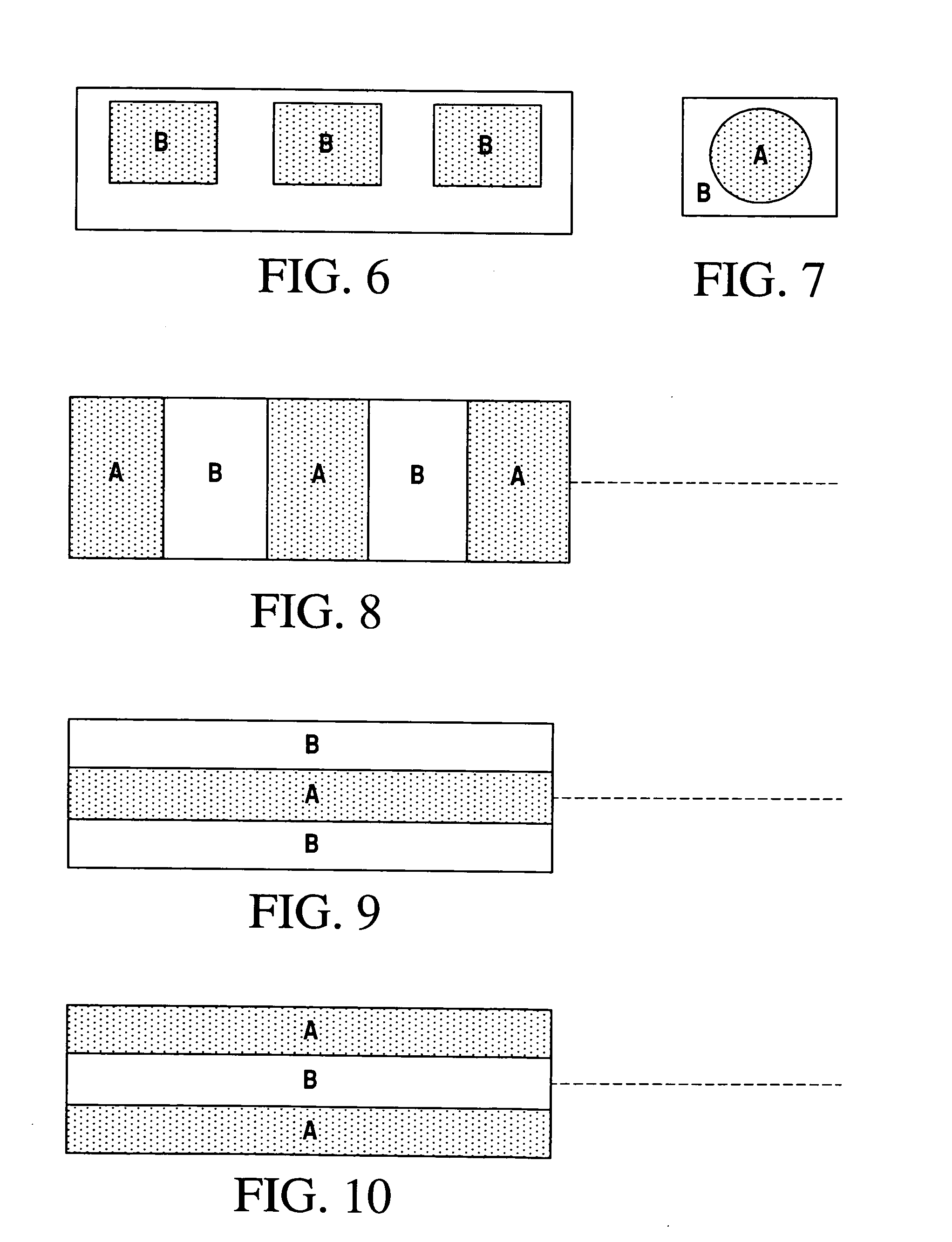

Ionically conducting, redox active additive composite electrolytes are disclosed. The electrolytes include an ionically conductive component and a redox active additive. The ionically conductive component may be an ionically conductive material such as an ionically conductive polymer, ionically conducting glass-ceramic, ionically conductive ceramic, and mixtures thereof. Electrical energy storage devices that employ the ionically conducting, redox active additive composite electrolytes also are disclosed

Owner:RECAPPING +1

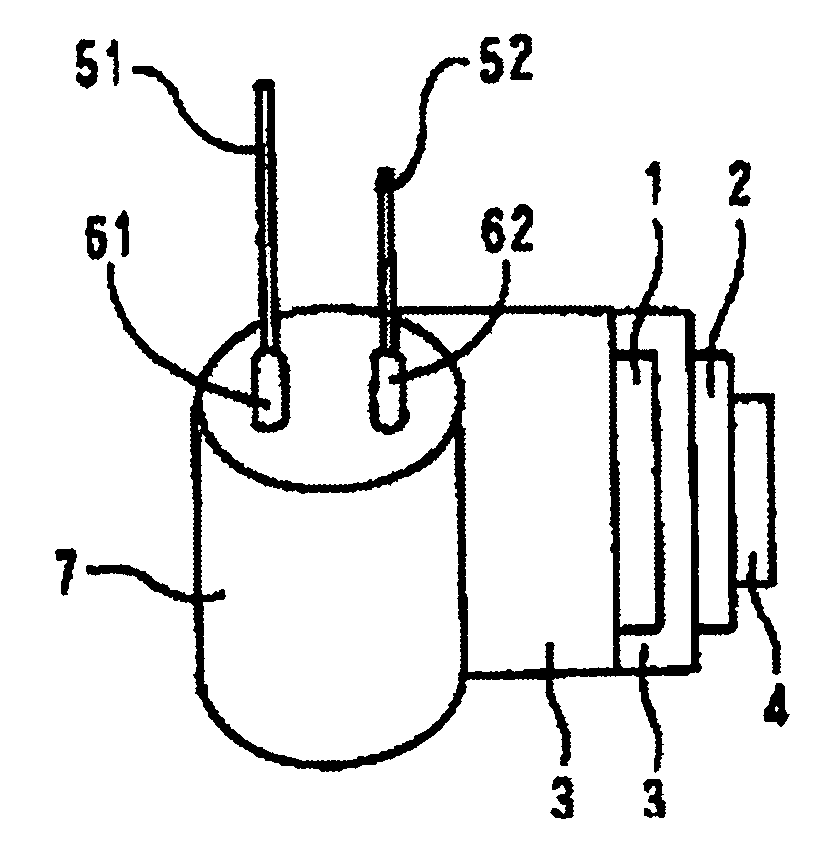

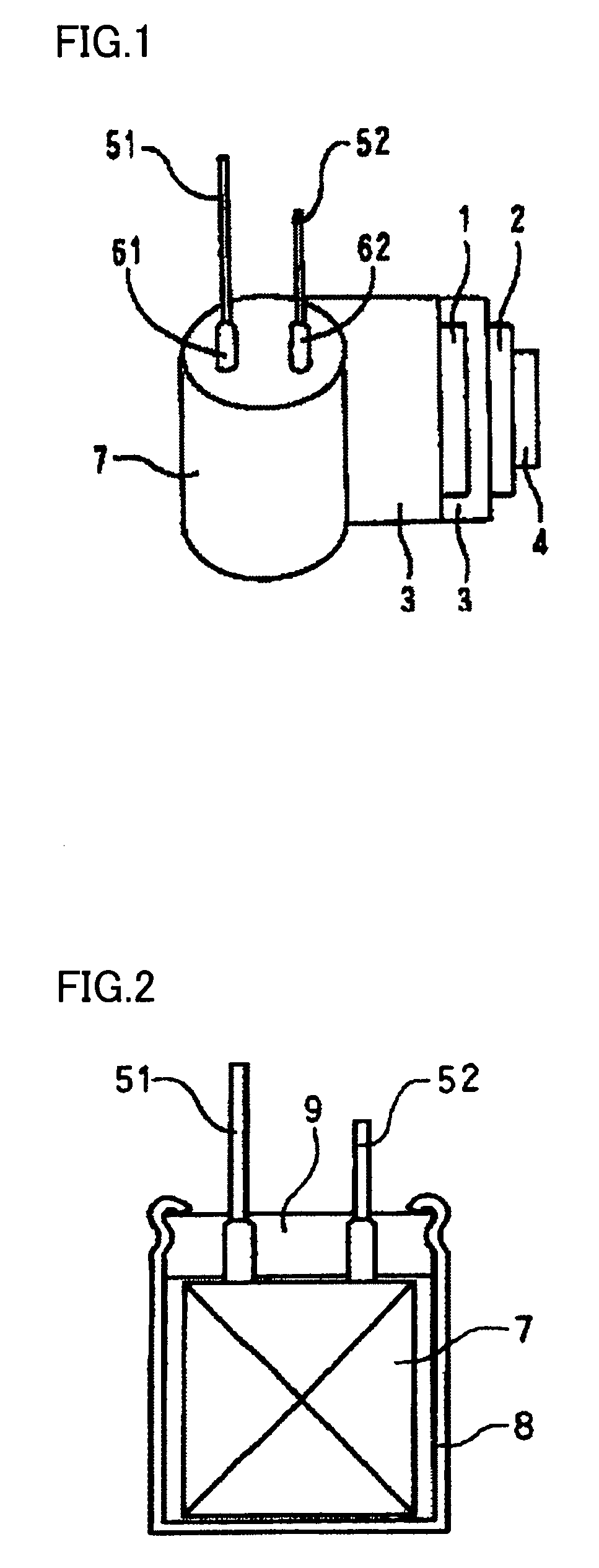

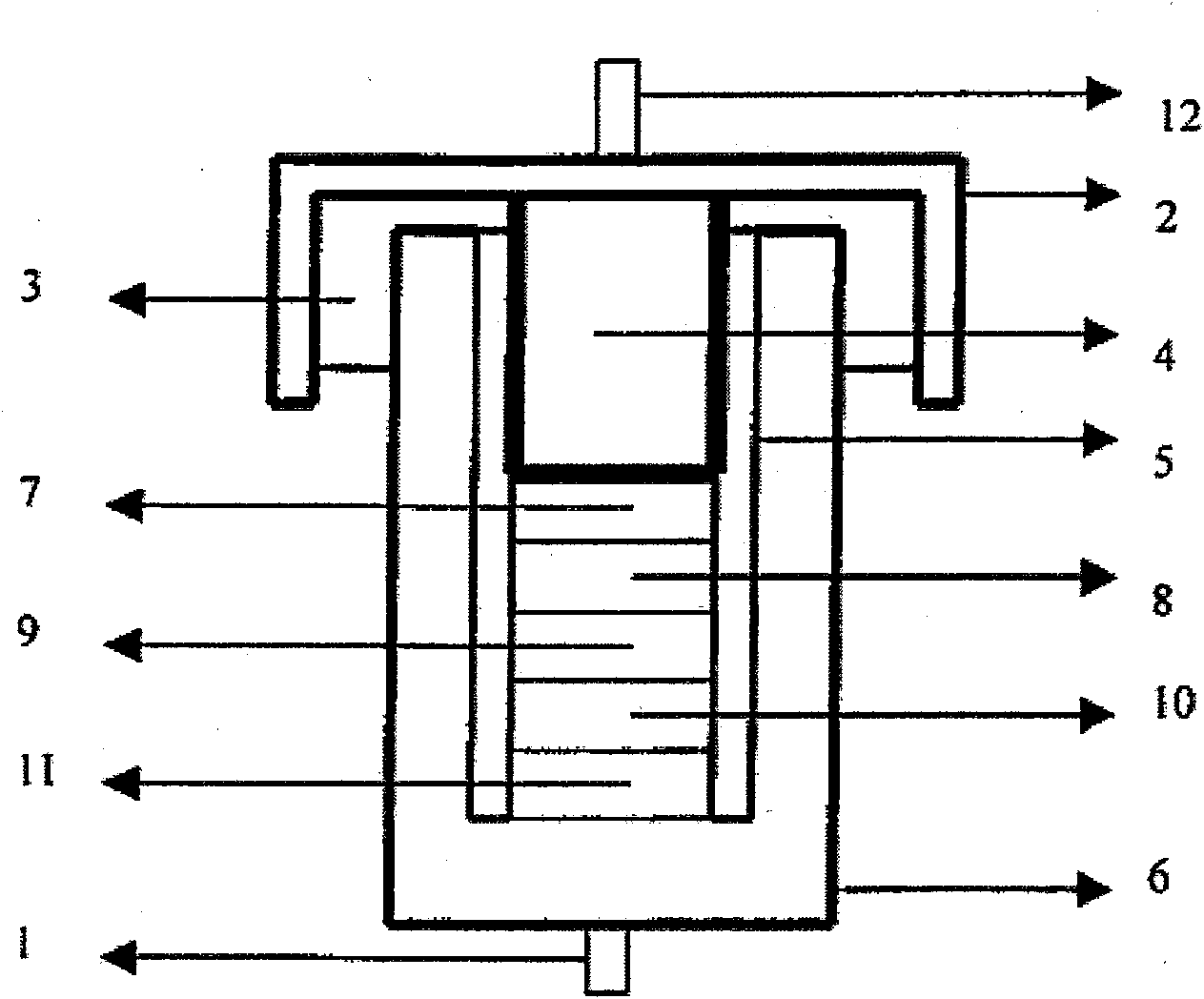

Method of manufacturing electrolytic capacitor and electrolytic capacitor

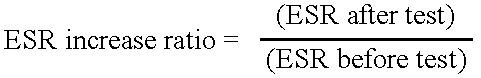

ActiveUS7497879B2Improve pressure resistanceSmall currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

Electrolyte compositon, photoelectric converter and dye-sensitized solar cell using same

ActiveUS20060174932A1Improve conductivityDecrease in flowabilityMaterial nanotechnologyLight-sensitive devicesElectrolyte compositionPhotoelectric conversion

An electrolyte composition containing an ionic liquid and conductive particles as main components, an electrolyte composition containing an ionic liquid, and oxide semiconductor particles or oxide semiconductor particles, and conductive particles, and an electrolyte composition containing an ionic liquid and insulating particles are provided. Furthermore, a photoelectric conversion element comprising: a working electrode, the working electrode comprising an electrode substrate and an oxide semiconductor porous film formed on the electrode substrate and sensitized with a dye; a counter electrode disposed opposing the working electrode; and an electrolyte layer made of these electrolyte compositions is provided.

Owner:THE FUJIKURA CABLE WORKS LTD

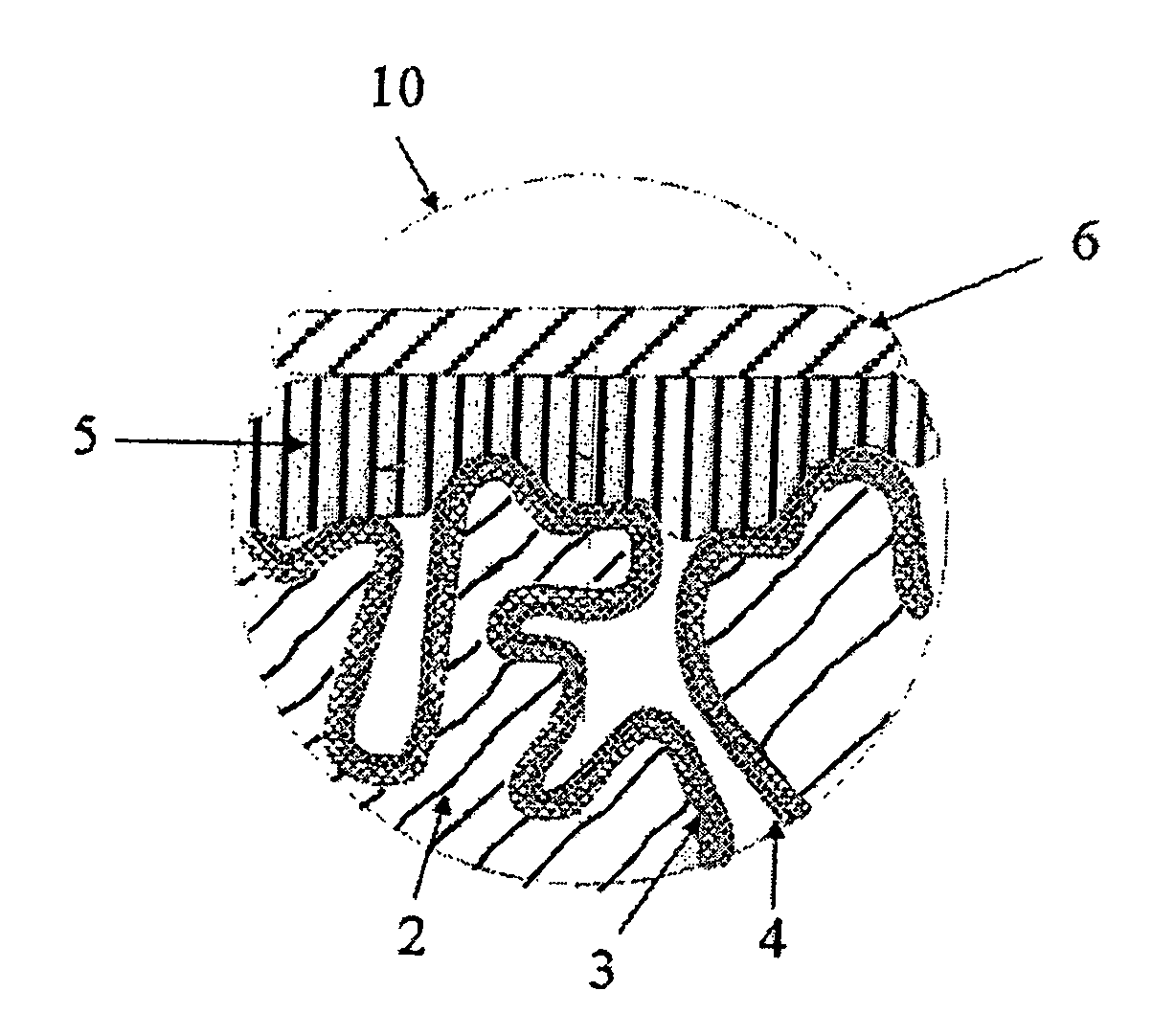

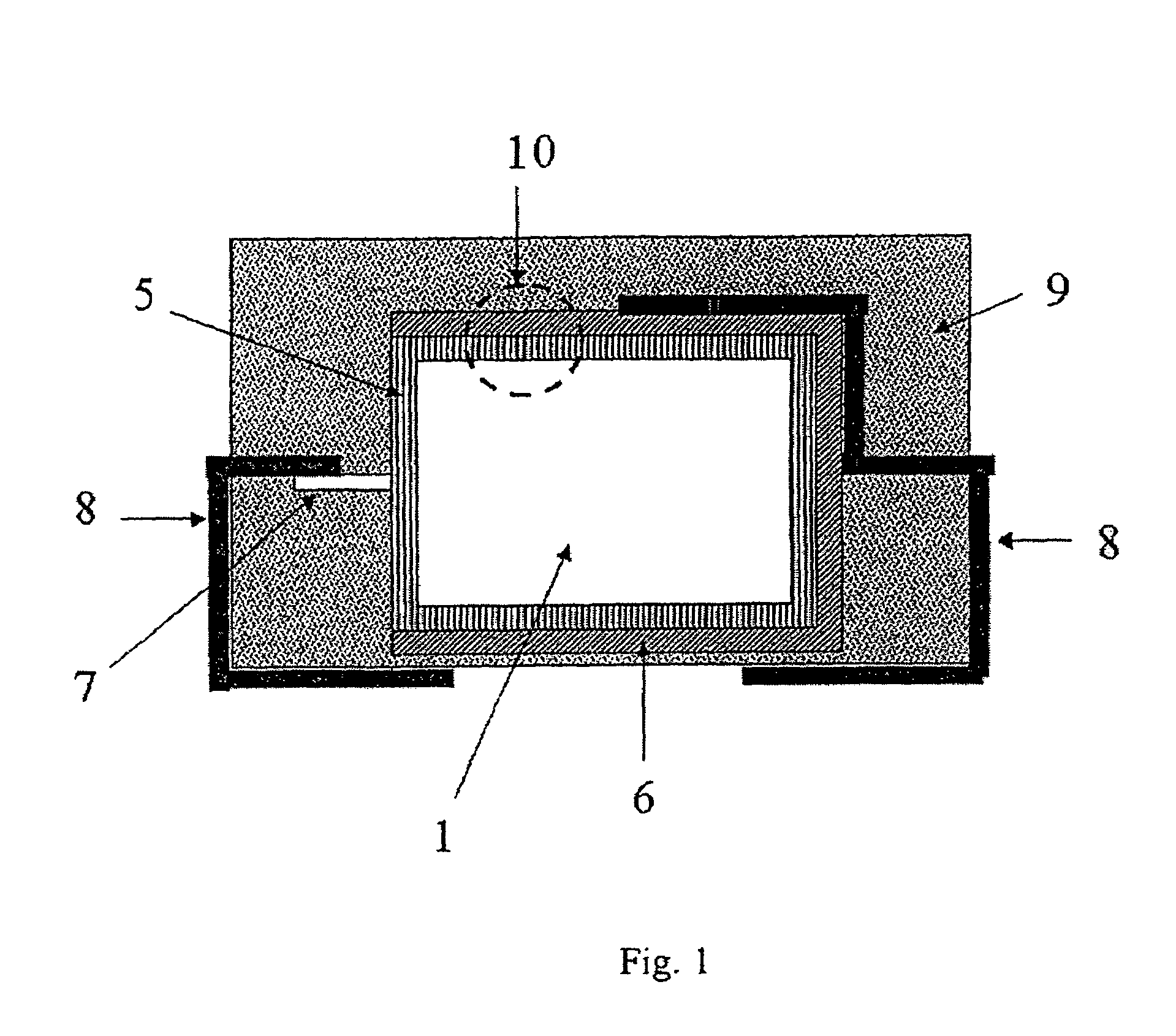

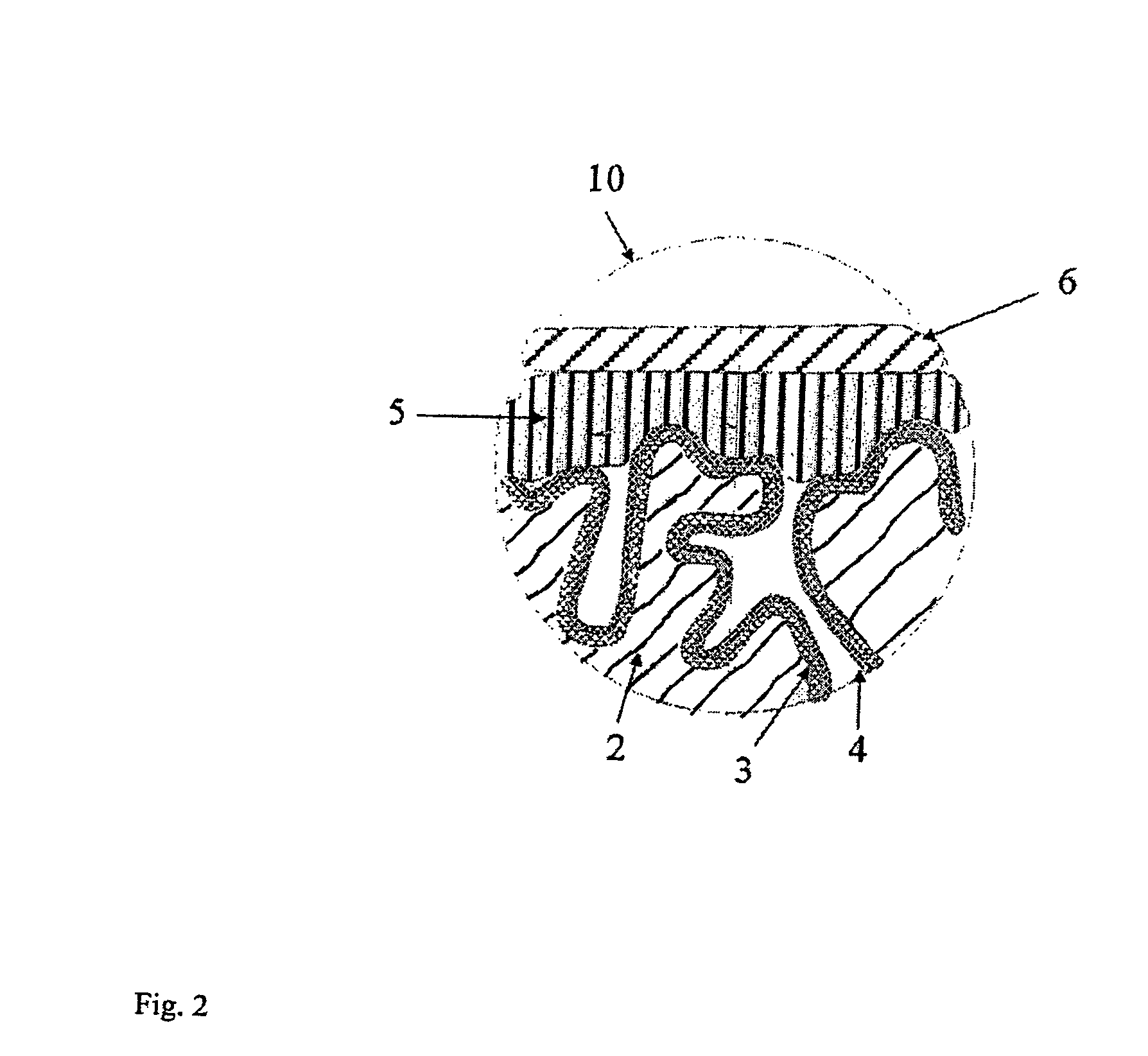

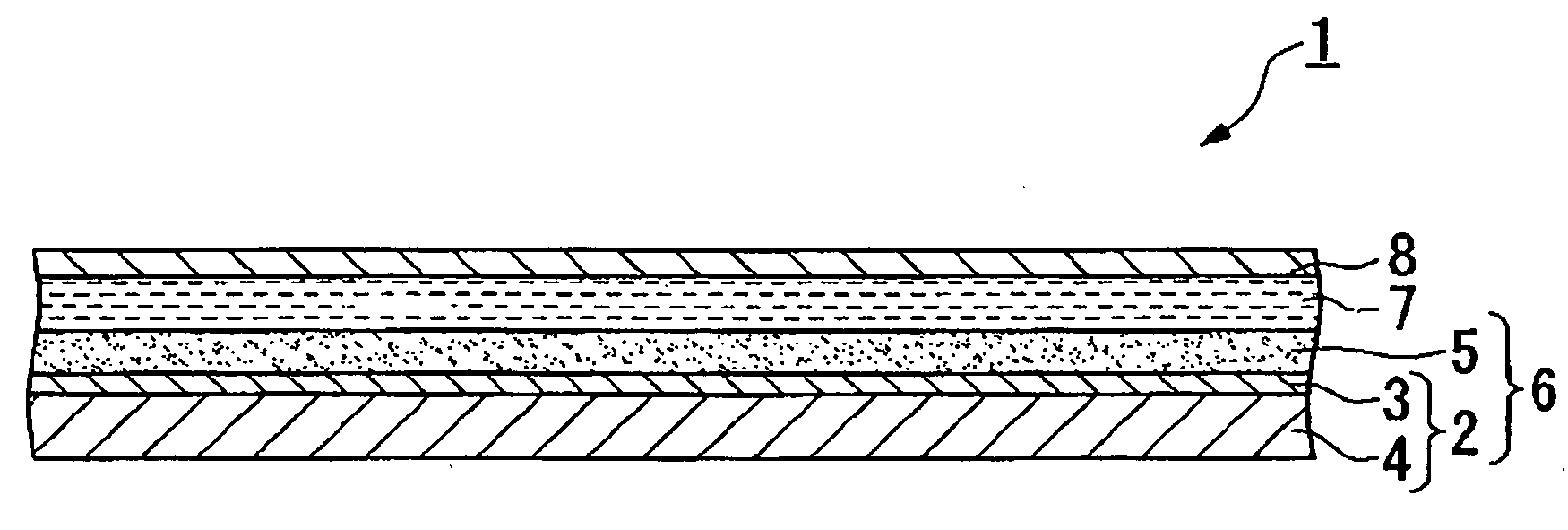

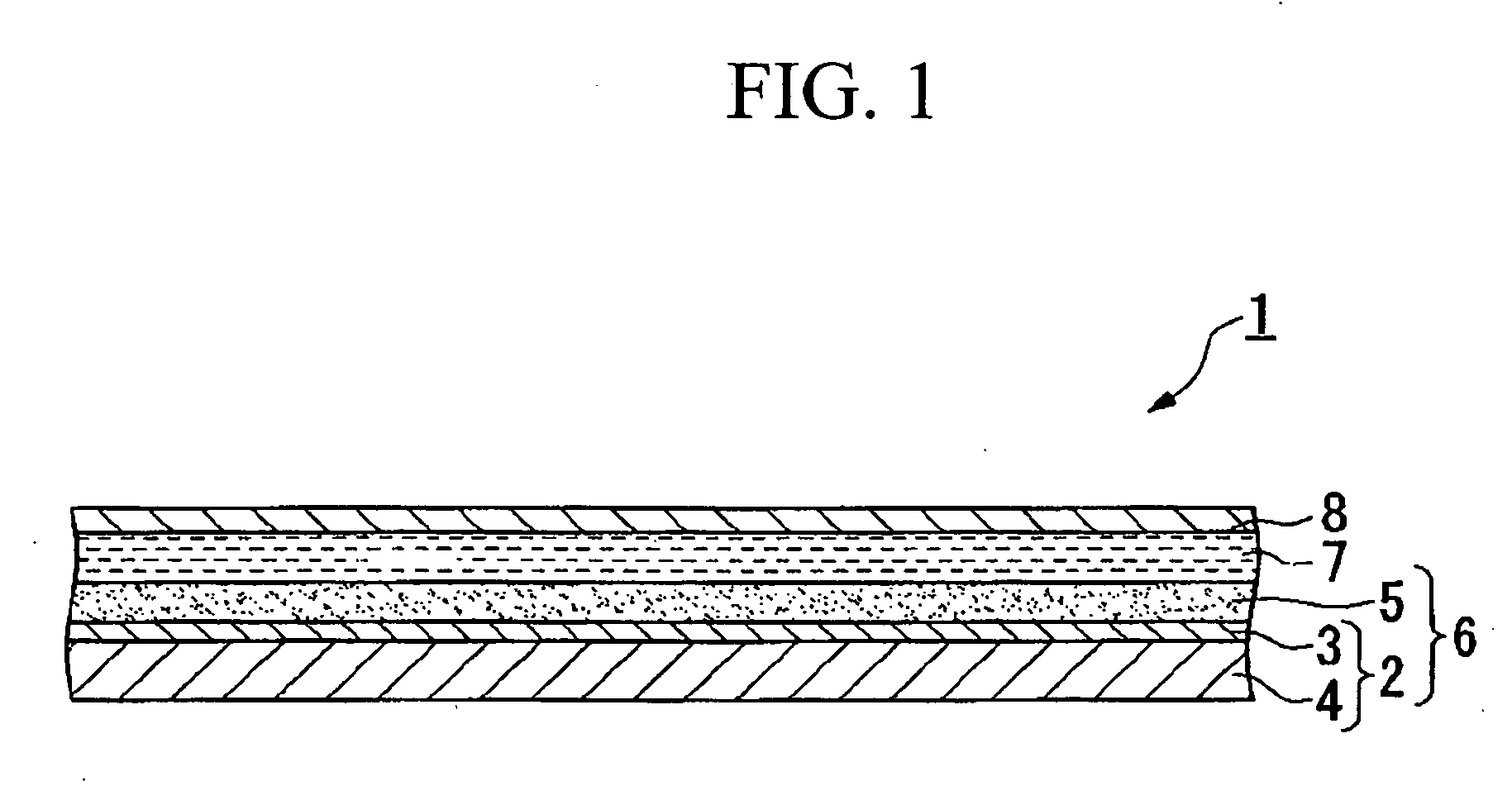

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

ActiveUS7411779B2Lower equivalent series resistanceIncrease coverageHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisConductive polymer

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

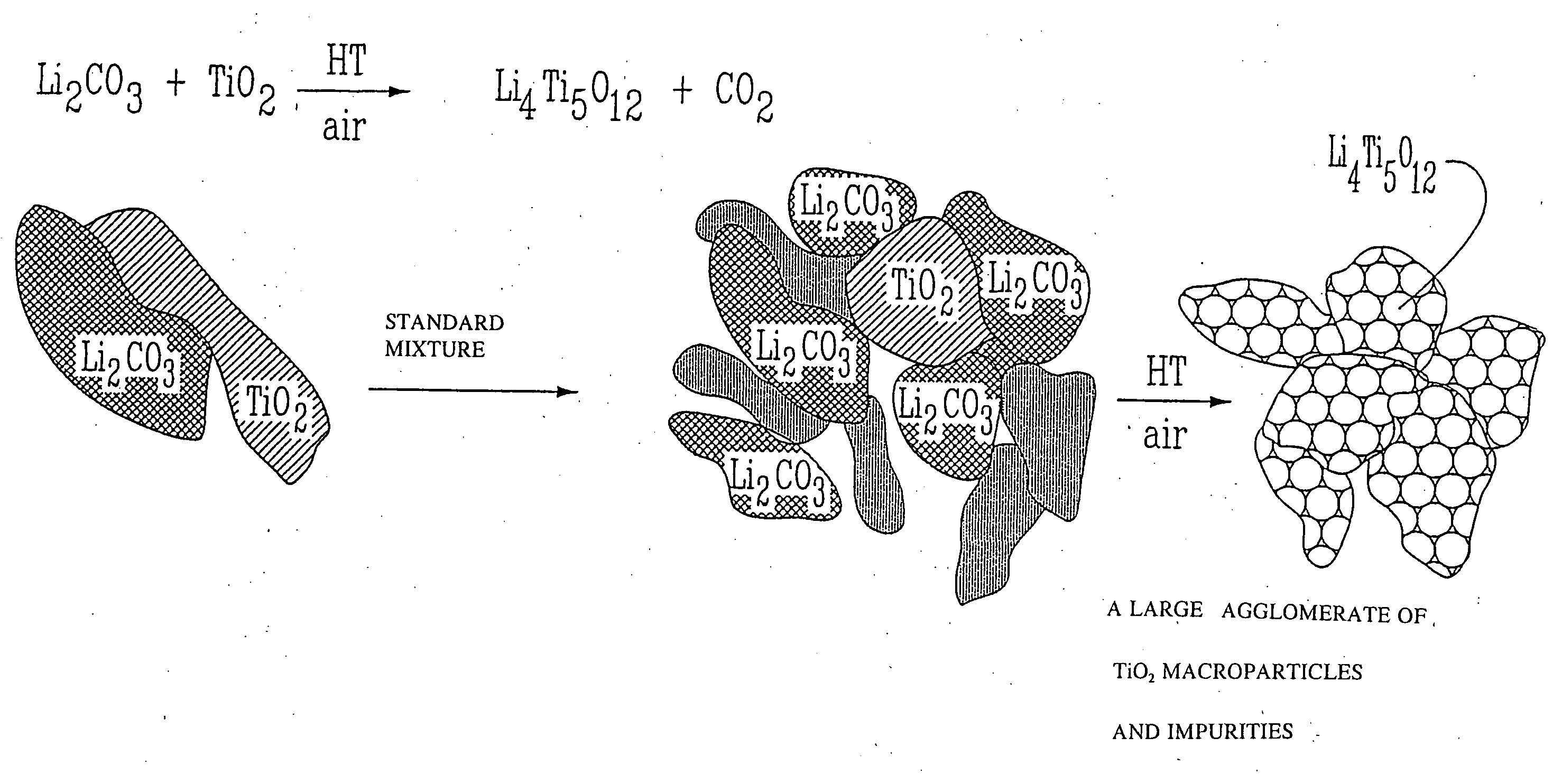

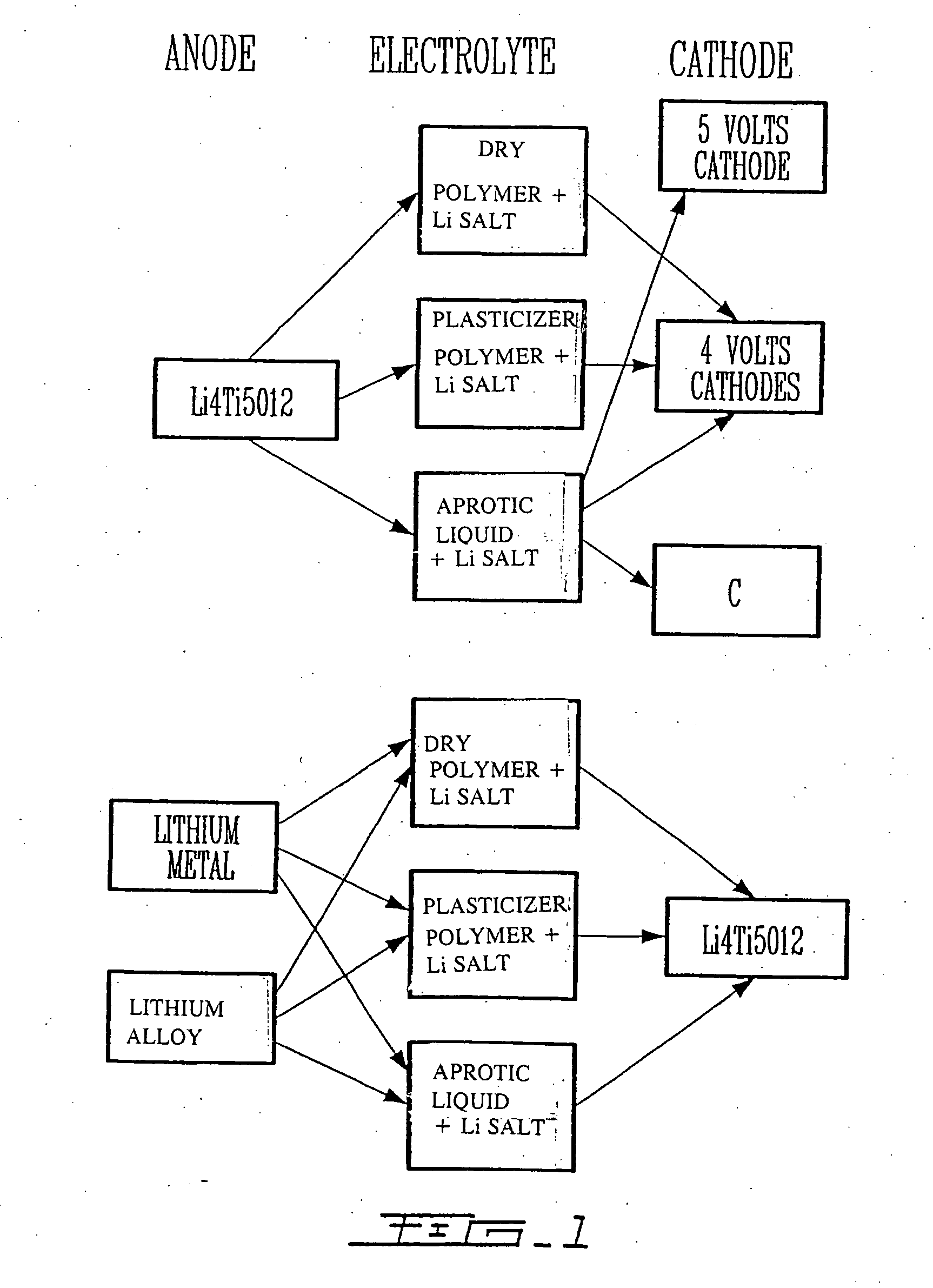

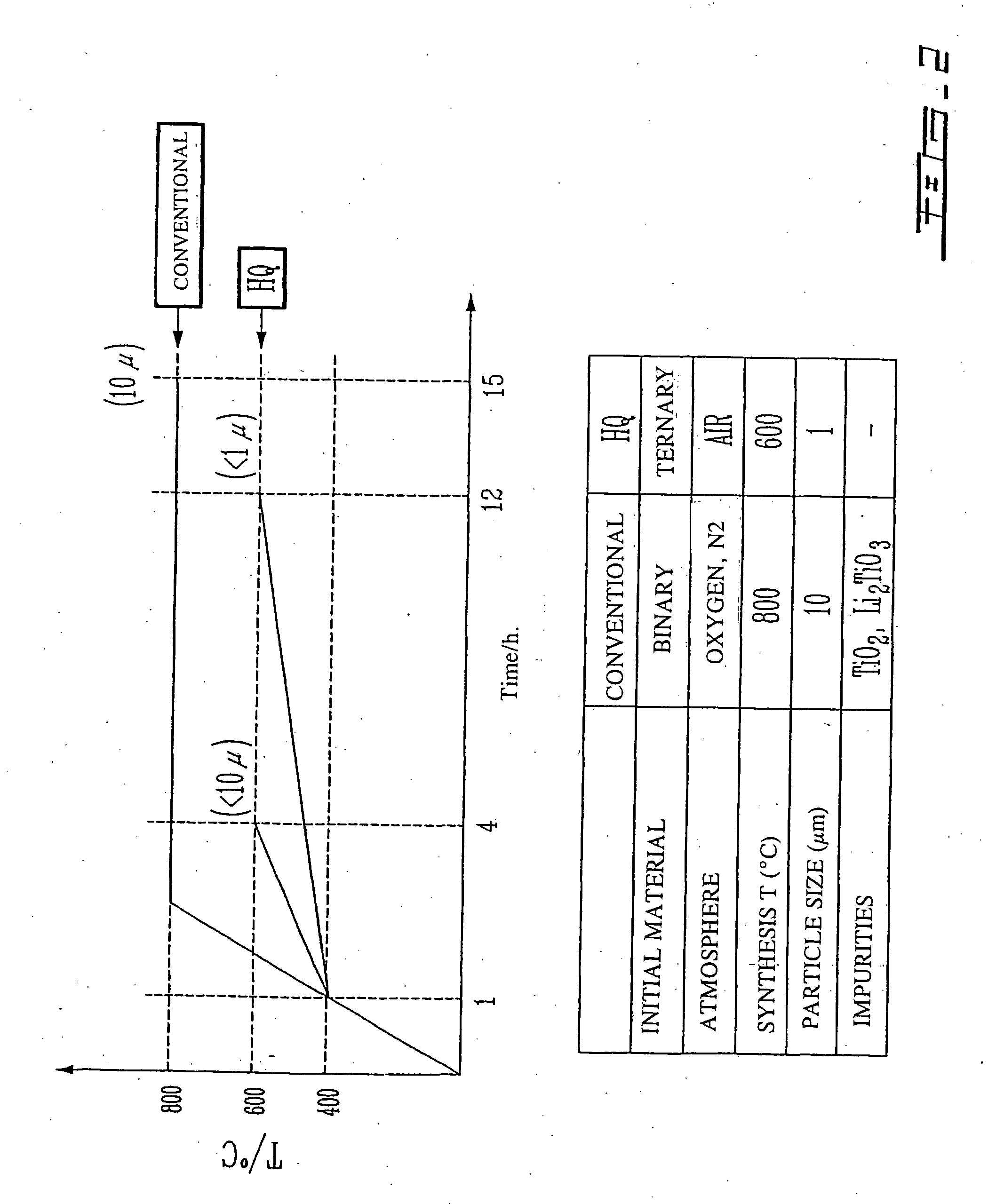

Li4Ti5O12, Li(4-alpha)Zalpha Ti5O12 or Li4ZbetaTi(5-beta)O12 particles, processes for obtaining same and use as electrochemical generators

Synthesis process for new particles of Li4Ti5O12, Li(4-alpha)ZalphaTi5O12 or Li4ZbetaTi(5-beta)O12, preferably having a spinel structure, wherein beta is greater than 0 and less than or equal to 0.5 (preferably having a spinel structure), alpha representing a number greater than zero and less than or equal to 0.33, Z representing a source of at least one metal, preferably chosen from the group made up of Mg, Nb, Al, Zr, Ni, Co. These particles coated with a layer of carbon notably exhibit electrochemical properties that are particularly interesting as components of anodes and / or cathodes in electrochemical generators.

Owner:HYDRO QUEBEC CORP

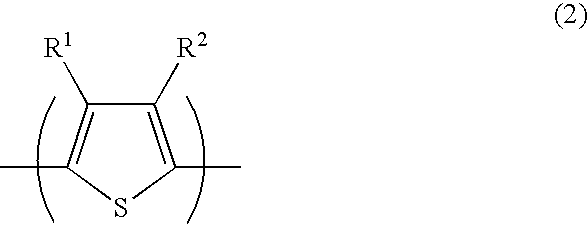

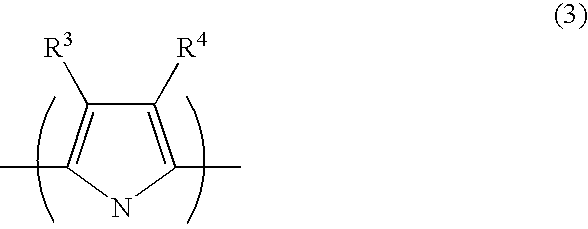

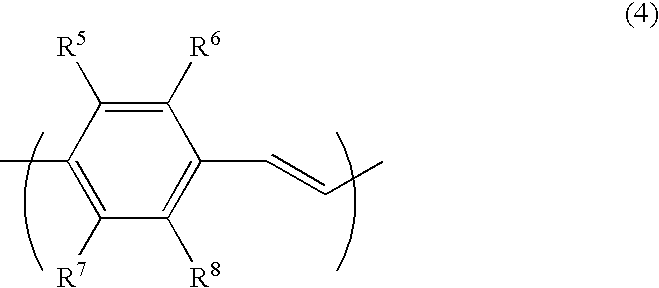

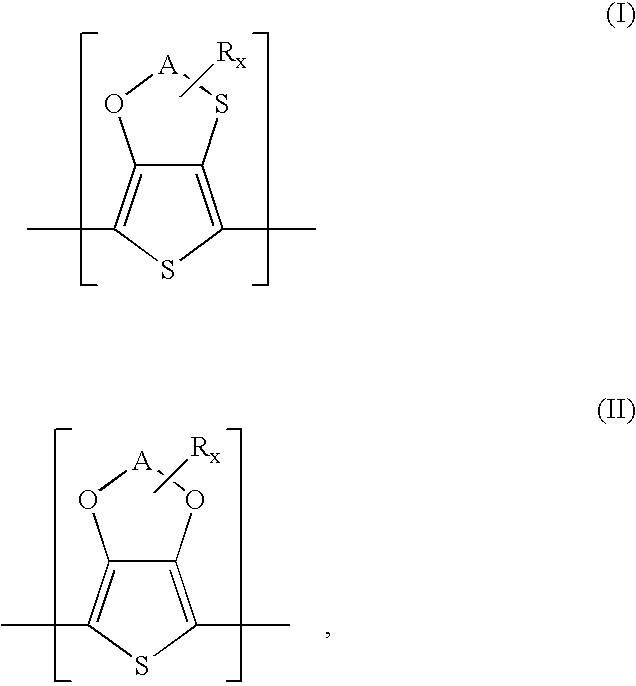

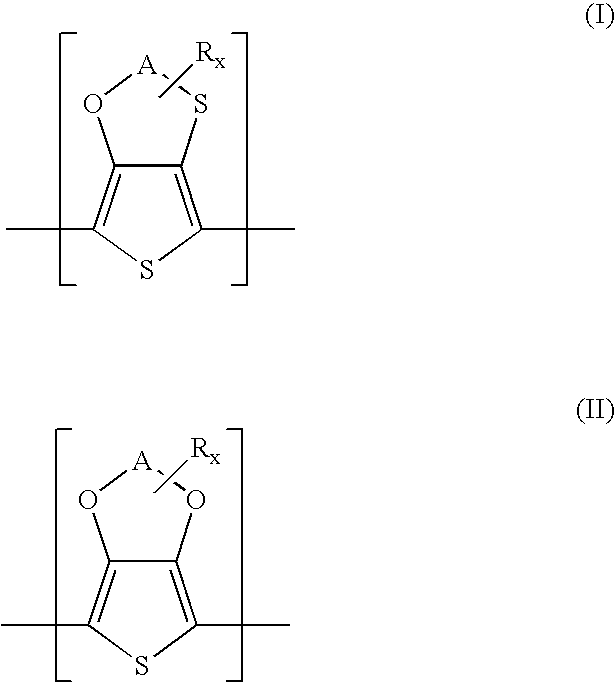

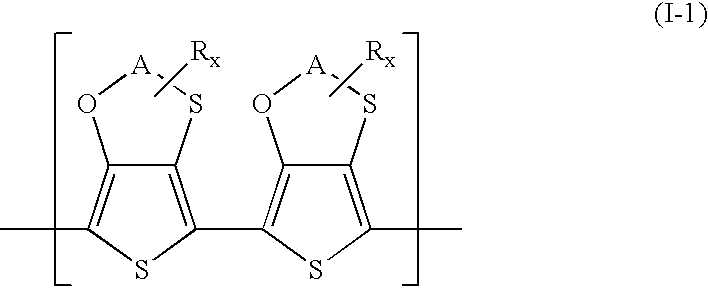

Polythiophenes having alkyleneoxythia thiophene units in electrolyte capacitors

InactiveUS7341801B2Reduce conductivityConductivity adjustableHybrid capacitor electrolytesHybrid capacitor electrodesPolymer scienceElectrolysis

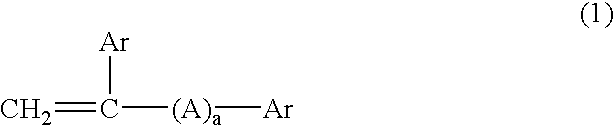

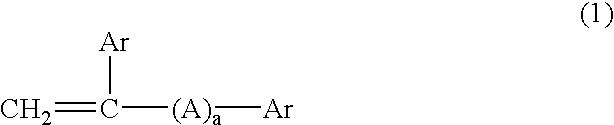

Electrolyte capacitors containing certain polythiophenes are described. More particularly, the polythiophenes have backbones containing repeating units of the following general formula (I) and / or repeating units of the following general formula (II),wherein A is, for example, a C1-C5-alkylene radical, R is, for example, a C1-C18-alkyl radical, and x is an integer from 0 to 8. Also described are dispersions comprising such polythiophenes, and the use of such polythiophenes or dispersions thereof for producing conductive layers.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Electrolyte capacitors having a polymeric outer layer and process for their production

ActiveUS7377947B2Increase coverageHybrid capacitor electrolytesHybrid capacitor electrodesConductive polymerCapacitor

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current, and which comprise a solid electrolyte of conductive polymers and an outer layer comprising conductive polymers applied in the form of a dispersion. Electrolyte capacitors produced by this process and the use of such electrolyte capacitors are also provided.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

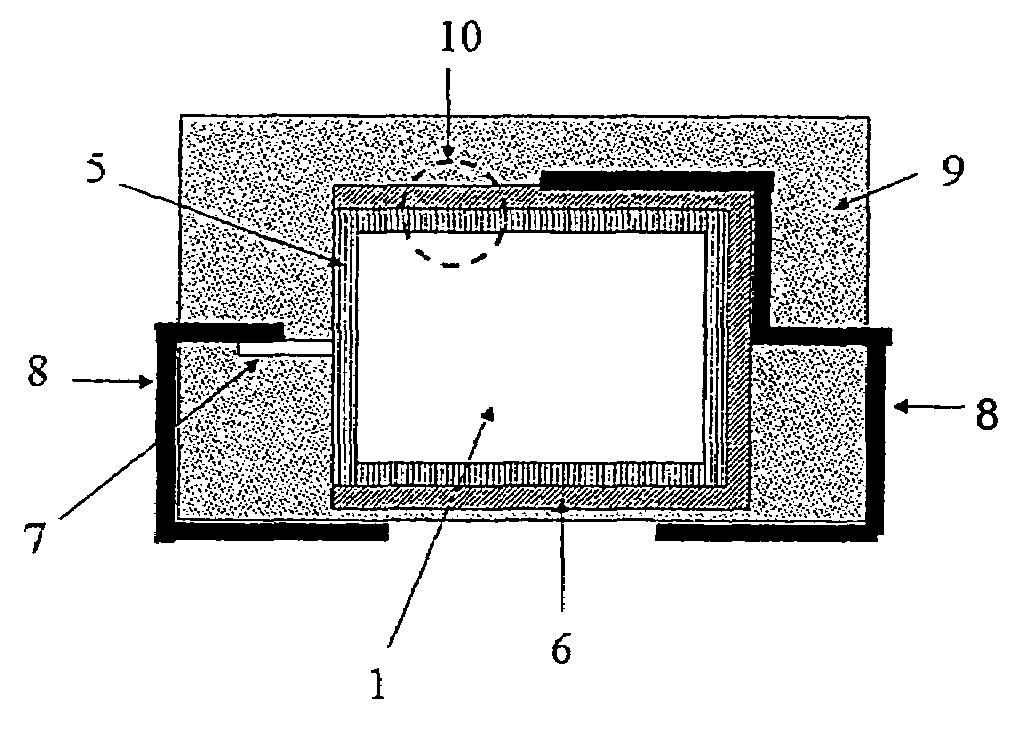

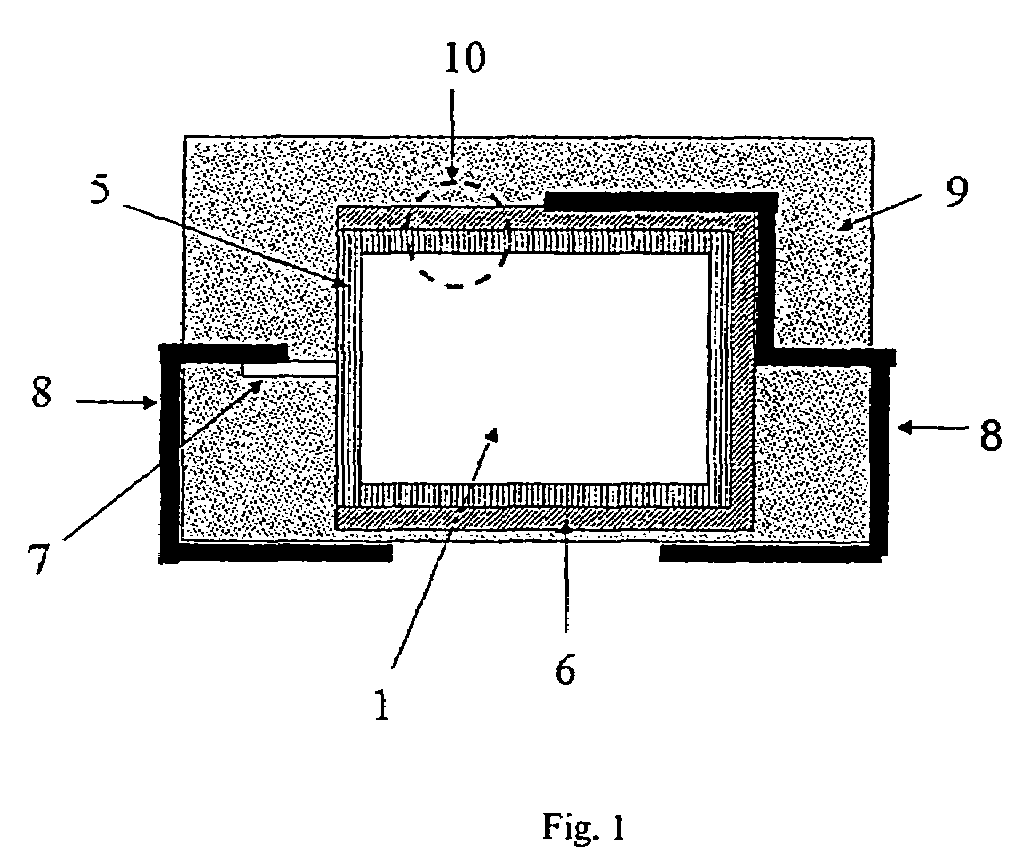

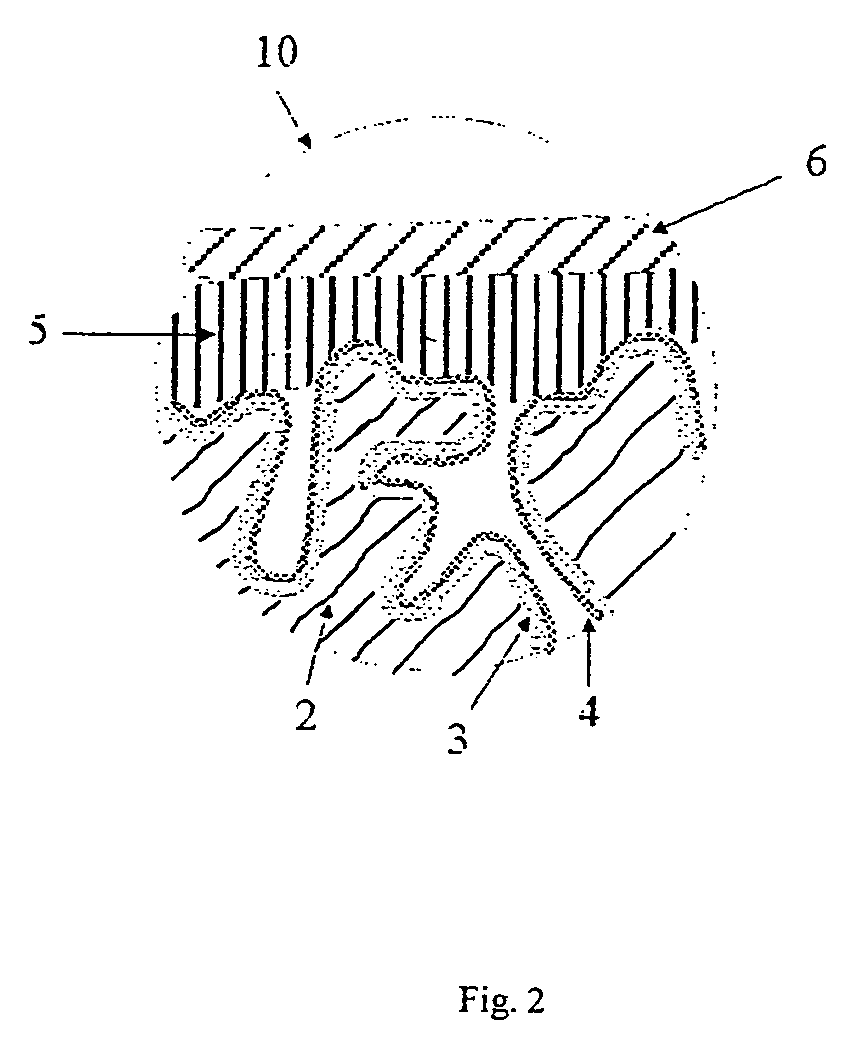

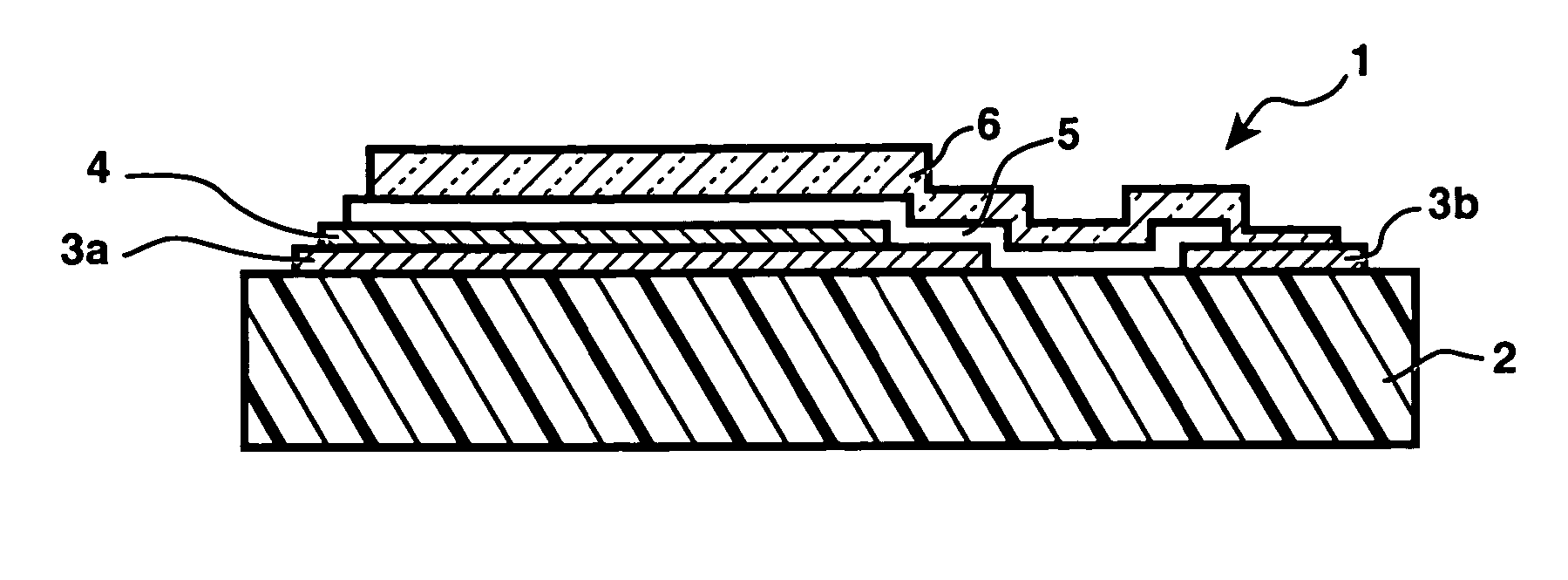

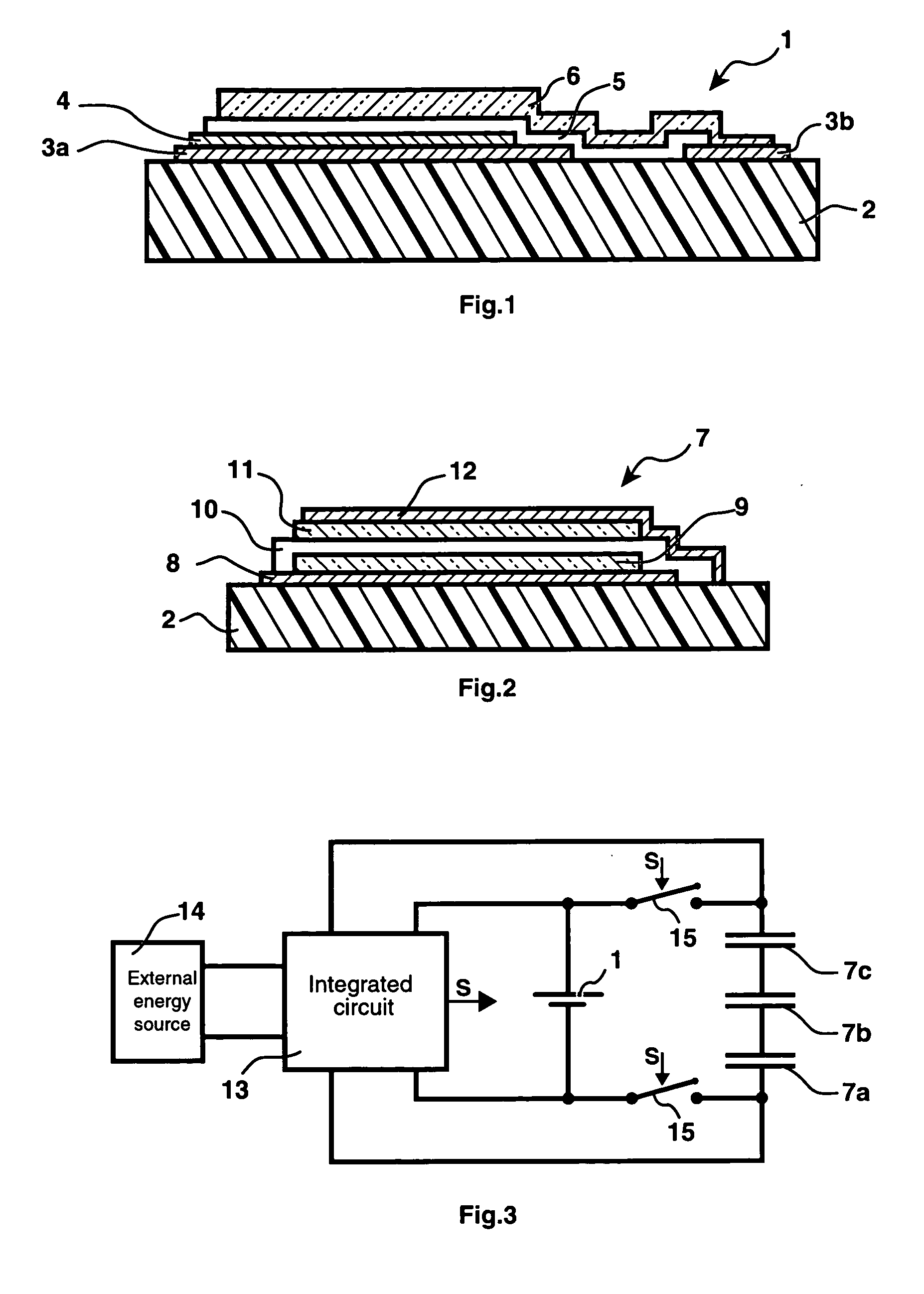

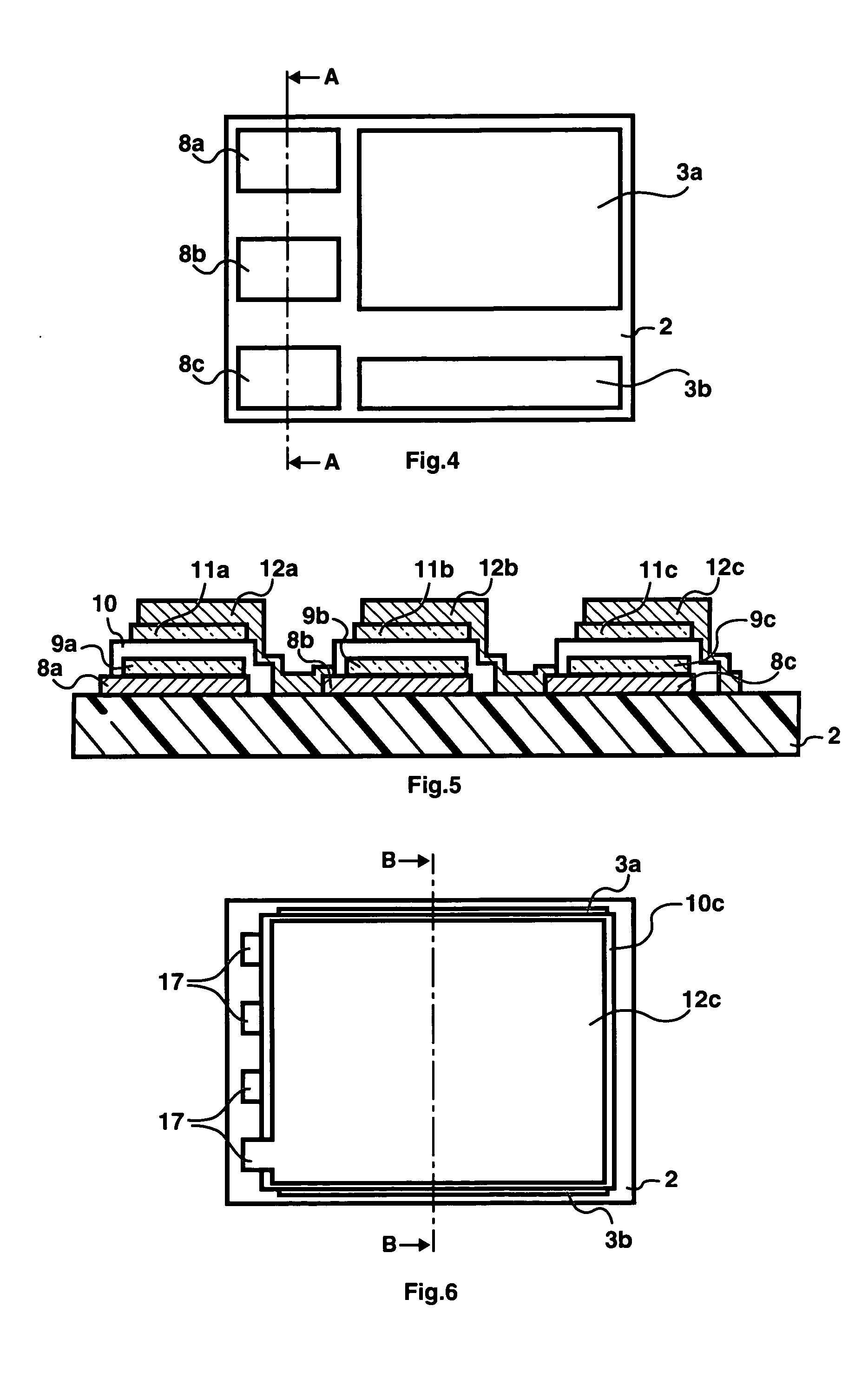

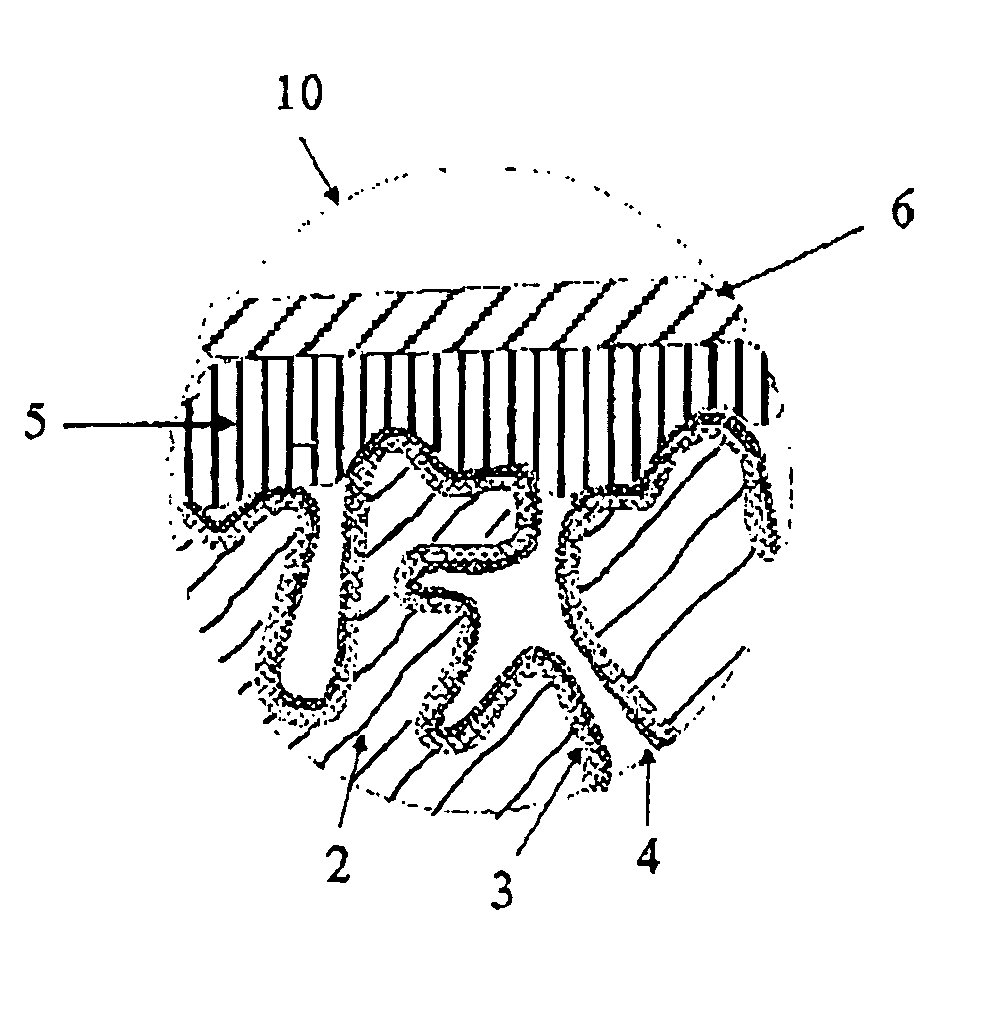

Quick recharge energy storage device, in the form of thin films

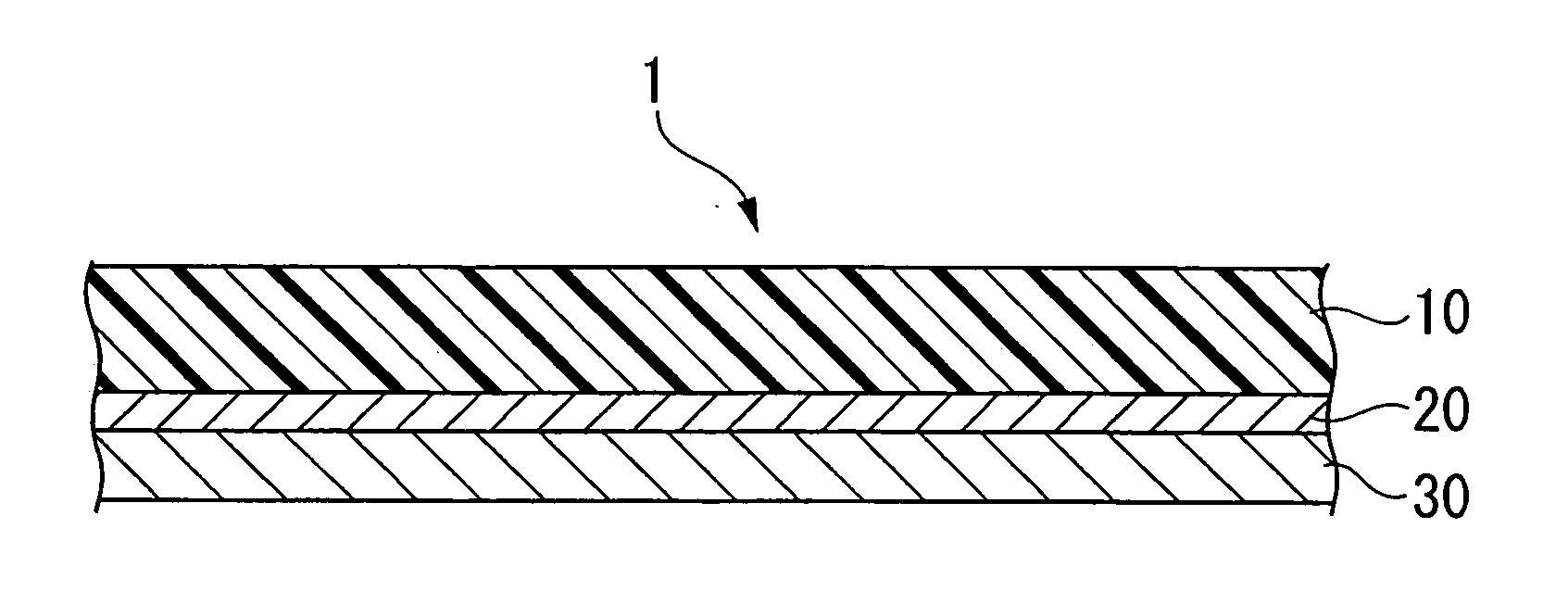

InactiveUS20040161640A1Without reducing energy capacityReduce capacityFinal product manufactureDouble layer capacitorsExternal energySupercapacitor

The quick recharge energy storage device has a sufficient capacity due to the combination of a micro-battery and at least one micro-supercapacitor connected between two terminals of an integrated circuit. The integrated circuit, powered by the micro-battery, monitors high-speed (less than one second) charge of the micro-supercapacitors from an external energy source. The micro-supercapacitor can be connected in parallel with the micro-battery so as to subsequently recharge the micro-battery during the necessary time. The micro-battery provides a sufficient energy capacity, while the micro-supercapacitors allow high recharging speeds compatible with various applications (smart cards, smart labels, micro-system power supply, etc . . . ). The micro-battery and micro-supercapacitors are preferably formed on the same substrate, either side by side or stacked. Series connection of several micro-supercapacitors provides sufficient voltage for charging the micro-battery.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Process for the production of electrolyte capacitors of high nominal voltage

ActiveUS8313538B2Solid electrolytic capacitorsLiquid electrolytic capacitorsPhysical chemistryCapacitor

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current for high nominal voltages, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

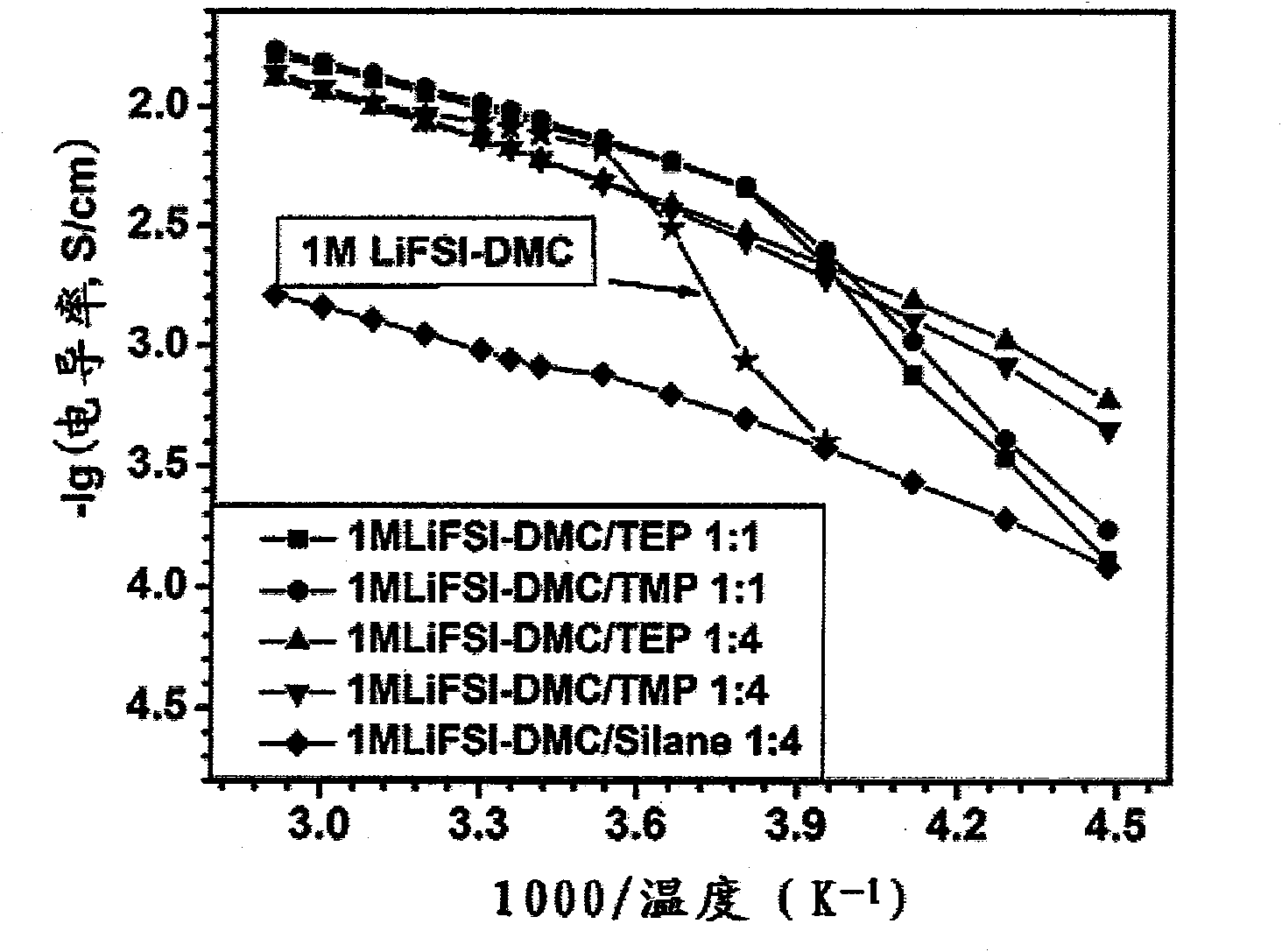

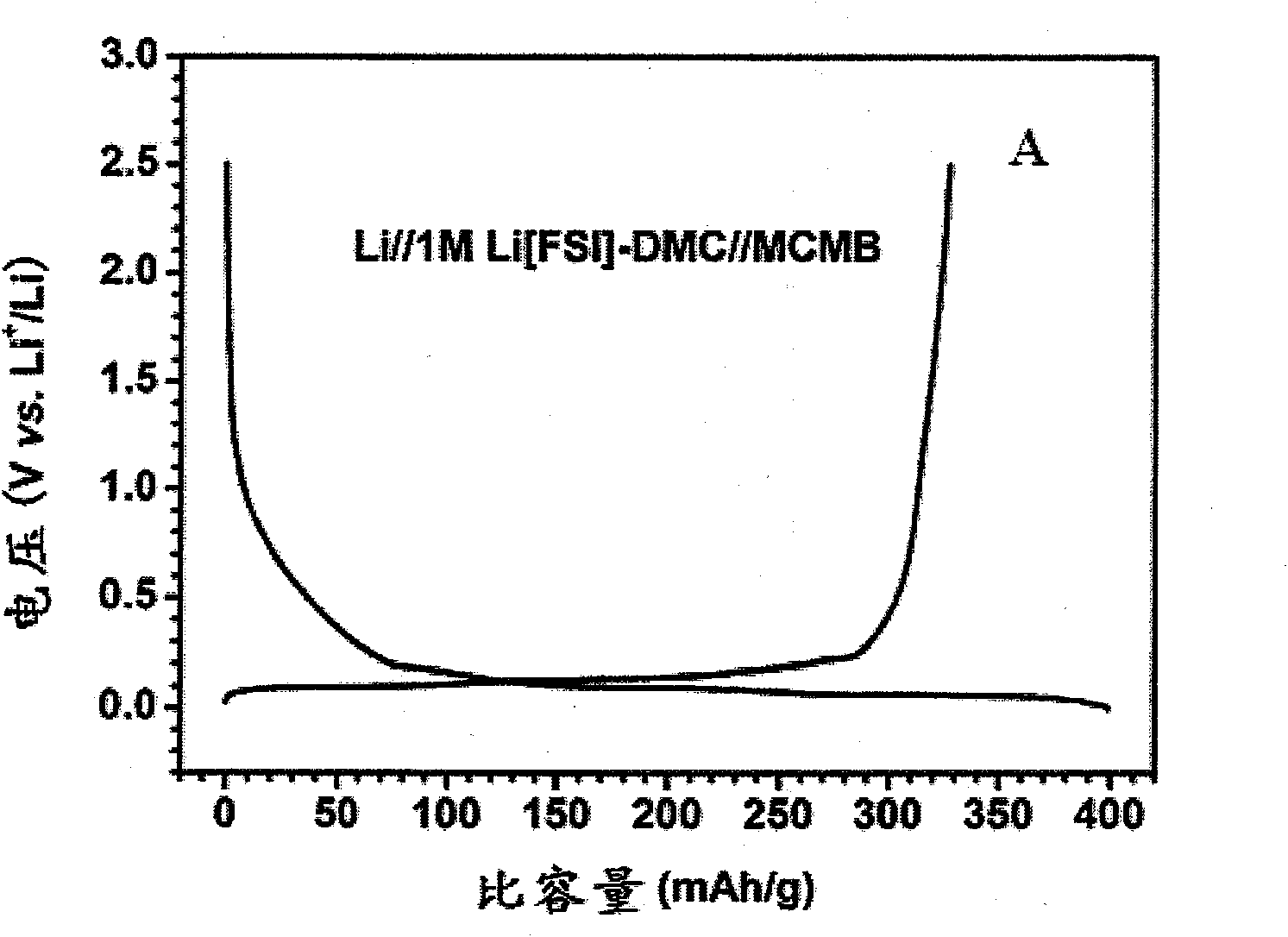

Nonaqueous electrolyte material of fluorosulfonylimide lithium and application thereof

ActiveCN101882696AImprove solubilityNot easy to crystallizeOrganic chemistryCapacitor electrolytes/absorbentsDielectricPhosphate

The invention provides a nonaqueous electrolyte material, which consists of fluorosulfonylimide lithium and organic solvent with dielectric constant less than 30, and the organic solvent is selected from one or more of chain-like carbonate solvent, phosphate solvent, siloxane solvent, boroxane solvent, acetate solvent, propionate solvent, butyrate solvent, CF3OCH2CH2OCF3 solvent, C2H5OCH2CH2OCH3 solvent, C2F5OCH2CH2OCF3 solvent, 1,3-dioxolane solvent and aliphatic nitrile solvent with more than two carbon atoms. The ionic conductivity of the nonaqueous electrolyte material is 0.01mS / cm to 18mS / cm, the lithium ion transference number is tLi plus equal to 0.2 to 0.8, and the applicable temperature range is 80DEG C below zero to 60DEG C below zero. The invention also provides an application of the nonaqueous electrolyte material in the preparation of lithium batteries and super capacitors. Furthermore, the invention provides a lithium battery and a super capacitor which contain the nonaqueous electrolyte material of fluorosulfonylimide lithium.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

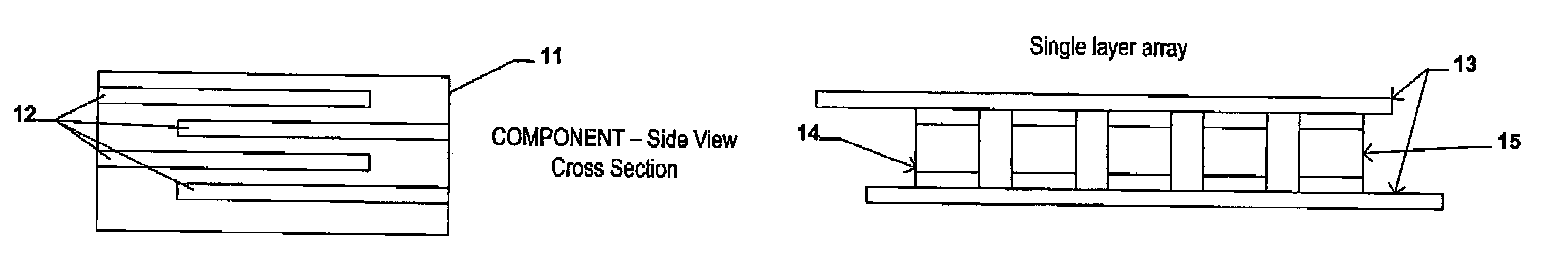

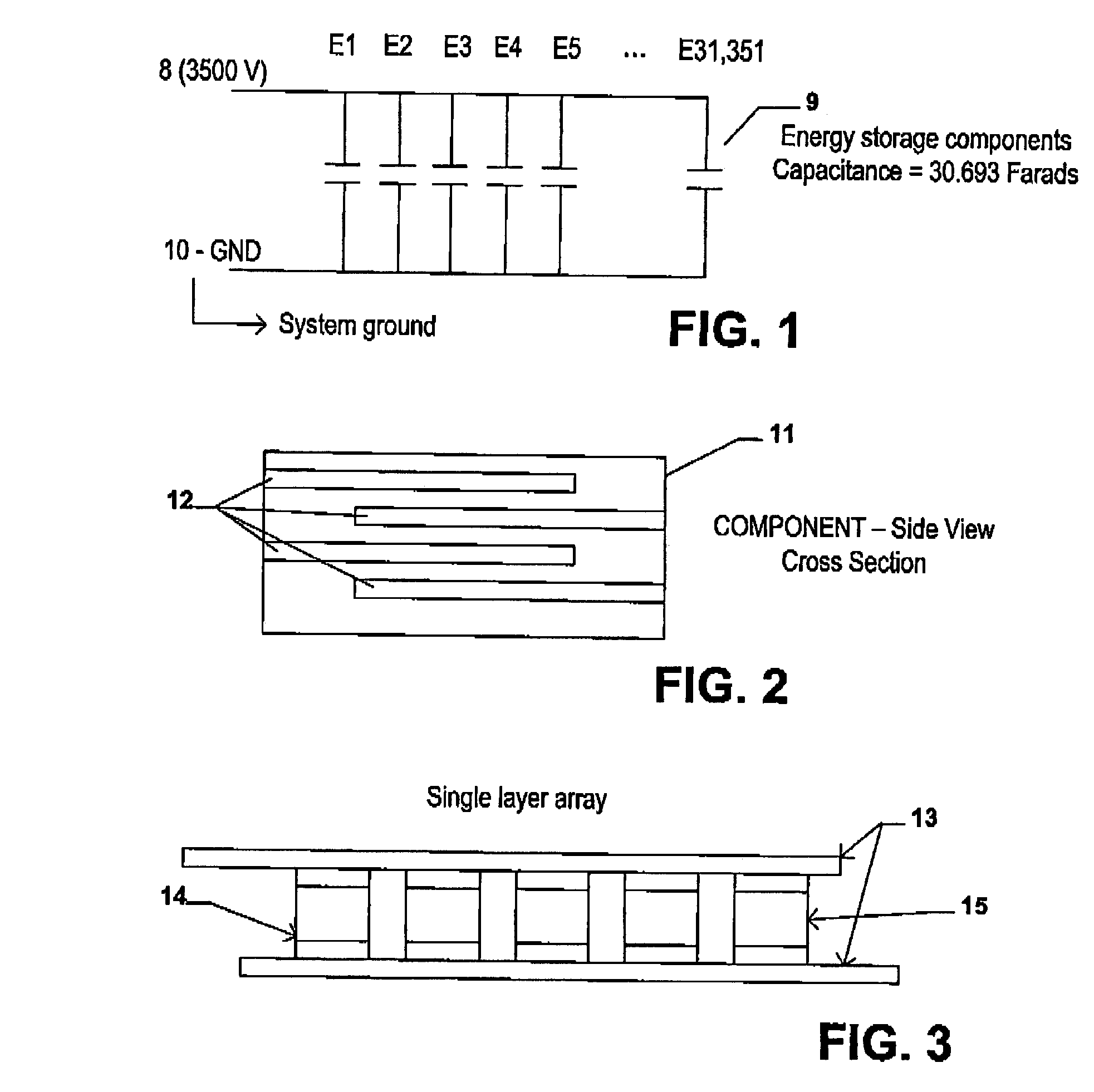

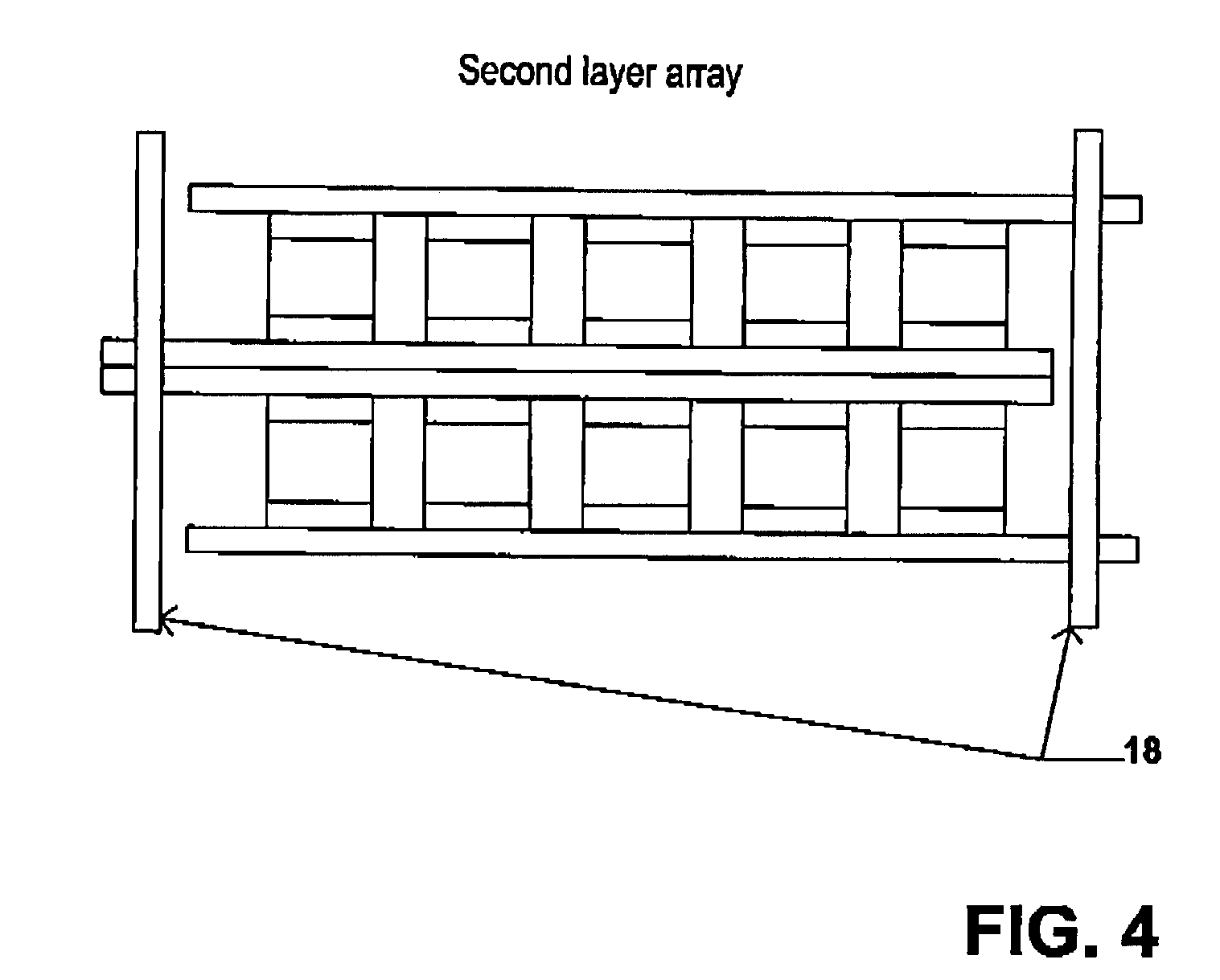

Utilization of poly(ethylene terephthalate) plastic and composition-modified barium titanate powders in a matrix that allows polarization and the use of integrated-circuit technologies for the production of lightweight ultrahigh electrical energy storage units (EESU)

InactiveUS7466536B1Low costLower sintering temperatureCell electrodesFixed capacitor dielectricManufacturing technologyBarium titanate

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is single coated with aluminum oxide and then immersed in a matrix of poly(ethylene terephthalate) (PET) plastic for use in screen-printing systems. The ink that is used to process the powders via screen-printing is based on a nitrocellulose resin that provide a binder burnout, sintering, and hot isostatic pressing temperatures that are allowed by the PET plastic. These lower temperatures that are in the range of 40° C. to 150° C. also allows aluminum powder to be used for the electrode material. The components of the EESU are manufactured with the use of conventional ceramic and plastic fabrication techniques which include screen printing alternating multilayers of aluminum electrodes and high-permittivity composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The 31,351 components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store at least 52.22 kW·h of electrical energy. The total weight of an EESU with this amount of electrical energy storage is 281.56 pounds including the box, connectors, and associated hardware.

Owner:EESTOR

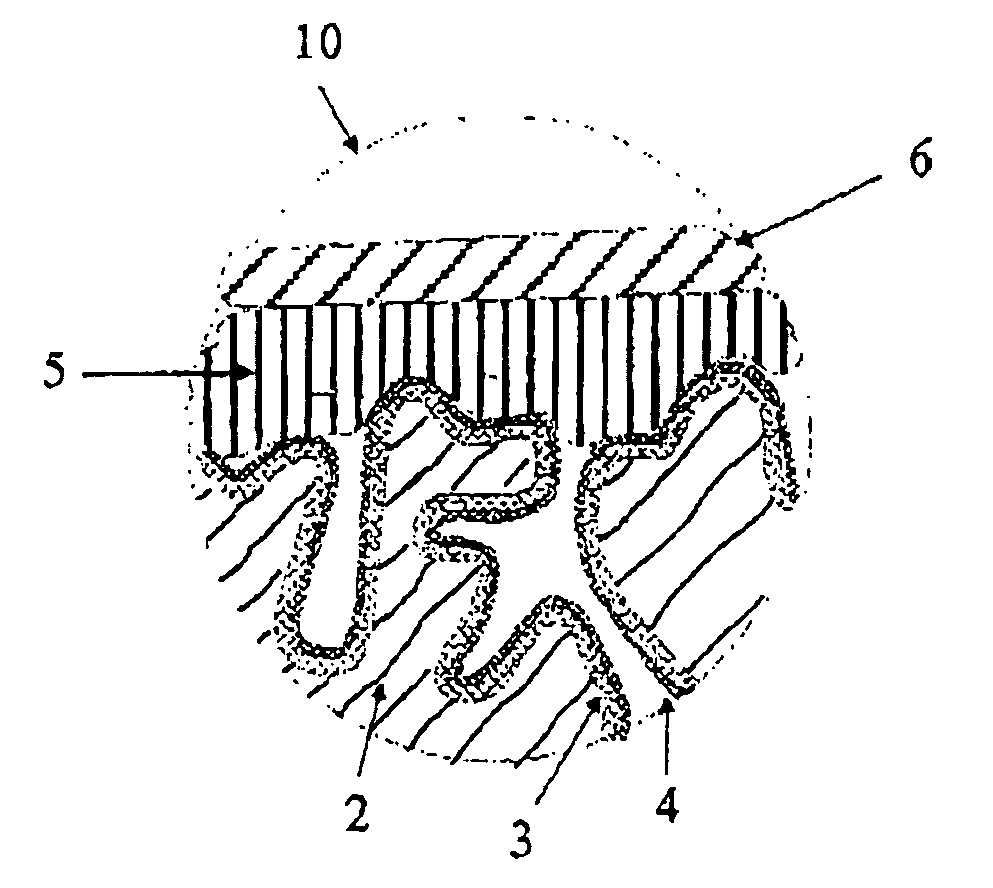

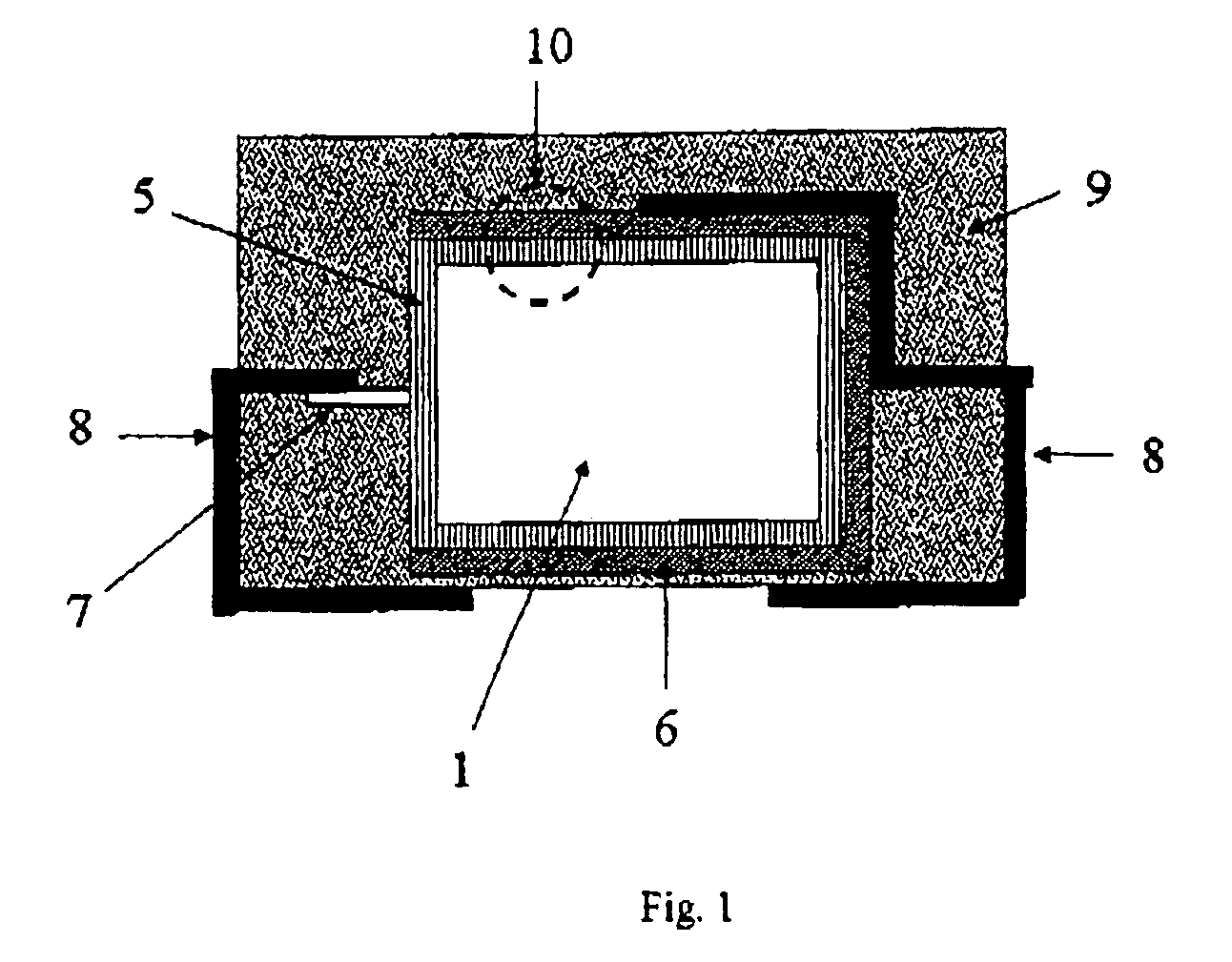

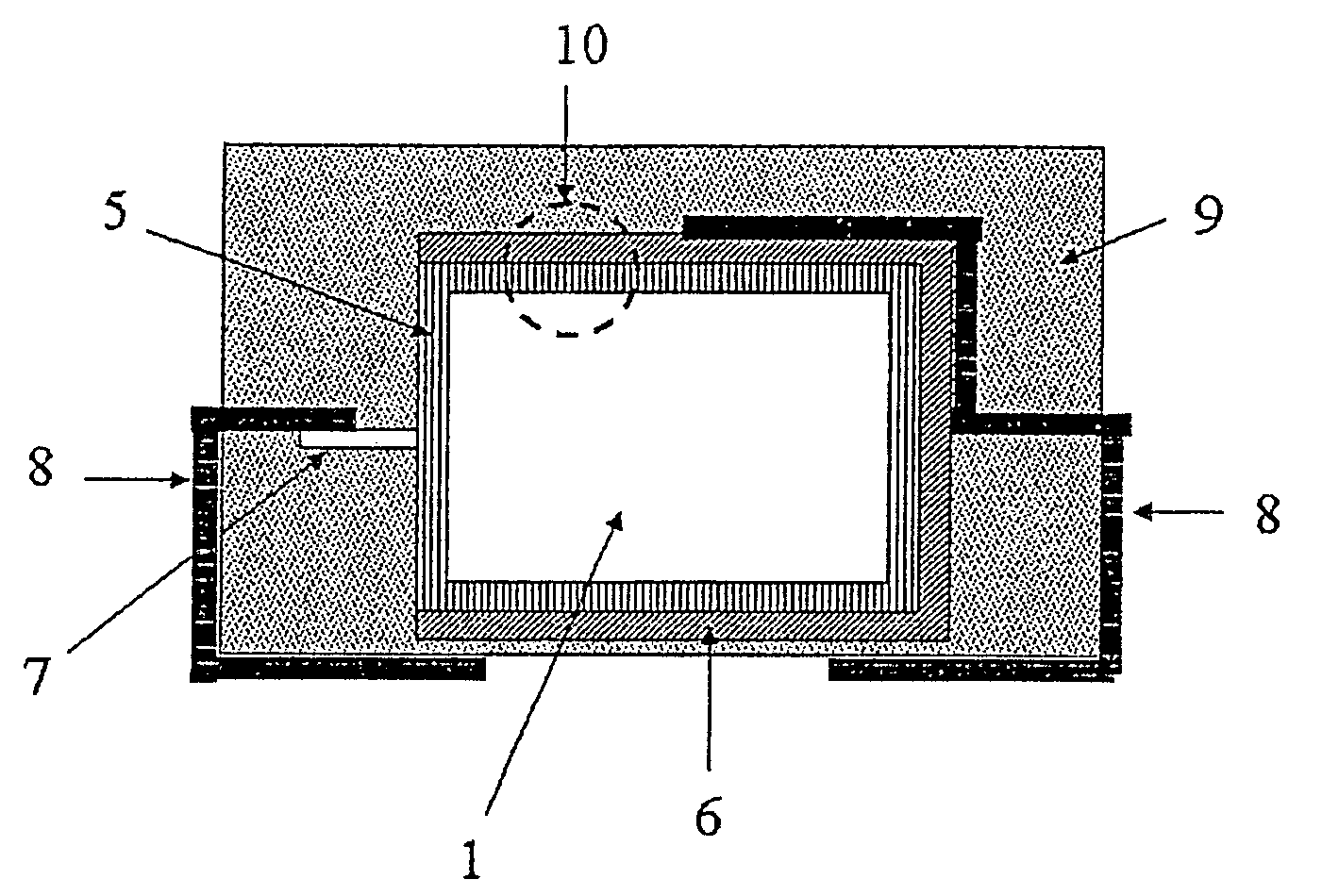

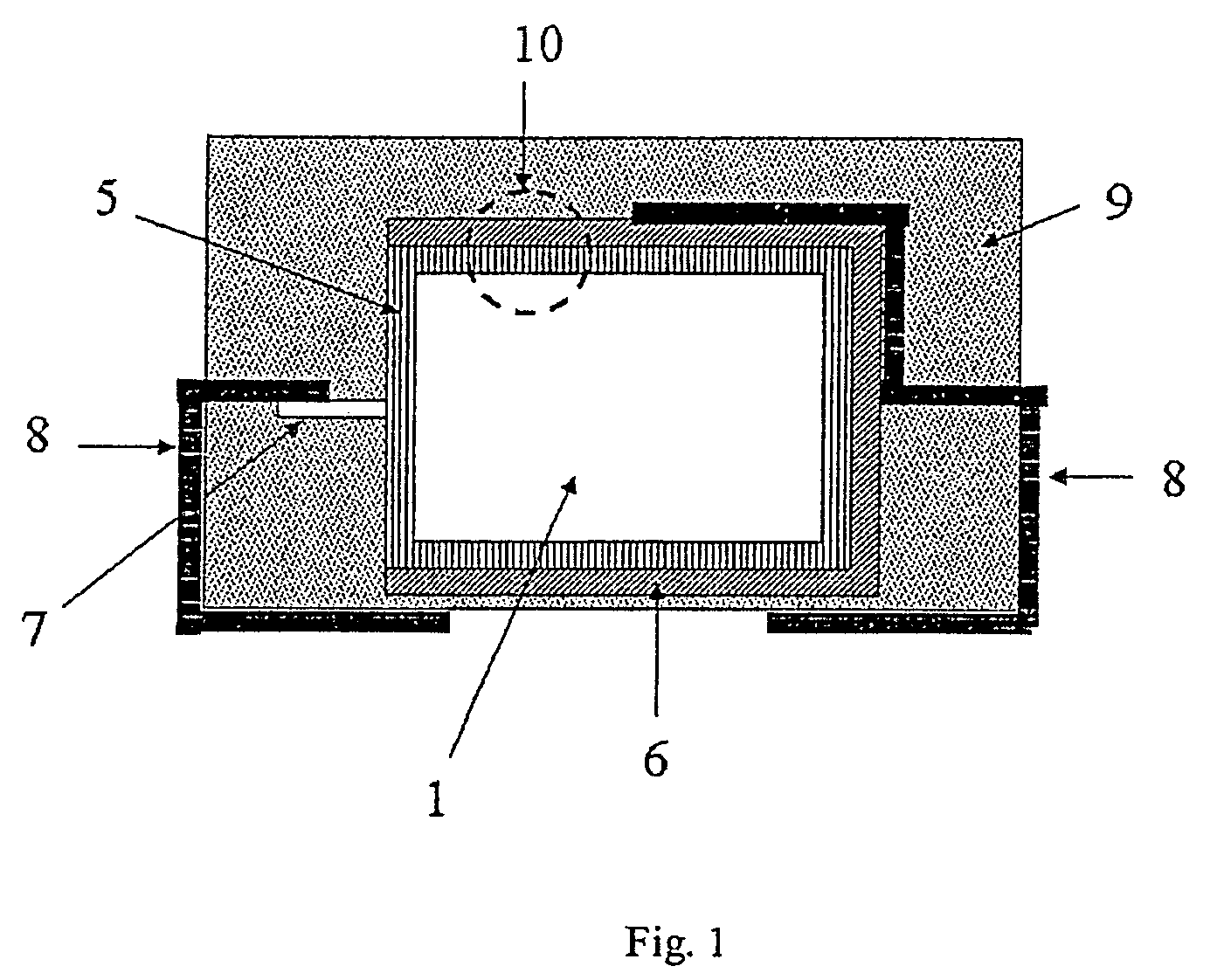

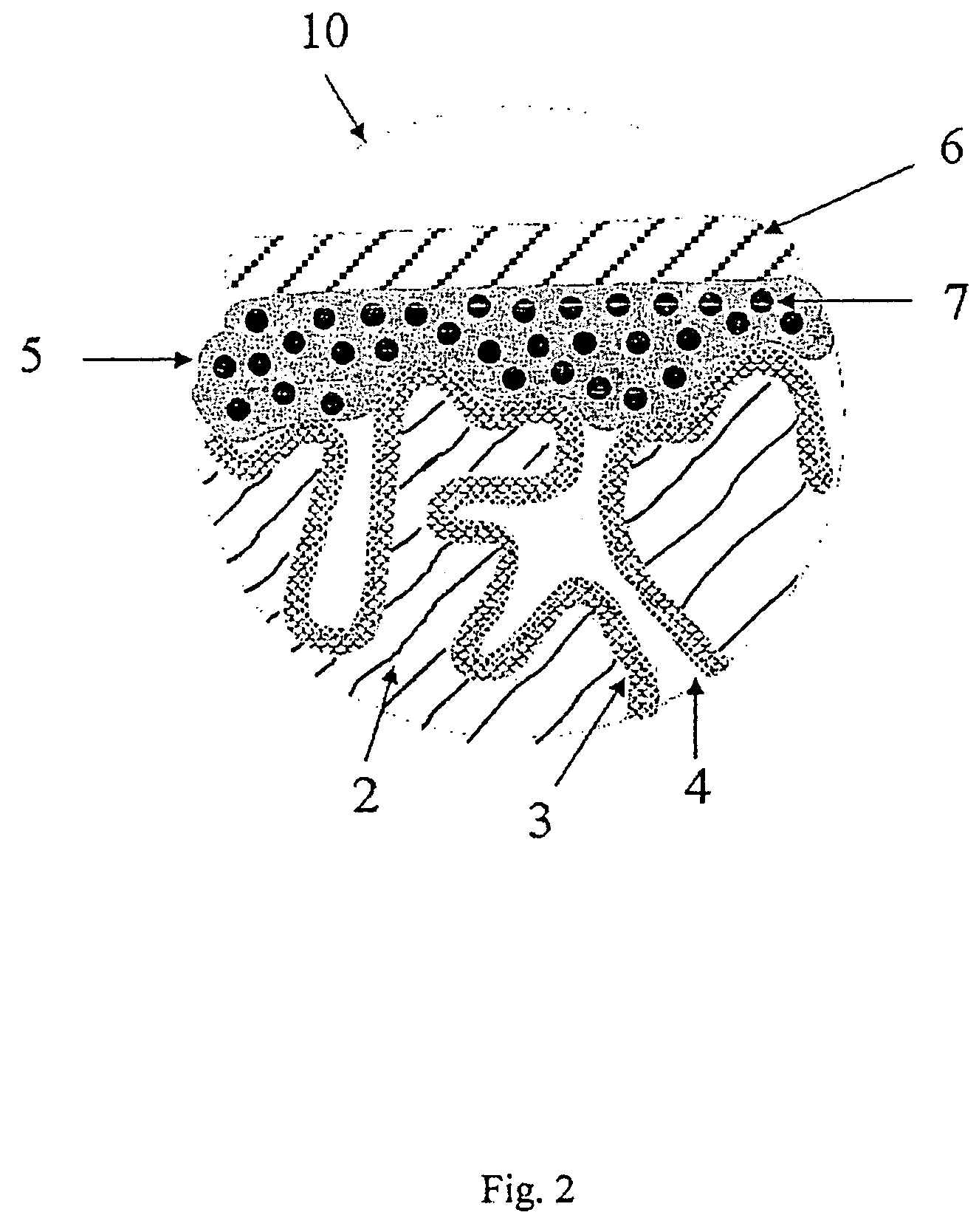

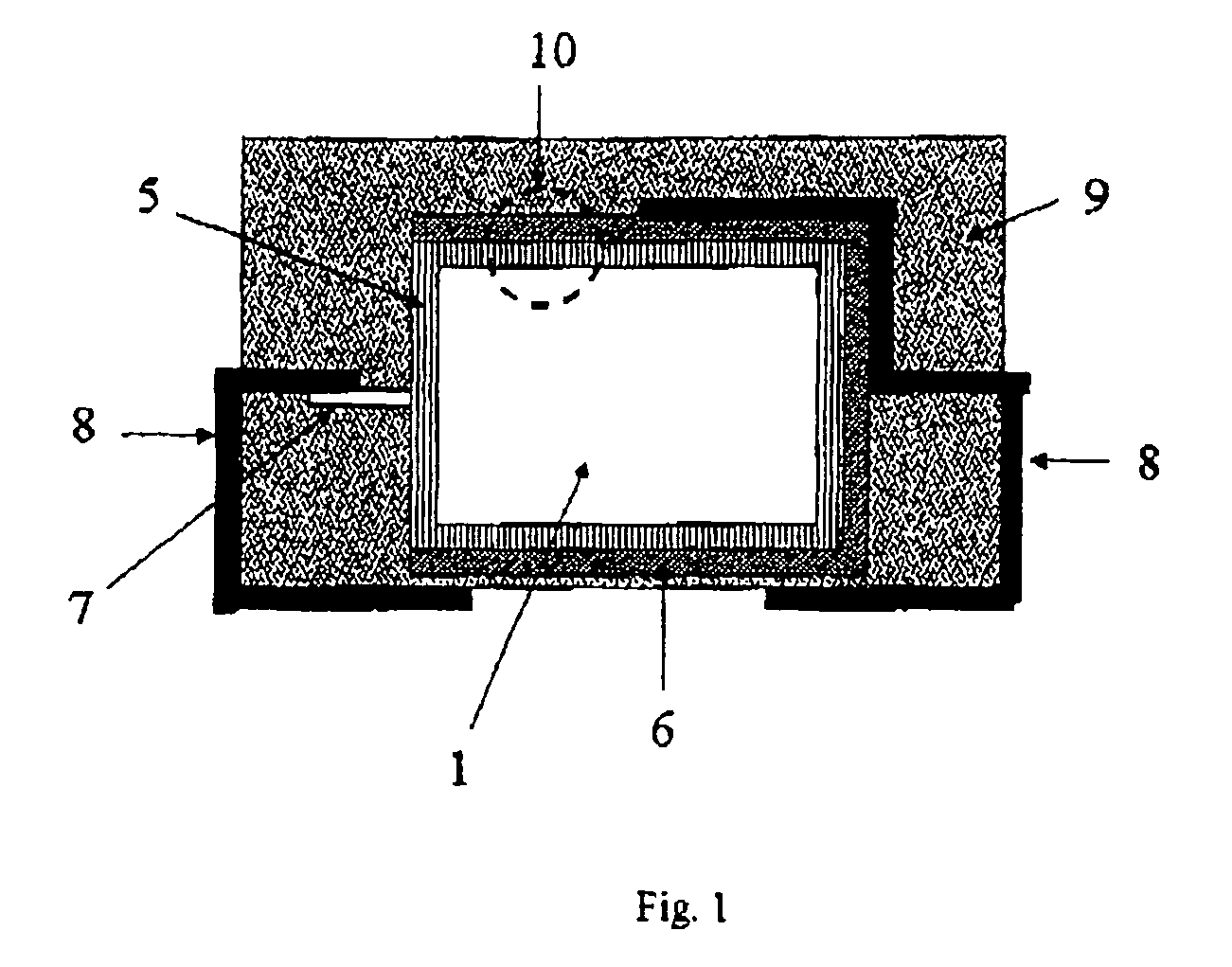

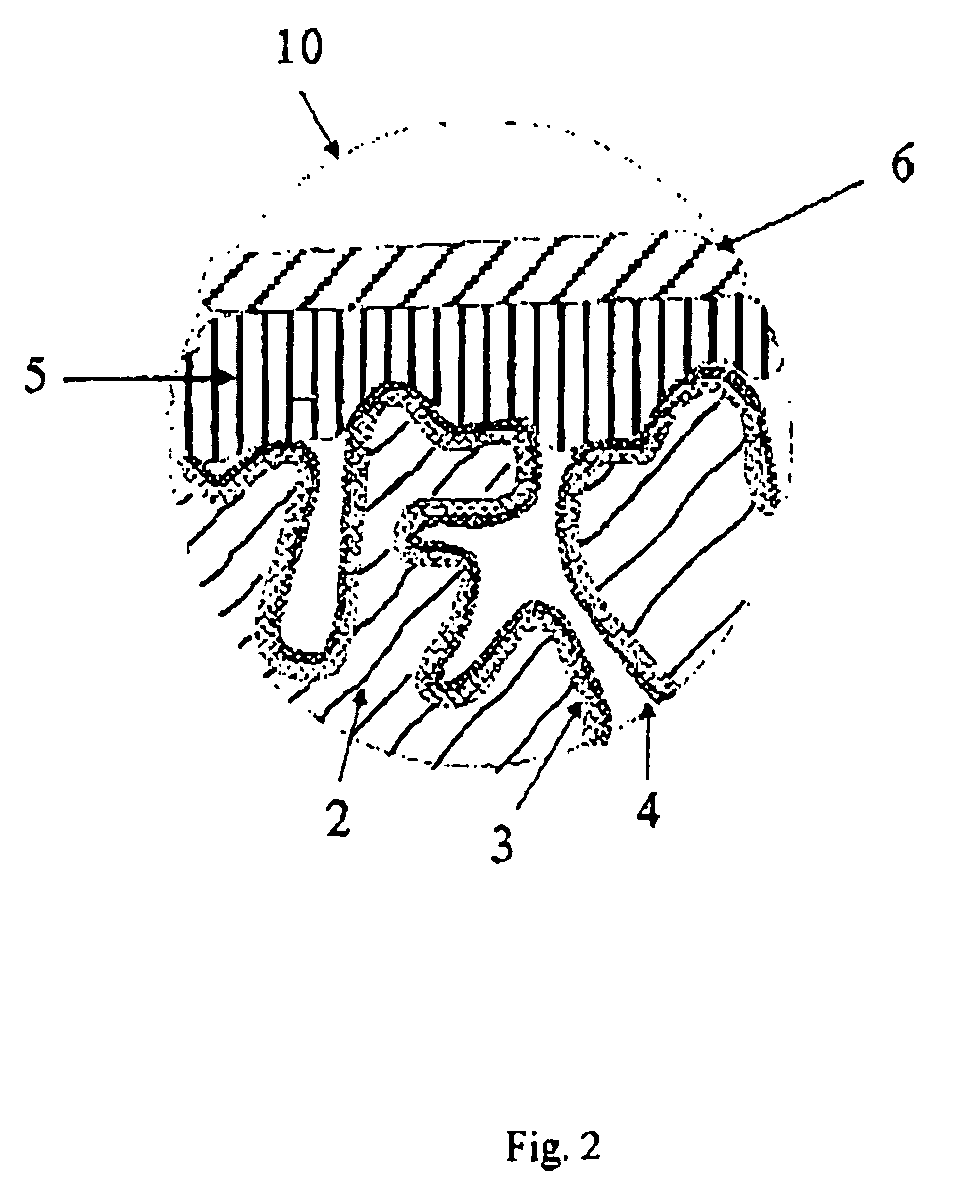

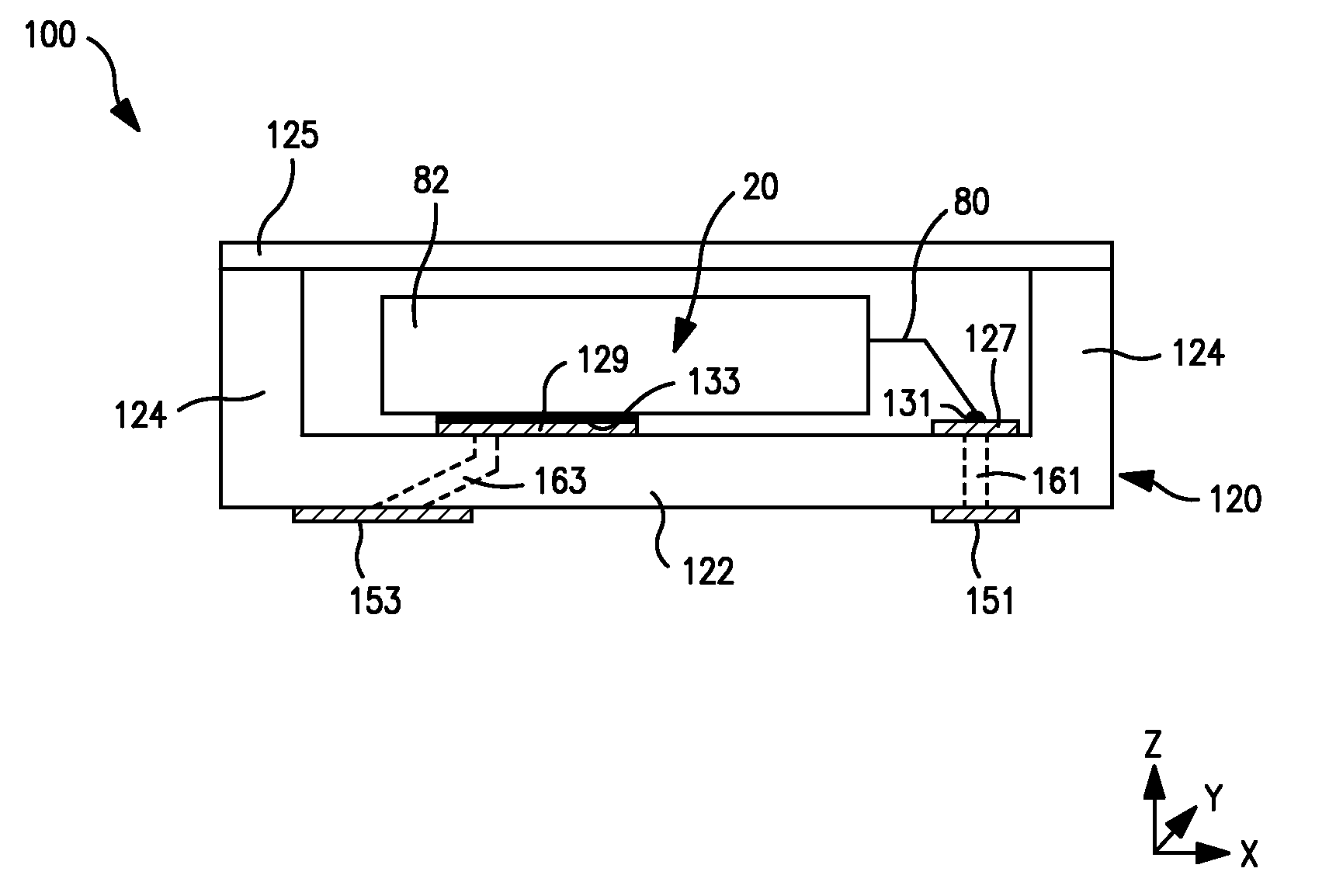

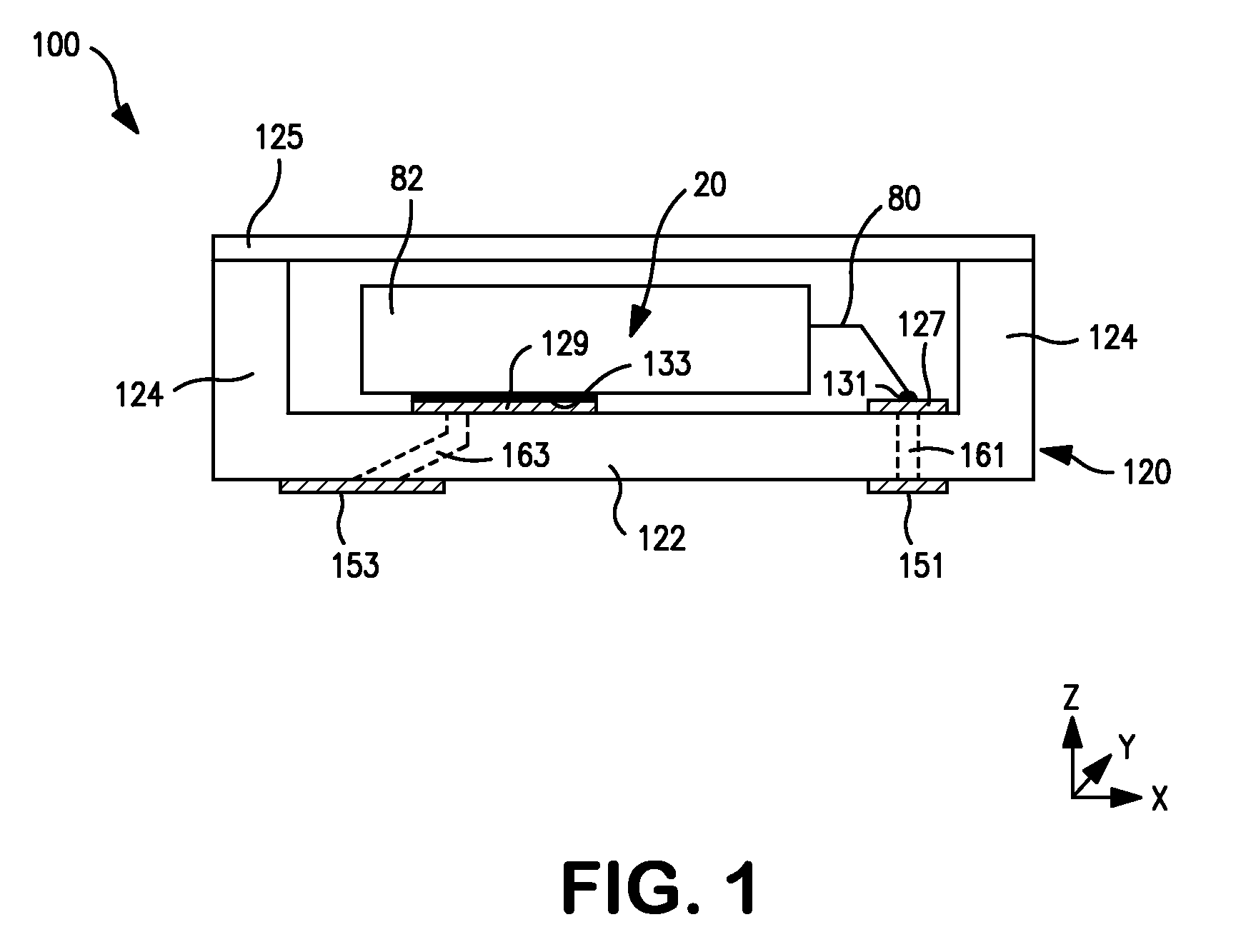

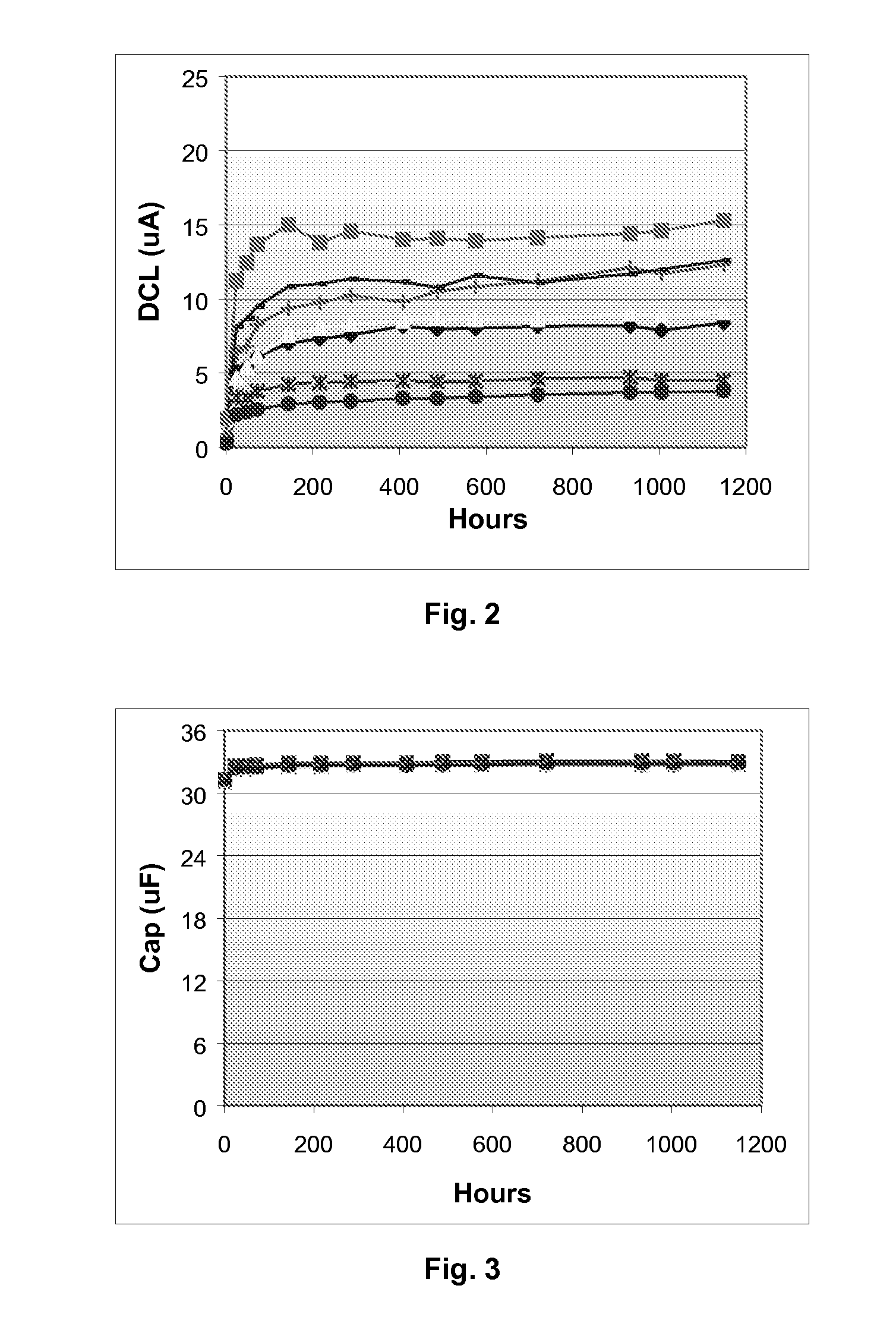

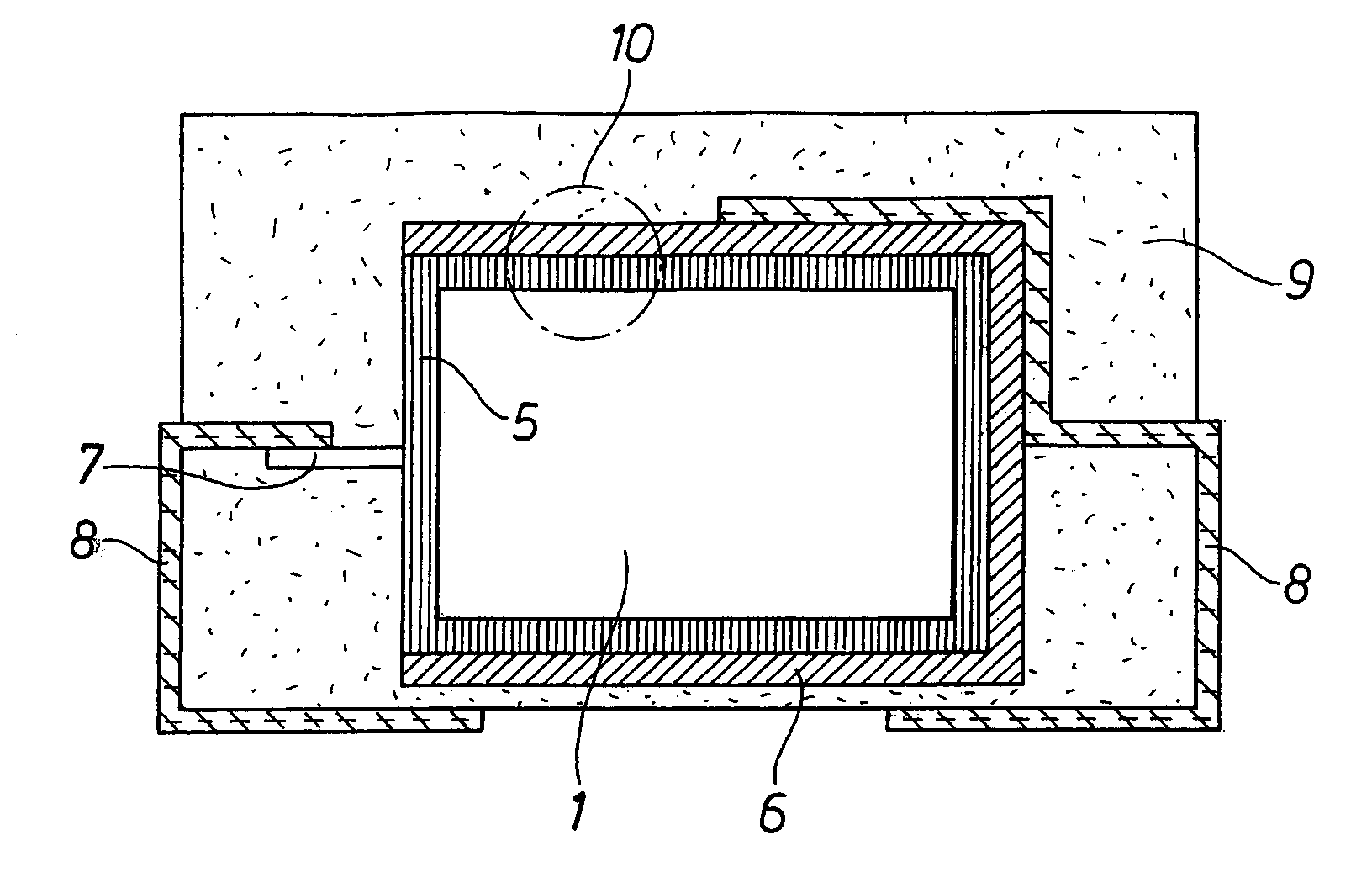

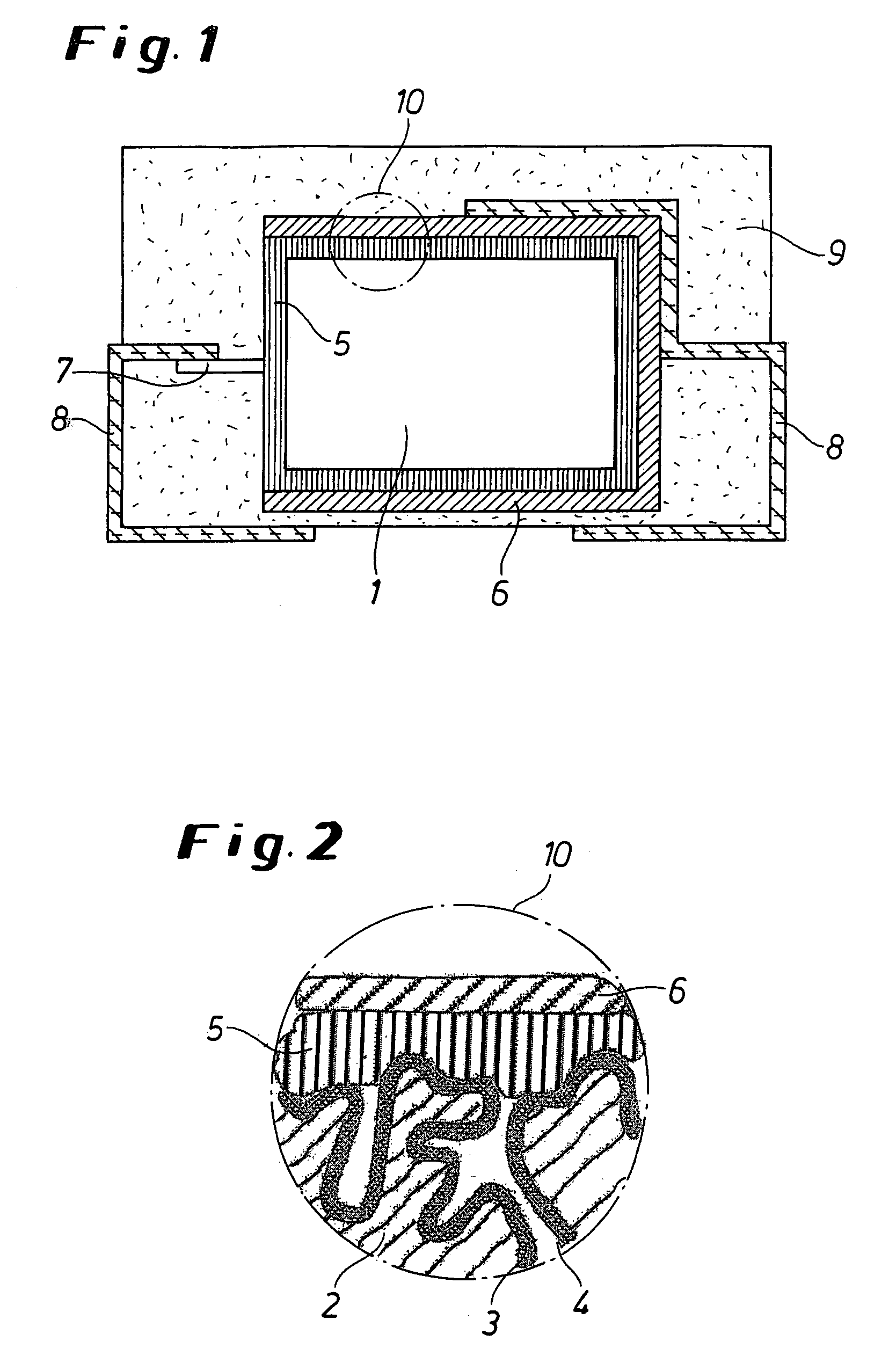

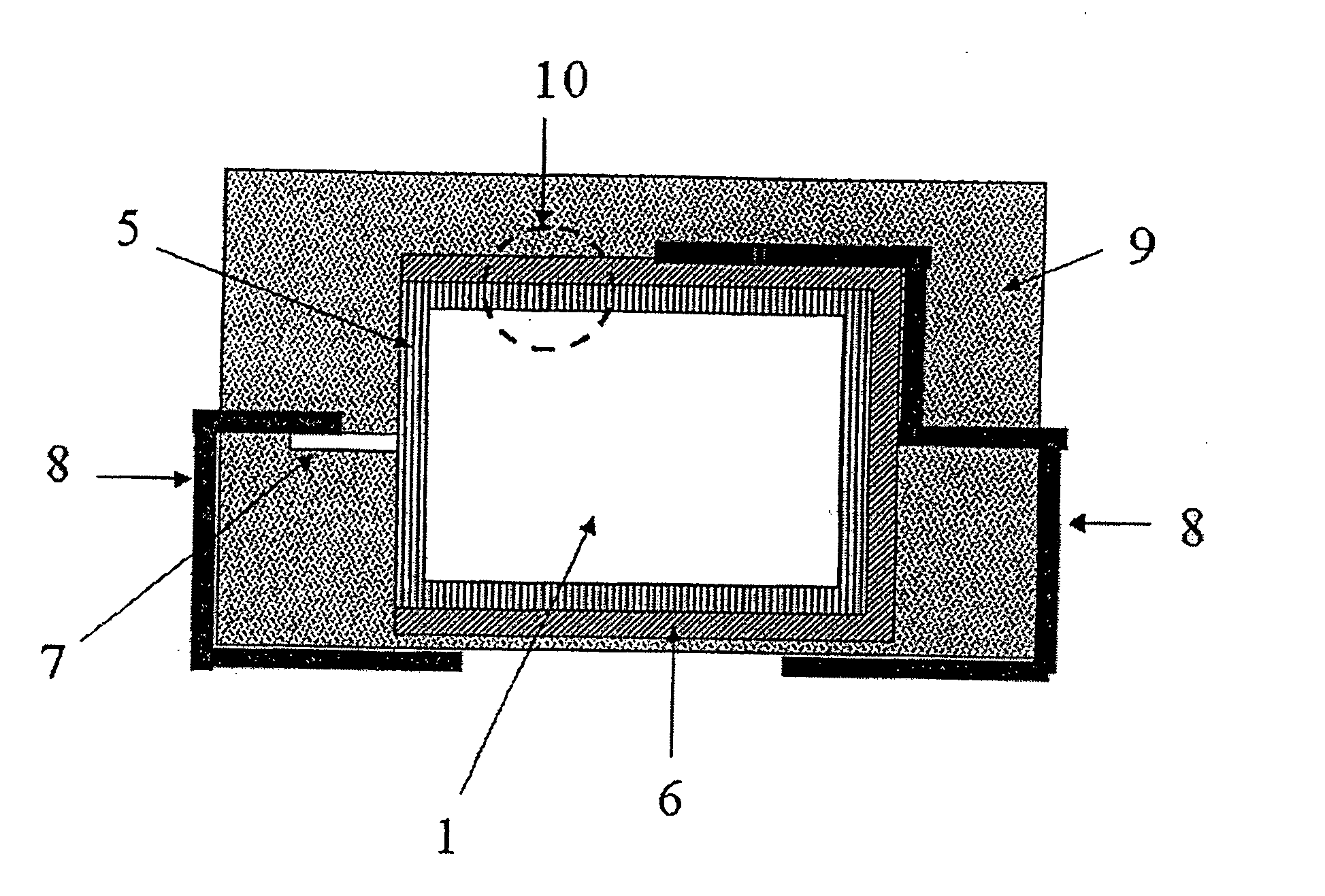

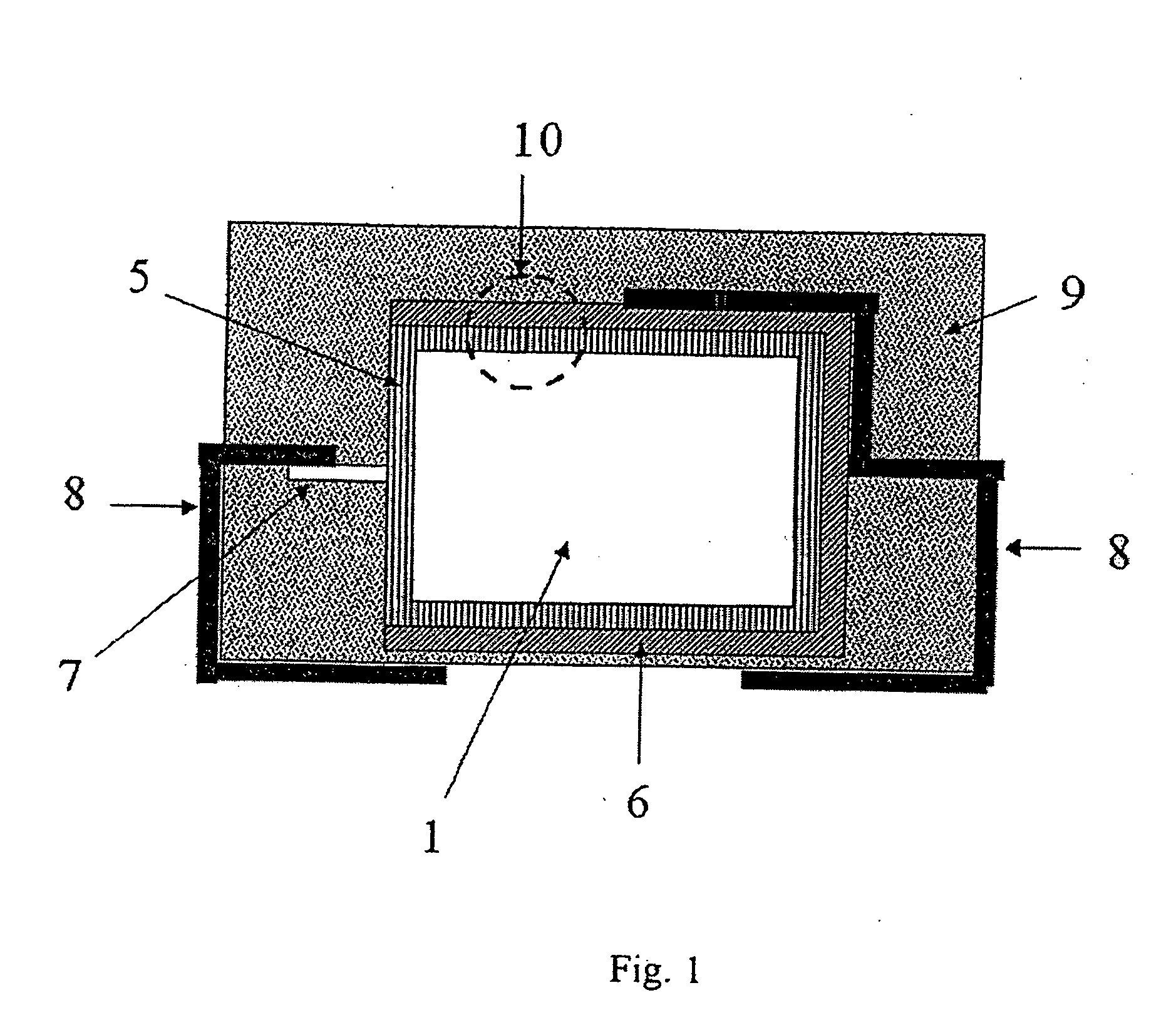

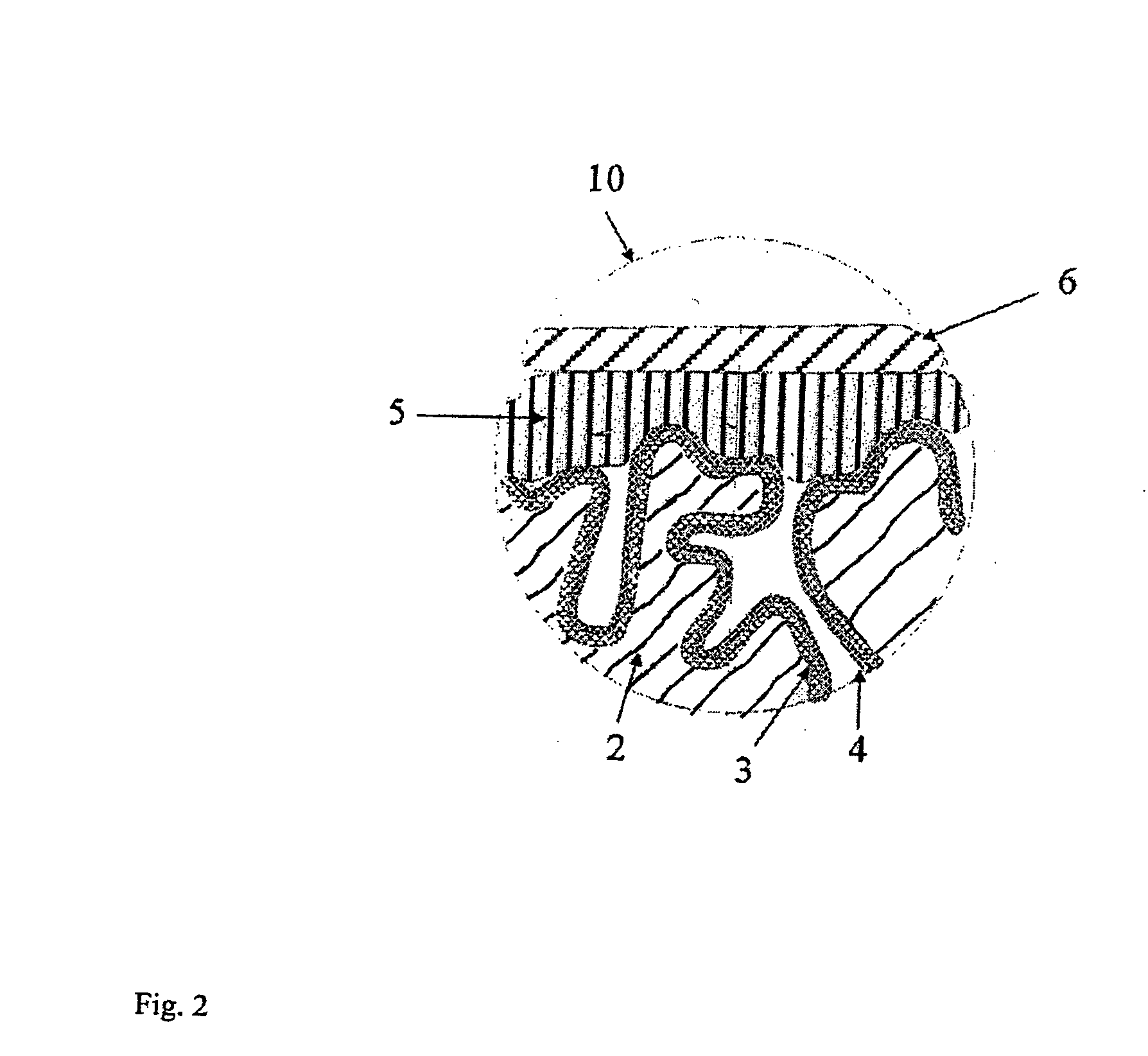

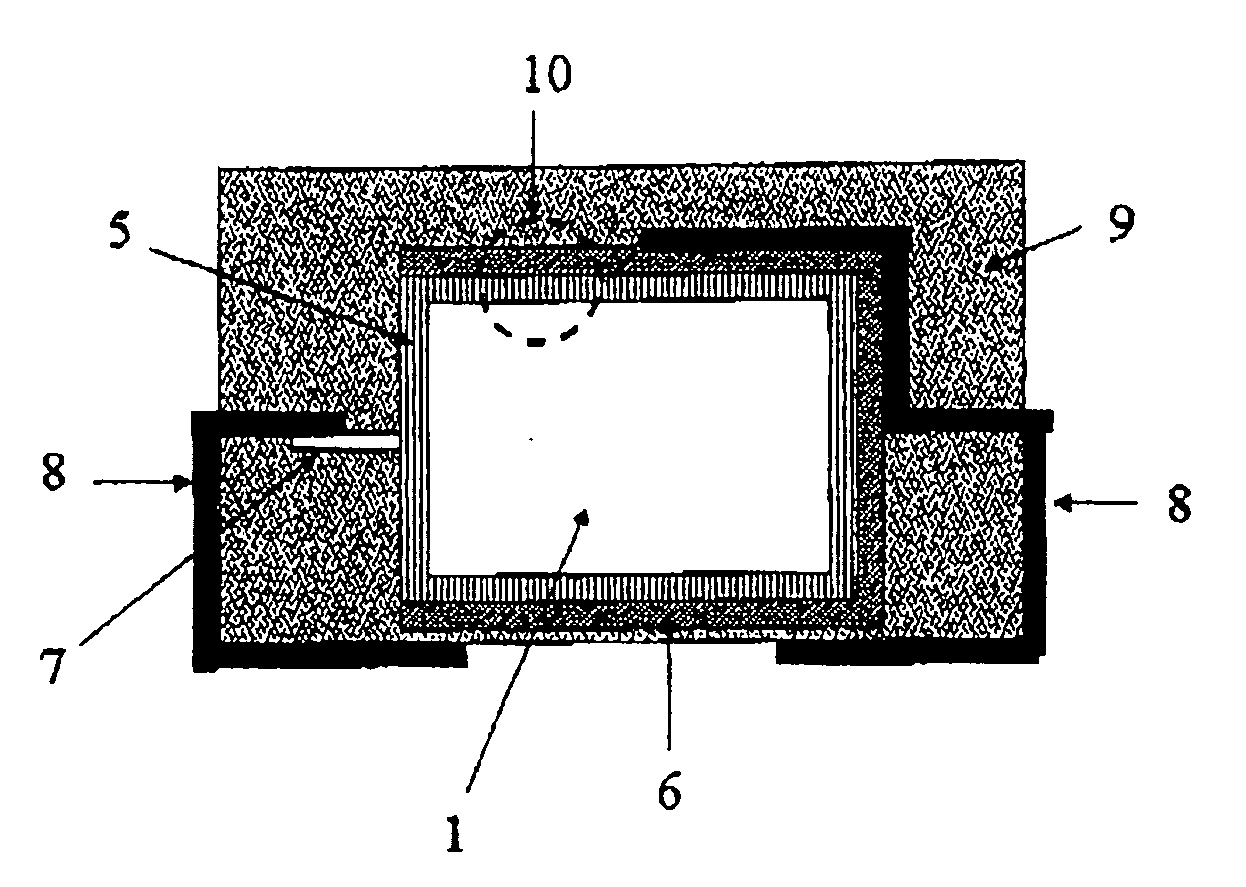

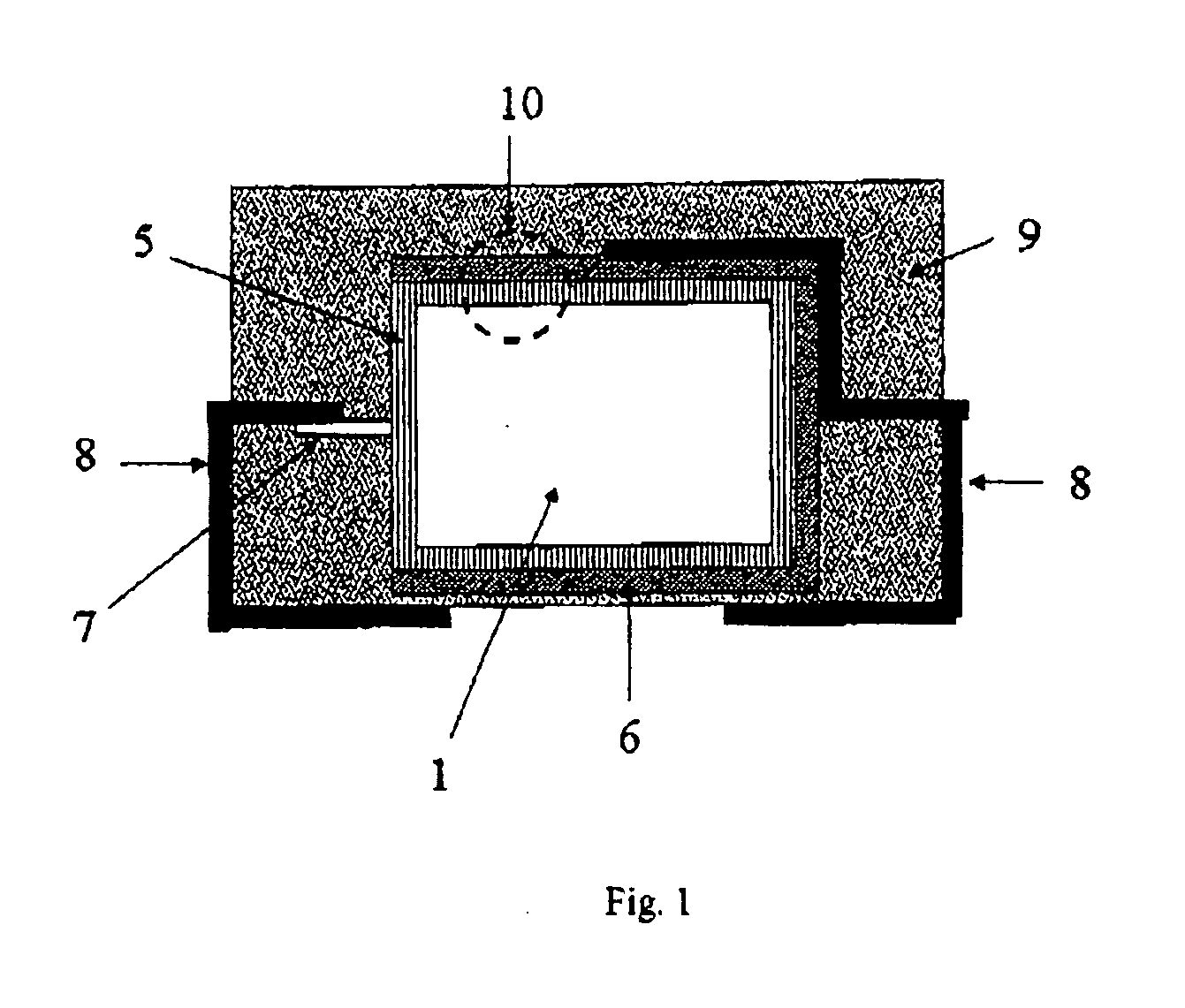

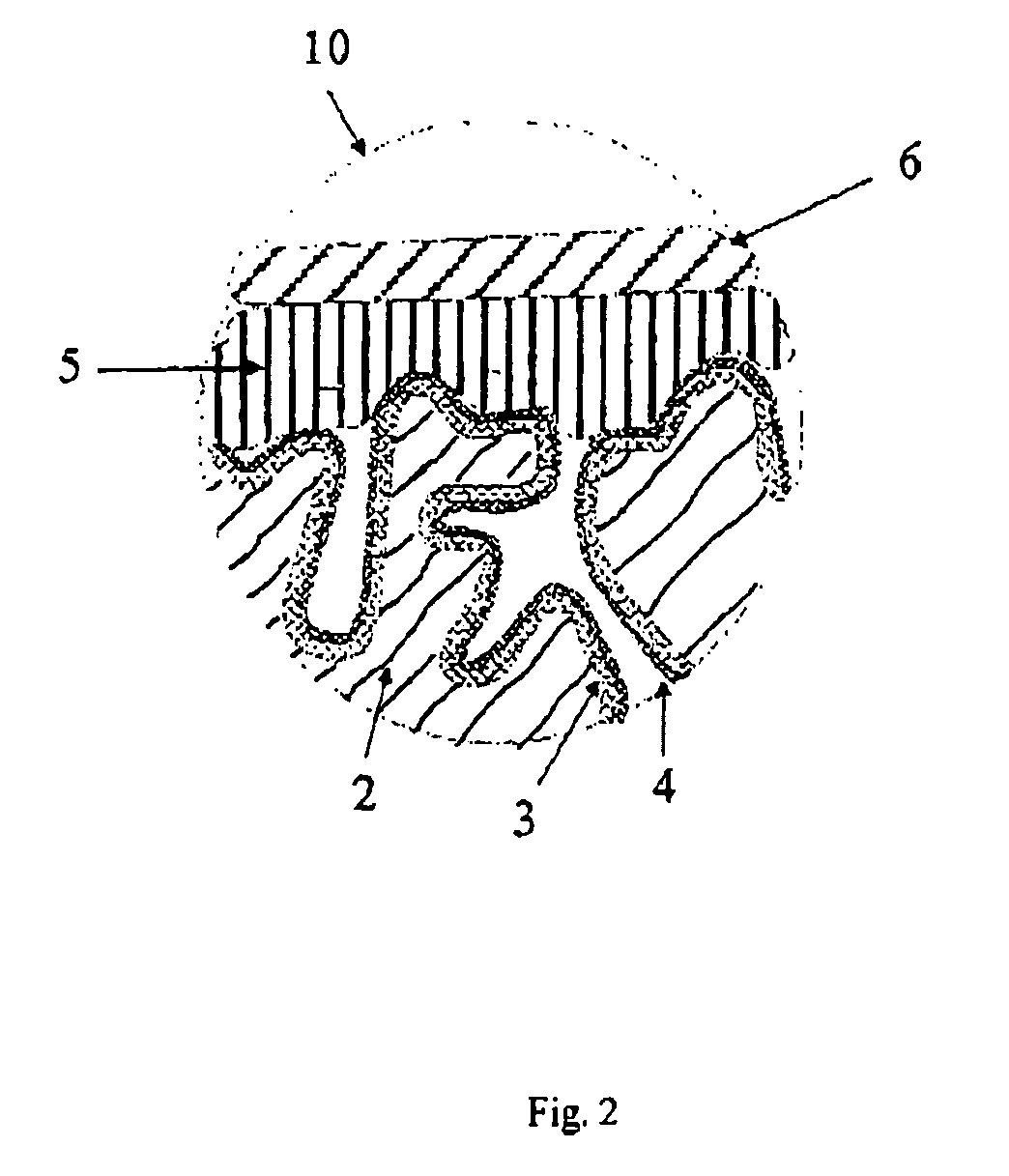

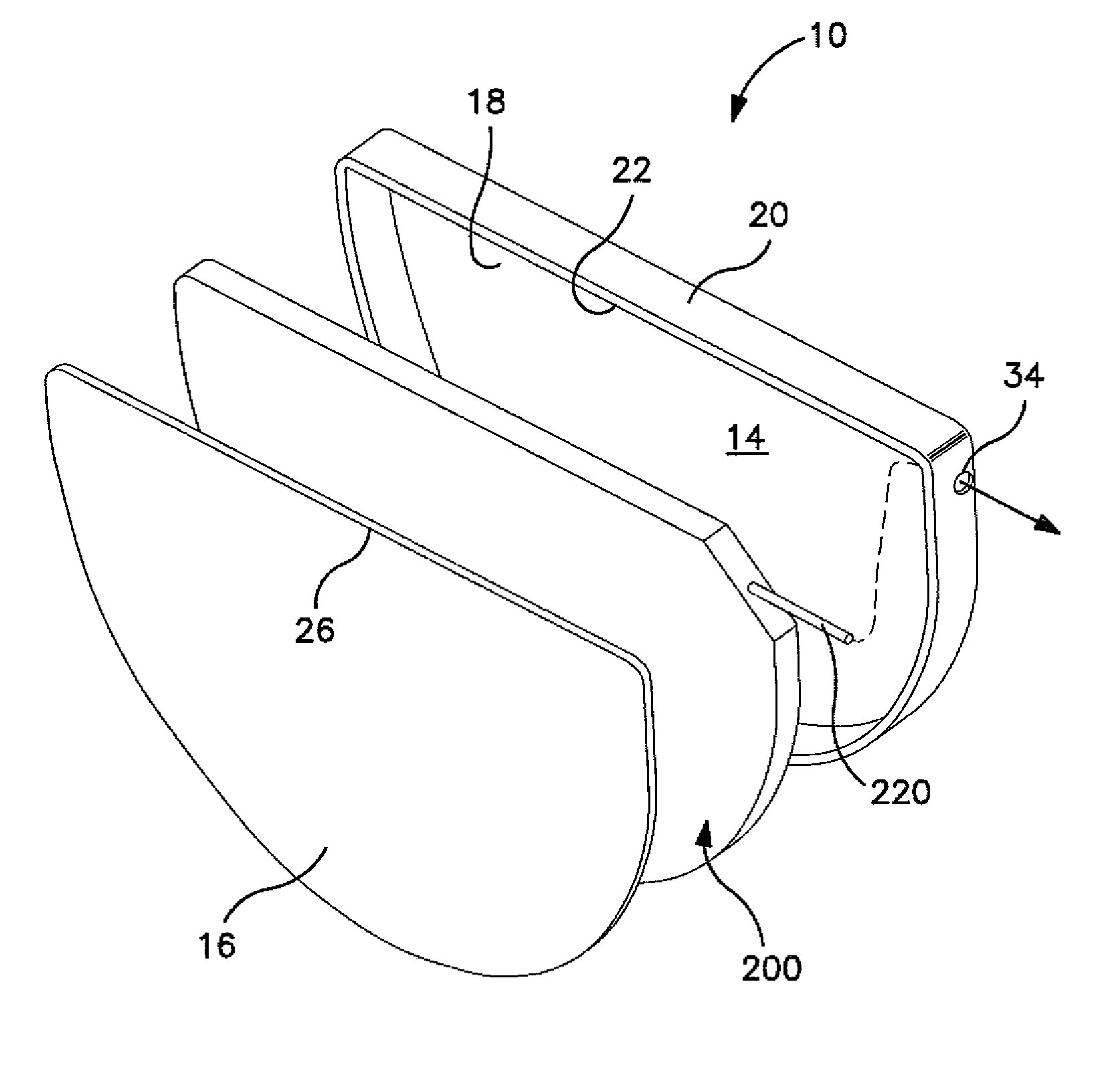

Hermetically Sealed Capacitor Assembly

ActiveUS20090244812A1Hybrid capacitor electrolytesSolid electrolytic capacitorsHermetic sealConductive polymer

A capacitor assembly that includes a conductive polymer electrolytic capacitor that is enclosed and hermetically sealed within a ceramic housing in the presence of an inert gas is provided. Without intending to be limited by theory, the present inventors believe that the ceramic housing is capable of limiting the amount of oxygen and moisture supplied to the conductive polymer of the capacitor. In this manner, the conductive polymer is less likely to oxidize in high temperature environments, thus increasing the thermal stability of the capacitor assembly.

Owner:KYOCERA AVX COMPONENTS CORP

Process for the producing of electrolytic capacitors

InactiveUS7279015B2Hybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisPolymer science

Process for the production of electrolytic capacitors with low equivalent series resistance and low residual current, having a solid electrolyte formed from conducting polymers and an outer layer containing conducting polymers and a binder, electrolytic capacitors produced by the process and their use.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Electrolytic capacitors with a polymeric outer layer

ActiveUS20050111165A1Reduce leakage currentLow ESRHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisCompound (substance)

Electrolytic capacitors having low equivalent series resistance and low leakage current are described. The electrolytic capacitors include a solid electrolyte layer of a conductive material in particular a conductive polymer, and an outer layer that includes binders, polymeric anions and conductive polymers (e.g., polythiophenes). Also described is a method of preparing electrolytic capacitors that involves forming the conductive polymer of the solid electrolyte layer in situ by means of chemical oxidative polymerization or electrochemical polymerization. Electronic circuits that include the electrolytic capacitors are also described.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

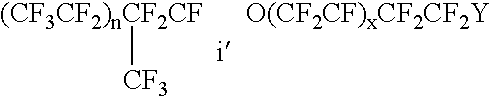

Thermopolymerizable composition for battery use

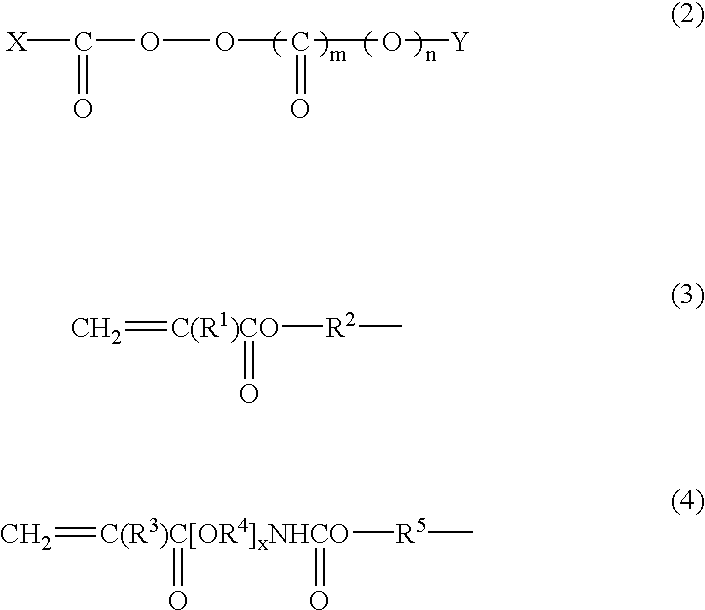

InactiveUS6562513B1Good storage stabilityHigh strengthCell electrodesFinal product manufactureMeth-Carbonate ester

The present invention provides (1) a thermopolymerizable composition containing a thermopolymerizable compound having (meth)acrylate having a moiety consisting of oxyalkylene, fluorocarbon, oxyfluorocarbon and / or carbonate group within the molecule, an electrolyte salt, an organic polymerization initiator having no benzene ring, and a polymerization retarder having vinyl group within the molecule, (2) a solid electrolyte obtained by heat-curing the composition, (3) a primary battery, a secondary battery and an electric double-layer capacitor each using the solid electrolyte, and processes for manufacturing the same.

Owner:SHOWA DENKO KK

Conductive composition and production method thereof, antistatic coating material, antistatic coating, antistatic film, optical filter, and optical information recording medium, and capacitors and production method thereof

ActiveUS20060076541A1Improve conductivityImprove heat stabilityHybrid capacitor separatorsHybrid capacitor electrolytesConductive polymerSolvent

A conductive composition comprises a π conjugated conductive polymer, a polyanion, and a hydroxy group-containing aromatic compound containing two or more hydroxy groups. An antistatic coating material comprises the conductive composition and a solvent. An antistatic coating is produced by applying the antistatic coating material. A capacitor comprises an anode composed of a porous valve metal body; a dielectric layer formed by oxidizing a surface of the anode; and a cathode formed on the dielectric layer, wherein the cathode has a solid electrolyte layer comprising the conductive composition.

Owner:SHIN-ETSU POLYMER CO LTD

Solid electrolyte capacitor and method for manufacturing the same

InactiveUS6229689B1Increase resistanceImprove efficiencyHybrid capacitor electrolytesLiquid electrolytic capacitorsOrganic sulfonic acidProduct layer

A solid electrolyte capacitor having a solid electrolyte layer that is formed of a polymeric product layer of a polymerizable monomer. The polymeric product layer is doped with an organic sulfonic acid selected from the group consisting of an aromatic polysulfonic acid, an organic sulfonic acid having a hydroxy group, an organic sulfonic acid having a carboxyl group, an alicyclic sulfonic acid, and a benzoquinone sulfonic acid.

Owner:TOKIN CORP

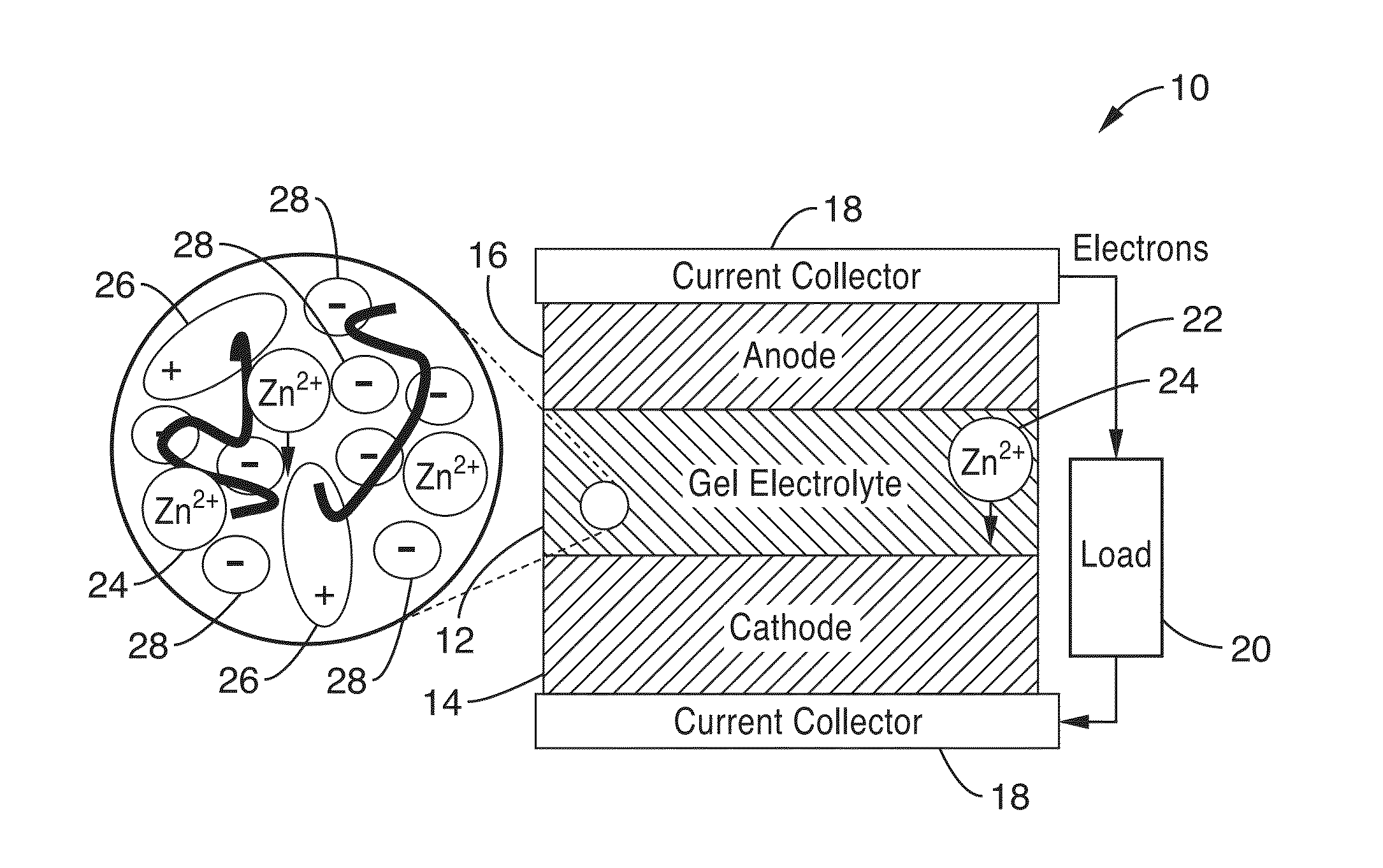

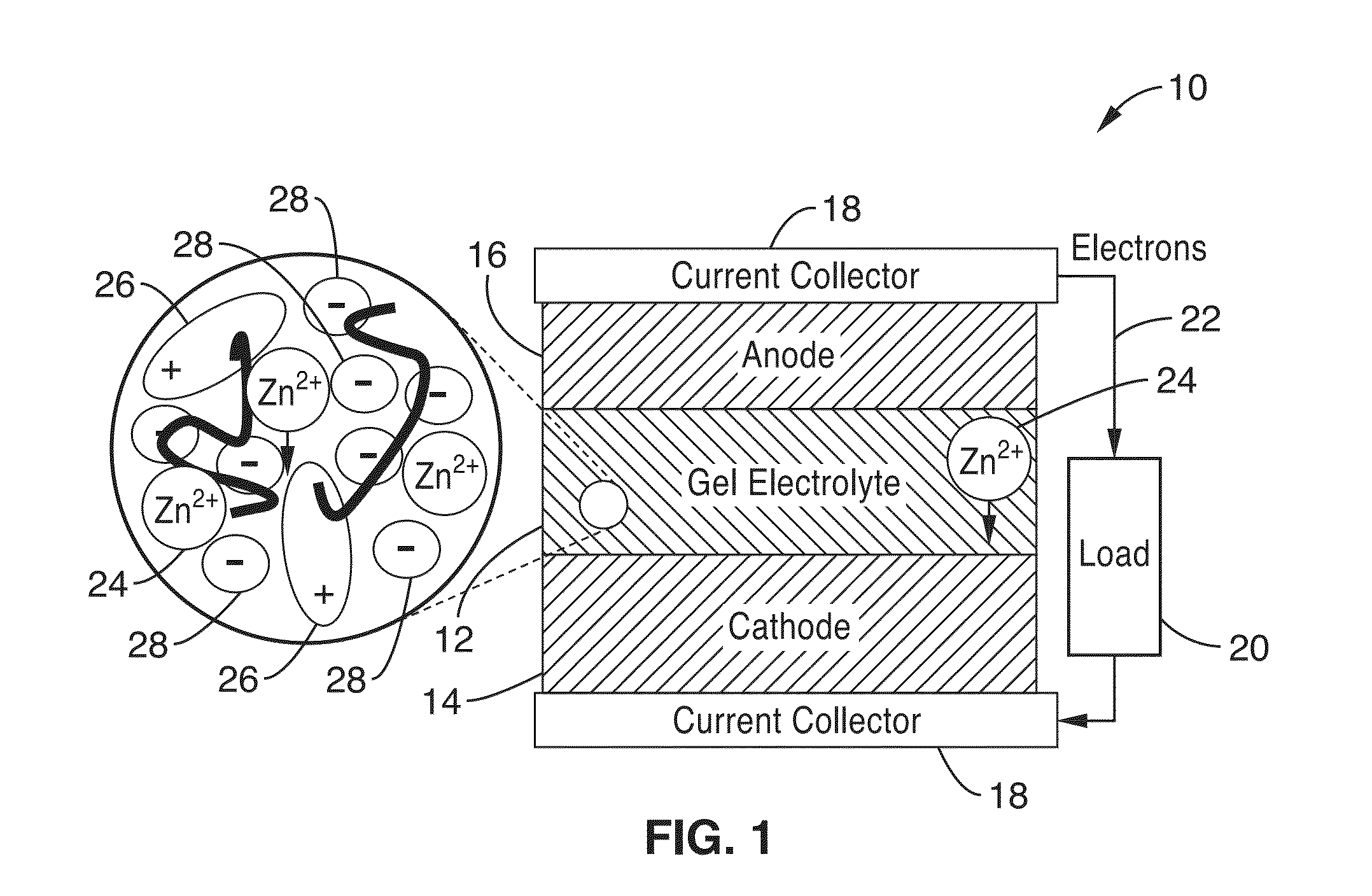

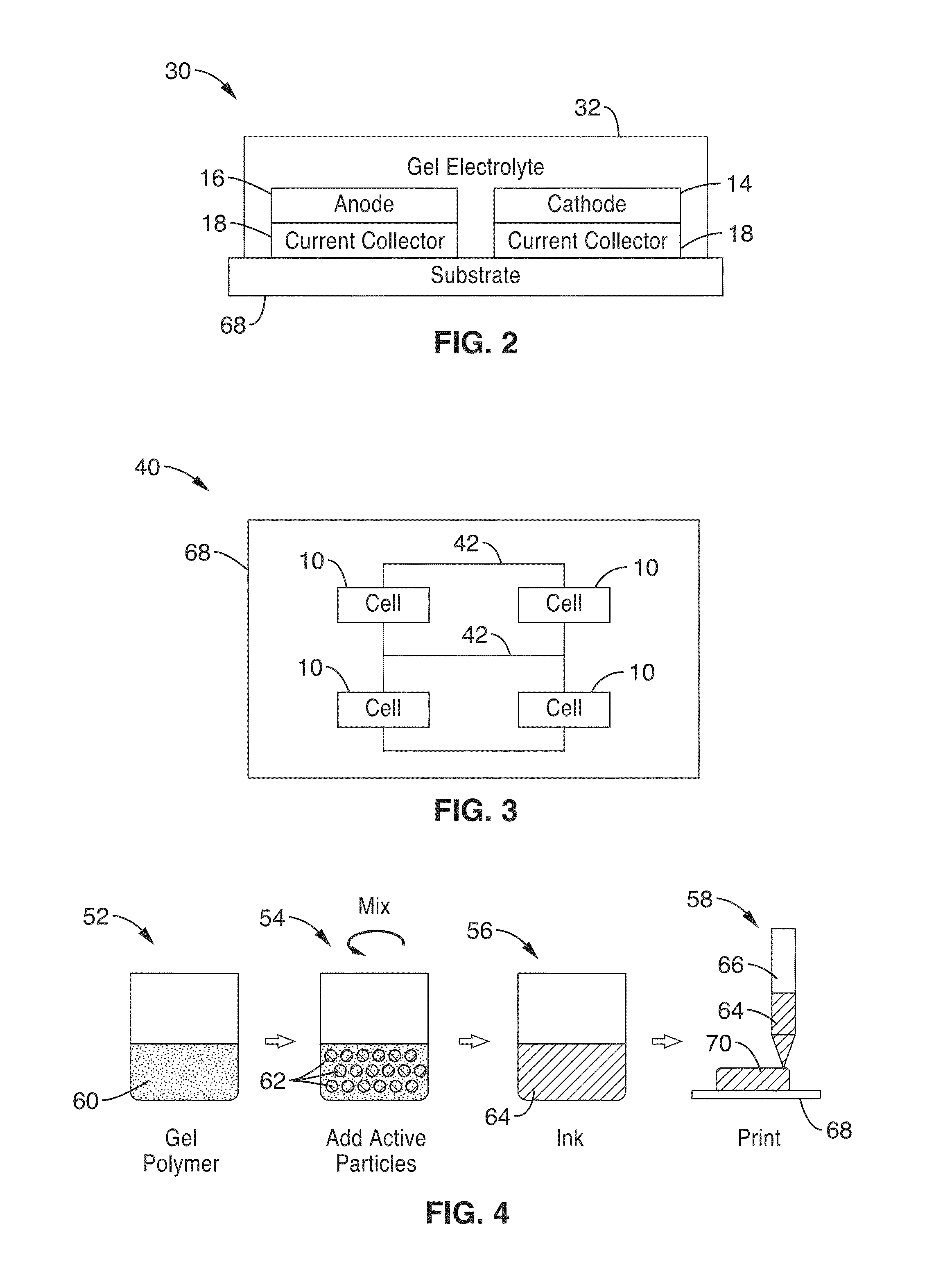

Ionic gel electrolyte, energy storage devices, and methods of manufacture thereof

ActiveUS20130280579A1Promote disseminationSolid electrolytic capacitorsLiquid electrolytic capacitorsPhysical separationElectrochemical cell

An electrochemical cell includes solid-state, printable anode layer, cathode layer and non-aqueous gel electrolyte layer coupled to the anode layer and cathode layer. The electrolyte layer provides physical separation between the anode layer and the cathode layer, and comprises a composition configured to provide ionic communication between the anode layer and cathode layer by facilitating transmission of multivalent ions between the anode layer and the cathode layer.

Owner:CCL LABEL INC +1

Process for the production of electrolyte capacitors

ActiveUS20080005878A1Lower equivalent series resistanceHeat stableCellsSolid electrolytic capacitorsElectrical resistance and conductanceElectrolysis

The invention relates to a process for the production of electrolyte capacitors having a low equivalent series resistance and low residual current, electrolyte capacitors produced by this process and the use of such electrolyte capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Wet electrolytic capacitor containing a gelled working electrolyte

ActiveUS9105401B2Hybrid capacitor electrolytesCapacitor electrolytes/absorbentsElectrolysisConductive polymer

A wet electrolytic capacitor is provided. The capacitor contains an anode comprising an anodically oxidized pellet formed from a pressed and sintered powder, a cathode that contains a metal substrate coated with a conductive polymer, and a working electrolyte in communication with the anode and the cathode. The working electrolyte is in the form of a gel and comprises an ammonium salt of an organic acid, inorganic oxide particles, an acid, and a solvent system that comprises water. The working electrolyte has a pH value of from about 5.0 to about 8.0.

Owner:KYOCERA AVX COMPONENTS CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com